Patents

Literature

563 results about "Thermodynamic cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

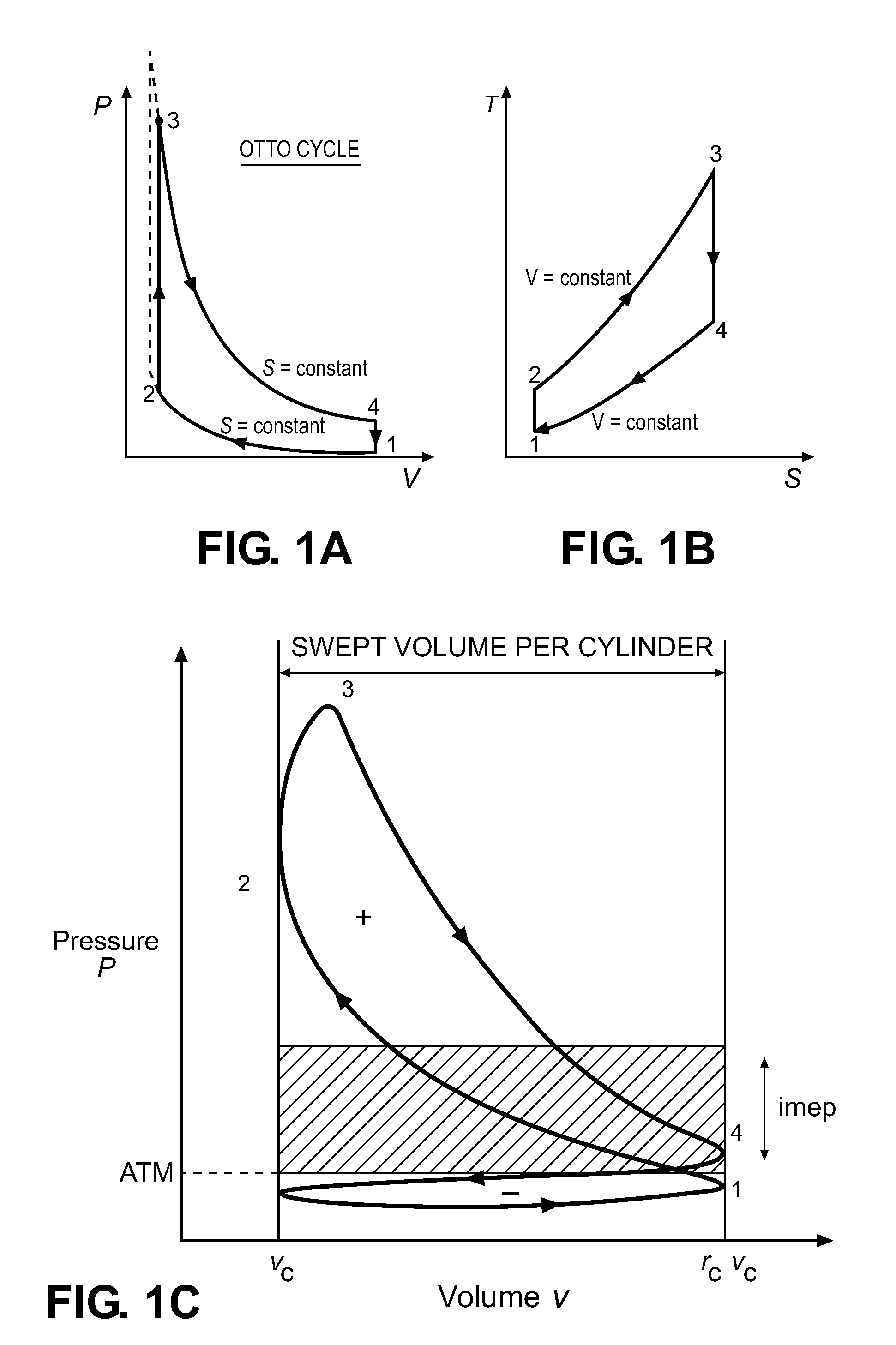

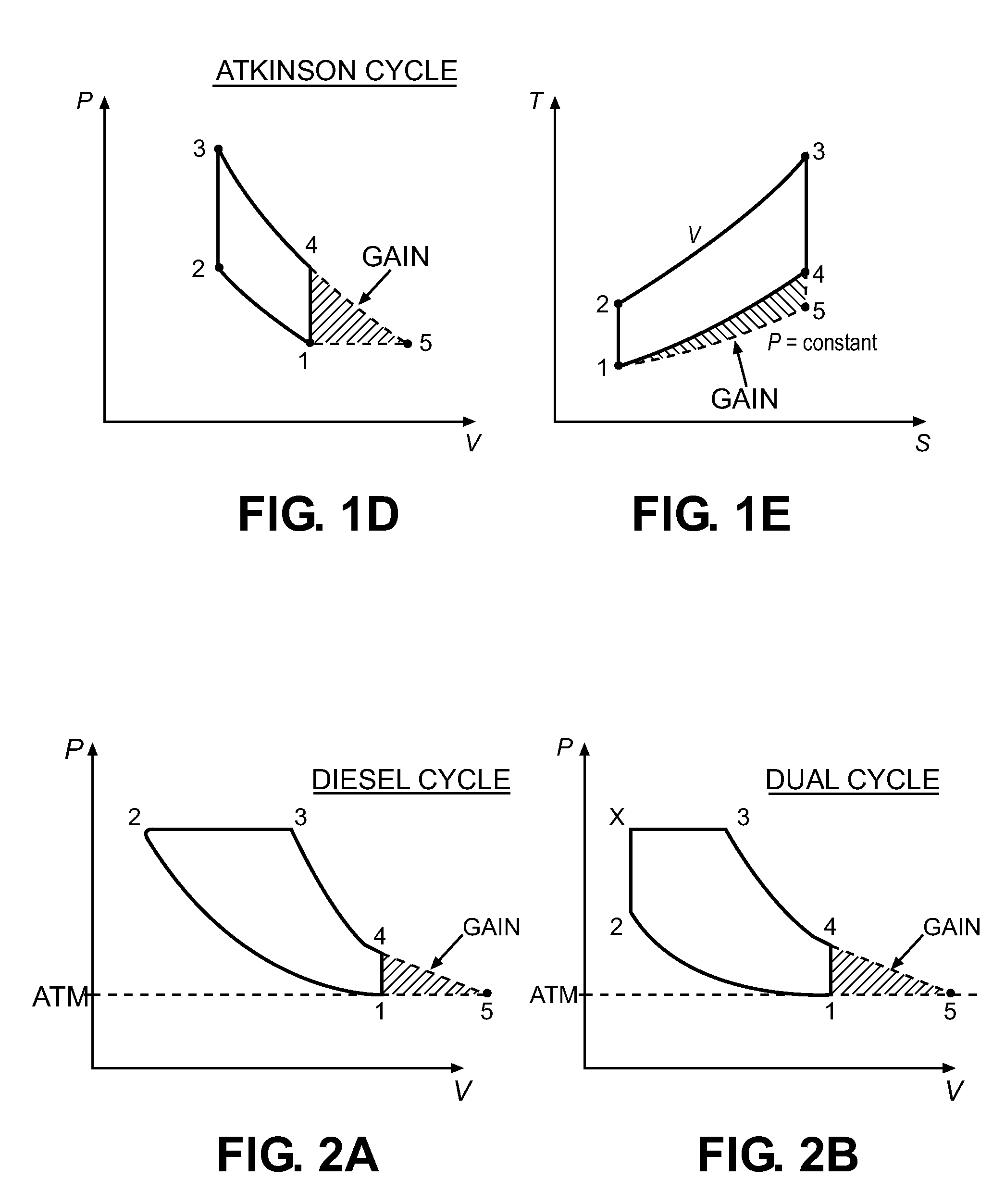

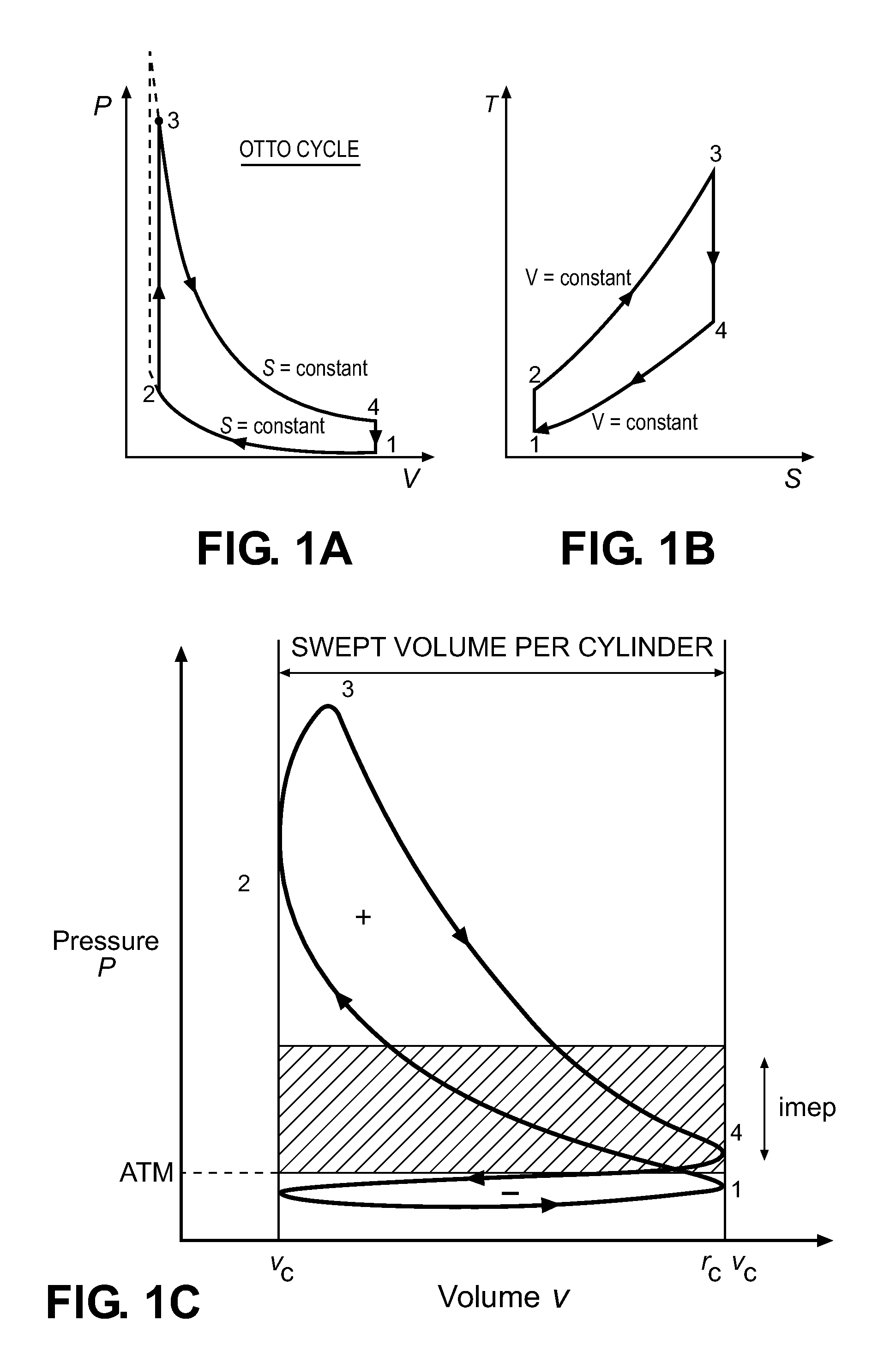

A thermodynamic cycle consists of a linked sequence of thermodynamic processes that involve transfer of heat and work into and out of the system, while varying pressure, temperature, and other state variables within the system, and that eventually returns the system to its initial state. In the process of passing through a cycle, the working fluid (system) may convert heat from a warm source into useful work, and dispose of the remaining heat to a cold sink, thereby acting as a heat engine.

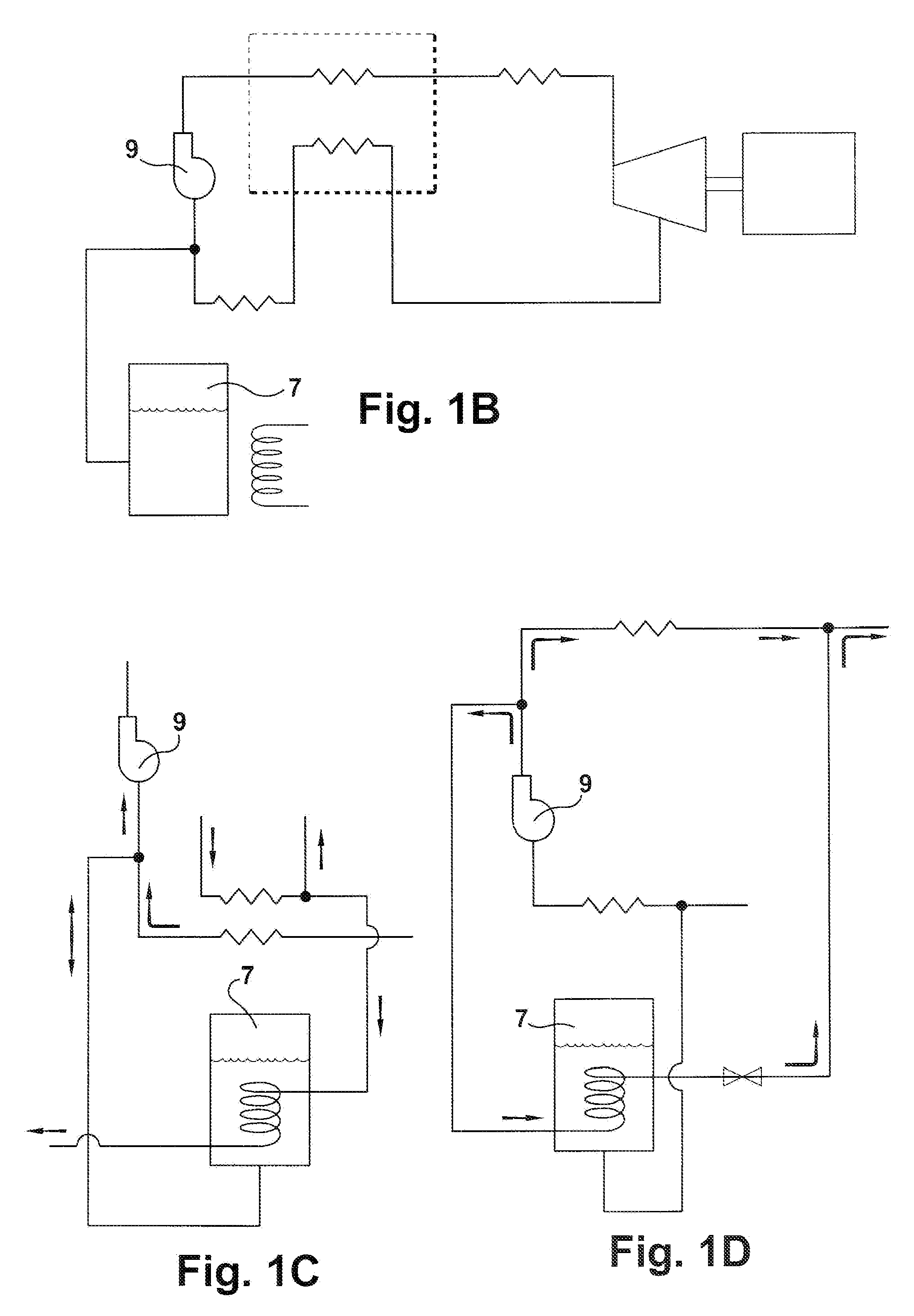

Thermodynamic cycles using thermal diluent

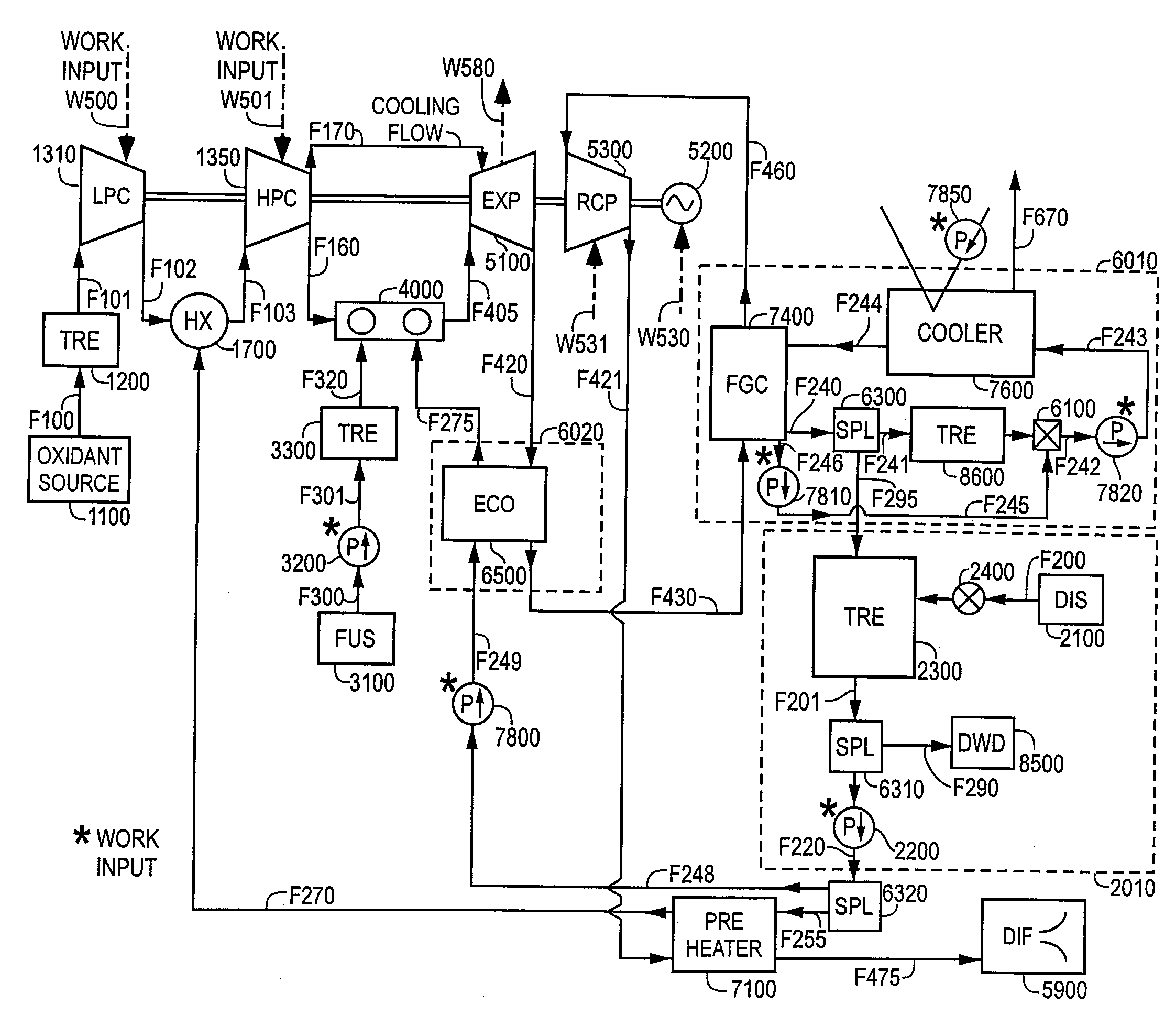

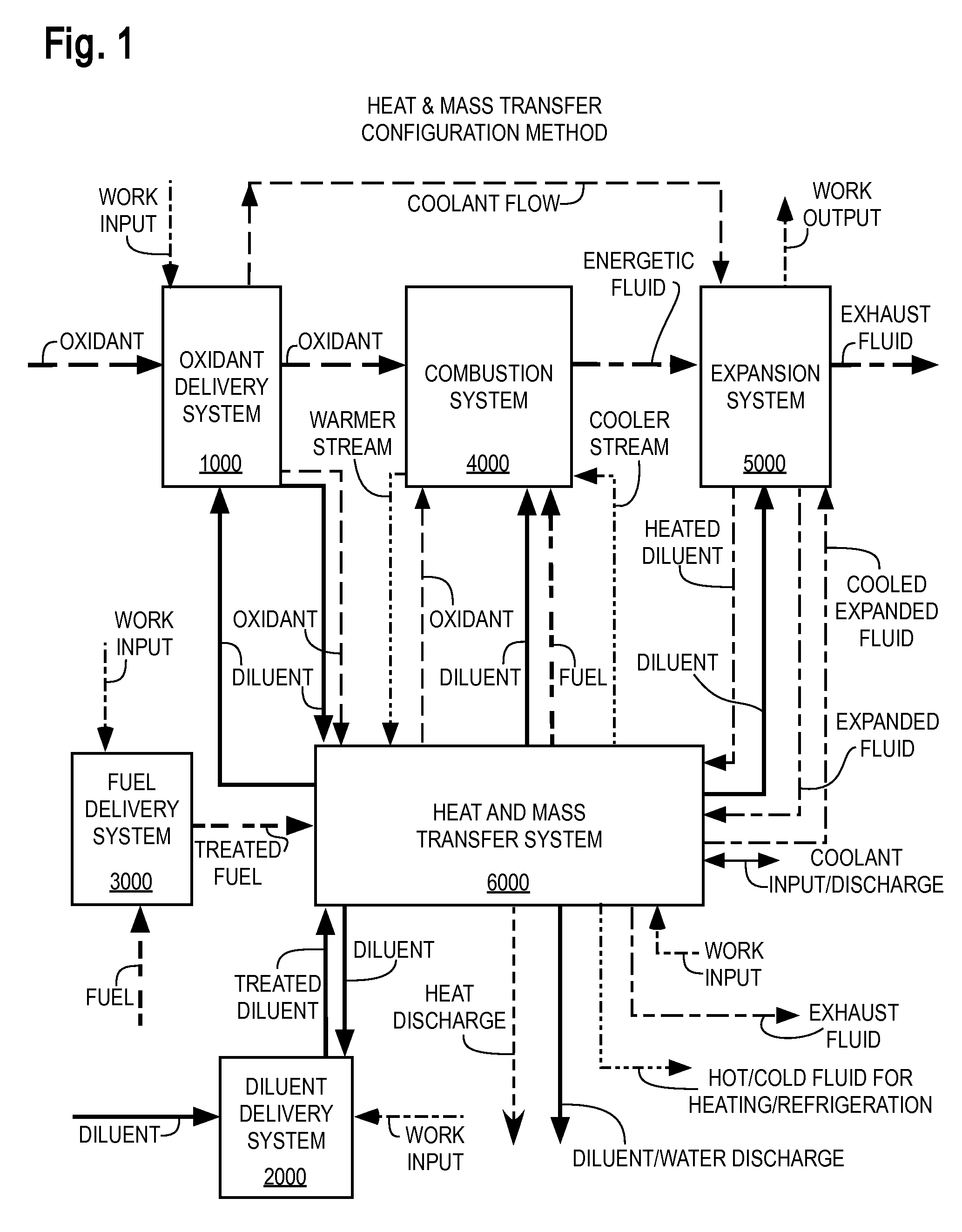

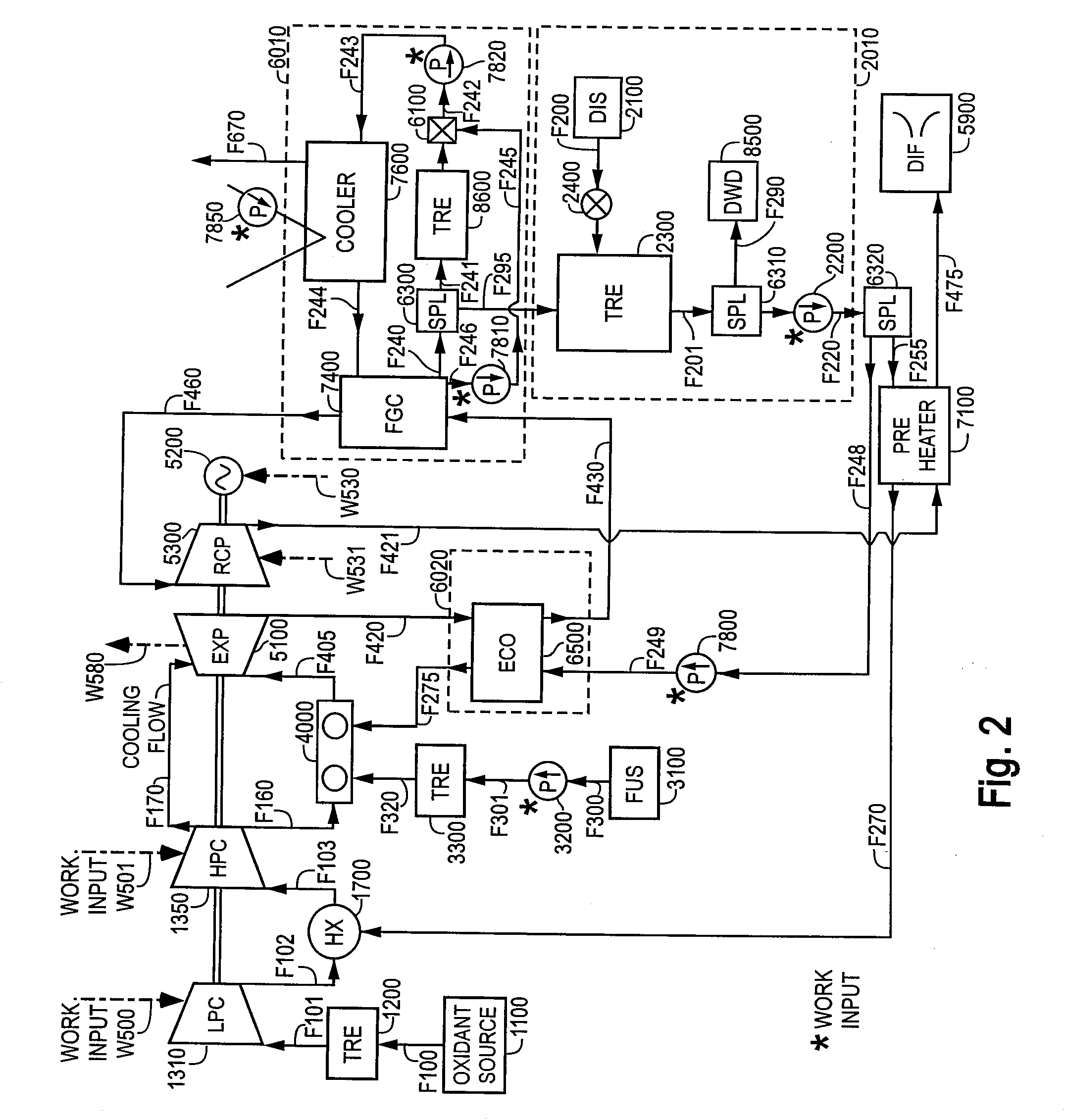

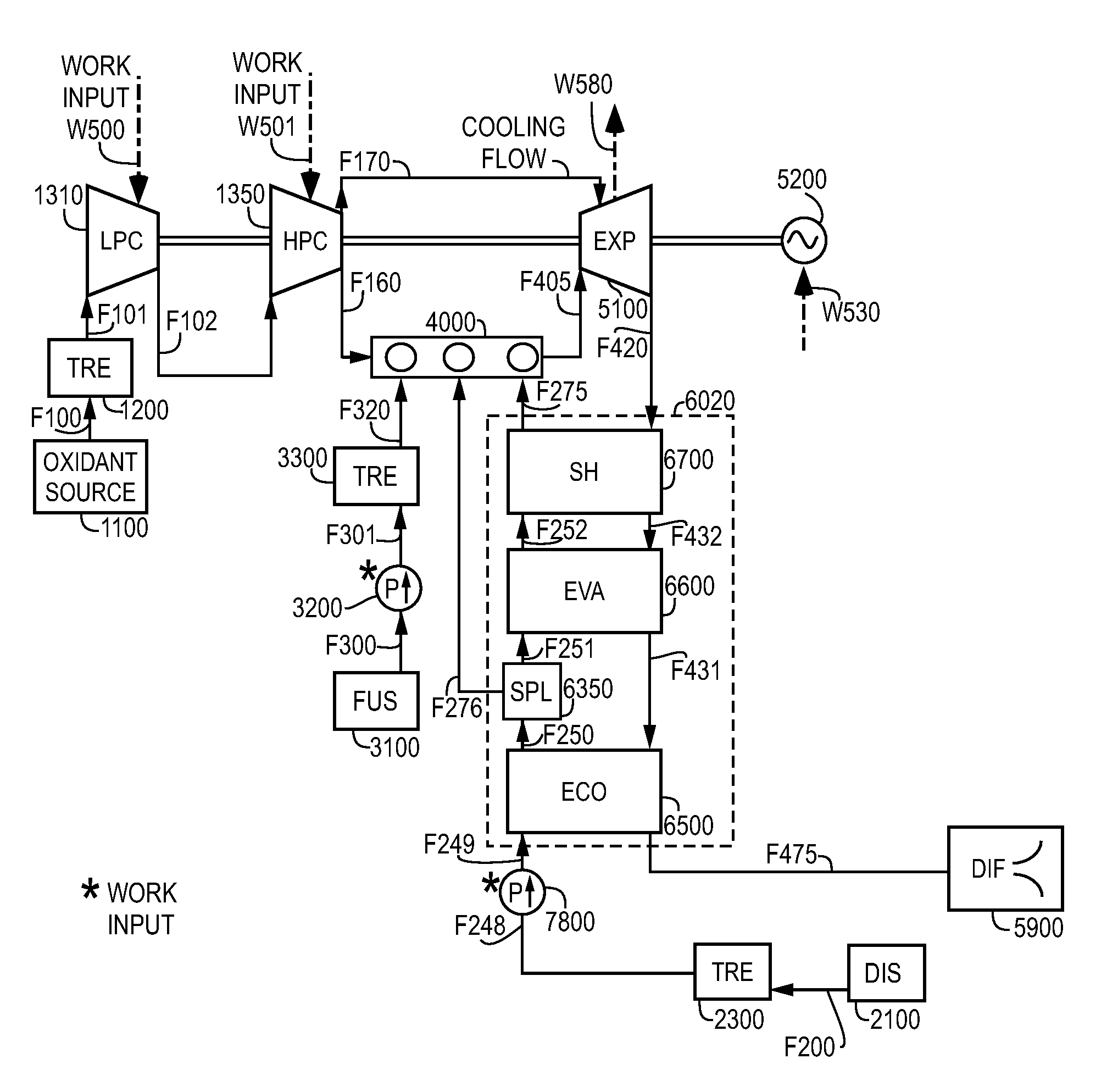

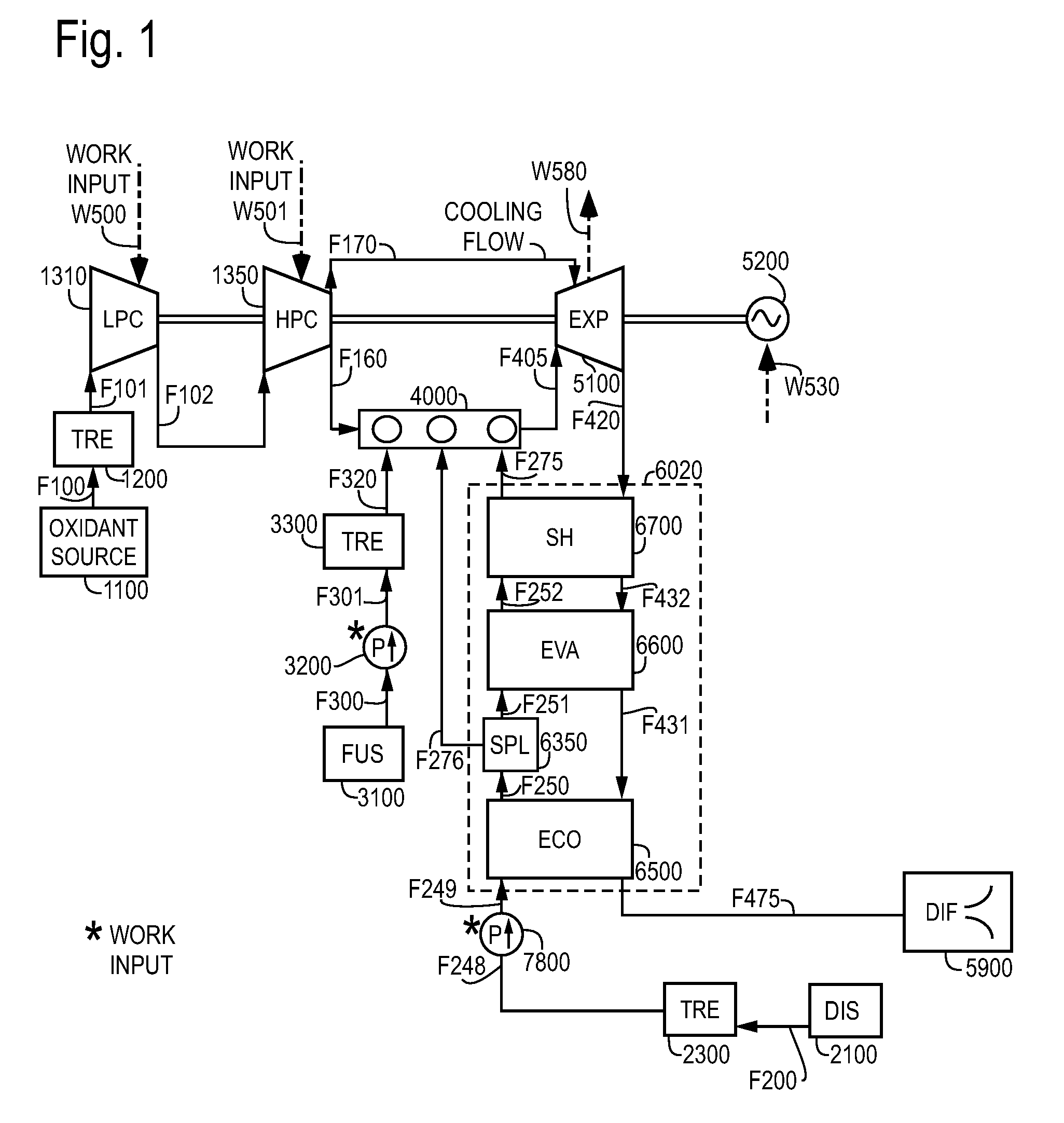

ActiveUS20090071166A1Low costEmission reductionSpace heating and ventilationSulfur compoundsCombustion systemCombustion

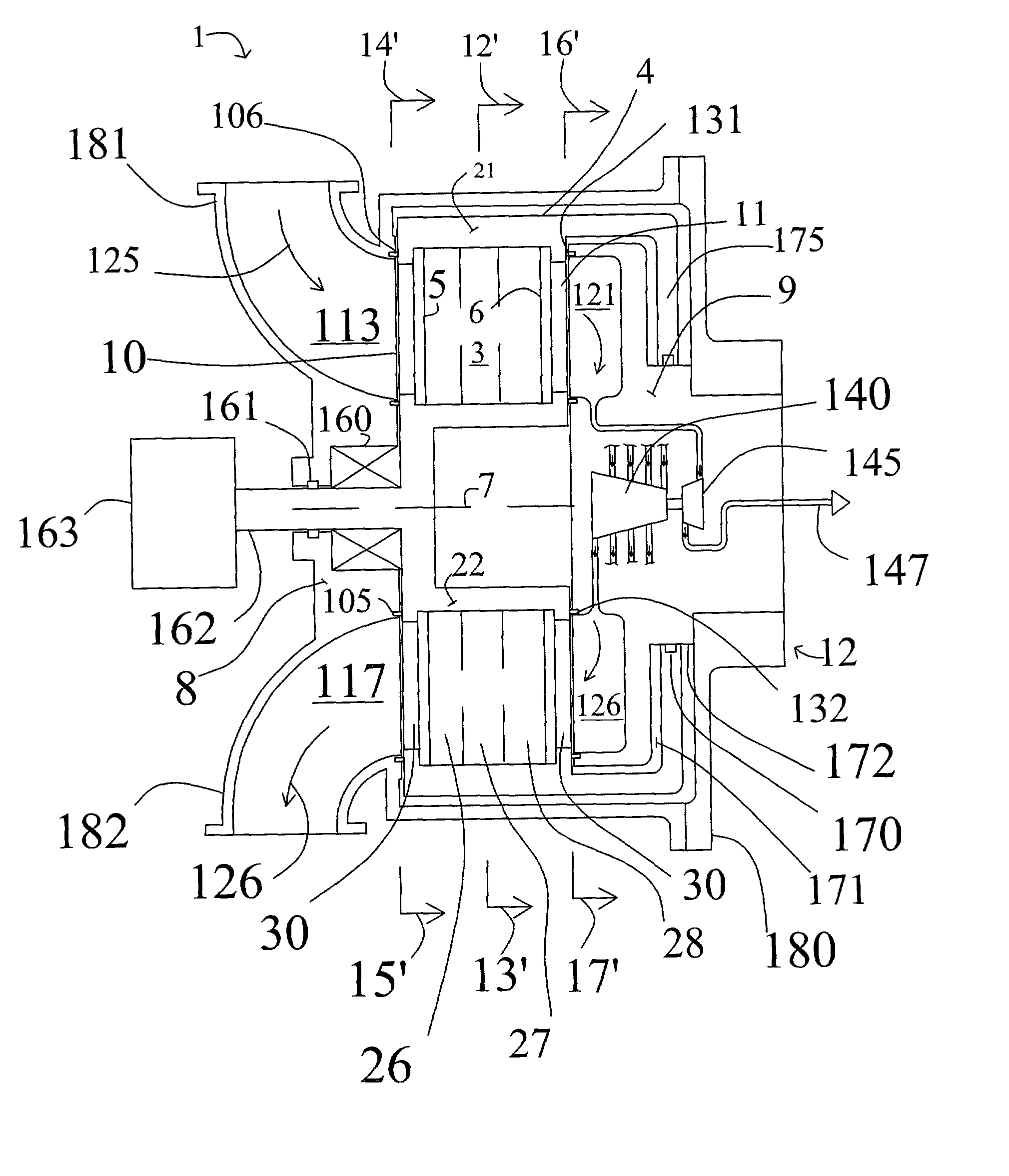

A thermodynamic system that produces mechanical, electrical power, and / or fluid streams for heating or cooling. The cycle contains a combustion system that produces an energetic fluid by combustion of a fuel with an oxidant. A thermal diluent may be used in the cycle to improve performance, including but not limited to power, efficiency, economics, emissions, dynamic and off-peak load performance, and / or turbine inlet temperature (TIT) regulation and cooling heated components. The cycle preferably includes a heat recovery system and a condenser or other means to recover and recycle heat and the thermal diluent from the energetic fluid to improve the cycle thermodynamic efficiency and reduce energy conversion costs. The cycle may also include controls for temperatures, pressures, and flow rates throughout the cycle, and controls power output, efficiency, and energetic fluid composition.

Owner:VAST HLDG LLC

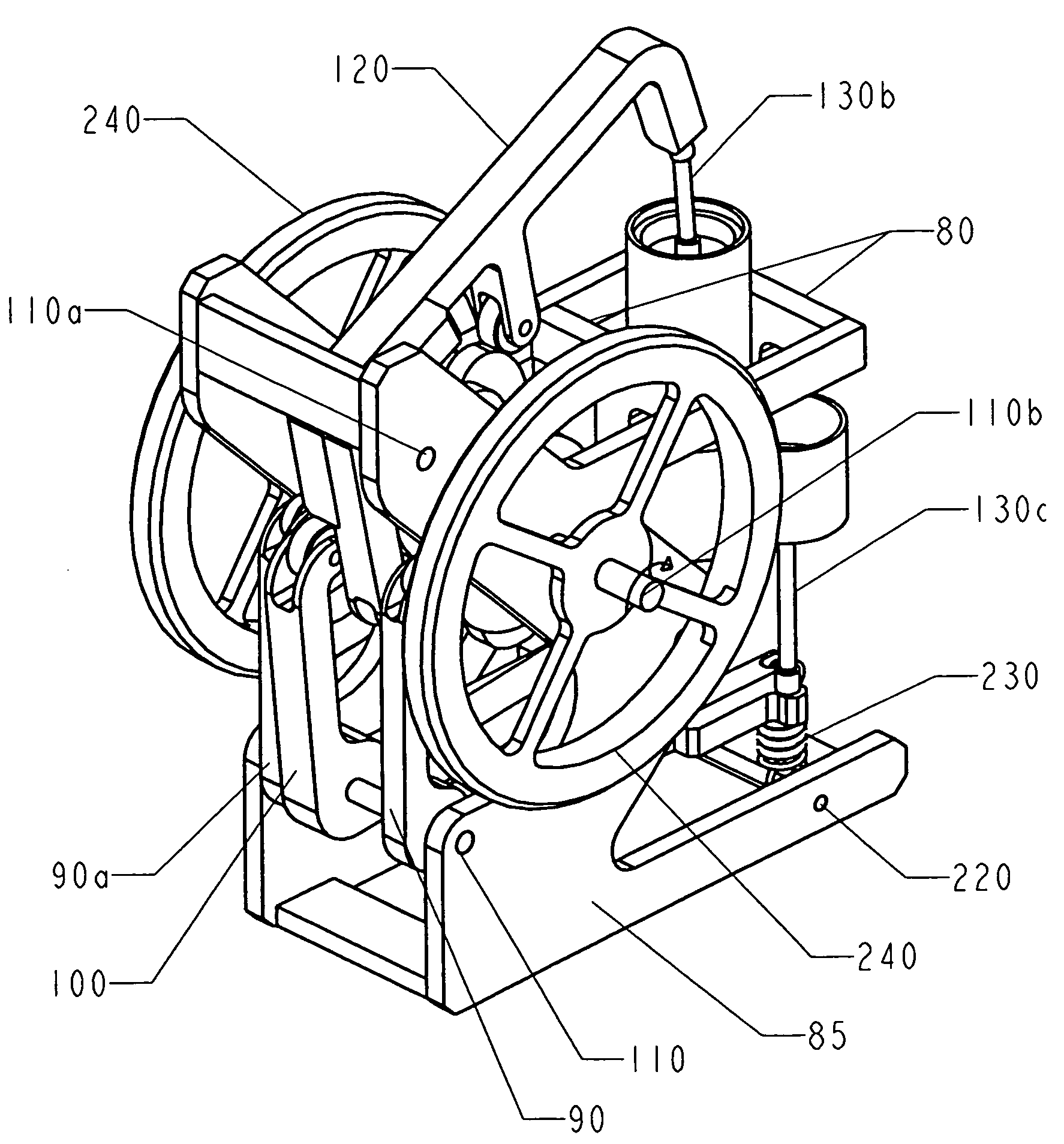

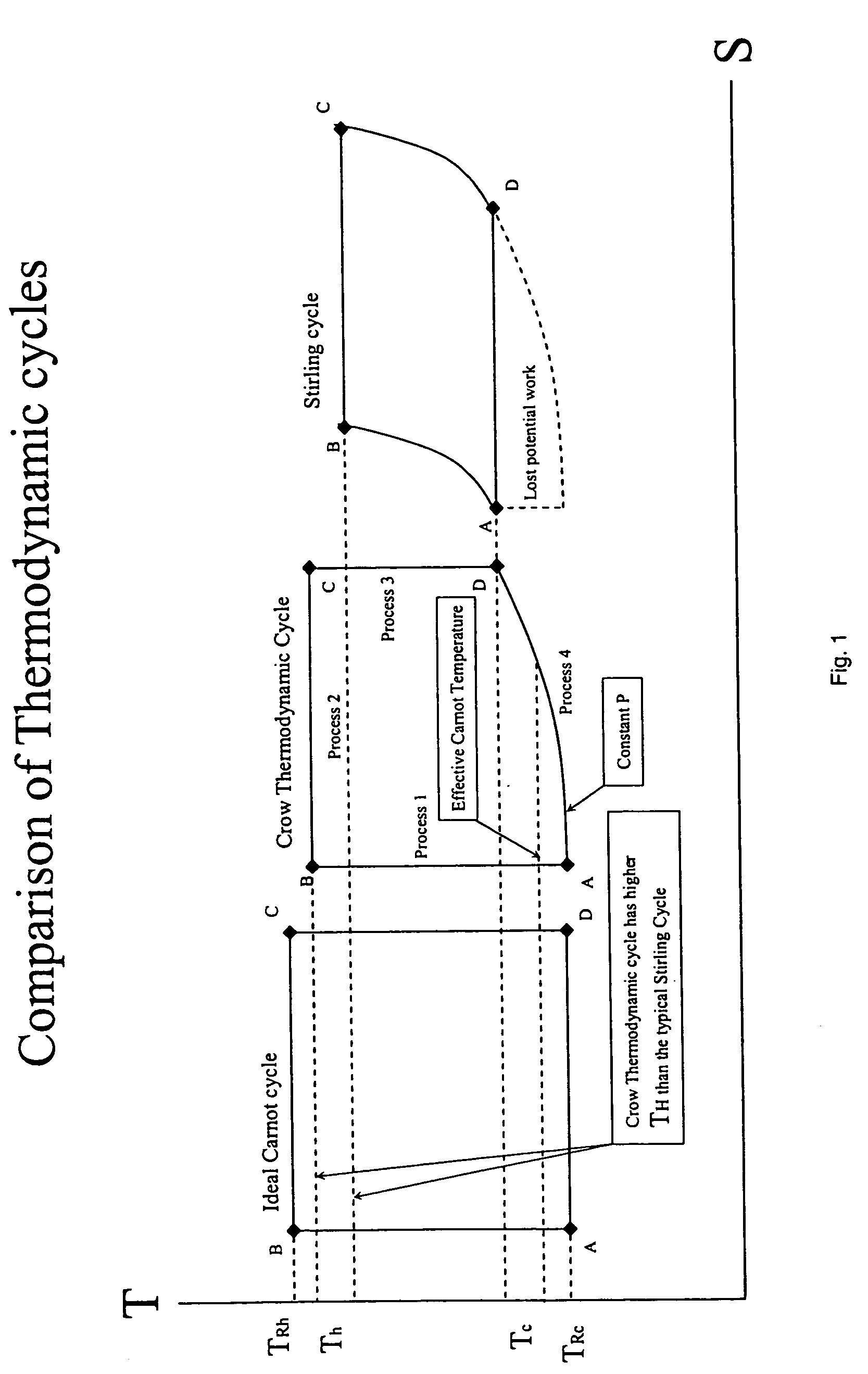

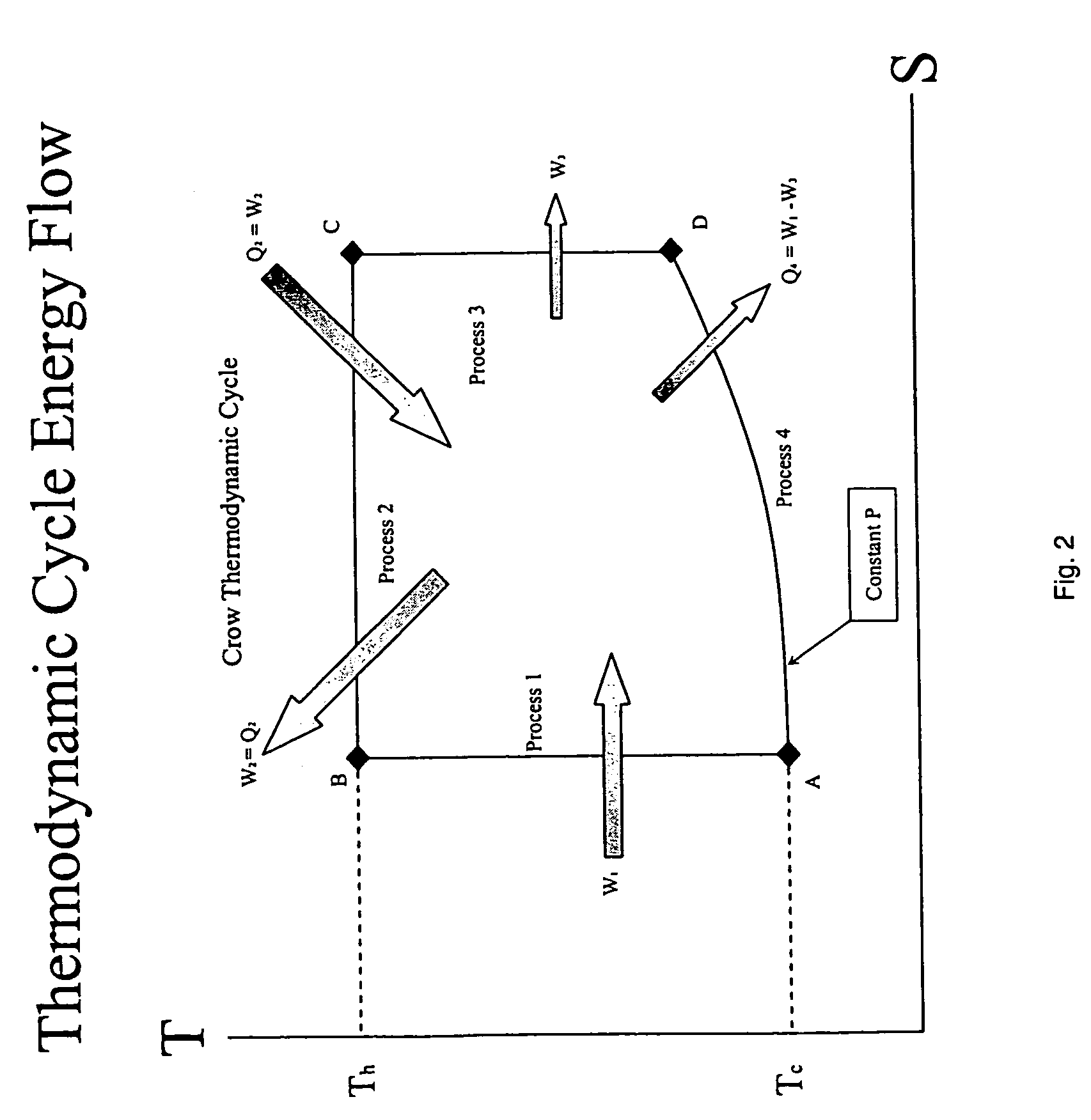

Method and apparatus for converting thermal energy to mechanical energy

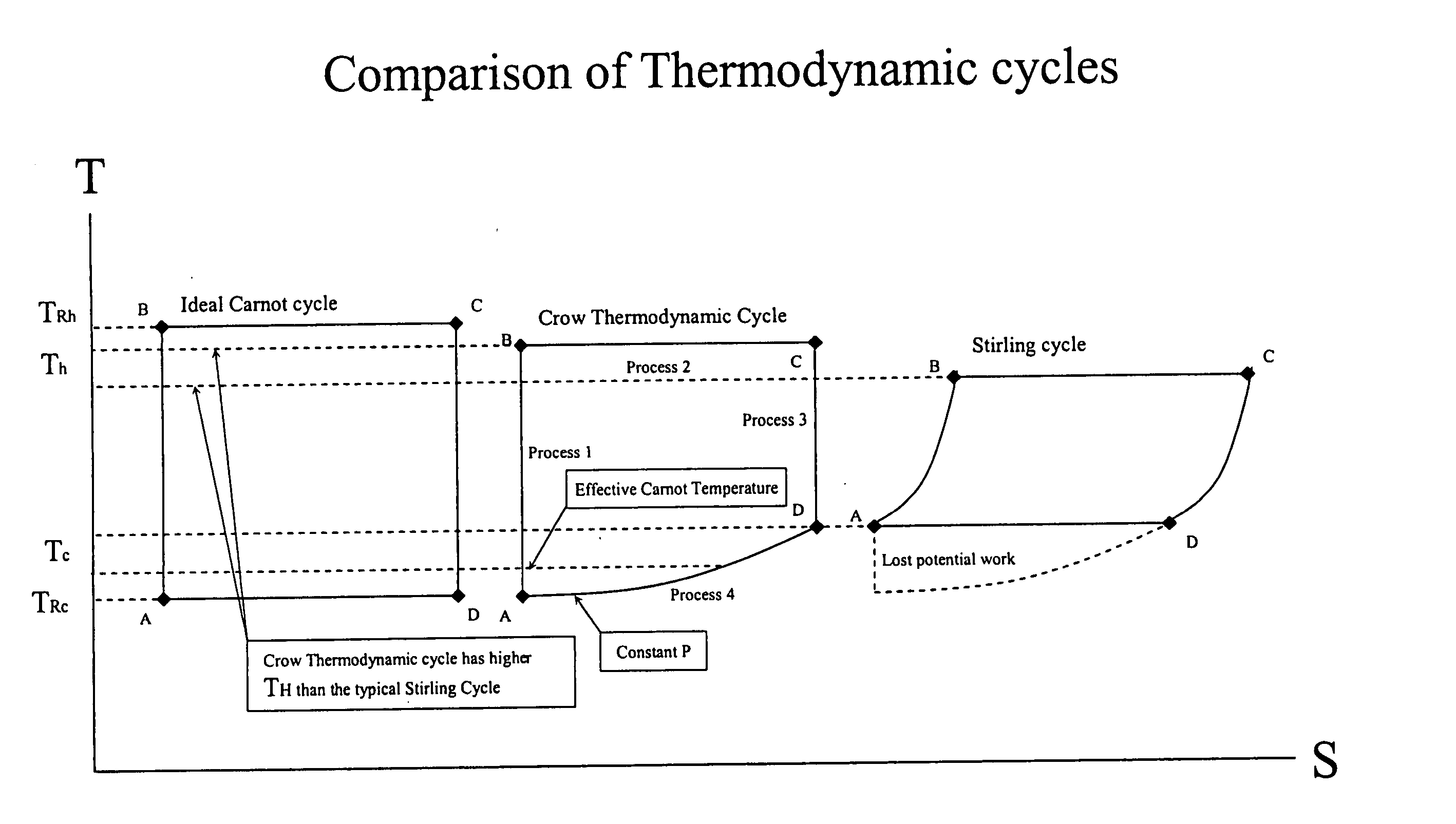

InactiveUS20060090467A1Improve efficiencyEfficient regenerationEricsson type enginesSteam engine plantsThermal energyWorking fluid

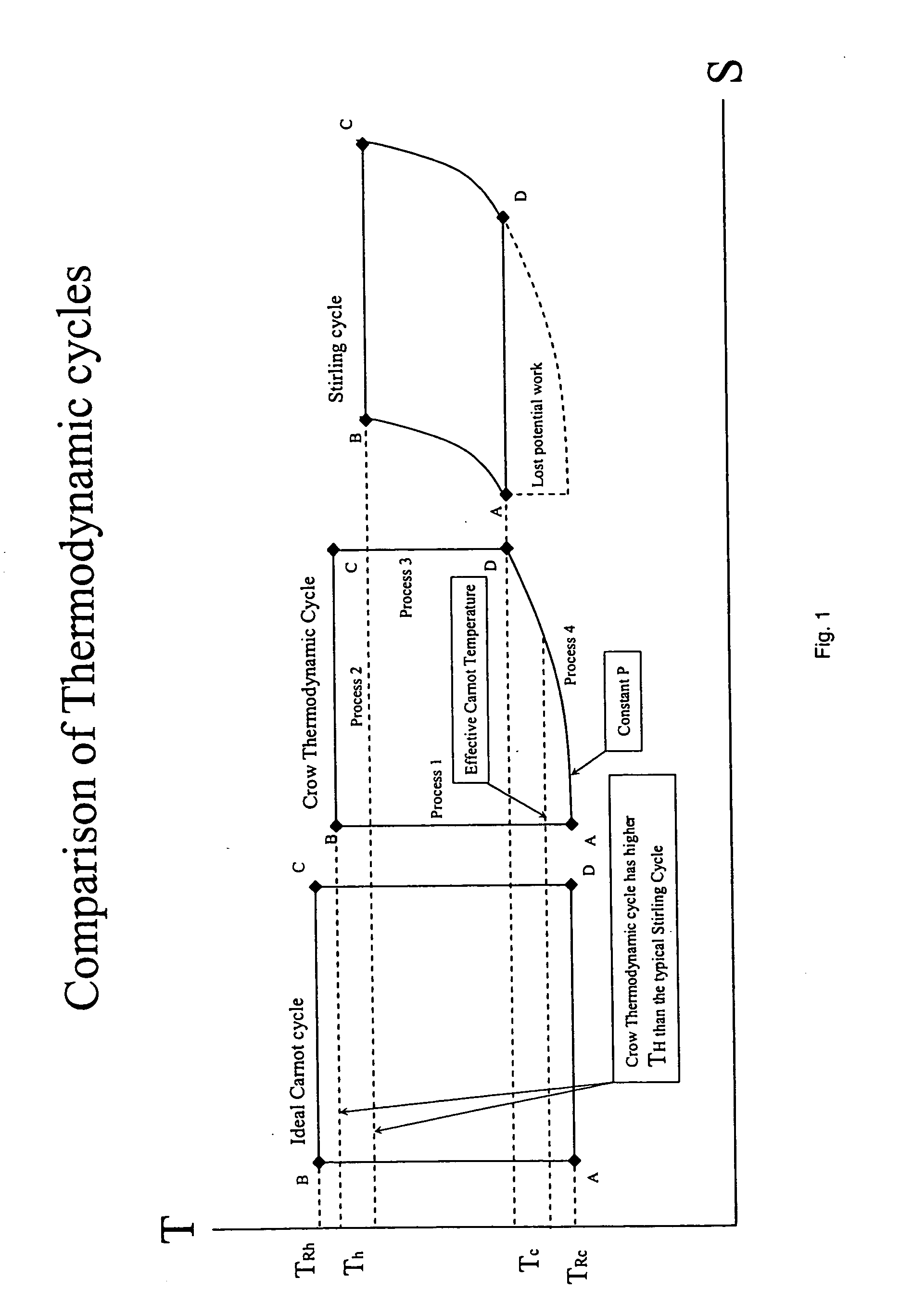

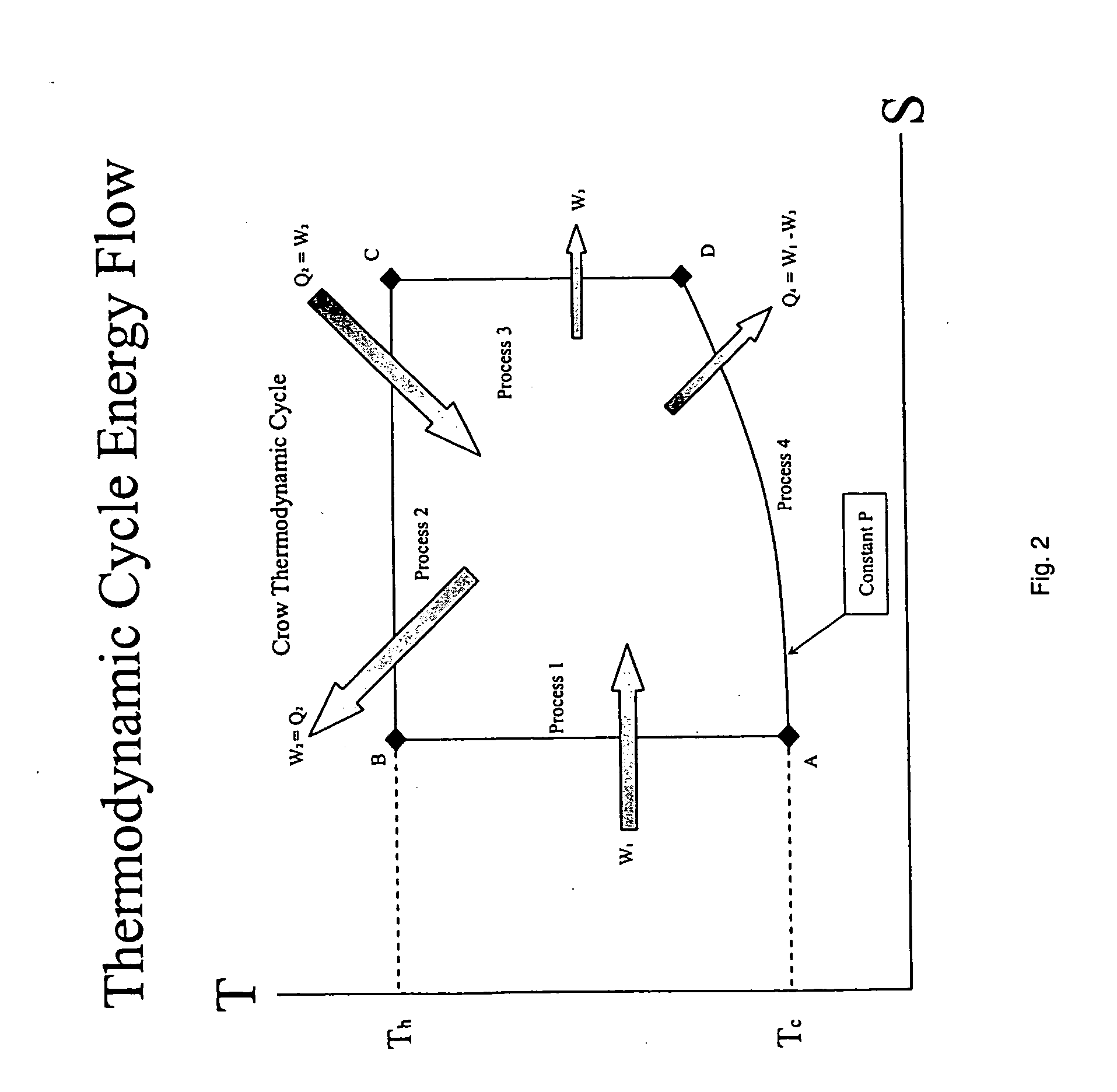

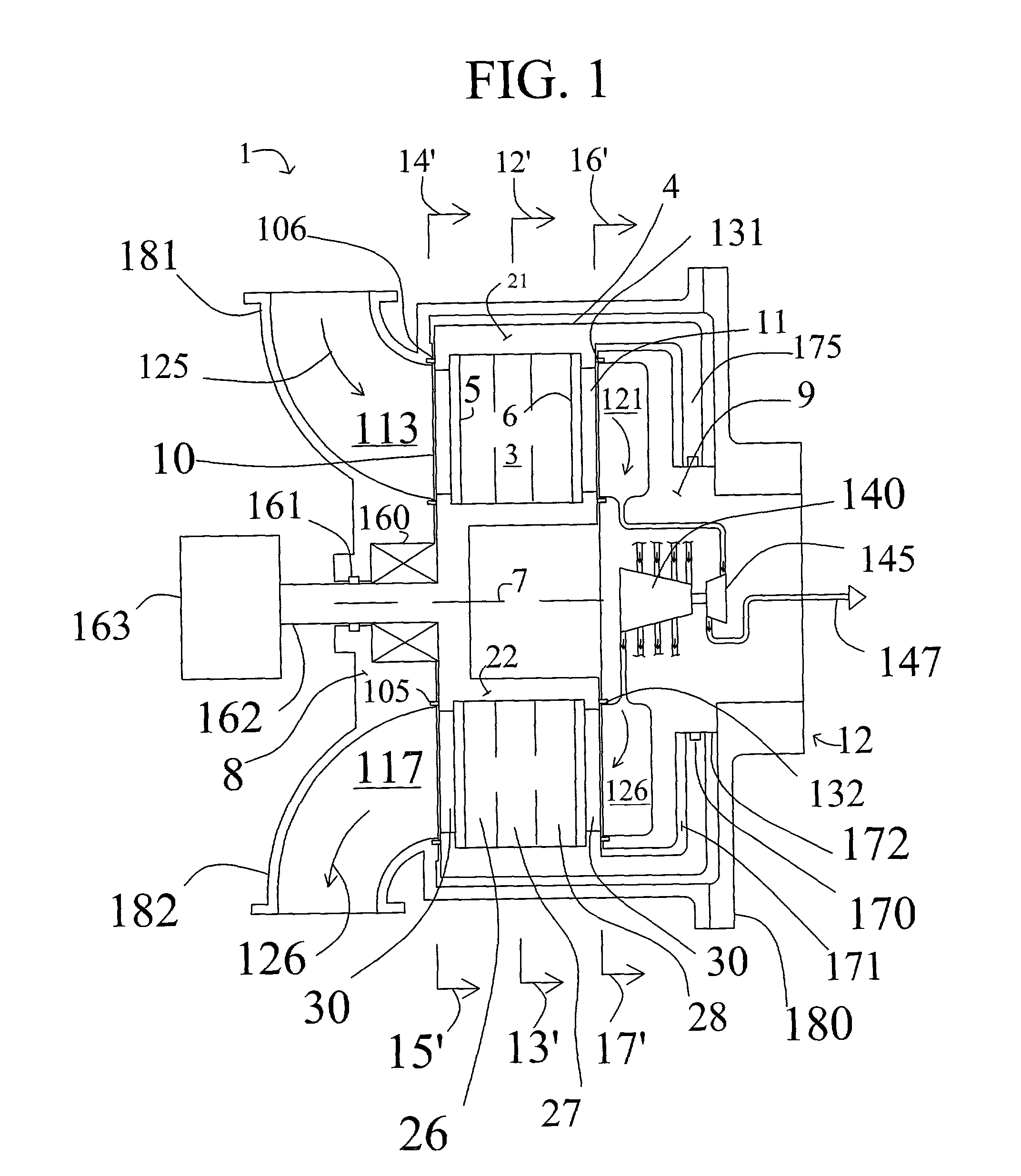

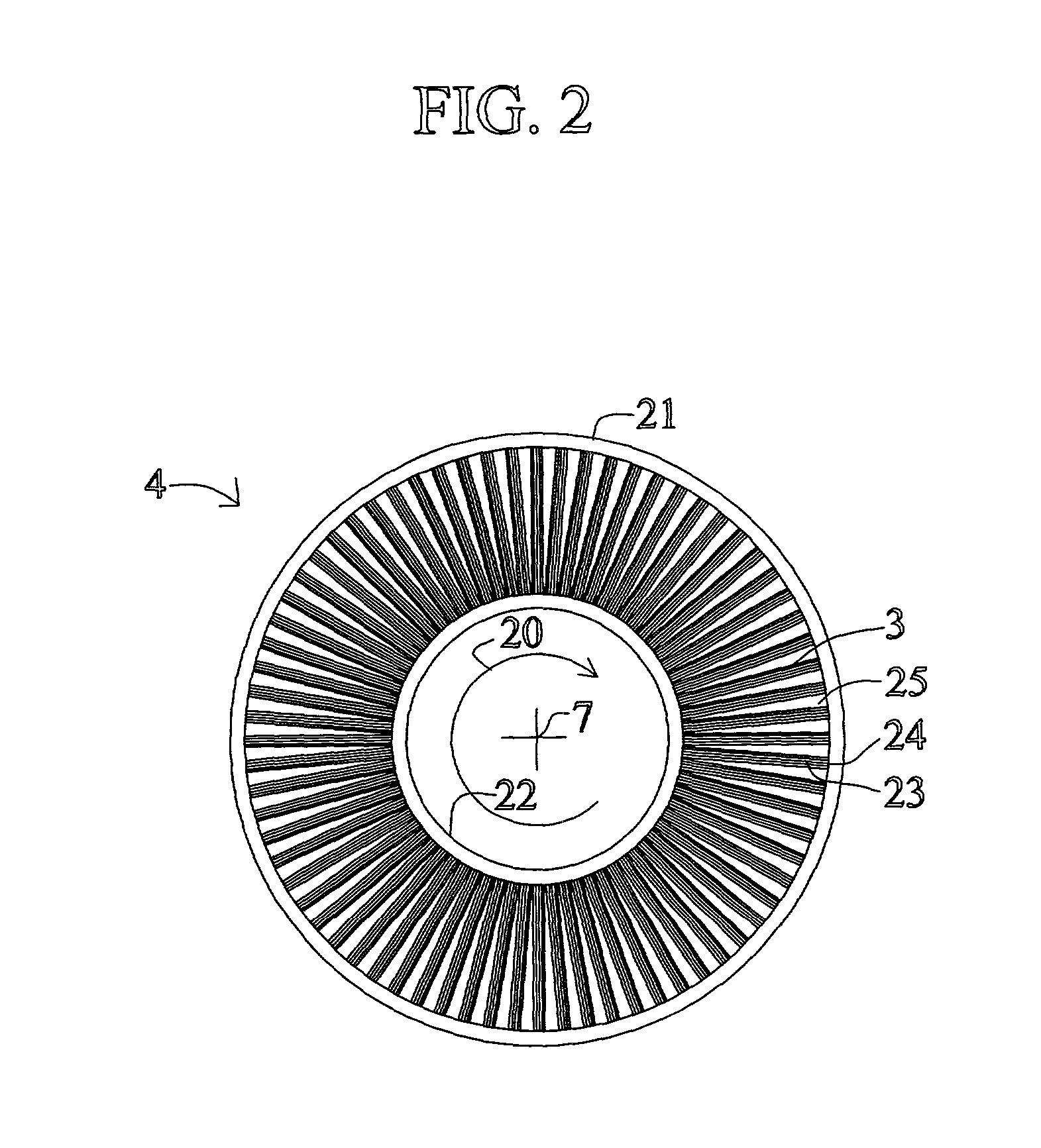

A method and apparatus for converting thermal energy to mechanical energy which can use a wide range of fuels and perform with a high efficiency. Operating on a little utilized thermodynamic cycle of isentropic compression, isothermal expansion, isentropic expansion and finally constant pressure cooling and contraction. The external heat engine utilizes a heat exchanger carrying heat from the external energy source to the working parts of the engine. Pistons and cylinders are activated by appropriate means to adiabatically compress the working fluid, for example ambient air, to transfer the entire mass of the air through the heat exchanger to accomplish isothermal expansion followed by adiabatic expansion and, finally, exhaust the air to ambient to allow for constant pressure cooling and contraction. Valve pistons in conjunction with the cylinders form valves that allow for the exchange of working fluid with ambient. Energy is added to the engine during isothermal expansion, whereby the energy of compression is added by a flywheel or other appropriate energy storage means, said flywheel stores energy recovered during adiabatic expansion. The thermodynamic cycle described and the engine embodiments disclosed, when run in reverse, perform as a heat pump or refrigeration device.

Owner:CROW DARBY

Partial load combustion cycles

ActiveUS20090064653A1Improve efficiencyReduced Power RequirementsGas turbine plantsVehicle heating/cooling devicesBrayton cycleCombustion

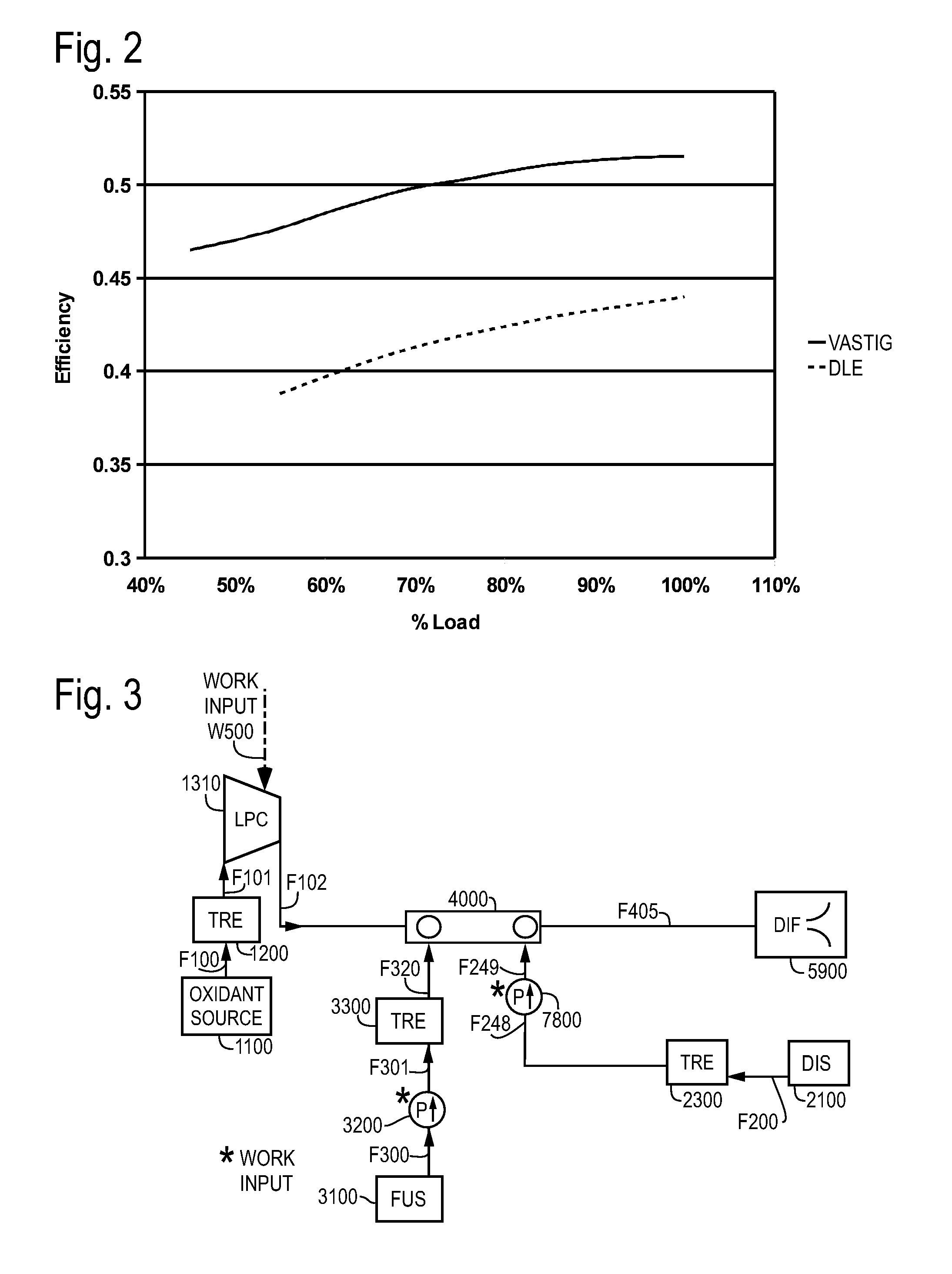

The part load method controls delivery of diluent fluid, fuel fluid, and oxidant fluid in thermodynamic cycles using diluent, to increase the Turbine Inlet Temperature (TIT) and thermal efficiency in part load operation above that obtained by relevant art part load operation of Brayton cycles, fogged Brayton cycles, or cycles operating with some steam delivery, or with maximum steam delivery. The part load method may control the TIT at the design level by controlling one or both of liquid and / or gaseous fluid water over a range from full load to less than 45% load. This extends operation to lower operating loads while providing higher efficiencies and lower operating costs using water, steam and / or CO2 as diluents, than in simple cycle operation.

Owner:VAST HLDG LLC

Power plant with energy recovery from fuel storage

InactiveUS20020112479A1Fuel cell heat exchangeInternal combustion piston enginesWorking fluidPower station

Power plant systems and processes are described that enable recovery of at least a portion of the fuel storage energy associated with a storage system for supplying fuel to the power plant systems. A first embodiment of an energy-recovery power plant system includes at least one fuel storage container and at least one expander that can receive fuel from the fuel storage container at a first pressure and provide the fuel to the power plant at a second pressure that is lower than the first pressure. A second embodiment of an energy-recovery power plant system includes a first conduit fluidly coupling the fuel storage container and the power plant for delivering fuel from the fuel storage container to the power plant and at least one regenerative thermodynamic cycle engine thermally coupled to the first conduit such that heat may be exchanged between the fuel and a working fluid for the regenerative thermodynamic cycle engine.

Owner:QUSIR TECH

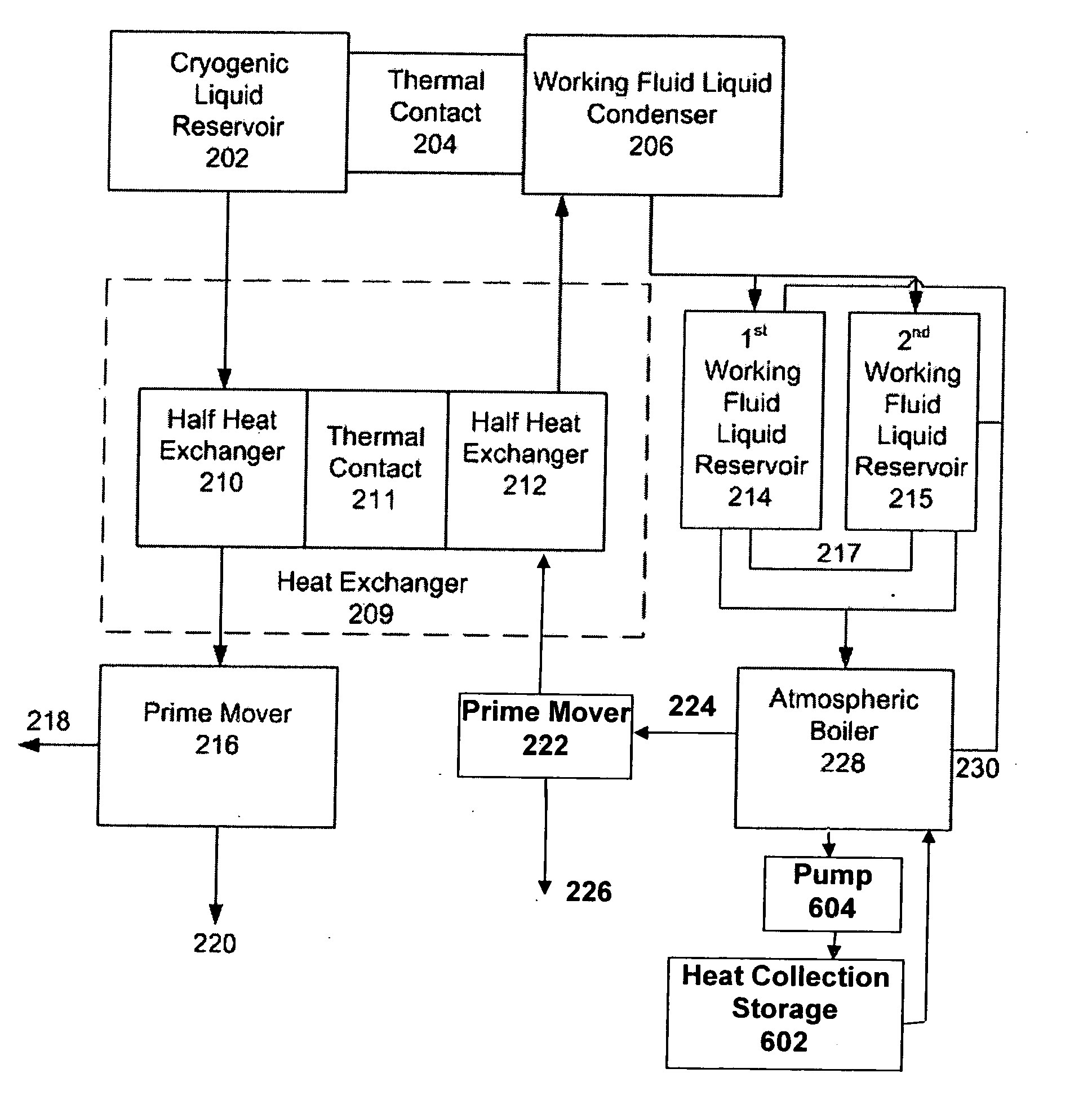

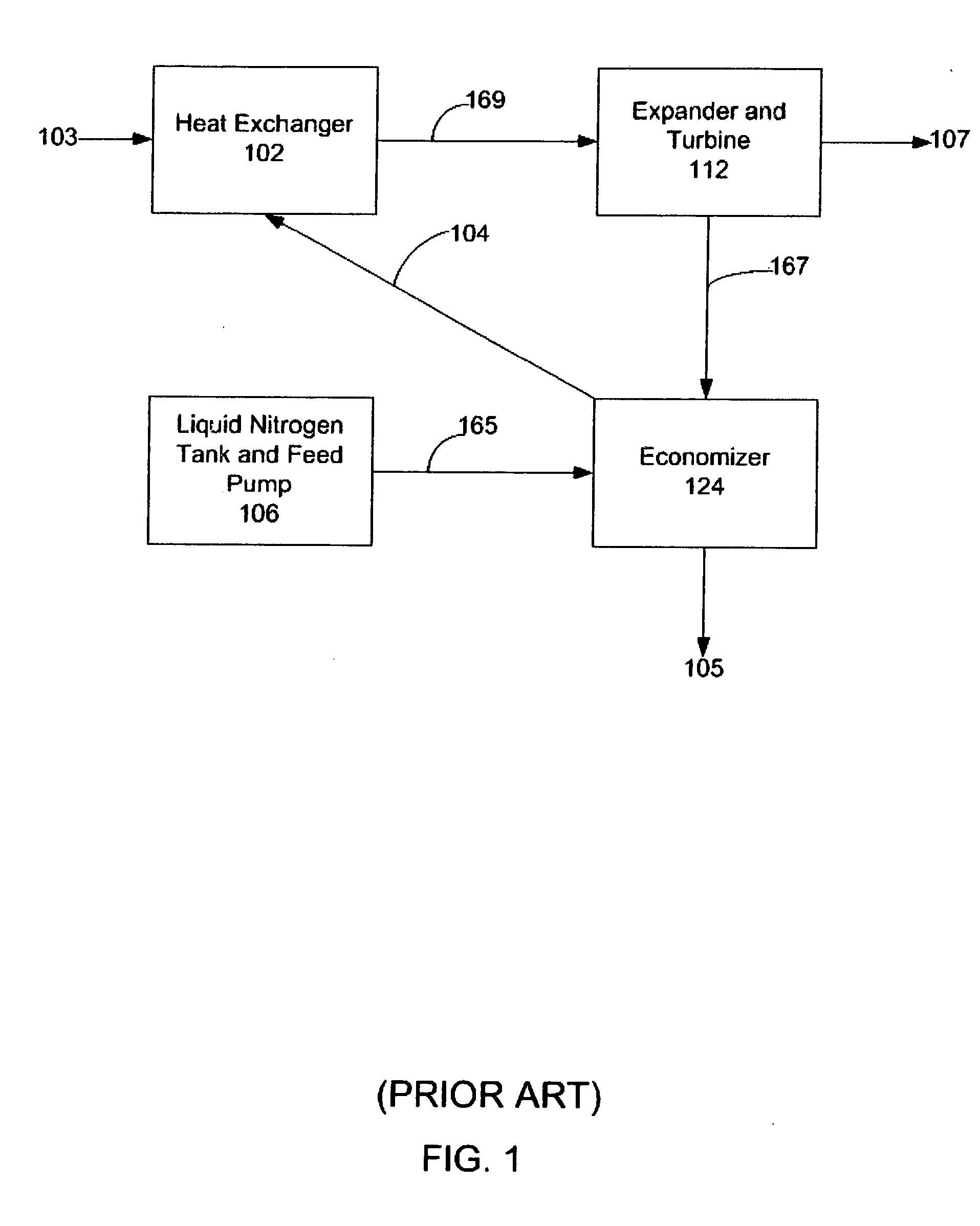

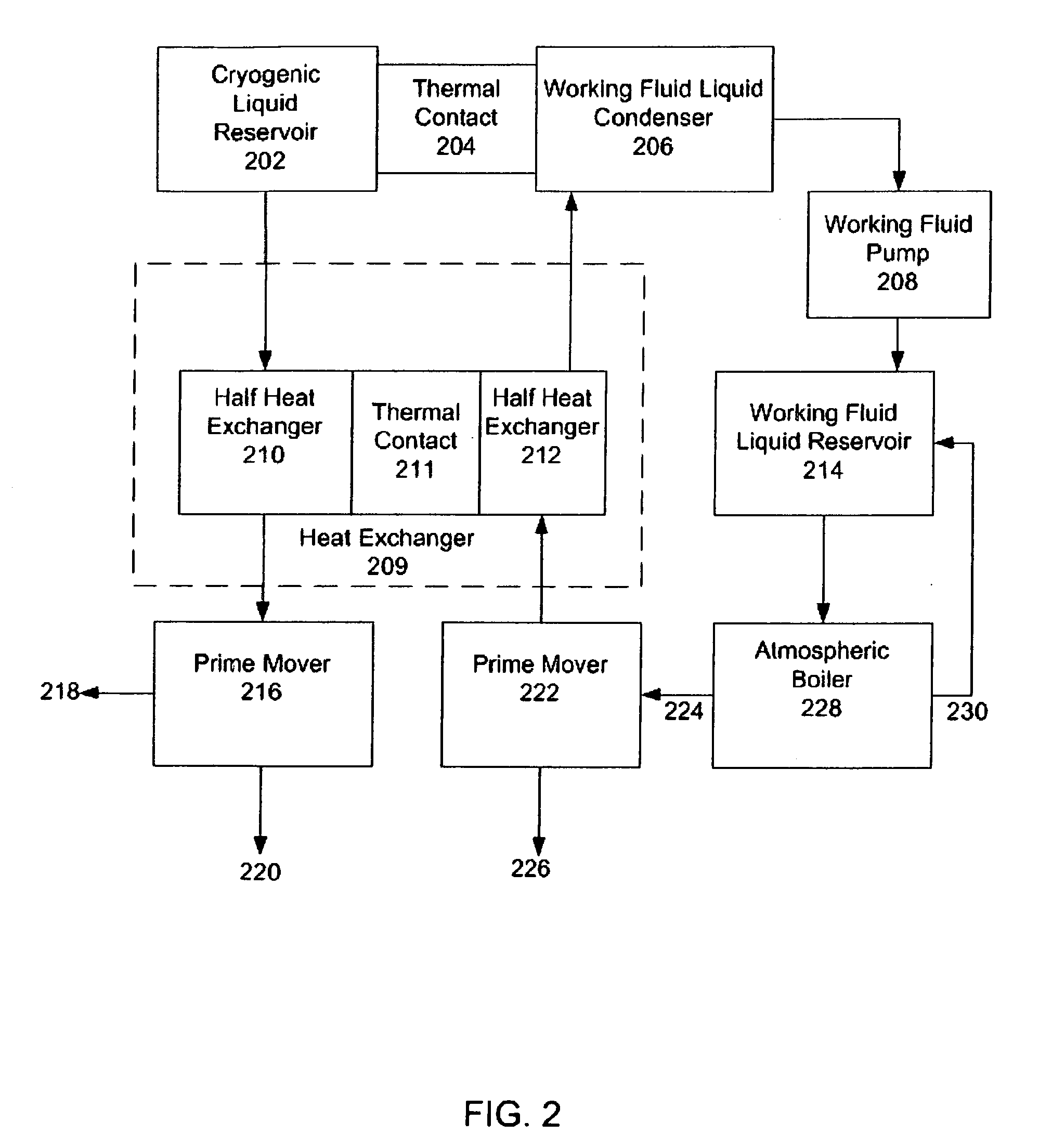

Dual thermodynamic cycle cryogenically fueled systems

Systems and methods for converting thermal energy, such as solar energy, from a localized thermal energy source to another form of energy or work comprise dual thermodynamic cycle systems that utilize the liquid-to-gas phase transitions of a cryogenic fluid such as liquid nitrogen and a working fluid such as sulfur hexafluoride to drive prime movers. Heat transfer between the fluids as they undergo the phase transitions is used to increase the energy in the system and its work output, and improve system efficiency.

Owner:MEV TECH

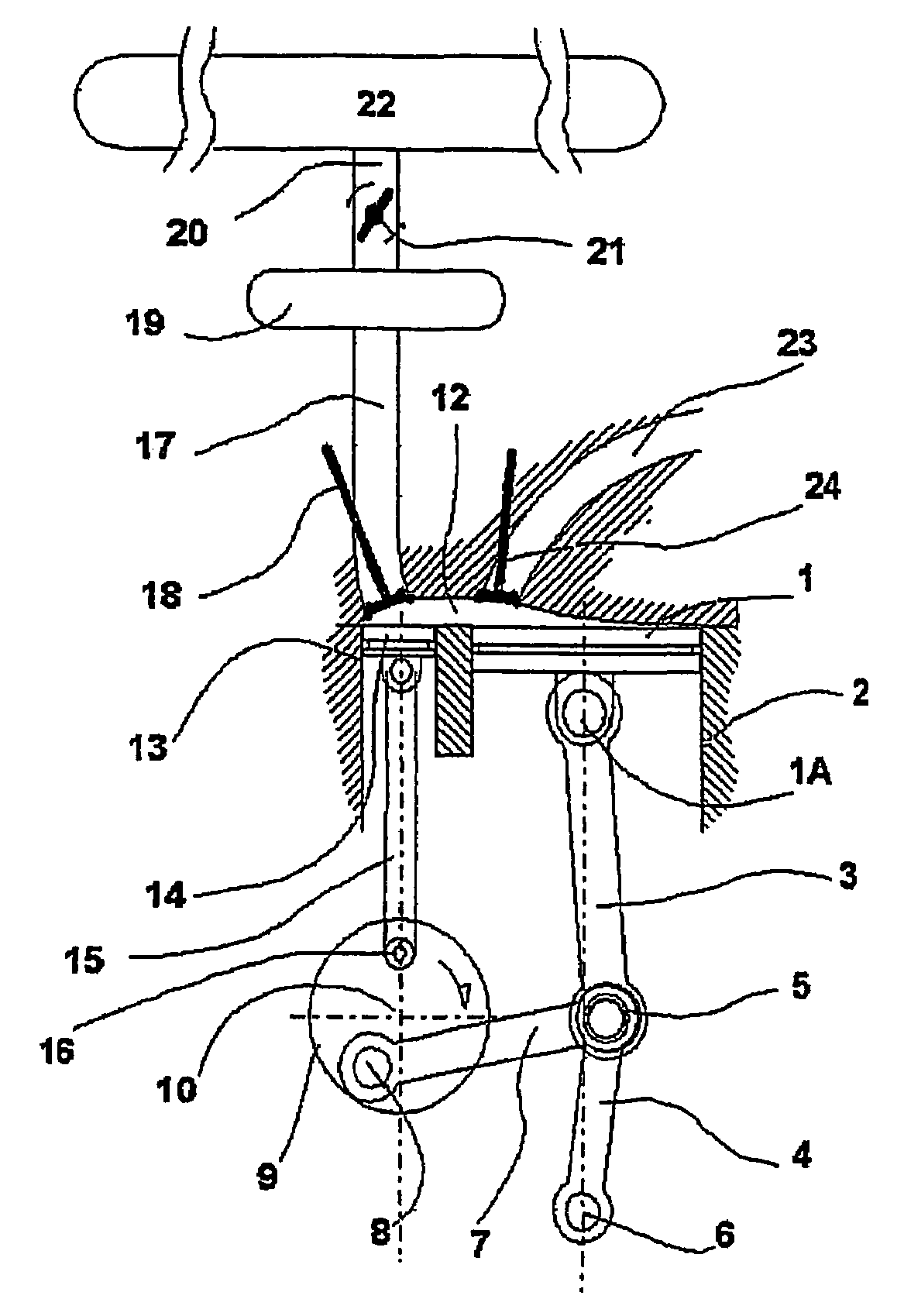

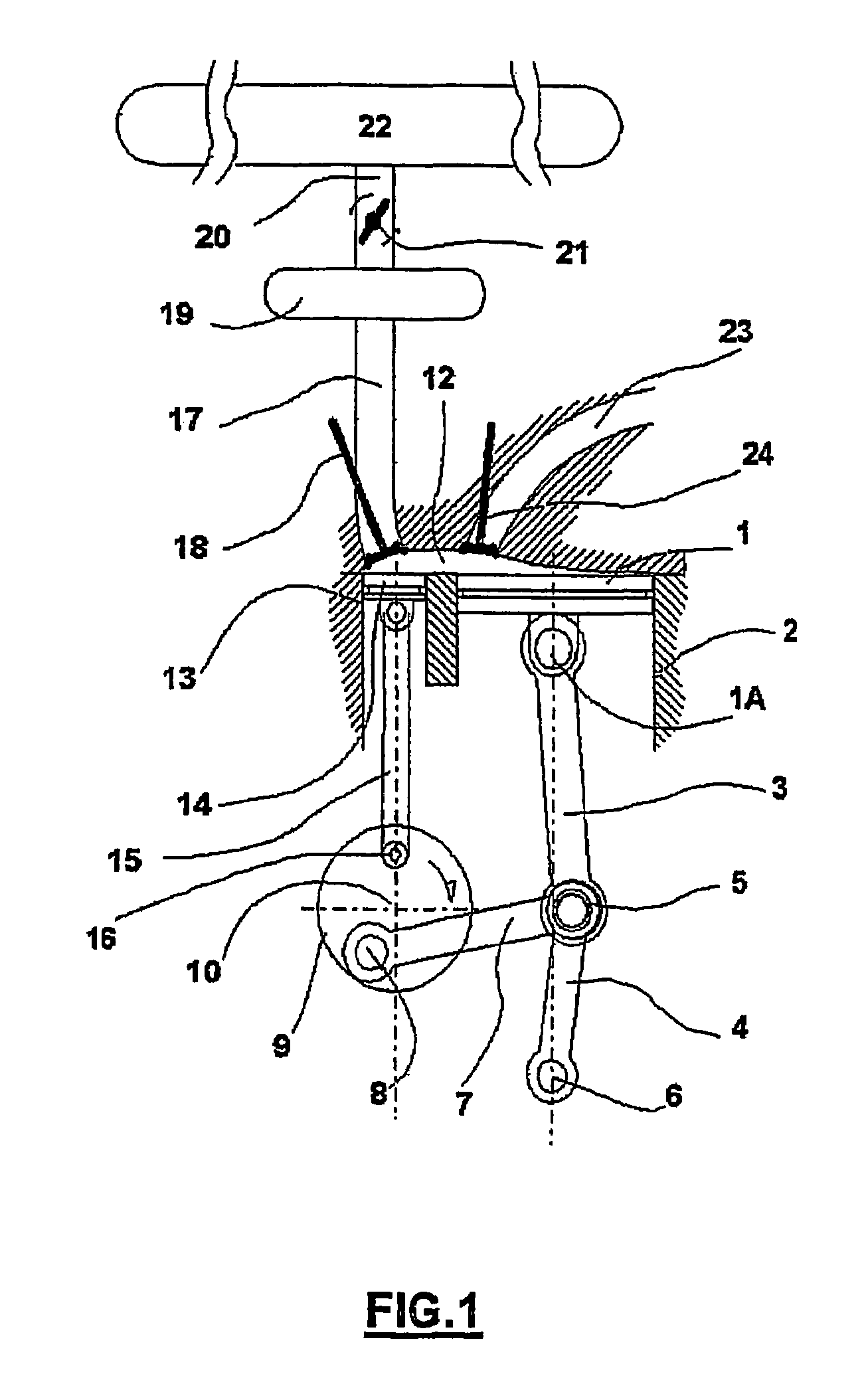

Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

ActiveUS7469527B2Usable and available energyQuantity of usable and availableFlexible wall reciprocating enginesCombustion enginesTop dead centerEngineering

An engine uses a top dead center piston stop device. It is fed by compressed air, via a working capacity, which, in the bi-energy version, includes a device for heating the air supplied by additional energy. The active expansion chamber consists of a variable volume or charge piston sliding in a cylinder, coupled to a space above the engine piston via a passage. When stoped at upper dead center, the pressurized air is admitted into the expansion chamber with the smallest volume thereof and, under the effect of thrust, increases the volume thereof by producing work; the expansion chamber is then kept at a maximum volume during expansion of the engine cylinder driving back the engine piston in its downward stroke, providing work of its own. During exhaust, the two pistons travel in an upward stroke and simultaneously reach top dead center in order to resume a new cycle.

Owner:MDI MOTOR DEV INT SA

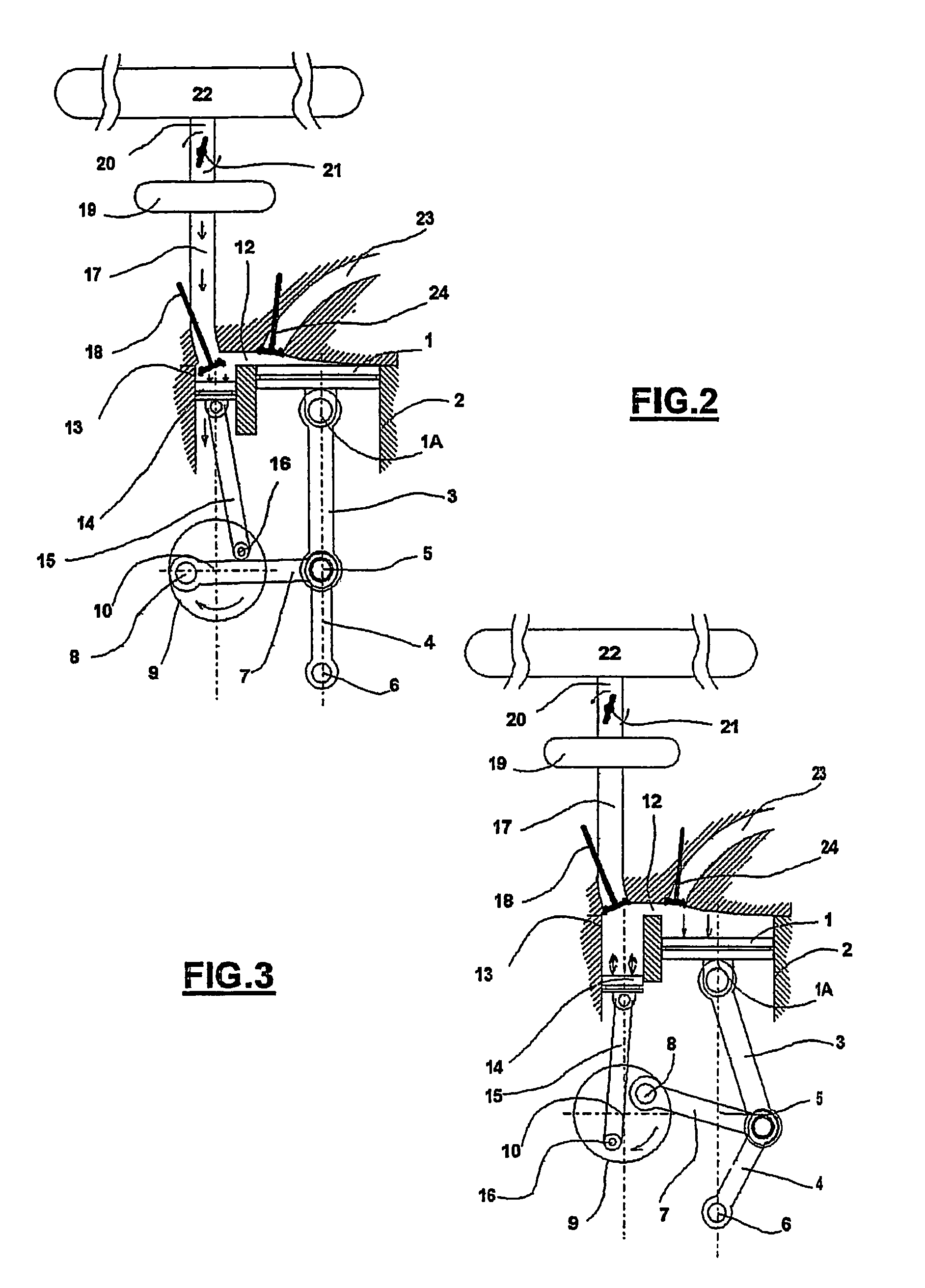

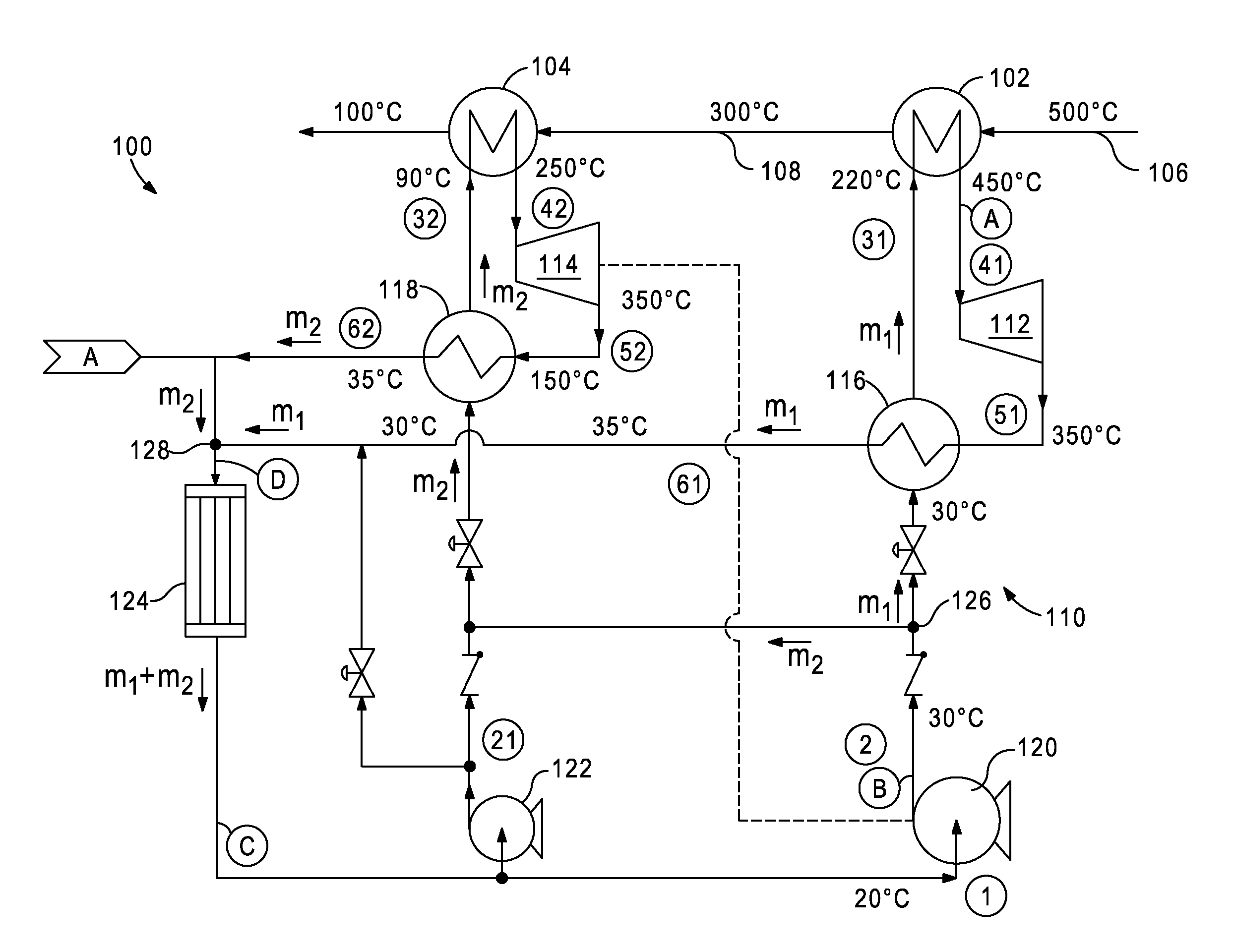

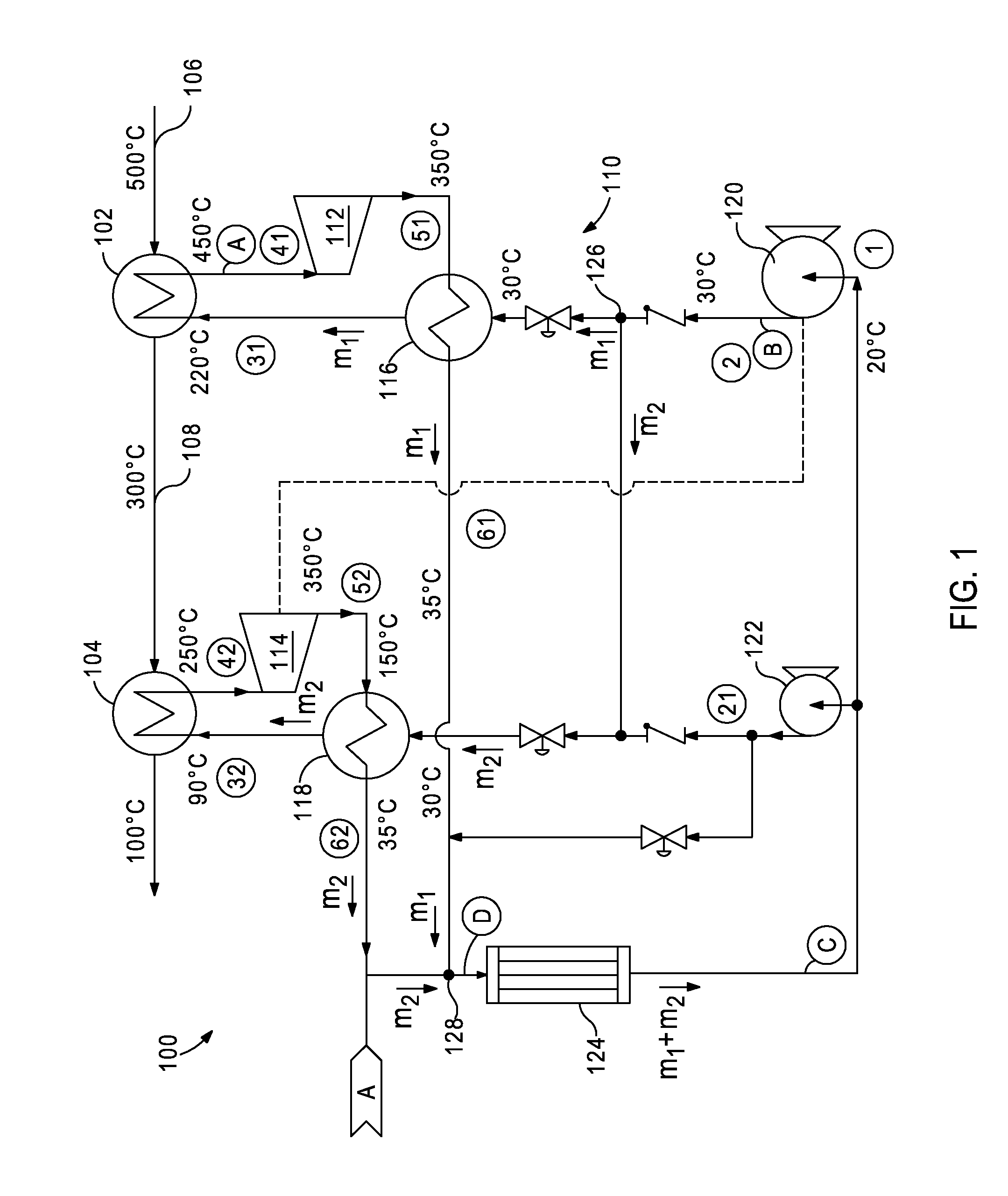

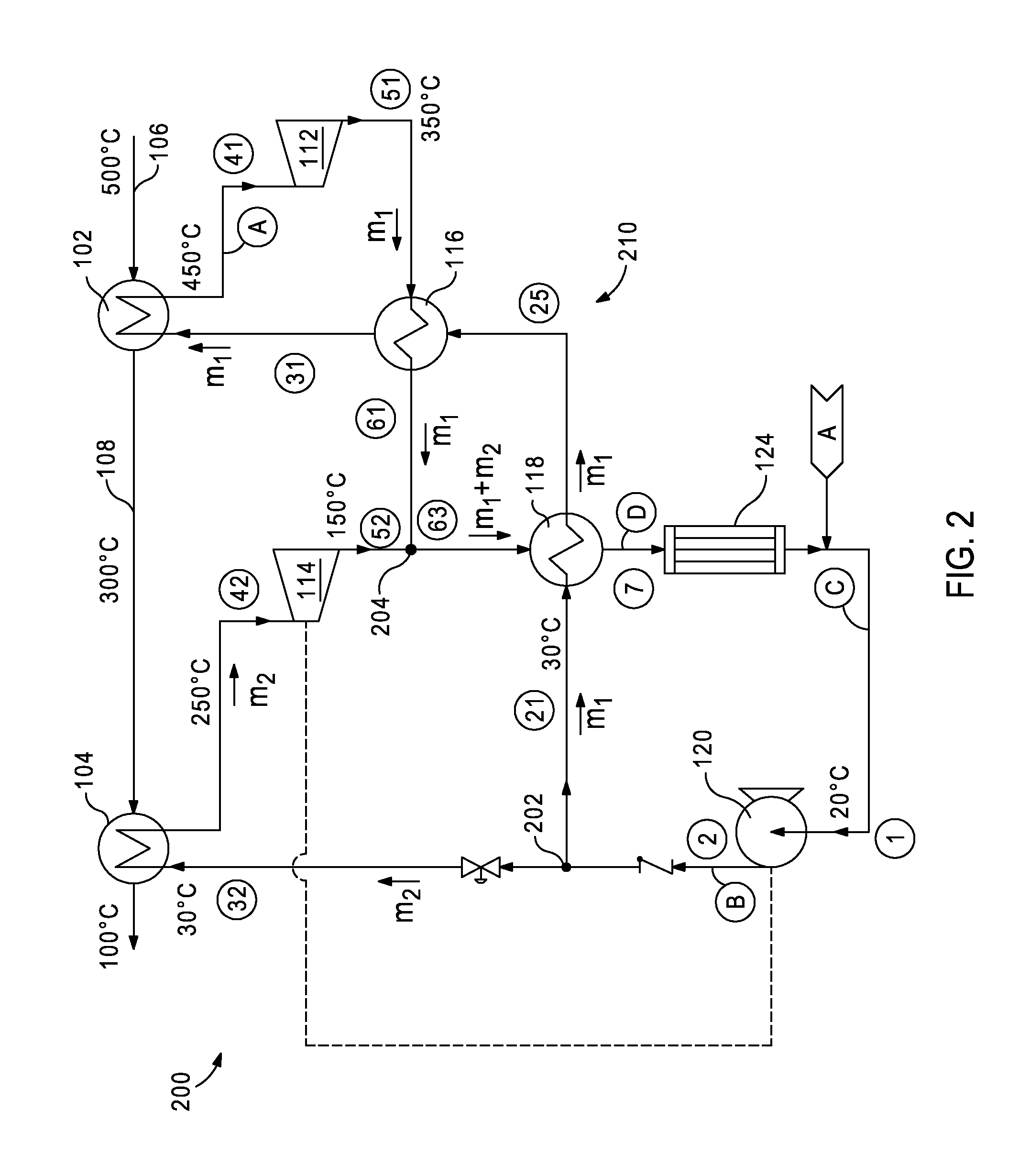

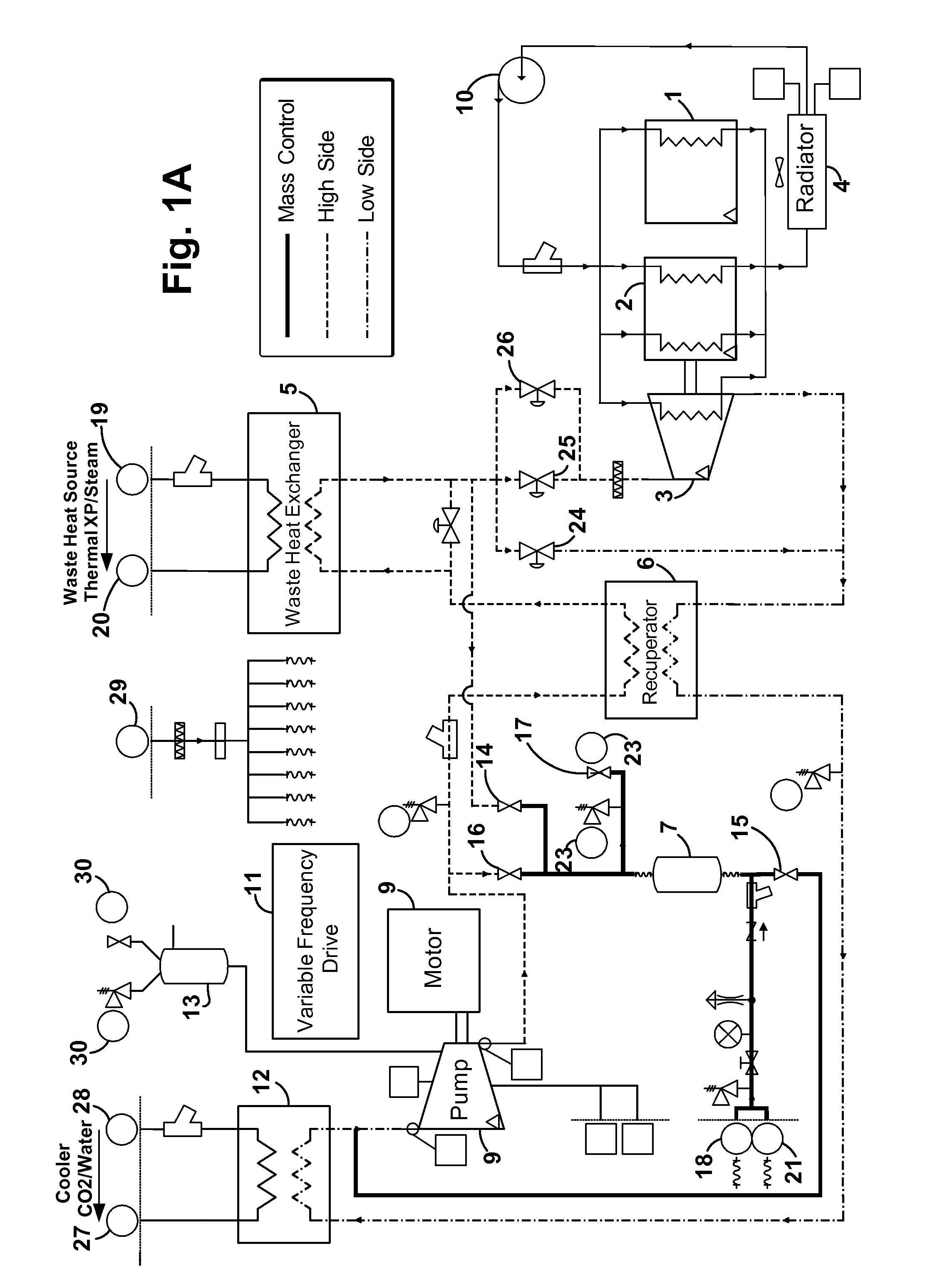

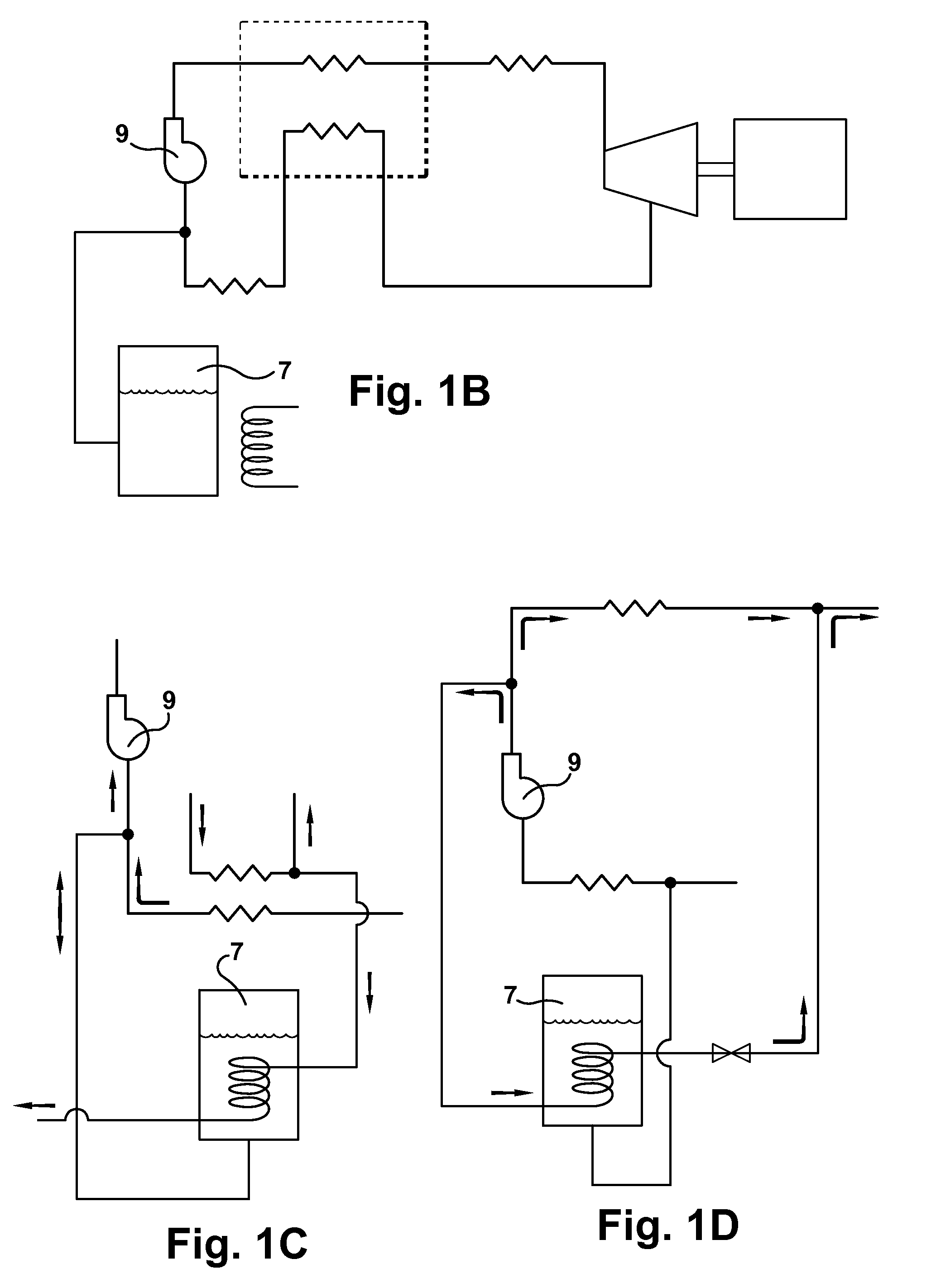

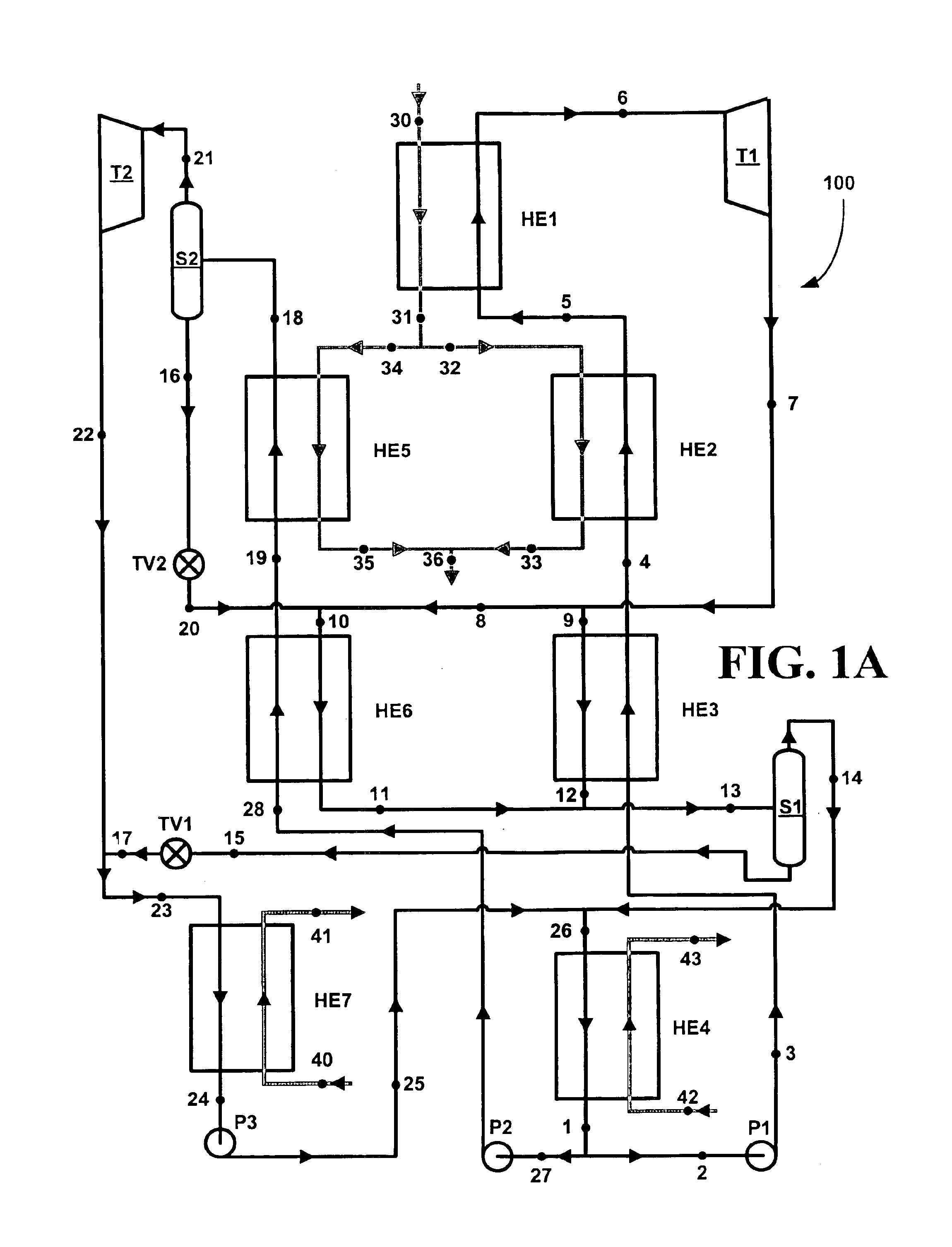

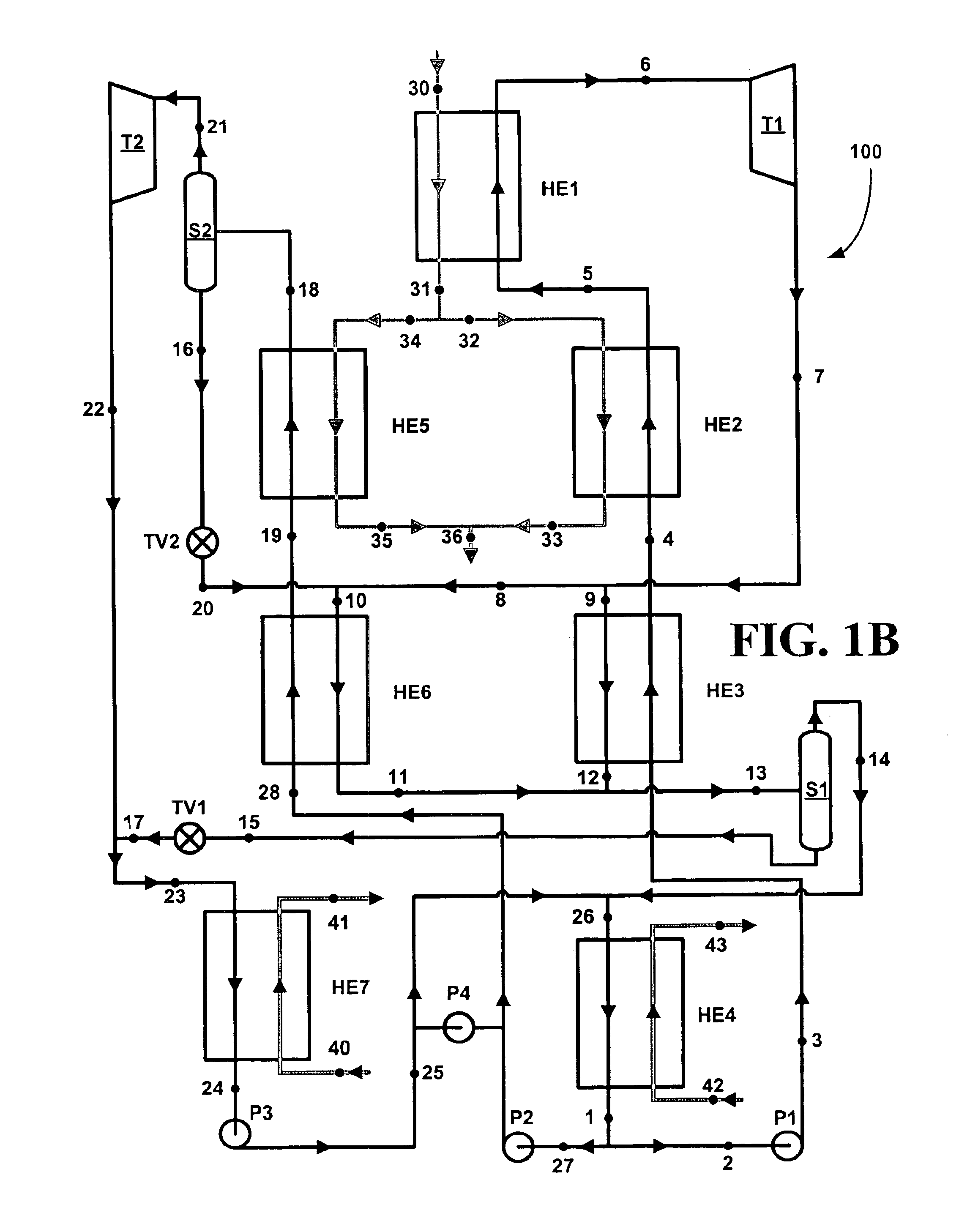

Parallel cycle heat engines

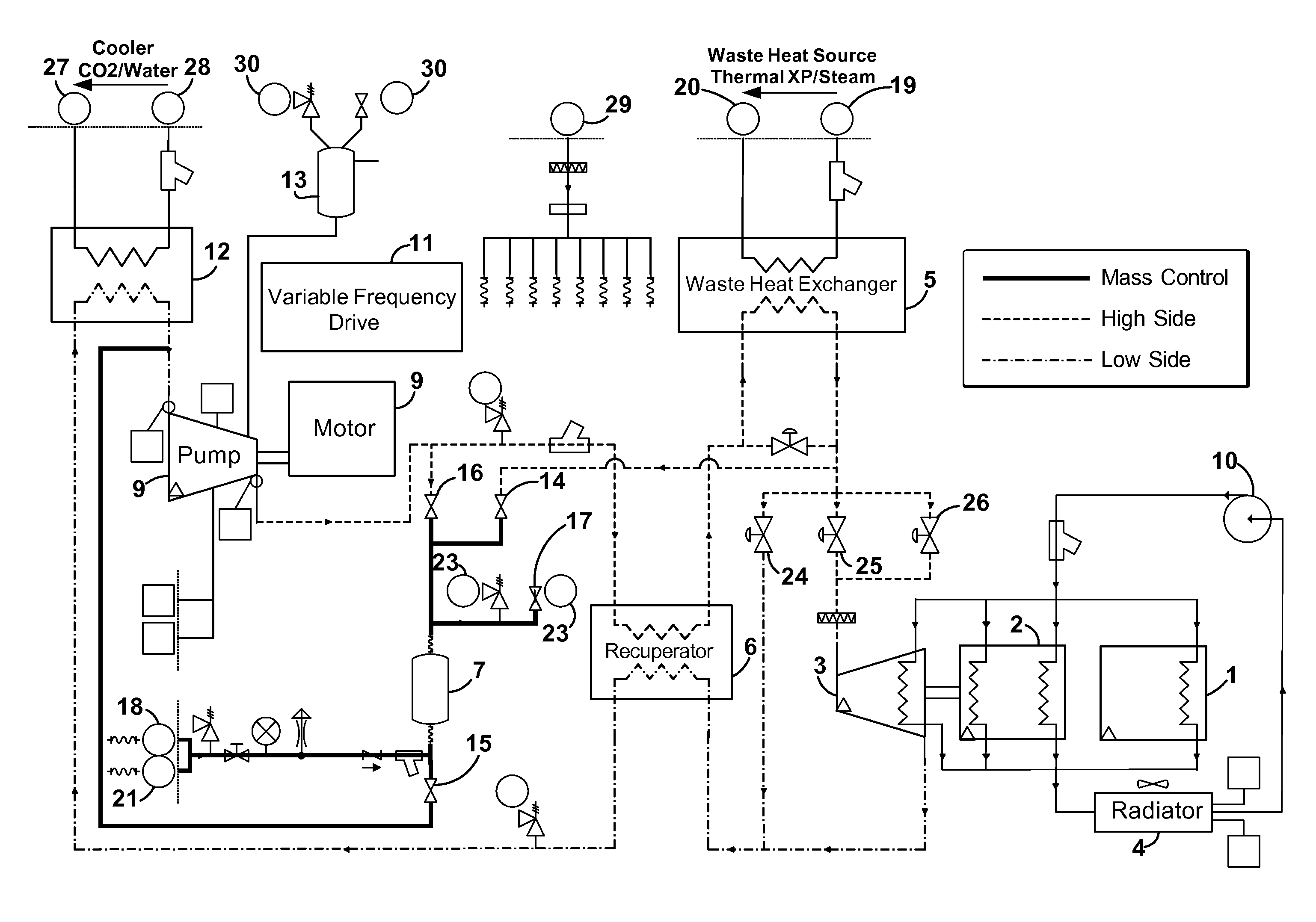

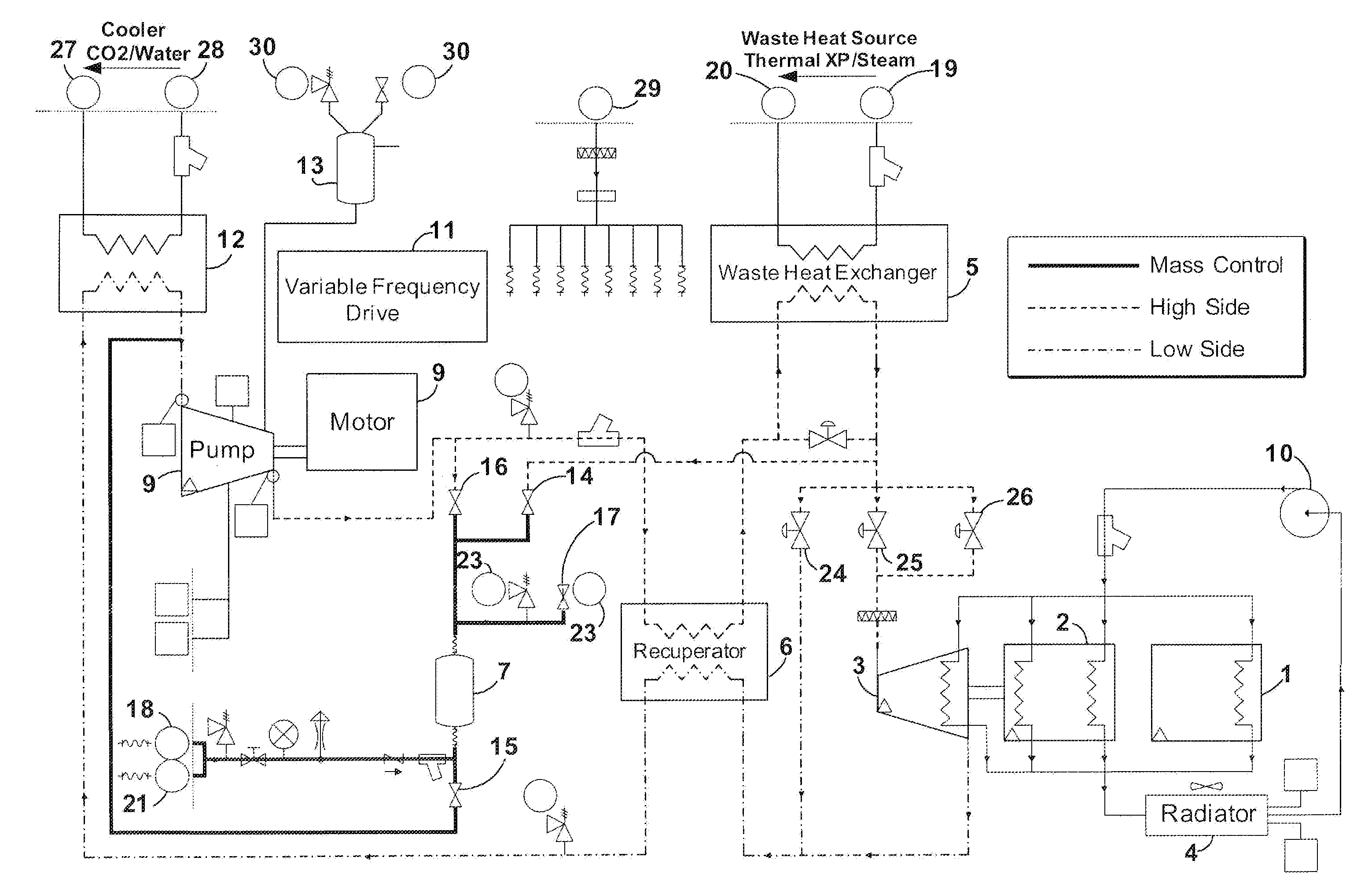

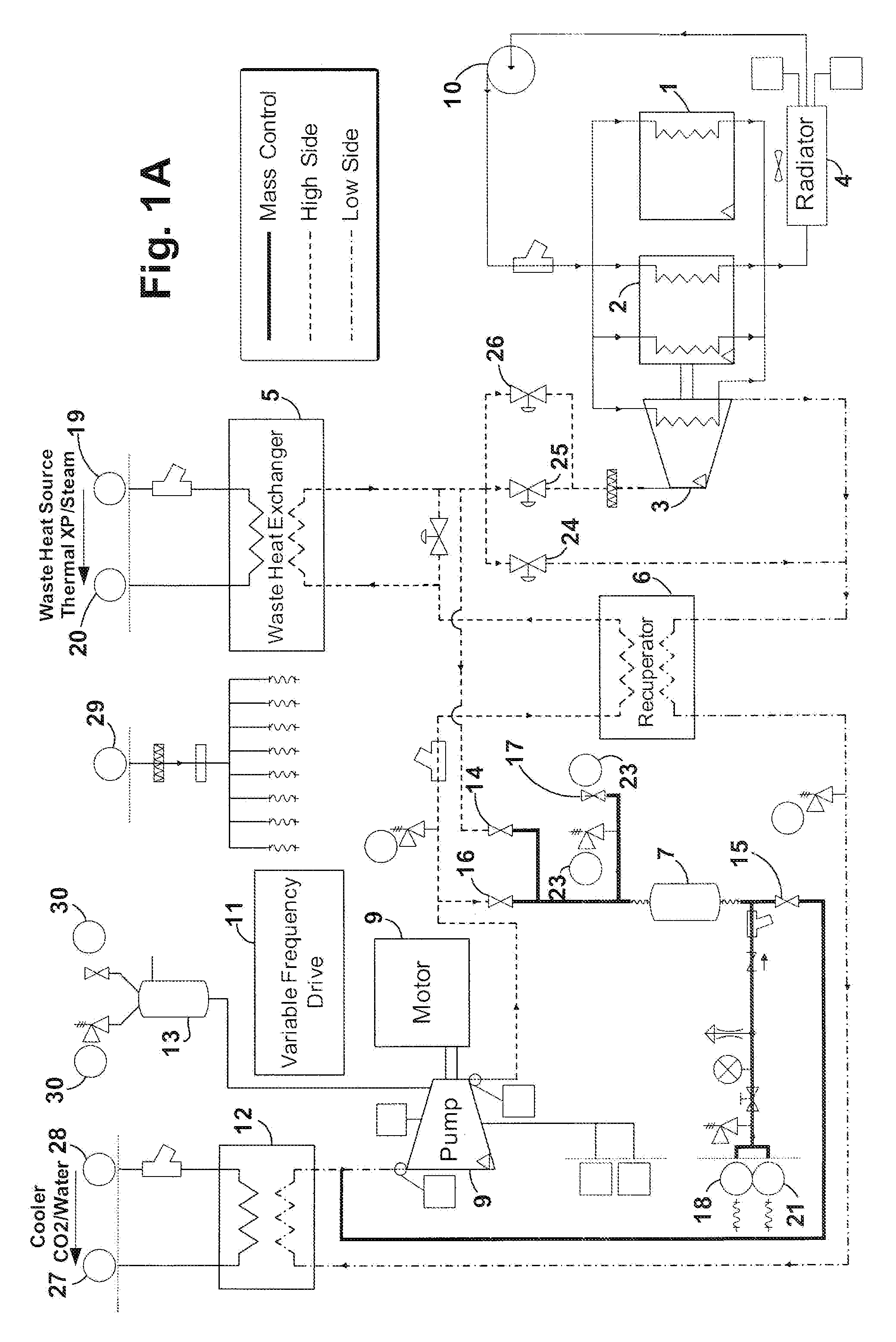

Waste heat energy conversion cycles, systems and devices use multiple waste heat exchangers arranged in series in a waste heat stream, and multiple thermodynamic cycles run in parallel with the waste heat exchangers in order to maximize thermal energy extraction from the waste heat stream by a working fluid. The parallel cycles operate in different temperature ranges with a lower temperature work output used to drive a working fluid pump. A working fluid mass management system is integrated into or connected to the cycles.

Owner:ECHOGEN POWER SYST

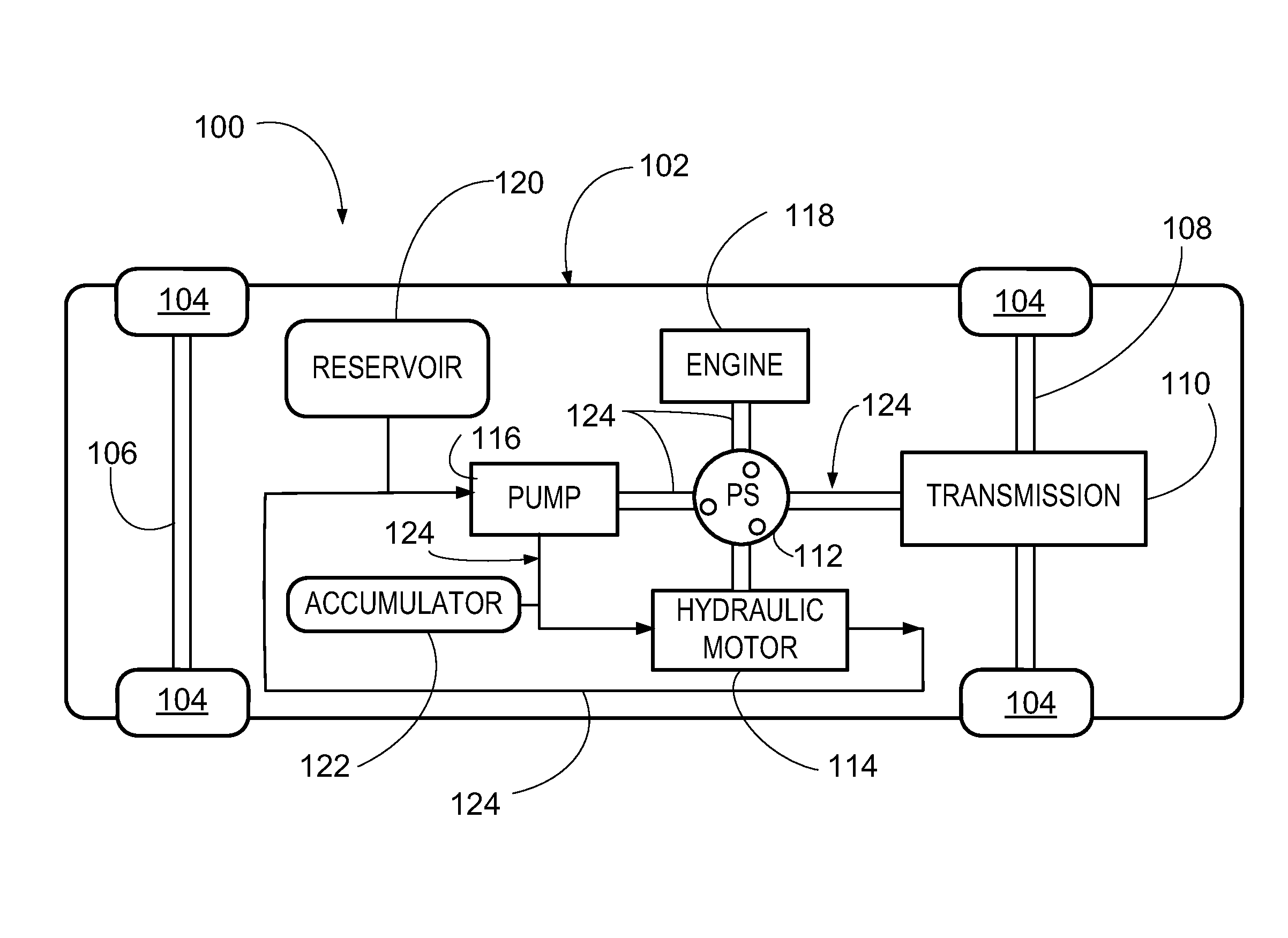

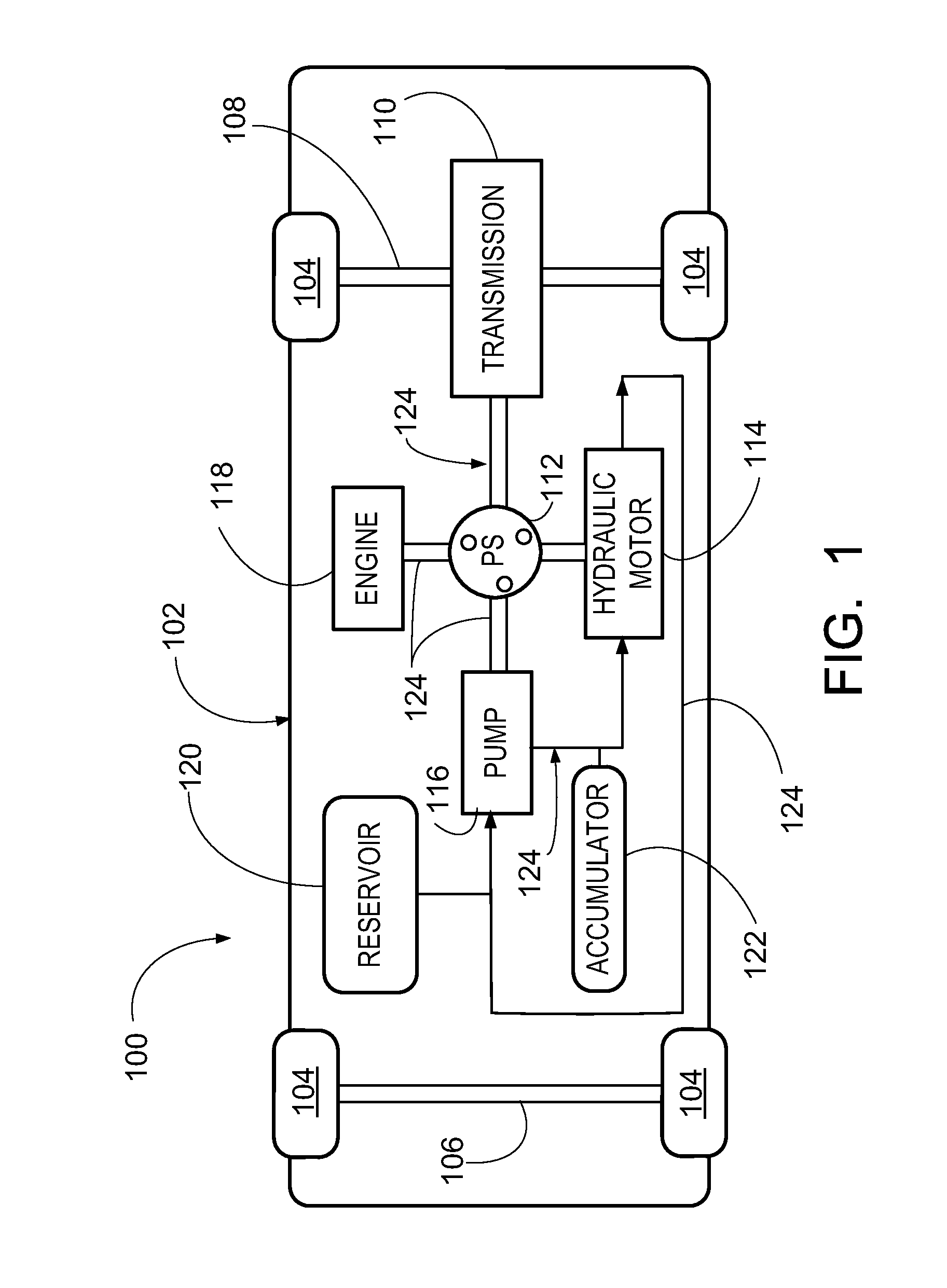

Hybrid power systems

The present invention generally relates to hybrid power systems for vehicles. In one embodiment, the present invention relates to hybrid power systems for various types of transportation vehicles where the hybrid power systems is partially, or even totally, based on the use of at least one hydraulic system to provide supplemental, or even the primary, motion power for a hybrid vehicle. In another embodiment, the hybrid power systems of the present invention are capable of providing both motion power as well as cabin comfort heating and / or cooling. In still another embodiment, a hybrid vehicle according to the present invention comprises a power generating system and passenger cabin comfort system, wherein the power generating system comprises a thermodynamic working fluid (FA) in a first thermodynamic cycle (C1), a pump (P1), a motor (M1), a high pressure accumulator, a low pressure reservoir, and at least one heat exchanger, wherein the thermodynamic working fluid (FA) is concurrently operable to create either vehicle motion through the motor (M1) or electricity through a generator and is operable to create passenger cabin cooling or heating through the expansion or contraction of the thermodynamic working fluid (FA).

Owner:ECHOGEN POWER SYST

Power system and apparatus for utilizing waste heat

ActiveUS6968690B2Increase temperatureAvoid componentsSteam engine plantsReciprocating piston enginesWorking fluidDistillation

A new Kalina thermodynamic cycle is disclosed where a multi-component working fluid is fully vaporized in a boiler utilizing waste heat streams such as flue gas streams from cement kilns so the energy can be extracted from the streams and converted to usable electrical or mechanical energy in a turbine subsystem and after extraction, the spent stream is fully condensed in a distillation-condensation subsystem using air and / or water coolant streams. A new method for implementing the improved Kalina thermodynamic cycle is also disclosed.

Owner:KALINA POWER LTD

Heat engine and heat to electricity systems and methods

ActiveUS20100156112A1Efficiently and effectively produce powerFluid heatersInternal combustion piston enginesThermal energyWorking fluid

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit.

Owner:REXORCE THERMIONICS INC +1

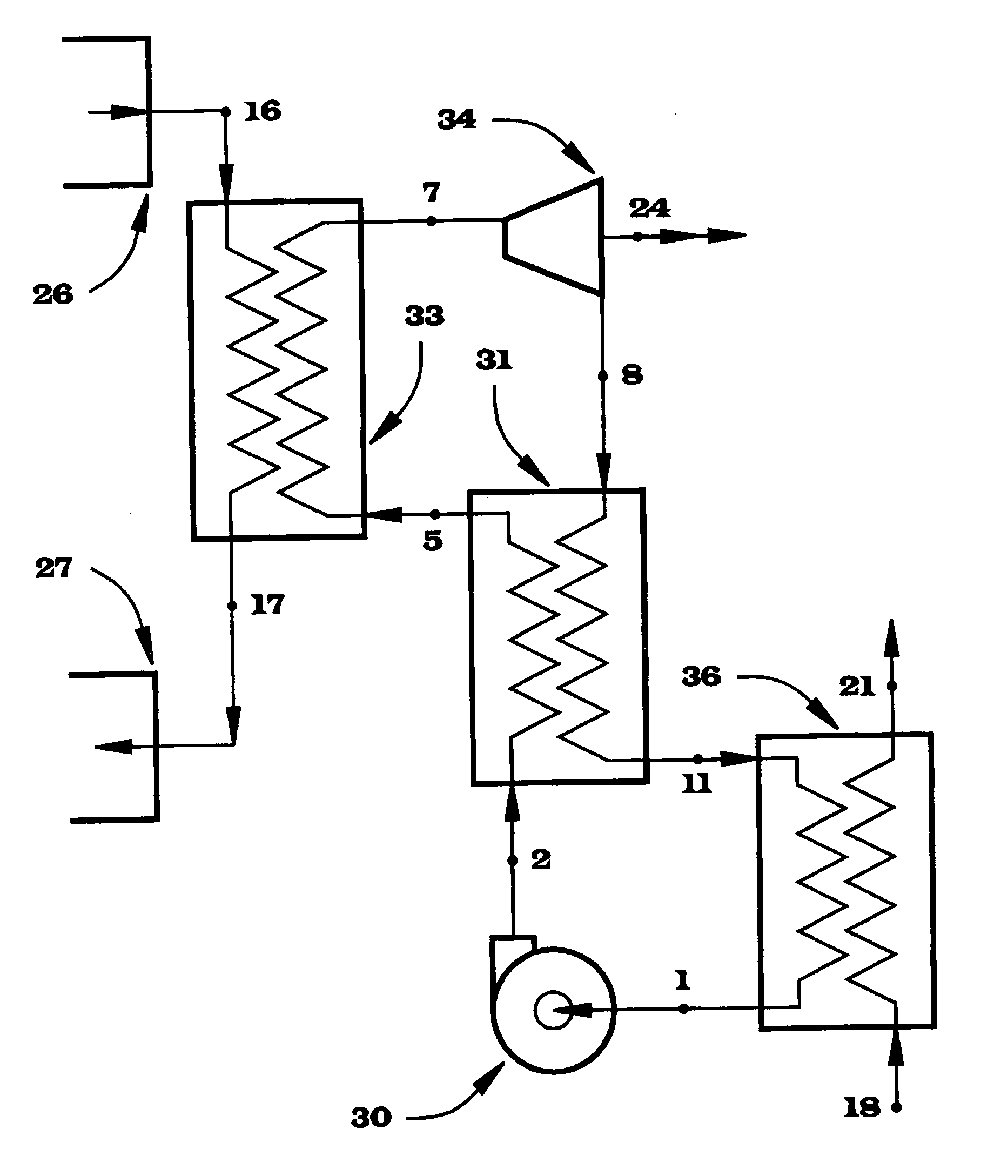

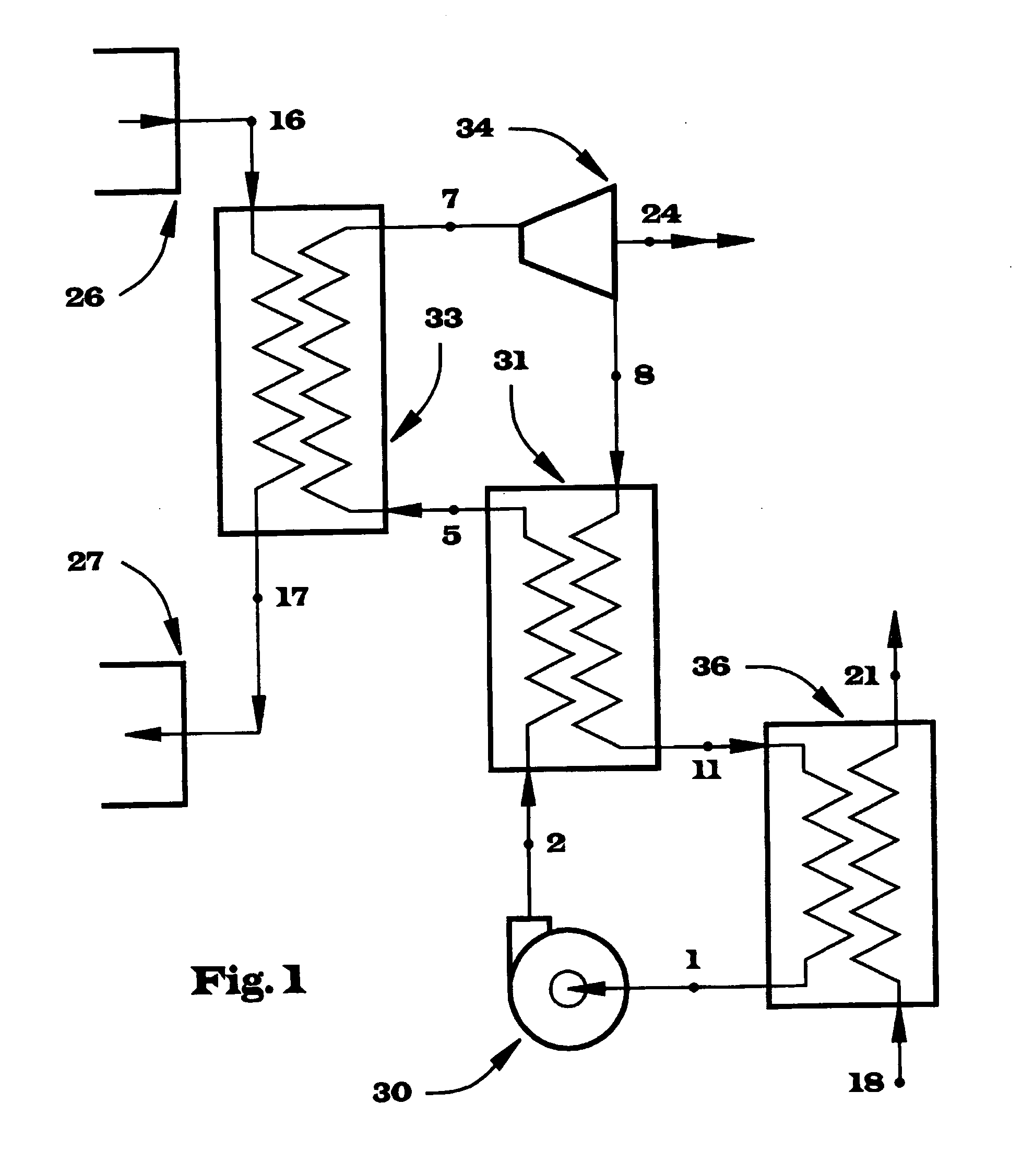

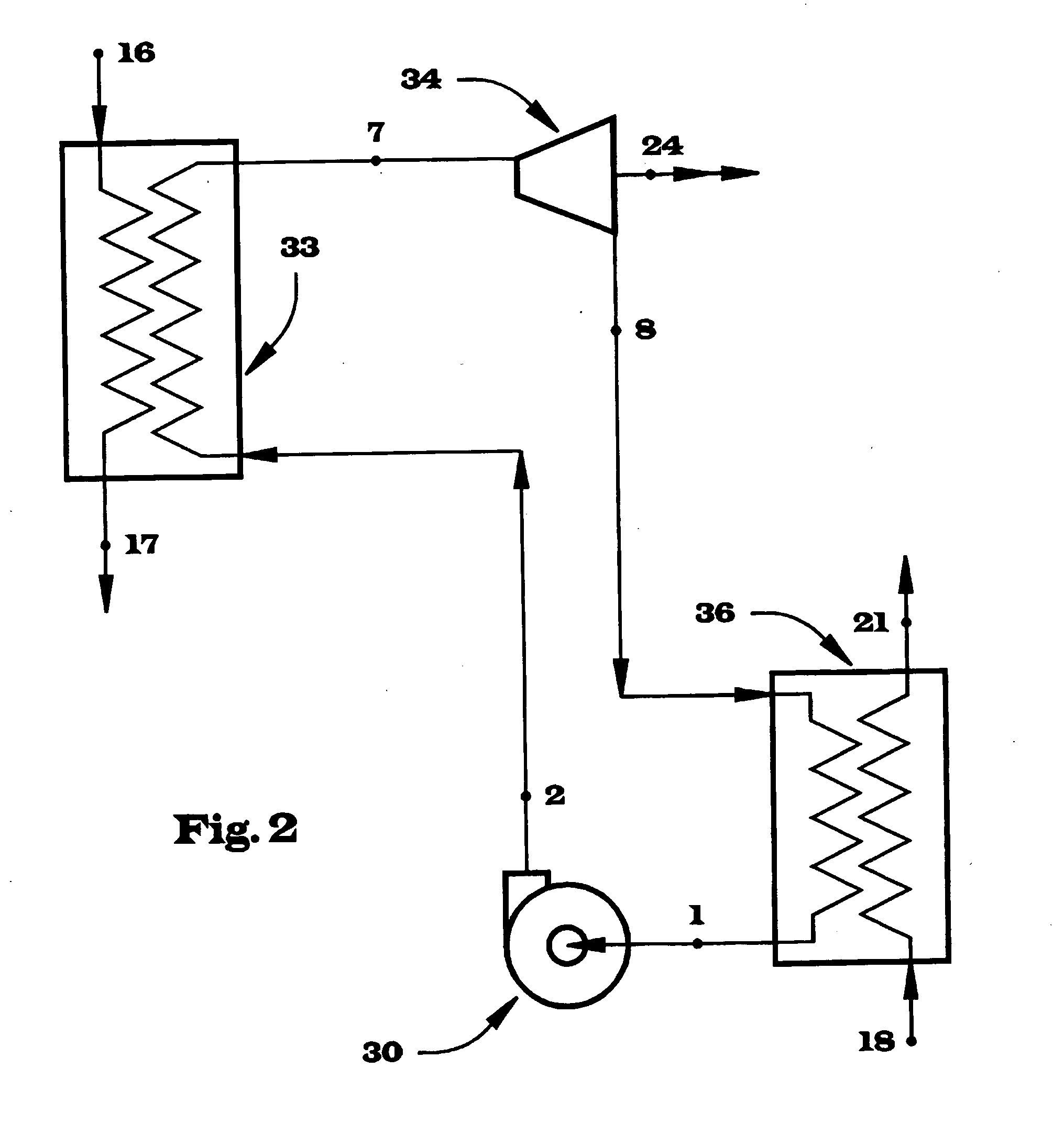

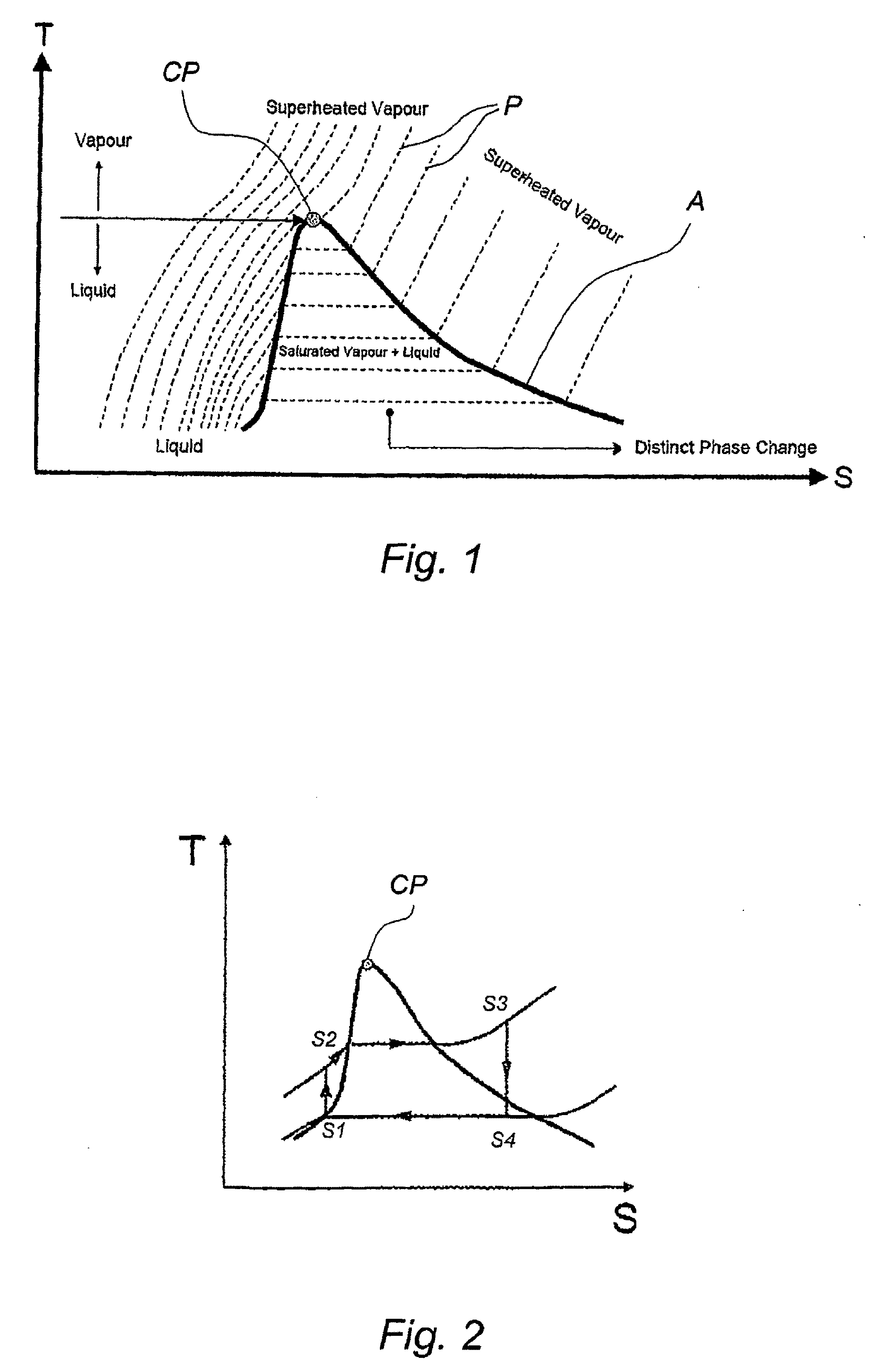

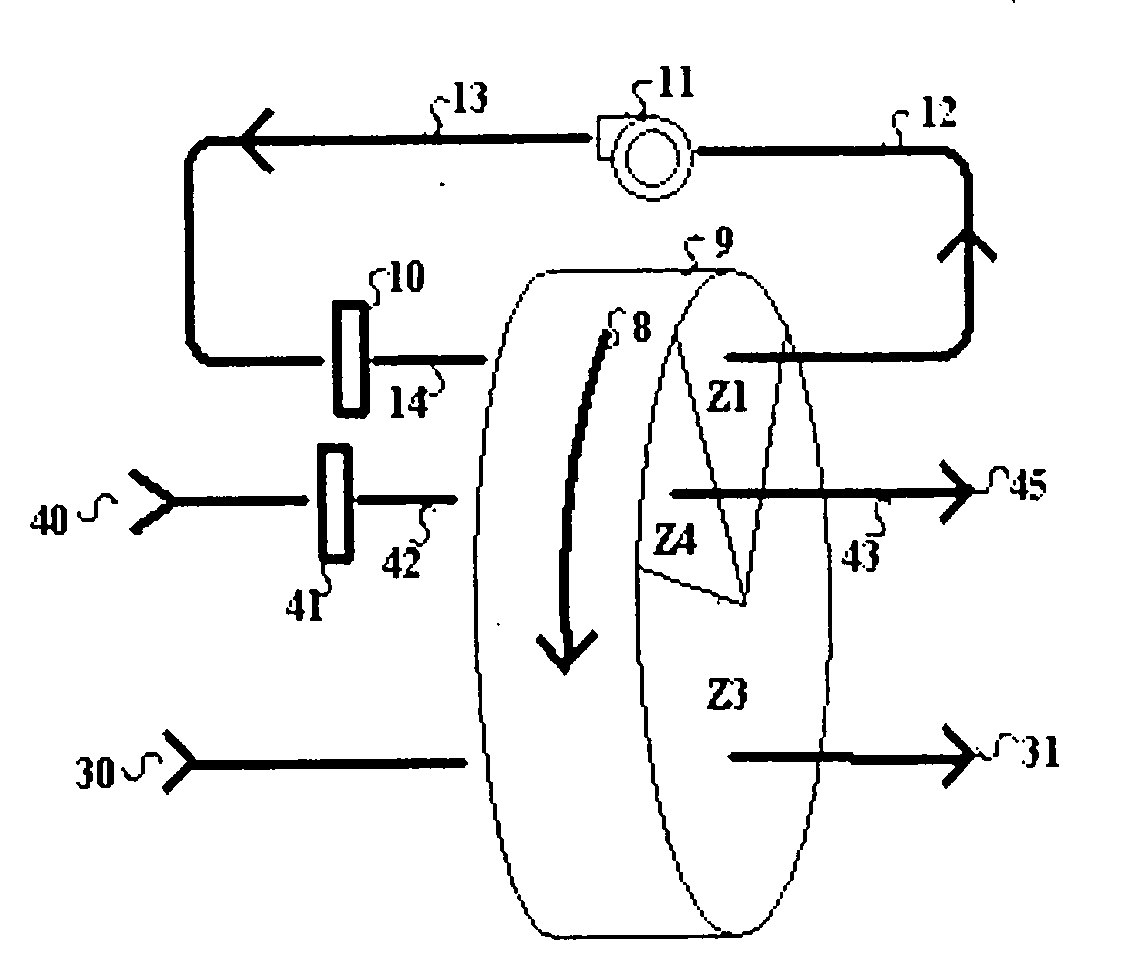

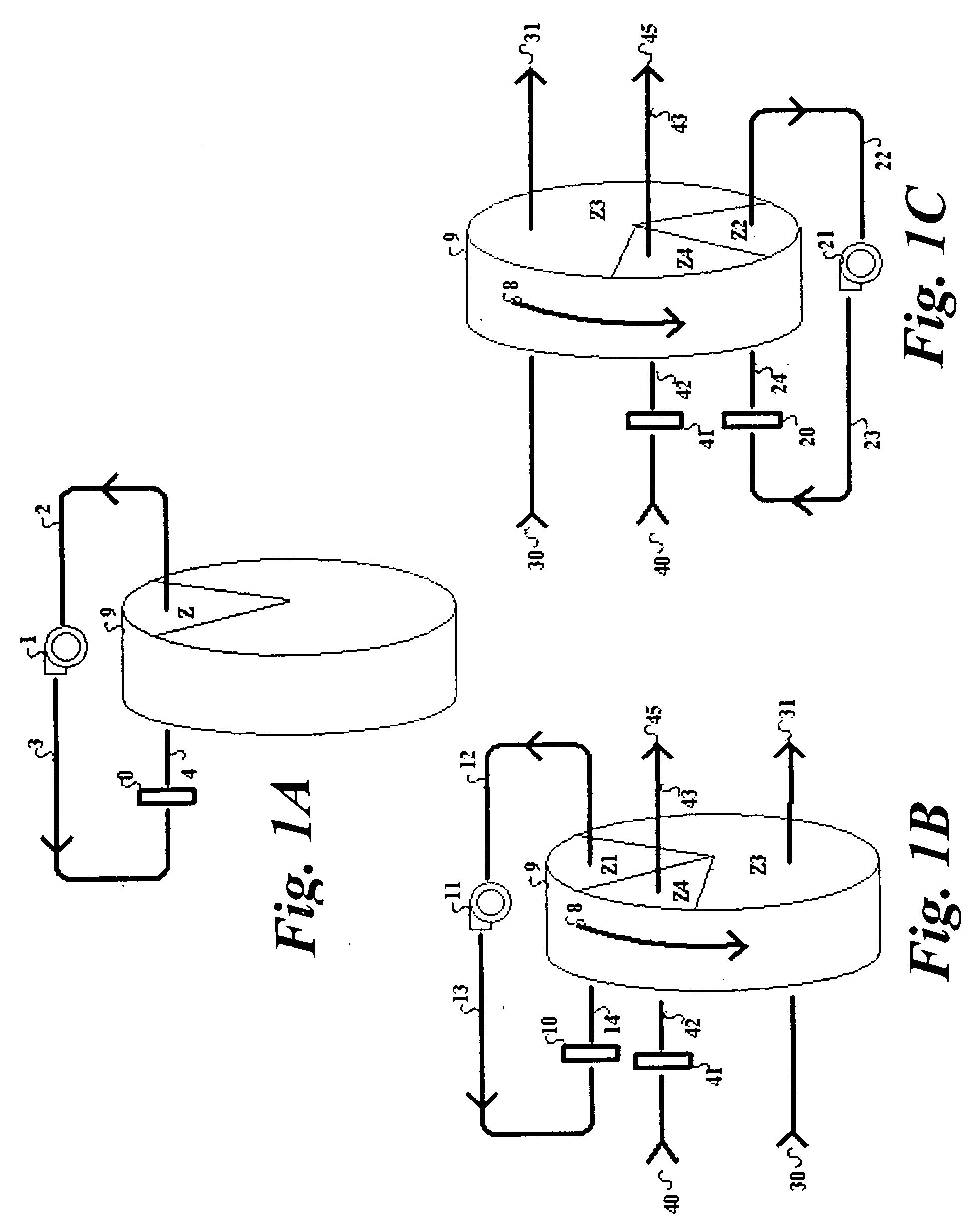

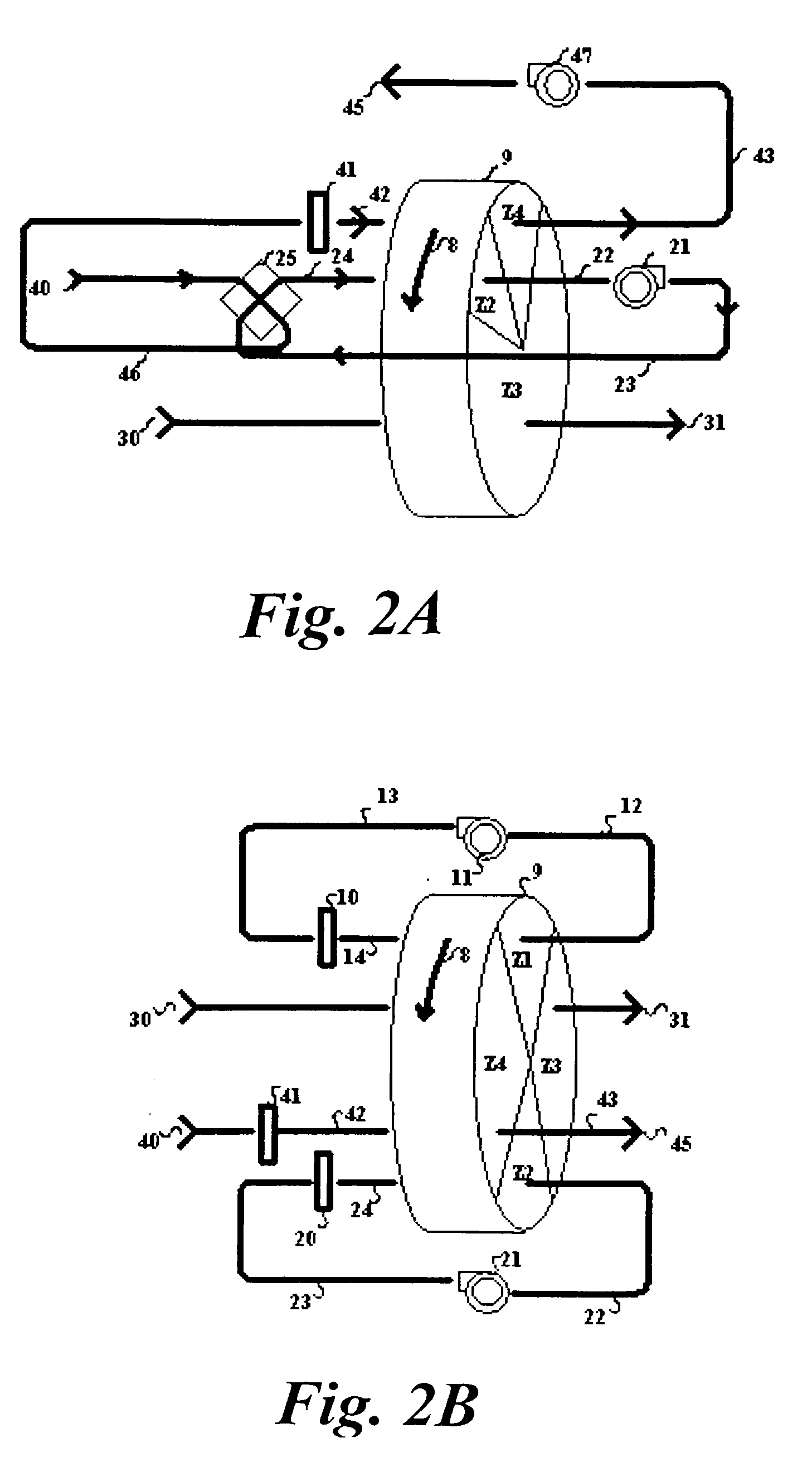

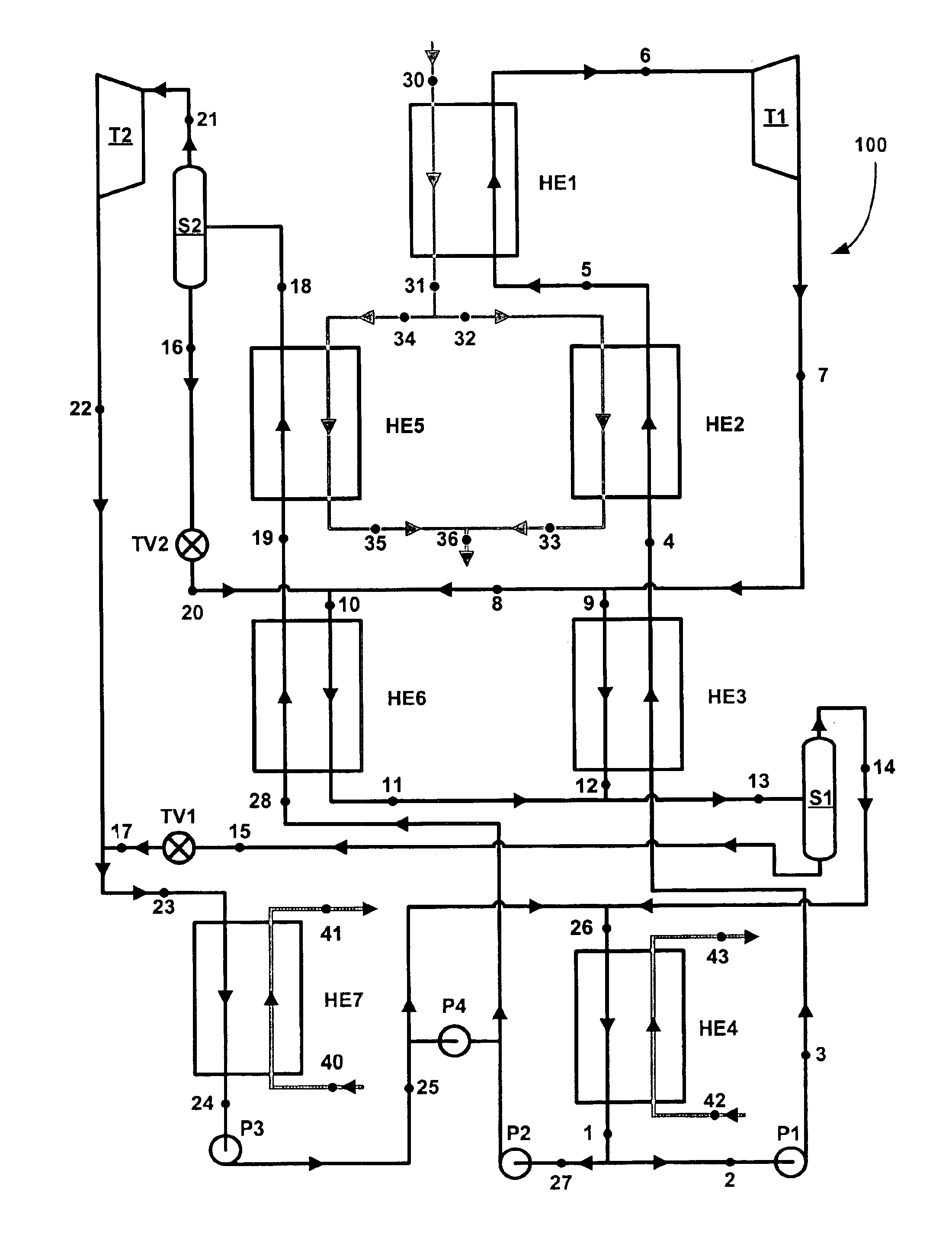

Method of converting energy

The invention provides a method of converting heat energy to a more usable form using a multi-component working fluid mixture that contains ammonia and water. The working fluid is operated in a thermodynamic cycle that includes liquid compression (30), vaporization (33), expansion through a turbine (34) and condensing (36). The multi-component fluid varies in temperature during phase change allowing for the use of counter-flow heat exchangers for the heater (33), cooler (36), recuperator and pre-heater (32). Significant recuperation is possible due to the temperature change during phase change. A pre-heater (32) can be applied to ensure only single-phase vapour exists within the heater. The invention can be used in conjunction with a biomass combustor or with waste flue gas from an existing industrial process. The coolant exits at a temperature sufficient to allow use in external heating applications or to minimize the size of external heat rejection equipment

Owner:SMITH & WESSON

Cooling electronics via two-phase tangential jet impingement in a semi-toroidal channel

InactiveUS20060162365A1Domestic cooling apparatusSemiconductor/solid-state device detailsEvaporationEngineering

A two-fluid-phase cooling device for absorbing high thermal flux from electronics devices and other thermally dissipating devices. It consists of a thermally conductive plate with thermally dissipating elements on one face and a semi-toroidal cavity in the opposite face with the cavity's axis perpendicular to the face of the plate, a liquid refrigerant supply tube ending in a thermodynamic cycle's refrigeration expansion valve that directs jets of liquid to impact the conical surface in the center region of the semi-toroidal cavity in a direction along the cavity's axis and tangent to the conical surface, a second plate with a semi-toroidal protrusion extending into the semi-toroidal cavity to form a thin, semi-toroidal channel between the two plates, and a seal between the liquid supply tube and the second semi-toroidal plate. In operation liquid refrigerant jets strike the conical surface generally tangential to the surface and flow at high velocity in a thin film on the surface of the semi-toroidal cavity from its center radially to the outer edge of the toroidal channel, absorbing heat and boiling as it does so. The high radial acceleration forces caused by the liquid film moving at high velocity on the cavity's concave surface force the liquid film against the surface and create a pressure gradient that biases evaporation toward the liquid / vapor interface. The vapor moves parallel to the liquid flow radially outwards between the liquid film and the surface of the semi-toroidal protrusion at very high velocity, causing extreme turbulence in the liquid film and highly augmented heat transfer between the heated plate and the liquid film, while the liquid film nevertheless remains intact and forced against the heated surface by radial acceleration and carried to a distance significantly greater than in conventional jet impingement systems. The device may also be composed of wedge-shaped sections of the semi-toroidal plates. It may further have two expansion valves in series in the liquid supply line, the first generating a small amount of vapor (increase in quality) so the resulting increase in flow volume greatly increases the velocity through the second expansion valve toward the heated surface to further enhance heat transfer.

Owner:HOANG TRIEM T +1

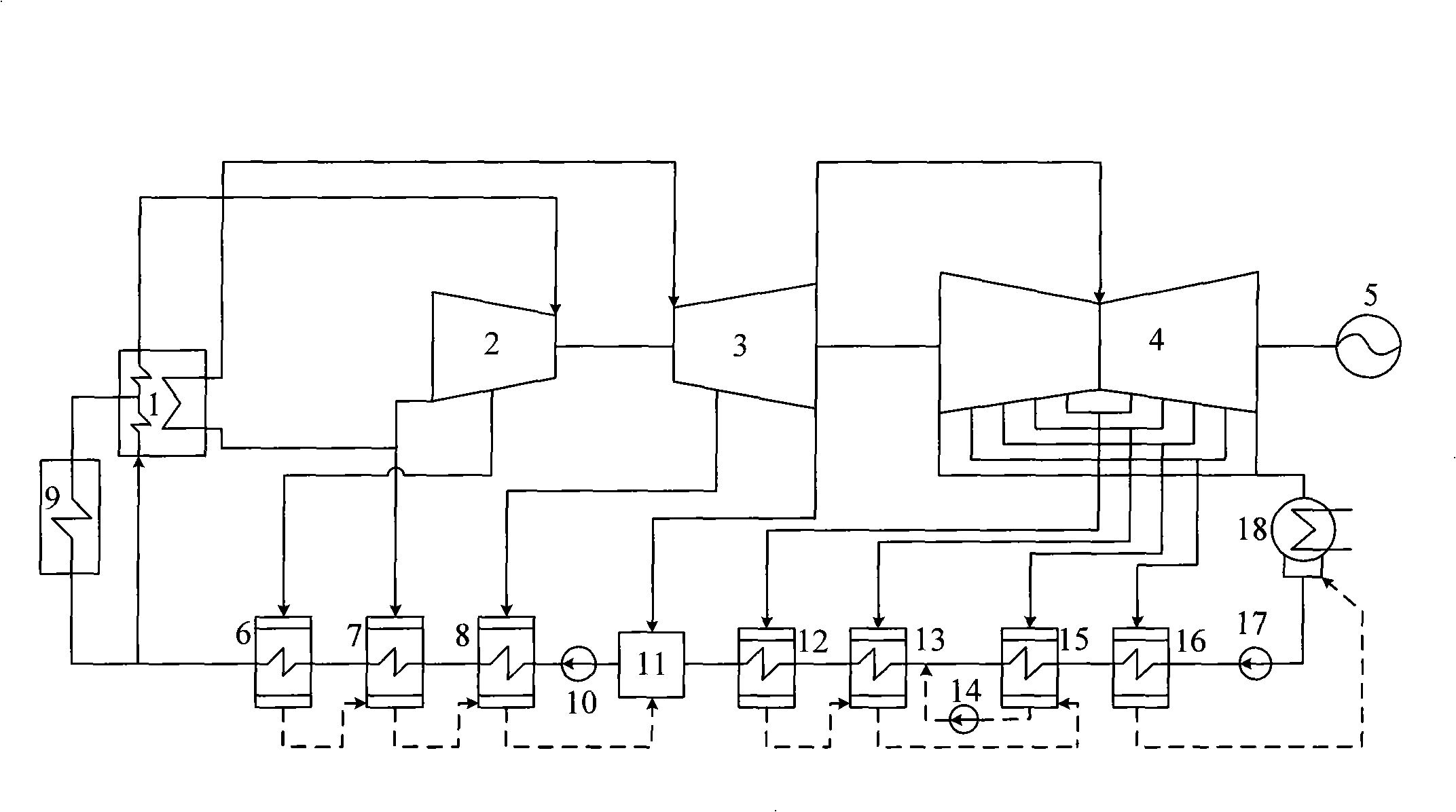

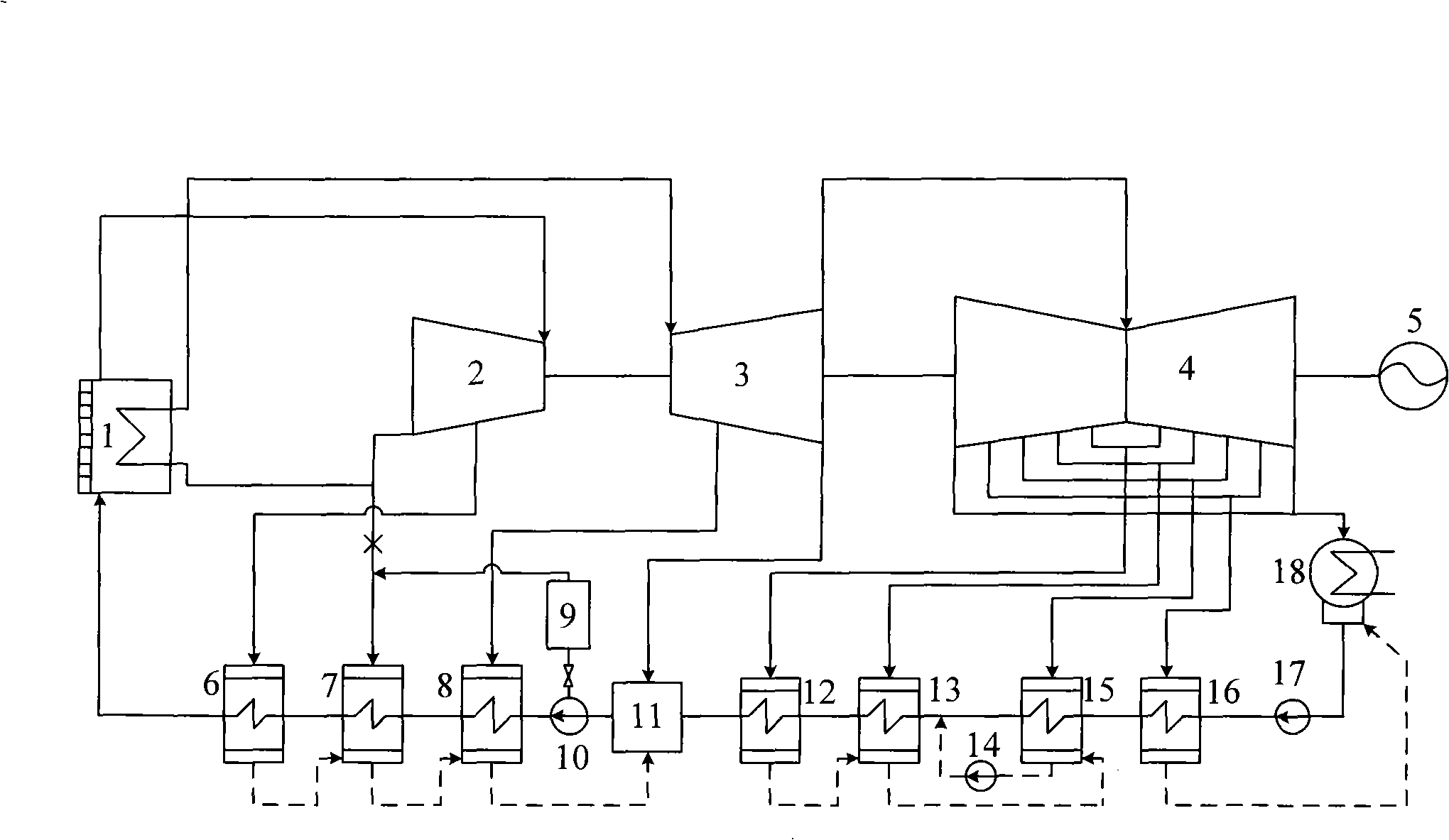

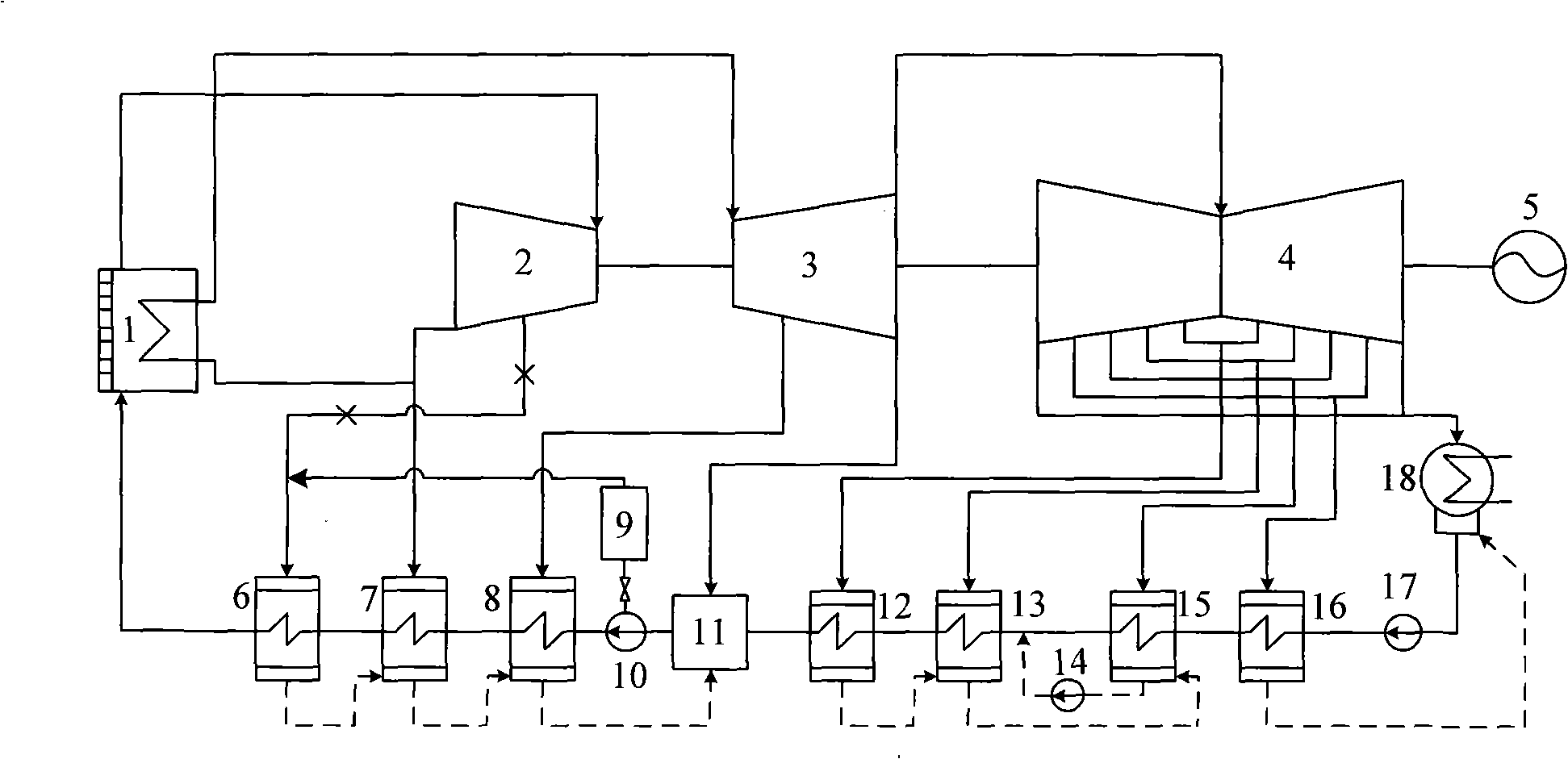

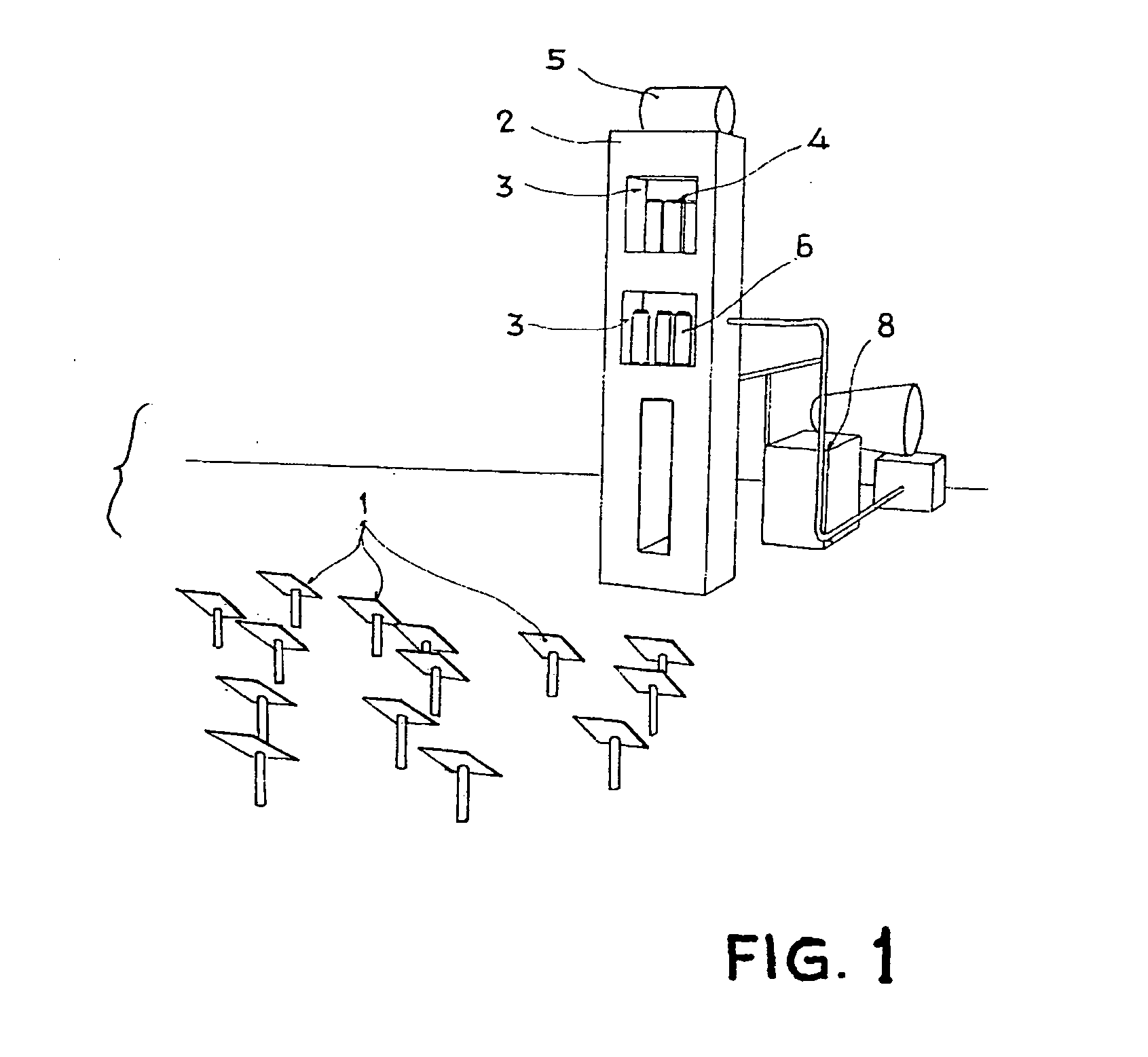

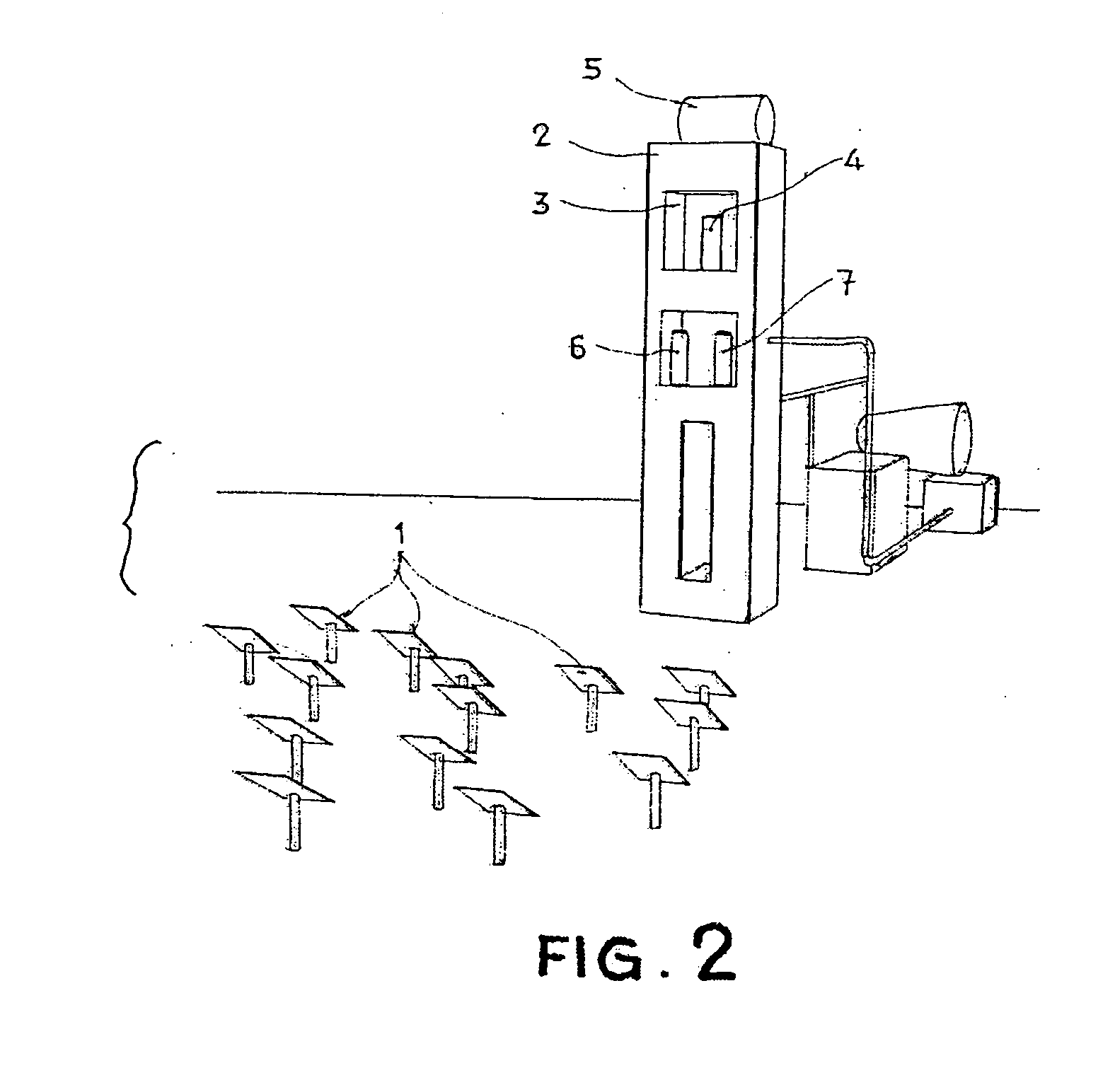

Solar energy and coal-burning unit combined thermal power generation system

InactiveCN101270675AHigh thermal efficiencyImprove thermal efficiencySteam engine plantsDeaeratorEngineering

The invention relates to a generating system, in particular to the heat generating system consisting of a solar heat collector and a coal-fired unit. The heat generating system adopts solar energy to take the place of the partial coal-fired heat energy of a coal-fired unit boiler. A condenser, an extraction pump, a low pressure heater, a deaerator, a water-feeding pump, a high pressure heater and the heat collector, a coal burning boiler and a steam turbine that are connected in parallel are connected in series. The steam turbine drives the generator and discharges gas into the condenser. Condensed water flows into a heater from the condenser to be heated up and pressurized, is deoxidized by the deaerator, then goes through the solar heat collector to be heated to be saturated vapor and goes into the coal burning boiler or directly goes into the coal burning boiler to become the steam with high temperature and high pressure. And then the steam goes into the steam turbine for applying work to drive the generator to generate electricity. The extracted steam of the steam turbine goes into each heater to finish thermodynamic cycle. The thermal efficiency of solar thermal power generation is improved, investment in the trough solar electrical energy generation of single paraboloid is reduced and the coal consumption of the coal-fired unit is decreased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

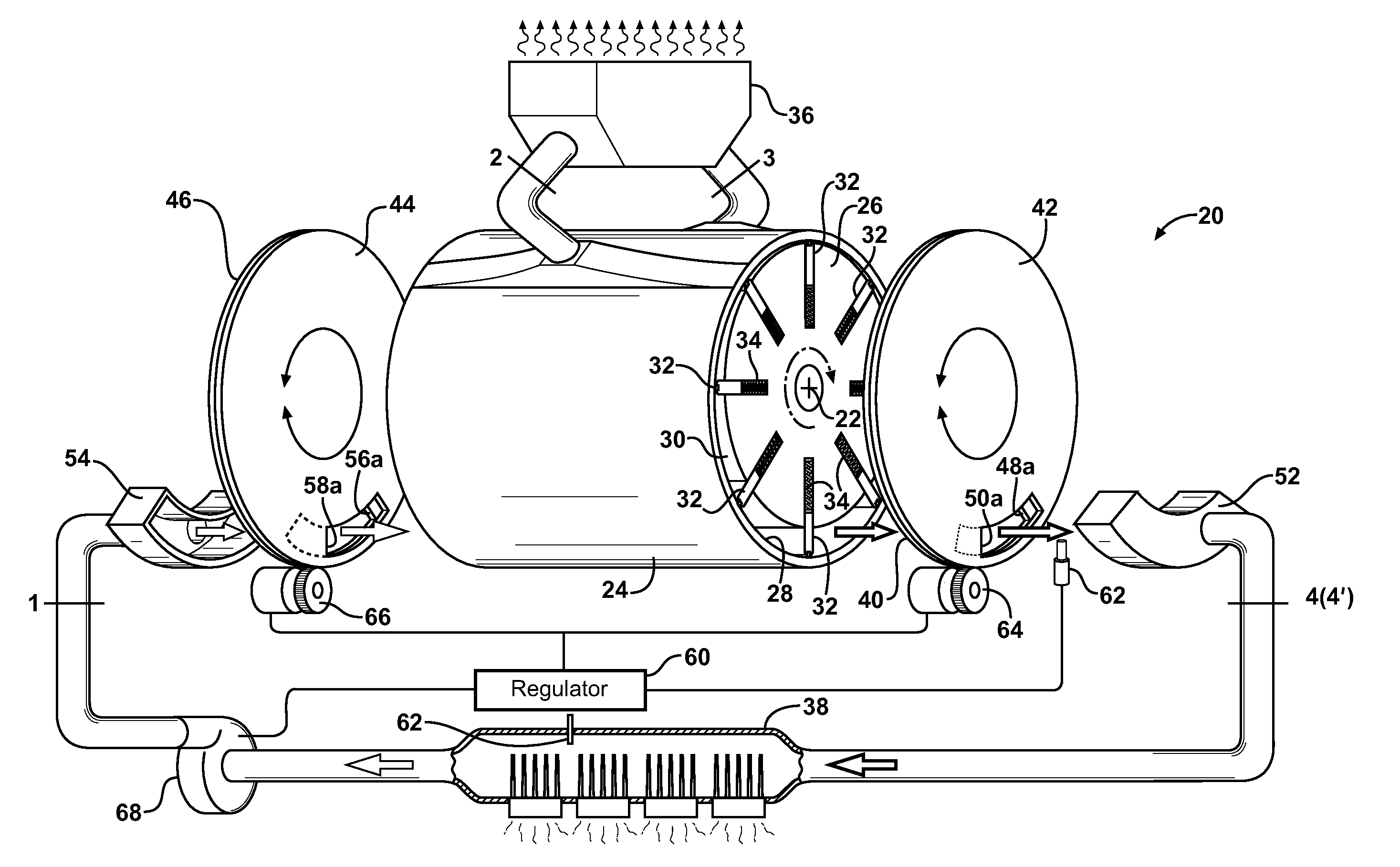

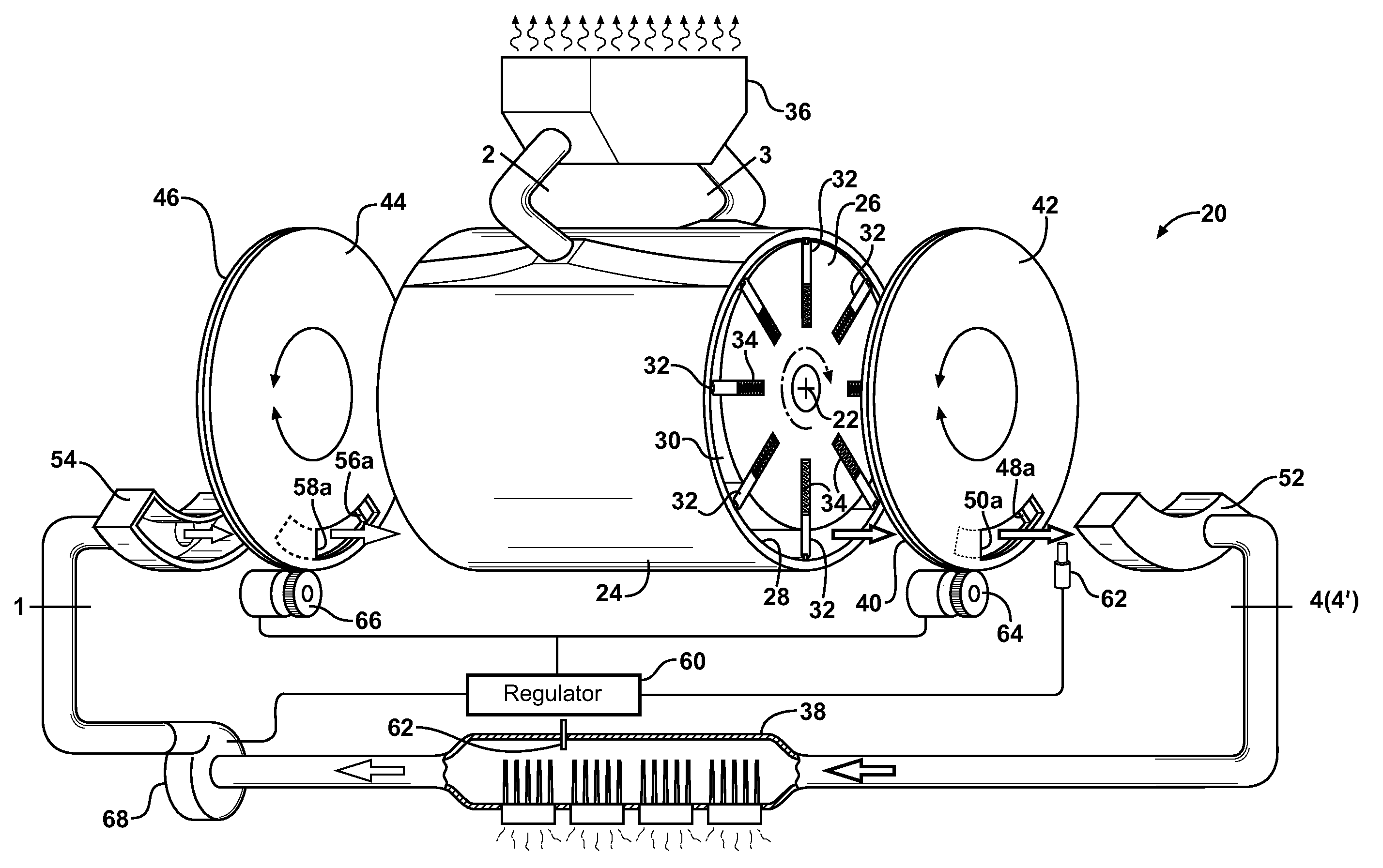

High efficiency positive displacement thermodynamic system

ActiveUS8424284B2Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

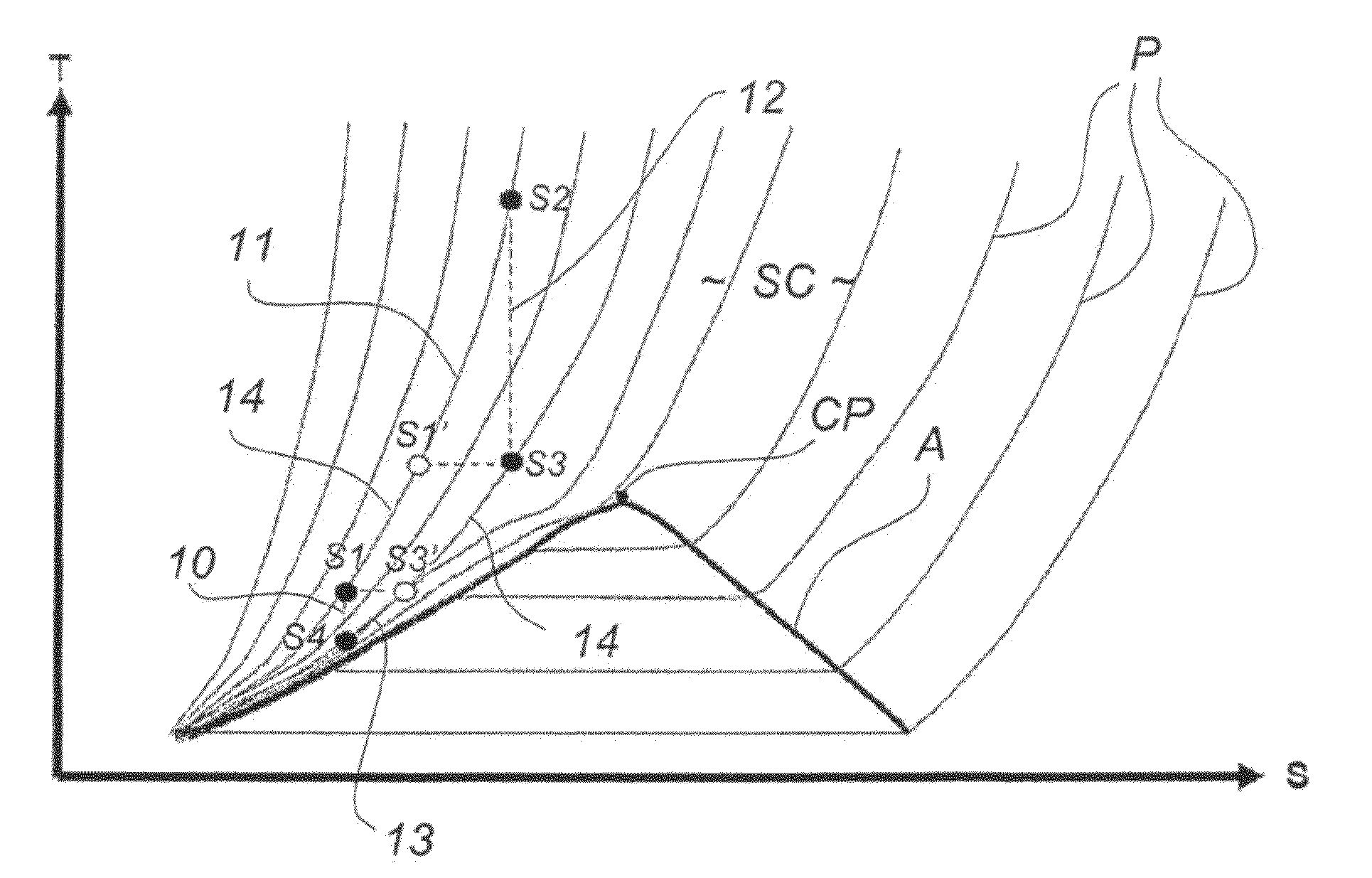

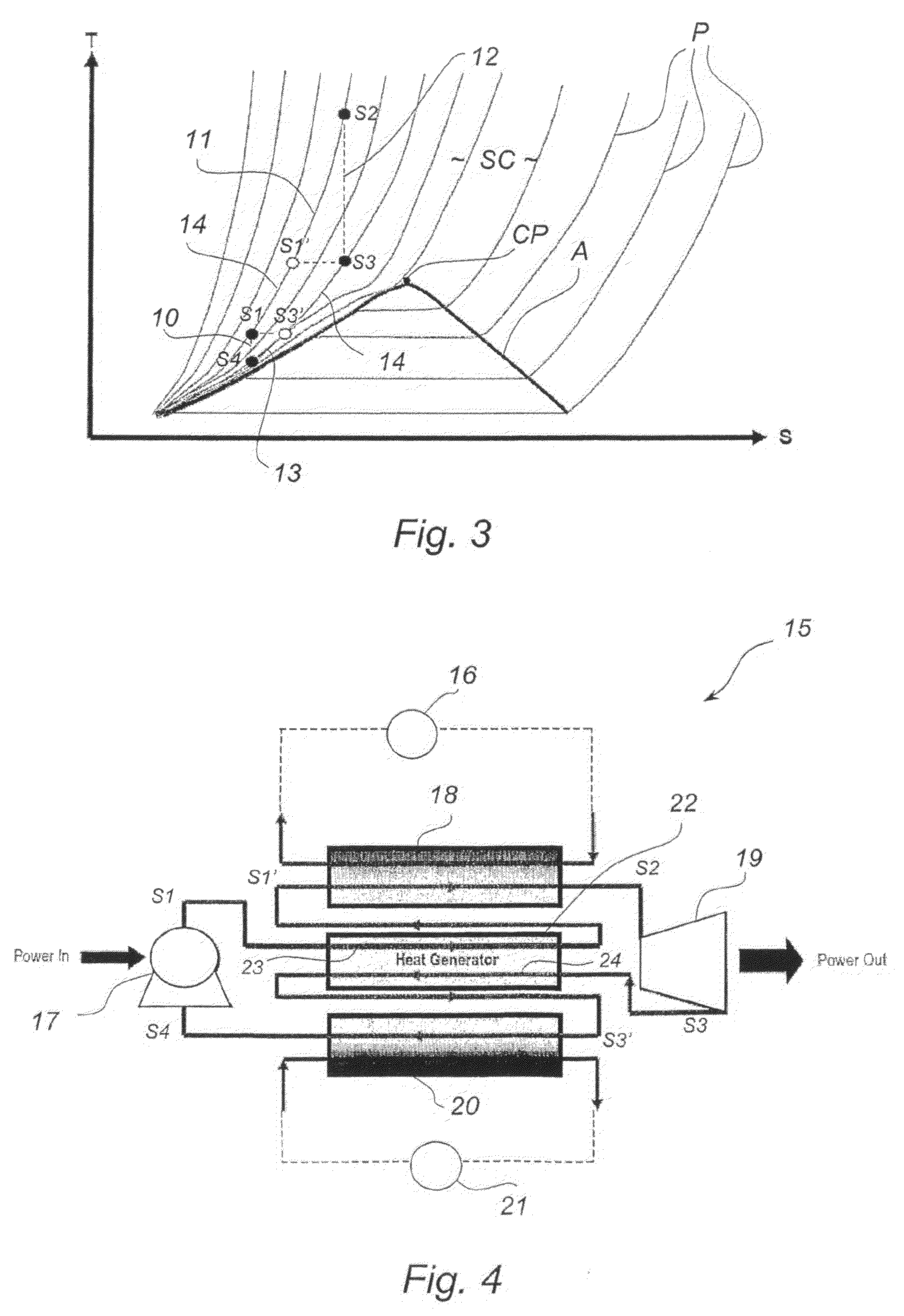

Method and system for generating power from a heat source

ActiveUS20090107144A1Reduce the temperatureTemperature controlOther heat production devicesGas turbine plantsWorking fluidEngineering

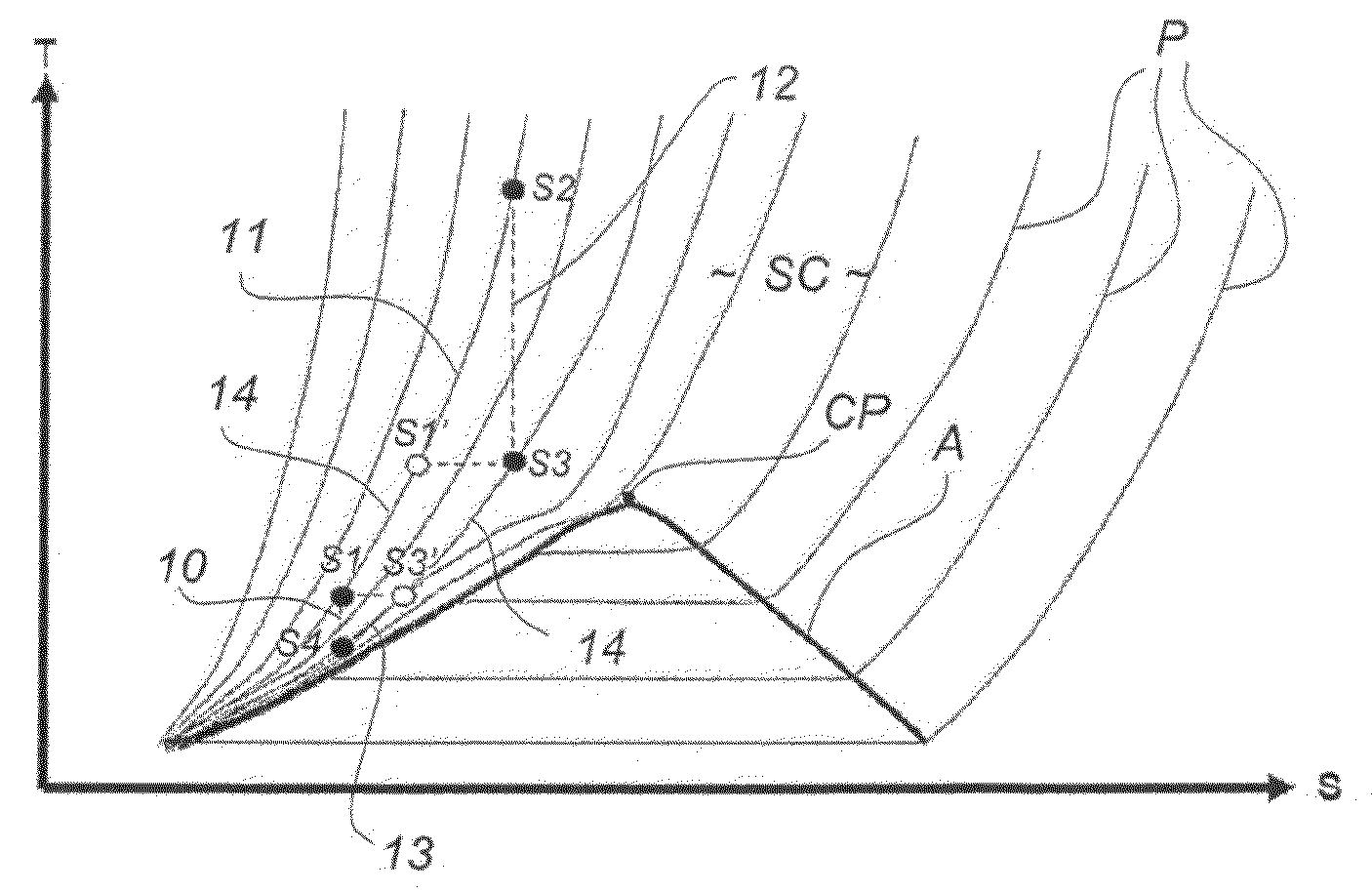

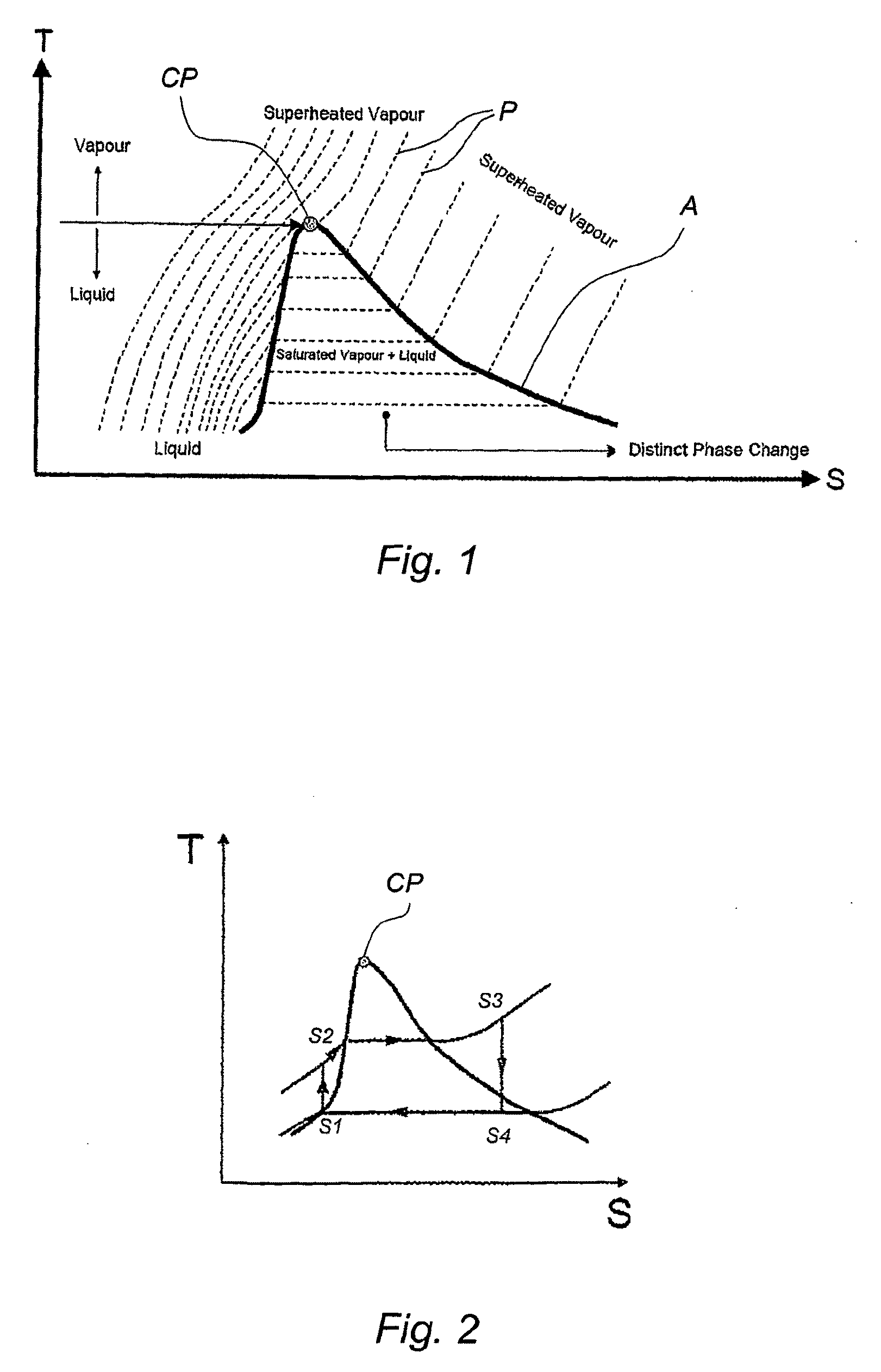

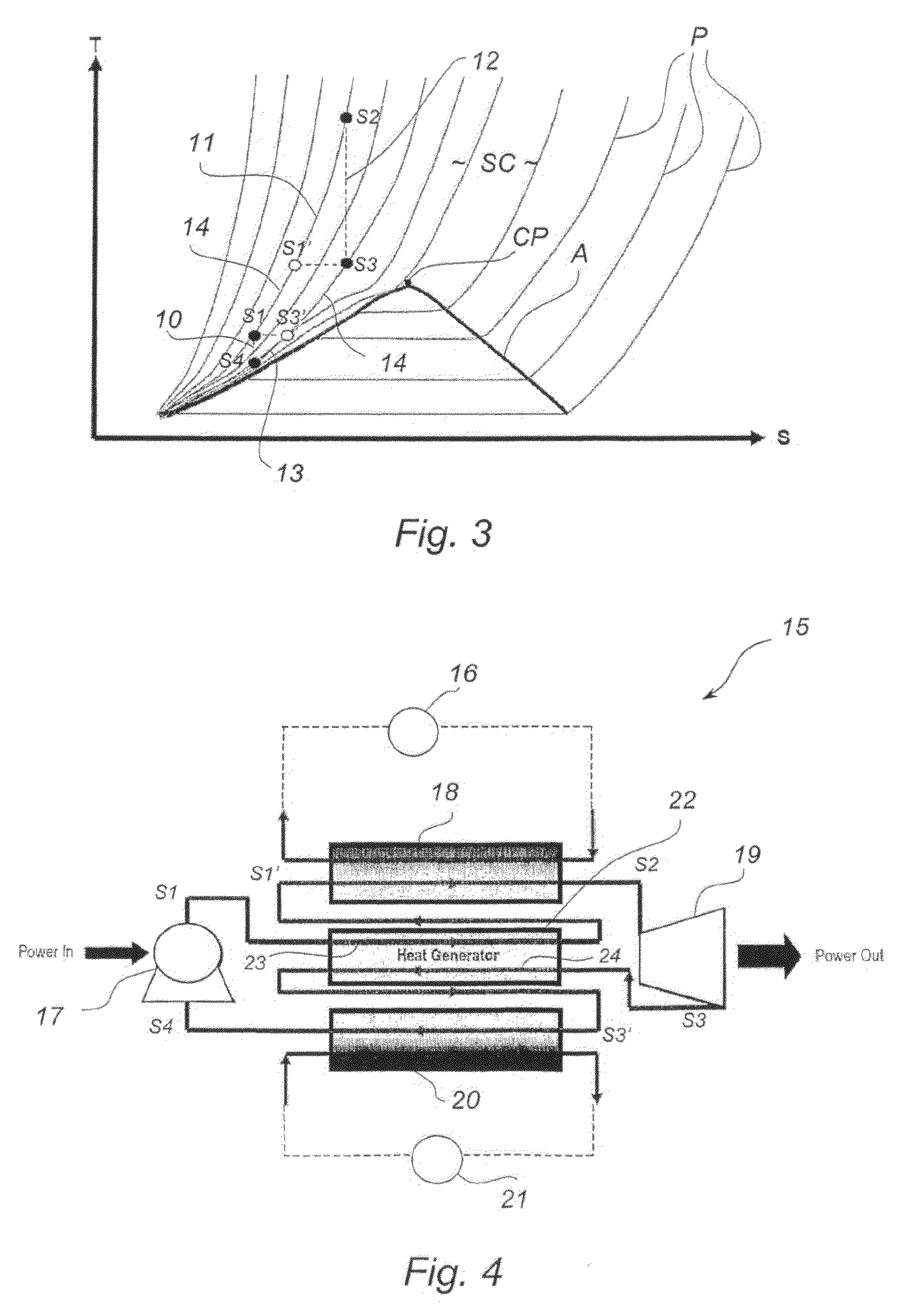

A method of generating power from a heat source, said method including: compressing (10) a working fluid to increase its temperature; exchanging (11) heat between said working fluid and said heat source to superheat said working fluid; expanding (12) said superheated working fluid to drive a turbine, thereby reducing its temperature; condensing (13) said working fluid to further reduce its temperature: and returning said working fluid to said compressing step (10), the method further including the step (14) of regenerating the heat of said working fluid wherein working fluid passing between said compressing step (10) and said heat exchanging step (11) exchanges heat with working fluid passing between said expanding step (12) and said condensing step (13); wherein said steps are performed in a thermodynamic cycle (S1-S1′-S2-S3-S3′-S4) within a supercritical region (SC) above the saturation dome (A) of said working fluid, and wherein said heat regenerating step (14) is performed under isenthalpic conditions to induce continuous heat exchange. A system for generating power from a heat source is also provided.

Owner:GRANITE POWER LTD

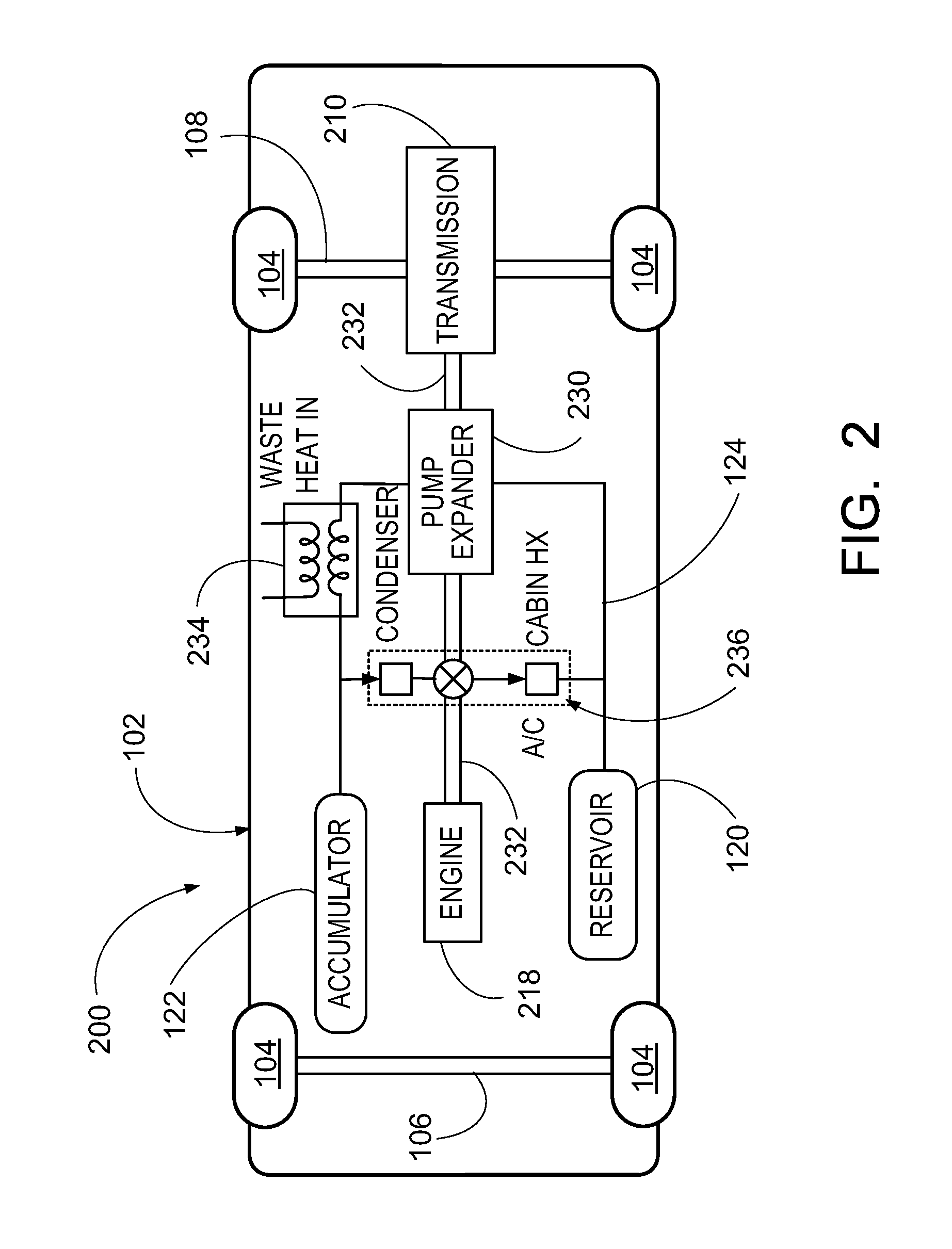

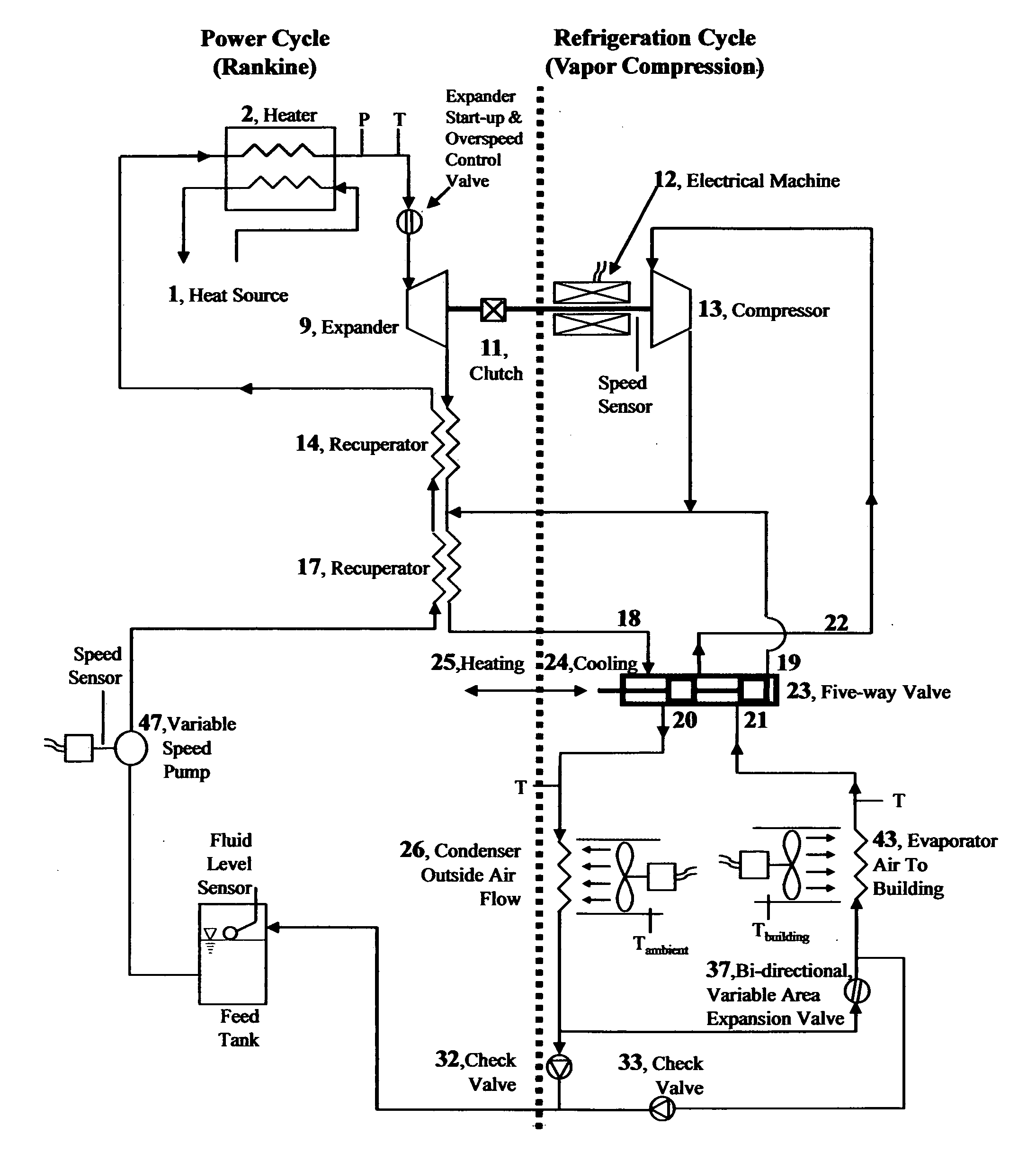

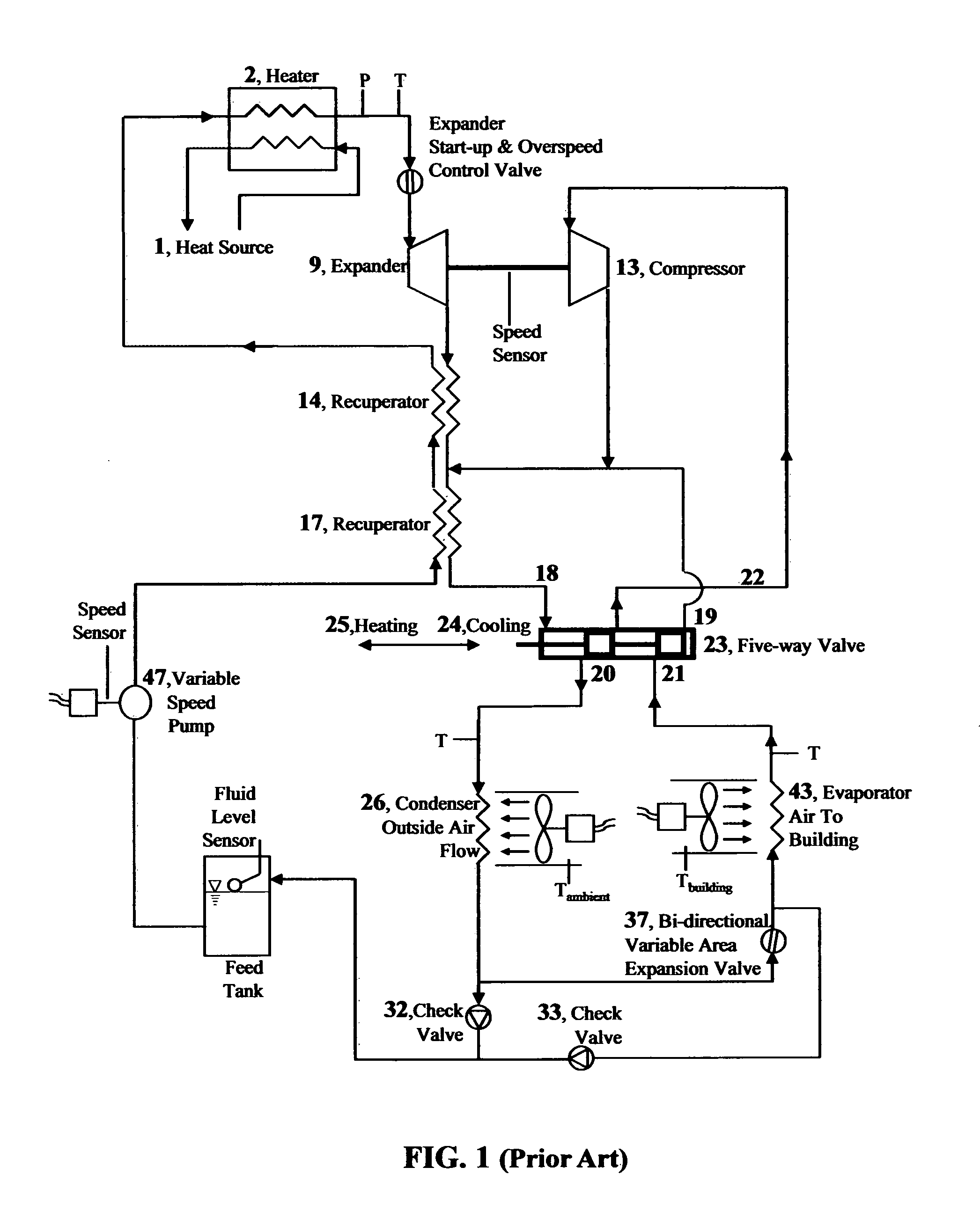

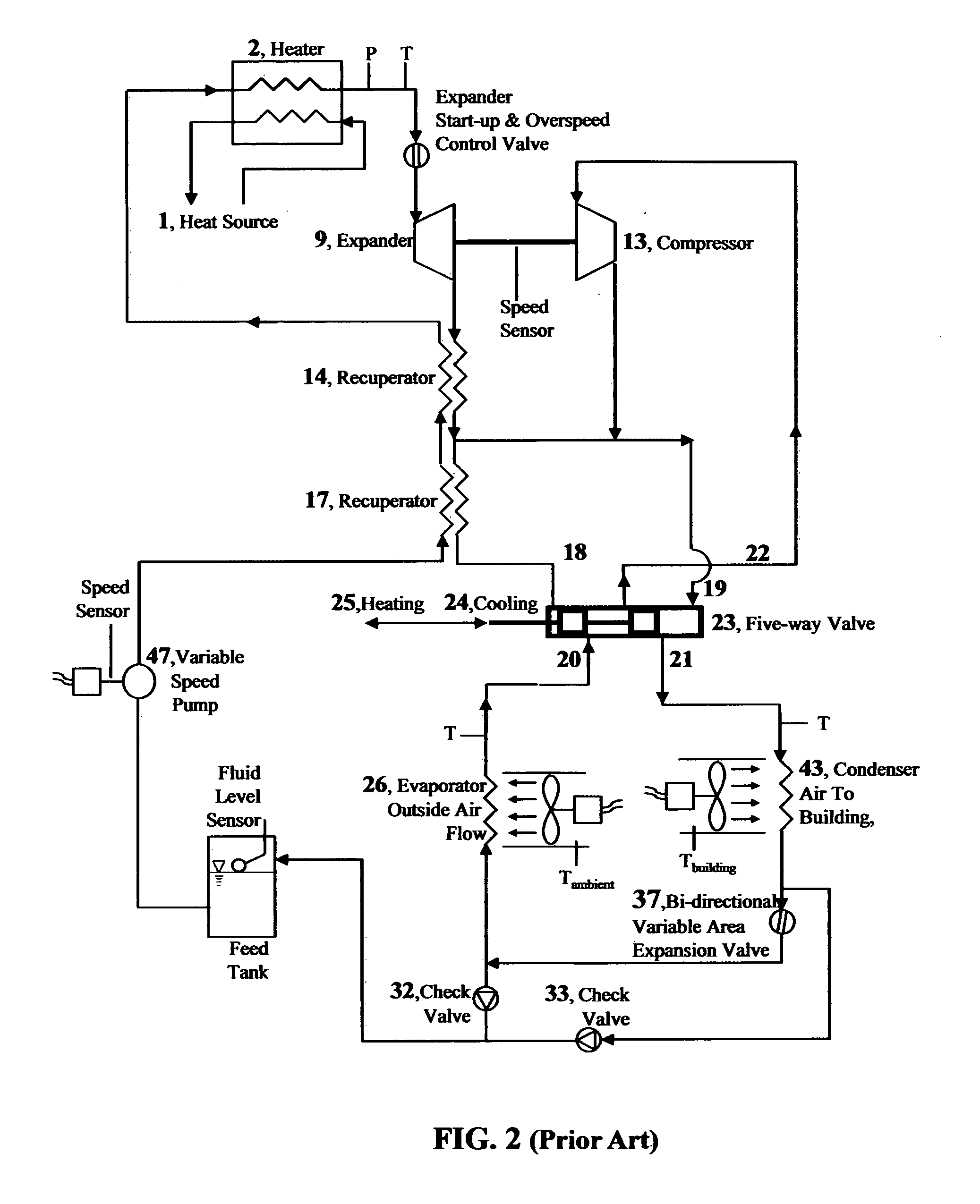

Integrated power, cooling, and heating apparatus utilizing waste heat recovery

ActiveUS20110296849A1Simple designCost-effective manufacturingClimate change adaptationCompression machines with cascade operationCost effectivenessElectric machine

The present invention provides an apparatus for utilizing waste heat to power a reconfigurable thermodynamic cycle that can be used to selectively cool or heat an environmentally controlled space, such as a room, building, or vehicle. The present invention also integrates an electric machine, which may operate as a motor or generator, or both, and an additional prime mover, such as an internal combustion engine. Different combinations of these components are preferable for different applications. The system provides a design which reasonably balances the need to maximize efficiency, while also keeping the design cost-effective.

Owner:BENSON DWAYNE M

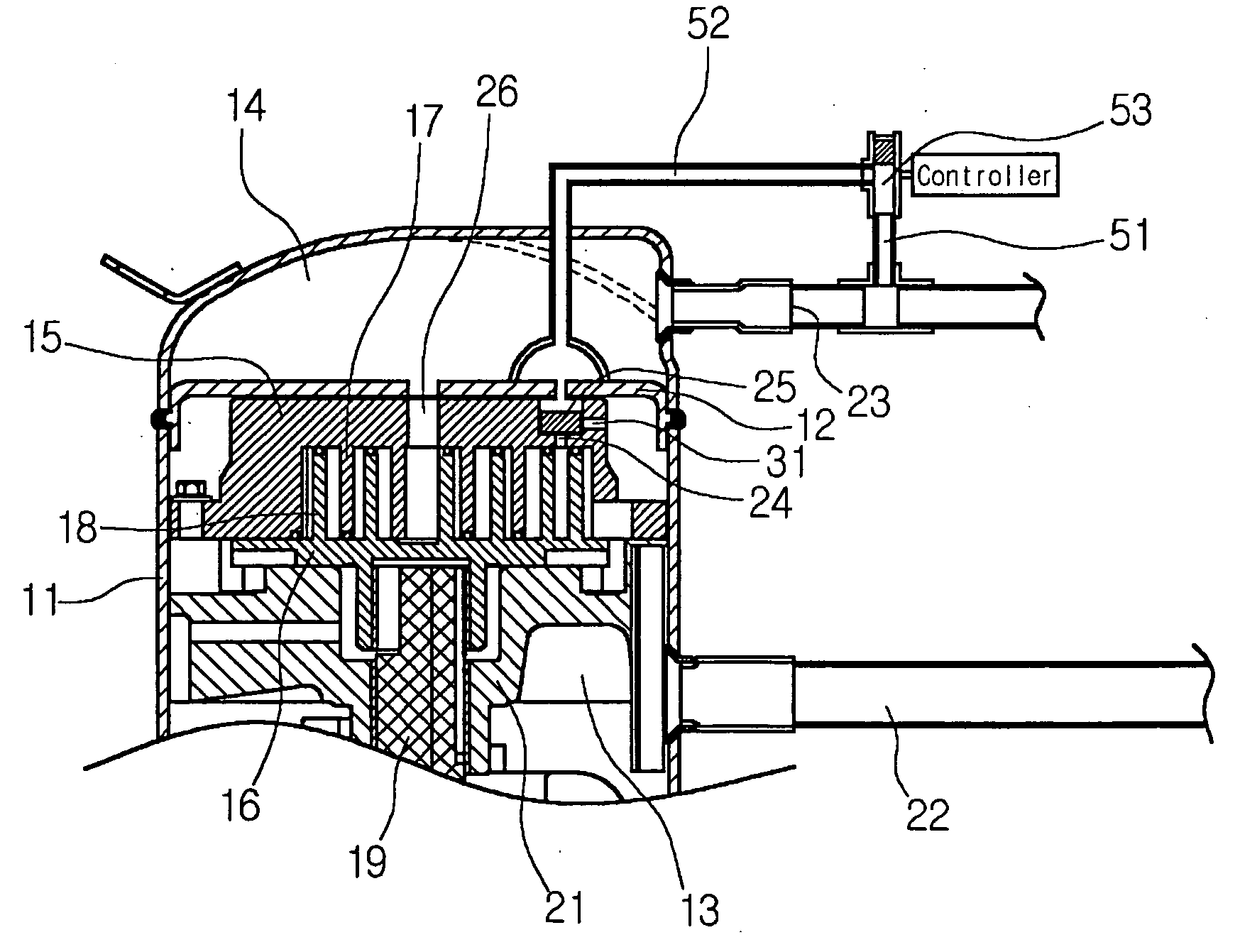

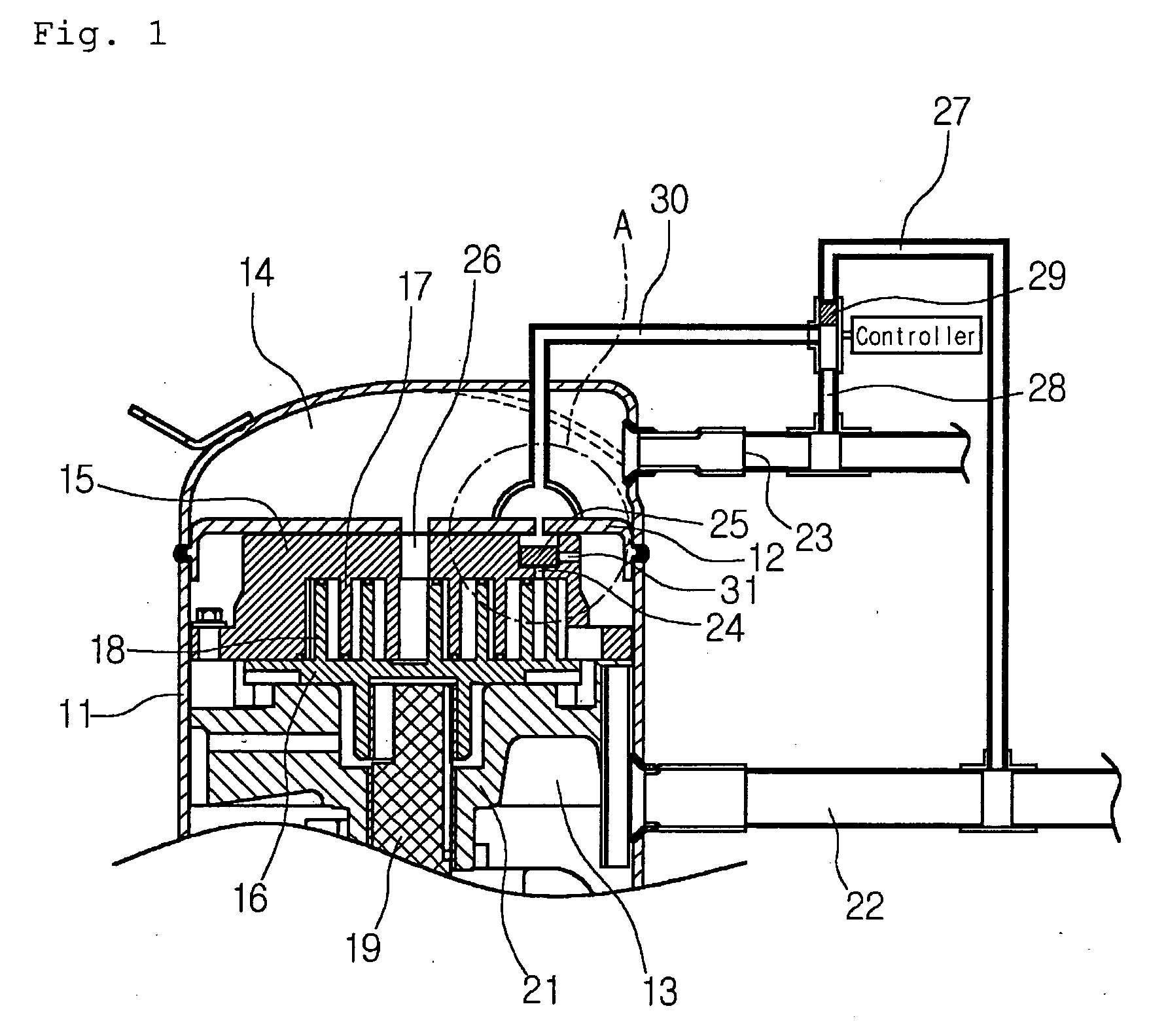

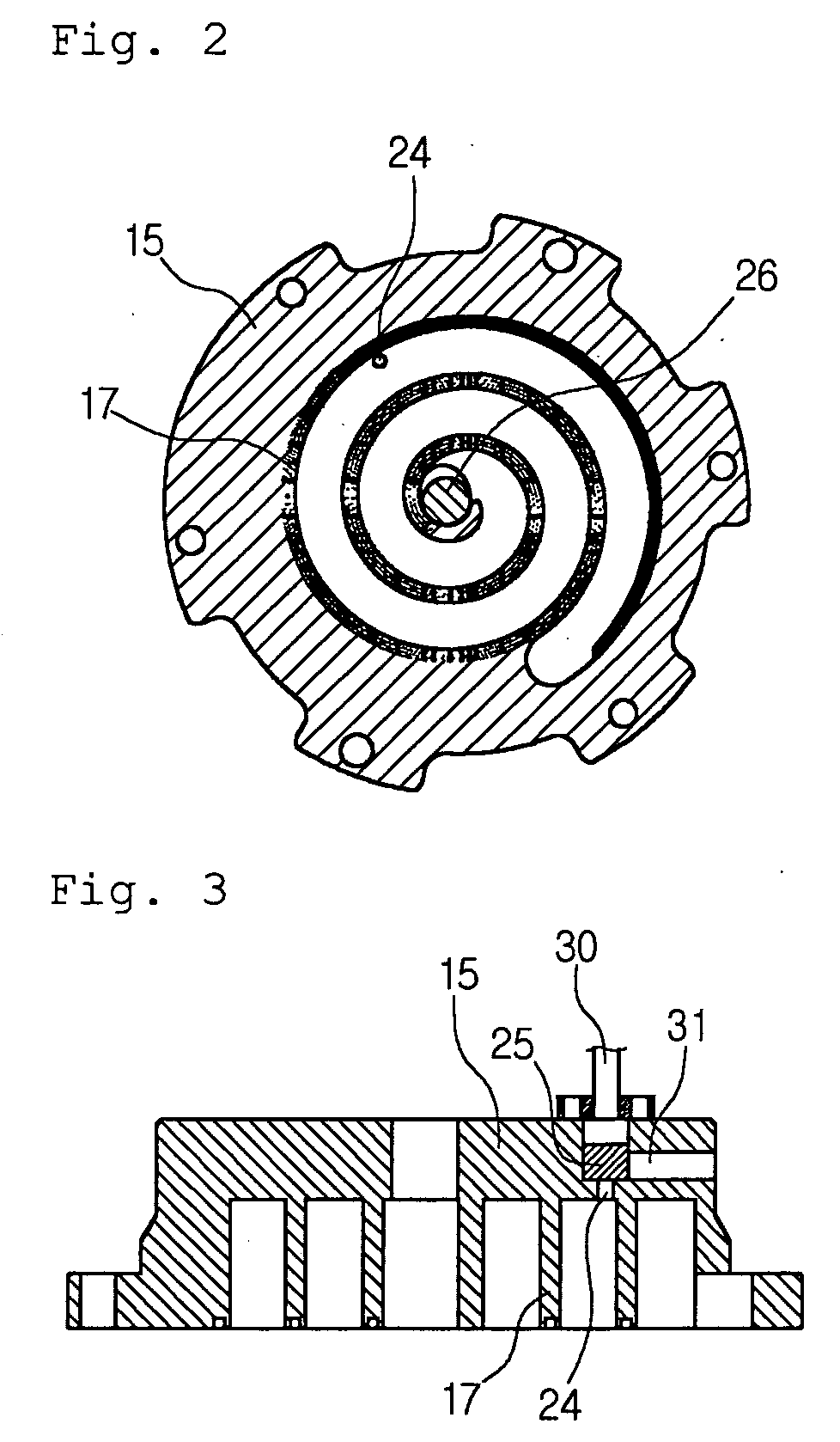

Variable capacity scroll compressor

ActiveUS20050019178A1Easy to changeRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

Disclosed is a variable capacity scroll compressor in which a high-pressure fluid within a thermodynamic cycle is introduced into the inside of the compressor to increase the compression volume and also the fluid inhaled / exhausted from the compressor allows the fluid being compressed to be bypassed in multi-stages, thereby varying the capacity of the compression fluid.

Owner:LG ELECTRONICS INC

Method and system for generating power from a heat source

ActiveUS8166761B2Reduce the temperatureTemperature controlGas turbine plantsSteam engine plantsWorking fluidEngineering

A method of generating power from a heat source, said method including: compressing (10) a working fluid to increase its temperature; exchanging (11) heat between said working fluid and said heat source to superheat said working fluid; expanding (12) said superheated working fluid to drive a turbine, thereby reducing its temperature; condensing (13) said working fluid to further reduce its temperature: and returning said working fluid to said compressing step (10), the method further including the step (14) of regenerating the heat of said working fluid wherein working fluid passing between said compressing step (10) and said heat exchanging step (11) exchanges heat with working fluid passing between said expanding step (12) and said condensing step (13); wherein said steps are performed in a thermodynamic cycle (S1-S1′-S2-S3-S3′-S4) within a supercritical region (SC) above the saturation dome (A) of said working fluid, and wherein said heat regenerating step (14) is performed under isenthalpic conditions to induce continuous heat exchange. A system for generating power from a heat source is also provided.

Owner:GRANITE POWER LTD

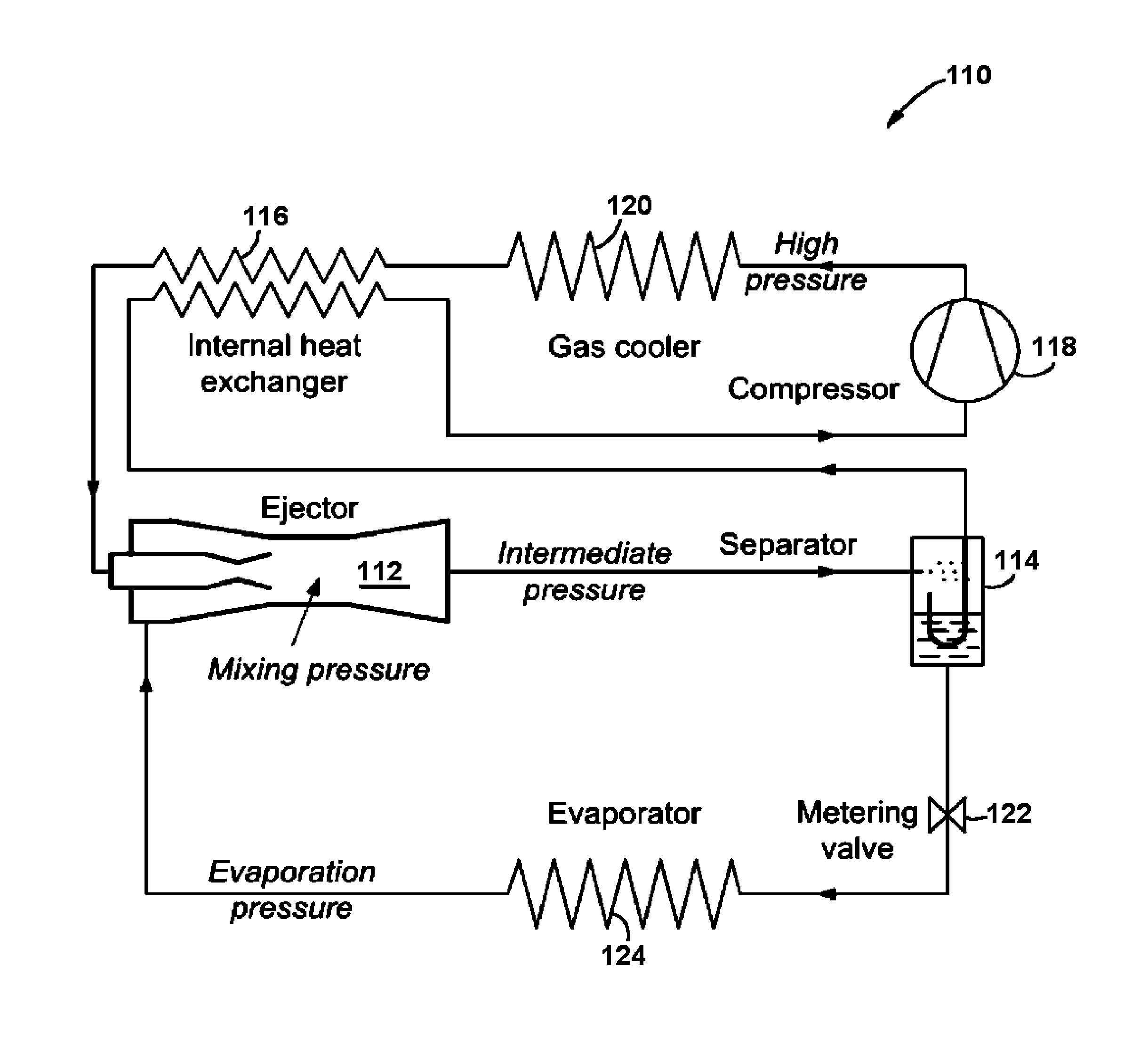

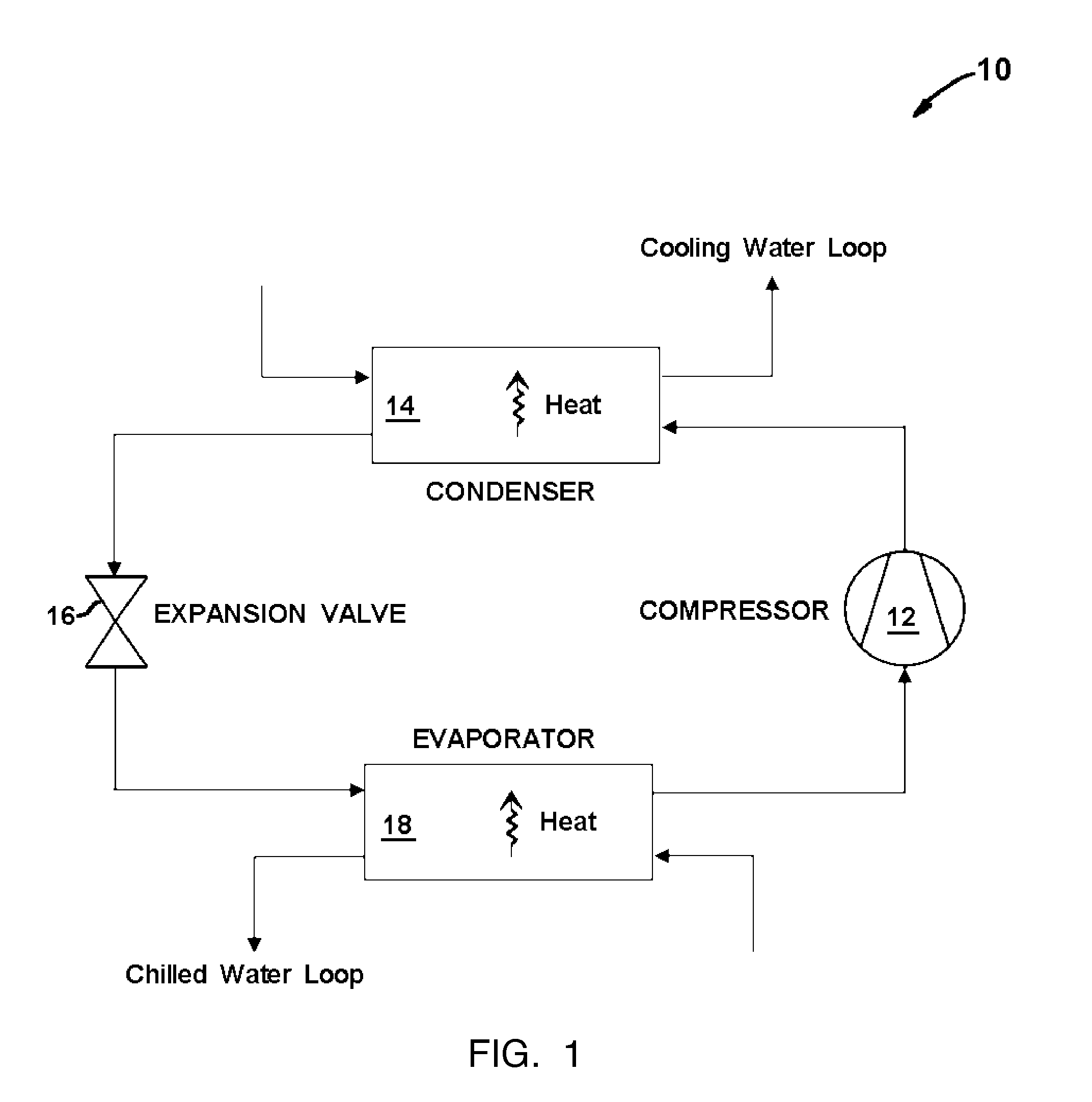

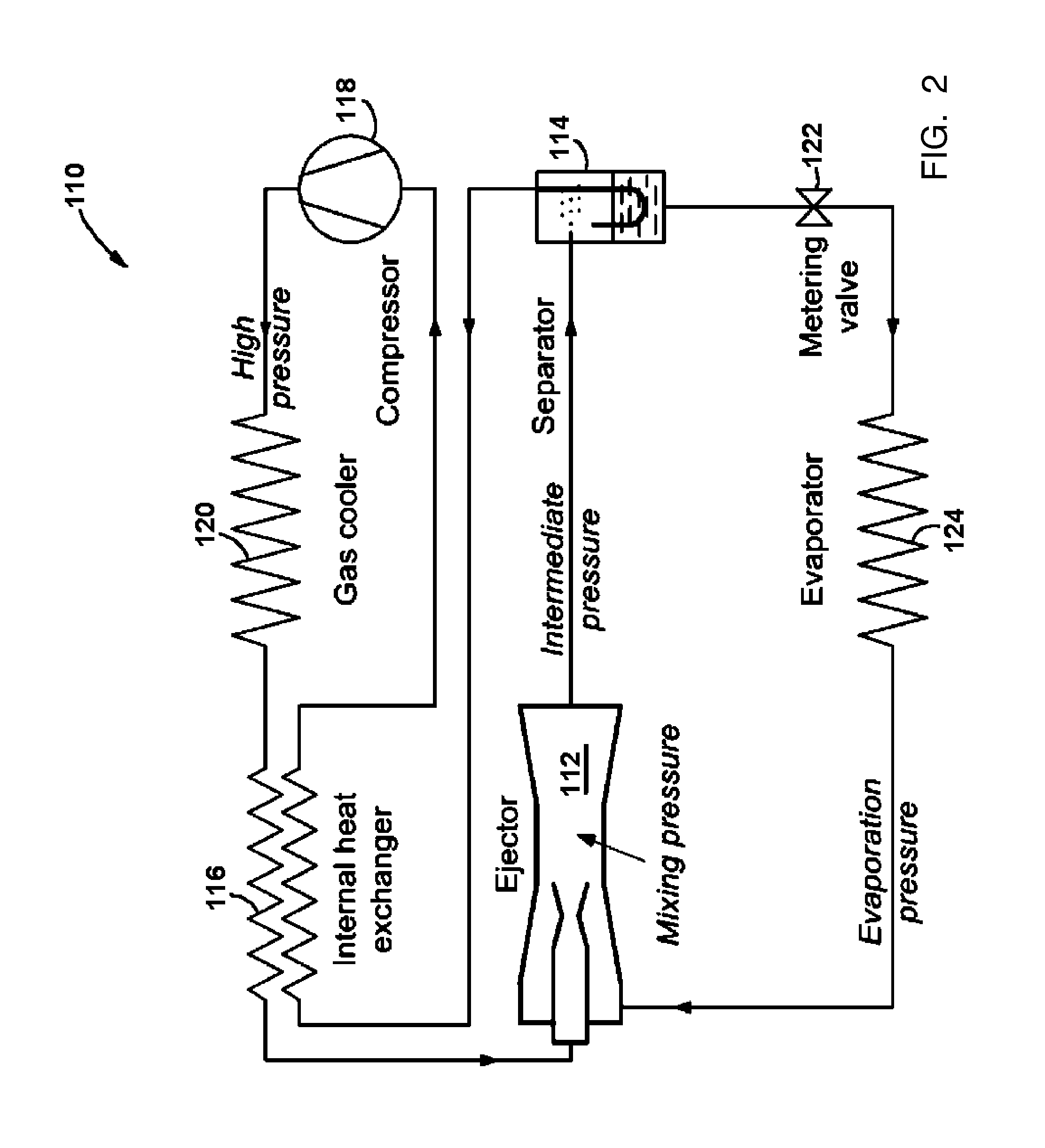

High efficiency r744 refrigeration system and cycle

InactiveUS20100313582A1Reduce compressionImprove cycle efficiencyCompression machines with non-reversible cycleFluid circulation arrangementEngineeringHigh pressure

A high efficiency R744 air conditioning and refrigeration system and cycle comprises a vapor compressor and two independent ejectors operatively connected to high and low-pressure sides of the compressor, respectively. The two ejectors reduce the overall pressure ratio of the mechanical vapor compressor resulting in dramatically increased thermodynamic cycle efficiency. As one example of its potential applications for residential, commercial or industrial uses, a 150 ton capacity of a water-cooled chiller designed in accordance with the present invention is predicted to provide the power consumption as low as 0.47 kW / ton, when operated in accordance with the cooling methods of the present invention, which corresponds to 7.47 of Coefficient of Performance (COP).

Owner:R & D DYNAMICS

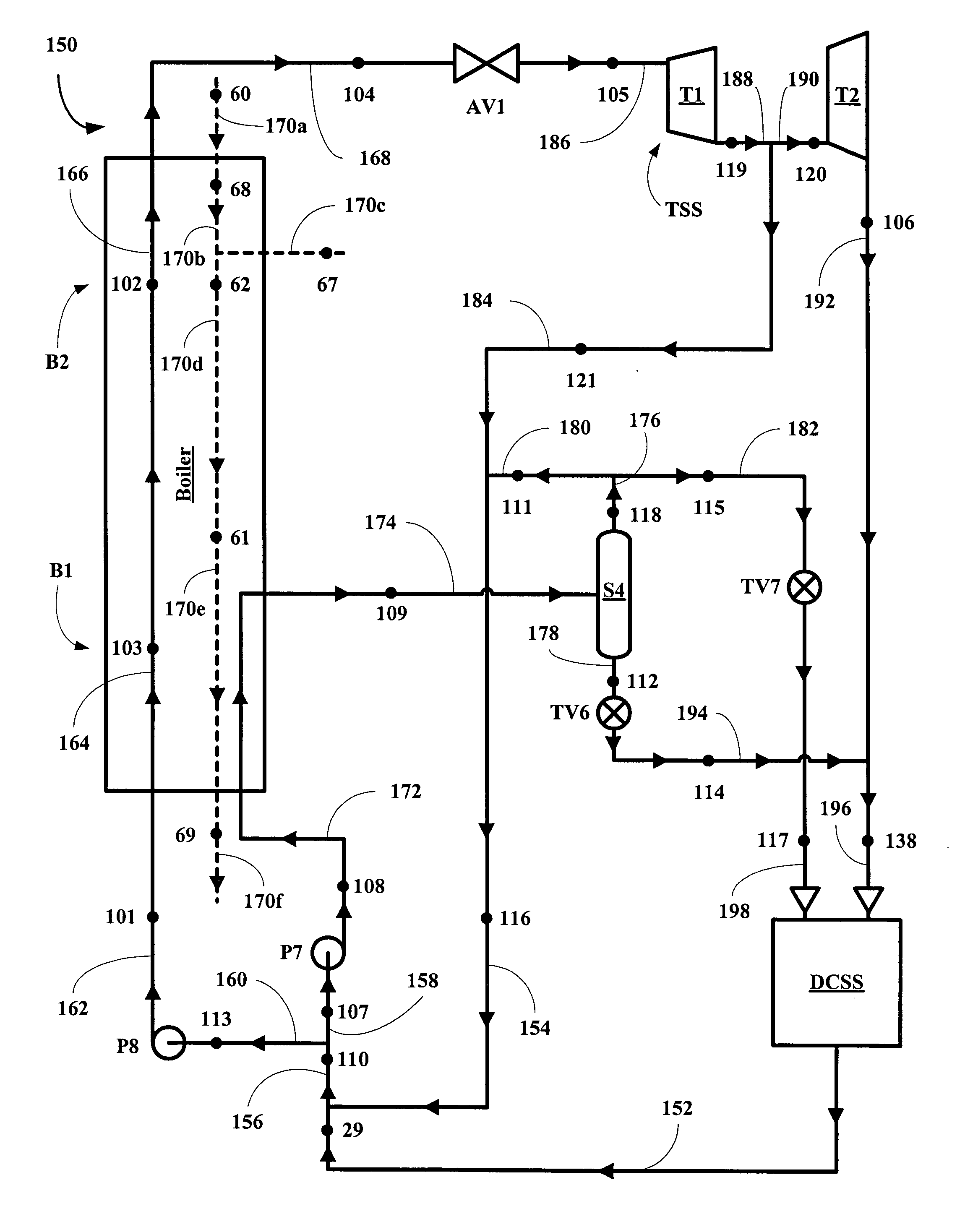

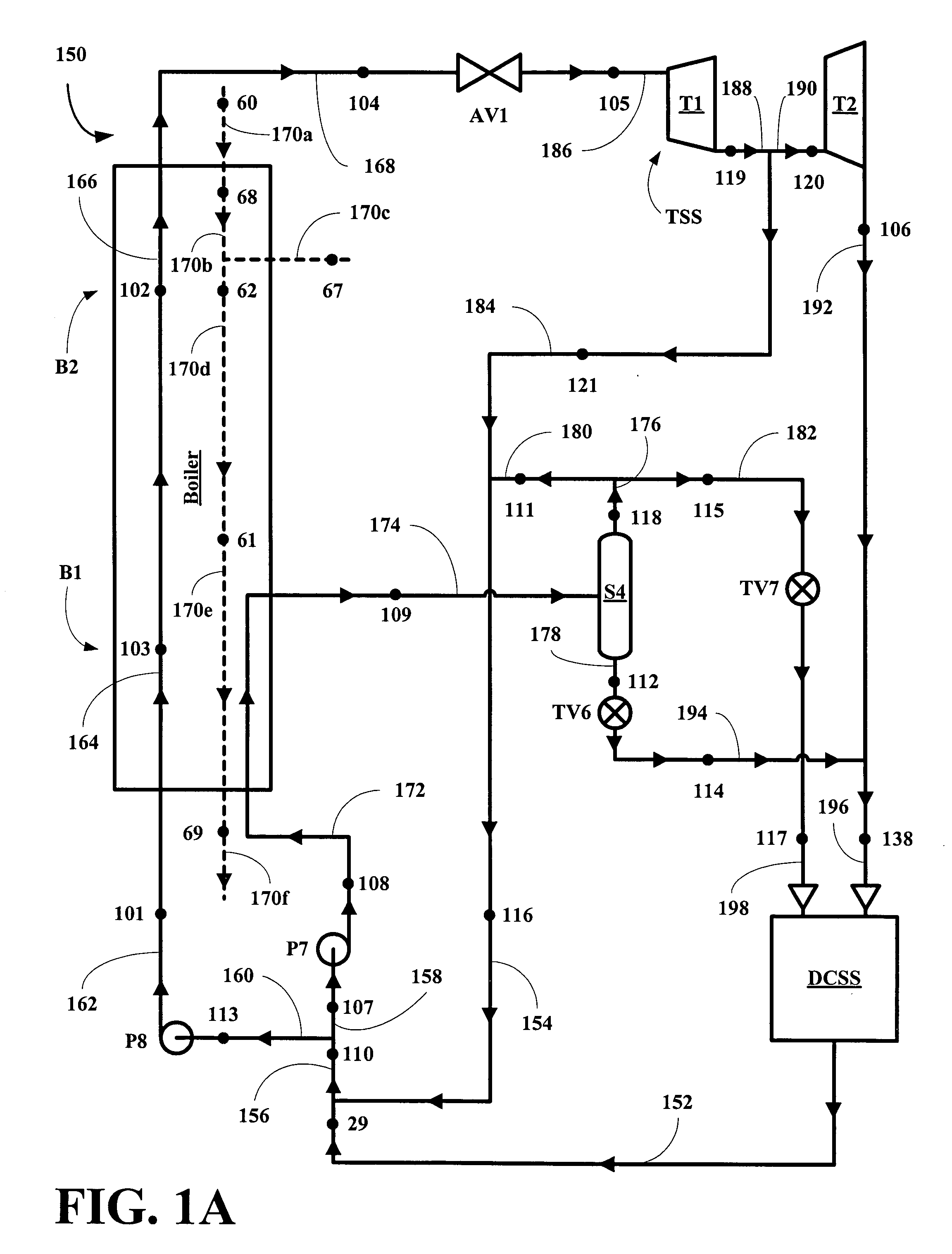

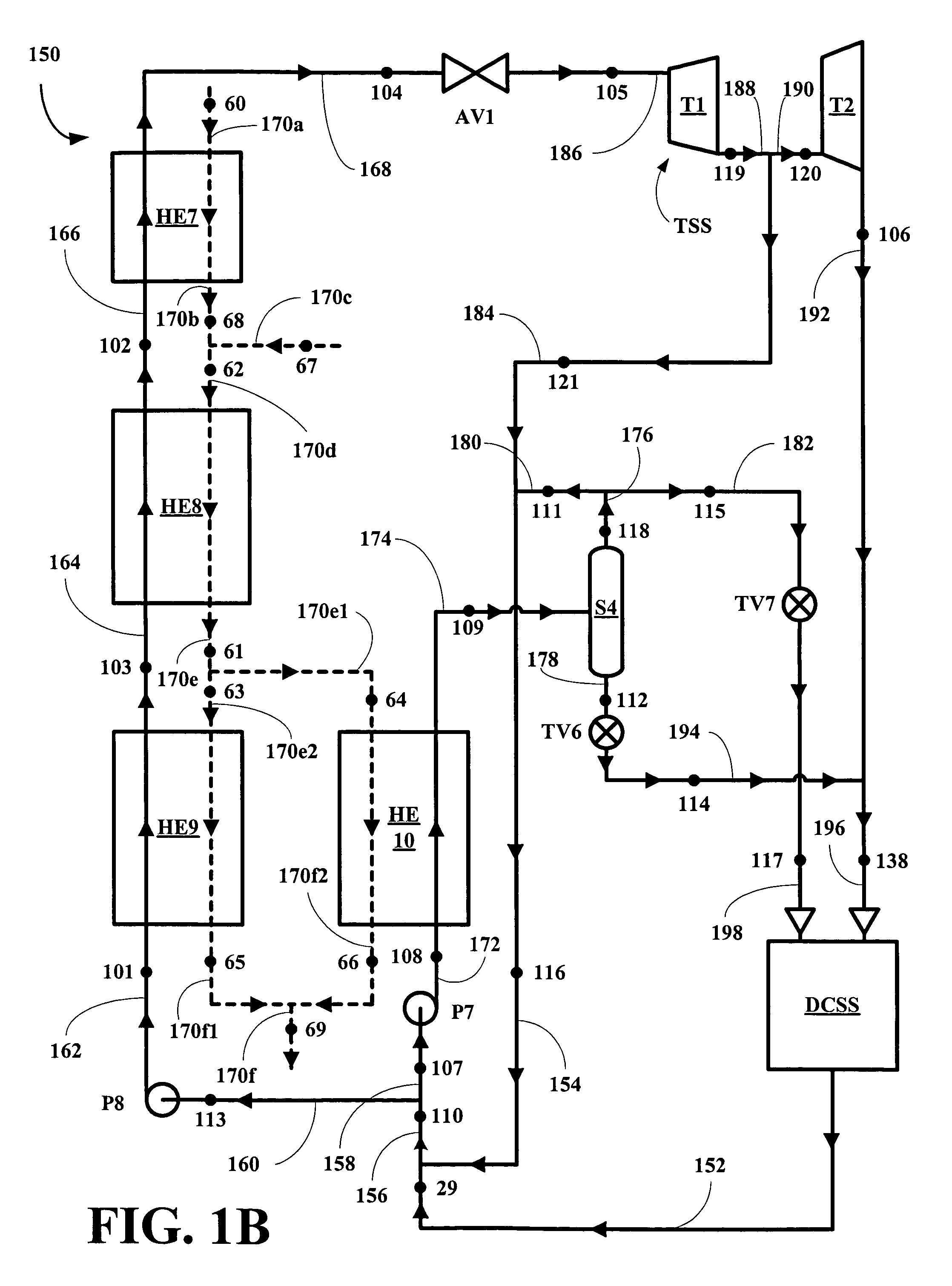

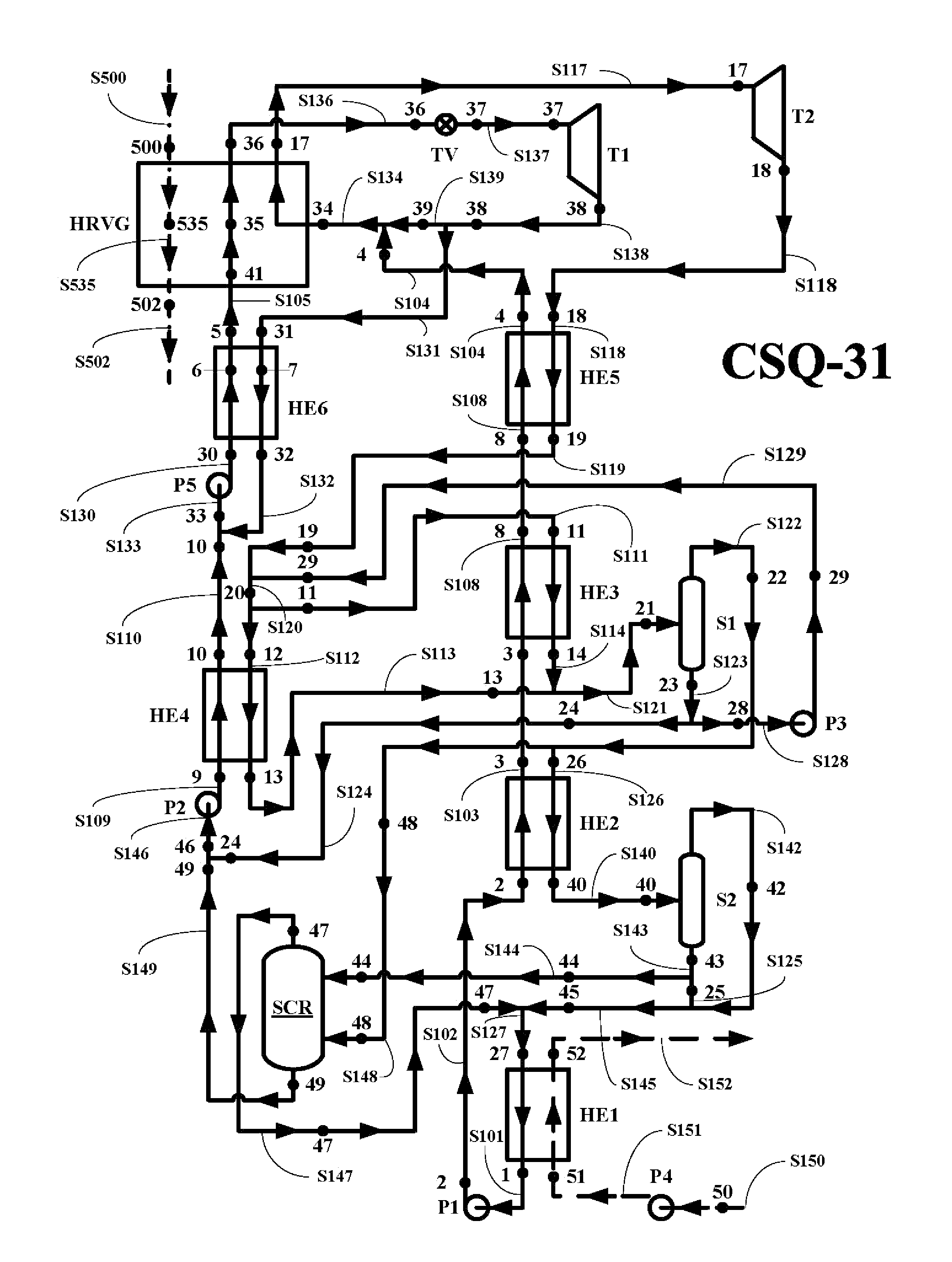

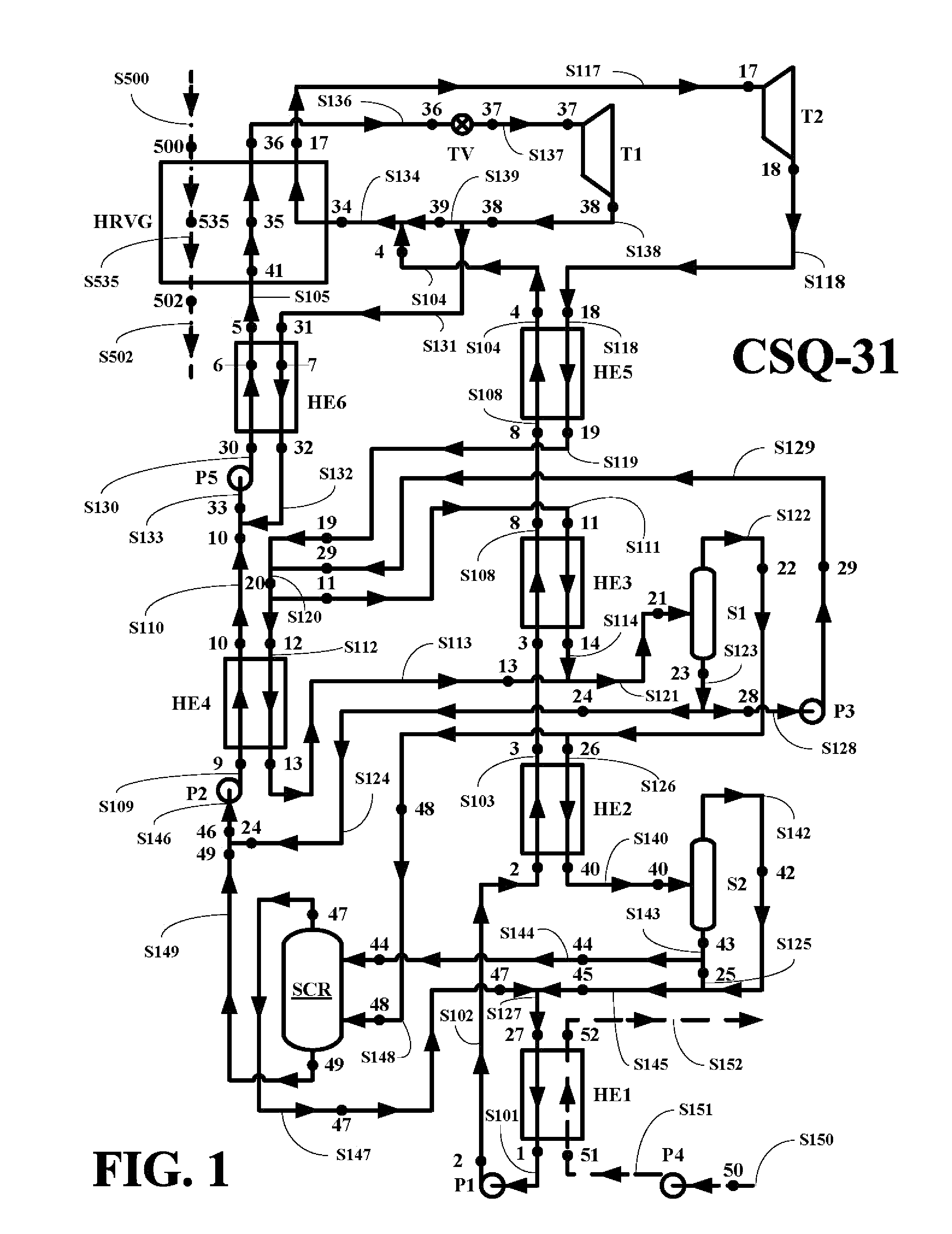

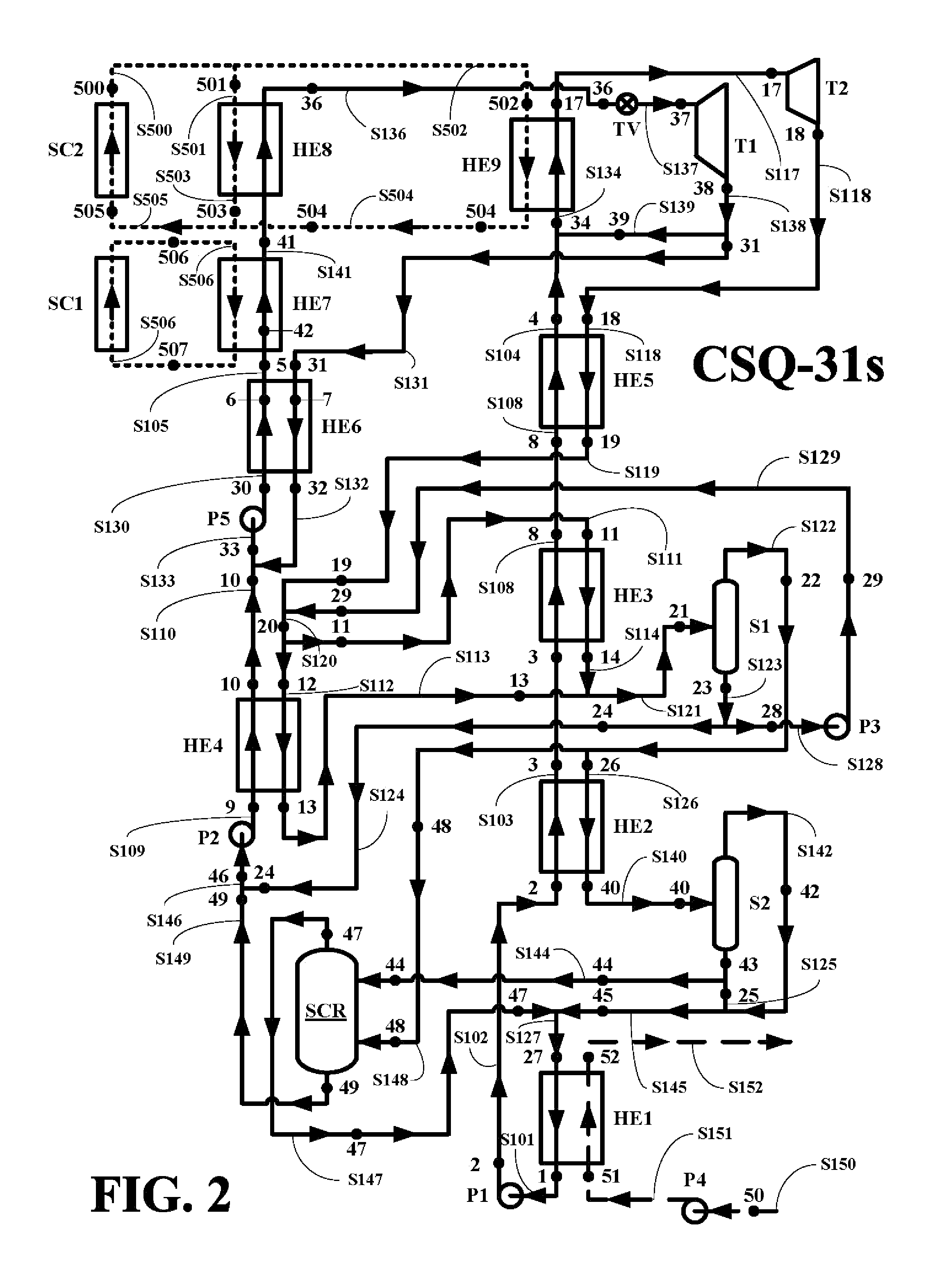

Systems, methods and apparatuses for converting thermal energy into mechanical and electrical power

The present invention discloses systems and methods for converting heat from external heat source streams or from solar energy derived from a solar collector subsystem. The systems and methods comprise a thermodynamic cycle including three internal subcycles. Two of the subcycles combine to power a higher pressures turbine and third or main cycle powers a lower pressure turbine. One of the cycles increases the flow rate of a richer working solution stream powering the lower pressure turbine. Another one of the cycles is a leaner working solution cycle, which provides increased flow rate for leaner working solution stream going into the higher pressure turbine.

Owner:KALINA POWER LTD

Heat engine and heat to electricity systems and methods with working fluid fill system

ActiveUS20110061384A1Easy to storeFluid heatersInternal combustion piston enginesThermal energyWorking fluid

A waste heat recovery system, method and device executes a thermodynamic cycle using a working fluid in a working fluid circuit which has a high pressure side and a low pressure side. Components of the system in the working fluid circuit include a waste heat exchanger in thermal communication with a waste heat source also connected to the working fluid circuit, whereby thermal energy is transferred from the waste heat source to the working fluid in the working fluid circuit, an expander located between the high pressure side and the low pressure side of the working fluid circuit, the expander operative to convert a pressure / enthalpy drop in the working fluid to mechanical energy, a recuperator in the working fluid circuit operative to transfer thermal energy between the high pressure side and the low pressure side of the working fluid circuit, a cooler in thermal communication with the low pressure side of the working fluid circuit operative to control temperature of the working fluid in the low side of the working fluid circuit, a pump in the working fluid circuit and connected to the low pressure side and to the high pressure side of the working fluid circuit and operative to move the working fluid through the working fluid circuit, and a mass management system connected to the working fluid circuit, the mass management system, method and device having a working fluid vessel connected to the low pressure side of the working fluid circuit and configured to passively control an amount of working fluid mass in the working fluid circuit. Systems and methods for supplying a working fluid to the working fluid circuit are disclosed.

Owner:ECHOGEN POWER SYST

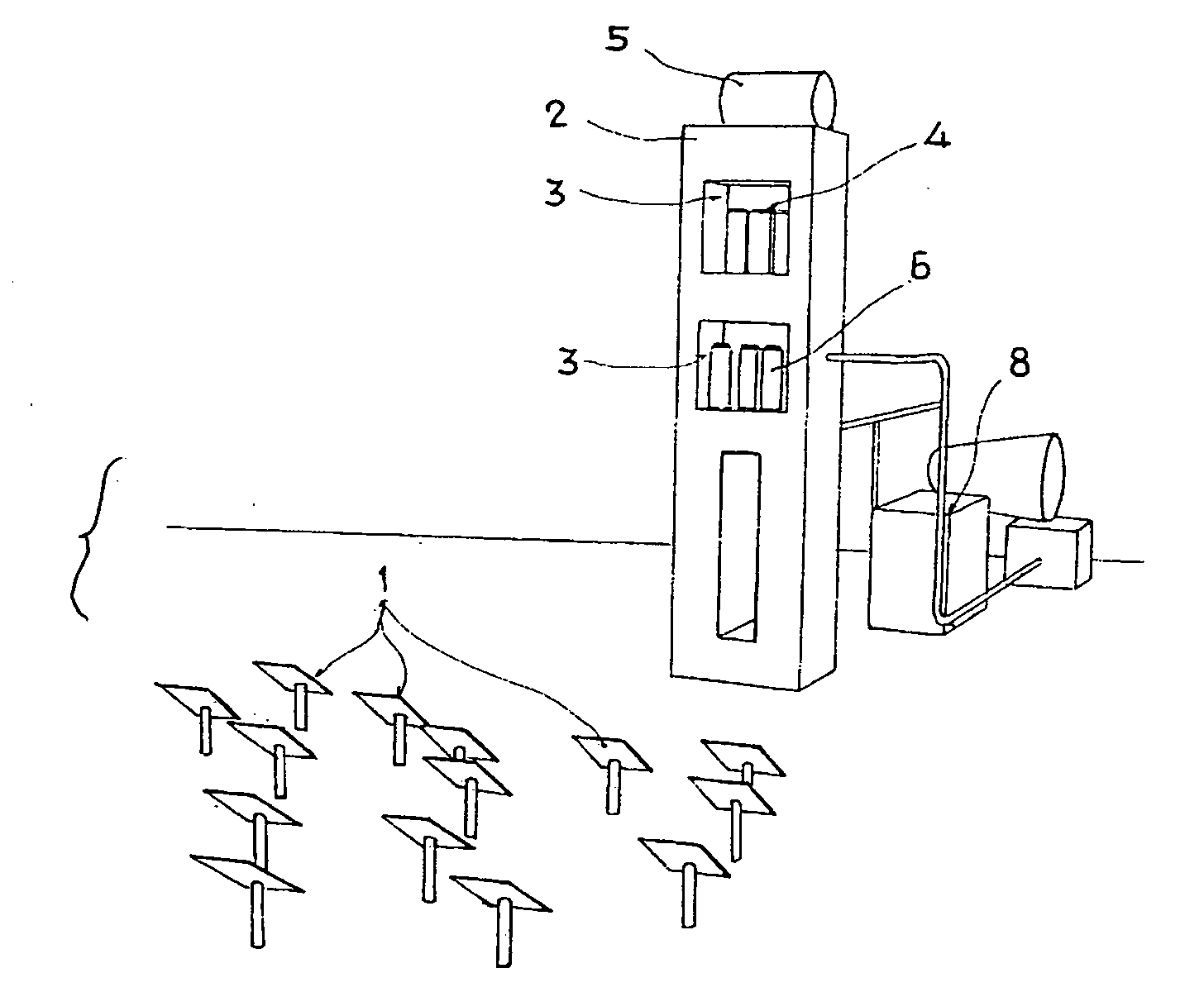

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

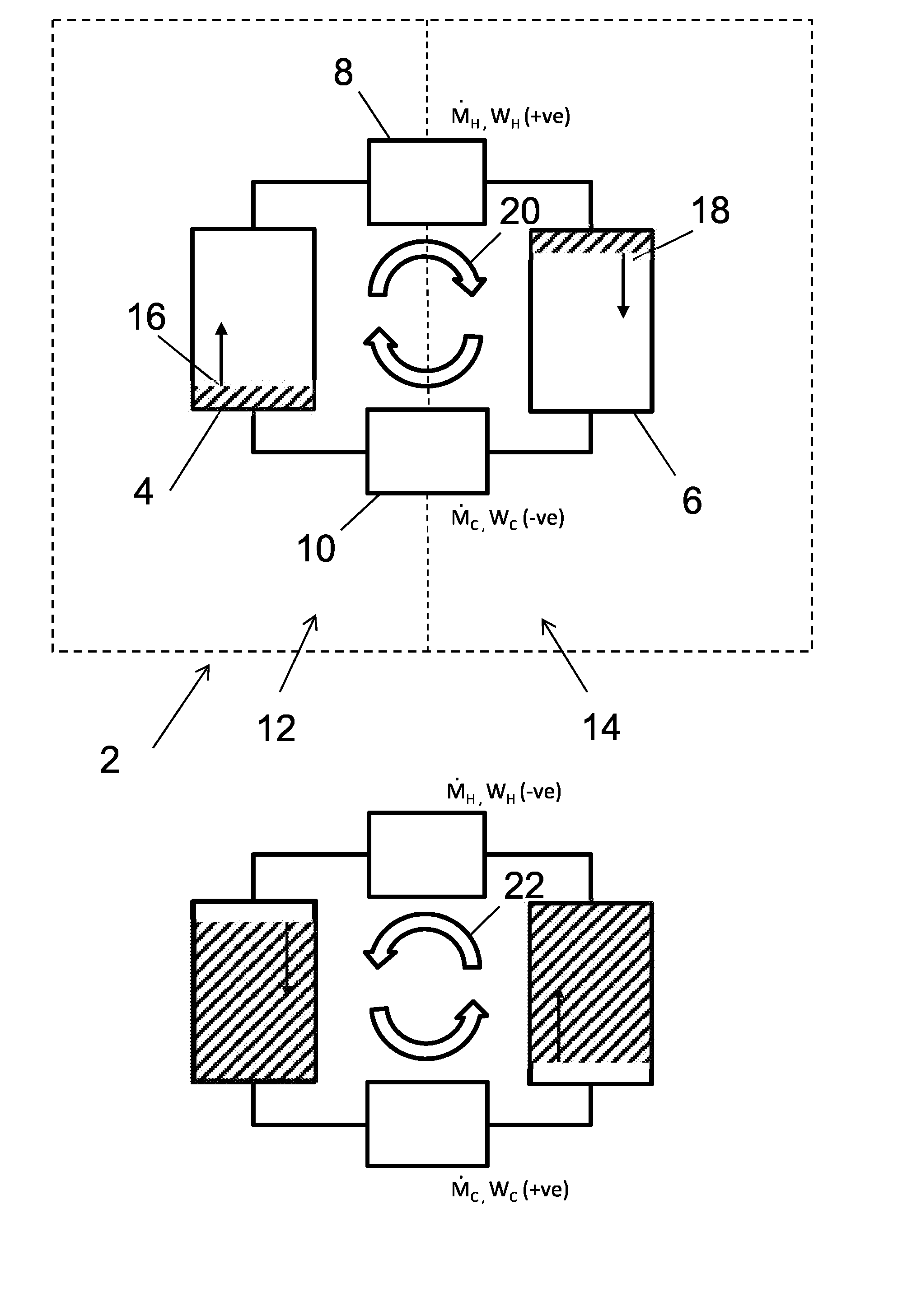

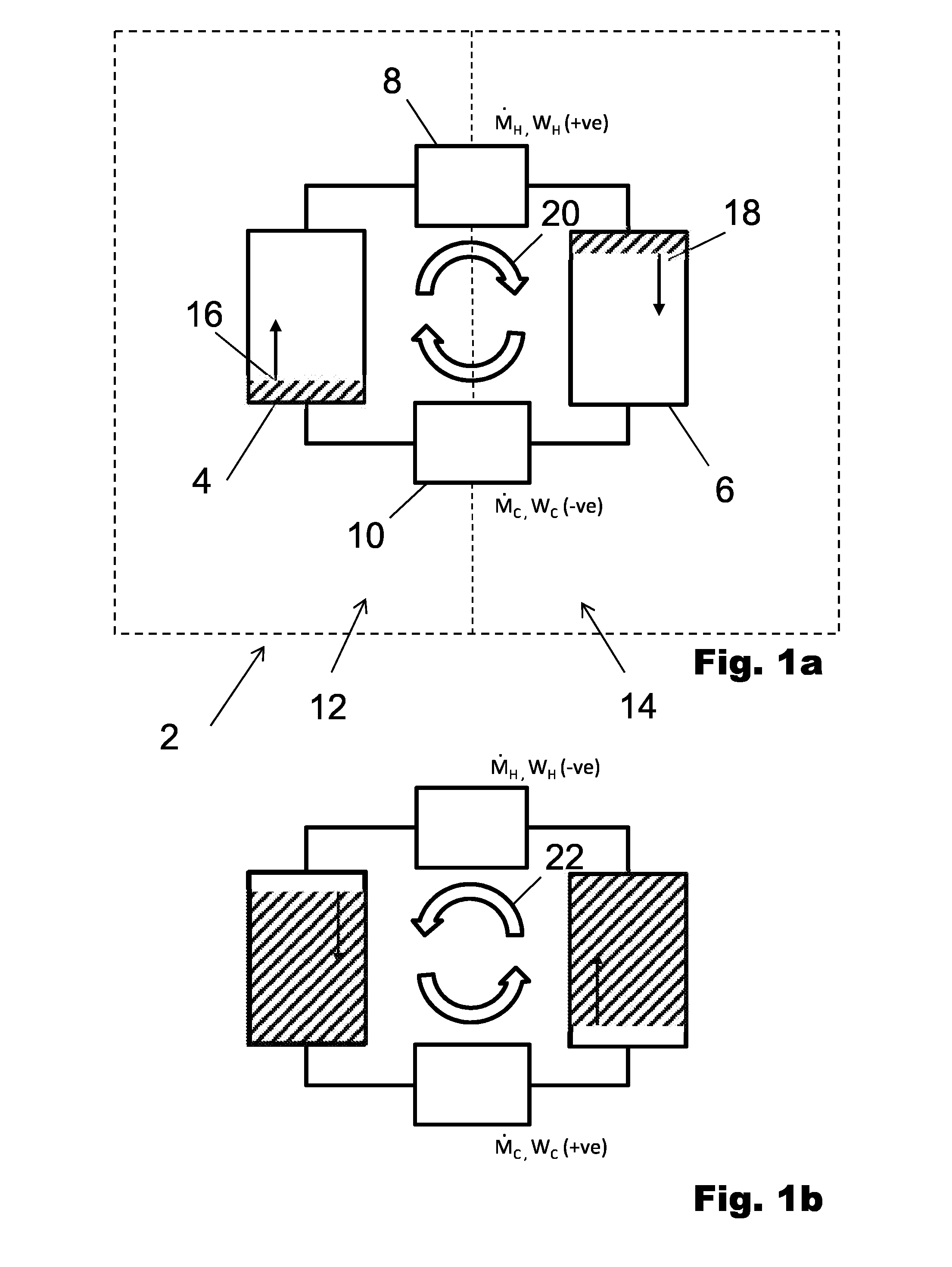

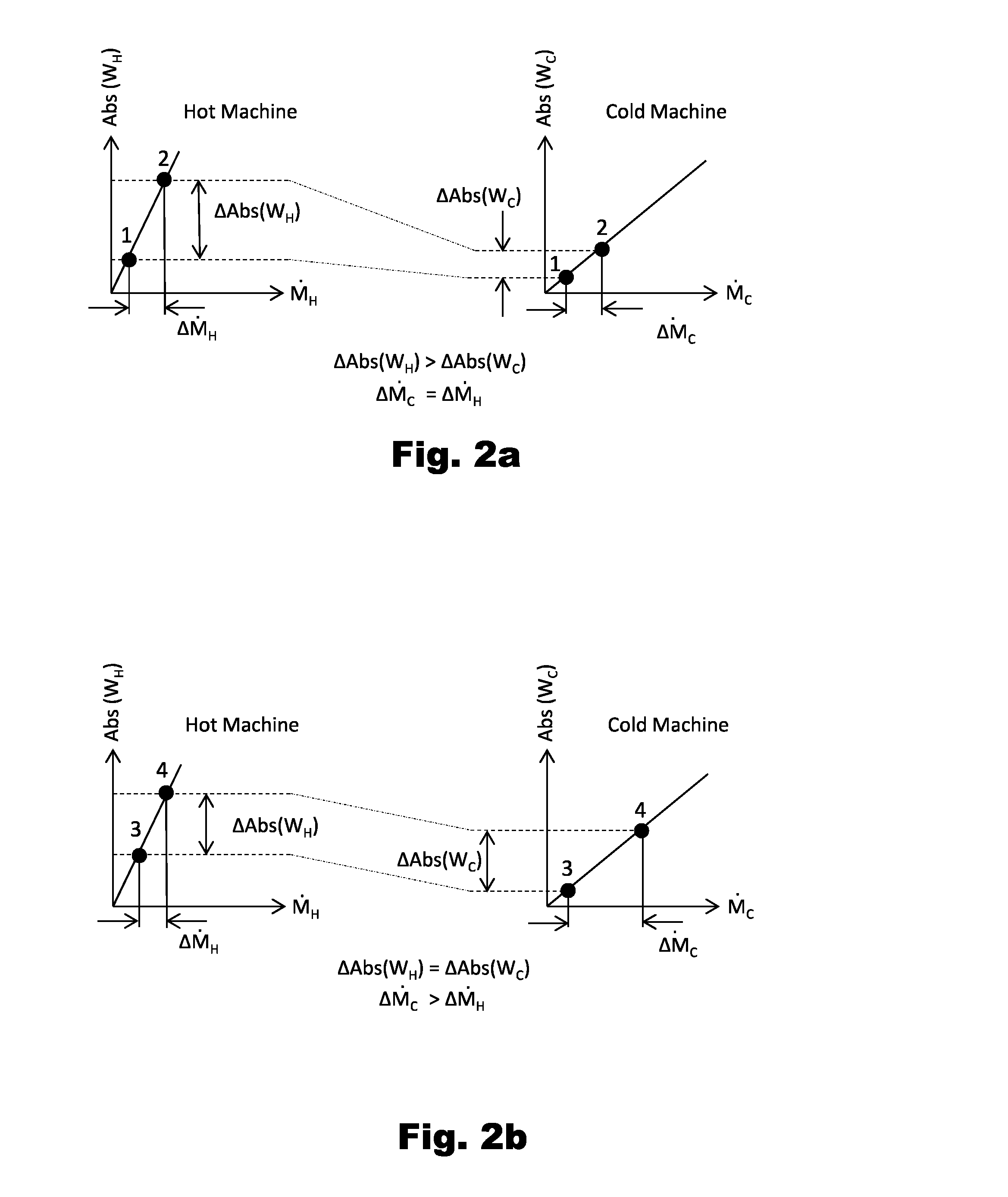

Control of System with Gas Based Cycle

InactiveUS20150211386A1Resp increasedControl moreSteam accumulatorsGas turbine plantsThermal energy storageControl system

System (2) for carrying out a gas based thermodynamic cycle in which a gas is compressed in at least one compressor (8) in one part of the cycle and is expanded in at least one expander (10) operating simultaneously in an upstream or downstream part of the cycle, wherein the change in absolute internal power with gas mass flow rate differs as between the compressor and the expander and wherein the system comprises a control system configured to make selective adjustments so as individually to control, either directly or indirectly, the respective gas mass flow rates through each of the compressor and expander. The system may be an energy storage system including a pumped heat energy storage system configured to provide independent graduated control of system pressure and output power by selective adjustment of the respective gas mass flow rates through each half-engine.

Owner:ENERGY TECH INST

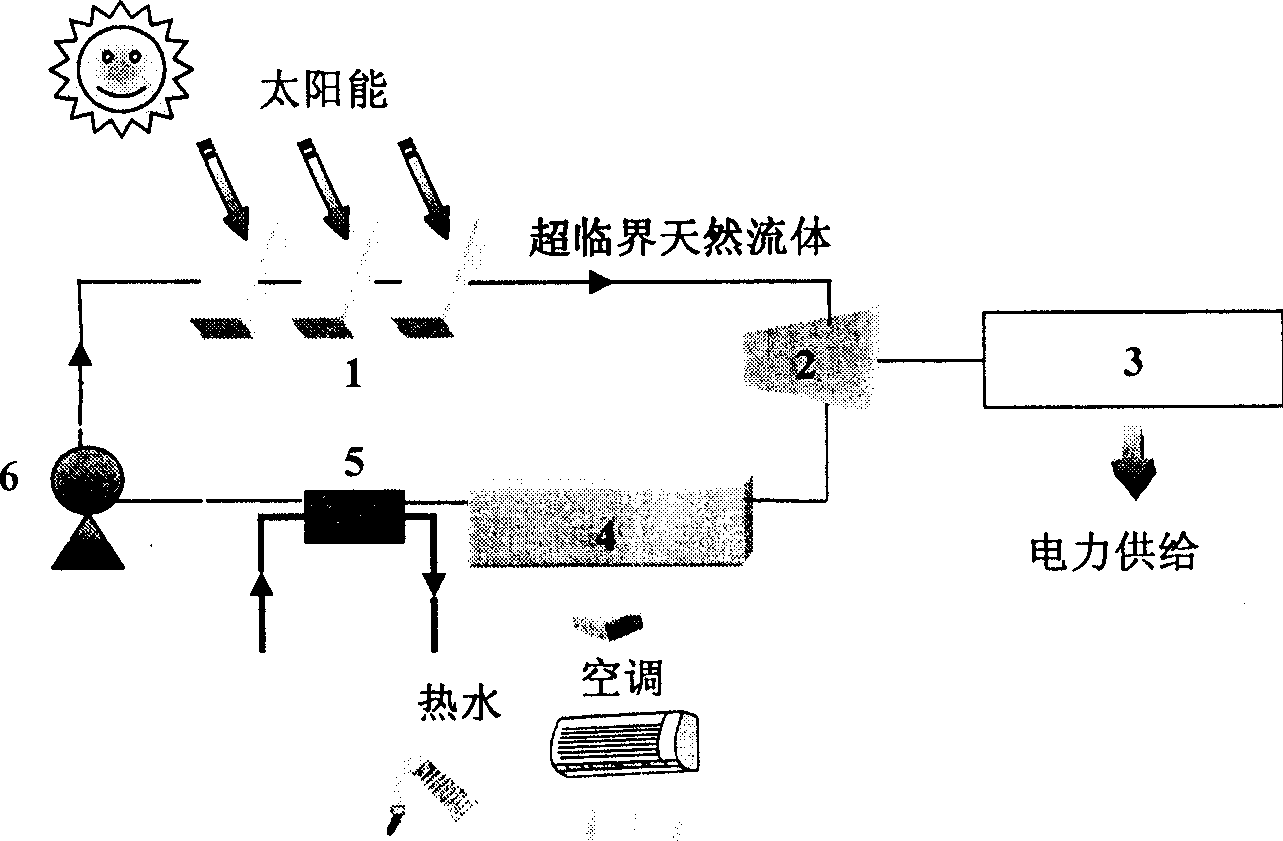

Electricity generating, air conditioning and heating apparatus utilizing natural medium and solar energy or waste heat

The invention relates to an electric generation, air conditioning and heating device which can use natural working substance, solar energy or waste heat. It comprises a solar energy collector or a waste heat collector, a pump, a turbine, a generator, a refrigerator, a heat exchanger and the pipeline. Wherein, the inlet and outlet of solar energy collector or waste heat collector are individually connected to the outlet of pump and the inlet of turbine to form the natural working substance circuit; the liquid natural working substance with low boiling point via the pressurizing of pump can reach hypercritical pressure condition and via the heating of solar energy collector or waste heat collector to form hypercritical liquid with high temperature and high pressure, then via the thermal insulation expanding, to form low pressure gas, and via the heat recycle to be cooled into liquid, at last via the pump to be feedback to the solar energy collector or the waste heat collector to realize the thermodynamics cycle. The hypercritical liquid with high temperature and high pressure can drive the turbine generator to generate electricity; and the heat recycle process uses the adsorption refrigerator to supply the cool and warm air conditioner as well as supply the hot water.

Owner:杜培俭

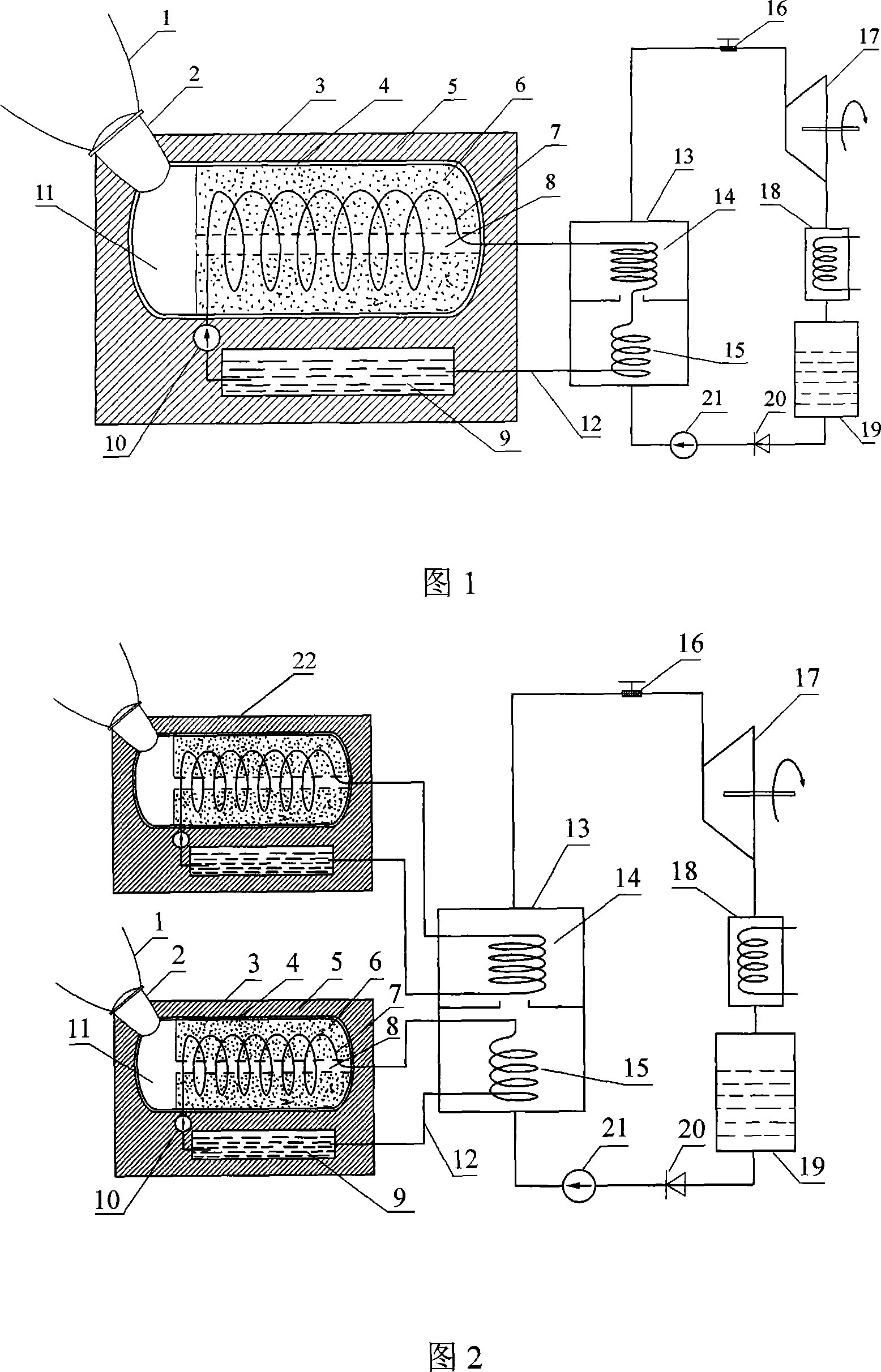

Convergence type condensation high temperature energy-concentrated heat-stored double loop driven solar energy heat power device

InactiveCN101105342AUniform and more rapid incomingEven and faster exportSolar heating energyFrom solar energyHigh temperature storageThermal energy

The invention relates to a converging type solar thermal power device capable of condensing sunlight, storing heat using high temperature phase change energy storage material and driving double loops, belonging to the technical field of solar energy collection and solar energy heat utilization. The device comprises a funnel-shaped converging type solar energy condenser, a transparent light transmitting window, an energy accumulator, a high temperature heat-conducting oil heat supply circulating system, a superheated steam generator, and a Rankine cycle-based heat-power converting system. The sunlight is condensed by the funnel-shaped converging type solar energy condenser, and entered into the energy accumulator through the transparent light transmitting window to realize high temperature storage therein, the high temperature heat-conducting oil heat supply circulating system transmits the high temperature in the energy accumulator to the superheated steam generator to heat working fluid to generate high pressure high temperature superheated steam therein, and converts heat energy to power through thermodynamic cycle. The invention is a device for supplying power or electric energy for user by condensing sunlight, storing heat using high temperature phase change energy storage material, and driving heat-power converting system using high temperature heat energy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Solar concentration plant for the production of superheated steam

InactiveUS20080302314A1Easy to controlReduce riskSolar heating energySuperheating controlHeliostatEvaporation

A solar concentration plant which uses water / steam as a heat-carrying fluid, in any thermodynamic cycle or system for the exploitation of process heat, which is comprised of an evaporation subsystem, where saturated steam is produced under the conditions of pressure of the system, and a superheater subsystem through which the steam reaches the required conditions of pressure and temperature at the turbine inlet, and in which an attemperation system (10) may be incorporated, these being physically separated and interconnected by means of a drum (5) in which the separation of water and steam takes place, and in which a strategic control of the pointing of the field of heliostats (1) towards either of the subsystems (evaporator or superheater) may be carried out, with individual or group pointing of the heliostats, in such a way that they jointly control both the pressure within the drum (5) and the outlet temperature of the superheated steam (11).

Owner:ABENGOA SOLAR NEW TECH SA

Thermodynamic closed loop desiccant rotor system and process

InactiveUS20090139254A1Maximize interchangeableMaximize recovered energy capabilityAir treatment detailsLighting and heating apparatusDesiccantConservation energy

A thermodynamic closed loop desiccant rotor system and process utilizes at least one closed recirculation loop that provides interchangeable energy directly to the desiccant material and various rotor isolated zoning configurations in combination with various arrangements of energy exchange devices and refrigeration components to maximize the interchangeable and recovered energy capability and capacity through both closed thermodynamic cycles and open cycle processes for significantly improved efficiency and energy conservation. The present desiccant rotor system may be utilized in an air conditioning system for dehumidification, humidification, moisture removal, and capture of moisture, and in other applications to remove unwanted gases.

Owner:BOLAND GREEN ENERGY SOLUTIONS

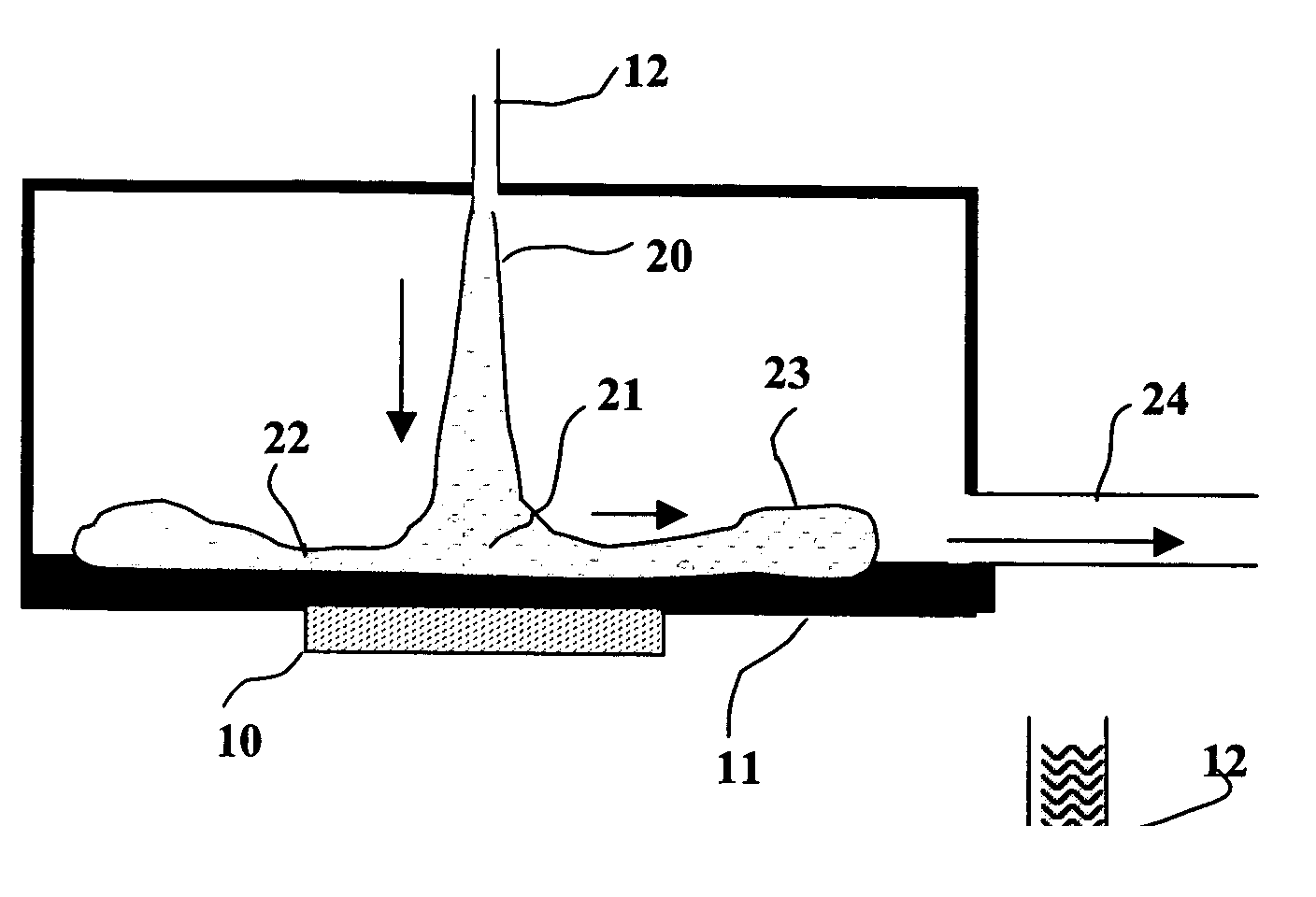

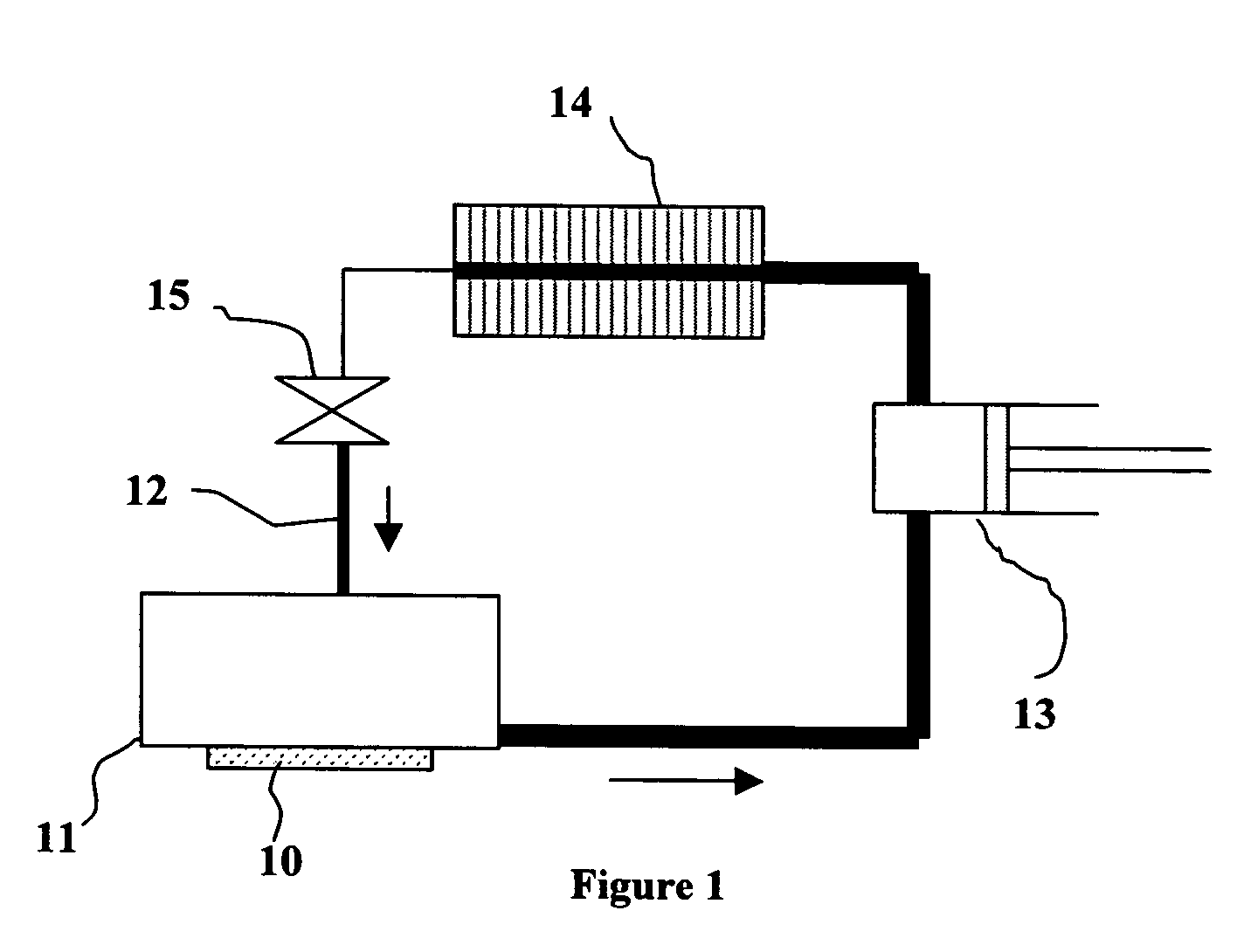

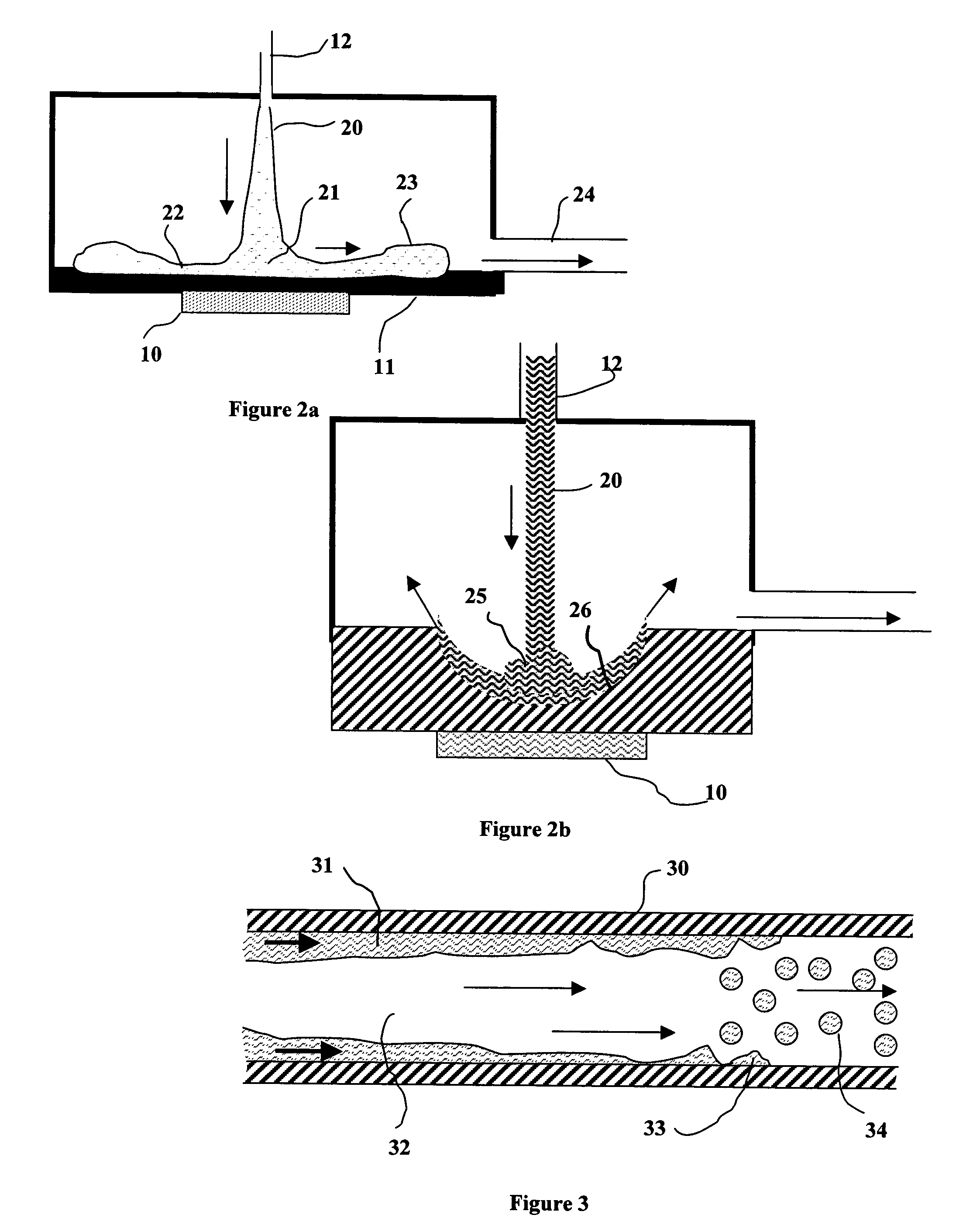

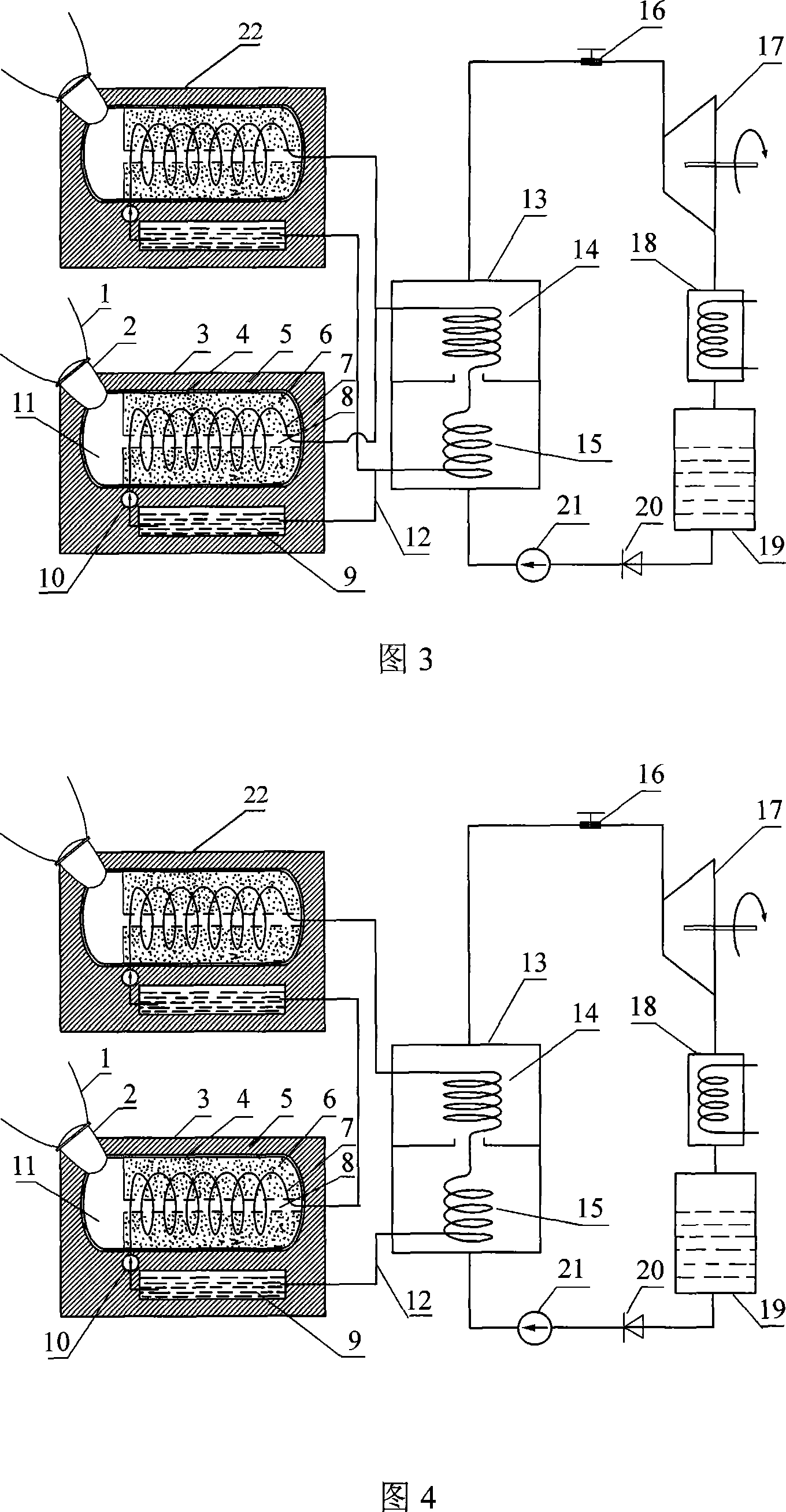

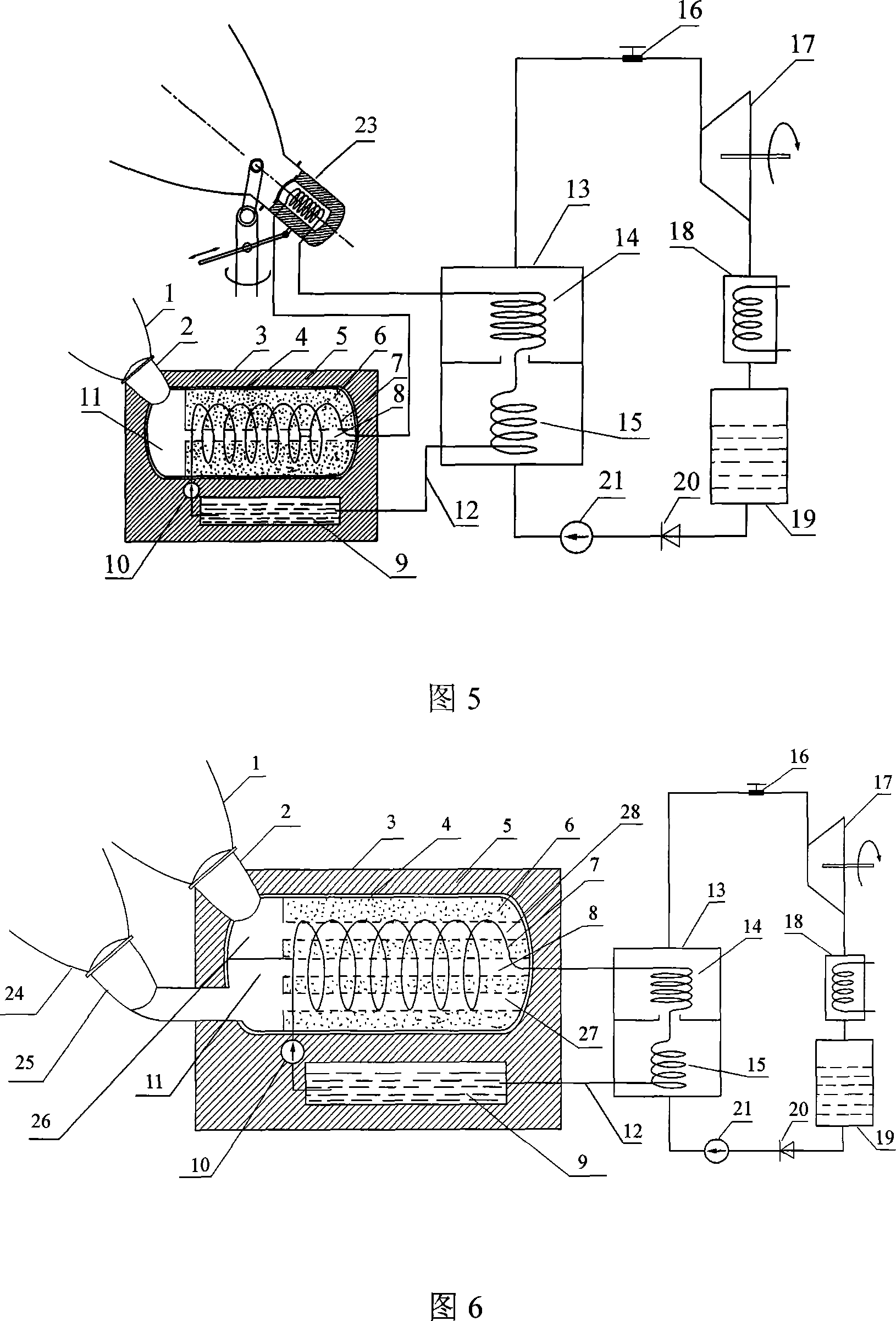

Method and apparatus for converting thermal energy to mechanical energy

InactiveUS7284372B2Improve efficiencyEfficient regenerationEricsson type enginesSteam engine plantsThermal energyExternal energy

A method and apparatus for converting thermal energy to mechanical energy which can use a wide range of fuels and perform with a high efficiency. Operating on a little utilized thermodynamic cycle of isentropic compression, isothermal expansion, isentropic expansion and finally constant pressure cooling and contraction. The external heat engine utilizes a heat exchanger carrying heat from the external energy source to the working parts of the engine. Pistons and cylinders are activated by appropriate means to adiabatically compress the working fluid, for example ambient air, to transfer the entire mass of the air through the heat exchanger to accomplish isothermal expansion followed by adiabatic expansion and, finally, exhaust the air to ambient to allow for constant pressure cooling and contraction. Valve pistons in conjunction with the cylinders form valves that allow for the exchange of working fluid with ambient. Energy is added to the engine during isothermal expansion, whereby the energy of compression is added by a flywheel or other appropriate energy storage means, said flywheel stores energy recovered during adiabatic expansion. The thermodynamic cycle described and the engine embodiments disclosed, when run in reverse, perform as a heat pump or refrigeration device.

Owner:CROW DARBY

Dual pressure geothermal system

A new thermodynamic cycle is disclosed for converting energy from a low temperature stream from an external source into useable energy using a working fluid comprising of a mixture of a low boiling component and a higher boiling component and including a higher pressure circuit and a lower pressure circuit. The cycle is designed to improve the efficiency of the energy extraction process by mixing the liquid stream from the high pressure circuit with the spent low pressure circuit stream forming a lean system that can be condensed at a low pressure. The new thermodynamic process and the system for accomplishing it are especially well-suited for streams from low-temperature geothermal sources.

Owner:KALINA POWER LTD

High efficiency positive displacement thermodynamic system

ActiveUS20100050628A1Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com