Three-dimensional measuring mechanism for realizing quality characteristic of flying object with wings

A technology of quality characteristics and three-dimensional measurement, which is applied in the direction of measuring devices, machine/structural component testing, static/dynamic balance testing, etc., and can solve problems such as time-consuming, labor-intensive operations, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

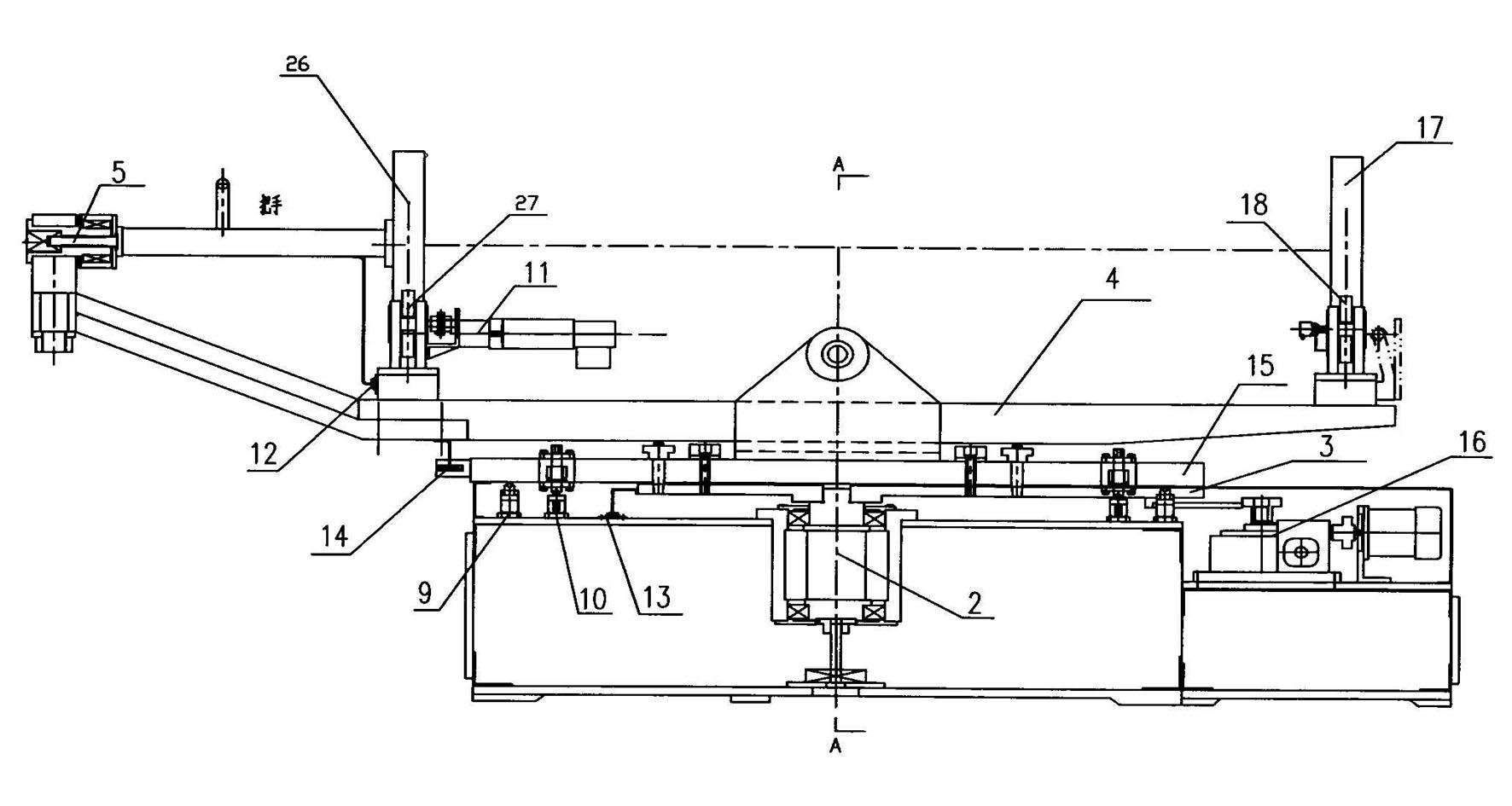

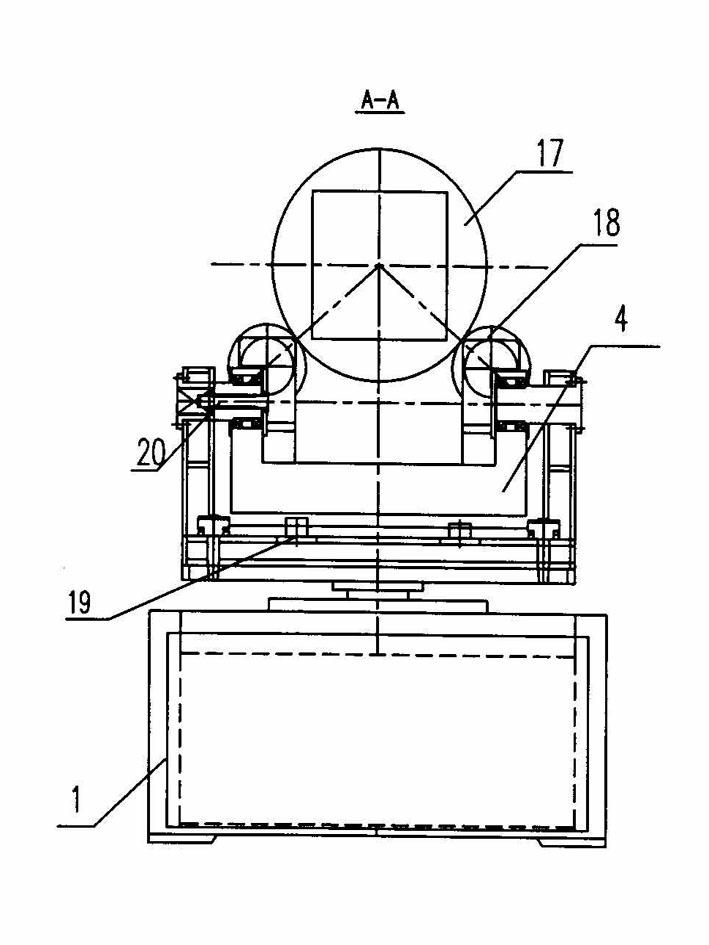

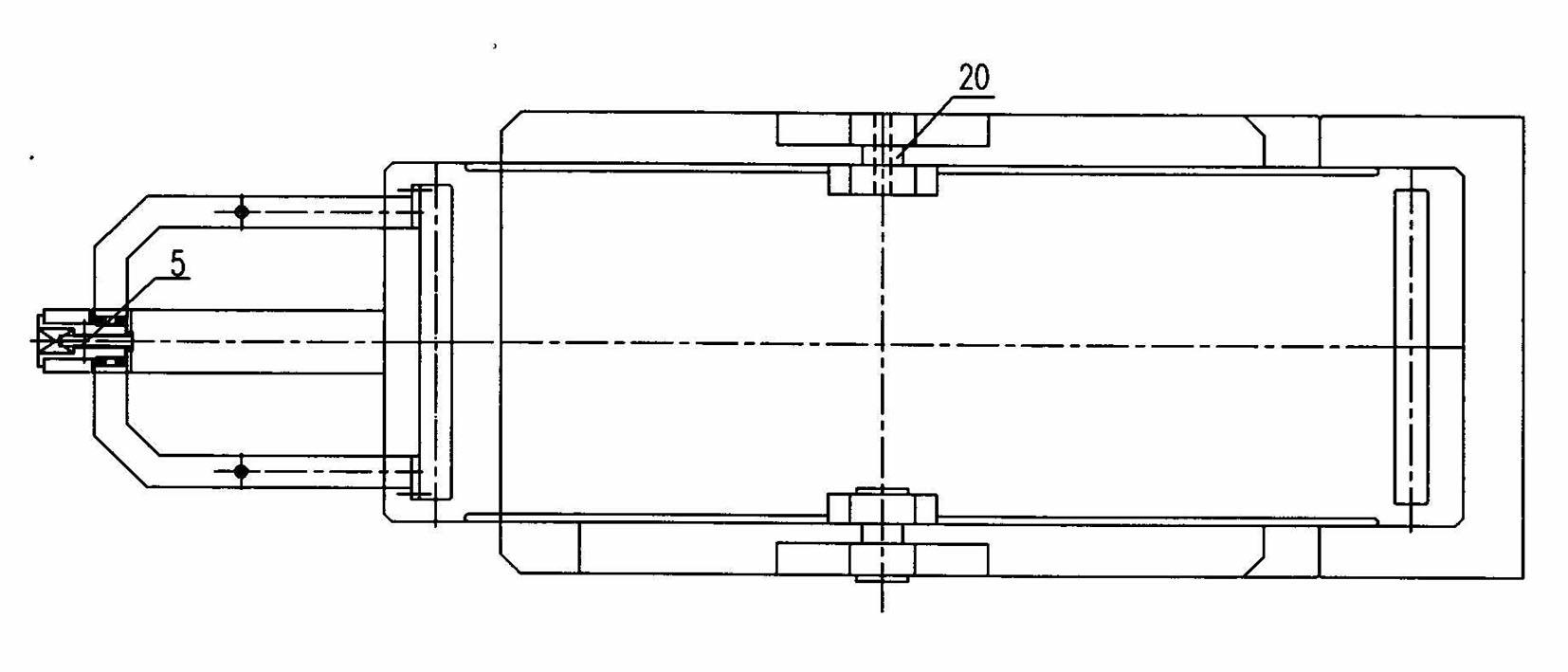

[0025] like figure 1 , figure 2 , image 3 As shown, the three-dimensional measuring mechanism for realizing the quality characteristics of the winged flying body of the present invention includes a base 1 with a Y-axis of rotation 2 at its center, and a Y-axis of rotation installed at the lower end of the Y-axis of rotation. 2 The torsion bar mechanism for periodical swing, the support plate installed on the upper end of the Y-direction rotation axis 3, the horizontal beam installed above the support plate, the support frames symmetrically arranged on both sides of the middle of the horizontal beam and the Z To the center torsion bar mechanism 20, the inertia bracket 4 installed on the horizontal beam; between the bottom surface of the horizontal beam and the top surface of the machine base 1, a plurality of groups of load cells 10 arranged around the perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com