Patents

Literature

64 results about "Periodic oscillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

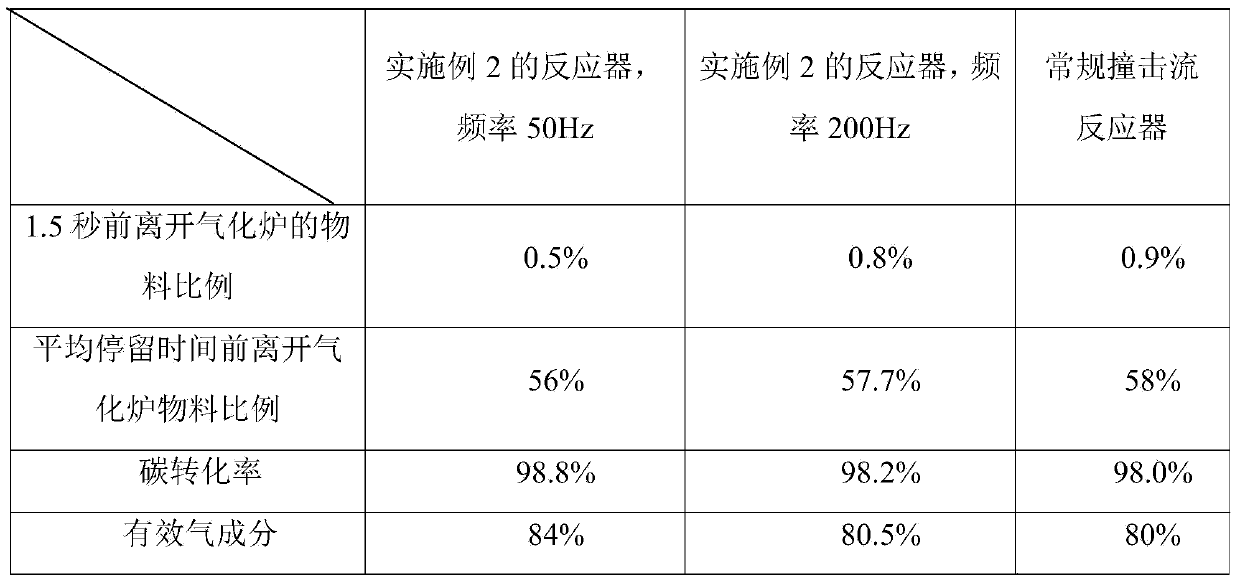

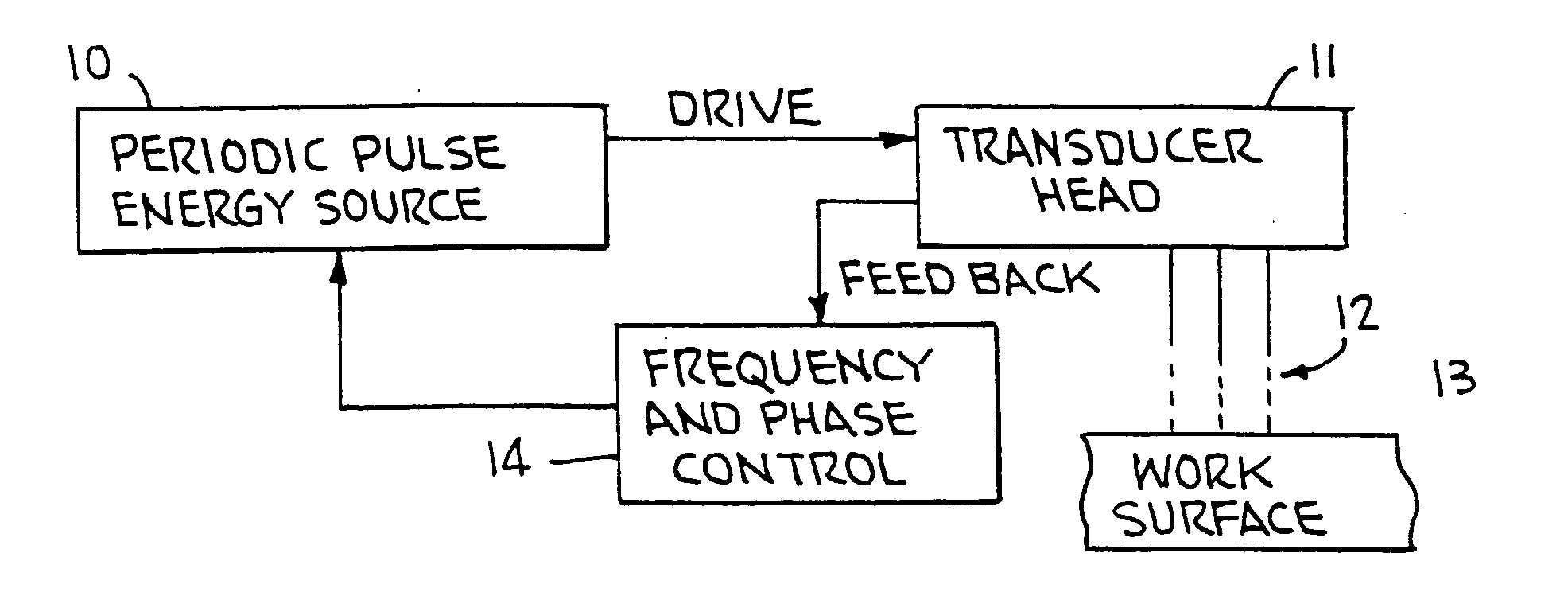

Ultrasonic impact machining of body surfaces to correct defects and strengthen work surfaces

InactiveUS6932876B1Improve power transfer efficiencyEfficient transferMechanical vibrations separationFurnace typesUltrasonic sensorPeriodic oscillation

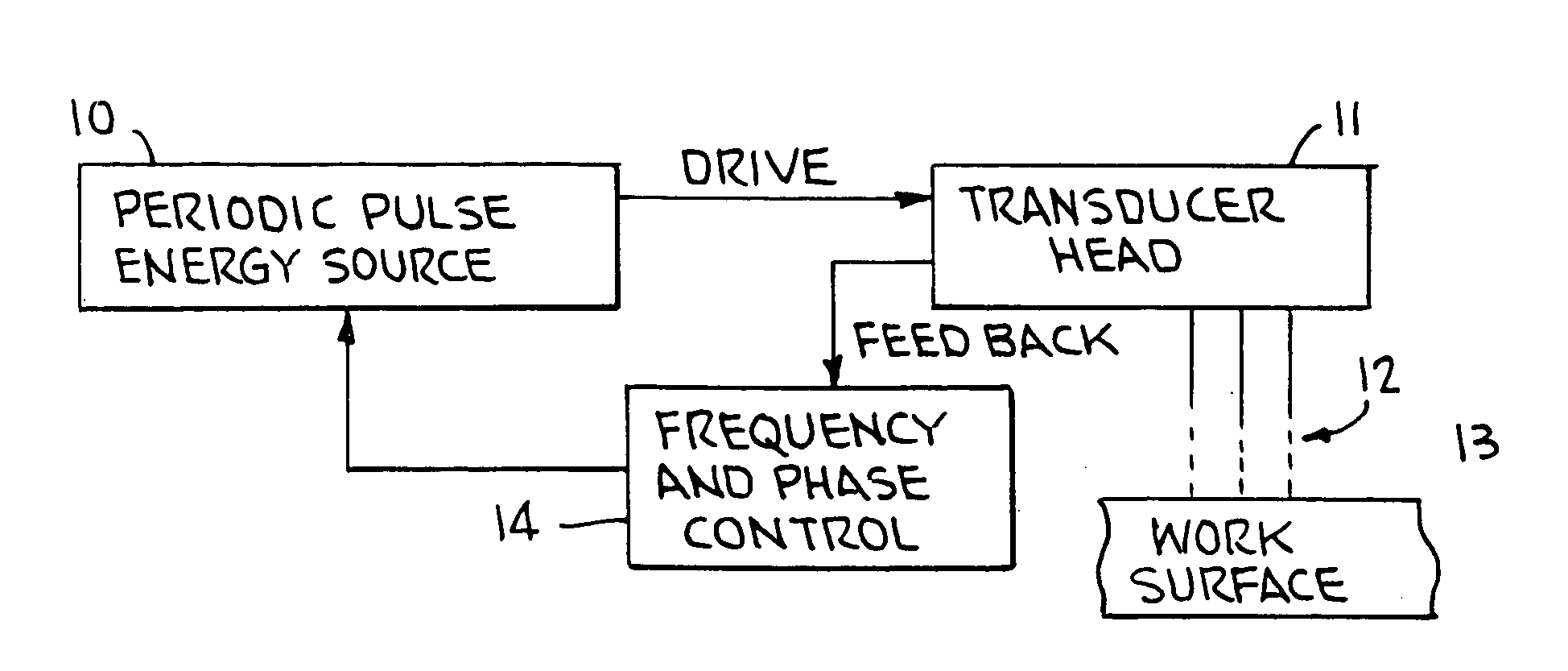

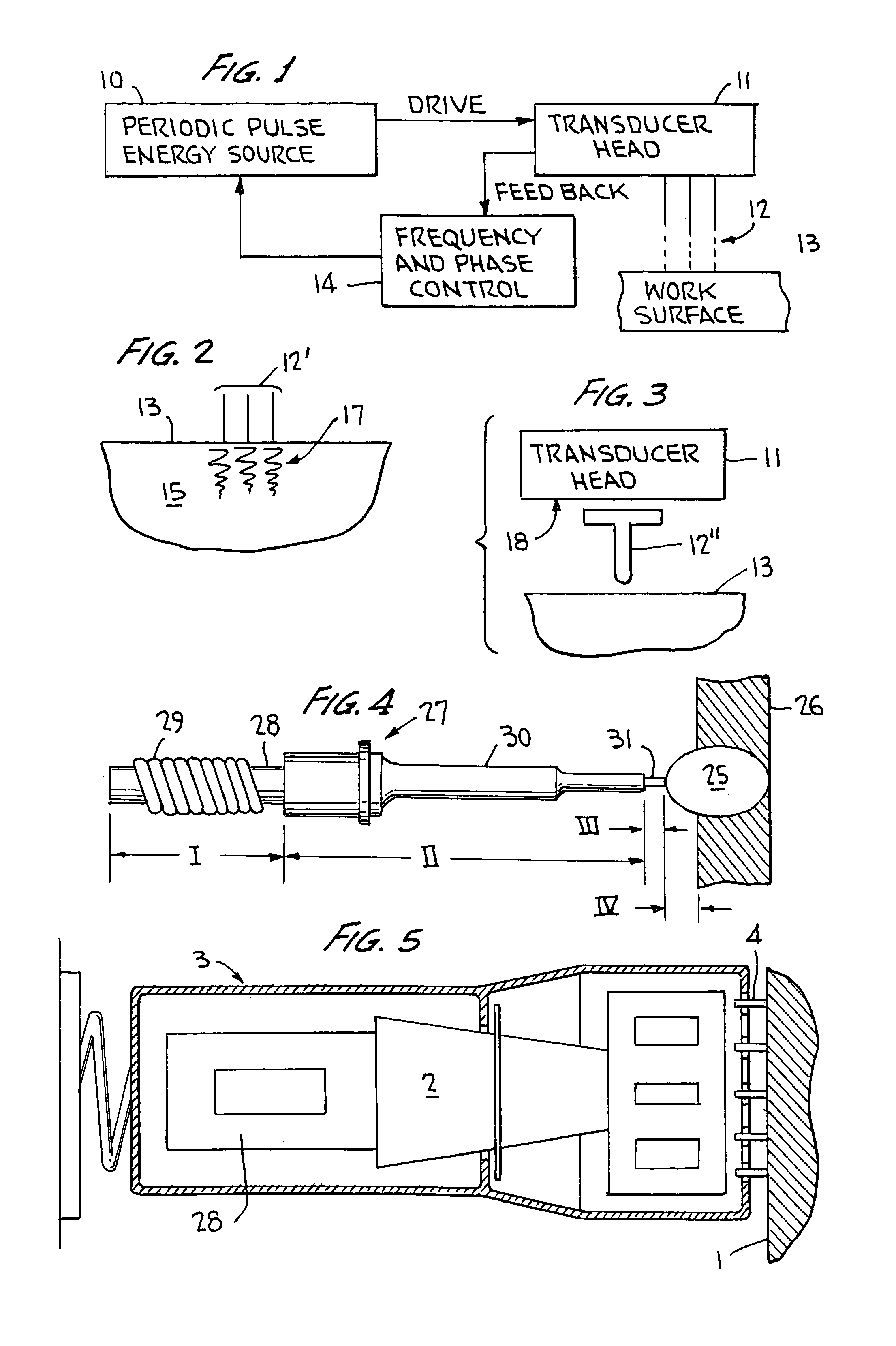

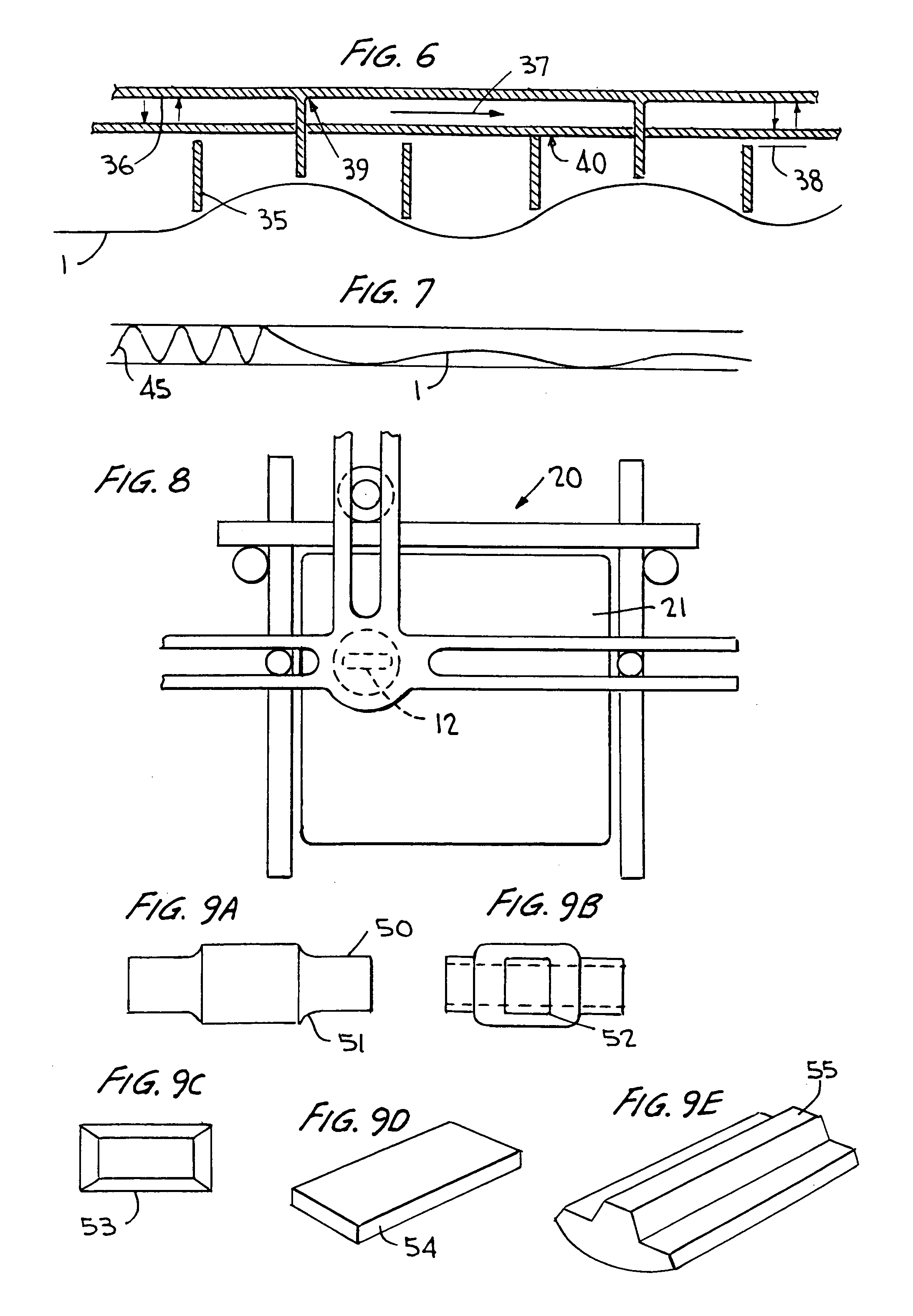

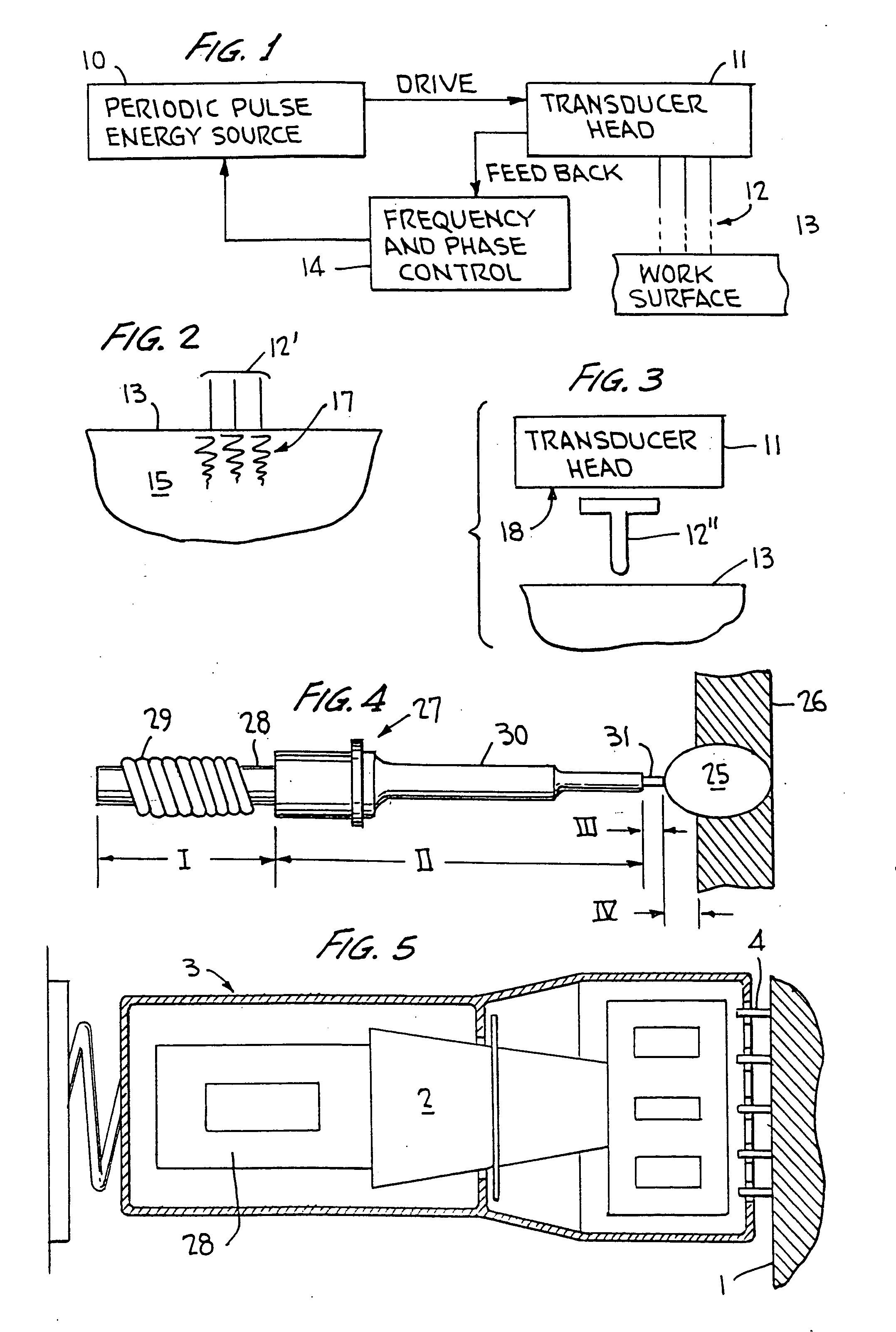

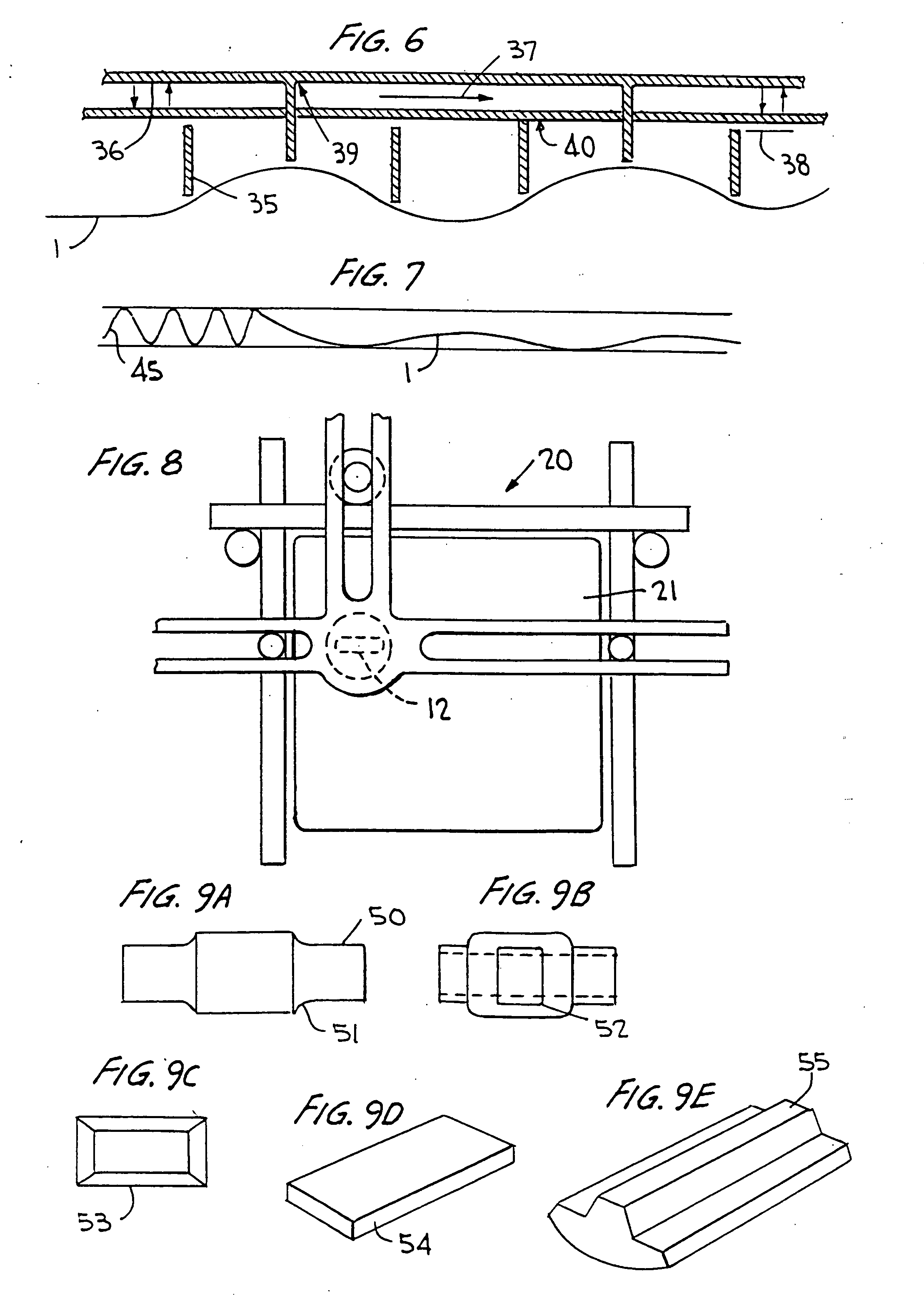

Metallic workpieces of diverse shapes having work surfaces which are deformed at the surface and adjacent sub-surface layers by surface impact from ultrasonic transducers employing freely axially moving impacting elements propelled and energized by a transducer oscillating surface vibrating periodically at an ultrasonic frequency. The impacting elements are propelled in a random aperiodic and controlled impact mode at different phases of the periodic oscillation cycles. The transducer may be portable and provides a series of mechanically interconnected stages having mechanical resonances harmonically related as a multiple of the primary ultrasonic frequency and have matched stage resistances under instantaneous loading when the impact elements are driven by the transducer oscillating surface into the surface of the workpiece. This mode of operation produces Q-factor amplification of the input ultrasonic power oscillator energy at the impact needles and high propulsion velocities making it possible to machine metallic workpiece bodies to greater depths for compressing the metal to increase compressive strength of the workpiece work surfaces to substantially the ultimate material strength. The impact machining is done at ambient temperatures.

Owner:PROGRESS RAIL SERVICES

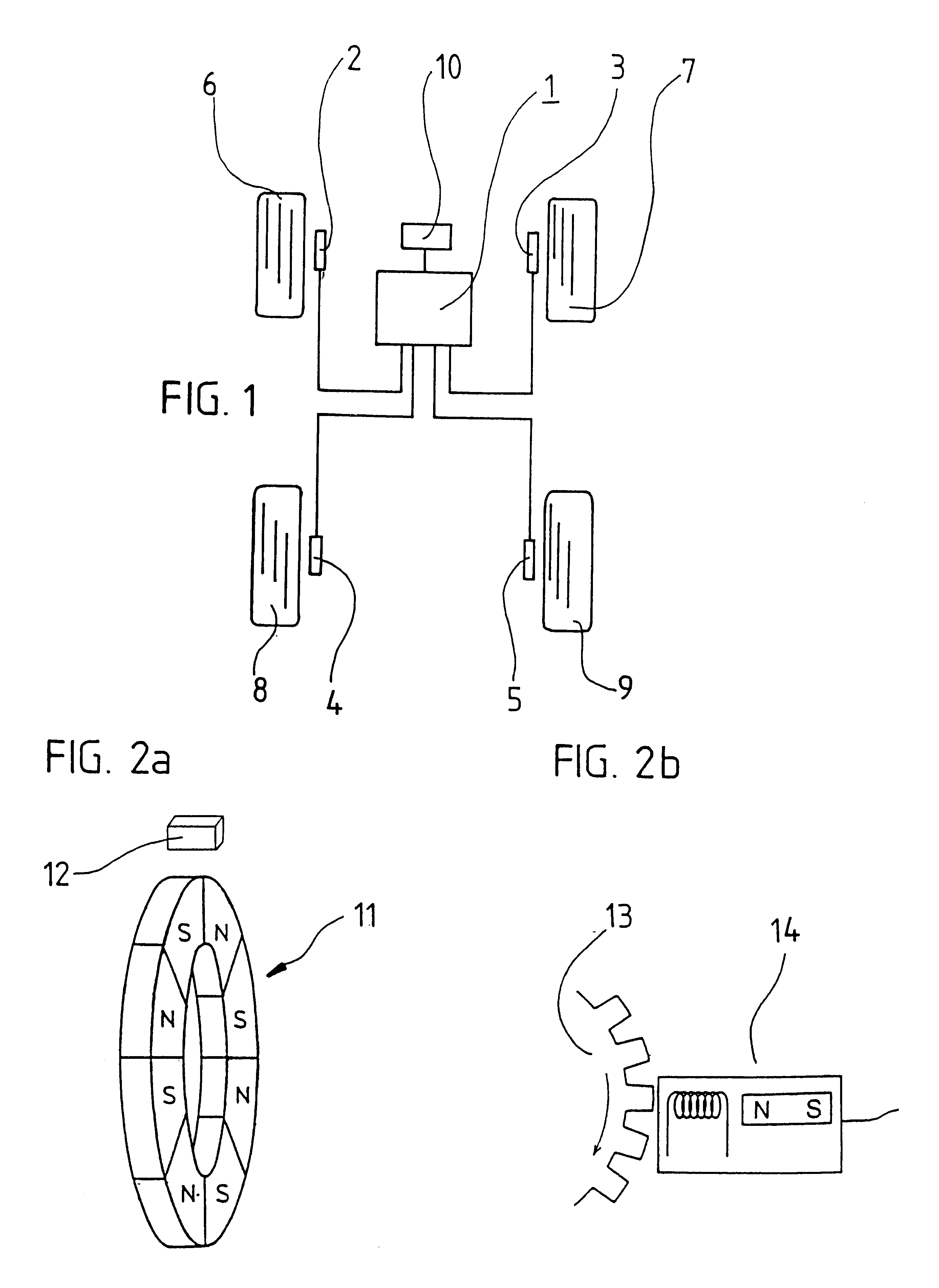

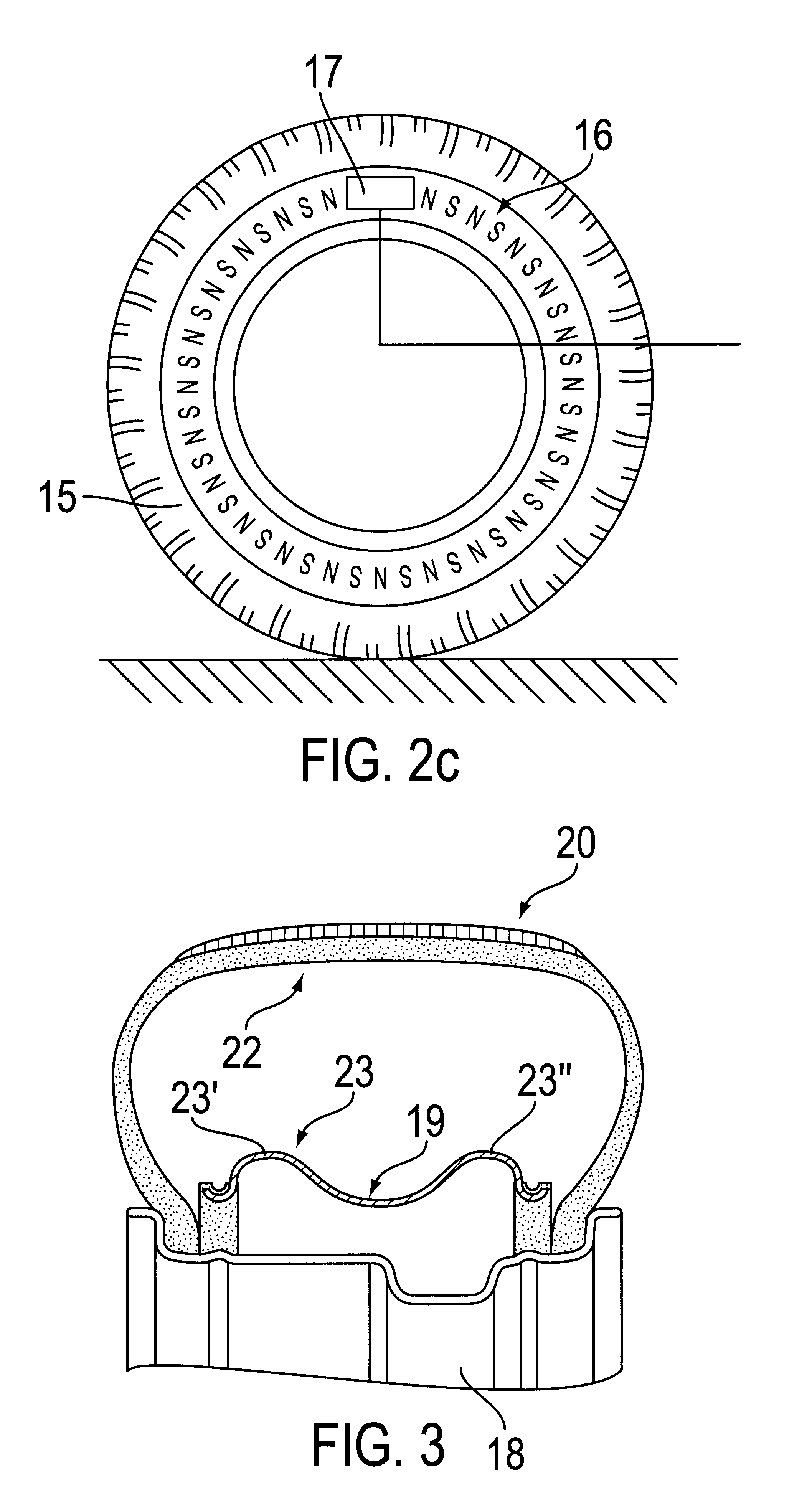

Method and system for ascertaining the emergency running condition of a pneumatic tire

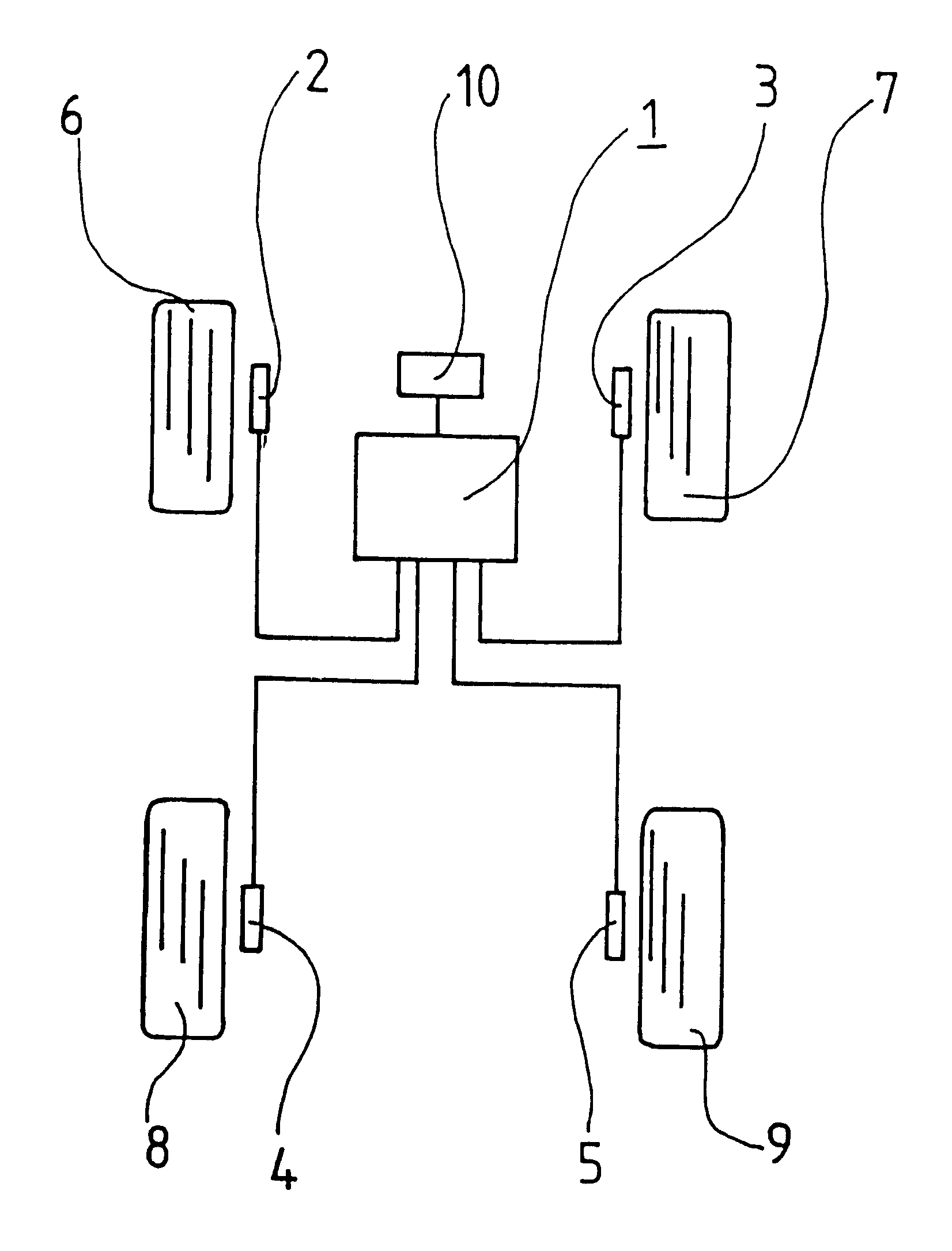

System and method for ascertaining the emergency running condition of a pneumatic tire on a motor vehicle. The system includes at least one sensor device arranged at least on each axle. The at least one sensor device is adapted to supply a permanently present first periodic oscillation proportional to a wheel rotation speed as a speed output signal. The at least one sensor device includes one of an active and a passive magnetic field sensor being mounted to one of rotate with the tire and be stationary. The transmitter device is arranged complementary to the at least one passive and active magnetic field sensor and is adapted to produce a periodic magnetic field change in proportion to the wheel rotation speed in a detection range. At least one signal processing device is used for processing and evaluating the speed output signal. A transmission and a display device are used for at least one of the transmission and the display of the speed output signal, and for one of the transmission and the display of at least one of the output control and the warning signal. An emergency running device is arranged on the vehicle wheel.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH +1

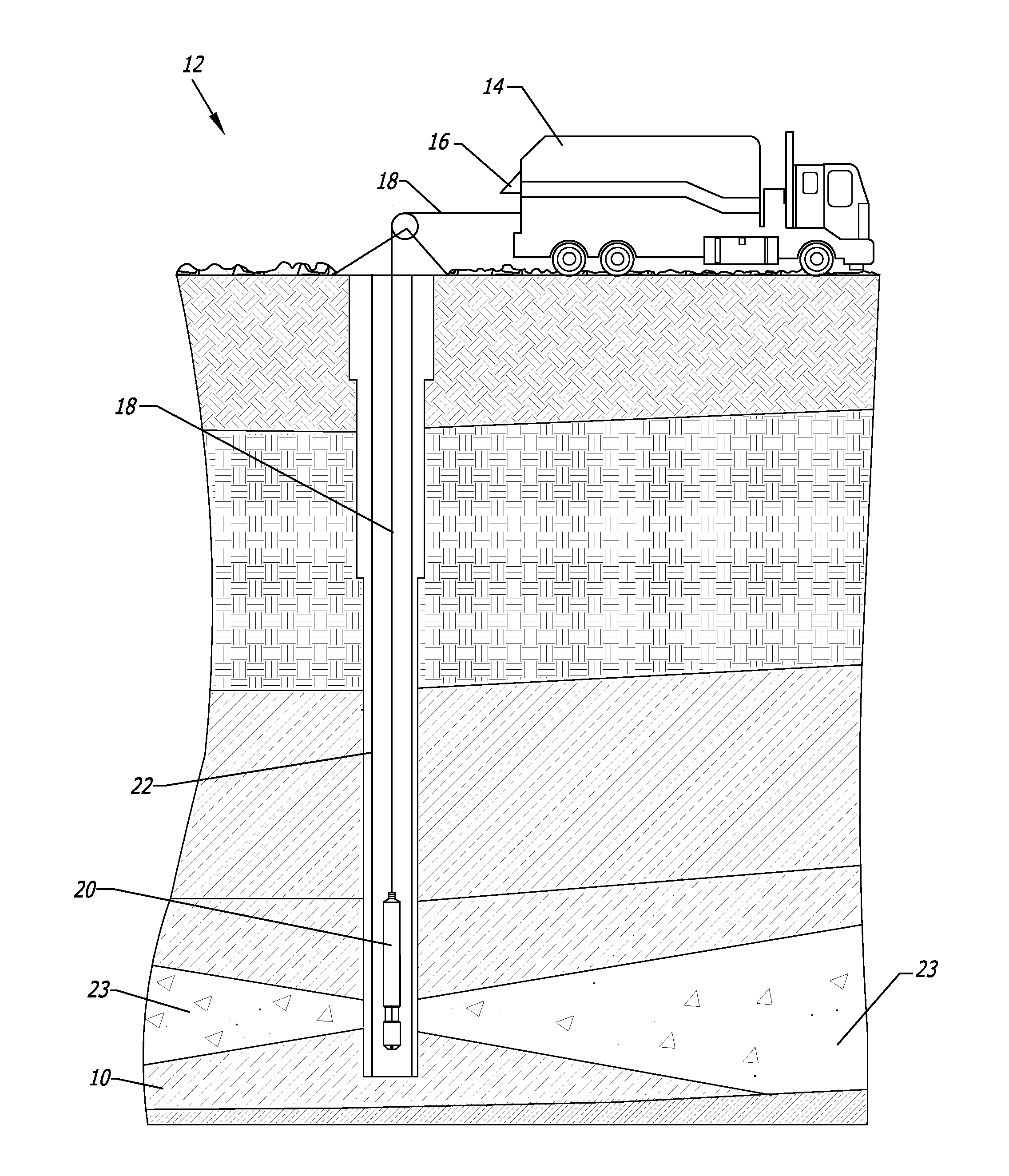

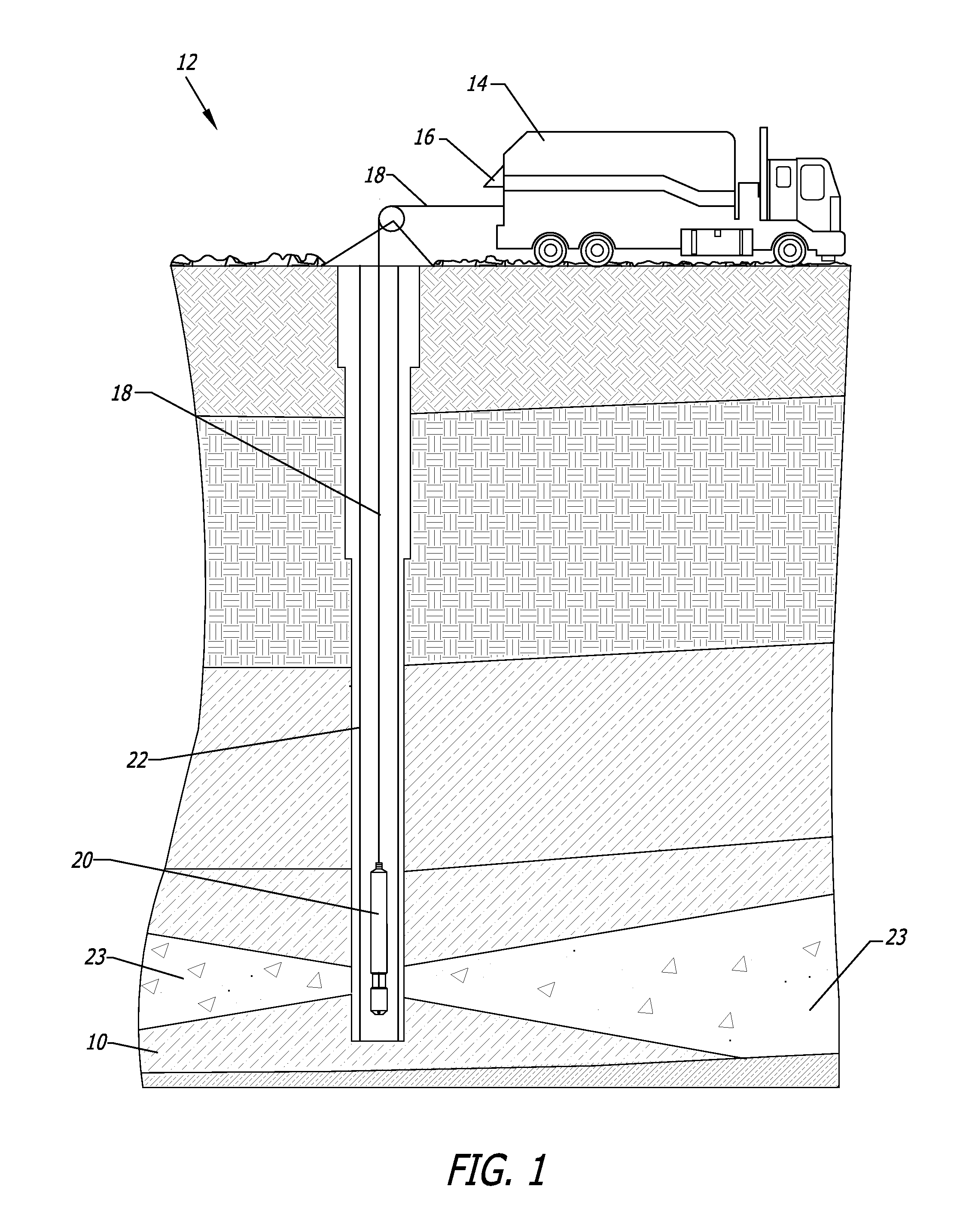

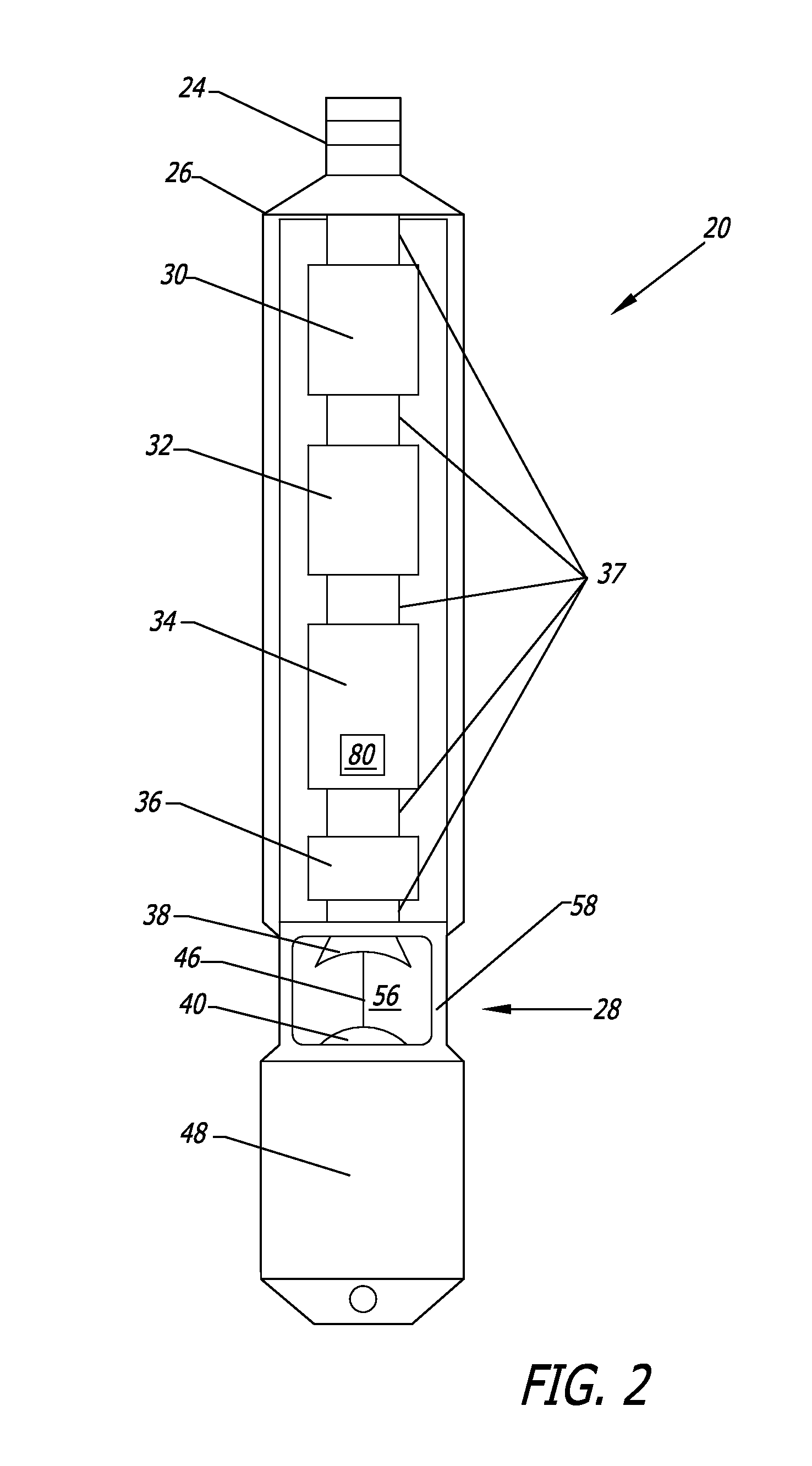

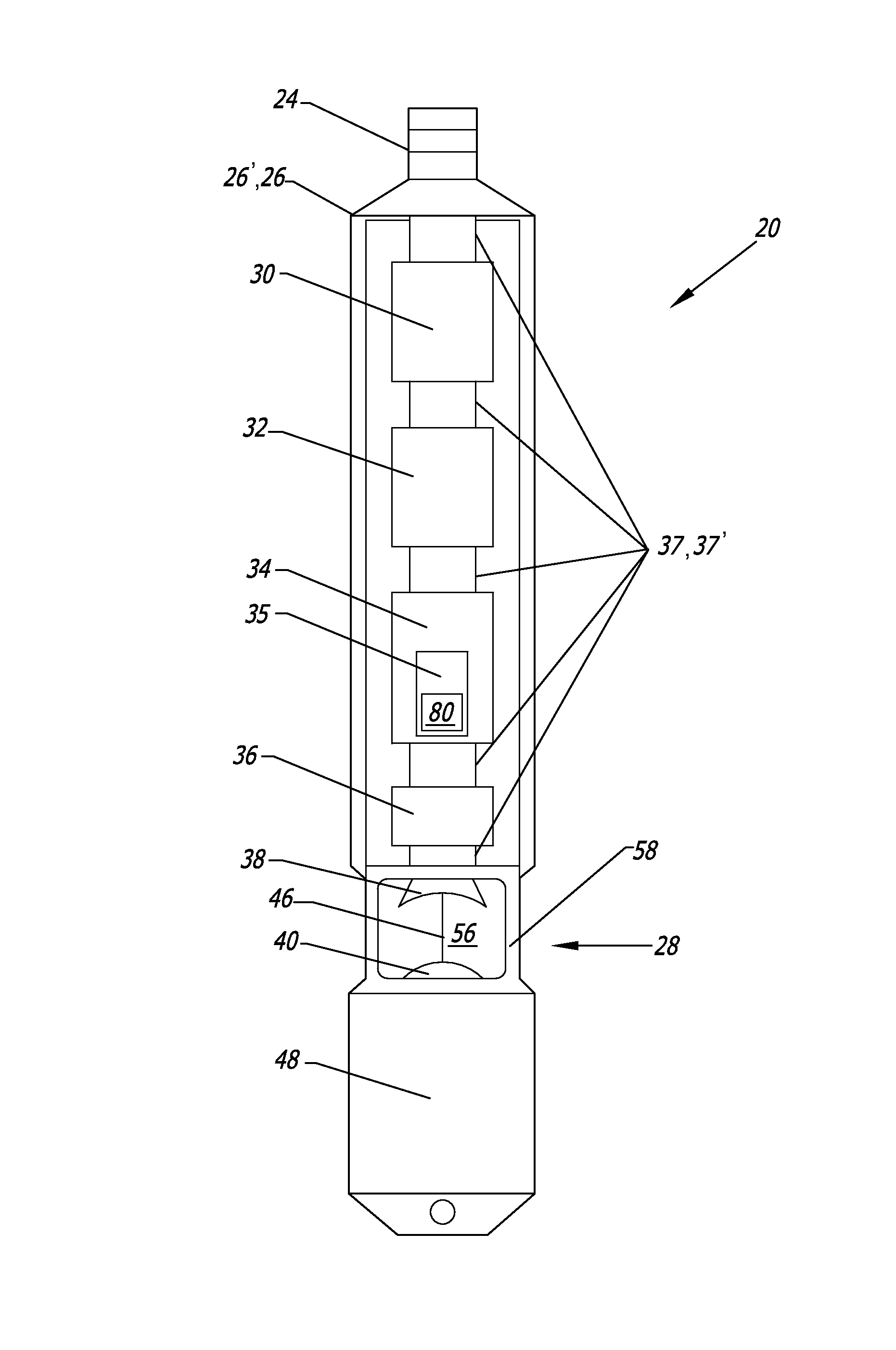

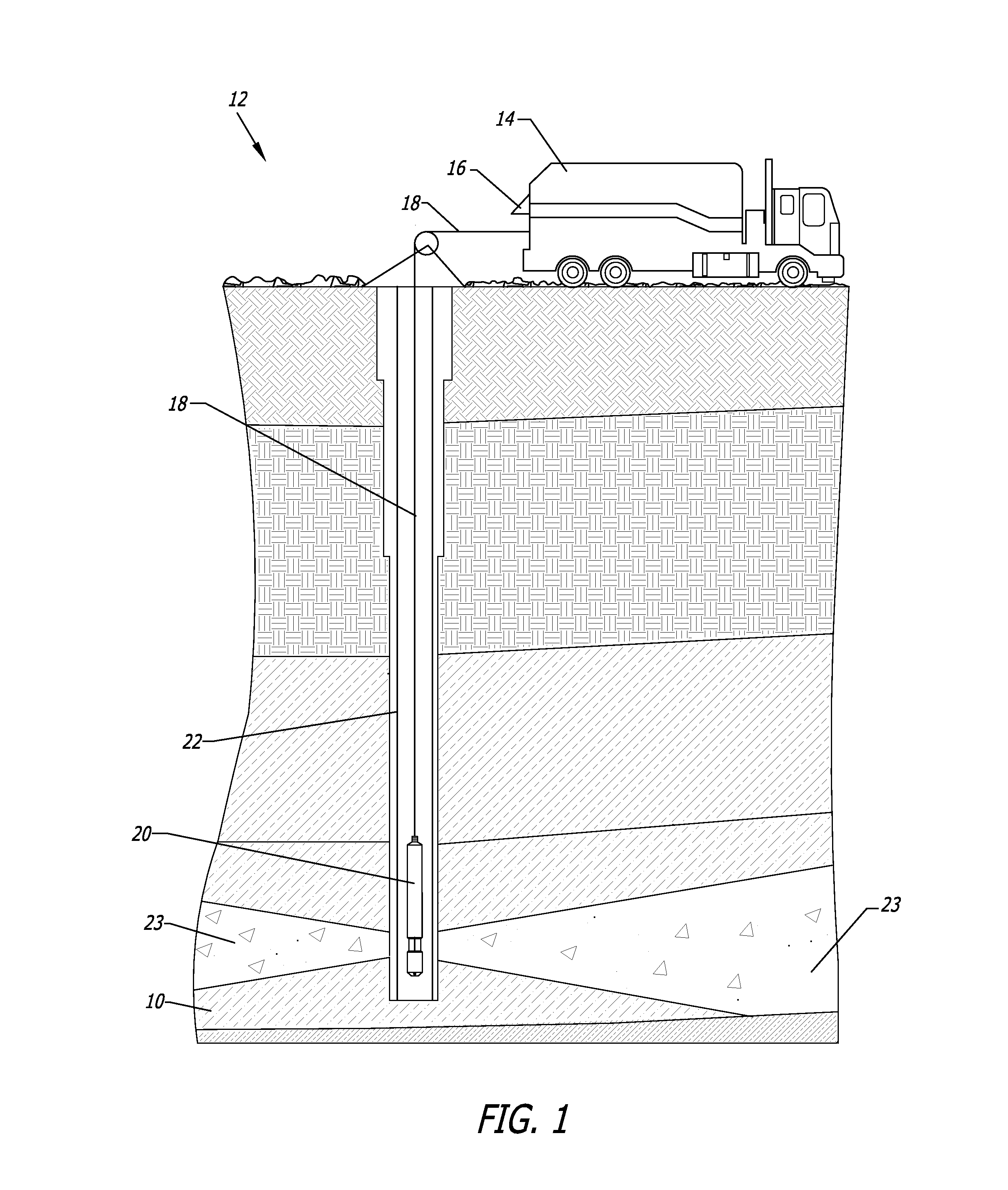

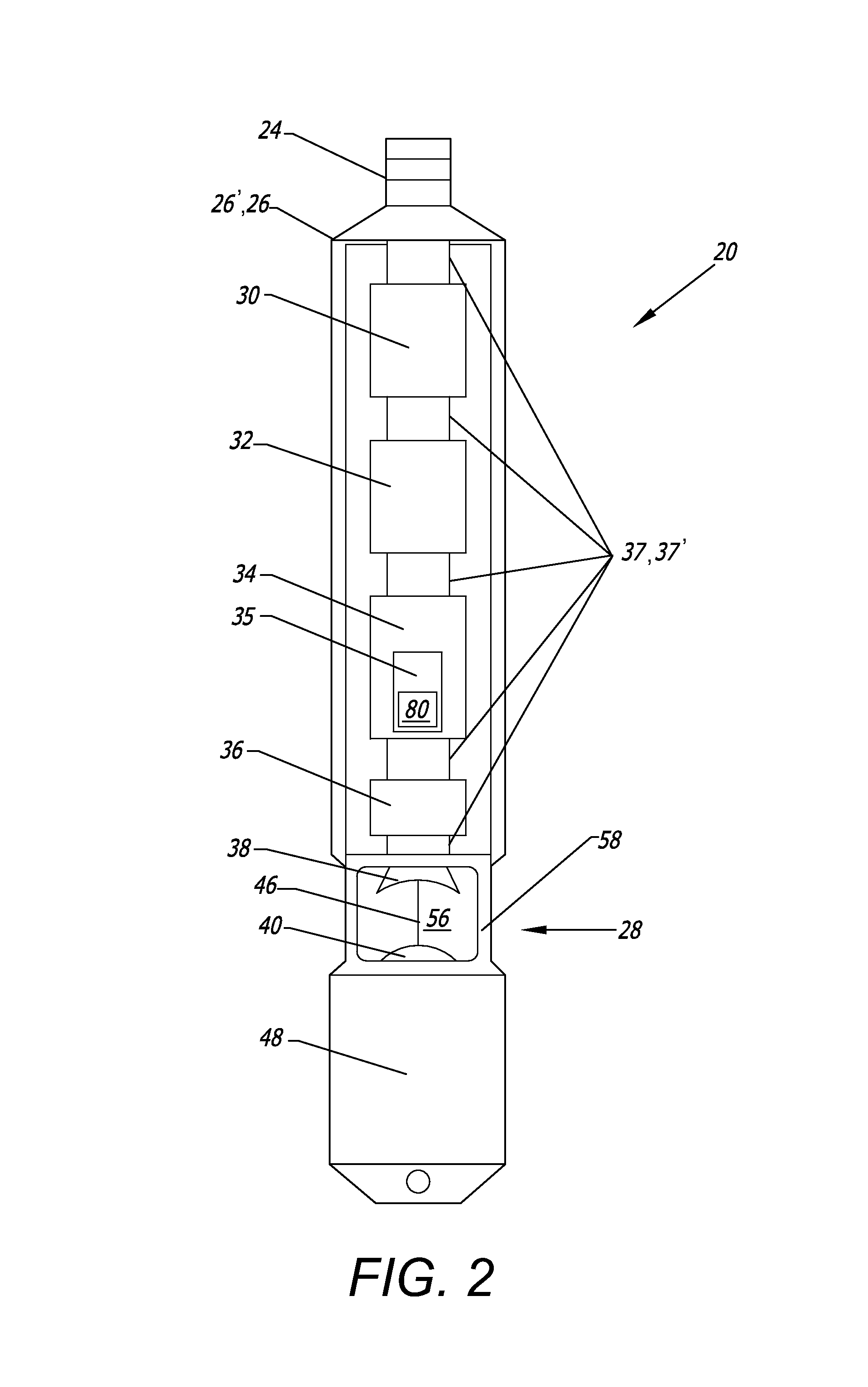

Plasma source for generating nonlinear, wide-band, periodic, directed, elastic oscillations and a system and method for stimulating wells, deposits and boreholes using the plasma source

ActiveUS20140027110A1Extended service lifeSmall sizeFluid removalVibration devicesElectrical conductorWide band

A plasma source for generating nonlinear, wide-band, periodic, directed, elastic oscillations in a fluid medium. The plasma source includes a plasma emitter having two electrodes defining a gap, a delivery device for introducing a metal conductor into the gap, and a high voltage transformer for powering the plasma emitter. A system and method for stimulating wells, deposits, and boreholes through controlled periodic oscillations generated using the plasma source. The system includes the plasma source, a ground control unit, and a support cable. In the method, the plasma source is submerged in the fluid medium of a well, deposit, or borehole and is used to create a metallic plasma in the gap. The metallic plasma emits a pressure pulse and shockwaves, which are directed into the fluid medium. Nonlinear, wide-band, periodic and elastic oscillations are generated in the fluid medium, including resonant oscillations by passage of the shockwaves.

Owner:NOVAS ENERGY GRP

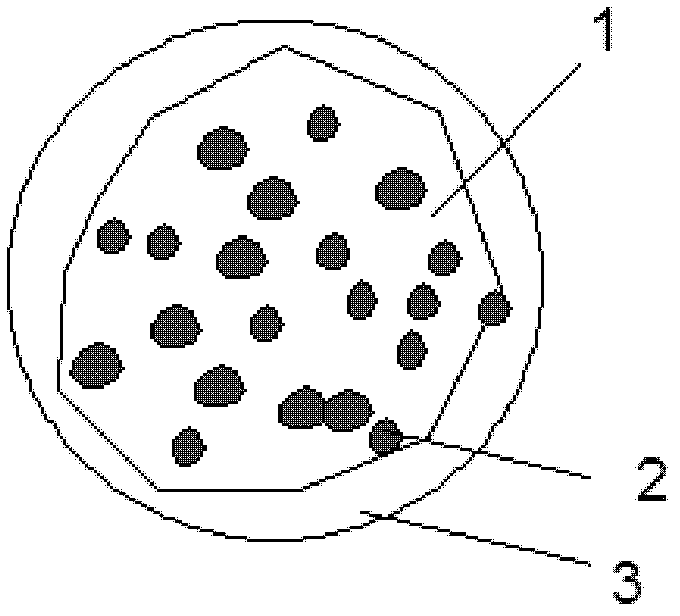

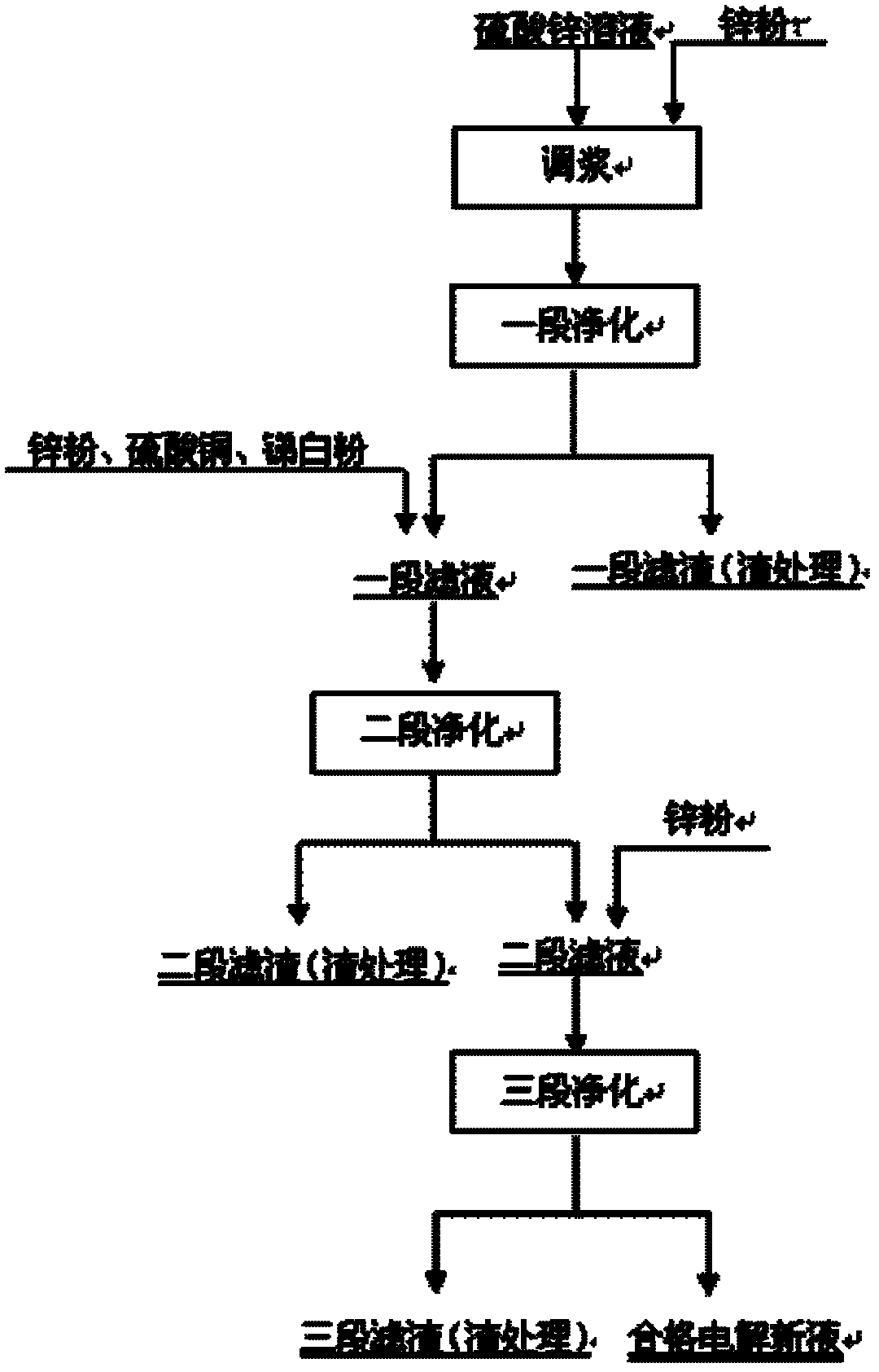

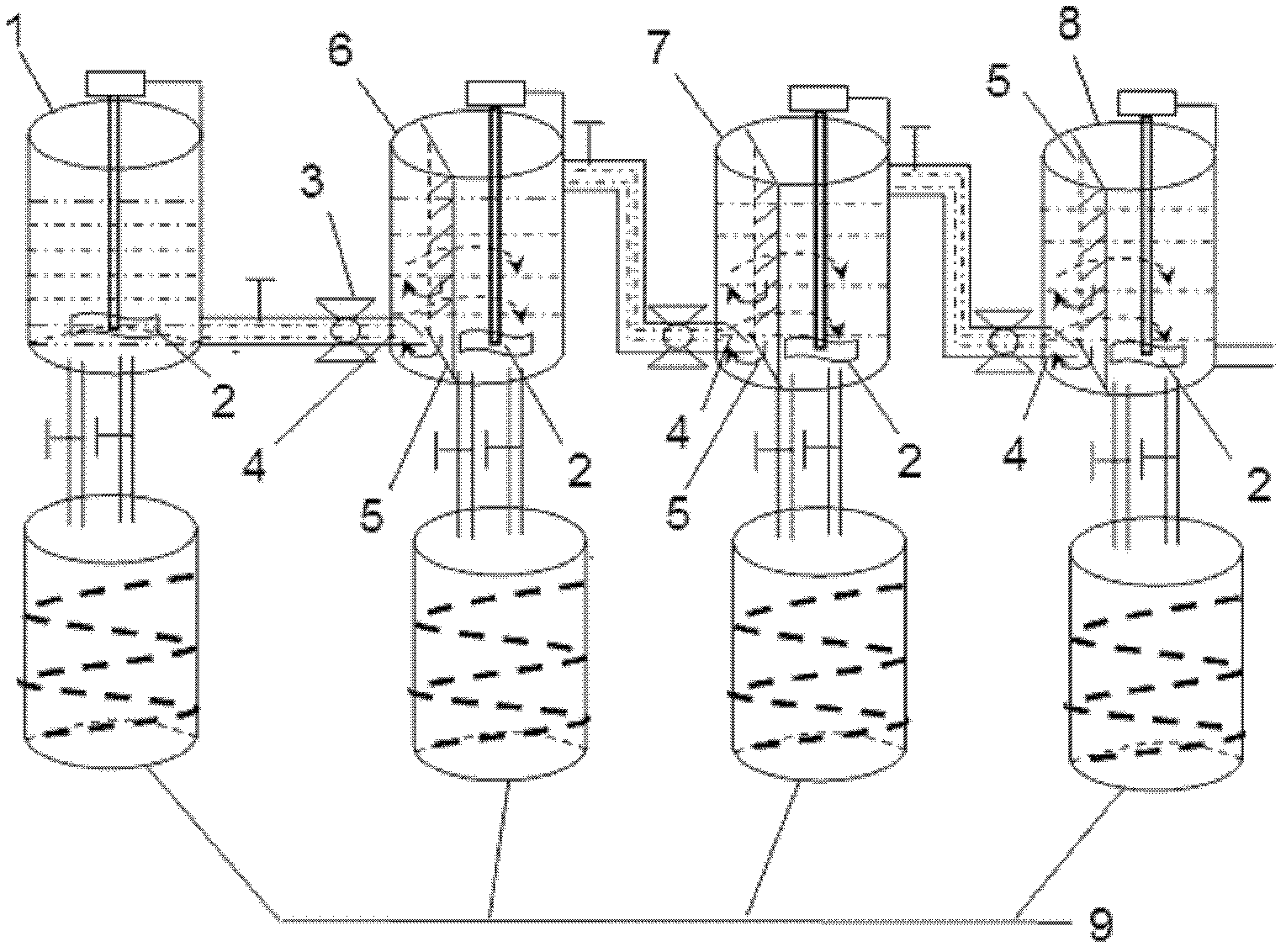

Method and device for purifying zinc sulfate solution based on action of cavitation effect

The invention relates to a method and a device for purifying a zinc sulfate solution based on action of a cavitation effect. The method comprises the following steps: adding zinc powder into a solution before purifying the zinc sulfate, and conveying the solution to a partition plate in a purifying container or forming cavitation effect bubbles through the periodic oscillation action of a vibration device for stripping impurities which are displaced out from the surface of the zinc powder, thereby keeping the reaction surface of the zinc powder exposed at any time, being capable of participating in displacement, purification and removal of the impurities and reducing the consumption amount of the zinc powder; and filtering the solution which passes through a 1-3 grade cavitation effect generation device for acting for 20-50 minutes, and obtaining filtrate which is a new qualified electrolysis solution and filter residue which is high-grade copper-cadmium slag or nickel-cobalt slag. When in purification and removal of cobalt and nickel, the zinc powder, copper sulfate and antimony white powder are further added into the purifying container, the energy consumption is low and the using quantity of the zinc powder is reduced from 100-200 times of the content in traditional displacement of the cobalt by using the zinc powder to 20-50 times of the content.

Owner:KUNMING METALLURGY INST

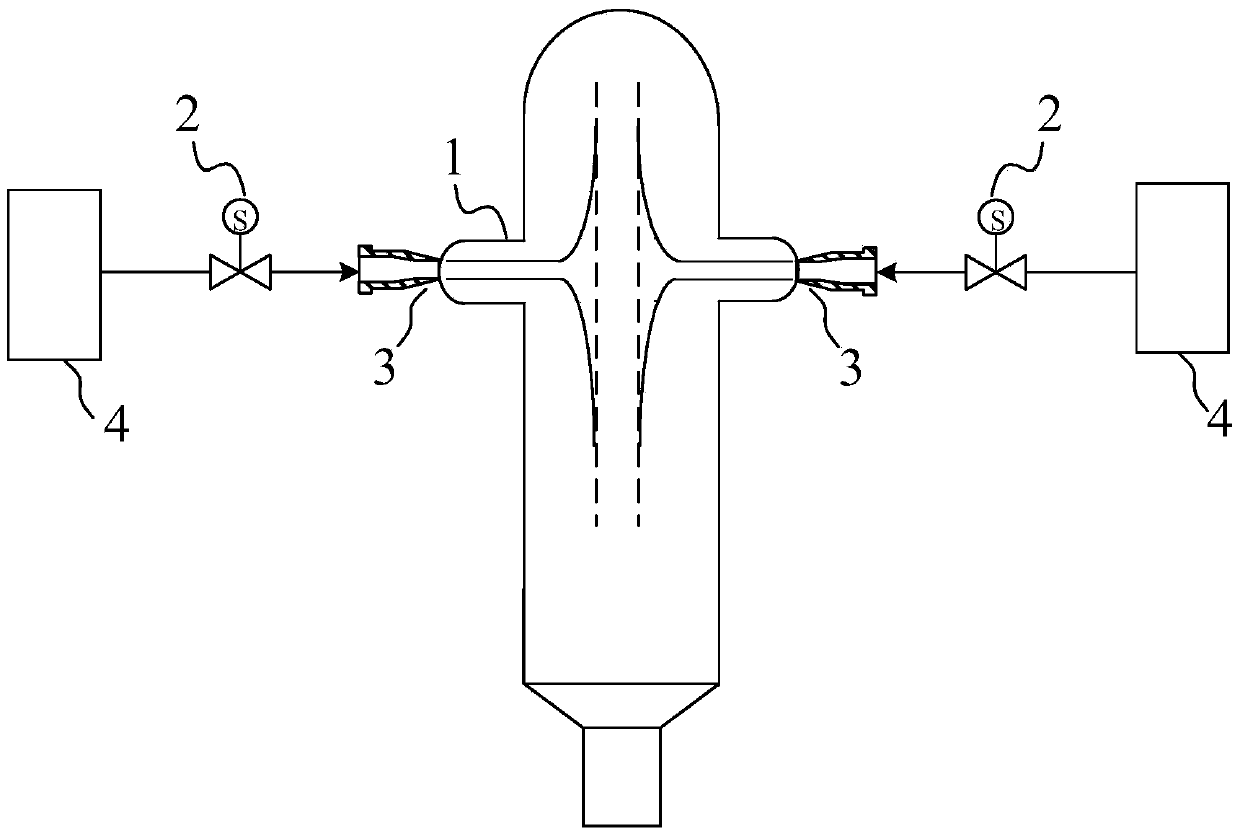

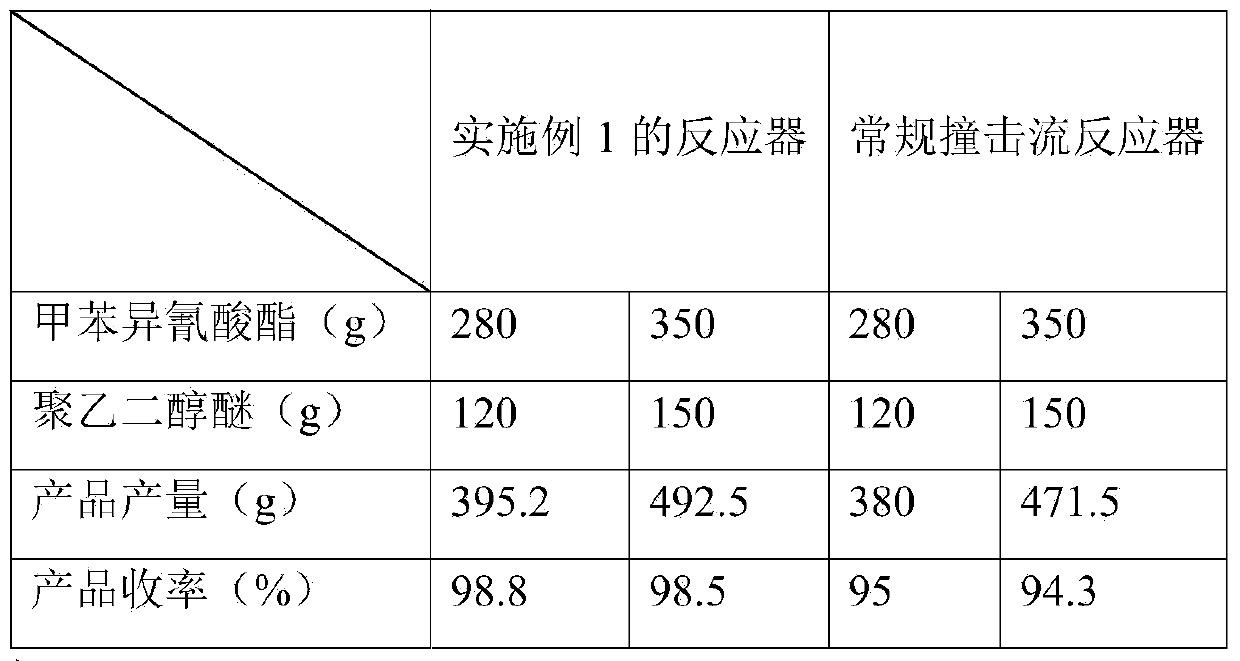

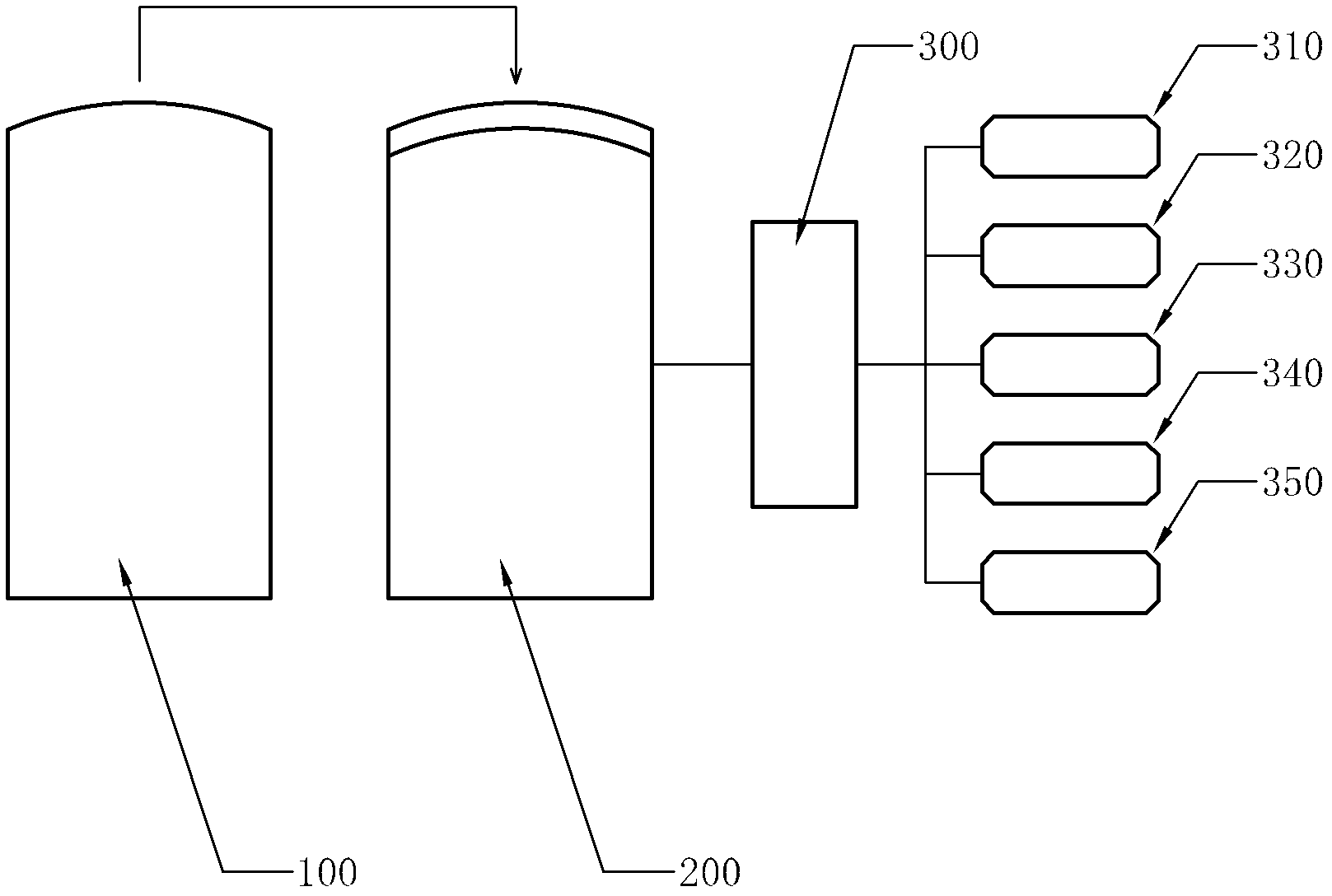

Impinging stream reactor

ActiveCN103611487AImprove promotion effectWell mixedChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesChemical reactionPeriodic oscillation

The invention discloses an impinging stream reactor which comprises a chamber, two storage tanks and two nozzles, wherein the two storage tanks are respectively used for feeding materials to the two nozzles, and the two nozzles are oppositely arranged on the side wall of the chamber. The impinging stream reactor also comprises a control unit and two proportional valves, wherein the control unit is used for controlling the two proportional valves to adjust the feeding flows to the two nozzles to flocculate according to a first preset waveform and a second preset waveform respectively, and the first preset waveform and the second preset waveform both have periodicity. In the impinging reactor disclosed by the invention, by controlling the two proportional valves to adjust the feeding flows to the two nozzles to flocculate according to the preset waveforms respectively, the periodic oscillation of the impinging surface of the impinging stream is caused, so that the acceleration effect on the fluid mixing and chemical reaction of the impinging stream reactor is improved, and the impinging stream reactor can obtain an ideal mixing effect when applied to a fluid mixing reaction with low Reynolds number.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Ultrasonic impact machining of body surfaces to correct defects and strengthen work surfaces

InactiveUS20060237104A1Increase speedHigh energyFurnace typesMechanical vibrations separationUltrasonic sensorPeriodic oscillation

Metallic workpieces of diverse shapes having work surfaces which are deformed at the surface and adjacent sub-surface layers by surface impact from ultrasonic transducers employing freely axially moving impacting elements propelled and energized by a transducer oscillating surface vibrating periodically at an ultrasonic frequency. The impacting elements are propelled in a random aperiodic and controlled impact mode at different phases of the periodic oscillation cycles. The transducer may be portable and provides a series of mechanically interconnected stages having mechanical resonances harmonically related as a multiple of the primary ultrasonic frequency and have matched stage resistances under instantaneous loading when the impact elements are driven by the transducer oscillating surface into the surface of the workpiece. This mode of operation produces Q-factor amplification of the input ultrasonic power oscillator energy at the impact needles and high propulsion velocities making it possible to machine metallic workpiece bodies to greater depths for compressing the metal to increase compressive strength of the workpiece work surfaces to substantially the ultimate material strength. The impact machining is done at ambient temperatures.

Owner:APPLIED ULTRASONICS INT PTY LTD

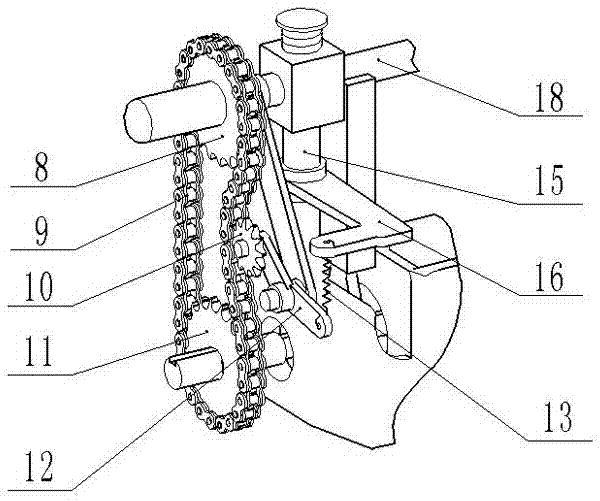

Rotary oscillation seedling transplanting device of dry filed plug seedling transplanter

InactiveCN102405716ACompact structureOne-way translational transport of trays is easy to realizeTransplantingPeriodic oscillationDrive shaft

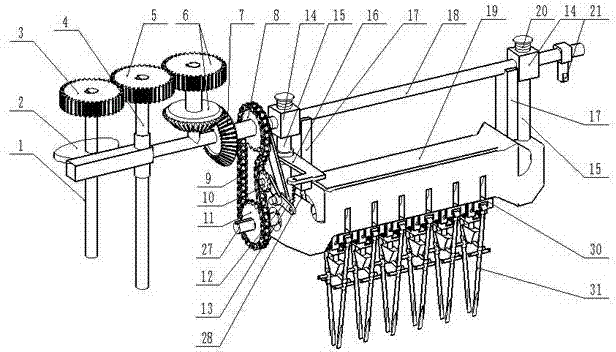

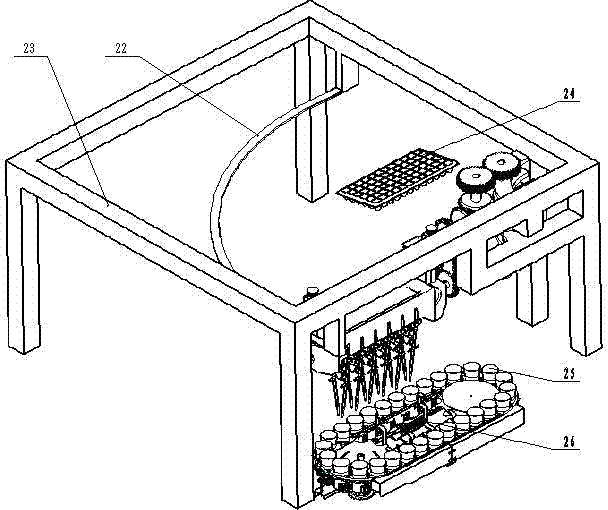

The invention relates to a seedling transplanting device of a dry filed plug seedling transplanter. The seedling transplanting device is characterized by comprising an oscillating bar cam mechanism, a planet gear mechanism, a chain transmission mechanism, a full line seedling picking device, a plug tray, a rotary support cup and a frame, wherein an oscillating bar is idly sleeved on a driving shaft and is driven by a cam I, and the oscillating bar is driven by the cam I to carry out periodic oscillation including stopping, 90-degree forward rotation, stopping and 90-degree inverse rotation; the planet gear mechanism is driven by a gear II to drive the chain transmission mechanism, and a chain transmits and drives a cam shaft II to rotate circularly; two vertical slide bars are installed in an oscillating bar sliding sleeve and are connected to a seedling picking support, and the full line seedling picking device can move up and down in the oscillating bar sliding sleeve through the two vertical slide bars; and by virtue of contact between a cam II on a cam shaft II and an oscillating bar top block, the full line seedling picking device is controlled to move according to a movement rule of descending for seedling picking, stopping without movement, lifting for seedling taking, lifting stopping, 90-degree forward rotation along with the oscillating bar and 90-degree inverse rotation. The seedling transplanting device has relatively simple structure and can effectively realize seedling picking automation.

Owner:JIANGSU UNIV

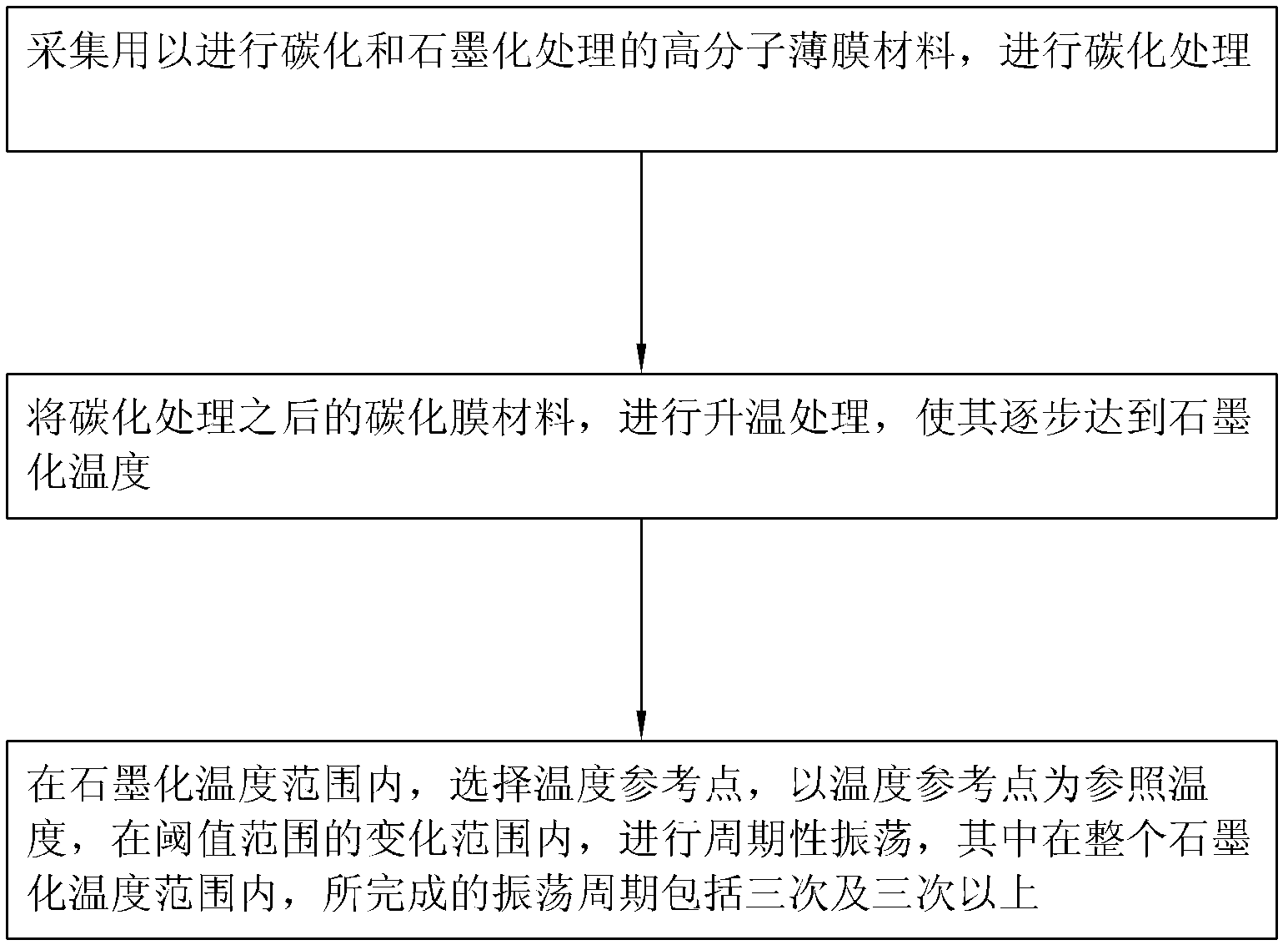

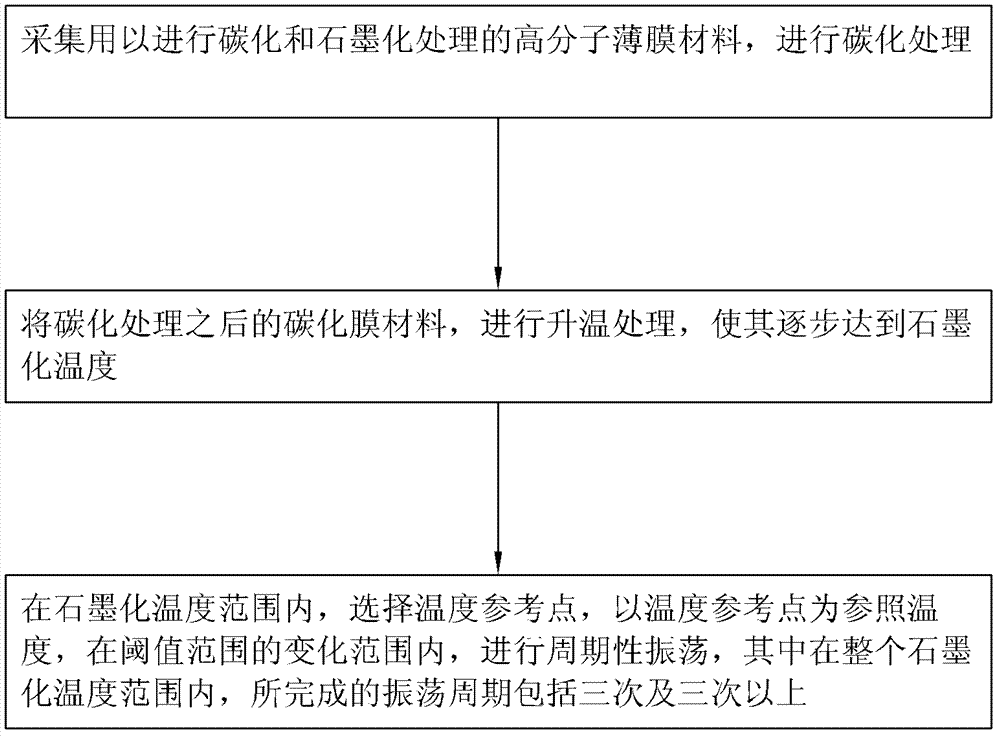

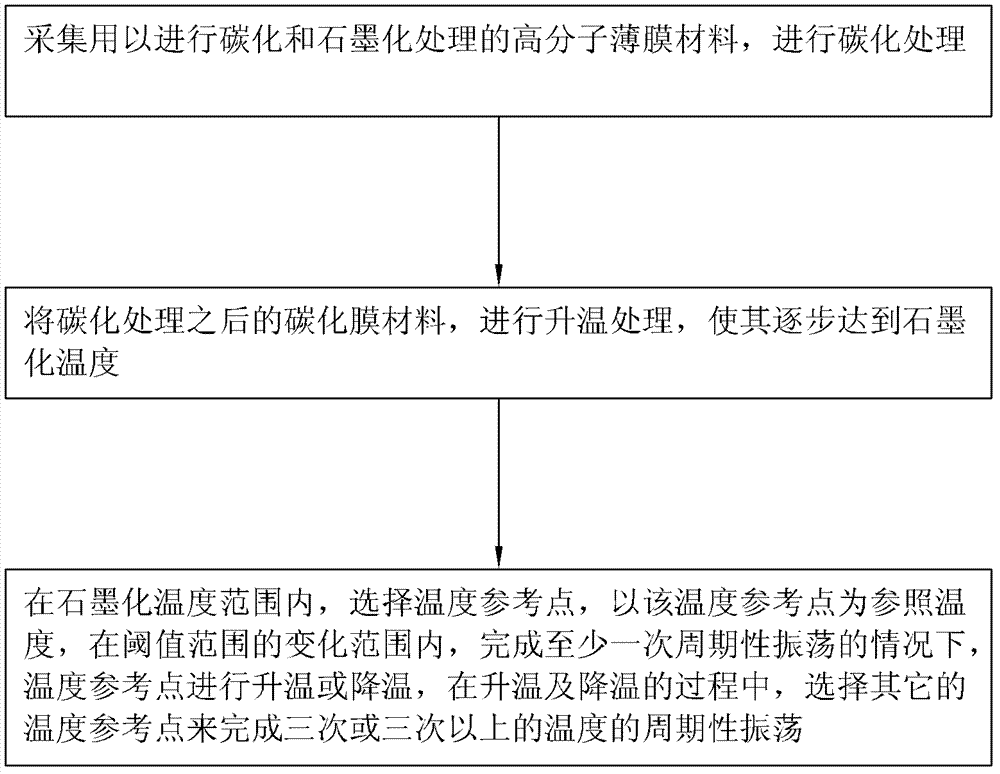

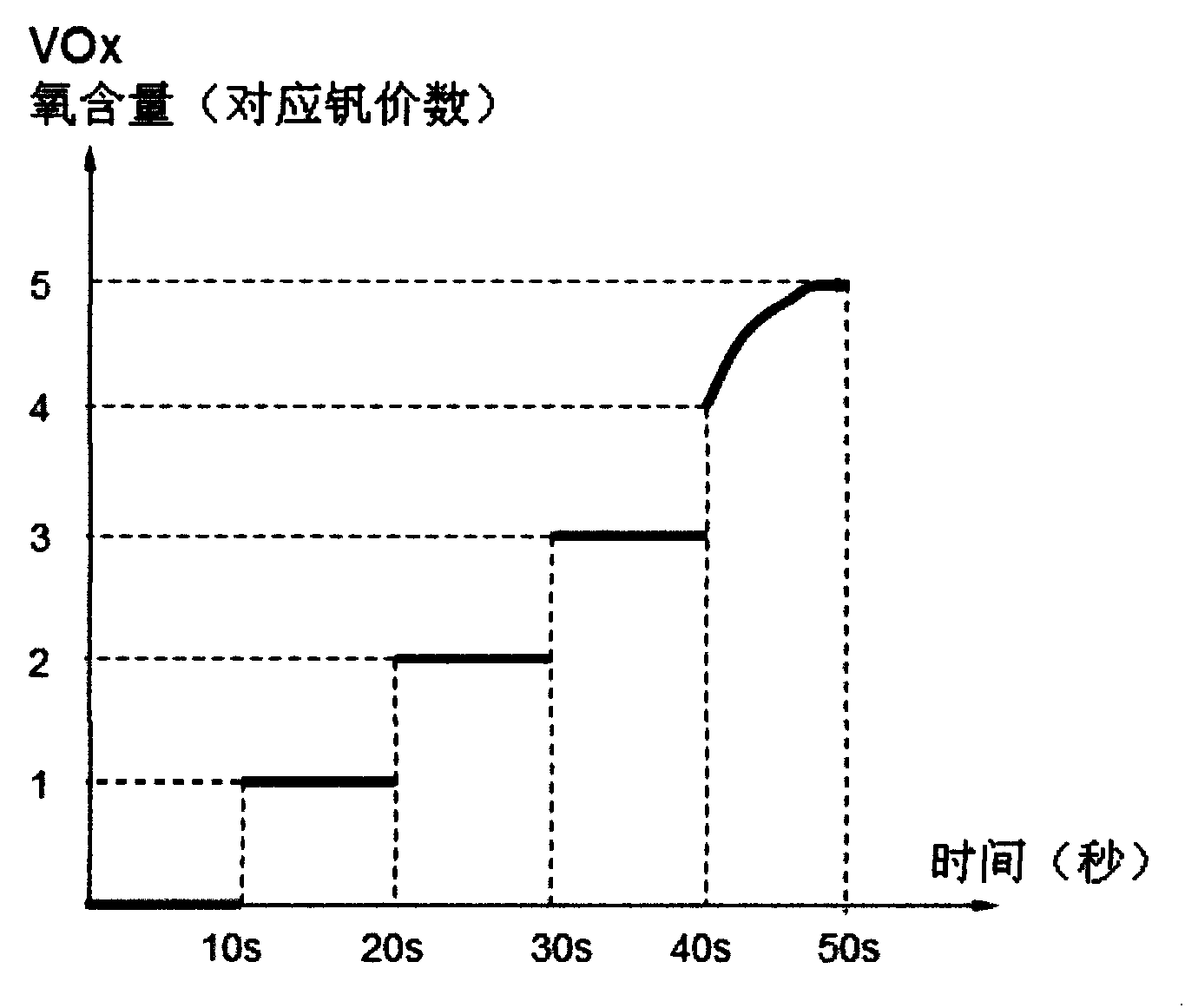

Ultrathin high-thermal-conductivity graphite film and preparation method thereof

The invention relates to the technical field of heat dissipation and in particular relates to an ultrathin high-thermal-conductivity graphite film. The thickness of the graphite film is 8-10 microns, and the thermal conductivity coefficient is 1800-1900W / m.k. The method for preparing the ultrathin high-thermal-conductivity graphite film comprises the following steps: 1, collecting a polymer film material subjected to carbonization and graphitization treatment, and performing carbonization treatment; 2, heating a carbonized carbon film, so that the graphitization temperature is gradually reached; and 3, performing periodic oscillations for two times in a graphitization temperature range under the condition of the threshold range of 50-150 DEG C. According to the ultrathin high-thermal-conductivity graphite film disclosed by the invention, the high thermal conductivity coefficient of the graphite film is guaranteed, the thickness of the graphite is reduced, and the using cost of the graphite film is reduced. According to the method for preparing the ultrathin high-thermal-conductivity graphite film provided by the invention, the conventional process is optimized, raw materials are greatly saved, the production cost is reduced, and the production time is shortened.

Owner:SHANGHAI JIEYUAN ENVIRONMENTAL SCI & TECH

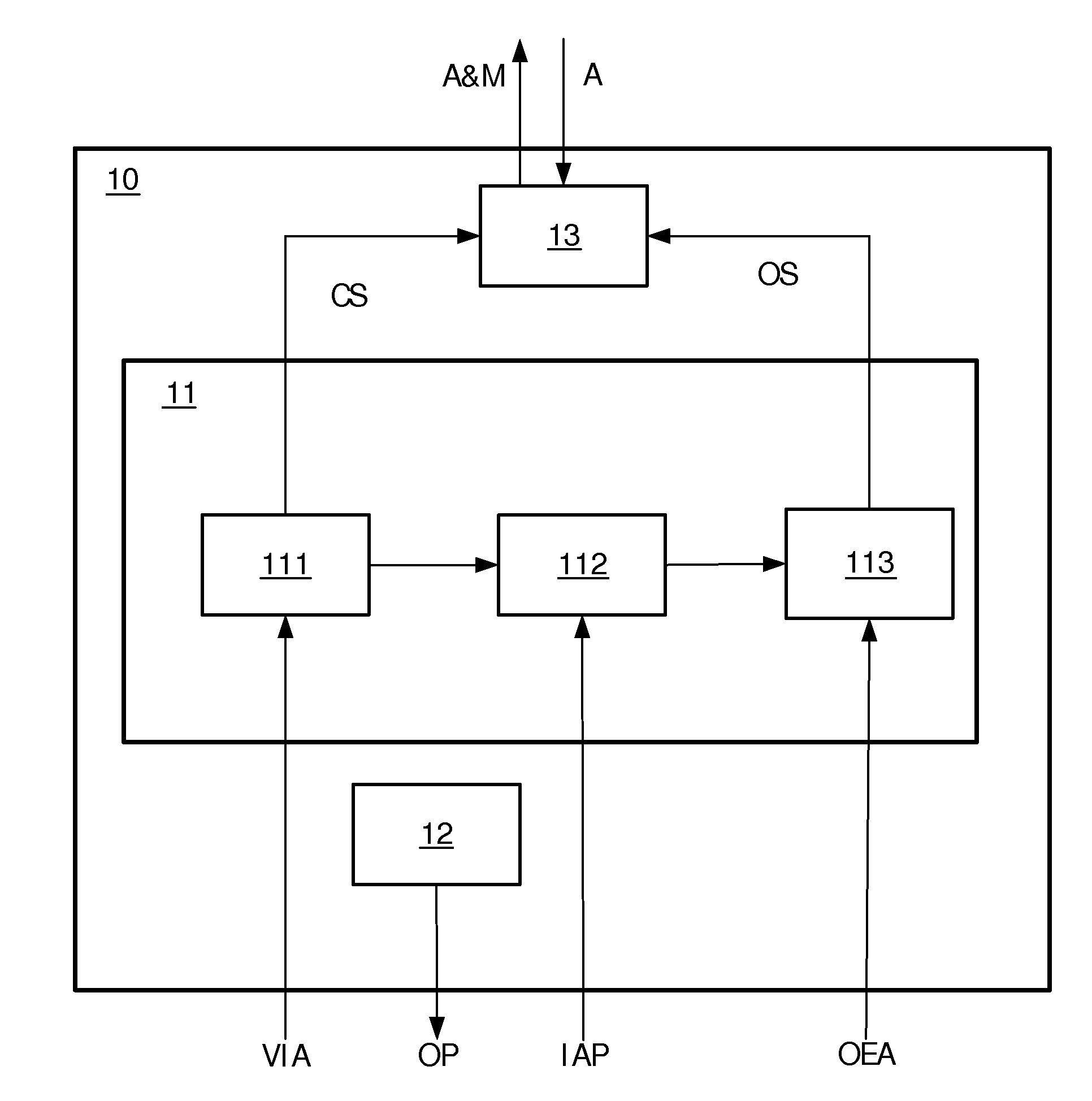

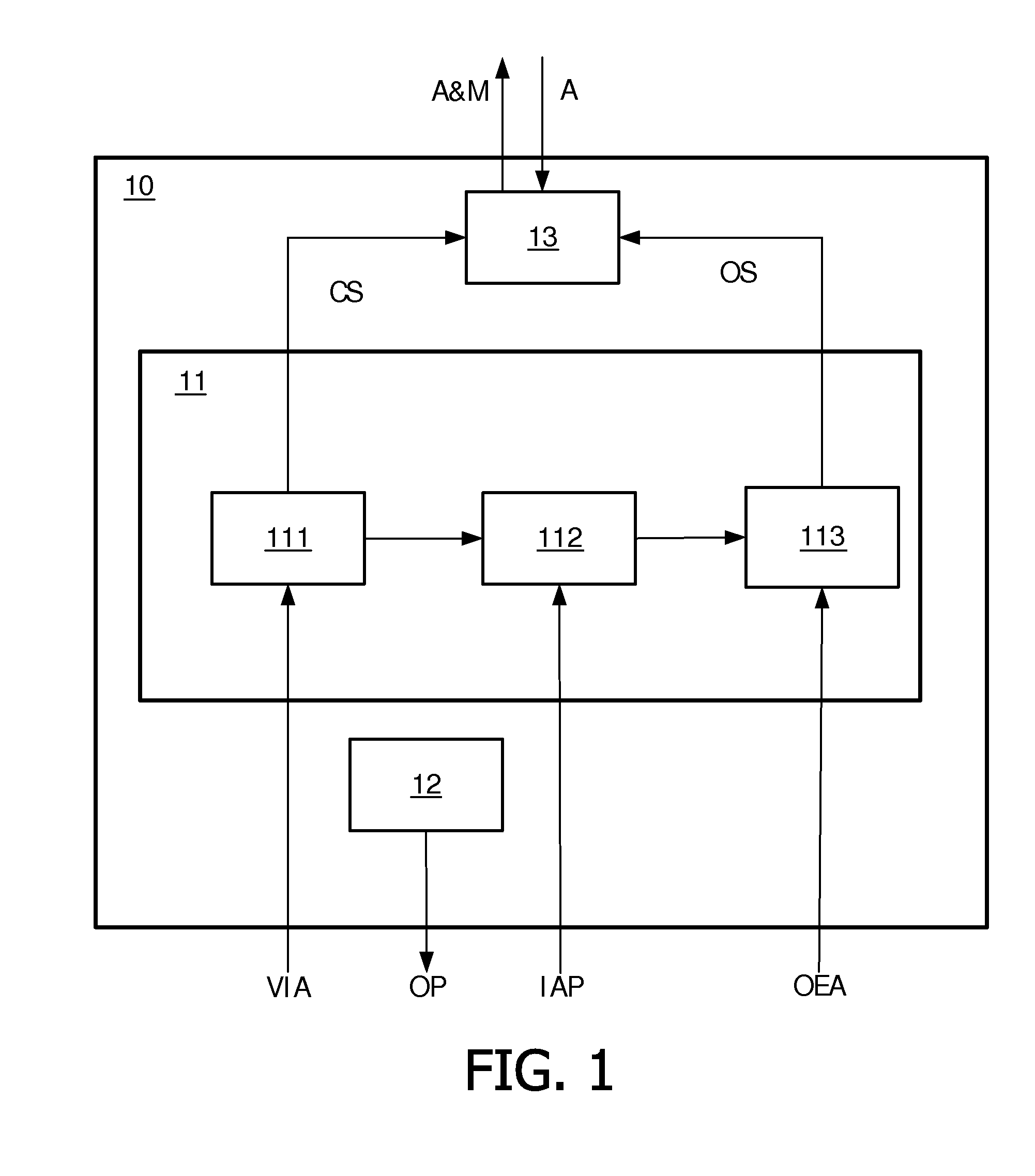

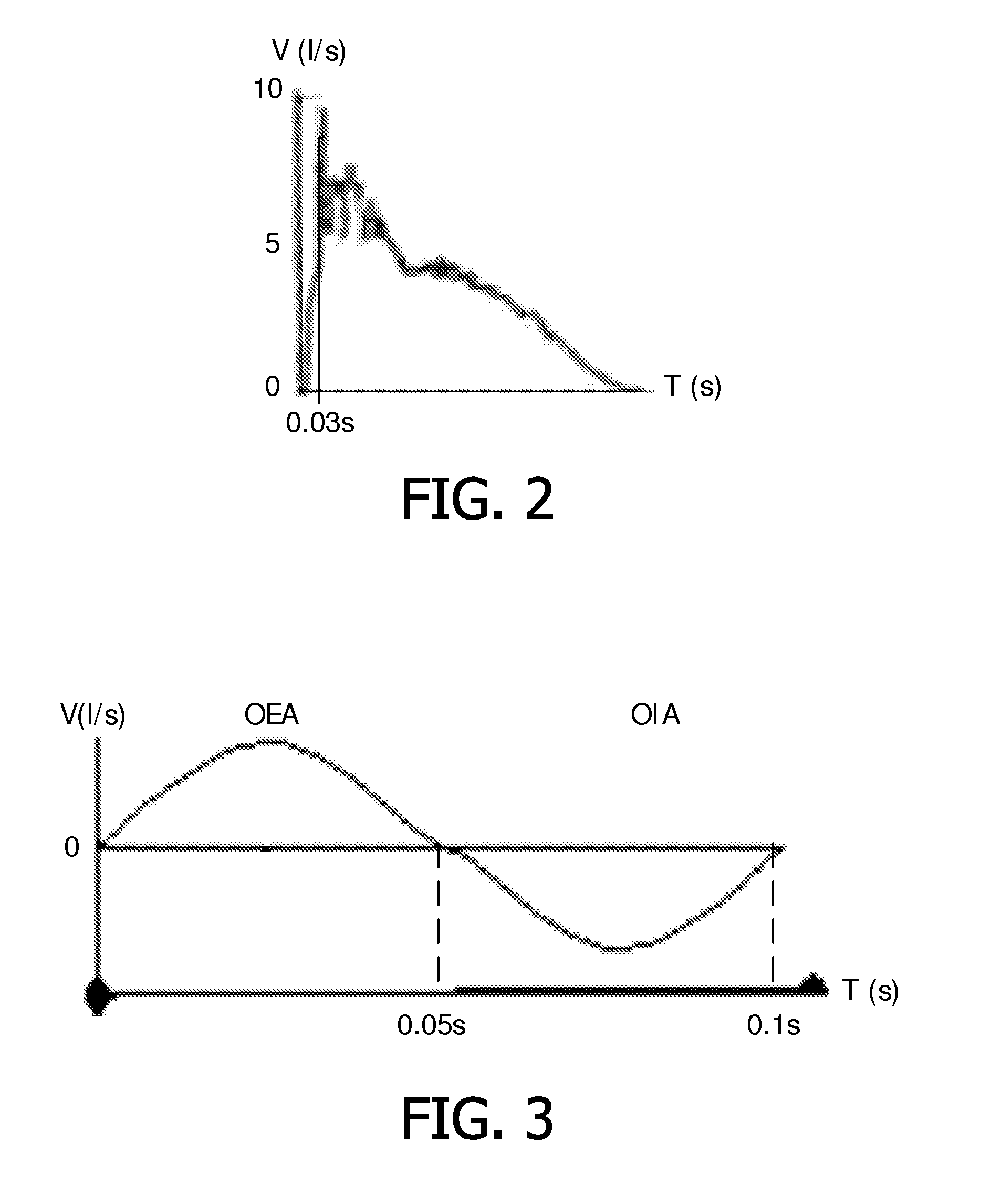

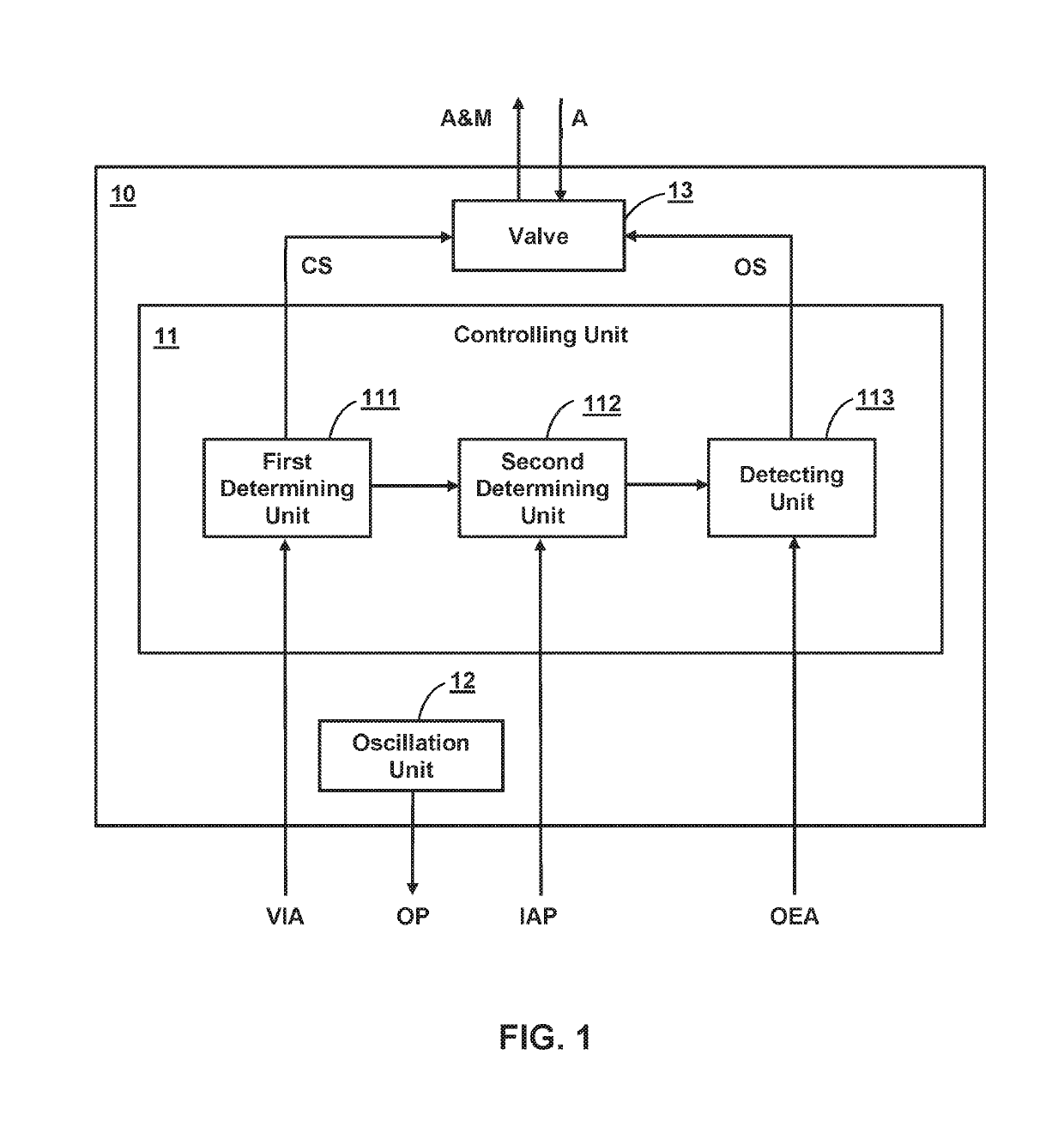

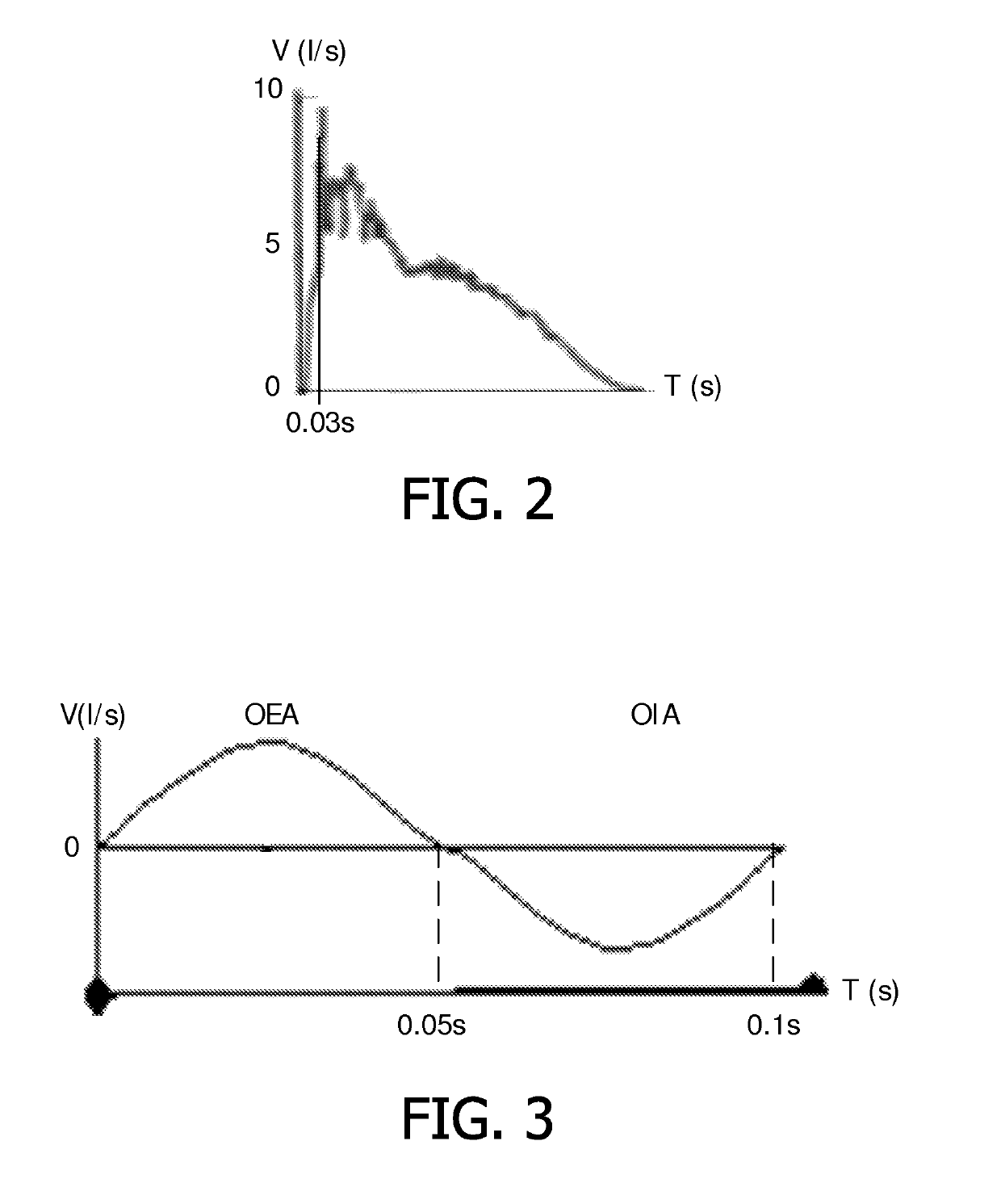

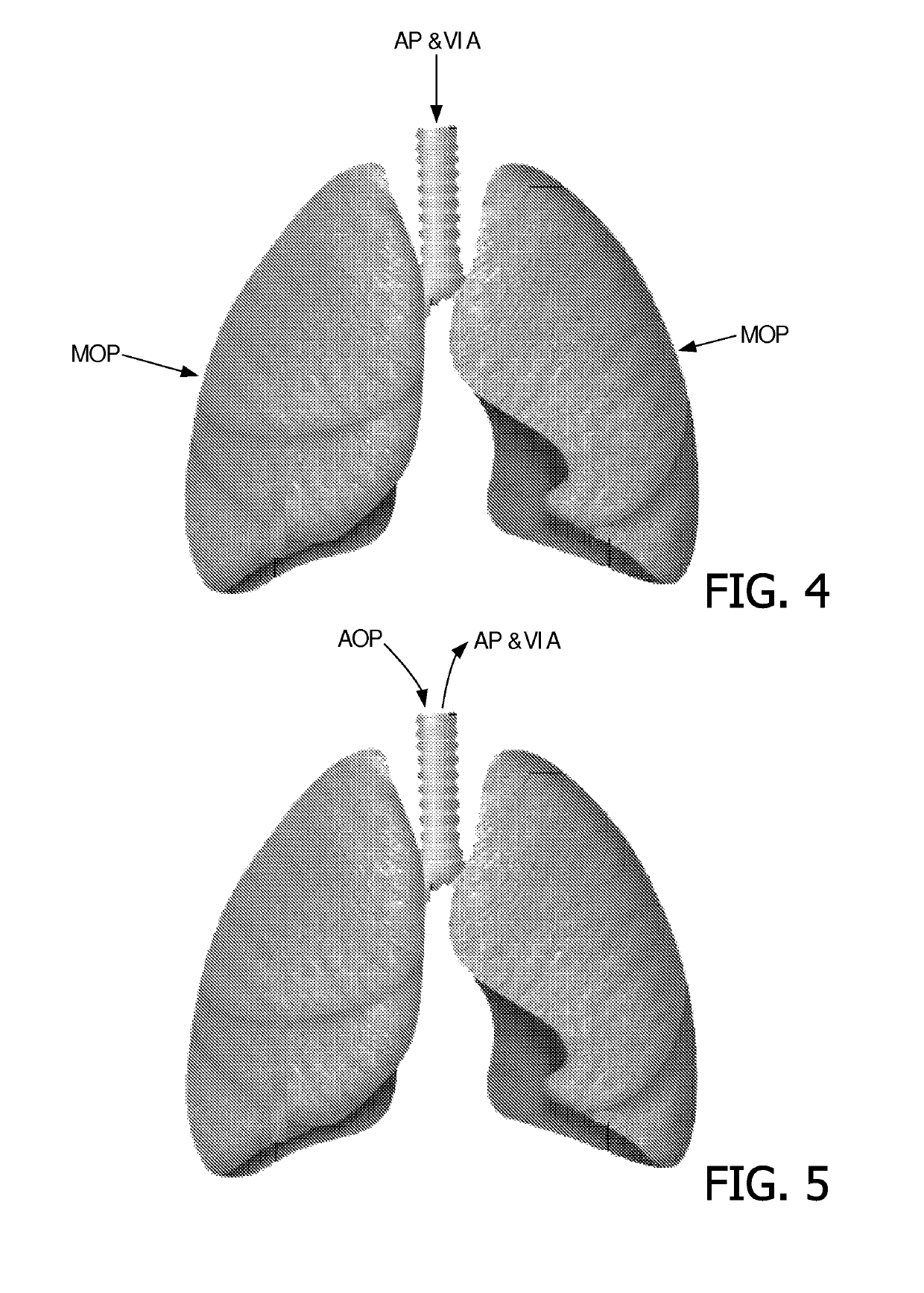

Device and method for assisting a cough

ActiveUS20120111329A1Effectively assisting coughAssist a cough more effectivelyRespiratorsOperating means/releasing devices for valvesPeriodic oscillationInhalation

The invention provides a device (11) for assisting a cough, based on an oscillation pressure. The oscillation pressure causes a periodic oscillation airflow in a lung system and the periodic oscillation airflow comprises an oscillation exhalation airflow and an oscillation inhalation airflow. The device (10) comprises a controlling unit (11), and the controlling unit (11) comprises:—a first determining unit (111) for determining whether an inhalation of the lung system is complete, so as to control a valve (13) which is to be closed for isolating the lung system from the external environment,—a second determining unit (112) for determining whether an internal air pressure in the lung system is larger than a pre-defined pressure threshold, and—a detecting unit (113) for detecting the start of the oscillation exhalation airflow, so as to control the valve (13) which is to be opened for starting a cough.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

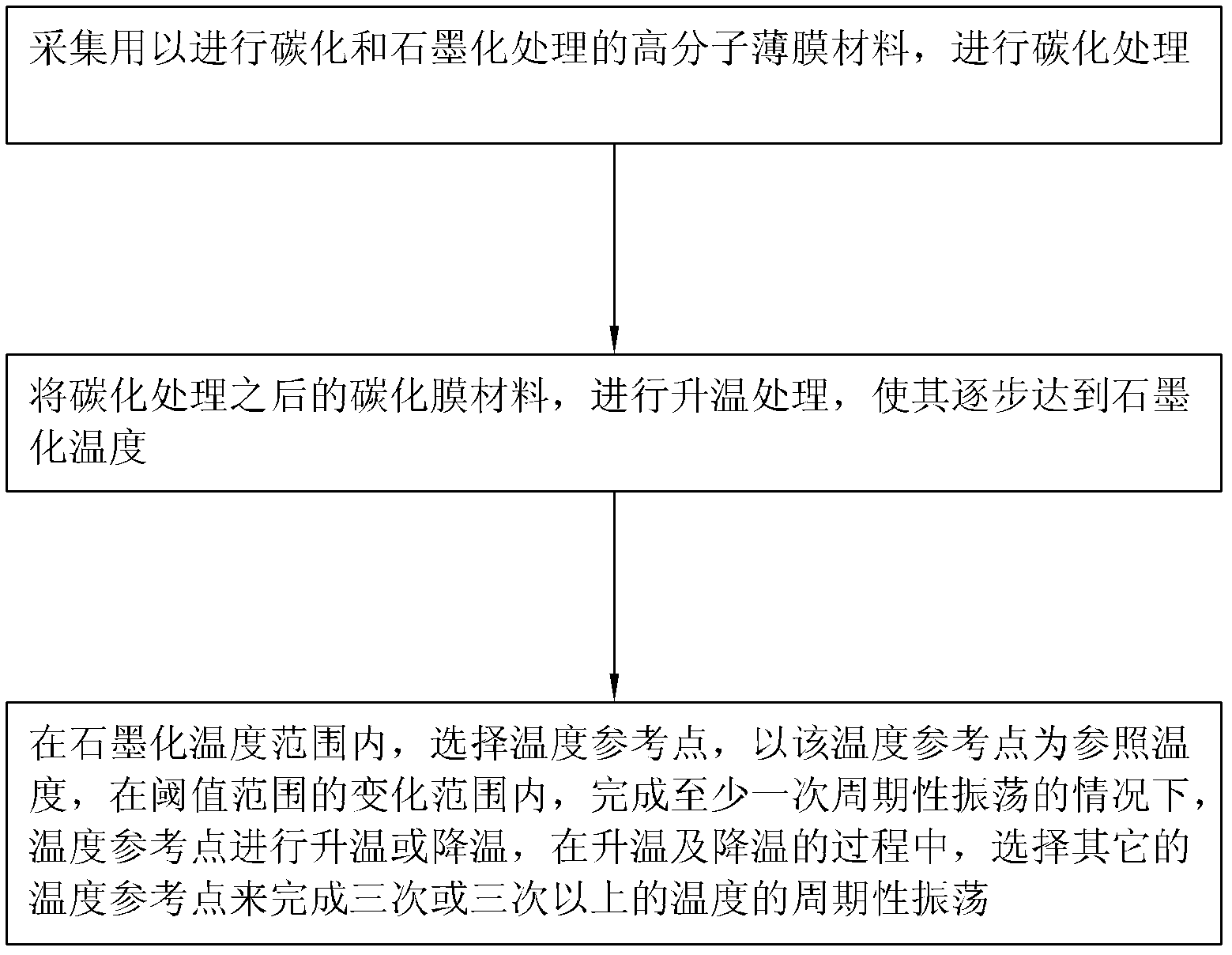

Preparation method and system of high-conductivity graphite film

The invention provides a preparation method and system of a high-conductivity graphite film and belongs to the technical field of radiation. The method comprises the following steps of: 1, collecting a polymer thin film material for carbonization and graphitization, and carbonizing; 2, carrying out hyperthermic treatment on the carbonized carbide film material so as to gradually achieve the graphitization temperature; and 3, selecting a temperature reference point within the graphitization temperature range so that the temperature reference point is taken as a reference temperature, and carrying out periodic oscillation within the change range of a threshold range, wherein three or more oscillation periods are finished within the entire graphitization temperature range. By the preparation method, the preparation technology of the graphite film material is improved in a temperature oscillation manner, and the quality of the graphite film material is also improved.

Owner:SHANGHAI JIEYUAN ENVIRONMENTAL SCI & TECH

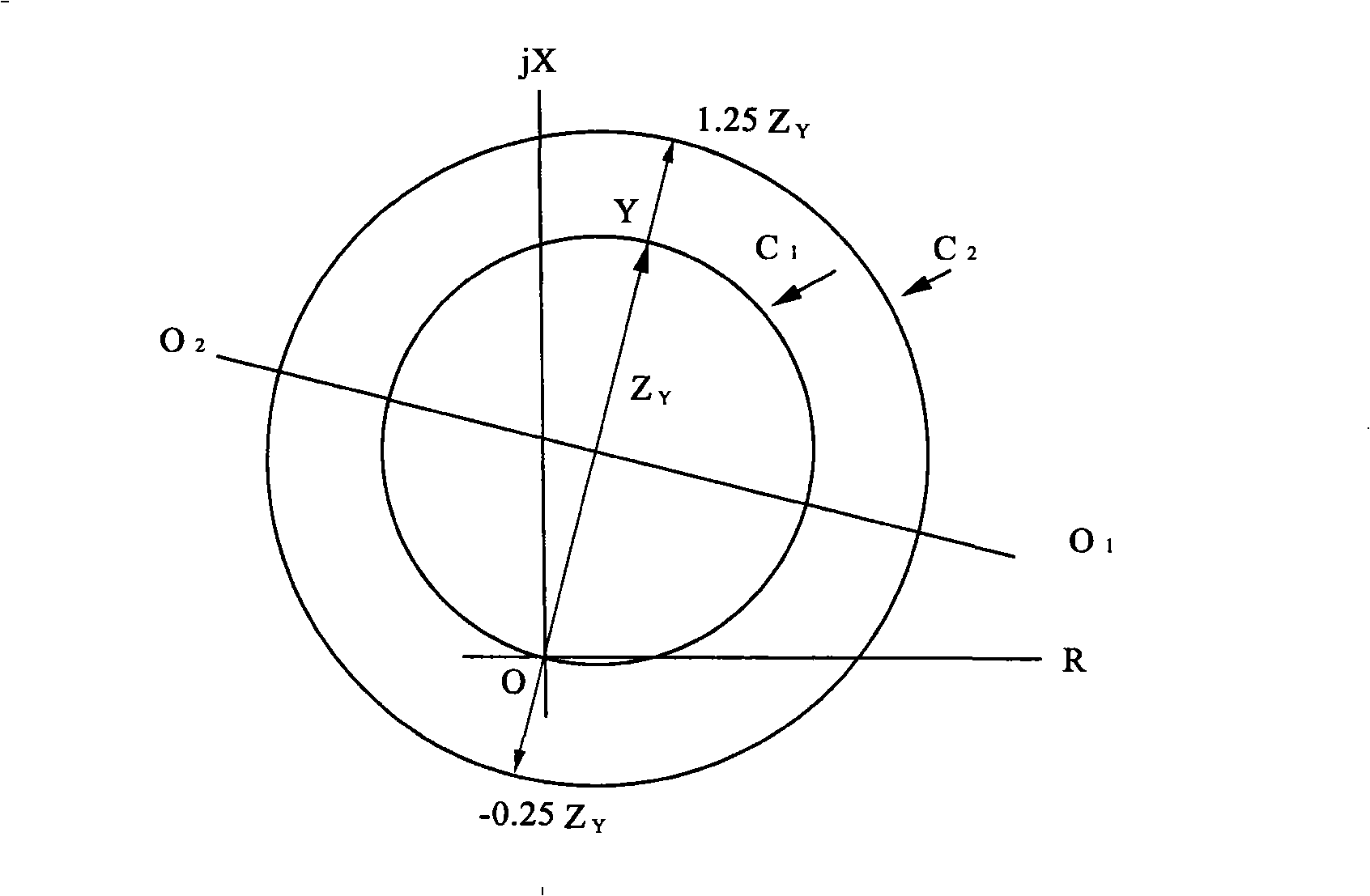

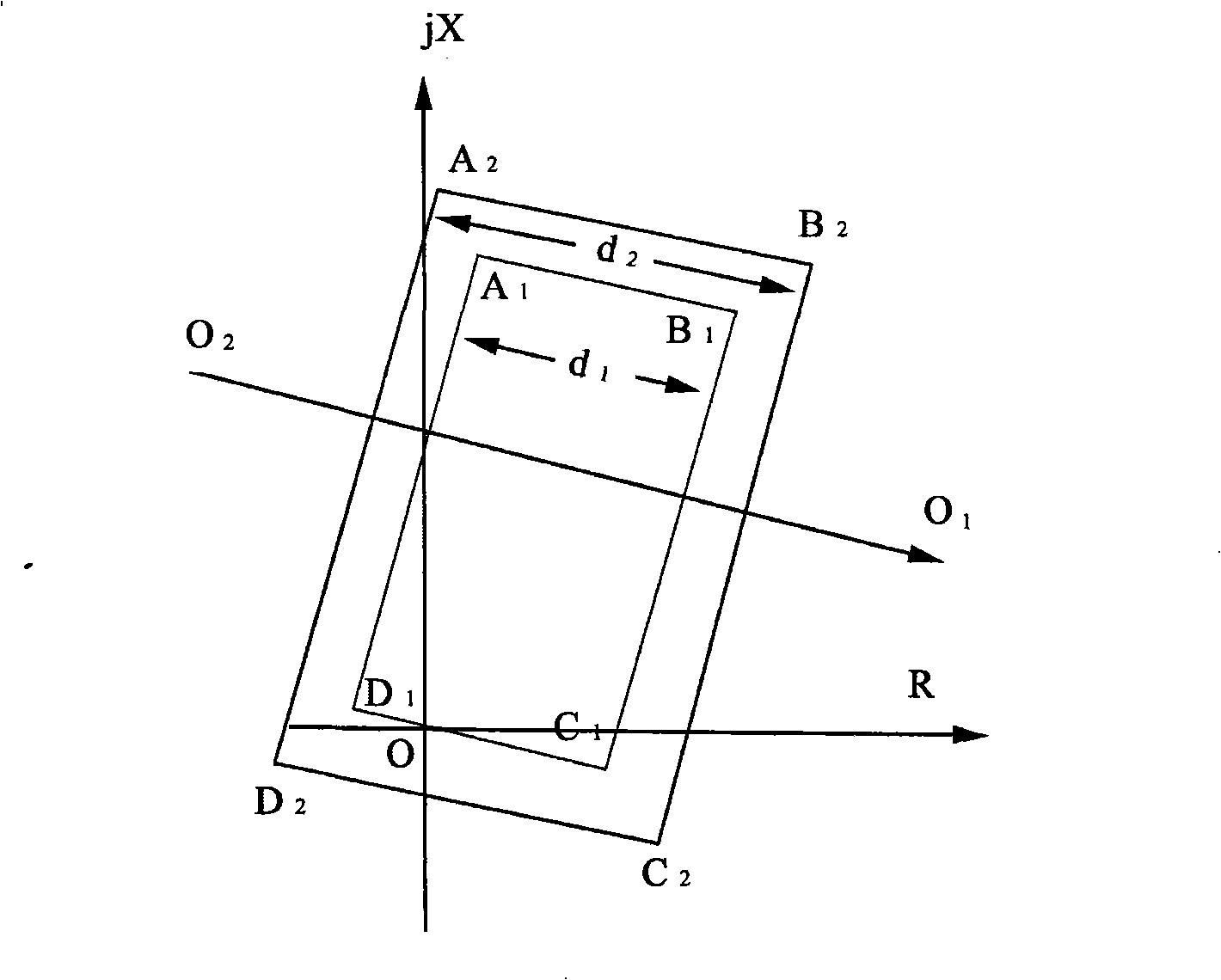

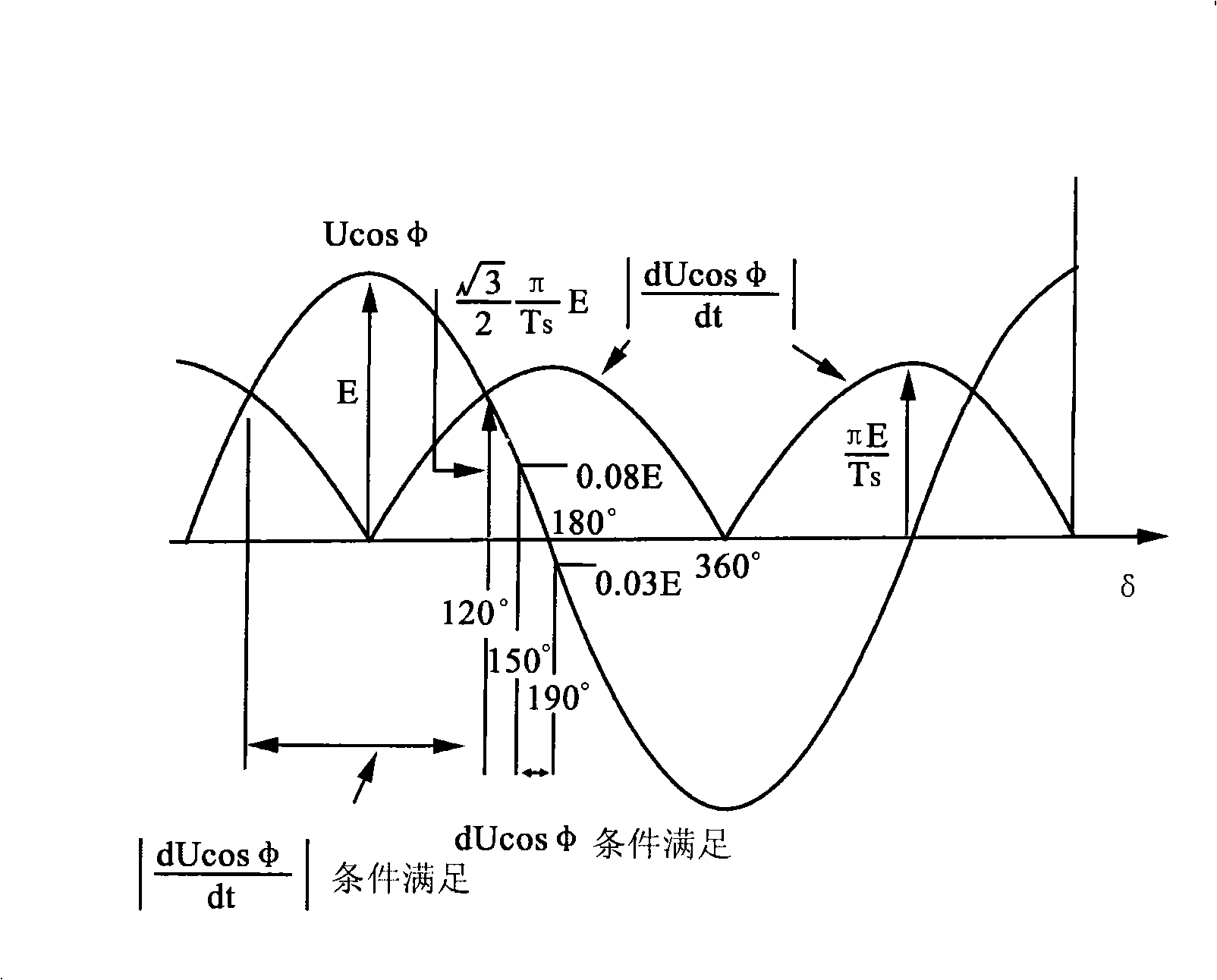

New method for distance protection surge lock of high voltage output line

ActiveCN101267109ANo malfunctionAvoid blackoutsEmergency protective circuit arrangementsFault locationPeriodic oscillationHigh pressure

The present invention provides a blocking method of distance protection swing of a high voltage transmission line, the swing blocking technique in the high voltage transmission line distance protection has always been one of the focus discusses. The technical scheme of the invention has two swing blocking methods having different principles, automatically selecting one swing blocking method according the length of the protection line. When the protection judgement is a short line, periodic oscillation change rate and the position of the apparent impedance are real-time detected by a stackable counter, the dwell is relatively adjusted and the relieved, the method is not only applied to the great round covering the small round type operation characteristics, but also applied to the great quadrilateral covering the small quadrilateral type operation characteristics; when the protection judgement is a long transmission line, the swing blocking pattern fpr detecting Ucos fai and its change rate is utilized. Two patterns is automatically switched by the command set in a microcomputer software program, according to the size of the setting impedance.

Owner:北京衡天北斗科技有限公司

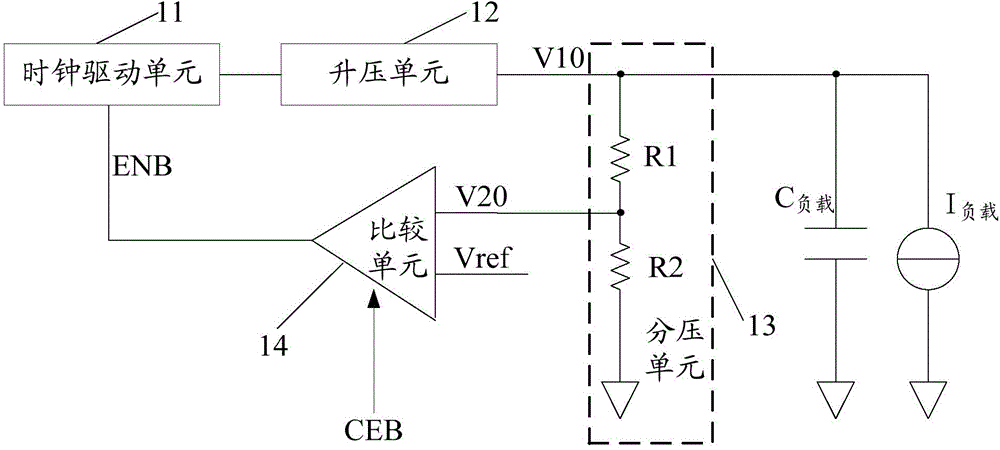

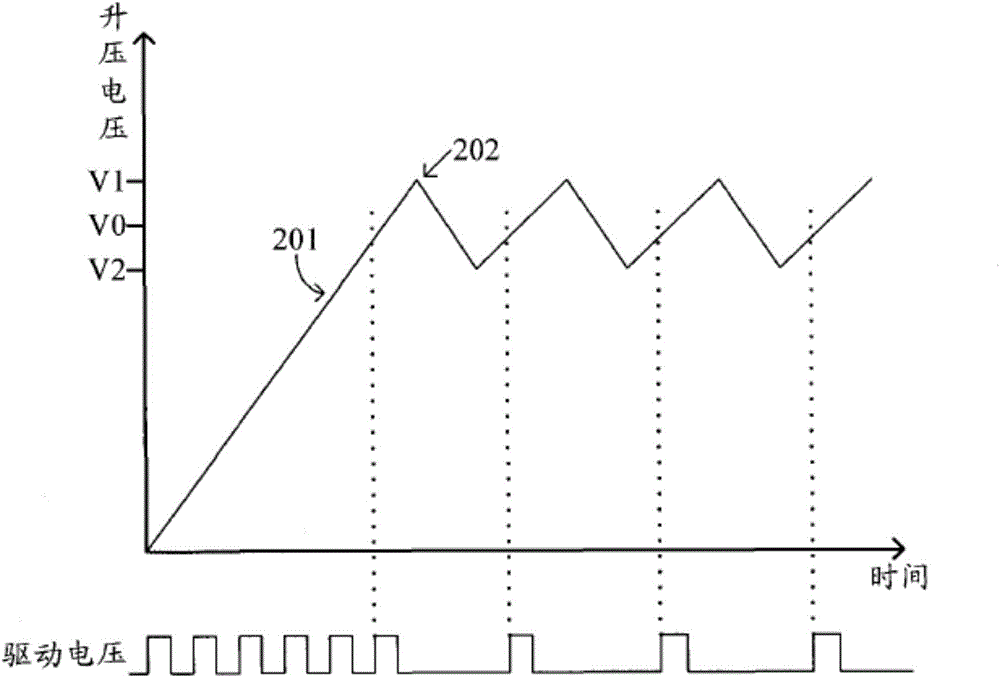

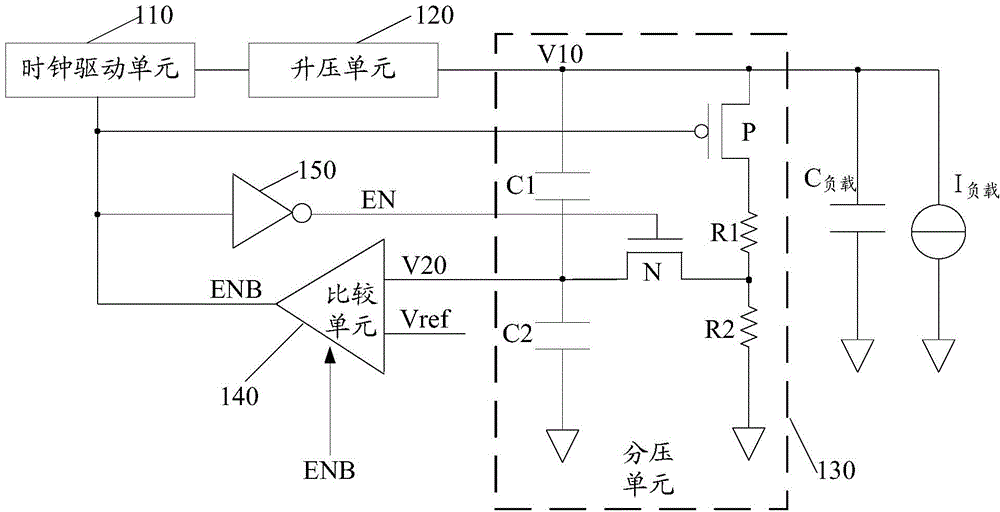

Charge pump circuit and storage device

InactiveCN104467405AReduce power consumptionApparatus without intermediate ac conversionStopped workElectricity

The invention discloses a charge pump circuit and a storage device. The charge pump circuit comprises a time clock driving unit, a boosting unit, a voltage dividing unit and a comparison unit. When receiving a first control level, the time clock driving unit stops working; otherwise, driving voltage is output; the boosting unit is used for boosting the driving voltage and then outputting boosted voltage; when the boosted voltage changes from the maximum voltage value to the minimum voltage value, a capacitance voltage dividing sub-unit divides the boosted voltage and outputs divided voltage; otherwise, a non-capacitance voltage dividing sub-unit divides the boosted voltage and outputs divided voltage; delay exits on the path from the comparison unit to the input end of the boosting unit, after the boosted voltage reaches target voltage from initial voltage, the boosted voltage and the divided voltage change in a periodic oscillation mode, and when the divided voltage changes from the maximum value to the minimum value, the comparison unit outputs the first control level; otherwise, a second control level is output. The power of the charge pump circuit can be effectively reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Plasma source for generating nonlinear, wide-band, periodic, directed, elastic oscillations and a system and method for stimulating wells, deposits and boreholes using the plasma source

ActiveUS9181788B2Extended service lifeSmall sizeFluid removalVibration devicesElectrical conductorPeriodic oscillation

Owner:NOVAS ENERGY GRP

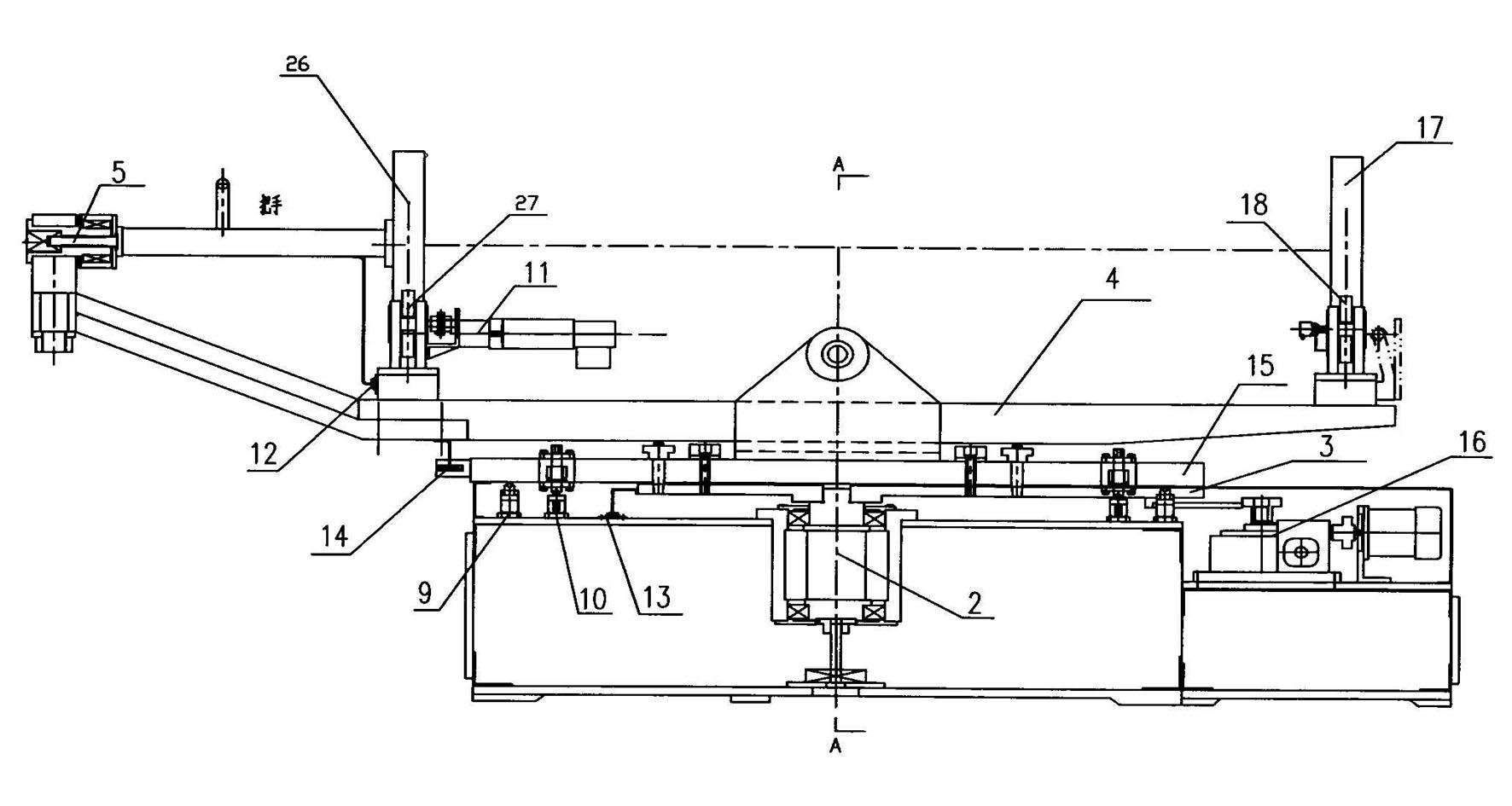

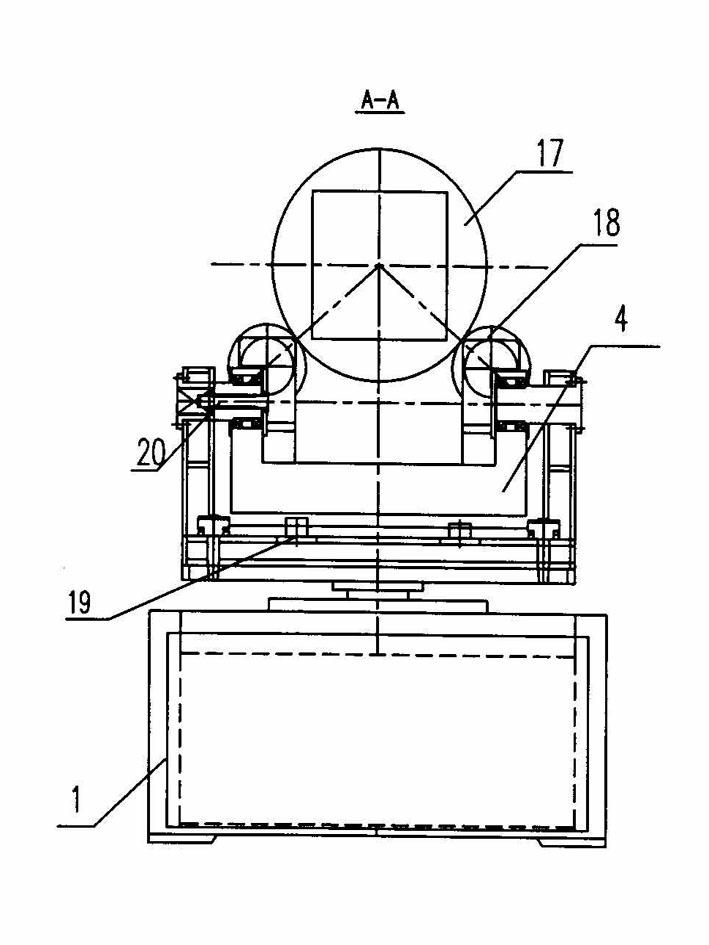

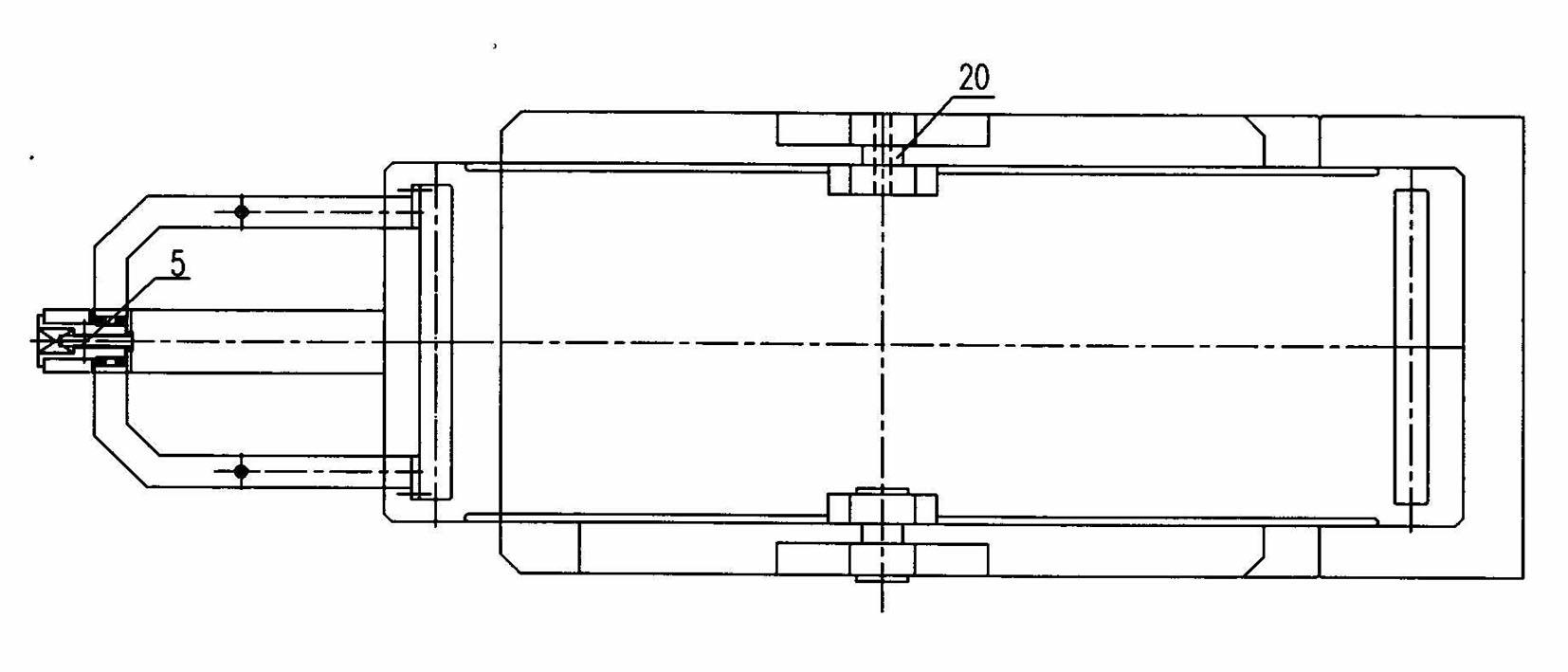

Three-dimensional measuring mechanism for realizing quality characteristic of flying object with wings

ActiveCN102213633ATo achieve the purpose of measuring contentStatic/dynamic balance measurementPeriodic oscillationThree dimensional measurement

The invention relates to a three-dimensional measuring mechanism for realizing the quality characteristic of a flying object with wings, which comprises a machine base which is provided with a Y-axis rotating shaft on the central part of the machine base, a torsion bar mechanism which is arranged at the lower end of the Y-axis rotating shaft and is used for oscillating the Y-axis rotating shaft periodically, a support supporting plate arranged at the upper end of the Y-axis rotating shaft, a horizontal beam arranged above the support supporting plate and an inertia support which is arranged on the horizontal beam by supports arranged on both sides of the middle part of the horizontal beam symmetrically and a Z-axis central torsion bar mechanism which performs periodic oscillation, wherein a plurality of groups of weighing sensors and lifting mechanisms are arranged between the bottom surface of the horizontal beam and the top surface of the machine base; left and right support rollers which are driven to rotate by a rotary driving device and left and right support roller paths which perform the periodic oscillation in the auxiliary X axial direction and are arranged on the left and right support rollers are arranged on the inertia support; and the left end of the inertia support is provided with an X-axis central torsion bar mechanism which performs the periodic oscillation by a connecting piece.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

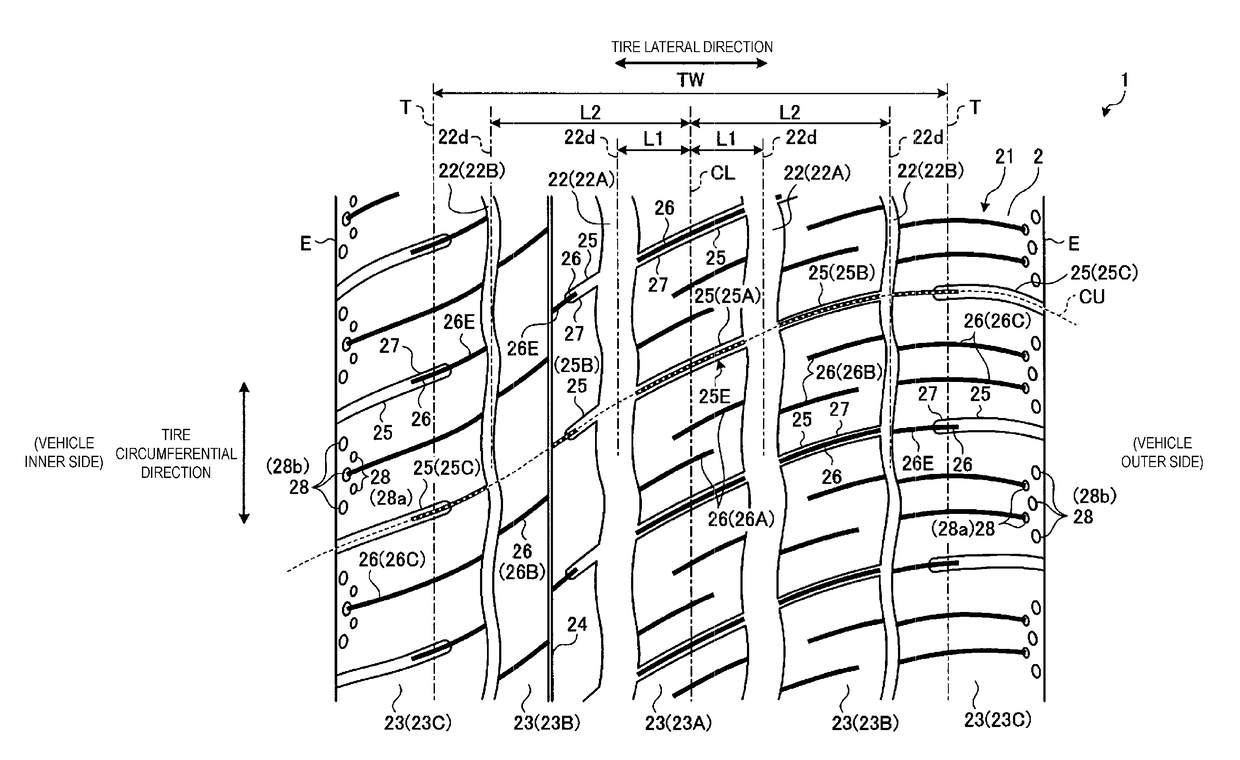

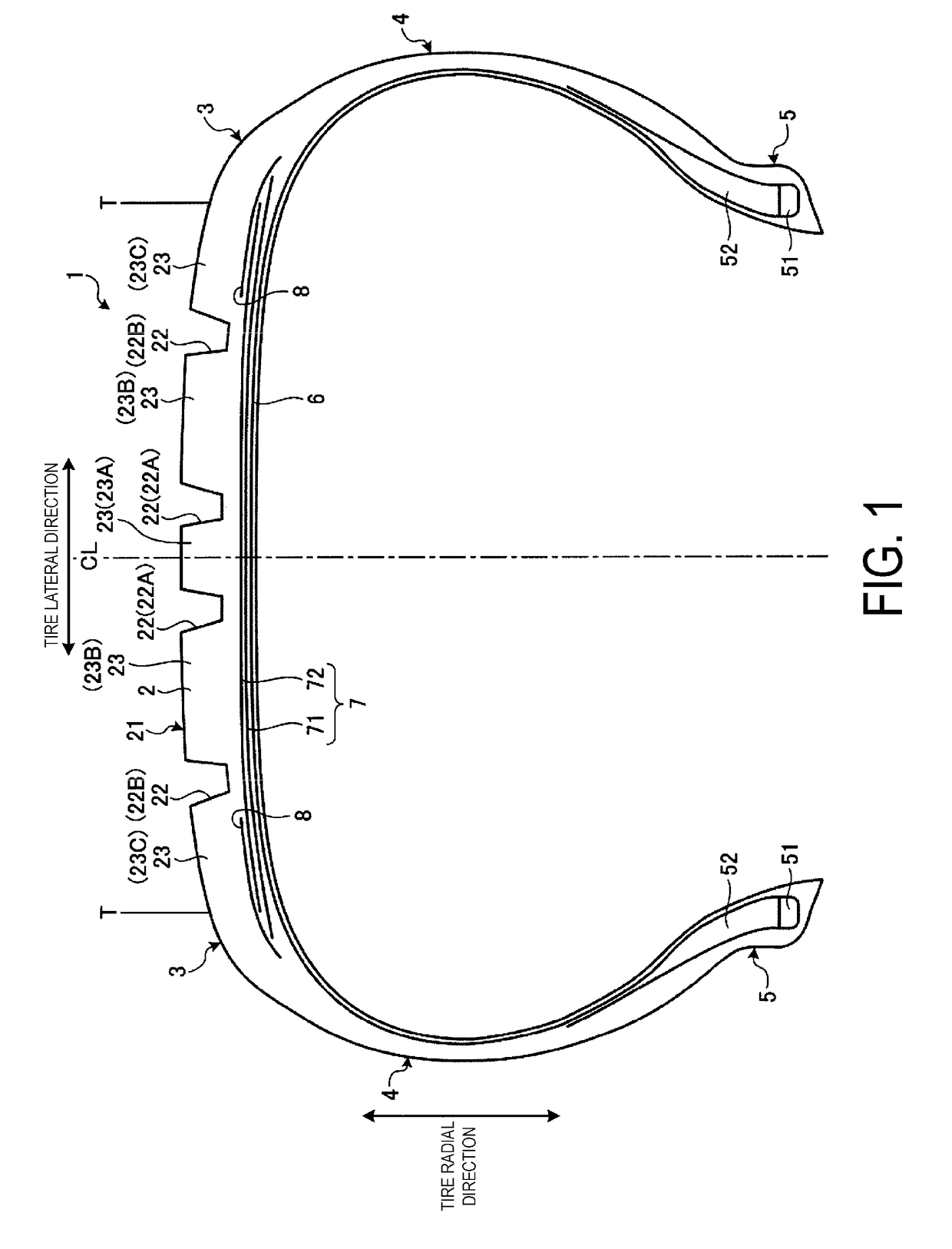

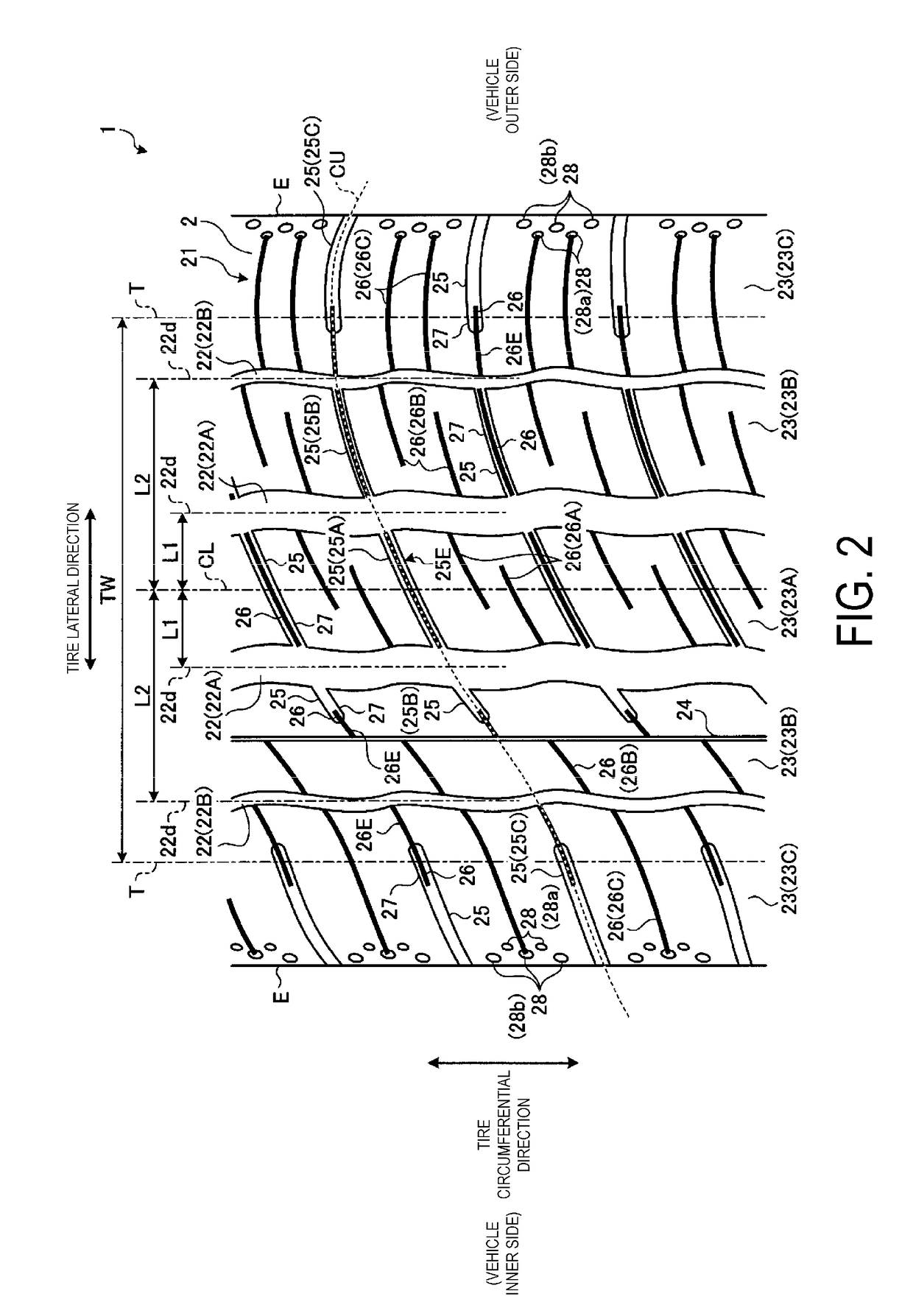

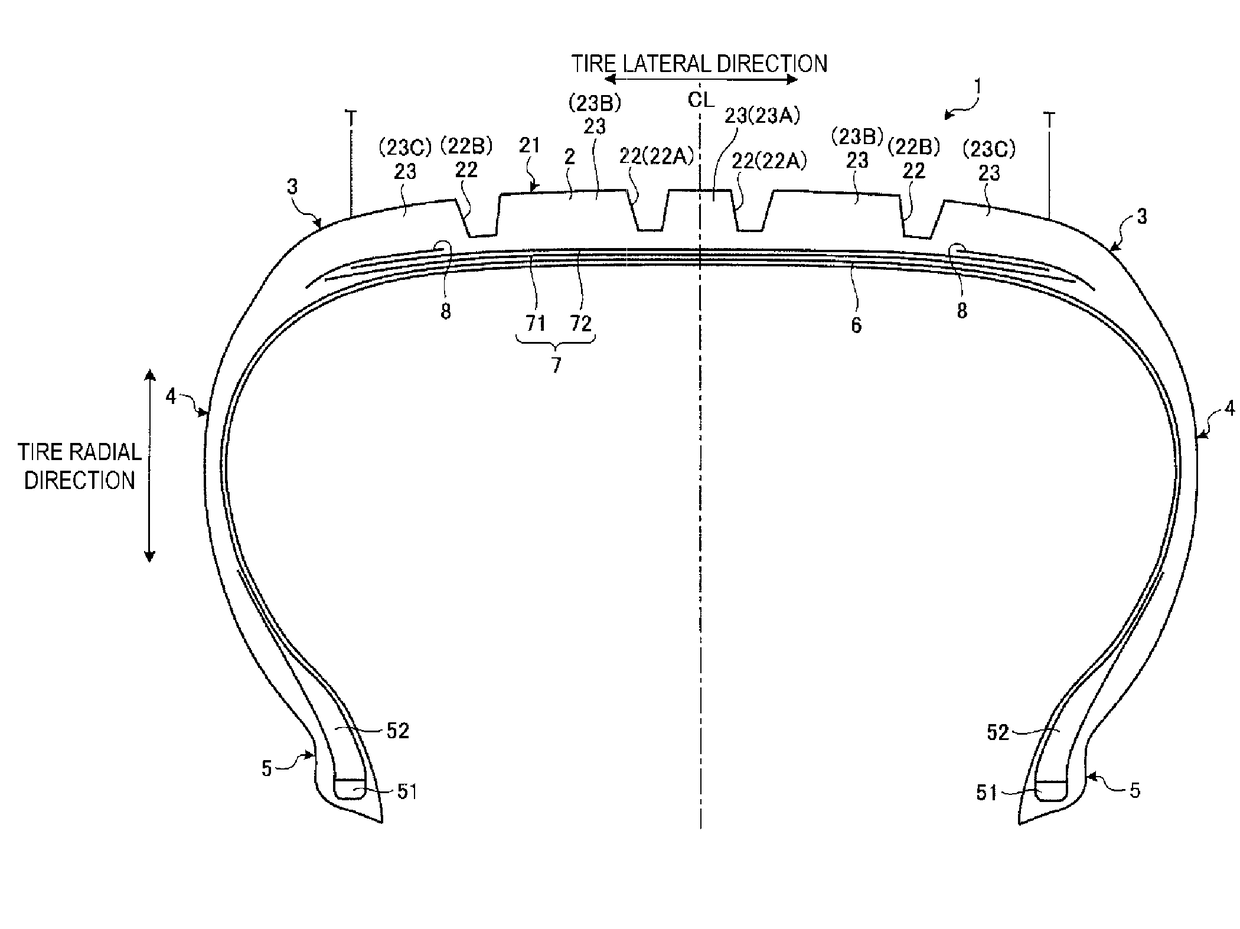

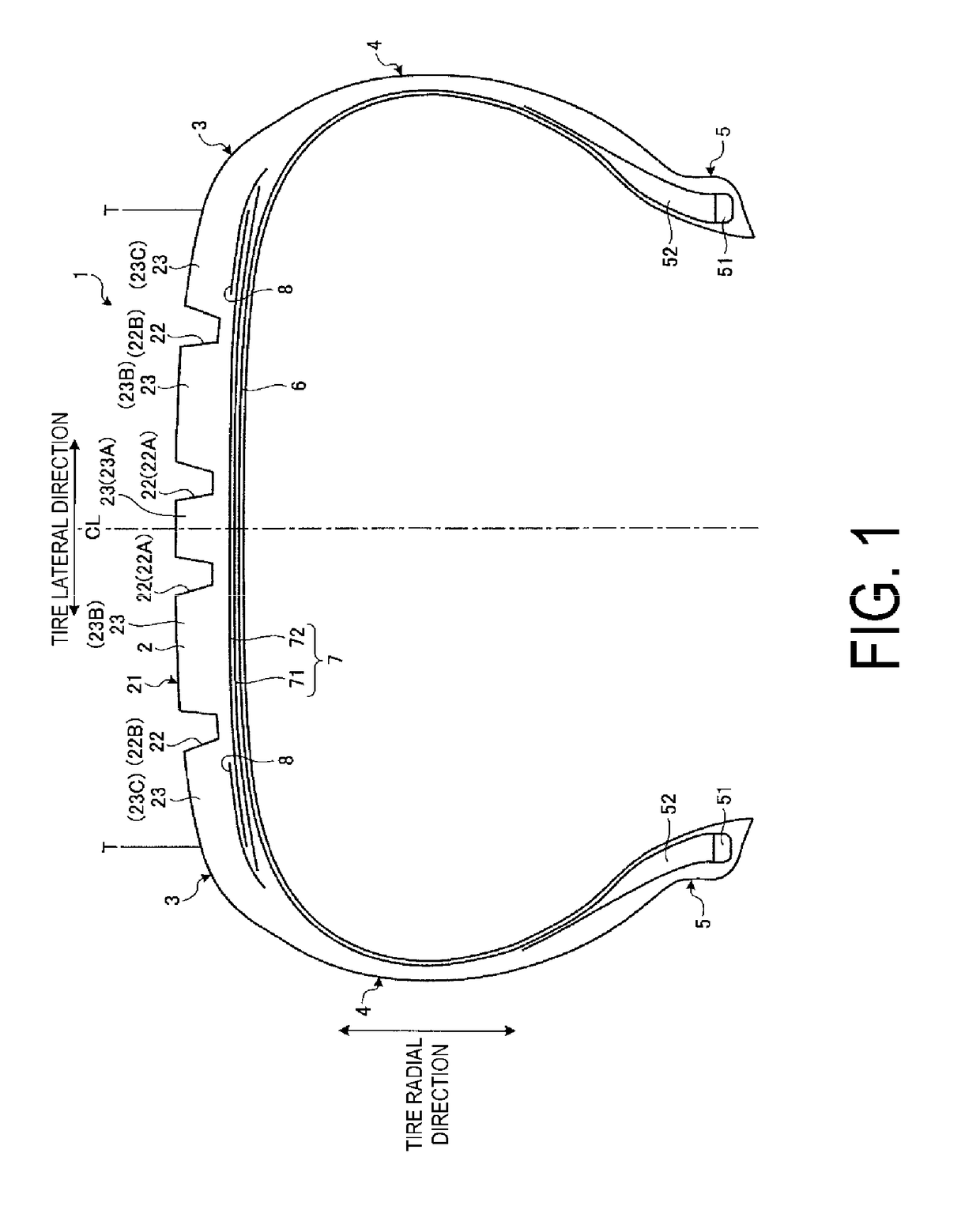

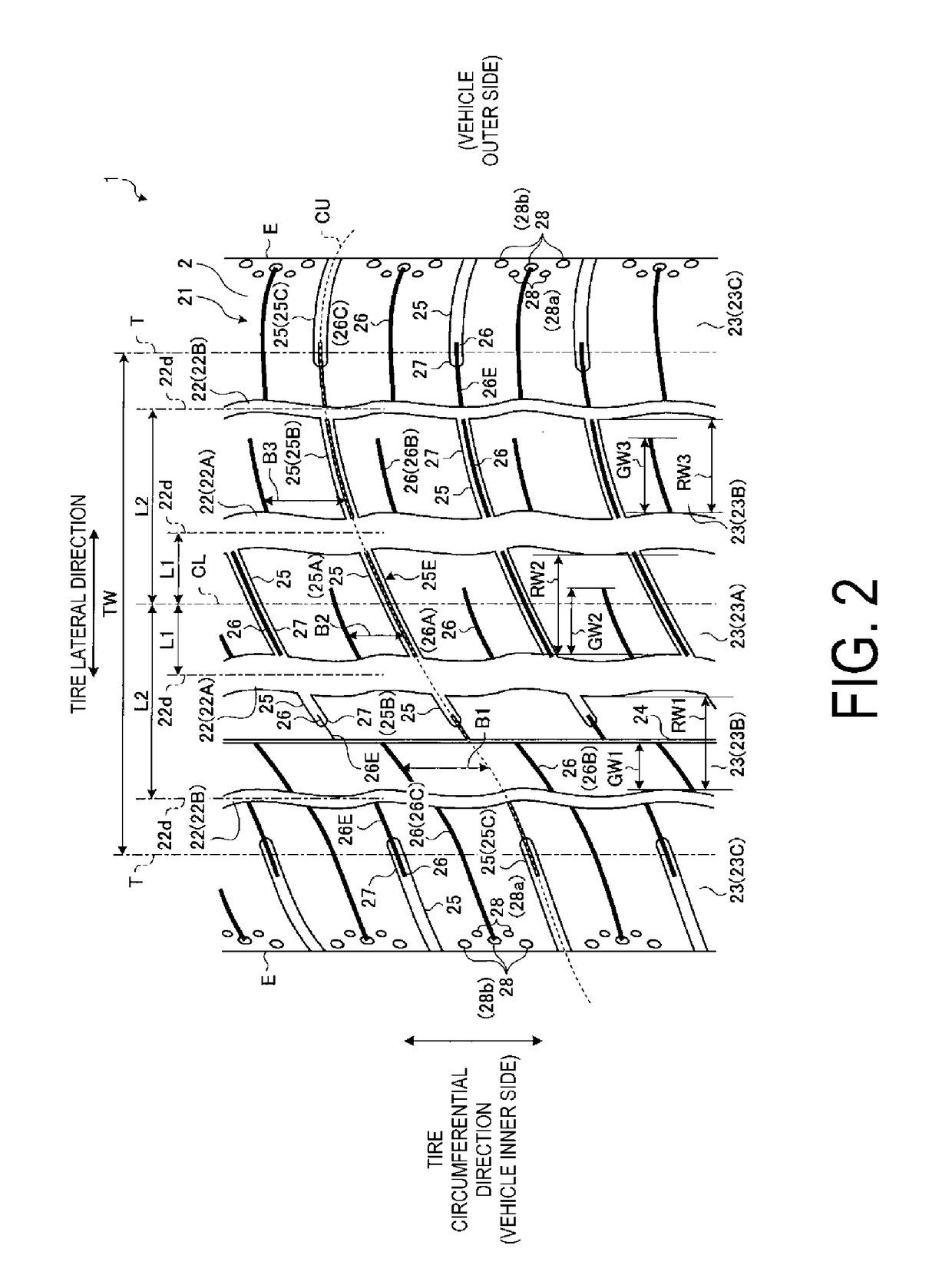

Pneumatic Tire

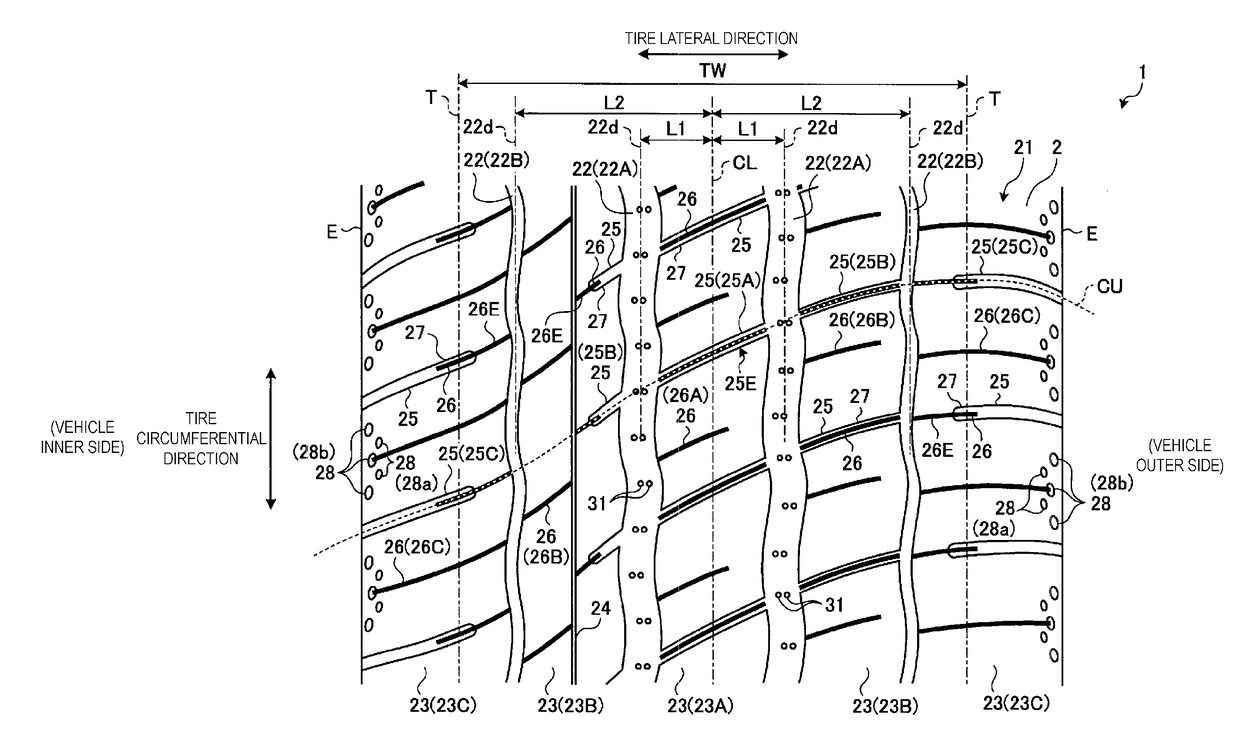

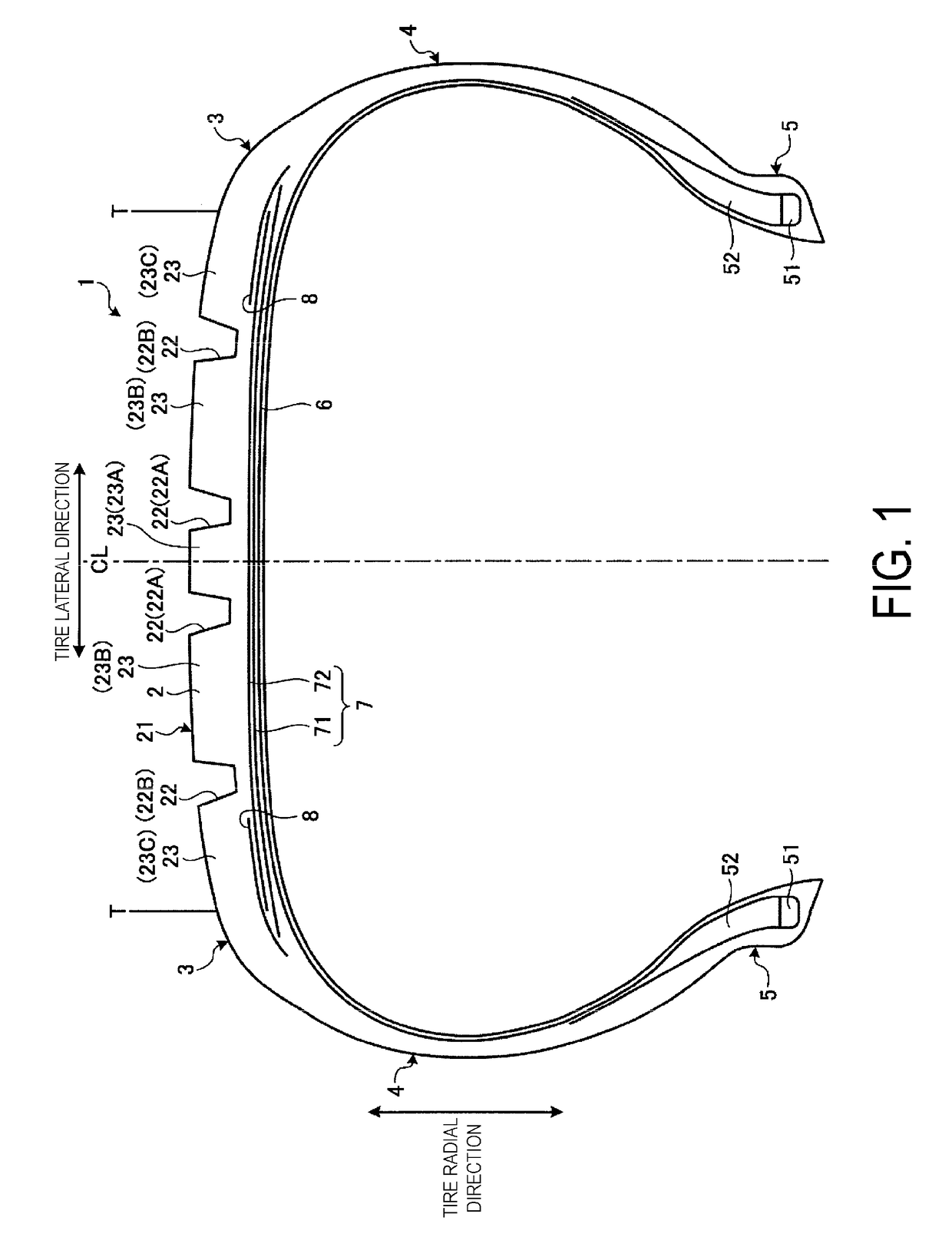

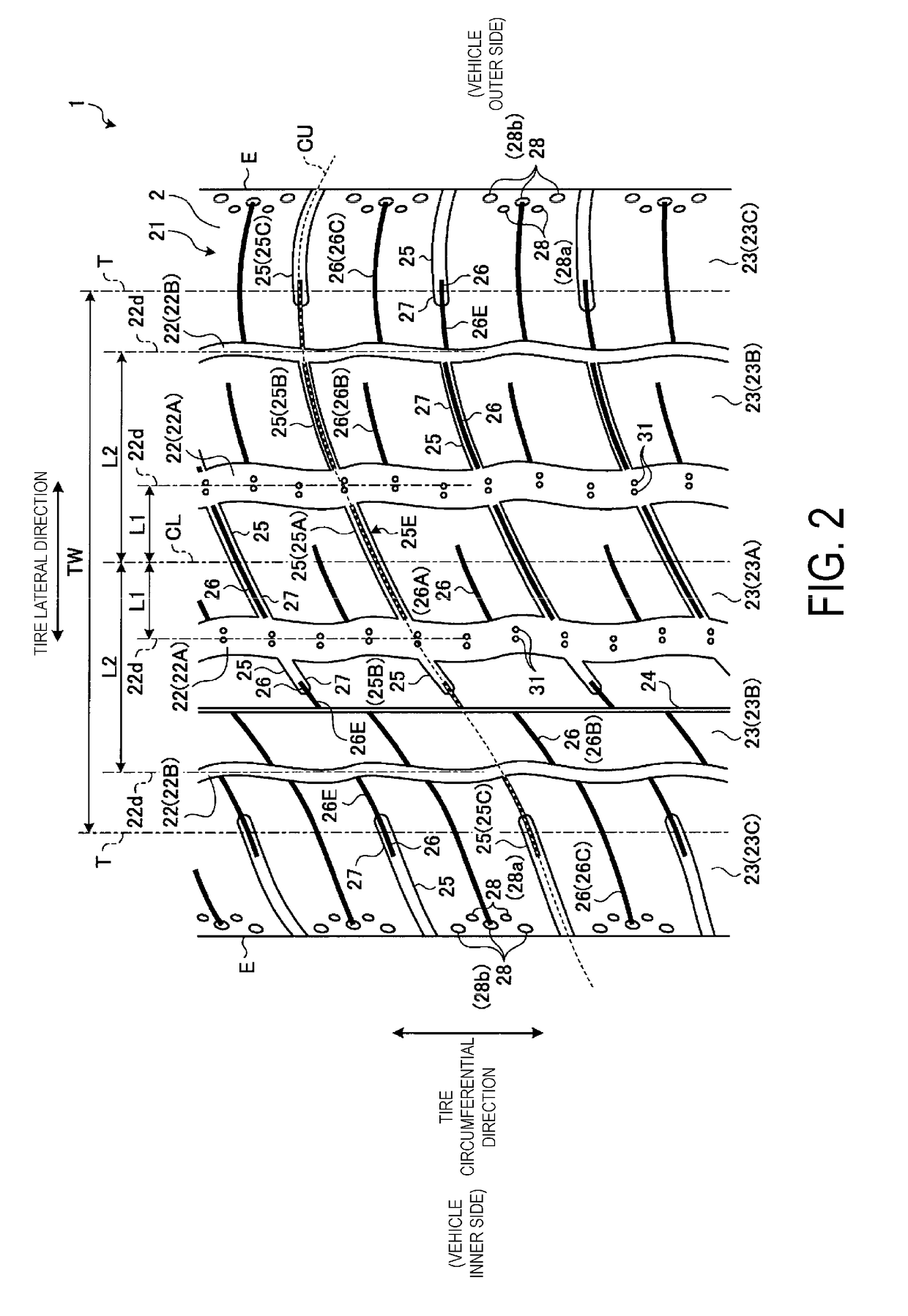

ActiveUS20180215206A1Reduce rigidityImprove wear resistanceTyre tread bands/patternsGroove widthPeriodic oscillation

A pneumatic tire comprises a tread surface comprising main grooves extending in a tire circumferential direction, at least two of the main grooves adjacent in the tire circumferential direction having a wave shape with periodic oscillation; adjacent land portions in a tire lateral direction formed by the main grooves; lug grooves disposed in a row in the tire circumferential direction in the land portion formed between the wave-shaped main grooves, the lug grooves intersecting the tire circumferential direction and communicating with the wave-shaped main grooves at both ends; and narrow grooves disposed between pairs of the lug grooves adjacent in the tire circumferential direction in a row in the tire circumferential direction, the narrow grooves intersecting the tire circumferential direction, communicating with one of the main grooves at a first end, terminating within the land portion at a second end, and having a narrower groove width than the lug grooves.

Owner:YOKOHAMA RUBBER CO LTD

Preparation method and system of high-conductivity graphite film

The invention provides a preparation method and system of a high-conductivity graphite film and belongs to the technical field of radiation. The method comprises the following steps of: 1, collecting a polymer thin film material for carbonization and graphitization, and carbonizing; 2, carrying out hyperthermic treatment on the carbonized carbide film material so as to gradually achieve the graphitization temperature; and 3, selecting a temperature reference point within the graphitization temperature range so that the temperature reference point is taken as a reference temperature, and carrying out periodic oscillation within the change range of a threshold range, wherein three or more oscillation periods are finished within the entire graphitization temperature range. By the preparation method, the preparation technology of the graphite film material is improved in a temperature oscillation manner, and the quality of the graphite film material is also improved.

Owner:SHANGHAI JIEYUAN ENVIRONMENTAL SCI & TECH

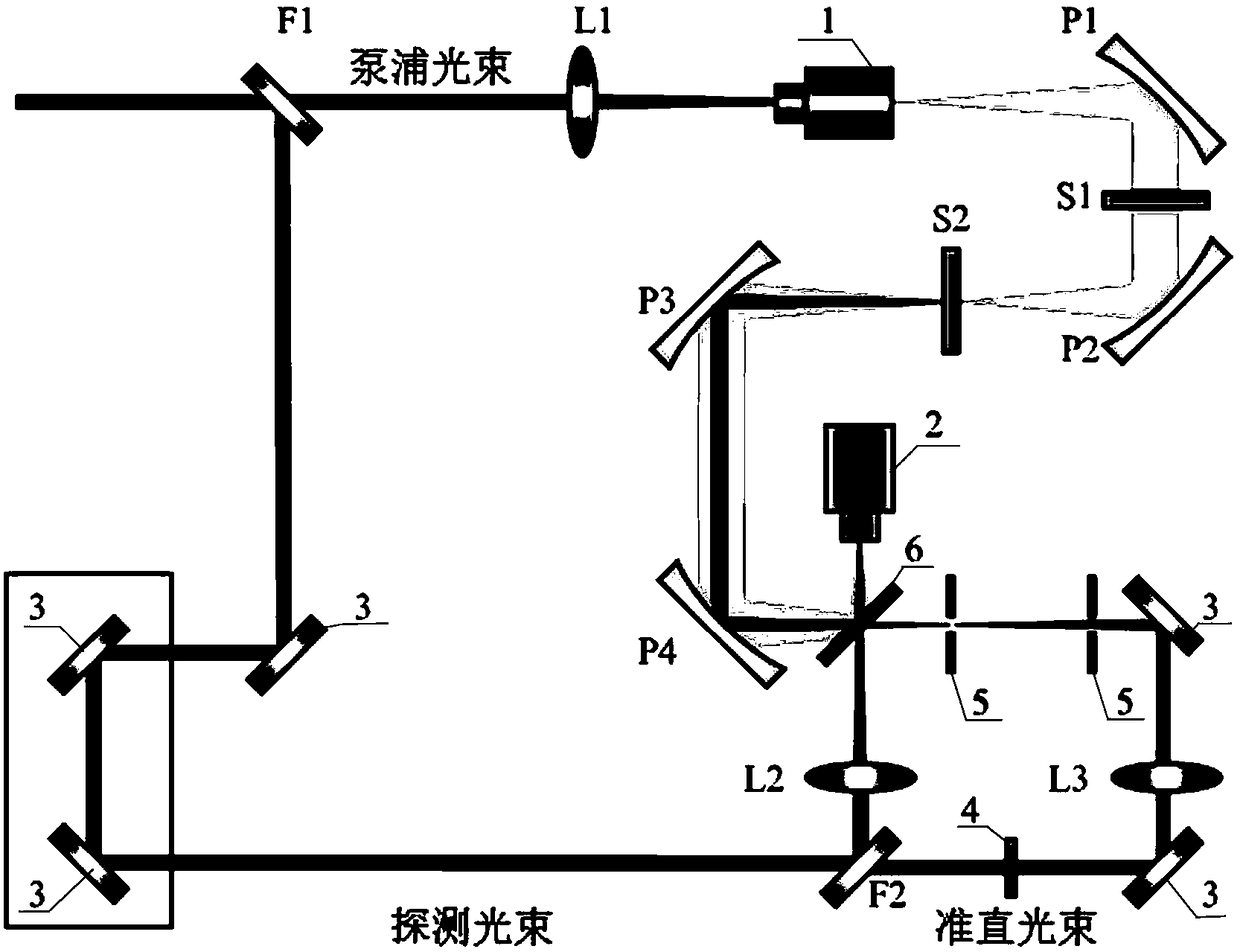

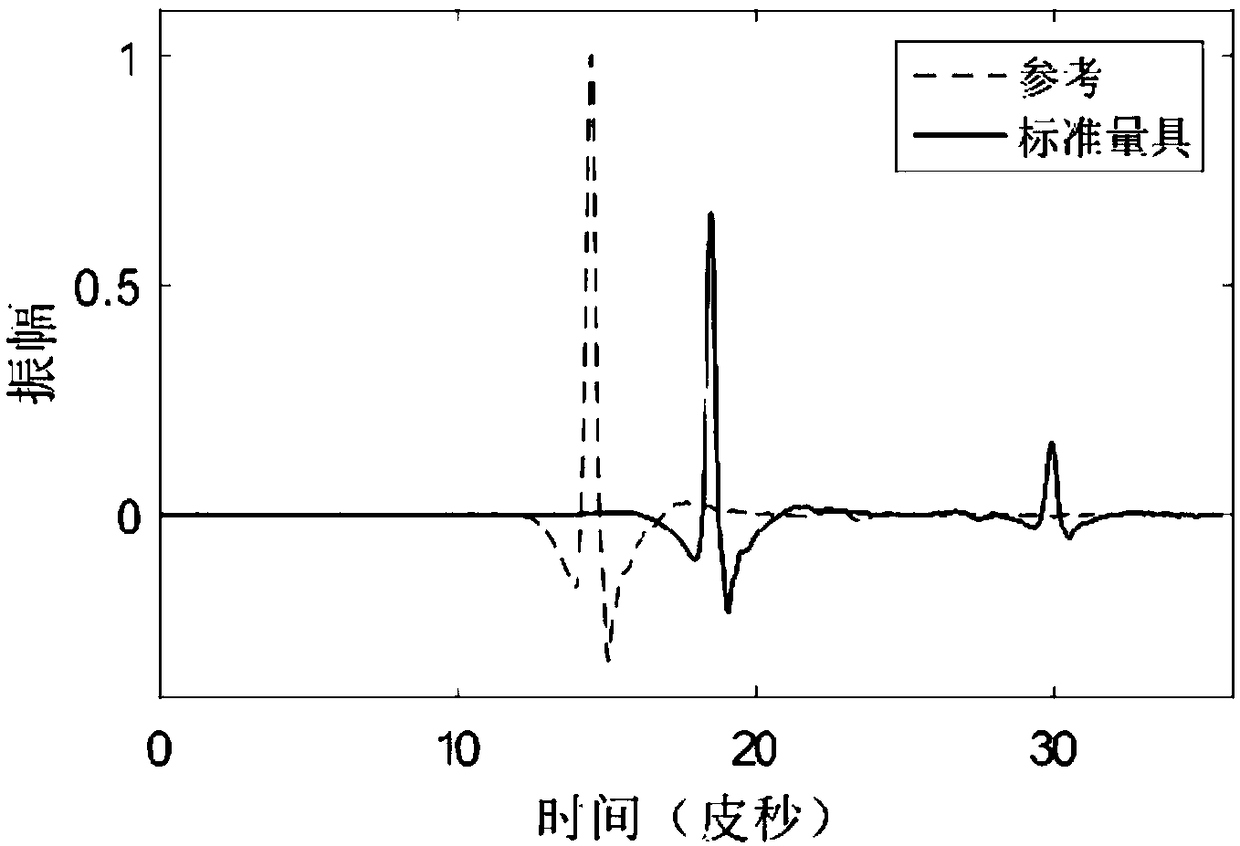

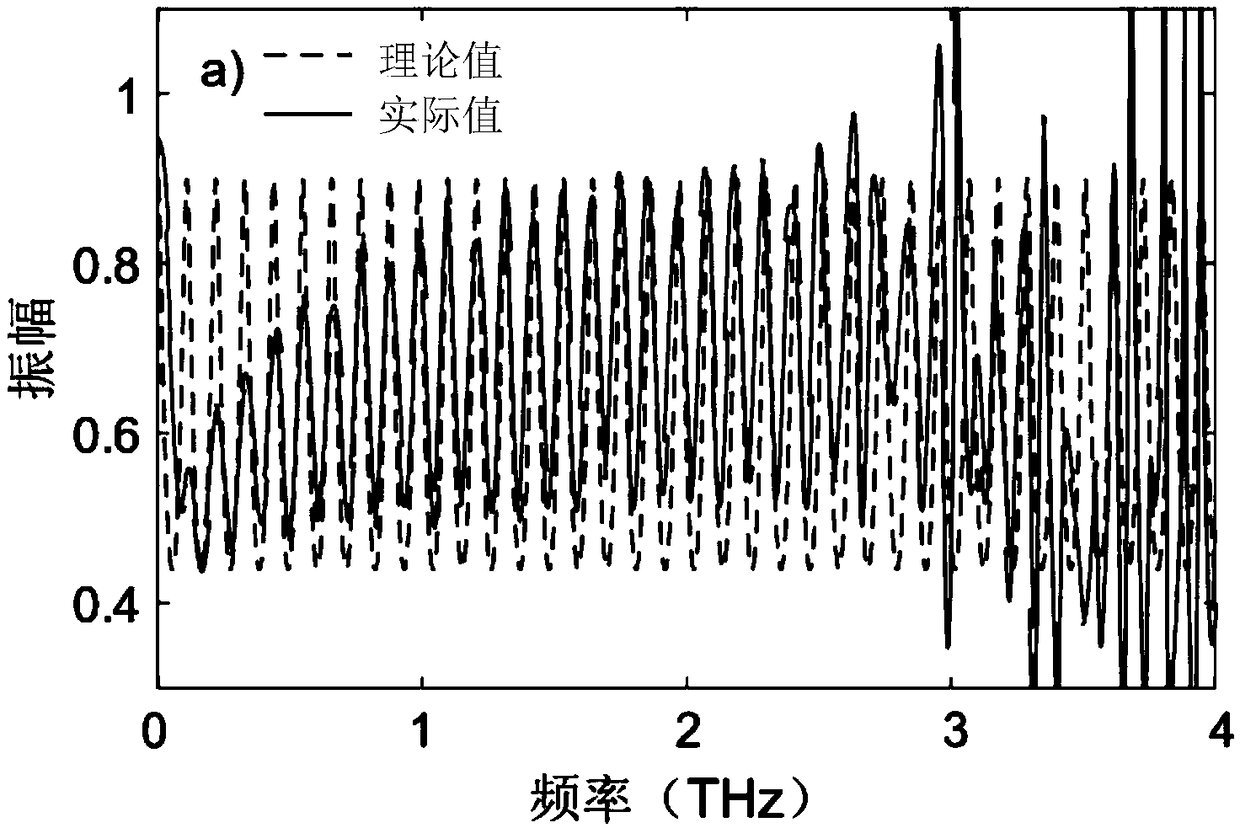

Terahertz spectrum calibration system and terahertz spectrum calibration method

ActiveCN109030406APrecisely adjustable spectral resolutionImprove accuracyMaterial analysis by optical meansTime domainFrequency spectrum

The invention relates to a terahertz spectrum calibration system, comprising a laser light source, a terahertz wave generating unit, a detecting unit, terahertz optical paths, a collimating optical path, a transmission reflector, a light splitting element and a standard measuring tool. The system performs frequency calibration on a terahertz time domain spectrum by utilizing periodic oscillation of the standard measuring tool formed by multiple reflections in the standard measuring tool through a terahertz wave, and the system realizes indirect calibration between terahertz wave optical pathsusing homologous collimating lights by introducing a collimating optical path to make the terahertz wave be perpendicular to the standard measuring tool, thereby reducing spectral errors caused by non-normal incidence, and effectively improving the accuracy and reliability of the system. The invention also provides a terahertz spectrum calibration method, which performs spectrum calibration by theterahertz spectrum calibration system, and uses the collimating light reversely input into the terahertz optical paths to adjust the terahertz optical paths, so that the standard measuring tool is perpendicular to the terahertz wave, and the spectral errors caused by the standard measuring tool on terahertz tilt angles are reduced.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

Pneumatic Tire

InactiveUS20180215204A1Improve braking effectIncrease widthTyre tread bands/patternsPeriodic oscillationWave shape

A pneumatic tire comprises a tread portion; a plurality of main grooves extending in a tire circumferential direction in a tread surface of the tread portion, at least one of the plurality of main grooves having a wave-like shape with periodic oscillation; a plurality of land portions adjacent to one another in a tire lateral direction formed by the plurality of main grooves; and a plurality of projections disposed on a groove bottom of the wave-shaped main groove disposed in a row in the tire circumferential direction in accord with periodic oscillations of the wave-shaped main groove.

Owner:THE YOKOHAMA RUBBER CO LTD

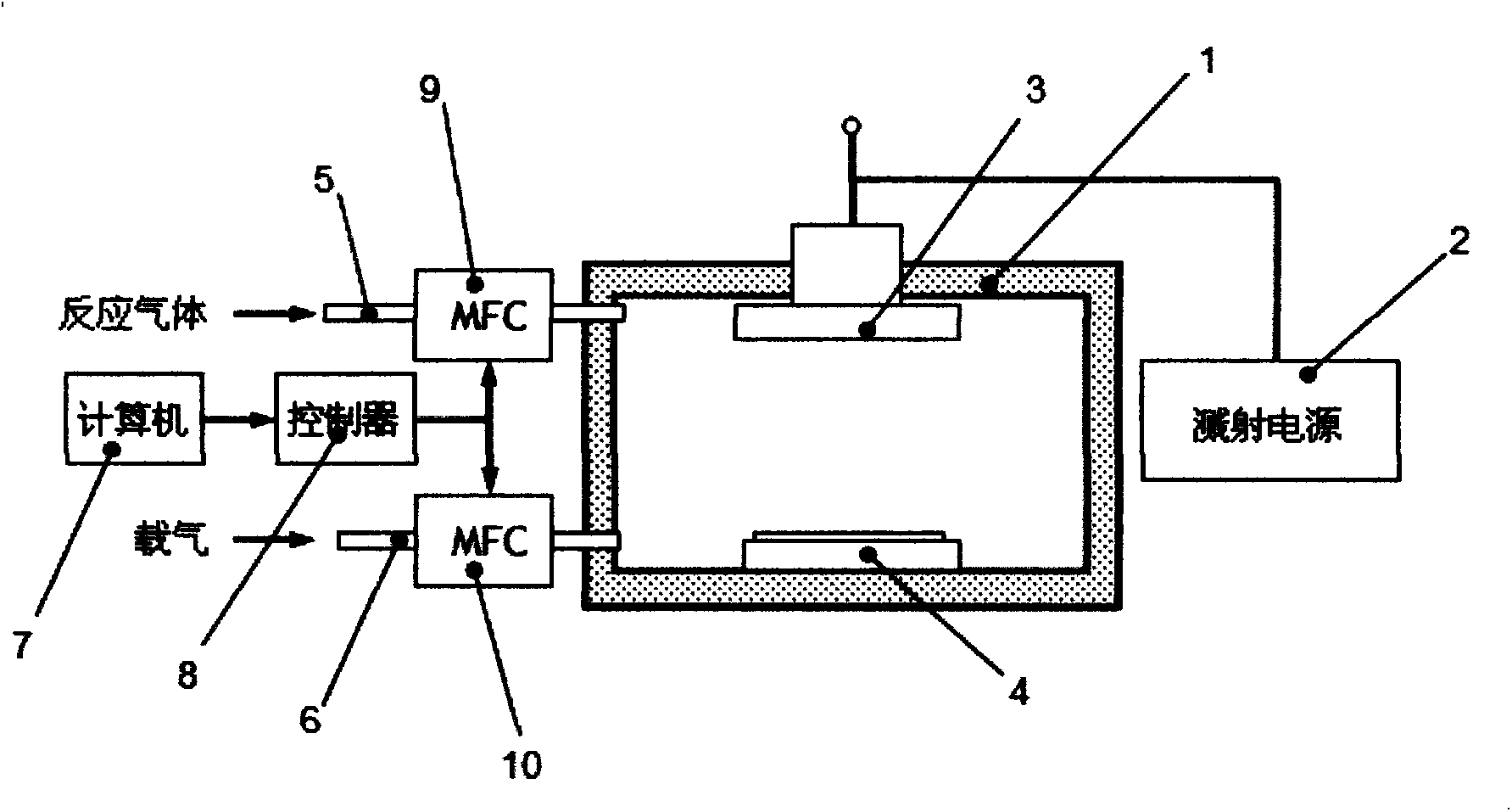

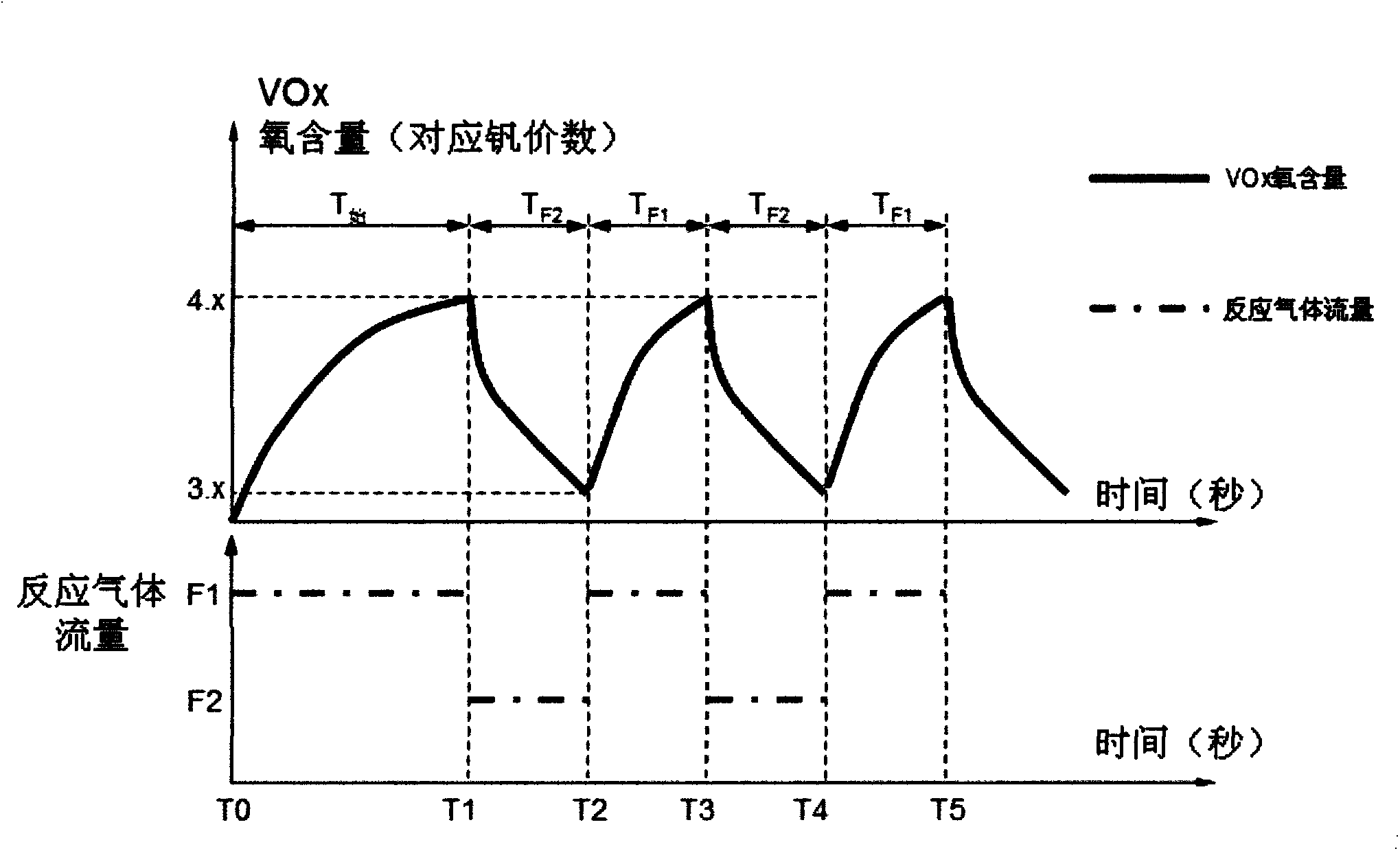

Reaction sputtering system based on oscillation-type reaction gas control

ActiveCN103436847AGet stableStable sputtering processVacuum evaporation coatingSputtering coatingSputteringPeriodic oscillation

Owner:WUXI YUANCHUANGHUAXIN MICROELECTROMECHANICAL CO LTD +1

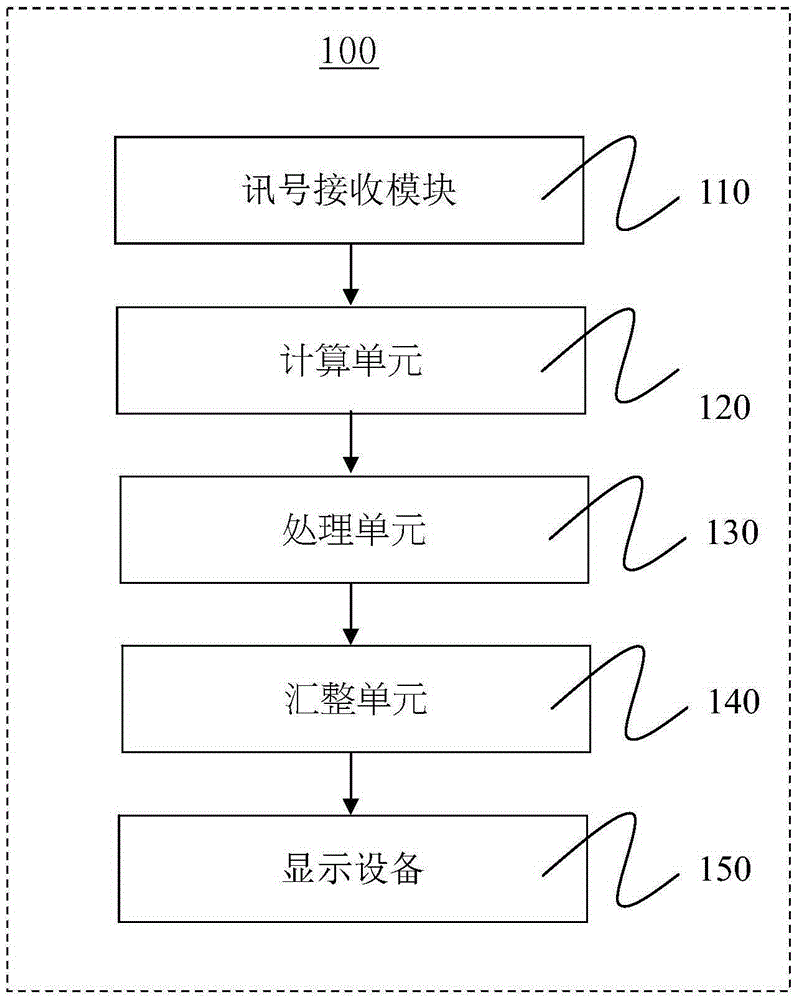

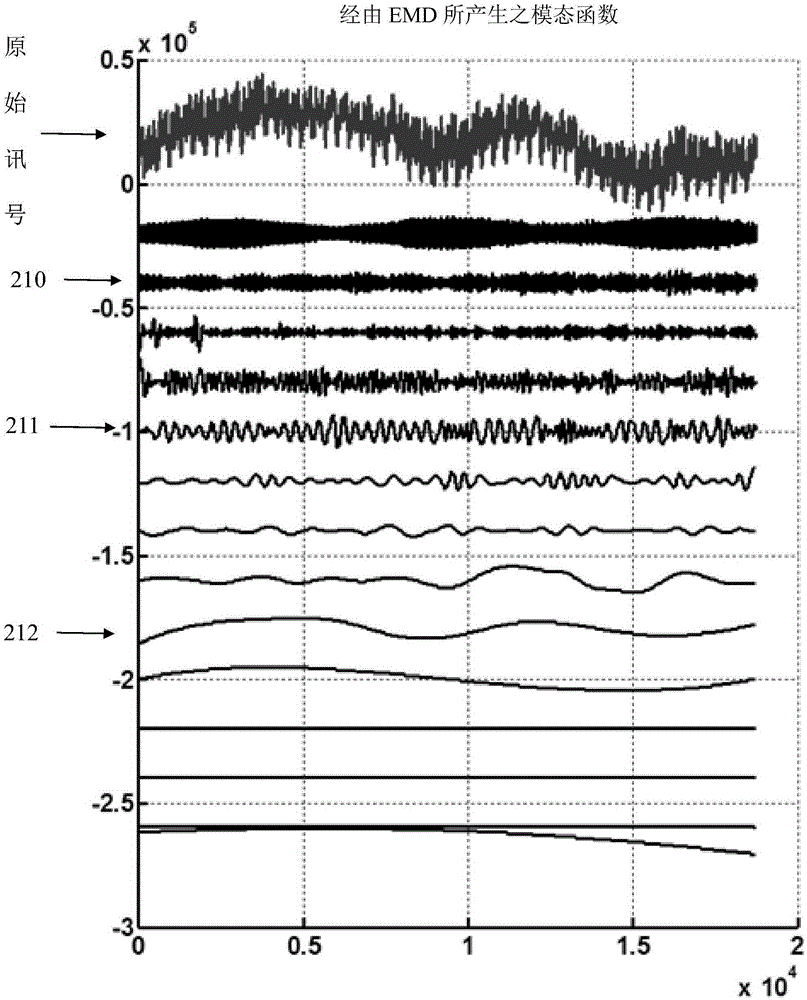

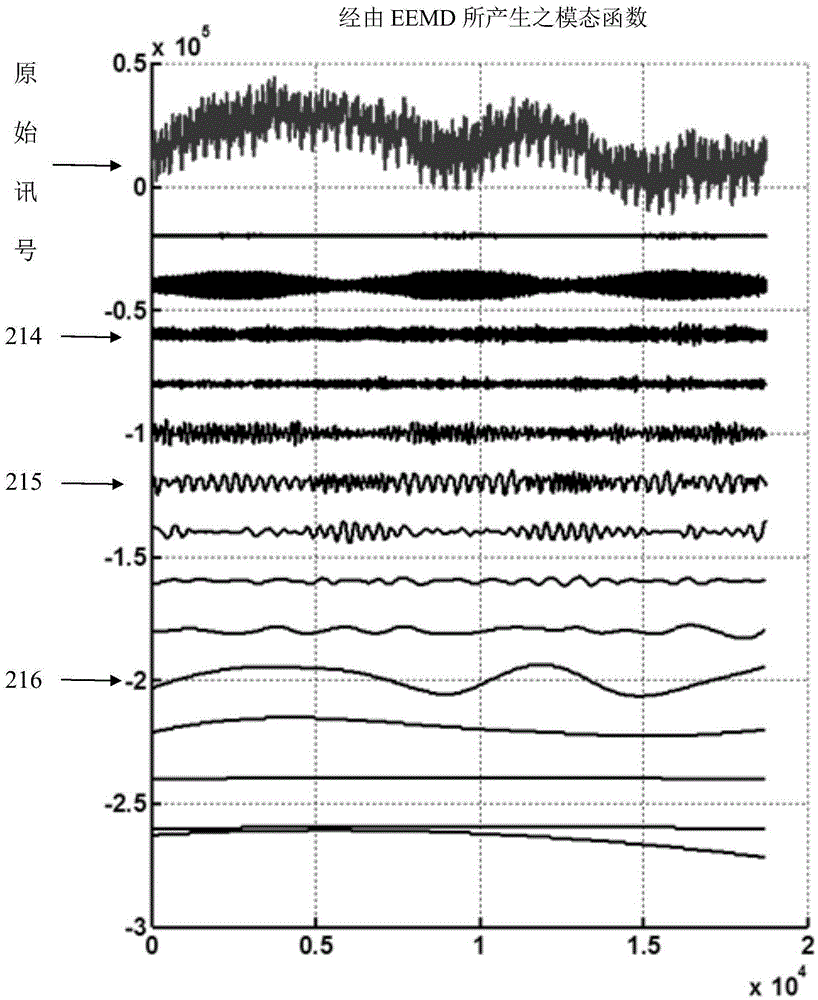

Empirical mode decomposition method and system for adaptive binary and conjugate shielding network

InactiveCN106610918AReduce calculation timeEvaluation of blood vesselsSensorsPeriodic oscillationDecomposition

The invention provides a signal processing method. The method comprises the steps of firstly, decomposing an original signal by utilizing an empirical mode decomposition method, obtaining an intrinsic mode function, and calculating n-order conjugate shielding functions; secondly, adding the n-order conjugate shielding functions to the original signal to generate a modulation signal, performing decomposition through the empirical mode decomposition method to generate n-order modulation mode functions; and performing addition on the n-order modulation mode functions, performing division by the number of the n-order conjugate shielding functions to generate n-order model functions, and repeating the process until the n-order model functions are monotonic functions, wherein the mode functions of different orders are non-steady-state and nonlinear periodic oscillation signals of the original signal in different frequency ranges. According to the method, the advantages of the existing mode decomposition method are integrated but the mixed mode problem caused by intermittent disturbance in original data is excluded, so that an analytic numerical value of the original signal can be directly and quickly obtained.

Owner:NAT CENT UNIV

Device and method for assisting a cough

ActiveUS10300239B2Effectively assisting coughAssist a cough more effectivelyRespiratorsElectrotherapyPeriodic oscillationPressure threshold

The invention provides a device (11) for assisting a cough, based on an oscillation pressure. The oscillation pressure causes a periodic oscillation airflow in a lung system and the periodic oscillation airflow comprises an oscillation exhalation airflow and an oscillation inhalation airflow. The device (10) comprises a controlling unit (11), and the controlling unit (11) comprises:a first determining unit (111) for determining whether an inhalation of the lung system is complete, so as to control a valve (13) which is to be closed for isolating the lung system from the external environment,a second determining unit (112) for determining whether an internal air pressure in the lung system is larger than a pre-defined pressure threshold, anda detecting unit (113) for detecting the start of the oscillation exhalation airflow, so as to control the valve (13) which is to be opened for starting a cough.

Owner:KONINK PHILIPS ELECTRONICS NV

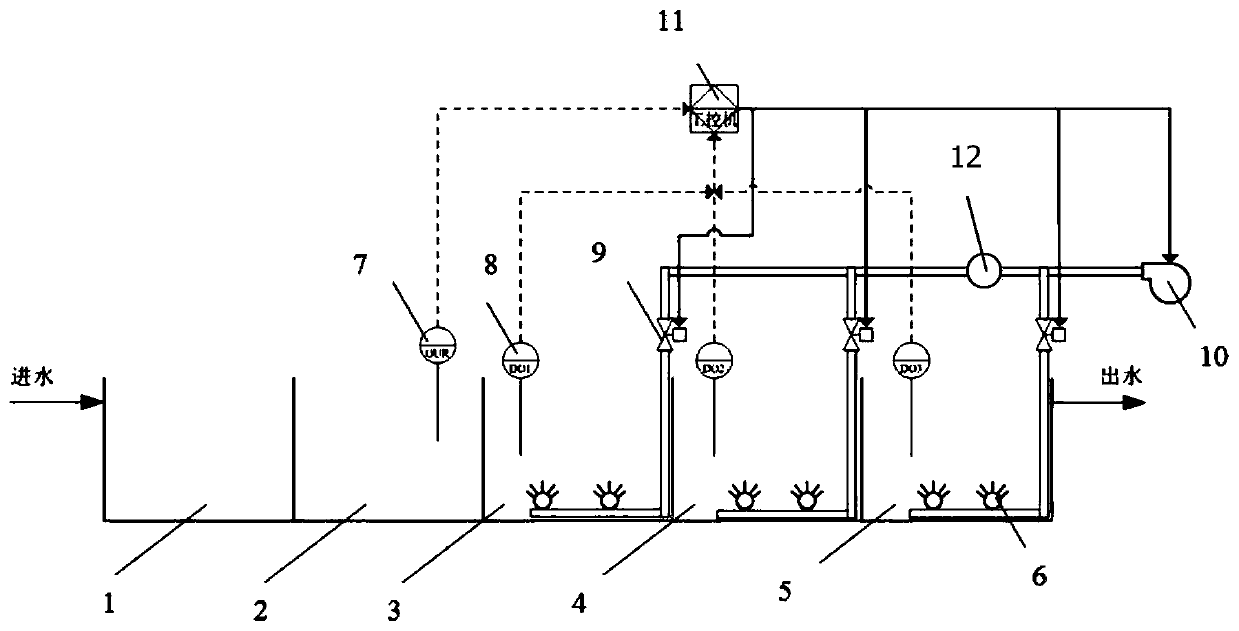

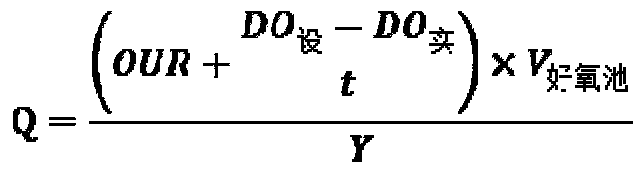

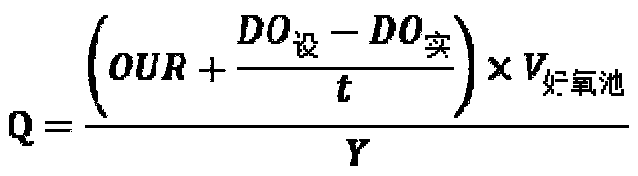

Air volume control system

InactiveCN110104778AAutomatically adjust air demandSmall time lagWater aerationTreatment with aerobic and anaerobic processesActivated sludgeAir volume

The invention provides an air volume control system. The system comprises an activated sludge oxygen consumption respiration rate meter, an industrial computer, an electric gas flow regulating valve,an air flow meter and a blower; the activated sludge oxygen consumption respiration rate meter is arranged at the tail end of an anoxic tank, and detects an OUR value of the sewage entering an aeration tank in real time; the industrial computer converts the OUR value into a required gas volume, then a required gas volume signal is transmitted to a blower control cabinet to adjust the blower and output the required gas volume; a control system adjusts the air volume of each aeration branch pipe by adjusting the opening degree of the valve and makes the sum of the air volumes of the branch pipesequal to the total gas volume value. The control system can effectively shorten the time lag of a sewage biochemical treatment system, reduce the repeated periodic oscillation of the system, and prolong the service life of the system; the influence of external interference factors is effectively reduced, and stable running of the system is ensured.

Owner:江苏复星节能环保有限公司

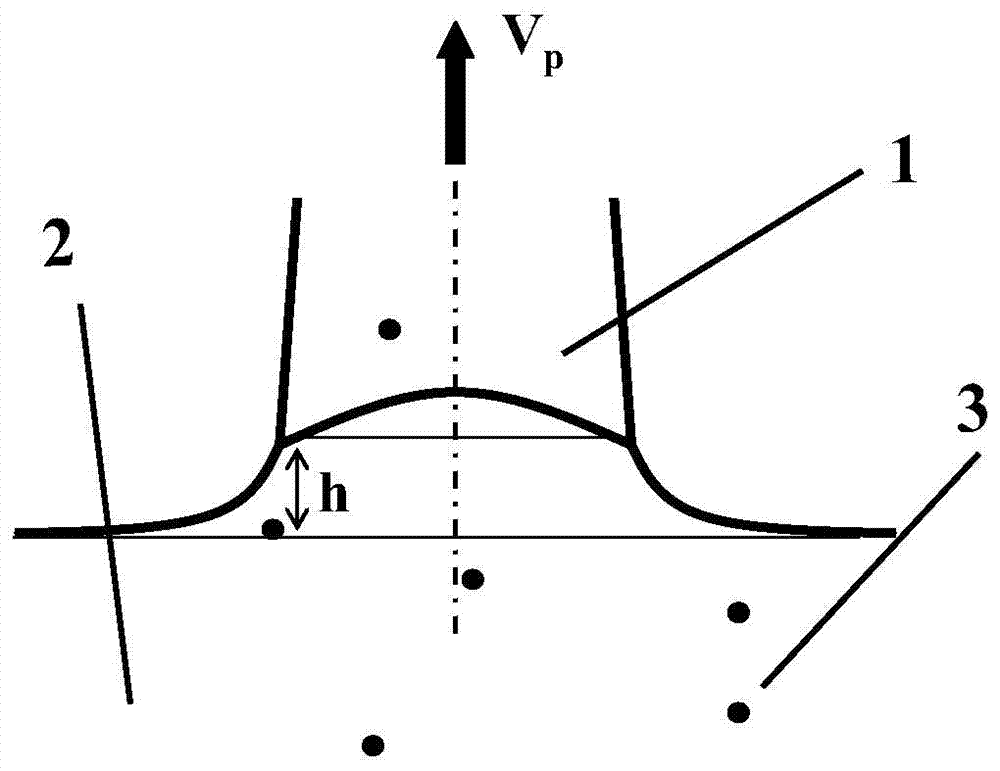

Method for reducing density of micro-pinholes in monocrystalline Czochralski silicon

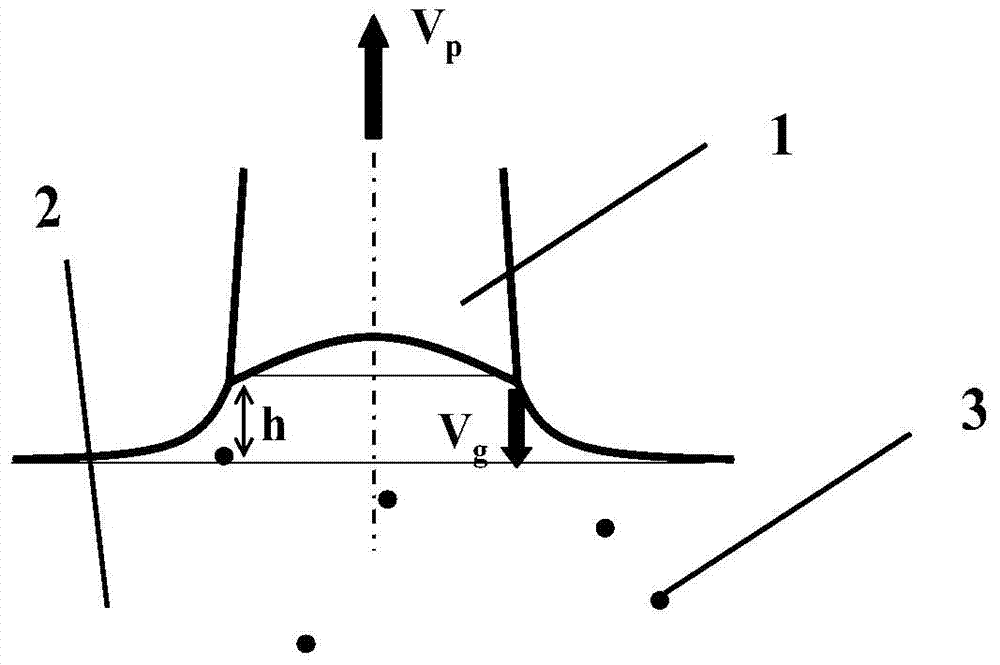

ActiveCN104711674AStop approachingAvoid enteringPolycrystalline material growthBy pulling from meltPeriodic oscillationCzochralski method

The invention provides a method for reducing a density of micro-pinholes in monocrystalline Czochralski silicon. During a process of monocrystalline silicon growth by using the Czochralski method, crystal seeds soaked in a silicon melt is subjected to periodic oscillation operation when pulled up at a front edge of crystallization. The oscillation operation comprises a vertical upward pull process and a vertical downward falling process, wherein the speed Vp of the vertical upward pull process is larger than the speed Vg of the vertical downward falling process. According to the invention and based on a principle of formation of a hole-type defect, periodic oscillation force is generated at the front edge of crystallization, so that periodic oscillation is generated in parts of the melt; micro-pinholes are prevented against adjoining the front edge of crystallization; and micro-pinholes are prevented from entering the inside of silicon crystal. The method is applied to a whole production process of a monocrystalline silicon bar; the density of micro-pinholes in the monocrystalline Czochralski silicon is effectively reduced; and surface defects such as Pit and LLPD of polished wafers are decreased.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

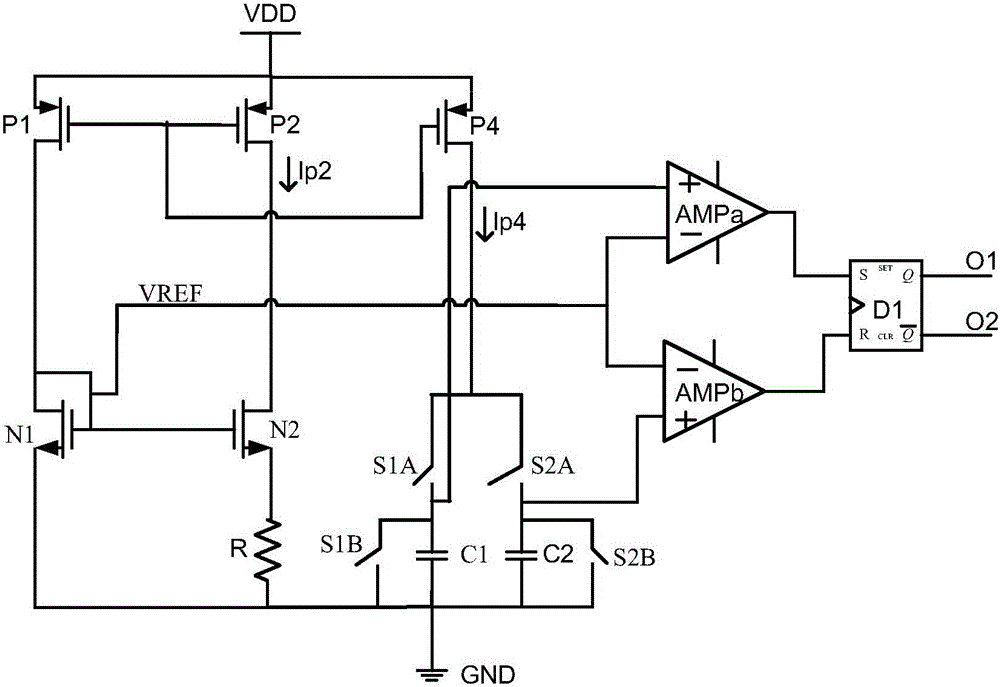

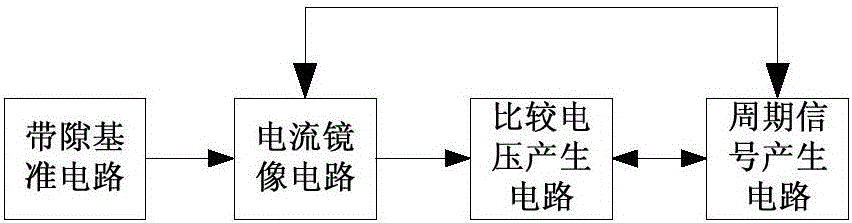

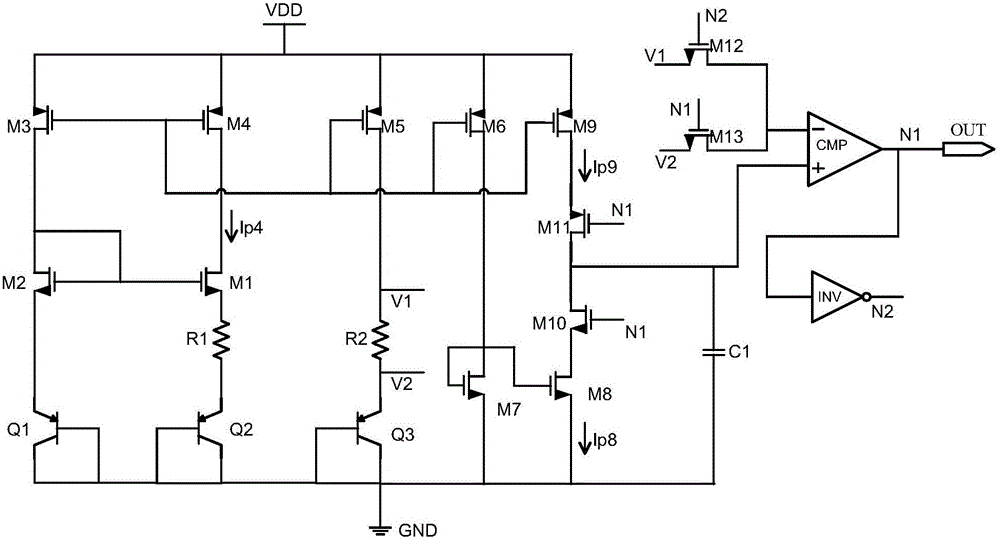

RC oscillator

The invention discloses an RC oscillator comprising a band gap reference circuit, a current mirror circuit, a comparison voltage generating circuit, and a periodic signal generating circuit. The band gap reference circuit is connected with the current mirror circuit and an external power supply, and the band gap reference circuit is used to generate the current provided with the positive temperature coefficient. The current mirror circuit is also respectively connected with the comparison voltage generating circuit and the periodic signal generating circuit, and the current mirror circuit is used to mirror the current generated by the band gap reference circuit to the periodic signal generating circuit. The comparison voltage generating circuit is also connected with the periodic signal generating circuit, and is used to generate the comparison voltage according to the current of the current mirror circuit, and the voltage can be input in the periodic signal generating circuit. The periodic signal generating circuit is used to output the periodic oscillation signal according to the input voltage and the input current. The RC oscillator is advantageous in that the structure is simple, the number of the required comparators and capacitors can be reduced, the power consumption can be reduced, the circuit area can be saved, and the influence of the comparator input imbalance on the oscillator output frequency can be eliminated.

Owner:IPGOAL MICROELECTRONICS (SICHUAN) CO LTD

Pneumatic Tire

ActiveUS20180215203A1Good lookingImprove wear resistanceTyre tread bands/patternsGroove widthPeriodic oscillation

A pneumatic tire comprises a tread portion with a tread surface; four main grooves in the tread surface of the tread portion, extending in a tire circumferential direction; and a center land portion, middle land portions adjacent to the center land portion on either side in a tire lateral direction, and shoulder land portions outwardly adjacent to the middle land portions in the tire lateral direction formed by the main grooves. The main grooves have a wave-like shape with a constant groove width in the tire circumferential direction and with periodic oscillation.

Owner:YOKOHAMA RUBBER CO LTD

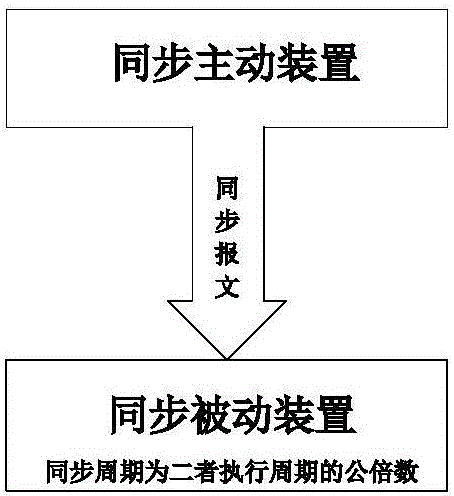

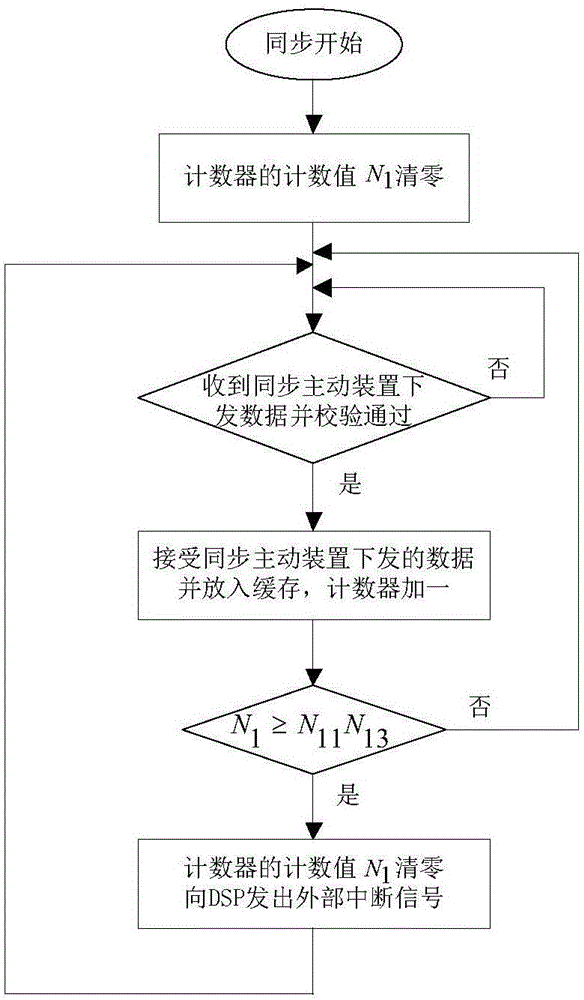

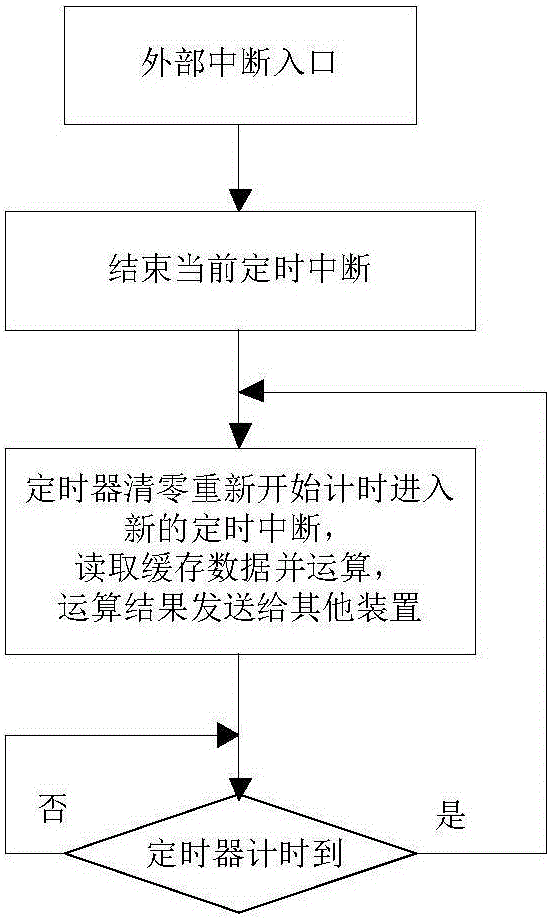

Synchronization method for asynchronous device

ActiveCN105049173AAvoid Power Periodic OscillationsGood synchronizationSynchronising arrangementPeriodic oscillationSystem stability

The invention discloses a synchronization method for an asynchronous device. The method comprises a first step that an interface unit of a synchronous passive device verifies the data received from a synchronous active device, the data passing through the verification is cached, and a count value N1 of a counter is added by 1; a second step that the count value N1 is compared with N11N13, if N1 is greater than or equal to N11N13, a step 3 is performed, if not, the step 1 is performed; a third step that the count value N1 is reset, and an external interruption signal is sent to an arithmetic unit of the synchronous passive device; a fourth step that the arithmetic unit of the synchronous passive device receives the external interruption signal, and then finishes current timer interruption; a fifth step that a timer is reset and restarts timing, when in a new timer interruption, cache data is read and calculated, and an operation result is sent to other devices; and a sixth step that if T12 of a timing time of the timer is not achieved, it needs to keep waiting, or else, the step 5 is performed. No extra synchronous device is added; the synchronization performance is excellent, the power of a converter is prevented from periodic oscillation, and the system stability is improved; and the method has high flexibility and high engineering application feasibility.

Owner:NR ELECTRIC CO LTD +1

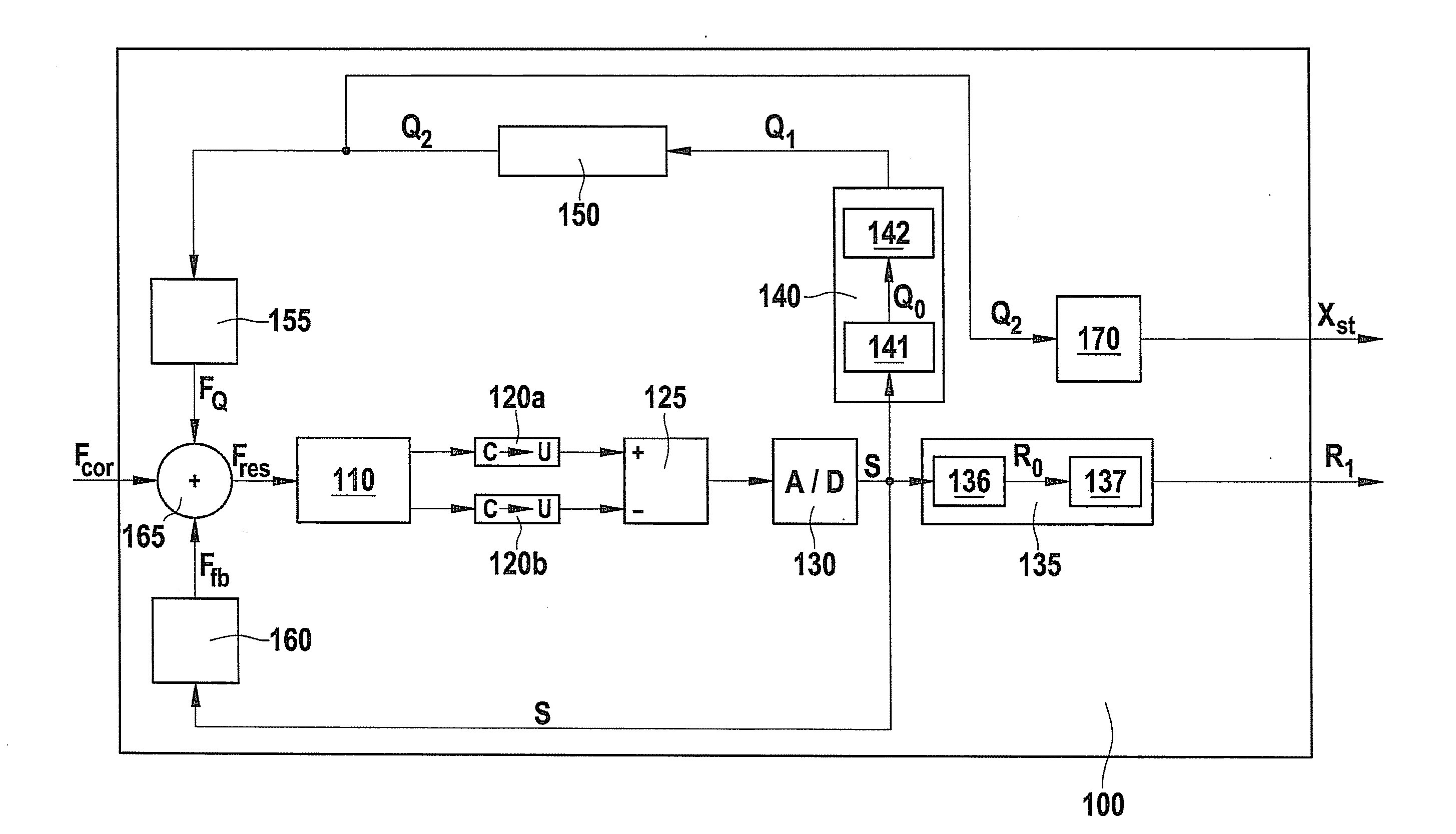

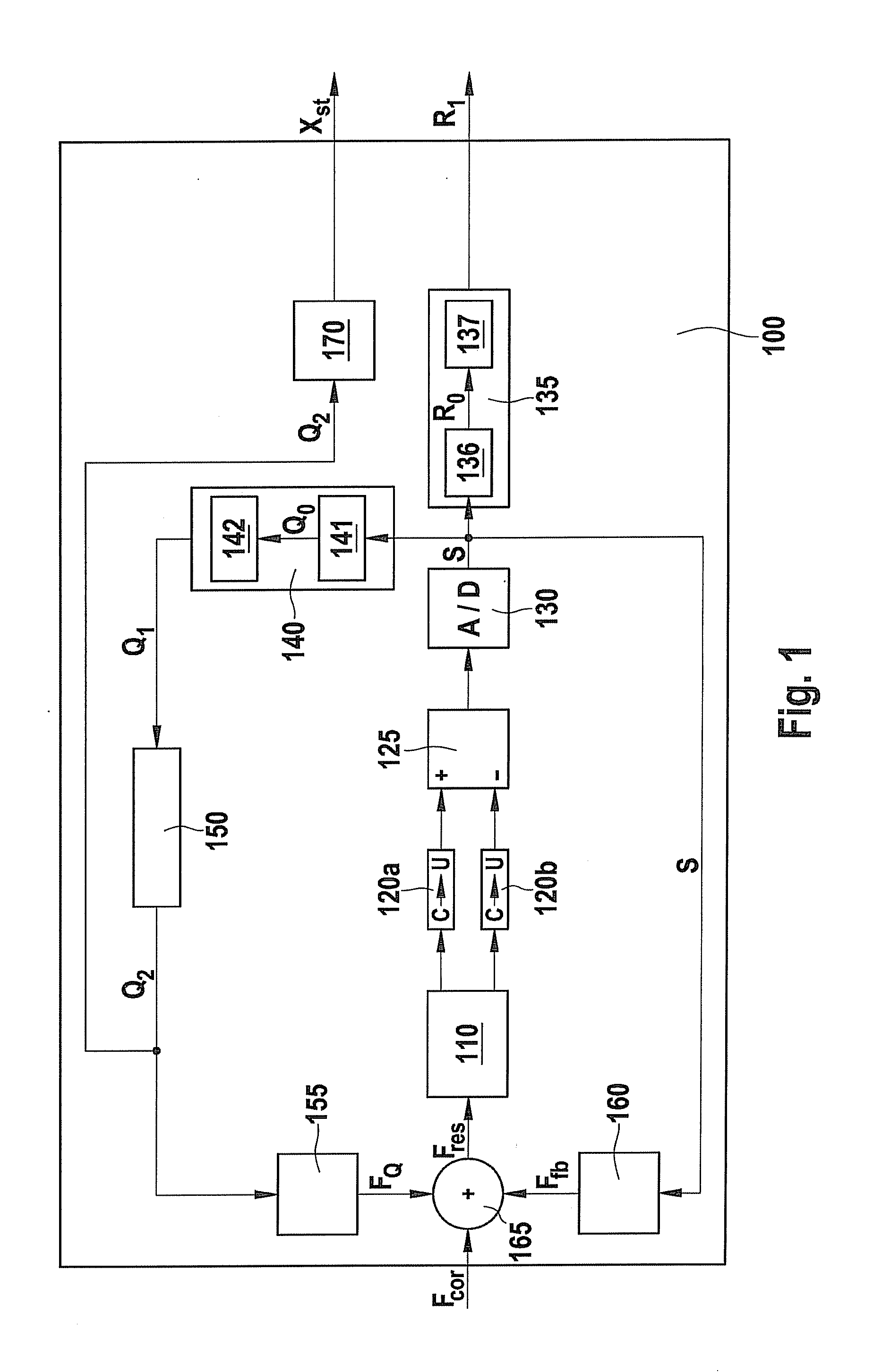

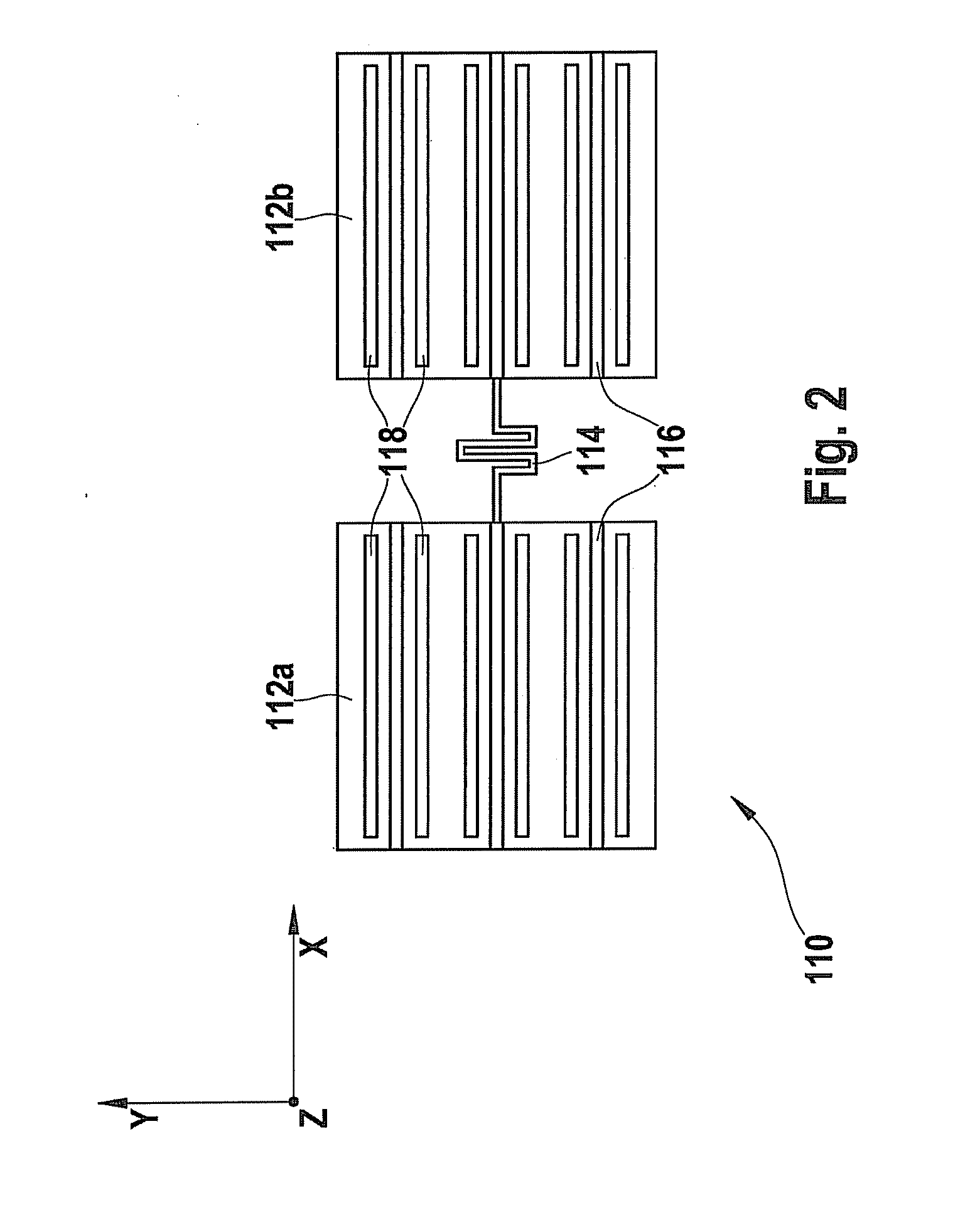

Sensor and method for operating a sensor

ActiveUS20120136632A1Hamper decisionCompensation effectAmplifier modifications to reduce noise influenceDigital computer detailsPeriodic oscillationEngineering

A sensor (100, 200) for measuring a variable generates a sensor signal (S), oscillates at a drive frequency (fx), and includes: a rate demodulator (135), which demodulates the sensor signal (S) by multiplying it by a first demodulation signal, in order to generate a rate signal (R1), which contains information about the measured variable to be measured; a quadrature demodulator (140), which demodulates the sensor signal (S) by multiplying it by a second demodulation signal shifted by 90° with respect to the first demodulation signal, to generate a quadrature signal (Q1); and an analysis circuit (170), which determines whether the quadrature signal (Q1) or a signal (Q2) derived therefrom is subject to a periodic oscillation and, if a periodic oscillation is present, outputs a status signal (Xst) having a value which indicates that the instantaneous rate signal (R1) is influenced by an external interference acting on the sensor (100, 200).

Owner:ROBERT BOSCH GMBH

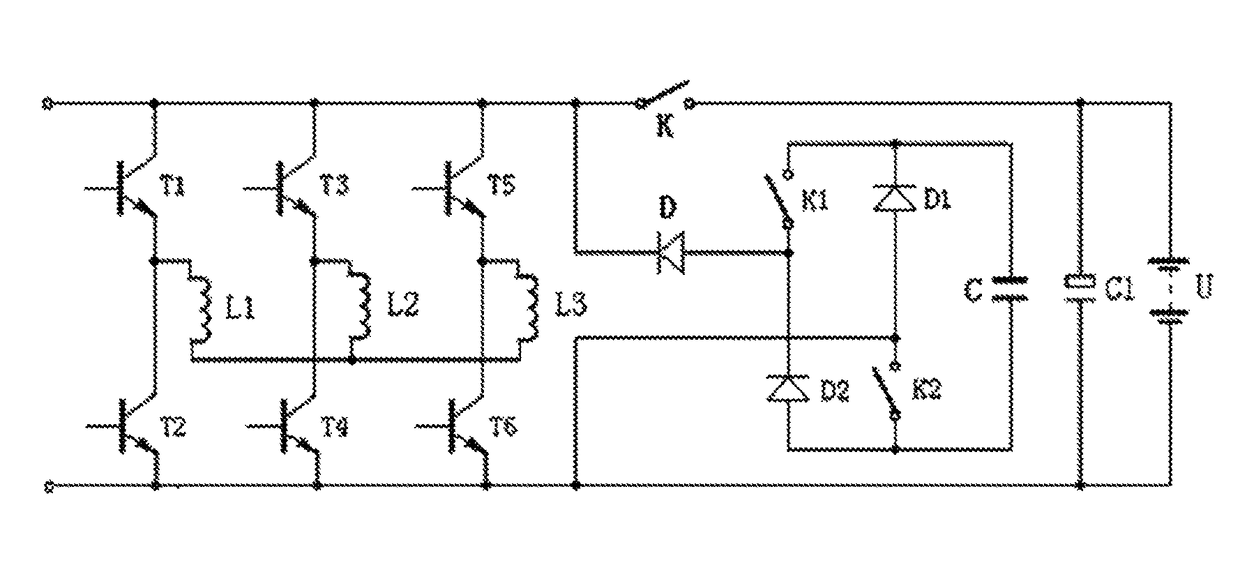

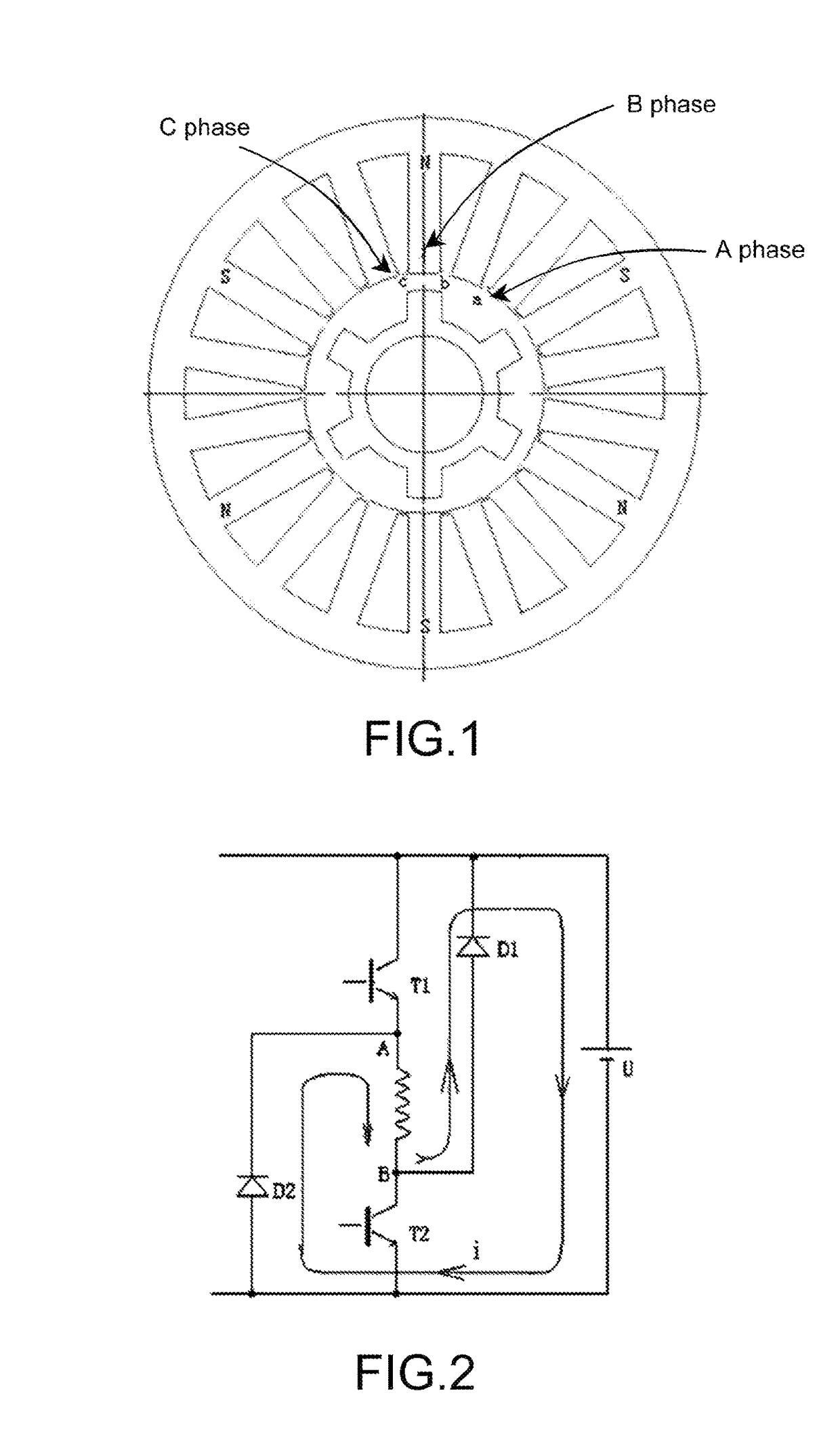

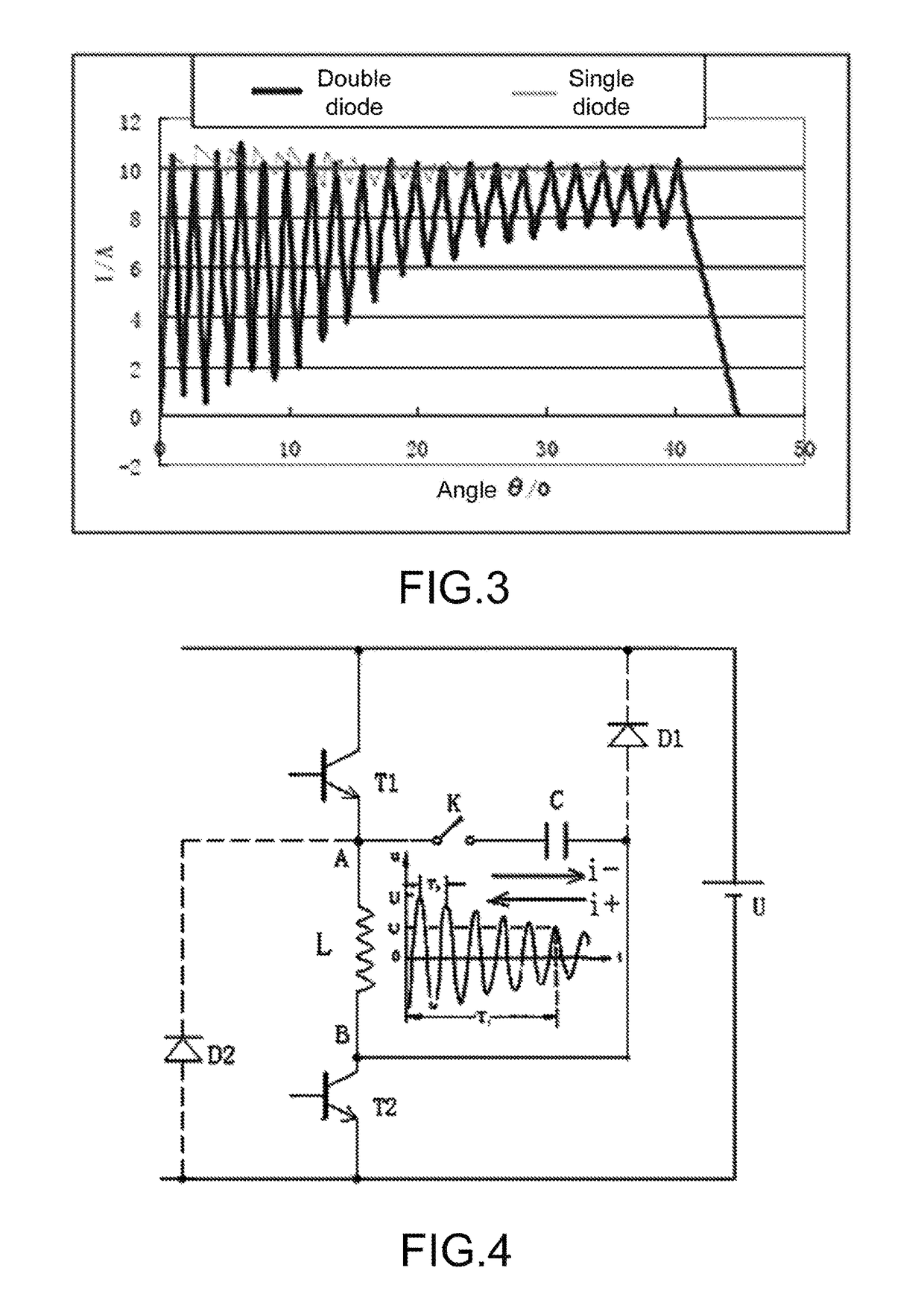

Flyback control mode-based controller and motor-controlling method thereof

A flyback control mode-based controller includes a power supply circuit, a position-checking circuit, a current-checking circuit, a control circuit, and a power output circuit. The power output circuit includes a controlled energy conversion unit. The energy conversion unit includes a control switch and an energy conversion circuit. The energy conversion circuit uses the capacitor C circuit, the inductor L circuit, or the LC circuit to connect parallelly or serially with an inductor in a motor winding L so as to form an oscillation circuit, such that periodic oscillations with attenuation are enabled by relying on the energy stored in the motor winding L. By applying the controller to motors having forward control mode or motors having flyback control mode, the current to be released by the motor during discharging can be repeated used, thereby achieving maximum energy conservation.

Owner:SHANGHAI DINGTE ELECTRICAL APPLICANCES CO LTD +1

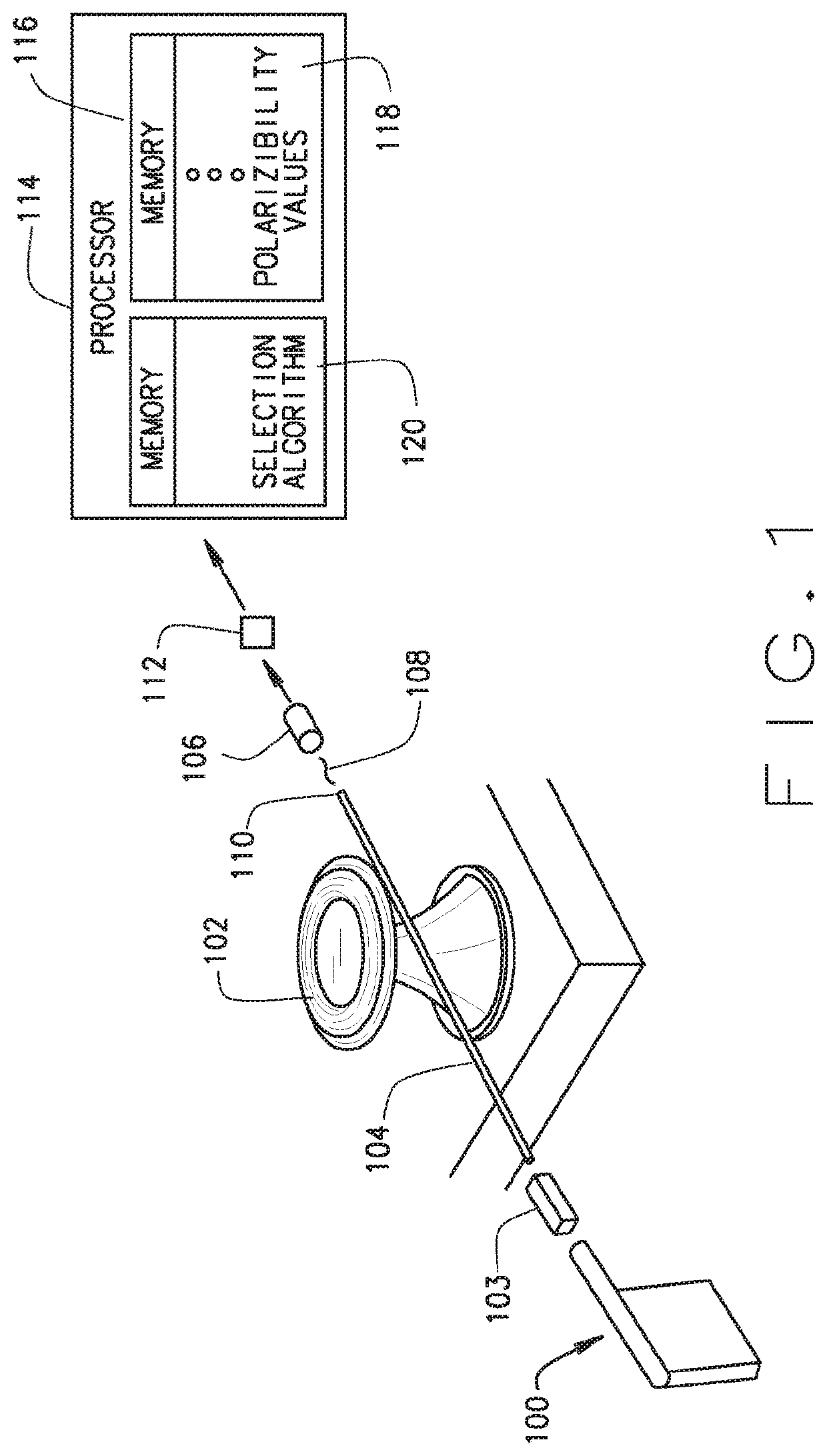

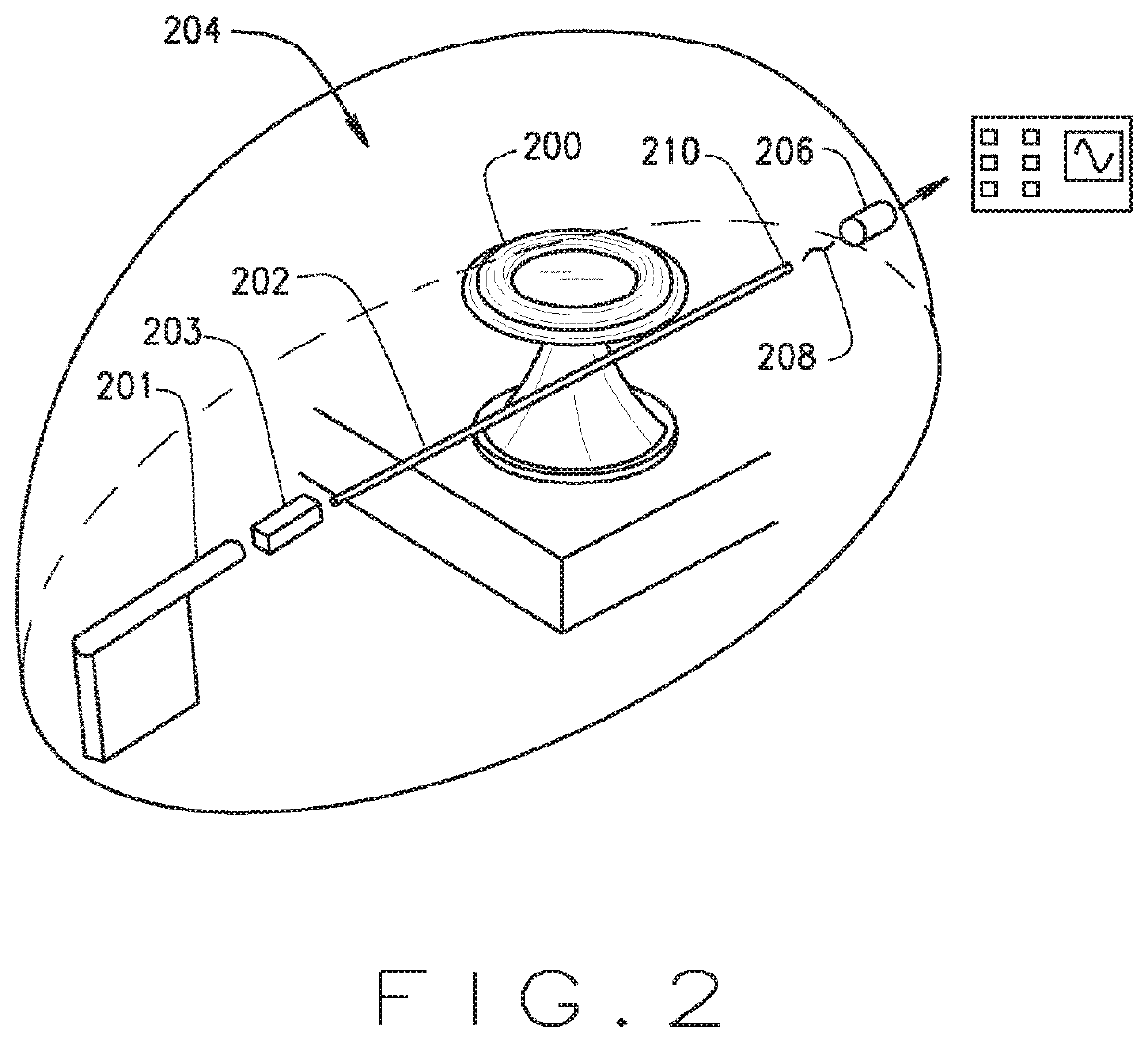

Opto-mechanical system and method having chaos induced stochastic resonance and opto-mechanically mediated chaos transfer

ActiveUS20220050043A1Simultaneous transmissionEliminate the problemNanotechMaterial analysis by observing effect on chemical indicatorPeriodic oscillationParticle physics

An a system and method for chaos transfer between multiple detuned signals in a resonator mediated by chaotic mechanical oscillation induced stochastic resonance where at least one signal is strong and where at least one signal is weak and where the strong and weak signal follow the same route, from periodic oscillations to quasi-periodic and finally to chaotic oscillations, as the strong signal power is increased.

Owner:WASHINGTON UNIV IN SAINT LOUIS

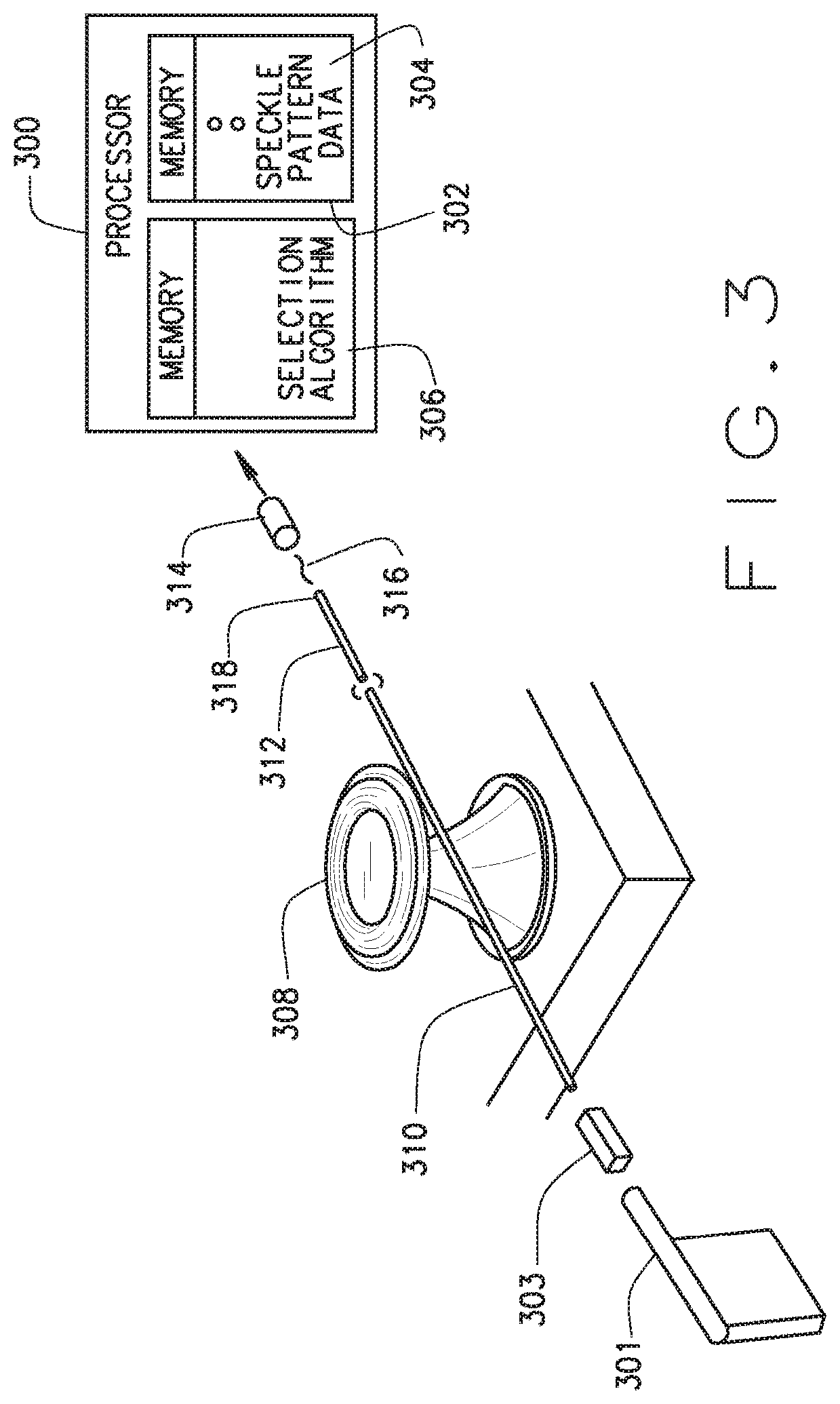

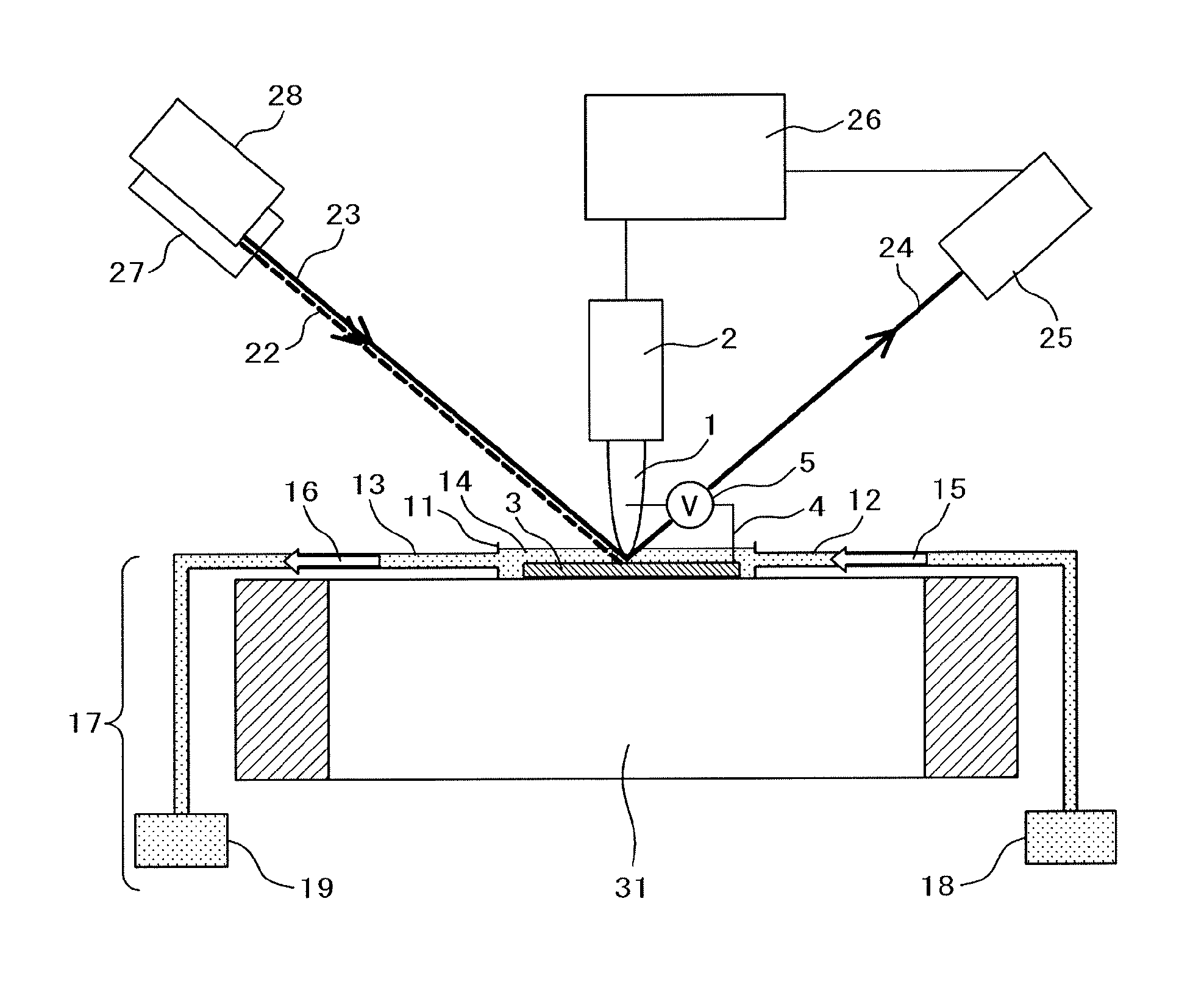

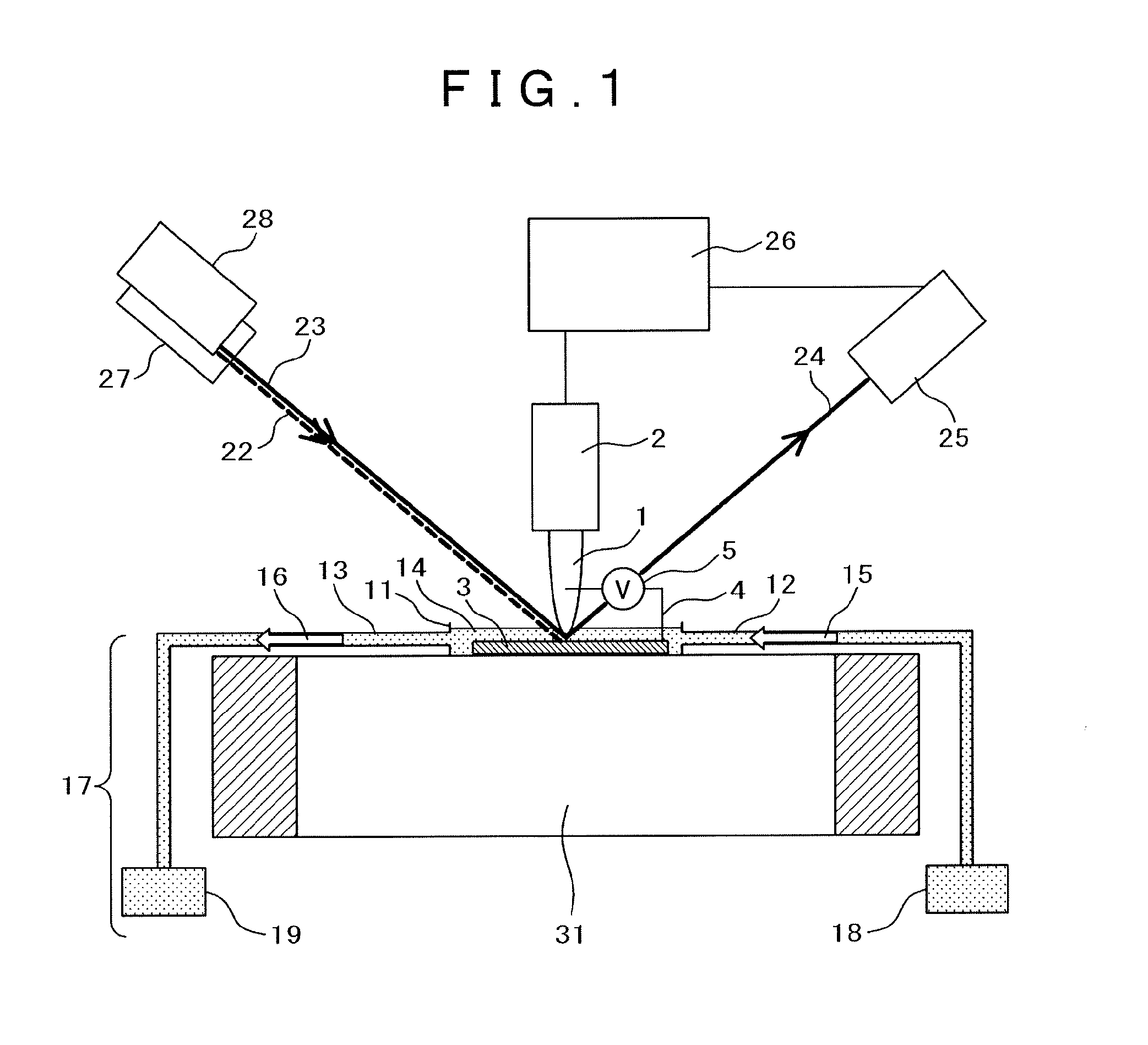

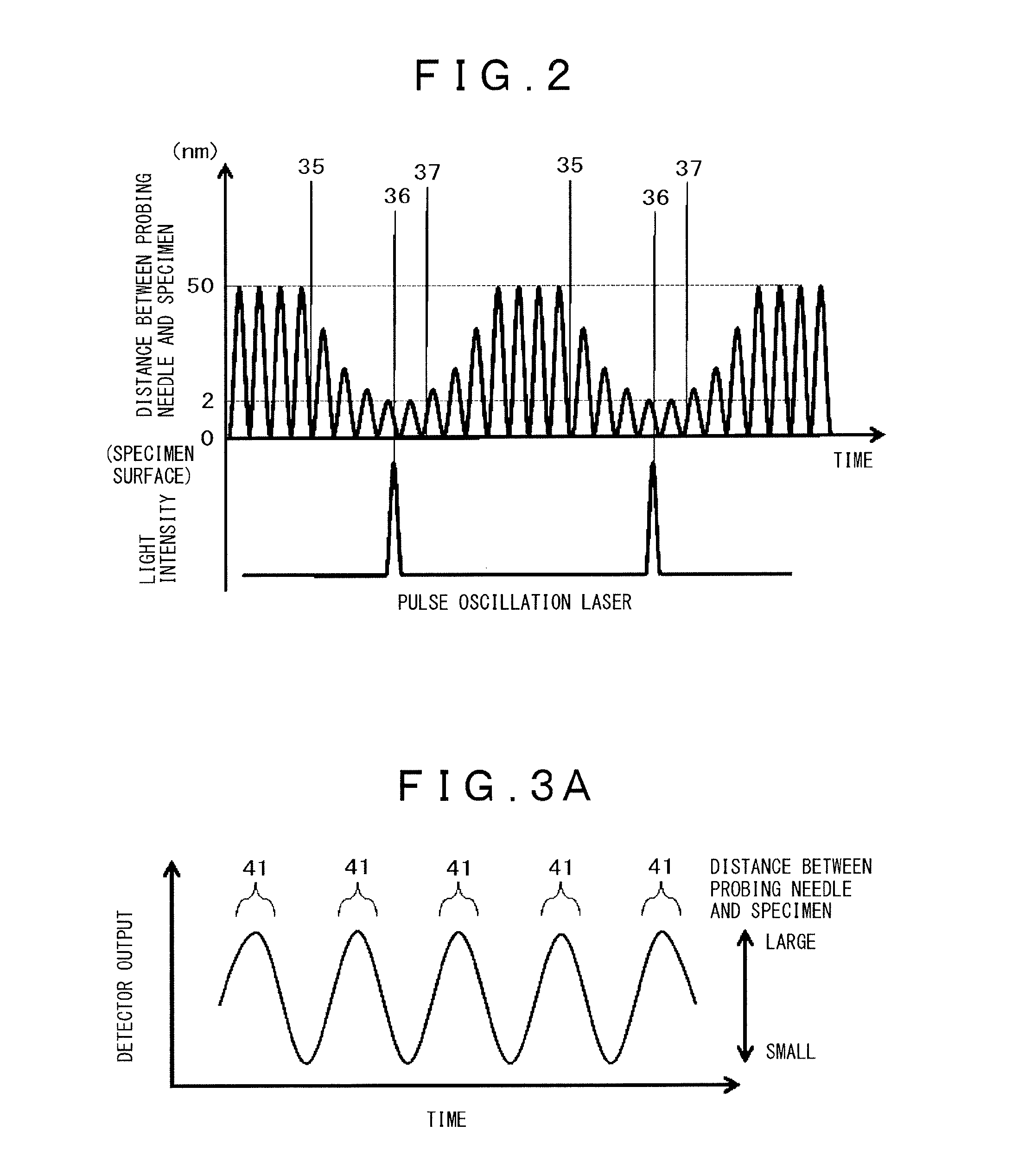

Scanning probe microscope and measuring method using same

InactiveUS20150177275A1Improve spatial resolutionScanning probe microscopyCulture fluidPeriodic oscillation

Provided is a scanning probe microscope that takes measurements at high spatial resolution on physical information such as array structure of water molecules at a specimen-culture fluid interface in a culture fluid as well as irregularities of the surface of a specimen and composition distribution and array structure of molecules, proteins, etc. even in the atmosphere, an ambient air, vacuum, among others. The scanning probe microscope includes: a probing needle (1); a specimen holder (11) in which a specimen (3) is mounted; an oscillator (2) that produces a periodic oscillation to change the probing needle position; a pulse oscillation type laser light source (27, 28) that emits light toward a spot, which is put under measurement by the probing needle, on the specimen; a detector (25) that measures intensity of output light which is output from the specimen by energy spectroscopy; and a control device (26). The control device decreases amplitude of the periodic oscillation to change the probing needle position by the oscillator, shortens a relative distance between the probing needle and the specimen, and synchronizes shortening of the distance between the probing needle and the specimen and emission of pulse oscillation laser light, thus optimizing efficiency of tip-enhanced detection.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com