Multistage absorption refrigerating/heat pump unit

A technology of absorption refrigeration and heat pump units, which is applied in the direction of refrigerators, adsorption machines, refrigeration and liquefaction, etc., and can solve the problems of reducing the heat exchange temperature difference between the refrigerant solution and cooling water, reducing irreversible losses, and the appearance of the unit is huge. , to achieve the effect of compact structure, reduced irreversible loss and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

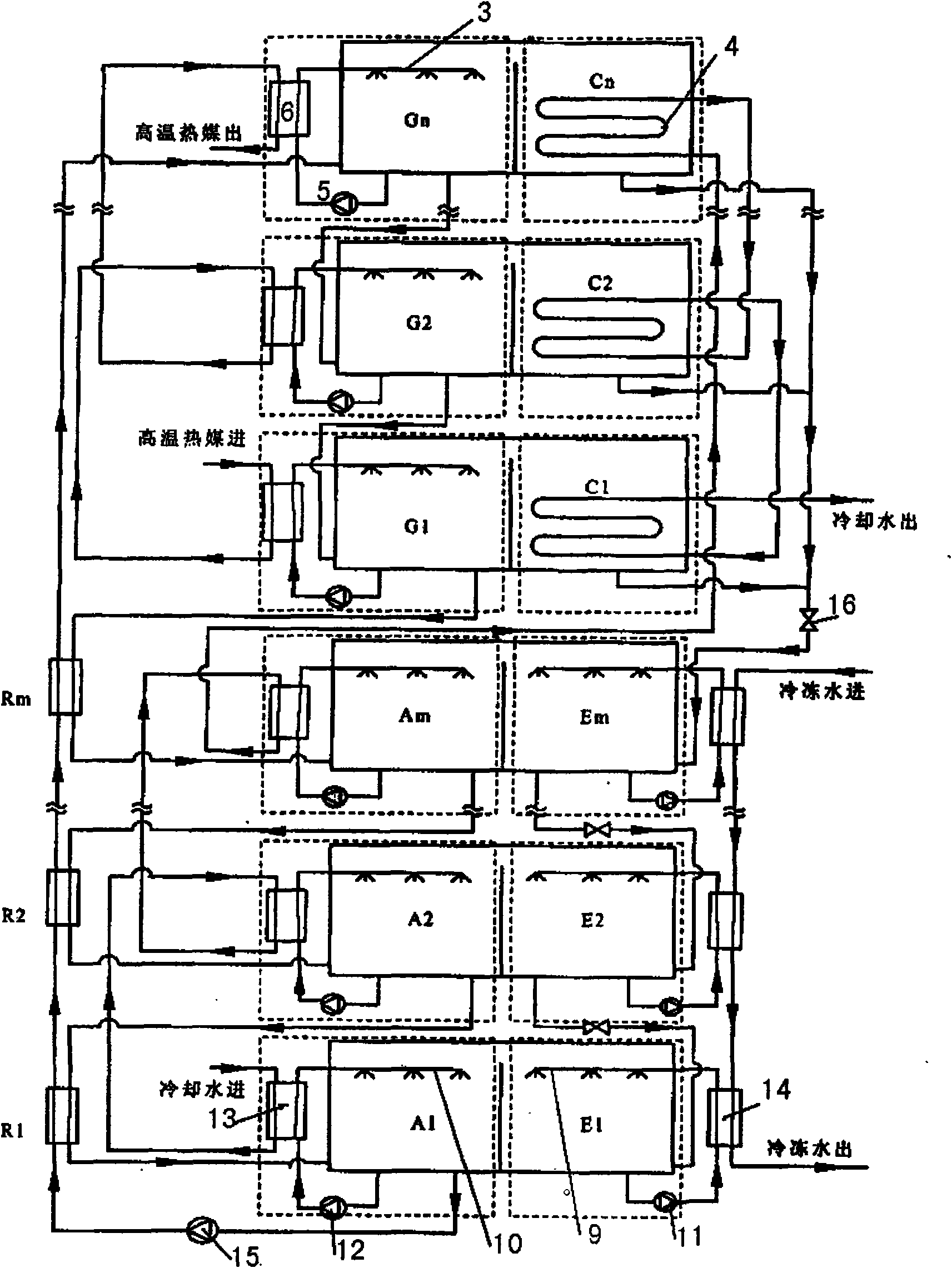

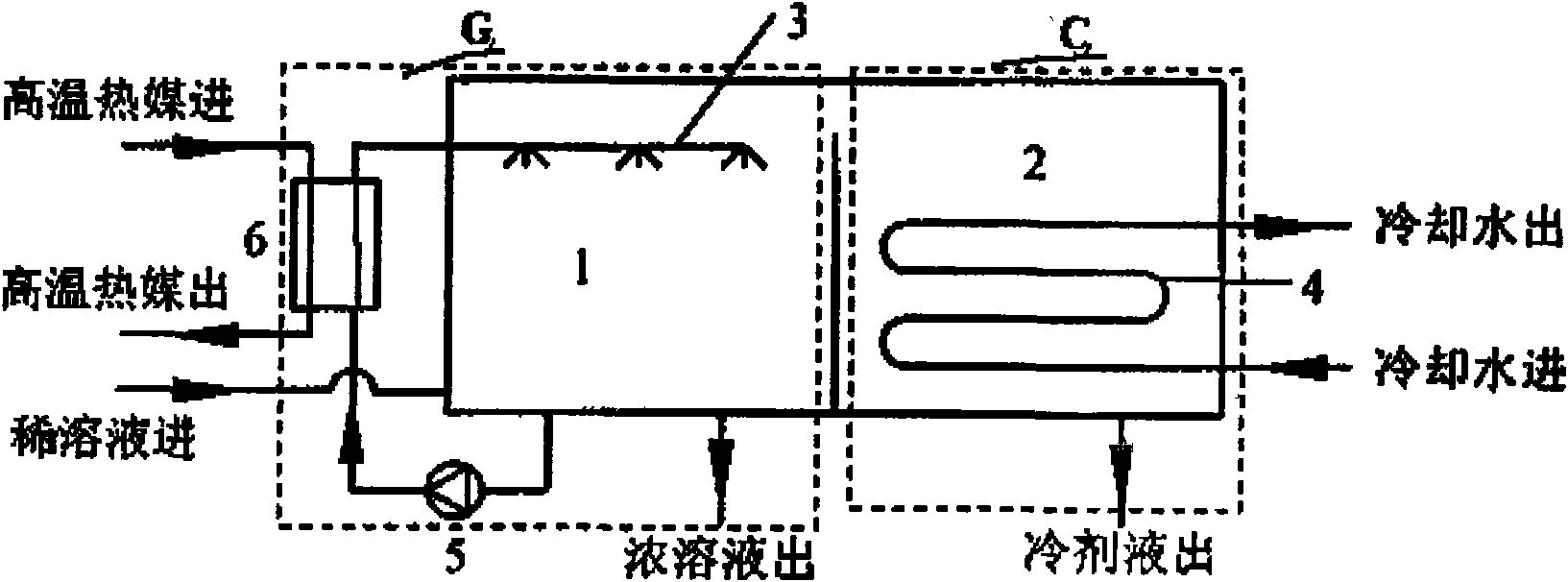

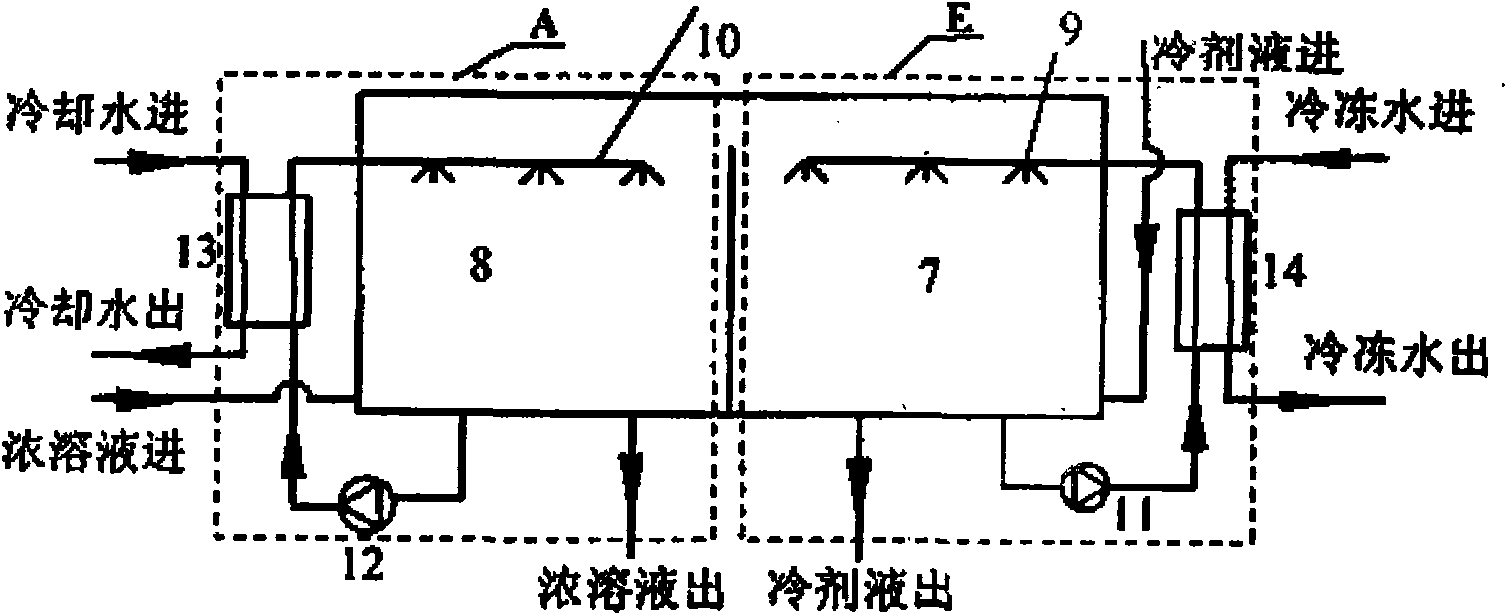

[0019] Embodiment 1: as figure 1 , 2 、 As shown in 3, the multi-stage absorption refrigeration / heat pump unit consists of an adiabatic generator G 1 ~G n , Conventional condenser C 1 ~C n , Adiabatic absorber A 1 ~A m , evaporator E 1 ~E m , solution heat exchanger R 1 ~ Rm, solution pump, 2m throttling valves are connected through pipelines according to the heat exchange process of working fluid. The high-temperature heat medium passes through the adiabatic generator G in sequence 1 , adiabatic generator G 2 , ..., adiabatic generator G n , heating refrigerant solution; from adiabatic absorber A 1 dilute solution, through the solution heat exchanger R 1 , solution heat exchanger R 2 , ..., the solution heat exchanger Rm, after being heated by the high-temperature and high-concentration refrigerant solution, it enters the adiabatic generator G in sequence n , adiabatic generator G (n-1) , ..., adiabatic generator G 1 Carry out stepwise variable temperature hea...

Embodiment 2

[0021] Embodiment 2: as Figure 4 As shown, the absorber and the cooling water of the condenser are connected in parallel. The absorption unit consists of an adiabatic generator G 1 , adiabatic generator G 2 , ..., adiabatic generator G n , Conventional condenser C 1 , Conventional condenser C 2 , ..., conventional condenser C n , Adiabatic absorber A 1 , Adiabatic absorber A 2 , ..., adiabatic absorber A m , evaporator E 1 , evaporator E 2 , ..., evaporator E m , solution heat exchanger R 1 , solution heat exchanger R 2 , ..., a solution heat exchanger Rm, a solution pump, and 2m throttling valves 16 are formed by connecting pipelines. The high-temperature heat medium enters the adiabatic generator G sequentially 1 , adiabatic generator G 2 , ..., adiabatic generator G n , heating refrigerant solution; from adiabatic absorber A 1 Refrigerant dilute solution, through the solution heat exchanger R 1 , solution heat exchanger R 2 , ..., the solution heat excha...

Embodiment 3

[0023] Embodiment 3: as Figure 5 As shown, the high-temperature heat medium from the generator passes through the heat exchanger to exchange heat with the cooling water, then enters the evaporator after lowering the temperature, and further releases heat, which can effectively realize the cascade utilization of energy, improve energy utilization rate, and cool water two ways. The absorption unit consists of an adiabatic generator G 1 , adiabatic generator G 2 , ..., adiabatic generator G n , Conventional condenser C 1 , Conventional condenser C 2 , ..., conventional condenser C n , Adiabatic absorber A 1 , Adiabatic absorber A 2 , ..., adiabatic absorber A m , evaporator E 1 , evaporator E 2 , ..., evaporator E m , solution heat exchanger R 1 , solution heat exchanger R 2 , ..., the solution heat exchanger Rm, the third solution pump 15, the water-to-water heat exchanger 17, and 2m throttling valves 16 are connected by connecting pipelines. and Figure 4 The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com