Method for conveniently realizing variable curvature accurate drum correcting of parameterized involute straight bevel gear

A straight-toothed bevel gear and variable curvature technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of weak function, small effect of finite element simulation accuracy of modified bevel gear model, and graphics that cannot be used directly Mechanical design and other issues to achieve the effect of increasing the load-carrying capacity, improving the stress distribution in the tooth direction, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

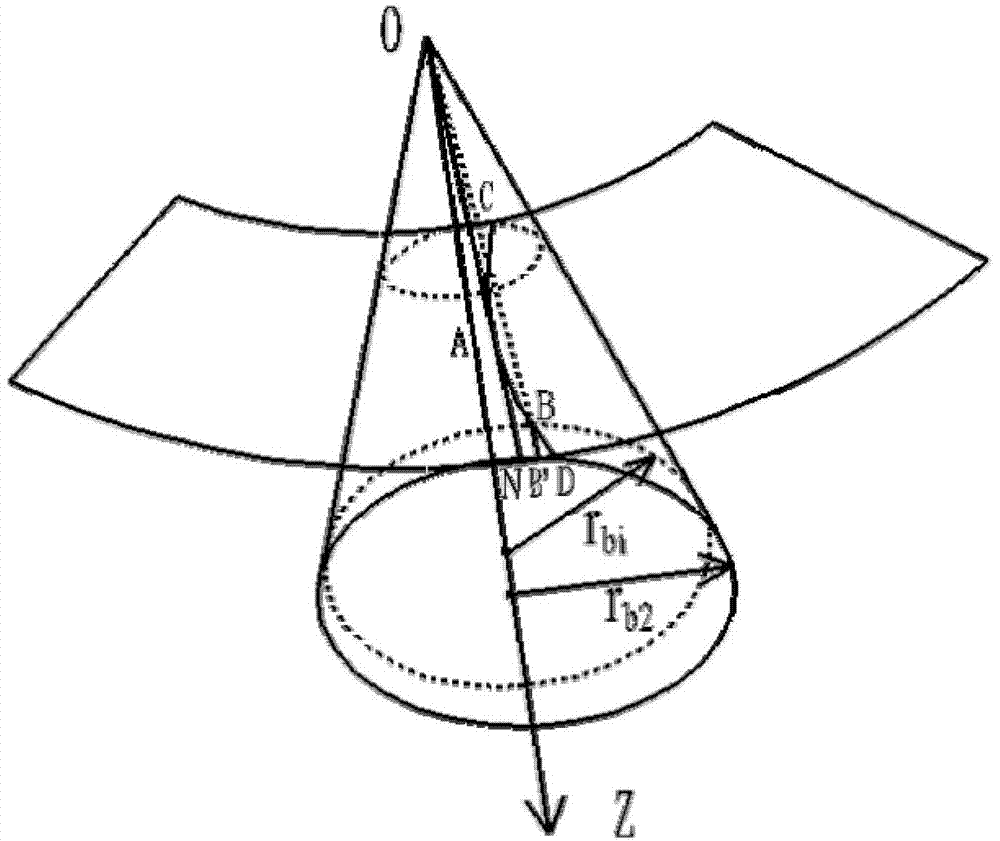

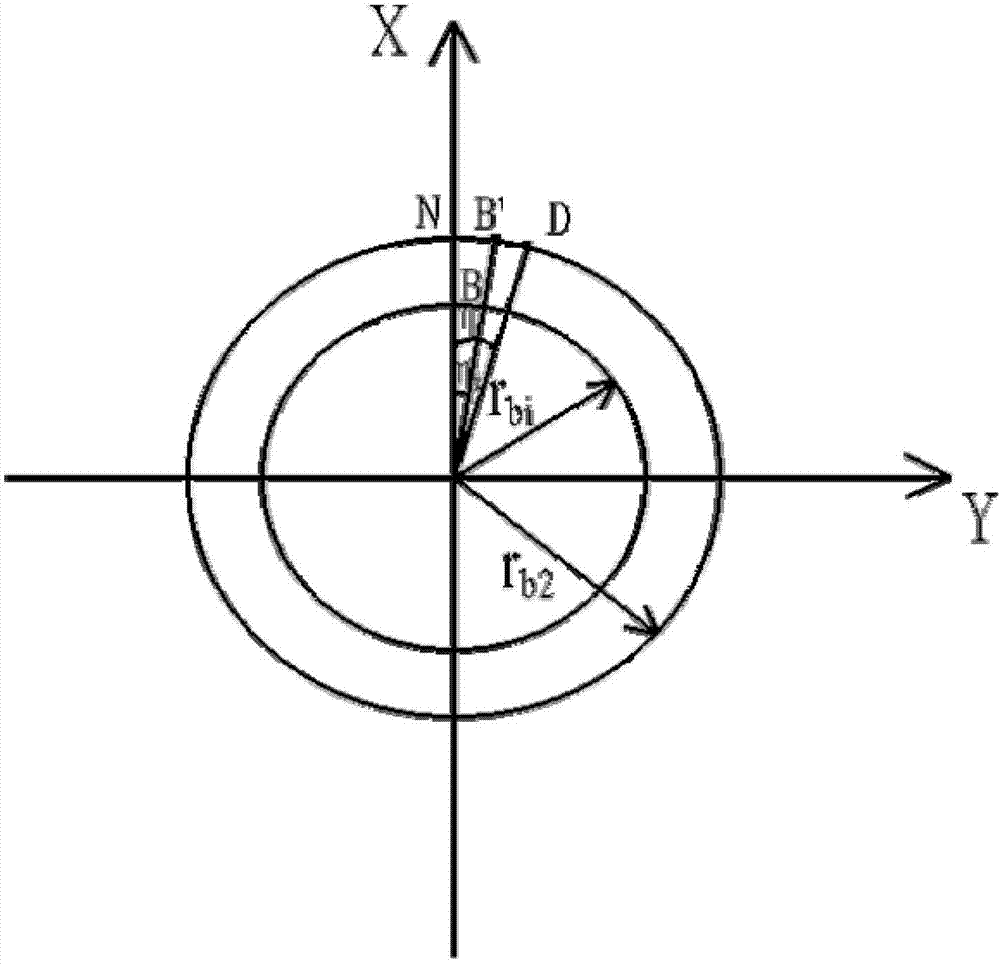

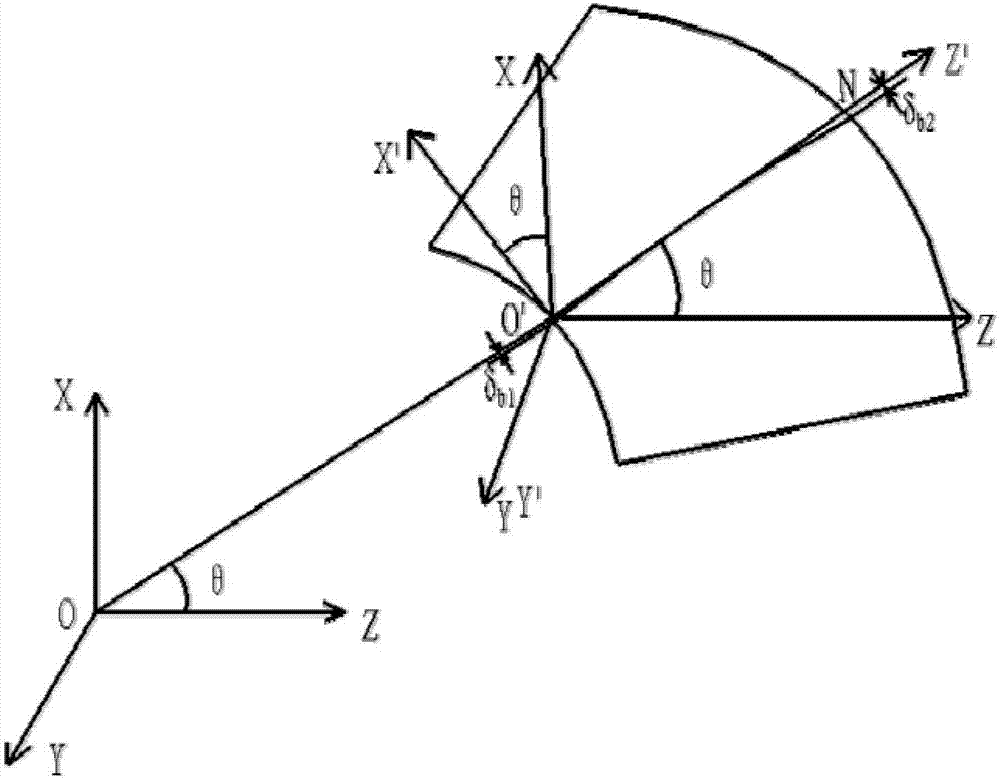

[0033] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0034] Taking the involute spur bevel gear of the rear axle differential of a car as an example, the basic structural parameters of the planetary gear and the side gear are:

[0035]

[0036] The relevant steps are as follows:

[0037] (1) Adjust the coordinate system of the 3D solid modeling tool Solidworks and the finite element analysis tool ANSYS to make them consistent, and use ANSYS grid division technology to extract the node coordinates of the representative pitch cone on the tooth surface, and import them into Solidworks for drawing All nodes at the pitch cone along the tooth width direction on the exit tooth surface;

[0038] (2) Only the driving gear is modified, and the passive gear is not modified;

[0039]Based on the ANSYS / LS-DYNA dynamic contact finite element an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com