Deformation heat treatment method of petroleum drill pipe friction welding joint

A deformation heat treatment and welded joint technology, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of low weld toughness, increase weld brittle failure, reduce weld zone fatigue life, etc. Poor seam toughness, improving production efficiency, and overcoming the effects of low local heat treatment boundary strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

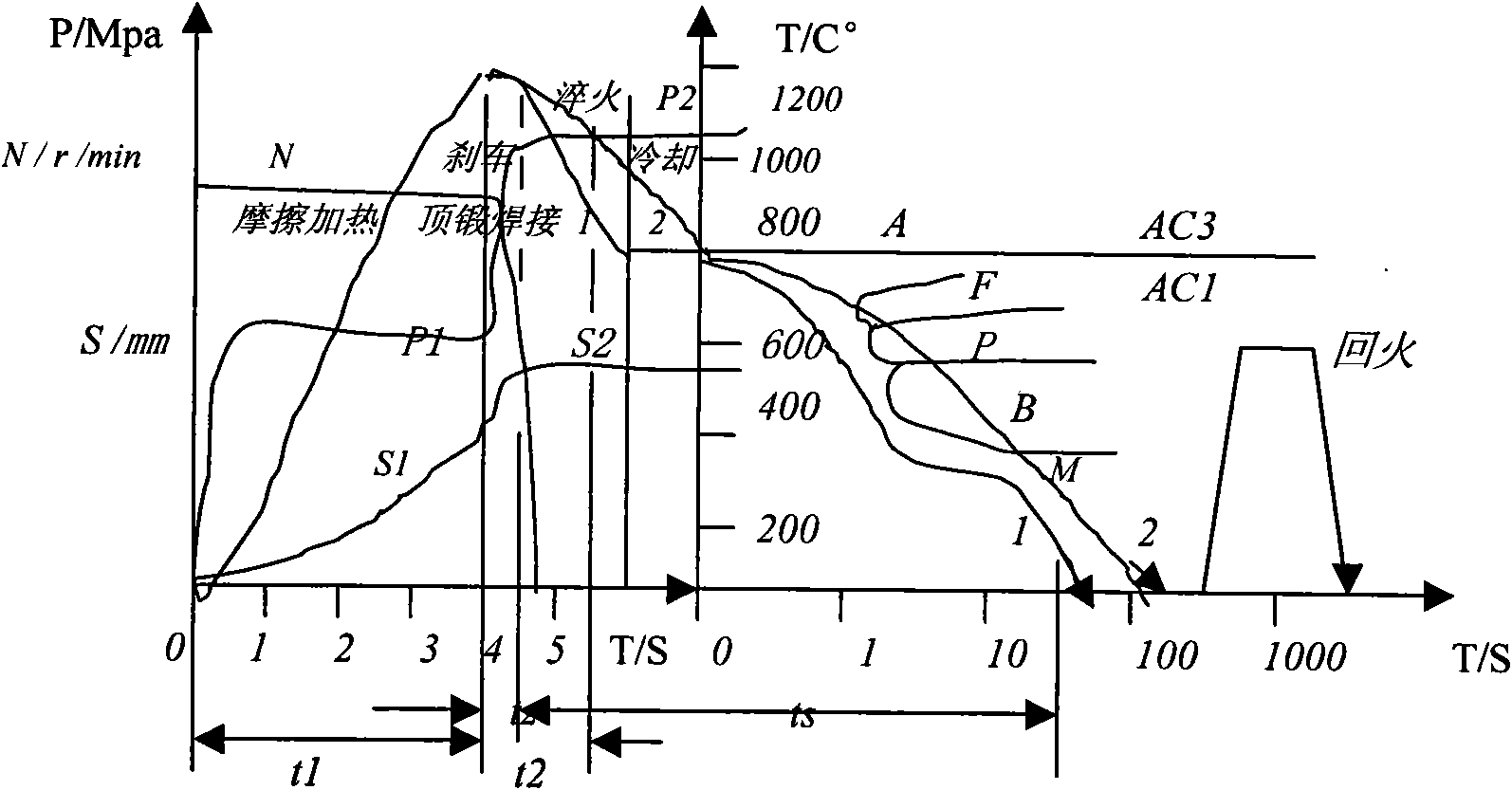

[0009] For the convenience of explanation, the process of direct air cooling after continuous drive friction welding brake upsetting is called ordinary friction welding to show the difference from friction welding deformation heat treatment process. And test the relevant friction welding thermal cycle curve, establish the corresponding continuous cooling structure transition diagram (abbreviated as HCCT diagram, see figure 1 ).

[0010] Depend on figure 1 It can be seen that different thermal cycle curves will correspond to different tissue properties. Curve 1 is the thermodynamic cycle curve of ordinary friction welding. It is not difficult to see that only by adjusting the welding parameters to change its thermal cycle curve is limited. In order to improve the performance of joints, several deformation heat treatment test programs can be designed. Among them, curve 2 is the welding heat quenching test. The welding heat quenching is direct quenching under the local high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com