Patents

Literature

2228 results about "Three dimensional measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional solids have measurements analogous to perimeter and area; they are called surface area and volume. Where perimeter is a measure of length only--it is a one- dimensional measure for figures of two dimensions--surface area is a measure solely of area, a two-dimensional measure of solids that exist in three dimensions.

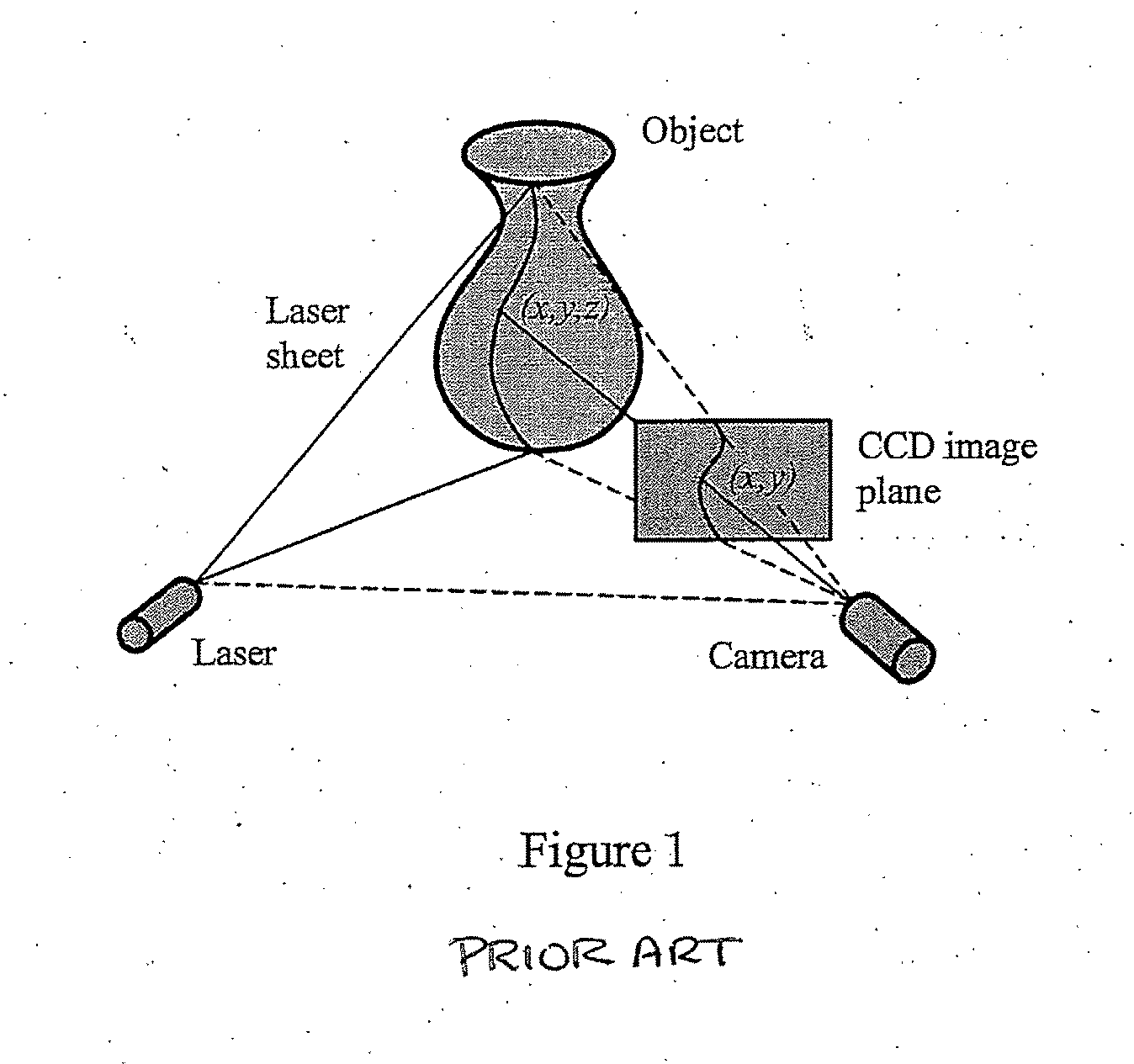

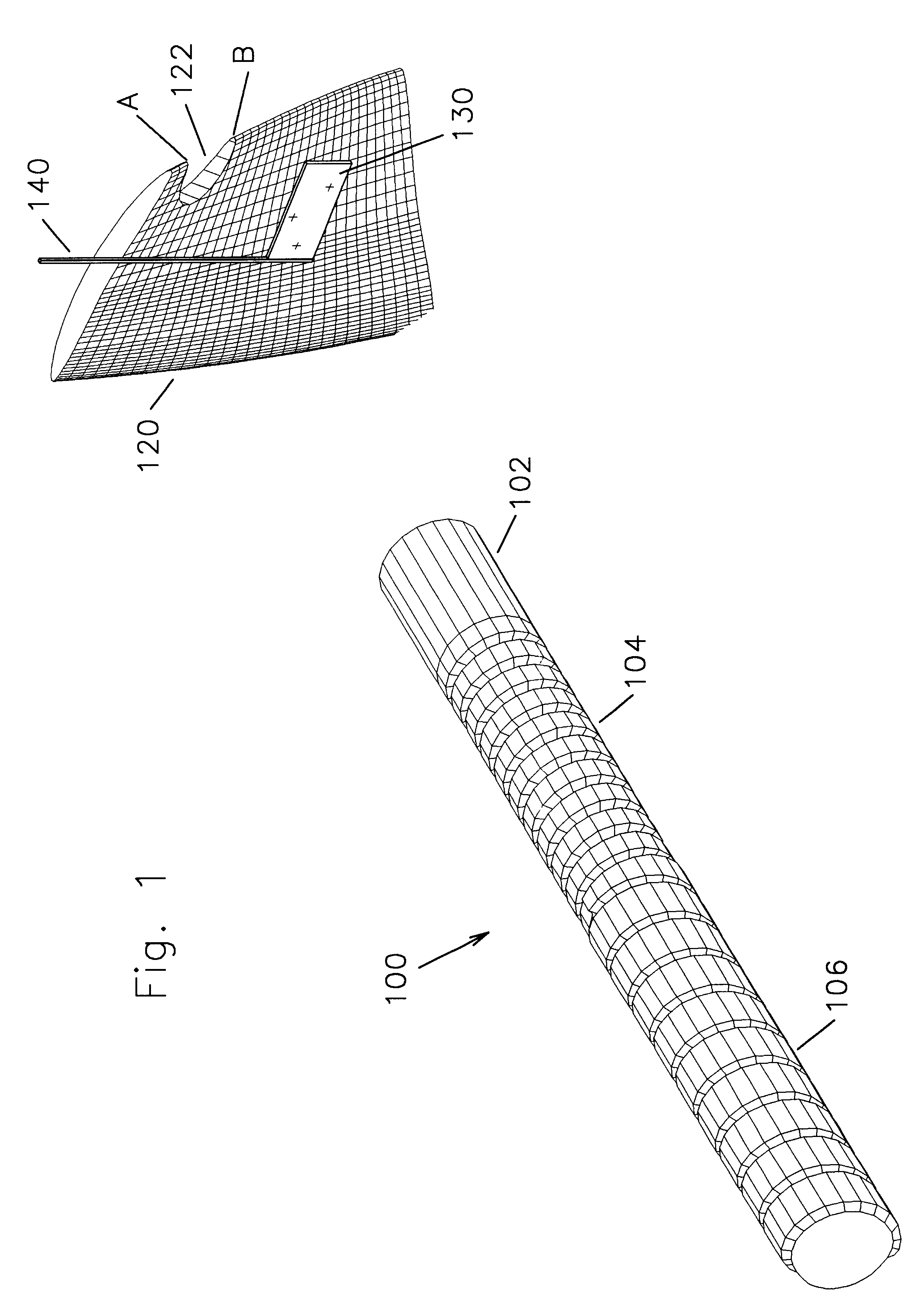

Three-dimensional measurement method and apparatus

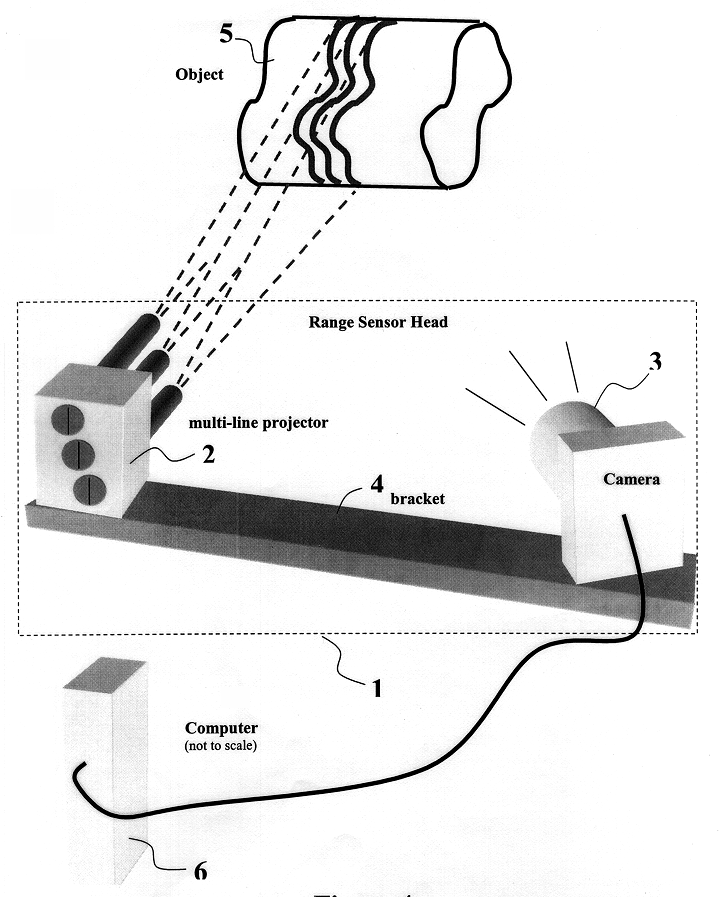

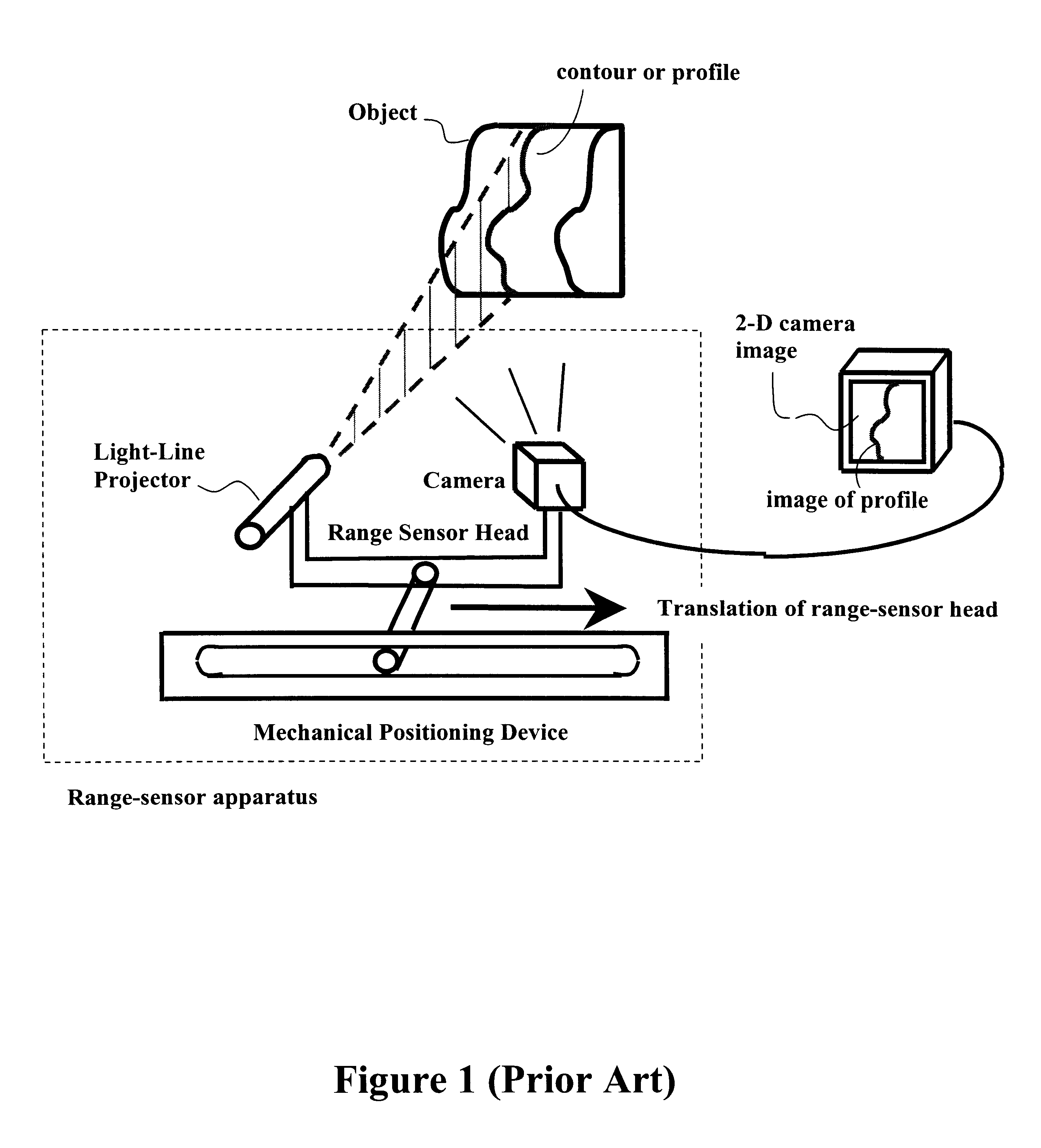

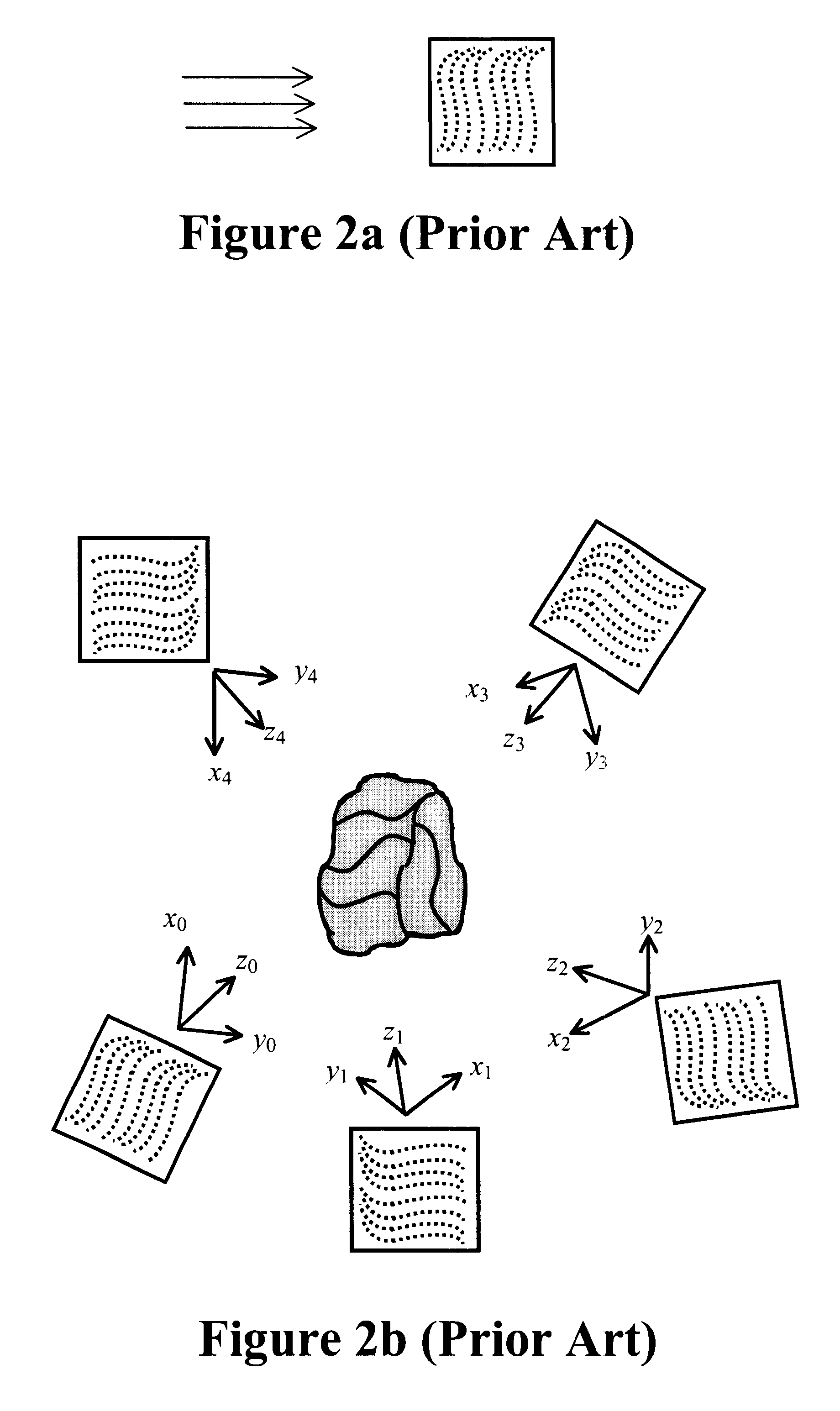

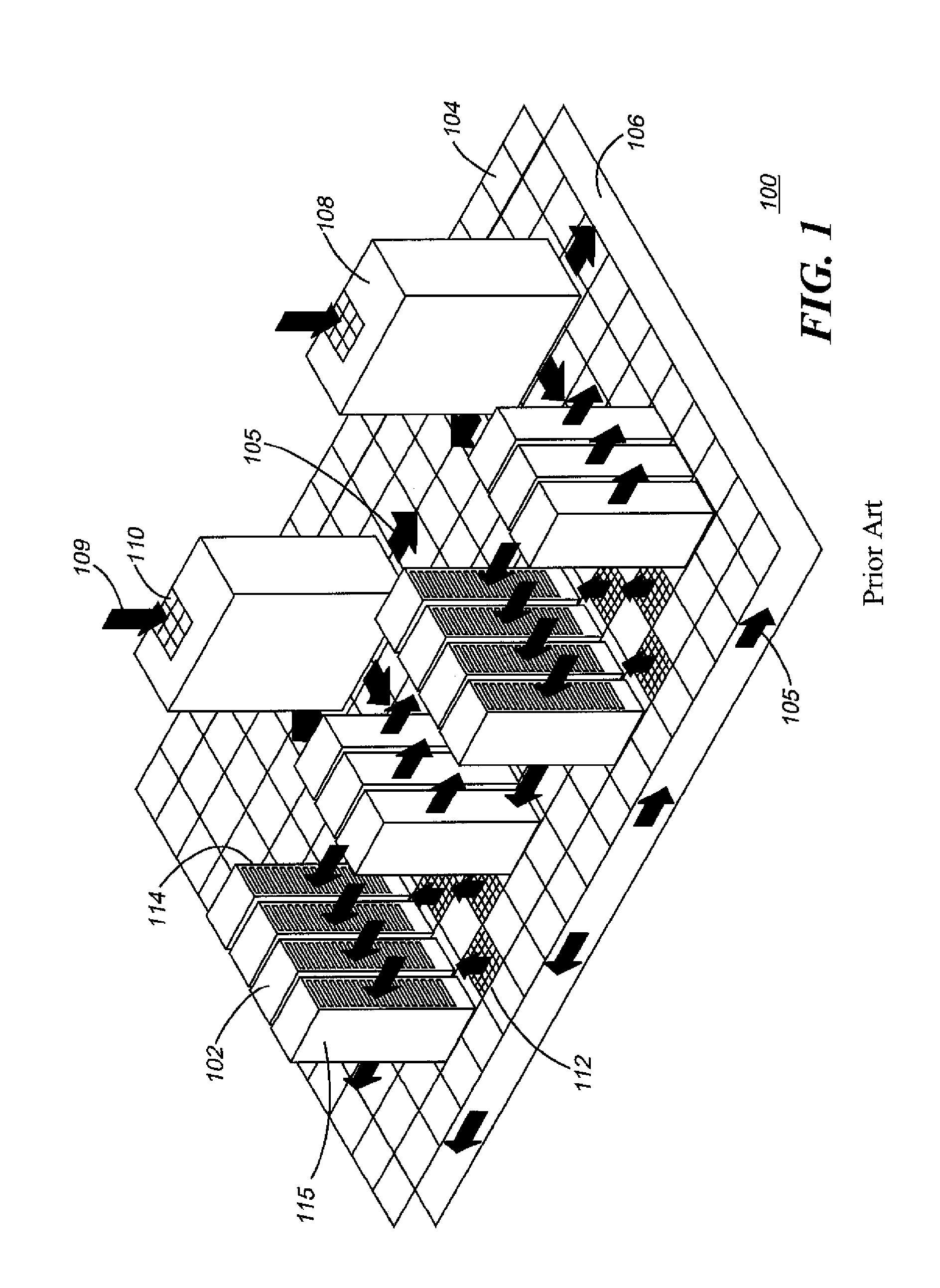

The apparatus and method measure the three-dimensional surface shape of a surface without contact with the surface, and without any physical constraint on the device during measurement. The device is a range-sensor or scanner, and in one embodiment is a laser-camera sensor, which has a portable camera and multi-line light projector encased in a compact sensor head, and a computer. The apparatus provides three-dimensional coordinates in a single reference frame of points on the surface. The sensor head does not have to be physically attached to any mechanical positioning device such as a mechanical arm, rail, or translation or rotation stage, and its position in three-dimensional space does not have to be measured by any position-tracking sensor. This allows unrestricted motion of the sensor head during scanning, and therefore provides much greater access to surfaces which are immovable, or which have large dimensions or complex shape, and which are in confined spaces such as interior surfaces. It also permits measurement of a surface to be made by a continuous sweeping motion rather than in stages, and thus greatly simplifies the process of measurement. The apparatus can be hand-held, mounted on any moving device whose motion is unknown or not accurately known, or airborne. The apparatus and method also permit unknown and unmeasured movement of the object whose surface is to be measured, which may be simultaneous with the movement of the range-sensor head.

Owner:ALIGN TECH

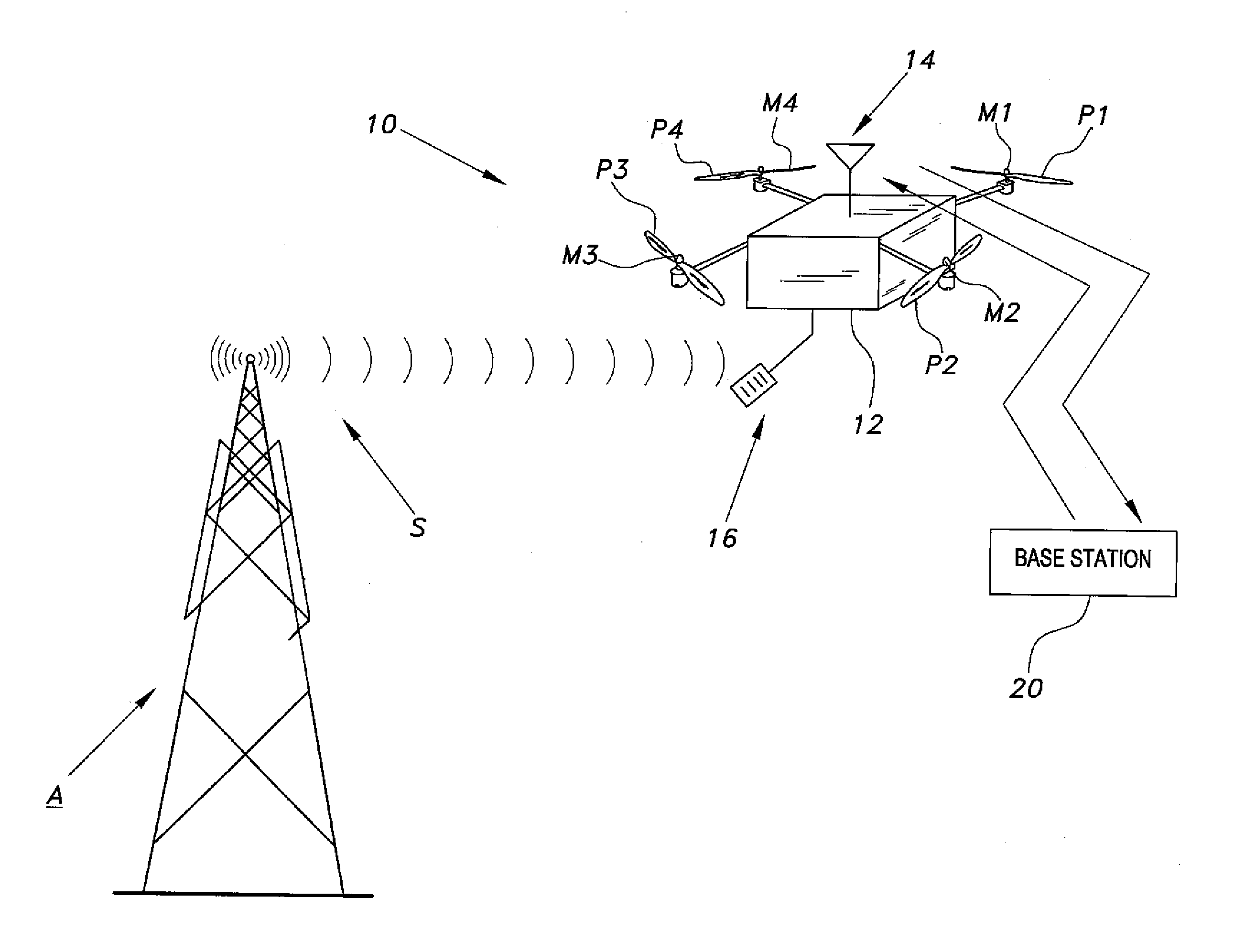

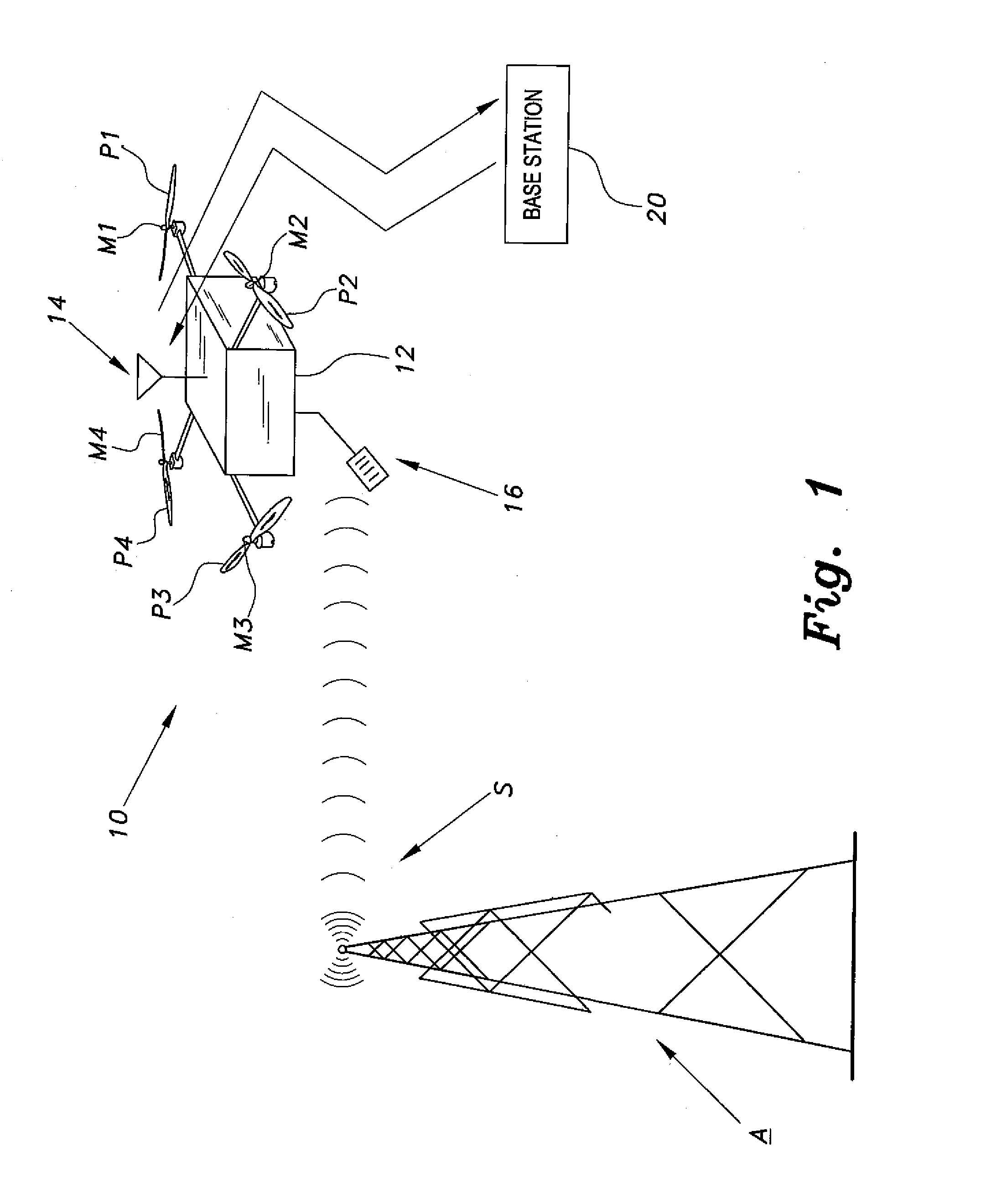

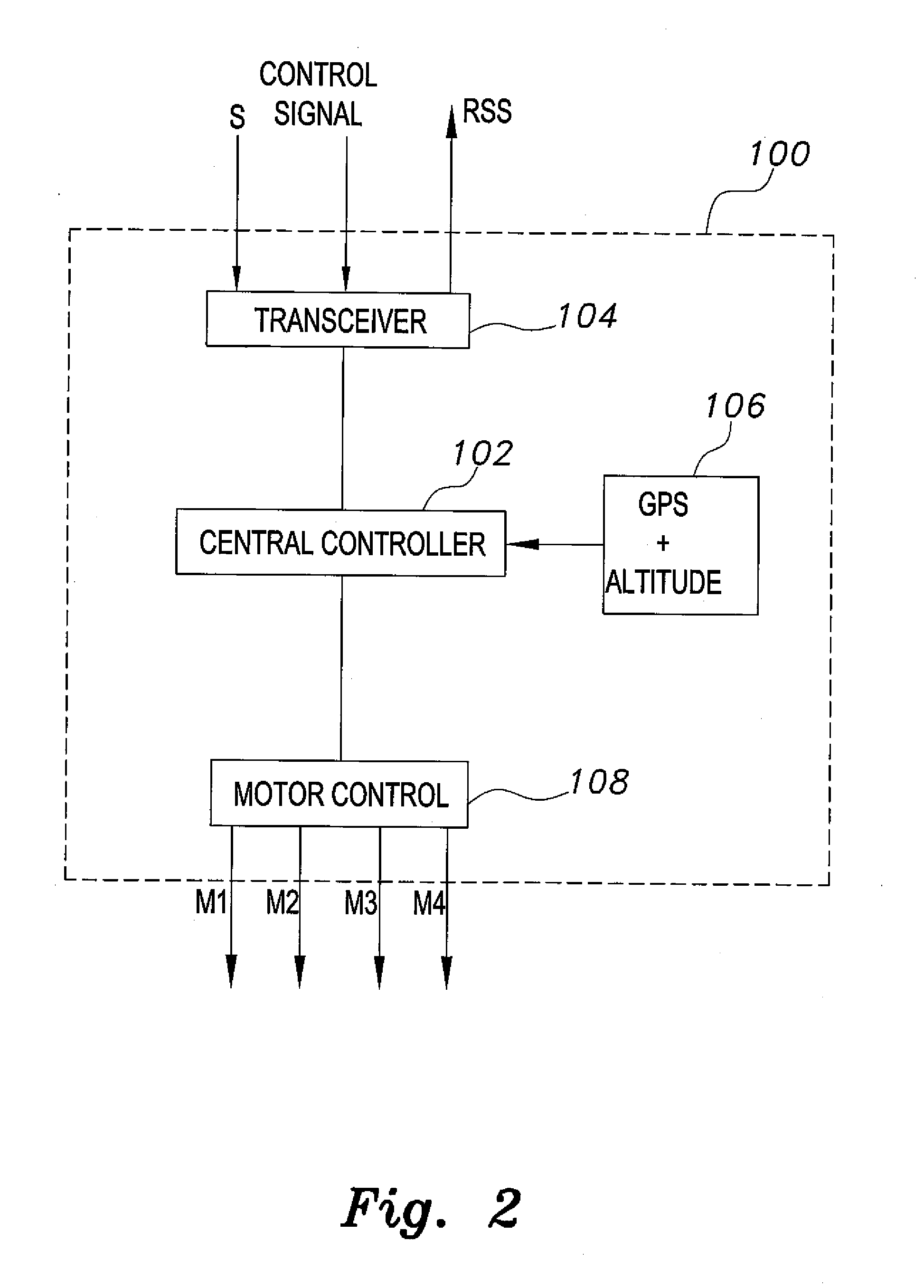

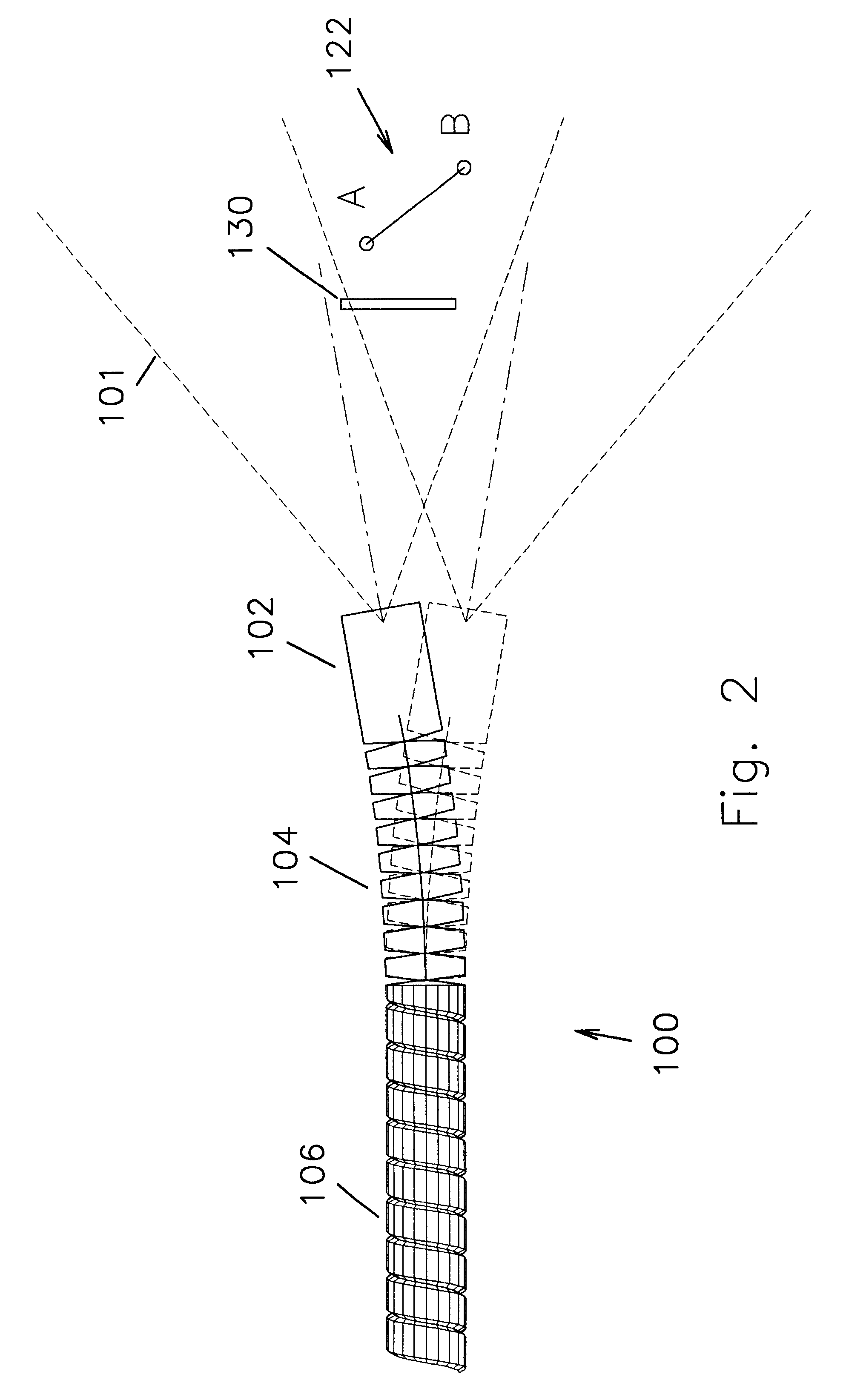

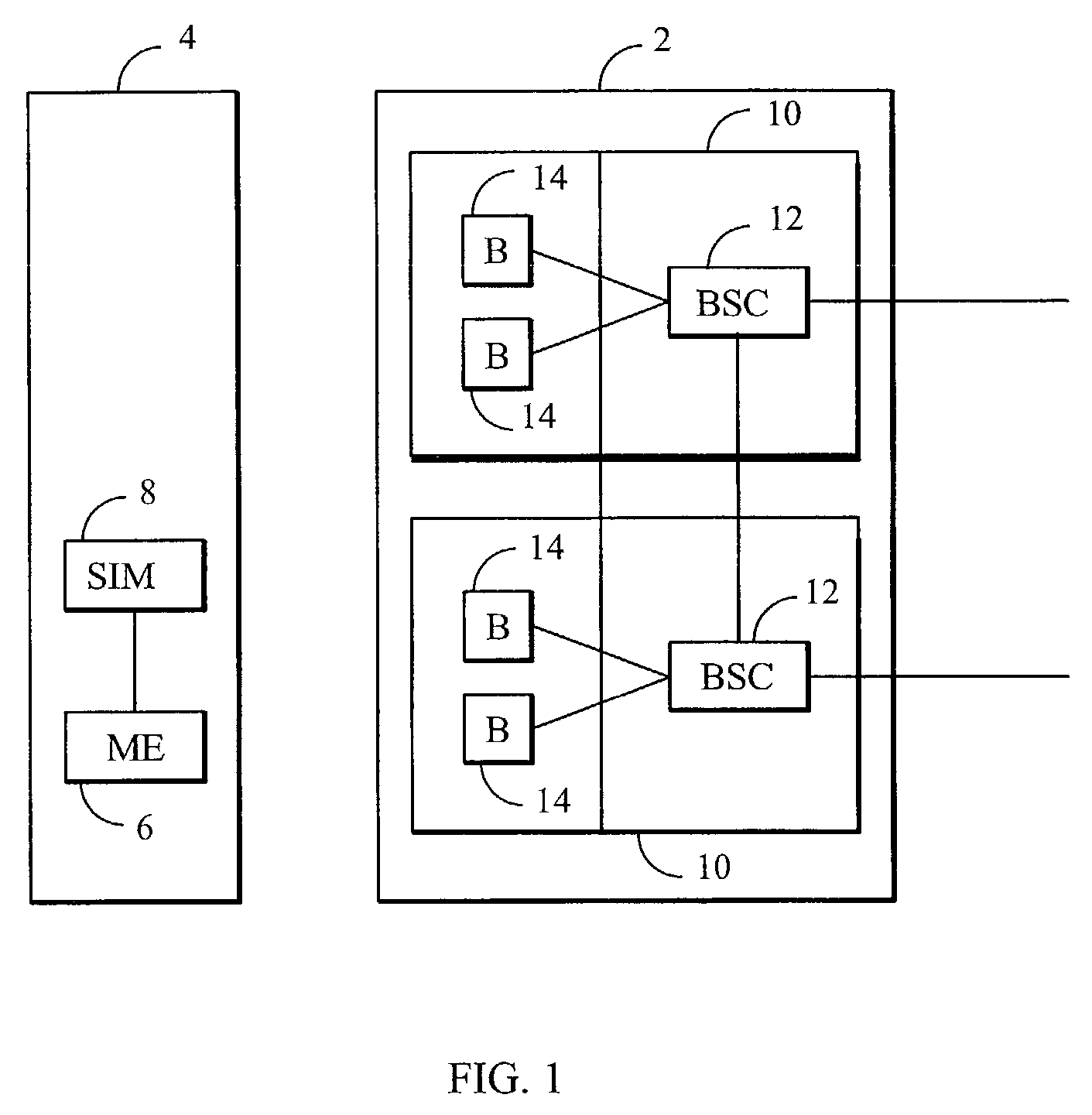

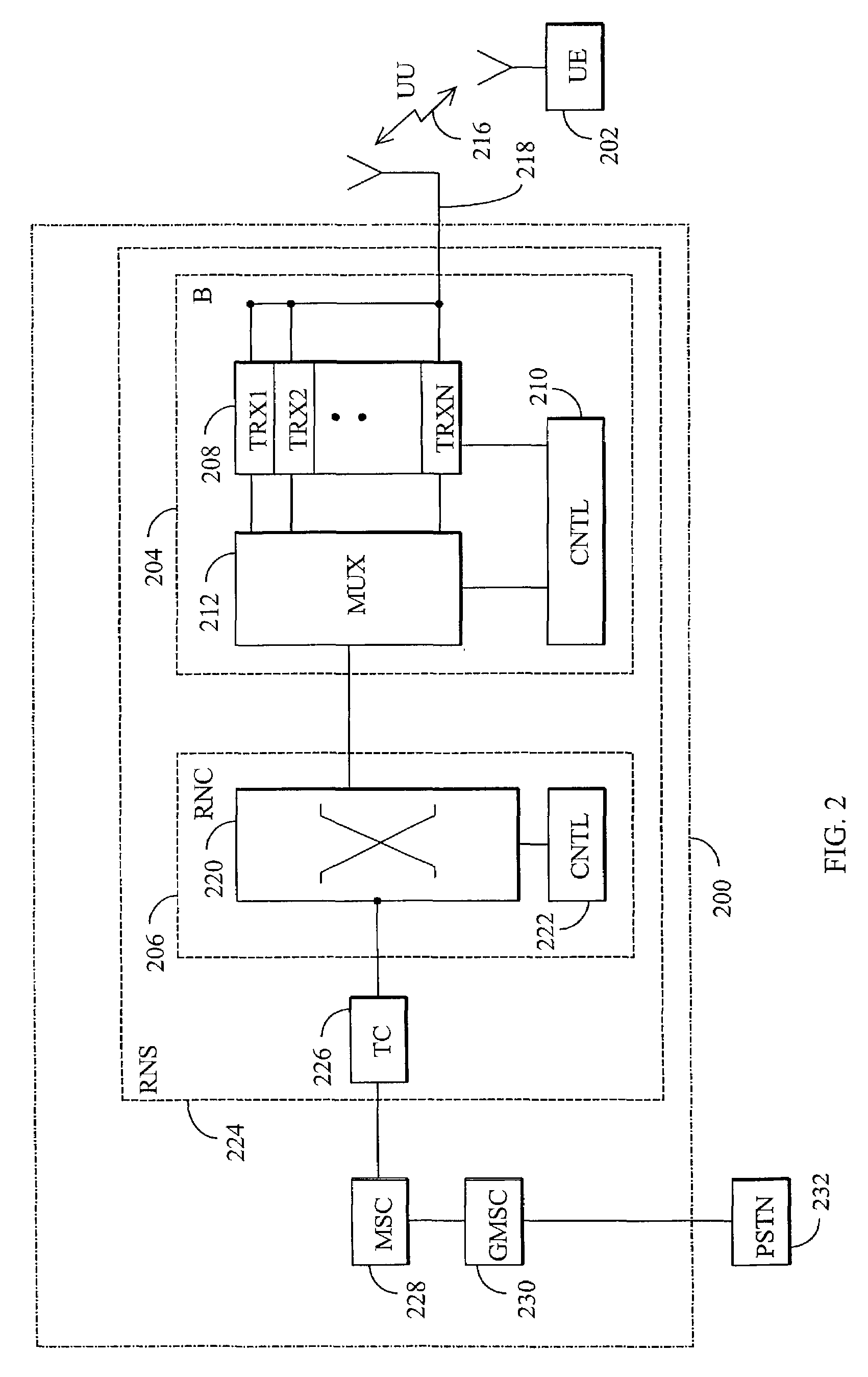

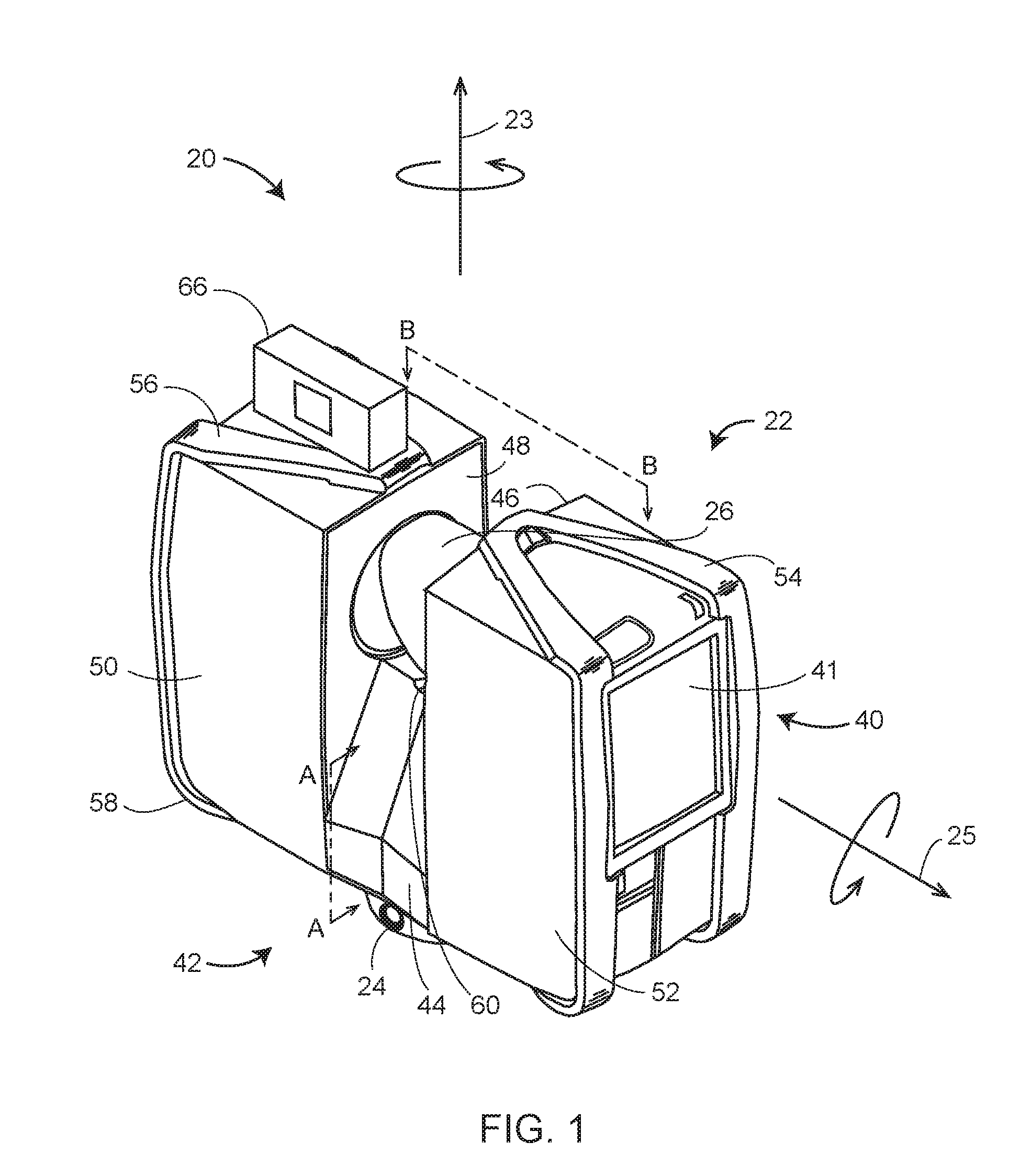

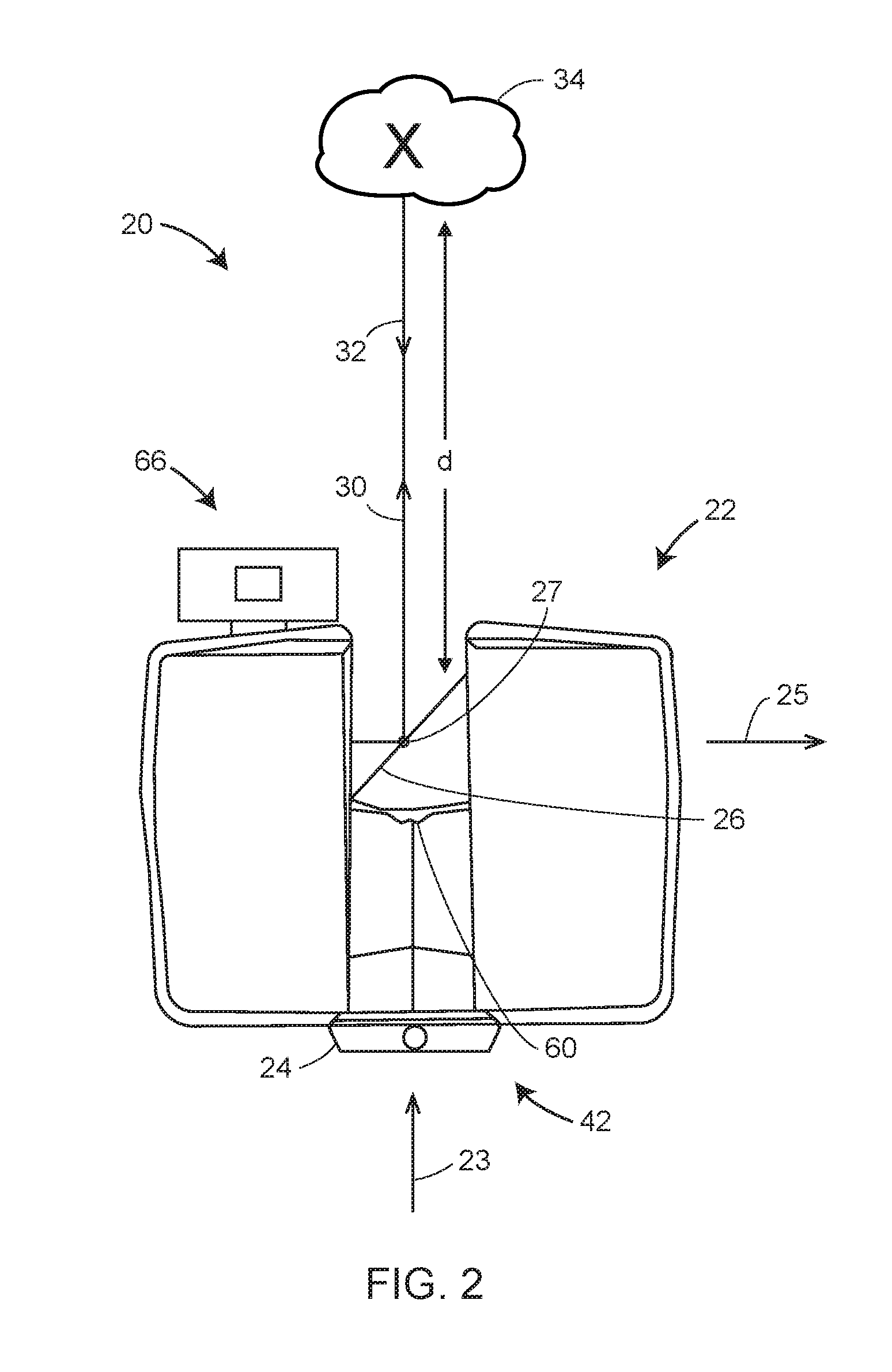

Unmanned aerial vehicle for antenna radiation characterization

InactiveUS20160088498A1Readily apparentError preventionTransmission systemsTransceiverControl signal

The unmanned aerial vehicle for antenna radiation characterization is an unmanned aerial vehicle having a propulsion system and a transceiver. Control signals are transmitted from a base station to position the unmanned aerial vehicle adjacent an antenna of interest. The unmanned aerial vehicle for antenna radiation characterization further includes a signal strength antenna for receiving an antenna signal generated by the antenna of interest for calculating or determining the received signal strength of the antenna signal. A received signal strength signal is then transmitted back to the base station, in real time. The received signal strength signal is representative of a set of received signal strengths of the antenna signal corresponding to a set of three-dimensional measurement coordinates such that the received signal strength signal represents a three-dimensional radiation pattern associated with the antenna of interest.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

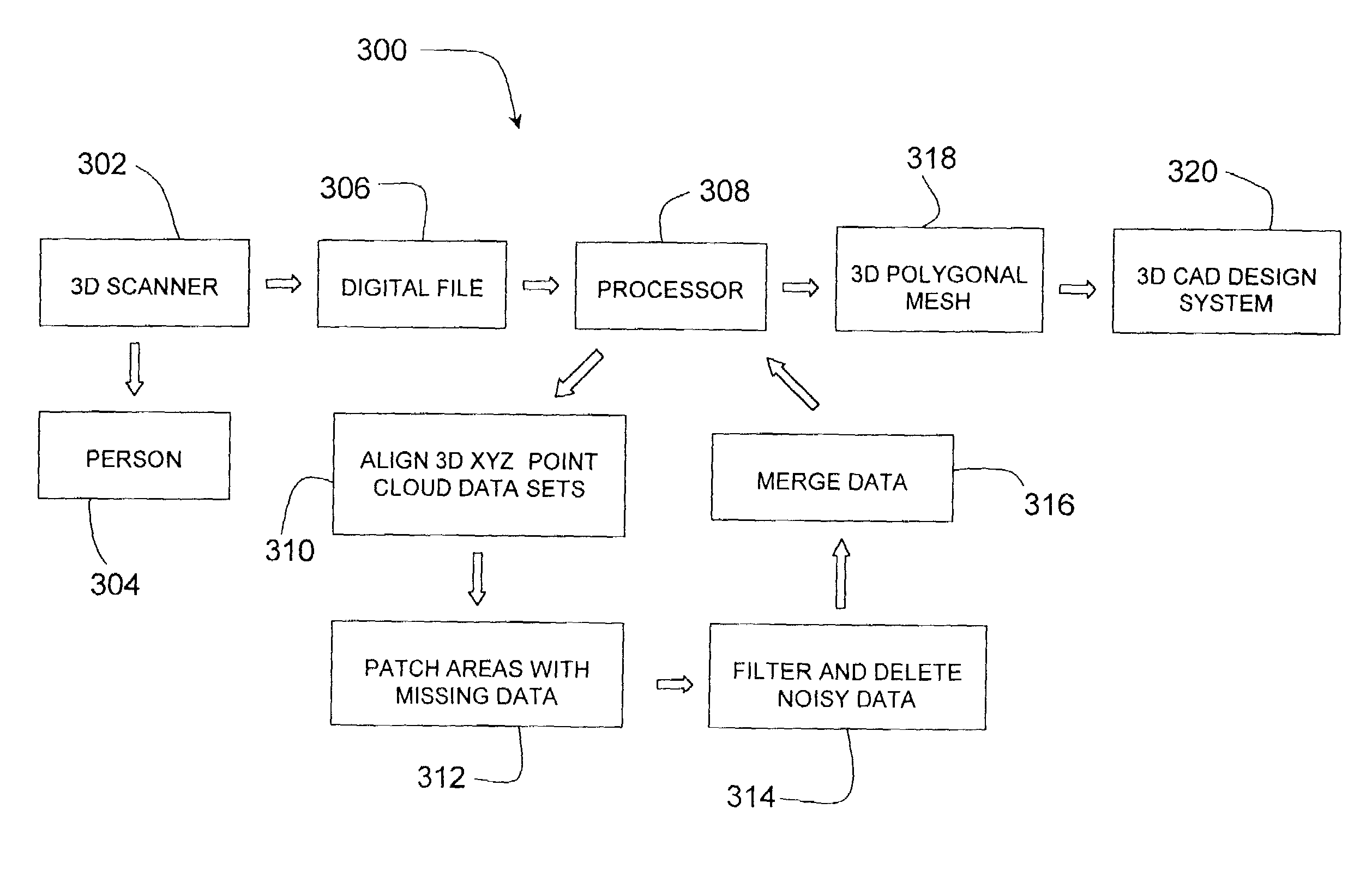

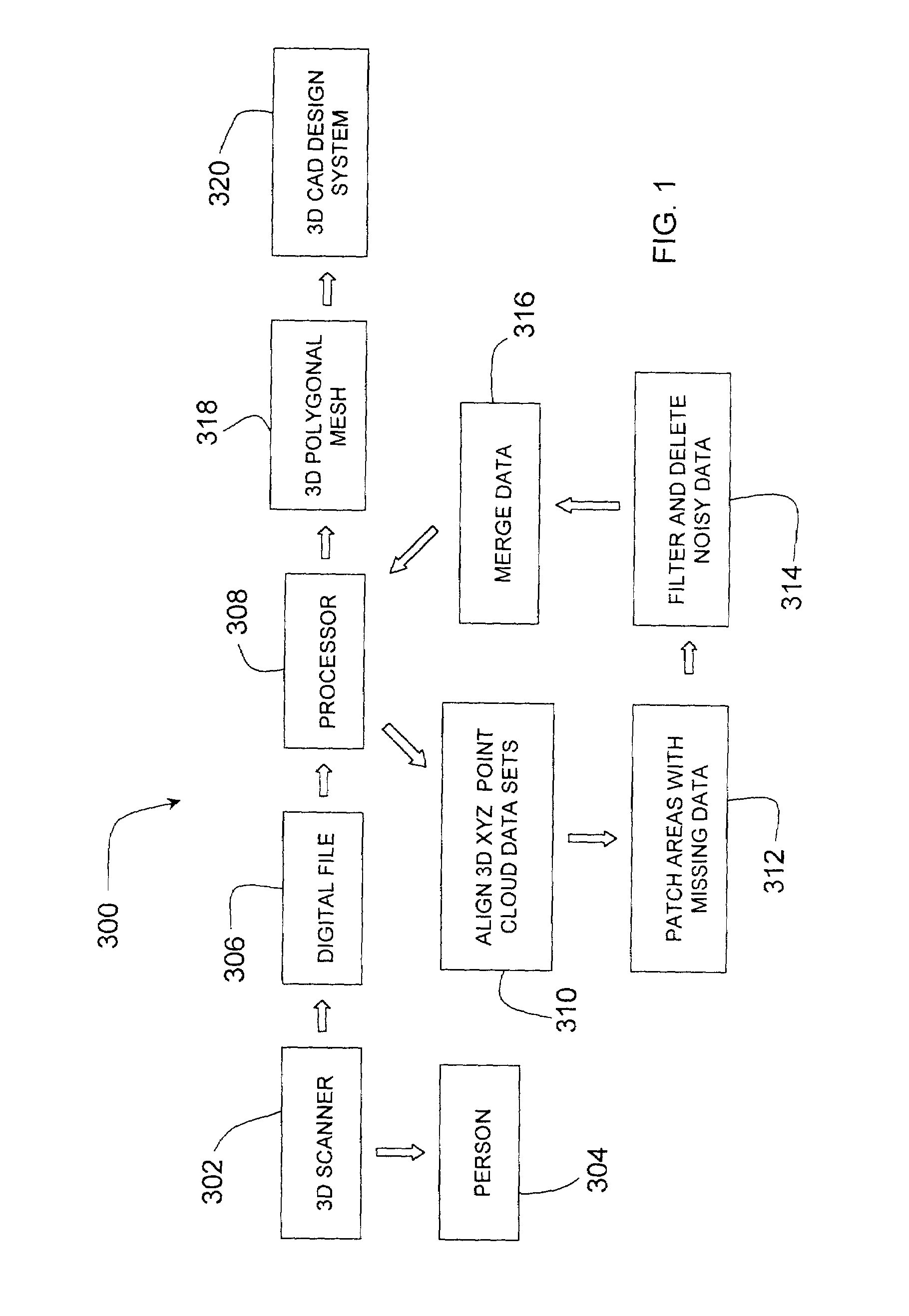

System and method for three-dimensional shape and size measurement

InactiveUS6968075B1Accurate measurementData augmentationData processing applicationsSpecial data processing applicationsComputer Aided DesignSize measurement

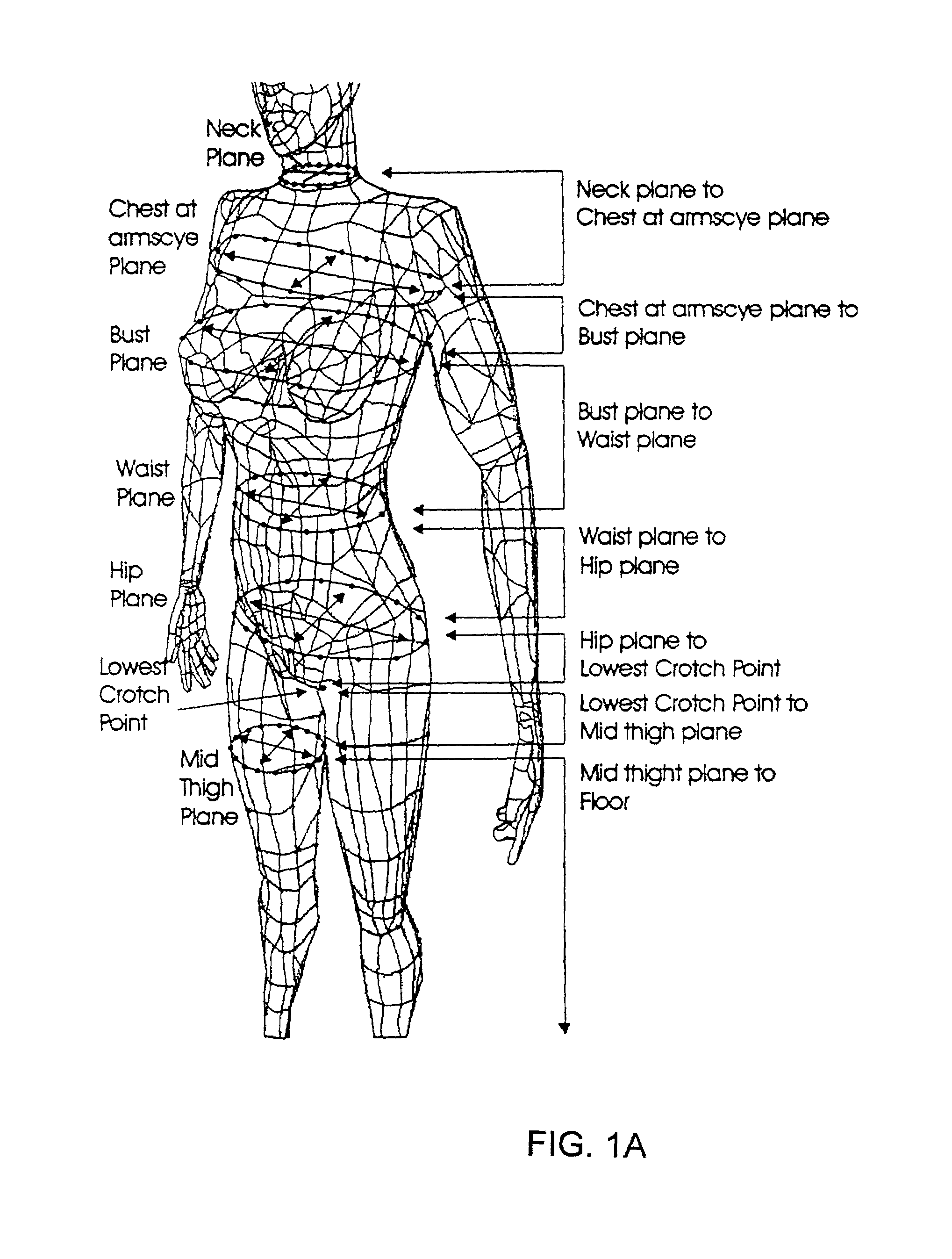

A method for three-dimensional shape and size measurement of a three-dimensional body surface comprising providing a three-dimensional scanner, providing a processor, providing a three-dimensional Computer Aided Design system, scanning in three dimensions with the three-dimensional scanner at least a portion of the three-dimensional body surface, creating a data file representative of the three-dimensional body surface, processing the data file with the processor, importing the data file into the three-dimensional Computer Aided Design System, employing the three-dimensional Computer Aided Design System relative to the data file to define and record three-dimensional measuring data relative to at least a portion of the three-dimensional body surface, A and employing the three-dimensional Computer Aided Design System to exploit the three-dimensional measuring data.

Owner:CHANG KURT C

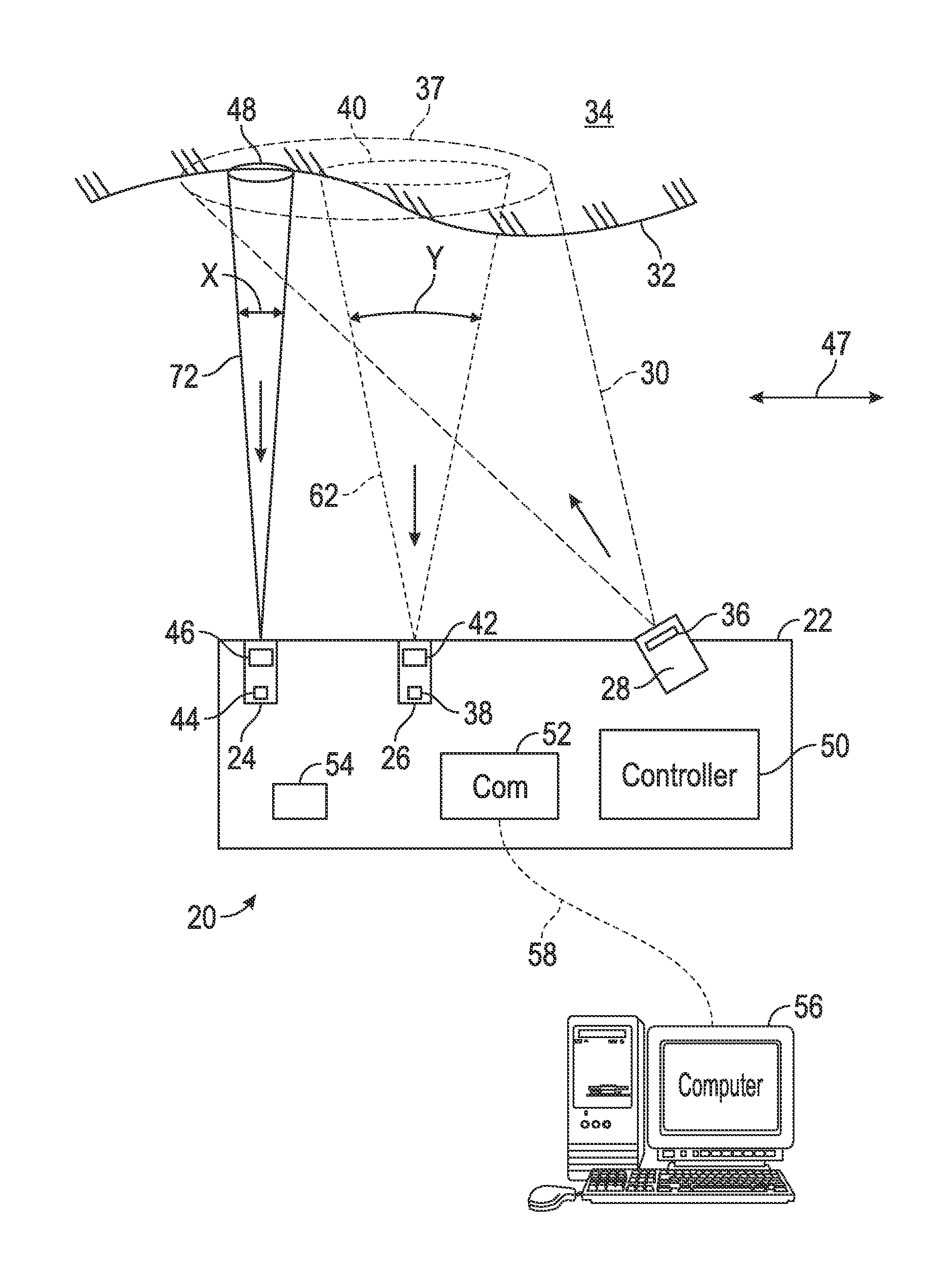

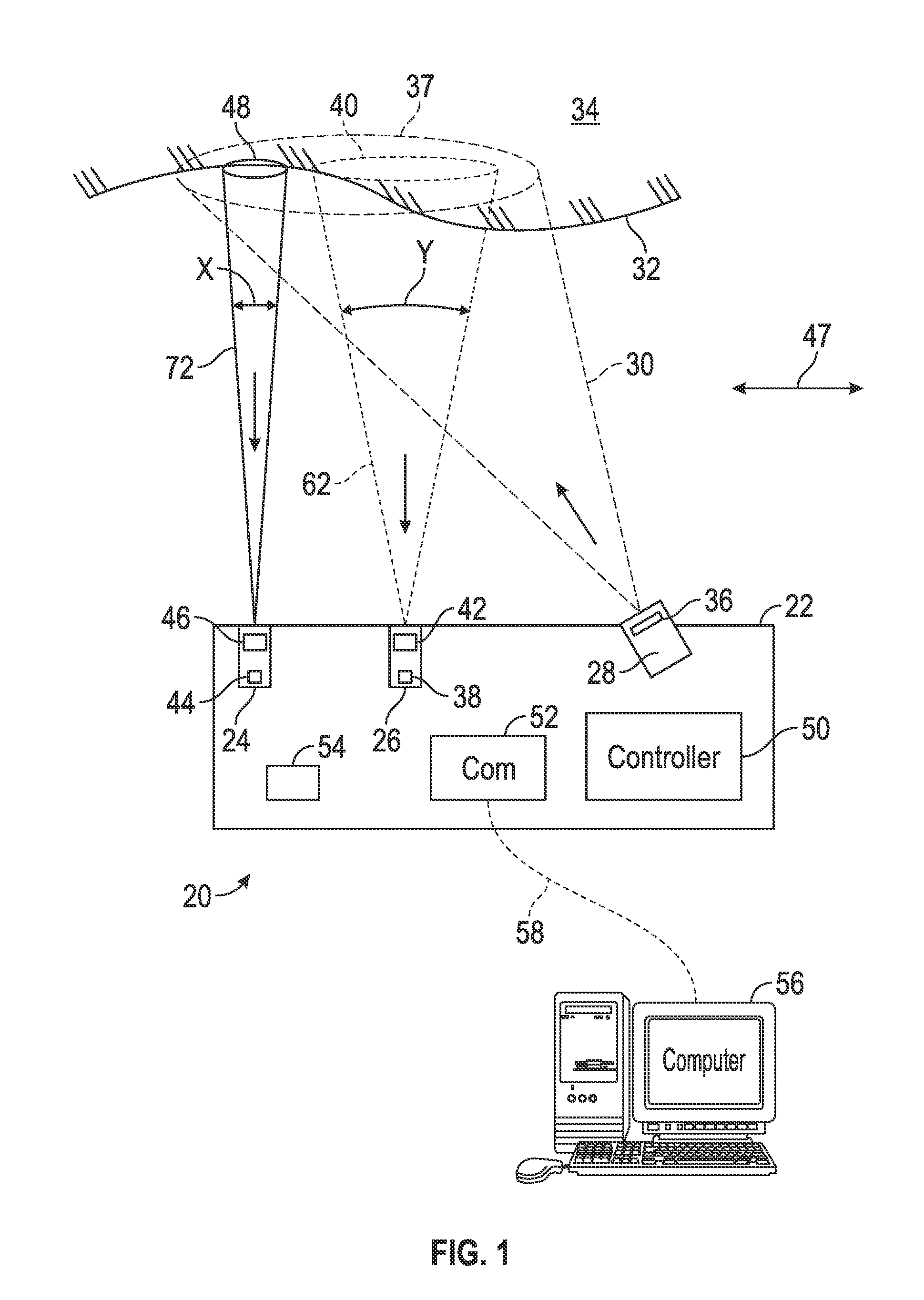

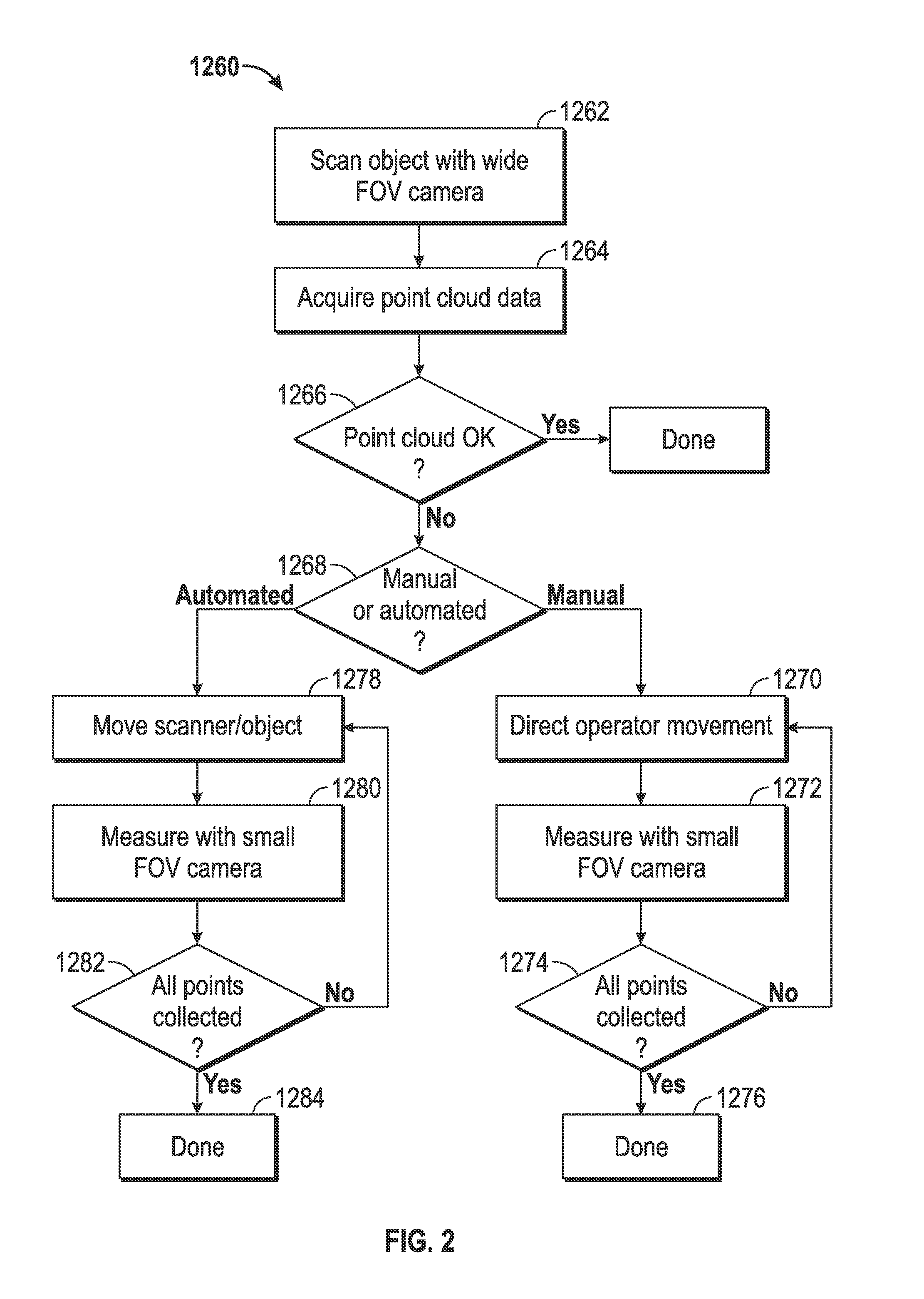

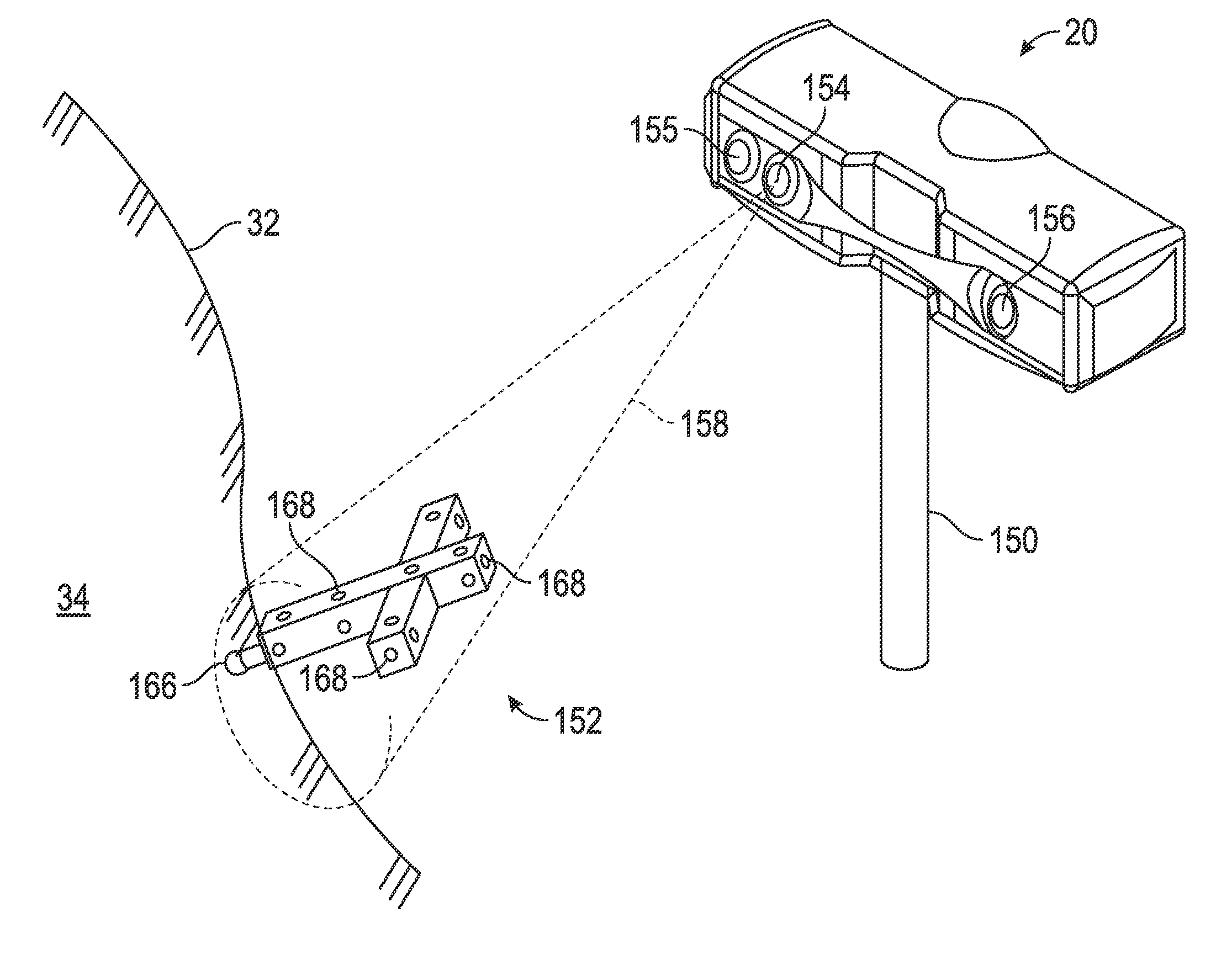

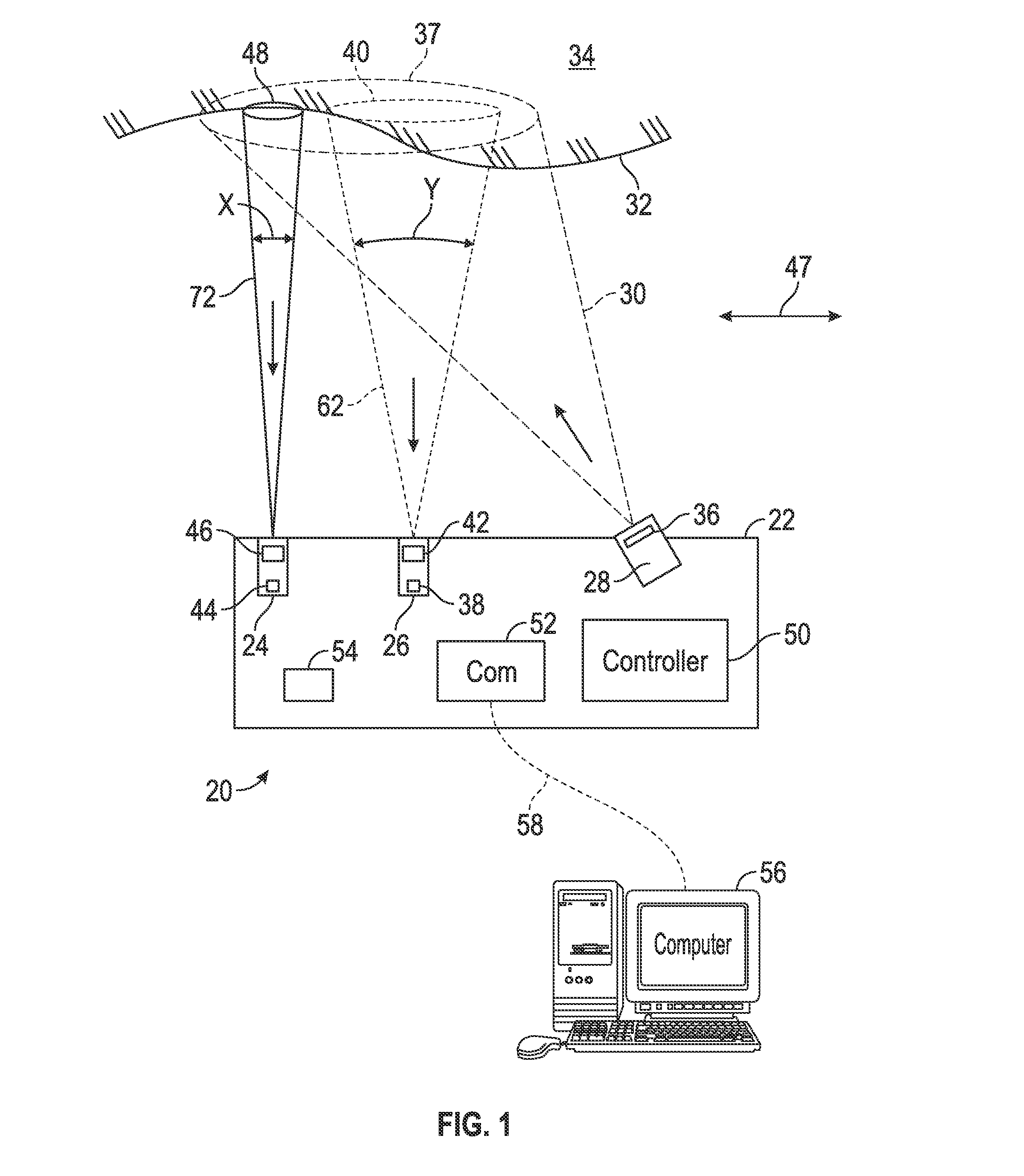

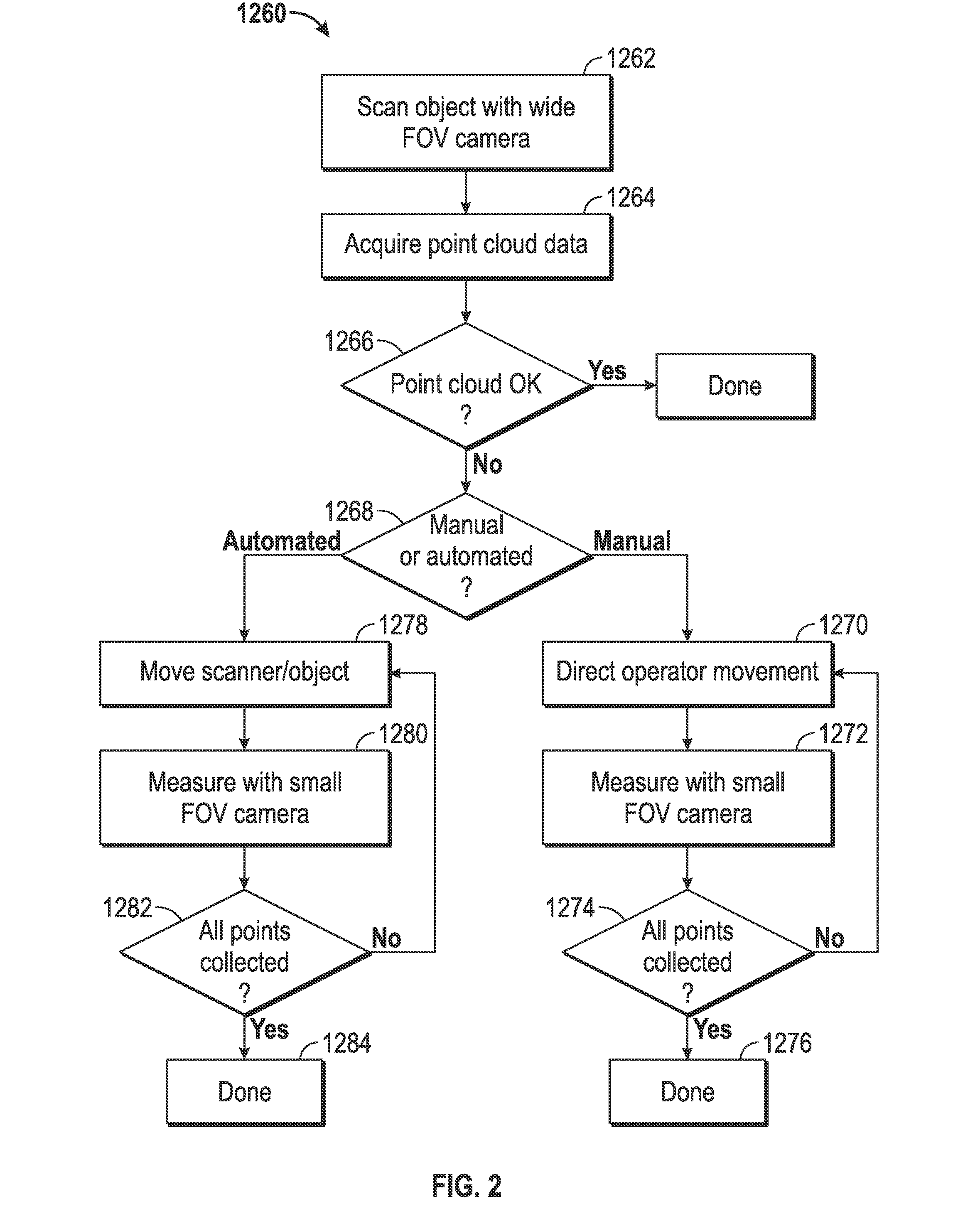

Three-dimensional coordinate scanner and method of operation

ActiveUS20130293684A1Photogrammetry/videogrammetryActive open surveying meansThree dimensional measurementDigital signal

A noncontact optical three-dimensional measuring device that includes a first projector, a first camera, a second projector, and a second camera; a processor electrically coupled to the first projector, the first camera, the second projector, and the second camera; and computer readable media which, when executed by the processor, causes the first digital signal to be collected at a first time and the second digital signal to be collected at a second time different than the first time and determines three-dimensional coordinates of a first point on the surface based at least in part on the first digital signal and the first distance and determines three-dimensional coordinates of a second point on the surface based at least in part on the second digital signal and the second distance.

Owner:FARO TECH INC

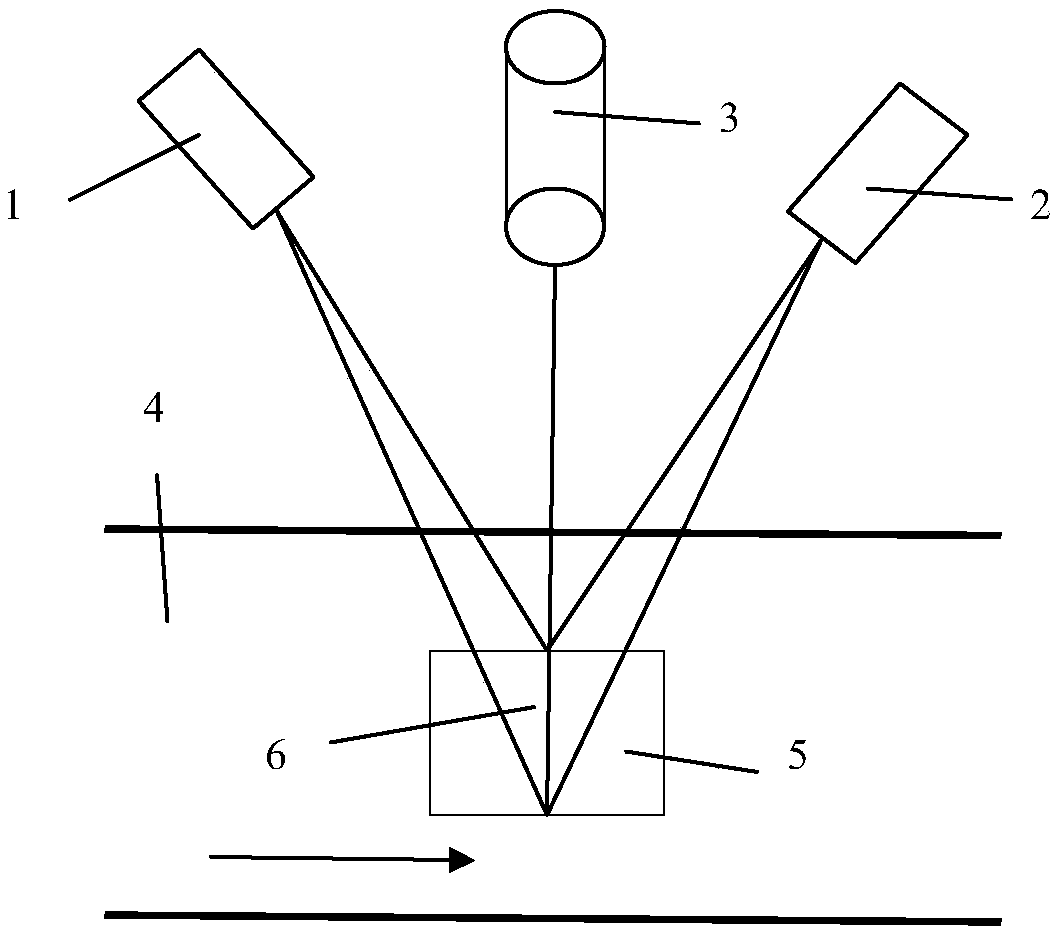

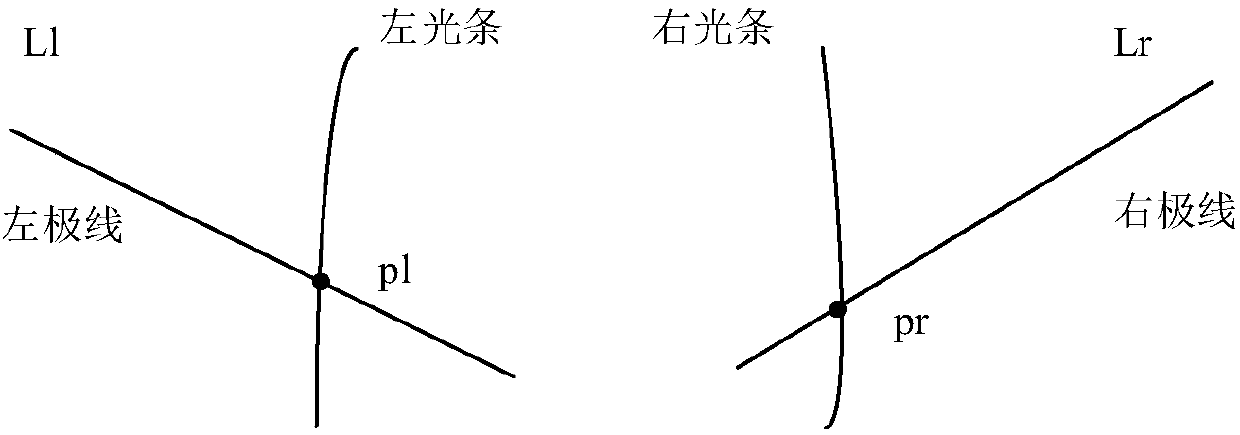

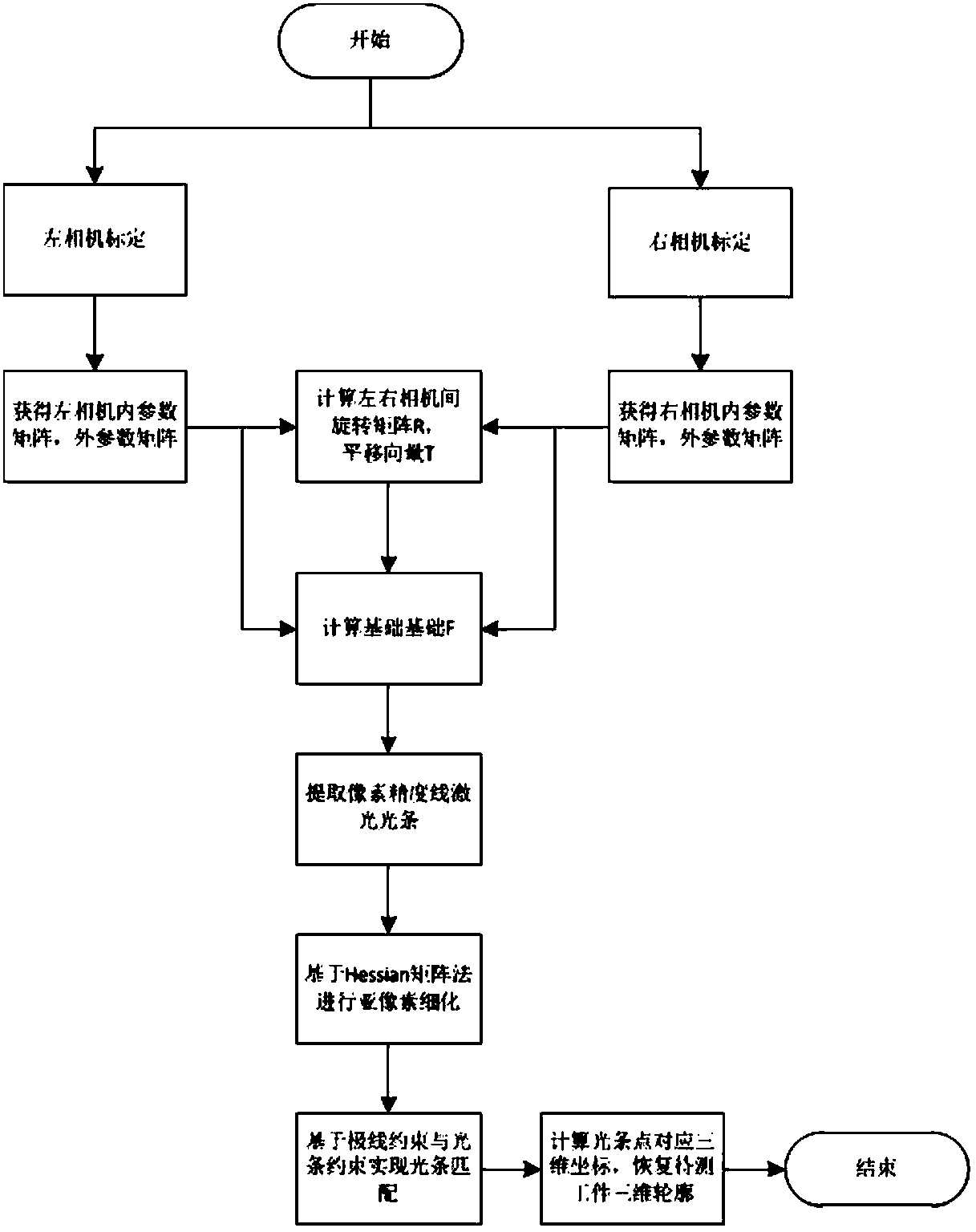

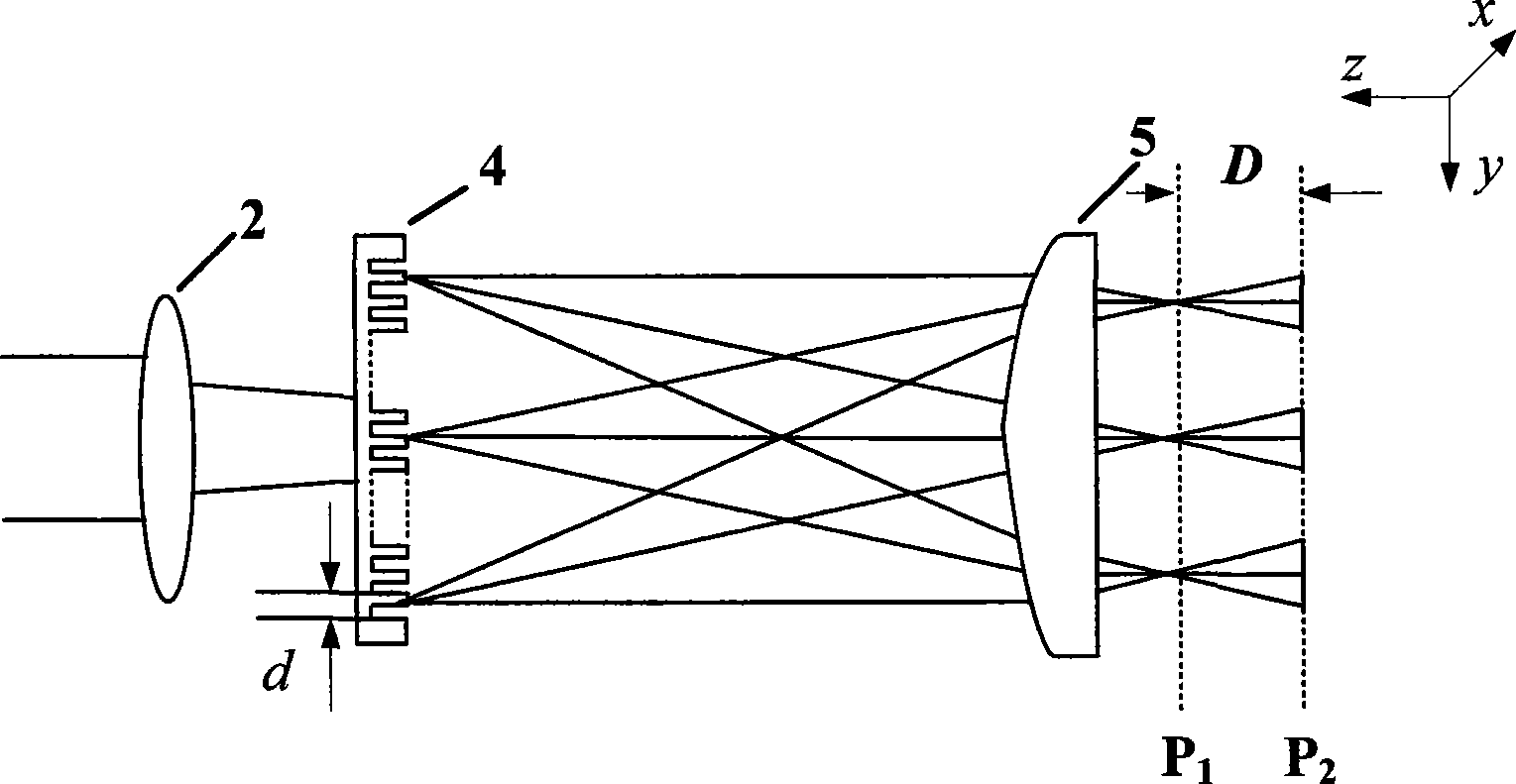

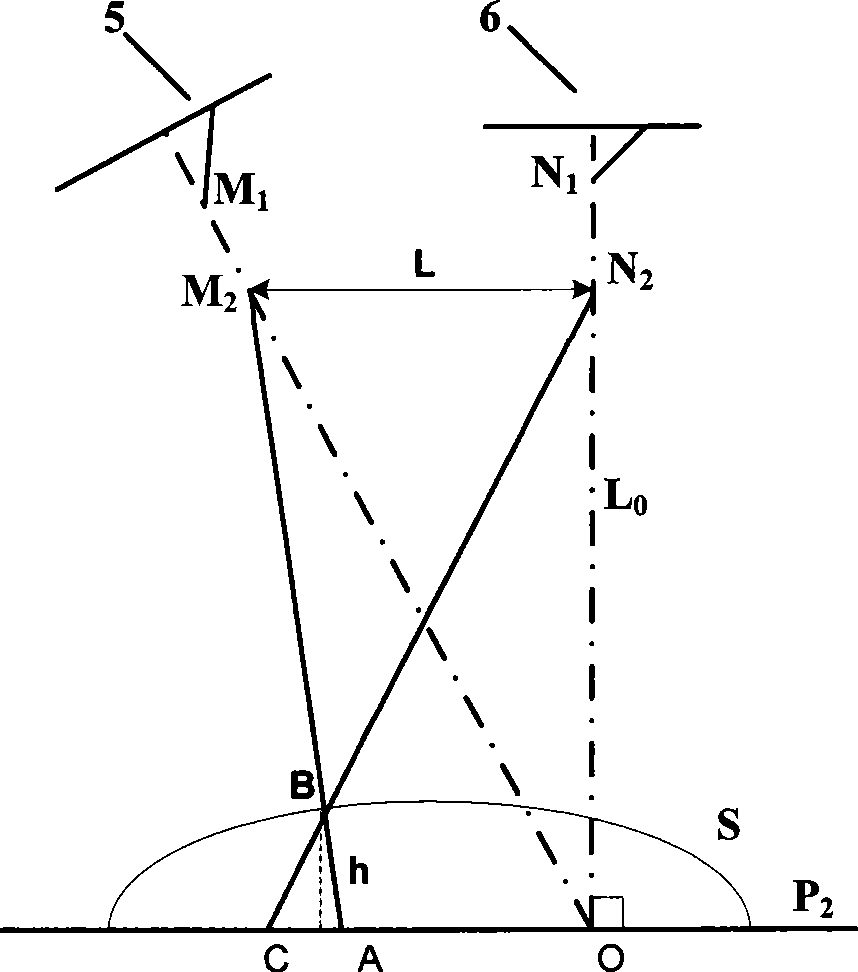

Binocular stereo vision three-dimensional measurement method based on line structured light scanning

InactiveCN107907048AReduce the difficulty of matchingImprove robustnessUsing optical meansThree dimensional measurementLaser scanning

The invention discloses a binocular stereo vision three-dimensional measurement method based on line structured light scanning, which comprises the steps of performing stereo calibration on binocularindustrial cameras, projecting laser light bars by using a line laser, respectively acquiring left and right laser light bar images, extracting light bar center coordinates with sub-pixel accuracy based on a Hessian matrix method, performing light bar matching according to an epipolar constraint principle, and calculating a laser plane equation; secondly, acquiring a line laser scanning image of aworkpiece to be measured, extracting coordinates of the image of the workpiece to be measured, calculating world coordinates of the workpiece to be measured by combining binocular camera calibrationparameters and the laser plane equation, and recovering the three-dimensional surface topography of the workpiece to be measured. Compared with a common three-dimensional measurement system combininga monocular camera and line structured light, the binocular stereo vision three-dimensional measurement method avoids complicated laser plane calibration. Compared with the traditional stereo vision method, the binocular stereo vision three-dimensional measurement method reduces the difficulty of stereo matching in binocular stereo vision while ensuring the measurement accuracy, and improves the robustness and the usability of a visual three-dimensional measurement system.

Owner:CHANGSHA XIANGJI HAIDUN TECH CO LTD

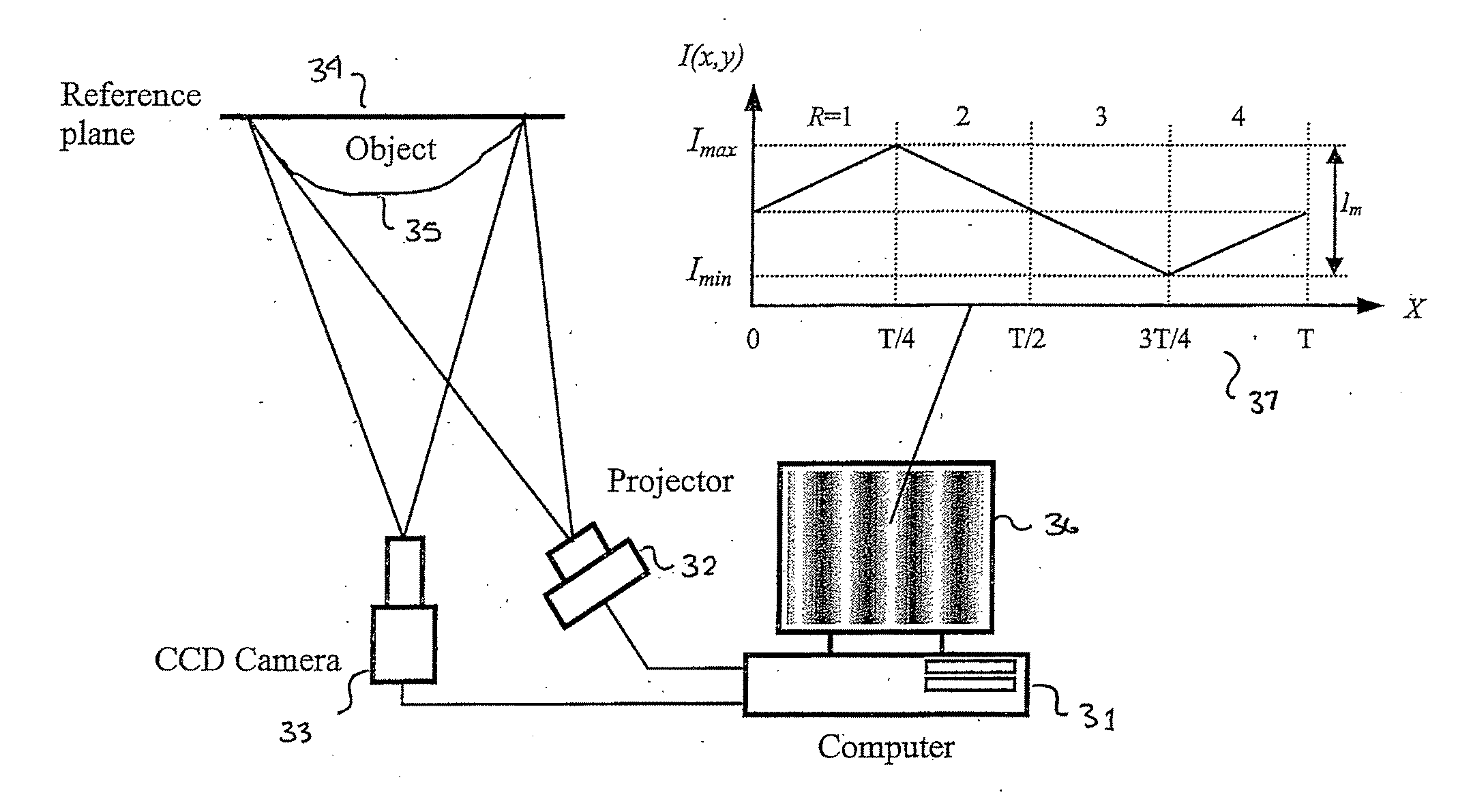

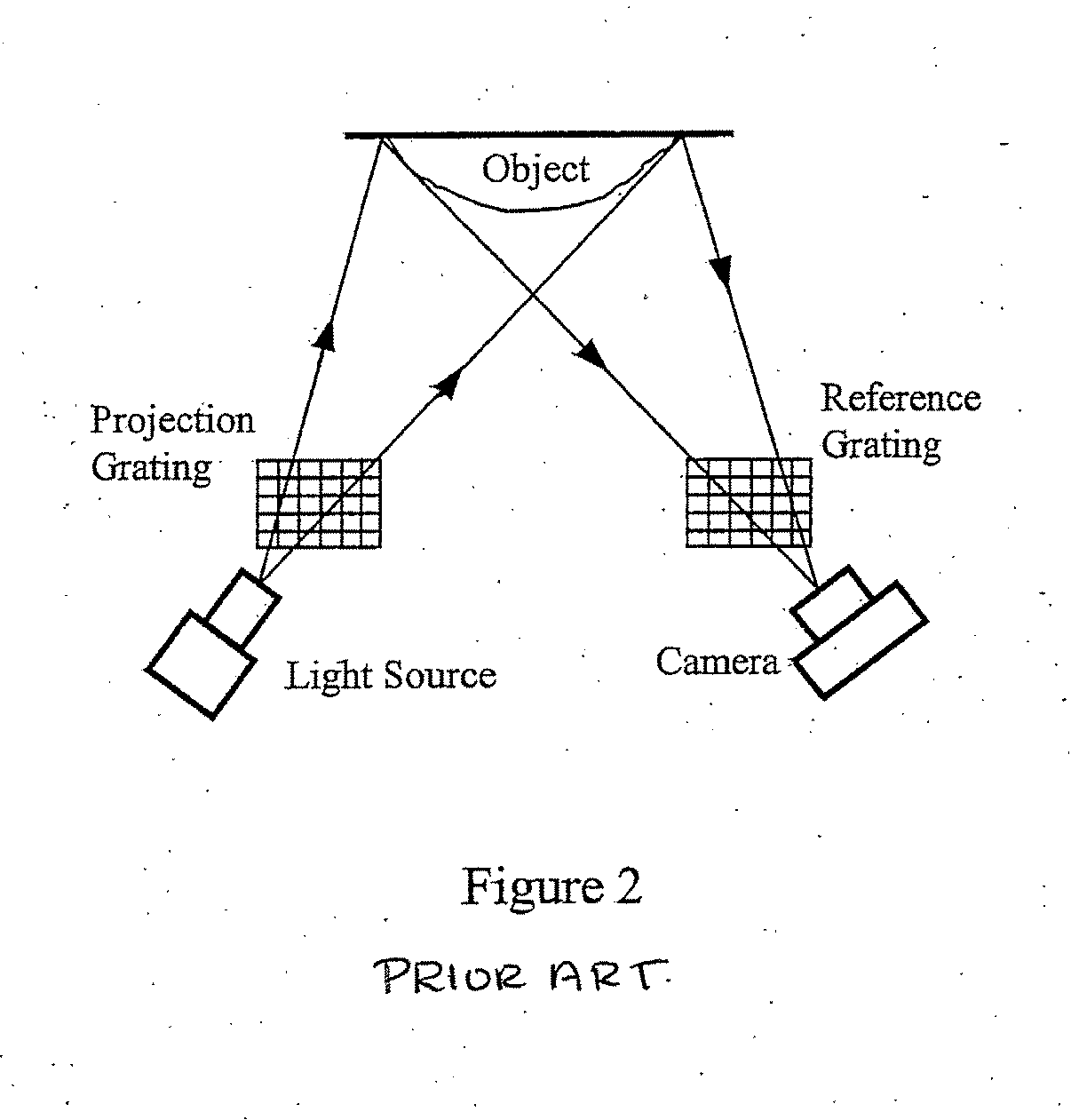

Full-field three-dimensional measurement method

InactiveUS20070206204A1Improve processing speedSimple calculationUsing optical meansTriangulationFull field

A method and system for full-field fringe-projection for 3-D surface-geometry measurement, referred to as “triangular-pattern phase-shifting” is disclosed. A triangular grey-scale-level-coded fringe pattern is computer generated, projected along a first direction onto an object or scene surface and distorted according to the surface geometry. The 3-D coordinates of points on the surface are calculated by triangulation from distorted triangular fringe-pattern images acquired by a CCD camera along a second direction and a triangular-shape intensity-ratio distribution is obtained from calculation of the captured distorted triangular fringe-pattern images. Removal of the triangular shape of the intensity ratio over each pattern pitch generates a wrapped intensity-ratio distribution obtained by removing the discontinuity of the wrapped image with a modified unwrapping method. Intensity ratio-to-height conversion is used to reconstruct the 3-D surface coordinates of the object. Intensity-ratio error compensation involves estimating intensity-ratio error in a simulation of the measurement process with both real and ideal captured triangular-pattern images obtained from real and ideal gamma non-linearity functions. A look-up table relating the measure intensity-ratio to the corresponding intensity-ratio error is constructed and used for intensity-ratio error compensation. The inventive system is based on two-step phase-shifting but can be extended for multiple-step phase-shifting.

Owner:UNIVERSITY OF WATERLOO

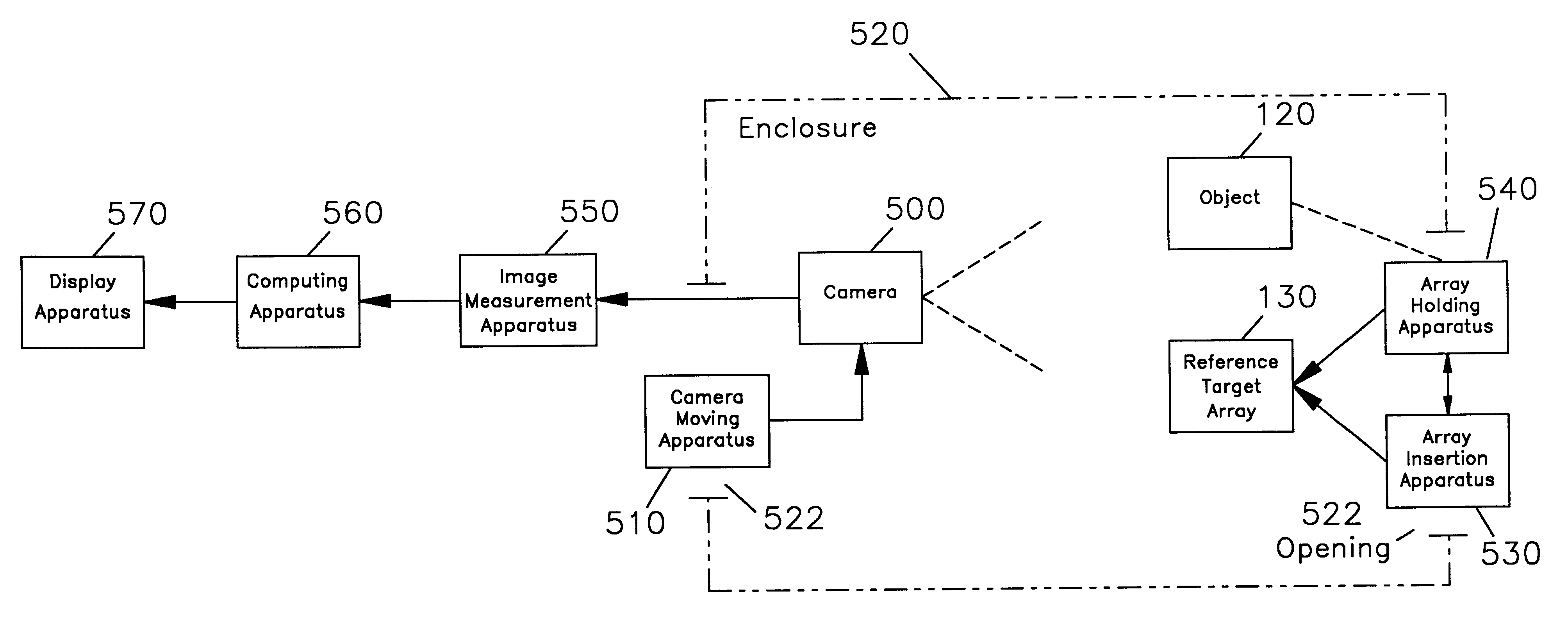

Simple system for endoscopic non-contact three-dimentional measurement

InactiveUS6459481B1Upgrade accuracyUpgrade usefulnessEndoscopesMaterial analysis by optical meansTarget arrayMeasurement device

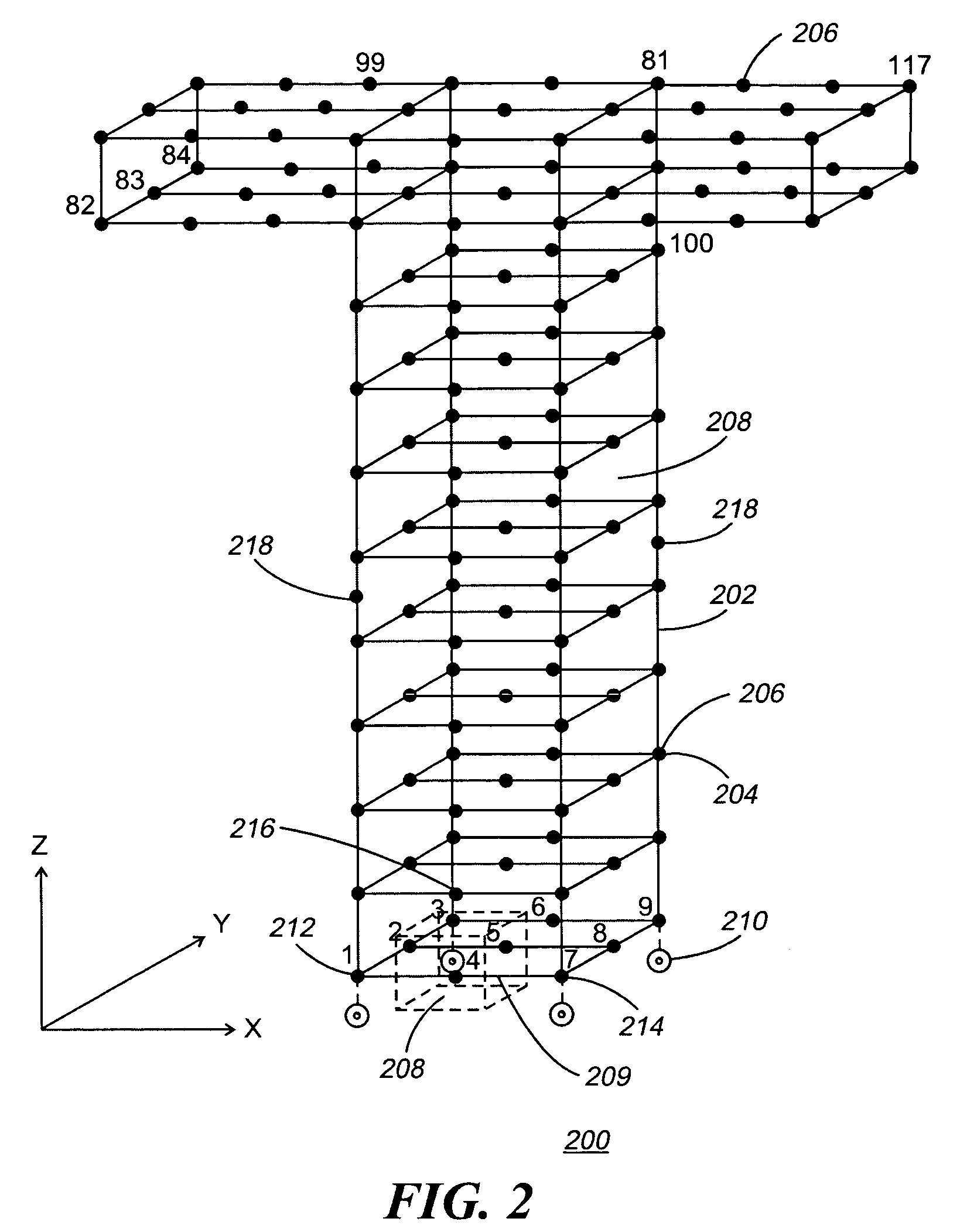

Three-dimensional endoscopic measurements are made by adding an array of reference target points to the scene viewed by an endoscopic camera and characterizing the image formed by the camera when it views the scene from two or more viewing positions. Methods and apparatus are taught which allow one to make accurate measurements with any endoscope, without requiring any modification to the endoscope. Under certain circumstances, the measurements can be made without any pre-calibration of the endoscopic camera.A general measurement reference apparatus comprises a reference target array which is placed near to and fixed with respect to an object of interest inside an enclosure by means of a reference array holding apparatus and a reference array insertion apparatus. This measurement reference apparatus can be used to make either perspective dimensional measurements or to make conventional photogrammetric measurements of the object of interest.A general measurement apparatus to be used with the new methods comprises a reference target array which is placed near to and fixed with respect to an object of interest inside an enclosure by means of a reference array holding apparatus and a reference array insertion apparatus. In a version of this apparatus the reference array holding apparatus may attach the reference array directly to the object of interest and the combination may be inserted into the enclosure by the insertion apparatus. The general measurement apparatus also comprises an endoscopic camera located inside the enclosure. The camera is moved with respect to the object by a camera moving apparatus. Images formed by the camera are measured with an image measurement apparatus. These measurements are supplied to a computing apparatus which computes the desired three-dimensional distances. The measurement results are displayed to the user by a display apparatus.

Owner:SCHAACK DAVID F

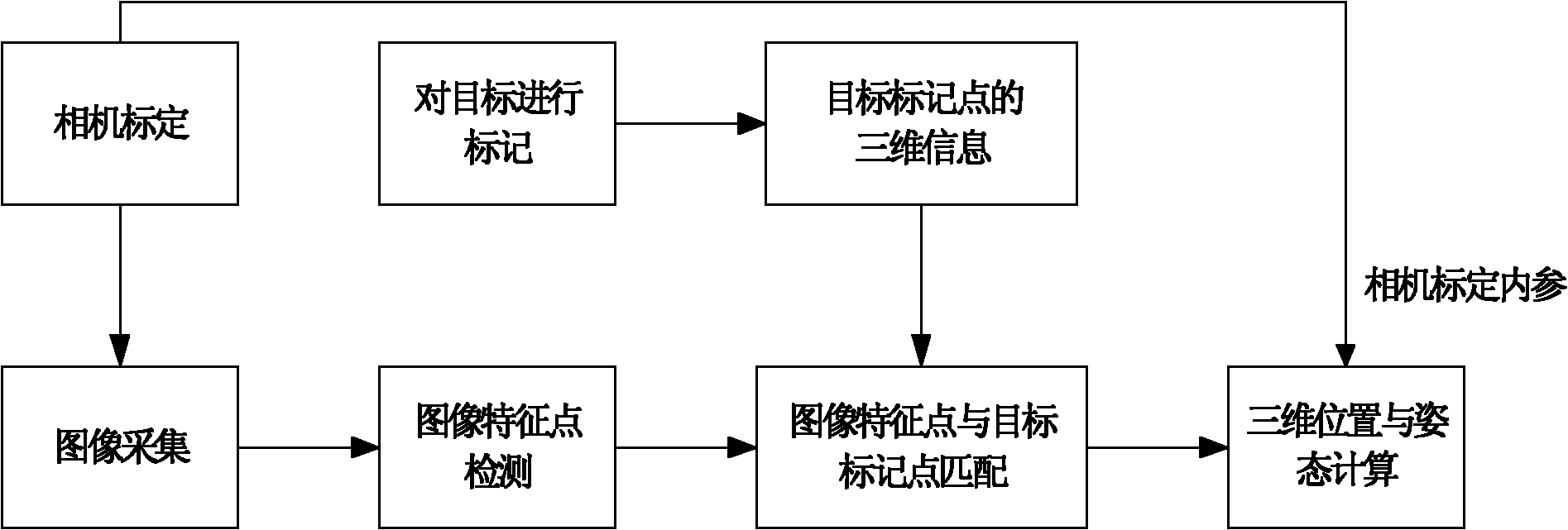

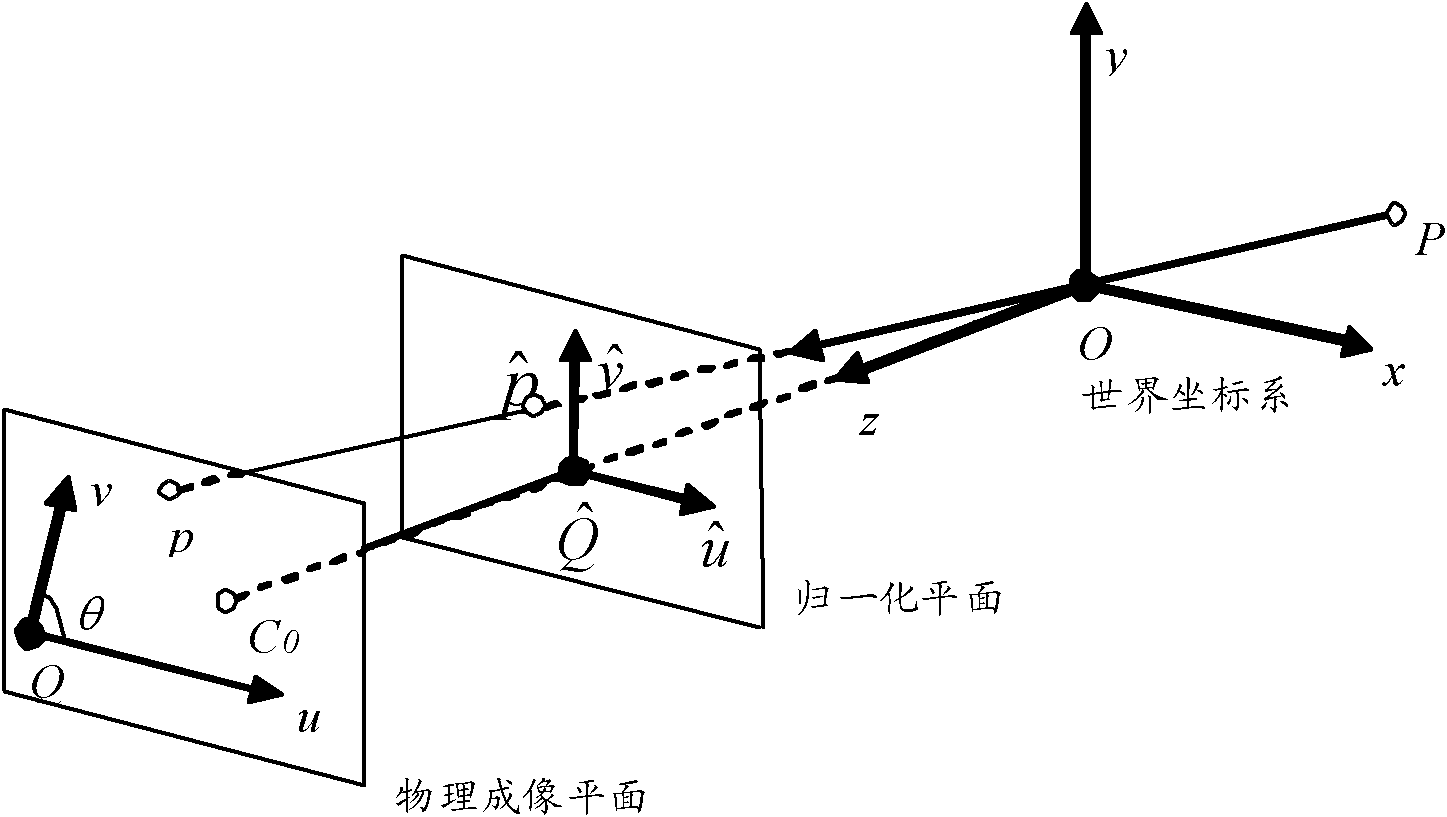

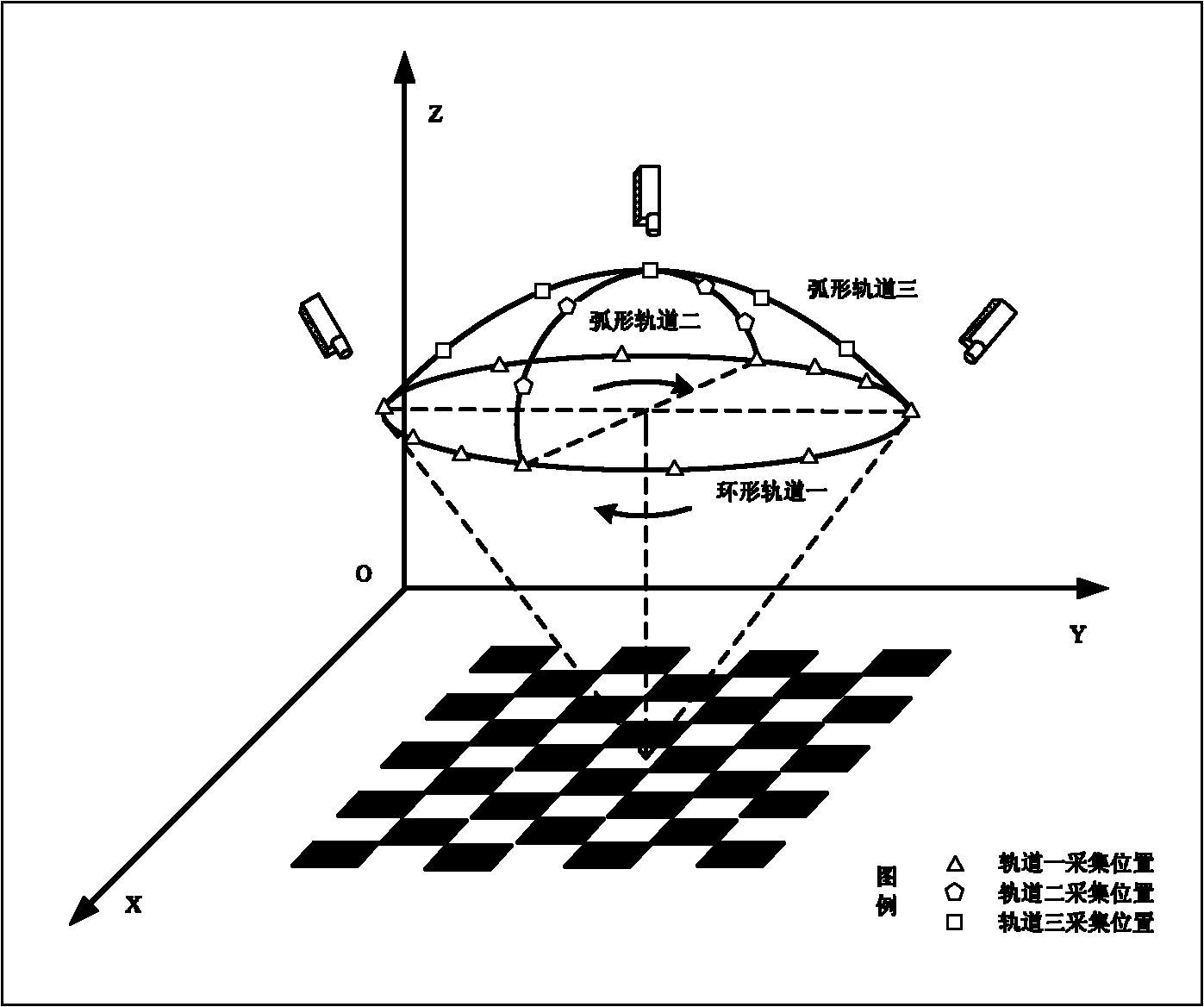

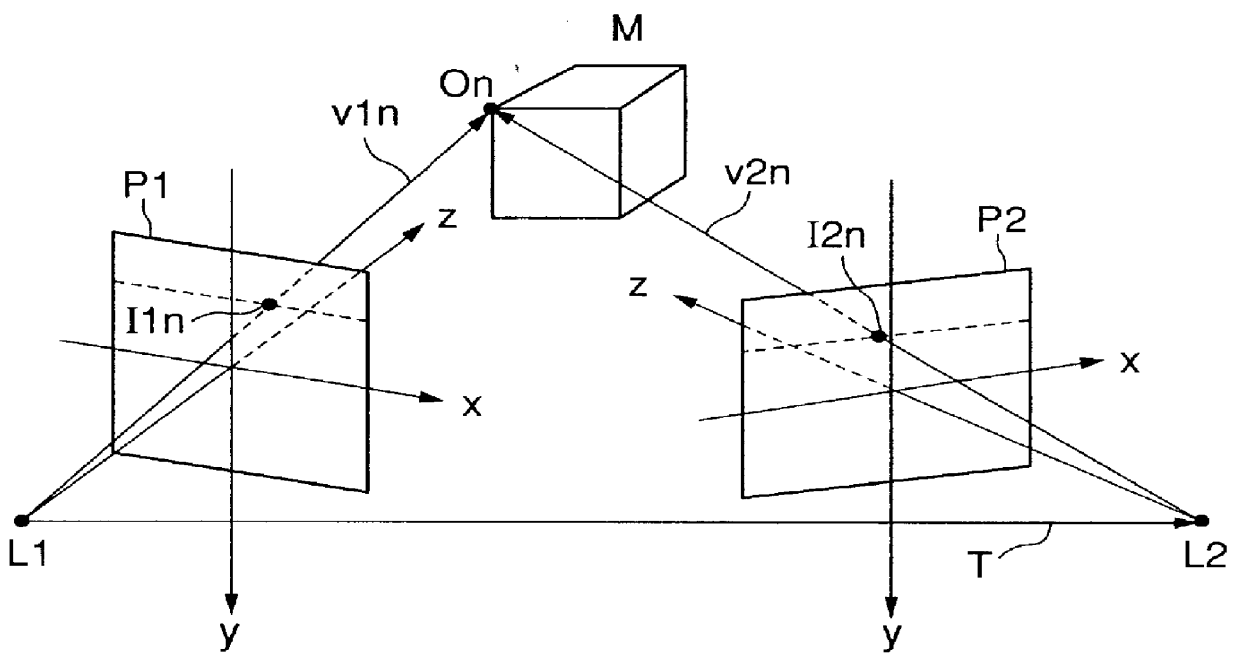

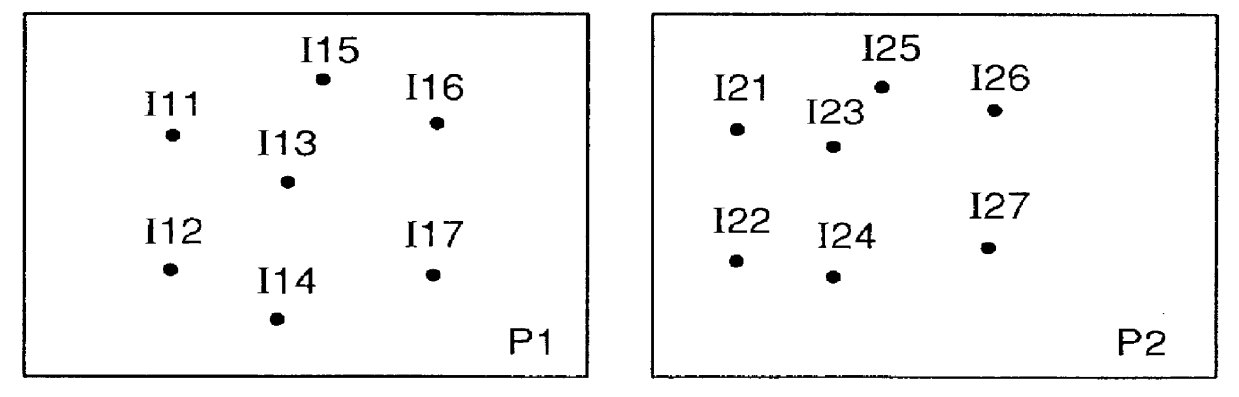

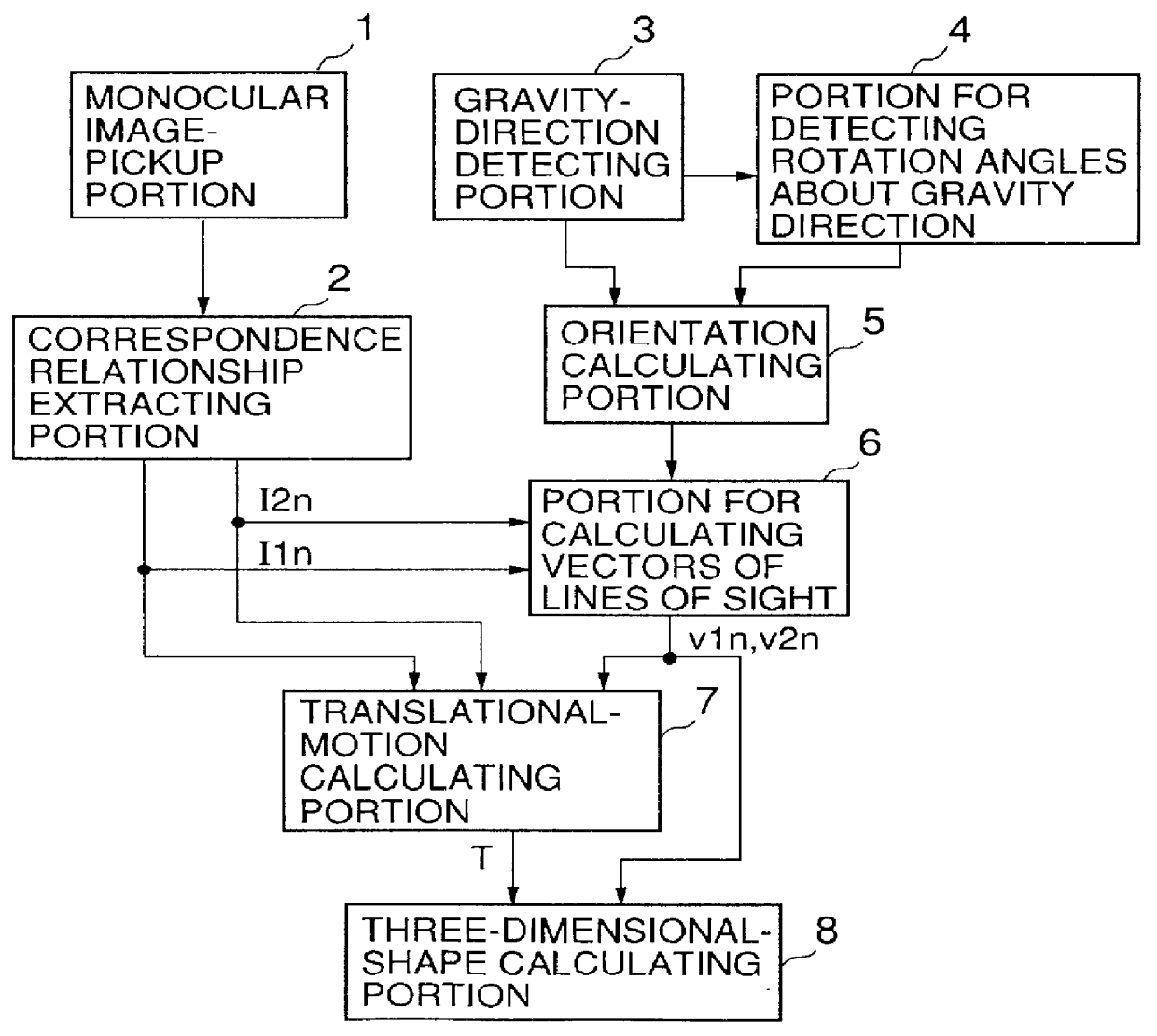

Method for measuring three-dimensional position and stance of object with single camera

InactiveCN101839692AReduce cost of measurementReduce volumeUsing optical meansPicture interpretationThree-dimensional spaceMeasurement point

The invention discloses a method for measuring the three-dimensional position and the stance of an object with a single camera. The method comprises the following steps of: acquiring an image of a target to be measured by utilizing a single camera; confirming the real-time three-dimensional position and stance information of the target to be measured by accurately identifying marking points on the target to be measured; selecting a suitable camera according to a detection scene and a range and calibrating the camera to acquire inner and outer parameters of the camera; designing target marking points according to the target to be measured and reasonably arranging the marking points; then, detecting the target, identifying characteristic points according to the image shot by the camera, and matching the detected characteristic points with the marking points; and finally, solving the three-dimensional position and stance information of the target to be measured according to the corresponding relation between the measuring points and the object marking points. Whether a non-rigid object is deformed or not can also be detected by using the method. In the invention, the single camera is adopted to realize three-dimensional measurement, acquire the information of the target in a three-dimensional space, such as space geometrical parameters, position, stance, and the like, decrease the measuring cost and the size of a measuring system, and facilitate the operation.

Owner:XI AN JIAOTONG UNIV

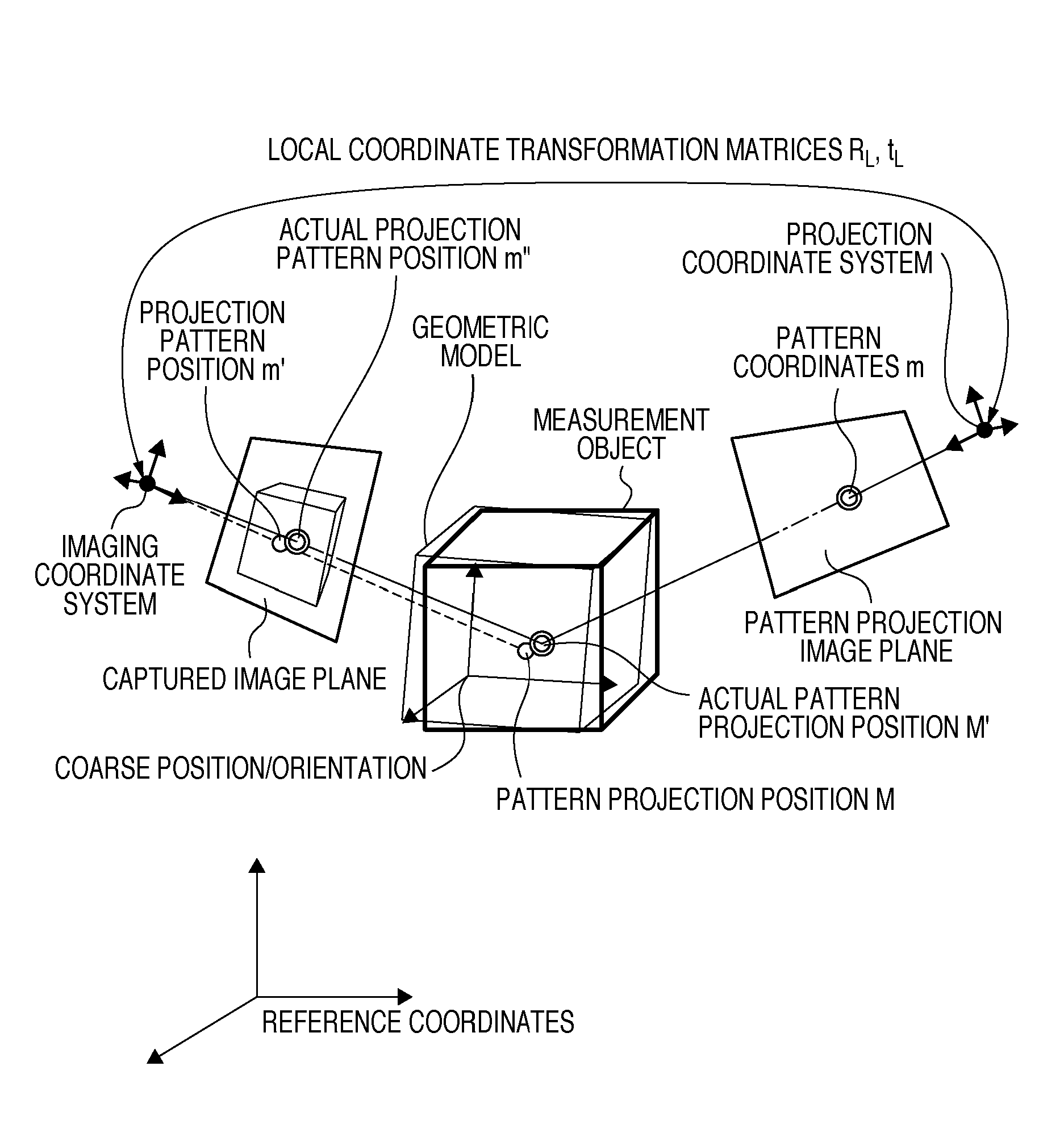

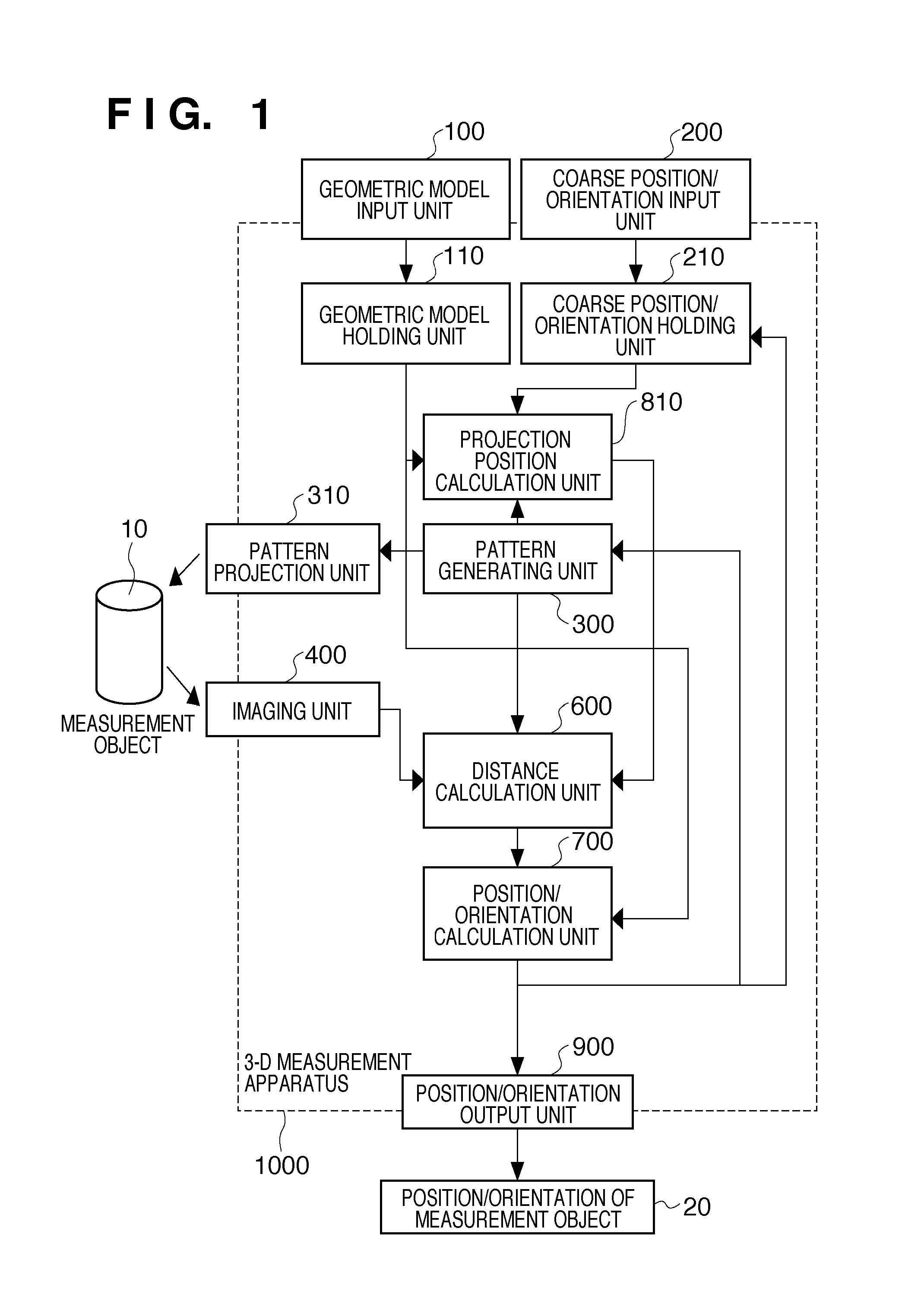

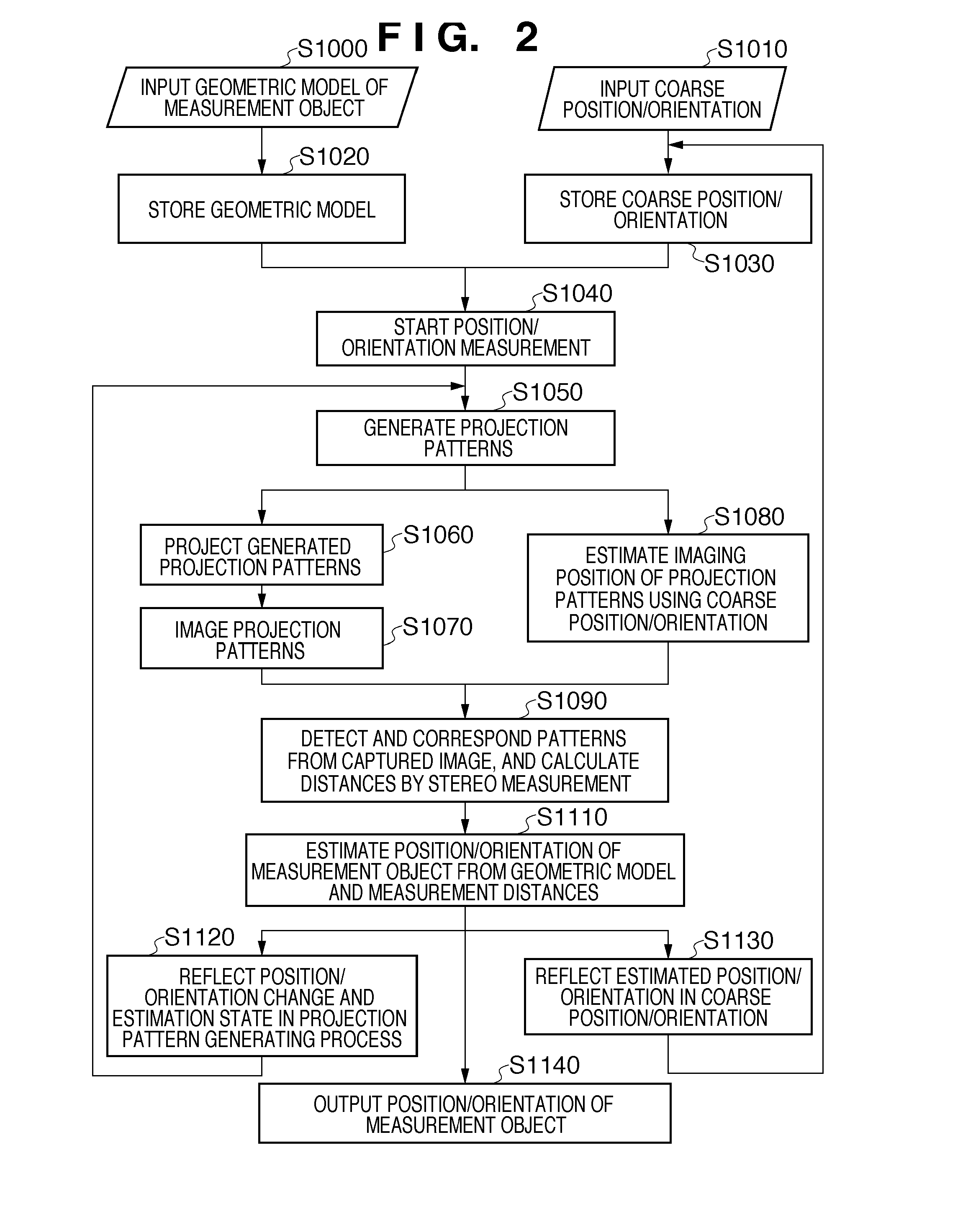

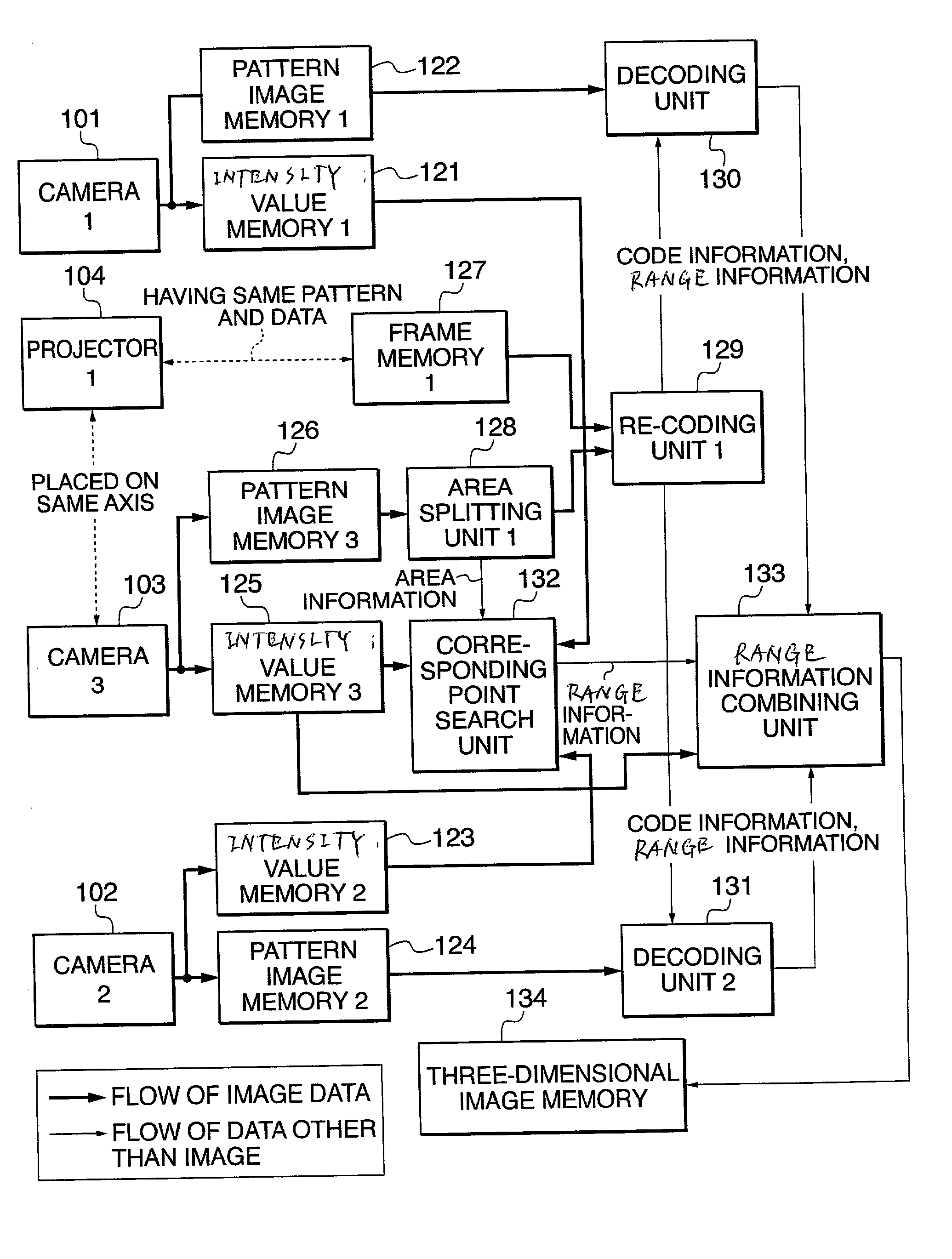

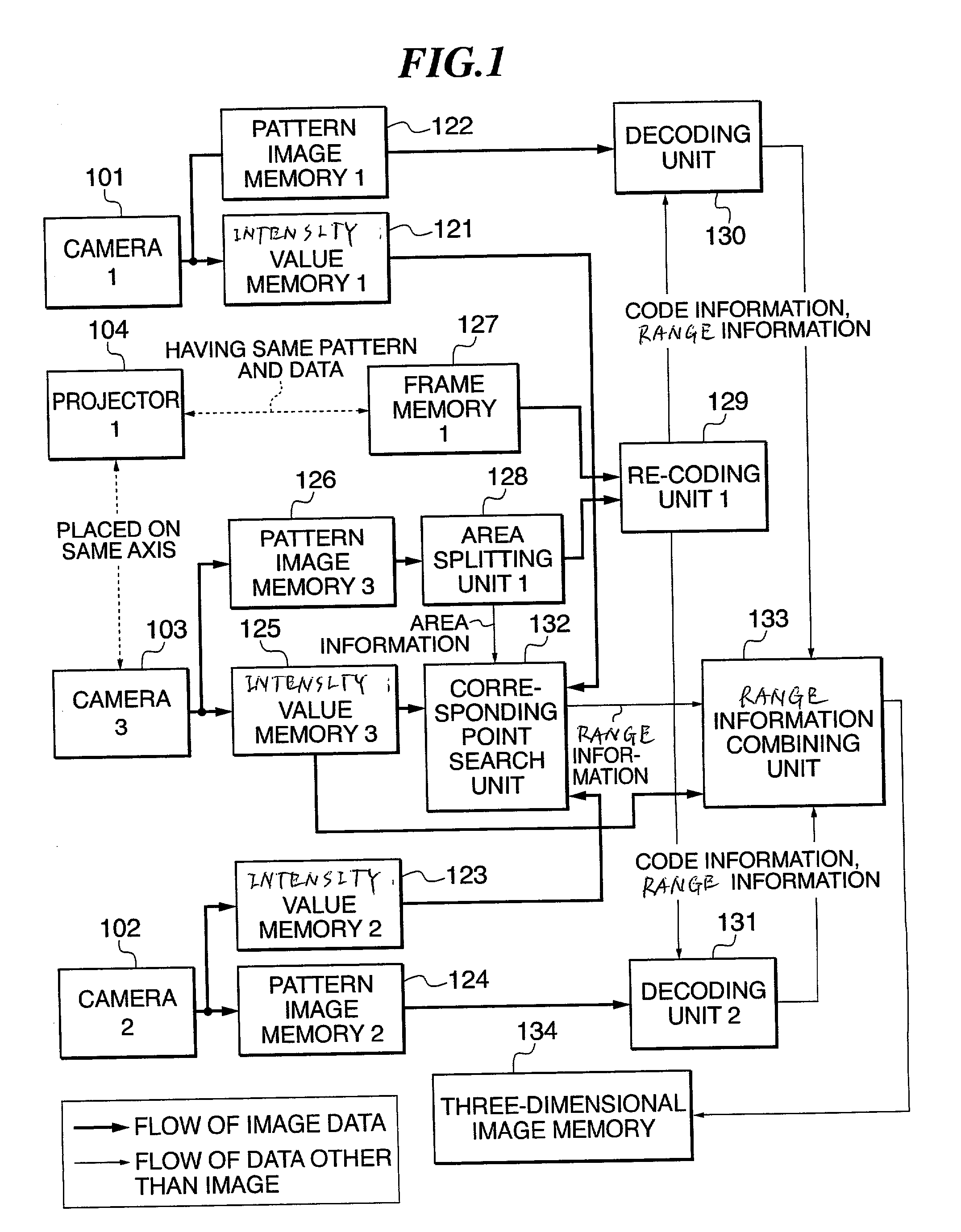

Three-dimensional measurement apparatus and control method therefor

ActiveUS20110164114A1Using optical meansSteroscopic systemsGeometric modelingThree dimensional measurement

Owner:CANON KK

Three-dimensional coordinate scanner and method of operation

A noncontact optical three-dimensional measuring device that includes a projector, a first camera, and a second camera; a processor electrically coupled to the projector, the first camera and the second camera; and computer readable media which, when executed by the processor, causes the first digital signal to be collected at a first time and the second digital signal to be collected at a second time different than the first time and determines three-dimensional coordinates of a first point on the surface based at least in part on the first digital signal and the first distance and determines three-dimensional coordinates of a second point on the surface based at least in part on the second digital signal and the second distance.

Owner:FARO TECH INC

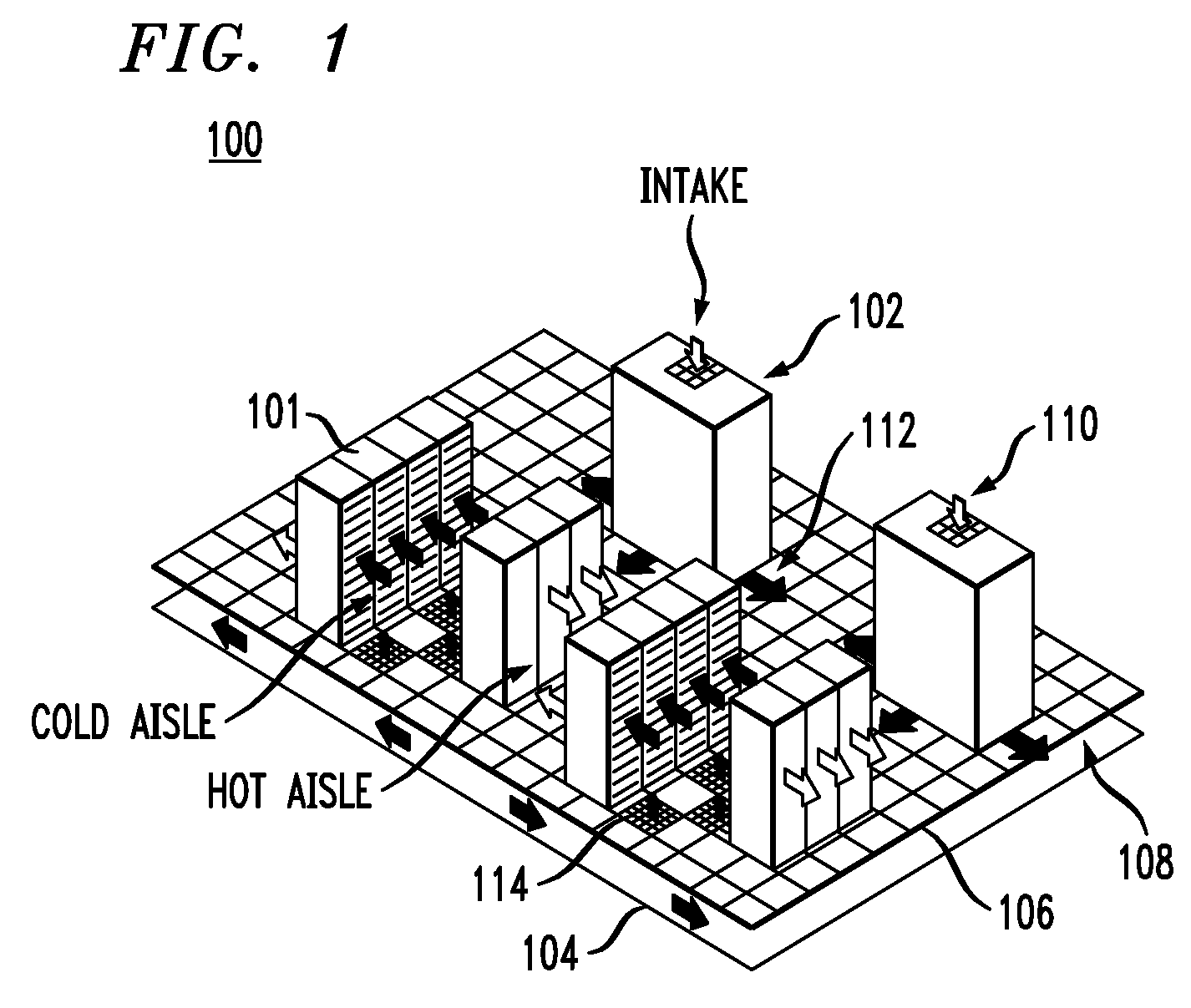

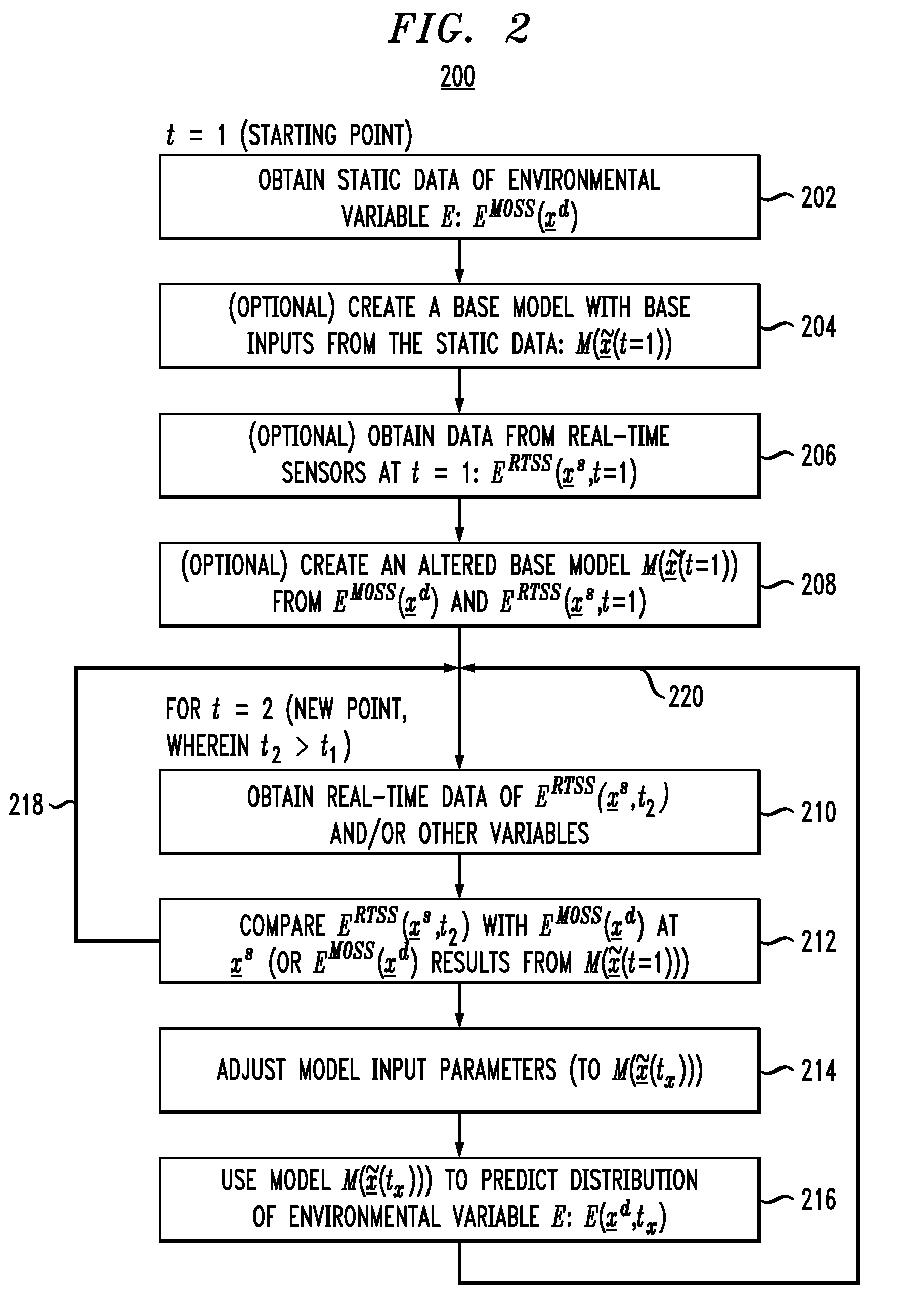

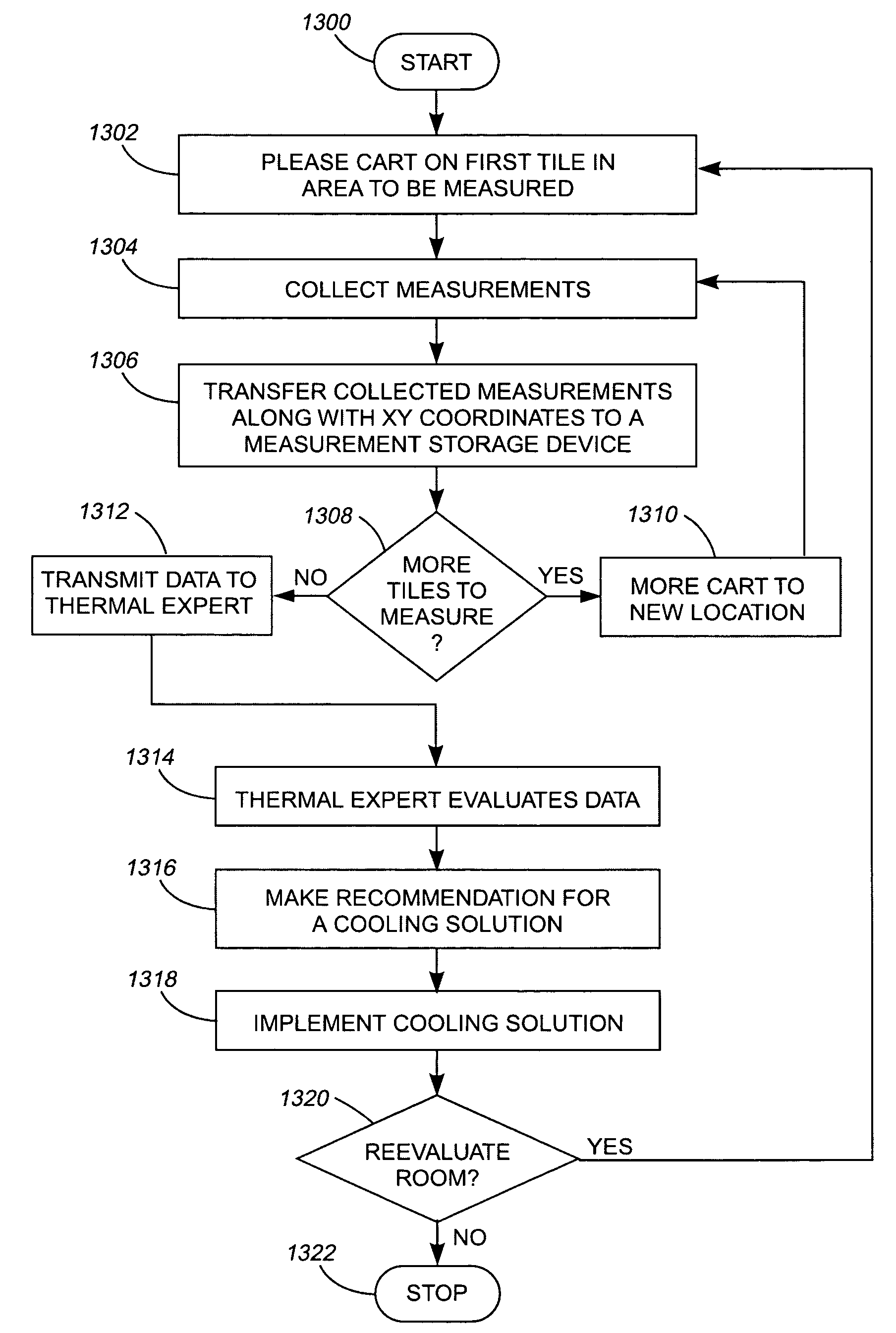

Techniques to Predict Three-Dimensional Thermal Distributions in Real-Time

ActiveUS20090326884A1Improve spatial resolutionMeasurement resolutionEnergy efficient ICTComputation using non-denominational number representationImage resolutionHigh spatial resolution

Techniques for monitoring and predicting environmental operating conditions in a data center are provided. In one aspect, a method for real-time, three-dimensional analysis of environmental operating conditions in a data center includes the following steps. High spatial resolution three-dimensional measurements of one or more environmental variables in the data center made at a time t1 are obtained. Real-time measurements of the environmental variables in the data center made at a time t2, wherein t2 is later in time than t1, are obtained. The high spatial resolution three-dimensional measurements are combined with the real-time measurements to derive a model for the environmental variables in the data center at the time t2. The model is used to predict three-dimensional distributions of the environmental variables in the data center at the time t2. A base model can be created and used to derive the model for the data center at the time t2.

Owner:IBM CORP

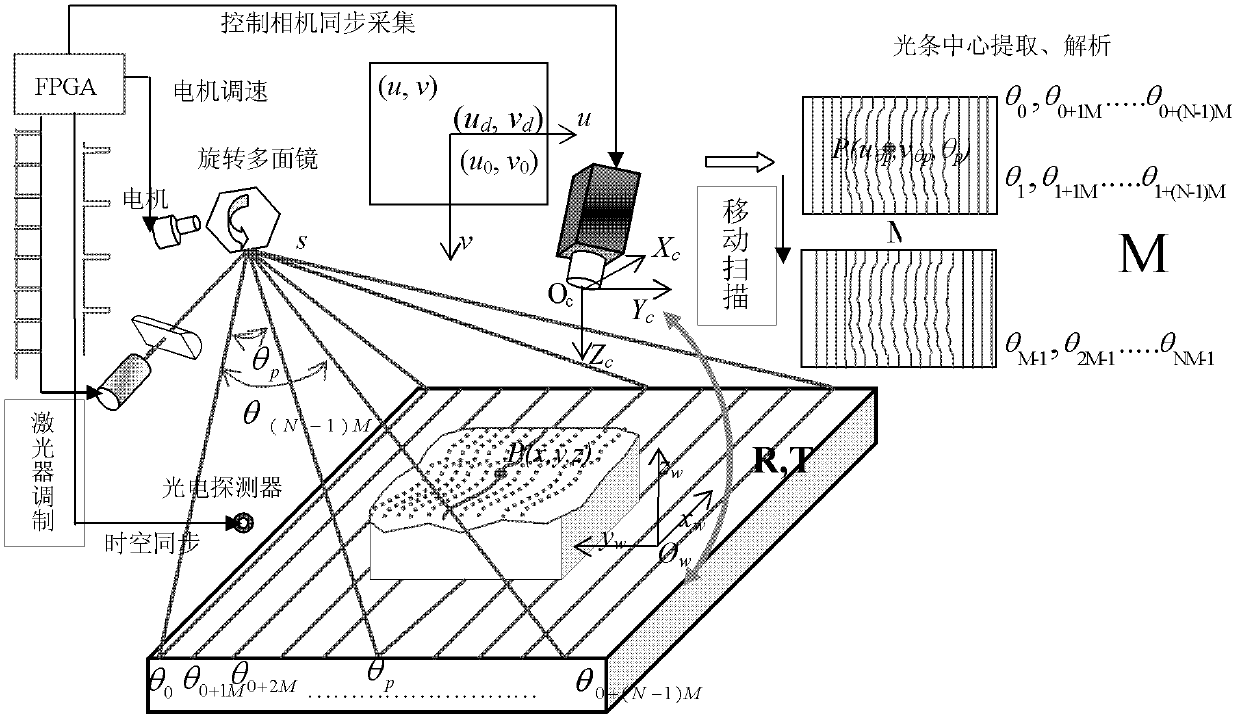

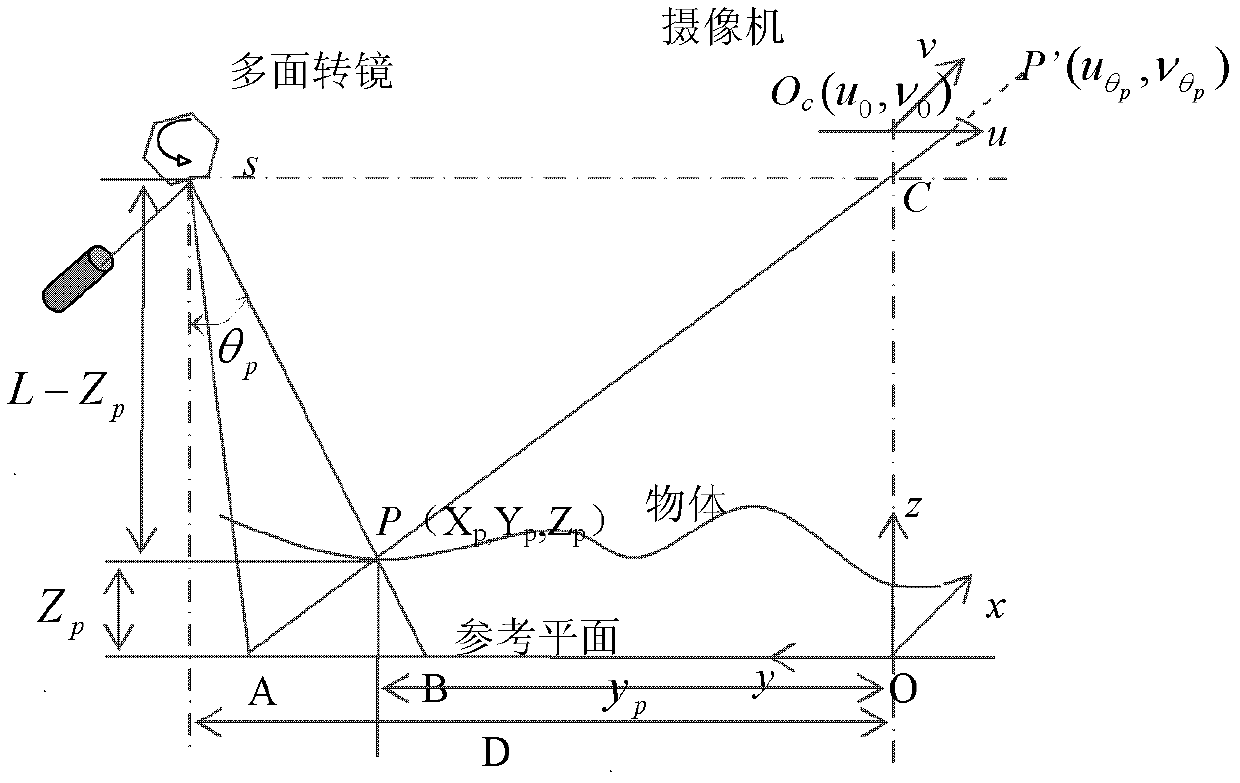

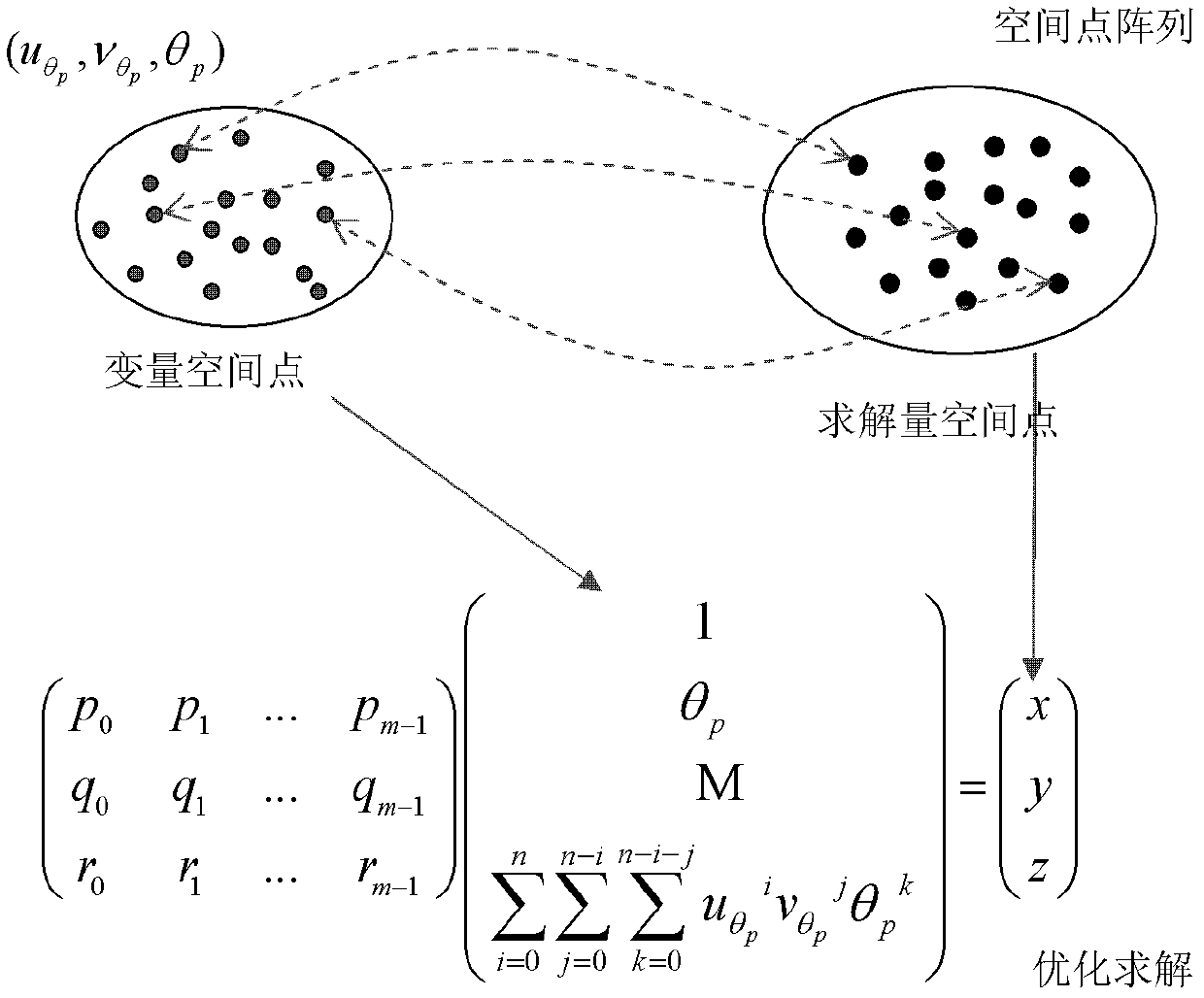

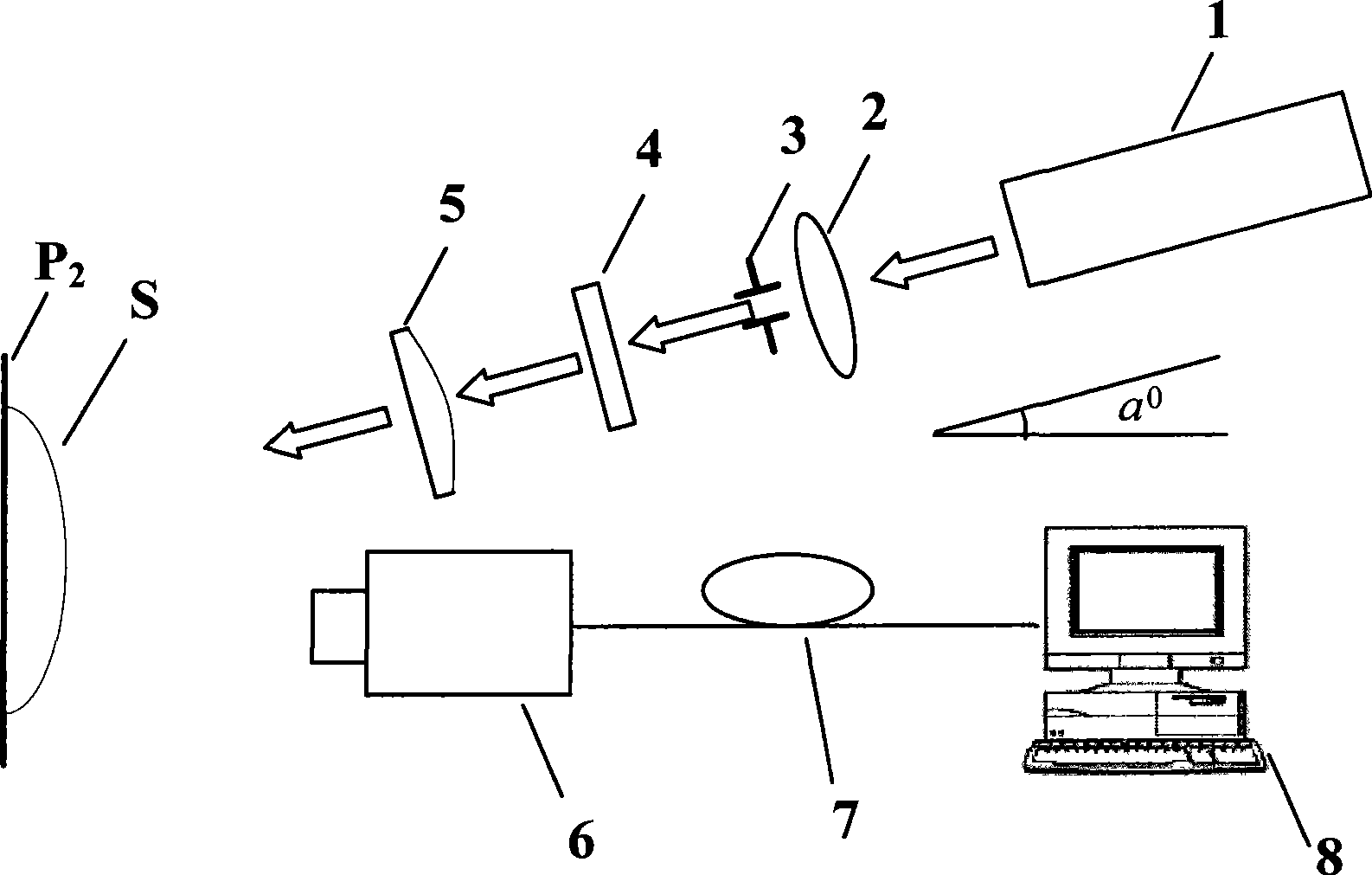

High-speed scanning and overall imaging three-dimensional (3D) measurement method

InactiveCN102589476AFast measurementLittle effect on reflectivityUsing optical meansThree dimensional measurementPrism

The invention relates to a visual inspection technology. In order to meet the requirements of fast and high-accurate surface three-dimensional (3D) topography online measurement and the detection requirements of a production line on intelligence, fastness, high accuracy and low cost, the invention adopts the technical scheme that: a high-speed scanning and overall imaging 3D measurement method comprises the following steps of: carrying out external modulation on a driving power supply by using a laser so as to control the output of a word line laser; rotating a multifaceted prism under the drive of a high-speed motor, wherein line-structured light outputted by the laser is reflected and projected to the surface of a measured object by the multifaceted prism; and placing a photoelectric detector at a position which is the limit position projected by the line-structured light during the rotating process of the multifaceted prism, carrying out exposure on an area-array CCD (Charge-Coupled Device) camera during the process that the line-structured light scans the whole area, and establishing a measurement model, wherein the 3D coordinate (xp, yp, zp) of the surface feature point of the measured object is obtained according to a formula by using an image coordinate (u[theta]p, v[theta]p) formed by the area-array CCD camera and [theta]p. The high-speed scanning and overall imaging 3D measurement method is mainly applied to the fast and high-accurate surface 3D topography online measurement.

Owner:TIANJIN UNIV

Method and apparatus for three-dimensional measurements

ActiveUS7366632B2Thermometer detailsDigital data processing detailsData centerThree dimensional measurement

An apparatus and method for measuring the physical quantities of a data center during operation and method for servicing large-scale computing systems is disclosed. The apparatus includes a cart that supports a plurality of sensors. The cart is moveable within the data center. The sensors capture temperature or other physical parameters within the room. The sensor readings, along with position and orientation information pertaining to the cart are transmitted to a computer system where the data is analyzed to select the optimum temperature or other system environmental parameters for the data center.

Owner:GLOBALFOUNDRIES U S INC

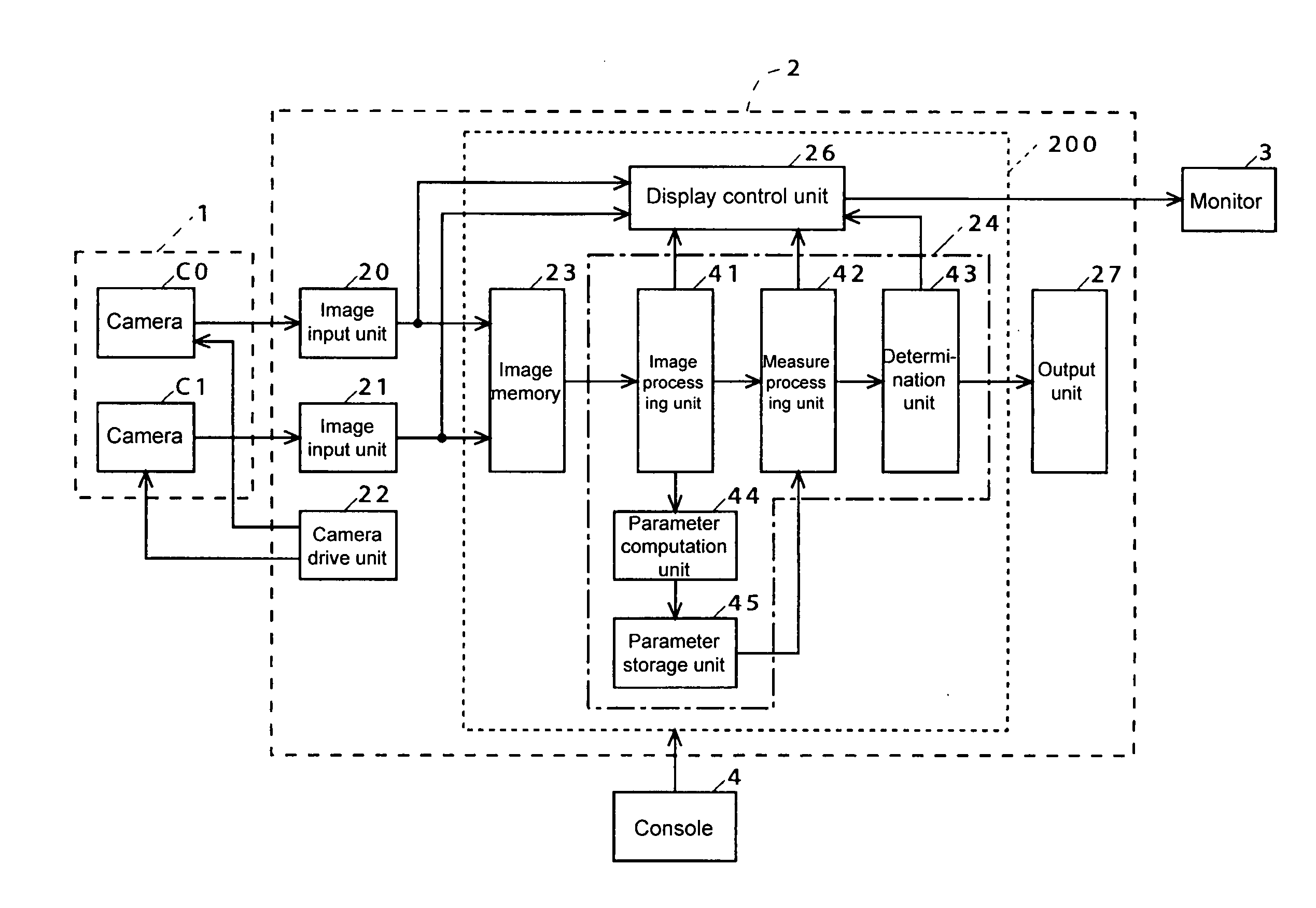

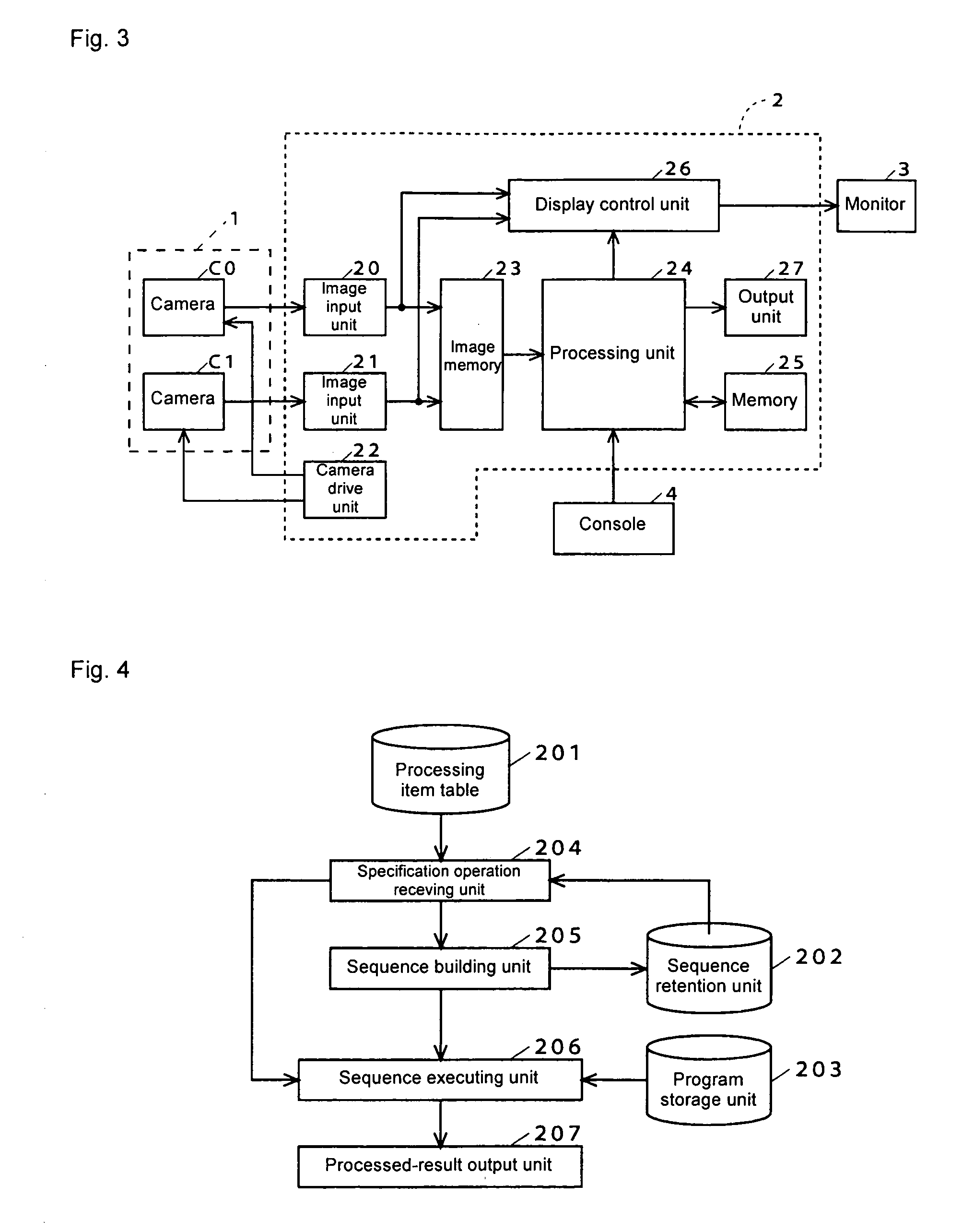

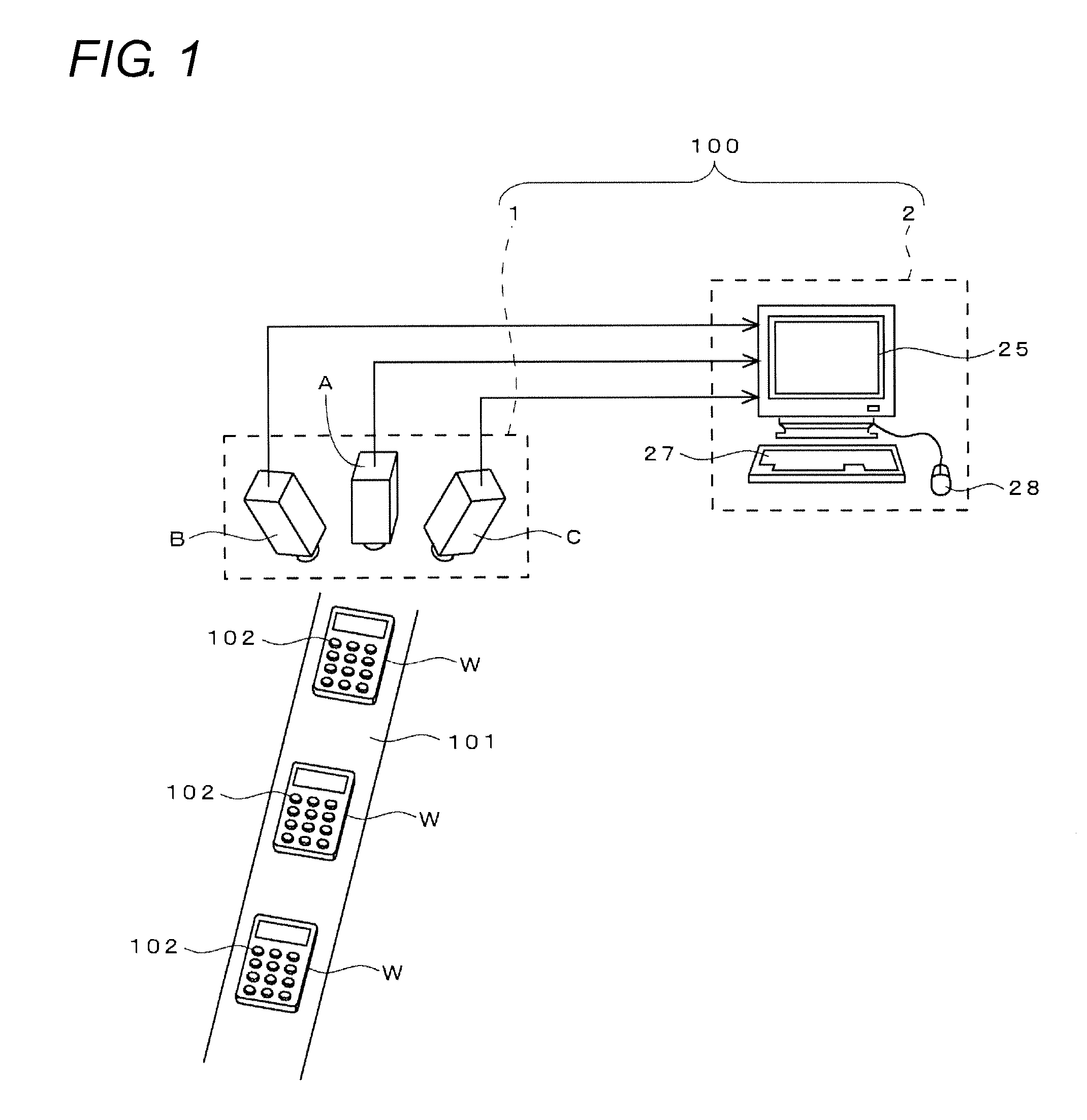

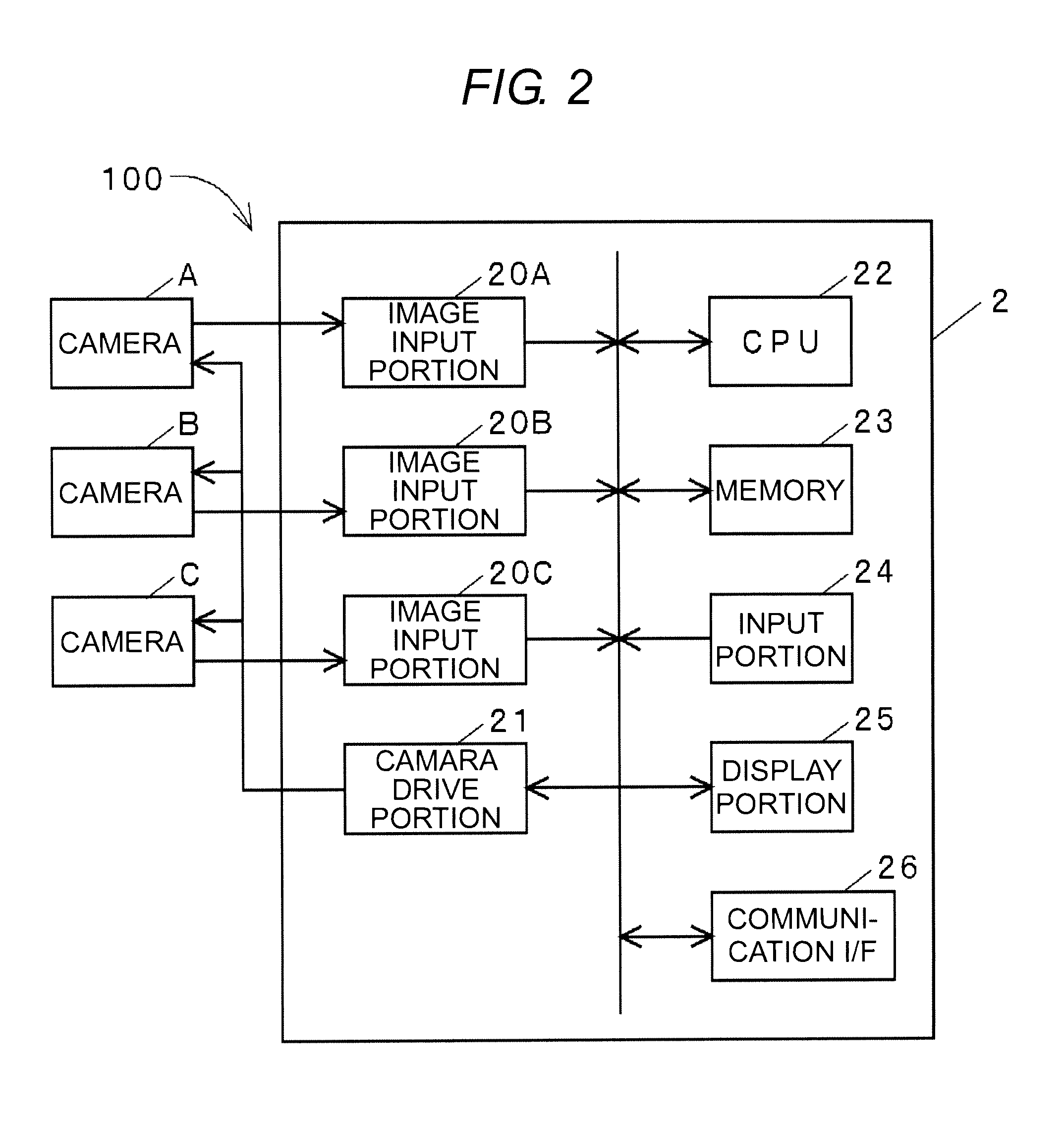

Image processing apparatus

ActiveUS20060291719A1Easy to useImprove compatibilityImage enhancementImage analysisImaging processingComputer graphics (images)

Plural items of two-dimensional image processing and at least one item of a three-dimensional measurement process are registered in a processing item table. The items of two-dimensional image processing include at least one item of an on-first-image position specification process of specifying a position on a physical object in a first image. A sequence building unit combines the item of the on-first-image position specification process and the item of the three-dimensional measurement process to set the sequence for three-dimensional measurement by selection of a user.

Owner:ORMON CORP

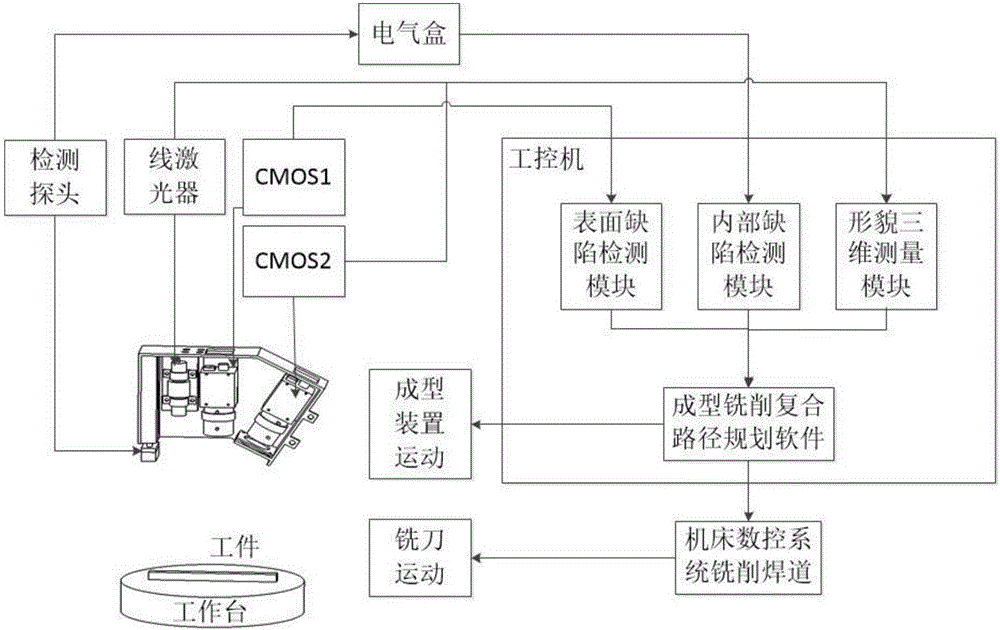

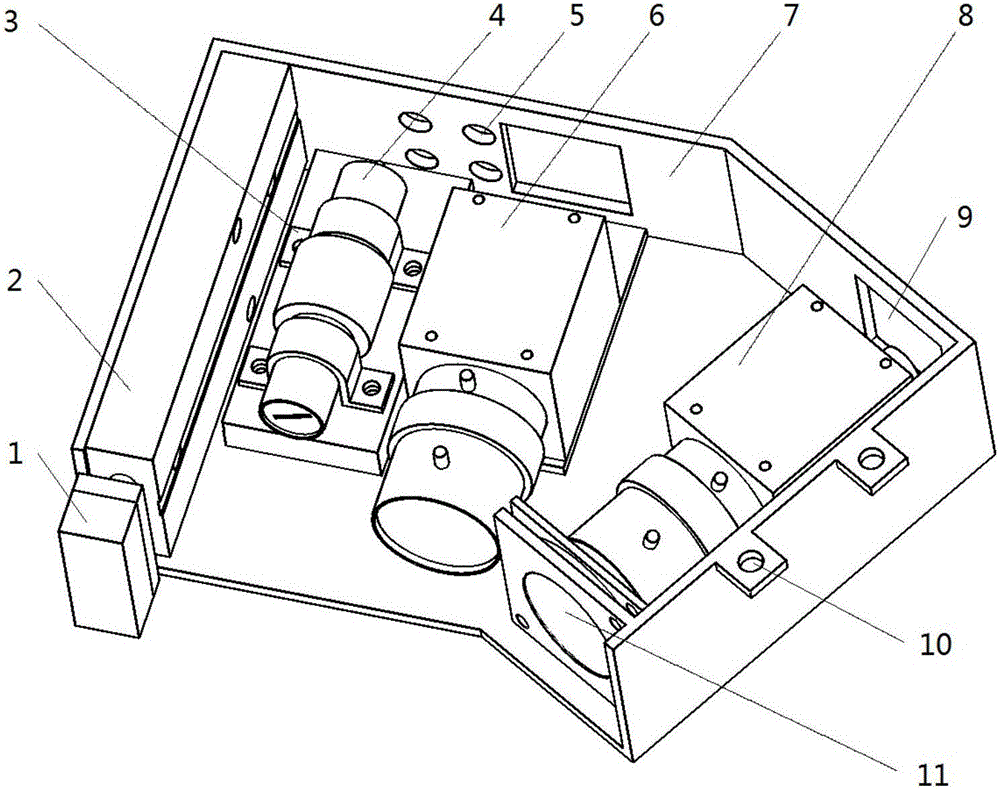

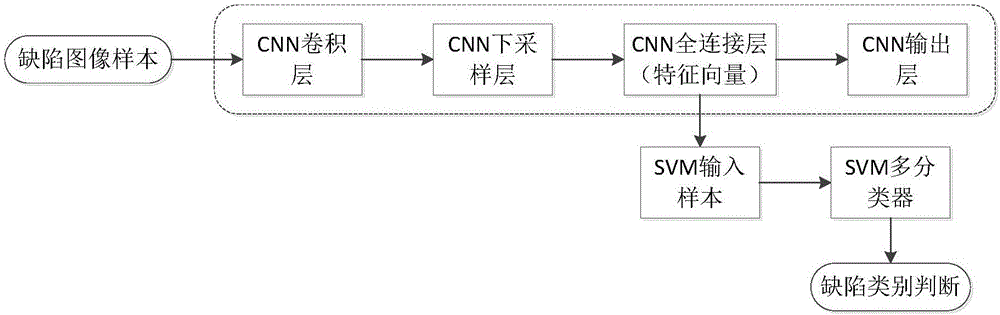

Additive manufacturing surface defect, internal defect and shape composite detection method and device

ActiveCN106338521AReal-time detectionOptically investigating flaws/contaminationUsing optical meansCMOSMagnetic disturbance

The invention discloses an additive manufacturing surface defect, internal defect and shape composite detection device which comprises a surface defect detection system, an internal defect detection system, a shape three-dimensional measurement system and a clamping device, wherein the surface defect detection system comprises a first CMOS industrial camera; the internal defect detection system comprises an air cylinder and a detection probe; the detection probe is used for generating a magnetic field to be close to the detected surface and establish magnetic mutual action with a workpiece to form a magnetic disturbance environment; the shape three-dimensional measurement system comprises a line laser, a light filter and a second CMOS industrial camera. The device can perform real-time and comprehensive detection on the surface defect, the internal defect and the shape three-dimensional size in additive manufacturing, transmits data to an industrial personal computer for analysis, interacts with forming milling composite route planning software, and can control a shaping device in real time to perform formation and generate a milling code and control a milling cutter to perform milling on the additive manufacturing surface.

Owner:HUAZHONG UNIV OF SCI & TECH

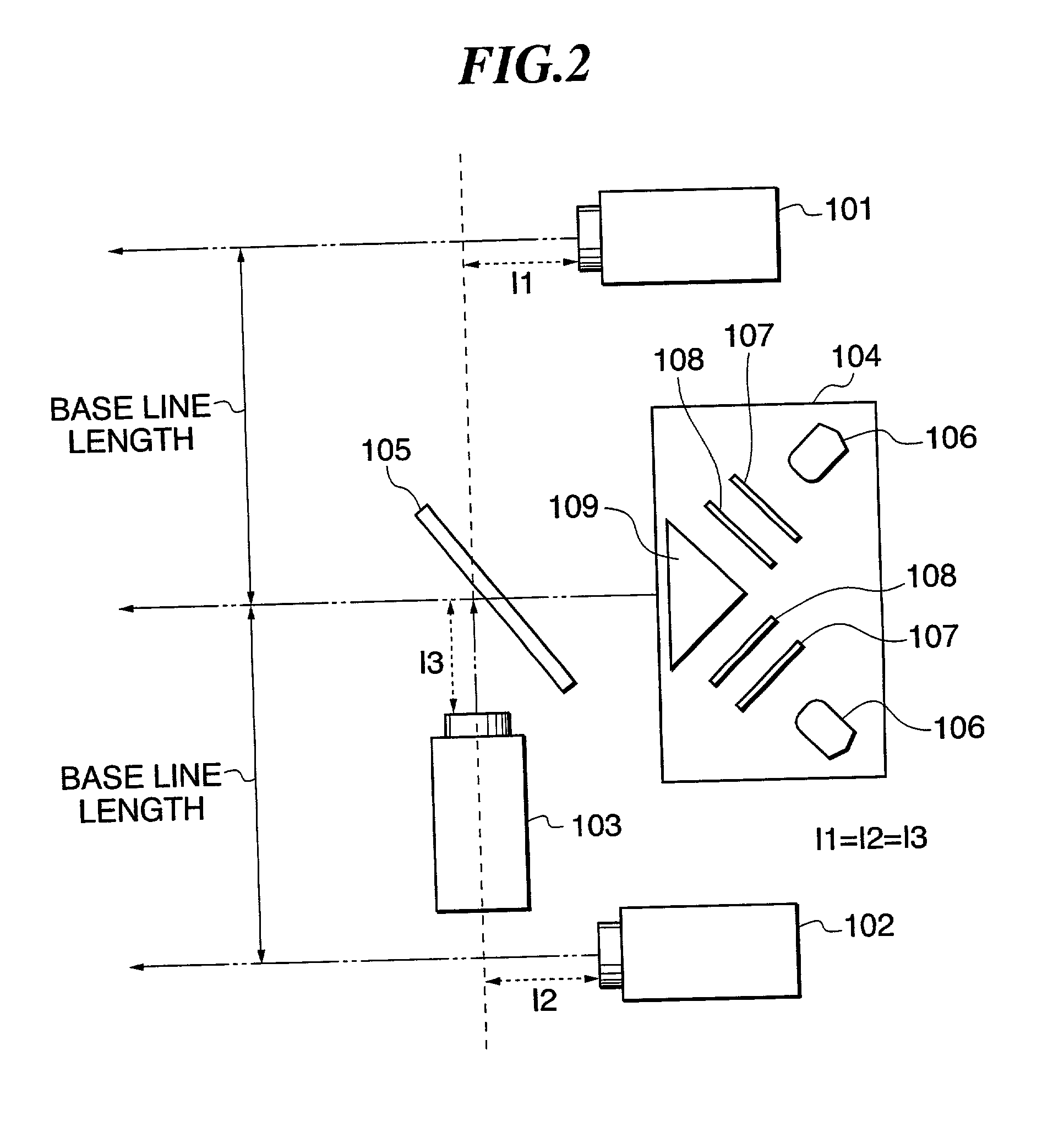

Three-dimensional measuring apparatus and method, image pickup apparatus, and apparatus and method for inputting image

InactiveUS6038074AUltrasonic/sonic/infrasonic diagnosticsAngle measurementObject pointThree dimensional measurement

Owner:RICOH KK

Object three-dimensional contour outline measuring set and measuring method

ActiveCN101451826AUniform light intensity at the spectral pointImprove energy utilizationUsing optical meansInformation processingMeasurement device

An object three-dimensional outline measurement device and a measurement method are disclosed, the device is composed of a laser diode, a lens, an aperture diaphragm, a two-dimensional Dammam grating, a cylindrical mirror and an area array CCD camera, a transmission line and a computer, the connection relationship therebetween is as below: a beam emitted by the laser diode passes through the lens, the aperture diaphragm, the two-dimensional Dammam grating, and the cylindrical mirror sequentially to form one-dimensional projection array stripes, which illuminates the surface of an objective to be measured, the area array CCD camera collects the grating projection strips modulated by three-dimensional digital shape on the surface of the measured objective and outputs the strips to the computer via the transmission line, the computer includes an image collecting interface, image collecting software and three-dimensional measurement information reconstruction algorithm software. The invention has, by utilizing the Fourier transform three-dimensional outline measurement structure, the advantages of high energy utilization rate, simple measurement structure, high measurement precision, convenient computer reconstruction information processing and great easiness for operation.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

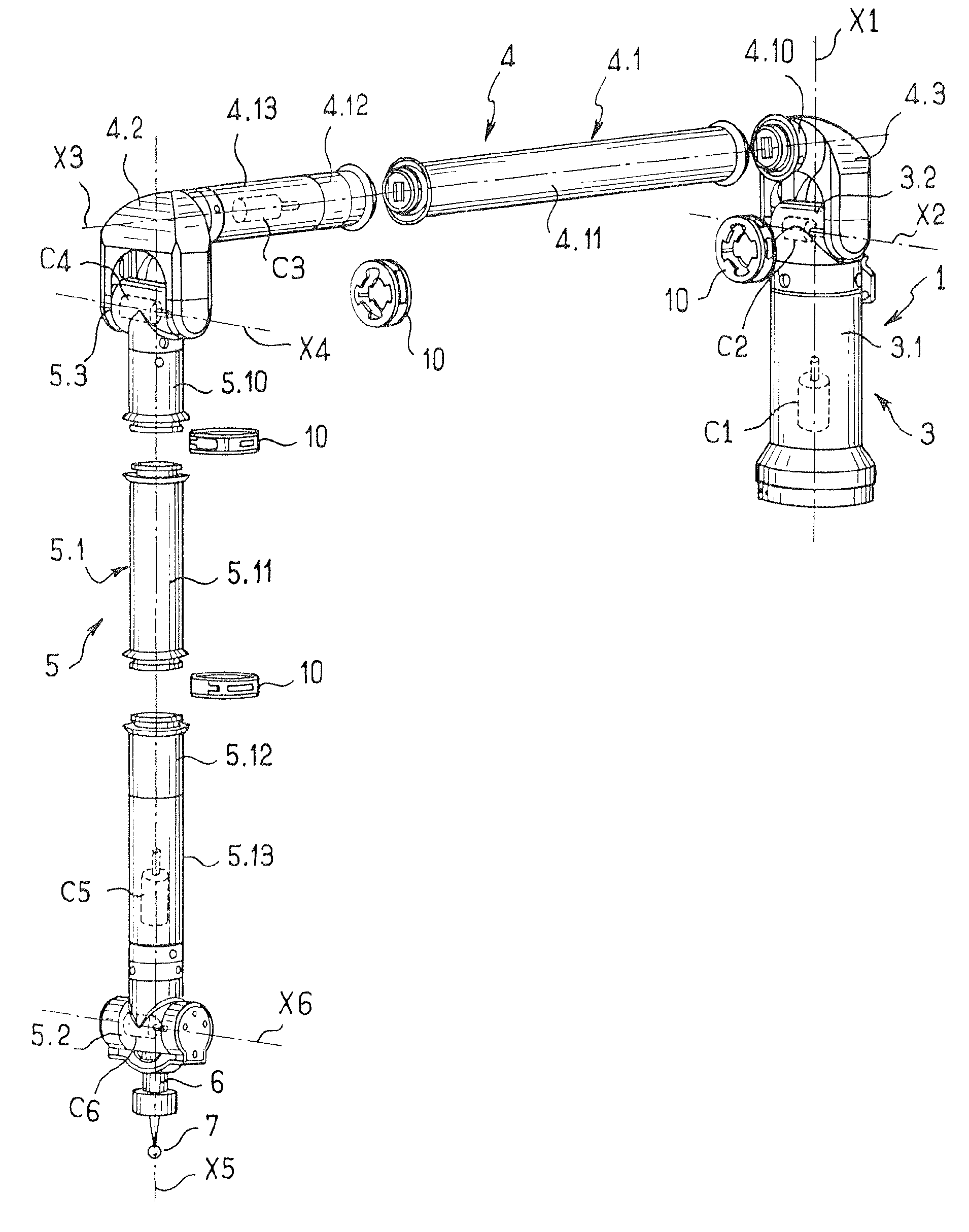

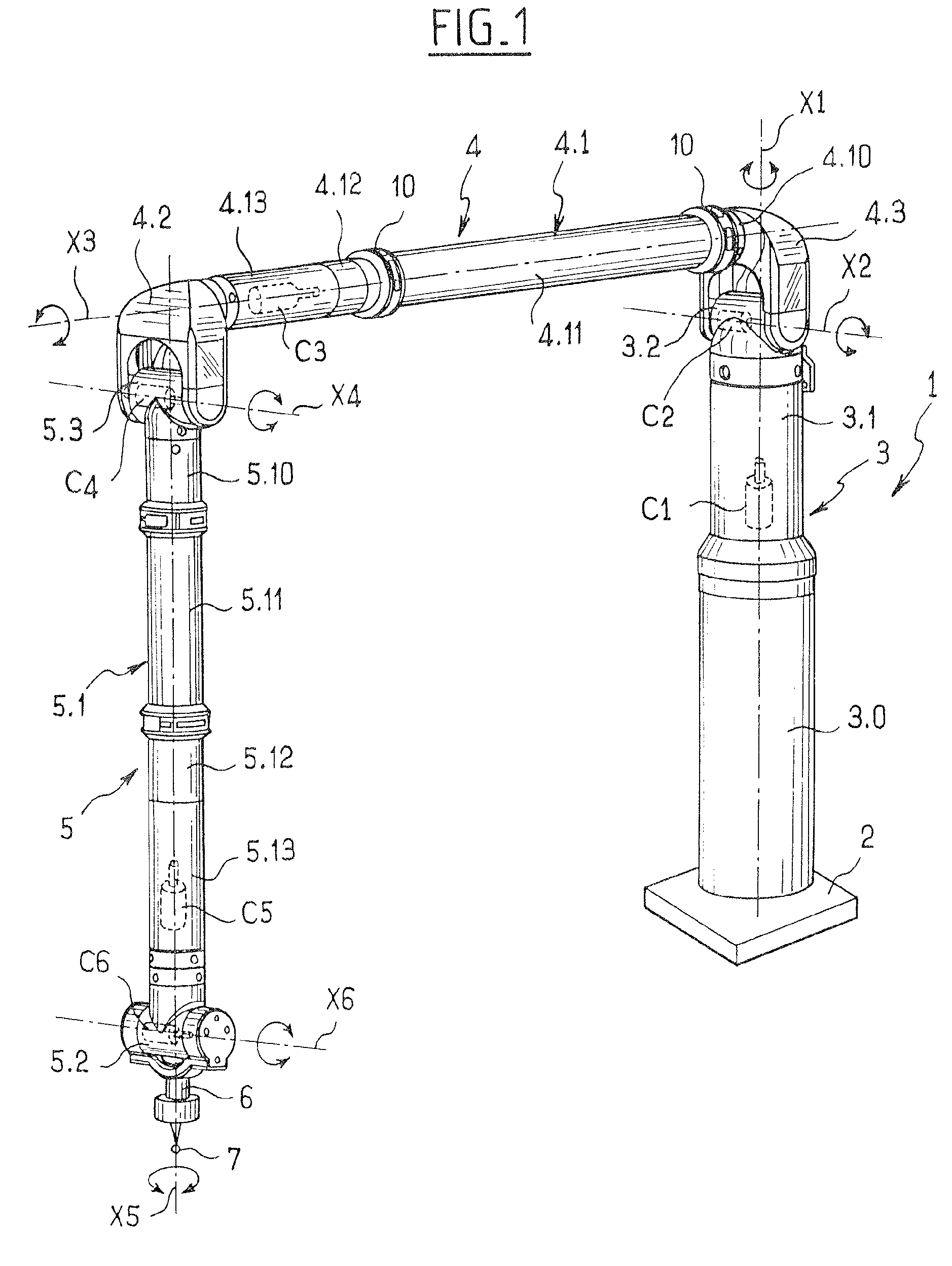

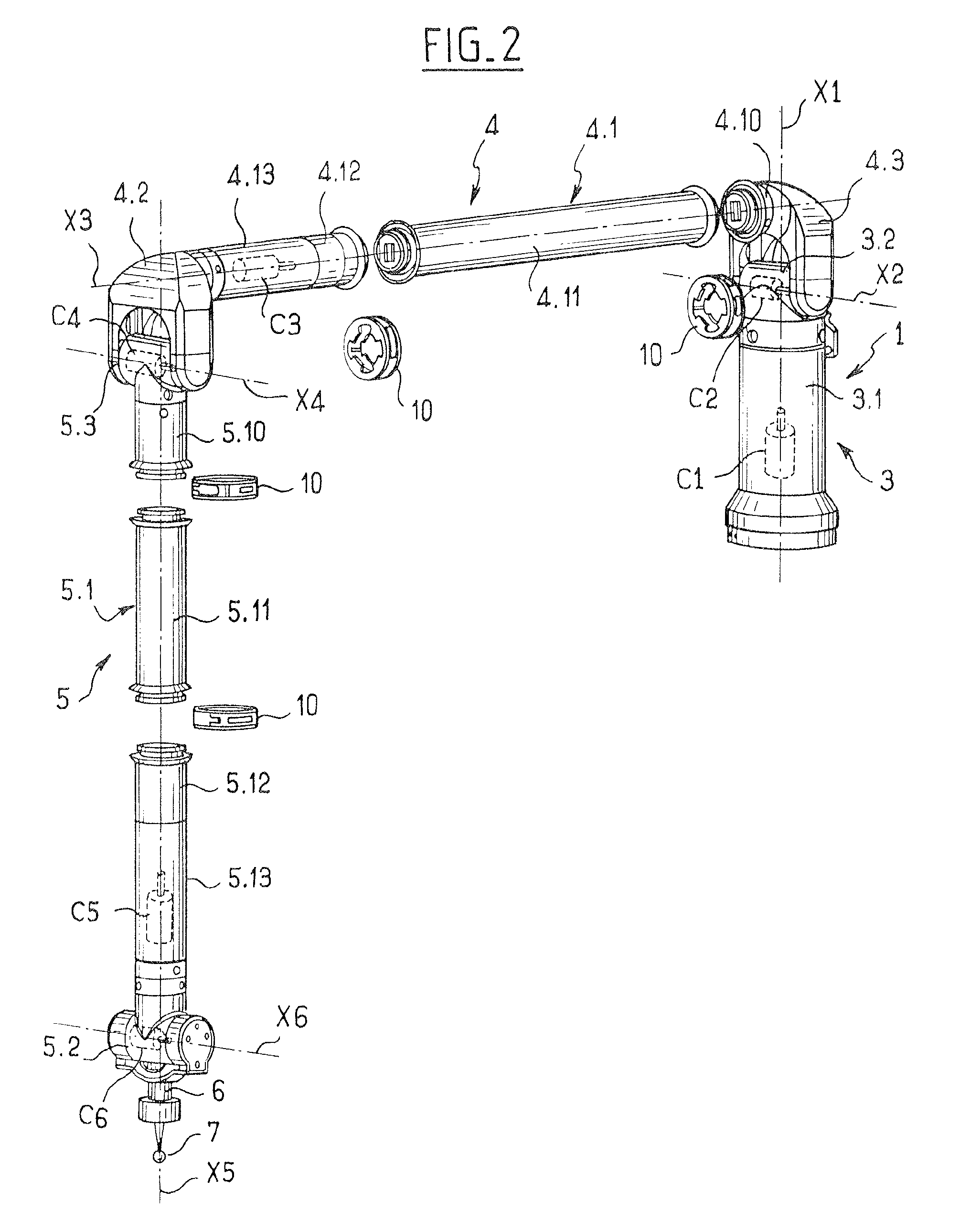

Articulated-arm three-dimensional measurement apparatus having a plurality of articulated axes

InactiveUS7614157B2Perform operationEasy to useMechanical measuring arrangementsPoint coordinate measurementsThree dimensional measurementEngineering

The invention relates to an articulated-arm three-dimensional measurement apparatus having a plurality of articulation axes with angle encoders integrated in said arms for individually measuring the angles of rotation about each of said articulation axes. In accordance with the invention, at least one of the arms (4; 5) of the apparatus (1) includes a hollow tube (4.11; 5.11) interposed between two arm segments, one of which receives an angle encoder measuring the angle of rotation about the longitudinal axis of said arm, said hollow tube presenting at each of its ends respective abutment configurations complementary to abutment configurations at the adjacent arm segment ends so as to ensure alignment on the axis of the arm that is accurate, stable, and repeatable independently of the clamping of the abutting ends in question one against the other, coupling between said hollow tube and said arm segment being provided at said abutting ends by demountable clamping means (10) enabling the hollow tube to be replaced on site by another hollow tube of different length without it being necessary to recalibrate the entire apparatus.

Owner:ROMER INC

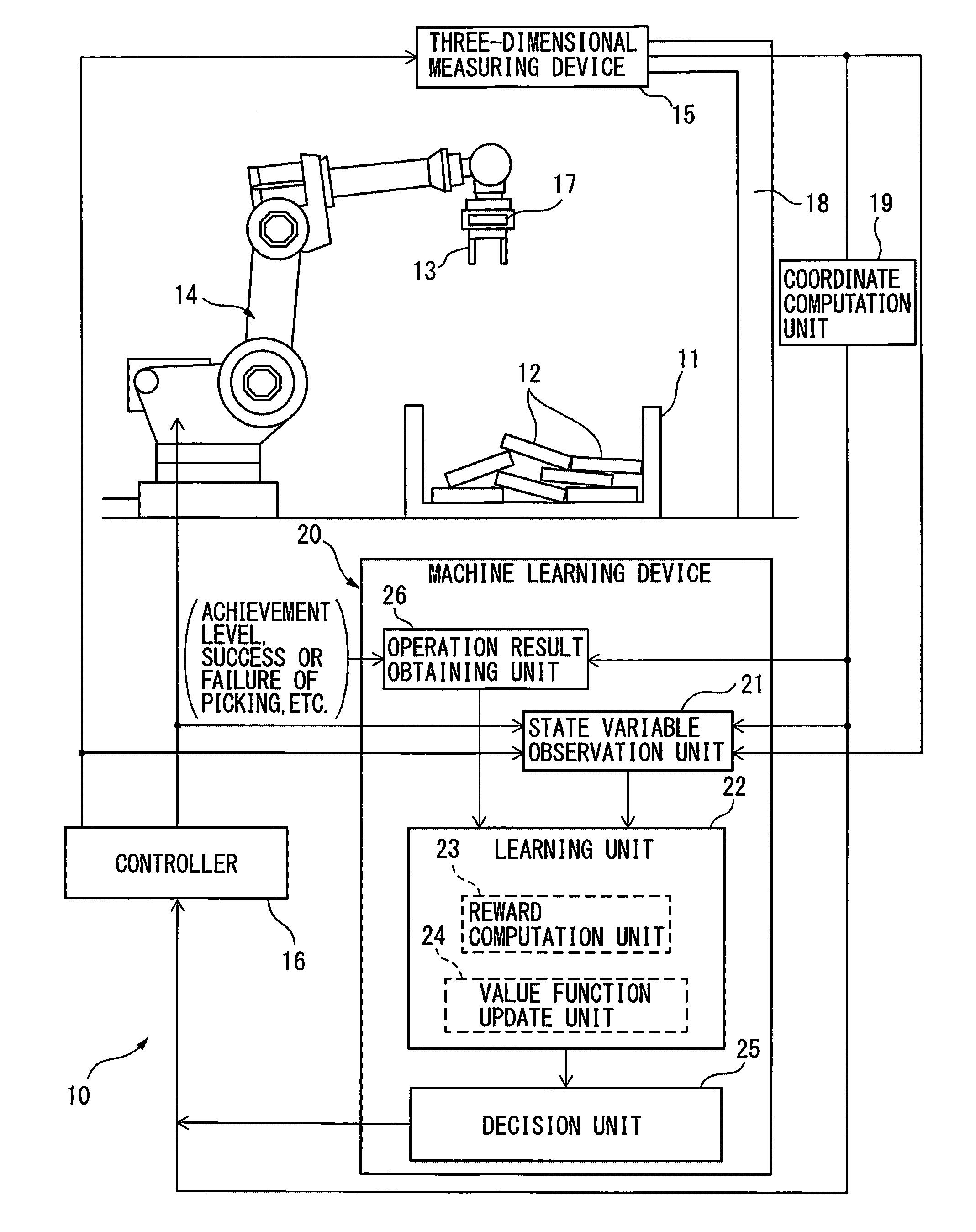

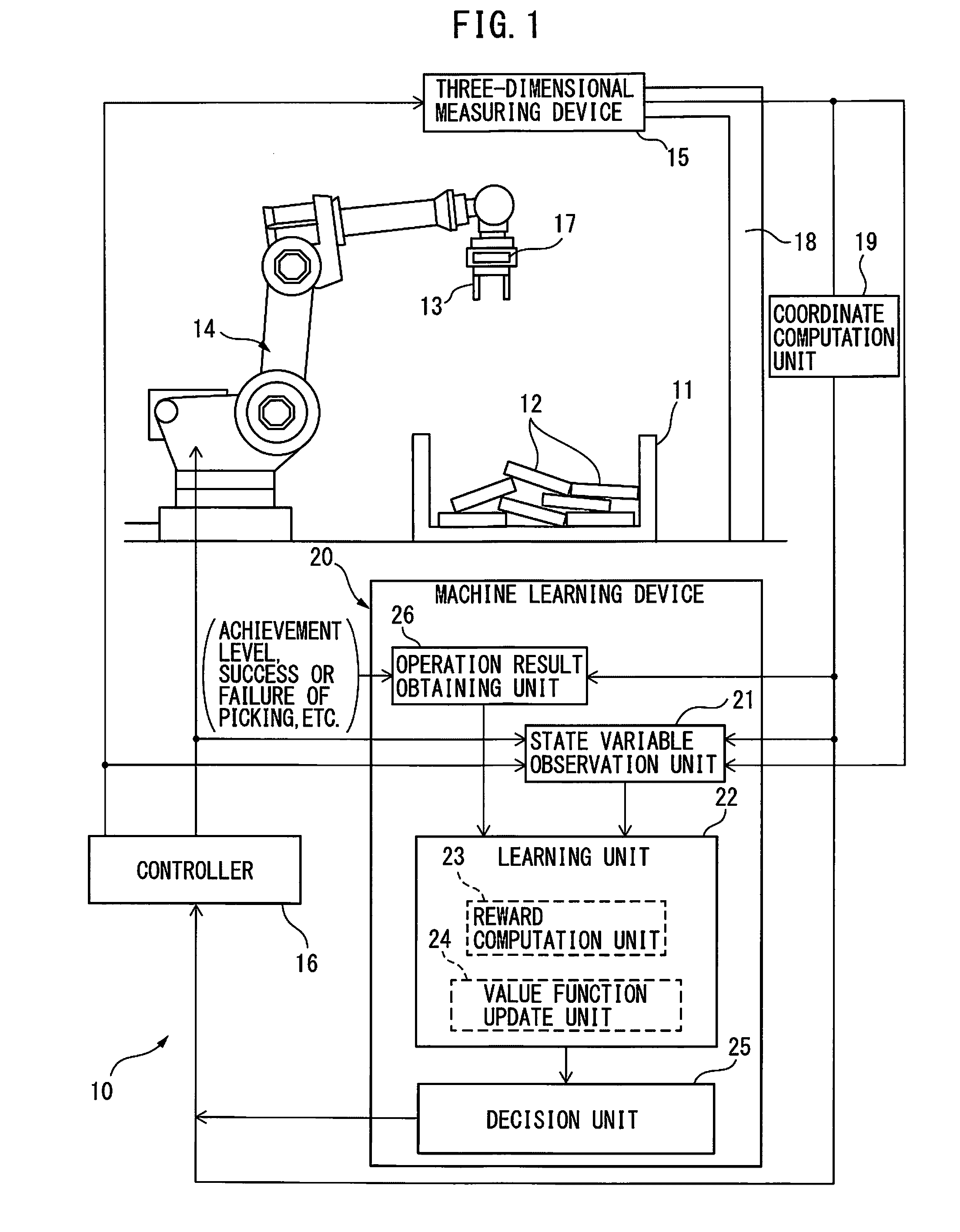

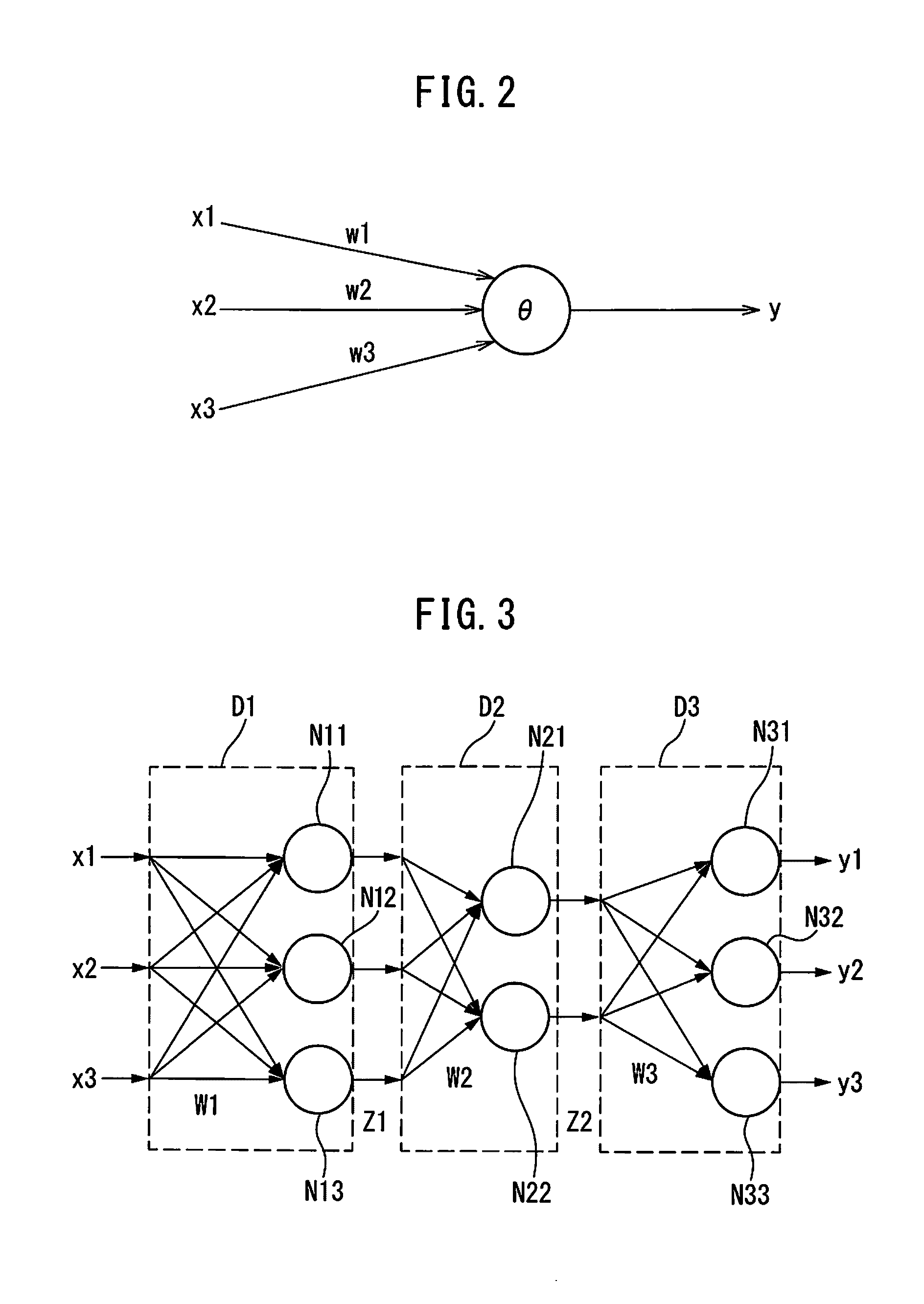

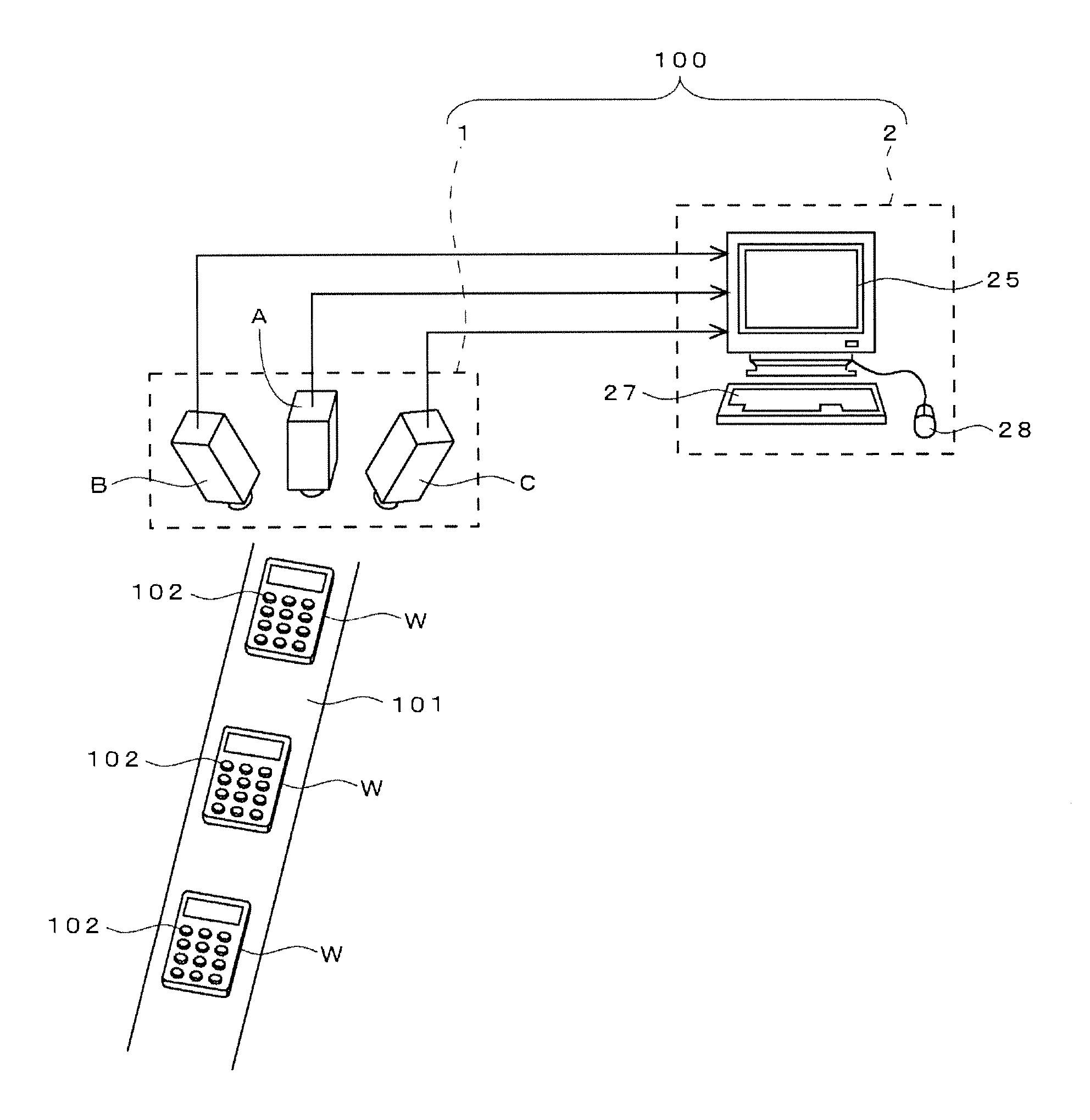

Machine learning device, robot system, and machine learning method for learning workpiece picking operation

A machine learning device that learns an operation of a robot for picking up, by a hand unit, any of a plurality of workpieces placed in a random fashion, including a bulk-loaded state, includes a state variable observation unit that observes a state variable representing a state of the robot, including data output from a three-dimensional measuring device that obtains a three-dimensional map for each workpiece, an operation result obtaining unit that obtains a result of a picking operation of the robot for picking up the workpiece by the hand unit, and a learning unit that learns a manipulated variable including command data for commanding the robot to perform the picking operation of the workpiece, in association with the state variable of the robot and the result of the picking operation, upon receiving output from the state variable observation unit and output from the operation result obtaining unit.

Owner:PREFERRED NETWORKS INC

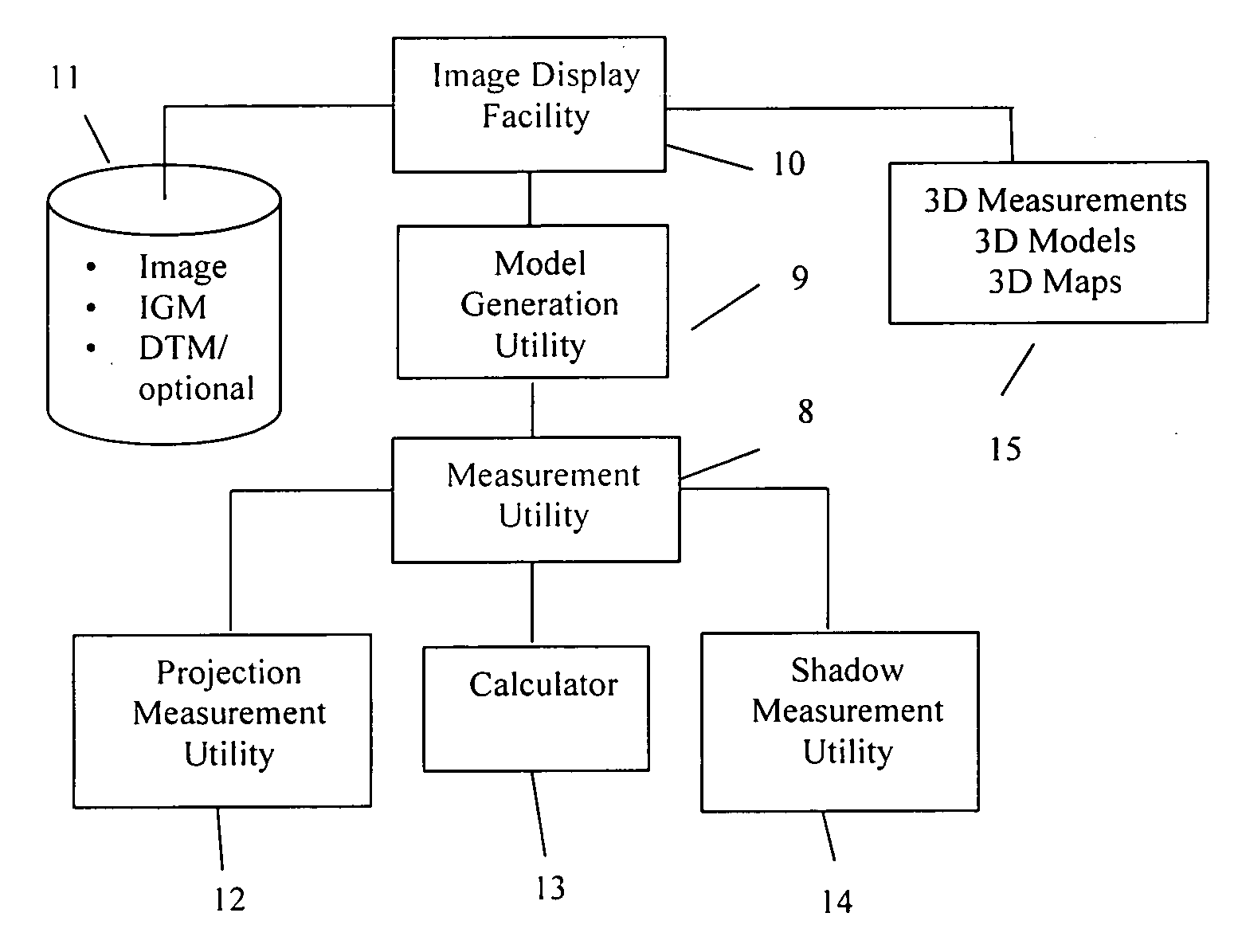

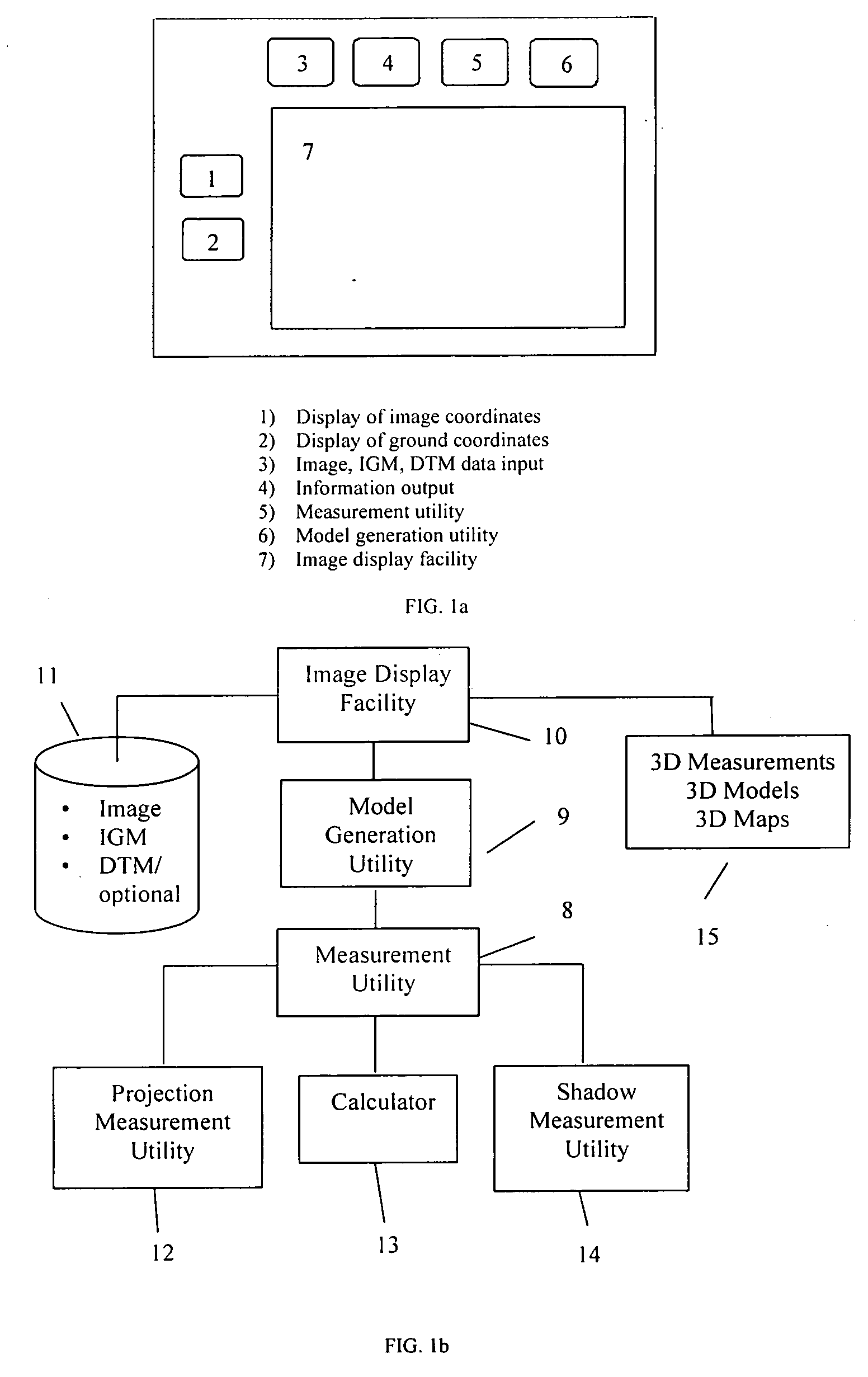

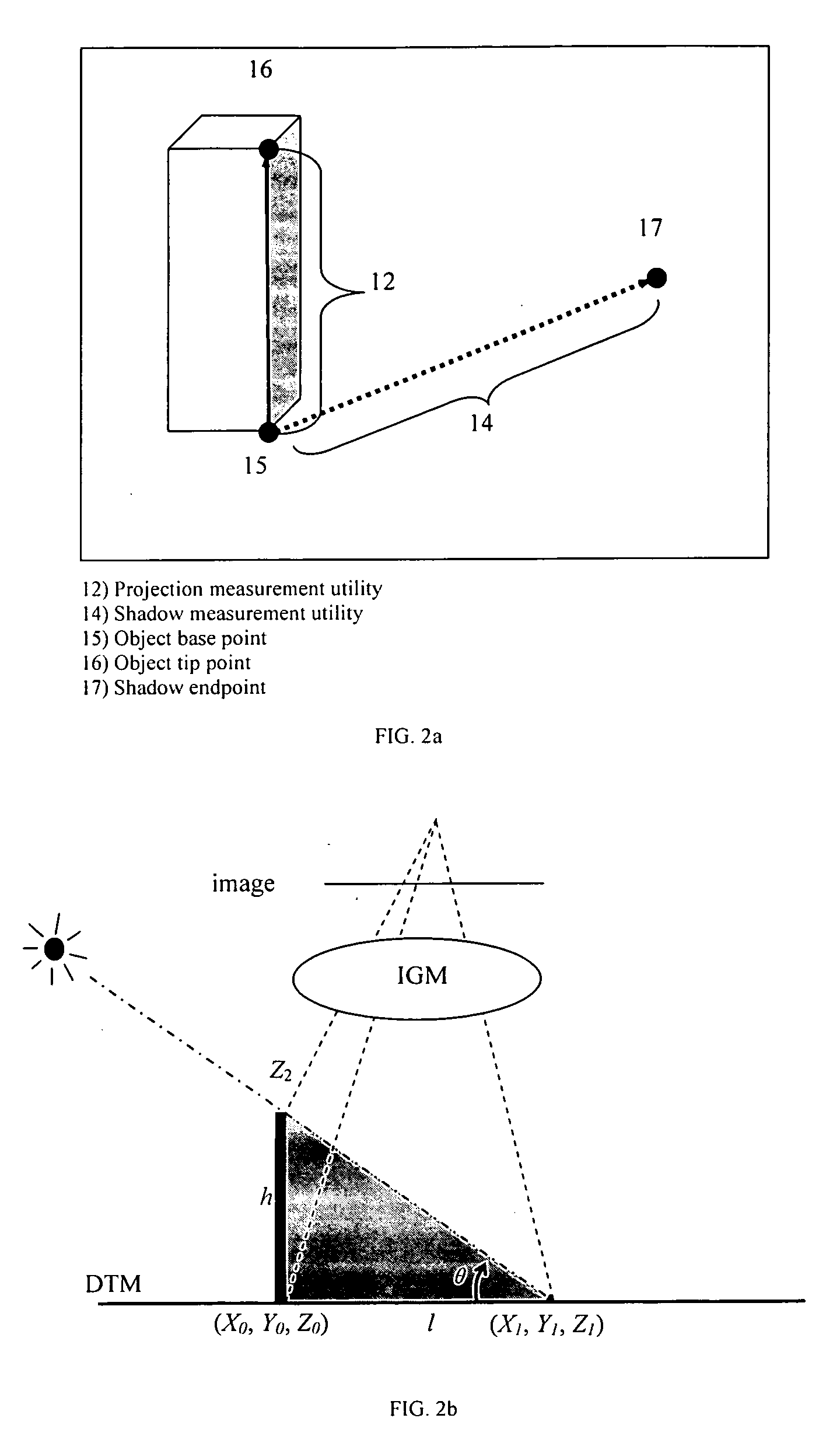

System, computer program and method for 3D object measurement, modeling and mapping from single imagery

InactiveUS20080089610A1Create efficientlyImage analysisCharacter and pattern recognitionThree dimensional measurementComputerized system

A method for deriving three-dimensional measurement information and / or creating three-dimensional models and maps, from single images of at least one three-dimensional object is provided. The method includes the steps of: (a) obtaining at least one two-dimensional single image of the object, the image consisting of image data and being associated with an image geometry model (IGM); (b) deriving three-dimensional coordinate information associated with the image, based on the IGM, and associating the three-dimensional coordinate information with the image data; (c) analyzing the image data so as to: (i) measure the projection of the object using the IGM to derive measurement data including the height and / or point-to-point distances pertaining to the object; and / or (ii) measure the shadow of the object to derive measurement data including the height and / or point-to-point distance pertaining to the object; and (d) obtaining three-dimensional measurements based on the projection and / or shadow measurements of the object. In another aspect of the method, the method includes the further step of creating three-dimensional models or maps based on the projection and / or shadow measurements. A series of algorithms are also provided for processing the method of the invention. A computer system and related computer program for deriving three-dimensional measurement information and / or creating three-dimensional models and maps, from single images of at least one three-dimensional object is provided based on the disclosed method is also provided.

Owner:MICROSOFT CORP

Three-dimensional vision sensor

InactiveUS20100232681A1Avoid performanceCancel noiseImage enhancementImage analysisTransformation parameterThree dimensional measurement

An object of the present invention is to enable performing height recognition processing by setting a height of an arbitrary plane to zero for convenience of the recognition processing. A parameter for three-dimensional measurement is calculated and registered through calibration and, thereafter, an image pickup with a stereo camera is performed on a plane desired to be recognized as having a height of zero in actual recognition processing. Further, three-dimensional measurement using the registered parameter is performed on characteristic patterns (marks m1, m2 and m3) included in this plane. Three or more three-dimensional coordinates are obtained through this measurement and, then, a calculation equation expressing a plane including these coordinates is derived. Further, based on a positional relationship between a plane defined as having a height of zero through the calibration and the plane expressed by the calculation equation, a transformation parameter (a homogeneous transformation matrix) for displacing points in the former plane into the latter plane is determined, and the registered parameter is changed using the transformation parameter.

Owner:ORMON CORP

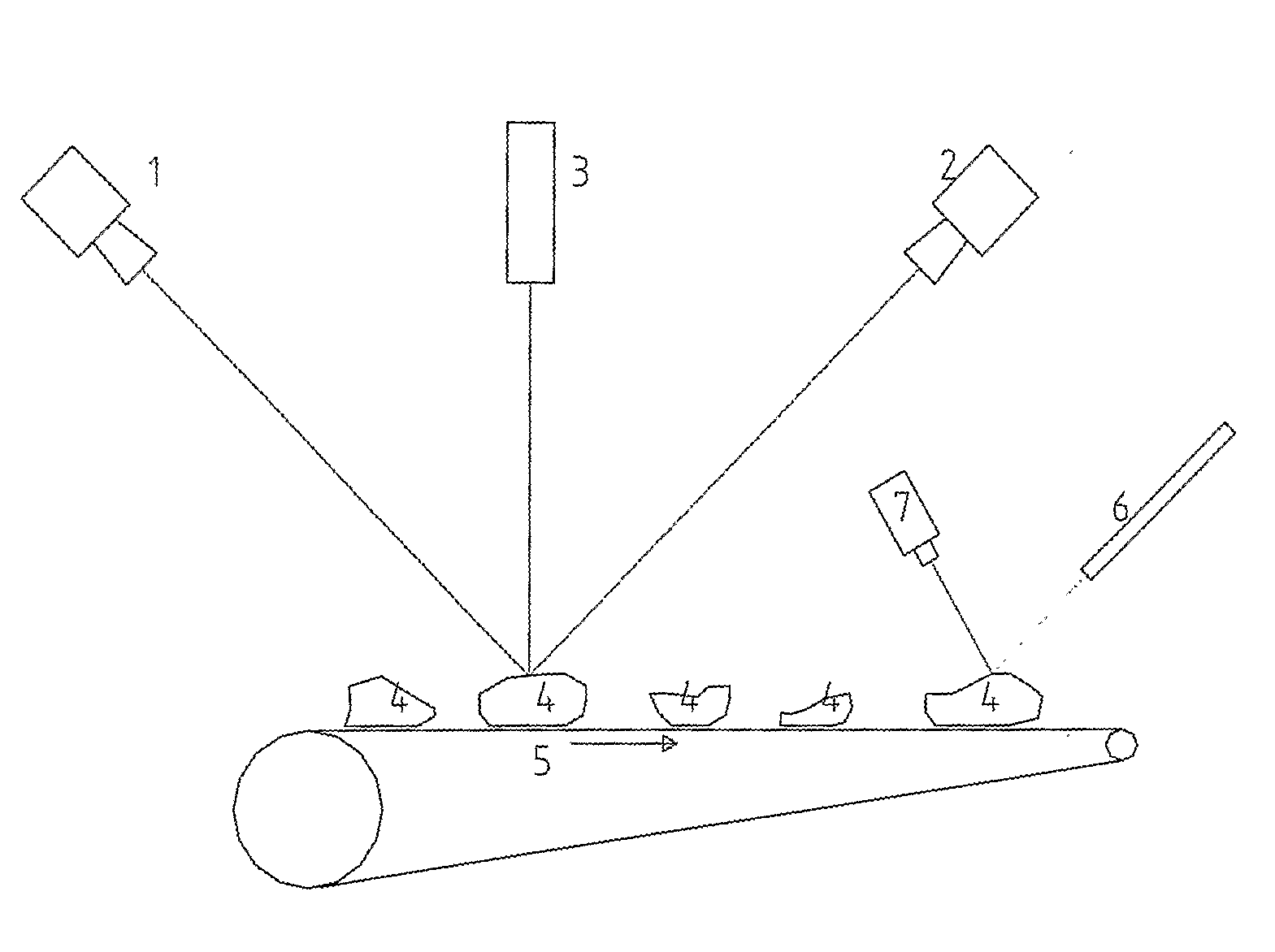

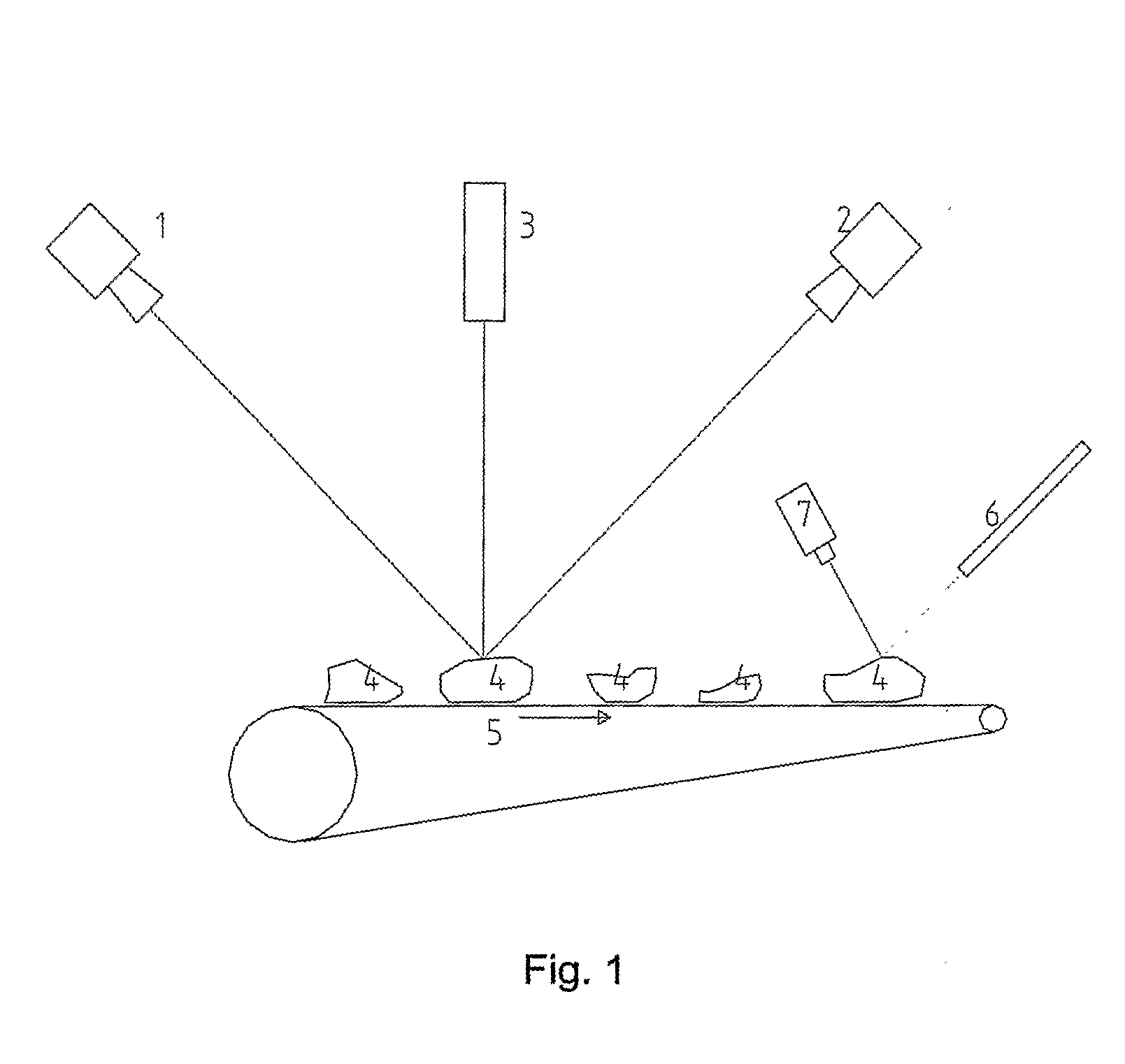

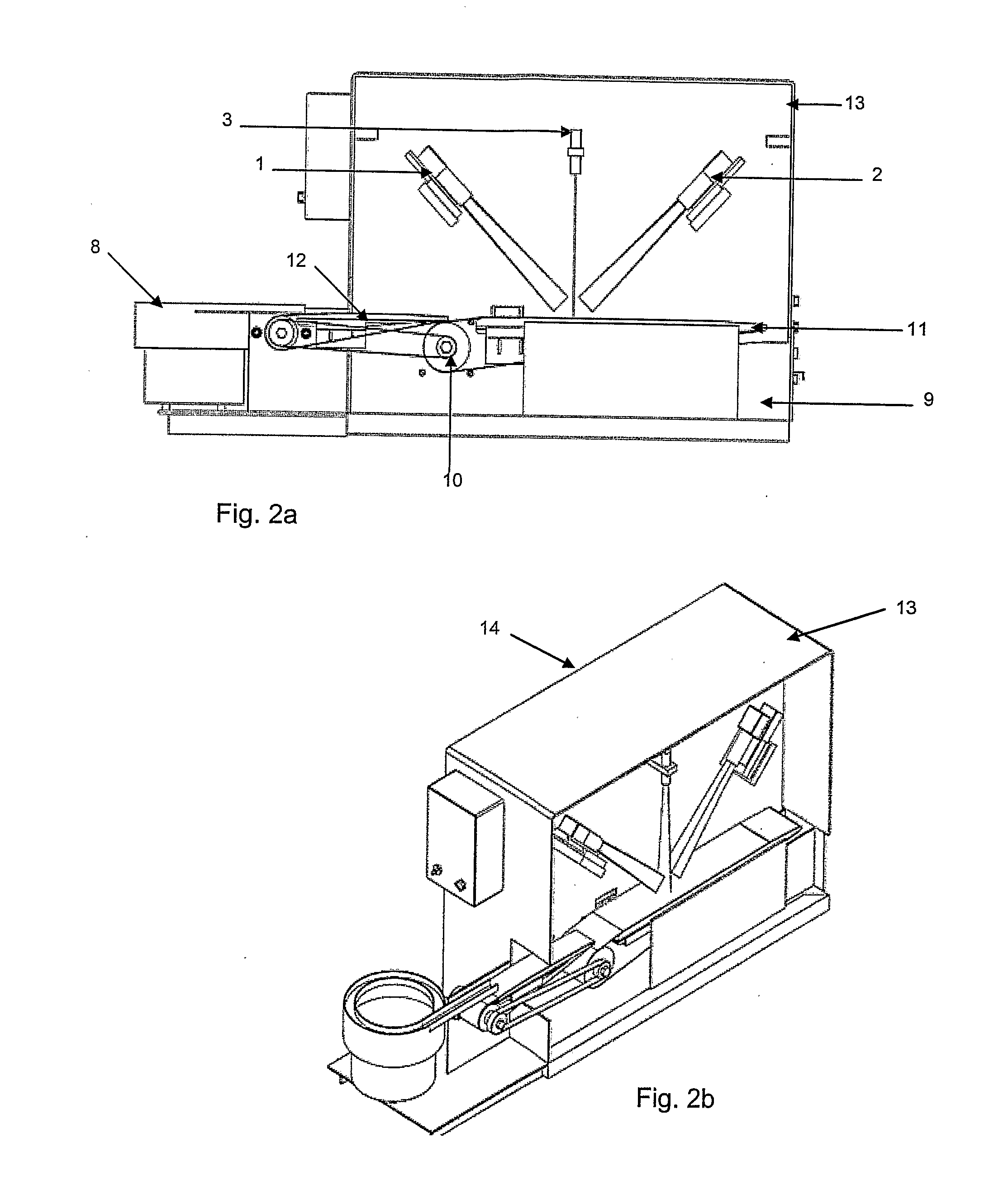

Apparatus and Method For Analysis of Size, Form and Angularity and For Compositional Analysis of Mineral and Rock Particles

ActiveUS20080192987A1Automatically and rapidly analyzeEarth material testingCharacter and pattern recognitionMachine visionThree dimensional measurement

Equipment and process for three-dimensional measurement of size and shape and for compositional analysis of mineral and rock particles and the like objects. A mixture of particles or objects of same or different sizes of minerals or rocks or the like are fed individually and automatically onto a conveyor belt for three-dimensional machine vision measurements using laser and two cameras and subsequently for spectroscopic measurements using visible and infrared light and are then collected at the end of the conveyor. Computer software is used to perform the measurement automatically and to calculate size, form, roundness, and preferably petrographic composition and other characteristics or properties of each individual object and the statistical distribution of relevant properties, either according to built-in measurement processes or user specific methods.

Owner:PETROMODEL EHF

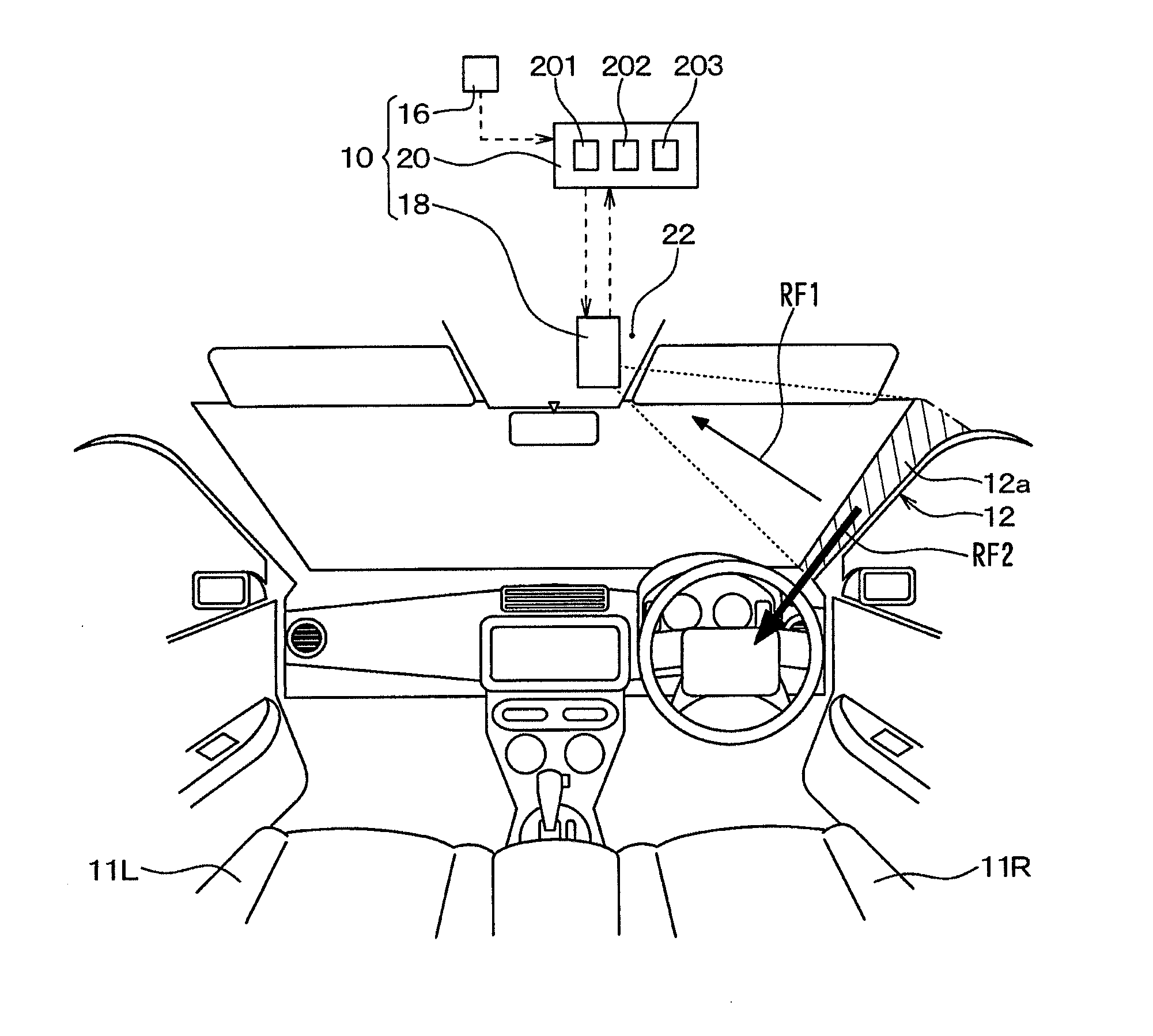

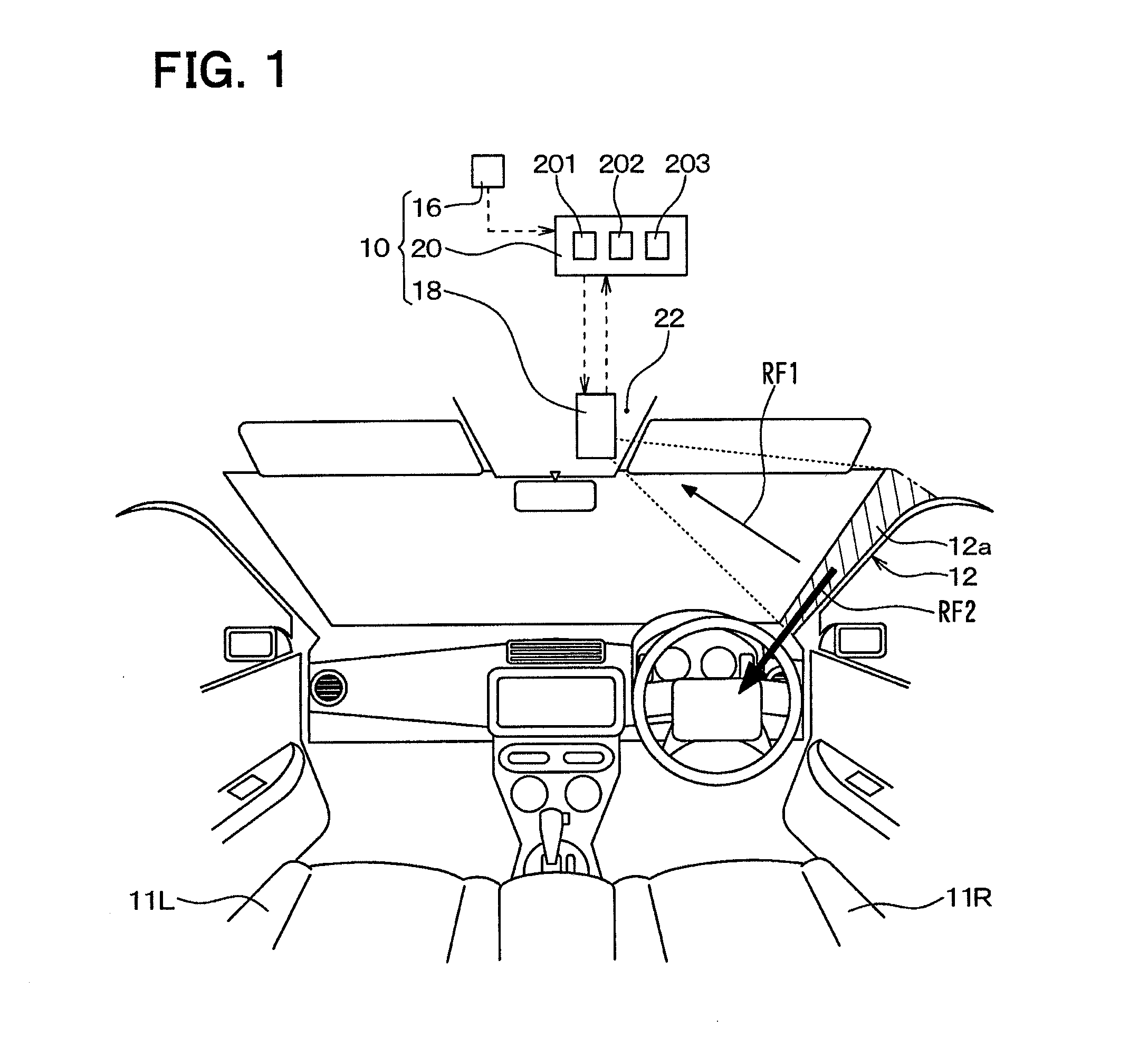

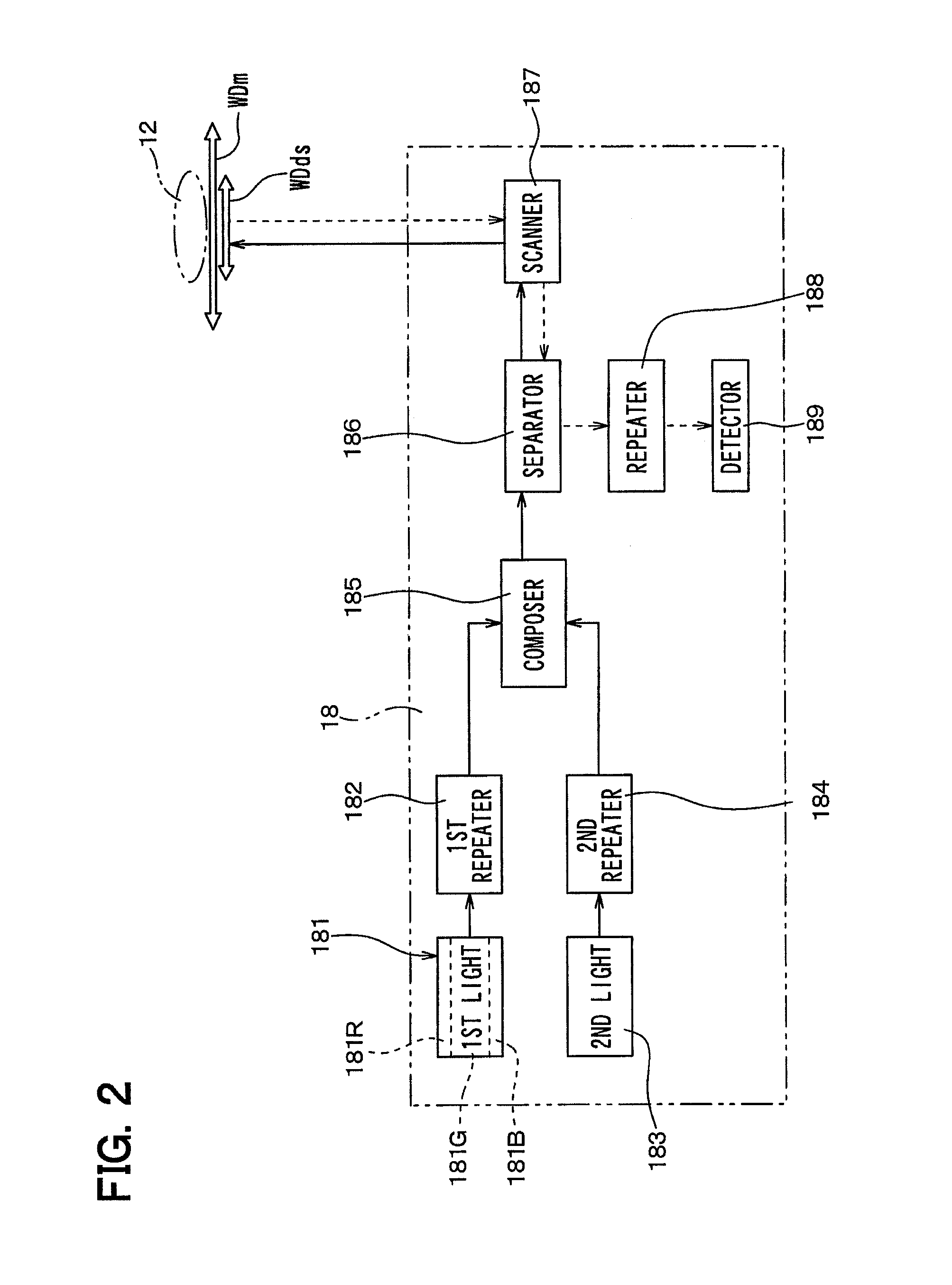

Projection type image display device

InactiveUS20150009100A1Less recognizableAvoid uneven brightnessCathode-ray tube indicatorsOptical viewingDriver/operatorComputer graphics (images)

A projection type image display device includes a processor having a measuring part for performing a three-dimensional measurement of an A-pillar and a projection range controller for controlling a projection range of an image light, which is matched to an A-pillar surface based on a result of the three-dimensional measurement. Thus, the projection of an image onto the A-pillar surface by the projection type image display device is easily performed regardless of whether the A-pillar surface is a two-dimensional flat surface or a three-dimensional surface. The projection type image display device also directs a retro-reflective component in a reflected image light away from a driver's seat based on a positioning of an image projection device. Speckled uneven image brightness on an image display surface is thereby prevented.

Owner:DENSO CORP

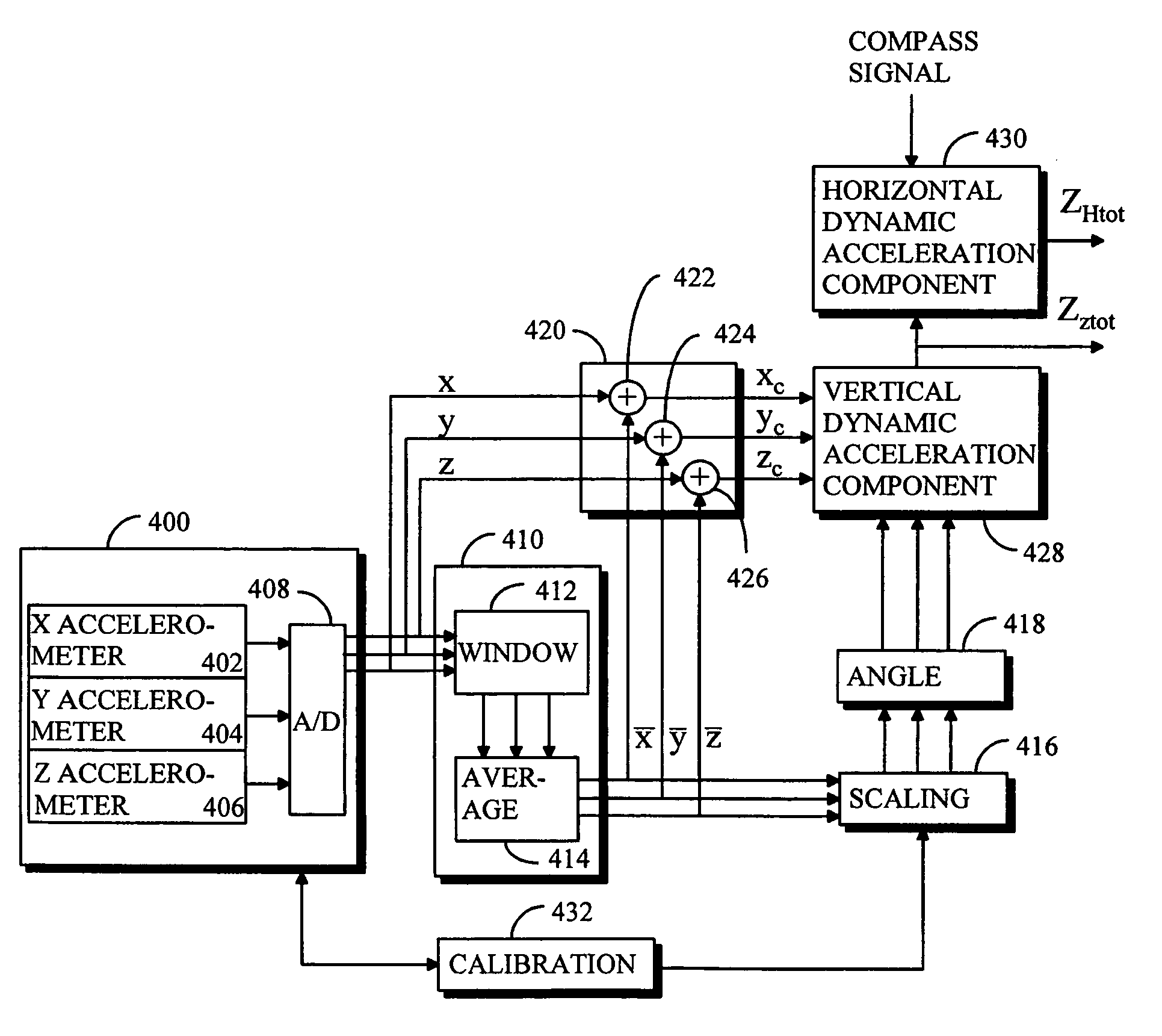

Method and arrangement for determining movement

Owner:III HLDG 3

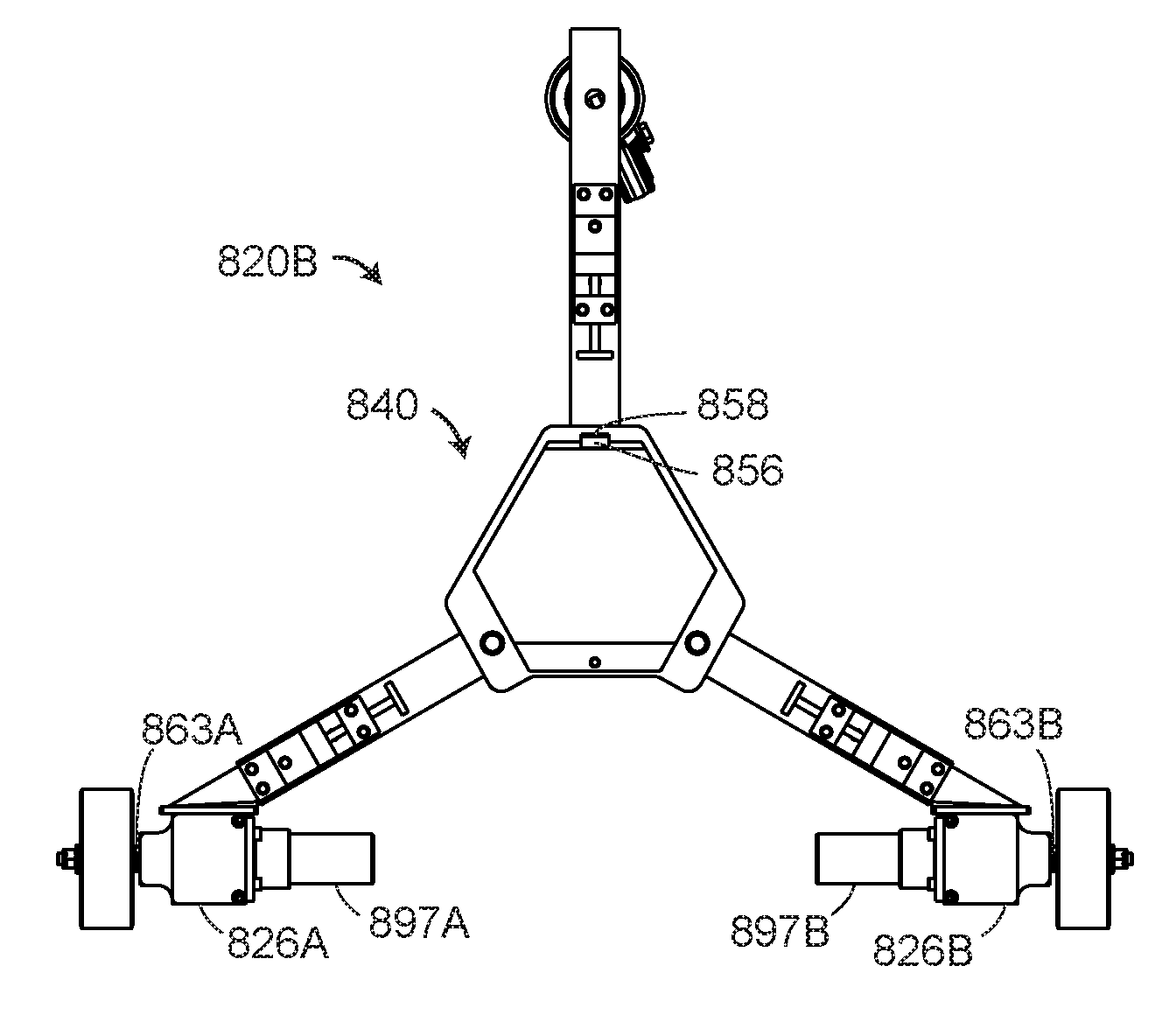

Mobile three-dimensional measuring instrument

ActiveUS20160291160A1Network topologiesUsing optical meansMeasuring instrumentThree dimensional measurement

A mobile three-dimensional (3D) measuring system includes a 3D measuring device, a multi-legged stand coupled to the 3D measuring device, and a motorized dolly detachably coupled to the multi-legged stand.

Owner:FARO TECH INC

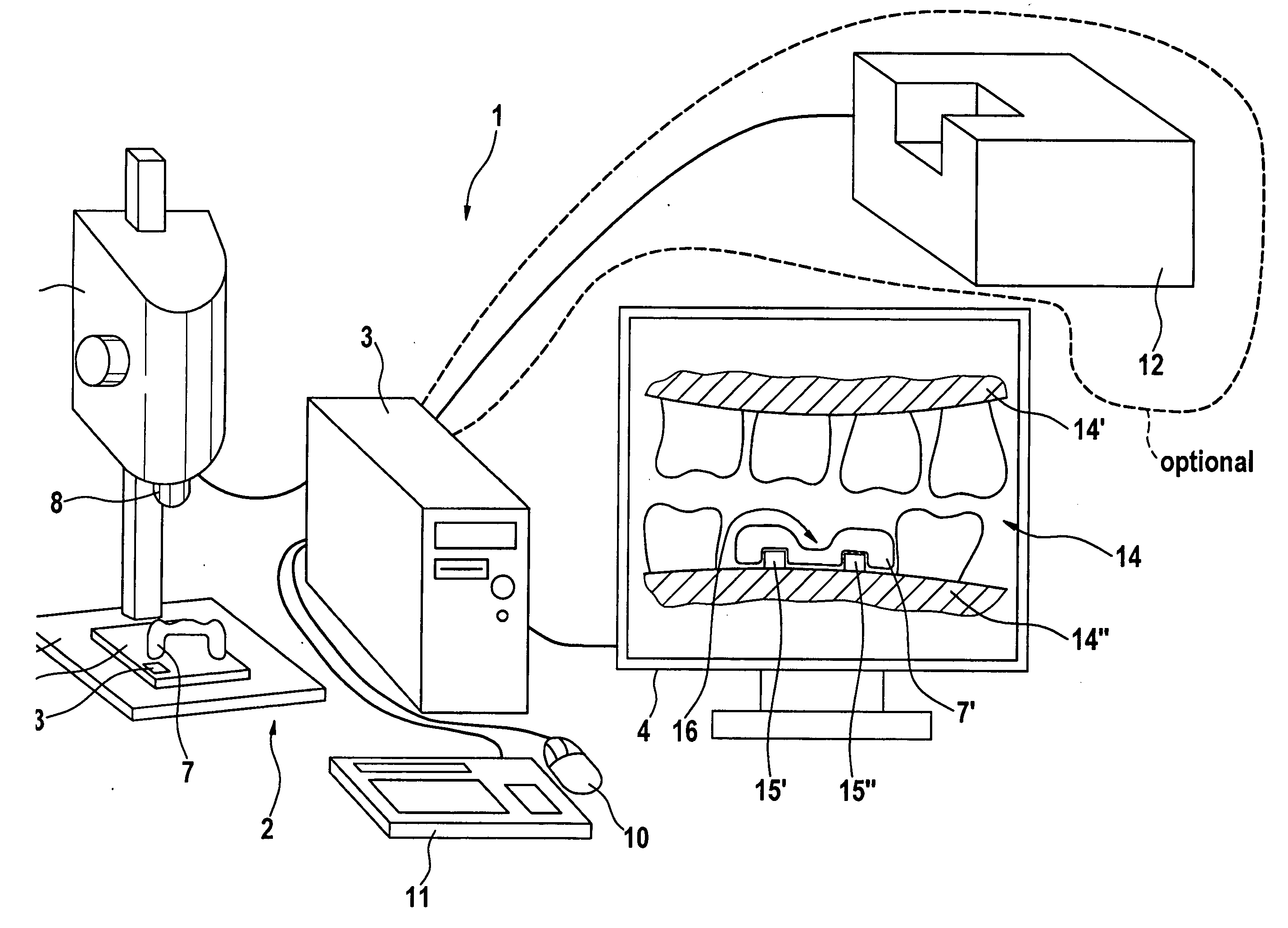

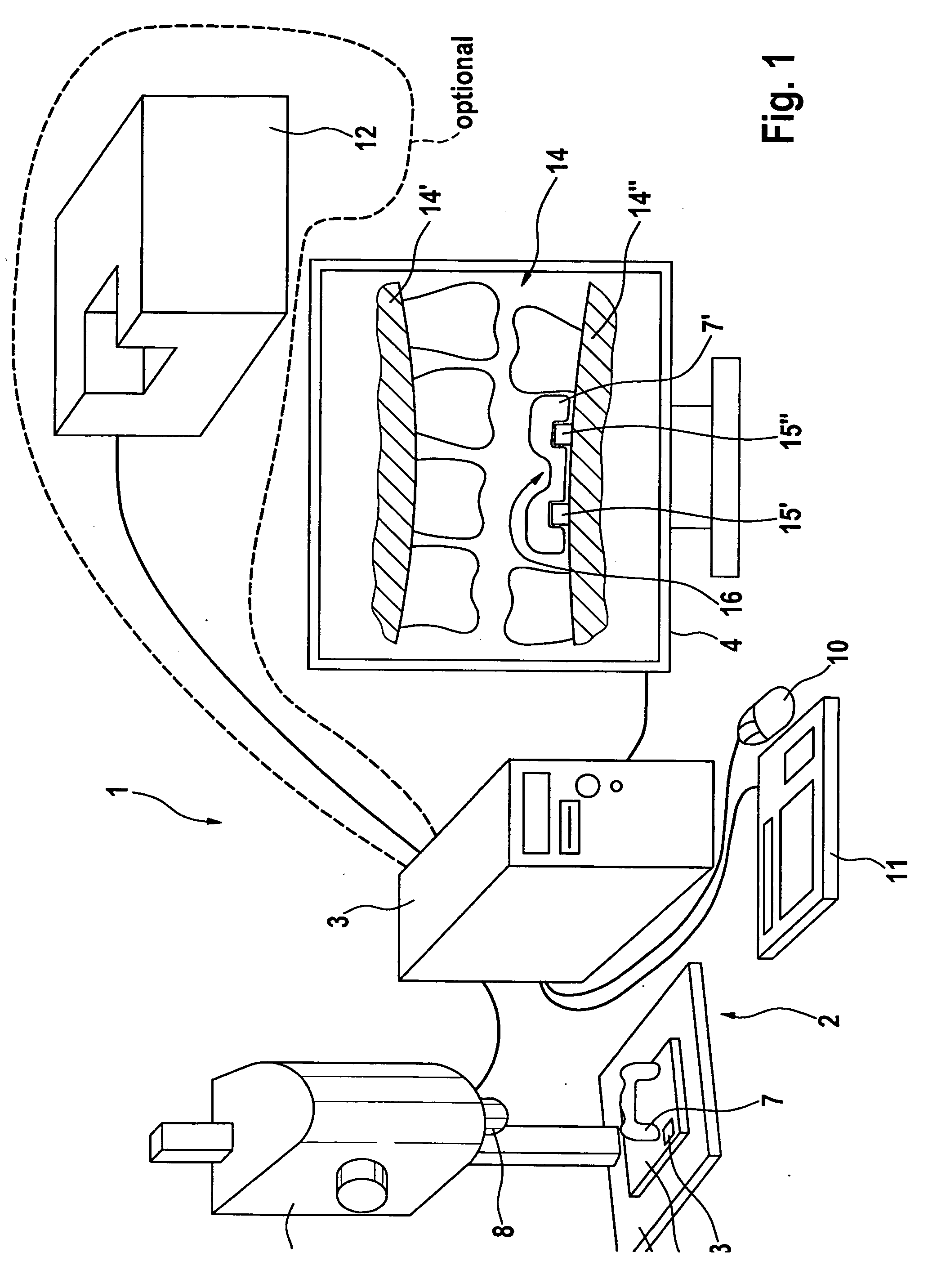

Method and Device for Producing Dental Prosthesis Elements

InactiveUS20090081616A1Easy to monitorAccurate fitDental implantsAdditive manufacturing apparatusDenturesProsthesis

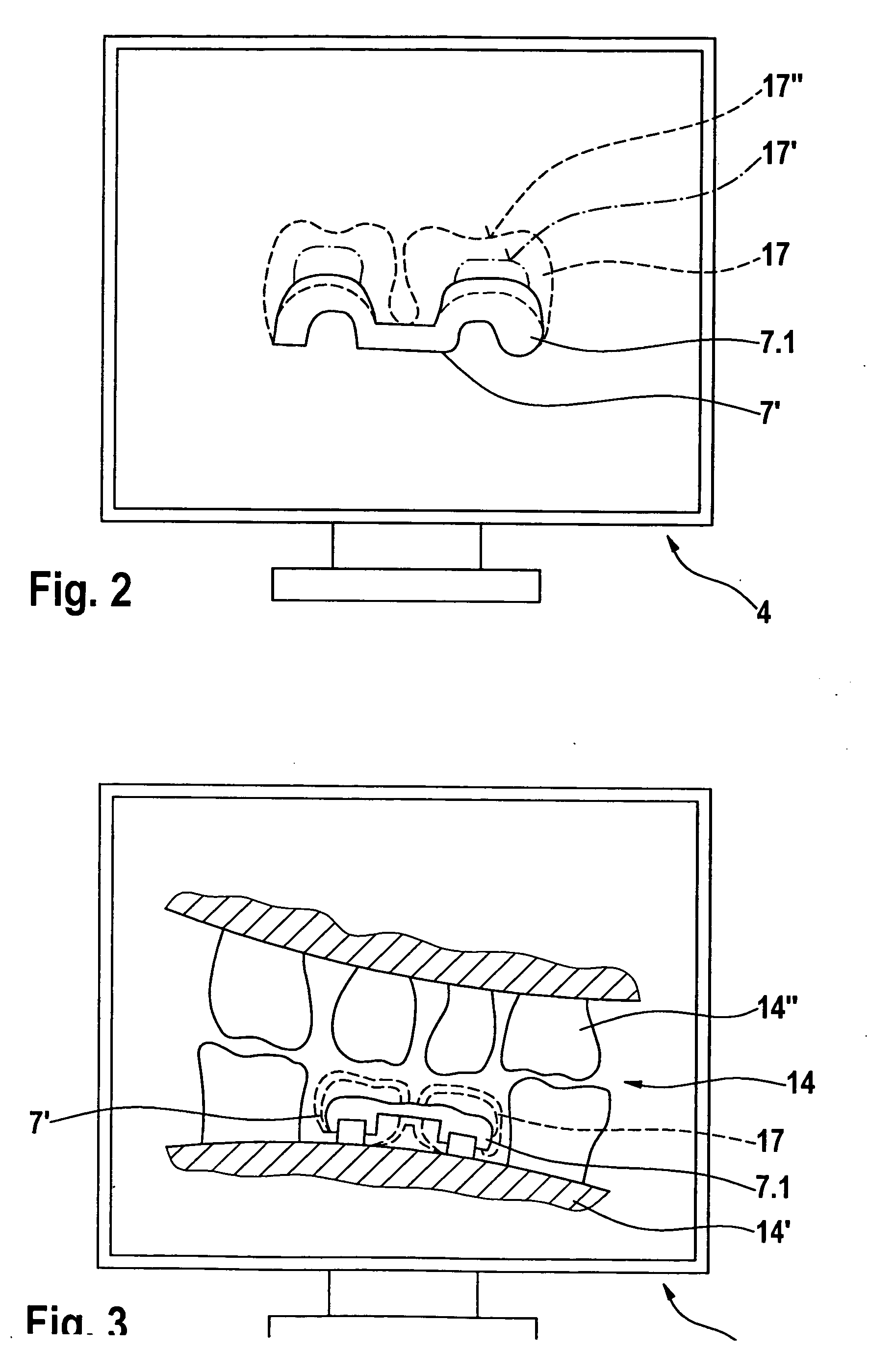

The invention relates to a method for producing a dental prosthesis element (7), according to which the dental prosthesis element (7) is manually reworked. Construction data (17, 17′, 17″) relating to the dental prosthesis element to be produced is recorded together with measurement data (7′) relating to the dental prosthesis element (7) to be produced and is reproduced on a display (4), the measurement data having been recorded by means of a three-dimensional measurement device (2). The invention also relates to one such method whereby a 3D data record of the tooth situation (14) is reproduced on the display (4) instead of the construction data. The invention further relates to a device for the partial manual treatment of the dental prosthesis element. Said device comprises a three-dimensional measurement device (2), a display (4), and a computer unit (3) comprising means for the correlation and comparison of two data records and for graphically presenting the data generated by the comparison.

Owner:SIRONA DENTAL SYSTEMS

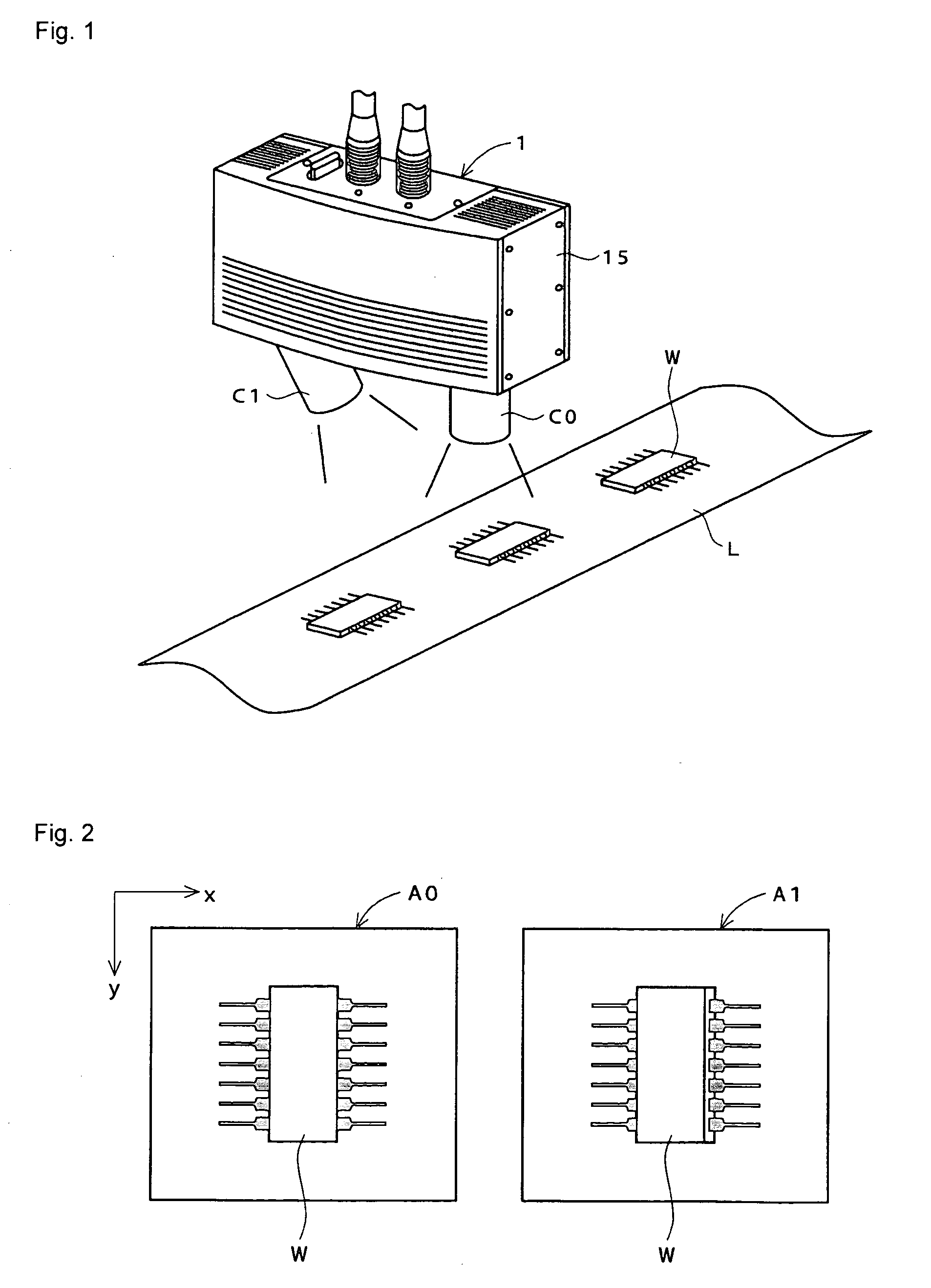

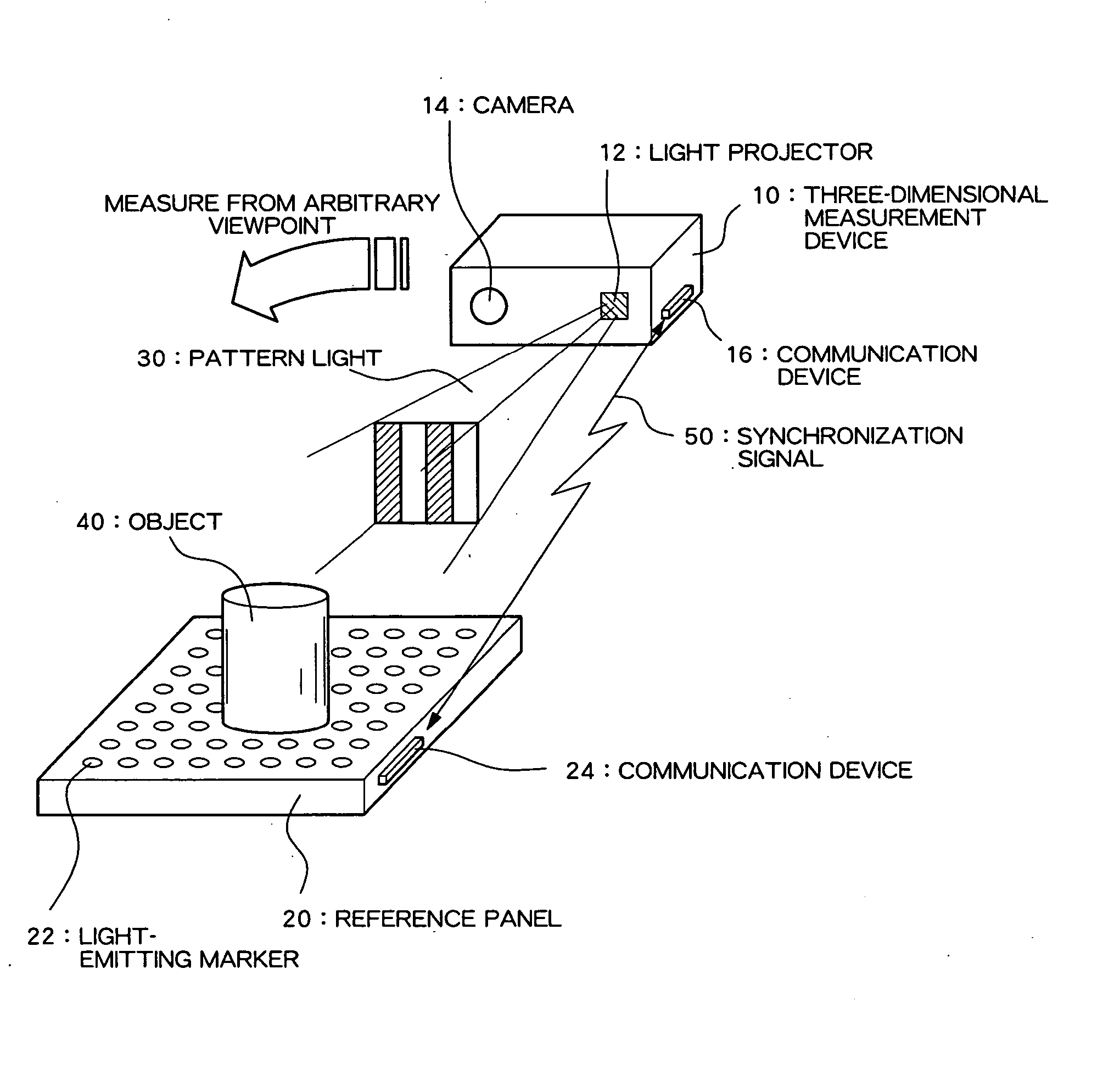

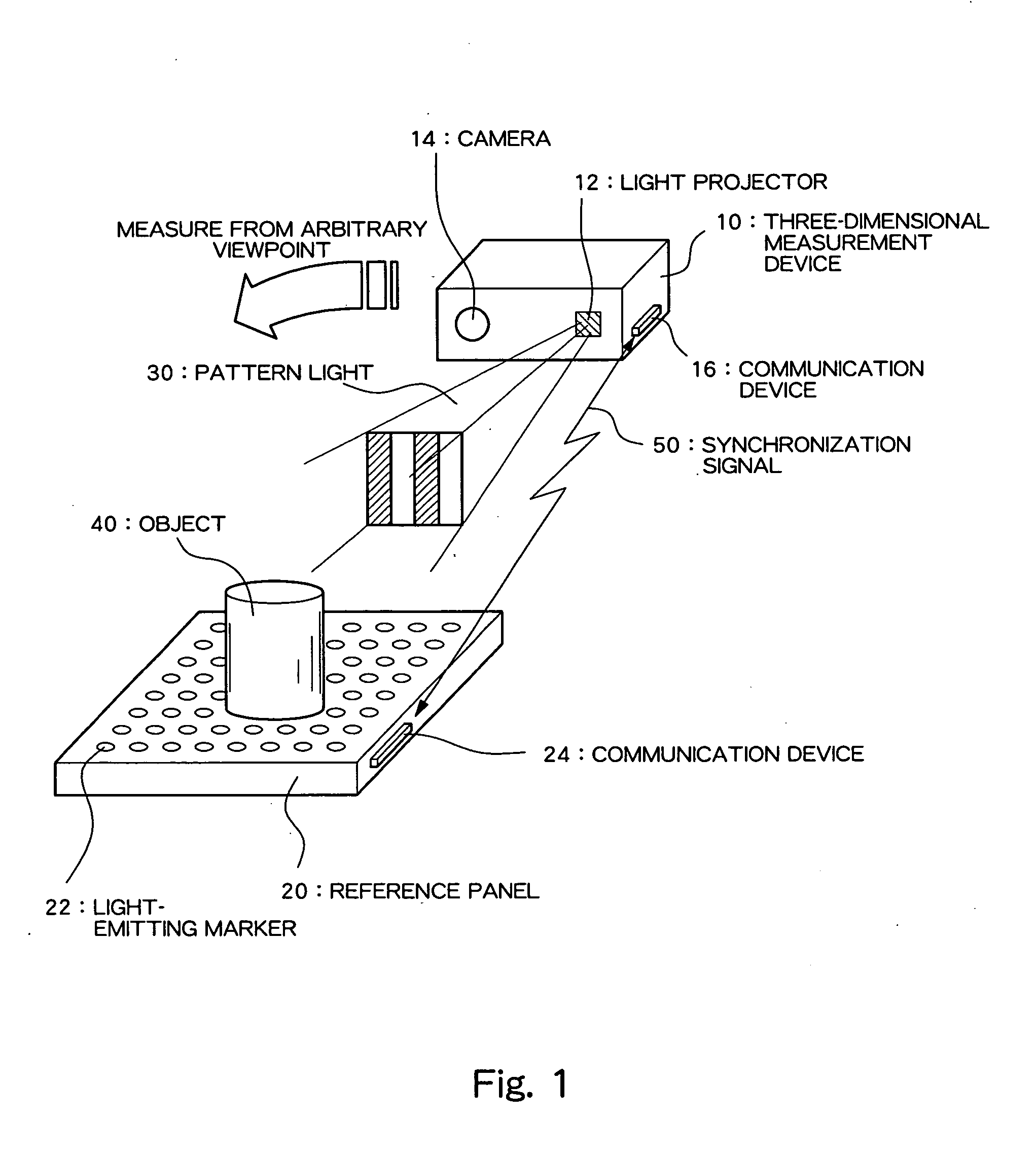

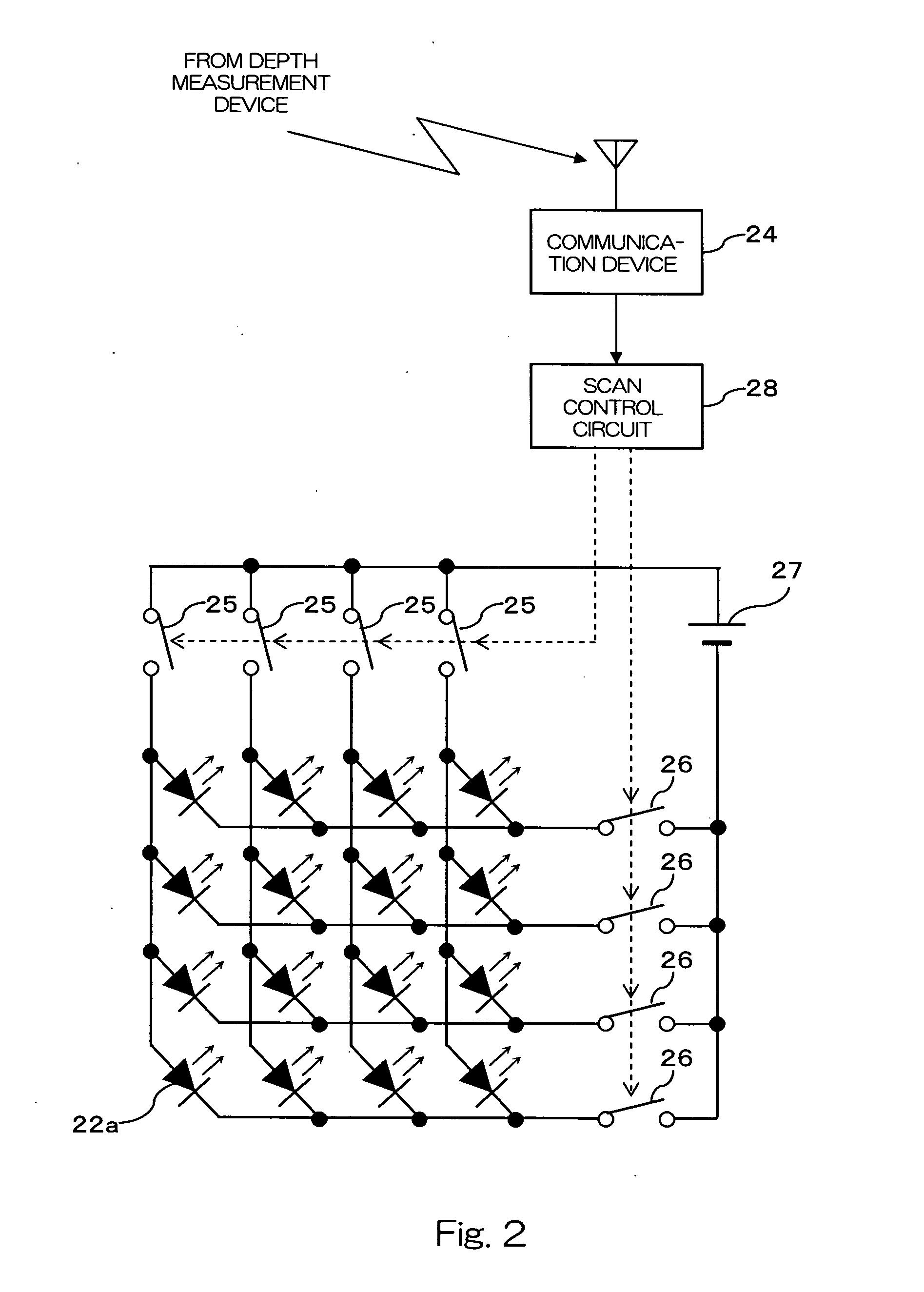

Camera Calibration System and Three-Dimensional Measuring System

InactiveUS20080075324A1Television system detailsImage analysisMeasuring instrumentTransformation parameter

Camera calibration which is robust against noise factors such as variation in environmental lighting and obstructions is realized. Light-emitting markers, whose on / off states can be controlled, are arrayed in a matrix on a reference panel on which an object is placed. The light-emitting markers blink in accordance with respective switching patterns in synchronism with the frame of continuous imaging of a camera. A three-dimensional measuring instrument determines the time-varying bright-and-dark pattern of a blinking point from the image of each frame and identifies, on the basis of the pattern, to which light-emitting marker each point corresponds. By reference to the identification results, camera calibration is performed, and a coordinate transformation parameter is computed.

Owner:SPACEVISION

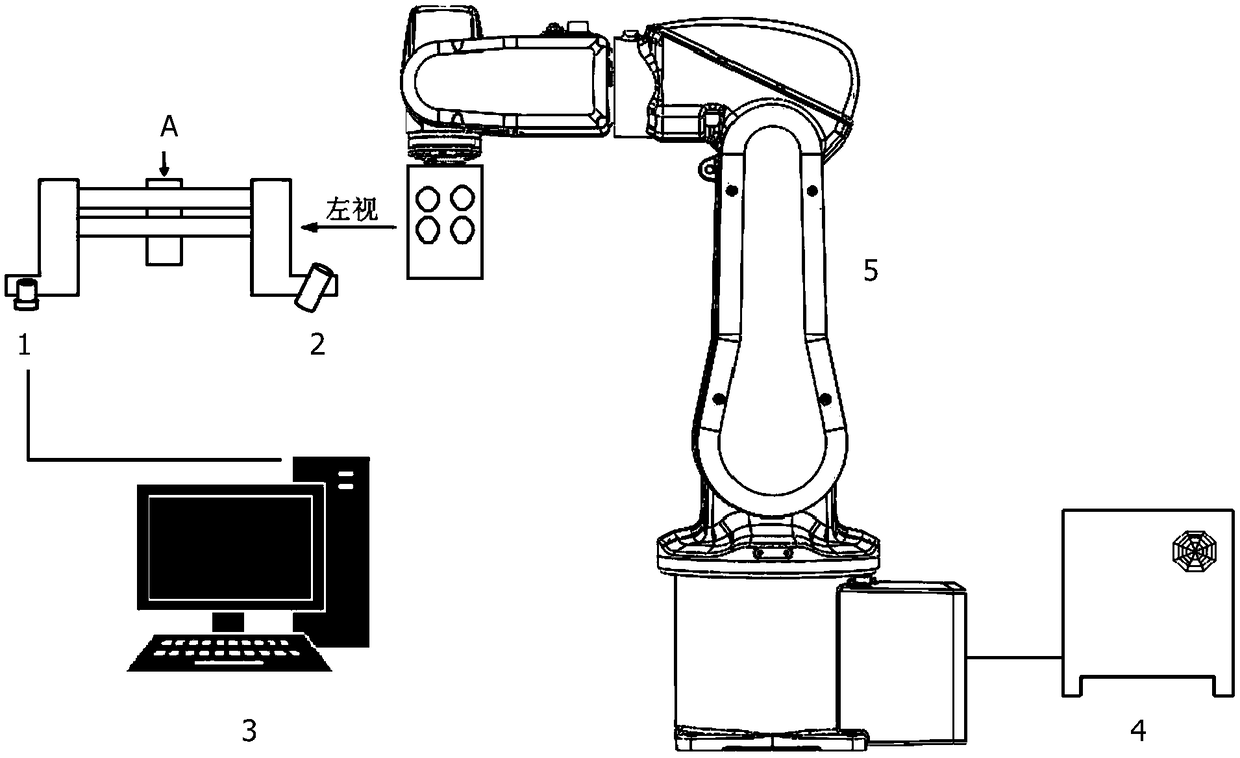

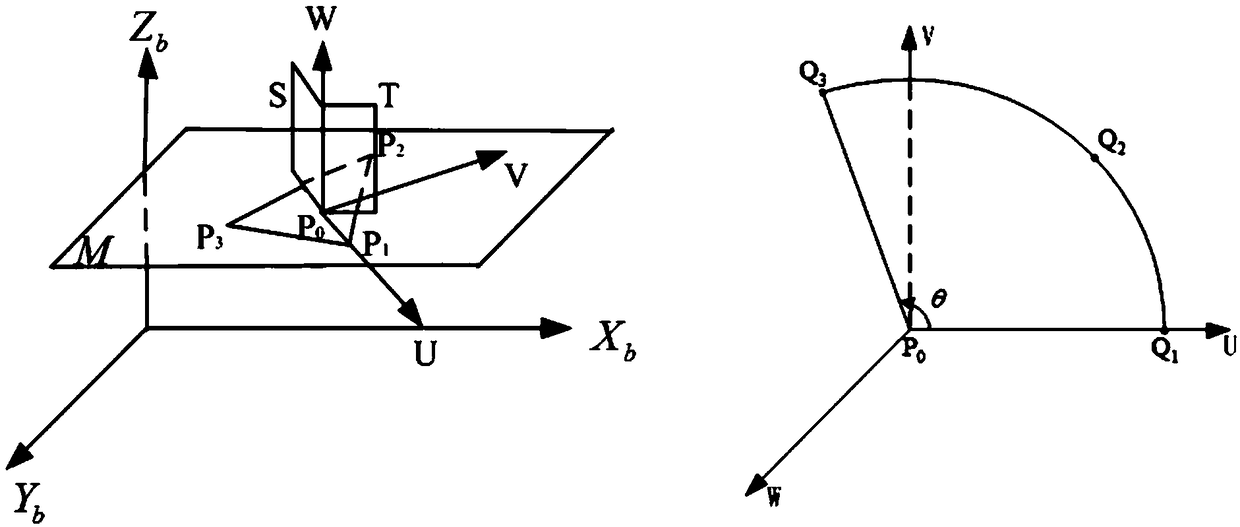

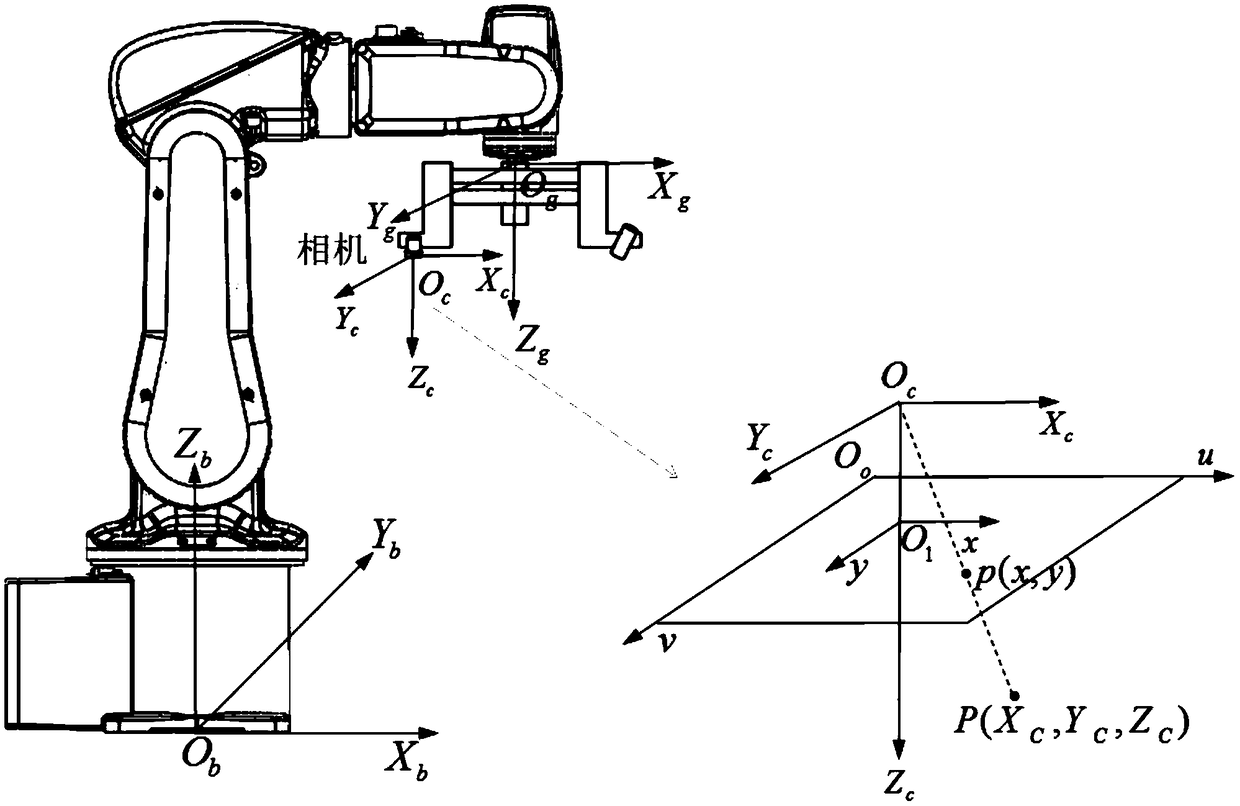

Simulation method and device of digital twin system of industrial robot

InactiveCN108724190AAvoid exceptionImprove adaptabilityProgramme-controlled manipulatorVisual technologyWork task

The invention provides a simulation method and device of a digital twin system of an industrial robot. The simulation device comprises the industrial robot, a vision perception unit and a computer, wherein the vision perception unit is arranged at the tail end of the robot and is composed of a camera and a wire structure light emitter; an industrial robot simulation system is established, the robot is modeled, and three instructions are analyzed and run; a target three-dimensional measurement model of a robot visual system is acquired by using a wire structure optical geometric triangular method; a motion instruction is determined for the working task of the robot, virtual simulation is carried out through the computer, and reachable points and collision point detection are carried out; and the robot is actually used for identifying a target object through the visual perception unit, and the actual movement of the robot is driven. The simulation device is safe and reliable in virtual simulation, abnormal operation possibly in actual operation is avoided, the visual perception unit is used for identifying the target object through three-dimensional visual technology, the self-adaptive capacity of the robot to the field environment is improved, and flexibility and intelligence are enhanced.

Owner:XI AN JIAOTONG UNIV

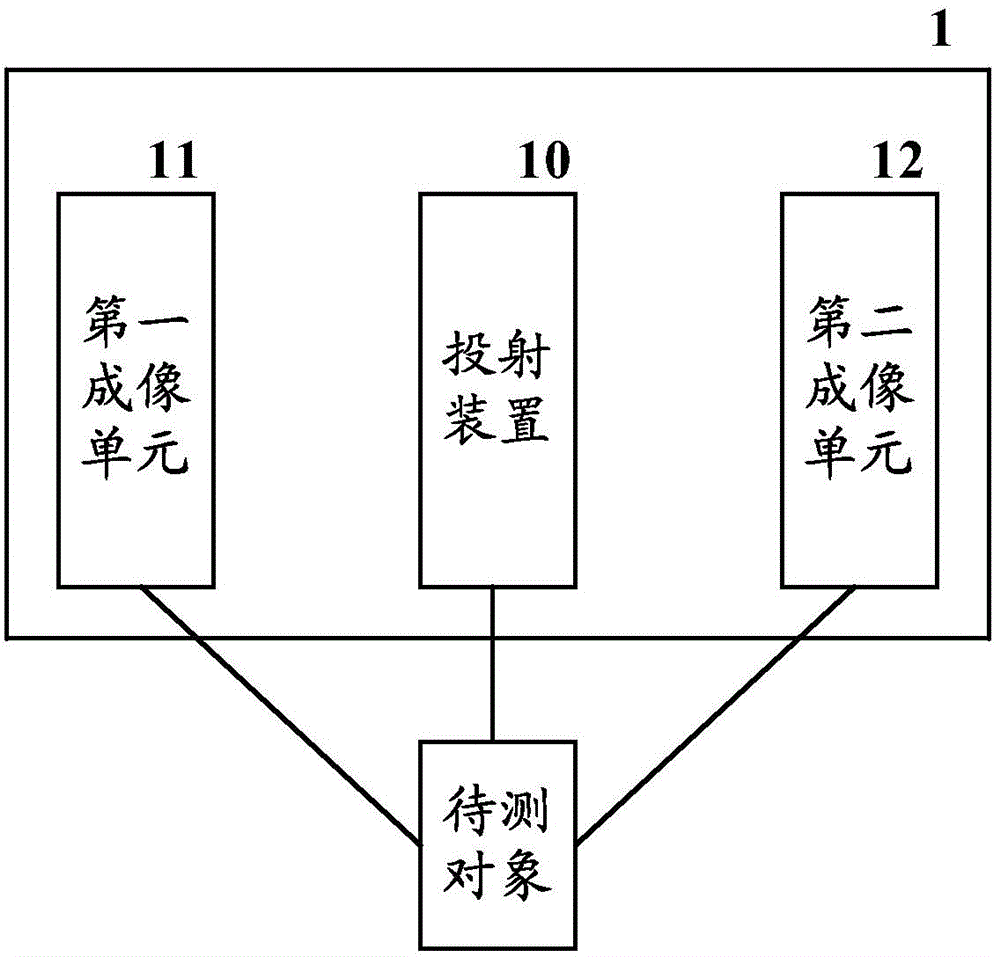

Three-dimensional measuring system, photographing device, photographing method, depth calculation method and depth calculation device

ActiveCN104634276AImprove accuracyAccurately obtainedImage analysisUsing optical meansComputer graphics (images)Three dimensional measurement

The invention provides a three-dimensional measuring system, a photographing device, a photographing method, a depth calculation method and a depth calculation device. The photographing device comprises a projection device, a first imaging unit and a second imaging unit, wherein the projection device is used for projecting discrete beams to a photographing area, the discrete beams are modulated to form a plurality of discrete spots in the photographing area, and the discrete spots can be recognized by other discrete spots in a peripheral preset space range; the first imaging unit is used for photographing the photographing area to acquire a first two-dimensional image; the second imaging unit and the first imaging unit have a predetermined relative position relation, and the second imaging unit is used for photographing the photographing area to acquire a second two-dimensional image. Therefore, under the situation of not being subjected to the influence of the ambient light and the background, the spatial depth information of a detected object can be accurately acquired. For example, when the detected object is arranged in an environment with a single background or in an environment with similar background textures, the spatial depth information of the detected object still can be accurately obtained.

Owner:SHANGHAI TUYANG INFORMATION TECH CO LTD

Image processing apparatus, image processing method, and storage medium

The present invention provides an image processing apparatus that efficiently identifies input characters and the like by an intensity image analysis based on range information. The image processing apparatus performs distance measurement by performing three-dimensional measurement by pattern projection to characters written to a manuscript, whiteboard, and the like, gets an intensity image used as a so-called actual image and an image for distance measurement in parallel, and identifies input characters by an intensity image analysis based on range information. The image processing apparatus picks up characters, patterns, and the like written onto paper or the like with a pen, performs geometric transformation for picked-up images, and performs natural input character analysis and reading processing. Furthermore, by comparing images picked up in a time-series, noise elimination and manuscript position modifications become possible.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com