Patents

Literature

693results about "Rails" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

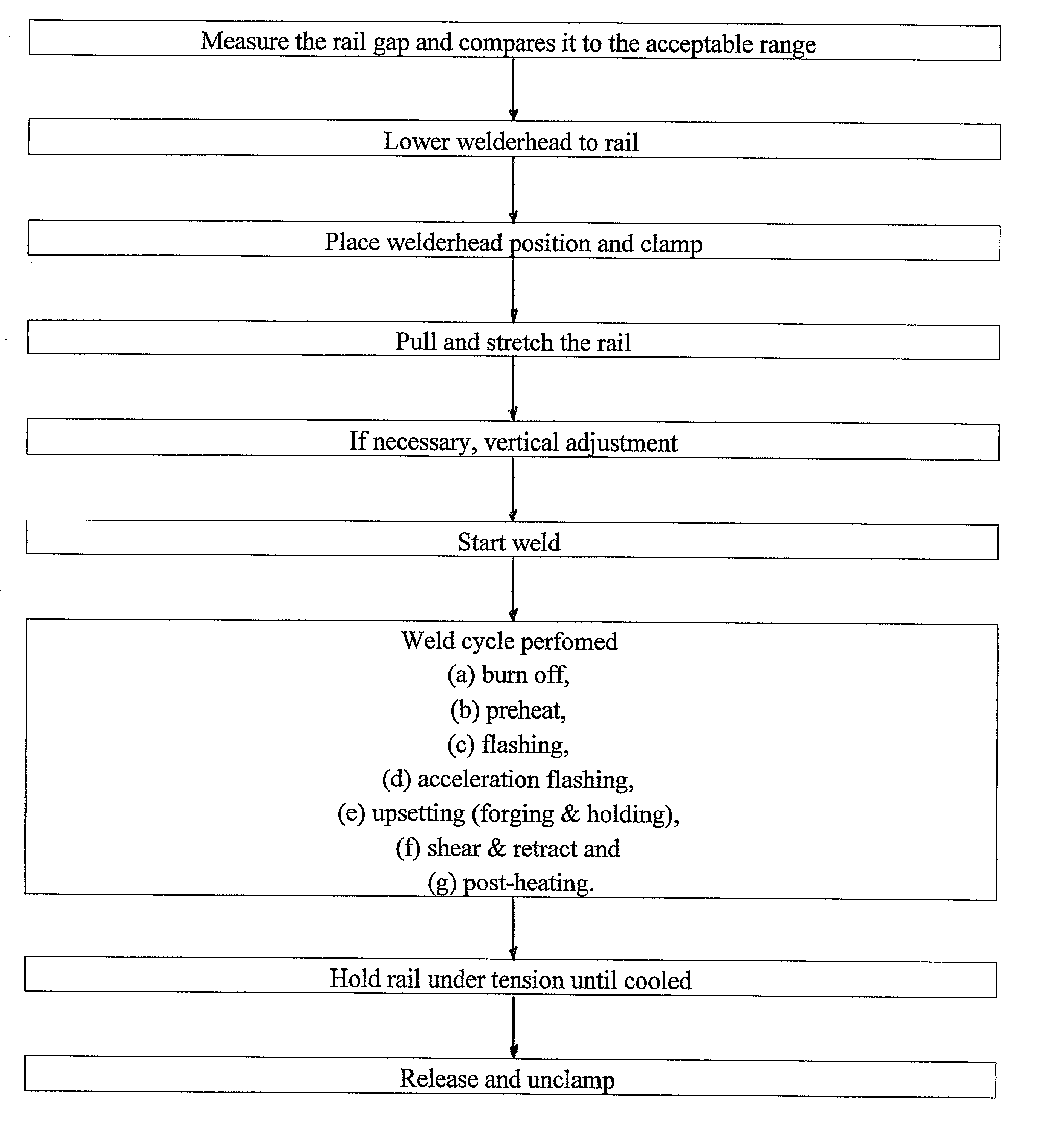

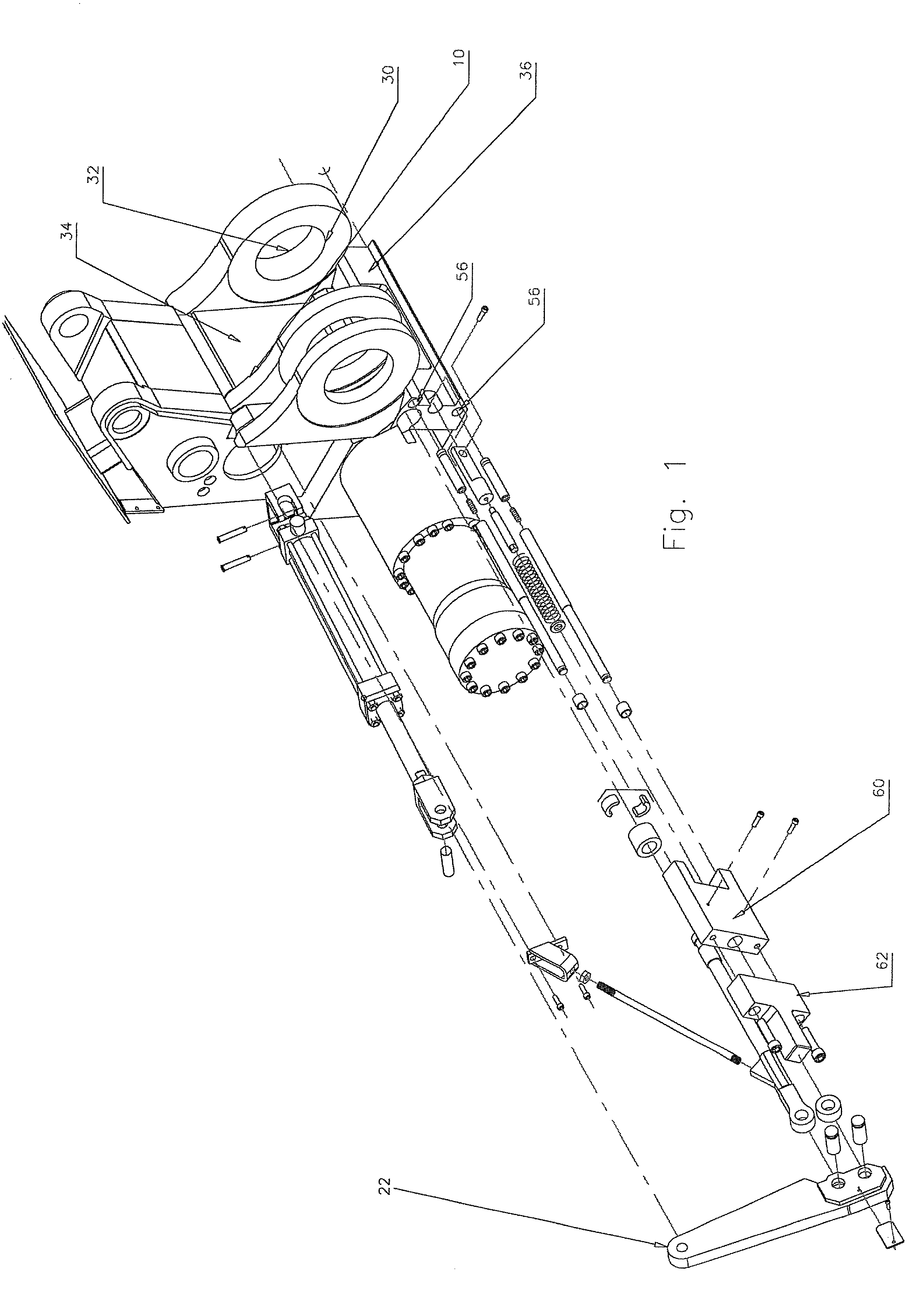

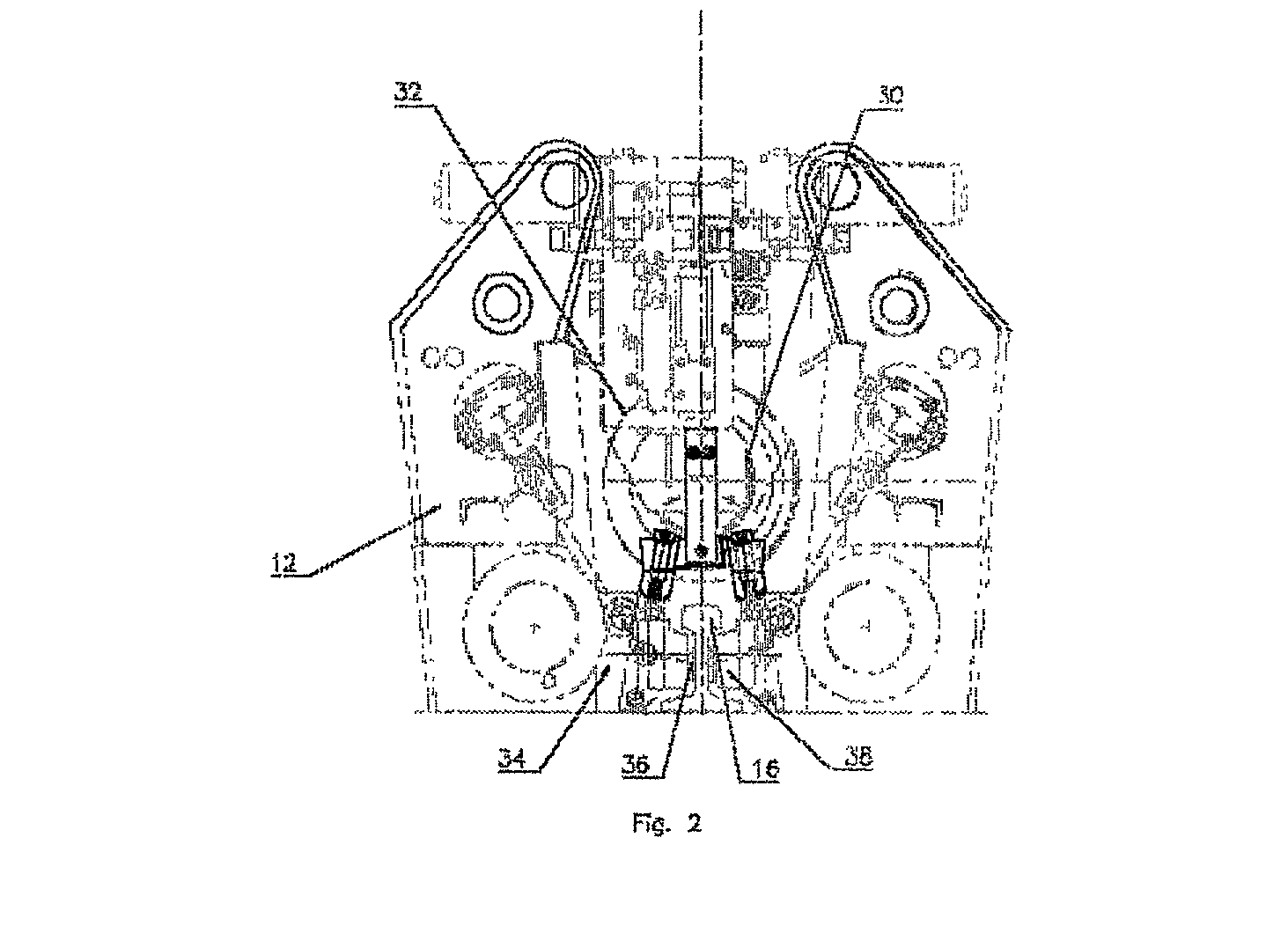

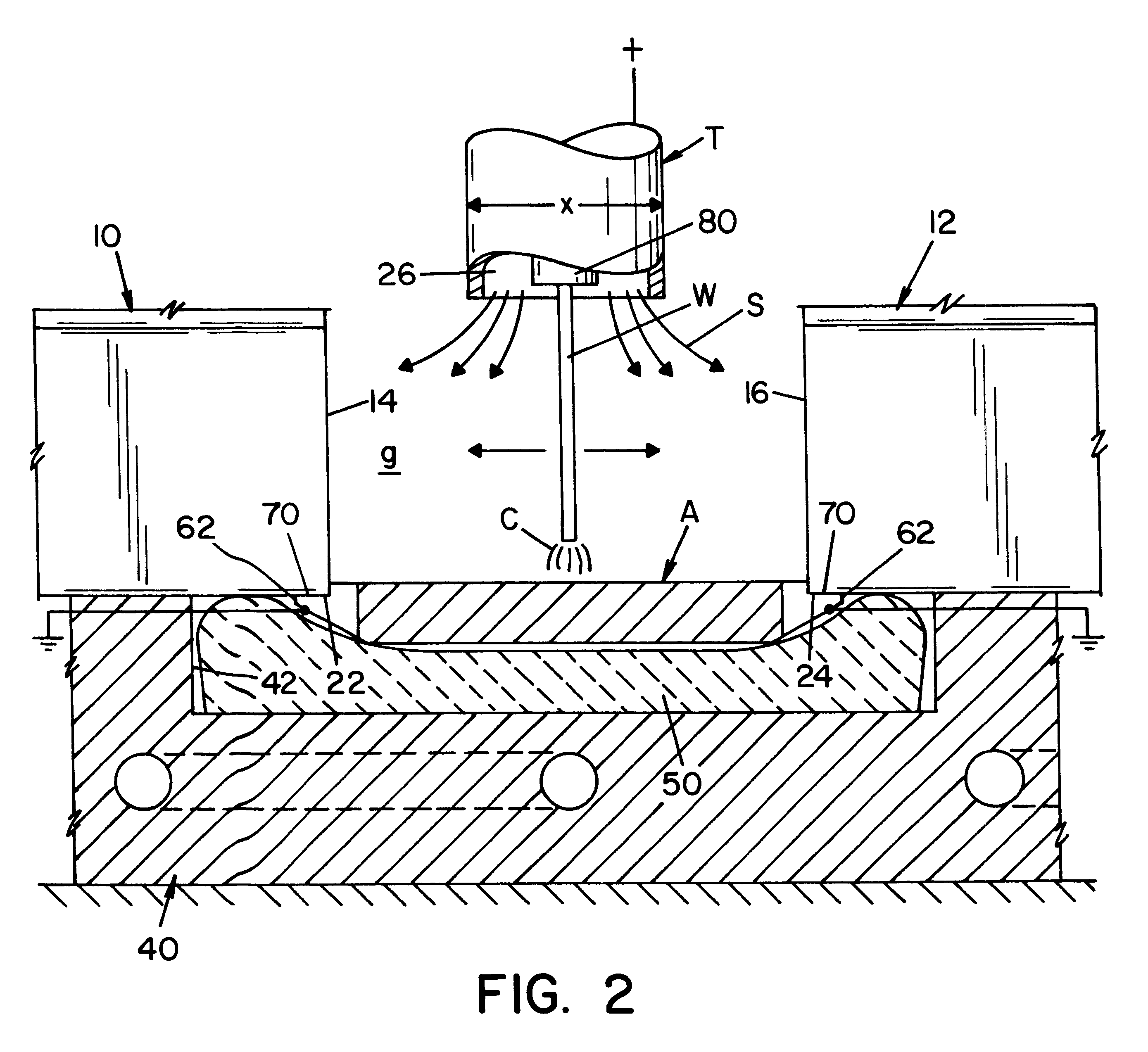

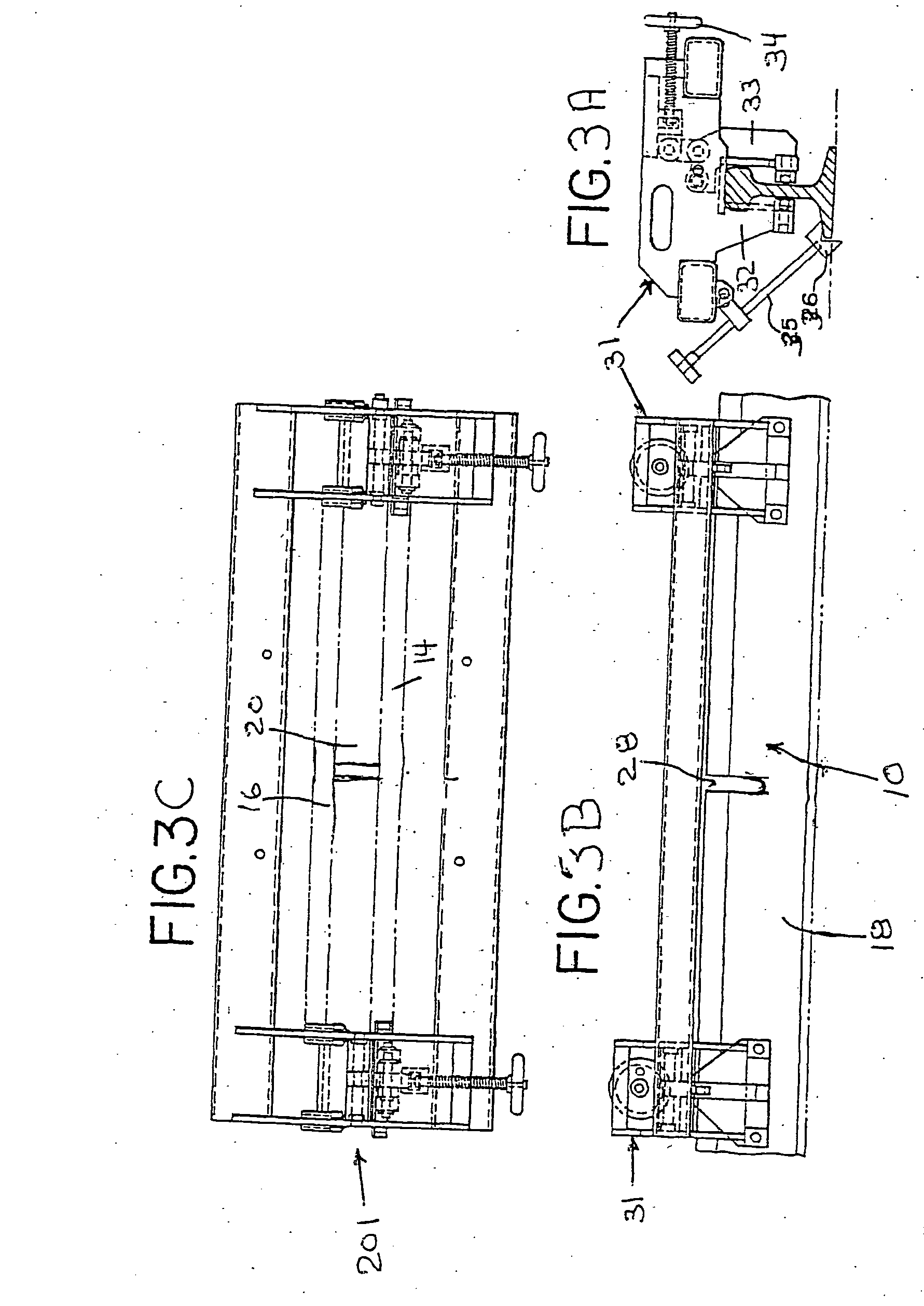

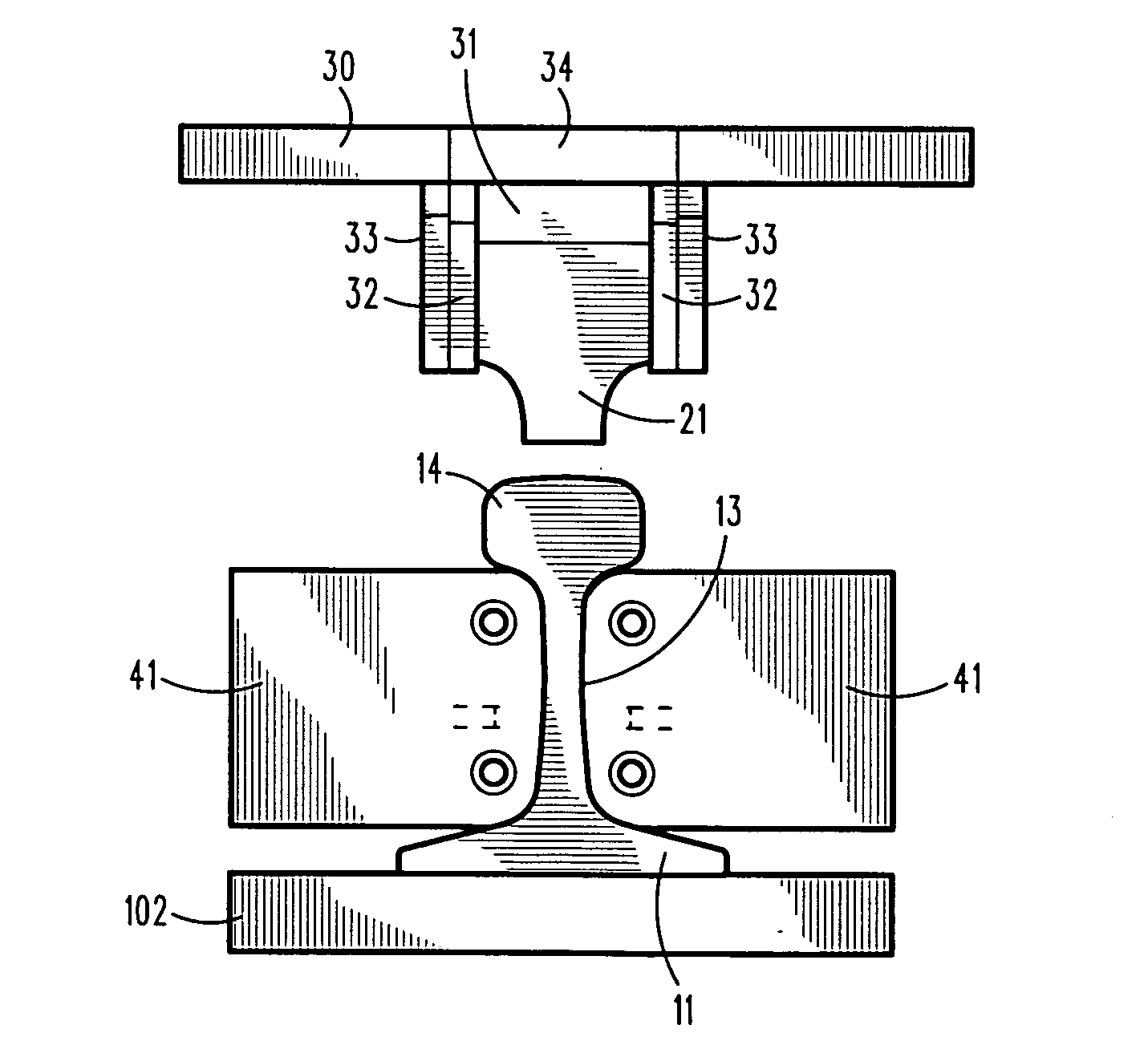

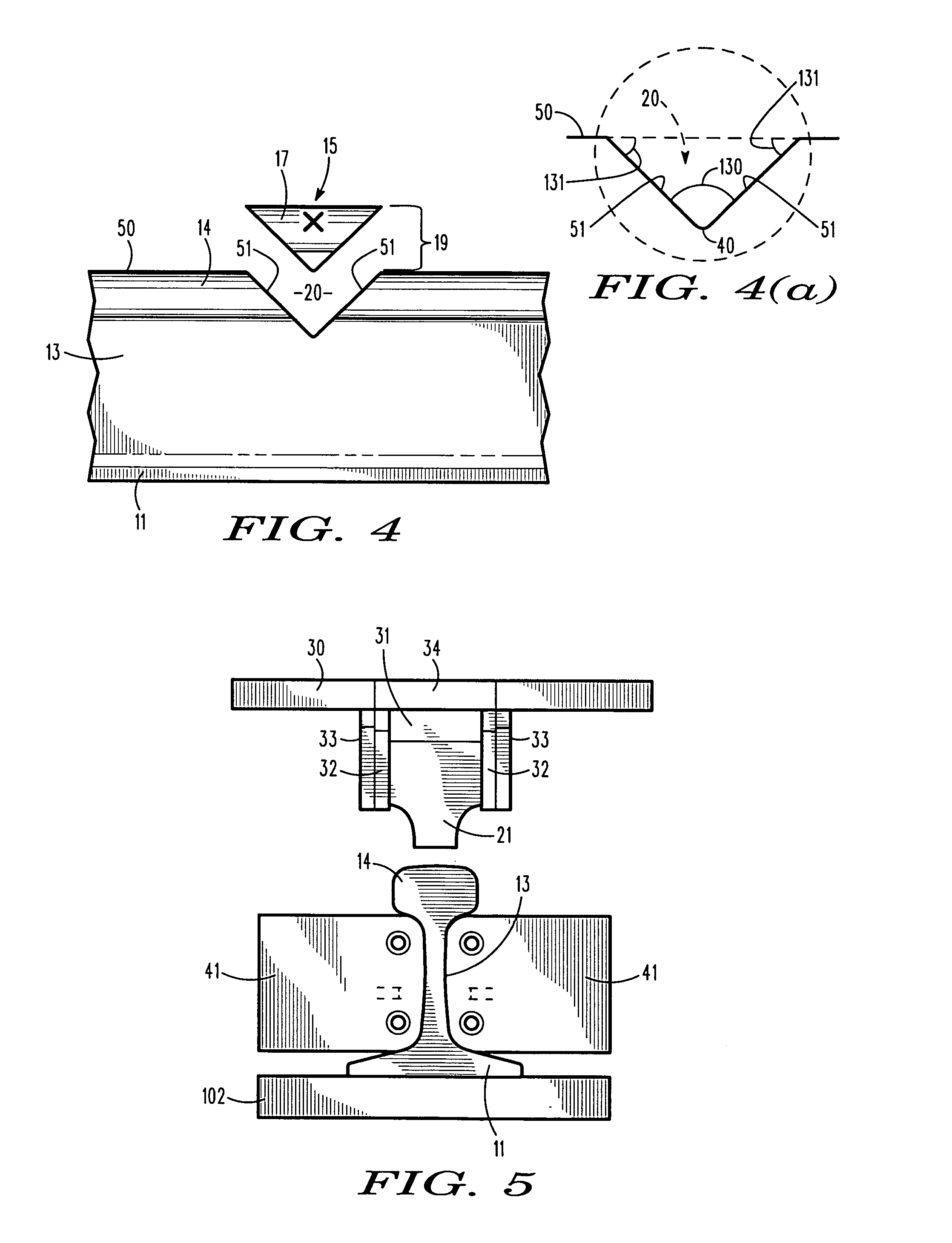

Rail welderhead shear apparatus

A flash butt rail welding welderhead combines in a single unit, the ability for the three functions of rail pulling, flash butt forging and maintaining the "after forged" displacement without any change in platen position such that shearing may be accomplished in three stages, a single stage, multiple stages or a progressive stage, all while maintaining clamping and stretching force on the rails.

Owner:HOLLAND CO

Production process for intelligent temperature adjusting steel rail with laser cladding layer and heat insulation coating

InactiveCN102146563AHigh hardnessHigh Yield Stress LimitRailsMetallic material coating processesTemperature stressAlloy

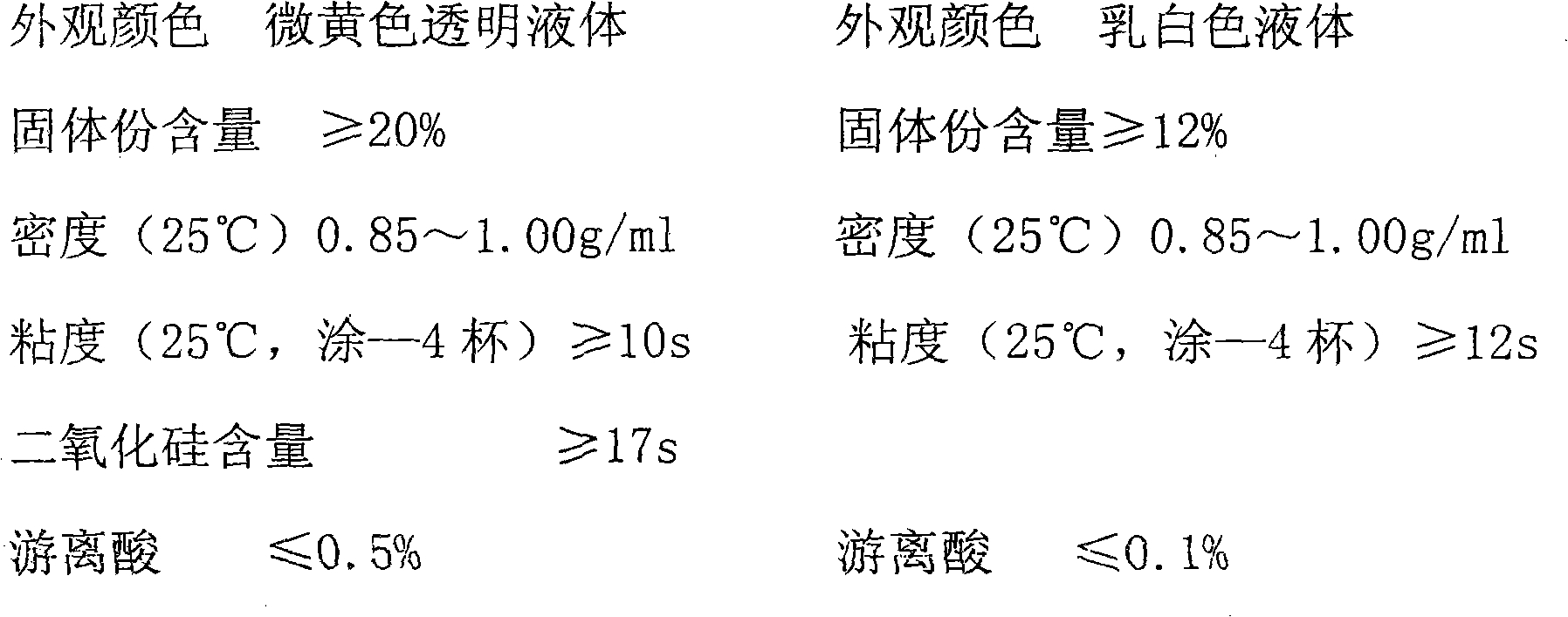

The invention discloses a production process for an intelligent temperature adjusting steel rail with a laser cladding layer and a heat insulation coating. The production process comprises the following steps of: (1) cladding the laser cladding of one layer or superposed inner and outer two-layer structures in thickness of 0 to 4 millimeters on the surface of the steel rail by adopting the laser cladding technology, wherein the laser cladding layer consists of mixed powder formed by mixing alloy powder and ceramic powder comprising oxide powder or / and nickel clad oxide powder in a certain ratio; (2) performing slow cooling treatment on the surface of the steel rail; (3) moderately performing surface treatment and drying treatment on the surface of the steel rail; and (4) coating a functional coating with corrosion resistance, abrasion resistance, heat insulation performance, heat dissipation and cooling performances and intelligent temperature adjustment function at normal temperatureon the surface of the steel rail. The steel rail has corrosion resistance, abrasion resistance and good electric conductivity, the cost of the steel rail can be saved, and the service life of the steel rail is long; and the steel rail can insulate heat and reduce temperature, the temperature stress of the steel rail can be greatly reduced, and the safety of train transport is improved.

Owner:张昆

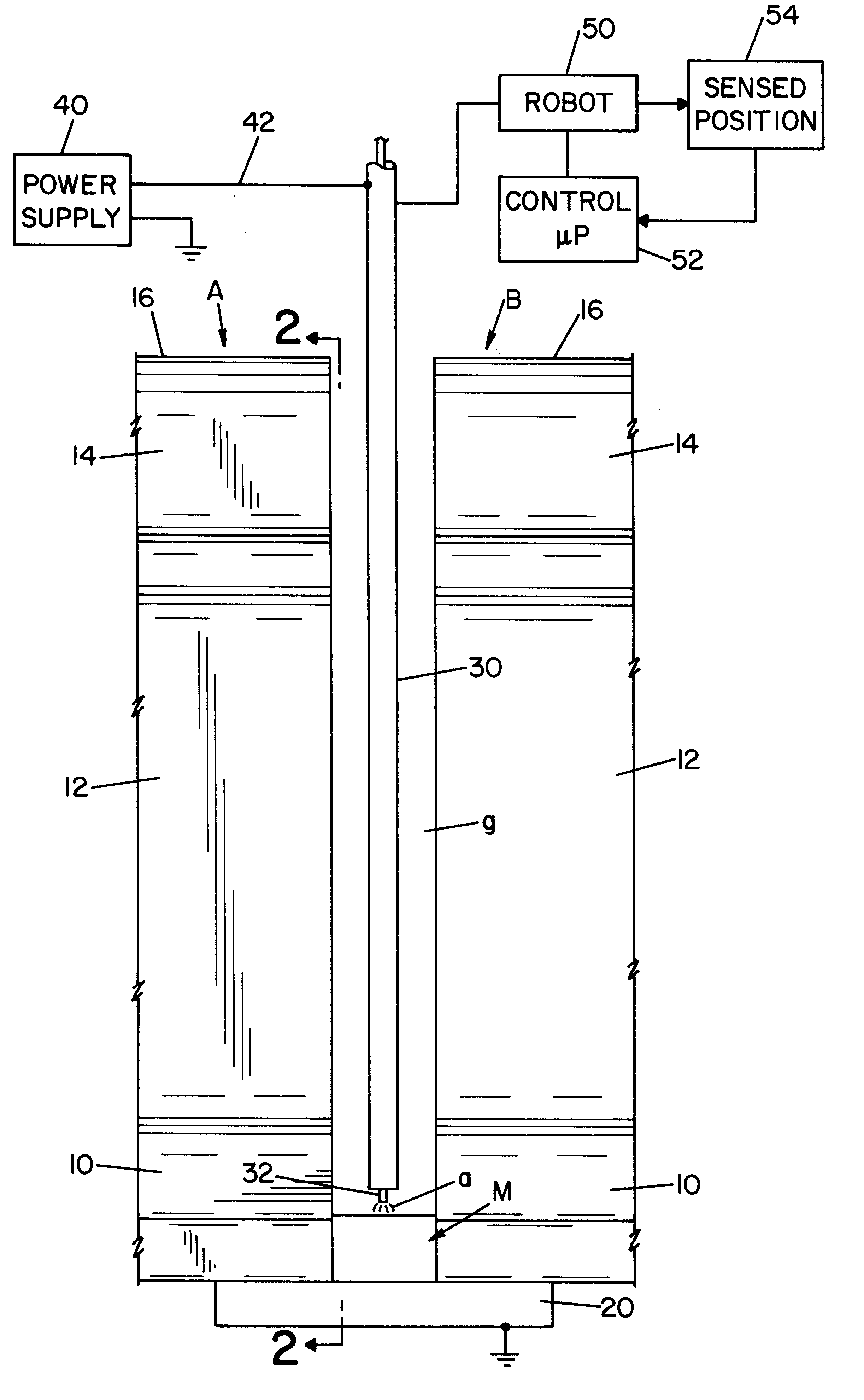

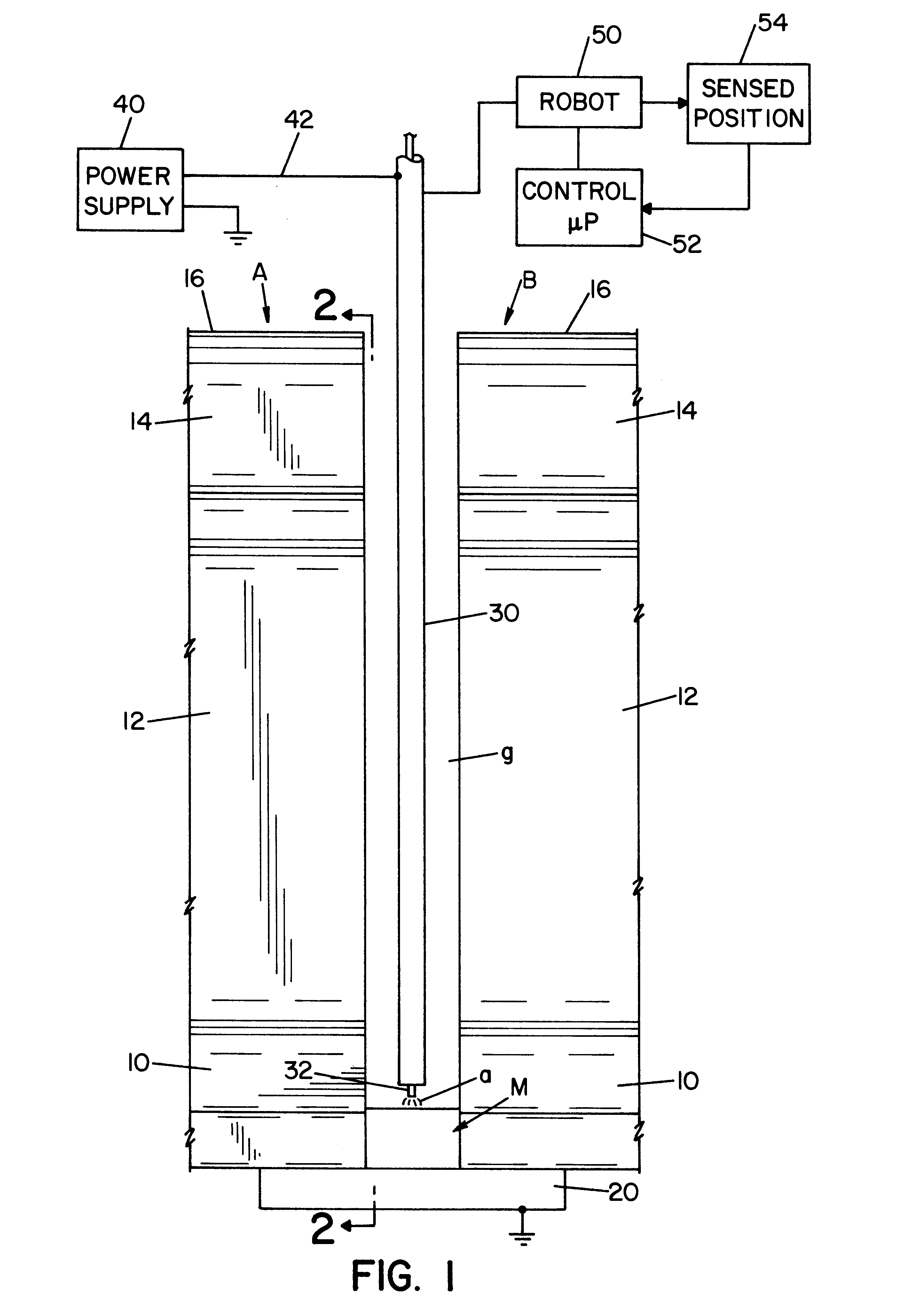

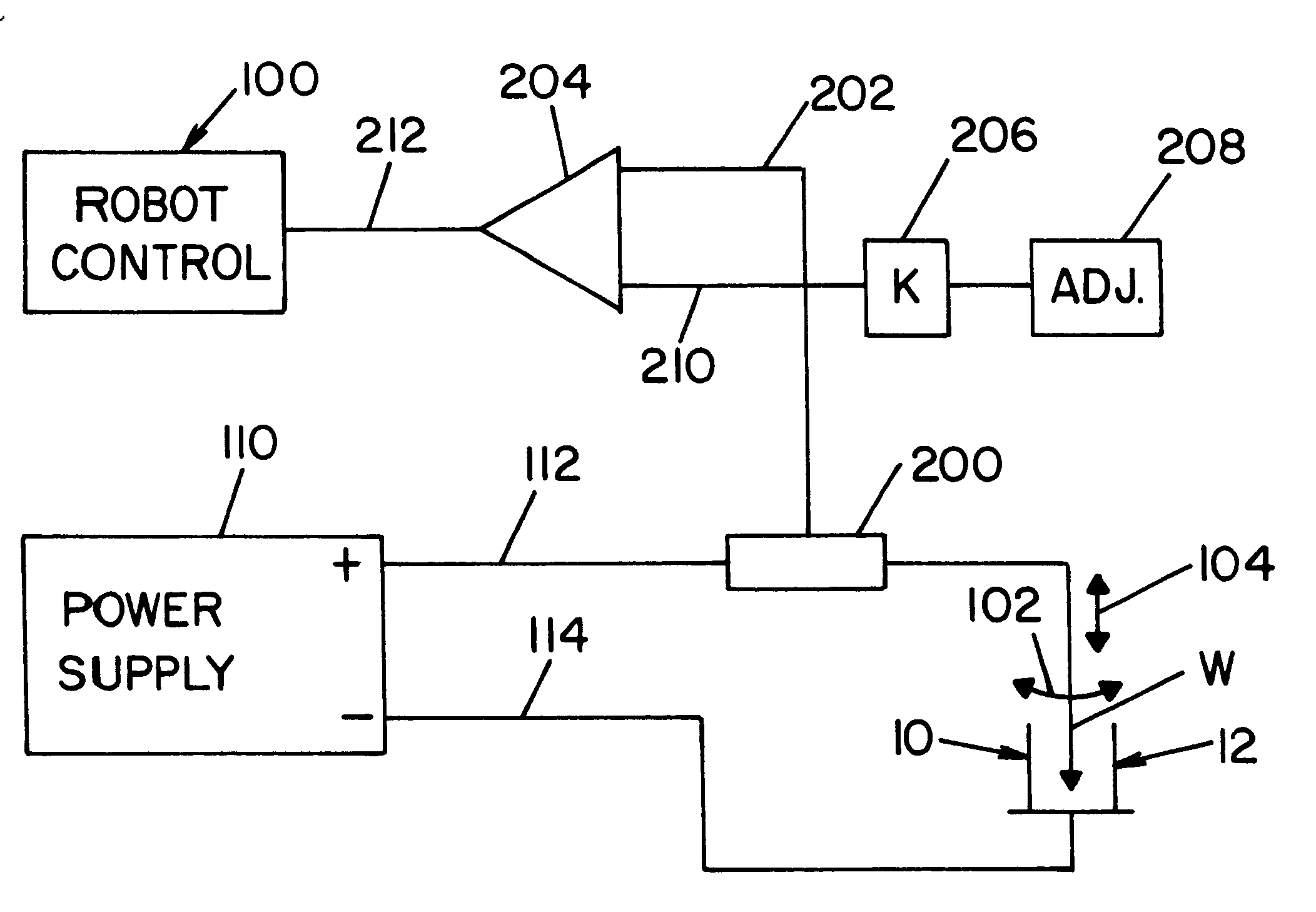

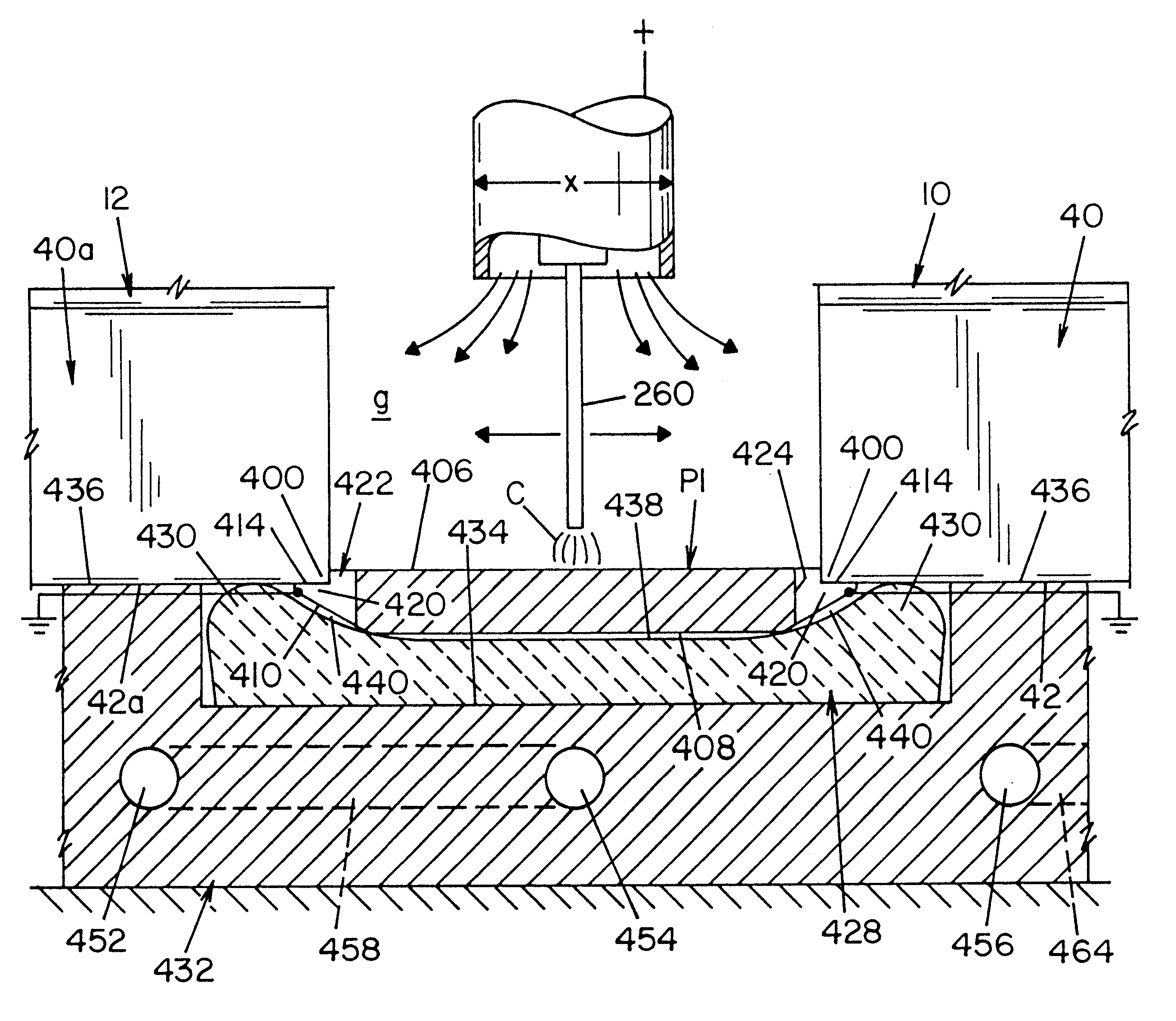

Method and system for welding railroad rails

A method and system for automatically filing the narrow gap between facing end walls of adjacent first and second railway rails by depositing vertically spaced layers of molten metal in the gap with an electric arc welding torch using a robotic mechanism that moves the torch in a pattern controlled by a low level robotic execute program from a spatial position to a next spatial position, said method and system comprising: constructing a data array for a specific gap, said array constituting a series of positions making up an idealized progression of said torch to fill said gaps in vertically spaced layers made up of multiple positions, each of said fixed positions identified by at least four coordinates, including (1) at least x, y and z, (2) the layer in which said position is a part and (3) the welding parameters to be executed while said torch moves toward the next position; outputting data relating to a specific position from said data array; processing said welding parameters associated with said outputted data using said robotic execute program; then, outputting the new fixed data relating to the next position in said series of points; processing said welding parameters associated with said new data using said robotic execute program; and, repeating said outputting and processing acts until said positions in said data array relating to a specific layer have been processed. Thereafter the method or system repeats the layer or processes the next layer comprising multiple stored positions.

Owner:LINCOLN GLOBAL INC

Bainite/martensite steel rail with 1,500 Mpa level of high toughness and manufacturing method thereof

The invention provides a bainite / martensite steel rail and a manufacturing method thereof. The steel rail is formed by performing steel hot rolling on the following components in percentage by weight: 0.10 to 0.40 percent of C, 0.80 to 2.00 percent of Si, 1.20 to 2.40 percent of Mn, 0.50 to 1.20 percent of Cr, 0.20 to 0.60 percent of Mo, and the balance of Fe and inevitable impurities. The steel rail comprises a rail head, a rail waist and a rail bottom, wherein the rail head is subjected to accelerated cooling at a cooling speed of higher than 1 DEG C / s and lower than and equal to 5 DEG C / s to an accelerated cooling stop temperature of lower than 300 DEG C and higher than 200 DEG C.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

Delivery system

A delivery system includes a delivery vehicle configured to ride along a flat track. The delivery vehicle includes a guiding pin. The guiding pin is configured to interlock with a guiding groove.

Owner:VILLAMAR DANIEL

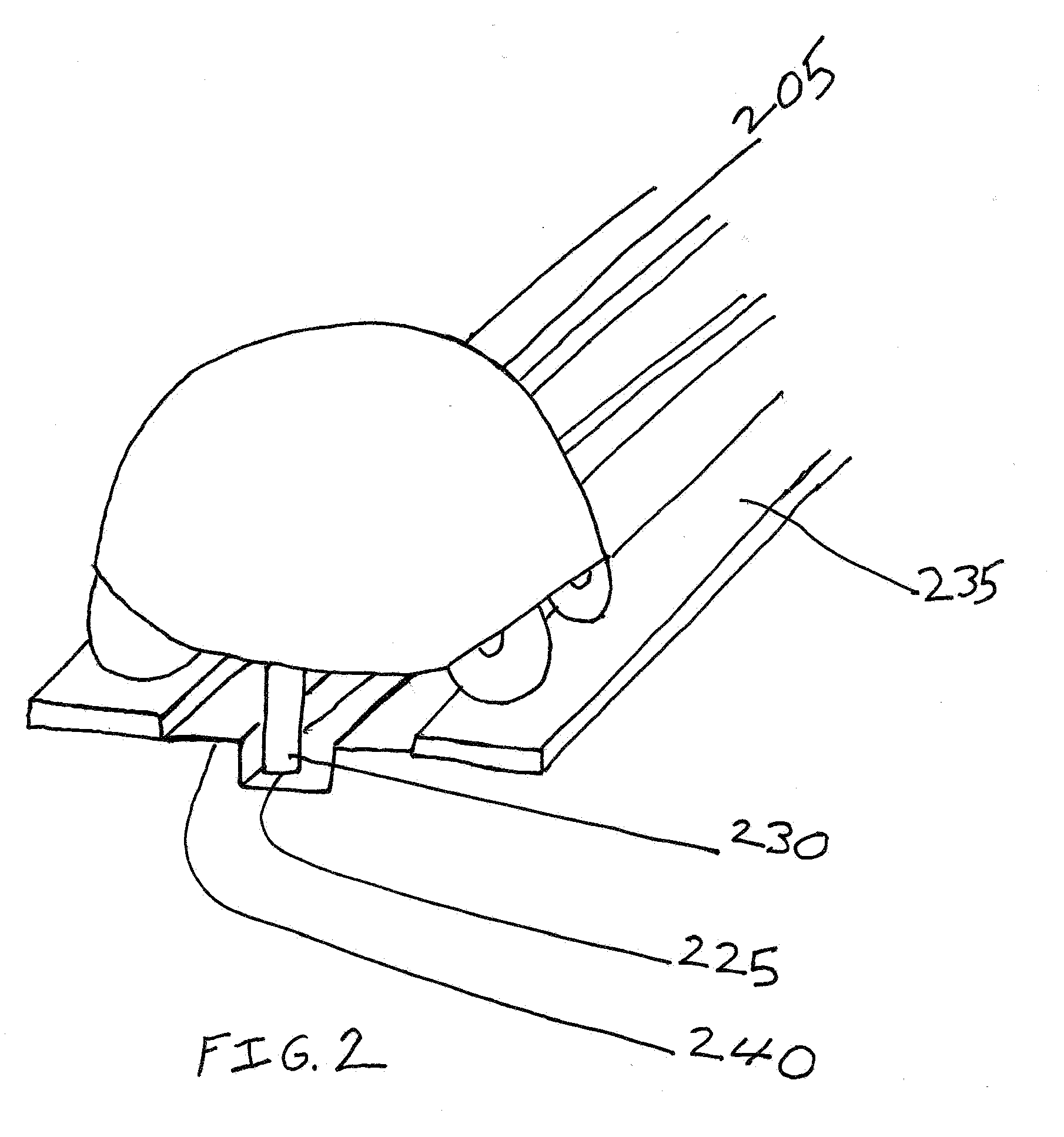

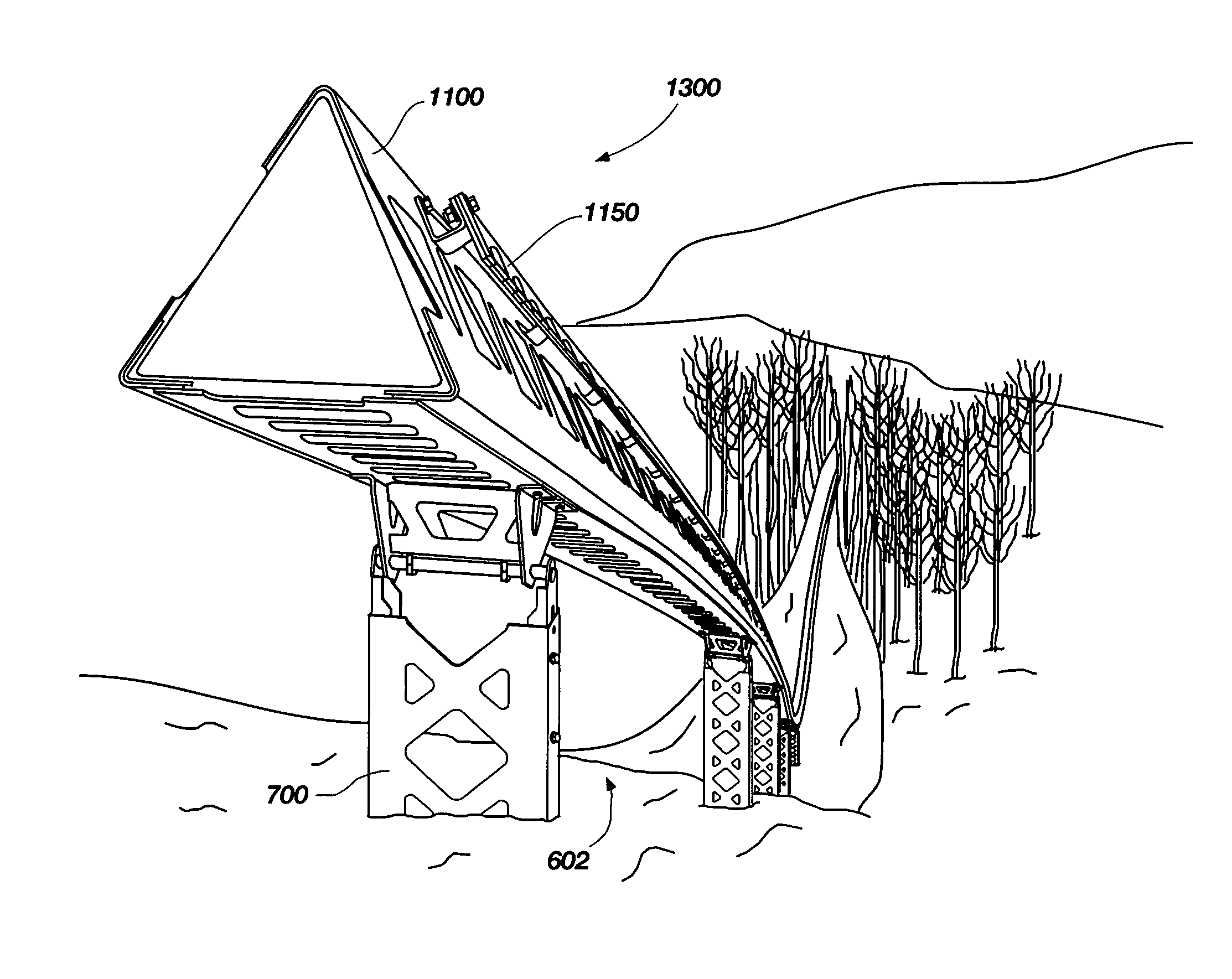

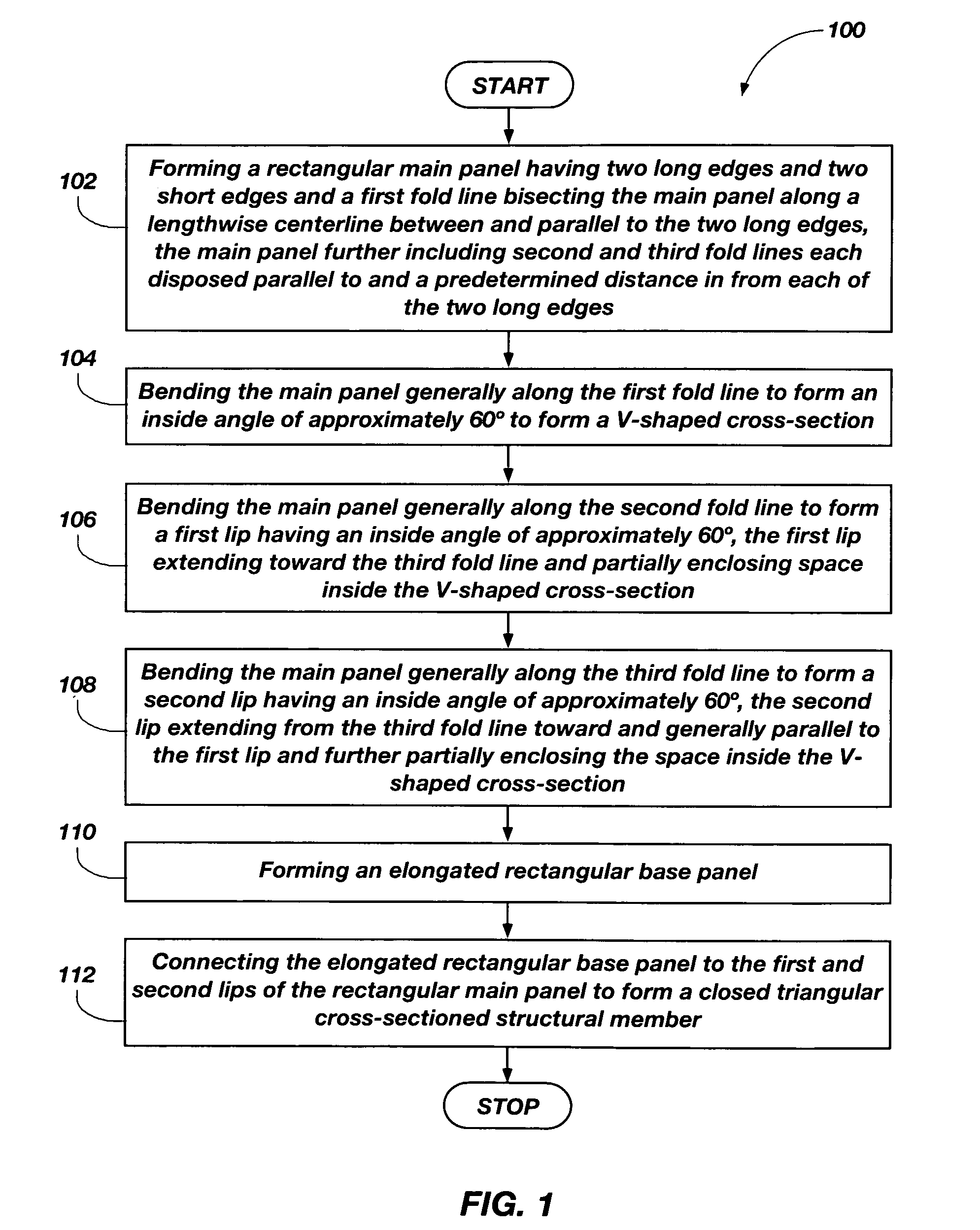

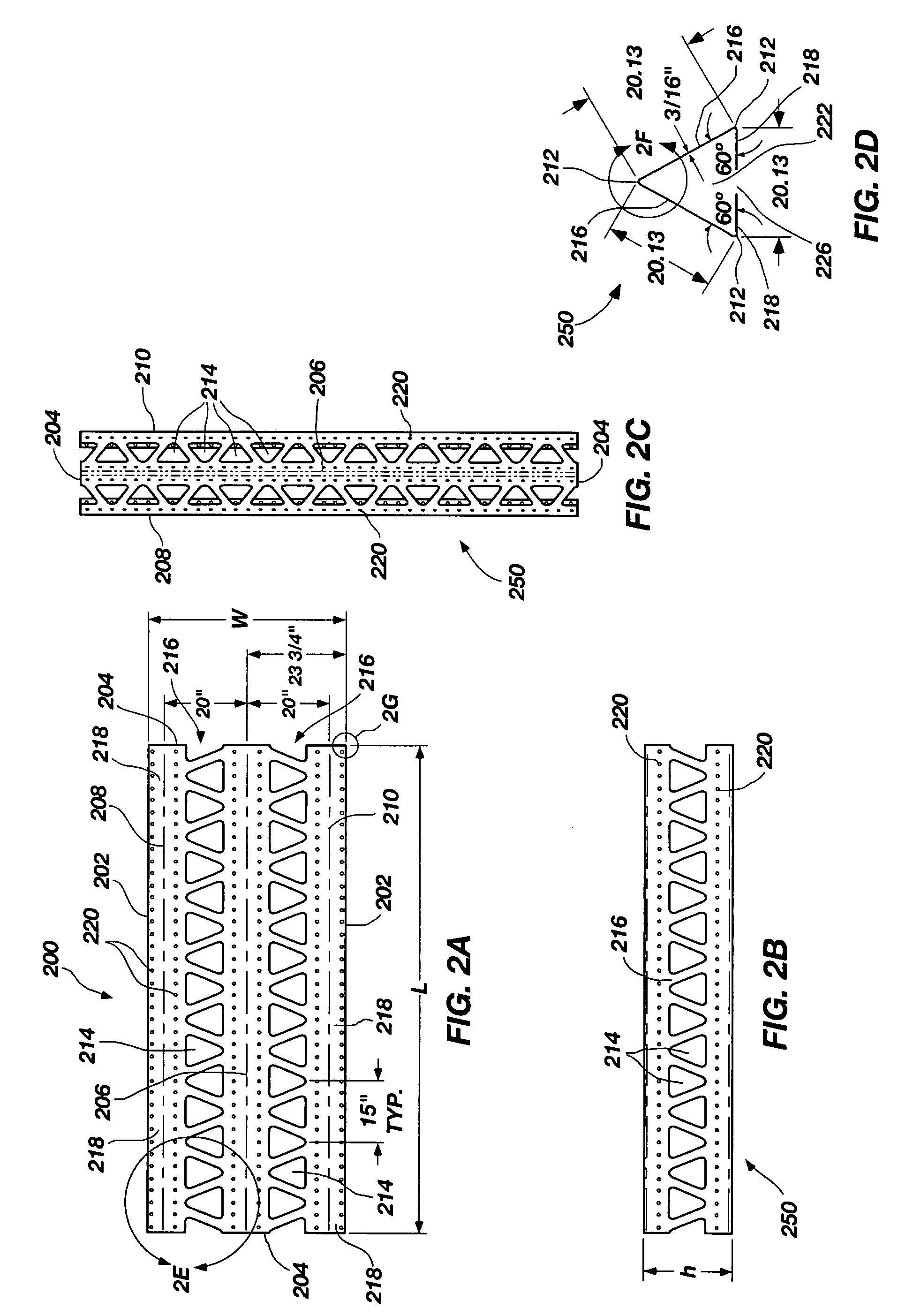

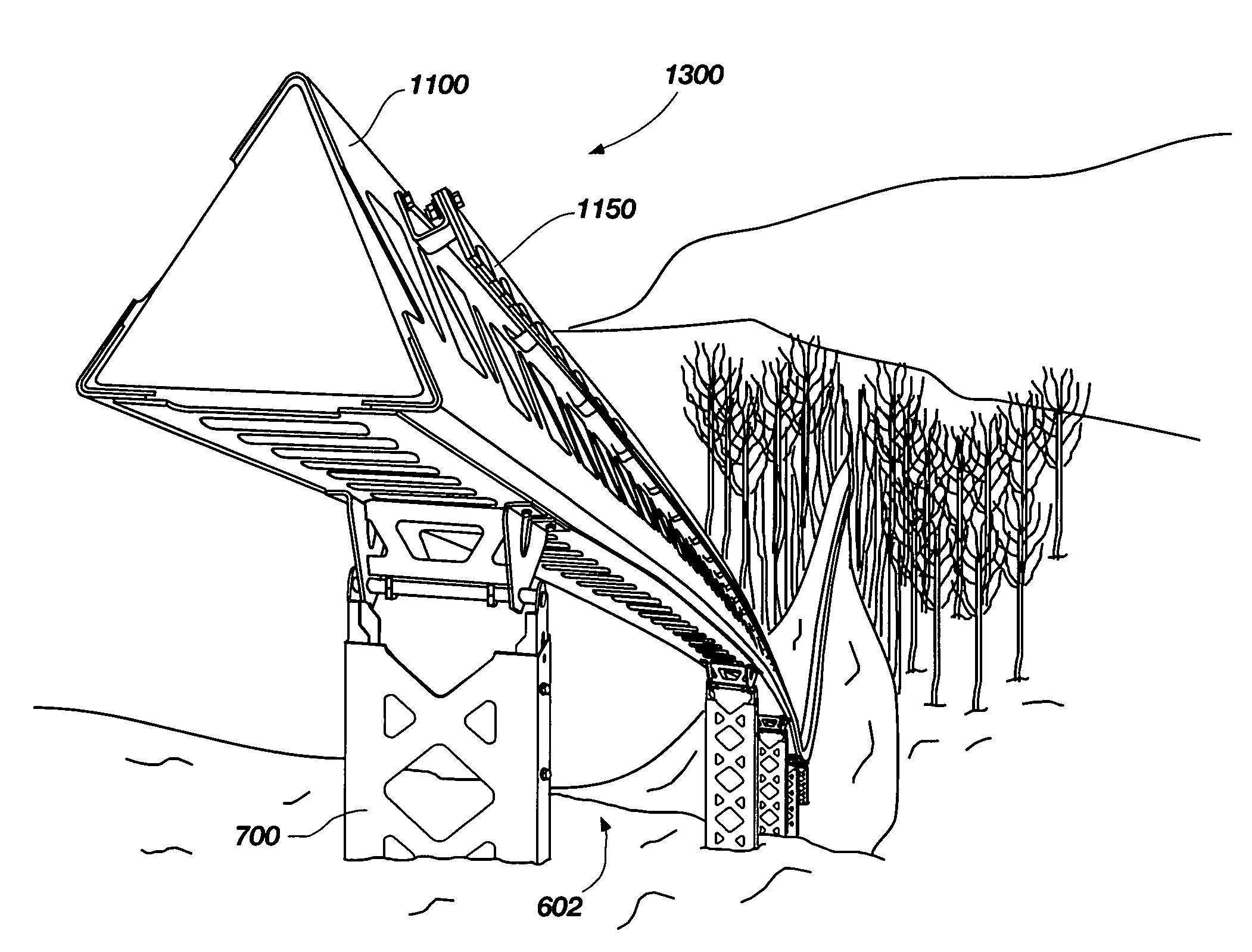

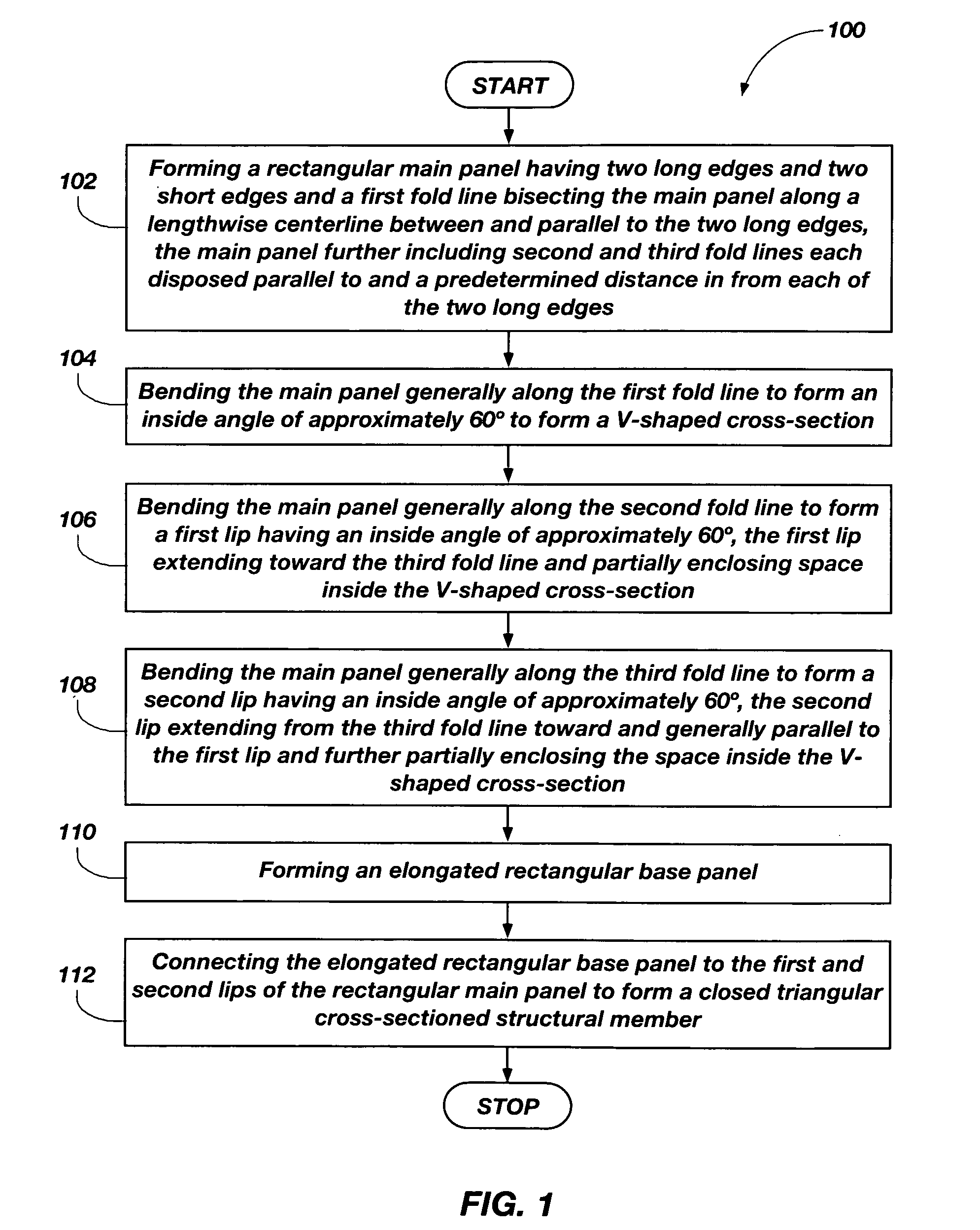

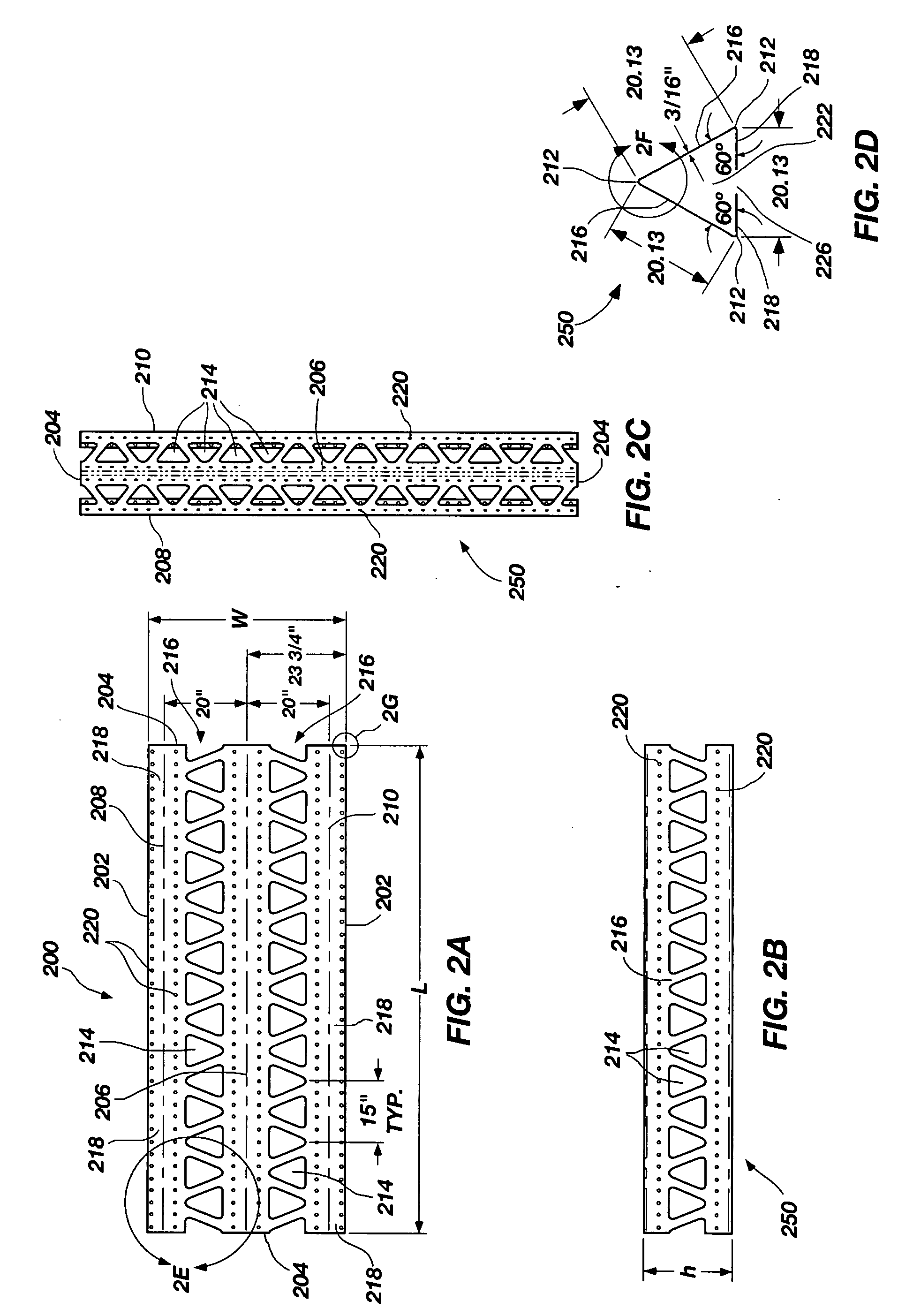

Hollow structural members, a rail system and methods of manufacturing

The invention is hollow structural members, a rail system based thereon and method of manufacturing such hollow structural members. Embodiments of the structural members may be hollow triangular prism-shaped with a cross-section that is triangular, isosceles, hexagonal or otherwise. Embodiments of rail systems based on hollow structural members are also disclosed. Embodiments of the rail systems disclosed herein may also include reaction assemblies for local dissipation of stresses due to thermal expansion of track materials.

Owner:HILLTRAC

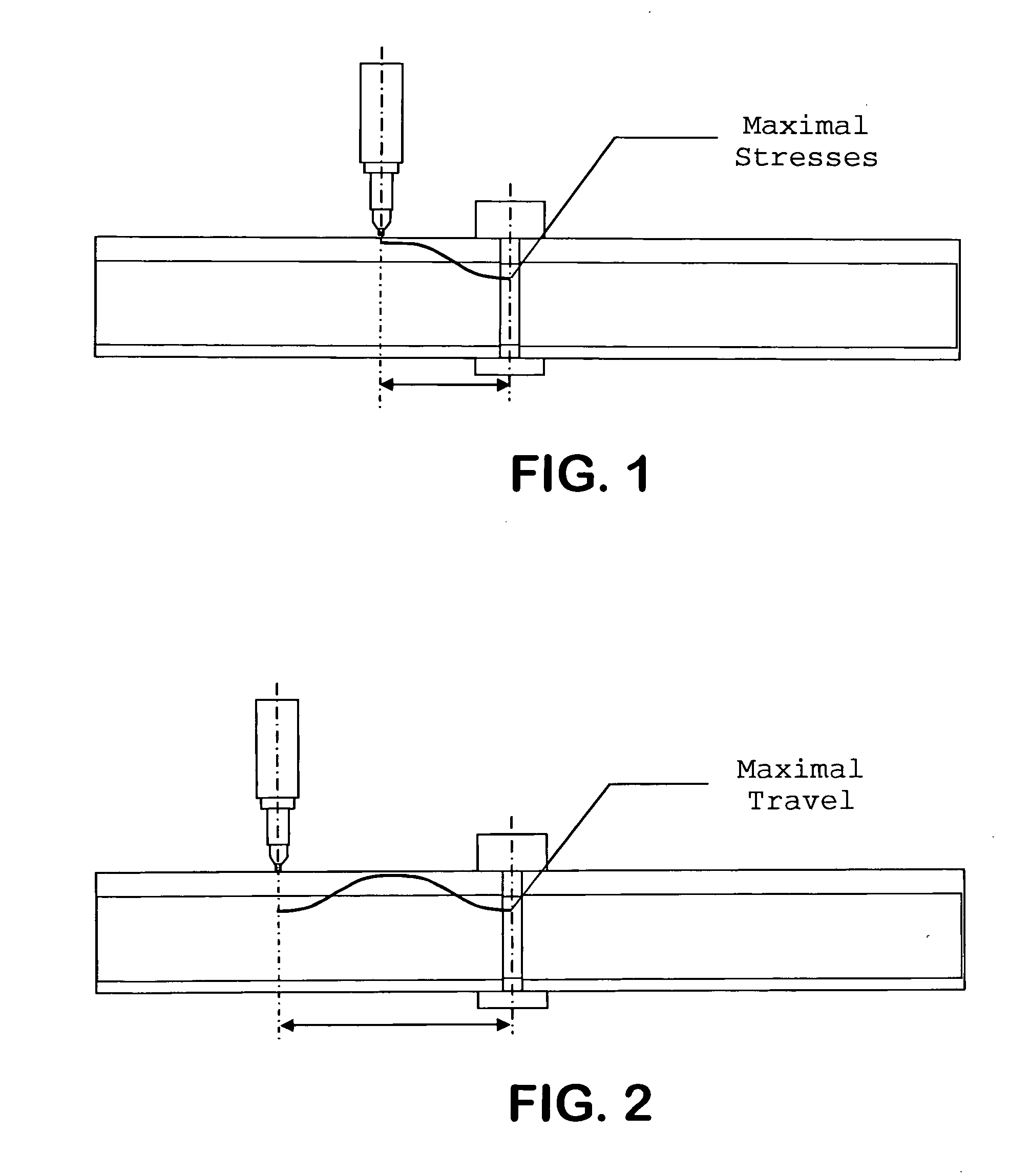

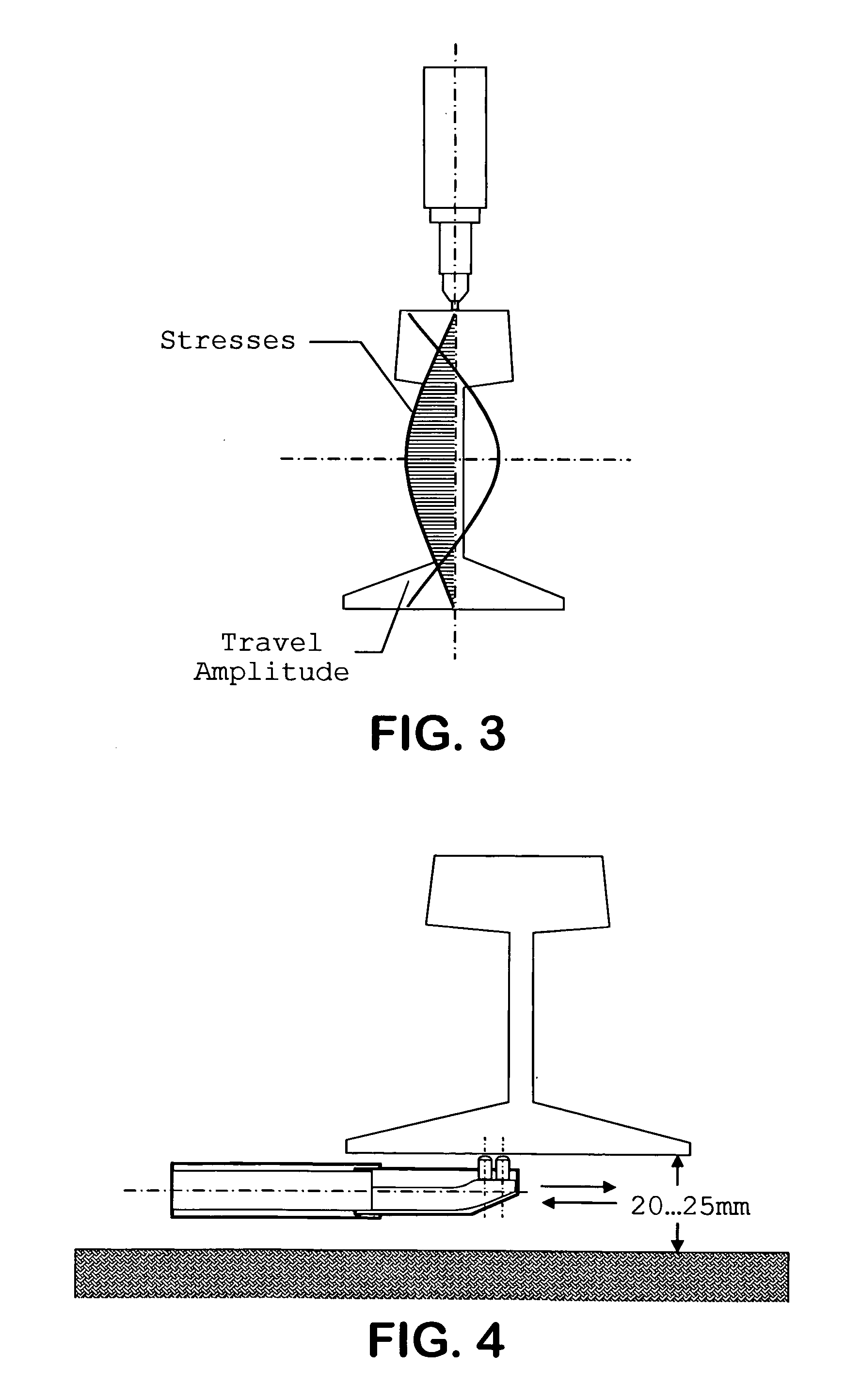

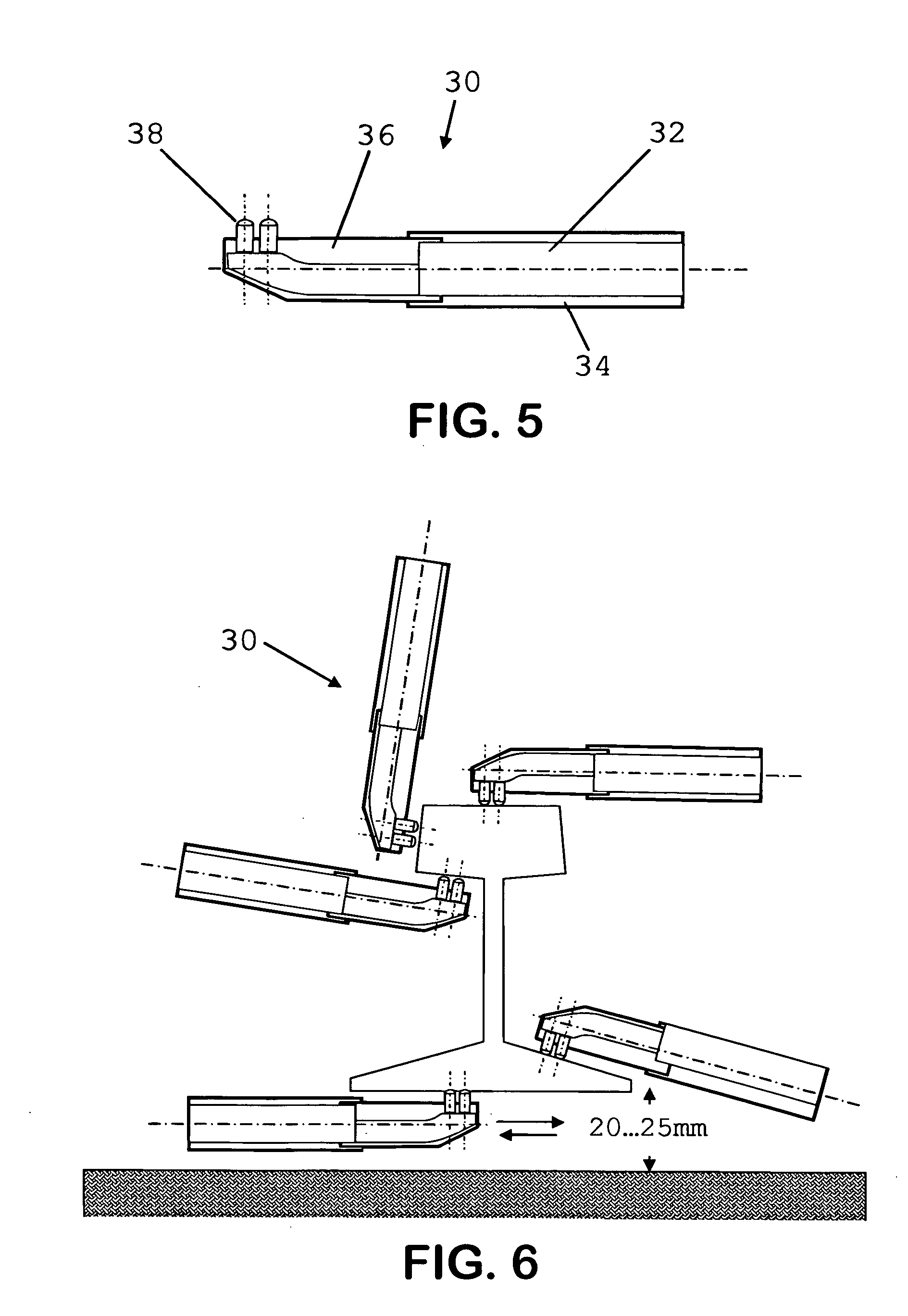

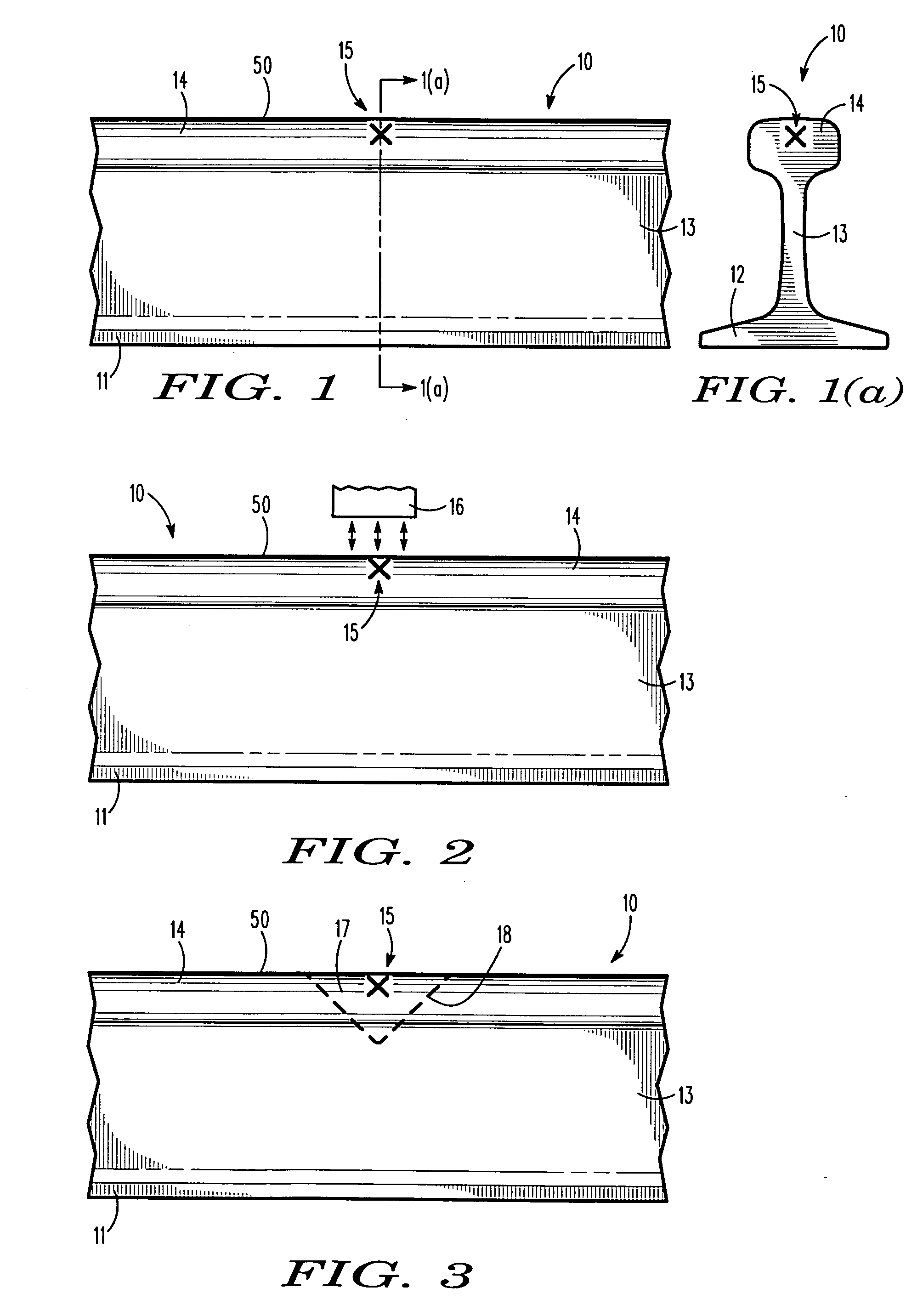

Method of improving quality and reliability of welded rail joint properties by ultrasonic impact treatment

InactiveUS20060016858A1Improving statistical reliabilitySolution to short lifeRailsCooking-vessel materialsIncreased fatiguePulse energy

A method for improving the performance of sections of rails joined together by welding by reworking welded joints utilizing an ultrasonic impact treatment (UIT) process either before welding, during welding, after welding or during repairs of used rails, including treatment of a joint, around a joint and / or length of a rail, in order to increasing fatigue life and / or other properties of welded rail sections is disclosed. The method provides reduction of stress defects and redistribution of internal stress patterns in the vicinity of weld seams of rails. The UIT provides periodic pulse energy impact treatment with surfaces in welded rails to induce internal compression waves inducing a metal plasticity state in the vicinity of the weld seam of the rail or in the rail itself.

Owner:UIT LLC

Hollow structural members, a rail system and methods of manufacturing

The invention is hollow structural members, a rail system based thereon and method of manufacturing such hollow structural members. Embodiments of the structural members may be hollow triangular prism-shaped with a cross-section that is triangular, isosceles, hexagonal or otherwise. Embodiments of rail systems based on hollow structural members are also disclosed. Embodiments of the rail systems disclosed herein may also include reaction assemblies for local dissipation of stresses due to thermal expansion of track materials.

Owner:HILLTRAC

Method and system for welding railroad rails

InactiveUS6201216B1Easy to implementReduce voltageRailsWelding/cutting auxillary devicesShortest distanceEngineering

A method and system of depositing molten metal from an advancing welding wire to form a root pass of weld metal in the bottom of a gap between first and second metal members having generally flat base elements joined by a metal backing plate extending between said base elements, which method and system includes passing welding current between the welding wire and the metal members from a power supply to create a heat generating welding arc, moving the welding wire in a given direction along selected path over the backing plate, sensing a blow through of the backing plate by the welding arc, reversing said given direction of said welding wire for a short distance when a blow through has been sensed and then, resuming movement of said welding wire in said given direction along the selected path.

Owner:LINCOLN GLOBAL INC

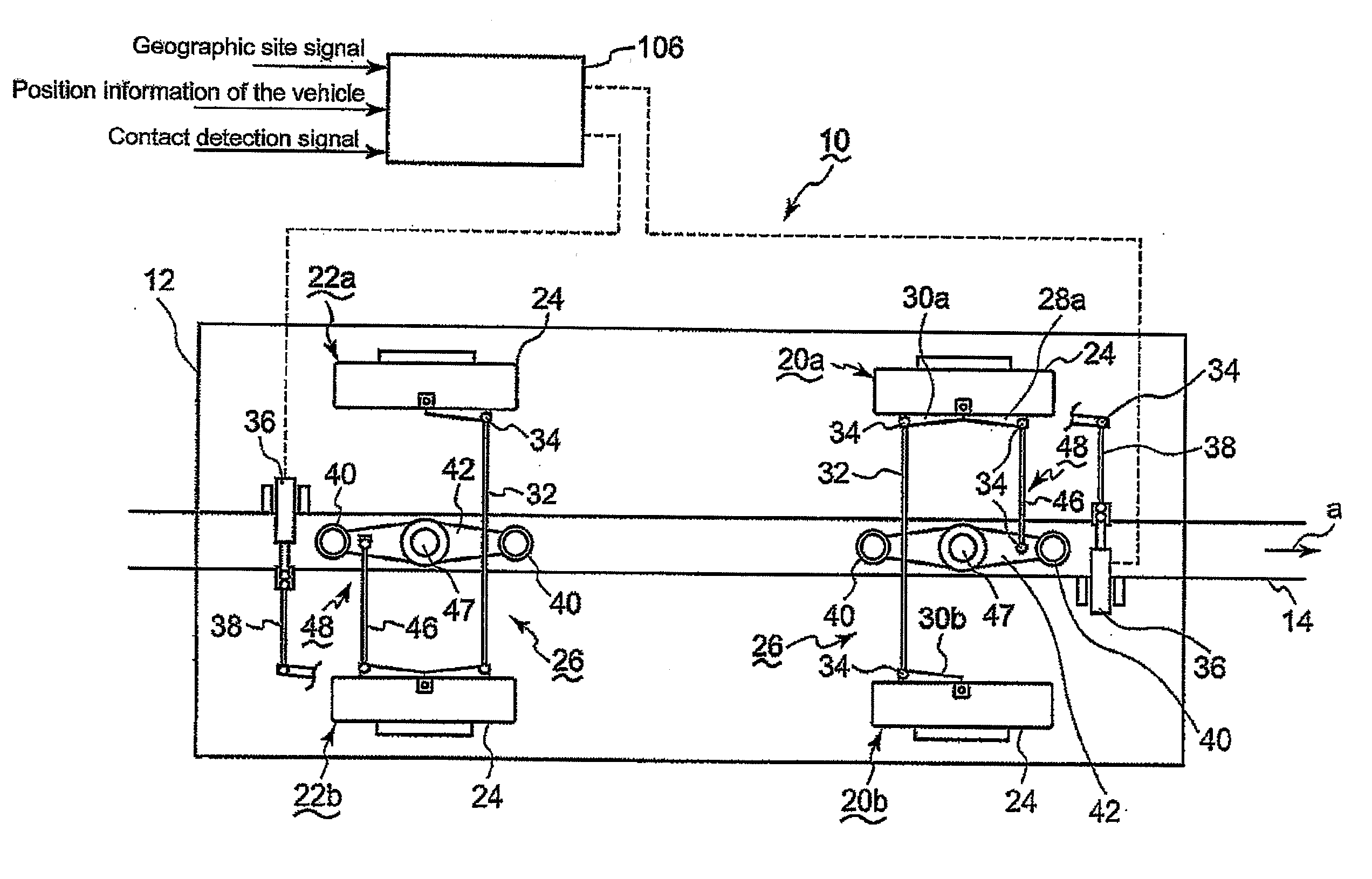

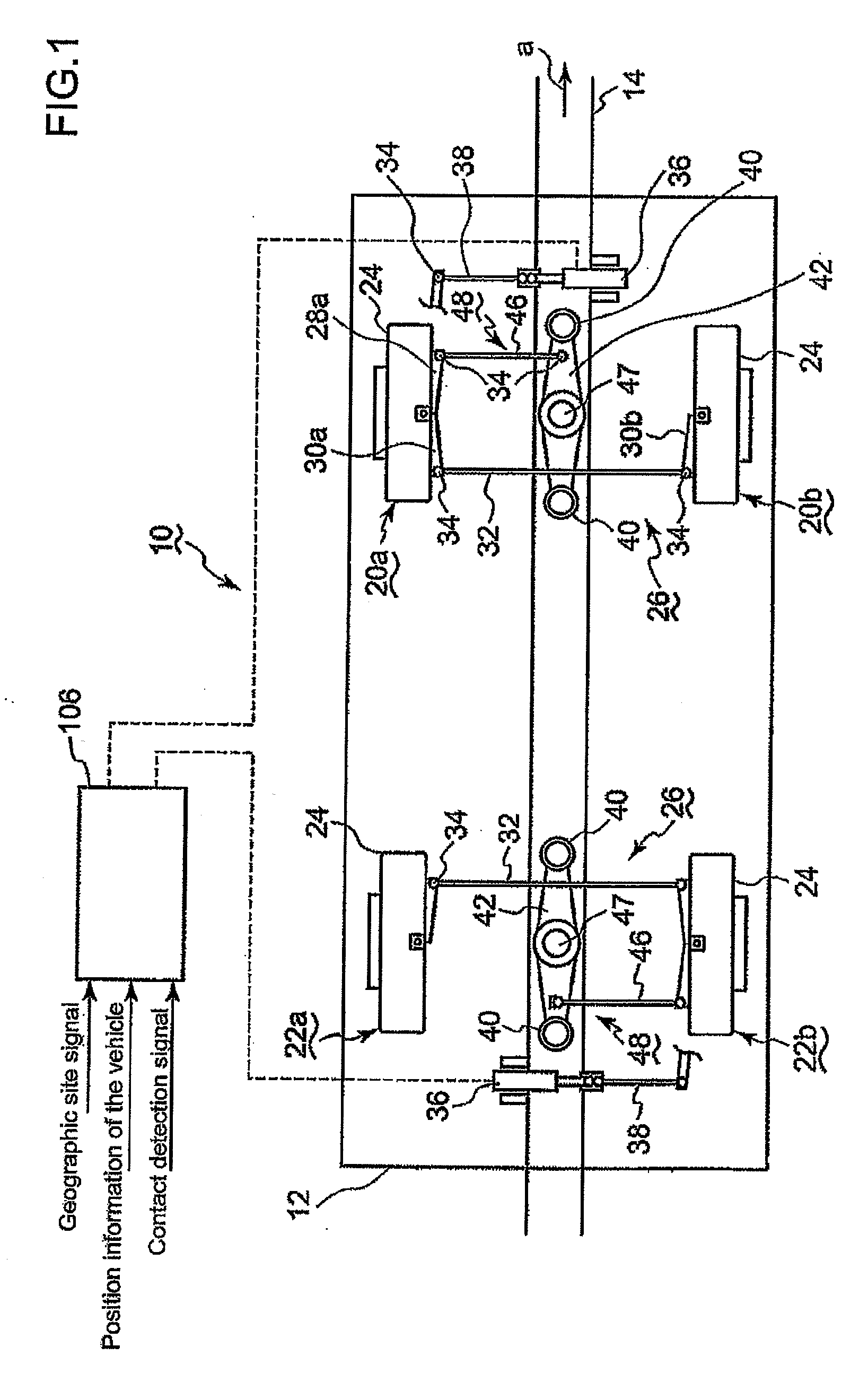

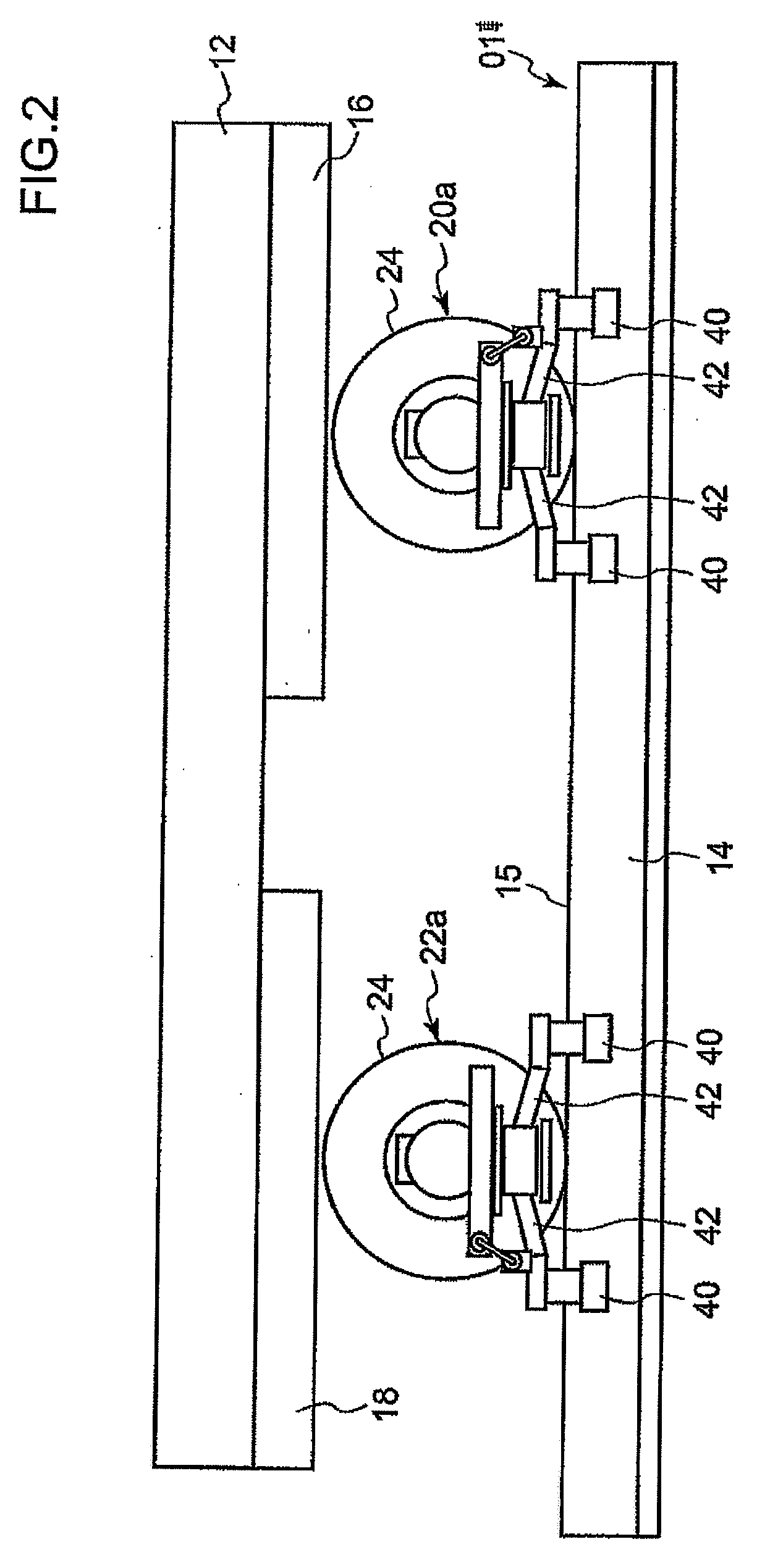

Tramway transit system

ActiveUS20080083345A1Efficient supplyEasy constructionRailsSteering linkagesHydraulic cylinderAutomatic steering

A tramway transit system for allowing a vehicle to travel along a track while automatically steered is proposed, in which the vehicle is provided with guard wheels and the track is provided with a protection track, and simplification in construction and weight saving of the automatic steering mechanism provided to the vehicle and space saving for the installation of the mechanism, can be attained. The vehicle (12) is provided with a steering mechanism (26) for steering the front and rear wheels (20, 22) by means of electrically driven oil hydraulic actuators 36, the protection track (14) is laid down on the road surface (15) of the track (01), the vehicle (12) is provided with guard wheels (40), and the interlocking mechanism (48) for connecting the guard wheels to the right or left wheels, the actuator (36) comprising the hydraulic cylinder (60), the two-way discharge pump (76), the variable speed, reversible rotation motor (78), and the closed circuit (82) provided with relief valves (86).

Owner:MITSUBISHI HEAVY IND ENG LTD

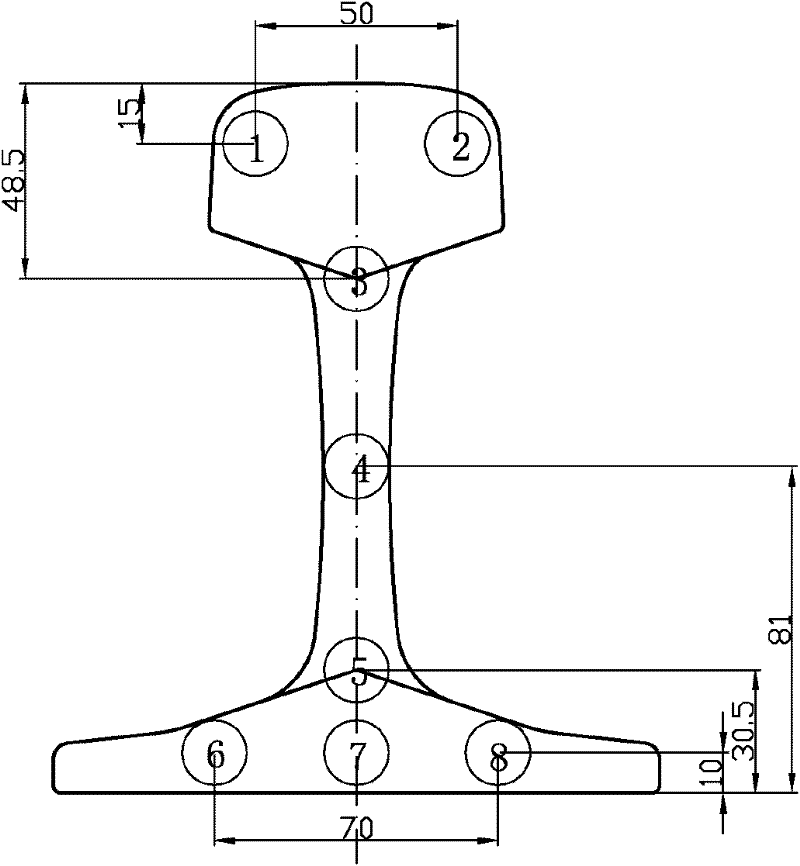

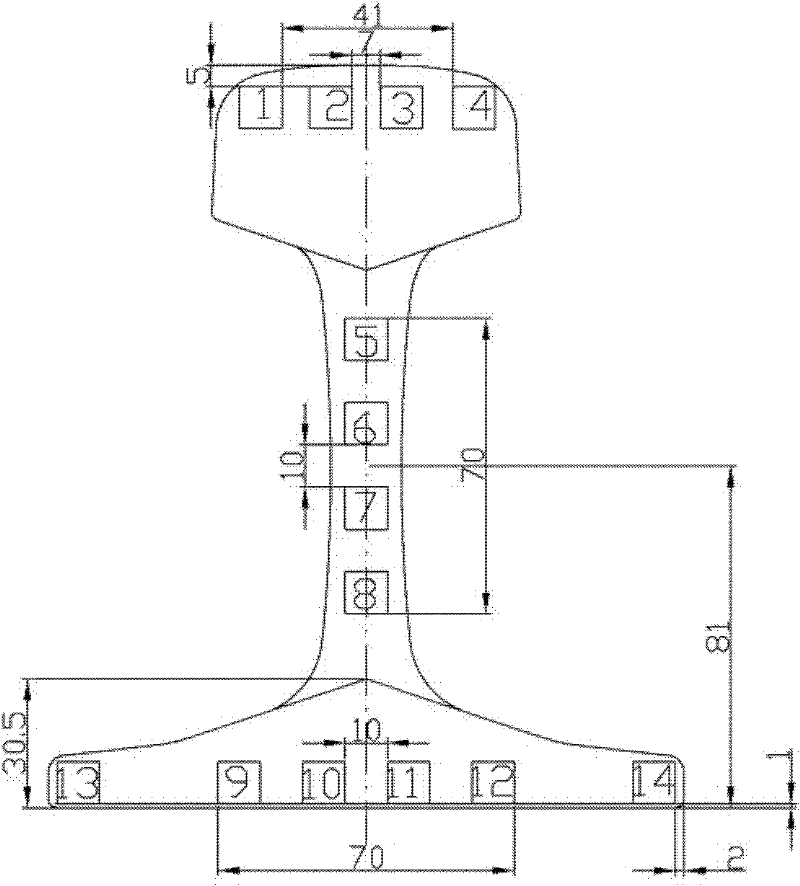

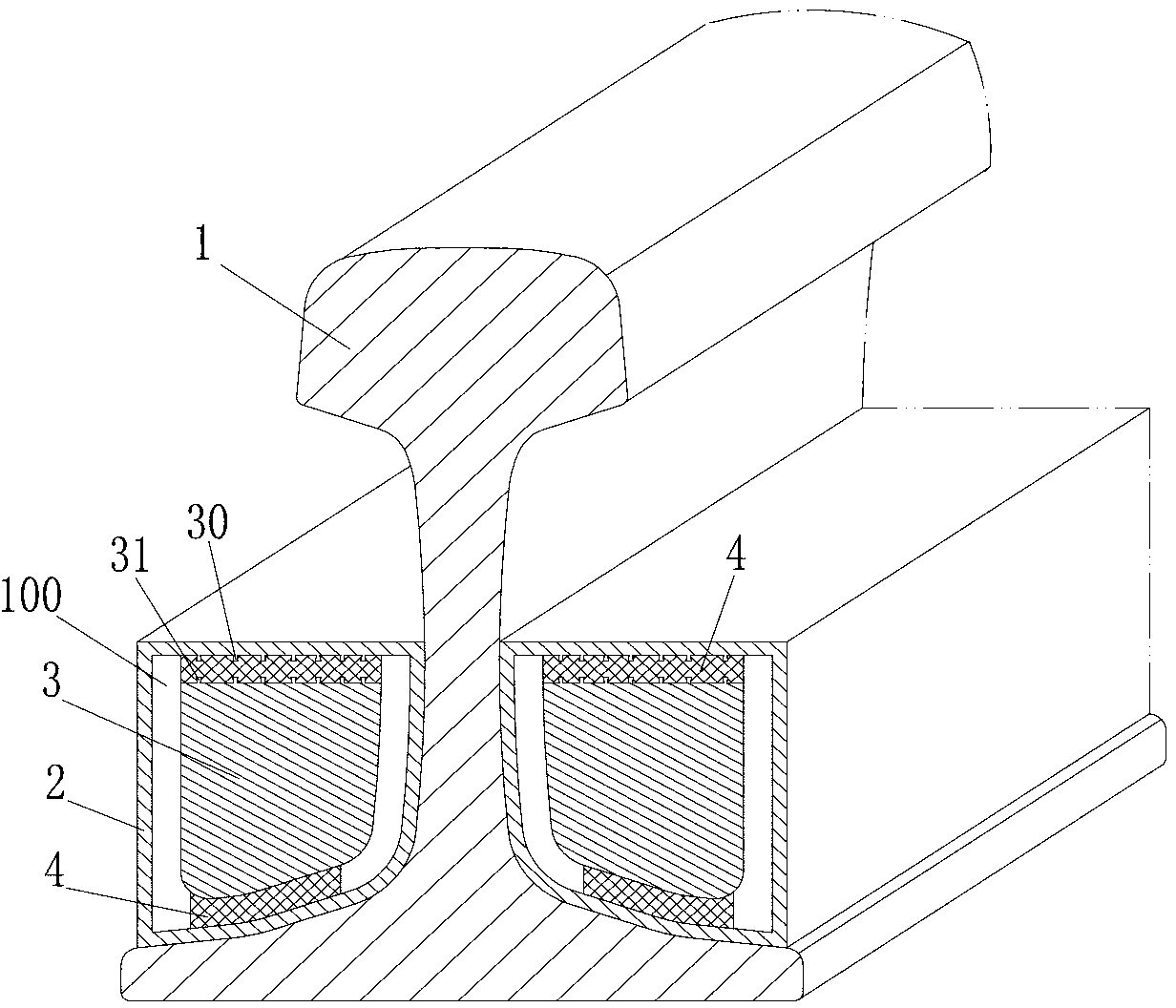

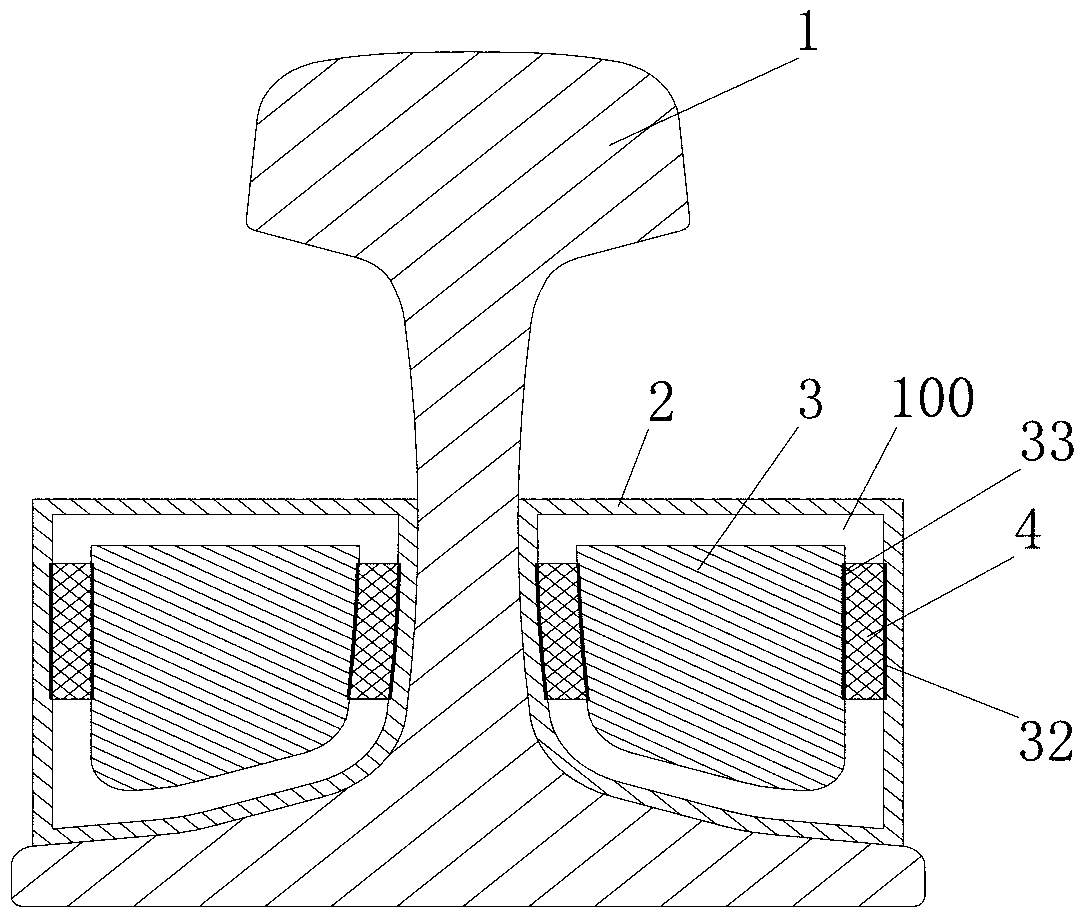

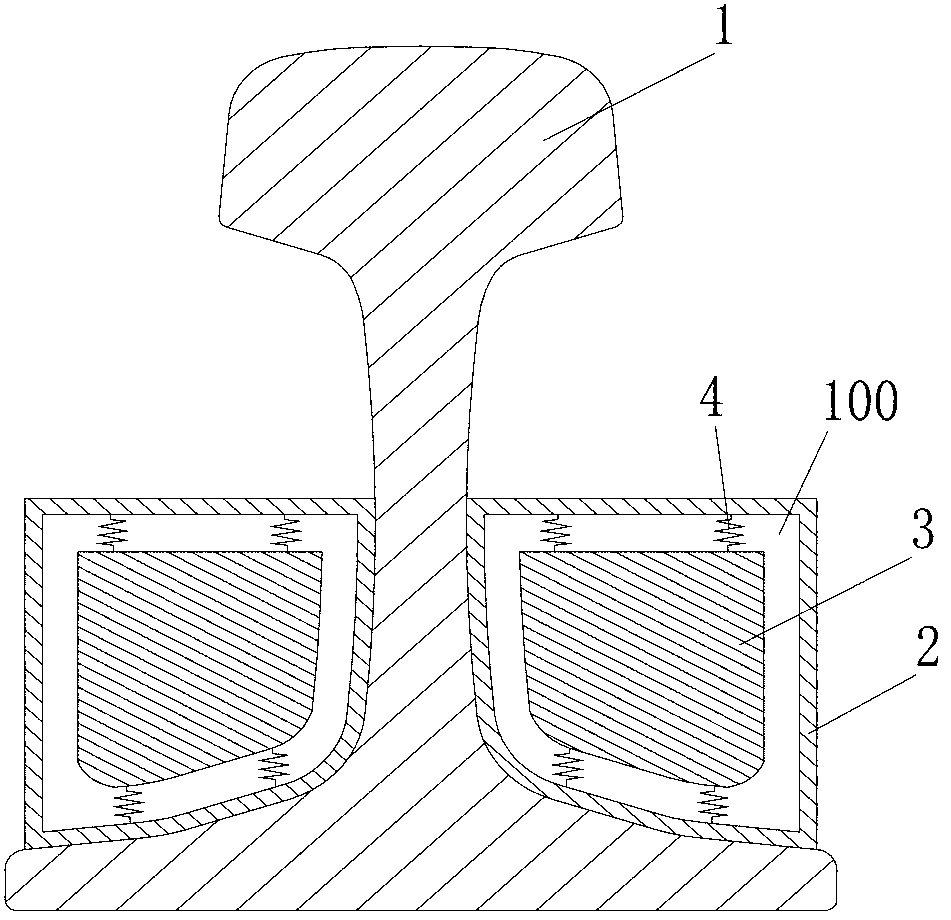

Rail vibration absorber

ActiveCN103343496AEffective protectionNot easy to ageRailsShock absorbersClassical mechanicsStructural engineering

The invention discloses a rail vibration absorber which comprises an elastic element, a mass block and at least one connection framework. The connection framework is the same as the surface of a steel rail non-working surface connection part in shape. The connection framework comprises at least one vibration absorption cavity. At least a part of the mass block is arranged in the vibration absorption cavity of the connection framework. The elastic element is arranged between the mass block and the cavity wall of the vibration absorption cavity. The rail vibration absorber has the advantages that due to the fact that a mass-spring system composed of the mass block and the elastic element is arranged in the connection framework, the mass block and the elastic element are effectively protected by the connection framework; the mass block is only connected with the elastic element in series so that the material selection range of the elastic element can be wide; the space occupied by the elastic element is small, so that a larger and heavier mass block is arranged under the same condition, and the quality tuning vibration reducing effect is achieved; the rail vibration absorber is simple in structure, stable in performance, good in weather resistance, wide in application frequency domain, long in service life, superior in cost-performance ratio, beneficial to delaying abrasion to a steel rail and prolonging the service life of the steel rail, and very wide in market application prospect.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

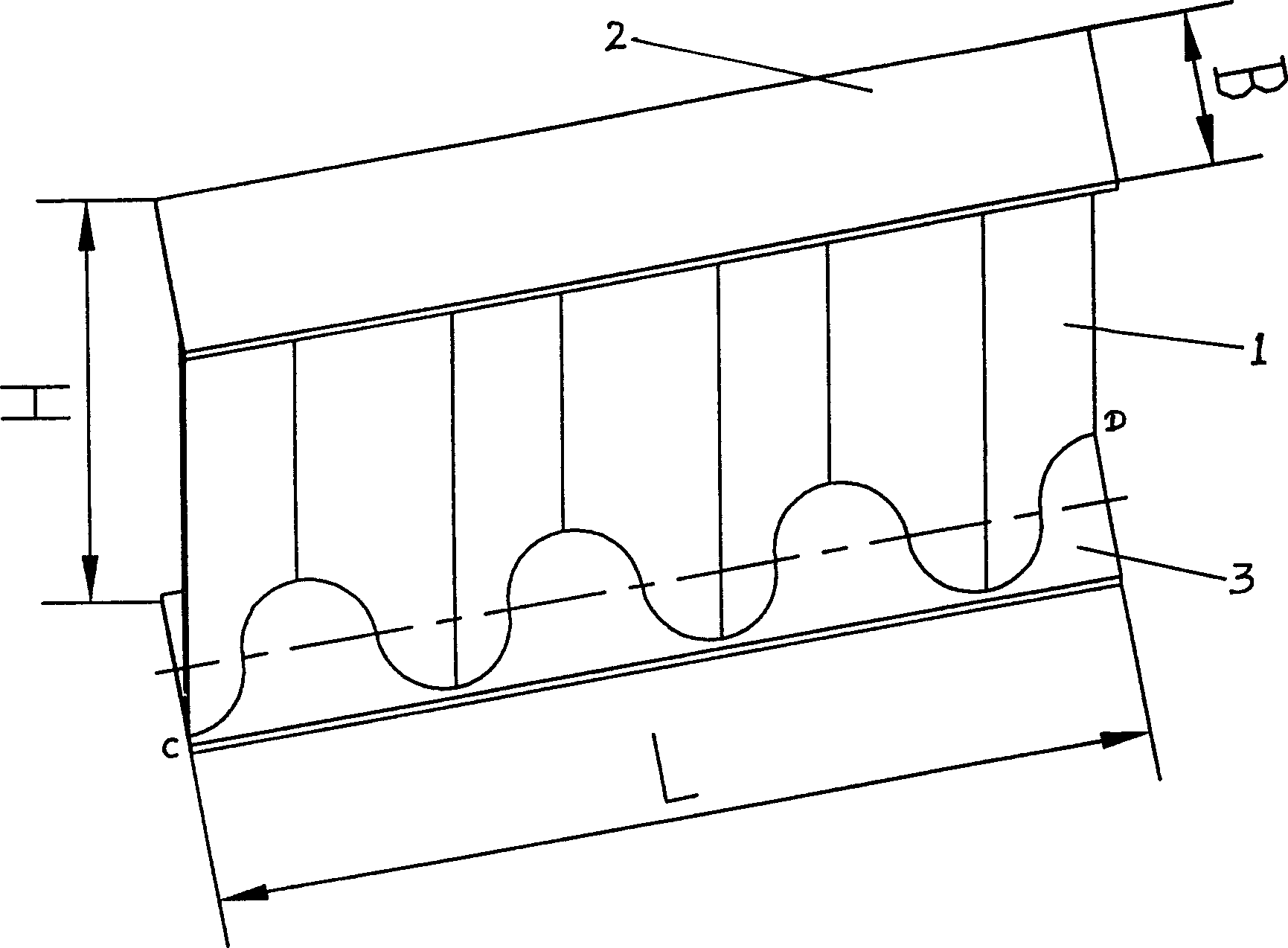

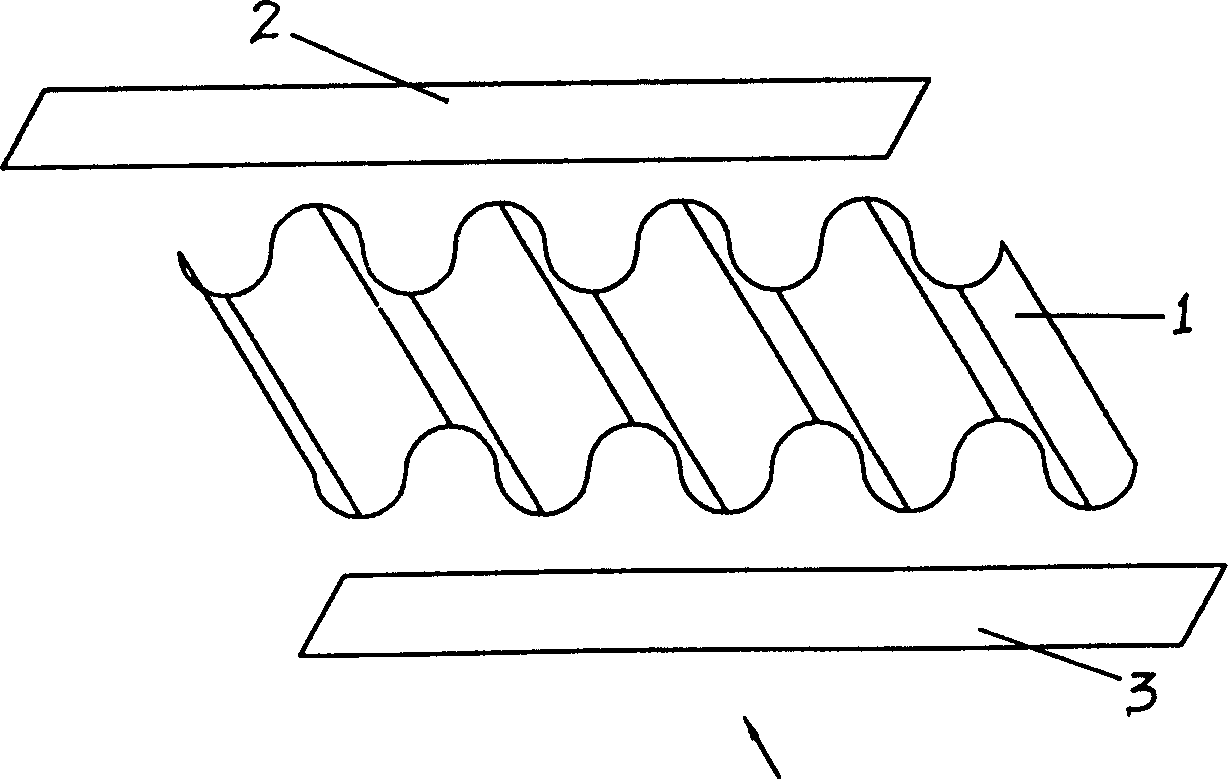

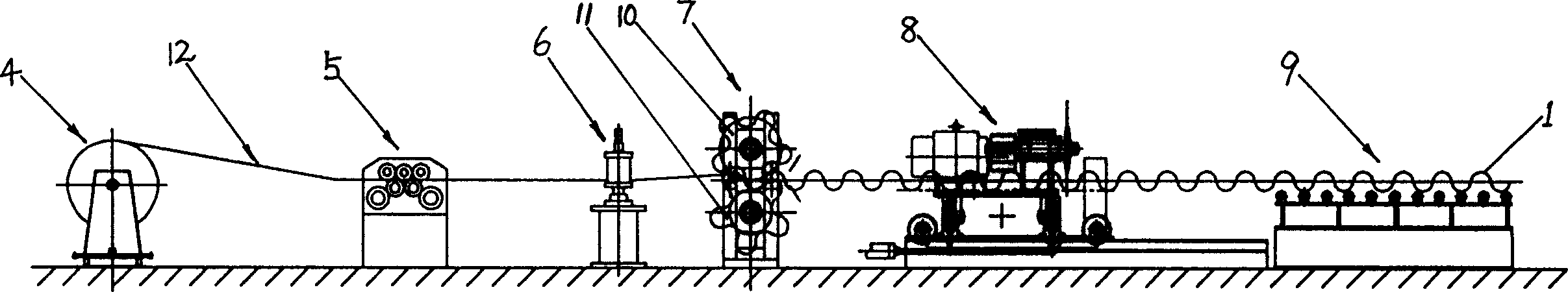

H-shaped section bar having transverse wave form webs, its making process and forming apparatus for transverse wave form webs

The invention discloses a transverse waveform web H-shaped rolled steel, composed by welding web and two flank plates, where the web is between the two flank plates and its characteristic: the web is a waveform web with transverse ripples. The invention also discloses its making technique and a molding device of making the above web by primarily connecting, cold-bending and rolling, where the key part of the molding device is a pair of tooth form roller molding device. The H-shaped rolled steel has the characters of lightness, large bearing capacity, simple making technique and device, etc.

Owner:王银

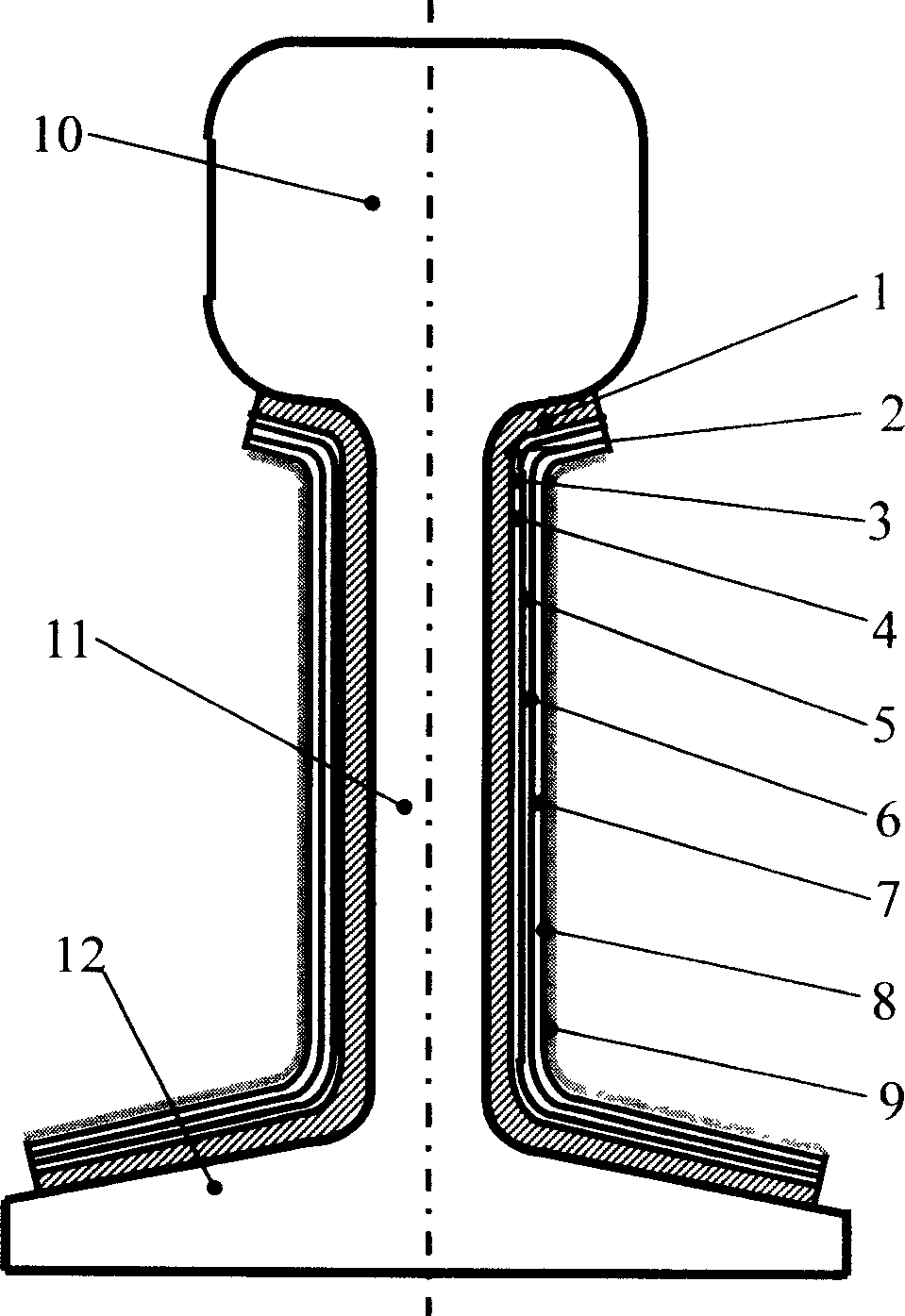

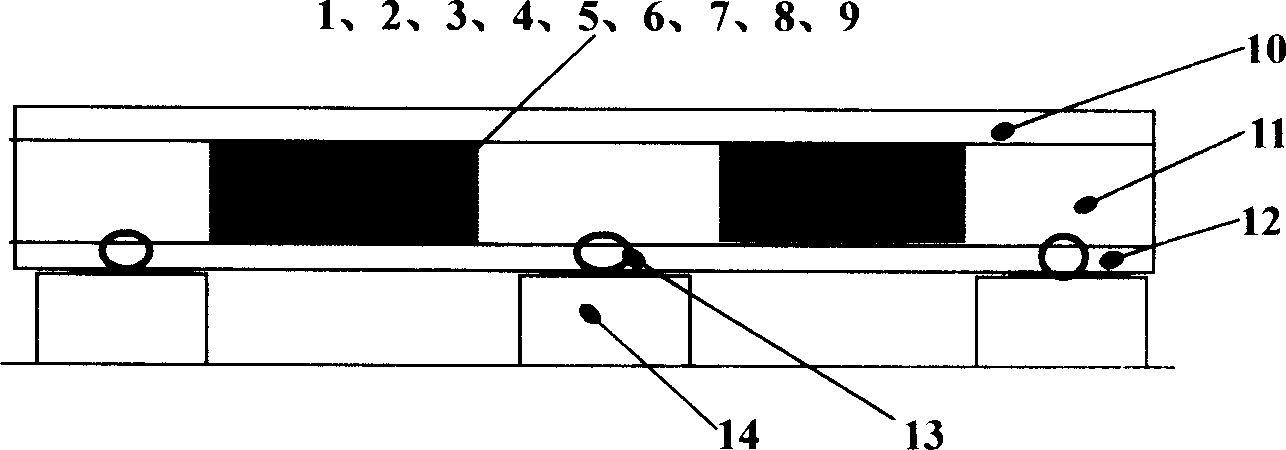

Dynamic vibration-absorbing multilayer damping-constraining steel rail silencer

The invention relates to a dynamic absorber multilayer restrict damping steel rail muffler, belonging to the noise control technique. Wherein, from inner to outer, it comprises the high-flexibility energy-consumption material layer, the first quality layer, the first damping layer, the first restrict layer, the second damping layer, the second restrict layer, the third damping layer, the third restrict layer, and the protective layer. Wherein, the high-flexibility energy consumption material layer forms the distributed flexible elements of said dynamic absorber; the first quality, three damping layers and the restrict layer form the distributed quality of dynamic absorber; the distributed flexible element and the distributed quality form a group of distributed parameters; and said distributed quality also be used as three layers of damping resistance to reduce the vibration deformation of distributed quality. The invention can be mounted at the rail waist of noise sensible area of railway or city traffic roads, to reduce the noise of wheel and rail especially the noise generated by the brake and friction.

Owner:SHANGHAI JIAO TONG UNIV

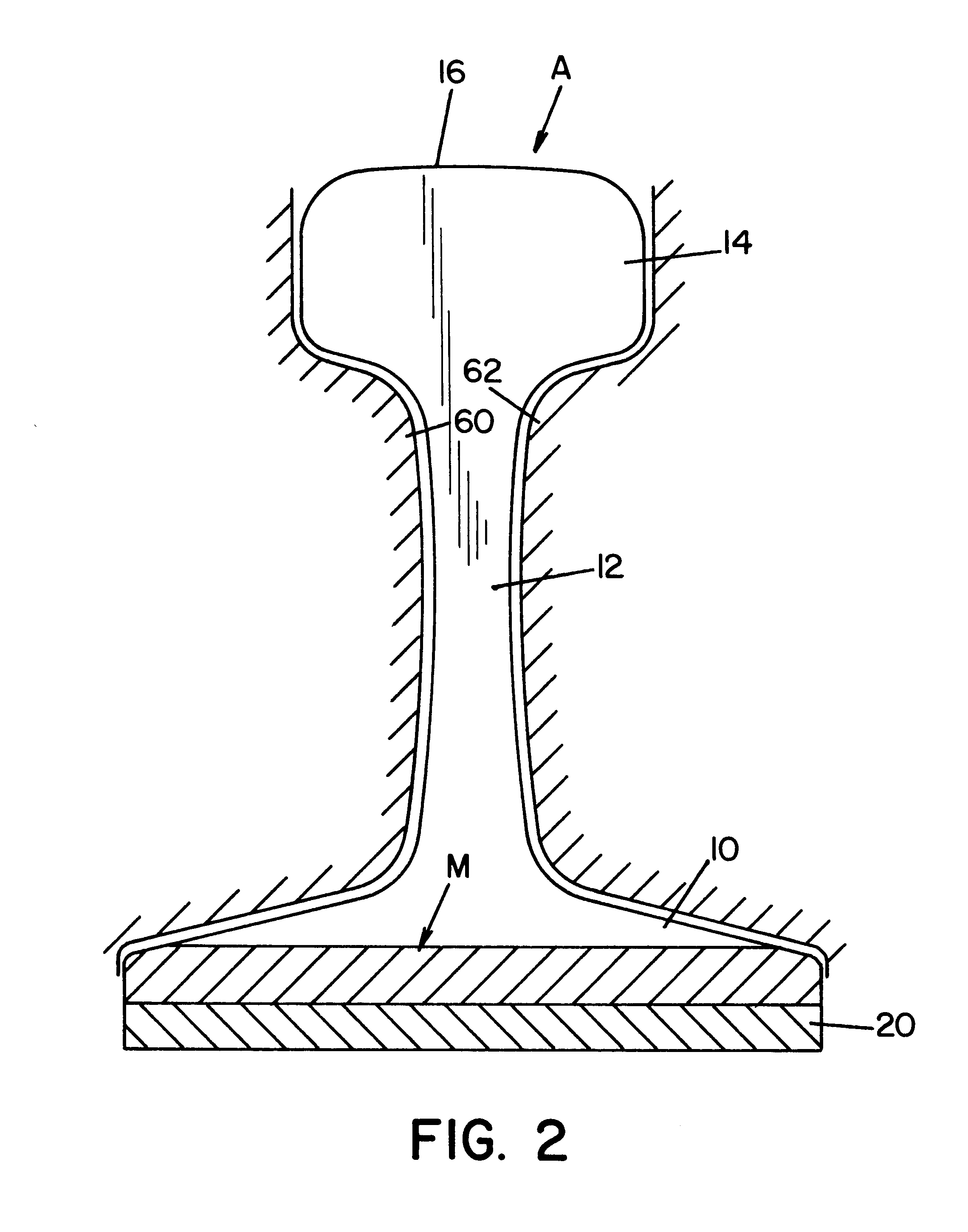

Method and system for welding railroad rails

InactiveUS6207920B1Avoid lostAvoid overall overheatingRailsWelding/cutting auxillary devicesMolten steelMechanical engineering

A method of gas shielded arc welding steel rails spaced from each other to define a longitudinal gap therebetween comprises the steps of providing an elongated steel barrier plate across the gap at the bottom of the spaced rails, and filling the gap above the barrier plate with a molten steel from an advancing filler metal electrode by a gas shielded electric arc welding process. The barrier plate has a central portion received in the gap and longitudinally extending recesses laterally outwardly adjacent to the central portion and which underlie the bottoms of the rails at the bottom of the gap.

Owner:LINCOLN GLOBAL INC

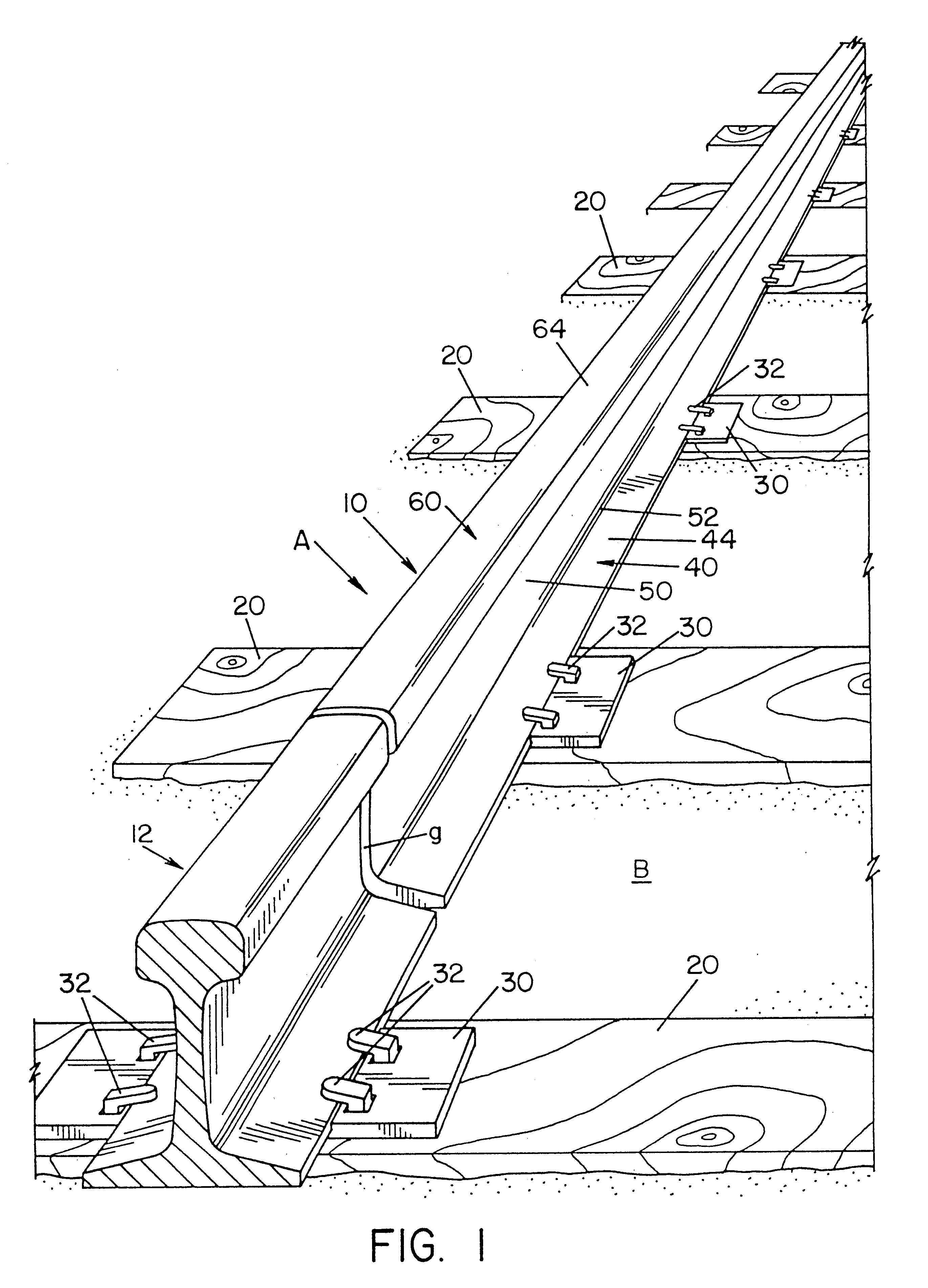

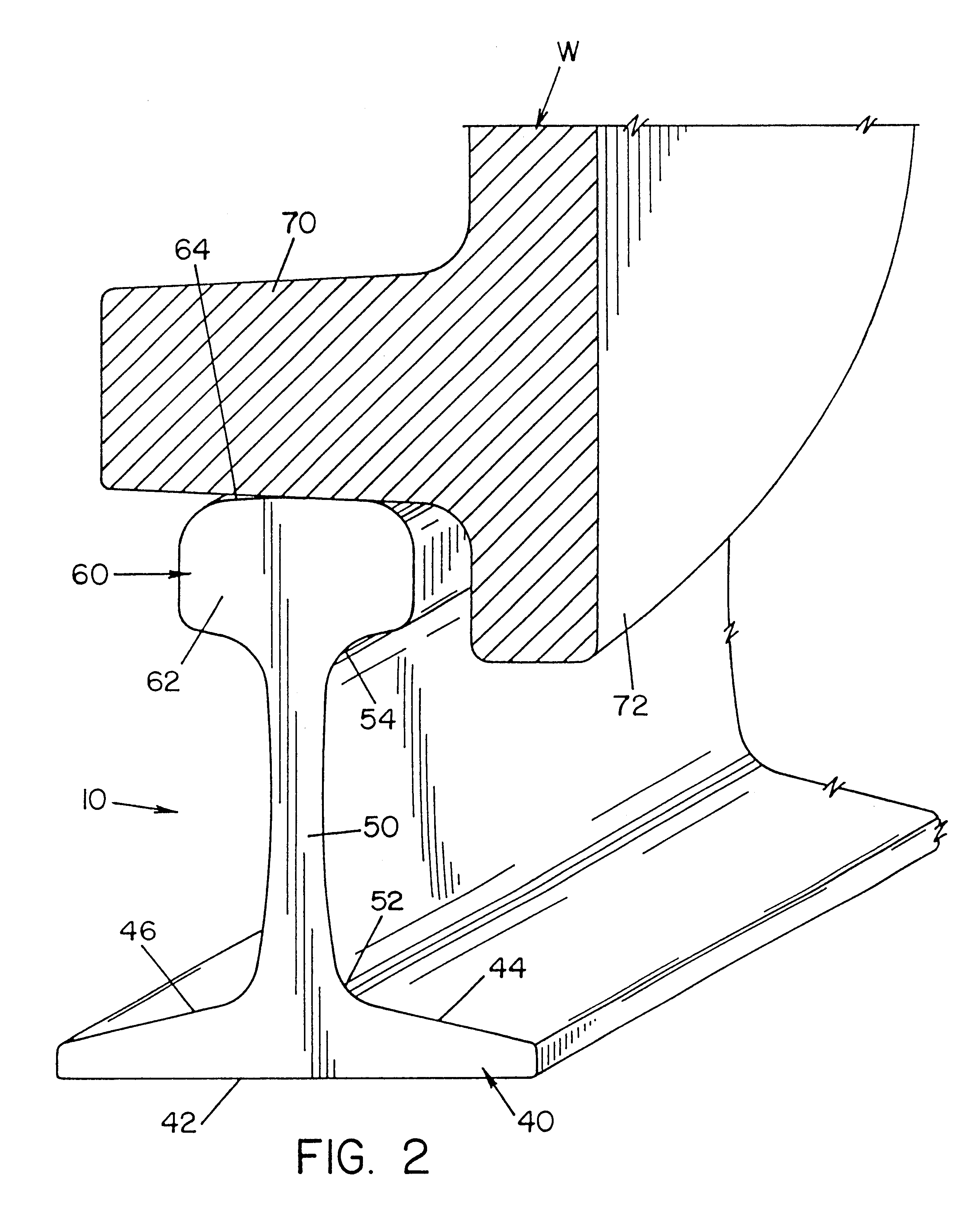

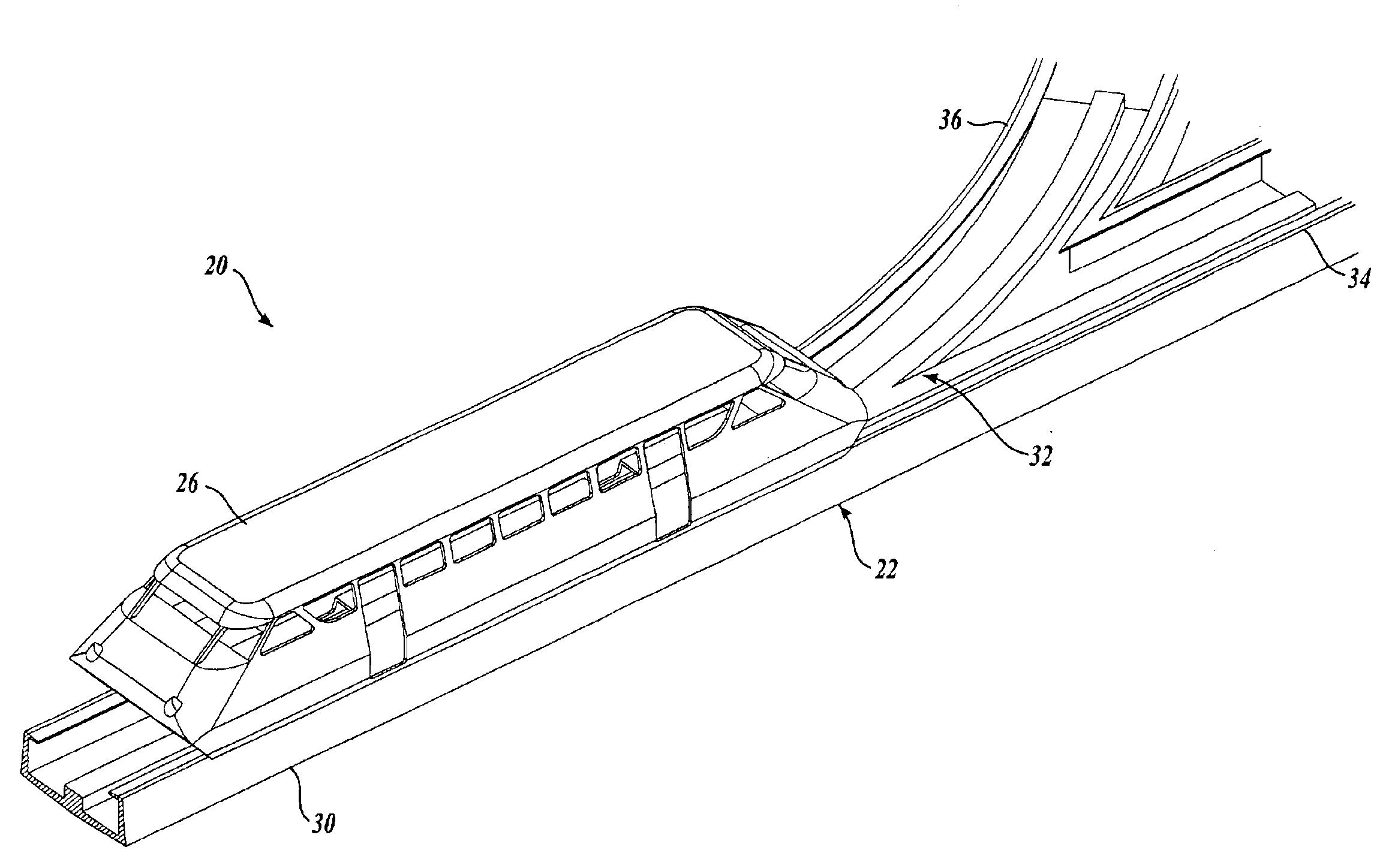

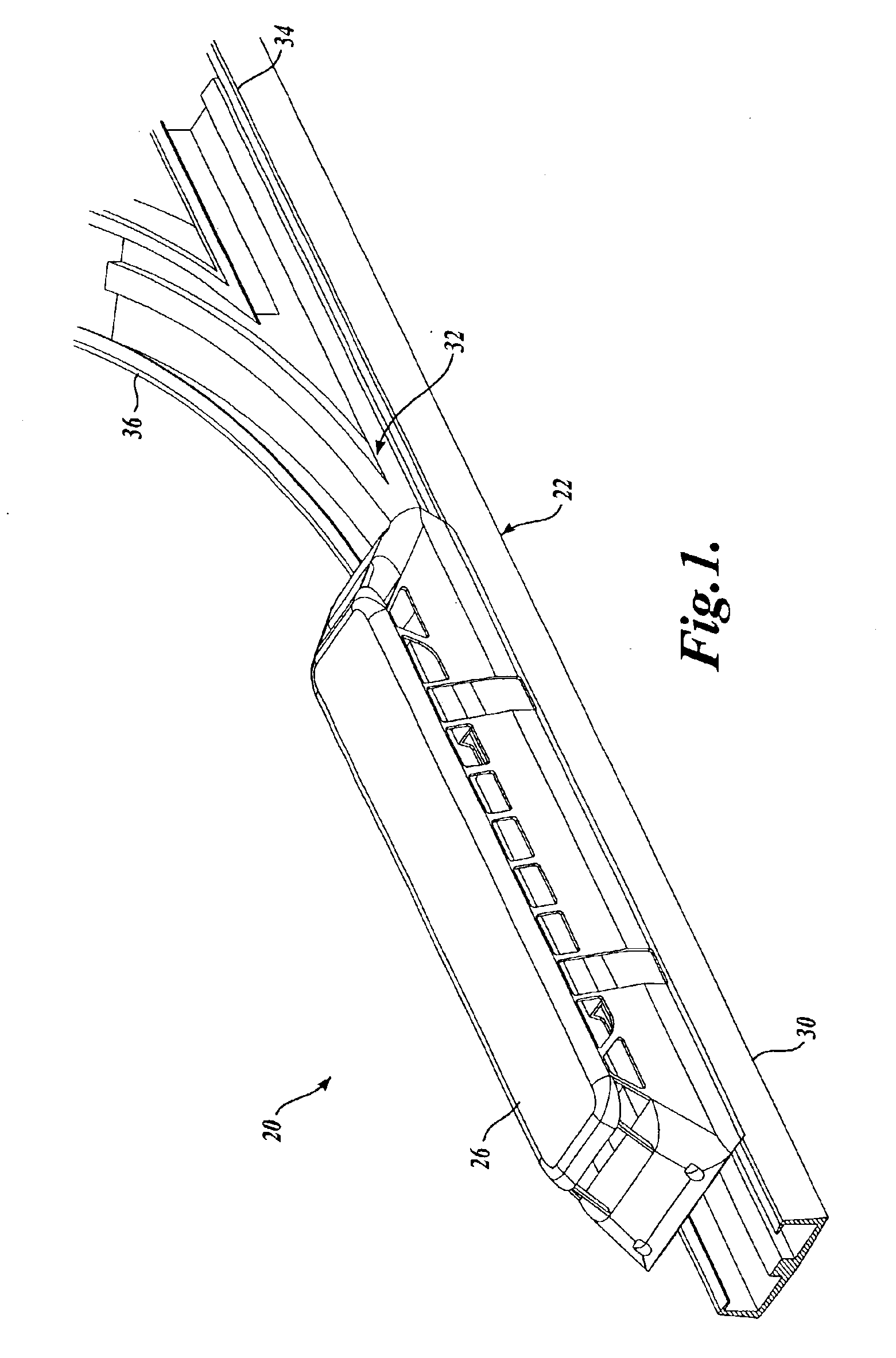

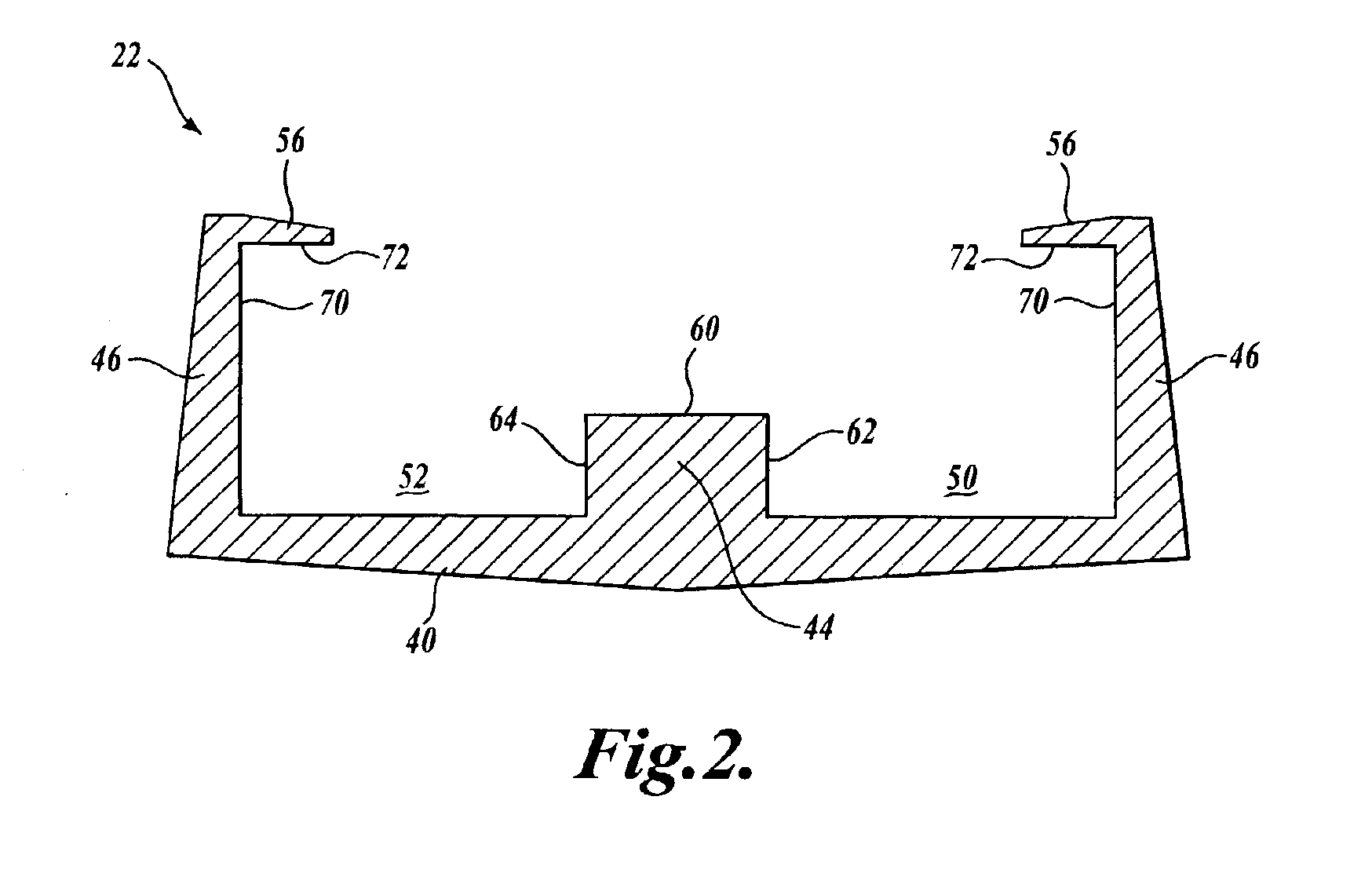

Guideway and vehicle for transportation system

The guideway-based transportation system includes a guideway and a mating vehicle. The guideway includes a main guideway section that may branch at a branch point into two separate branch sections. The guideway has a suitable geometry to support and guide the vehicle at any speed reasonably associated with such a transportation system. The vehicle includes both support and guide wheels to support the weight of the vehicle and to maintain contact between the vehicle and the guideway as it moves along the guideway, and may optionally include a switching wheel assembly for switching the path of travel of the vehicle from the main guideway section to either of the branch sections.

Owner:NOVACEK MILAN

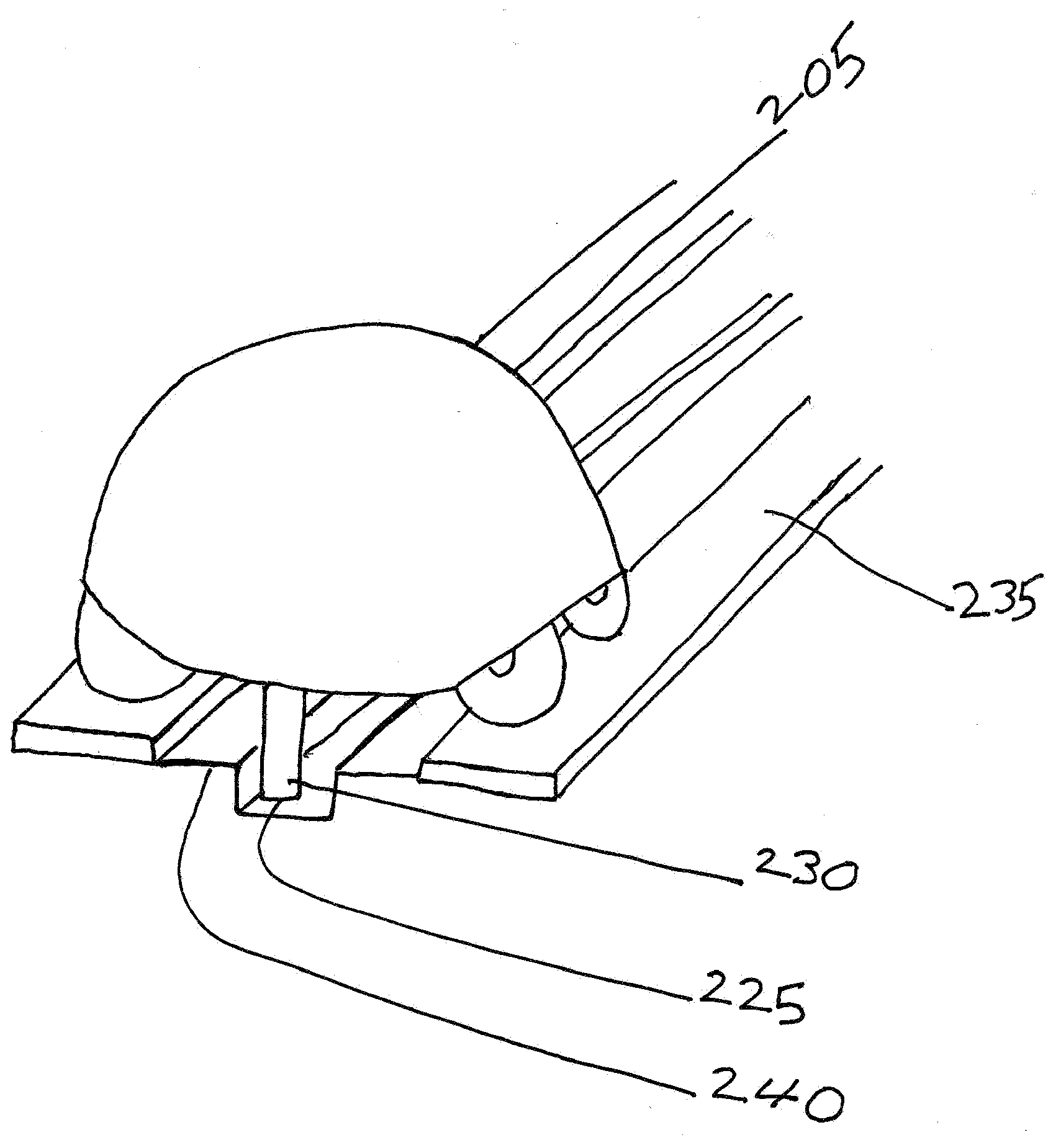

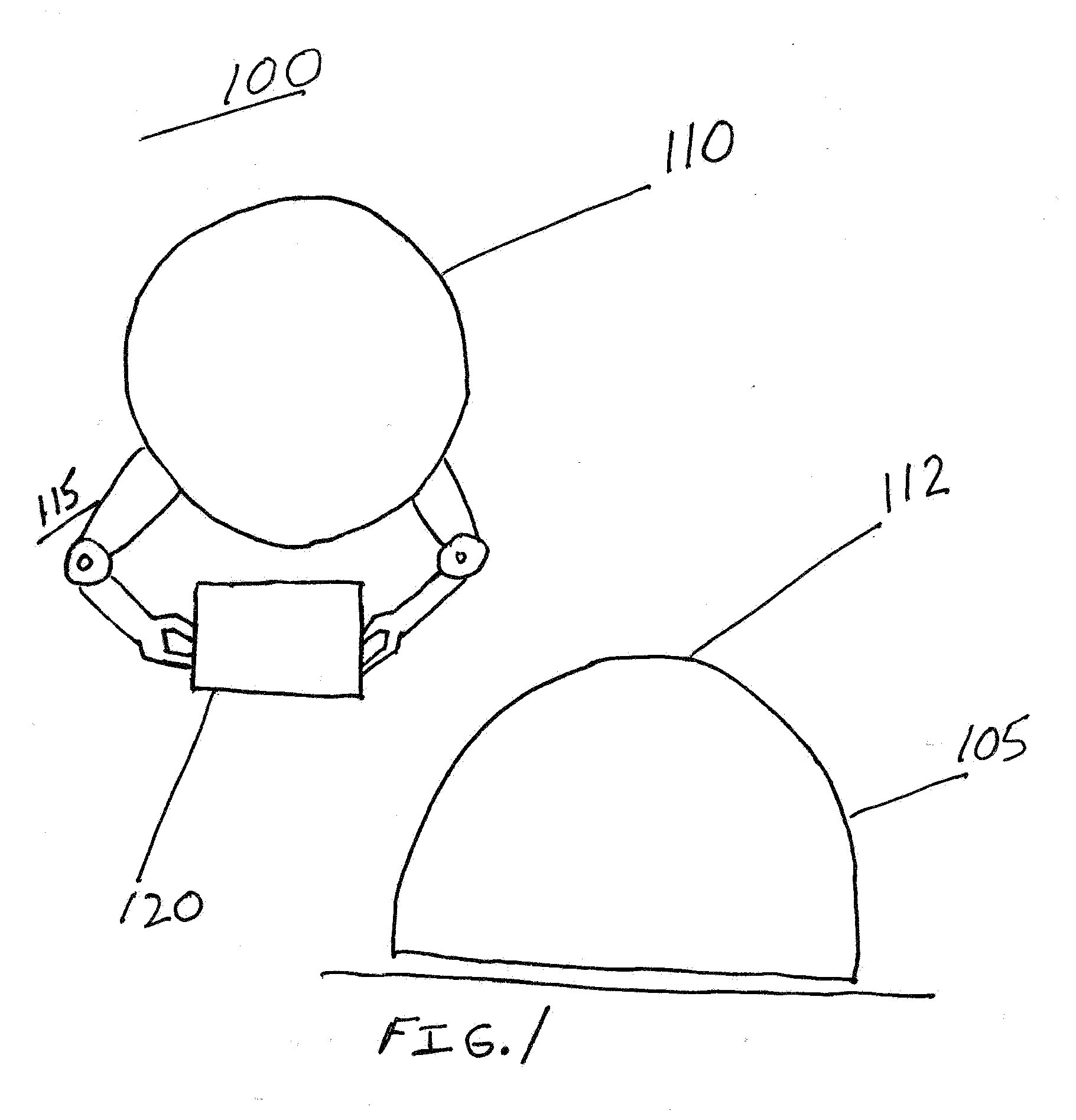

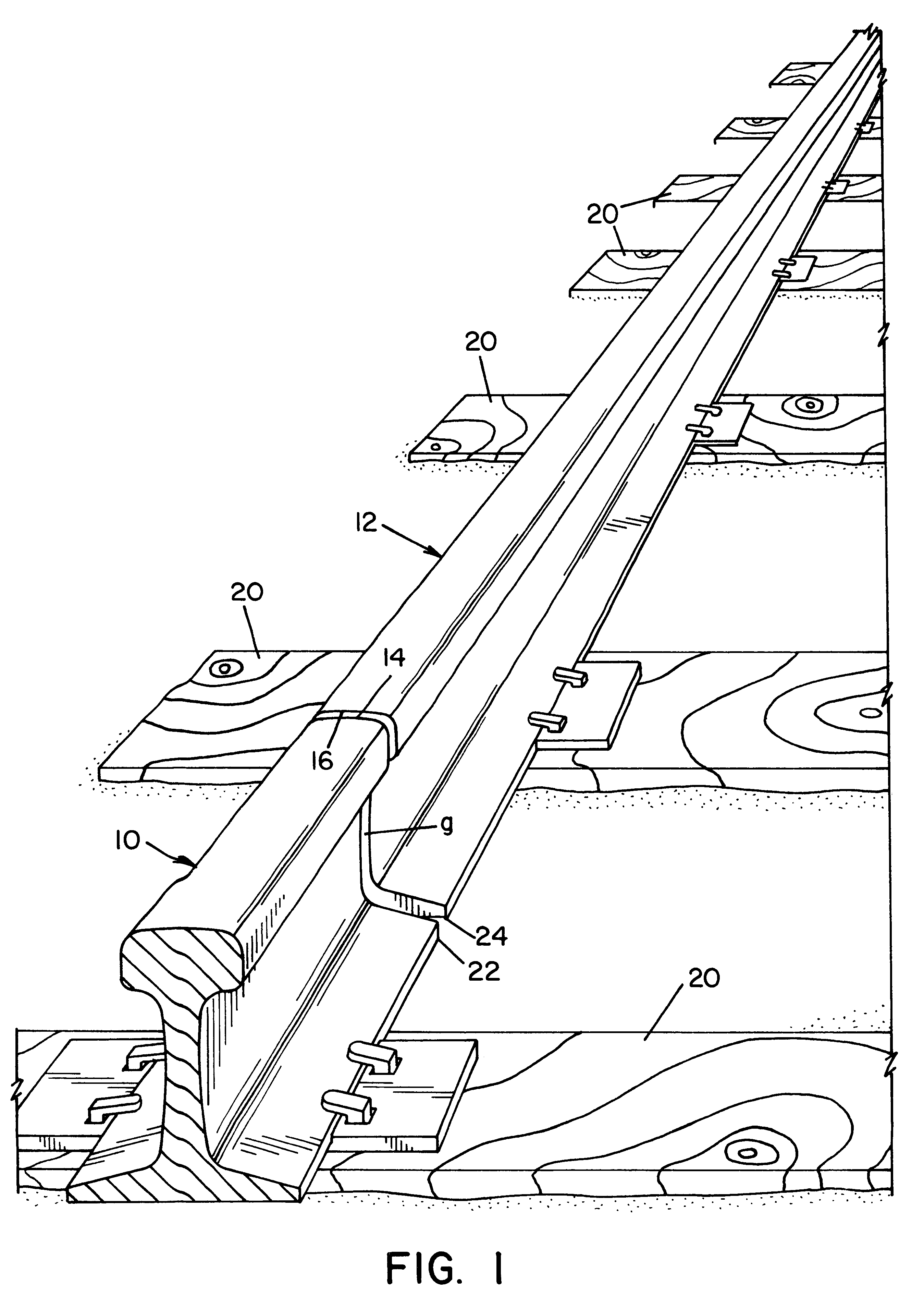

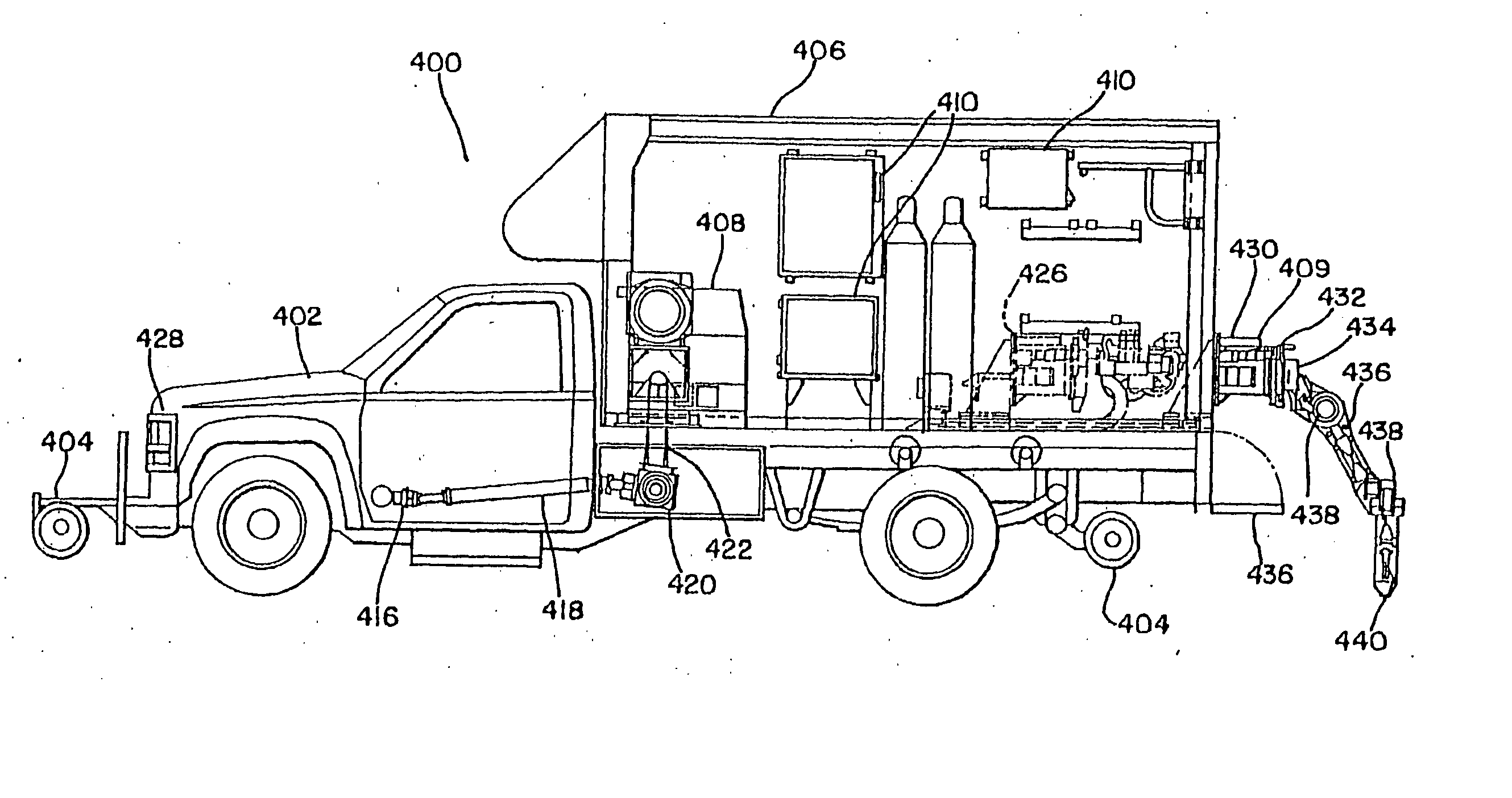

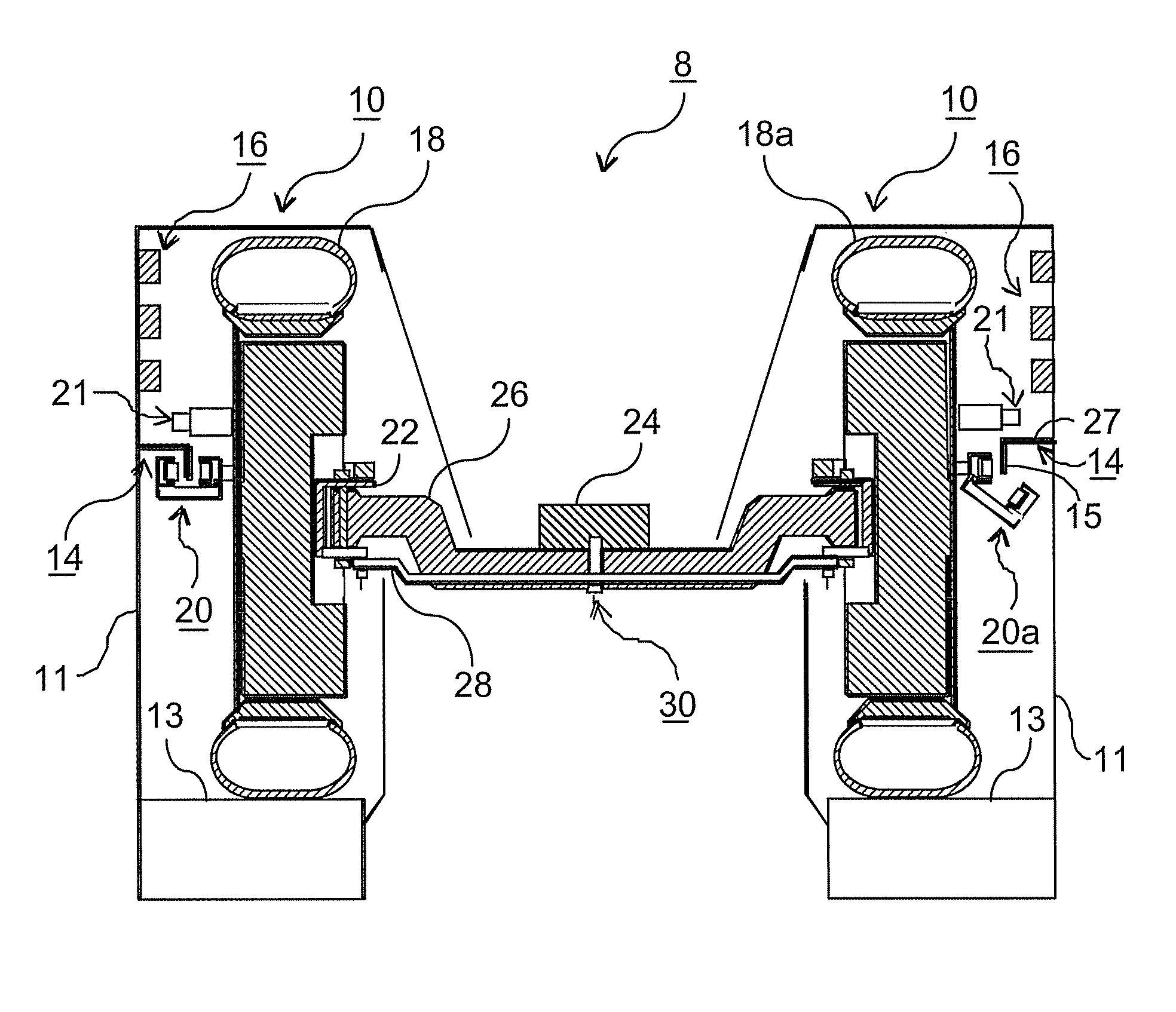

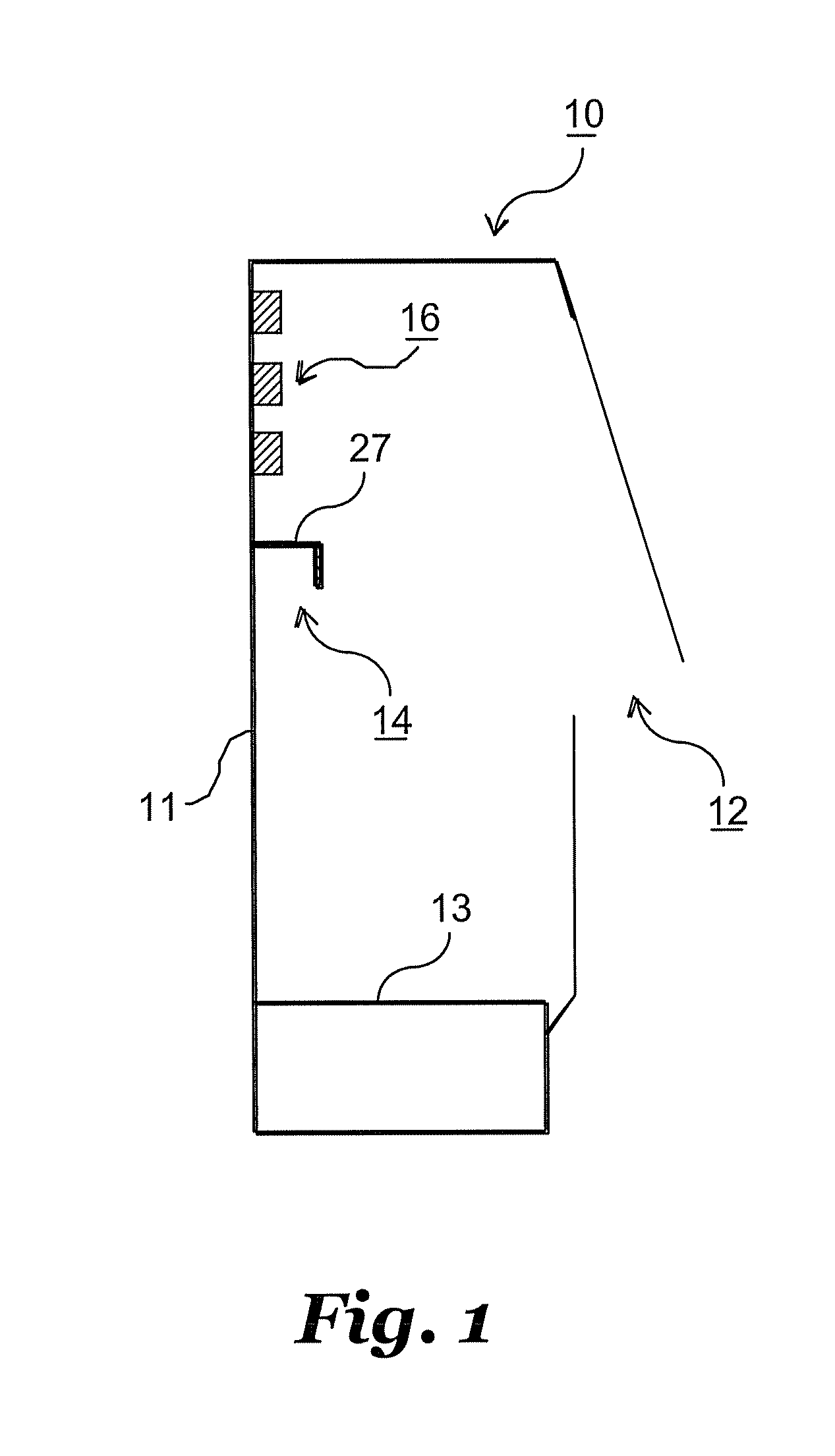

On-site rail welding apparatus

An on site railroad rail welding repair apparatus wherein a railroad rail is an operating railroad track and a defect in the rail has been removed to provide a void and a rail-void interface while maintaining continuity of the rail having pair of cooling blocks which have an internal configuration to complement the rail, and an arc welder that fills the void with appropriate molten metal and causes the molten metal and the rail at the rail-void interface to bond. Also, a robotic welding apparatus and a weld containment apparatus engageable with the rail-void interface by movement having a pivotal and longitudinal component. Further, a mobile weld delivery unit delivering materials through an umbilical to a robotic welding apparatus having a welding device proximate the rail-void interface so that a weld can be made joining the rail-void interface.

Owner:HOLLAND CO

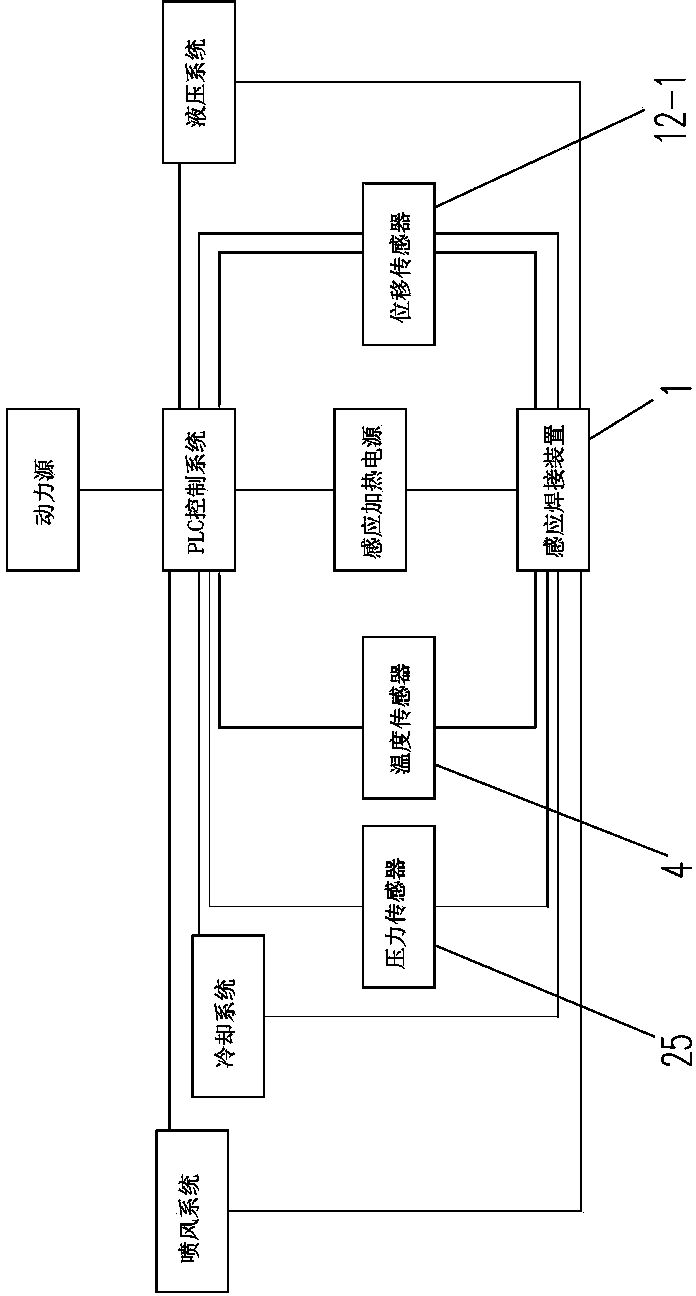

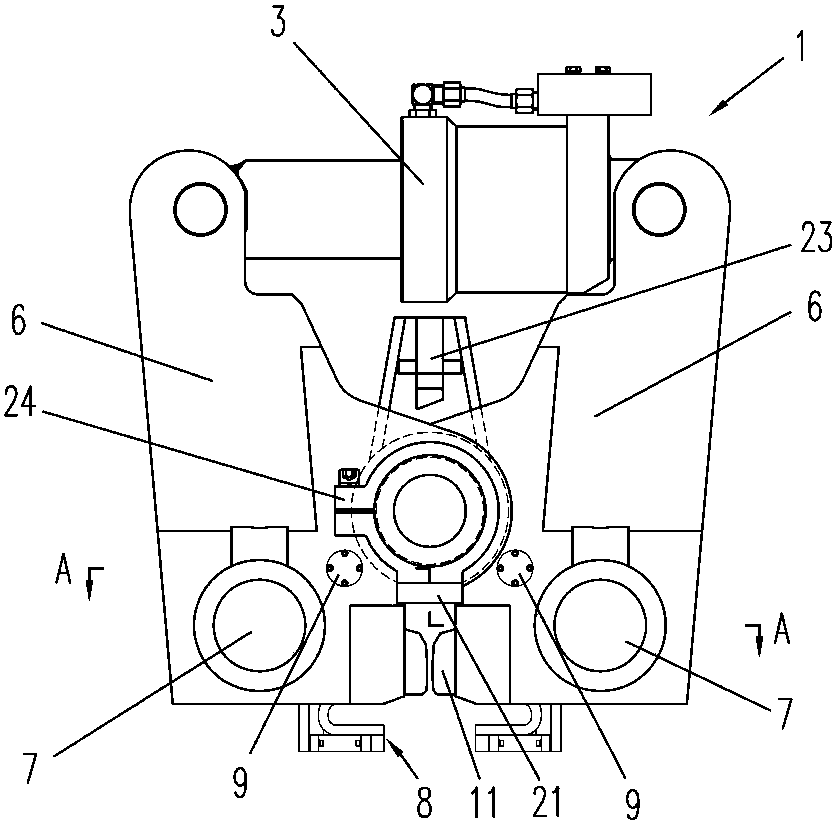

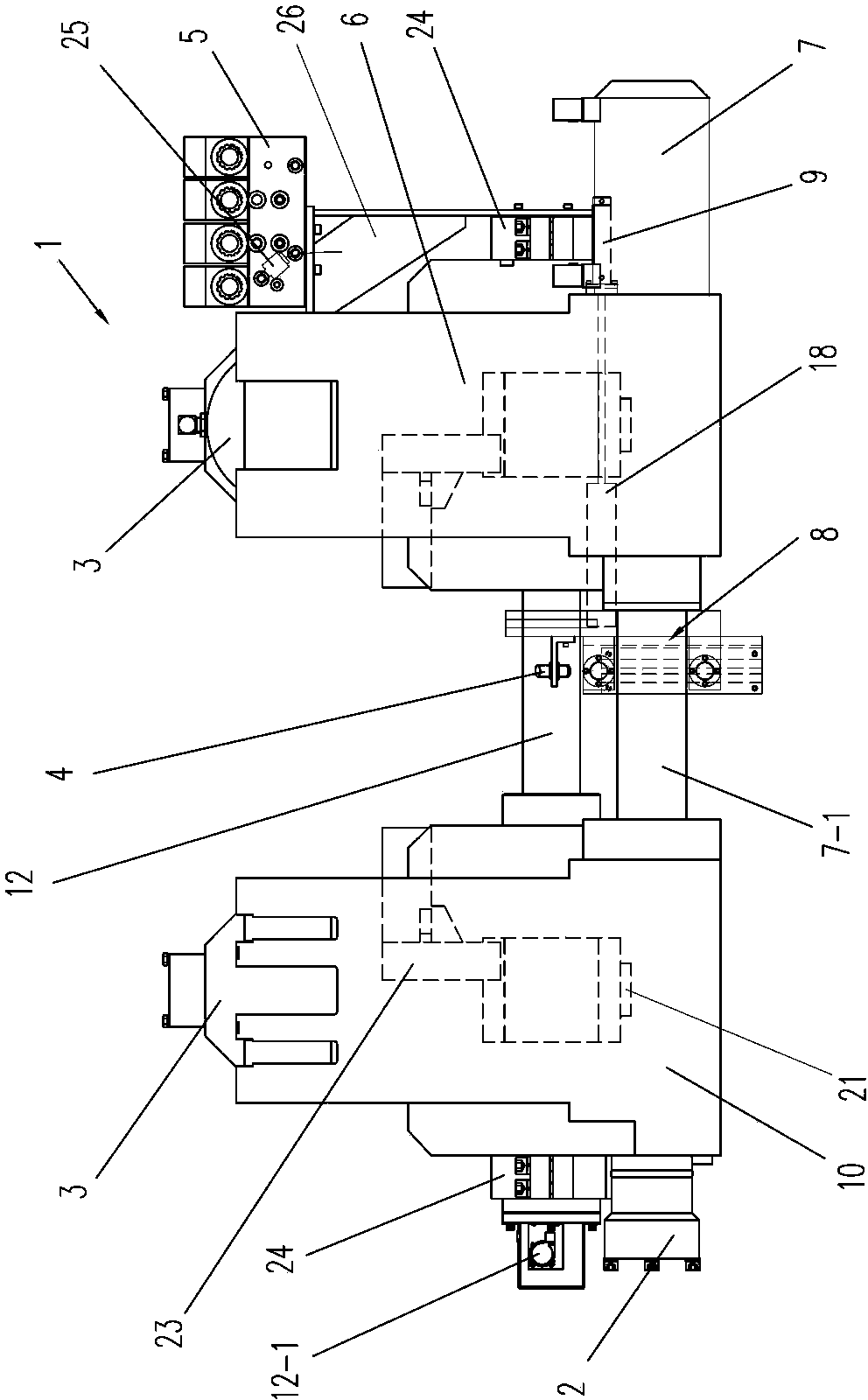

Steel rail induction butt welding and heat treatment method

ActiveCN103521935AImprove organizational efficiencyHigh degree of automationRailsWelding/cutting auxillary devicesButt weldingForceps

The invention discloses a steel rail induction butt welding and heat treatment method which includes the following steps: locating two steel rails through locating pieces which are installed on the lower portions of center shafts of an induction welding device in a connected mode, enabling jaws of two sets of clamp forceps to clamp the two steel rails respectively and carry out centring, enabling an opening-closing type induction heating coil to be moved to the joint of the two steel rails with the help of auxiliary oil cylinders and wrap the steel rails, enabling two sub-coils to be in contact with electrode structures, enabling a PLC to control the induction heating coil to heat the joint of the steel rails, when the temperature reaches the preset welding temperature of 1200 DEG C to 1430 DEG C, enabling upsetting oil cylinders to exert preset upsetting force to enable the end faces of the two steel rails to be tightly welded together, enabling a protrusion eliminating device to cut welding beading at the joint of the steel rails, enabling the induction heating coil to heat the weld joint of the steel rails again, after the temperature reaches the preset normalizing temperature of 830 DEG C to 950 DEG C, starting an air blasting system to cool the weld joint of the steel rails, and enabling the two sub-coils to be separated through the locating oil cylinders to enable the jaws of the two sets of clamp forceps to be opened to loosen the steel rails. The steel rail induction butt welding and heat treatment method is automatic in operation and high in efficiency.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Method and system for welding steel rails

InactiveUS6166347AEconomical and rapid and mechanically and metallurgically sound techniqueEconomical, rapid and mechanically and metallurgically sound techniqueRailsArc welding apparatusElectric arcFiller metal

A method for gas shielded arc welding steel rails spaced from each other to define a transverse gap comprising the steps of positioning an elongated steel barrier plate in the gap at the bottom of the spaced rails and filling the gap above the barrier plate with a molten steel from an advancing filler metal electrode by a gas shielded electric arc welding process initiated by an arc between the electrode and the barrier plate. A root pass is laid using the spray arc welding process, a second layer is laid using the pulsed arc welding process in part and the spray welding process in part, and the remainder of the base gap and the gaps between the webs and heads are filled by the continuous sequential laying of weld beads in the gaps using the pulsed arc process. In filling the head gap, the electrode is first moved along rectangular paths to fill the transition portion of the gap and then along paths having laterally extending sides and catercorner path portions therebetween to fill the full width upper end of the head gap. Movement of the electrode is controlled to provide adjacent, overlapping beads which have first ends extending outwardly of an edge of the head in cantilever relationship thereto and which first ends are vertically thicker than second ends of the beads which are spaced from the first ends in the direction toward the opposite edge of the head.

Owner:LINCOLN GLOBAL INC

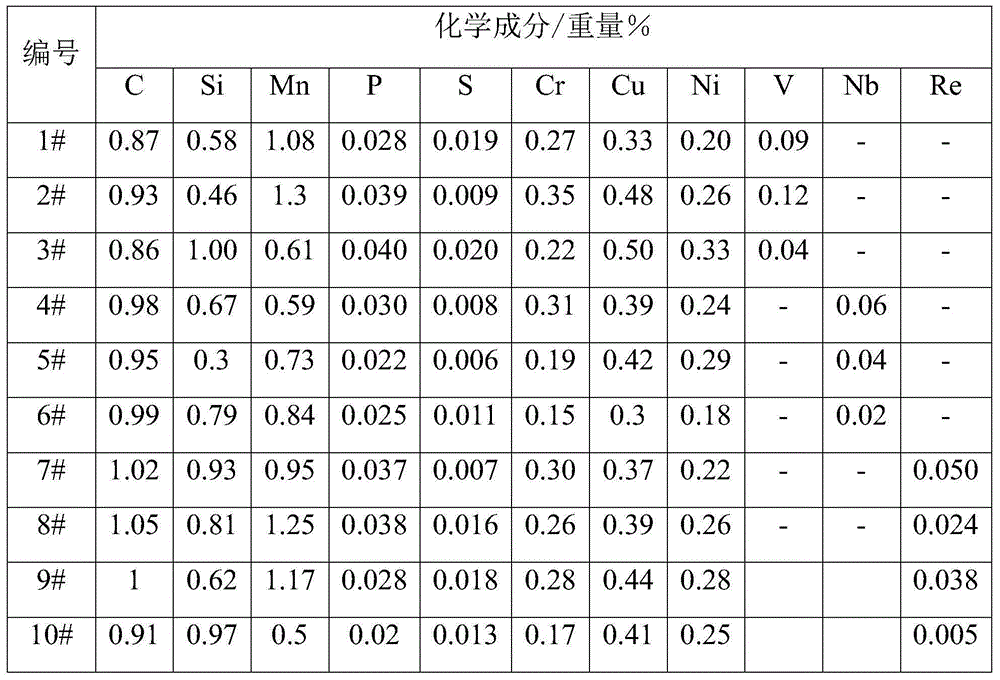

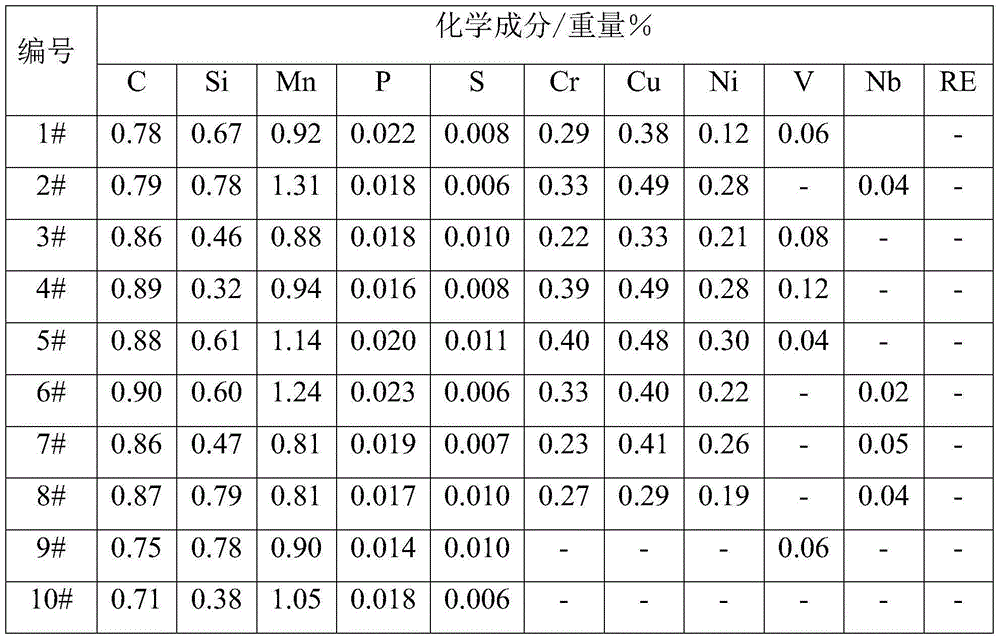

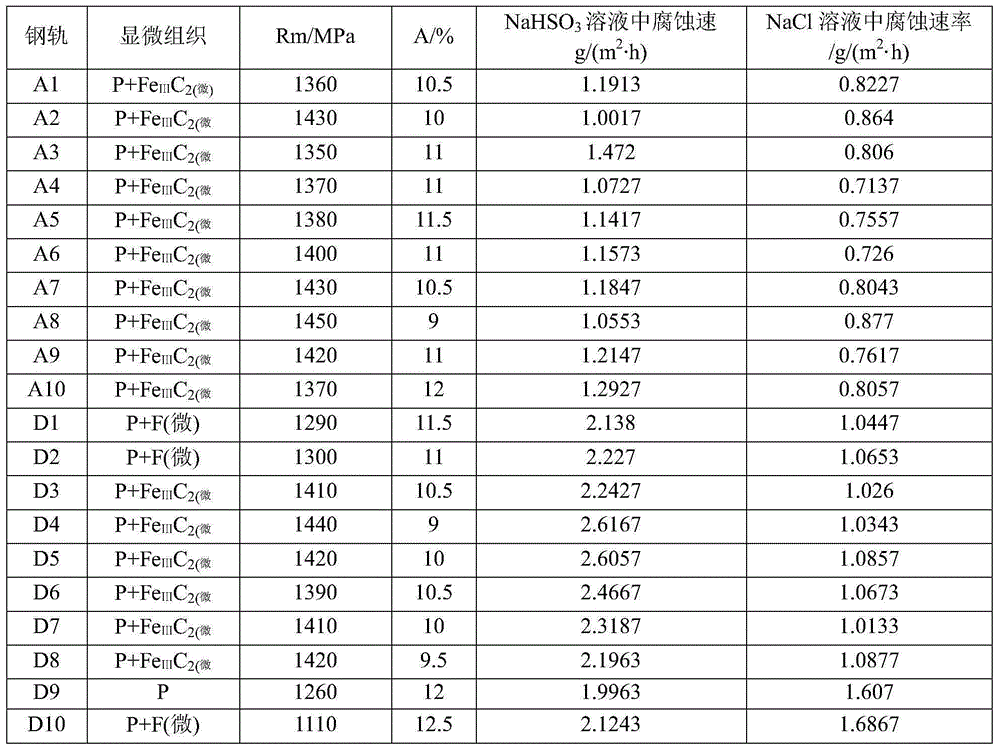

Hyper-eutectoid steel rail and manufacturing method thereof

The invention discloses a manufacturing method of a hyper-eutectoid steel rail. According to the method, an adopted steel billet comprises, by weight, 0.86-1.05% of C, 0.3-1% of Si, 0.5-1.3% of Mn, 0.15-0.35% of Cr, 0.3-0.5% of Cu, 0.02-0.04% of P, smaller than 0.02% of S, Ni, one of V, Nb and Re, and the balanced Fe and inevitable impurities, wherein the Ni is one half to two thirds of Cu. The invention further provides the hyper-eutectoid steel rail obtained through the method. According to the hyper-eutectoid steel rail, the high-carbon steel billet with the specific composition is made into the hyper-eutectoid steel rail with the good corrosion resistance and good tensile property.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

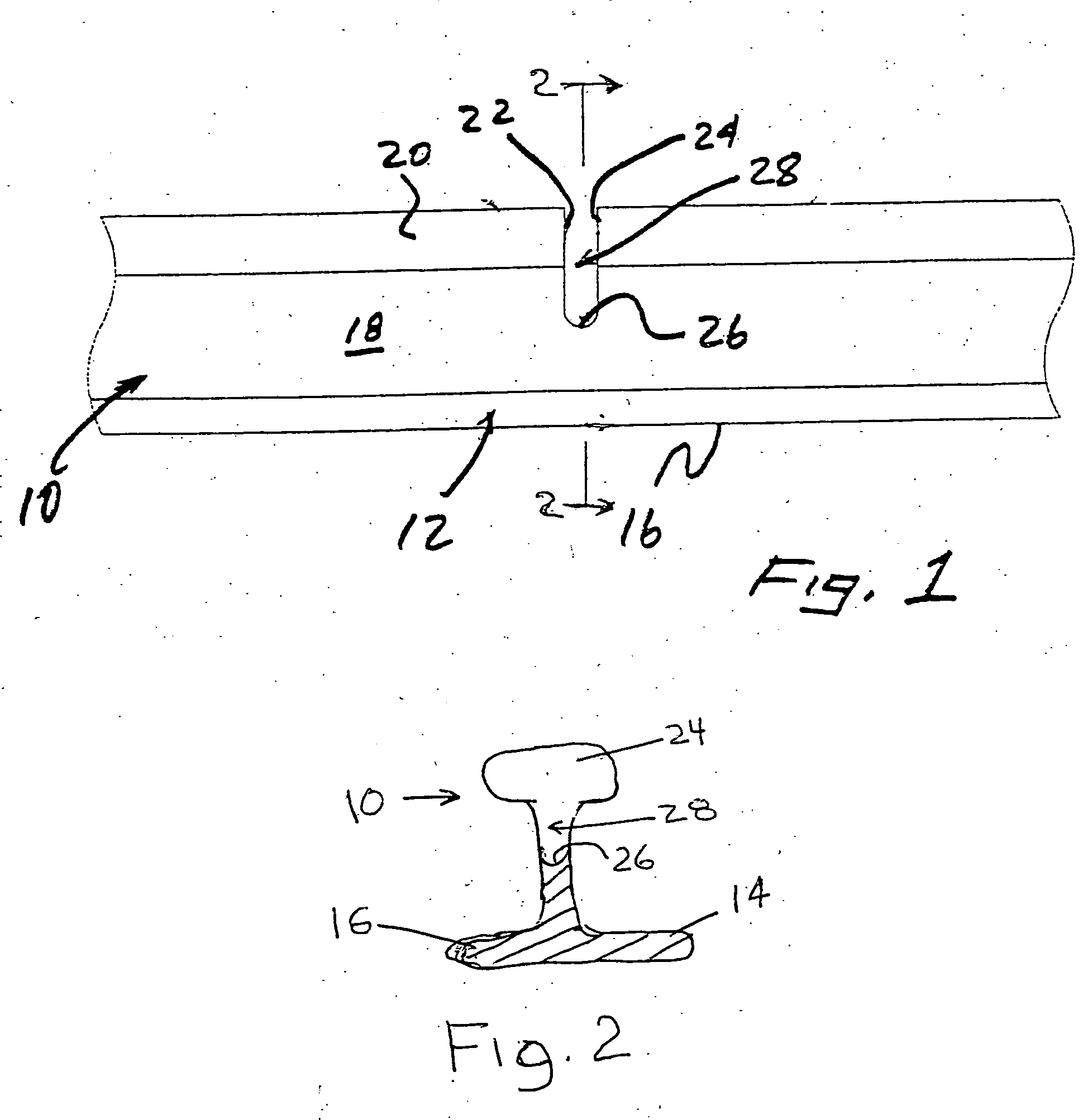

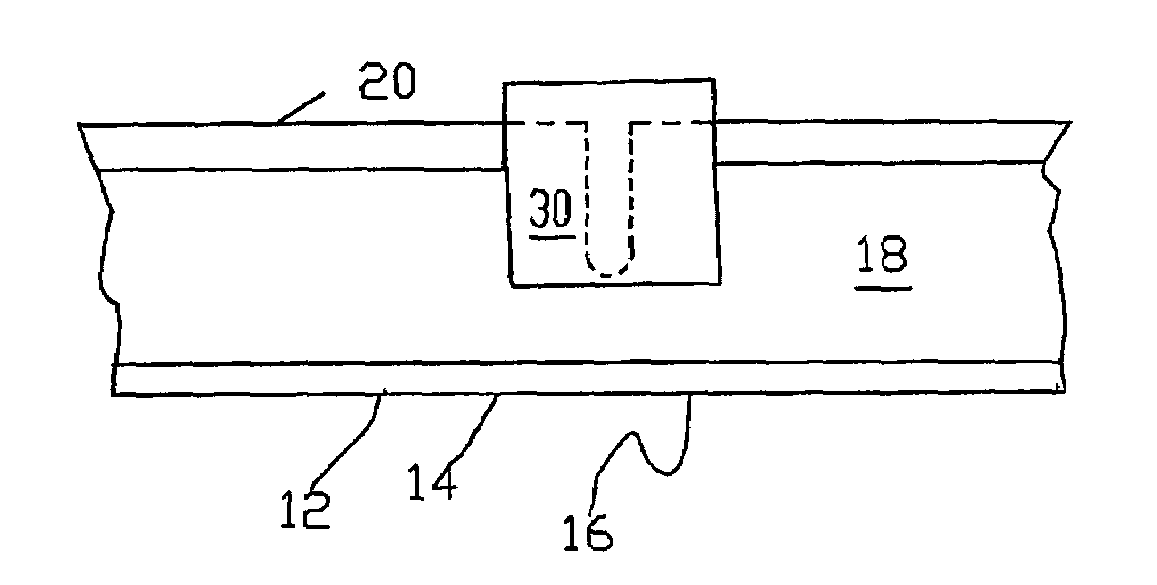

Method and repair insert for repairing metallic structure

InactiveUS20110233293A1Effective timeMore time of runningRailsRailway track constructionElectrical resistance and conductancePower flow

A rail repair method and insert therefor enables repair of rails and rail-like structures. A rail defect is initially identified and removed as contained within a volumetric material portion so as to form a contoured void while maintaining continuity of the rail opposite the void. A pre-formed insert is then placed into the void thereby effecting a rail-to-insert interface. Current is driven through the interface as force directs the insert against the rail. Resistance heat and pressure weld the insert to the rail. The flash welding aspects remove oxides and other impurities from the interface, and the forge welding aspects create a robust solid state weld. Excess material, whether flash, rail, or insert-based, is removed during the finishing processes to provide a virtually seamless rail repair. The solid state weld repair insert and underlying methodology enabled thereby may be used to repair any number of targeted metallic rail-like structures.

Owner:HOLLAND CO

Method for bead welding repair of high manganese steel cast steel frog and steel rail

InactiveCN103785924AThe implementation of welding repair process is simpleLower requirementRailsArc welding apparatusHeat treatedWelding

The invention discloses a method for bead welding repair of a high manganese steel cast steel frog and steel rail, and belongs to the technical field of welding. The method for bead welding repair of the high manganese steel cast steel frog and steel rail comprises the specific steps that quality judgment is carried out on the damaged portion of the high manganese steel cast steel frog and steel rail, machining before welding is carried out on the damaged portion of the high manganese steel cast steel frog and steel rail, over bead welding repair is carried out on the damaged portion of the high manganese steel cast steel frog and steel rail, polishing and forming are carried out on the high manganese steel cast steel frog and steel rail processed through bead welding repair, and quality inspection is carried out. The method for bead welding repair of the high manganese steel cast steel frog and steel rail has the advantages that preheating does not need to be carried out on the high manganese steel cast steel frog and steel rail before repair is carried out, heat treatment does not need to be carried out after welding is accomplished, implementation of the welding repair technology is easy, the cost is low, efficiency is high, labor intensity is low, quality is high after welding repair is accomplished, and performance is stable and reliable.

Owner:SHOUGANG CORPORATION

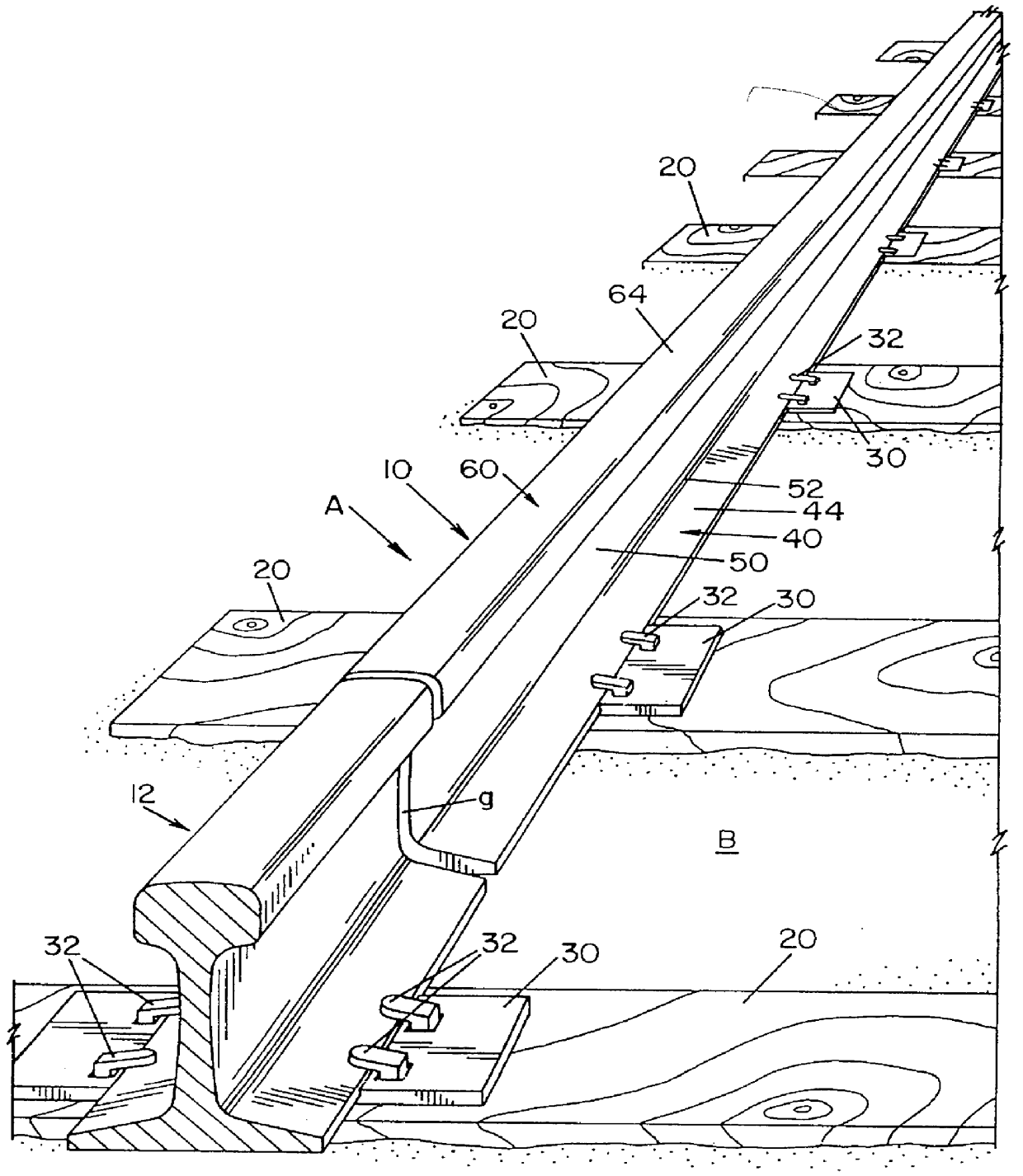

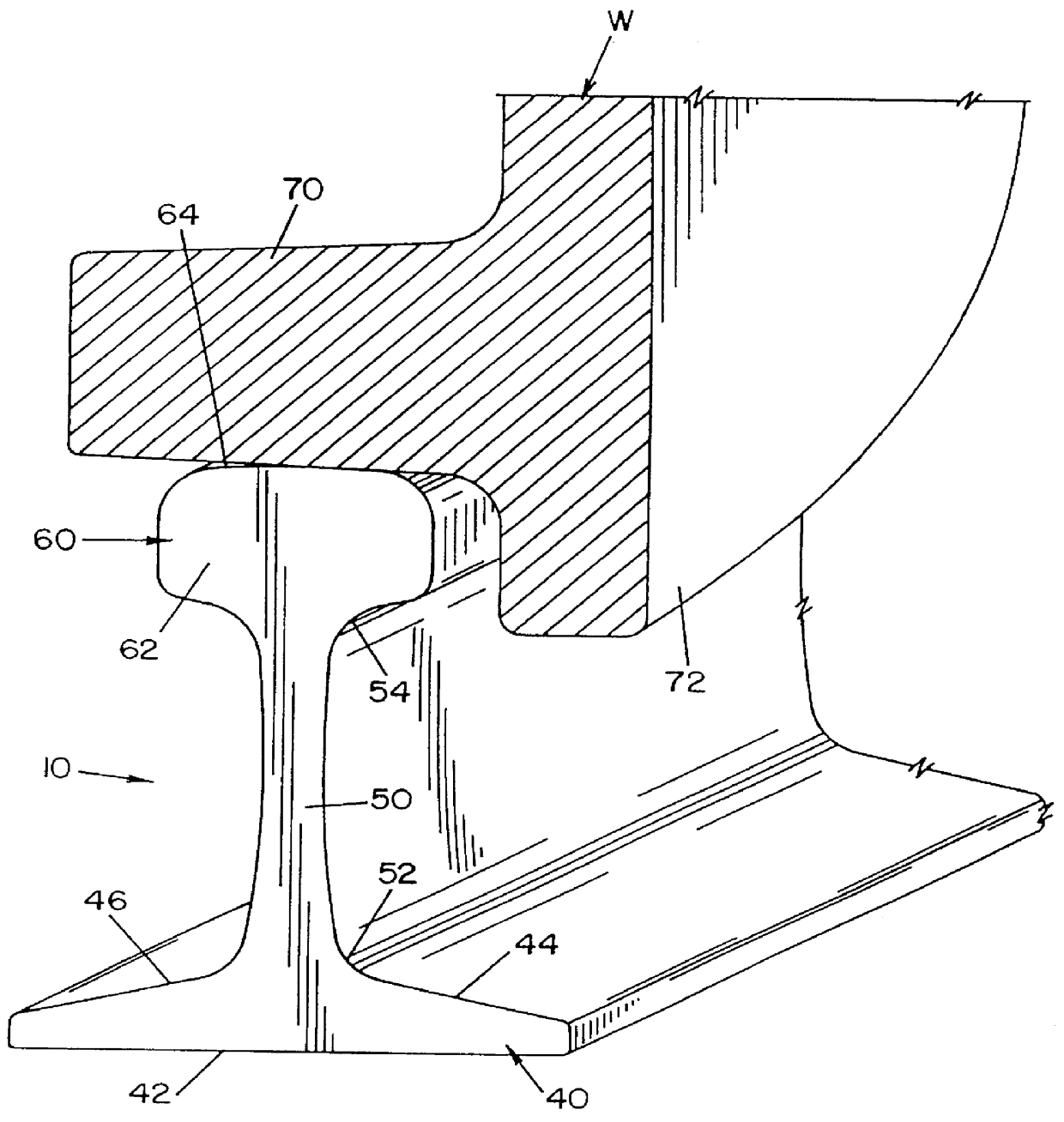

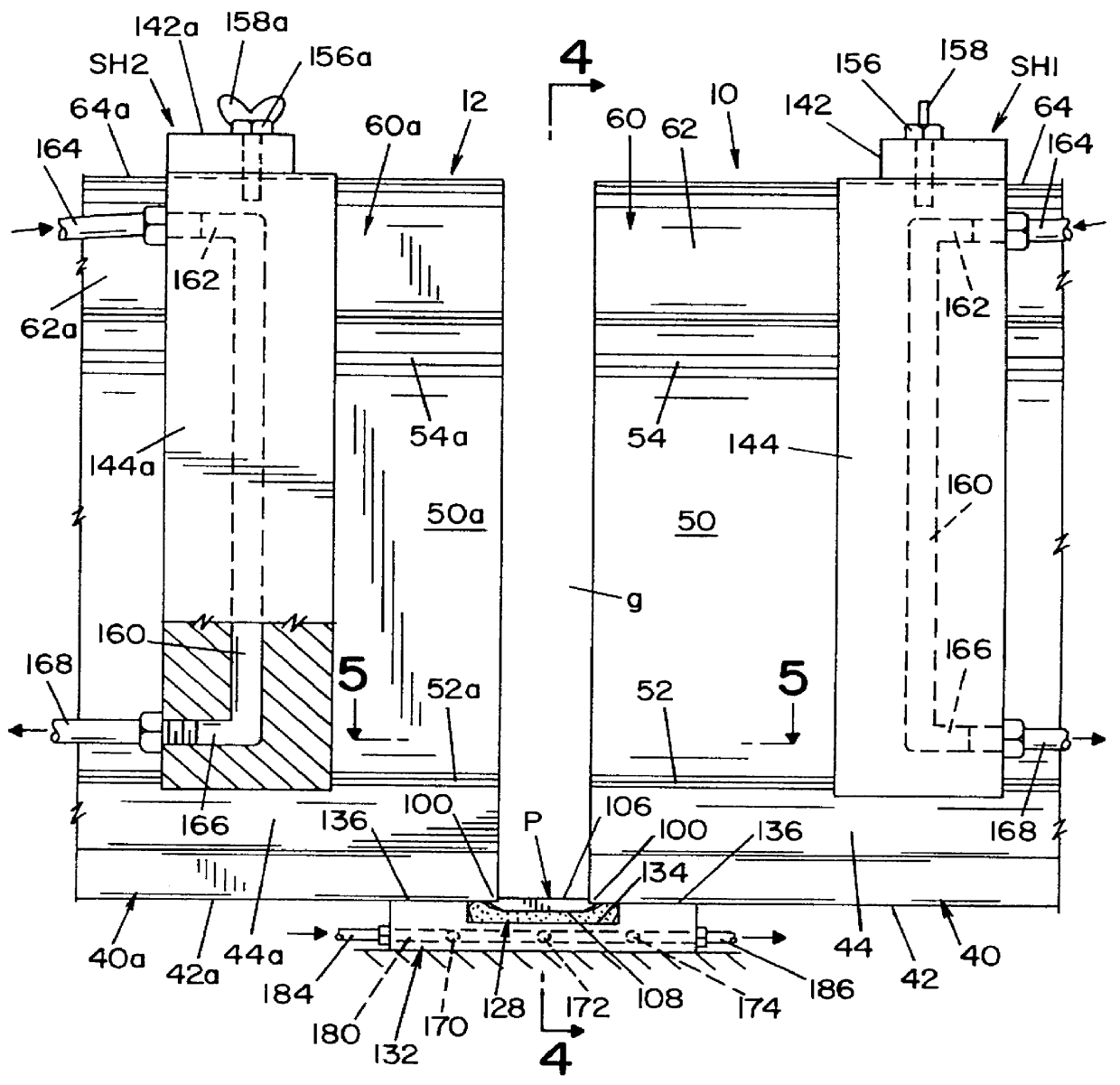

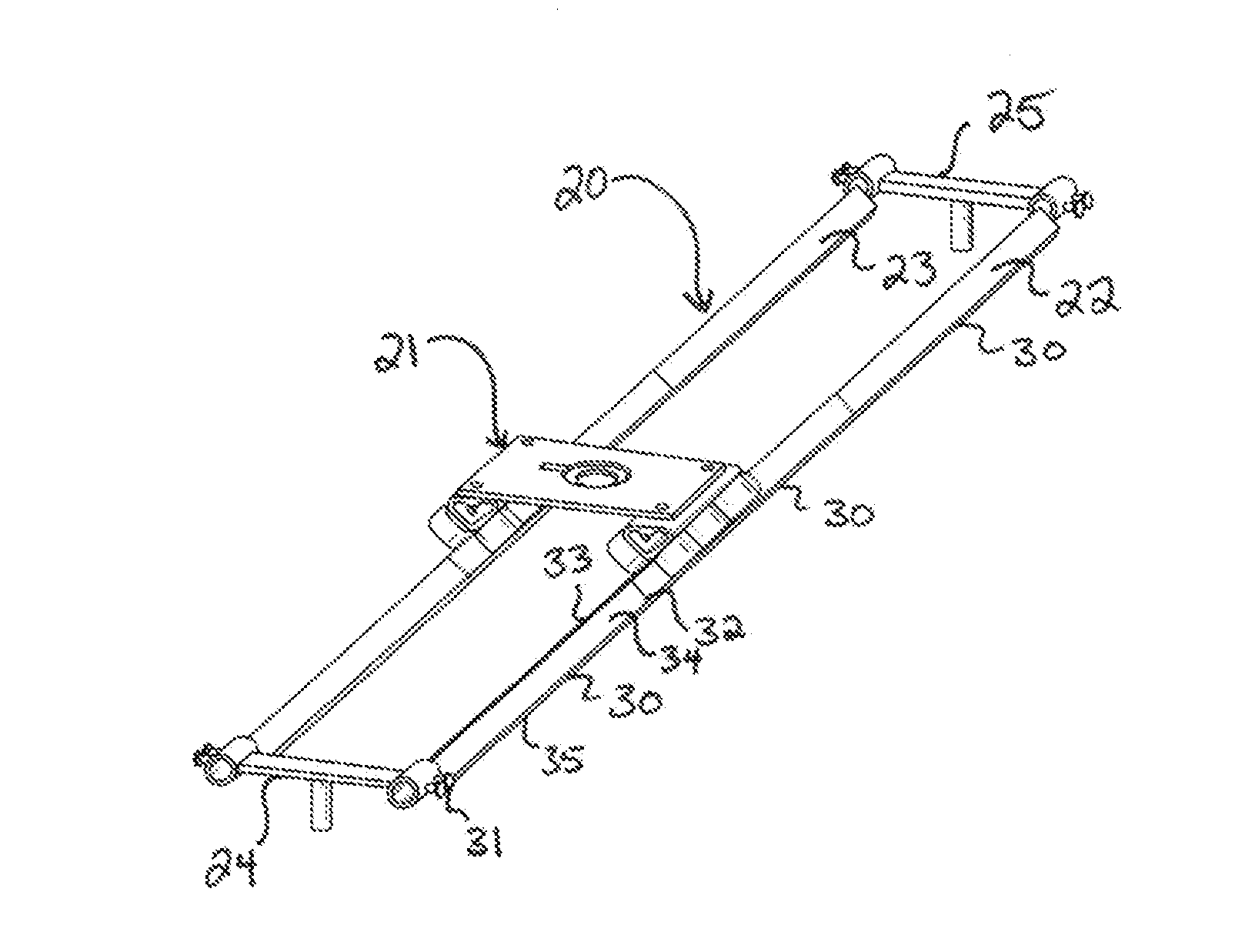

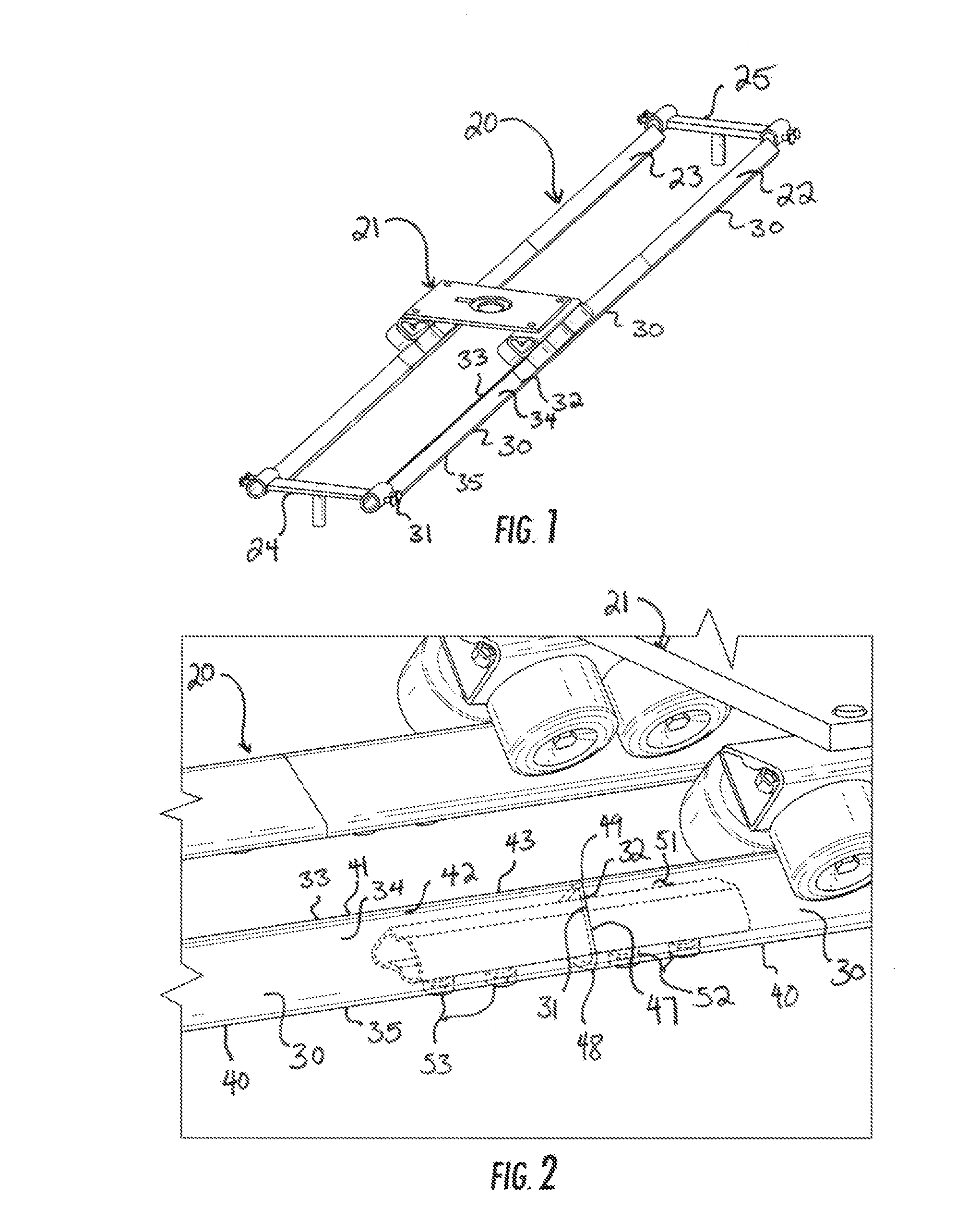

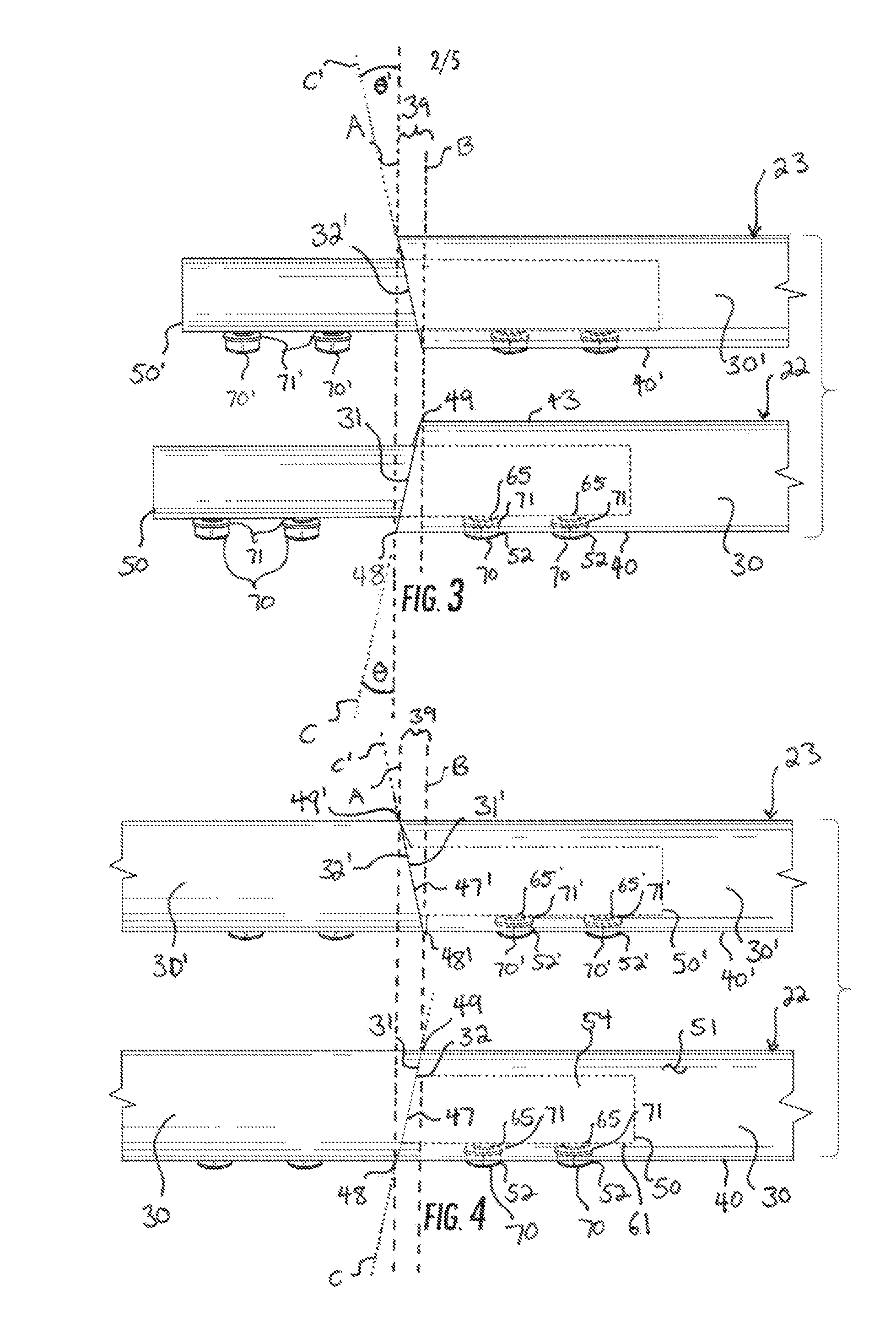

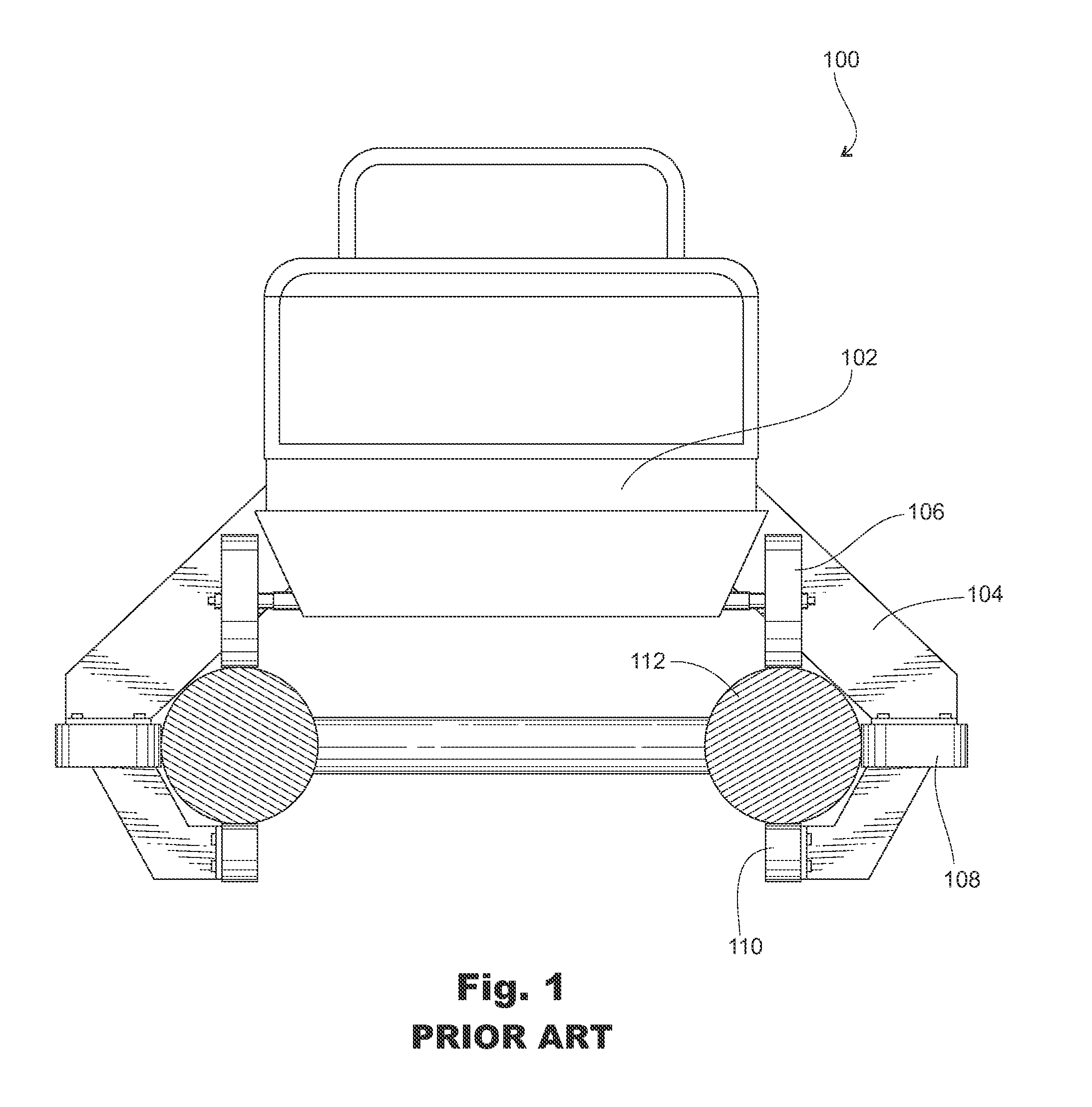

Camera Dolly Track Assembly

A support for a camera dolly comprising spaced-apart first and second rails comprised of longitudinal rail members. The first rail has a first seam between its rail members, and the second rail has a second seam between its rail members. The first seam in the first rail is directly opposed from a corresponding second seam in the second rail. The first and second seams have first and second leading edges formed at crowns on the first and second rails, and the leading edge of the first seam is offset longitudinally with respect to the leading edge of the corresponding second seam.

Owner:AZGRIP COM

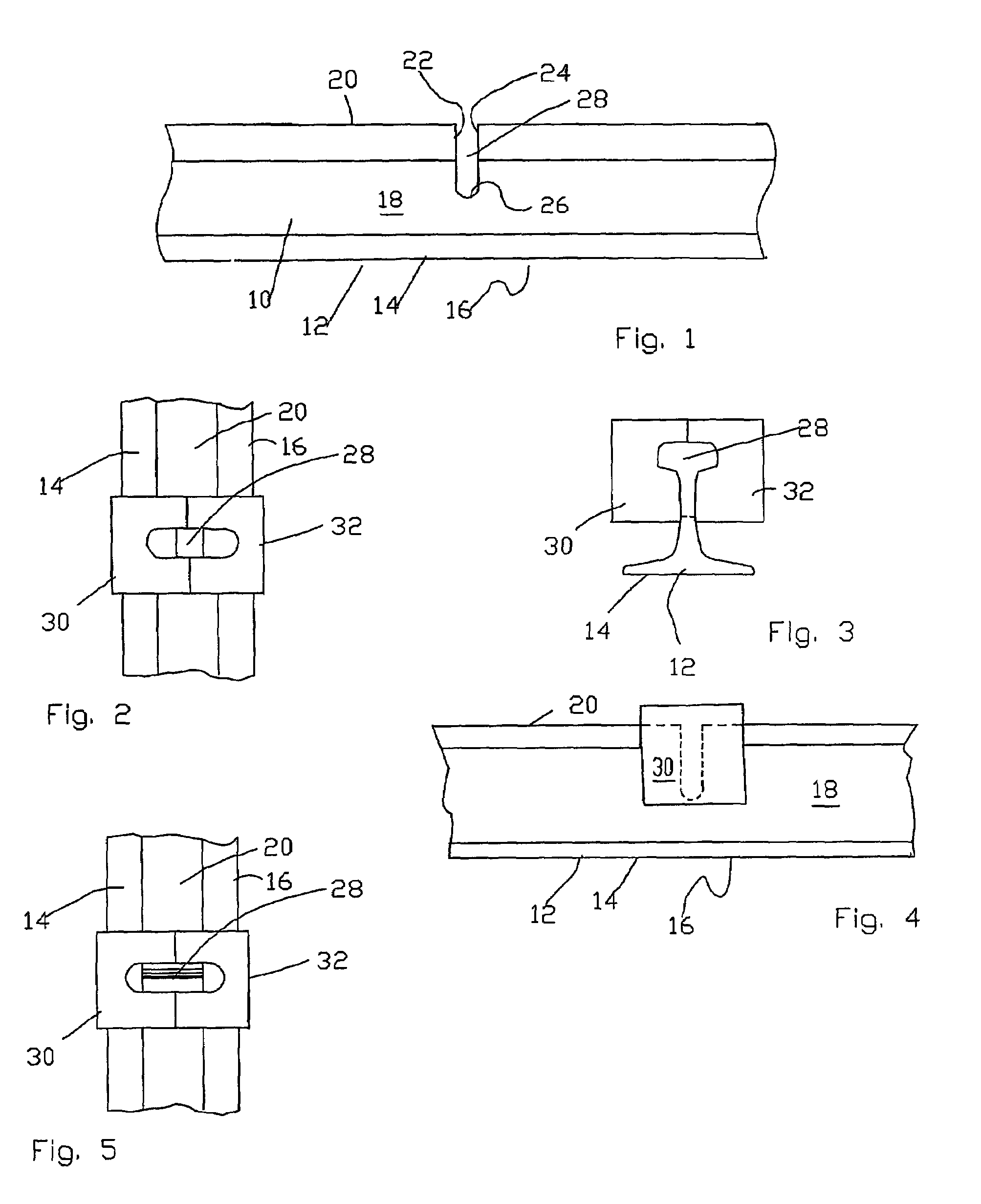

Method of repairing a rail

InactiveUS7520415B2High hardnessReduce hardnessRailsArc welding apparatusMaterials scienceMolten metal

A system or method of repairing railroad rails which includes a head, upright and base sections. The method includes at least the following steps: identifying and locating a defect in the rail, removing the defect by removing material from the rail surrounding the defect in at least the head section so as to form a void and a rail void interface while maintaining continuity of the rail, filling the void with molten metal having a high carbon content and causing the molten metal and the rail void interface to bond. The molten metal may be produced by gas shielded arc welding. The carbon content of the molten metal is near that of the rail to decrease carbon migration from the rails. High carbon welding electrode is used in the welding of high strength steel using gas shielded arc welding techniques whereby a plurality of beads of molten weld material join together rail ends or fill a slot in a rail for repair purposes, the high carbon electrode avoiding adjacent soft and brittle areas across a weld fusion line which result from migration of carbon from the carbon rich high strength steel to the lower carbon weld deposit.

Owner:HOLLAND CO

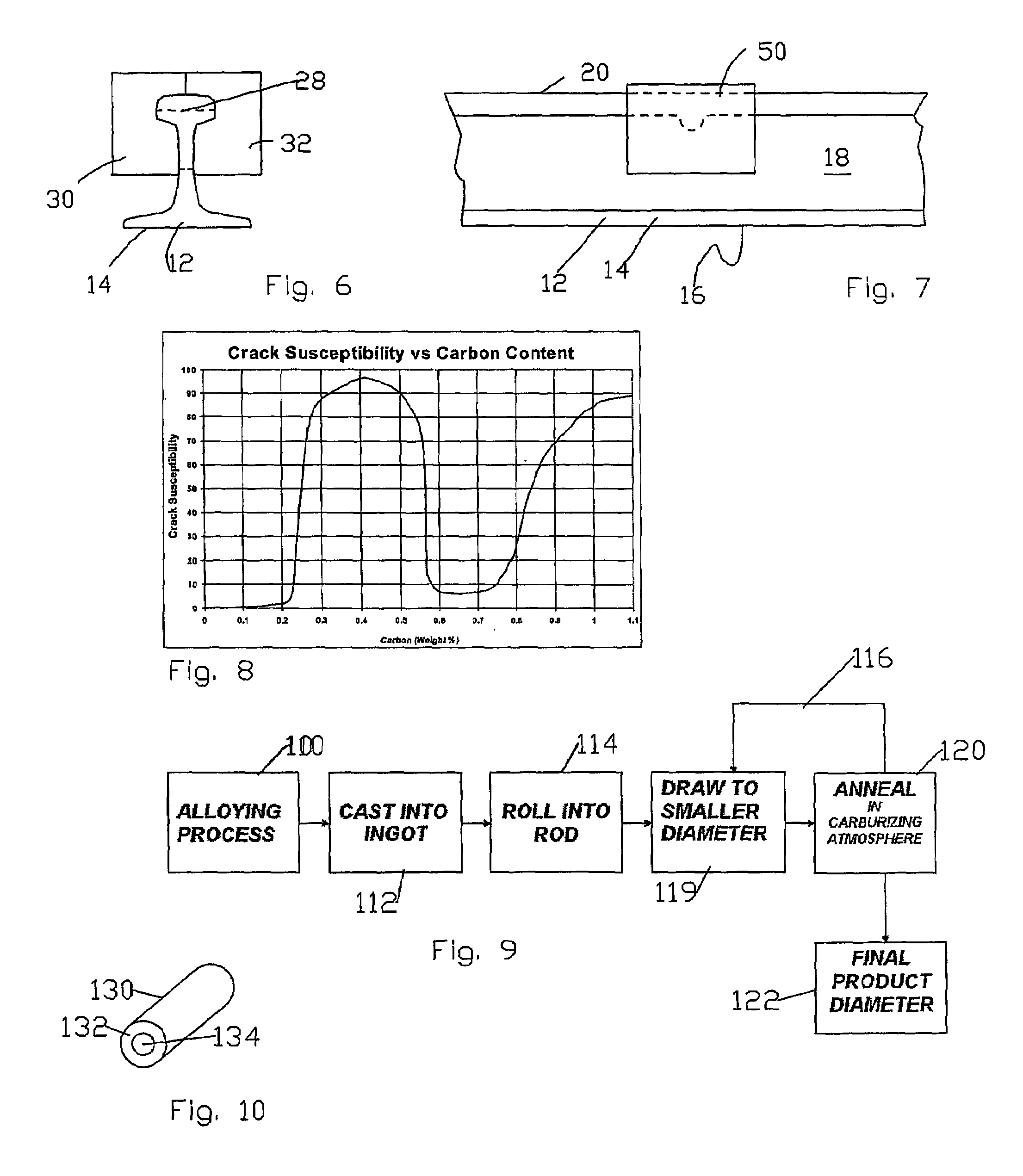

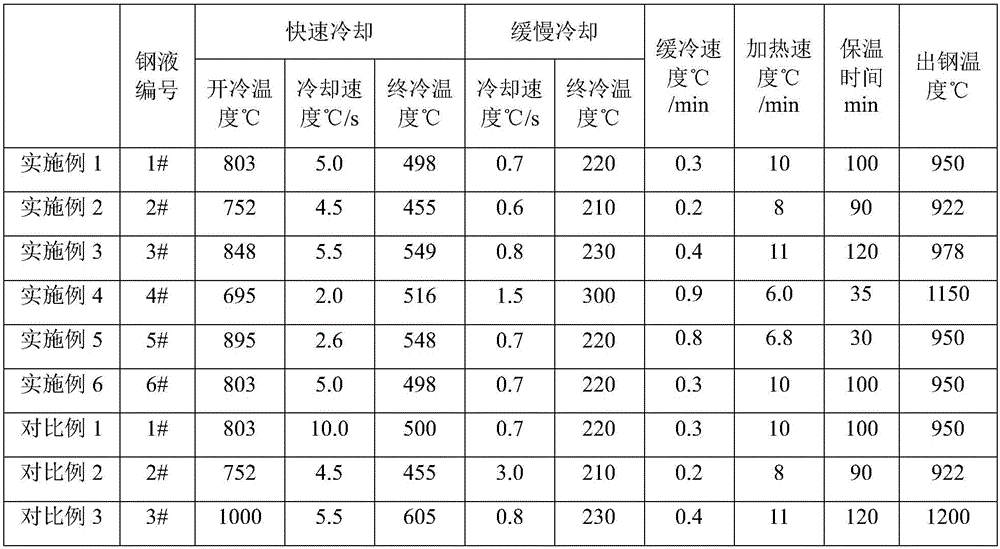

Method for reducing residual stress of steel rail, obtained steel rail and application of steel rail

ActiveCN106086370AReduce residual stressImprove straightnessRailsFurnace typesSlow coolingCooling temperature

The invention relates to the field of steel making, in particular to a method for reducing the residual stress of a steel rail, the steel rail obtained according to the method, and the application of the steel rail. The method for reducing the residual stress of the steel rail comprises the step of sequentially carrying out accelerated cooling, slow cooling and air cooling on the rail head tread centers, the two sides of each rail head and the center part of the rail base of the steel rail obtained after rolling, wherein the starting cooling temperature of accelerated cooling is 650 DEG C to 950 DEG C, the cooling rate of accelerated cooling is 2 DEG C per second to 8 DEG C per second, the finish cooling temperature of accelerated cooling is 400 DEG C to 600 DEG C, the cooling rate of slowing cooling is 0.1 DEG C per second to 1.5 DEG C per second, and the finish cooling temperature of slow cooling is 180 DEG C to 300 DEG C. With the method for reducing the residual stress of the steel rail, on the premise that the tensile property of the steel rail is guaranteed, the residual stress of the steel rail can be effectively reduced, and the flatness of the steel rail can be improved. The steel rail is particularly suitable for high-speed railways.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

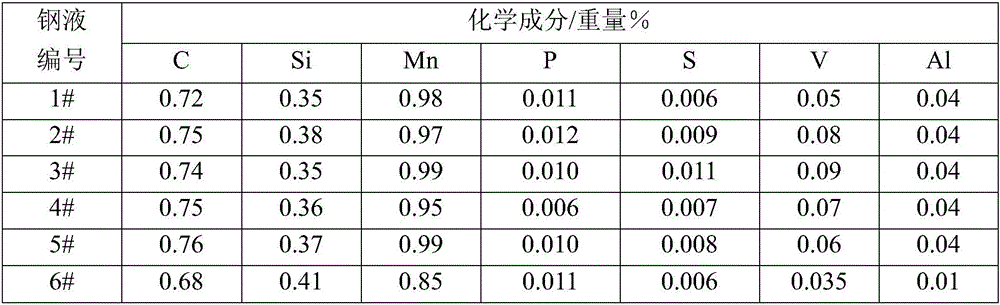

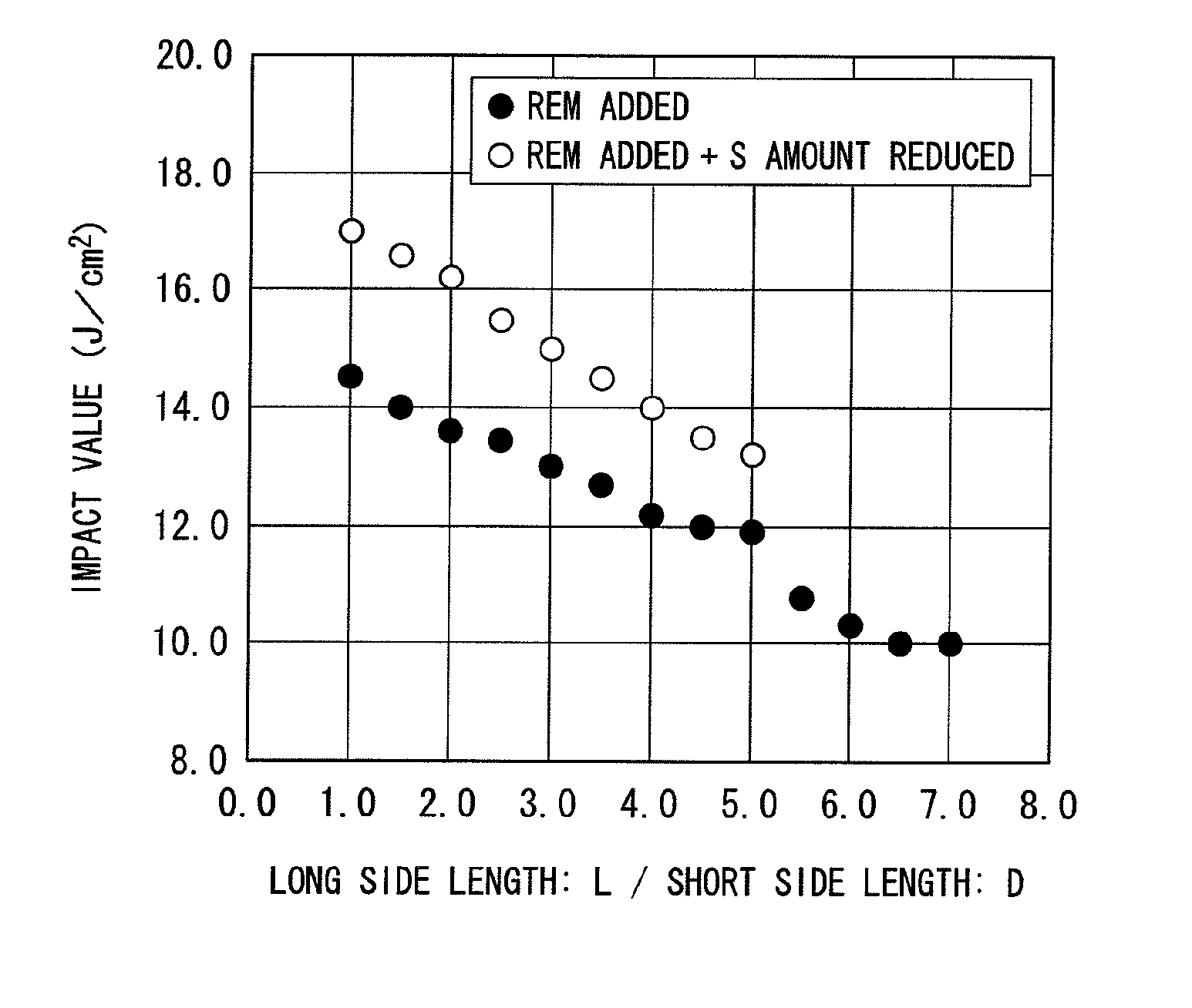

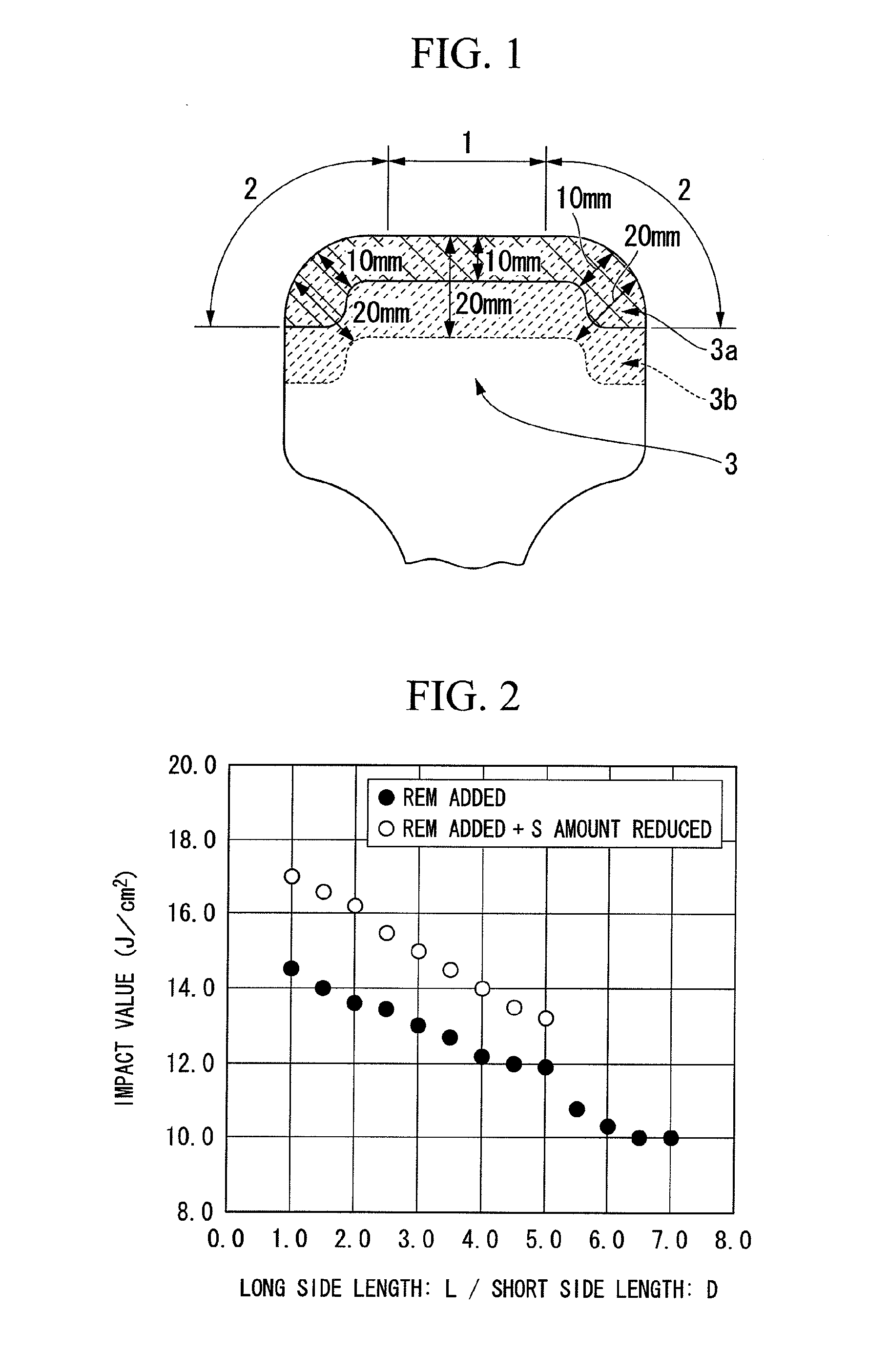

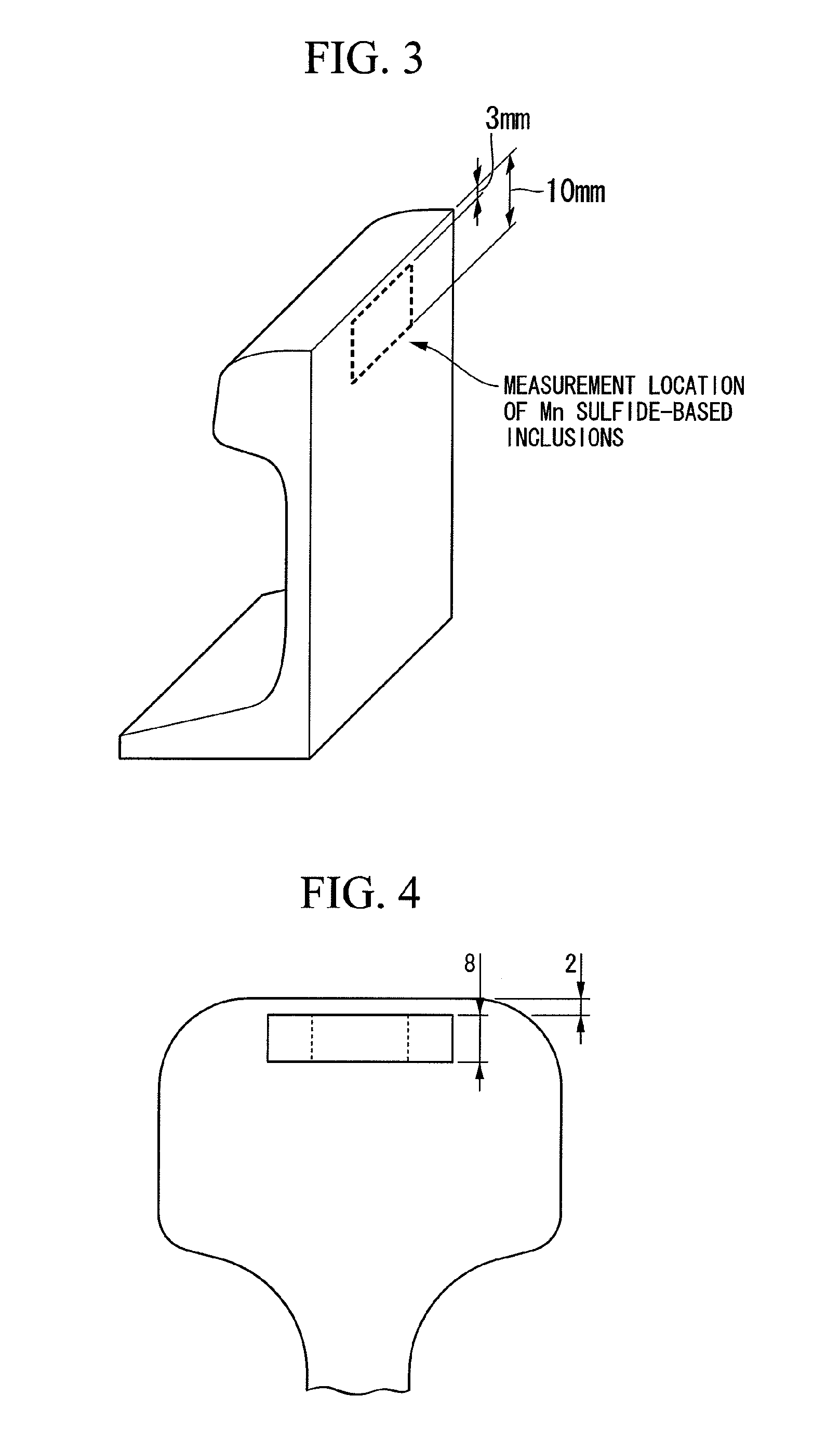

Pearlitic rail with excellent wear resistance and toughness

This pearlitic rail consists of a steel including: in terms of percent by mass, C: 0.65% to 1.20%; Si: 0.05% to 2.00%; Mn: 0.05% to 2.00%; and REM: 0.0005% to 0.0500%, with the balance being Fe and inevitable impurities, wherein, in a head portion of the rail, a head surface portion which ranges from surfaces of head corner portions and a head top portion to a depth of 10 mm has a pearlite structure, and the hardness Hv of the head surface portion is in a range of 320 to 500.

Owner:NIPPON STEEL CORP

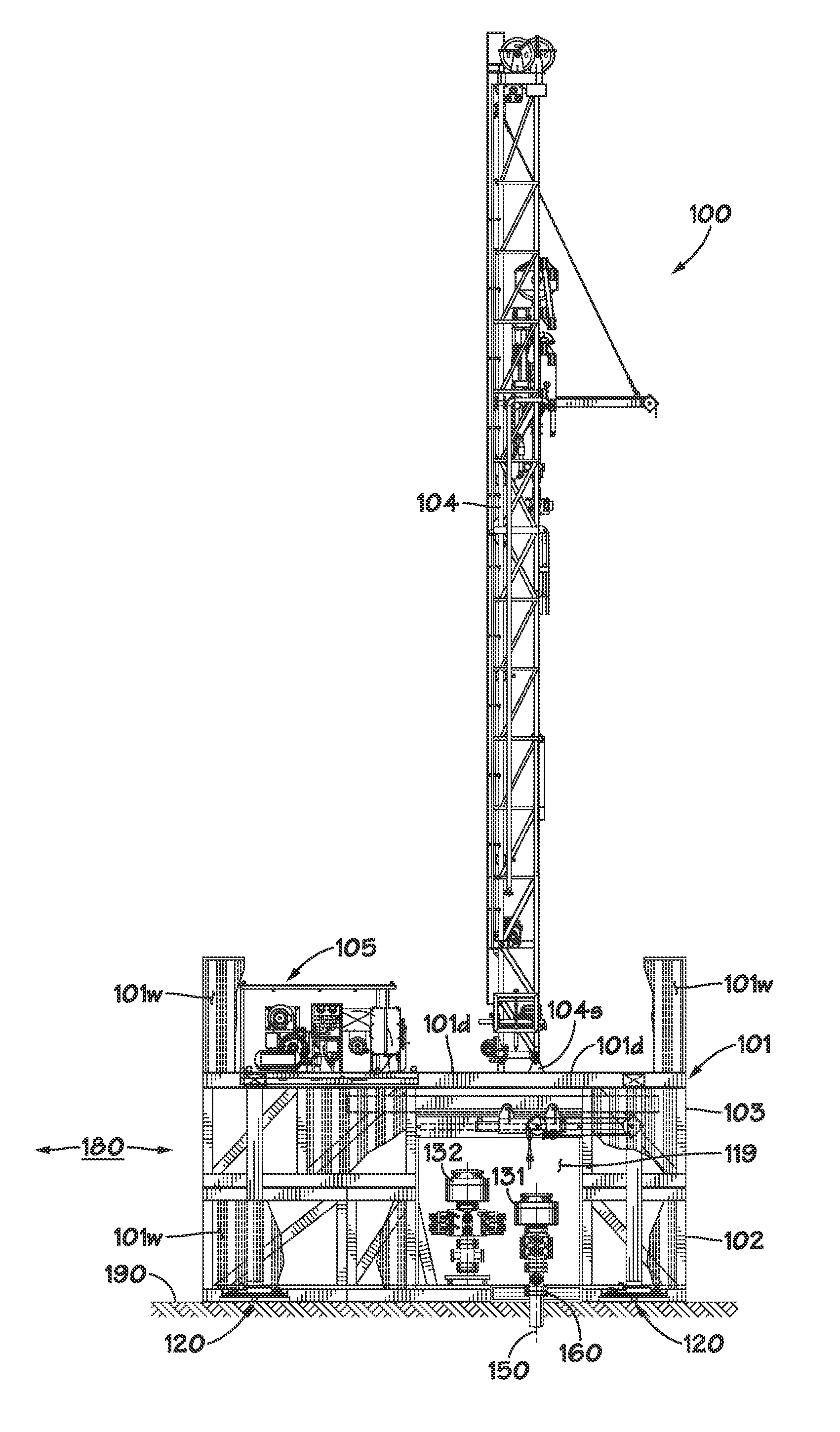

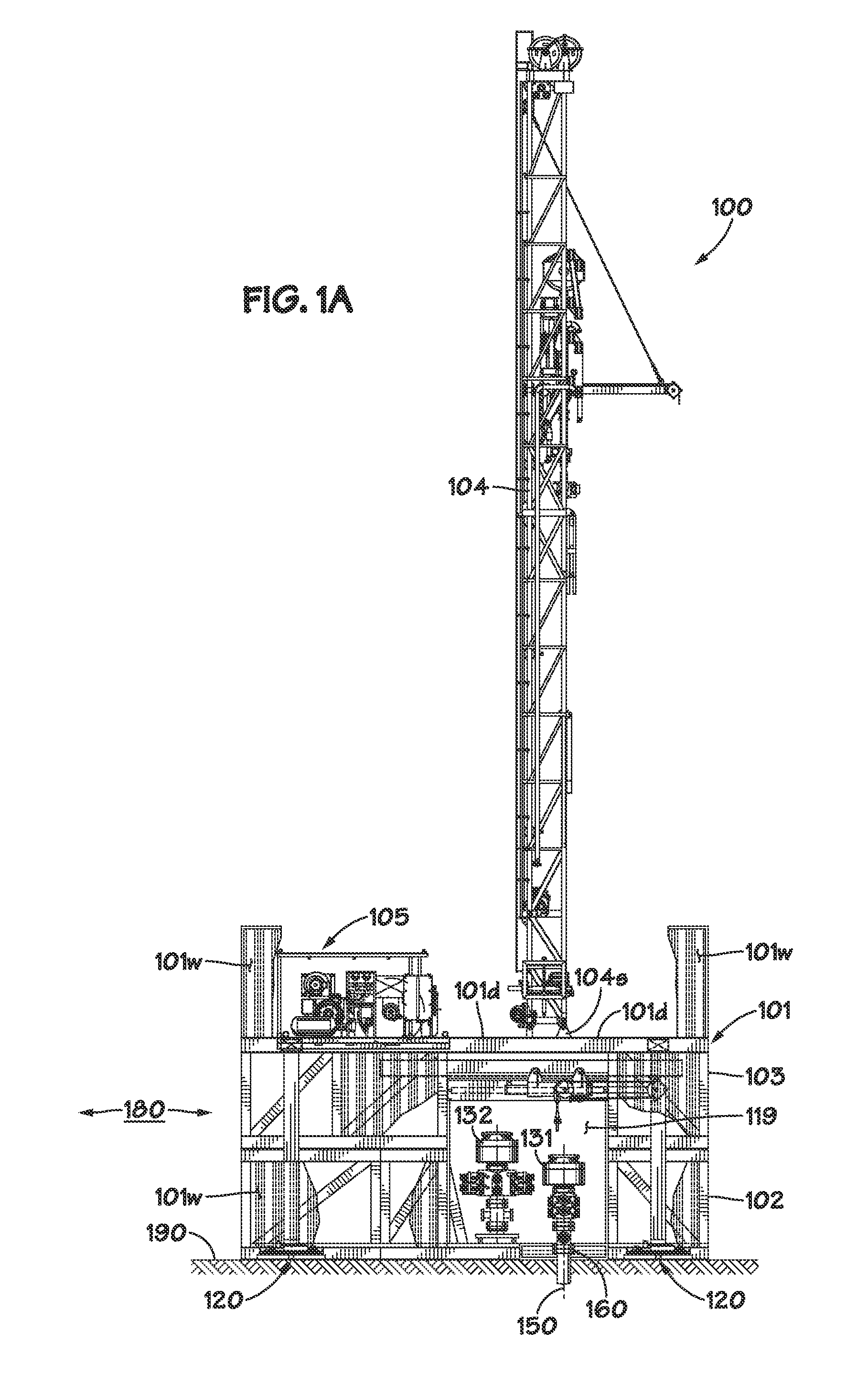

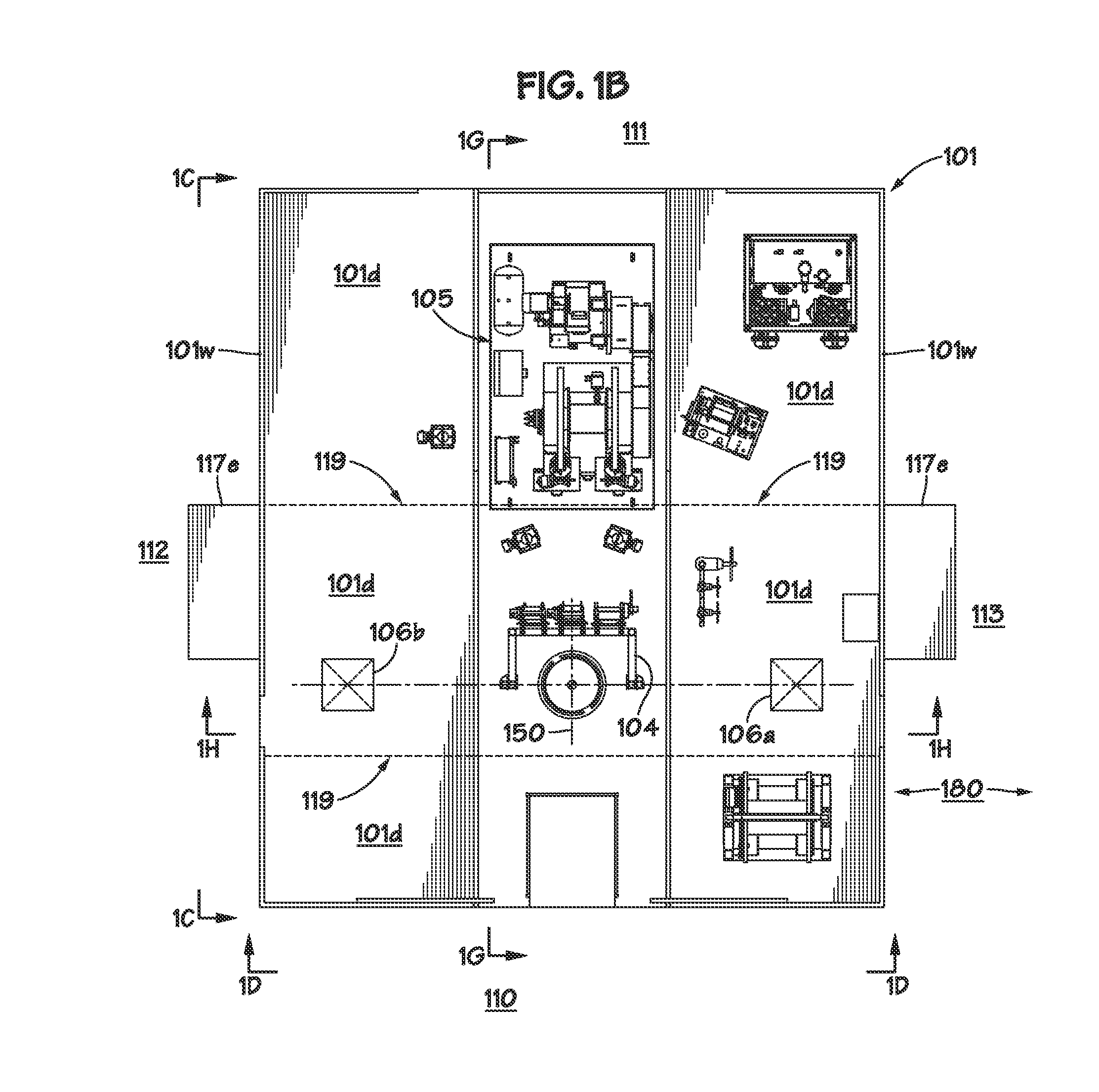

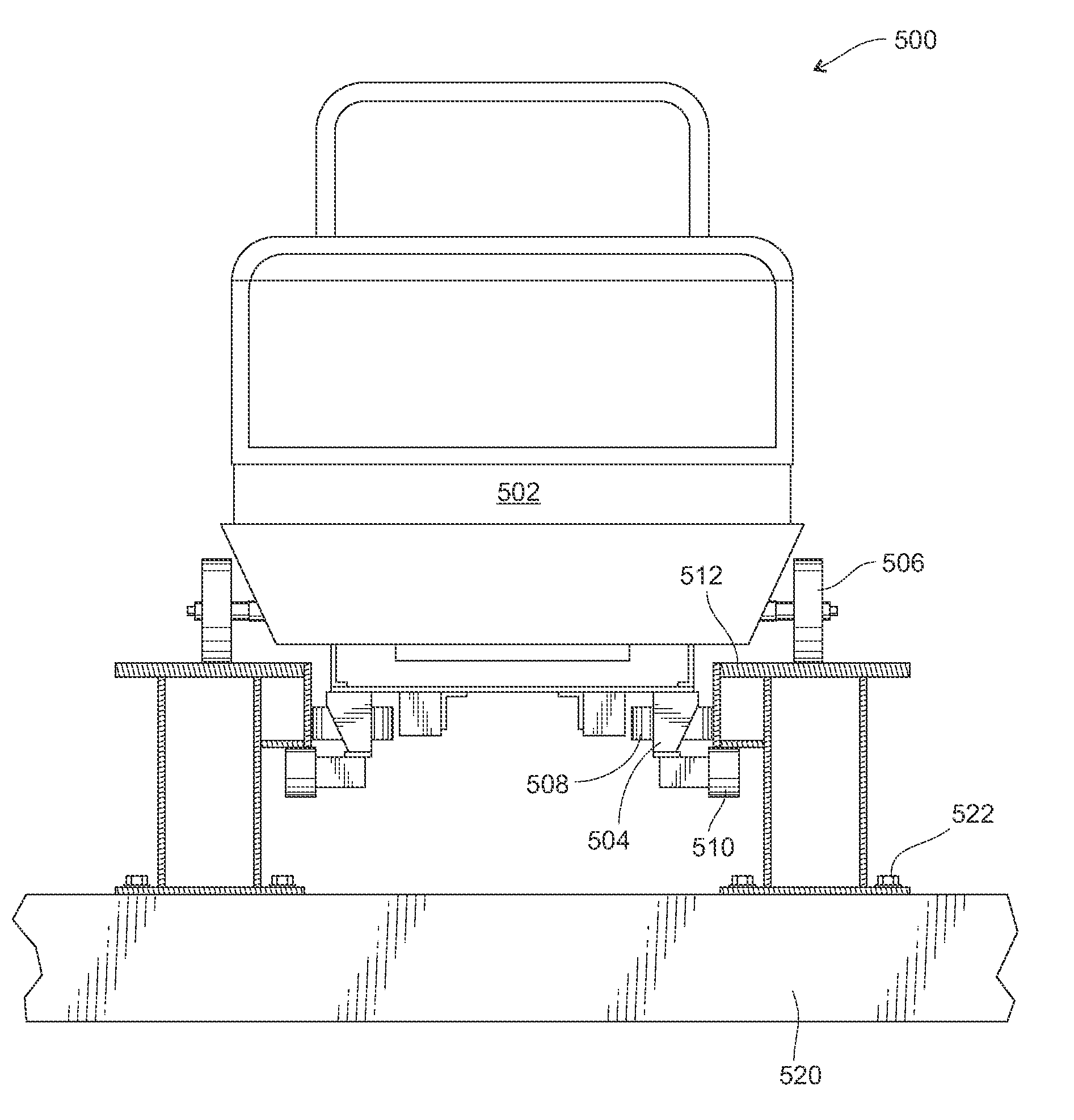

Performing simultaneous operations on multiple wellbore locations using a single mobile drilling rig

A system is disclosed that includes a drilling rig having a substructure, the drilling rig being adapted to be positioned above a plurality of wellbore location such that each of the plurality of wellbore locations is simultaneously positioned below the substructure, equipment movement means for moving pressure control equipment between positions proximate each of the plurality of wellbore locations, the equipment movement means being adapted to move the pressure control equipment between the positions while the drilling rig is performing a rig operation on at least a first one of the plurality of wellbore locations, and equipment positioning means for positioning pressure control equipment on one or more of the plurality of wellbore locations, the equipment positioning means being adapted to position the pressure control equipment on a second one of the plurality of wellbore locations while the rig operation is being performed on the first wellbore location.

Owner:NAT OILWELL VARCO LP

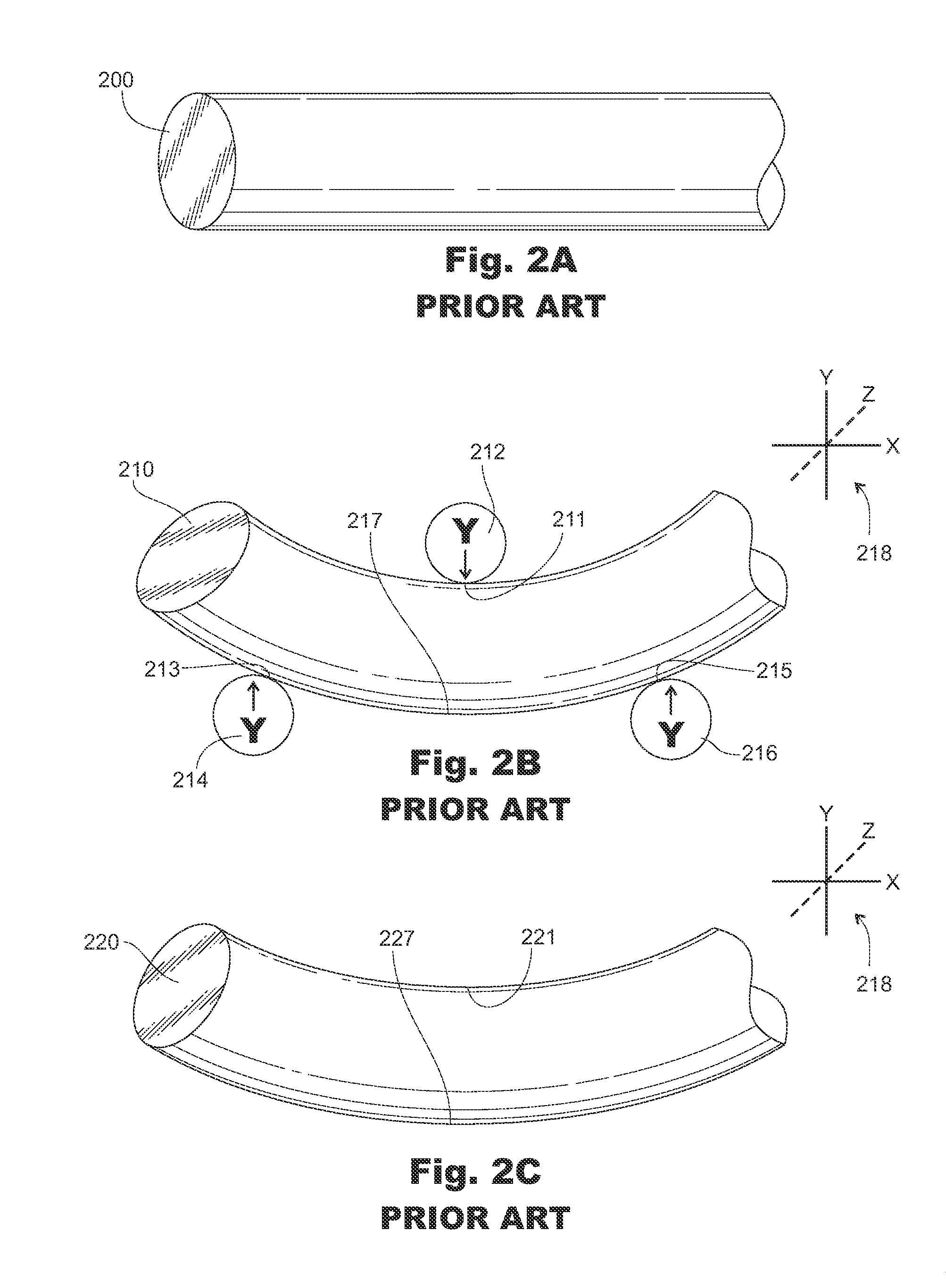

Rolling Vehicle Track

A method of fabricating an amusement park ride track utilizing stock, planar materials, namely comprising of creating elongated, curved structures from planar materials. A roller coaster track capable of being fabricated from multiple planar pieces without heating or bending. Other embodiments are described which utilize elongated, curved structures such as ski lifts, people movers, staircases and architectural structures. A jig is disclosed for providing for ease of manufacture of the elongated, curved structures.

Owner:ROCKY MOUNTAIN COASTERS

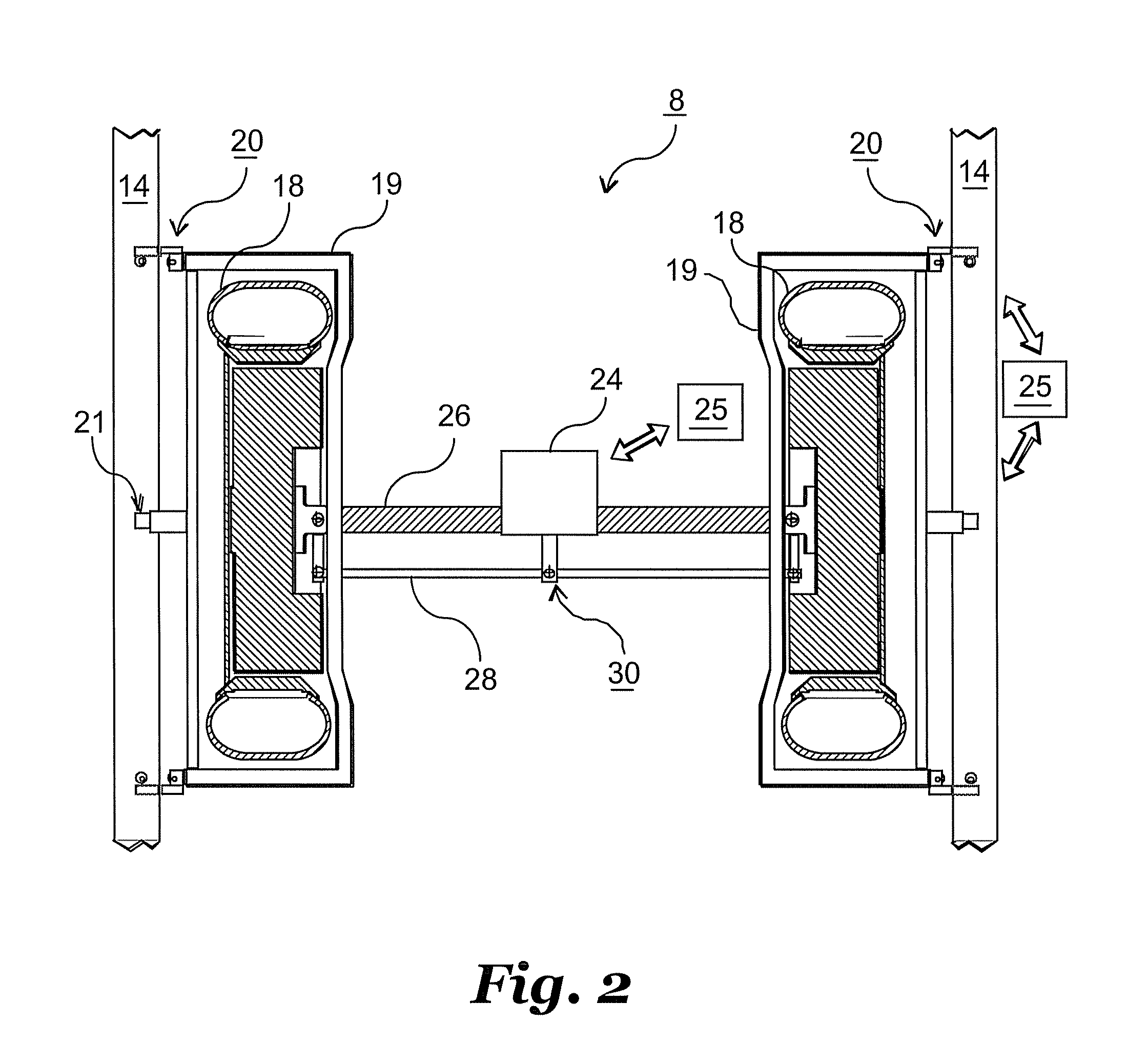

Redundant steering system for guideway vehicle

A guideway system and method of operating a guideway is included comprising a guideway with entrance and exit ramps and vehicles having both a smooth, servo-based primary steering systems based upon proximity sensing of the side of the guideway and a backup mechanical steering system. The backup steering system is selectively engaged and disengaged based on location with respect to the entrance and exit ramps and provides vehicle wheel steering in the event of a failure of the primary servo steering system. The backup steering comprises one or more vertical members affixed to the guideway and one or more steering elements engageable with the member(s). The elements may be pivoted into and out of backup steering engagement.

Owner:HENDERSON JOY KIRSTON

Railroad rail having thermal insulation below the railhead either coated in the field or at the rail production facility

Owner:JONES PAUL

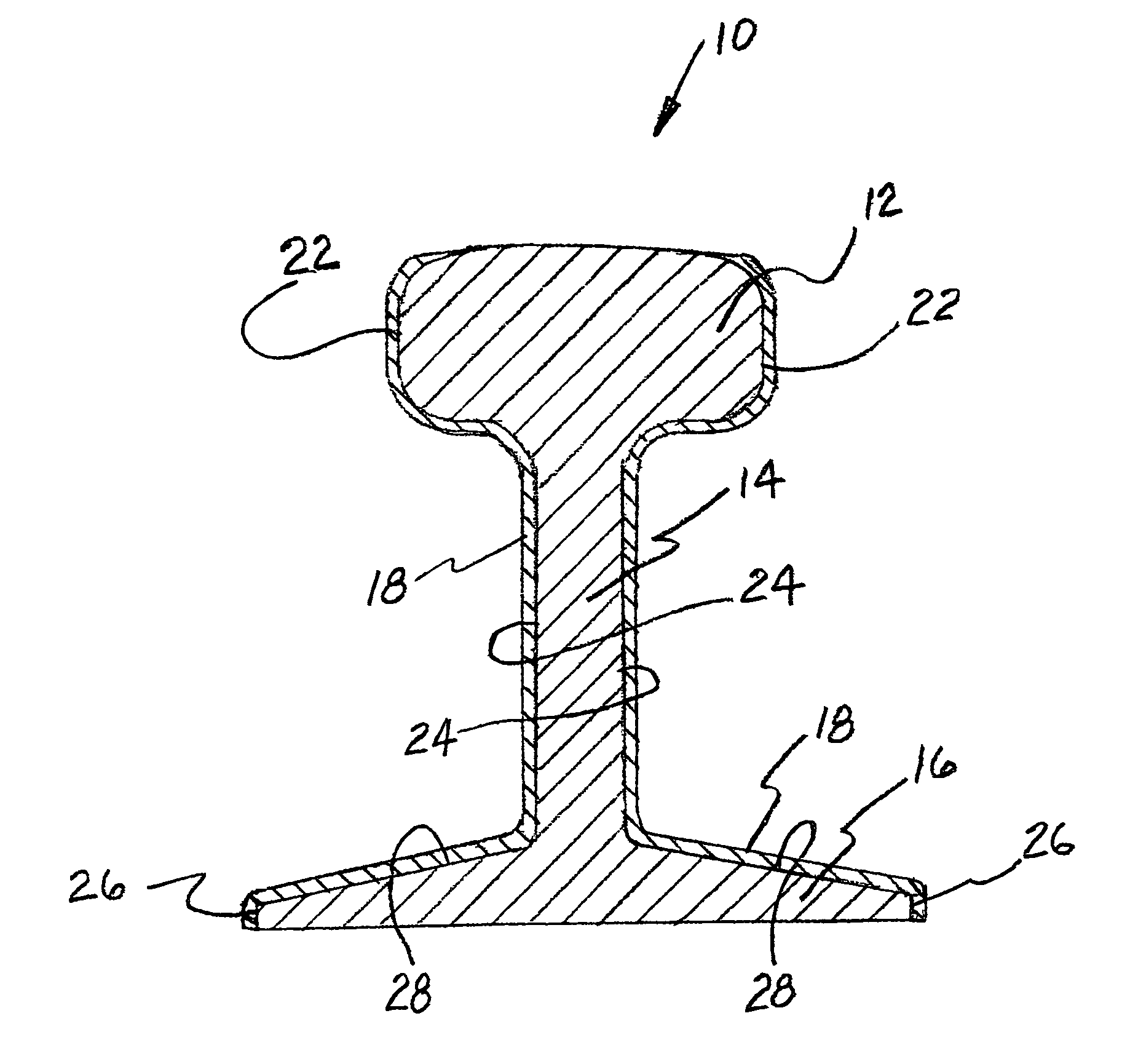

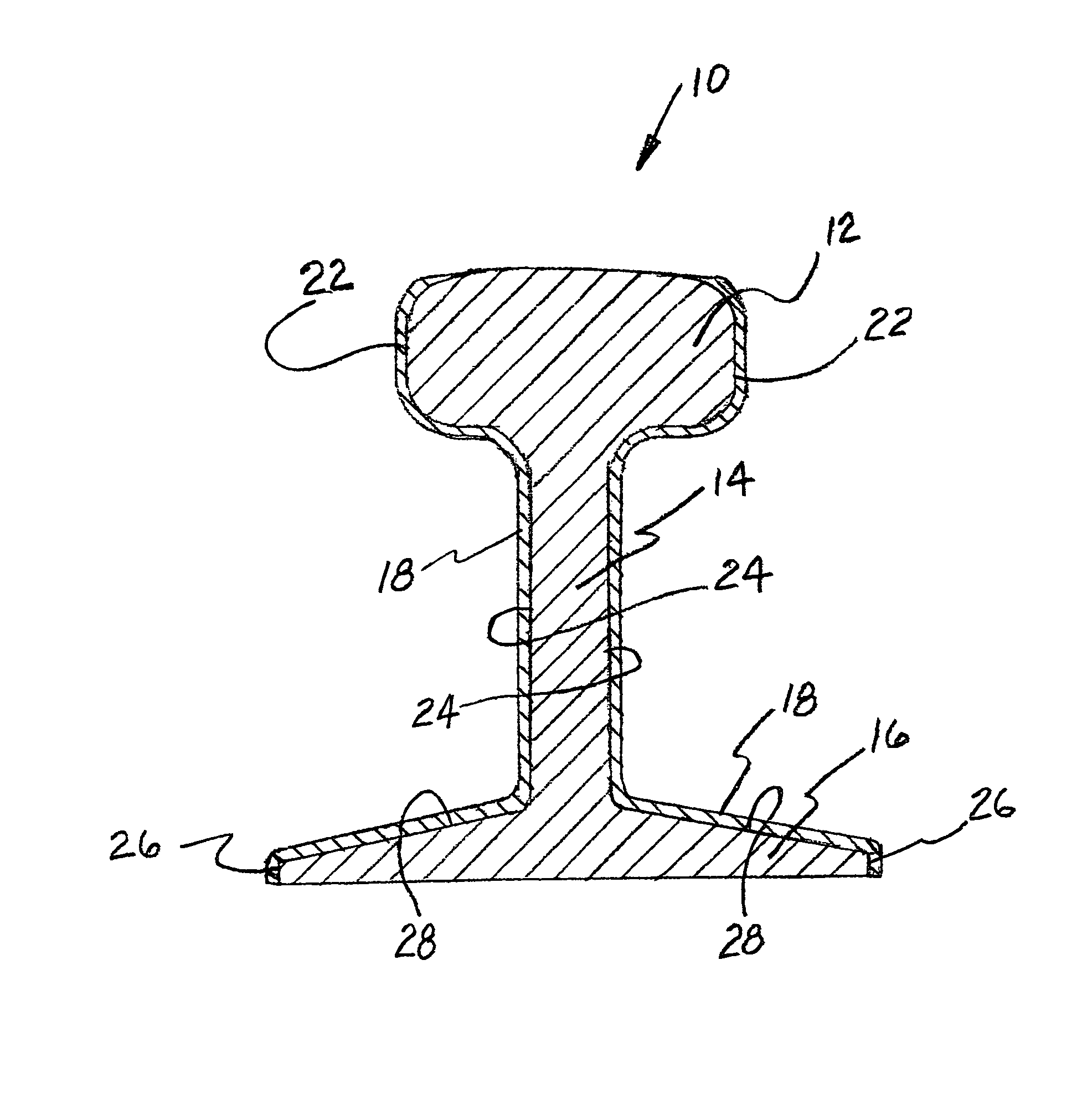

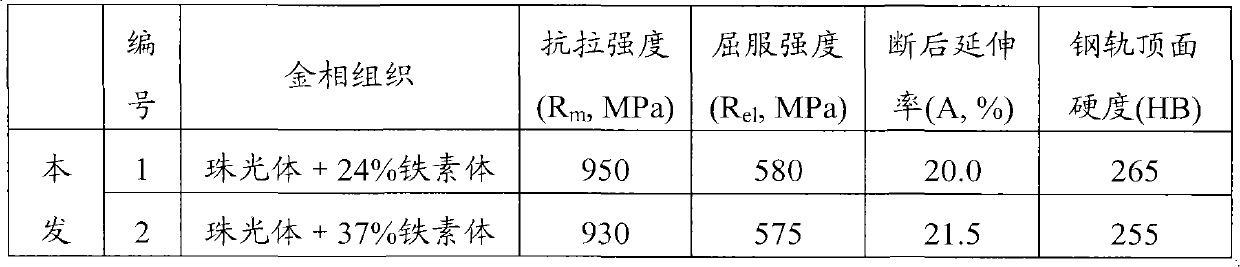

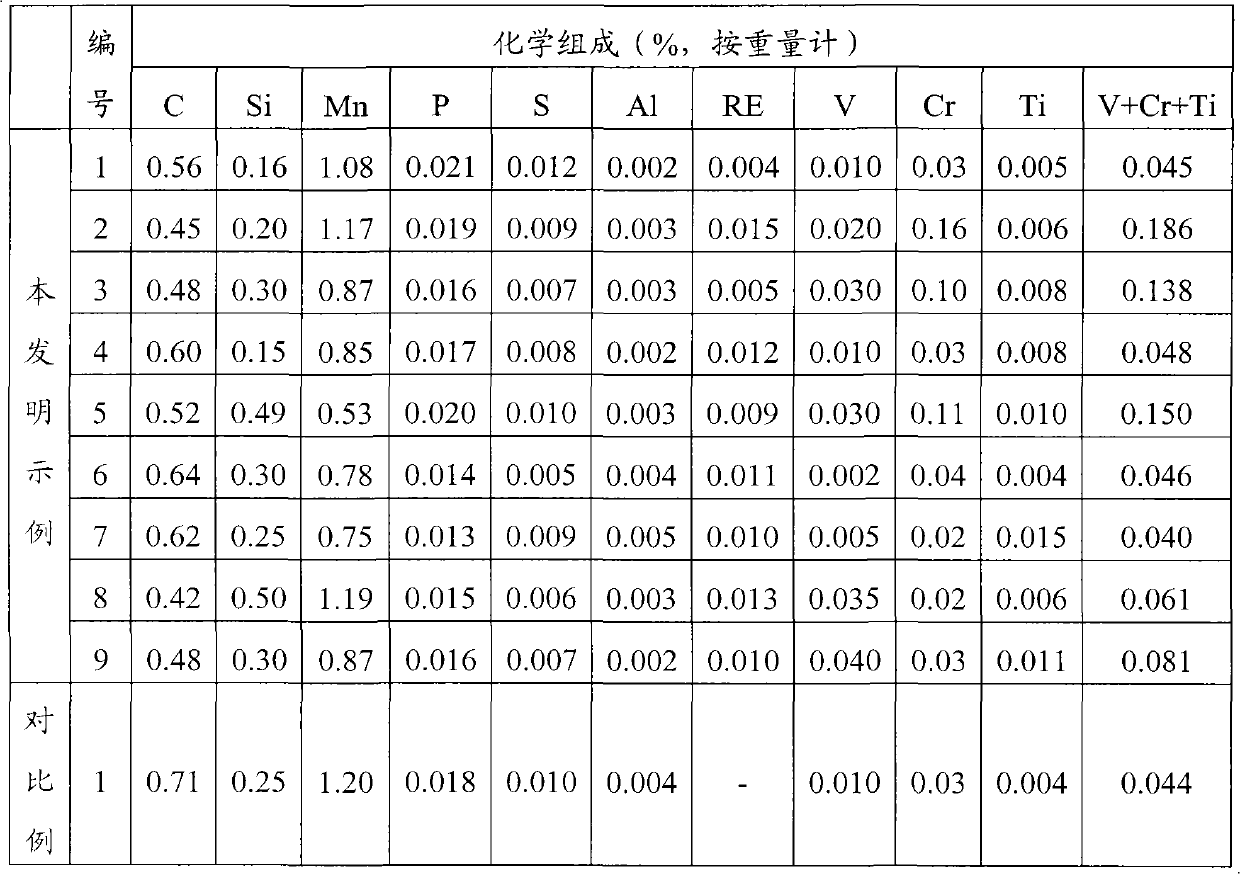

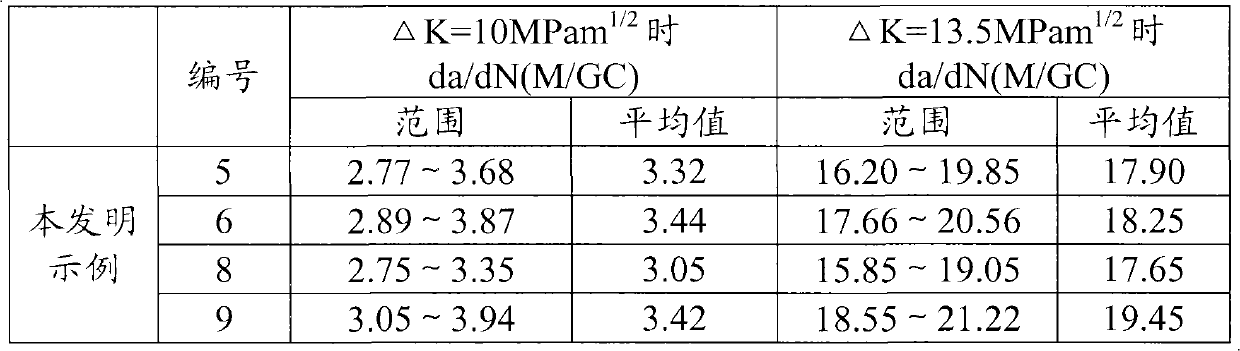

Steel rail used for high-speed and quasi-high speed railways and manufacturing method thereof

ActiveCN101921950AImprove toughnessHigh yield strengthRailsFurnace typesRare-earth elementChemical composition

The invention discloses a steel rail used for high-speed and quasi-high speed railways and a manufacturing method thereof. The method comprises: reducing carbon content and utilizing a mode of controlled cooling after rolling to manufacture the steel rail with favorable rolling contact fatigue performance. The steel rail comprises the following chemical compositions by weight percent: 0.40%-0.64% of C, 0.10%-1.00% of Si, 0.305-1.50% of Mn, less than or equal to 0.025% of S, less than or equal to 0.005% of Al, greater than 0% and less than or equal to 0.05% of rare-earth elements, greater than 0% and less than or equal to 0.20% of at least one of V, Cr and Ti and the balance of Fe and inevitable impurities. The steel rail manufactured by the method of the invention maintains the strength and hardness of the existing steel rail of the high-speed railways, and simultaneously has improved plasticity and yield strength; and the energy value needed for initiation and expansion of fatigue microcracks formed on the surface of the steel rail is improved, thus the rolling contact fatigue performance of the steel rail can be improved under the same condition, and finally the service life and transportation safety of the steel rail are improved.

Owner:PANZHIHUA IRON AND STEEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com