Patents

Literature

271results about How to "Good for condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

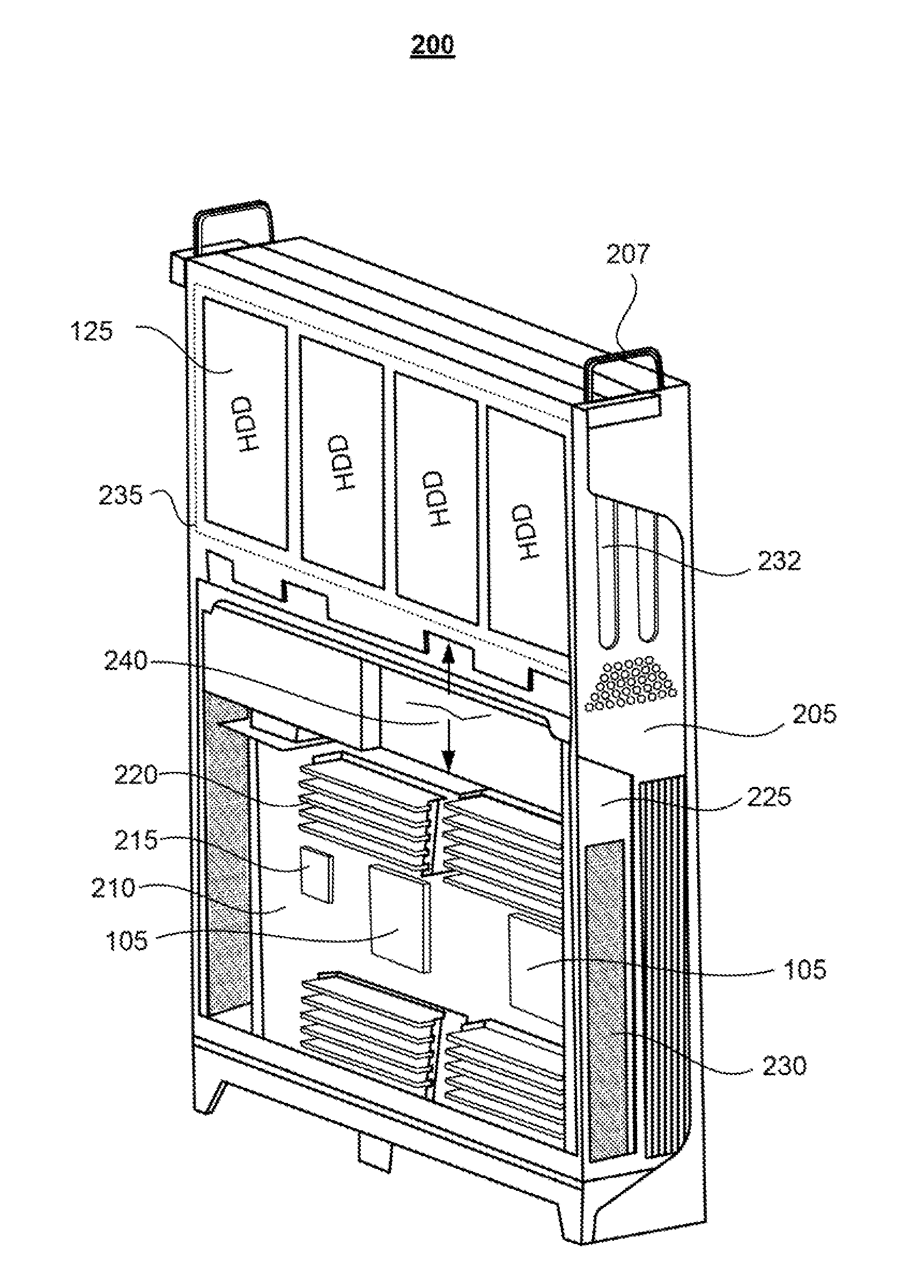

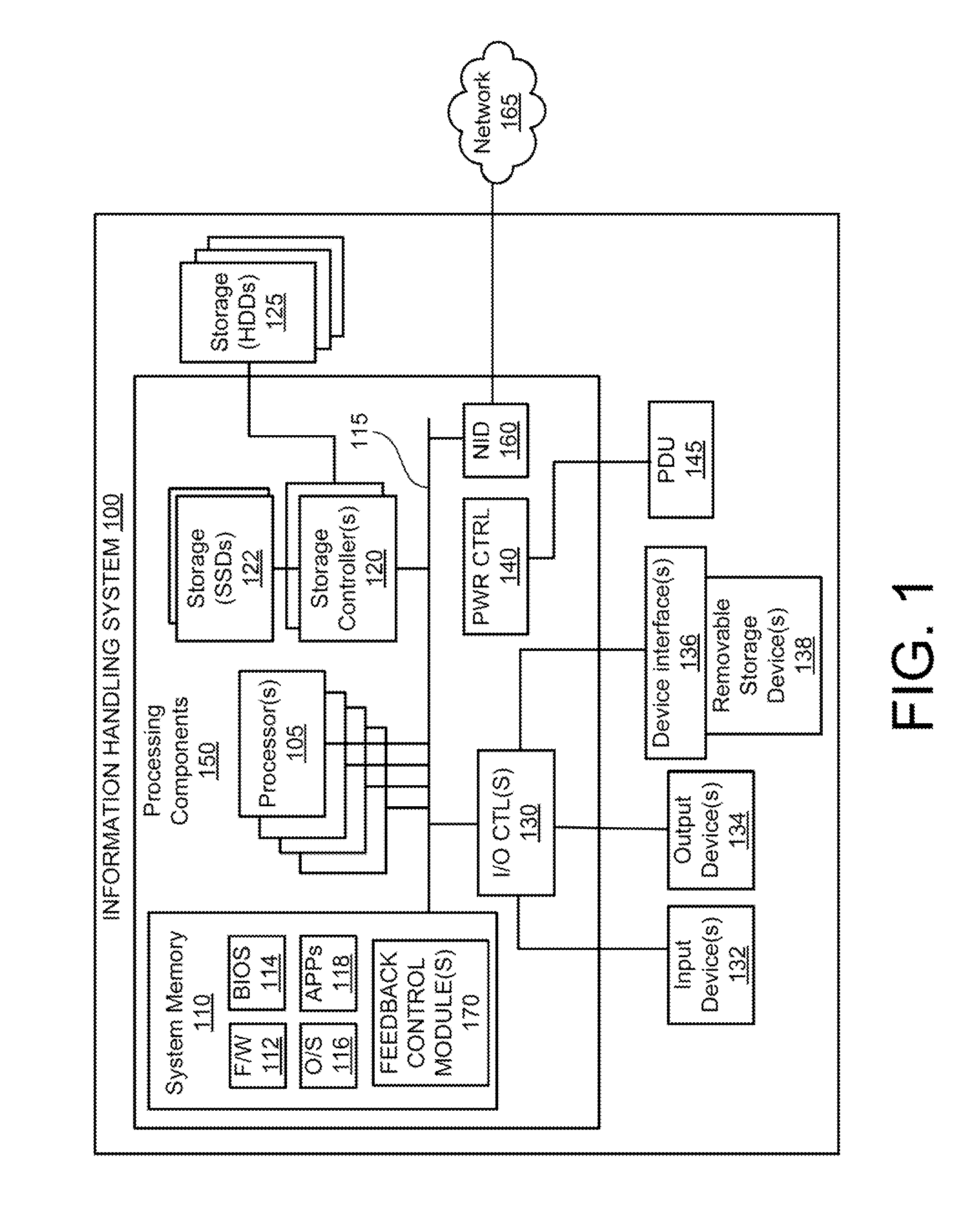

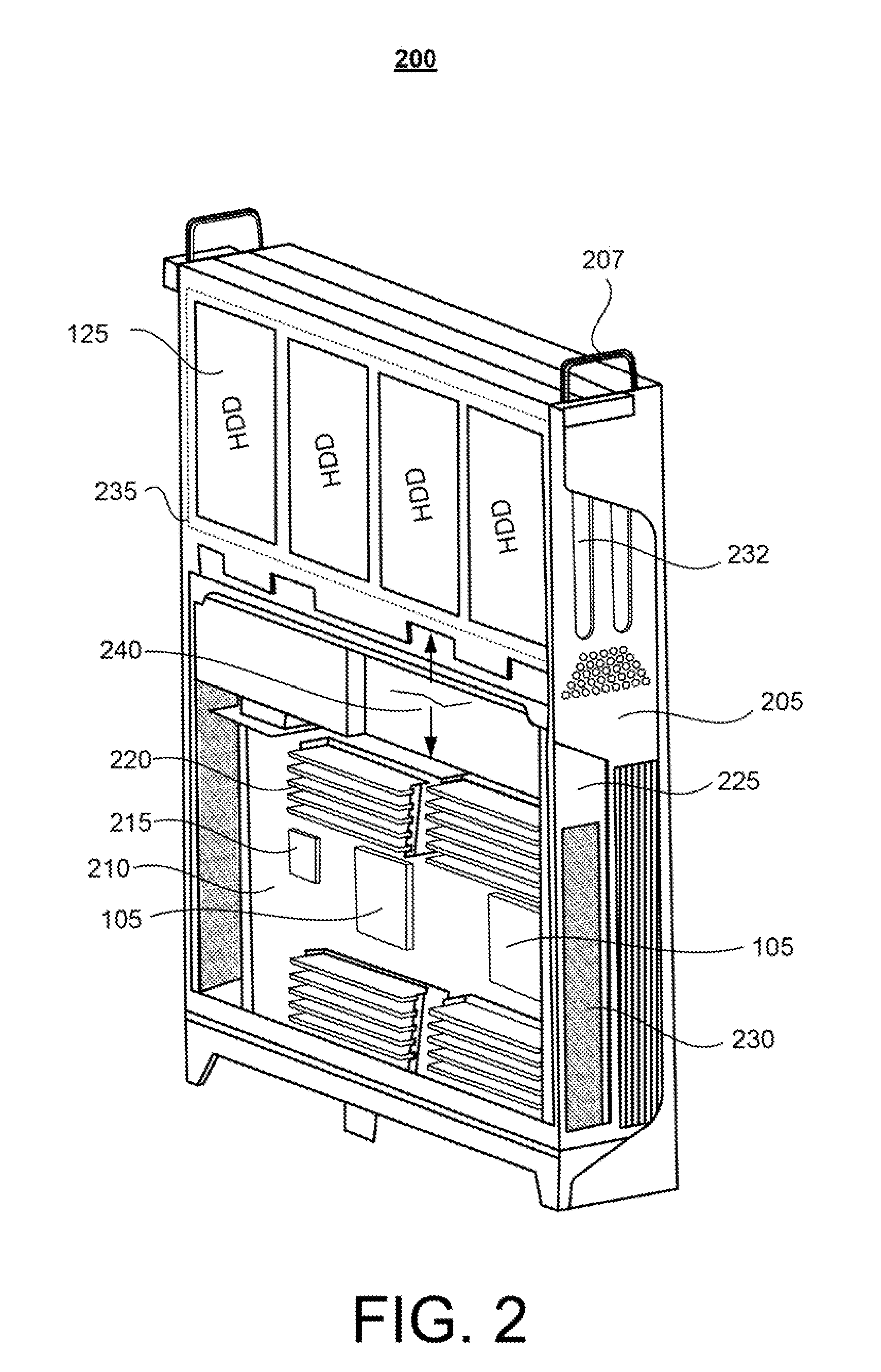

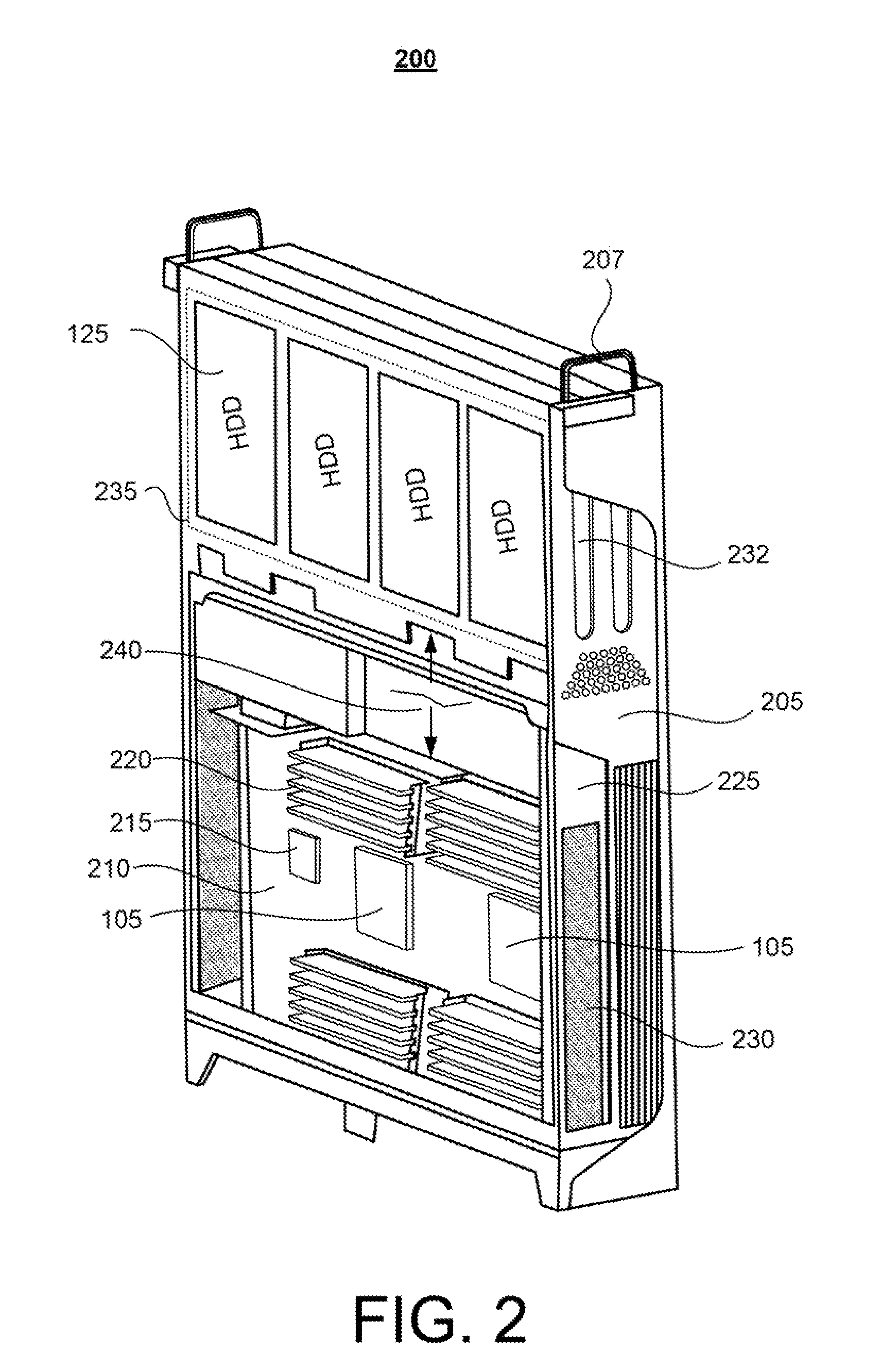

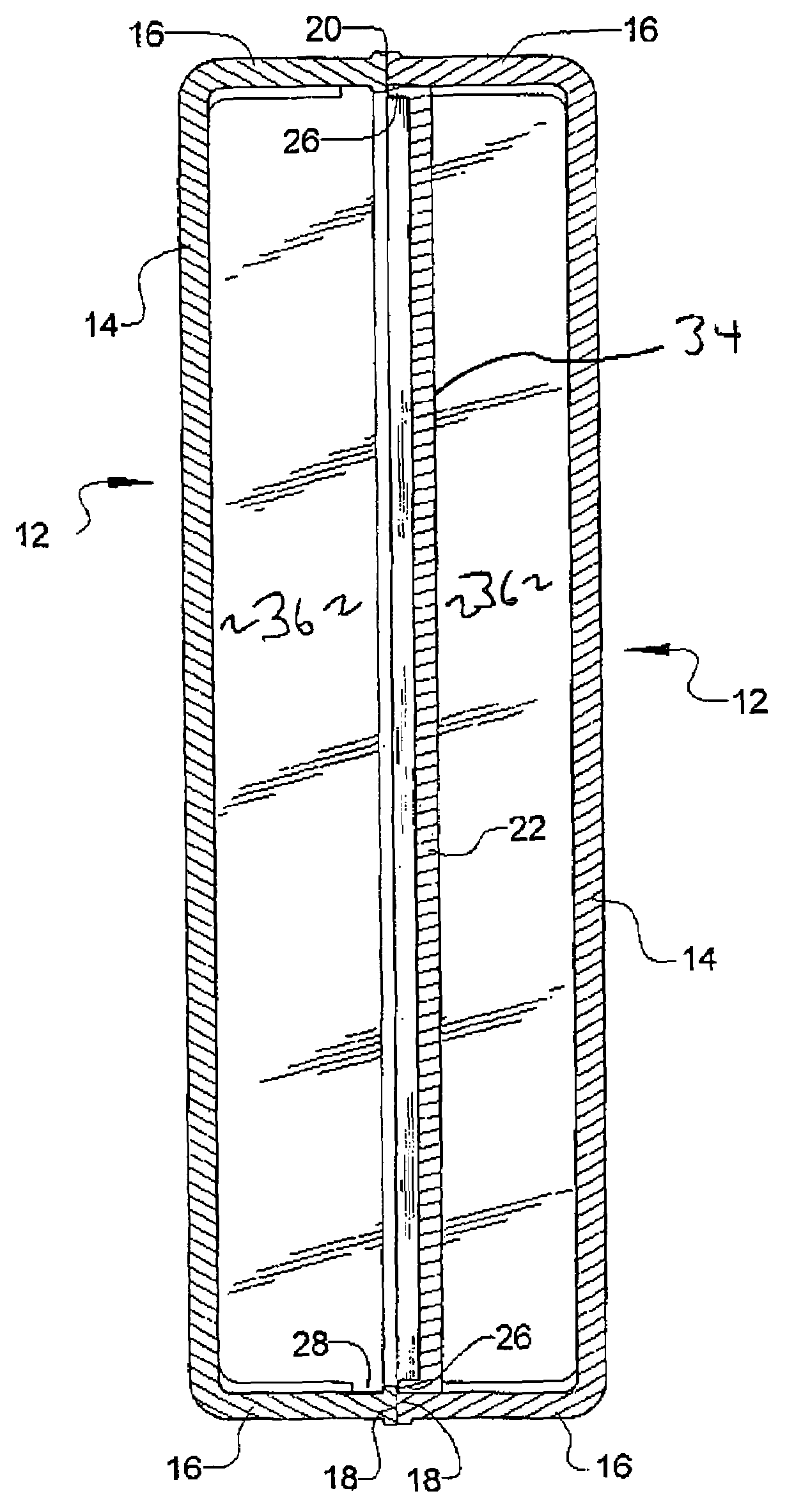

Techniques for Controlling Vapor Pressure in an Immersion Cooling Tank

ActiveUS20150060009A1Eliminate increase in pressureMaximize the effectAir-treating devicesTemperatue controlDifferential pressureTransducer

A method that controls pressure within an immersion cooling tank having condensation fluid flowing through a condenser, includes: a controller receiving a signal that indicates a current level of vapor pressure within the tank; determining from the signal when the current level of vapor pressure exceeds or is below a first preset threshold pressure level; and in response to the current level of vapor pressure exceeding or being below the first preset threshold pressure level, signaling a flow control mechanism that modulates a flow rate of the condensation fluid through the condenser to increase or decrease the rate of flow from a current rate of flow. The controller receives the signal by a pressure sensor within the immersion cooling tank detecting the current vapor pressure, generating the signal and forwarding the signal to the controller. The pressure sensor can be a differential pressure transducer that measures a differential pressure internal to and outside of the immersion tank.

Owner:DELL PROD LP

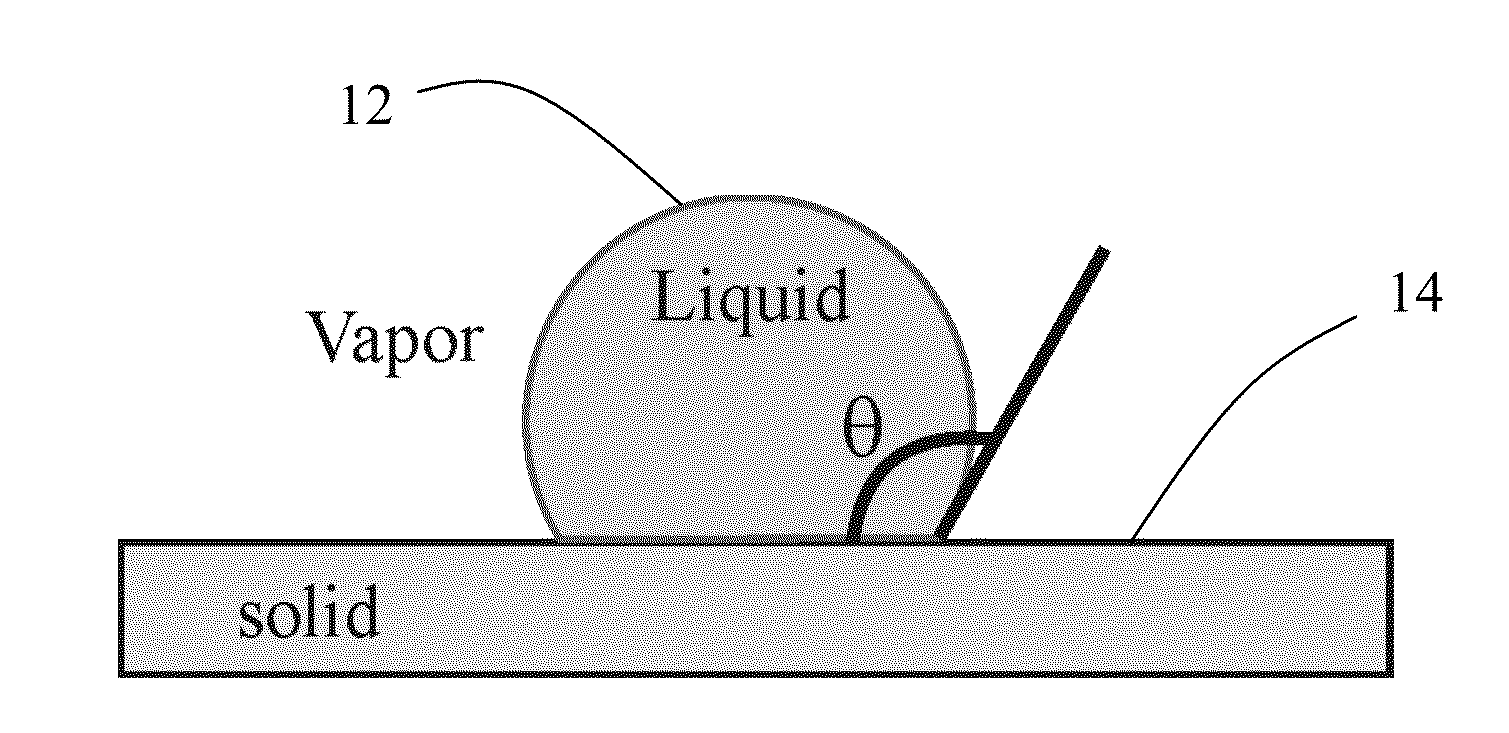

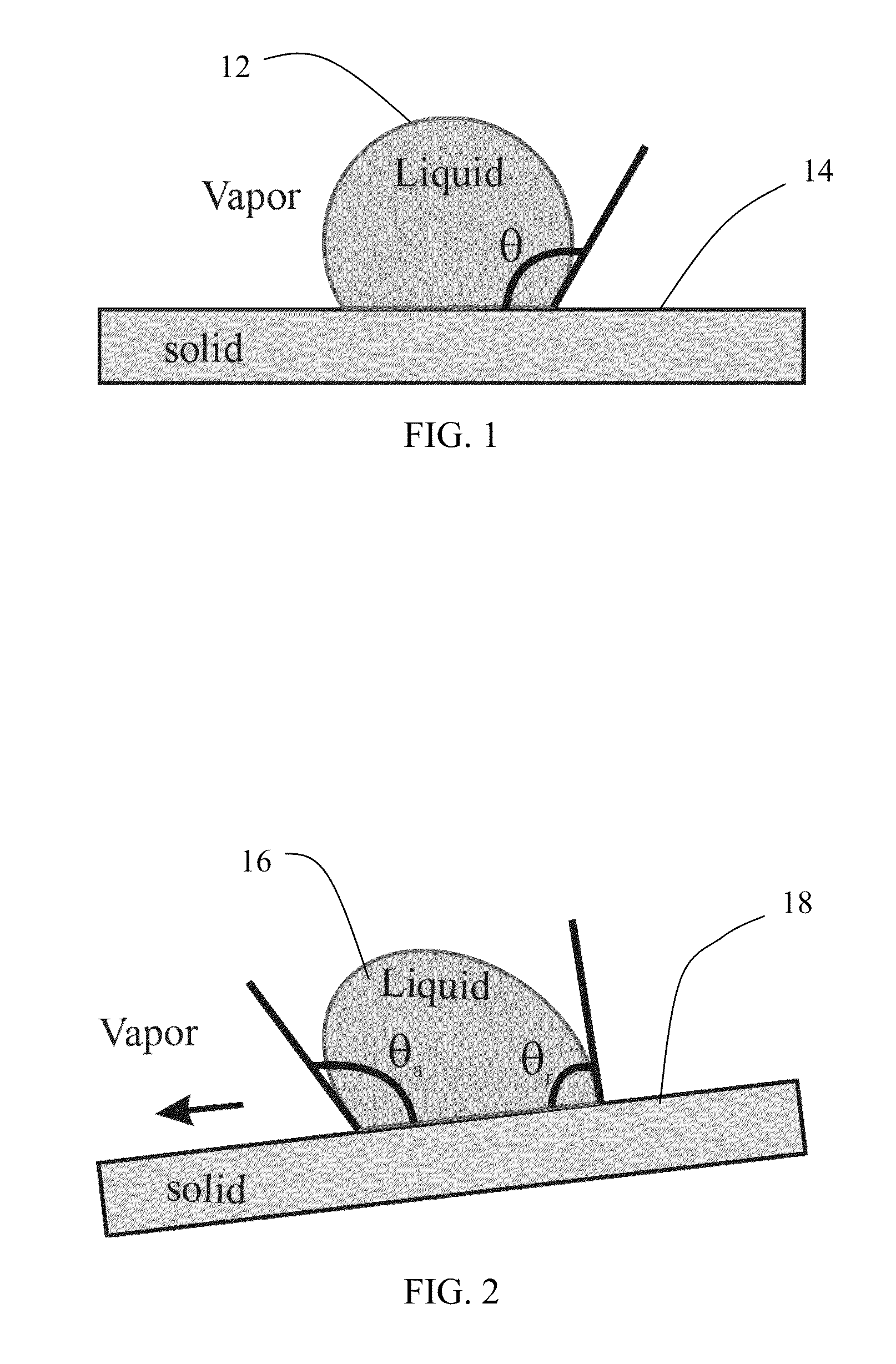

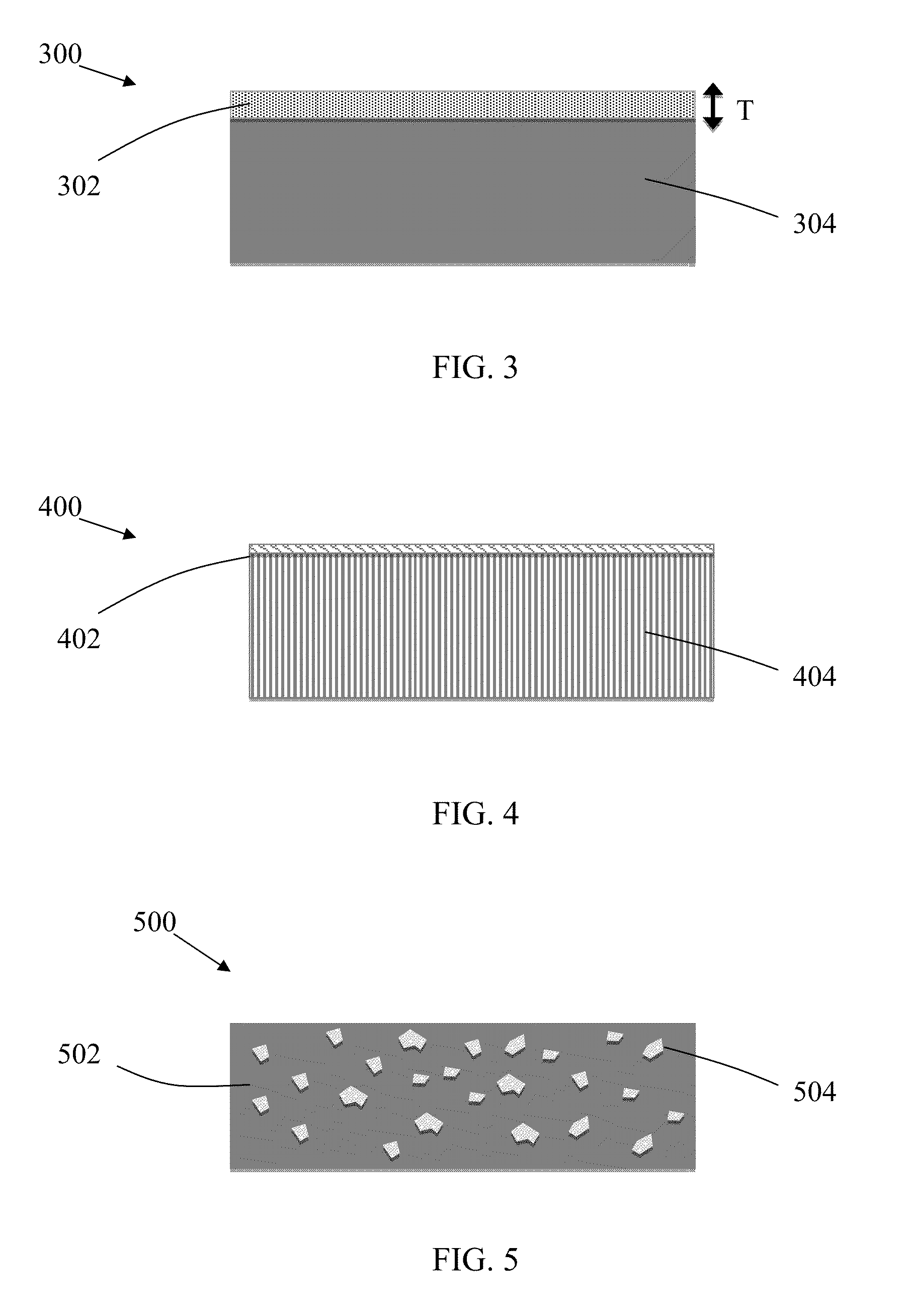

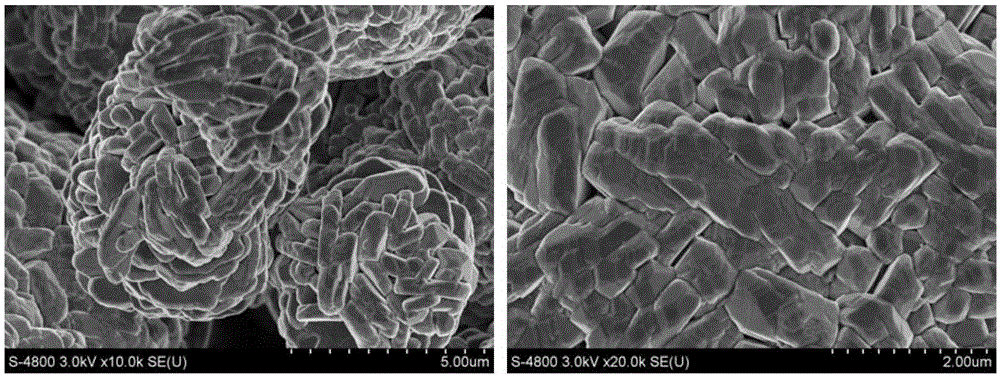

Hydrophobic Materials Incorporating Rare Earth Elements and Methods of Manufacture

InactiveUS20130251942A1Improve waterproof performanceGood for condensationVacuum evaporation coatingSputtering coatingRare-earth elementBoride

This invention relates generally to an article that includes a base substrate and a hydrophobic coating on the base substrate, wherein the hydrophobic coating includes a rare earth element material (e.g., a rare earth oxide, a rare earth carbide, a rare earth nitride, a rare earth fluoride, and / or a rare earth boride). An exposed surface of the hydrophobic coating has a dynamic contact angle with water of at least about 90 degrees. A method of manufacturing the article includes providing the base substrate and forming a coating on the base substrate (e.g., through sintering or sputtering).

Owner:MASSACHUSETTS INST OF TECH

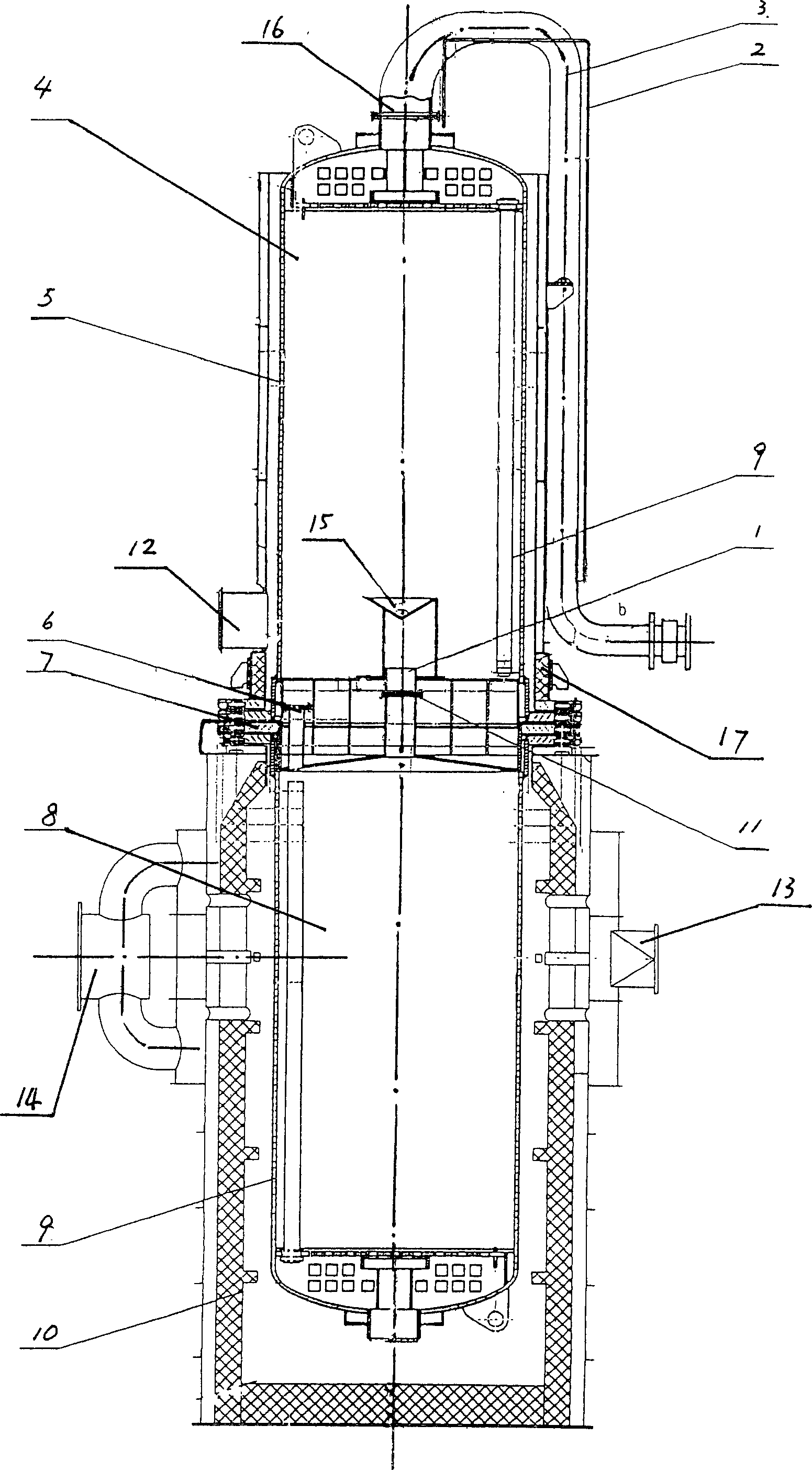

Fluid displacement system

In a fluid displacement system having a pressure vessel, an expansion vessel, first and second tubes in fluid communication with the two vessels, and an energy source, fluid contained within the system is transferred from one vessel to the other by activating the energy source, which in turn generates pressure in the pressure vessel. The generated pressure in the pressure vessel, in turn, displaces the fluid in the expansion vessel, and the system advantageously has no moving parts.

Owner:T D I THERMO DYNAMICS ISRAEL

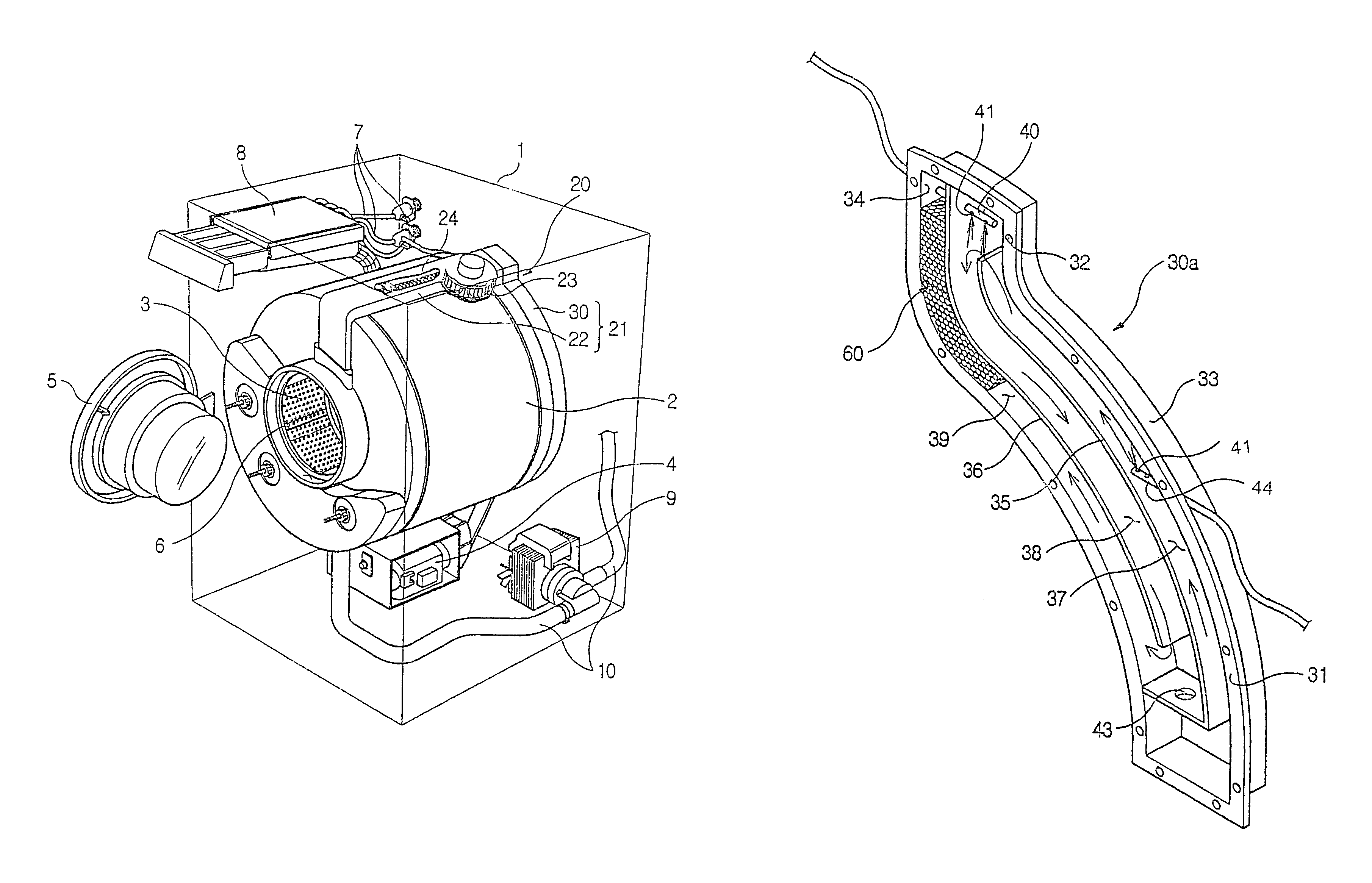

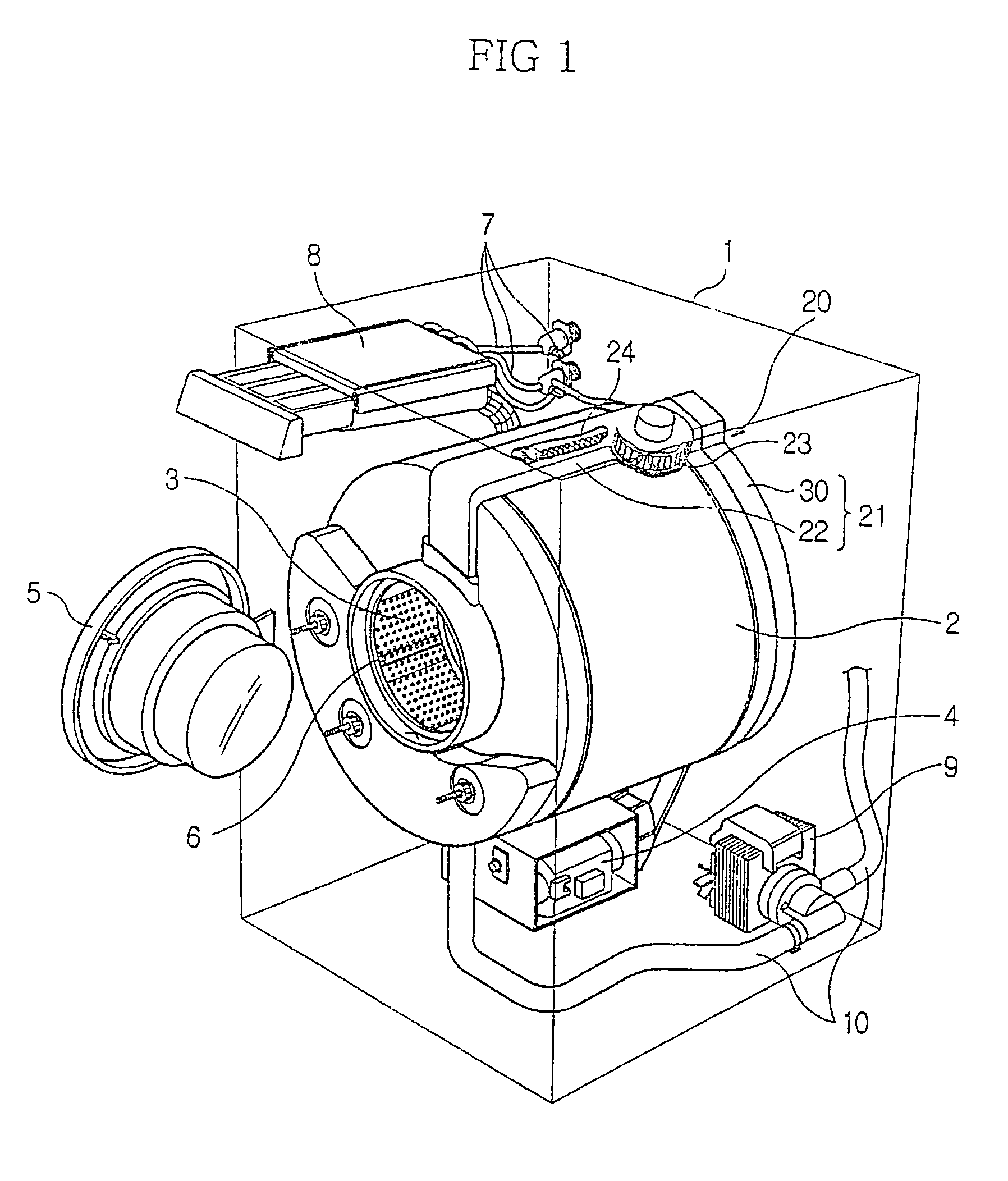

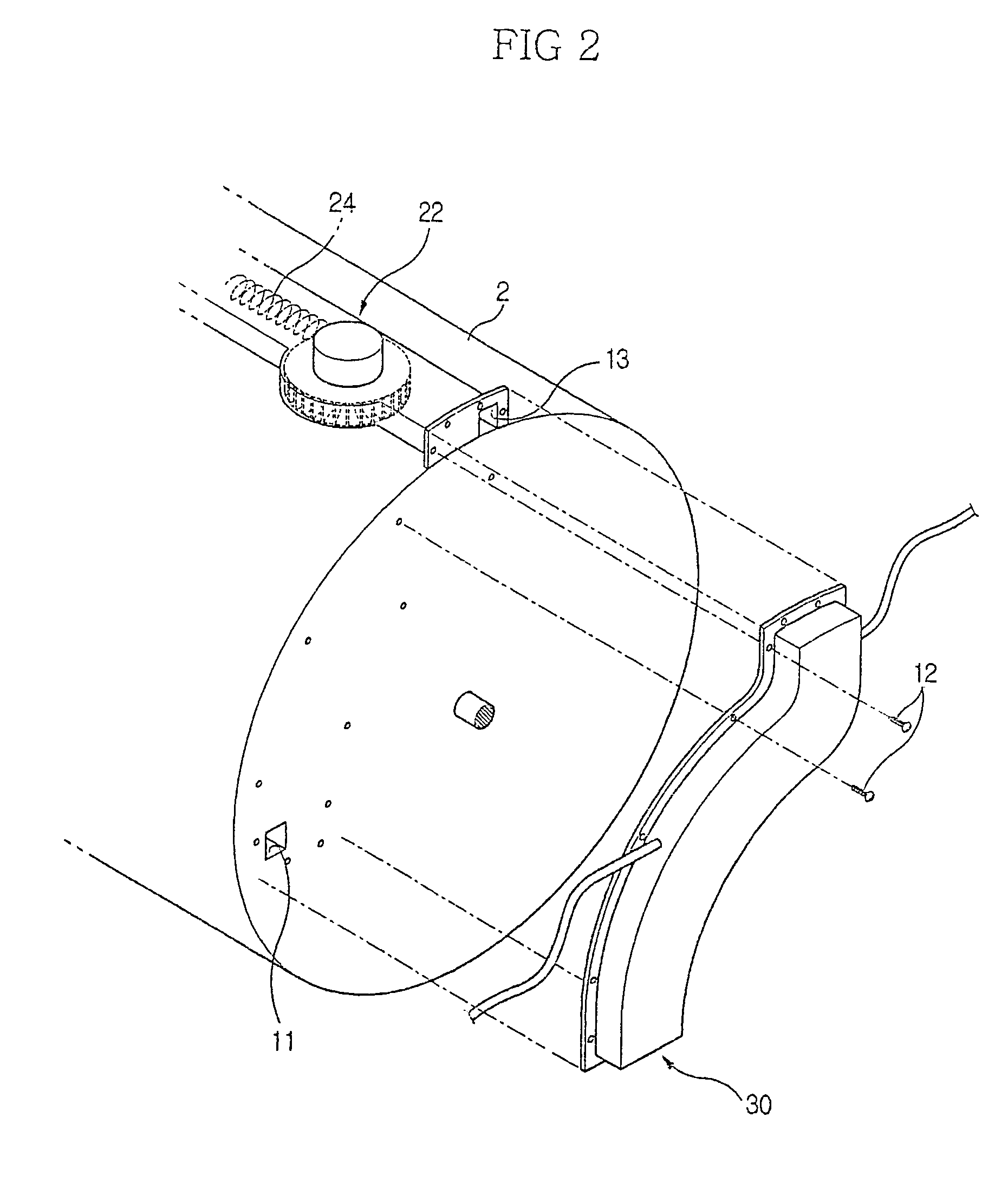

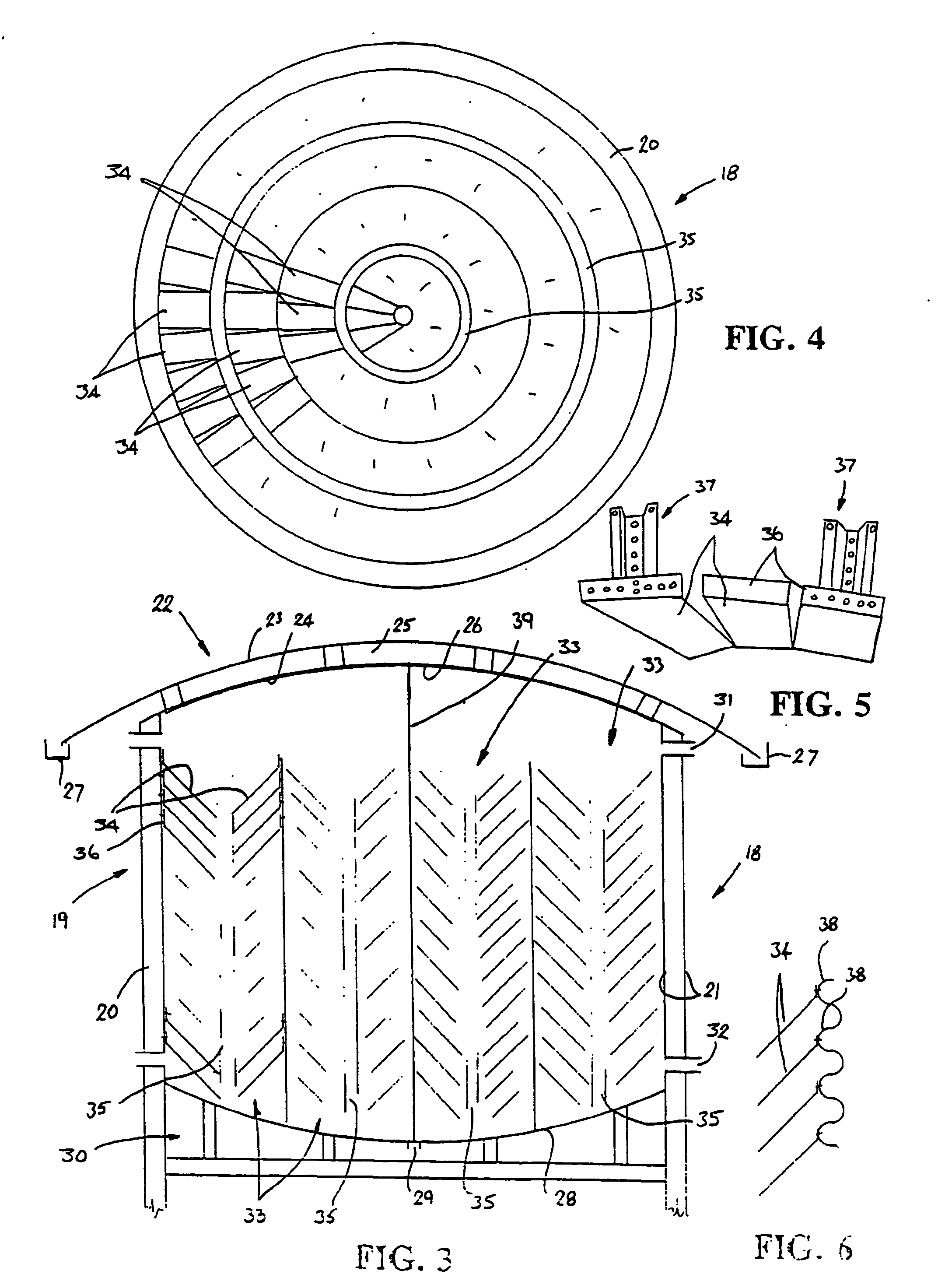

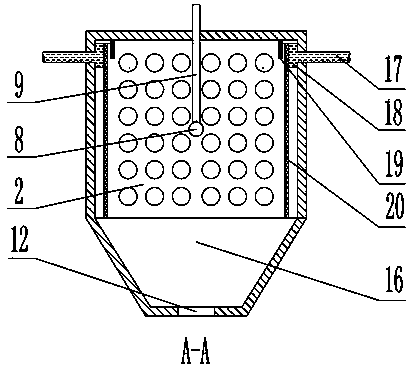

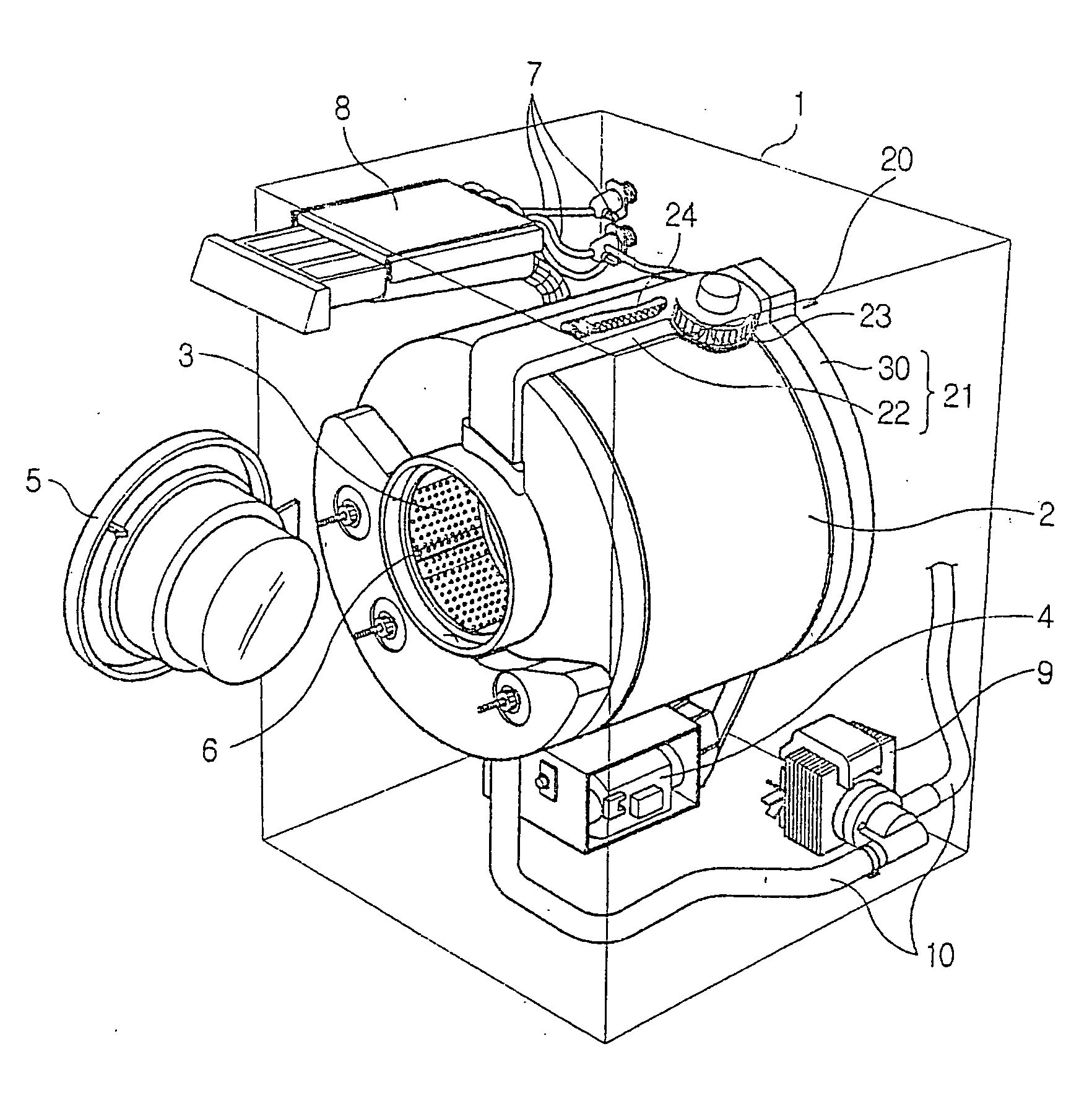

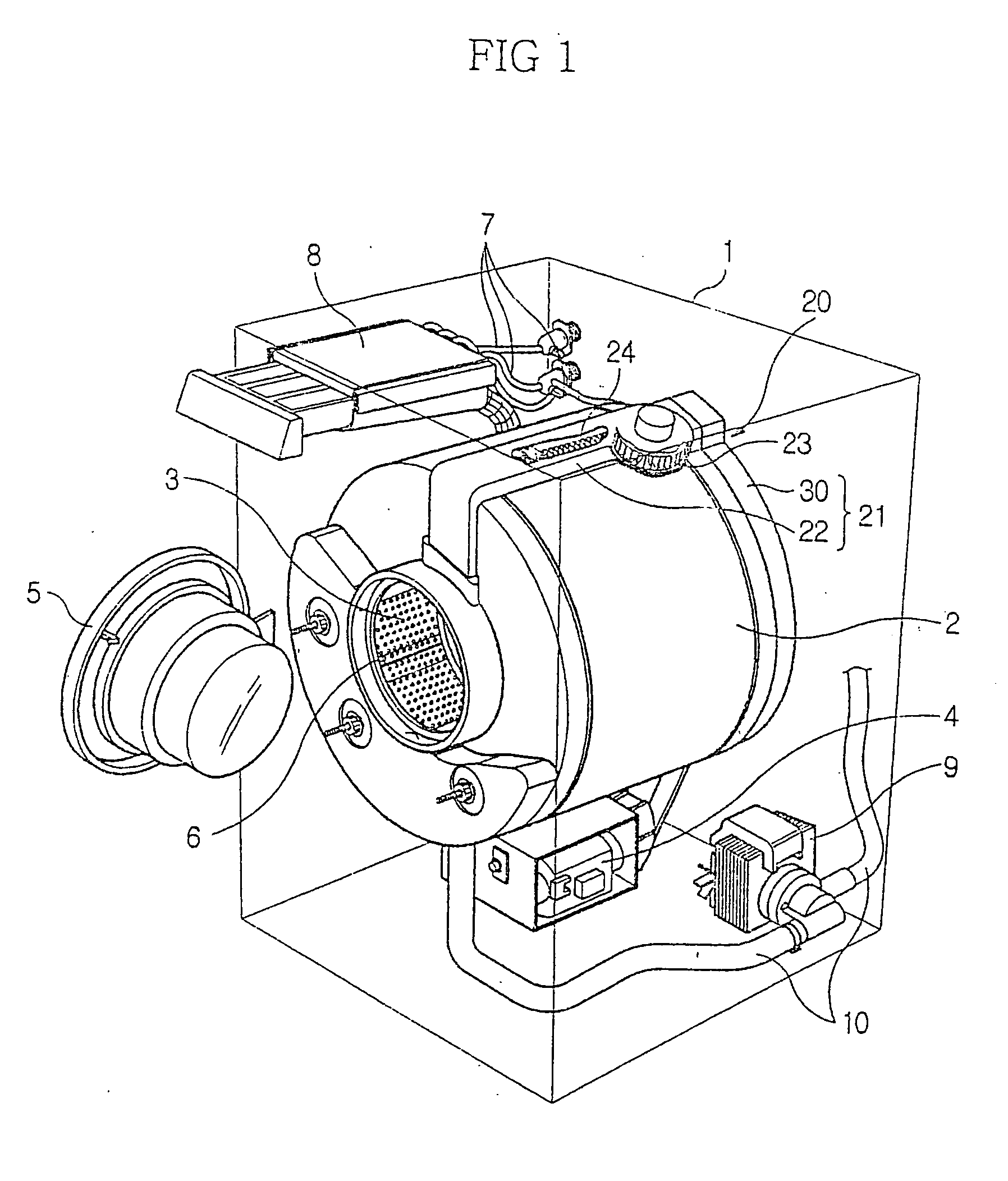

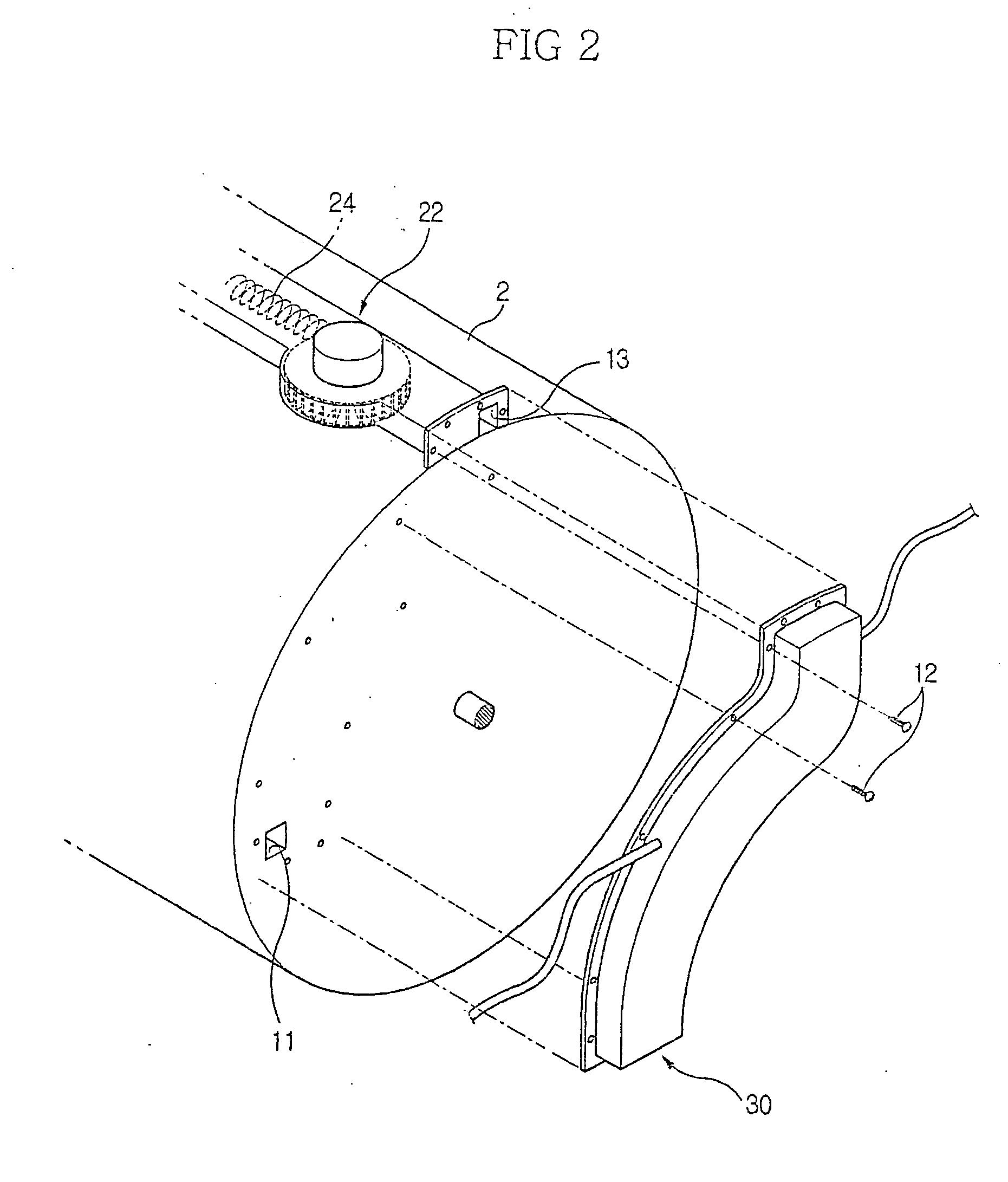

Drying apparatus and washing machine having the same

InactiveUS7017282B2Fast dryingEfficiently condensing and adsorbing vaporDrying machines with non-progressive movementsWashing machine with receptaclesEngineeringLaundry

A washing machine including a drying apparatus. The washing machine including the drying apparatus quickly dries wet laundry by efficiently condensing and adsorbing vapor from humid air of high temperature flowing from a water tub during a drying-mode operation. The drying apparatus includes a condensing duct and a blower duct respectively mounted on a rear surface and an upper surface of the water tub. The condensing duct has an ultrasonic atomizing unit, a condensing unit and a water adsorption unit therein, while the blower duct has a blower fan and a heater therein. An inner space of the condensing duct is partitioned into a first condensing path, a second condensing path and a third condensing path by a first air guide and a second air guide. The ultrasonic atomizing unit, the condensing unit and the water adsorption unit are installed in the first condensing path, the second condensing path and the third condensing path of the condensing duct, respectively, thus condensing and adsorbing vapor from the humid air which sequentially passes through the first to third condensing paths, thereby dehumidifying the air providing dry air which is fed to the water tub to dry the wet laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

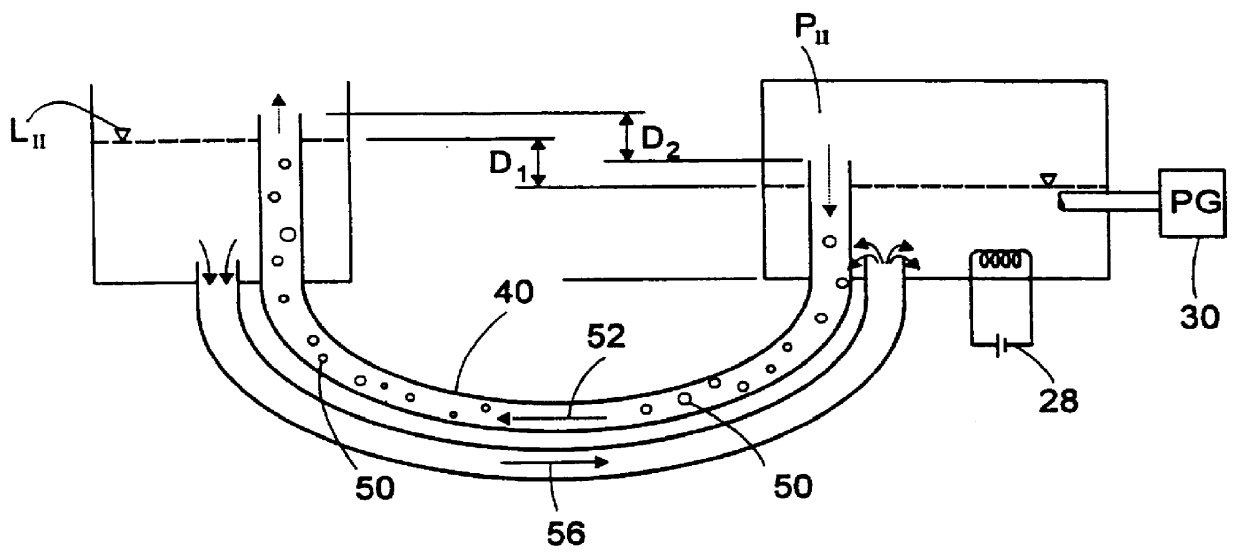

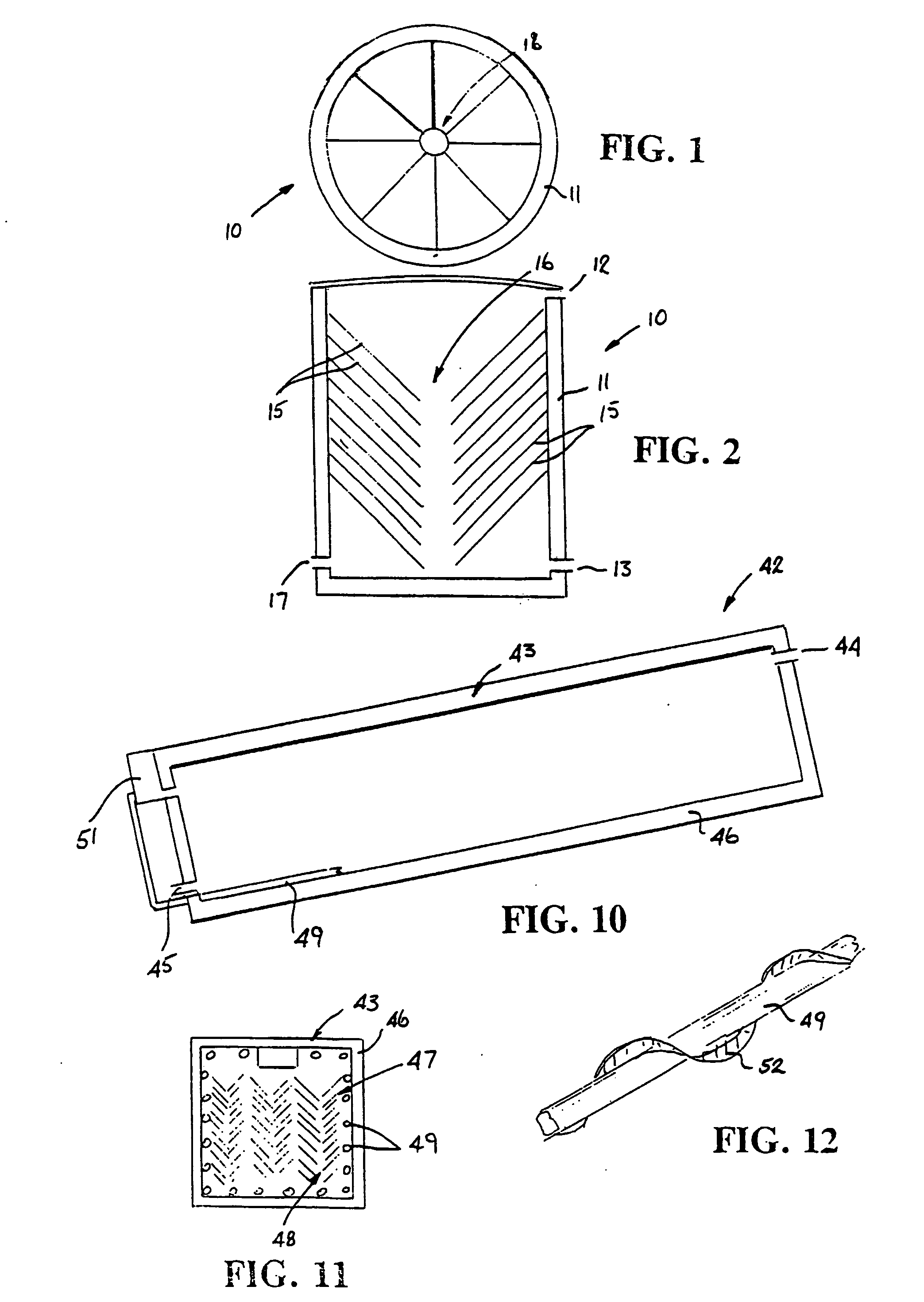

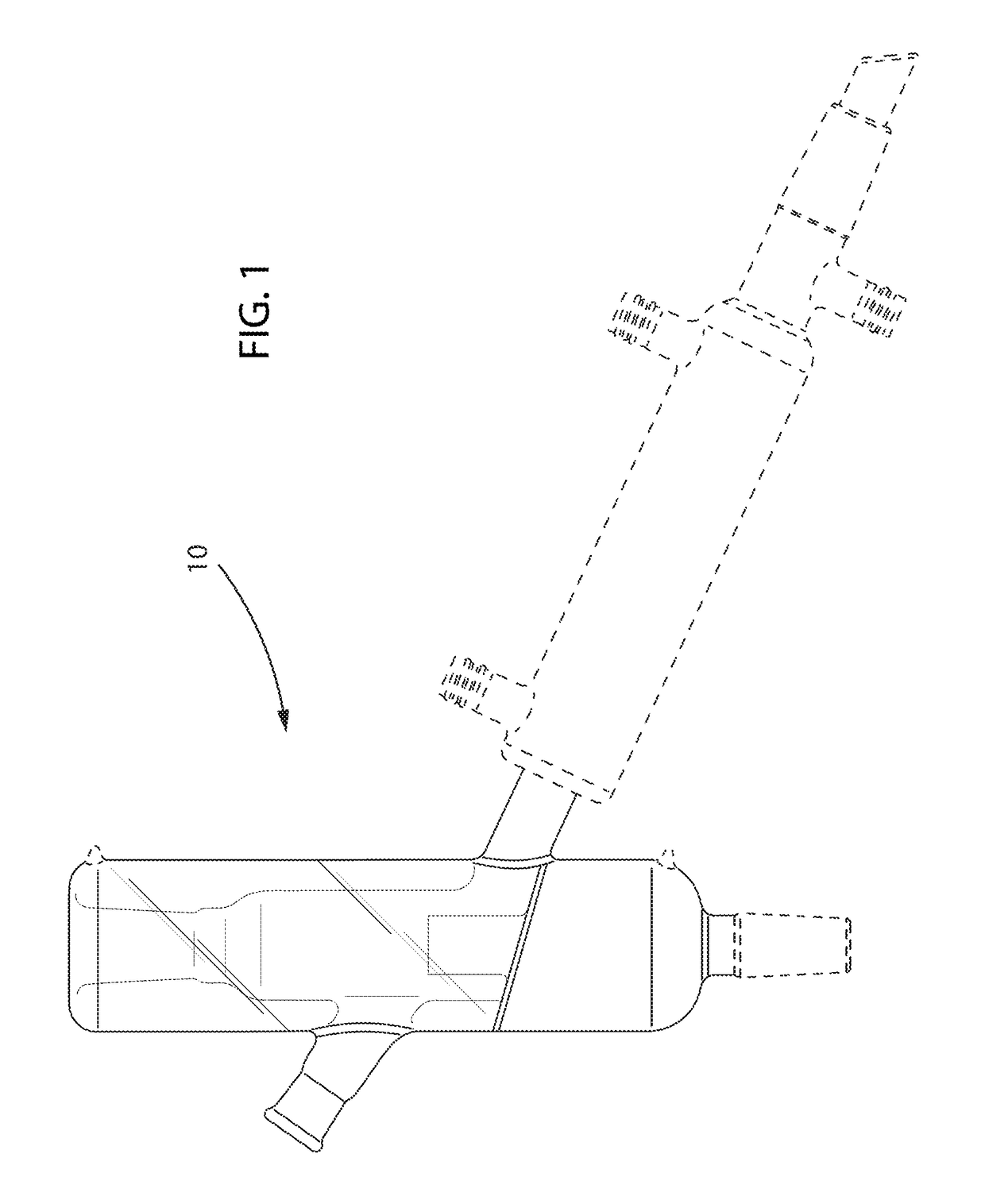

Method and apparatus for collecting atmospheric moisture

InactiveUS20060112709A1Maximise air throughputLow operating efficiencyLighting and heating apparatusVapor condensationMoisture condensationAtmospheric air

A number of apparatii for condensing water from the atmosphere are described, whereby atmospheric air is drawn through an enclosed space and moisture condenses on plates or similar contained within the enclosed space and subsequently collected. Most of the apparatii include means to increase the flow of air through the enclosed space to increase the efficiency of moisture collection. A typical apparatus includes a body (11) supporting condenser plates (15) of conical or frusto-conical configuration. Extractor fans, the operation of which are controlled by humidity sensing switches and temperature sensors, provide the increased flow. To promote condensation, typically, cooling ducts (49) are provided through which air-conditioned cool air is passed.

Owner:BOYLE PETER HAMILTON

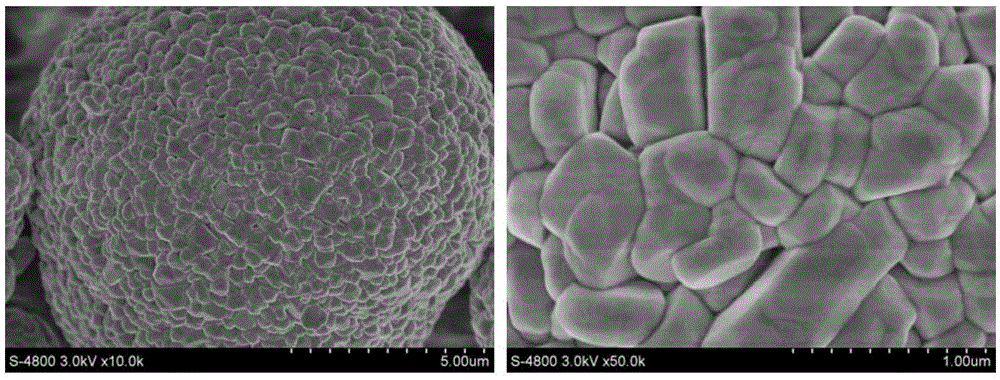

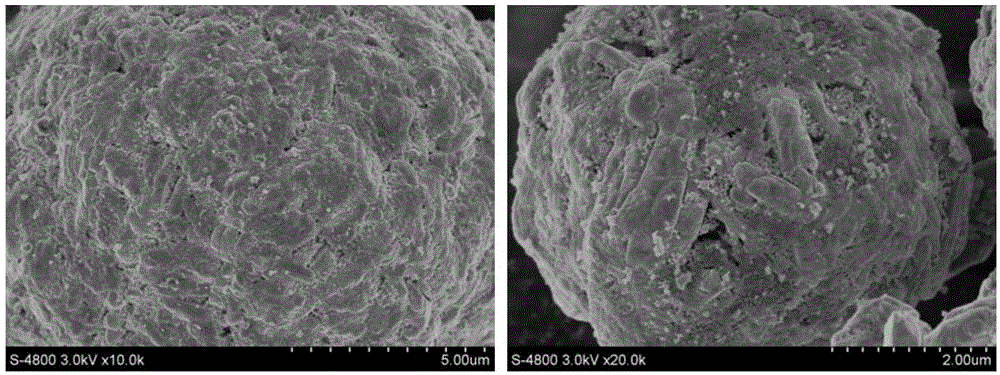

Method for processing ternary material by being clad with lithium ferric manganese phosphate

InactiveCN105406069AGood coating consistencyImprove consistencyCell electrodesSecondary cellsManganeseSlurry

The invention relates to a method for processing a ternary material by being clad with lithium ferric manganese phosphate. The invention belongs to the technical field of a cathode material of lithium ion batteries. The method for processing the ternary material by being clad with the lithium the ferric manganese phosphate comprises the steps of 1, preparation of LFMP precursor slurry: respectively weighing iron, manganese, lithium and phosphorus sources in proportion required by 0.1-100g LFMP, weighing 0-50g ascorbic acid, and adding a dispersion solvent, wherein the solid content is 10%-80%; 2, mixture of materials: weighing 100g ternary material with the constitute of Li(z)Ni(1-x-y)Co(x)Mn(y)O(2), or the mixture of two or more constitutes with the above proportion, adding the slurry, mixing the slurry and the mixture, and carrying out vacuum drying; 3, preparation of the ternary material / lithium ferric manganese phosphate composite cathode material: putting the materials into an argon protective atmosphere sintering surface, keeping warm at the temperature of 250-400 DEG C for 2-6h, then heating to 500-700 DEG C and keeping for 6-16h, cooling along with the furnace, and sieving. The method provided by the invention has the advantages of being simple in technology, convenient to operate, accordant in material performance, small in influence on cell capacity density, and being capable of improving safety performance of the ternary material.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

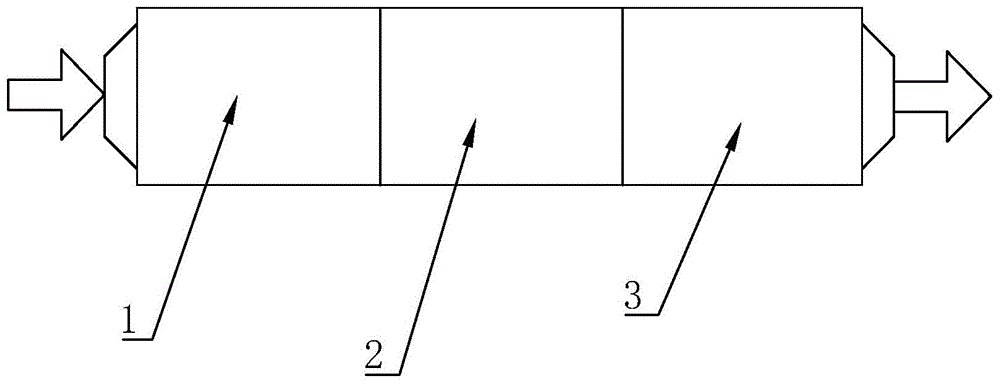

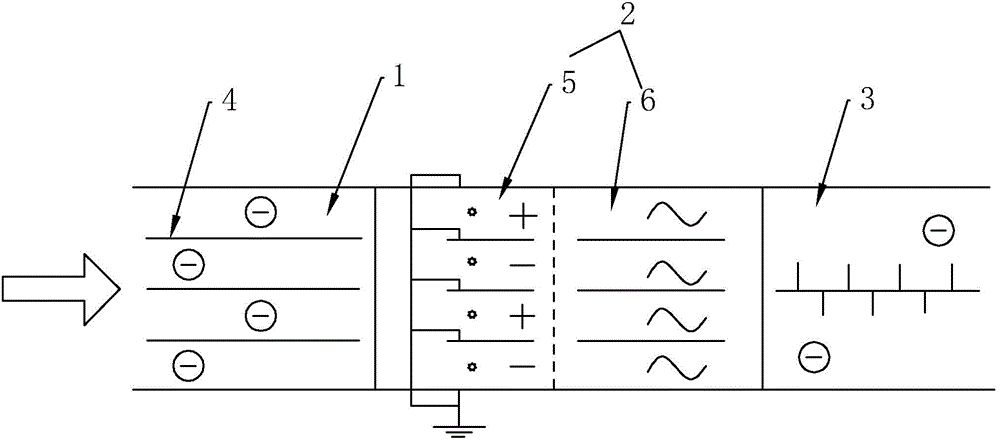

Novel electrostatic dust removing structure

InactiveCN104815755AImprove the effect of coagulation and reunionEfficient captureExternal electric electrostatic seperatorElectrostatic separation detailsFine particulateEngineering

The invention discloses a novel electrostatic dust removing structure. The novel electrostatic dust removing structure is characterized by comprising a dust pre-removing area, an electric agglomeration area and a fine particle capturing area communicated in sequence, wherein one end, far from the electric agglomeration area, of the dust pre-removing area is communicated with a smoke discharge outlet for filtering dust particles with medium and large particle sizes; the dust particles enter the electric agglomeration area after passing through the dust pre-removing area; the electric agglomeration area agglomerates the dust particles with small particle size as larger dust particles; and after the larger dust particles enter the fine particle capturing area, the fine particle capturing area captures the larger dust particles. The novel electrostatic dust removing structure is provided with the electric agglomeration area and the fine particle capturing area for filtering and capturing the dust particles with small particle size, so that the smoke filtering effect is improved, and the pollution of smoke on the environment is further prevented.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

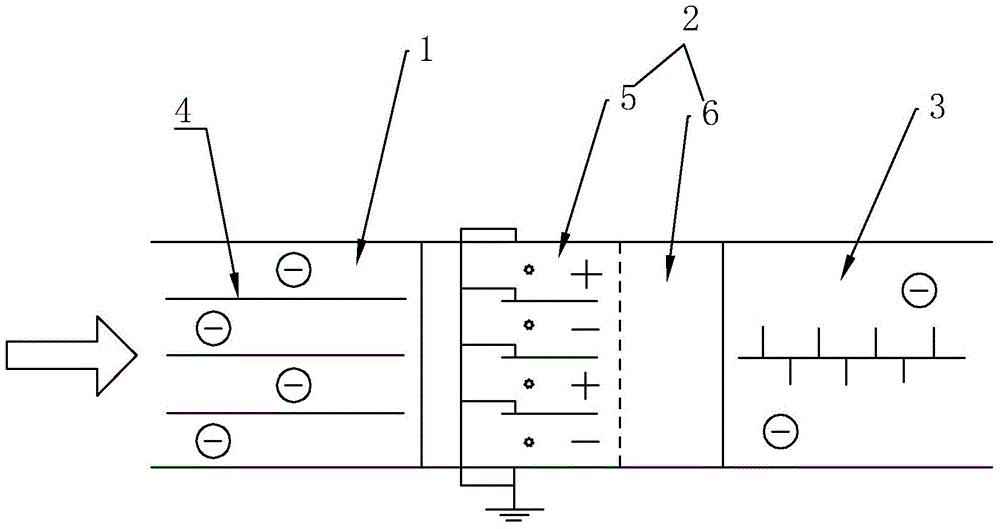

Efficient multi-field-coordination fine particulate matter removal device and method

ActiveCN103768886AAvoid back coronaAvoid secondary dustSemi-permeable membranesAuxillary pretreatmentMulti fieldWater vapor

The invention discloses an efficient multi-field-coordination fine particulate matter removal device and an efficient multi-field-coordination fine particulate matter removal method. The device comprises an outer field coagulation area, a direct current dust pre-collecting area, a pulse charge coagulation area and a direct current dust collecting area which are connected in sequence, wherein water steam and a chemical agglomeration agent are introduced from a nozzle of the outer field coagulation area respectively; the direct current dust pre-collecting area and the direct current dust collecting area are arranged in a line-plate type symmetric structure, a line electrode applies negative direct current high voltage, and a plate electrode is grounded and adopts layout of a water film electrode; the pulse charge coagulation area is arranged in the line-plate type symmetric structure, the line electrode applies positive pulse high voltage, and the plate electrode is grounded and adopts layout of the water film electrode. The device and the method aim at mineral particulate matters discharged by a fixed source; aerosol particulate matters, particularly fine particulate matters, can be subjected to efficient coagulation removal in a structural form of double coagulation areas and double dust collecting areas by using a multi-field-coordination method combined by a phase-change coagulation growth technology, a chemical agglomeration and flocculation mechanism and an electric coagulation technology, so that the phenomena of back corona, re-entrainment of dust, ash deposition and corrosion of the plate electrode are effectively avoided.

Owner:ZHEJIANG UNIV

Drying apparatus and washing machine having the same

InactiveUS20050016010A1Fast dryingEfficiently condensing and adsorbing vaporDrying machines with non-progressive movementsWashing machine with receptaclesInterior spaceEngineering

A washing machine including a drying apparatus. The washing machine including the drying apparatus quickly dries wet laundry by efficiently condensing and adsorbing vapor from humid air of high temperature flowing from a water tub during a drying-mode operation. The drying apparatus includes a condensing duct and a blower duct respectively mounted on a rear surface and an upper surface of the water tub. The condensing duct has an ultrasonic atomizing unit, a condensing unit and a water adsorption unit therein, while the blower duct has a blower fan and a heater therein. An inner space of the condensing duct is partitioned into a first condensing path, a second condensing path and a third condensing path by a first air guide and a second air guide. The ultrasonic atomizing unit, the condensing unit and the water adsorption unit are installed in the first condensing path, the second condensing path and the third condensing path of the condensing duct, respectively, thus condensing and adsorbing vapor from the humid air which sequentially passes through the first to third condensing paths, thereby dehumidifying the air providing dry air which is fed to the water tub to dry the wet laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

Wall scraping gypsum powder and its production process

InactiveCN1974470AGood for condensationImprove physical and chemical propertiesAdhesiveSuspending Agents

The present invention provides one kind of wall scraping paint with gypsum as main material and its production process. The wall scraping paint is produced with natural gypsum or chemical gypsum, water retaining agent, adhesive, retarding agent, suspending agent and calcium carbonate powder. The production process includes crushing natural gypsum or chemical gypsum to fineness smaller than 80 mesh, calcining in a kiln at 180 -400 deg.c for 2-4, mixing with water retaining agent, adhesive, retarding agent, suspending agent and calcium carbonate powder, and milling into 250-600 mesh fine powder. The wall scraping paint is scraped to wall and has excellent anticracking capacity, high waterproof property, no pollution and other advantages.

Owner:利文海

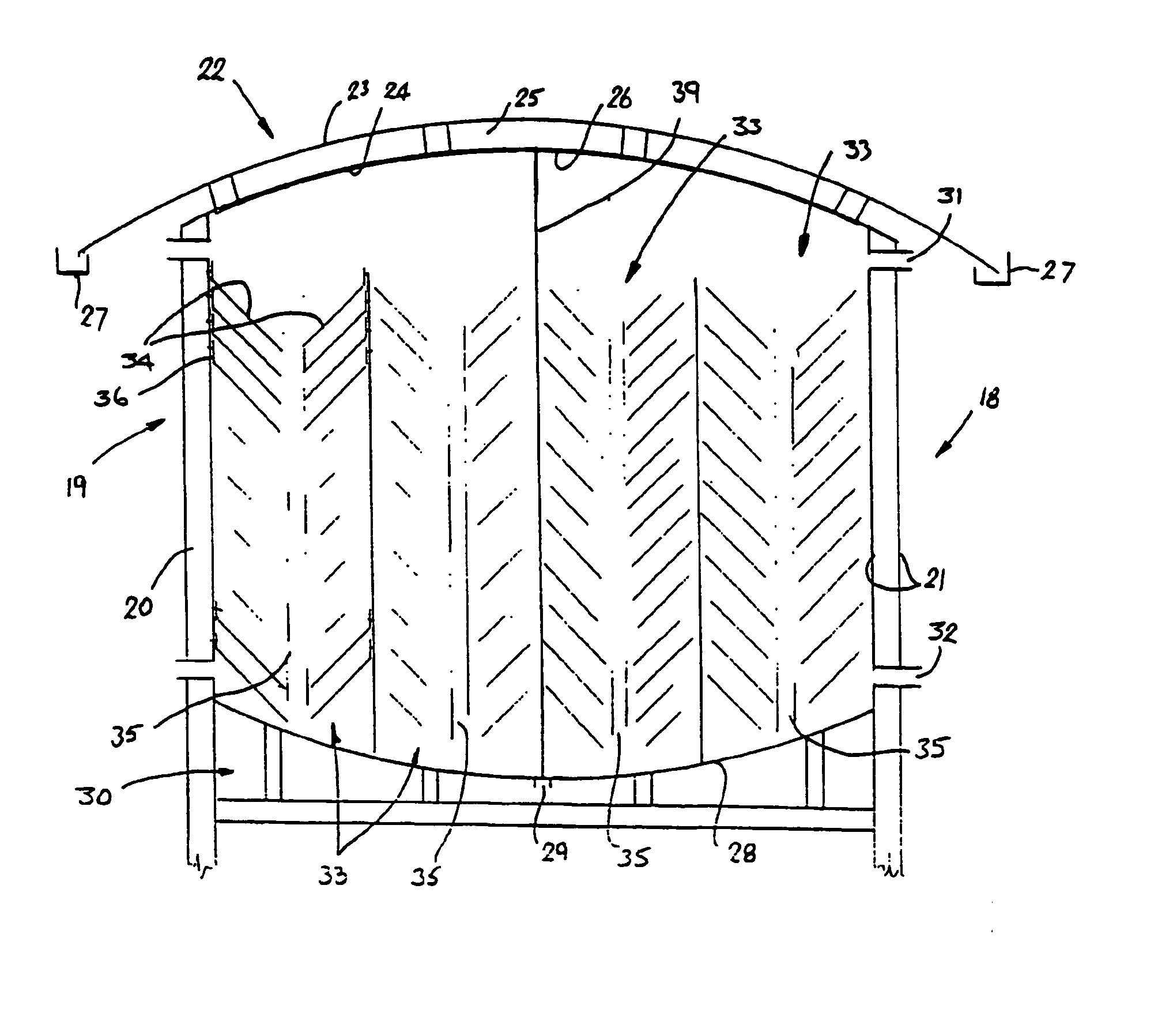

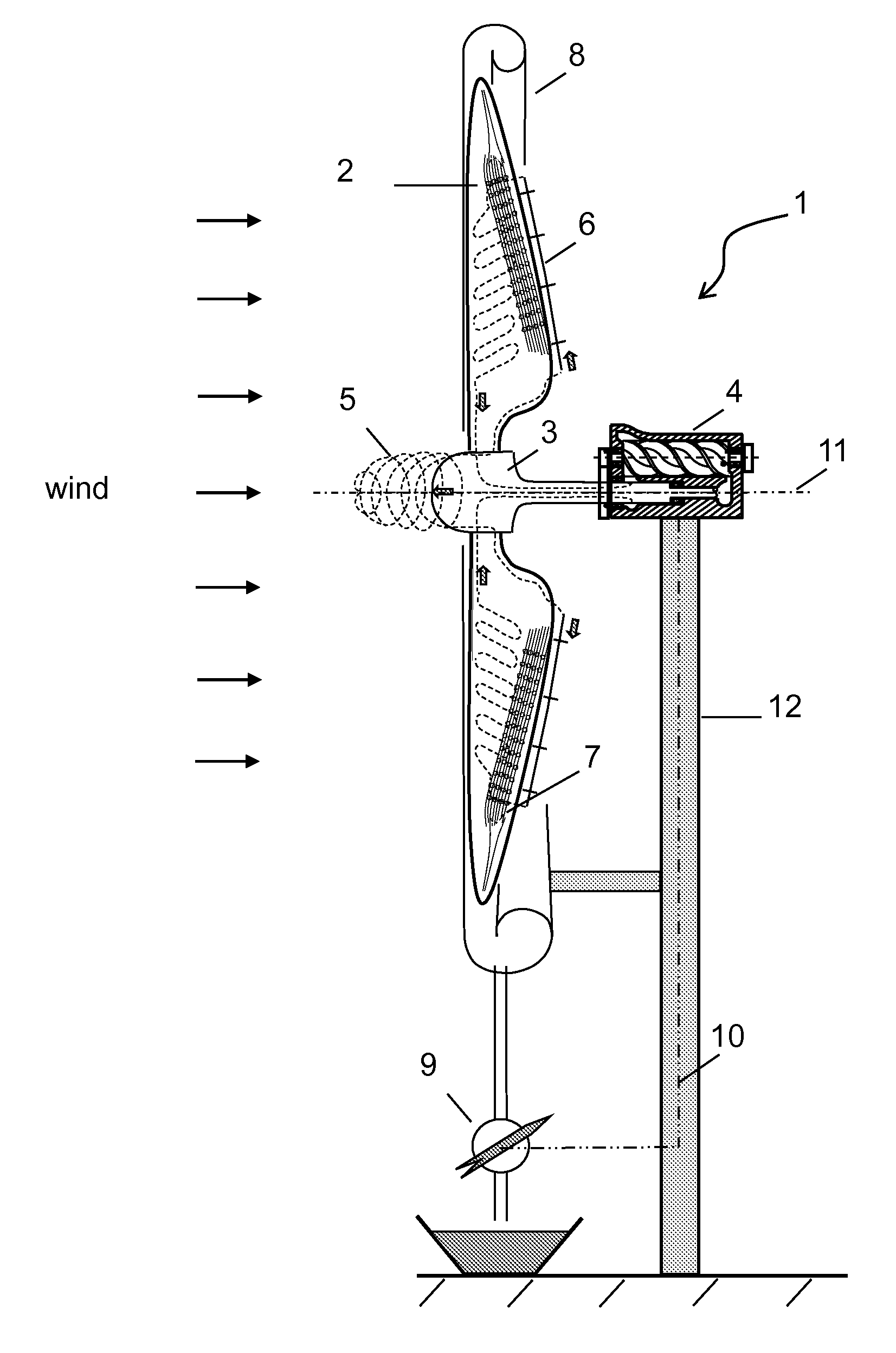

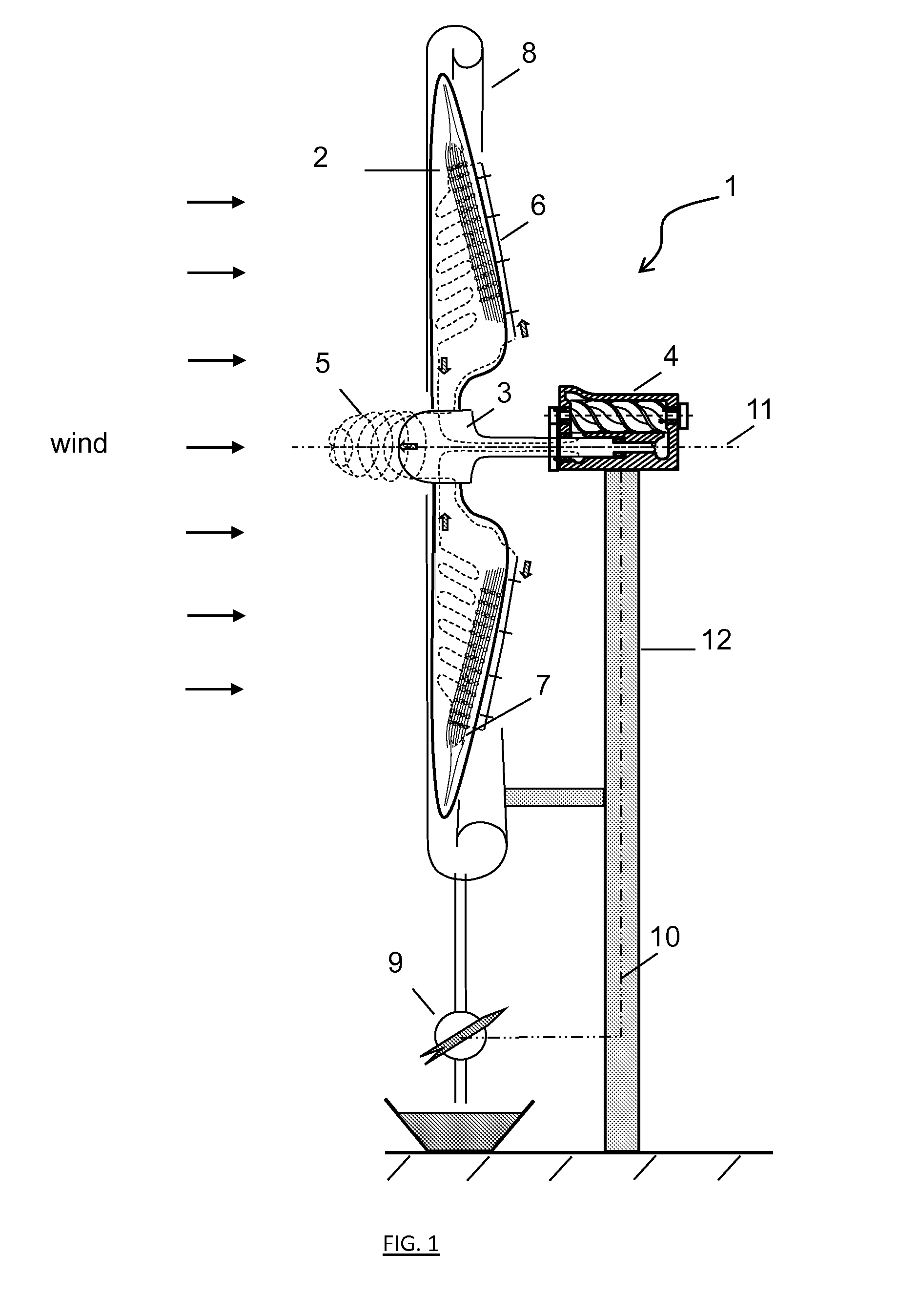

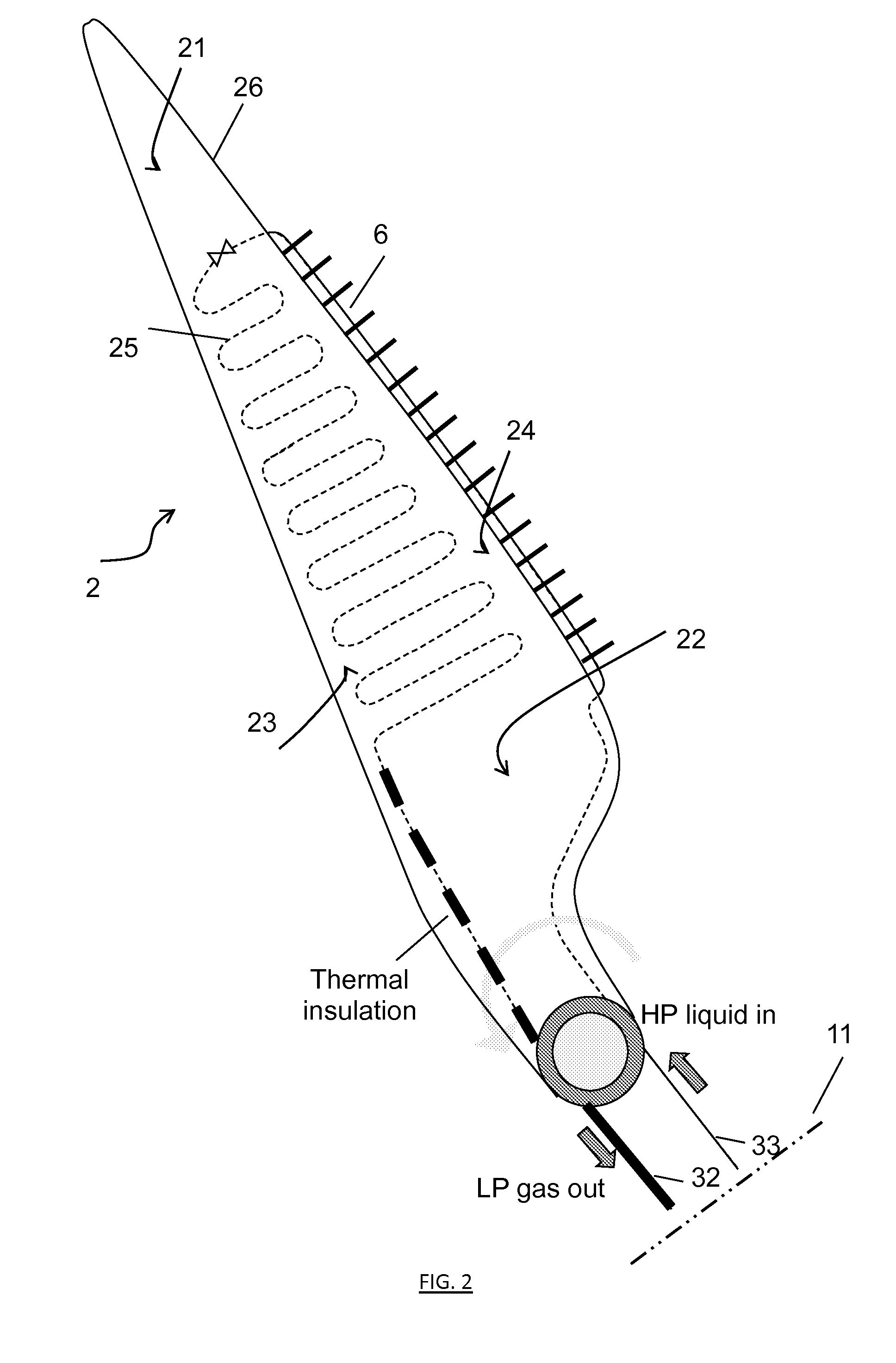

Wind Qanat, an Apparatus for Atmospheric Moisture Recovery

InactiveUS20160145837A1Maximizes liquid water productionReduce the required powerLighting and heating apparatusEngine fuctionsRotary evaporatorAtmospheric air

An apparatus and method for recovering atmospheric moisture is disclosed utilizing the blade system of a wind turbine to both drive the compressor of a rotary refrigeration system and to provide a rotary turbo-machinery surface for its evaporator; whereon atmospheric moisture is recovered by reducing the temperature and pressure of the driving humid air. The rotational speed of the wind turbine is then used to maximize the rate of condensation; which is continuously centrifuged out from the rotary frame of blades into a stationary circular gutter where they accumulate and discharge. In the practice of this invention, a compressor with a rotary intake & discharge port is directly connected to a rotary evaporator & rotary condenser, generating a rotary refrigeration system wherein pressure of the liquid refrigerant is enhanced by the centrifugal force of rotation, enhancing the refrigeration capacity and condensation output.

Owner:ABRARI SEYED FARID

Leaking stoppage reinforcing agent

InactiveCN103740348APrevent precipitationGood for condensationDrilling compositionSulfite saltSlurry

The invention discloses a leaking stoppage reinforcing agent comprising the following components in parts by weight: 20-30 parts of sodium silicate, 20-30 parts of phenolic resin, 30-50 parts of calcium carbonate, 1-5 parts of potassium silicate, 1-5 parts of sodium sulfite, 0.5-3 parts of polyacrylamide (PAM), 0.5-3 parts of sodium carboxymethylcellulose CMC-LV and 0.5-3 parts of hydroxyethyl cellulose (HEC). According to a conventional preparation method, the materials are added into a kneading machine in sequence in parts by weight at normal temperature and under normal pressure and then are uniformly mixed and stirred, and then the mixture is crushed into granular products, of which the particle size is 0.01mm-0.3mm, after being dried. The leaking stoppage reinforcing agent disclosed by the invention has the characteristics of easily available raw materials, scientific and simple process, safe construction, capability of reinforcing the wall of a leakage stratum well, capability of being added into different types of leaking stoppage slurry when being used together with other materials for reinforcement, capability of improving the reinforcing performance of leaking stoppage slurry and the like, and is widely applied to petroleum and geological drilling engineering.

Owner:DONGYING TAIER GASOLINE TECH

Method for improving quality of bio-oil

ActiveCN104560102ARaise the pHImprove qualityBiofuelsEfficient propulsion technologiesAlkaneNitrogen atmosphere

The invention relates to a method for improving the quality of bio-oil. The method comprises the following steps: adding bio-oil produced by the pyrolysis into an autoclave, adding calcium oxide and reacting for 1-4 hours at 30-80 DEG C under nitrogen atmosphere, heating to 160-180 DEG C, reacting for 0.5-2 hours, and finally cooling to 80-120 DEG C, and further carrying out heat preservation and reacting for 0.5-2 hours to obtain precursors of C7-C15 alkane fuels. By the method, the content of acid in the bio-oil can be well decreased, the pH and stability of the bio-oil are increased and meanwhile, produced ketone substances and aldehyde substances in the bio-oil can be reacted to obtain the precursors of the C7-C15 alkane fuels and thus the quality of the bio-oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

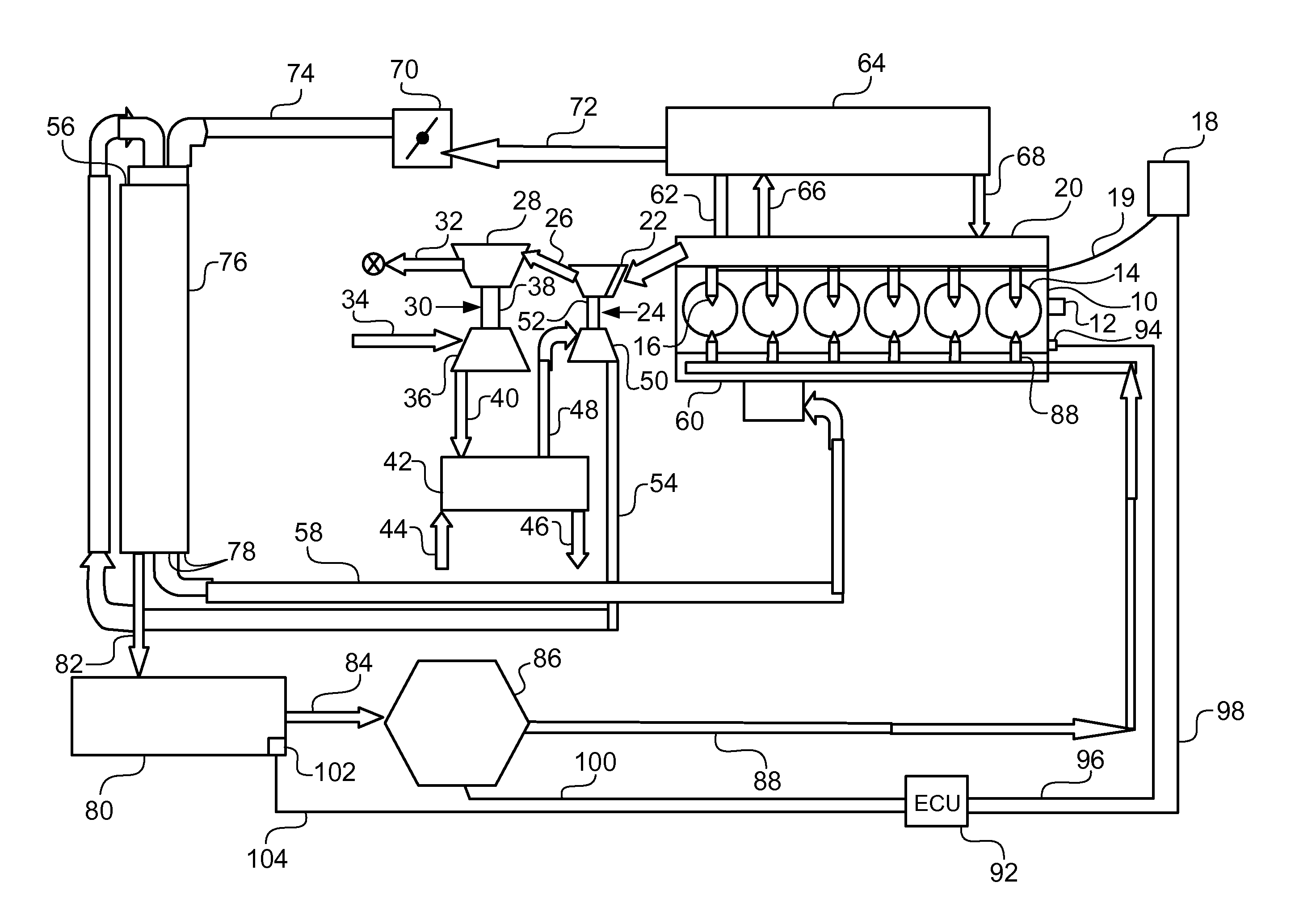

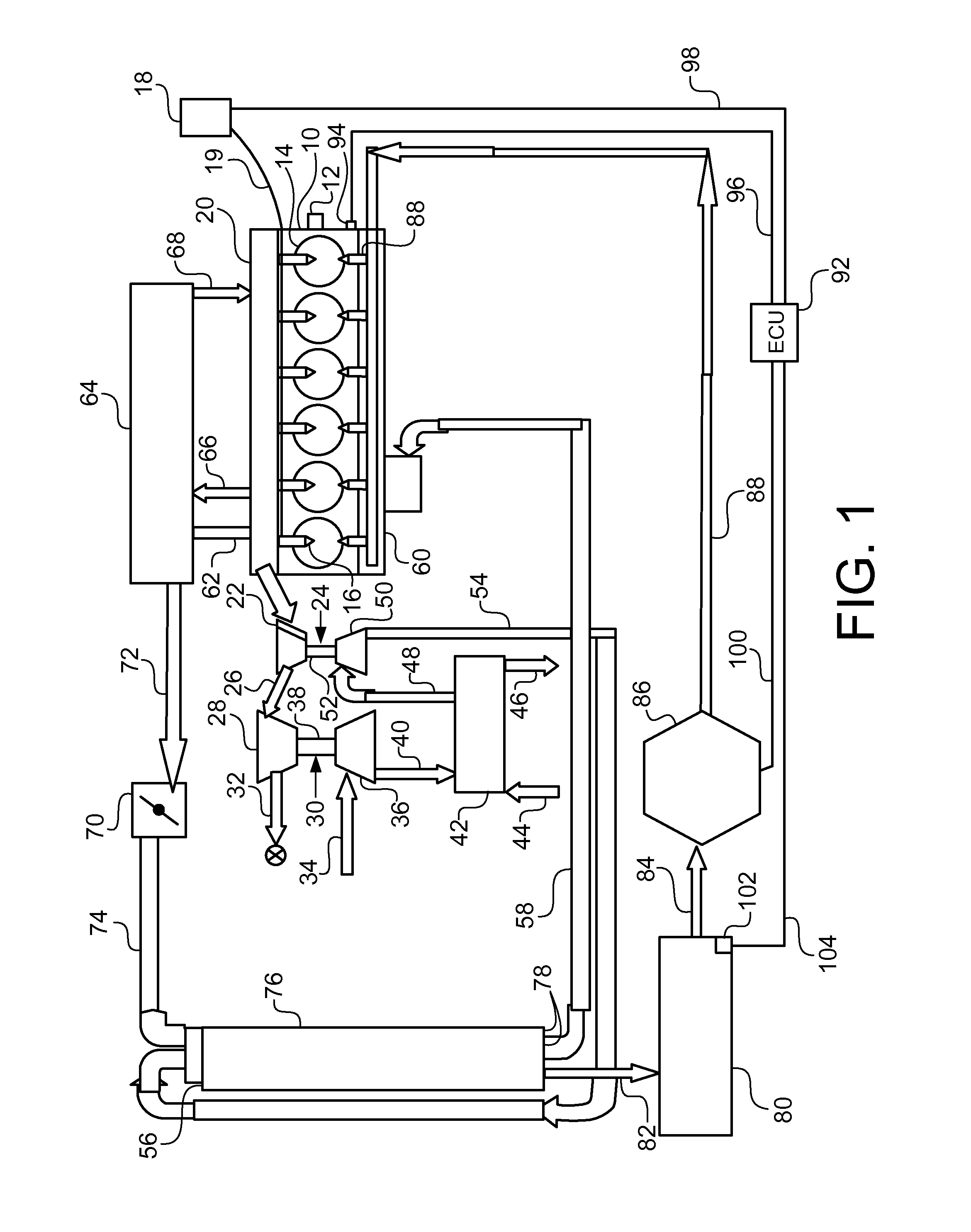

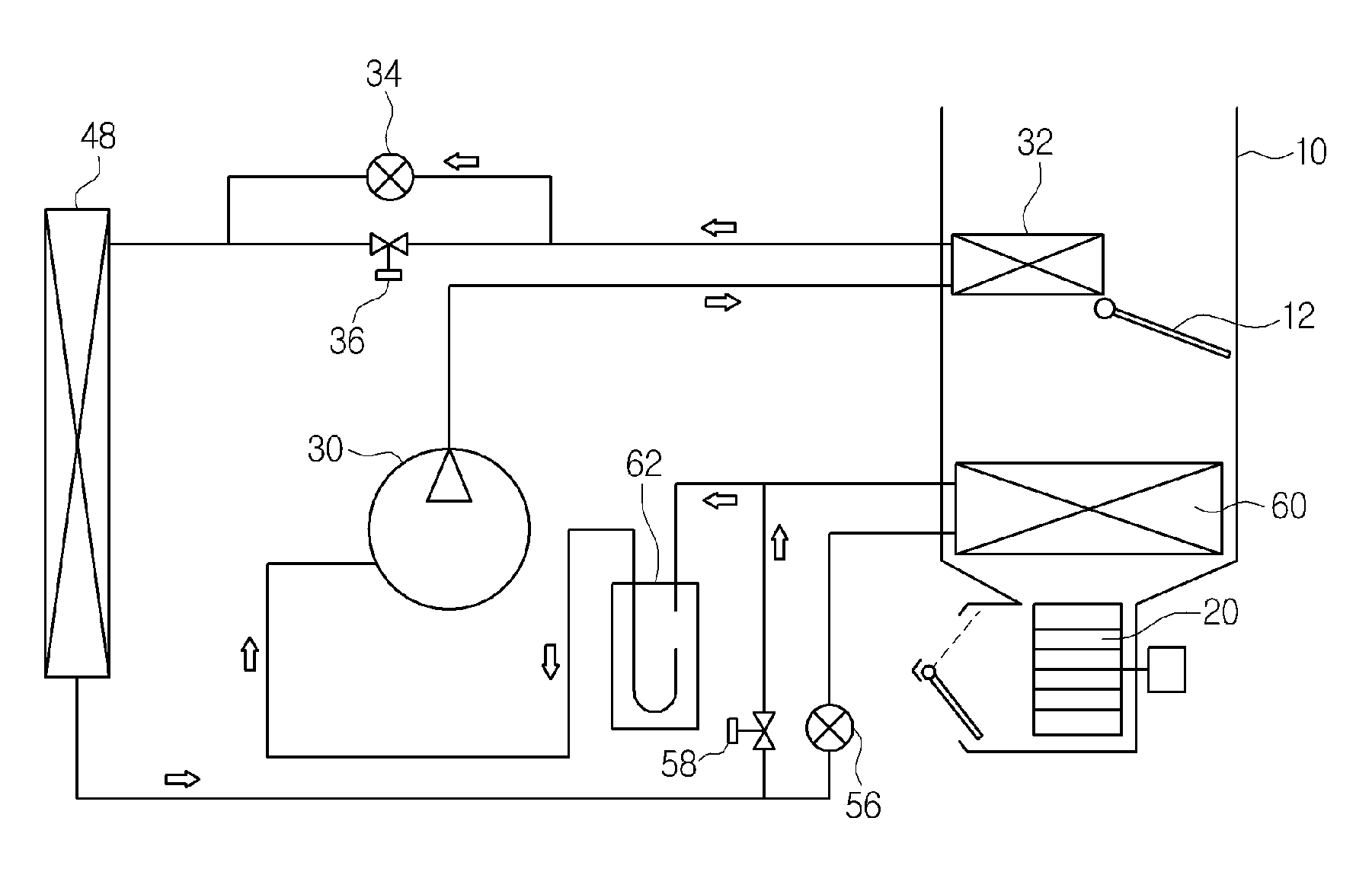

High flow egr system

ActiveUS20110259306A1Promoting condensation of moistureExtensive coolingNon-fuel substance addition to fuelInternal combustion piston enginesAirflowExternal combustion engine

A high flow EGR system for an internal combustion engine having a pair of series connected EGR coolers and a water droplet condensation collector and reservoir connected to the gas flow. The reservoir feeds a pump which is actuated to inject the liquid to the engine adjacent each cylinder for uniform distribution of the water to the engine cylinders. The pump is controlled to inject the water at appropriate conditions during the engine operating cycle.

Owner:DEERE & CO

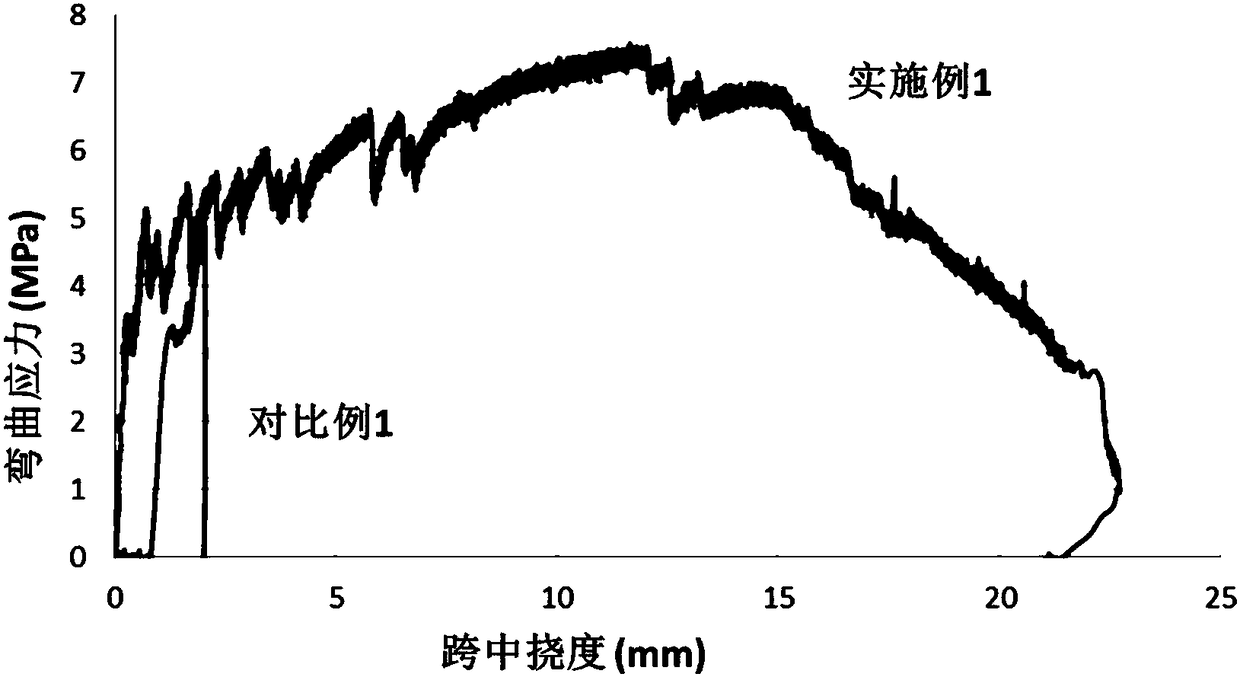

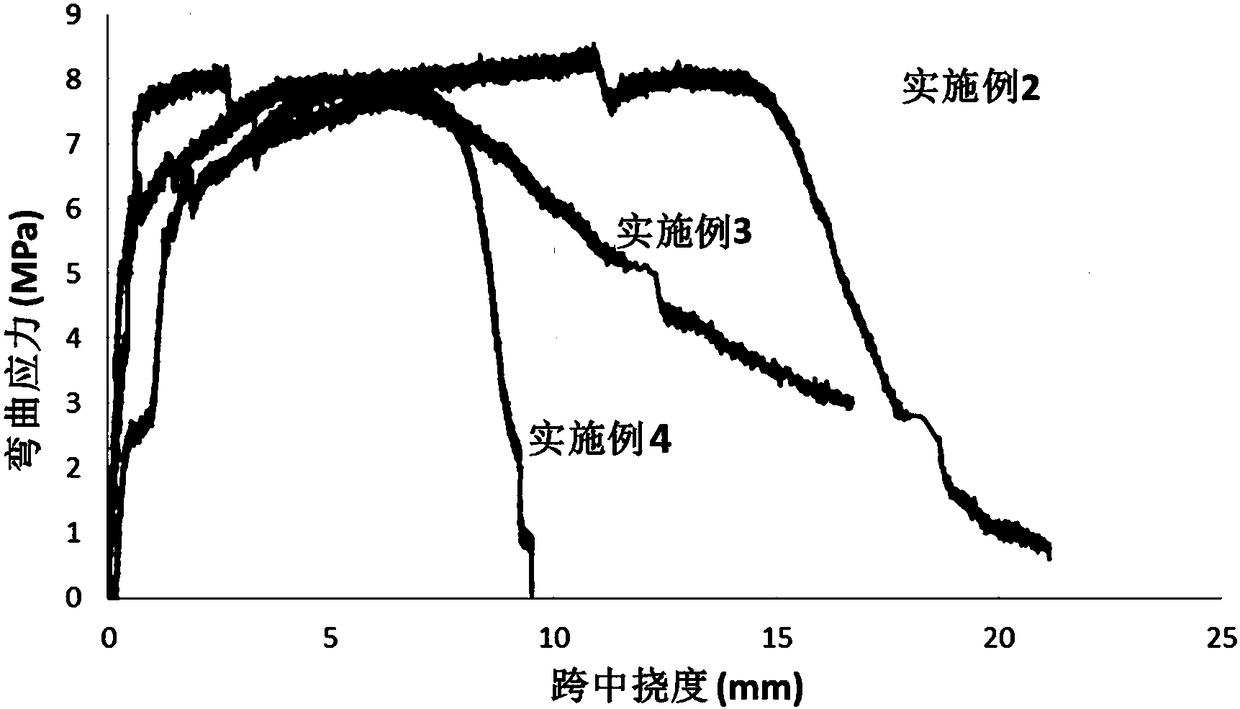

PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and use method thereof

ActiveCN108129102AHigh mechanical strengthImprove impact resistanceAdditive manufacturing apparatusAdditive ingredientPortland cement

The invention relates to PVA-basalt hybrid fiber high-toughness concrete capable of realizing 3D printing and a use method thereof. Through being metered in parts by weight, the concrete is preparedfrom the following ingredients including 0.8 to 1.2 parts of fast hardening ordinary Portland cement, 0.96 to 1.44 parts of grade F fly ash, 0.64 to 0.96 part of quartz sand (with the particle diameter range being 0.075 to 0.15mm), 0.29 to 0.43 part of water, 0.005 to 0.01 part of water reducing agents, 0.0017 to 0.0018 part of PVA fiber and 0.0043 to 0.0078 part of basalt fiber. According to thematerials of the concrete, the PVA fiber and the basalt fiber are used for optimizing and improving the intensity and the toughness of the concrete material; the printing performance is high; the intensity is high; the cost is low; the practical engineering application of the 3D printing concrete can be favorably promoted.

Owner:HEBEI UNIV OF TECH

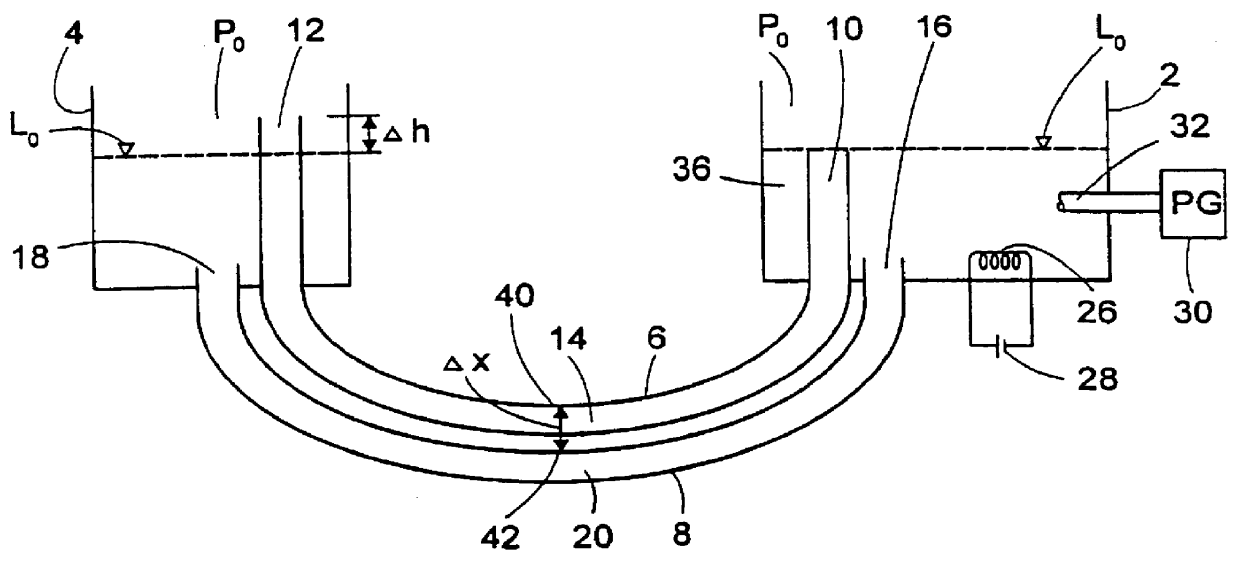

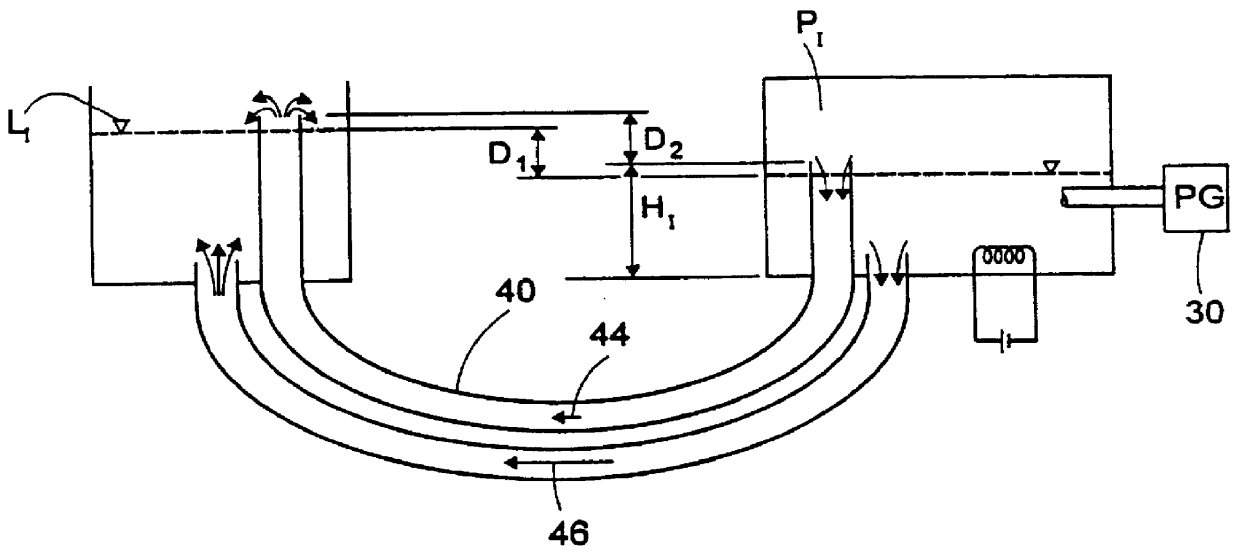

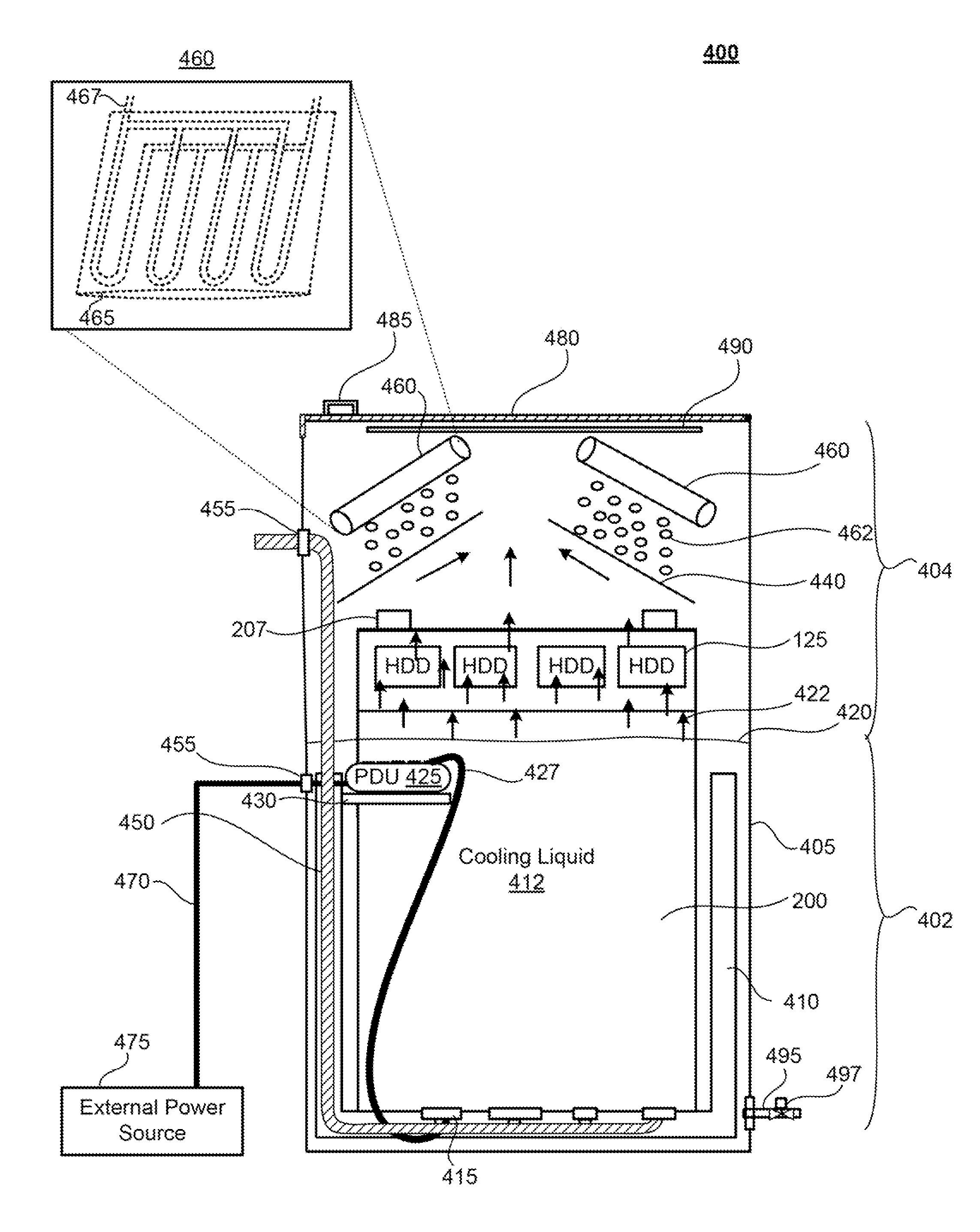

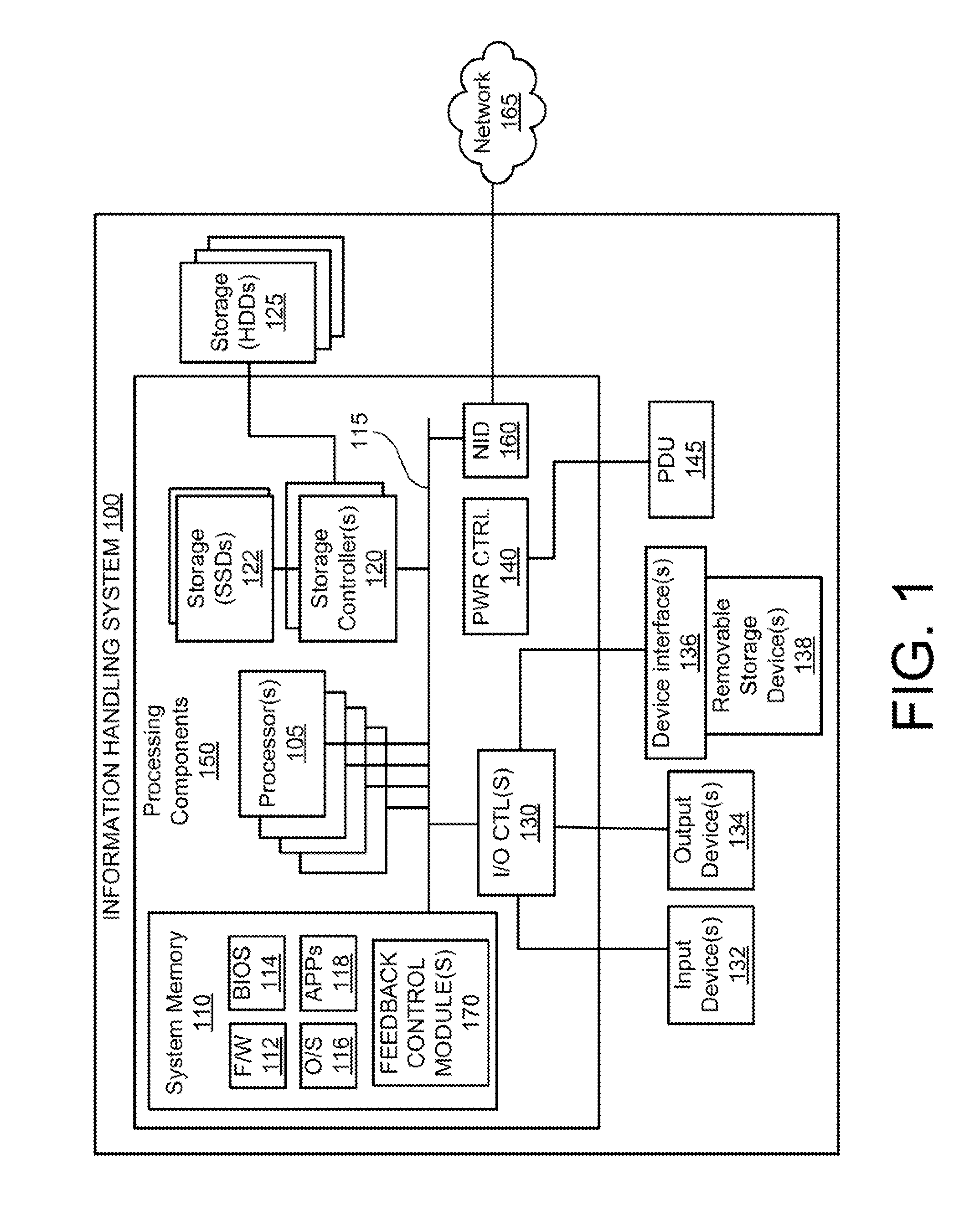

Techniques for controlling vapor pressure in an immersion cooling tank

ActiveUS9464854B2Decrease the amount of vapor in the tankGood for condensationVolume/mass flow measurementElectrical apparatus contructional detailsSteam pressureDifferential pressure

A method that controls pressure within an immersion cooling tank having condensation fluid flowing through a condenser, includes: a controller receiving a signal that indicates a current level of vapor pressure within the tank; determining from the signal when the current level of vapor pressure exceeds or is below a first preset threshold pressure level; and in response to the current level of vapor pressure exceeding or being below the first preset threshold pressure level, signaling a flow control mechanism that modulates a flow rate of the condensation fluid through the condenser to increase or decrease the rate of flow from a current rate of flow. The controller receives the signal by a pressure sensor within the immersion cooling tank detecting the current vapor pressure, generating the signal and forwarding the signal to the controller. The pressure sensor can be a differential pressure transducer that measures a differential pressure internal to and outside of the immersion tank.

Owner:DELL PROD LP

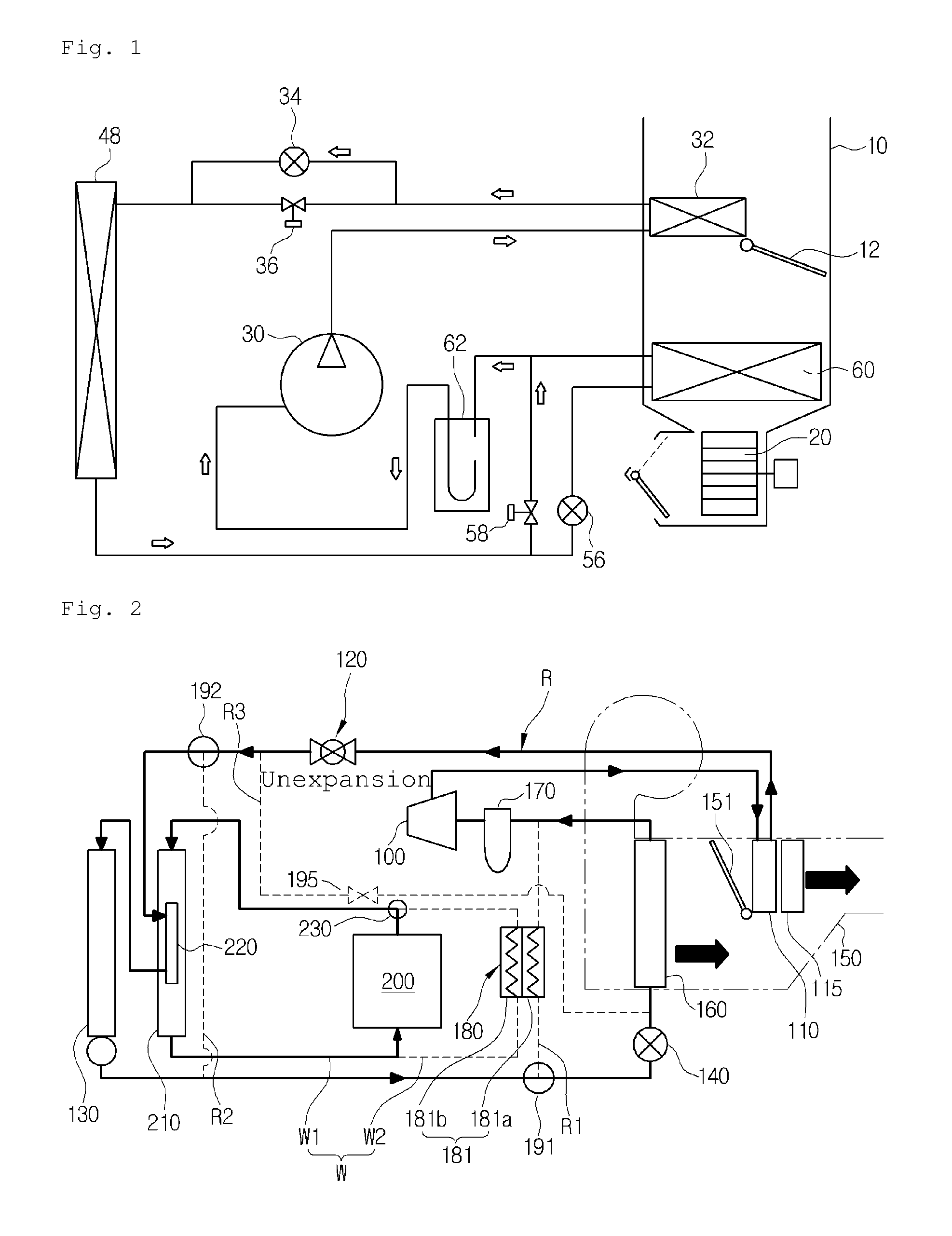

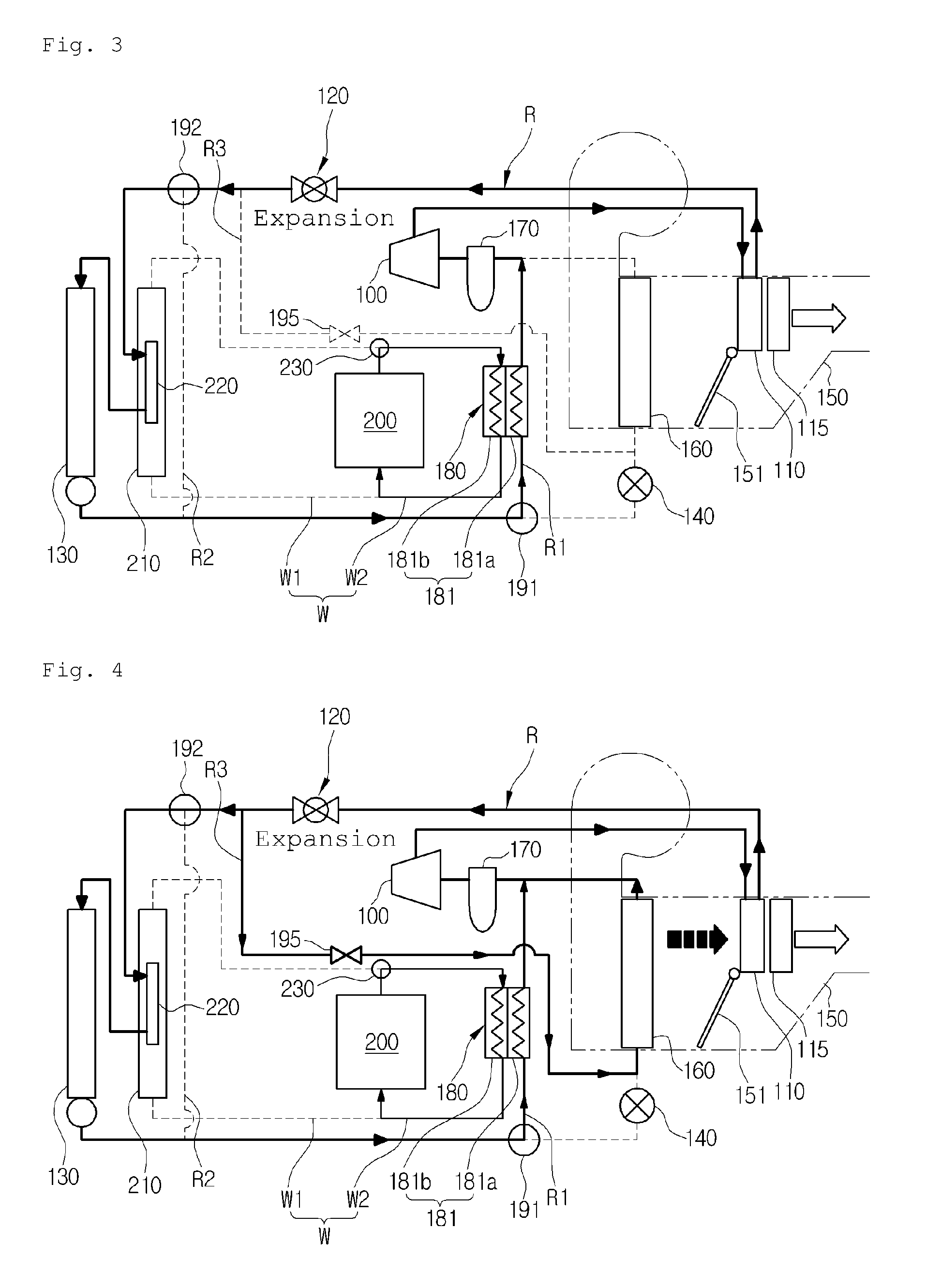

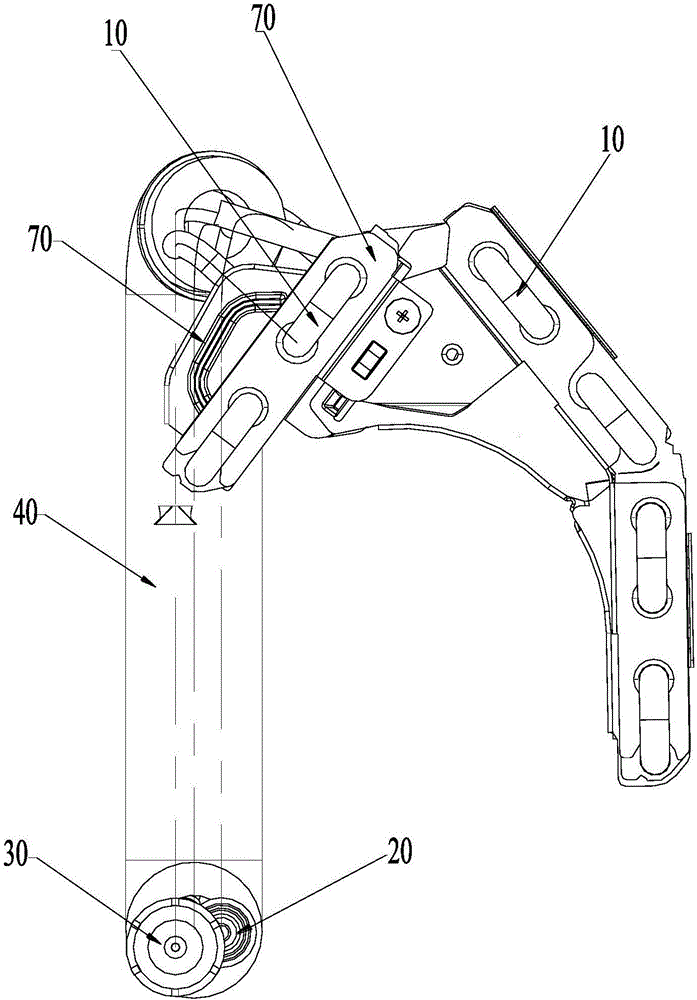

Heat pump system for vehicle

ActiveUS20160339766A1Improve the heating effectReduce power consumptionAir-treating devicesCompression machines with several evaporatorsEvaporationEngineering

The present invention relates to a heat pump system for a vehicle which includes a refrigerant-coolant heat exchanger mounted on a refrigerant circulation line of an inlet side of an external heat exchanger to exchange heat between coolant induced into the external heat exchanger and coolant circulating through electronic units of the vehicle, thereby enhancing cooling performance and reducing power consumption without an increase in size of the external heat exchanger by increasing a condensation amount because refrigerant radiates heat while passing through the refrigerant-coolant heat exchanger and the external heat exchanger in an air-conditioning mode and enhancing heating performance and reducing power consumption by increasing an evaporation amount because refrigerant absorbs heat while passing through the refrigerant-coolant heat exchanger, the external heat exchanger and a chiller in a heat pump mode, and increasing temperature of the refrigerant induced into the external heat exchanger to delay frosting of the external heat exchanger.

Owner:HANON SYST

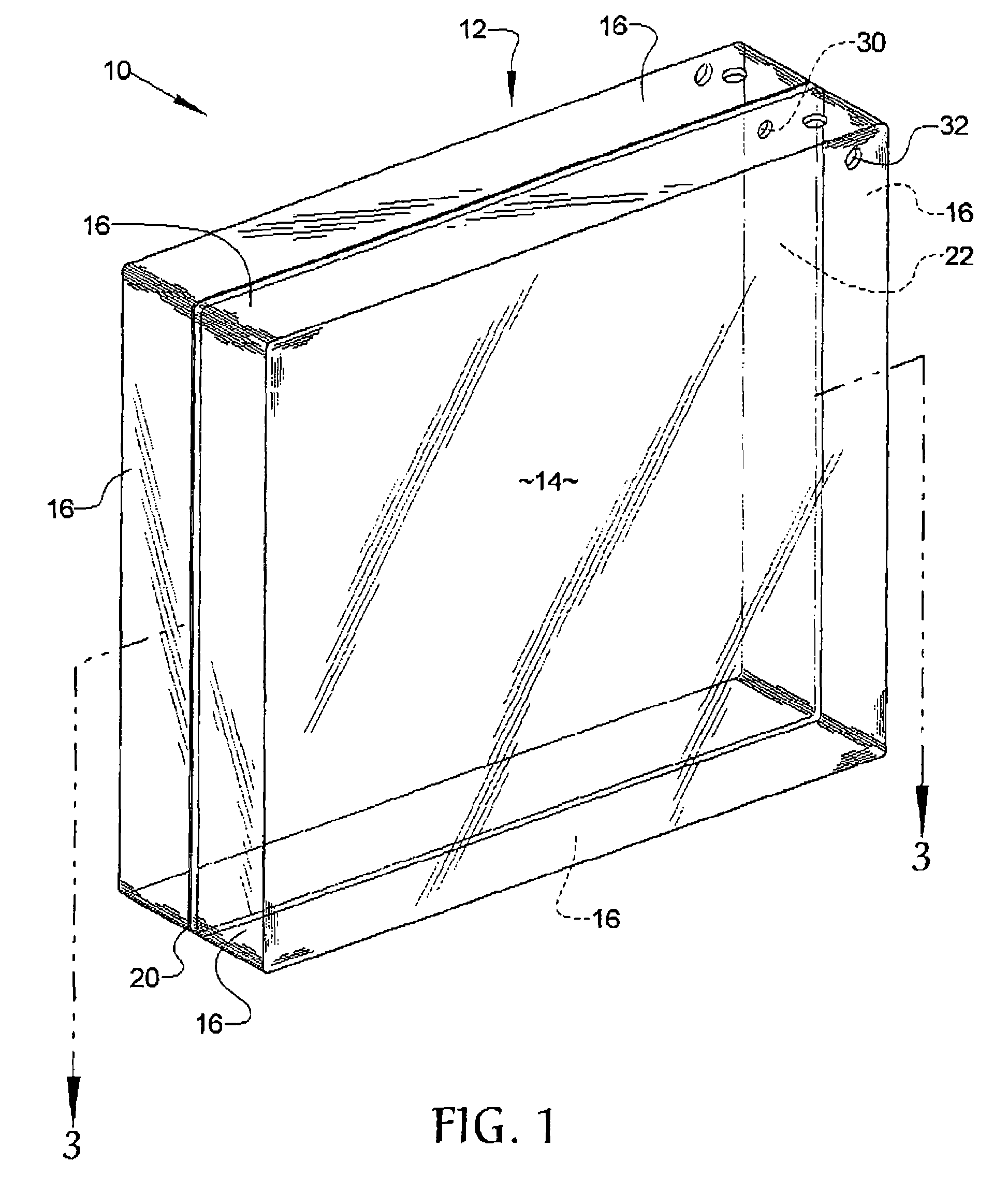

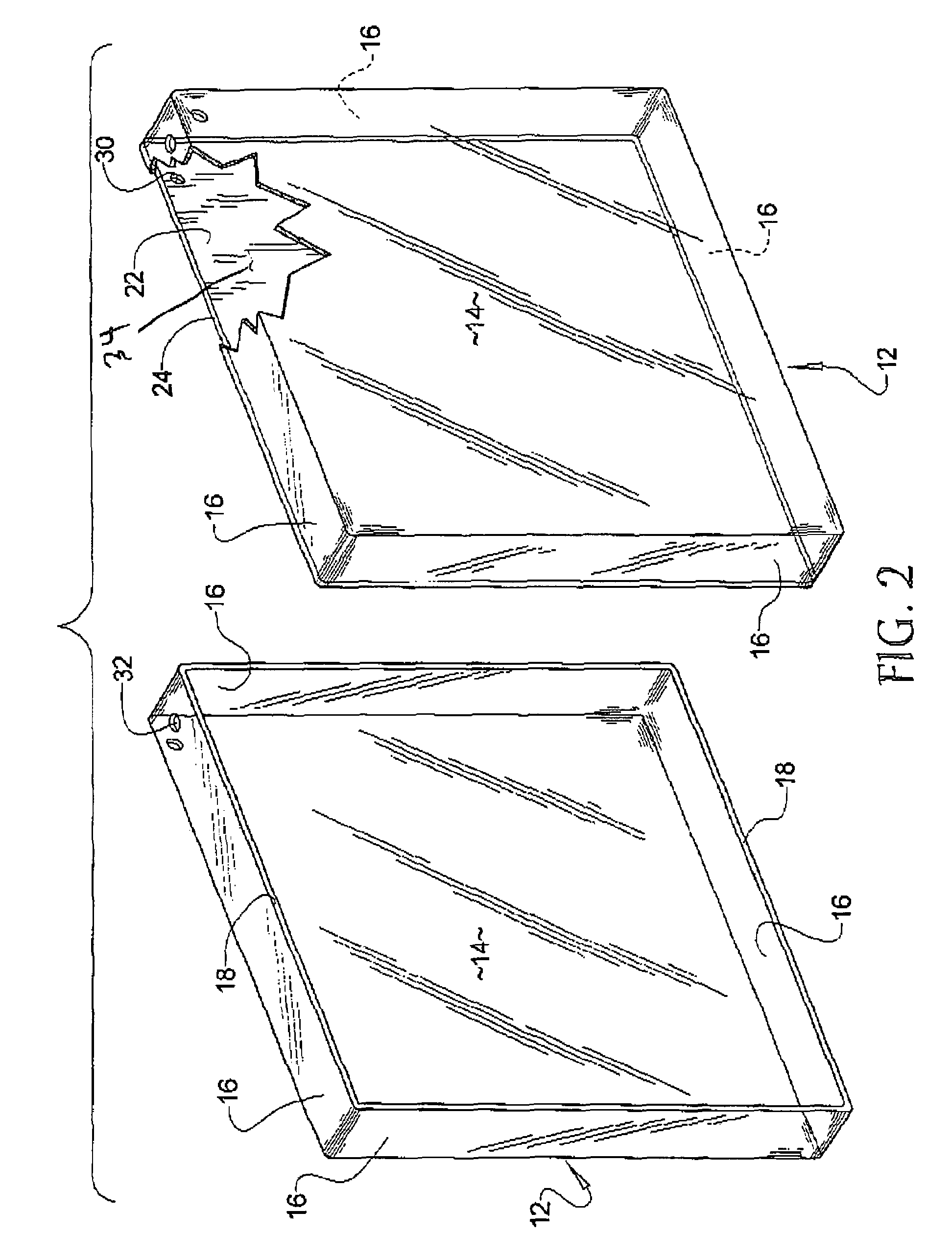

Construction block

InactiveUS7266930B1Reduces bellow effectImprove aesthetic qualityConstruction materialFloorsThermal insulationArchitectural engineering

A construction block which has improved thermal insulation qualities, has improved sound transmission migration reduction properties, and which reduces or outright eliminates the effects of a seam failure. The construction block is comprised of a pair of generally parallel faces joined by a plurality of sides. At least one baffle is disposed within the interior chamber and is located along the weld seam that joins the two body member halves of the construction block. A desiccant or insulation gas, or both can be disposed within the interior chamber of the block.

Owner:US BLOCK WINDOWS

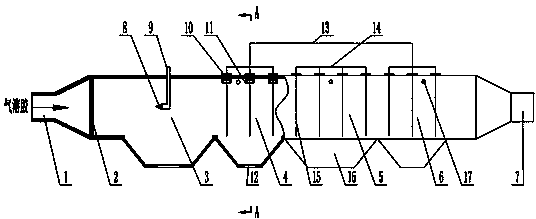

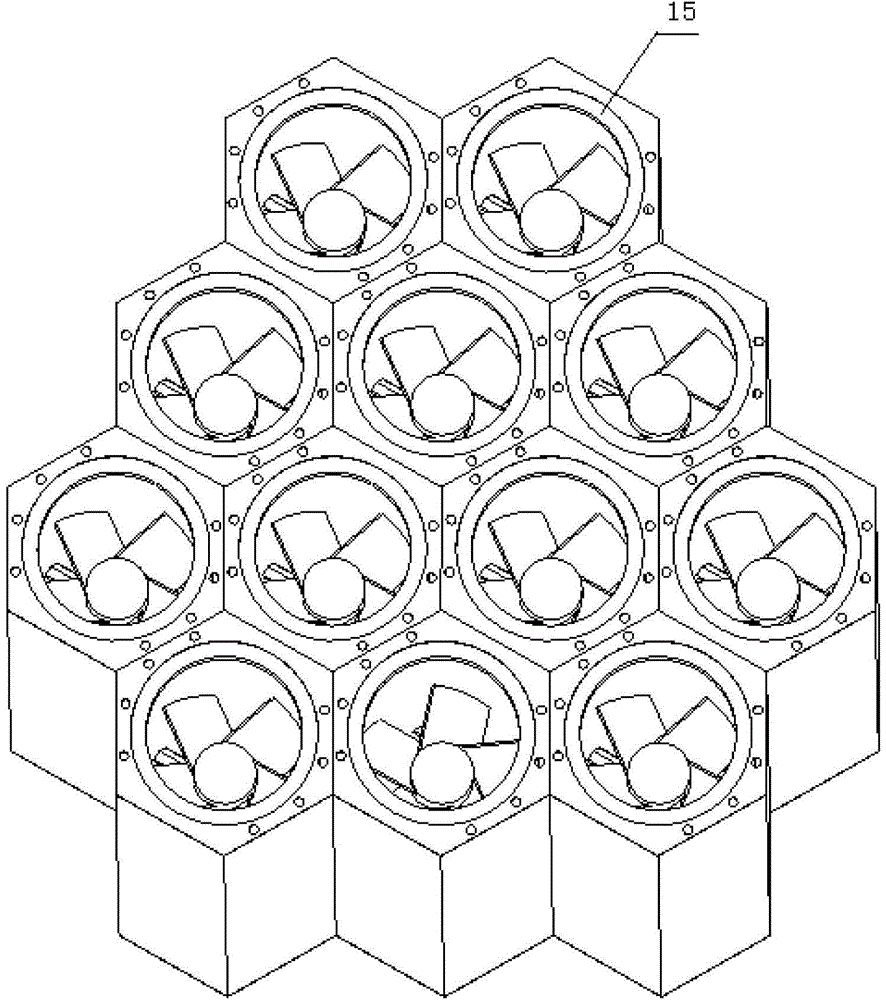

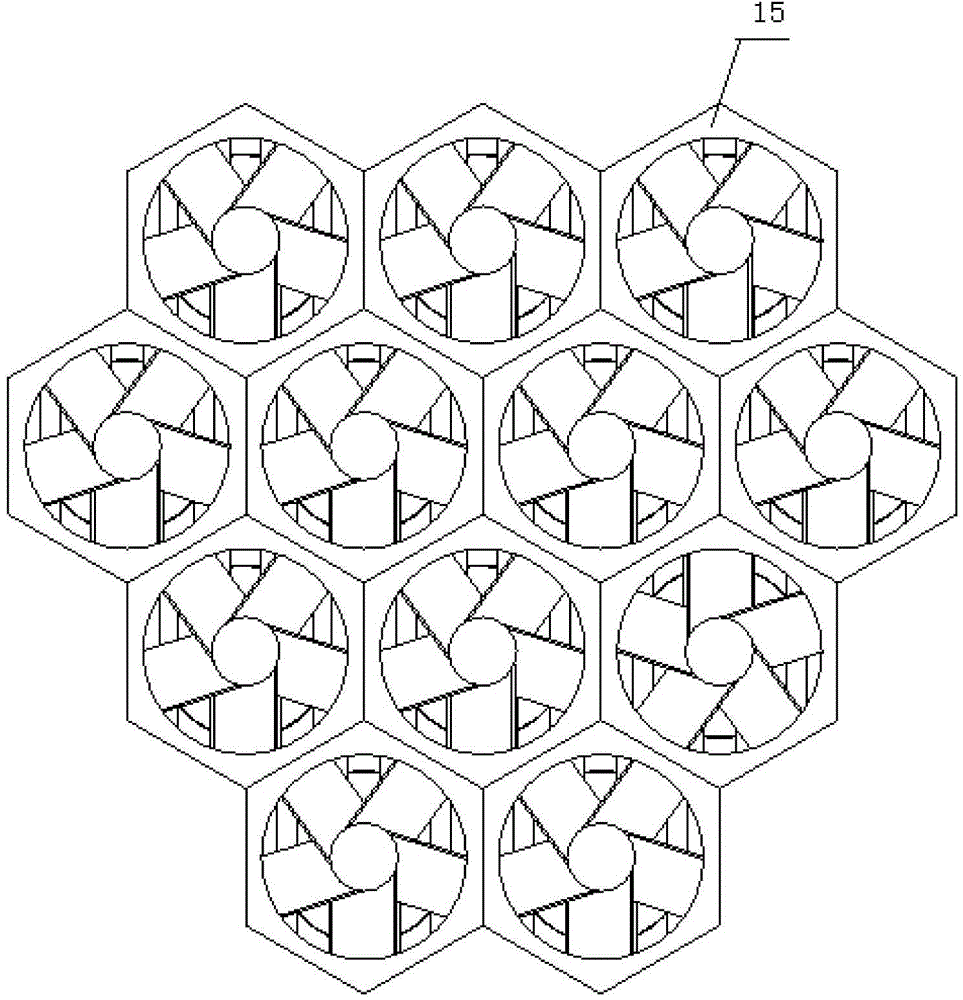

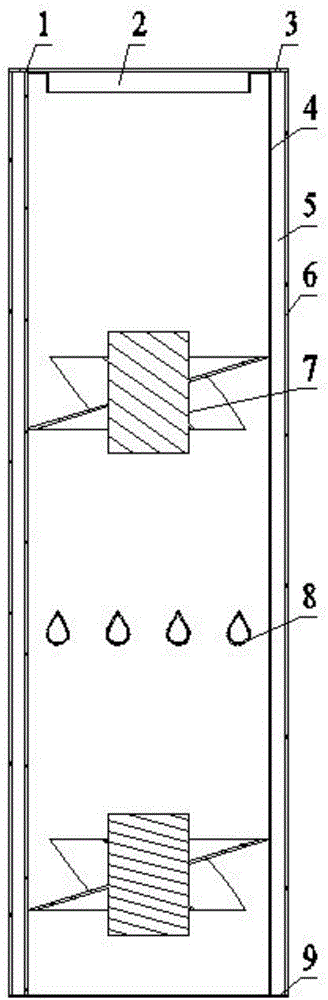

Phase-change dust-removing and mist-removing paralleling device of high-efficiency pneumatic pipe bundle and application

The invention relates to a phase-change dust-removing and mist-removing paralleling device of a high-efficiency pneumatic pipe bundle and an application. The phase-change dust-removing and mist-removing paralleling device comprises a plurality of phase-change dust-removing and mist-removing devices of the high-efficiency pneumatic pipe bundle, which are connected together in parallel; each of the phase-change dust-removing and mist-removing device comprises a hollow drum body with the openings at the two ends, a drum-body upper sealing plate, a drum-body lower sealing plate, a cyclone section, a pipe-bundle type water-mist distributing section and a water blocking section. The paralleling device has the advantages that the plurality of phase-change dust-removing and mist-removing devices are connected together in parallel, so that a user can assemble and adjust according to the treating capability needed practically, single phase-change dust-removing and mist-removing devices can be connected by adopting bonding, welding or hole grooves and the like; the manufacture is convenient and the waste-gas treating range is greatly expanded.

Owner:AEROSPACE ENVIRONMENTAL ENG

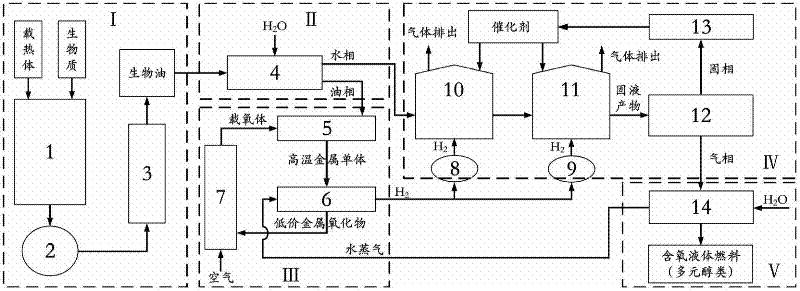

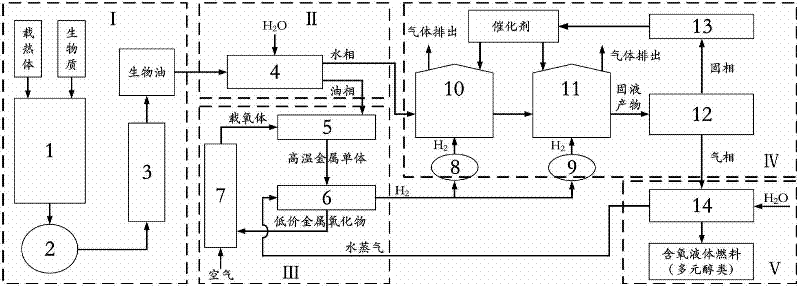

Device and method for preparing oxygen-containing liquid fuel by catalytically converting biological oil

InactiveCN102653691AHigh yieldReduce processing costsDirect heating destructive distillationBiofuelsCatalytic transformationLiquid fuel

The invention provides a device and a method for preparing oxygen-containing liquid fuel by catalytically converting biological oil. The device comprises a biomass rapid thermal cracking oil preparing system (I), a biological oil oil-water phase separation system (II), an oil phase biological oil chemical chain hydrogen production system (III) and a hydrogen output water supply phase biological oil catalytic hydrogenation system (IV), wherein the biomass rapid thermal cracking oil preparing system is used for preparing the biological oil; the biological oil oil-water phase separation system is used for receiving the biological oil and separating the biological oil into oil-phase biological oil and water-phase biological oil to be respectively output to the oil phase biological oil chemical chain hydrogen production system (III) and the hydrogen output water supply phase biological oil catalytic hydrogenation system (IV). The method comprises the following steps of: carrying out heat cracking on a biomass to prepare oil; carrying out water phase and oil phase separation on the obtained biological oil; carrying out chemical chain method on the oil-phase biological oil to produce hydrogen; and providing a'hydrogen source' to the water-phase biological oil to carry out two-step catalytic hydrogenation in a slurry bed; and directly separating and extracting a hydrogenated product to obtain the oxygen-containing liquid fuel. The device and method disclosed by the invention can be used for realizing full-component'graded conversion' of the biological oil.

Owner:SOUTHEAST UNIV

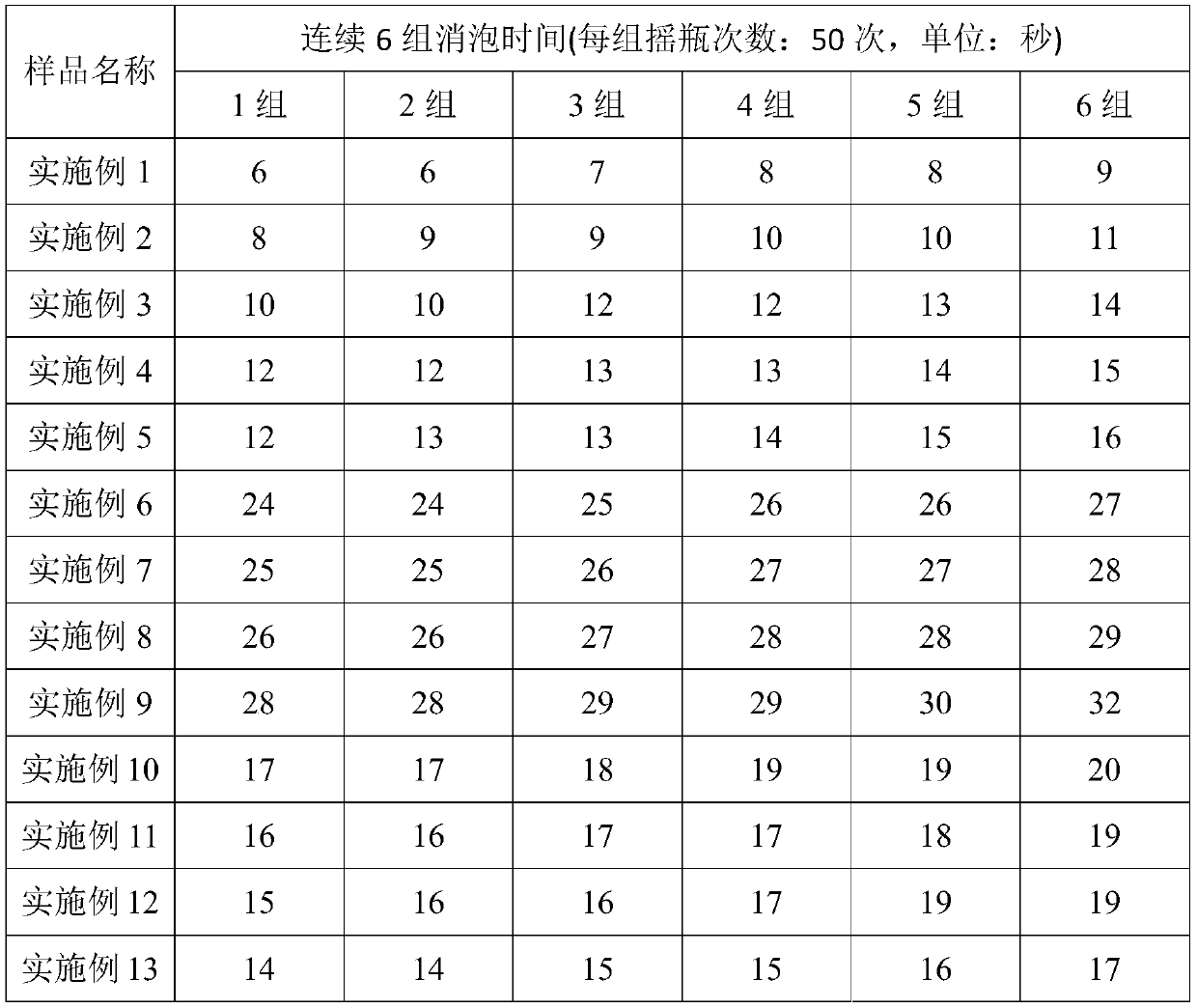

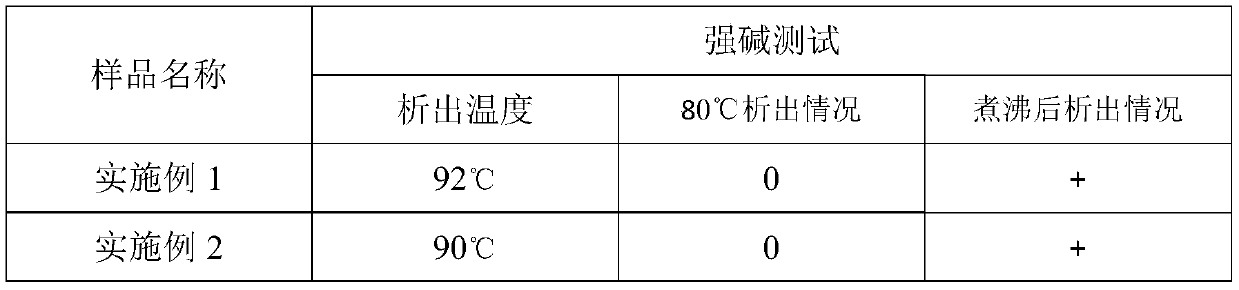

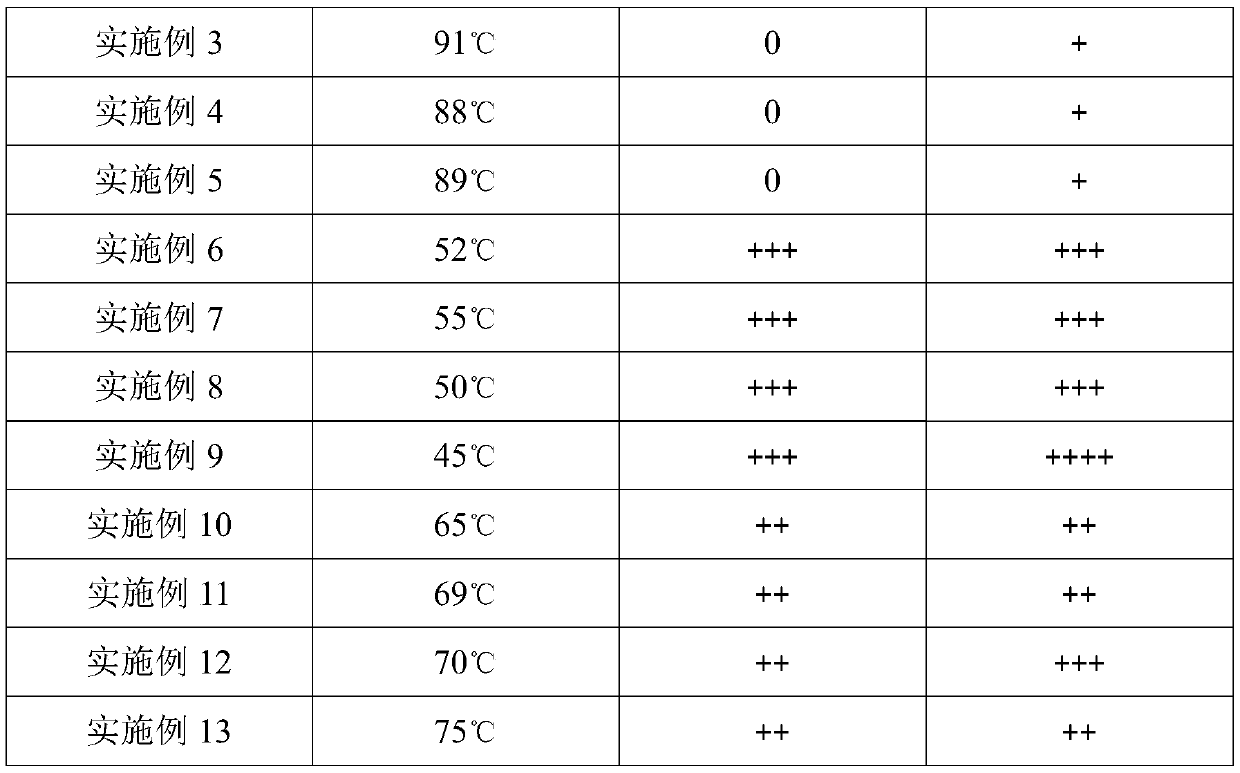

Defoaming agent

PendingCN110681187AImprove defoaming abilityLong foam suppression timeFoam dispersion/preventionPtru catalystPreservative

The invention relates to the technical field of chemical additives, and specifically discloses a defoaming agent. The defoaming agent is at least prepared from the following preparation raw materials:10 to 30 parts of an organic silicon composition, 1 to 10 parts of hydrogen-containing polysiloxane, 1 to 10 parts of vinyl polysiloxane, 2 to 12 parts of allyl polyether, 0.1 to 2 parts of a catalyst, 5 to 20 parts of an emulsifier, 1 to 5 parts of a thickener, 1 to 5 parts of a preservative and 50 to 90 parts of water. The organic silicon defoaming agent which is high in defoaming speed, long in foam inhibition time, excellent in dispersing performance and outstanding in defoaming durability is prepared through a special formula and process, and what's more important, the defoaming agent prepared through the preparation method is good in product stability, not prone to demulsification and free of oil floating under the conditions of high temperature and strong alkali, and the preparation method is simple and low in cost.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

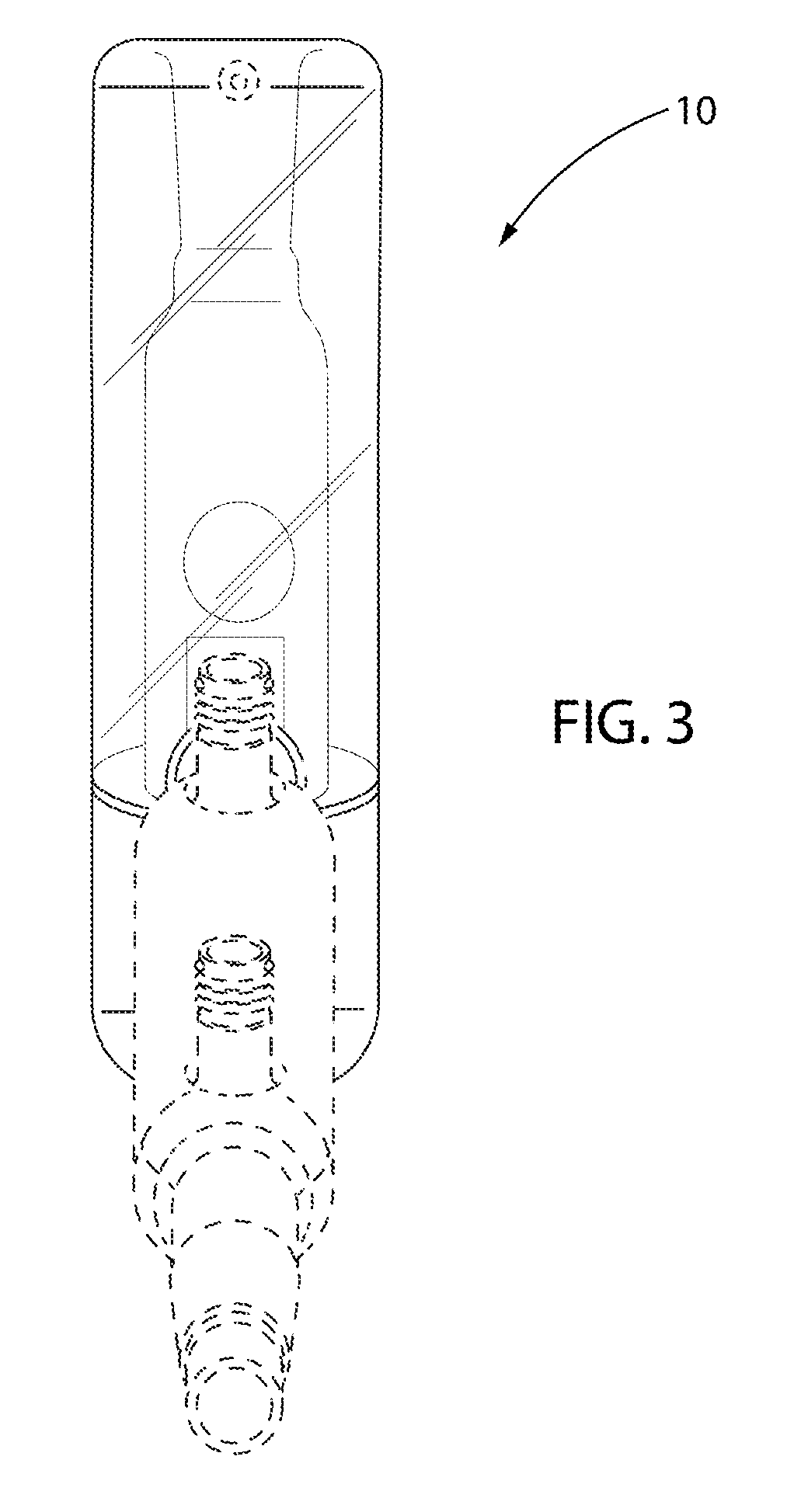

High efficiency distillation head and methods of use

ActiveUS20190076752A1Increase thermalIncrease infrared heat retentionDistillation in boilers/stillsVapor condensationBoiling pointFractionating column

A high efficiency distillation head and methods of use has a distillation head that may be used for efficient fractional distillation of high boiling point compounds, and includes a lower insulated jacket surrounding a fractionating column and an upper insulated jacket surrounding a condenser. An exit path of equal or greater cross sectional area to the fractionating column is located at or below the top of the fractionating column.

Owner:LAB SOC LLC

Preparation method of strip-shaped black tea

InactiveCN104605043AIncrease contentPromote formationPre-extraction tea treatmentTea flavoringTemperature controlBlack tea

The invention discloses a preparation method of strip-shaped black tea. The method comprises the steps of picking fresh leaves, withering, rolling, fermenting, drying and carrying out far-infrared fragrance enhancing, wherein the step of far-infrared fragrance enhancing is carried out after the step of drying, temperature control fermentation is adopted by the step of fermenting, the step of drying comprises primary drying and sufficient drying, and sufficient drying is carried out after primary drying. The prepared strip-shaped black tea is fine, tight, uniform and tidy, has multiple tips and exposed golden tips, is black and oily in color, is brilliant red in liquor color, is fragrant, sweet and rich in fragrance with fruity flavor, is fresh, mellow, thick, tasty and refreshing in flavor, has aftertaste sweet, and is red, and the tea residue is red bright.

Owner:成都市碧涛茶业有限公司

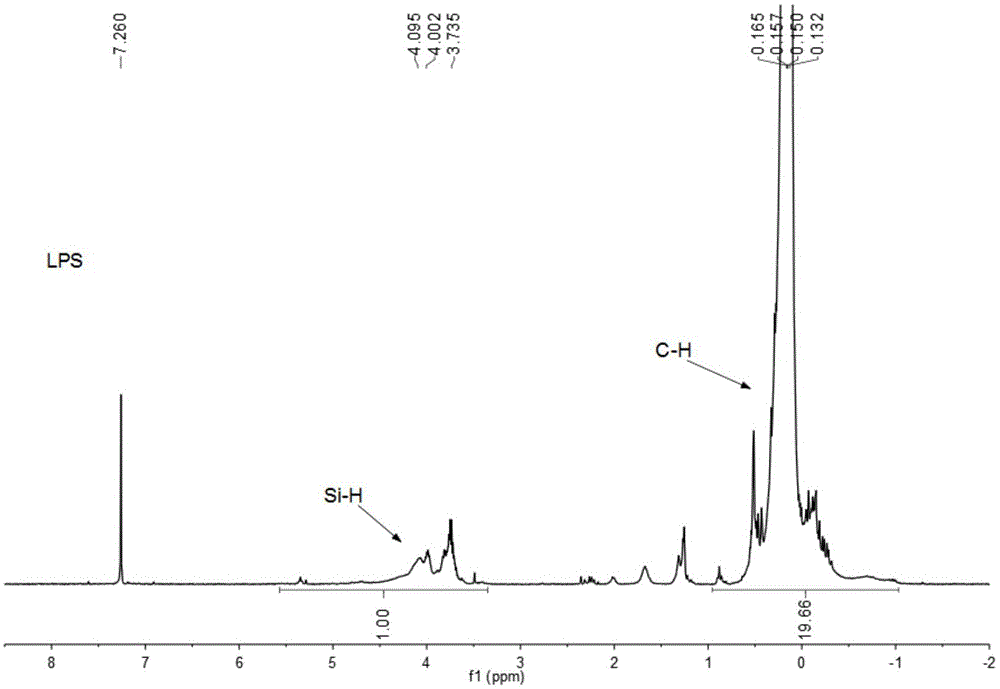

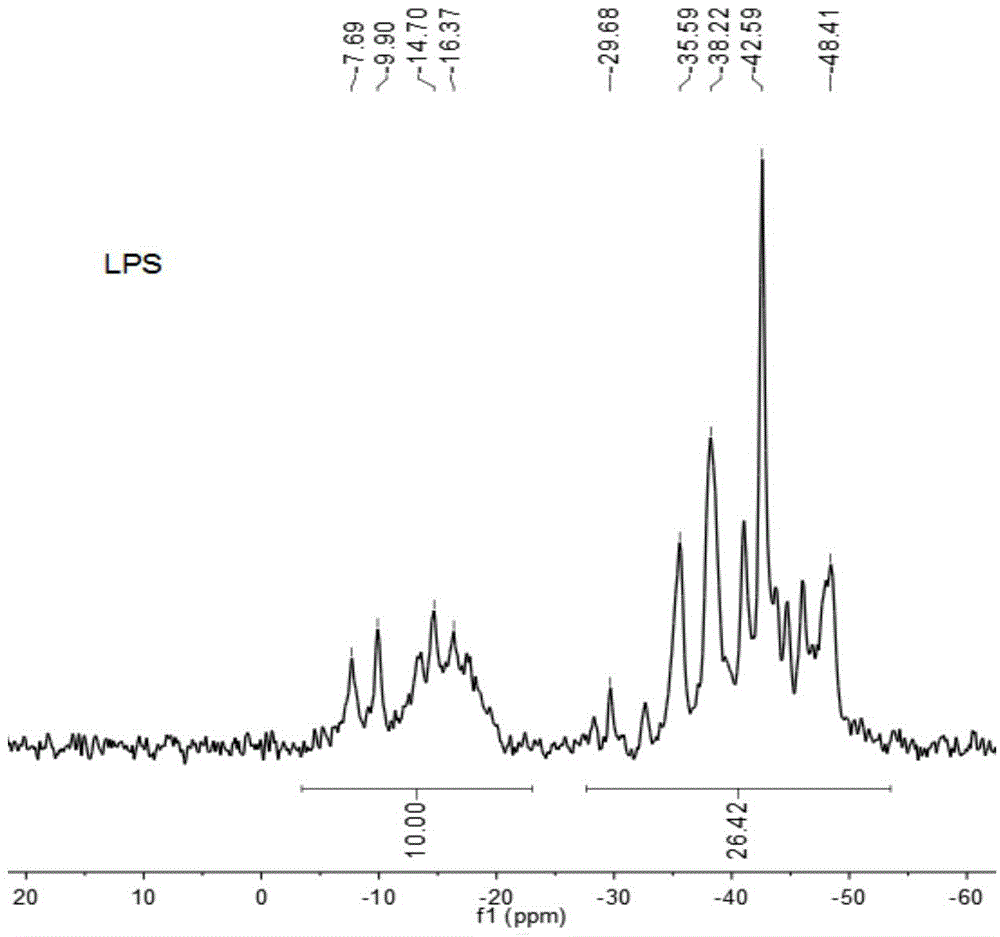

Catalytic rearrangement preparation method of polycarbosilane

ActiveCN105273199AHigh synthetic yieldStrong Lewis acidityFibre chemical featuresSilanesReaction temperature

The invention relates to a method for preparing polycarbosilane through cracking rearrangement of a cyclic silane compound or chain polysilane under the catalytic effect of trace (lower than 1wt%) boron-containing catalyst. According to the invention, polydimethylsilane (PDMS) or a pyrolysis product thereof which is a liquid-state silane-carbosilane compound (LPS) is adopted as a raw material; lower than 1wt% (relative to the amount of the raw material) of the boron-containing catalyst is added; the temperature is gradually increased to a reaction temperature under a normal pressure or a high pressure, such that a pyrolysis / rearrangement reaction is carried out, and solid-state polycarbosilane (PCS) with relatively high ceramic yield is obtained. The method provided by the invention has the advantages of short reaction time, high synthesis yield, good product quality, simple equipment and safe operation. The prepared polycarbosilane is a SiC precursor polymer, and can be used in the preparations of SiC fiber and SiC-based composite materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

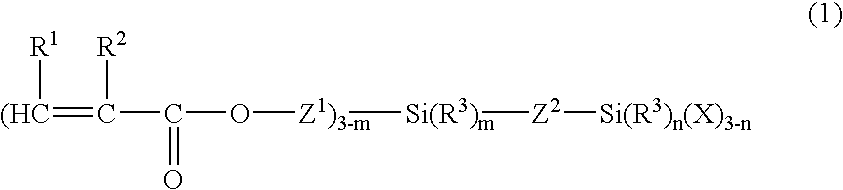

Organosilicon compound

InactiveUS6849755B2Well balance photopolymerizability with condensation curabilityGood for condensationSilicon organic compoundsCross-linkHydrogen atom

An organosilicon compound represented by the following general formula (1): wherein R1 is a hydrogen atom, a phenyl group or a halogenated phenyl group; R2 is a hydrogen atom or a methyl group; R3's are each a substituted or unsubstituted monovalent hydrocarbon group having 1 to 10 carbon atoms; X is a hydrolyzable group; Z1 is —R4—, —R4O— or —R4(CH3)2SiO—, where R4 is a substituted or unsubstituted divalent hydrocarbon group having 1 to 10 carbon atoms; Z2 is an oxygen atom or a substituted or unsubstituted divalent hydrocarbon group having 1 to 10 carbon atoms; and m is 0, 1 or 2 and n is 0, 1 or 2. When incorporated in silicone compositions, the organosilicon compound acts as a cross-linking agent having well-balanced photopolymerizability and condensation curability.

Owner:SHIN ETSU CHEM IND CO LTD

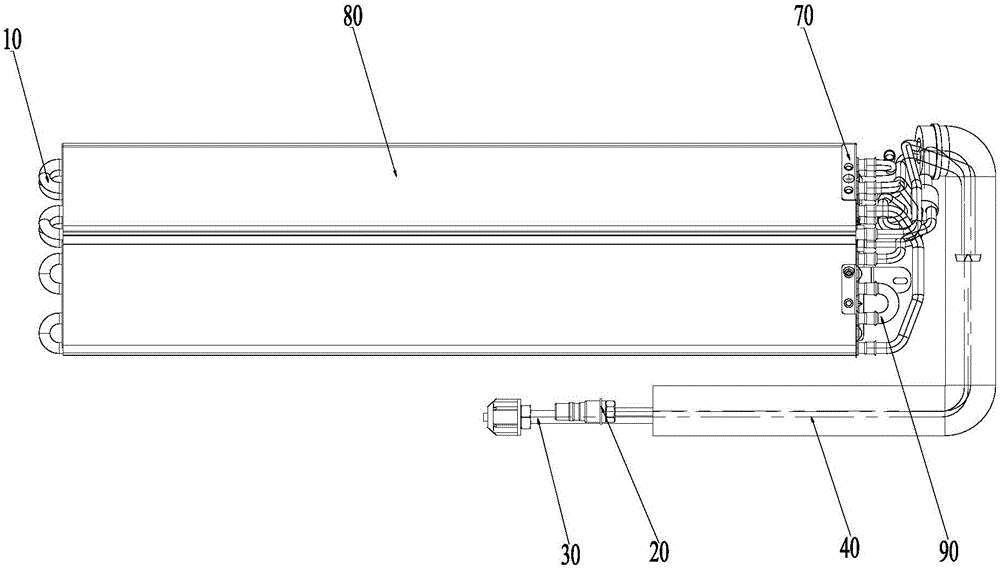

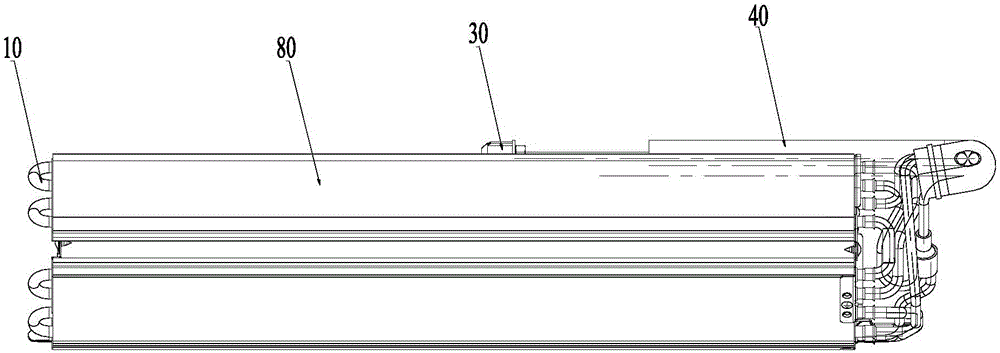

Indoor heat exchanger and air conditioner with indoor heat exchanger

ActiveCN106322730AGuaranteed heat transfer efficiencyReduce in quantityLighting and heating apparatusSpace heating and ventilation detailsEngineeringMicro heat exchanger

The invention provides an indoor heat exchanger and an air conditioner with the indoor heat exchanger. The indoor heat exchanger comprises multiple sets of heat exchange pipes which are arranged in a single layer manner. An inlet and an outlet of each set of heat exchange pipes are arranged adjacently. By the application of the indoor heat exchanger of the technical scheme, the multiple sets of heat exchange pipes are arranged and are arranged in the indoor heat exchanger in the single layer manner, the inlet and the outlet of each set of heat exchange pipes are arranged adjacently, and therefore the number of the heat exchange pipes is reduced, and the production cost is effectively reduced; and meanwhile, the heat exchange efficiency of the indoor heat exchanger can be ensured, and the condensation condition can be effectively improved.

Owner:GREE ELECTRIC APPLIANCES INC

Method for accelerating aging of litchi distilled spirit by virtue of synergistic effects of ozone and ultrasonic waves

ActiveCN104531496APromote esterification reactionIncrease effective collisionAlcoholic beverage preparationEthyl lactateChemistry

The invention discloses a method for accelerating aging of a litchi distilled spirit by virtue of synergistic effects of ozone and ultrasonic waves. The method comprises the following step: sequentially performing five steps, namely primary ultrasonic treatment, primary ozone treatment, secondary ultrasonic treatment, secondary ozone treatment and ultra-filtration on a litchi distilled spirit which is obtained by fermenting whole litchi juice and then distilling to obtain the litchi distilled spirit. The litchi distilled spirit treated by using the method disclosed by the invention has typical litchi aroma, and is soft and mellow in taste; and the content of aroma substances such as ethyl acetate, ethyl propionate, ethyl lactate, ethyl laurate, phenylethanol and the like can be increased by more than 50% compared with that of the litchi distilled spirit before treatment so as to ensure that the content of fusel oil components in the litchi distilled spirit can be reduced by more than 40%, indexes of each component are close to that of a litchi distilled spirit subjected to five years of natural aging, and the ozone treatment can also play a certain turbidity removal effect on a wine liquid.

Owner:HUIZHOU UNIV +1

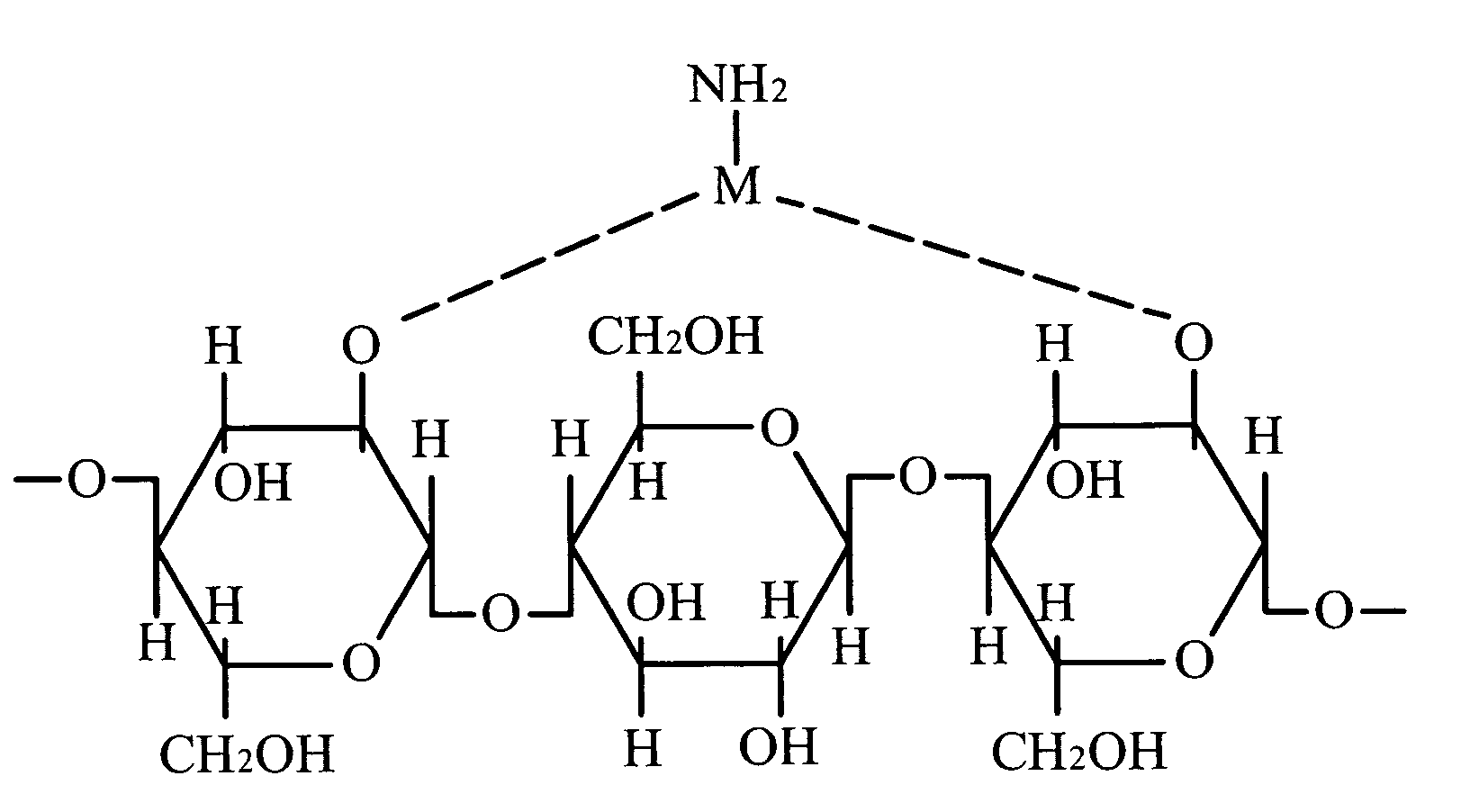

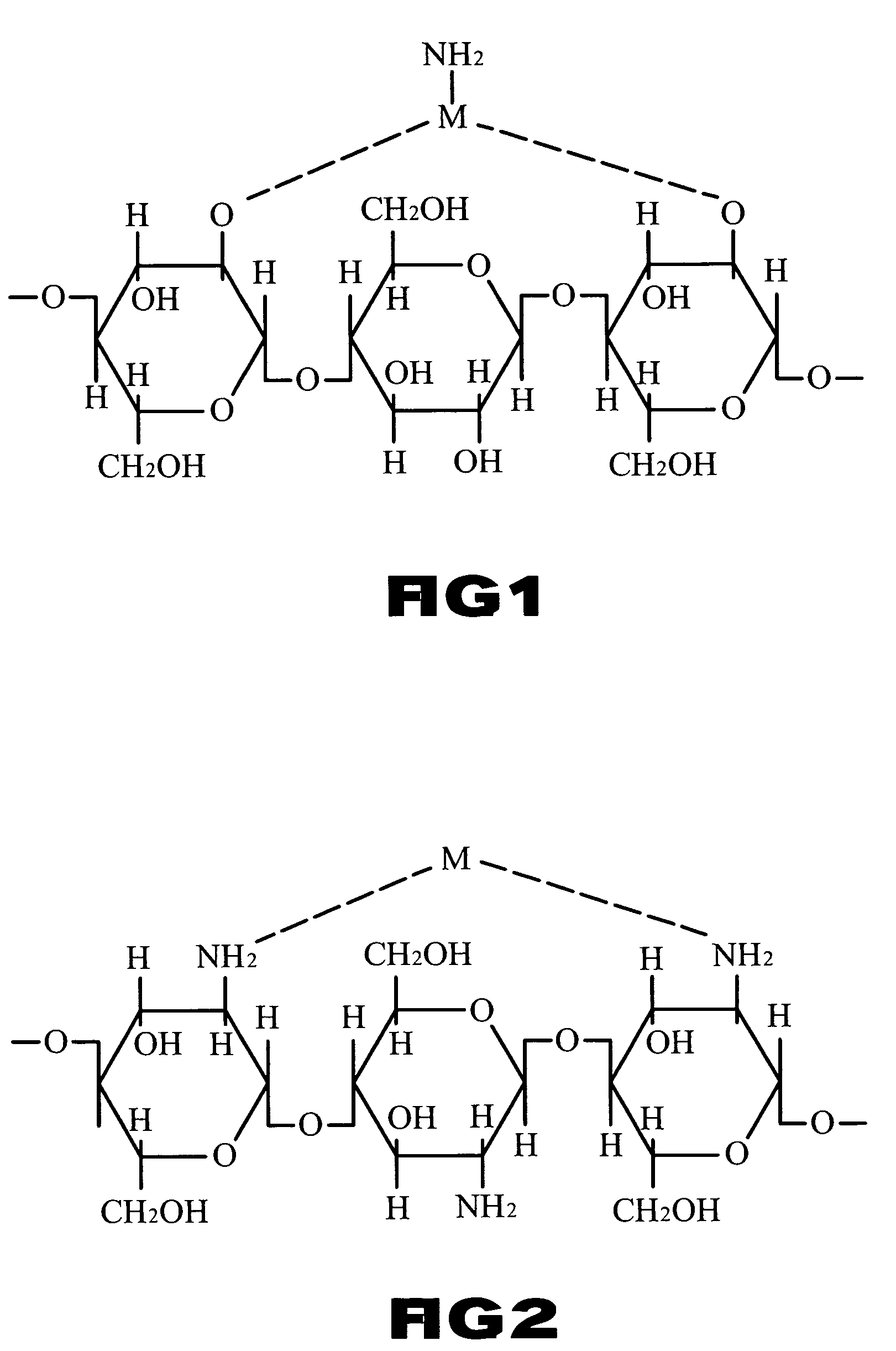

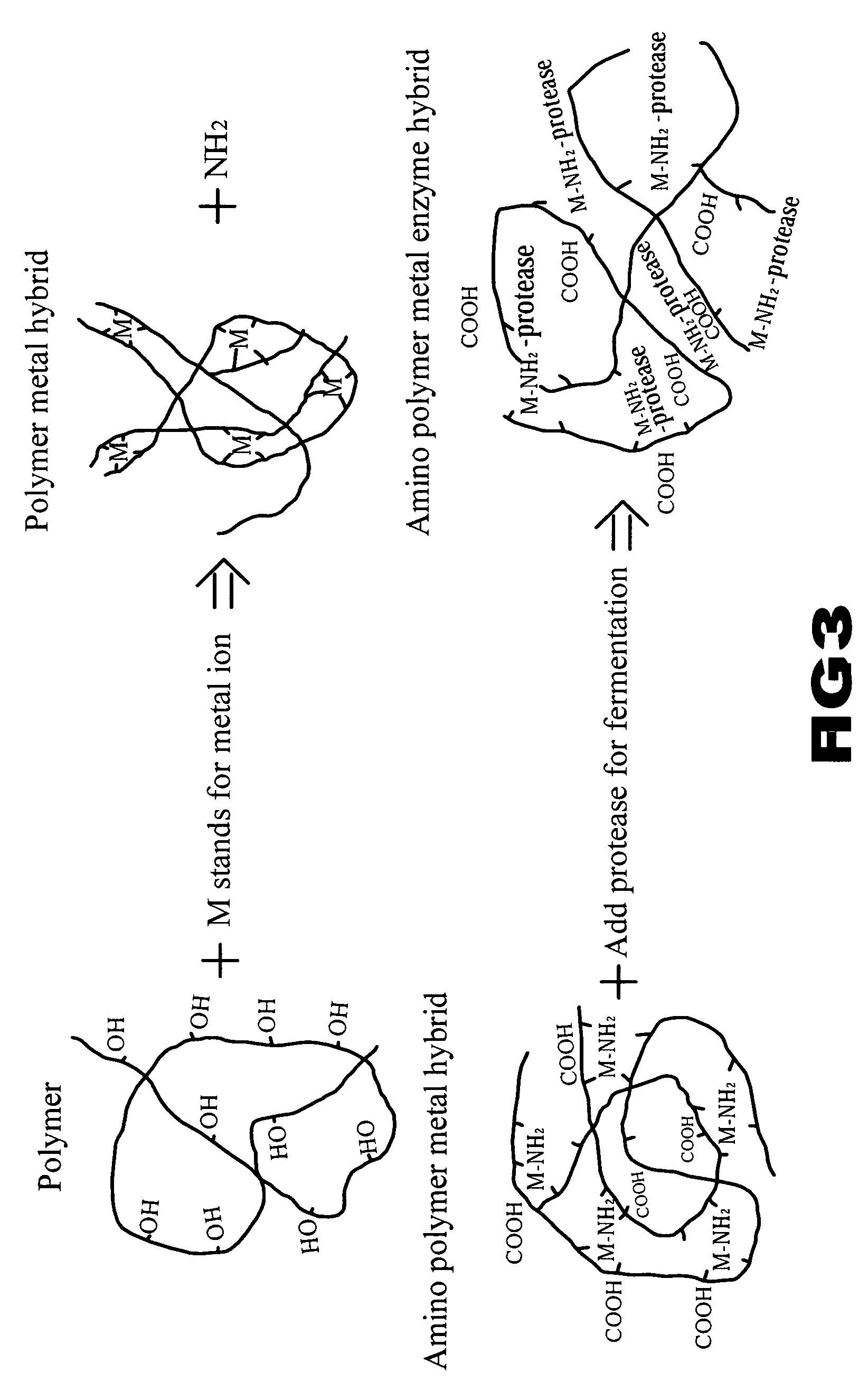

Solution of metal-polymer chelate(s) and applications thereof

InactiveUS8193291B2Improve rendering capabilitiesGood for condensationCosmetic preparationsBio-organic fraction processingFiltrationDisinfectant

In a solution of metal-polymer (chelate(s) and applications thereof, a metal-polymer chelate is prepared by mixing water and R—COOH soluble carbohydride molecules and / or hydroxyl or hydroxyl amino and / or carboxyl and / or carbohydrate polymers, metal salts and / or ammonia or amines. The solution of metal-polymer chelate(s) is used extensively in different technical areas including oxidation, condensation, degradation, oxidizing condensation, gas detection, artificial imitated chitosan solution, artificial imitated glucosamine, disinfectant, biochemical reaction for fermentation, biological protein and its metabolite purification, metal enzyme biocatalyst, dry activation of protein enzyme, bacteria preservation systems, oil product, plant, semiconductor, nano filtration, nano material production, nano inorganic matter, nano ceramic, nano plastic, nano textile, battery, liquid crystal, and biochip. These reactions give effects for chemical engineering, gas removal, and waste solvent treatment.

Owner:ZHANG CAITENG

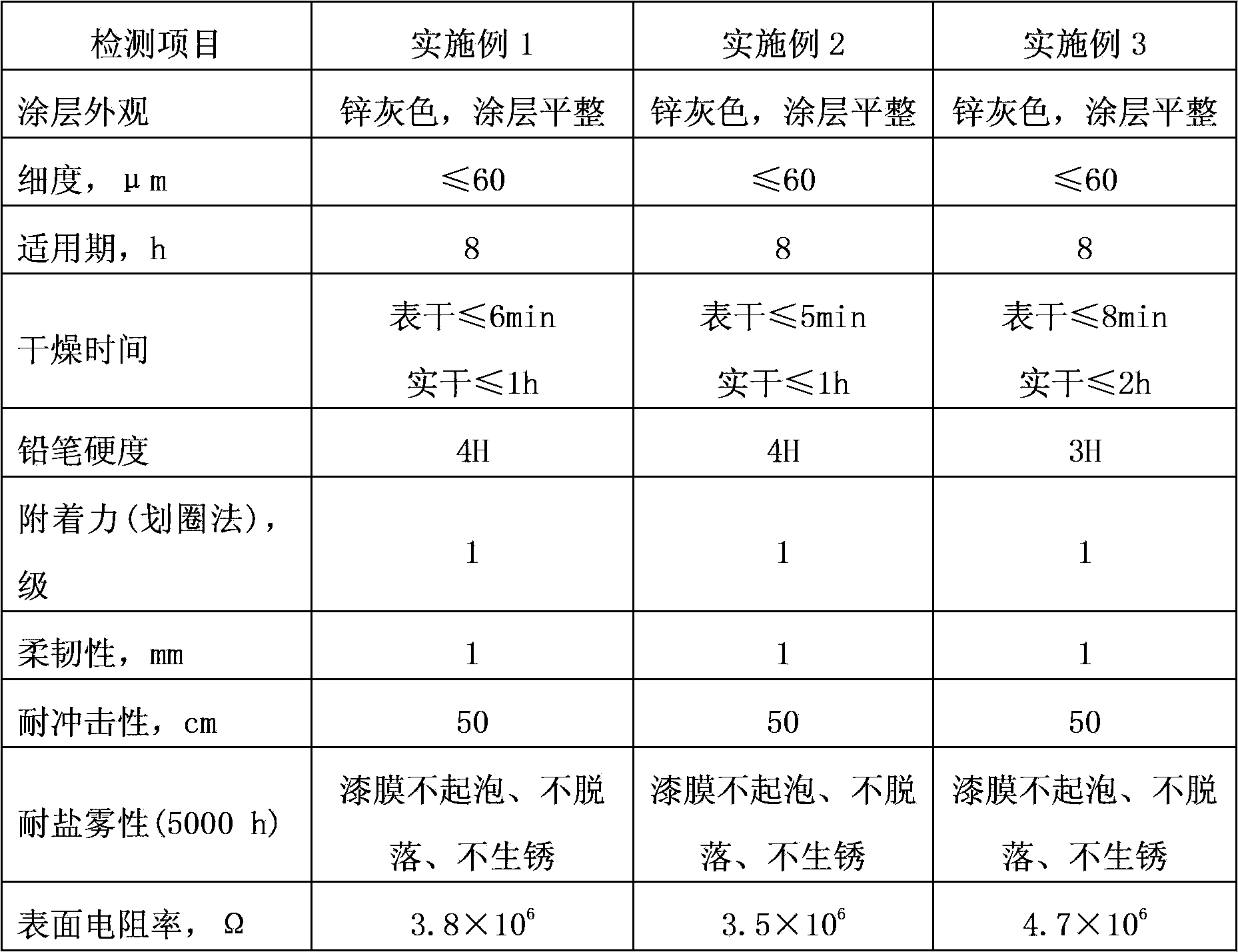

Antistatic paint for steel structure surface and preparation method thereof

InactiveCN103788726AGood for condensationIncrease crosslink densityElectrically-conductive paintsCarbon nanotubeSlurry

The invention provides a antistatic paint for a steel structure surface and a preparation method thereof. The paint is prepared by mixing zinc-aluminum alloy powder slurry and ethyl orthosilicate slurry in a mass ratio of 3:1-5:1. The ethyl orthosilicate in the ethyl orthosilicate slurry is subjected to hydrolytic condensation under the action of a catalyst, and a furfural-furfuryl alcohol resin is added as a modifier into the zinc-aluminum alloy powder slurry. After the zinc-aluminum alloy powder slurry and ethyl orthosilicate slurry are mixed, the furfural-furfuryl alcohol resin is cured to release water molecules when meeting with acid so as to promote the further condensation of the ethyl orthosilicate hydrolytic condensation substances, and the furfural-furfuryl alcohol resin and the zinc-aluminum alloy powder react to form a interpenetrating network, thereby enhancing the crosslinking density between the paint and the steel structure substrate surface and increasing the wettability and adhesive force of the coating for the substrate.Preferably, a carbon nanotube dispersion solution and conductive mica powder can be added into the zinc-aluminum alloy powder slurry to correspondingly improve the antistatic property of the obtained coating. Therefore, the protective paint is suitable for various steel storage tank internal and external walls, large bridges, ships, offshore oil drilling platforms and other steel structure surfaces.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com