Patents

Literature

443 results about "Thermodynamic system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermodynamic system is a group of material and/or radiative contents. Its properties may be described by thermodynamic state variables such as temperature, entropy, internal energy, and pressure. The simplest state of a thermodynamic system is a state of thermodynamic equilibrium, as opposed to a non-equilibrium state.

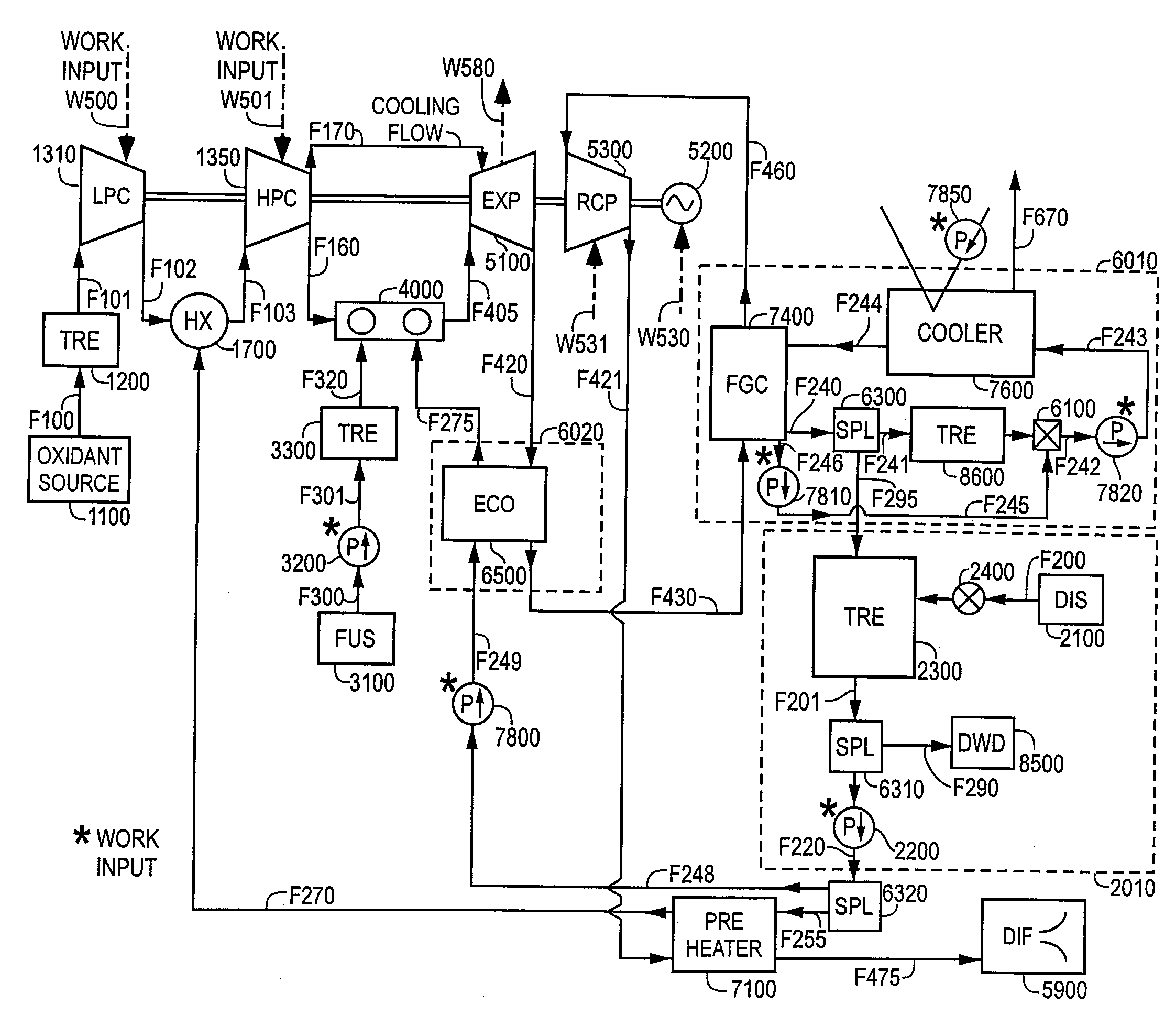

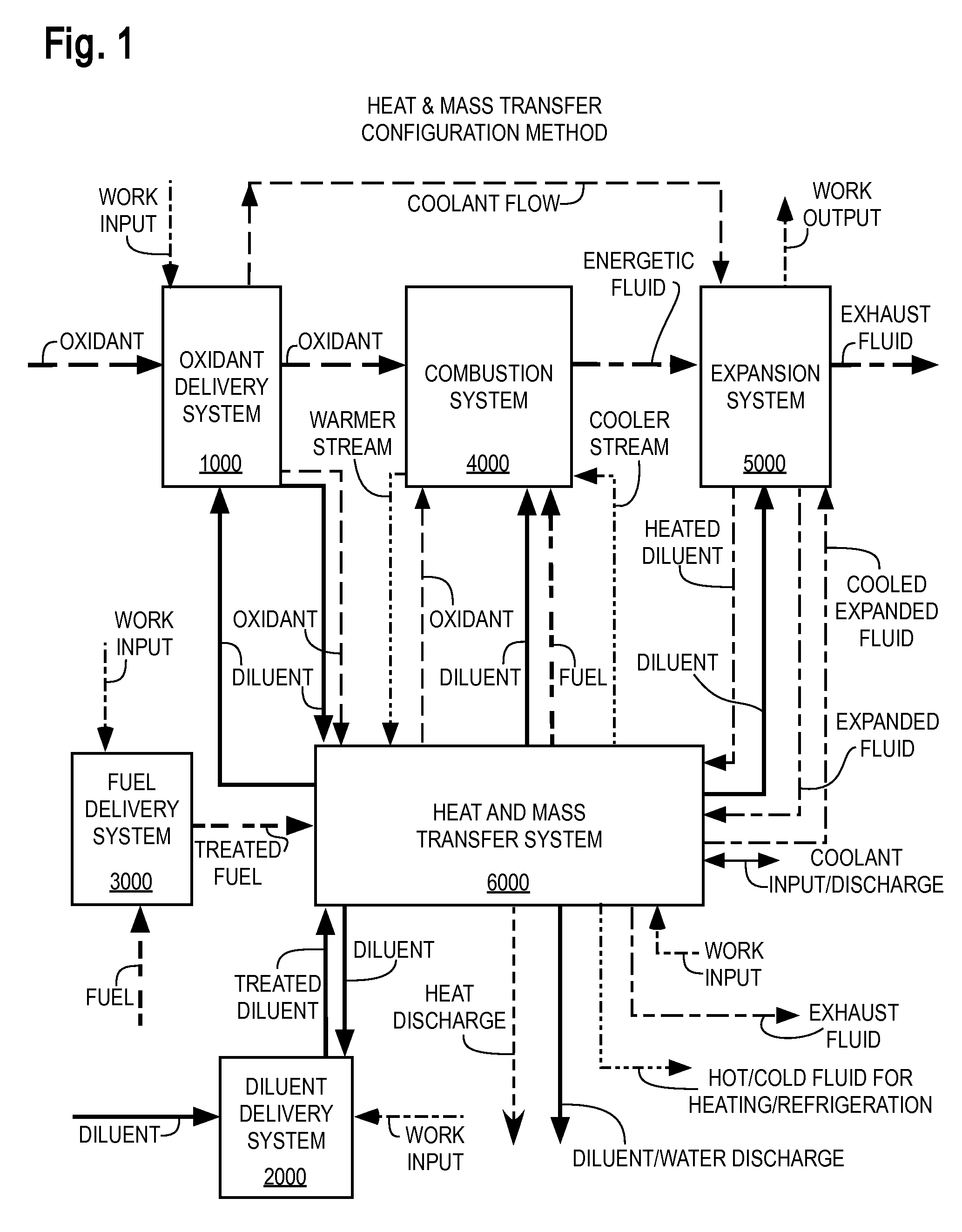

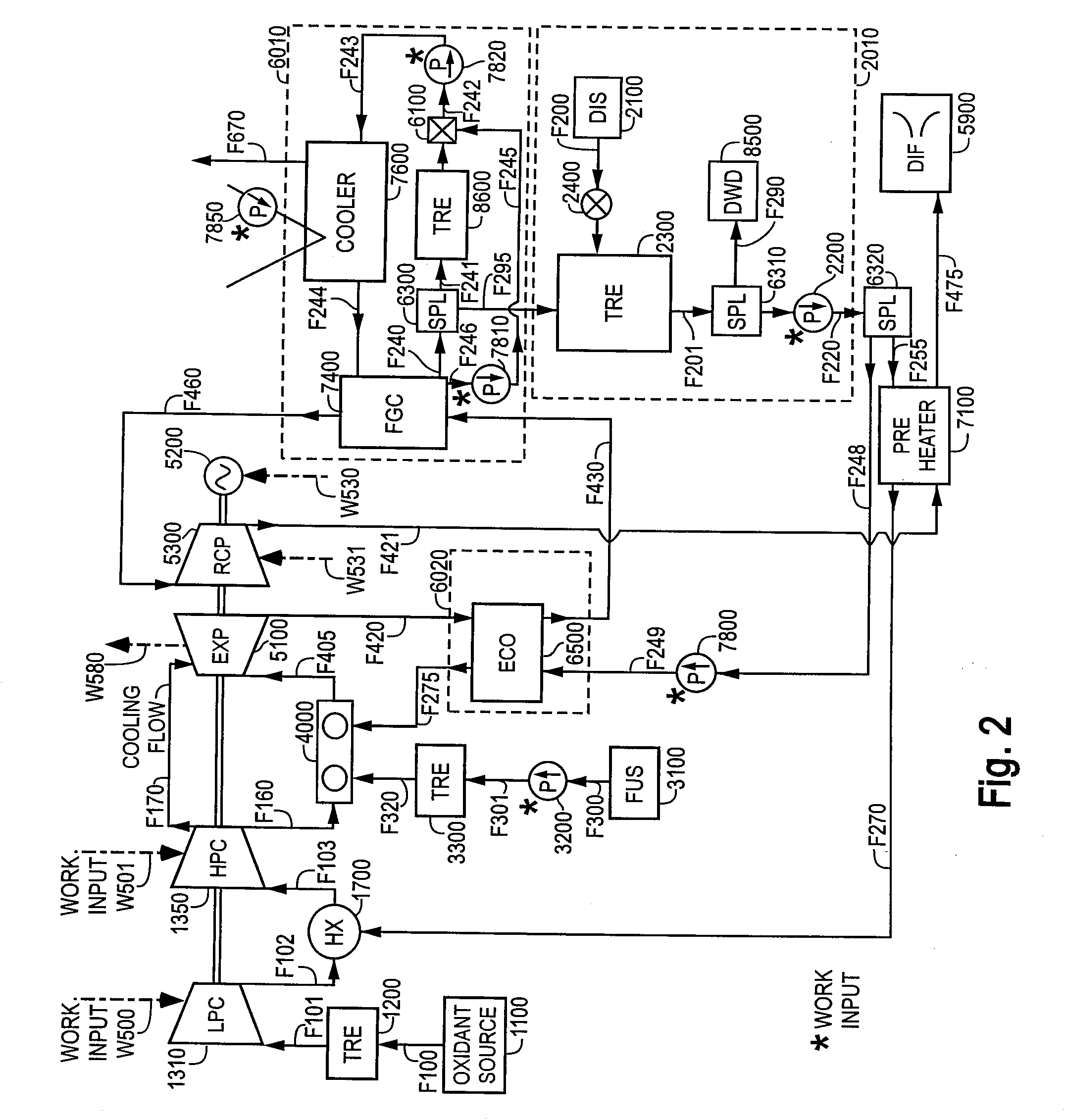

Thermodynamic cycles using thermal diluent

ActiveUS20090071166A1Low costEmission reductionSpace heating and ventilationSulfur compoundsCombustion systemCombustion

A thermodynamic system that produces mechanical, electrical power, and / or fluid streams for heating or cooling. The cycle contains a combustion system that produces an energetic fluid by combustion of a fuel with an oxidant. A thermal diluent may be used in the cycle to improve performance, including but not limited to power, efficiency, economics, emissions, dynamic and off-peak load performance, and / or turbine inlet temperature (TIT) regulation and cooling heated components. The cycle preferably includes a heat recovery system and a condenser or other means to recover and recycle heat and the thermal diluent from the energetic fluid to improve the cycle thermodynamic efficiency and reduce energy conversion costs. The cycle may also include controls for temperatures, pressures, and flow rates throughout the cycle, and controls power output, efficiency, and energetic fluid composition.

Owner:VAST HLDG LLC

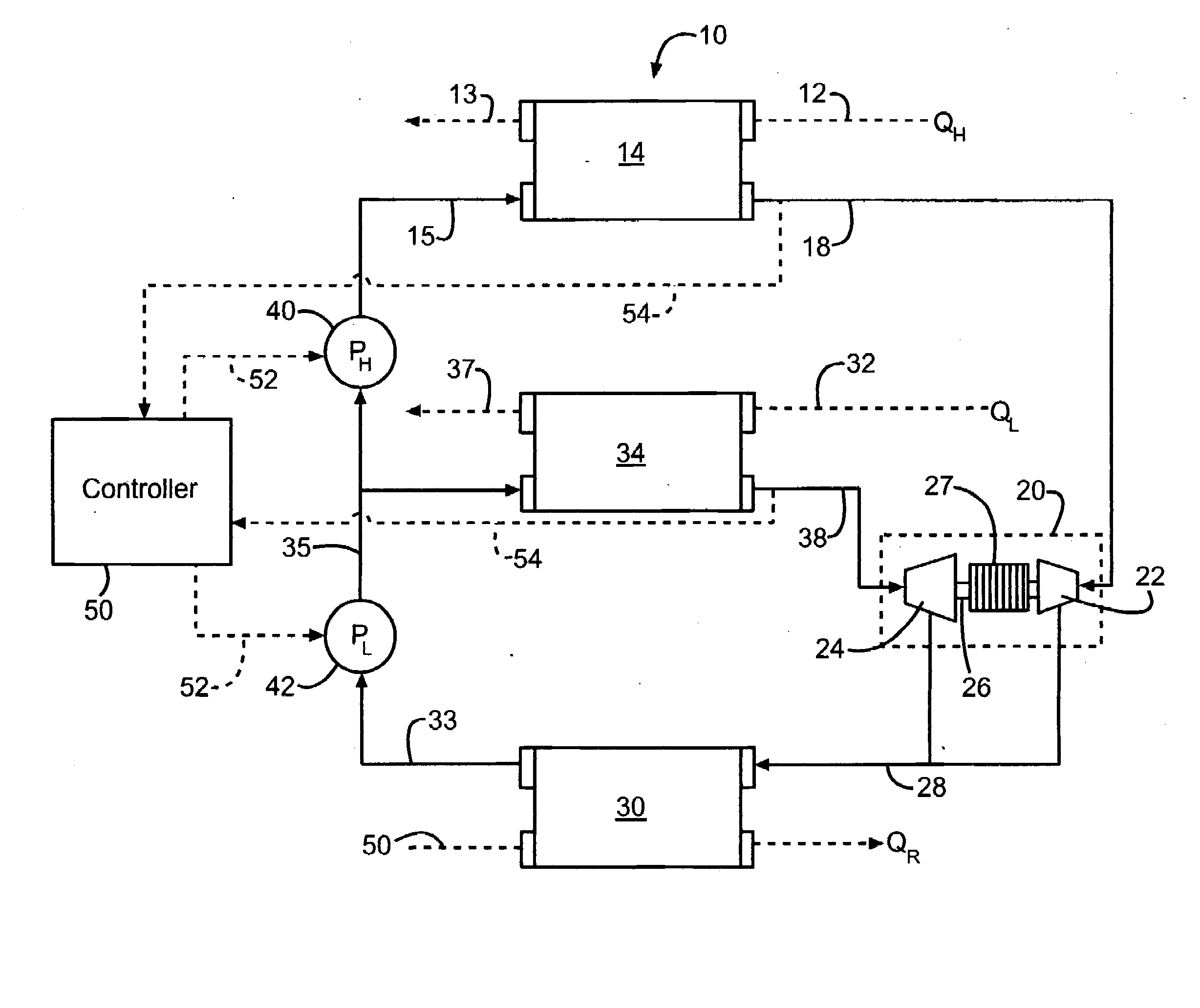

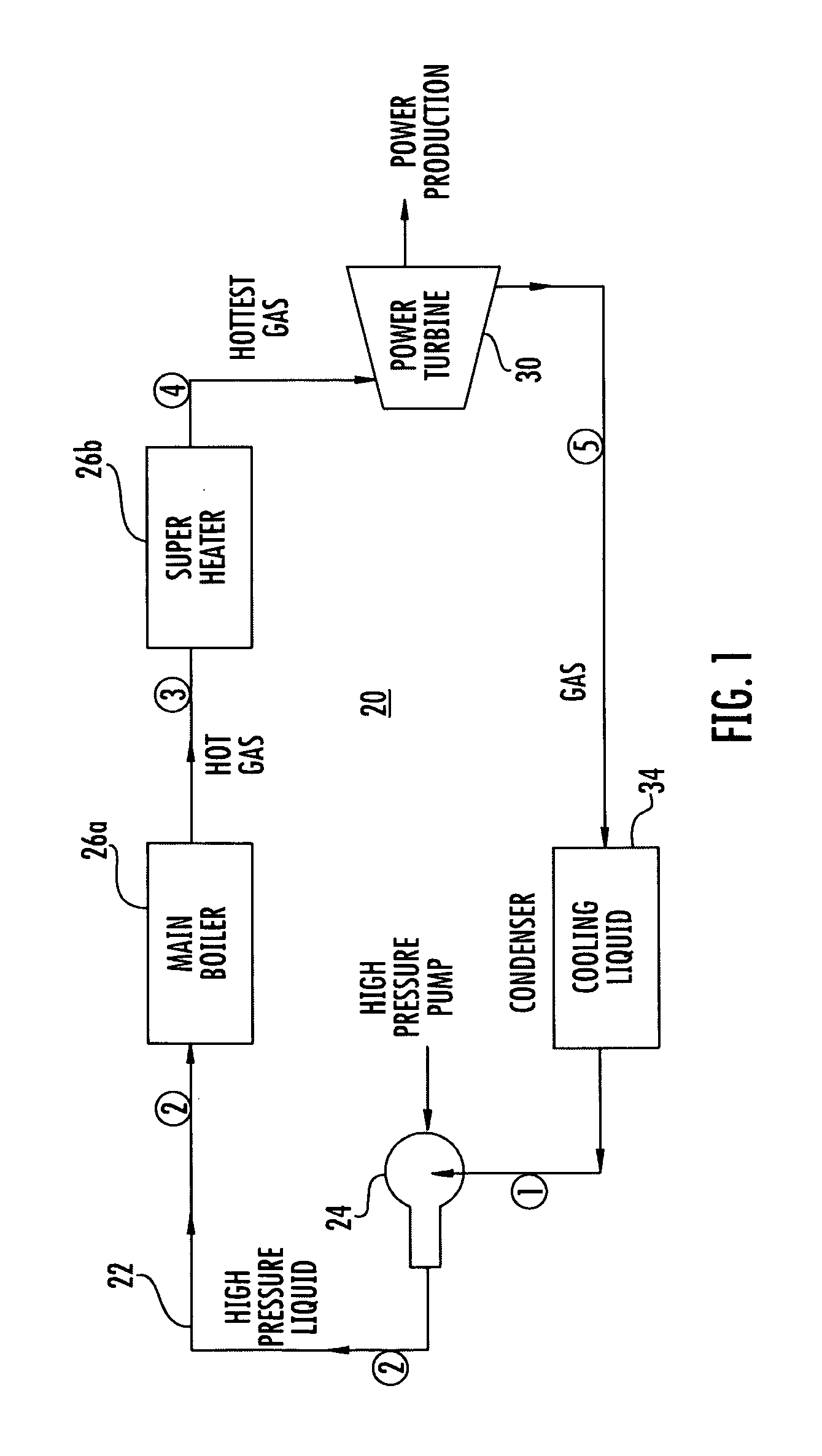

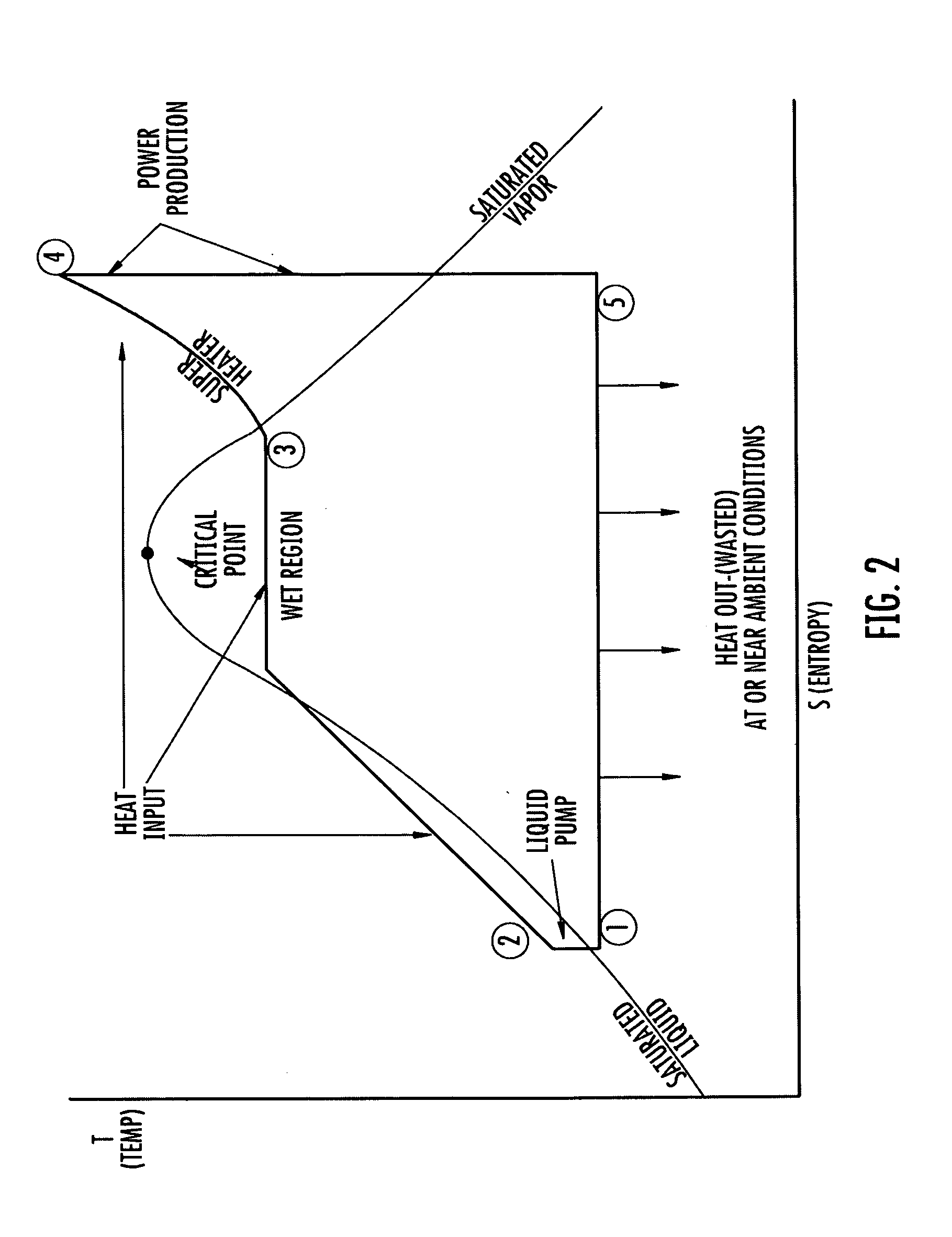

Energy recovery system using an organic rankine cycle

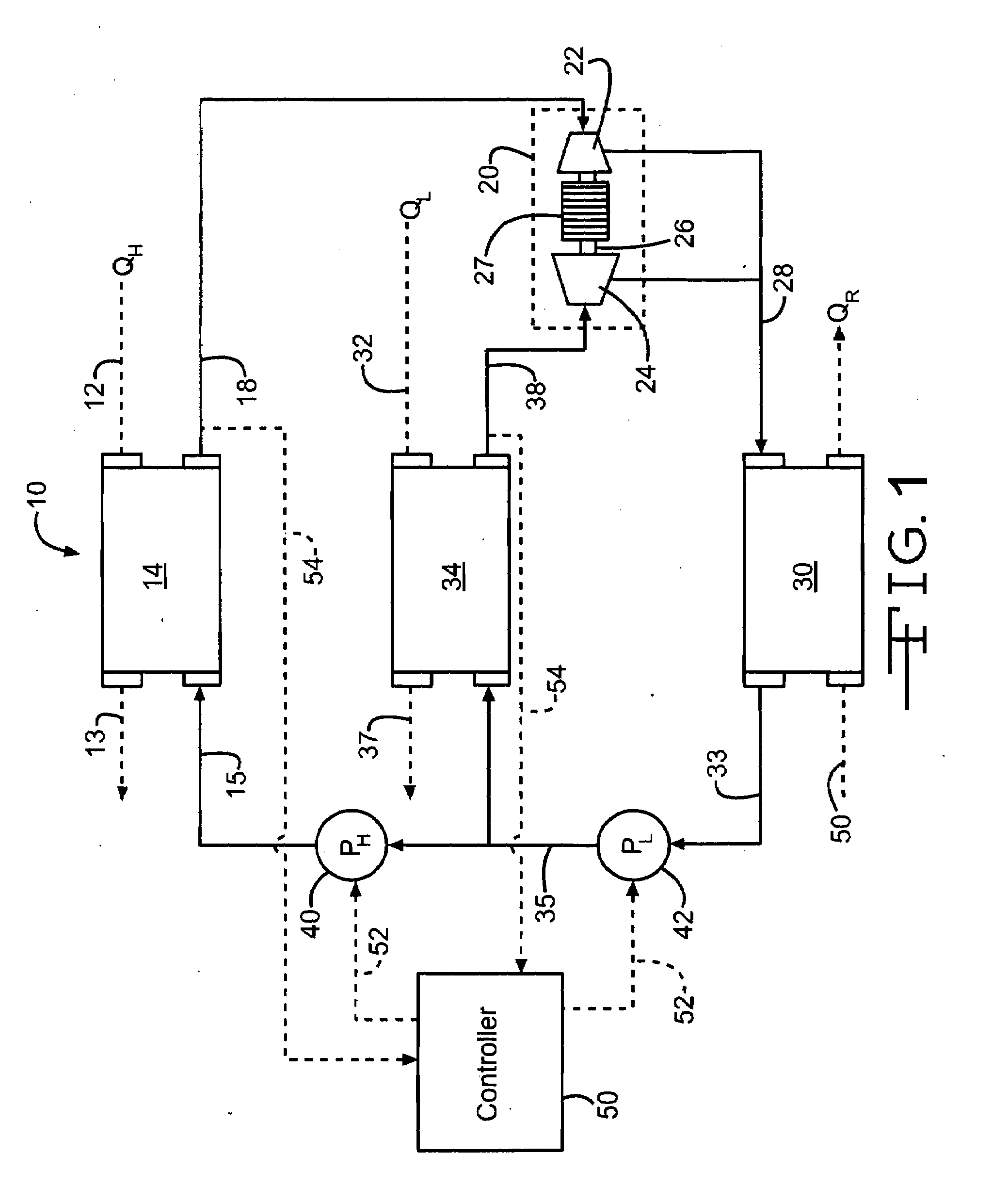

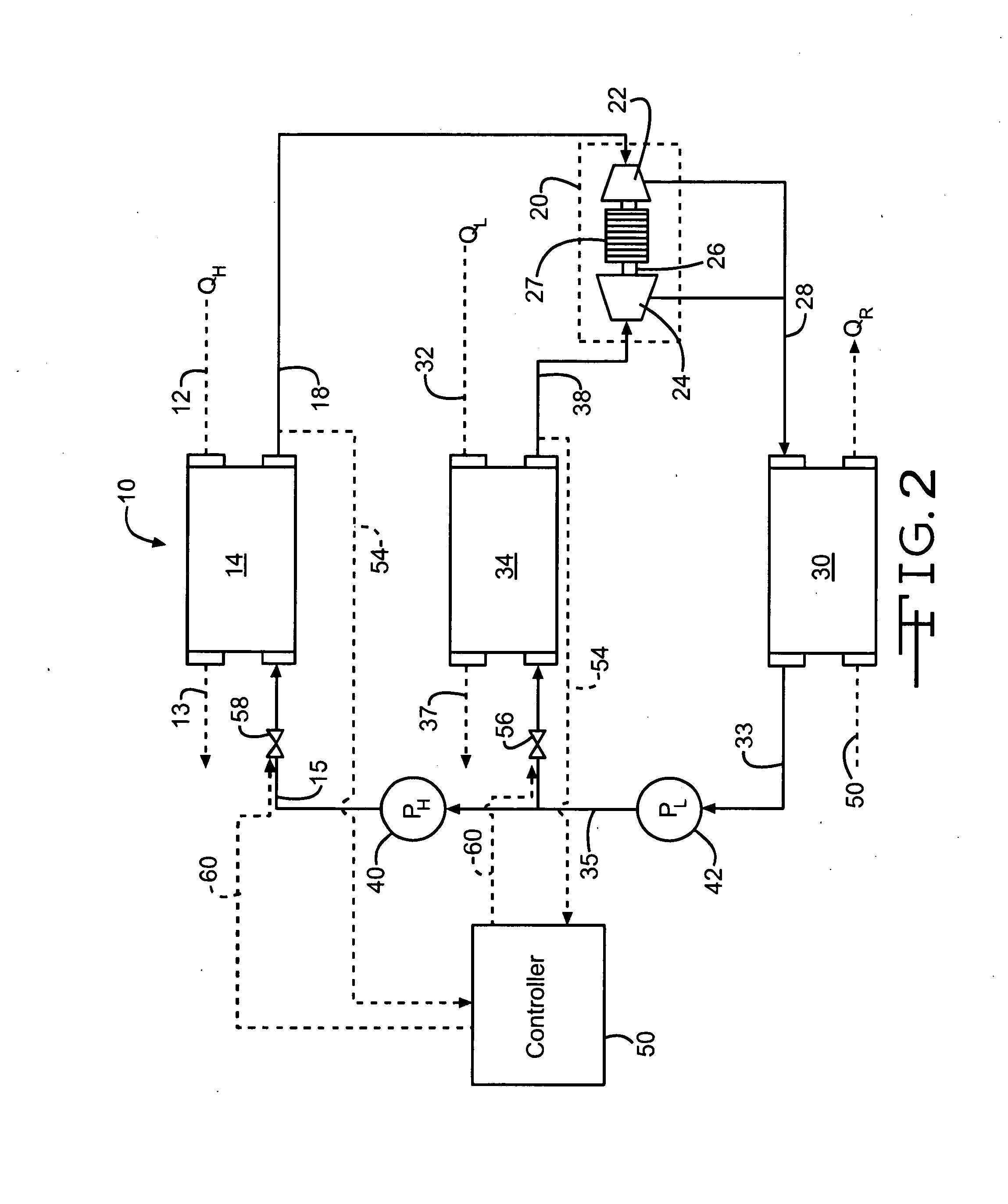

ActiveUS20110016863A1Improve energy recoveryDifferent temperatureSteam useGas turbine plantsThermal energyHeat flow

A thermodynamic system for waste heat recovery, using an organic rankine cycle is provided which employs a single organic heat transferring fluid to recover heat energy from two waste heat streams having differing waste heat temperatures. Separate high and low temperature boilers provide high and low pressure vapor streams that are routed into an integrated turbine assembly having dual turbines mounted on a common shaft. Each turbine is appropriately sized for the pressure ratio of each stream.

Owner:CUMMINS INTPROP INC

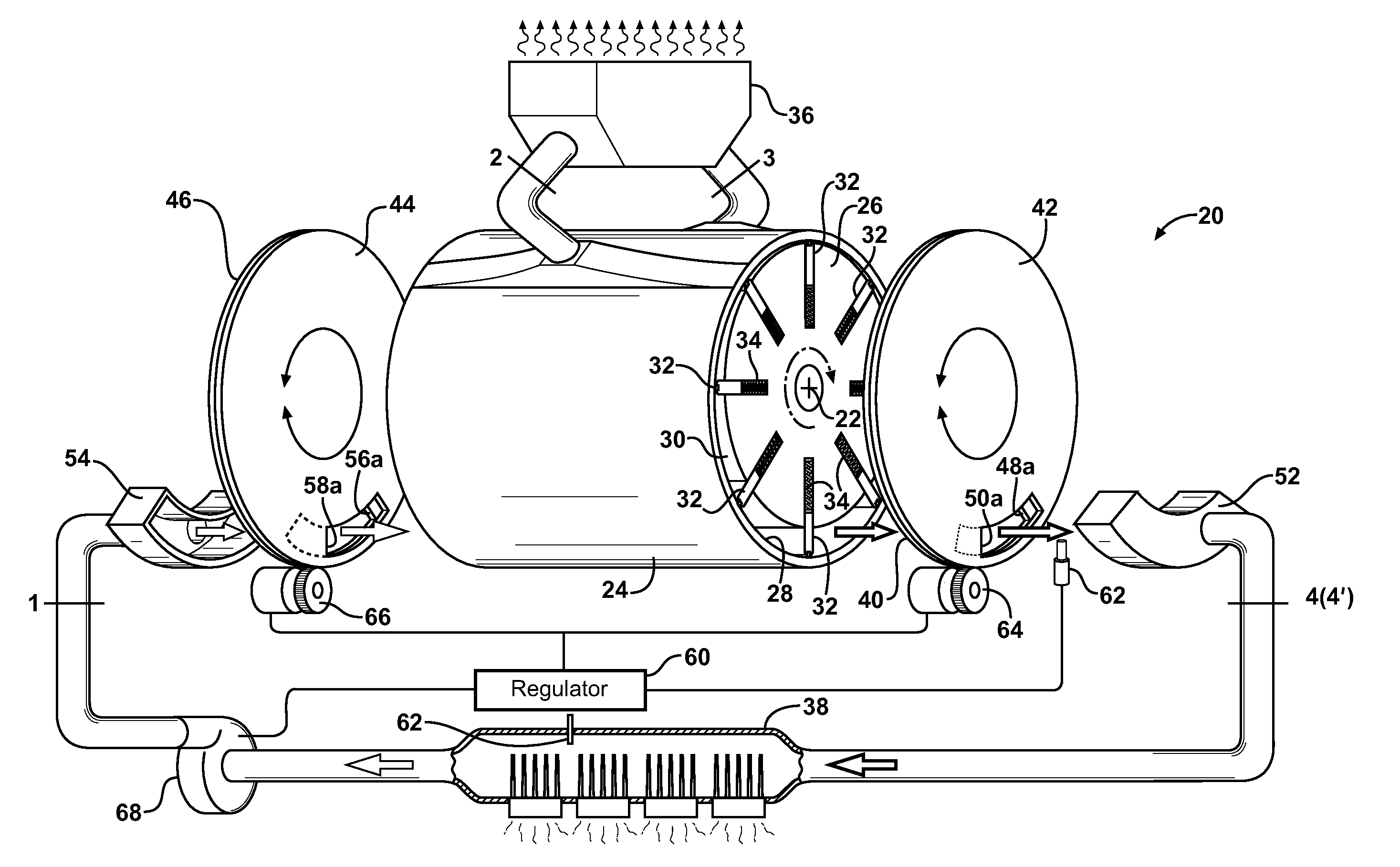

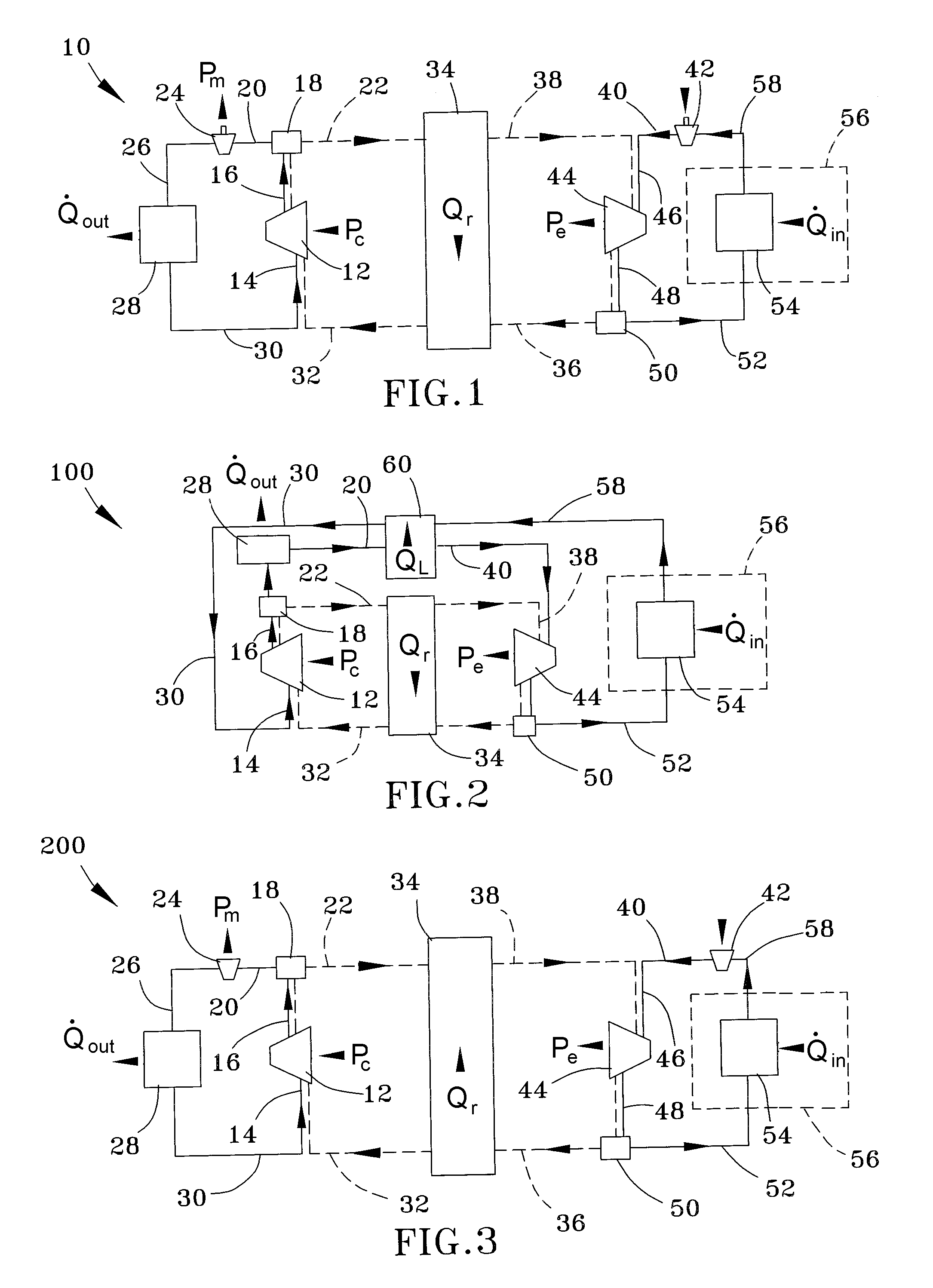

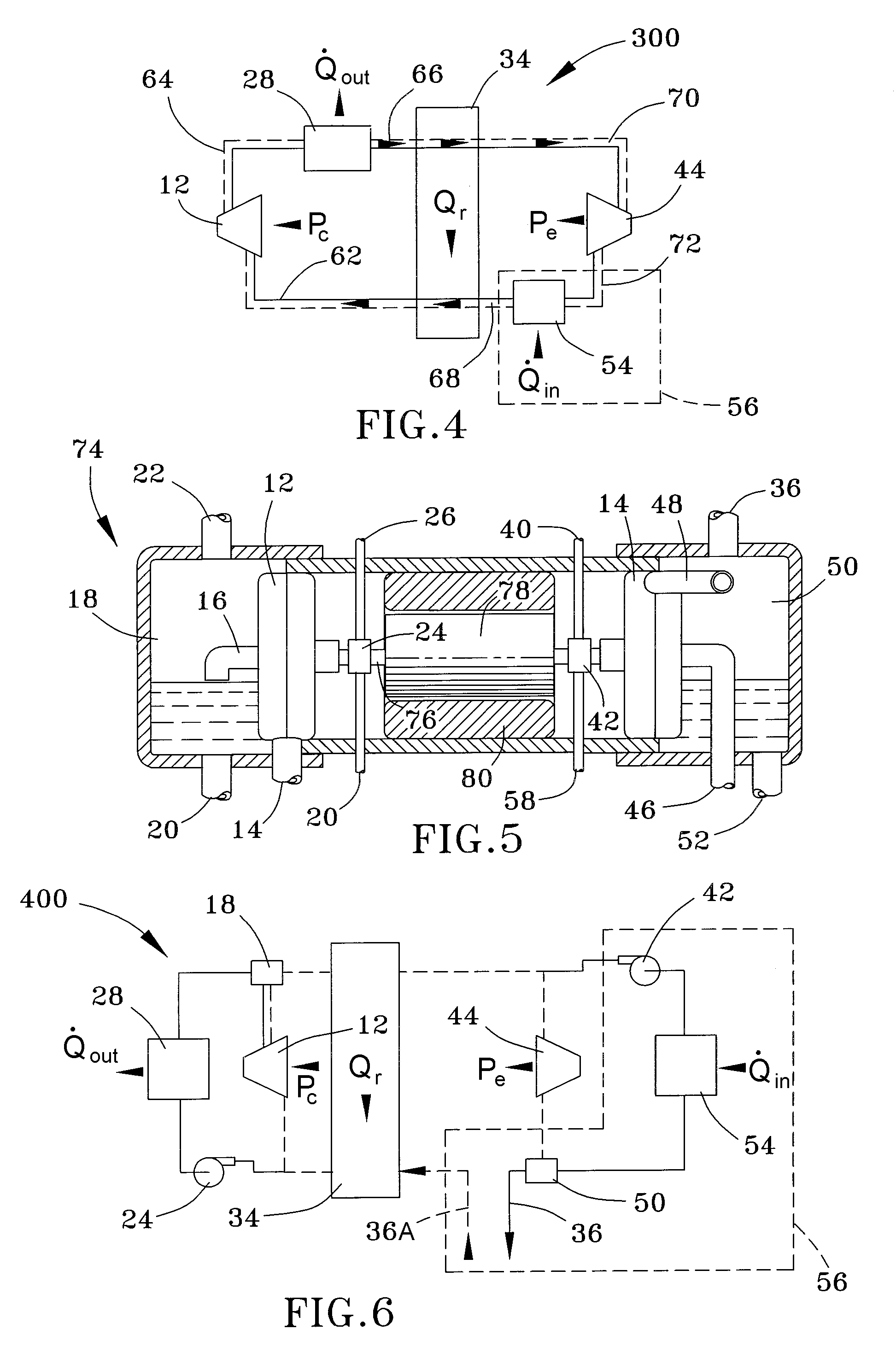

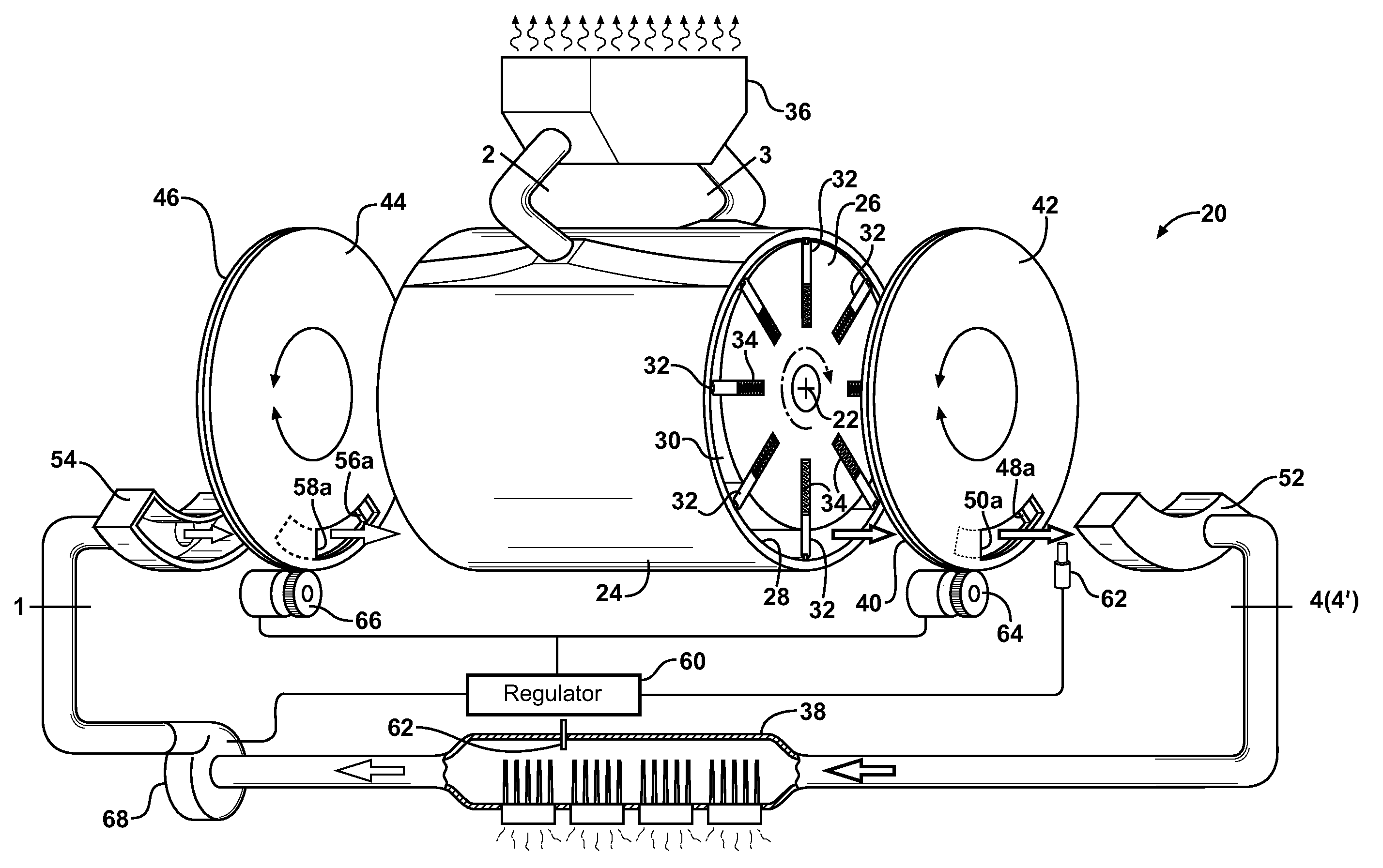

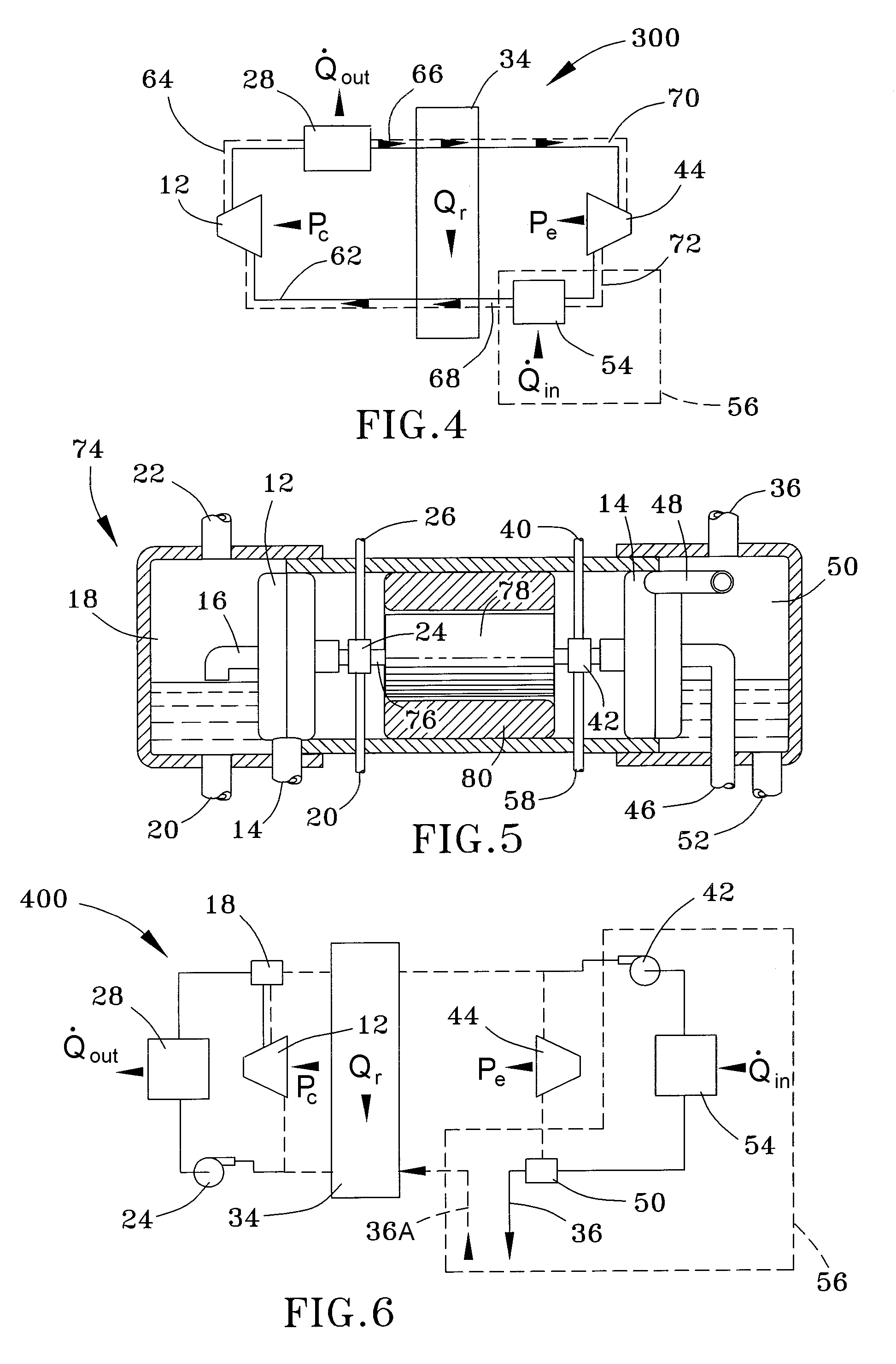

High efficiency positive displacement thermodynamic system

ActiveUS8424284B2Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

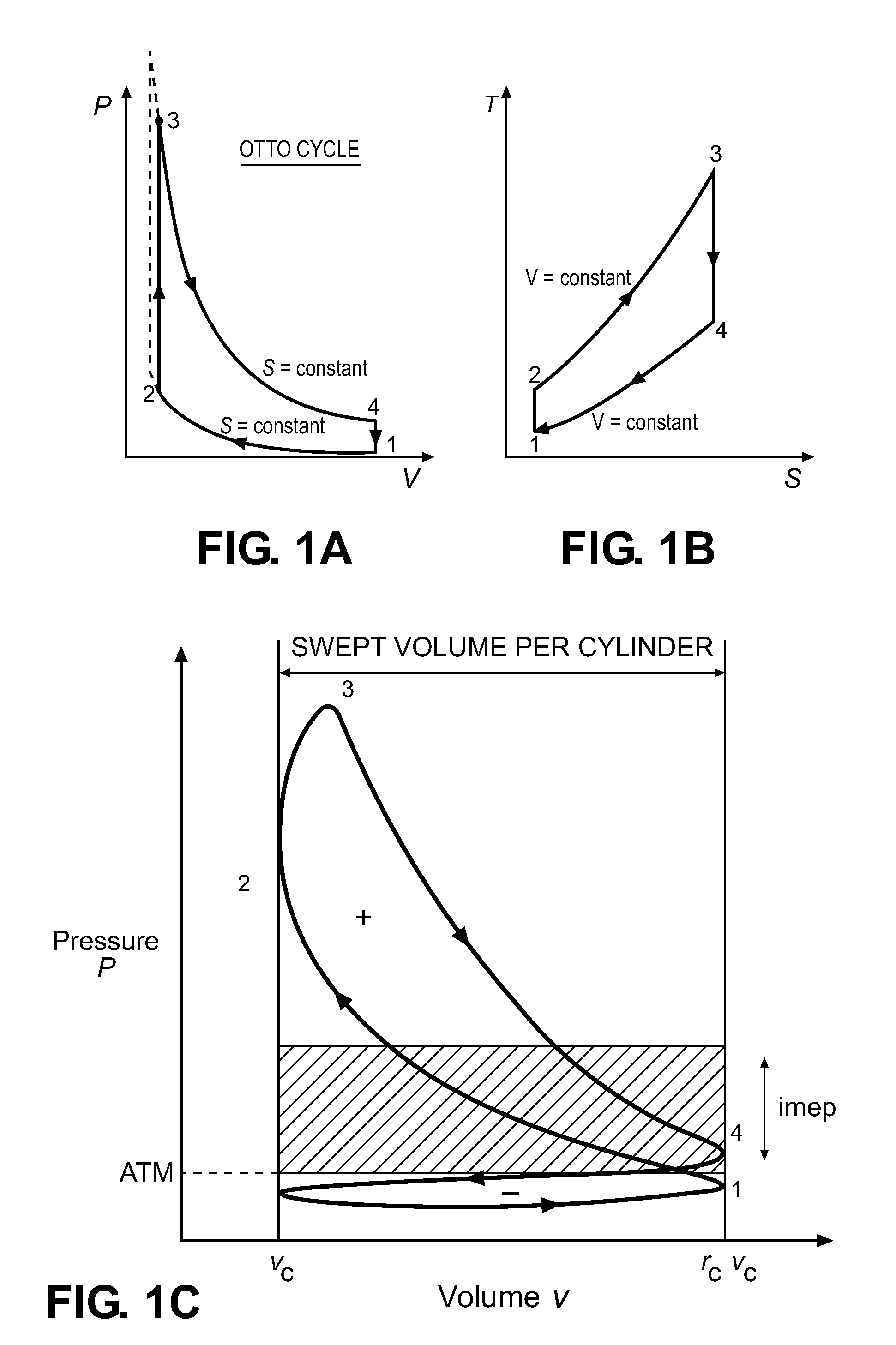

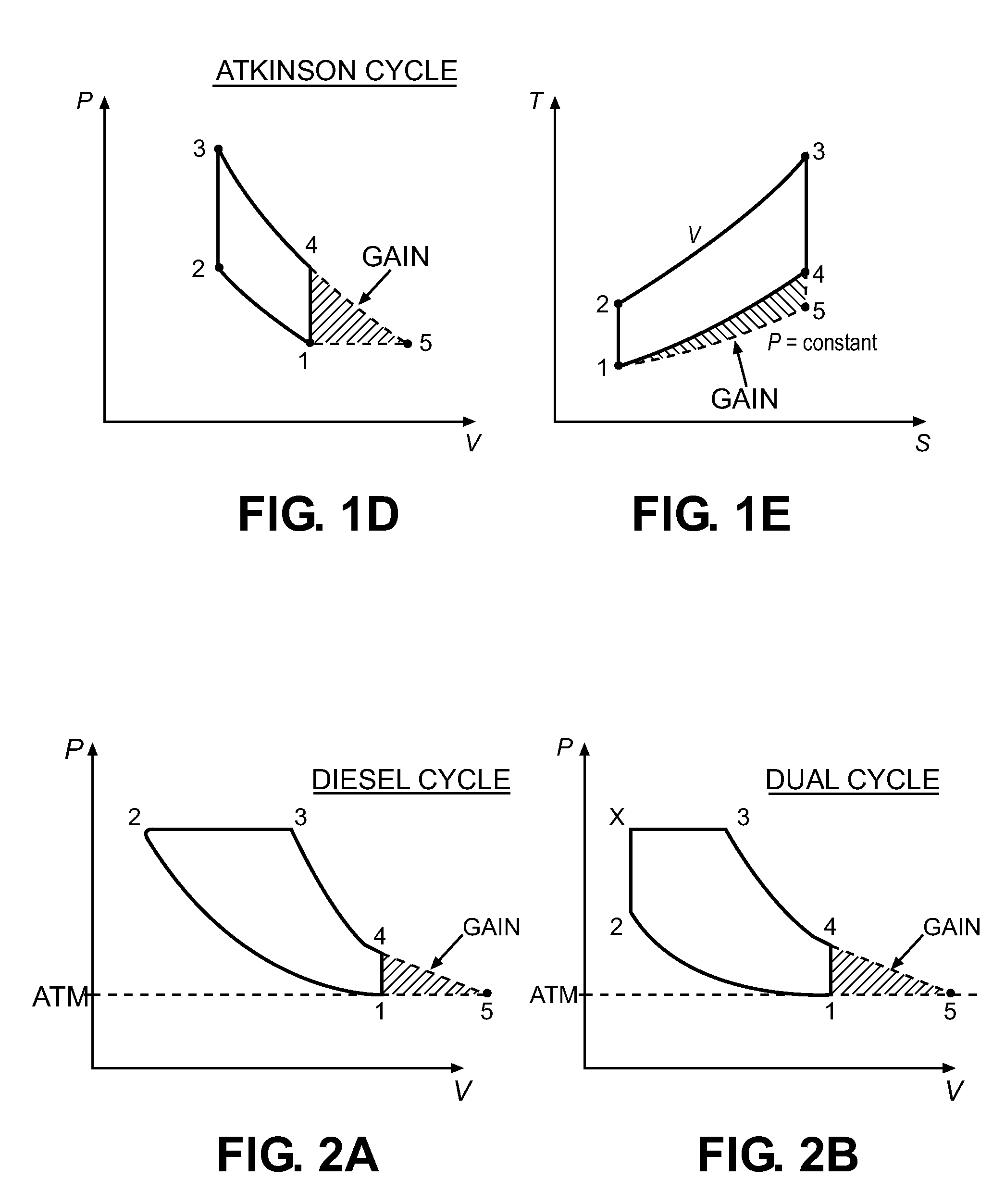

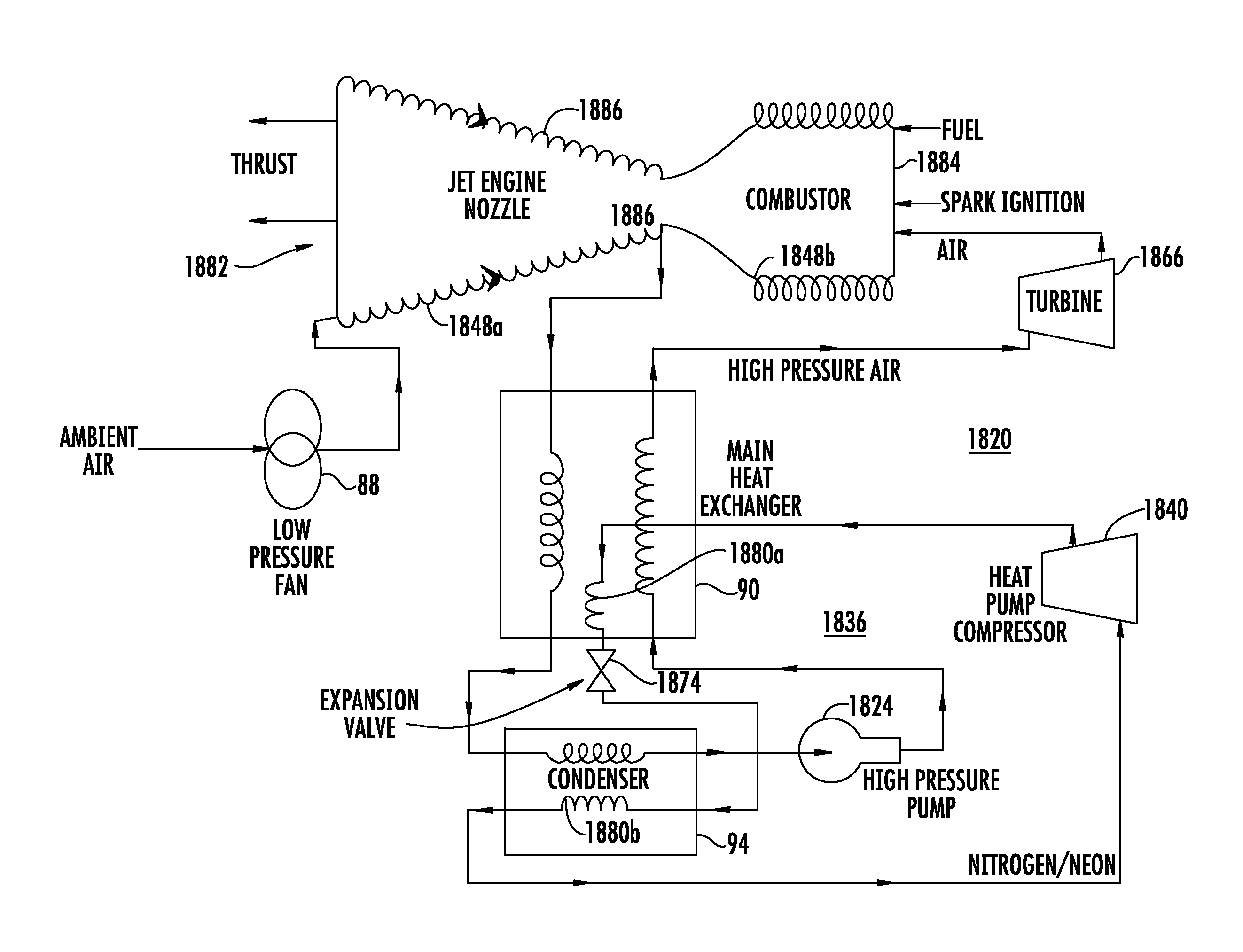

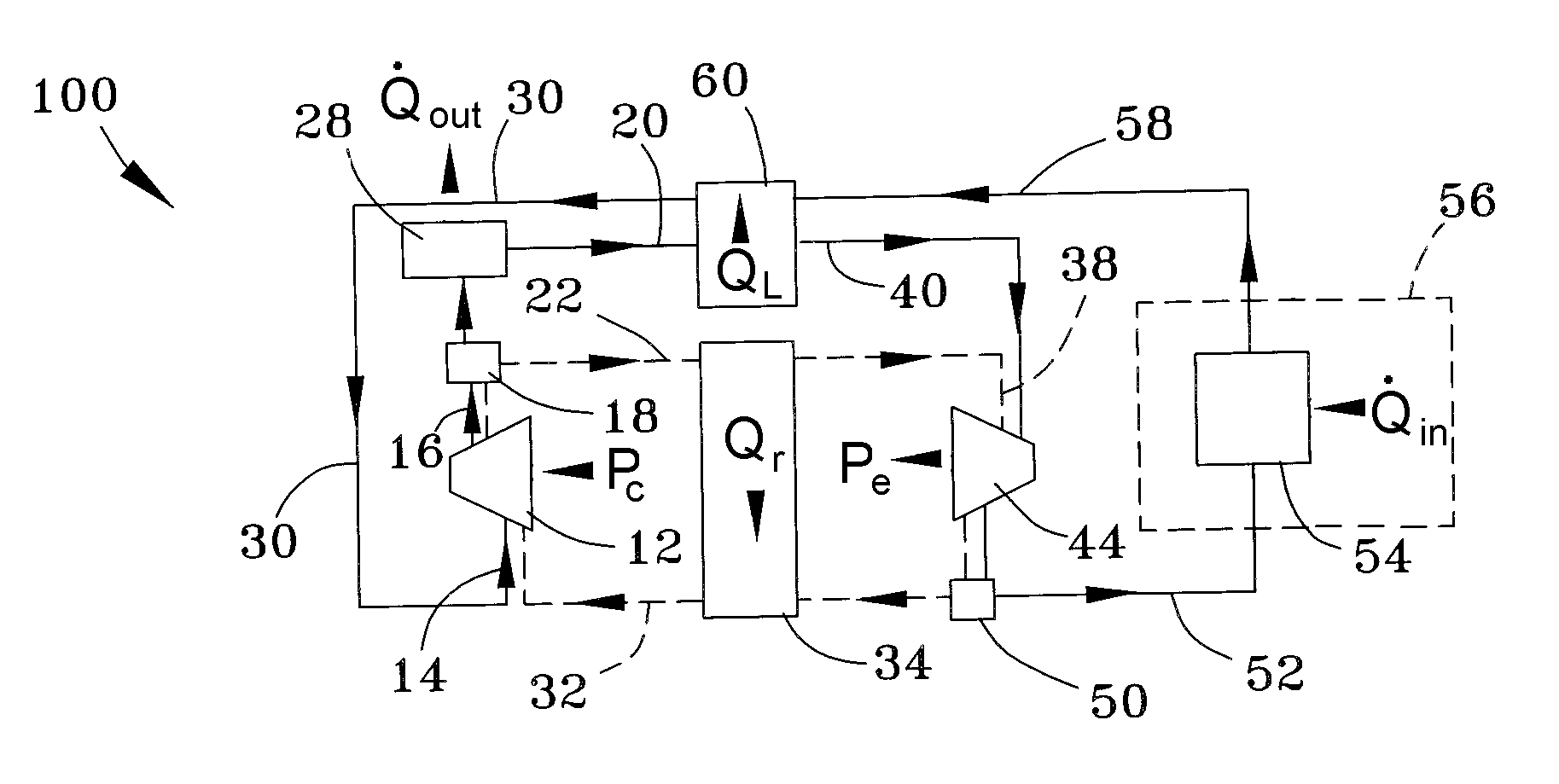

Ultra-high-efficiency engines and corresponding thermodynamic system

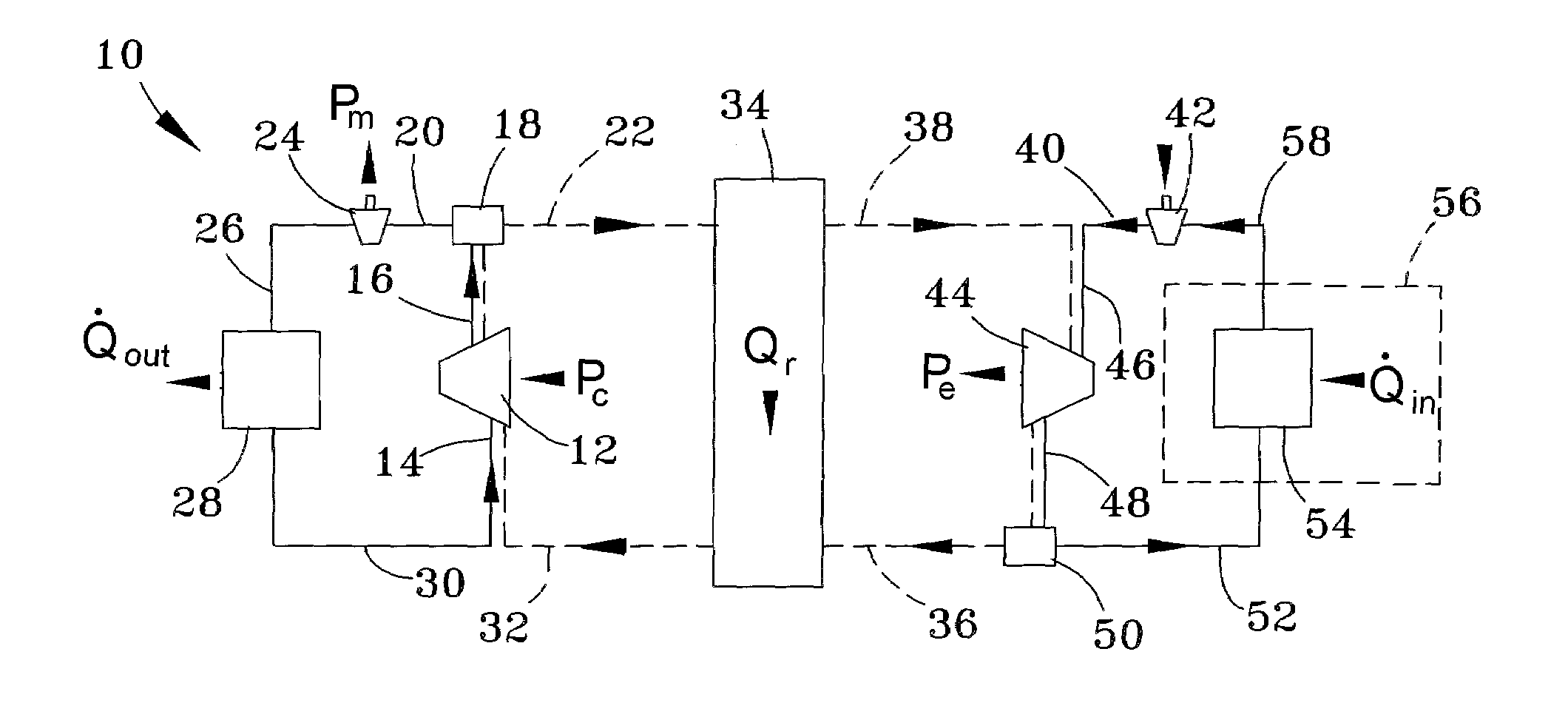

ActiveUS20110252796A1Improving the thermodynamic efficiency of a number of enginesImprove engine efficiencyGas turbine plantsEfficient propulsion technologiesWorking fluidEngineering

A thermodynamic system and method of producing useful work includes providing a working fluid and a fluid pump, or compressor, for pumping the working fluid in a cycle. A thermal input is provided for supplying heat to the working fluid. An expansion device downstream of the thermal input converts motion of the working fluid to useful work. A heat pump is provided. A number of different means of implementing the heat pump are presented, including direct transfer of working fluid mass flow. The heat pump pumps heat from one portion of the working fluid to another portion of the working fluid. For some applications, a regenerator, or recuperator, may be used to transfer heat from a high temperature portion of the working fluid to a lower temperature portion.

Owner:BURKHART TECH

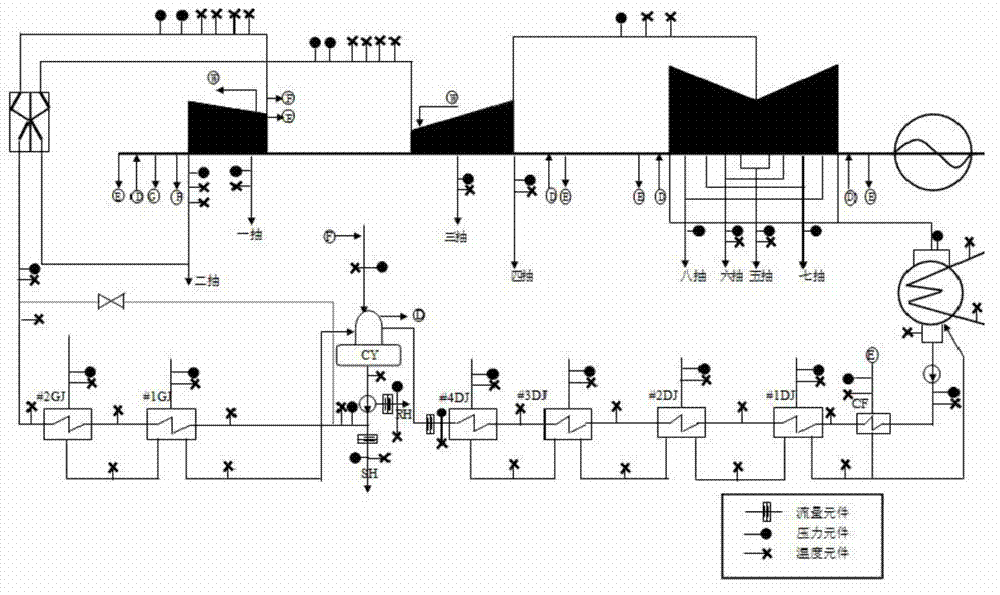

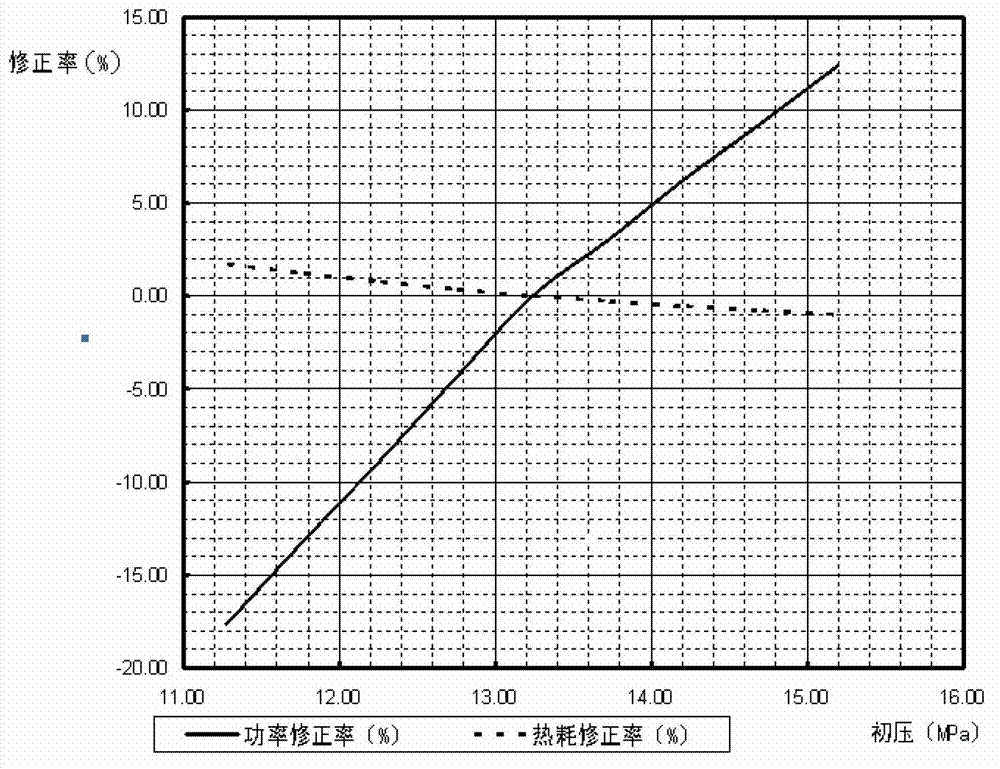

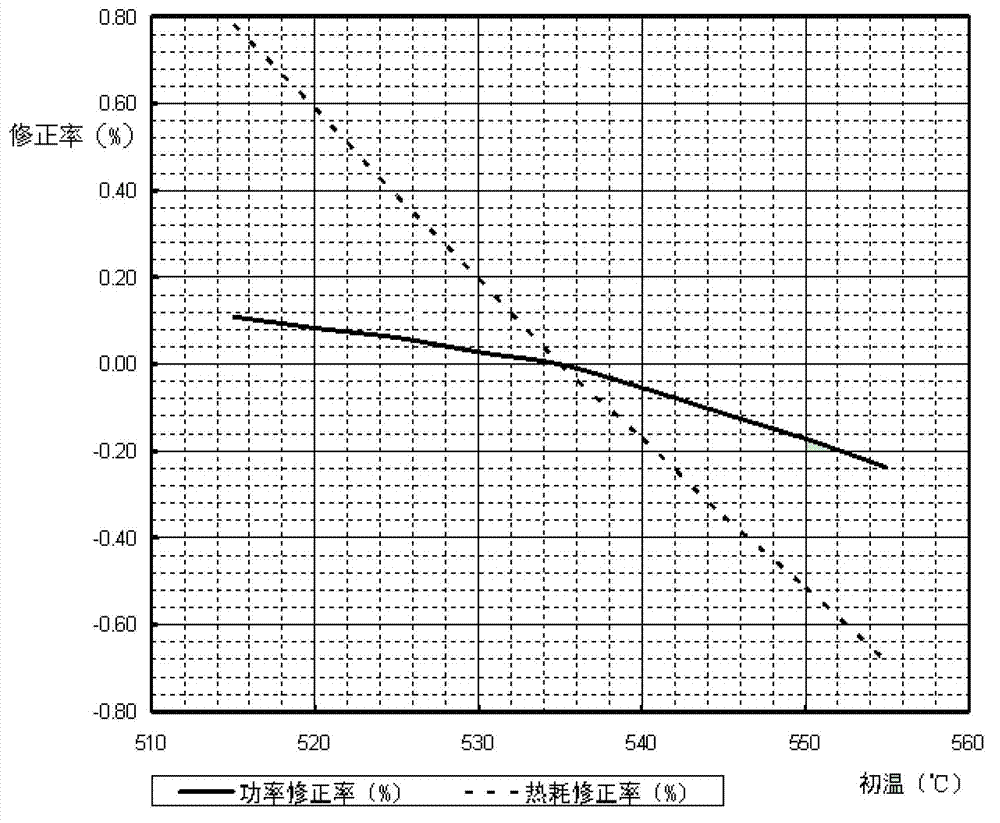

Method for evaluating performances of condensing steam turbine after high back pressure improvement

The invention discloses a method for evaluating performances of a condensing steam turbine after high back pressure improvement. The method comprises the following steps: distributing sufficient pressure, temperature, flow and electric power test points on a thermodynamic system of a turbine unit; stopping heating steam extraction on a low pressure cylinder gap bridge pipe; calculating the main steam flow, the cold reheat steam flow and the reheat steam flow; calculating the low pressure cylinder efficiency of a unit; taking a high back pressure heat supply unit as a pure condensing unit running under a high back pressure working condition, calculating the heat loss efficiency of the unit, and performing the second-type correction on the heat rate; and comparing the heat rate and the lower pressure cylinder efficiency with design values of a manufacture plant, and evaluating the lower pressure cylinder improvement technology and the unit improvement effect. The method disclosed by the invention is easy and feasible.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

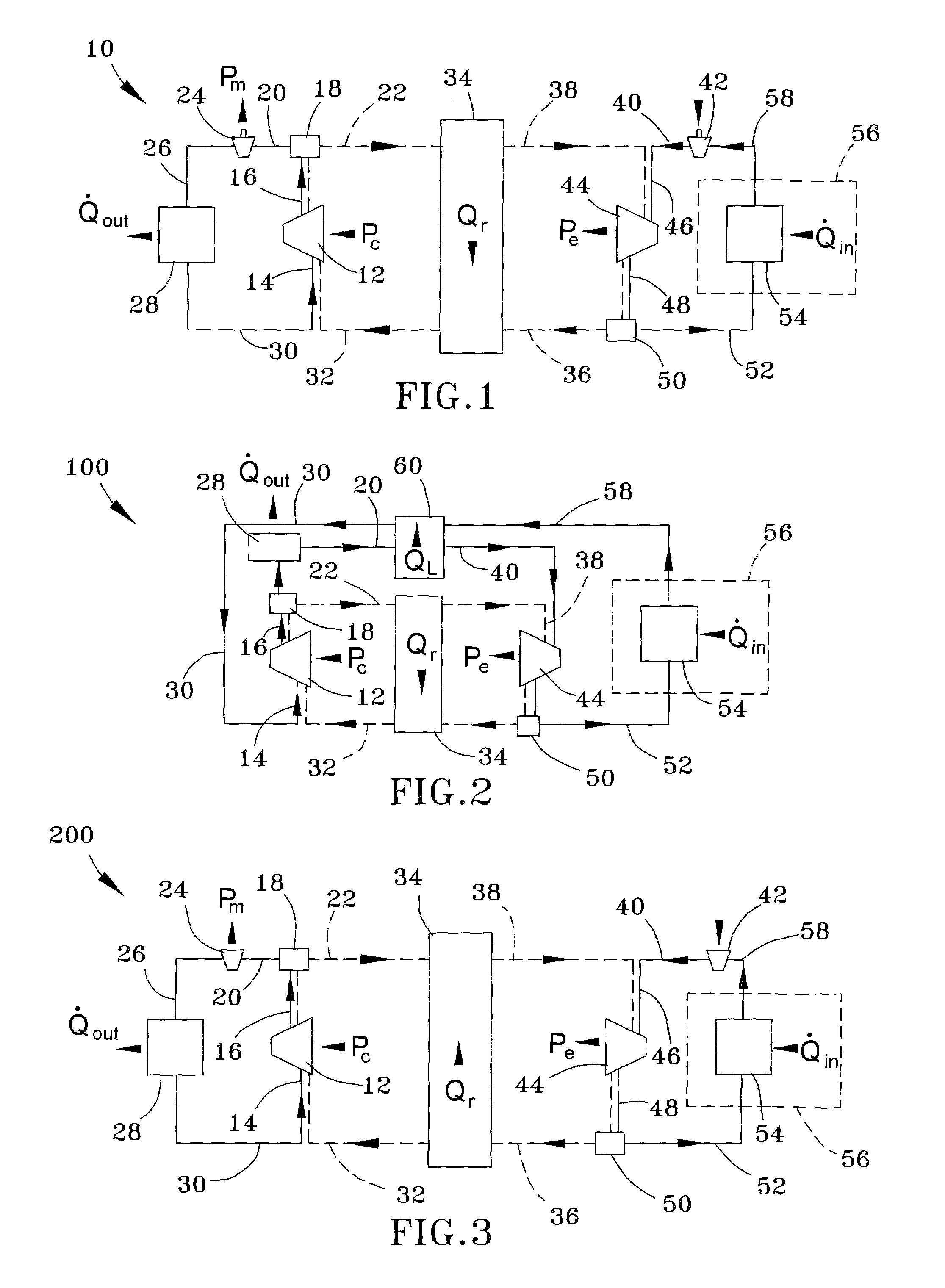

Thermodynamic systems operating with near-isothermal compression and expansion cycles

InactiveUS20070074533A1Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleEngineering

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

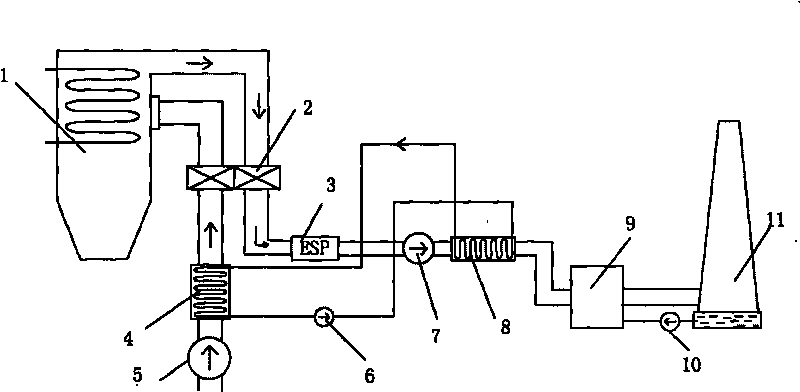

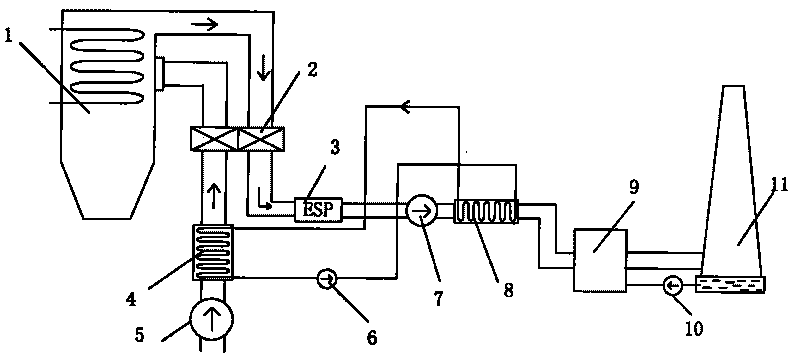

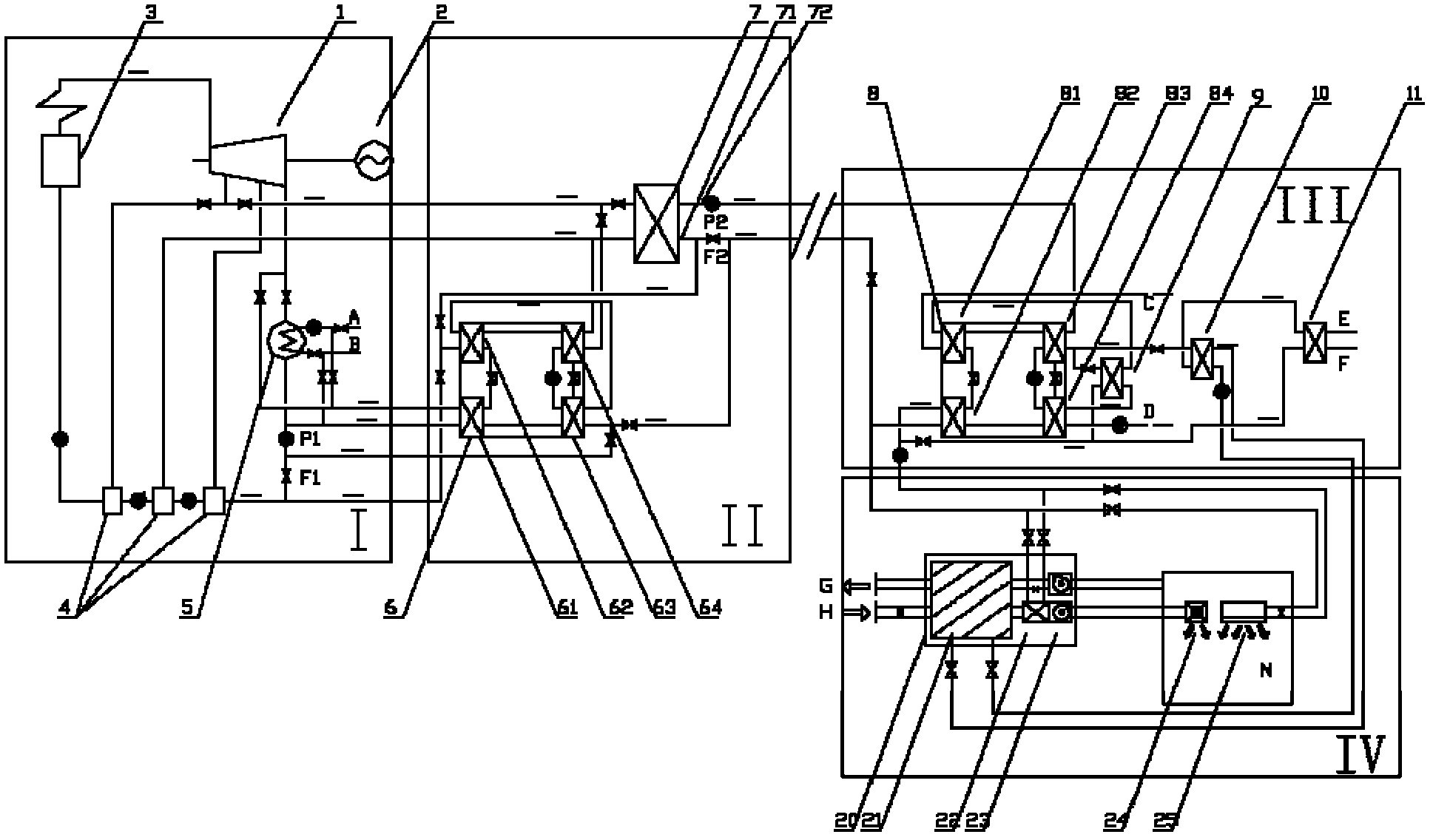

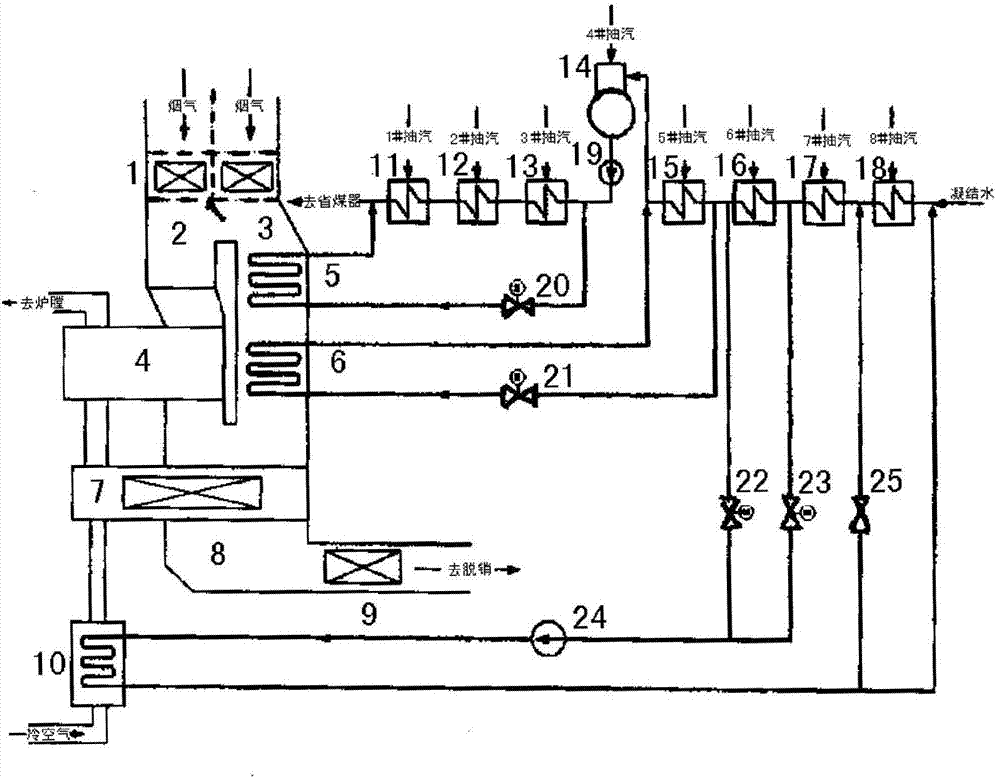

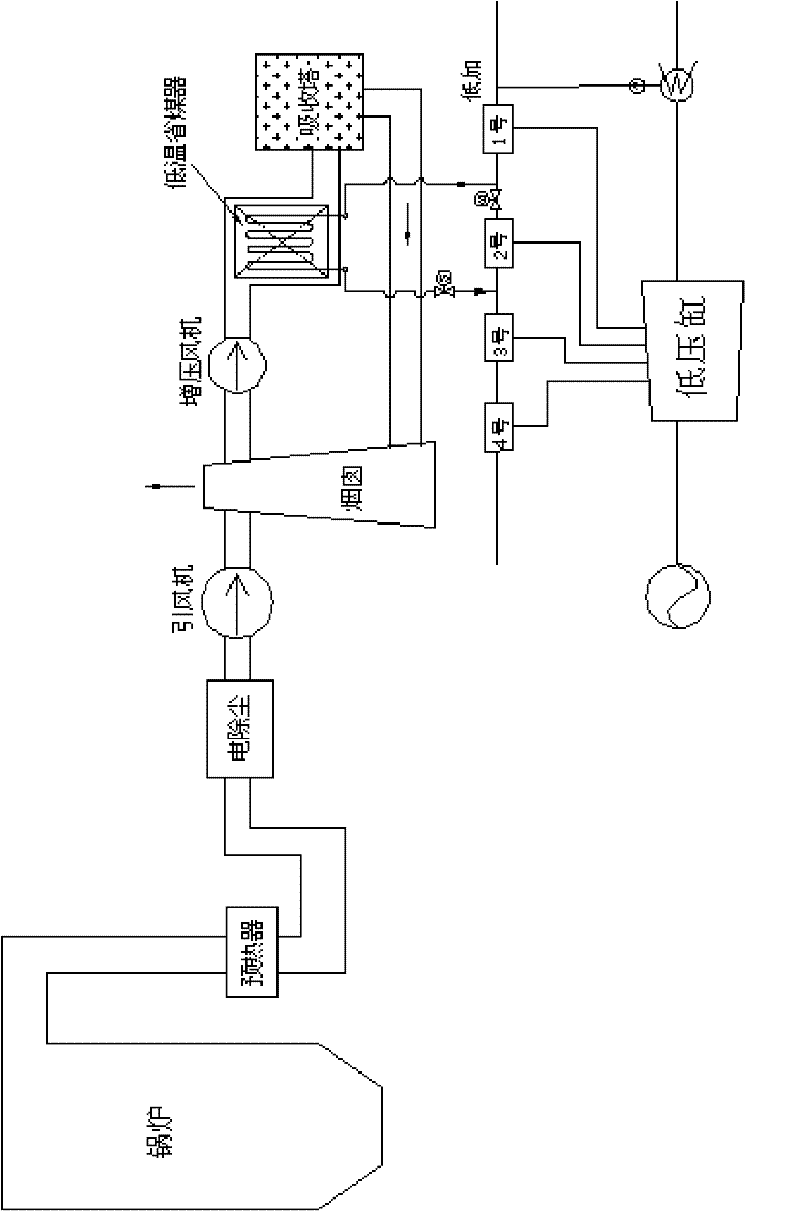

System for deep cooling and waste heat recovery of smoke gas in boiler

ActiveCN101709879AGreat effortDoes not affect normal operationCombustion processIndirect carbon-dioxide mitigationEngineeringWater circulation

The invention relates to a system for deep cooling and waste heat recovery of smoke gas in a boiler with an independent operating system, which comprises a smoke gas deep cooler, an air heater and an independent water circulation system comprising the smoke gas deep cooler and the air heater. The smoke gas of which the dust is removed by an electrostatic dust remover is used for heating the cold water in the smoke gas deep cooler to recover the waste heat of the exhausted smoke, and the hot water at the outlet of the smoke gas deep cooler is transferred to the air heater for preheating the air, thereby increasing the temperature of the combustion-supporting air in the boiler; after the smoke gas passes through the smoke gas deep cooler, the smoke gas is directly introduced into a desulfurizing tower for desulfurization and recovery processing; and finally, the smoke gas is exhausted through a wet chimney. The system of the invention does not need to change the traditional thermodynamic system of the machine unit, and the long-period safe operation of the system can not be influenced in the process of recovering the waste heat of the smoke gas, thereby lowering the temperature of the exhausted smoke, saving the desulfurization water consumption, improving the machine unit efficiency and increasing the machine unit output.

Owner:XI AN JIAOTONG UNIV +1

High efficiency positive displacement thermodynamic system

ActiveUS20100050628A1Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

Thermodynamic systems operating with near-isothermal compression and expansion cycles

InactiveUS7401475B2Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleProduct gas

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

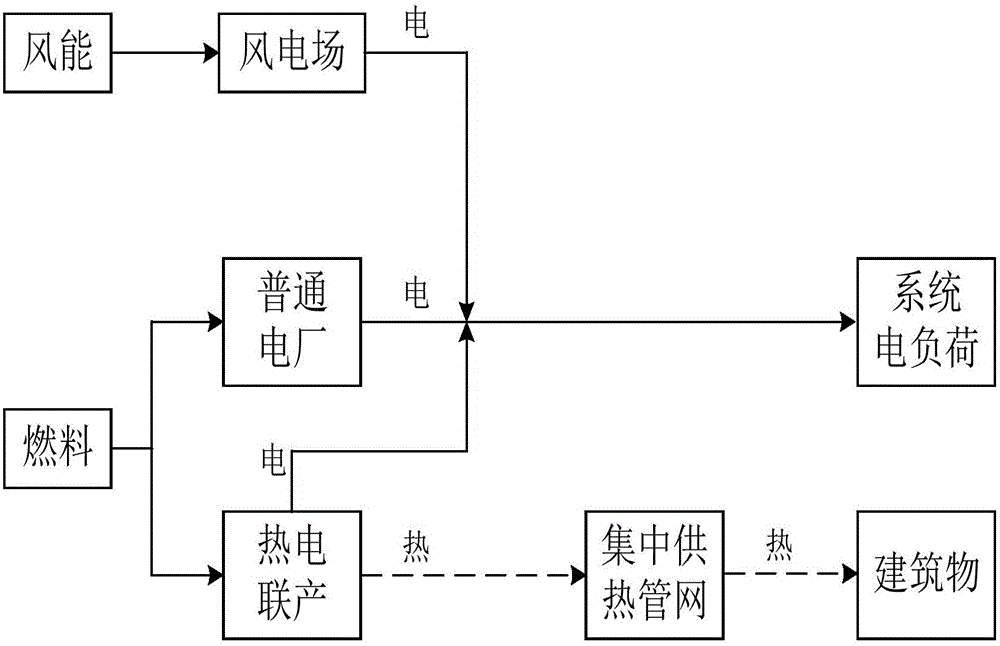

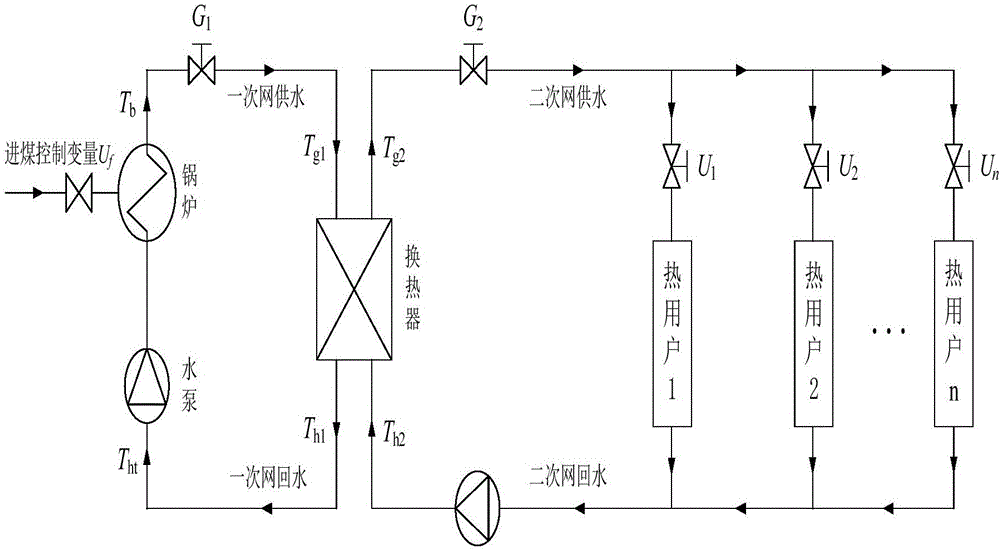

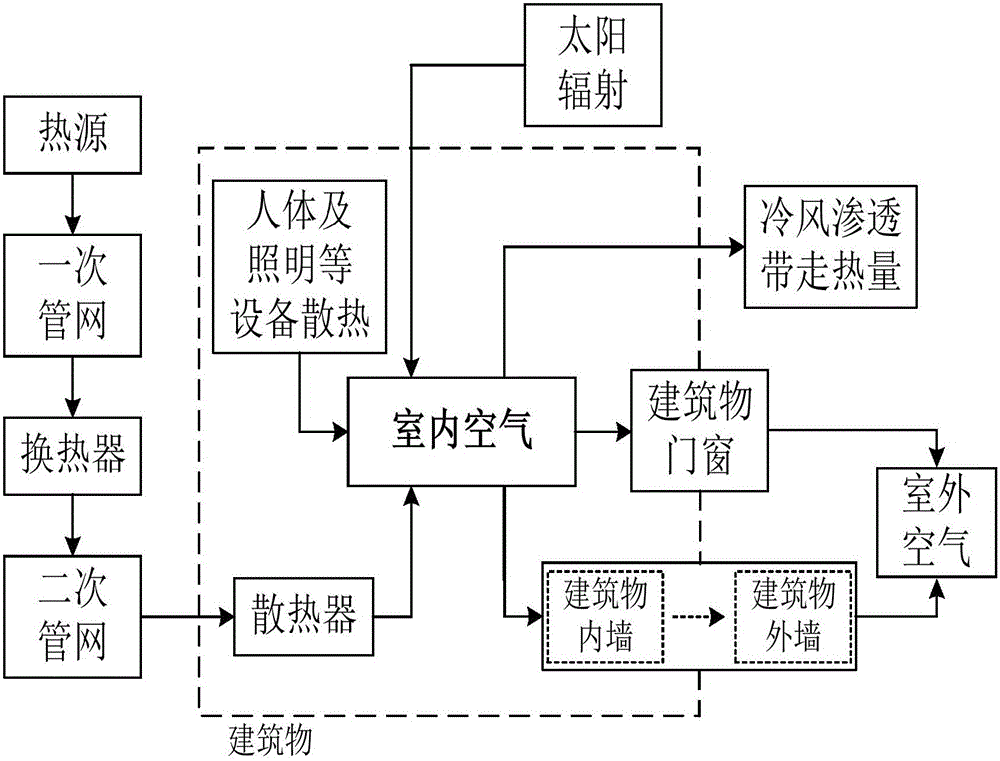

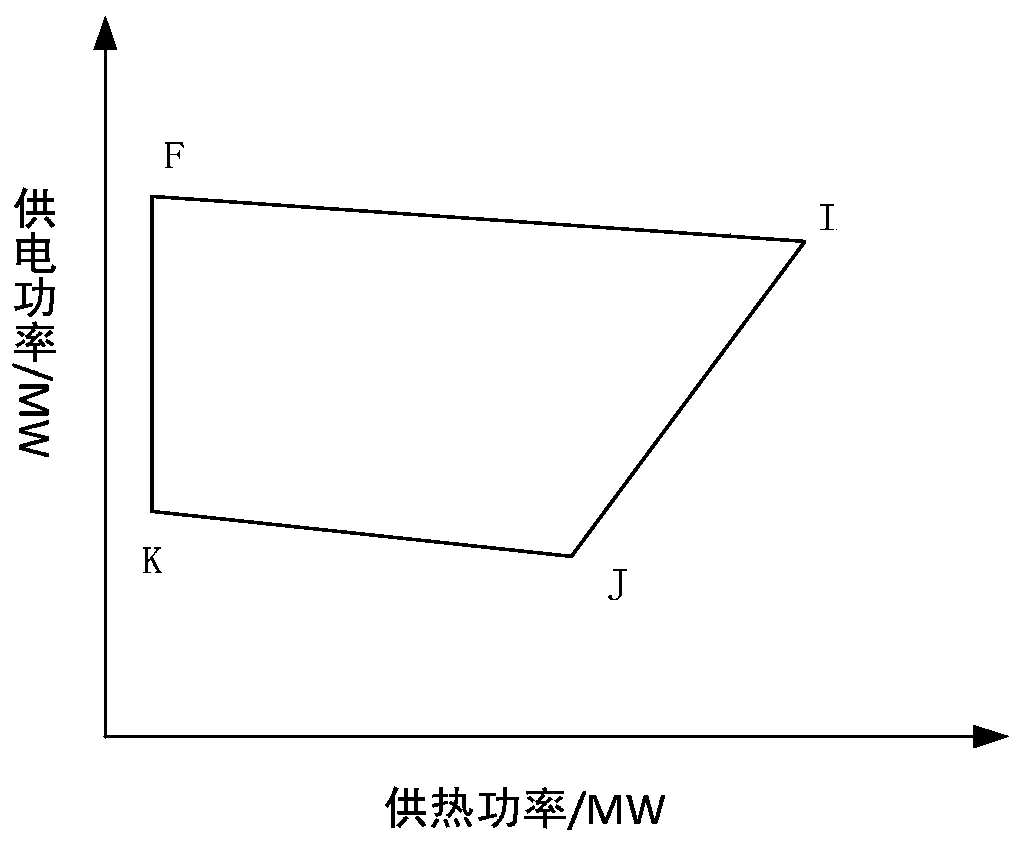

Thermoelectric combined system scheduling method for achieving wind power absorption based on energy storage of centralized heat supply pipe network and buildings

InactiveCN105807633AImprove peak shaving flexibilityAchieve interactionSimulator controlThermal energyElectric power system

The invention discloses a thermoelectric combined system scheduling method for achieving wind power absorption based on energy storage of a centralized heat supply pipe network and buildings.The thermoelectric combined system scheduling method includes the following steps that S1, a wind power absorption thinking based on energy storage characteristics of the centralized heat supply pipe network of a thermoelectric combined system and the buildings is proposed; S2, thermal dynamic characteristics of the centralized heat supply pipe network and the buildings are analyzed; S3, a thermoelectric combined system optimization scheduling model is established based on the energy storage characteristics of the centralized heat supply pipe network and the buildings; S4, coordinative optimization is conducted on hour-by-hour power supply of energy supply bodies of a power system and a thermodynamic system in the thermoelectric combined system according to the solution to obtain an optimal control strategy for achieving in-regional wind power absorption and cross-regional wind power coordinative absorption.The method can change an original local wind power absorption mode, integrates the characteristics that electric energy is easy to transmit and is not easy to store and heat energy is easy to store but is not easy to transmit and achieves the purposes of wide-area interaction between wind power and thermal power and wide-area wind power absorption.

Owner:DALIAN UNIV OF TECH

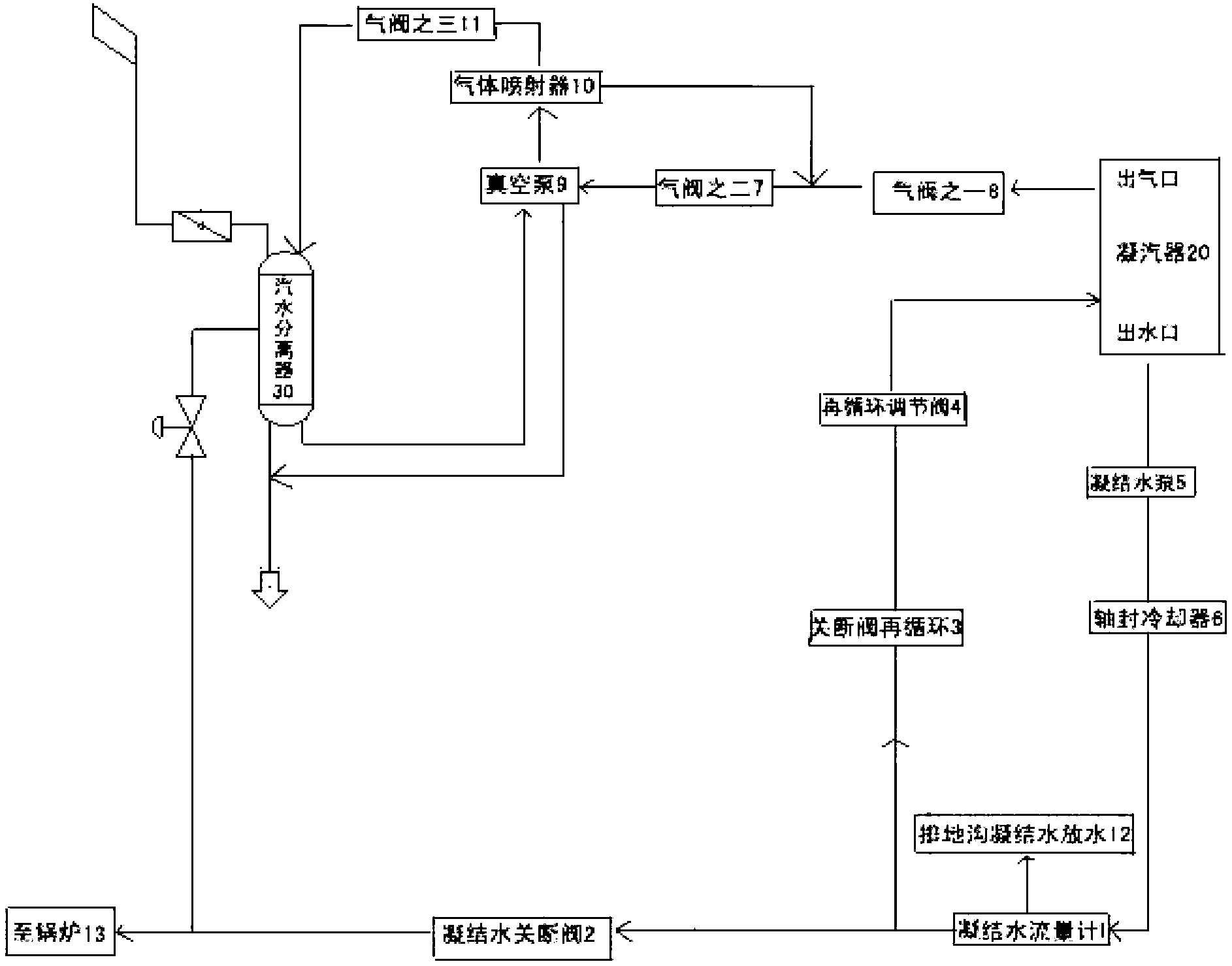

Quick start method and system of combined cycle unit

InactiveCN102997215ASimple structureImprove operating economyBoiler controlOperation modeEngineering

The invention relates to a quick start method and system of a combined cycle unit, which mainly detect and control the PH value of the condensed water by controlling the dissolved oxygen in the water and steam of a thermodynamic system and controlling the dissolved oxygen corrosion according to the relationship among temperature, pressure and content of dissolved oxygen of water and steam, by setting the content of dissolved oxygen in the condensed water to be less than or equal to 50microgram / L and by setting the content of dissolved oxygen in the water feed to be less than or equal to 15microgram / L, and adopts the combined deoxygenization manners of condenser vacuum deoxygenization and chemical dosing deoxygenization, and optimized operation mode and maintenance mode to ensure that the oxygen content in the condensed water in the combined cycle unit reaches the standard so as to avoid oxide etch of the metal due to that the oxygen content in the condensed water of the unit is excessive. The quick start system used for the combined cycle unit comprises a condenser; the water outlet of the condenser is connected with the input end of a condensed water flow meter through a condensed water pump and a shaft-sealing cooler; one loop of the outlet end of the condensed water flow meter is communicated with a boiler of the combined cycle unit through a condensed water cut-off valve, and the other loop is connected with a water return port of the condenser through a recycle cut-off valve and a recycle control valve; and a steam outlet of the condenser is connected with a vacuum pump through an air valve. The quick start method and system have the advantages that the overall structure of the thermodynamic system is simplified and the reliability and the economical efficiency of the system are improved.

Owner:SHENZHEN GUANGQIAN ELECTRIC POWER

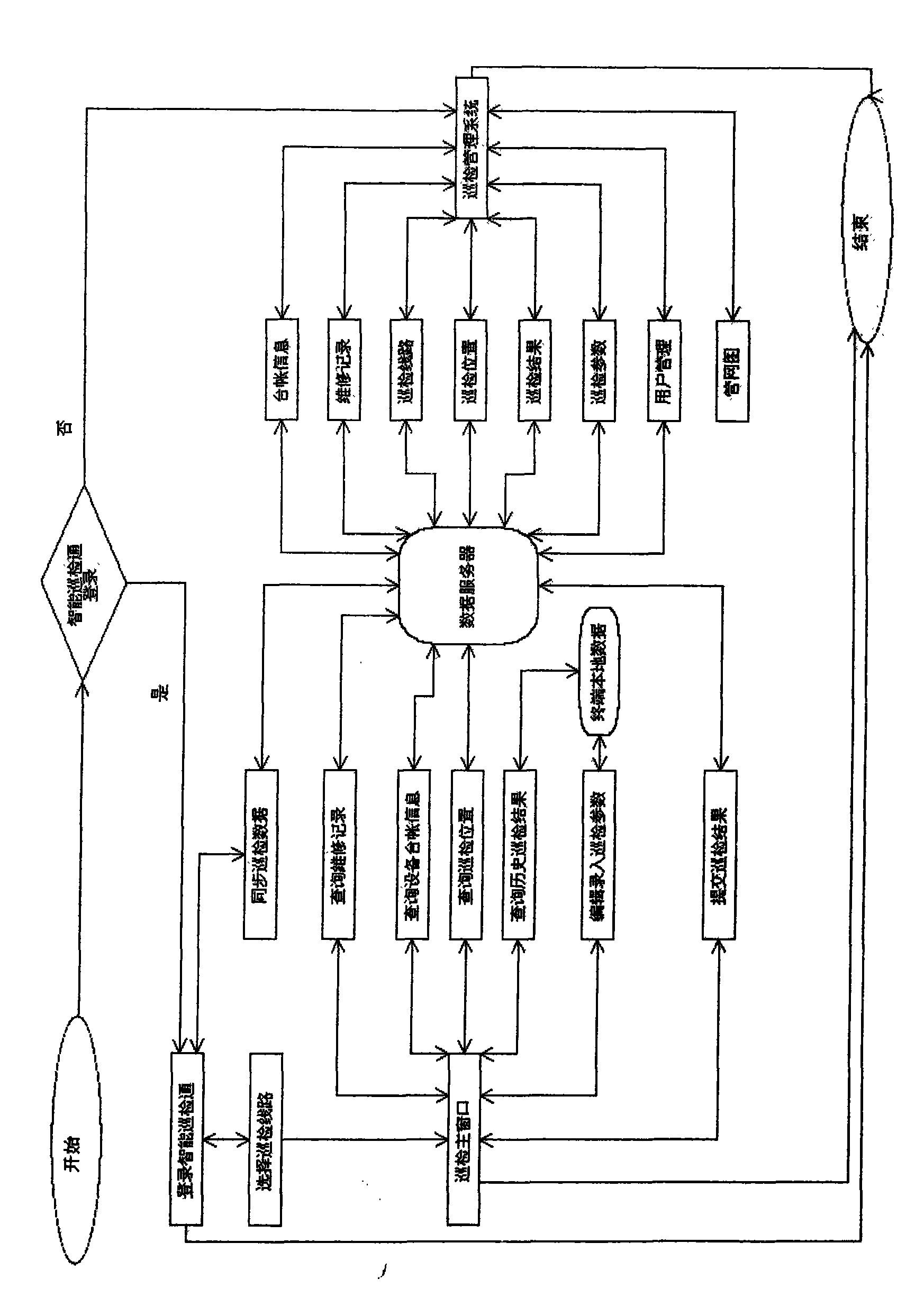

Method for examining and managing thermodynamic system

InactiveCN101540069ADiscover hidden dangers in timePrevent breakdowns and even accidentsChecking time patrolsChecking apparatusReverse orderJob number

The invention relates to a method for examining and managing a thermodynamic system, which comprises the following main steps: scanning information of an examiner, inquiring records of an examining spot, inquiring an examining route, inquiring an examining position and equipment and recording data. Firstly, the information of a job number or a bar code of a working card of the examiner is scanned by a bar code scanner; secondly, the history records of the examining spot are inquired, if no examining spot is found, a prompting message is given, and if the examining spot is found, parameter details are displayed according to a reverse order mode of examining time; thirdly, the examining route is inquired, and the examined examining position is displayed on a display screen; fourthly, the examining position and the equipment are inquired; and finally, a bar code of the examining position is scanned by the bar code scanner to record the data. The invention has simple principle, safe and reliable operation, high degree of automation and wide application range.

Owner:青岛能源热电集团有限公司 +1

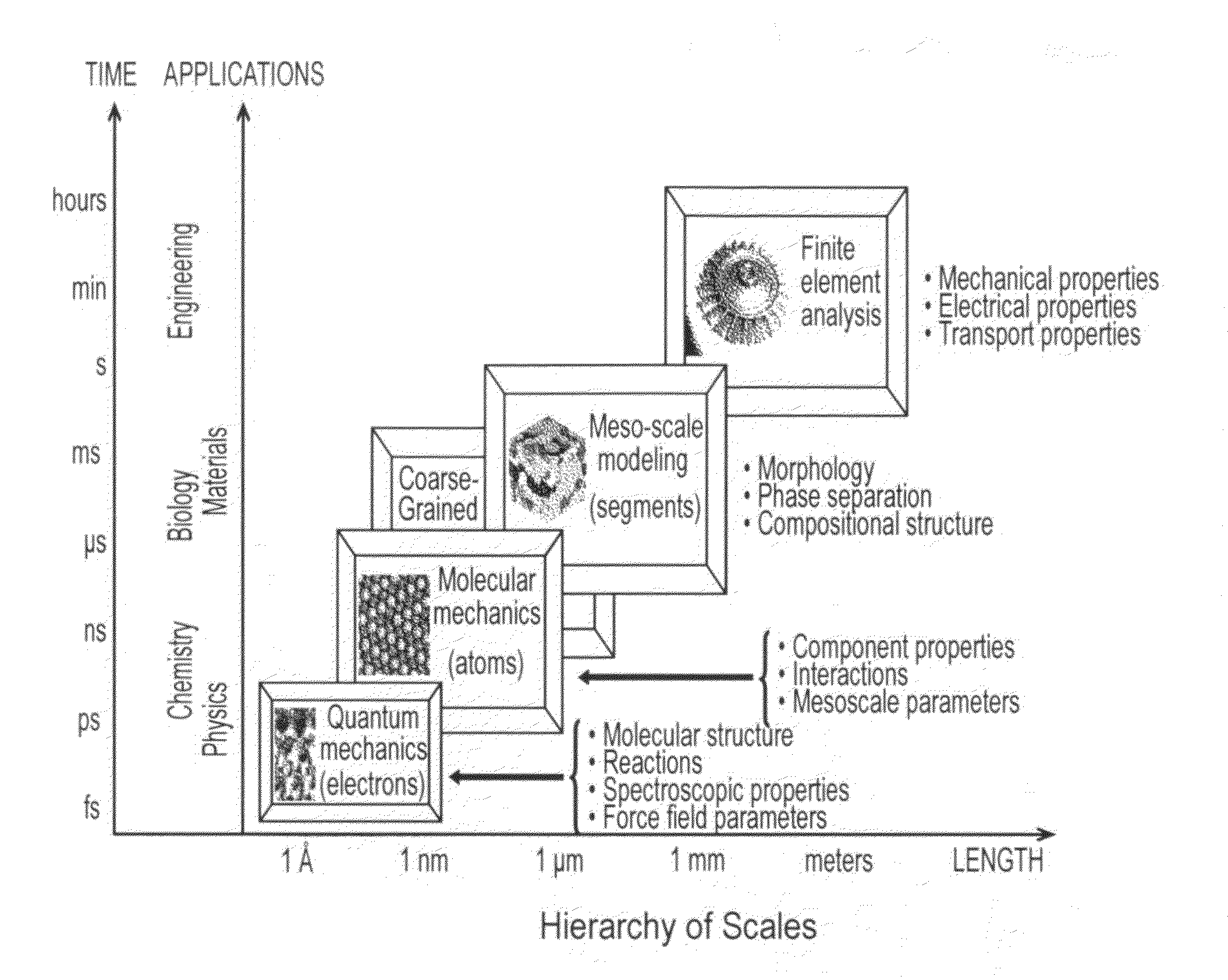

Method, apparatus and computer program for simulating behaviour of thermodynamic systems

ActiveUS20100030534A1Fast convergenceIncrease acceptance rateComputation using non-denominational number representationDesign optimisation/simulationMomentumLinearity

A method and system thereof for simulating behaviour of a thermodynamic system over time, including a momentum refreshment process and a conservative dynamics process, where the momentum refreshment process includes partially refreshing a momentum to define refreshed momentum by considering solutions for a starting momentum determined by a numerical implementation for integrating a generating linear differential equation.

Owner:FUJITSU LTD

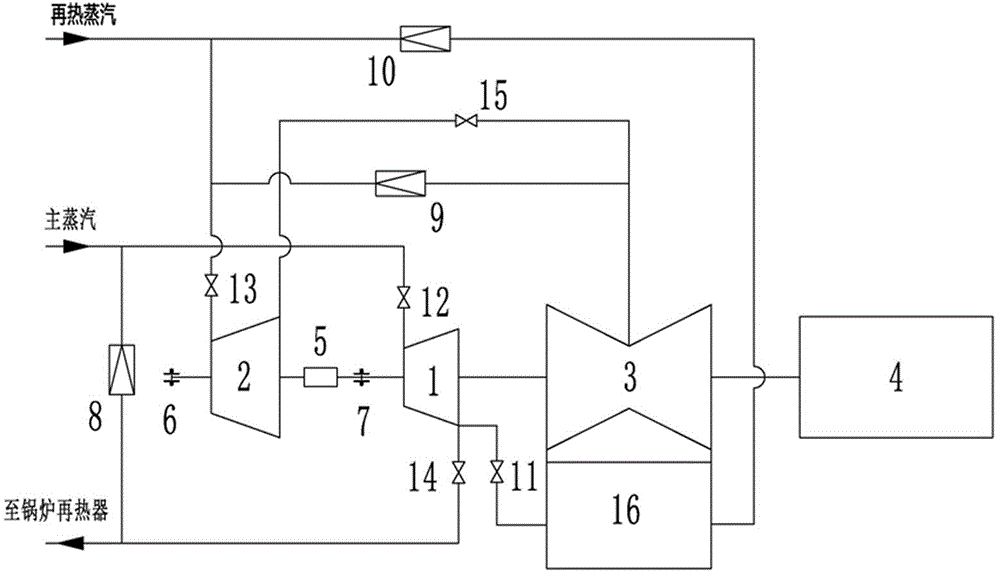

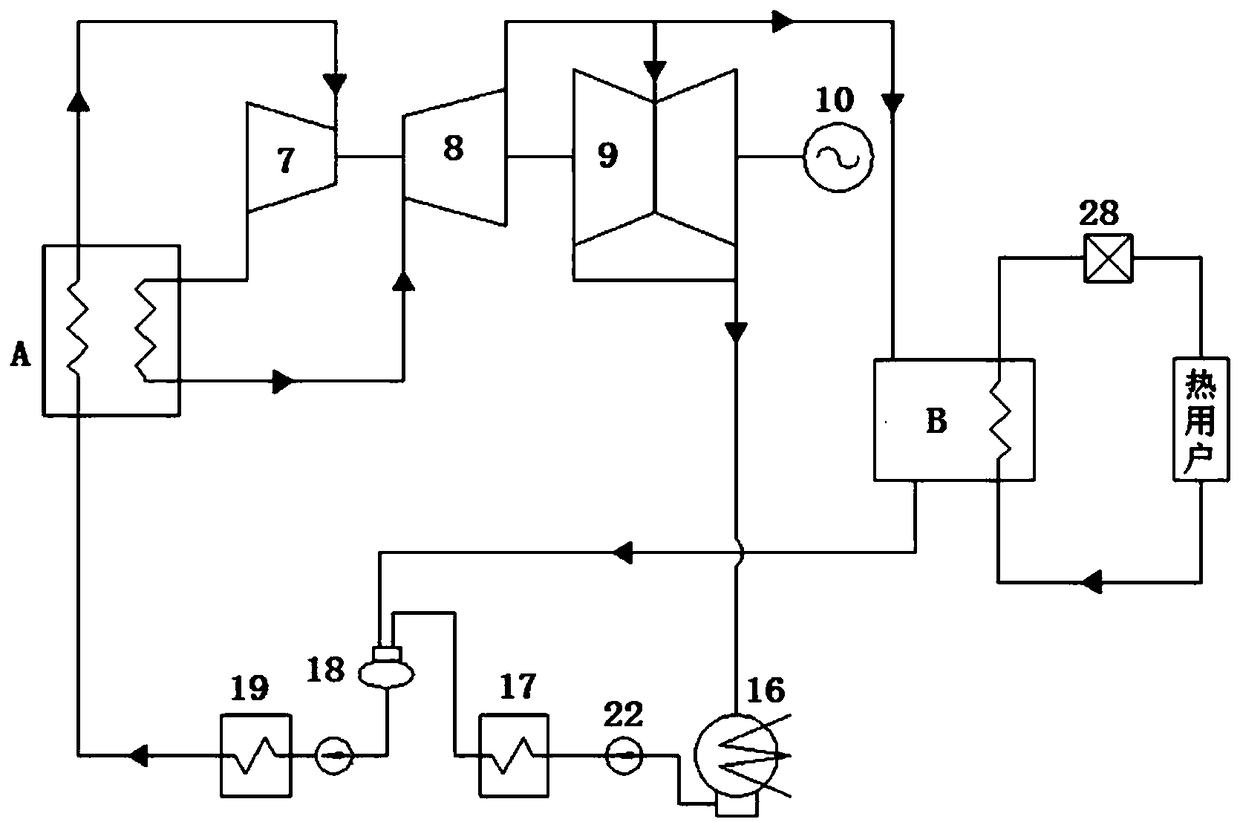

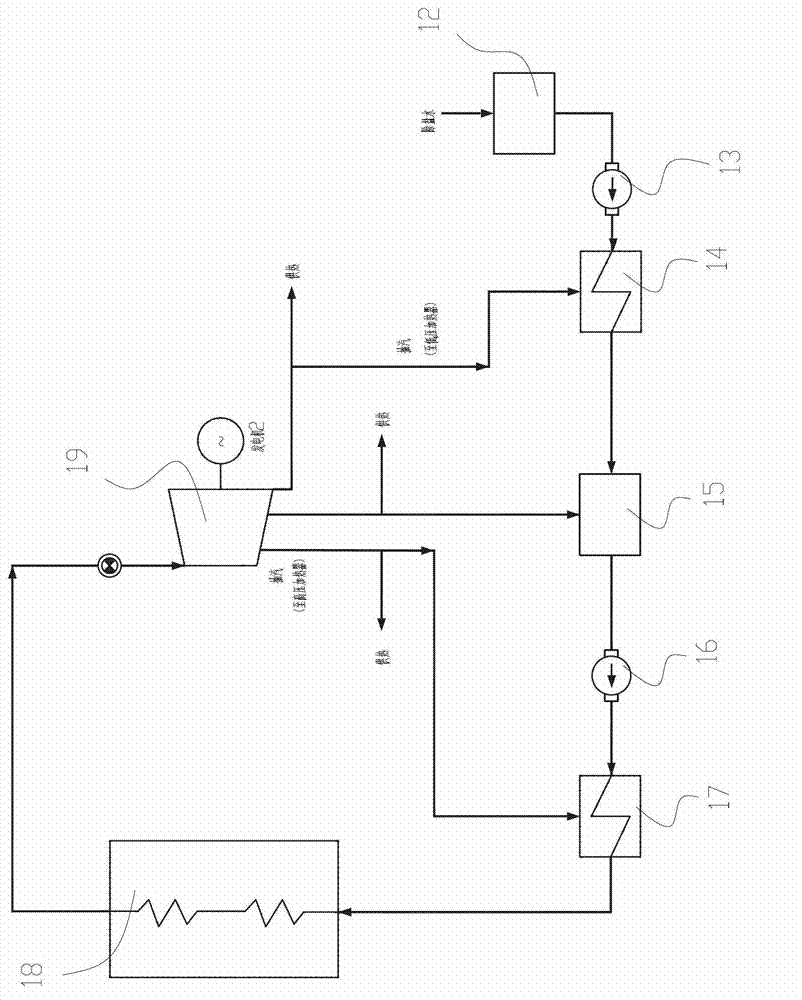

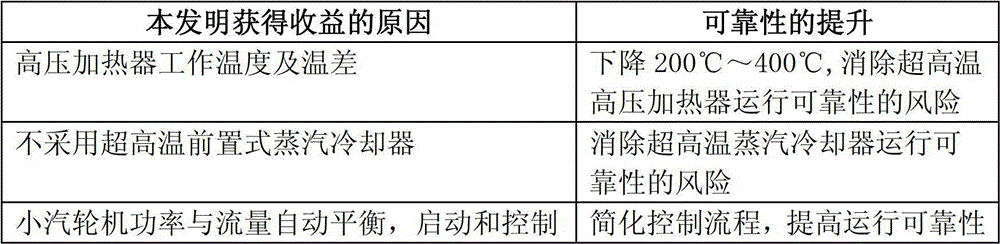

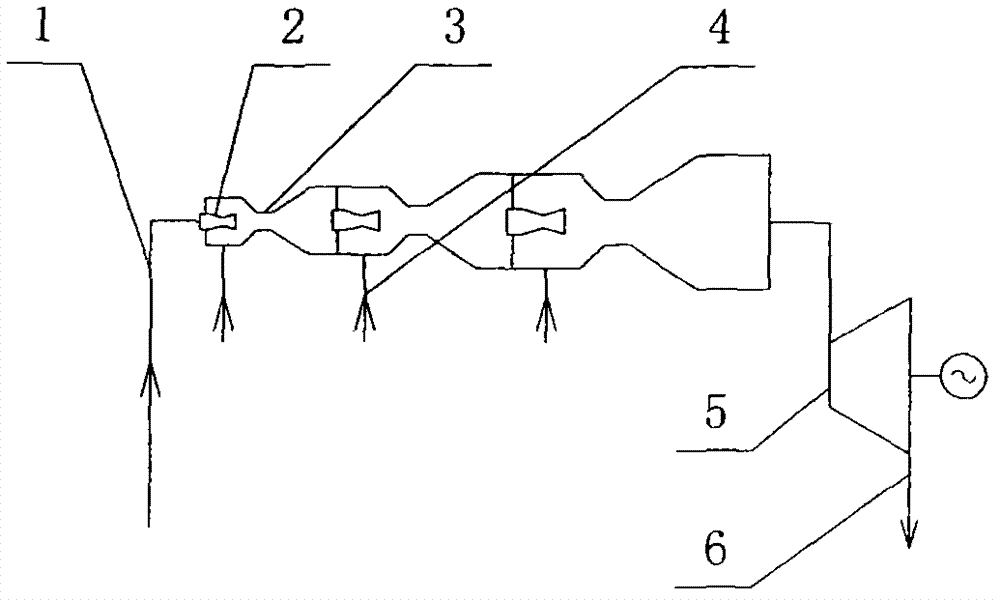

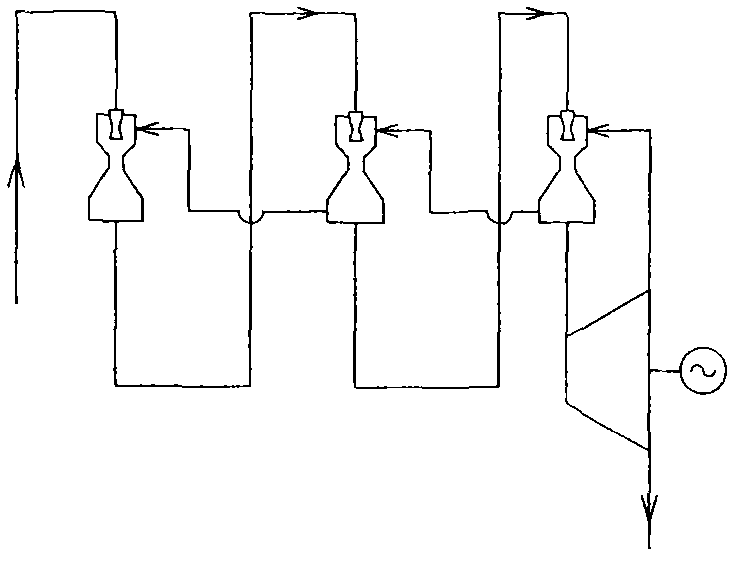

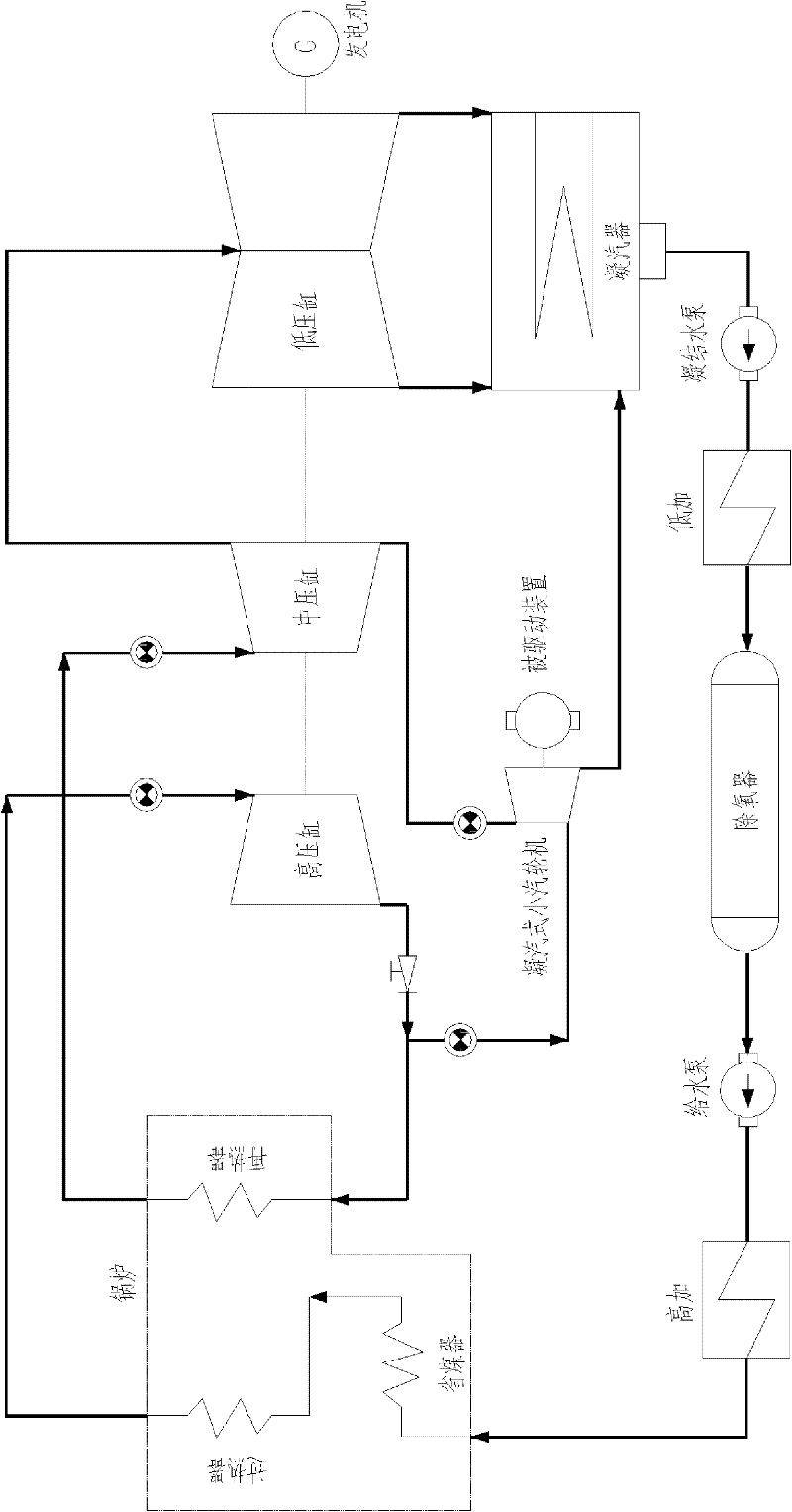

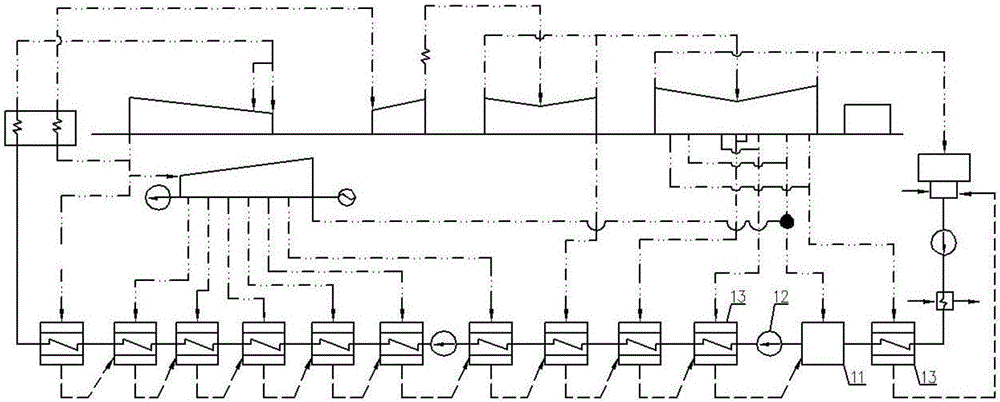

Double-turbine steam thermodynamic system with regenerative steam extraction function

InactiveCN103195521AImprove flow efficiencyReduce axial sizeSteam useCombined combustion mitigationEngineeringDeaerator

The invention provides a double-turbine steam thermodynamic system with a regenerative steam extraction function. The double-turbine steam thermodynamic system comprises a large steam turbine, a small steam turbine and a regenerative cycle unit. The regenerative cycle unit comprises one or a plurality of high-pressure heaters, one or a plurality of medium-pressure heaters, one or a plurality of low-pressure heaters and two deaerators, and a water circulating pipeline is communicated with a boiler via the low-pressure heaters, the low-pressure deaerator, the medium-pressure heaters, the high-pressure deaerator and the high-pressure heaters sequentially. The double-turbine steam thermodynamic system with the regenerative steam extraction function has the advantages that medium-pressure cylinders of the large steam turbine do not need to be provided with steam extraction openings for regenerative steam extraction owing to the double-deaerator structure, medium-pressure cylinder structures of the large steam turbine are greatly simplified, the axial dimension of an integral unit is reduced, and the through-flow capacity of the large steam turbine is improved; and sufficient flow and sufficient power for the small steam turbine can be guaranteed, a complicated logic balance system for the power of the small steam turbine is omitted, and accordingly the integral system is simple and reliable.

Owner:SHANGHAI TURBINE

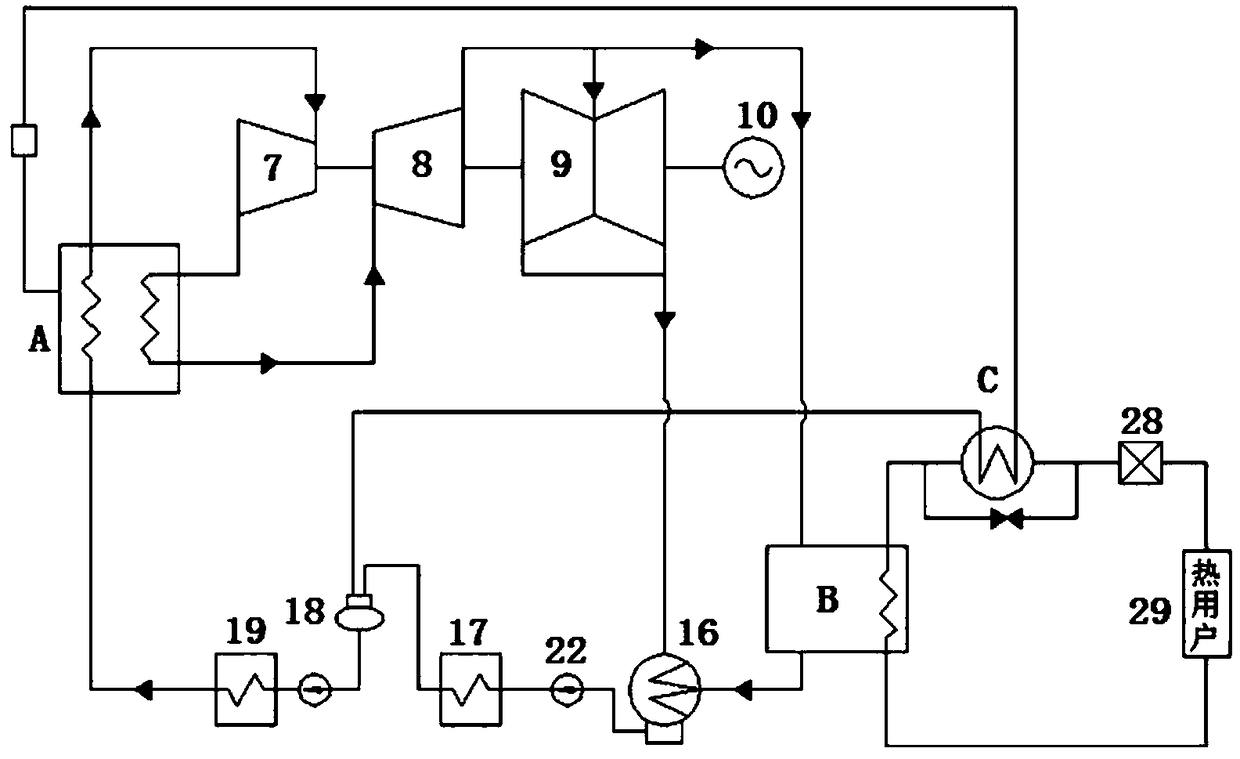

Regional heating, cooling and power combined energy system and method based on absorption heat exchange

ActiveCN102331110ABest Energy Saving AdjustmentLow recovery temperatureEnergy efficient heating/coolingClimate change adaptationEngineeringThermal water

The invention relates to a regional heating, cooling and power combined energy system and method based on absorption heat exchange. The system comprises four parts of equipment and is formed by connecting energy transmission and distribution networks formed by pipes with various water pumps and valves; the four parts of equipment are respectively a heat and power plant steam turbine power generation circulation sub system, an absorption dead steam afterheat recycling sub system, an absorption heat exchanging station / energy center and a distributed or semi-centralized air conditioner water heating sub system, wherein the heat and power plant steam turbine power generation circulation sub system is arranged on a thermal power plant and used for generating power and supplying heat; the absorption dead steam afterheat recycling sub system is arranged at an initial station of the thermal power plant and used for increasing the heat supplying and power generating efficiency by using the afterheat; the absorption heat exchanging station / energy center is arranged in a secondary network thermal substation and cold supply station; and the distributed or semi-centralized air conditioner water heating sub system is arranged at the user building and provided to the heat supply / air conditioner user. The method comprises three parts of operation regulation in a heating stage in winter, operation regulation in a cold supply stage in summer and operation regulation in a transitional stage beyond the two stages. According to the invention, the comprehensive energy utilization efficiency of a thermodynamic system can be effectively improved.

Owner:SHENYANG HUAYU GROUND SOURCE HEAT PUMP HEATING

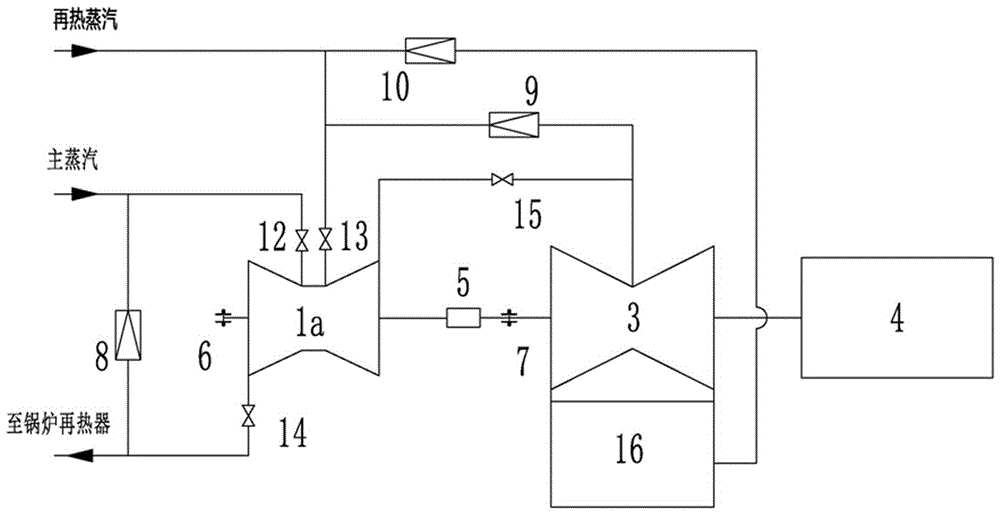

Turbine with deep peak regulation function and thermodynamic system

The invention relates to the field of thermal power generation, in particular to a turbine with a deep peak regulation function and a thermodynamic system. The turbine comprises an intermediate-pressure cylinder, a synchronous automatic clutch, a high-pressure cylinder, a low-pressure cylinder, an intermediate-pressure by-pass valve and the like, wherein the intermediate-pressure cylinder, the synchronous automatic clutch, the high-pressure cylinder and the low-pressure cylinder are connected with one another through a coupler and connected with a power generator through the output end of a low-pressure rotor. During deep peak regulation of a unit, a high-pressure steam inlet regulation valve and an intermediate-pressure steam inlet regulation valve are closed, the intermediate-pressure cylinder is cut off through the synchronous automatic clutch, the high-pressure cylinder is vacuumized through a vent valve, a high-pressure by-pass valve and the intermediate-pressure by-pass valve of the unit are opened, steam from a boiler directly enters the low-pressure cylinder for acting, the unit is maintained to operate with low power output, and the purpose of deep peak regulation of the unit is achieved.

Owner:山西漳电科学技术研究院(有限公司) +2

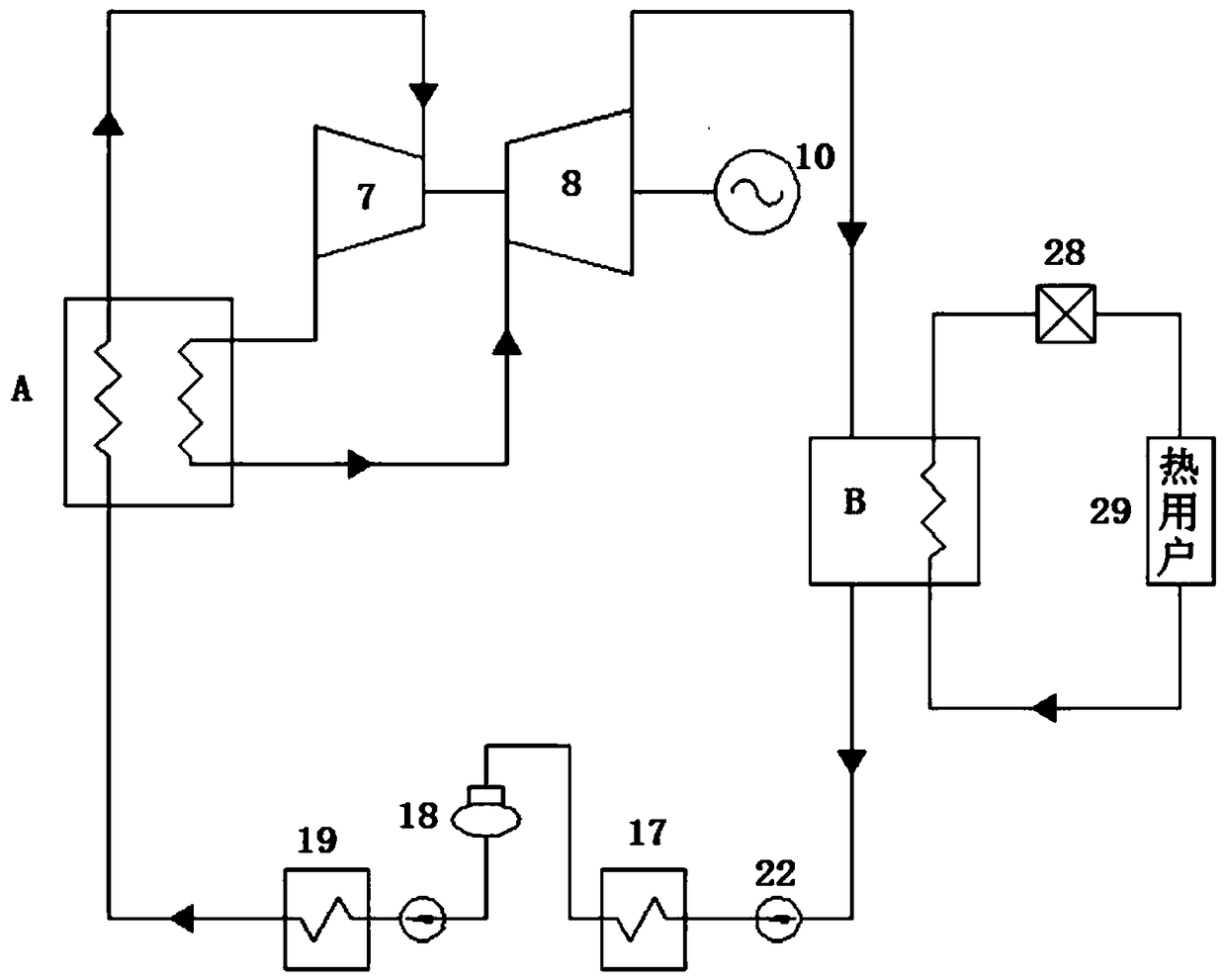

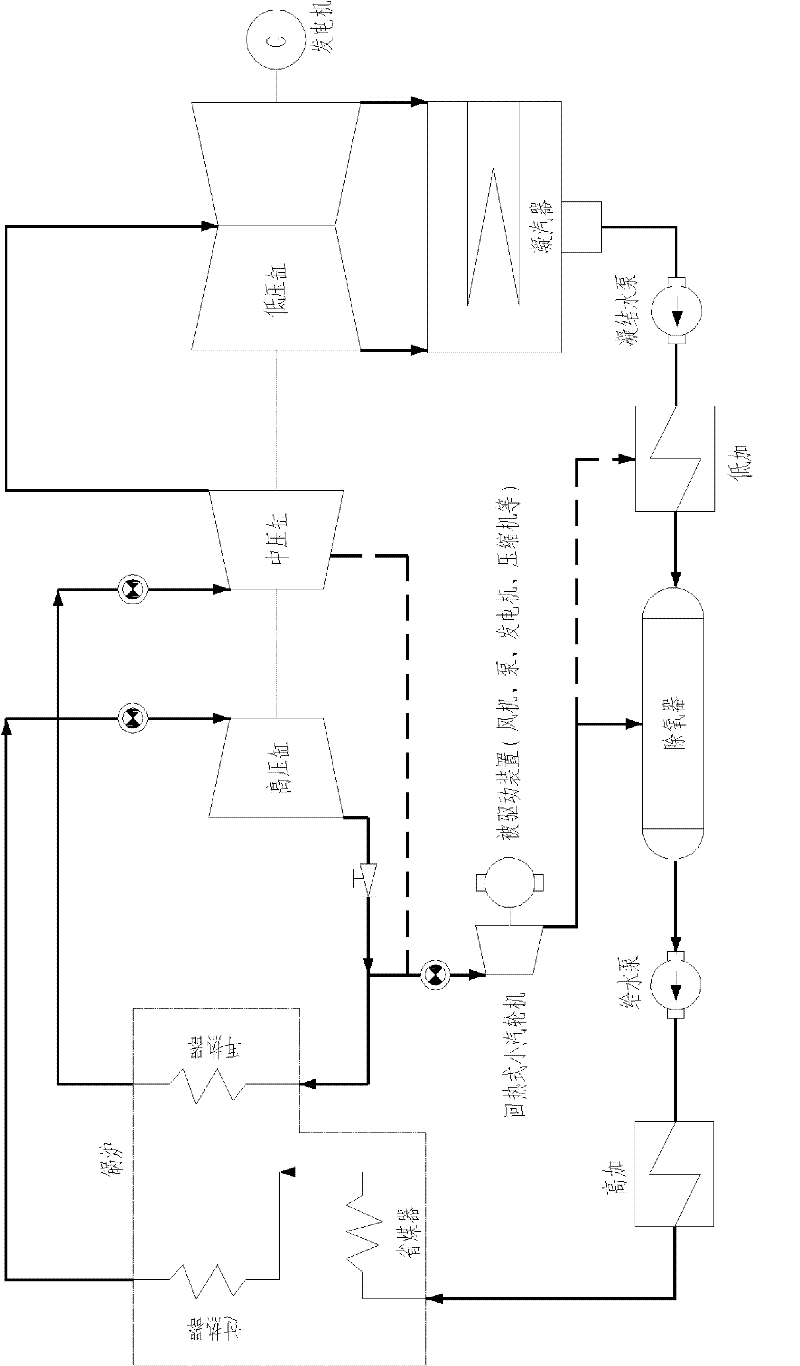

Thermodynamic system for improving heat supply unit electric output adjusting capacity

The invention relates to a thermodynamic system for improving heat supply unit electric output adjusting capacity. The thermodynamic system is characterized in that main steam or reheating section steam is subject to temperature and pressure reduction to directly serve as heat source steam for industrial heat users; an absorption heat pump 23 of a first-stage heat exchange device serves as a heatsource of a first-stage heat exchange station 25 in the heating period to supply heat to heat users 29 and supplies cold to the users in the non-heat supply period; a high-pressure electric boiler 24of a second-stage heat exchange device improves the boiler water feeding temperature, reduces heat absorbed by boiler fed water in an economizer 4, accordingly improves the boiler tail smoke discharging temperature, and guarantees normal running of an SCR denitration device 5; and according to a three-stage heat exchange device, exhaust steam of a turbine intermediate pressure cylinder 8 serves asheat source steam of a third-stage heat exchange station 27, the unit heat load is guaranteed, and the heat using requirement of the heat users 29 is met. The electric output adjusting capacity of the heat supply unit can be improved, it is guaranteed that the unit heat supply capacity is not decreased under the low load running working conditions, pyroelectric decoupling is achieved, and the electric output adjusting capacity of the heat supply unit is improved.

Owner:NORTHEAST DIANLI UNIVERSITY +2

Thermal power plant and united thermodynamic system for thermal power plant

ActiveCN102828791AImprove thermal cycle efficiencyReduce consumptionSteam useCombined combustion mitigationPollutant emissionsDeaerator

The invention discloses a thermal power plant and a united thermodynamic system for the thermal power plant. The thermal power plant comprises a secondary reheating coagulated steam unit and a backpressure unit; the united thermodynamic system comprises a thermodynamic system of the secondary reheating coagulated steam unit and the thermodynamic system of the backpressure unit; a reheating system from a condenser to a deaerator is shared by the thermodynamic system of the secondary reheating coagulated steam unit and the thermodynamic system of the backpressure unit; the condensed water of the secondary reheating coagulated steam unit and the replenished desalted water of the backpressure unit pass through the shared reheating system and then are divided into two paths; one path enters the secondary reheating coagulated steam unit; and the other path enters the backpressure unit. The united thermodynamic system provided by the invention can meet the industrial requirements of large capacity and high parameter heat supply; the thermodynamic cycle efficiency is greatly increased; the fuel consumption is reduced; the pollutant emission is reduced; and meanwhile, the investment of the thermal power plant is greatly reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

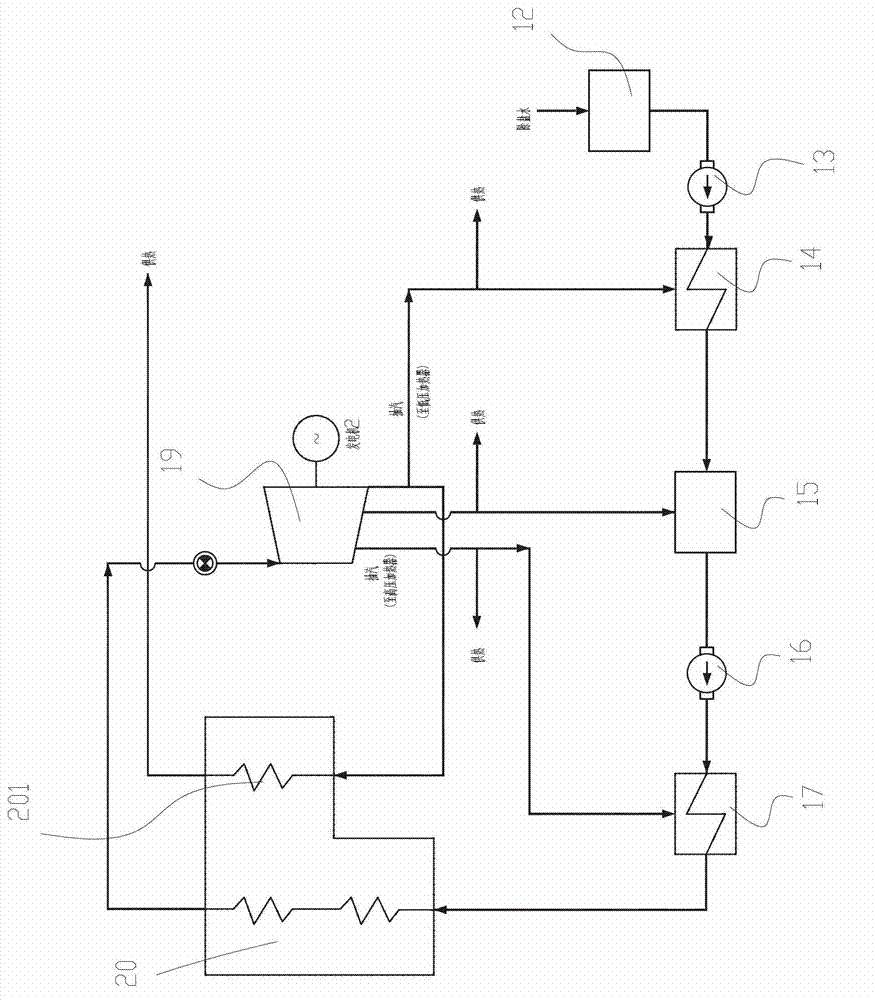

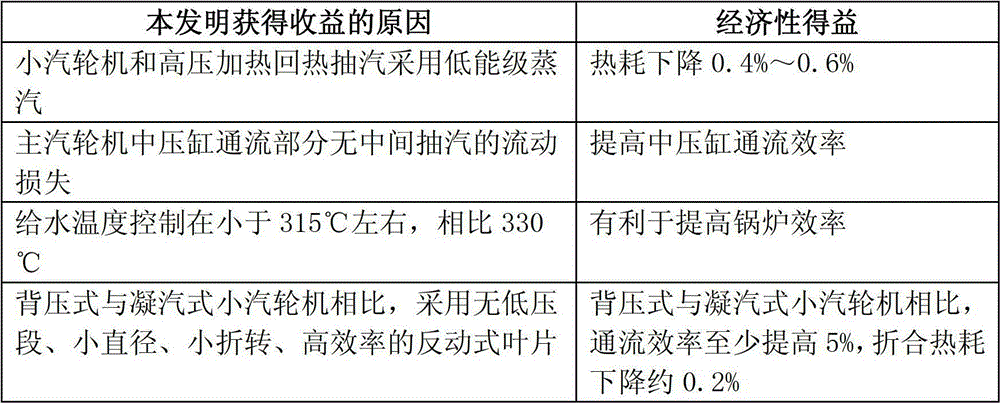

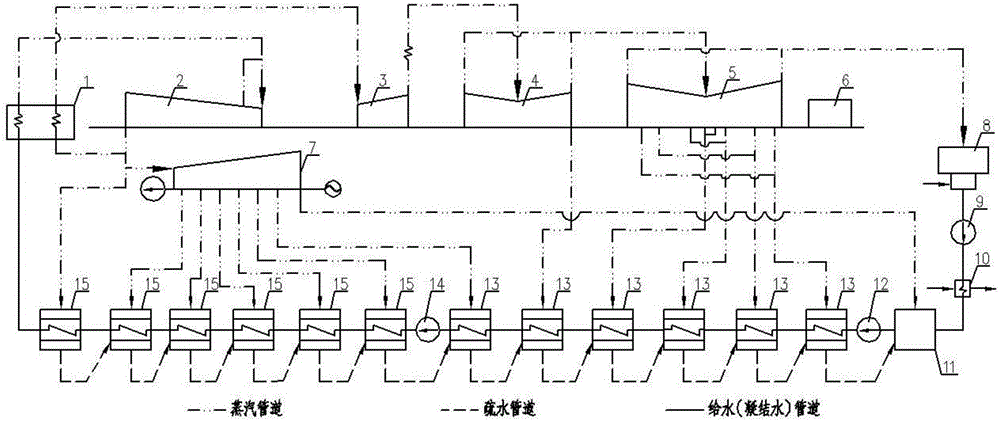

Dual-machine regenerative steam extraction steam thermodynamic system

ActiveCN102720550AReduce the temperatureImprove efficiencySteam useEnergy industryEngineeringIntermediate stage

The invention provides a dual-machine regenerative steam extraction steam thermodynamic system. In the system, the intermediate stage of a high pressure cylinder of a main steam turbine is provided with a high pressure steam extraction opening, the high pressure steam extraction opening is respectively connected with a steam inlet of a small steam turbine and one high pressure heater with the highest steam inlet parameter in a plurality of high pressure heaters through high pressure steam extraction pipelines, the intermediate stage of the small steam turbine is provided with a plurality of regenerative steam extraction openings which are connected with the rest high pressure heaters except the high pressure heater with the highest steam inlet parameter through regenerative steam extraction pipelines, and a steam exhaust port of the small steam turbine is connected with a deaerator through a steam exhaust pipeline of the small steam turbine. According to the system disclosed by the invention, a high-temperature preposed steam cooler can be omitted, and the feed-water temperature of a boiler is reduced, which helps to improve the efficiency of the boiler and reduce the heat consumption of a machine set; and flow loss can be effectively reduced, the circulation efficiency is improved, and the cost of equipment is reduced.

Owner:SHANGHAI TURBINE

Energy-saving method by adopting jetting exhausting in thermal process

InactiveCN102852567AAvoid direct contactSolve the problem of high parameter operation and low parameter emissionJet pumpsGas turbine plantsThermal energyWater quality

An energy-saving method by adopting jetting exhausting in a thermal process belongs to the field of heat power. A high-parameter power air source is adopted in order to improve thermal efficiency, a jetting exhausting thermodynamic system adopts a circulation exhausting mode, or an over-one-stage multistage jetting exhausting device adopts a mode combining series connection, parallel connection and circulation to form a composite jetting system, and the high-parameter air source enters the jetting exhausting system and a gas turbine to sufficiently act to achieve high-efficiency operation through a mode combining the heat-into-power conversion equipment such as the jetting exhausting system and the gas turbine. In addition, a jetting cooling scheme for reducing throttling loss is provided, the energy-saving method can be popularized to wide energy-saving fields such as various heat and power processes and seawater or other water quality thermal purification systems, and the energy-saving method is high in efficiency and low in cost.

Owner:张玉良

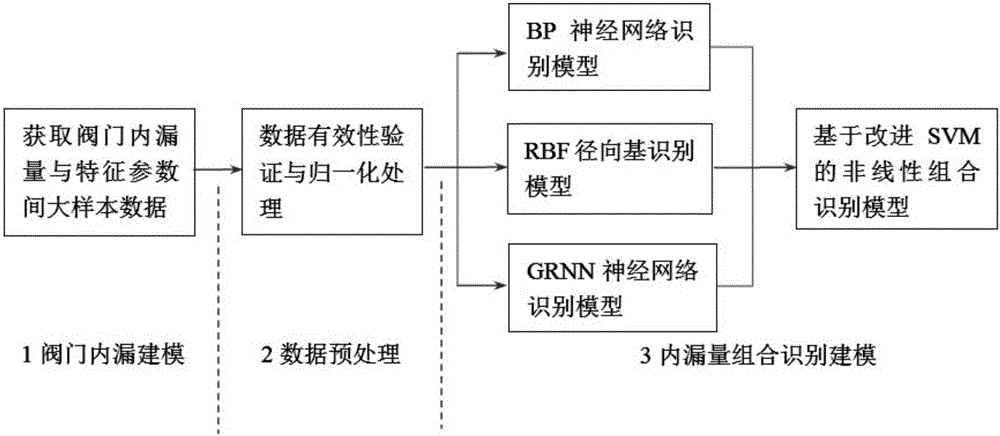

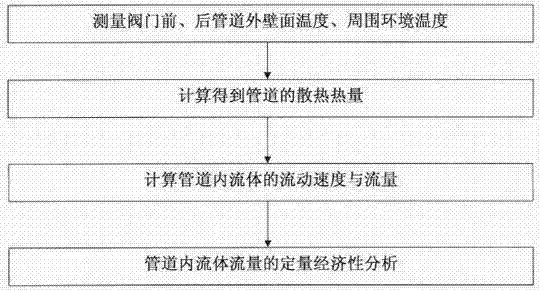

Thermodynamic system valve inner leakage monitoring method

InactiveCN106706215AImprove accuracyFluid-tightness measurementNeural architecturesEngineeringFeature parameter

The invention provides a thermodynamic system valve inner leakage monitoring method. The monitoring method comprises the steps that (1) valve inner leakage modeling is carried out to acquire sample large data between the valve inner leakage and a characteristic parameter; (2) data preprocessing is carried out to improve the learning precision and efficiency of a recognition model, and validity verification is carried out on sample large data between the valve inner leakage and the characteristic parameter in the step (1) to remove error data and normalize the data; and (3) based on an improved SVM nonlinear combination recognition model, a BP neural network recognition model, an RBF radial recognition model and a GRNN neural network recognition model are combined to calculate the thermodynamic system valve inner leakage under the specific characteristic parameter to monitor the valve inner leakage. According to the invention, a scientific professional basis is provided for an enterprise to arrange overhauling and change a planned overhauling mode according to the valve leakage condition, and the method plays an important role in reducing the valve leakage of the enterprise and improving the economy of production operation.

Owner:深圳市天成智能控制科技有限公司

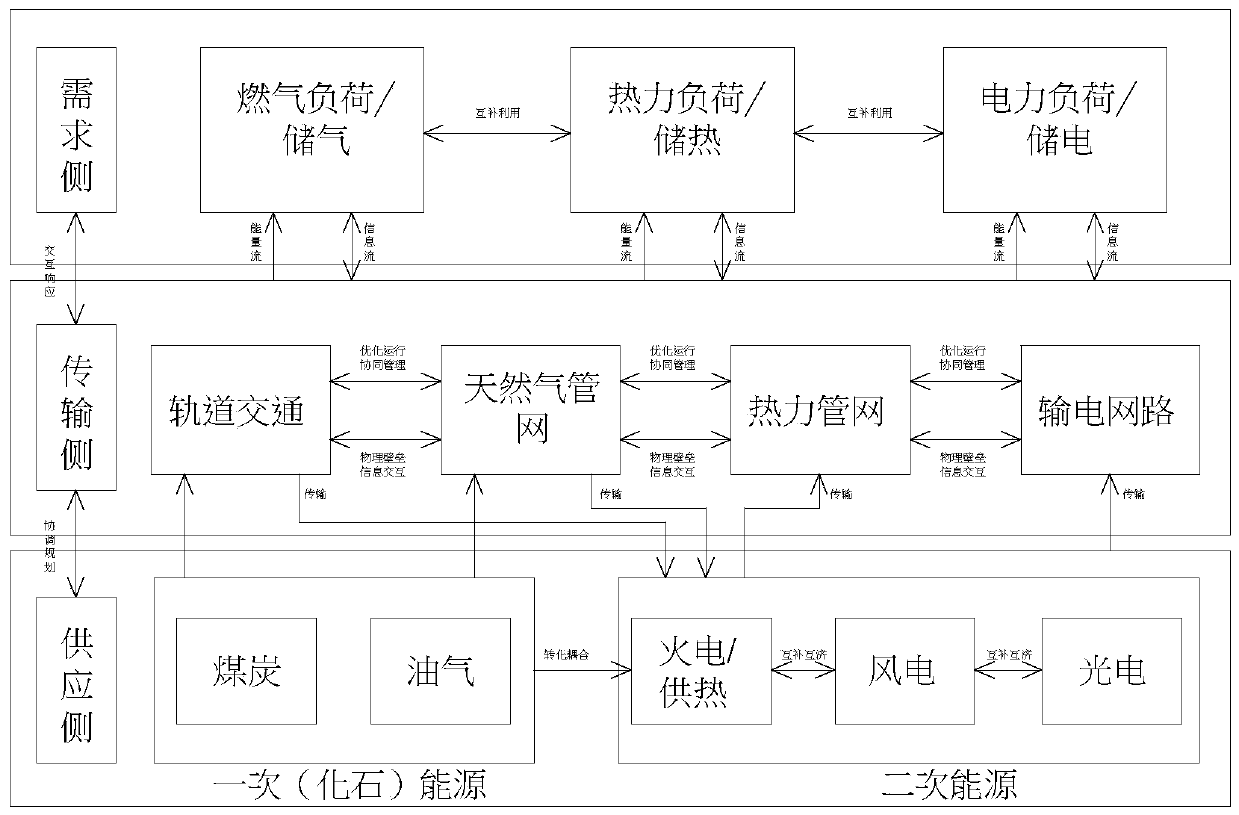

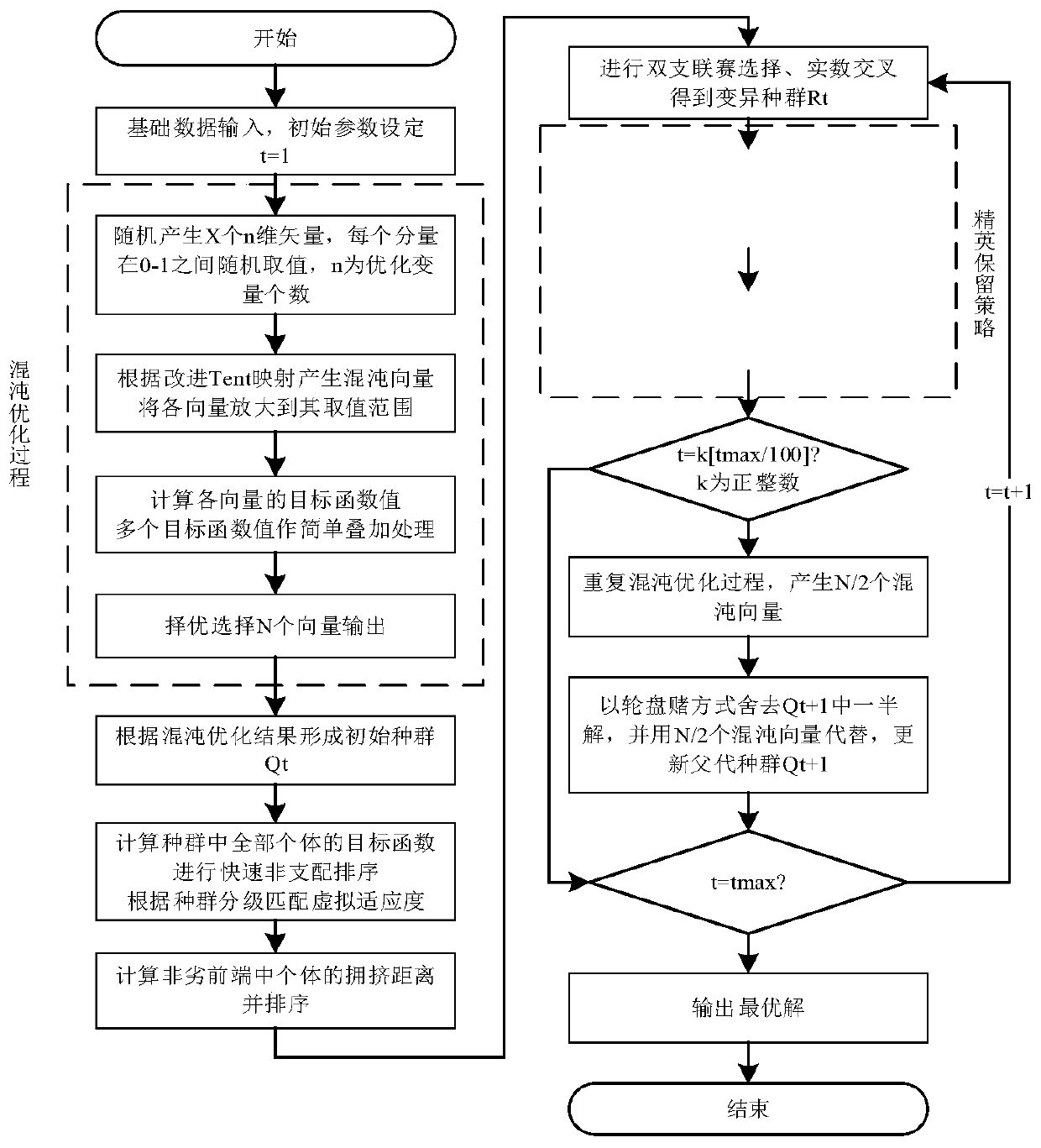

Multi-energy microgrid planning method for integrated energy system

PendingCN110659830ARealize synergyMeet various types of energy needsResourcesGenetic algorithmsMicrogridIntegrated energy system

The invention discloses a multi-energy microgrid planning method for an integrated energy system. The method comprises the following steps: 1), designing a multi-energy microgrid basic architecture: interconnecting and integrating a traditional power system, a natural gas system and a thermodynamic system in a region; 2), constructing a multi-energy microgrid multi-objective collaborative planningmodel taking minimum system planning operation cost, minimum wind and light curtailment and minimum pollutant emission as objective functions, and realizing collaborative optimization planning of a plurality of energy subsystems; and 3), improving the traditional multi-objective genetic algorithm by using a Tent mapping improved chaotic optimization algorithm to form a chaotic optimization multi-objective genetic algorithm, and solving the model by using the chaotic optimization multi-objective genetic algorithm on the basis of verifying the robustness of the algorithm. According to the method, the system cost is effectively reduced while the multi-element load requirement is met, the resource allocation efficiency is remarkably improved, a forward effect is achieved on safe operation ofa large power grid system, and the method has a good application prospect.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

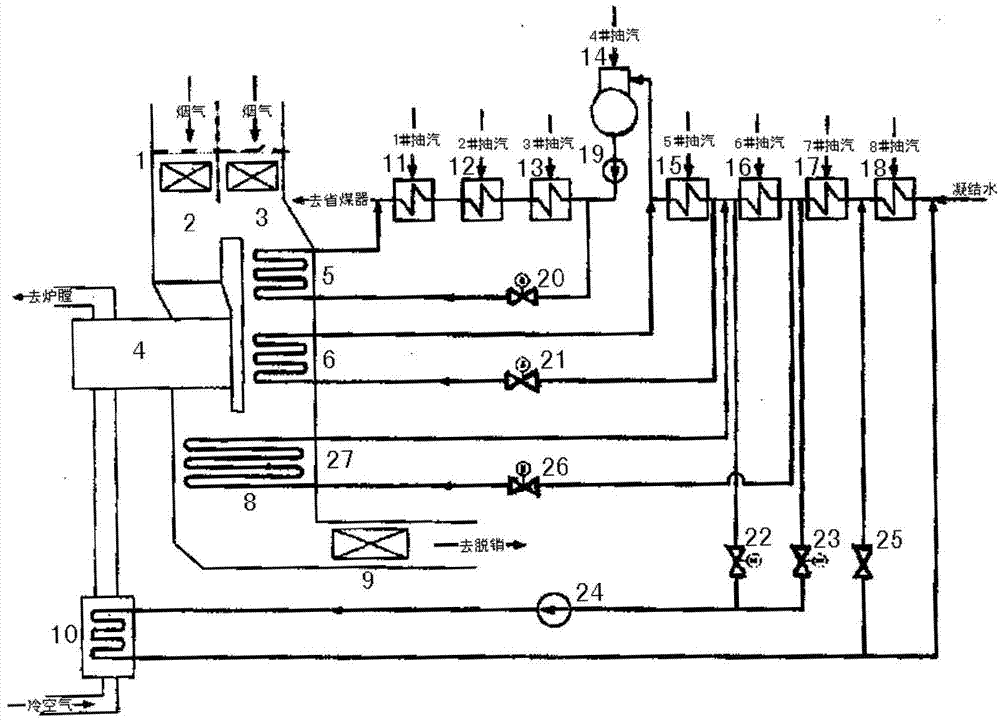

Boiler-turbine coupled flue gas waste heat utilization system capable of preheating air based on condensed water

InactiveCN103486567ANo corrosion problemsReduce the temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterDeaerator

The invention discloses a boiler-turbine coupled flue gas waste heat utilization system capable of preheating air based on condensed water, which belongs to the field of energy conservation of electric stations. The boiler-turbine coupled flue gas waste heat utilization system mainly comprises a main economizer, a main flue, a bypass flue, a confluence flue, a main air preheater, smoke water heat exchangers, a high-pressure heater, a low-pressure heater, a deaerator, a flue gas-air heater and a condensed water-air heater. Cold air is preheated by extracting low-temperature condensed water in some of thermodynamic systems and low-temperature flue gas of a boiler through utilizing the condensed water-air heater; a primary smoke water heat exchanger and a secondary smoke water heat exchanger are used for heating the feeding water and the condensed water so as to replace extraction steam, with higher pressure, of a steam turbine. According to the flue gas waste heat utilization system, waste heat is effectively utilized, and the air is preheated by utilizing the low-level condensed water and the low-temperature flue gas of the boiler, so that the high-pressure extraction steam used for heat return is saved, thus work of a machine set is remarkably increased, and deep energy conservation and consumption reduction of a coal-fired generator set can be realized; furthermore, a problem of low-temperature corrosion of a waste heat utilization heating surface is relieved, and remarkable economic benefit is obtained.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

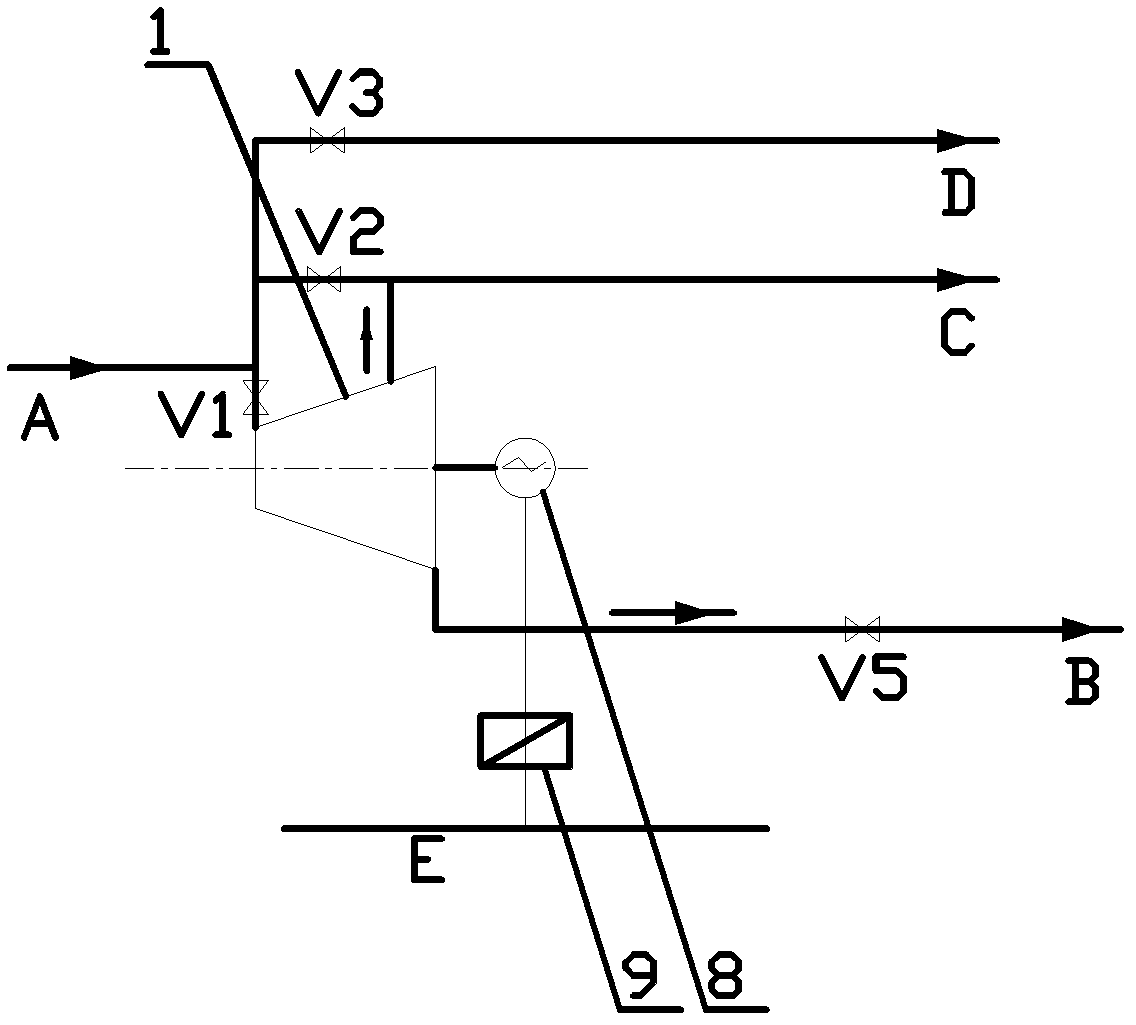

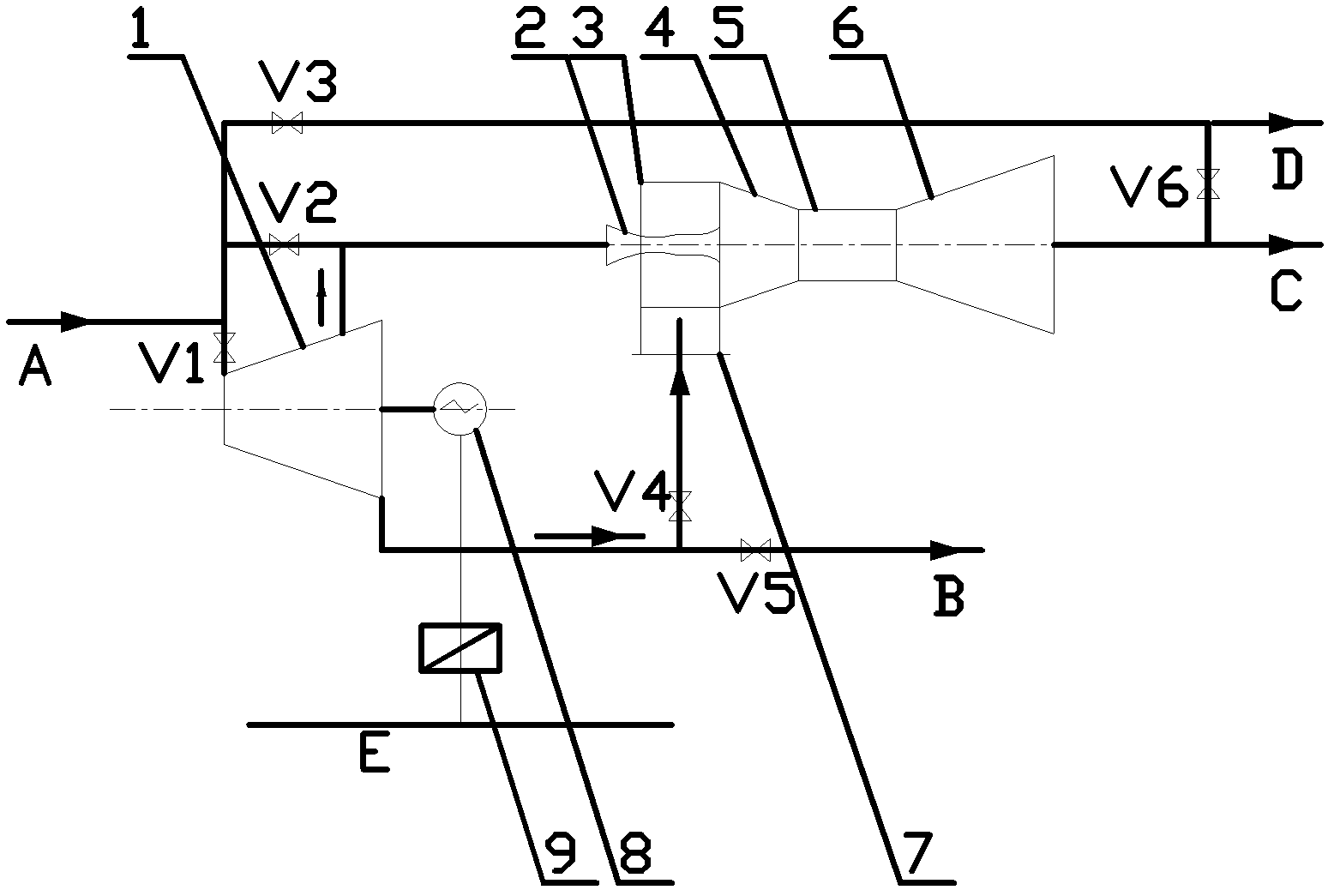

Modularized steam waste pressure and waste heat power generation and balanced steam and heat supply system

InactiveCN102518483AMeet needsImprove utilization efficiencySteam useCombined combustion mitigationPower gridEngineering

The invention relates to a modularized steam waste pressure and waste heat power generation and balanced steam and heat supply system, which belongs to the field of industrial and civil waste heat and waste pressure power generation and steam and heat supply. The system comprises a backpressure-type steam turbine, a generator, valves and connecting pipelines; a high-pressure steam inlet pipe is connected with a main steam inlet of the backpressure-type steam turbine through a power generation control valve; the high-pressure steam inlet pipe is also connected with a first low-pressure steam supply pipe through a temperature and pressure reduction valve; an exhaust outlet of the backpressure-type steam turbine is connected with a first low-pressure steam supply pipe through a first steam supply control valve; a shaft of the backpressure-type steam turbine is connected with a shaft of the generator; and the output end of the generator is connected with a power grid through a grid-connected device. According to the modularized steam waste pressure and waste heat power generation and balanced steam and heat supply system, the common problem that the irreversible loss is too high because high-pressure steam is delivered to steam heat users with different pressure requirements in the manner of temperature and pressure reduction in practical projects at present is solved, and the benefit of the comprehensive utilization of energy of a whole thermodynamic system is improved. The scheme of the system can be generally popularized to all steam users.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

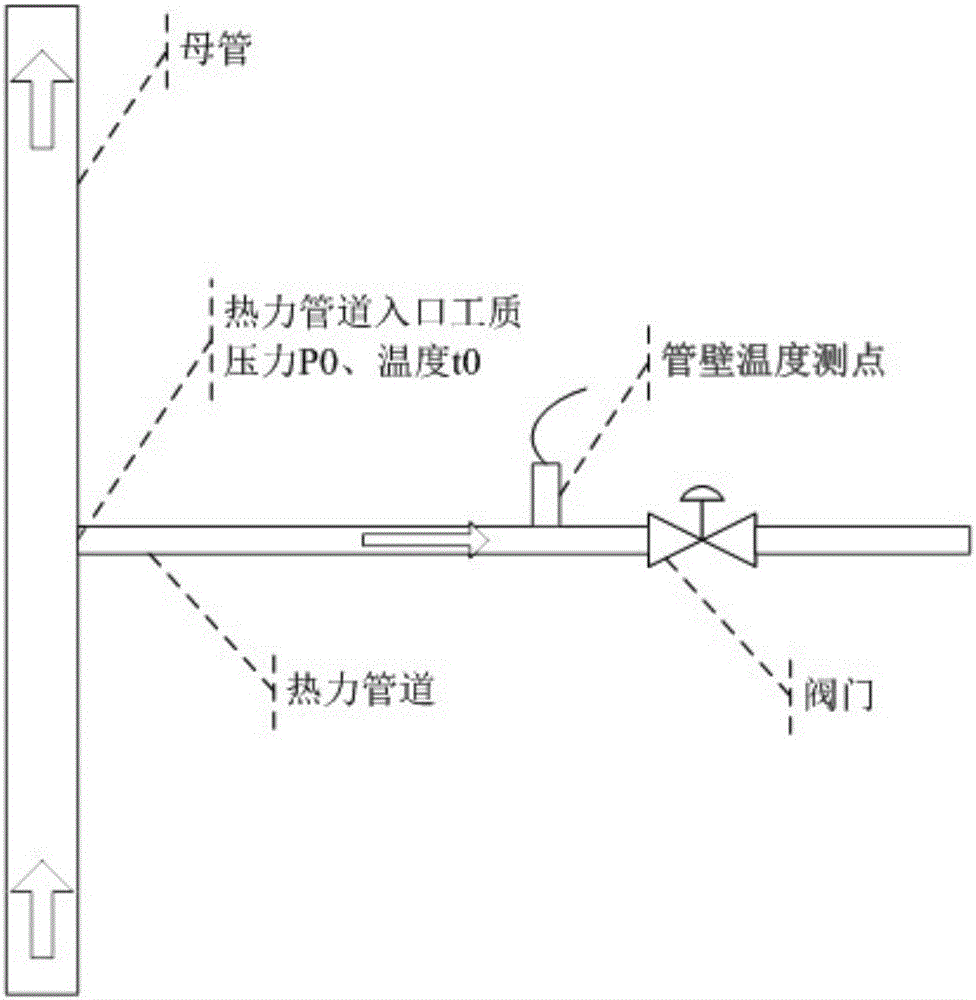

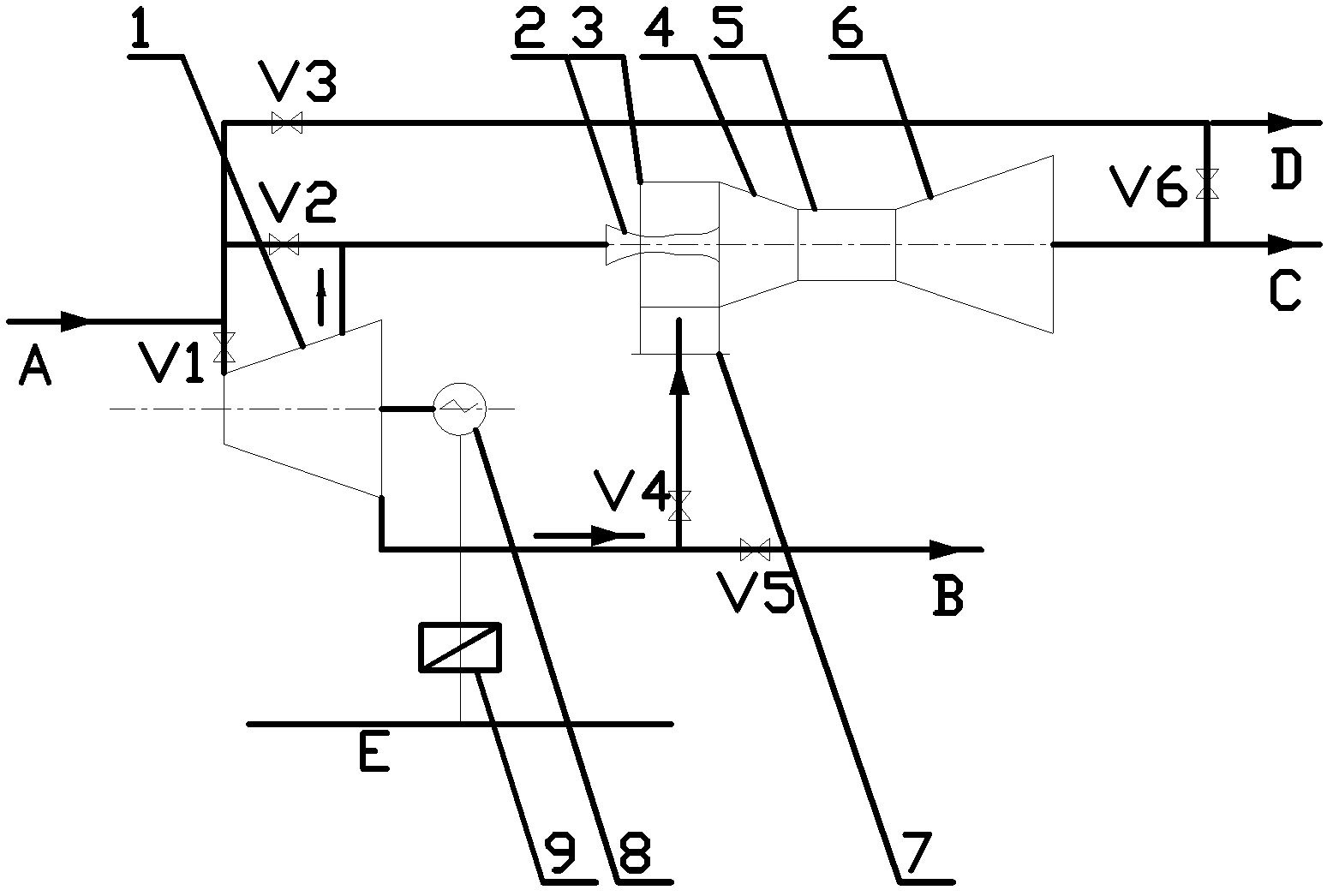

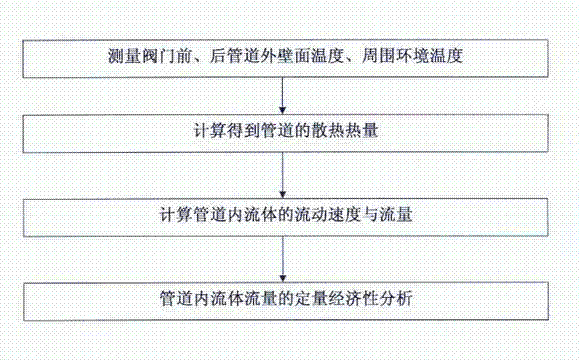

Method for detecting internal leakage of valve of thermodynamic system in power plant

InactiveCN102478445AReduce leakage flowReduce coal consumption for power supply operationFluid-tightness measurement using fluid/vacuumPower stationEngineering

The invention relates to a method for detecting internal leakage of a valve of a thermodynamic system in a power plant. The method comprises the following steps of: measuring outer wall temperatures of pipe segments in front of and at the back of the valve and ambient temperatures; calculating to obtain quantities of heat emission of the pipe; calculating to obtain flow velocity and flow rate of a fluid inside the pipe; and performing quantitative economic analysis on the flow rate of the fluid inside the pipe. When the leakage of working medium of the valve occurs, the pipe wall temperature rises due to heat emission. The heat transfer process tends to be stable after a certain time period if the leakage of the valve keeps unchanged, and the heat emission and the pipe wall temperatures maintain a certain value. When the calculation control volume used is short enough, the heat transfer quantities Q4 and Q5 in the longitudinal direction of the pipe are minimal and can be neglected in calculation. As a result, the heat emission of the pipe wall and the heat emission of the heat-insulating layer are close to the heat transfer of a single-layer homogenous cylindrical wall. The detection method is significant in determining inspection and repair according to the running state of the valve in the power plant, reducing internal leakage of working media of the valve in the power plant, reducing power and coal consumptions during operation and increasing operating economy.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST +1

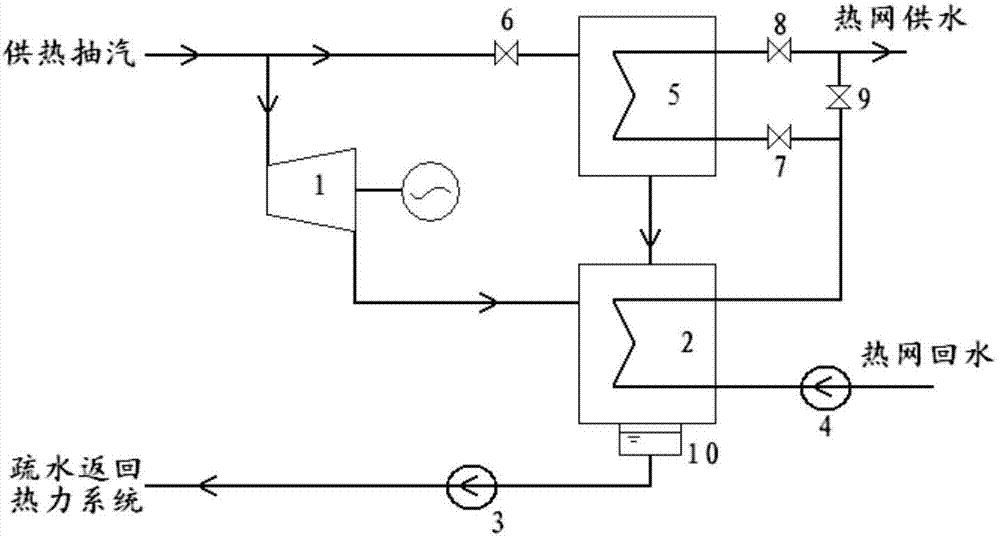

Thermal power plant heat supply and steam extraction overbottom pressure utilization system with back pressure turbine

InactiveCN104121047AShort payback periodSave spaceLighting and heating apparatusSteam useElectricityThermal energy

A thermal power plant heat supply and steam extraction overbottom pressure utilization system with a back pressure turbine comprises the back pressure turbine connected with a heat supply and steam extraction pipeline. A steam exhaust port of the back pressure turbine is connected with an inlet in a heat releasing side of a vacuum type heating network heater, drain water of the vacuum type heating network heater flows through an outlet in the heat releasing side of the vacuum type heating network heater to return back to a thermodynamic system through a pipeline, an inlet in the heat absorbing side of the vacuum type heating network heater is connected with heating network returned water through a pipeline, and an outlet in the heat absorbing side of the vacuum type heating network heater is connected with heating network supplied water through a pipeline. The overbottom pressure produced through heat supply and steam extraction of a thermal power plant are recycled through the back pressure turbine to generate electricity, and the steam discharged through the back pressure turbine is supplied to the heating network heater to form a heat supply and steam overtbottom pressure recycling system. The system can efficiently utilize the thermal energy of heat supply and steam extraction, the generating capacity of a heat supply unit is increased, economic benefits of the system are improved, the coal consumption rate of the unit can be obviously reduced, and the system has obvious economic benefits and energy saving and emission reducing effects.

Owner:XI AN JIAOTONG UNIV

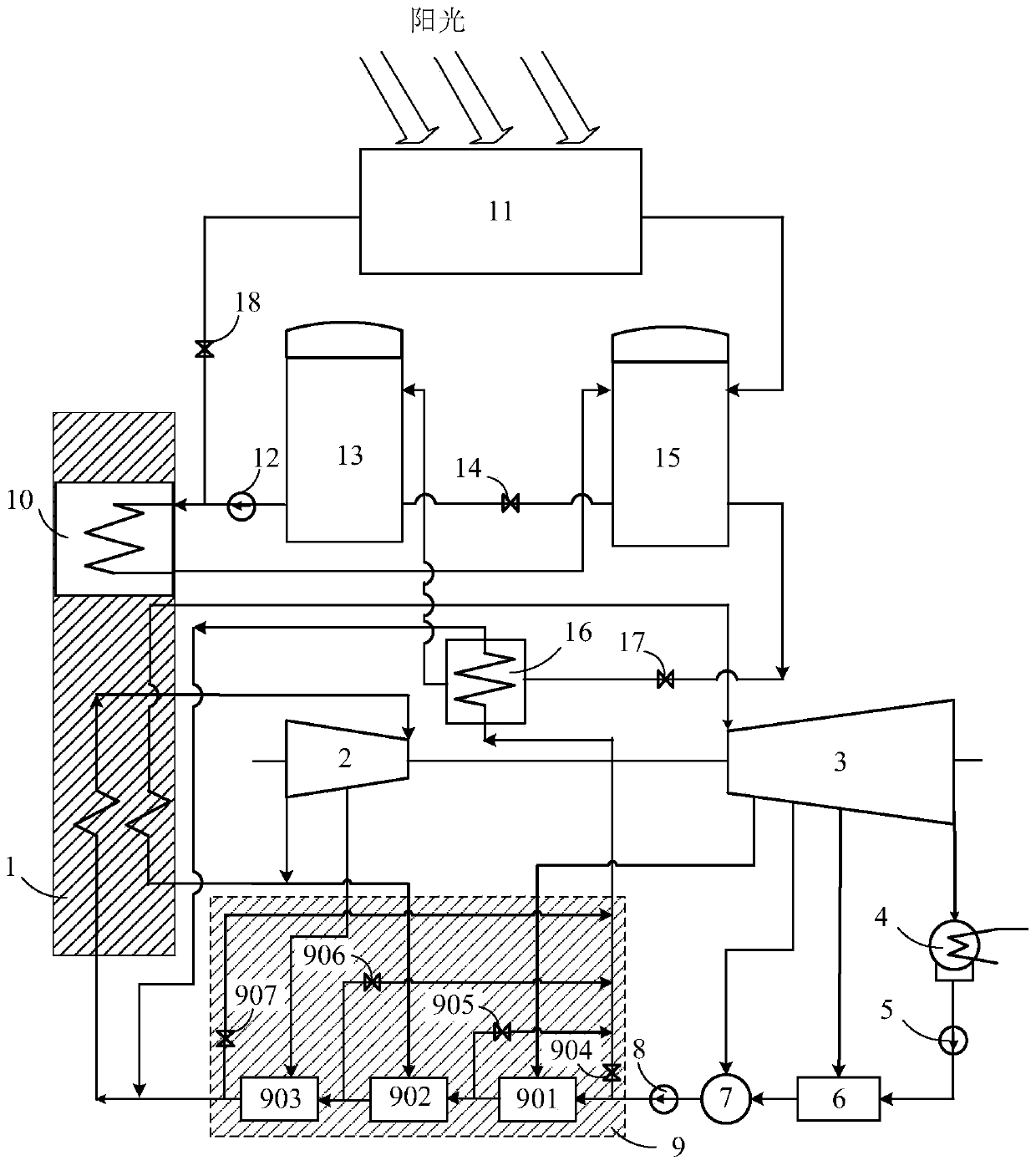

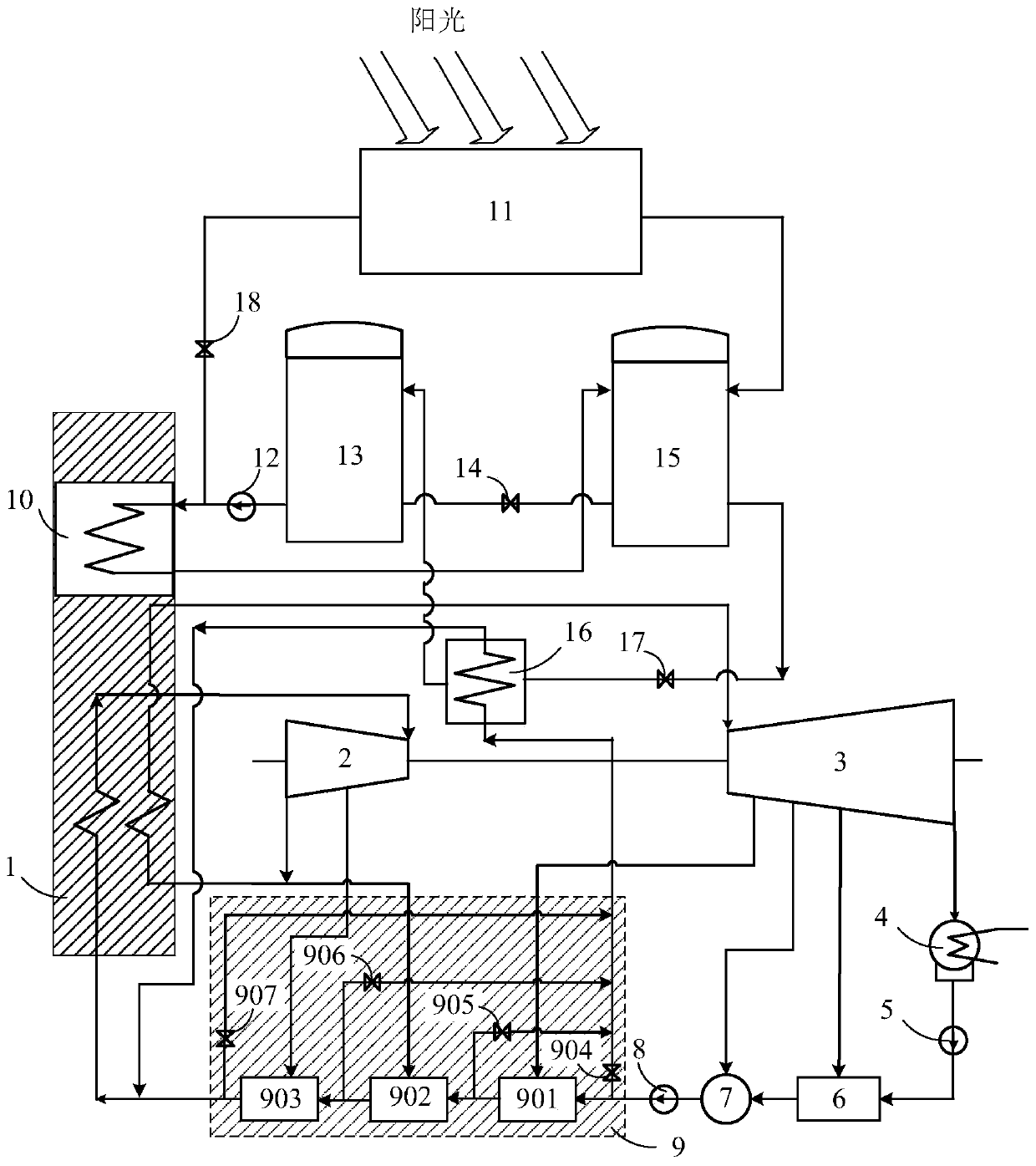

Solar energy and fuel coal coupled flexible power generation system and running method

ActiveCN109958593ARealize generation couplingAchieve decouplingFrom solar energySteam engine plantsCollection systemEngineering

The invention discloses a solar energy and fuel coal coupled flexible power generation system and a running method. The system comprises a coal-fired power generation unit thermodynamic system and a high-temperature heat storing system which comprises a solar heat collection system, cold and hot heat storing medium tanks, a heat storing medium pump, a heat storing medium and feed water heat exchanger and the like and is coupled with solar thermal power generation; a heat storing medium heater is arranged in a boiler flue; the flow of a heat storing medium entering the solar heat collection device and the heat storing medium heater is adjusted through cooperation of a solar heat storing medium adjusting valve and the heat storing medium pump, therefore, influences of sunlight irradiation changes are eliminated, and the output power is kept stable; peak regulation is conducted through the heat storing medium tank, and the steam turbine output power is reduced under the stable combustioncondition of a boiler; and the flow and temperature of feed water entering the heat storing medium and feed water heat exchanger are adjusted through opening and closing of a high-pressure heater adjusting valve group, and then the system meets the requirements of the quick load changing rate of a unit. According to the solar energy and fuel coal coupled flexible power generation system and the running method, solar energy and fuel coal power generation coupling can be achieved, coal consumption is reduced, and the flexibility and economical efficiency of the unit are significantly improved.

Owner:XI AN JIAOTONG UNIV

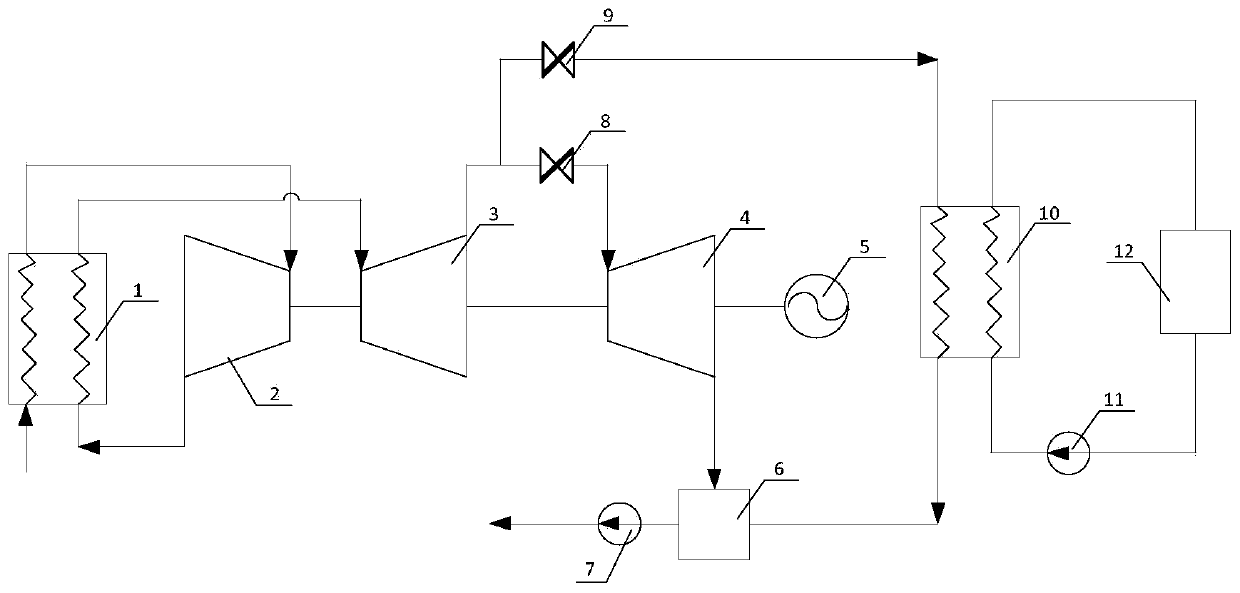

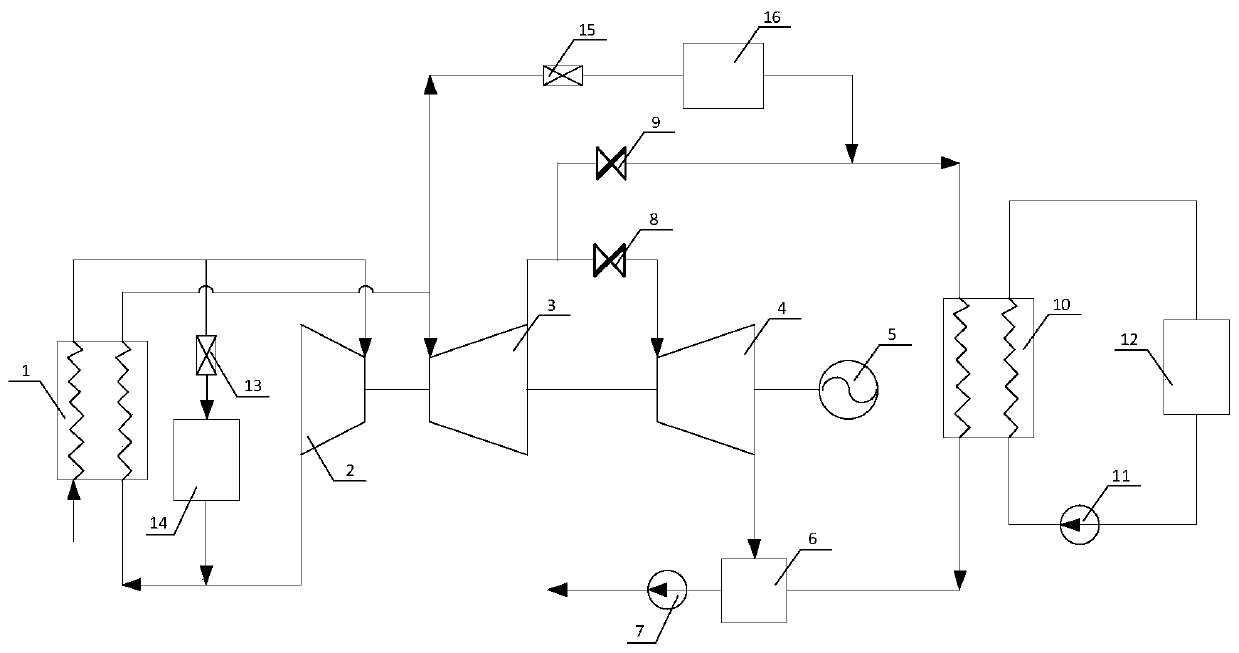

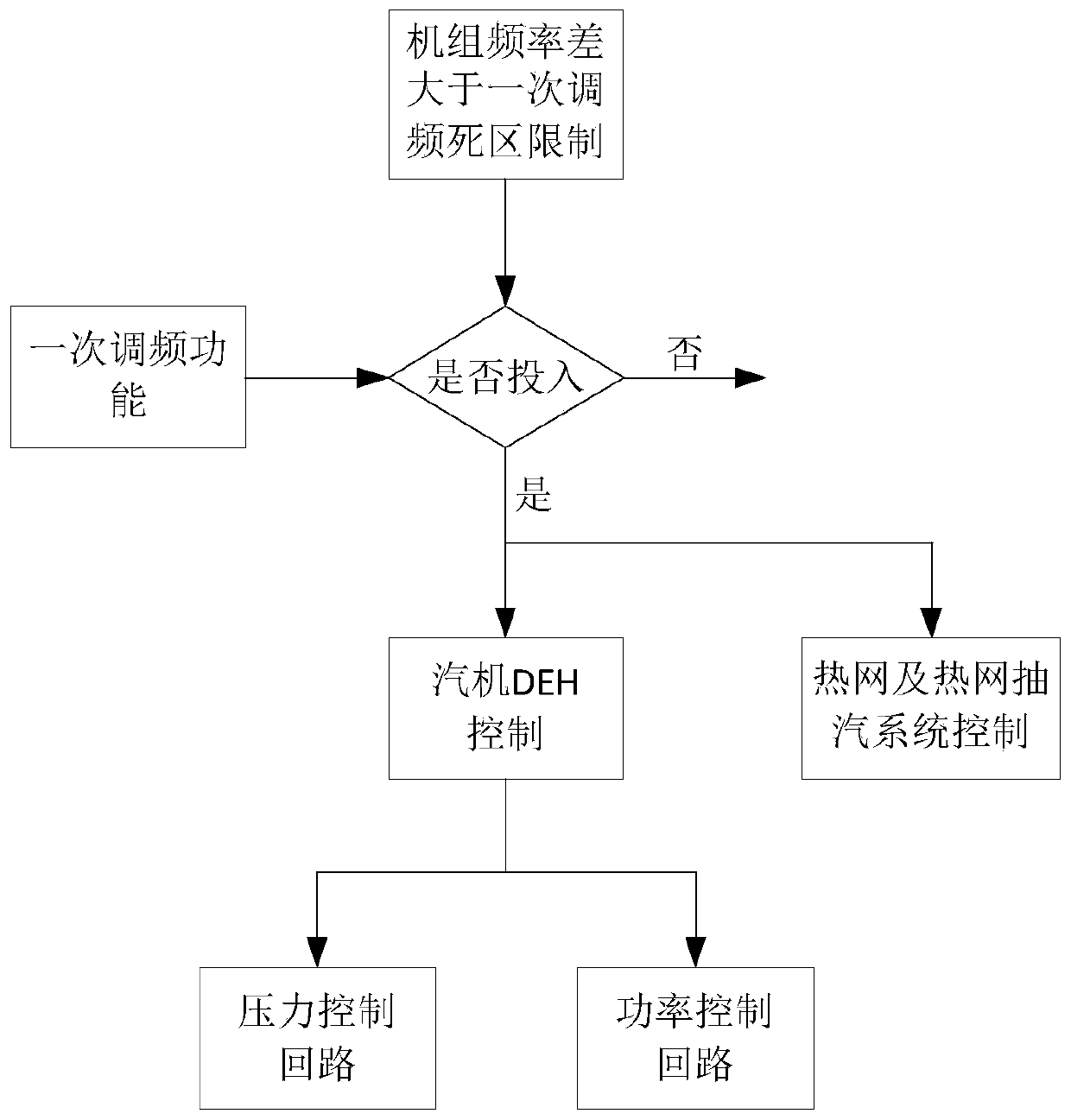

Thermodynamic system and regulation and control method for rapid load responses of heat supply unit

PendingCN110608072ASolve the technical problems of poor stability and high maintenance costsImprove the ability to quickly lift the loadLighting and heating apparatusSteam useLoad instructionEngineering

The invention discloses a thermodynamic system and a regulation and control method for rapid load responses of a heat supply unit. The technical problems that an existing thermodynamic system is poorin stability and high in cost are solved. The system is based on the heat supply unit, and the heat supply unit comprises a boiler, a high-pressure cylinder, a medium-pressure cylinder, a low-pressurecylinder and a generator which are sequentially connected. A medium-low-pressure communication butterfly valve is arranged between the medium-pressure cylinder and the low-pressure cylinder and is used for regulating the flow of steam entering the low-pressure cylinder. A heat supply steam outlet is formed between the medium-pressure cylinder and the medium-low-pressure communication butterfly valve, and a steam extraction butterfly valve is arranged on a steam extraction pipeline and is used for adjusting and controlling the flow of steam entering a heat supply network heater. The system isused for rapidly responding to AGC load instructions and primary frequency modulation instructions through the heat supply unit. The steam extraction device and a heat supply network system are adjusted through the heat supply unit, the instantaneous heat supply steam flow of the heat supply unit is quickly changed, and the instantaneous thermoelectric ratio of the whole unit is adjusted, so thatthe quick responses to power generation loads of the unit are achieved.

Owner:SPIC POWER PLANT OPERATION TECH (BEIJING) CO LTD

Thermodynamic system for combined heat recovery of power plant

ActiveCN102678206AImprove thermal cycle efficiencyReduce lossesSteam useCombined combustion mitigationPower stationEngineering

The invention discloses a thermodynamic system for combined heat recovery of a power plant. A smoke heat recovery system and a small exhaust system of turbine driven equipment are optimized for combined recovery. The technical scheme is as follows: the system comprises a fan exhaust afterheat recovery heater located on the fan side, a drainage pump and a smoke afterheat recovery device, wherein steam in a thermodynamic cycle system of the power plant is accessed into a regenerative driving steam turbine on the fan side to act; exhaust steam of the regenerative driving steam turbine enters the fan exhaust afterheat recovery heater, and the exhaust afterheat is utilized by the fan exhaust afterheat recovery heater to heat the water for heating; the drainage pump is connected with a water pipe at the outlet of the fan exhaust afterheat recovery heater or a water pipe at the inlet of the fan exhaust afterheat recovery heater for returning the water to the outlet or inlet of the fan exhaust afterheat recovery heater; and the smoke afterheat recovery device is used for receiving the water for heating at the outlet of the heater in the thermodynamic cycle system of the power plant and exchanging heat with the smoke.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

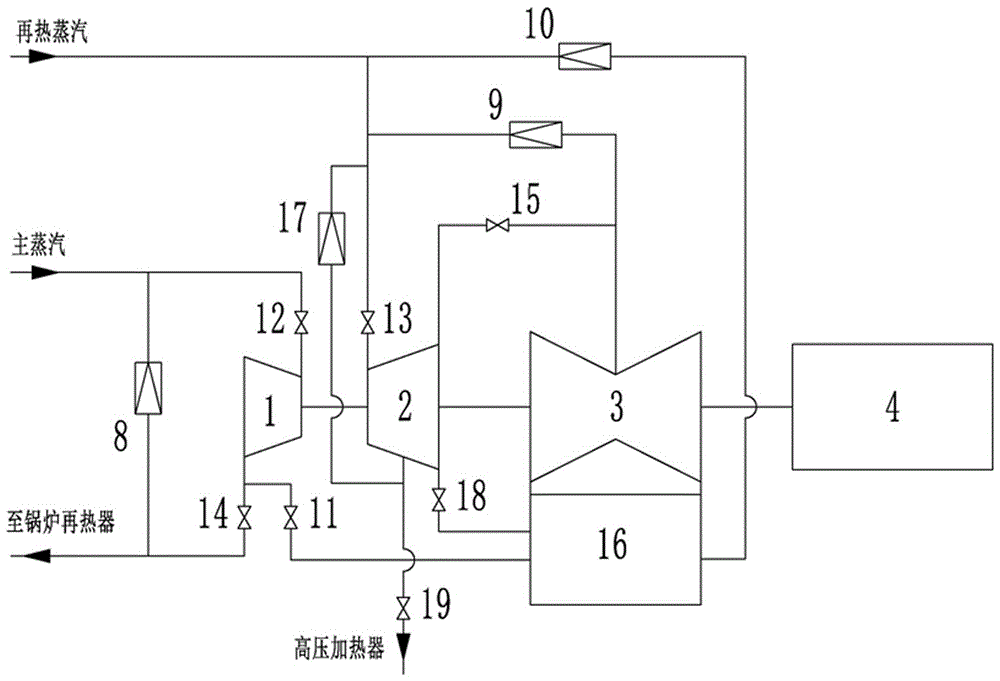

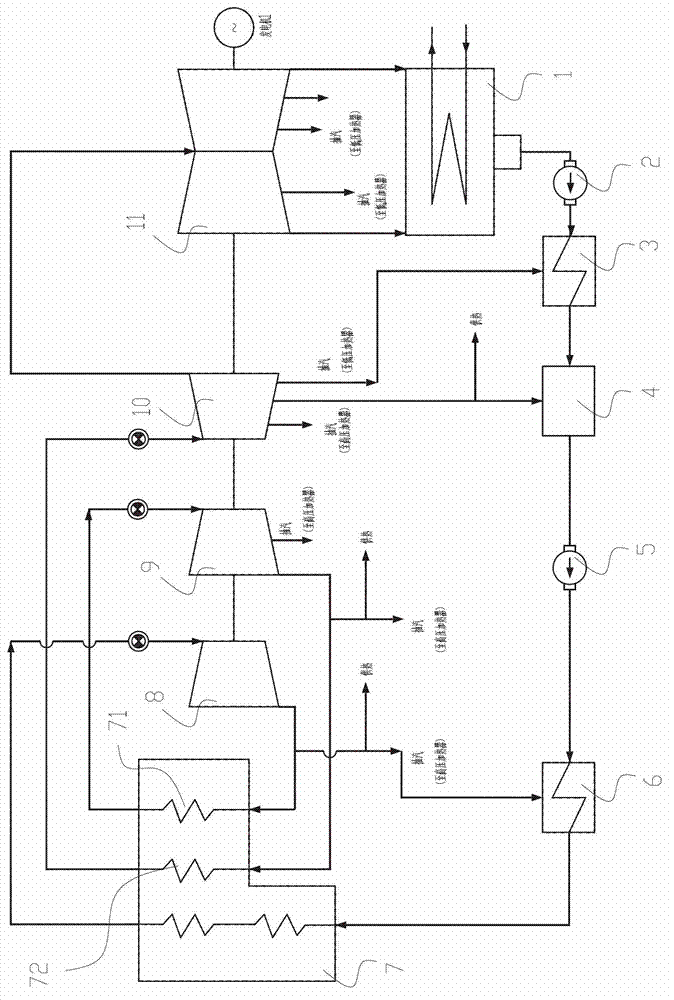

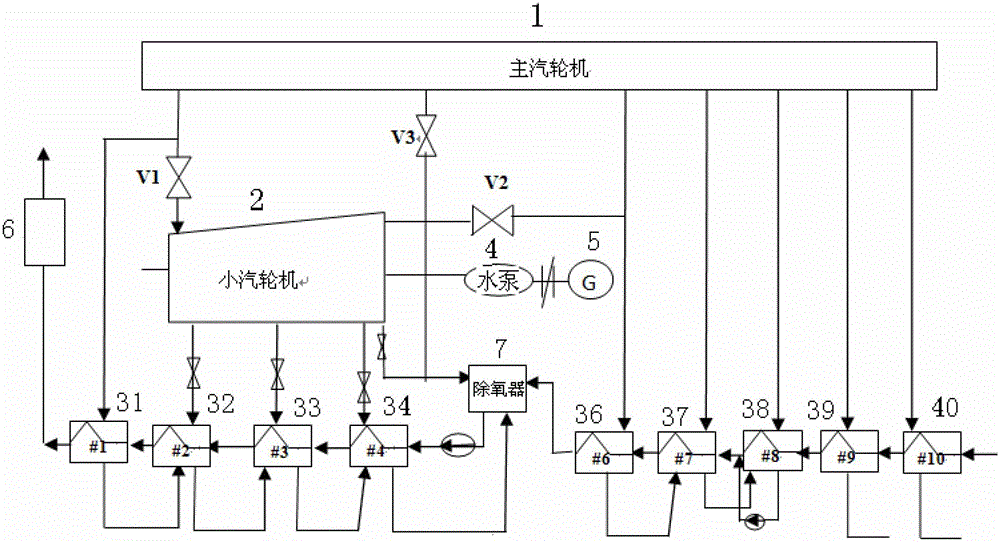

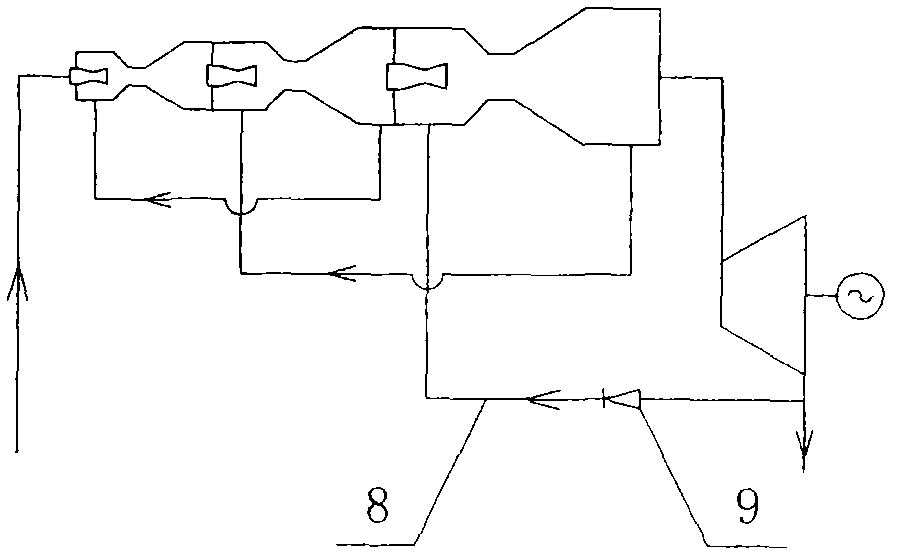

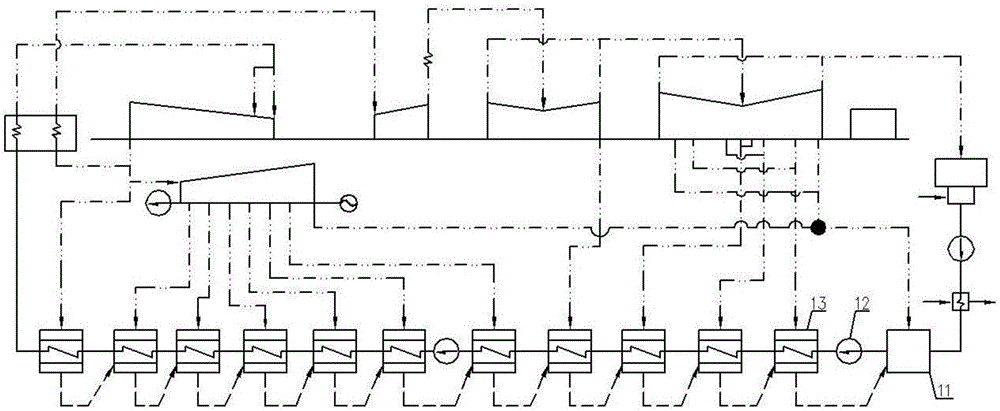

Secondary reheating double-machine back-heating thermodynamic system without deaerator for ultra-supercritical unit

The invention discloses a secondary reheating double-machine back-heating thermodynamic system without a deaerator for an ultra-supercritical unit. The system is characterized in that steam enters a large steam turbine super-high pressure cylinder via a boiler for working, and exhaust steam enters the boiler again for reheating; the steam enters a backpressure extraction steam turbine (BEST) for working, and high-pressure extraction steam is provided; and the steam enters a high-pressure heater to heat boiler water. The steam entering the boiler enters a large steam turbine for working after being reheated, the exhaust steam is condensed into condensed water in a condenser, and the condensed water flows through a primary condensed water pump, a shaft seal, a low-pressure mixed heater, a secondary condensed water pump, a surface type low-pressure heater, a water feeding pump and a surface type high-pressure heater sequentially and finally enters the boiler to complete circulation. The exhaust steam after the steam entering the backpressure extraction steam turbine works is introduced into the low-pressure mixed heater, heated, deoxidized and condensed into the water. The low-temperature and low-pressure condensed water is heated to the saturated water state by the low-pressure mixed heater by using the exhaust steam of a small turbine, dissolved oxygen in the condensed water and other non-condensed gases are removed, the surface type low-pressure heater replaces the deaerator, and high-position arrangement is not required.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com