Apparatus for making sponge iron by direct-cooled combination method

A technology of combined method and sponge titanium, which is applied in the field of devices for preparing sponge titanium by direct cooling combined method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

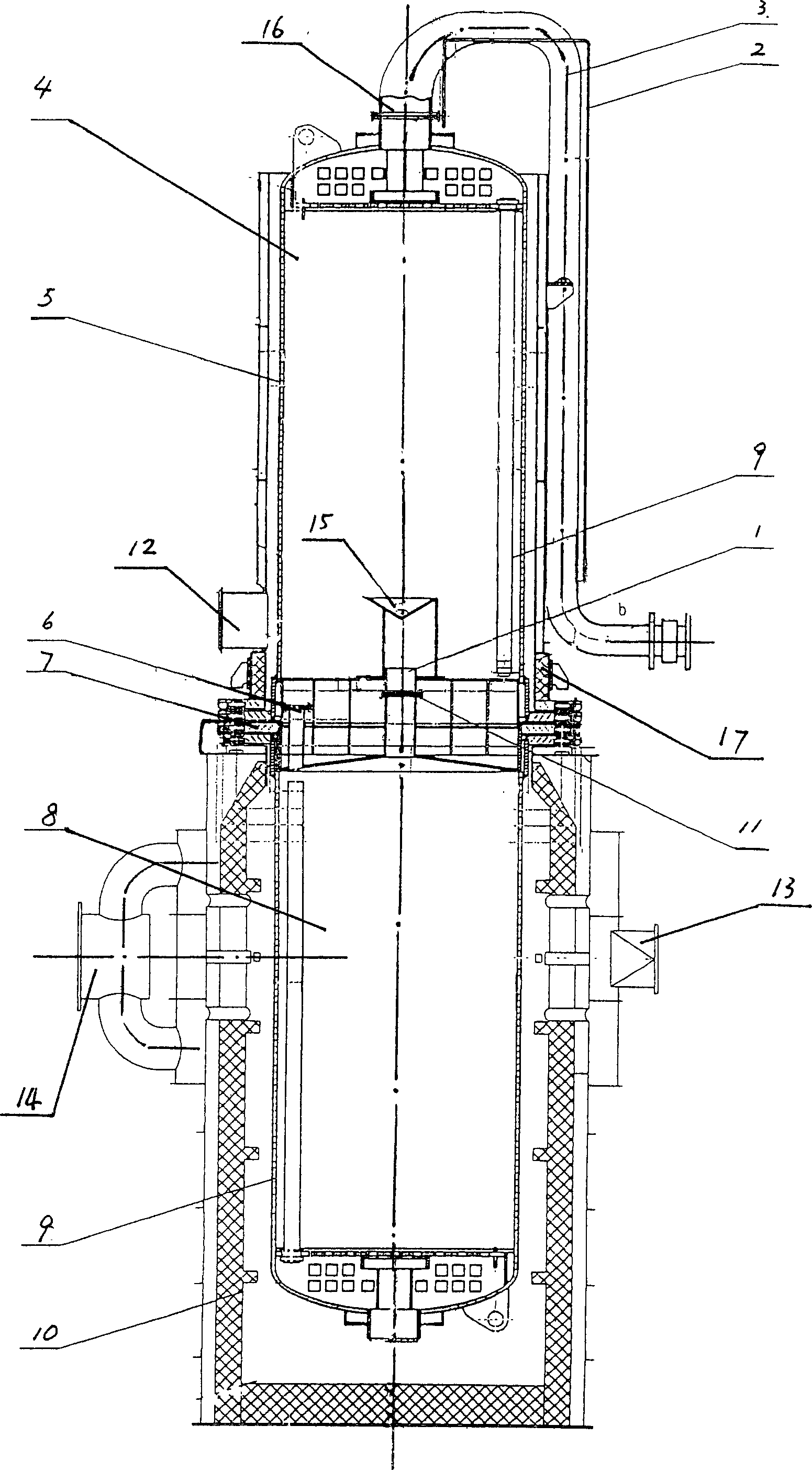

[0009] As shown in the drawings, the device of the present invention is mainly composed of an intermediate channel 1, a cooling water pipe 2, an elbow 3, an upper reactor 4, a condensation sleeve 5, an outer sleeve 6 connected to a magnesium chloride tube, a middle cover 7, and a lower reactor 8 , Magnesium chloride discharge casing 9, combined electric furnace 10, middle channel easy-to-open partition device 11, ventilation hole 12, air inlet 13, air outlet 14, heat shield 15, upper reactor tail pipe 16, 17 insulation rings. A lower reactor 8 is installed in the cavity of the combined electric furnace 10, and a magnesium chloride discharge sleeve 9 is installed in the lower reactor 8. The upper part of the lower reactor 8 is sealed and connected with the middle cover 7 through a gasket and bolts, and the middle cover 7 is welded with Connect the outer casing 6 of the magnesium chloride tube, set the middle channel 1 in the middle of the middle cover 7, install the middle chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com