Patents

Literature

199 results about "Irreversible loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

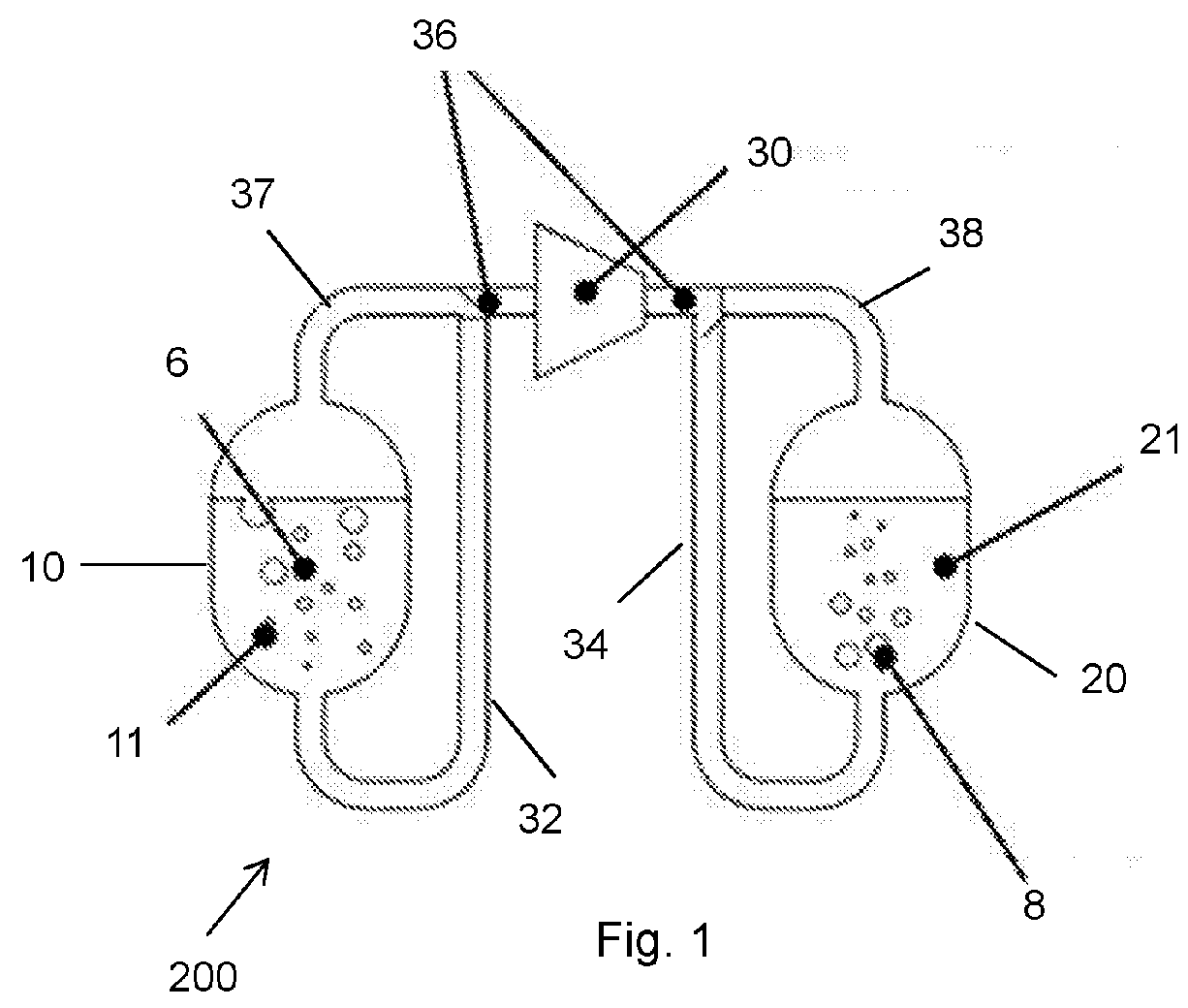

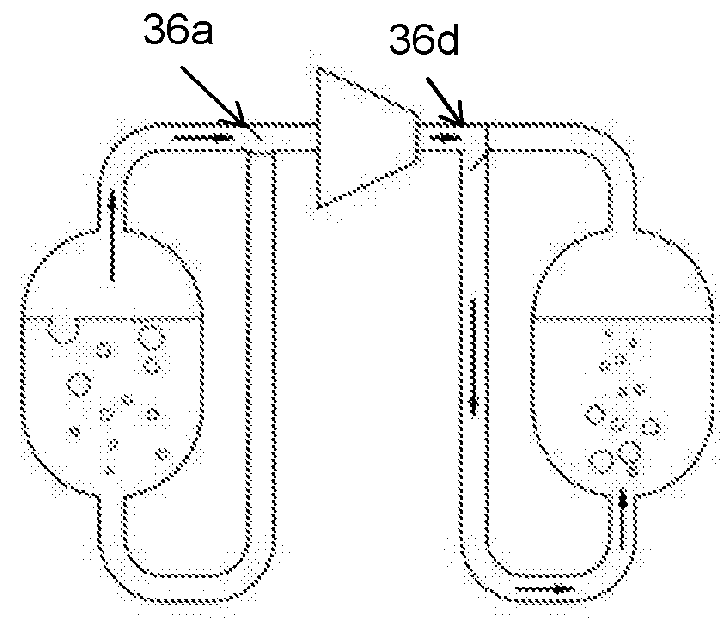

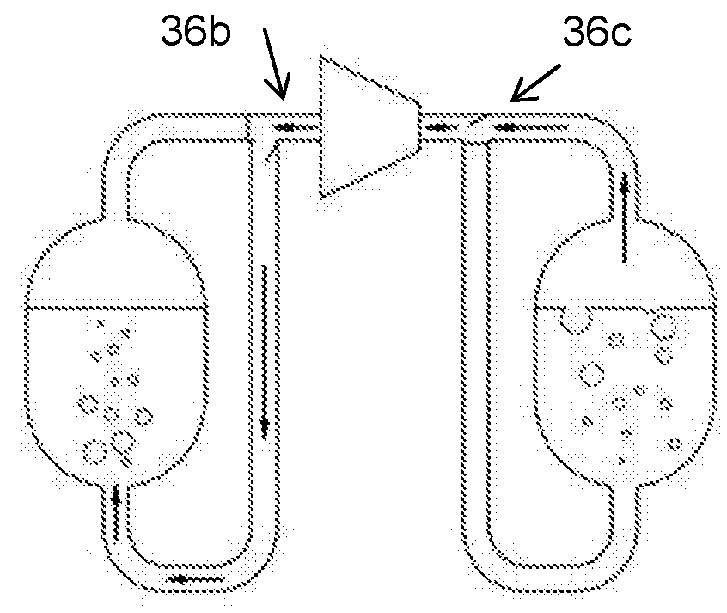

Apparatus and Method for Storing Energy

InactiveUS20160032783A1Reduce probabilityEliminateSteam accumulatorsGas turbine plantsStored energyThermal energy

In an energy storage and recovery system, working fluid from a first vessel is compressed by power machinery and passes, via a regenerator, into a second vessel, where it is forced to condense, the temperature and pressure of the saturated working liquid / vapour mixture continuously rising during storage. The stored energy is recovered by the vapour returning through the regenerator and power machinery where it expands to produce work before condensing back into the first vessel. The regenerator comprises a gas permeable, solid thermal storage medium which, during storage, stores superheat and some latent heat from the vapour passing through it in respective downstream regions that exhibit continuously increasing temperature profiles during storage and a small temperature difference with the surrounding vapour, thereby minimising irreversible losses during the thermal energy transfers.

Owner:ENERGY TECH INST

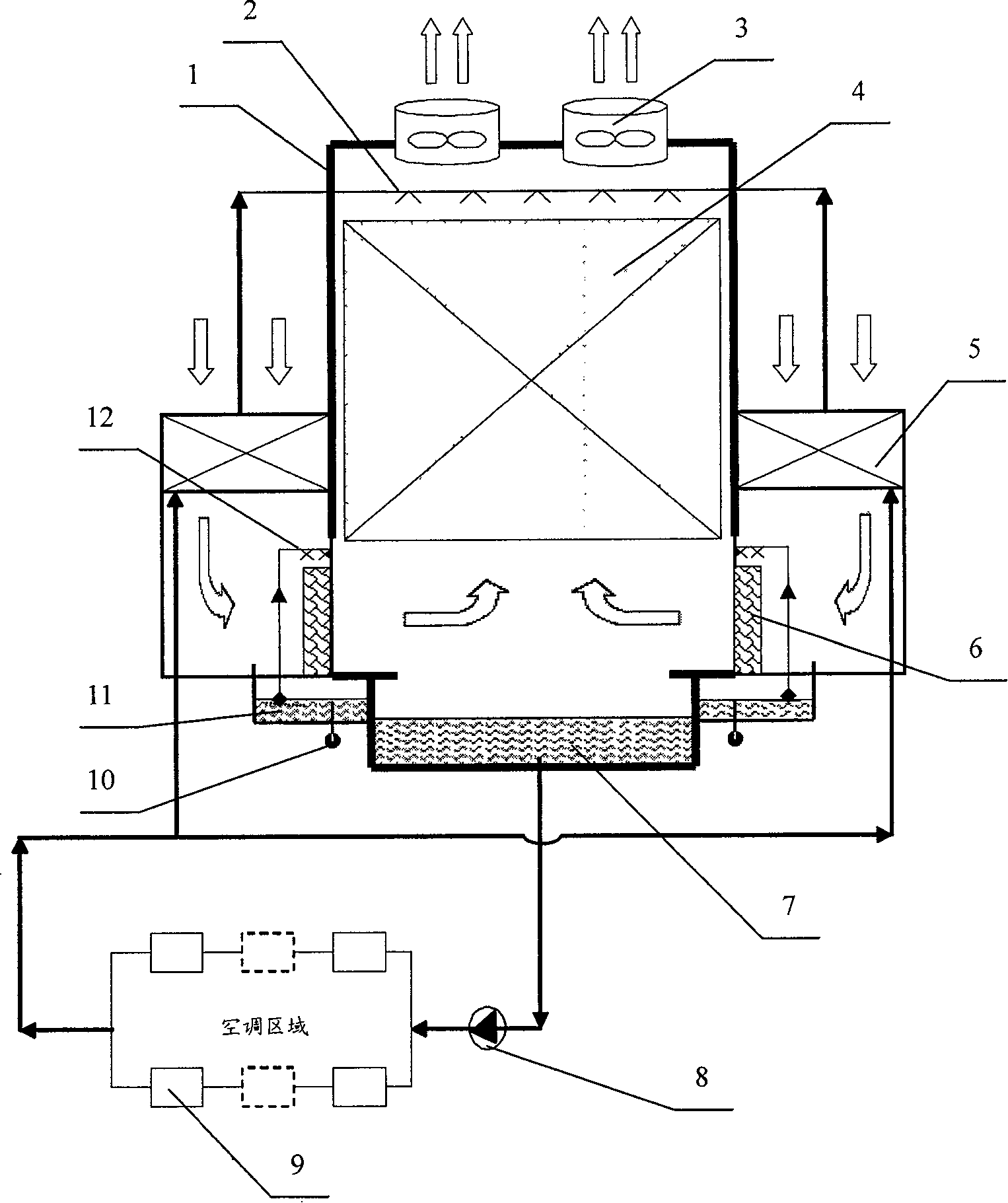

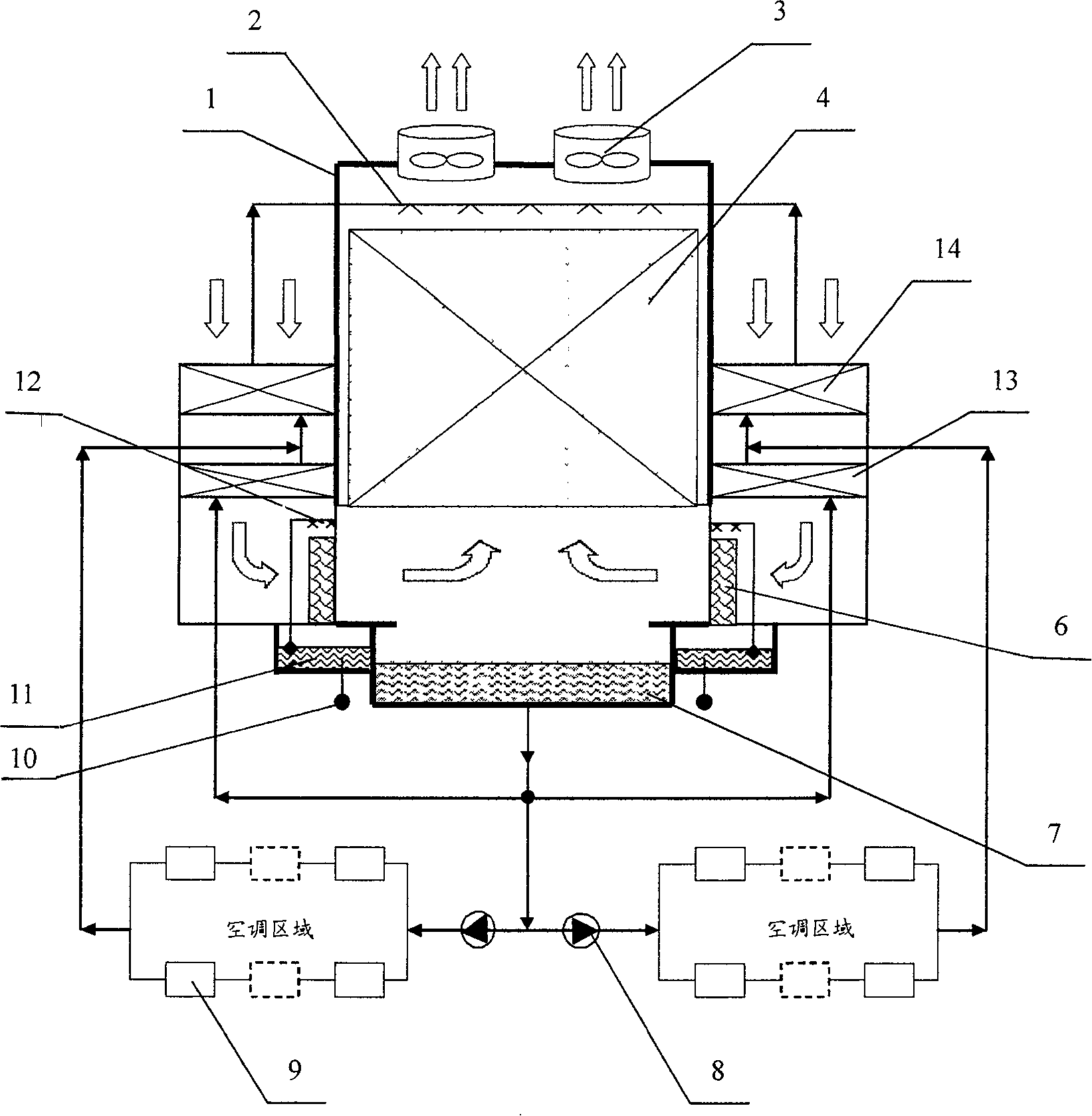

Evaporation regrigerating water chilling unit

ActiveCN101191646AEfficient use ofAchieve recyclingLighting and heating apparatusAir conditioning systemsWater storageHEAT/MOISTURE EXCHANGE

The present invention belongs to an improvement of an evaporative cooling cool supply device with dry air energy as power source, and in particular relates to an evaporative refrigeration water chilling unit. A spraying water distributor and a blower are arranged above a direct evaporative cooling heat exchanger; a water storage pool with a circulating water pump is arranged inside a casing on the lower part of the direct evaporative cooling heat exchanger; an air inlet of the casing is provided with a surface air cooler; a water inlet of the circulating water pump is connected with a water outlet at the bottom of the water storage pool through pipelines; a water outlet of the circulating water pump is connected with an indoor sensible heat cool supply terminal through pipelines; an outlet of the indoor sensible heat cool supply terminal is connected with the surface air cooler through pipelines; a water outlet of the surface air cooler is connected with a spraying water distributor through pipelines. The present invention can realize the effective utilization of the cold energy of cold water, reduces the irreversible loss of heat-moisture exchange, improves heat-moisture exchange efficiency, ensures that outlet water temperature can approach to the dew point temperature of inlet air, and improves the efficiency of utilizing dry air energy.

Owner:新疆绿色使者空气环境技术有限公司 +1

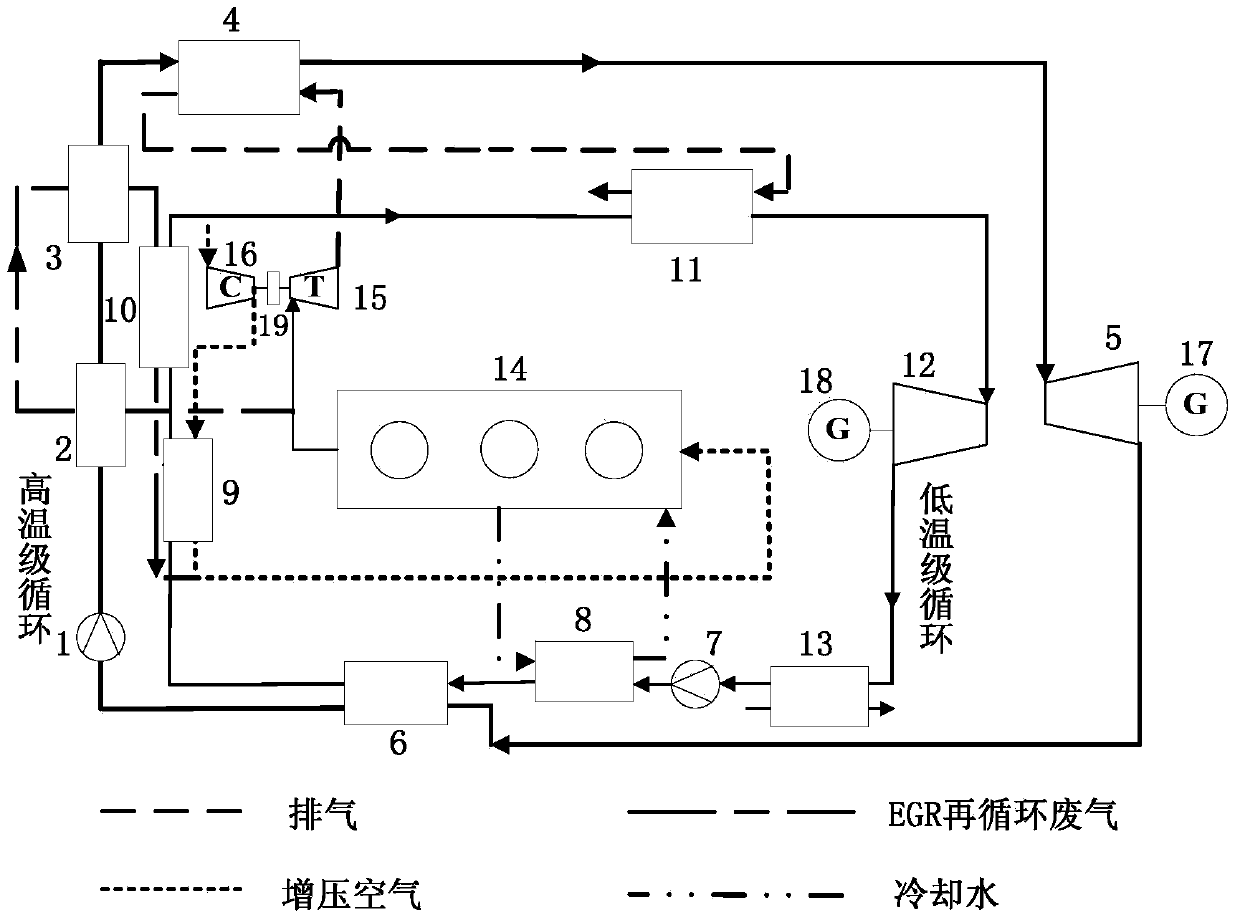

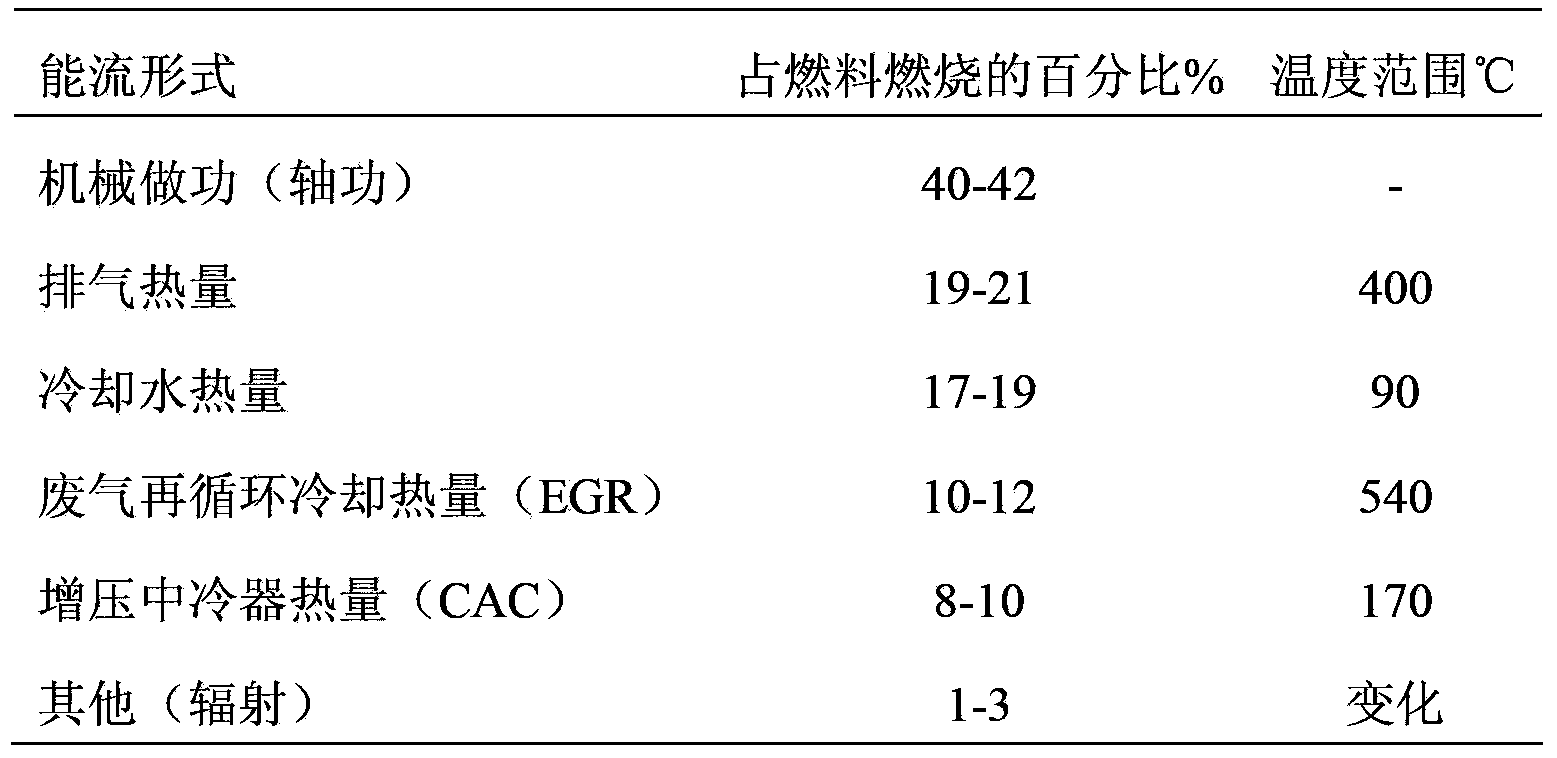

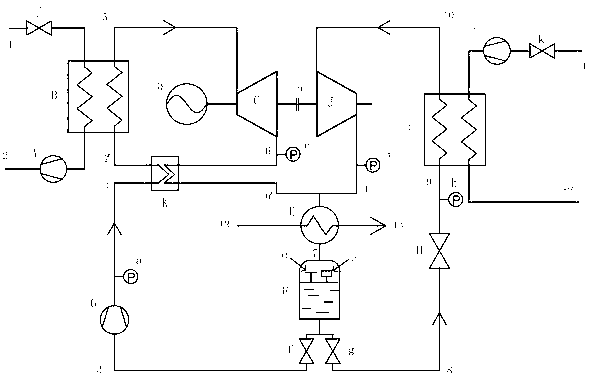

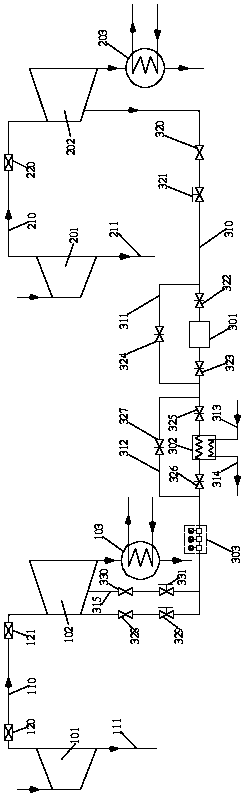

Combined-type diesel engine waste heat energy recycling system

InactiveCN104265502AMake up for the defect of small output powerReduce irreversible lossNon-fuel substance addition to fuelInternal combustion piston enginesOrganic Rankine cycleDiesel engine

The invention discloses a multi-grade waste heat energy cascade recycling system for a diesel engine, and particularly relates to a combined-type diesel engine waste heat energy recycling system. The waste heat energy recycling system is structurally characterized in that a high-temperature Rankine cycle system is composed of a working medium pump, a thermoelectric generator, an EGR heat exchanger, an exhaust heat exchanger, a steam turbine, a condenser and the like of a high-temperature system; a low-temperature Rankine cycle system is composed of a working medium pump, an EGR heat exchanger, an exhaust heat exchanger, the cylinder body cooling water heat exchanger, the supercharged air heat exchanger, a steam turbine, a condenser and the like of a low-temperature system. A middle electrical machine is arranged between a turbine motor and a supercharger; the waste heat of cooling water, supercharged air, exhausted gas, EGR recirculated waste gas and the like are utilized, and through the high-temperature and low-temperature organic Rankine cycles, thermoelectric power generation, turbine direct power generation and the like, heat exchange can be carried out between various kinds of waste heat generated by the diesel engine and working media sequentially according to the grade. Due to arrangement of the middle electrical machine, the expansion ratio of the exhausted gas can be improved, and excess pressure energy of the exhausted gas can be directly recycled. Full recycling of multi-grade waste heat energy of an internal combustion engine can be achieved, irreversible losses of the system are reduced, the fuel economical efficiency is effectively improved, and therefore the aims of saving energy and reducing emissions are achieved.

Owner:TIANJIN UNIV

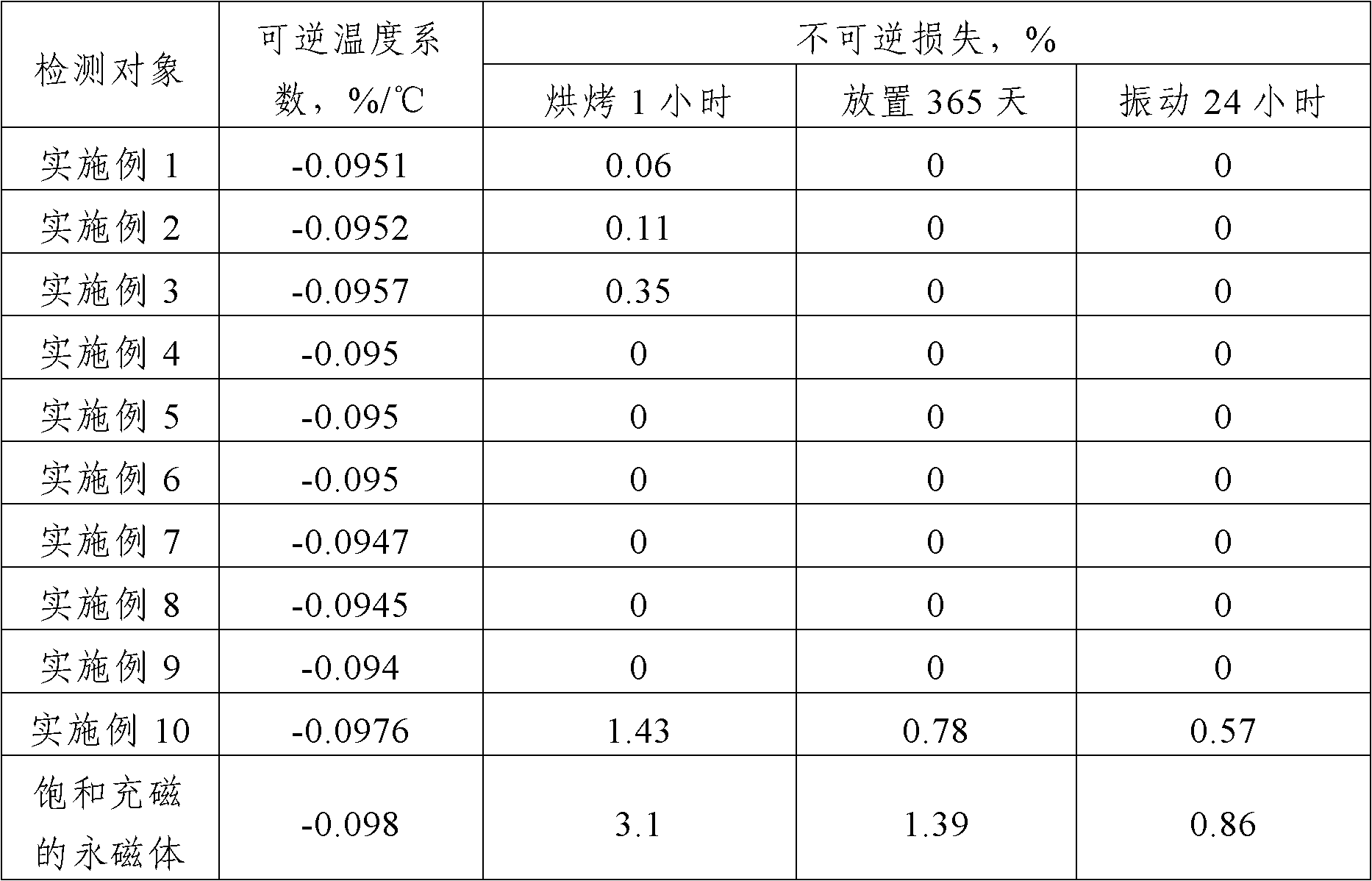

Cold-heat circulation aging treatment method for increasing magnetic stability of permanent magnets

ActiveCN102568808ASimple processEasy to operatePermanent magnetsInductances/transformers/magnets manufactureMagnetic stabilityRadiation resistant

The invention discloses a cold-heat circulation aging treatment method for increasing magnetic stability of permanent magnets. The method comprises the following steps of: putting one or more permanent magnets magnetized in a saturated manner on a non-magnetic bottom plate; then putting in a high-low temperature chamber, and freezing at minus 70 DEG C to minus 20 DEG C for 30-120 min; then, heating the high-low temperature chamber to 60-250 DEG C at the temperature increasing rate of 1-10 DEG C / min, and keeping the temperature for 30-240 min; and finally, naturally cooling to room temperature, and completing cold-heat circulation aging treatment. By adopting the method disclosed by the invention, total loss, irreversible loss, reversible loss and reversible temperature coefficients when temperature of the permanent magnets is changed can be effectively eliminated or reduced; and heat stability, time stability, magnetic stability and radiation-resistant magnetic stability of the permanent magnets under a vibration condition can be increased.

Owner:西安西工大思强科技股份有限公司

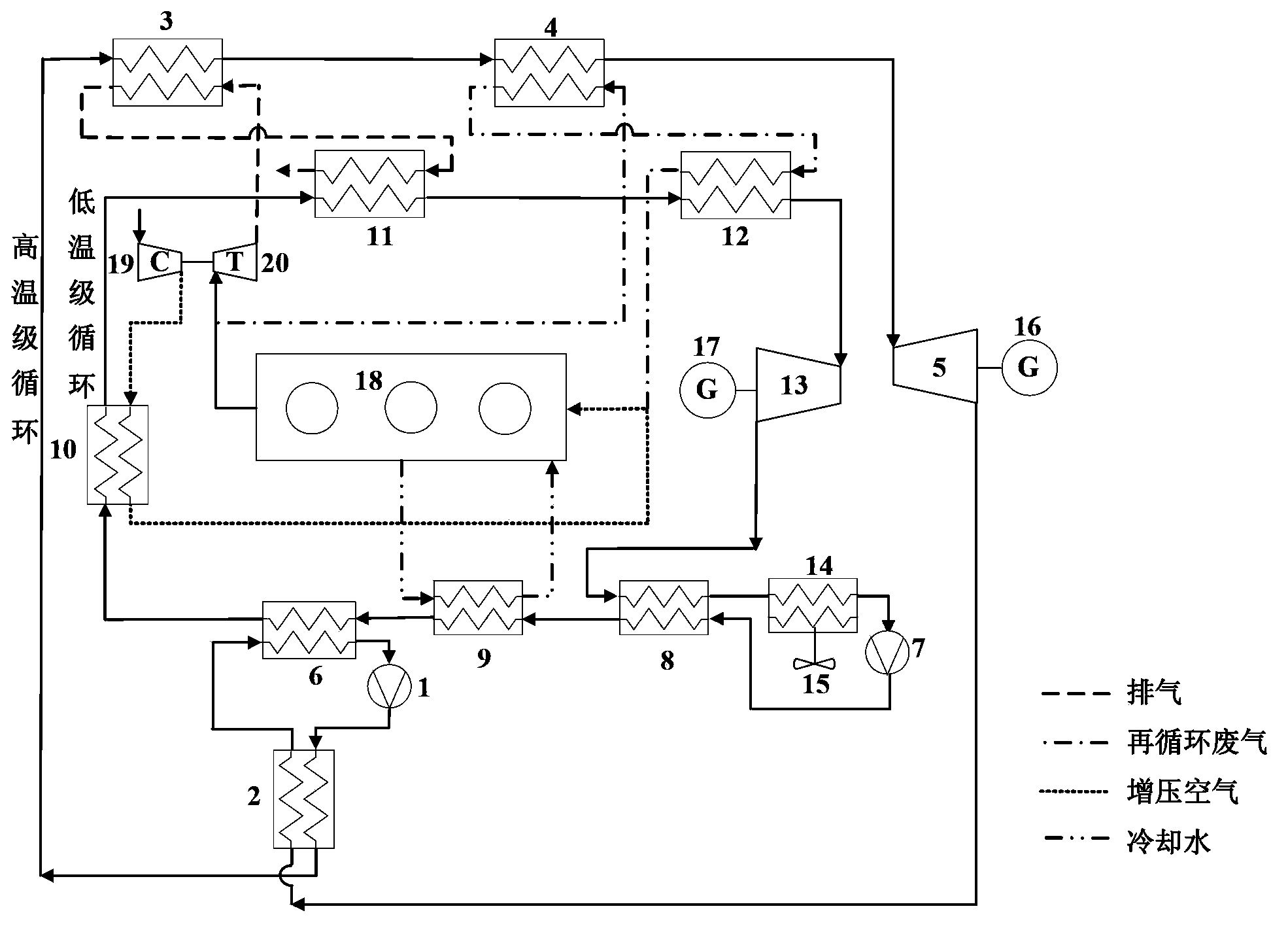

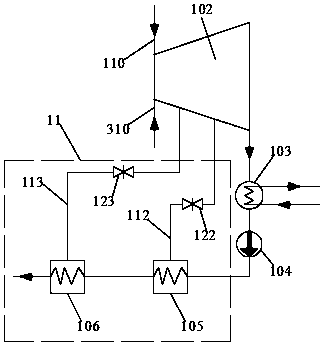

Combined cycle thermoelectric conversion system utilizing multi-grade waste heat of internal combustion engine

ActiveCN103352772ARealize comprehensive utilizationImprove fuel economyInternal combustion piston enginesEngine componentsOrganic Rankine cycleExhaust gas recirculation

The invention provides a combined cycle thermoelectric conversion system utilizing multi-grade waste heat of an internal combustion engine. According to the system, combined organic Rankine cycle is formed by high-temperature grade cycle and low-temperature grade cycle, heat is supplied by exhaust waste heat of the internal combustion engine, supercharged and mid-cooling waste heat, exhaust gas recirculation waste heat and cooling water waste heat, a cooling quantity is provided by cold wind, and the system comprises a high-temperature grade working medium pump, a high-temperature grade heat regenerator, a high-temperature grade exhaust heater, a high-temperature grade EGR (exhaust gas recirculation) heater, a high-temperature grade expansion engine, a high-temperature grade condenser, a low-temperature grade working medium pump, a low-temperature grade heat regenerator, a low-temperature grade cooling water heater, a low-temperature grade supercharged air heater, a low-temperature grade exhaust heater, a low-temperature grade EGR heater, a low-temperature grade expansion engine, a low-temperature grade condenser, a low-temperature grade condenser fan and a power generator. According to the combined cycle thermoelectric conversion system utilizing multi-grade waste heat of the internal combustion engine, comprehensive and efficient utilization of multi-grade waste heat of the internal combustion engine can be achieved, further, irreversible loss is smaller when both the high temperature and the low temperature adopt supercritical expanding cycle, and the integral efficiency of the internal combustion engine can be effectively improved.

Owner:TIANJIN UNIV

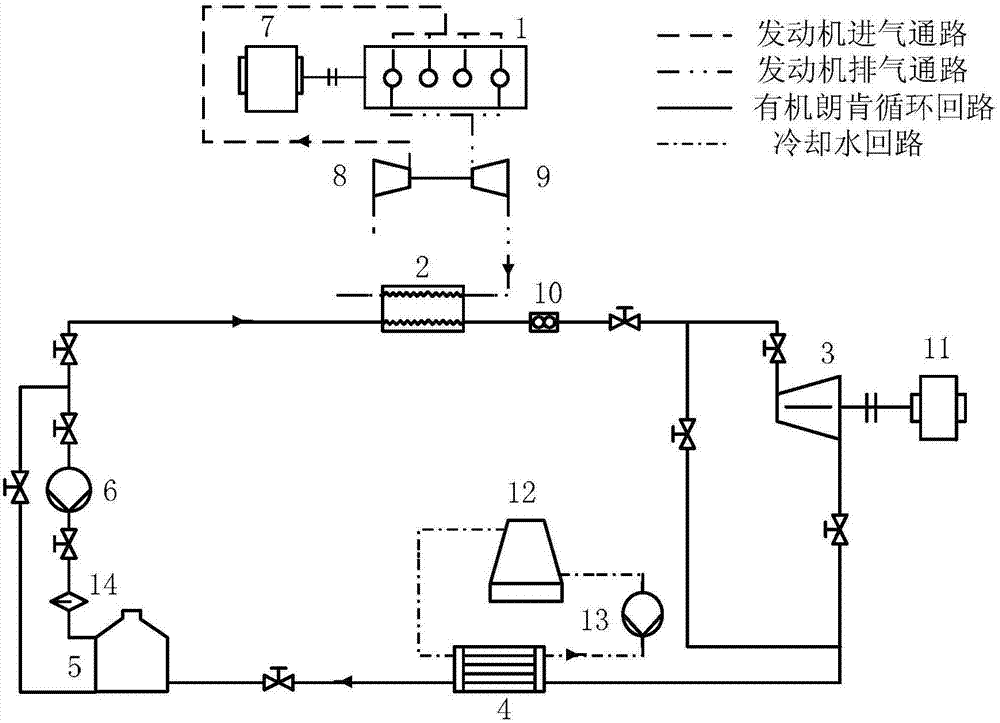

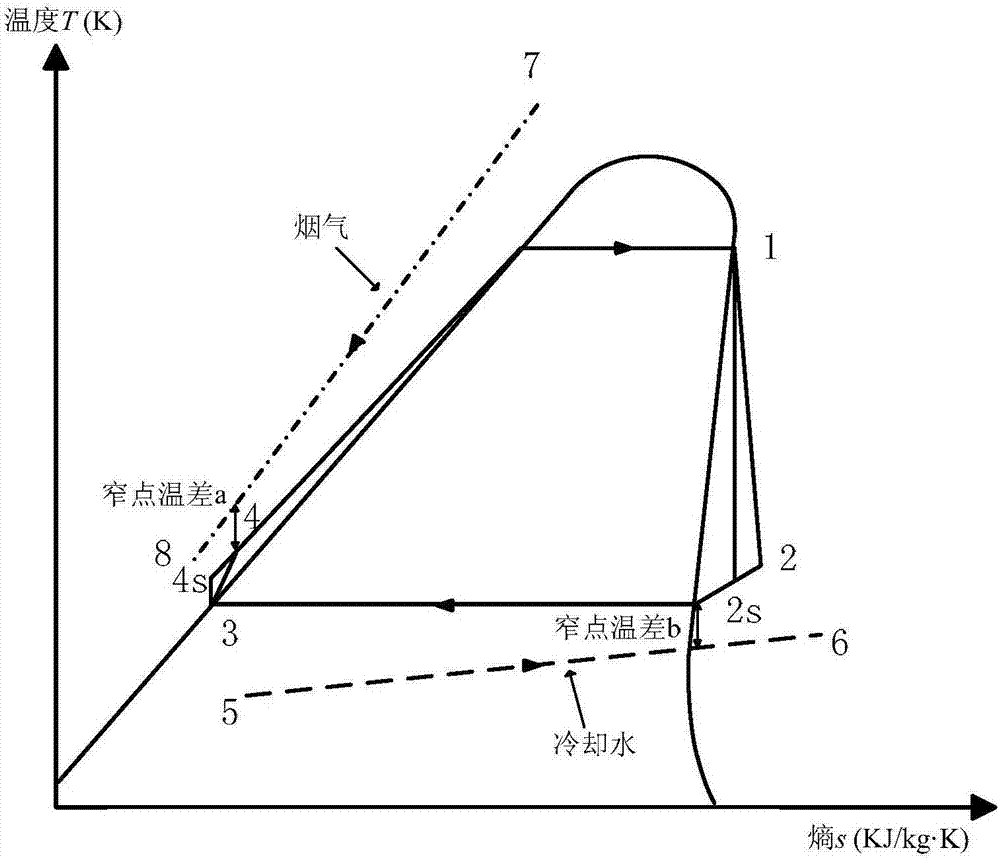

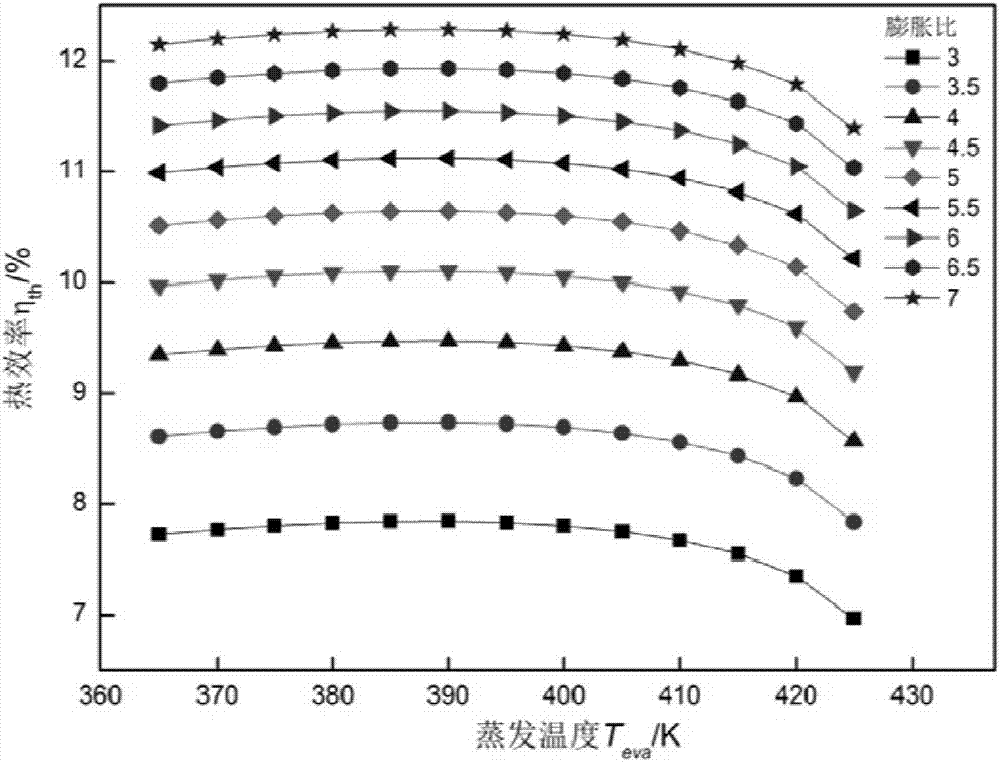

Optimization method for determining flue gas excess heat organic Rankine cycle system parameter

InactiveCN107016187AIncrease profitEmission reductionGeneral water supply conservationForecastingOrganic Rankine cycleSecond law of thermodynamics

The invention provides an optimization method for determining a flue gas excess heat organic Rankine cycle system parameter. The optimization method comprises the steps of taking into account of a cooling water cycle to establish a thermodynamic model; through a first law of thermodynamics and a second law of thermodynamics, obtaining system net output power, water pump waste power, heat efficiency, (the formula is shown in the description) efficiency and irreversible loss, and according to the influence of an evaporation temperature and an expansion ratio on system thermodynamic performance, determining an optimal evaporation temperature; under the optimal evaporation temperature, calculating heat exchange areas of an evaporator and a condenser, wherein it is defined that an economical objective function is the ratio of the system net output power to the area of the evaporator to the area of the condenser, and the comprehensively evaluation function is the weighted sum the economical objective function (the formula is shown in the description) and the efficiency; with the comprehensive evaluation function being an optimization target, determining an optimal condensation temperature; according to the optimal evaporation temperature and the optimal condensation temperature, determining system parameters of work medium mass, cooling water mass, evaporation pressure, condensation pressure, an expansion ratio, the net output power, the heat efficiency and the irreversible loss. According to the optimization method for determining the flue gas excess heat organic Rankine cycle system parameter, the optimal evaporation temperature and the condensation temperature can be determined, and thus the optimal system parameter is determined.

Owner:TIANJIN UNIV

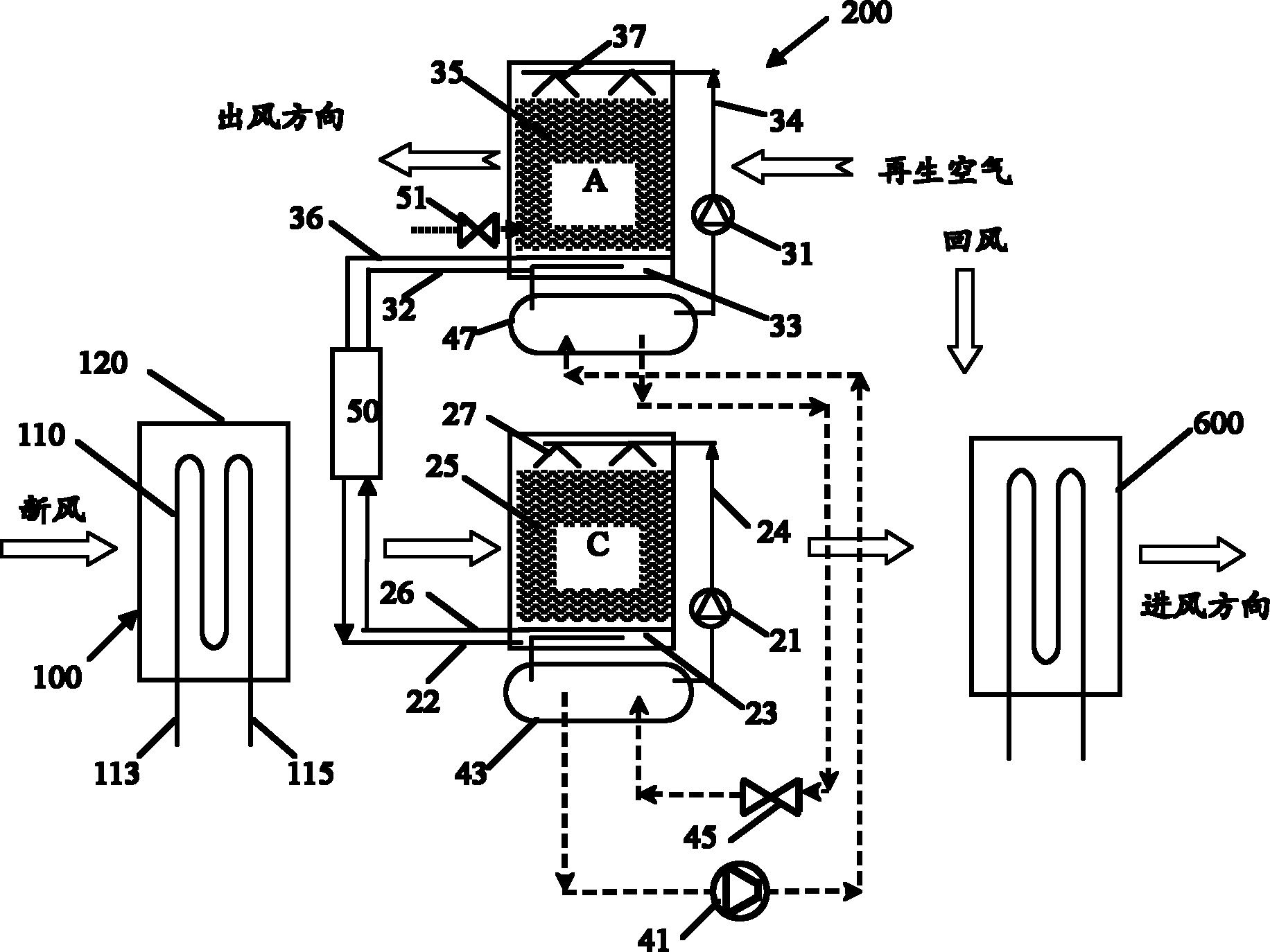

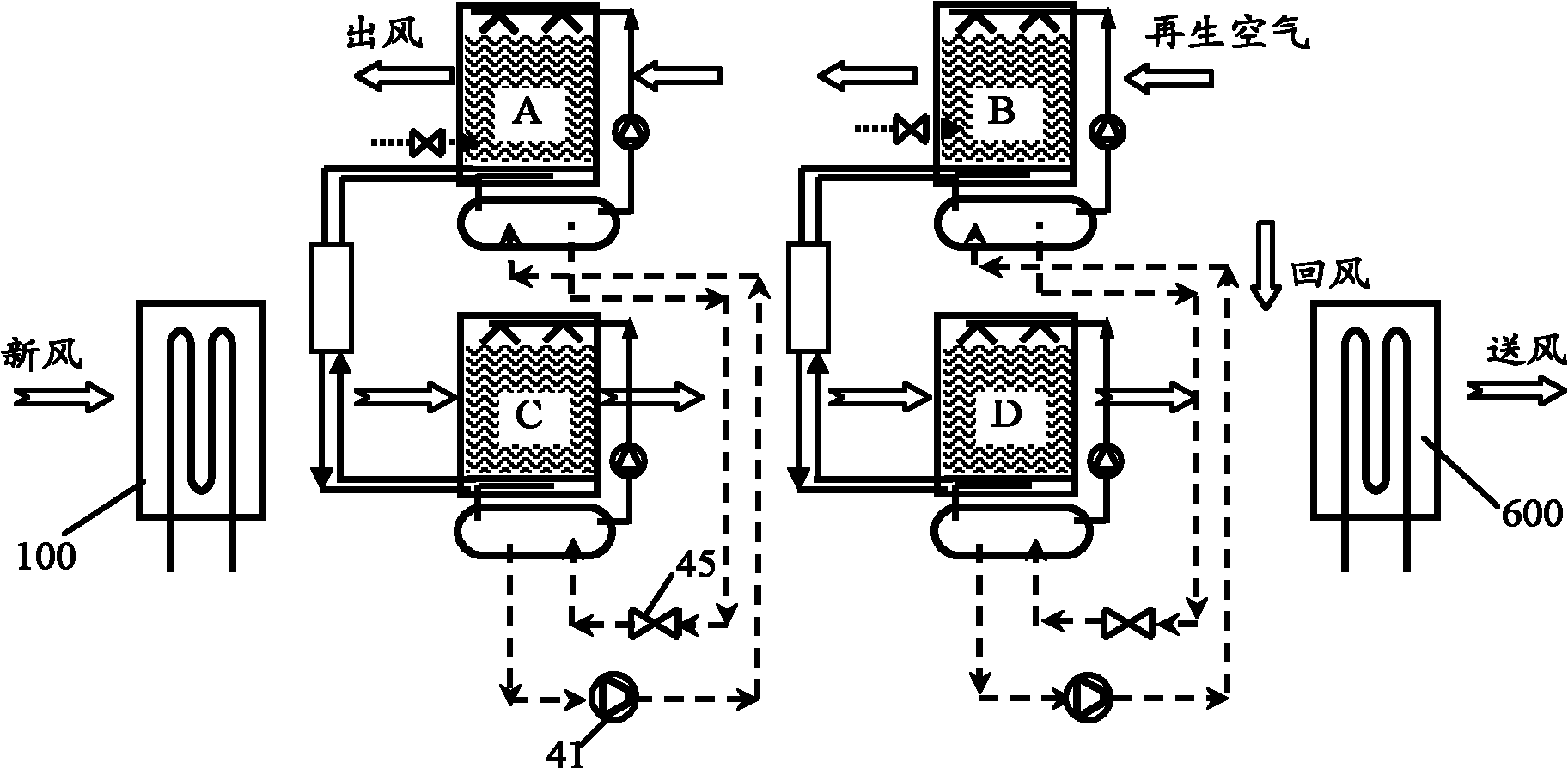

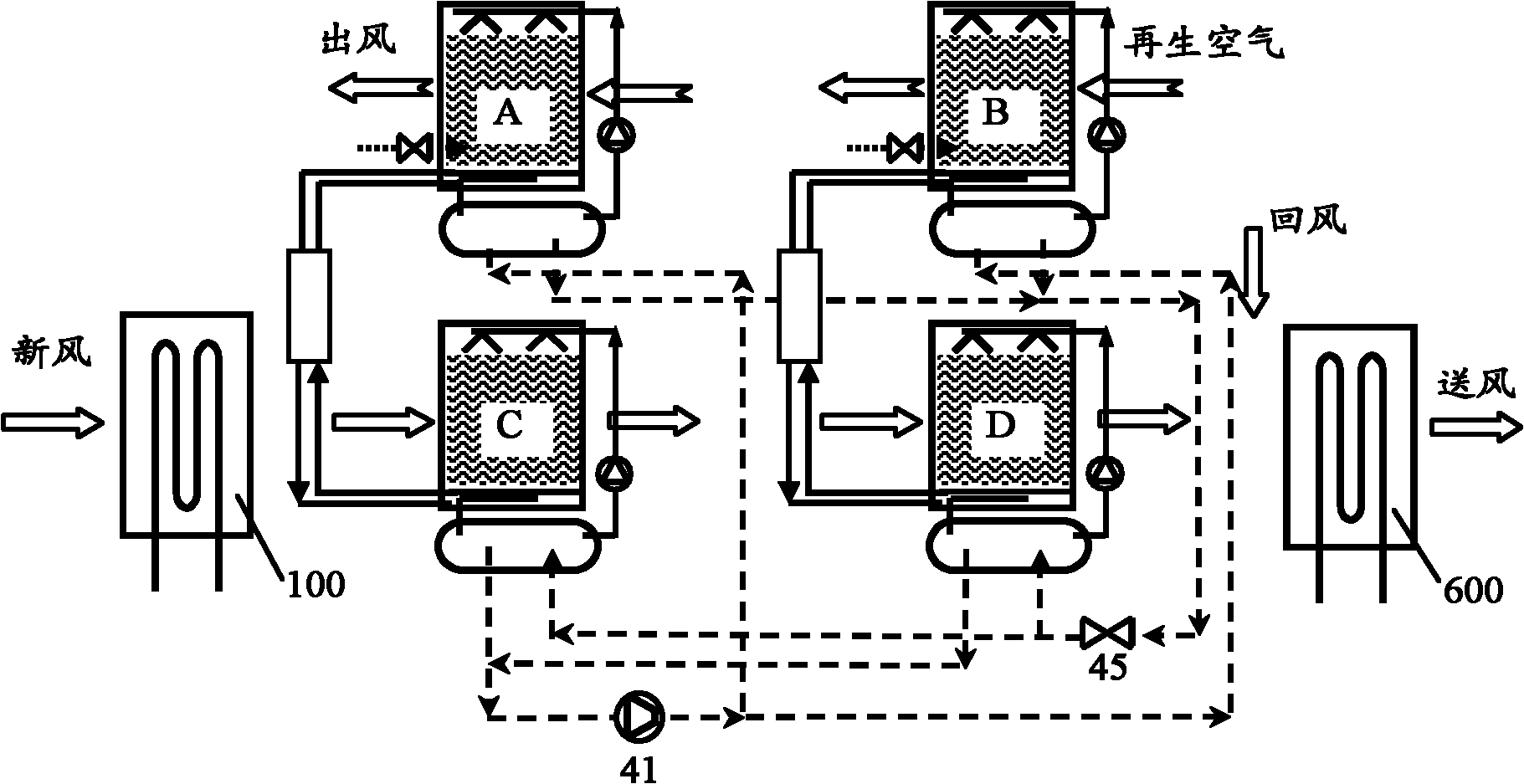

Solution humidifying air conditioning unit with fresh air pretreatment device

InactiveCN102252380AAvoid the problem of reduced dehumidification capacityReduce moisture contentLighting and heating apparatusAir conditioning systemsAir treatmentFresh air

The invention provides a solution humidifying air conditioning unit with a fresh air pretreatment device. The solution humidifying air conditioning unit comprises a solution humidifying air treatment unit and a first pre-cooling / heating device; the solution humidifying air treatment unit is provided with a first air inlet passage and an air outlet passage; and the first pre-cooling / heating device is positioned at the upstream of the first air inlet passage. The solution humidifying air conditioning unit reduces the irreversible loss, can achieve relatively high thermodynamic completeness, and remarkably improves the dehumidifying / humidifying efficiency.

Owner:BEIJING SINOREFINE AIR CONDITIONING TECH

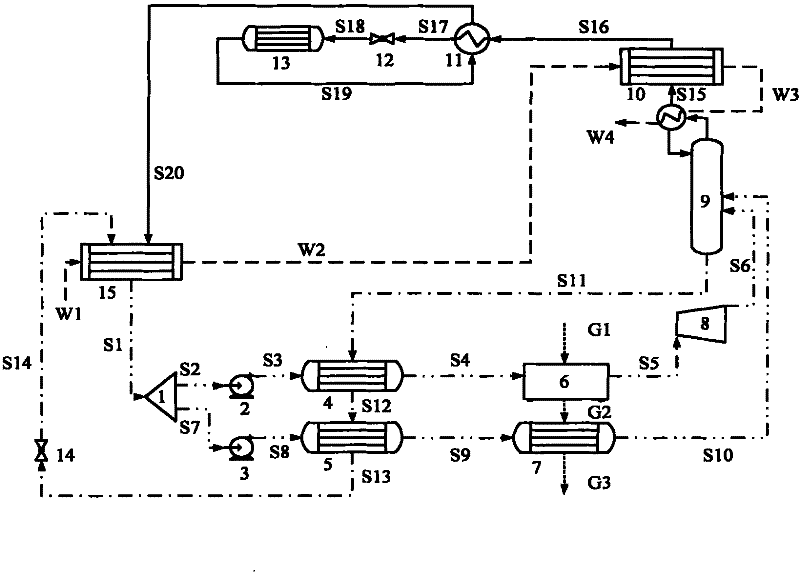

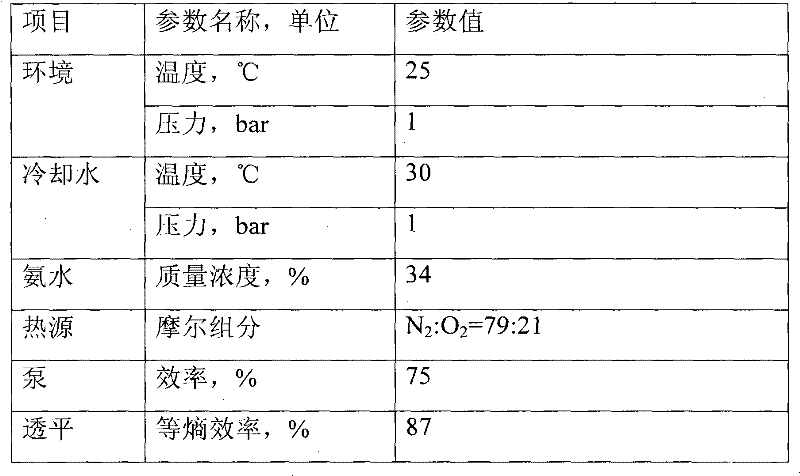

Low-temperature multi-effect seawater desalination process

InactiveCN1837075AEfficient recyclingIncrease temperatureGeneral water supply conservationSeawater treatmentSpecial designEnergy recovery

This invention refers to a method about low-temperature multiple-effect desalination of sea water, especially about a new method which effectively applied thermal pumping power-saving technology to desalination of sea water. The desalination of sea water system which apply this method has n effect evaporator(n=2-50) and one condensator aggregately, containing six systems of feeding seawater, recirculated salt water, product water, vacuum, incoagulable gas removal, thermal pumping circulation and starting heating in addition. This invention is based on irreversible thermodynamics principle, via organic integration of evaporator, condensator and low-temperature multiple-effect desalination of sea water system in closed circuit thermal pumping system, as well as special design of energy recovery tache in low-temperature multiple-effect desalination of sea water, decreasing irreversible loss of diversified thermal transmission course which the desalination of sea water refers to in maximum limit, sequentially letting the entropy increasing of whole desalination of sea water course be the least, realizing efficient energy-saving desalination of sea water course.

Owner:QINGDAO UNIV

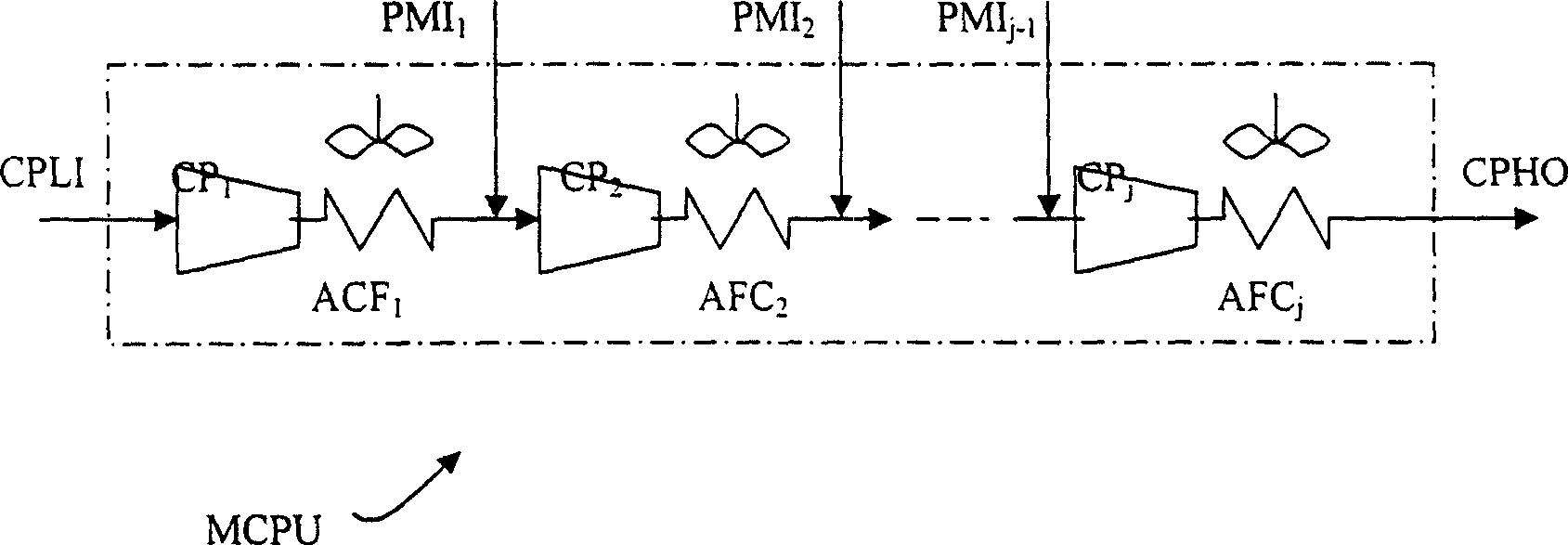

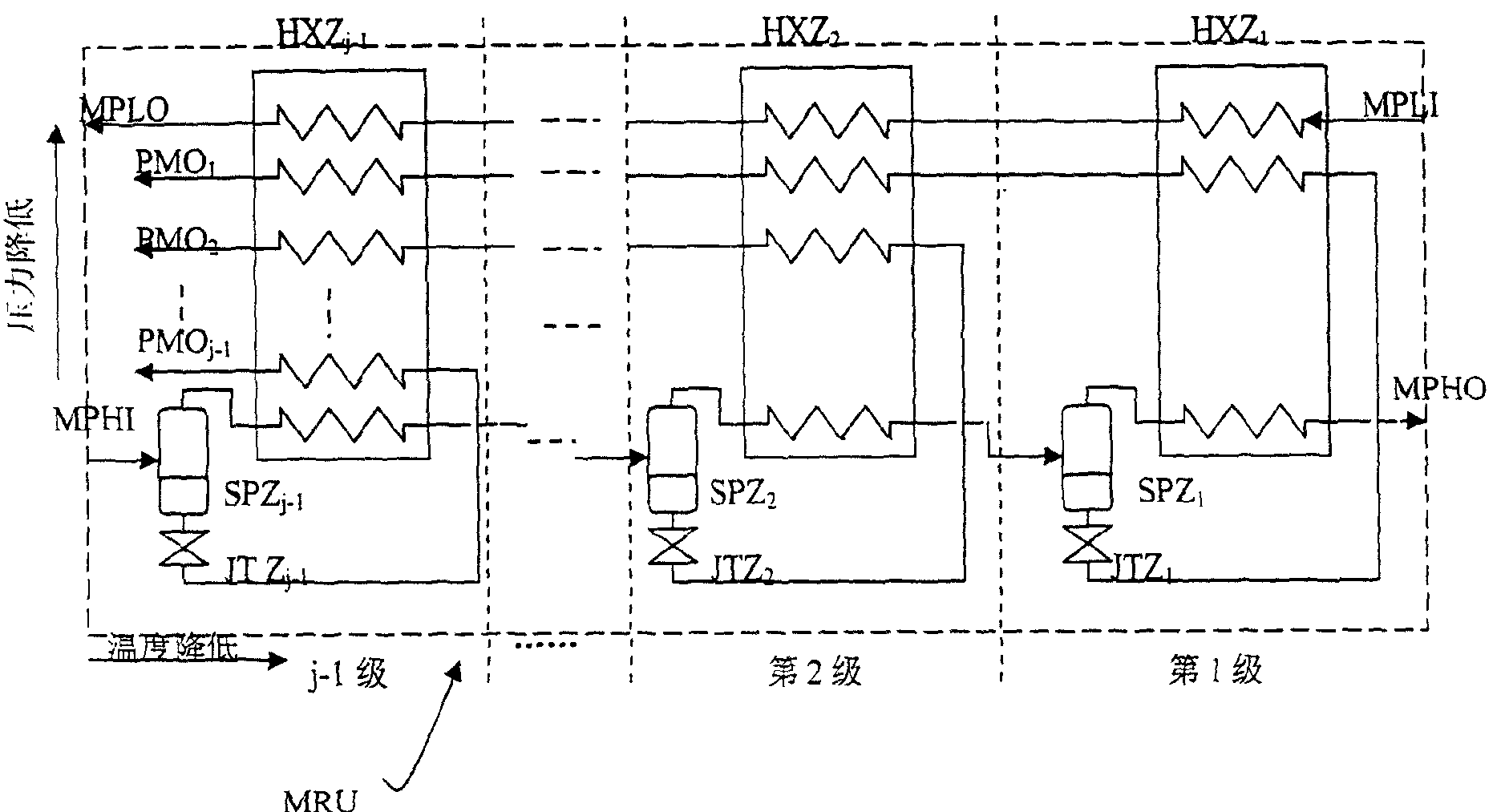

Multiple pressure grade mixed working medium cryogenic throttling refrigeration system

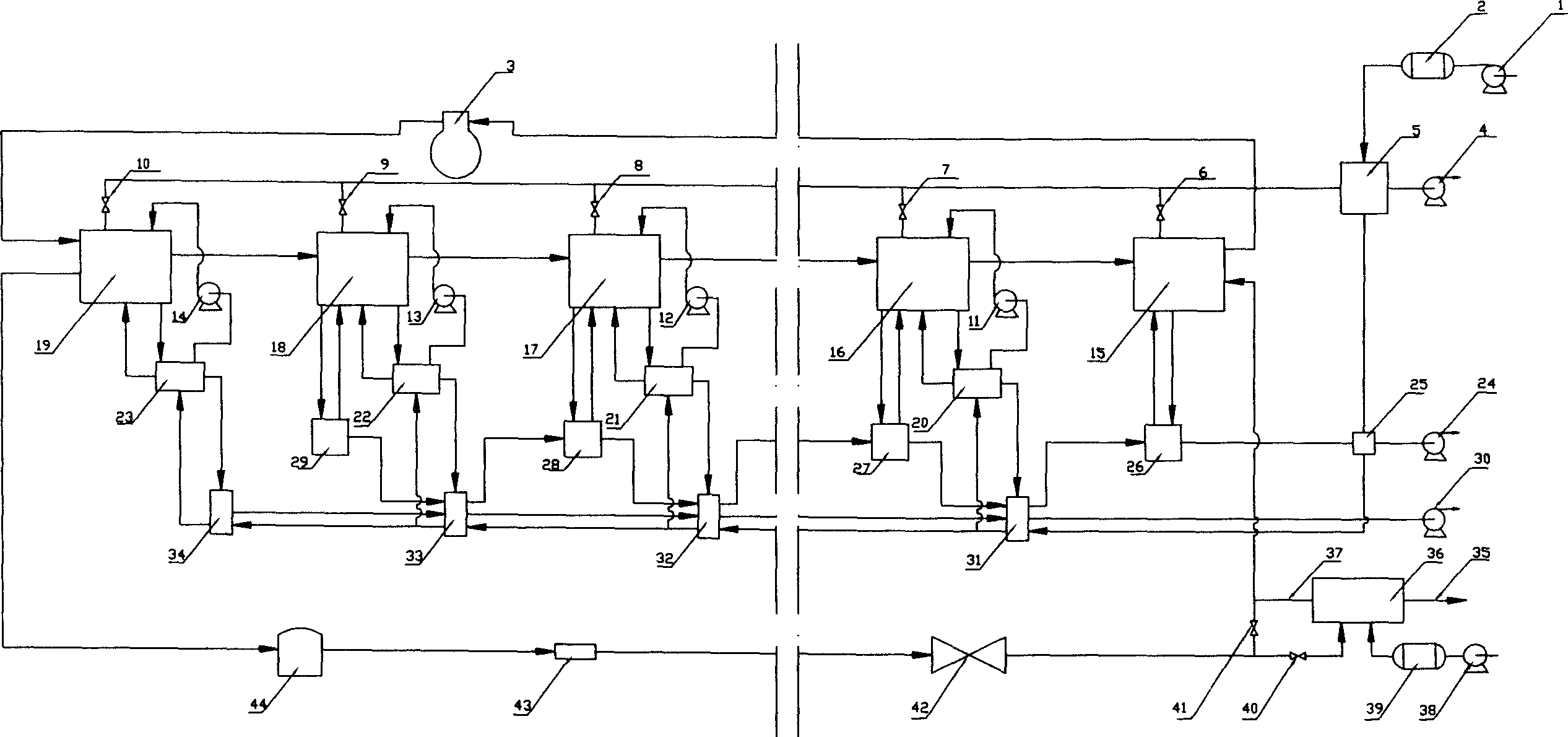

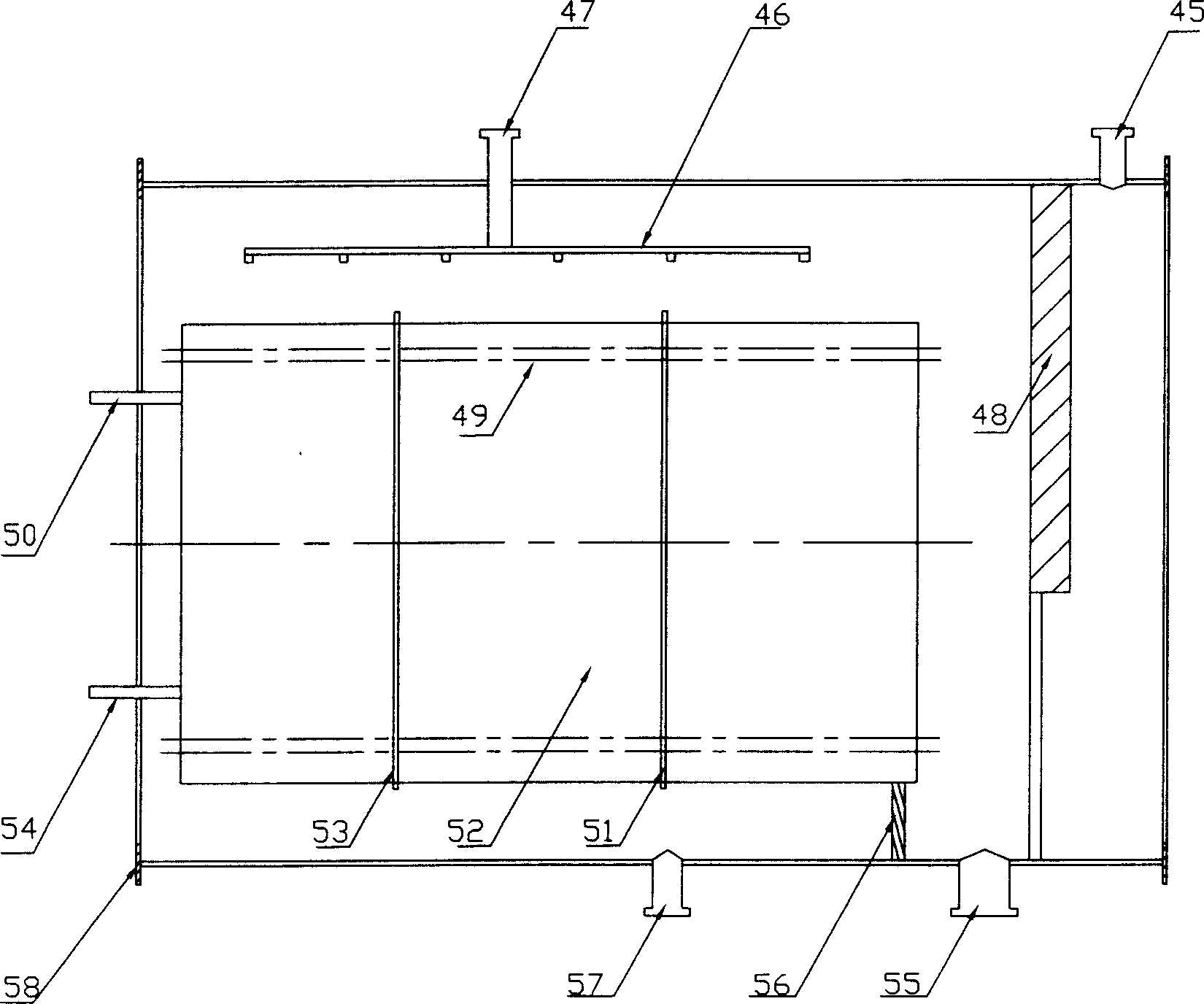

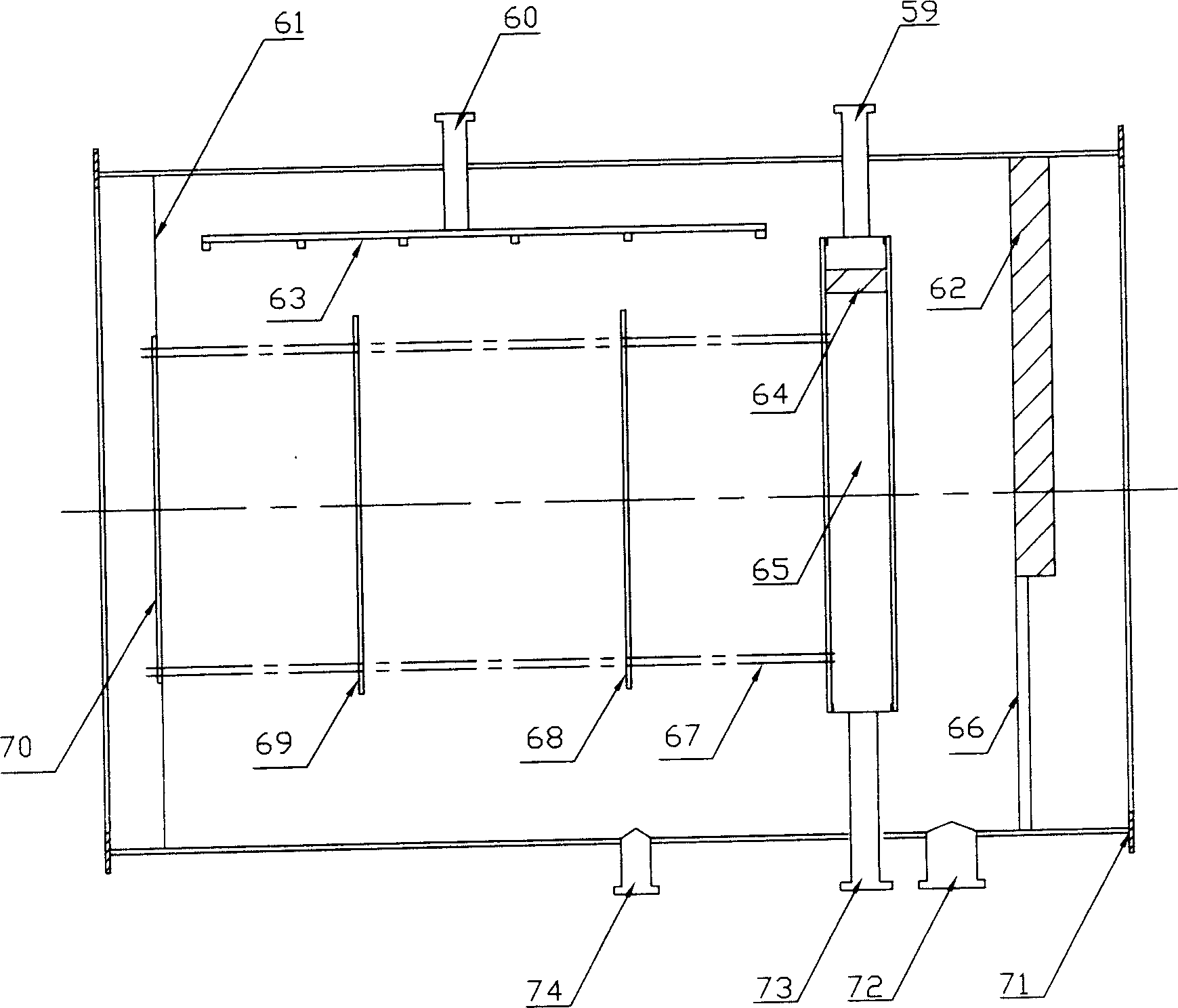

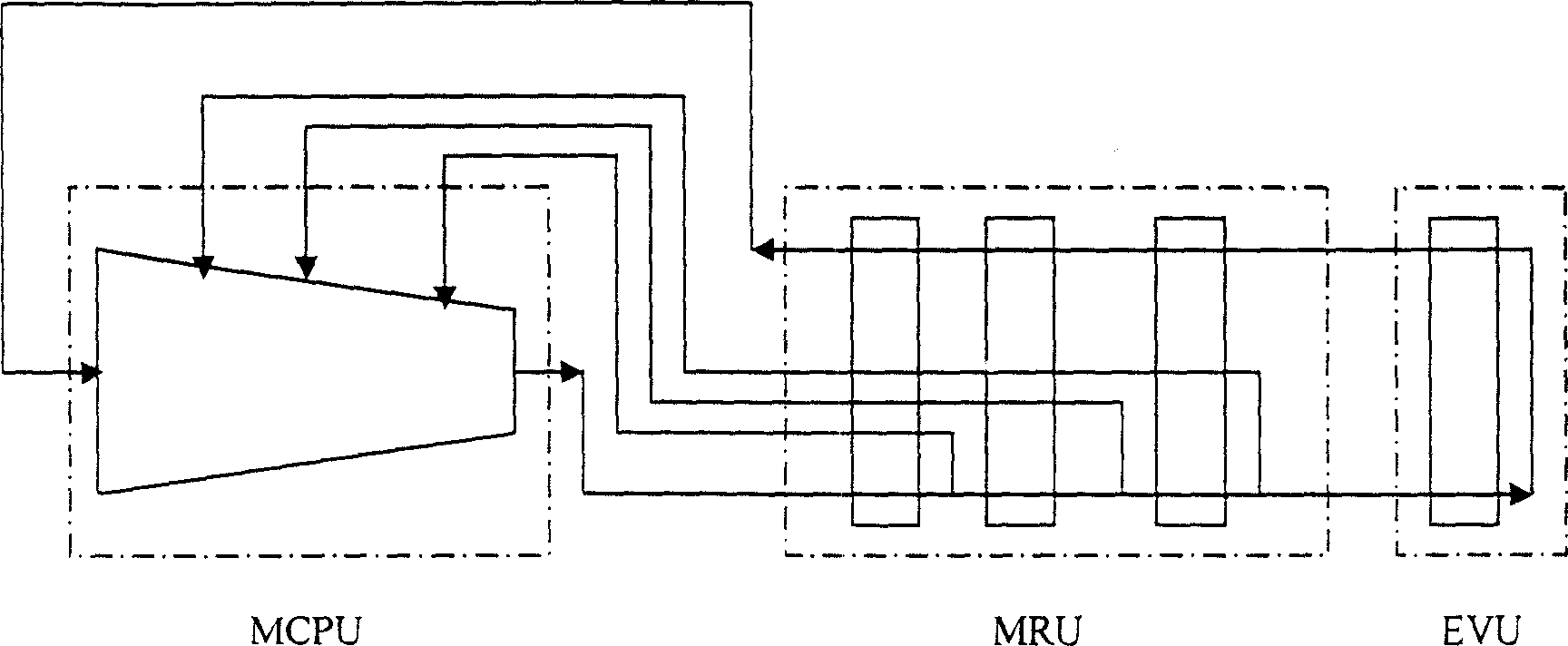

ActiveCN1683844AHigh thermal efficiencyGood throttling effectSolidificationLiquefactionProduct gasEngineering

The multiple pressure stage mixed work medium cryogenic throttling refrigeration system consists of several stages of compressor set unit MCPU, back heating pre-cooling unit MRU and evaporator unit EVU. The connection mode includes connecting the high pressure outlet of MCPU to the high pressure inlet of MRU, connecting the low pressure inlet of MCPU to the low pressure outlet one MRU, connecting the high pressure outlet operate MRU to the inlet of EVU, and connecting the outlet of EVU to the low pressure inlet of MRU. The present invention adopts high efficiency multiple-element mixed work medium. The refrigeration system has lowered irreversible loss of compression and back heating process thermodynamically, reduced loss in the practical flow and heat exchange process, and thus high thermodynamic efficiency, and is especially suitable for large and middle scale low temperature refrigerating and gas liquefying fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Combined cooling power generation composite system based on supercritical organic Rankine cycle

InactiveCN103195526AGuaranteed uptimeGuaranteed safe operationCompression machines with non-reversible cycleSteam useElectricityOrganic Rankine cycle

The invention provides a combined cooling power generation composite system based on a supercritical organic Rankine cycle and belongs to the field of industrial energy conservation. An expansion machine, a power generator and a steam compressing cold cycling compressor of the Rankine cycle are connected coaxially, same organic working medium is used to be simultaneously cooled in a condenser, and a steam compressing refrigerating cycle is coupled effectively on the basis of basic organic Rankine cycle. In addition, supercritical pressure is used to allow heat rising of organic working medium in a heat absorber to be well matched with temperature changing curve of a heat source, system irreversible loss is further lowered, and waste heat recycling rate is improved. Industrial smoke water heat or other water heat sources are used as driving force, combined cooling power generation is performed by taking refrigerating as priority, refrigerating is not performed by using smoke waste heat for power generation and using power for refrigerating, and accordingly loss caused by energy conversion is reduced. Cooling amount and power output amount can be flexibly adjusted according to cooling amount requirements.

Owner:CHONGQING UNIV

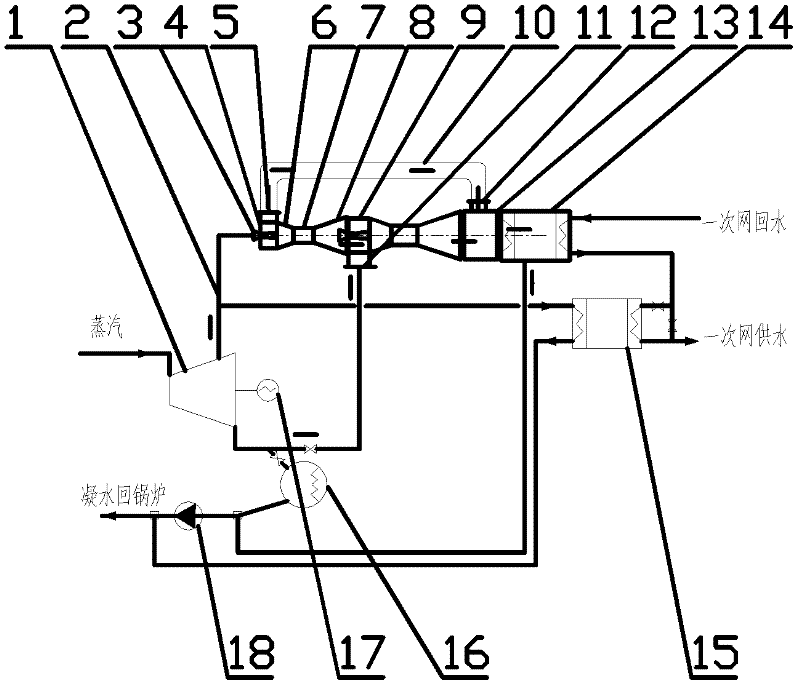

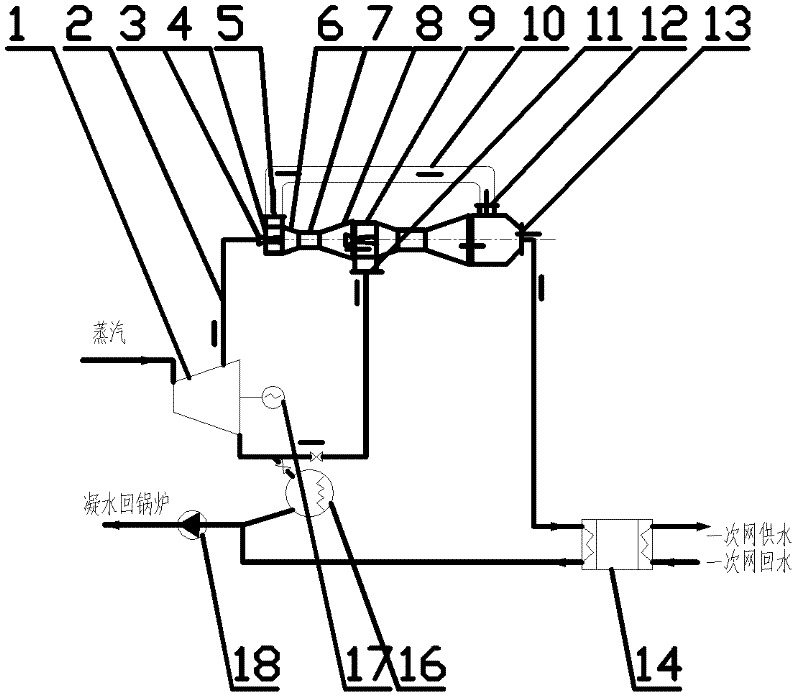

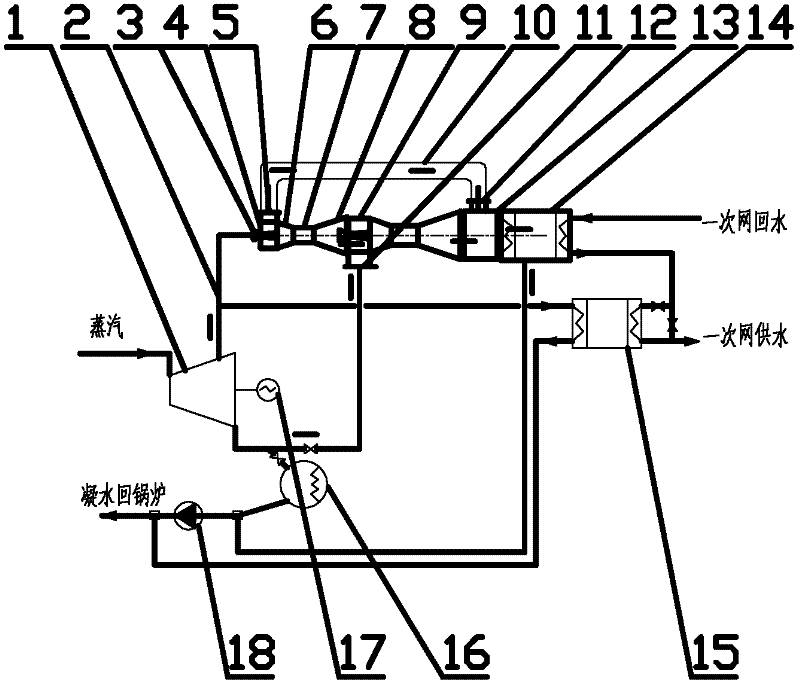

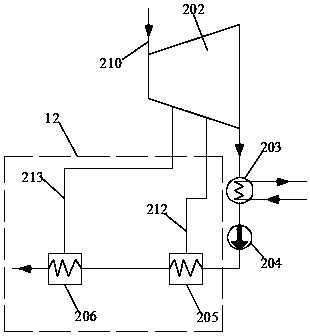

Multi-effect cascade jet type heat exchange based exhaust steam waste heat recovering and heat and power jointly producing system

InactiveCN102519069AIncrease heating rateImprove energy efficiencyHeat recovery systemsLighting and heating apparatusWhole bodyCogeneration

The invention relates to a multi-effect cascade jet type heat exchange based exhaust steam waste heat recovering and heat and electrical jointly producing system, belonging to the field of exhaust steam waste heat recovering and heat and power joint producing. The system comprises a steam turbine, a multi-effect cascade jet heat pump, a heating network last-stage heater, a low-pressure steam-water heater, a high-temperature heating network heater, a steam condenser, a power generator and a condensate pump. The multi-effect cascade jet heat pump comprises a cascade first-stage mixing section, a cascade first-stage throat part, a cascade first-stage diffusing section, a cascade last-stage diffusing section, and a cascade last-stage distributor which are connected into a whole body in sequence, wherein the cascade first-stage mixing section is provided with a cascade first-stage jet opening. The system adopts the multi-effect cascade workflow, thereby the irreversible loss of the jet heat pump is greatly reduced, a large proportion of the exhaust steam is mixed with the medium-pressure extraction steam used as the driving steam, and the pressure is increased greatly. The primary heating network returns water, the technical problems of recovering the exhaust steam waste heat efficiently by adopting the jet heat pump and supplying heat by using the recovered exhaust steam waste heat are solved, and the waste heat recovering capacity is improved by several times.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

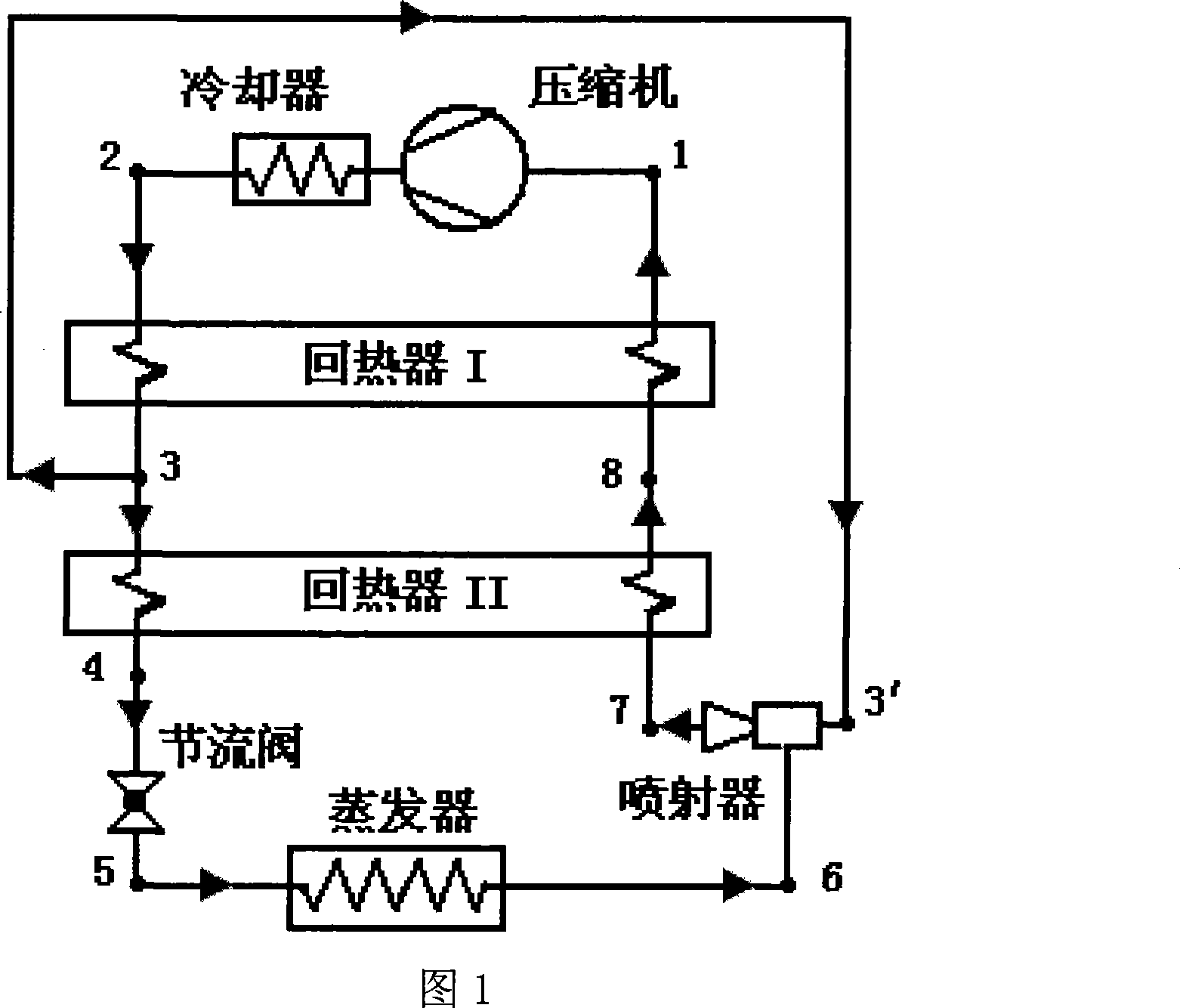

Small-sized throttle low temperature refrigerator circulating system with injector

InactiveCN101158517ASimple structureNo moving partsCompression machinesFluid circulation arrangementEngineeringCooling capacity

The invention discloses a small-scale throttling low-temperature refrigerator circulation system with an ejector, which comprises a compressor connected to a pipeline, a cooler, two regenerators and a throttle valve. Another ejector is further arranged between a second regenerator and an evaporator. By utilizing the effects of expansion and pressurization of the ejector, the invention can enhance the suction pressure of the compressor, lower the pressure ratio and the air absorption ratio capacity of the compressor, thus correspondingly lowering the unit power consumption of the compressor and enhancing the gas transmission rate of the compressor, increasing the cooling capacity of the system and enhancing the performance coefficient of the system. On the other hand, the ejector is adopted to result in that the heat exchange water equivalent of two sides of the regenerator is more matched, thus improving the heat recovery process and reducing the irreversible loss in the heat recovery process. Thereby, the small-scale throttling low-temperature refrigerator circulation system with an ejector has obvious advantages with respect to improving the performance of the throttling refrigeration system.

Owner:XI AN JIAOTONG UNIV

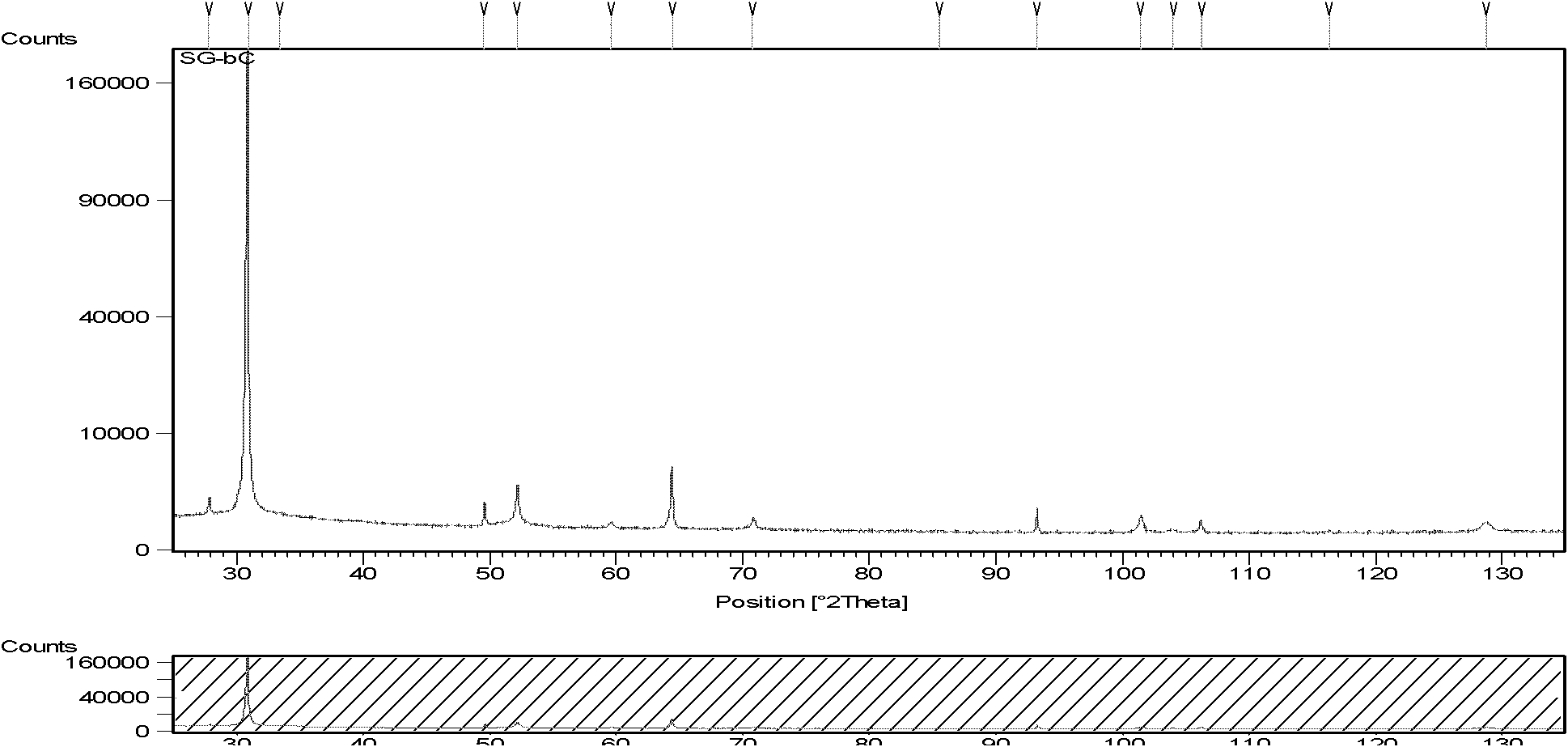

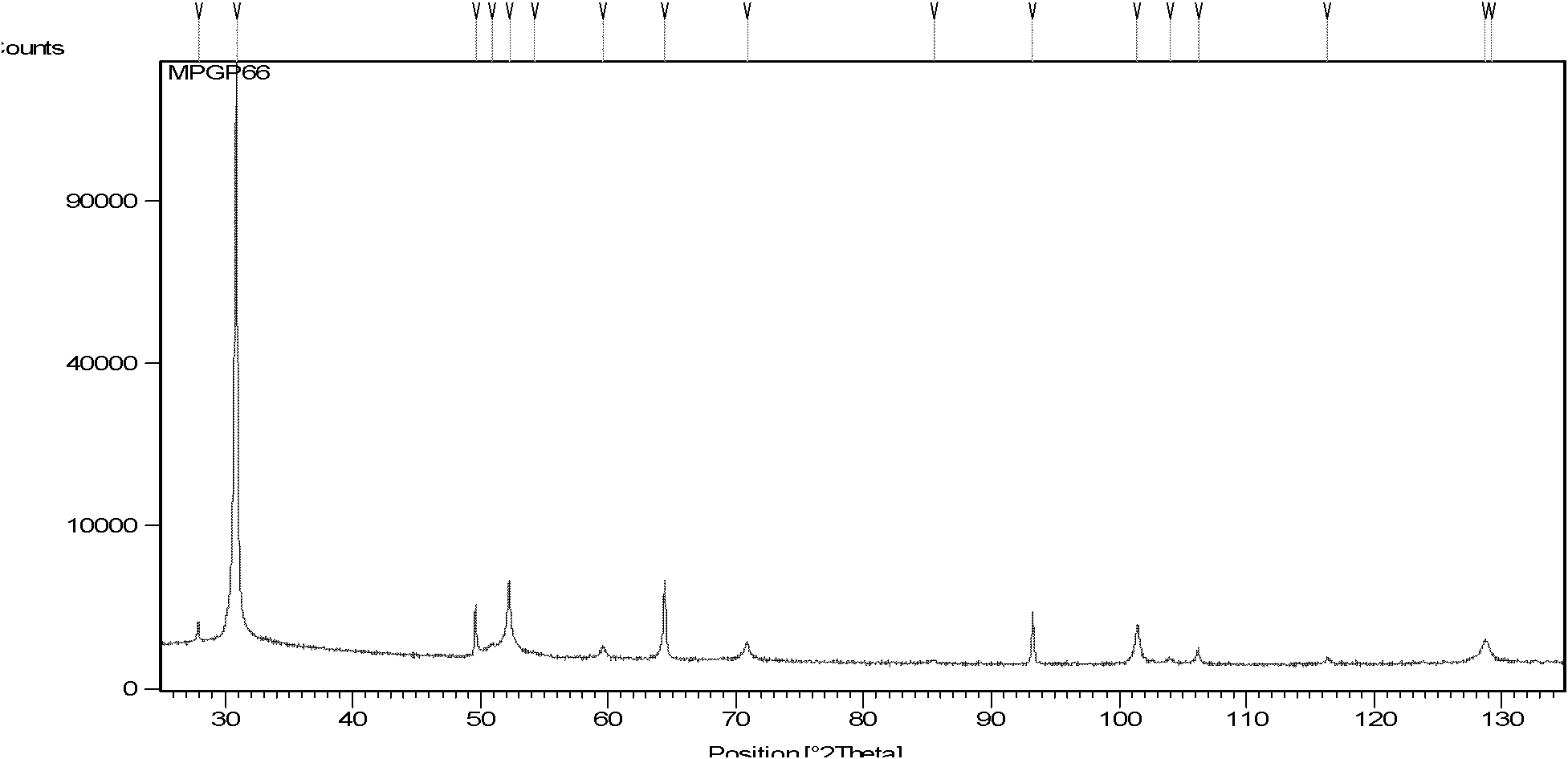

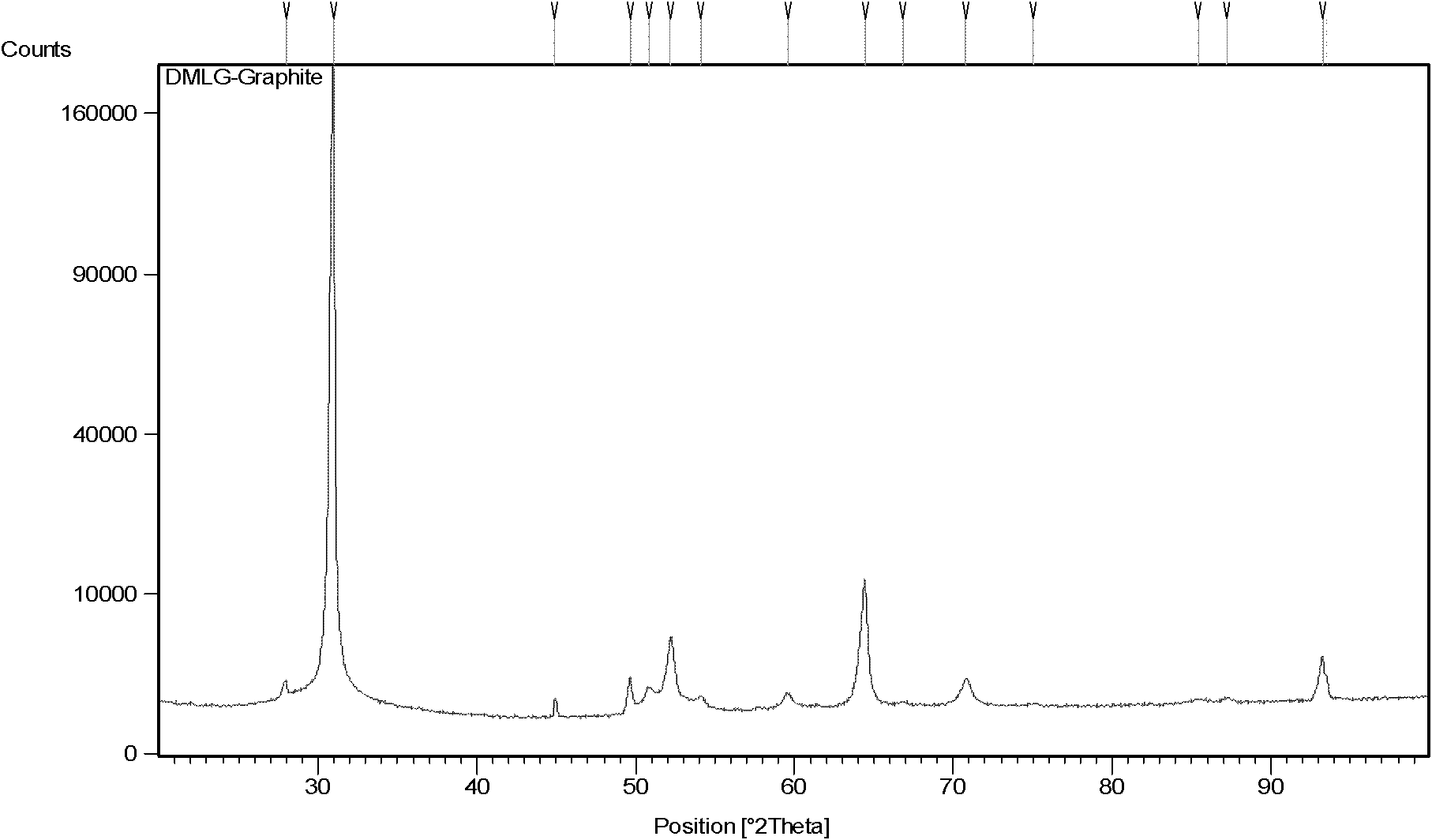

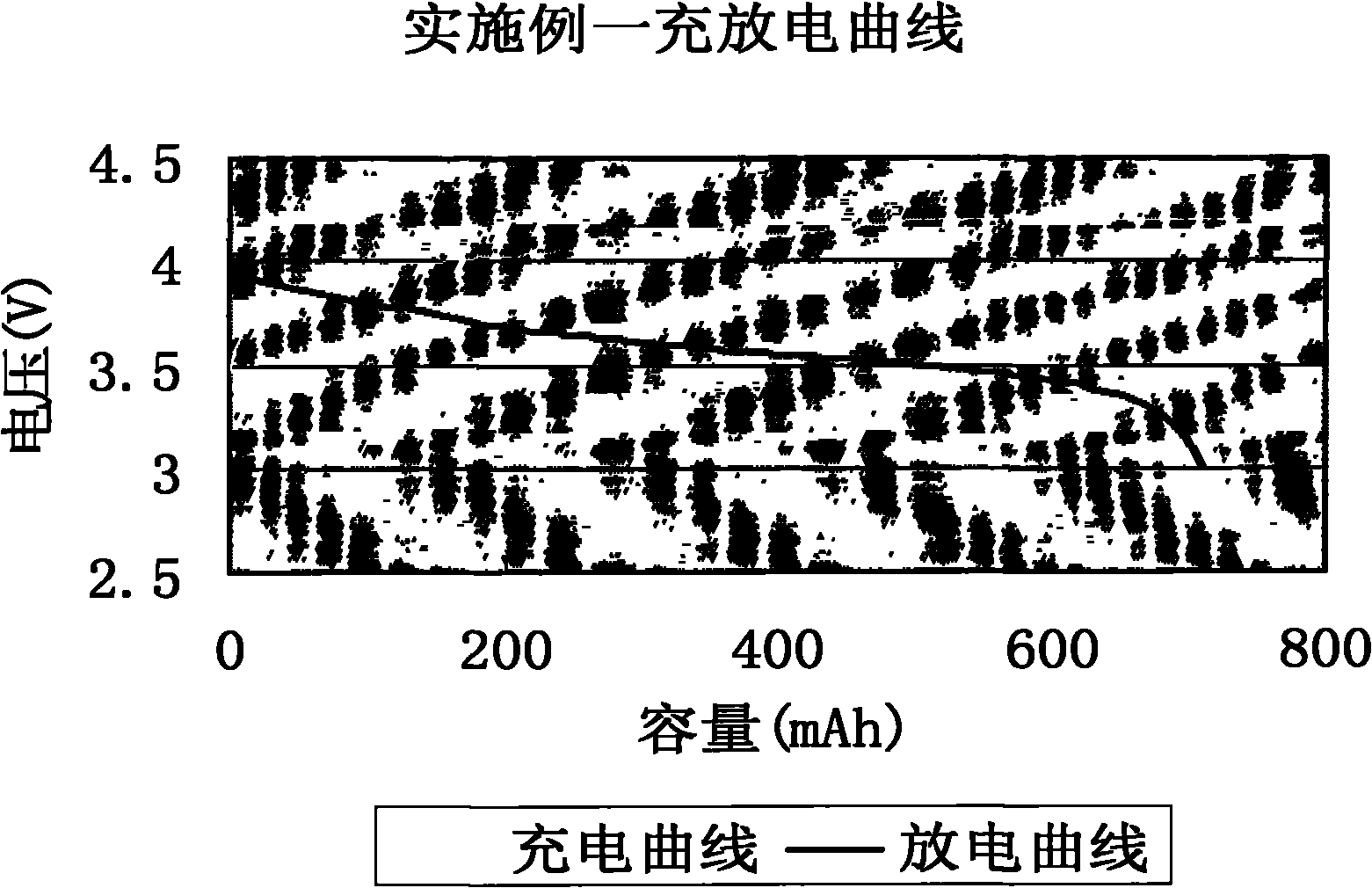

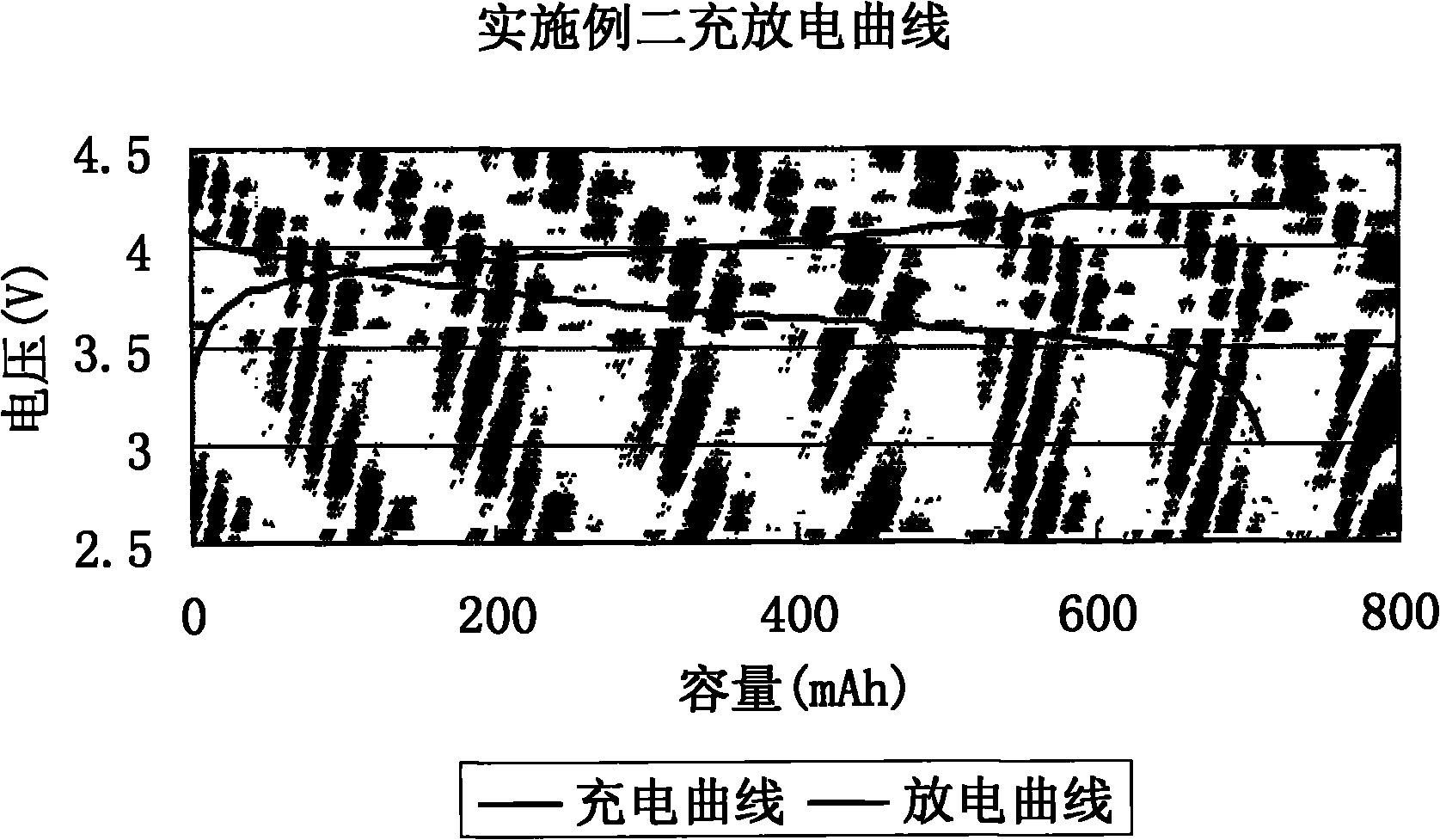

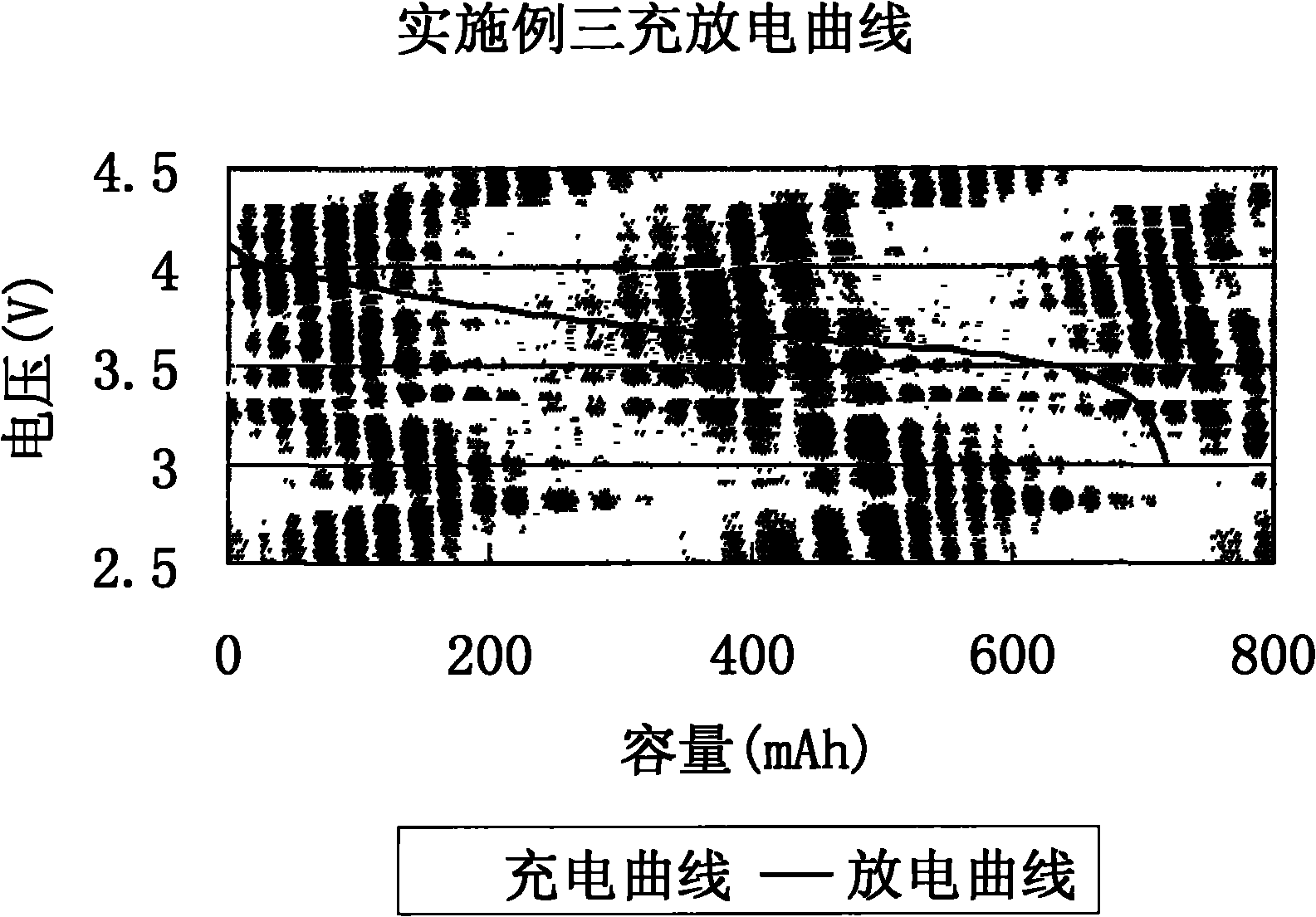

Lithium ion battery cathode material and preparation method thereof

The invention discloses a lithium ion battery cathode material and a preparation method thereof. The preparation method adopts graphite micropowder as a core material and comprises the following steps of coating at least one carbon compound on the surface of the core material to form a first coating layer, carrying out a secondary coating process by utilizing at least one carbon compound to form a second coating layer, and carrying out graphitization processing to form a graphite material with a shell-core structure. In the invention, a novel cathode material is synthesized through a two-step granulation method, and can reduce or avoid that a lithium ion battery produces a lithium precipitating phenomenon when the lithium ion battery is charged and discharged at low temperature, thus reduce irreversible loss which belongs to Li <+> and is produced in a lithium ion battery charging-discharging process at low temperature.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

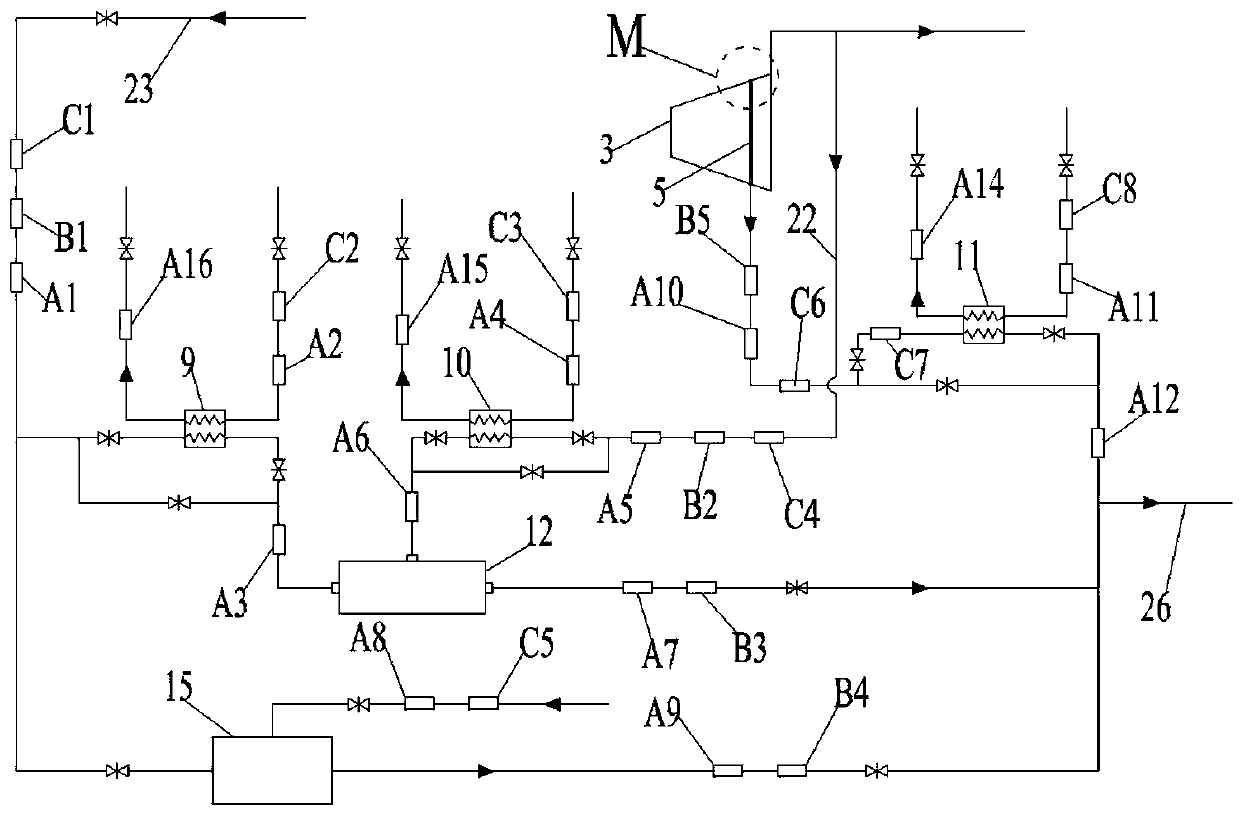

Mixed working medium thermal circulating system and method for power and refrigeration cogeneration

ActiveCN102242985AAchieve the goal of energy saving and emission reductionReduce irreversible lossClimate change adaptationEnergy efficient heating/coolingEvaporationCogeneration

The invention discloses a mixed working medium thermal circulating system and method for power and refrigeration cogeneration. In the system, an ammonia and water mixture is utilized as a working medium, and the middle / low temperature heat is utilized as a heat source. The method comprises the following steps: heating the ammonia water working medium to obtain superheated steam; introducing the superheated steam into a turbine to do work; introducing the exhaust steam of the turbine into a rectification tower to supply heat for the rectification process; introducing the ammonia generated by the rectification tower into an evaporator after condensing, undercooling and throttling; throttling a dilute solution subjected to waste heat recovery, introducing the throttled dilute solution into aabsorber, mixing with the ammonia from the evaporator and condensing; and introducing a heat source into a steam generator firstly, and then introducing the heat source into a waste heat solution heat exchanger. The steam generator adopts the ammonia water strong solution as the working medium, the variable temperature evaporation feature of the ammonia water strong solution is well matched with the temperature of the heat source, thus the irreversible loss of the heat exchange process in the steam generator is reduced; simultaneously the exhaust steam of the turbine directly enters into the rectification tower to supply the rectifying heat without condensation, thus the irreversible loss caused by the variable temperature condensation of the ammonia water working medium is avoided; and the mixed type heat transfer is adopted, thus the irreversible loss of the heat exchange process is reduced.

Owner:江苏中国科学院能源动力研究中心 +1

Energy-saving system for multi-heat-source industry heating of thermal power plant and intelligent control method of energy-saving system

ActiveCN107605553AIncrease diversityReduce work capacity lossSteam useEngine componentsPower capabilityProcess engineering

The invention discloses an energy-saving system for multi-heat-source industry heating of a thermal power plant and an intelligent control method of the energy-saving system. The energy-saving systemis characterized by comprising a boiler, a turbine high-pressure cylinder, a turbine intermediate-pressure cylinder, a turbine low-pressure cylinder, a rotation partition plate, an h-grade regenerative heater, a k-grade regenerative heater, a j-grade regenerative heater, a first heat exchanger, a second heat exchanger, a third heat exchanger, a pressure matcher, a deaerator, a water feed pump, a temperature reducing and pressure reducing device and a steam user. By means of the energy-saving system for multi-heat-source industry heating of the thermal power plant and the intelligent control method of the energy-saving system, the superheat degree of heating steam can be sufficiently recycled, the energy efficiency of the system is improved, power capability losses of a regenerative systemare reduced, the control method for industry heating is further optimized based on the principle that the power capability losses are minimum and the irreversible losses are minimum, and therefore itis ensured that a heating unit can run with the maximum efficiency during full-working-condition running.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

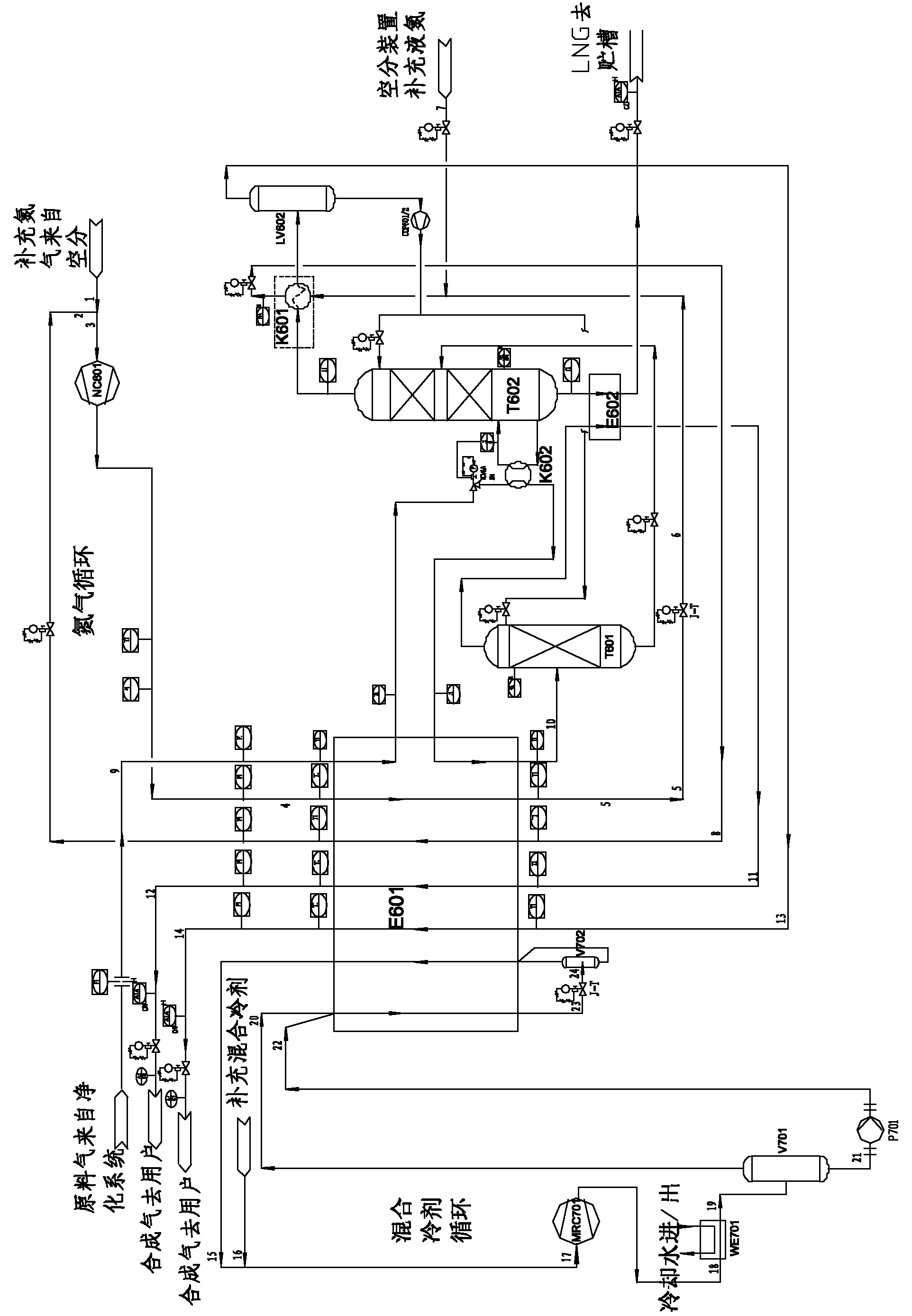

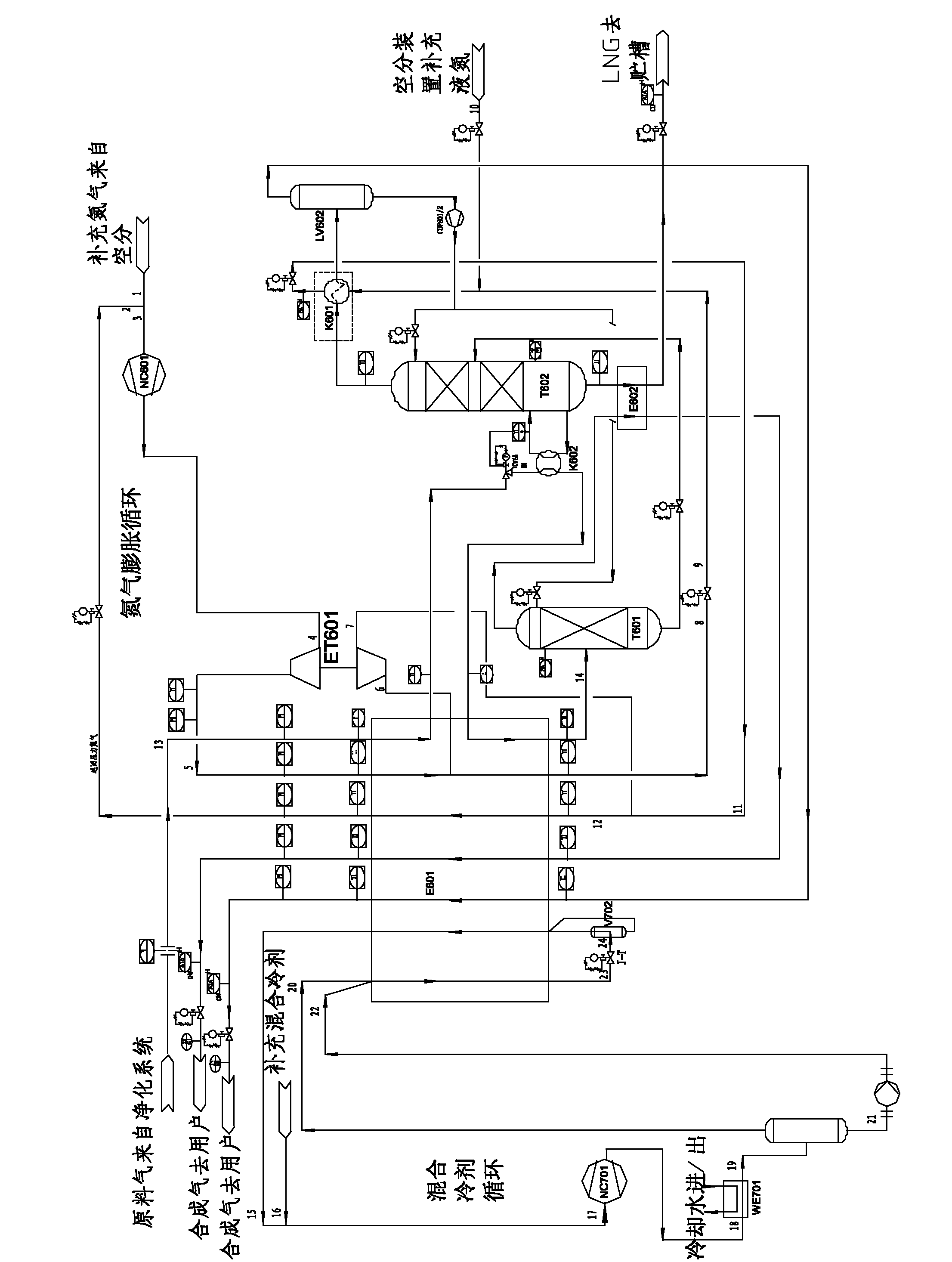

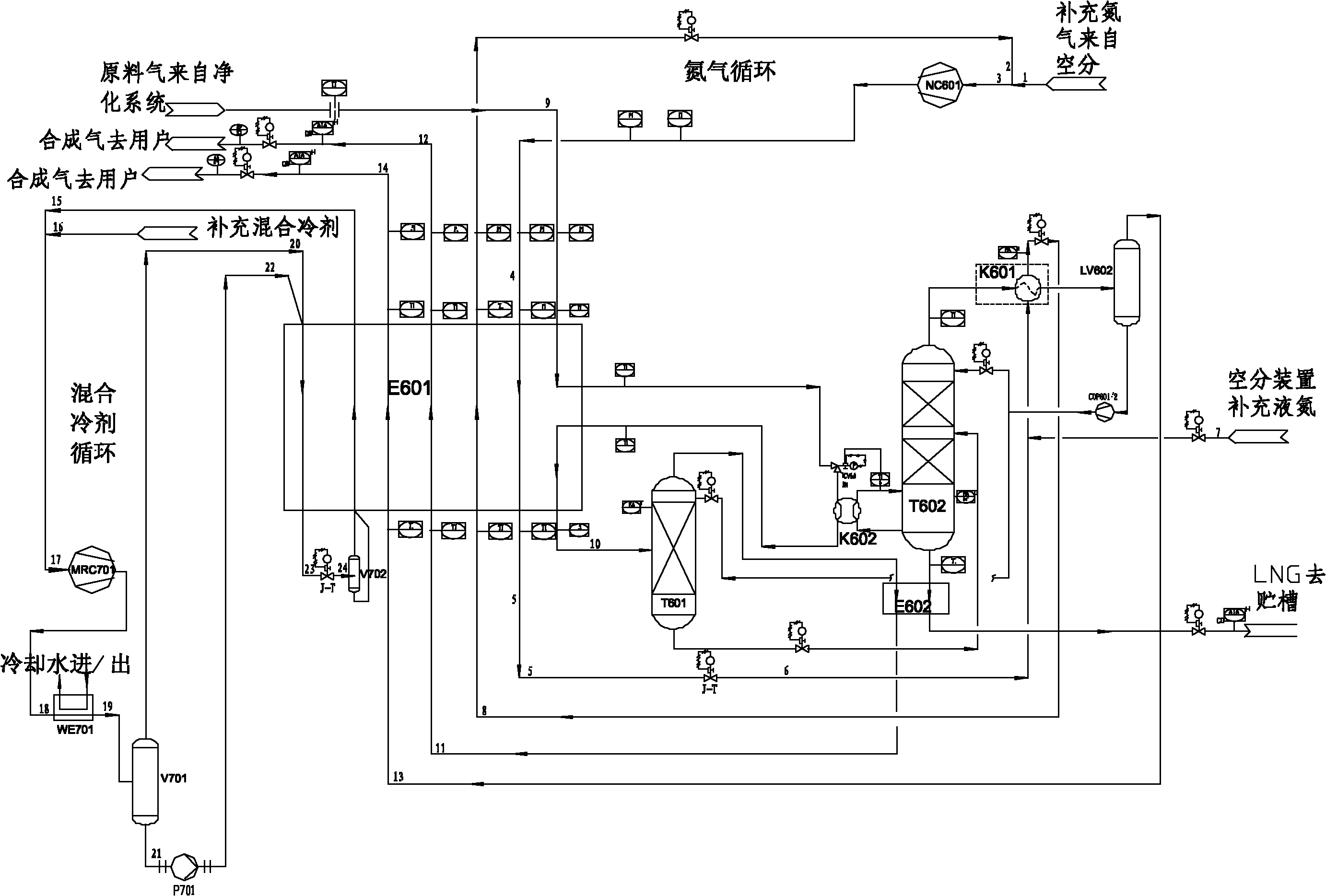

Heat exchange system for cryogenic separation device for coal gasification device feed gas methane

InactiveCN101782308AImprove heat transfer temperature differenceReduce irreversible lossSolidificationLiquefactionReboilerNitrogen gas

The invention discloses a heat exchange system for a cryogenic separation device for coal gasification device feed gas CH4, which comprises a plate-fin main heat exchanger, a mixed refrigerant circulating compressor and a nitrogen circulating compressor. A feed gas channel, a mixed refrigerant channel and a nitrogen channel are arranged in the main heat exchanger. The feed gas from an upstream coal gasification device is subjected to heat exchange in the main heat exchanger, is cooled by a reboiler, and enters the main heat exchanger to be further cooled and partially condensed to a washing tower. An inlet / outlet of the mixed refrigerant heat exchange channel in the main heat exchanger is connected to an inlet / outlet of closed mixed refrigerant circulation respectively. An inlet / outlet of the nitrogen heat exchange channel in the main heat exchanger is connected to an inlet / outlet of the nitrogen circulating compressor. Due to the adoption of the mode of combining the closed mixed refrigerant refrigeration cycle and the nitrogen refrigeration cycle and due to the use of an air-separation liquid nitrogen complementation method, the heat transfer temperature difference of the main heat exchanger can be improved, the irreversible loss of the main heat exchanger can be reduced, and the energy consumption of the whole set of the cryogenic separation device can be reduced.

Owner:成都蜀远煤基能源科技有限公司

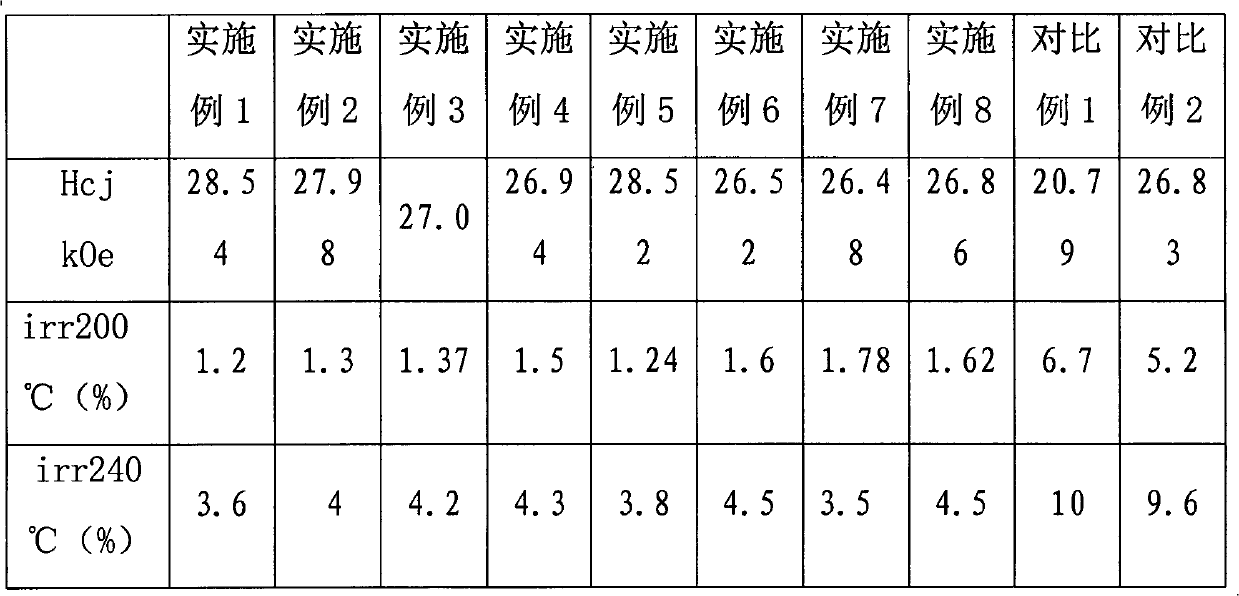

Rare-earth permanent magnet material and preparation method thereof

ActiveCN102024544AInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses a rare-earth permanent magnet material and a preparation method thereof. The rare-earth permanent magnet material comprises the following components: R(a-x-y)Ho(x)Dy(y)Fe(1-a-b-c-d)Co(d)M(c)B(b), wherein x, y, a, b, c and d are weight percentage of all elements, a is more than or equal to 28% and less than or equal to 34%, b is more than or equal to 0.95% and less than or equal to 1.3%, c is more than or equal to 0% and less than or equal to 1.5%, d is more than or equal to 1% and less than or equal to 10%, x is more than or equal to 15% and less than or equal to 20% and y is more than or equal to 3% and less than or equal to 8%; R is a rare earth element and is selected from one or more of Nd, Pr, La, Ce, Gd and Tb; and M is selected from one or more elements of Al, Cu, Ti, V, Cr, Zr, Hf, Mn, Nb, Sn, Mo, Ga and Si. A casting technique is adopted to prepare a rare-earth permanent magnet material casting ingot, or a fast setting sheet technique is adopted to prepare a fast setting sheet, and the rare-earth permanent magnet material provided by the invention is prepared by procedures of grinding, molding, sintering and the like. By the rare-earth permanent magnet material provided by the invention, the coercive force is improved, the flux irreversible loss of the permanent magnet at the high temperature of 200 DEG C is less than or equal to 5%, and the permanent magnet can work normally at the temperature of 240 DEG C.

Owner:BYD CO LTD

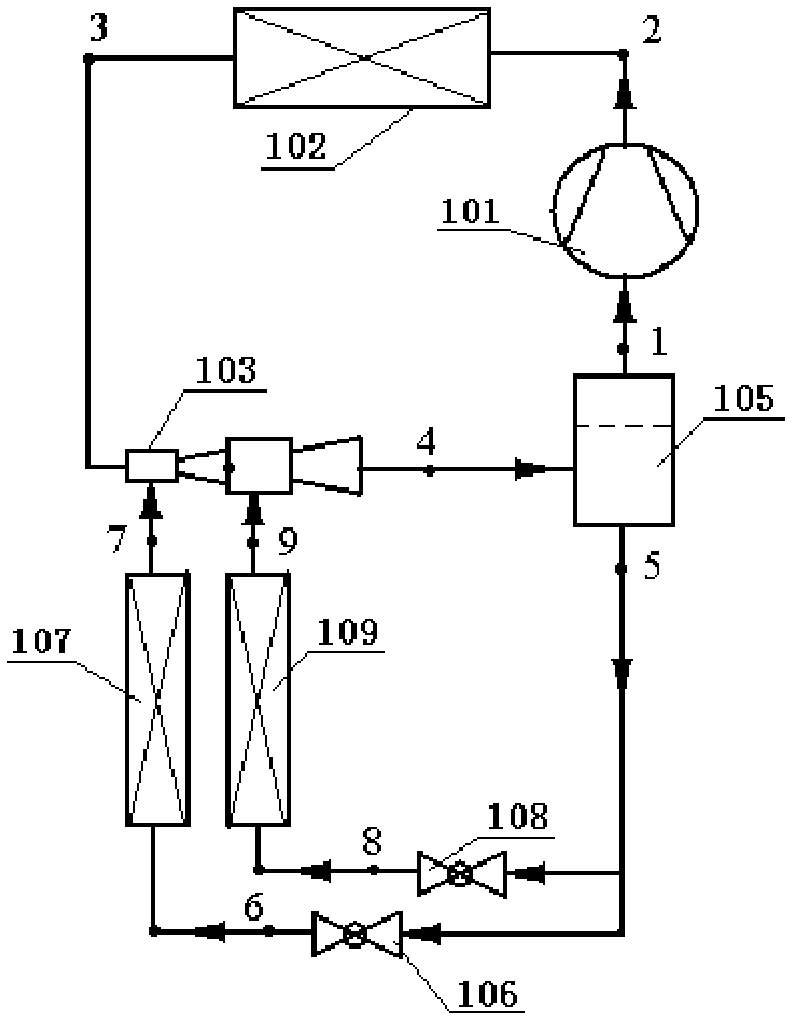

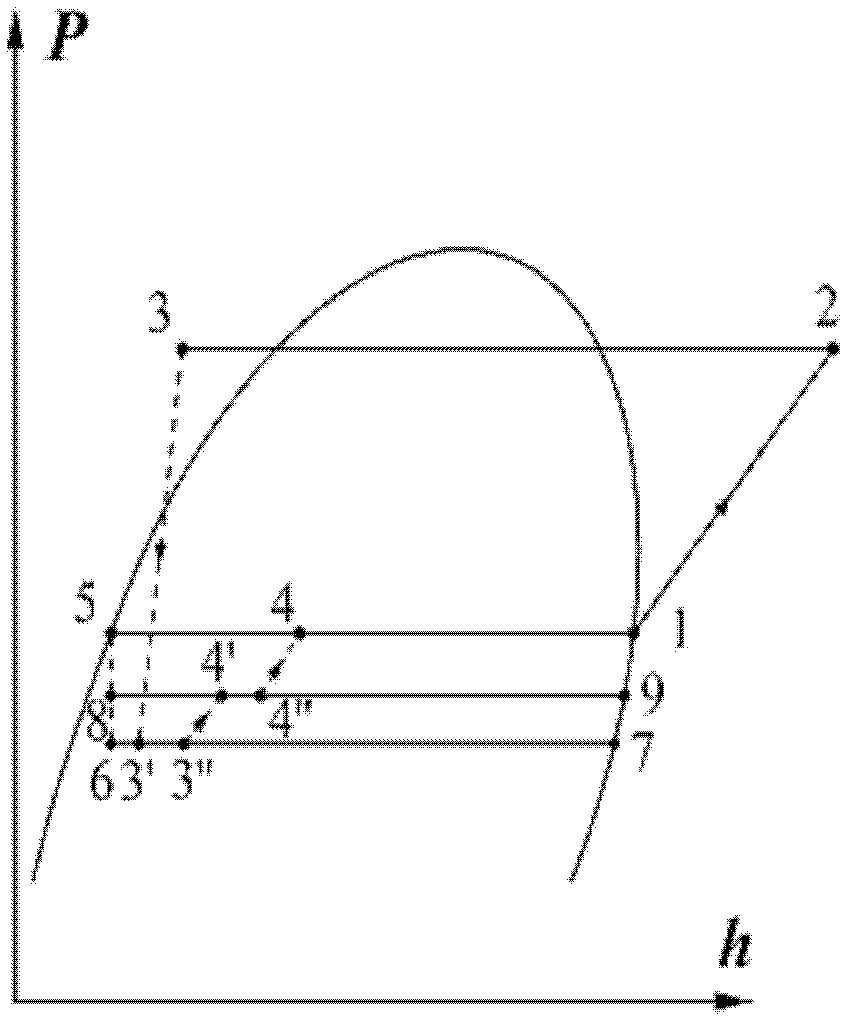

Pump-free organic Rankine cycle power generation system with compression refrigeration efficiency

ActiveCN108005743AFix startup issuesTake advantage ofJet pumpsSteam engine plantsOrganic Rankine cycleEvaporation

The invention discloses a pump-free organic Rankine cycle power generation system with compression refrigeration efficiency. The system comprises a supersonic steam-liquid two-phase flow jet pump, anevaporator, an expansion machine, an evaporation condenser, an expansion pressure reduction device, a cooler, a throttling valve, a compressor and a generator which are connected with one another to form an organic Rankine cycle and a steam compression refrigeration cycle. According to the pump-free organic Rankine cycle power generation system with the compression refrigeration efficiency, the supersonic steam-liquid two-phase flow jet pump is adopted to replace a working medium pump in a conventional system, the organic Rankine cycle is coupled with the steam compression refrigeration cyclethrough the evaporation condenser, cooling capacity is provided for the organic Rankine cycle through refrigerating capacity produced by the refrigeration cycle, and the condensation temperature of exhaust gas at an outlet of the expansion machine is reduced; and meanwhile, the expansion pressure reduction device is adopted to recycle pressure energy of the high-pressure liquid working medium in aloop in the steam compression refrigeration circulation, and the irreversible loss of the side throttling process of the refrigeration cycle is reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

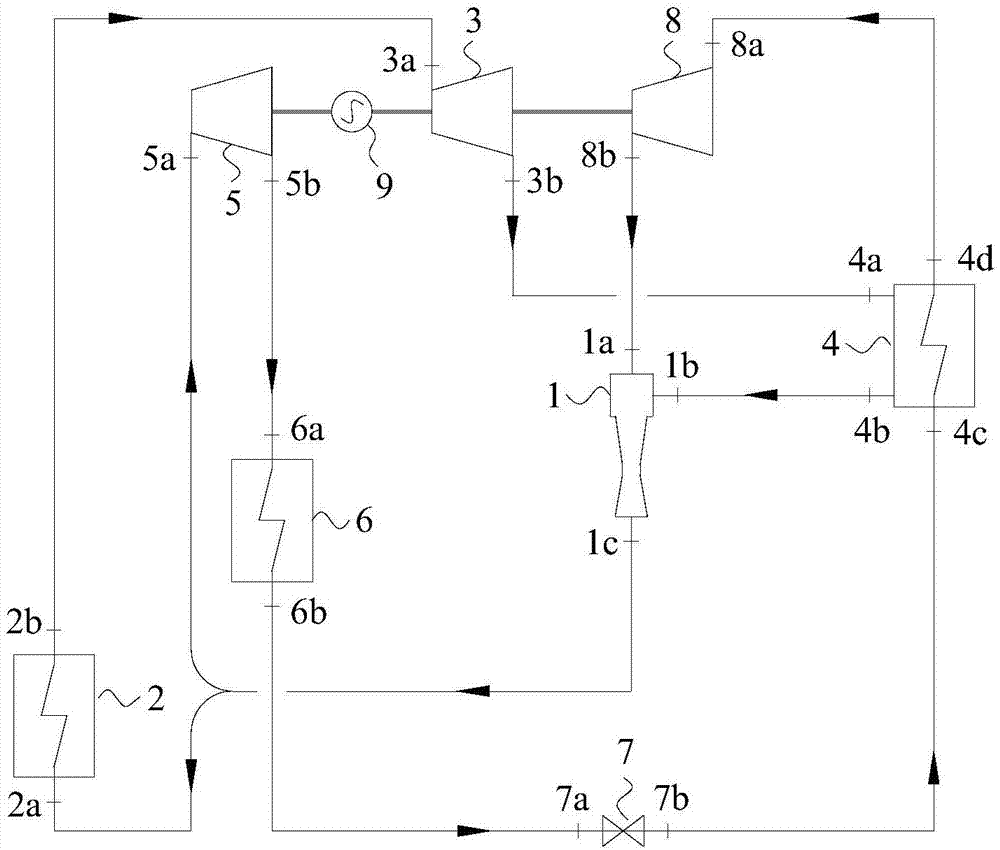

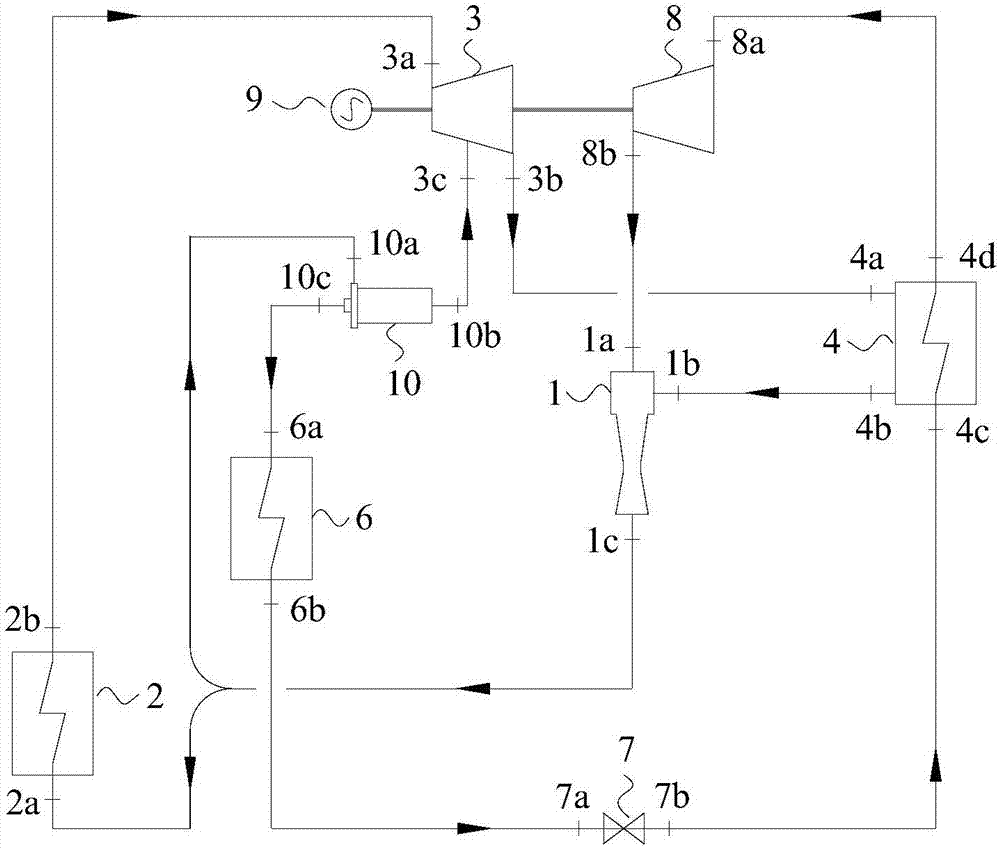

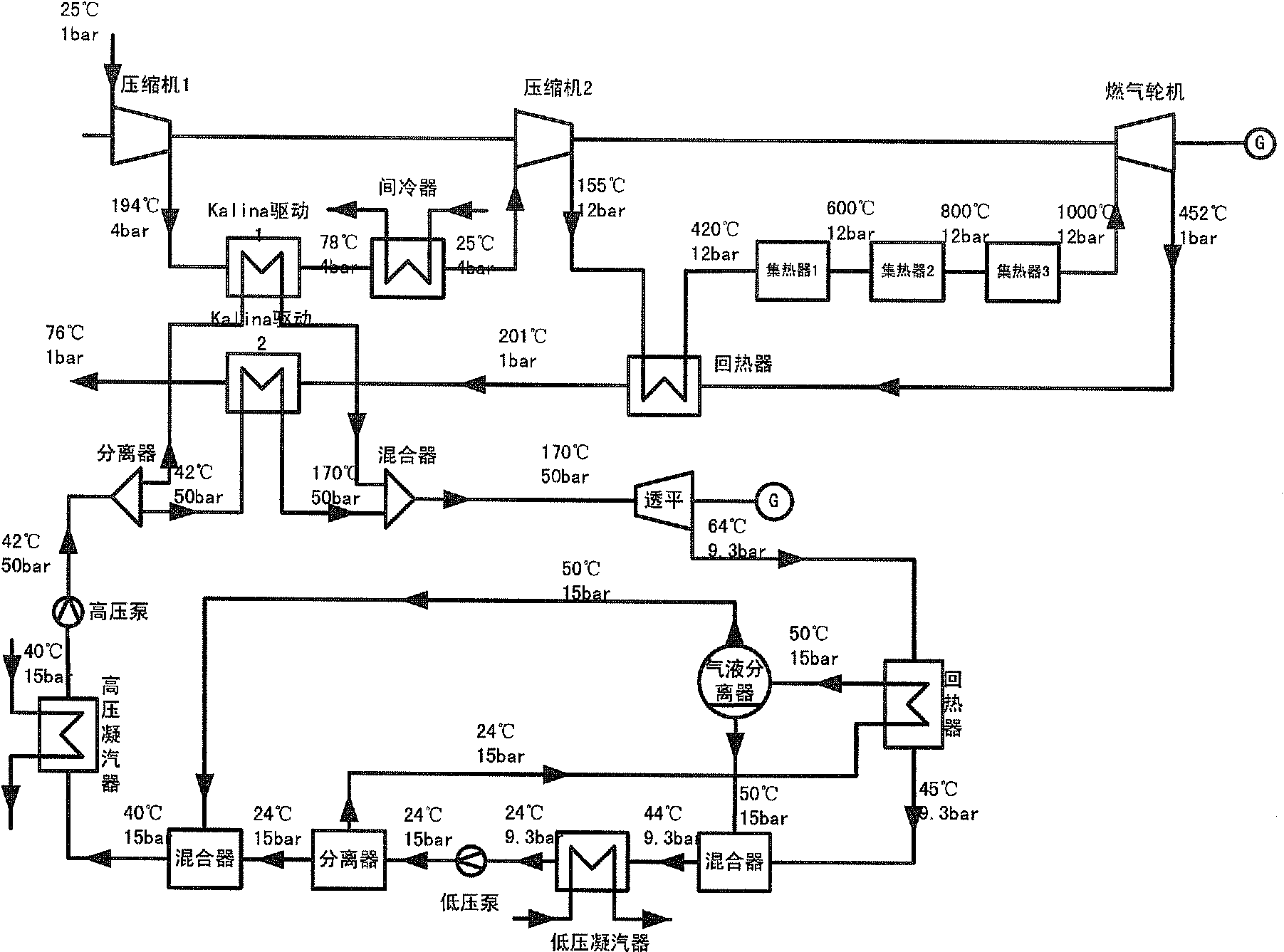

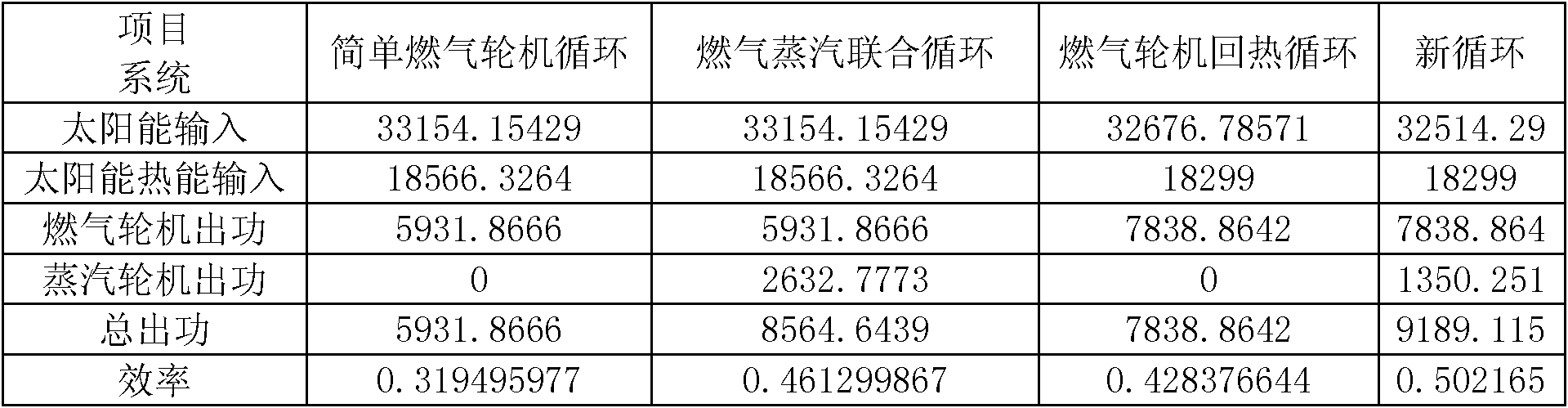

Thermal power generation system combined by water saving type solar combustion gas turbine and kalina cycle

InactiveCN102734094AGood water saving effectThe proportion of power generation accounts for a small shareFrom solar energyGas turbine plantsEngineeringHeat energy

The invention discloses a thermal power generation system combined by a water saving type solar combustion gas turbine and a kalian cycle, which comprises a tower type heat collecting system for preheating air, a combustion gas turbine system, a combustion gas turbine power generation system and a kalian cycle power generation system, wherein the combustion gas turbine system is used for receiving and gathering solar irradiation energy, converting the received solar irradiation energy to heat energy, transmitting the heat energy to compressed air and then outputting the compressed air to the combustion gas turbine driven by complementation of solar energy and fuel; the combustion gas turbine power generation system is used for receiving heat energy generated by the solar heat generating system and burning of the fuel and converting the heat energy to electric energy; and the kalian cycle power generation system is used for receiving intermediate cold and hot and waste heat of gas exhausted by the combustion gas turbine and converting the intermediate cold and hot and the waste heat to electric energy. According to the invention, the top cycle takes air as a working medium, and the bottom cycle is kalian cycle, so that water consumption in the solar thermal power generation system is reduced, the disadvantage of keeping high vacuum degree in the traditional steam bottom cycle condenser is solved, the cost is reduced, exhaust gas temperature is further decreased, irreversible loss during heat exchanging process is reduced, and the generating efficiency of the cycle is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

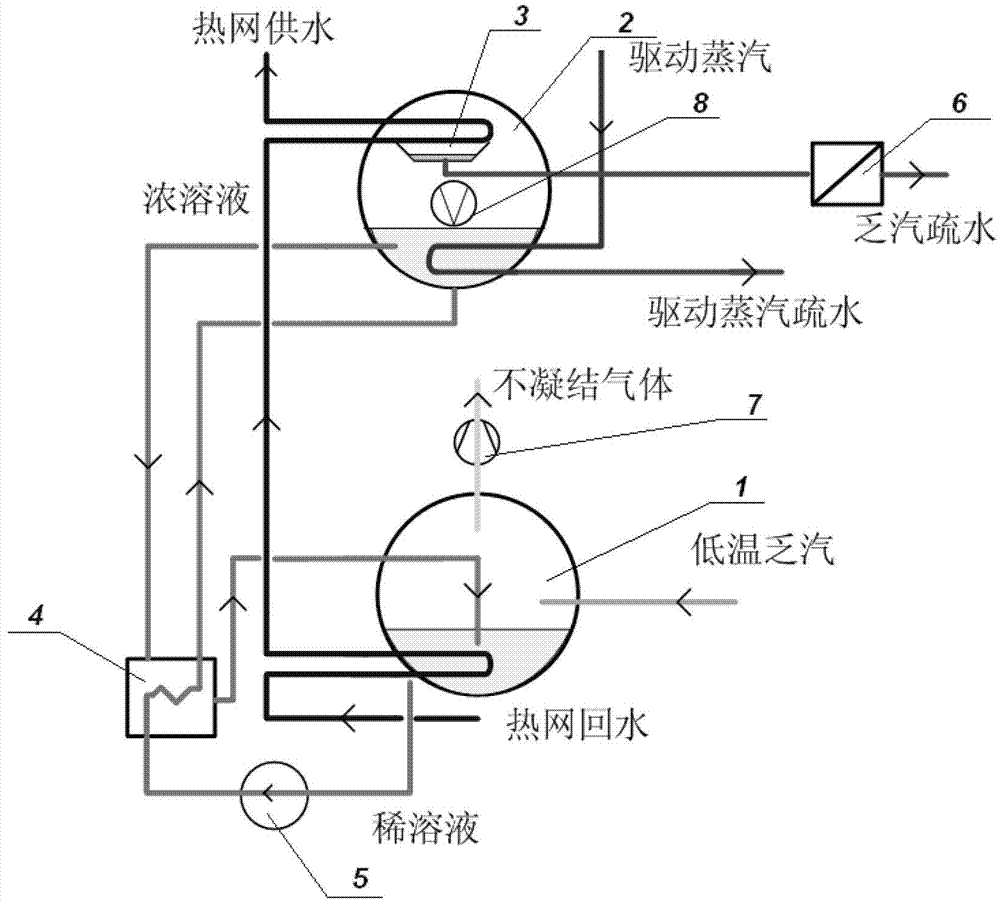

Exhaust steam direct-absorption type lithium bromide heat pump system

ActiveCN102954616AReduce pump powerLess investmentClimate change adaptationEnergy efficient heating/coolingSteam condensationLithium bromide

The invention provides an exhaust steam direct-absorption type lithium bromide heat pump system which comprises an absorber, wherein a low-temperature exhaust steam pipeline is externally connected to the absorber; a liquid outlet of the absorber is communicated with a generator which is internally provided with a condenser through a dilute solution pipeline and then is connected with a liquid inlet through a concentration solution pipeline; a heating pipeline is connected to the generator; the heating pipeline is outputted through the generator and a steam-driving draining pipeline; a heat network pipeline is connected to the absorber, sequentially passes through the absorber and a heat exchange tube in the condenser of the generator and then is outputted; and a liquid outlet of the condenser is communicated with a steam condensation water pipeline for outputting exhaust steam and draining. According to the exhaust steam direct-absorption type lithium bromide heat pump system disclosed by the invention, two links of heat exchange of the exhaust steam and circulating water and heat release of the circulating water in an evaporator in a heat pump are omitted, so that the heat pump system is greatly simplified and the system investment is reduced. Meanwhile, the pulsation of the circulating water is saved and the operation cost is reduced. In addition, two intermediate heat exchange processes are omitted, so that the irreversible loss of the system is reduced and the performances of the system are greatly improved.

Owner:XI AN JIAOTONG UNIV

Composite positive pole material for lithium ion battery and preparation method of the composite material

InactiveCN102610803AImprove cycle performanceAvoid irreversible lossCell electrodesLithium iron phosphateSulfur

The invention provides a composite positive pole material for a lithium ion battery, belonging to the technical field of composite functional materials. The composite positive pole material for the lithium ion battery is formed by compounding LiFePO4 as a compound with elemental sulfur, wherein LiFePO4 is a porous compound with nanometer pores; and elemental sulfur is present in the nanometer pores of LiFePO4. According to the invention, Li3PO4, FeC2O4.2H2O and (NH4)2HPO4 serve as the raw materials to prepare porous lithium iron phosphate (LiFePO4) by a hydrothermal template method; and a method of compounding gaseous sulfur with porous lithium iron phosphate is adopted to prepare the composite positive pole material. The elemental sulfur is fixed in the pores of LiFePO4, therefore, the irreversible loss of active materials caused by dissolution of the discharging product of sulfur into an electrolyte can be prevented, and the recycling performance of the positive pole material and the utilization rate of active materials can be improved. Meanwhile, the porous LiFePO4 serving as the supporting material of elemental sulfur is a good positive pole material for the lithium ion battery, and contributes to the specific capacity of the whole composite positive pole material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

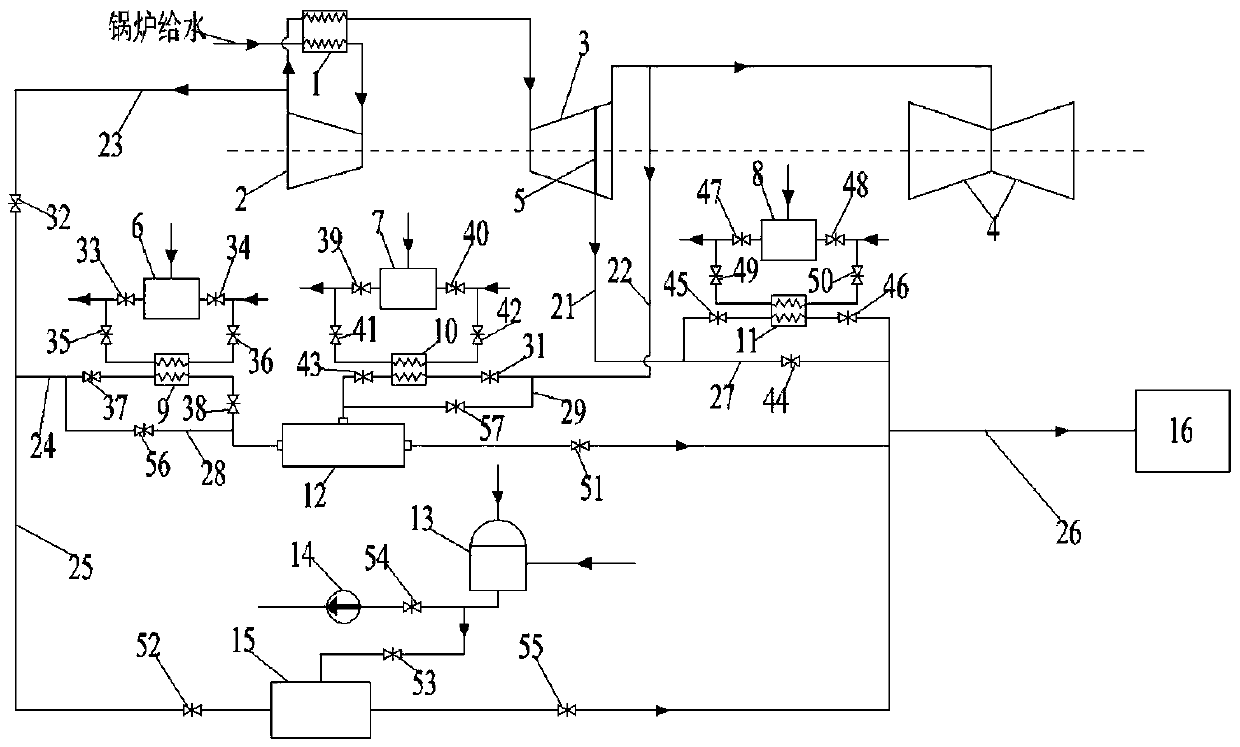

Modularized steam waste pressure and waste heat power generation and balanced steam and heat supply system

InactiveCN102518483AMeet needsImprove utilization efficiencySteam useCombined combustion mitigationPower gridEngineering

The invention relates to a modularized steam waste pressure and waste heat power generation and balanced steam and heat supply system, which belongs to the field of industrial and civil waste heat and waste pressure power generation and steam and heat supply. The system comprises a backpressure-type steam turbine, a generator, valves and connecting pipelines; a high-pressure steam inlet pipe is connected with a main steam inlet of the backpressure-type steam turbine through a power generation control valve; the high-pressure steam inlet pipe is also connected with a first low-pressure steam supply pipe through a temperature and pressure reduction valve; an exhaust outlet of the backpressure-type steam turbine is connected with a first low-pressure steam supply pipe through a first steam supply control valve; a shaft of the backpressure-type steam turbine is connected with a shaft of the generator; and the output end of the generator is connected with a power grid through a grid-connected device. According to the modularized steam waste pressure and waste heat power generation and balanced steam and heat supply system, the common problem that the irreversible loss is too high because high-pressure steam is delivered to steam heat users with different pressure requirements in the manner of temperature and pressure reduction in practical projects at present is solved, and the benefit of the comprehensive utilization of energy of a whole thermodynamic system is improved. The scheme of the system can be generally popularized to all steam users.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

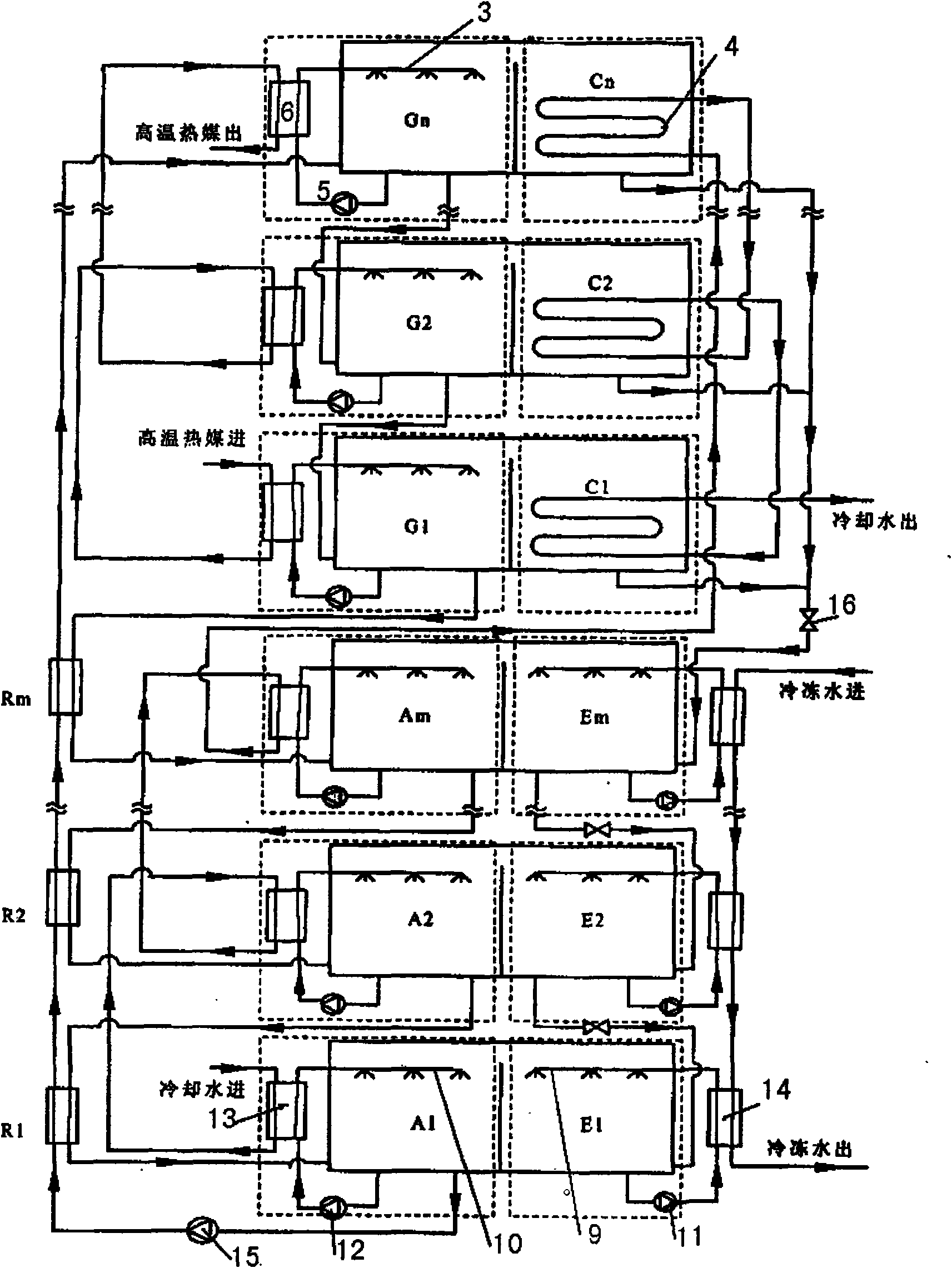

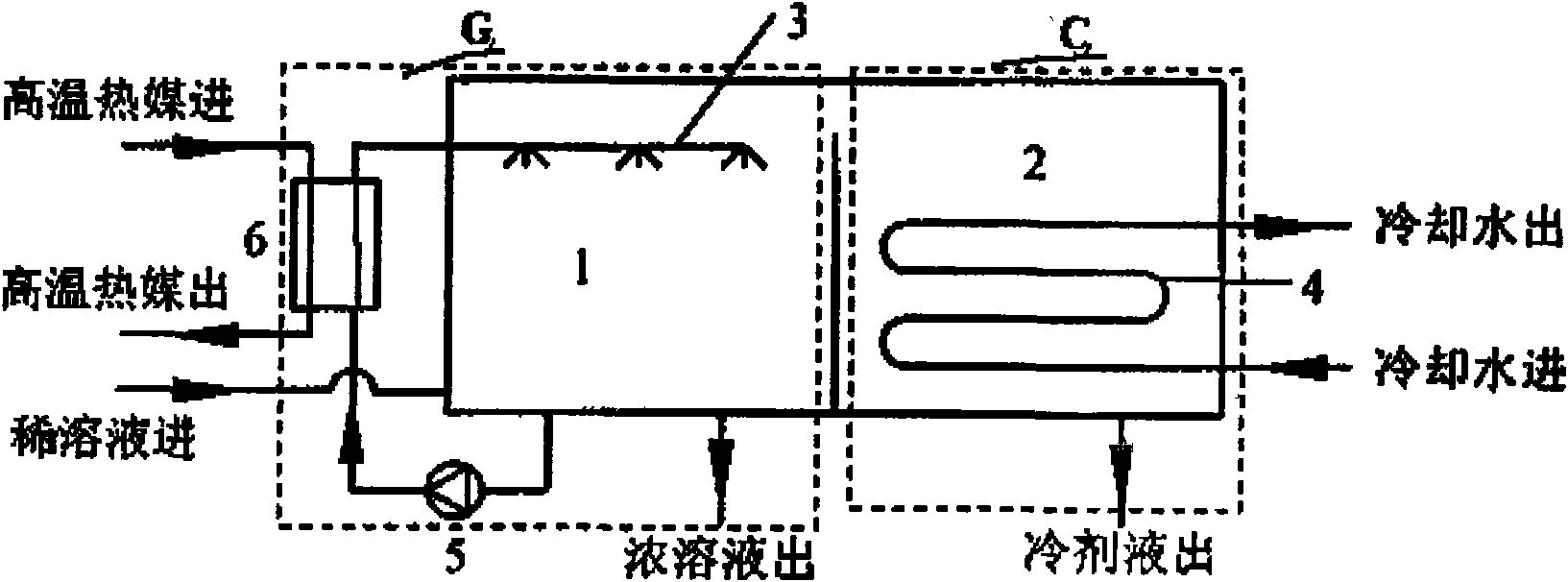

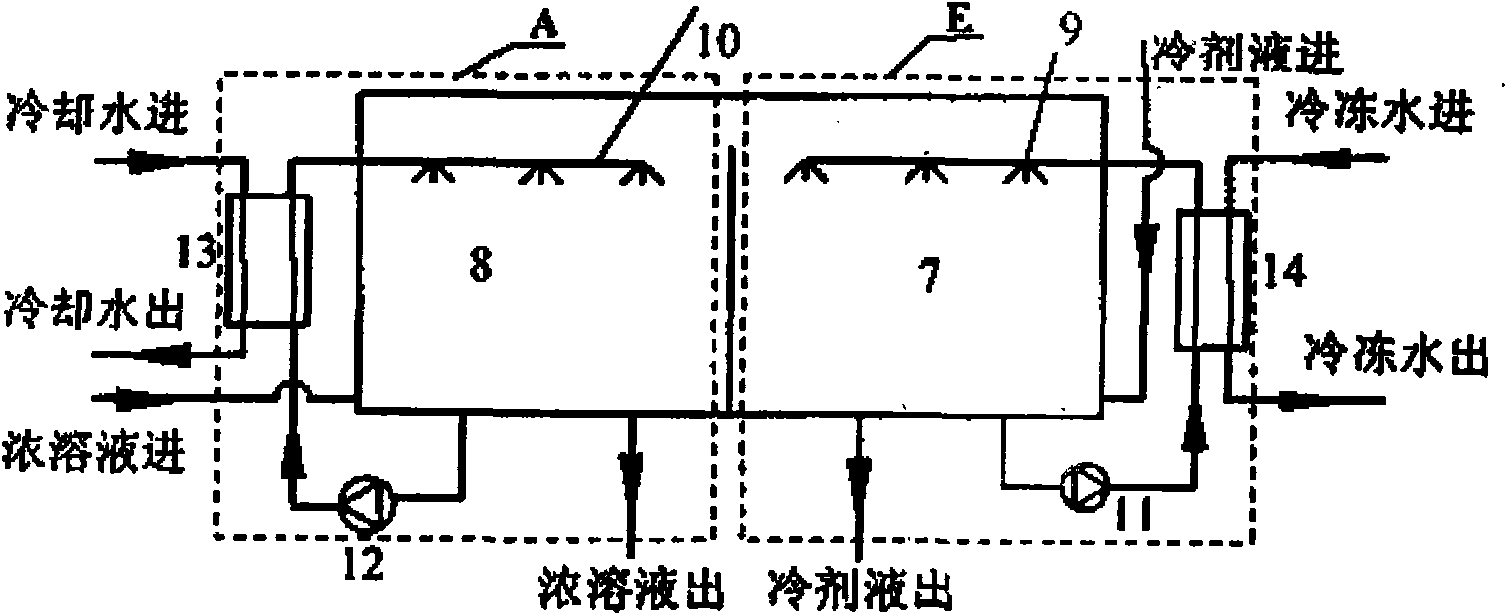

Multistage absorption refrigerating/heat pump unit

ActiveCN101650095AImprove performanceReduce sizeClimate change adaptationEnergy efficient heating/coolingSingle stageEvaporation

The invention discloses a multistage absorption refrigerating / heat pump unit, consisting of two or more single-stage generating-condensation units and two or more single-stage absorption-evaporation units, a solution heat exchanger, a throttling device, a meter, a valve and a connection pipeline. The single-stage generating-condensation unit consists of a heat insulating generator and a regular condenser, the single-stage absorption-evaporation unit consists of a heat insulating absorber and an evaporator, the single-stage generating-condensation units are serially connected, and the single-stage absorption-evaporation units are serially connected. A refrigerating working medium diluted solution is gradually heated and flash-evaporated in each heat insulating generator, the flash-evaporated concentrated solution is gradually cooled to absorb refrigerant steam in each heat insulating absorber to become the diluted solution, and refrigerant solution is gradually throttled, decompressed and evaporated in each evaporator. Through gradually changing temperature and exchanging heat, reducing the temperature difference of exchanging heat and lowering irreversible loss in the process of exchanging heat, the performance of the unit is improved, and the unit is convenient to be inspected and fixed.

Owner:TSINGHUA UNIV +1

Lithium-ion battery preparation method and battery prepared

InactiveCN102148401AReduce wasteIncrease energy densityCell electrodesFinal product manufactureEngineeringCharge discharge

The invention discloses a lithium-ion battery preparation method. The lithium-ion battery preparation method comprises the steps which are as follows: an anode piece, a cathode piece, and a membrane are assembled together into a battery; before, the anode piece, the cathode piece, and the membrane are together assembled into the battery, an SEI film is formed on the cathode piece. The invention also discloses a lithium-ion battery obtained through the lithium-ion battery preparation method. The lithium-ion battery preparation method reduces the irreversible losses of Li+ during the first charging-discharging process of the lithium-ion battery, improves the first discharging capacity and the first charging-discharging efficiency, and improves the energy density of the lithium-ion battery.

Owner:SHENZHEN BAK BATTERY CO LTD

NCB heat supply system based on two units and adjustment method

ActiveCN108343479AGuaranteed qualityReduce irreversible lossSteam useEngine componentsCogenerationEngineering

The invention relates to a NCB heat supply system based on two units and an adjustment method. According to the NCB heat supply system based on the two units and the adjustment method, the utilizationefficiency of energy of the system can be improved through gradient utilization of the energy. The heat supply system comprises a first cogeneration unit, a second cogeneration unit and a cooling steam system; the cooling steam system is provided with a pressure reducing device and a temperature reducing device; the first cogeneration unit is provided with the cooling steam system; a steam inletof a cooling steam pipe is connected to a regenerative extraction opening of a low-pressure cylinder of the second cogeneration unit; and a steam outlet of the cooling steam pipe is connected to a steam inlet of a low-pressure cylinder and the regenerative extraction opening of the low-pressure cylinder of the second cogeneration unit. The NCB heat supply system based on the two units and the adjustment method have the advantages that indirect heat exchange is used for reducing the temperature of cooling steam, and therefore the quality of the cooling steam can be guaranteed; and regenerativeextraction steam of the other steam turbine low-pressure cylinder after applying work serves as a steam source for the cooling steam, and therefore irreversible loss caused by temperature reduction and pressure reduction of the cooling steam can be reduced, the reliability of the cooling steam source can be guaranteed, and the safety of the operation without steam inlet of the steam turbine low-pressure cylinders can be improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

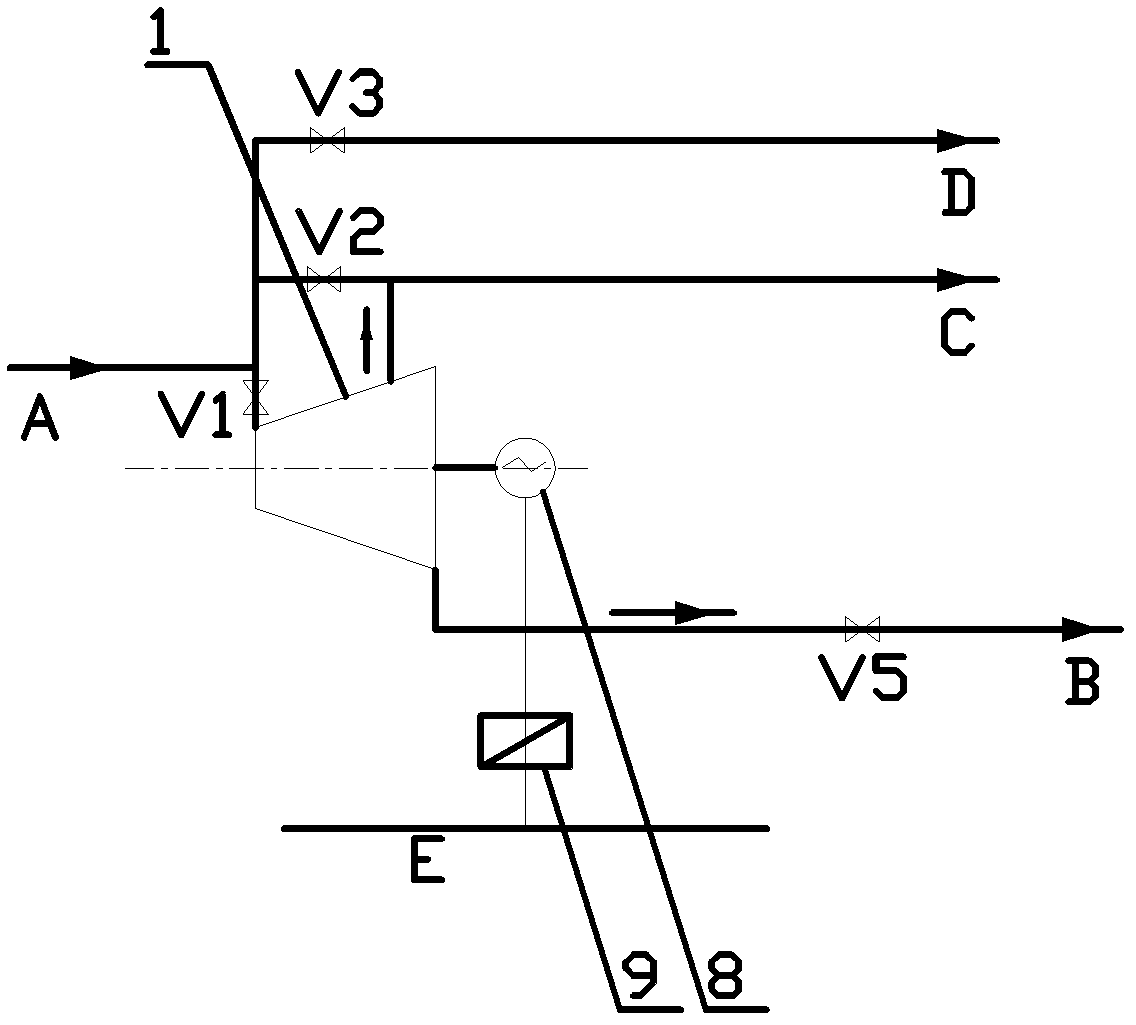

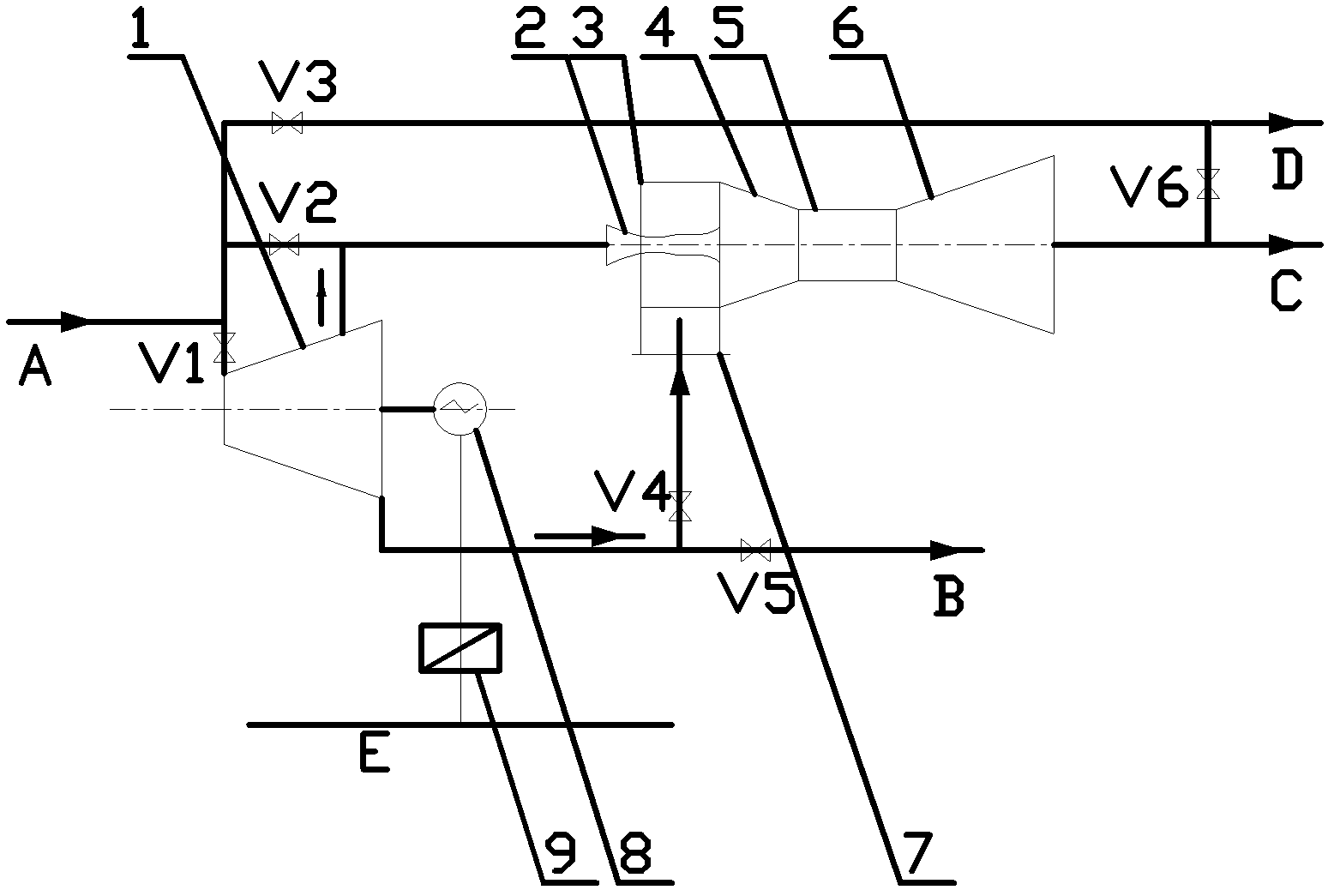

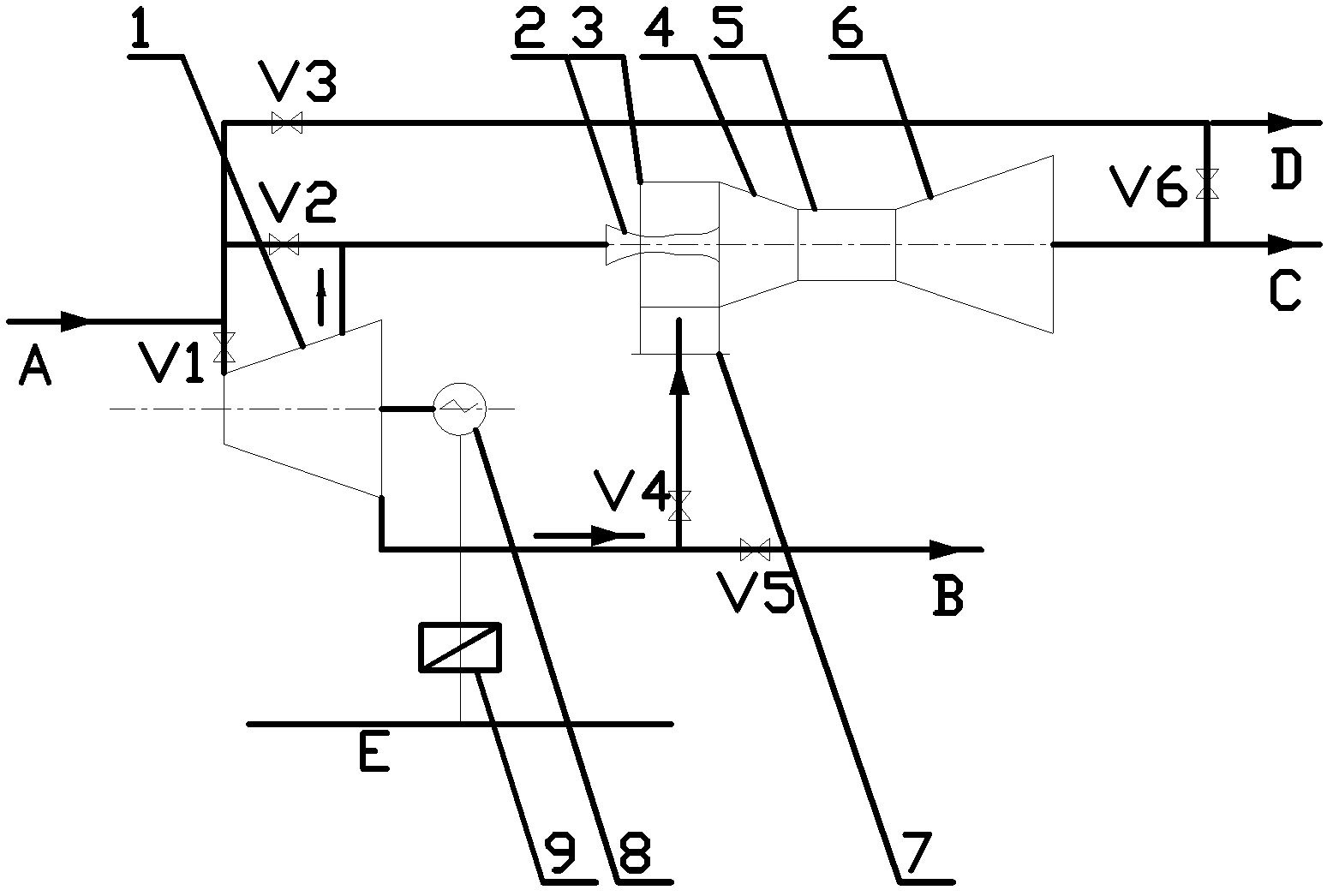

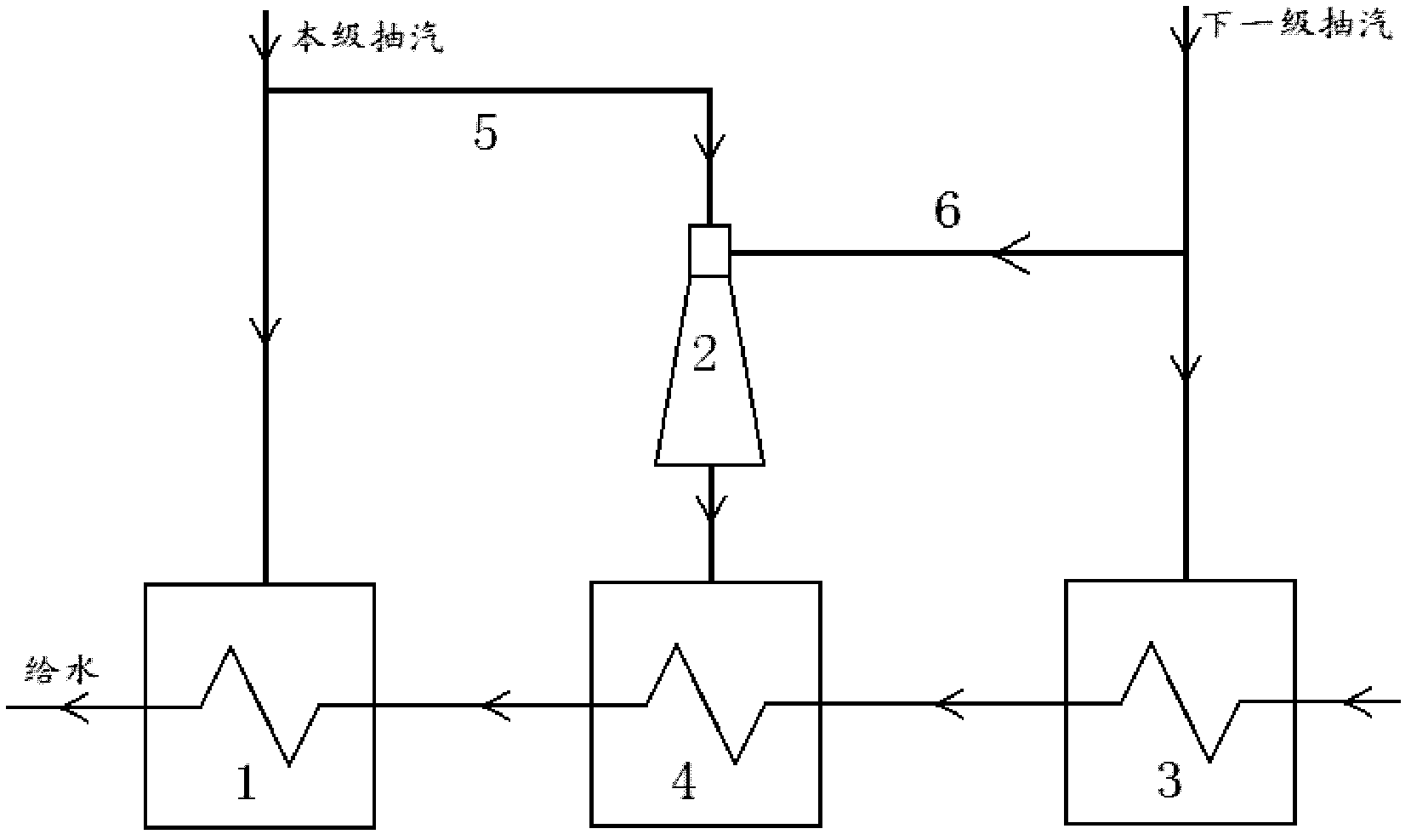

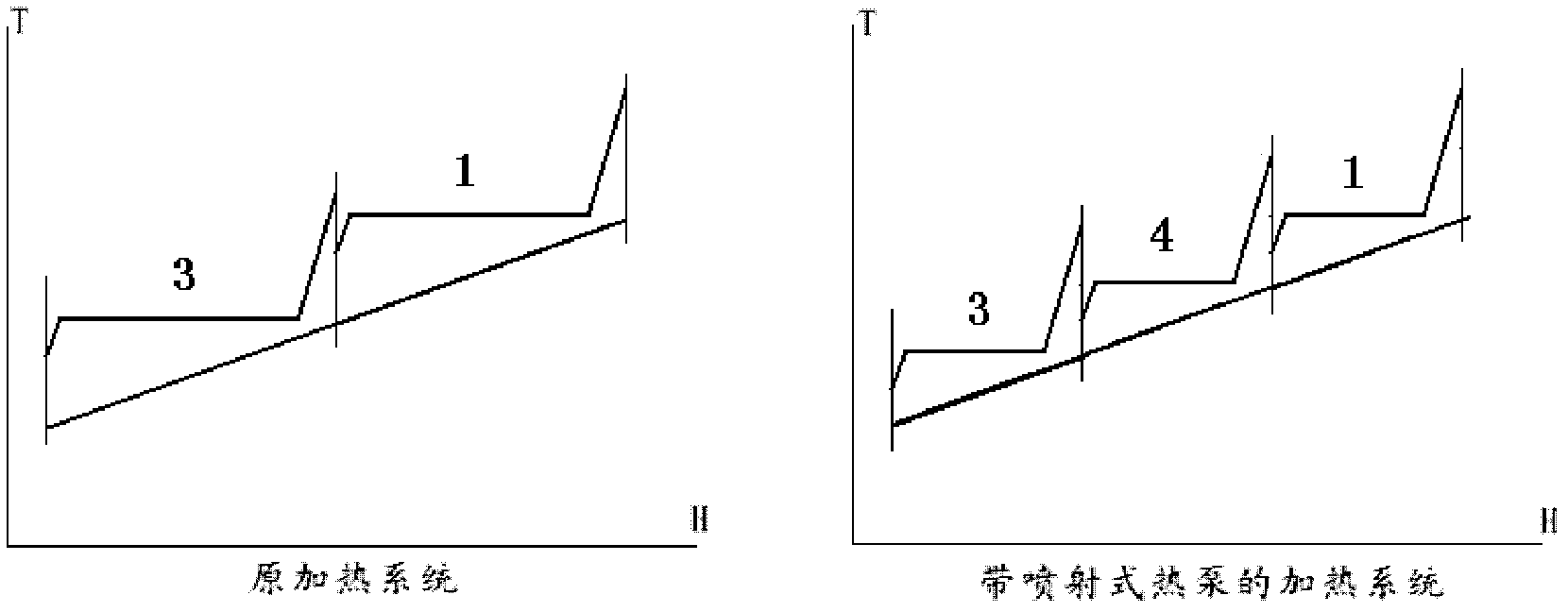

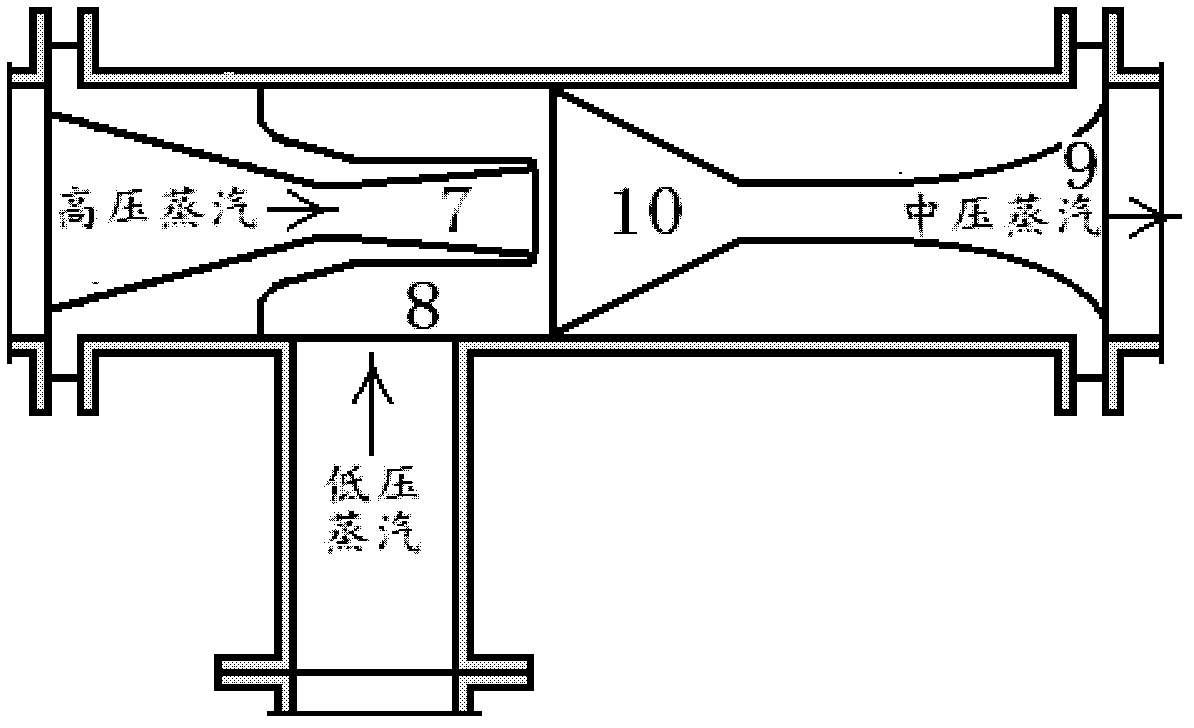

Heat regenerative system adopting jet-type heat pumps

ActiveCN102537935AHigh thermal efficiencyReduce irreversible lossFeed-water heatersRegenerative processEngineering

The invention relates to a heat regenerative system adopting jet-type heat pumps. The heat regenerative system comprises a plurality of levels of heaters which are successively connected, wherein the heater of each level is respectively connected with an extraction steam pipeline of the level, and an indirect heater is arranged between the heaters of every two adjacent levels and is communicated with the heaters of the two adjacent levels; and a jet-type heat pump is arranged between the extraction steam pipelines of the heaters of every two adjacent levels, is communicated with the extraction steam pipelines of the heaters of the two adjacent levels and are corresponding to the indirect heater of the level, and the outlet of each jet-type heat pump is connected with the inlet of each indirect heater. The jet-type heat pumps are arranged in the heat regenerative system provided by the invention, extraction steam with higher pressure is utilized to inject lower-level extraction steam with lower pressure, so that mixed steam the pressure of which is between the pressures of two levels of extraction pressure is generated; and an indirect regenerative heater utilizing the mixed streamas a heating stream source is additionally arranged, thereby reducing the irreversible loss of a regenerative process, and improving the heat efficiency of a machine set.

Owner:XI AN JIAOTONG UNIV

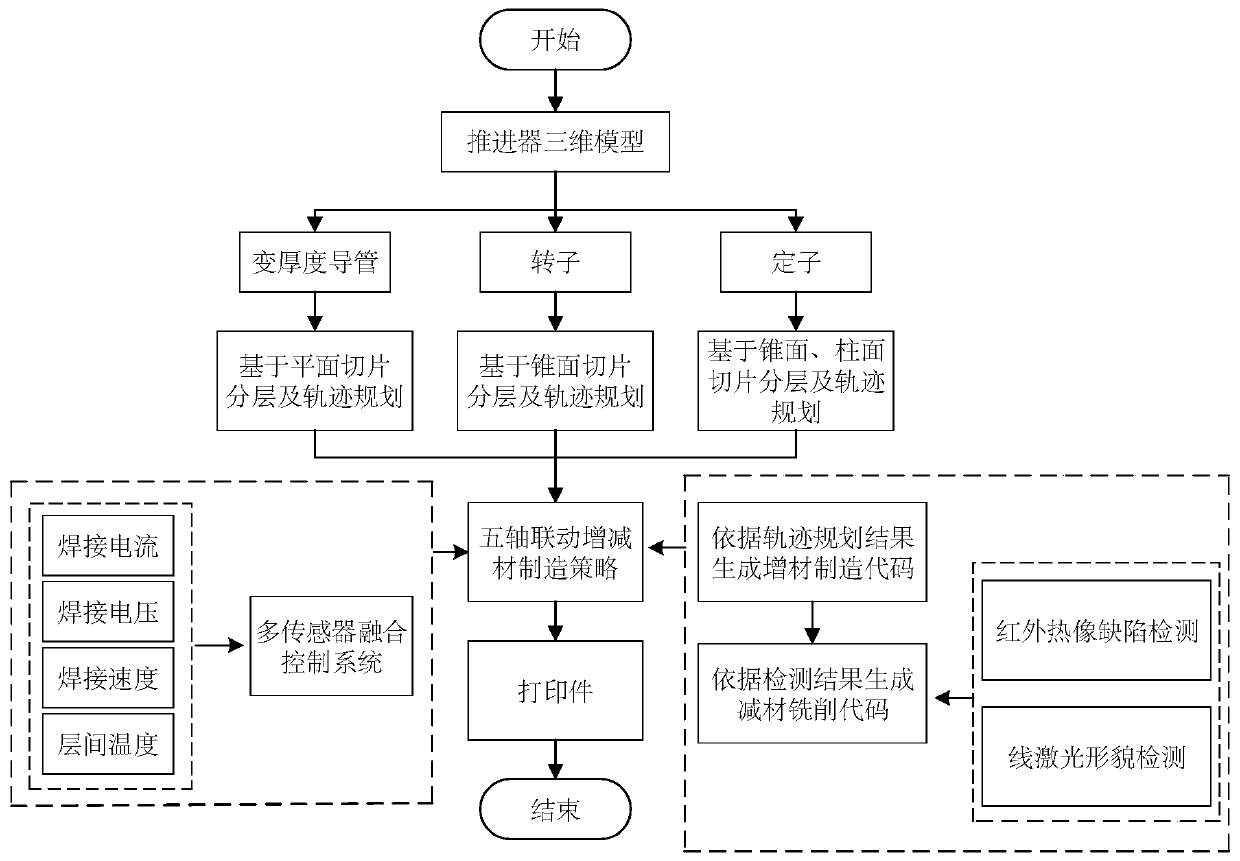

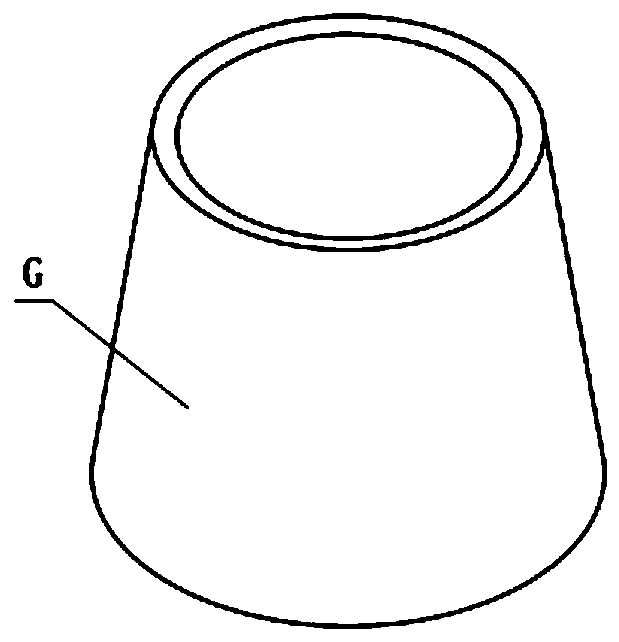

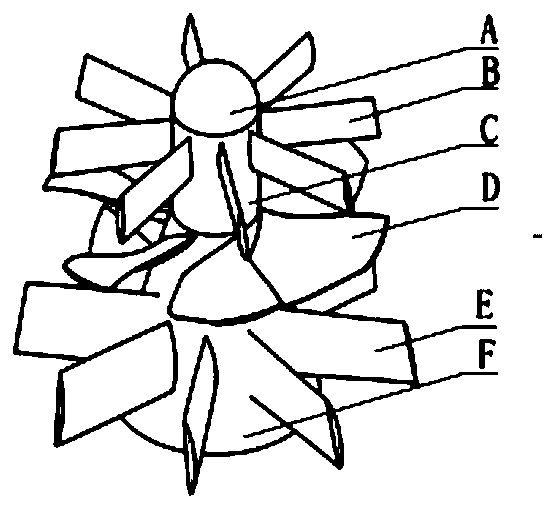

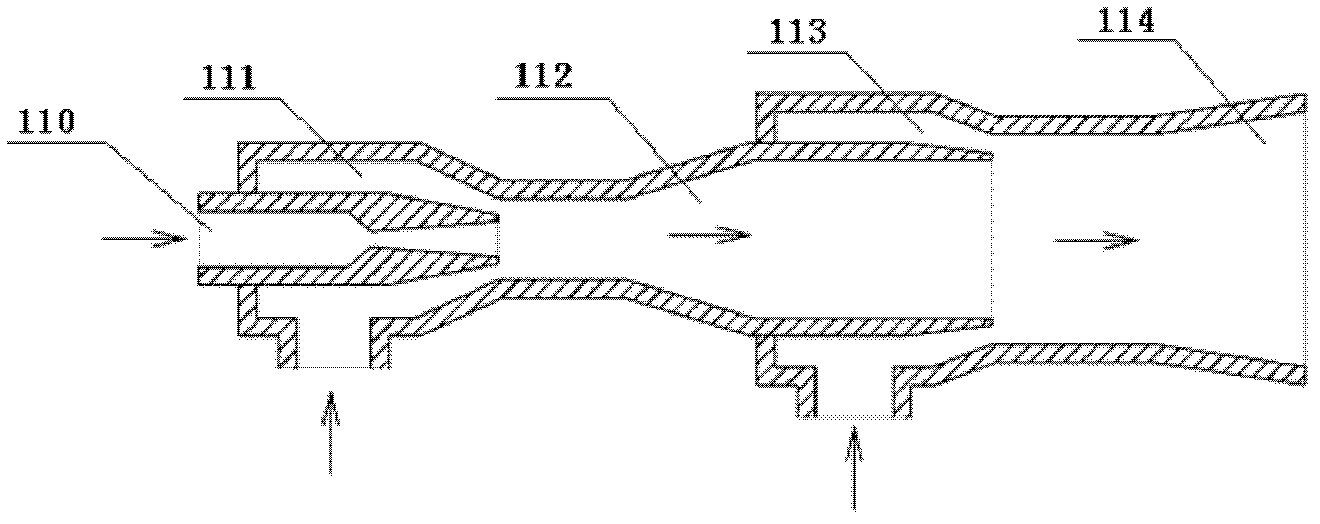

Electric arc additive and subtractive composite integrated manufacturing method of thruster model

ActiveCN110000381AReduce energy consumptionReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencyWaste productEngineering

The invention belongs to the field of electric arc additive manufacturing, and discloses an electric arc additive and subtractive composite integrated manufacturing method of a thruster model. The method comprises the steps of (a) dividing the thruster model into three parts, slicing and layering the three parts, and planning a filling trajectory of each slicing layer, wherein the slicing directions of a rotor and a stator are along the outer normal direction of a spindle, each slicing layer forms a slicing contour on the spindle, a filling trajectory is planned in each slicing contour, and obtaining the filling trajectory of each slicing layer; (b) molding the spindle; and (c) molding the rotor and the stator. In the project for layer-by-layer processing the slicing layers, the slicing layers are detected in real time through infrared thermography defect detecting and line laser appearance detecting, so that additive and subtractive composite integrated manufacturing is realized. Through the electric arc additive and subtractive composite integrated manufacturing method of the thruster model provided by the invention, the irreversible loss caused since waste products are detectedafter parts are printed is avoided, the energy and raw material consumption is reduced, and the manufacturing period is shortened.

Electrolyte solution for lithium metal batteries

InactiveCN108539272ALow costReduce dosageSecondary cellsOrganic electrolytesOrganic solventLithium metal

The invention discloses electrolyte solution for lithium metal batteries. Esters, ethers or ether ester blend solution is used as an organic solvent for the electrolyte solution. The electrolyte solution comprises lithium salt with the molar concentration of 1.0-5.0 mol / L and additives with lithium nitrate and metal halide. The electrolyte solution has the advantages that electrolyte solution systems with the additives can be used for the lithium metal batteries, accordingly, stable mixed ionic conductor interface layers can be formed on the surfaces of lithium negative electrodes, direct contact between the electrolyte solution and metal lithium can be prevented to the greatest extent, lithium dentrite growth and irreversible loss of lithium sources can be reduced, lithium ions can be quickly migrated on the interface layers and can be uniformly deposited on electrodes, the coulombic efficiency of the metal lithium can be obviously improved by the electrolyte solution with the additives, the service lives of the total batteries can be obviously prolonged by the electrolyte solution with the additives, and the electrolyte solution has an excellent application prospect.

Owner:TSINGHUA UNIV

Refrigeration circulating system with double-stage-injection ejector

InactiveCN102563945AThe overall structure is simple and reliableEasy to implementCompression machinesFluid circulation arrangementVapor–liquid separatorSingle stage

The invention discloses a refrigeration circulating system with a double-stage-injection ejector. The refrigeration circulating system comprises a compressor, a condenser, a gas and liquid separator, a first throttling mechanism, a second throttling mechanism, a first evaporator, a second evaporator and the ejector with a double-stage injection function which are connected on a pipeline, the ejector is provided with two suction chambers and two diffusers, and two refrigerant flows with different evaporating temperatures from the two evaporators are respectively injected. The double evaporators with different evaporating temperatures are arranged and can match with change of the temperature of an air side better, and irreversible loss in an evaporation heat exchange process can be reduced. Simultaneously, higher outlet pressure of the ejector with the double-stage injection function can be obtained as compared with a conventional single-stage ejector, air suction pressure of the compressor is improved, air suction specific volume is reduced, and accordingly a performance coefficient and refrigerating capacity or heating capacity of unit volume of the system are further increased. Accordingly, the refrigeration system has remarkable advantages in terms of improving performances of a refrigeration system.

Owner:山东铠宇机械装备有限公司

Cathode material of lithium ion battery, and preparation method

InactiveCN1728425AElectrode manufacturing processesSecondary cellsAluminium-ion batterySodium-ion battery

The invention solves technical issues existed in carbon cathode material: larger energy loss; poor charging and discharging performance in high scale factor; easy of forming passive film co cause irreversible loss in initial capacity; when overcharge, because of near potential between carbon and lithium, it is easy to separate out lithium on surface of carbon pole to form dendritic crystal to cause short circuit possibly; low electrochemical capacity of carbon material, theoretical capacity as 327mAh / g. main points of the invention are: as main body, stibiumis combined with metals such as iron, lead, tin and germanium form stibiumis based composite oxides, stibiumis based alloys or stibiumis based metal compound powder to be as cathode material. Advantages are: high electrochemical capacities of the said stibiumis based composite oxides, stibiumis based alloys or stibiumis based metal compound powder, and good charging and discharging performance in high scale factor. The disclosed material meets actual need.

Owner:沈阳大学师范学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com