Patents

Literature

531 results about "Dynamic contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

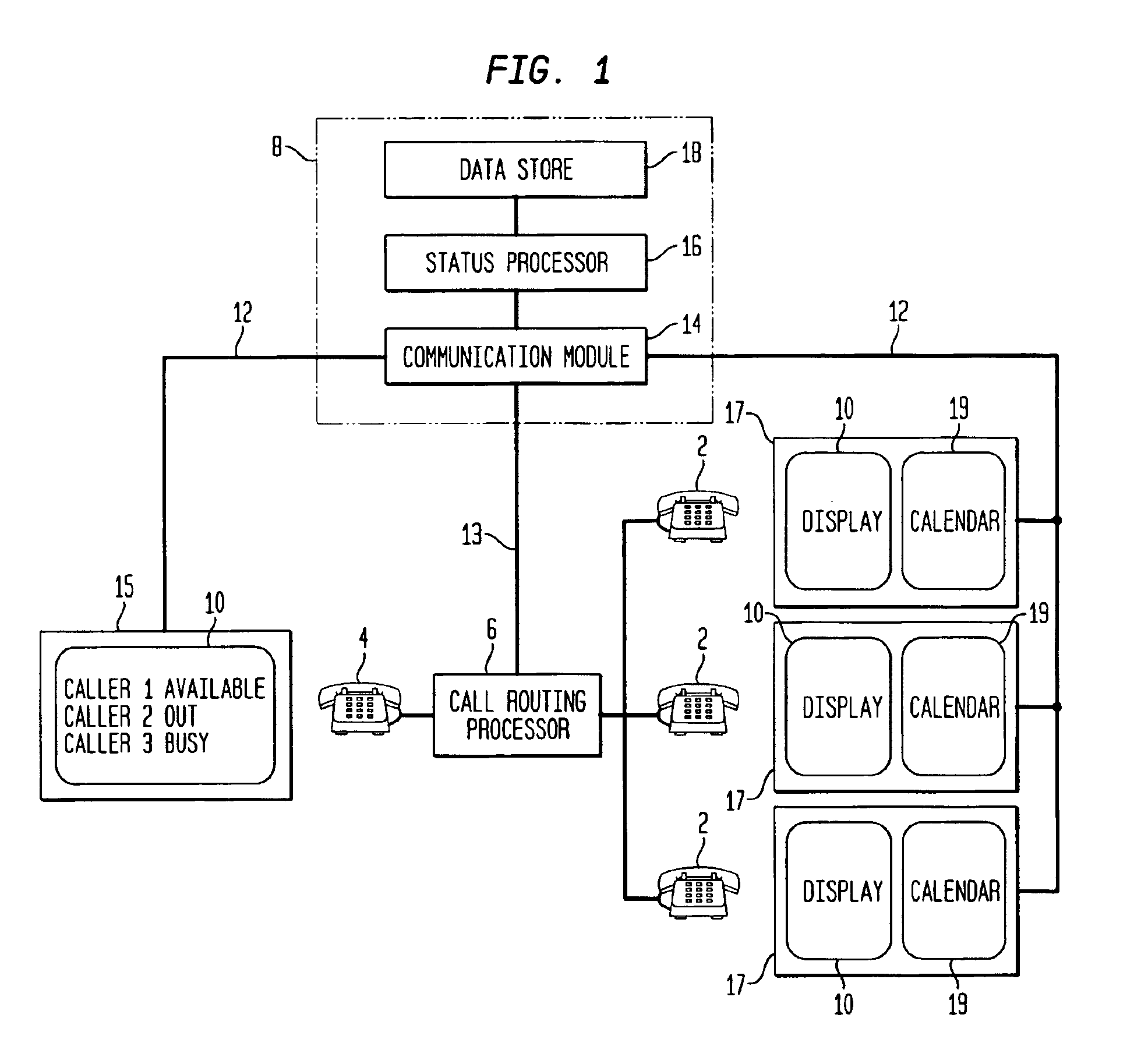

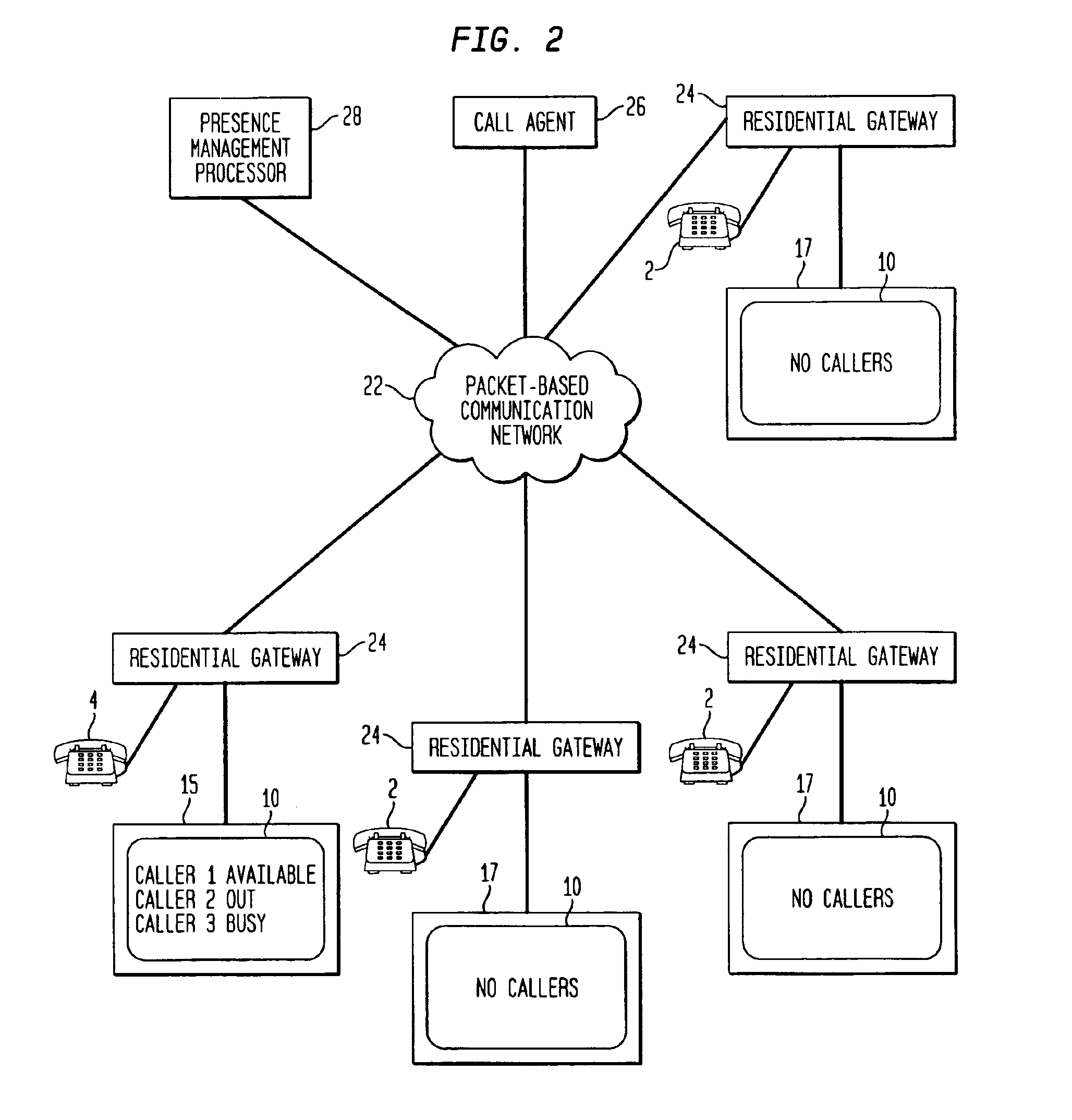

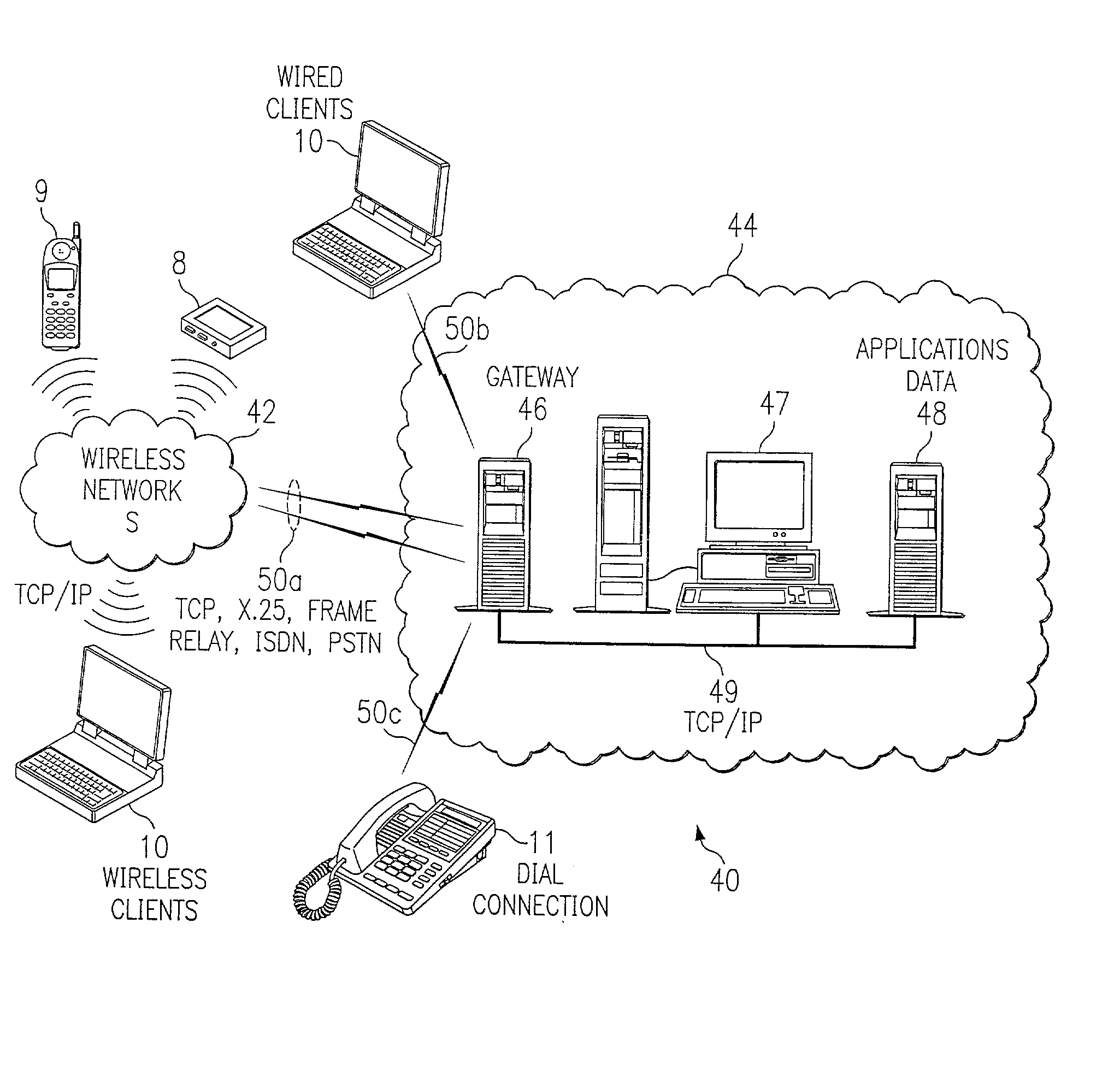

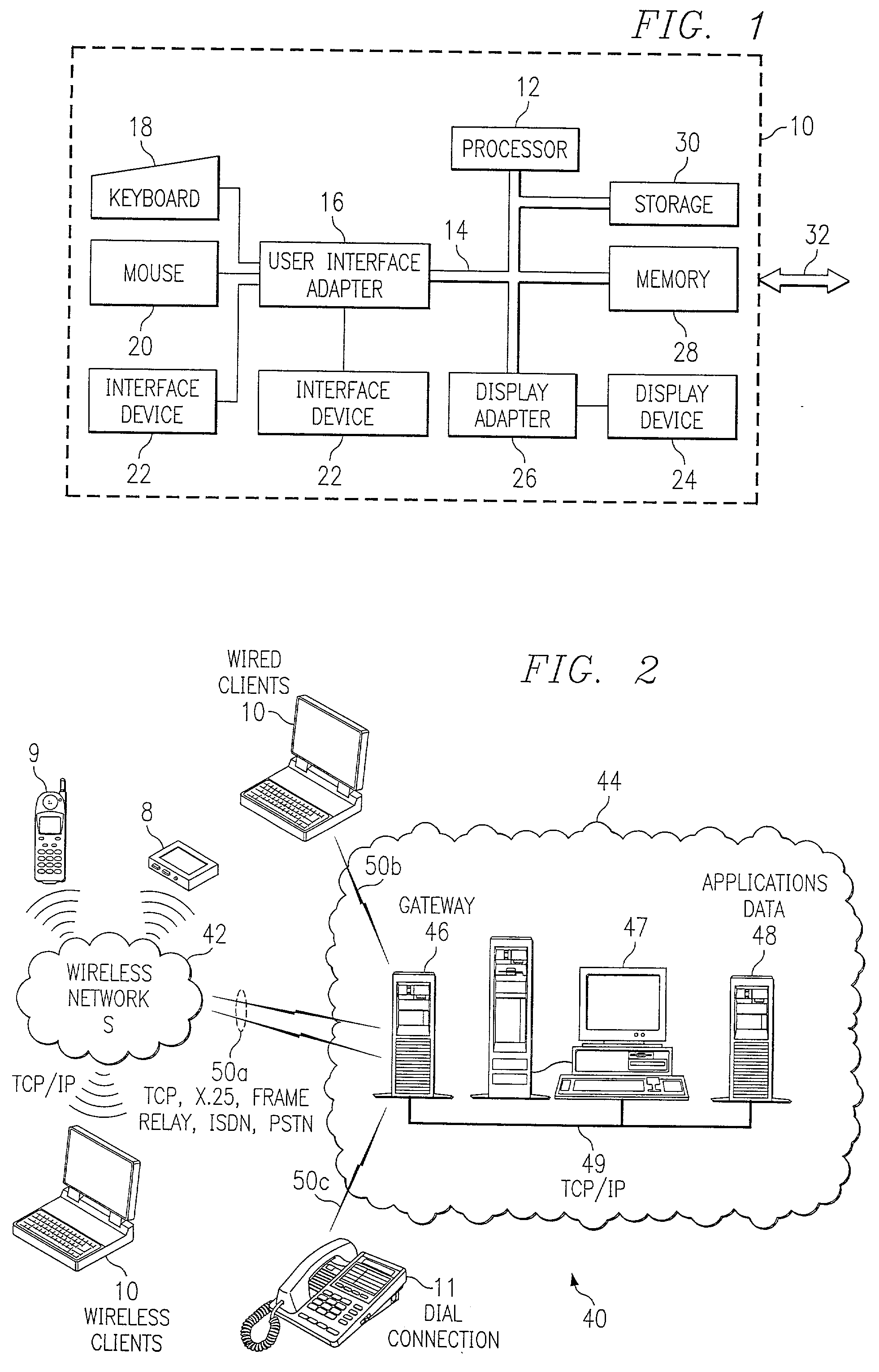

Method and apparatus for creating a presence monitoring contact list with dynamic membership

InactiveUS6968052B2Ensuring privacySpecial service for subscribersAutomatic call-answering/message-recording/conversation-recordingCommunications systemComputer science

Method and apparatus to generate a dynamic contact list of contact and presence information about contact events in a communication system when a calling entity unsuccessfully attempts to communicate with a called entity. When such a contact event occurs, a routing processor or call agent generates contact information about the contact event, including the calling party, called party, time of the contact event, and purpose of the contact event. A presence management processor also generates the presence information about the calling party's subsequent availability for return communication, including if a calling party is available for return communication, when the calling party is available for return communication, how long the calling party is available for return communication, and how the calling party is available for return communication. This contact and presence information is displayed to the called party in a dynamic contact list that includes contact and presence information for a plurality of contact events and calling parties, respectively. The called party is thereby able to determine what contact events occurred while the called party was unavailable for communication, and in what manner to return communicate with those calling parties that attempted to communicate with the called party while it was unavailable.

Owner:INTELLECTUAL VENTURES ASSETS 186 LLC

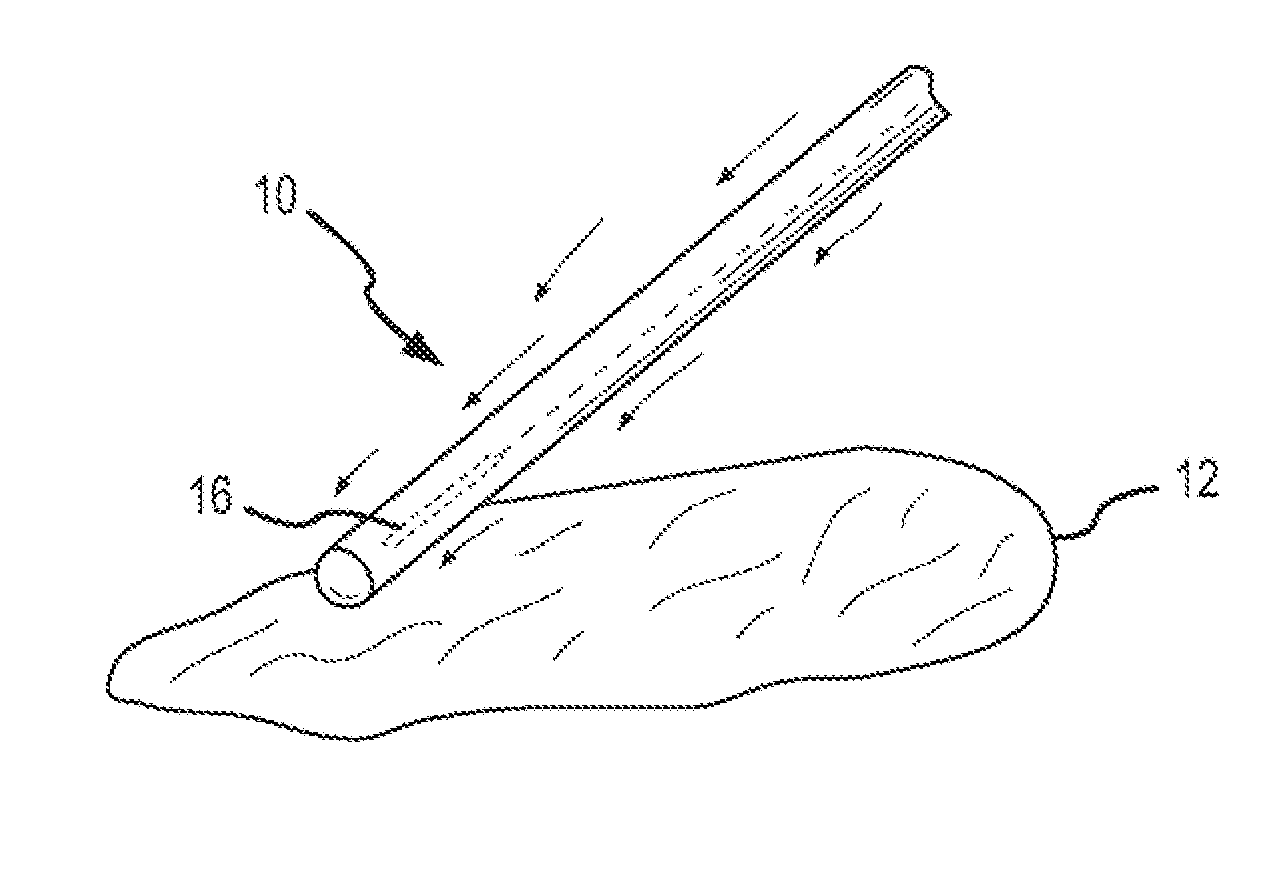

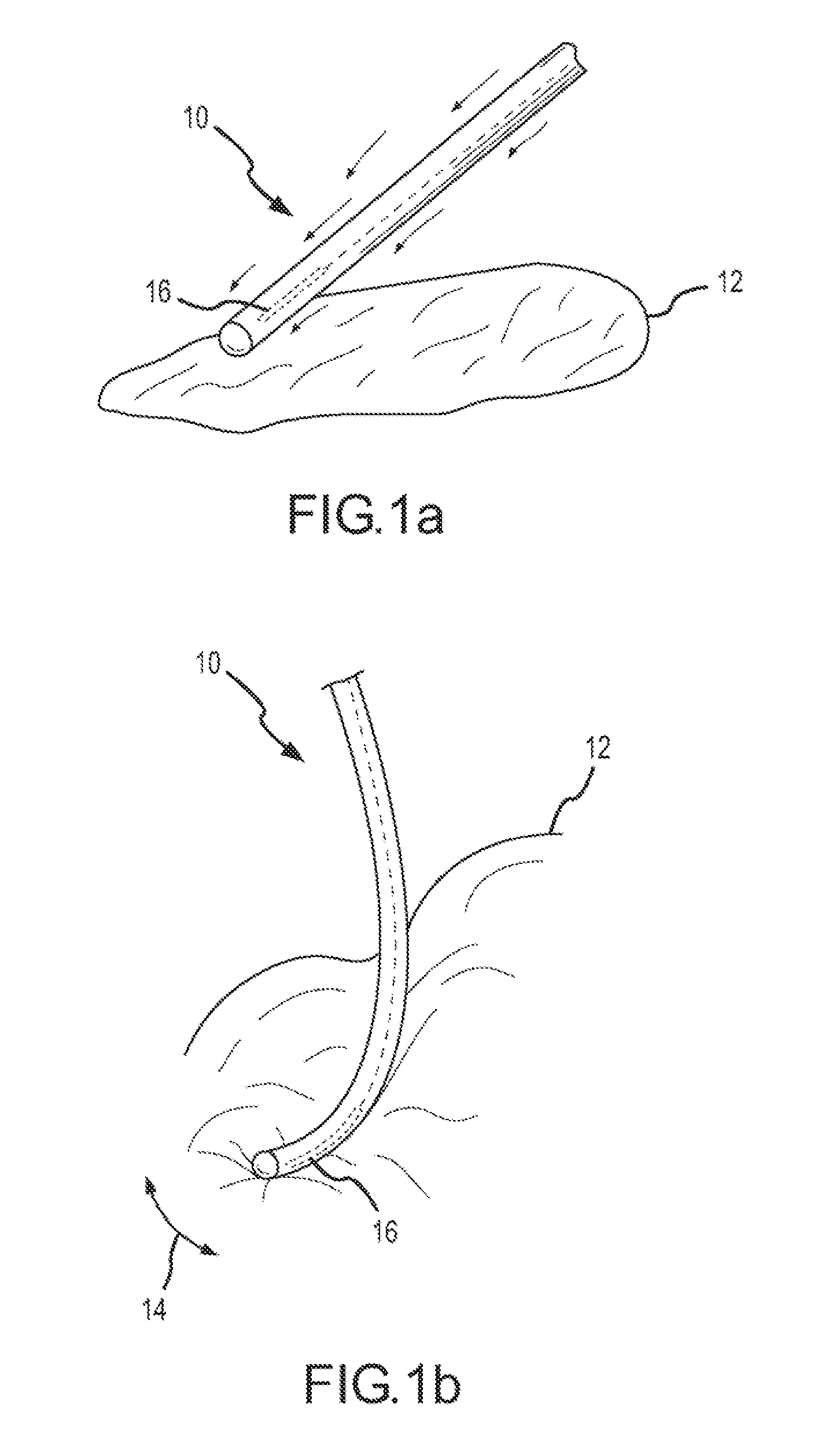

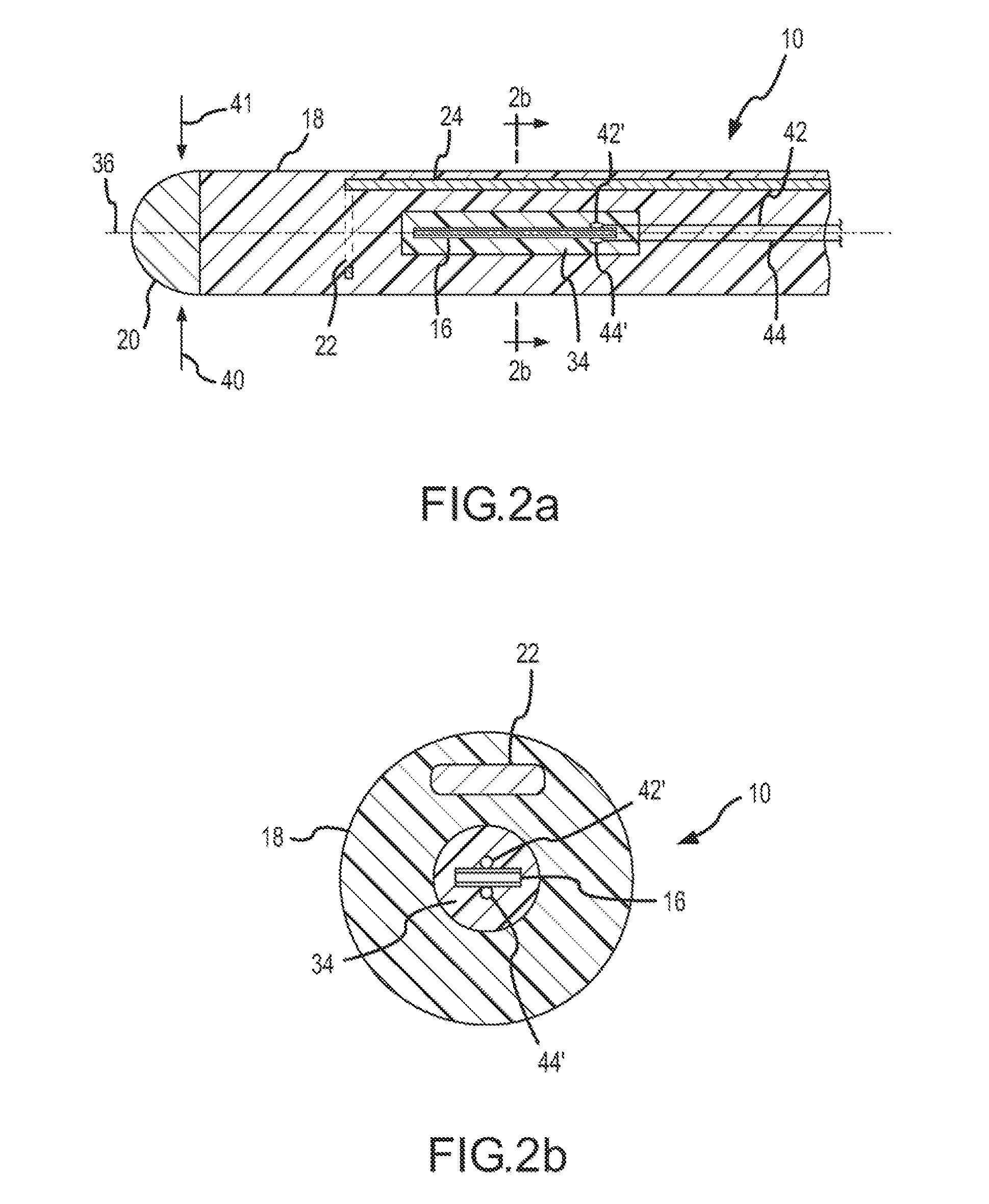

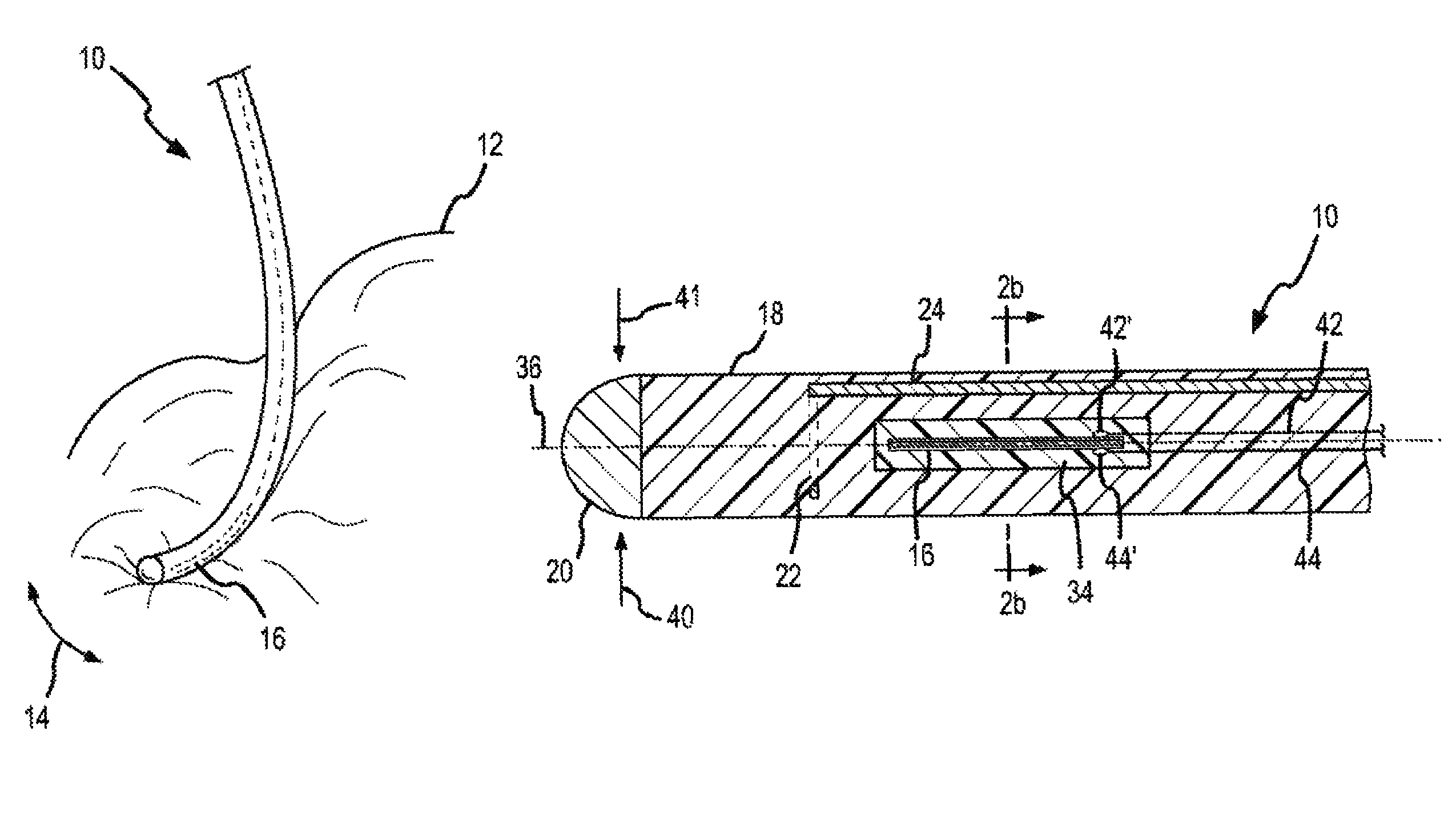

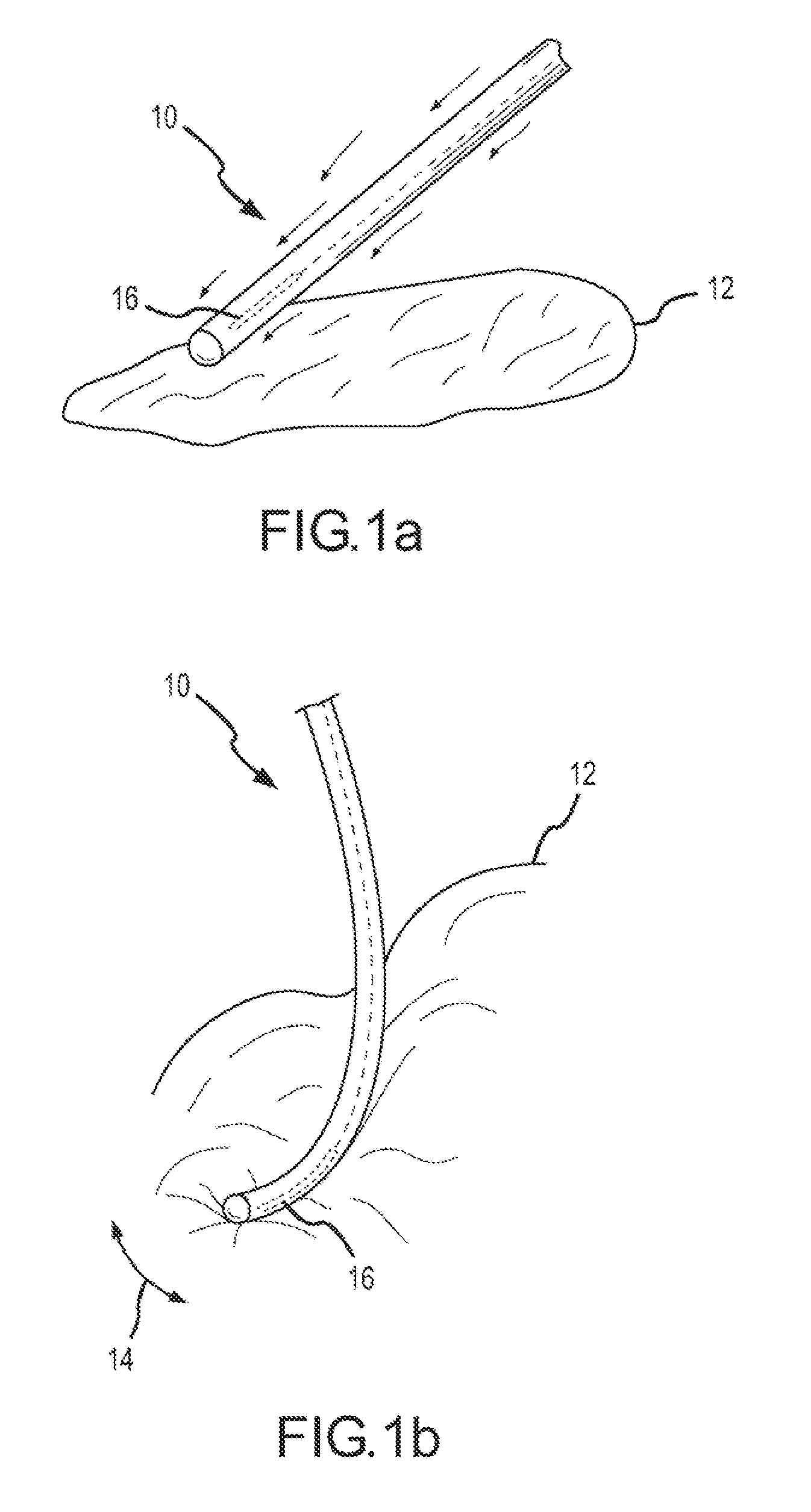

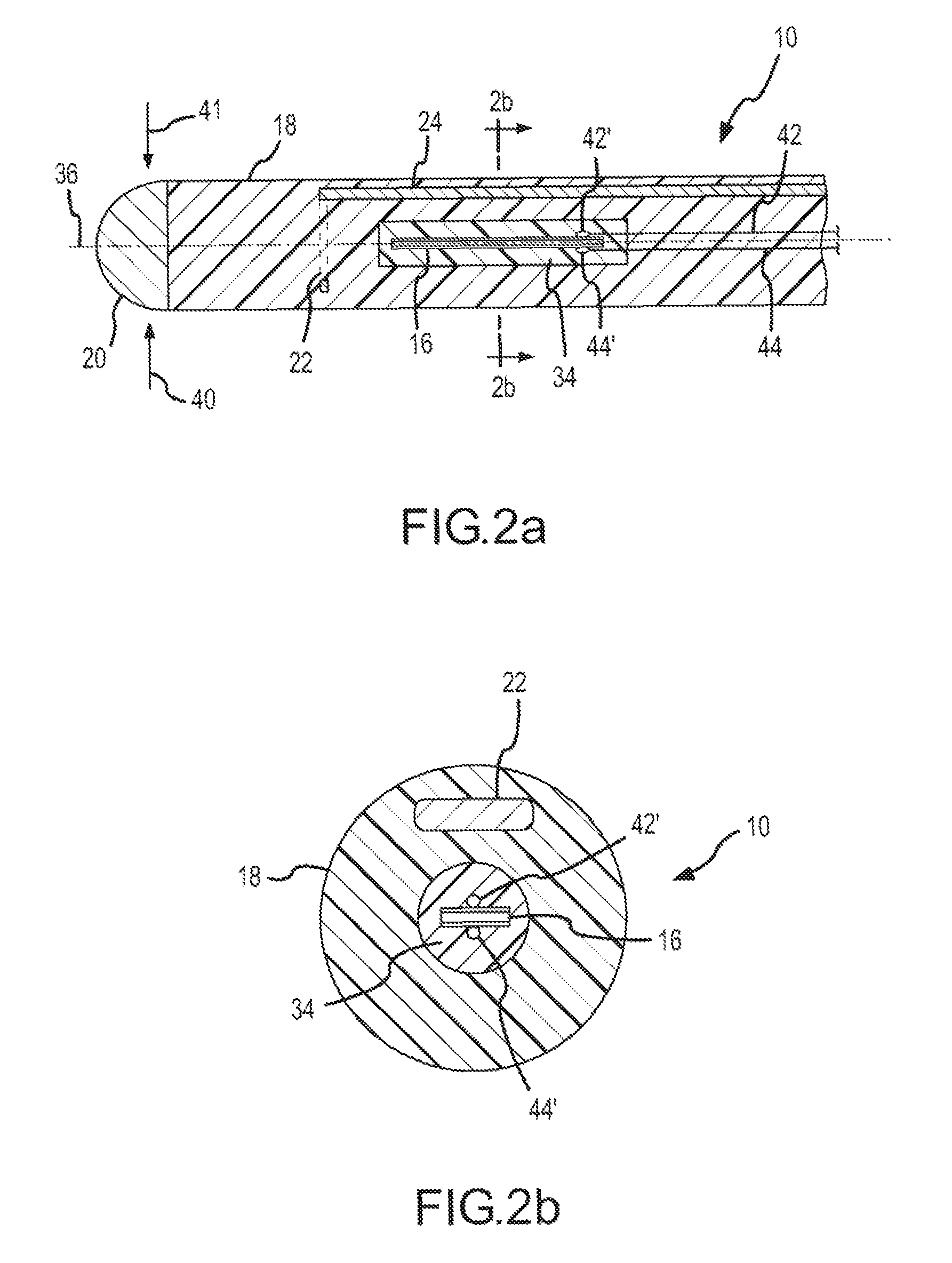

Dynamic contact assessment for electrode catheters

ActiveUS20080015568A1Reduce contact pressureIncrease contact pressureSurgical instrument detailsDiagnostic recording/measuringElectricityOutput device

An electrode catheter and a method for assessing catheter-tissue contact for tissue ablation are disclosed. An exemplary electrode catheter comprises a flexible catheter shaft. At least one piezoelectric sensor is oriented coaxial to the flexible catheter shaft. The at least one piezoelectric sensor is responsive to movement of the flexible catheter shaft by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one piezoelectric sensor. The output device receives the electrical signals for dynamically assessing a level of contact between the flexible catheter shaft and a moving tissue. In another exemplary embodiment, the system may be implemented in a hydrodynamic environment.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

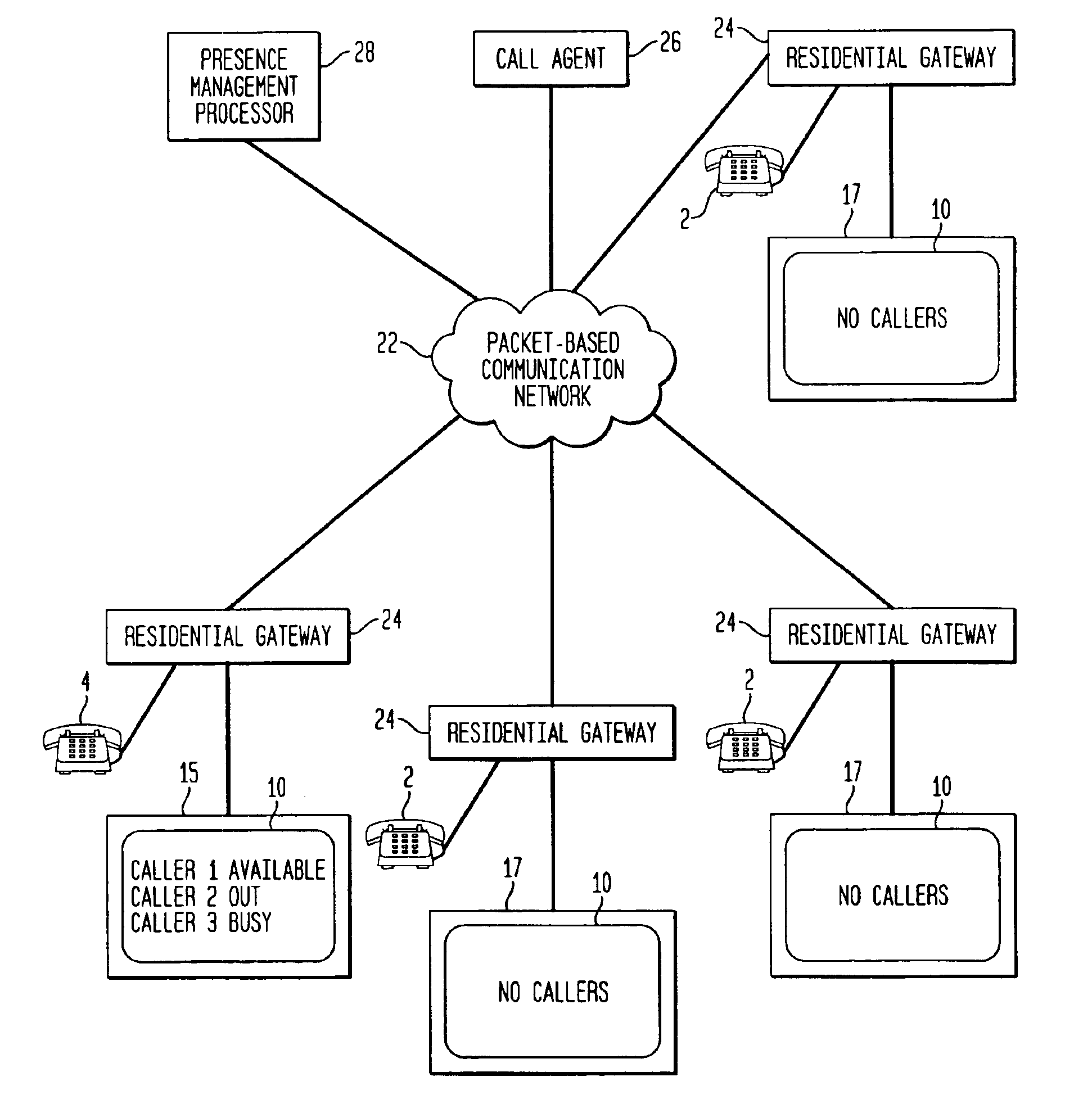

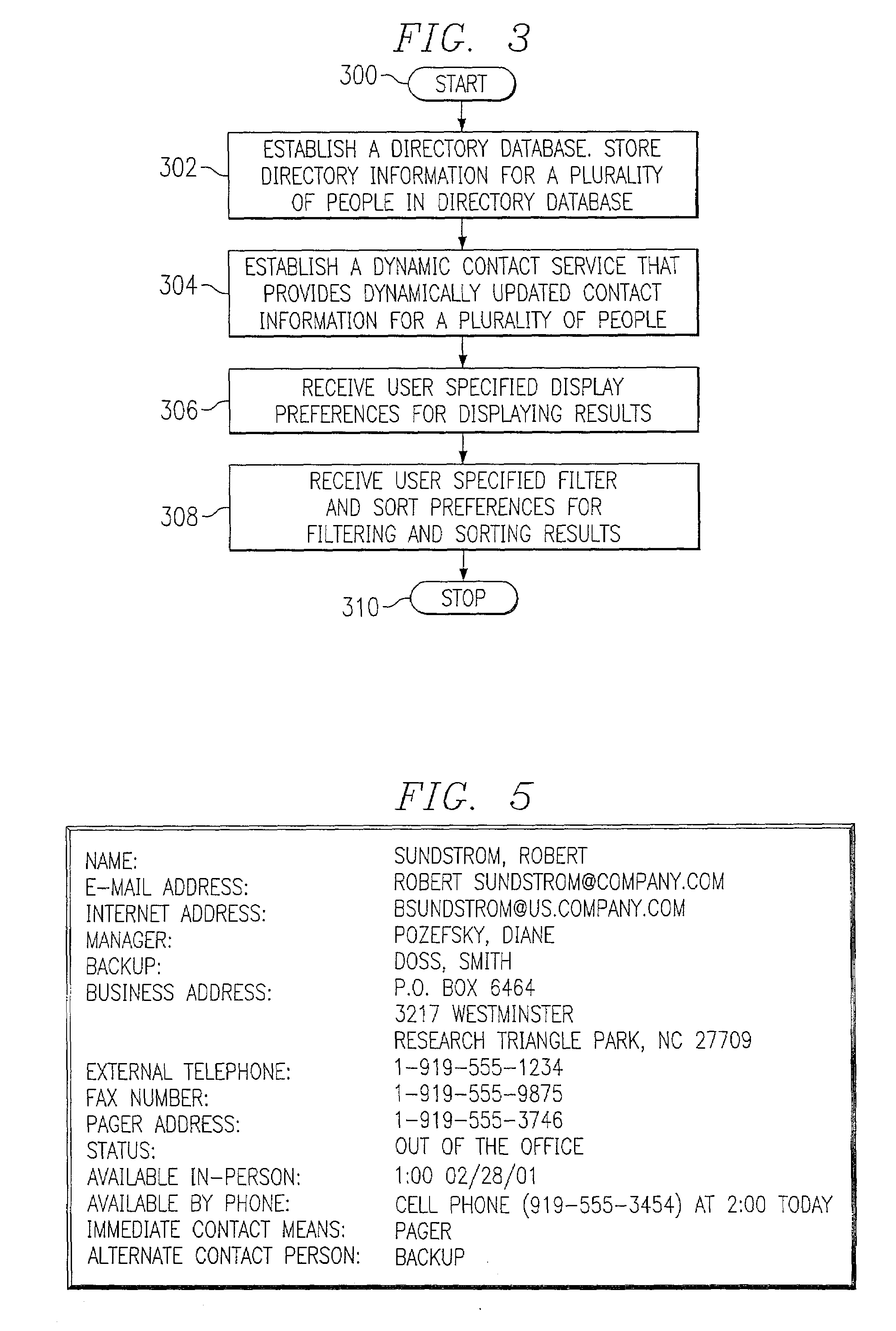

Calendar-enhanced directory searches including dynamic contact information

InactiveUS7096232B2Digital data processing detailsMultiple digital computer combinationsResult setDirectory service

A method, system, and product are disclosed for displaying directory information and dynamically updated contact information for one or more people in response to a directory search. A user submits a query criteria when the directory search is requested. A search of the directory information is first executed utilizing the query criteria to return a first result set. A search of dynamically updated contact information is then executed using the first result set to produce a second result set. A final result of the directory search request is then produced by coalescing the first and second result sets. This final result includes both directory information and dynamically updated contact information for each person whose name was included in the final result.

Owner:IBM CORP

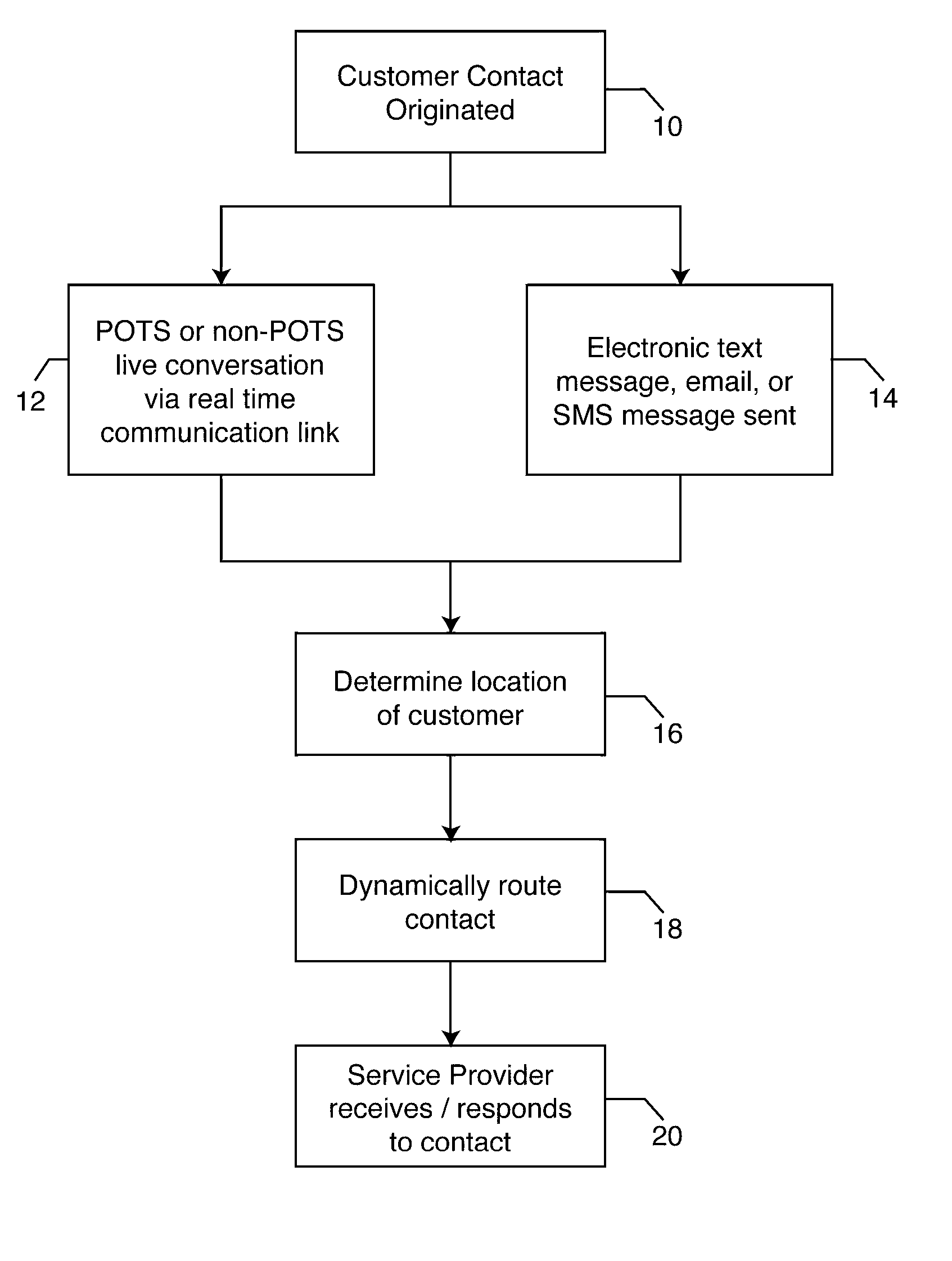

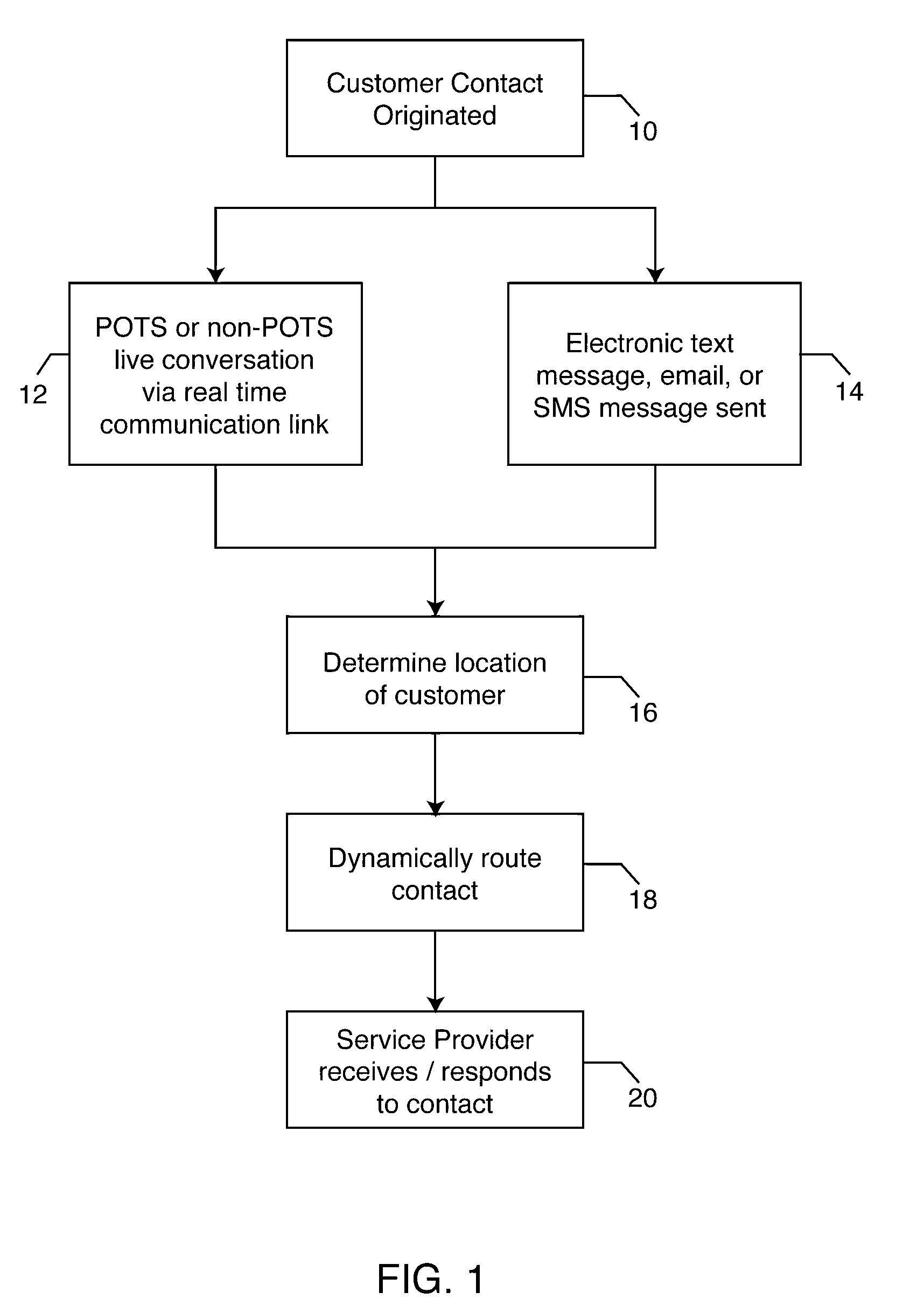

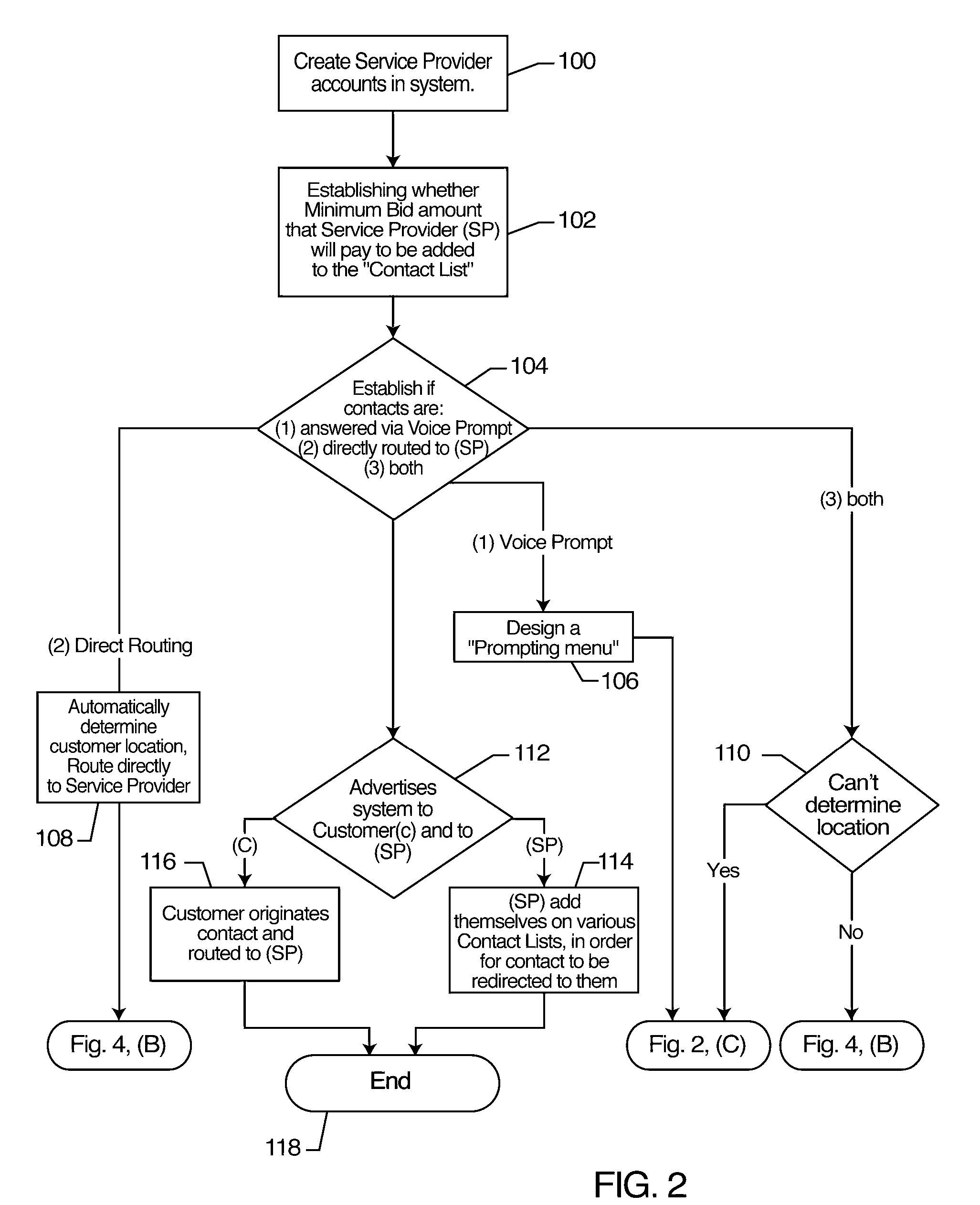

Process for dynamic routing of customer contacts to service providers in real time

InactiveUS20060136310A1Complete banking machinesInterconnection arrangementsAdaptive routingPayment service provider

A dynamic contact routing system includes establishing a plurality of service provider accounts. The service providers submit bids for a per-contact charge. A contact list is created wherein the service providers are ranked from the highest bidder to the lowest bidder. A contact received from a potential customer is routed to the highest ranked bidder service provider on the contact list. If the contact is not responded to or rejected, the contact is rerouted to the next highest ranked service provider on the contact list. The service provider's account who has received the contact is charged the pre-contact amount by that service provider.

Owner:METRO ENTERPRISES INC

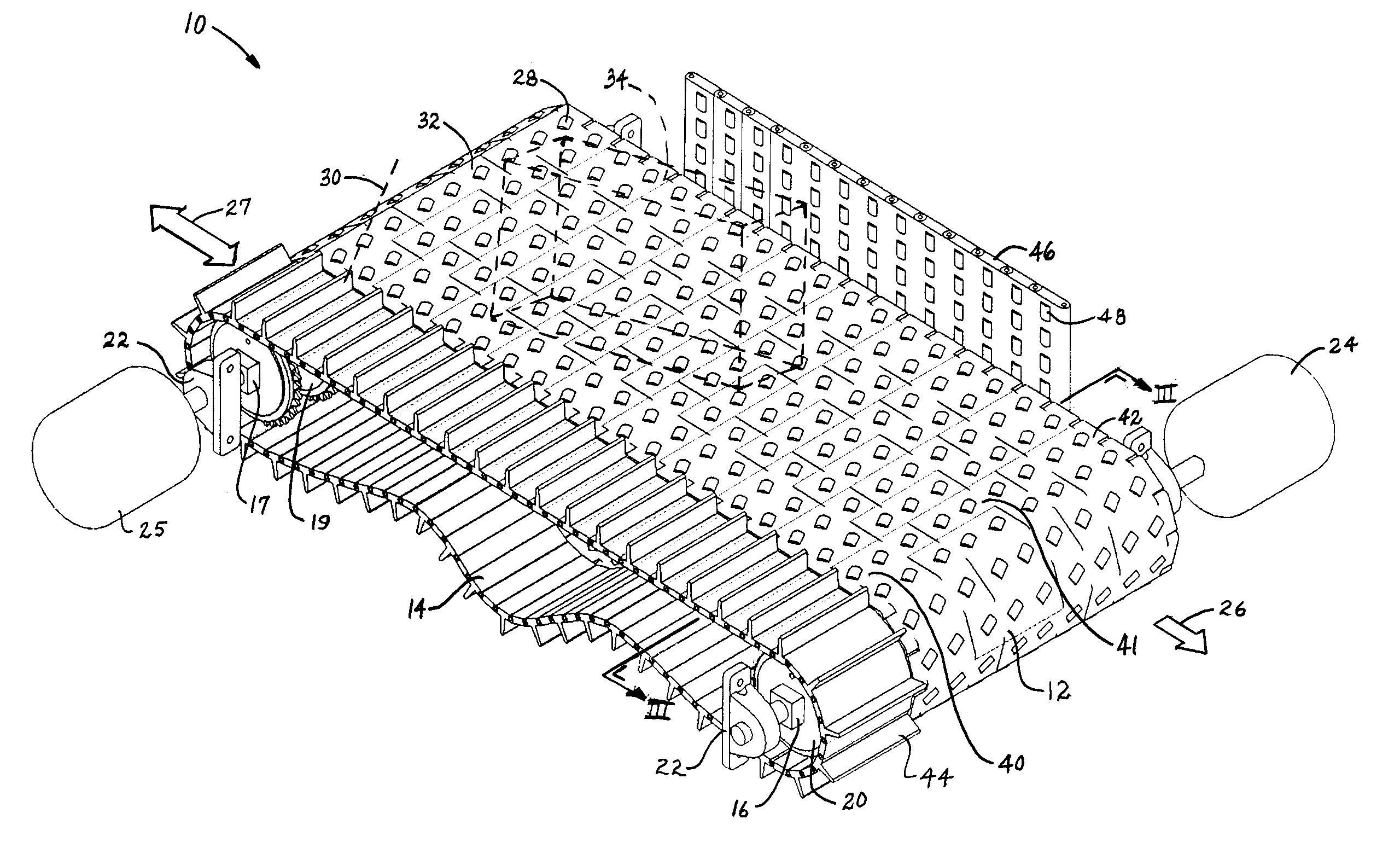

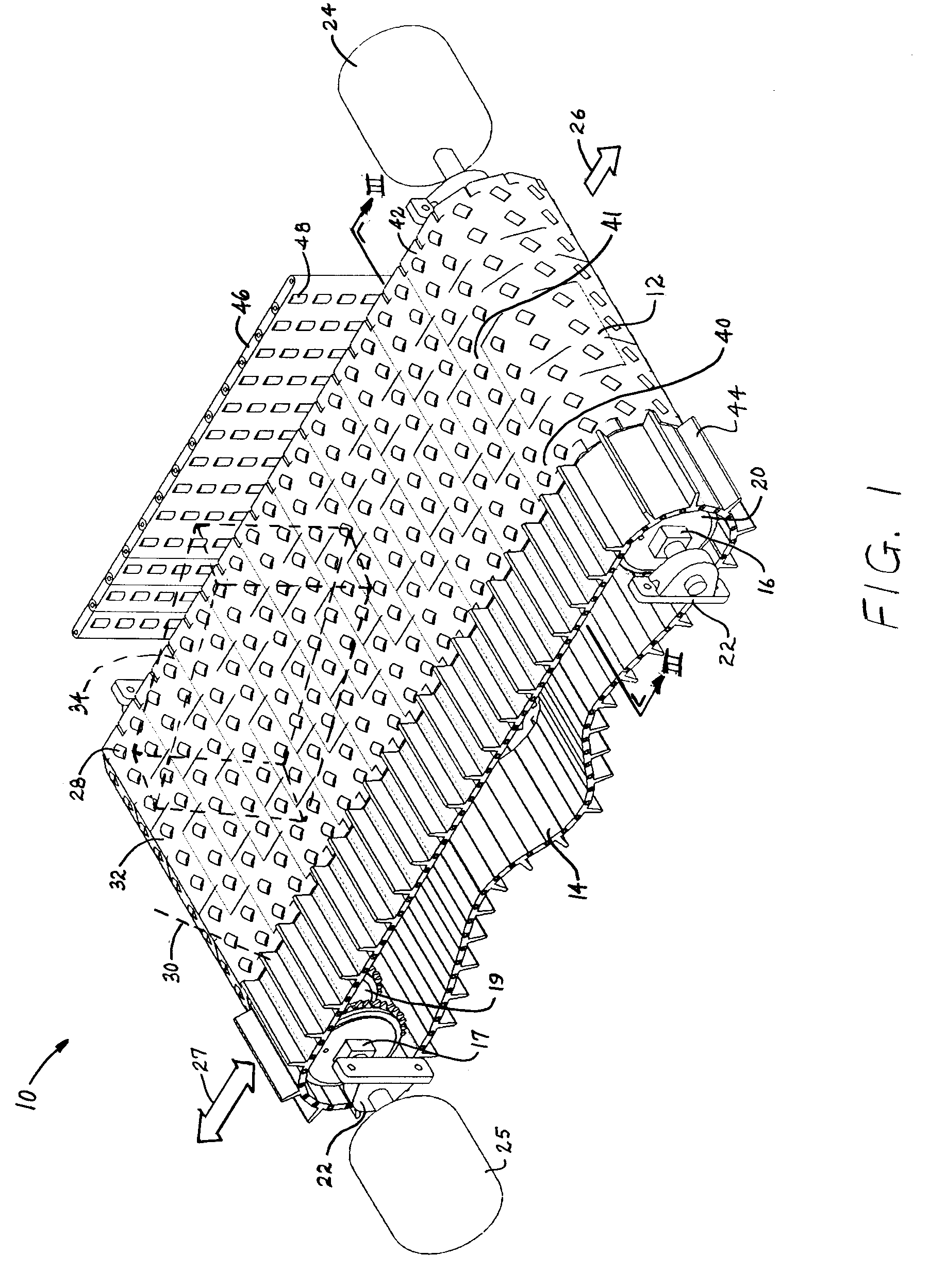

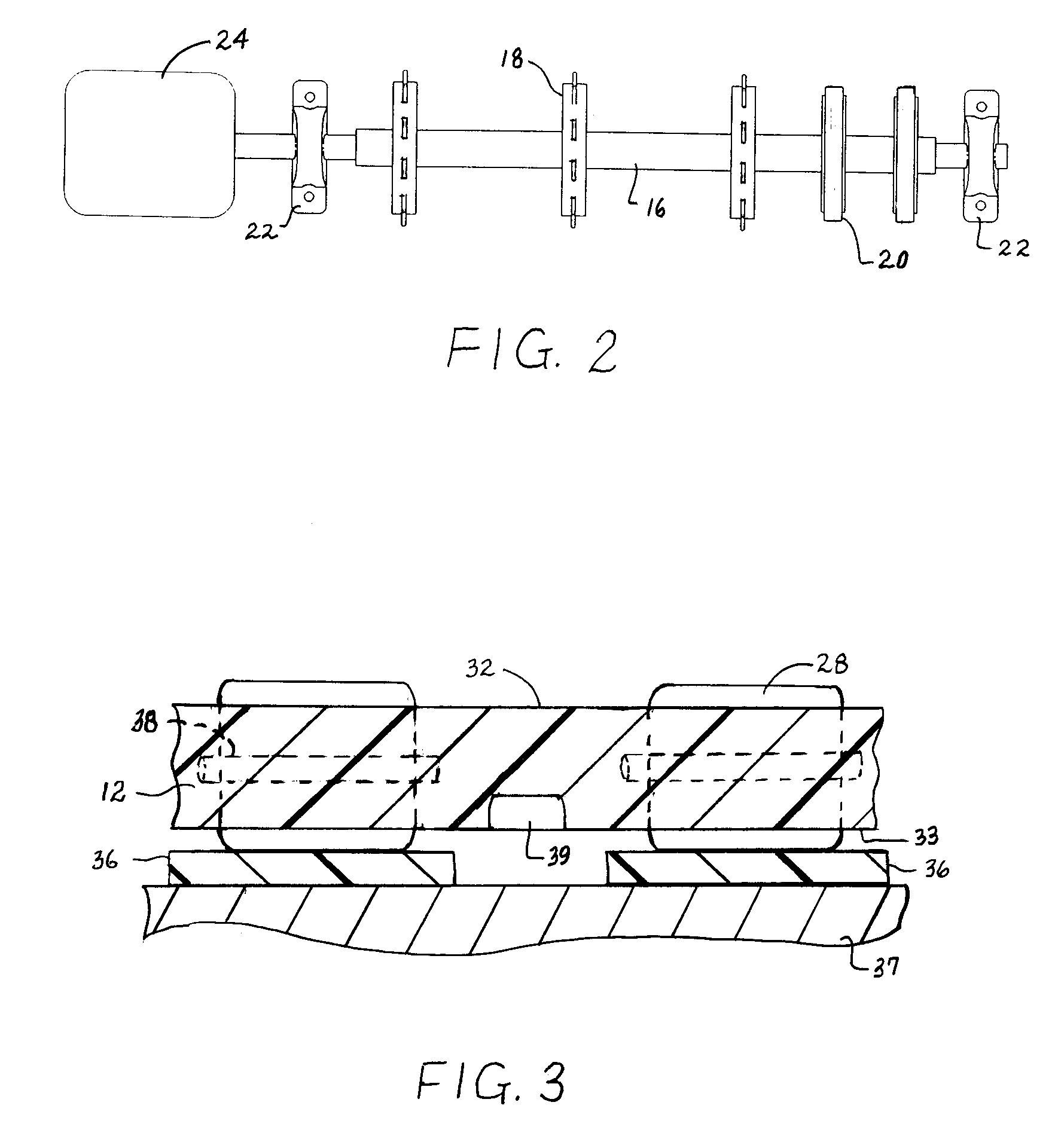

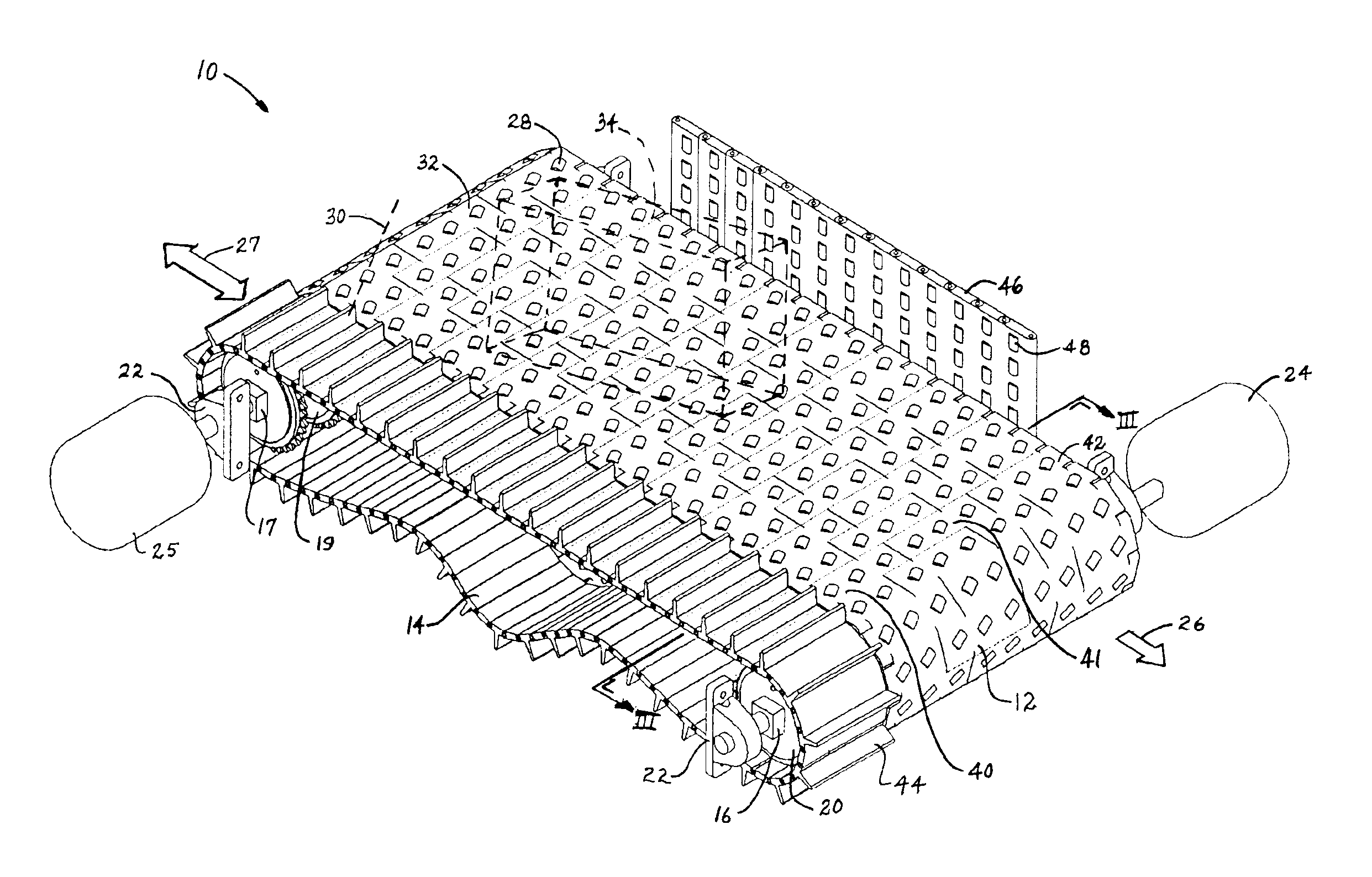

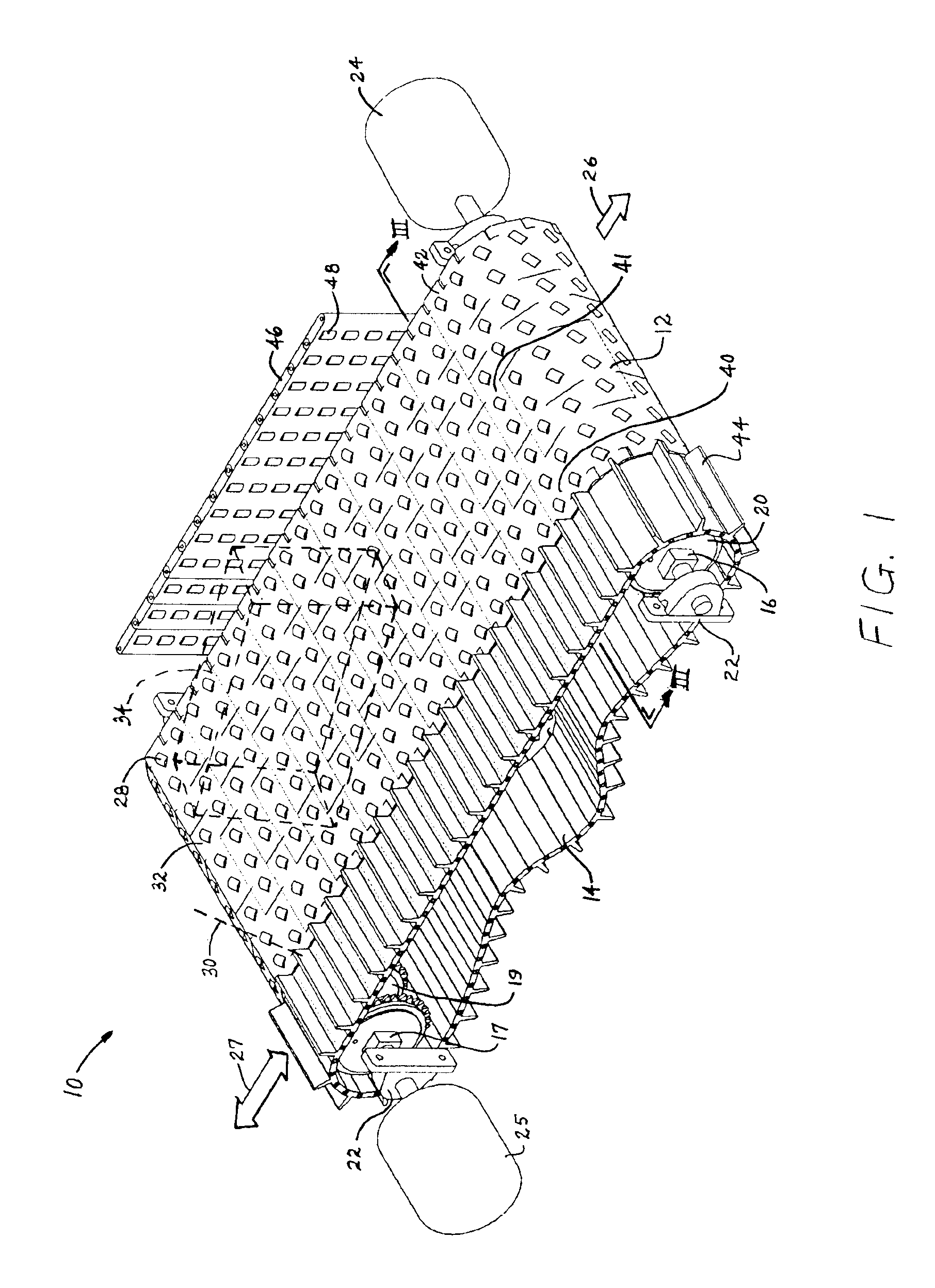

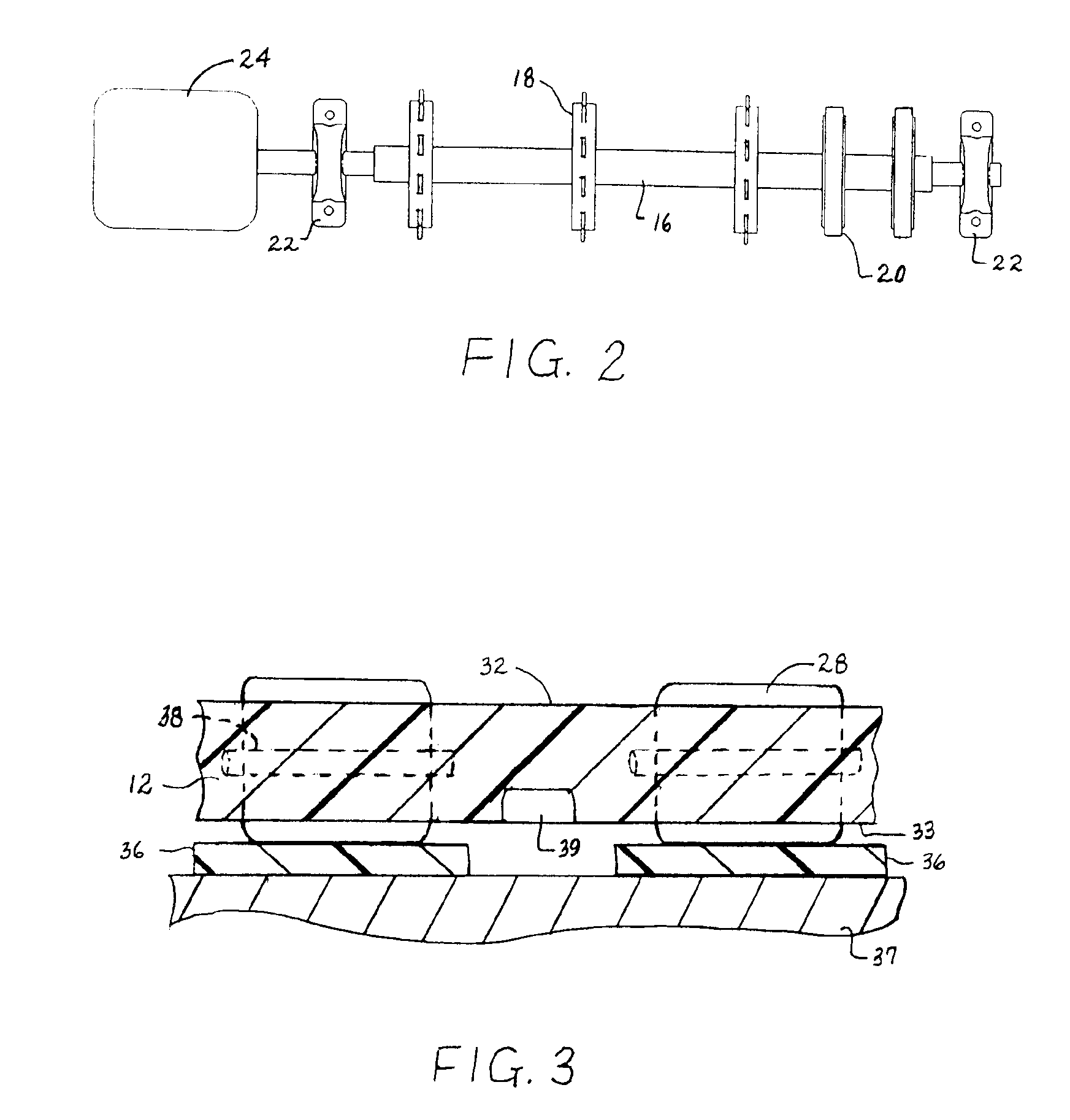

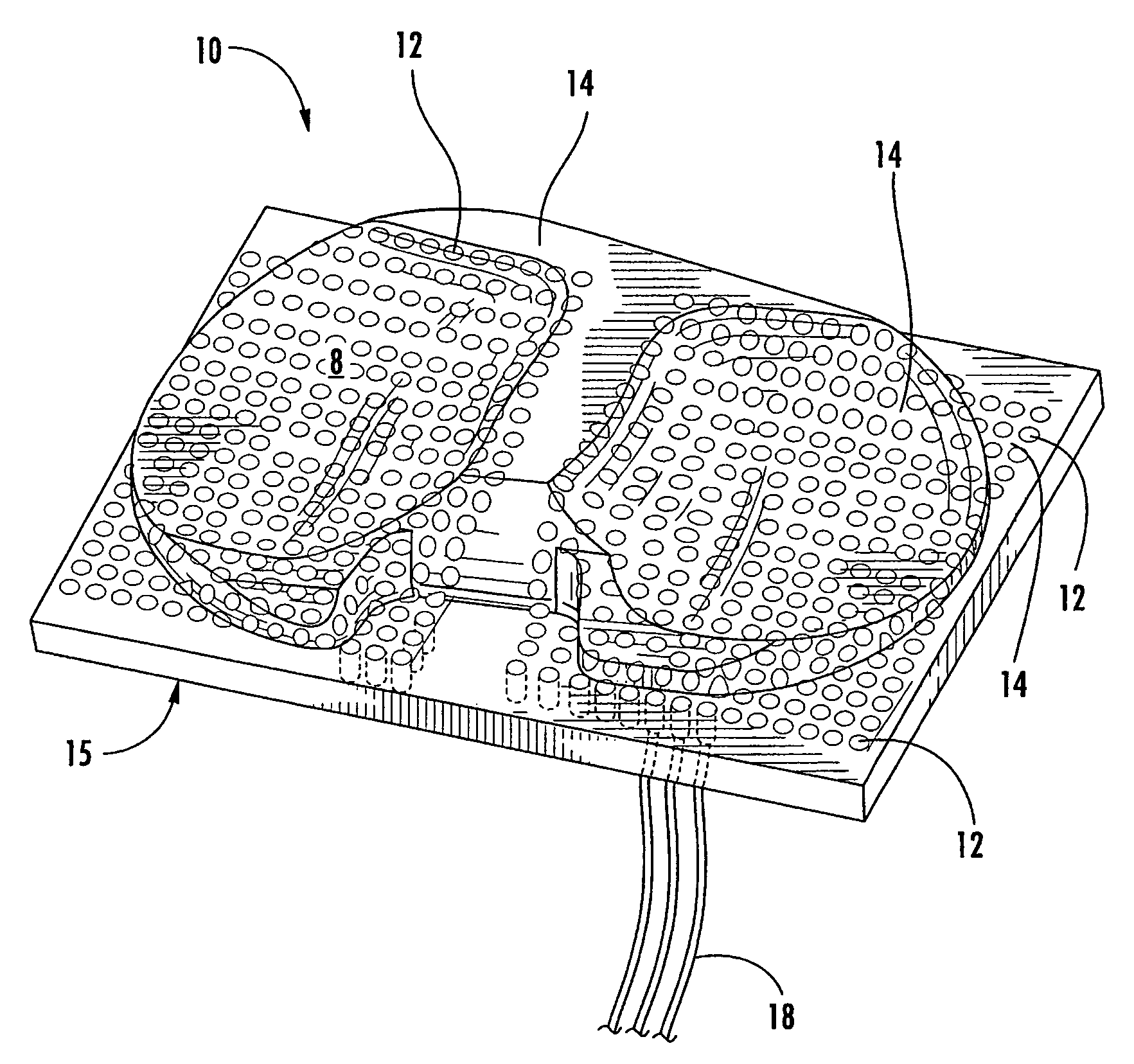

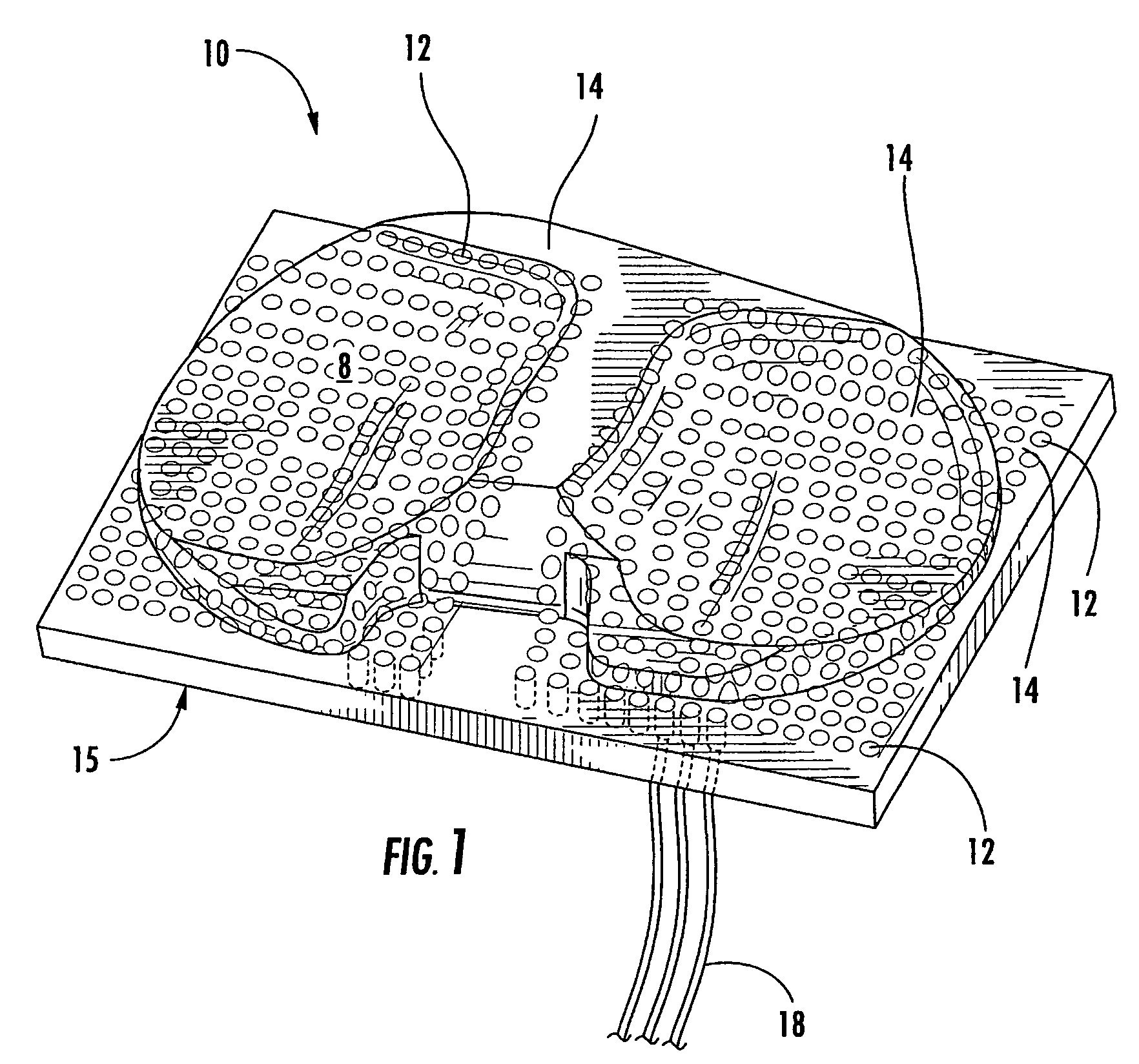

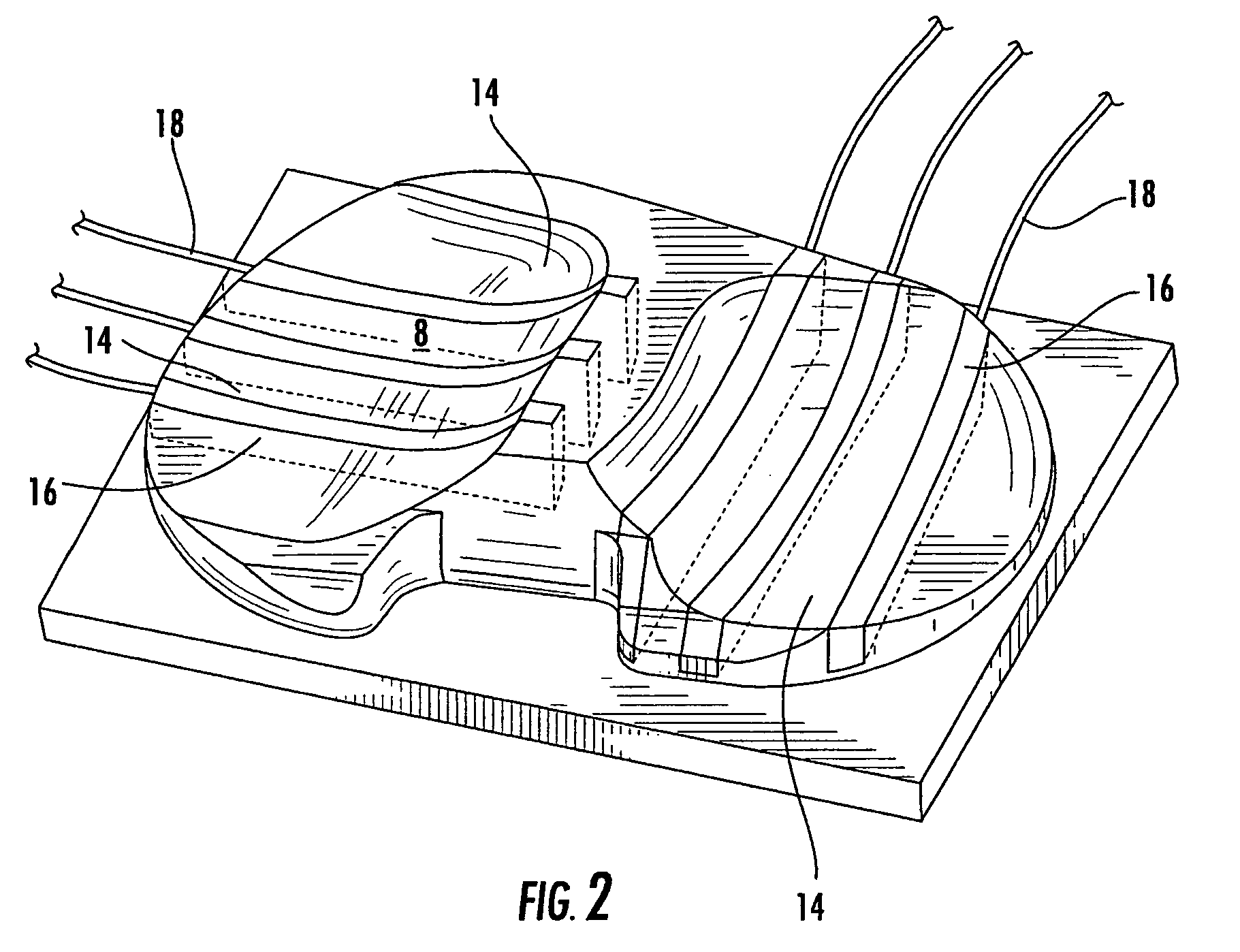

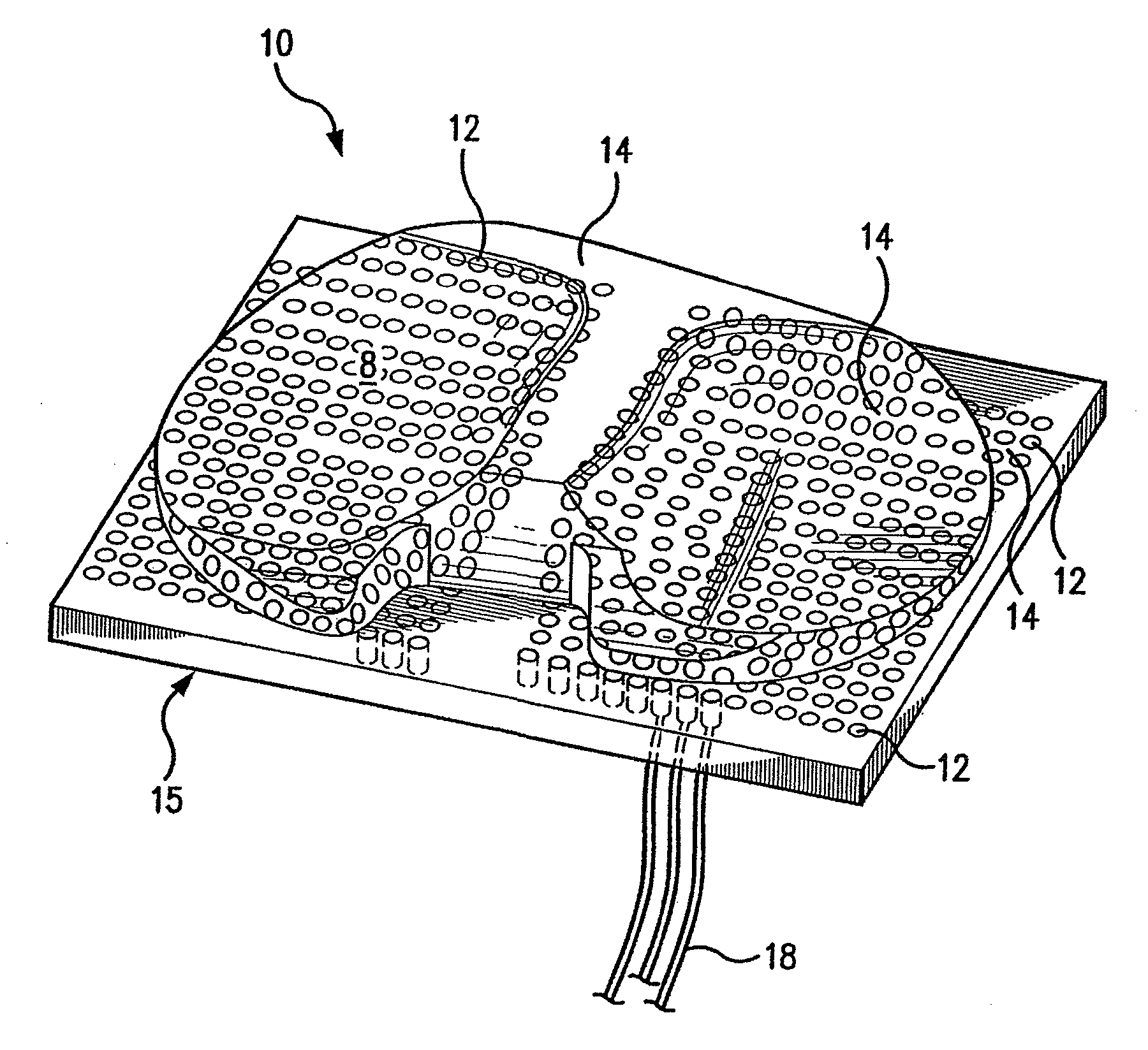

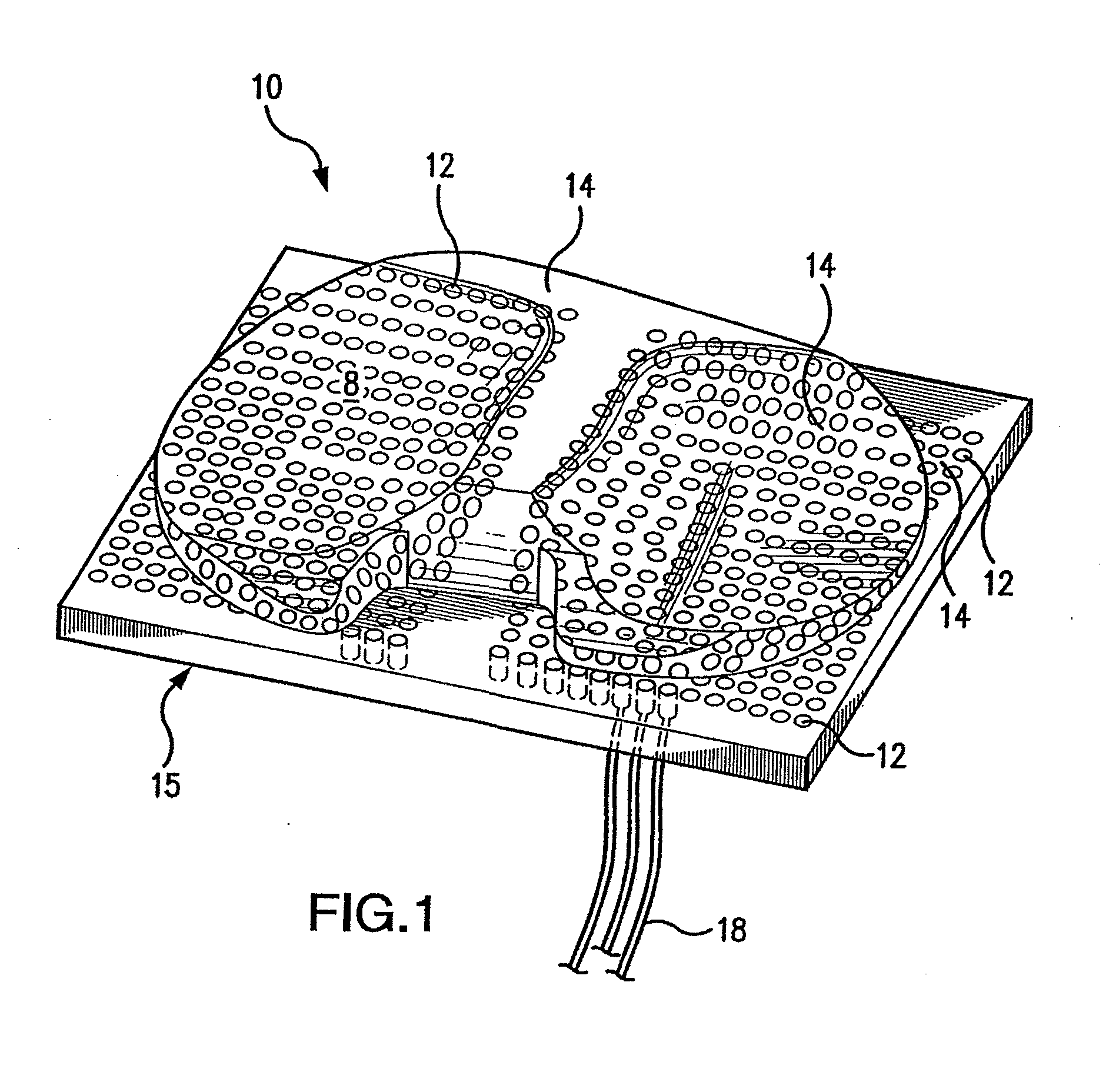

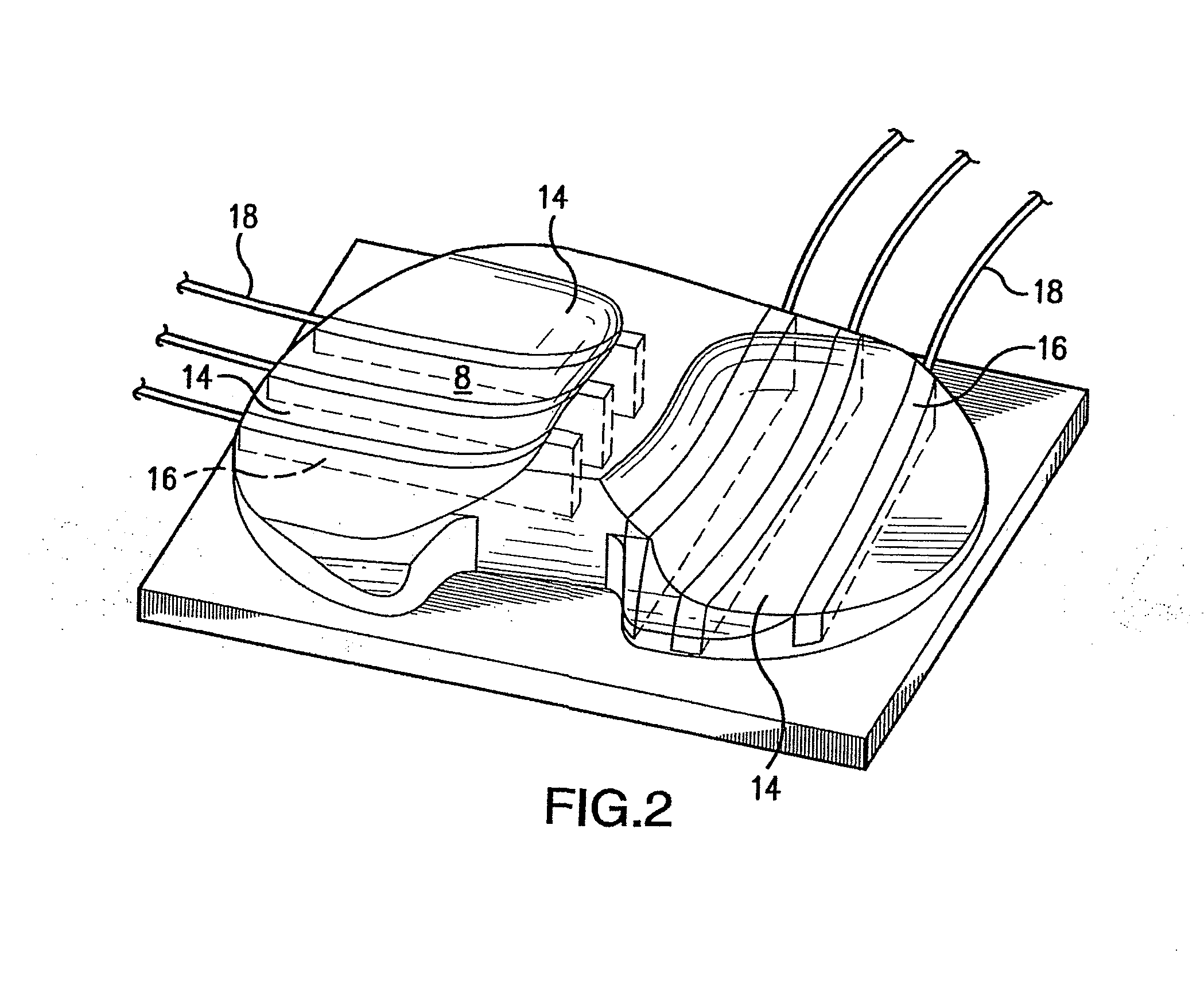

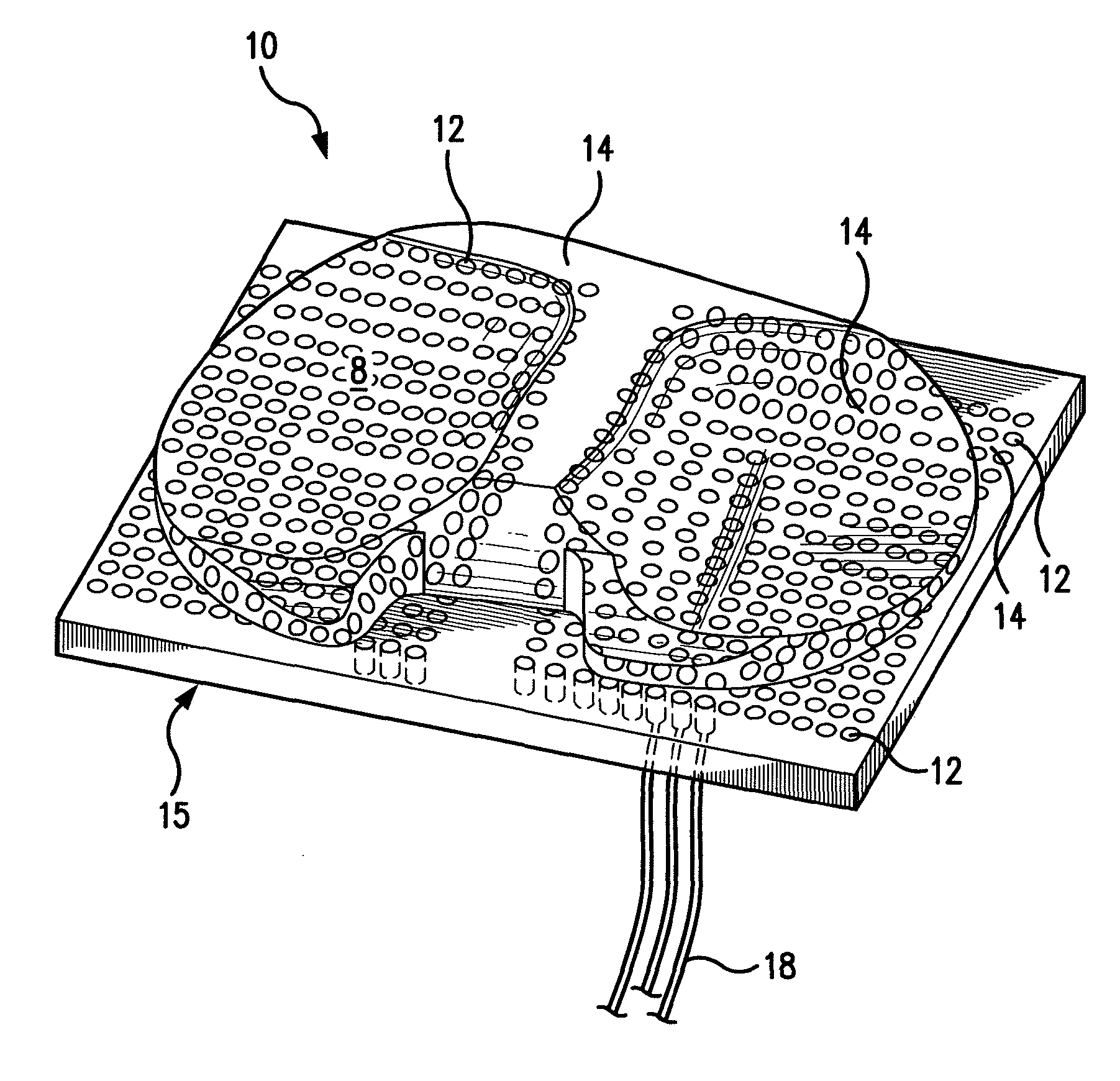

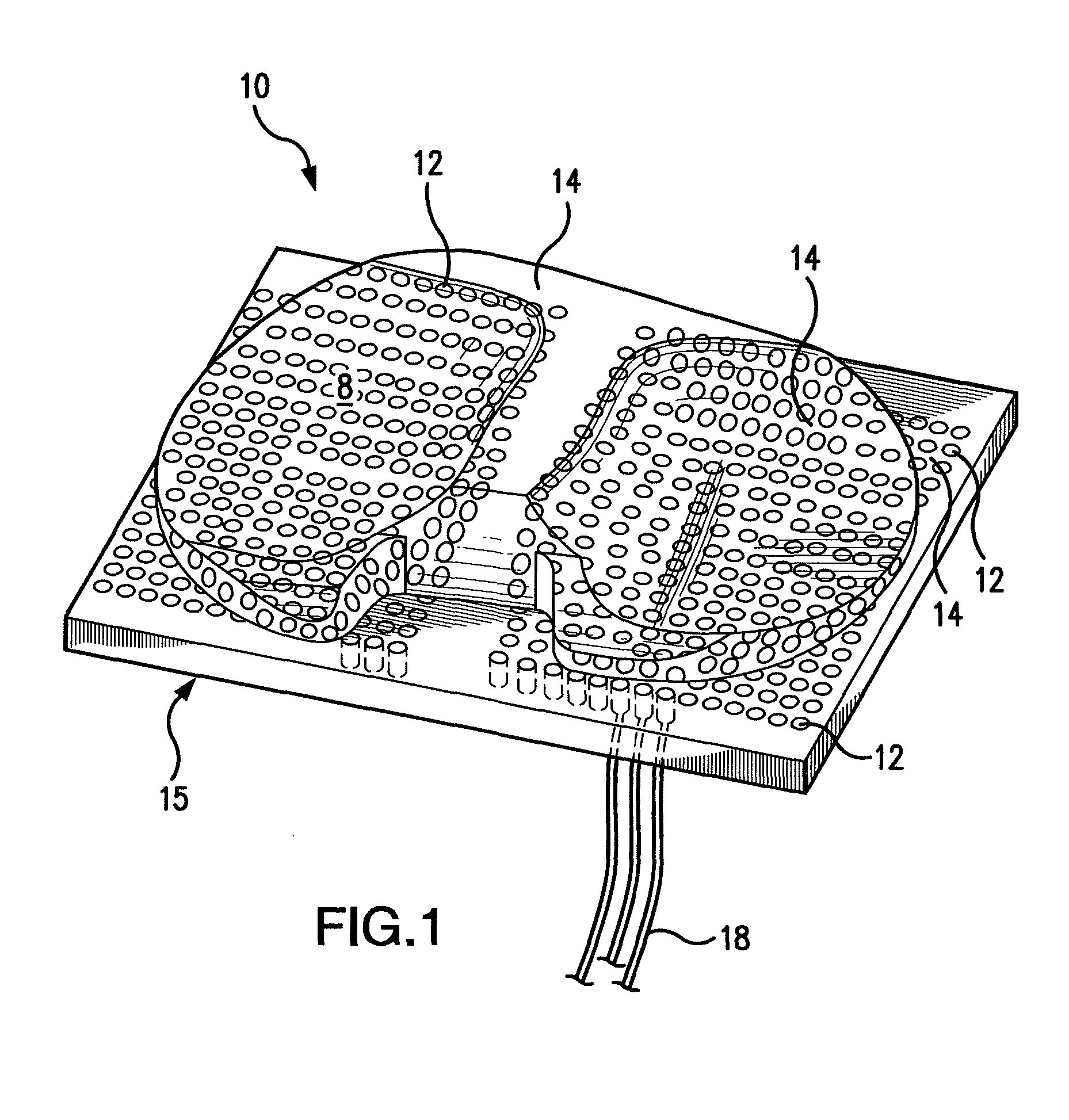

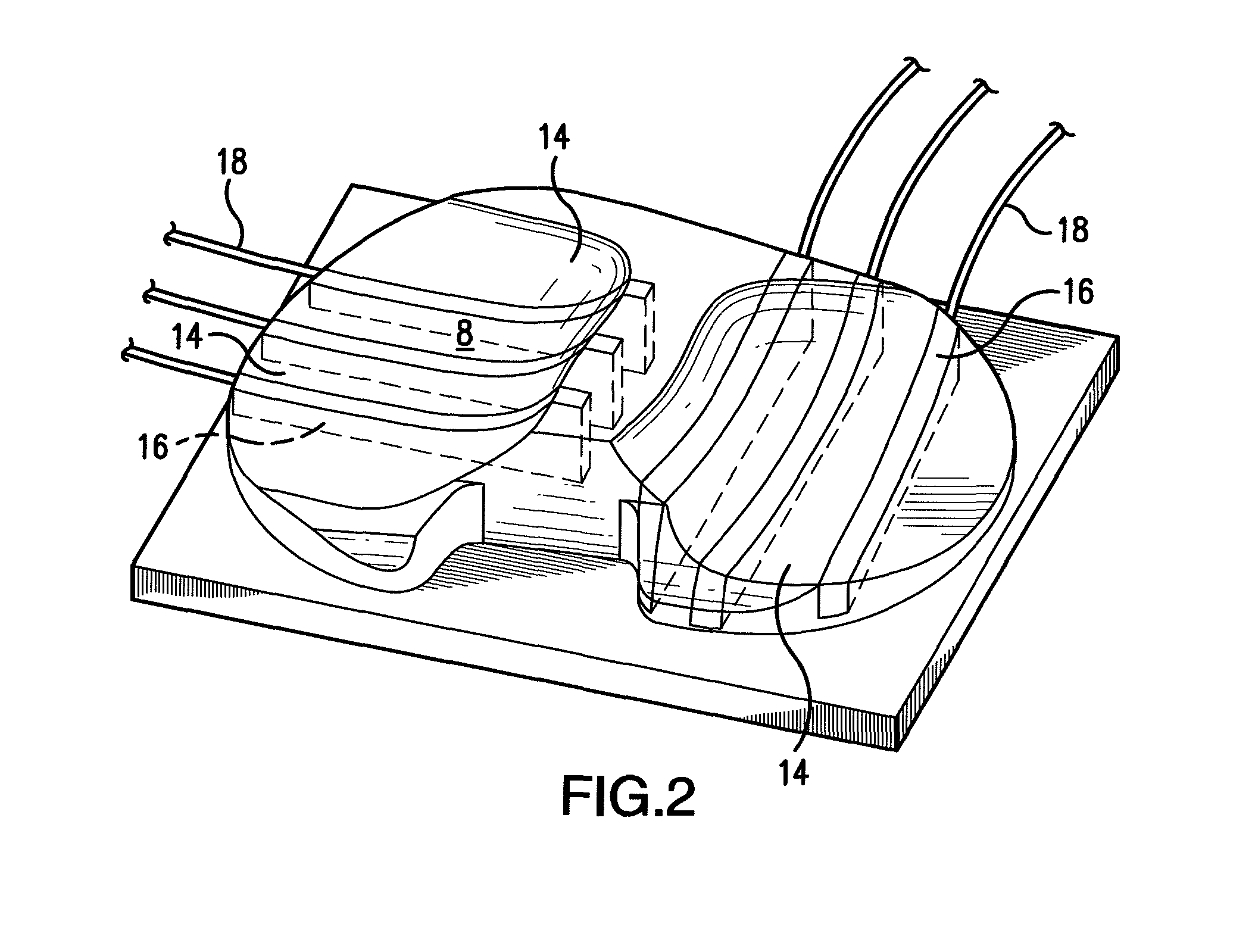

Article-orienting conveyor

A conveyor for orienting and registering articles in a preferred orientation and position for accurate downstream processing. The conveyor includes a conveyor belt running in a conveyance direction next to an orientation belt running parallel in an opposite direction or more slowly in the same direction. The orientation belt has upstanding structure, such as flights, or a high-friction surface. The conveyor belt includes article-supporting rollers on a top side. The rollers are arranged to rotate about axes oblique to the conveyance direction. The rollers also extend below the bottom side of the belt and are rotated by dynamic contact with bearing surfaces supporting the belt as it advances in the conveying direction. The rotating rollers direct conveyed articles toward a side rail. If a portion of a conveyed article extends past the side edge of the conveyor belt into the path of the orientation belt, the obstructions or high-friction surface of the slower- or oppositely-moving orientation belt strikes the conveyed articles and cause them to rotate clockwise toward an alignment of the article in the conveyance direction and into registration against the side rail at the downstream end of the conveyor. In other versions of the article-orienting conveyor, the orientation belt is replaced by a row of posts or a rotating paddle wheel that strikes conveyed articles extending past the side edge of the conveyor belt.

Owner:LAITRAM LLC

Article-orienting conveyor

A conveyor for orienting and registering articles in a preferred orientation and position for accurate downstream processing. The conveyor includes a conveyor belt running in a conveyance direction next to an orientation belt running parallel in an opposite direction or more slowly in the same direction. The orientation belt has upstanding structure, such as flights, or a high-friction surface. The conveyor belt includes article-supporting rollers on a top side. The rollers are arranged to rotate about axes oblique to the conveyance direction. The rollers also extend below the bottom side of the belt and are rotated by dynamic contact with bearing surfaces supporting the belt as it advances in the conveying direction. The rotating rollers direct conveyed articles toward a side rail. If a portion of a conveyed article extends past the side edge of the conveyor belt into the path of the orientation belt, the obstructions or high-friction surface of the slower- or oppositely-moving orientation belt strikes the conveyed articles and cause them to rotate clockwise toward an alignment of the article in the conveyance direction and into registration against the side rail at the downstream end of the conveyor. In other versions of the article-orienting conveyor, the orientation belt is replaced by a row of posts or a rotating paddle wheel that strikes conveyed articles extending past the side edge of the conveyor belt.

Owner:LAITRAM LLC

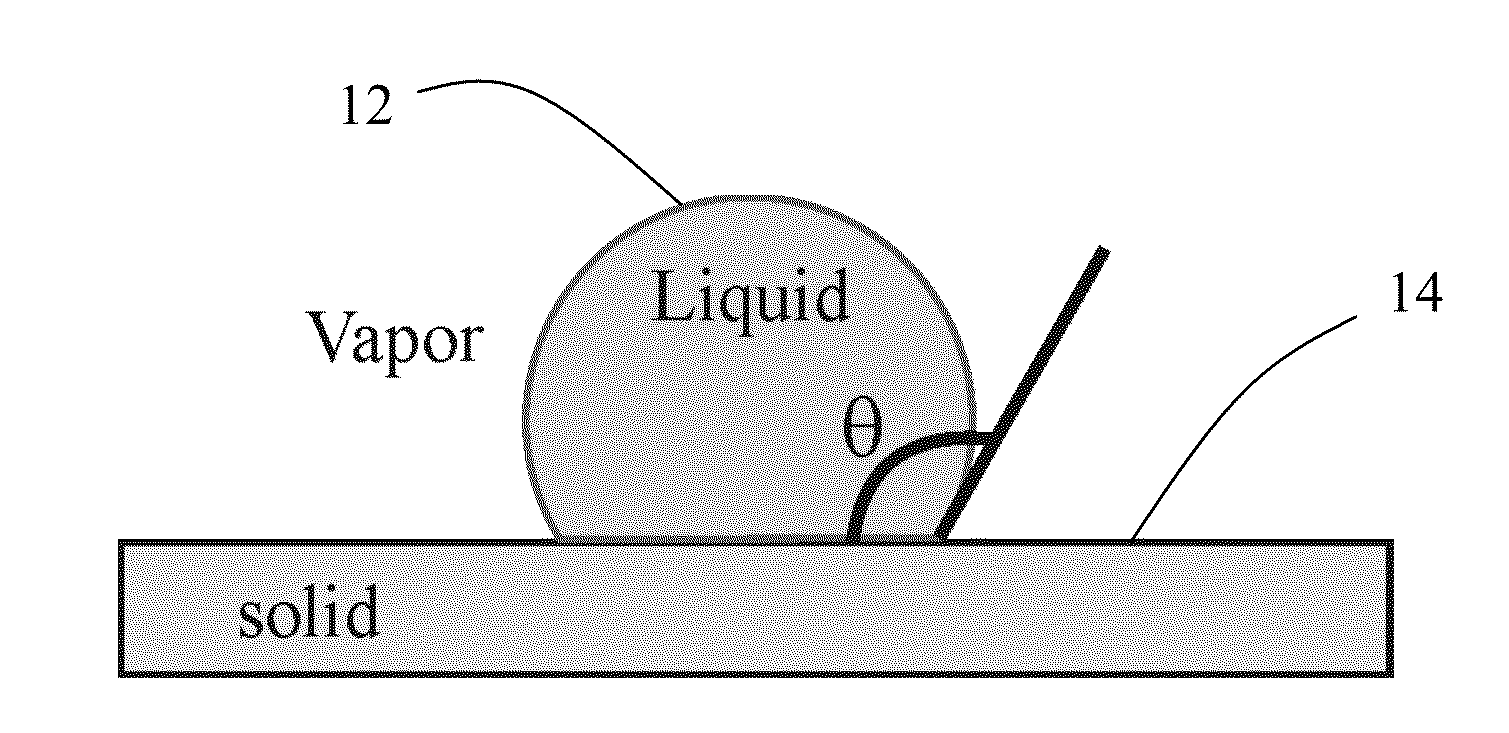

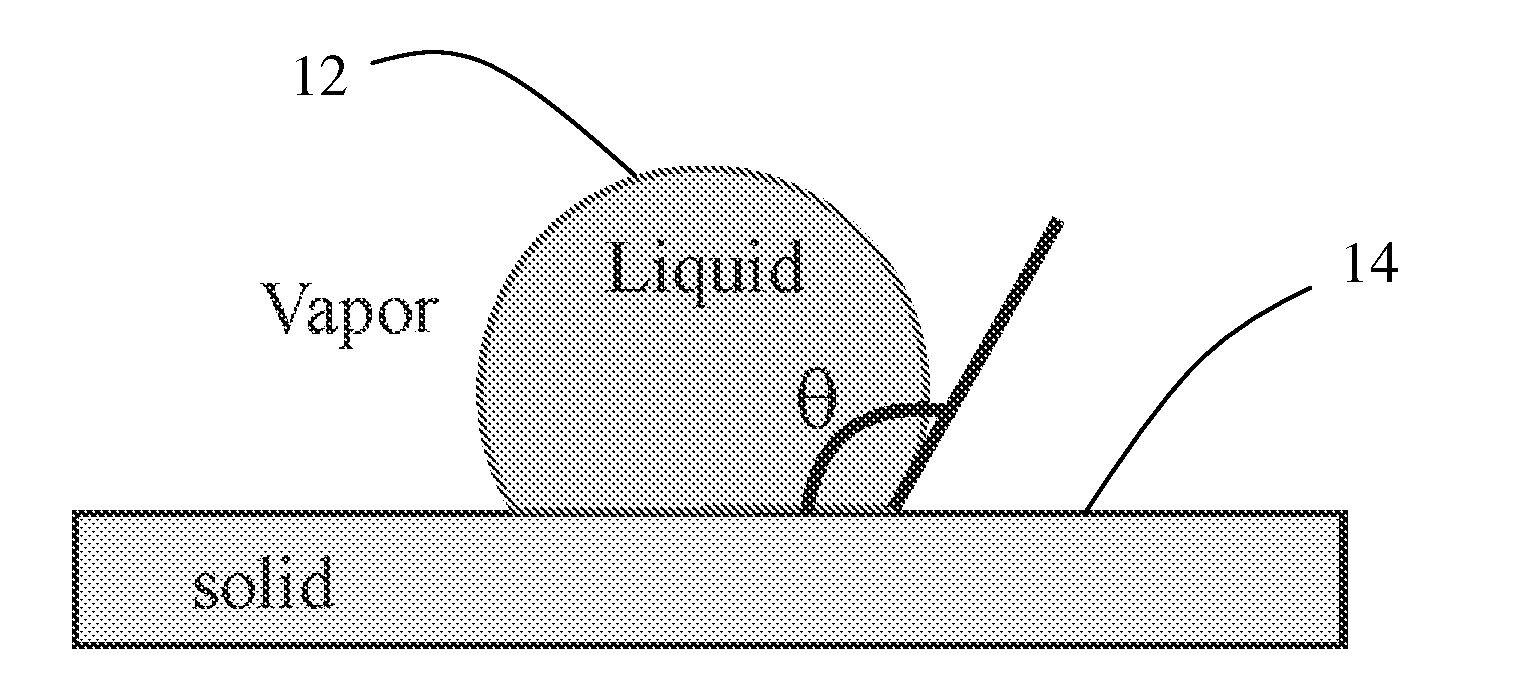

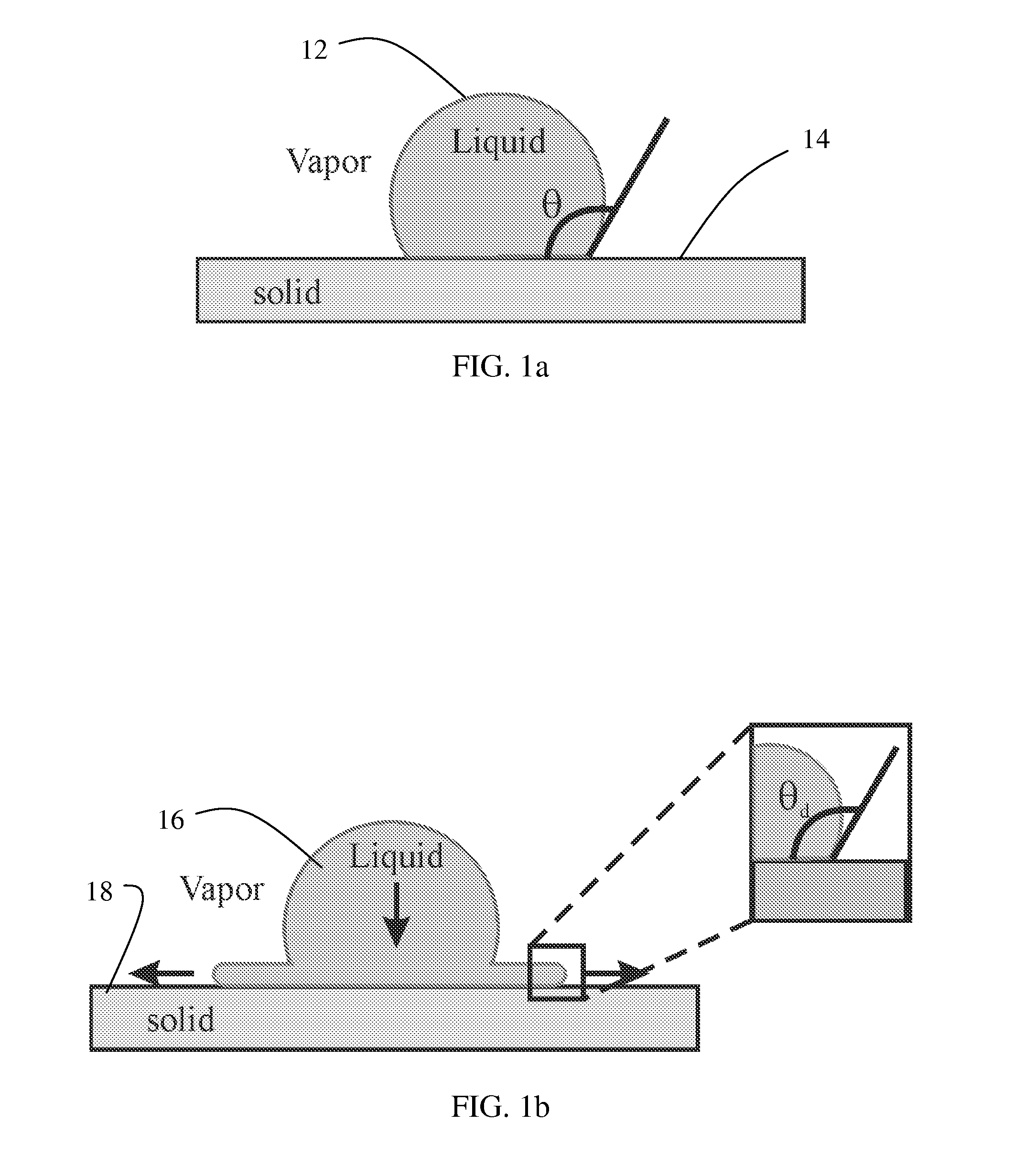

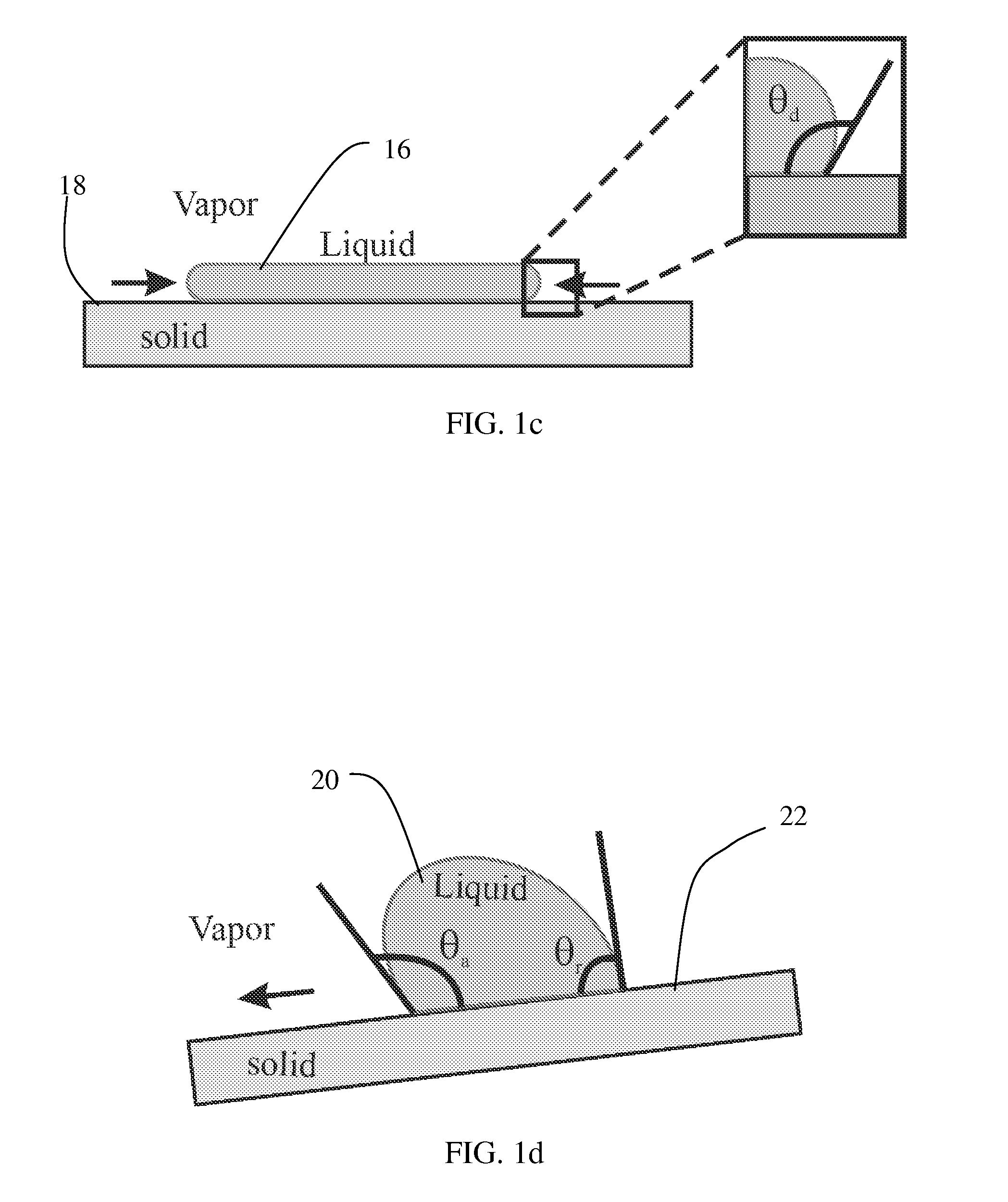

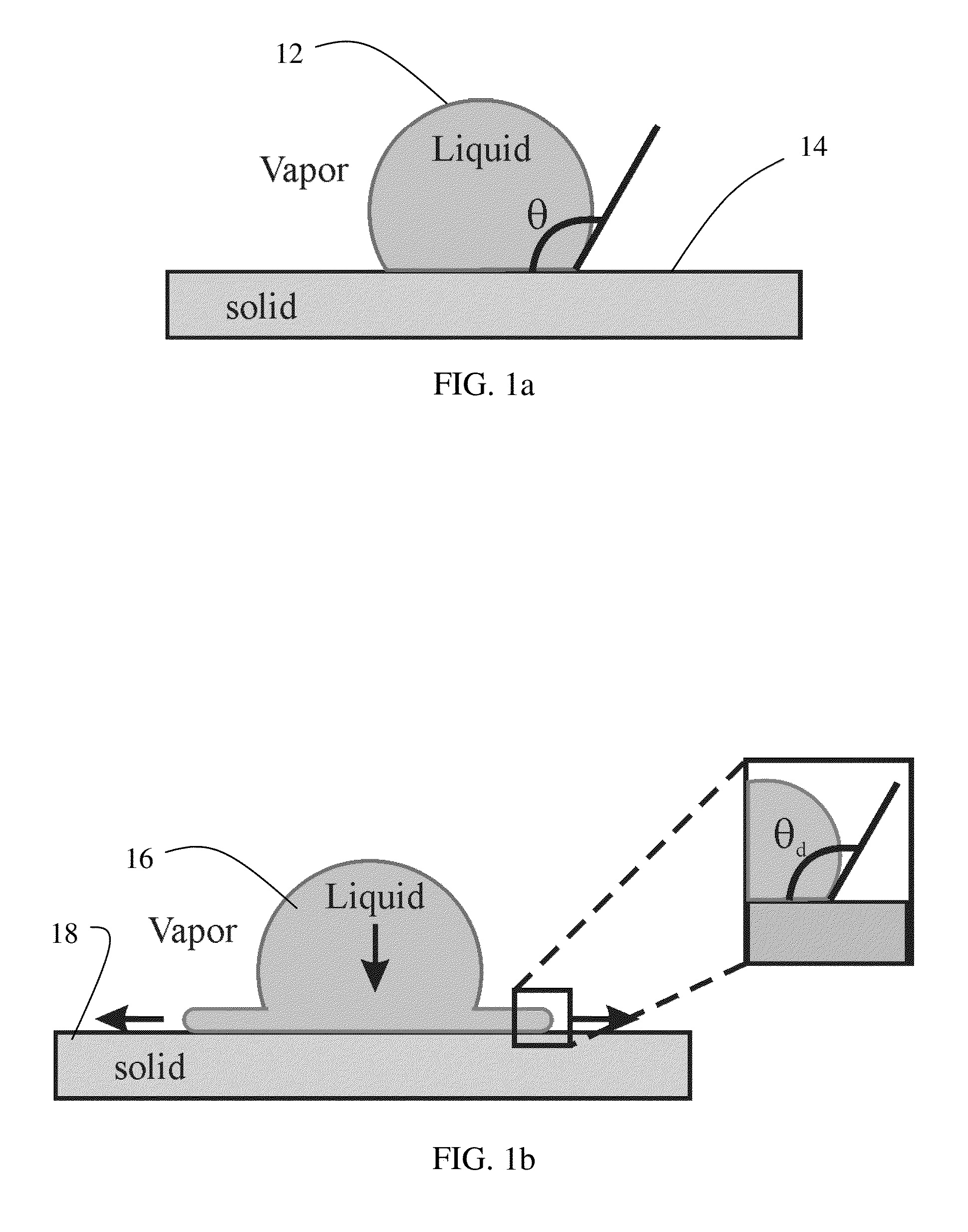

Hydrophobic Materials Incorporating Rare Earth Elements and Methods of Manufacture

InactiveUS20130251942A1Improve waterproof performanceGood for condensationVacuum evaporation coatingSputtering coatingRare-earth elementBoride

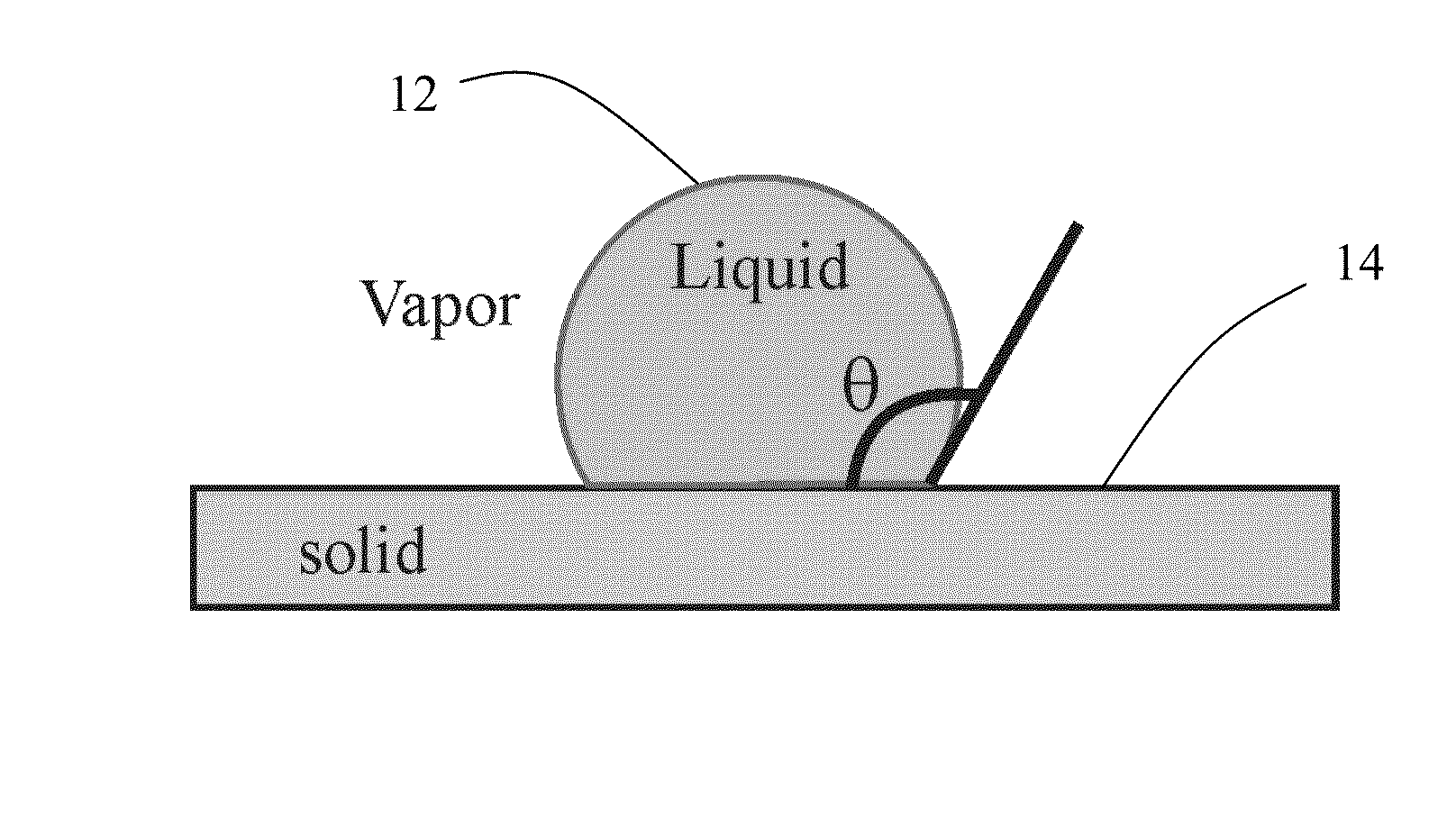

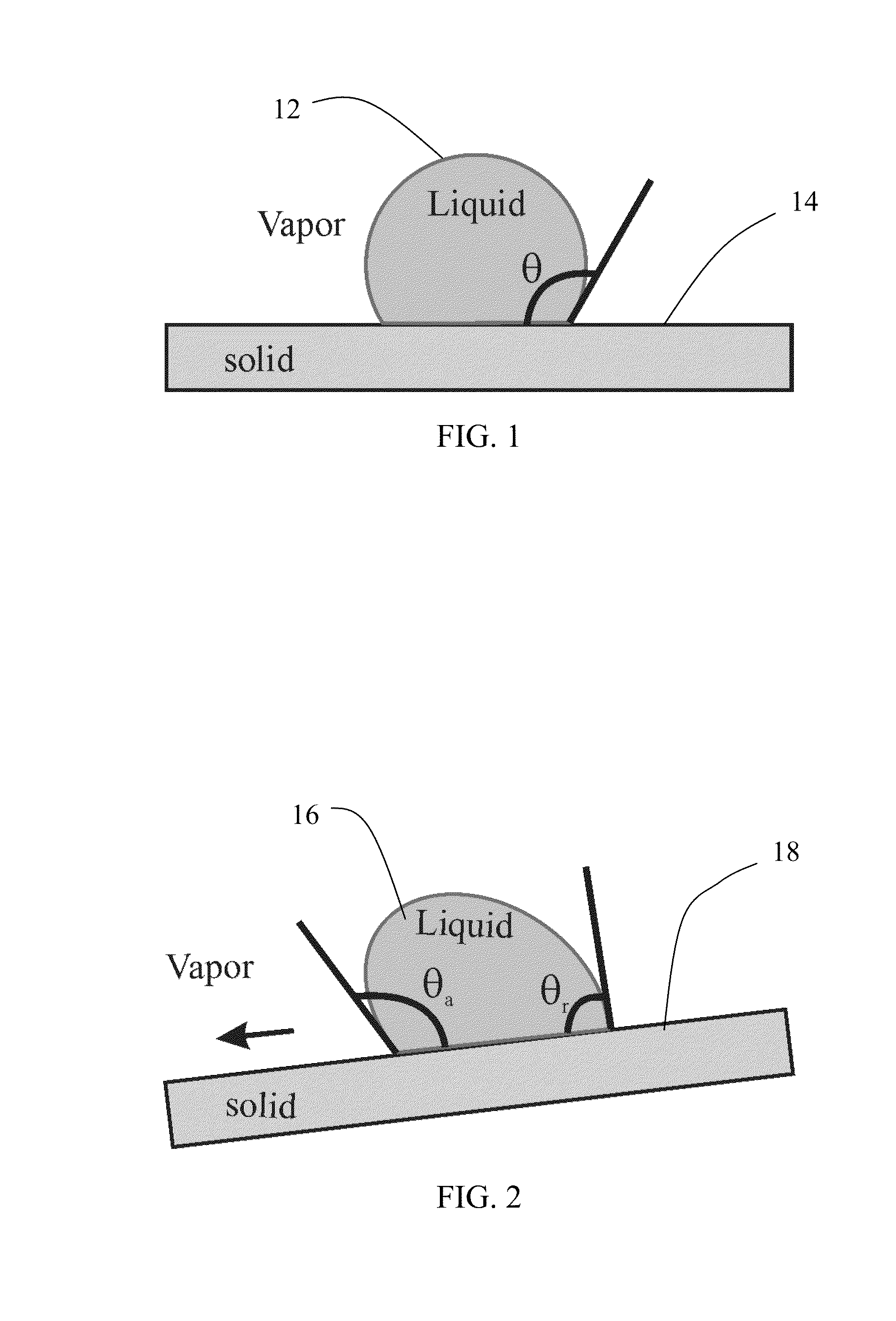

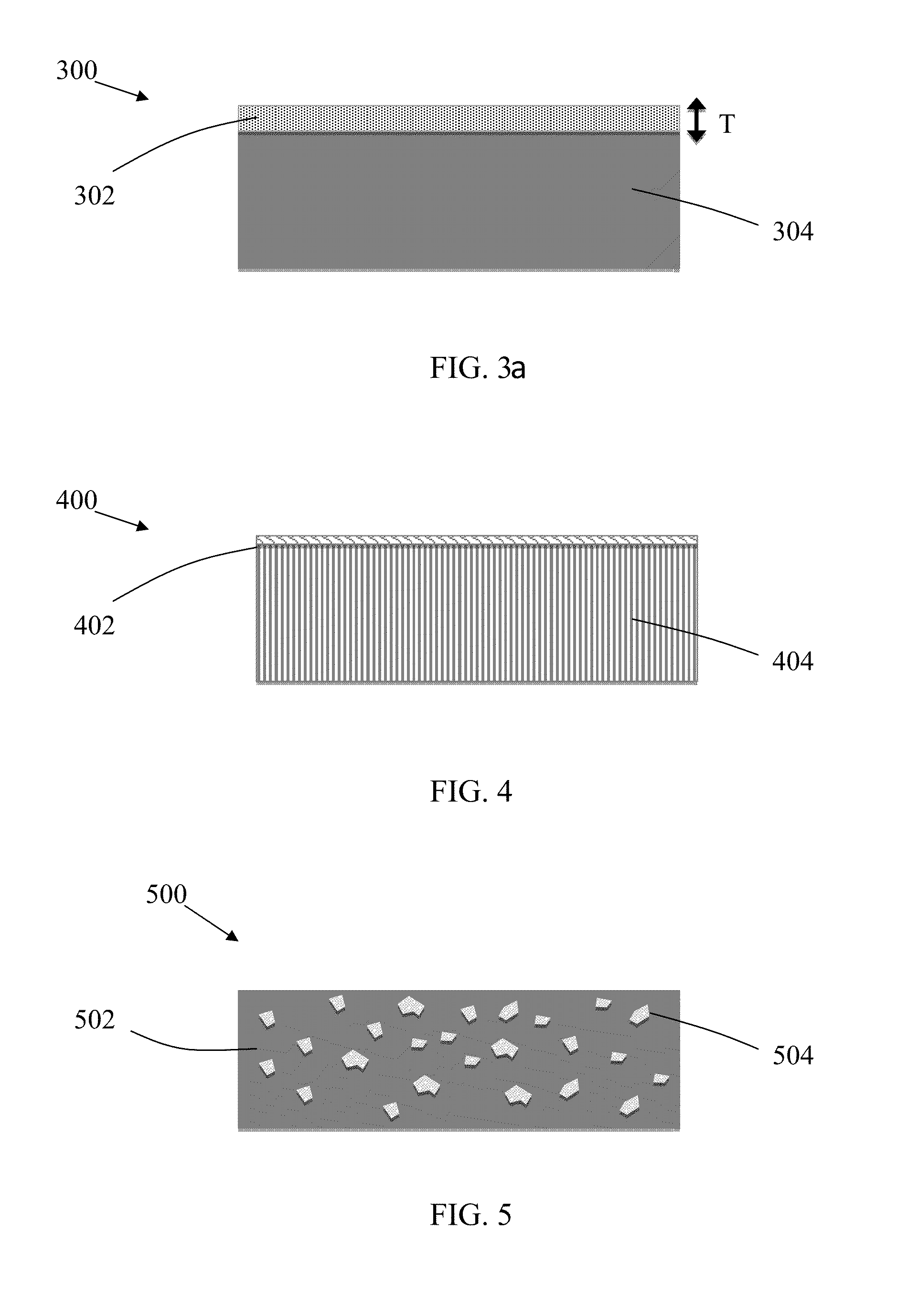

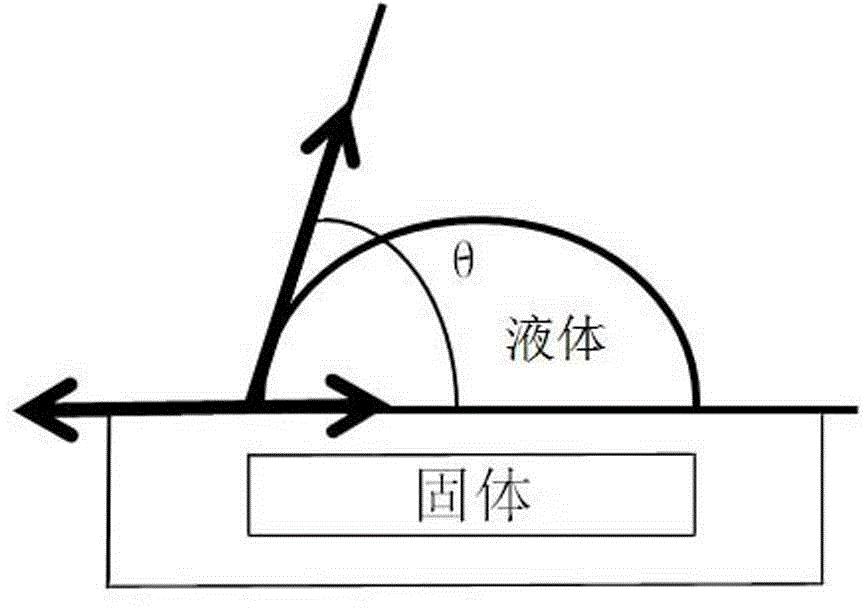

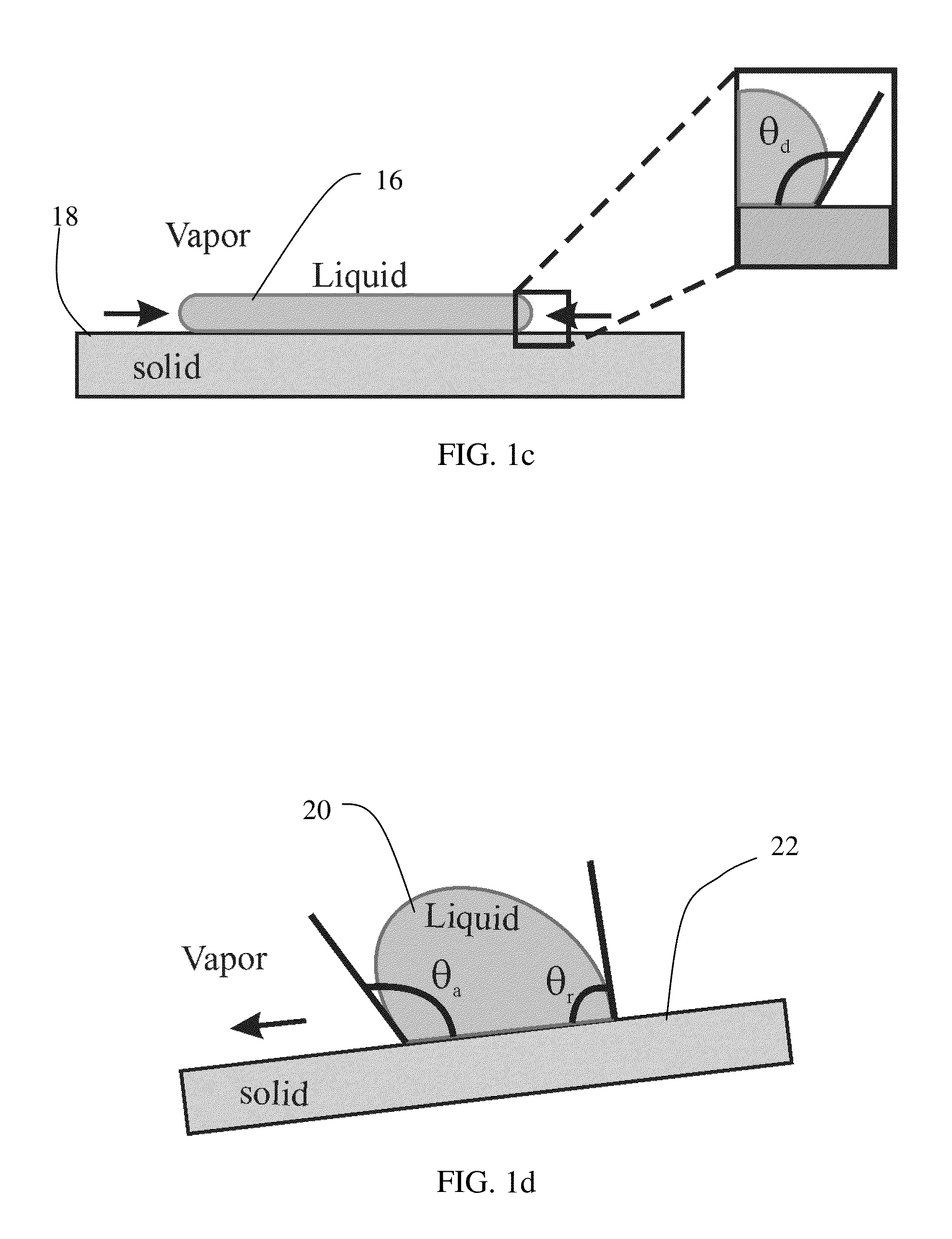

This invention relates generally to an article that includes a base substrate and a hydrophobic coating on the base substrate, wherein the hydrophobic coating includes a rare earth element material (e.g., a rare earth oxide, a rare earth carbide, a rare earth nitride, a rare earth fluoride, and / or a rare earth boride). An exposed surface of the hydrophobic coating has a dynamic contact angle with water of at least about 90 degrees. A method of manufacturing the article includes providing the base substrate and forming a coating on the base substrate (e.g., through sintering or sputtering).

Owner:MASSACHUSETTS INST OF TECH

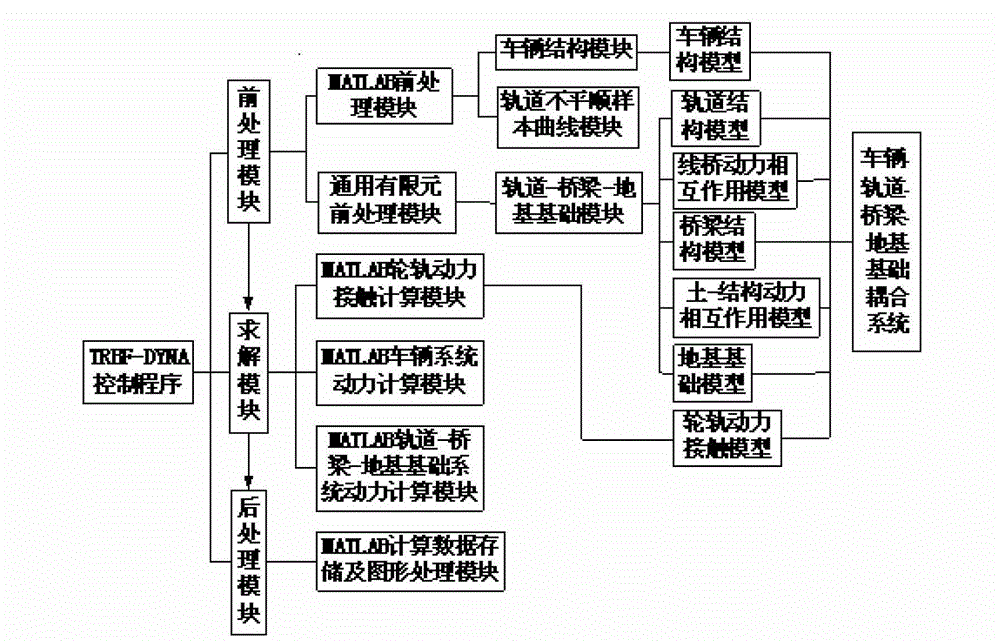

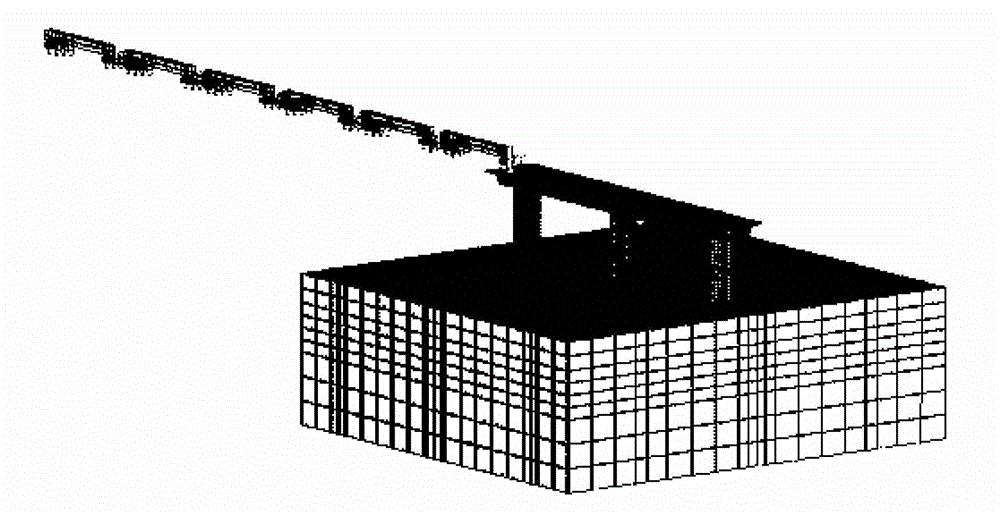

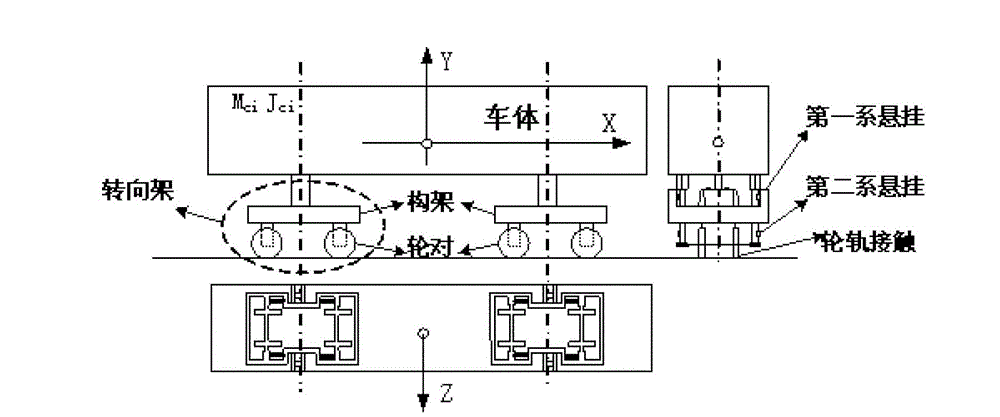

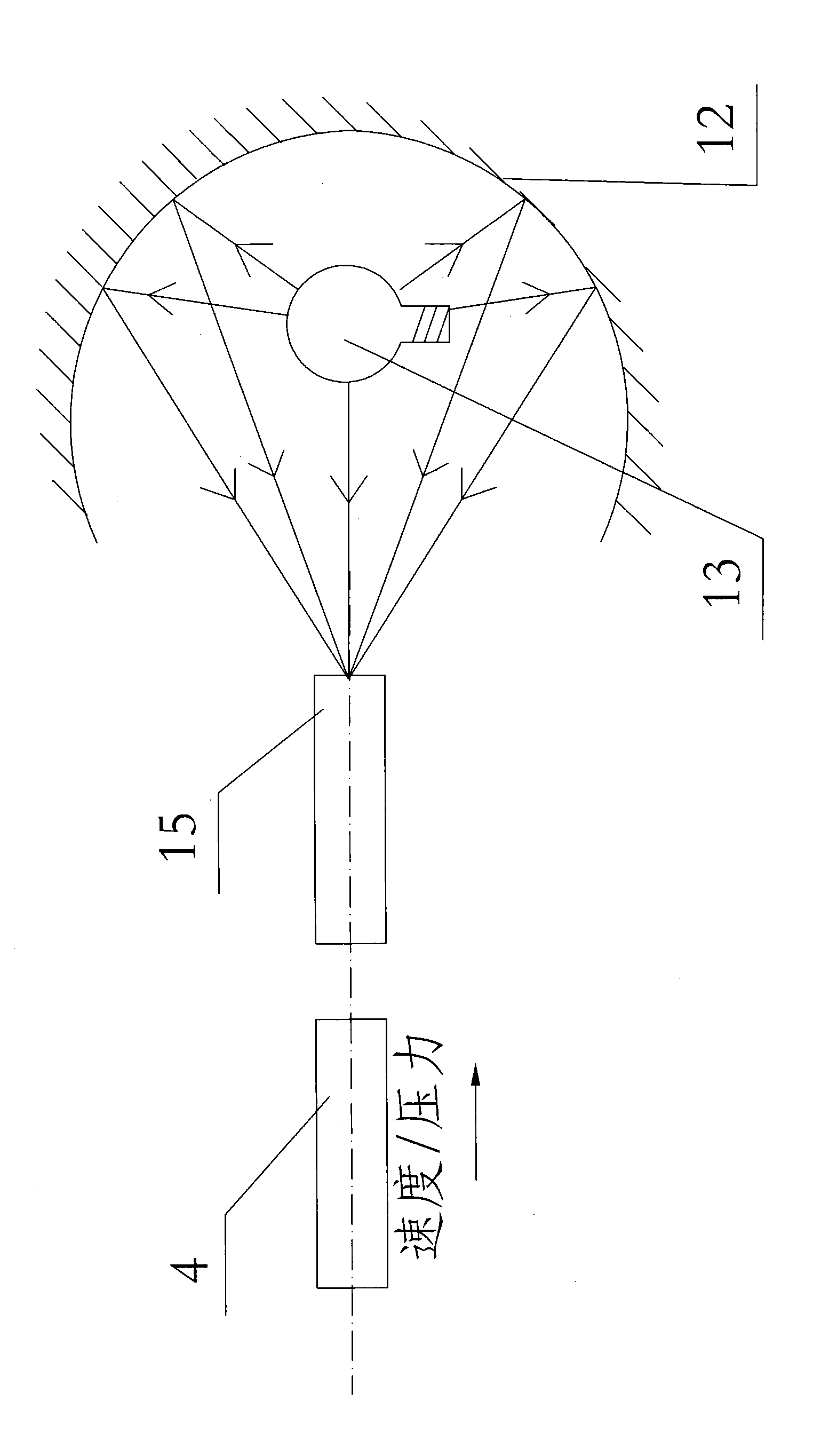

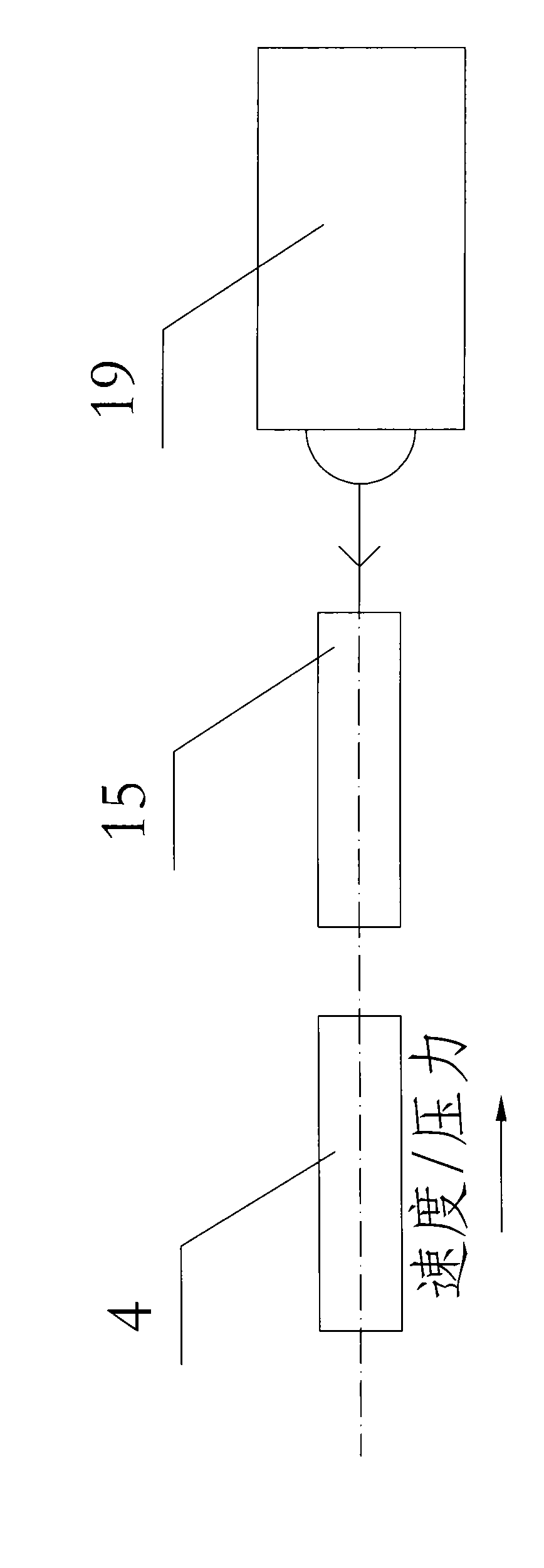

Car-track-bridge-foundation coupling system and dynamic analysis method thereof

InactiveCN103150458AFlexible modelingImprove good performanceSpecial data processing applicationsStructure of the EarthSimulation

The invention relates to a car-track-bridge-foundation coupling system. A pre-processing module is realized through an MATLAB car structure module and an MATLAB track irregularity sample curve module. A track-bridge-foundation module is realized based on general finite-element software and comprises a track structure model, a track-bridge dynamic interaction model, a bridge structure model, a soil-structure dynamic interaction model and a foundation model. A solving module is realized through an MATLAB wheel-rail dynamic contact calculation module, an MATLAB car system dynamic calculation module and an MATLAB track-bridge-foundation system dynamic calculation module, wherein the MATLAB wheel-rail dynamic contact calculation module is simulated through a track dynamic contact model. A post-processing module is realized through an MATLAB calculation data storage and graphic processing module. Therefore, the car-track-bridge-foundation coupling system is formed.

Owner:CENT SOUTH UNIV +1

Contact sensors and methods for making same

The present invention is directed to novel contact sensors. The contact sensors of the invention include a conductive composite material formed of a polymer and a conductive filler. In one particular embodiment, the composite materials can include less than about 10 wt % conductive filler. Thus, the composite material of the contact sensors can have physical characteristics essentially identical to the polymer, while being electrically conductive with the electrical resistance proportional to the load on the sensor. If desired, the sensors can be formed of the same polymeric material as the bearing that is being examined. The sensors can provide real time dynamic contact information for joint members under conditions expected during use. In one particular embodiment, the sensors can be used to examine dynamic wear characteristics of artificial joint bearings such as artificial knee, hip, or shoulder bearings.

Owner:CLEMSON UNIV RES FOUND

Multifunctional star-shaped prepolymers, their preparation and use

The present invention relates to coatings that possess a dynamic contact angle hysteresis in water, measured by means of a Wilhelmy balance according to DIN EN 14370, of at most 15°, and are can be manufactured from star-shaped prepolymers and / or star-shaped prepolymer-nanoparticle complexes that are cross-linkable with one another and with the surface of the substrate to be coated, the star-shaped prepolymers and / or star-shaped prepolymer-nanoparticle complexes possessing, before being cross-linked, at least three hydrophilic polymer arms that, considered of themselves, are soluble in water, and that carry on all or on some of their free ends R1 silyl terminal groups of the following general formula (I): R1 is —CRa2—Si(ORb)r(Rc)3-r, where Ra denotes hydrogen or a linear or branched alkyl group having 1 to 6 carbon atoms, ORb denotes a hydrolyzable group, Rc denotes a linear or branched alkyl group having 1 to 6 carbon atoms, and r denotes a number from 1 to 3, and that carry, on the optionally present ends not carrying silyl terminal groups, reactive groups that are reactive with respect to themselves, the substrate to be coated, entities optionally introduced into the coating, and / or with the silyl terminal groups. The present invention furthermore relates to a method for manufacturing such coatings, and to star-shaped prepolymers that are used in the coatings. The invention moreover relates to use of the star-shaped prepolymers as additives to various agents for temporary or permanent anti-soiling finishing of surfaces.

Owner:HENKEL KGAA

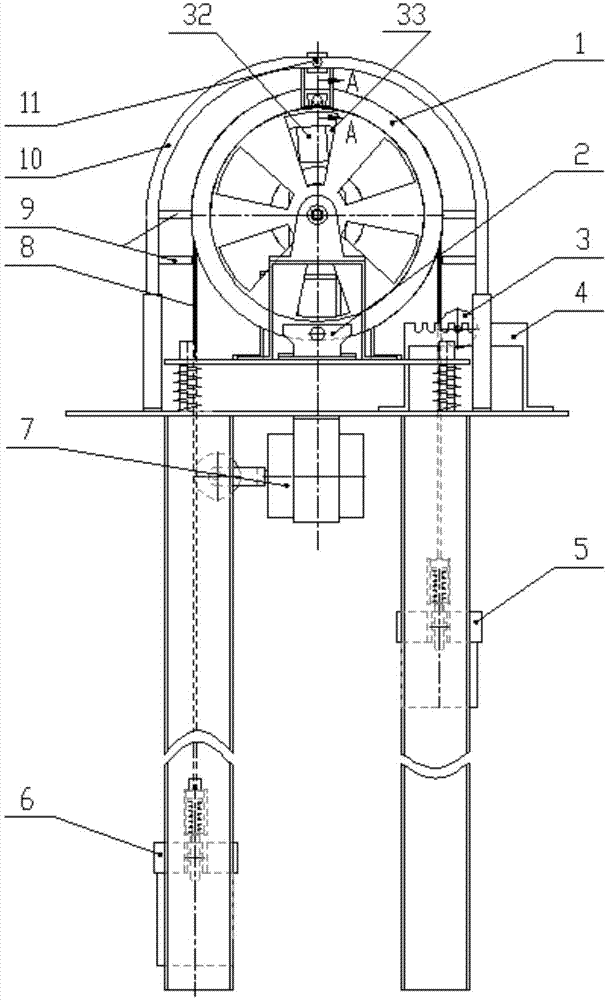

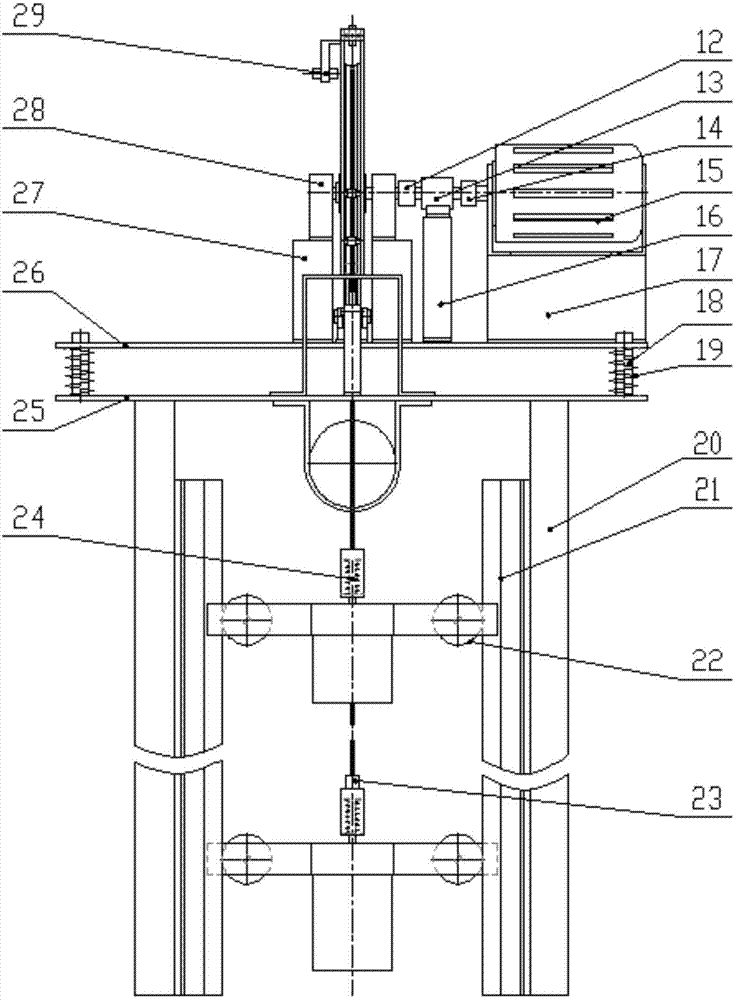

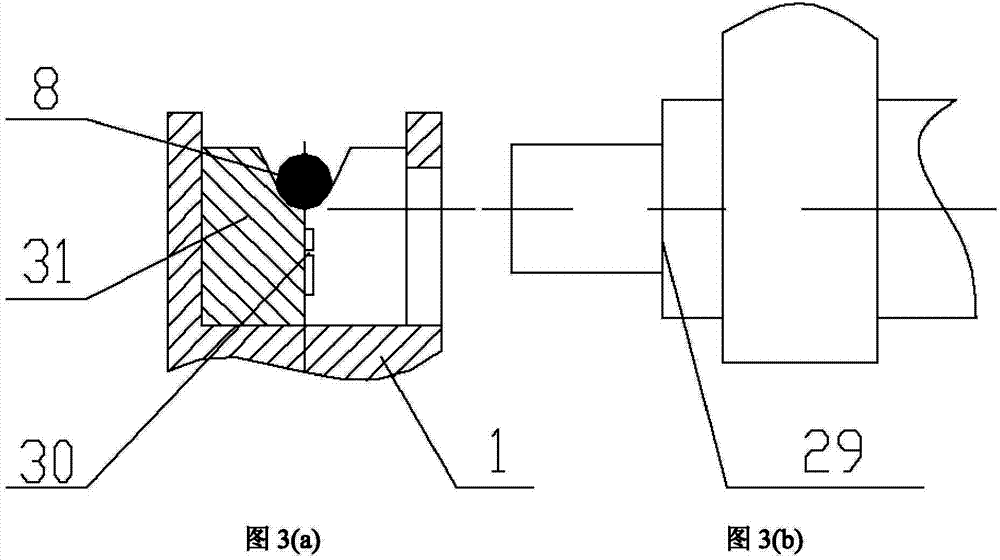

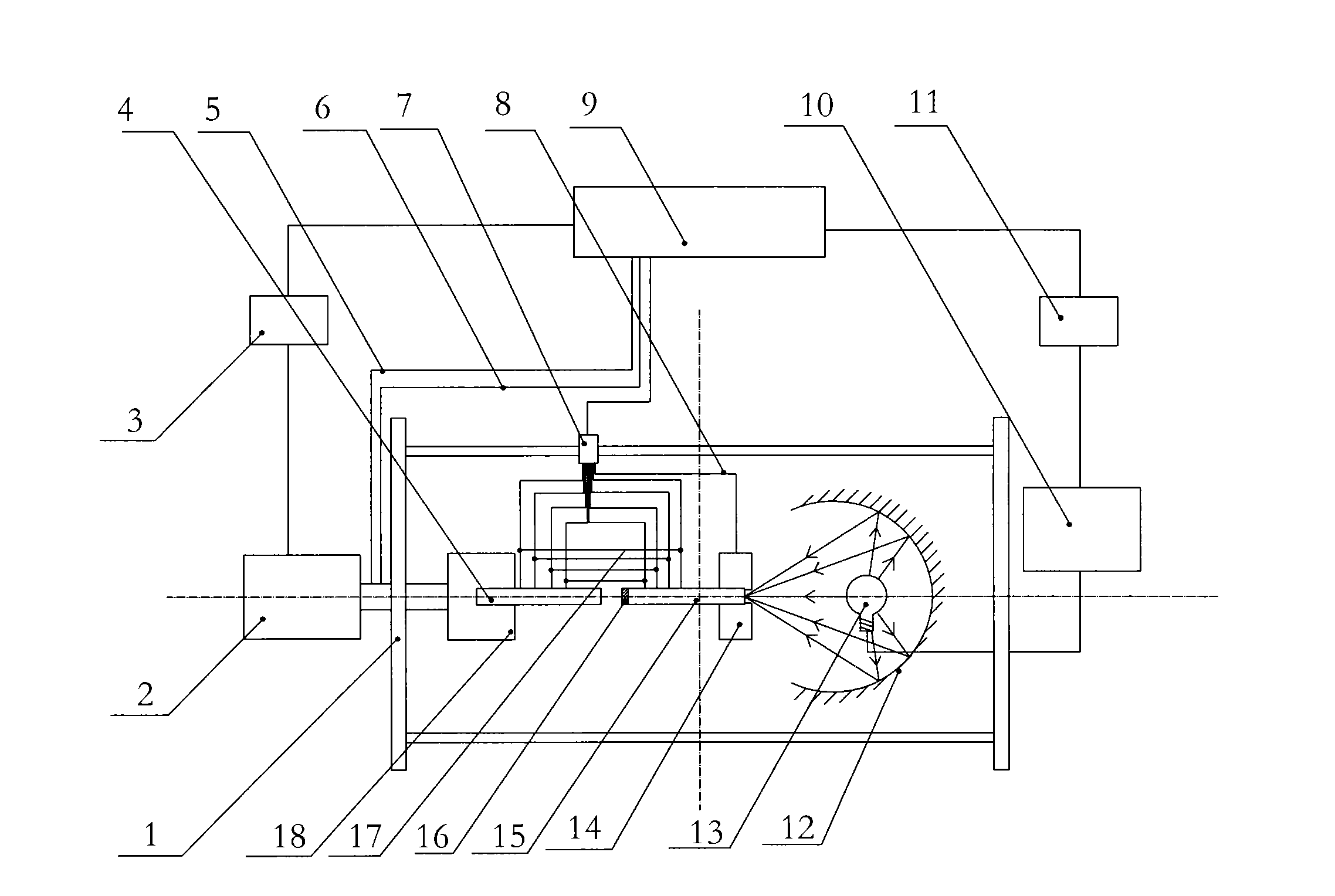

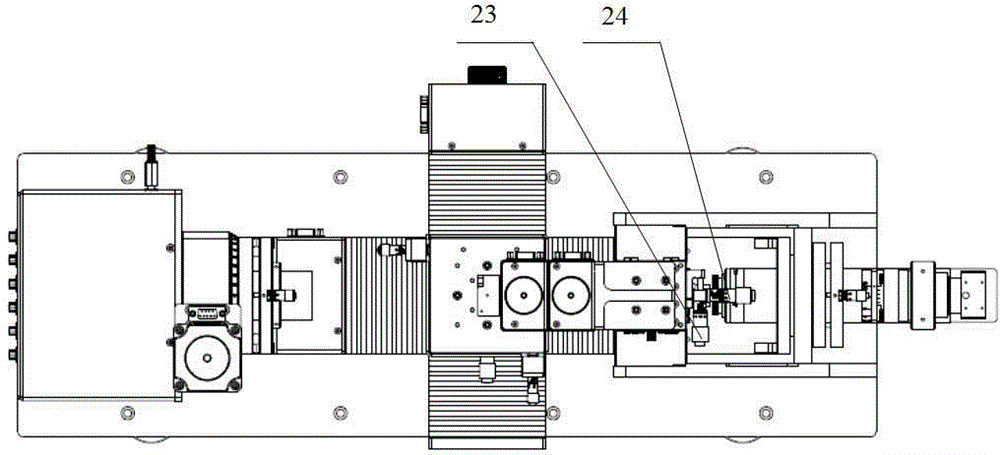

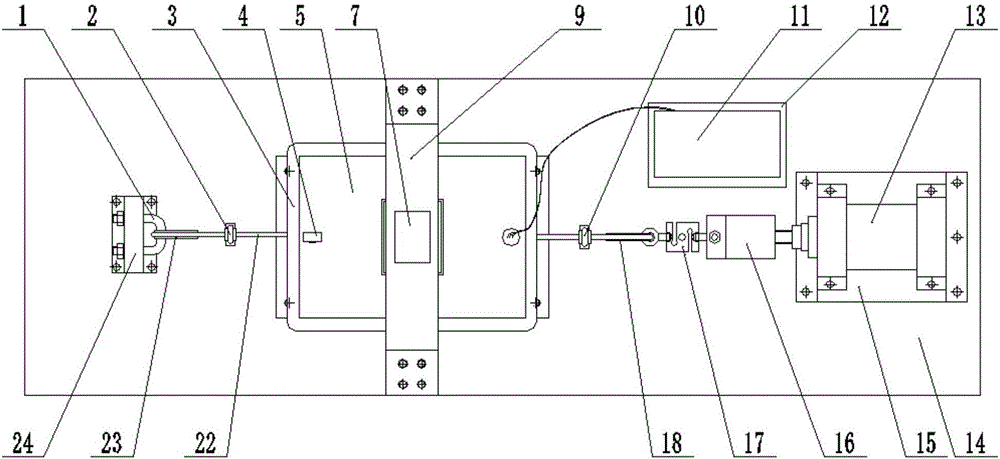

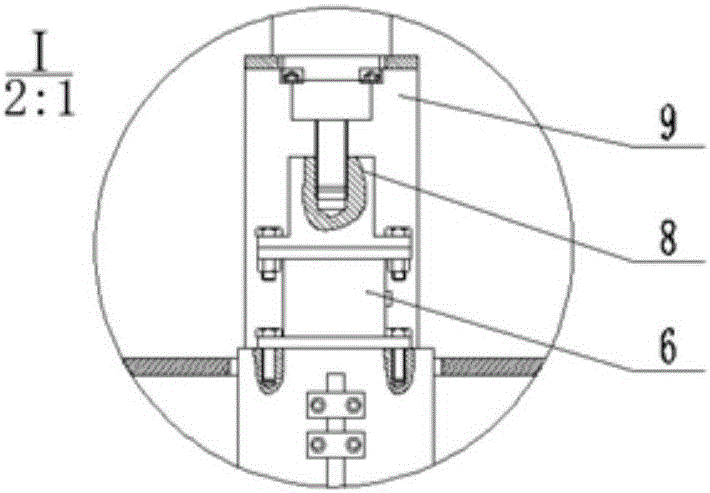

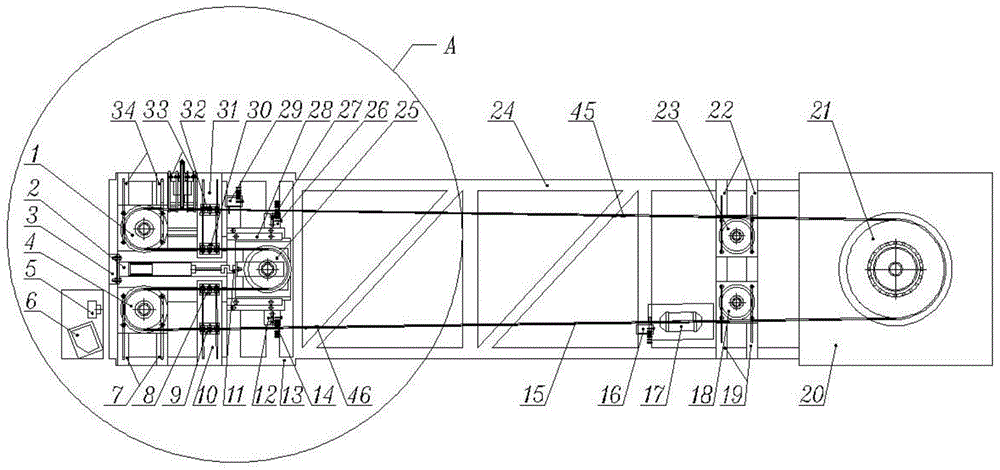

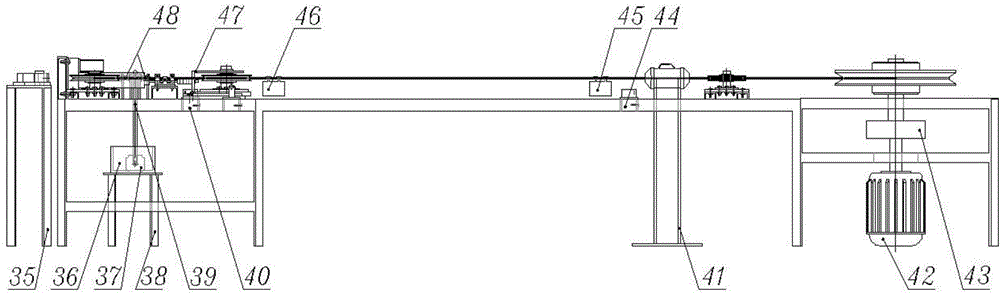

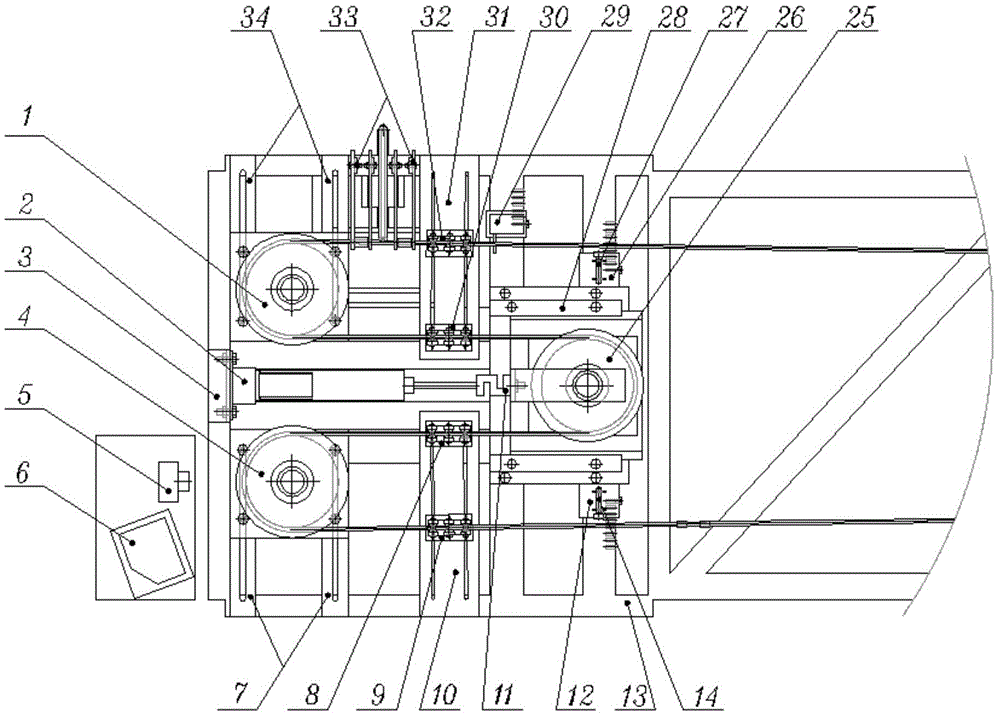

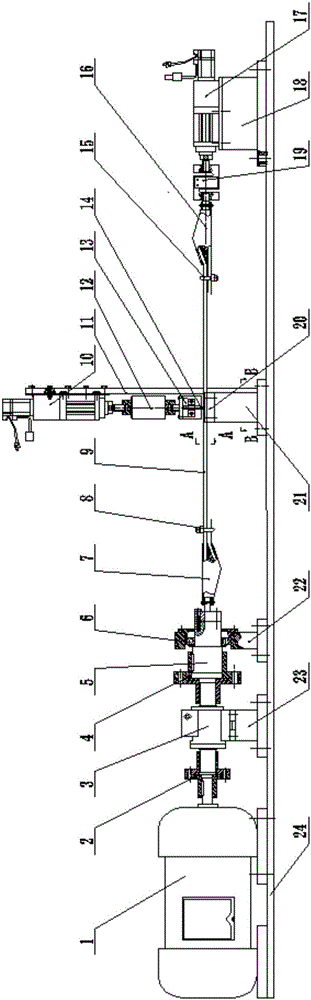

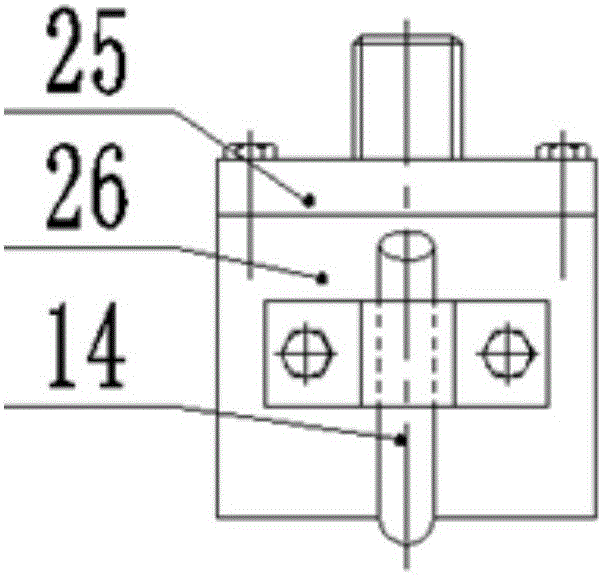

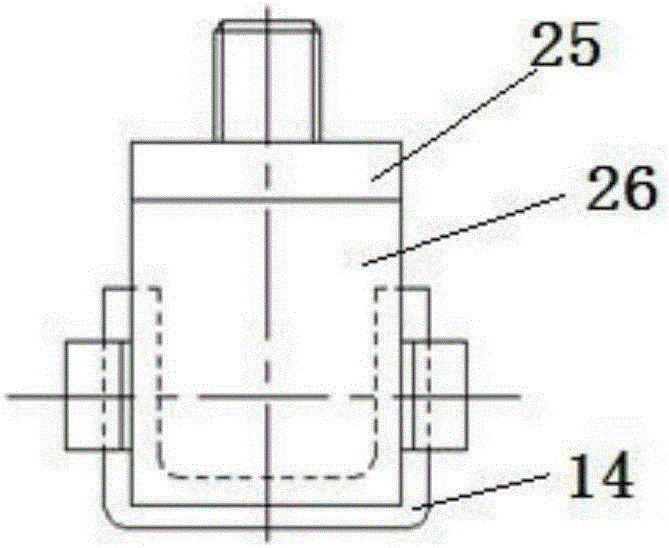

Friction liner-hoisting steel wire rope dynamic friction drive test device and friction liner-hoisting steel wire rope dynamic friction drive test method

ActiveCN104122198AImproved dynamic friction transmission characteristicsGood effectUsing mechanical meansMaterial analysisLongitudinal vibrationDynamical friction

The invention discloses a friction liner-hoisting steel wire rope dynamic friction drive test device and a friction liner-hoisting steel wire rope dynamic friction drive test method. The device comprises a base frame, a driving mechanism, a friction drive mechanism, a surrounding angle adjusting mechanism, a shock excitation mechanism, a steel wire rope and a condition monitoring mechanism, wherein the base frame comprises a stand column, a lower support platform and an upper support platform; the driving mechanism comprises a motor and a torque sensor; the friction drive mechanism comprises a friction wheel and a brake device; the surrounding angle adjusting mechanism comprises a C bracket and an adjusting wheel; the shock excitation mechanism comprises a transverse shock excitation mechanism and a longitudinal shock excitation mechanism; the condition monitoring mechanism comprises a steel wire rope tension monitoring device, a dynamic contact monitoring device, a steel wire rope vibration monitoring device and a micro-slippage monitoring device. After the device and the method are adopted, the dynamic friction drive characteristic between a friction liner and a hoisting steel wire rope can be simulated in a friction hoisting system when the hoisting steel wire rope is in a dynamic coupling vibration state, so that various changes in the friction drive process under the actions of transverse vibration, longitudinal vibration and transverse and longitudinal coupled vibration can be researched.

Owner:CHINA UNIV OF MINING & TECH

Dynamic contact assessment for electrode catheters

ActiveUS8679109B2Increase contact pressureReduce contact pressureSurgical instrument detailsDiagnostic recording/measuringElectricityOutput device

An electrode catheter and a method for assessing catheter-tissue contact for tissue ablation are disclosed. An exemplary electrode catheter comprises a flexible catheter shaft. At least one piezoelectric sensor is oriented coaxial to the flexible catheter shaft. The at least one piezoelectric sensor is responsive to movement of the flexible catheter shaft by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one piezoelectric sensor. The output device receives the electrical signals for dynamically assessing a level of contact between the flexible catheter shaft and a moving tissue. In another exemplary embodiment, the system may be implemented in a hydrodynamic environment.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Contact sensors and methods for making same

InactiveUS20120123716A1Reduced probability of early failureAccurately carry-outResistance/reactance/impedenceForce measurementElectrical resistance and conductanceTotal knee replacement surgery

Disclosed herein are novel contact sensors. The contact sensors disclosed herein include a conductive composite material formed of a polymer and a conductive filler. In one particular aspect, the composite materials can include less than about 10 wt % conductive filler. Thus, the composite material of the contact sensors can have physical characteristics essentially identical to the polymer, while being electrically conductive with the electrical resistance proportional to the load on the sensor. The sensors can provide real time dynamic contact information for joint members under conditions expected during use. In one particular aspect, the sensor can be used to properly balance the knee ligaments in a total knee replacement surgery.

Owner:SENCORABLES

Hydrophobic materials incorporating rare earth elements and methods of manufacture

InactiveUS20150111063A1Improve processing efficiencyLow costVacuum evaporation coatingSputtering coatingBorideRare-earth element

This invention relates generally to an article that includes a base substrate, an intermediate layer including at least one element or compound selected from titanium, chromium, indium, zirconium, tungsten, and titanium nitride on the base substrate, and a hydrophobic coating on the base substrate, wherein the hydrophobic coating includes a rare earth element material (e.g., a rare earth oxide, a rare earth carbide, a rare earth nitride, a rare earth fluoride, and / or a rare earth boride). An exposed surface of the hydrophobic coating has a dynamic contact angle with water of at least about 90 degrees. A method of manufacturing the article includes providing the base substrate and forming an intermediate layer coating on the base substrate (e.g., through sintering or sputtering) and then forming a hydrophobic coating on the intermediate layer (e.g., through sintering or sputtering).

Owner:MASSACHUSETTS INST OF TECH

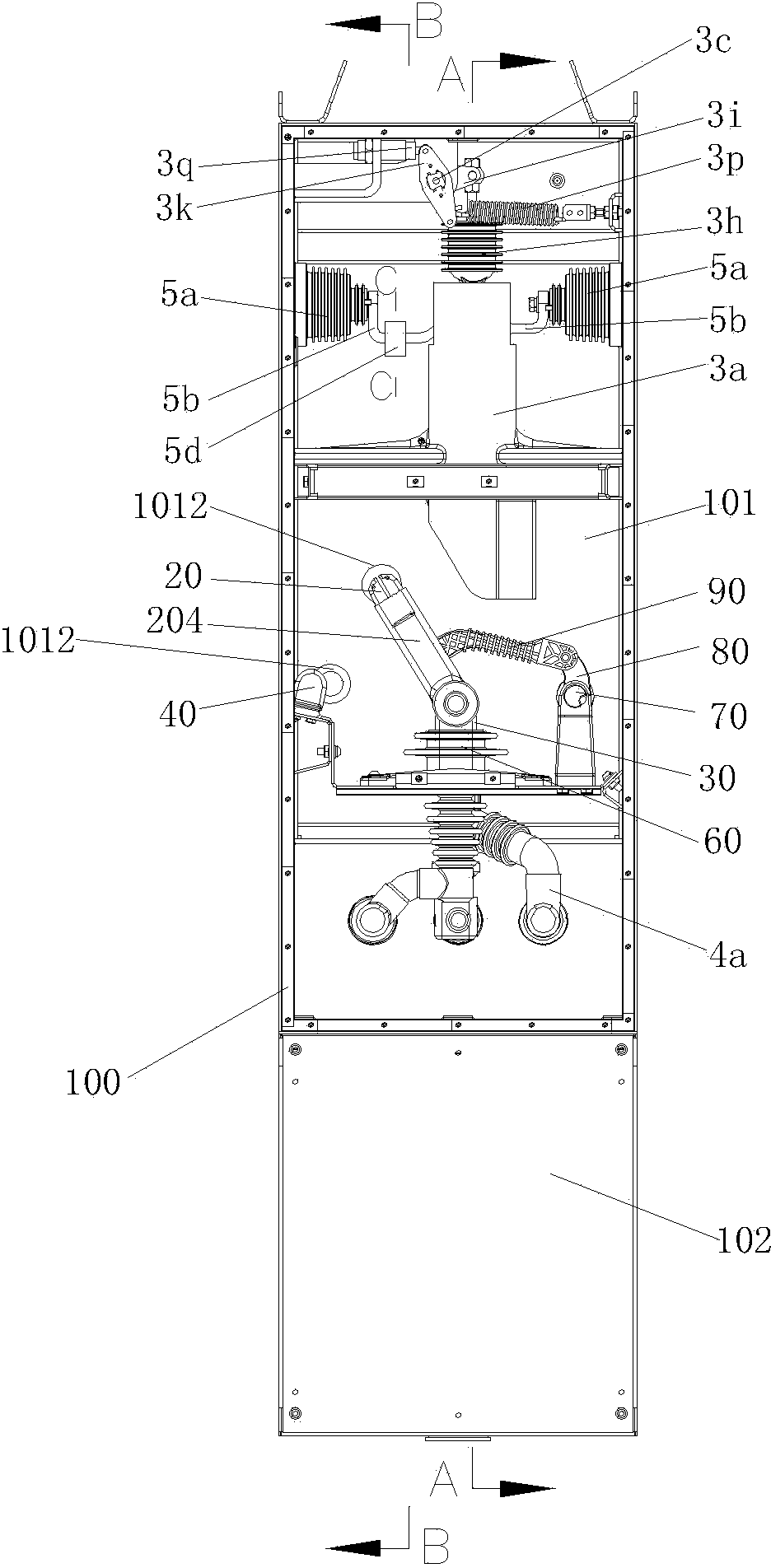

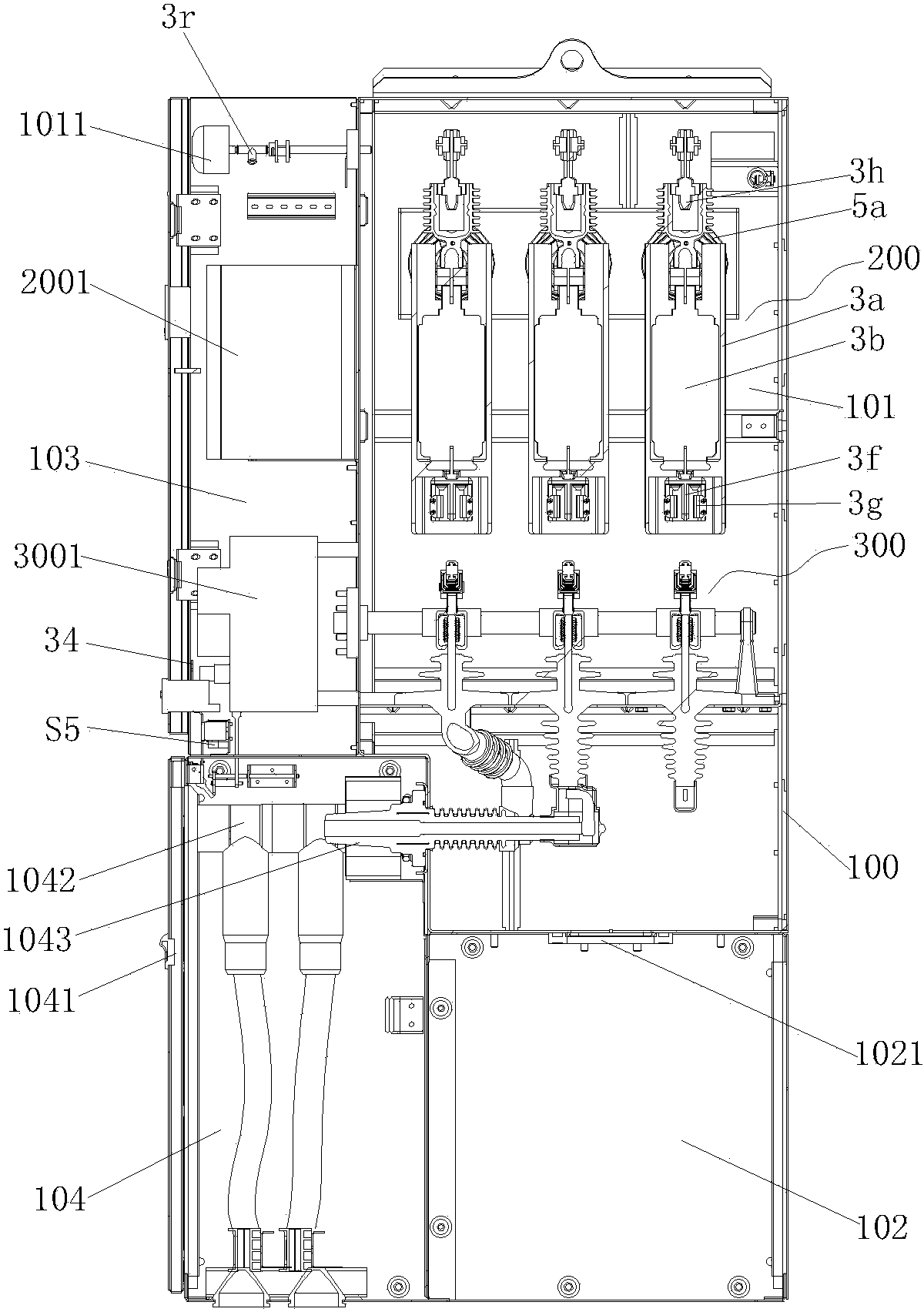

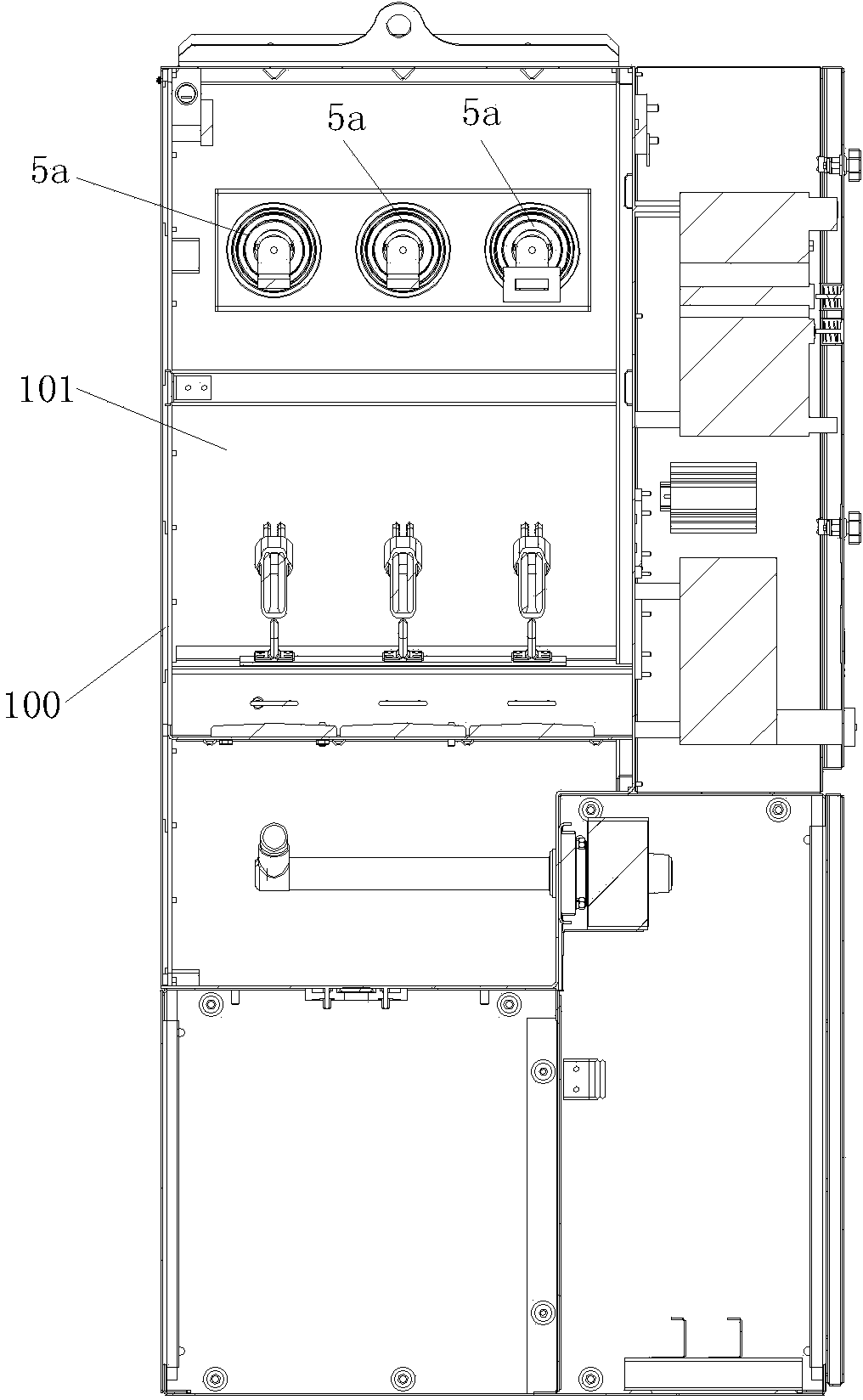

Novel inflatable switch cabinet

ActiveCN103996990AEasy to disassembleEasy to assembleSwitchgear arrangementsEngineeringVacuum interrupter

The invention discloses a novel inflatable switch cabinet which comprises a cabinet body. A gas tank is arranged on the rear side of the cabinet body, a control chamber is arranged on the upper portion of the front side of the cabinet body, a cable chamber is arranged on the lower portion of the front side of the cabinet body, a vacuum breaker is arranged on the upper portion of the gas tank, an isolating switch is arranged in the middle of the gas tank, a main loop is arranged on the lower portion of the gas tank, and an isolating switch operating mechanism and a vacuum breaker operating mechanism are arranged in the control chamber. The isolating switch operating mechanism achieves switch-on, switch-off and ground connection of a disconnecting link by operating a first operating shaft and a second operating shaft, and power-driven operation can be achieved. The vacuum breaker comprises an insulation support, a vacuum bubble and an operating main shaft, the vacuum bubble is arranged in the insulation support in the mode with an upward dynamic contact, a conductive contact and a conductive piece are fixedly arranged on the lower portion of the insulation support and are fixedly connected with a static contact at the lower end of the vacuum bubble, the conductive contact and the disconnecting link are matched for switch-on, and the operating main shaft drives the dynamic contact at the upper end of the vacuum bubble to vertically move to achieve switch-on and switch-off of the vacuum breaker. The novel inflatable switch cabinet is compact in structure, reliable in motion, safe in use and convenient to maintain.

Owner:XIAMEN XEC ELECTRIC

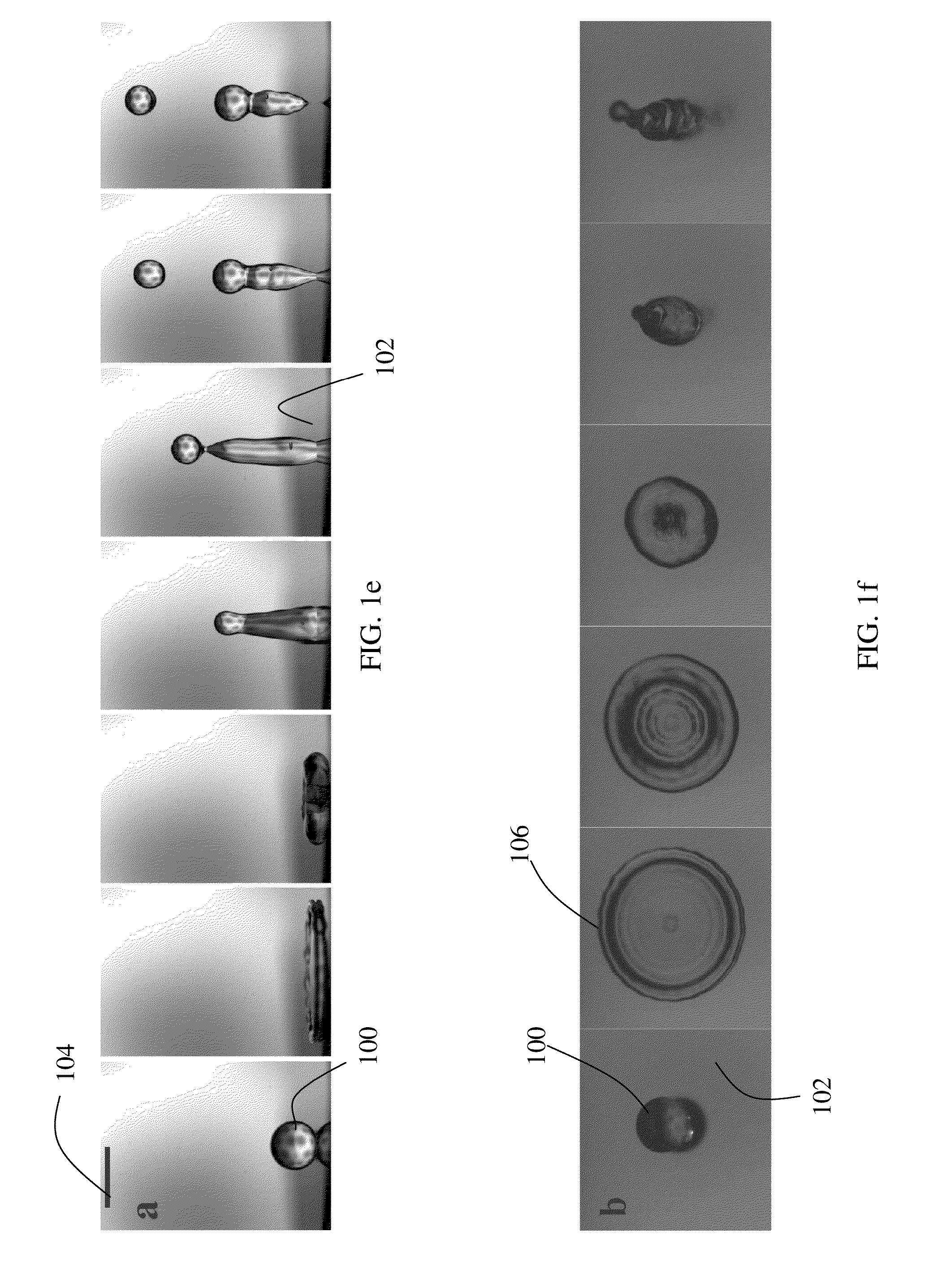

Articles for manipulating impinging liquids and methods of manufacturing same

ActiveUS20130032646A1Improve performanceMore practicalMaterial nanotechnologyLayered productsNon wettingMacroscopic scale

This invention relates generally to an article that includes a non-wetting surface having a dynamic contact angle of at least about 90°. The surface is patterned with macro-scale features configured to induce controlled asymmetry in a liquid film produced by impingement of a droplet onto the surface, thereby reducing time of contact between the droplet and the surface.

Owner:MASSACHUSETTS INST OF TECH

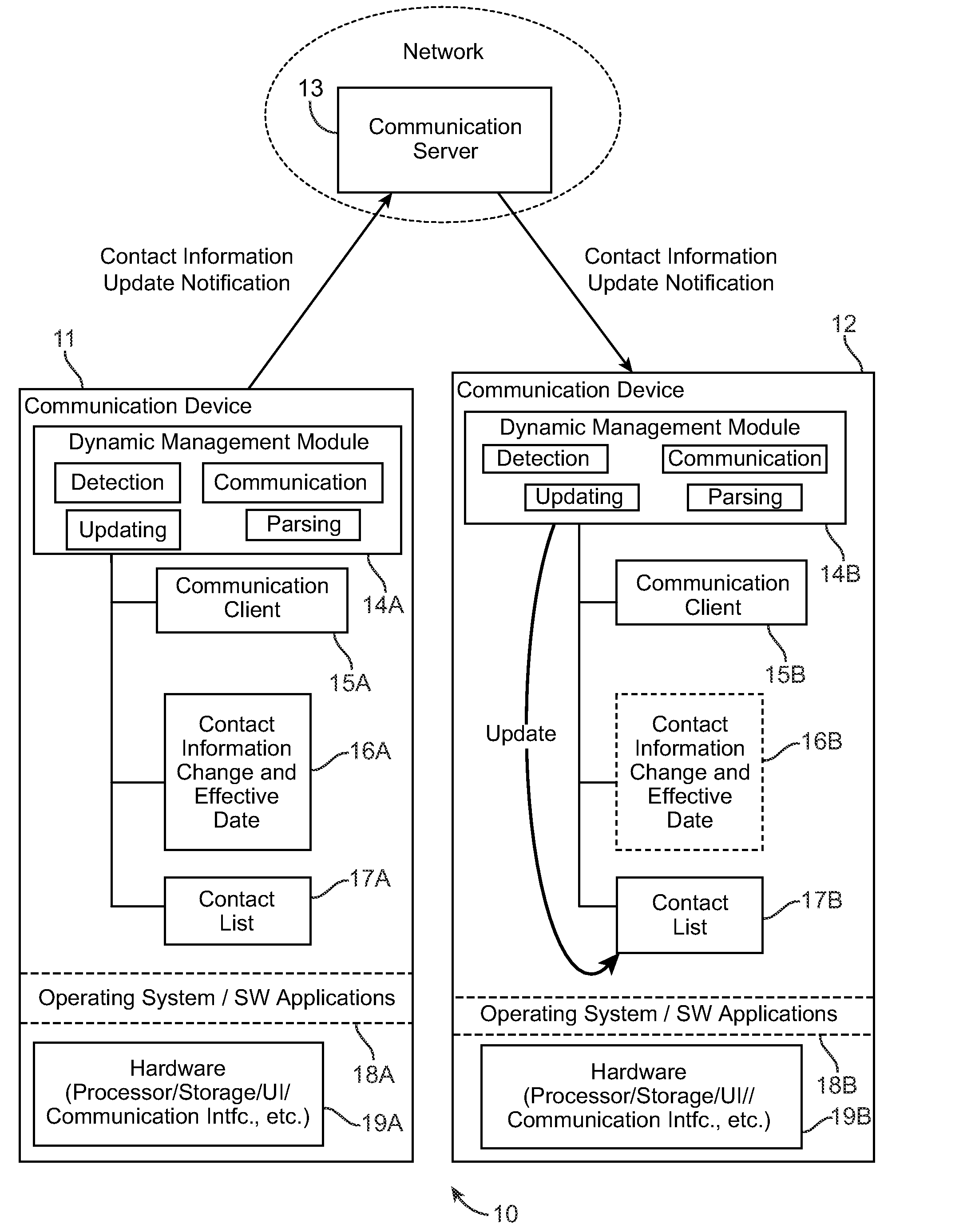

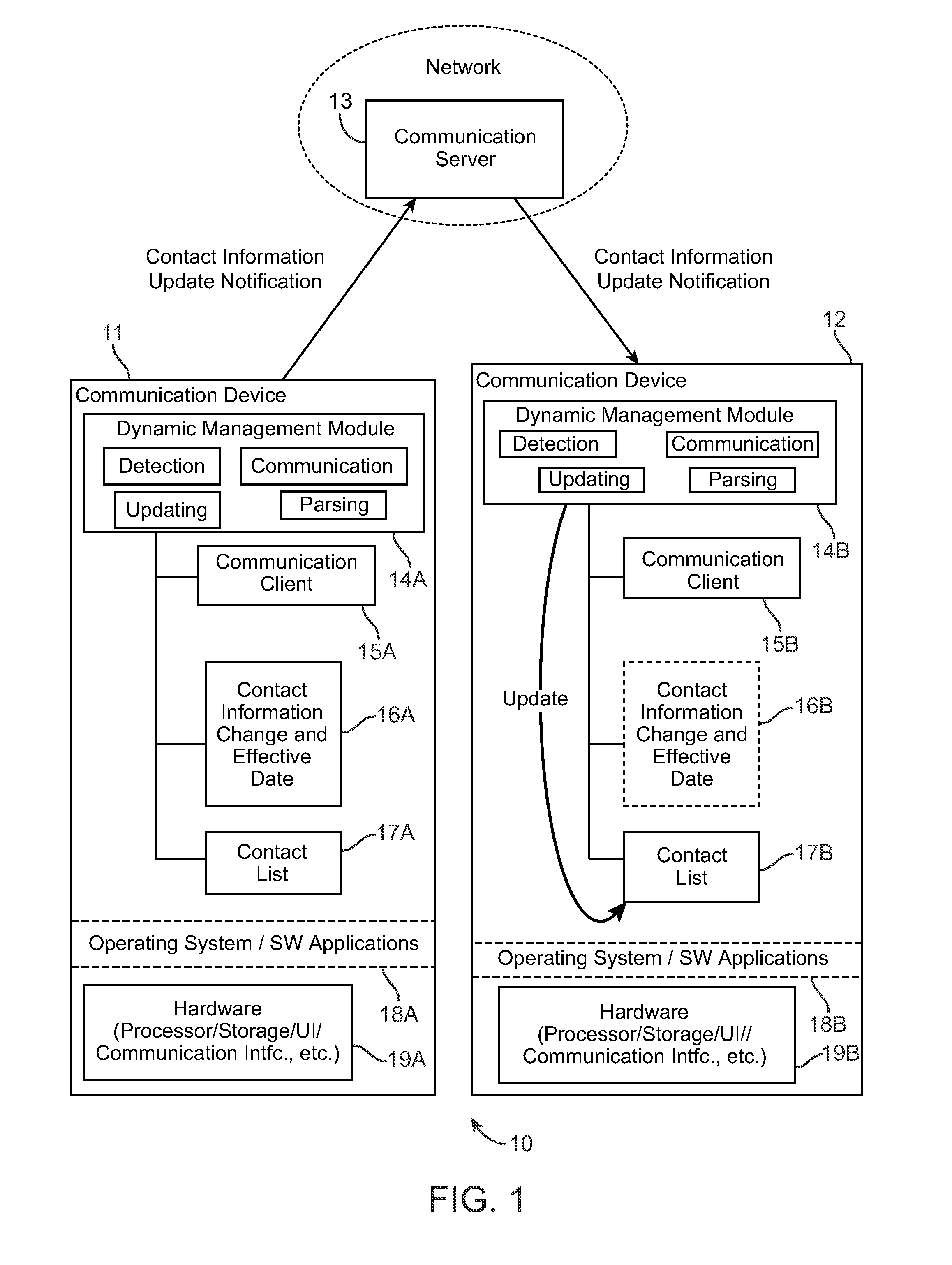

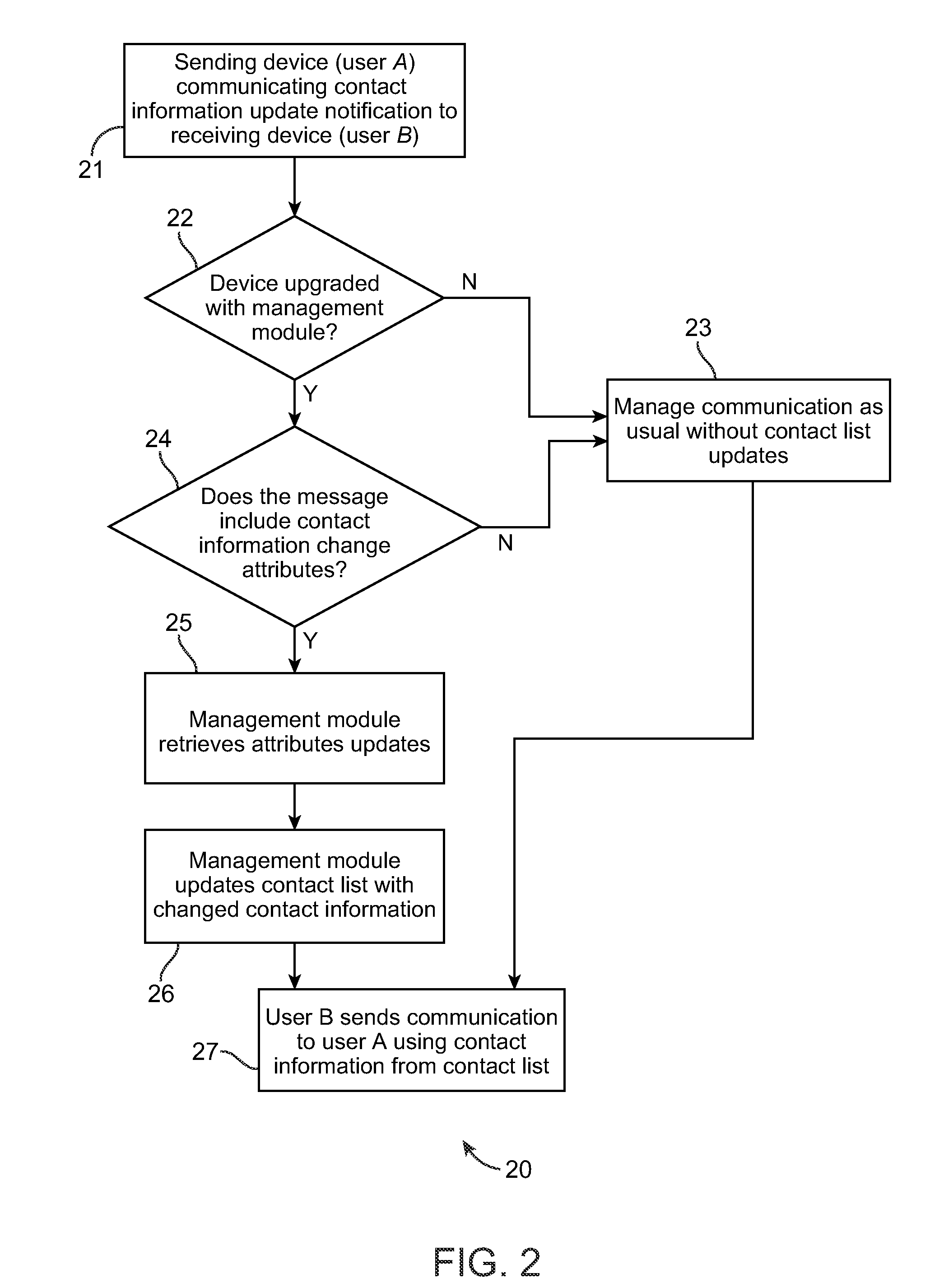

Method and system for dynamic contact information management in electronic communication devices

InactiveUS20100076926A1Digital data processing detailsSubstation equipmentEffective dateElectronic communication

A method and system for user contact information in electronic devices is provided. One implementation involves detecting a change in a user contact information at a first electronic device, determining effective date of the change in the contact information, storing the contact information change and effective date in a memory store, automatically communicating the contact information change and effective date to a second electronic device, and applying the received contact information change to a contact information list in a memory store of the second device, on or after the effective date.

Owner:IBM CORP

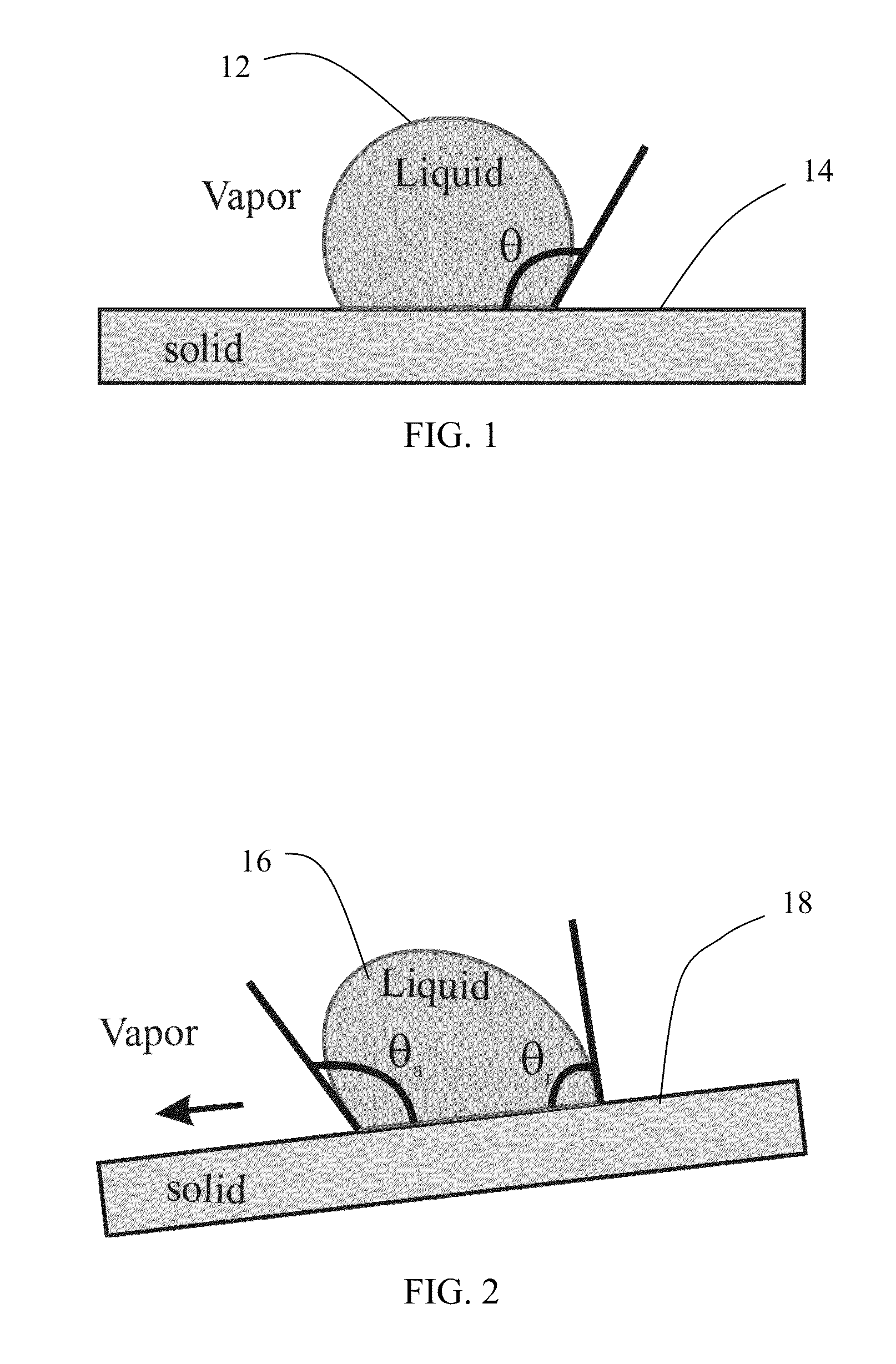

Self-cleaning member and coating composition

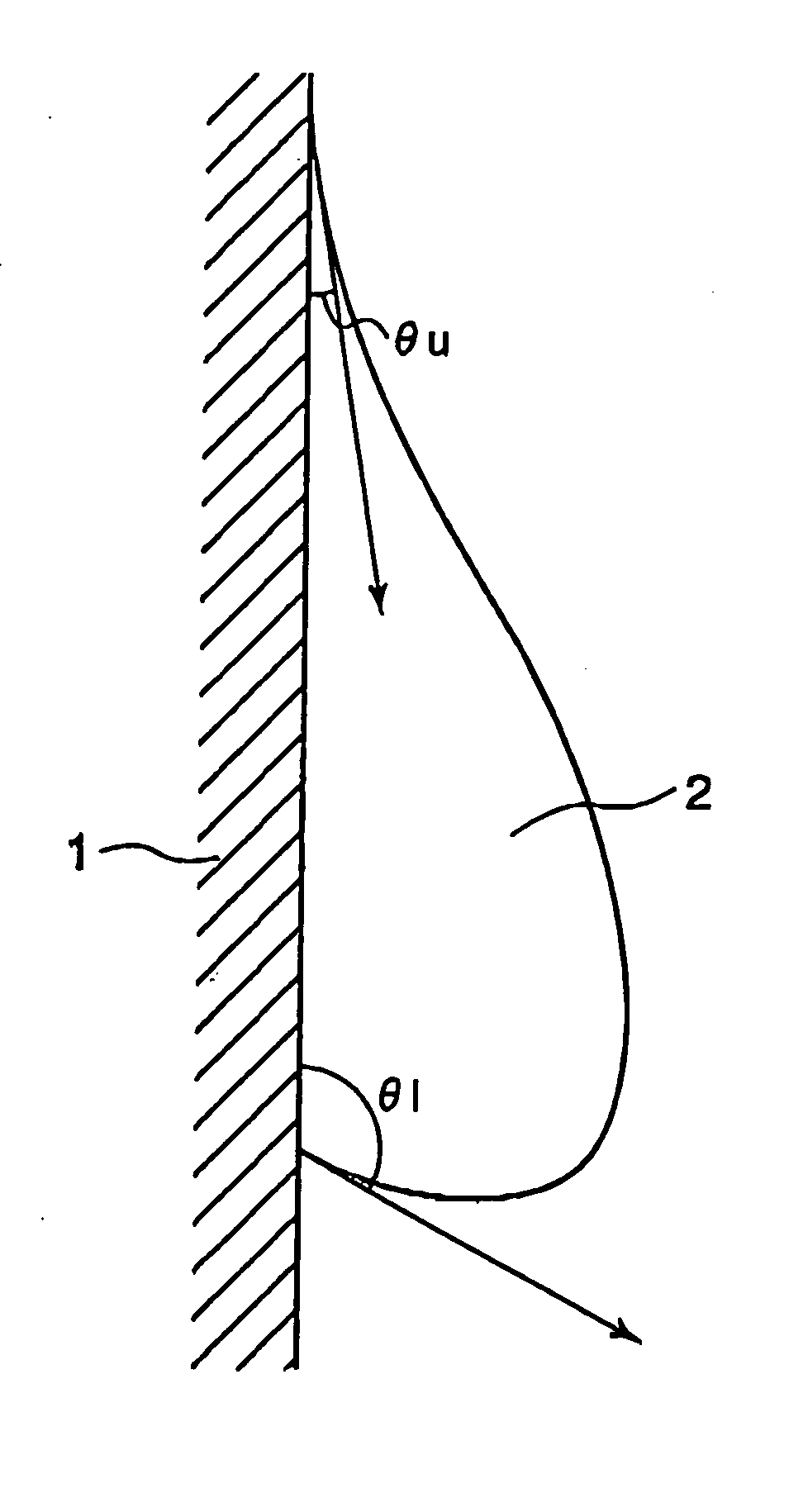

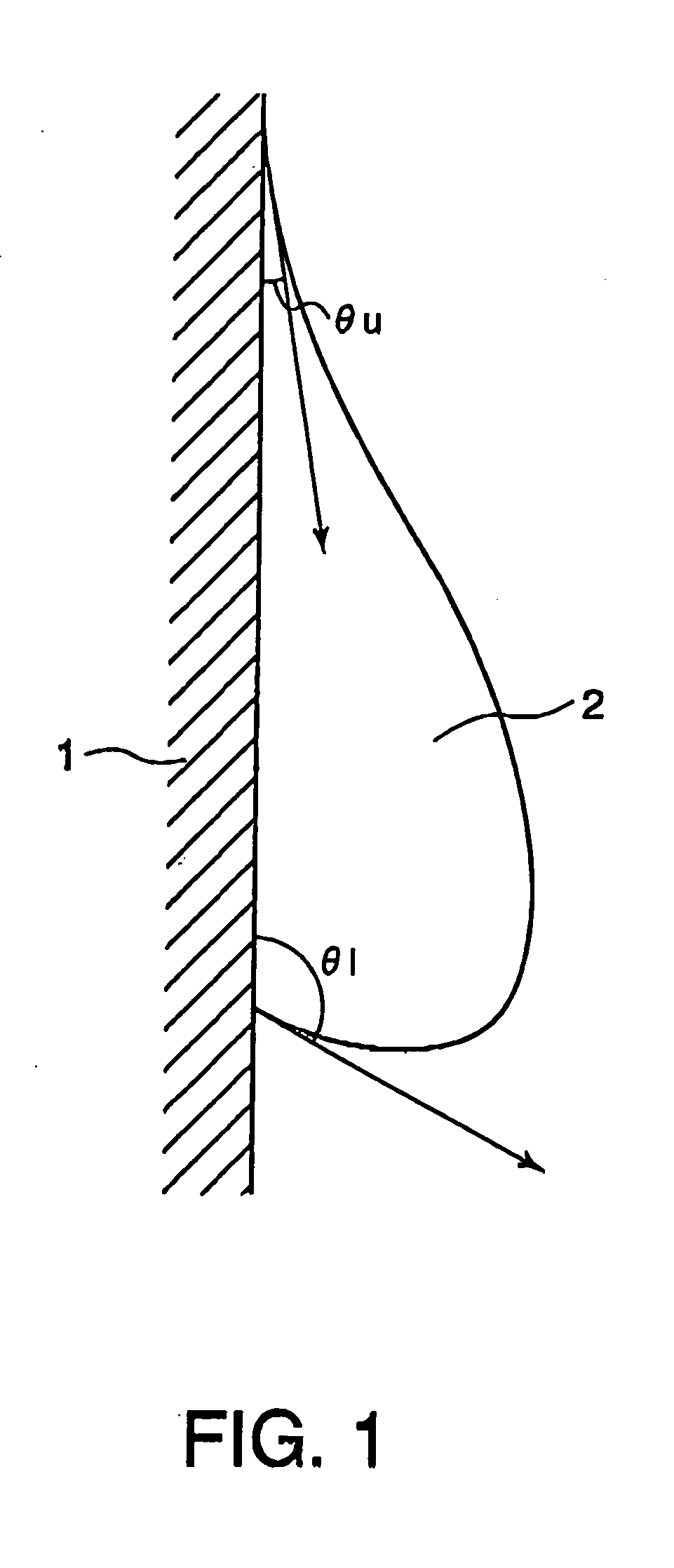

InactiveUS20100304120A1Easily washing awayEasily washed awayFouling preventionOther chemical processesHysteresisSurface layer

A self-cleaning member comprising a member having a porous surface is disclosed. The member has a contact angle hysteresis Δθ (=θa−θr), which is a difference between an advancing contact angle θa and a receding contact angle θr measured by a dynamic contact angle measurement with an extension / contraction method, of 80 degree or more at the surface layer and a receding contact angle θr of 25 degree or less, is capable of forming a water film on the surface by water provided and of allowing an ionic or reactive contaminant to be washed away without fixation.

Owner:TOTO LTD

Method and device for measuring dynamic contact heat exchange coefficient of high-temperature solid interface

InactiveCN101661009ARealize measurementEfficient heatingMaterial thermal conductivityMaterial heat developmentContact pressureMeasurement device

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

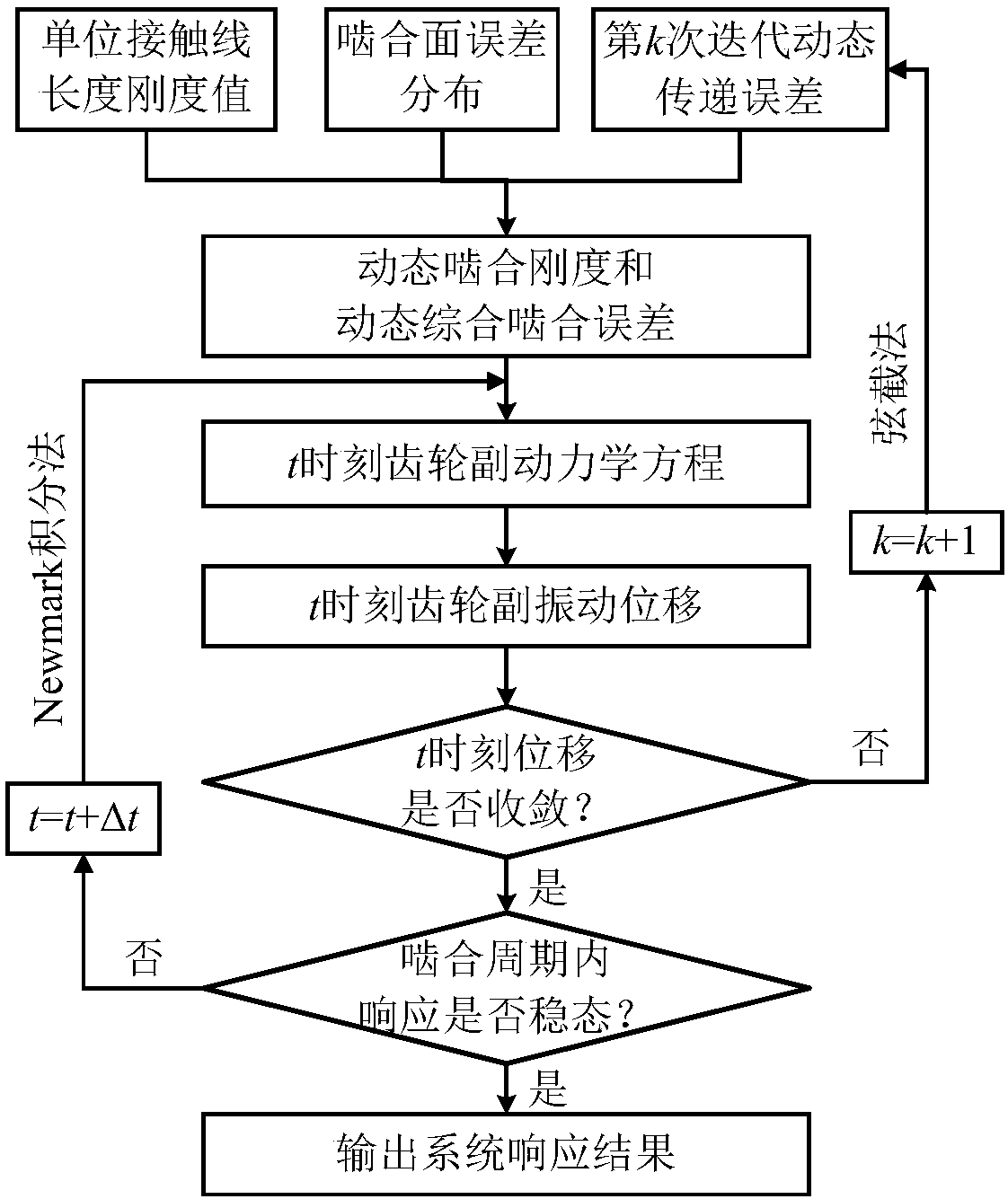

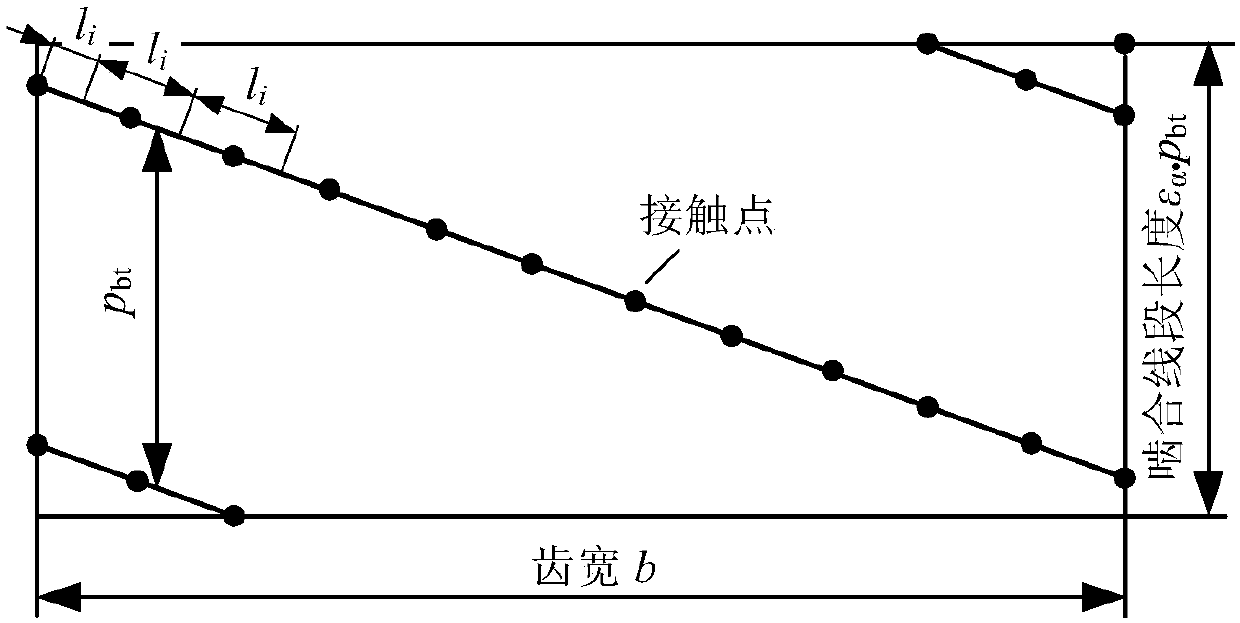

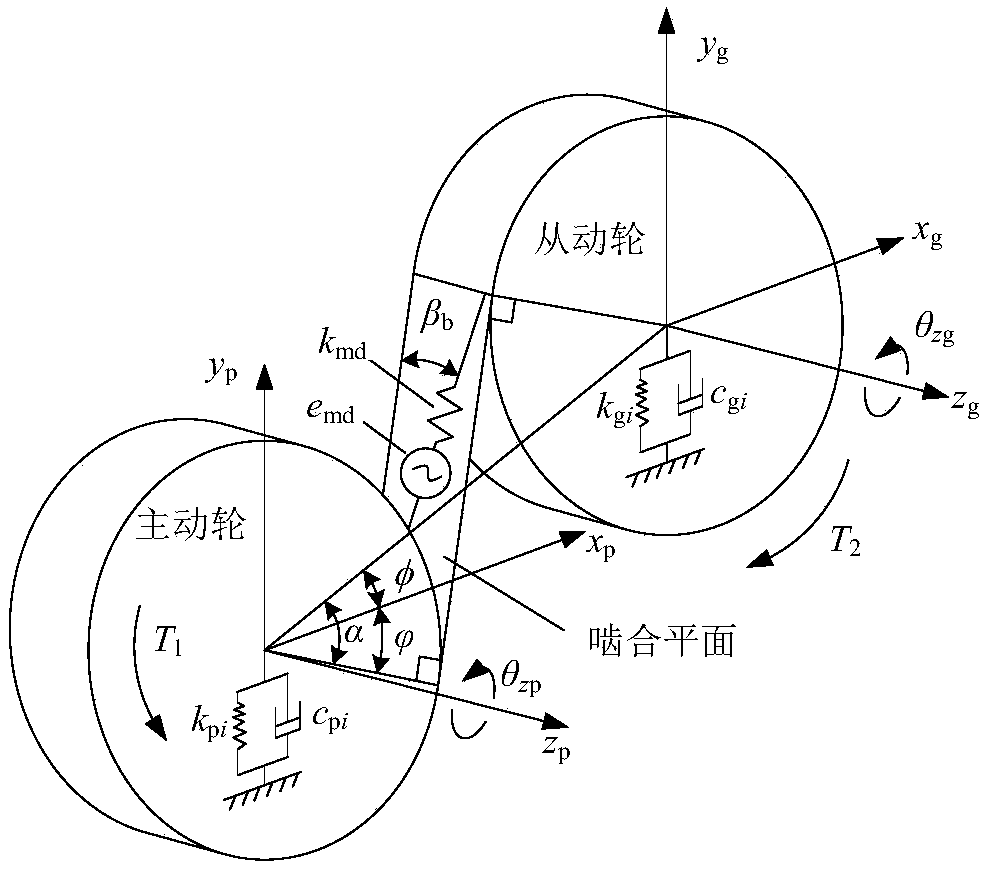

Nonlinear dynamics calculation method for gear pair

ActiveCN108052760AImprove calculation accuracySimulate the realGeometric CADSpecial data processing applicationsFeedback effectEngineering

The invention discloses a nonlinear dynamics calculation method for a gear pair. The method comprises the steps that the feedback effect of vibration displacement to the dynamic contact condition of agear surface of the gear pair in the actual running process is considered, and the nonlinear excitation of the dynamic meshing rigidity and dynamic comprehensive meshing errors is calculated. Dynamiccontact analysis of the gear pair and a system dynamics solution process are combined, and an excitation-response-feedback loop-locked calculation process of the system is achieved. According to themethod, the nonlinear dynamics phenomenon of the gear pair due to parameters such as gear surface errors and shape correction can be acquired, the dynamics behavior of the system in the dynamic contract process can be more truly simulated, and the calculation accuracy of dynamics is improved.

Owner:CHANGAN UNIV

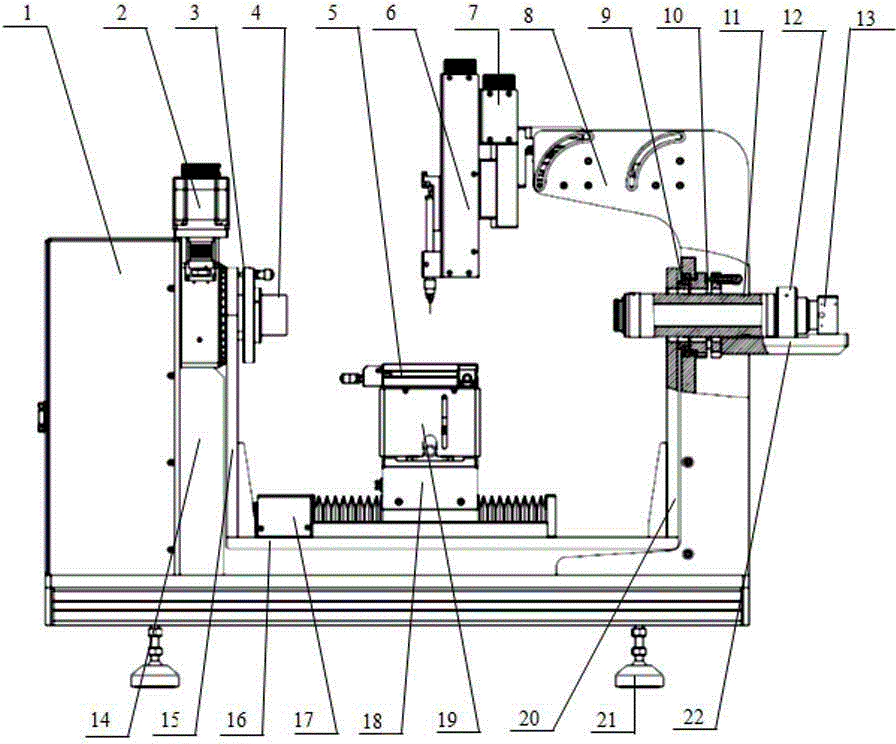

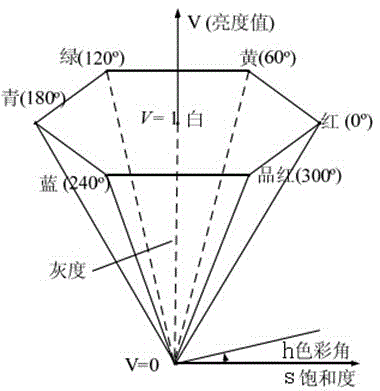

Intrinsic contact angle test and test method thereof

The invention discloses an intrinsic contact angle test apparatus and a test method thereof. A true drop technology or an image fitting technology is adopted to fit the test dynamic contact angle of a Young-Laplace equation, and Wenzel-Casie-Baster stimulation is used to derive an intrinsic contact angle calculating equation. The invention also provides the intrinsic contact angle test apparatus. The apparatus comprises a combination boy controlled by the rotating mechanism of a worm and gear structure and having a lens and a sample bench which rotate together, a XYZ and horizontally-adjustable sample bench combination body, a sample clamp, an injection pump and an XYZ control mechanism combination body thereof, a camera with a telecentric lens, and a parallel light source. The contact angle is obtained by shooting the profile image of a liquid drop and adopting the Young-Laplace equation fitting test. The apparatus and the test method can be used to analyze the chemical anisotropy of a material and the intrinsic contact angle under contact angle hysteresis condition due to surface roughness, and has extremely broad popularization values in fields of new materials and bionic materials.

Owner:上海梭伦信息科技有限公司

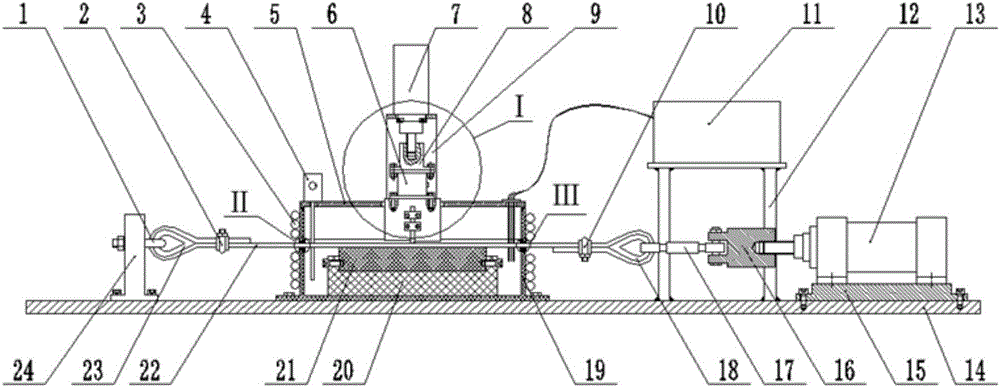

Device and method for monitoring friction and corrosion fatigue damage to twisted type lifting steel wire rope of super deep vertical shaft

ActiveCN106290035APredicted service lifeWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceSupporting systemMonitoring system

The invention discloses a device for monitoring friction and corrosion fatigue damage to a twisted type lifting steel wire rope of a super deep vertical shaft. The device comprises a supporting system, a tension-tension fatigue system, a constant-temperature corrosion system, a dynamic loading system and a monitoring system, wherein the supporting system supplies supporting to the tension-tension fatigue system, the constant-temperature corrosion system, the dynamic loading system and the monitoring system; the fatigue steel wire rope to be monitored is provided with a fatigue load supplied by the tension-tension fatigue test system in the horizontal direction, a dynamic contact load supplied by the dynamic loading system in the vertical direction, and a constant-temperature corrosion environment supplied by the constant-temperature corrosion system respectively; the monitoring system monitors the fatigue load, the dynamic contact load and a change of friction force on the fatigue steel wire rope. The device can realize the friction and corrosion fatigue damage to steel wire ropes on adjacent twisted layers of a twisted type lifting machine of the super deep vertical shaft under different temperatures, corrosion solutions, different dynamic tensile loads and different dynamic contact load parameters and dynamically monitor the damage.

Owner:CHINA UNIV OF MINING & TECH

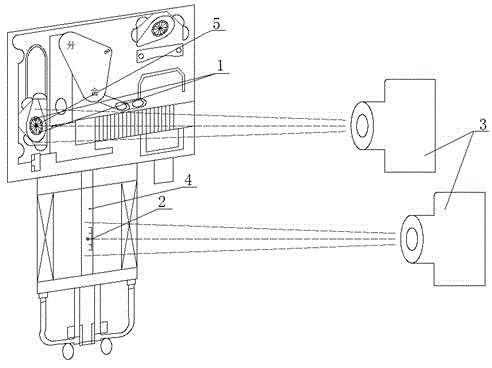

Method for testing movement characteristics of dynamic contact of high-voltage circuit breaker

InactiveCN104697768AEasy to implementImprove test accuracyMachine part testingCoordinate changeEngineering

The invention provides a method for testing movement characteristic of a dynamic contact of a high-voltage circuit breaker. The method comprises the steps of arranging auxiliary markers on an insulating pulling rod and a rotating shaft of the dynamic contact of the high-voltage circuit breaker; acquiring image sequences of the auxiliary markers during disconnecting and connecting the circuit breaker through a camera; tracking the auxiliary markers by the particle filtering method; acquiring centroid coordinates of the auxiliary markers of each image; acquiring a movement track of the dynamic contact according to the time intervals of adjacent frames in the image sequences and the coordinate change of the auxiliary markers in the images; then acquiring the movement characteristics according to the movement track of the dynamic contact. According to the method, the particle filter directional, frame correcting and quick capturing method is carried out to obtain the movement track of the auxiliary markers on the insulating pulling rod and the rotating shaft which are in rigid connection with the circuit breaker, so as to gain the movement characteristics of the dynamic contact; the method is convenient to carry out and high in test precision; reliable basis is provided to the state test and performance evaluation of the high-voltage circuit breaker.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Bending fatigue damage monitoring system for steel wire under action of corrosion-alternating load coupling

InactiveCN104614261ASimple and fast operationVersatileWeather/light/corrosion resistanceMaterial strength using steady bending forcesFatigue damageControl system

The invention discloses a bending fatigue damage monitoring system for a steel wire under action of corrosion-alternating load coupling. The bending fatigue damage monitoring system comprises a driving system, an alternating force loading system, a reversing control system, a surrounding angle adjusting system, a corrosion liquid addition system, a steel wire and a steel wire status monitoring system. According to the bending fatigue damage monitoring system, the bending fatigue test for the steel wire under the action of corrosion-alternating load coupling can be realized, and the quantitative monitoring on the internal damage of the steel wire and the disclosure on the bending fatigue damage failure mechanism can be achieved. The bending fatigue damage monitoring system can be used for exploring the dynamic contact between the steel wire rope and a friction liner of a friction wheel under the working condition of simulating mine hoisting, local microslip amplitude and the dynamic tension evolution of the steel wire rope. The bending fatigue damage monitoring system can provide effective experimental equipment for the quantitative analysis of the bending fatigue failure characteristic of the steel wire under action of corrosion-alternating load coupling; and the bending fatigue damage monitoring system is simple and convenient to operate, complete in functions, good in effect, and has wide practicability in the technical field.

Owner:CHINA UNIV OF MINING & TECH

Ultra-deep vertical shaft winding type hoisting steel cable multi-axial friction fatigue damage monitoring device and method

InactiveCN105823696AWide applicabilityUsing mechanical meansMaterial strength using repeated/pulsating forcesFatigue damageLow speed

The invention discloses an ultra-deep vertical shaft winding type hoisting steel cable multi-axial friction fatigue damage monitoring device .The monitoring device comprises a tension-torsional fatigue system and a dynamic loading monitoring system which are arranged on a supporting system; the tension-torsional fatigue system comprises a low-speed large-torque motor and a servo electric cylinder A, the low-speed large-torque motor is connected with one end of a fatigue steel cable through a coupling A, a torque sensor, a coupling B, a shaft and a steel cable fixture A, and a threaded rod of the servo electric cylinder A is connected with the other end of the fatigue steel cable through a tension sensor and a steel cable fixture B; the dynamic loading monitoring system comprises a servo electric cylinder B, a threaded rod of the servo electric cylinder B is connected with a loading steel cable fixture through a two-dimension force sensor, a fixture block is arranged on a fixture rotary table of the loading steel cable fixture, and the loading steel cable is fixed on the fixture block .According to the ultra-deep vertical shaft winding type hoisting steel cable multi-axial friction fatigue damage monitoring device, cable multi-axial friction fatigue properties among steel cables under the dynamic tension-torsional combined fatigue loading action and dynamic contact and creep properties between the steel cables and a friction liner can be researched.

Owner:CHINA UNIV OF MINING & TECH

Articles for manipulating impinging liquids and methods of manufacturing same

ActiveUS20140291420A1Improve performanceMore practicalMaterial nanotechnologyFouling preventionNon wettingEngineering

This invention relates generally to an article that includes a non-wetting surface having a dynamic contact angle of at least about 90°. The surface is patterned with macro-scale features configured to induce controlled asymmetry in a liquid film produced by impingement of a droplet onto the surface, thereby reducing time of contact between the droplet and the surface.

Owner:MASSACHUSETTS INST OF TECH

Ink jet recording liquid and ink jet recording method

InactiveUS6620229B2Jetting is detrimentalLong-term stabilityMaterial nanotechnologyLiquid surface applicatorsOrganic solventTemporal change

An ink jet recording liquid of high optical density, good rub resistance, and excellent feathering and long-term preservation stability when the liquid is used for printing on plain paper is used in an ink jet recording method. In the ink jet recording liquid which contains a pigment, water soluble organic solvent, and water as the essential components, and additionally containing water soluble resin and / or surfactant, 1) the temporal change rate of dynamic contact angle on plain paper is in a range from 0.5 to 3.5 degrees / second, 2) the number average particle diameter in the ink jet recording liquid is in a range from 15 to 100 nm, and 3) the volume average particle diameter in the ink jet recording liquid is in a range from 30 to 200 nm. The above-mentioned ink jet recording liquid is printed by means of ink jet recording.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Contact sensors and methods for making same

Disclosed herein are novel contact sensors. The contact sensors disclosed herein include a conductive composite material formed of a polymer and a conductive filler. In one particular aspect, the composite materials can include less than about 10 wt % conductive filler. Thus, the composite material of the contact sensors can have physical characteristics essentially identical to the polymer, while being electrically conductive with the electrical resistance proportional to the load on the sensor. The sensors can provide real time dynamic contact information for joint members under conditions expected during use.

Owner:SENCORABLES

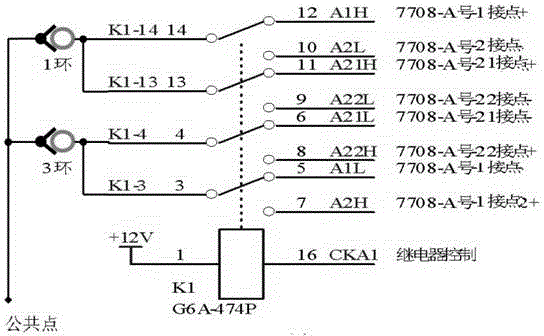

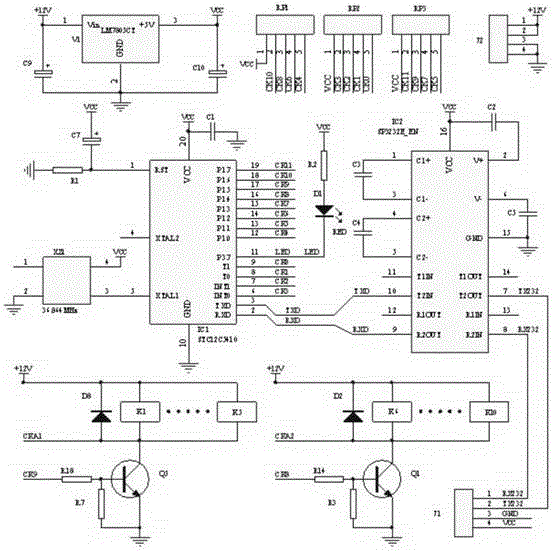

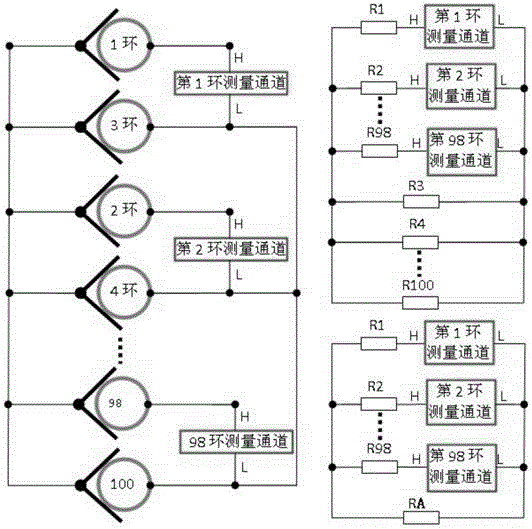

Measuring device and measuring method for dynamic contact resistors of conductive devices

ActiveCN103604993ATest accurateHigh measurement accuracyResistance/reactance/impedenceAviationElectrical resistance and conductance

A measuring device and a measuring method for dynamic contact resistors of conductive devices are disclosed. The invention provides a special-purpose measuring device for accurately measuring dynamic and static contact resistors which are applied to conductive devices in a variety of models in the aviation and aerospace field. The measuring device comprises a liquid crystal display, an industrial control computer system, a multipath micro resistor measurement unit, a switch control module, a keyboard, a mouse, a system power supply, a test connection cable, conductive devices to be measured and the like. According to the invention, dynamic and static contact resistors between conducting rods and electric brushes of conductive devices in a variety of models such as 96 rings, 76 rings, 60 rings, 54 rings and the like can be accurately measured, parameters such as the measuring ring number, the measuring mode, the measuring number of times and the like of the conductive devices can be set, and functions such as automatic sampling, storage, processing of measured data, and report generation, historical data query and the like are achieved.

Owner:SHAANXI AEROSPACE TIMES NAVIGATION EQUIP CO LTD

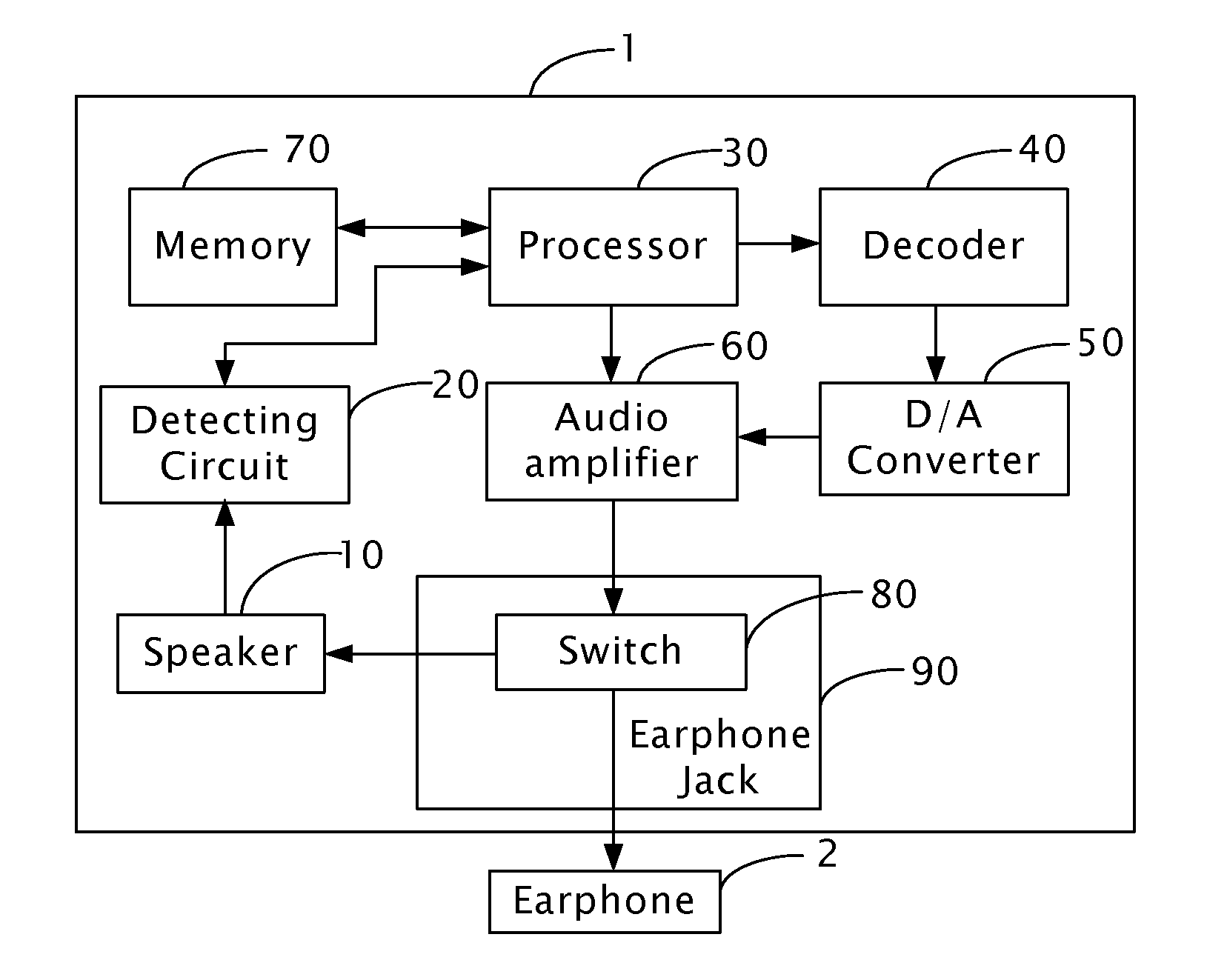

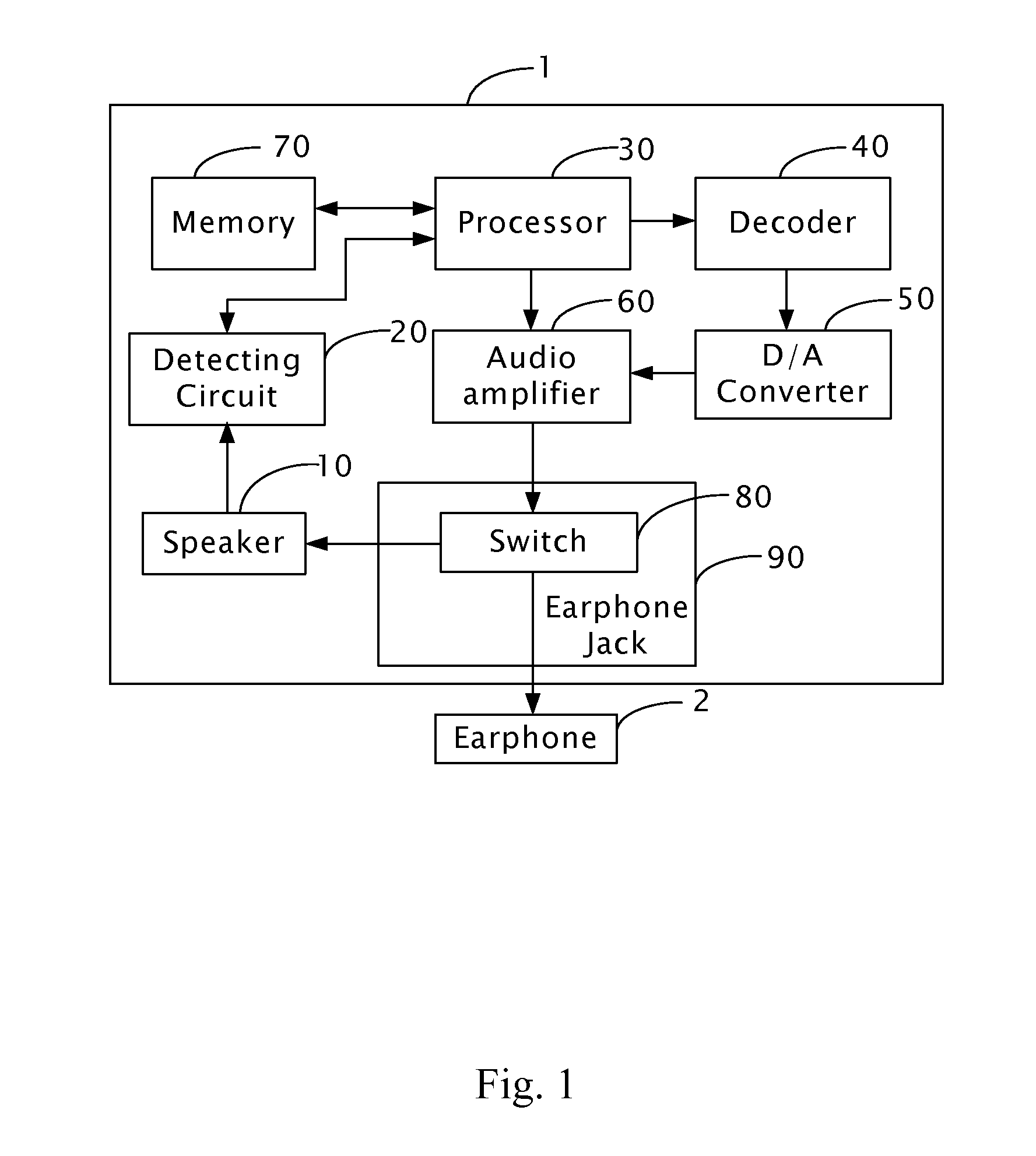

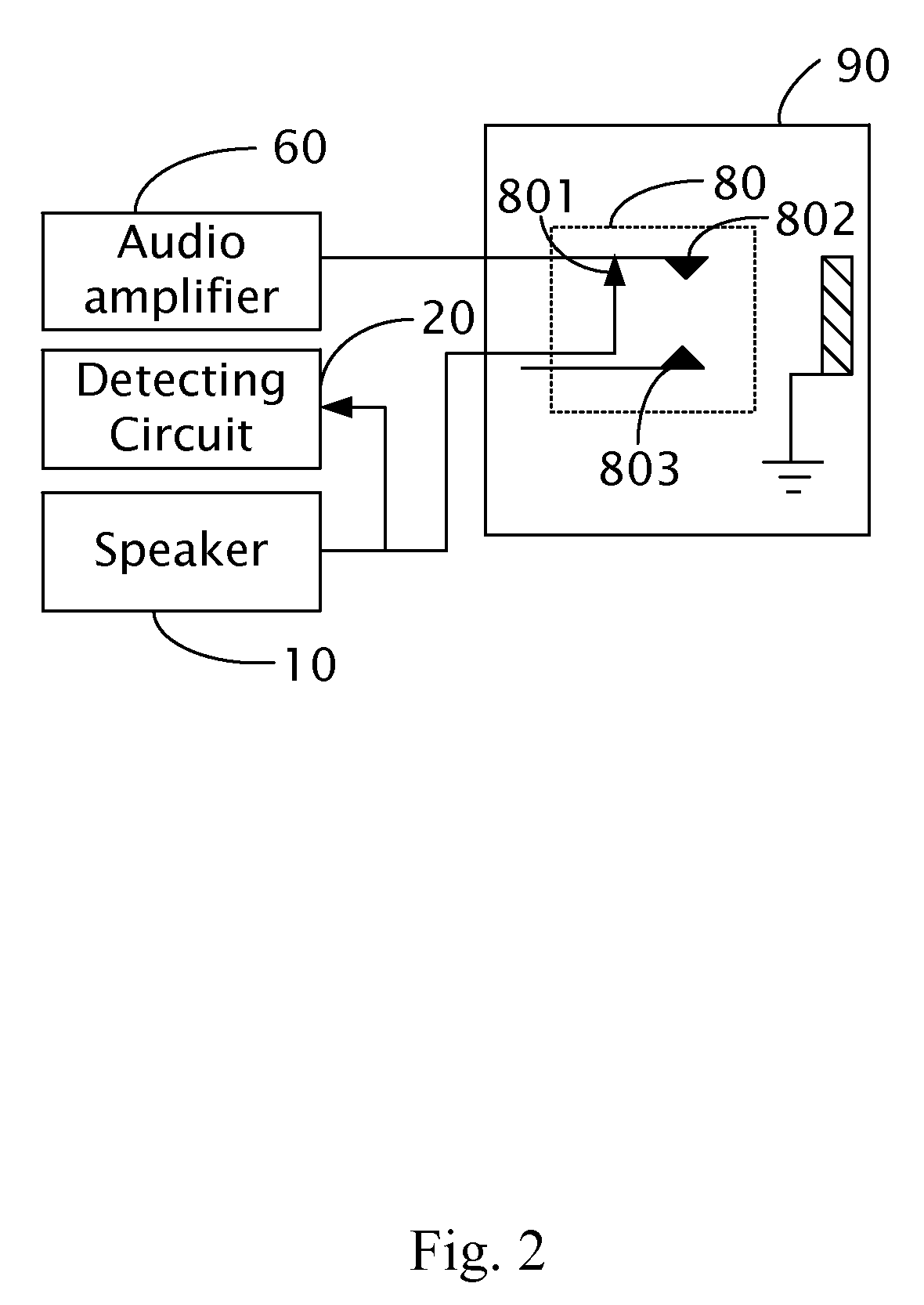

Media player capable of automatically adjusting equalizer parameters thereof

InactiveUS20080175420A1Realize automatic adjustmentIdeal effectLoudspeaker spatial/constructional arrangementsLoudspeakerComputer science

A media player capable of automatically adjusting equalizer parameter thereof is provided. The media player includes a speaker, a processor, a memory, an audio amplifier, a decoder, an analog to digital (D / A) converter, an earphone jack for connecting with an earphone, a switch and a detecting circuit. The memory stores audio files and a voltage value-equalizer parameter look-up table. The detecting circuit detects a voltage of the speaker or the second dynamic contact of the switch and obtains a voltage value. The processor compares the voltage value with predetermined voltage values and obtains a comparison result, and reads corresponding equalizer parameters from the table according to the comparison result. The media player plays an audio files according to the equalizer parameters, thus to obtain audio effect optimization.

Owner:PENGZHI TECH SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com