Patents

Literature

144results about How to "Overcome resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carburizing alloy steel, and preparation method and application thereof

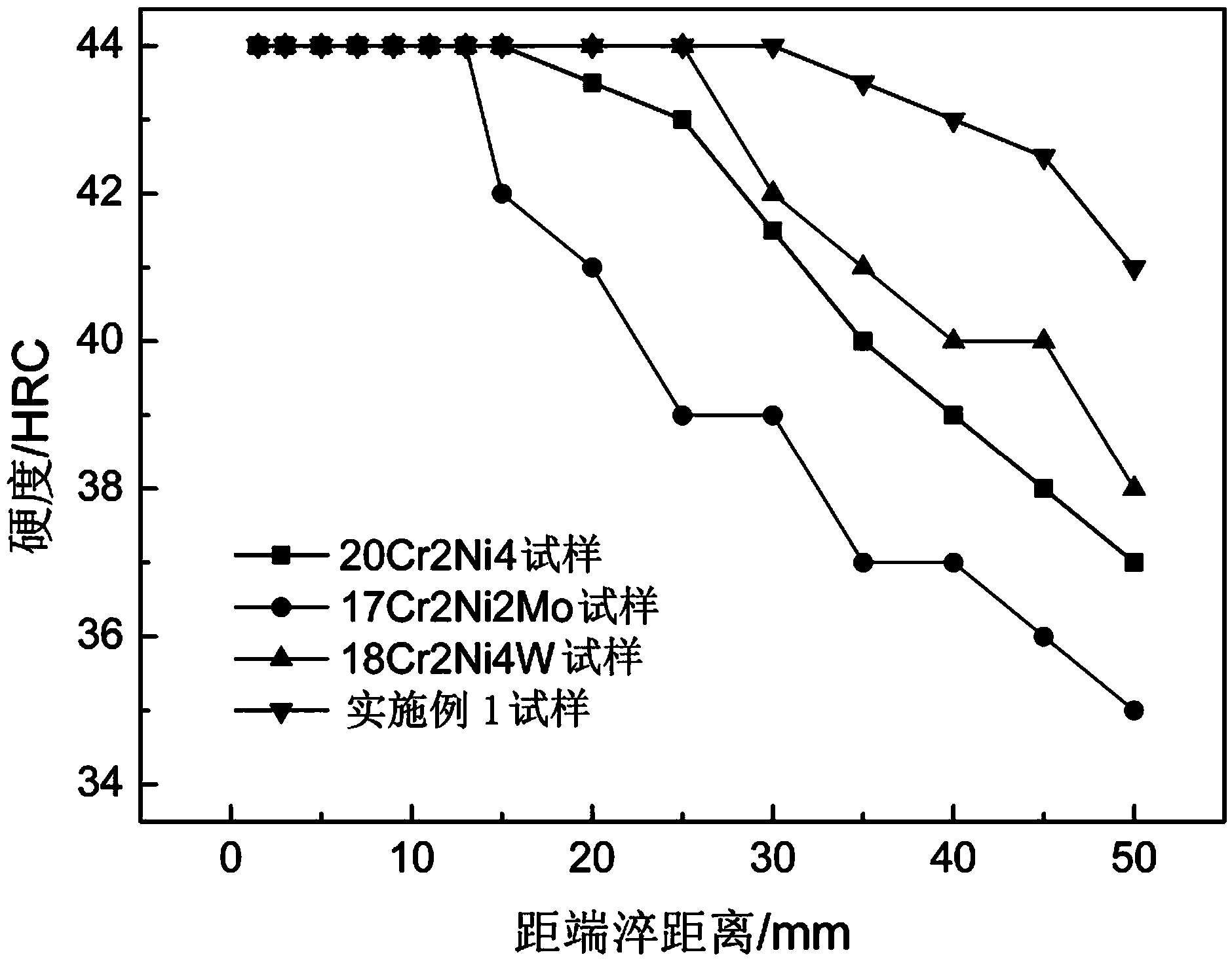

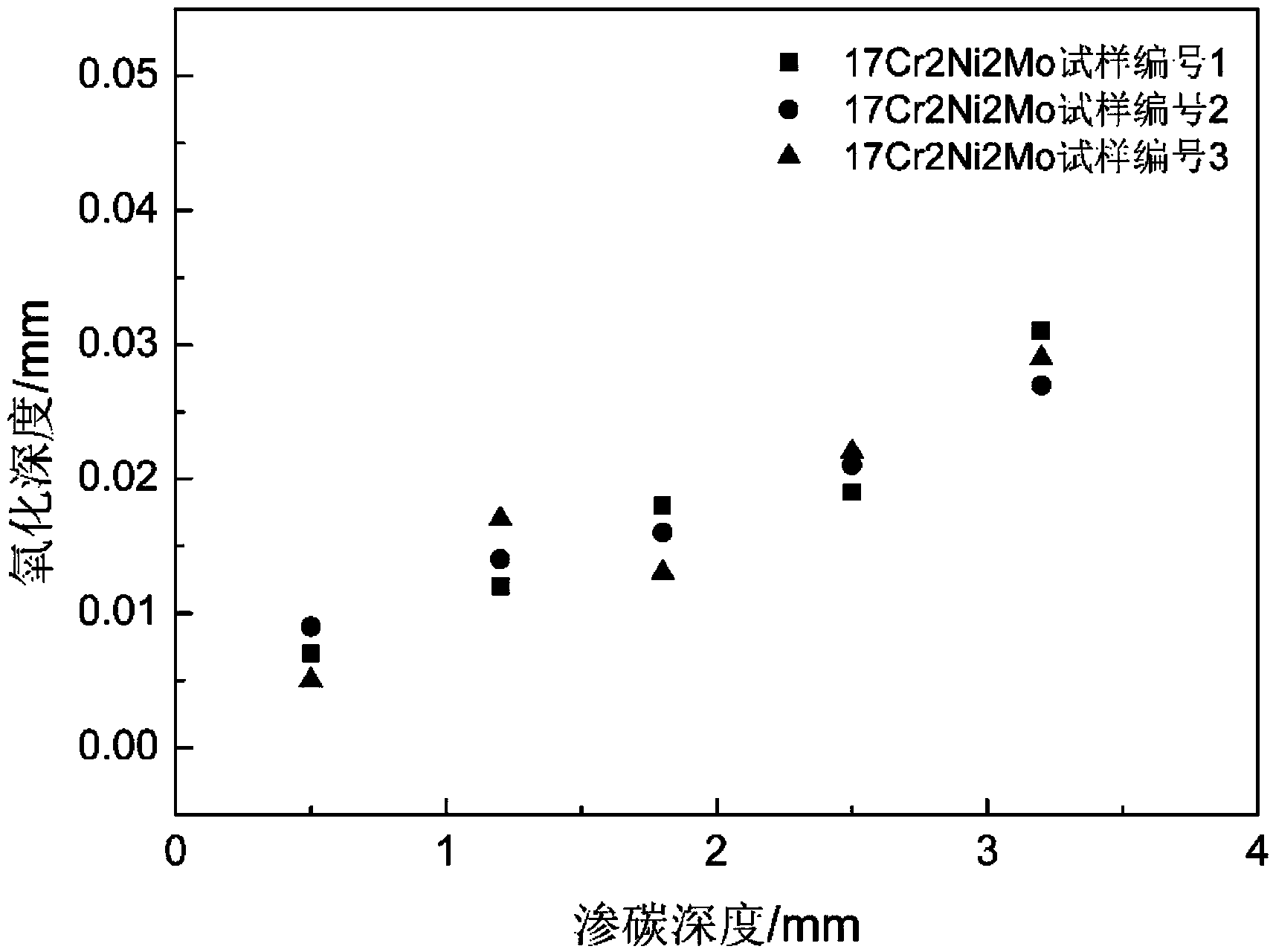

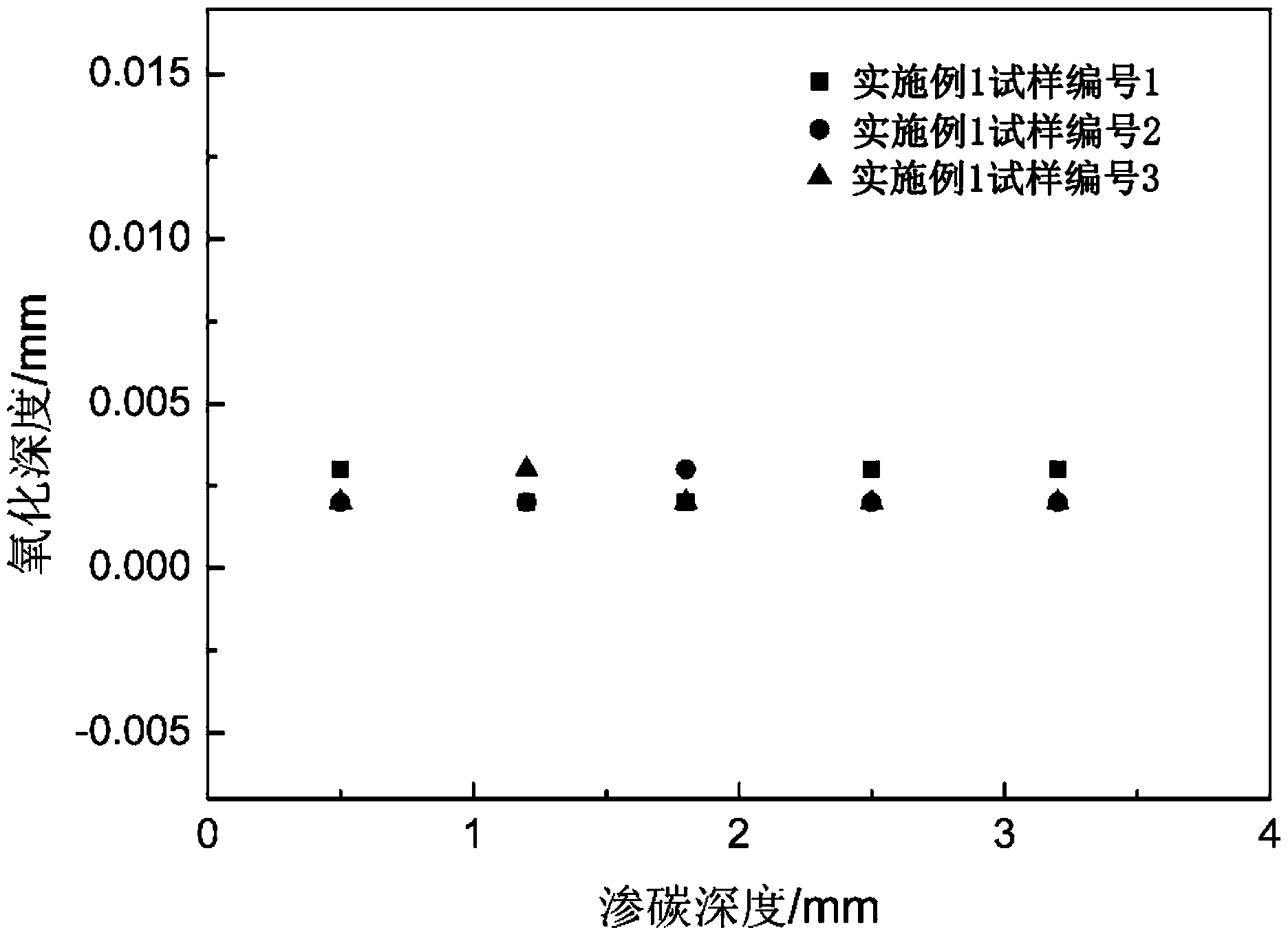

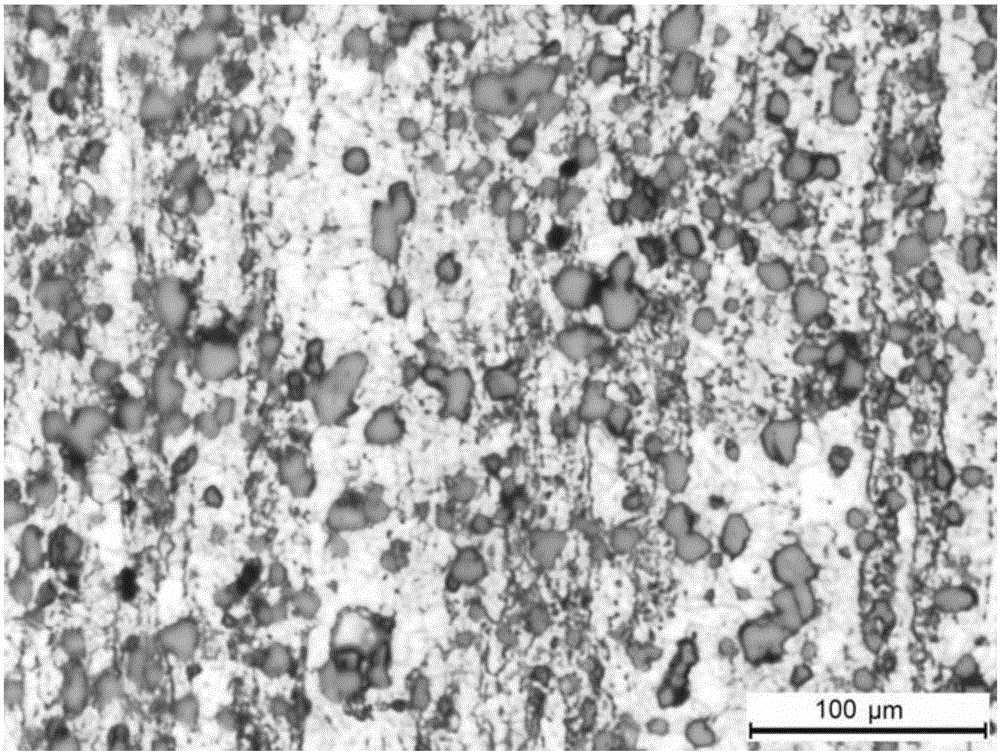

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Halogen-free intumescent flame-retardant polypropylene/ethylene vinyl acetate cable material

ActiveCN101649088AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesExtensibilityUv absorber

The invention relates to a halogen-free intumescent flame-retardant polypropylene / ethylene vinyl acetate cable material which is characterized by comprising the following components by weight part: 20-40 parts of polypropylene, 60-80 parts of ethylene vinyl acetate, 45-65 parts of compound flame retardant, 5-15 parts of grafting agent, 1.0-2.0 parts of antioxidizer, 1.0-2.0 parts of ultraviolet absorbent and 1.0-3.0 of processing aid. With the advantages of favorable flexibility, high breakage extensibility, favorable tensile strength, excellent electrical insulating property and good flame retardant, the material favorably meets the requirements on the burning property, the mechanical property and the heat property of the cable material and is mainly used as the outer coating material ofcables.

Owner:应急管理部四川消防研究所

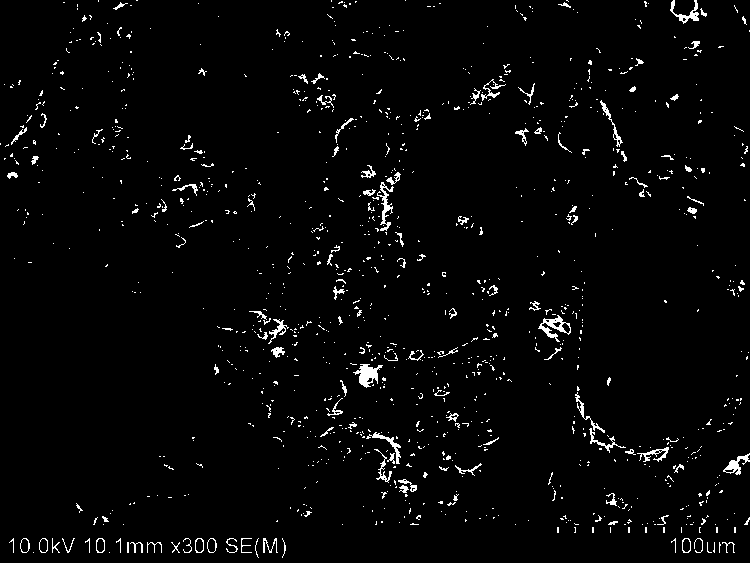

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

Manufacturing method for nodular cast iron

A technology for producing nodular graphite cast iron QT800-6 features that it contains Ca (0.001-0.05 wt.%) and Ba (0.006-0.1) beside conventional components, and its heat treatment includes normalizing at 860+ / -40 deg.C for 1.5+ / -1.0 hr and tempering at 600+ / -50 deg.C for 2.0+ / -1.0 hr. Its casting features high tension strength, elongation, impact toughness and hardness, and low cost.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

Method for preparing PLGA/PCL/nHA composite bone repair porous scaffold by 3D printing technology as well as product and application of method

InactiveCN107754012AOvercome resilienceOvercome degradabilityAdditive manufacturing apparatusTissue regenerationFreeze-dryingBiocompatibility Testing

The invention relates to a method for preparing a PLGA / PCL / nHA composite bone repair porous scaffold by a 3D printing technology as well as a product and application of the method. The method comprises the following steps: mixing 1,4-dioxane which is used as a solvent with PLGA and PCL according to a mass ratio of 9:(1-5):5, adding nHA powder according to a mass fraction of 10-25%, and finally adding tributyl citrate as a compatibilizer to improve the uniformity of the material; using the solution as 3D printing 'ink', carrying out 3D printing with a 3D printer, selecting a 150-micron discharging needle, and setting printing parameters as follows: parallel printing is adopted for each layer with gaps of 0.1-0.3mm, the Z-axis direction is raised by 0.2mm each time, the layers are verticallycrossed and stacked, the extrusion speed is set to 1.5-2mm / s, and the temperature of a receiving platform is -20 to -10 DEG C; and after the scaffold is printed, carrying out freeze-drying for 48 hours, and then drying the scaffold in a vacuum oven at 50 DEG C for 24 hours or more to prepare a PLGA / PCL / nHA composite bone repair porous scaffold. The preparation method provided by the invention issimple and feasible; the prepared porous bone repair scaffold has proper pore size and porosity, good biocompatibility and mechanical strength, thereby providing a new idea for clinical treatment of large bone defects, and having a wide clinical application prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

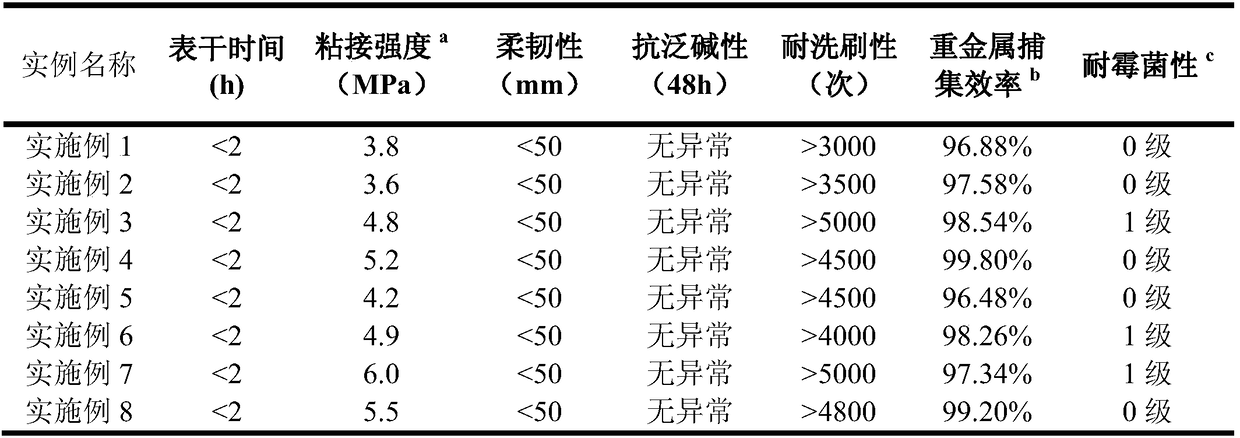

Geopolymer-based mold-proof antibacterial interior wall coating and preparation method thereof

InactiveCN108892978AReduce pollutionGood and long-lasting inhibitory effectAntifouling/underwater paintsPaints with biocidesWater basedBond strength

The invention discloses a geopolymer-based mold-proof antibacterial interior wall coating which is composed of a solid phase S and a liquid phase L, wherein the solid phase S comprises the following components in parts by weight: 10-90 parts of a gel binder, 5-85 parts of pigments and fillers, 0.1-5 parts of a film-forming agent, 0.5-10 parts of an anti-cracking additive and 0.4-5 parts of an anti-settling agent; and the liquid phase L comprises the following components in parts by weight: 5-90 parts of an alkali activator, 0.5-6 parts of a rheological modifier, 0.2-3 parts of an antifoaming agent and 2-90 parts of water. The invention further discloses a preparation method of the geopolymer-based mold-proof antibacterial interior wall coating. The geopolymer-based mold-proof antibacterialinterior wall coating disclosed by the invention realizes the zero-VOC (Volatile Organic Compound) advantage and high-efficiency mold-proof antibacterial functions of the novel water-based inorganicinterior wall coating, and has the advantages of being high in bonding strength with the base plane, excellent in scrubbing resistance, excellent in water resistance and penetration resistance, low inprice and the like, and the mold-proof antibacterial functions have long-term properties.

Owner:浙江航通舟新材料科技股份有限公司

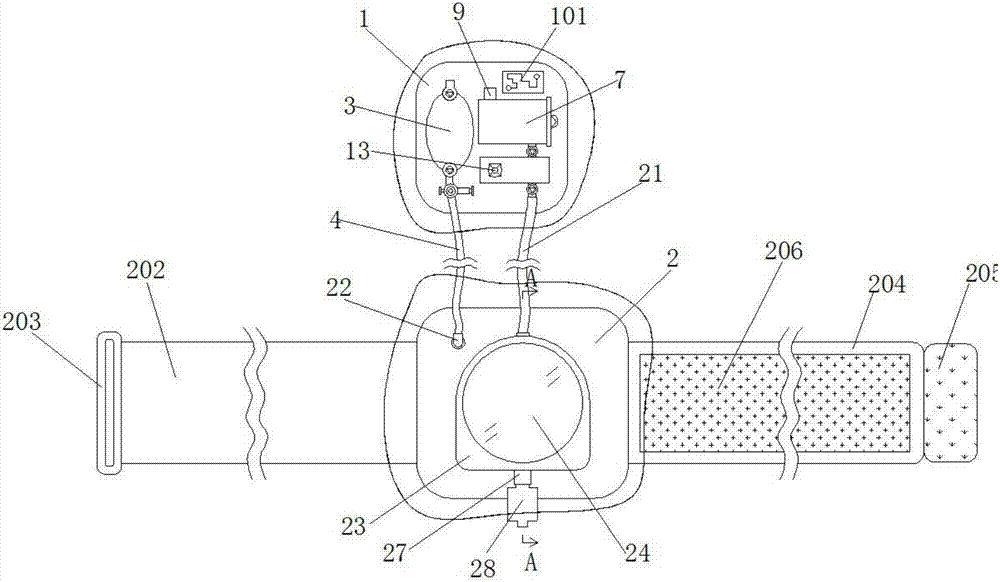

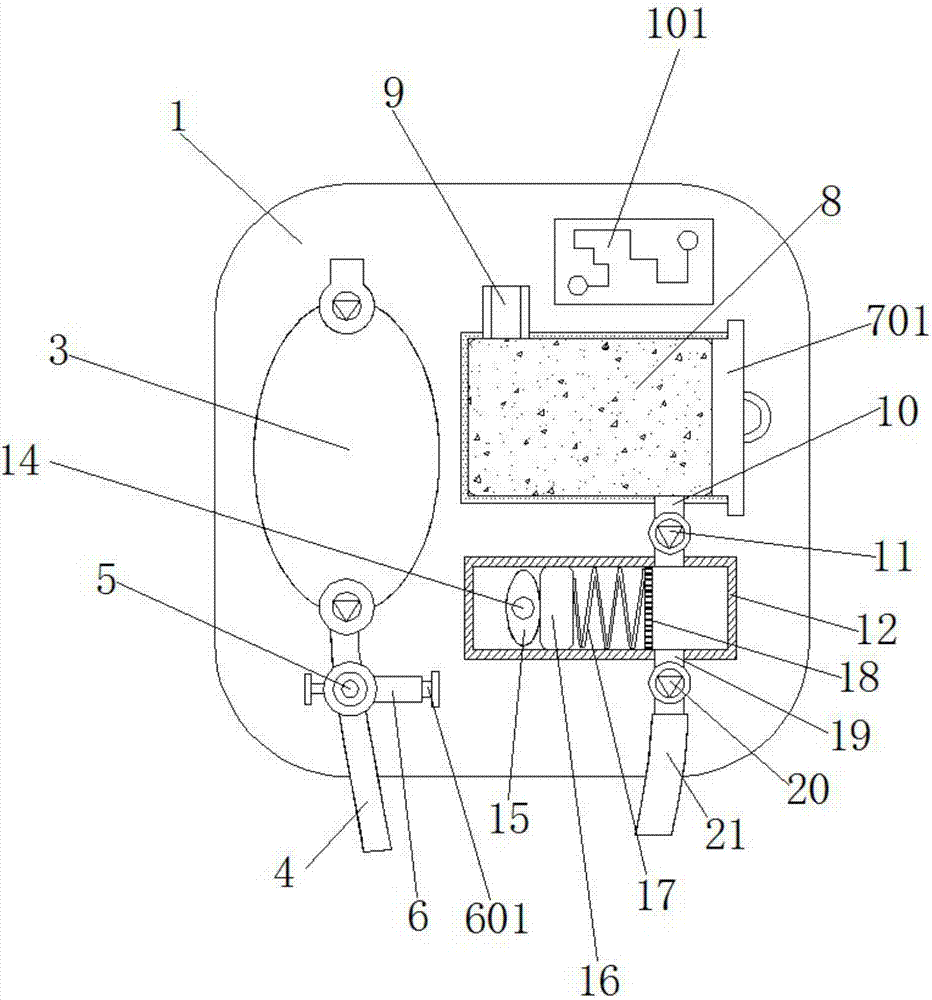

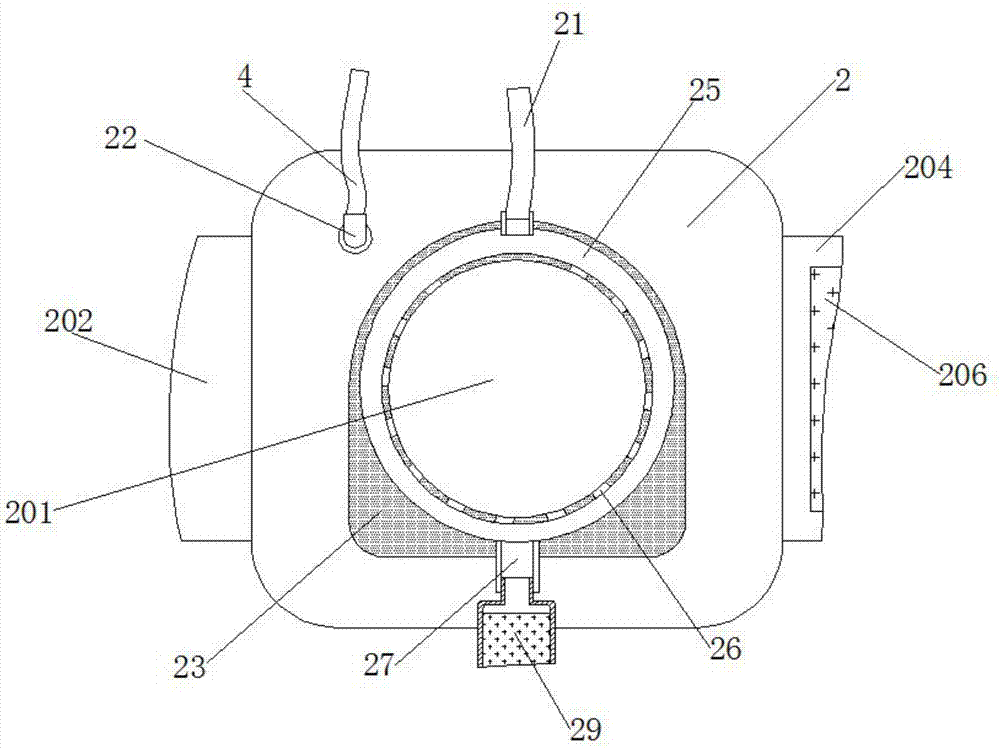

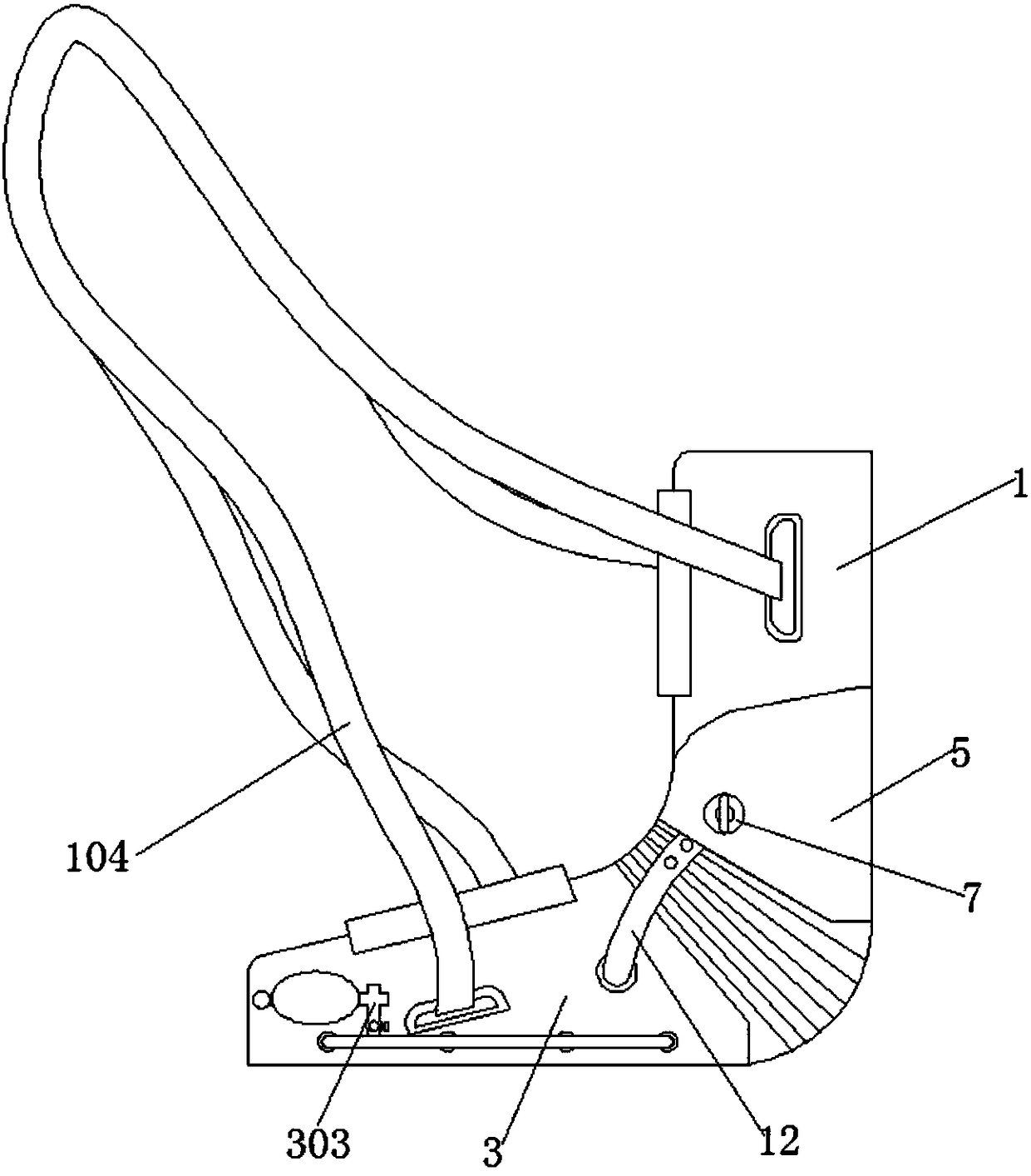

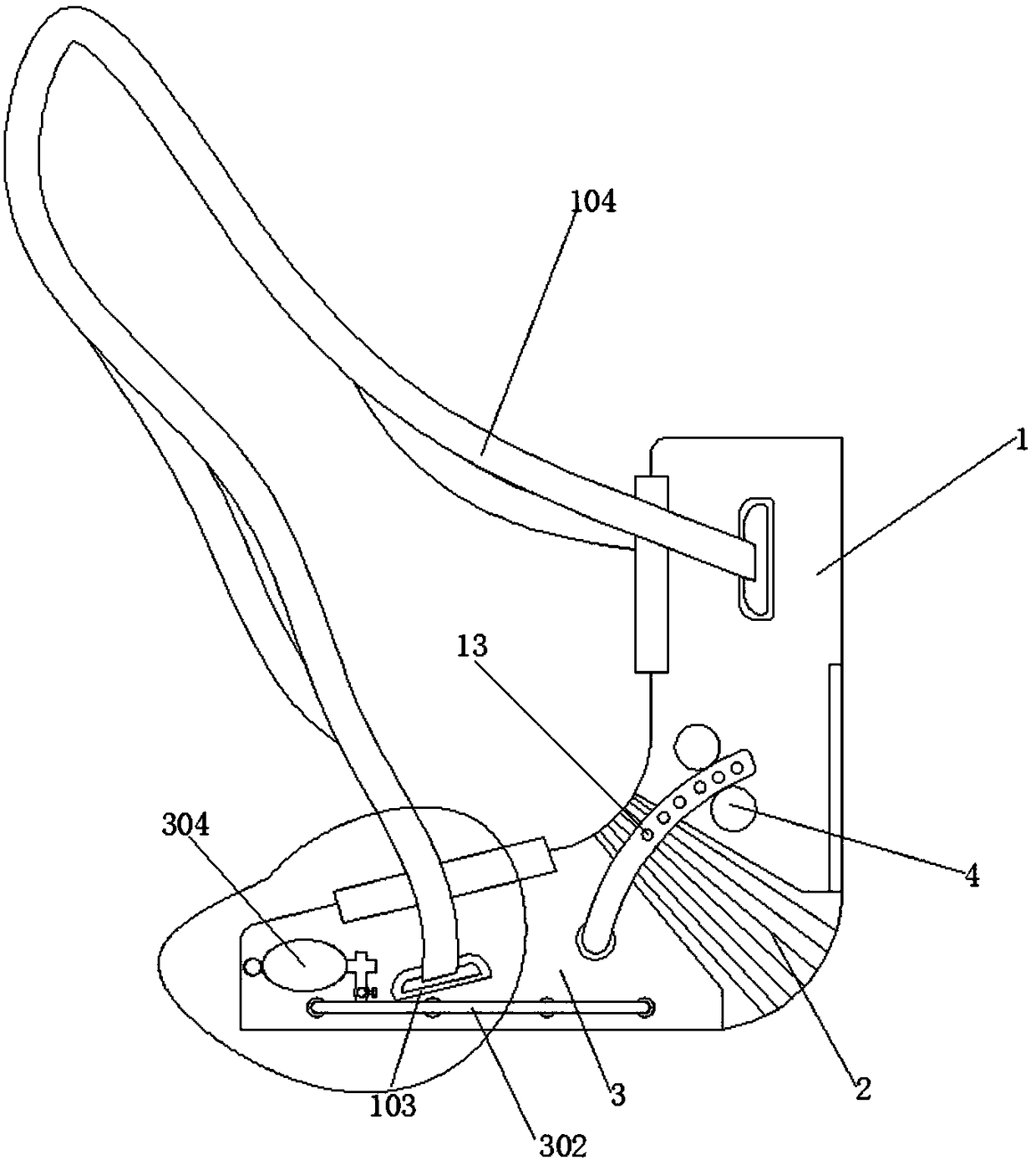

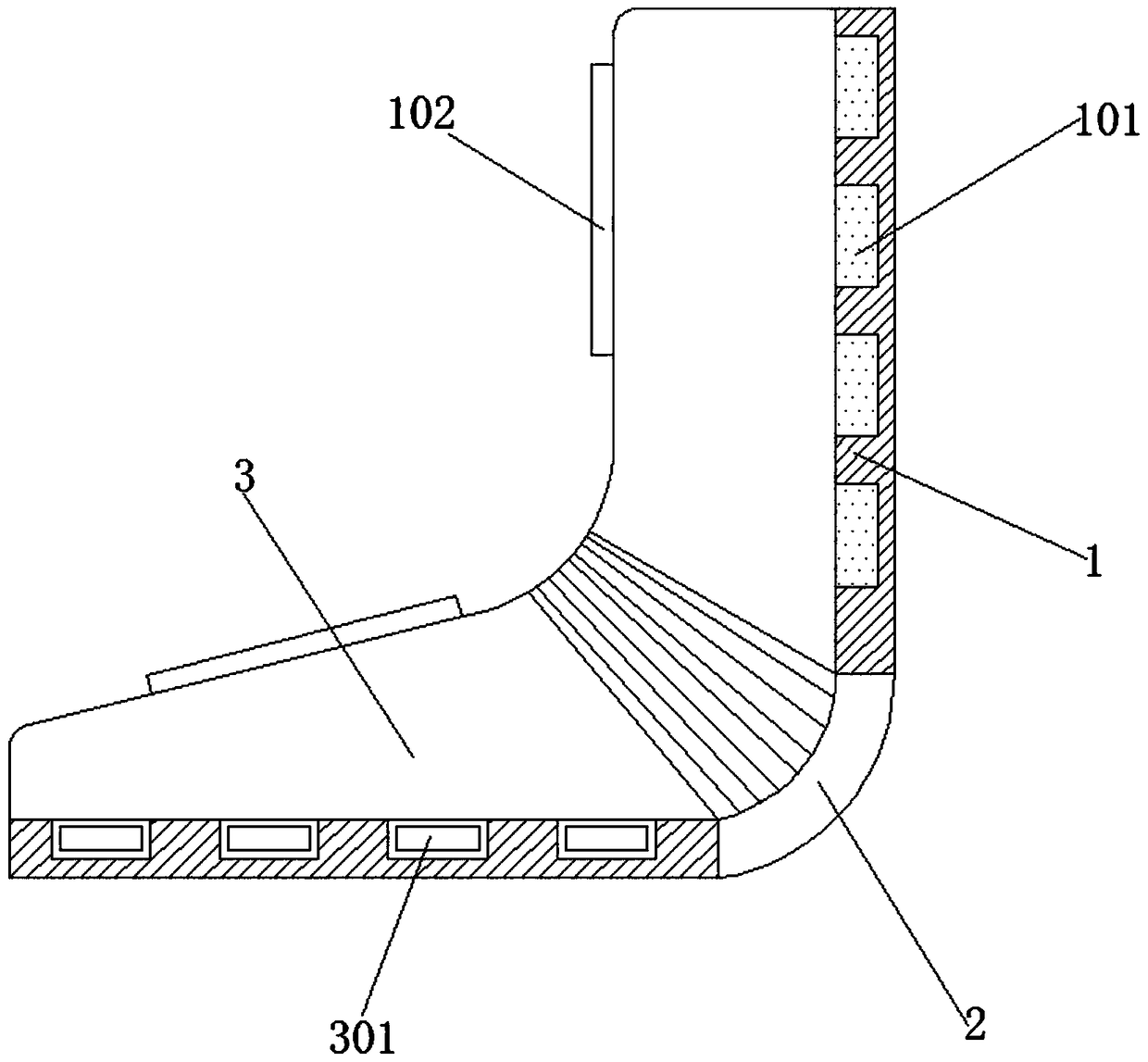

Multifunctional local nursing anti-infection device

InactiveCN107252374AAchieve tighteningRealize connection and fixationBathing devicesNon-surgical orthopedic devicesEngineeringMicro motor

The invention discloses a multifunctional local nursing anti-infection device. The multifunctional local nursing anti-infection device includes a fixing plate, a soft pad, an inflation balloon, a first flexible pipe, a three-way adjustment valve, an exhaust pipe, a filtering tank, a first filter element, an air inlet pipe, a first connection pipe, a first one-way valve, a fixing air cylinder, a micro motor, a rotation shaft, a cam, a piston, a spring, a filtering screen, a second connection pipe, a second one-way valve, a second flexible pipe, an air cushion ring, a fixing seat, an observation plate, a circulation chamber, air leakage holes, a discharging pipe, a filtering bag, and a second filter element. The multifunctional local nursing anti-infection device is skillful in structure, is powerful in function, can effectively protect a local wound of limbs of a patient from infection, can enhance local air circulation of a body of the patient through a simple operation according to the demands, can satisfy the nursing demands of different patients, can greatly facilitates the nursing operations of medical workers for the patients, and facilitates clinical promotion and application.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Method for preparing soaked chili squids

The invention discloses a method for preparing the soaked chili squids. The method comprises the following steps of: cleaning fresh squids serving as a raw material; according to specification requirements, separating heads, tentacles and bodies of the squids by cutting; performing embrittlement treatment, wherein 2.5 to 5 grams of baking soda and 2 to 4.5 grams of common salt are added into 1 kilogram of water to obtain embrittlement solution, a weight ratio of the squids to the embrittlement solution is 1:1, the temperature is between 20 and 30 DEG C, and the time is 24 and 48 minutes; cooling the squids in ice water at the temperature of between 5 and 15 DEG C for 30 to 60 minutes; boiling the squids with water at the temperature of between 90 and 100 DEG C for 3 to 8 minutes; draining and cooling the squids, wherein the cooling temperature is between 5 and 20 DEG C, and the cooling time is 20 and 50 minutes; soaking the squids in soaked chili solution at the temperature of between 15 and 28 DEG C for 3 to 10 hours, wherein the soaked chili solution is prepared by boiling a mixture of 300 to 600 grams of soaked chili, spices, salt, sodium glutamate and the like, and finally obtaining the soaked chili squids. The soaked chili squids have a unique flavor, overcomes a defect of hard taste and is rich in nutrition; and heads, tentacles and bodies of the squids can all be used for preparing the soaked chili squid products, so that the taste of soaked chili squids is more agreeable to modern people, and is worthy to be widely spread.

Owner:CNFC ZHOUSHAN MARINE FISHERIES

Continuous basalt fiber reinforced ceramic composite and preparation method for same

The invention discloses a continuous basalt fiber reinforced ceramic composite and preparation method for the ceramic composite, wherein the continuous basalt fiber (CBF) is compounded with ceramic, and then stirred, molded, dried and calcined to obtain the continuous basalt fiber reinforced ceramic composite. According to the invention, the advantages of CBF such as good mechanical property, high toughness, high strength, and good high-temperature resistance are fully utilized. Through the method mentioned above, the defects of low toughness, high fragileness, and easy cracking which are normal in ceramic materials are overcame. In addition, cracking is prevented and resisted, and the toughness and strength are increased so as to expand the application range of the ceramic.

Owner:郭丰亮

Thin-wall high-CTI-value flame-retardant polycarbonate blend and preparation method thereof

The invention relates to the technical field of alloy materials and discloses a thin-wall high-CTI-value flame-retardant polycarbonate blend and a preparation method thereof. Compared with the prior art, a phosphonitrile flame retardant is added into the raw material formula of the preparation method, so that on one hand, the drawbacks that the thermal distortion temperature and flexibility of polycarbonate are substantially decreased due to the addition of an organic phosphate flame retardant in the prior art can be effectively overcome, and the heat resistance and tenacity of a polycarbonatecomposition is effectively improved; and on the other hand, the phosphonitrile flame retardant with effective nitrogen and phosphorus amounts has very good flame-retardant effect, the flame-retardantlevel of the polycarbonate composition can be effectively increased, and meanwhile, the electric leakage marking resistance of the polycarbonate composition can be greatly improved by virtue of the phosphonitrile flame retardant.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Method of preparing modified benzoxazine glass cloth veneer sheet

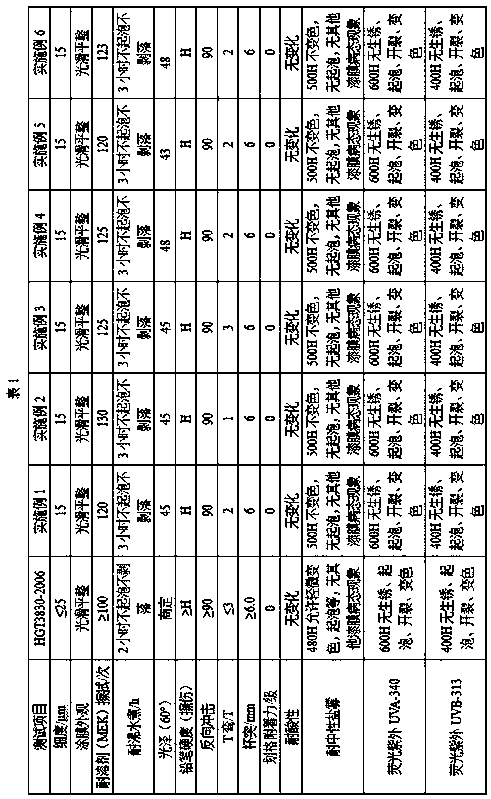

InactiveCN101177055ATroubleshoot technical issues with unbalanced performanceOvercome resilienceLamination ancillary operationsLaminationCross-linkPhenol

The invention discloses a manufacturing method for a new modified benzoxazine glass cloth laminated board, which comprises the steps of modified benzoxazine resin preparation, glue solution preparation and dipping, baking and suppression; wherein, cardanolis is introduced to replace part of phenol in the process of benzoxazine resin synthesis; simultaneously, a dual crossing and curing combination system is adopted, namely a combination of an organic metal complex catalyze solidifying system and a thermal polymerization cross-linking system initiated by peroxide free radical. The invention has the advantages that the benzoxazine glass cloth laminated board has balanced performance; the toughness of benzoxazine is enhanced; simultaneously, the enhanced performance is the material electrical property of the reduced water absorbent of material, the increased resistivity and dielectric intensity strength, mediator loss and dielectric constant, the mechanical strength and heat-resistance are slightly declined, and the invention is applicable to the H class insulation material.

Owner:CHINESE ELECTRICAL EQUIP GRP CO LTD

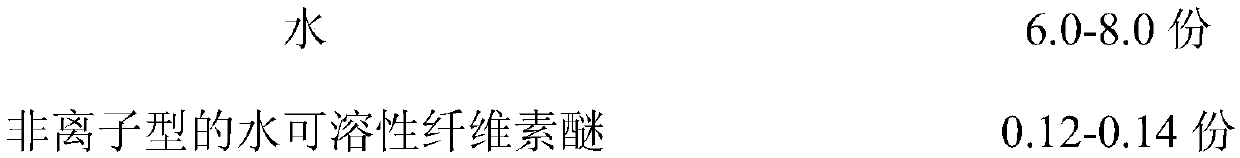

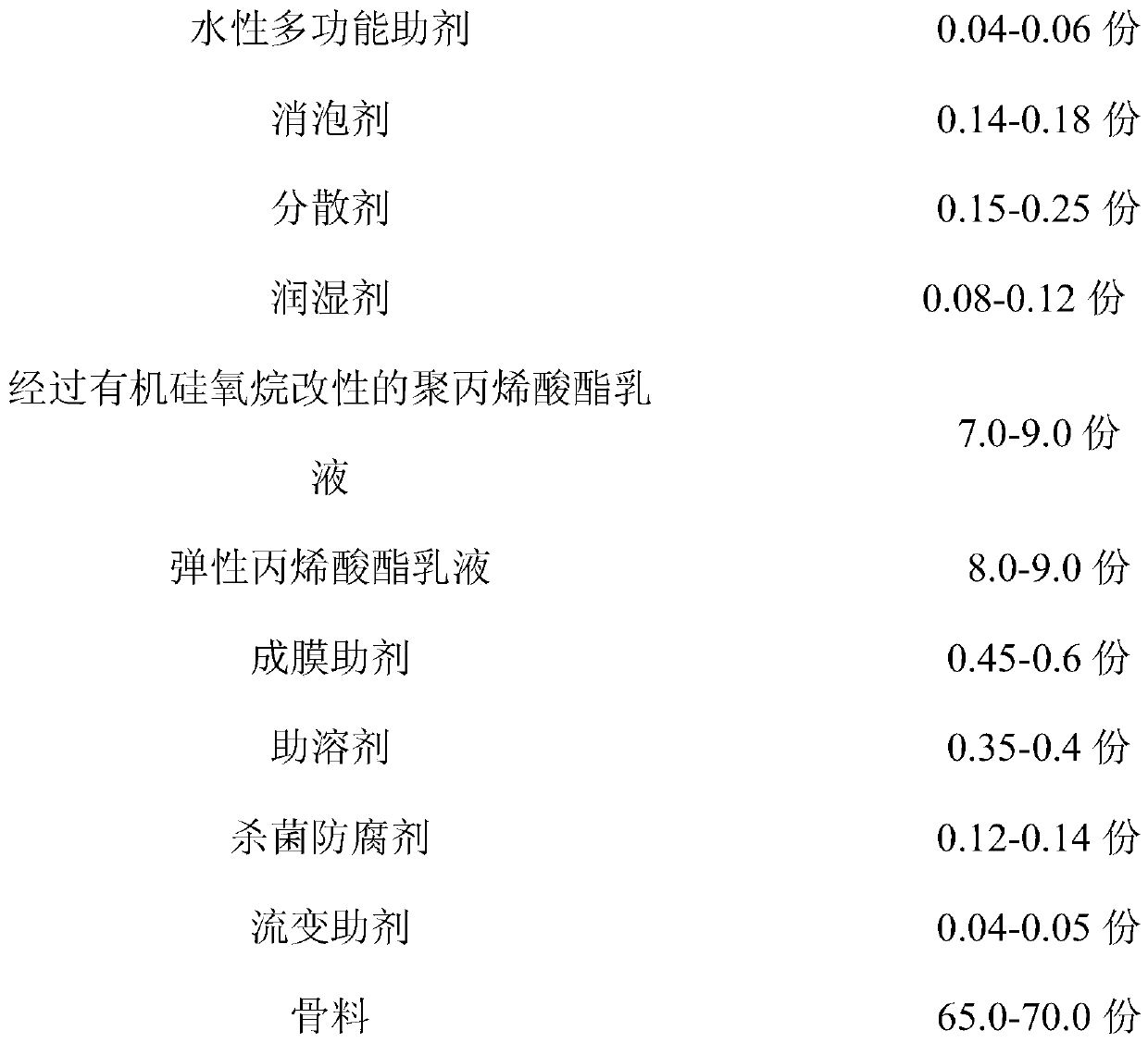

Flexible true stone paint and preparation method thereof

The invention relates to a flexible true stone paint which comprises the following components: water, non-ionic water soluble cellulose ether, a waterborne multifunctional additive, a defoaming agent, a dispersing agent, a wetting agent, acrylic composite emulsion modified by organo-siloxane, elastic acrylate emulsion, a coalescing agent, a complex solubilizer, an antibacterial preservative, a rheological agent and aggregates. The flexible true stone paint disclosed by the invention overcomes the defects of relatively insufficient toughness, high cracking possibility of a paint film and poor stain resistance of an existing true stone paint, and has the advantages of outstanding flexibility, good cracking resistance, and excellent water resistance, weather resistance and stain resistance.

Owner:ANHUI SKSHU PAINT CO LTD

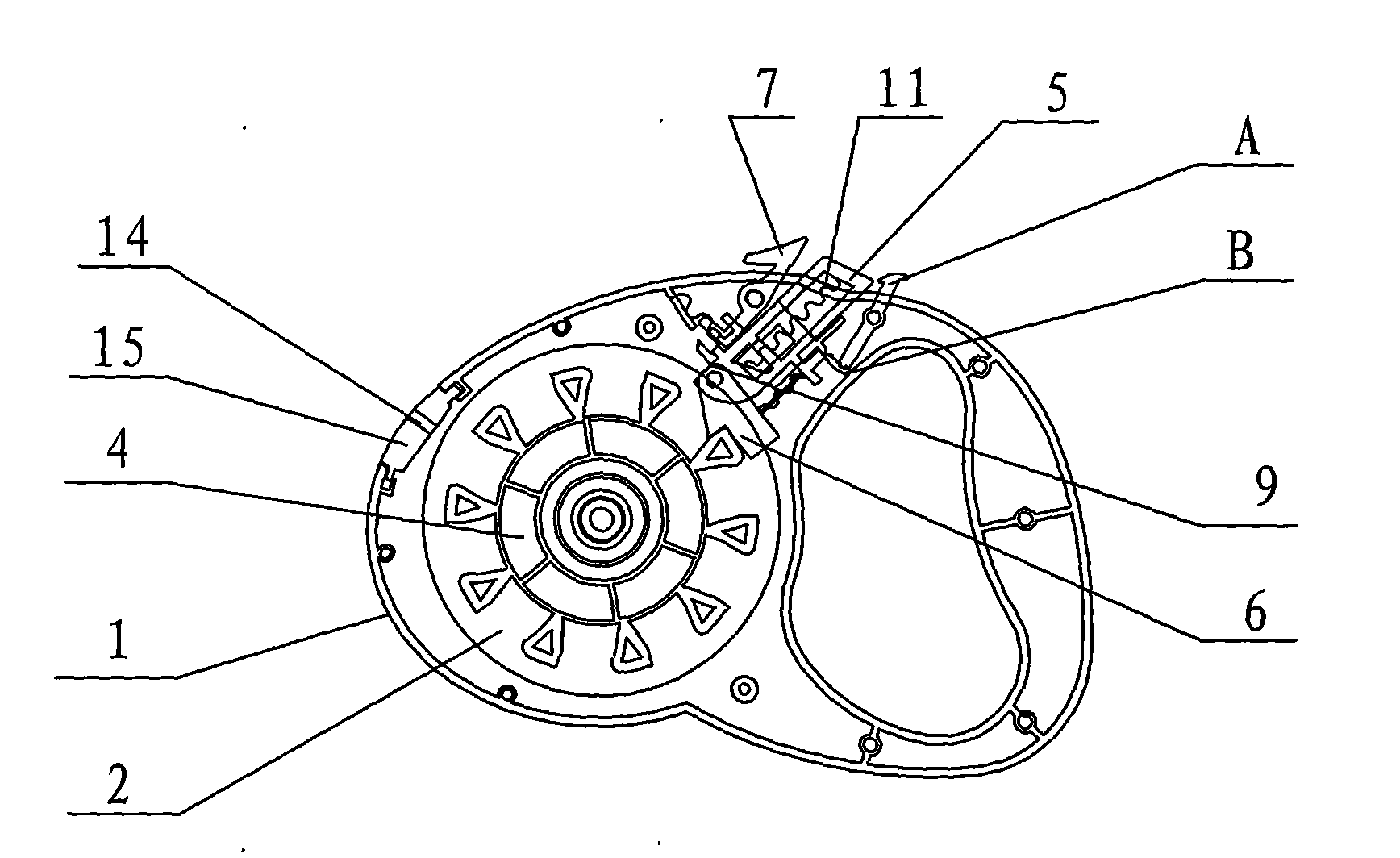

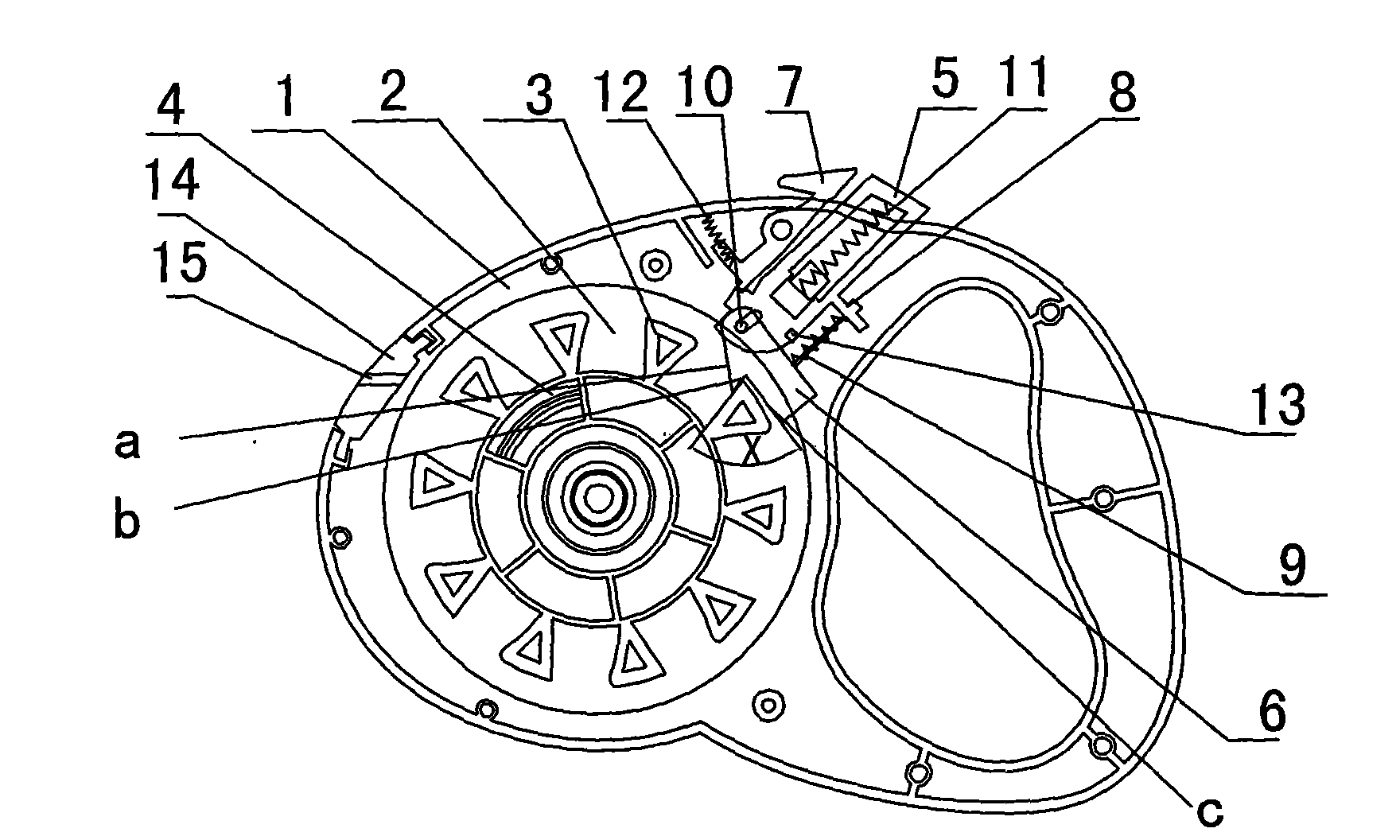

Multi-functional pet traction reel

InactiveCN101637135AEasy accessOvercome resilienceTaming and training devicesEngineeringCompanion animal

The invention belongs to the technical field of pet tools and relates to a multi-functional pet traction reel. The multi-functional pet traction reel comprises a reel which is provided with ratchets and arranged on a shell with a handle; the outer end of a traction rope extends from a pulling opening; a main push button is inserted and arranged around the handle of the shell; one side of the mainpush button is provided with a rotatable card button; the inner end of the main push button is articulated with a pawl; one side of the main push button which deviates from the card button is providedwith a pressure spring; the inner end of the main push button is provided with a locating block and two gear steps which can be respectively engaged with the card button; the ratchets are circumferentially clamped by the pawl when the card button is engaged with a first gear step; and the ratchets are circumferentially clamped by the pawl and the locating block radially presses the ratchets by the pawl when the card button is engaged with a second gear step. The multi-functional pet traction reel has advantages of saving such original parts as a lever-type push button and a limit strip, etc.in structure and reducing the number of operating parts, thus causing operation to be simpler and more convenient and bringing more convenience to owners of pets.

Owner:NANJING TAIFENG IND

Finishing coat of waterborne coiled steel coating and preparation method of finishing coat

ActiveCN109468029AGood flexibilityOvercome resilienceAnti-corrosive paintsPolyester coatingsSolvent basedPolyester resin

The invention relates to the field of waterborne coatings and particularly discloses a finishing coat of a waterborne coiled steel coating and a preparation method of the finishing coat, wherein the finishing coat of the waterborne coiled steel coating comprises the following components: a waterborne polyester resin, a rust-proof sizing agent, an amino resin, an acid catalyst, a wetting agent, a levelling agent, a defoamer, an adhesion promoter, a wetting dispersant, an anti-settling agent, a PH regulator, a cosolvent and water. the provided finishing coat of the coiled steel coating is a waterborne product, the VOC (volatile organic compounds) content is very low, the environment pollution is small, the performance of a T-bend is greatly improved, the T-bend does not crack in winter and is anti-sticking in summer, and the physical and mechanical properties equivalent to those of the solvent based coating are achieved.

Owner:南通科顺建筑新材料有限公司

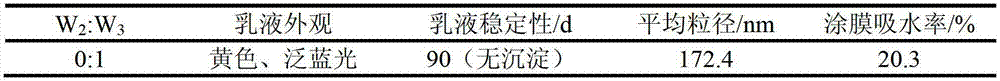

Preparation method of acrylic-resin-modified water-based nitrocellulose emulsion for paint

The invention provides a preparation method of an acrylic-resin-modified water-based nitrocellulose emulsion for paint, which comprises the following steps: in an oxygen-free environment, reacting dehydrated dibutyltin dilaurate, isophorone diisocyanate tripolymer and N-methylpyrrolidone dissolved dimethylolpropionic acid at 40-45 DEG C for 1 hour, adding butanone dissolved nitrocellulose at 72 DEG C to react for 2 hours, cooling to 40 DEG C, regulating the pH value of the reaction solution to 8-9, cooling to room temperature, and adding water into the reaction solution while stirring uniformly to obtain a water-based nitrocellulose emulsion; and physically mixing the water-based acrylic emulsion and water-based nitrocellulose emulsion at room temperature to obtain the acrylic-resin-modified water-based nitrocellulose emulsion for paint. The preparation technique is simple; and the prepared acrylic-resin-modified water-based nitrocellulose emulsion for paint has the advantages of high stability, high flexibility, high adhesive force, certain fullness, yellowing resistance, water resistance and no pollution.

Owner:SHAANXI UNIV OF SCI & TECH

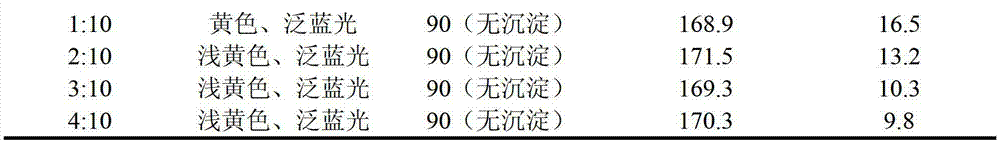

Wheat bran rice cake and preparation method thereof

InactiveCN105831593AAvoid condensationFully and effectively combinedFood ingredientsSucroseCarrageenan

The present invention relates to a wheat bran rice cake and a preparation method thereof. The wheat bran rice cake is characterized by being prepared from the following raw materials in parts by weight: 10-15 parts of wheat bran, 85-90 parts of glutinous rice flour, 10-20 parts of white granulated sugar, 1.6-2.0 parts of an emulsification enhancer and 60-70 parts of water. A low-temperature and hot-air drying technology is used to remove parts of water content in the wheat bran and the dried wheat bran is ground into a size of 50 [mu]m or below using a ultrafine grinder. Sucrose fatty acid ester is used to disperse the wheat bran and prevent the aging of the rice cakes. A compounding of carrageenan and potassium chloride is used to improve the waxiness and toughness, and prevent collapses of the rice cakes. Finally, the rice cakes are prepared by processing the white granulated sugar and the glutinous rice flour in normal processing methods of the rice cakes. The wheat bran rice cakes are fat, fragrant and soft, sweet, loose, glutinous and tough, and rich in dietary fibers. The preparation method is simple and low in costs.

Owner:BENGBU COLLEGE +1

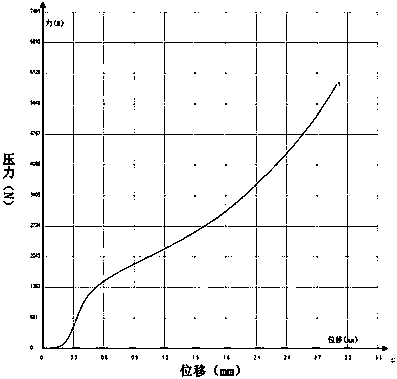

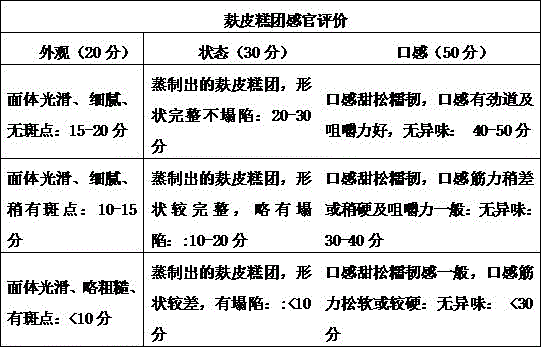

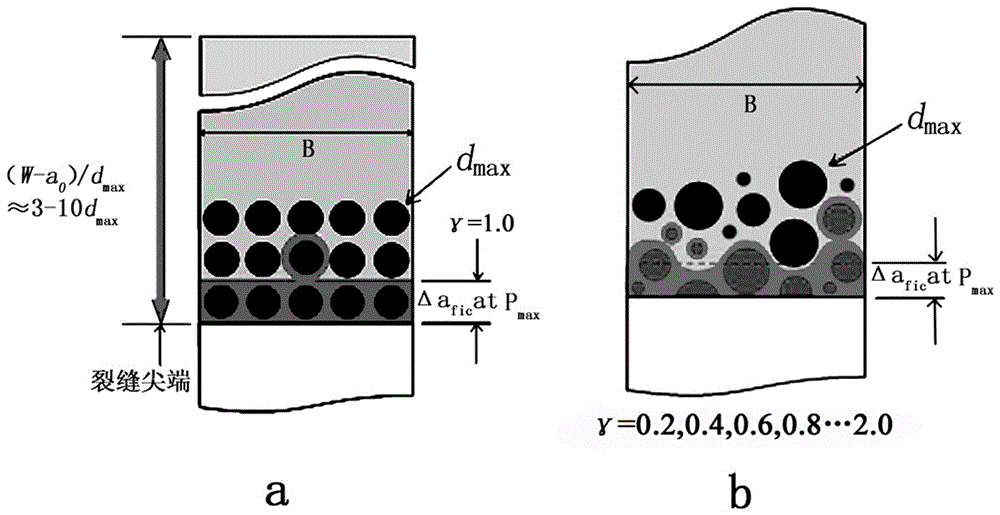

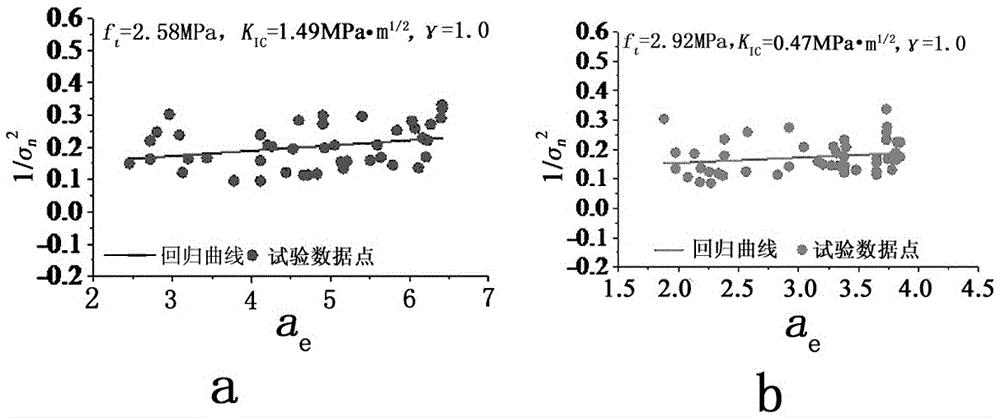

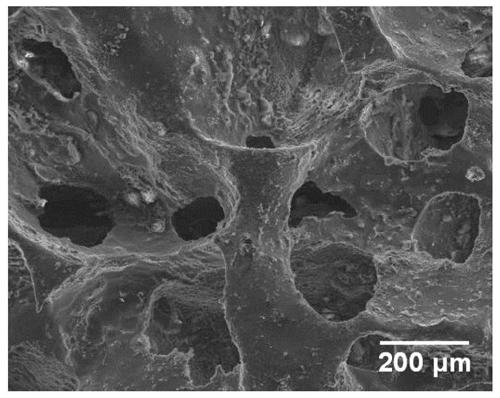

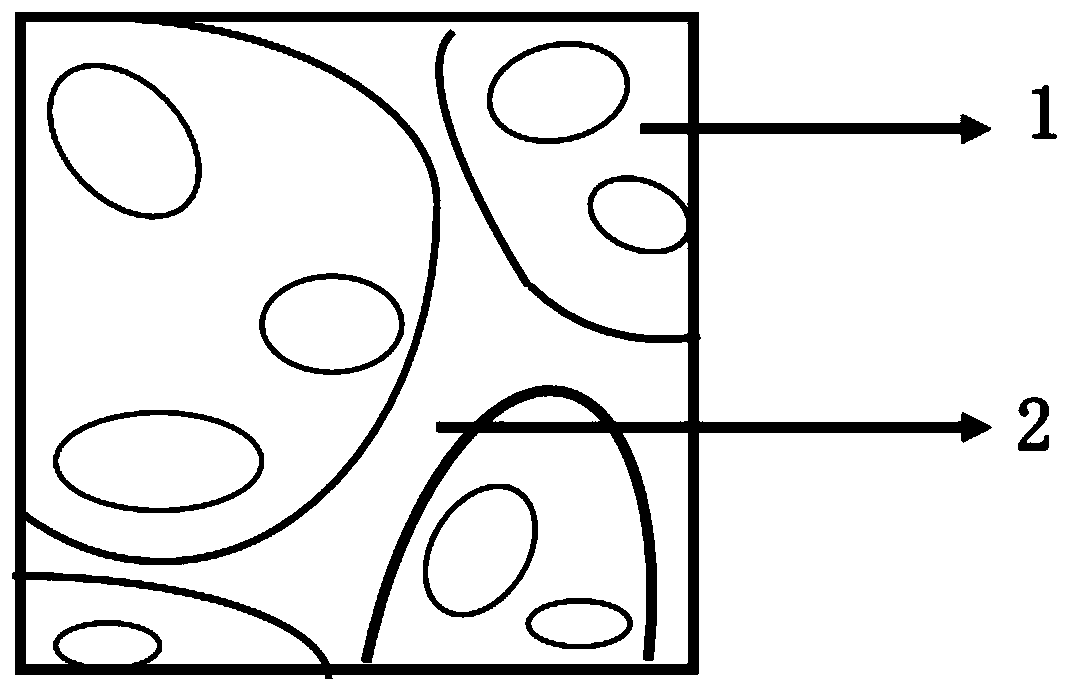

Method for measuring tensile strength and fracture toughness of cement mortar or concrete

InactiveCN105823686AReduce difficultyReduce workloadPreparing sample for investigationMaterial strength using tensile/compressive forcesRegression analysisPeak load

The invention discloses a method for measuring tensile strength and fracture toughness of cement mortar or concrete. The method comprises the steps of pouring test pieces, cutting cracks, static loading, recording peak loads, calculating a nominal intensity (Sigma)n, calculating an equivalent crack length ae, and finally obtaining the tensile strength ft and the fracture toughness KIC of cement mortar or concrete simultaneously through regression analysis. The method provided by the invention is simple in form, easy to operate tests, sufficient in accuracy and easy to judge the reasonableness of results; the tensile strength ft and fracture toughness KIC of cement mortar or concrete can be determined simultaneously just by peak loads of small-size test pieces.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Medical degradable antibacterial composite material as well as preparation method and application thereof

InactiveCN111068106AImprove toughnessEnhancement effect is goodTissue regenerationProsthesisMg alloysOrthopedic department

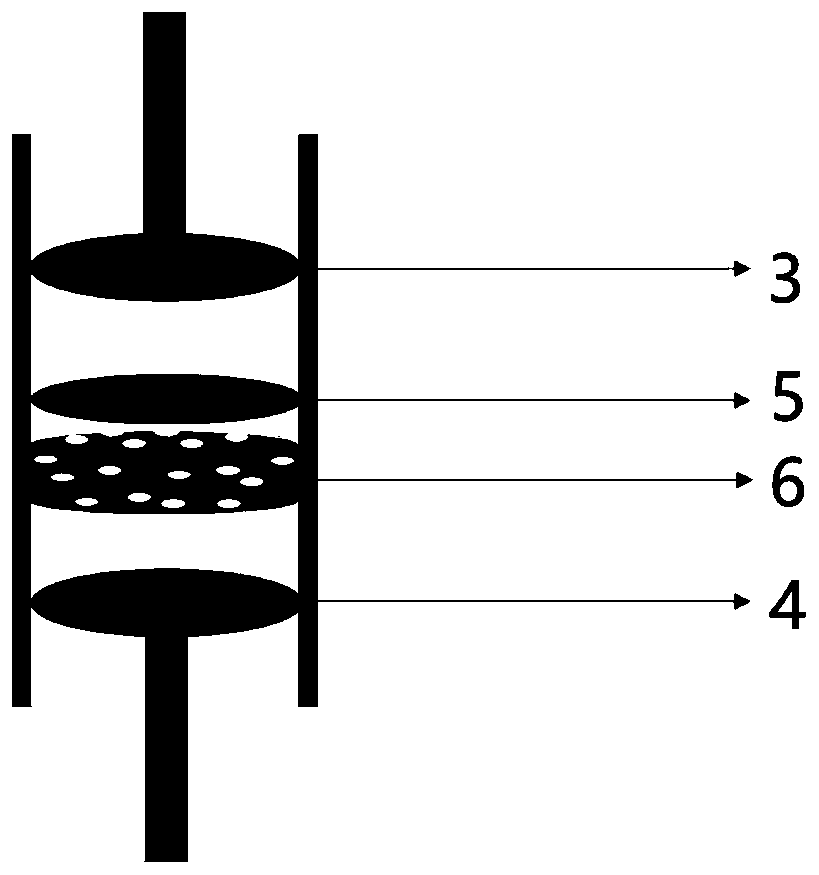

The invention discloses a medical degradable antibacterial composite material as well as a preparation method and application thereof. The composite material uses a porous magnesium alloy (6) having through holes as a reinforcement body, the holes (1) of the reinforcement body are filled with degradable polymer materials polycaprolactone and polylactic acid, and nano-magnesium oxide powder is uniformly dispersed in the degradable polymer materials. The preparation method of the composite material comprises the following steps: 1) preparing the porous magnesium alloy (6) reinforcement body; 2)mixing the nano-magnesium oxide powder, the polylactic acid and the polycaprolactone, performing mold pressing to obtain a polymer thin sheet (5); and 3) placing the polymer thin sheet (5) on the porous magnesium alloy (6), and performing extrusion and solidification to obtain the composite material. The composite material has good biocompatibility, safe, stable and controllable degradation, goodmechanical properties and an antibacterial function, is suitable for small orthopedic restoration products with various shapes, and can be used as a new generation of degradable materials to be used in bone trauma surgery, bone defect repair surgery, plastic surgery and other medical implantation fields.

Owner:SOUTHEAST UNIV

3D laser carving high-toughness UV type PVD finish paint

ActiveCN108300277ASolve extensive versatility problems such as poor matchingExcellent resistance to high temperature and high humidityPolyurea/polyurethane coatingsDiluentPliability

The invention relates to 3D laser carving high-toughness UV type PVD finish paint, which is mainly prepared from the following ingredients in parts by weight: 5 to 35 parts of high-functionality urethane acrylate, 5 to 30 parts of thermoplastic acrylate, 1 to 10 parts of reactive diluent, 0.1 to 5.0 parts of photoinitiators, 0.1 to 0.6 part of auxiliary agents and 35 to 80 parts of diluents. The finish paint provided by the invention effectively solves the wide universal problems that the paint adhesion and the toughness of the UV light curing vacuum film plating paint are low, and the matching of the primer of the UV light curing vacuum film plating paint and finish paint in the PU color paint is poor, and the like. The finish paint provided by the invention has a good protection effect and very high flexibility; an obtained paint film has the characteristics of high toughness, high bending performance, excellent annular testing performance and yellowing resistance performance and thelike. Meanwhile, the finish paint has the characteristics that the operation is convenient; the construction is simple; the normal temperature curing is realized; the applicability is wide, and the like. the appearance effect and the service life of the electronic product are effectively improved.

Owner:YIXING HONGTAI CHEM

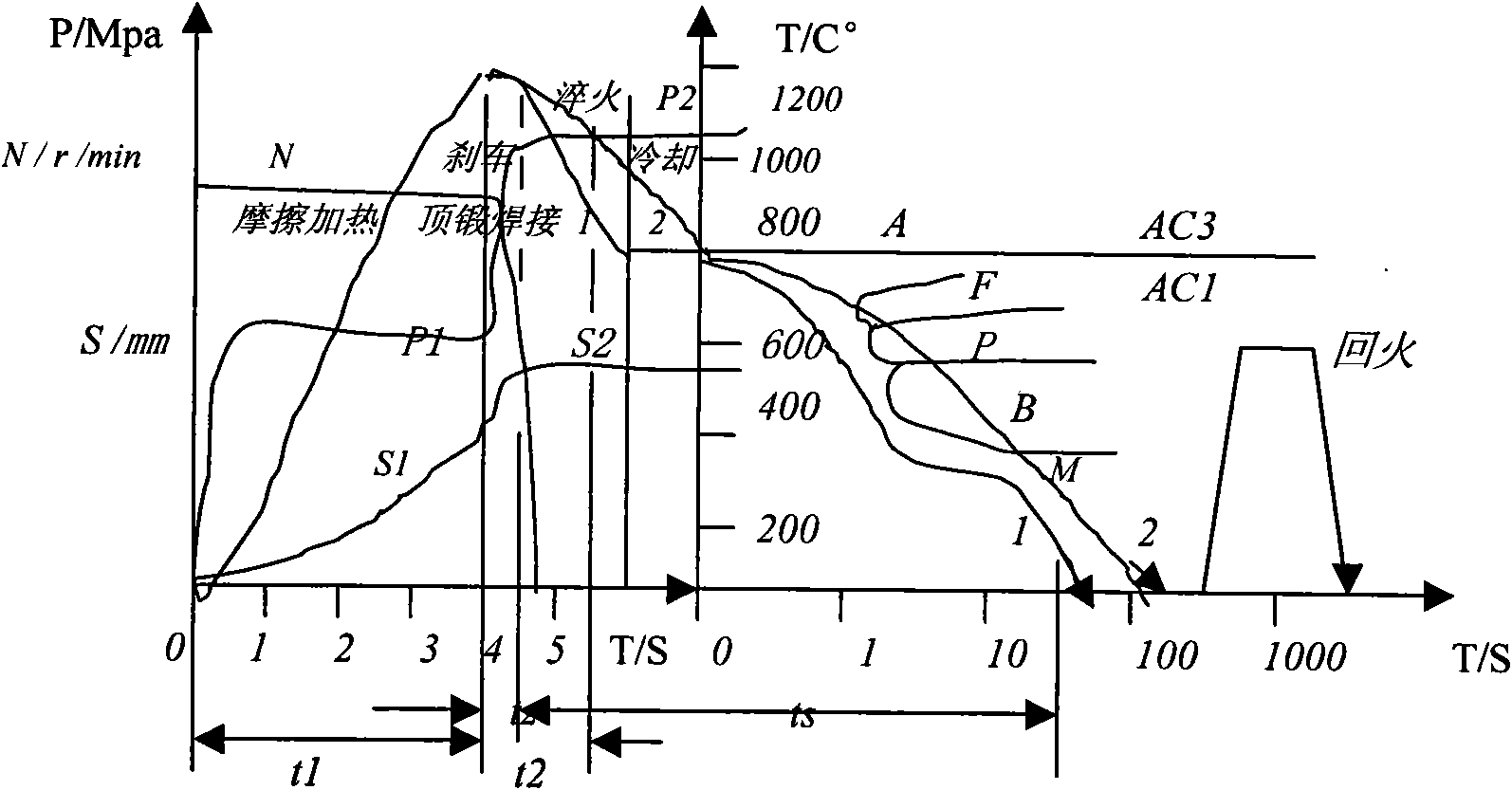

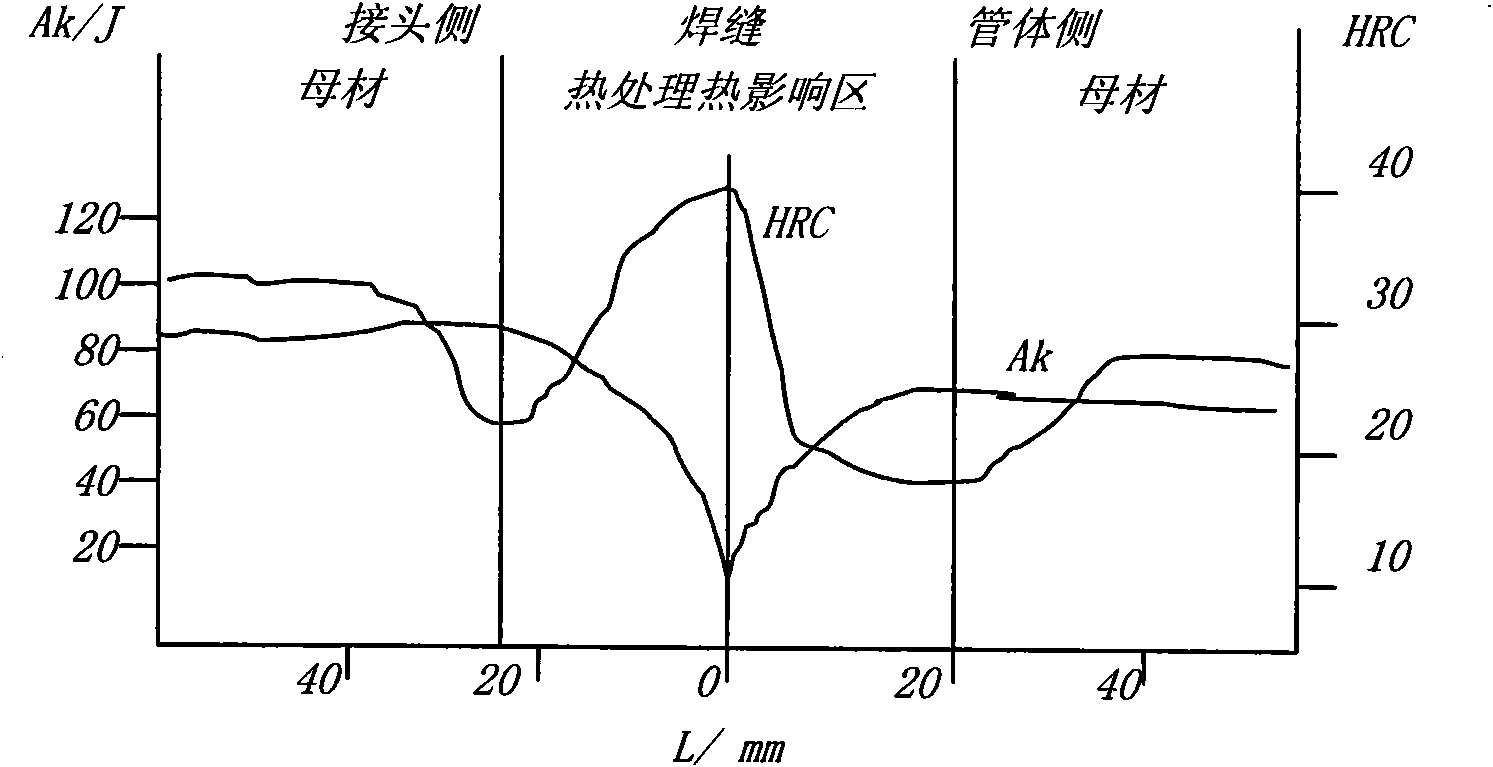

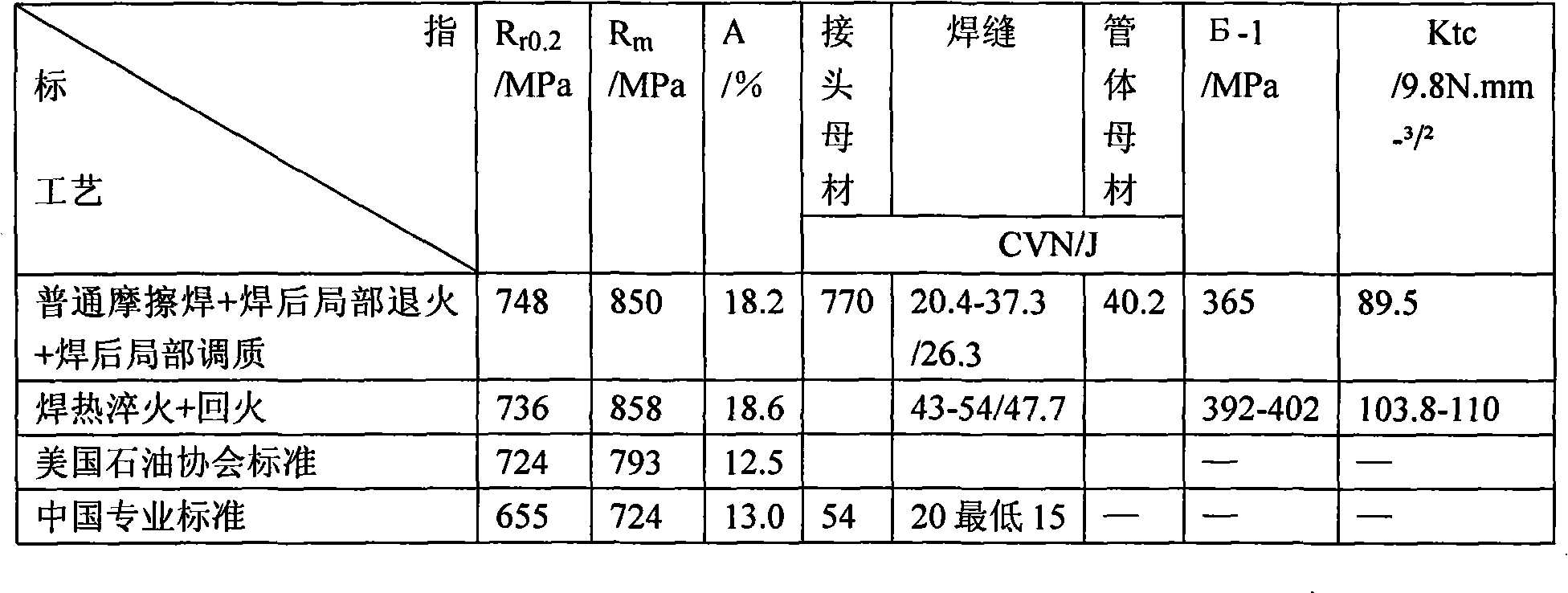

Deformation heat treatment method of petroleum drill pipe friction welding joint

InactiveCN101649376AOvercome resilienceOvercome strengthNon-electric welding apparatusFriction weldingPhase change

The invention relates to a deformation heat treatment method of a petroleum drill pipe friction welding joint. The method is characterized in that: a welded friction heating heat source is taken as aheating heat source of welding joint quenching treatment; a joint area is rapidly cooled by using a quenching device arranged on a welder to spray a quenching medium to a welding area in time at a moment after a friction heating stage is finished and before upsetting welding is finished in the process of friction welding; then the welding area is tampered by a tampering device arranged on the welder likewise; and a metal of the welding area is strengthened by both deformation and phase change. Thus, the method can complete friction welding of weldments and hardening and tempering treatment ofthe welding area on the welder and saves three working procedures of annealing, quenching and tempering in the prior welding process. The method improves fatigue life of the welding area and reduces tendency of welding line brittle failure during using the drill pipe.

Owner:江阴兴鼎石油管具有限公司

Radiation-resistant anti-cracking heat-insulating concrete

The invention provides radiation-resistant anti-cracking heat-insulating concrete, which comprises the following raw materials in parts by weight: 60 to 70 parts of cement, 3 to 6 parts of zirconium oxide, 3 to 6 parts of magnetite, 5 to 10 parts of inorganic fibers, 1 to 3 parts of a water-reducing agent, 35 to 45 parts of sand, 35 to 45 parts of coal ash, 7 to 10 parts of sodium dodecyl benzene sulfonate, 3 to 5 parts of bone glue, 5 to 10 parts of polyvinyl alcohol, 3 to 6 parts of silicon micropowder and 60 to 70 parts of water. The heat-insulating concrete provided by the invention guarantees excellent strength on the premise of reducing the cost, has excellent radiation resistance and toughness, overcomes the defects that the foam concrete has low toughness and low strength and is liable to crack in the prior art, and has heat-insulating and sound-insulating properties, impermeability, erosion resistance and other performance.

Owner:JIANGSU SUZHONG CONSTR GROUP

Reactive extrusion toughening carbon fiber reinforced polylactic acid 3D printing material and preparation method thereof

ActiveCN106867213AOvercome resilienceOvercoming the problem of low elongation at breakAdditive manufacturing apparatusFiberCarbon fibers

The invention discloses a reactive extrusion toughening carbon fiber reinforced polylactic acid 3D printing material and a preparation method thereof, and relates to the technical field of 3D printing materials. Raw materials are mixed according to the formula and then the mixed raw materials are put into a twin-screw extruder to be extruded after frit reaction and a reaction extrusion toughening modification carbon fiber reinforced polylactic acid 3D printing wire material is obtained after cooling. The reactive extrusion toughening technology overcomes the problems of poor toughness and low elongation at break of the wire material with high carbon fiber content, is beneficial to improvement of the interface compatibility between carbon fiber and polylactic acid, and effectively ensures that the printing process of the printed pieces is smooth. The processing time is short, the working process is environmentally friendly, the use of a large number of mixed acid is avoided, environmental pollution is reduced, the cost is low, and the reactive extrusion toughening carbon fiber reinforced polylactic acid 3D printing material and the preparation method thereof are suitable for industrial production.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Nylon/carbon nano-tube composite material and preparation method thereof

The invention relates to the technical field of nylon composite materials, and particularly relates to a nylon / carbon nano-tube composite material and a preparation method thereof. The nylon / carbon nano-tube composite powdered material for selective laser sintering (SLS) is prepared from the following components: nylon resin, solvent, carbon nano-tubes, a carbon nano-tube dispersing agent, a flow promoting agent and an antioxidant. The nylon / carbon nano-tube composite powdered material has excellent mechanical performance, the carbon nano-tube has excellent dispersibility, the molded part prepared by sintering SLS has excellent molding effect and excellent size accuracy, and the material is simple in preparation process, environment-friendly and pollution-free.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

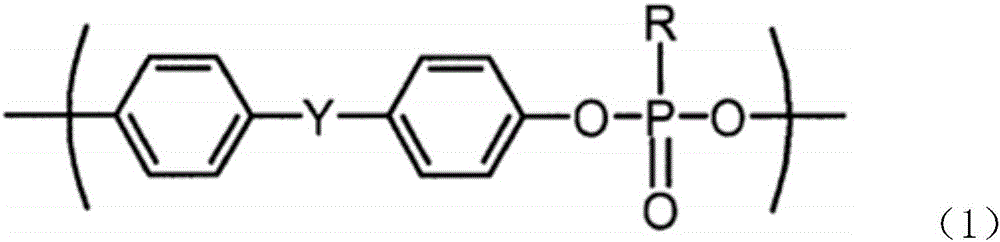

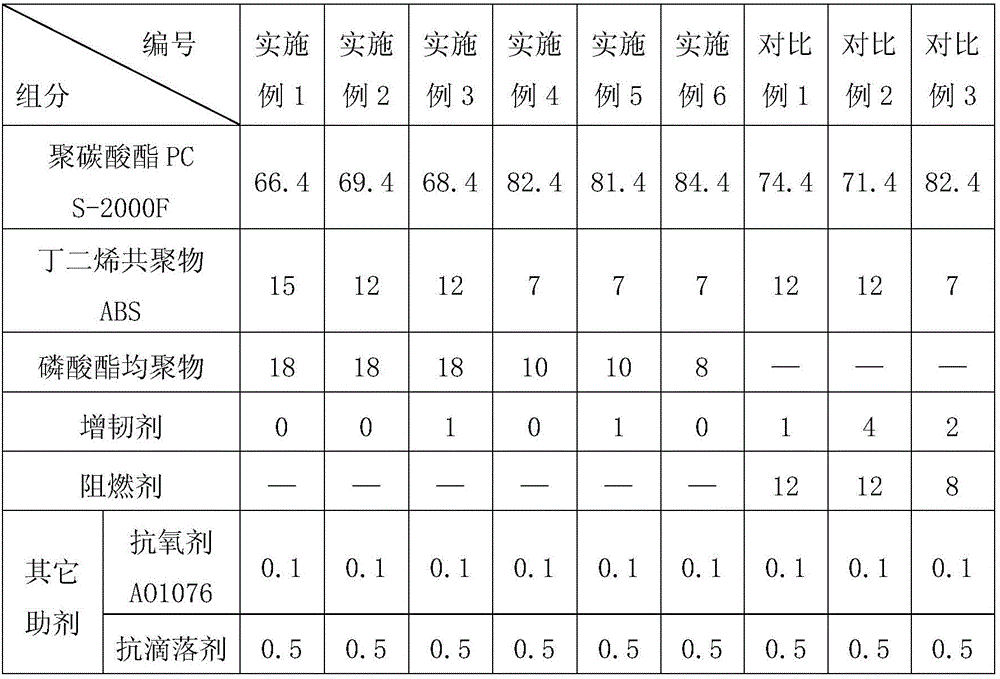

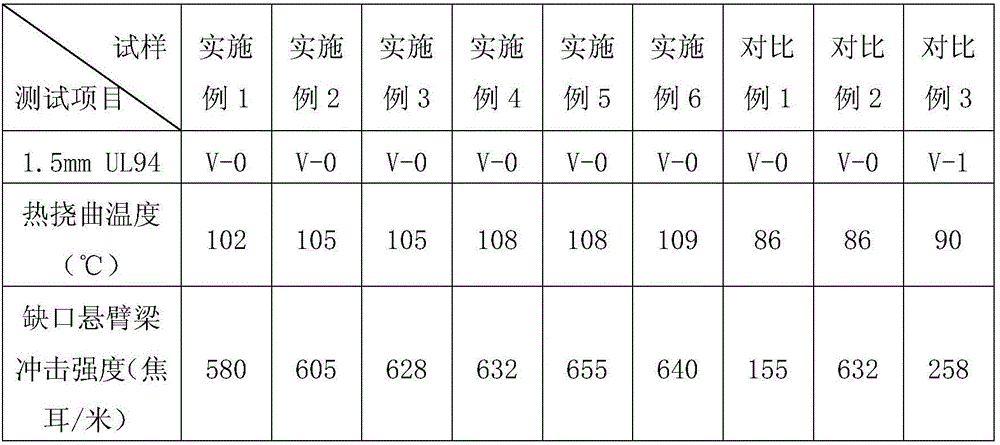

High-heat resistance and high-toughness polycarbonate composition and preparation method thereof

ActiveCN106084717AImprove flame retardant performanceOvercome the heat distortion temperaturePhosphateHeat resistance

The invention discloses a high-heat resistance and high-toughness polycarbonate composition and a preparation method thereof. The composition comprises, by weight, 60-90 parts of polycarbonate, 1-20 parts of a butadiene copolymer, 5-25 parts of a phosphate ester homopolymer, 0-8 parts of a flexibilizer and 0-9.6 parts of other assistants, and the quantity sum of weight parts of all above components is 100. Compared with the prior art, the preparation method has the following advantages: addition of the phosphate ester homopolymer to the raw material formula well overcomes an abuse that present organophosphate flame retardant greatly reduces the heat deformation temperature and the toughness of polycarbonate, effectively improves the heat resistance and the toughness of the polycarbonate composition, has a very good flame retardation effect, and effectively improves the flame retardation grade of the polycarbonate composition; and the phosphate ester homopolymer has extremely good compatibility with polycarbonate, has no plasticizing effect on alloy, and obviously improves the heat resistance of the polycarbonate composition without influencing the flame retardation grade or the toughness of the polycarbonate composition.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Anti-exposure eucalyptus laminated wood veneer and production method thereof

ActiveCN103406950AAvoid drum deformationImprove insulation performanceWood veneer joiningWood veneerAdhesive

The invention provides a production method of an anti-exposure eucalyptus laminated wood veneer. The artificial board is composed of a base material, softwood and melamine impregnated paper or aluminum oxide abrasion-resistant paper, wherein the base material is formed by bonding 3-15 layers of eucalyptus veneers through adhesives, the softwood is bonded on two sides of the base material, and the melamine impregnated paper or the aluminum oxide abrasion-resistant paper is pasted onto the surface of the softwood. The production method comprises the steps of veneer sorting, gluing, cold pressing, hot pressing, stacking maintenance, pasting of the softwood and pasting of the melamine impregnated paper or the aluminum oxide abrasion-resistant paper. The production method is characterized in that the base material is produced through three times of cold pressing and hot pressing, two times of thermostatic chamber standing maintenance and cooling maintenance processes; and the softwood is pasted onto the two sides of the base material. The anti-exposure eucalyptus laminated wood veneer is used for manufacturing furniture or wood floors and has the advantage that the wood veneer does not bulge and deform after exposed for a long time.

Owner:莫明鑫

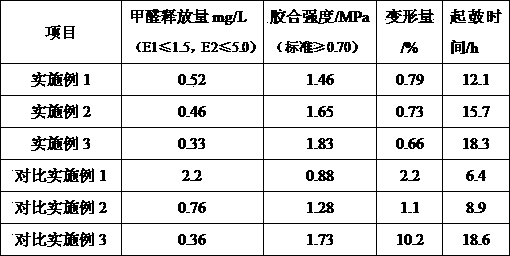

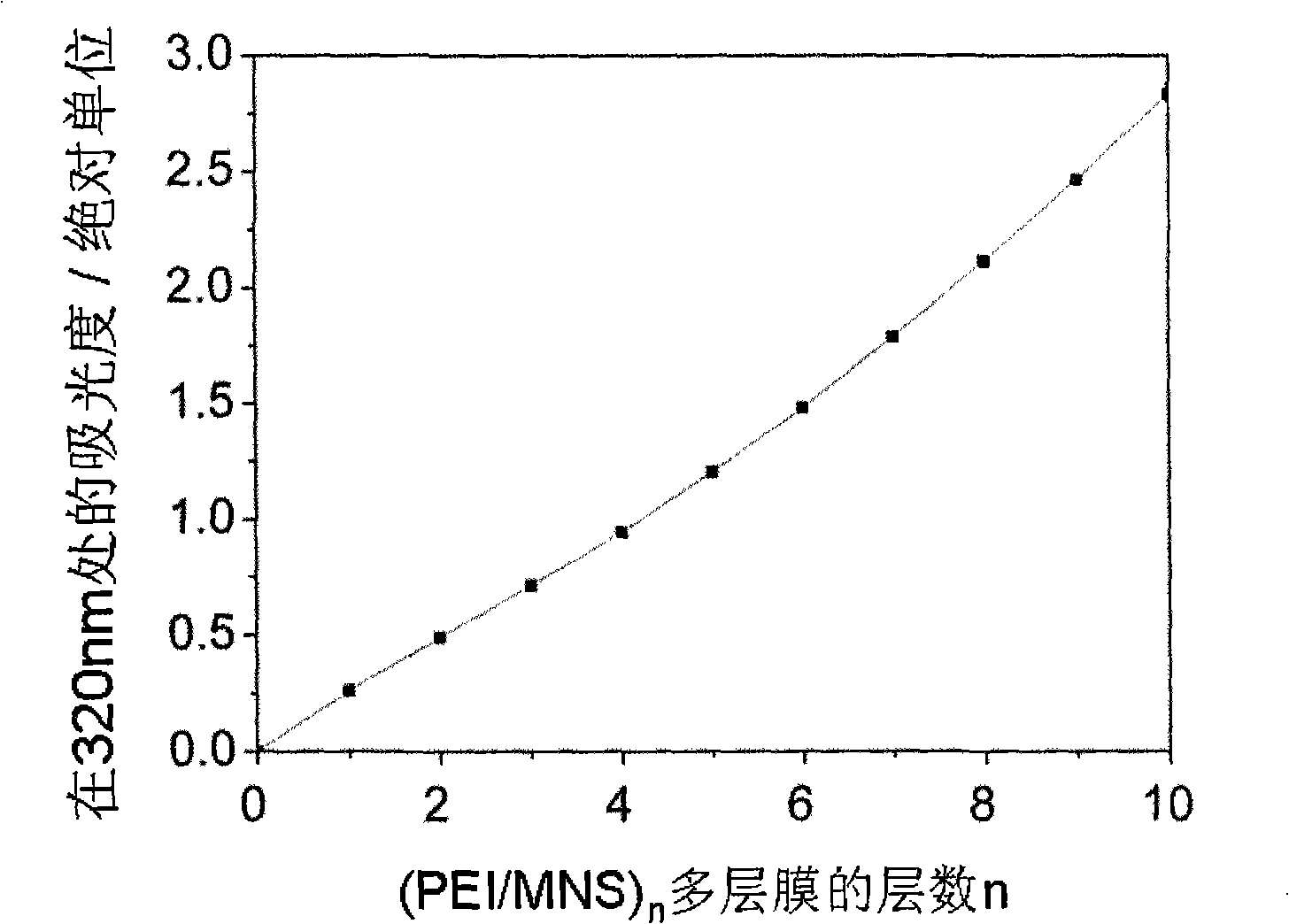

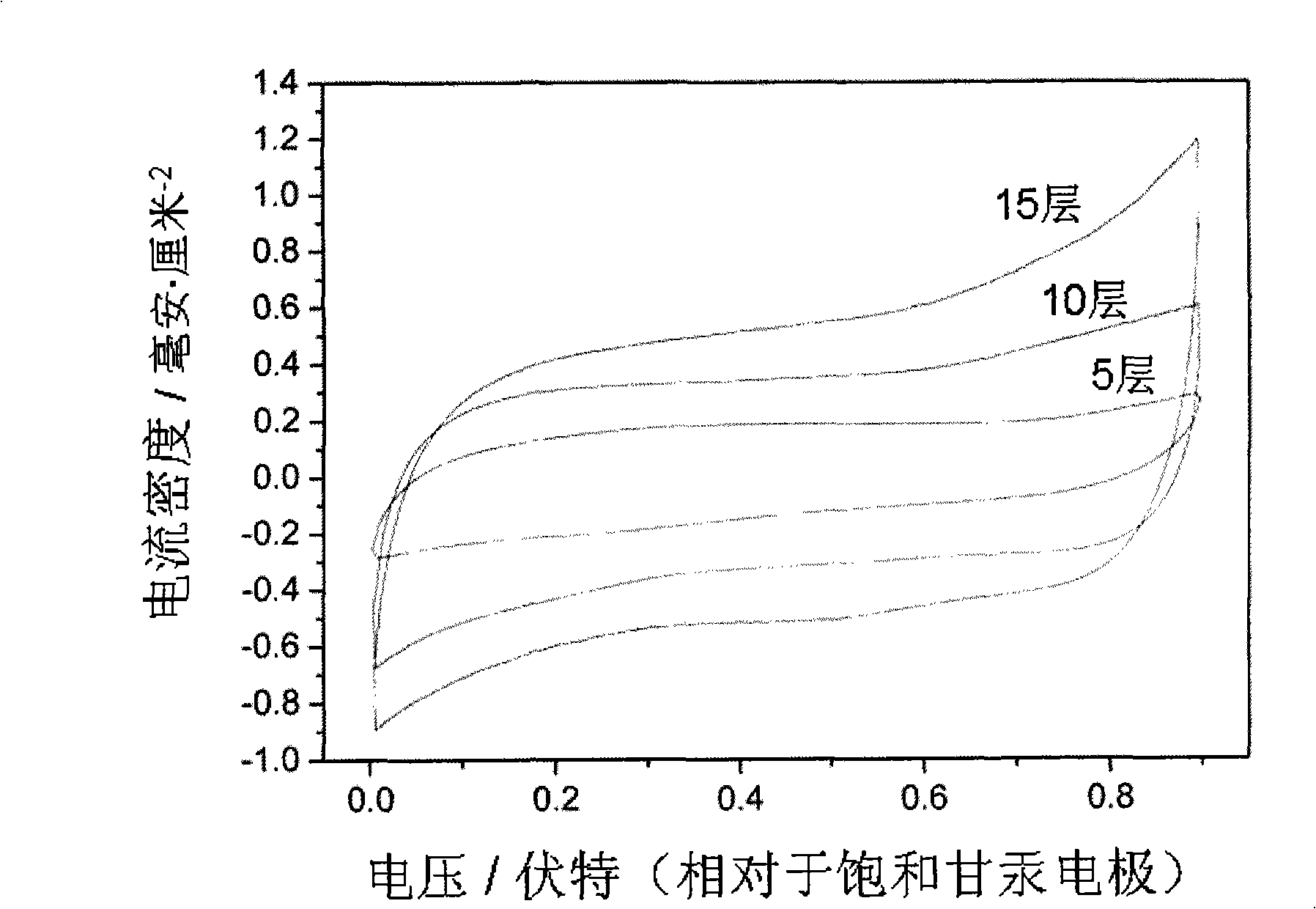

Polyethylene imine/manganese dioxide nano sheet multiple-layer composite film and preparation method thereof

InactiveCN101255261AIncrease profitHigh specific capacityLamination ancillary operationsSynthetic resin layered productsCapacitanceComposite film

The invention provides a polyethyleneimine / manganese dioxide nm multilayer composite membrane and preparation method, belonging to super capacitor electrode material technical field. The chemical composition of multilayer composite membrane is PEI / MNS)n, wherein PEI is polyethyleneimine, MNS is manganese dioxide nm sheet with negative charge, n is number of layers of multilayer composite membrane and 3<=n<=20. The polyethyleneimine with positive charge and managanese dioxide nm sheet with negative charge are recurrently deposited in turn on a substrate after surface treatment by static self-assembly technique. The multilayer composite membrane as electrode material of super capacitor has features of high specific capacitance, good magnification characteristic and excellent electrochemical cycle performance, in addition, the preparation method can perform at room temperature and under solution system. The dear device is not necessary and the operation is convenient and material cost is low.

Owner:BEIJING UNIV OF CHEM TECH

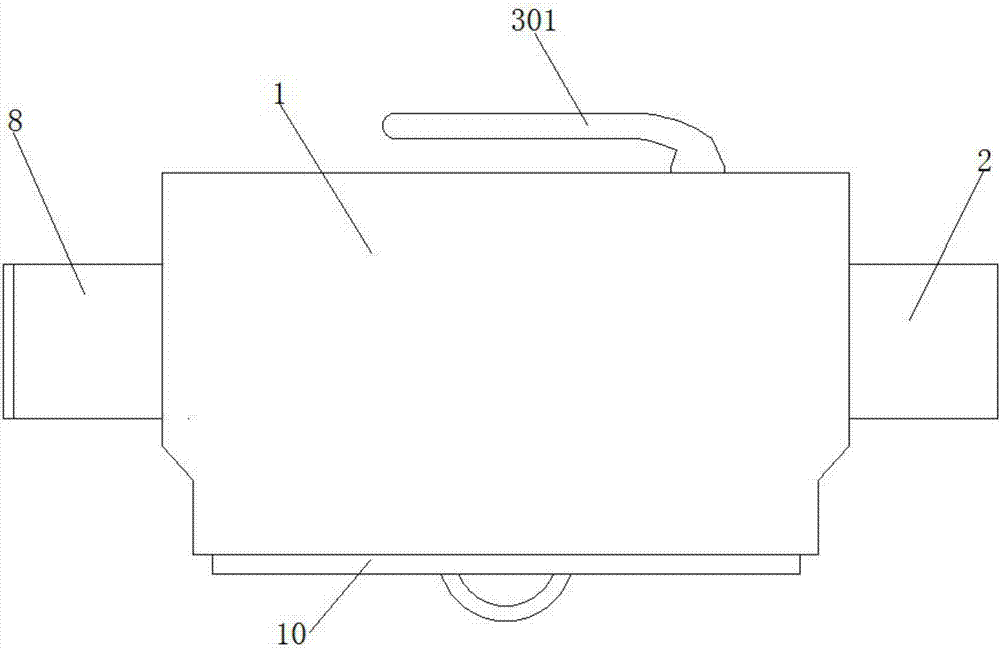

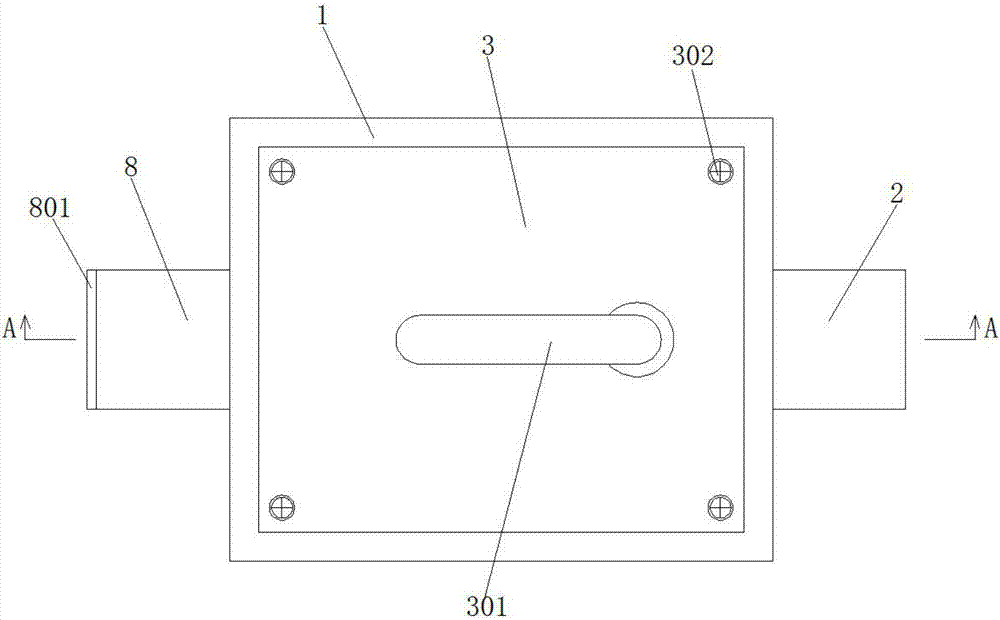

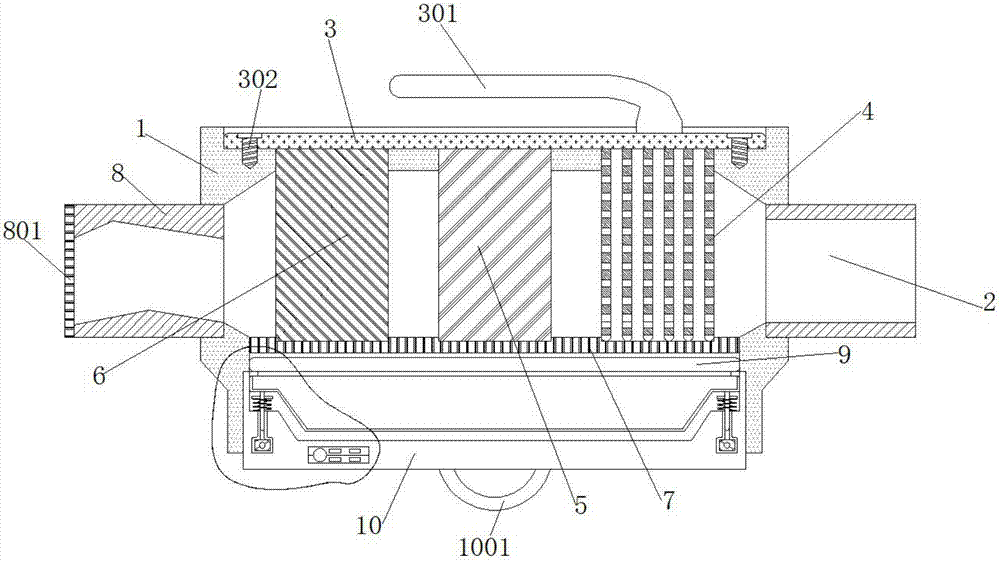

Multiple-filtering environmental protection device for automobile exhaust gas

InactiveCN106958476AImprove adsorption capacityEffective blockingInternal combustion piston enginesExhaust apparatusEngineeringExhaust pipe

The invention discloses a multiple-filtering environmental protection device for automobile exhaust gas. The multiple-filtering environmental protection device comprises a shell, a connection pipe, a cover plate, a first filter element, a second filter element, a third filter element, a supporting net, a gas exhaust pipe, oil suction cotton, a pedestal, an alarm device, a guide sleeve, a pressure sensor, a triggering rod, a baffle, a spring and an oil receiver. The multiple-filtering environmental protection device for automobile exhaust gas is ingenious in structure and strong in function; by the use of the device, the automobile exhaust gas can be effectively filtered, and pollution to the environment due to the exhaust gas can be avoided; besides, collected waste oil particles can be cleared through simple operation according to a requirement, so that the device can be continuously used; and finally by the arrangement, the environmental protection is greatly enhanced, and the investment cost of a user is also reduced.

Owner:龚岑越

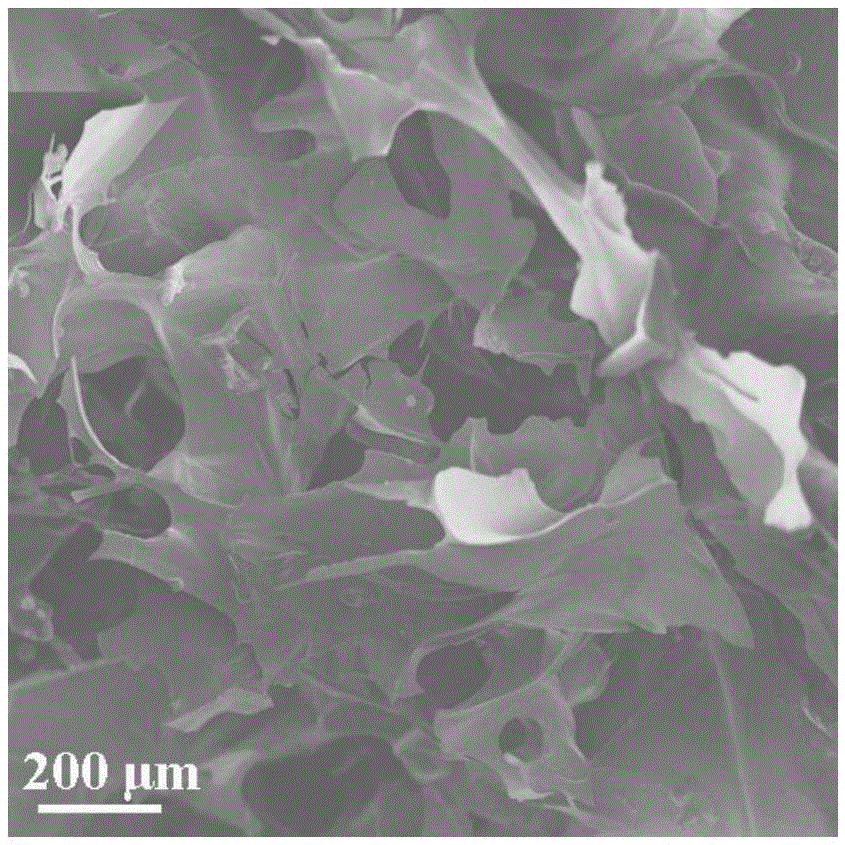

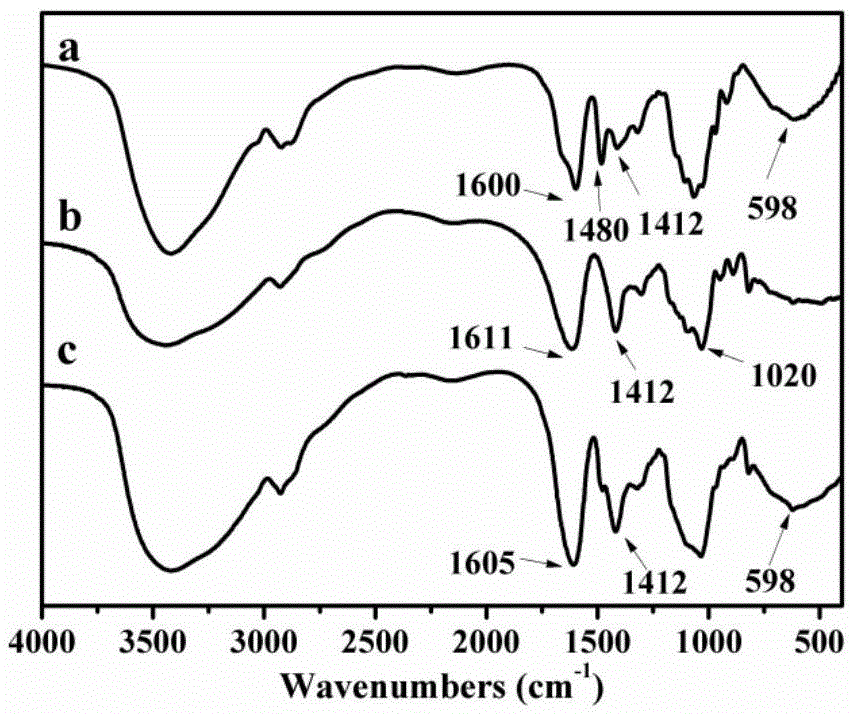

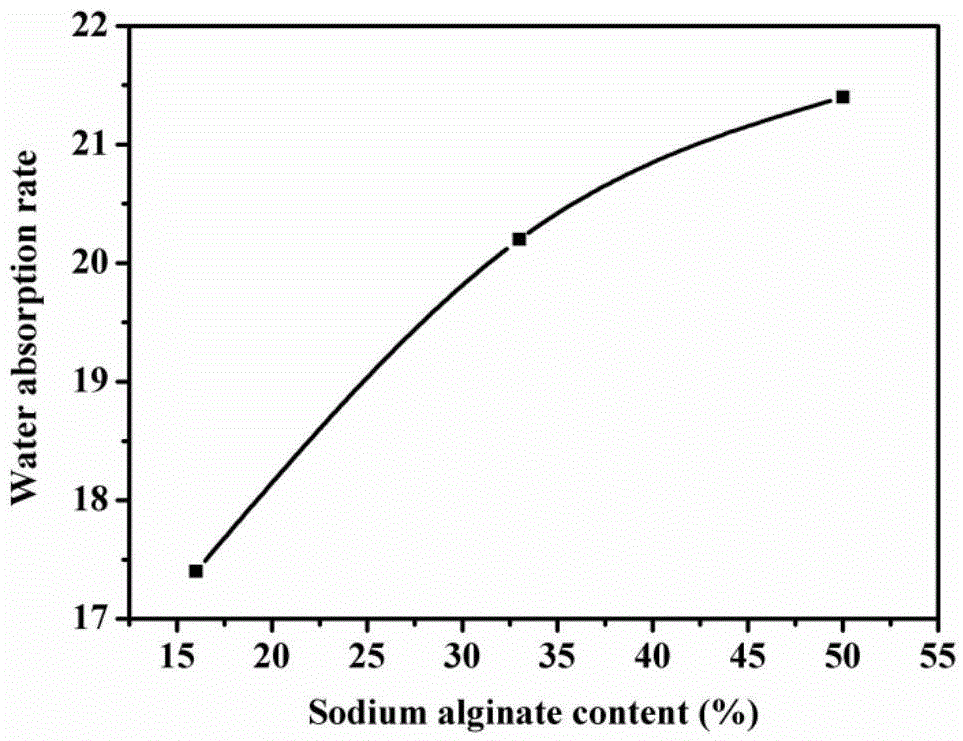

Antibacterial and hemostasia compound sponge and preparation method thereof

InactiveCN105641739AReduce usageGrowth inhibitionSurgical adhesivesPharmaceutical delivery mechanismFreeze-dryingGreen chemistry

The invention discloses an antibacterial and hemostasia compound sponge and a preparation method thereof. The method includes the steps of using carboxymethyl chitosan quaternary ammonium salt / organic montmorillonite nanocomposite and sodium alginate as raw materials, and conducting blending, ion crosslinking and freeze-drying to finally obtain the compound sponge. The antibacterial and hemostasia compound sponge of the three-dimensional network structure is obtained by controlling the concentration of carboxymethyl chitosan quaternary ammonium salt / organic montmorillonite and the concentration and crosslinking time of sodium alginate. The operation in the process is simple, organic crosslinking agents are avoided, and the preparation method is green and environmentally friendly and completely conforms to the requirement for 'green chemistry'. The compound sponge prepared through the method has good physical strength and antibacterial performance, and has the advantages of being high in water absorption, capable of achieving hemostasis and promoting wound healing and the like. Therefore, the antibacterial and hemostasia compound sponge has great application prospects in the field of biomechanical materials.

Owner:SOUTH CHINA UNIV OF TECH

High-strength composite ceramic tool and preparation method thereof

The invention provides a high-strength composite ceramic tool and a preparation method thereof, and relates to the field of ceramic preparation. The high-strength composite ceramic tool mainly comprises, by weight, 60-75 parts of zirconium oxide, 4-8 parts of scandium oxide, 1-5 parts of diboride chromium, 3-7 parts of diatomite, 1-7 parts of magnesium oxide, 2-4 parts of borax, 0.5-3 parts of tantalum silicide, 0.12-0.5 part of titanium oxide, 0.02-0.10 part of lanthanum nitrate, 0.01-0.5 part of cerium chloride, 2-5 parts of dispersing agents, 0.2-5 parts of binding agents, 0.2-0.5 part of tetramethyl ammonium hydroxide, 13-17 parts of diethanol amine and 23-28 parts of ammonium hydroxide, and further comprises, by weight, 2-6 parts of yttrium oxide and 3-6 parts of aluminum oxide. The composite ceramic tool provided by the invention has the characteristics of high hardness, high corrosion resistance, good chemical stability, high abrasion resistance and the like, and the problem that existing composite ceramic tools are poor in toughness and fracture resistance is solved.

Owner:FOSHAN LANTU TECH CO LTD

External orthopedic fixator for elbow joint

InactiveCN108210146AIngenious structurePowerfulSuspensory bandagesFracturePhysical medicine and rehabilitationSlide plate

The invention discloses an external orthopedic fixator for an elbow joint. The external orthopedic fixator comprises a first fixing sleeve, a soft rubber sleeve, a second fixing sleeve, a limiting column, a protective cover, an insertion pin sleeve, a sealing sleeve, an insertion pin, a baffle plate, a pull rod, a spring, an arc-shaped sliding plate and an insertion hole. The external orthopedic fixator for the elbow joint is ingenious in structure and powerful in function. Firstly, through the action of an external fixing and protecting mechanism, the elbow joint of a patient can be strengthened and protected, and rehabilitation after an operation is improved; secondly, through the matching effect of a rotary adjusting device, the elbow joint of the patient can be adjusted and changed according to the actual situation, the rehabilitation and activity needs of different patients are met, the wearing comfort of patients is improved, and clinical popularization and application are facilitated.

Owner:张艳梅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com