Patents

Literature

21184results about "Bio-organic fraction processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of automotive diagnostics console to diagnose vehicle

InactiveUS7376497B2Less costlyPromote repairVehicle testingBio-organic fraction processingPaymentEngineering

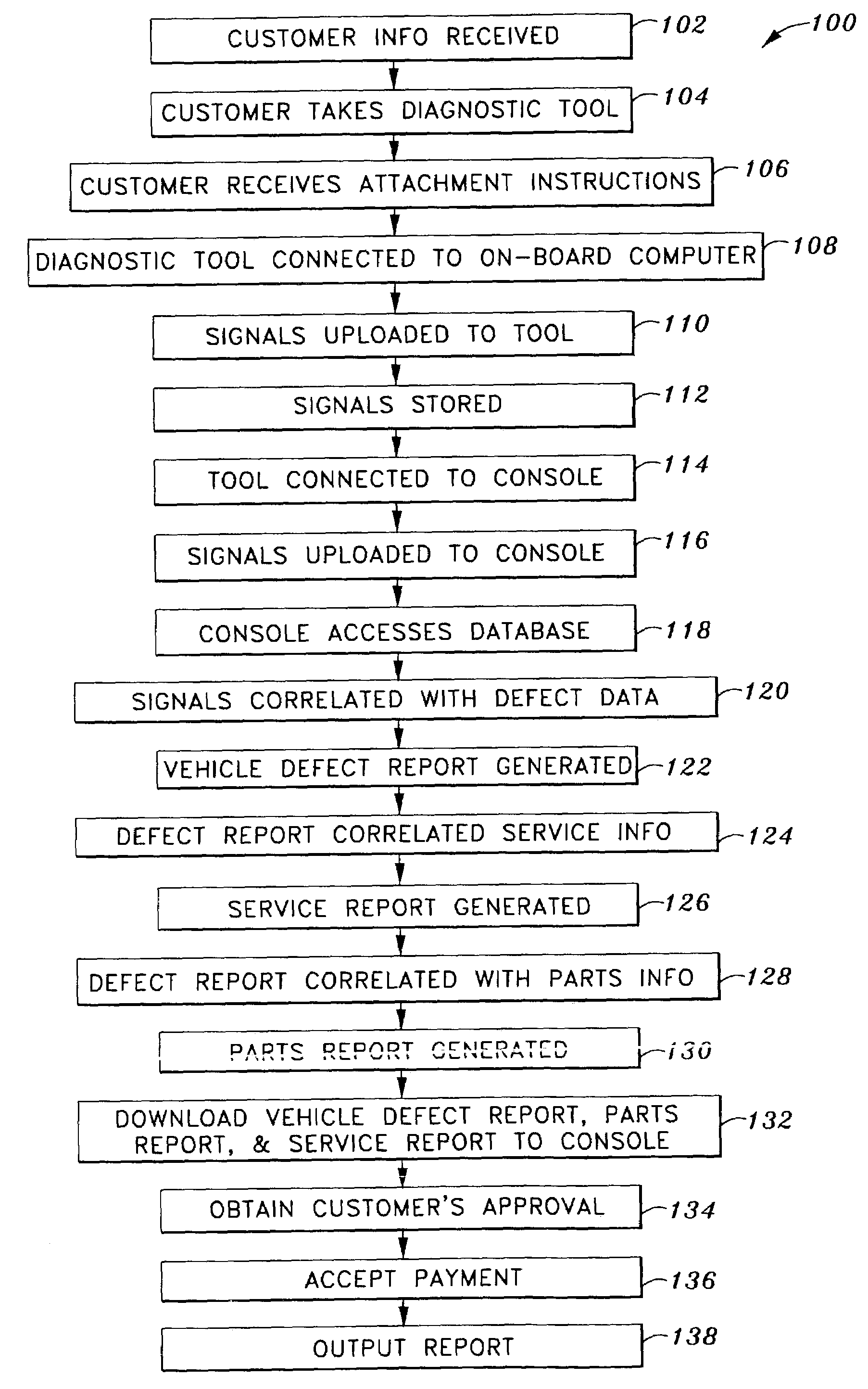

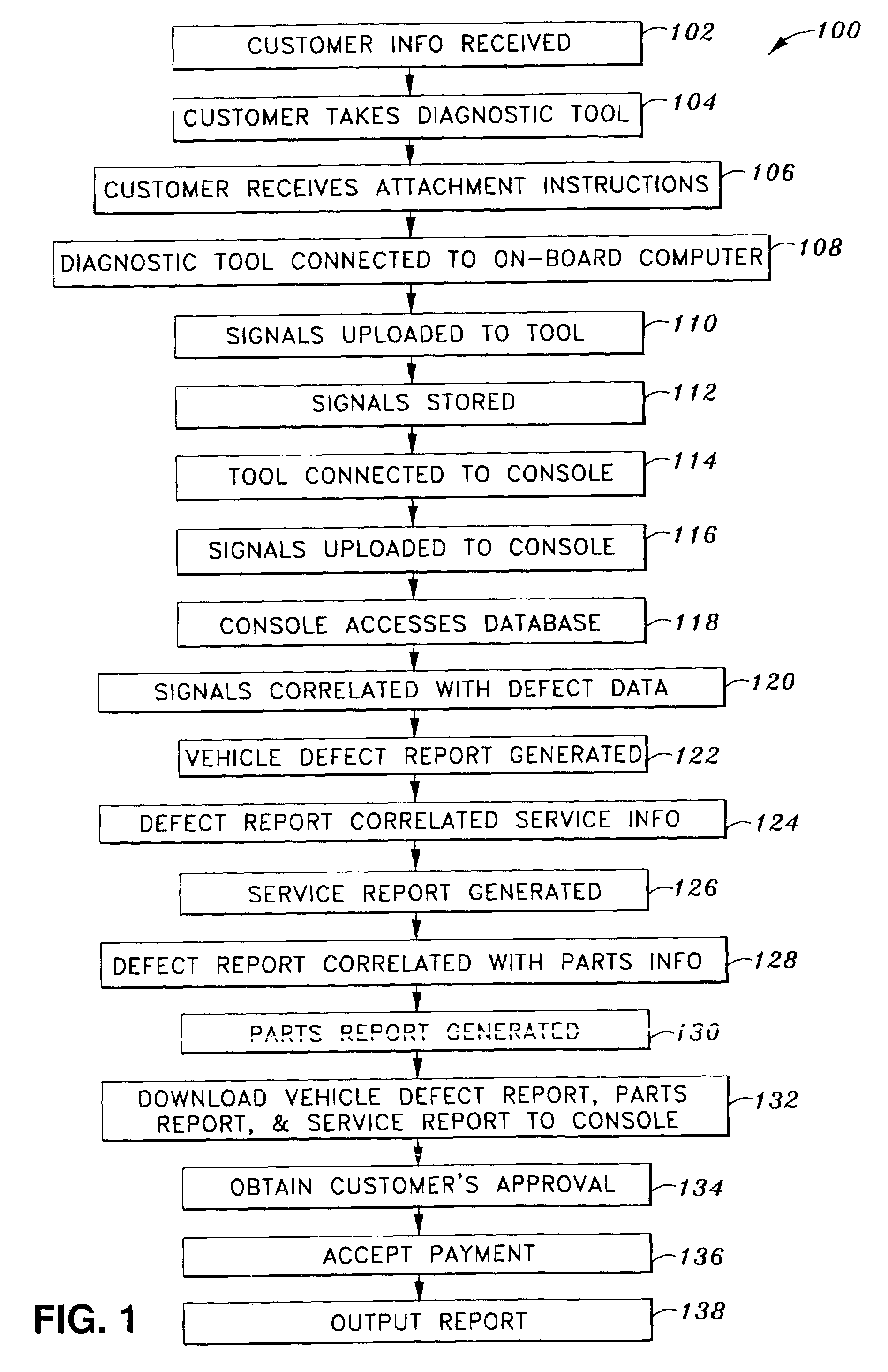

A customer driven process of diagnosing and repairing a vehicle. The process involves temporarily providing a customer with a diagnostic tool that can receive vehicle diagnostic signals from a vehicle on-board computer. The customer then uses the tool to upload diagnostic signals from the car, and returns the tool to the automotive parts / service facility. The vehicle diagnostic signals are communicated to a console, which then accesses a database(s). The database(s) includes information relating to the vehicle malfunction, the repairs needed, and the parts required to complete those repairs. The process also allows automatic scheduling of repairs and purchasing of parts from the automotive parts / service facility. Upon payment of any prescribed fees, the process outputs report information to the customer.

Owner:INNOVA ELECTRONICS

Slurry dewatering and conversion of biosolids to a renewable fuel

ActiveUS20060096163A1Readily removed mechanicallyLow oxygenBio-organic fraction processingBiofuelsEmission standardSlurry

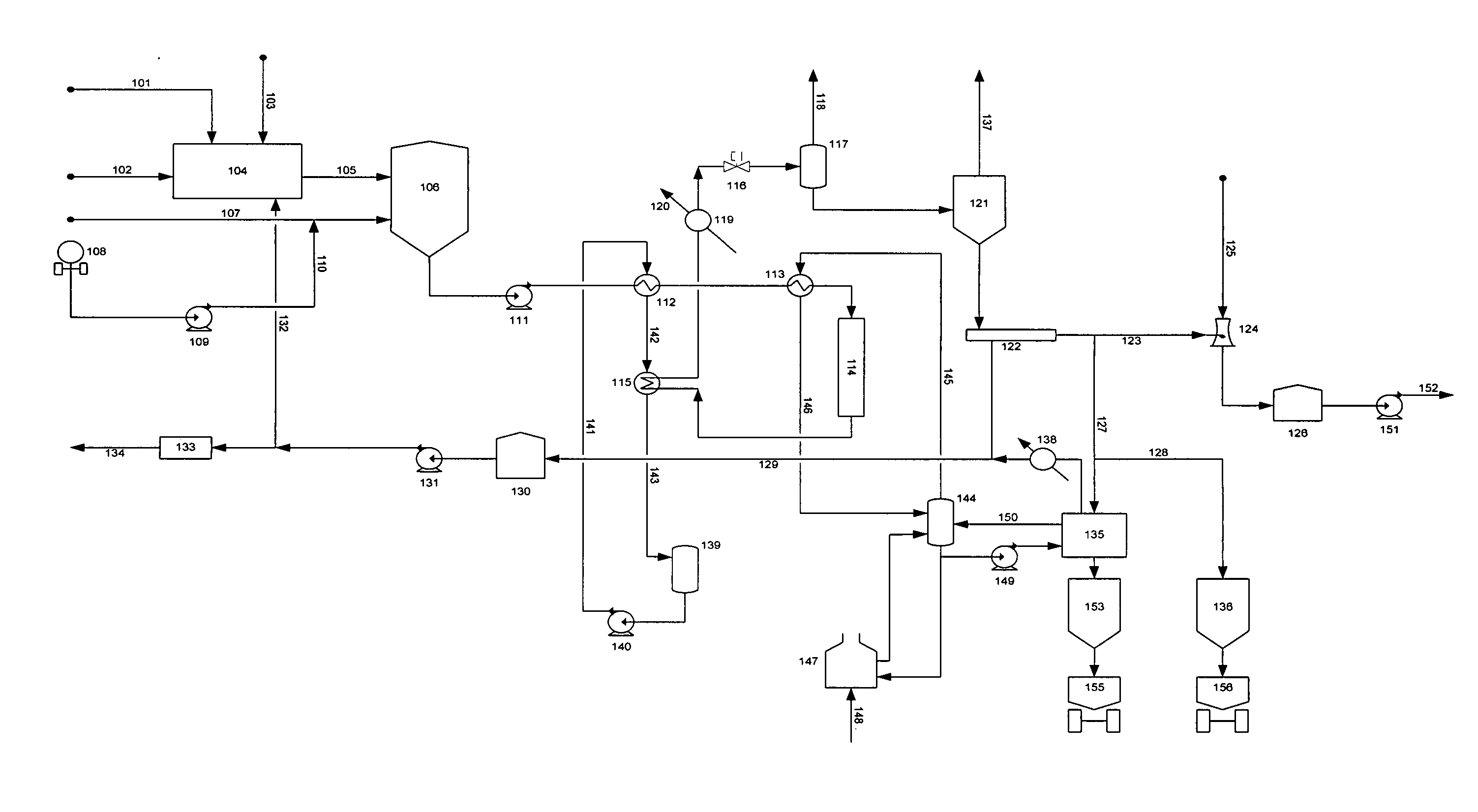

In the processes for treating municipal sewage and storm water containing biosolids to discharge standards, biosolids, even after dewatering, contain typically about 80% water bound in the dead cells of the biosolids, which gives biosolids a negative heating value. It can be incinerated only at the expense of purchased fuel. Biosolids are heated to a temperature at which their cell structure is destroyed and, preferably, at which carbon dioxide is split off to lower the oxygen content of the biosolids. The resulting char is not hydrophilic, and it can be efficiently dewatered and / or dried and is a viable renewable fuel. This renewable fuel can be supplemented by also charging conventional biomass (yard and crop waste, etc.) in the same or in parallel facilities. Similarly, non-renewable hydrophilic fuels can be so processed in conjunction with the processing of biosolids to further augment the energy supply.

Owner:SGC ADVISORS

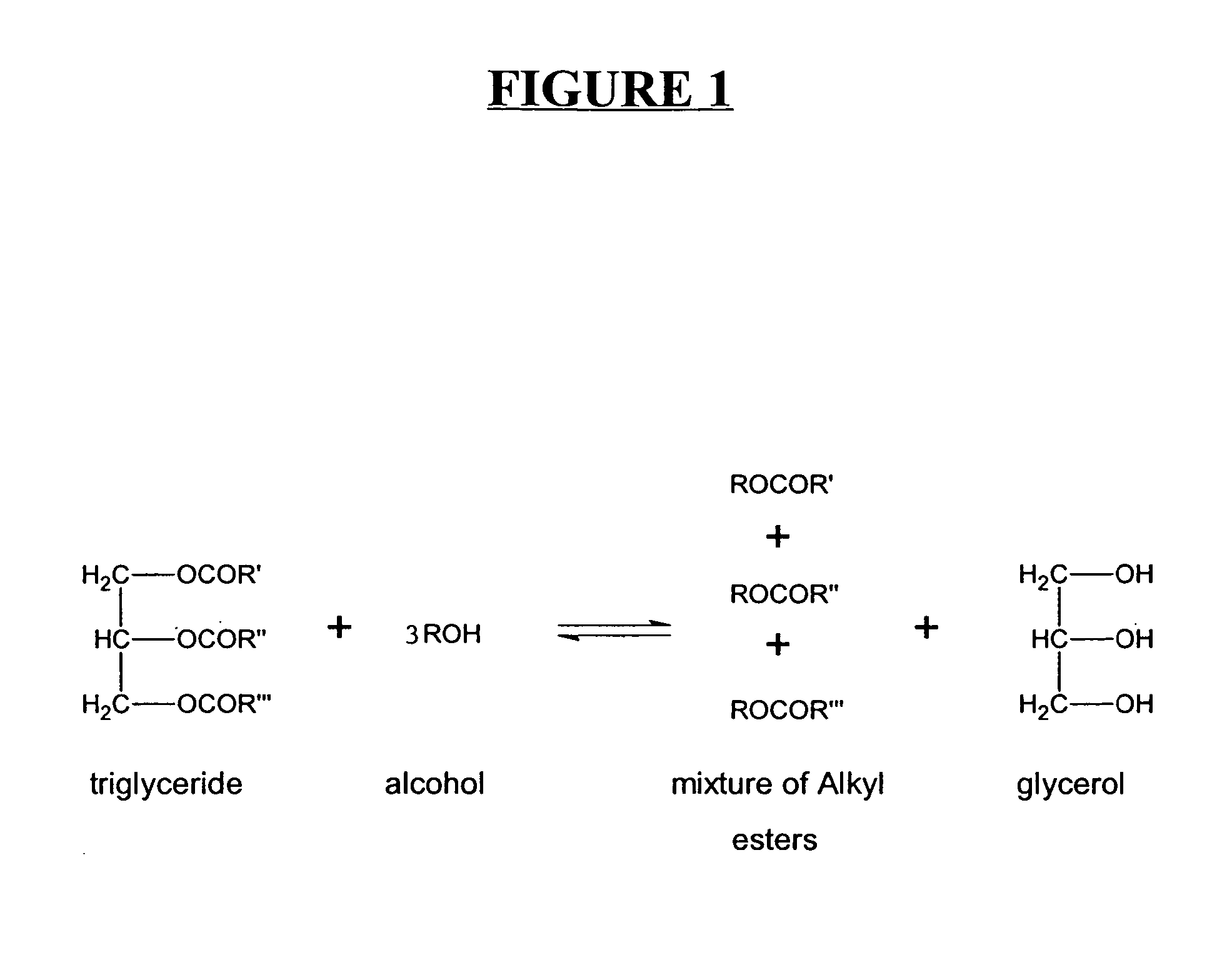

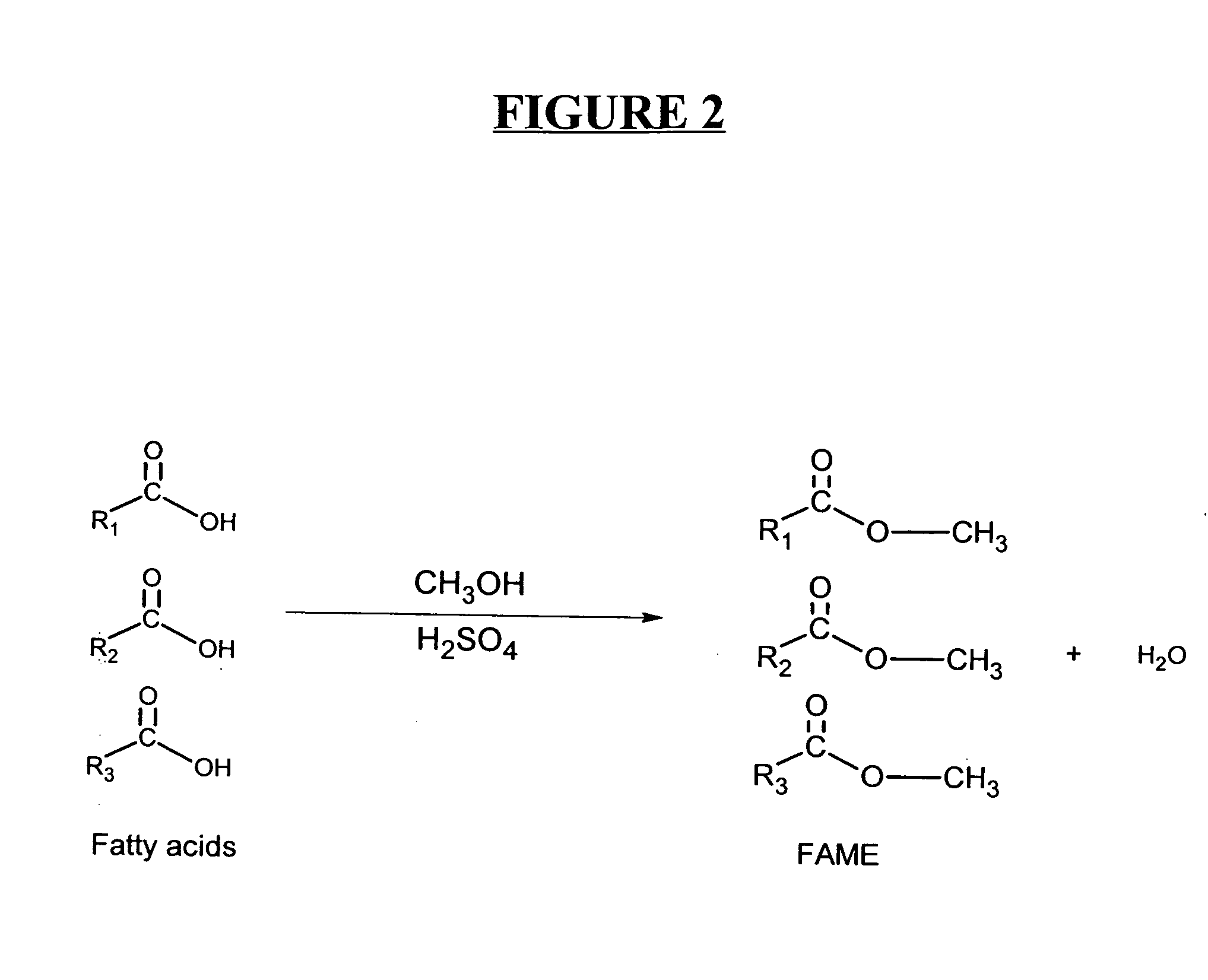

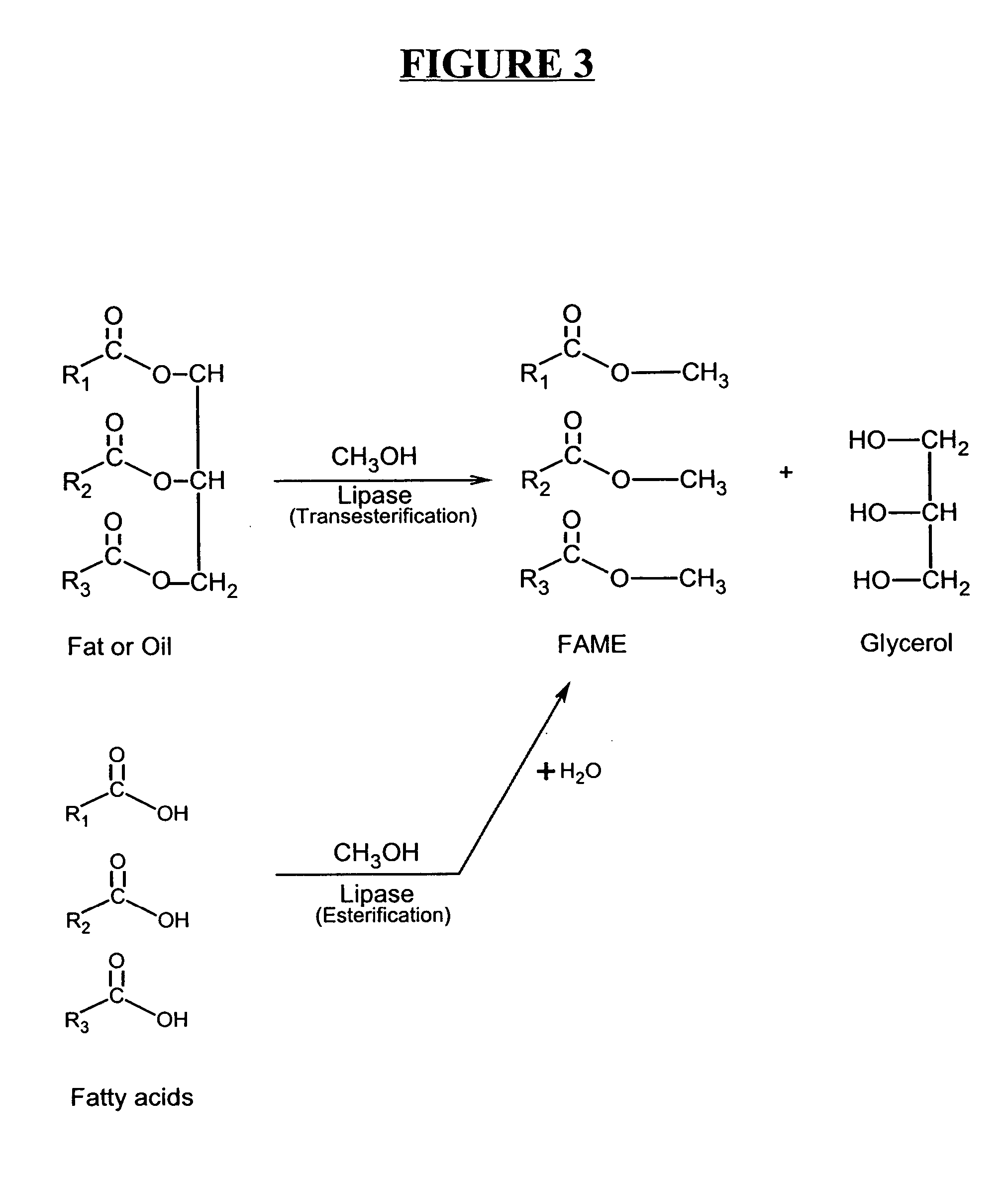

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

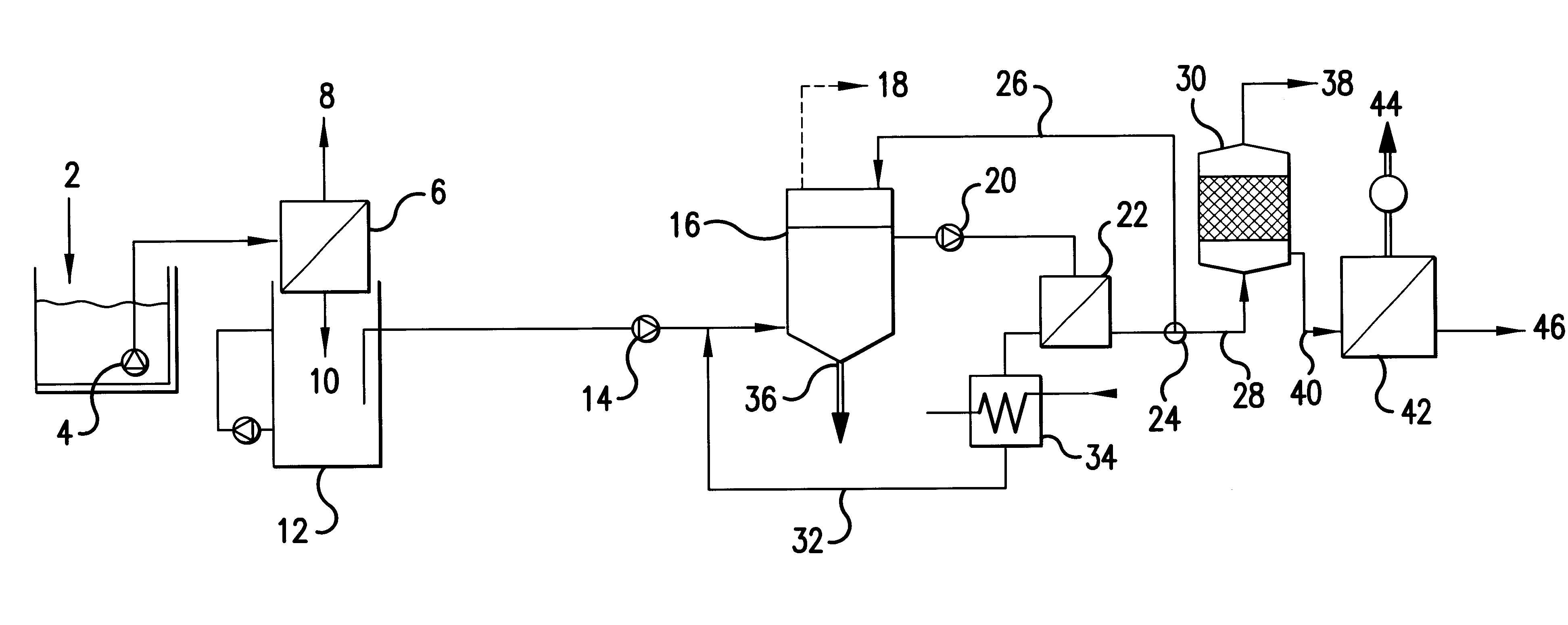

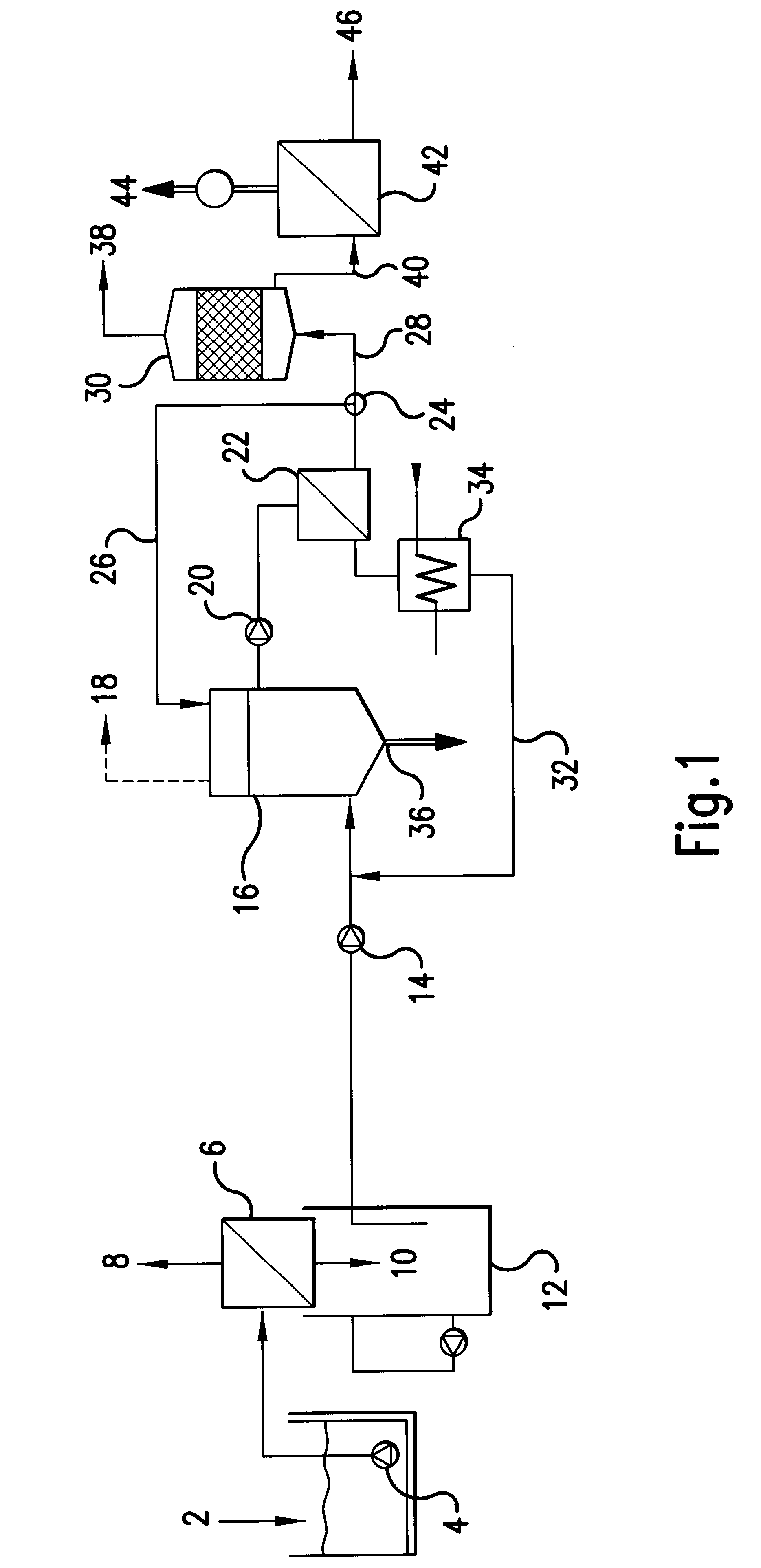

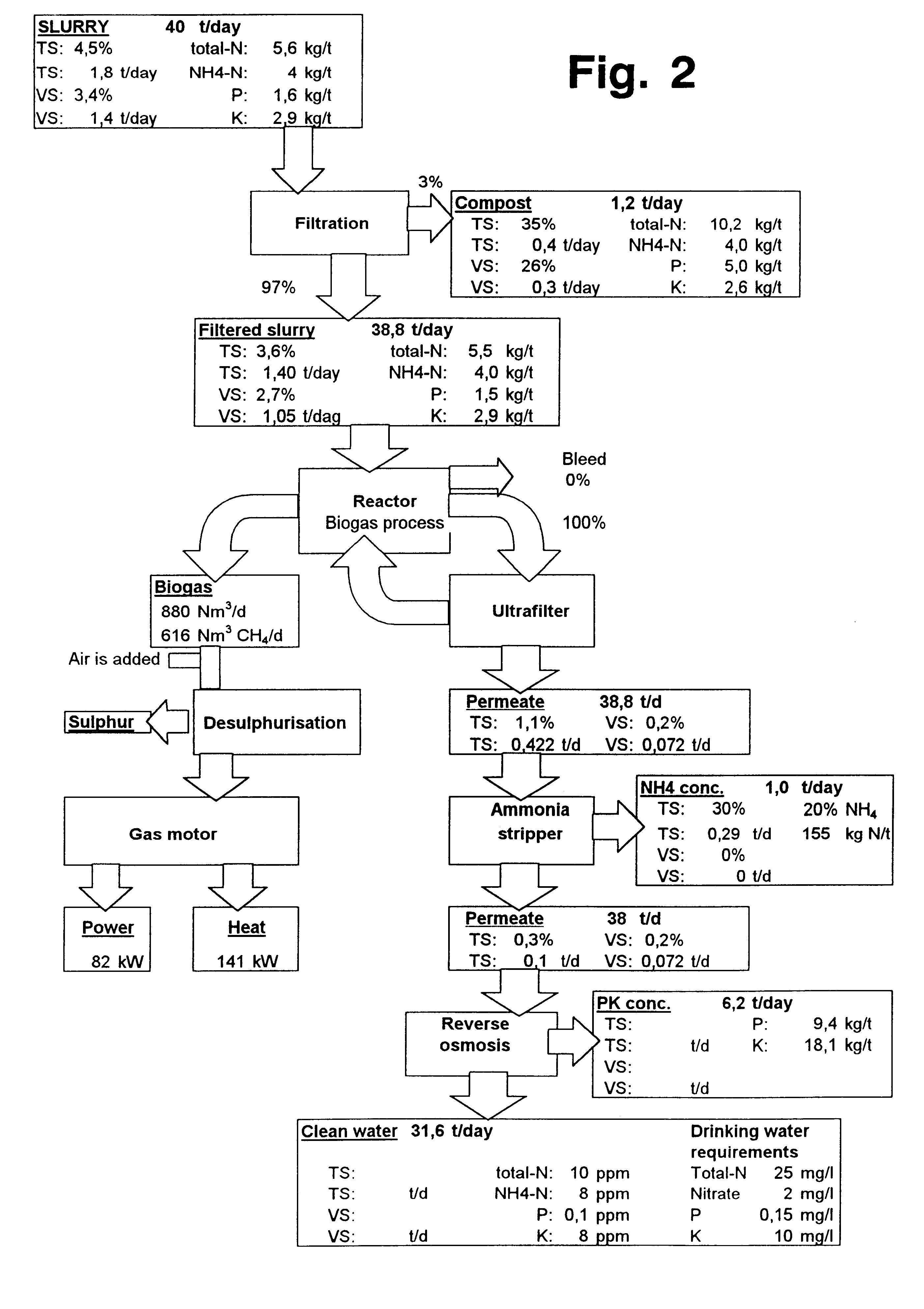

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

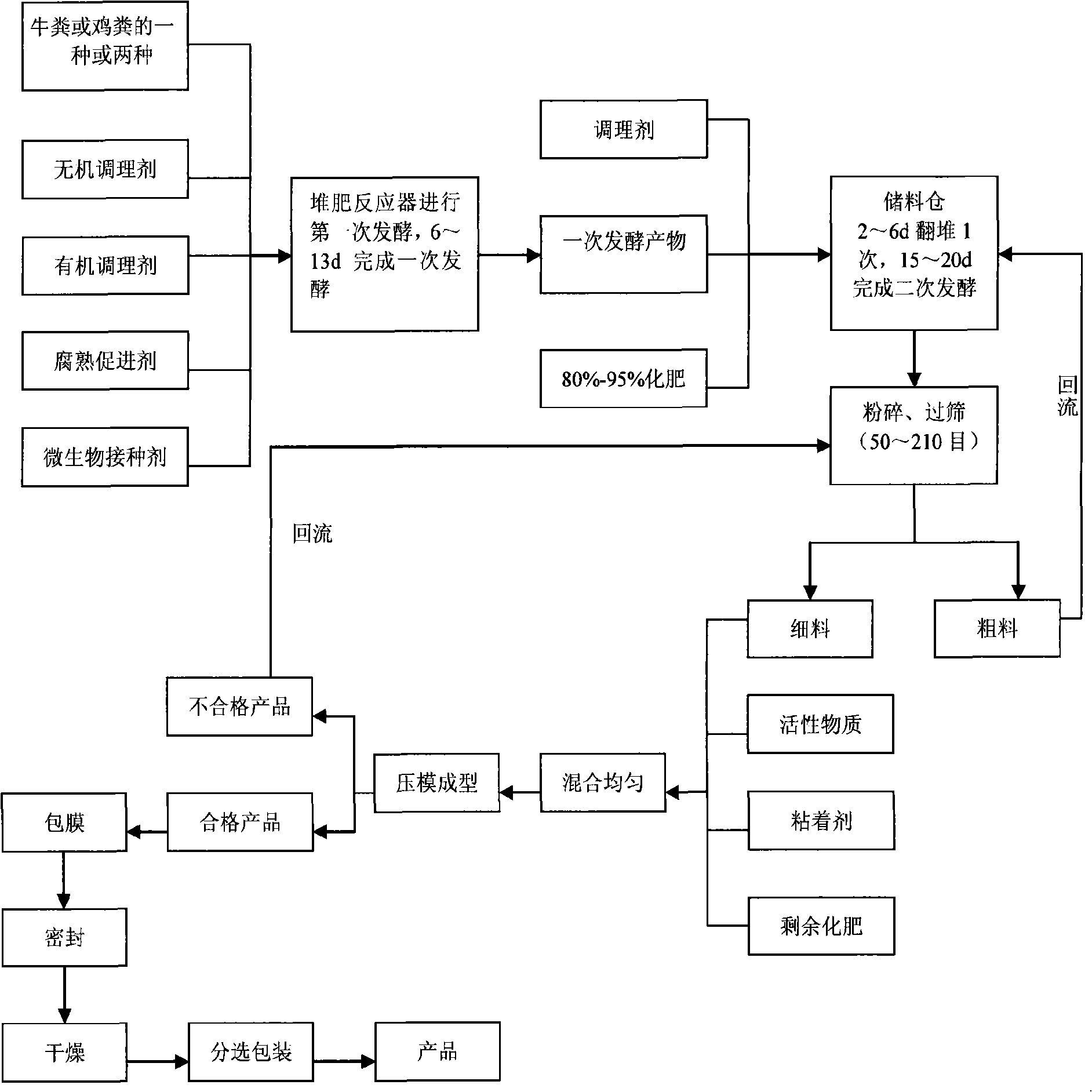

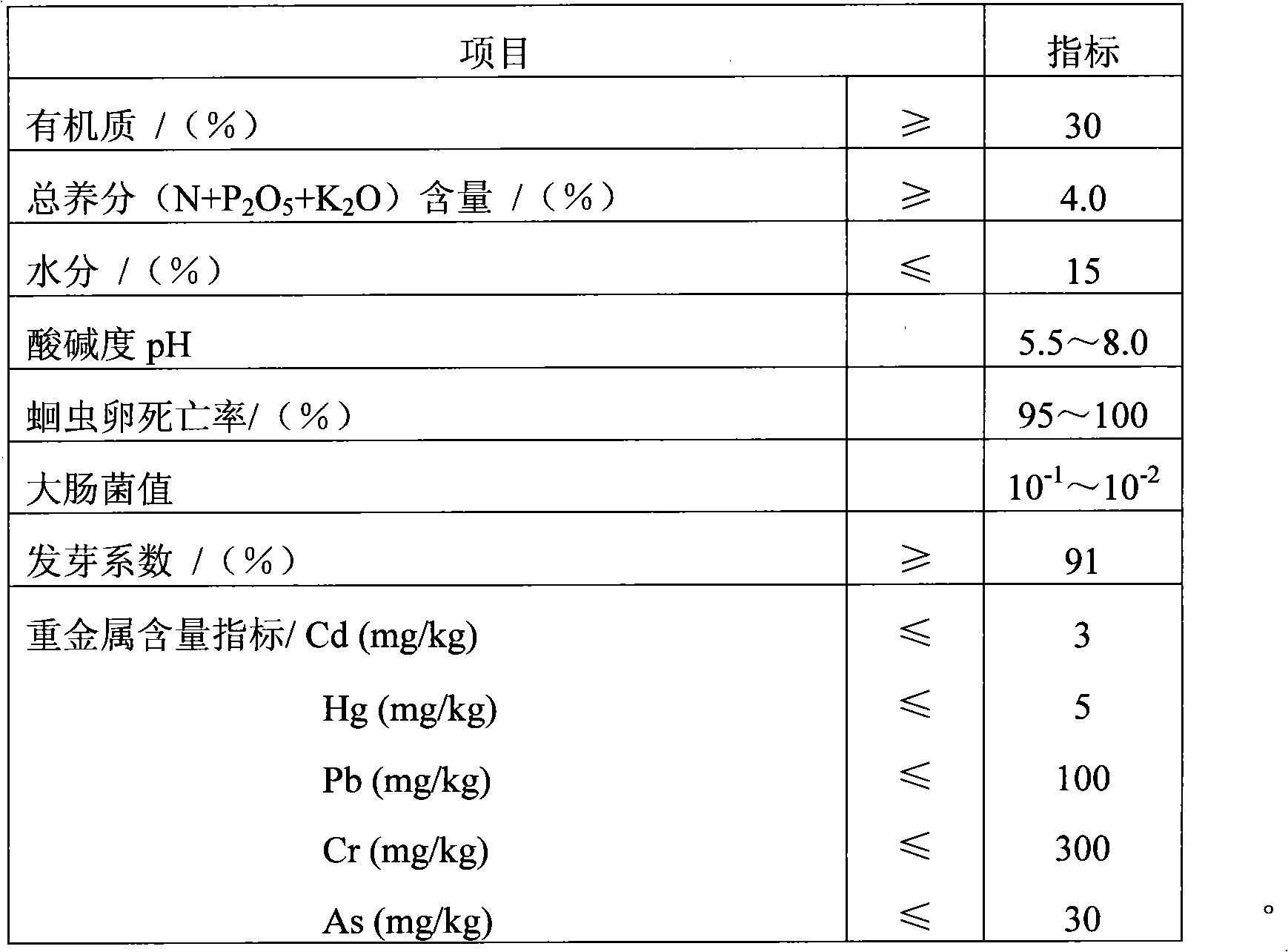

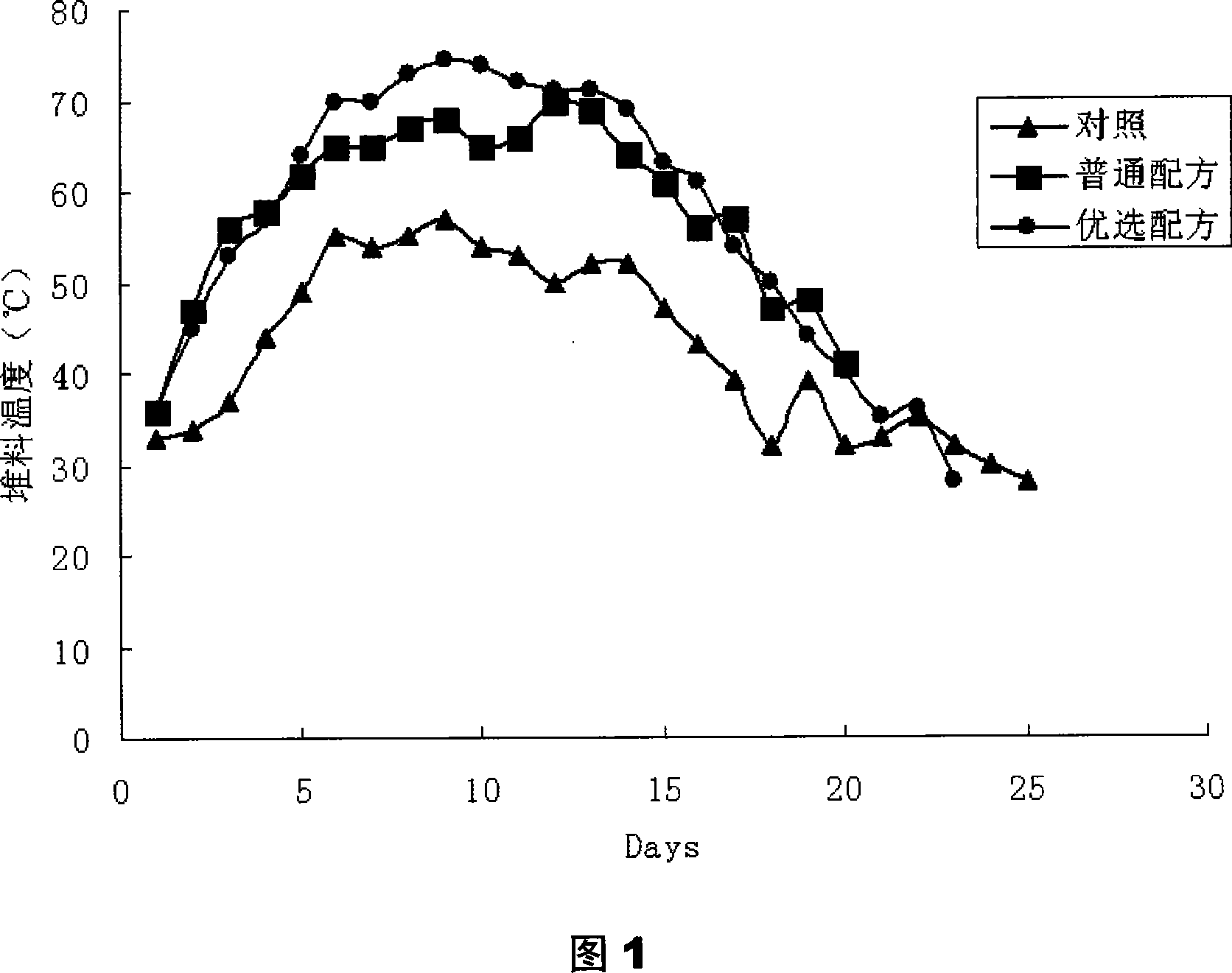

Organic-inorganic slow-released fertilizer and method for preparing same

InactiveCN101284747AHarmlessFastBio-organic fraction processingOrganic fertiliser preparationSealantFermentation

The invention discloses a flower organic-inorganic slow-release fertilizer as well as the preparation method thereof. The slow-release fertilizer contains the following materials by weight: primary fermentation products of 45 to 70 percent, chemical fertilizers of 2 to 35 percent, a conditioner of 5 to 30 percent, coating materials of 3 to 25 percent, an agglutinant of 1 to 10 percent, active materials of 0 to 15 percent and a sealant of 0 to 12 percent; the primary fermentation products, the chemical fertilizers and the conditioner are mixed for carrying out the secondary fermentation of composting, and then the products of the second fermentation are crushed for press molding; finally, compound fertilizer particles formed by the press molding are evenly sprayed with the coating materials and the agglutinant, thereby obtaining the flower organic-inorganic slow-release fertilizer; the flower organic-inorganic slow-release fertilizer of the invention has the advantages that the nutrition is rich, the composting process is fast, the rotten degree is good, the fertilizer is prone to be absorbed by flowers, the manufacturing process is simple, and the use is convenient.

Owner:广东省农业科学院土壤肥料研究所

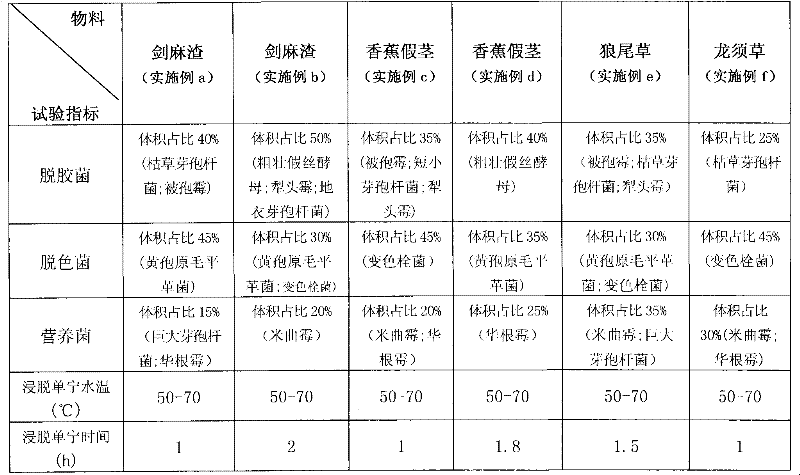

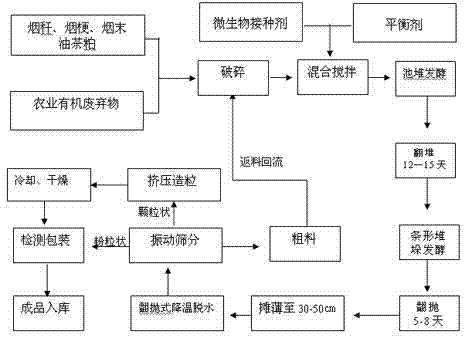

Agriculture castoff compost ternary microorganism composite microbial inoculum

ActiveCN101186879APromote degradationQuick conversionBio-organic fraction processingMicroorganismsMicroorganism resourceCompost

A composite biological agent with ternary microorganism for composting process of agricultural waste is composed of a composite biological agent I, a composite biological agent II, and a composite biological agent III, which is characterized in that the composite biological agent I is composed of bacillus, actinomycetes, microzyme and lactobacillus, the composite biological agent II is composed of trichoderma, ergillus, penicillium and trametes versicolor, and the composite biological agent III is composed of photosynthetic bacterium, azotobacter, phosphorus bacteria, and silicate bacterium. 30-60% composite biological agent I, 30-60% composite biological agent II, 10-20% composite biological agent III are mixed or applied to the process of composting process of agricultural waste in phases. Each component ratio and recruitment of biological agents can be both properly adjusted with different dung materials and dung purpose, thereby achieving purpose of using microorganism resources efficiently and raising fermentation efficiency.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

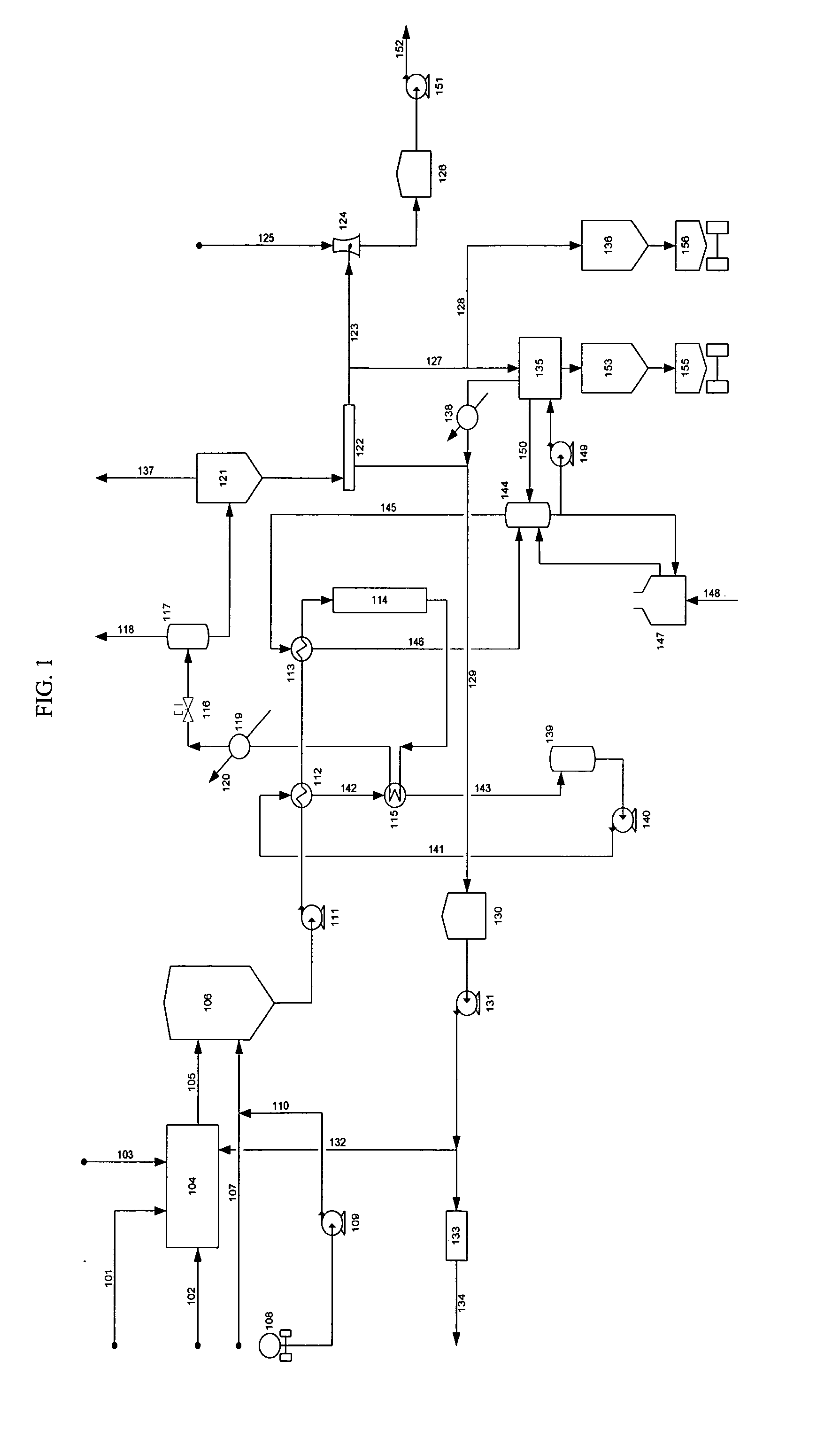

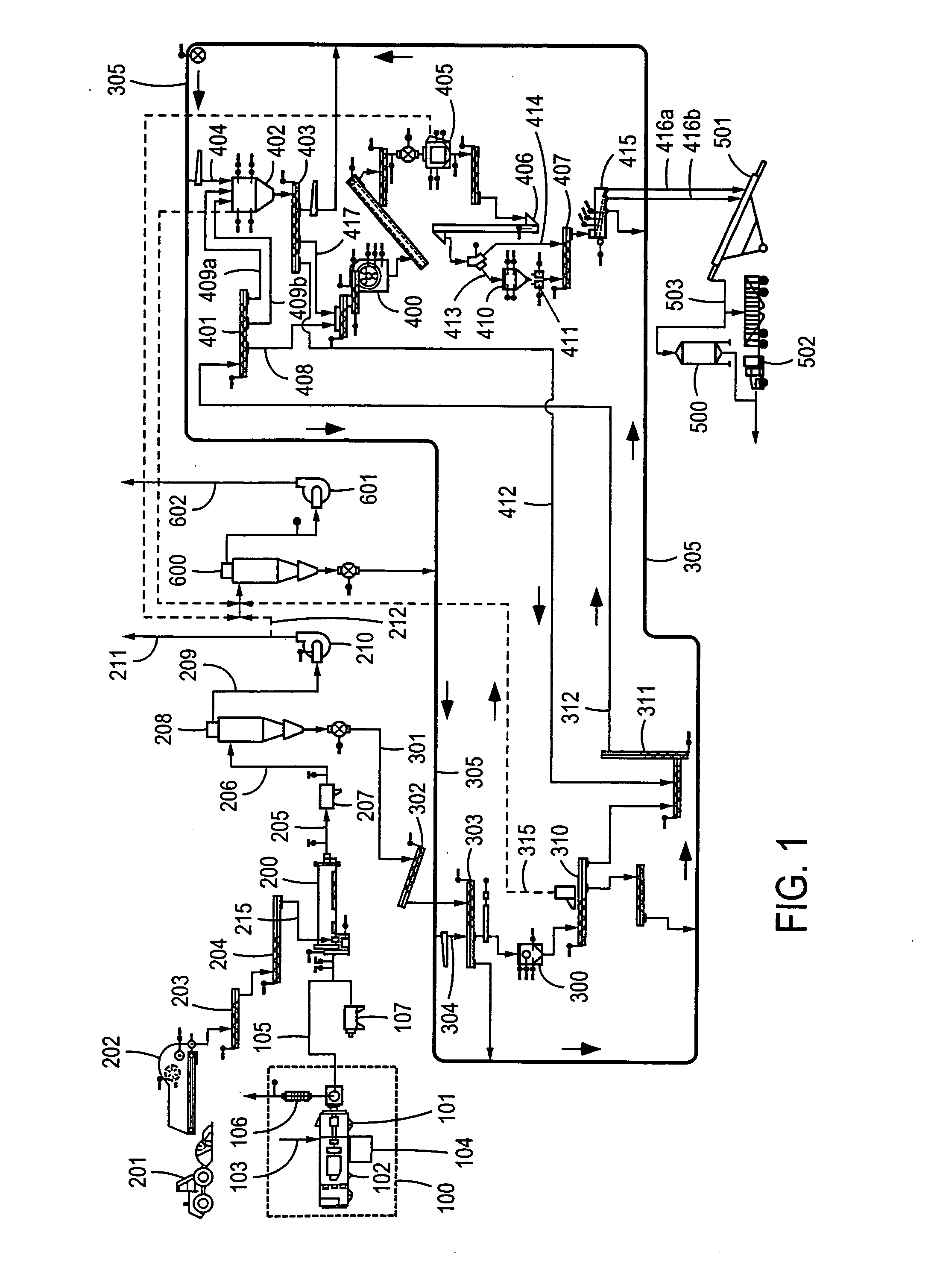

System and method for extracting energy from agricultural waste

InactiveUS7169821B2Reduce decreaseMinimize negative impactBioreactor/fermenter combinationsBio-organic fraction processingSyngasBiodiesel

Owner:BEST BIOFUELS LLC

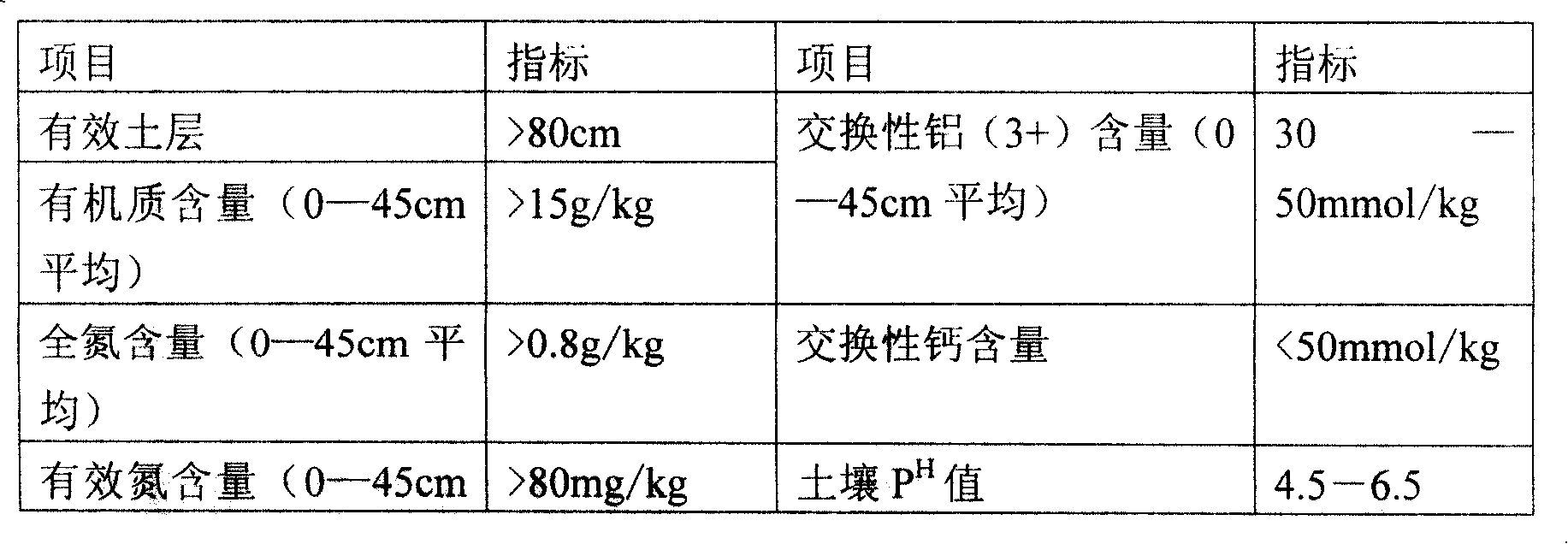

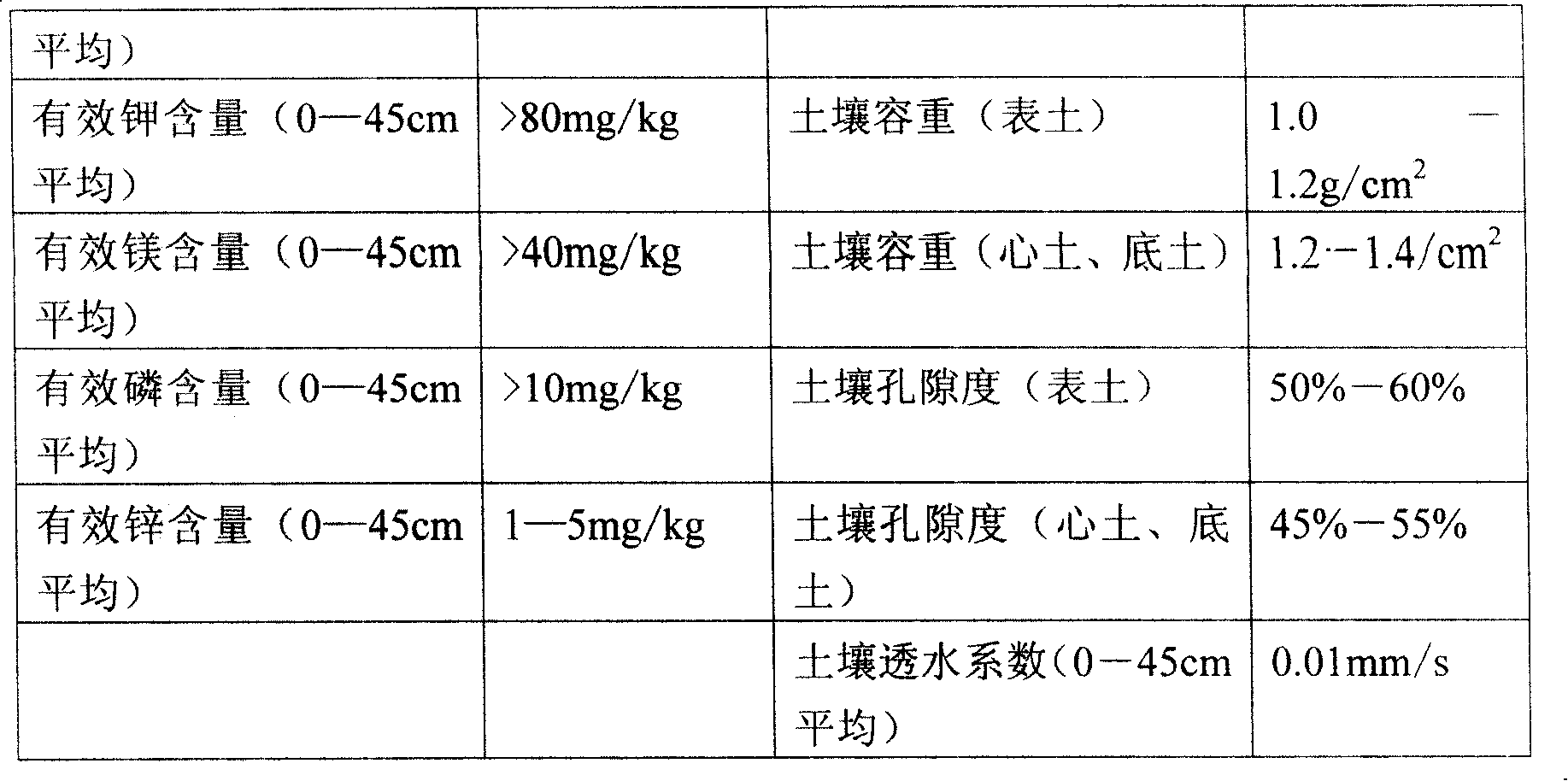

Organophilic cultivation method for tea

InactiveCN101233804AQuality assuranceStrong technical operabilitySoil lifting machinesBio-organic fraction processingOrganificationPest control

The invention relates to a method for cultivating tea, particularly the method for organically cultivating tea, which comprises the following processes: (I) establishing an artificial complex ecological organic tea garden; (II) selecting tea seeds of the organic tea garden; (III) planting tea; (IV) seedling stage management; (V) soil management of the organic tea garden; (VI) nutrient management and utilization of the organic tea garden; (VII) pest control of the organic tea garden; (VIII) tea pruning of organic tea. The method for cultivating tea has the following positive effects that: as the organic tea is the inevitable trend of future tea production, the invention regulates organic planting of tea in China and promotes the large-scale development of tea producing areas toward harmlessness and organification; the method for cultivating tea does not rely on advantage factors of microecological nature of producing areas, makes full use of modern technical achievements and has strong technical operability, thereby ensuring the quality of the organic tea.

Owner:四川圣硒贡茗茶业科技有限公司

Microbial culture liquors containing microorganisms differing in characteristics and living in symbiosis and metabolites thereof, carriers and adsorbents containing the active components of the culture liquors and utilization of the same

Solutions containing microorganisms differing in characteristics from each other and living in symbiosis with each other and enzymes characterized by containing aerobic microorganisms, anaerobic microorganisms and at least one basidiomycete belonging to the family Pleurotaceae living in symbiosis, metabolites thereof and enzymes; carriers obtained by adsorbing the components of the above solutions onto finely ground carbonaceous materials; and porous materials obtained by adsorbing the components of the above solutions onto porous materials. Because of having various effects of absorbing, adsorbing and decomposing harmful matters, deodorizing, decolorizing, etc., these materials are applicable to various uses in the fields of agriculture and environment.

Owner:ORIENT GREEN

Clear-white gold needle mushroom cultivation method

InactiveCN101366346AAvoid pollutionNo diseaseBio-organic fraction processingOrganic fertiliser preparationSucroseSaccharum

The invention discloses a method for cultivating pure white needle mushrooms. The method comprises the following steps: a strain is prepared; a culture material is prepared; bagging and sterilization are carried out; inoculation is carried out; a mycelium is cultured; nutrition, humidity, temperature, light, air and other culture conditions are strictly controlled during a fruiting period; and harvesting is carried out in an optimum period. the formulation of the culture material is 0 to 32 percent of weed tree sawdust, 0 to 93 percent of cotton seed hulls or wheat straw, straw, corncob and other crop straw, 0 to 20 percent of wheat bran, 0 to 10 percent of corn meal, 0 to 10 percent of soybean meal, 0 to 1 percent of calcium carbonate, 0 to 0.2 percent of monopotassium phosphate, 0 to 0.2 percent of magnesium sulfate, 1 to 1.2 percent of sucrose, 0 to 10 percent of rice bran, 0 to 1 percent of plaster and 0 to 0.02 percent of urea. Quicklime and wettable carbendazim are added during the preparation of the culture material so as to prevent the pollution of undesired bacteria. The technical proposal aims to select proper breeds, popularize local large scale planting and improve cultivation benefit.

Owner:WUHU YESHULIN BIOTECH

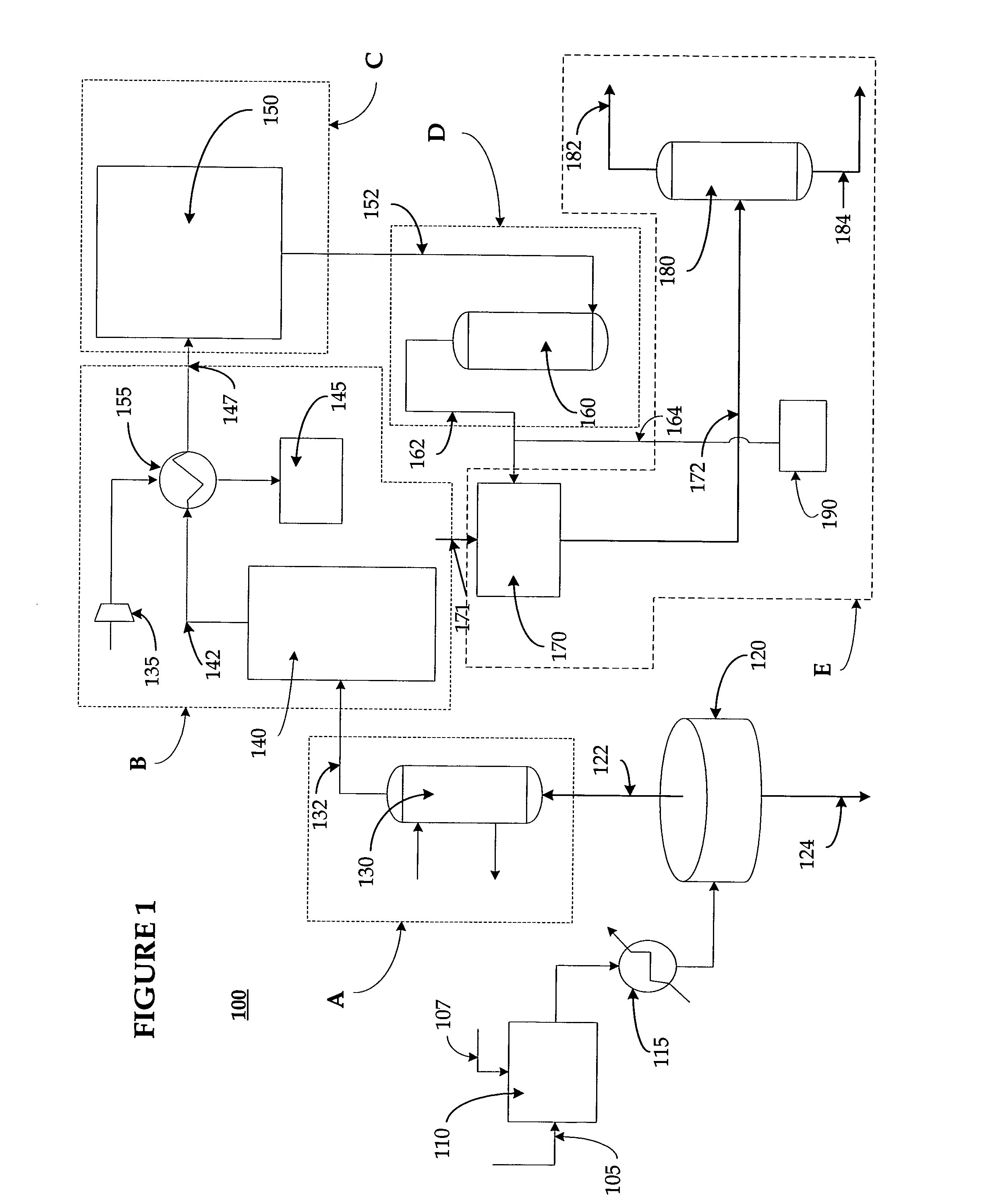

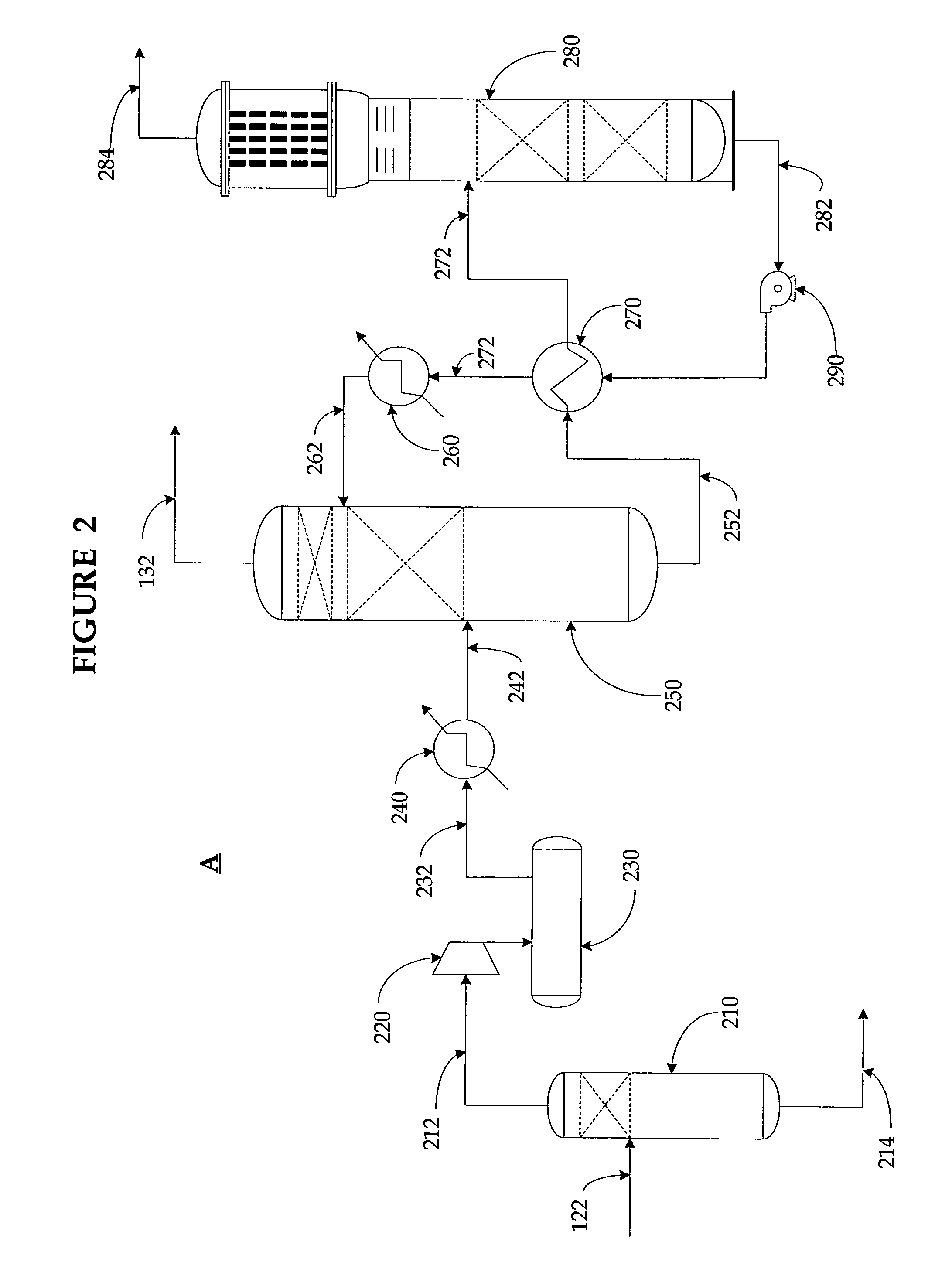

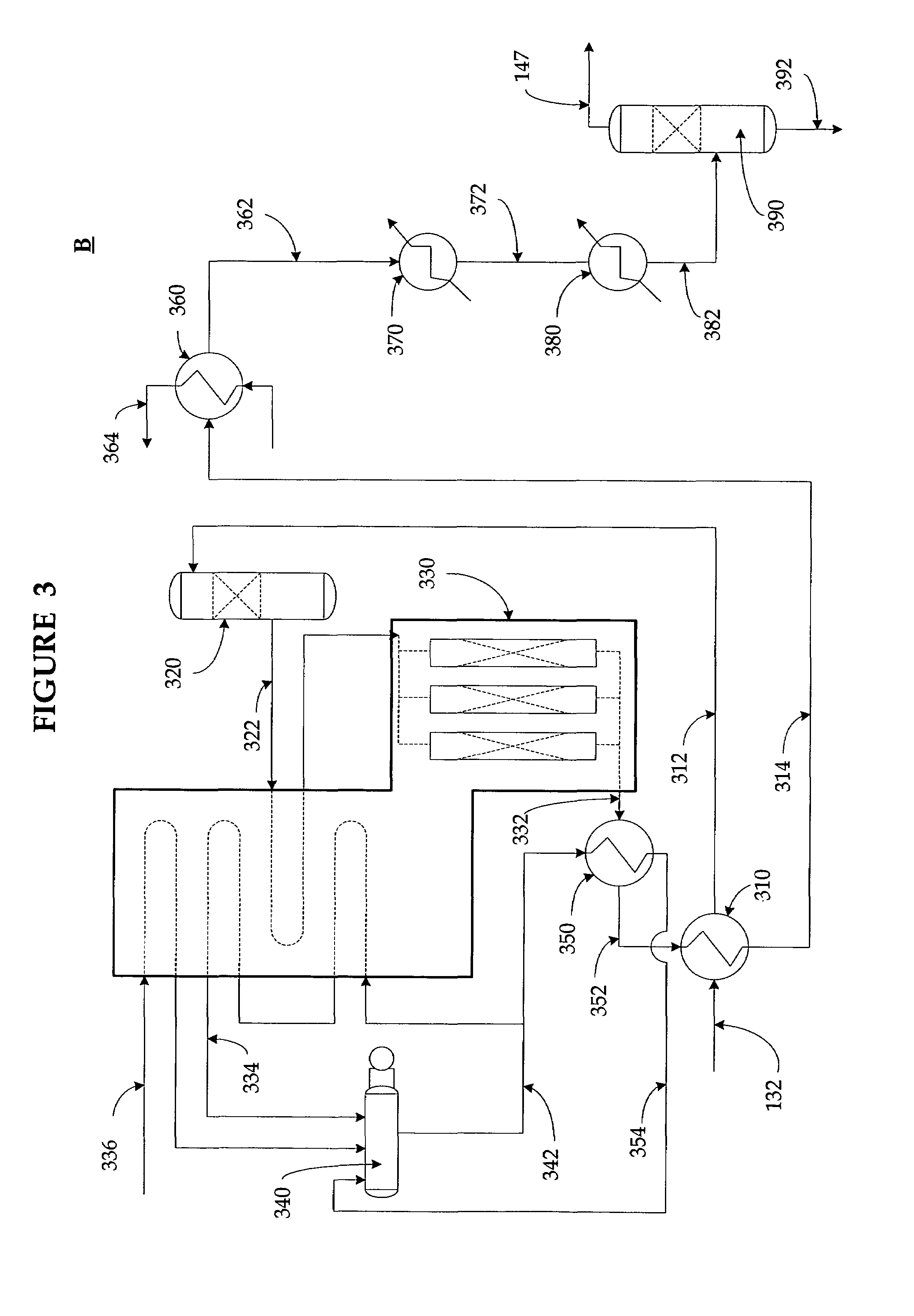

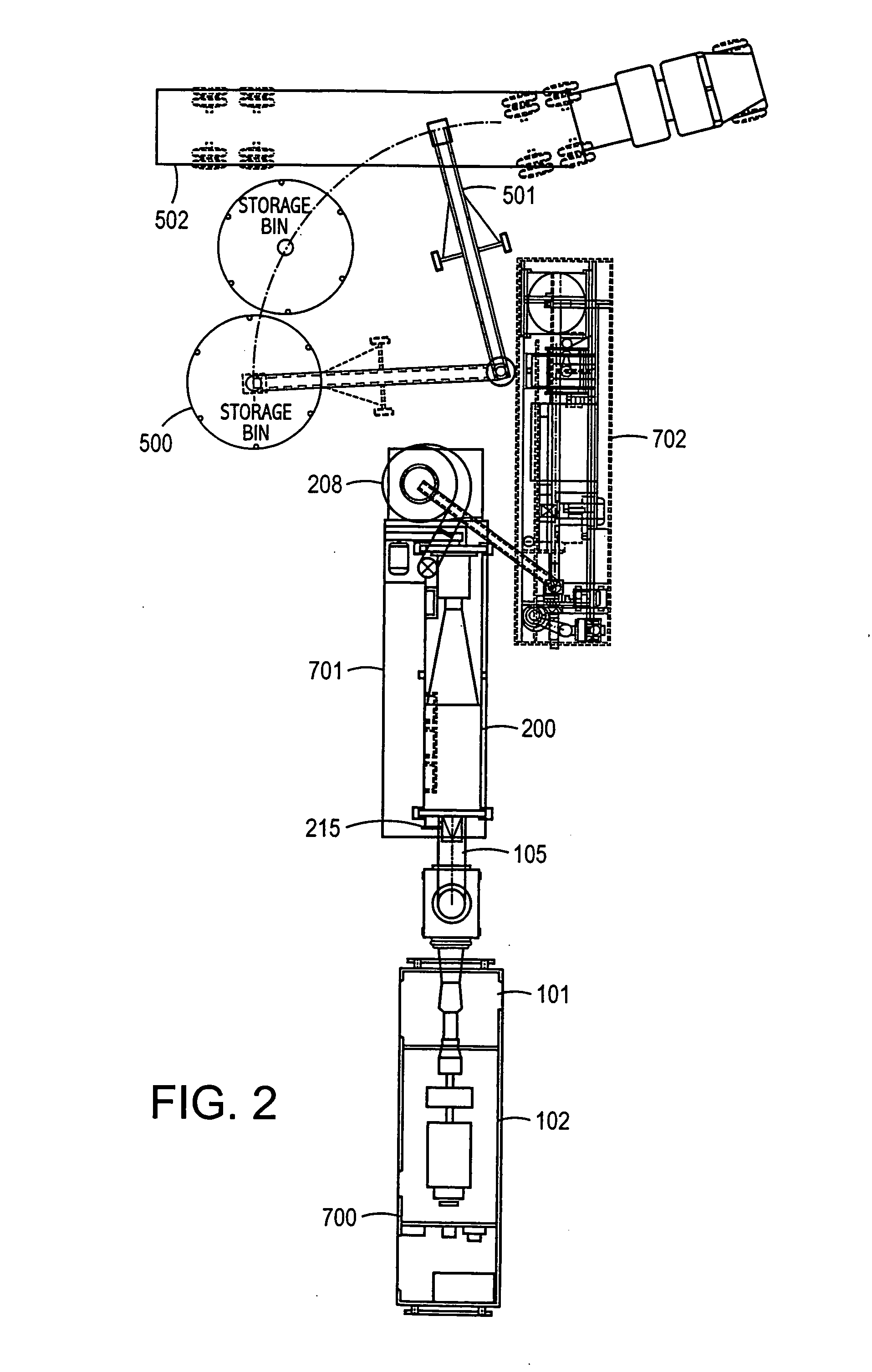

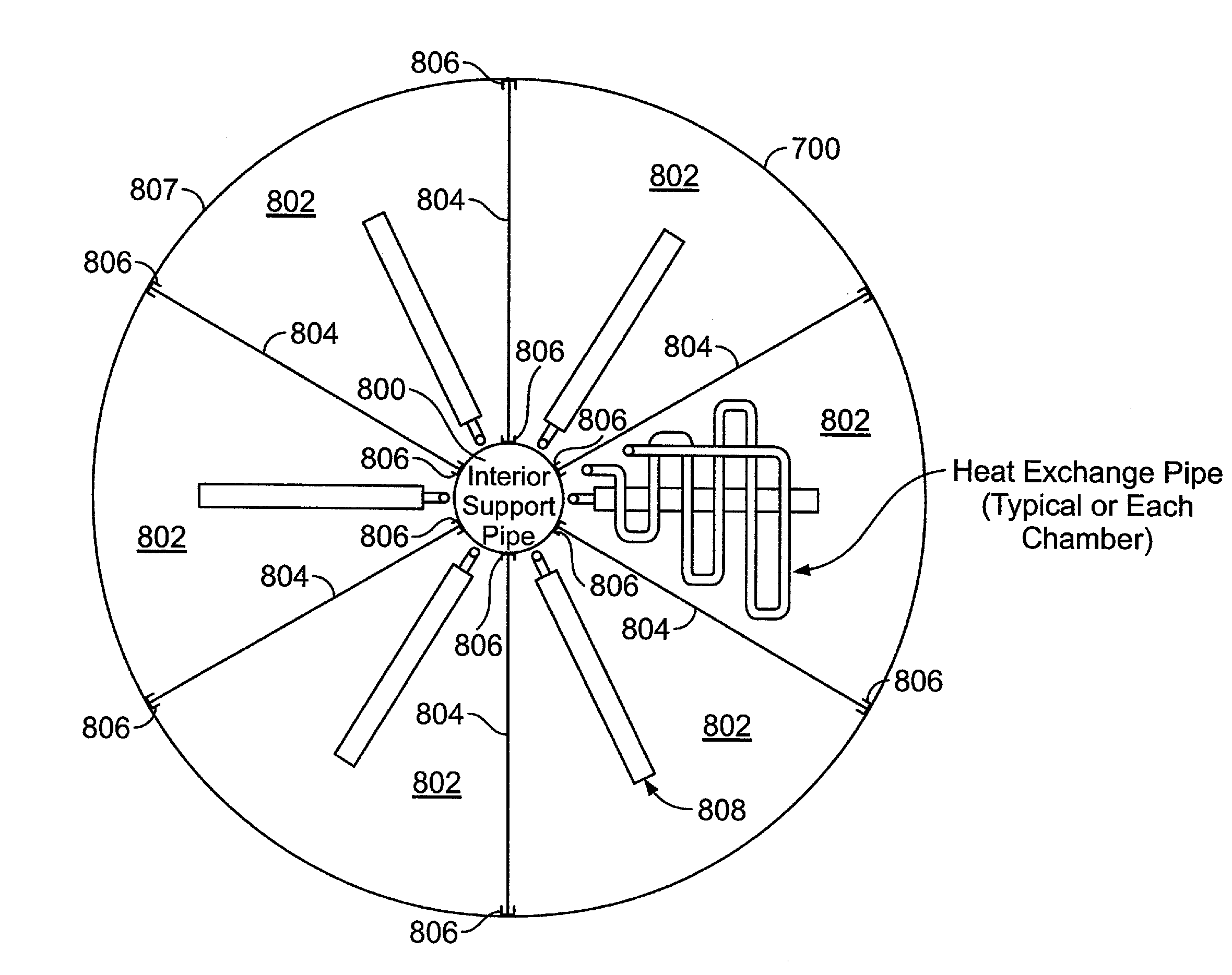

Conversion systems for biomass

ActiveUS20100064746A1Efficient and economical and convenient to moveEasy to transportBio-organic fraction processingBiofuelsBiomass transportationPetroleum

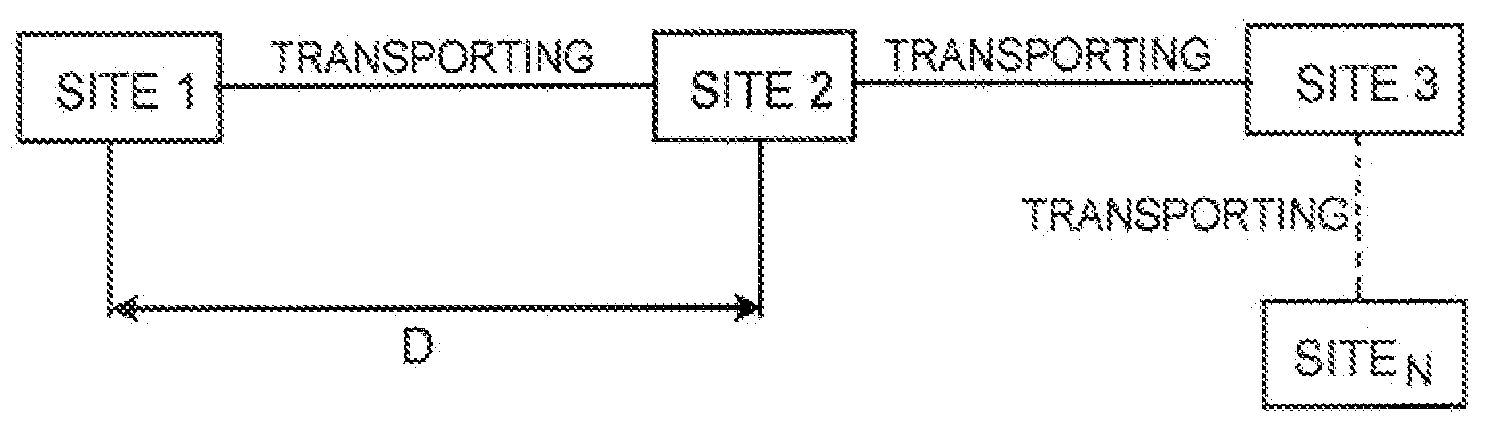

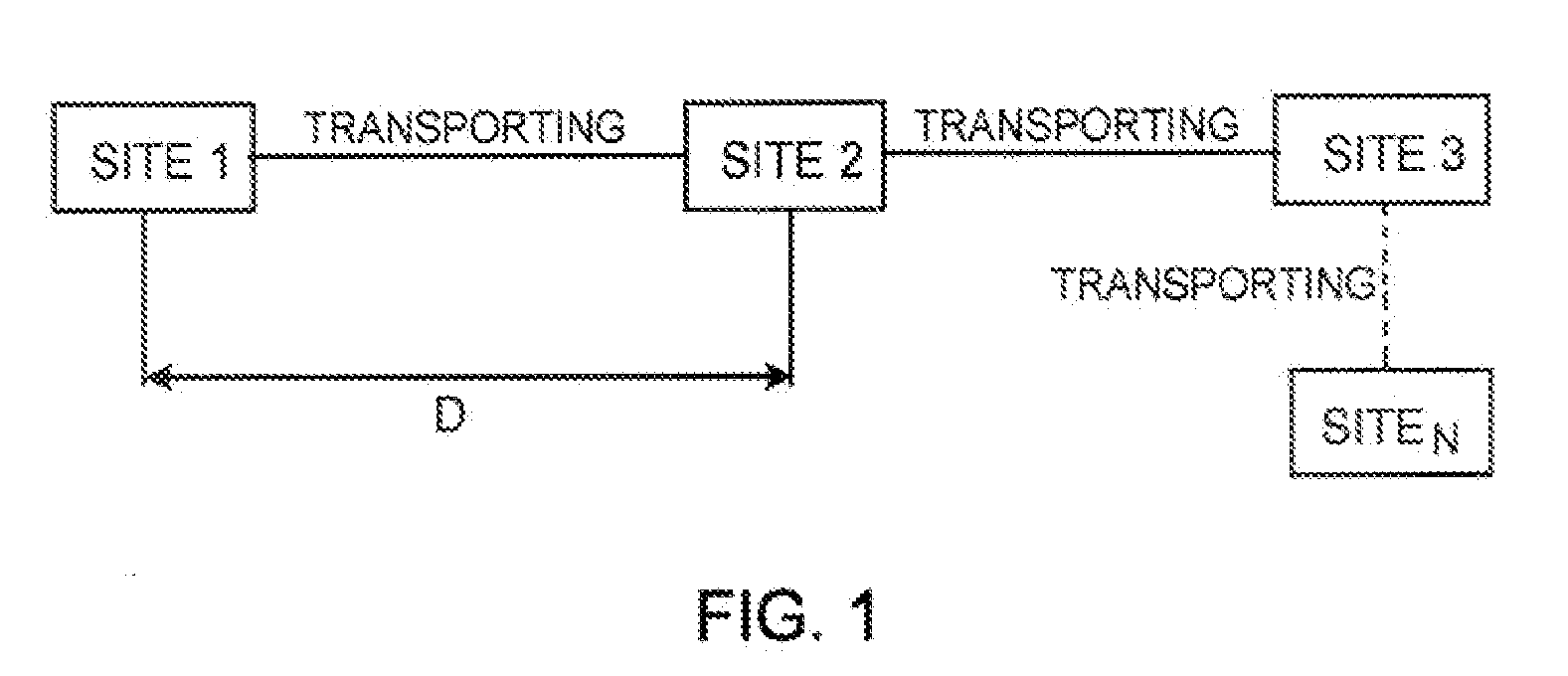

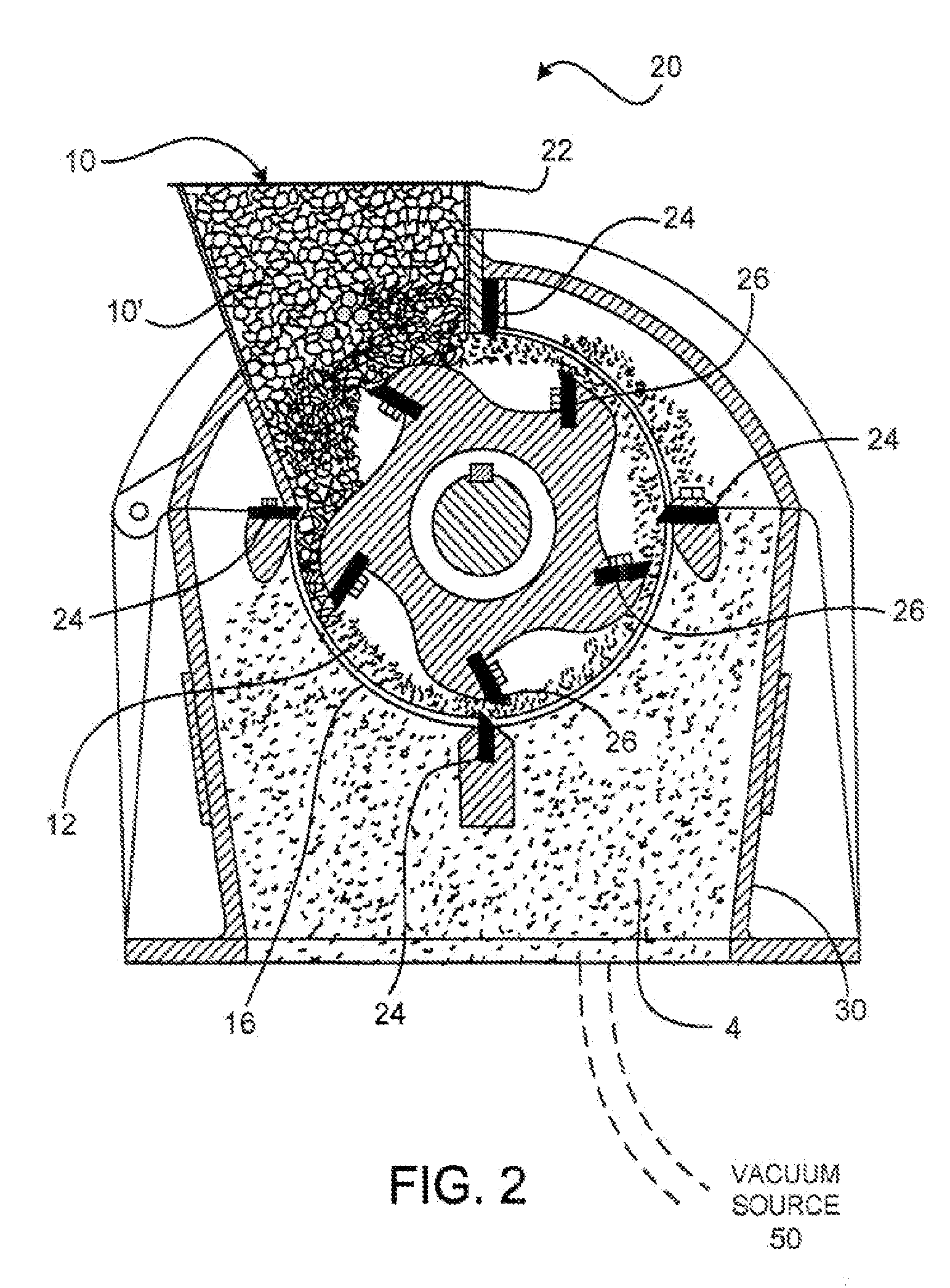

The efficient production of ethanol from low-cost biomass (e.g., corn, sugar beets, sugar cane, switchgrass and / or paper) has become increasingly important in making ethanol competitive with gasoline and decreasing the United States' dependence on foreign oil. For example, to reduce the cost of transporting biomass to ethanol production facilities, mobile systems for producing ethanol from biomass are provided. Also provided are small-scale ethanol production facilities. For example, instead of transporting biomass to the production facility, the facility is transported to the biomass or is located nearby the source of the biomass. The ethanol production facilities or components thereof may be transported via land, water, or air. Production of other products, such as hydrocarbons, natural gas, hydrogen gas, plastics, polymers, and proteins, can also be made by the methods and facilities. Any product described herein can be made in finished form or un-finished form and moved, e.g., to a fixed facility, e.g., fixed production facility.

Owner:XYLECO INC

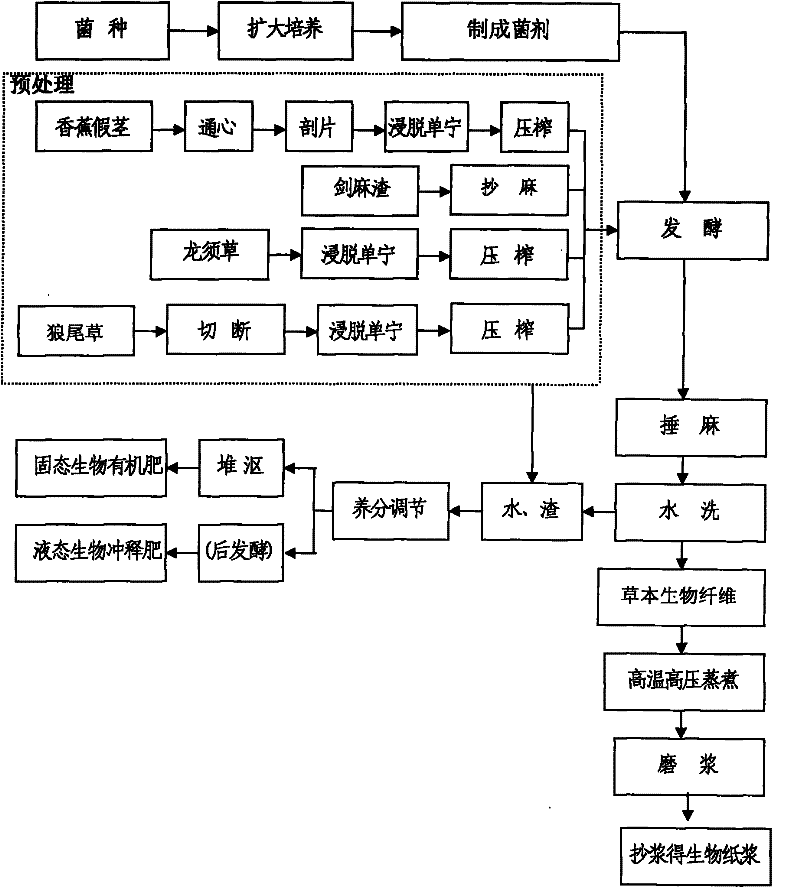

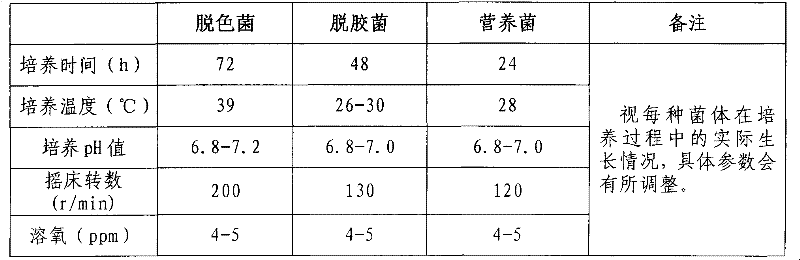

Method for preparing herbal biological fiber and biological paper pulp

InactiveCN102174399AOvercome color differenceOvercome resilienceFungiBio-organic fraction processingFiberWastewater

The invention discloses a method for preparing a herbal biological fiber and biological paper pulp, and the used microbial composite agent and a preparation method thereof. The biological fiber is prepared through pretreatment of a herbal raw material, biological degumming fermentation, and subsequent mechanical treatment of a fermentation product. The composite agent comprises degumming bacteria, nutrition bacteria and decolorizing bacteria, and various strains are synergistic without antagonistic reaction. In the method for preparing the biological fiber and the biological paper pulp, a chemical additive is not needed at all, but the high-cellulose and hemicellulose biological fiber and the biological paper pulp can be industrially produced; decolorization is complete, and the produced biological fiber and biological paper pulp have white color; a bleaching process is avoided, so investment in decolorizing production equipment is saved, and fiber extracting and pulping investment cost can be effectively reduced; in addition, waste gas and waste water are not generated in the fiber extracting and pulping process, inorganic pollutants are not generated, waste water and waste residues produced in each process step can be produced and converted into a biological fertilizer, and water is recycled.

Owner:GUANGXI SAIER PAPER IND

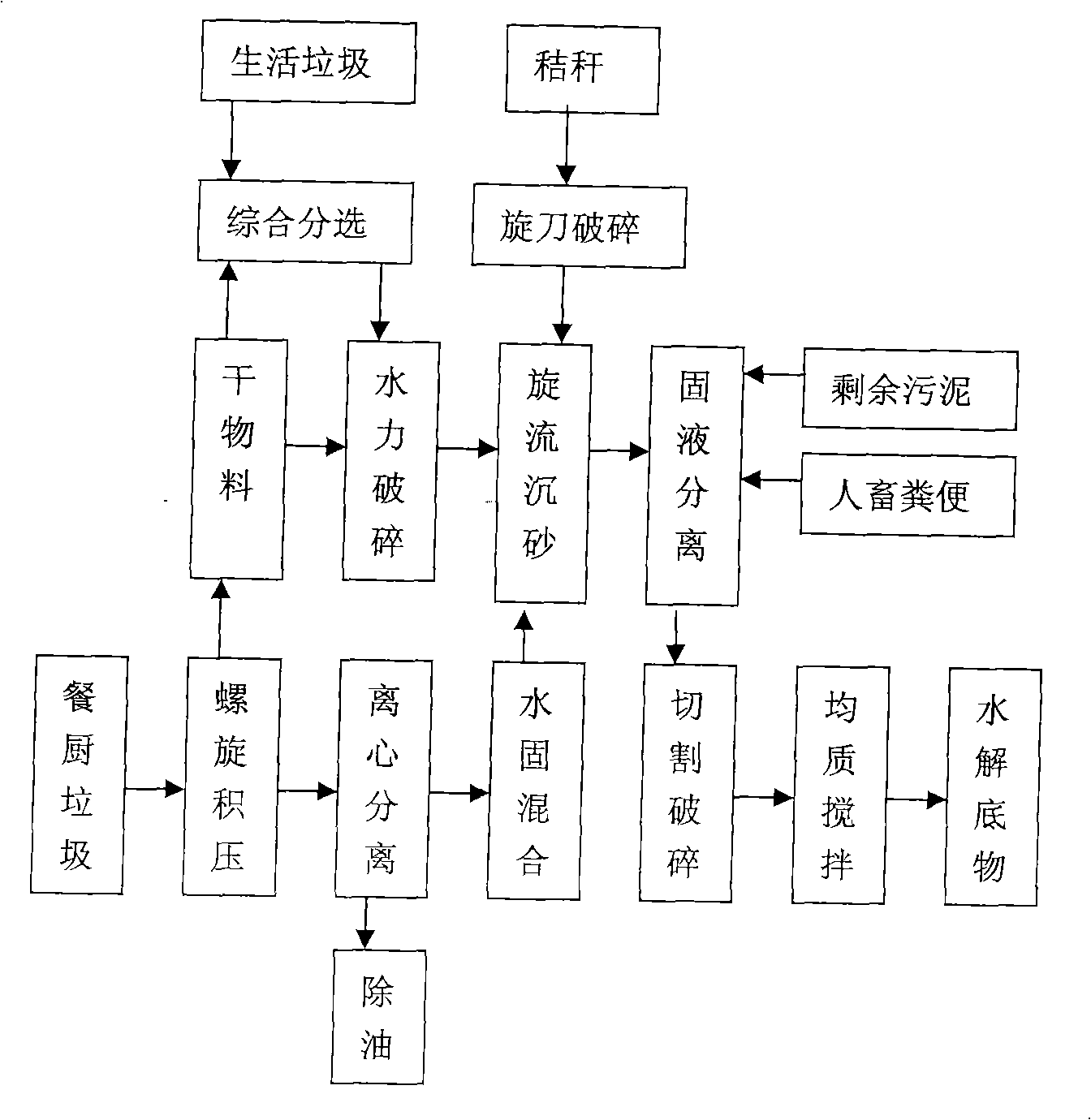

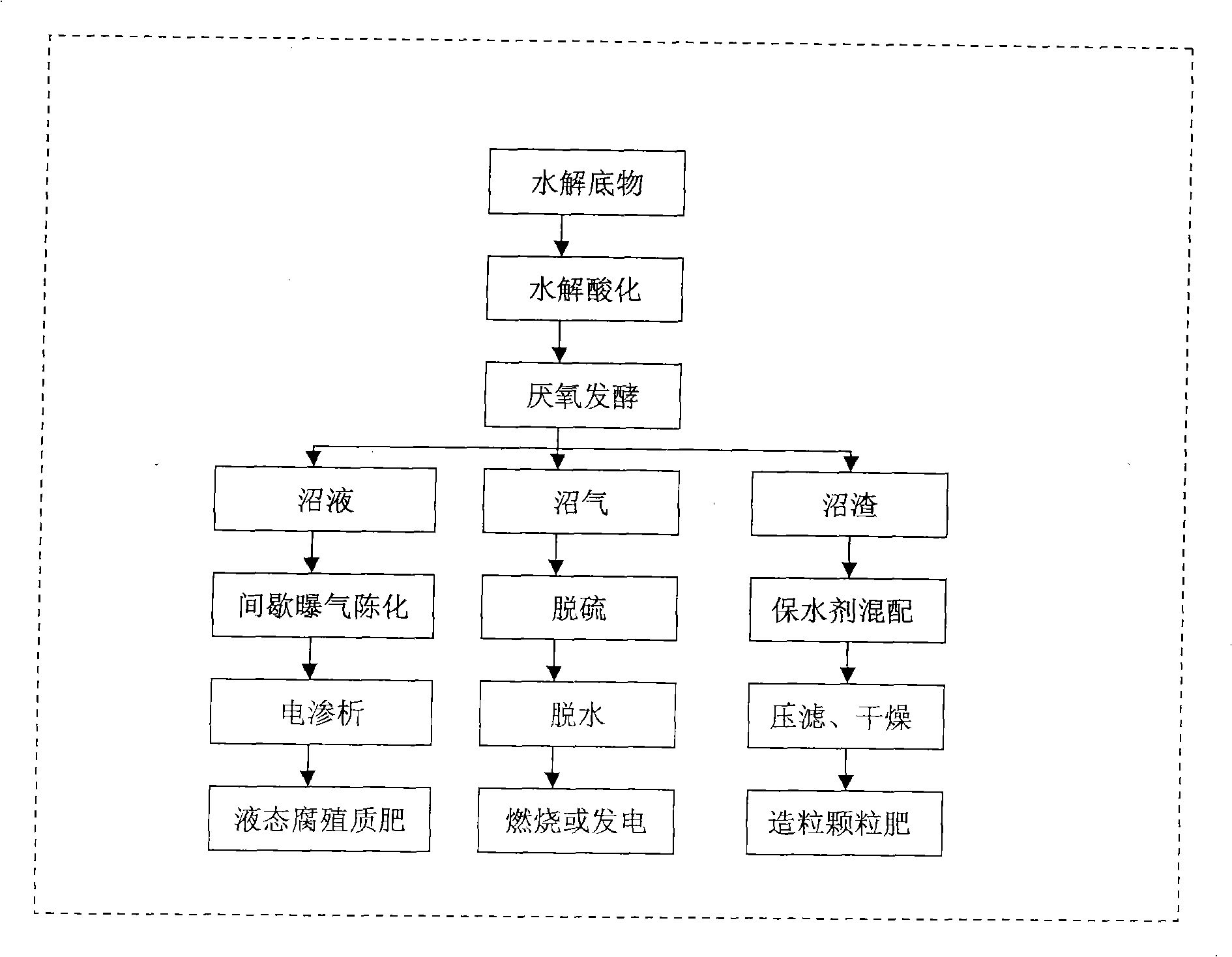

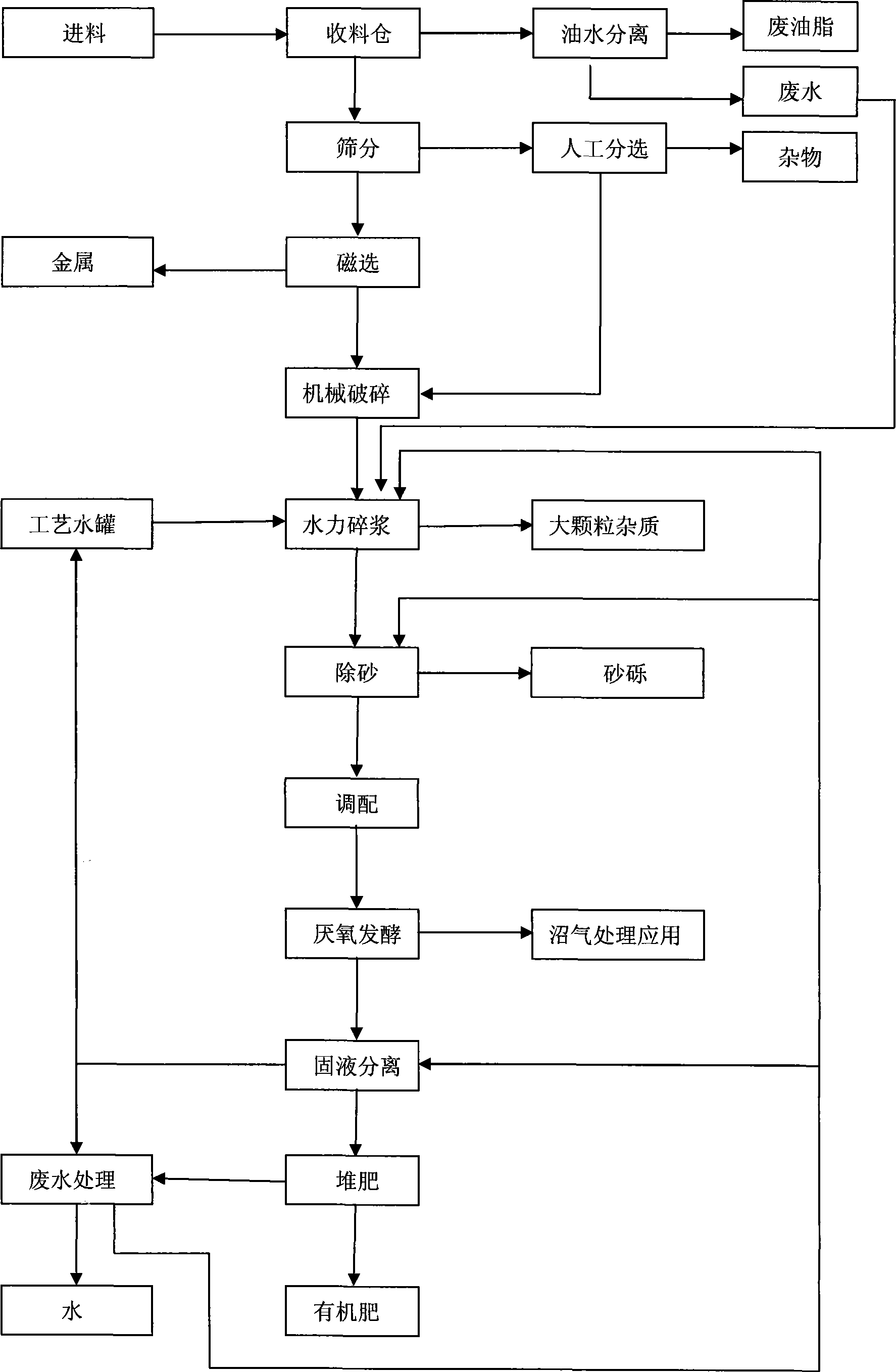

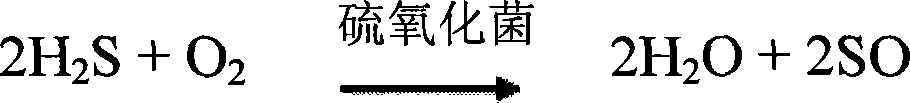

Combined anaerobic fermentation process for organic solid wastes

InactiveCN101337838AReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

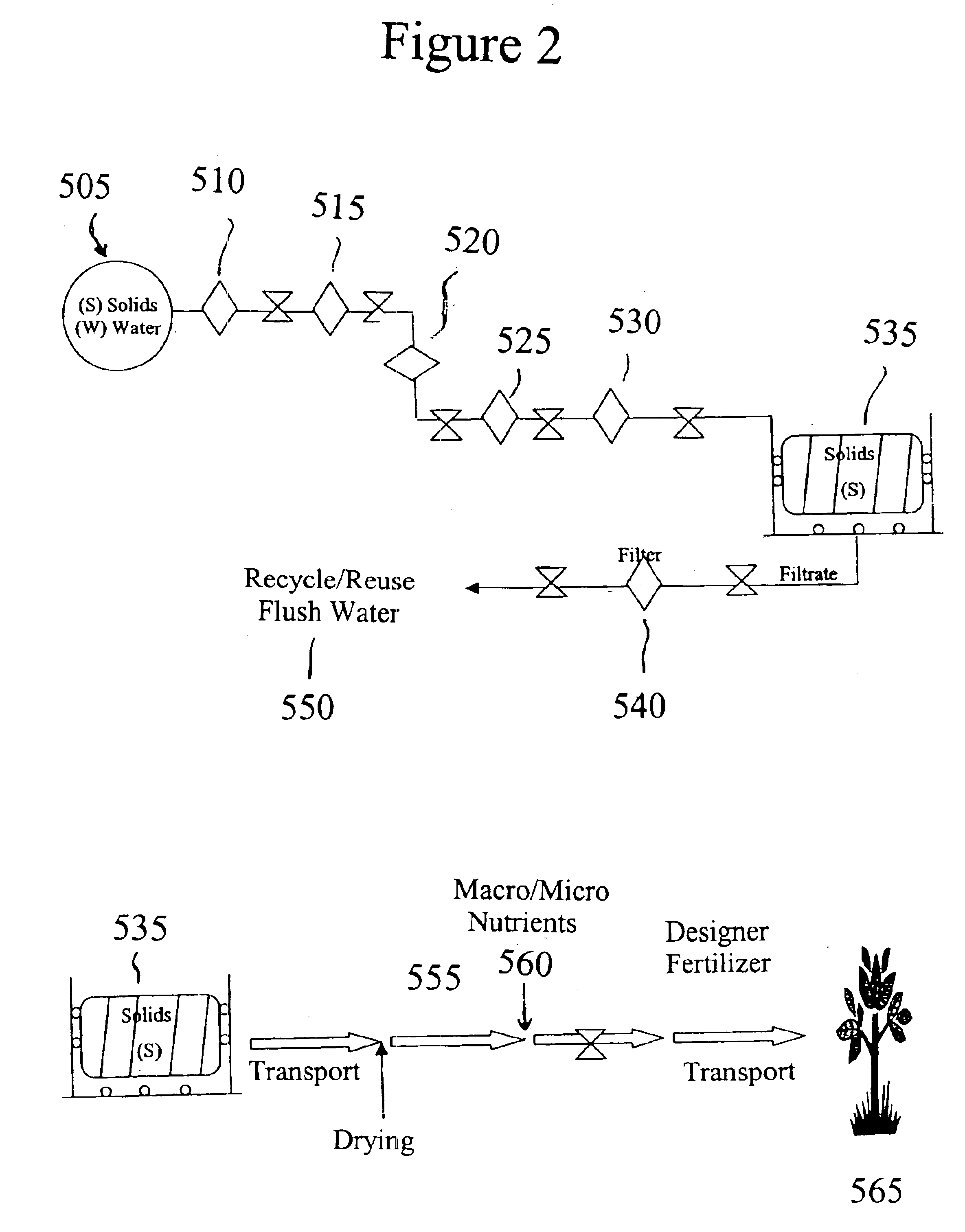

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS20060010712A1Drying using combination processesBio-organic fraction processingOrganic farmingSewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

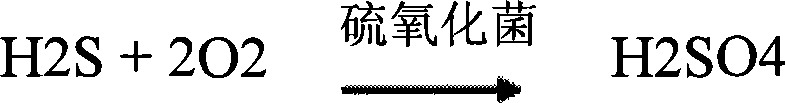

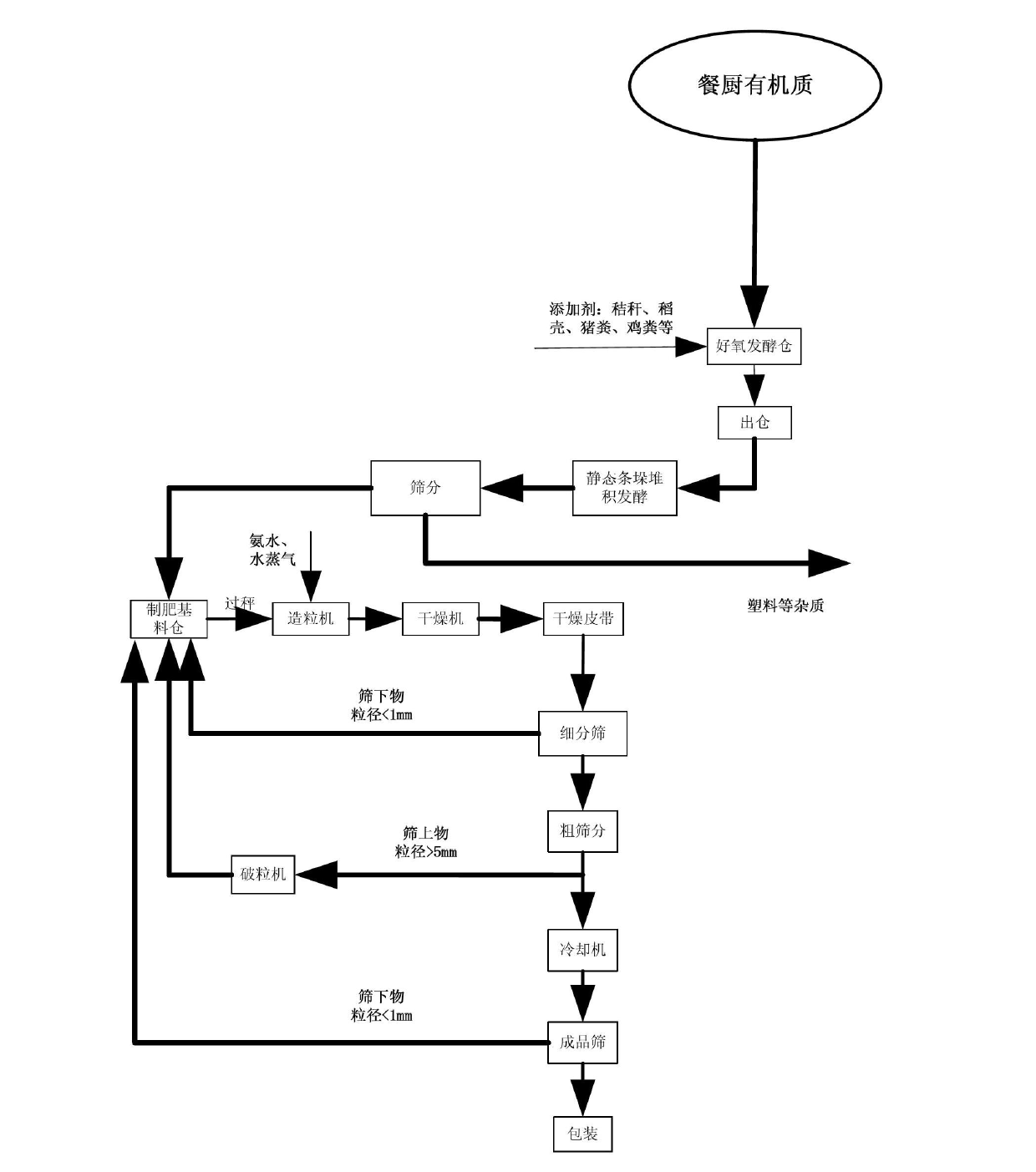

Anaerobic digestion handling method for restaurant garbage

ActiveCN101224999AHarmlessRealize resource processingBio-organic fraction processingClimate change adaptationSlurryOxygen

The invention provides a method for resourceful treatment of restaurant garbage, which is characterized in that the restaurant garbage is completely degraded after treatment with the working procedures of oil separating, preliminary selecting, mechanical crushing, hydraulic pulping, slurry blending, anaerobic fermentation and oxygen-control composting, finally the marsh gas is decomposed via anaerobic digestion and is utilized as energy after desulfurization treatment; the high-quality organic manure is produced from the biogas residues via oxygen-control composting; the separated oil can be recycled as the regenerated industrial raw oil; the wastewater generated in the treatment process can be recycled, and finally the redundant wastewater reaching the standard is discharged after biochemical treatment; and the odor generated by the garbage in the treatment process is directly discharged after reaching the standard via biofiltration treatment, thus the restaurant garbage can be transformed into the clean regenerated energy of electric power and the pollution-free organic manure to completely realize resourceful treatment of restaurant garbage. The resourceful treatment of restaurant garbage has the advantages of innocuity, no peculiar smell, no secondary pollution during the treatment process and realization of harmless and resourceful treatment of restaurant garbage.

Owner:宝林

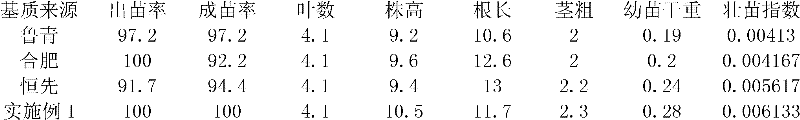

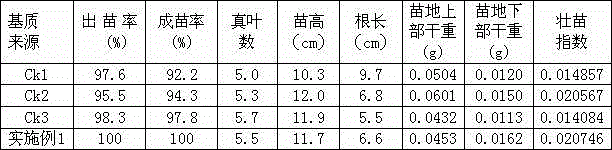

Seedling substrate for soilless culture for vegetables

ActiveCN102432394AHigh in potassiumRich in trace elementsBio-organic fraction processingAgriculture gas emission reductionPorosityBiology

The invention discloses a seedling substrate for vegetables, belonging to the technical field of soilless culture. The substrate formula comprises the following components based on volume ratios: 10-40% of fermented vinegar dreg, 5-30% of fermented cassava dreg, 5-30% of plant ash, 5-30% of perlite, 5-30% of vermiculite and 10-25% of turf. The water content of the substrate is not bigger than 50%, and the total porosity of the substrate is 65-95%, and the total nutrient content of the substrate (N+P2O5+K2O) is 3-5%, and the grain diameter of the substrate is 0.1-4.9 mm, and the volume weight of the substrate is 0.2-0.8 g / cm3, and the gas-water ratio of the substrate is 1: 2-4, and the EC (elastic coefficient) value of the substrate is 1-3 and the pH value of the substrate is 5.8-7.5. The seedling substrate for soilless culture for vegetables mainly uses organic wastes as raw materials, and produces seedling substrate by high temperature fermentation treatment, and changes wastes into wealth, and turns harm into good. The invention has a low production cost, a light weight and complete nutrients such that it is suitable for growth and development for vegetable seedlings, and is a good substrate for soilless culture industrialized tray seedling for vegetables.

Owner:江苏培蕾基质科技发展有限公司

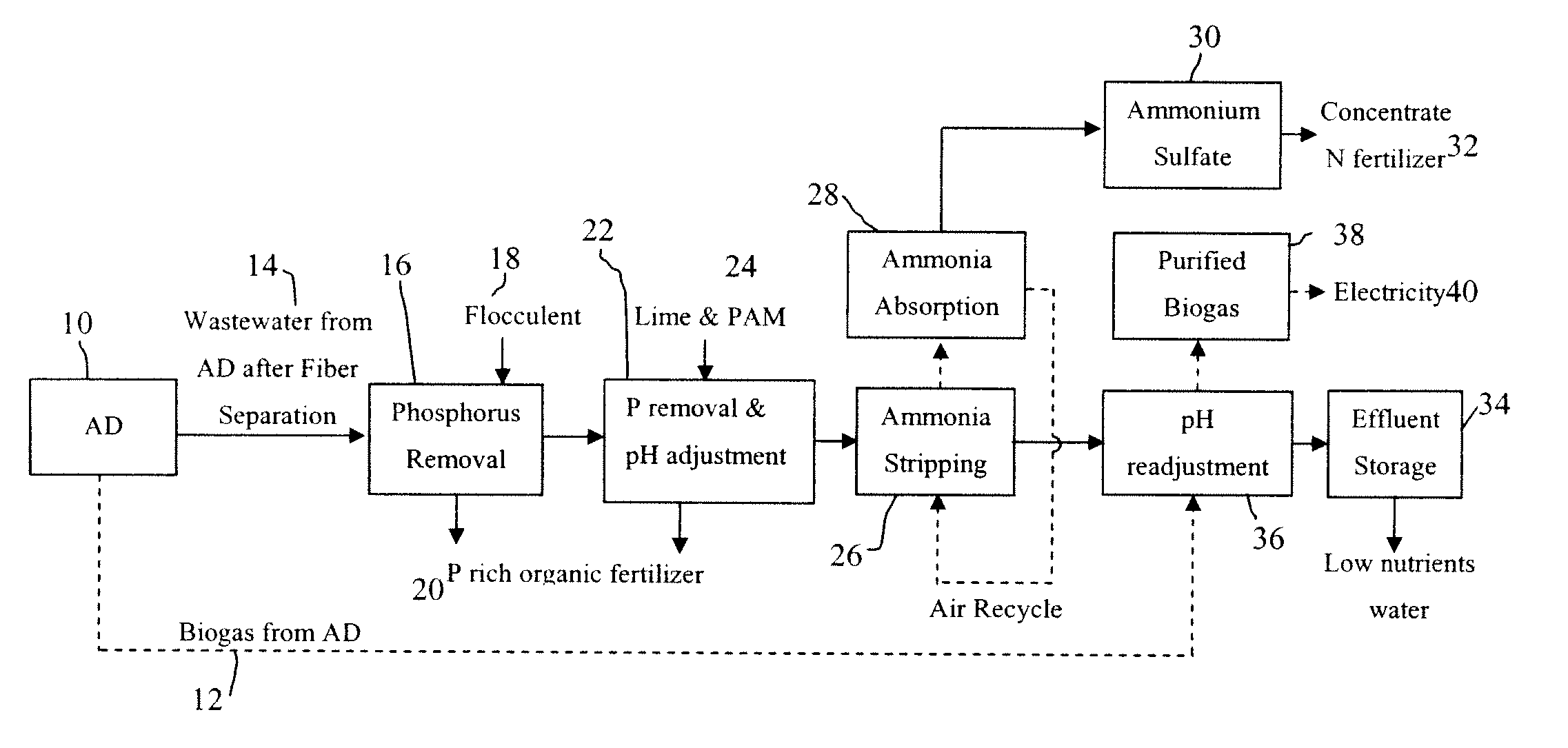

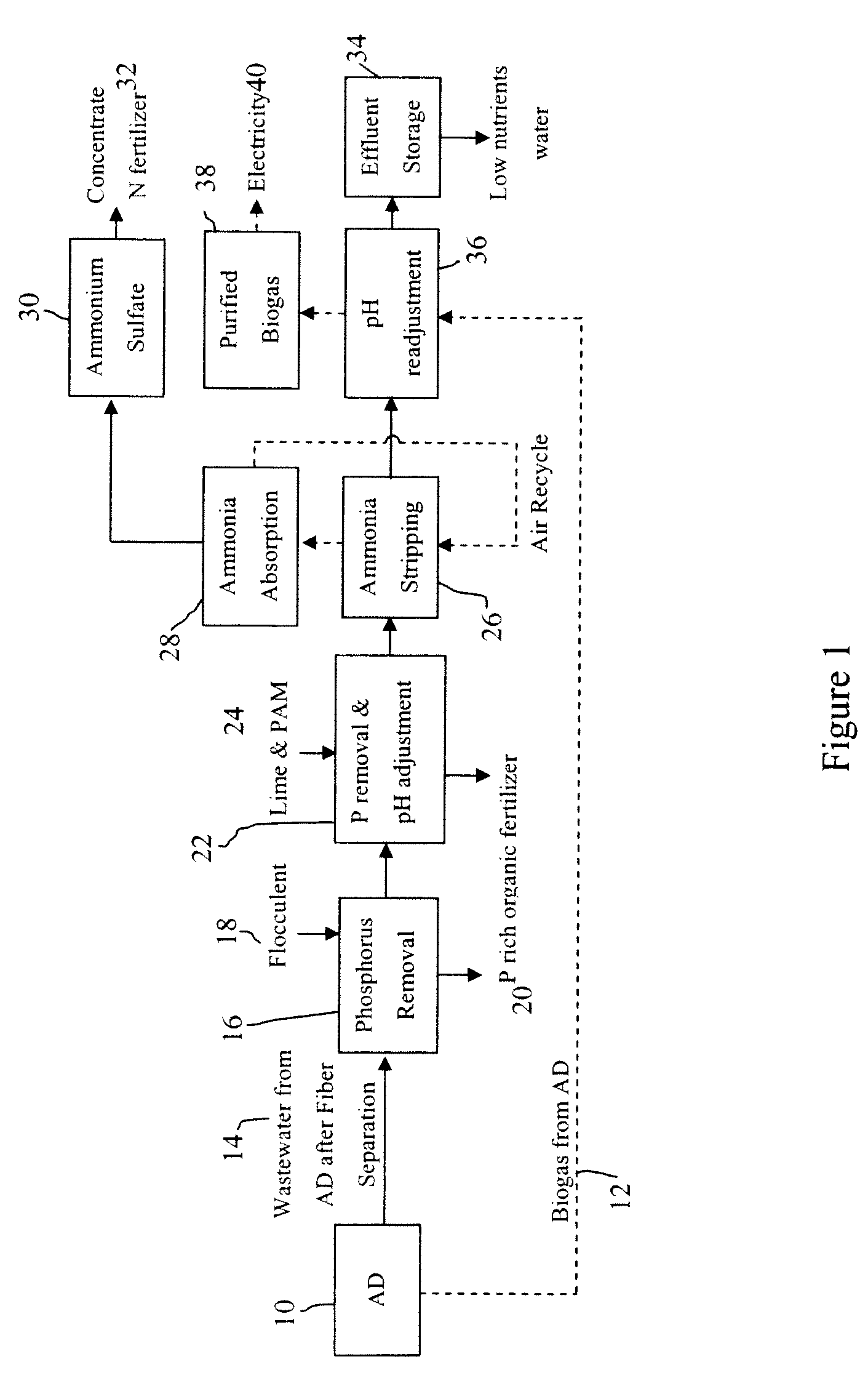

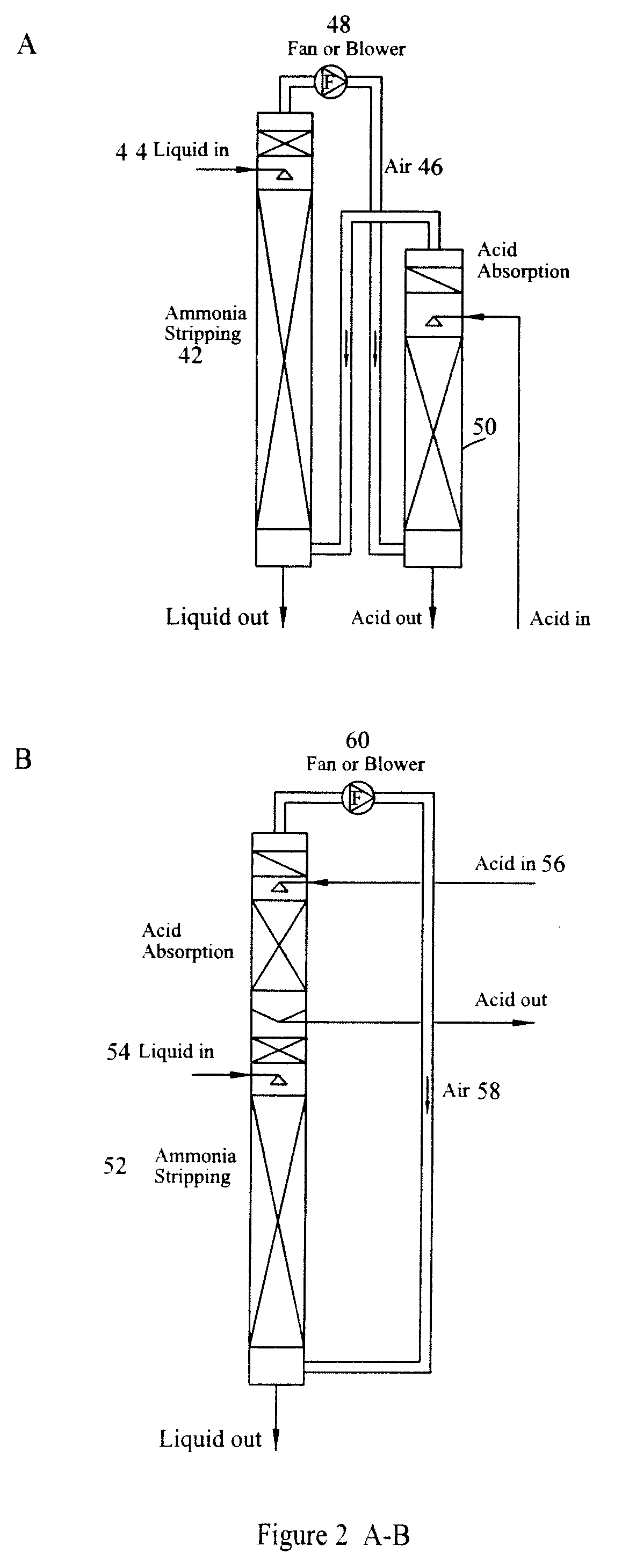

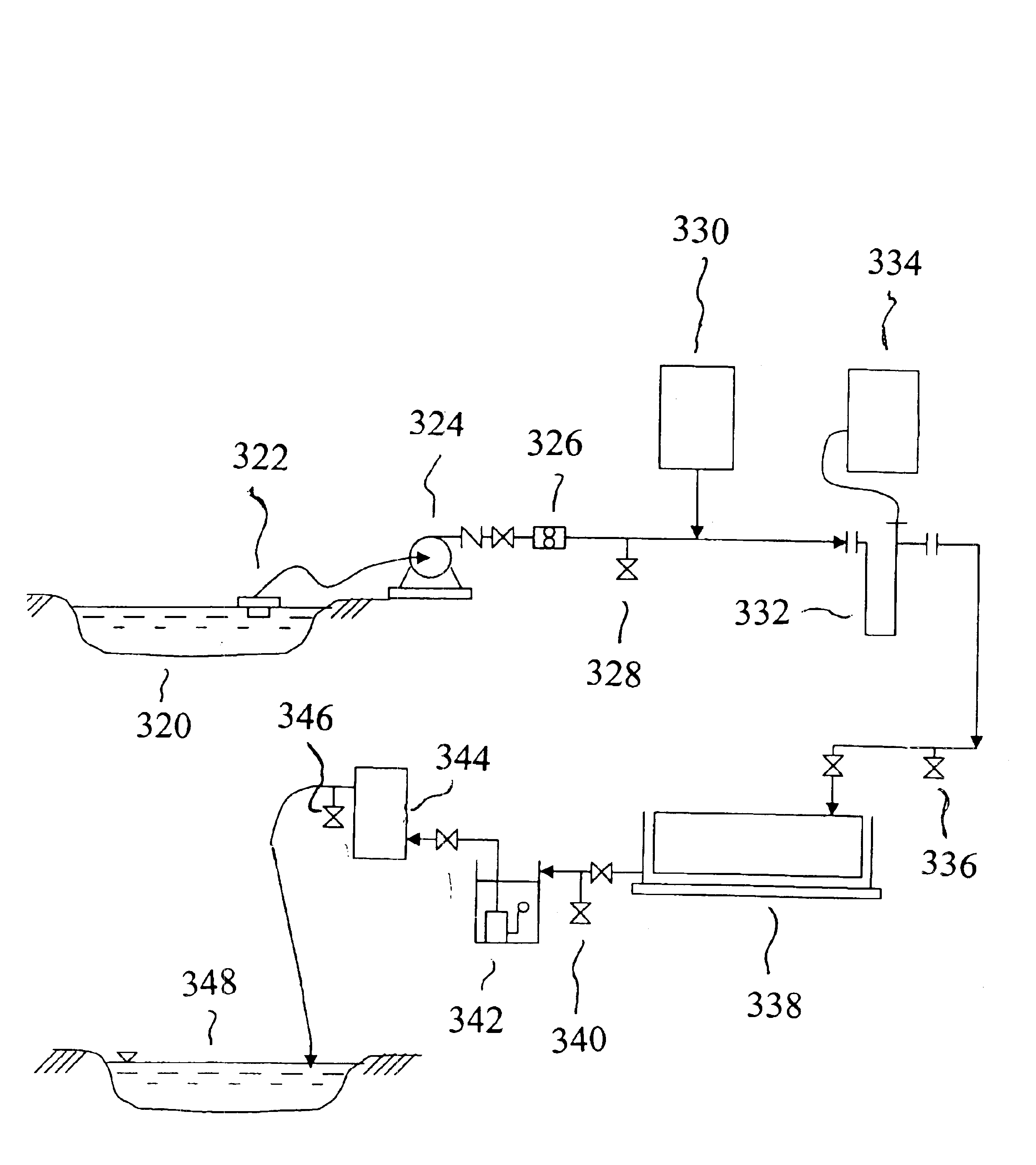

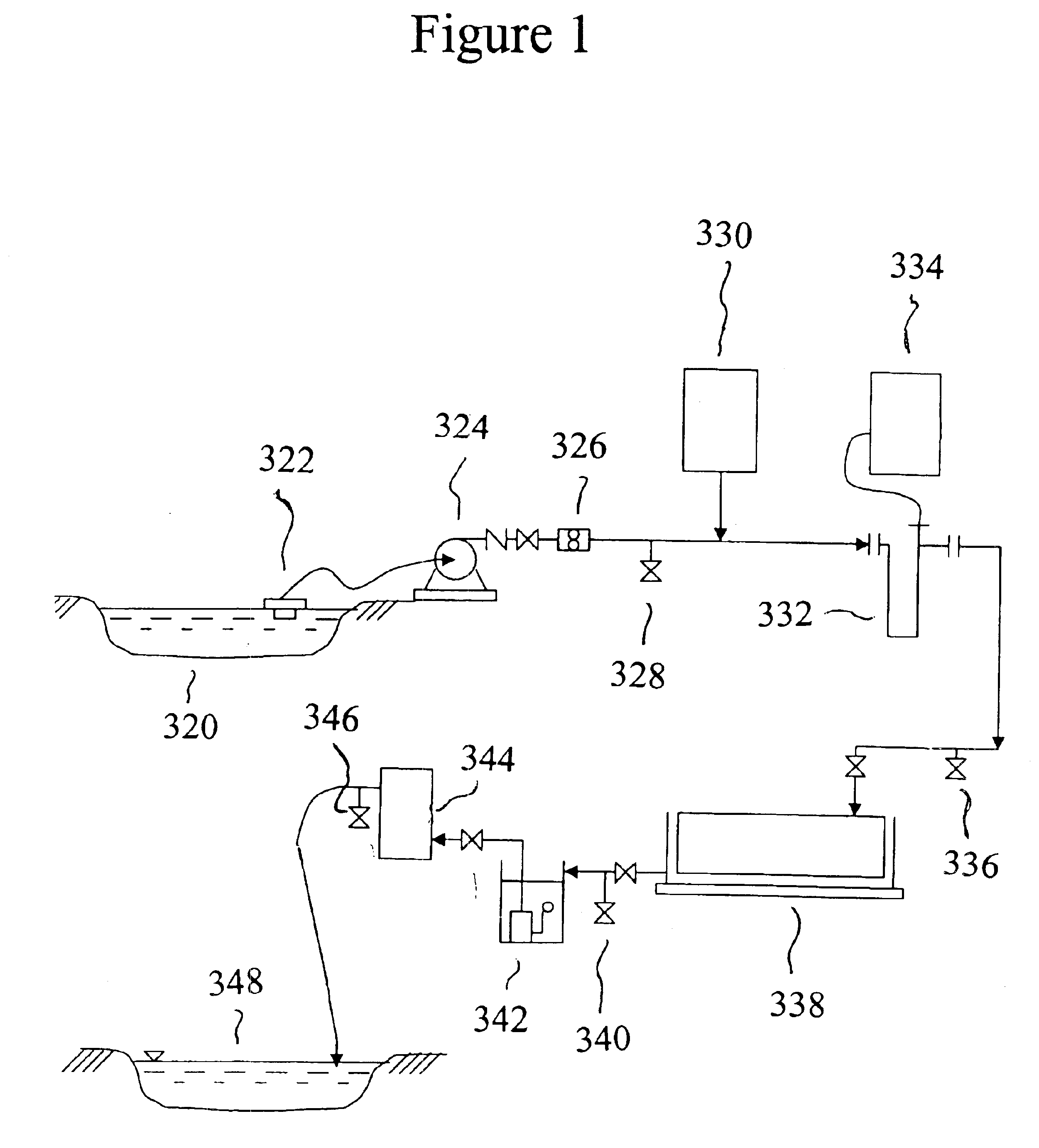

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

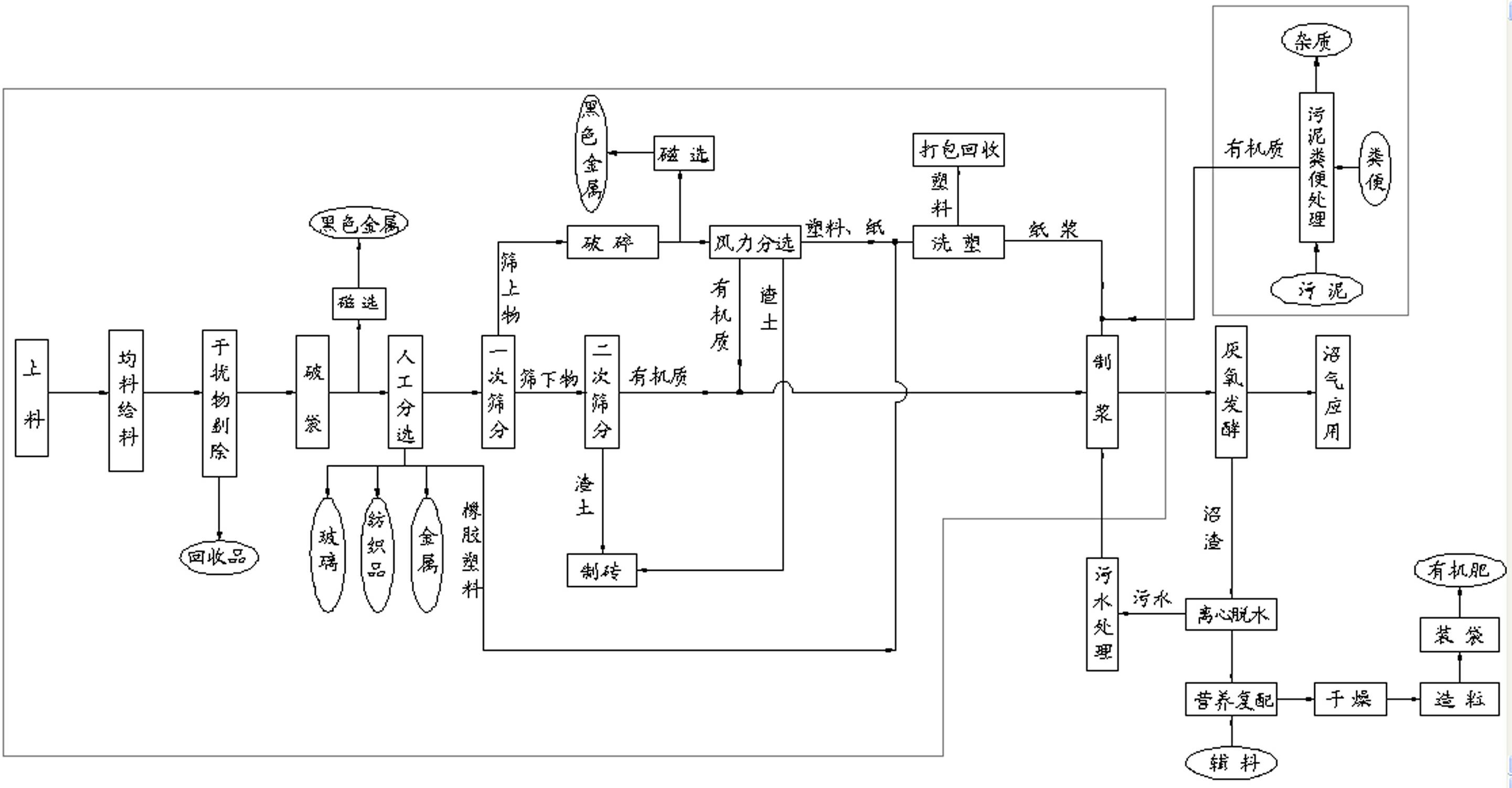

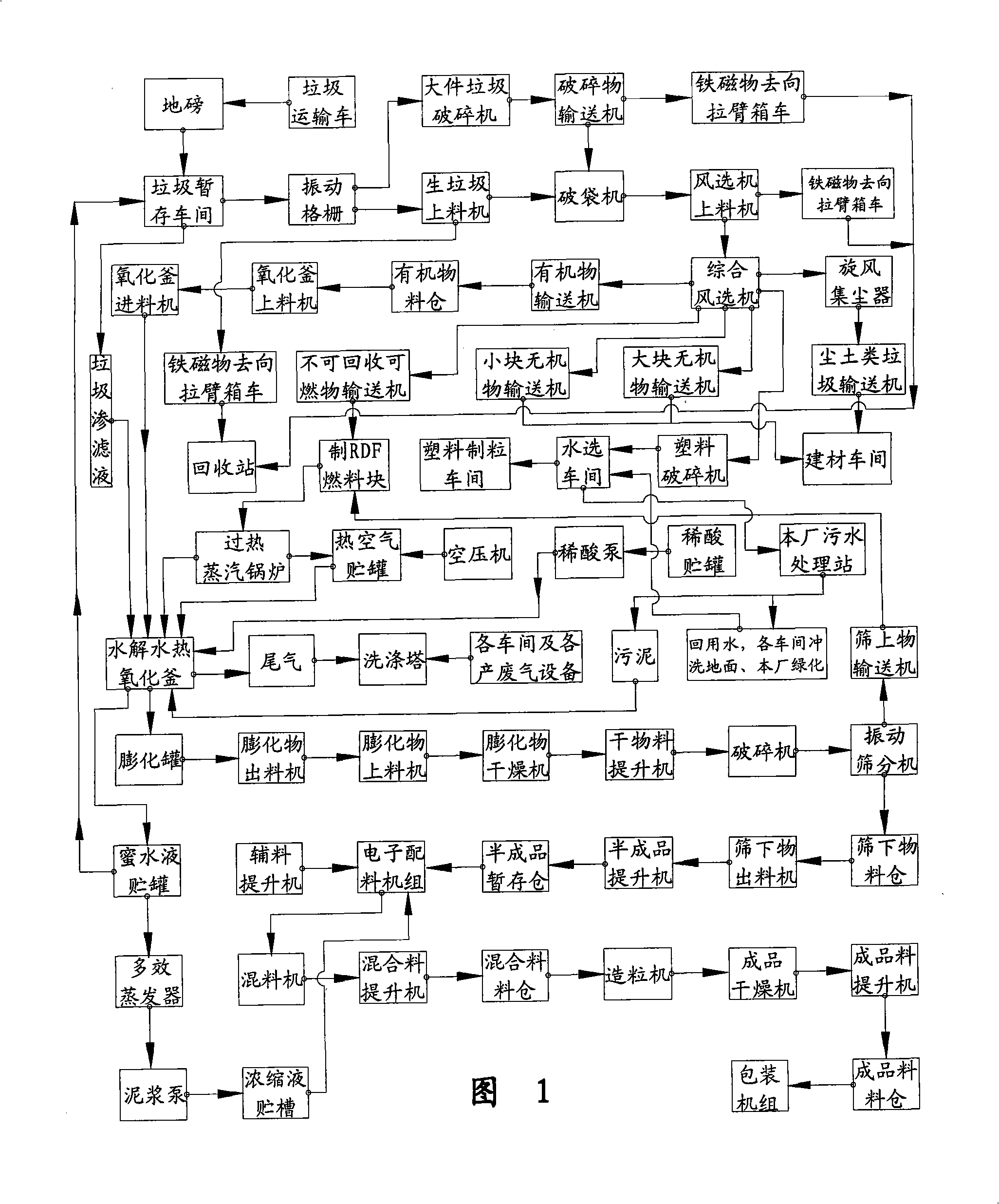

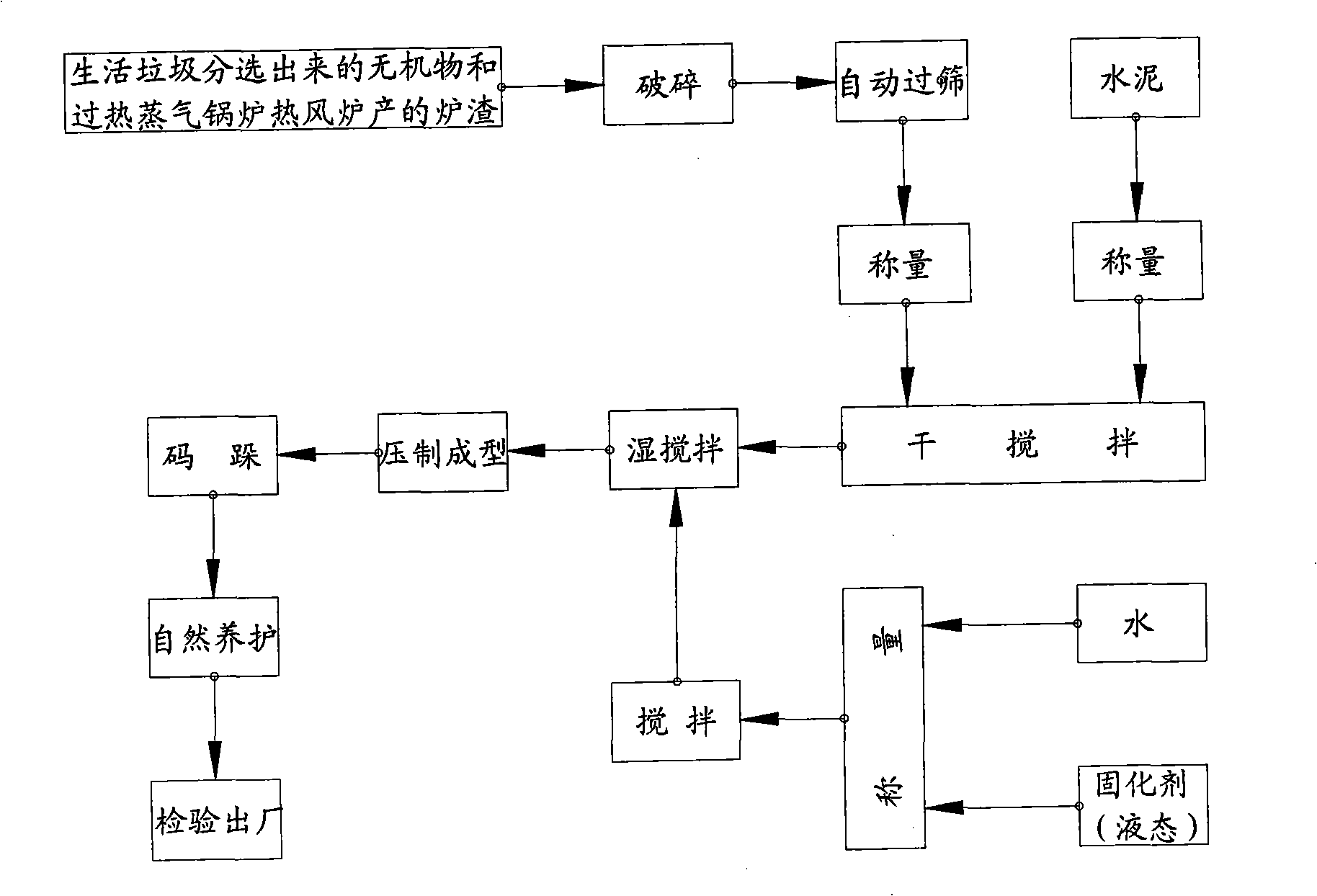

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

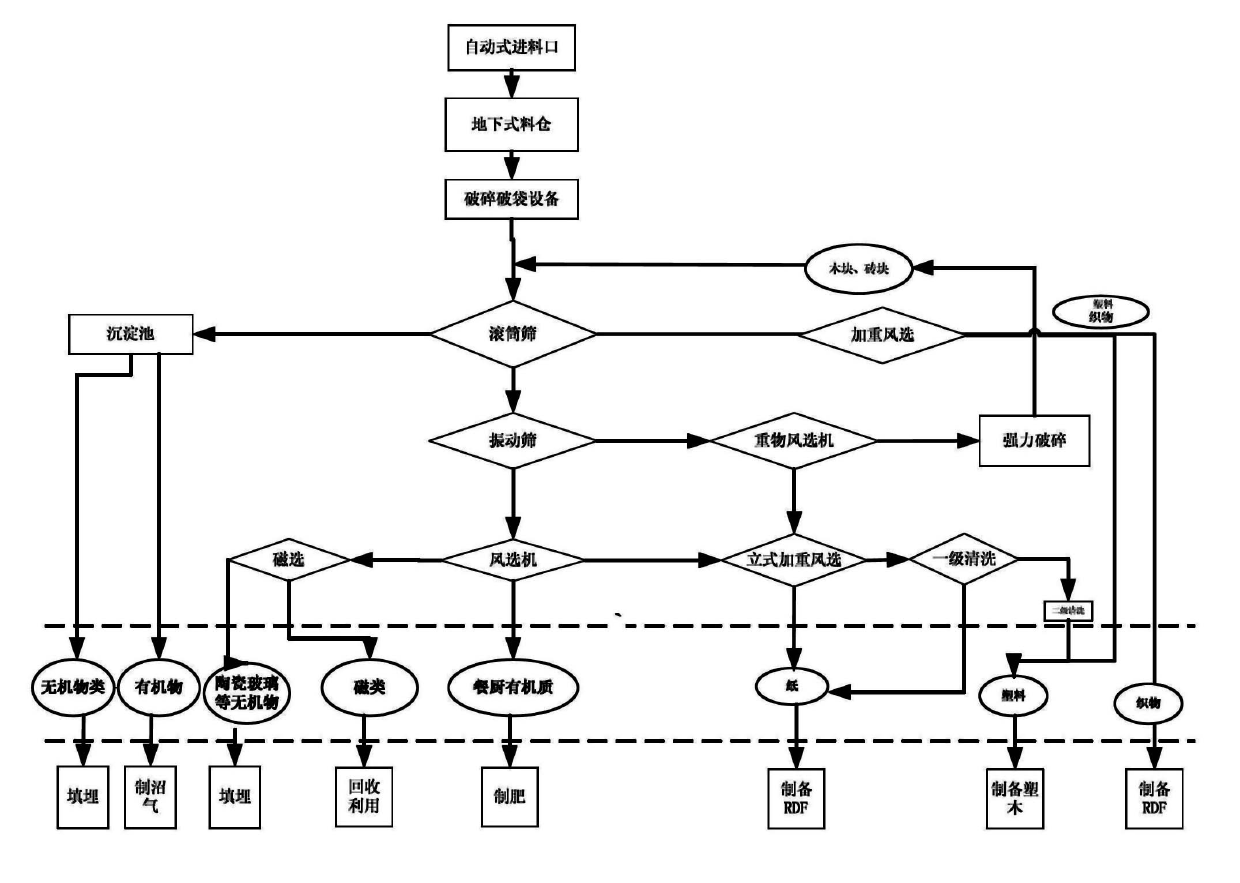

Method for sorting and comprehensively using urban mixed garbage

InactiveCN102671928AStructural innovationRealize full mechanizationBio-organic fraction processingSolid waste disposalRefuse-derived fuelPulp and paper industry

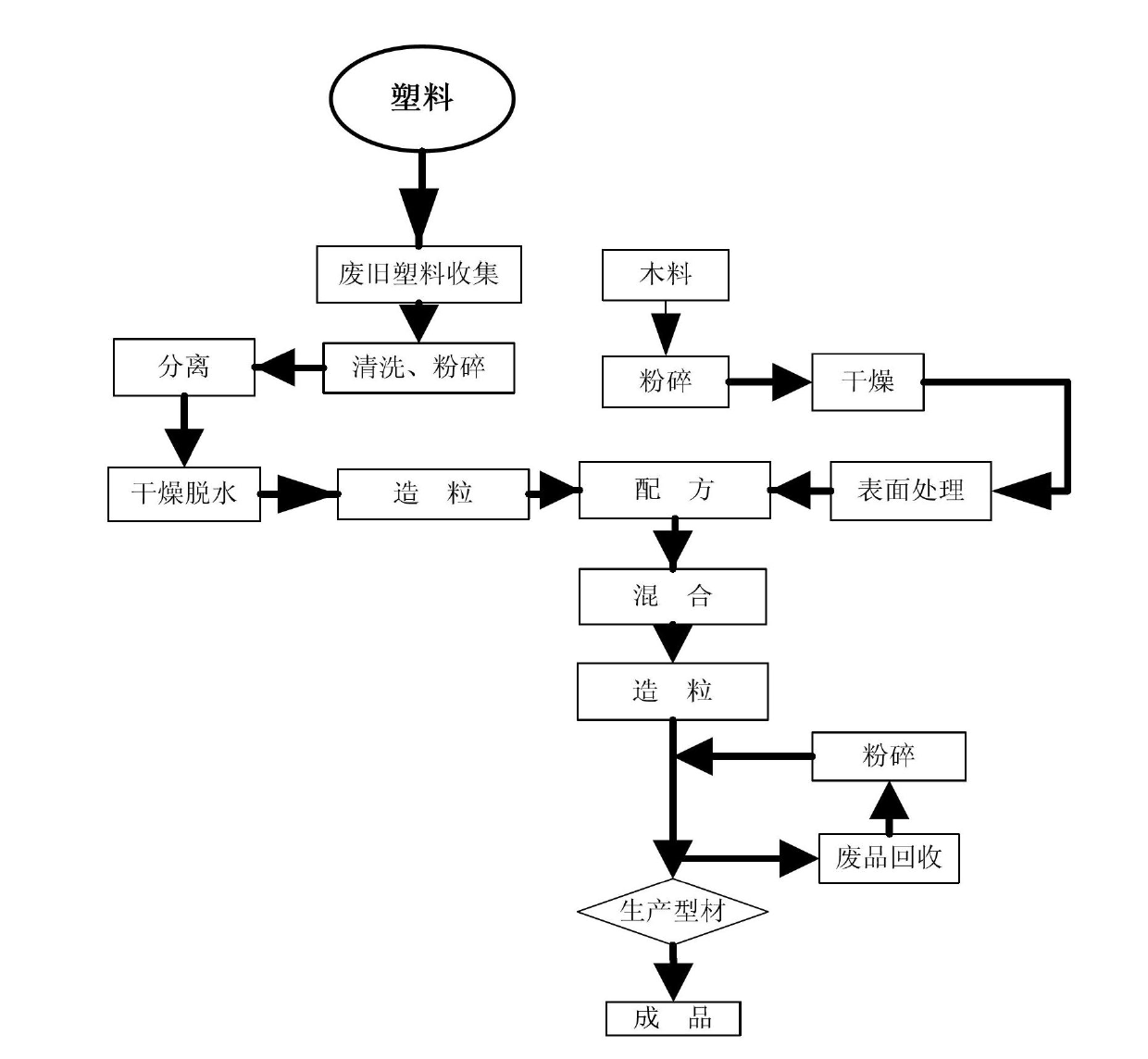

The invention discloses a method for sorting and comprehensively using urban mixed garbage. The method comprises the following steps: 1) allowing the urban mixed garbage to enter a feed bin through a feeding hole, discharging, and introducing into crushing and bag breaking equipment; 2) breaking garbage bags and crushing block garbage by using the crushing and bag breaking equipment; 3) feeding the garbage subjected to crushing and bag breaking into a two-stage rotary screen, screening out dust of which the grain size is less than 3mm, and picking out strip substances; and 4) feeding the mixed garbage into a vibration screen, separating inorganic cakes, large-sheet plastics and paper from an oversize material by using a heavy winnowing machine, and winnowing heavy substances, light substances and intermediate substances from an undersized material in a double-wind chamber multifunctional winnowing machine. Sorting equipment is effectively combined, so that the mixed garbage is efficiently sorted and recycled; and the sorted paper and textiles, plastics and kitchen organics are respectively used for preparing garbage derived fuel, plastic wood and fertilizers.

Owner:SICHUAN CRUN ENVIRONMENTAL PROTECTION ENERGY TECH CO LTD +1

Bio-organic fertilizer produced by using livestock manure

ActiveCN102219570ASimple structureImprove conversion rateBio-organic fraction processingFungiLivestock manureAgricultural science

The invention provides an efficient active bio-organic fertilizer produced by using livestock manure and a preparation method thereof. The preparation method comprises the following steps: pre-treating the livestock manure, straw and peat; mixing the livestock manure, straw and peat at a weight ratio of (3-5):(1-2):(1-2); adding a composite ageing bactericide based on the condition that the weight ratio of the mixture to the high-concentrated organic material ageing bactericide is (5000-10000):(1-2), evenly mixing, and then carrying out composting fermentation for 7-10 days, wherein during the composting fermentation, the material needs to be stirred 1-2 times each day; and mixing the material decayed by fermentation with a functional composite bactericide which is generated by single fermentation at a weight ratio of (5000-1000):(1-2), granulating and drying at low temperature so as to obtain the high-efficiency and active bio-organic fertilizer. The process is relatively simple, is easy to operate, and can be used for lowering the product cost is low, saving energy and turning wastes into wealth, thereby being beneficial to promotion of benign ecological circulation and environment conservation; and by utilizing the fertilizer, the quality of the product is good, thereby obviously improving the yield and quality of agricultural products.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

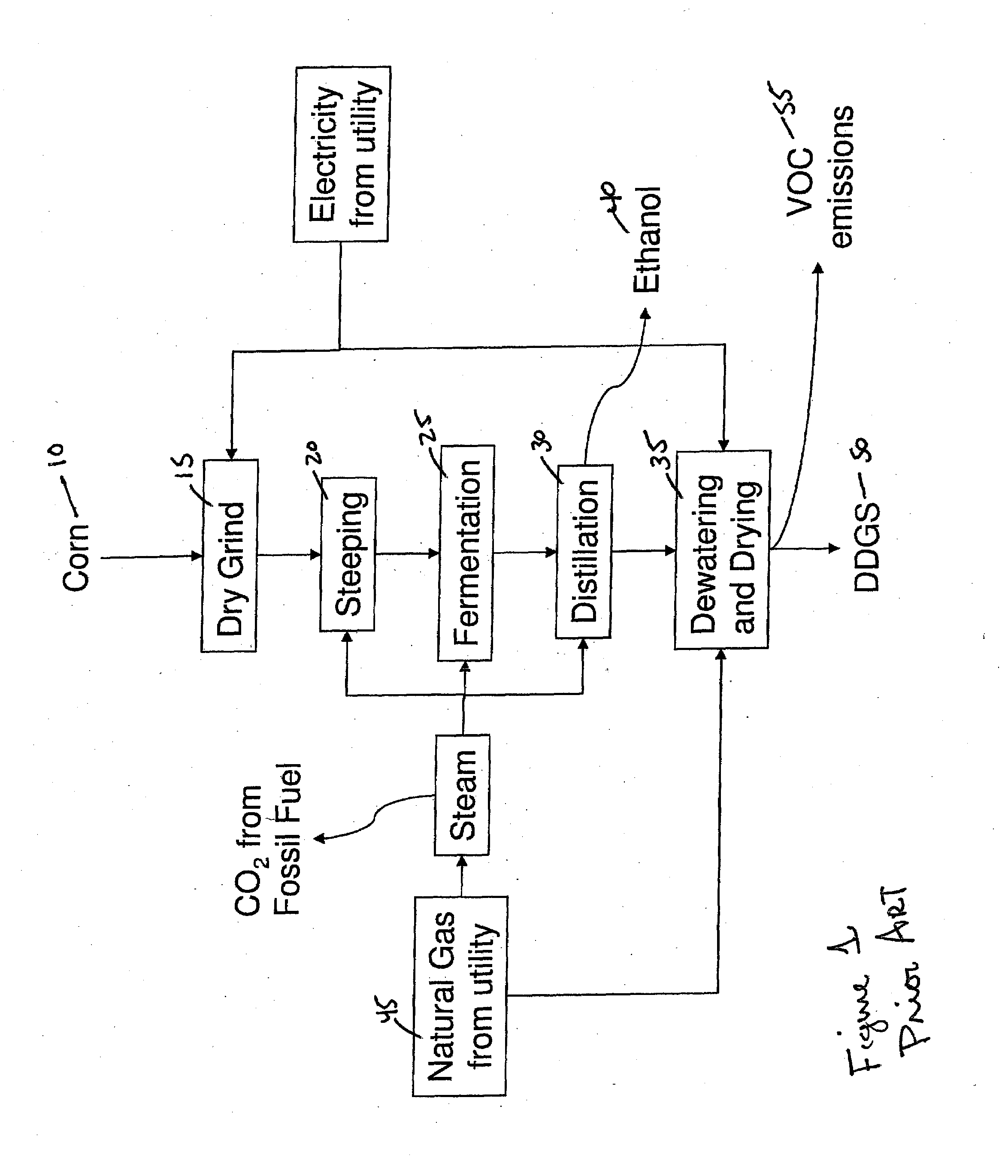

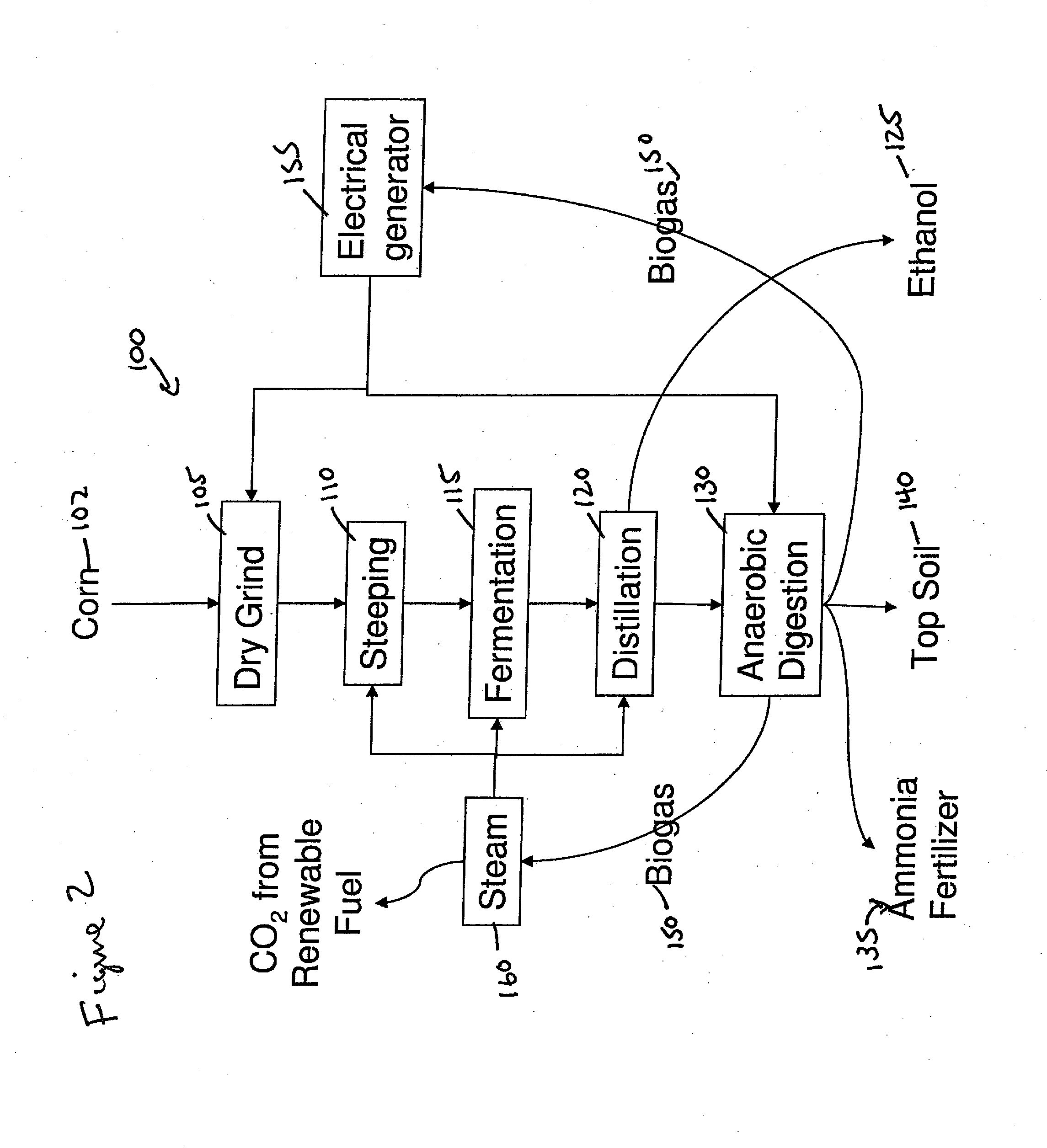

Process for producing ethanol and for energy recovery

InactiveUS20070141691A1Increasing net energy valueReducing the reliance of the ethanol industryBioreactor/fermenter combinationsBio-organic fraction processingElectricityDistillation

The present invention is directed to a process for the production of ethanol and energy. The process includes the steps of fermenting a corn mash in an aqueous medium to produce a beer. Next, the beer is distilled to produce ethanol and a whole stillage. The whole stillage is anaerobically digested to produce a biogas and a residue. The biogas is combusted to produce electricity and steam. The electricity and steam are used during the fermentation and distillation process. The residue may further be separated into a liquid fertilizer and top soil residue.

Owner:STANLEY CONSULTANTS

Organic fertilizer with livestock and poultry manure and preparation method thereof

InactiveCN103145463ANo pollution in the processImprove fertilizer efficiencyBio-organic fraction processingOrganic fertiliser preparationEffective microorganismMixed materials

The invention provides an organic fertilizer with livestock and poultry manure and a preparation method thereof. The organic fertilizer comprises cow manure, edible mushroom dregs, pig manure, chicken manure, maize straw powder and an Em (effective microorganisms) stock solution. The specific formula of the organic fertilizer comprises 19.7 percent of edible mushroom dregs, 10 percent of pig manure, 10 percent of chicken manure, 20 percent of maize straw powder, 0.3 percent of Em stock solution, and the balance of cow manure. The preparation method of the organic fertilizer is characterized in that a production technology of the organic fertilizer with the livestock and poultry manure mainly adopts a shallow pool type fermentation technology, namely the cow manure, the pig manure, the chicken manure, the edible mushroom dregs, the maize straw powder and the Em stock solution are poured into a mixer in proportion and are evenly mixed and stirred, the evenly mixed and stirred materials are sent into a shallow layer pool type fermentation pool, and the organic fertilizer fermentation environment temperature is controlled to be above 15 DEG C. Firstly, various raw materials including the livestock and poultry manure, the edible mushroom dregs, the straw powder and a fermentation bactericide are mixed, and then the mixed materials are put into a mixing and stirring machine to be evenly stirred, are sent into the material fermentation pool to be fermented for 8 days and are discharged from the pool to enter a secondary aerobic fermentation procedure. The organic fertilizer has the advantages of low cost and high yield and can improve the quality of crops.

Owner:郑晓华

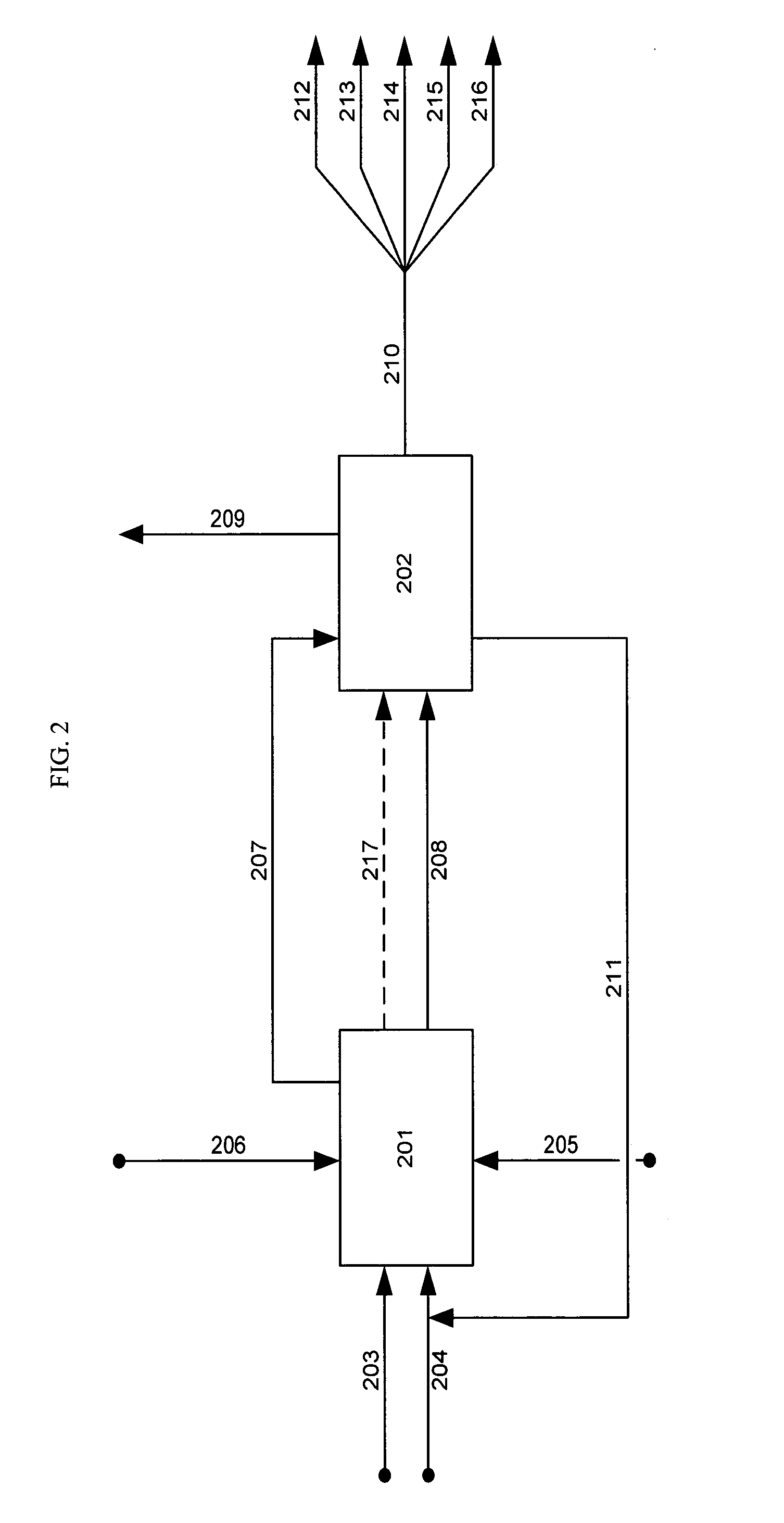

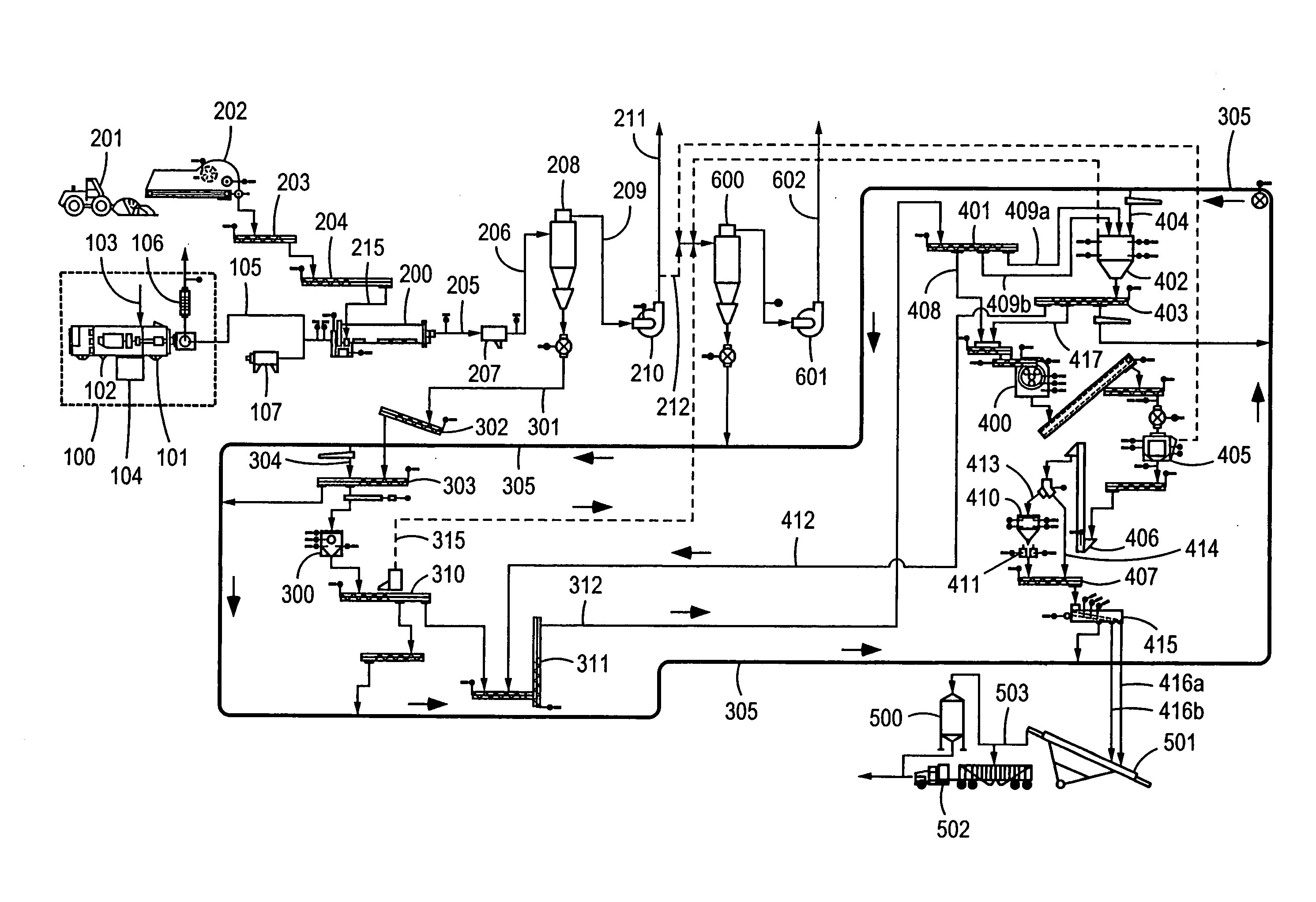

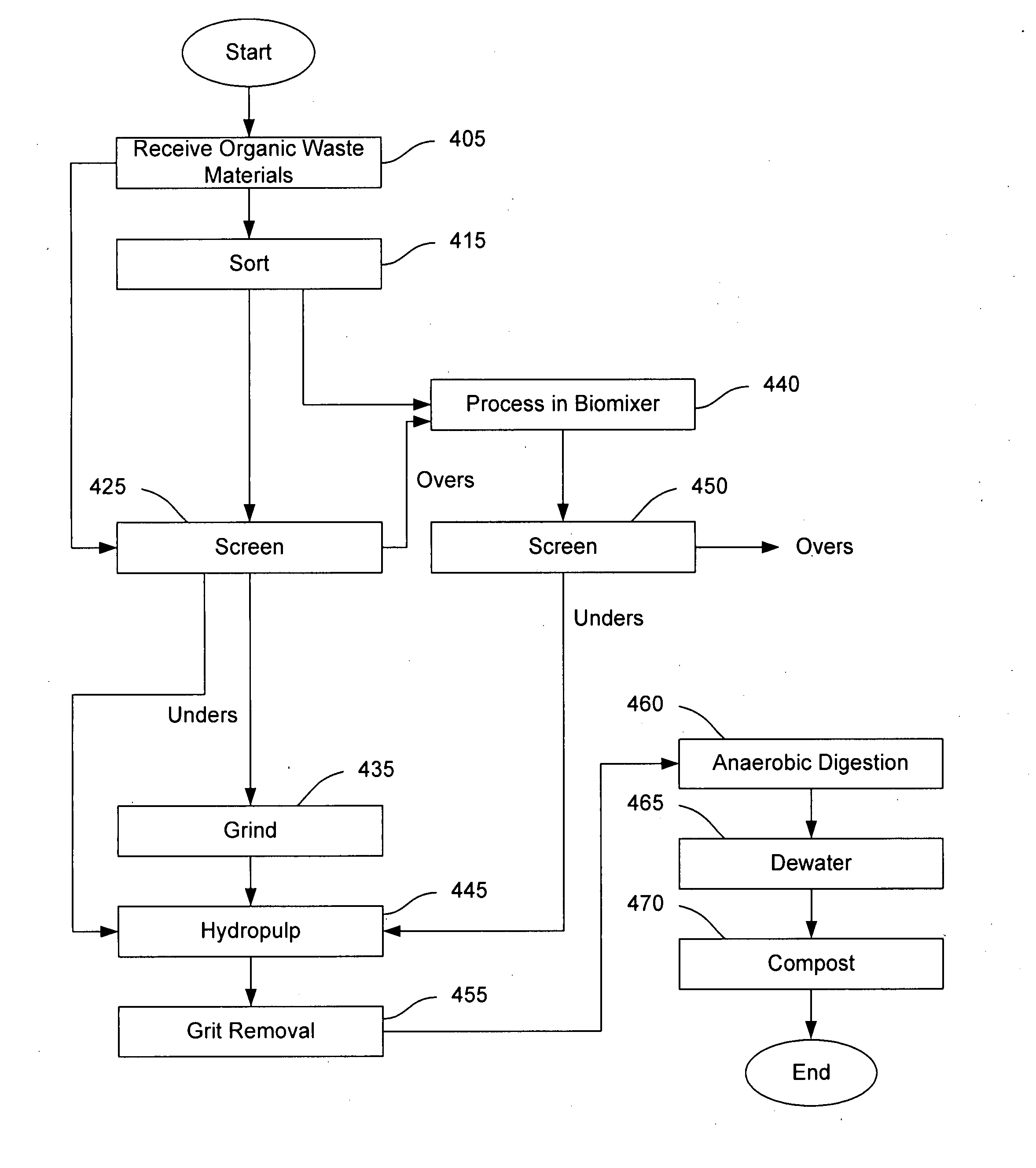

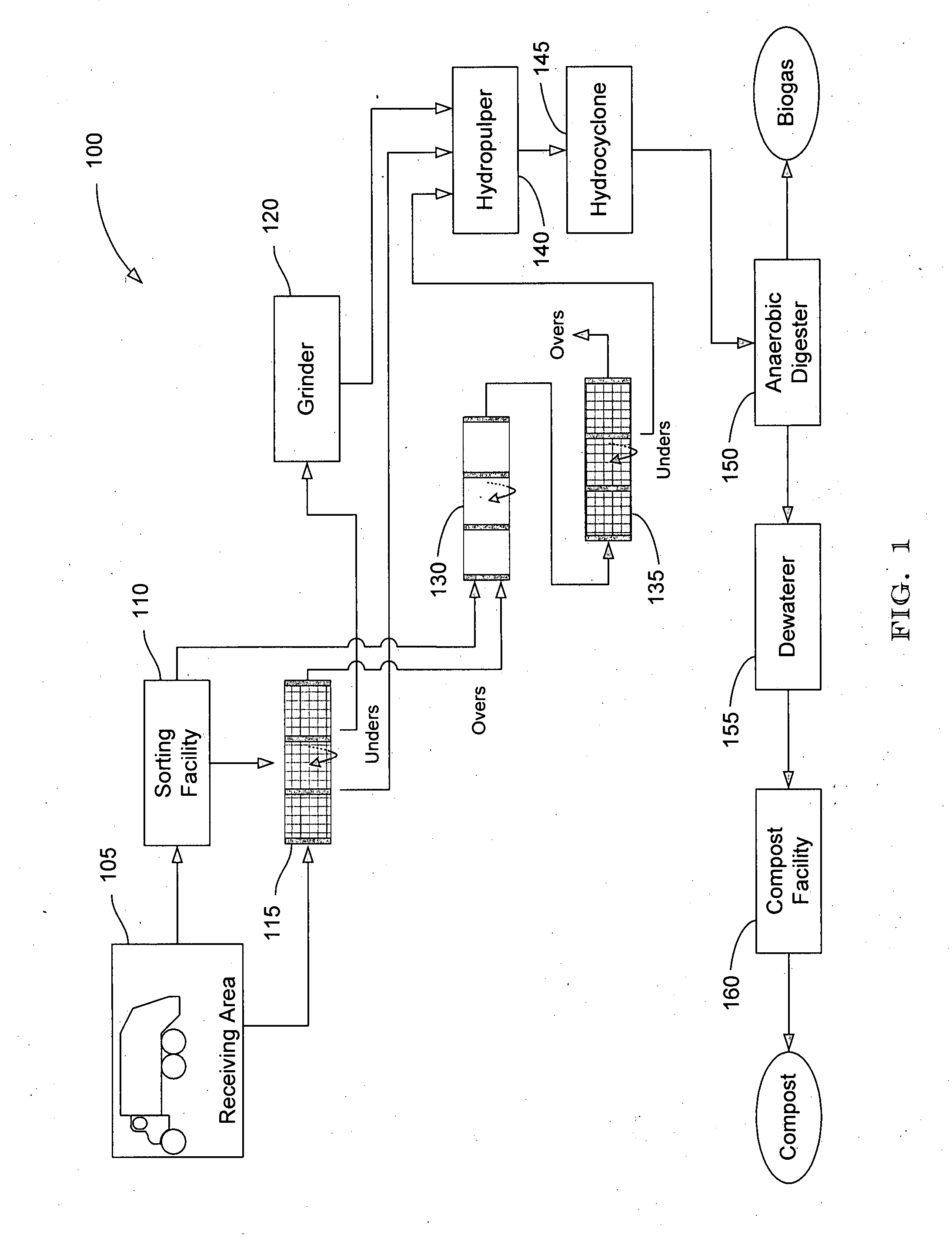

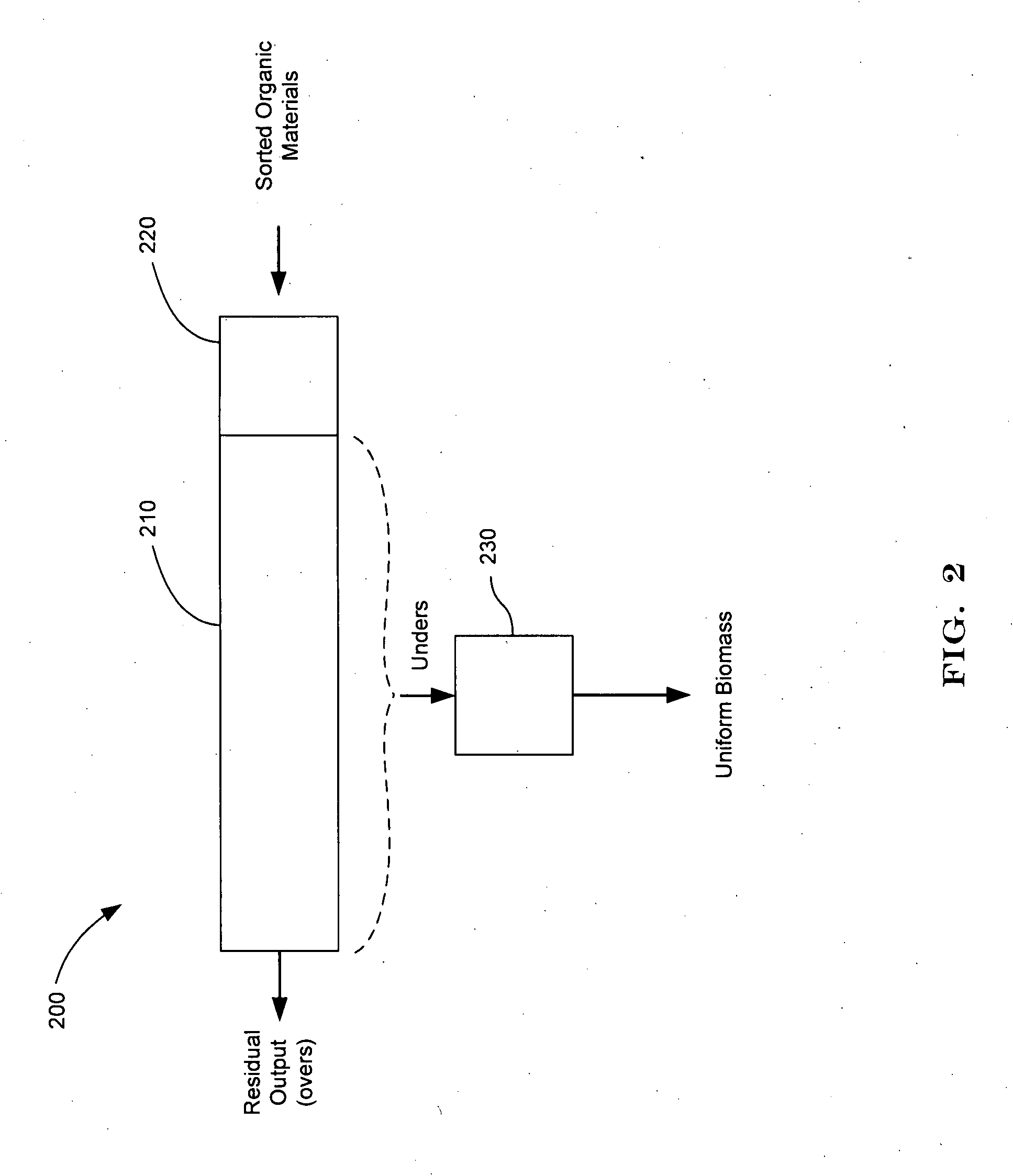

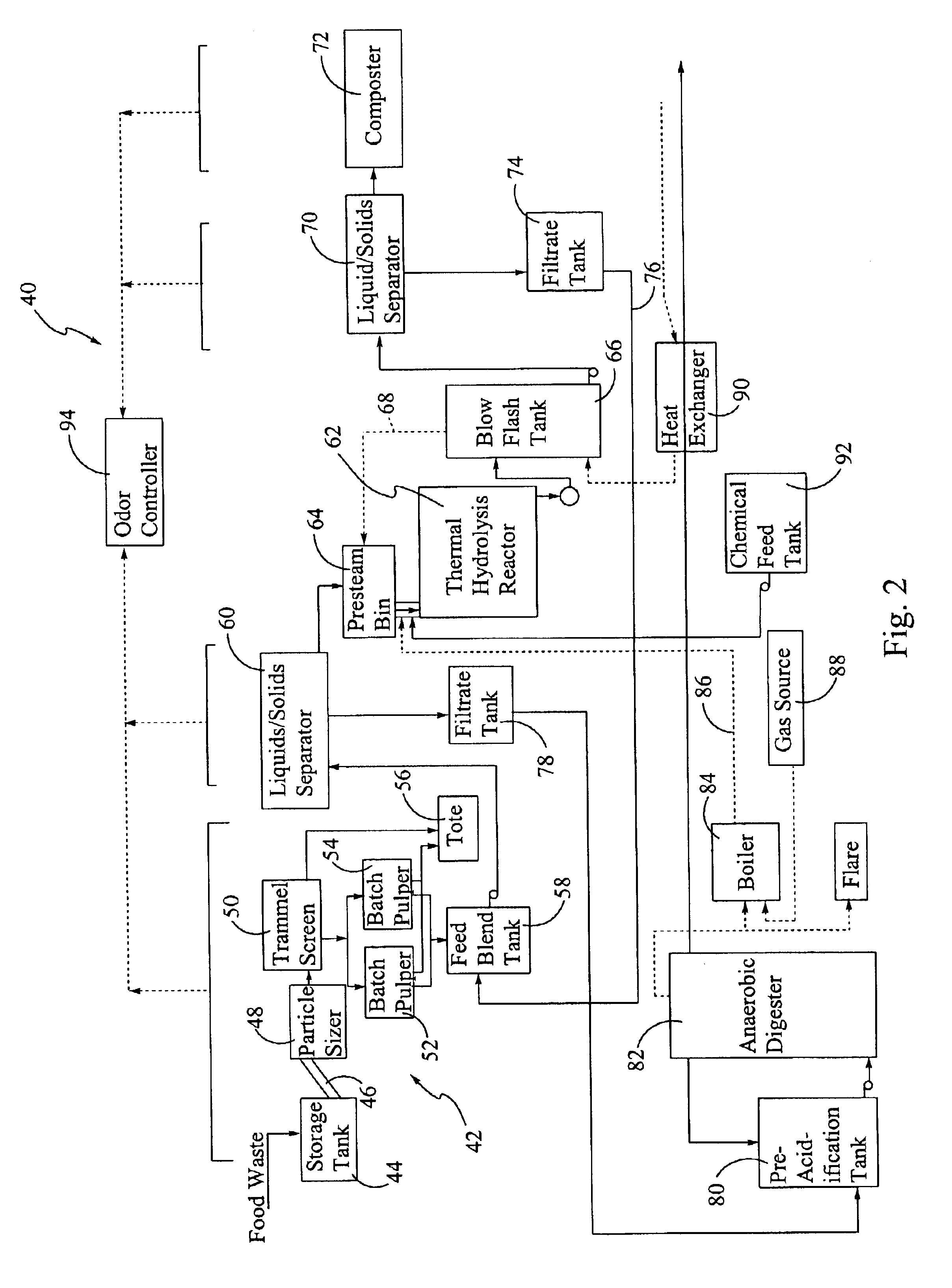

Systems and methods for converting organic waste materials into useful products

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

Method for processing food waste by using black soldier fly larvae and material formula

InactiveCN101889629AReduce capacityReduce odorBio-organic fraction processingClimate change adaptationLitterRapid processing

The invention belongs to the field of environmental protection, relating to a method for processing food waste by using black soldier fly larvae and comprising the following steps: coarse crushing the food waste and then adding auxiliary materials to obtain culture materials for the black soldier fly larvae; and grafting black soldier fly spawn on the surface of the culture materials for the black soldier fly larvae so that the larvae hatched by the black soldier fly spawn acquires the culture materials for the black soldier fly larvae, thereby processing and cleaning the food waste. Before the black soldier fly larvae ages, a polypide collecting container is externally connected to the area for piling up the culture materials for the black soldier fly larvae and is filled with dry rice bran powder so as to guide to collect the aged black soldier fly larvae; and the rest of the processed culture materials for the black solider fly larvae is dried and then prepared into microbial organic fertilizer. The invention has strong processing capability, rapid processing speed compared with the common compost, the processing period is 4-5 days; after being processed, the volume of the food waste is reduced by 10-30%, the peculiar smell of the waste is lightened; and the invention can obtain excellent microbial organic fertilizer and insect bioprotein at the same time.

Owner:SUN YAT SEN UNIV

Foliar fertilizer

InactiveCN102040408AImprove disease resistanceReduce usageBio-organic fraction processingFertilizer mixturesDiseaseWater Hyacinths

The invention discloses a foliar fertilizer comprising the following components in parts by weight: 10-25 parts of bean pulp, 150-250 parts of mixture of soybeans and corns, 20-40 parts of wheat germ, 10-30 parts of waste honey, 20-40 parts of fish meal and 300-700 parts of one or the mixture of water hyacinth or wormwood plants or kudzu plants or vegetables. The invention also comprises a herbal medicine extracting solution, a leaf extracting solution and the like. The foliar fertilizer in the invention contains various substances favourable for plant growth, such as amino acid, nucleic acid, organic acid, vitamins, sugars and the like, and also contains various trace elements. The foliar fertilizer is added with the herbal medicine extracting solution, leaf extracting solution and the like, and the foliar fertilizer can improve the disease resistance capability of plants and reduce the usage amount of pesticides after being used. The yield of plants can be increased by 20-30%, and the invention fully utilizes the common plants, such as the water hyacinth, the kudzu and the like, has wide resources and recycles waste materials.

Owner:HENAN LUOXIAOWANG BIOTECH CO LTD

Special seedling-raising medium for leaf vegetables

InactiveCN103058729AHigh in potassiumRich in trace elementsBio-organic fraction processingOrganic fertiliser preparationNutritionEngineering

The invention discloses a special seedling-raising medium for leaf vegetables, belonging to the technical field of soilless culture. The medium comprises vinegar residue, manioc waste and other organic wastes, as well as vermiculite, grass carbon, plant ash and perlite. The formula of the medium comprises the following components in volume ratio: 25-35 parts of vinegar residue, 5-10 parts of manioc waste, 10-15 parts of plant ash, 15-20 parts of vermiculite, 20-25 parts of grass carbon and 5-10 parts of perlite; and the medium has total nutrient content of 1-3%, free water content of 25-40%, total porosity of 65-85%, volume weight of 0.1-0.8g / m<3>, pH of 5.5-7.5, EC (electrical conductivity) value of 0.5-2.0mS / cm and dry base organic matter content of not less than 25%. The special seedling-raising medium disclosed by the invention mainly takes the vinegar residue, the manioc waste and other organic wastes as raw materials, and high-temperature fermentation treatment is performed for producing the soilless culture medium, so that the wastes are changed into valuables and harmful things are further turned to beneficial things. The special seedling-raising medium has the advantages of low cost, light texture and complete nutrition, is very suitable for raising seedlings of the leaf vegetables, and becomes a good seedling-raising medium for soilless culture of horticultural crops.

Owner:江苏培蕾基质科技发展有限公司

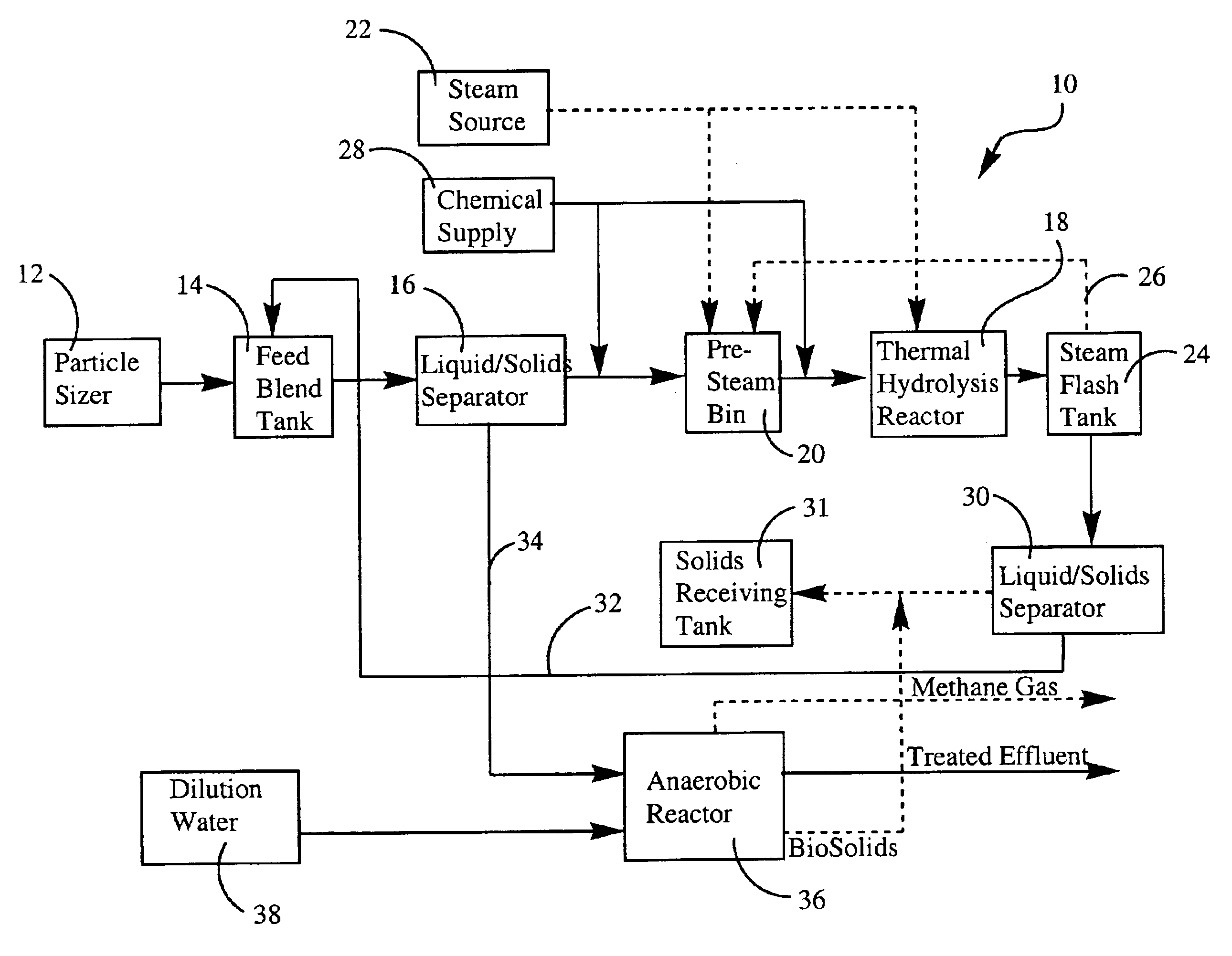

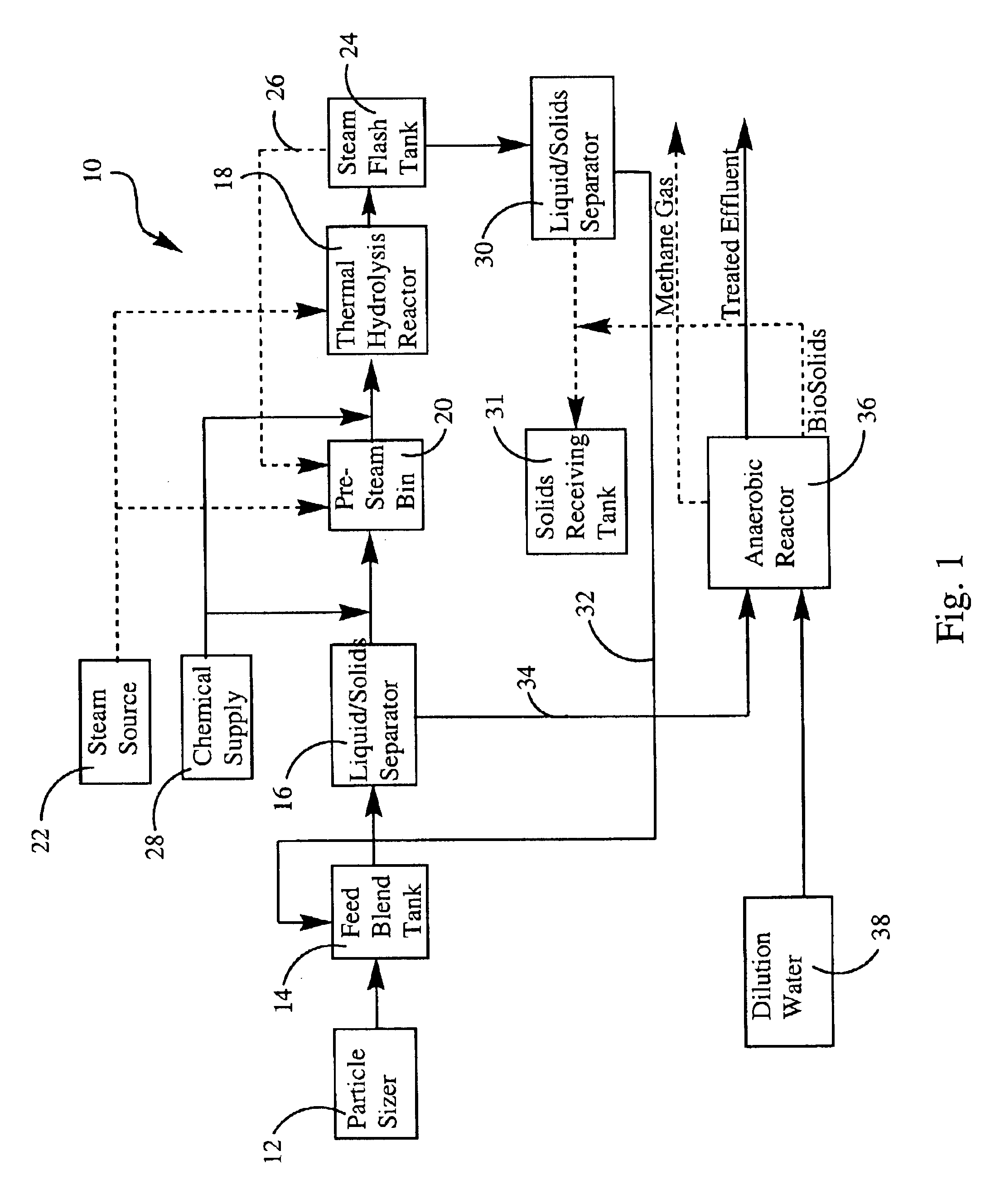

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

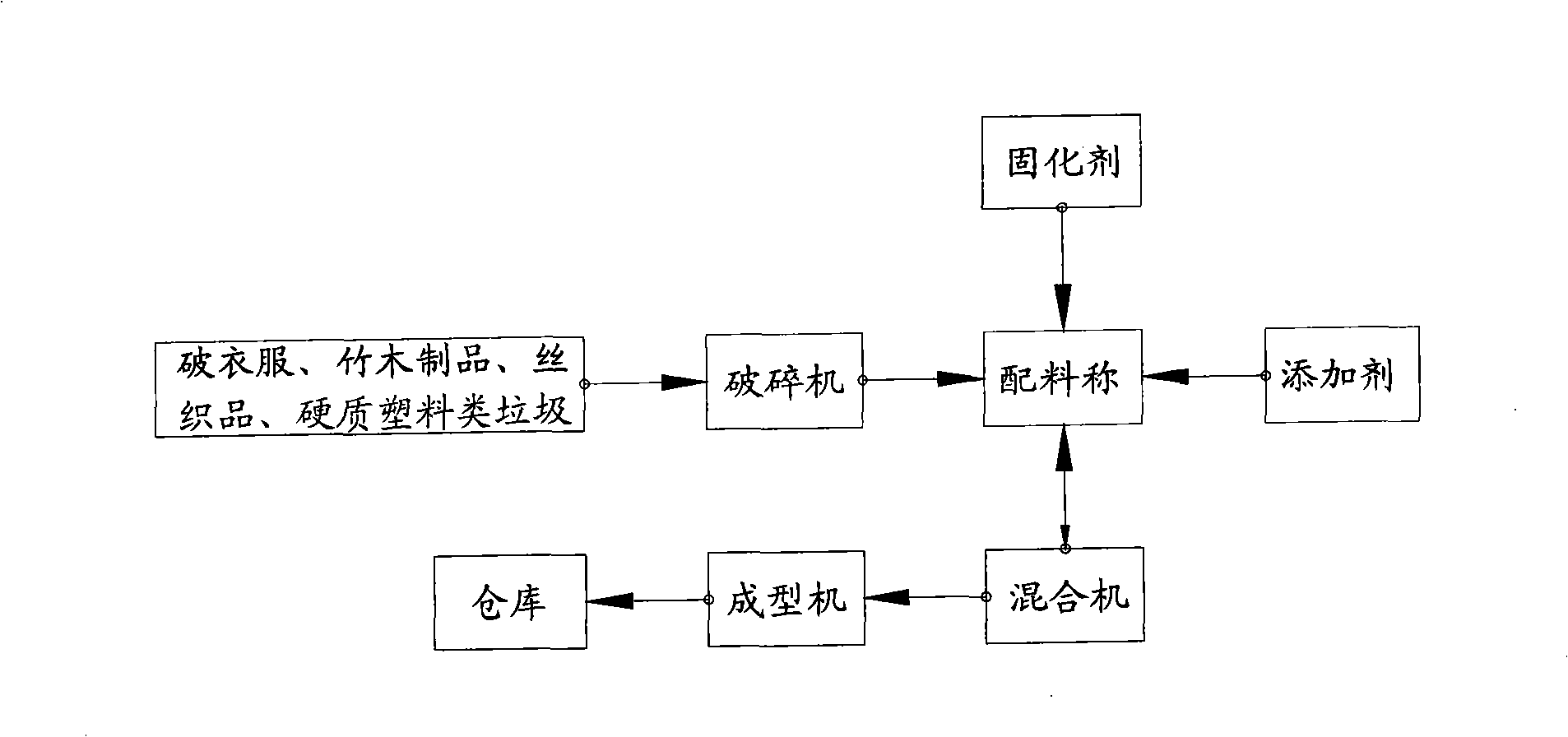

House refuse treatment method

InactiveCN101274331ANo spillageNo generationBio-organic fraction processingSolid waste disposalBrickSewage

The invention provides a household garbage processing method, comprising the following processing steps which are technique process of sorting, high-temperature and high-pressure hydrolysis and hydrothermal oxidation of organic substances, composting with organic substances, fuel brick production with non-recoverable and combustible substances, building material production with inorganic substances, plastic grain production, recyclable substances recycling, waste gas processing, sewage water processing and thermal power supply, etc. The household garbage processing method of the invention hasthe advantages of occupying little land area and having short processing time, pollution avoidance, low running cost, effective processing of noxious gas, high product quality, high-efficiency and environmental protection, and can be widely used for the processing of household garbage in various regions.

Owner:ENVIRONMENTAL PROTECTION EQUIP SHANGHAI JI MING

Pest-proof disease-resistant organic fertilizer and preparation method thereof

InactiveCN102775247AReduce diseaseReduce cropping diseasesBio-organic fraction processingOrganic fertiliser preparationMycoproteinHazardous substance

The invention relates to a pest-proof disease-resistant organic fertilizer and a preparation method thereof, belonging to the technical field of organic fertilizers. Tobacco waste and oil tea pulp are utilized as main raw materials to develop a method of the pest-proof disease-resistant organic fertilizer. The invention breaks through the limitations of harmful substances and single product effect due to addition of chemical materials in the traditional organic fertilizer. The pest-proof disease-resistant organic fertilizer is prepared from the following raw materials: tobacco waste, oil tea pulp, organic substances, a poising agent and a microbial inoculant. The preparation method of the organic fertilizer comprises the following steps: crushing tobacco straws, tobacco stems, tobacco powder, oil tea pulp and organic substances, spraying the poising agent and microbial inoculant, mixing, carrying out pool stack fermentation and strip stack fermentation, screening and granulating to obtain the insect-proof disease-resistant organic fertilizer. The high-efficiency biological insect-inhibiting factors contained in the organic substances containing massive mycoprotein can effectively inhibit and kill pests and pathogenic bacteria, and solve the problem of environmental pollution caused by the pesticide fertilizer.

Owner:刘奋安

Animal waste effluent treatment

Animal waste such as fecal material from swine, chicken, turkey, and cattle is converted into useful forms such as fertilizer, other types of soil builders, and even nutrient feed additives. Devices, systems, and methods are provided that allow economical conversion and in many instances, alleviate the production and release of undesirable gases such as sulfide and ammonia. In one embodiment, undesirable anaerobic and facultative anaerobic bacteria are killed at a greater rate than desirable soil compatible aerobic bacteria. The use of low temperature killing diminishes off gassing commonly associated with other techniques, and the use of gas trapping additives such as zeolites provides enhanced soil building qualities such as slow release of nitrogen and slow release of moisture to soil. The methods allow convenient adjustment of composition, allowing conversion of waste into tailored designer fertilizer suited for particular soils. Other embodiments provide other soil building qualities as well as nutrient qualities for feedstock used in animal husbandry such as aquaculture.

Owner:SHEETAB SR RICHARD G

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com