Hyper-eutectoid steel rail and manufacturing method thereof

A hypereutectoid, rail technology, applied in the direction of rails, rails, manufacturing tools, etc., can solve the problem of difficult to meet the needs of large axle load transportation, and achieve the effect of excellent corrosion resistance and excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The invention provides a method for preparing a hypereutectoid rail, the method comprising:

[0012] Roll the steel slab after the heat preservation treatment to obtain the rail. After the surface temperature of the rail head is naturally cooled to 750-850°C, the cooling medium is used for the first cooling stage to reduce the surface temperature of the rail head to 350-550°C, and then air-cooled The second cooling stage is carried out in a manner to reduce the surface temperature of the rail head to 15-40°C, wherein,

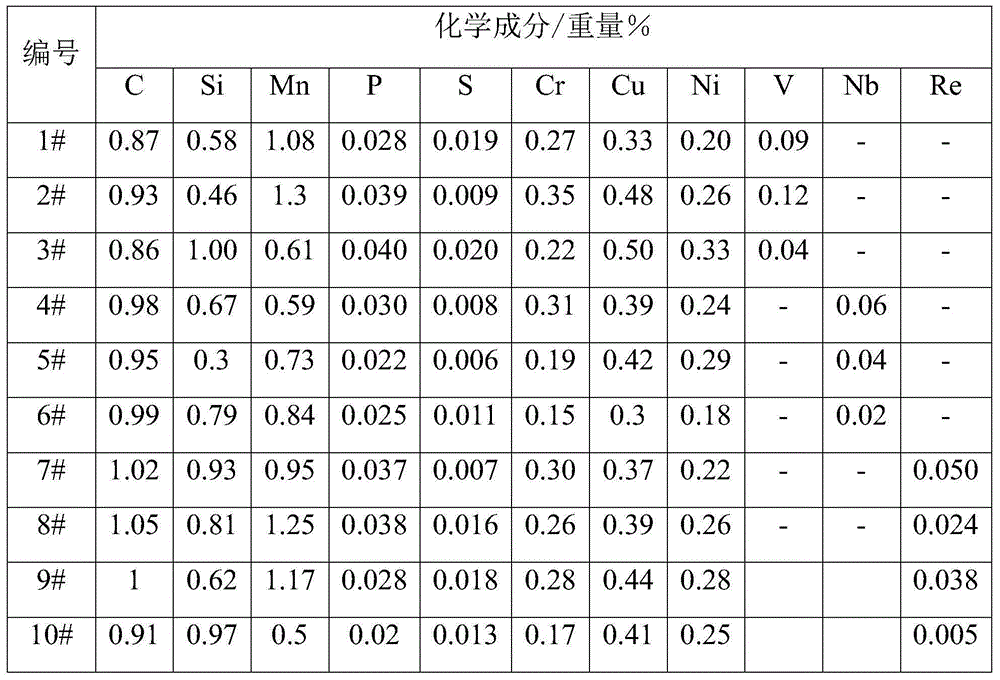

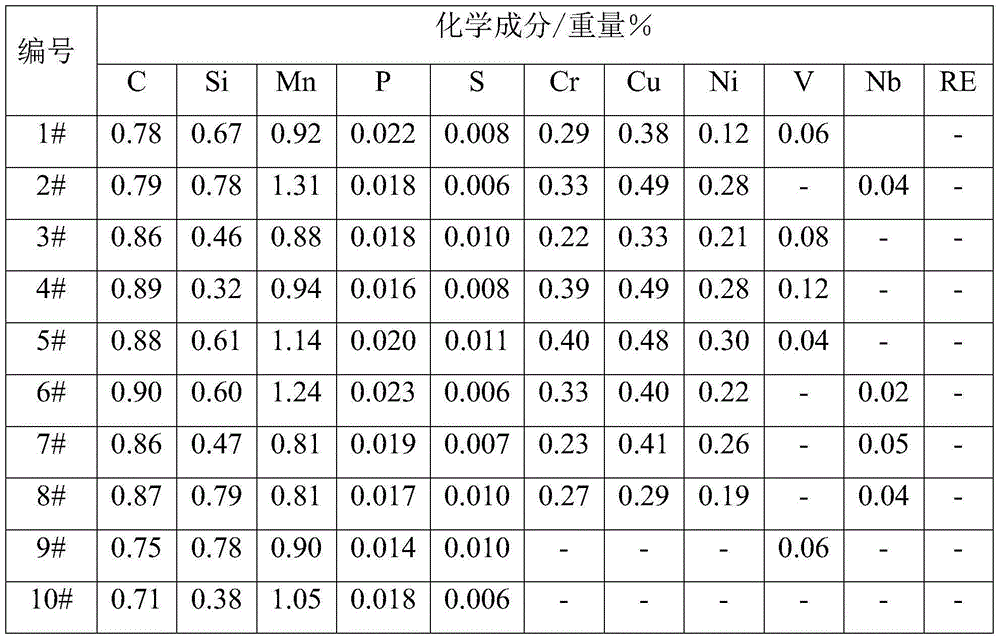

[0013] The composition of the billet is: 0.86-1.05% by weight of C, 0.3-1% by weight of Si, 0.5-1.3% by weight of Mn, 0.15-0.35% by weight of Cr, 0.3-0.5% by weight of Cu, 0.02-0.04% by weight %P by weight, S with a content of 0.02% by weight or less, and Ni with a content of 1 / 2-2 / 3 of Cu, and at least one of V, Nb and Re, and the balance is Fe and unavoidable impurities; Wherein, under the condition that at least one of V, Nb and Re is contained, the ...

Embodiment 1-10

[0035] This embodiment is used to illustrate the hypereutectoid rail of the present invention and its preparation method.

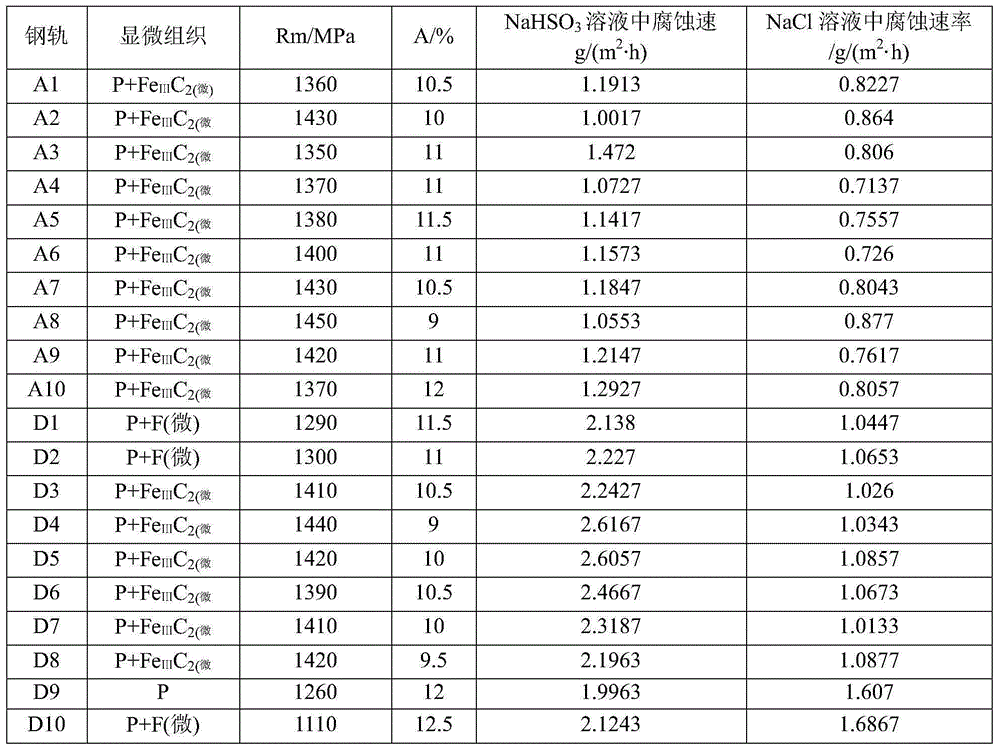

[0036] The 1# to 10# steel billets in Table 1 were respectively kept in a heating furnace at 1200°C for 3 hours to obtain a steel billet with a surface layer temperature of 1200°C. The surface temperature after rolling) is 910°C. After the surface temperature of the rail head after the final rolling is naturally cooled to 805°C, a cooling medium is applied to the top surface and both sides of the rail head of the rail. The cooling medium is a water mist mixture. The rail is cooled in the first stage at a cooling rate of 2.5°C / s to reduce the surface temperature of the rail head to 410°C; then the rail is air-cooled to about 20°C, and rails A1 to A10 are obtained after vertical composite straightening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com