Patents

Literature

45626results about "Furnace types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

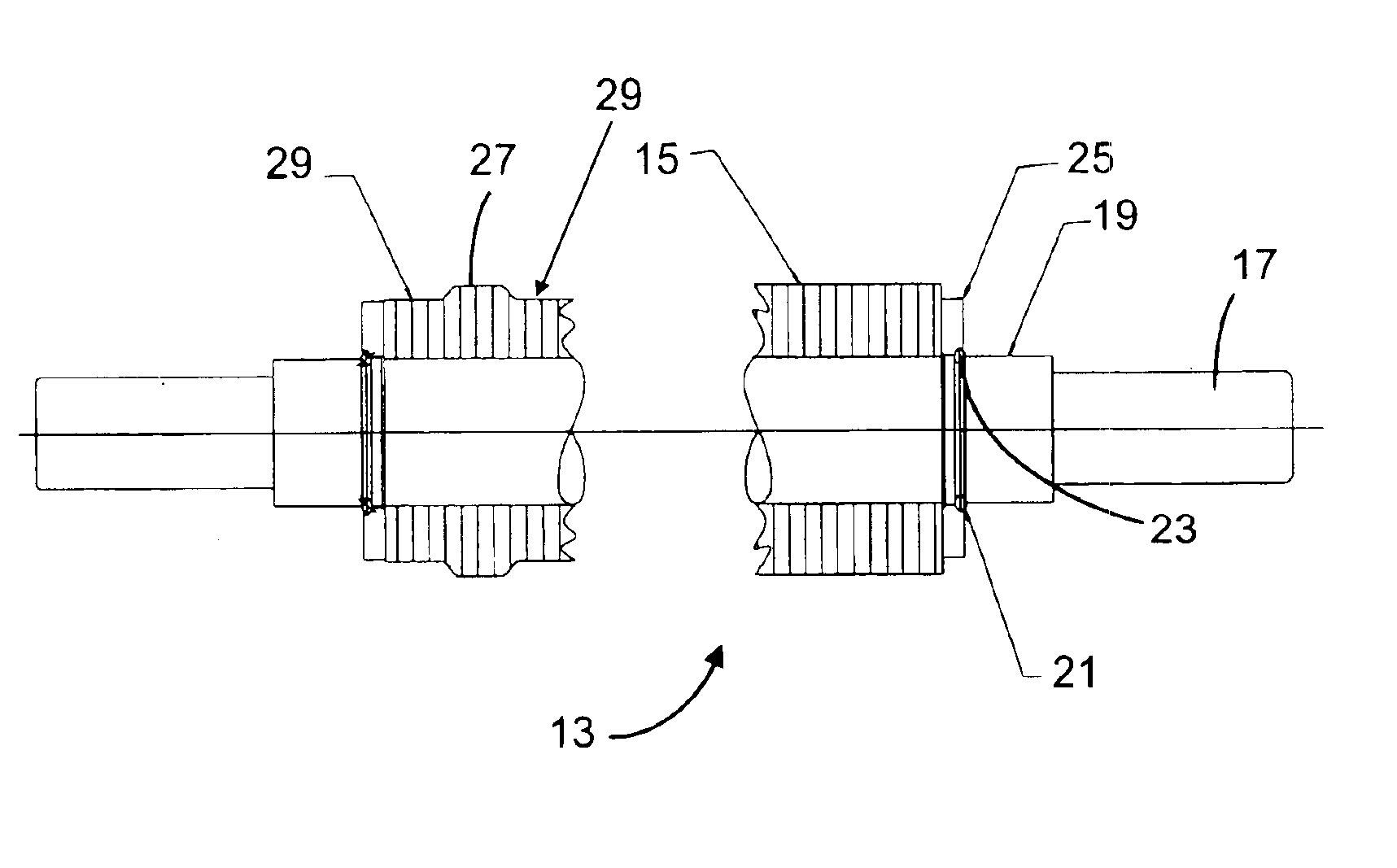

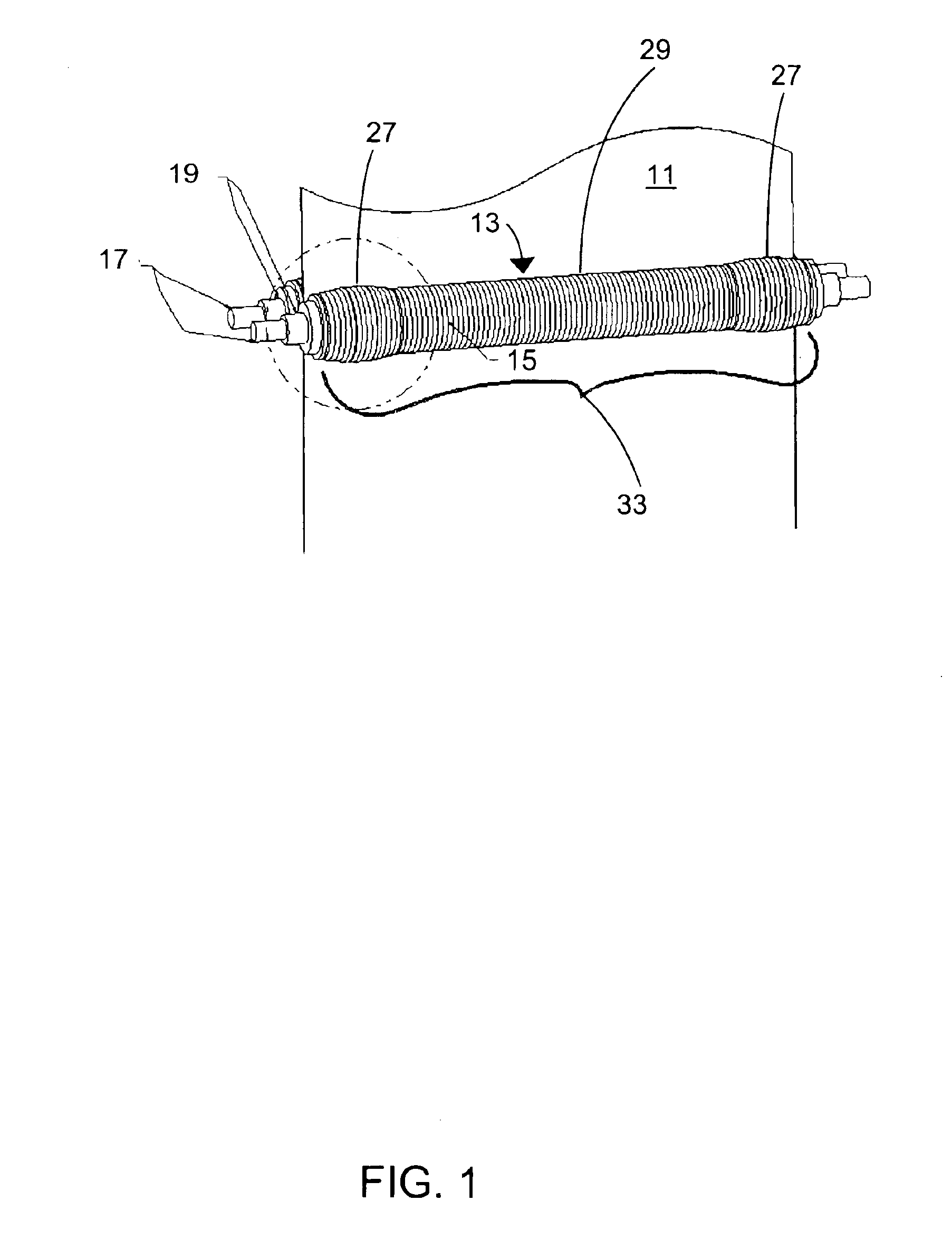

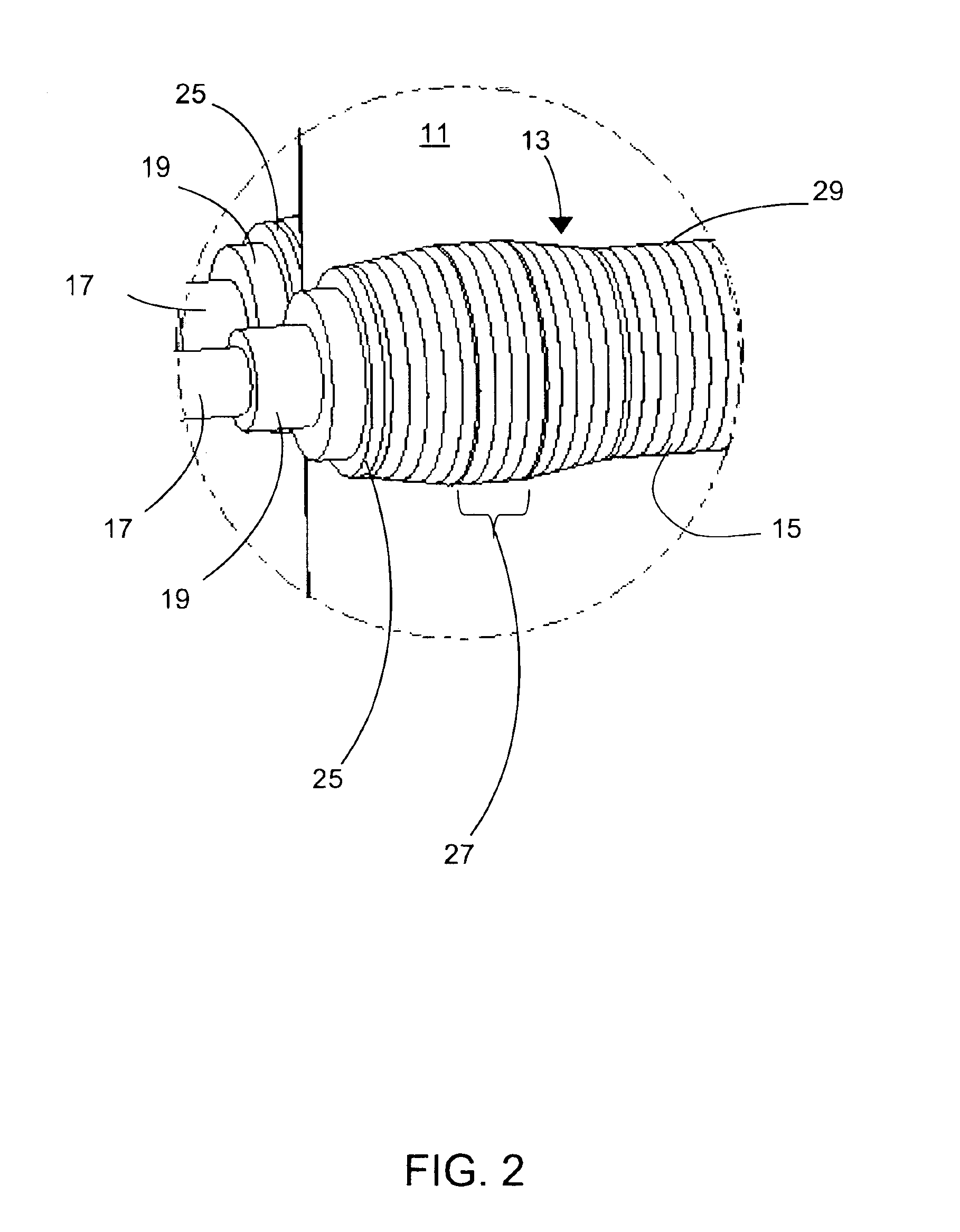

Systems for percutaneous bone and spinal stabilization, fixation and repair

InactiveUS6127597ASize of wire can be enlarged and reducedEnlarging and reducing sizeInternal osteosythesisFluid pressure measurement using pistonsSpinal columnProsthesis

Systems for bone and spinal stabilization, fixation and repair include intramedullar nails, intervertebral cages and prostheses, remotely activatable prostheses, tissue extraction devices, and electrocautery probes. The intramedullar nails, intervertebral cages and prostheses, are designed for expansion from a small diameter for insertion into place to a larger diameter which stabilizes, fixates or repairs the bone, and further can be inserted percutaneously. Remotely activatable prostheses can be activated from an external unit to expand and treat prosthesis loosening. Tissue extraction devices, and electrocautery probes are used to remove tissue from desired areas.

Owner:KYPHON

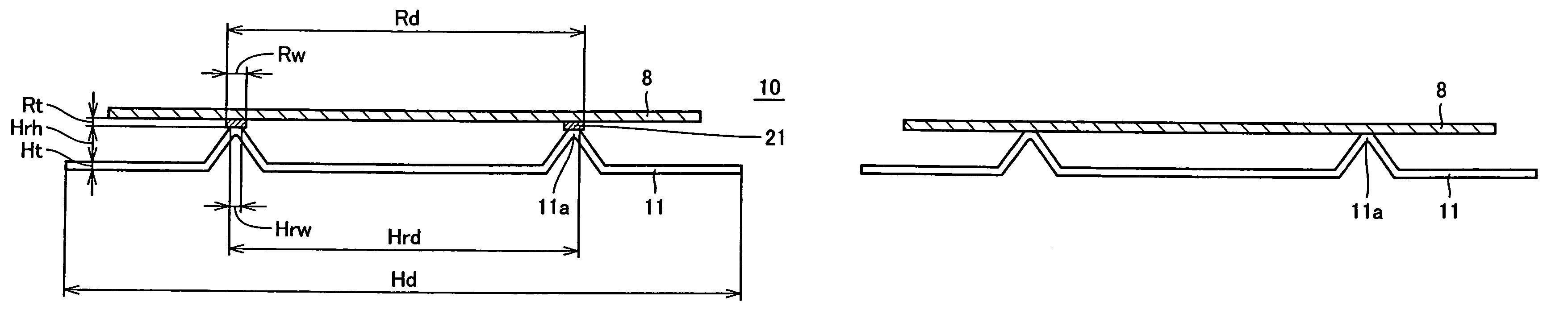

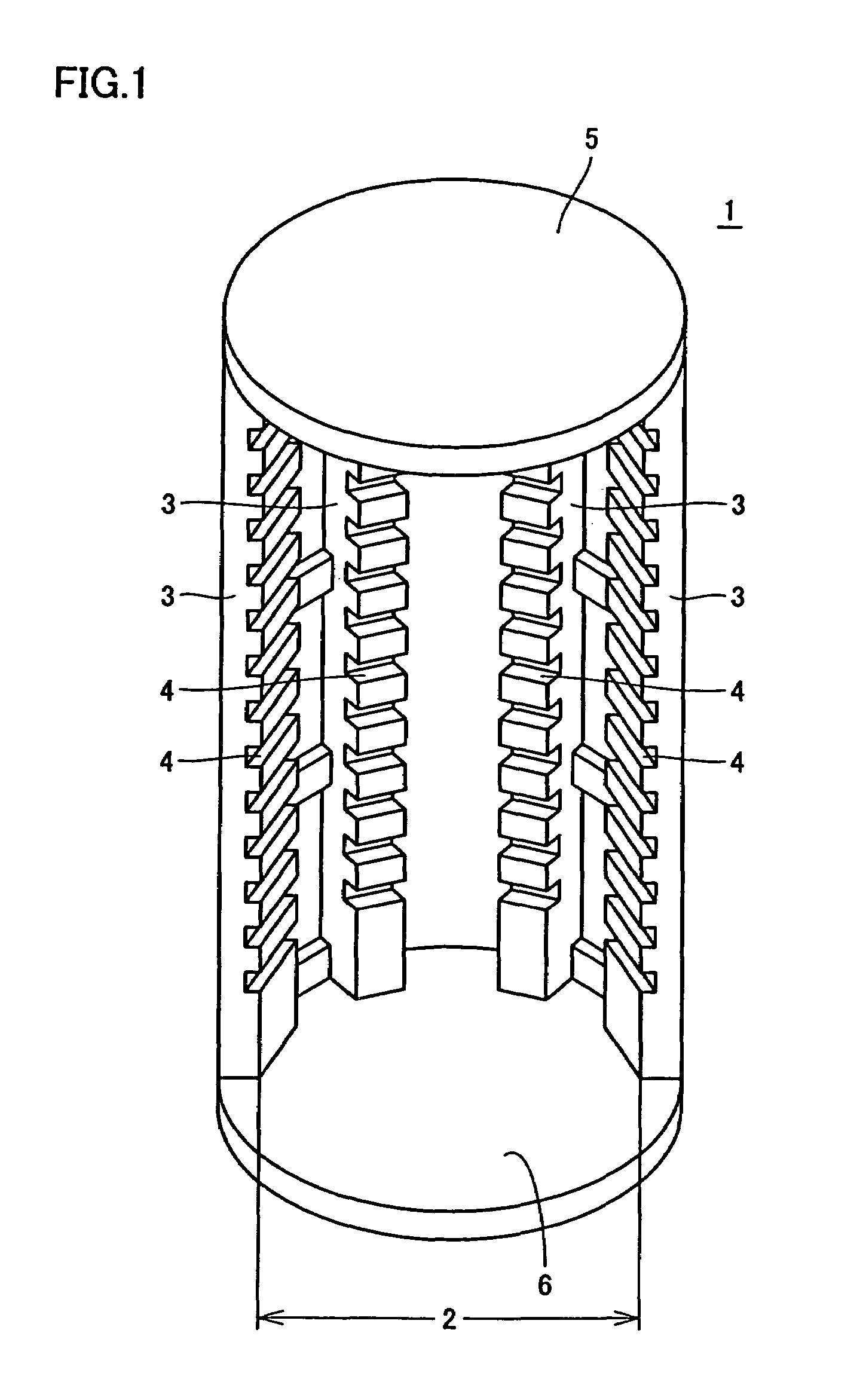

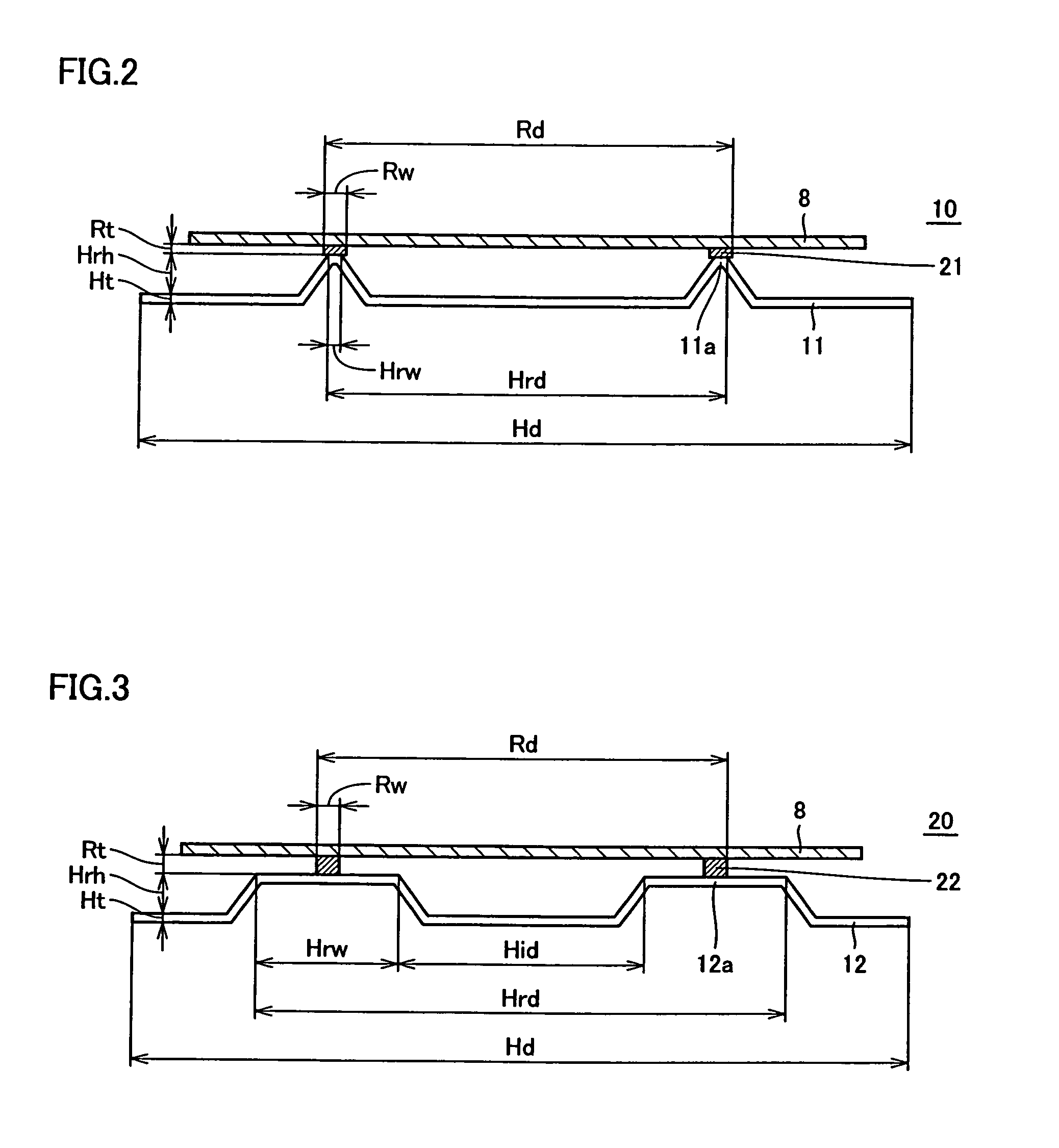

Heat treatment jig for semiconductor substrate

ActiveUS7329947B2Reduce stressSlips can be suppressed from occurringSemiconductor/solid-state device detailsCharge supportsSemiconductorSilicon

Owner:SUMITOMO MITSUBISHI SILICON CORP

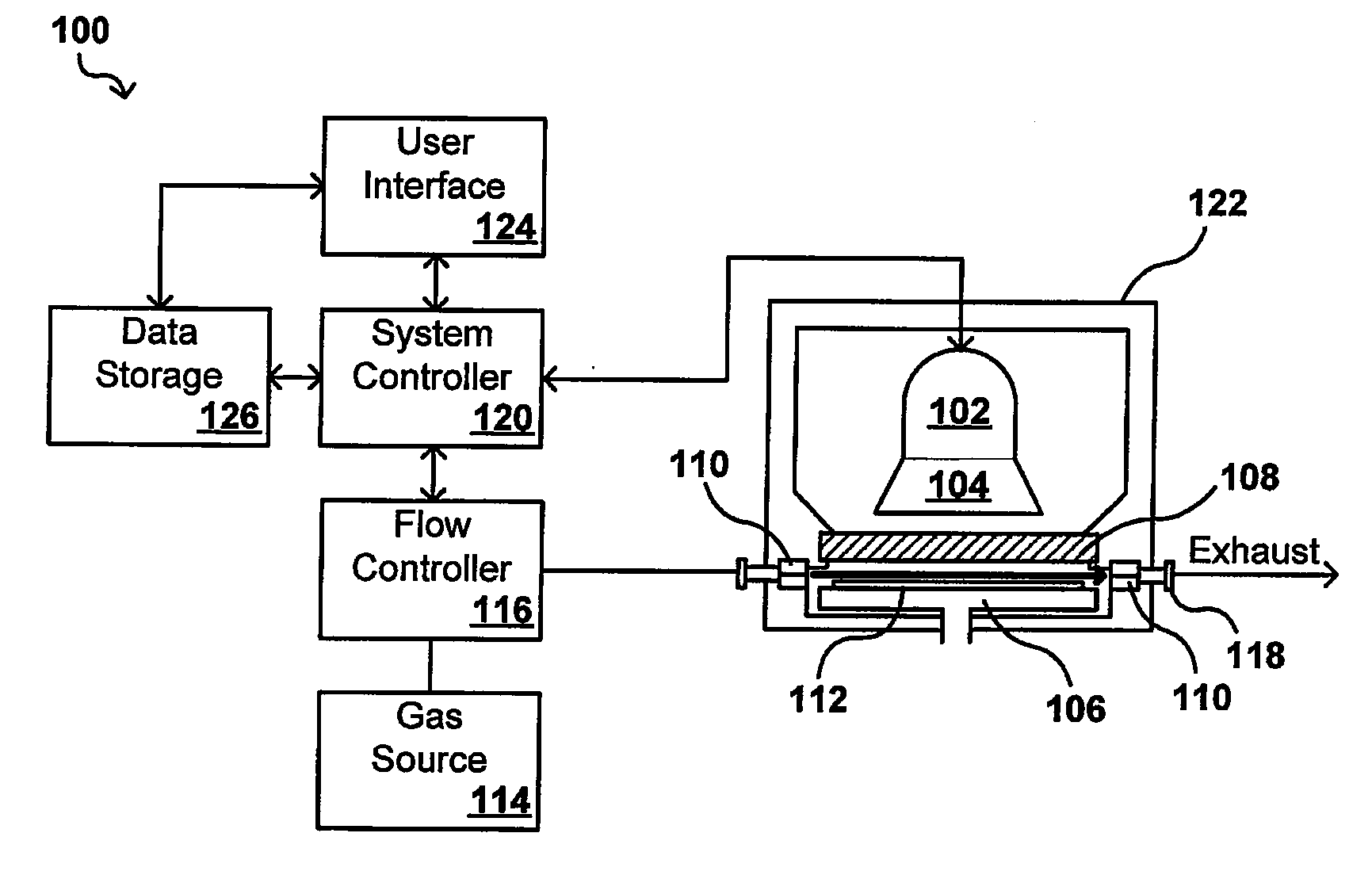

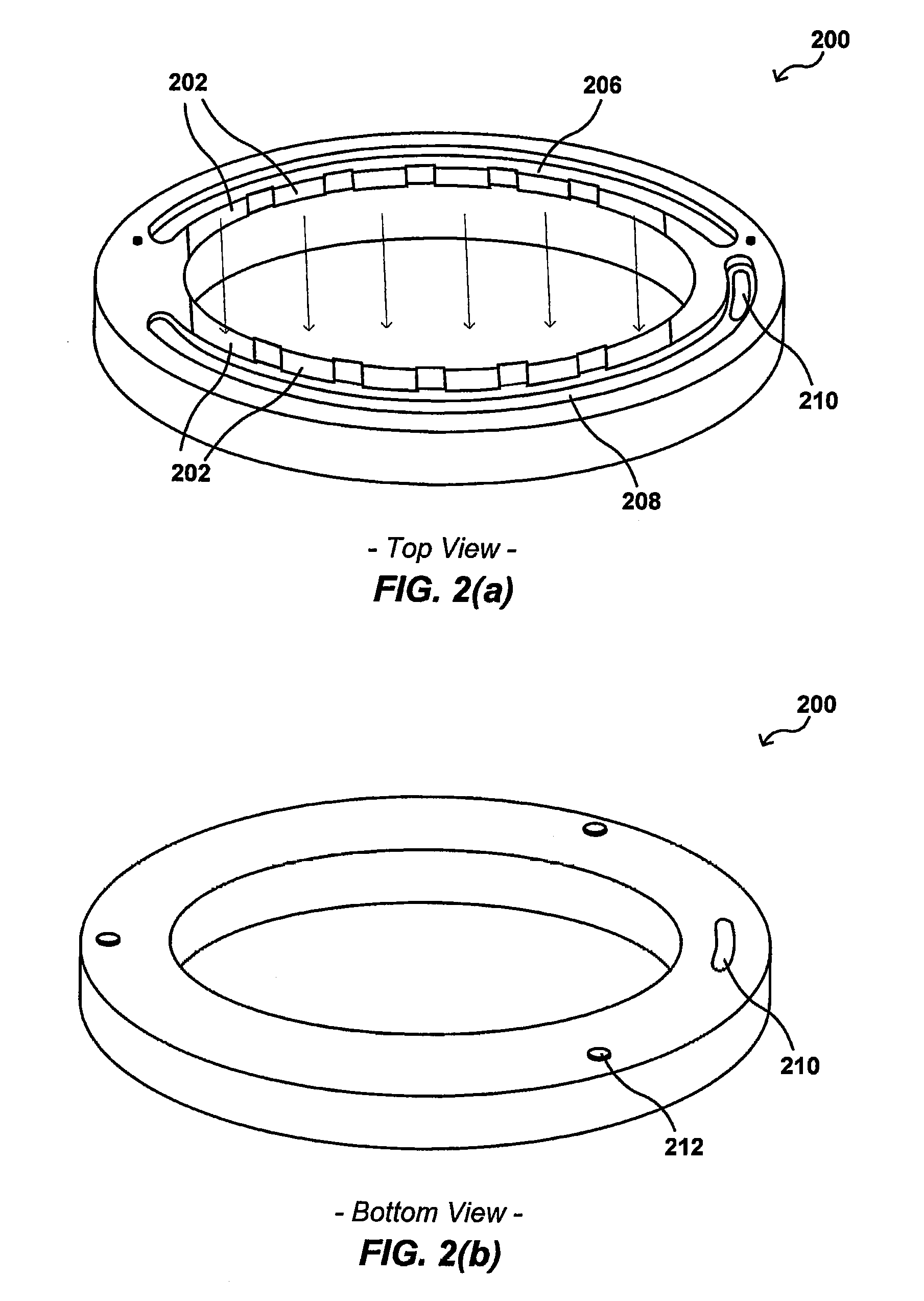

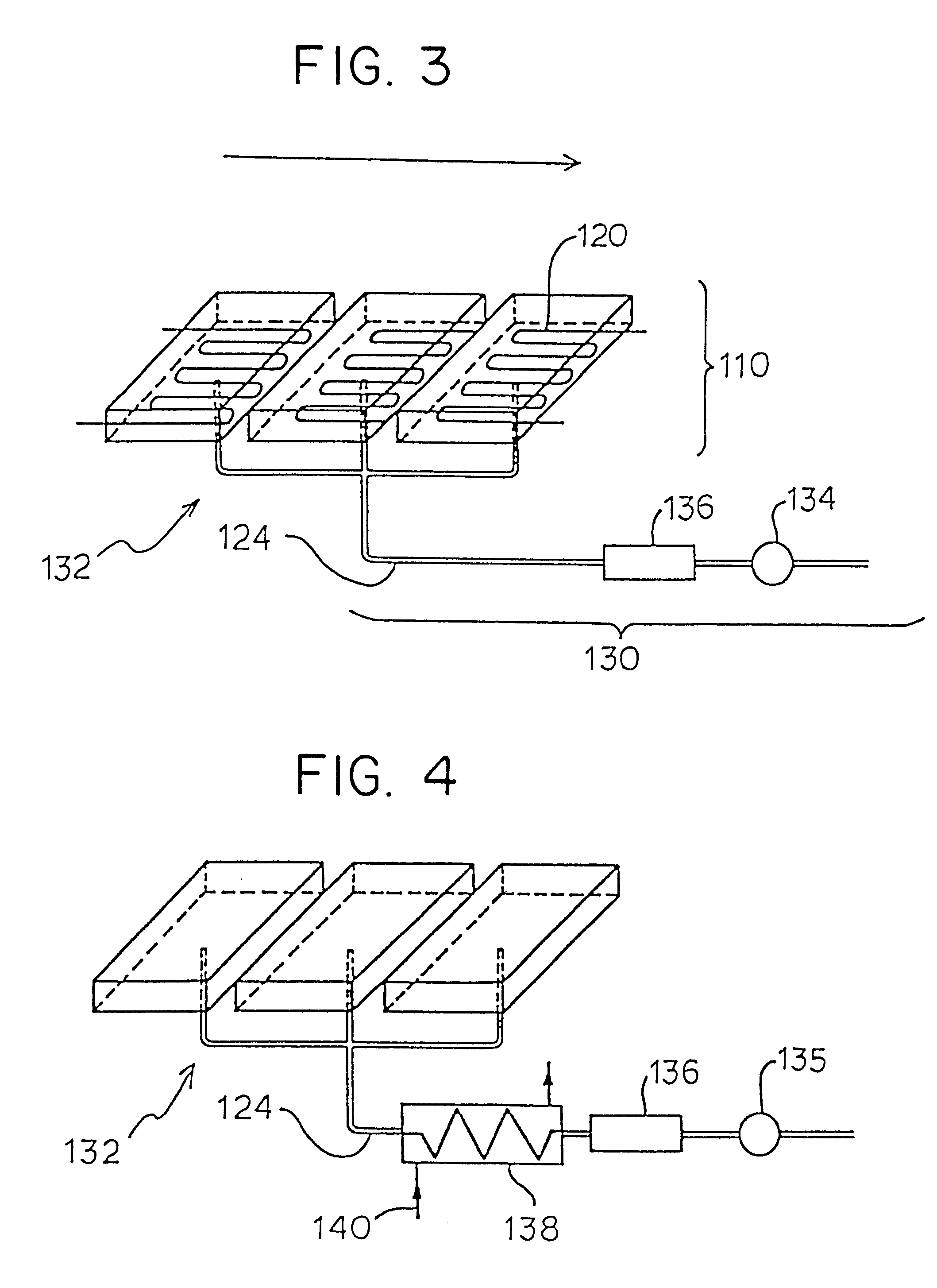

Increased tool utilization/reduction in mwbc for UV curing chamber

ActiveUS20070298362A1Avoid collectingHigh emissivitySemiconductor/solid-state device manufacturingCharge manipulationUV curingInjection port

A pump liner is used to direct a laminar flow of purge gas across a workpiece to remove contaminants or species outgassed or otherwise produced by the workpiece during processing. The pump liner can take the form of a ring having a plurality of injection ports, such as slits of a variety of shapes and / or sizes, opposite a plurality of receiving ports in order to provide the laminar flow. The flow of purge gas is sufficient to carry a contaminant or outgassed species from the processing chamber in order to prevent the collection of the contaminants on components of the chamber. The pump liner can be heated, via conduction and irradiation from a radiation source, for example, in order to prevent the condensation of species on the liner. The pump liner also can be anodized or otherwise processed in order to increase the emissivity of the liner.

Owner:APPLIED MATERIALS INC

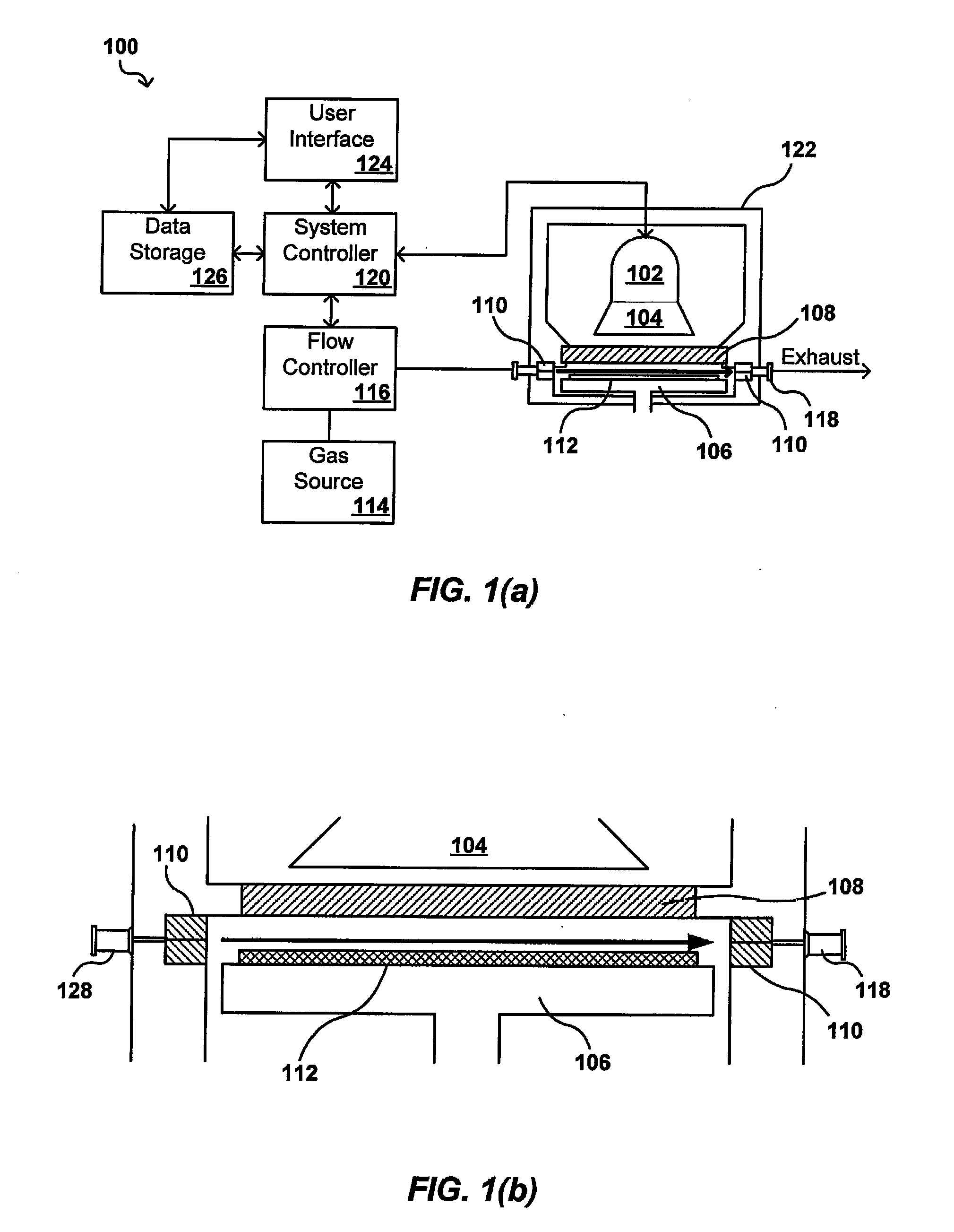

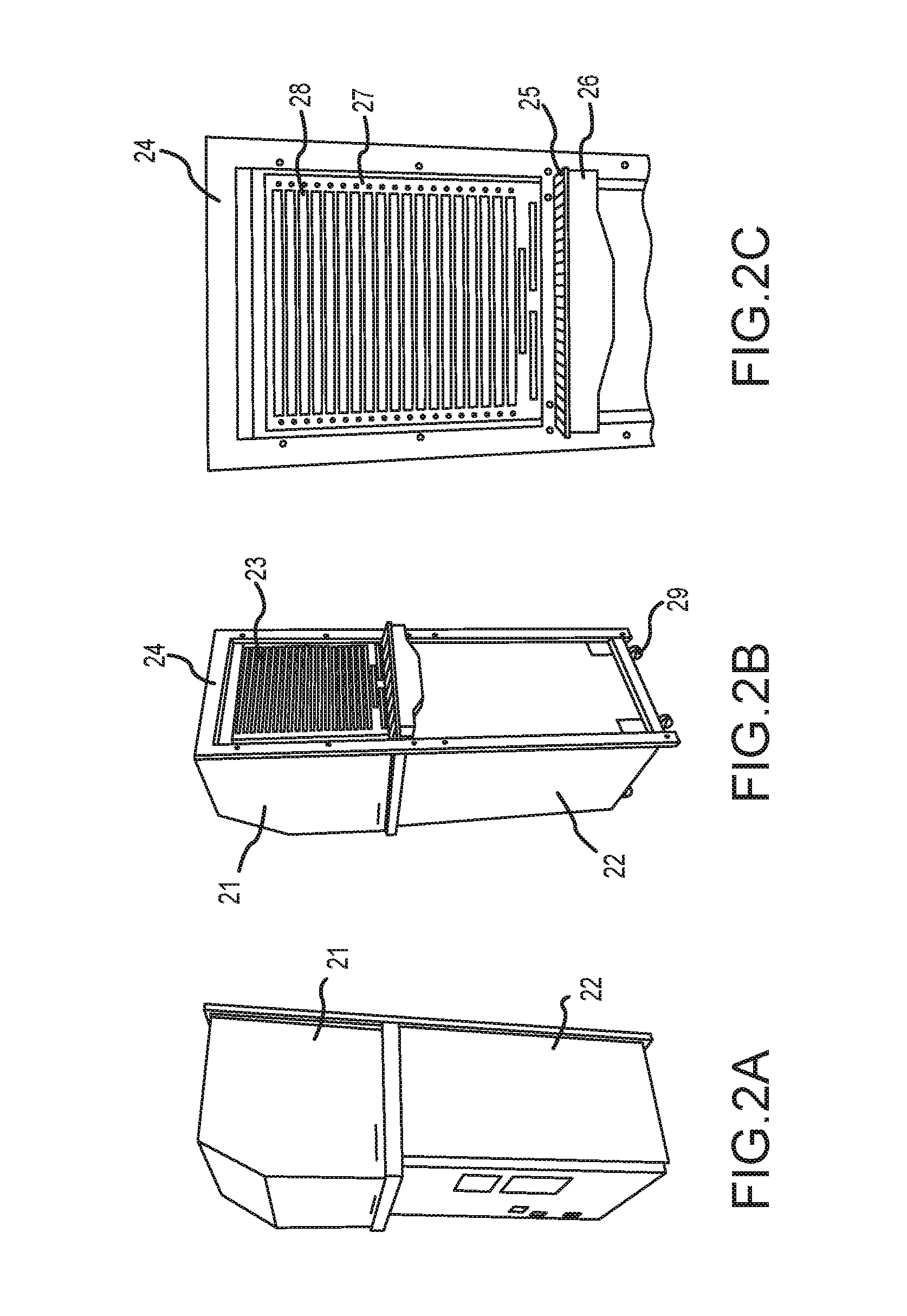

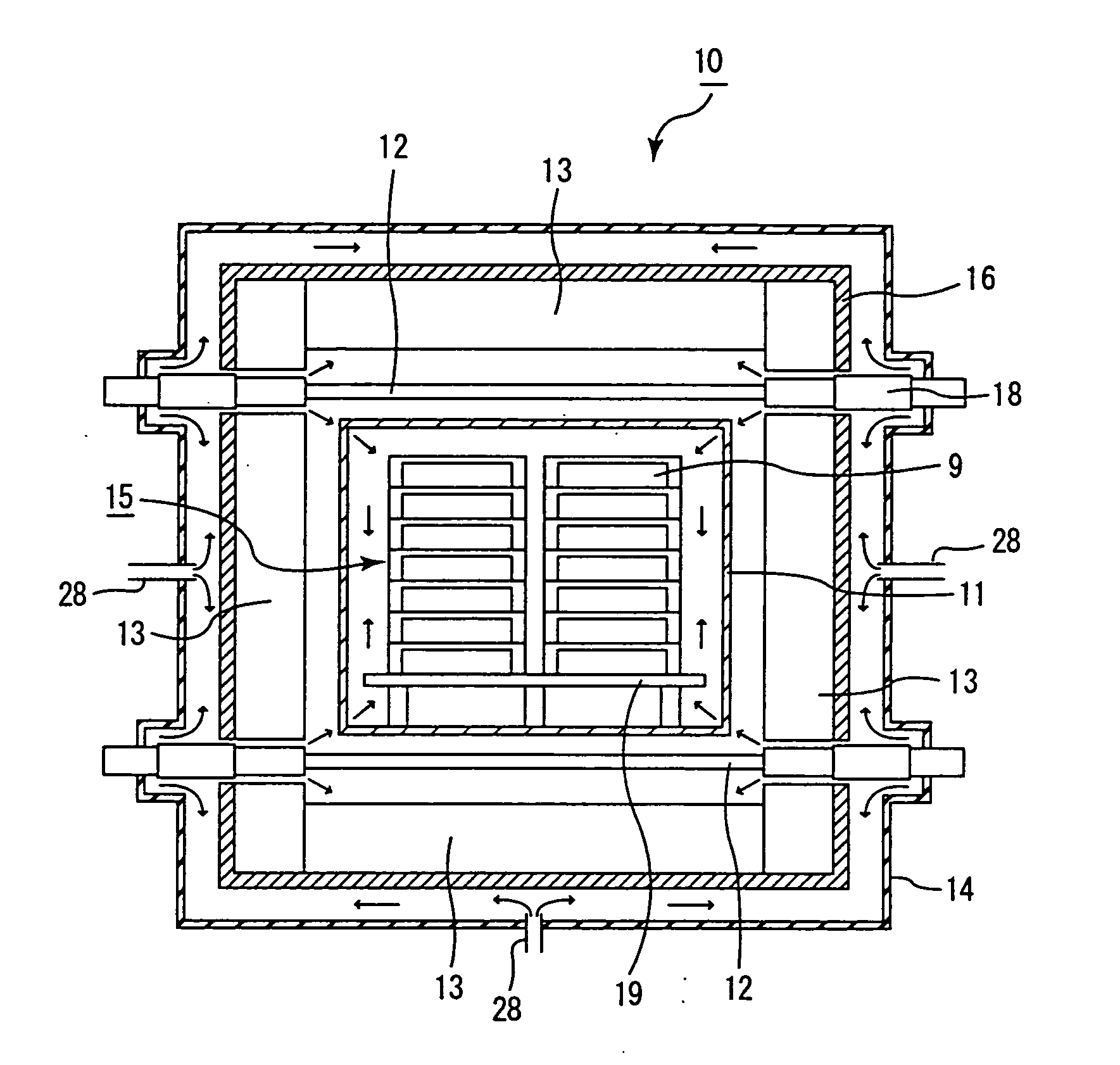

Thermal process station with heated lid

ActiveUS6884066B2Improve thermal uniformityImprove temperature uniformityCharge supportsSemiconductor/solid-state device manufacturingResistThermal energy

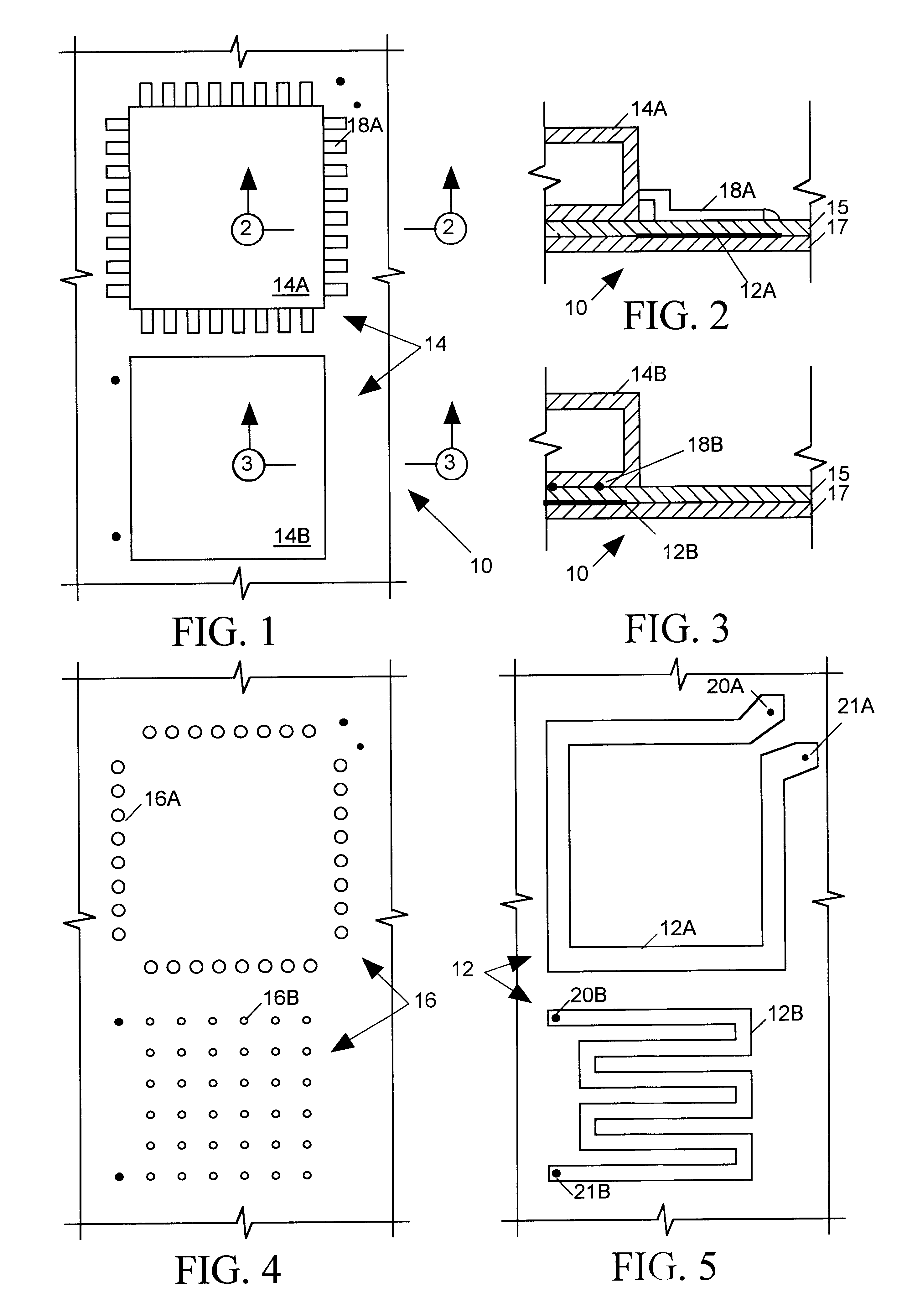

Methods and apparatuses to improve the temperature uniformity of a workpiece being processed on a heated platen of a thermal processing station. A heated platen is enclosed in a housing incorporating an additional heat source that uniformly outputs thermal energy into the process chamber in which the heated platen is positioned. In preferred embodiments, this heat source is positioned in the lid of the housing. It is additionally preferred that the heated lid includes features that provide a gas flow path to introduce to and / or purge gas from the process chamber. In terms of photoresist performance, the improved thermal uniformity provided by using such an additional heat source in the housing, e.g., in the lid, offers improved line width control and line uniformity across a wafer.

Owner:TEL EPION

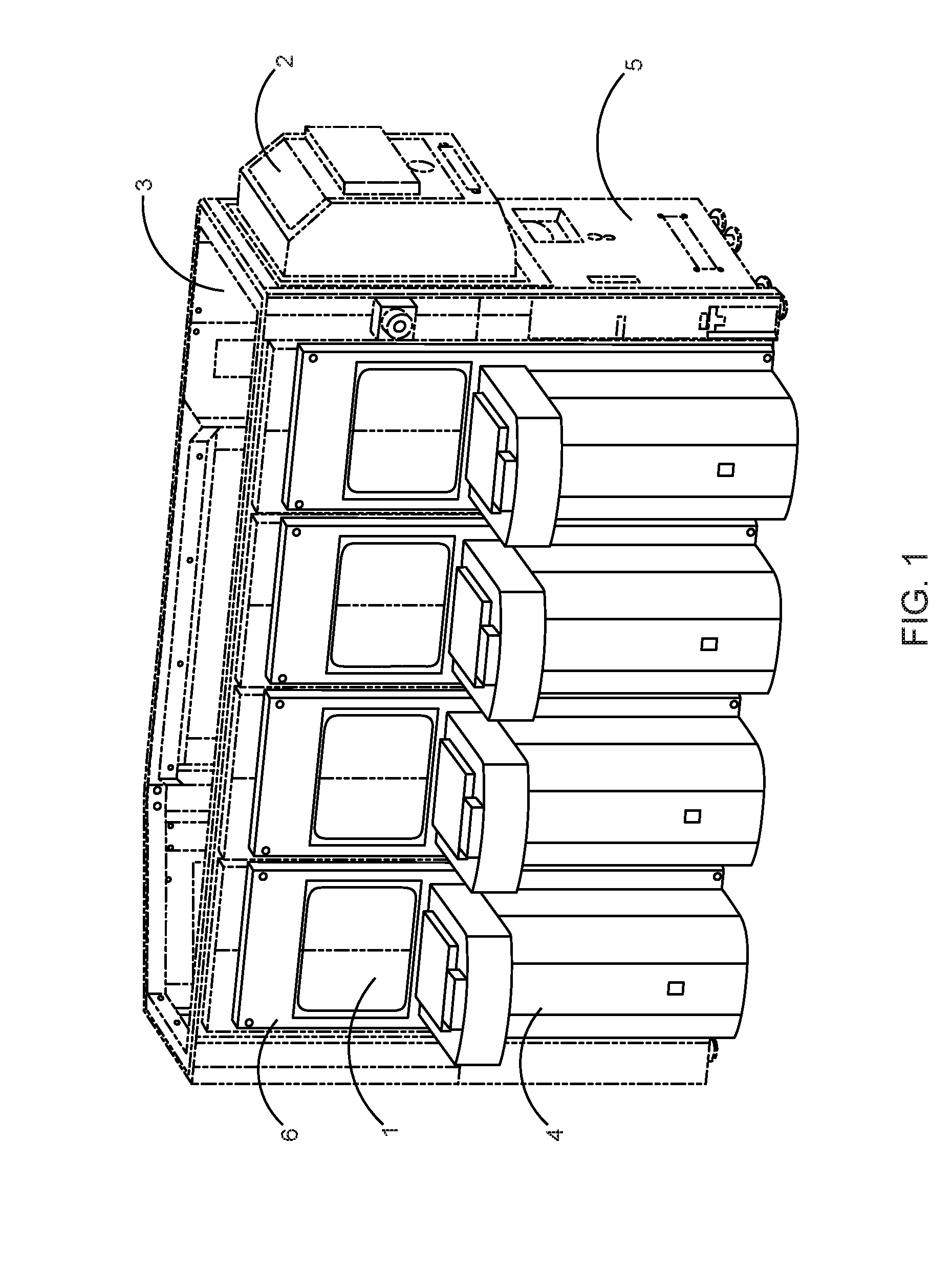

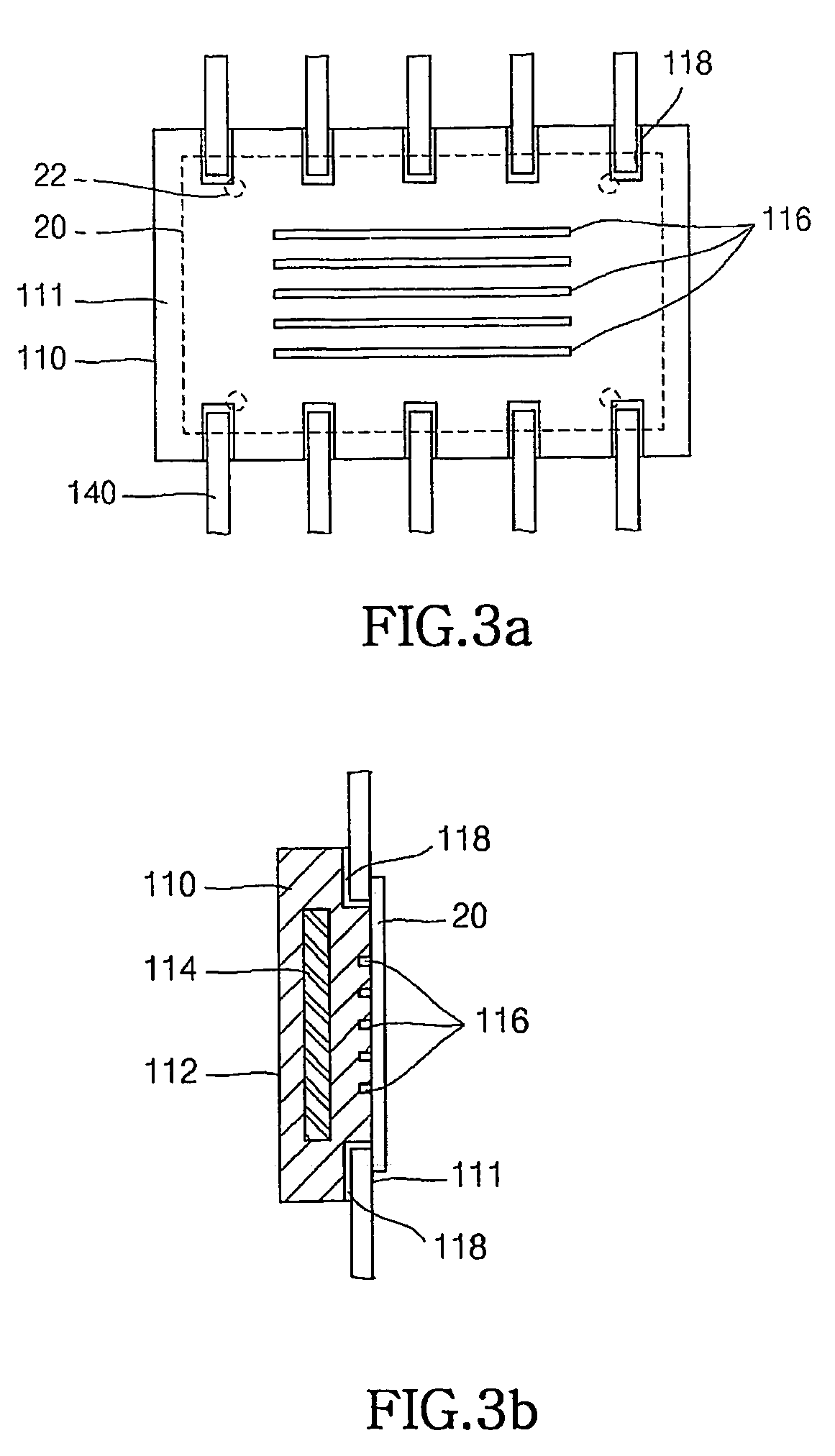

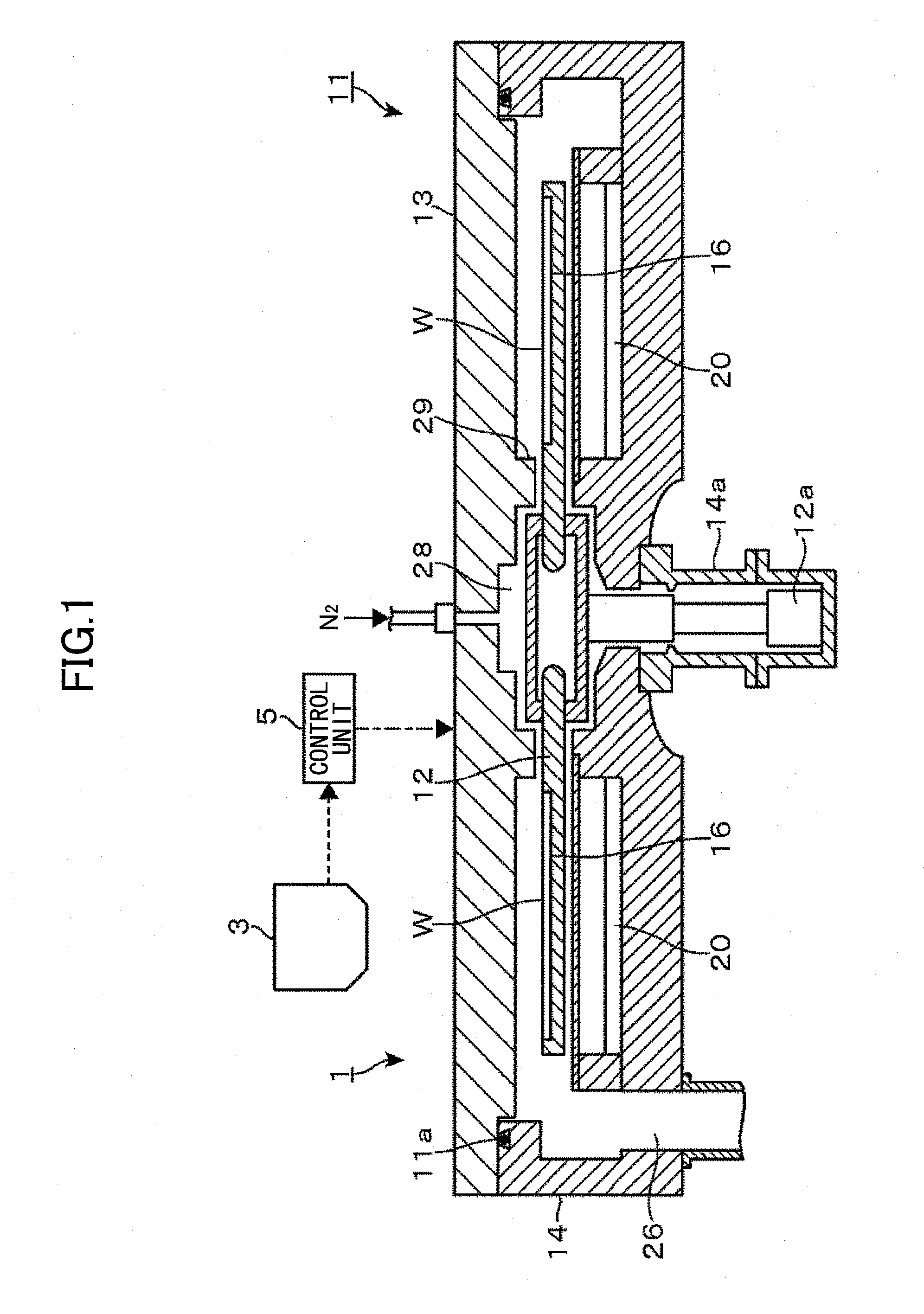

Apparatus and method for pre-baking substrate upstream of process chamber

ActiveUS9349620B2Efficient heatingGuaranteed uptimeSemiconductor/solid-state device manufacturingFurnace typesCooking & bakingInjection port

A pre-baking apparatus for heating a substrate upstream of a process tool is adapted to be connected to an EFEM (equipment front end module) and includes: a chamber which has a front face with multiple slots arranged in a height direction of the chamber, and which is divided into multiple compartments extending from the multiple slots, respectively, toward a rear end of the chamber for loading and unloading substrates; and a connecting frame for connecting the chamber to the process tool. The multiple compartments are separated from each other by a divider plate and provided with heaters for heating the multiple compartments, and each compartment has a gas injection port for blowing a hot inert gas over the substrate placed therein toward the slot.

Owner:ASM IP HLDG BV

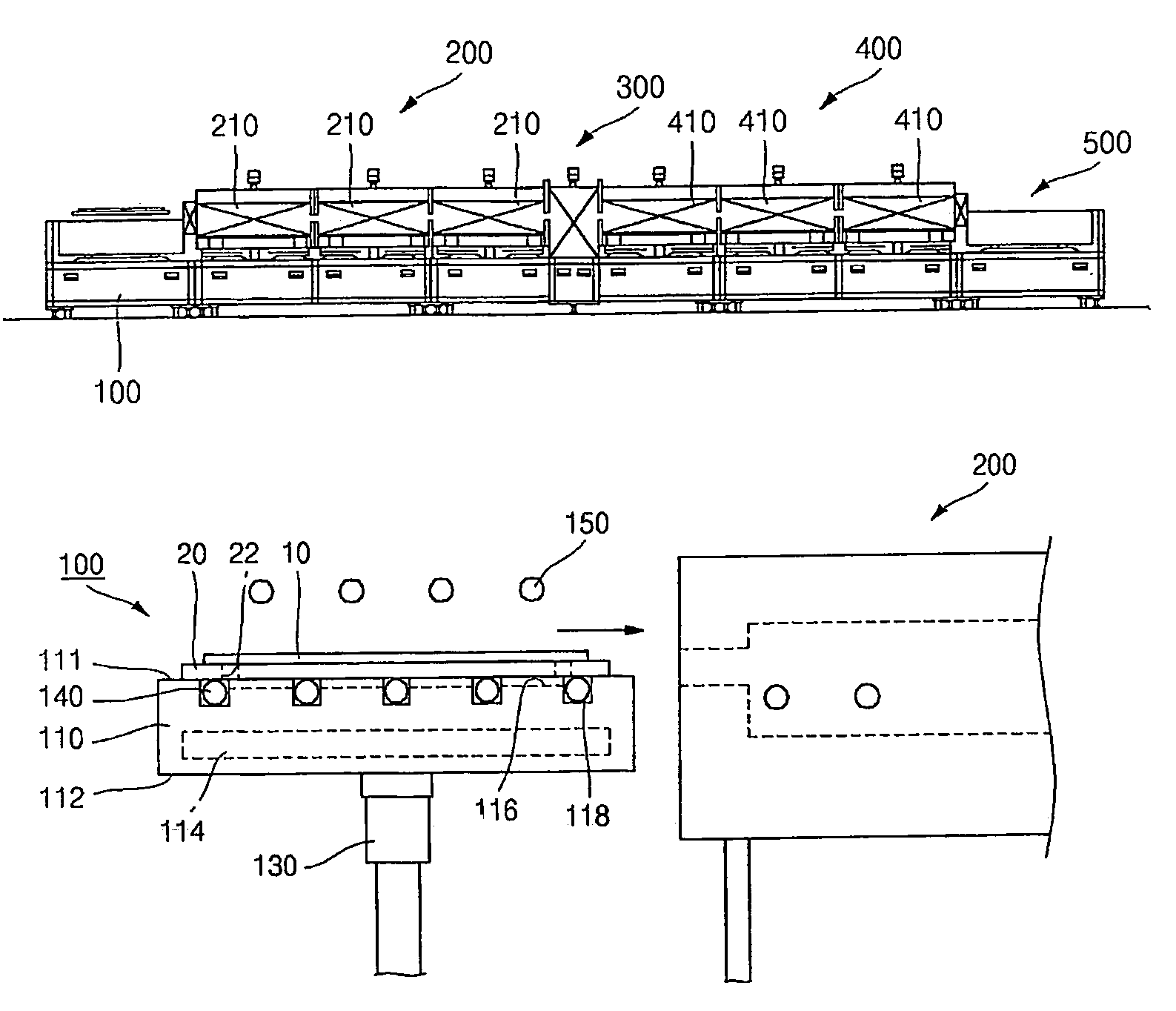

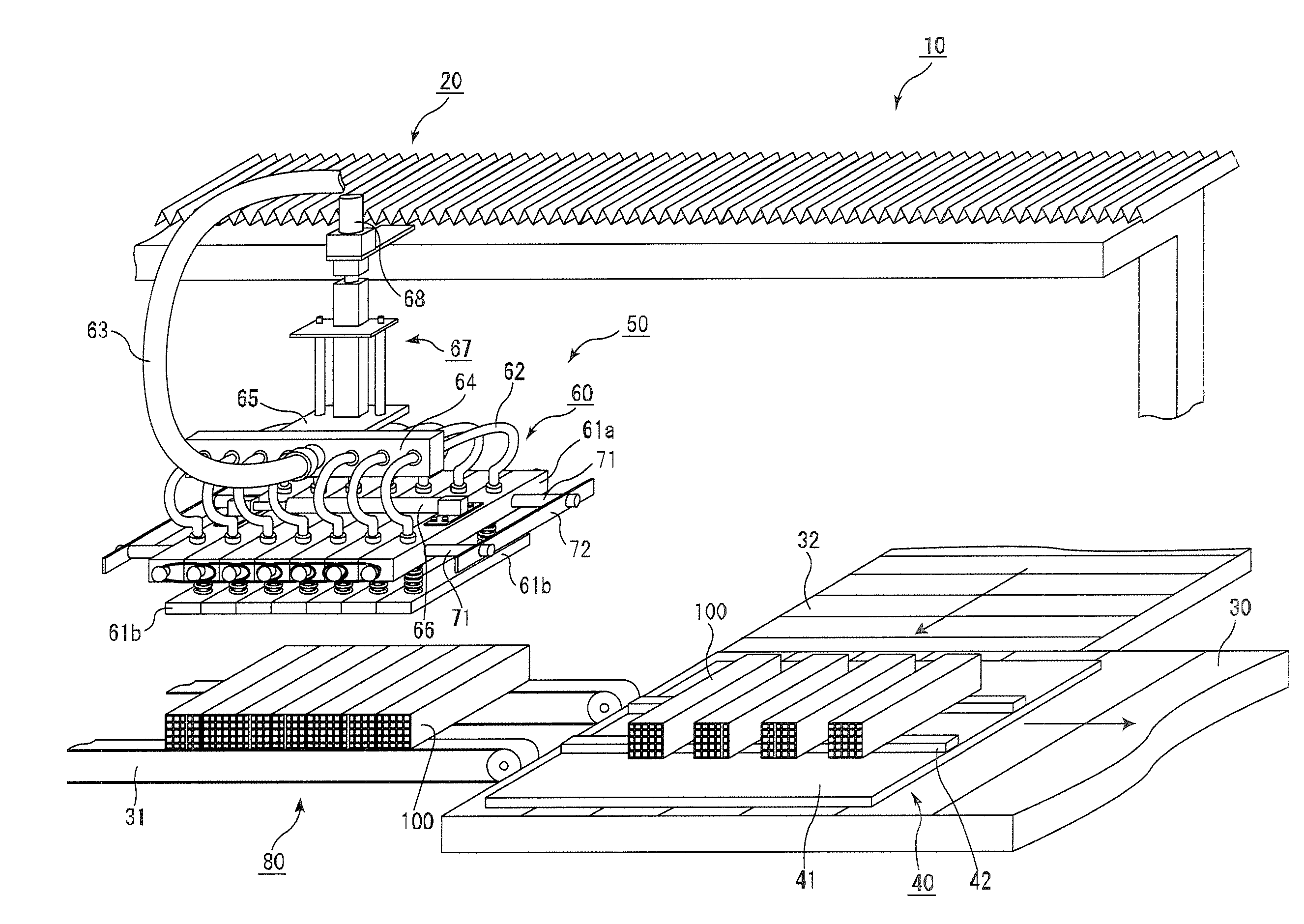

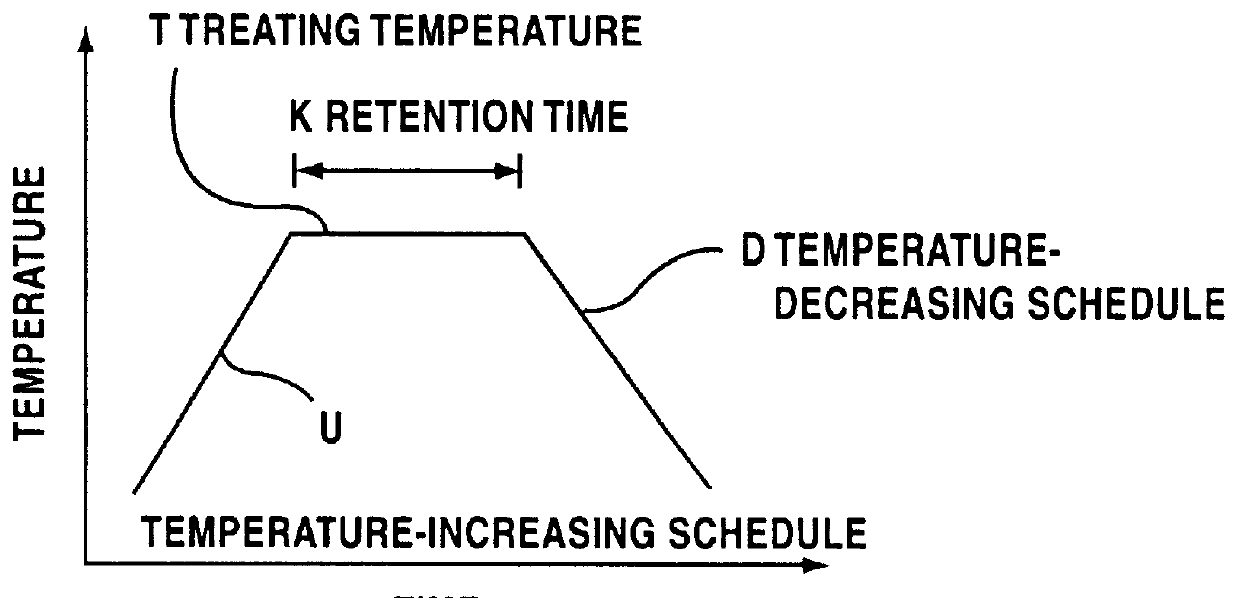

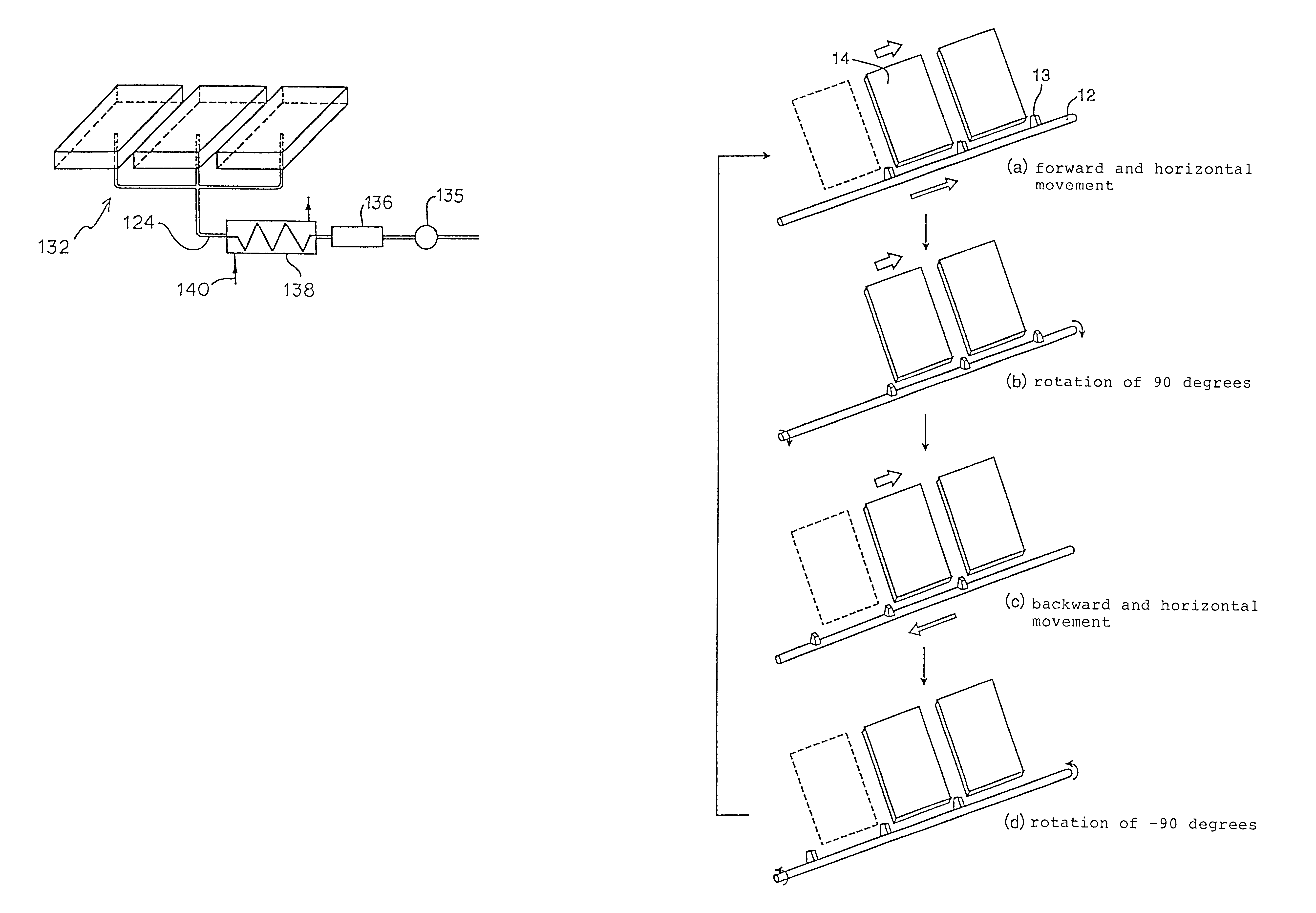

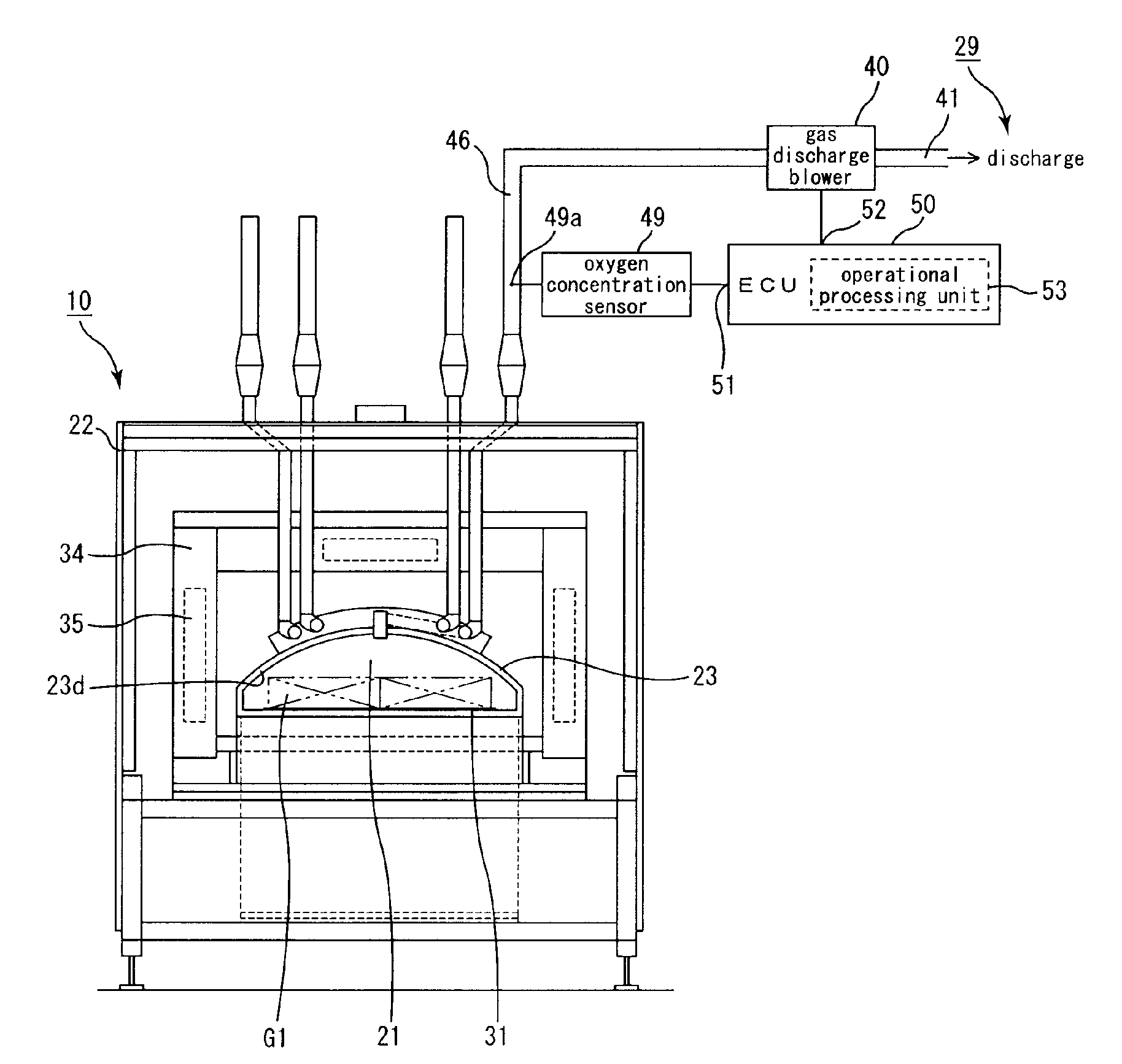

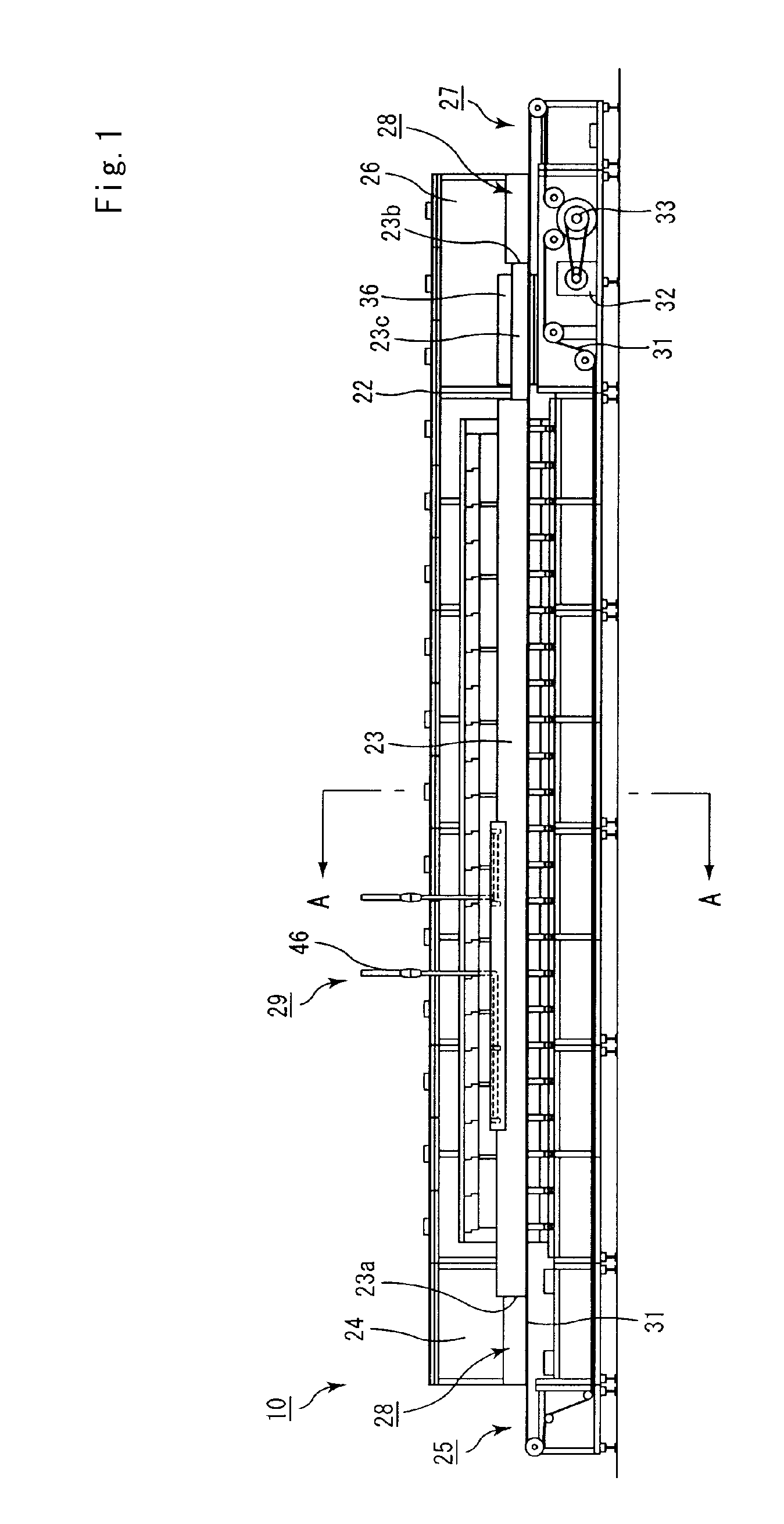

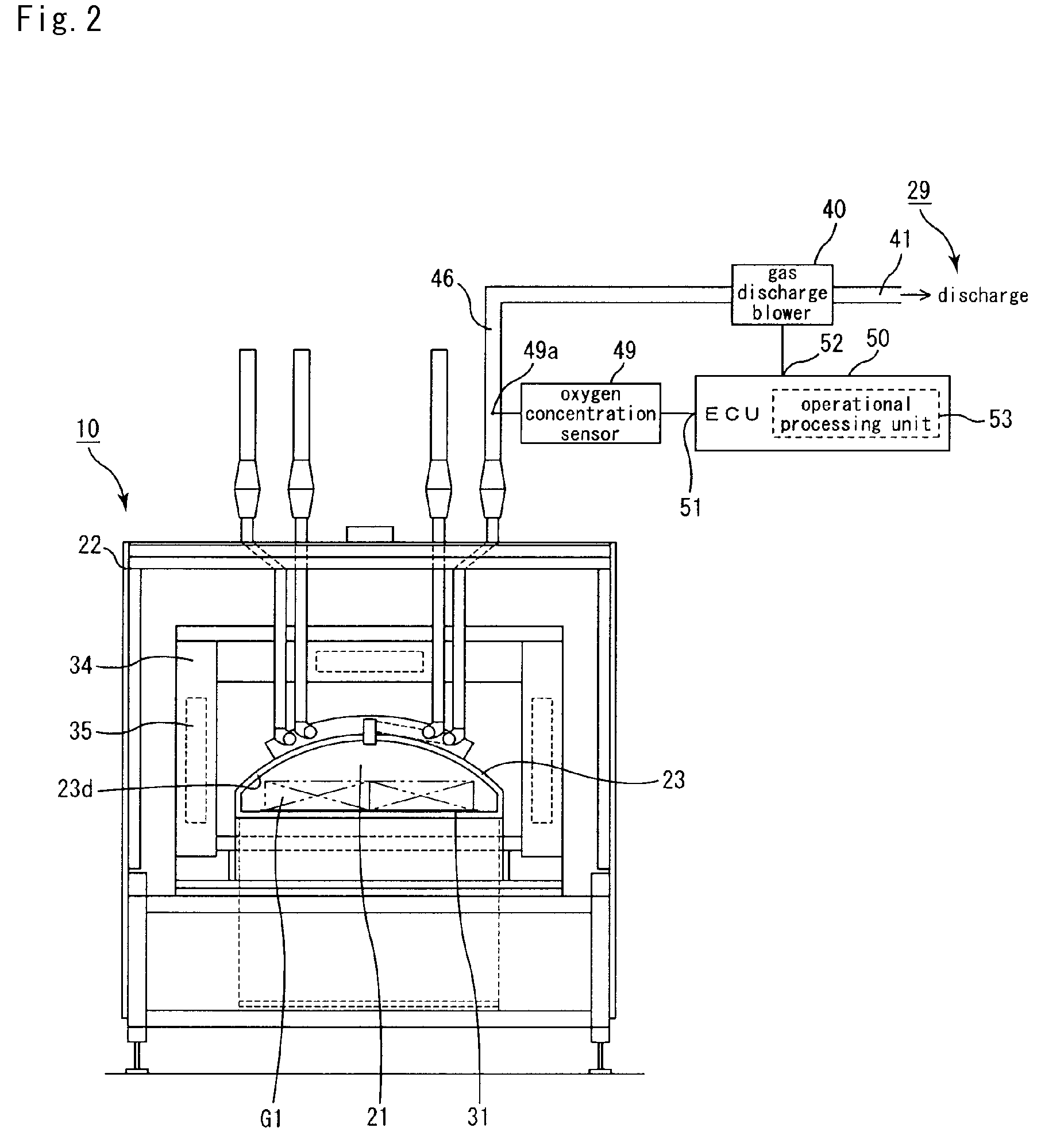

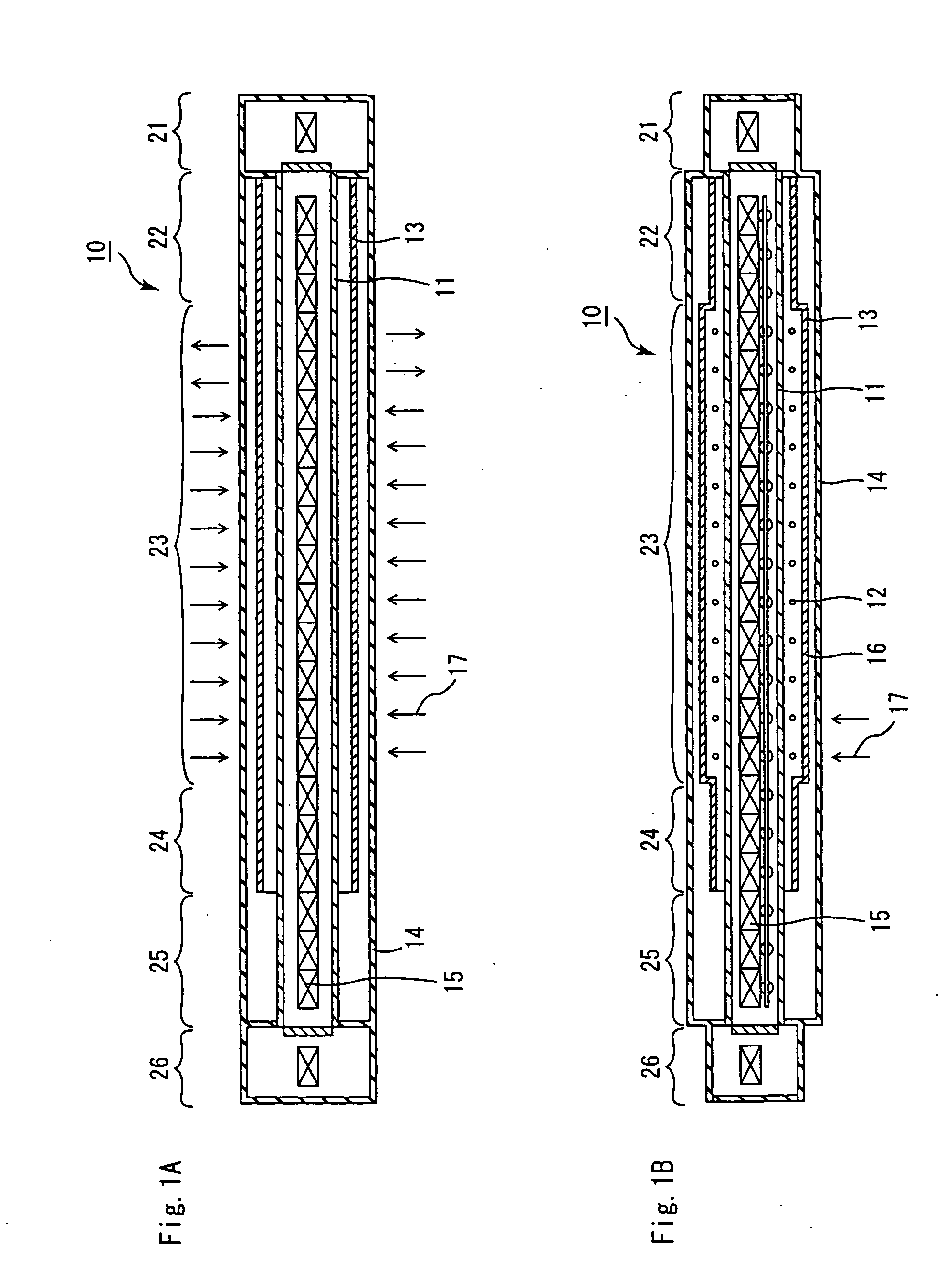

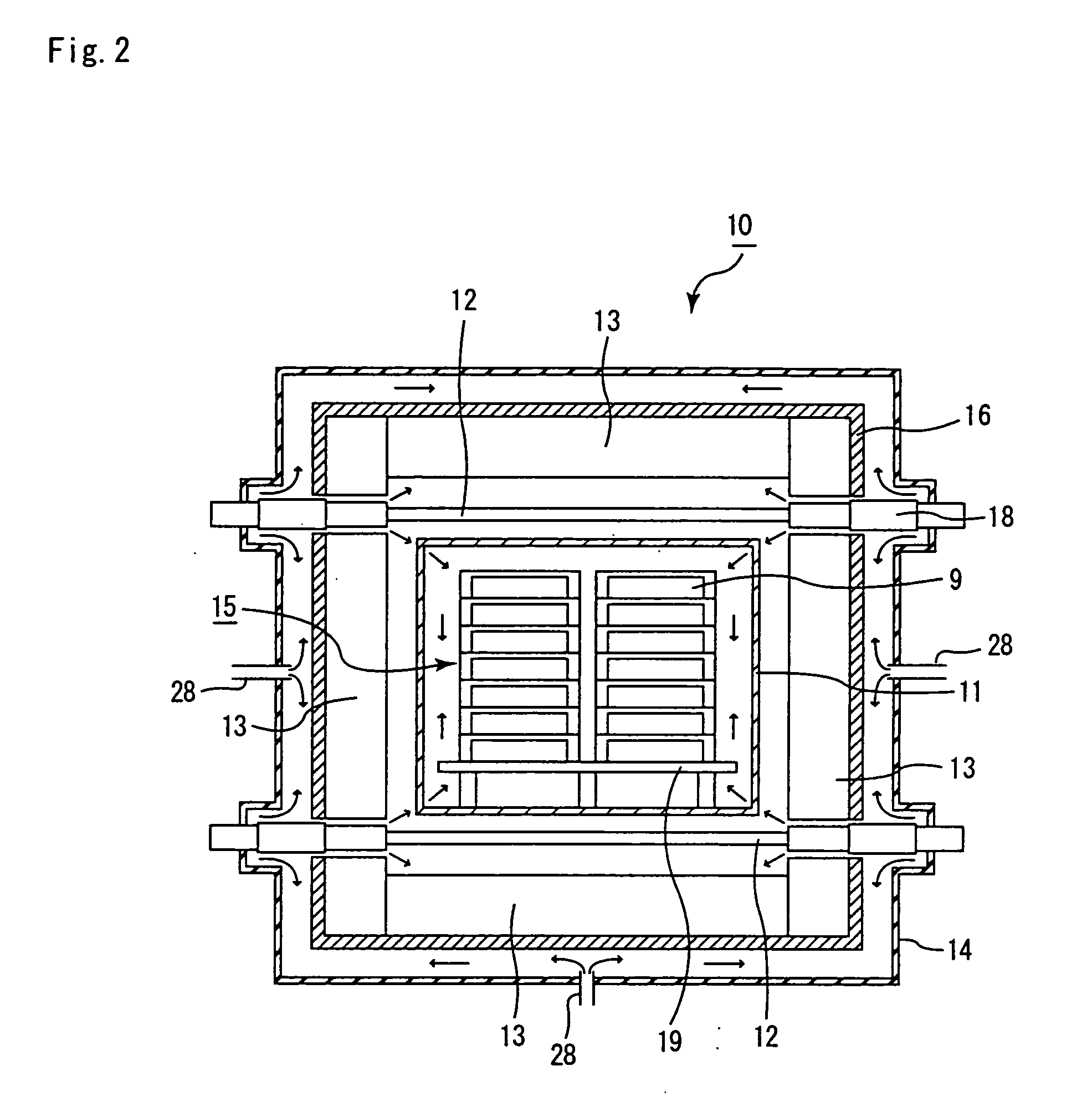

System for heat treatment of semiconductor device

InactiveUS7989736B2Avoid damageIncrease temperatureFurnaces without endless coreSemiconductor/solid-state device manufacturingElectromotive forceSilicon thin film

Disclosed is a heat treatment system for semiconductor devices. The heat treatment system is used in a heat treatment process for semiconductor devices, such as a crystallization process for an amorphous silicon thin film or a dopant activation process for a poly-crystalline silicon thin film formed on a surface of a glass substrate of a flat display panel including a liquid crystal display (LCD) or an organic light emitting device (OLED). The heat treatment system transfers a semiconductor device after uniformly preheating the semiconductor device in order to prevent deformation of the semiconductor device during the heat treatment process, rapidly performs the heat treatment process under the high temperature condition by heating the semiconductor device using a lamp heater and induction heat derived from induced electromotive force, and unloads the semiconductor device after uniformly cooling the semiconductor device such that the semiconductor device is prevented from being deformed when the heat treatment process has been finished. The heat treatment system rapidly performs the heat treatment process while preventing deformation of the semiconductor device by gradually heating or cooling the semiconductor device.

Owner:VIATRON TECH INC

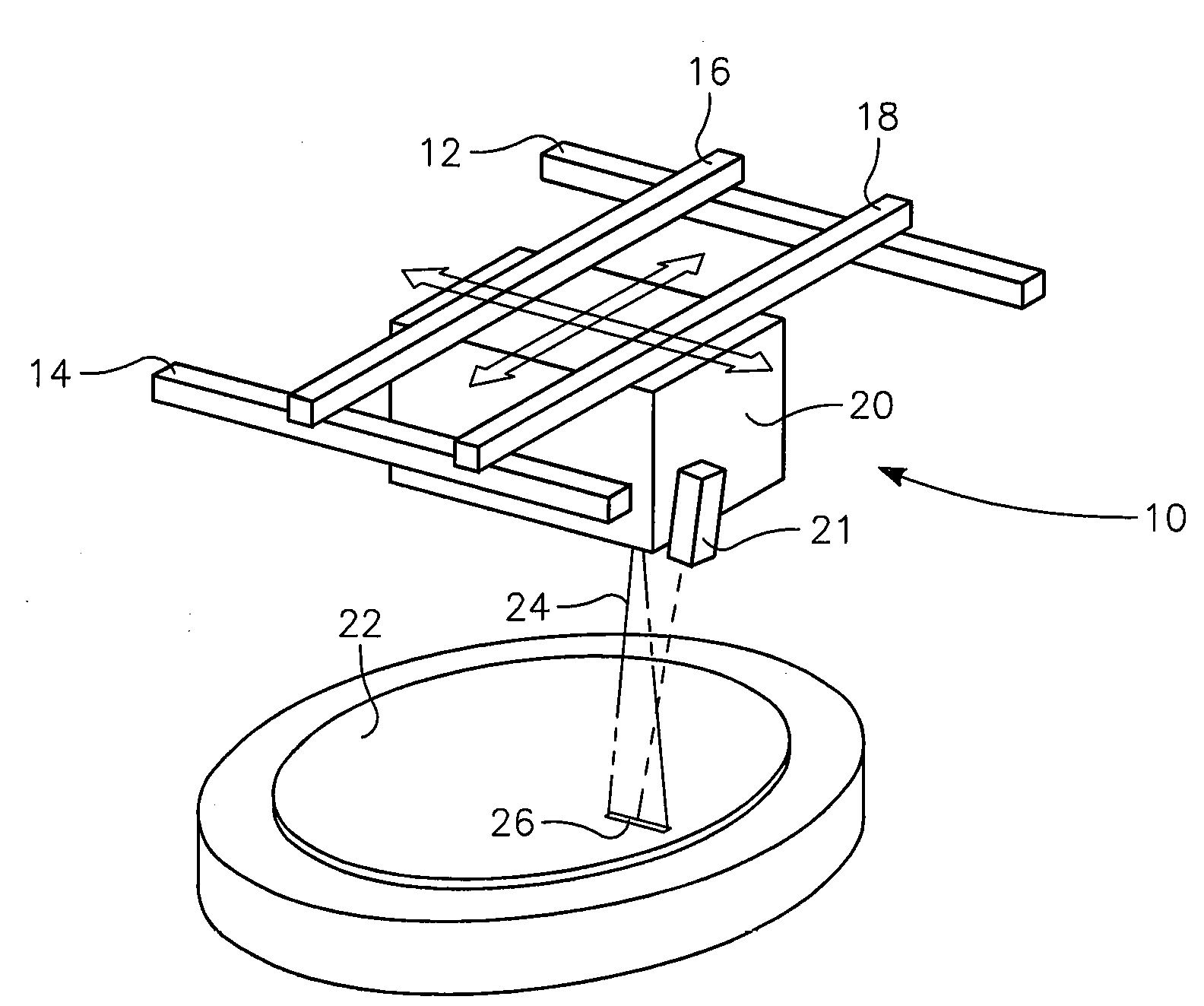

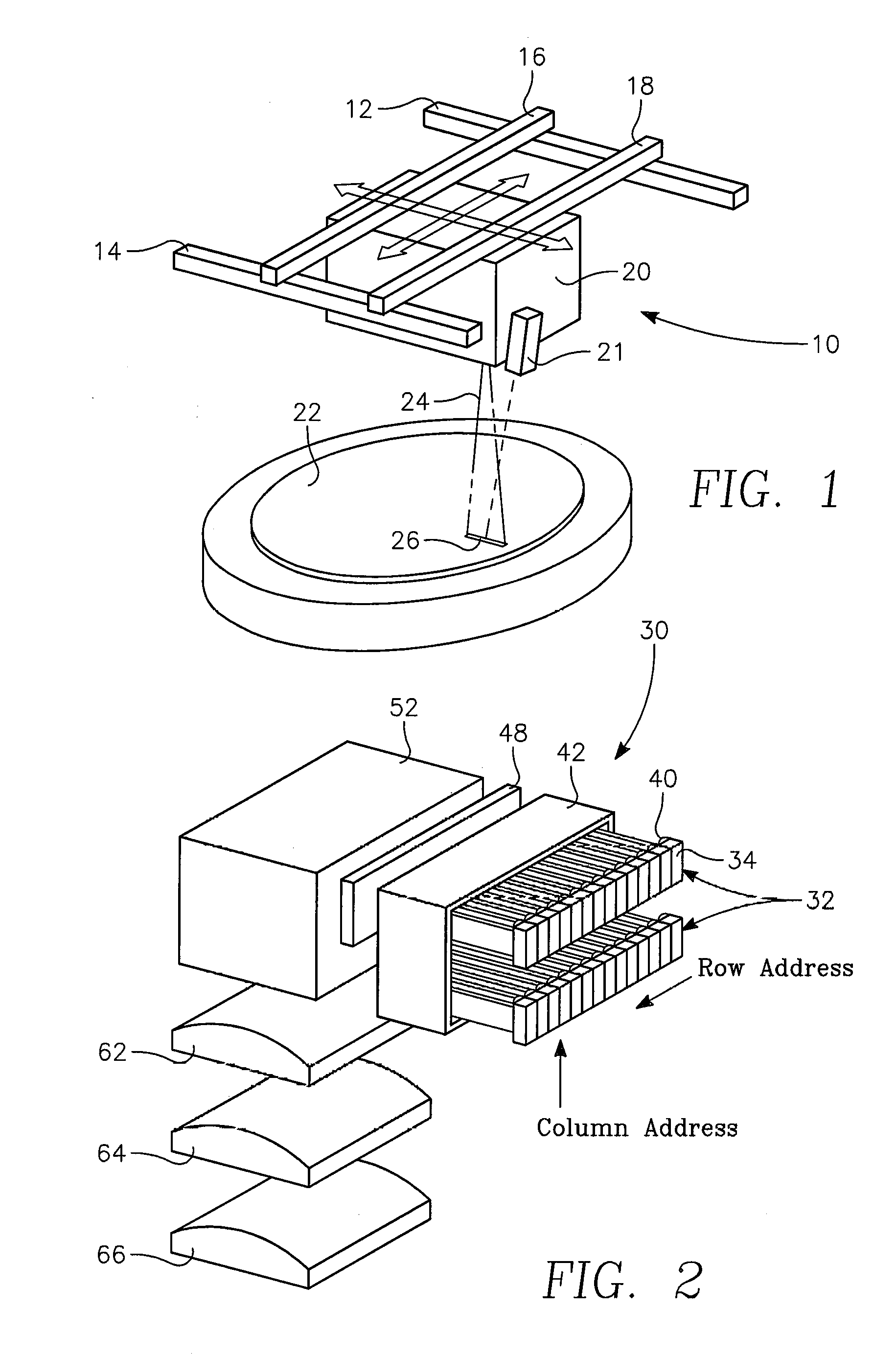

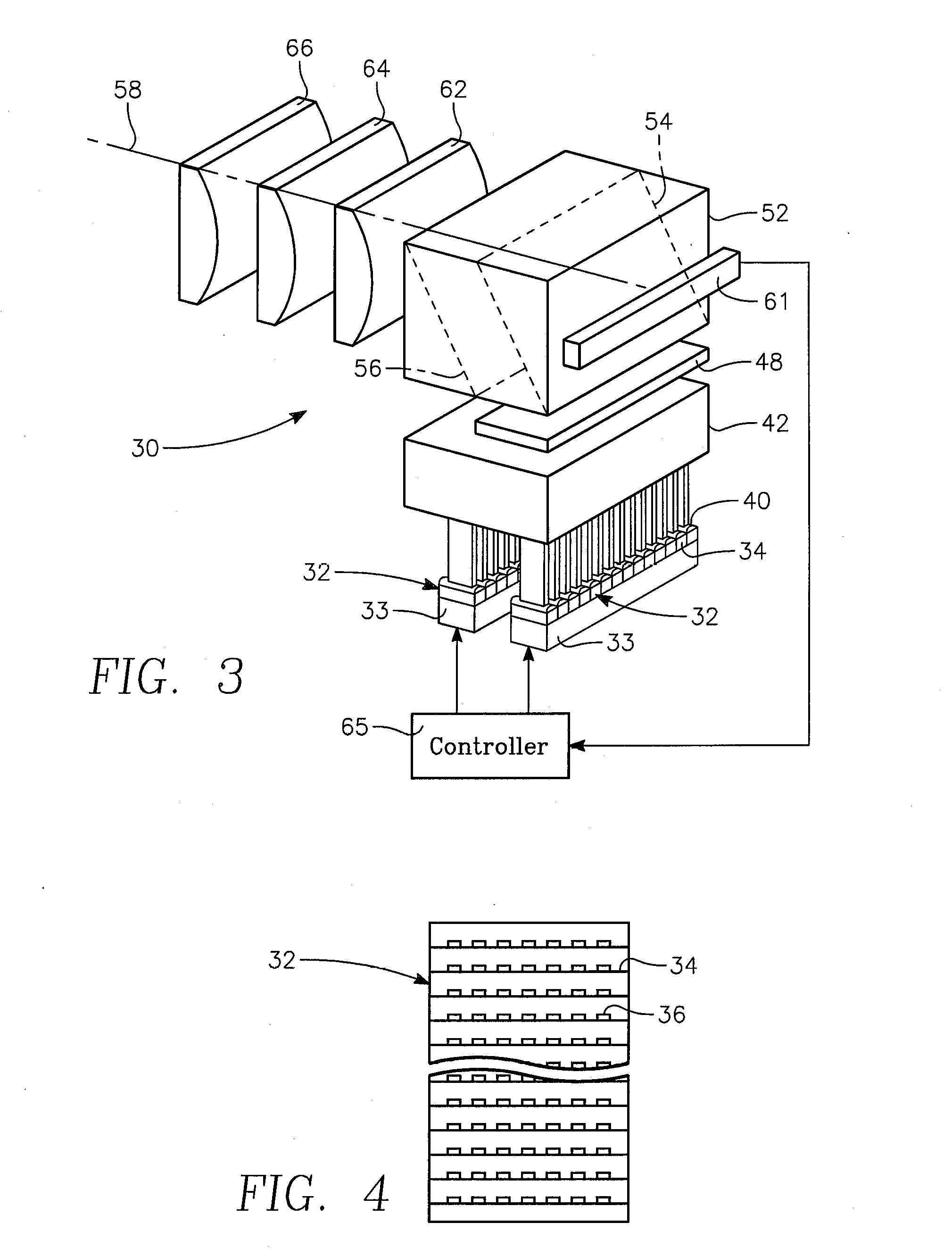

Dynamic surface annealing using addressable laser array with pyrometry feedback

Apparatus for dynamic surface annealing of a semiconductor wafer includes a source of laser radiation emitting at a laser wavelength and comprising an array of lasers arranged in rows and columns, the optical power of each the laser being individual adjustable and optics for focusing the radiation from the array of lasers into a narrow line beam in a workpiece plane corresponding to a workpiece surface, whereby the optics images respective columns of the laser array onto respective sections of the narrow line beam. A pyrometer sensor is provided that is sensitive to a pyrometer wavelength. An optical element in an optical path of the optics is tuned to divert radiation emanating from the workpiece plane to the pyrometry sensor. As a result, the optics images each of the respective section of the narrow line beam onto a corresponding portion of the pyrometer sensor. The apparatus further includes a controller responsive to the pyrometry sensor and coupled to adjust individual optical outputs of respective columns of the laser array in accordance with outputs of corresponding portions of the pyrometry sensor.

Owner:APPLIED MATERIALS INC

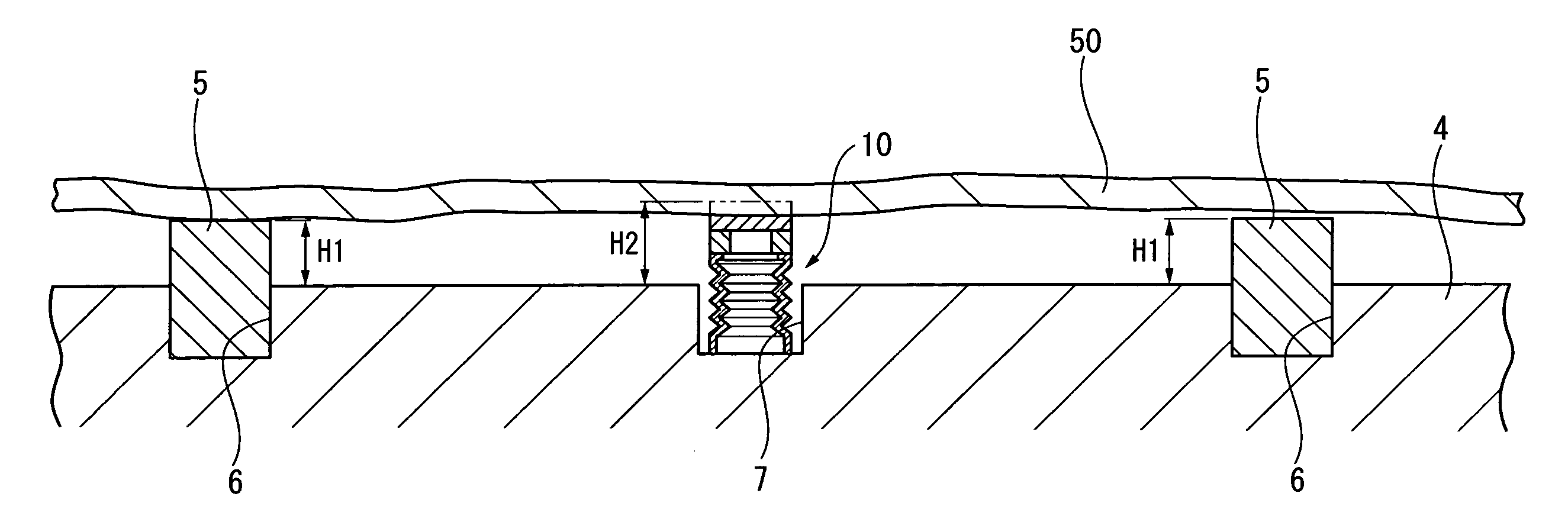

Temperature sensor, temperature control device, temperature controller and temperature-control method

ActiveUS20080043803A1High measurement accuracyThermometer detailsMechanical apparatusTemperature controlEngineering

A temperature sensor (10) includes: a temperature-sensing portion for measuring a temperature of an object (50) by contacting the object; and a supporting portion for supporting the temperature-sensing portion from a side opposite to a contact surface, the supporting portion having a space at a portion partially corresponding to the temperature-sensing portion. A temperature controller includes: a temperature control device; the temperature sensor (10) for measuring the temperature by contacting the object (50); and a controller for controlling the temperature control device. The controller includes: a mounting-state judging means for judging a mounting-state of the object (50); a switching means for switching a control gain and a target temperature of the temperature control device based on the judging result; and a control-command generating means for generating a control command based on the control gain, the target temperature and a measurement value of the temperature sensor (10).

Owner:KOMATSU LTD

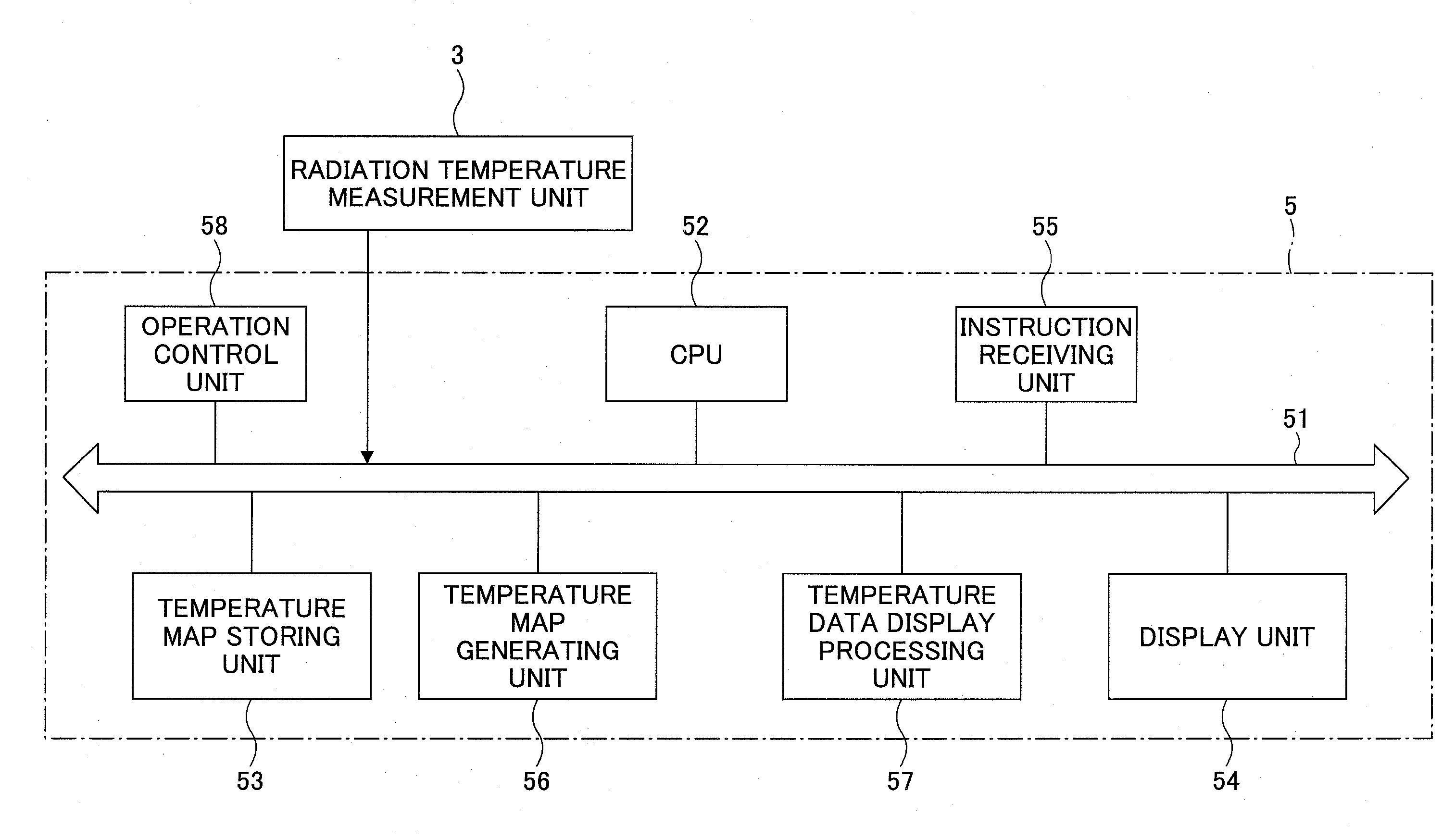

Temperature measurement apparatus, method of measuring temperature profile, recording medium and heat treatment apparatus

A temperature measurement apparatus for measuring a temperature profile of a substrate mounted on a rotating table, including a radiation temperature measurement unit configured to measure the temperature of plural temperature measurement areas on a surface of the rotating table in a radius direction of the rotating table by scanning the surface of the rotating table in the radius direction; a temperature map generating unit that specifies the address of the temperature measurement area based on the number of the temperature measurement areas measured by the radiation temperature measurement unit for each of the scanning operations in the radius direction of the rotating table, and the rotating speed of the rotating table, and stores the temperature in correspondence with the corresponding address in a storing unit; and a temperature data display processing unit that displays a temperature profile of the rotating table.

Owner:TOKYO ELECTRON LTD

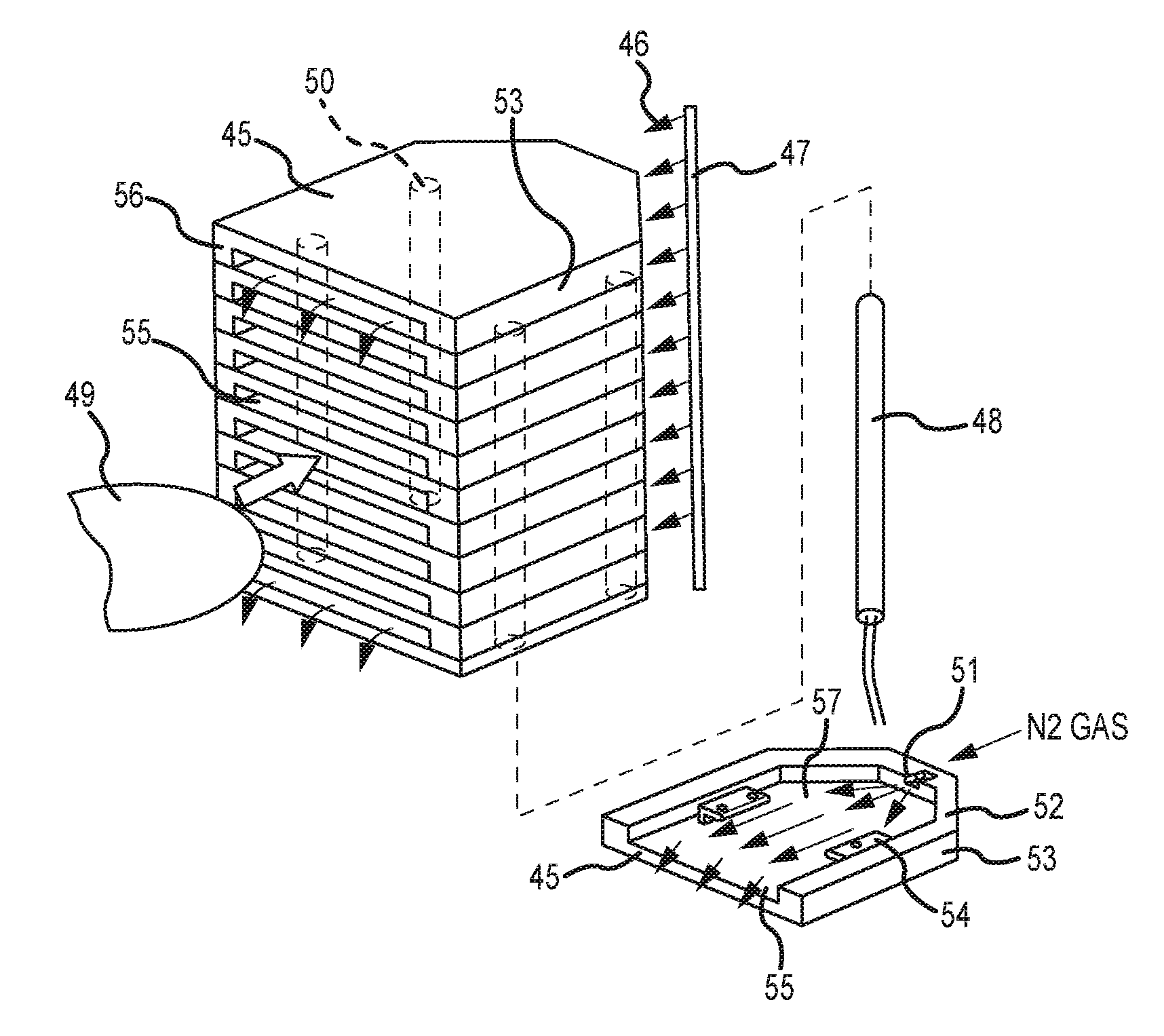

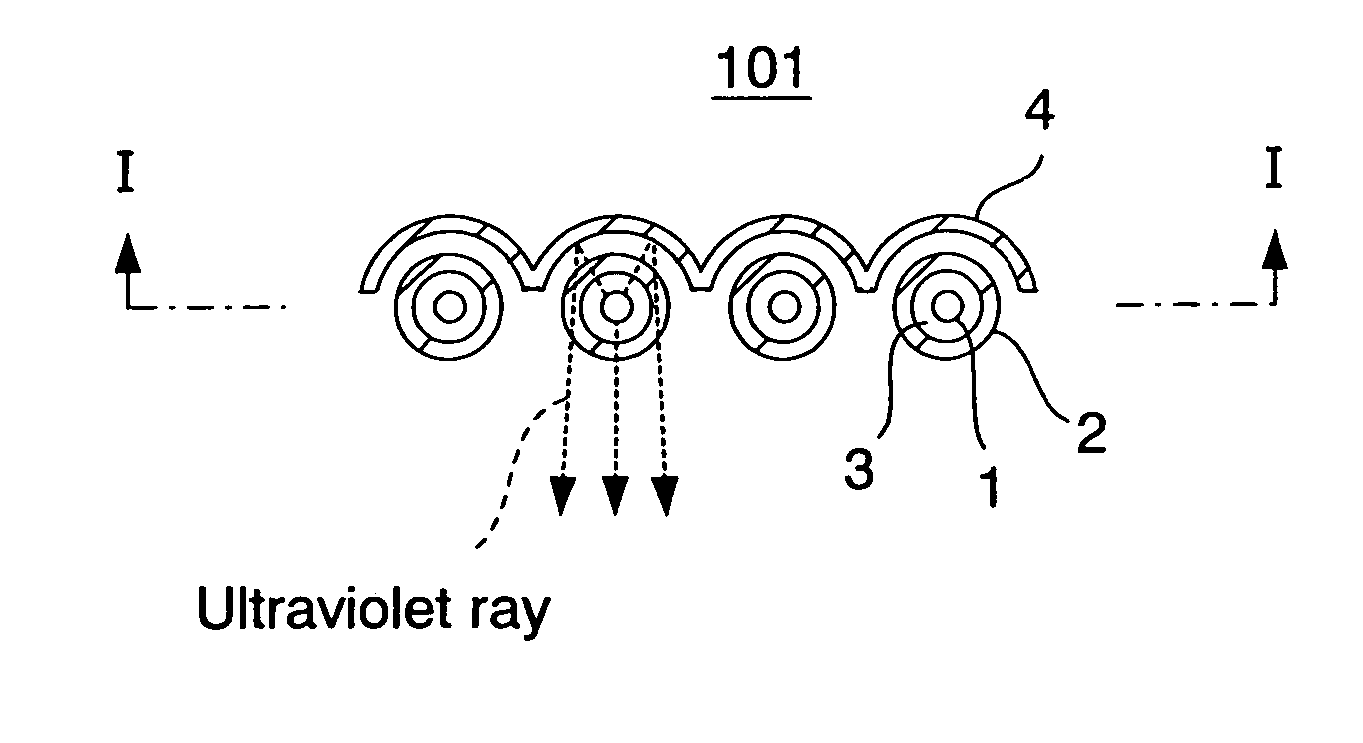

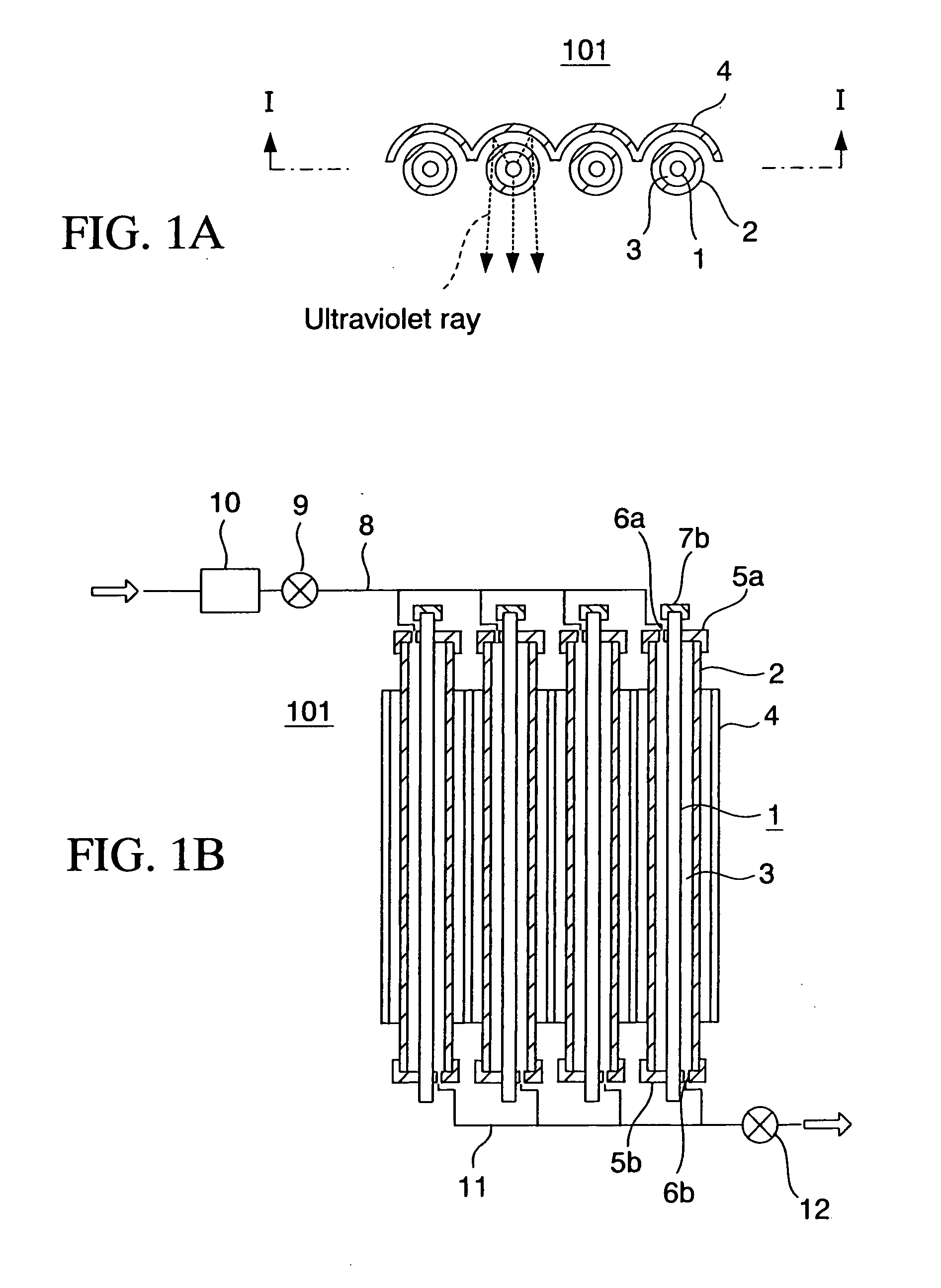

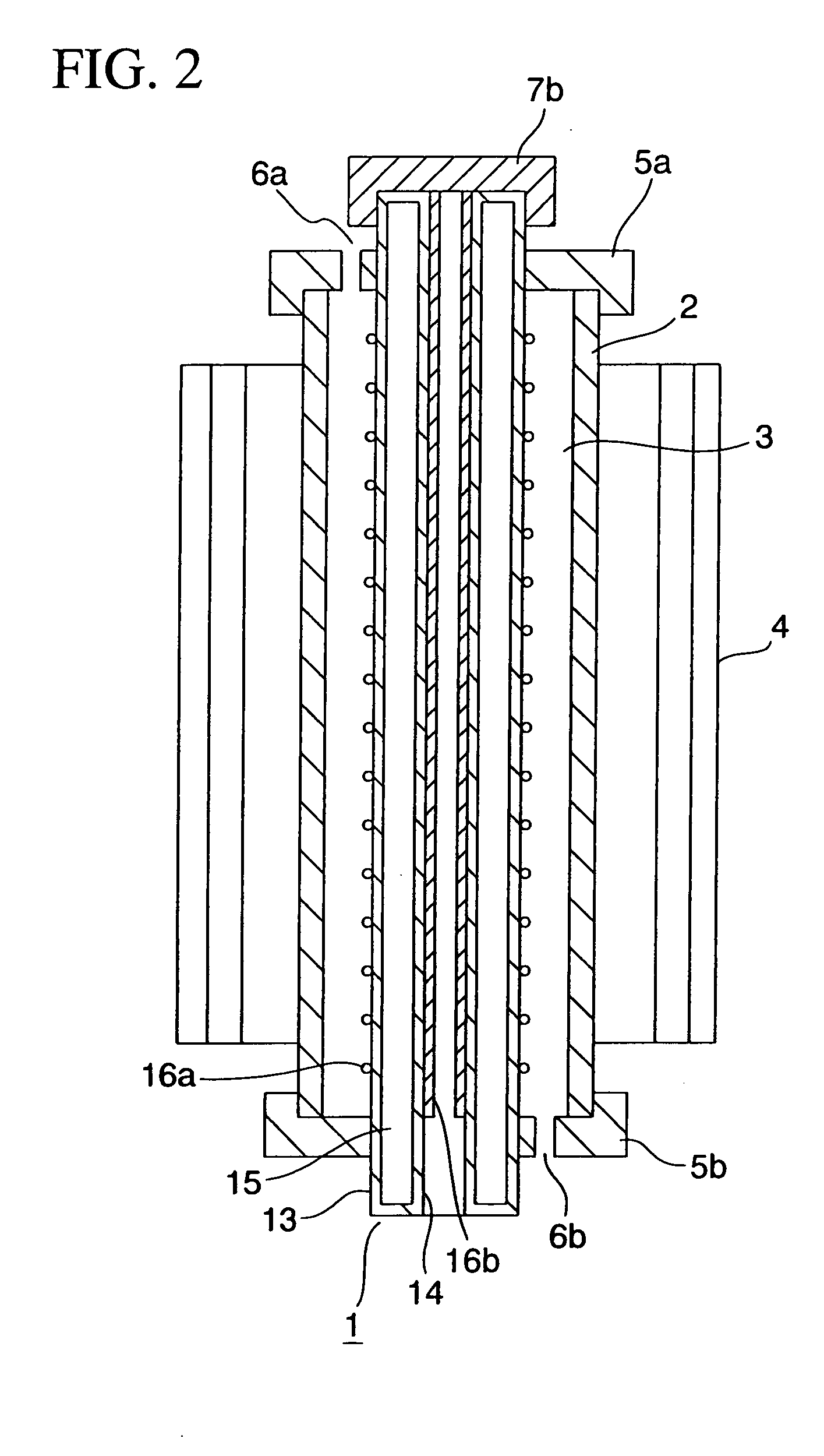

Ultraviolet ray generator, ultraviolet ray irradiation processing apparatus, and semiconductor manufacturing system

InactiveUS20050263719A1High dielectric constantReduce transmission intensityFurnace componentsLiving organism packagingUltravioletNitrogen gas

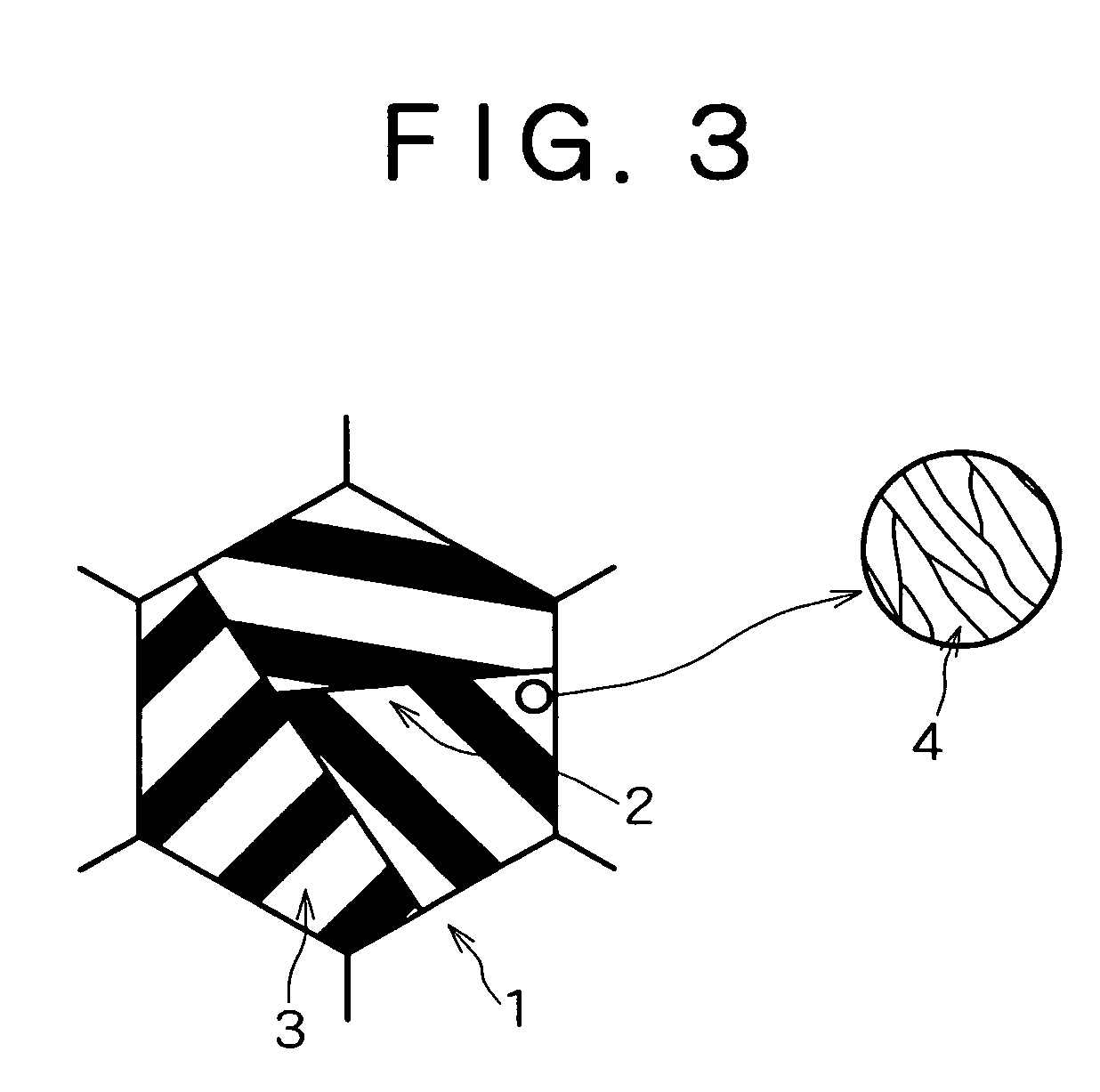

The present invention relates to an ultraviolet ray generator 101, and the generator 101 has an ultraviolet ray lamp 1, a protective tube 2 being made of a material which is transparent with respect to ultraviolet ray and housing the ultraviolet ray lamp 1, and gas introduction port 6a introducing nitrogen gas or inert gas into the protective tube 2.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

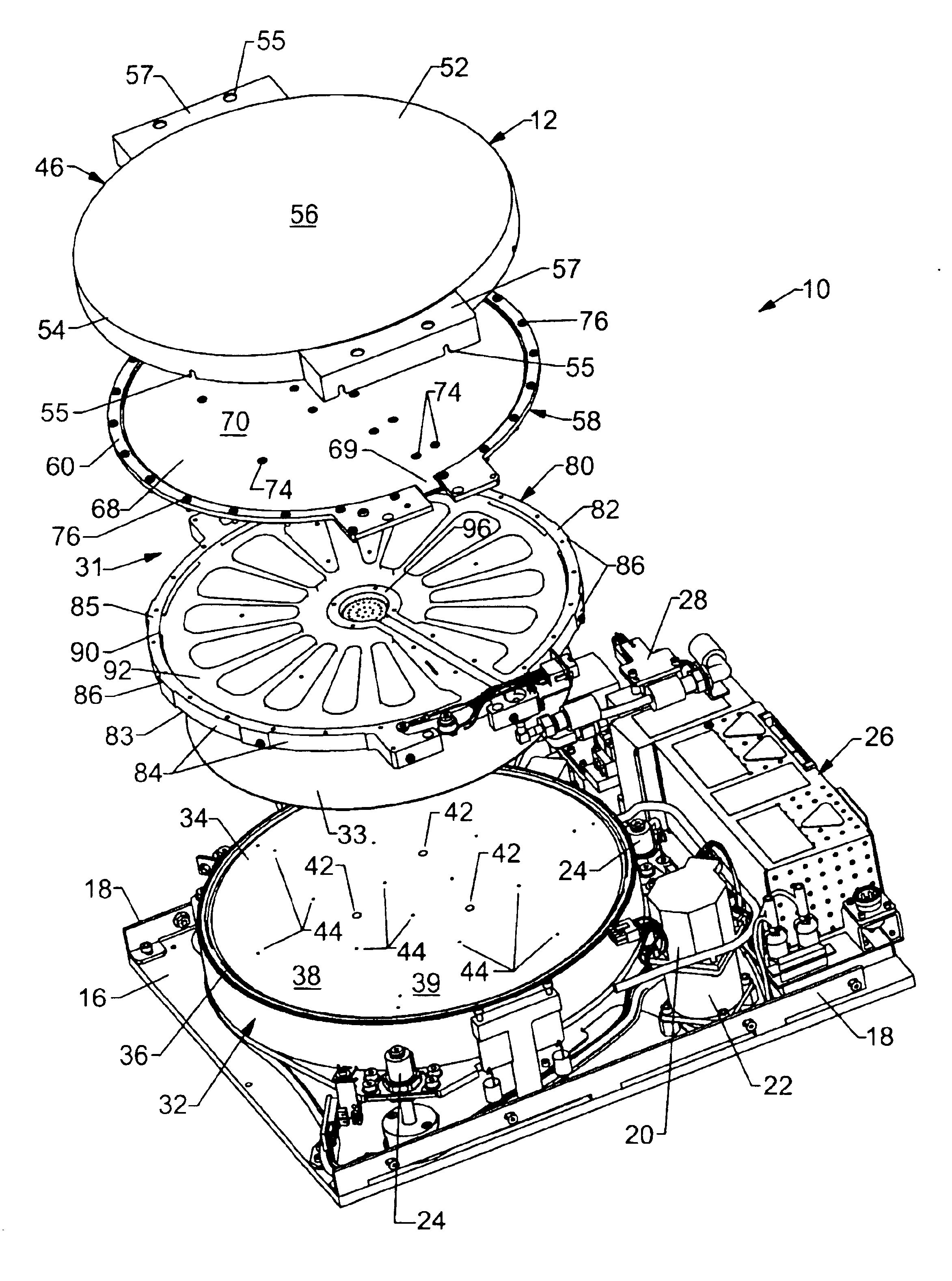

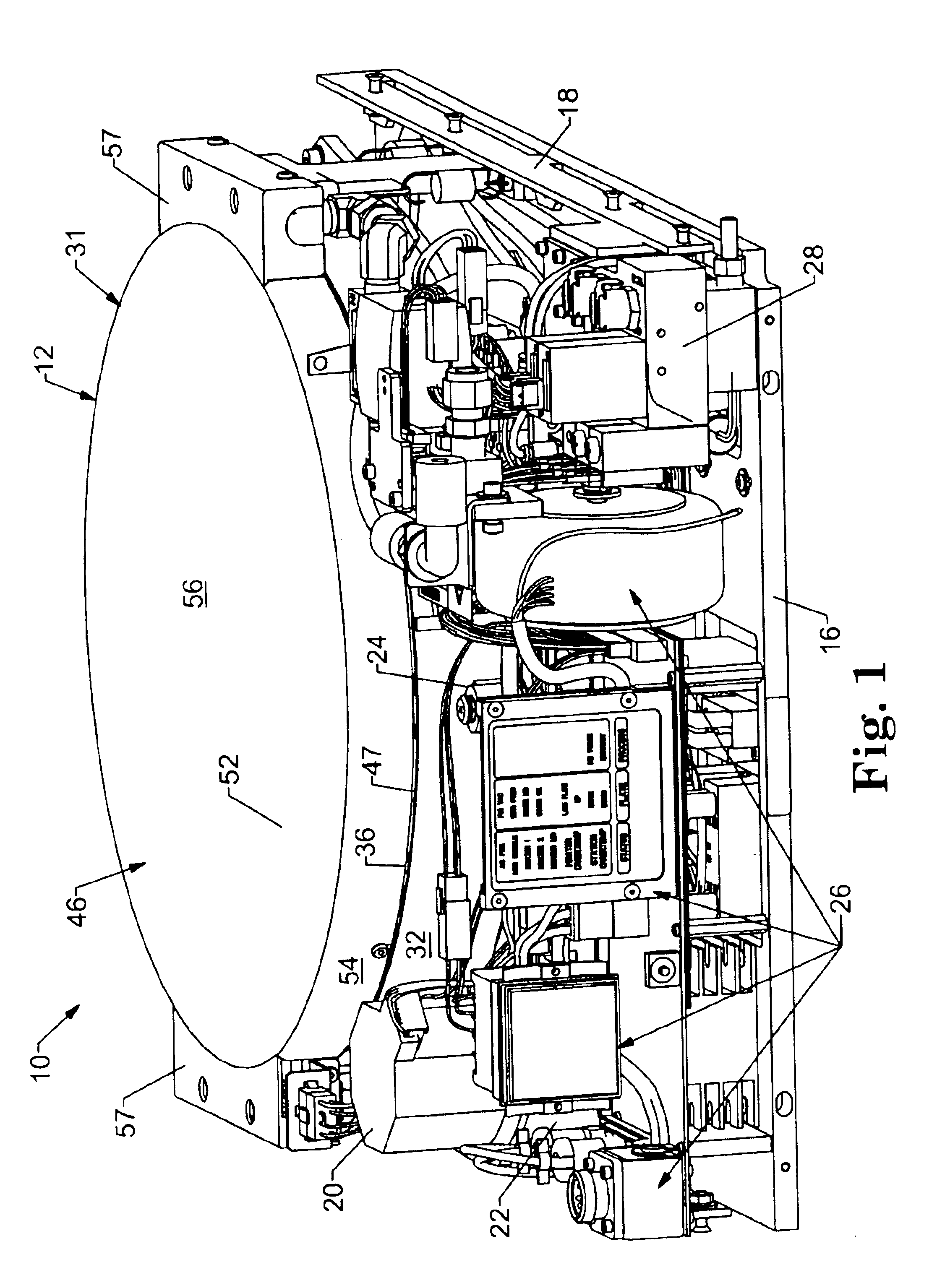

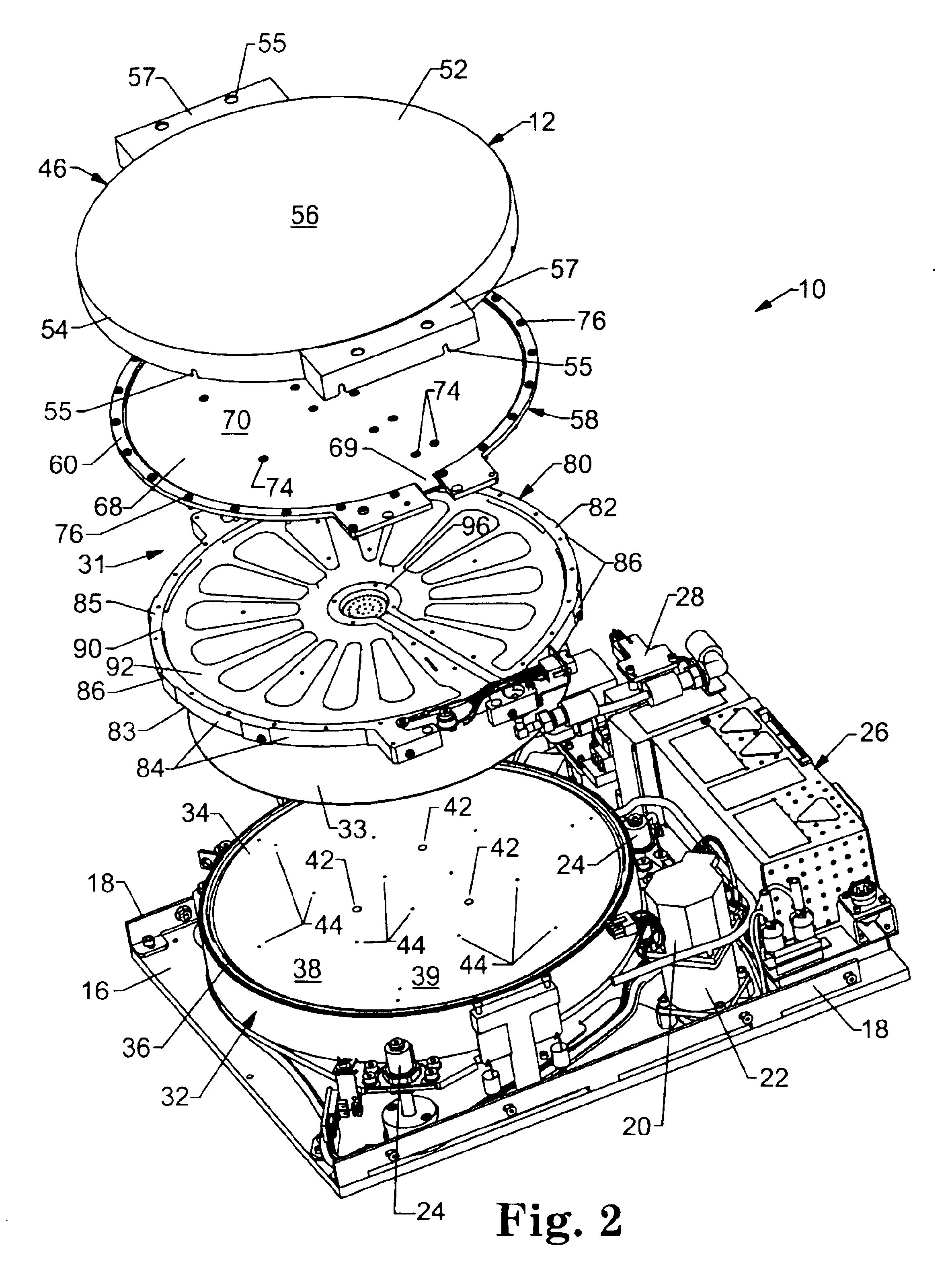

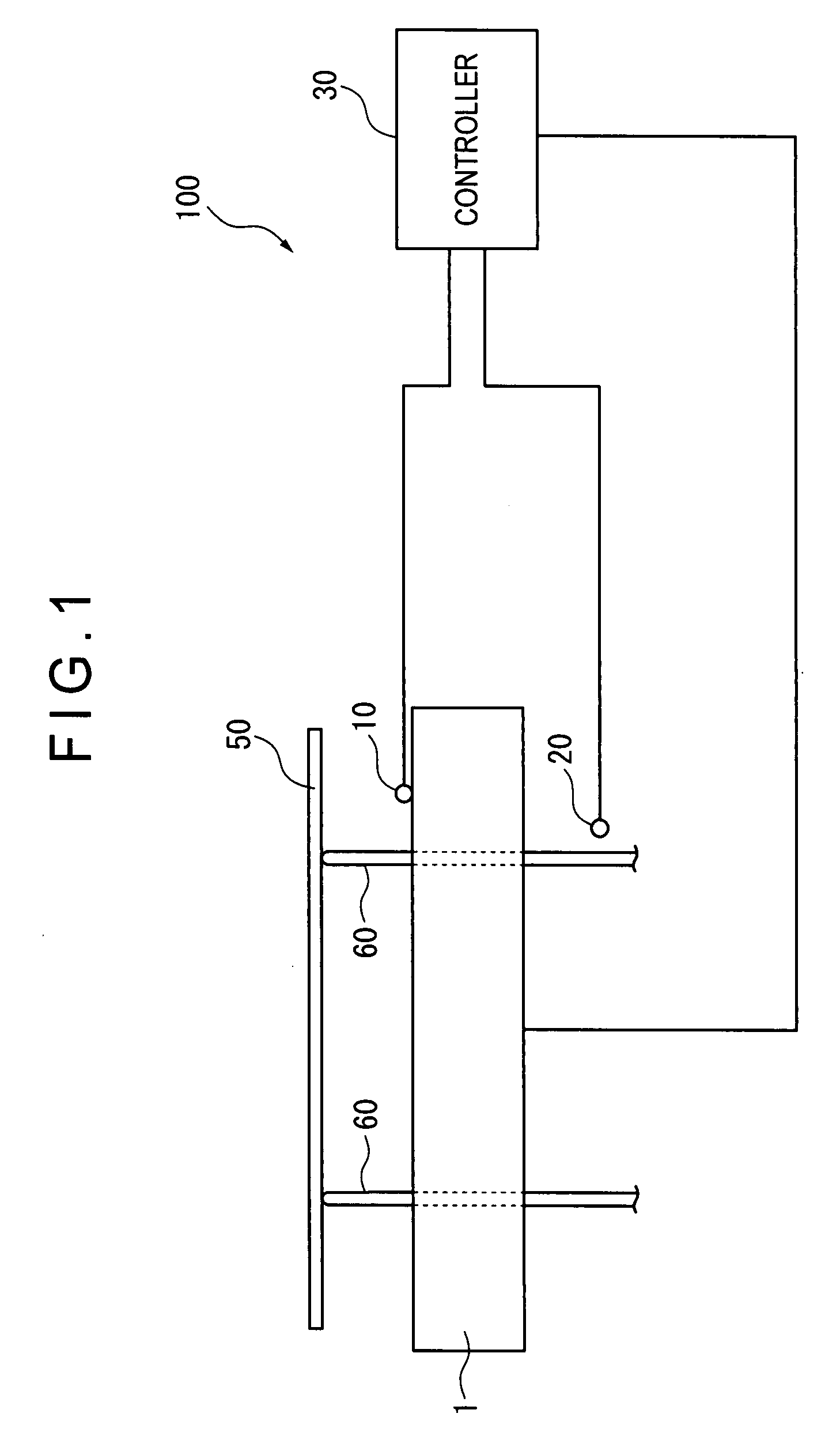

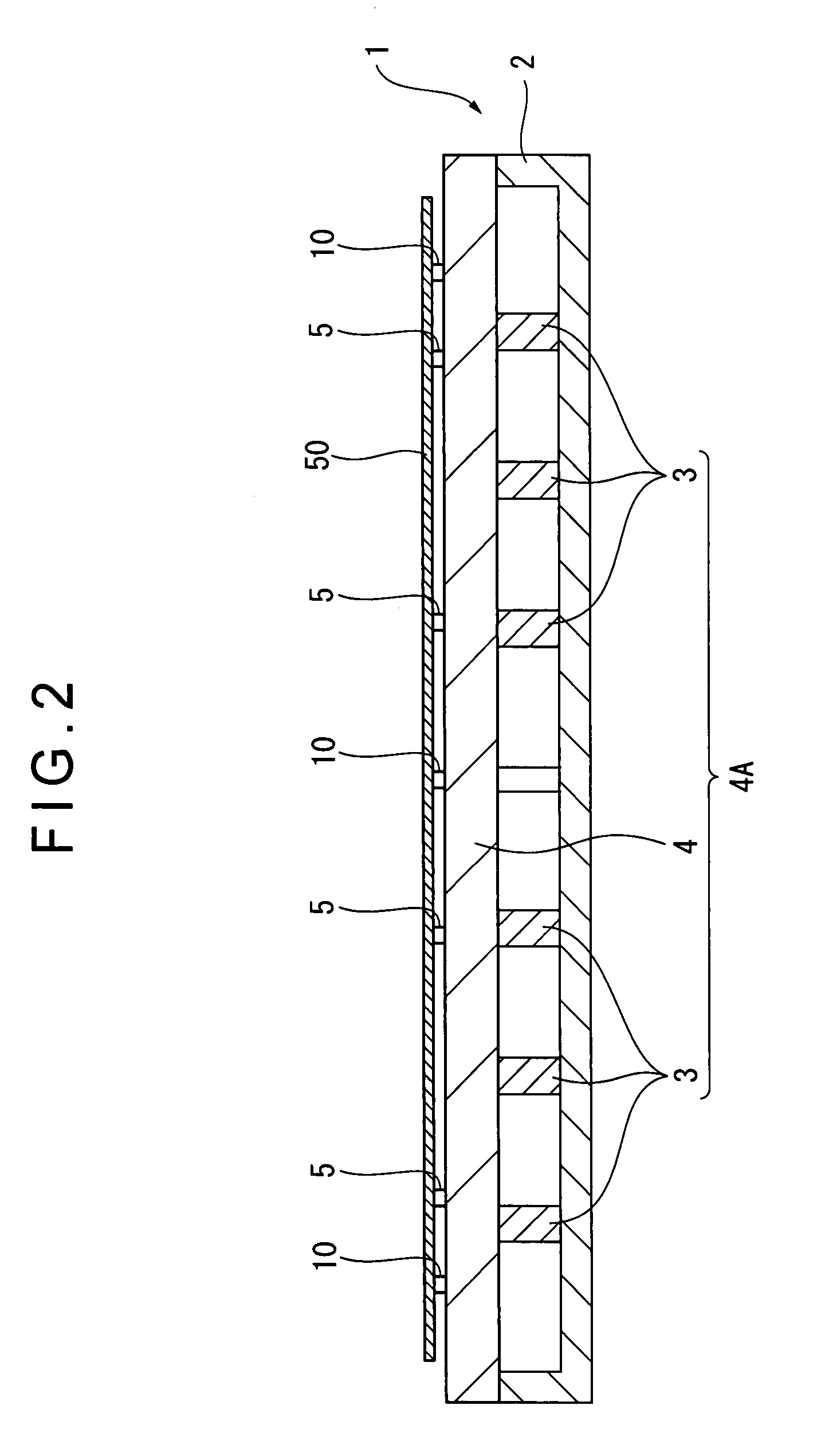

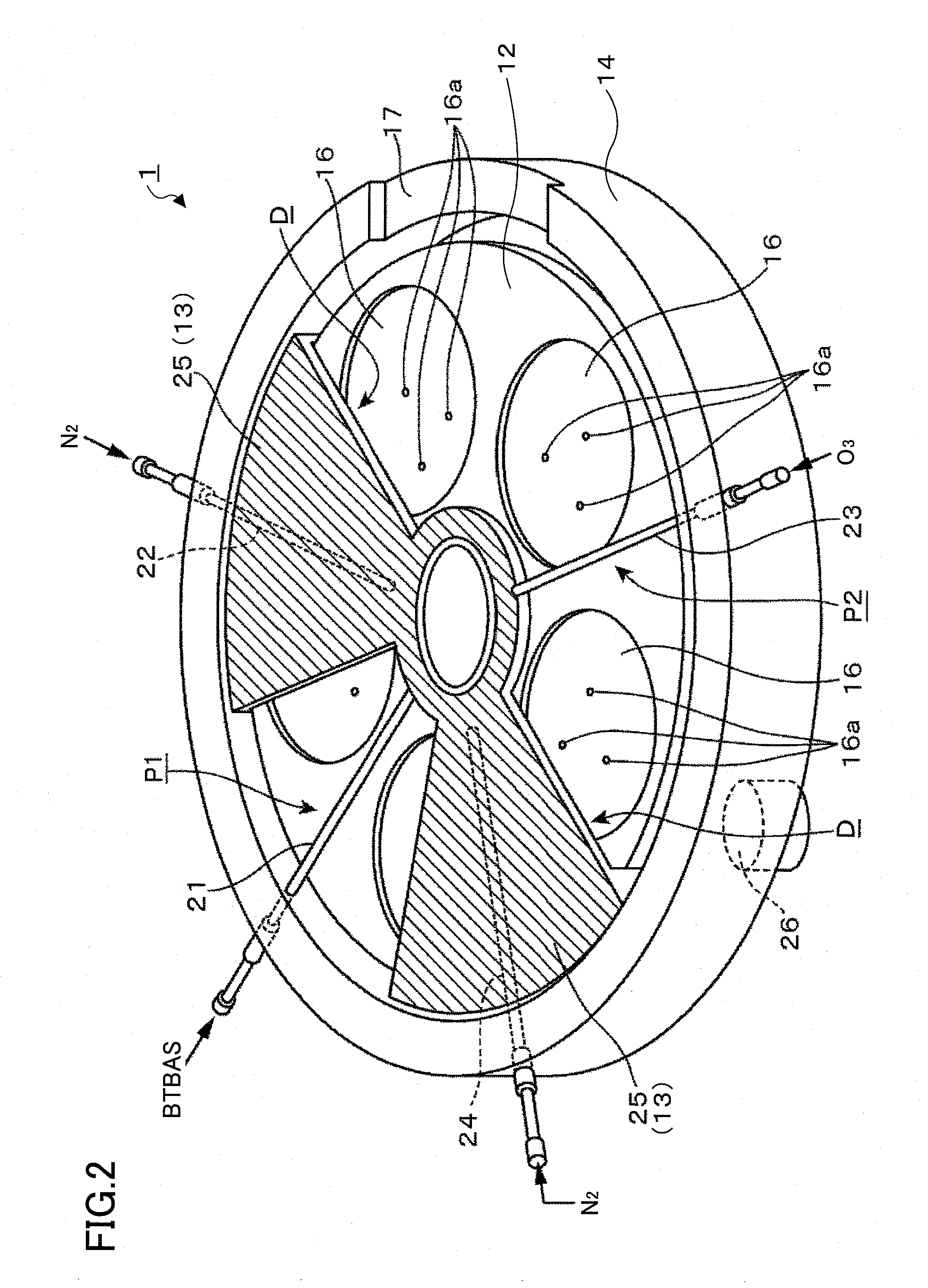

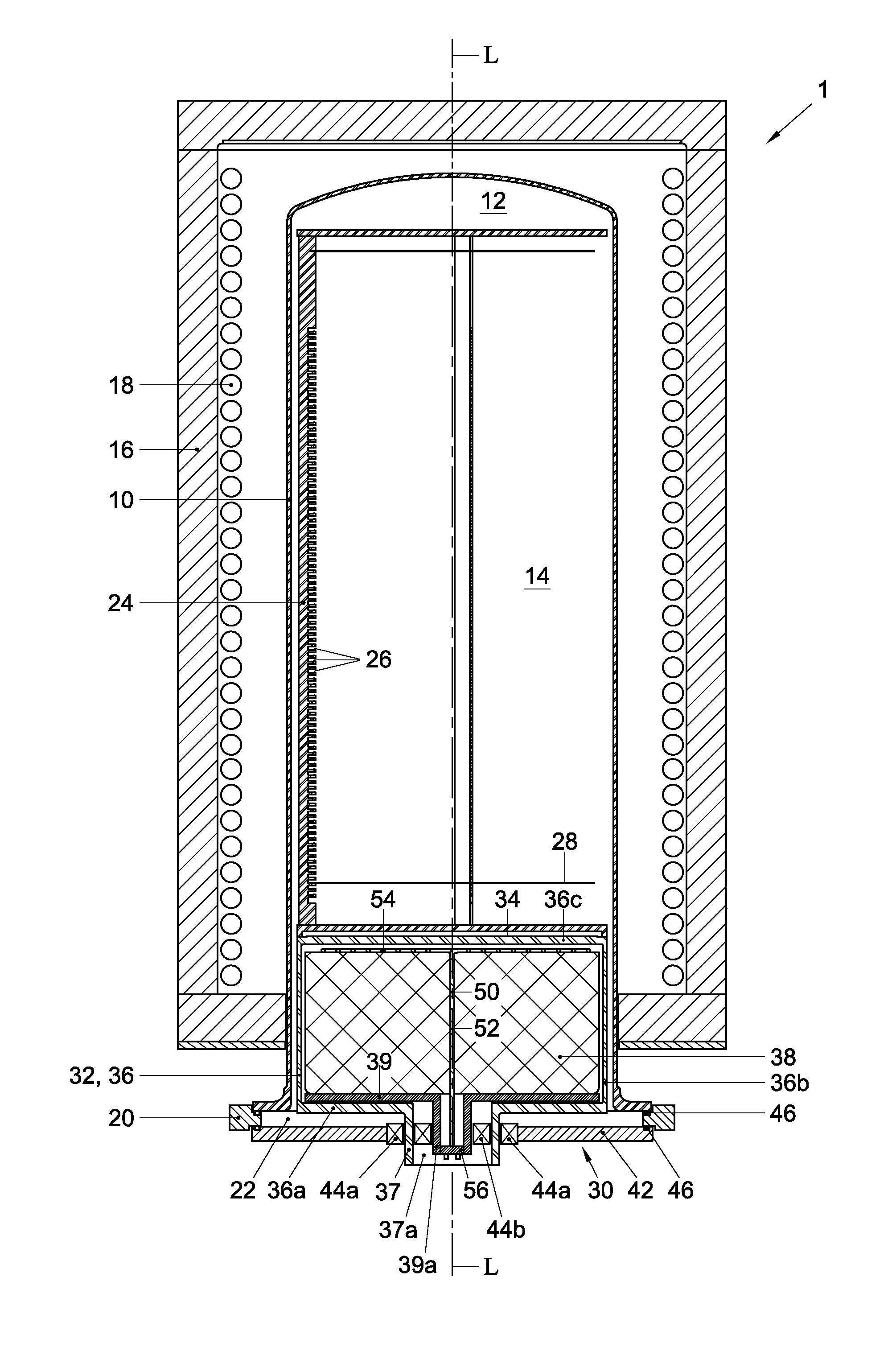

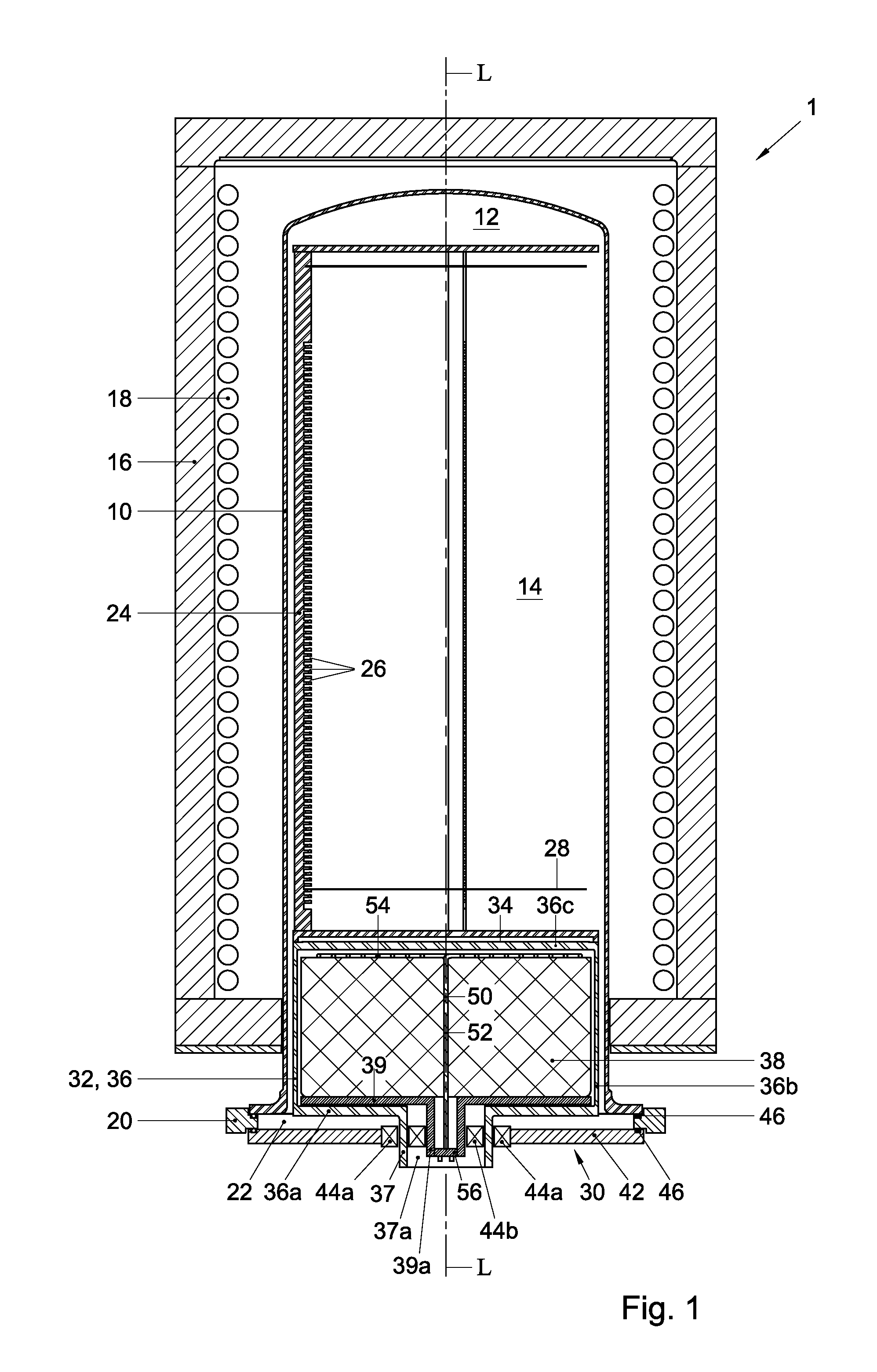

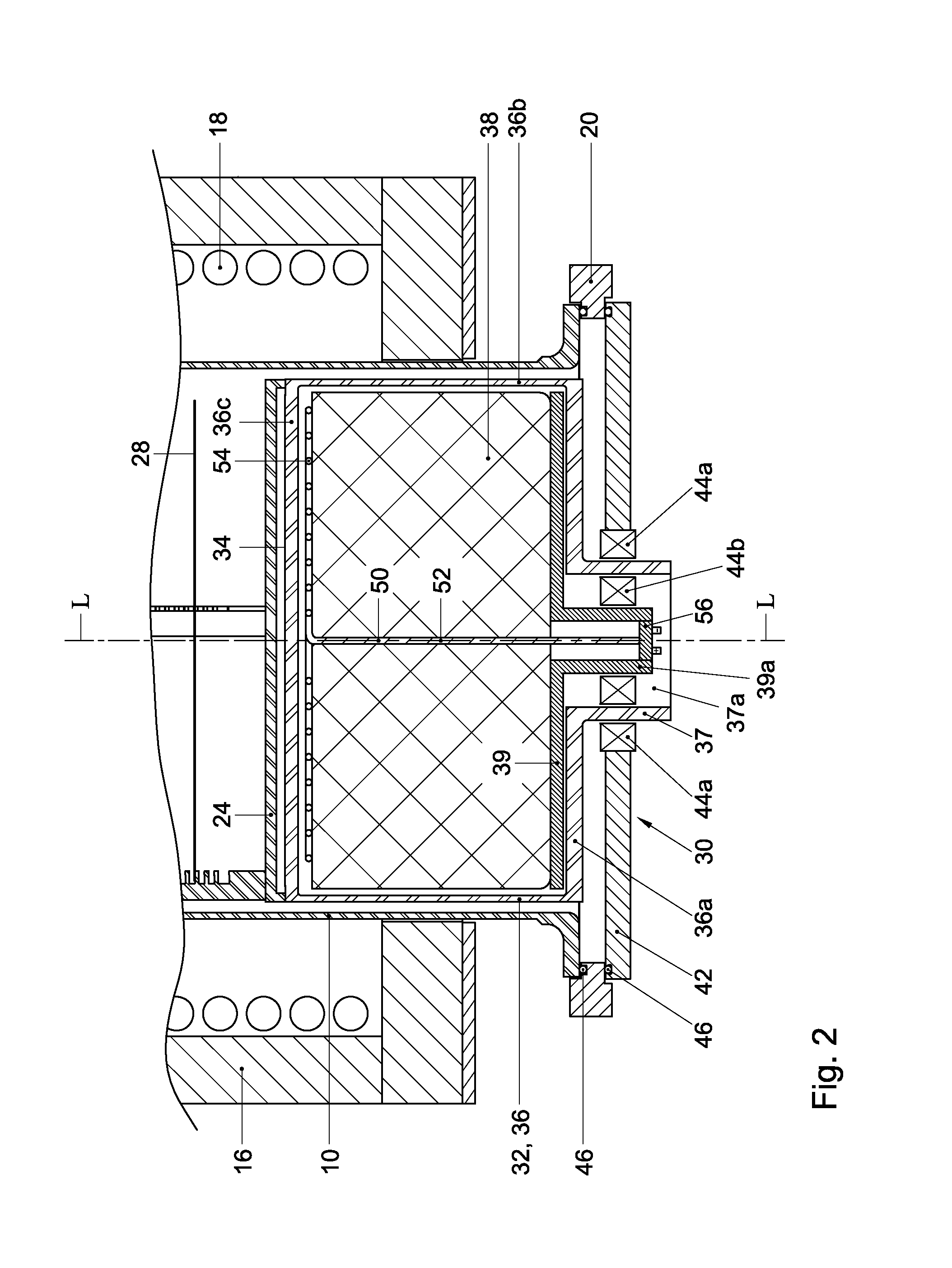

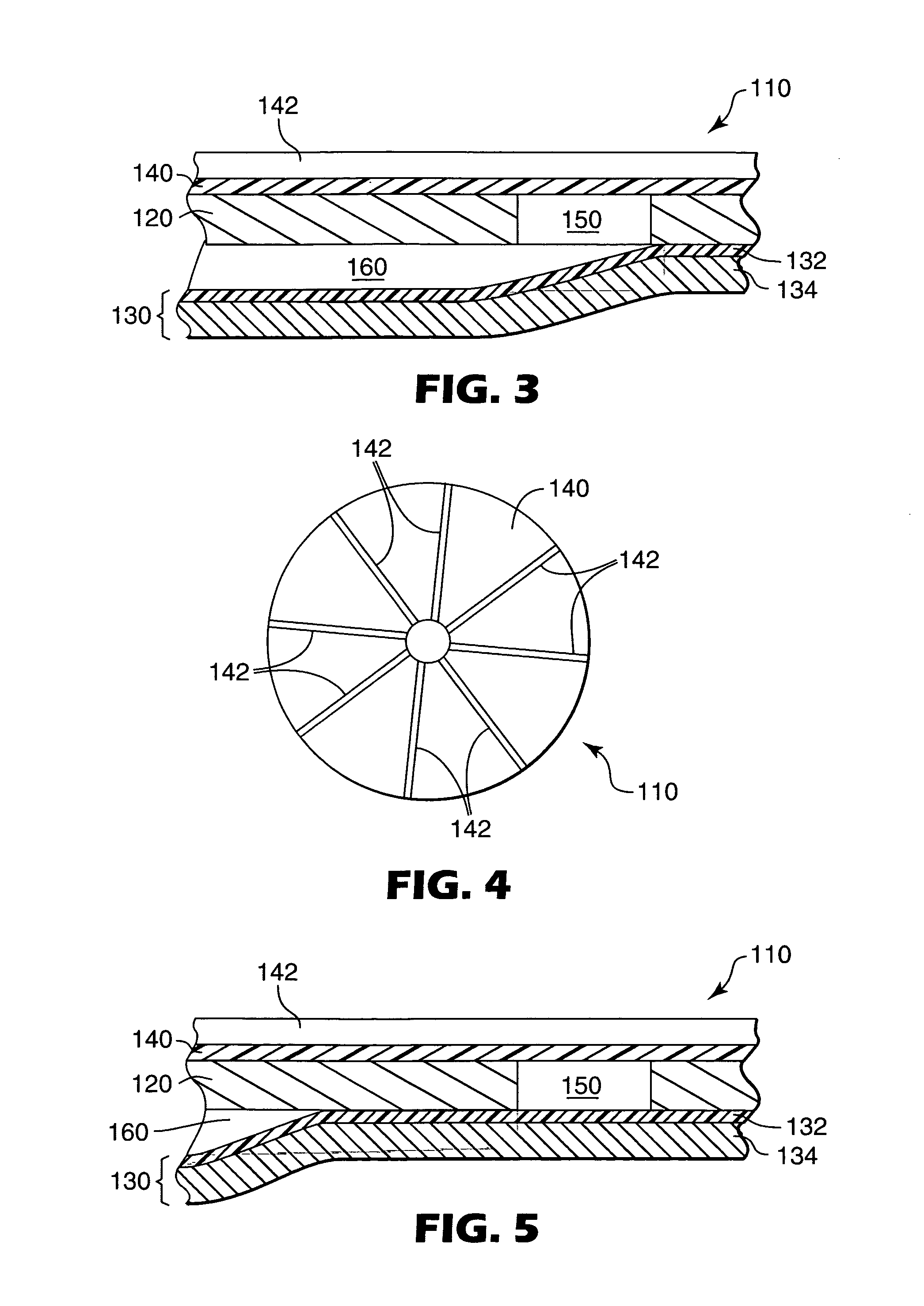

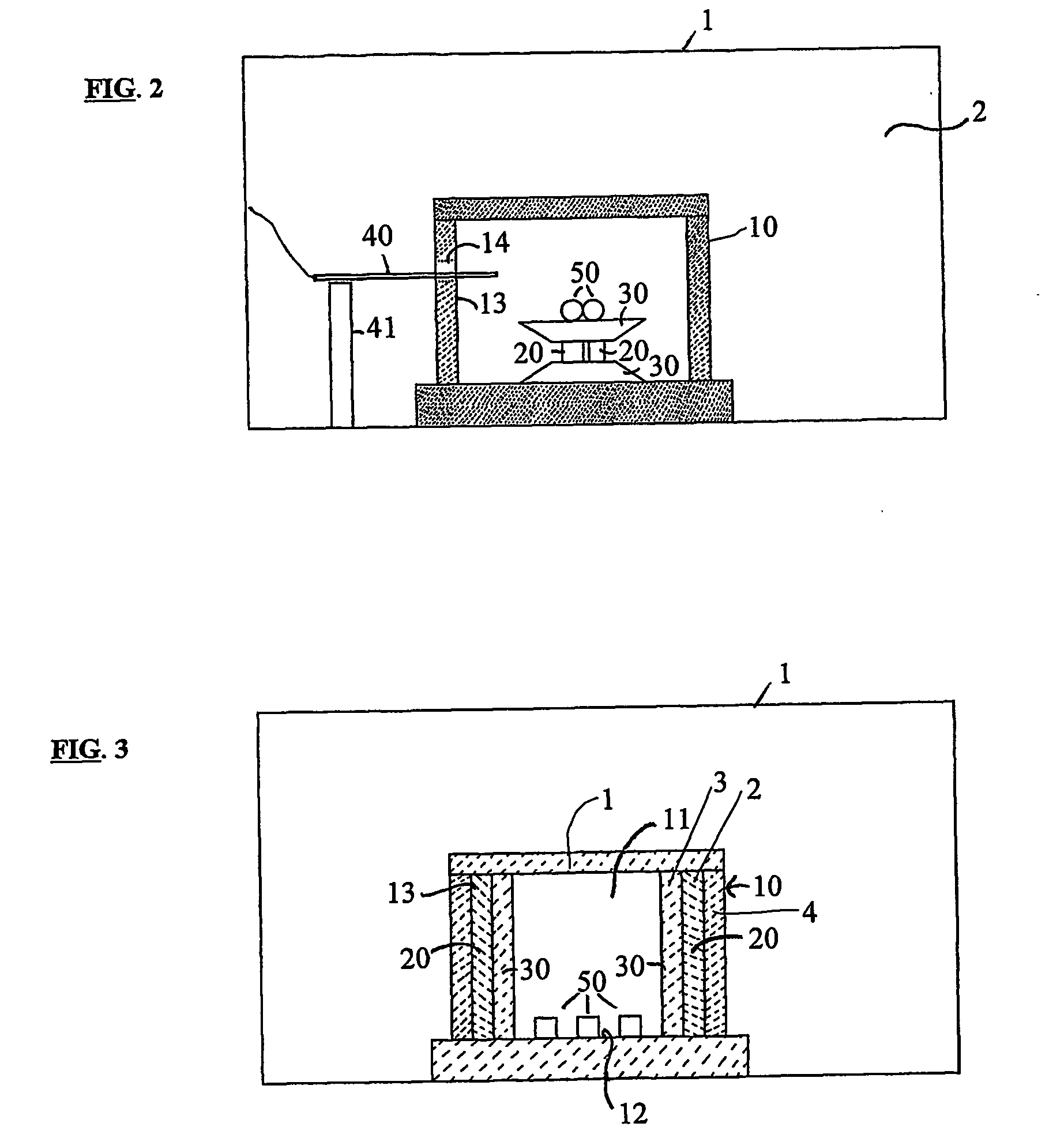

Wafer processing apparatus with heated, rotating substrate support

ActiveUS20130017503A1Easy constructionEasy and economical to constructCharge supportsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

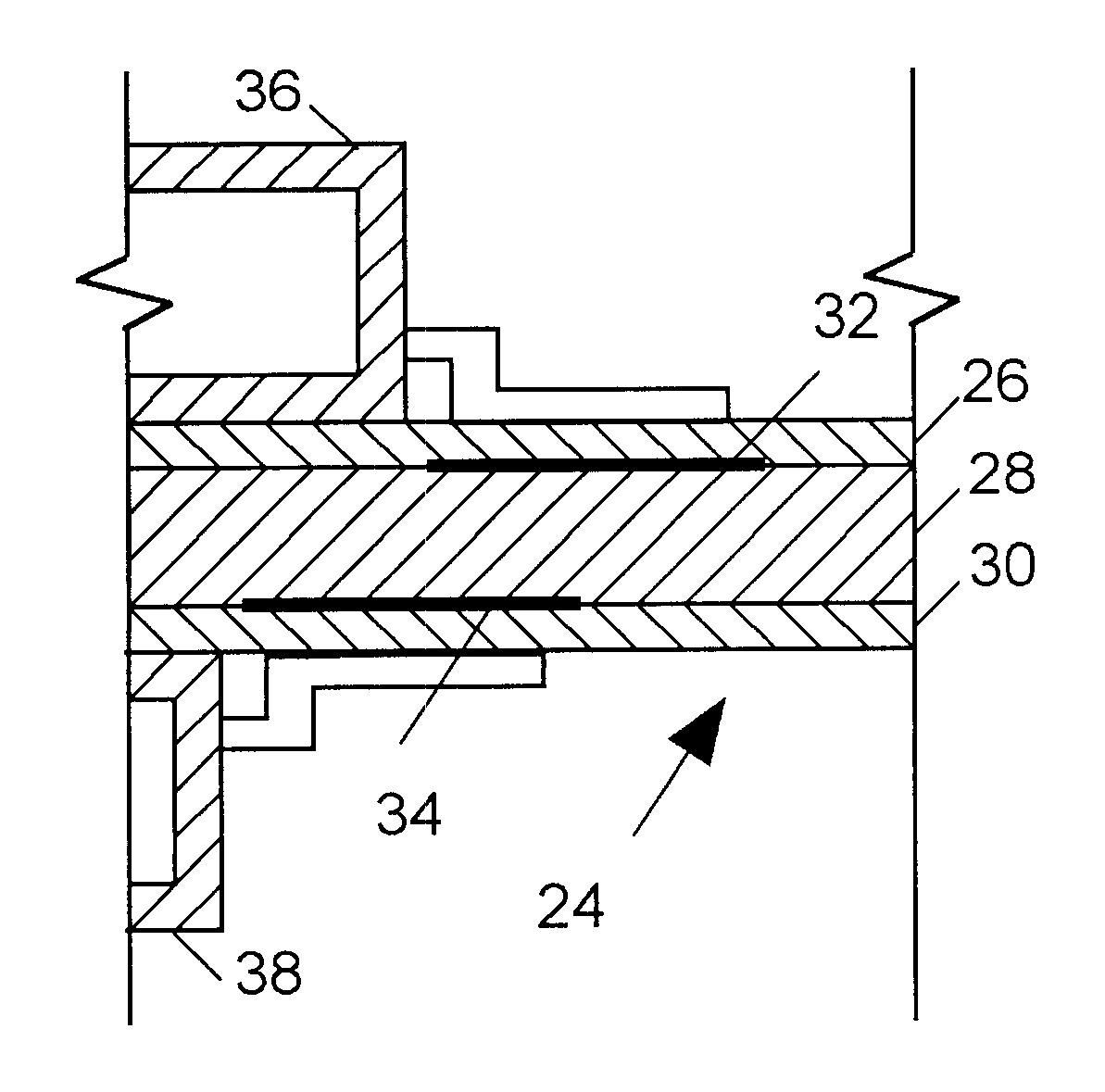

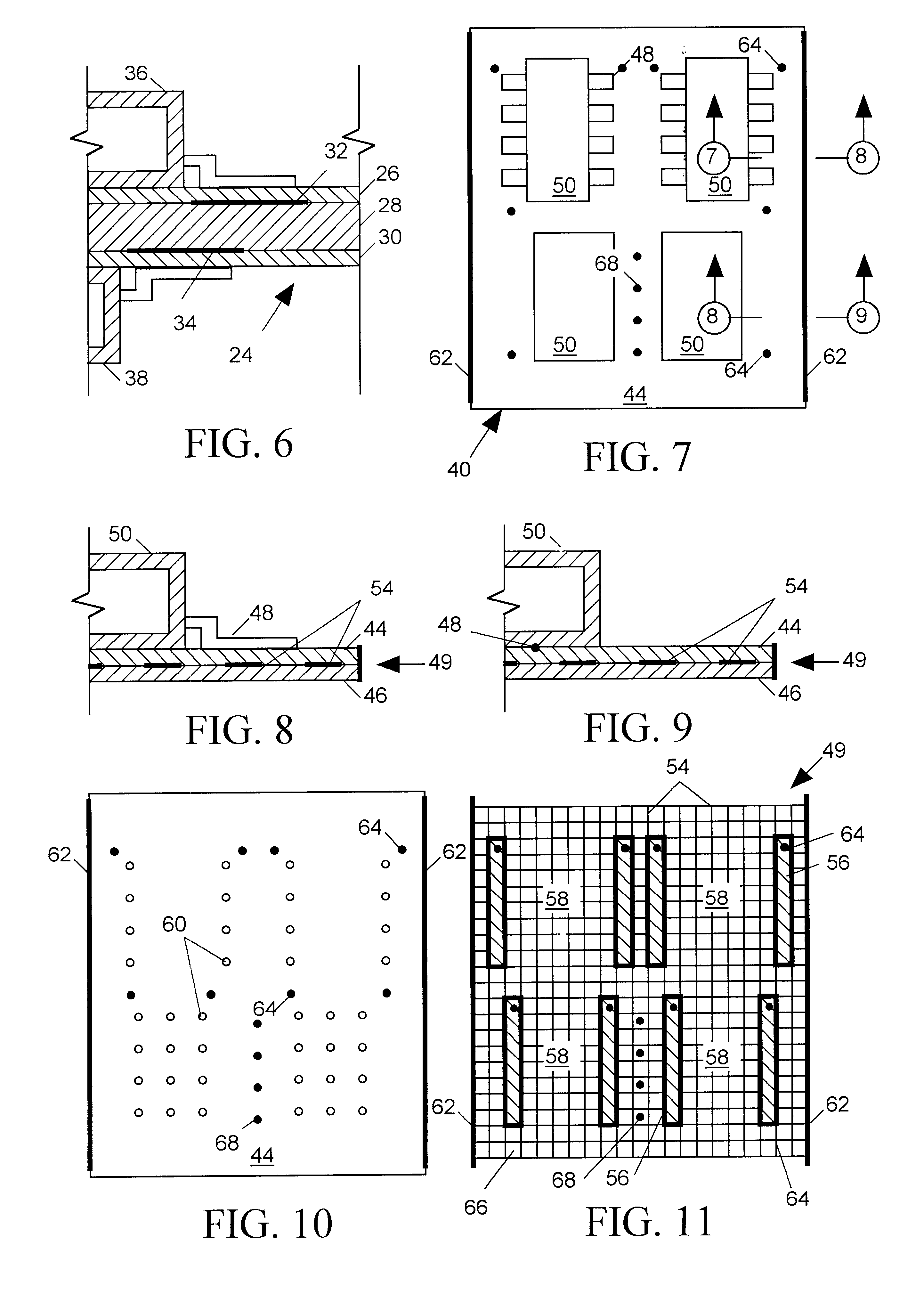

A semiconductor substrate processing apparatus (1), comprising a substrate support assembly (30), including a substrate support (32) defining an outer support surface (34) for supporting a substrate or substrate carrier (24) thereon, and a heater (50) comprising a heat dissipating portion (54) that is disposed within the substrate support (32) and that extends underneath and substantially parallel to the support surface (34), said substrate support (32) being rotatably mounted around a rotation axis (L) that extends through said support surface (34), such that the support surface (34) is rotatable relative to the heat dissipating portion (54) of the heater (50).

Owner:ASM IP HLDG BV

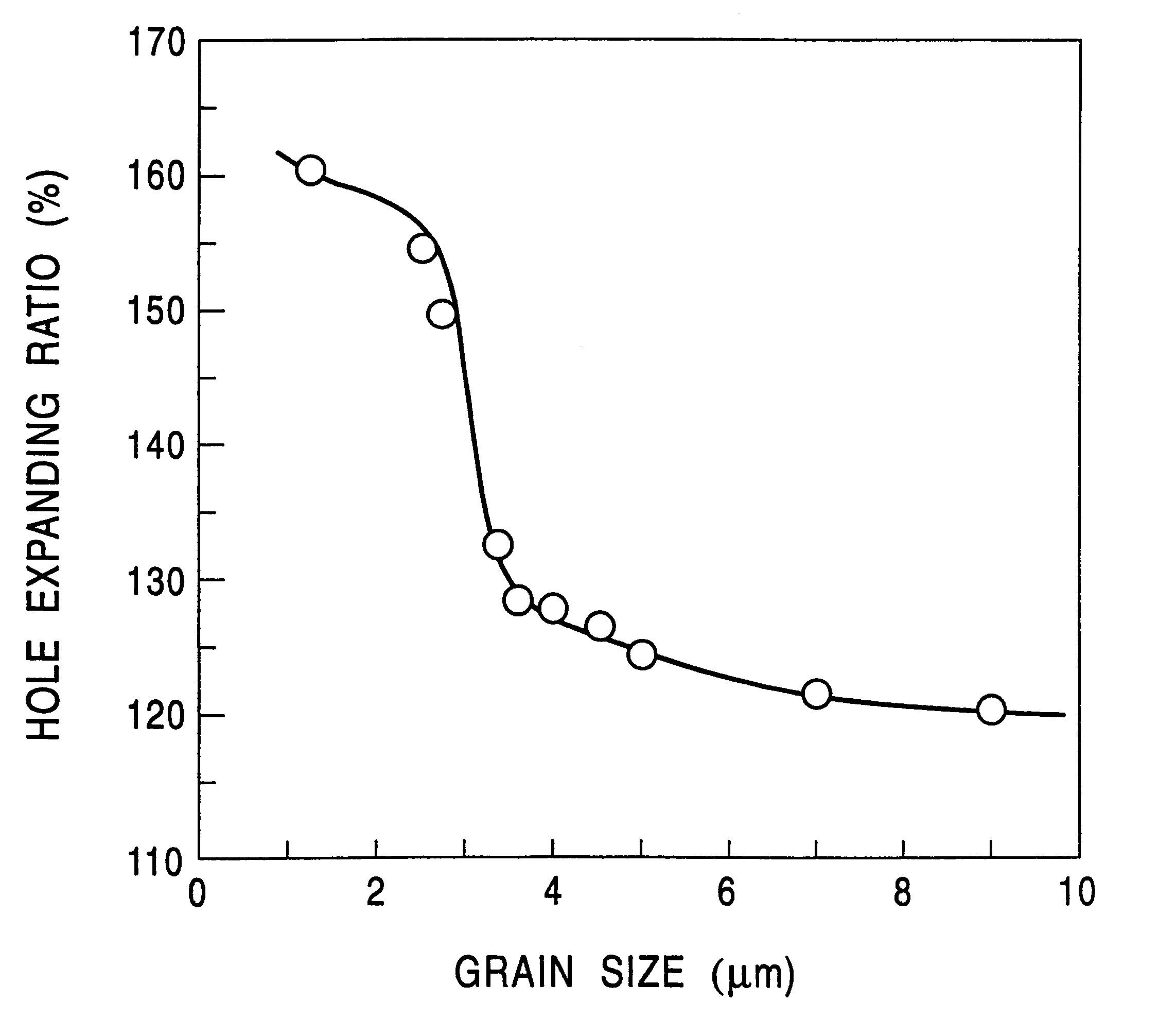

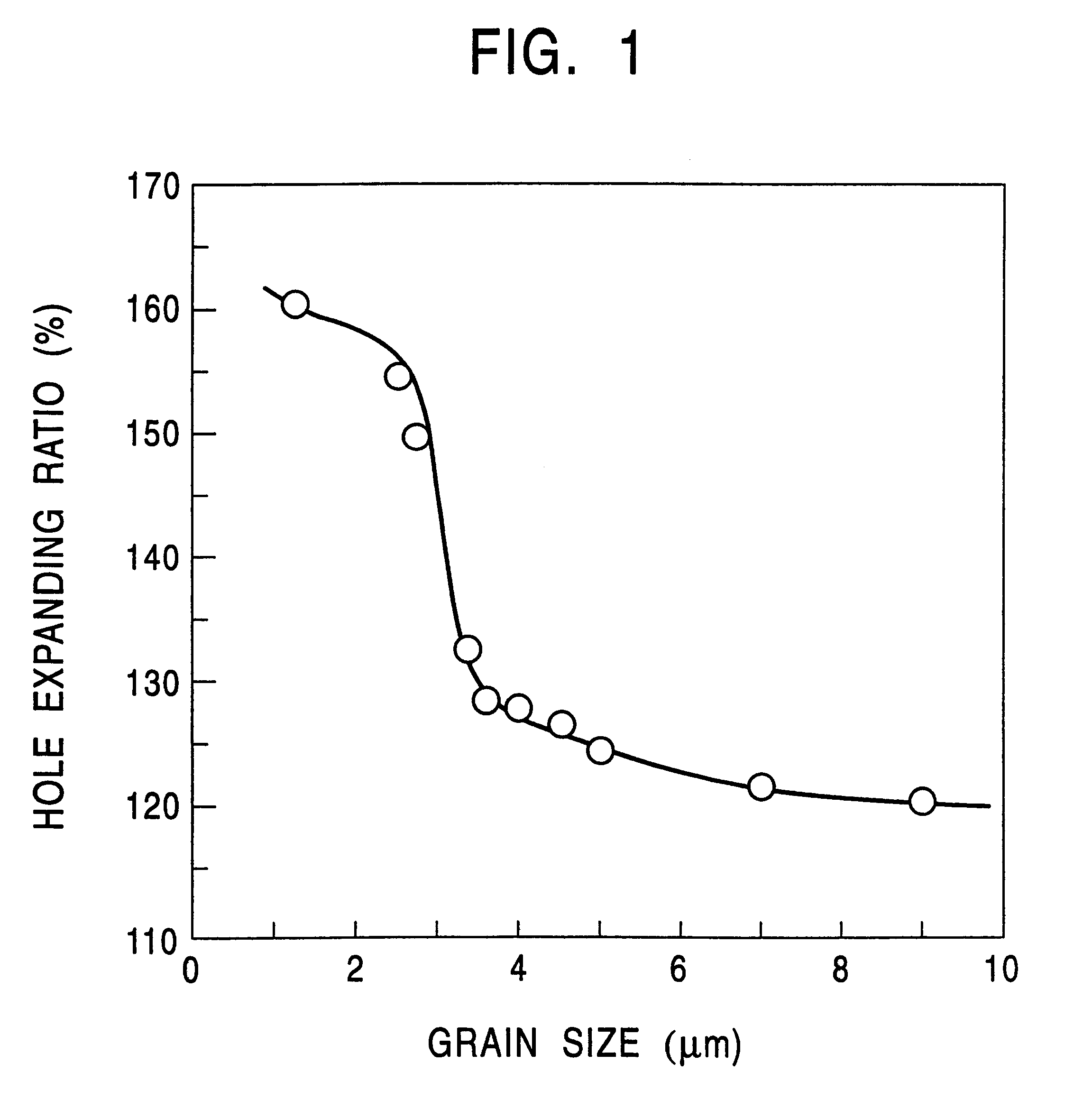

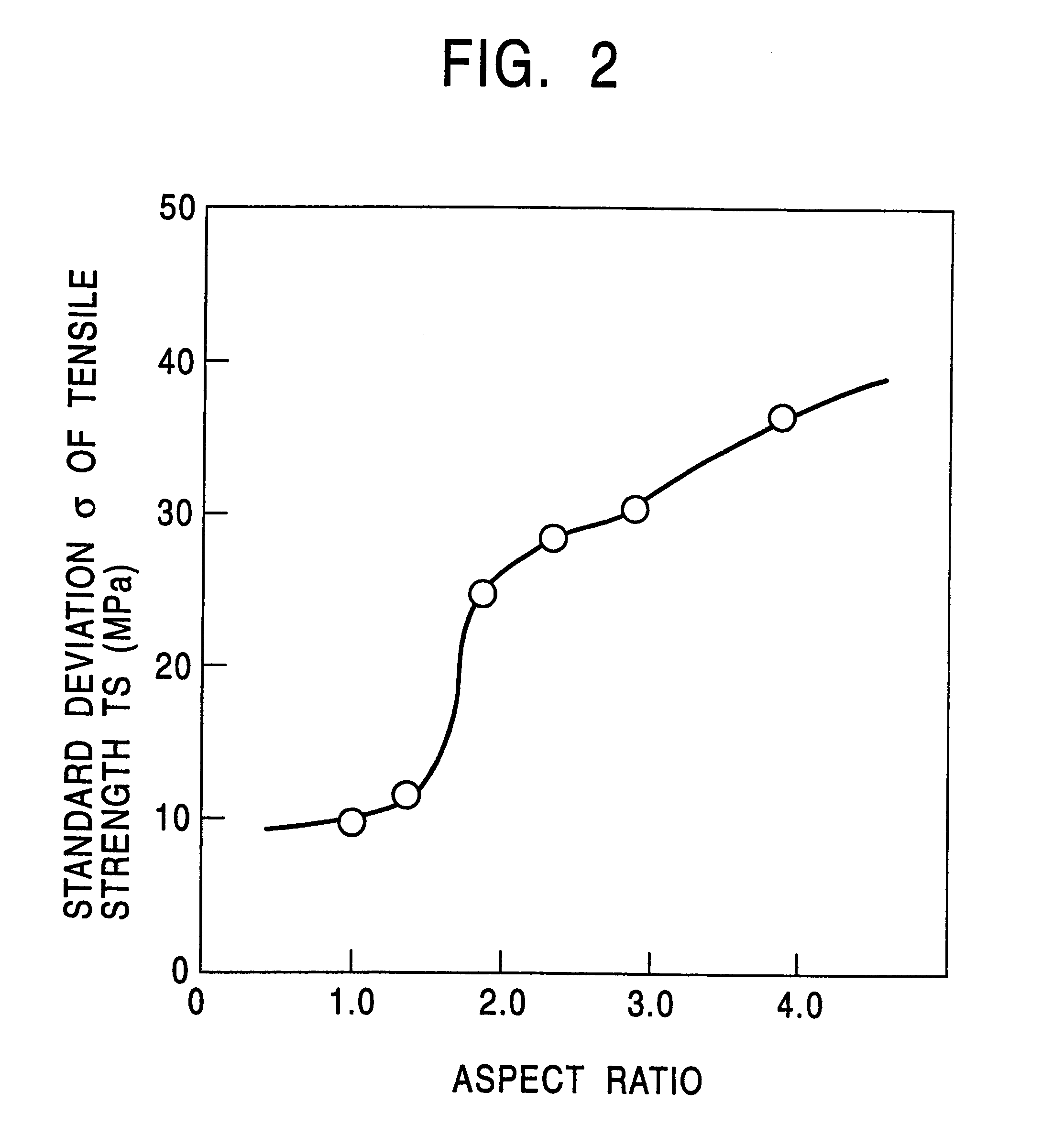

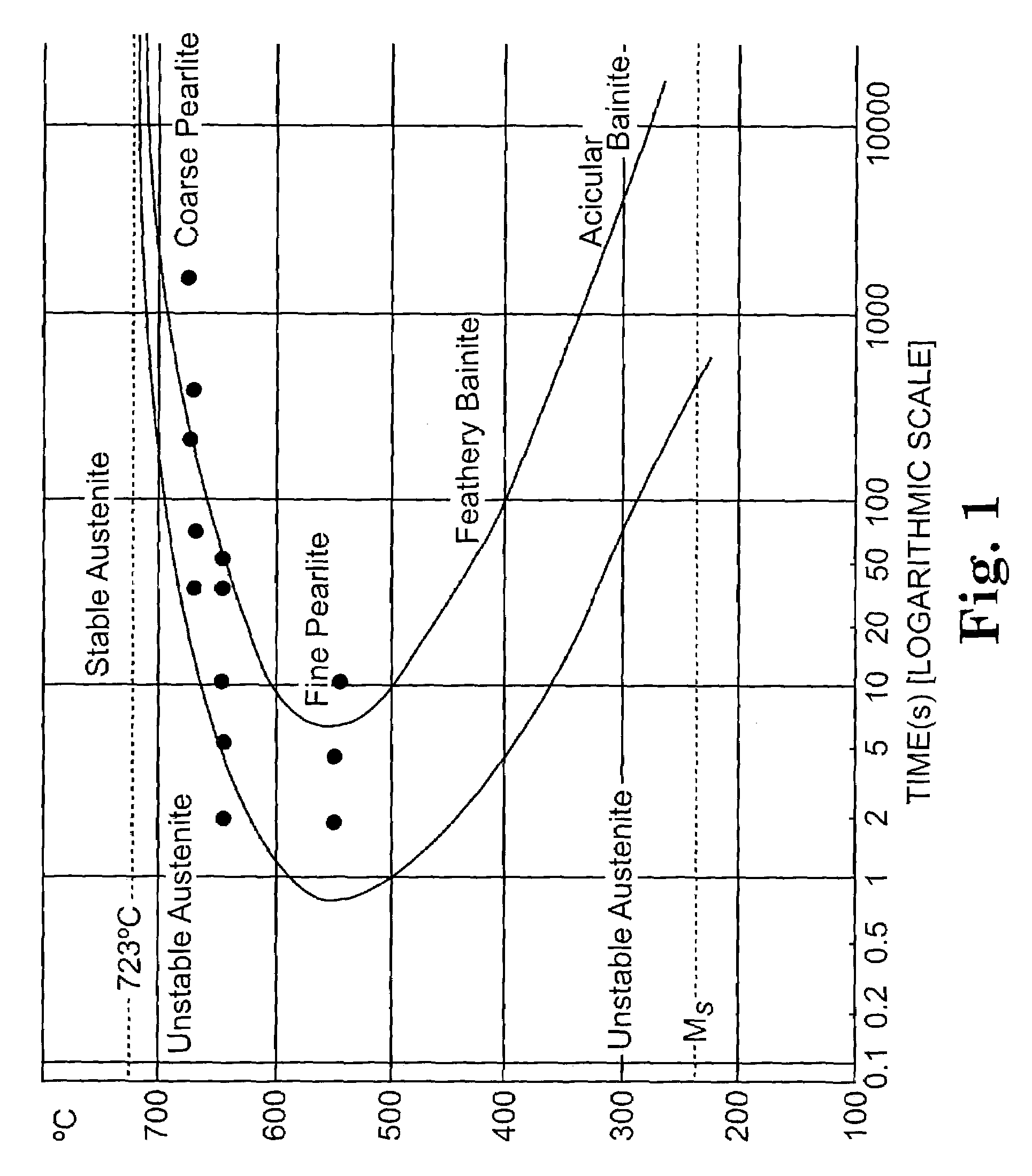

High-strength hot-rolled steel sheet having excellent stretch flangeability, and method of producing the same

InactiveUS6364968B1Easy to stretchImprove uniformityFurnace typesHeat treatment furnacesHigh intensityMechanical property

The invention provides a thin high-strength hot-rolled steel sheet with a thickness of not more than 3.5 mm which has excellent stretch flangeability and high uniformity in both shape and mechanical properties of the steel sheet, as well as a method of producing the hot-rolled steel sheet. A slab containing C: 0.05-0.30 wt %, Si: 0.03-1.0 wt %, Mn: 1.5-3.5 wt %, P: not more than 0.02 wt %, S: not more than 0.005 wt %, Al: not more than 0.150 wt %, N: not more than 0.0200 wt %, and one or two of Nb: 0.003-0.20 wt % and Ti: 0.005-0.20 wt % is heated at a temperature of not higher than 1200° C. The slab is hot-rolled at a finish rolling end temperature of not lower than 800° C., preferably at a finish rolling start temperature of 950-1050° C. A hot-rolled sheet is started to be cooled within two seconds after the end of the rolling, and then continuously cooled down to a coiling temperature at a cooling rate of 20-150° C. / sec. The hot-rolled sheet is coiled at a temperature of 300-550° C., preferably in excess of 400° C. A fine bainite structure is obtained in which the mean grain size is not greater than 3.0 mum, the aspect ratio is not more than 1.5, and preferably the maximum size of the major axis is not greater than 10 mum.

Owner:KAWASAKI STEEL CORP

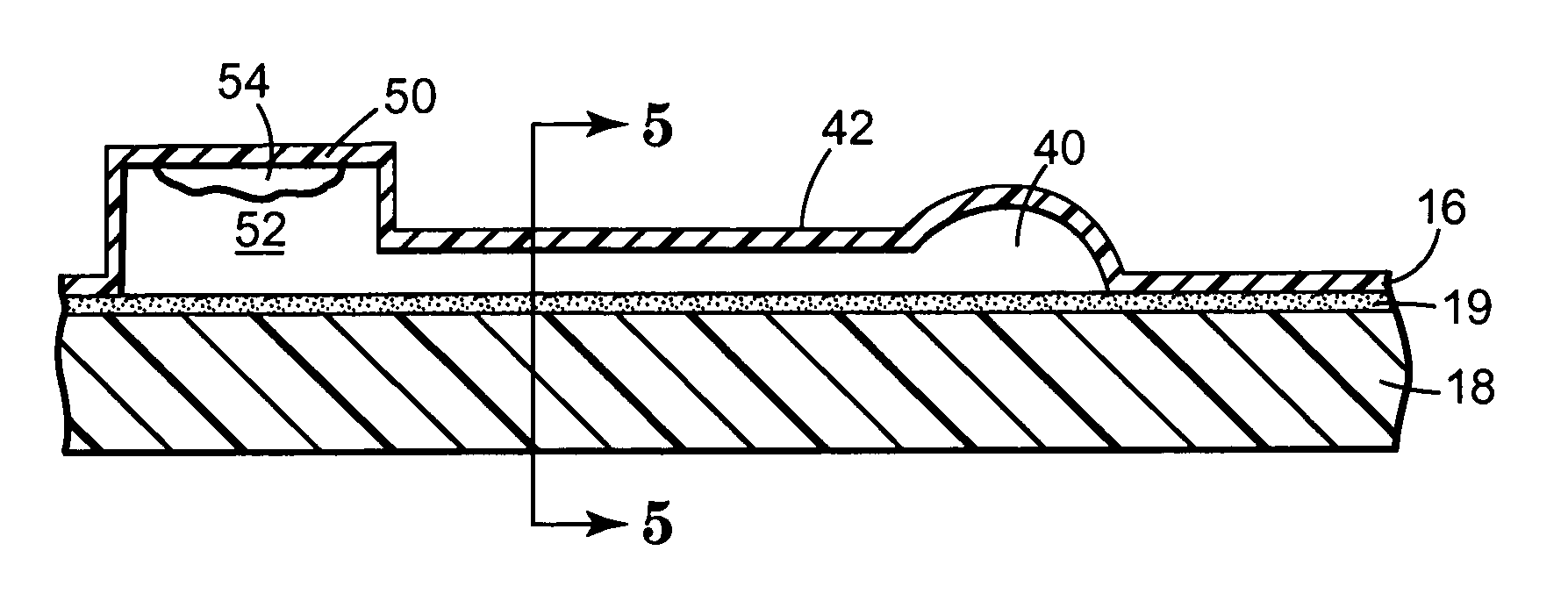

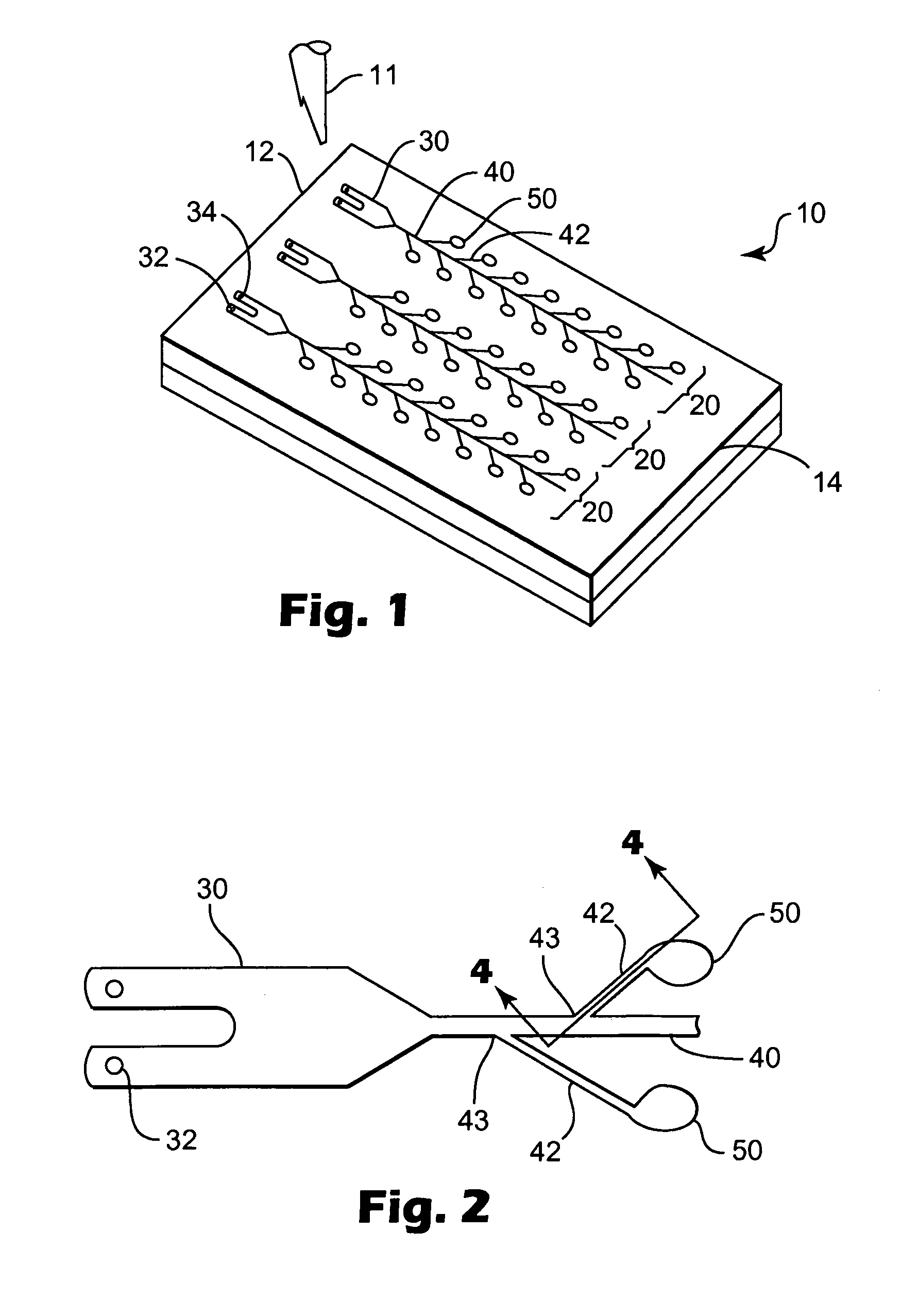

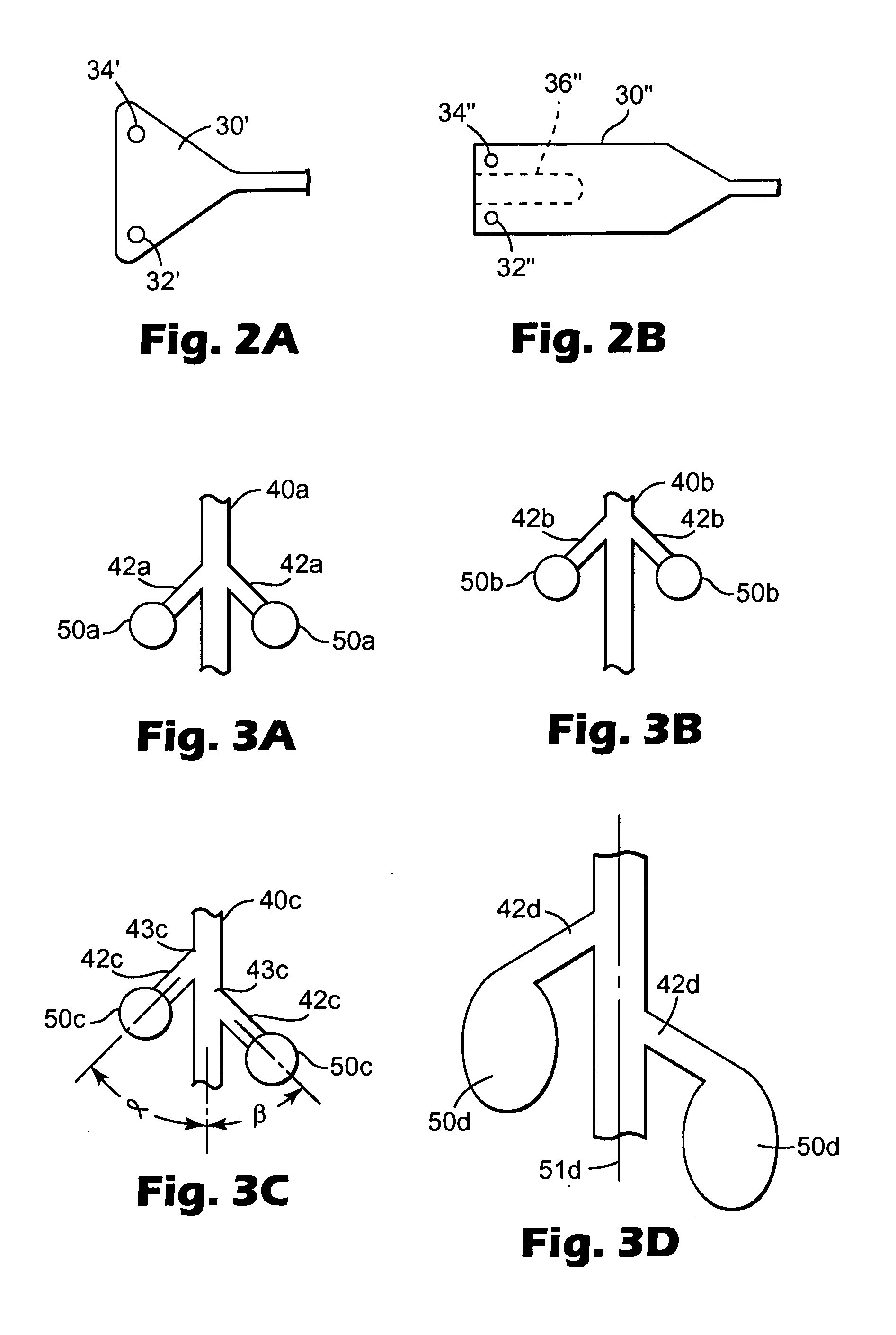

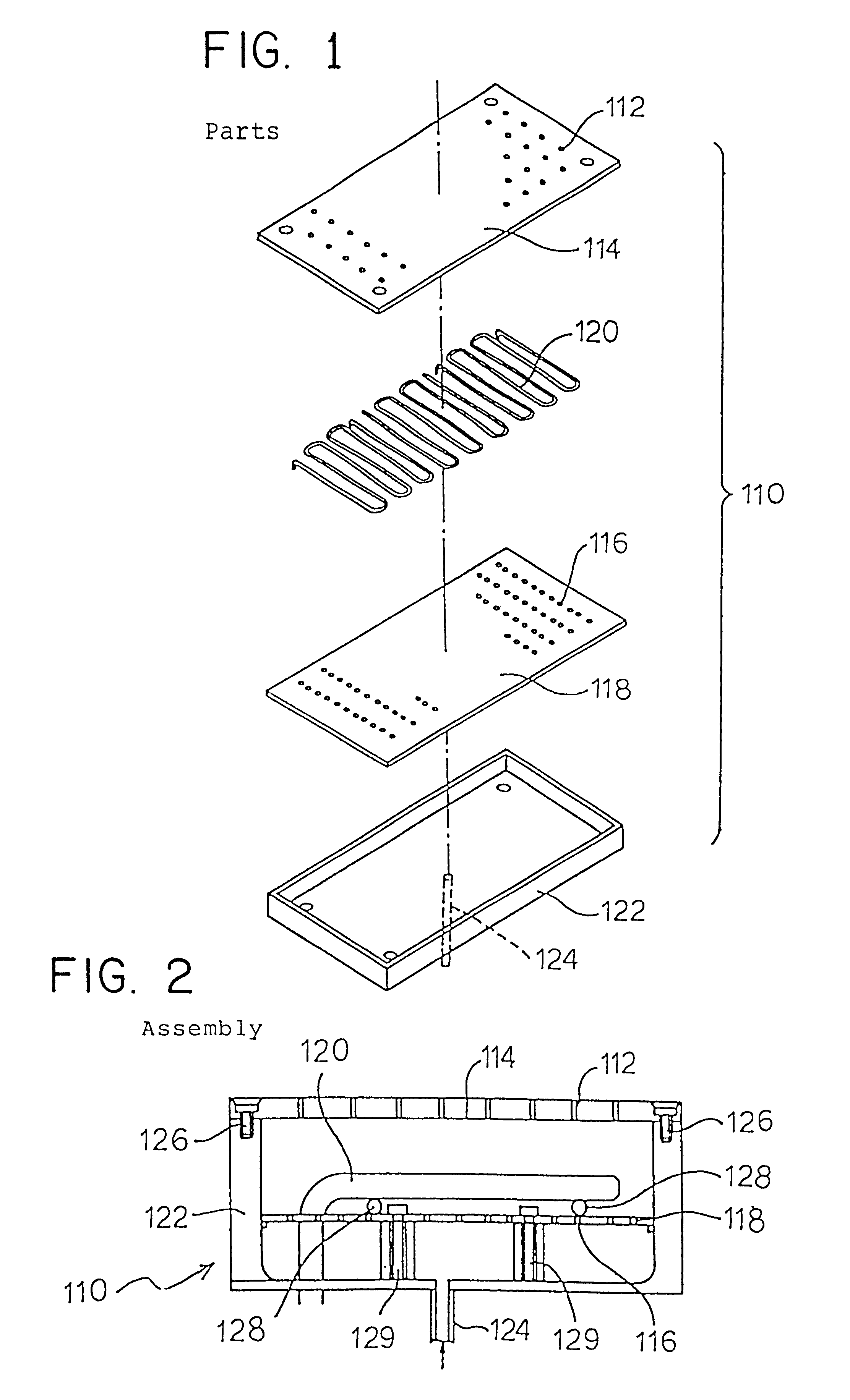

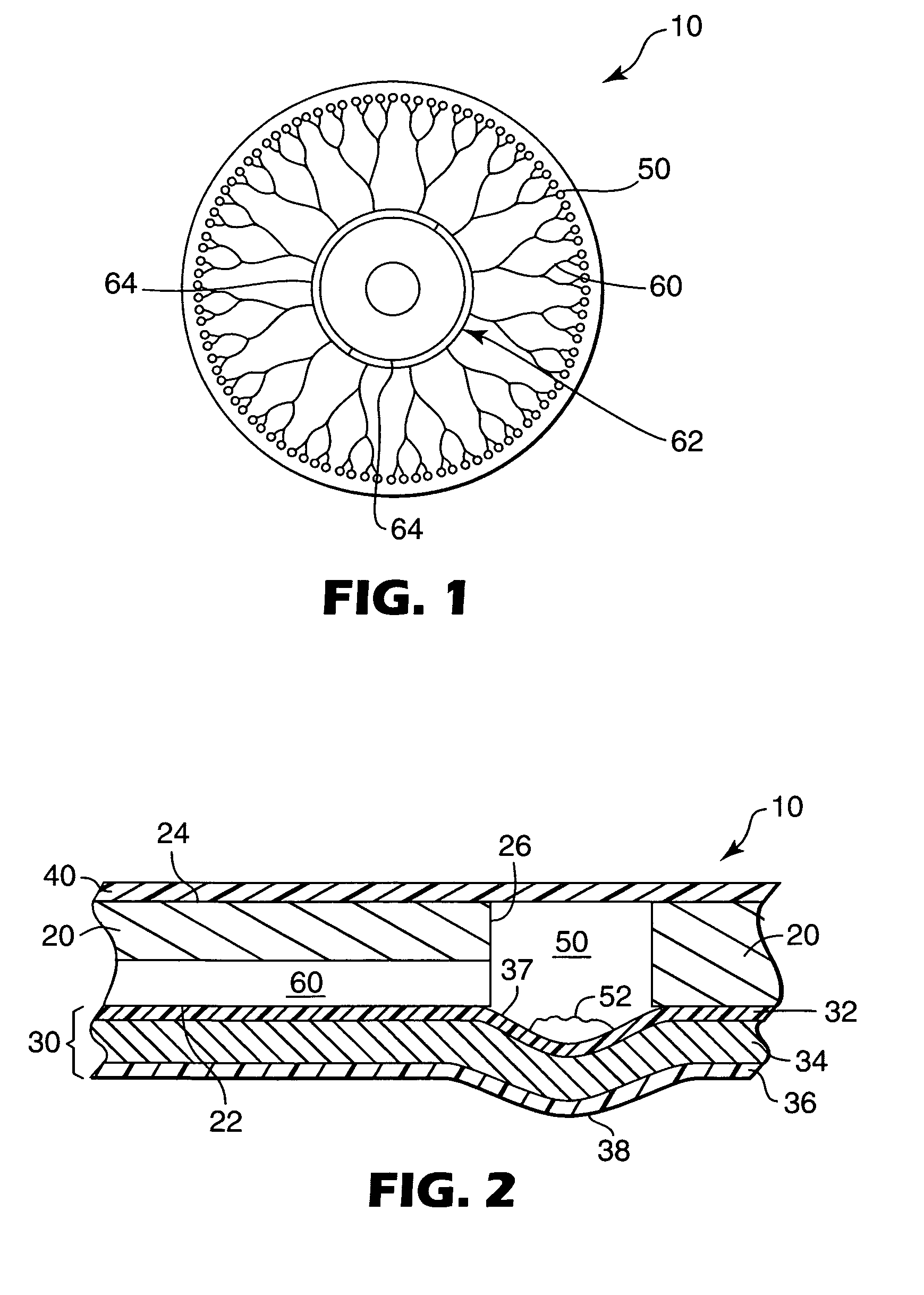

Sample processing devices

InactiveUS7026168B2Bioreactor/fermenter combinationsFixed microstructural devicesCatheterEngineering

Methods and devices for thermal processing of multiple samples at the same time are disclosed. The sample processing devices provide process arrays that include conduits useful in distributing sample materials to a group pf process chambers located in fluid communication with the main conduits. The sample processing devices may include one or more of the following features in various combinations: deformable seals, process chambers connected to the main conduit by feeder conduits exiting the main conduit at offset locations, U-shaped loading chambers, and a combination of melt bonded and adhesively bonded areas.

Owner:3M INNOVATIVE PROPERTIES CO

Degreasing furnace loading apparatus, and method for manufacturing honeycomb structure

A degreasing furnace loading apparatus including a molded body moving mechanism configured to move a plurality of ceramic molded bodies simultaneously, and a transporting table configured to transport a degreasing jig for mounting the ceramic molded bodies thereon to a degreasing furnace. The molded body moving mechanism is configured to simultaneously place the plurality of ceramic molded bodies on the degreasing jig, such that each of the ceramic molded bodies is placed to have predetermined intervals therebetween.

Owner:IBIDEN CO LTD

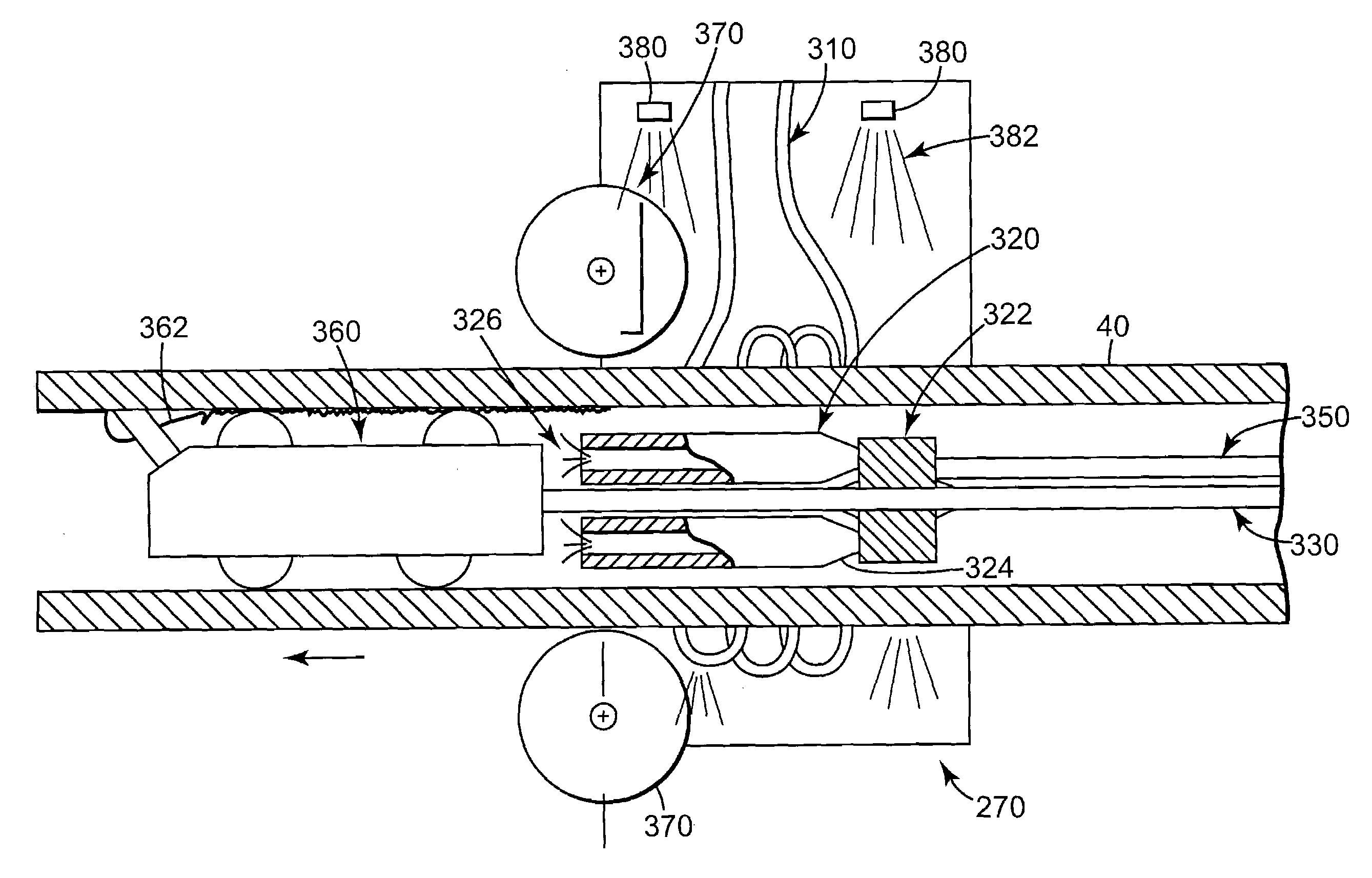

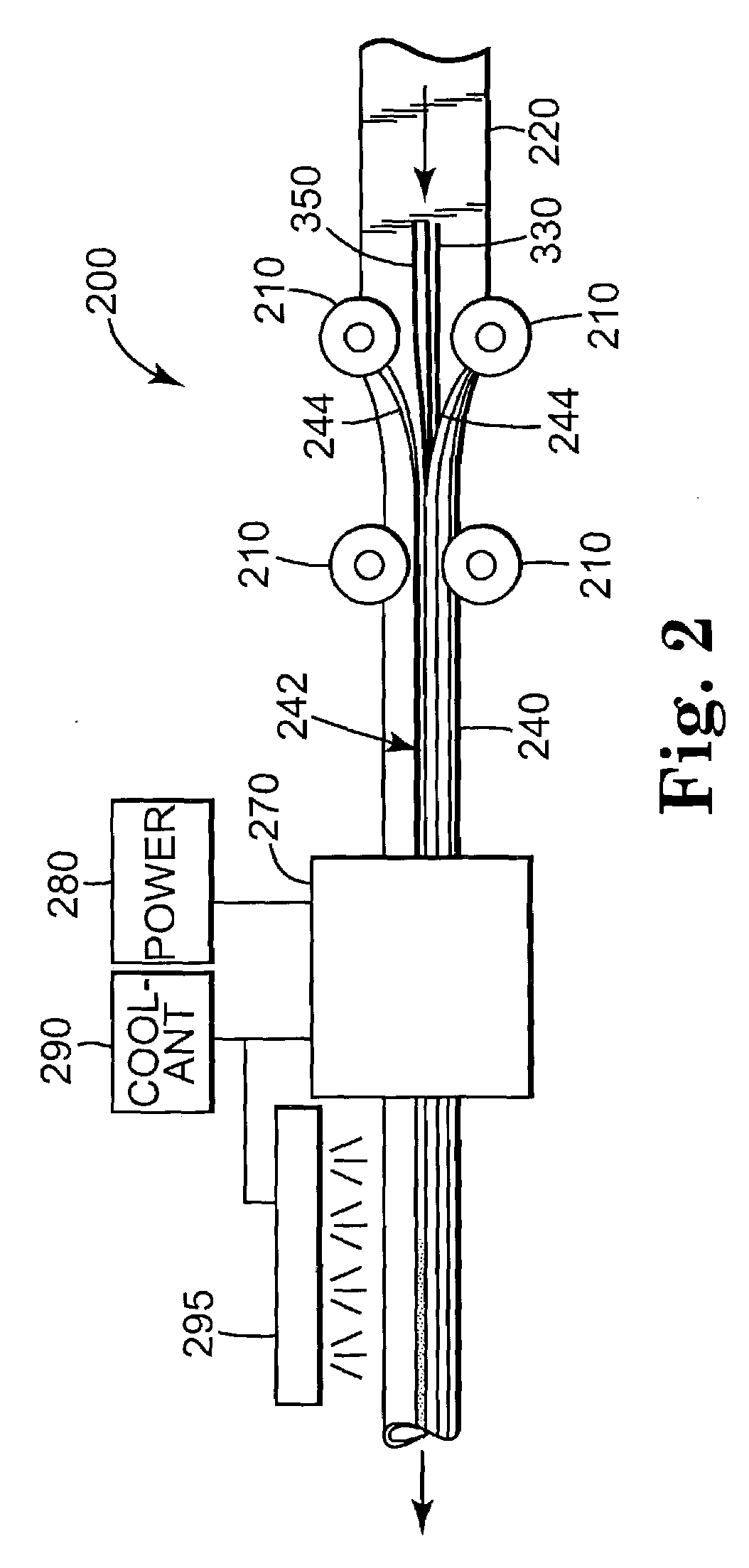

Seam-welded metal pipe and method of making the same without seam anneal

InactiveUS7032809B1Efficient processingEliminates annealing stepArc welding apparatusFurnace typesSufficient timeWeld seam

An apparatus and method for making a seam-welded steel pipe free of untempered martensite without seam anneal. The method includes selecting a steel containing a carbon concentration below a predetermined level, for example, 0.14% or 0.12% by weight. The method also includes flooding both outside and inside of the strip with a coolant while the weld seam is being formed, and continuing to immerse the welded strip for a sufficient time after the weld seam is formed to prevent the formation of untempered martensite. The apparatus includes a heater capable of heating the strip to a temperature sufficient to form a welded seam, a cooling module configured to supply a coolant to the welded seam both inside and outside of the strip as the weld seam is being formed, and another cooling module configured to immerse the welded strip in a coolant after the weld seam is formed for a sufficient length of time to prevent the formation of untempered martensite.

Owner:STEEL VENTURES

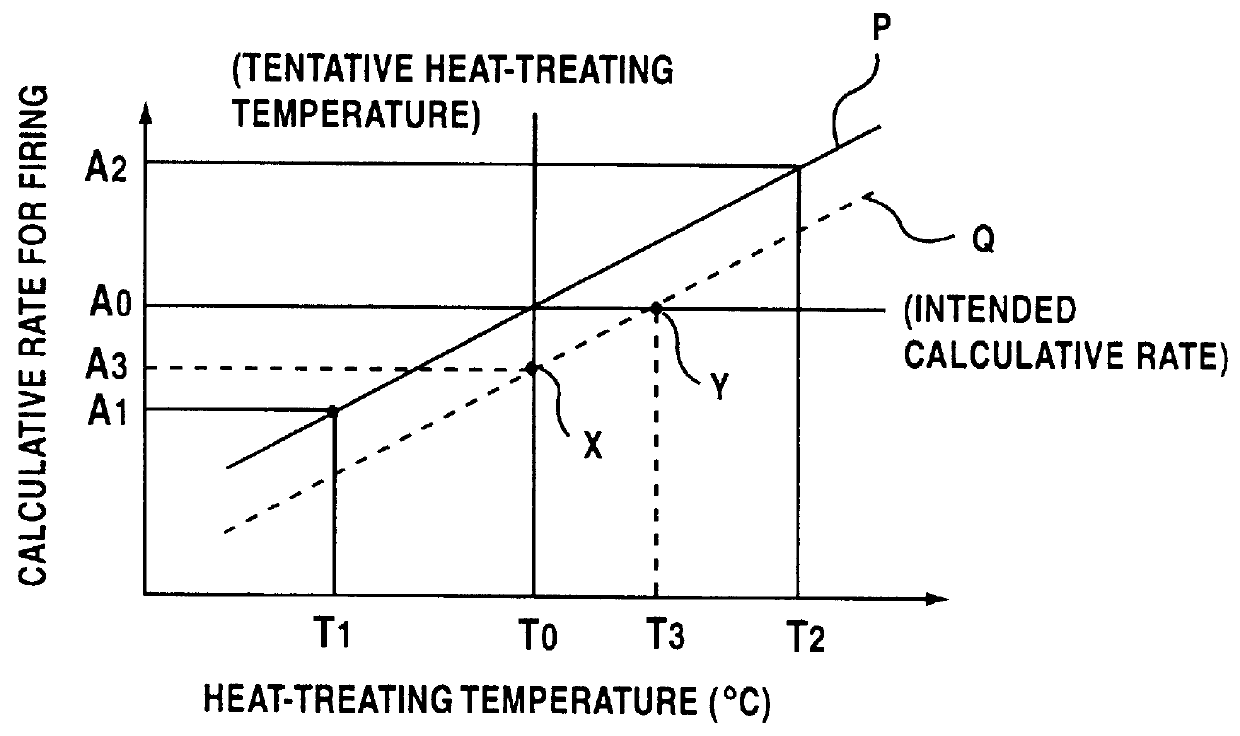

Method for controlling firing shrinkage of ceramic green body

A method of controlling the amount of firing shrinkage of a ceramic green body prepared by molding a ceramic powder (A) to a desired value A1 by heat treating the powder at a temperature T1 that provides the firing shrinkage A1 at a predetermined firing temperature. The temperature T1 is determined based on an established correlation between an amount of firing shrinkage at the predetermined firing temperature and a heat-treatment temperature of a powder (B) having a composition similar to that of the powder (A) in such an extent that a total amount of a greatest common content of an individual component common between the powders (A) and (B) in terms of percent is 90% by weight or more, and satisfying such a relation that the spherical diameter of powder (A) is within a range of + / - 30% relative to the spherical diameter (Rs) of the powder (B) and that its average degree of aggregation (+E,uns x+EE ) is within the range from +E,fra 1 / 2+EE fold to 2 fold relative to the average degree of aggregation (+E,uns x+EE ) of the powder (B).

Owner:NGK INSULATORS LTD

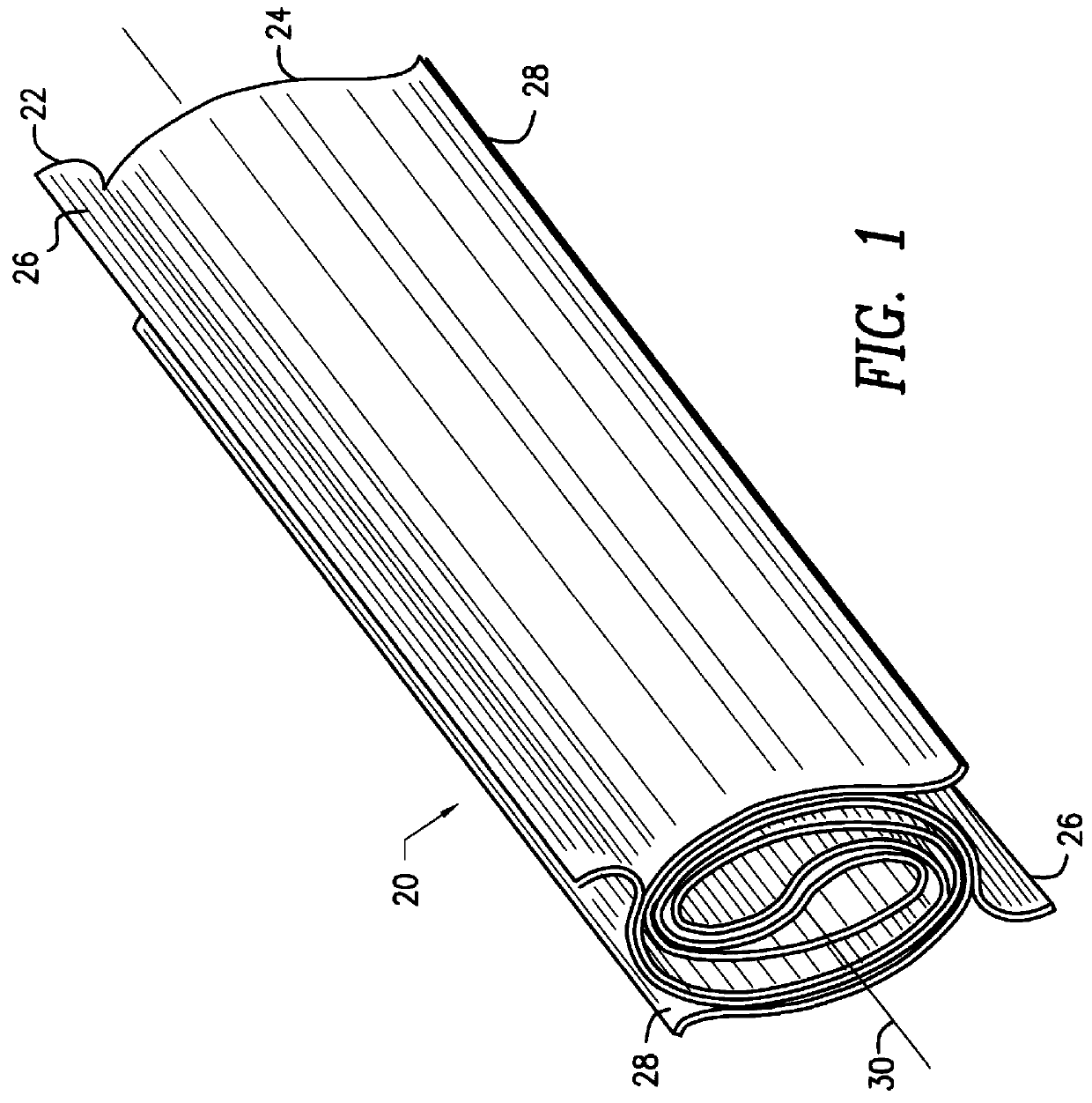

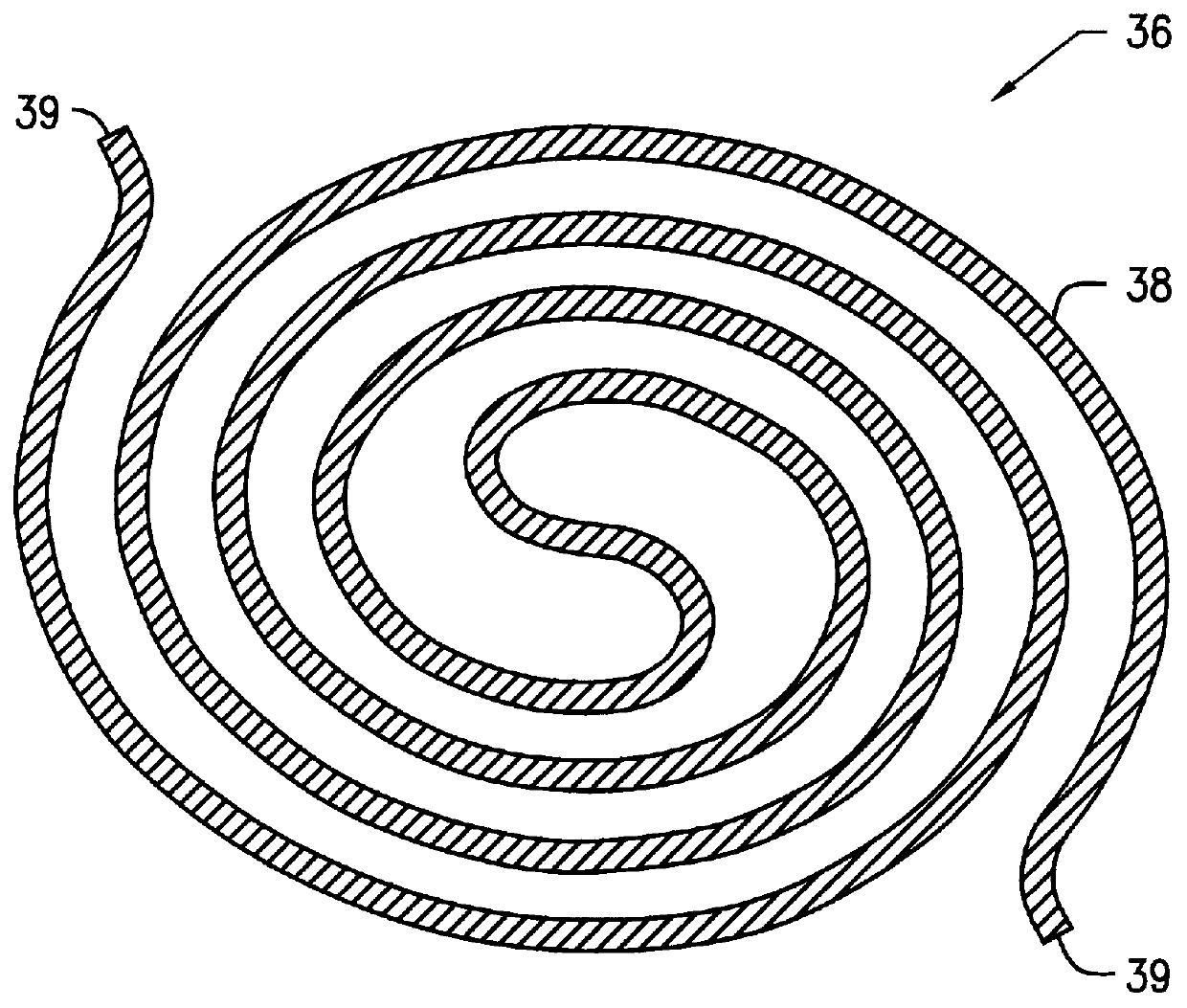

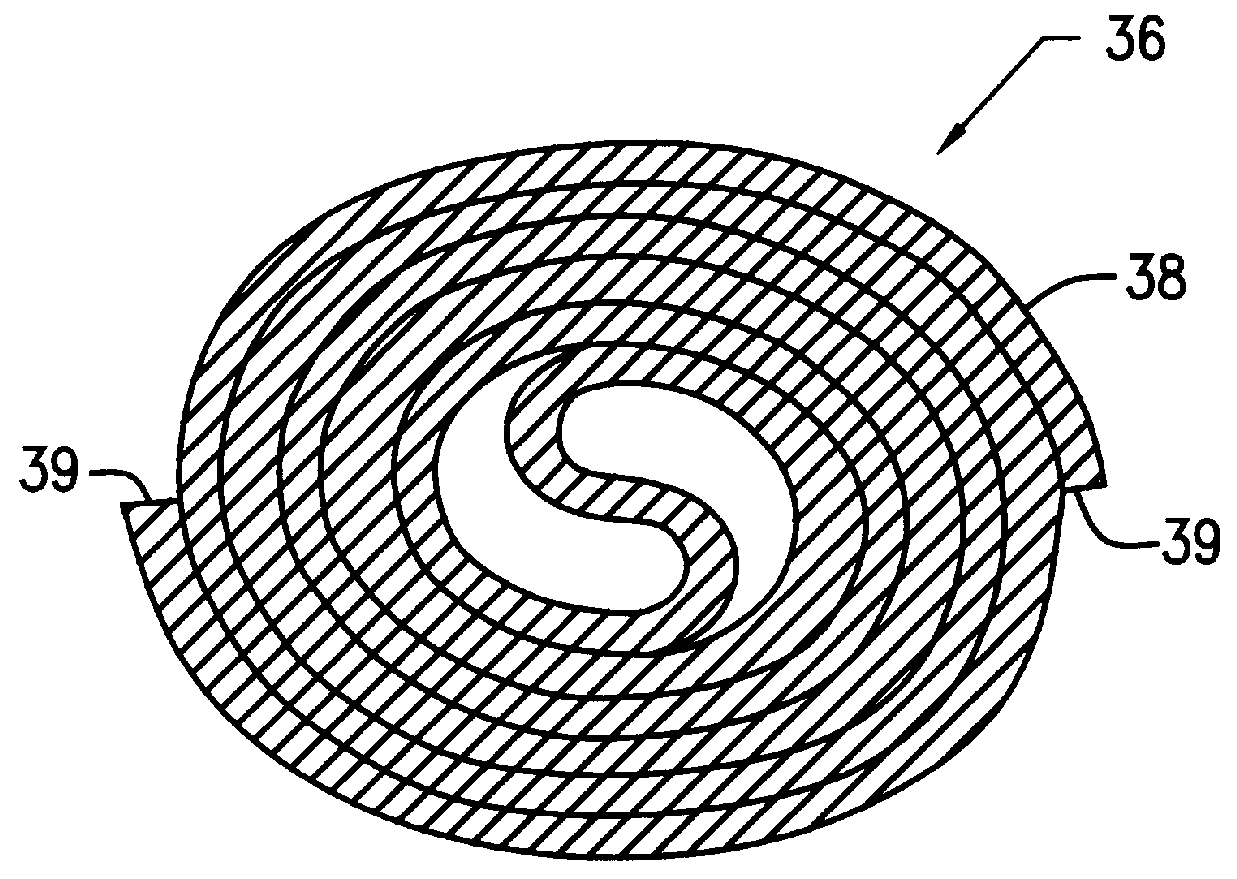

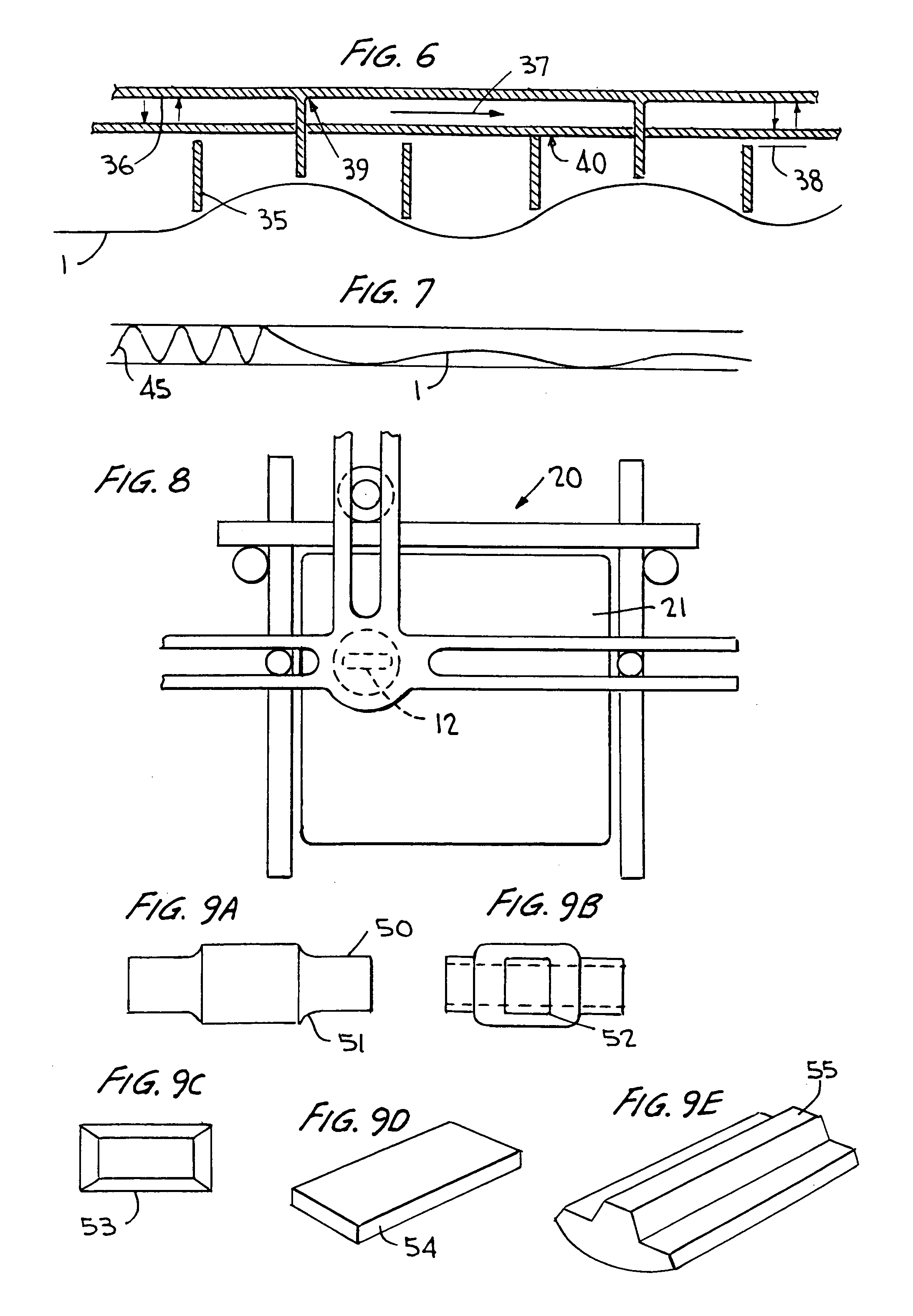

Pulling rolls for use in manufacturing sheet glass

InactiveUS6896646B2Easy to useImprove the level ofShaft and bearingsMetal-working apparatusFlat glassRoom temperature

Owner:CORNING INC

Gas floating apparatus, gas floating-transporting apparatus, and thermal treatment apparatus

InactiveUS6336775B1Large heat capacityWaste of energyGlass transportation apparatusSemiconductor/solid-state device manufacturingEngineeringThermal treatment

A gas floating-transporting apparatus transports a material to be treated along a predetermined direction in a thermal space so as to thermally treat the material to be treated. The apparatus includes a gas floating mechanism and a transporting mechanism. The gas floating mechanism includes a gas ejection device which expels the gas toward a portion of the material to be treated on which a floating force is acted so as to float the material to be treated, and a gas supply device which supplies the gas to the gas ejection means. The transporting mechanism includes an abutting member which abuts a trailing end of the floated material to be treated and moves along the predetermined direction, and which pushes the material to be treated by the movement thereof, whereby the floated material to be treated is moved along the predetermined direction.

Owner:PANASONIC CORP

Heating furnace and method for manufacturing honeycomb structure

InactiveUS20080197544A1Increase temperatureMaintainance of heating chambersCeramic shaping apparatusMeasurement deviceHeating furnace

A heating furnace for calcining an object to be heated. The heating furnace includes a wall defining a furnace space and configured to receive the object in the furnace space, and a heating device configured to raise a temperature within the furnace space. The heating furnace also includes an oxygen supply channel configured to introduce gases containing oxygen into the furnace space. The oxygen supply channel is formed as an opening in a part of the wall surrounding the furnace space. The heating furnace further includes a gas discharge channel fluidly connected to the furnace space and configured to discharge gases in the furnace space to an outside of the furnace space, and a measurement device installed in the gas discharge channel and configured to measure properties of the gases passing through the gas discharge channel.

Owner:IBIDEN CO LTD

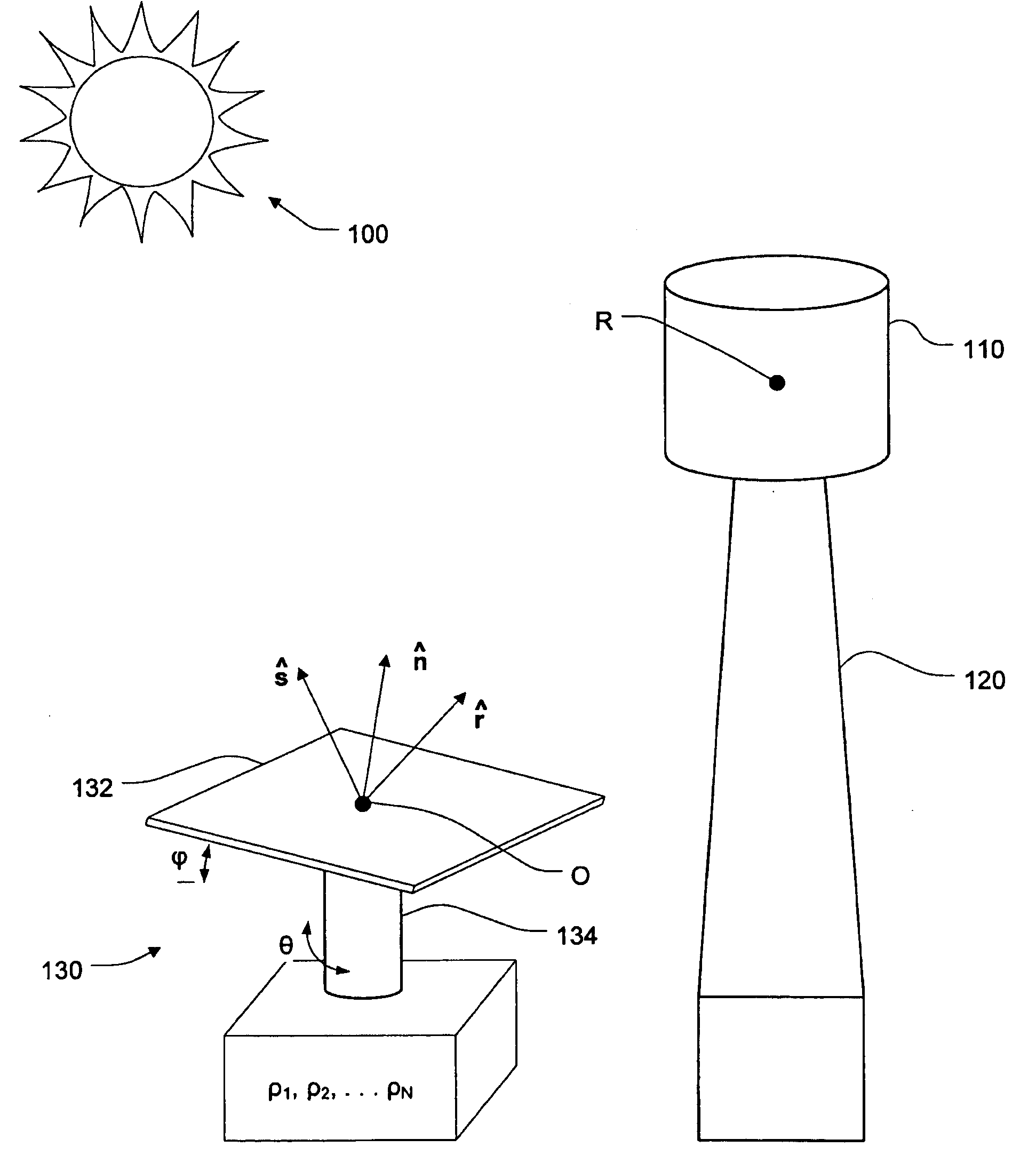

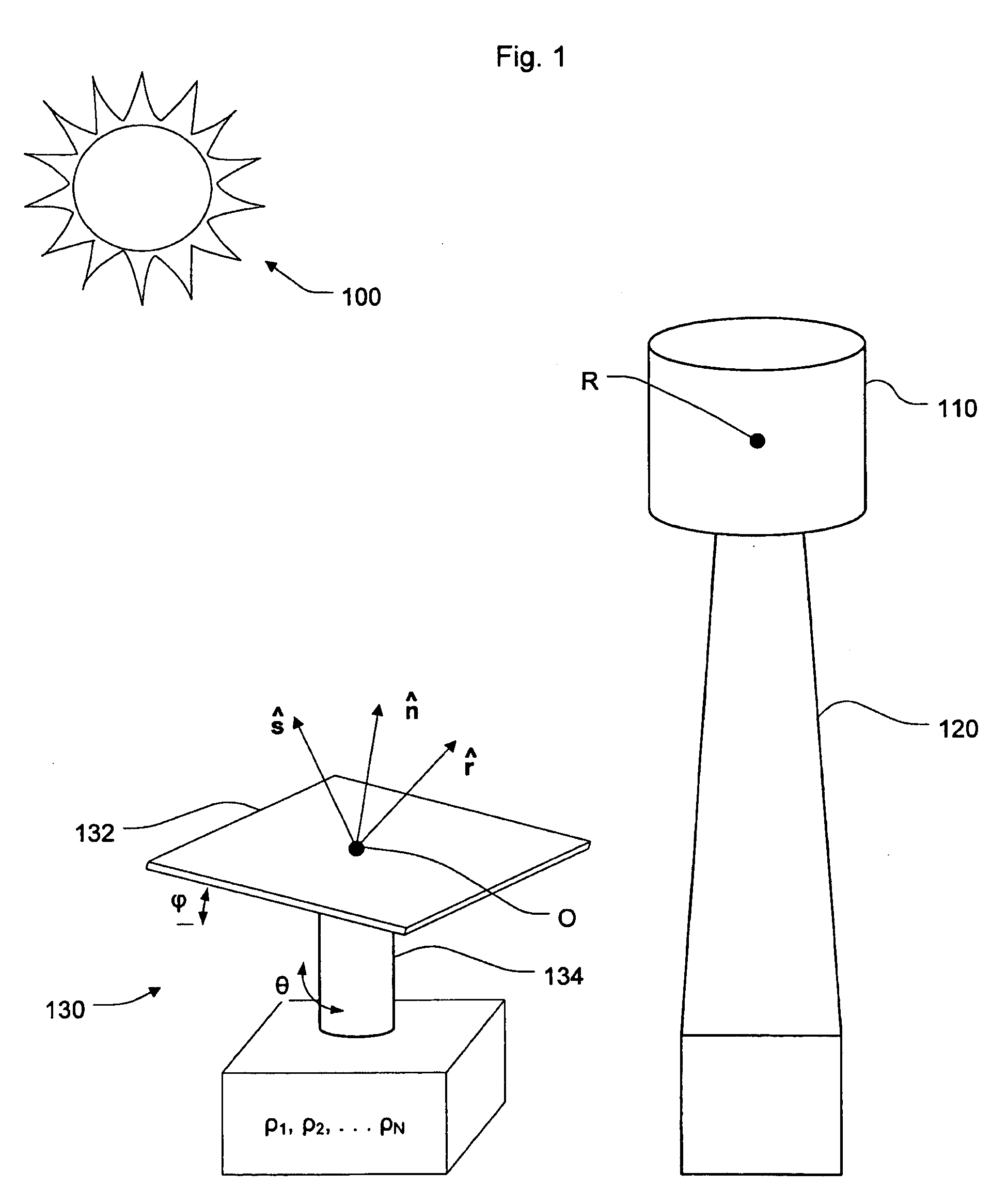

Calibration and tracking control of heliostats in a central tower receiver solar power plant

A suntracking system for a central receiver solar power plant includes a heliostat field for reflecting sunlight to a receiver, cameras directed toward at least a subset of the heliostats, and a controller. The cameras are configured to produce images of sunlight reflected from multiple heliostats. The heliostats include a mirrored surface having a settable orientation and have a geometry modeled by a set of parameters. A method of estimating heliostat parameters for open-loop suntracking includes acquiring pointing samples by setting the direction of reflection of the heliostats and detecting concurrent sunlight reflections into the cameras. The method uses the acquired pointing samples and surveyed locations of the cameras to estimate the heliostat parameters. The method accurately maintains the sun's reflection directed toward the receiver open-loop utilizing the estimated tracking parameters.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

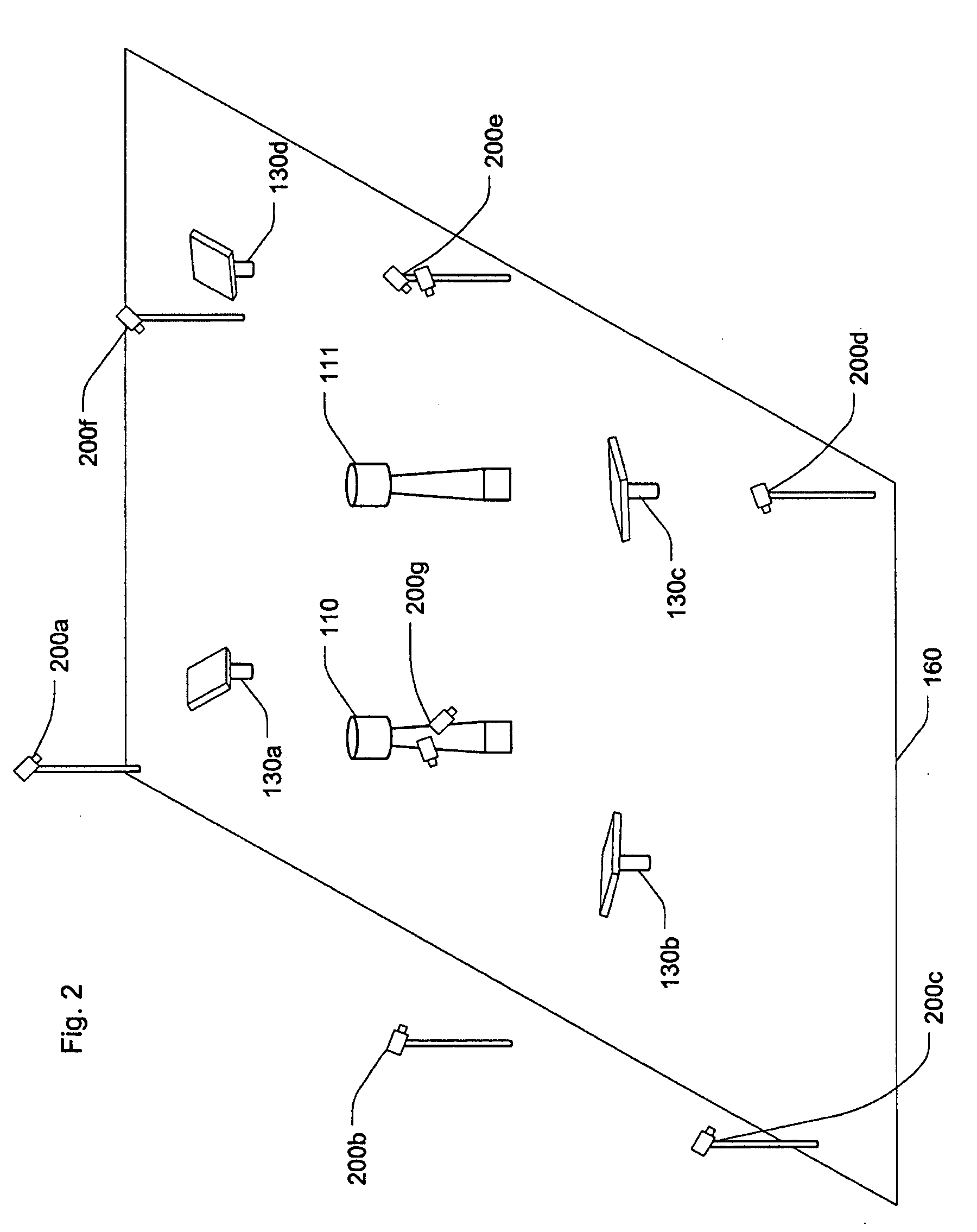

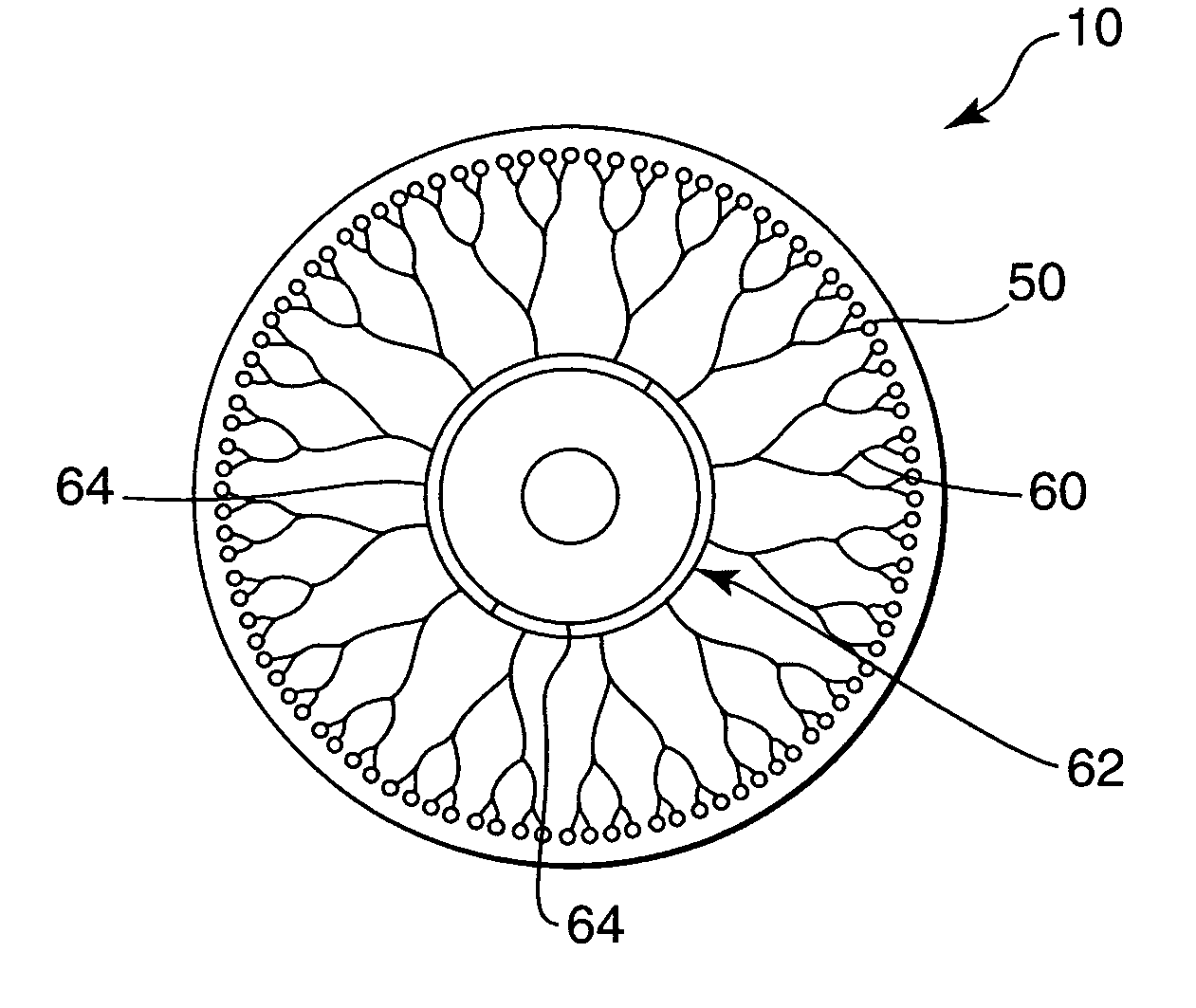

Enhanced sample processing devices, systems and methods

InactiveUS6987253B2Material is retainedImprove cooling effectHeating or cooling apparatusMicrobiological testing/measurementProcess engineeringSample processing

Devices, systems, and methods for processing sample materials. The sample materials may be located in a plurality of process chambers in the device, which is rotated during heating of the sample materials.

Owner:DIASORIN ITALIA SPA

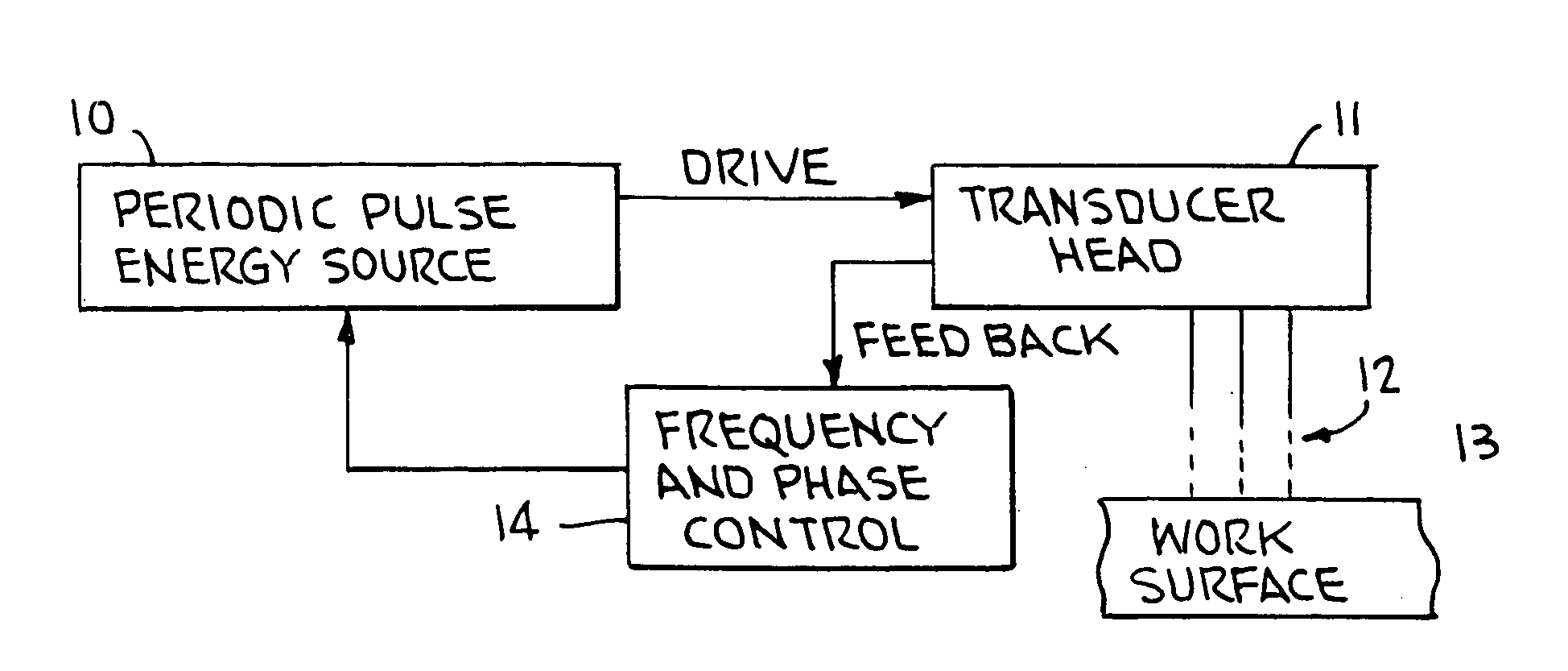

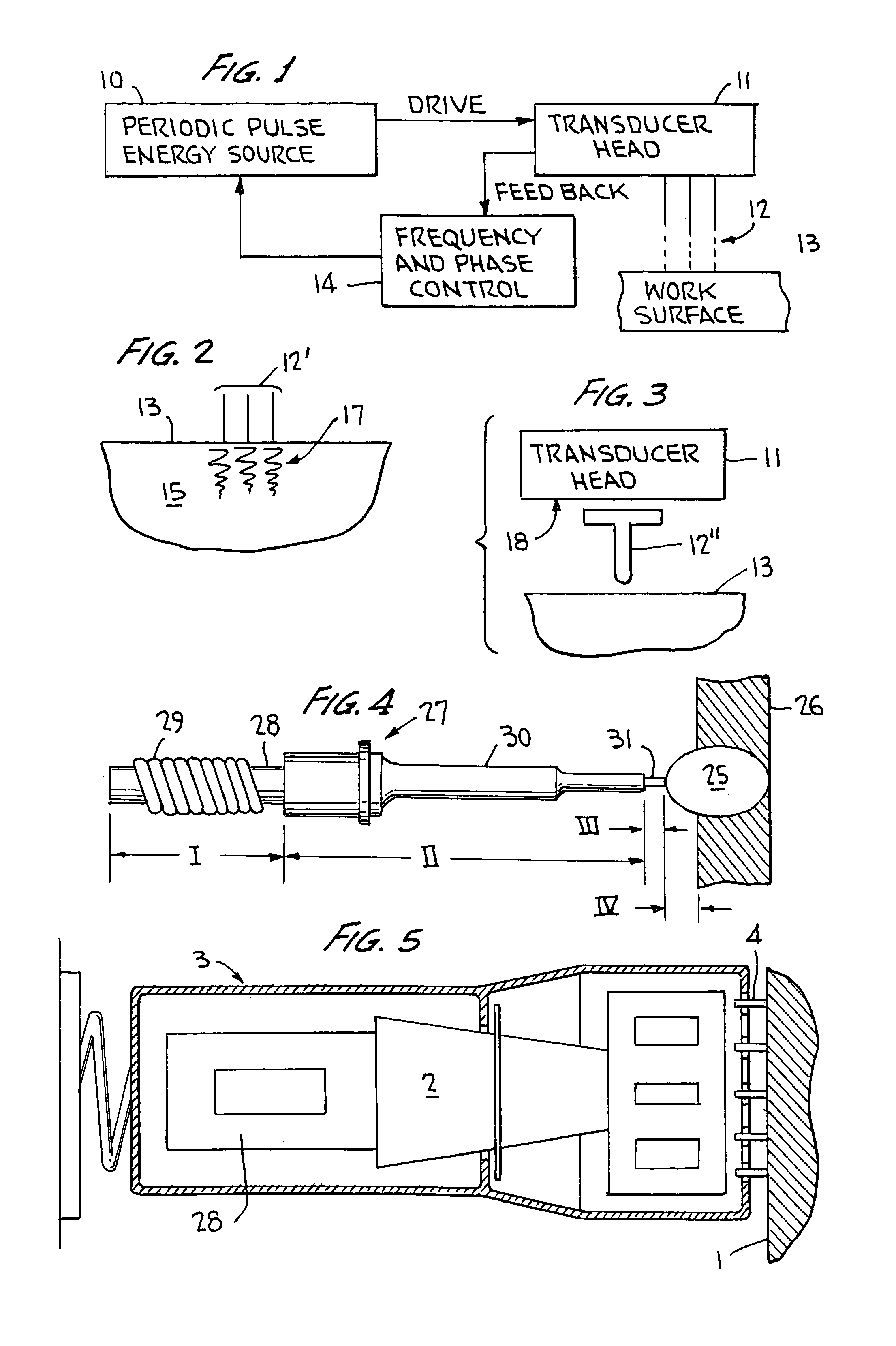

Ultrasonic impact machining of body surfaces to correct defects and strengthen work surfaces

InactiveUS6932876B1Improve power transfer efficiencyEfficient transferMechanical vibrations separationFurnace typesUltrasonic sensorPeriodic oscillation

Metallic workpieces of diverse shapes having work surfaces which are deformed at the surface and adjacent sub-surface layers by surface impact from ultrasonic transducers employing freely axially moving impacting elements propelled and energized by a transducer oscillating surface vibrating periodically at an ultrasonic frequency. The impacting elements are propelled in a random aperiodic and controlled impact mode at different phases of the periodic oscillation cycles. The transducer may be portable and provides a series of mechanically interconnected stages having mechanical resonances harmonically related as a multiple of the primary ultrasonic frequency and have matched stage resistances under instantaneous loading when the impact elements are driven by the transducer oscillating surface into the surface of the workpiece. This mode of operation produces Q-factor amplification of the input ultrasonic power oscillator energy at the impact needles and high propulsion velocities making it possible to machine metallic workpiece bodies to greater depths for compressing the metal to increase compressive strength of the workpiece work surfaces to substantially the ultimate material strength. The impact machining is done at ambient temperatures.

Owner:PROGRESS RAIL SERVICES

Method of microwave processing ceramics and microwave hybrid heating system for same

InactiveUS20070023971A1Shorten the sintering timeOhmic-resistance heating detailsFurnace typesMicrowave ovenSusceptor

A method for sintering ceramic materials using a microwave hybrid heating system includes the steps of providing a ceramic member to be sintered, providing a microwave furnace, providing a thermal containment box comprising a material that is virtually transparent to microwave energy, providing at least one susceptor comprising a material that directly couples to microwave energy at room temperature substantially immediately within the thermal containment box, positioning the ceramic member within the thermal containment chamber proximate the susceptor, and irradiating the thermal containment box with microwave energy. The susceptor couples to the microwave energy and generates heat within the thermal containment box and the temperature of the ceramic member increases to the microwave coupling-trigger temperature, at which time the ceramic member couples directly to the microwave energy and is directly sintered by the microwave energy in cooperation with radiant energy from the one susceptor.

Owner:ALFRED UNIVERSITY

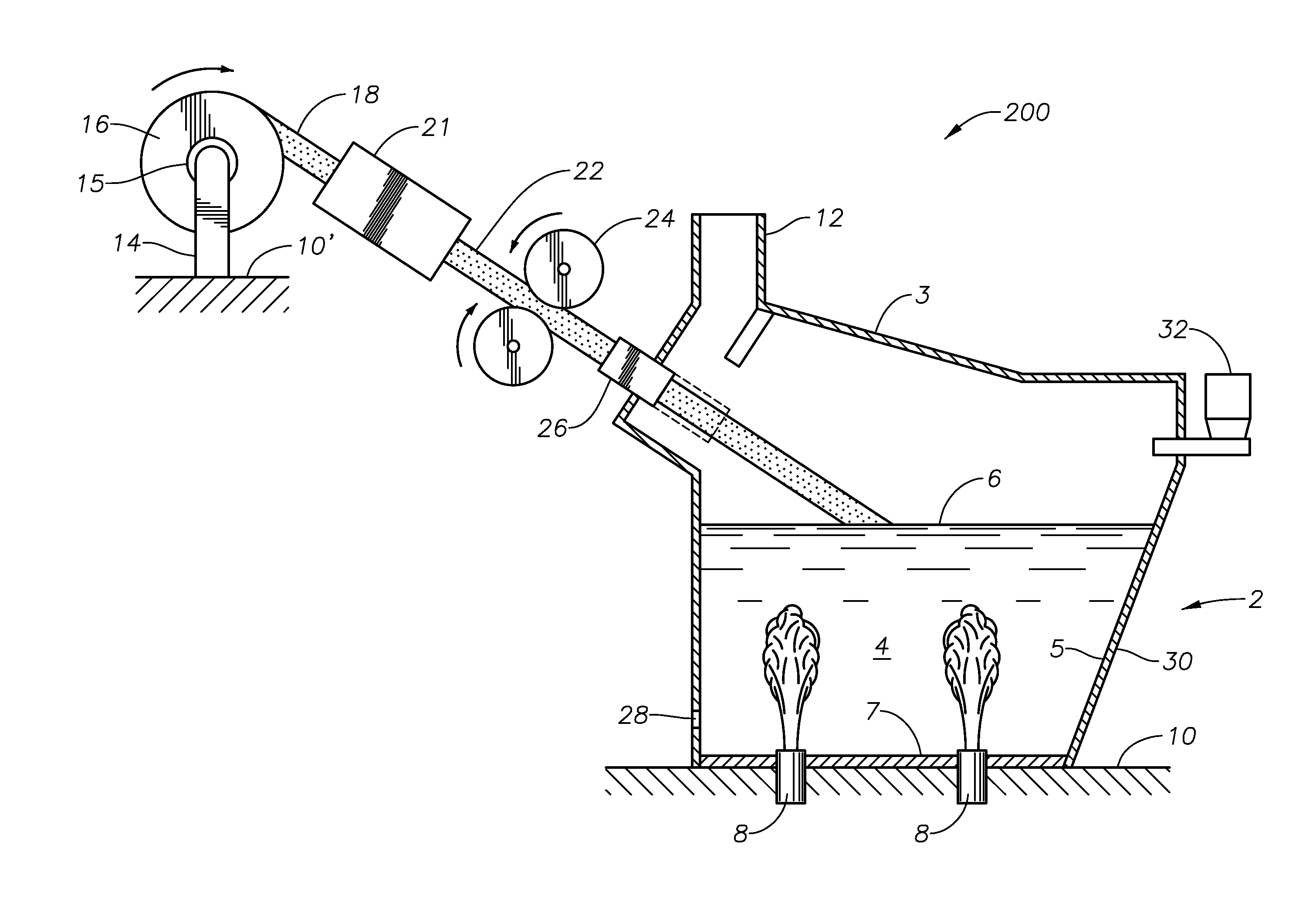

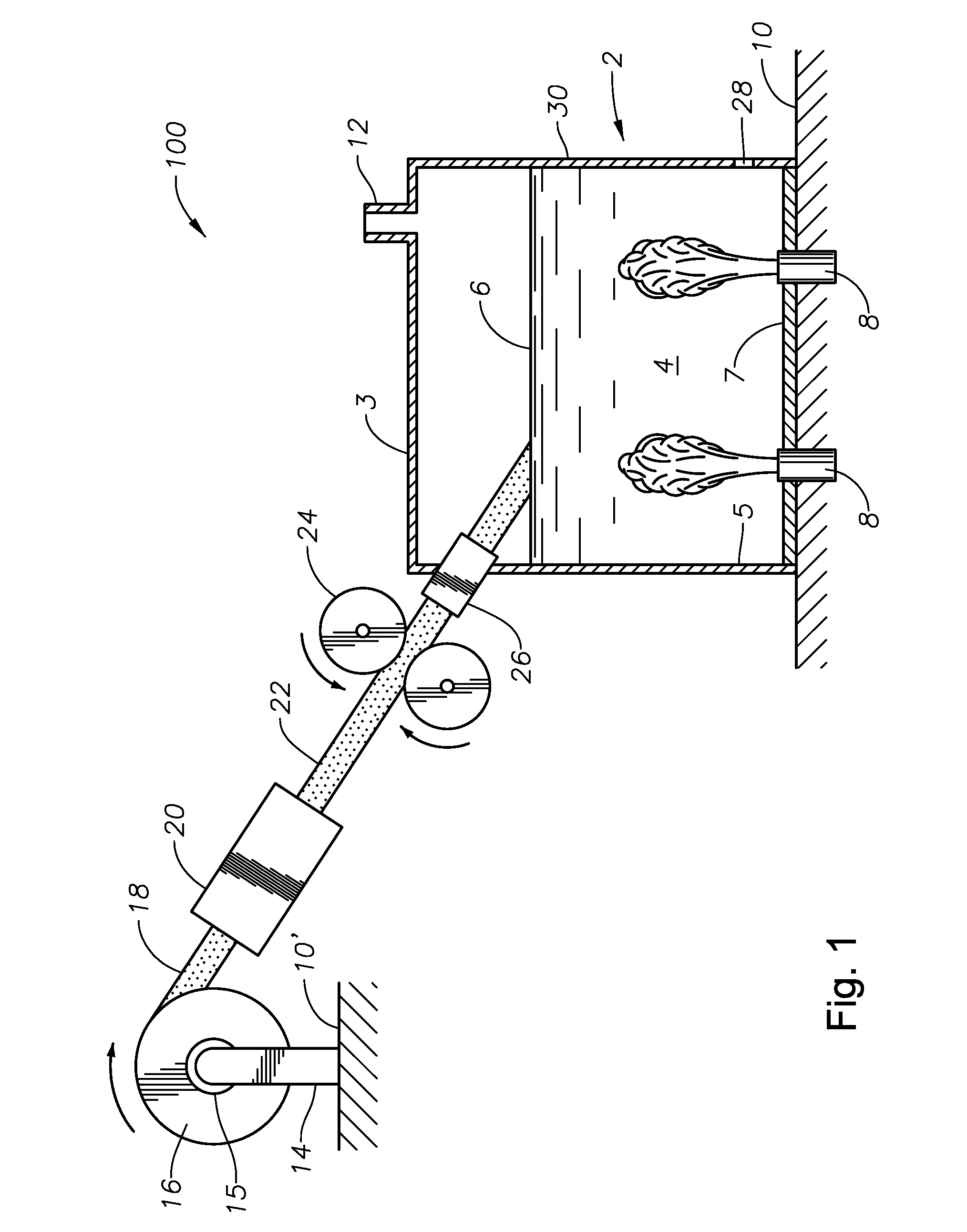

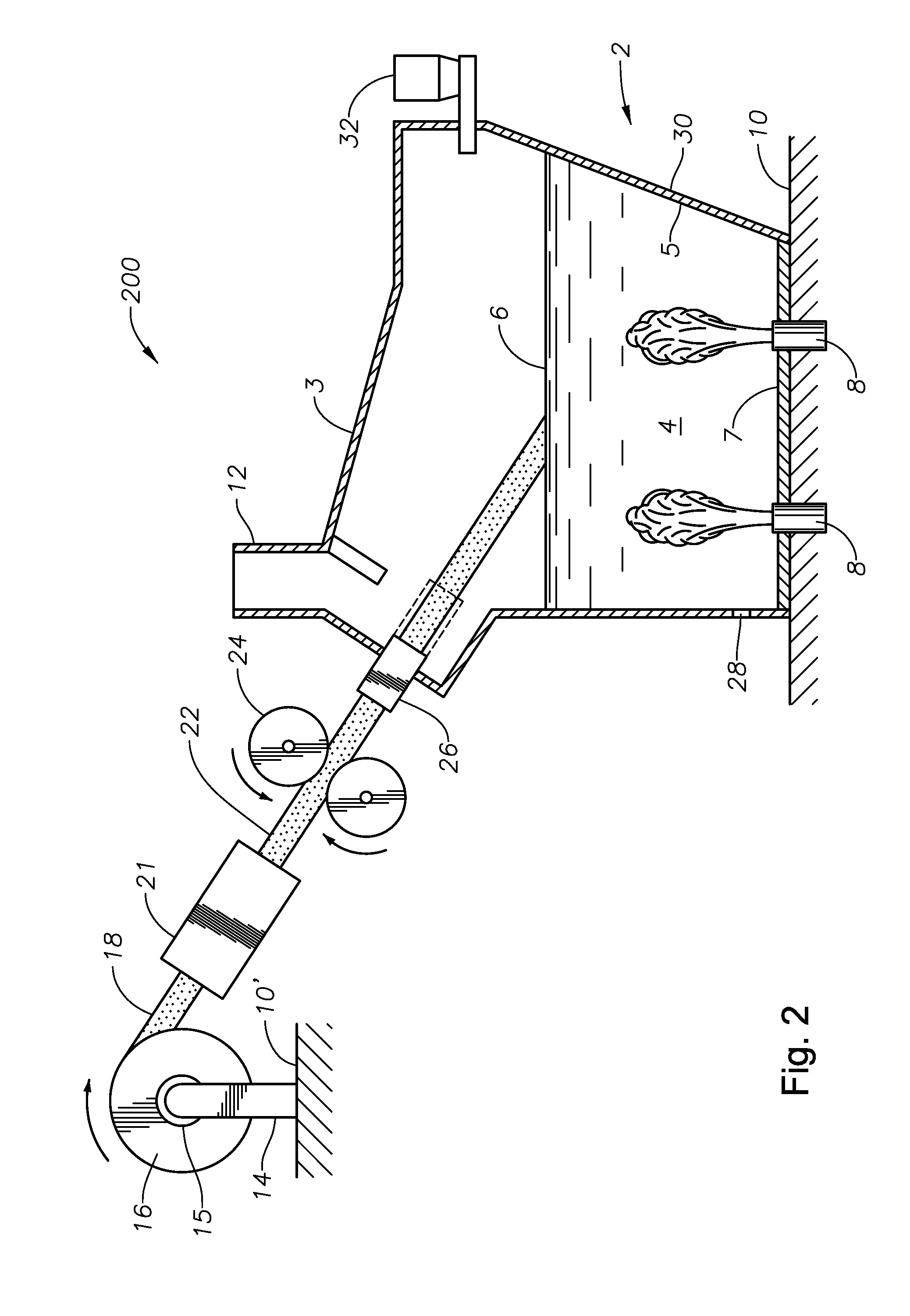

Methods and apparatus for recycling glass products using submerged combustion

ActiveUS20120077135A1Reduce eliminate needCharging furnaceGlass furnace apparatusCombustionEngineering

A method for recycling glass mat waste, wound rovings, and other products includes providing a source of glass mat, or a plurality of rovings, for example on a roll, and routing the glass mat or rovings into a submerged combustion melter. An unwind system and a pair of powered nip rolls, powered conveyors, or other arrangement may work in combination to provide a substantially consistent rate of material into the melter. The melter may operate under less than atmospheric pressure to avoid fumes escaping the melter. A slot in the melter allows ingress of the glass mat or rovings into the melter, and a glass mat former such as a folder may be used to ensure that the mat fits through the slot. Alternatively, the glass mat may be cut by a slitter prior to entering the slot.

Owner:JOHNS MANVILLE CORP

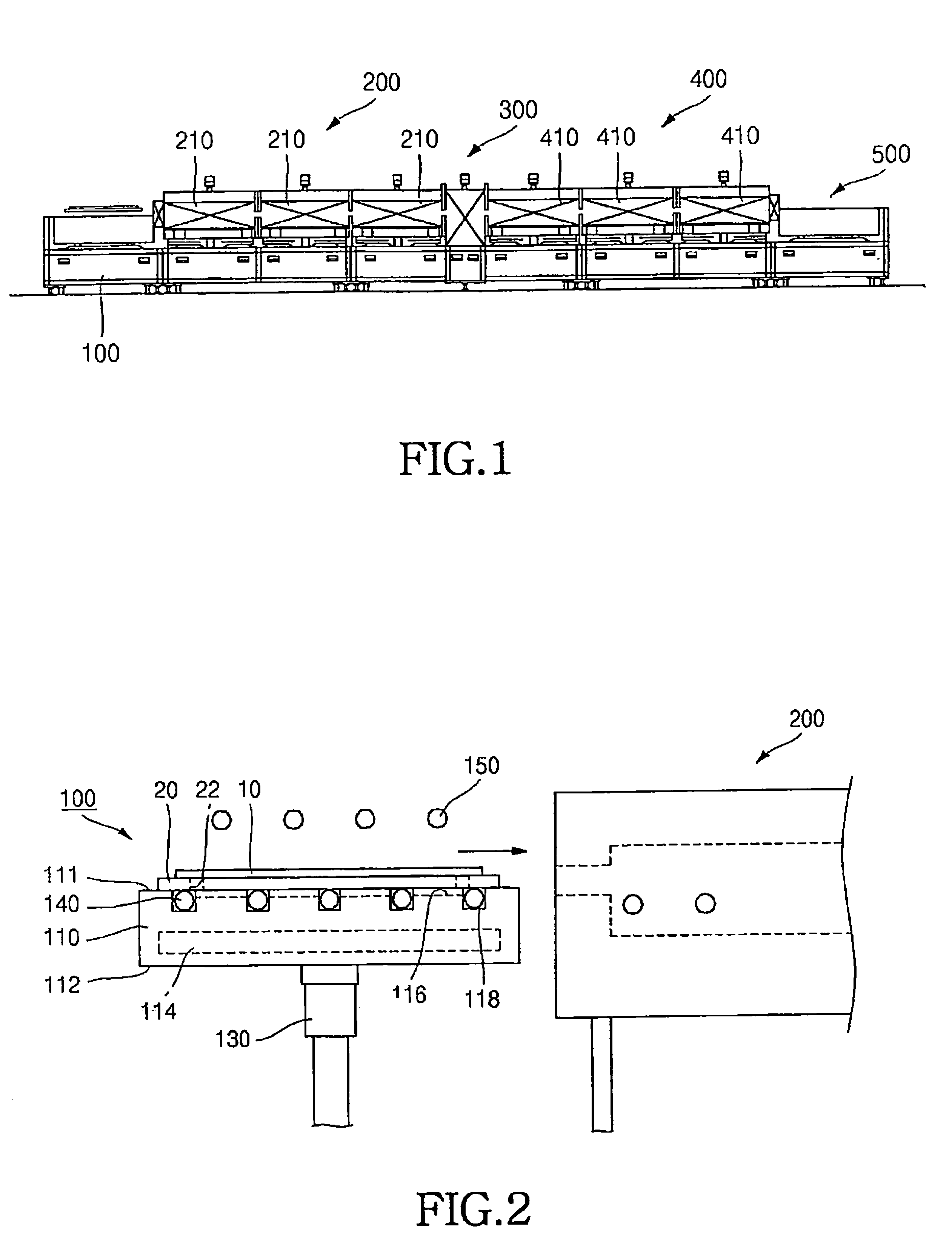

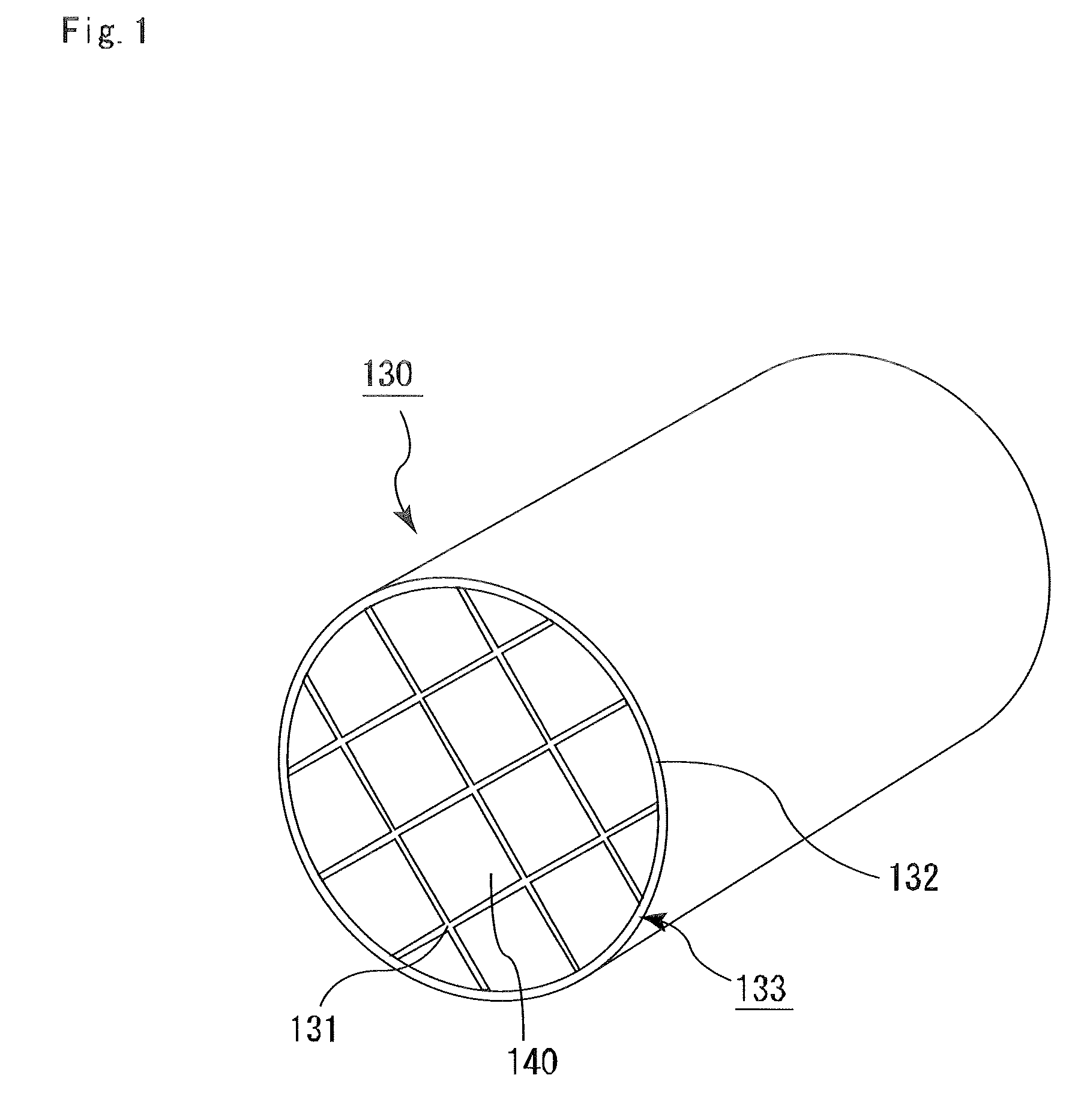

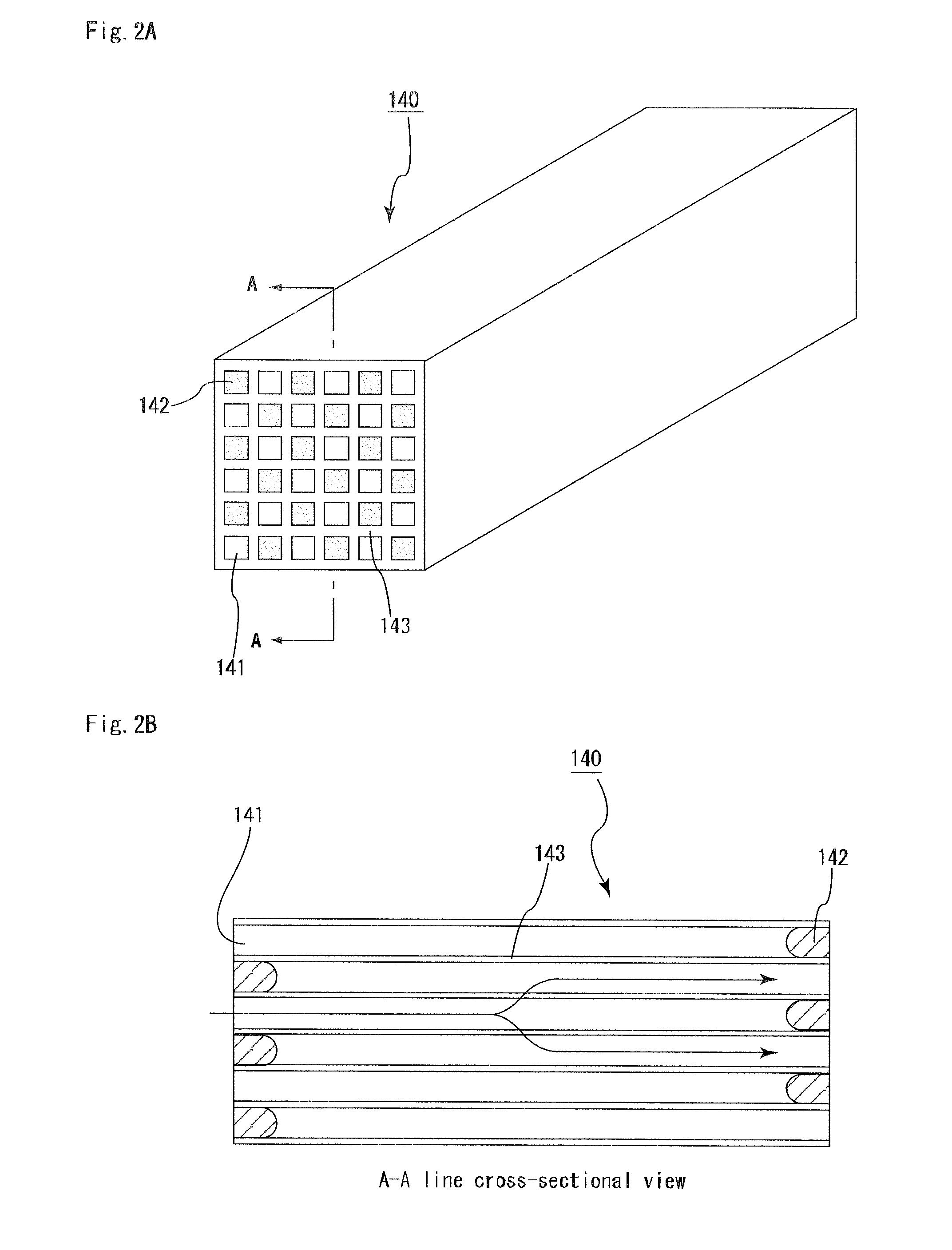

Continuous firing furnace, manufacturing method of porous ceramic member using the same, porous ceramic member, and ceramic honeycomb filter

InactiveUS20060029897A1Ensuring spaceMaintainance of heating chambersCharge manipulationMetallurgyPorous ceramics

A continuous firing furnace of the present invention comprises: a muffle formed into a cylindrical shape so as to ensure a predetermined space; a plurality of heat generators placed at the peripheral direction from the muffle; and a heat insulating layer formed in a manner so as to enclose said muffle and said heat generators therein, said continuous firing furnace being configured such that a formed body to be fired, which is transported from an inlet side, passes through the inside of said muffle at a predetermined speed in an inert gas atmosphere and, then, is discharged from an outlet so that said formed body is fired, wherein said inert gas flows through: a space between said muffle and said heat insulating layer; and a space inside the muffle, in sequence.

Owner:IBIDEN CO LTD

Method and apparatus for fabrication and sintering composite inserts

InactiveUS6011248AInhibit migrationNot adversely propertyMechanical apparatusLinings repairWear resistantWear resistance

The present disclosure is directed to the fabrication of a highly wear layer either directly upon an article or tool support structure or body, or as a wear resistant insert or element which is subsequently attached to the tool body. The wear material is formed by sintering particulate material using the absorption of microwave energy as a means of heating. The disclosure also encompasses post manufacture annealing, using heating by microwave radiation, of both highly wear resistant inserts and composite articles which consist of a wear resistant layer and a body. The wear resistant material, whether fabricated directly upon an article or fabricated separately and subsequently affixed to an article, provides an abrasive wear surface and greatly increases the life of the article. Microwave sintered wear resistant surfaces for mills, drills, grinders, brakes, bearings, saw blades and other articles and assemblies are disclosed.

Owner:PENN STATE RES FOUND +1

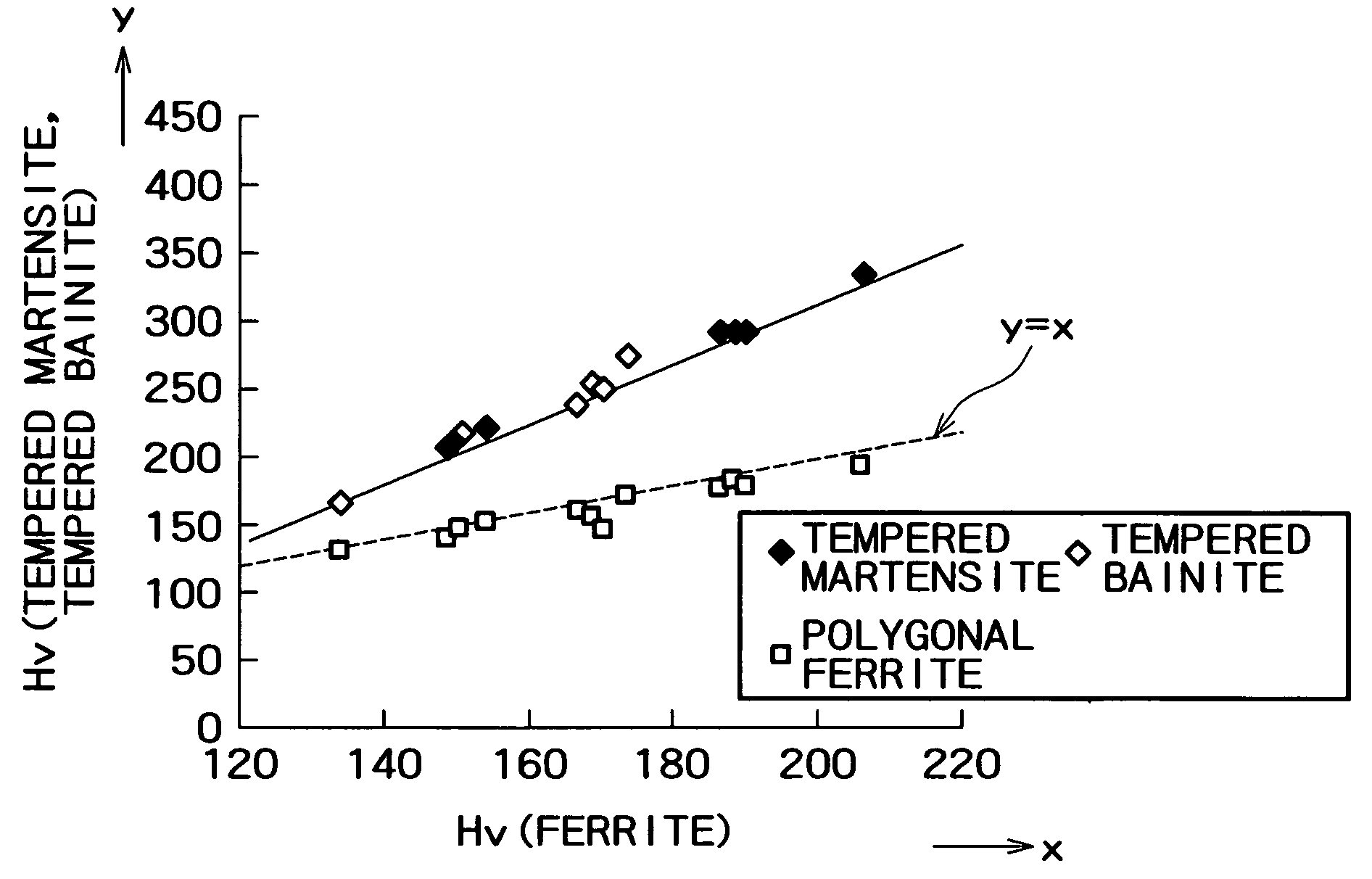

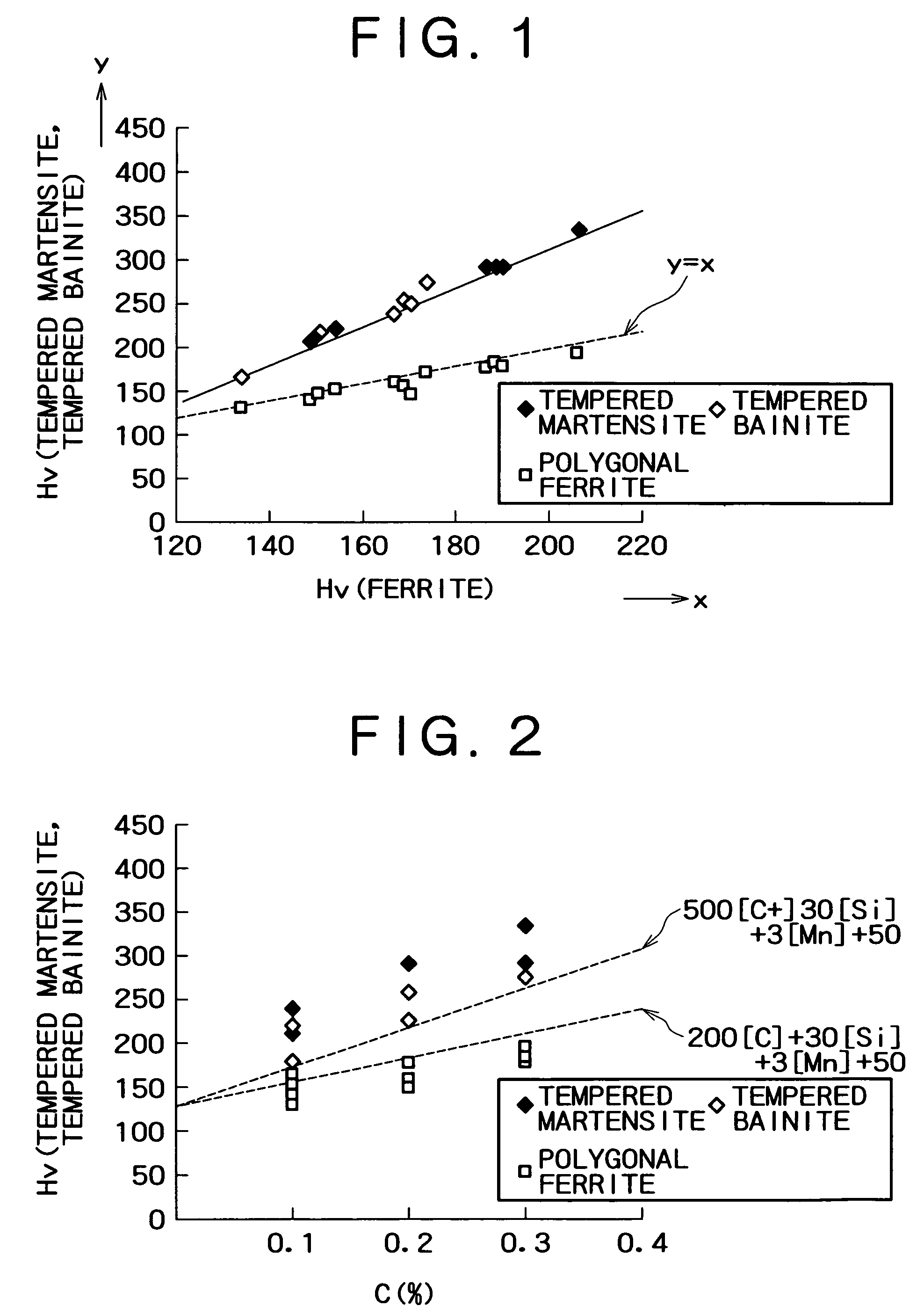

High strength steel sheet having excellent formability and method for production thereof

InactiveUS7090731B2Good molding effectHigh strengthHot-dipping/immersion processesFurnace typesHigh intensityHardness

A high strength steel sheet having (2-1) a base phase structure, the base phase structure being tempered martensite or tempered bainite and accounting for 50% or more in terms of a space factor relative to the whole structure, or the base phase structure comprising tempered martensite or tempered bainite which accounts for 15% or more in terms of a space factor relative to the whole structure and further comprising ferrite, the tempered martensite or the tempered bainite having a hardness which satisfies the relation of Vickers hardness (Hv)≧500[C]+30[Si]+3[Mn]+50 where [ ] represents the content (mass %) of each element, and (2-2) a second phase structure comprising retained austenite which accounts for 3 to 30% in terms of a space factor relative to the whole structure and optionally further comprising bainite and / or martensite, the retained austenite having a C concentration (CγR) of 0.8% or more.

Owner:KOBE STEEL LTD

Self-heating circuit board

InactiveUS6396706B1Inexpensive and convenientSemiconductor/solid-state device detailsSolid-state devicesVoltage pulseAdhesive

Separate heating elements are embedded in a printed circuit board near integrated circuit (IC) packages or other parts mounted on the circuit board. Each heating element supplies heat to the part residing near it in response to an input voltage pulse. The heating elements are used to selectively melt solder or adhesives attaching the parts to the circuit board so that they can be easily removed or to temporarily melt solder or cure adhesive when the parts are mounted on the circuit board. The heating elements are also used to supply heat to IC packages for regulating their operating temperatures.

Owner:MA ZHONGXIN +1

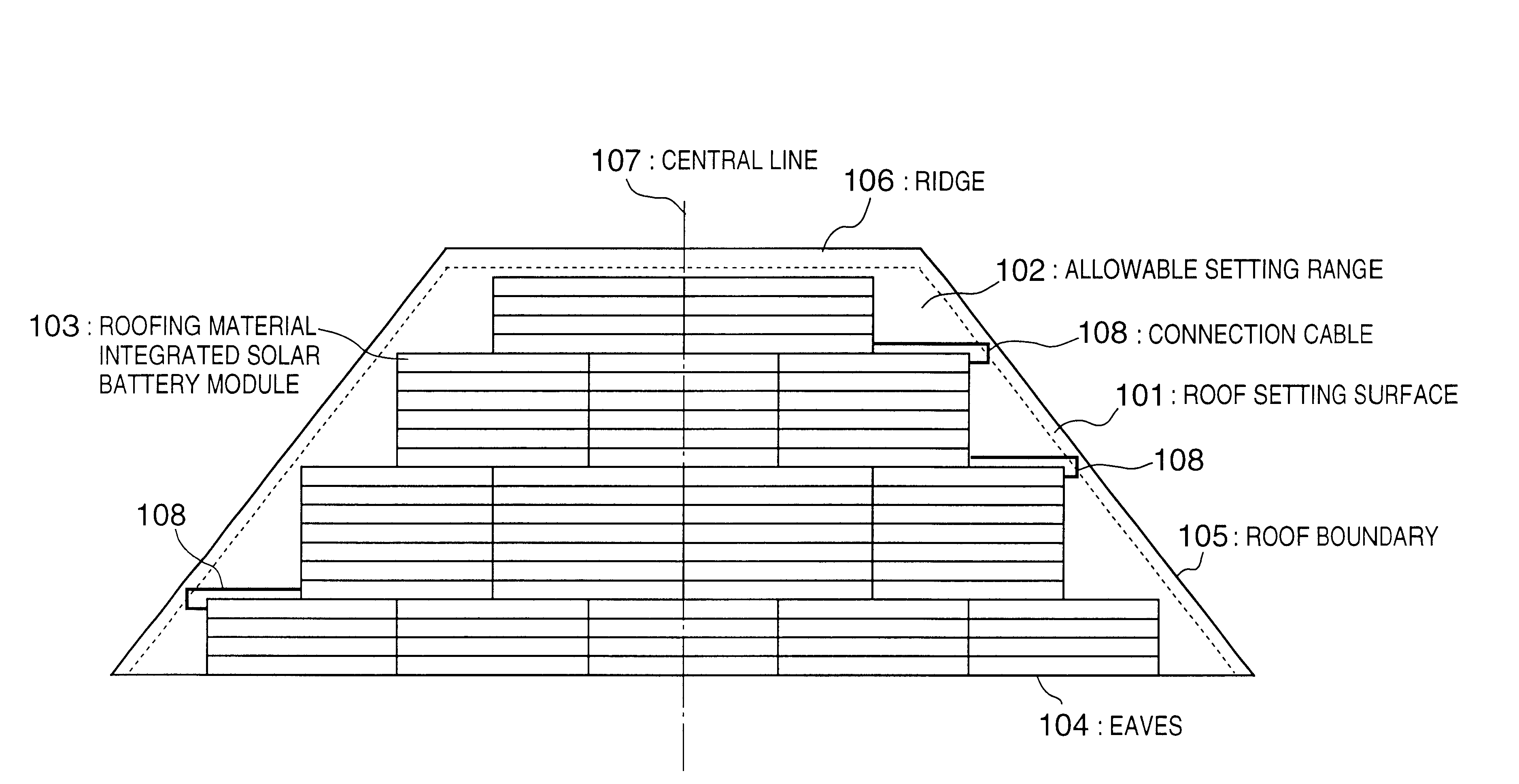

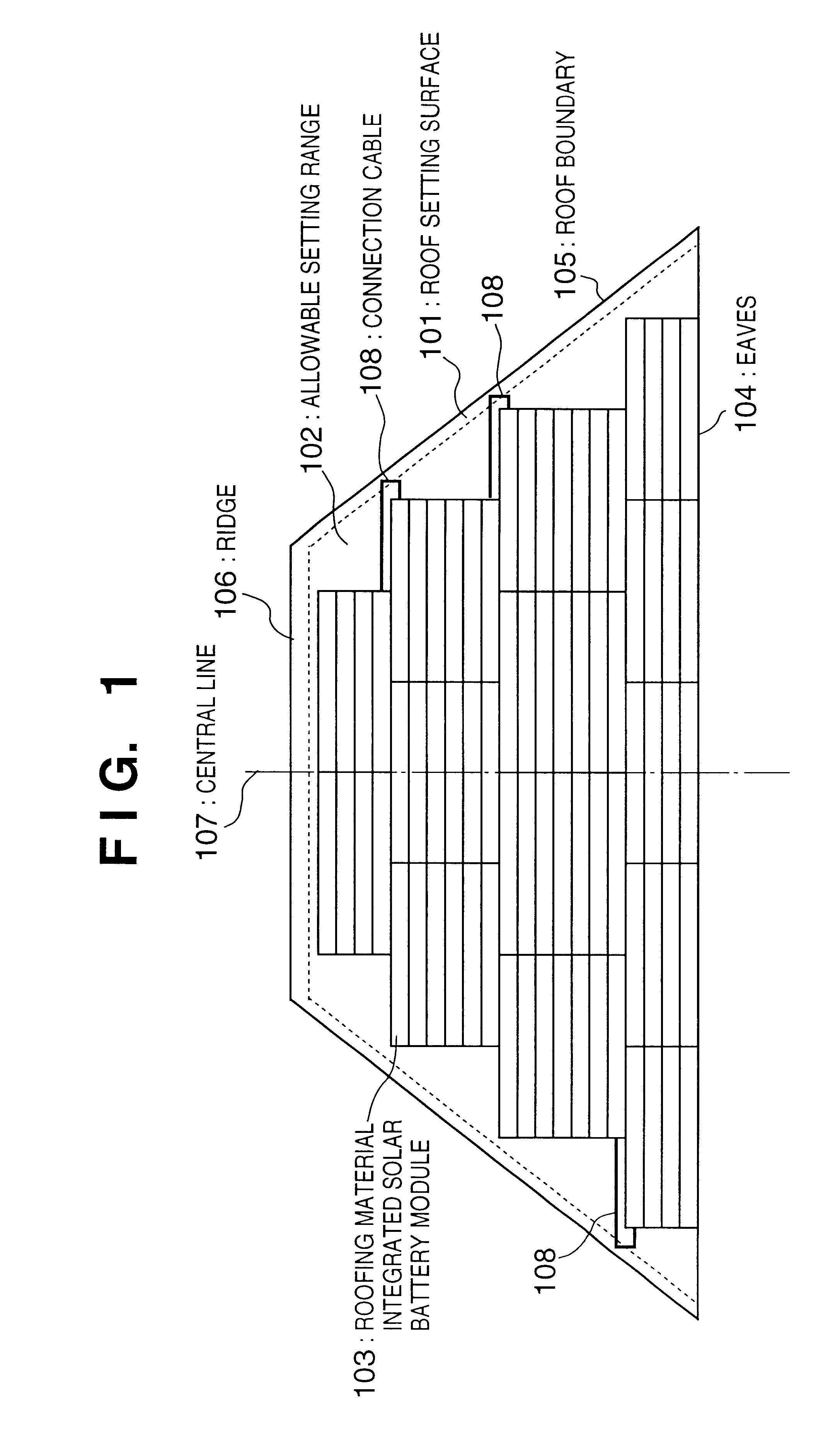

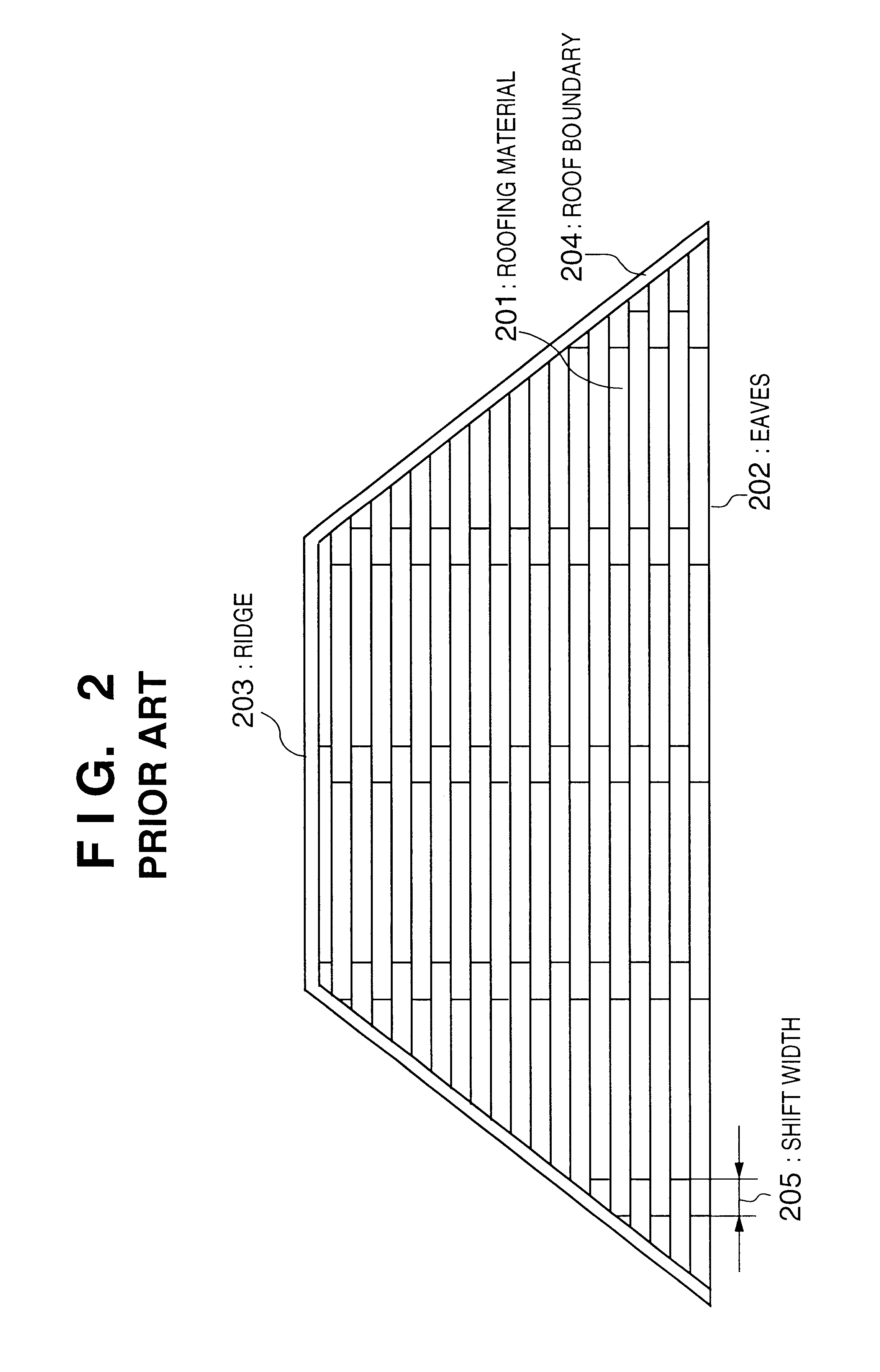

Solar battery module arranging method and solar battery module array

InactiveUS6534702B1Firmly connectedPhotovoltaic supportsSolar heating energyElectrical batteryComputer module

To optimally arrange roofing material integrated solar battery modules having a rectangular form and same size on a roof setting surface, an arrangement range in which the solar battery modules can be arranged on the roof setting surface is determined. An arranging direction of the solar battery modules is determined. The number of solar battery modules which can be arranged almost horizontally in a line in the determined arranging direction and within the arrangement range is calculated. Solar battery modules of a line in a number not more than the calculated number are combined to form a solar battery module group. The solar battery module groups are arranged to set a center of the solar battery module group within the determined arrangement range and near a line almost vertically dividing the surface into two parts. The above operations are repeated a number of times corresponding to the number of lines of solar battery module groups which can be vertically arranged in the determined arranging direction and within the arrangement range.

Owner:CANON KK

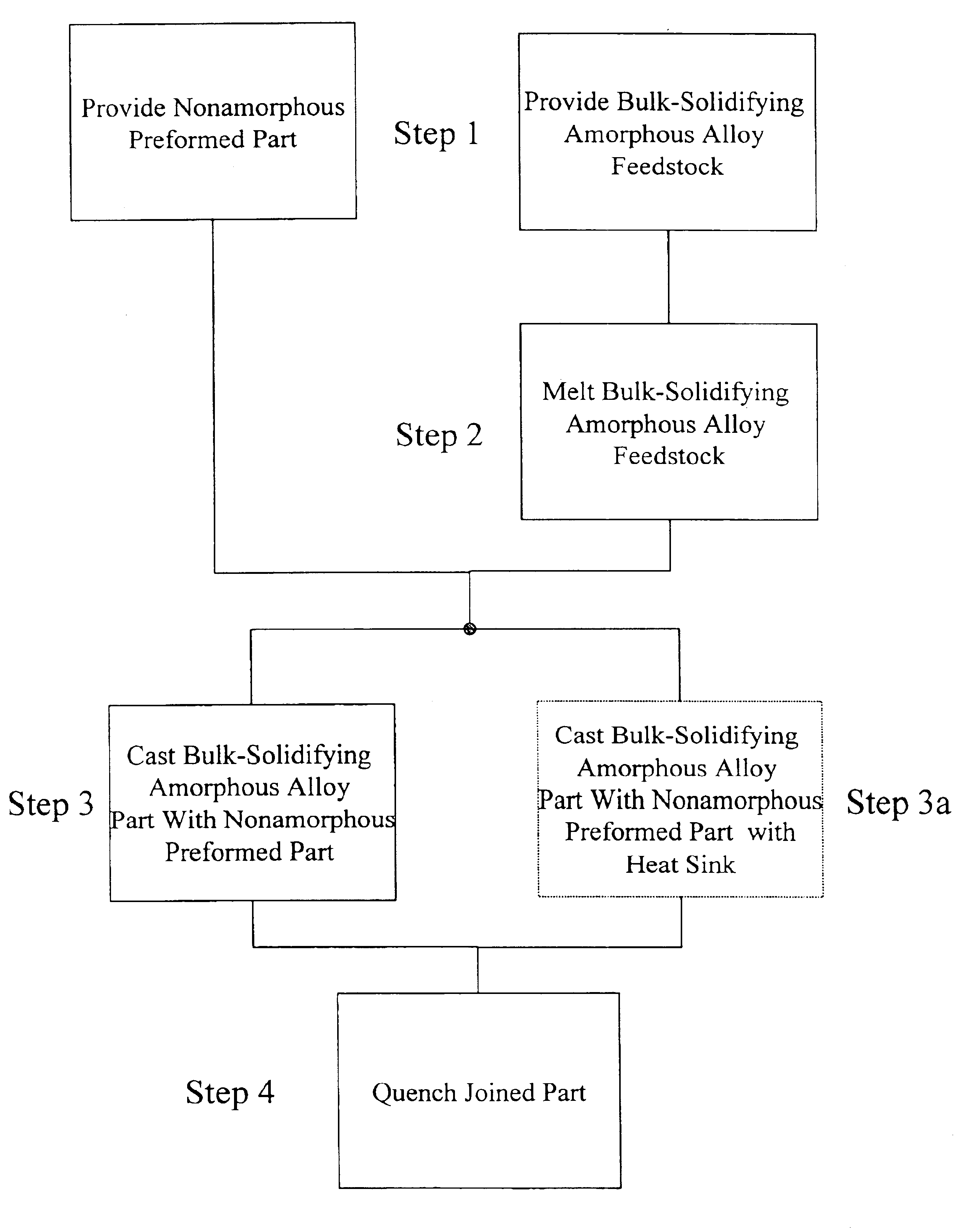

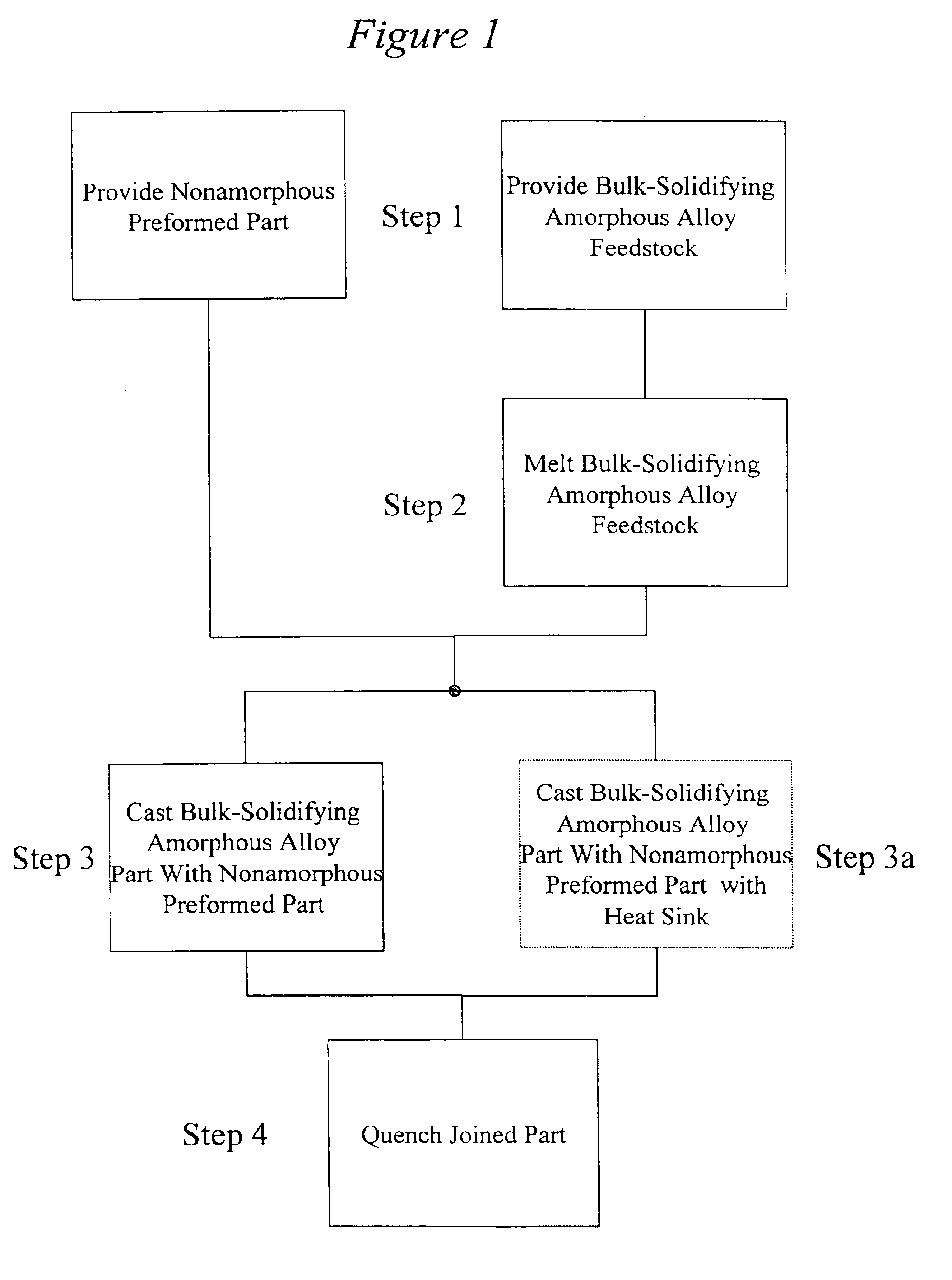

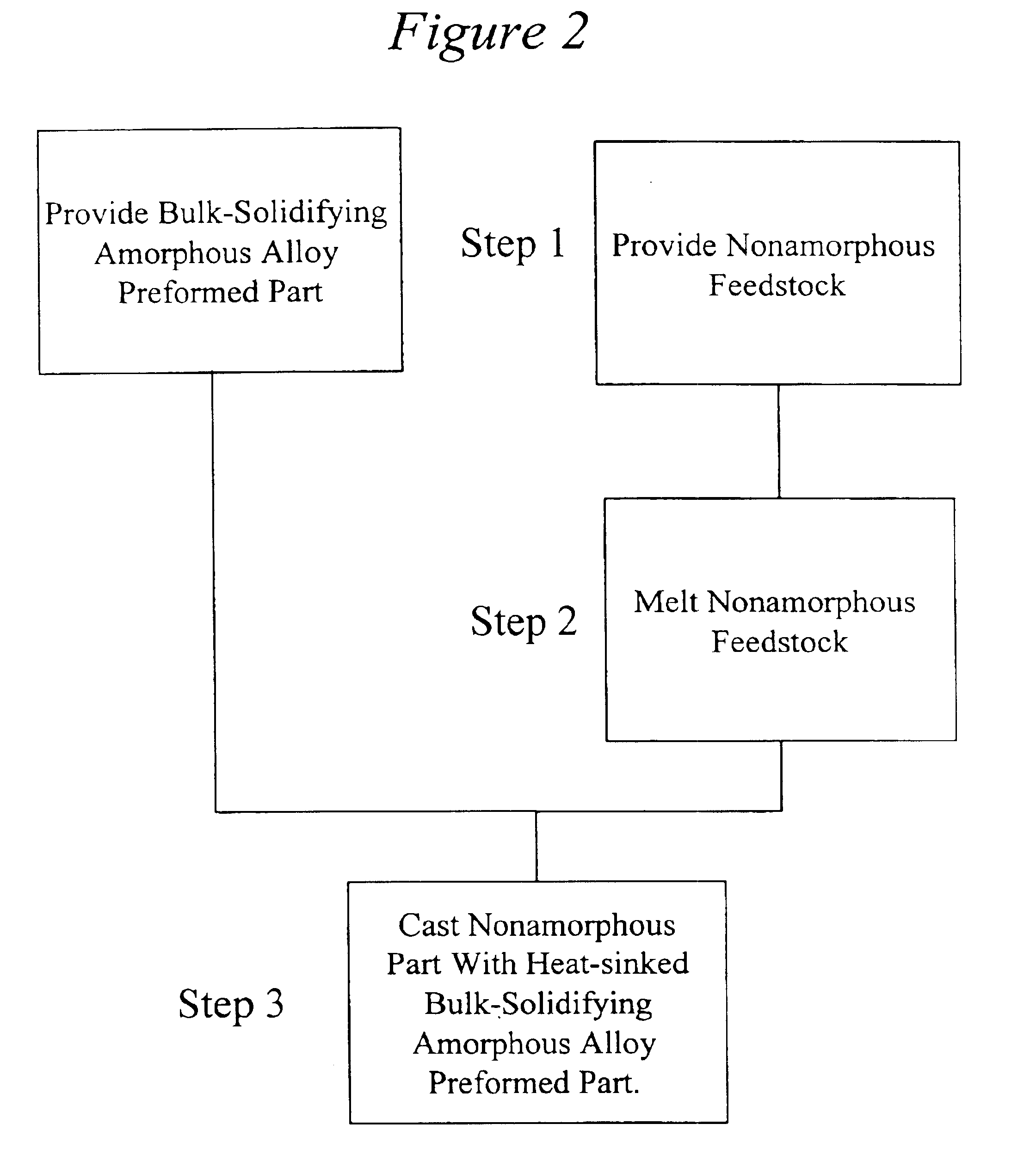

Joining of amorphous metals to other metals utilzing a cast mechanical joint

The present invention is directed to a method of joining an amorphous material to a non-amorphous material including, forming a cast mechanical joint between the bulk solidifying amorphous alloy and the non-amorphous material.

Owner:CRUCIBLE INTPROP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com