Patents

Literature

3775 results about "Single stage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of single-stage. : of one stage only : complete in one rather than in two or more operations. single-stage turbine. single-stage rocket. single-stage trigger.

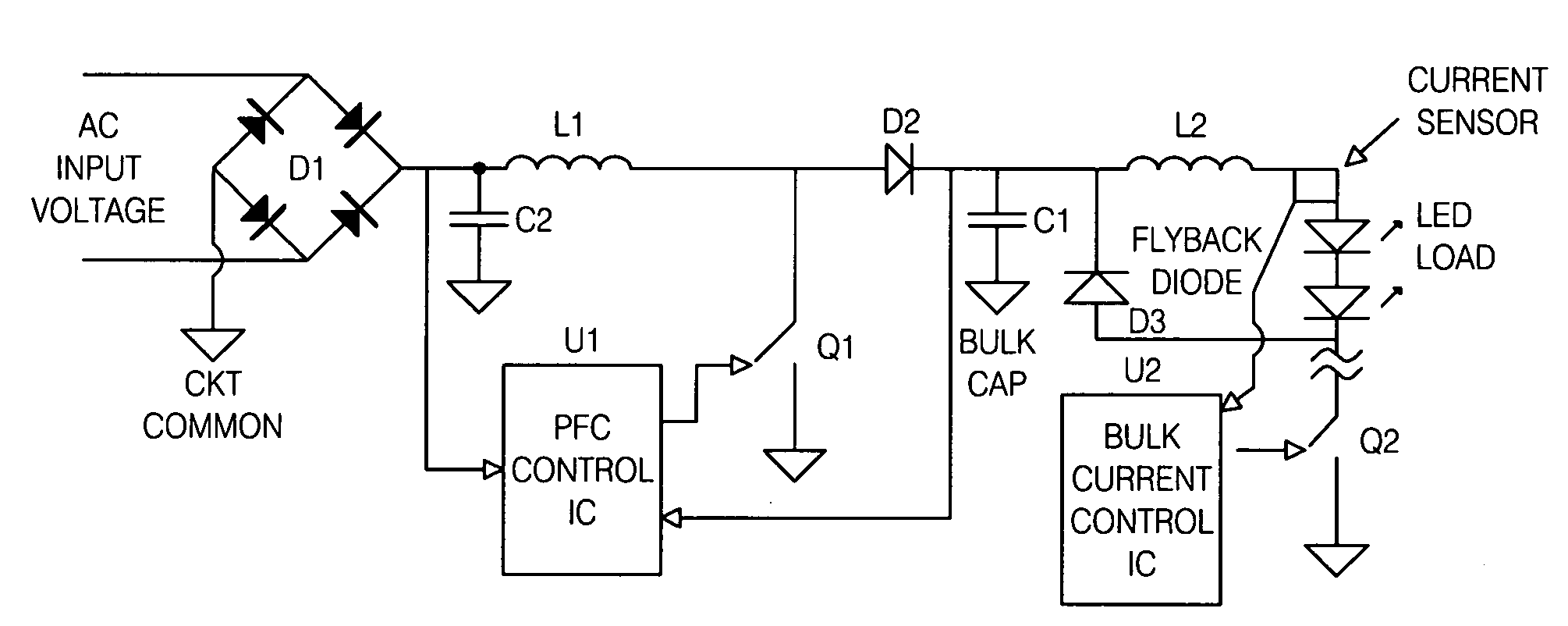

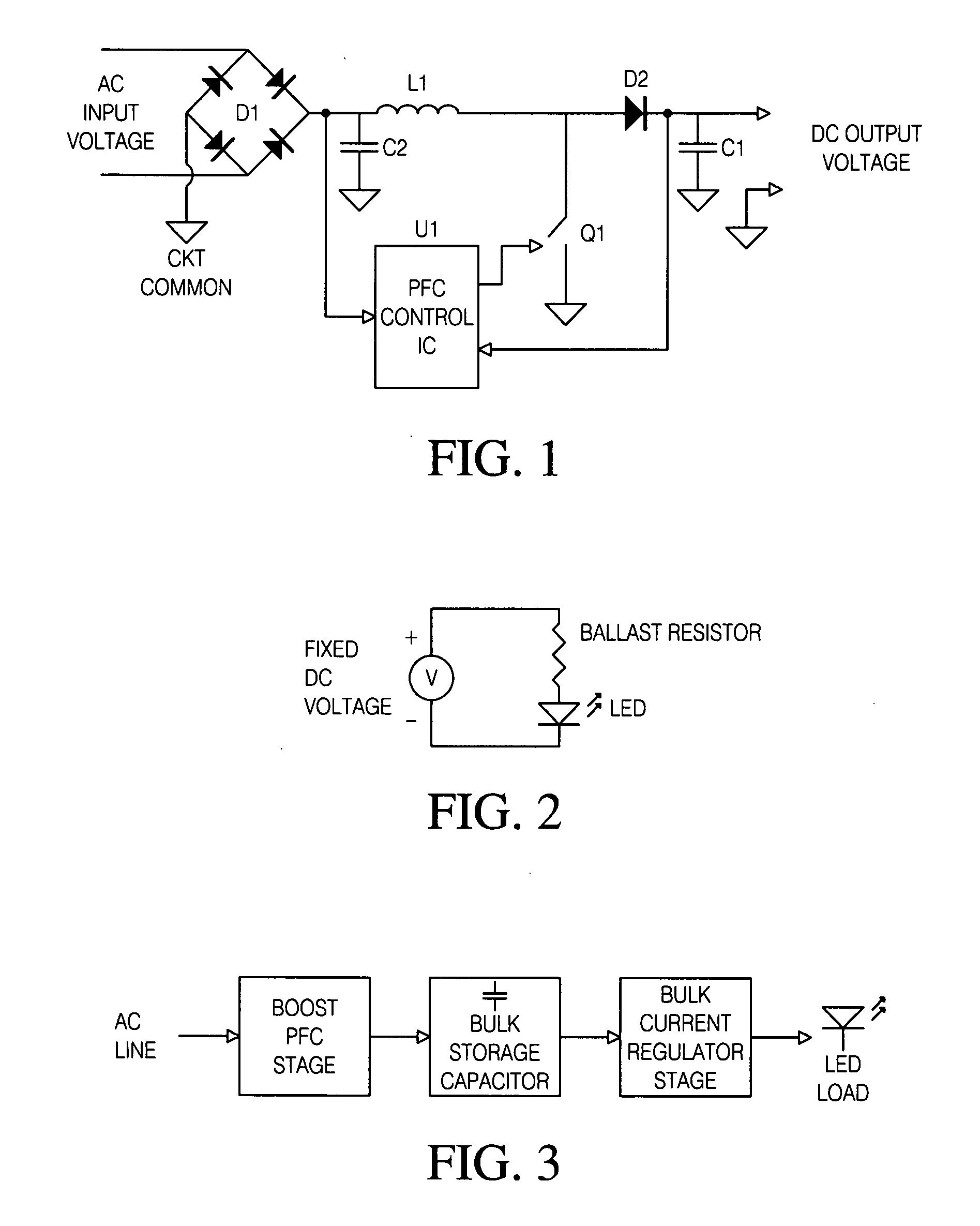

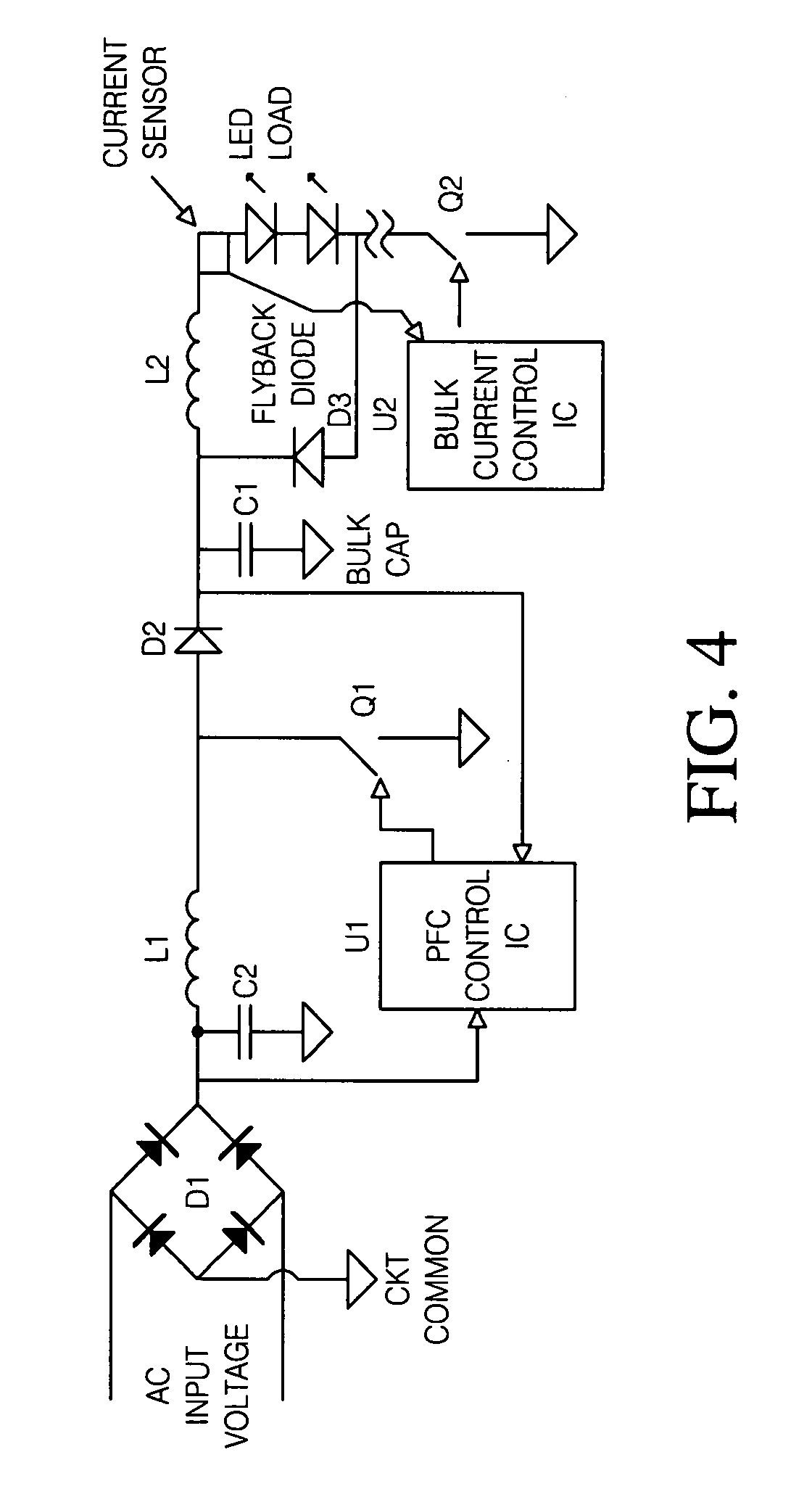

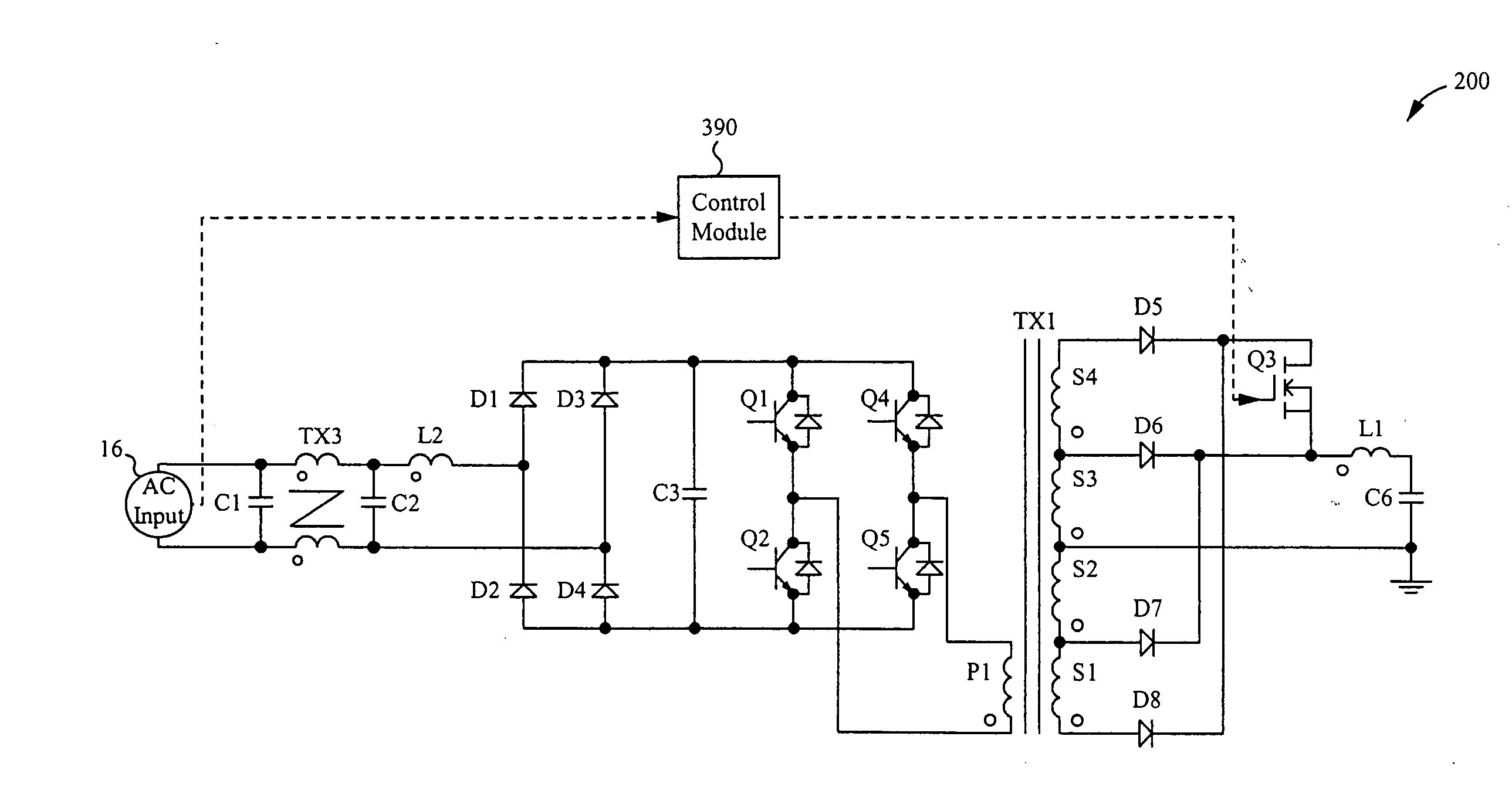

LED power supply with options for dimming

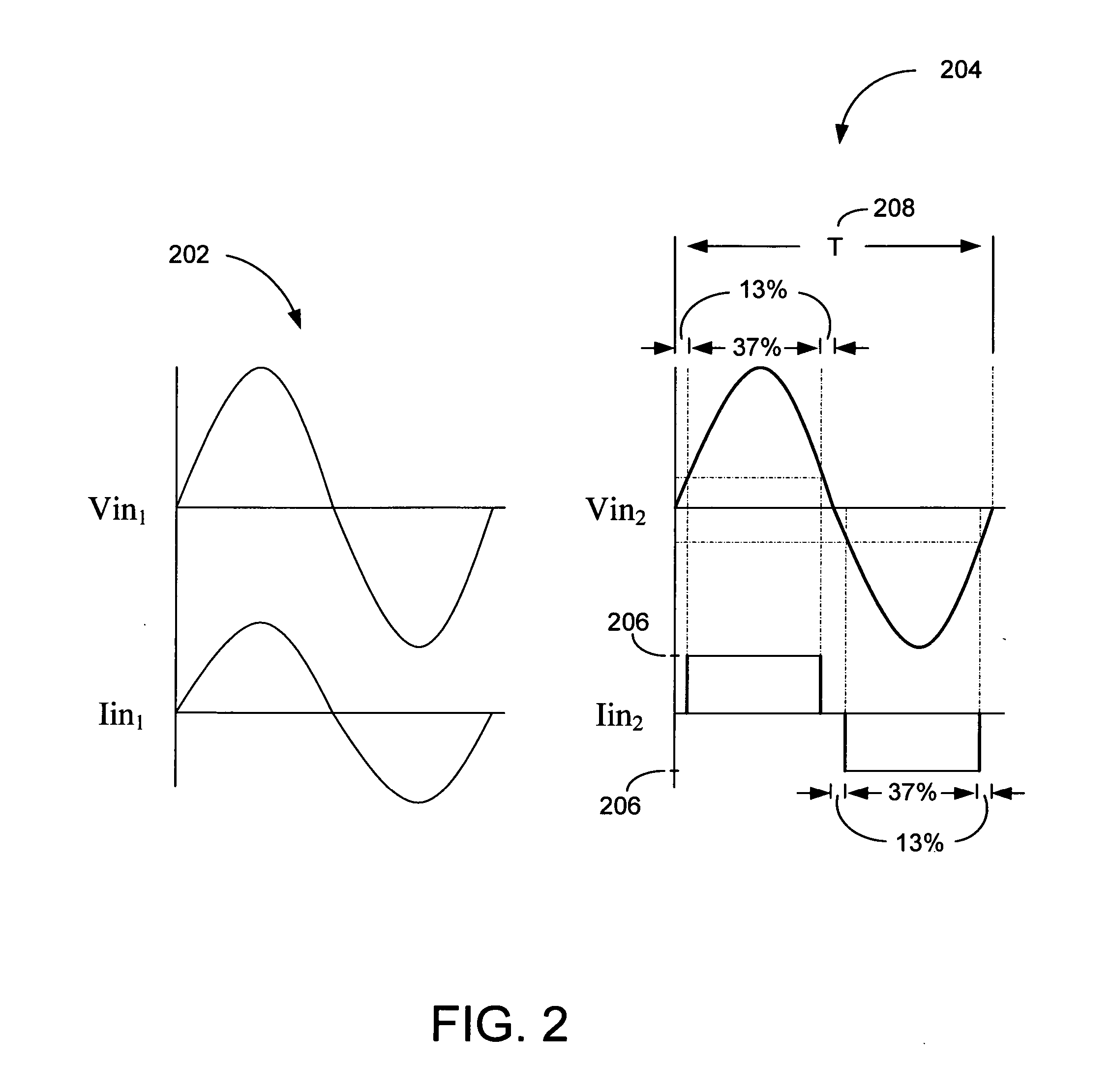

A LED driver circuit is disclosed that has the ability to drive a single series string of power LEDs. The LED driver circuit uses a single stage power converter to convert from a universal AC input to a regulated DC current. This single stage power converter current is controlled by a power factor correction unit. Furthermore, the LED driver circuit contains a galvanic isolation barrier that isolates an input, or primary, section from an output, or secondary, section. The LED driver circuit can also include a dimming function, a red, green, blue output function, and a control signal that indicates the LED current and is sent from the secondary to the primary side of the galvanic barrier.

Owner:KASTNER MARK ALLEN

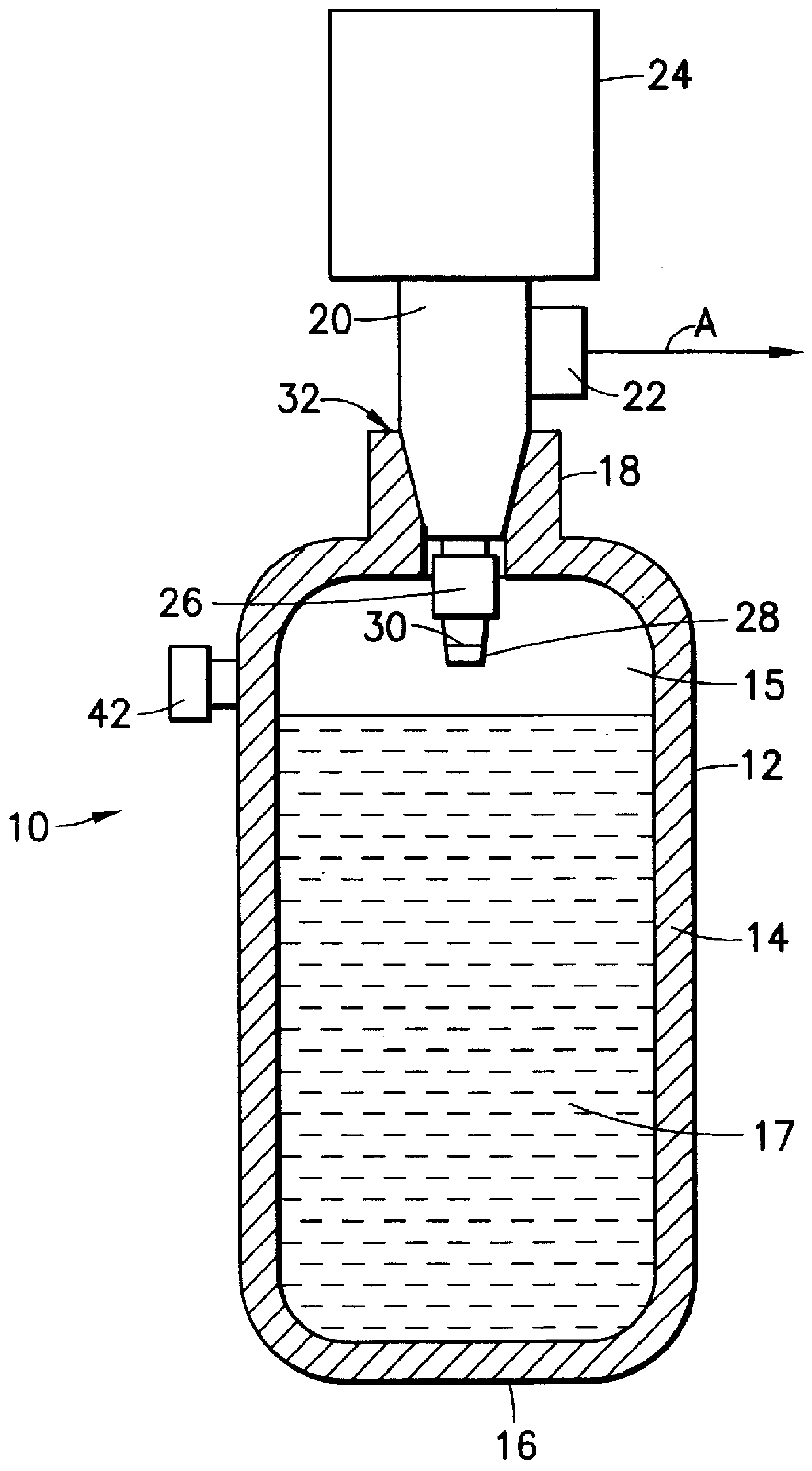

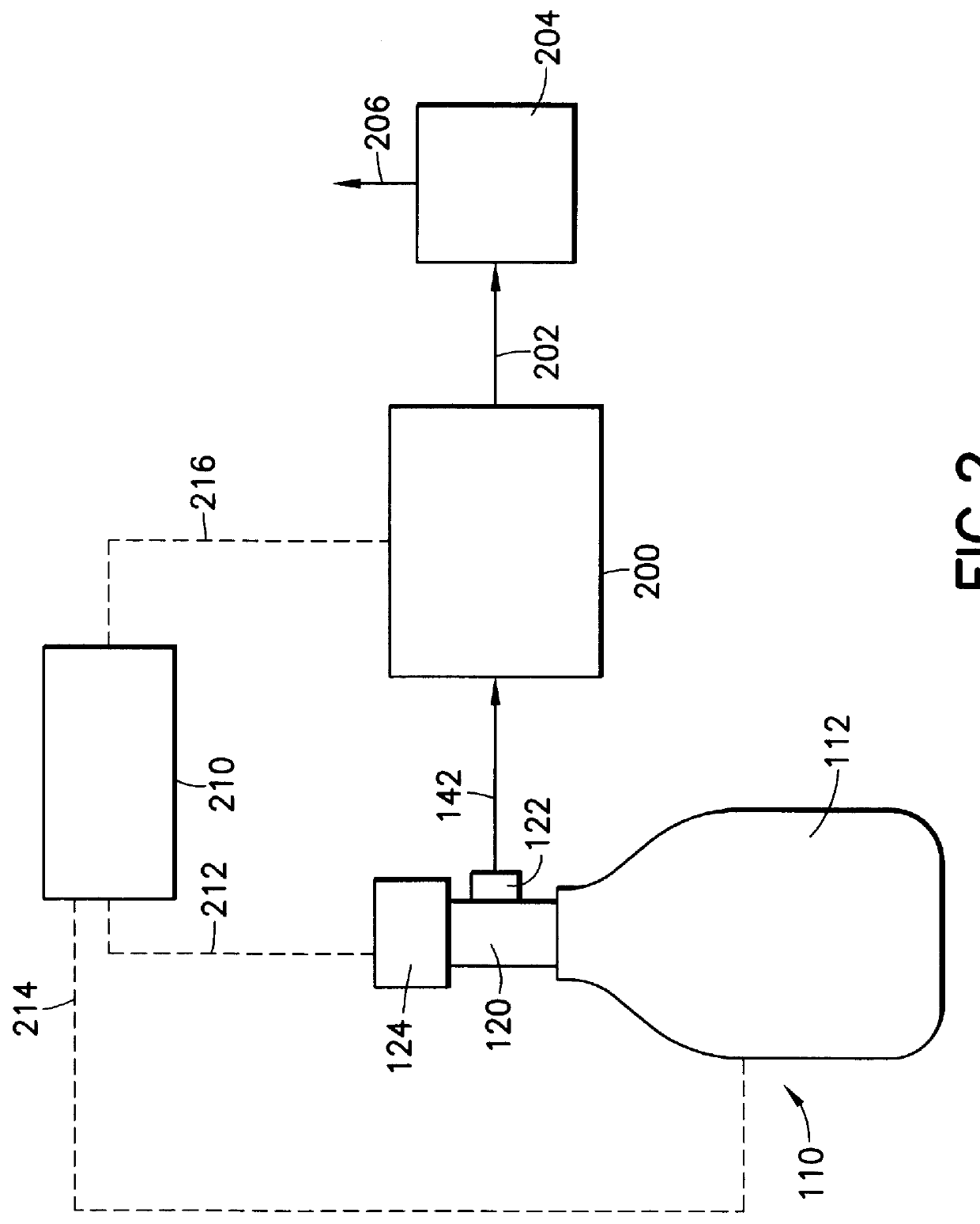

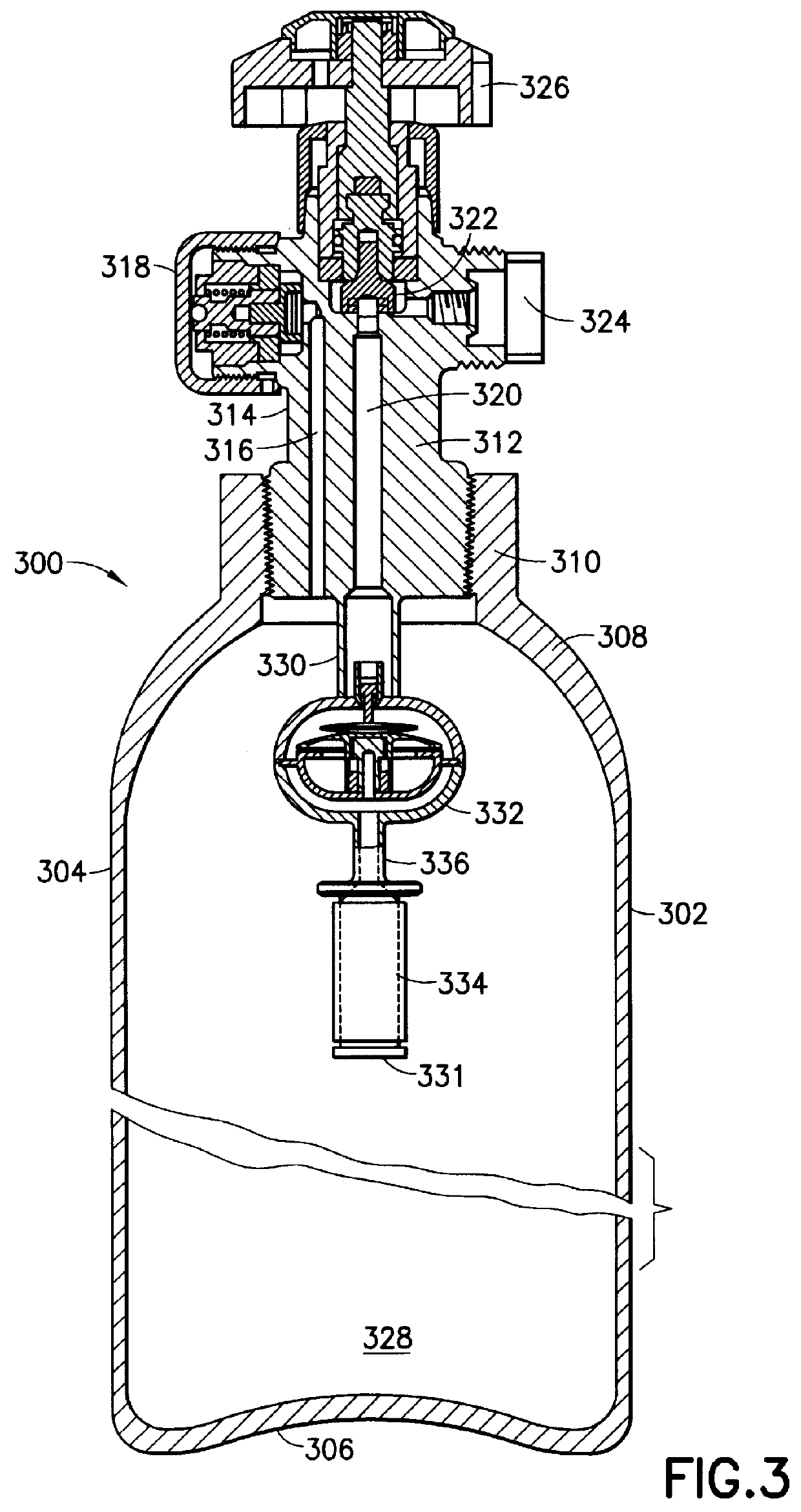

Fluid storage and dispensing system

InactiveUS6089027ACostPerformanceContainer filling methodsVacuum evaporation coatingSingle stageSorbent

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator, e.g., a single-stage or multi-stage regulator, associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g., including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid that is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. In another aspect, the vessel contains a solid-phase sorbent material having sorbable gas adsorbed thereon, at a pressure in excess of 50 psig. The vessel may have a >1 inch NGT threaded neck opening, to accommodate the installation of an interior regulator.

Owner:ENTEGRIS INC

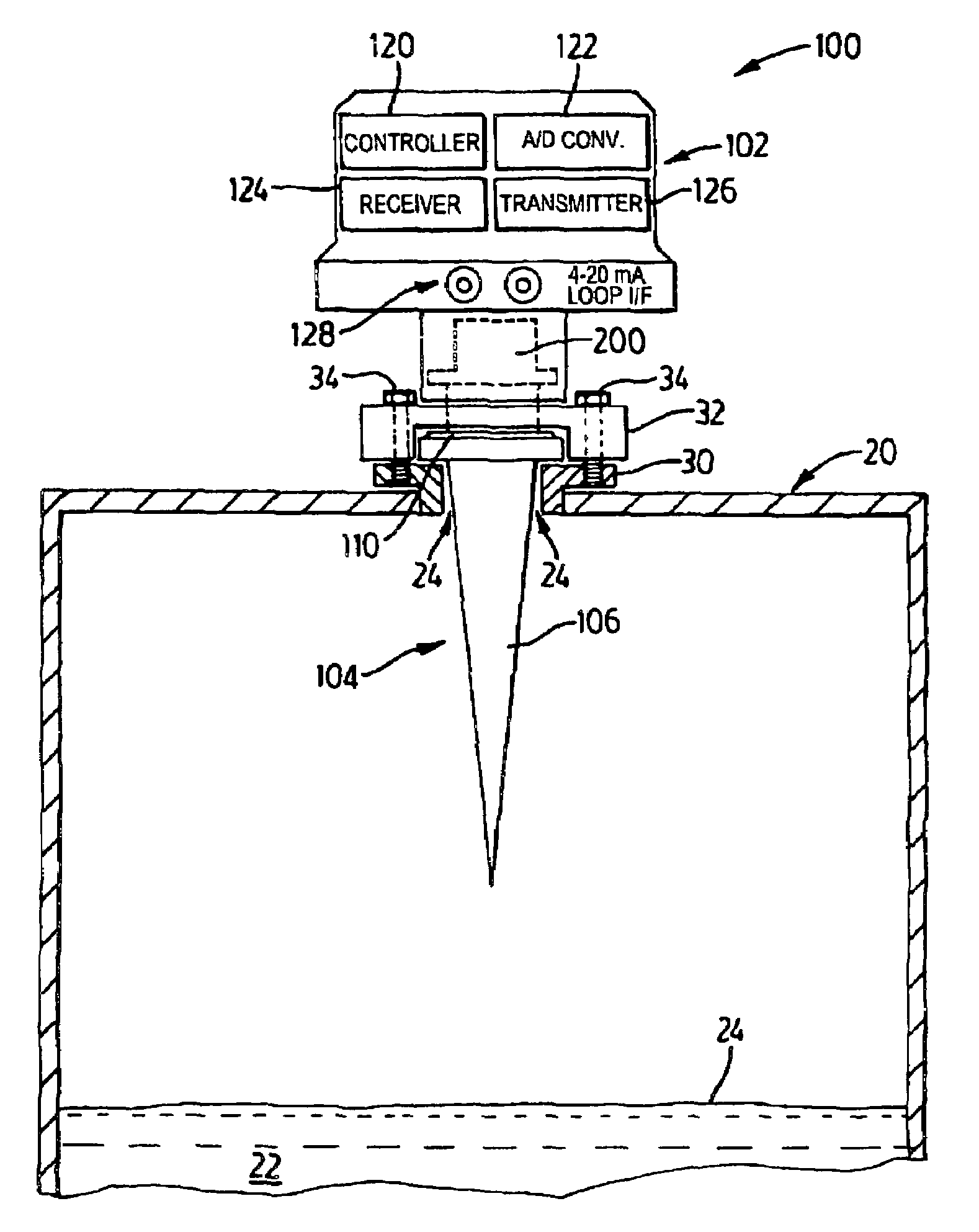

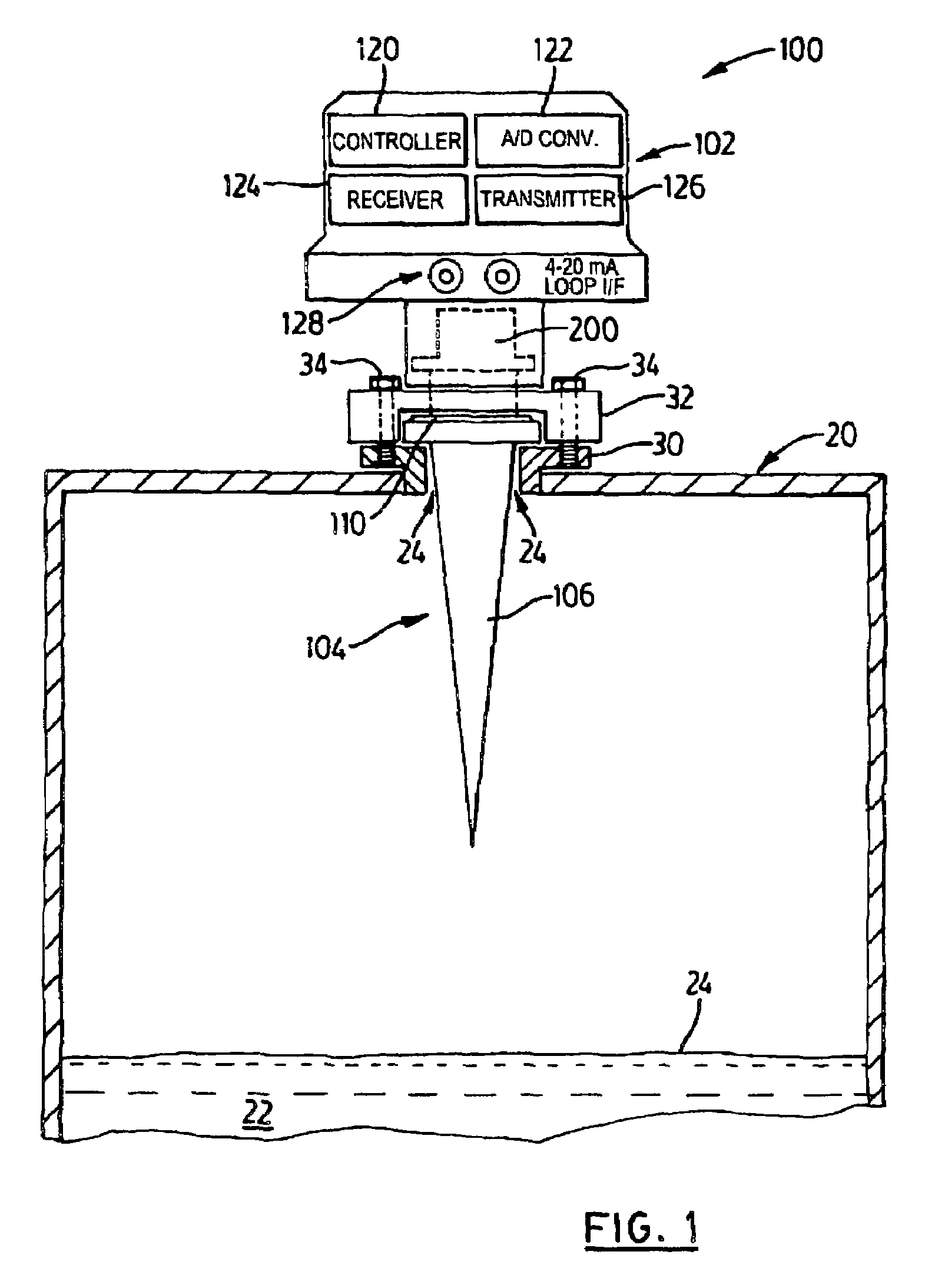

Coupler with waveguide transition for an antenna in a radar-based level measurement system

Owner:SIEMENS AG

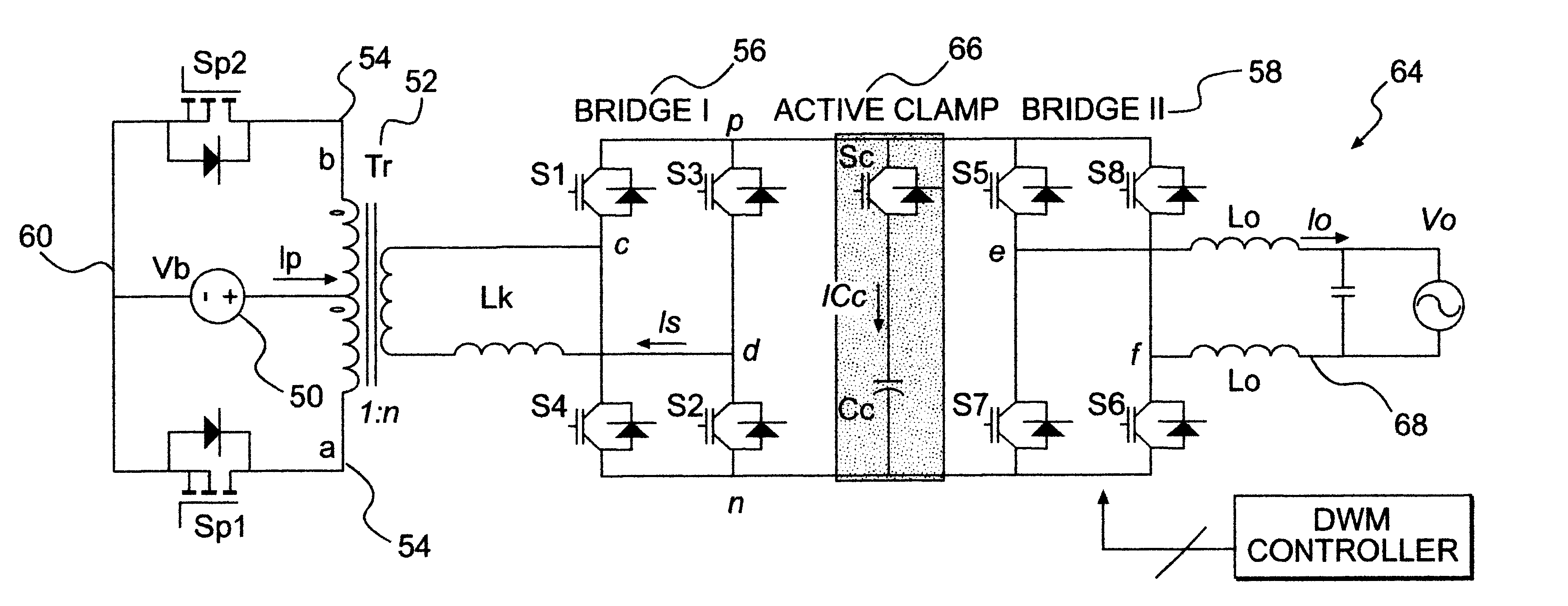

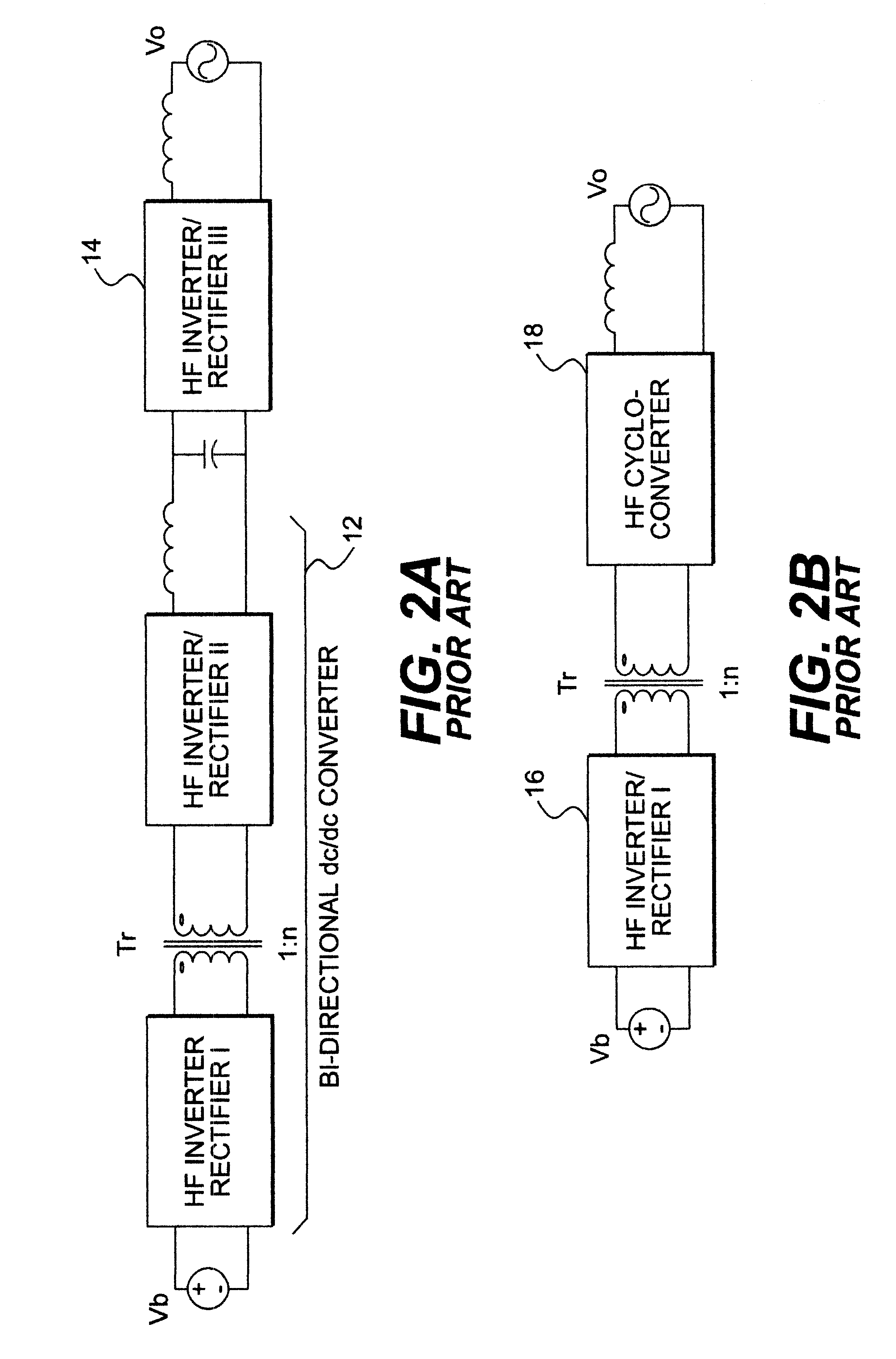

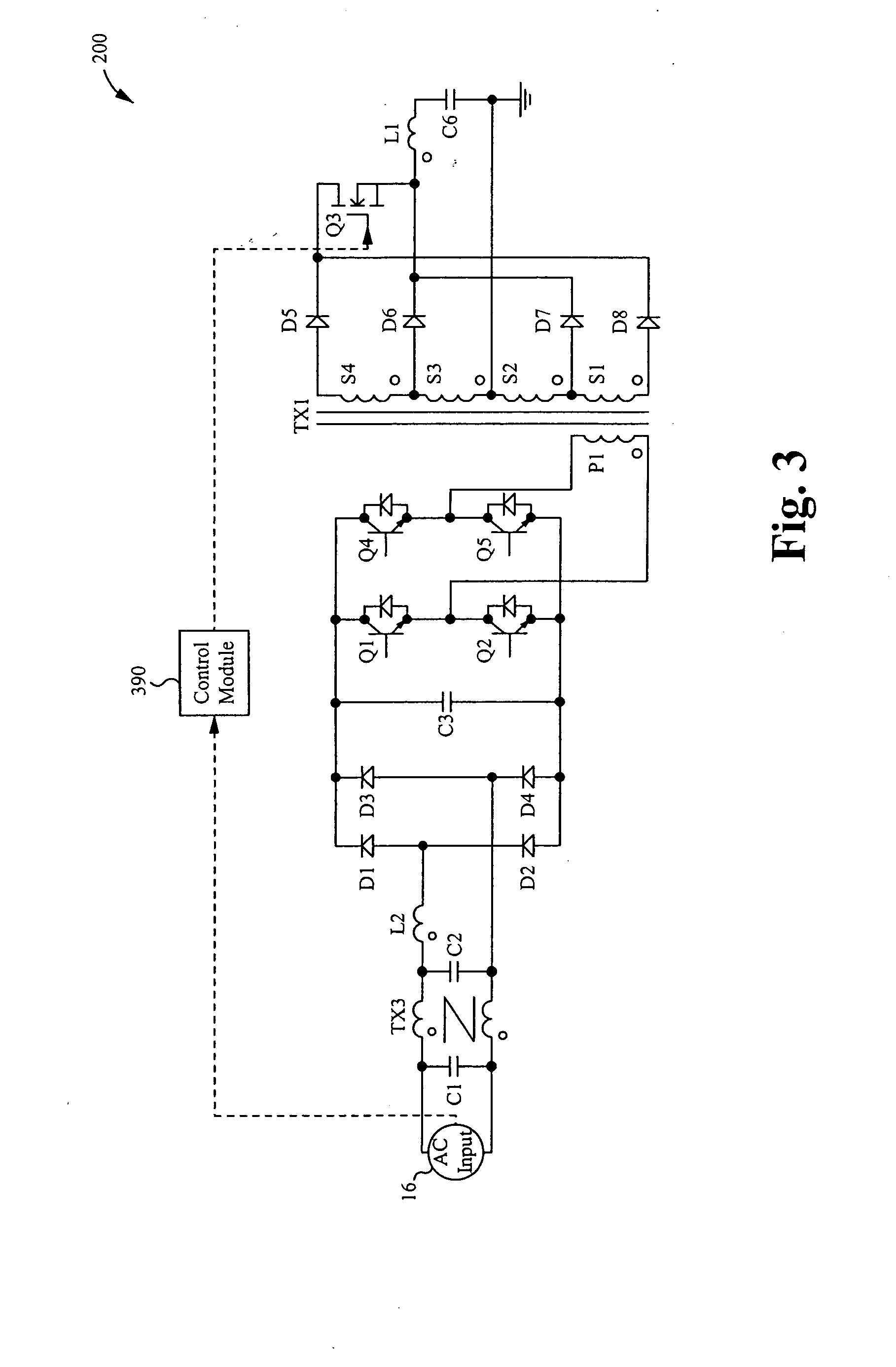

Soft-switched quasi-single-stage (QSS) bi-directional inverter/charger

A soft-switched single-phase quasi-single-stage (QSS) bi-directional inverter / charger converts AC-DC or DC-AC. The inverter / charger comprises a push-pull inverter / rectifier on the dc-side, an isolation transformer which provides ohmic isolation and voltage scaling, two full-bridges on the ac side in cascade, a voltage clamp branch comprising a capacitive energy storage element in series with an active switch with its anti-parallel diode, a passive filter at the ac side to smooth out the high frequency switching voltage ripple at the output, and a corresponding PWM scheme to seamlessly control the converter to operate in all four quadrant operation modes in the output voltage and output current plane, and is capable of converting power in both directions.

Owner:VIRGINIA TECH INTPROP INC

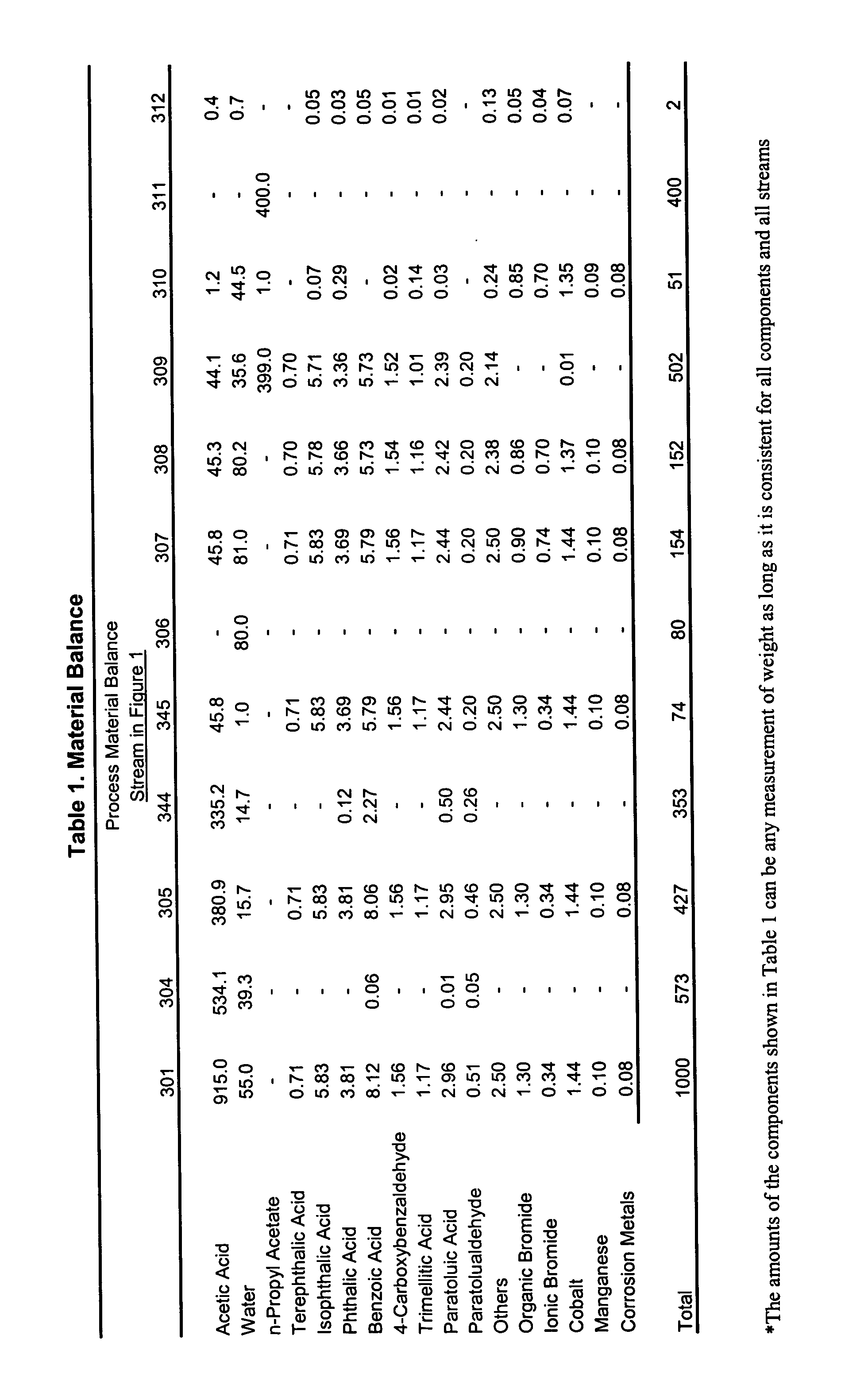

Extraction process for removal of impurities from an oxidizer purge stream in the synthesis of carboxylic acid

InactiveUS20050038288A1Easy to operateImprove reliabilityOrganic compound preparationOrganic chemistry methodsSingle stageMetal catalyst

Disclosed is a process that relates to the recovery of a metal catalyst from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic acid. The process involves the addition of a wash solution to a high temperature molten dispersion to recover the metal catalyst and then subjecting an aqueous mixture or purified aqueous mixture so formed to a single stage extraction to remove organic impurities to produce an extract stream and a raffinate stream comprising the metal catalyst.

Owner:GRUPO PETROTEMEX DE C V

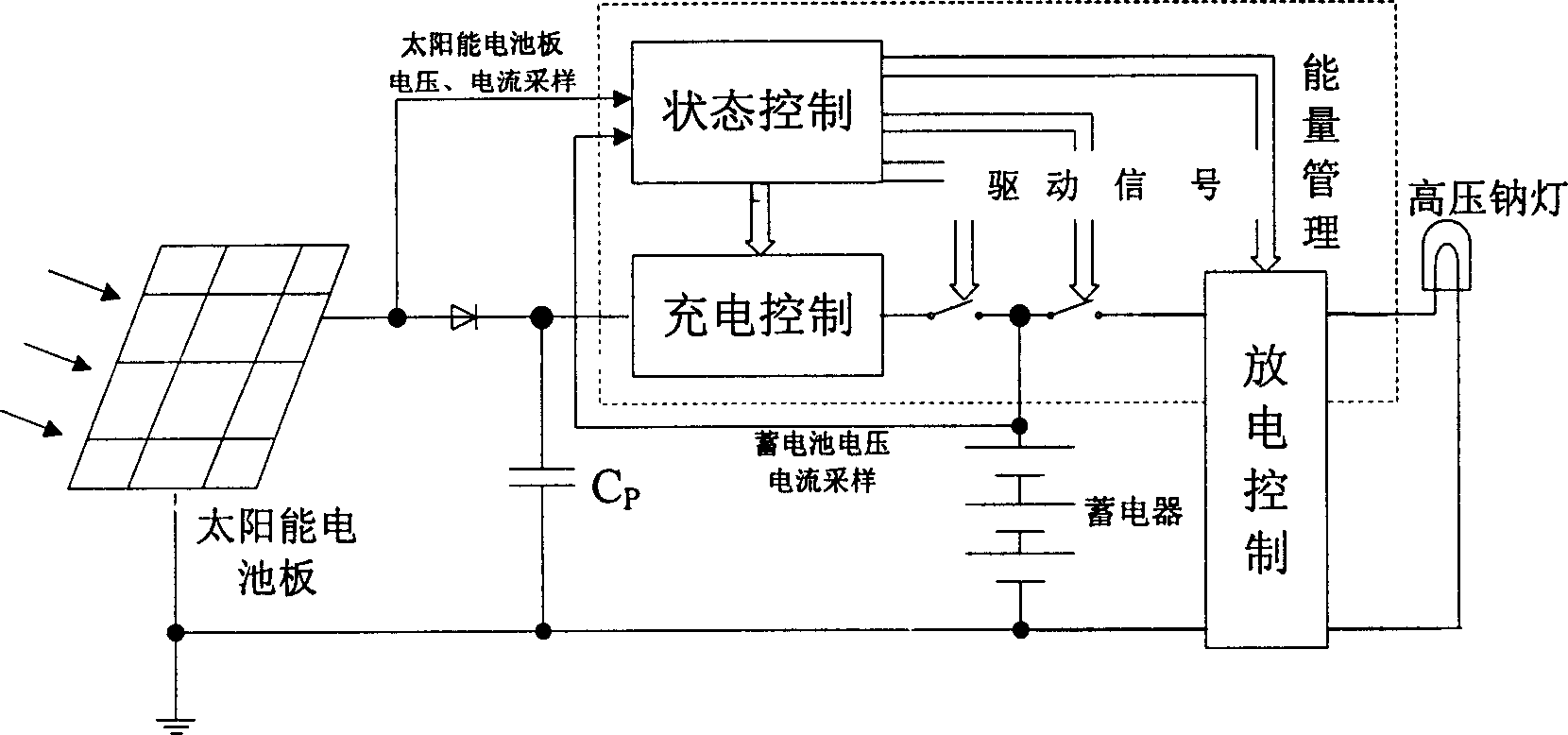

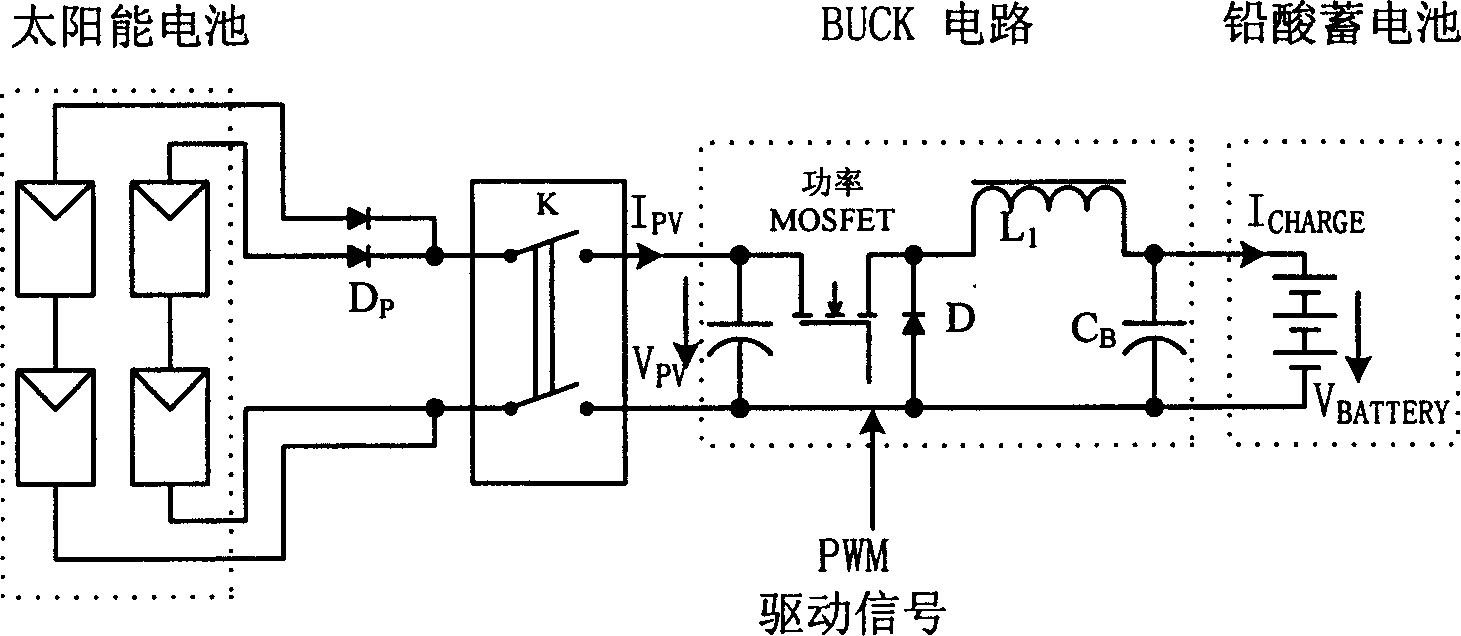

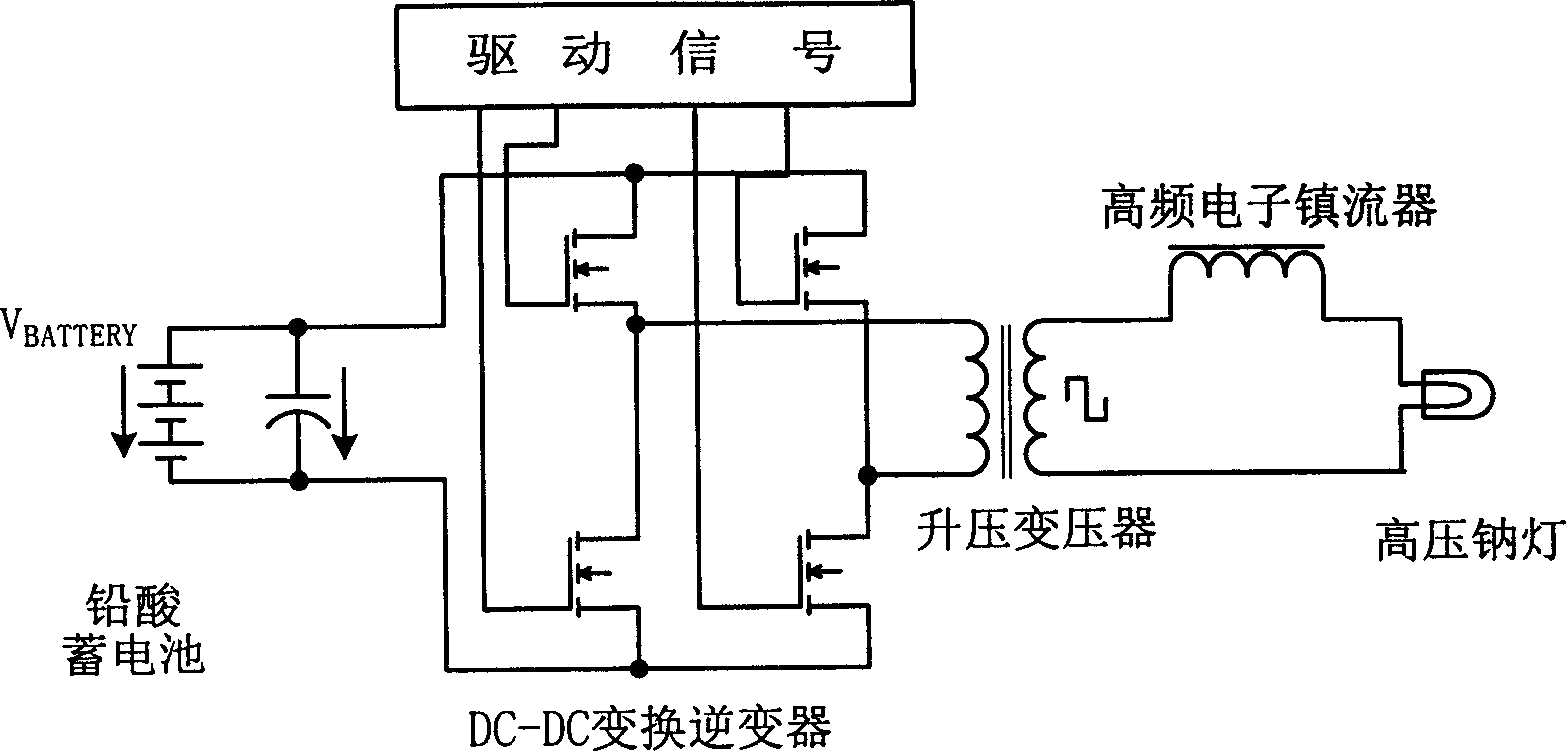

Solar energy high voltage sodium lamp controller based on single stage inverter

InactiveCN1787717ARealize intelligent controlImproved and enhanced charge and discharge capabilitiesBatteries circuit arrangementsElectric lighting sourcesMicrocontrollerEngineering

This invention relates to a solar energy high pressure Na-lamp controller based on a single stage inverter characterizing in applying a sectional charge control and a frequency conversion output control, in which, the hardware includes a singlechip control circuit, a single-stage total bridge inversion circuit, a storage battery charge circuit, a high frequency electronic ballast circuit, a solar energy cell, storage batteries and luminaries, the controller is charged by MPPT to increase the system efficiency and applies frequency conversion output to control the current of the lamp, besides, a design of machine-card separation is applied to the controller on the structure to meet the needs of different luminaries and lamination, the control structure is integrated in a control card suitable for software upgrading.

Owner:TSINGHUA UNIV

Adjustable multi-band antenna system

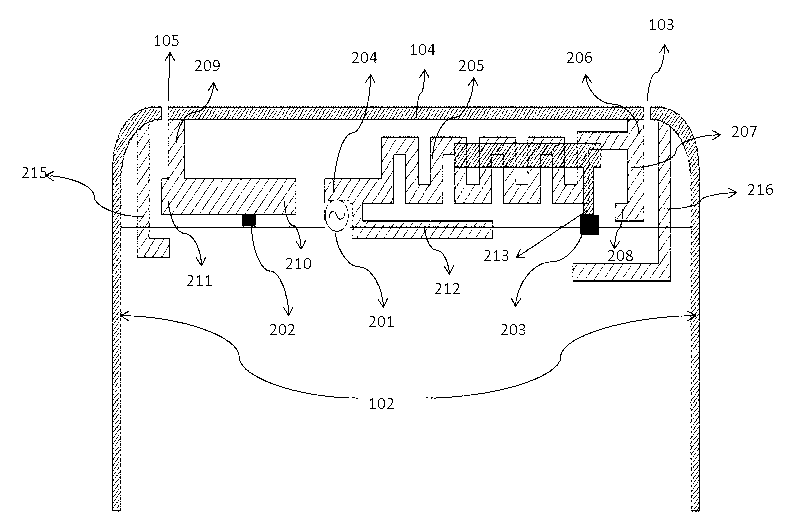

InactiveCN103296385AMetal Trim Frame Requirements RetainedMeet the needs of metal texture mobile terminal productsAntenna supports/mountingsAntenna equipments with additional functionsMulti bandSingle stage

The invention discloses an adjustable multi-band antenna system which is applicable to a mobile terminal with a metal frame structure. The antenna system comprises a metal frame, a PCB (printed circuit board) and an antenna portion. The metal frame is designed to be one portion of an antenna radiator, a loop is formed by the metal frame and the antenna radiator together, a single-stage branch portion is used for debugging low-frequency and high-frequency resonances, and a low-frequency coupling portion and a high-frequency coupling portion can be added according to requirements of working bands. The adjustable multi-band antenna system has the advantages that gaps of the metal frame are formed at the bottom, users are avoided from touching the gaps as much as possible in actual use, and poor antenna performance is avoided during actual handholding; the working bands of the adjustable multi-band antenna system are 704MHz-960MHz and 1710MHz-2700MHz, and a multi-frequency broadband is realized; compared with traditional common antennas, the adjustable multi-band antenna system has the advantages of multiple bands and wide bandwidth.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

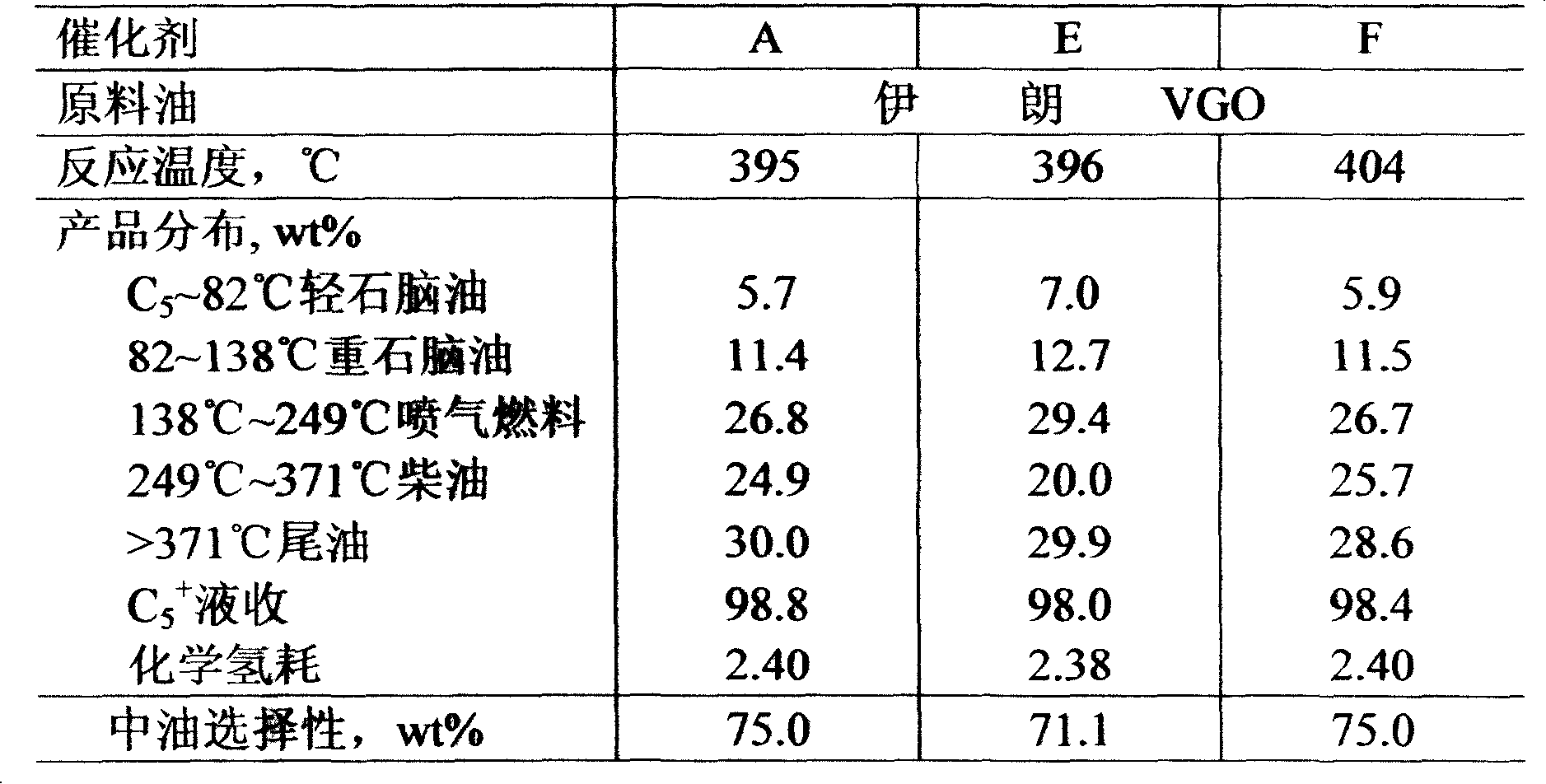

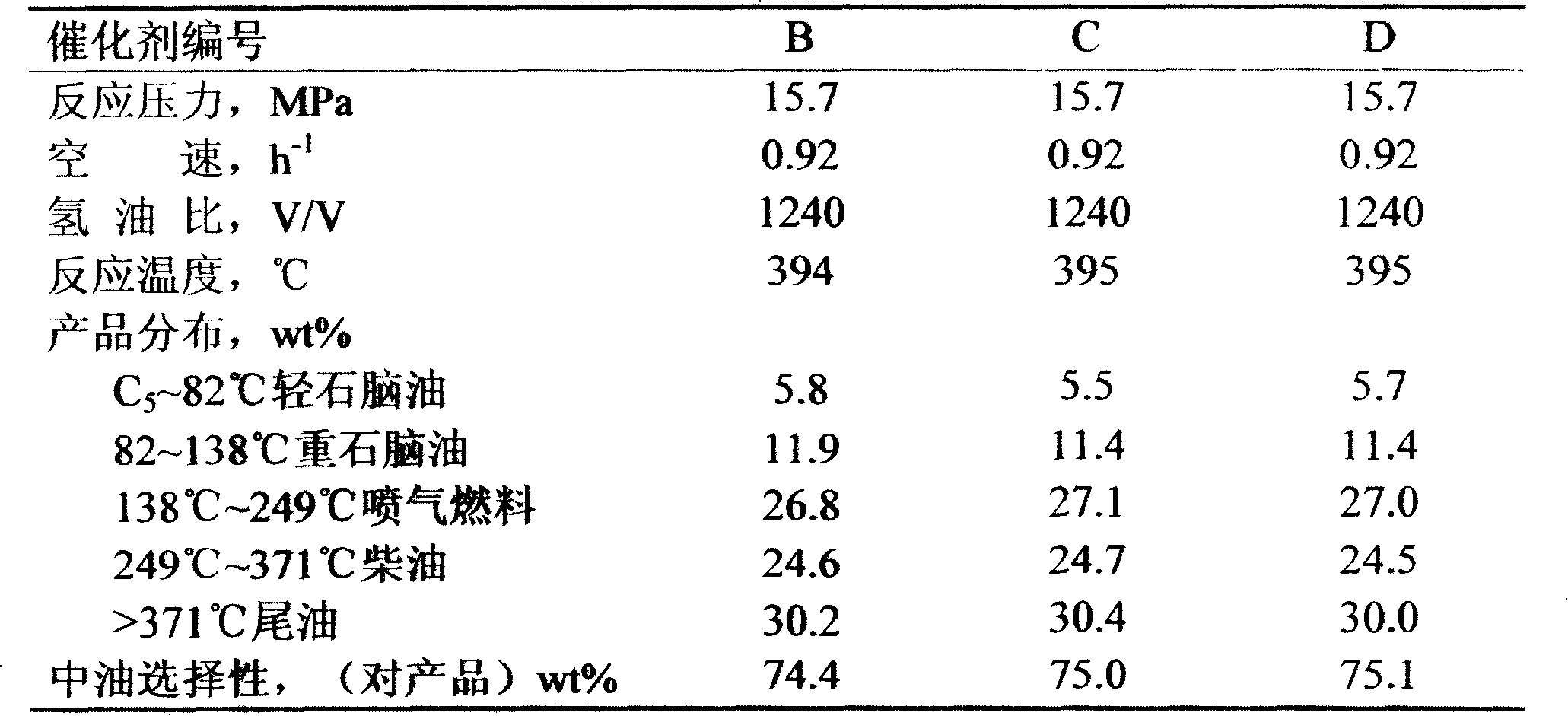

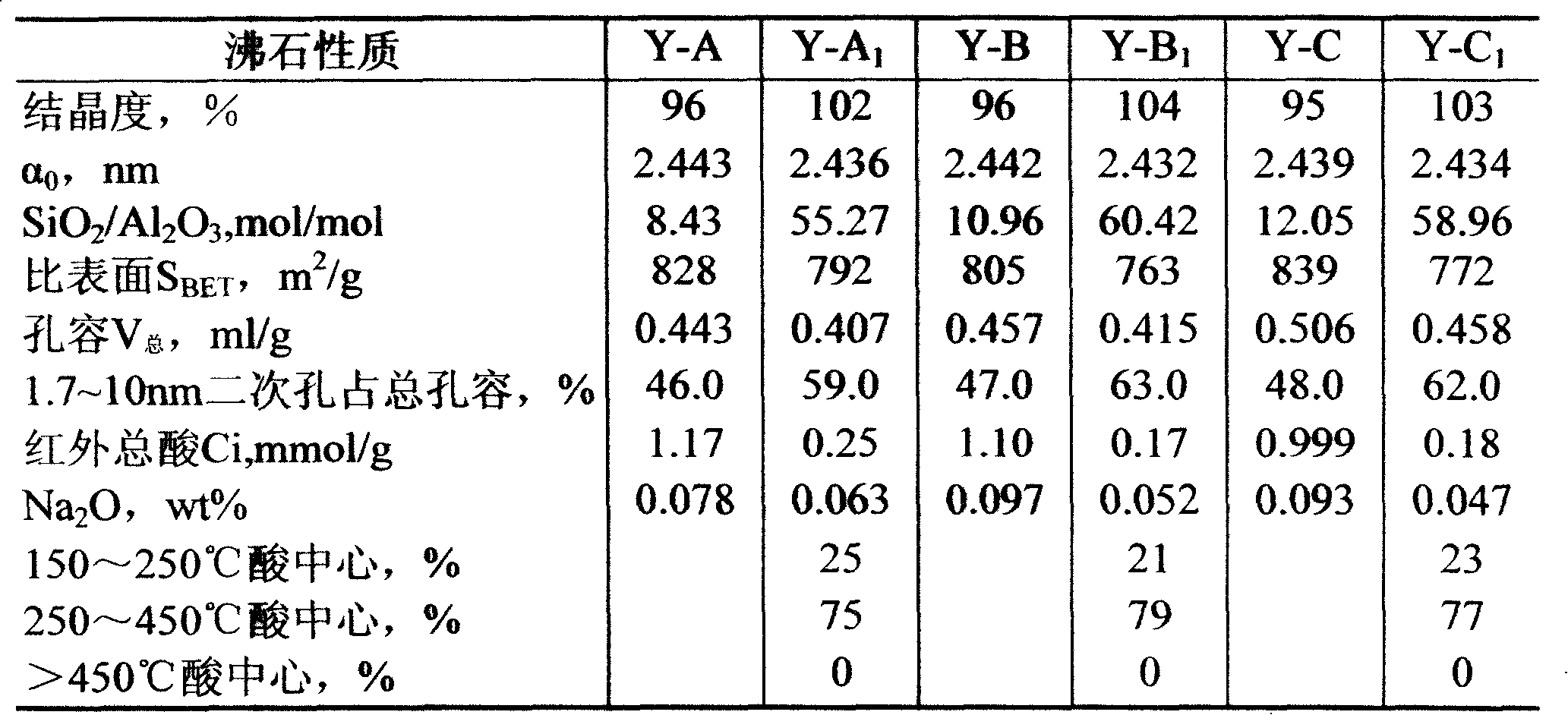

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

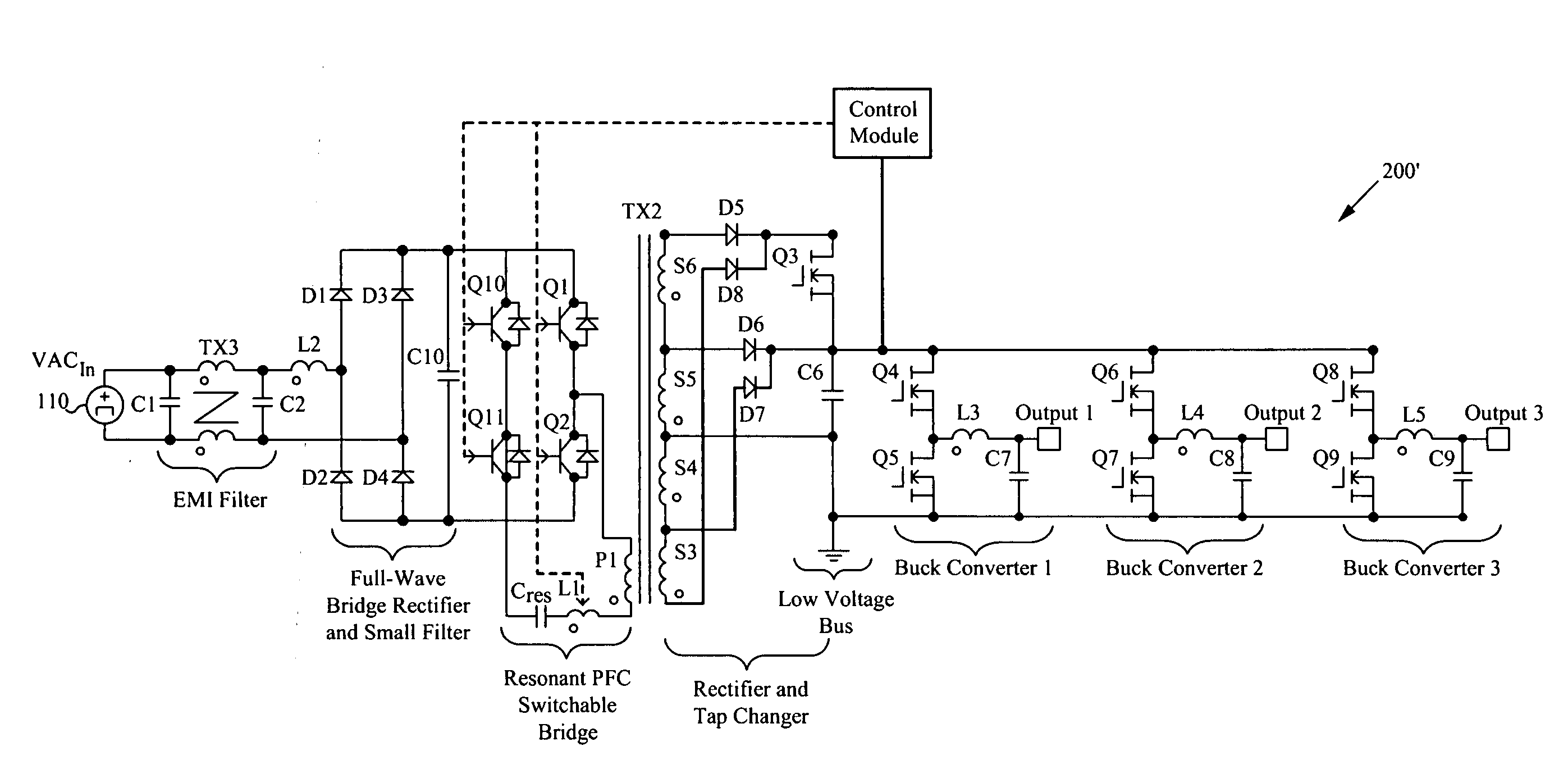

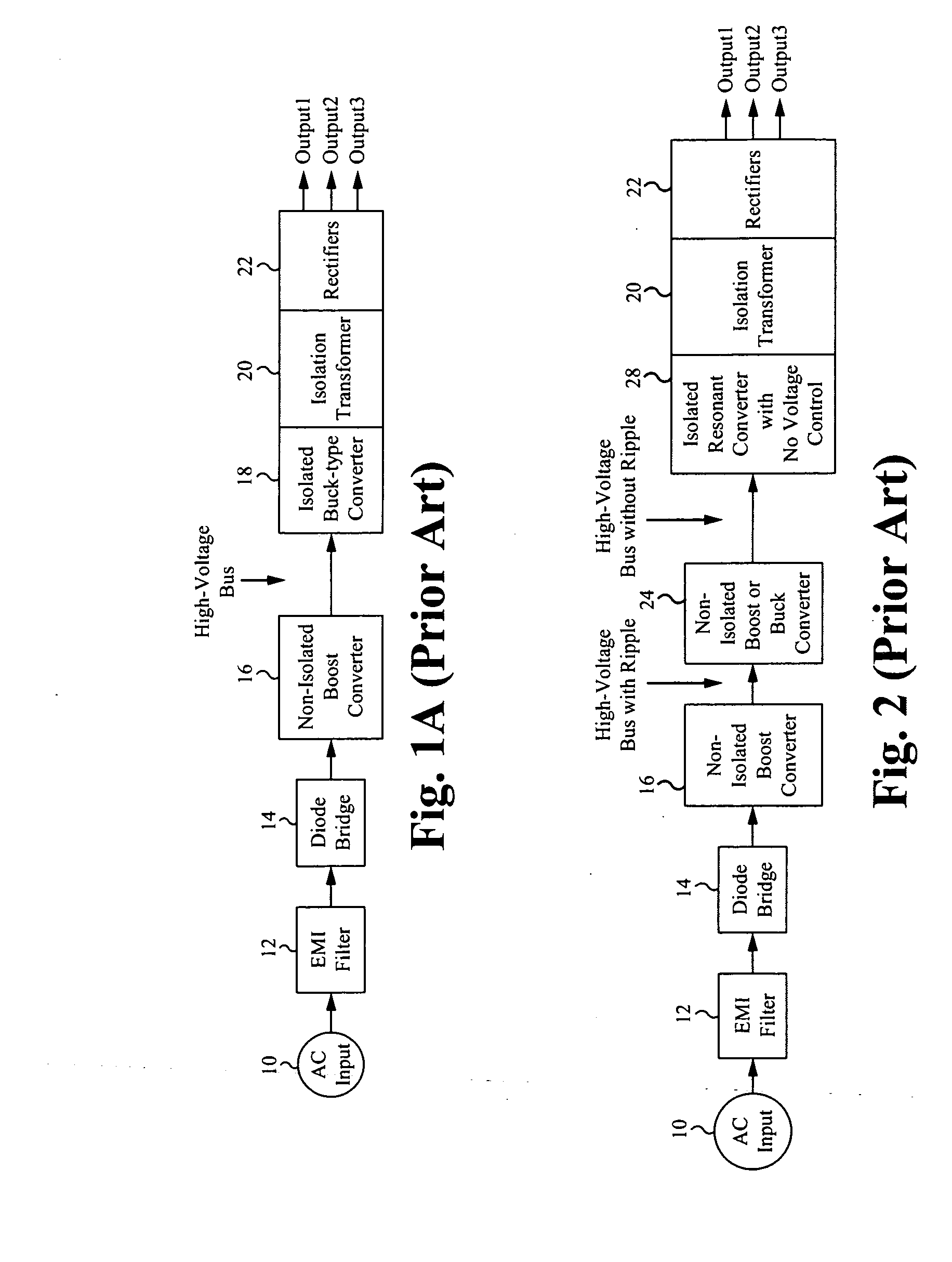

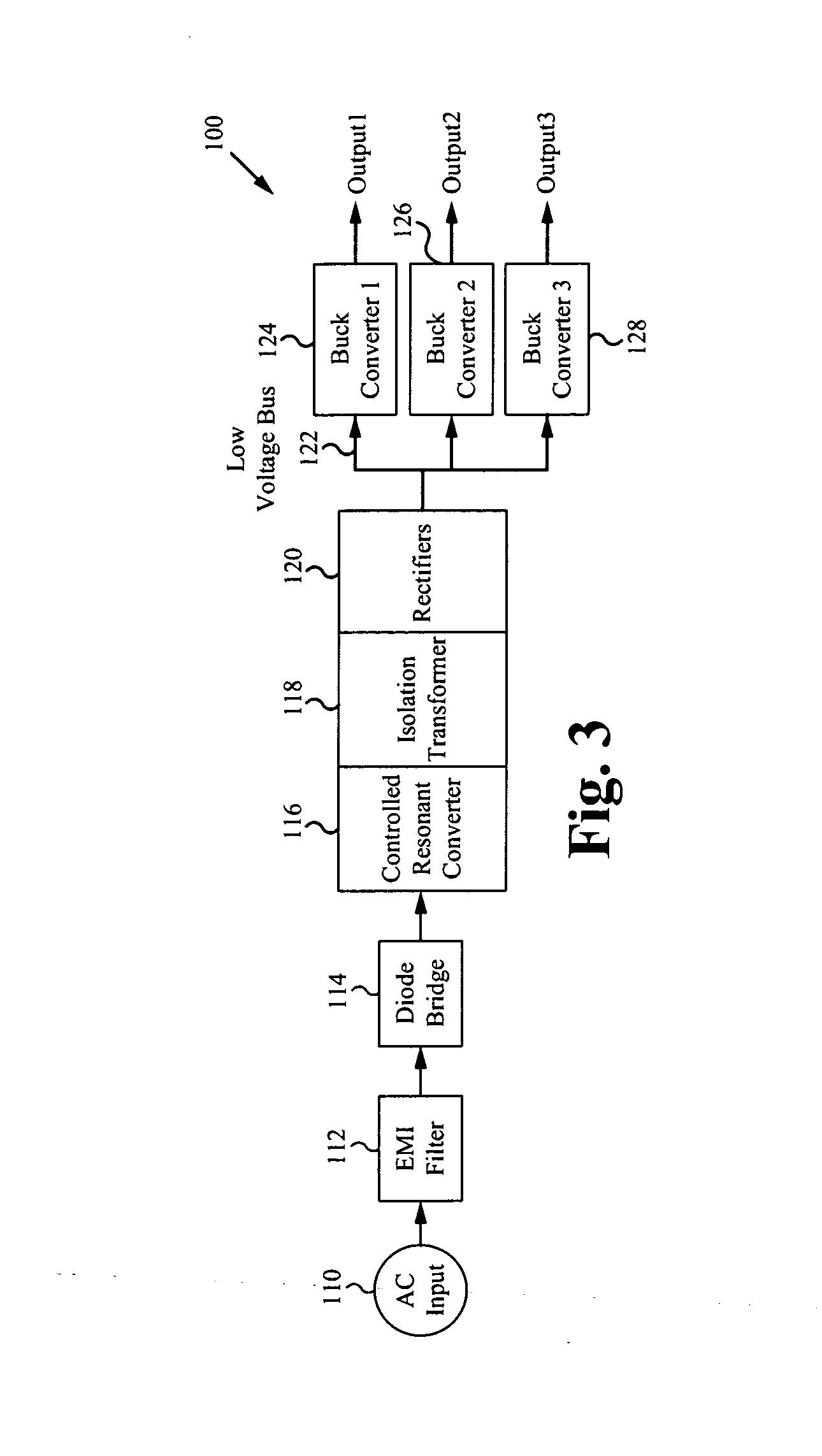

Resonant power factor correction converter

ActiveUS20090290385A1Increase pressureBurdenAc-dc conversion without reversalEfficient power electronics conversionMass storageSingle stage

An AC-to-DC power converter configured to provide power factor correction and a single isolated low-voltage output. The power converter includes a single-stage resonant power converter including an isolation transformer, a resonant tank, a rectifier, and a bulk storage capacitor coupled to an output of the isolation transformer. In typical applications, at least one non-isolated power converter is coupled to the output of the single-stage isolated power factor correction converter.

Owner:MYPAQ HLDG LTD

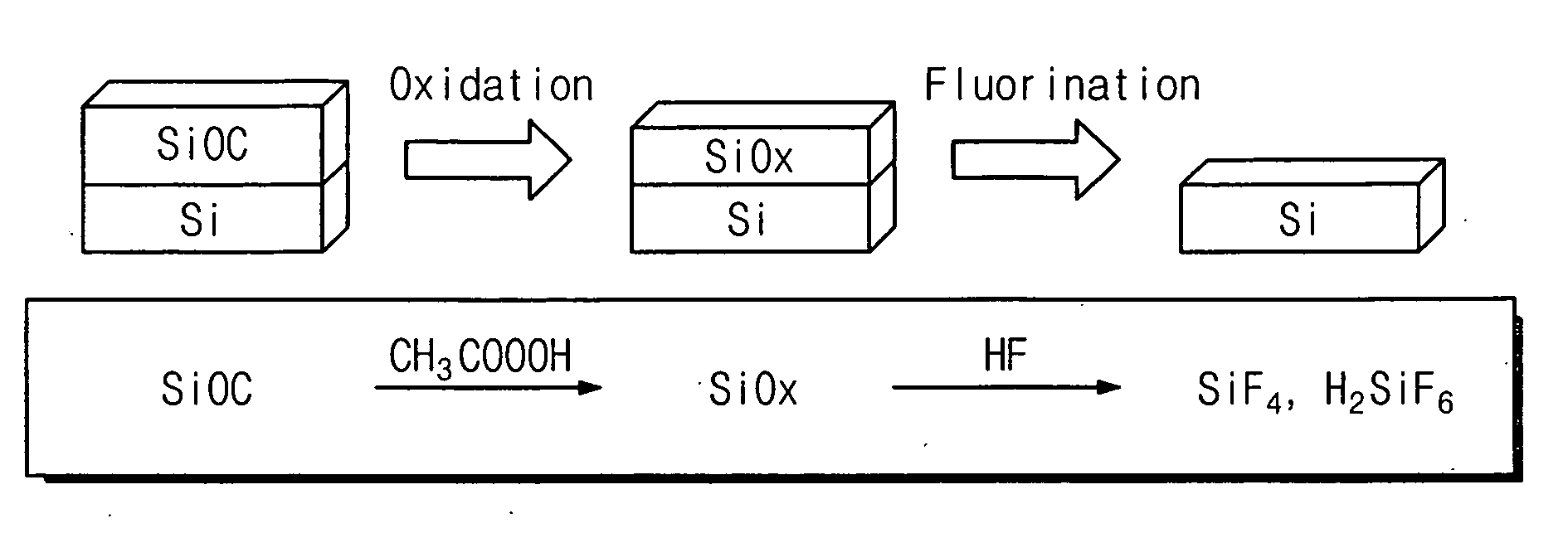

Etching solution and method for removing low-k dielectric layer

InactiveUS20060097220A1Easy to prepareReagents is relatively inexpensiveDecorative surface effectsDetergent mixture composition preparationSingle stageOxidizing agent

Etching solutions are disclosed for etching low-k dielectric layers on substrates, said solutions including effective proportions of an oxidant for oxidizing a low-k dielectric layer and effective proportions of an oxide etchant for removing oxides. It is possible to easily remove a low-k dielectric layer using such etching solutions by a single-stage treatment process.

Owner:SAMSUNG ELECTRONICS CO LTD

Thermal processing system for curing dielectric films

InactiveUS20080063809A1Easy to optimizeIncrease temperatureVacuum evaporation coatingSemiconductor/solid-state device manufacturingSingle stageUltraviolet radiation

A thermal processing system and method for curing a dielectric film. The thermal processing system is configured to treat the dielectric film with ultraviolet (UV) radiation and infrared (IR) radiation in order to cure the dielectric film. The thermal processing system can include an array if IR and UV light-emitting devices (LEDs) configured to irradiate a substrate having a low dielectric constant (low-k) film. The method dries the dielectric film to remove contaminants from the film and exposes the dielectric film at a single stage to ultraviolet radiation and IR radiation.

Owner:TOKYO ELECTRON LTD

Aqueous compositions comprising polymeric duller particle

ActiveUS7829626B2Limit scopeImprove consistencyLiquid surface applicatorsLayered productsSingle stageTert-butyl acrylate

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

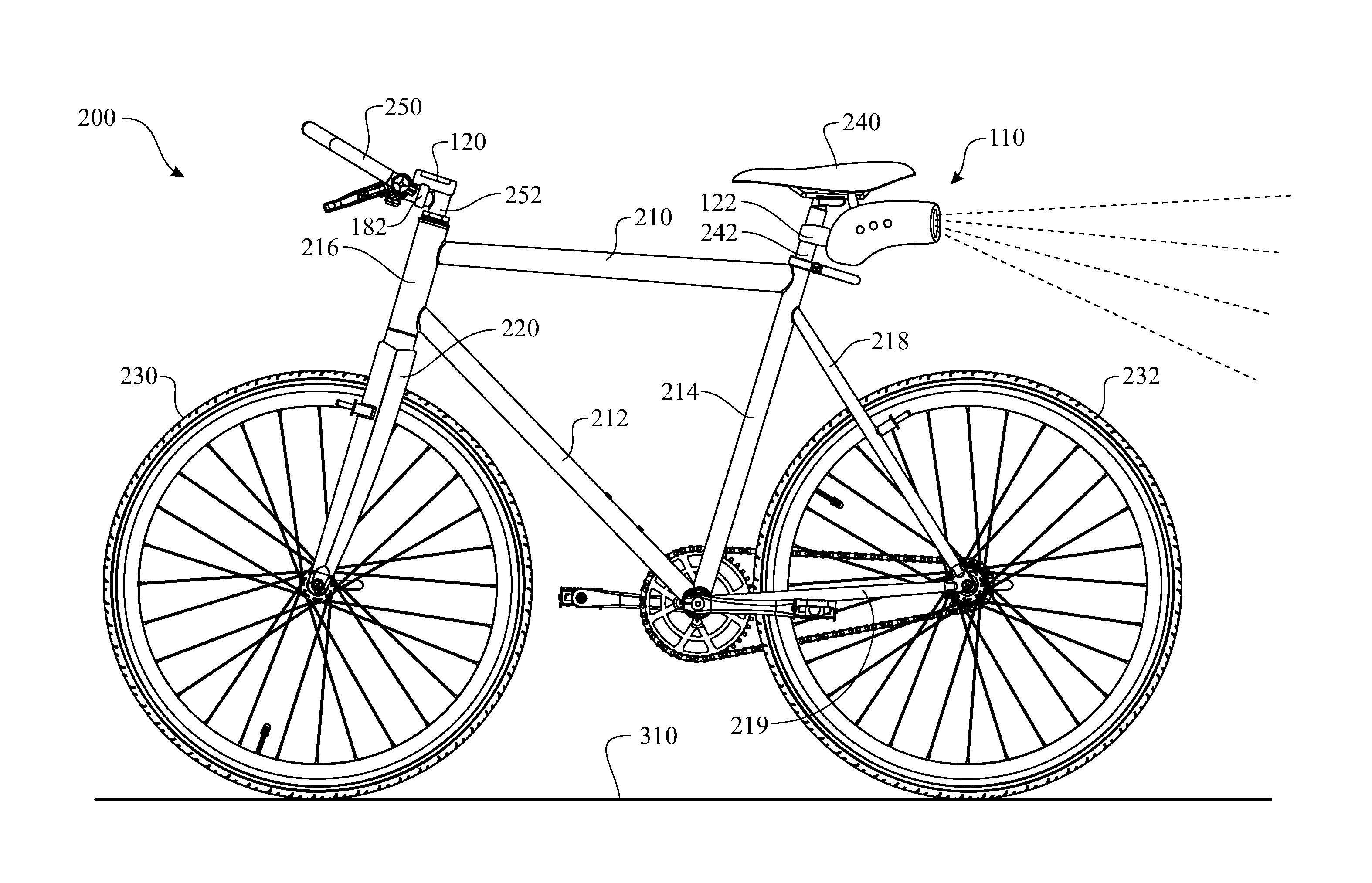

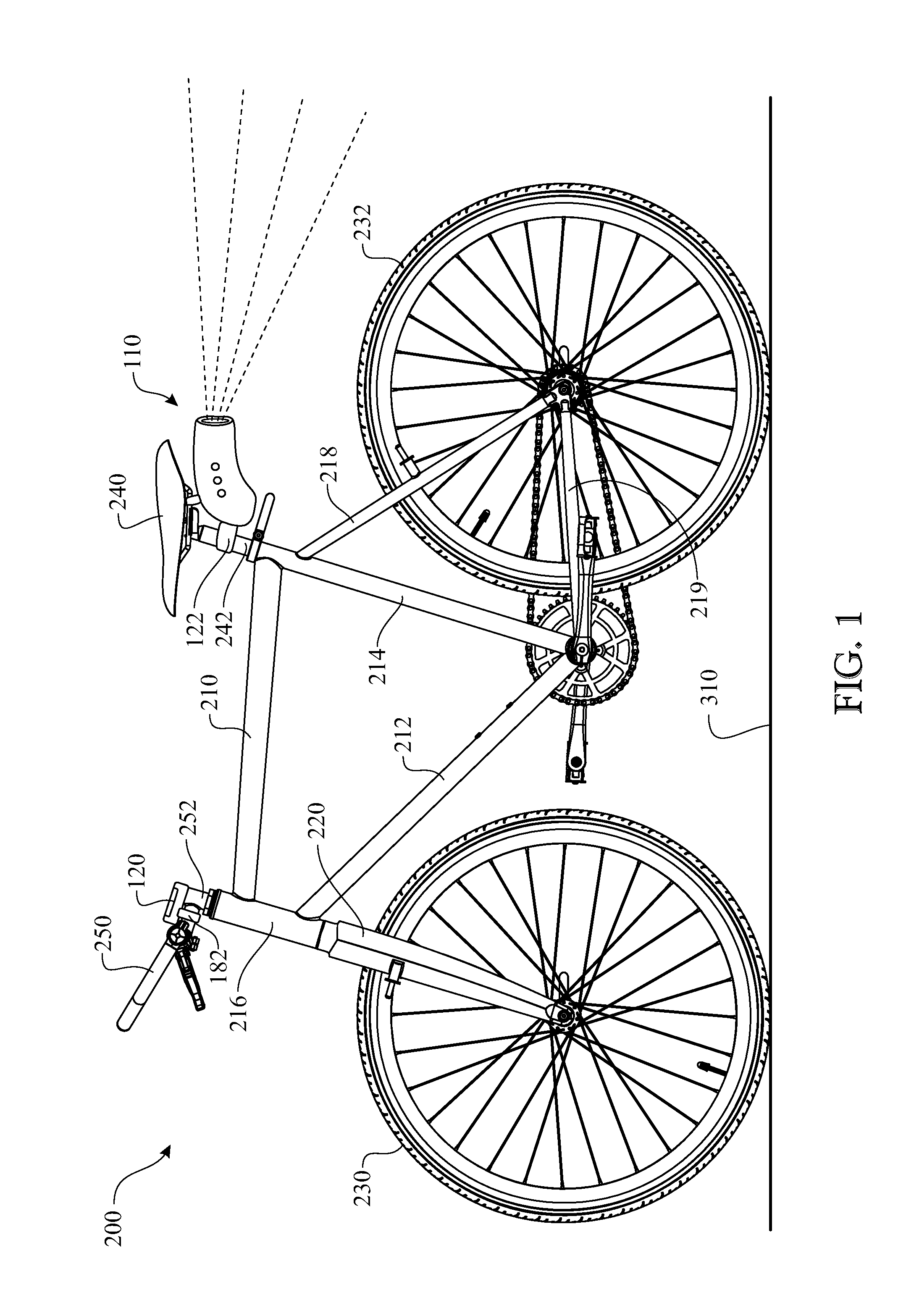

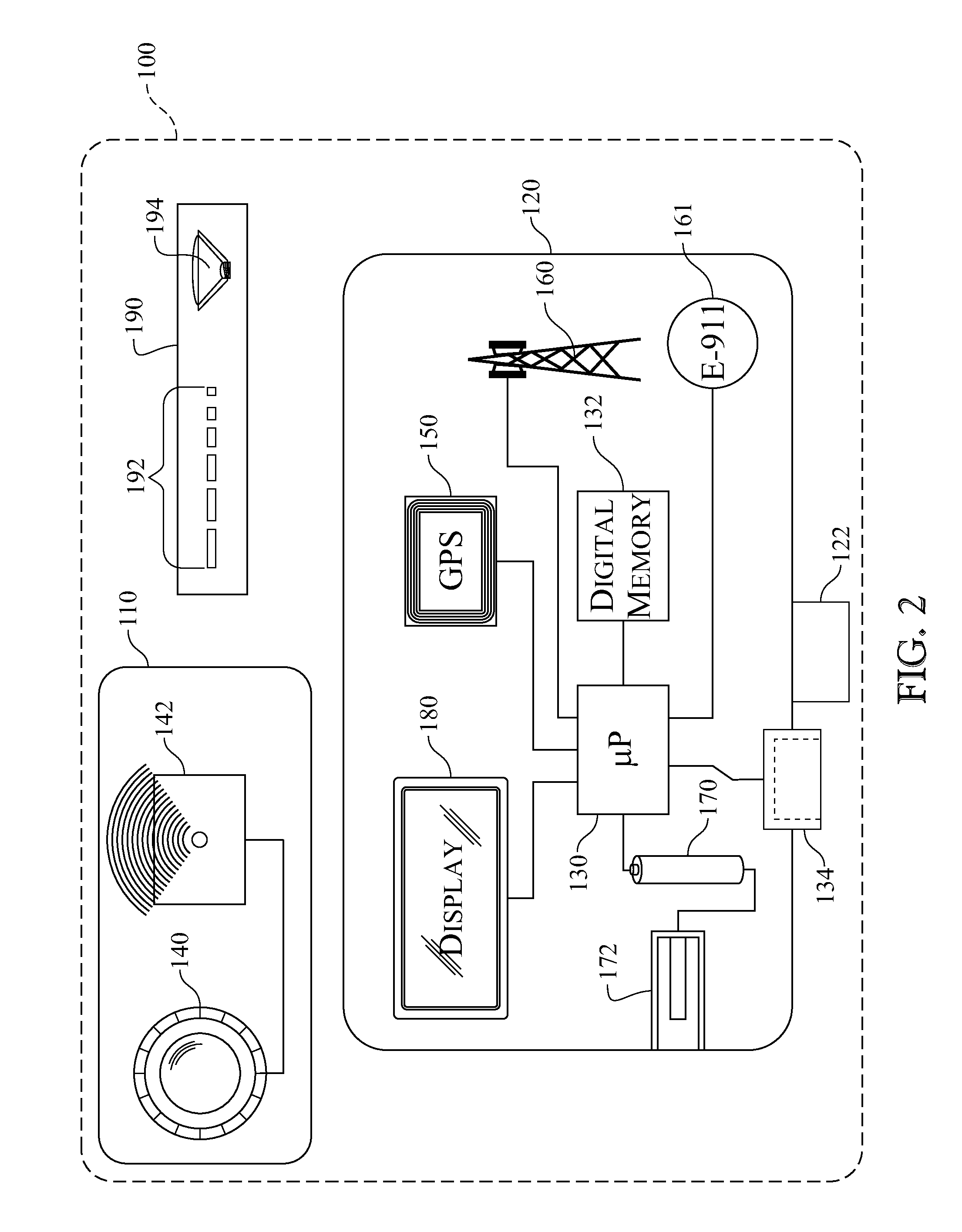

Rear Encroaching Vehicle Monitoring And Alerting System

A vehicle encroachment warning system comprising at least one rearward oriented sensing circuit for identifying a positional relationship and velocity of an approaching object. The sensing circuit can be a digital image capturing system, such as video. The system integrates a controller functioning as a user interface. The controller provides alerts and other various information to the user. The controller maintains a history of metrics throughout the period of use. An application enabled on a Smartphone can be used as the controller. Features of the Smartphone enhance the system, enabling communication between the system and vehicles in the proximity, automatic dialing to e-911 or others upon sudden motions (such as an impact), etc. The system can employ a single stage sensing system, such as a computer vision analysis or a two stage, using video analysis, then transitioning to a higher resolution system, such as radar.

Owner:FARB MICHAEL SCOT

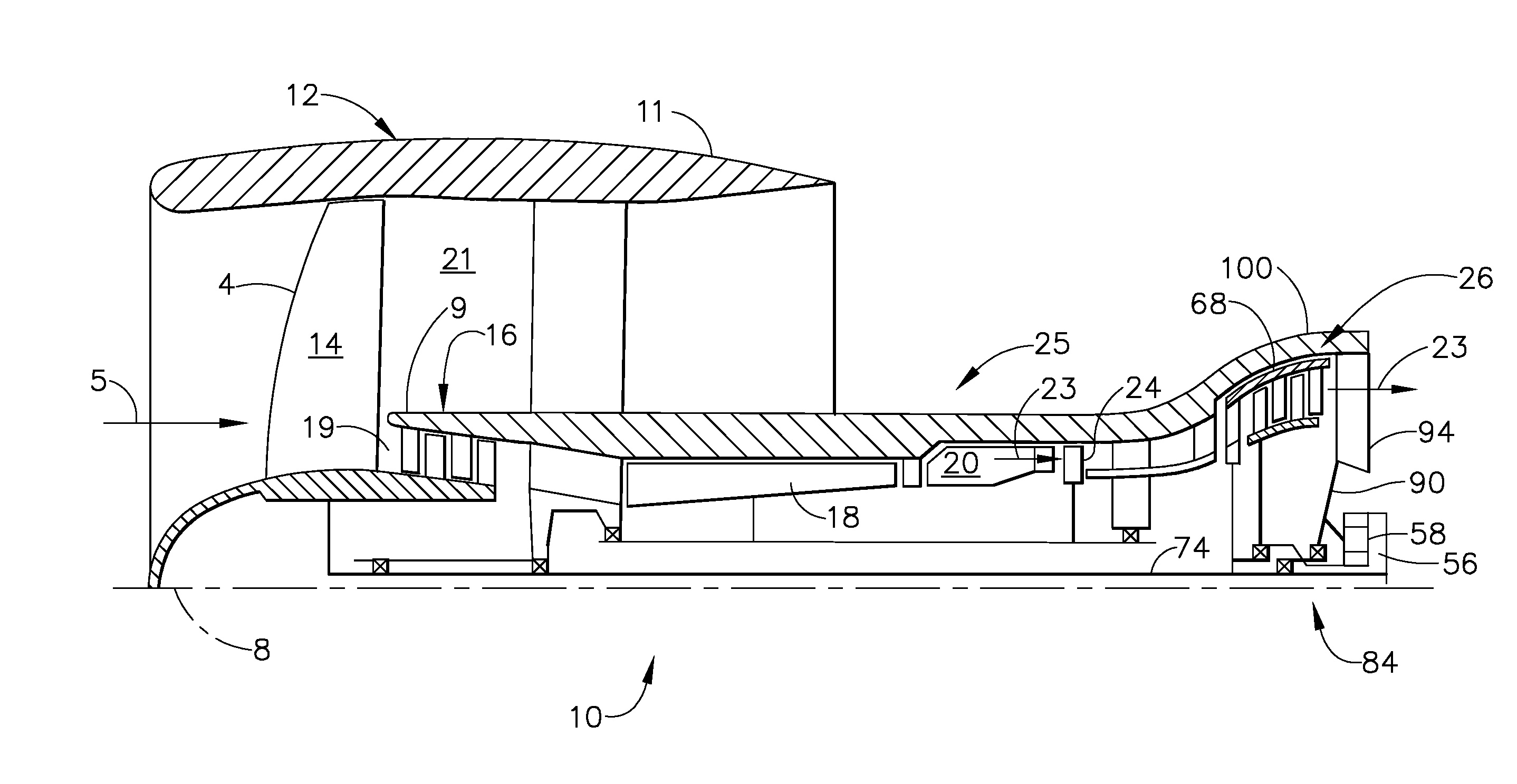

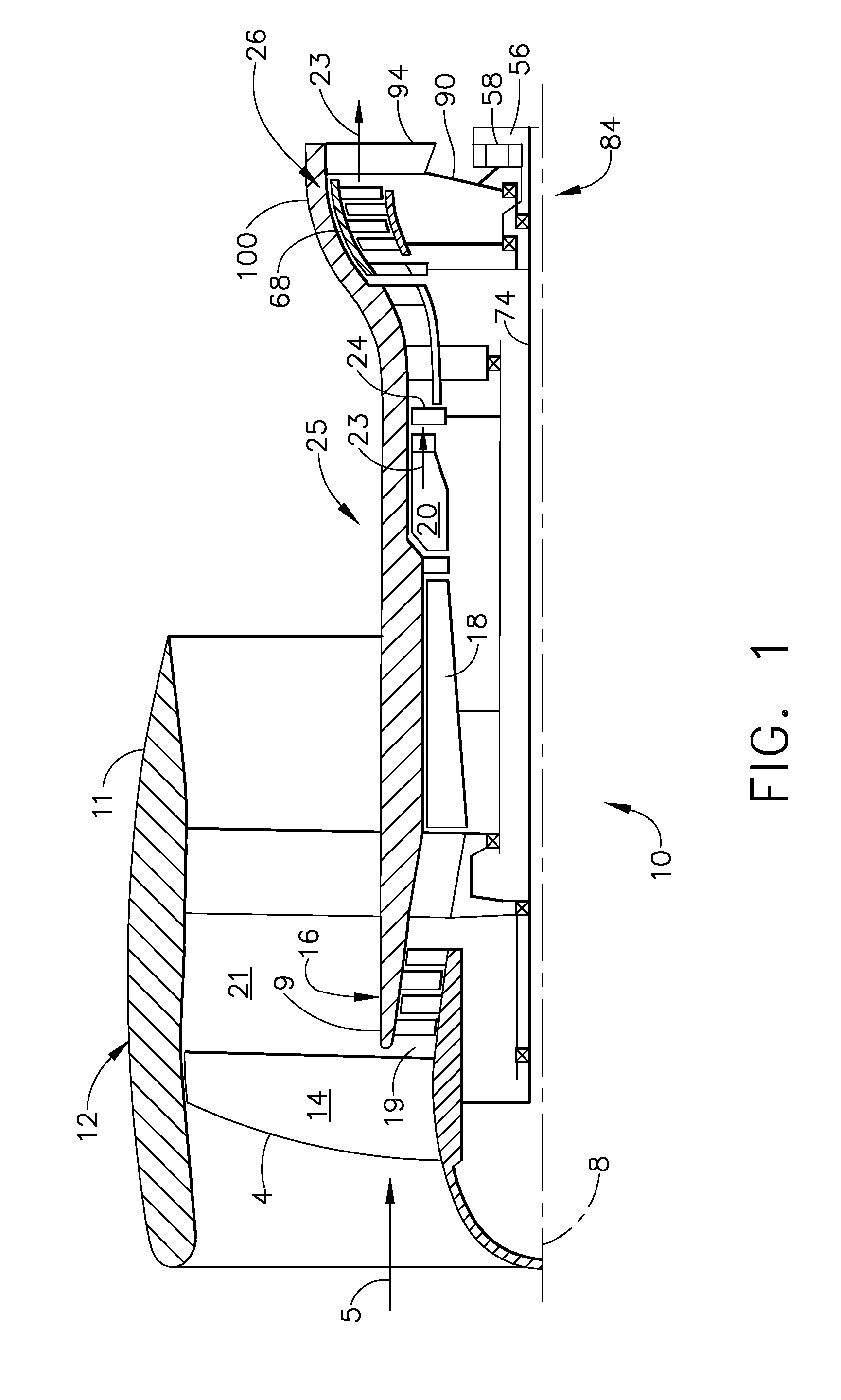

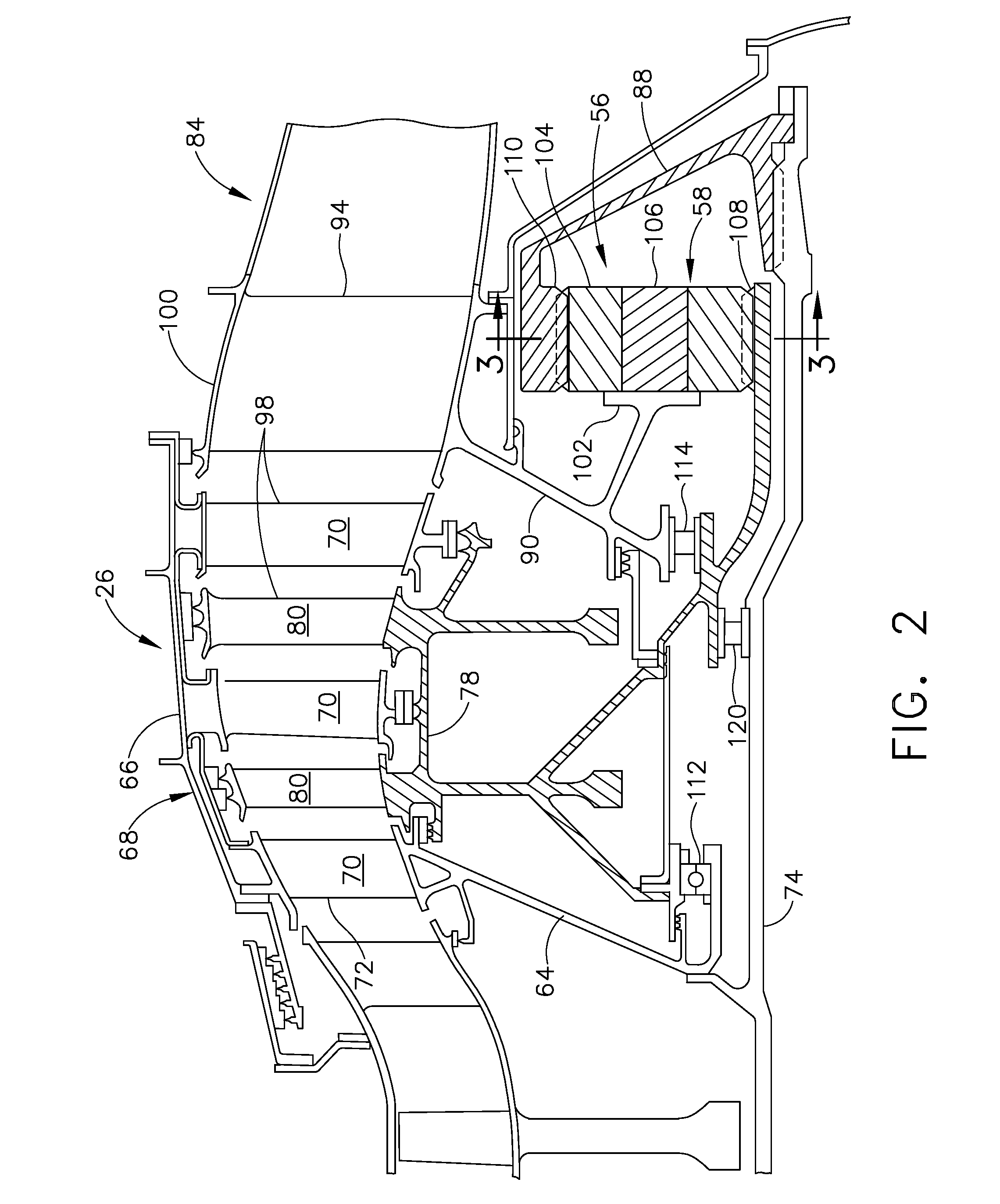

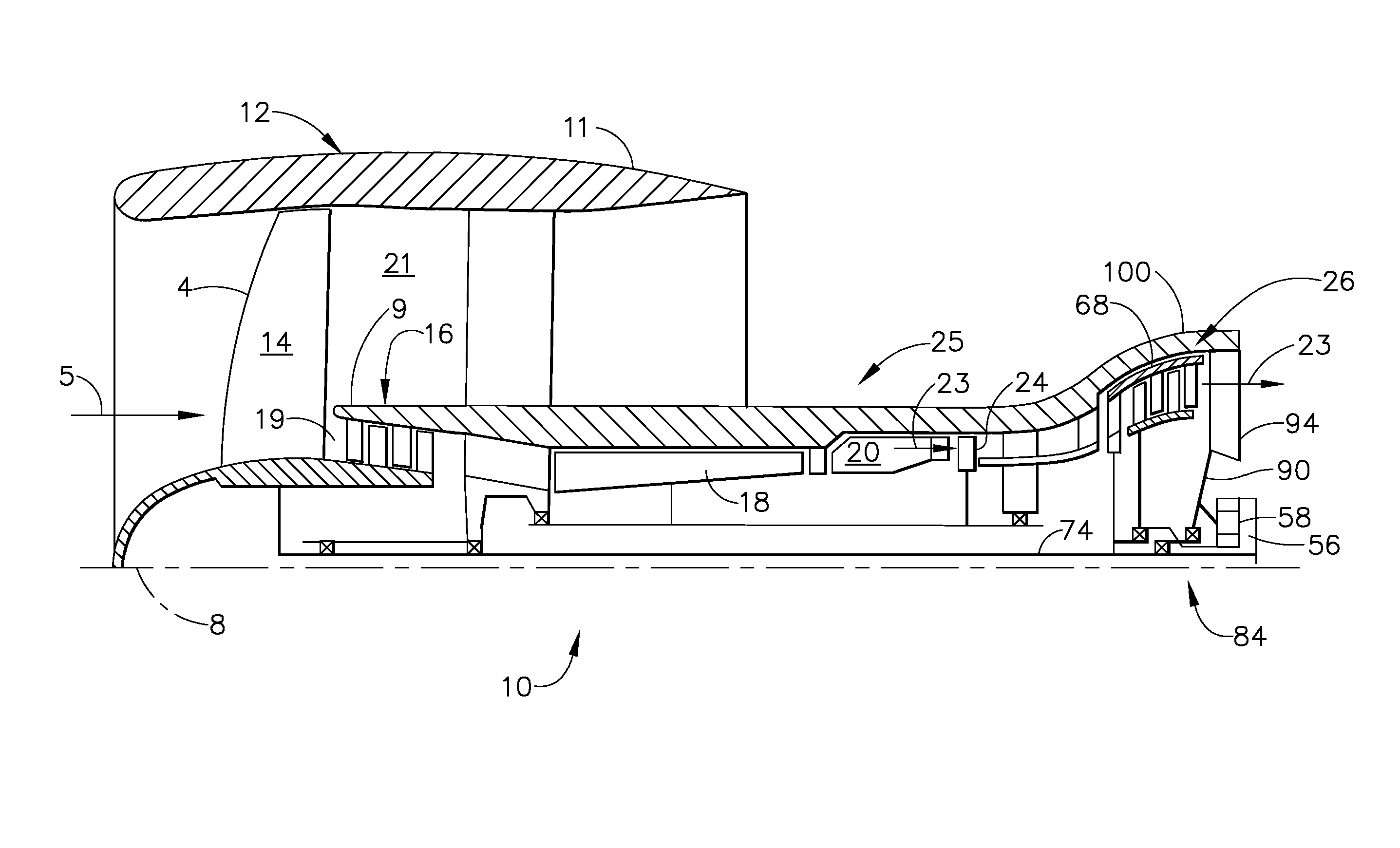

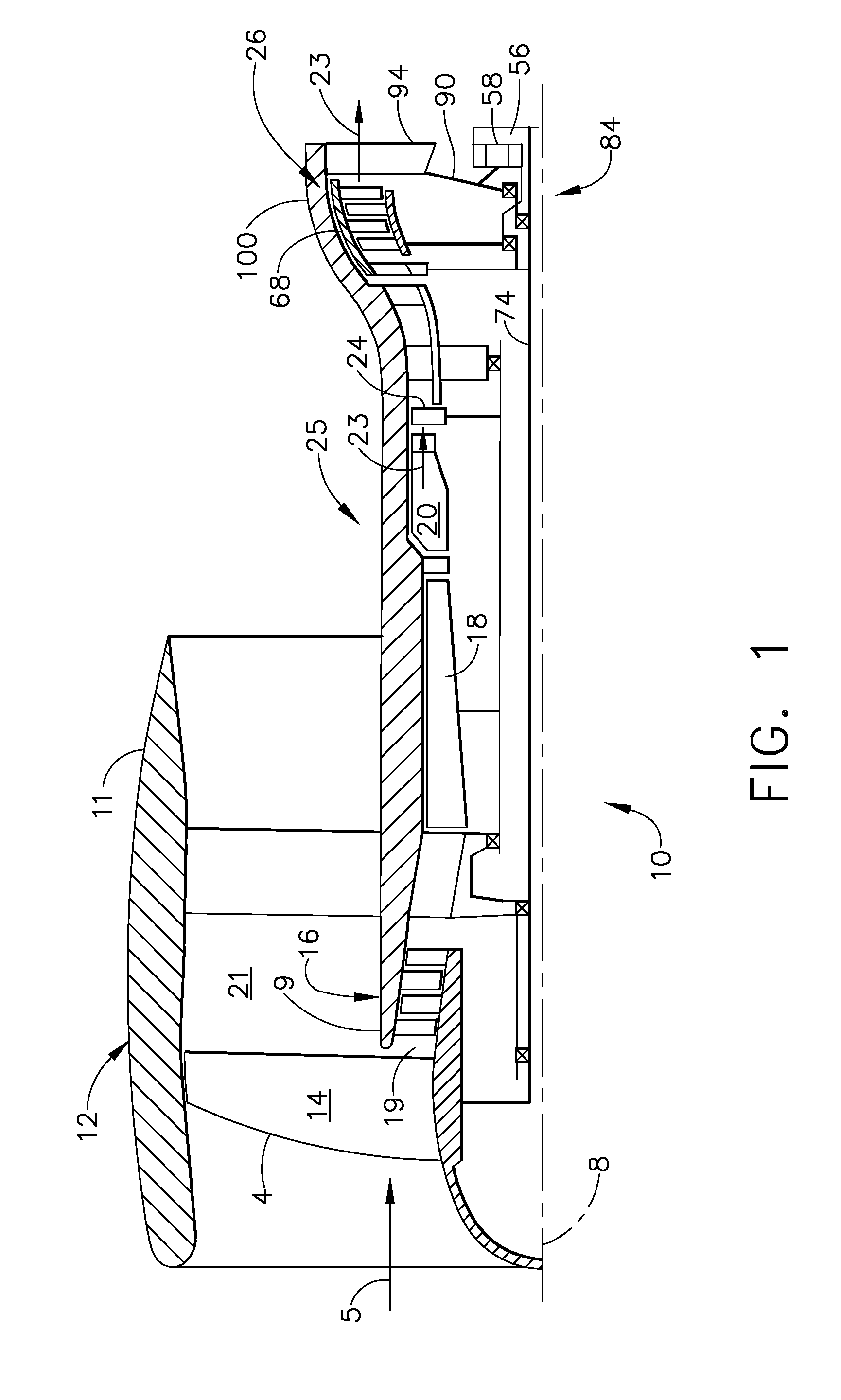

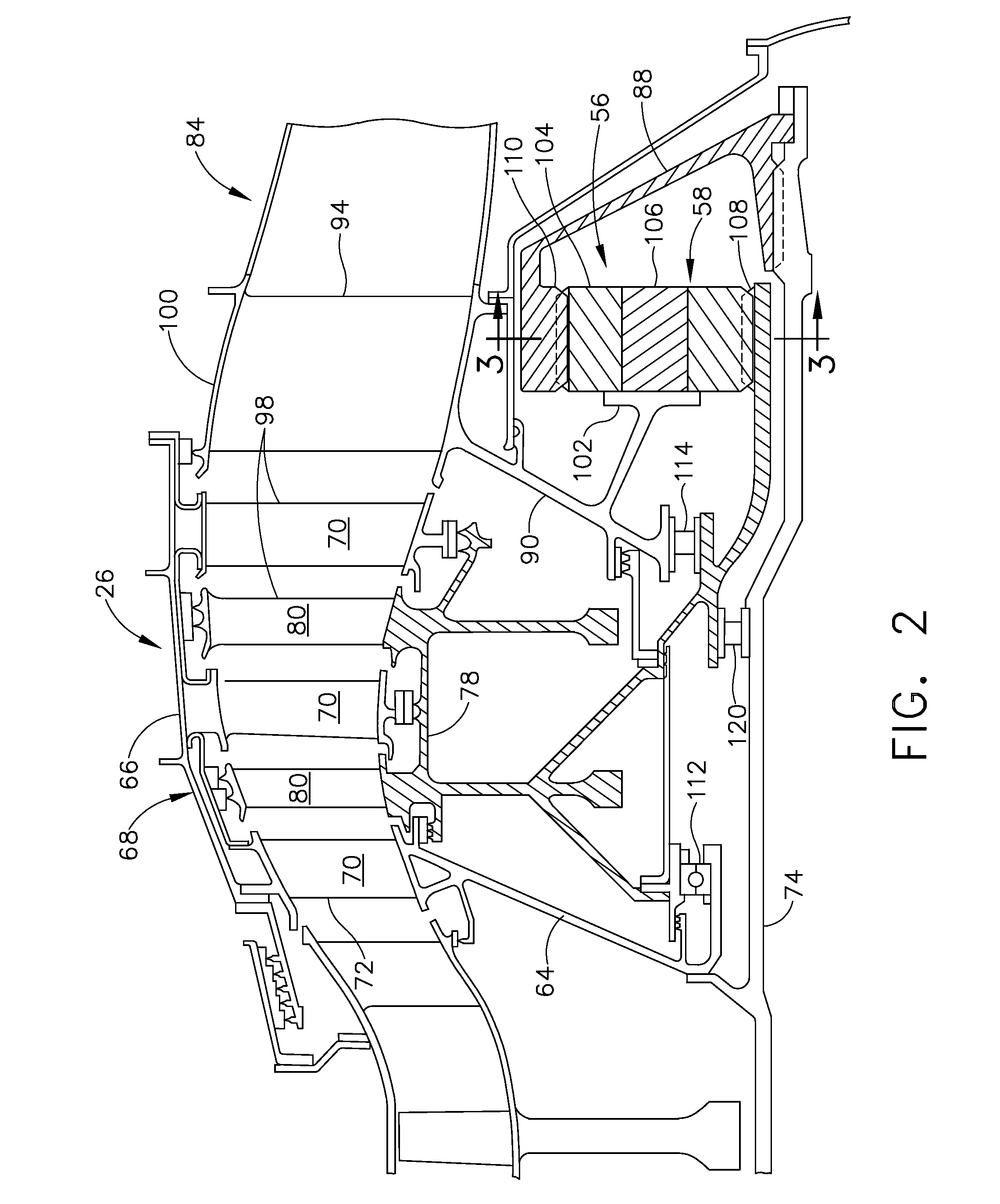

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

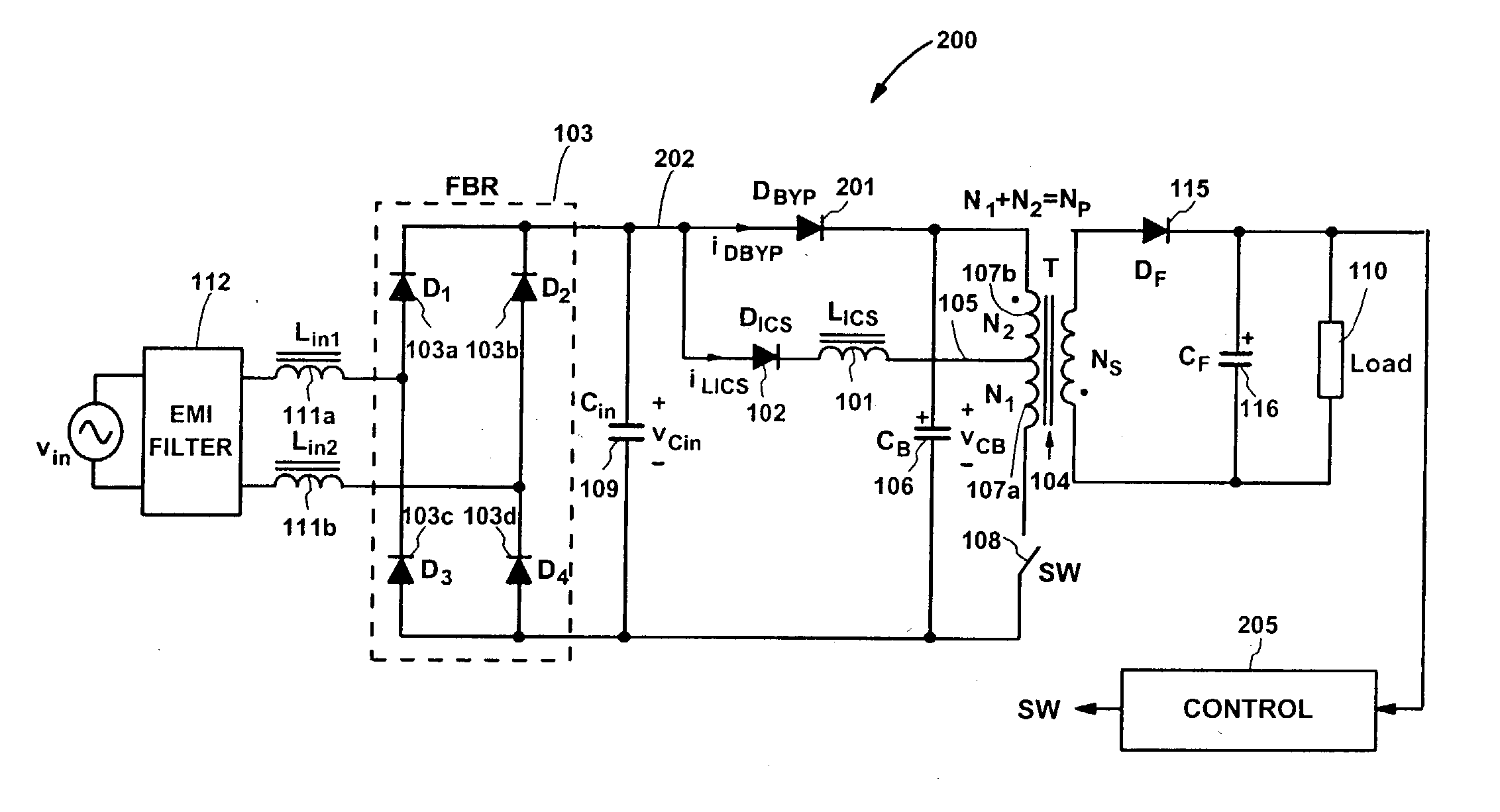

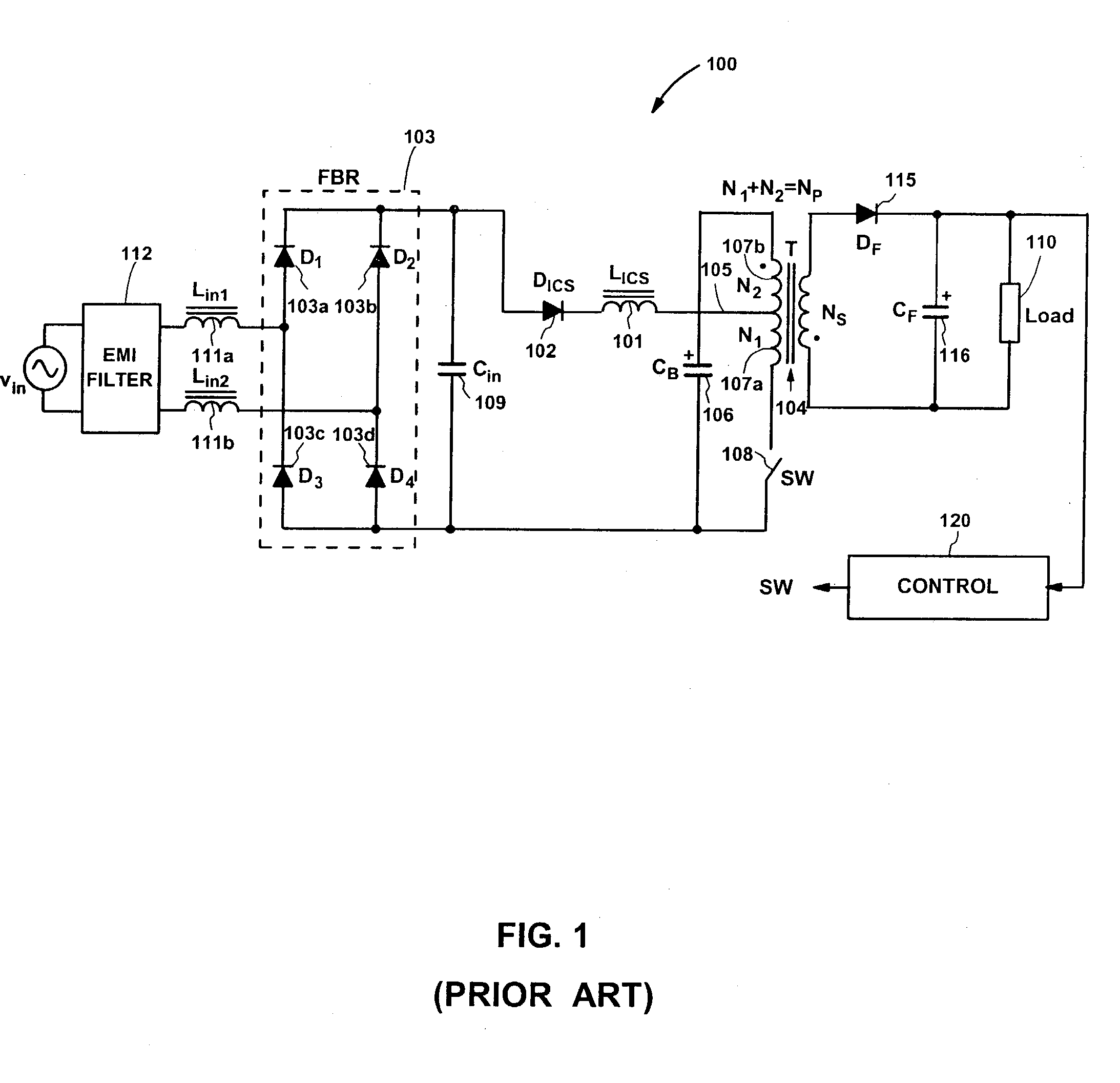

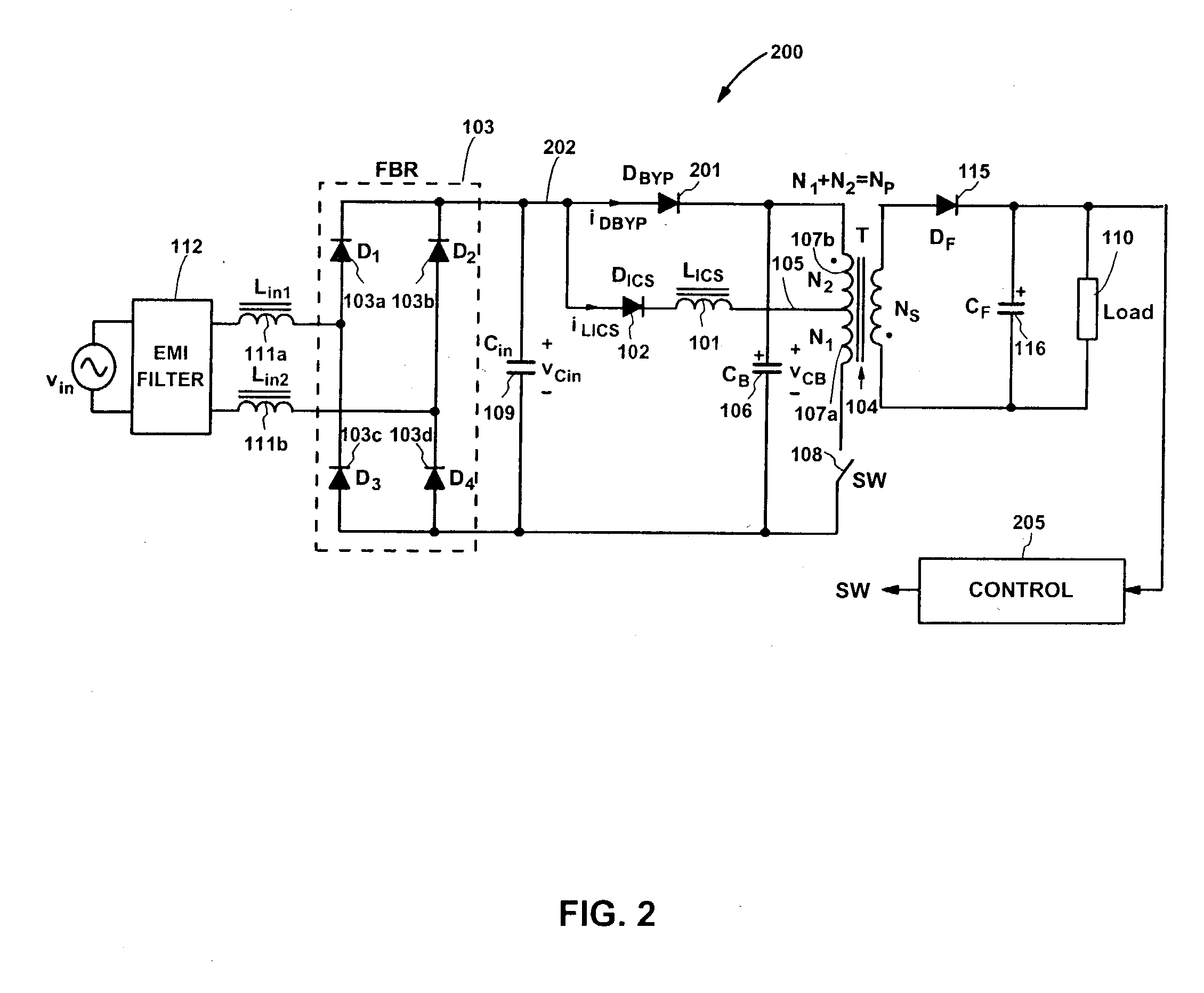

AC/DC flyback converter

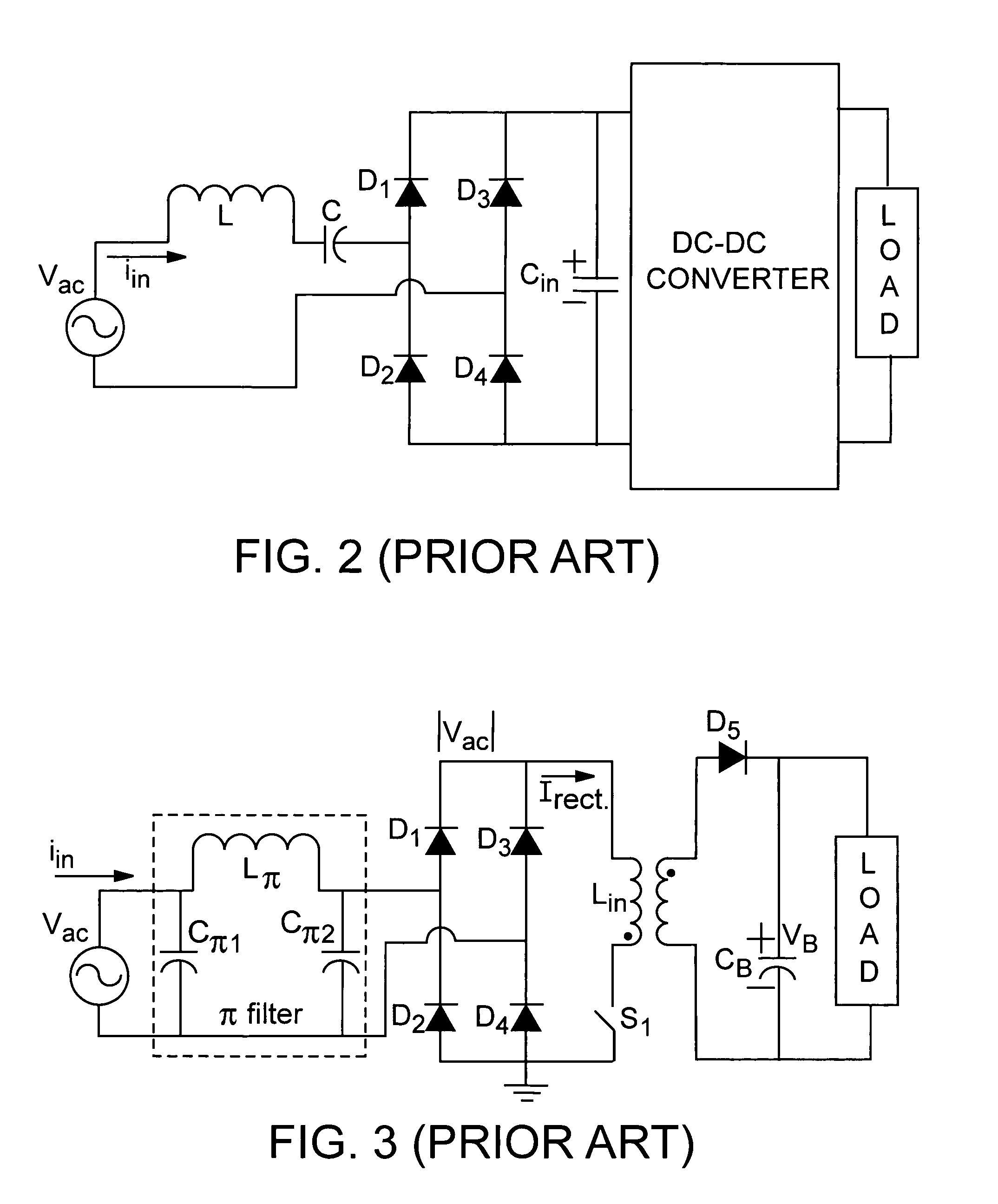

ActiveUS20040252529A1Reduce conduction lossImprove efficiencyEfficient power electronics conversionApparatus with intermediate ac conversionSingle stageFull bridge

A single-stage input-current-shaping (S<2>ICS) flyback converter achieves substantially reduced conduction losses in the primary side of the S<2>ICS flyback converter by connecting a bypass diode between the positive terminal of a full-bridge rectifier and the positive terminal of an energy-storage capacitor. An effective current interleaving between an energy-storage inductor and the bypass diode is thus obtained in the S<2>ICS flyback converter around the peak of the rectified line voltage, resulting in a significantly reduced input-current ripple and reduced current stress on the switch. Further, by rearranging the rectifiers in the ICS part of the S<2>ICS flyback converter in such a way that the energy-storage capacitor and the ICS inductor are connected to the ac line voltage through only two rectifiers, one diode forward-voltage drop is eliminated, which results in a substantially reduced conduction loss in the primary-side rectifiers.

Owner:DELTA ELECTRONICS INC

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

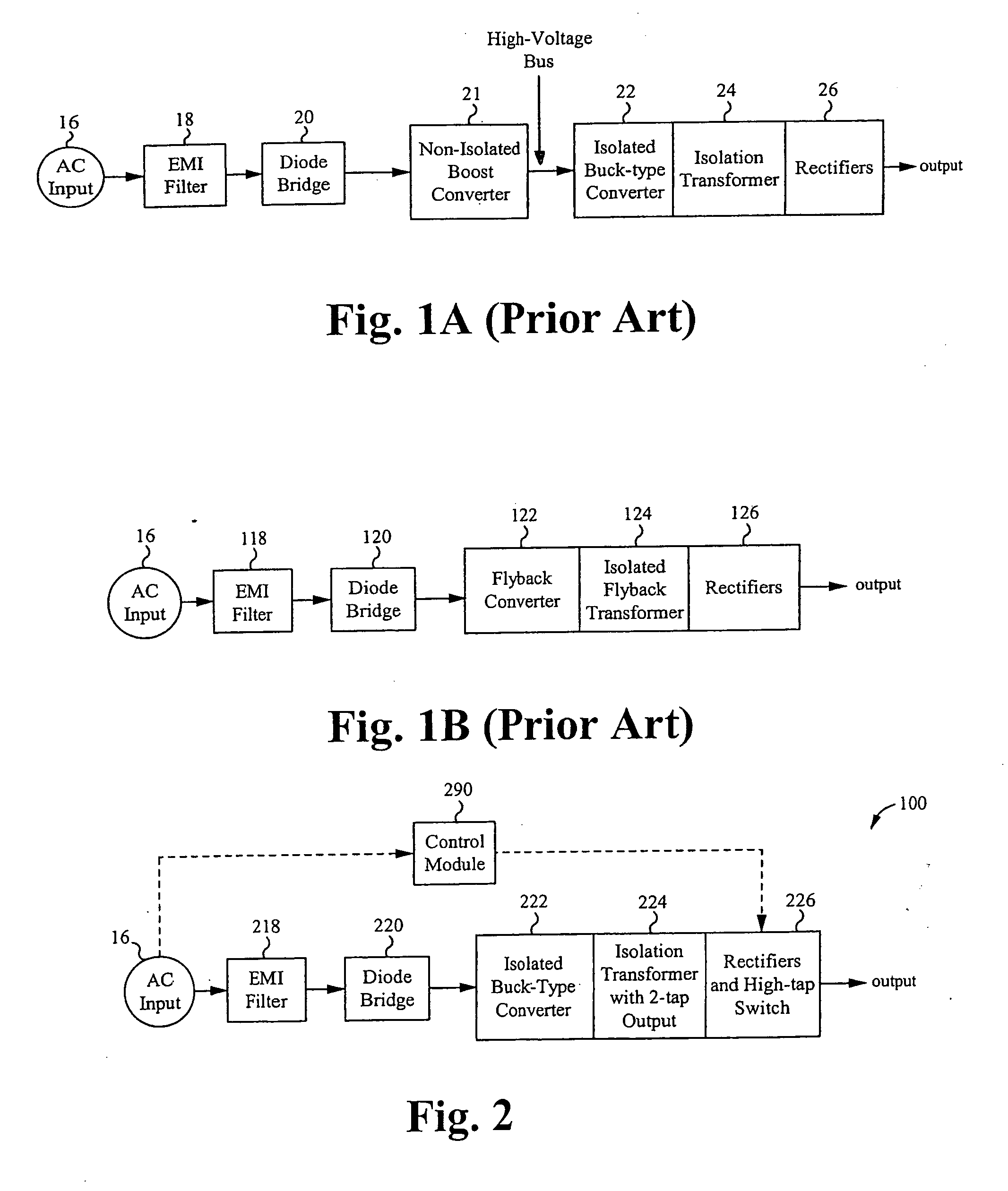

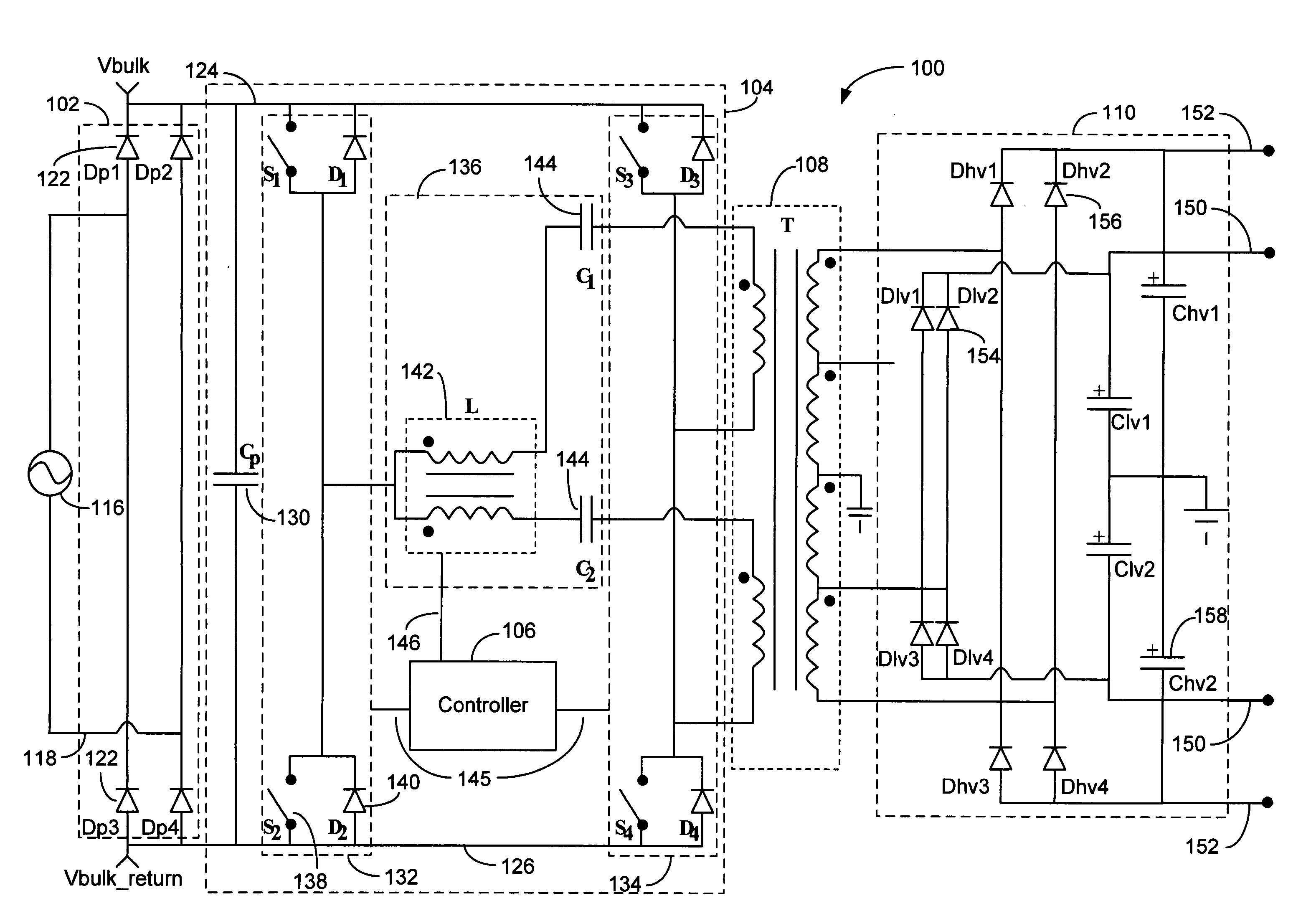

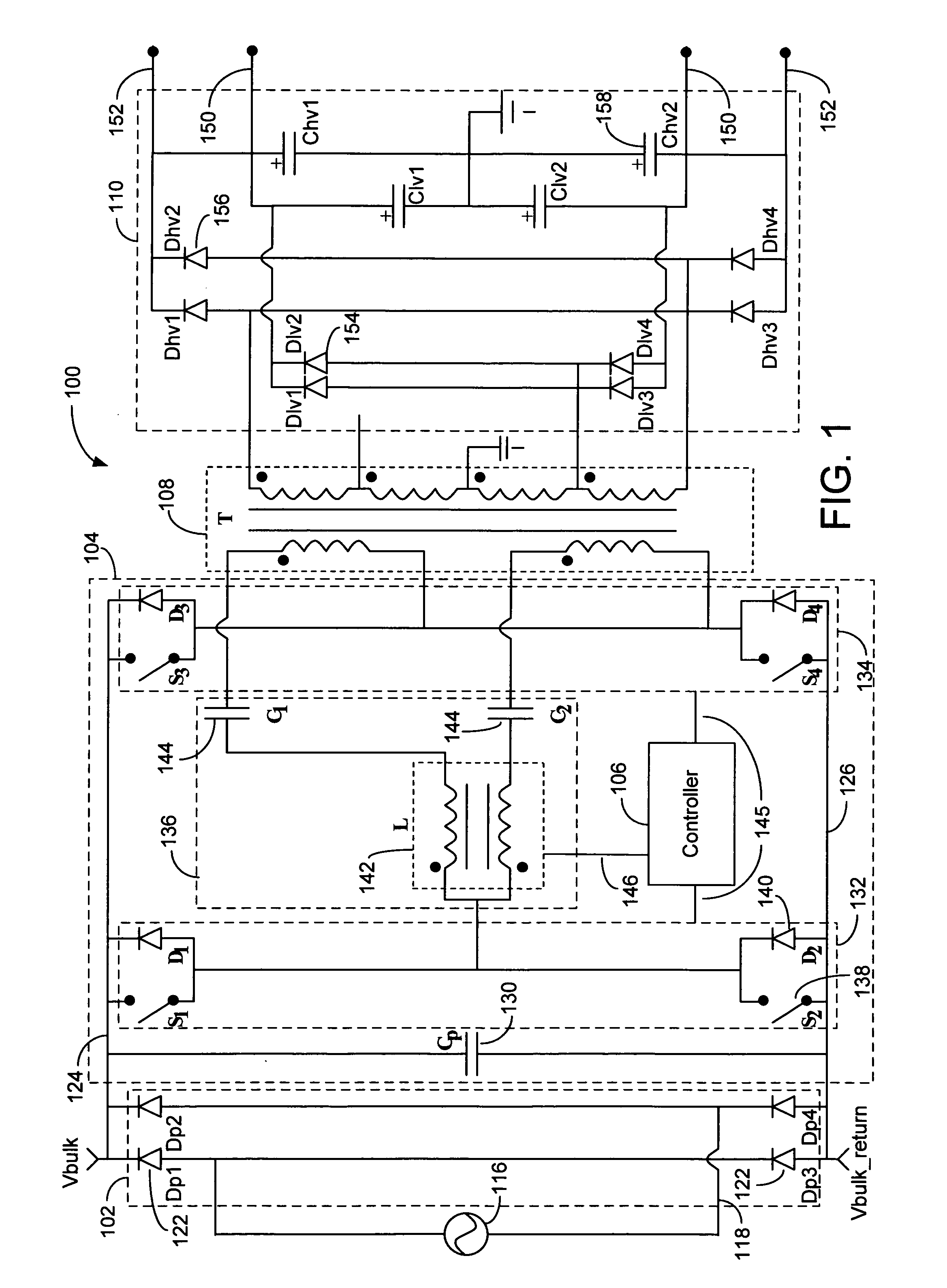

High power factor isolated buck-type power factor correction converter

ActiveUS20090290384A1Improve power factorMinimize component stressDc network circuit arrangementsEfficient power electronics conversionFull waveTap changer

A regulated power factor corrected power supply apparatus is provided. The apparatus includes an input rectifier circuit for receiving an input AC voltage and outputting a full-wave rectified DC voltage. A single-stage isolated buck-type converter is coupled with the input circuit. The converter circuit comprises an isolated buck-type converter circuit including an isolation transformer. An output rectifier and semiconductor tap switch are coupled to a secondary winding of the isolation transformer. The tap switch couples a larger portion of the secondary winding to an output bulk capacitor during the portions of the input sinewave half-cycle, which are low in amplitude. The tap switch enables the single-stage isolation buck-type converter to operate over a much larger portion of the input sinewave, but also allows the converter to operate at high-efficiency over the majority of the input sinewave.

Owner:MYPAQ HLDG LTD

Current controlled switch mode power supply

ActiveUS20060152947A1Improve power factorReduce equipment stressEfficient power electronics conversionConversion with intermediate conversion to dcSingle stageAudio power amplifier

A single stage switch mode power converter receives a supply line voltage and a supply line current from a power supply line, and provides one or more regulated output voltages for a load, such as an amplifier. The power converter is operable to regulate the output voltage(s) using a controller that includes a voltage controlled current loop. The controller can enable substantially constant supply line current to be drawn from the power supply line by selectively allowing conduction of the supply line current through the power converter. A power factor of the supply line voltage and the supply line current may be optimized by the controller at medium to high power levels thereby maximizing the power provided to the switch mode power converter from the power supply line. Due to the adaptive nature of the controller, the power converter can operate over a wide range of supply line voltage.

Owner:HARMAN INT IND INC

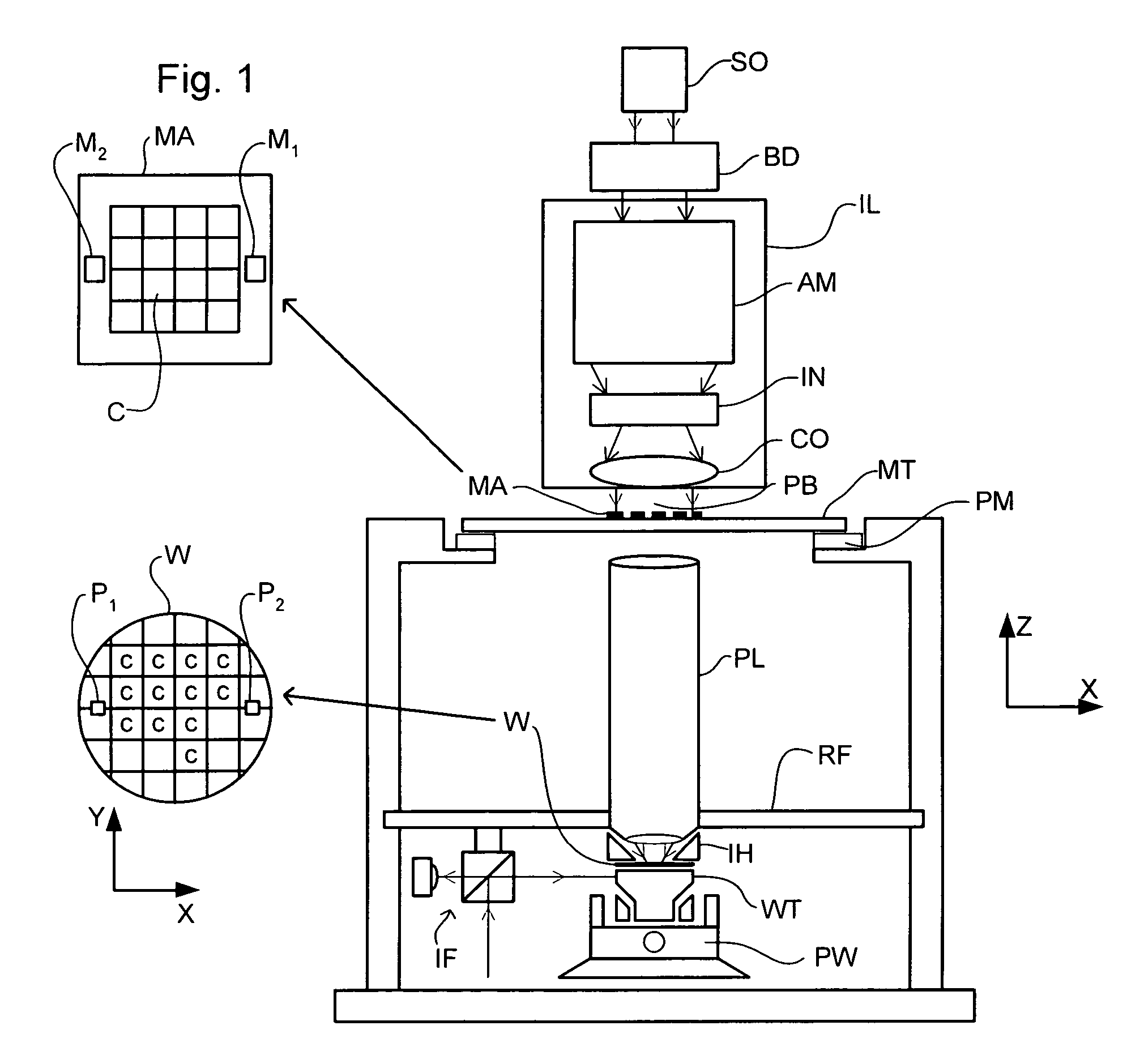

Two stage method

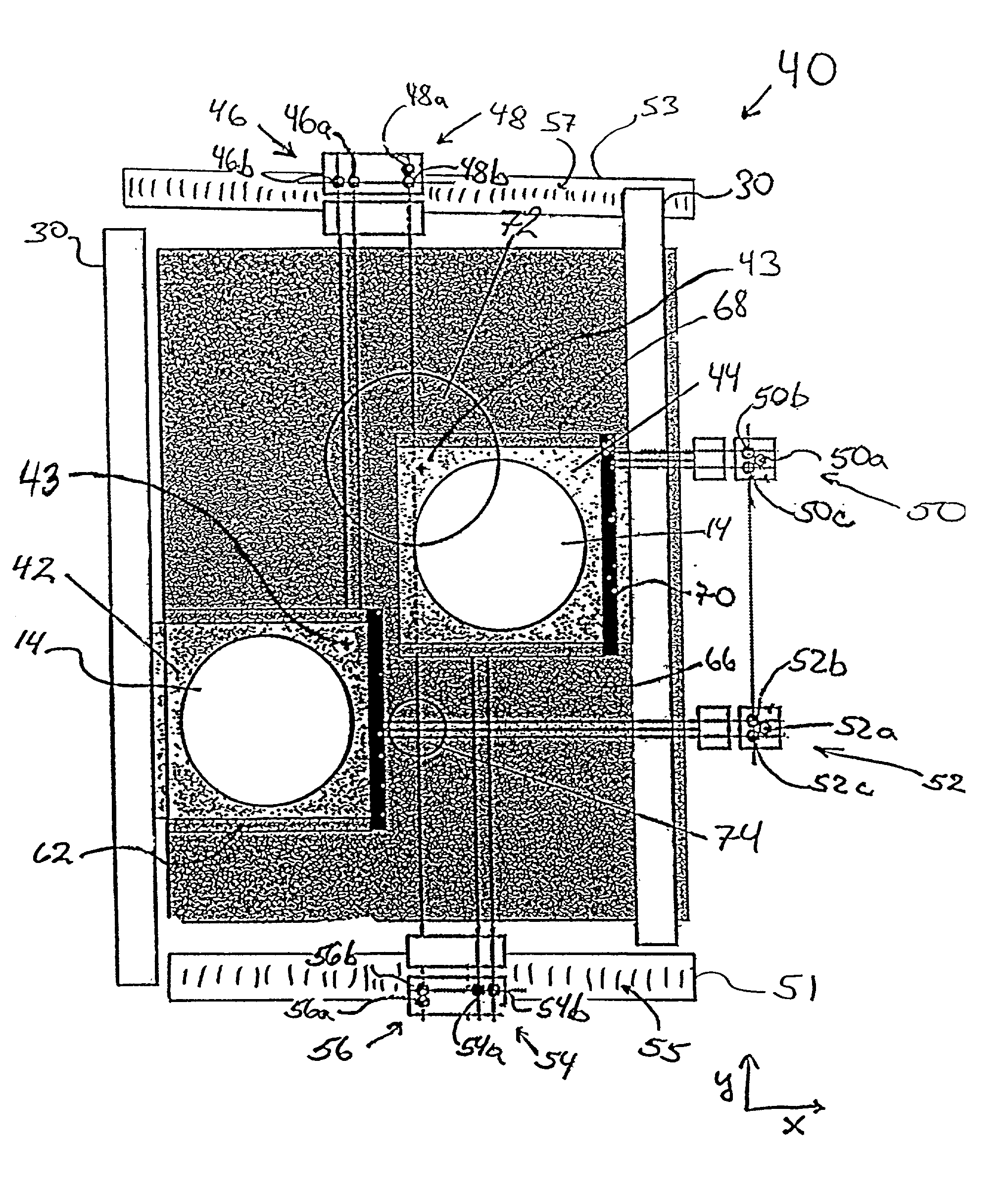

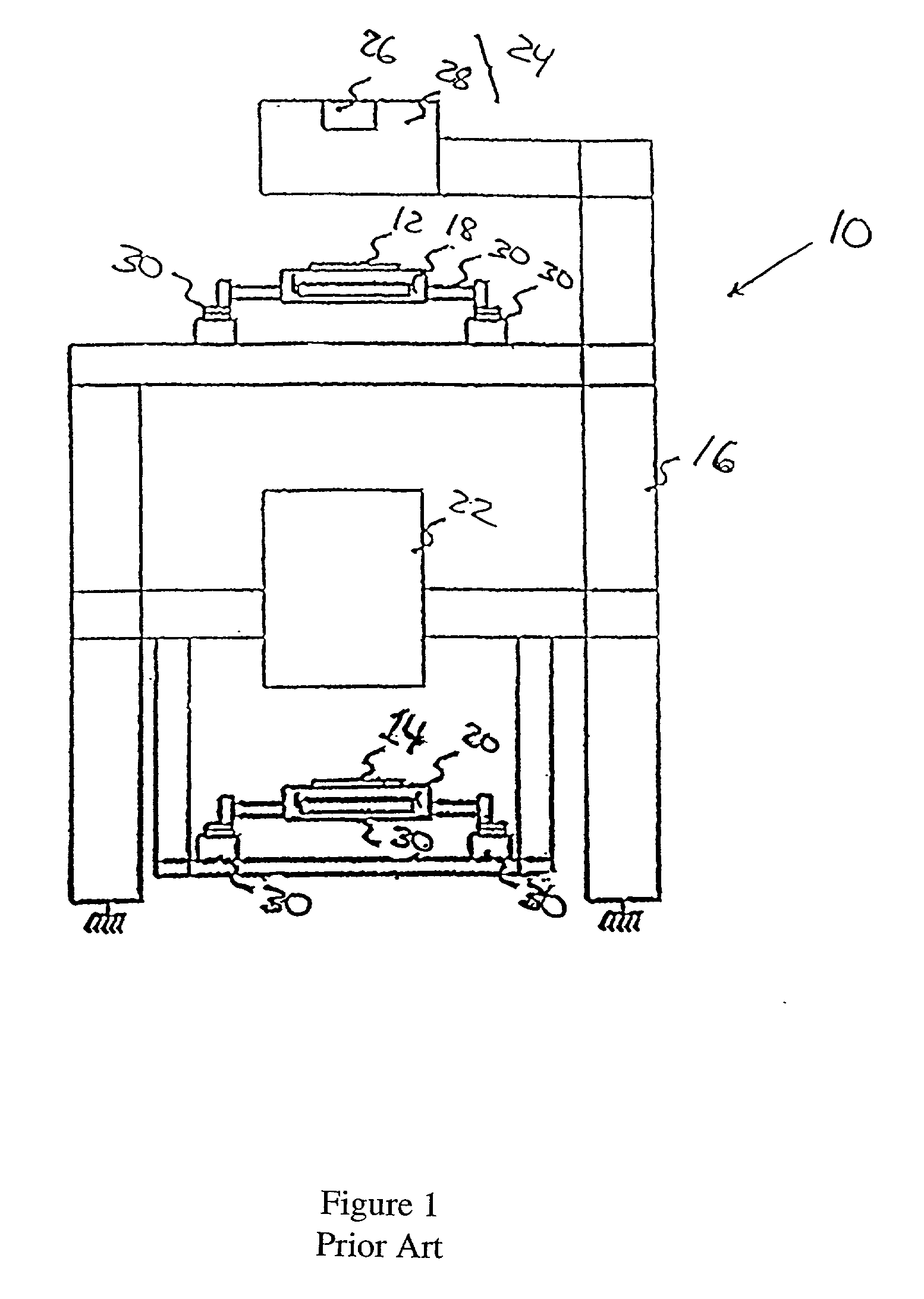

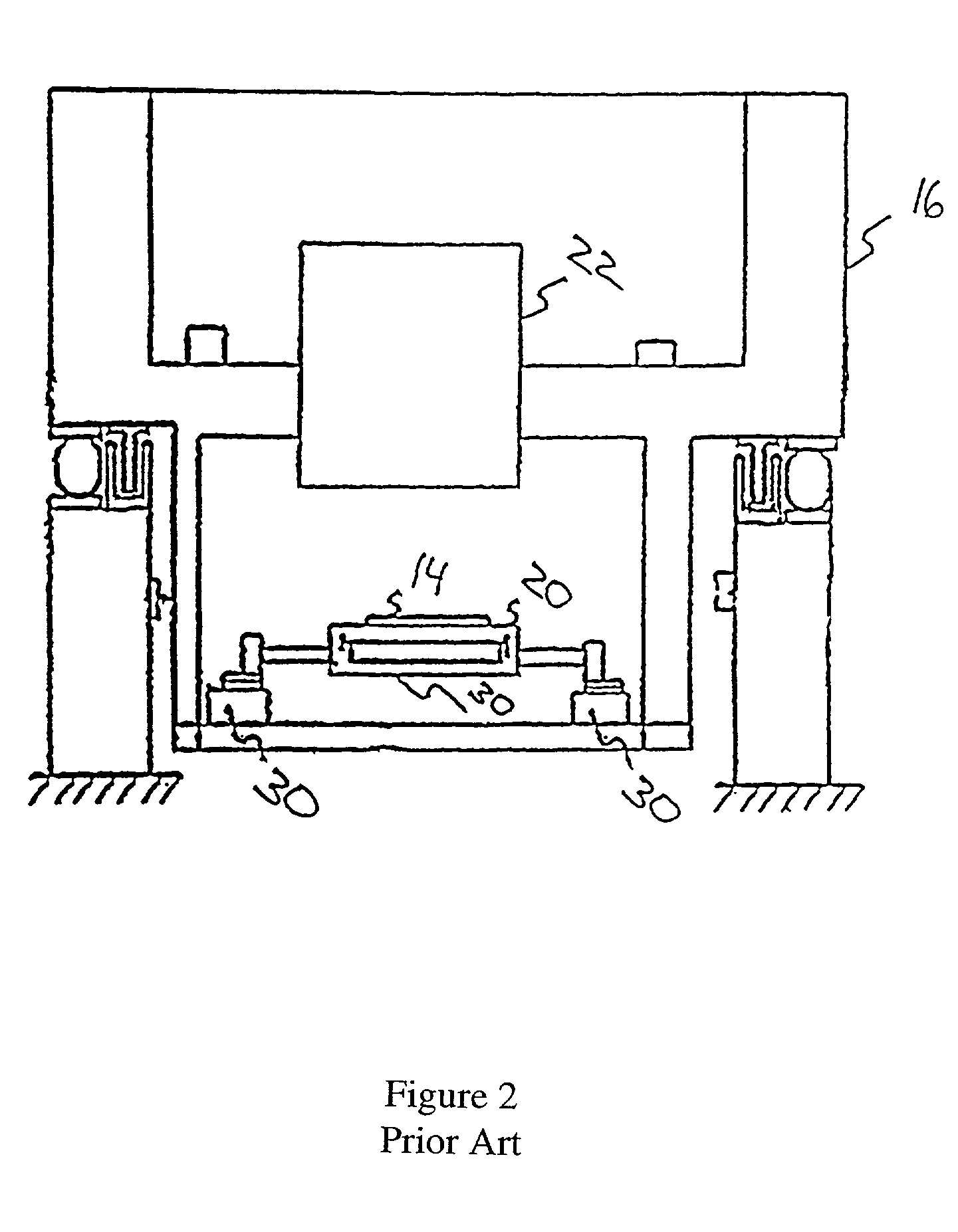

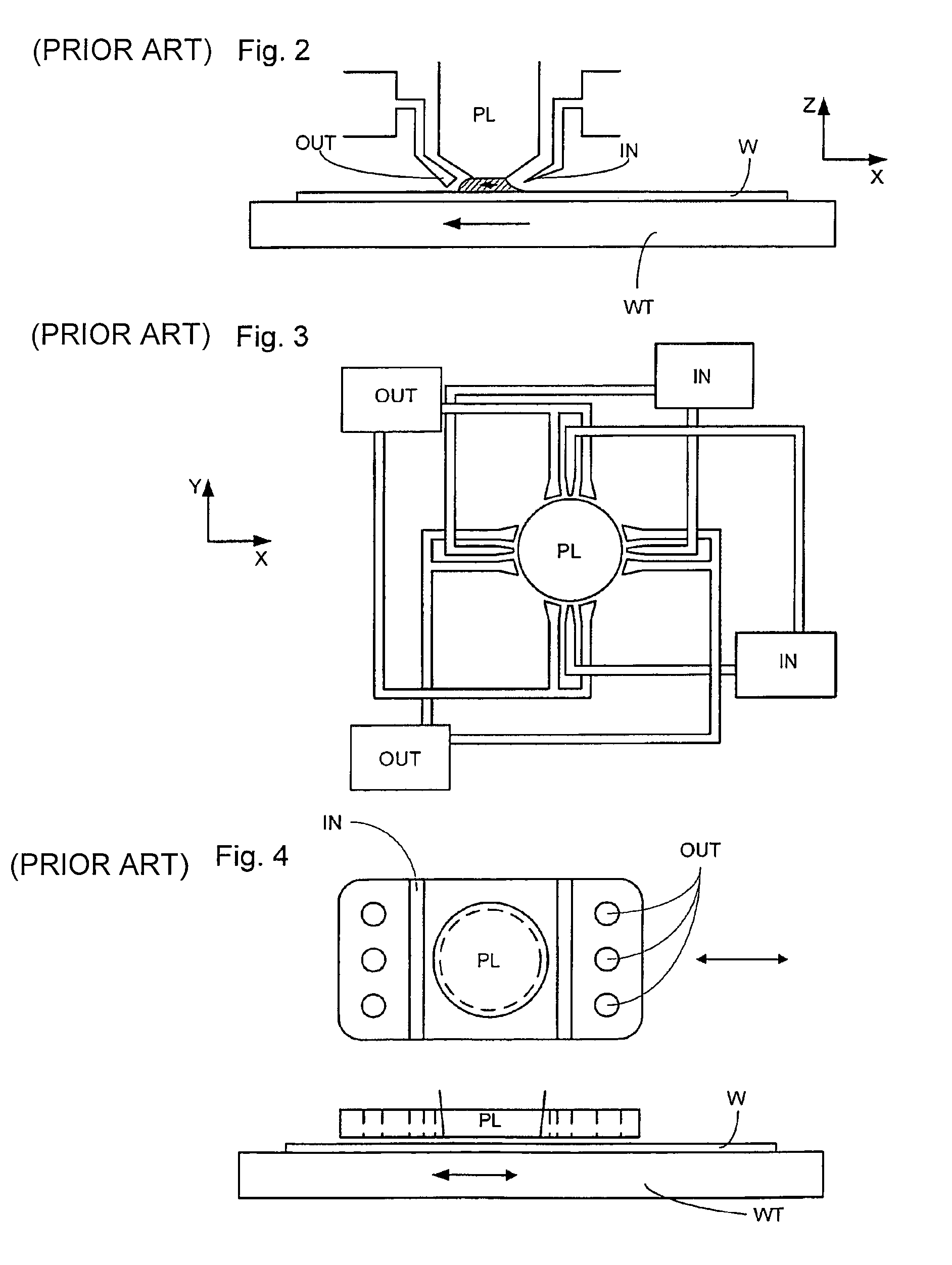

InactiveUS20030076482A1Not feasiblePhotomechanical exposure apparatusMicrolithography exposure apparatusResting timeSingle stage

This invention relates to a method for positioning two stages during semiconductor wafer processing. More particularly, the invention facilitates the use of two stages to improve system throughput by decreasing the rest-time of certain system components. While a typical single-stage apparatus requires that each step in the process be performed serially, this invention allows an amount of parallel processing with each stage at different steps of the process, and thus improves system throughput.

Owner:NIKON CORP

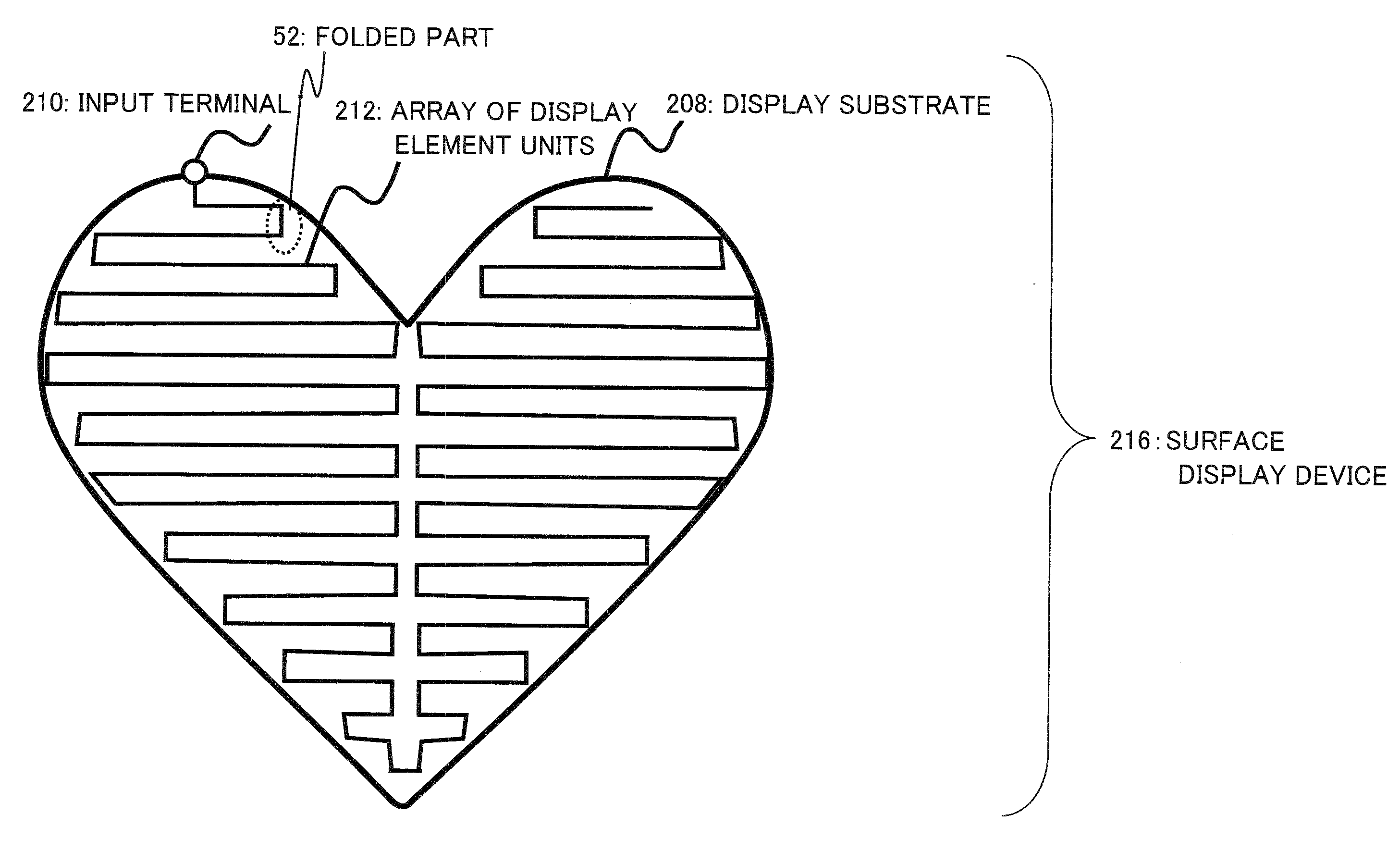

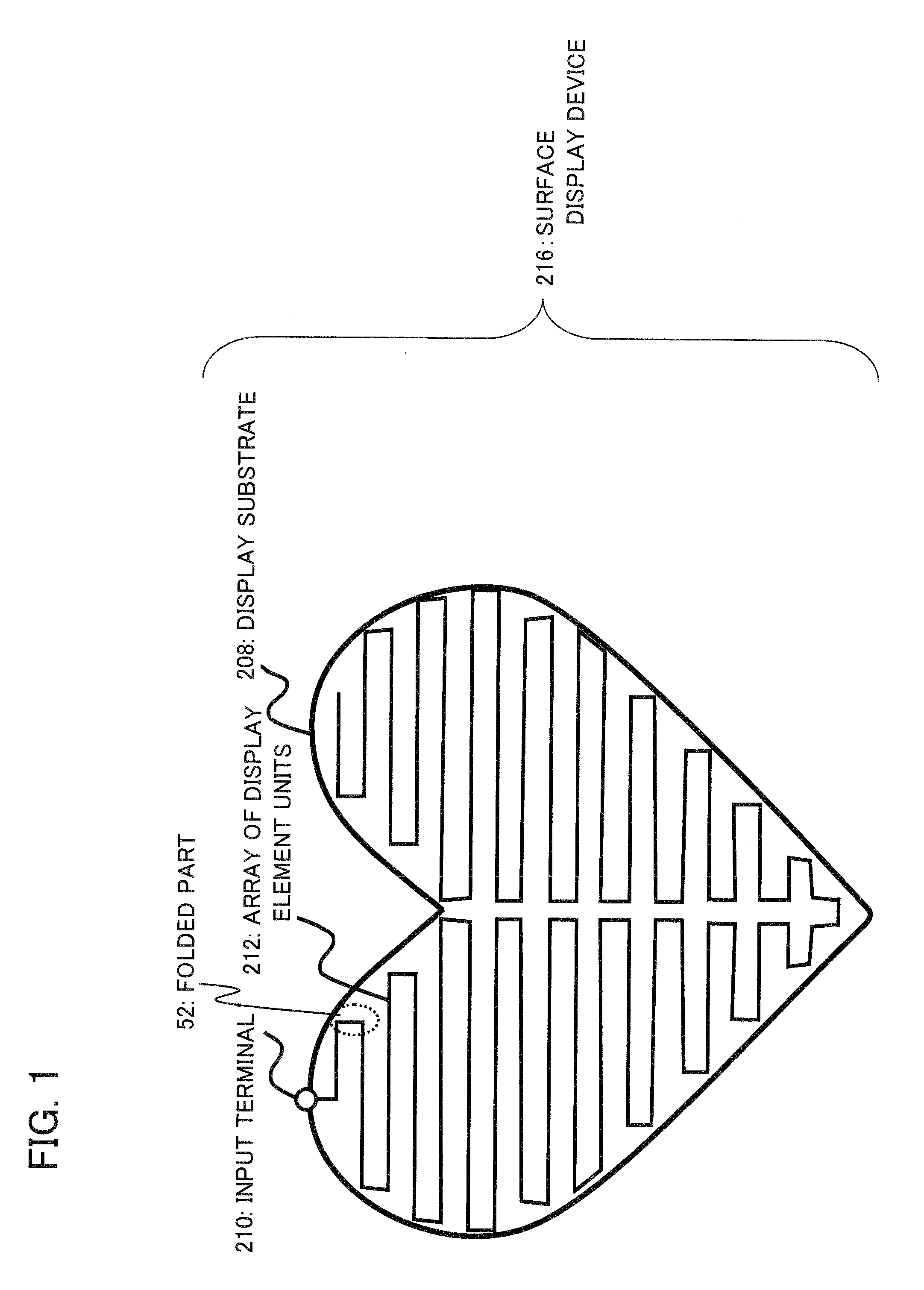

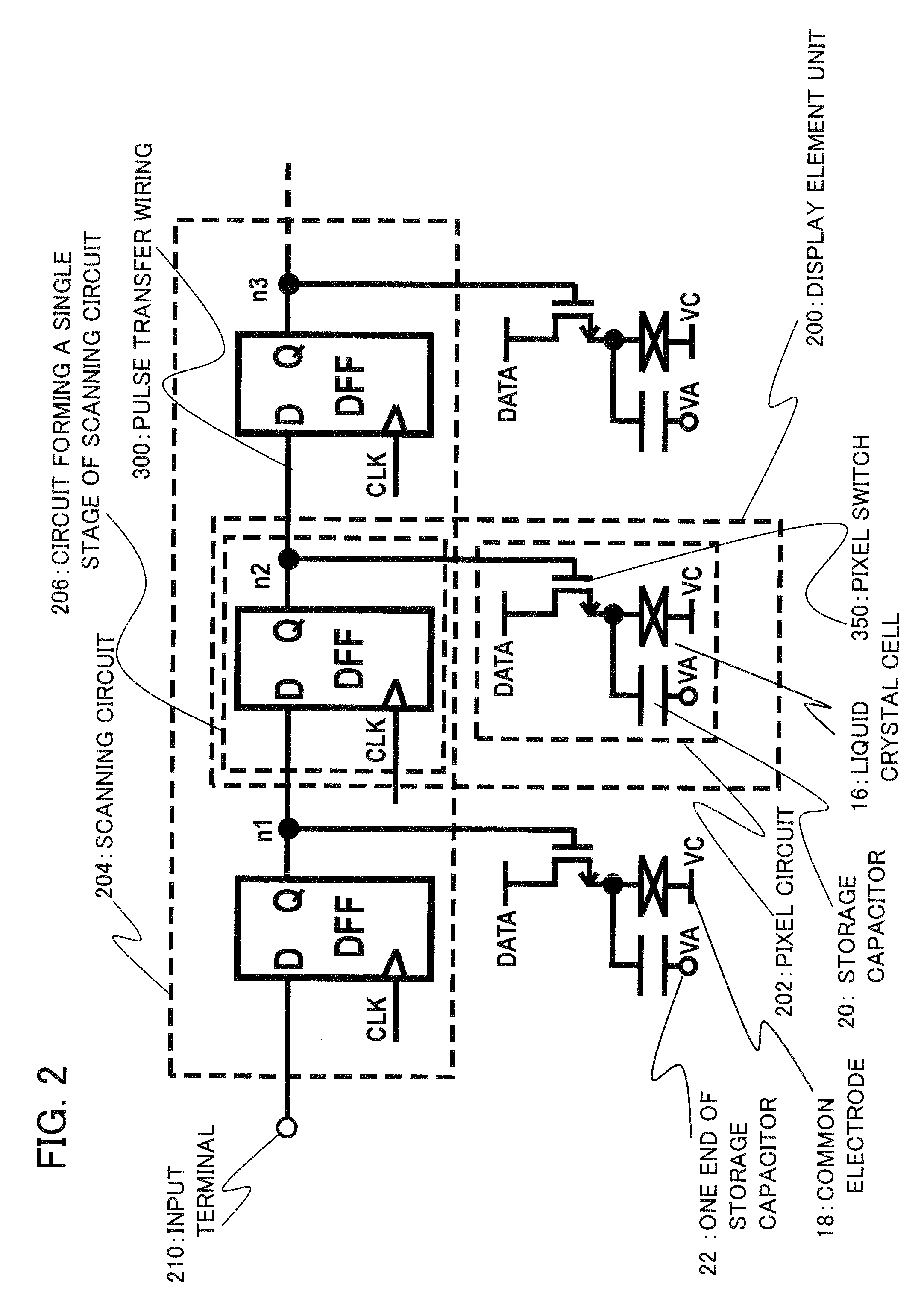

Display device

ActiveUS20080088568A1Reduce the number of connectionsReduce in quantityStatic indicating devicesNon-linear opticsSurface displaySingle stage

Disclosed is a display device for use of a surface display of an arbitrary shape, including a plural number of display element units, each made up of a circuit that forms a single stage of a scanning circuit and a pixel circuit connected to an output of the scanning circuit, are arranged in a unicursal fashion on a display substrate.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

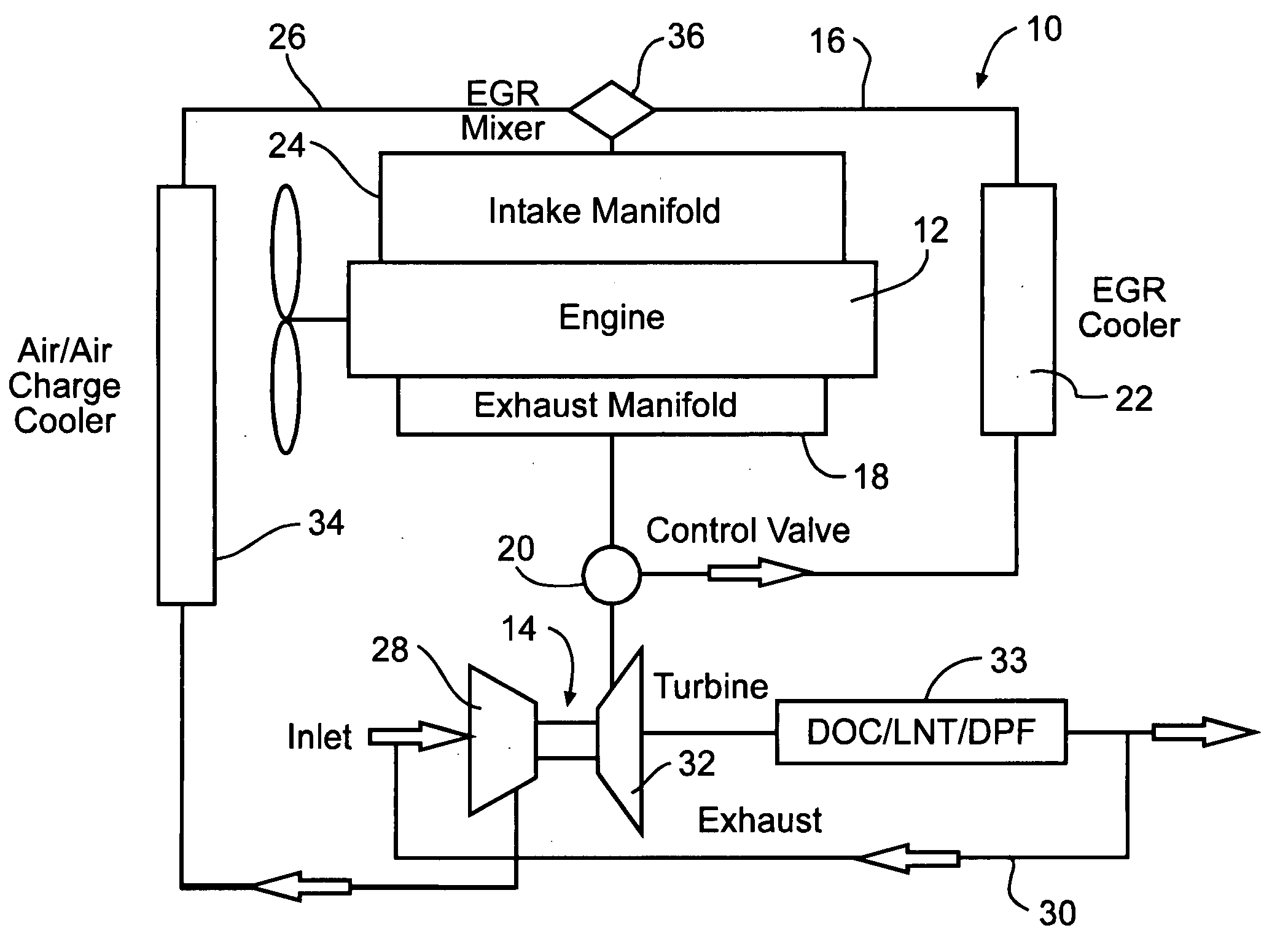

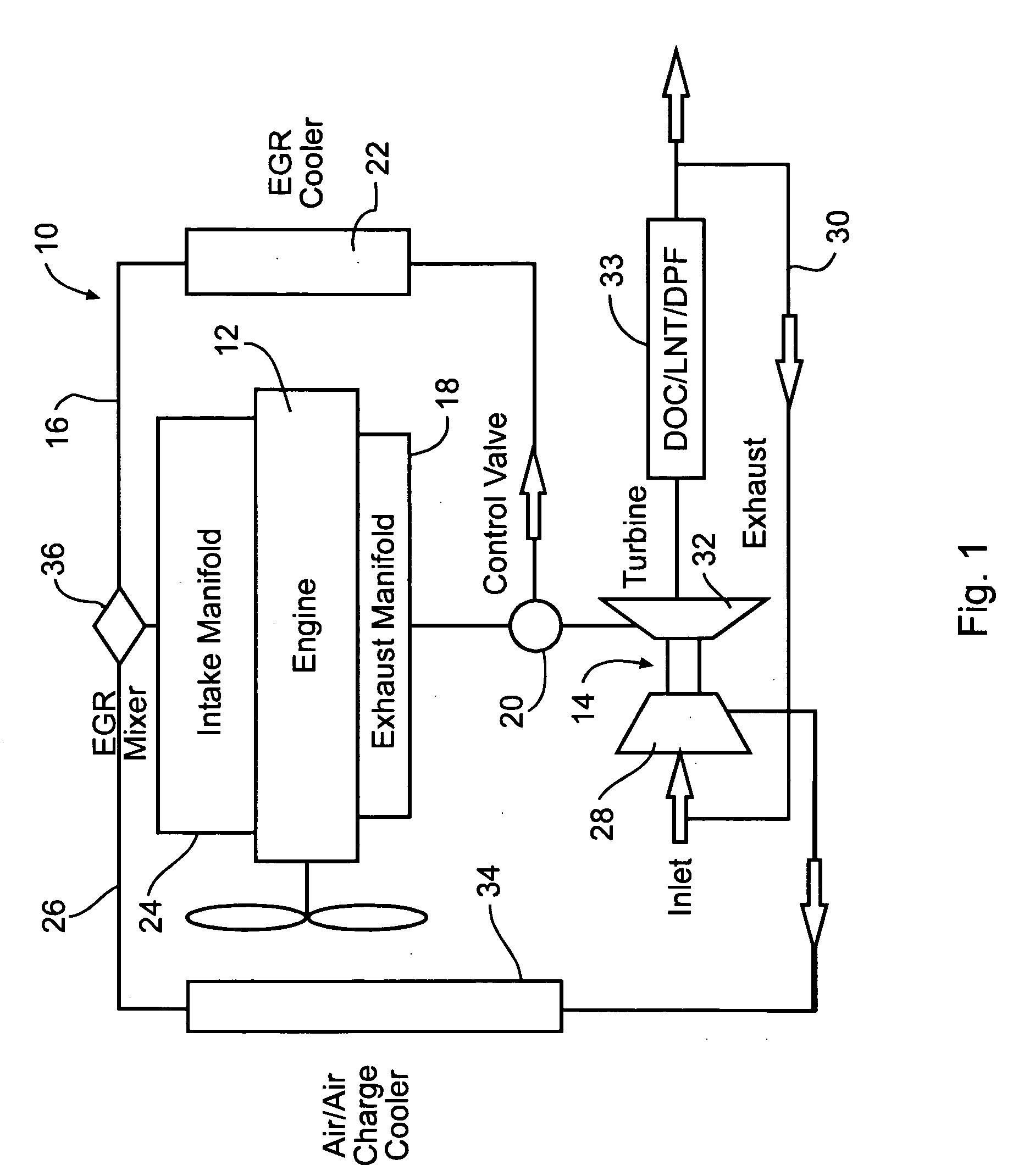

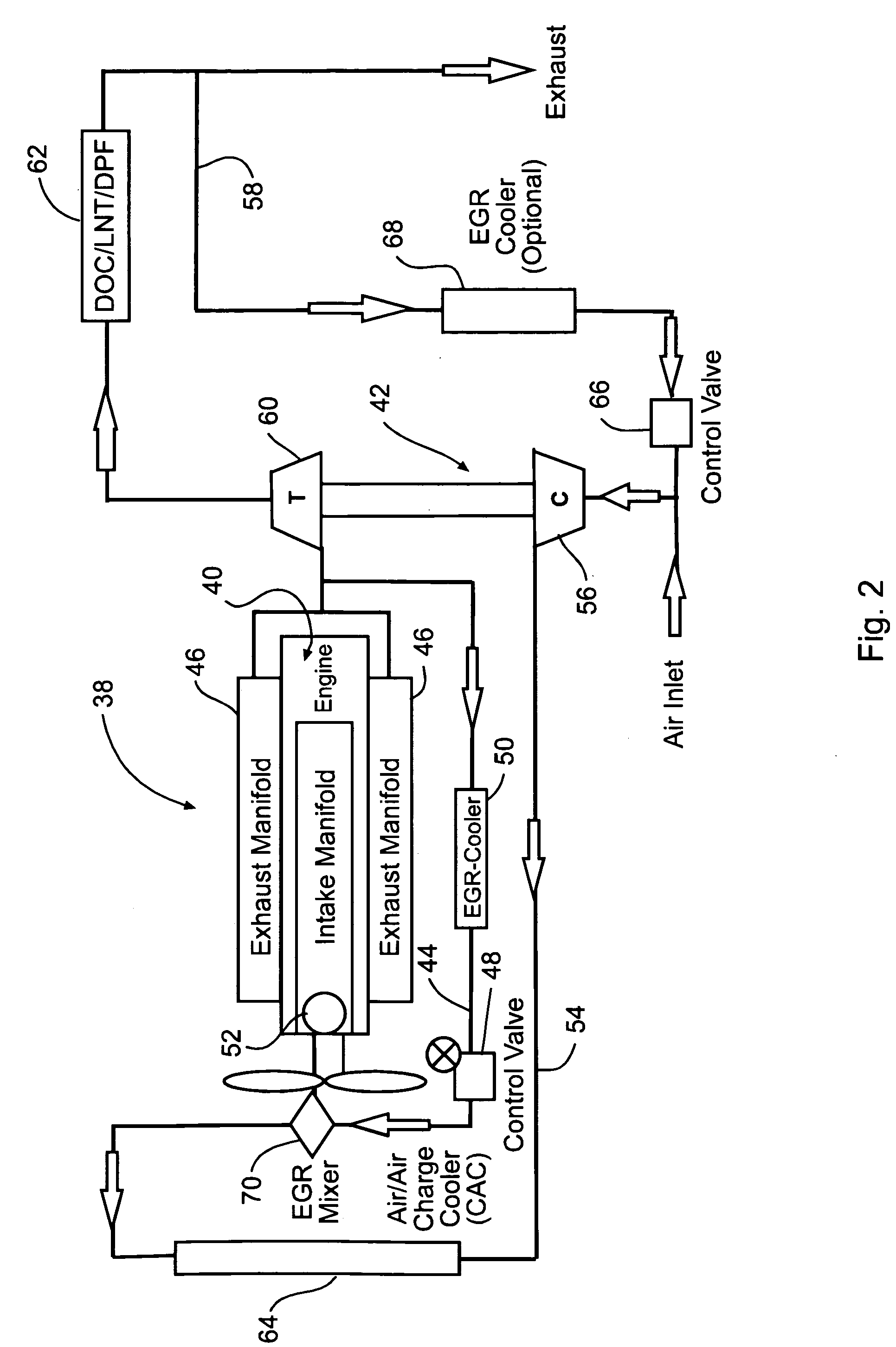

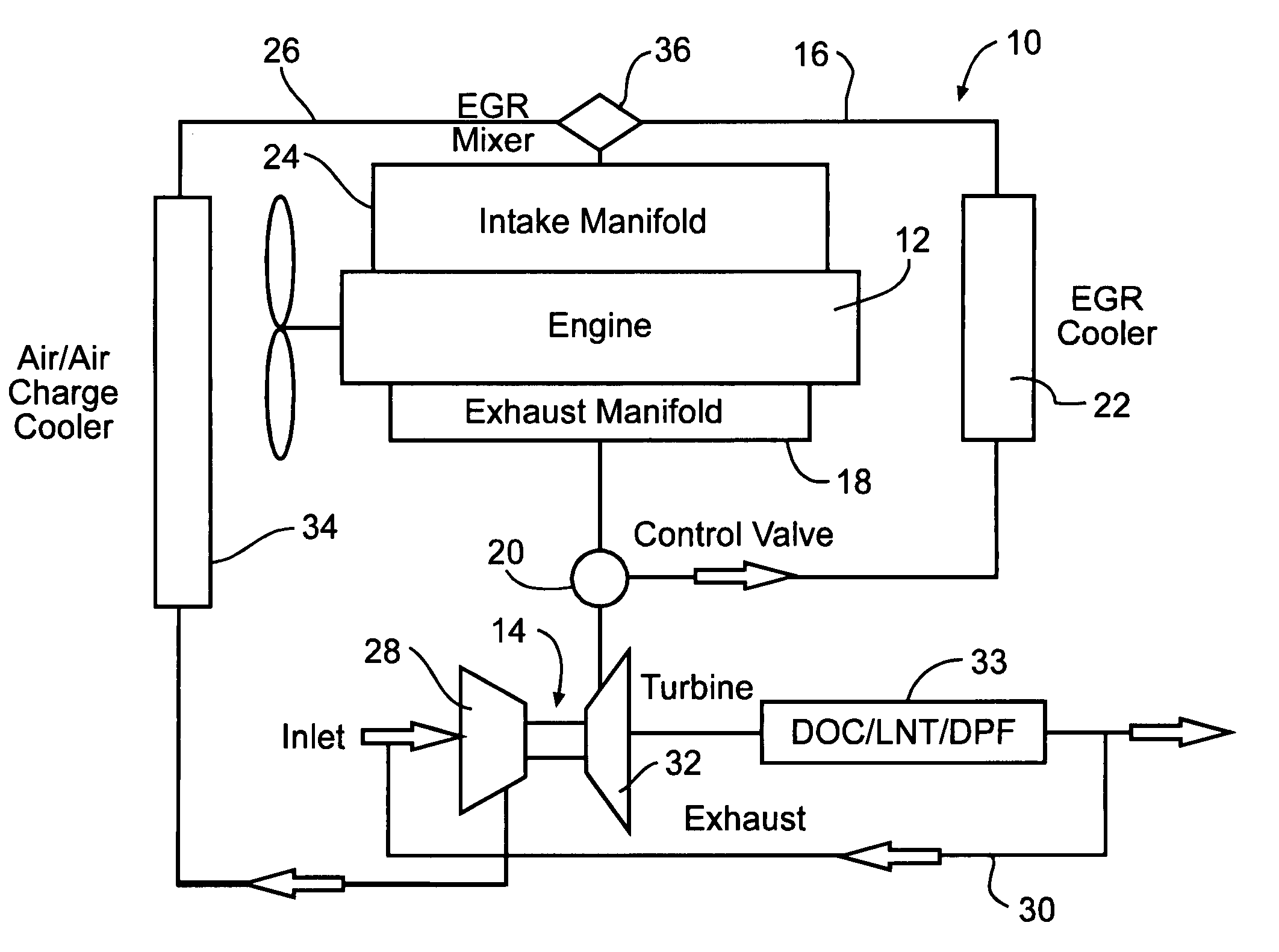

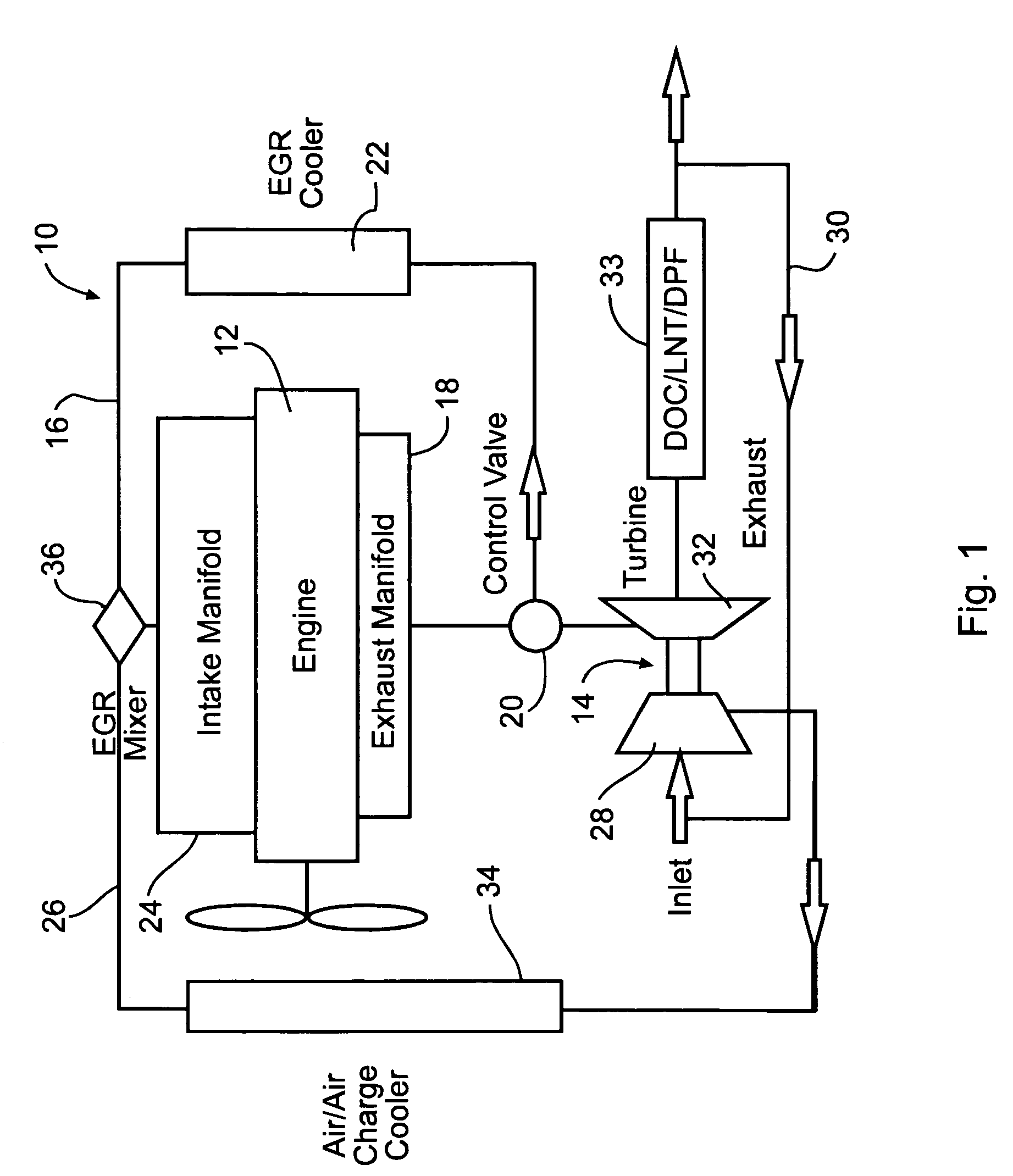

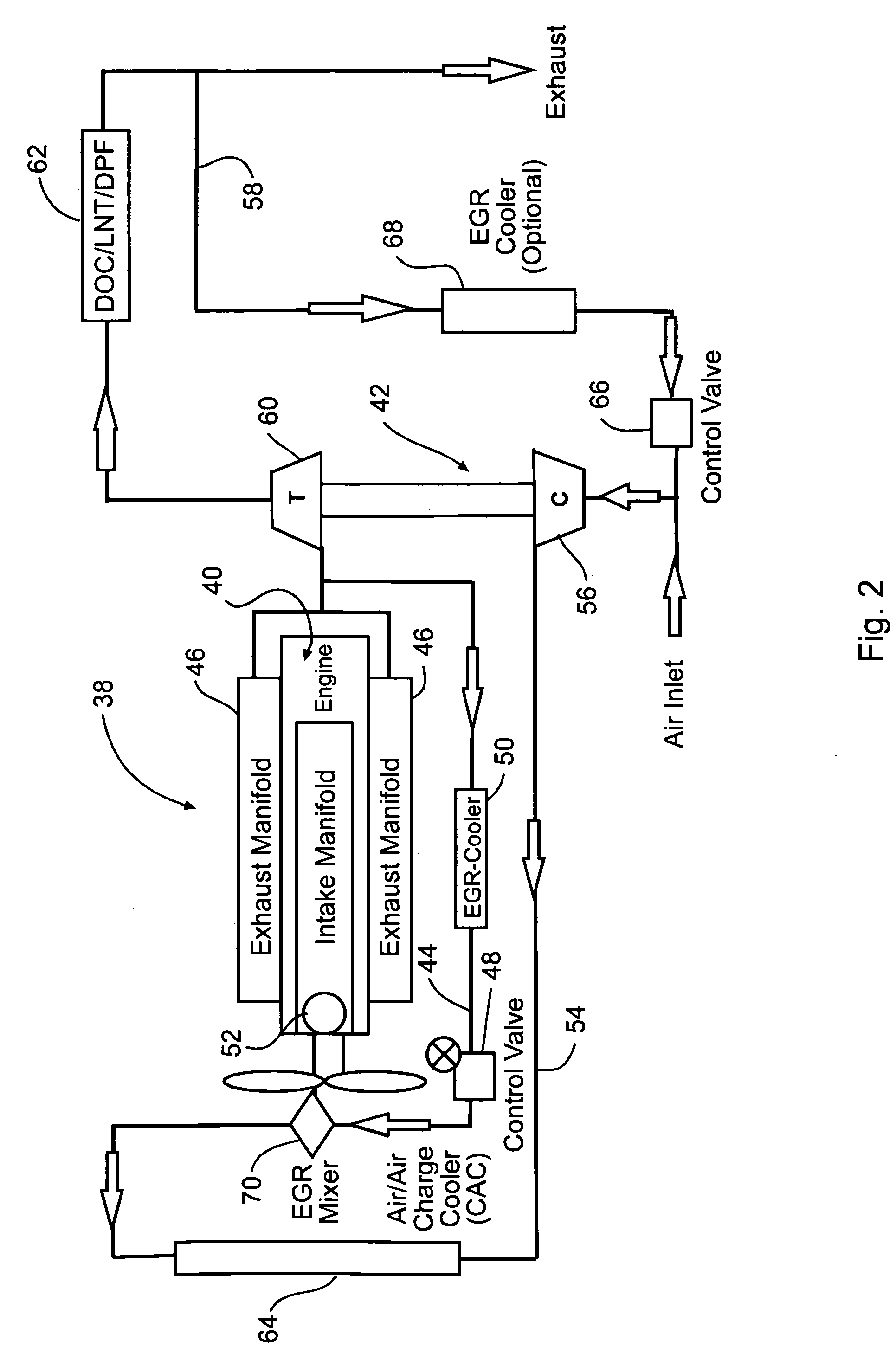

Dual and hybrid EGR systems for use with turbocharged engine

ActiveUS20050103013A1Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

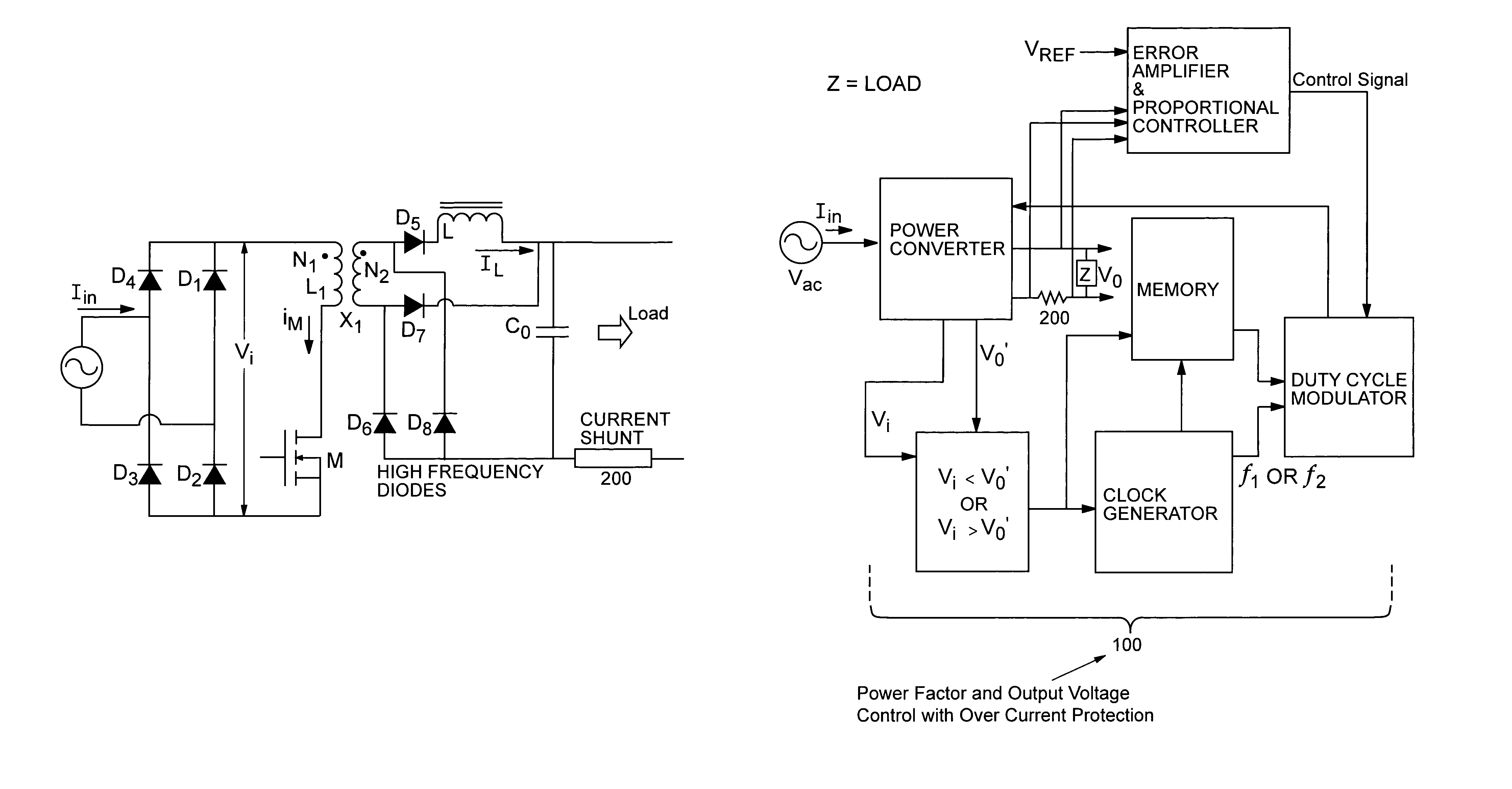

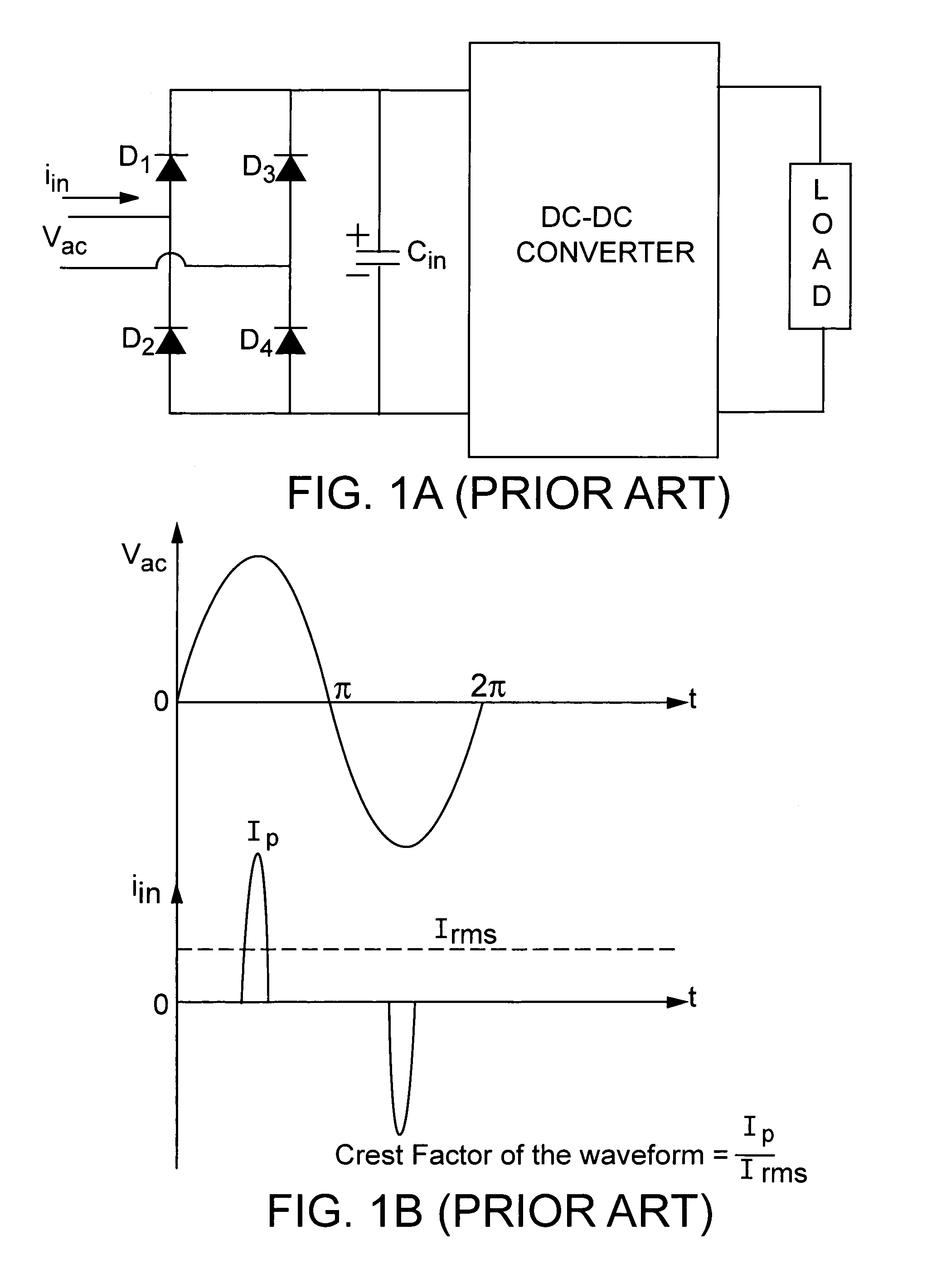

Power converter method and apparatus having high input power factor and low harmonic distortion

InactiveUS7157886B2Reduce complexityRelieve pressureAc-dc conversion without reversalEfficient power electronics conversionFrequency spectrumTotal harmonic distortion

A single stage, single switch, input-output isolated converter configuration which uses a hybrid combination of forward and flyback converters is disclosed. The converter operates at a high input power factor with a regulated DC output voltage. It makes use of a novel control scheme utilizing duty cycle control at two discrete operating frequencies. Although the invention employs two frequencies, it does not use a continuous frequency variation. This configuration has the advantage of reduced peak current stresses on the components and is specifically suited for ‘buck’ applications where low DC output voltages (e.g. 24V, 48V) are needed. This configuration will be of specific interest to industries associated with battery charging and uninterruptible power supply (UPS) systems. Apart from having several competitive features compared with prior art techniques, the dual frequency operation scheme reduces the amplitude of its noise spectrum by spreading it over a wider frequency range thus making it more electromagnetic compatible.

Owner:MICROSEMI

Dual and hybrid EGR systems for use with turbocharged engine

InactiveUS7013879B2Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

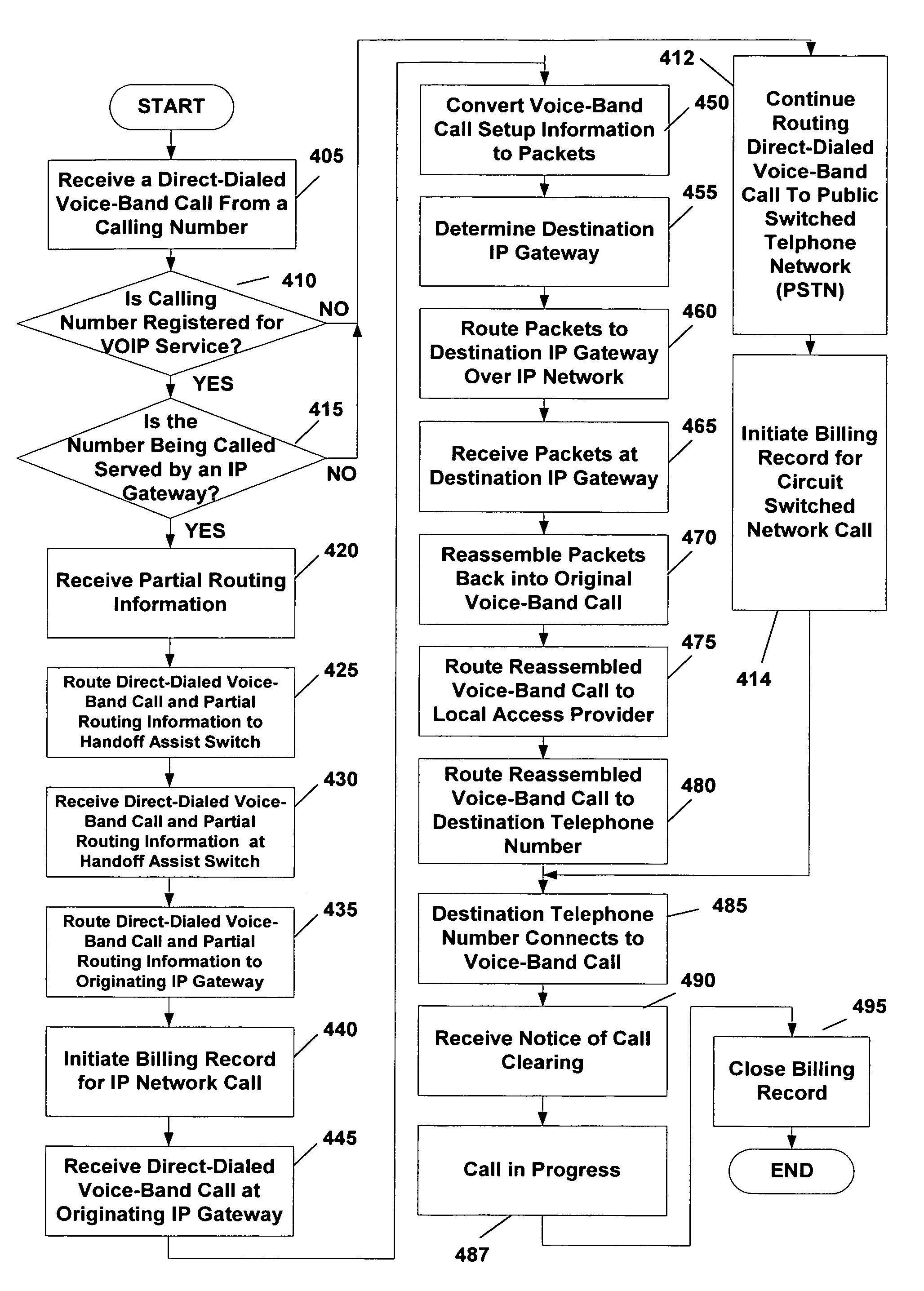

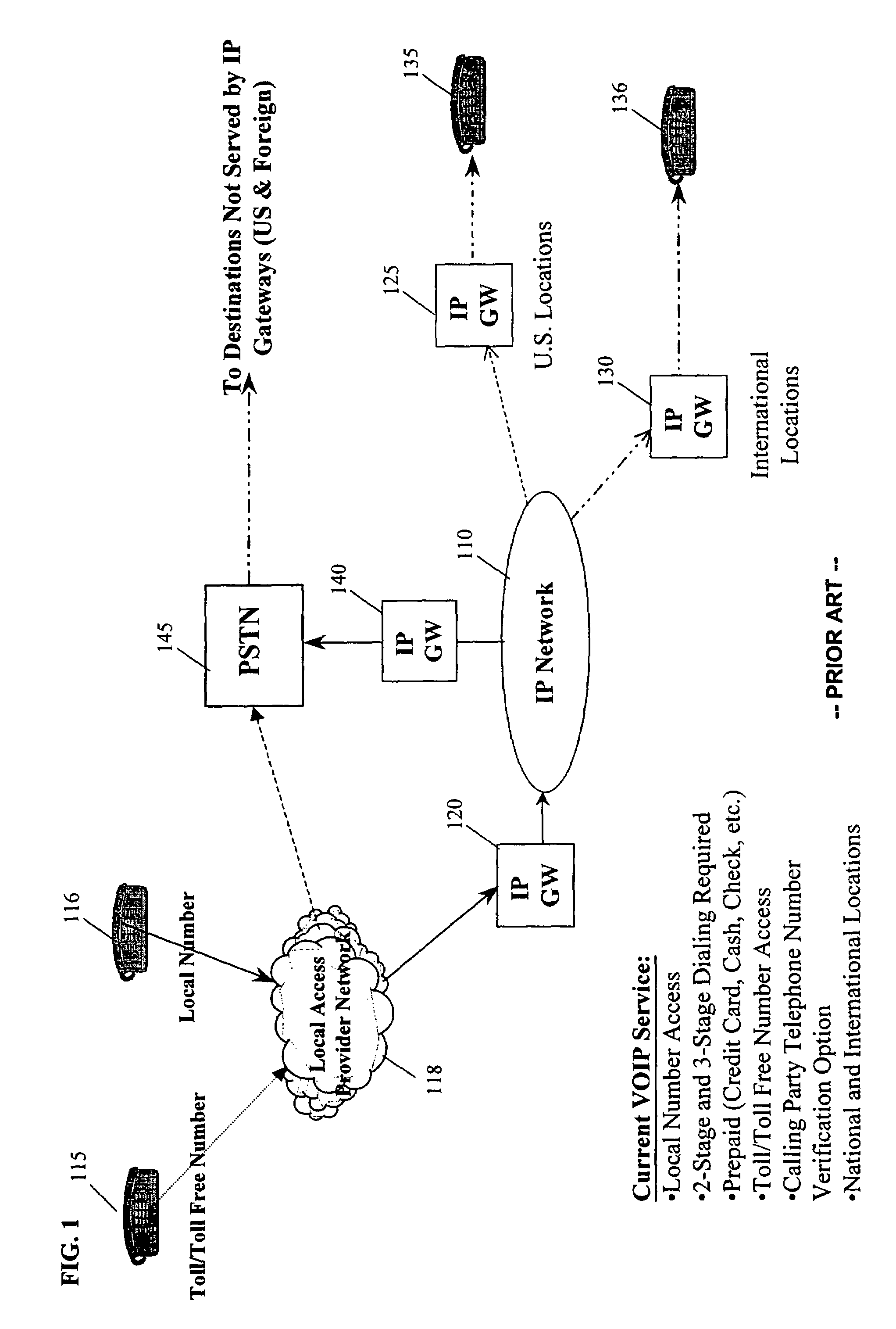

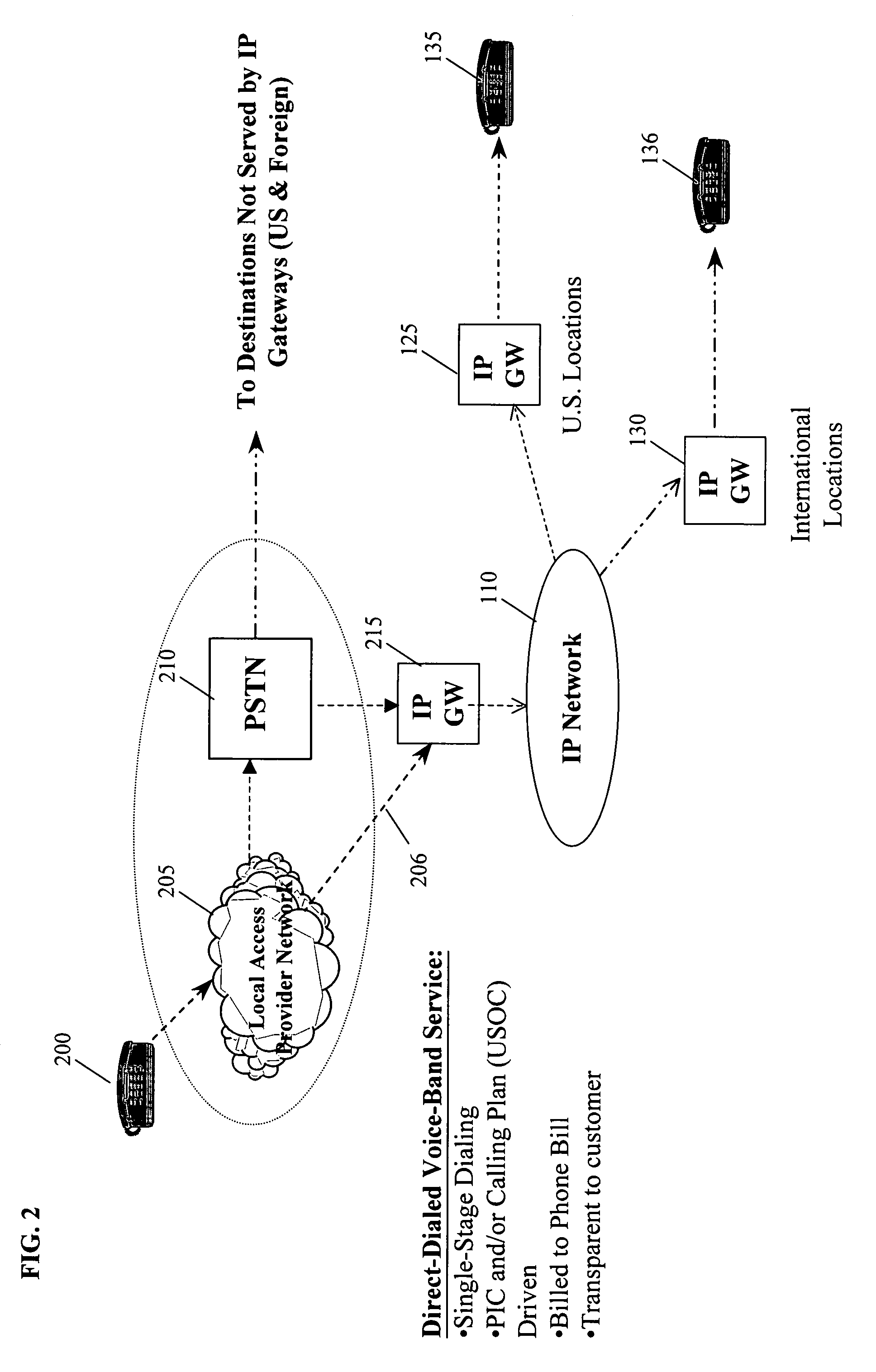

Method and system for customer selected direct dialed voice-over-internet protocol (VOIP)

A Voice-over-Internet protocol (VOIP) communications network system that enables direct-dialed (single-stage) access to the Internet Protocol (IP) network from the circuit-switched network. Specifically, the VOIP network system includes a VOIP service implemented on a communications system which, after a customer number has been registered for the service, automatically recognizes calls from the registered customer's telephone number and determines if the call can be routed as a VOIP call over the IP network. In embodiments of the present invention, the customer can register for the VOIP service by selecting both a provider (PIC) and a calling plan or by only selecting a provider. The system can be implemented to handle intra-state, inter-state and international voice-band calls (for example, regular telephone calls, facsimile transmissions and modem initiated calls) using standard circuit-switched telephone lines, cable, twisted pair, digital subscriber line (DSL) and wireless.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

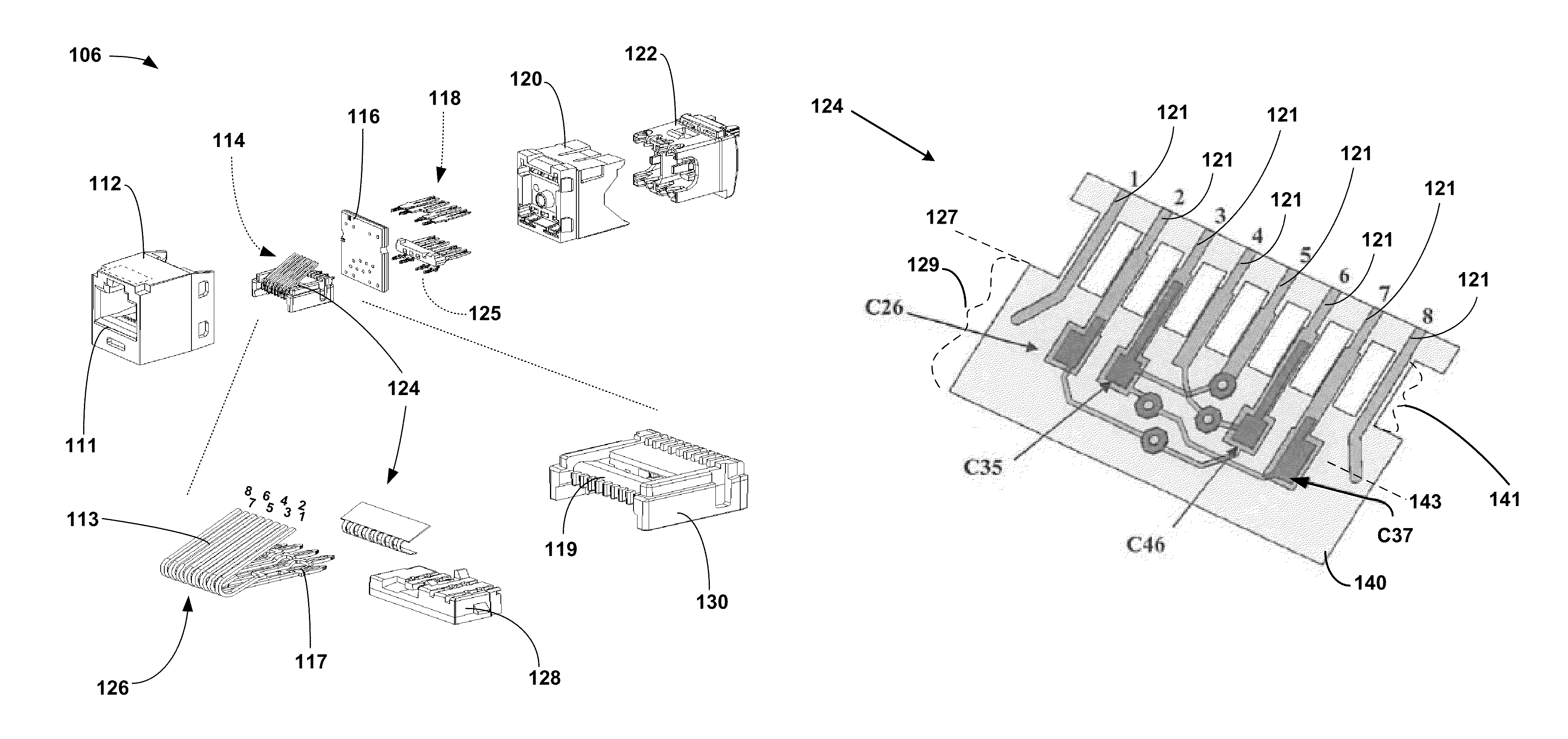

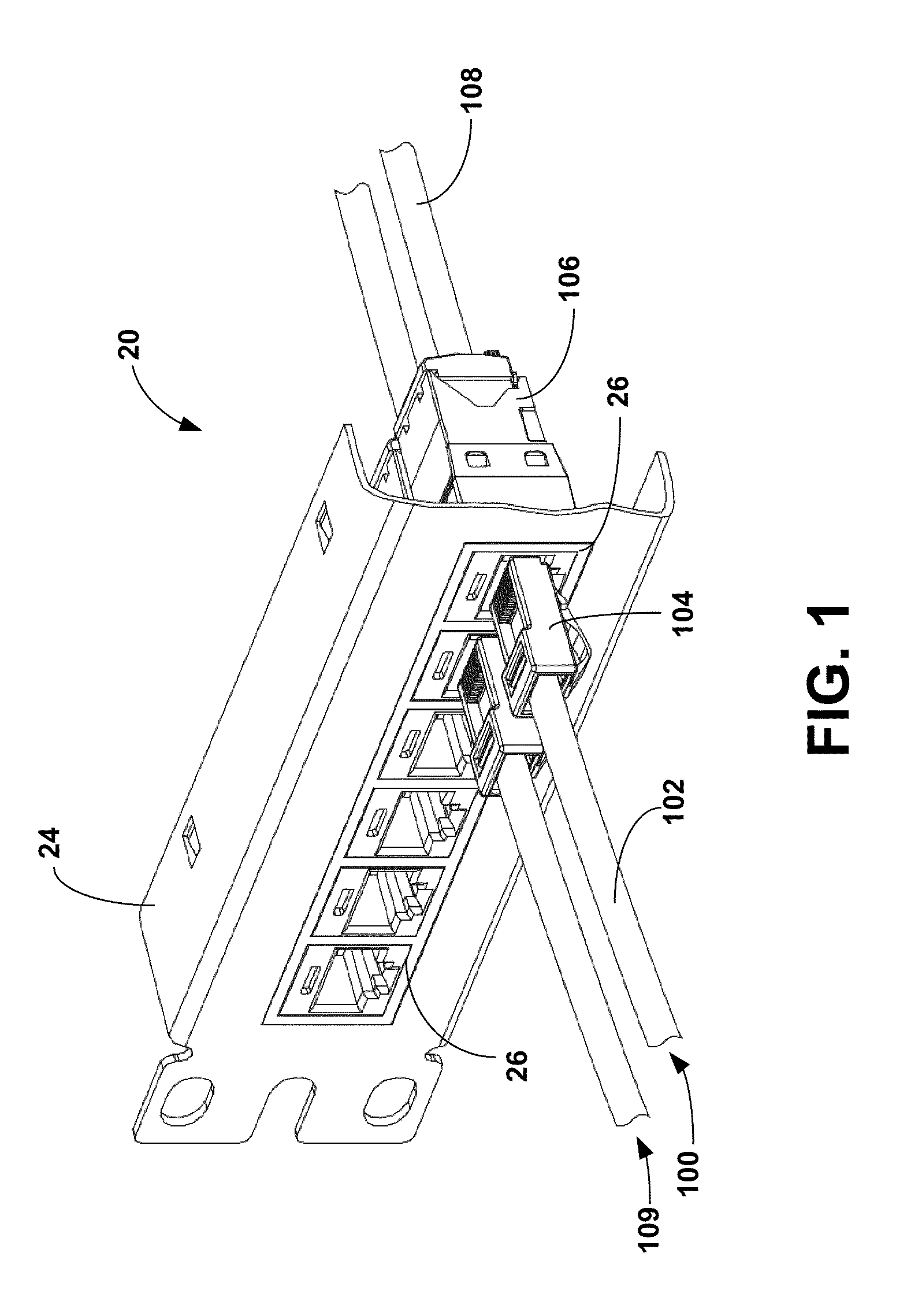

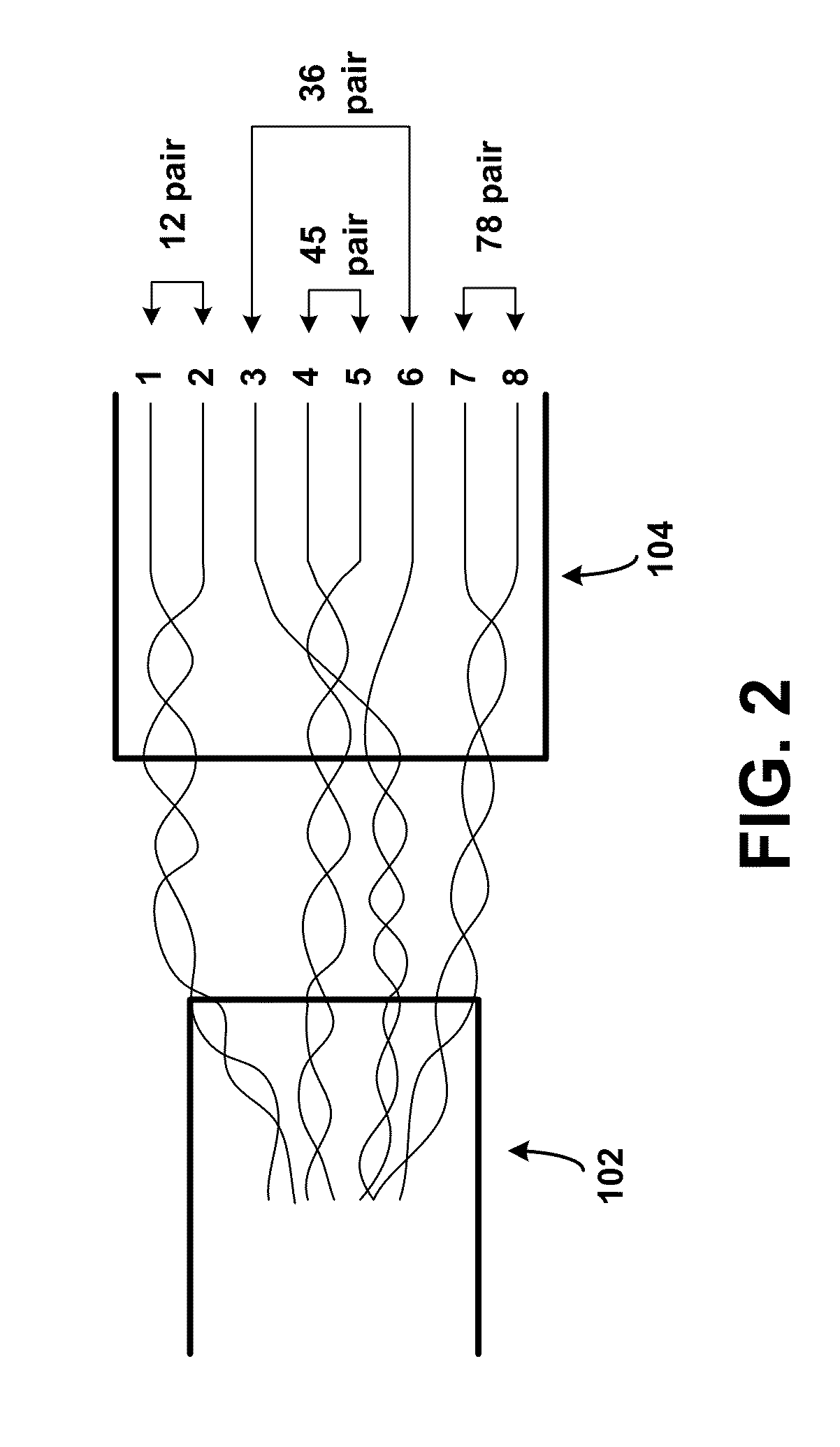

Communication connector with improved crosstalk compensation

ActiveUS7850492B1Minimal amountImproved production efficiency/reliabilityElectrically conductive connectionsCoupling device detailsSingle stageOperating frequency

A communication jack has a housing with a face having a plug receiving aperture. A plurality of conductive path pairs extends from corresponding plug interface contacts located at the plug receiving aperture to corresponding output terminals. A first circuit board is connected to the plug interface contacts and a second circuit board is connected to the plug interface contacts and the output terminals. The first circuit board has a first single stage of crosstalk compensation with opposite polarity of the crosstalk of a plug for a first combination of the conductive path pairs. The second circuit board includes a second single stage of opposite polarity crosstalk compensation for some of the conductive path pairs not compensated on the first circuit board. The stages cancel substantially all of the crosstalk caused by the plug, for the signal operating frequencies, for corresponding combinations of the conductive path pairs.

Owner:PANDUIT

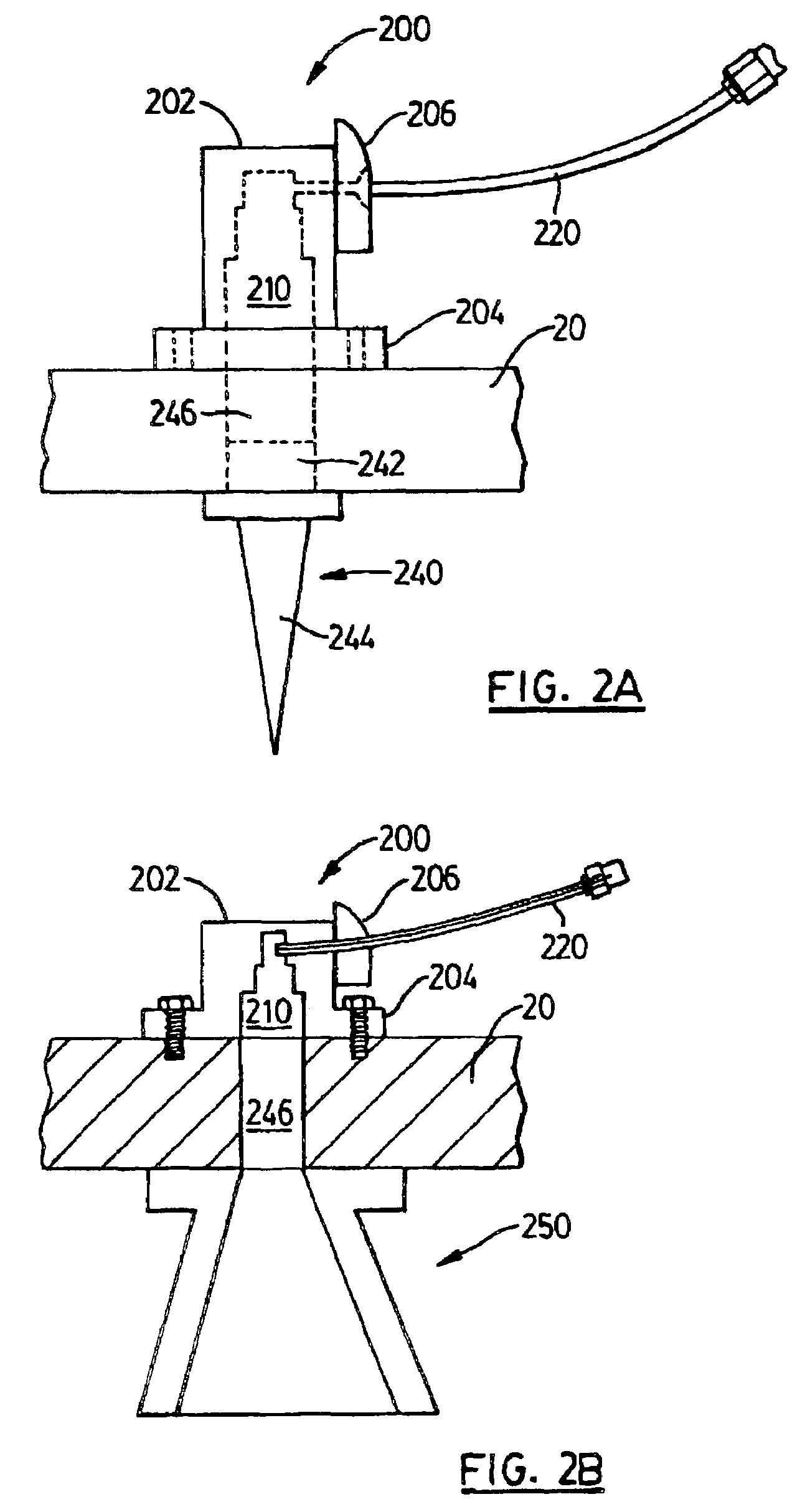

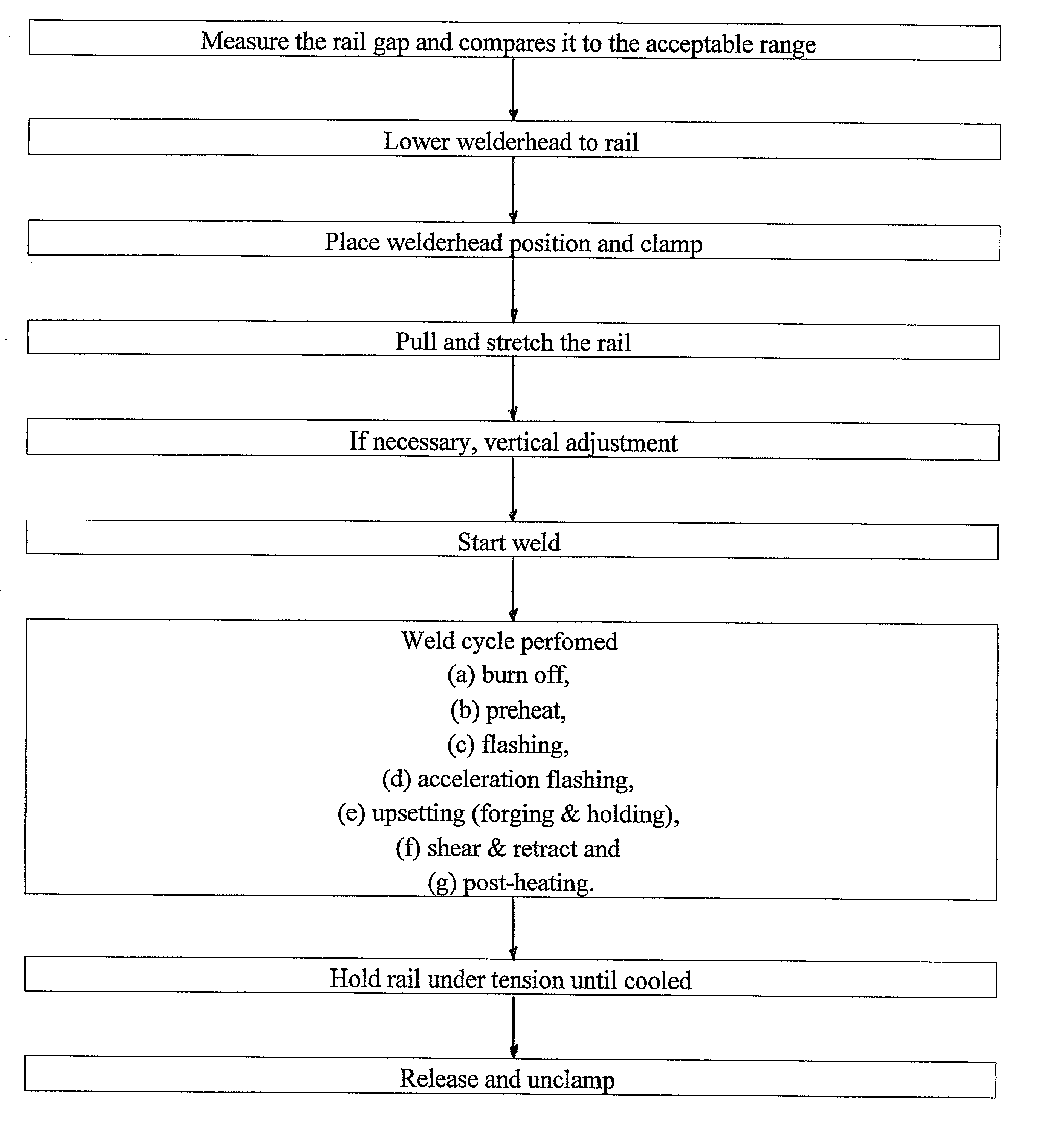

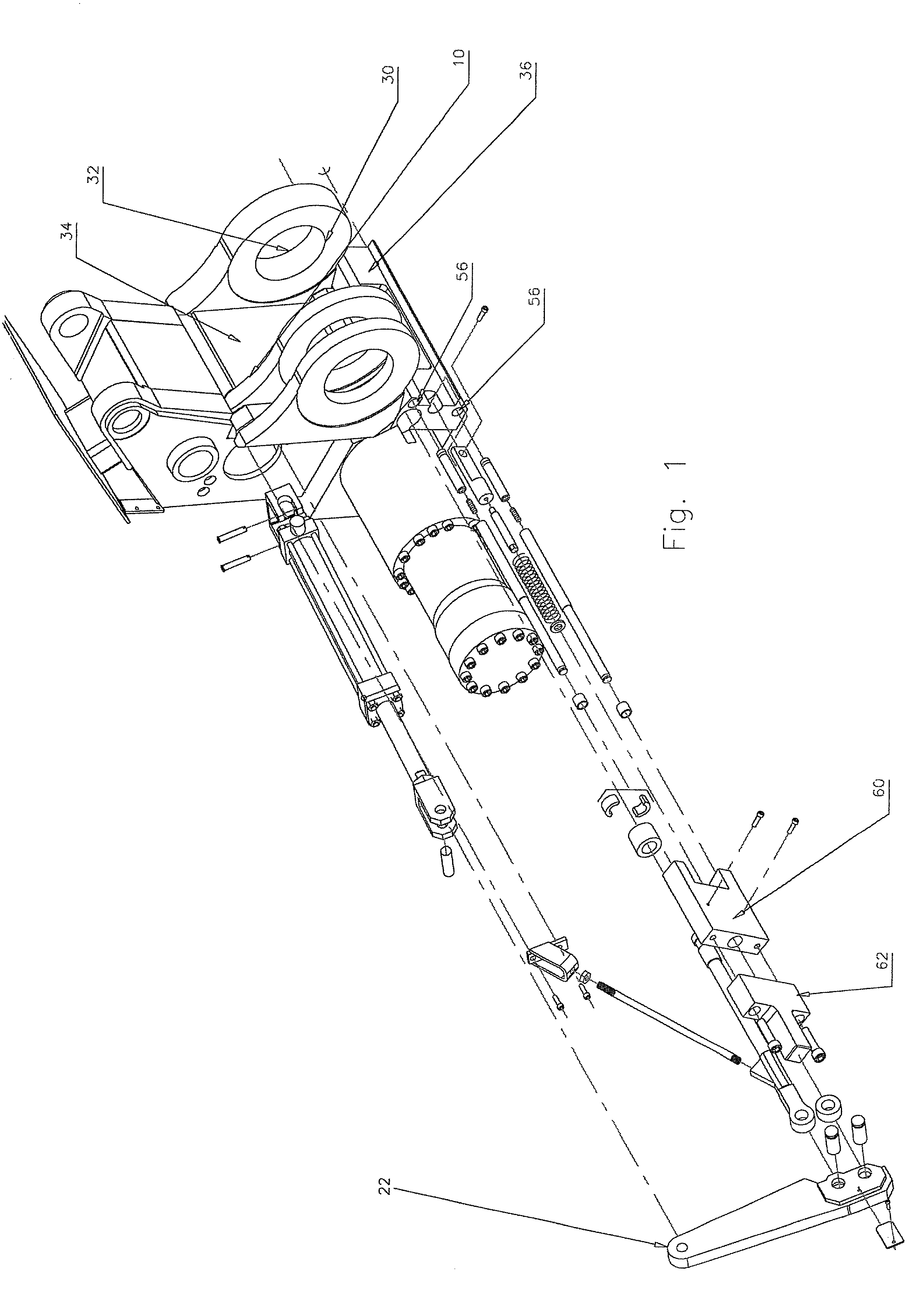

Rail welderhead shear apparatus

A flash butt rail welding welderhead combines in a single unit, the ability for the three functions of rail pulling, flash butt forging and maintaining the "after forged" displacement without any change in platen position such that shearing may be accomplished in three stages, a single stage, multiple stages or a progressive stage, all while maintaining clamping and stretching force on the rails.

Owner:HOLLAND CO

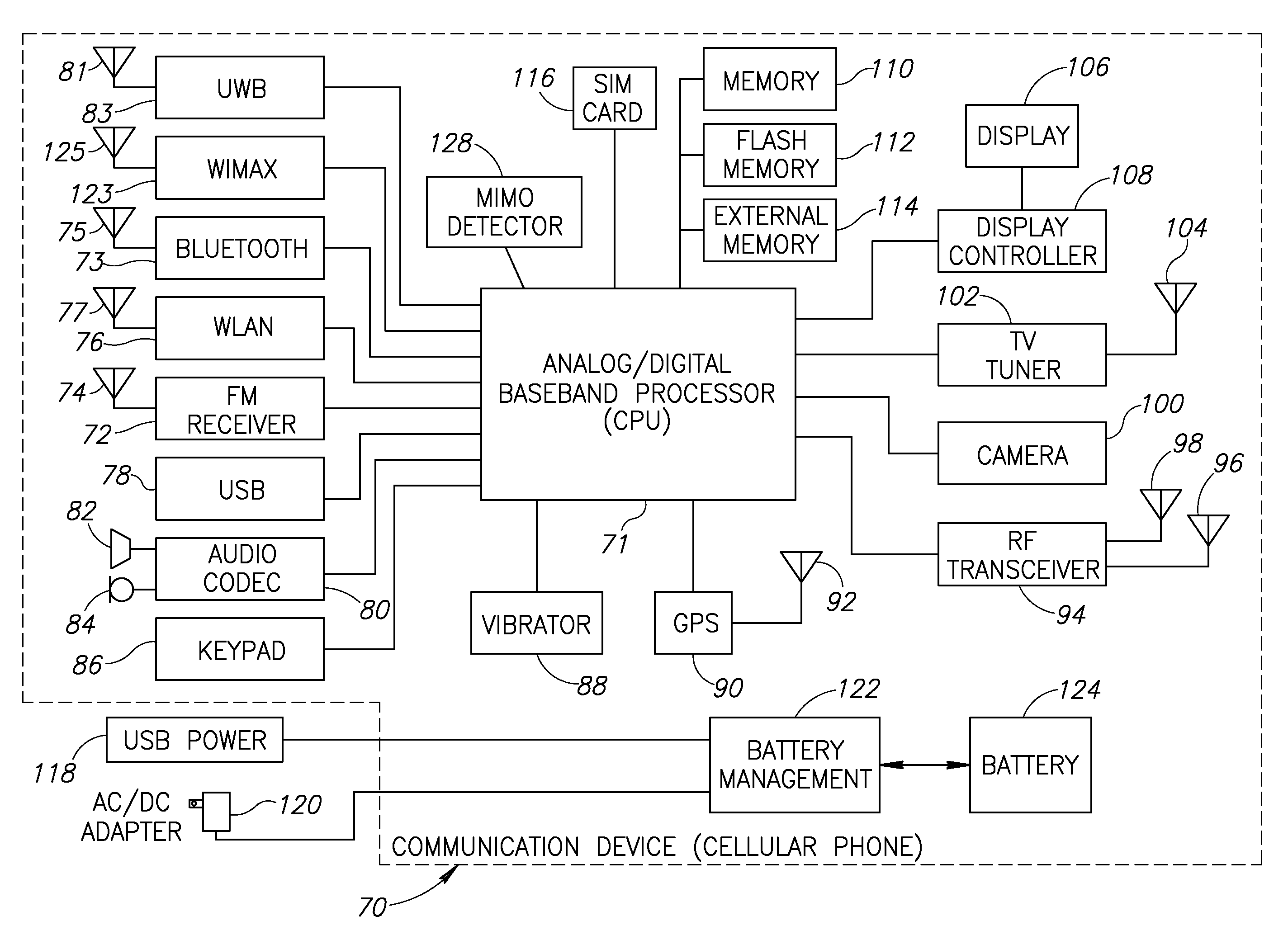

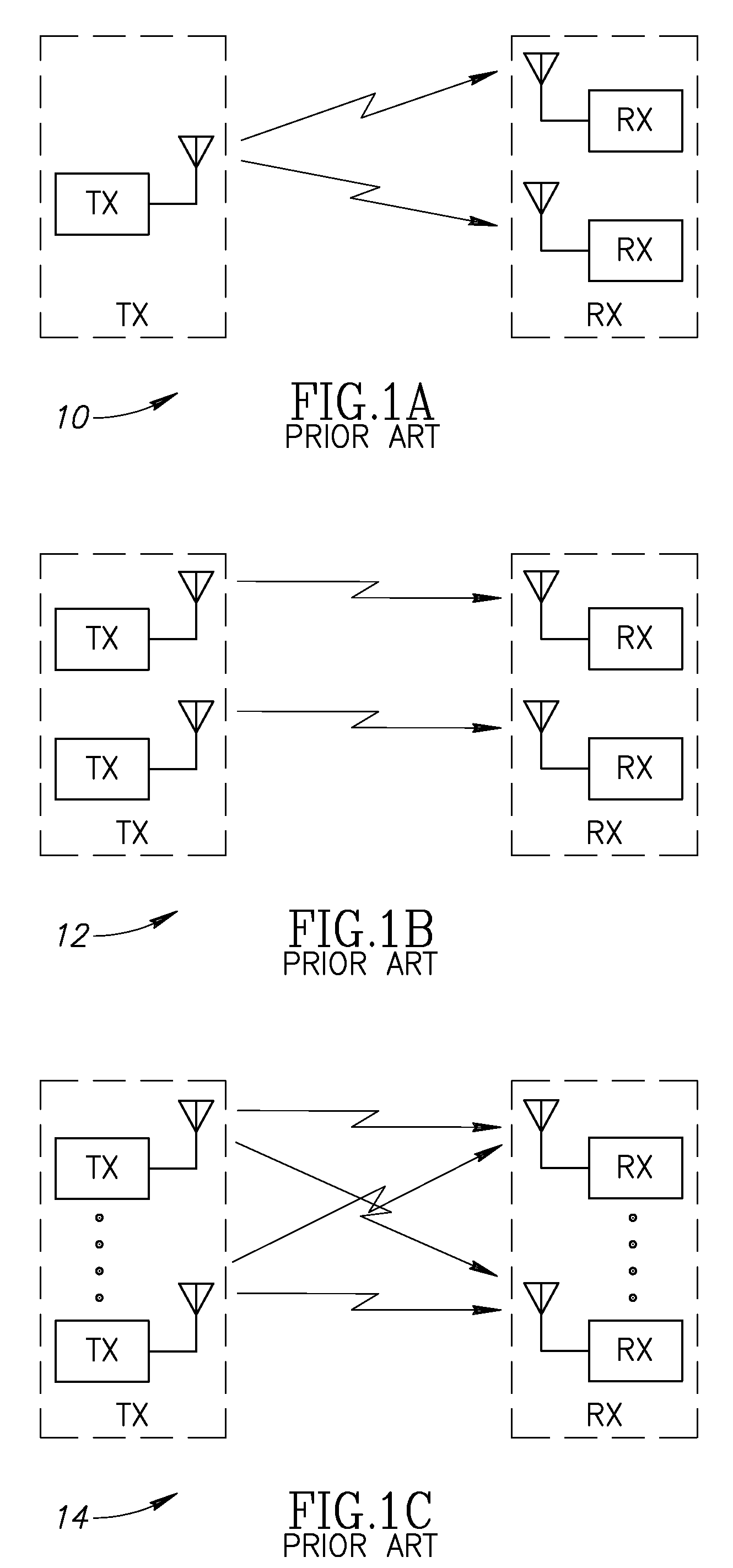

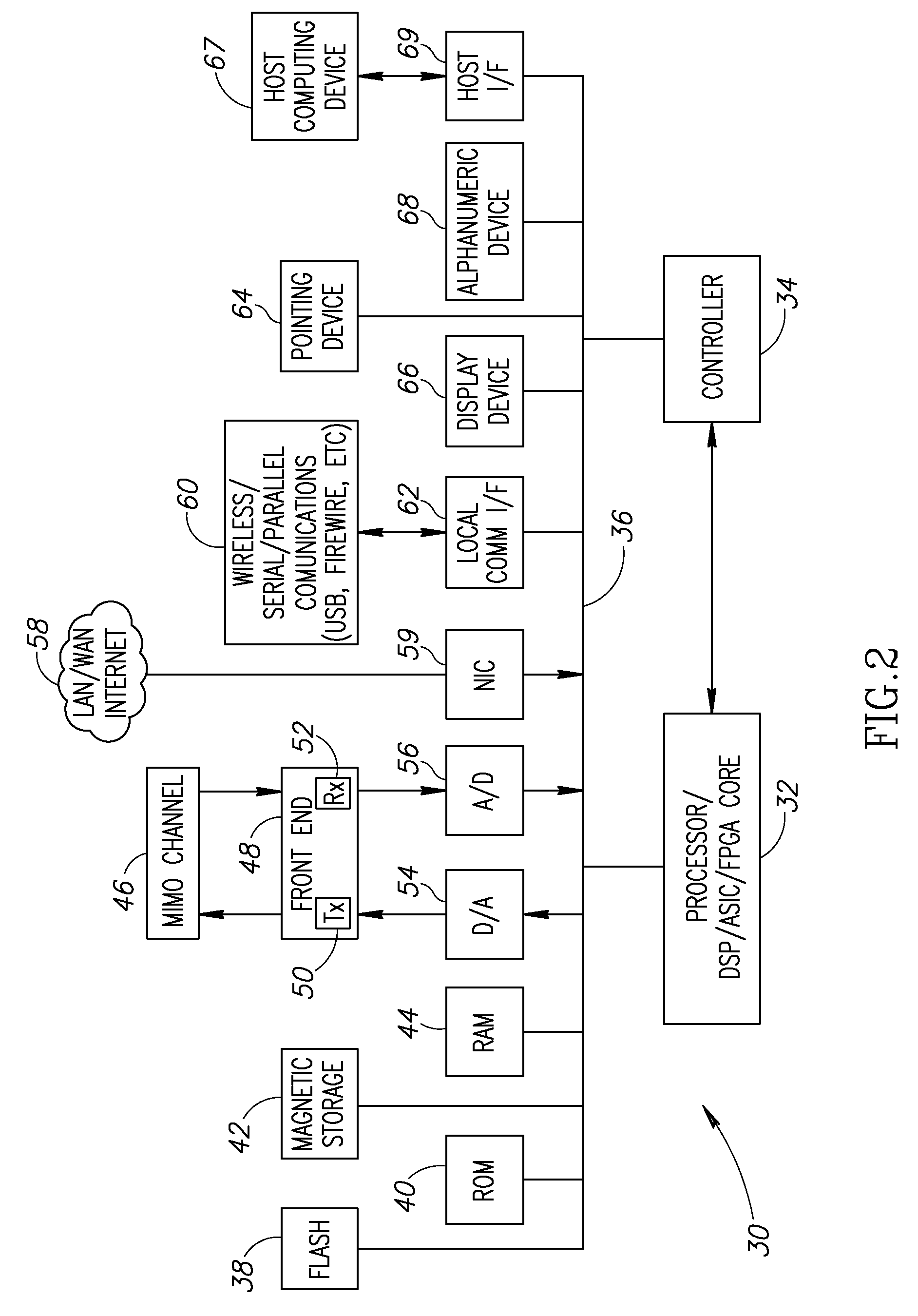

Multiple-input multiple-output (MIMO) detector incorporating efficient signal point search and soft information refinement

InactiveUS20080279299A1Reduce computational complexityImproved receiver bit error rate (BER) performancePolarisation/directional diversityAmplitude-modulated carrier systemsCommunications systemSingle stage

A novel and useful apparatus for and method of multiple input multiple output (MIMO) detection for use in MIMO based communication systems. The mechanism of the invention performs a simplified tree search utilizing a single stage expansion of the most likely first symbol candidates, in the case of a 2×2 MIMO system. The invention also provides a refinement mechanism that is operative to significantly improve the soft information (i.e. log likelihood ratio) of the list of candidates. To improve the soft information, the mechanism applies one or more refinements rounds to generate additional candidates for both first and second detected symbols.

Owner:COMSYS COMM & SIGNAL PROC

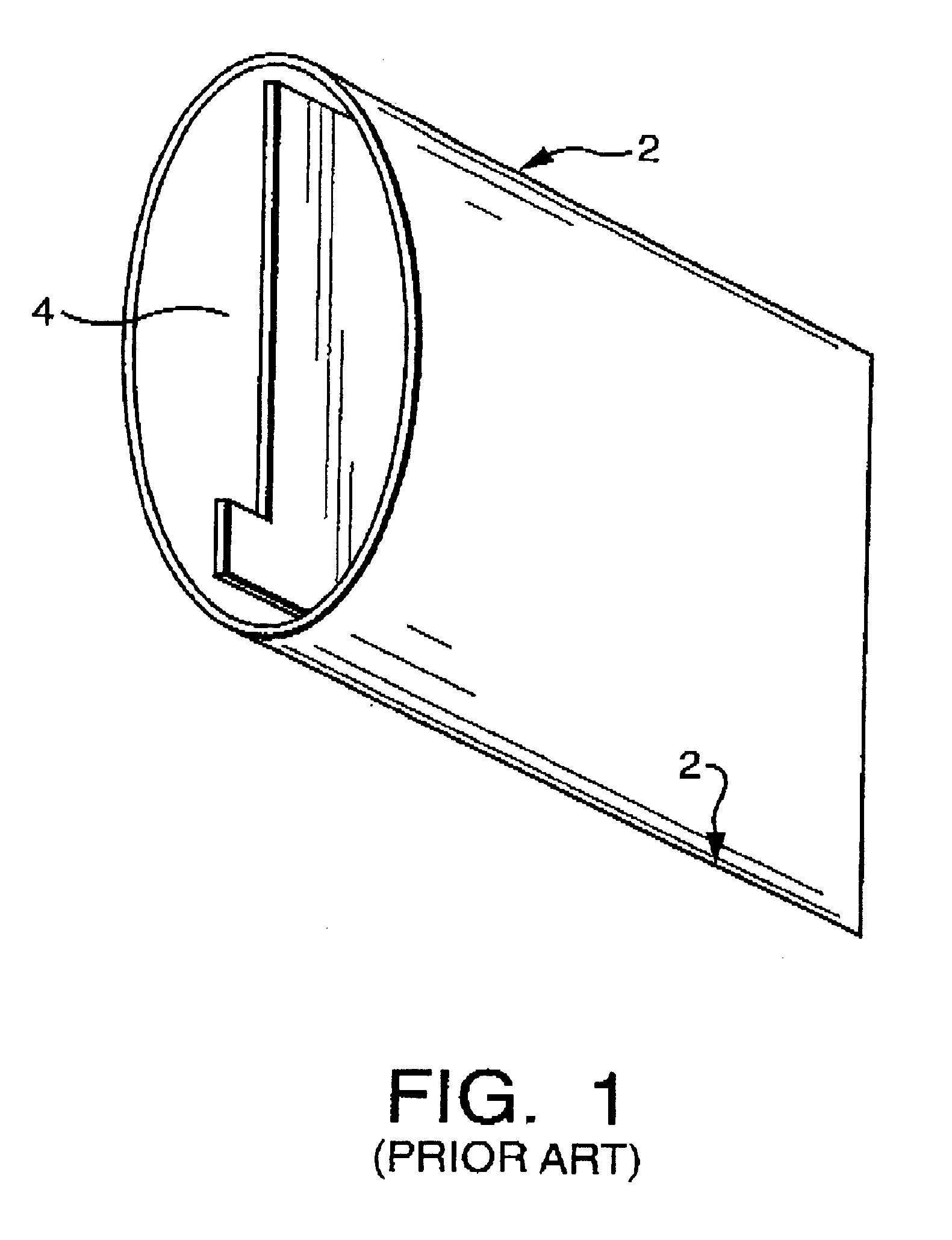

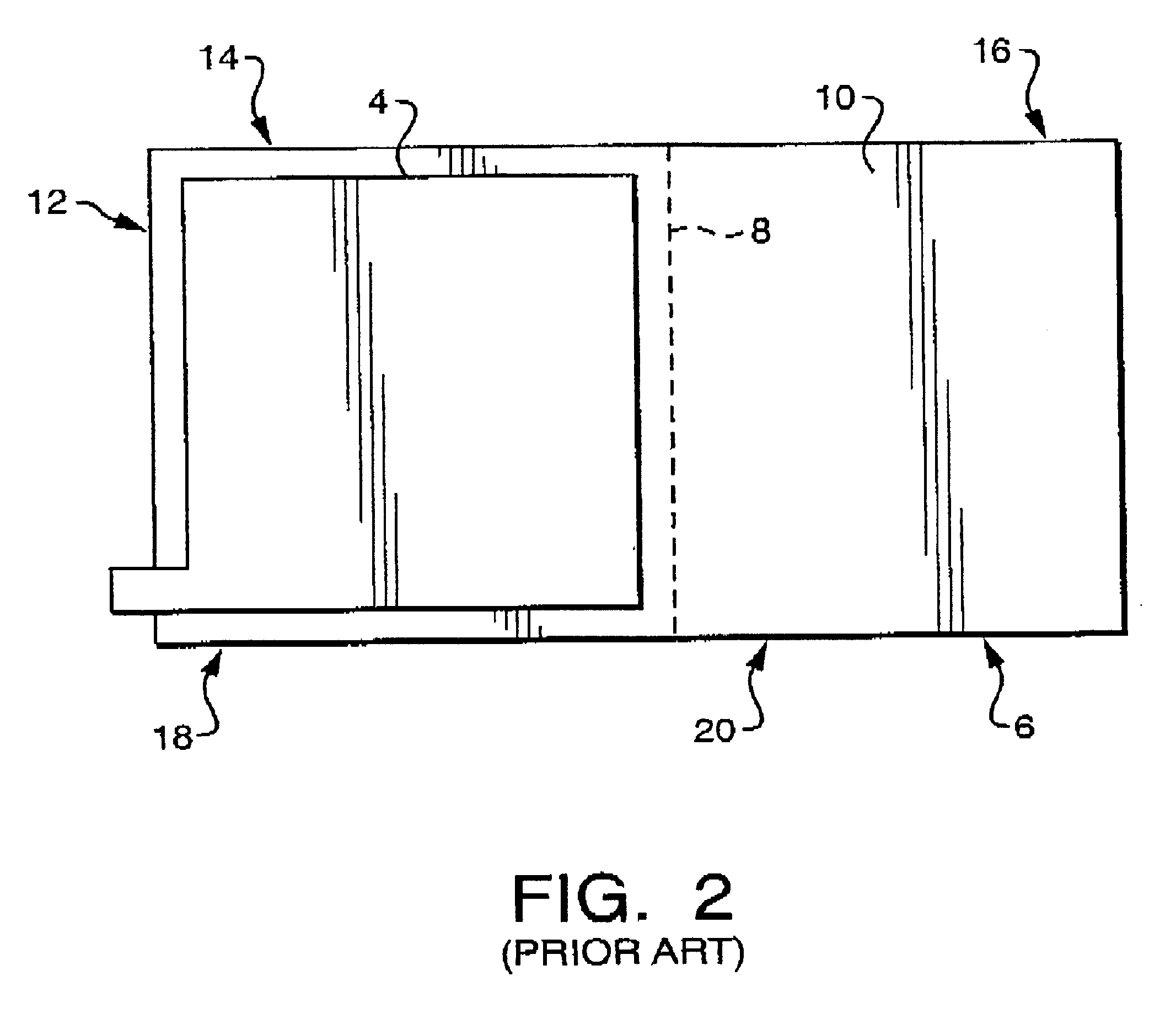

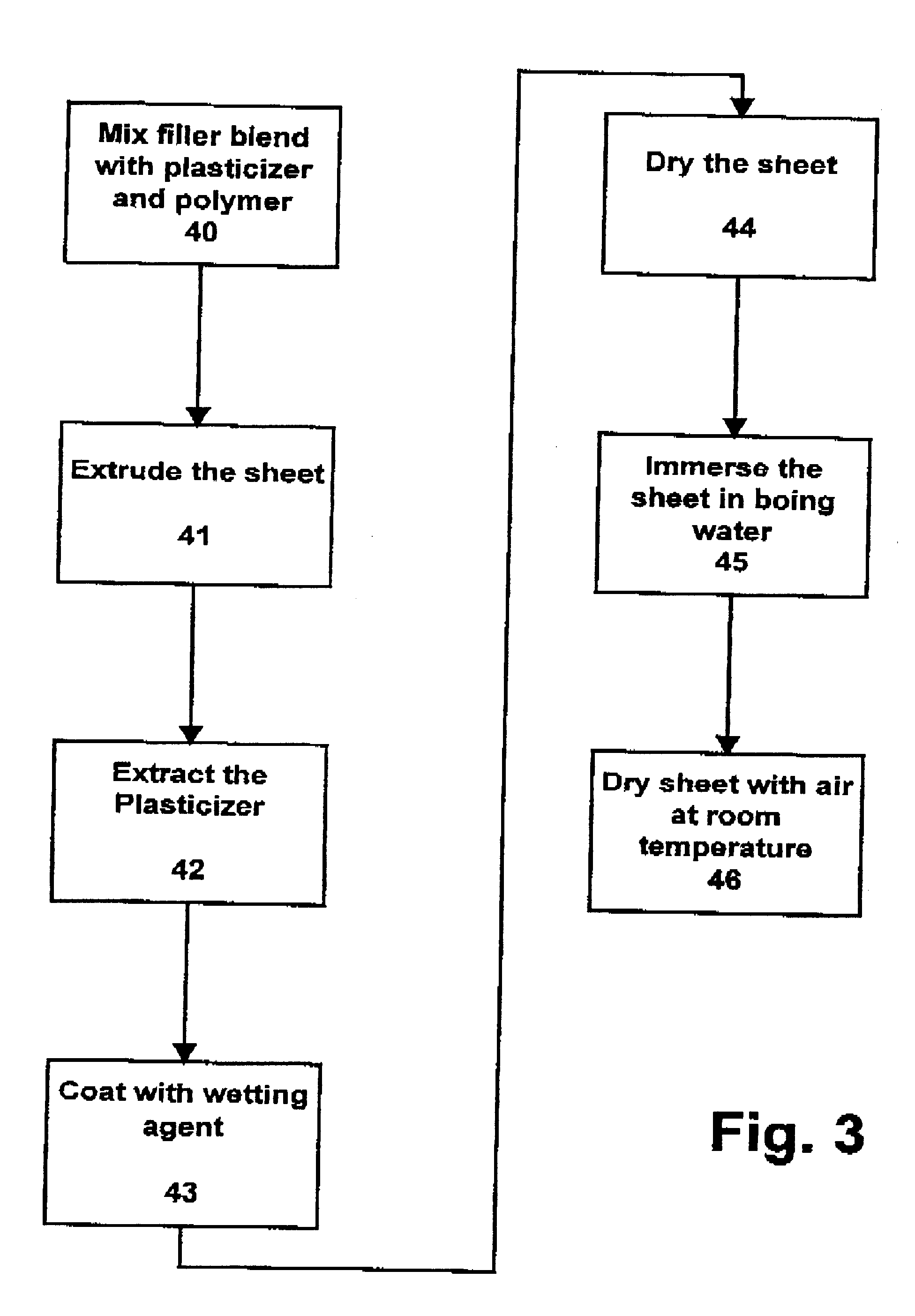

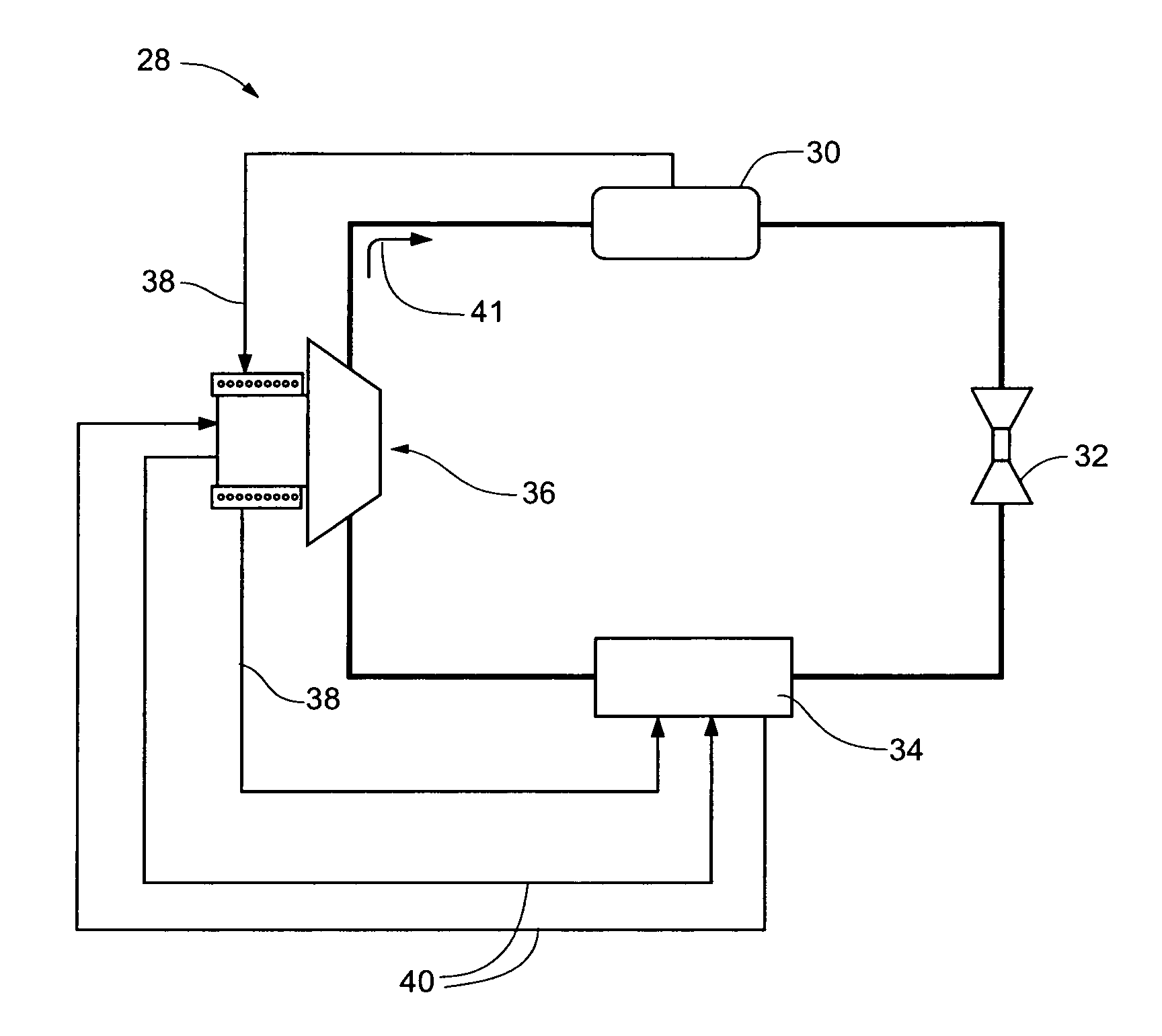

Microporous membrane battery separator for silver zinc batteries

InactiveUS6372379B1Improve cycle lifeExtended calendar lifeSilver accumulatorsCell component detailsPolyolefinFuel oil

A separator membrane for use in silver-zinc batteries is produced by extruding a blend of two fillers with the same chemical formula but different particle size. A polyolefine polymer and a plasticizer are blended and extruded to form a thin sheet of 1 to 10 mil thickness. The plasticizer is then extracted to leave submicron voids in the membrane. Plasticizers are added as processing aids, and can be either soluble or insoluble in water, and include petroleum oils, lubricating oils, fuel oils, and natural oils such as tall oils and linseed oils. The oil are then extracted from the membrane by conventional procedures such as single stage extraction using a suitable solvent. Commercially available wetting agents known to the art such as dodecylphenoxy polyethoxy ethanol and isooctyl phenyl polyethoxy ethanol are coated onto the sheet to improve wettability. The sheet is then dried, and boiled in distilled water for one minute or more, before being finally dried.

Owner:ZPOWER LLC

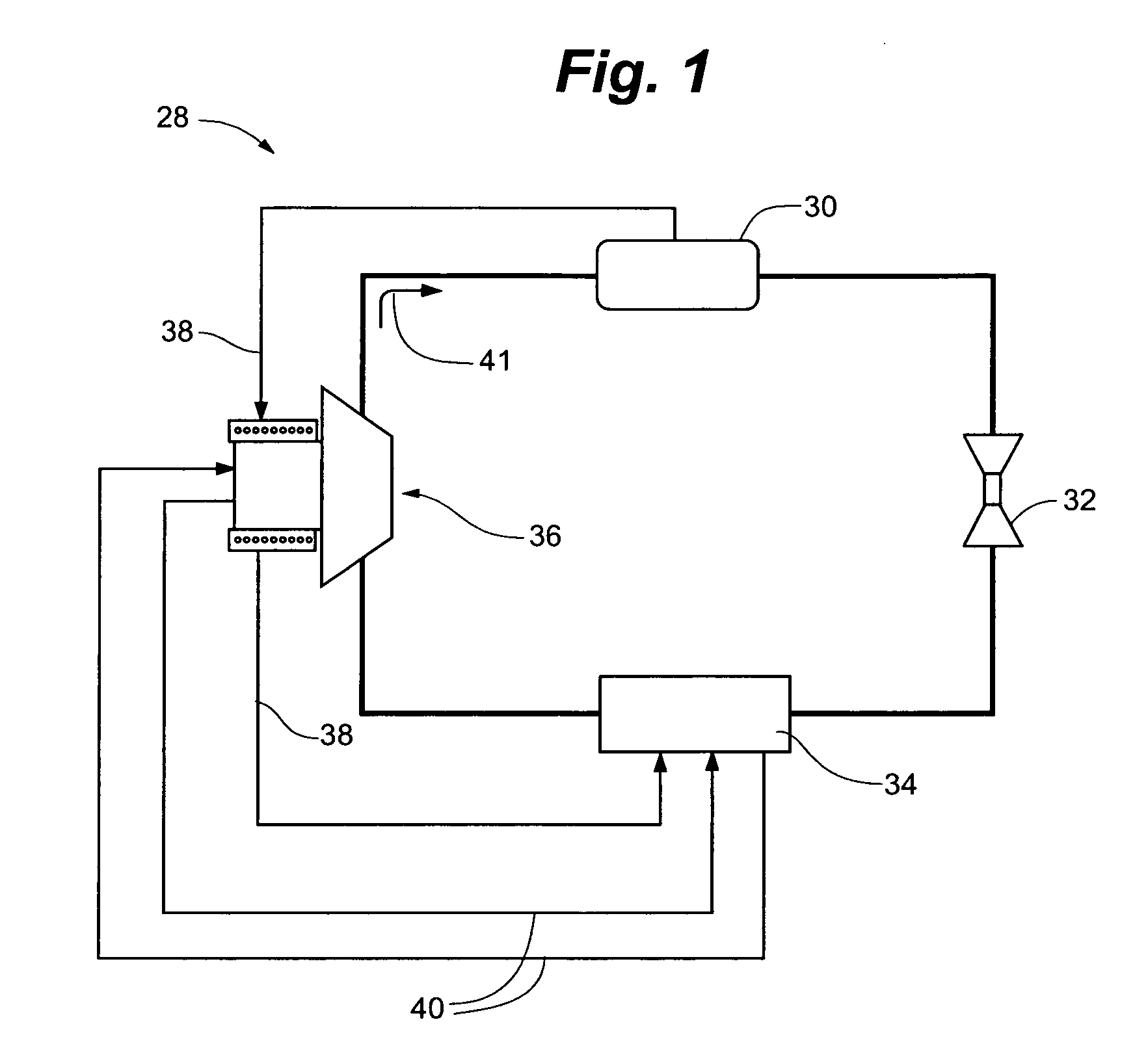

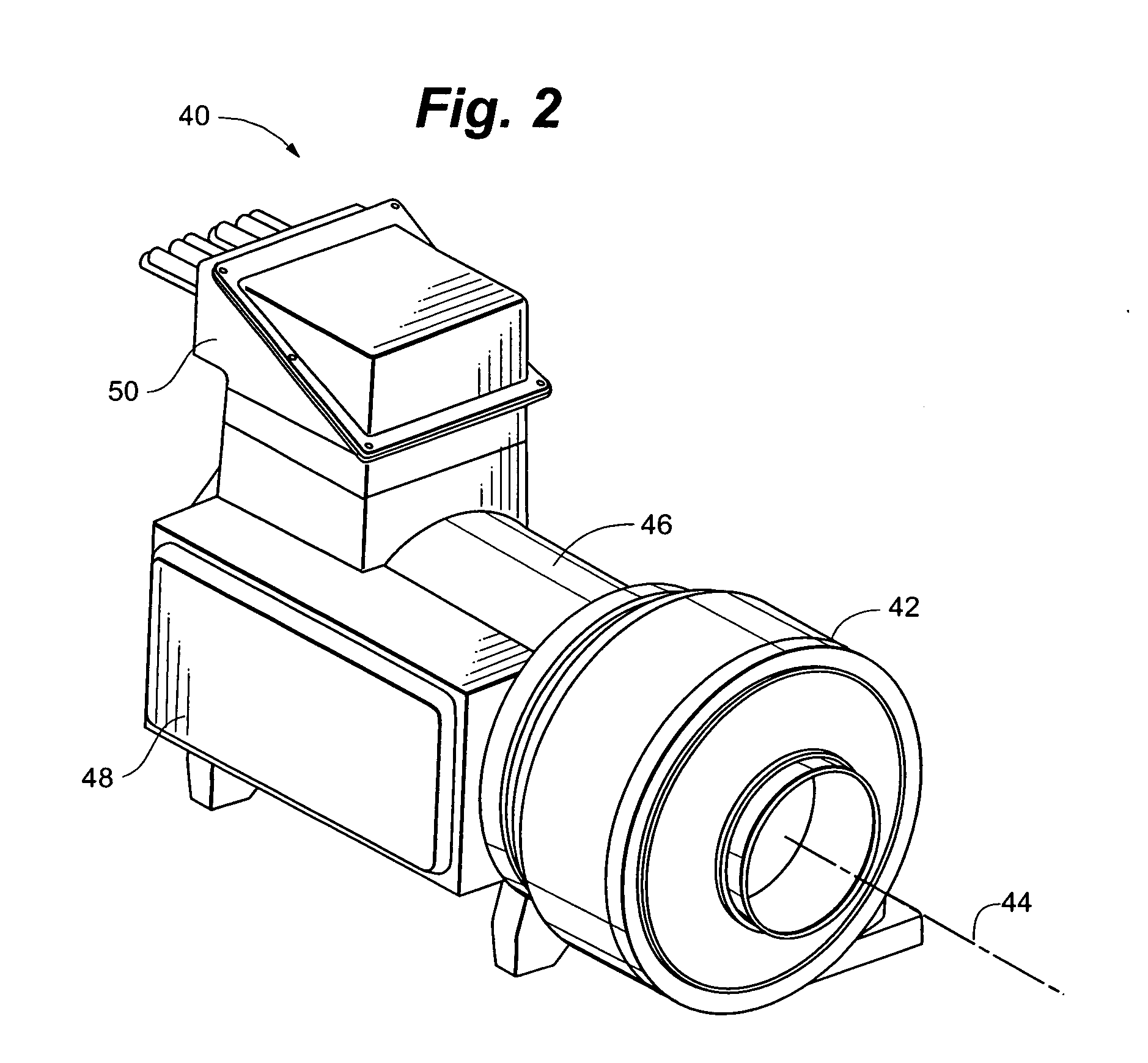

High capacity chiller compressor

ActiveUS20080115527A1Improve efficiencyIncrease power outputWind motor controlEfficient regulation technologiesMagnetic bearingEngineering

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. The assembly is highly efficient by virtue of a variable frequency drive (VFD) that drives a permanent magnet motor and matches compressor speed with compressor load, a direct drive impeller that eliminates gearing losses, and magnetic bearings that reduce frictional losses. The back-emf produced by the motor provides an intermediate power source for the magnetic bearings in the event of a loss of electrical power. A cooling system provides direct cooling of the rotor with gas refrigerant, and cooling of the stator with liquid refrigerant. Modular construction allows the compressor to be retrofit with upgrades. An inlet guide vane system operates without need for oil lubrication. The use of light metal castings and elimination of gearing reduces the weight to one-third or less of comparably powered conventional units.

Owner:DAIKIN IND LTD

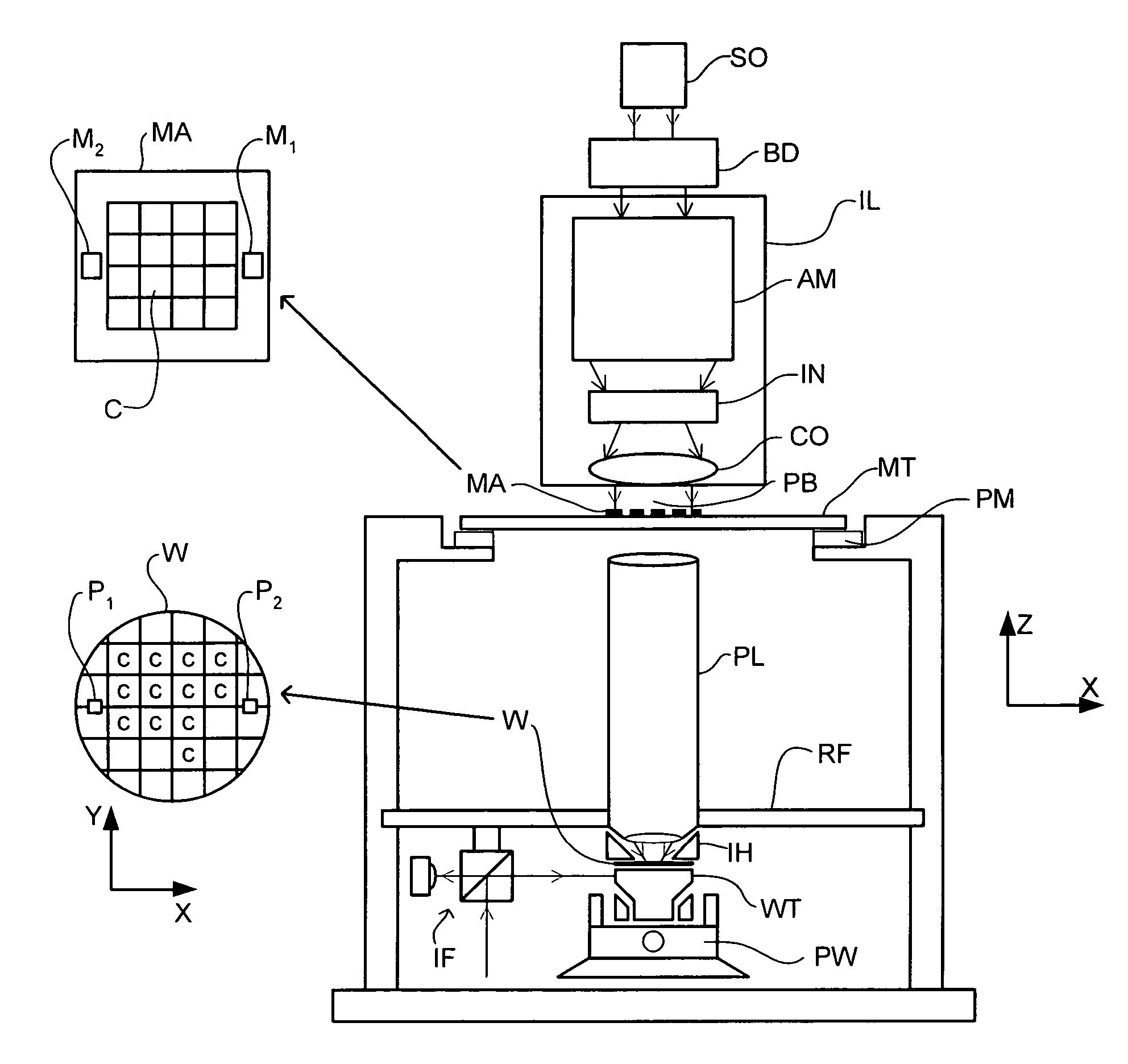

Lithographic apparatus and device manufacturing method

InactiveUS7528931B2Reduction in throughputPhotomechanical apparatusPhotographic printingSingle stageLithographic artist

In a single or multiple stage lithography apparatus, a table provides a confining surface to a liquid supply system during, for example, substrate table exchange and / or substrate loading and unloading. In an embodiment, the table has a sensor to make a measurement of the projection beam during, for example, substrate table exchange and / or substrate loading and unloading.

Owner:ASML NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com