Patents

Literature

1264 results about "Position tracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positional tracking. Positional tracking detects the precise position of the head-mounted displays, controllers, other objects or body parts within Euclidean space. Positional tracking registers the exact position due to recognition of the rotation (pitch, yaw and roll) and recording of the translational movements.

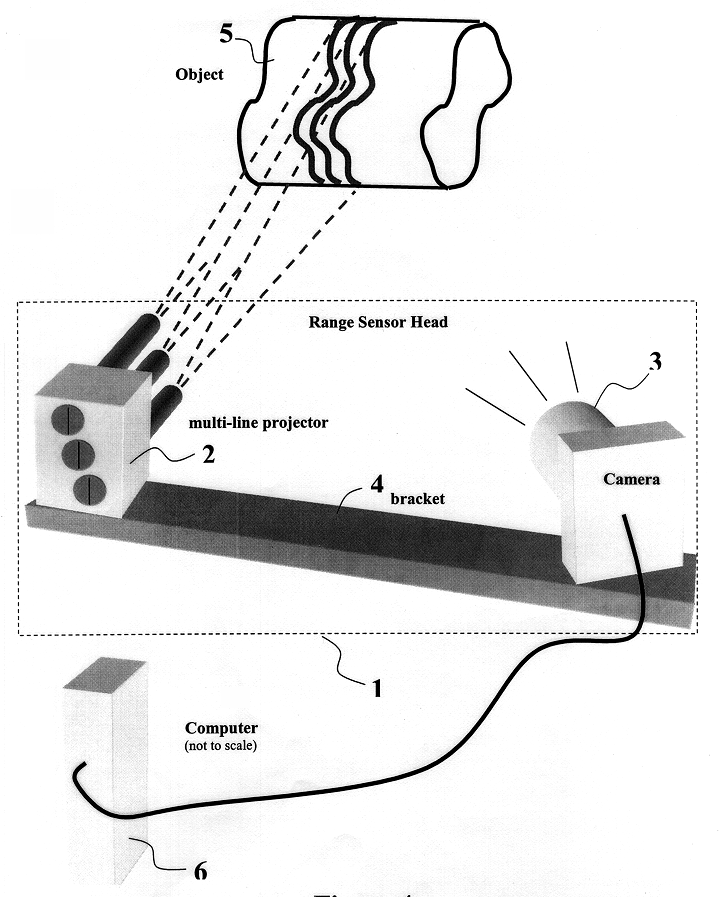

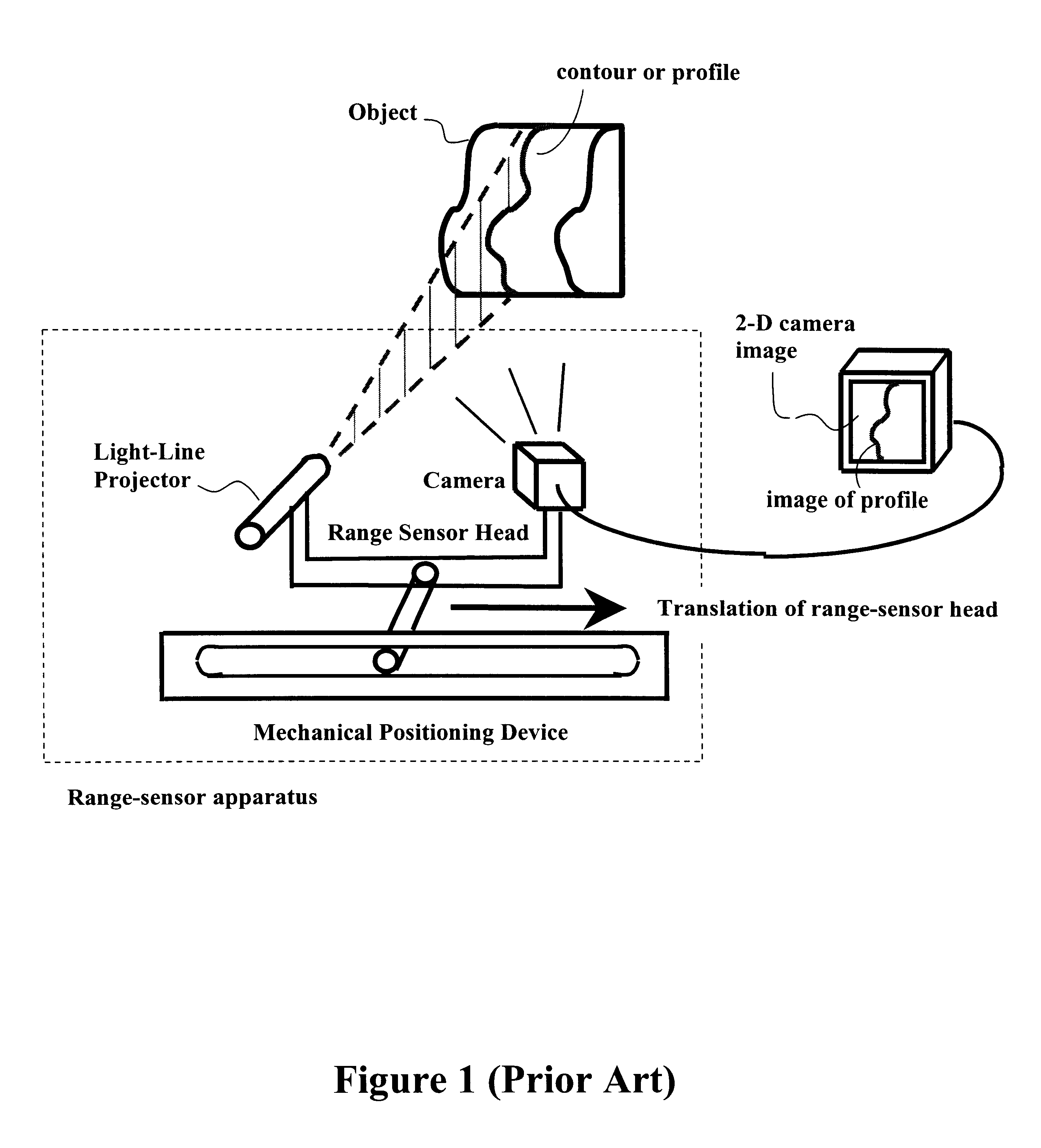

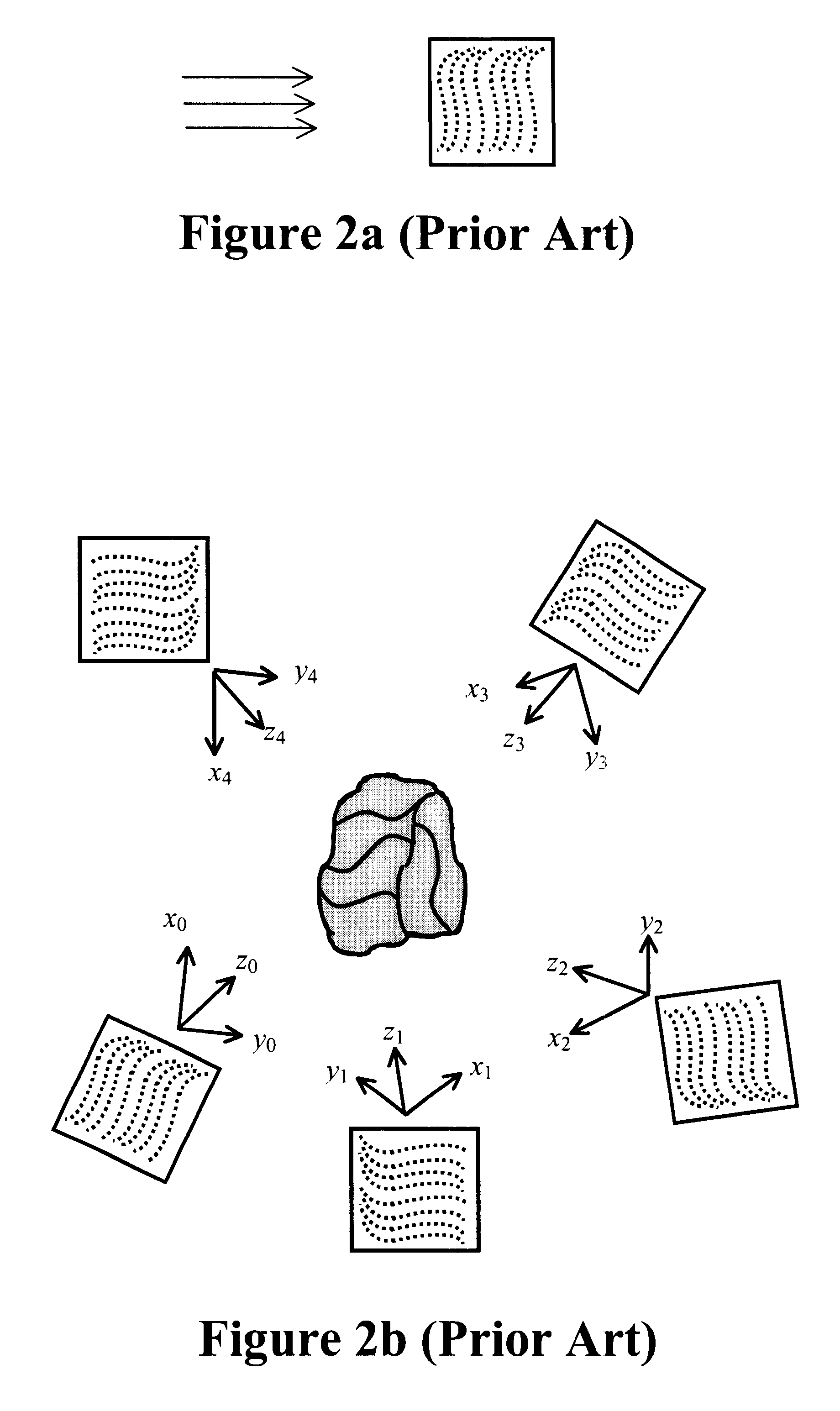

Three-dimensional measurement method and apparatus

The apparatus and method measure the three-dimensional surface shape of a surface without contact with the surface, and without any physical constraint on the device during measurement. The device is a range-sensor or scanner, and in one embodiment is a laser-camera sensor, which has a portable camera and multi-line light projector encased in a compact sensor head, and a computer. The apparatus provides three-dimensional coordinates in a single reference frame of points on the surface. The sensor head does not have to be physically attached to any mechanical positioning device such as a mechanical arm, rail, or translation or rotation stage, and its position in three-dimensional space does not have to be measured by any position-tracking sensor. This allows unrestricted motion of the sensor head during scanning, and therefore provides much greater access to surfaces which are immovable, or which have large dimensions or complex shape, and which are in confined spaces such as interior surfaces. It also permits measurement of a surface to be made by a continuous sweeping motion rather than in stages, and thus greatly simplifies the process of measurement. The apparatus can be hand-held, mounted on any moving device whose motion is unknown or not accurately known, or airborne. The apparatus and method also permit unknown and unmeasured movement of the object whose surface is to be measured, which may be simultaneous with the movement of the range-sensor head.

Owner:ALIGN TECH

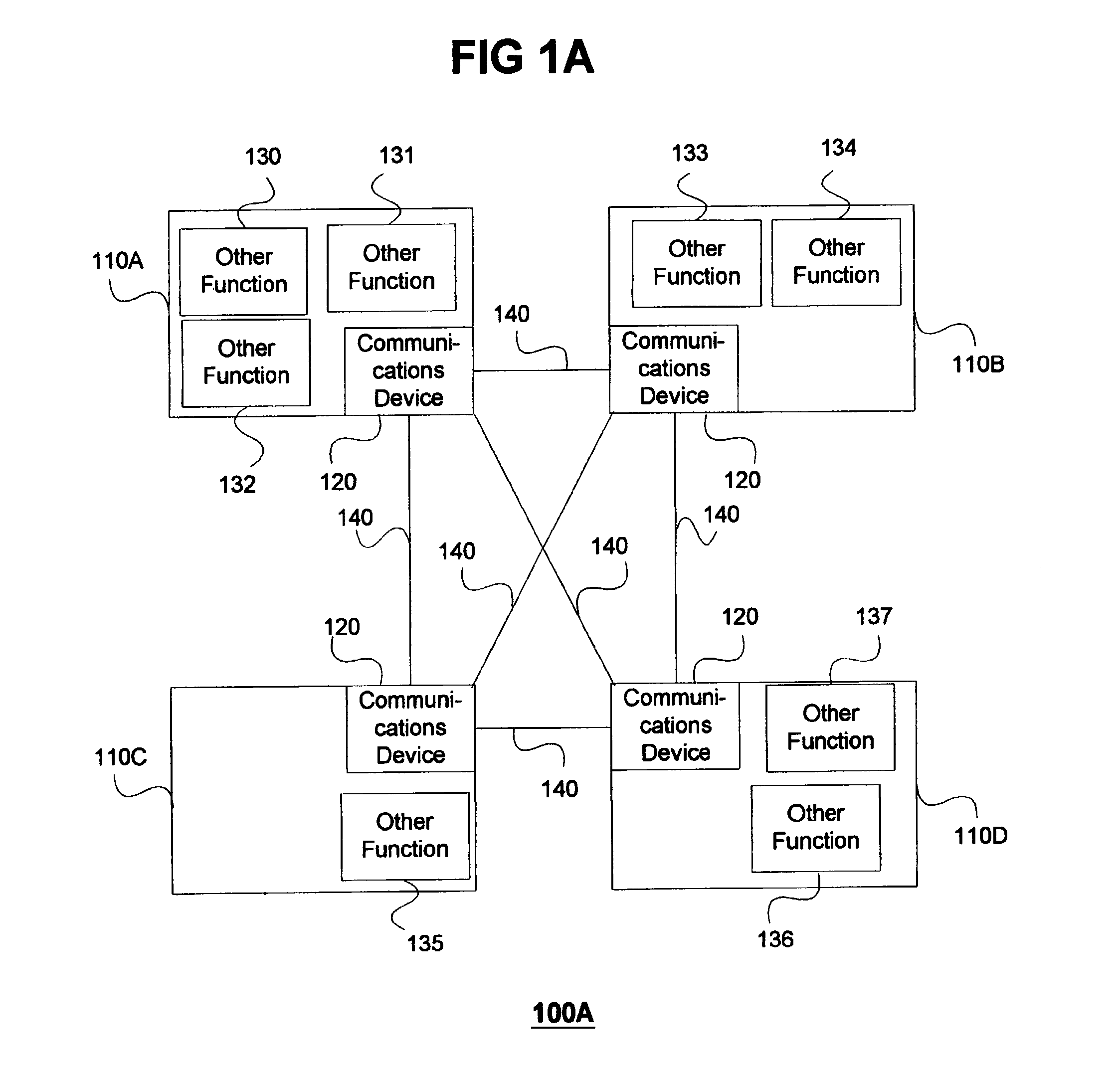

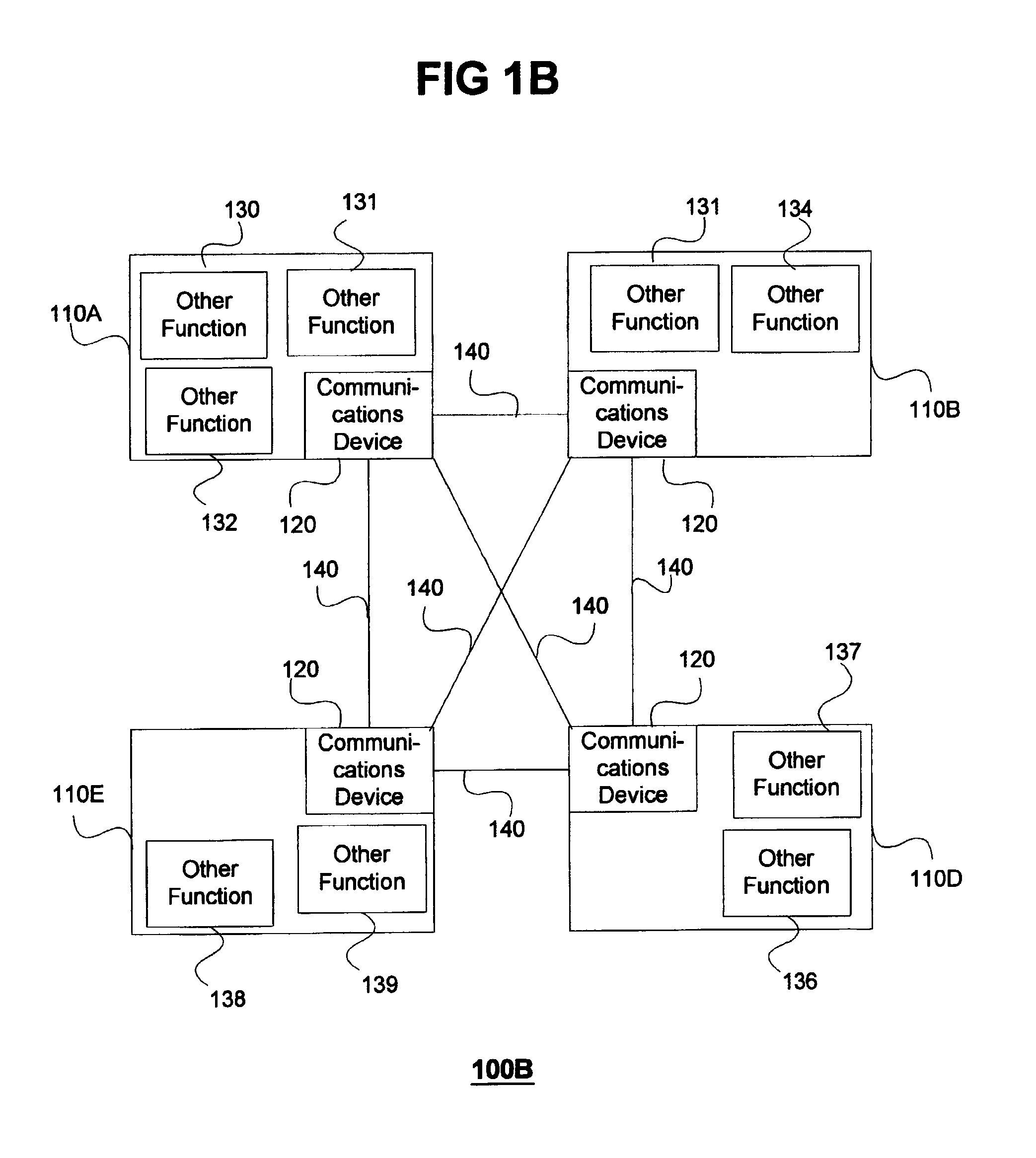

Motion tracking and analysis apparatus and method and system implementations thereof

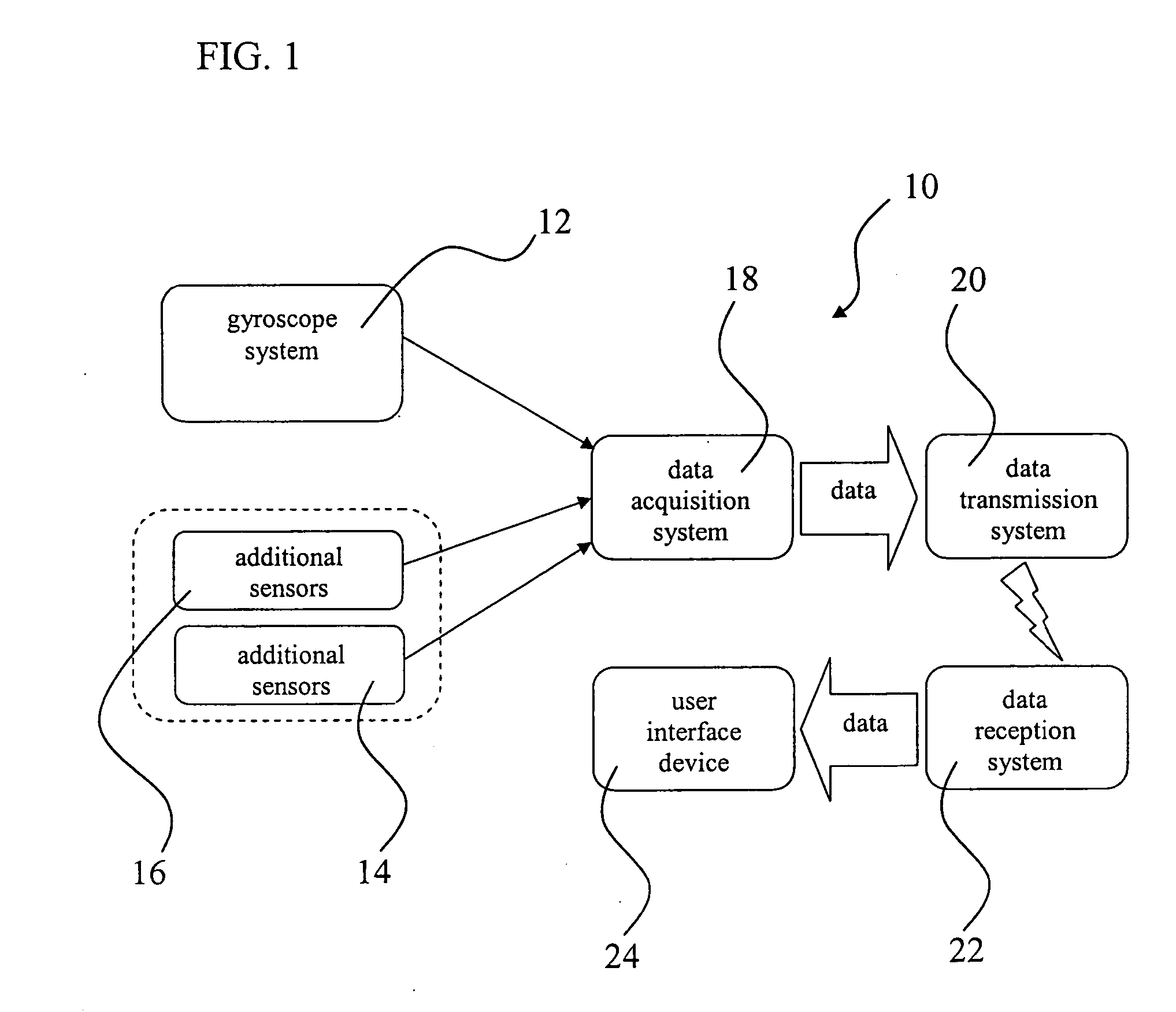

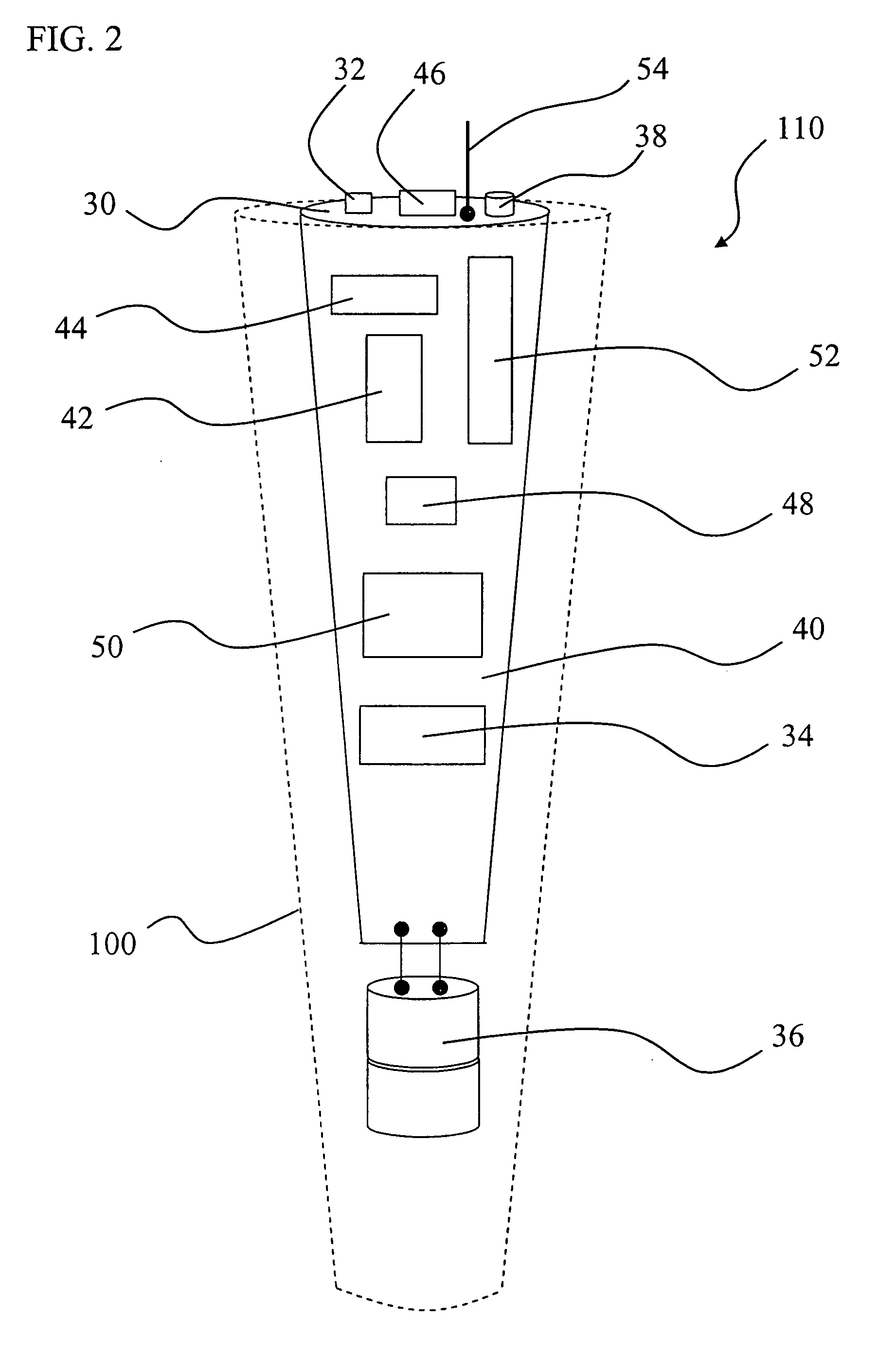

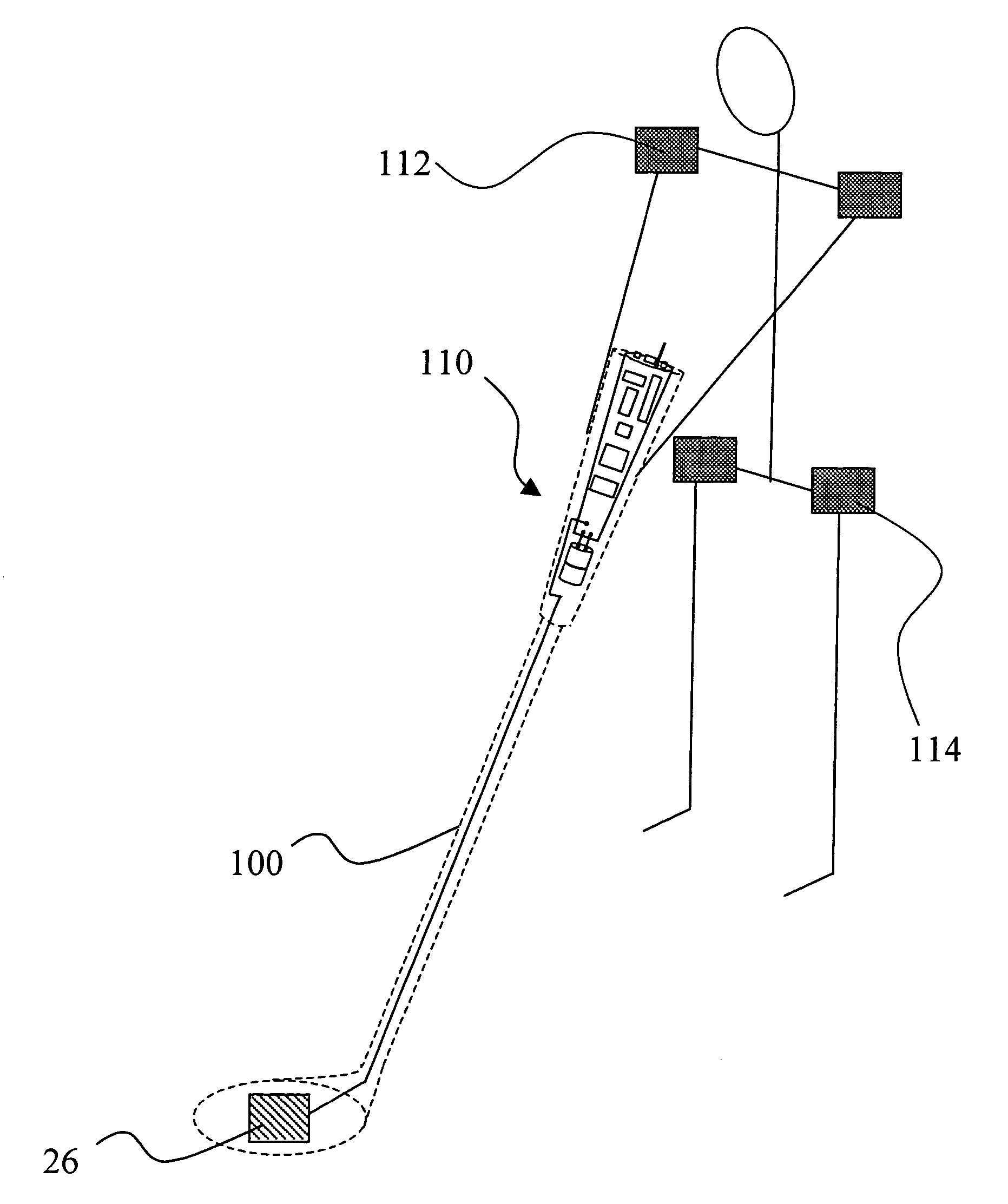

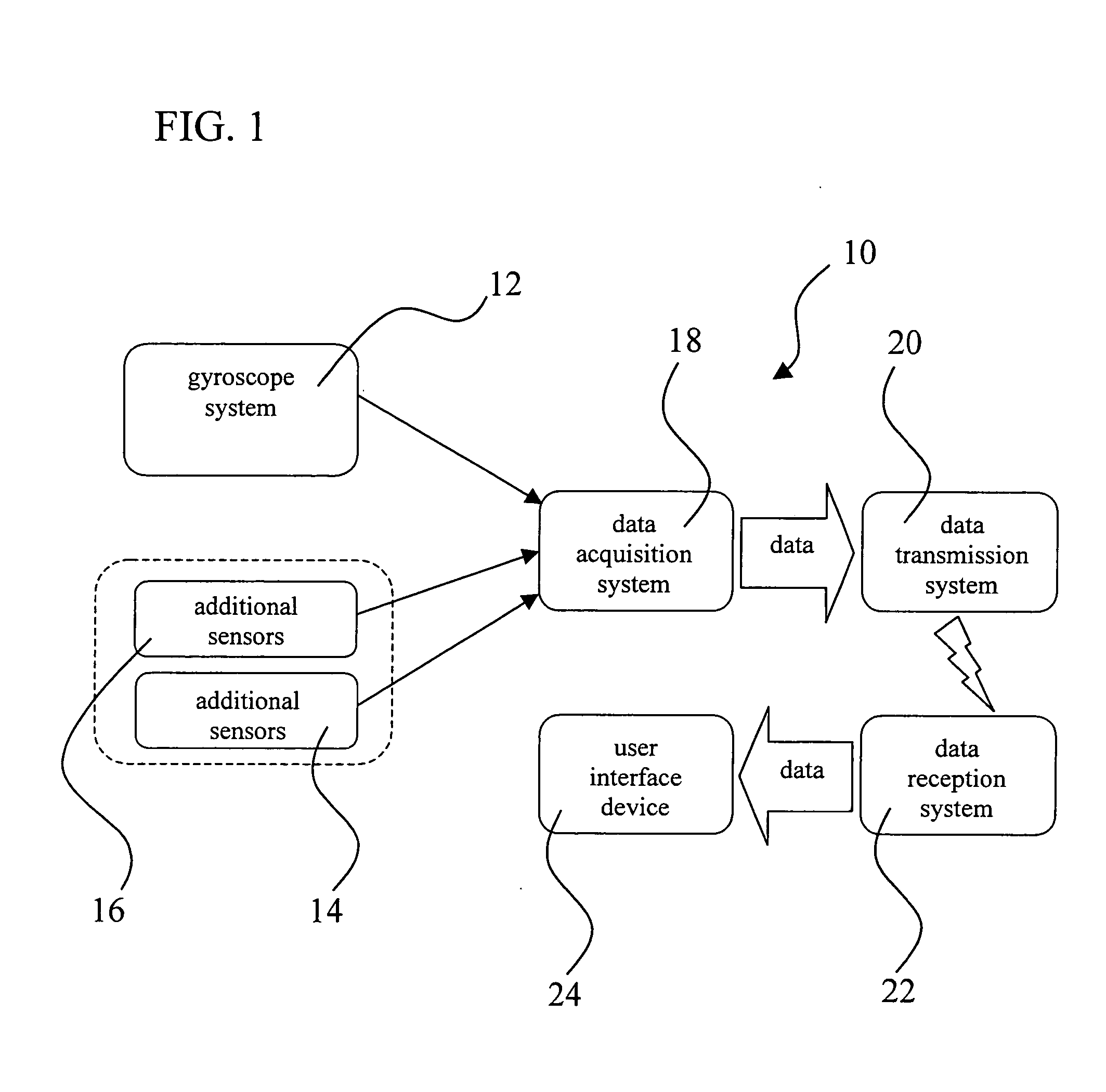

An orientation and position tracking system and method in three-dimensional space and over a period of time utilizing multiple inertial and other sensors for determining motion parameters to measure orientation and position of a moveable object. The sensors, for example vibrational and angular velocity sensors, generate signals characterizing the motion of the moveable object. The information is received by a data acquisition system and processed by a microcontroller. The data is then transmitted to an external data reception system (locally based or a global network), preferably via wireless communication. The information can then be displayed and presented to the user through a variety of means including audio, visual, and tactile. According to various embodiments, the present invention provides for a motion tracking apparatus and method for implementation in motion systems including systems to teach motion to a group and for body motion capture and analysis systems.

Owner:FORTESCUE CORP

Method and apparatus for determining orientation and position of a moveable object

InactiveUS20050032582A1Gymnastic exercisingNavigation by speed/acceleration measurementsMicrocontrollerObject motion

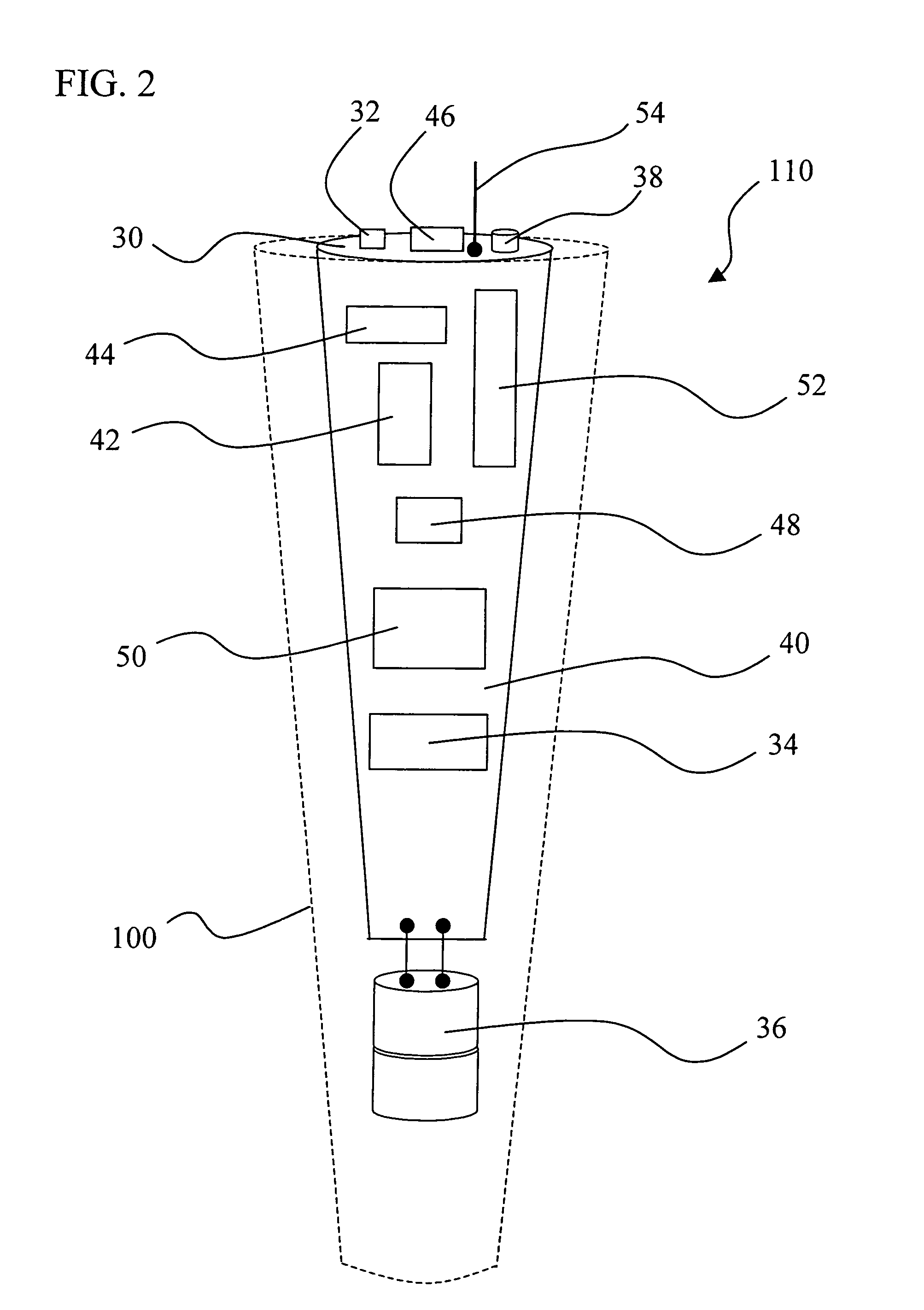

An orientation and position tracking system in three-dimensional space and over a period of time utilizing multiple inertial and other sensors for determining motion parameters to measure orientation and position of a moveable object. The sensors, for example vibrational and angular velocity sensors, generate signals characterizing the motion of the moveable object. The information is received by a data acquisition system and processed by a microcontroller. The data is then transmitted via wireless communication to an external data reception system (locally based or a global network). The information can then be displayed and presented to the user through a variety of means including audio, visual, and tactile.

Owner:FORTESCUE CORP

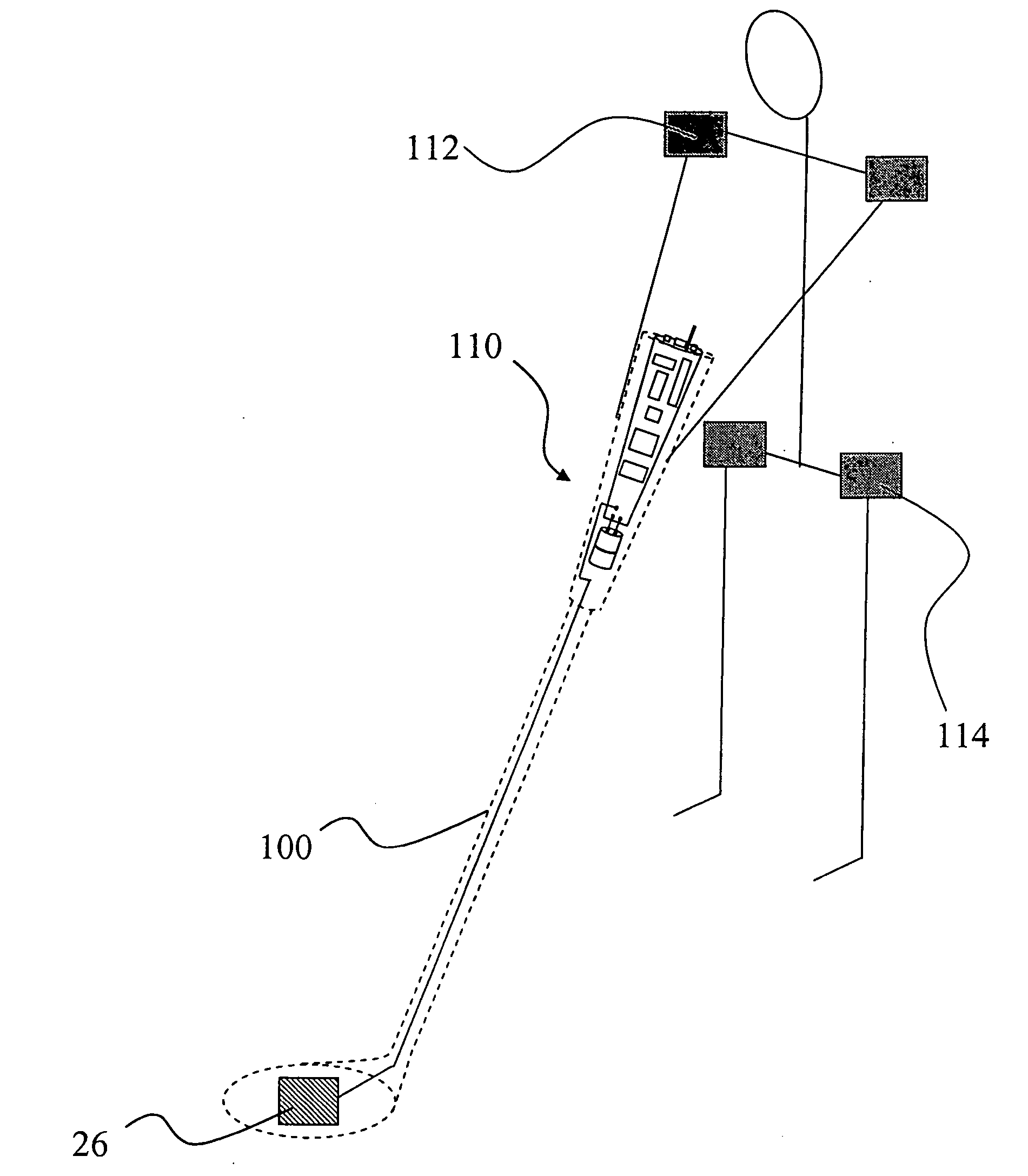

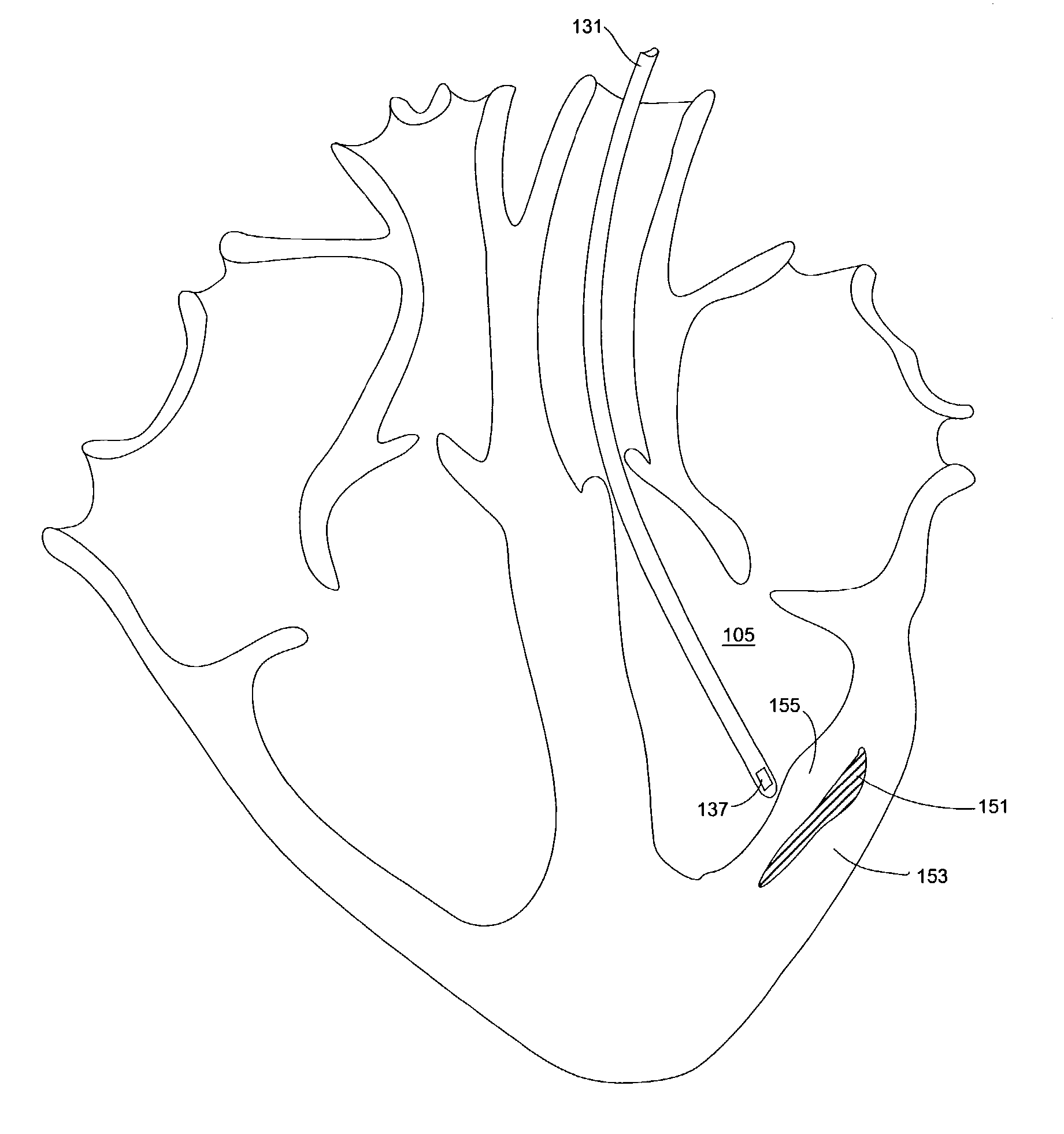

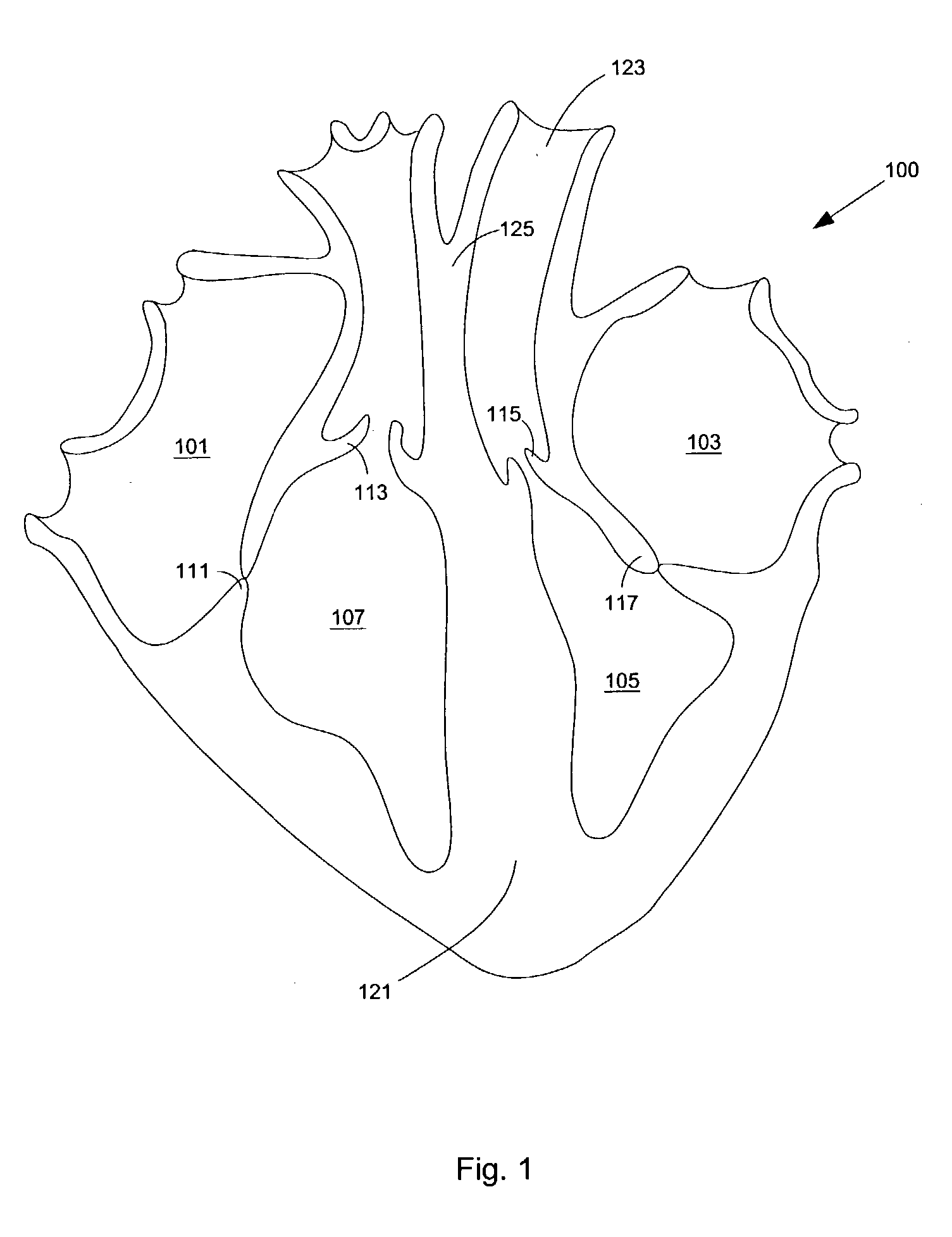

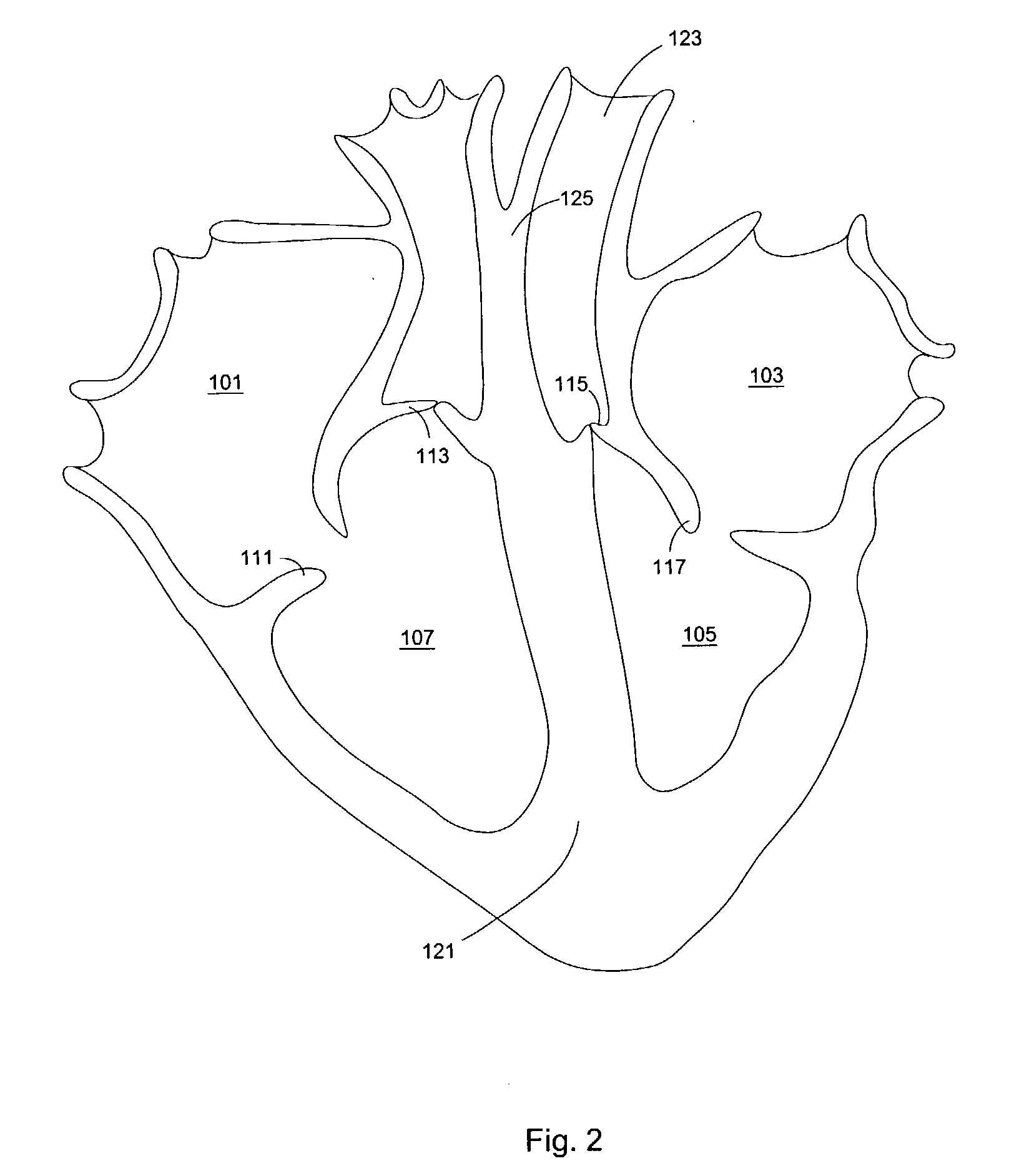

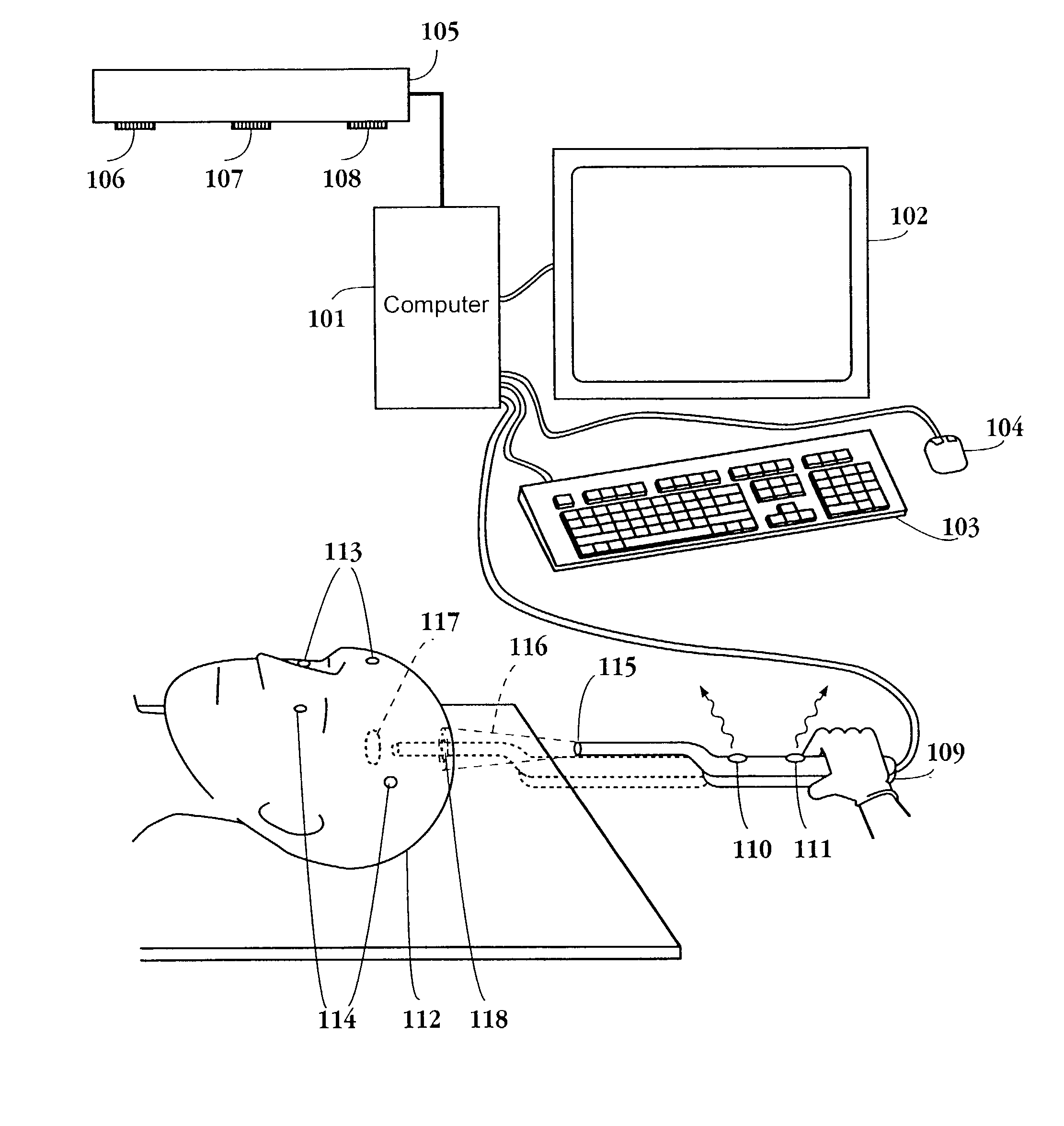

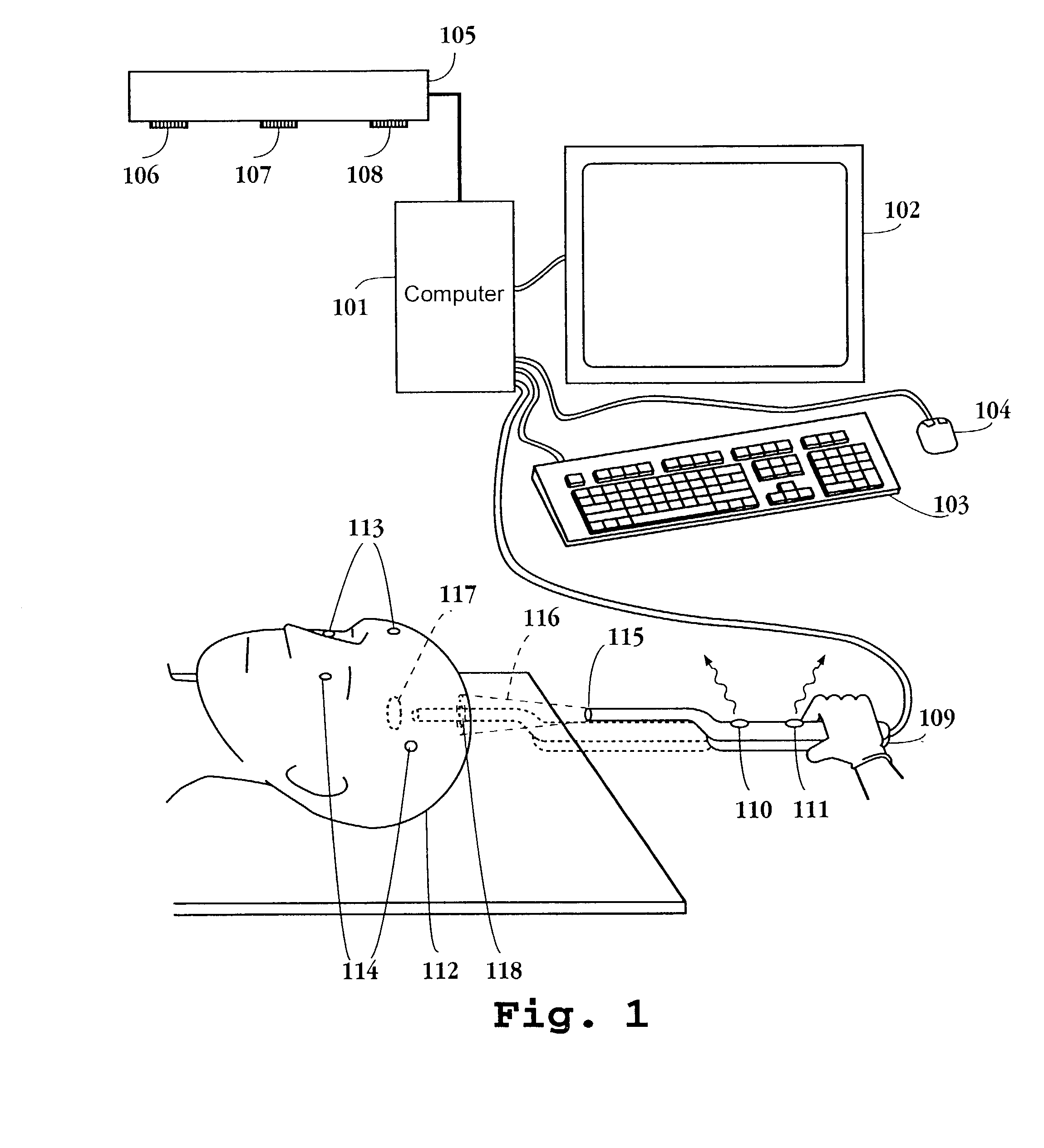

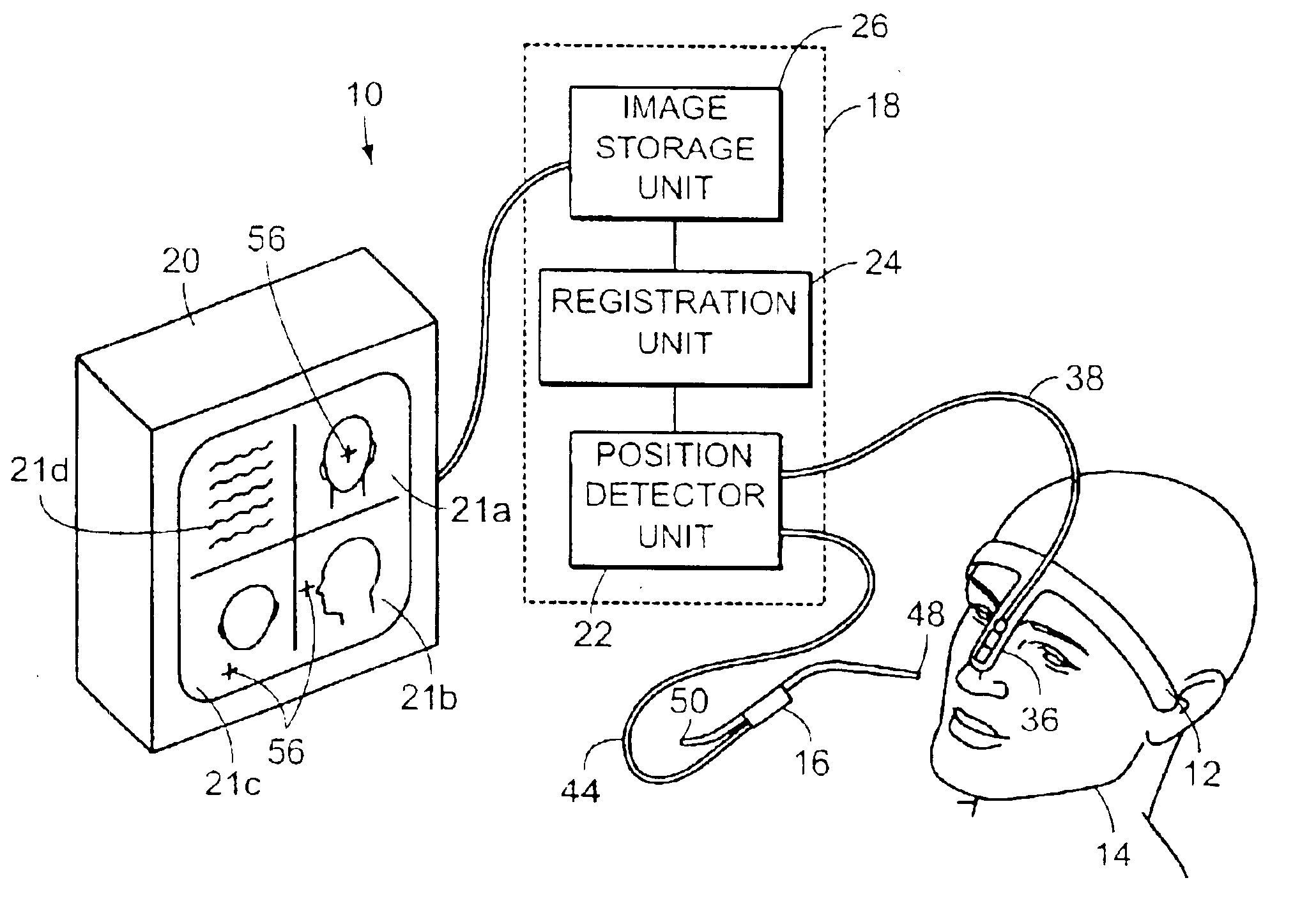

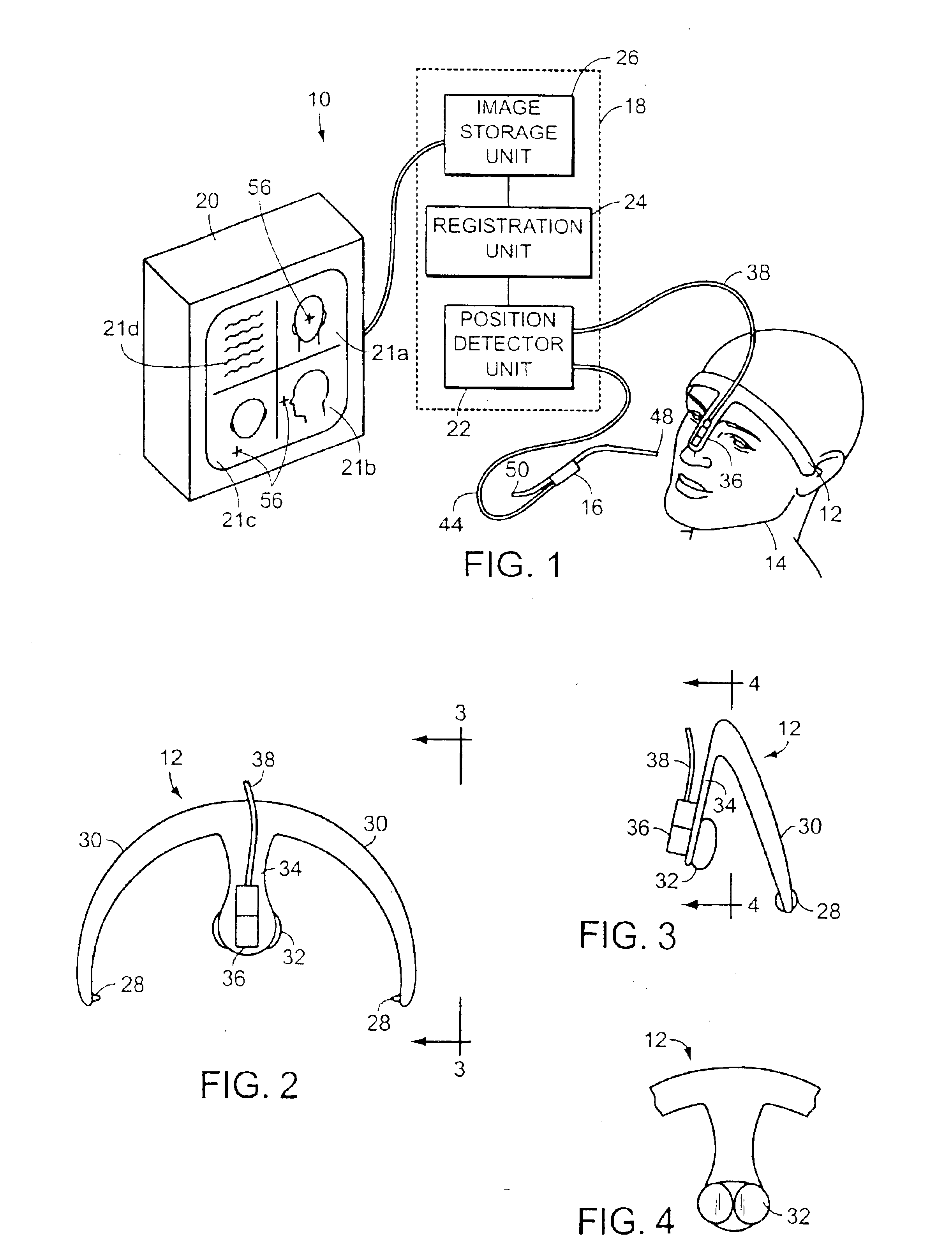

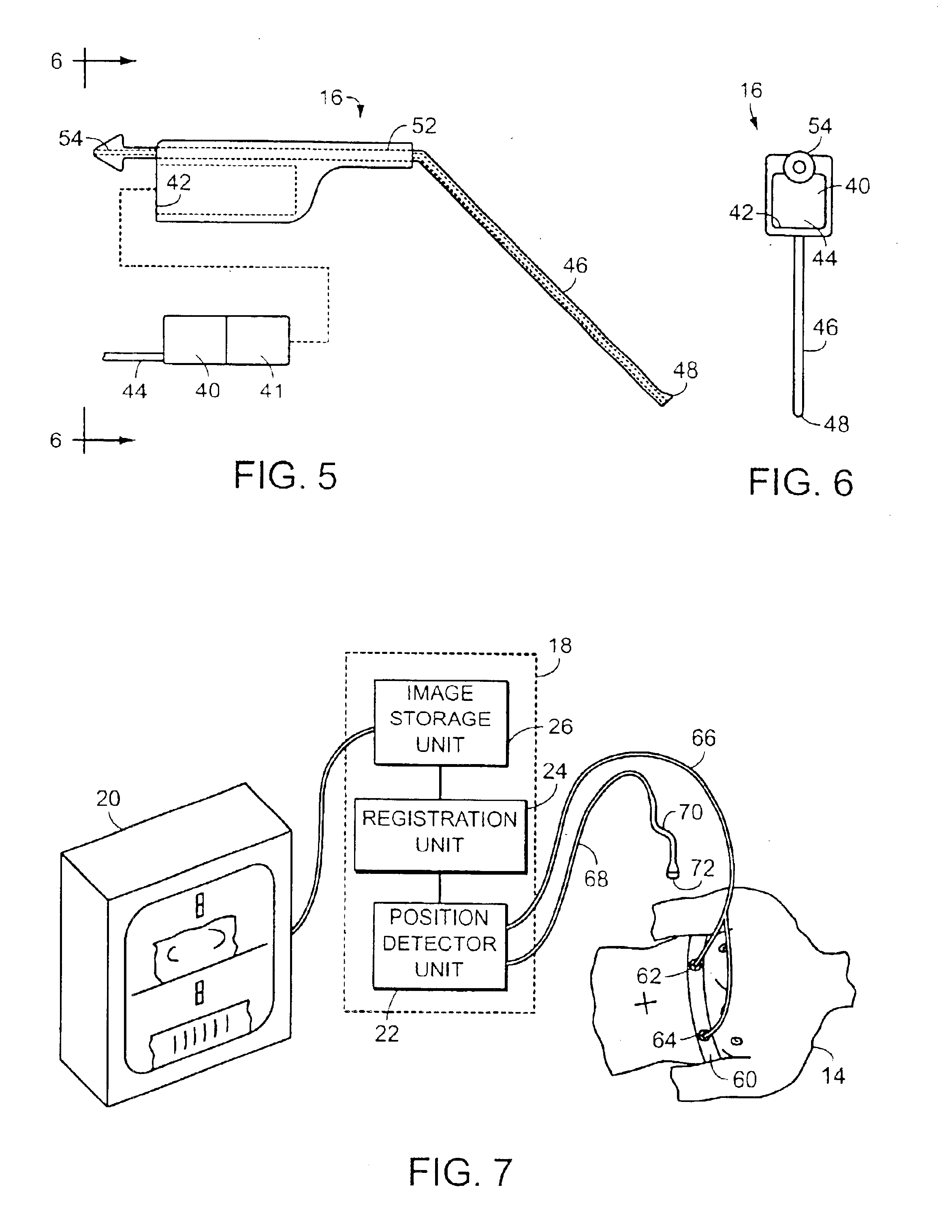

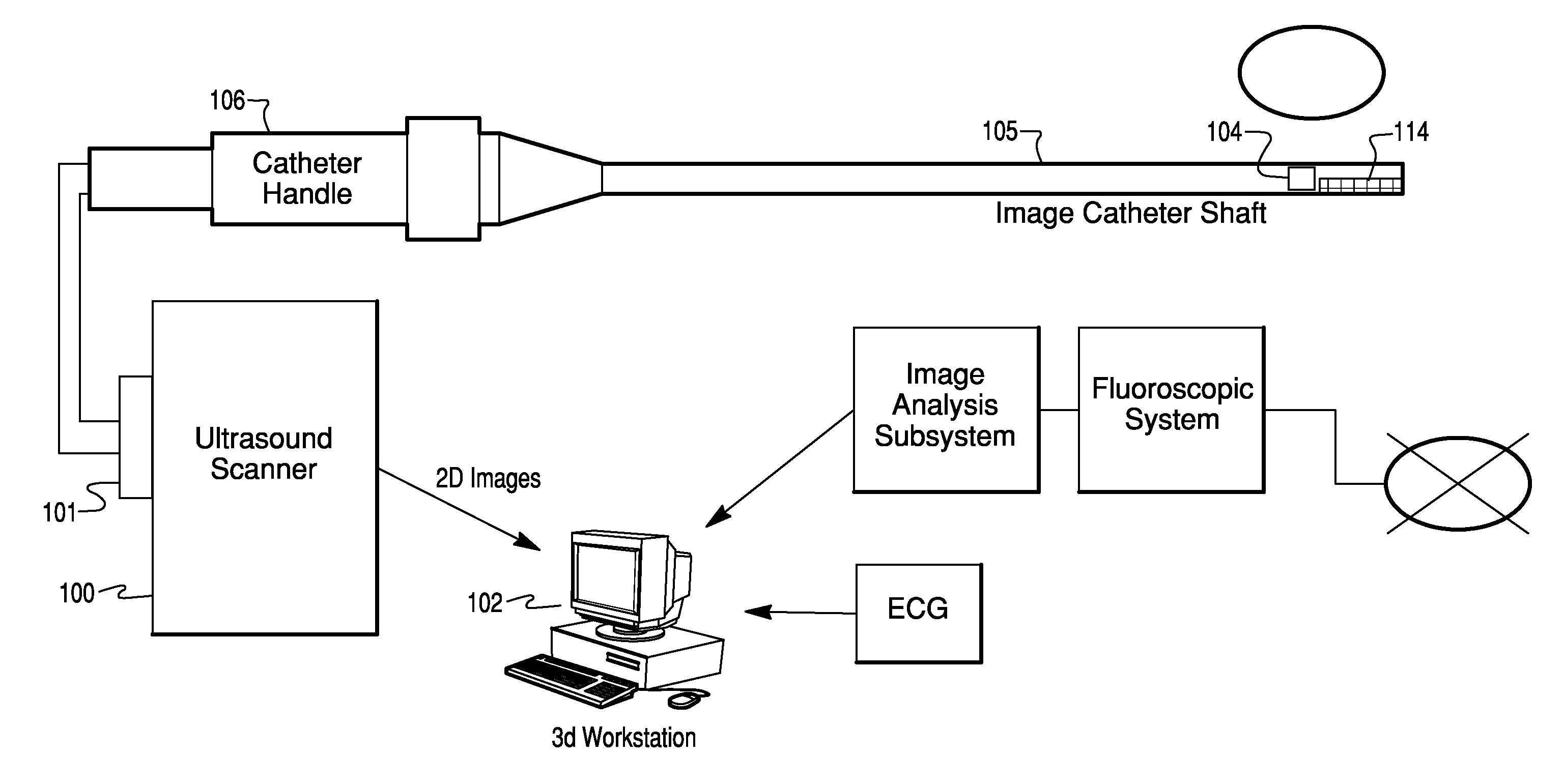

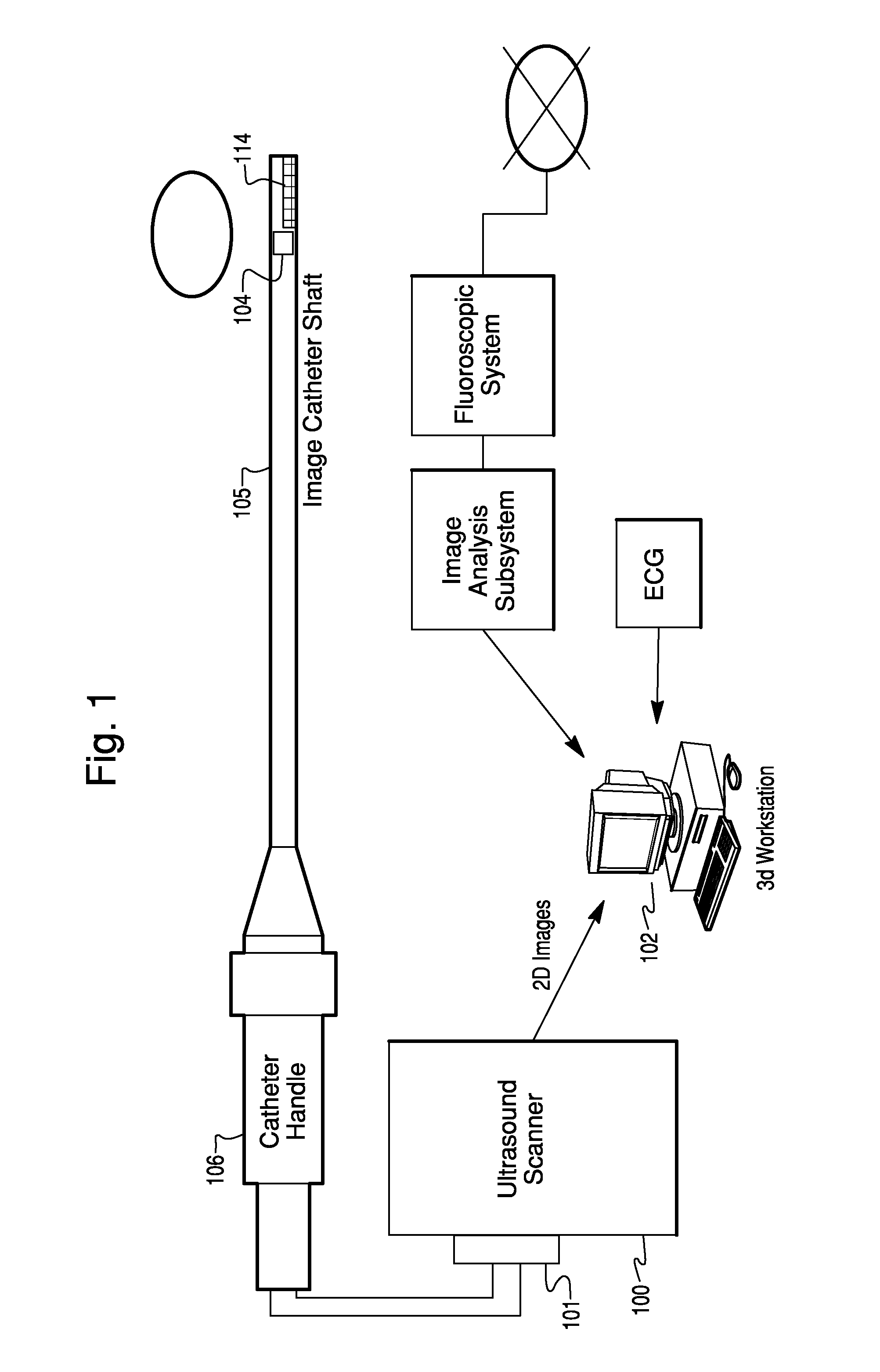

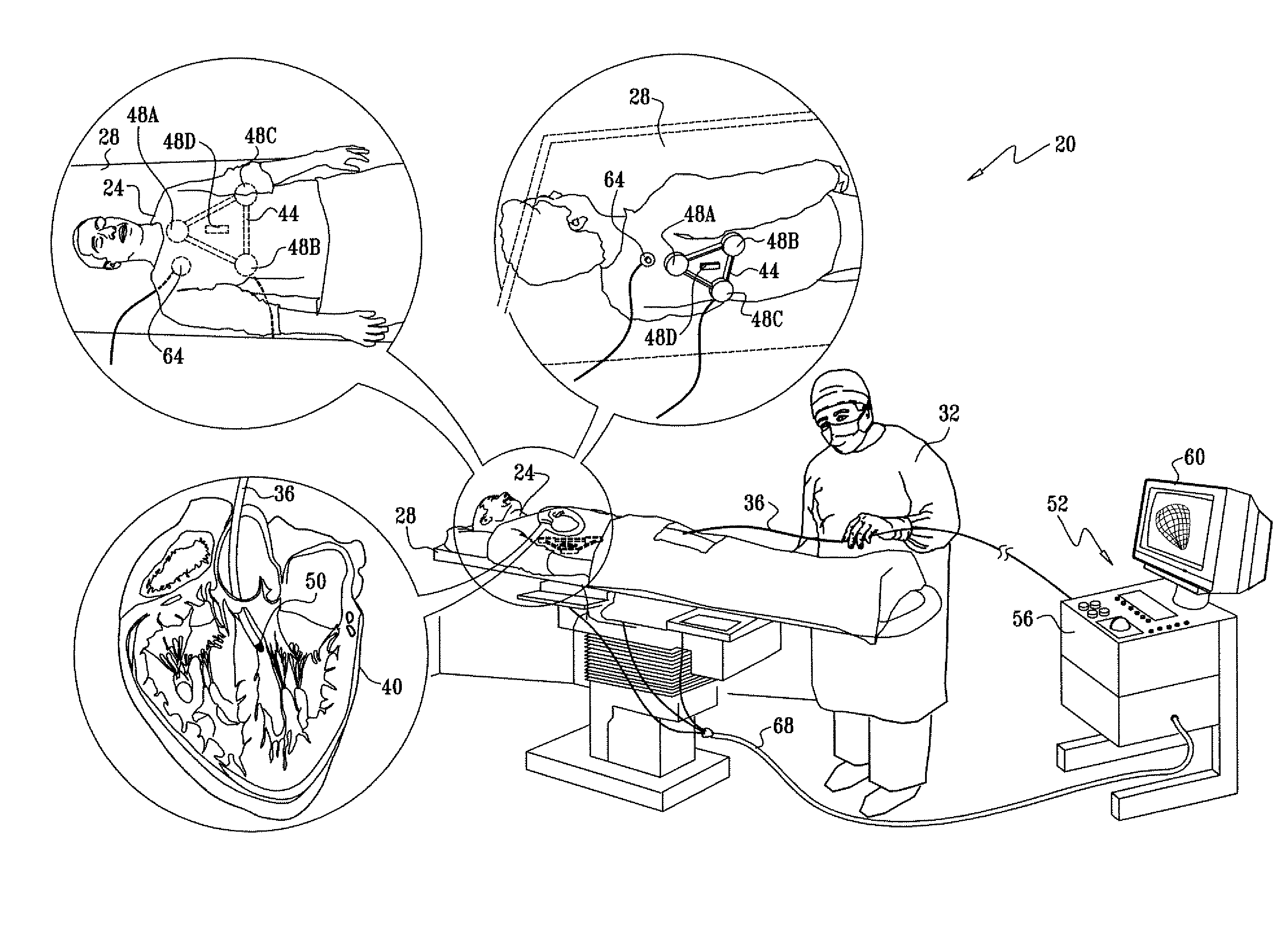

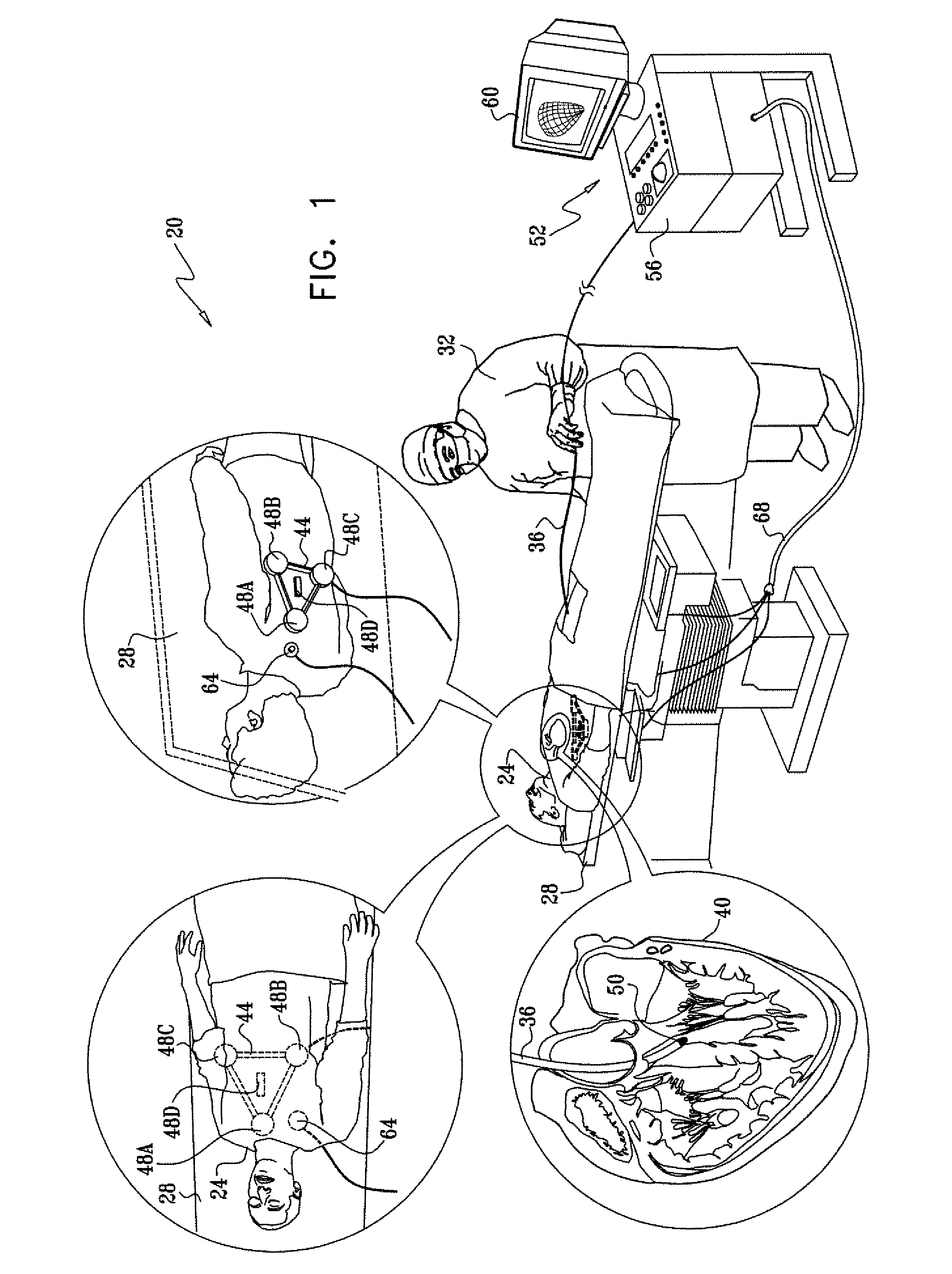

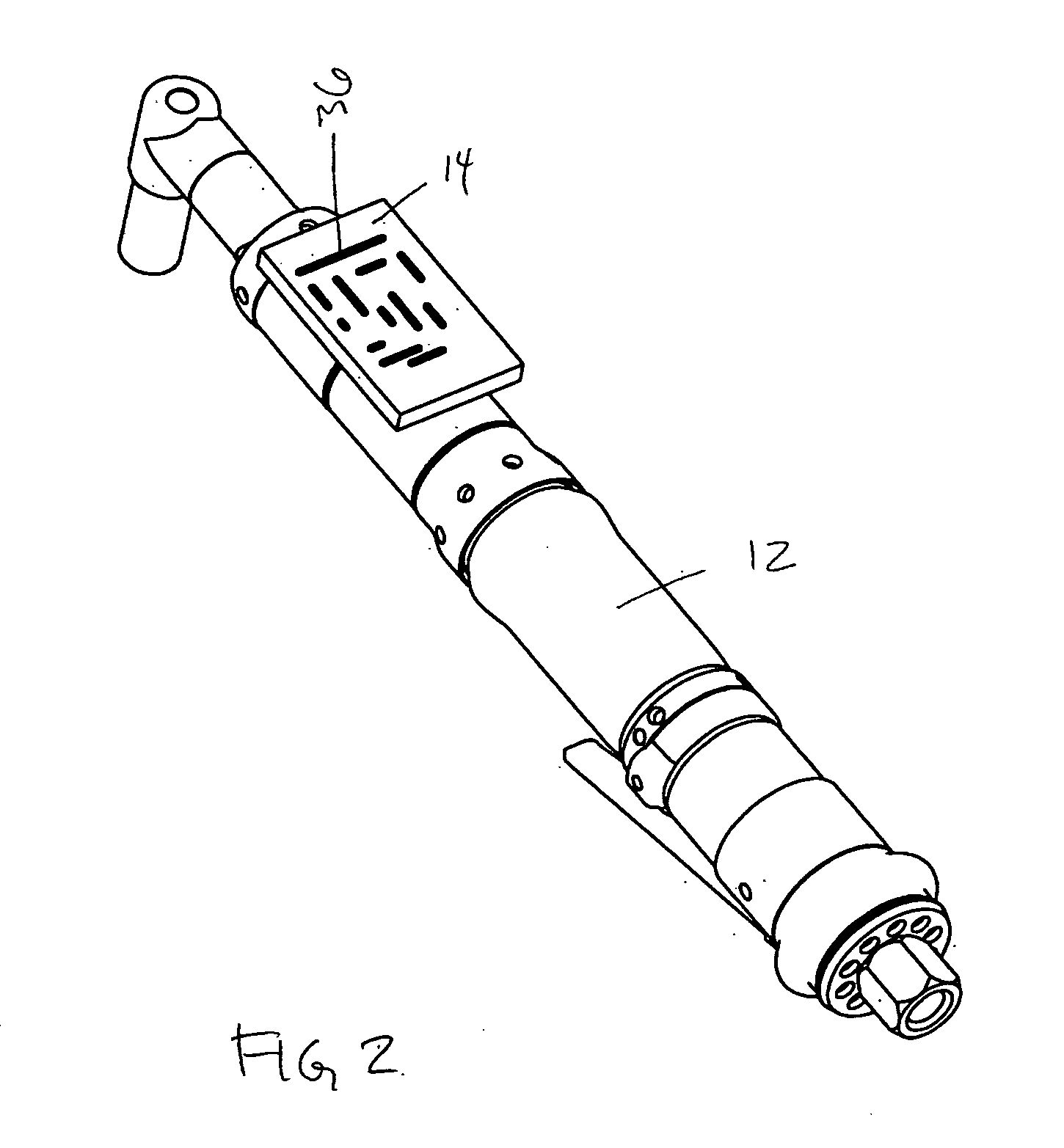

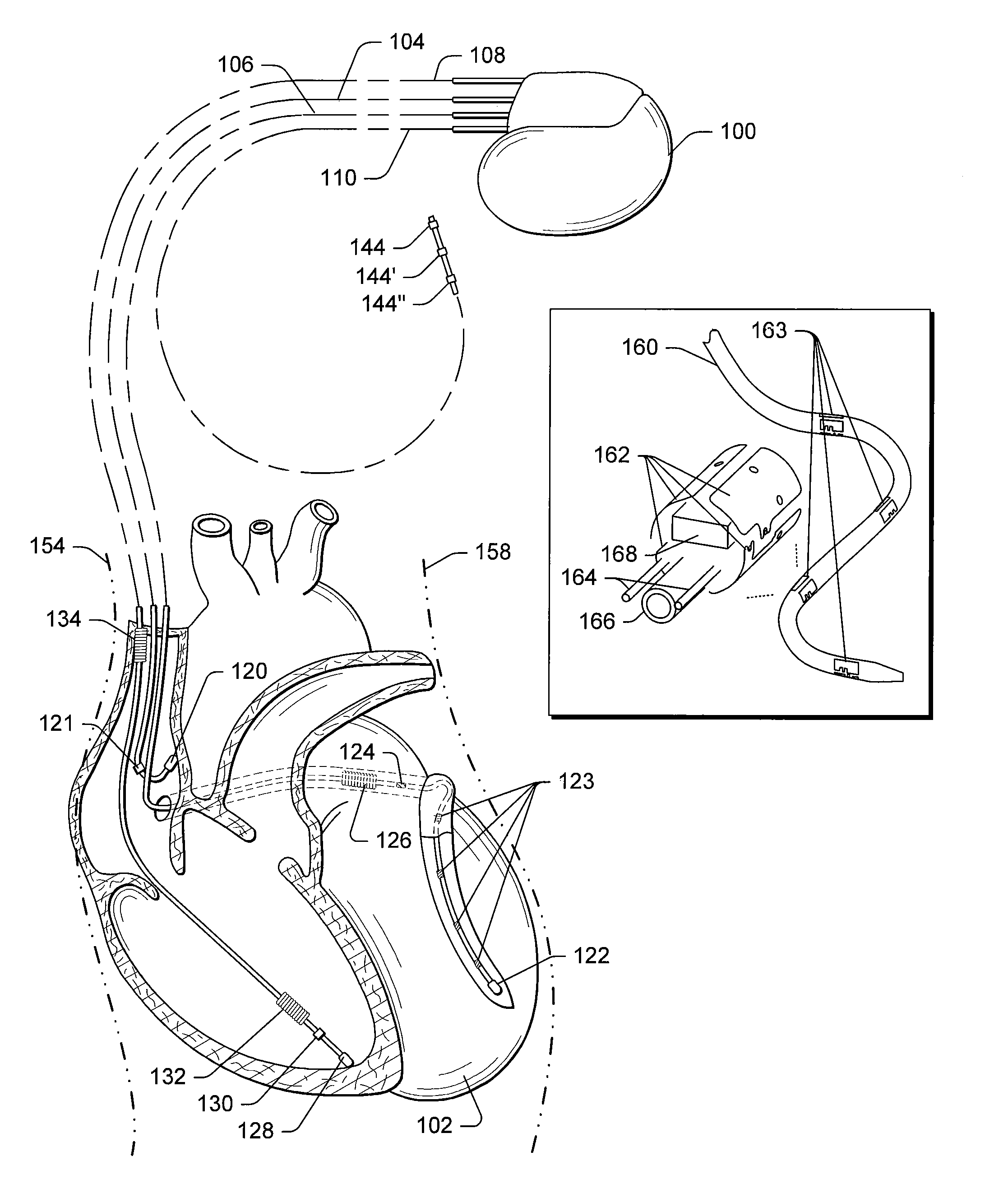

Method and apparatus for image guided position tracking during percutaneous procedures

InactiveUS20070055142A1Easily performed/calibratedUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringLocation trackingCatheter

Methods and apparatuses for guiding the positioning of a device with a position tracking sensor and pre-recorded images. At least one embodiment of the present invention uses pre-recorded time-dependent images (e.g., anatomical images or diagnostic images) to guide the positioning of a medical instrument (e.g., catheter tips) using real time position tracking during diagnostic and / or therapeutic operations with pre-recorded images. In one embodiment of the present invention, predetermined spatial relations are used to determine the position of a tracked medical instrument relative to the pre-recorded images.

Owner:ABBOTT CARDIOVASCULAR

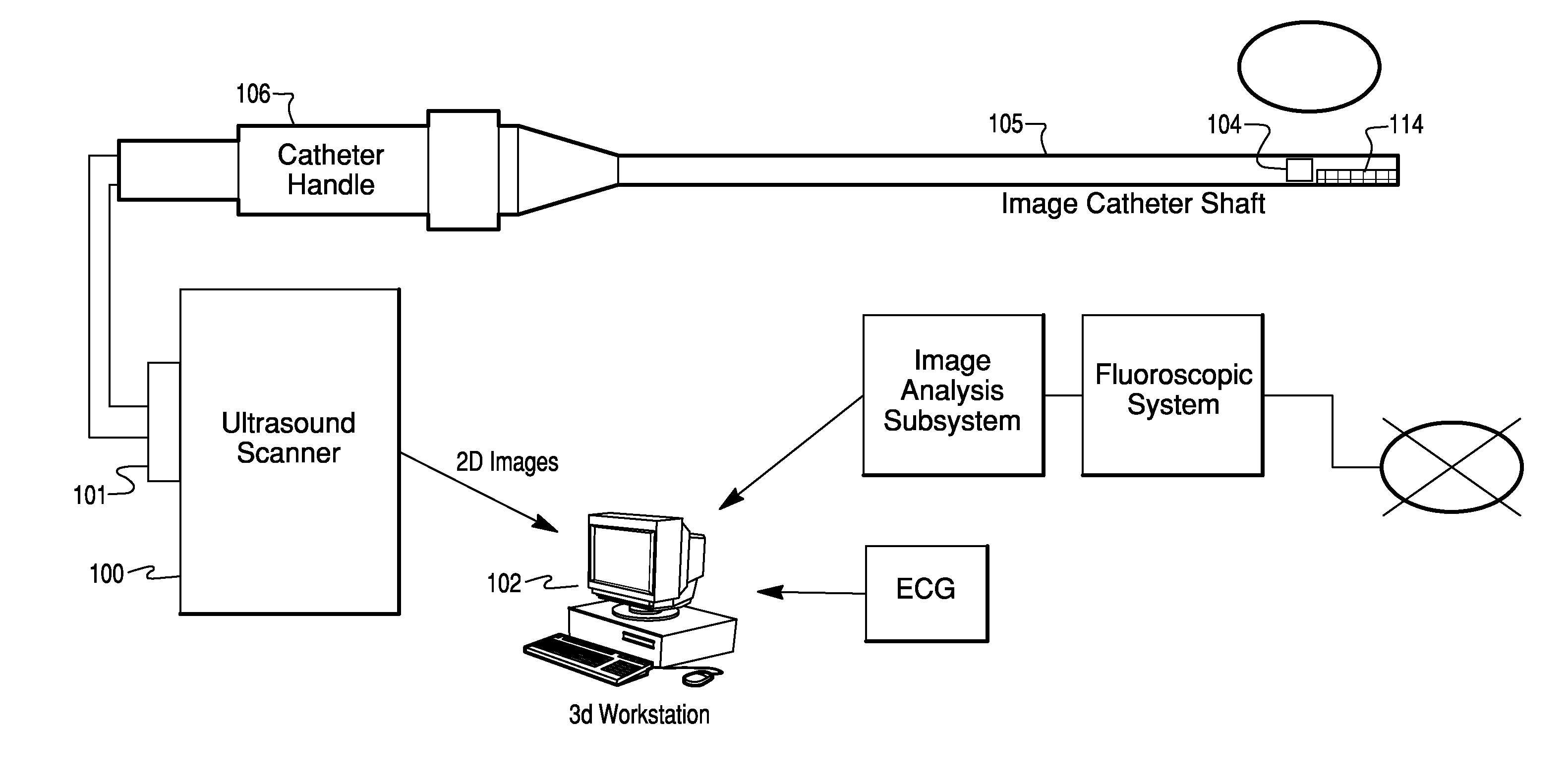

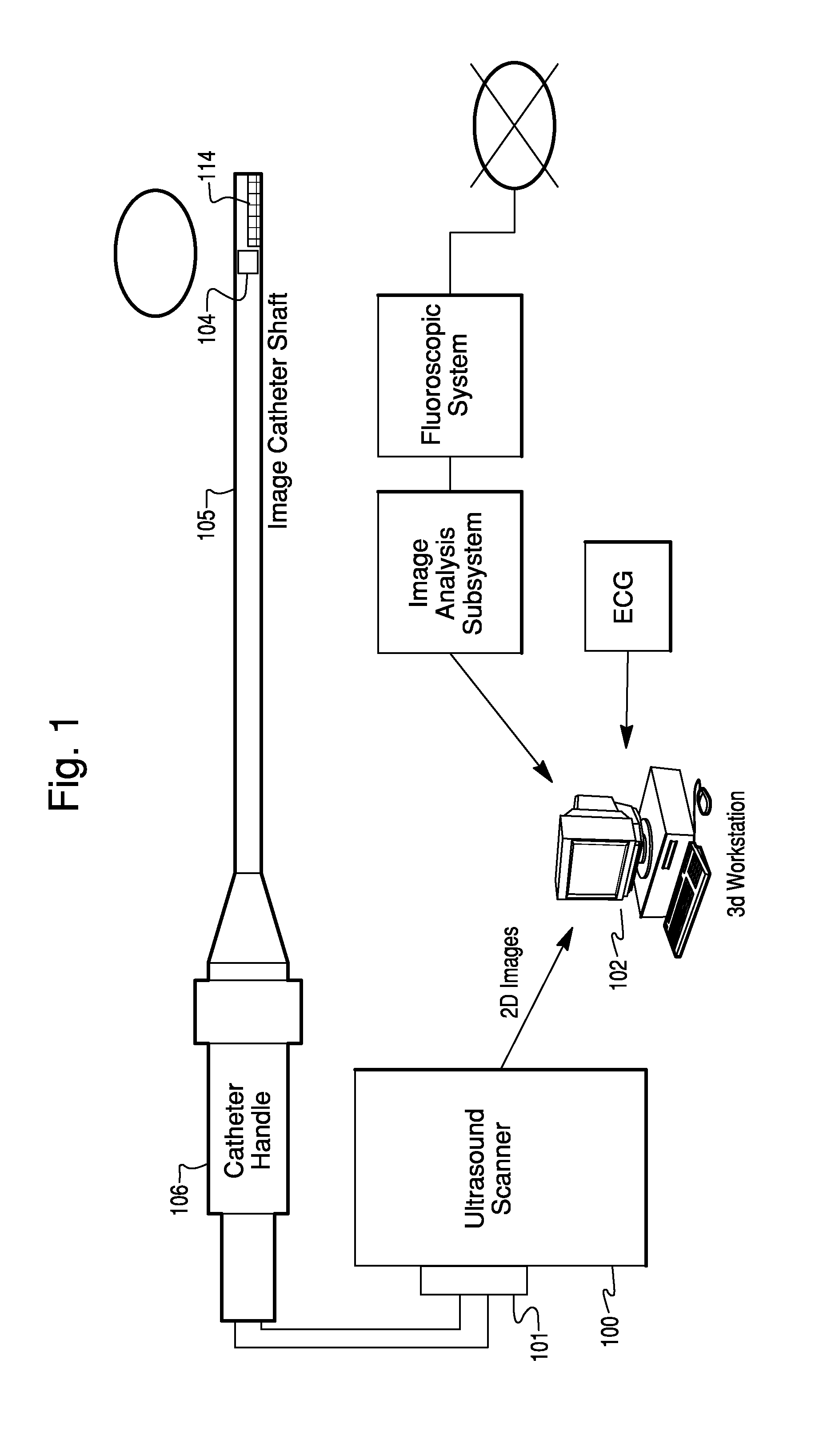

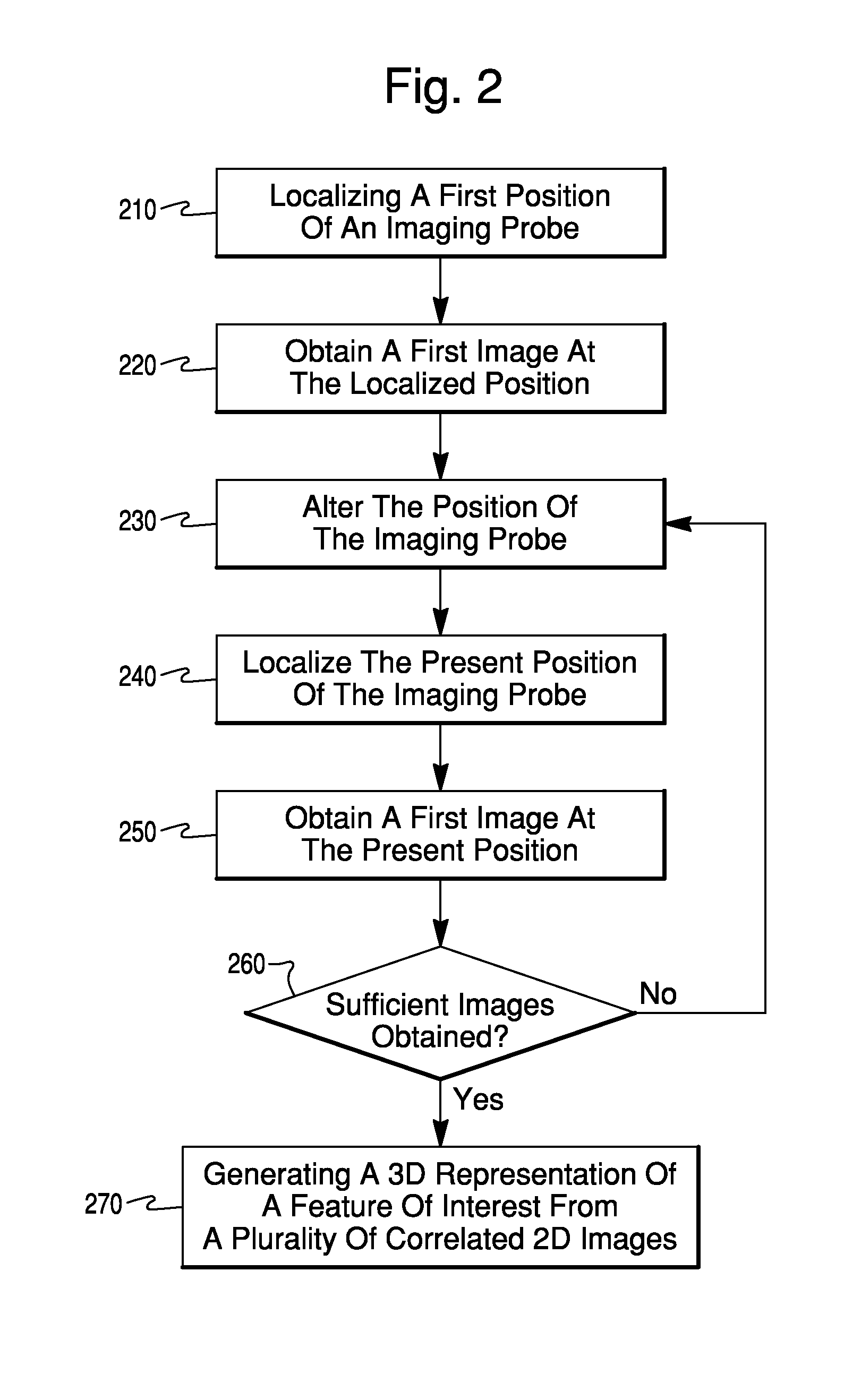

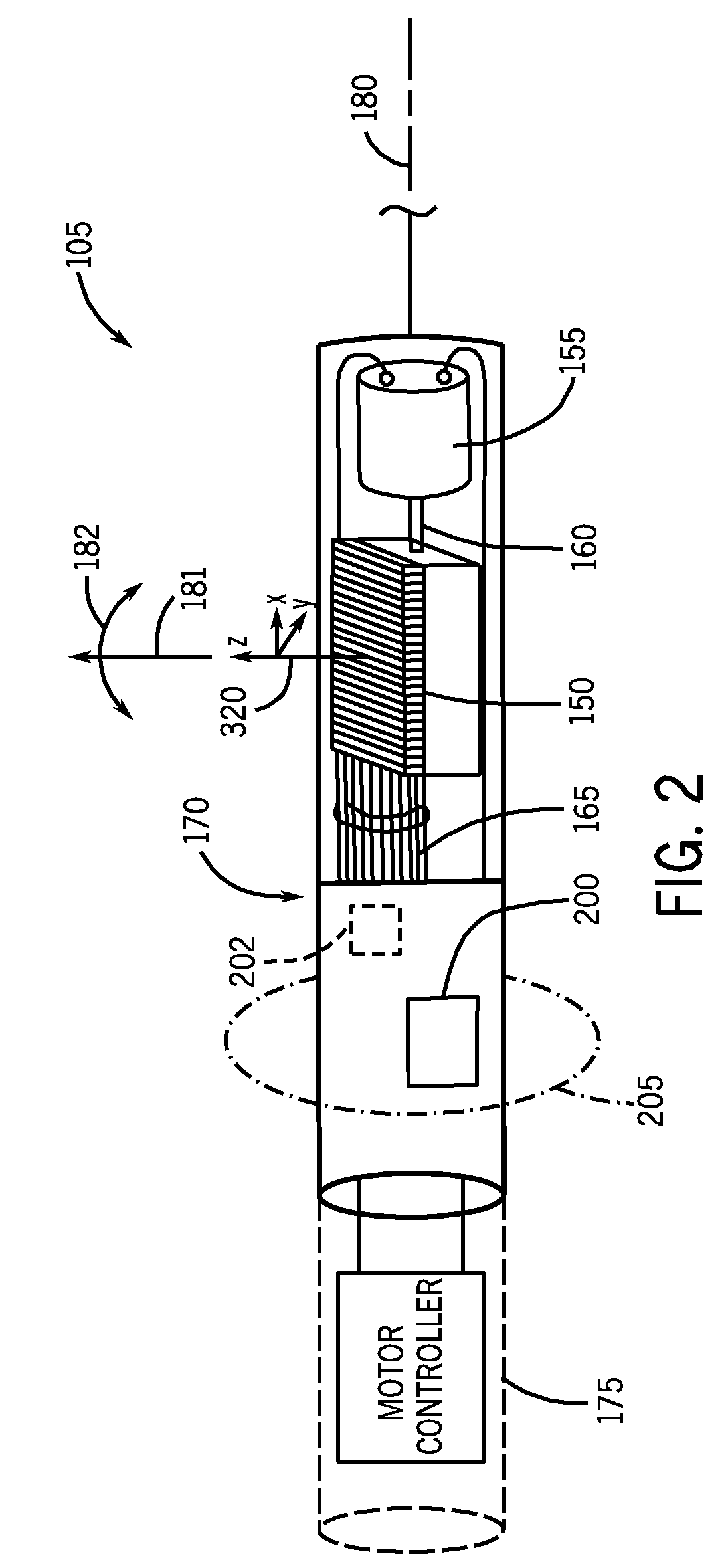

Catheter Position Tracking Methods Using Fluoroscopy and Rotational Sensors

Methods for determine the position and rotational orientation of the transducer array of an ultrasound imaging catheter within a patient include imaging the distal end of the catheter using fluoroscopy and determining the angular orientation based upon the shape and dimensions of the image of the transducer array and wire connecting harness. Additional rotational and translational information may be obtained from sensors located at the proximal end of the catheter. By combining position information obtained using fluoroscopy with information from relative rotation / translation sensors, the imaging transducer position and orientation can be determined more accurately. The resulting accurate imaging transducer position information enables combining multiple images from different positions or orientations to generate multi-dimensional images. Catheters including rotation and translation motion sensors at the proximal end, and radio-opaque materials near the distal end can be provided to enhance the methods.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

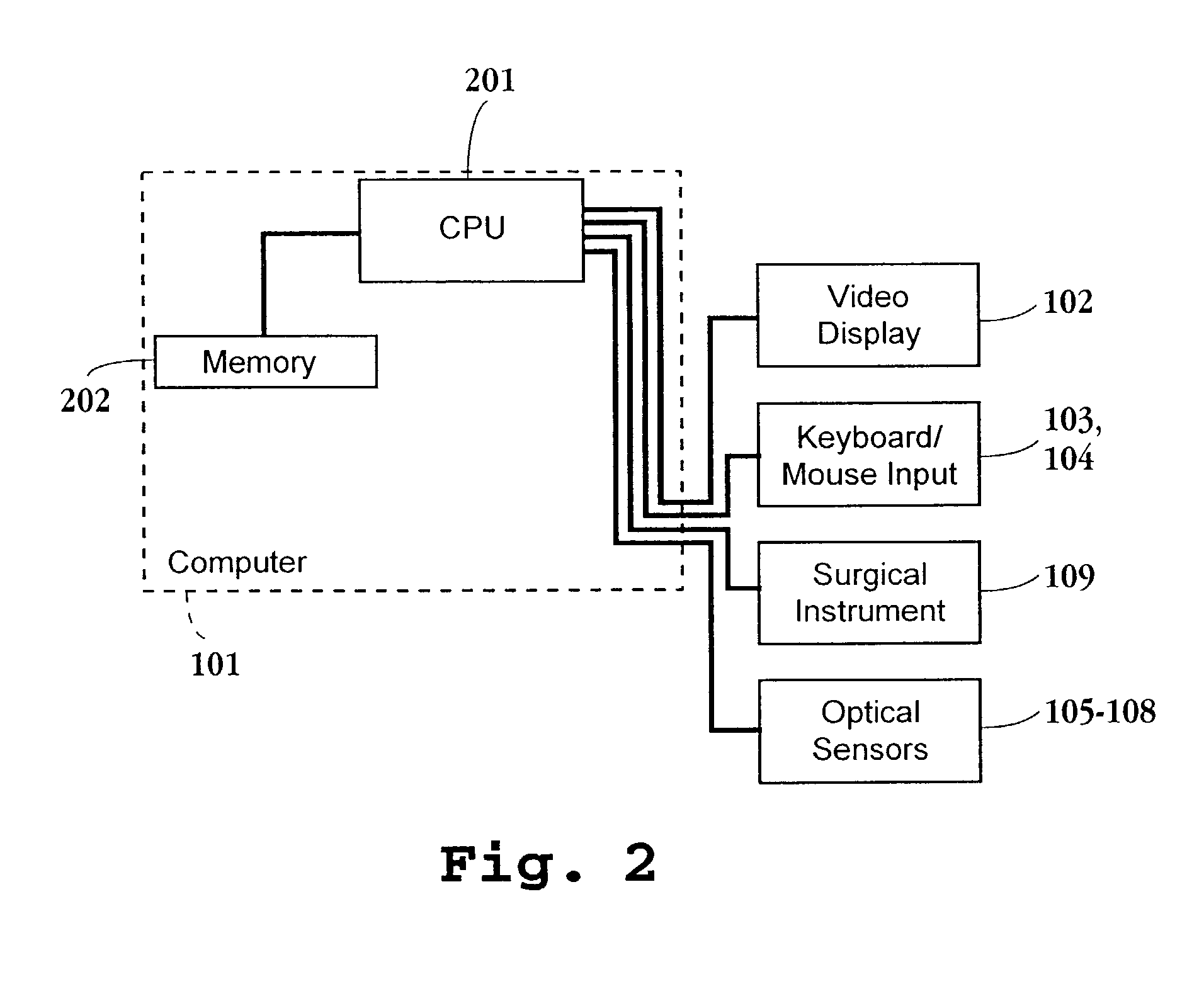

Method and apparatus for volumetric image navigation

InactiveUS7844320B2Effectively “ seeUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsUltrasonic sensorViewpoints

A surgical navigation system has a computer with a memory and display connected to a surgical instrument or pointer and position tracking system, so that the location and orientation of the pointer are tracked in real time and conveyed to the computer. The computer memory is loaded with data from an MRI, CT, or other volumetric scan of a patient, and this data is utilized to dynamically display 3-dimensional perspective images in real time of the patient's anatomy from the viewpoint of the pointer. The images are segmented and displayed in color to highlight selected anatomical features and to allow the viewer to see beyond obscuring surfaces and structures. The displayed image tracks the movement of the instrument during surgical procedures. The instrument may include an imaging device such as an endoscope or ultrasound transducer, and the system displays also the image for this device from the same viewpoint, and enables the two images to be fused so that a combined image is displayed. The system is adapted for easy and convenient operating room use during surgical procedures.

Owner:CICAS IP LLC

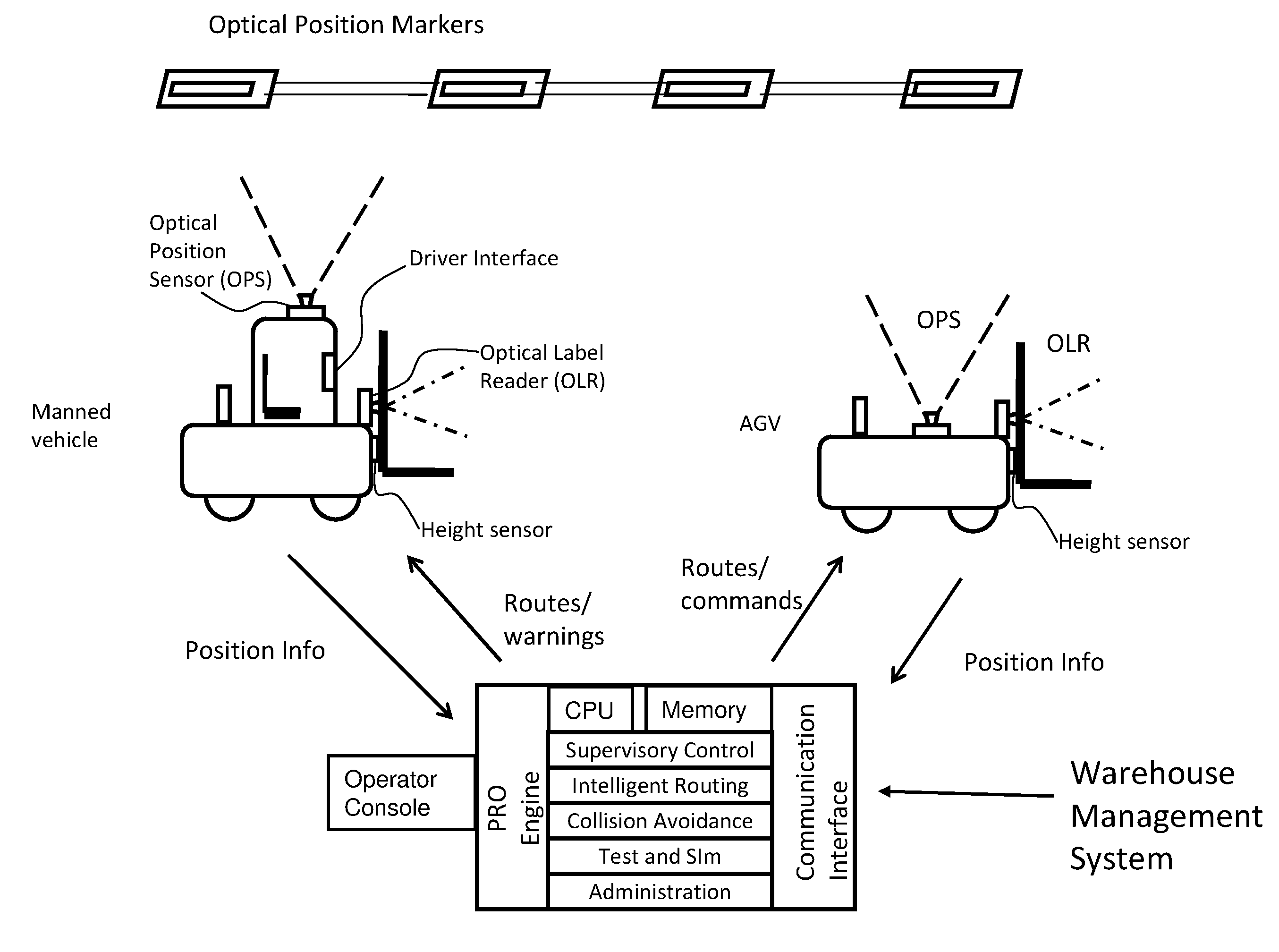

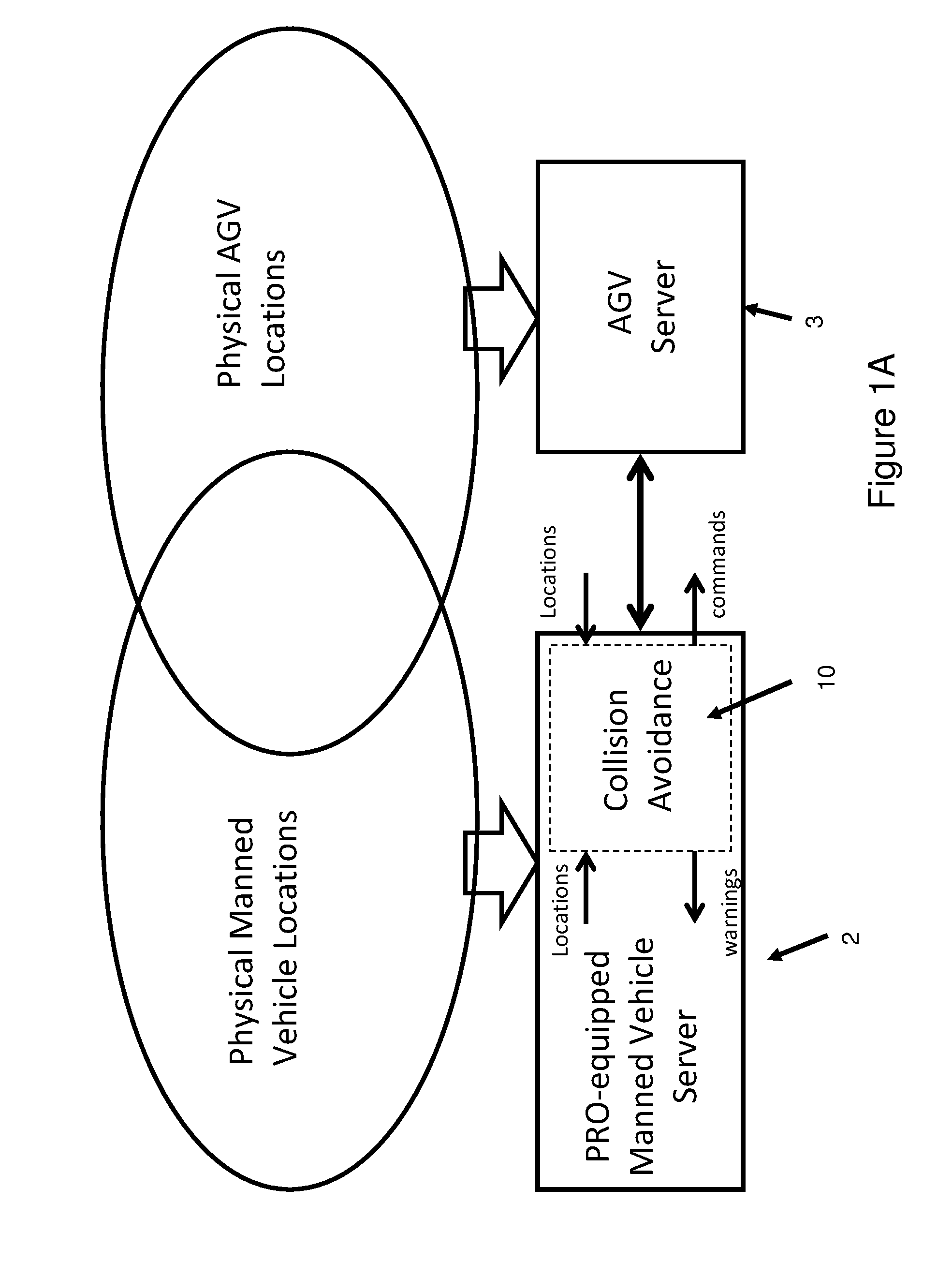

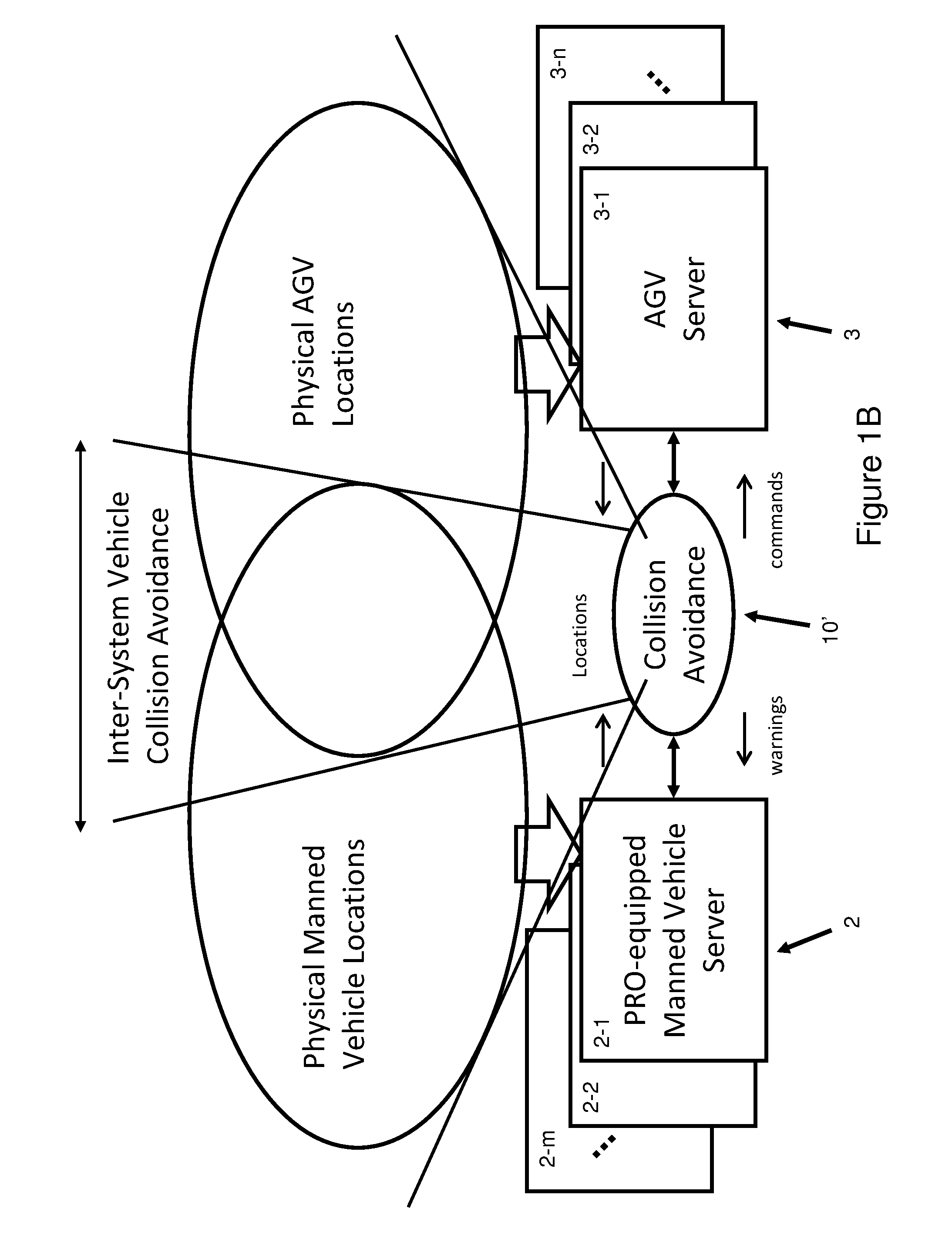

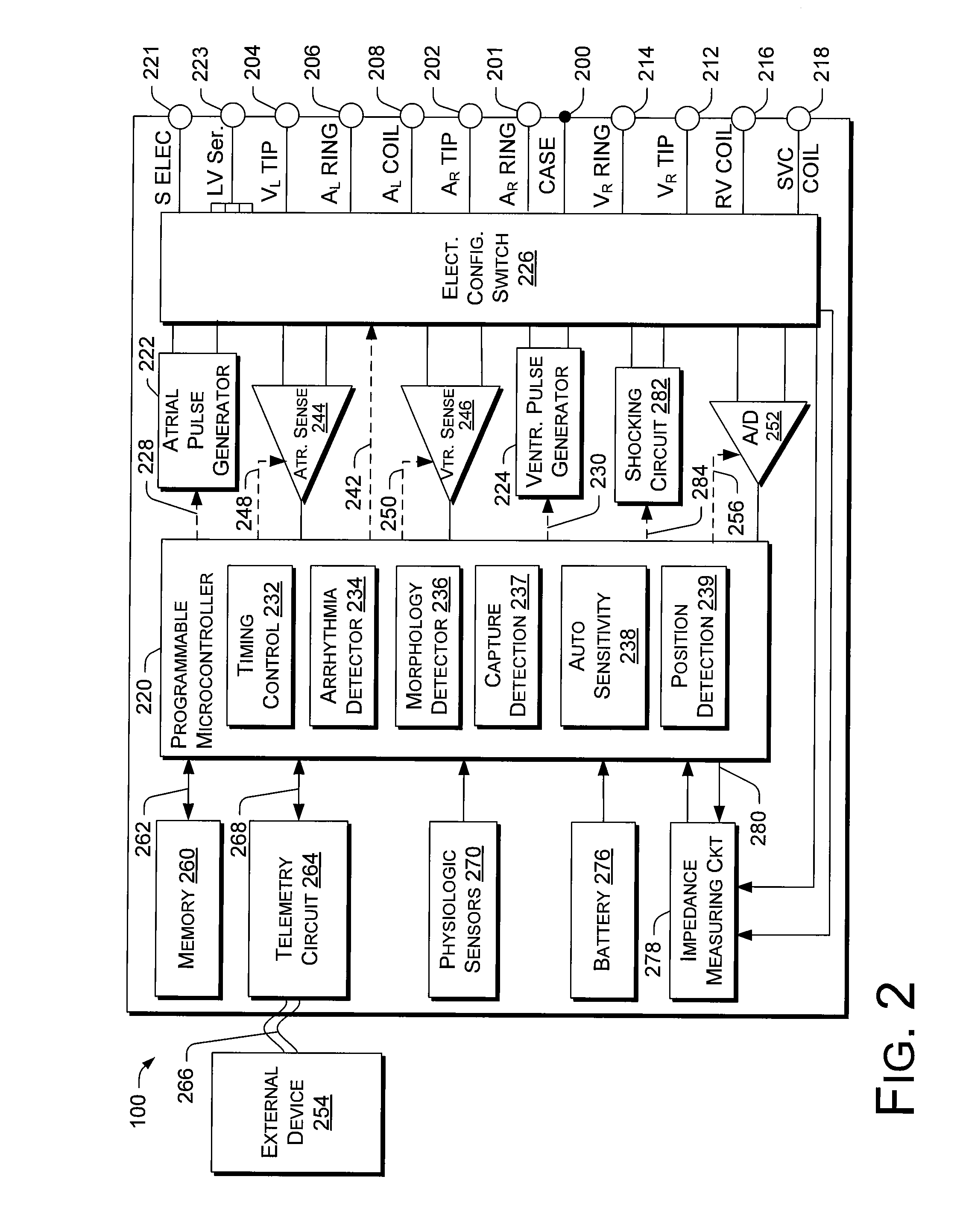

Method and apparatus for collision avoidance

ActiveUS20110093134A1Safety devices for lifting equipmentsDigital data processing detailsMobile vehicleLocation tracking

A method and apparatus for avoiding collisions of moving vehicles in an environment that utilizes a position and rotational orientation system to track vehicle locations within a preconfigured operational zone, the method comprising using position tracking data to calculate a predicted trajectory and safety zone of each vehicle for a predetermined prediction time period and determining potential areas of intersection with vehicles to predict collisions.

Owner:TOTALTRAX

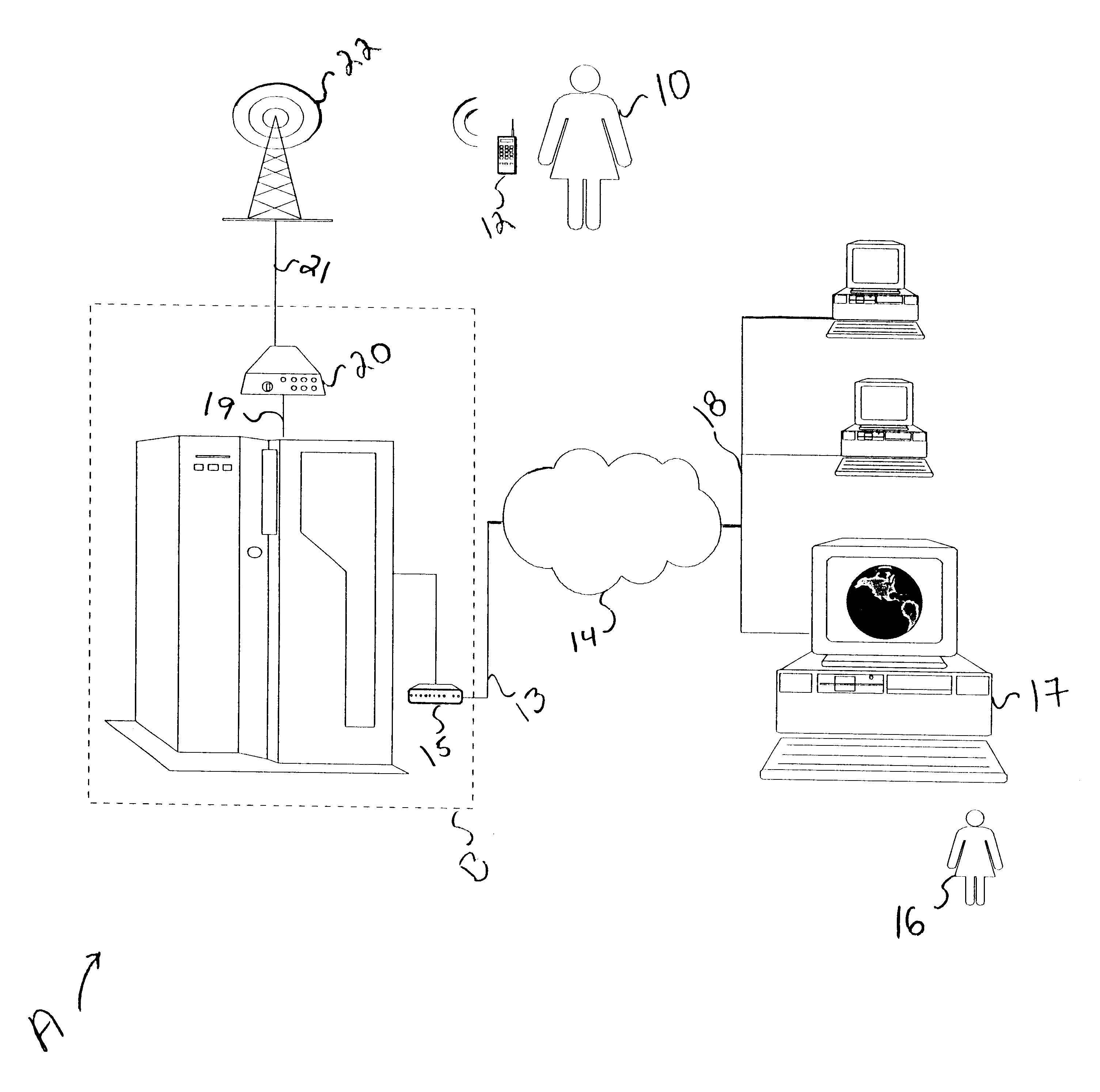

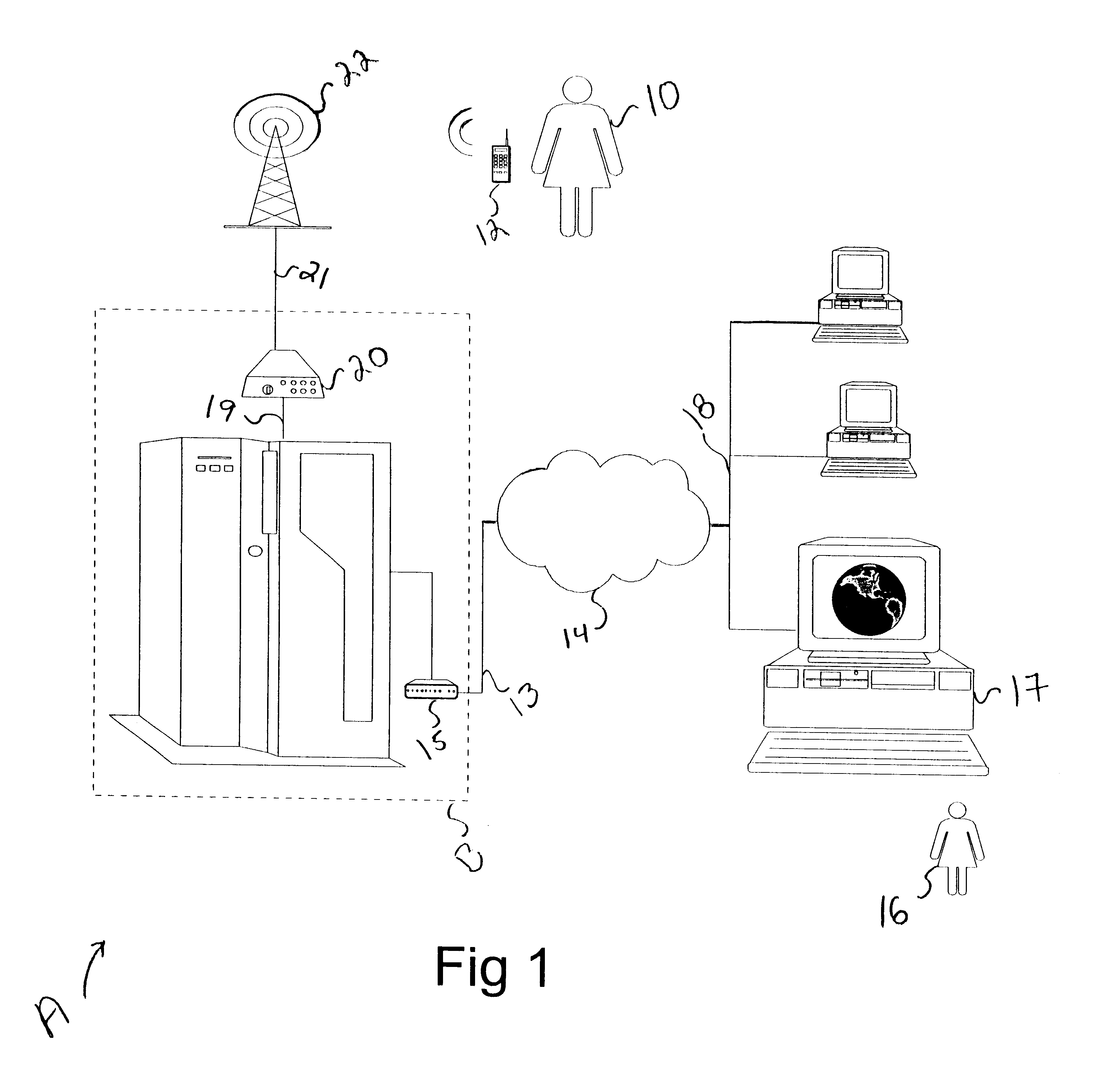

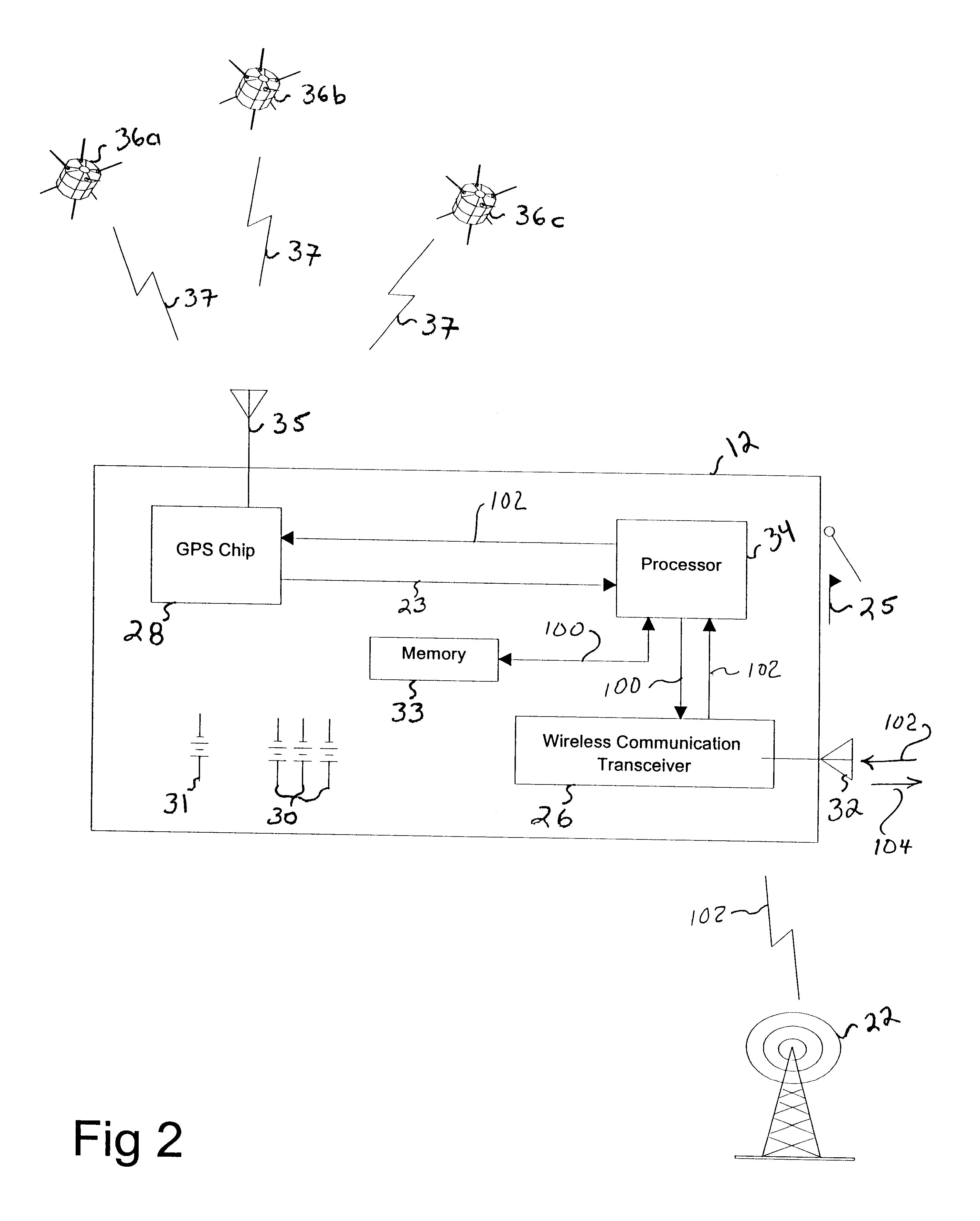

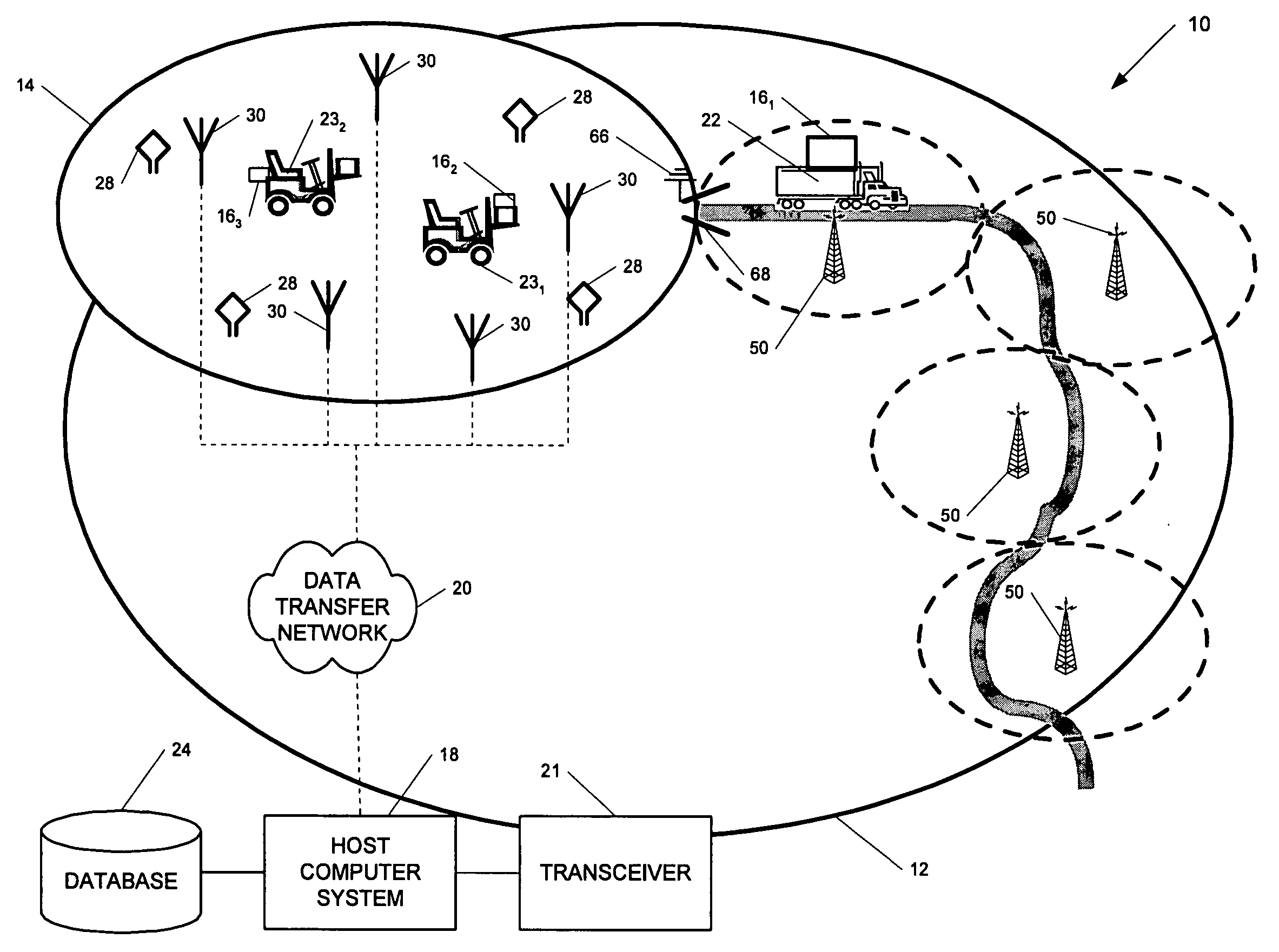

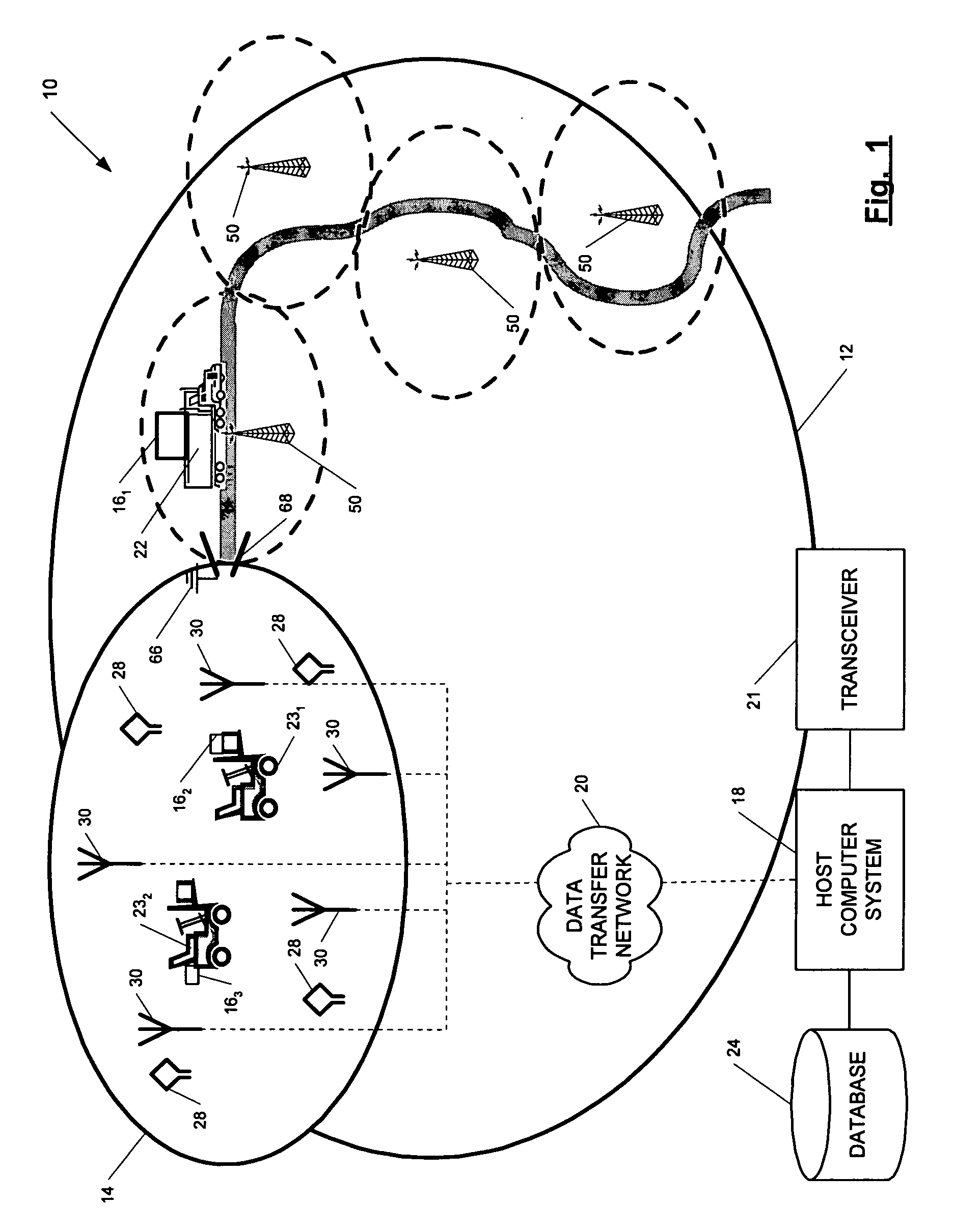

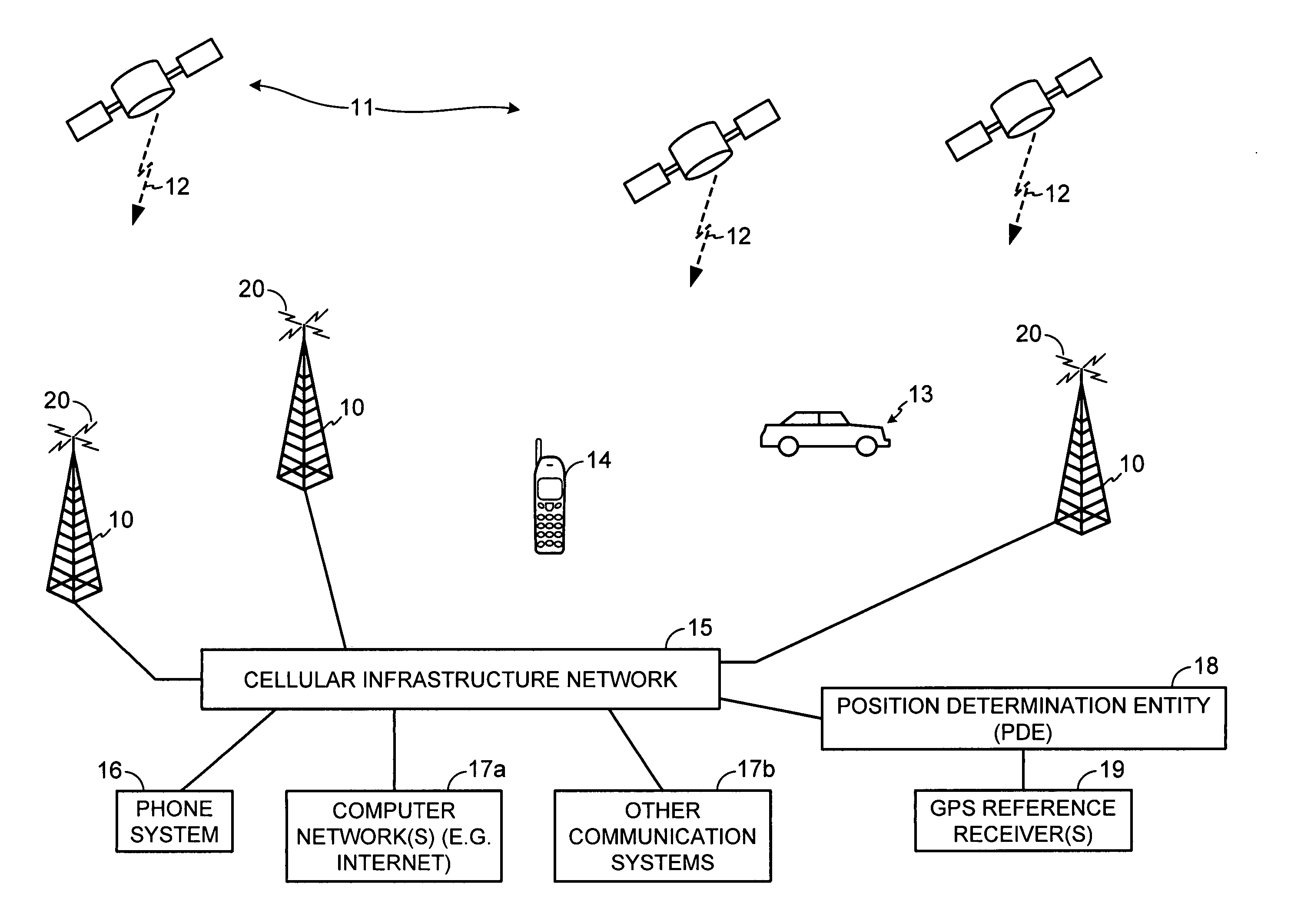

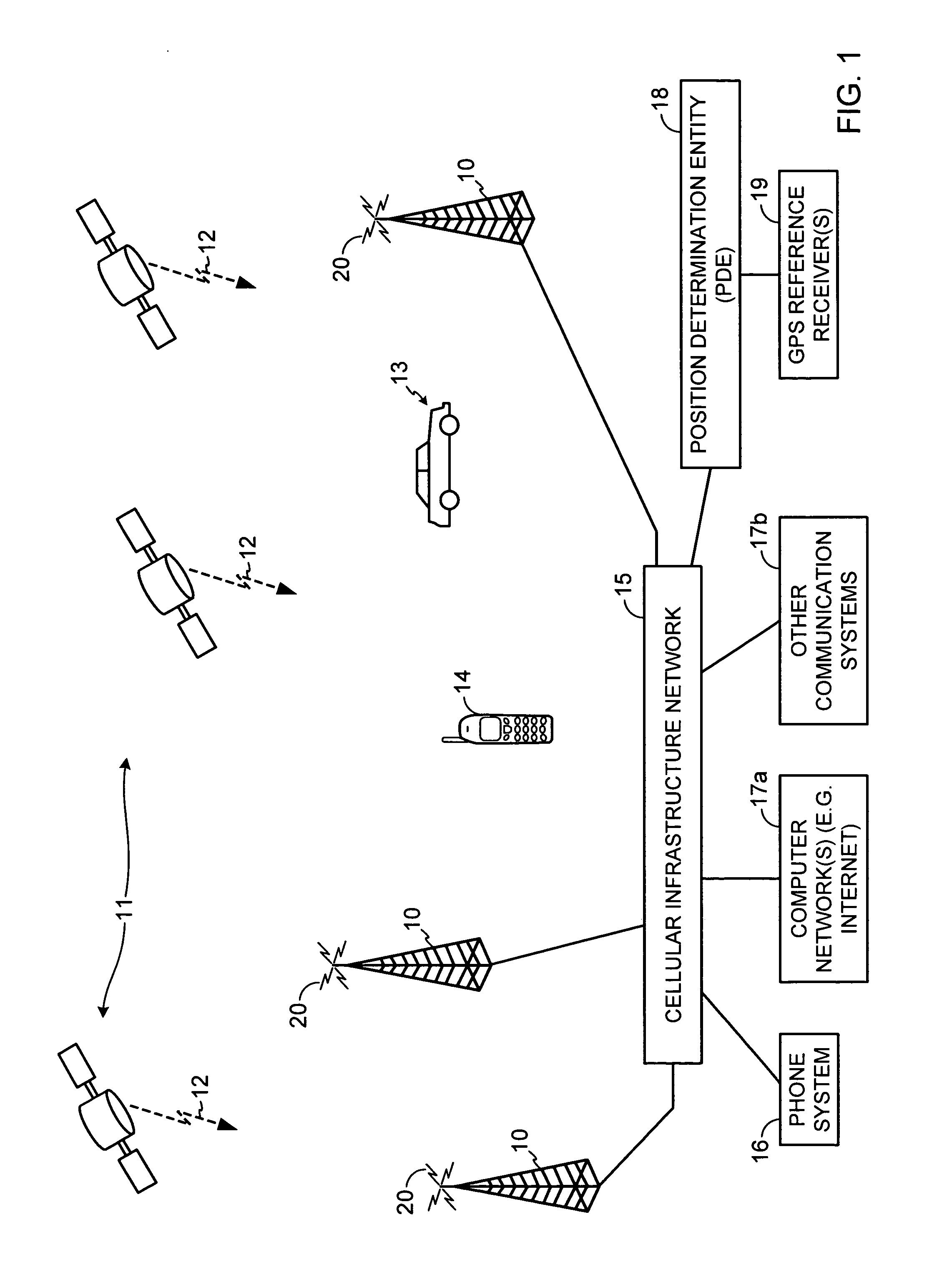

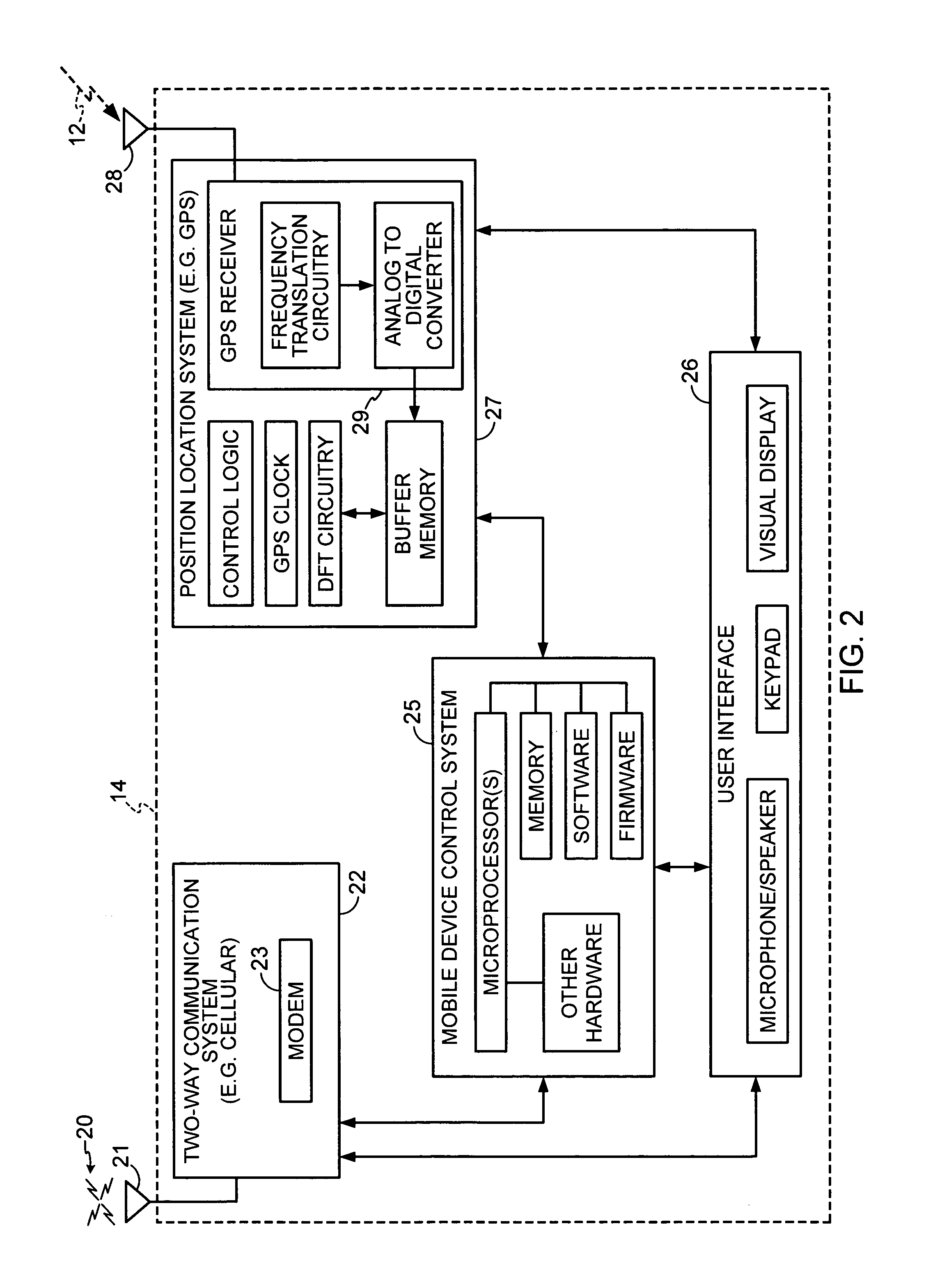

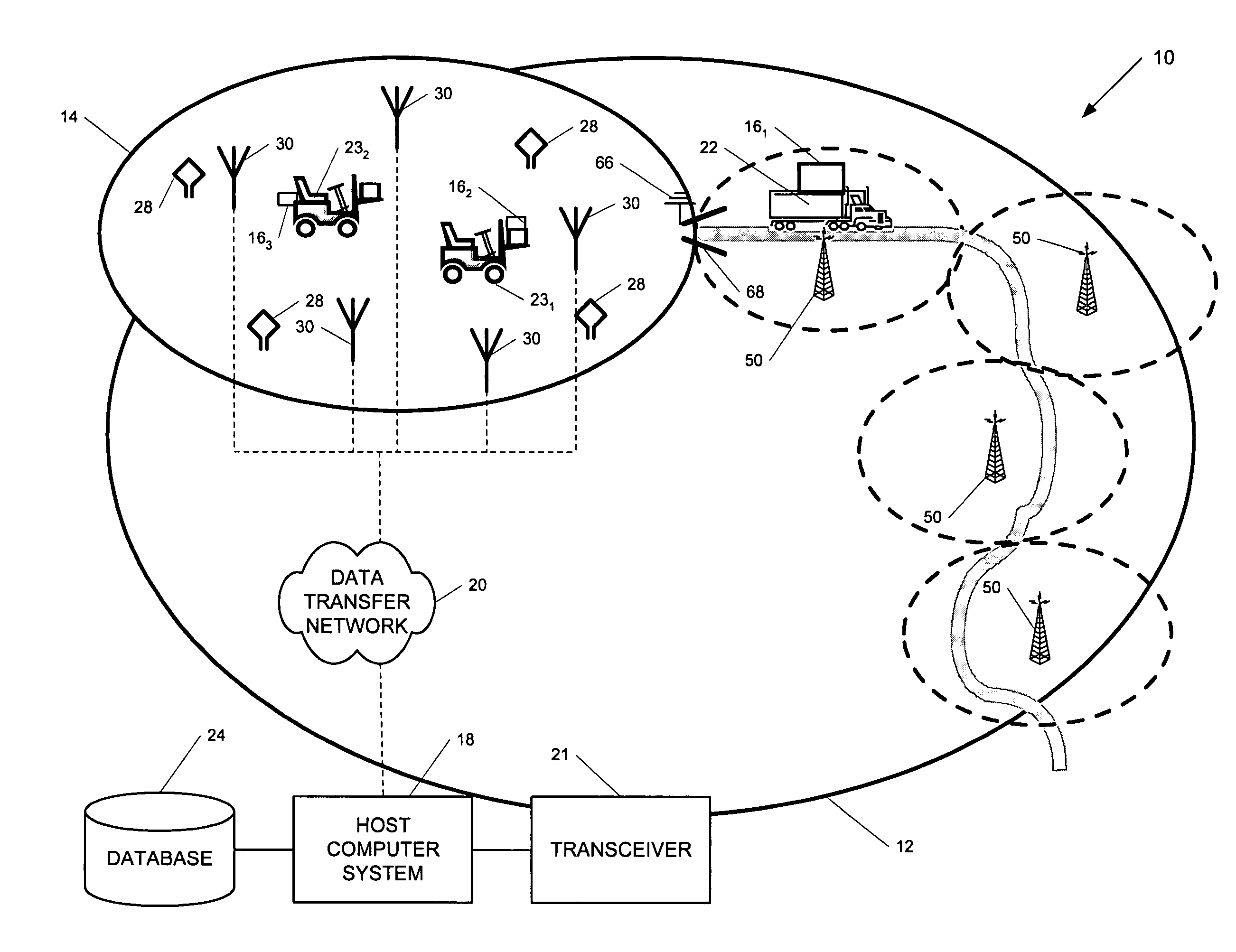

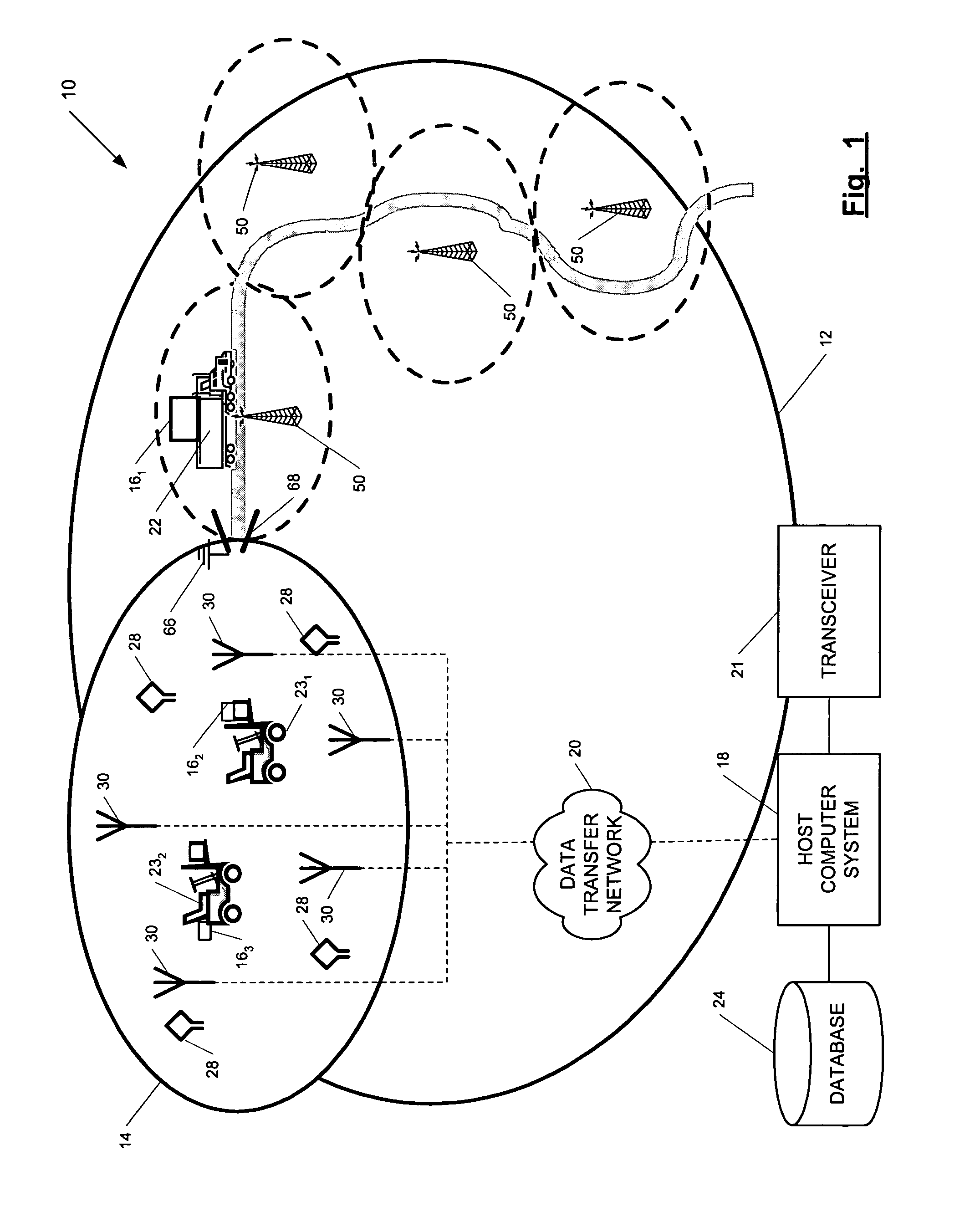

Multi-user global position tracking system and method

InactiveUS6838998B1Low powerSimple and reliable processElectric signal transmission systemsRoad vehicles traffic controlTransceiverData set

An Internet based personal tracking system for tracking the position of a portable location unit by a remote user comprising a web host connected to the Internet having a computer storage medium, a portable location unit having a processor for receiving geo-position information, and generating geo-position data representing the position of said location unit, a transceiver included in said location unit for transmitting said position signal to said web host in response to a call signal being received from said web host, a power supply for supplying power to said processor and said transceiver; and a computer program residing on said web host having an input module for receiving a tracking request signal from the remote user via the Internet, a processing module for processing said tracking request signal, and a communication module for initializing communication with said location unit in response to tracking said request signal, and a location module for outputting said call signal to said location unit and for receiving said geo-position data from said location unit; and a display module for outputting said position dataset to the remote user via the Internet for display of the location unit's position at the remote user's site.

Owner:APPLE INC

Position tracking and imaging system for use in medical applications

A method of monitoring a position of a medical instrument with respect to a patient's body, including positioning a patient reference unit on a portion of the patient's body; positioning a remote unit with respect to the medical instrument; associating at least one field sensor with at least one of the patient reference unit and the remote unit; generating an electromagnetic position characteristic field; producing position data responsive to a sensor output signal that is responsive to the presence of the electromagnetic position characteristic field such that the sensor output signal is representative of a position of the remote unit with respect to the patient reference unit; determining image data representing a plurality of images of the patient's body; and displaying an image of the patient's body based on the image data and responsive to position image data that varies for different position data.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

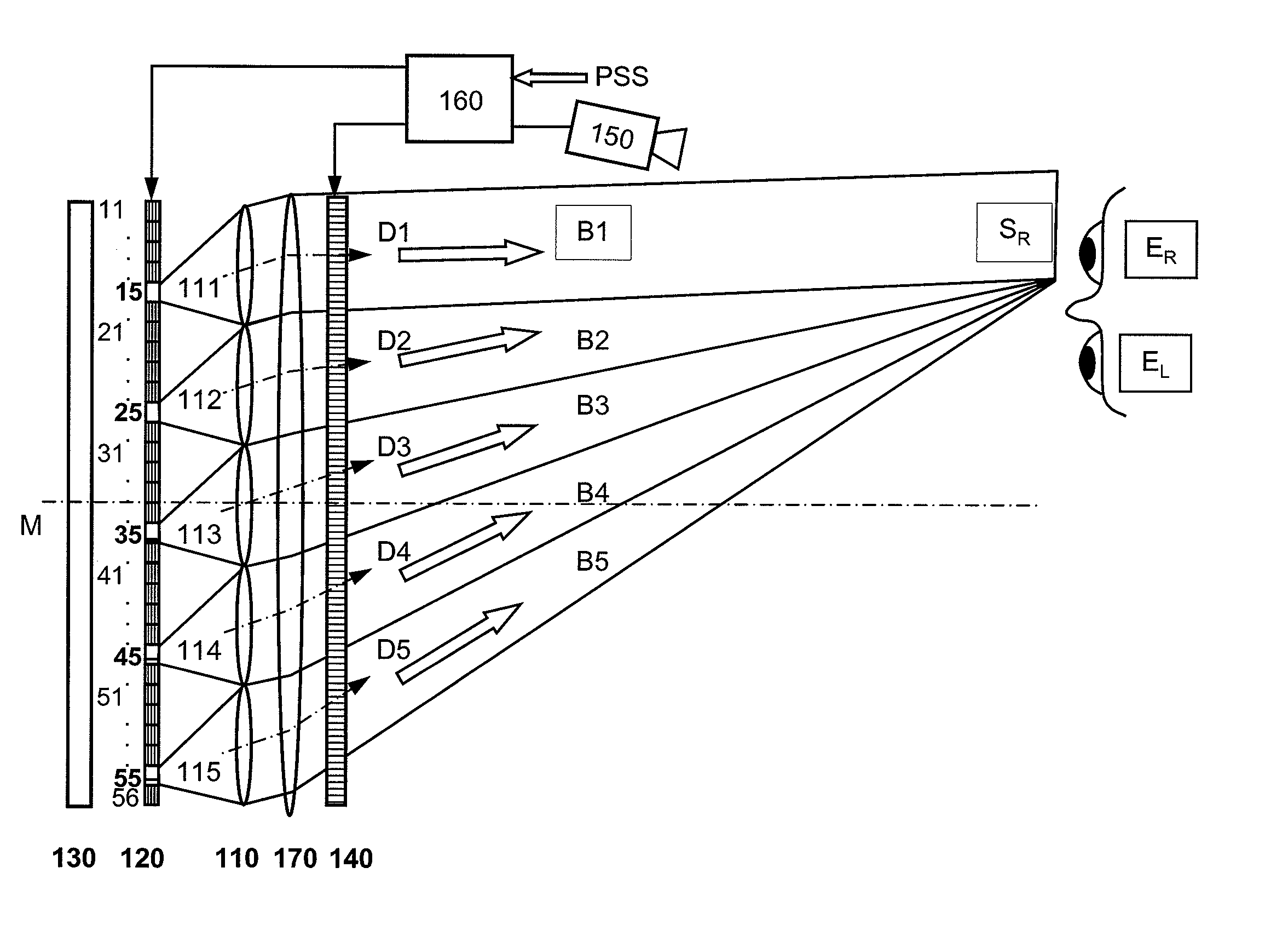

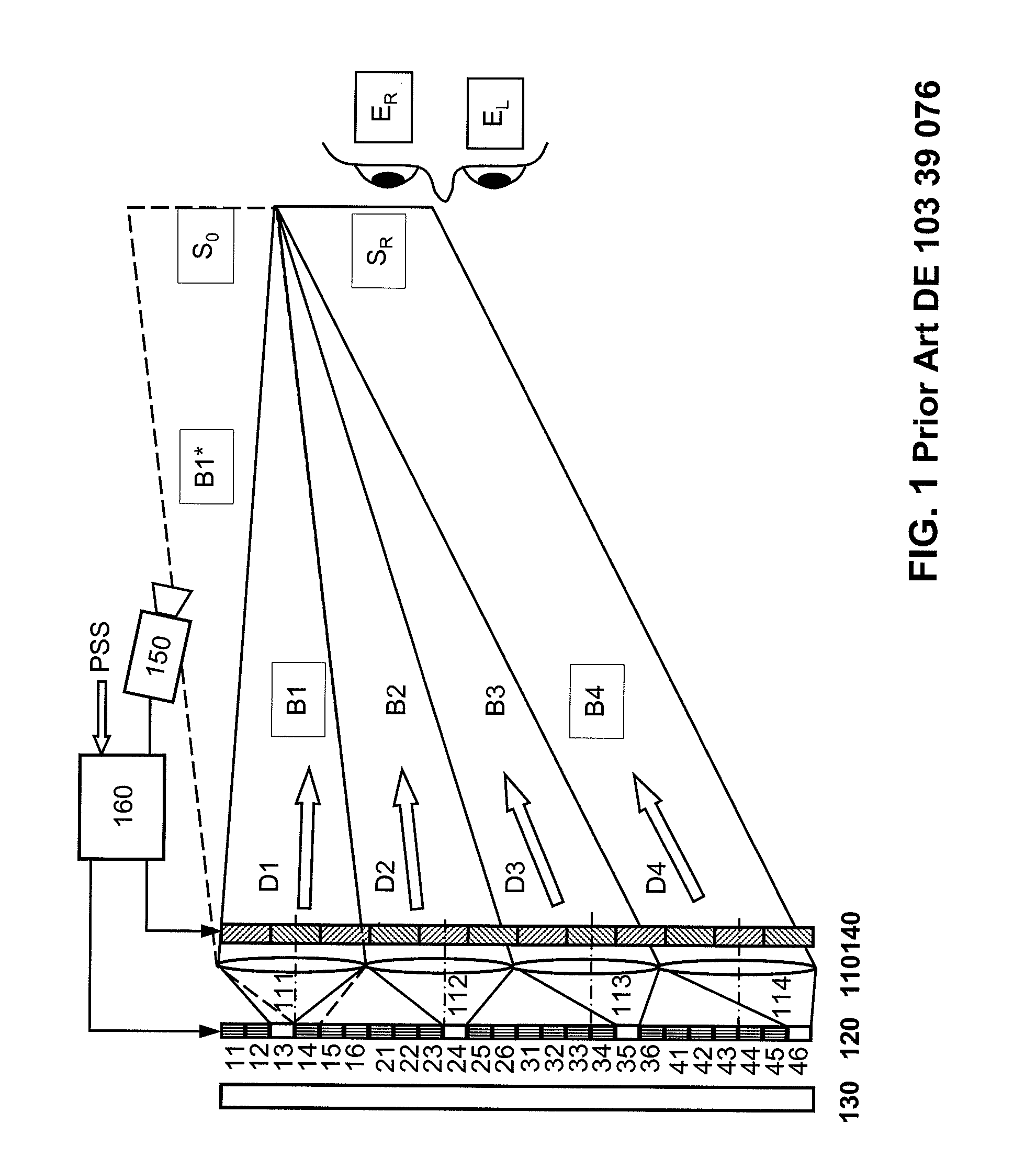

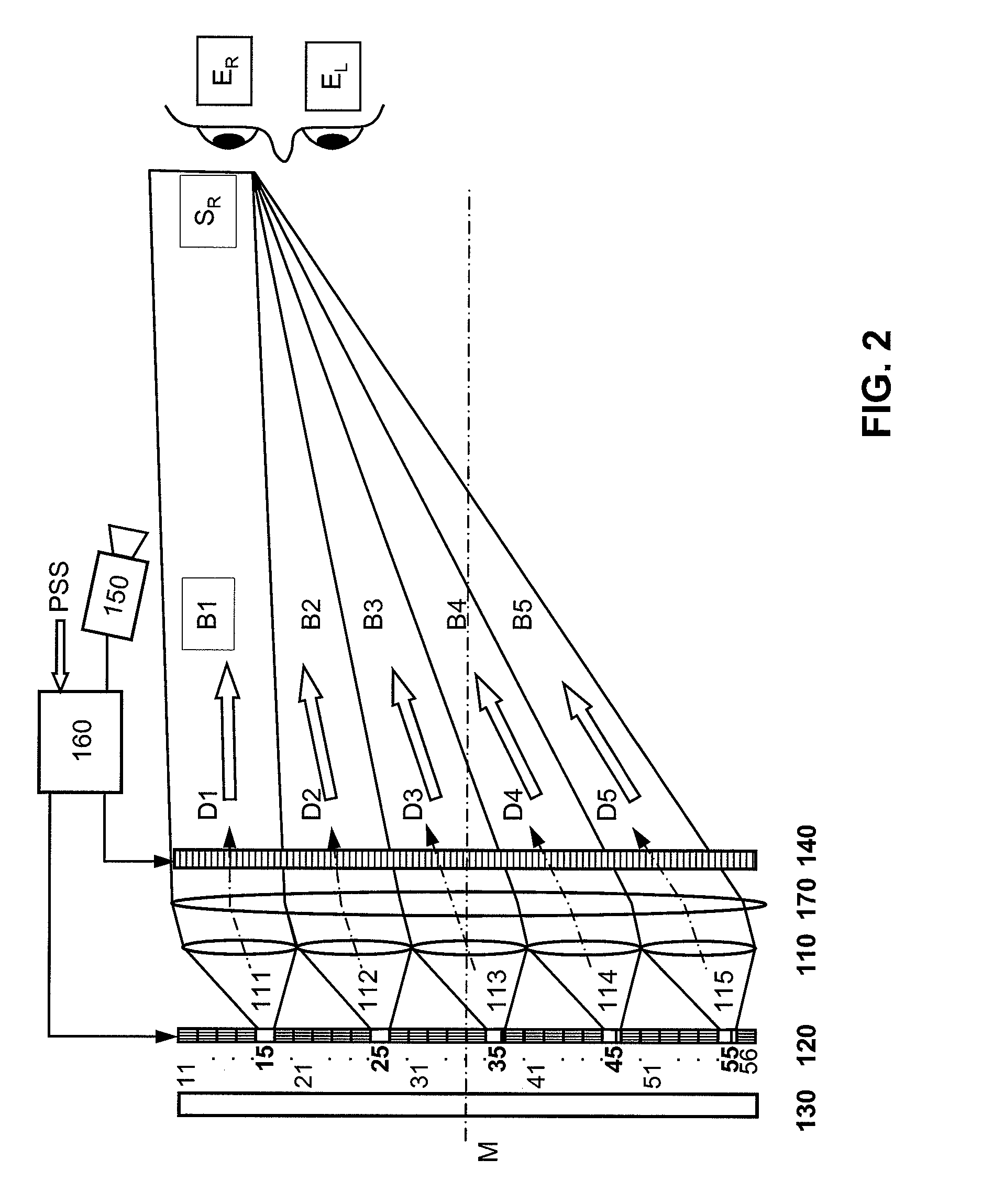

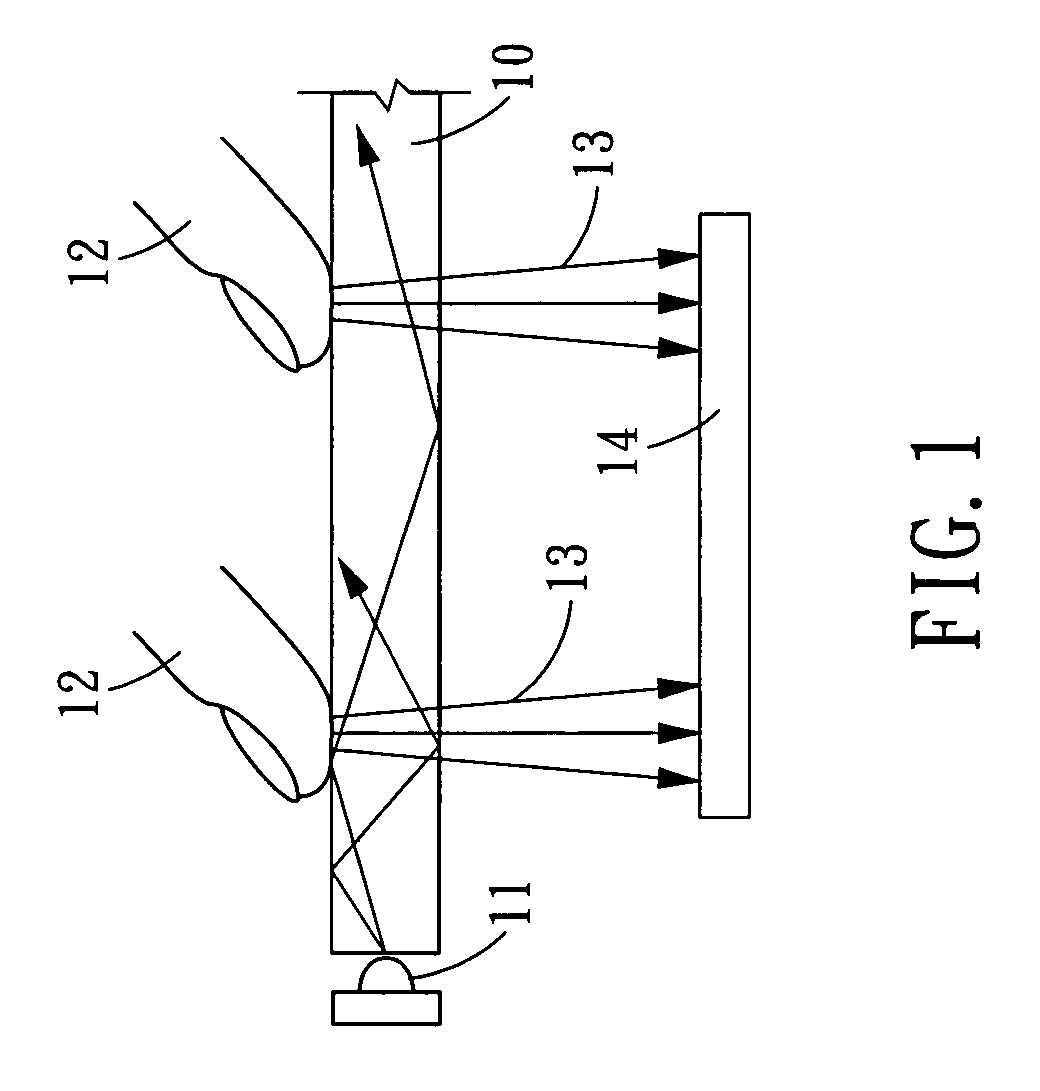

Multi-user autostereoscopic display with position tracking

InactiveUS20070188667A1Low costLittle laborOptical rangefindersMicroscopesDisplay deviceImaging equipment

An autostereoscopic multi-user display comprising a sweet-spot unit which is directionally controlled by a tracking and image control device (160), wherein an illumination matrix (120) is provided with separately activatable illuminating elements (11 . . . 56), in addition to an imaging device used to alternatingly image active illuminating elements, for making expanded sweet spots (SRI / SR2) visible to various eye positions (EL1 / ERI, EL2 / ER2) of viewers observing alternating images or a stereoscopic image sequence on a transmissive image matrix (140) with the aid of directed beams (B1R . . . B5L). According to the invention, the imaging device comprises an imaging matrix (110) provided with a plurality of lens elements (111 115) whose focal length is small in order to image the active illuminating elements in an enlarged manner onto the sweet spots (SRI / SR2), and a field lens (171), which follows the imaging matrix (110), in order to keep the distances of the activated illuminating elements between adjacent beams (B1, B2,B4, B5) as constant as possible and in order to assist selection of the directions (D1. . . D5) with the illumination matrix (120) for the beams.

Owner:SEEREAL TECHNOLOGIES

Catheter Position Tracking for Intracardiac Catheters

InactiveUS20080146941A1Ultrasonic/sonic/infrasonic diagnosticsInertial sensorsUltrasound imagingAccelerometer

An ultrasound imaging system includes one or more accelerometers positioned near the imaging transducer. Acceleration data from the accelerometers are used to estimate the position of the imaging transducer. By combining position information calculated based on acceleration data with position information obtained by other methods, the imaging transducer position can be determined more accurately and closer in time to when images are obtained. The resulting accurate imaging transducer position information enables combining multiple images from different positions or orientations to generate multi-dimensional images.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

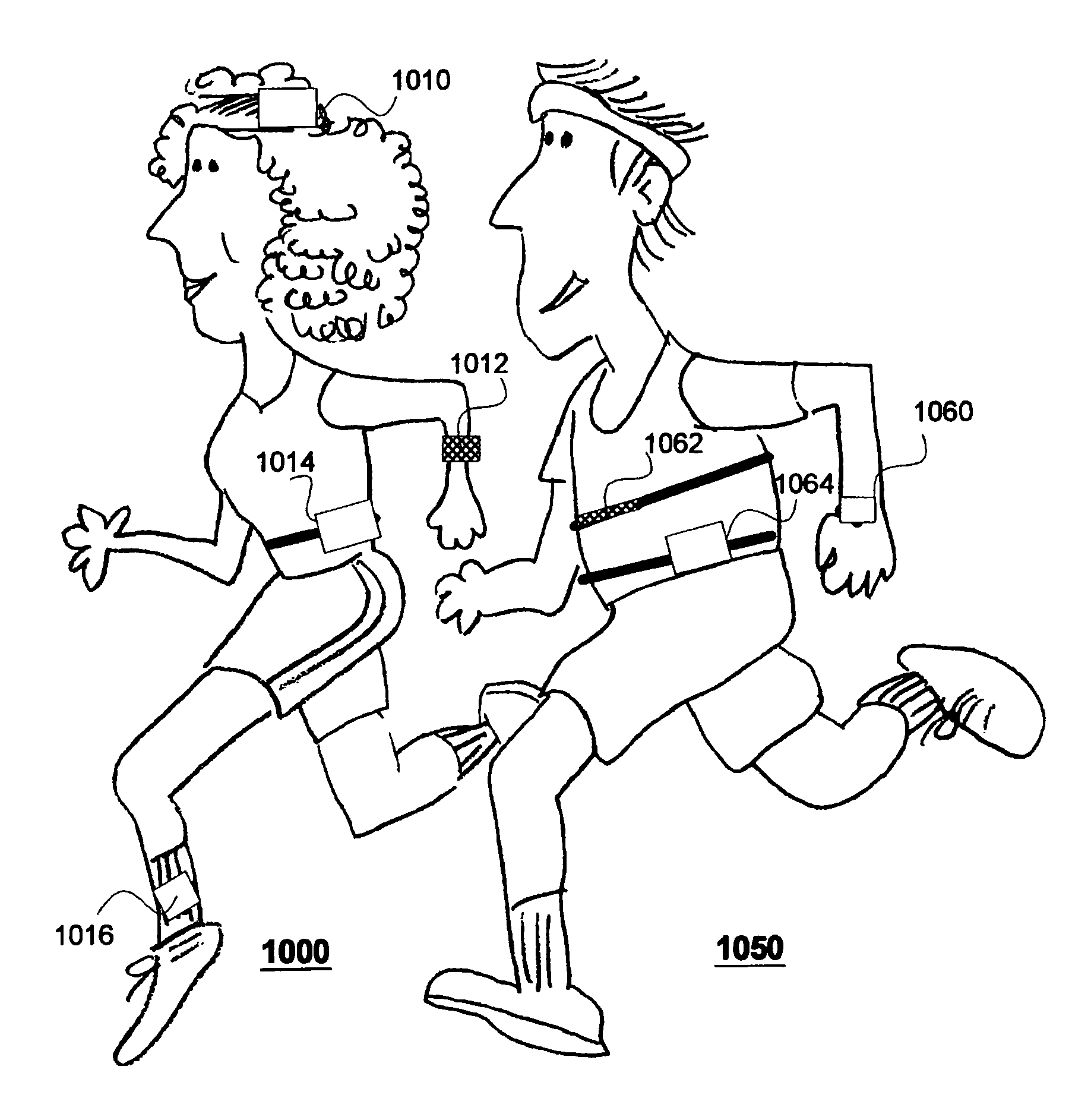

Position tracking and guidance methods

InactiveUS20100056340A1Prevent illegal useAvoid interferencePhysical therapies and activitiesMechanical/radiation/invasive therapiesGeneral purposeUser input

We have disclosed a modular personal network (MPN) that includes multiple devices that may be worn, carried, or used in close proximity to a user. The devices communicate wirelessly. Functions of the MPN may be modified by adding or removing components. The MPN may communicate with a personal computer. General purpose devices may include a control unit, a display, a user input, and an audio output. The MPN may provide a variety of functions, including time, communication, entertainment, organization, guidance, athletic, medical, travel, outdoors, identity, security, and military.

Owner:ADIDAS

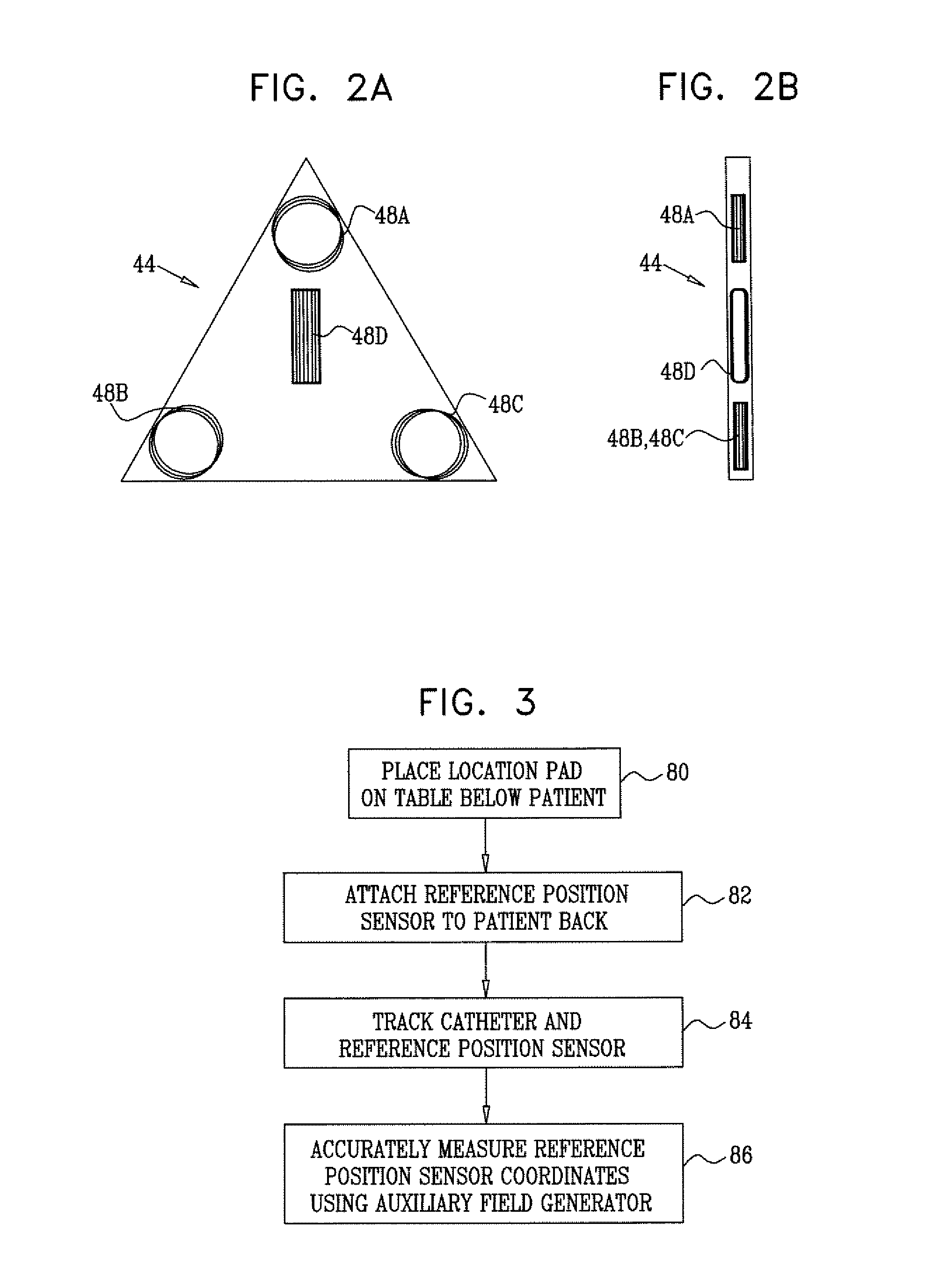

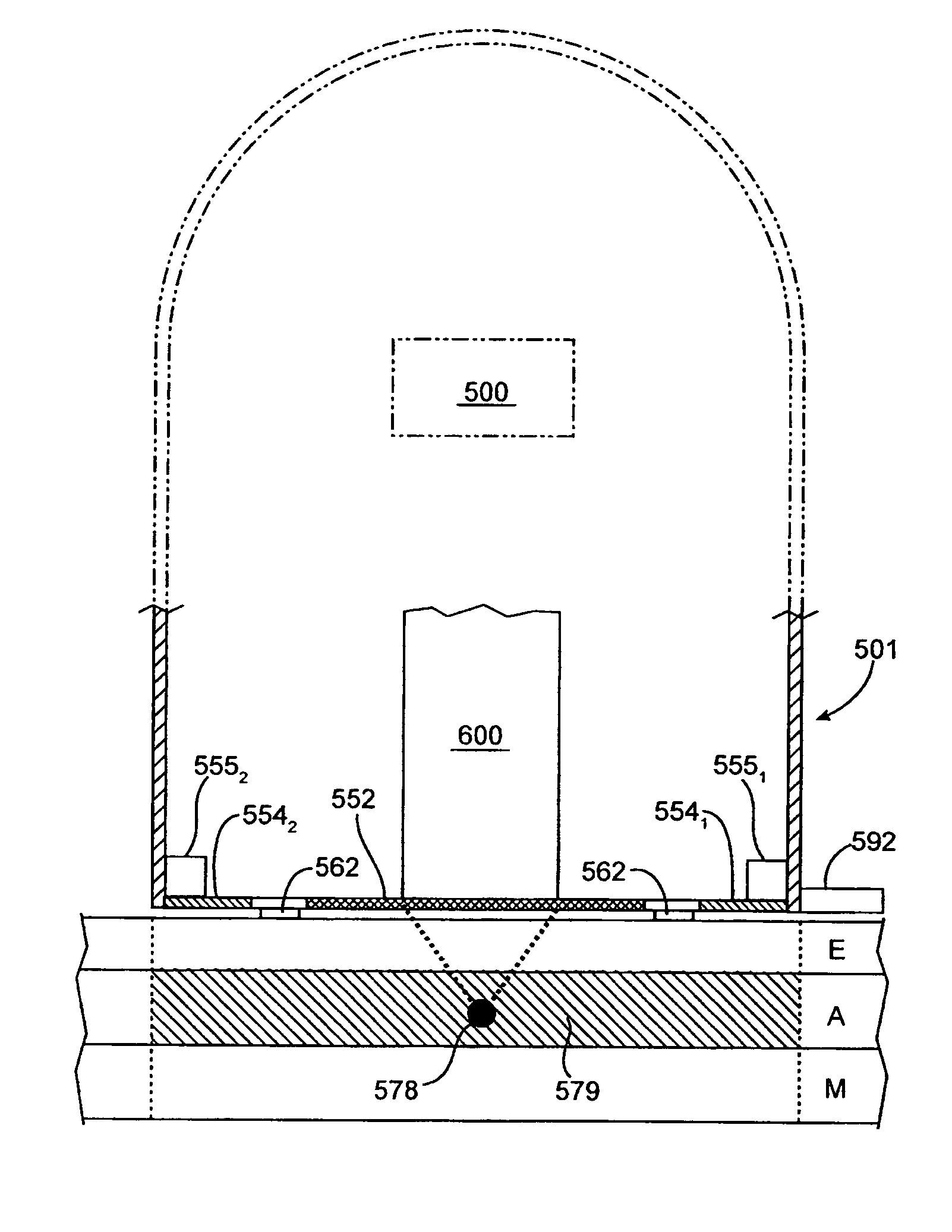

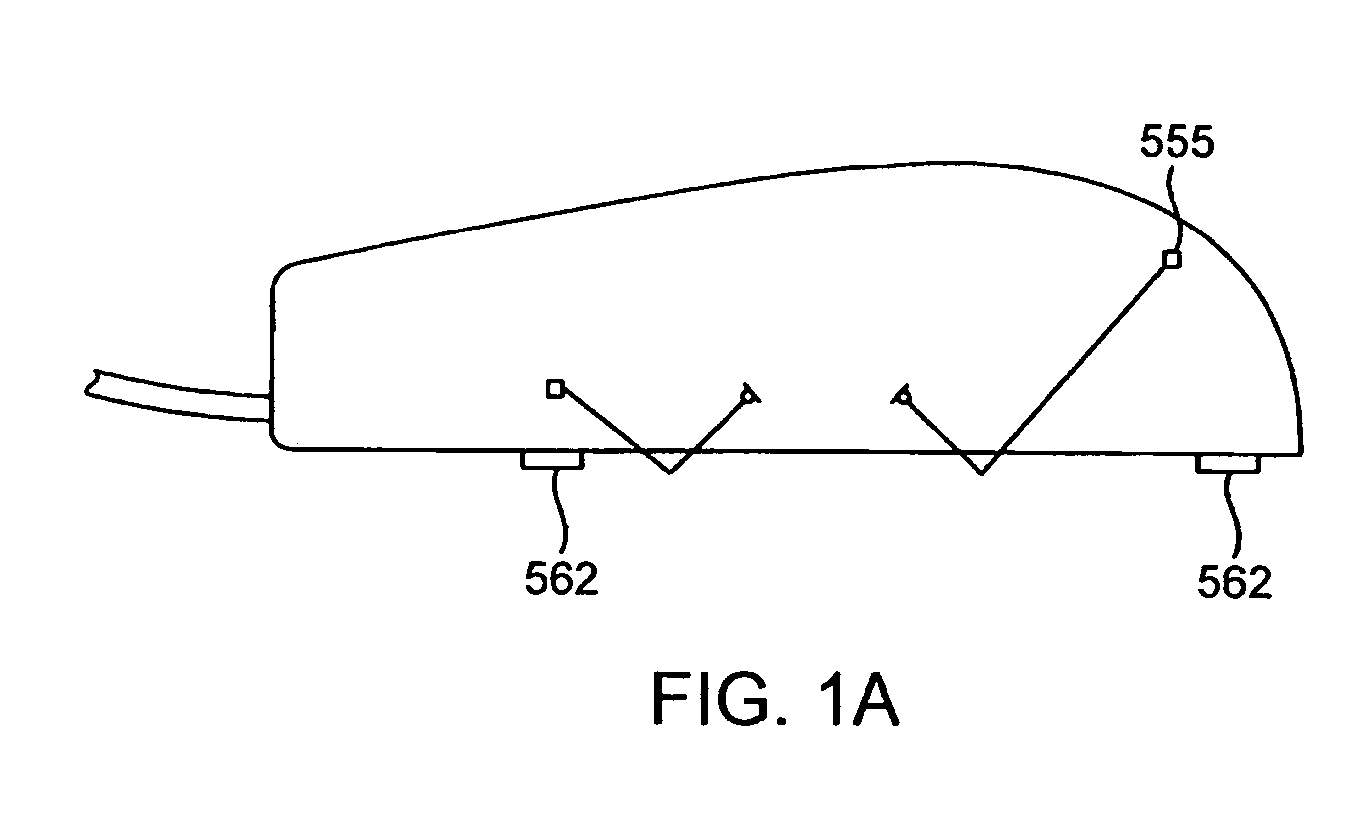

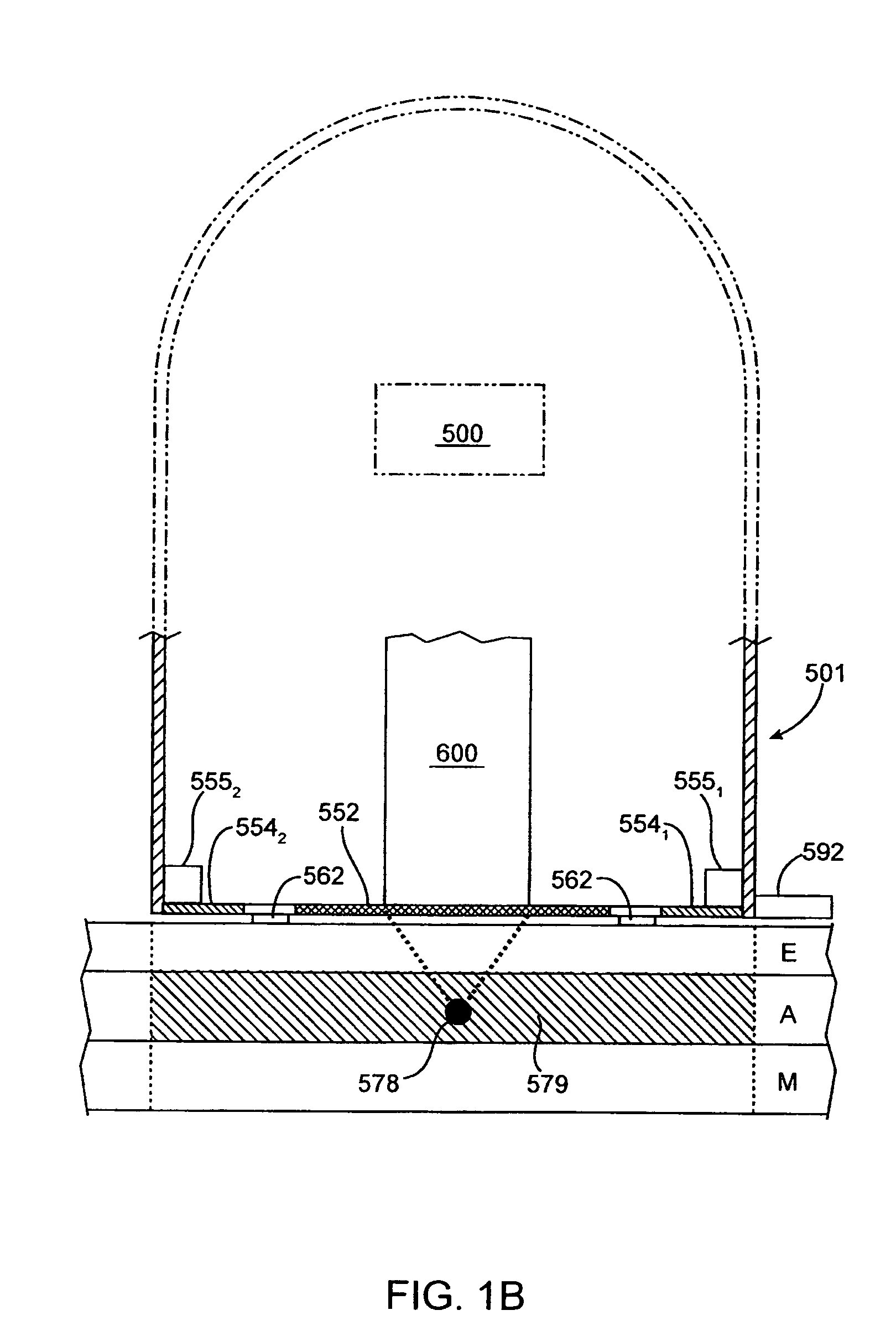

Low-profile location pad

InactiveUS20070265526A1Low profileReduced overall height dimensionSurgical navigation systemsEndoscopesMedical devicePosition sensor

A magnetic position tracking system for performing a medical procedure on a patient who is positioned on an upper surface of a table includes a location pad, which is positioned on the upper surface of the table beneath the patient. The location pad includes one or more field generators, which are operative to generate respective magnetic fields and are arranged so that a thickness dimension of the location pad is no greater than 3 centimeters. A position sensor is fixed to an invasive medical device for insertion into a body of the patient, and is arranged to sense the magnetic fields so as to measure a position of the medical device in the body.

Owner:BIOSENSE WEBSTER INC

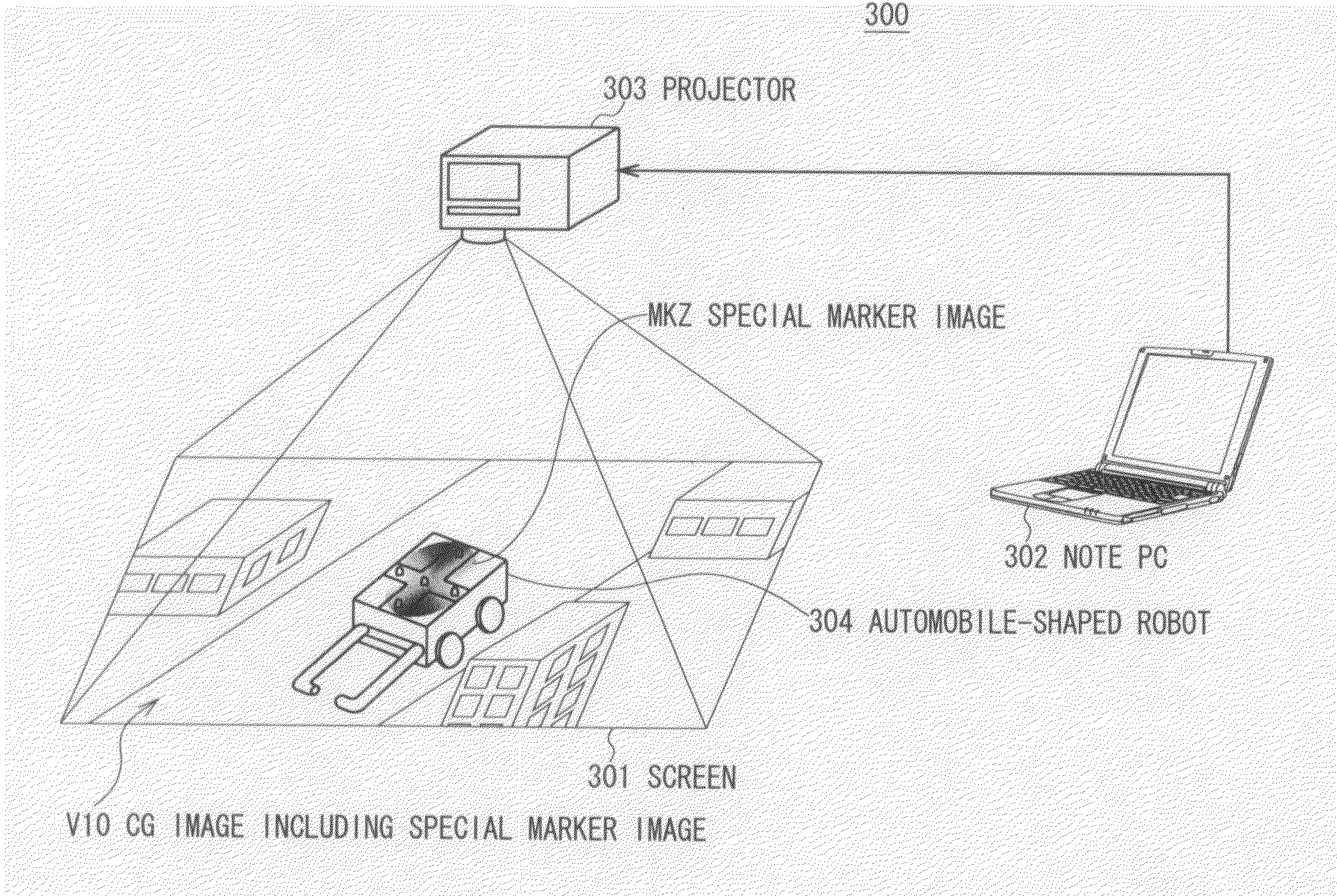

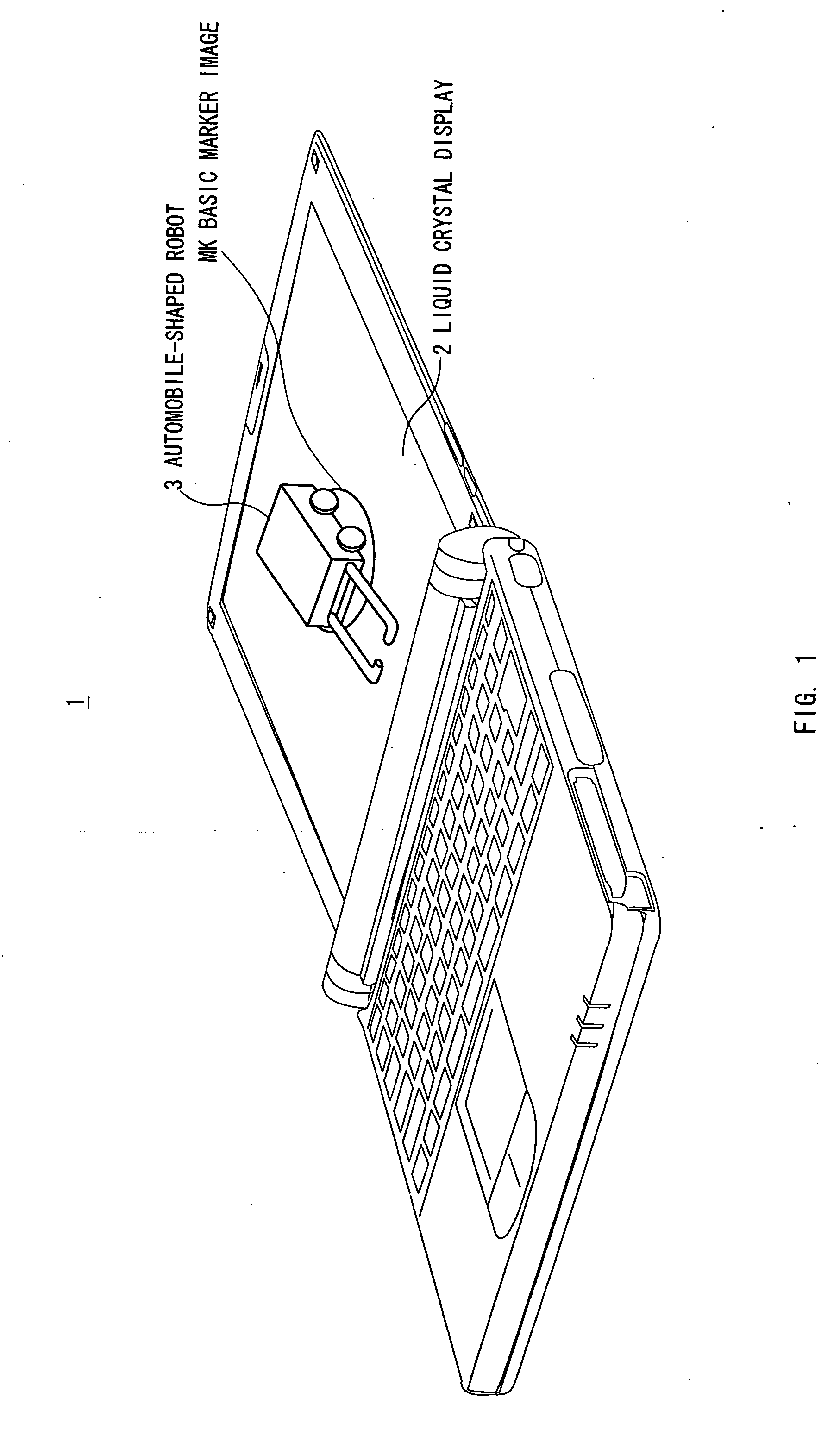

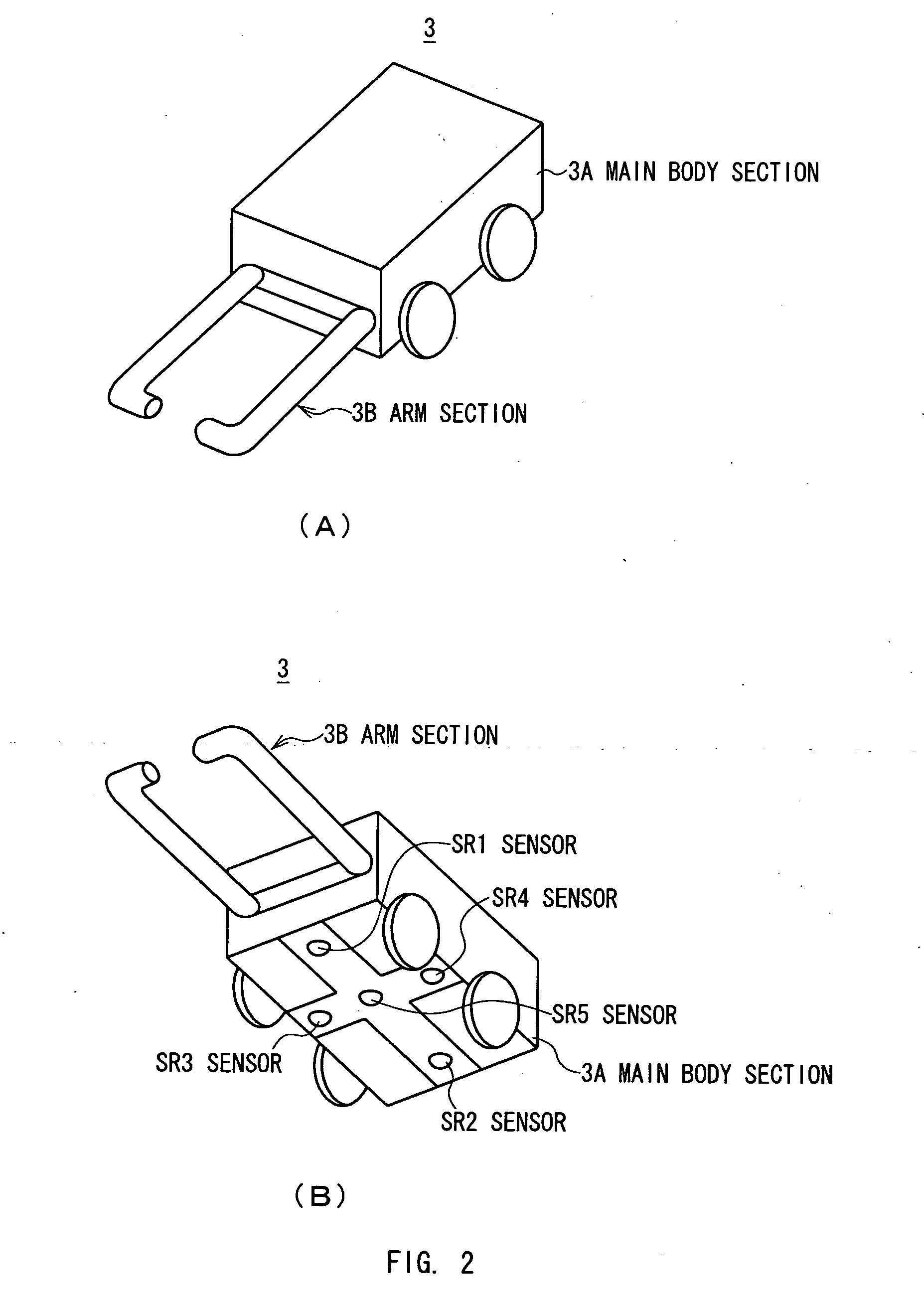

Position Tracking Device, Position Tracking Method, Position Tracking Program and Mixed Reality Providing System

InactiveUS20080267450A1Accurate detectionImage enhancementImage analysisMixed realityLiquid-crystal display

The present invention has a simpler structure than before and is designed to precisely detect the position of a real environment's target object on a screen. The present invention generates a special marker image MKZ including a plurality of areas whose brightness levels gradually change in X and Y directions, displays the special marker image MKZ on the screen of a liquid crystal display 2 such that the special marker image MKZ faces an automobile-shaped robot 3, detects, by using sensors SR1 to SR4 provided on the automobile-shaped robot 3 for detecting the change of brightness level of position tracking areas PD1A, PD2A, PD3 and PD4 of the special marker image MKZ in the X and Y directions, the change of brightness level, and then detects the position of the automobile-shaped robot 3 on the screen of the liquid crystal display 2 by calculating, based on the change of brightness level, the change of relative coordinate value between the special marker image MKZ and the automobile shaped robot 3.

Owner:UNIVERSITY OF ELECTRO-COMMUNICATIONS

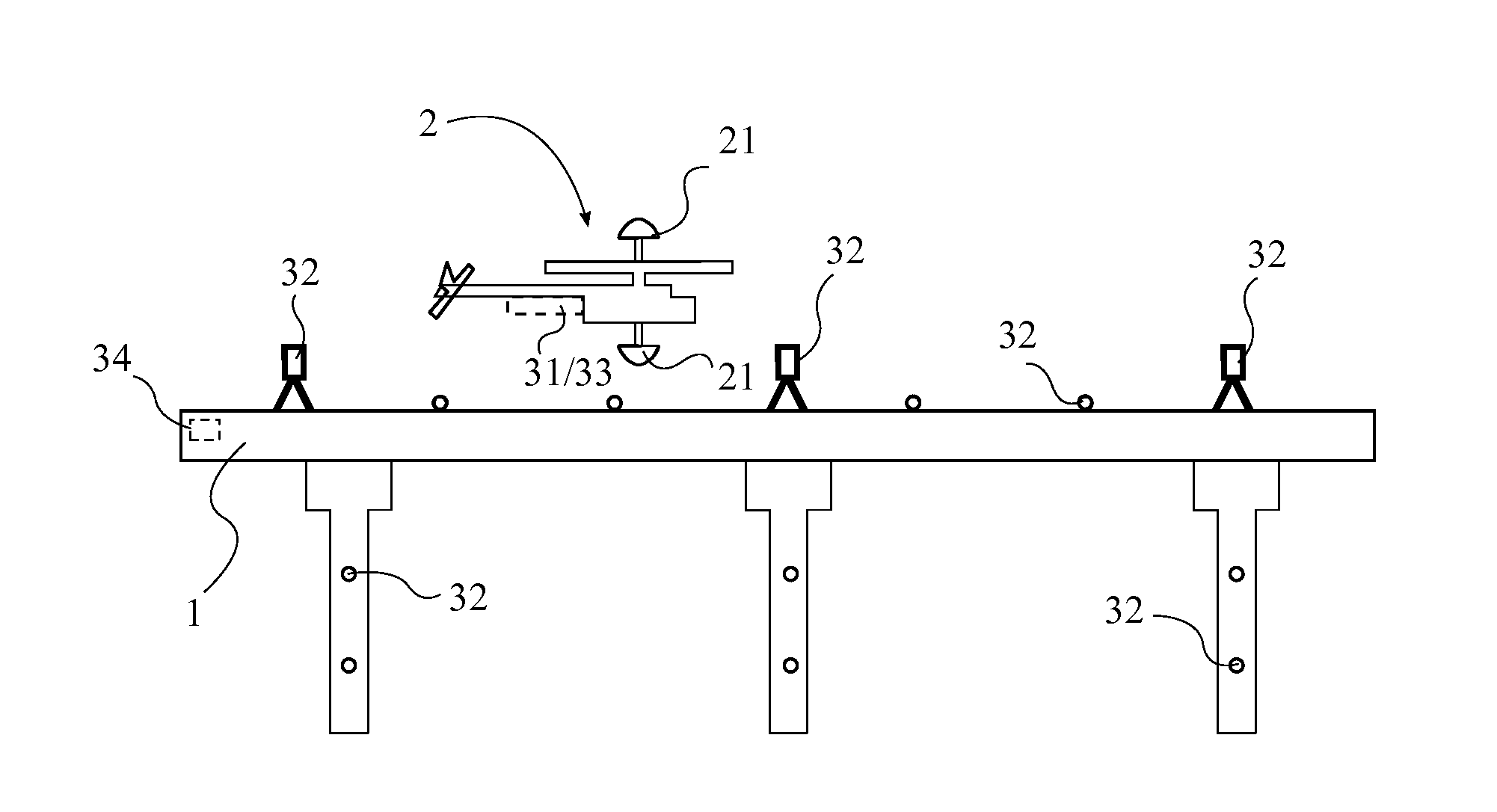

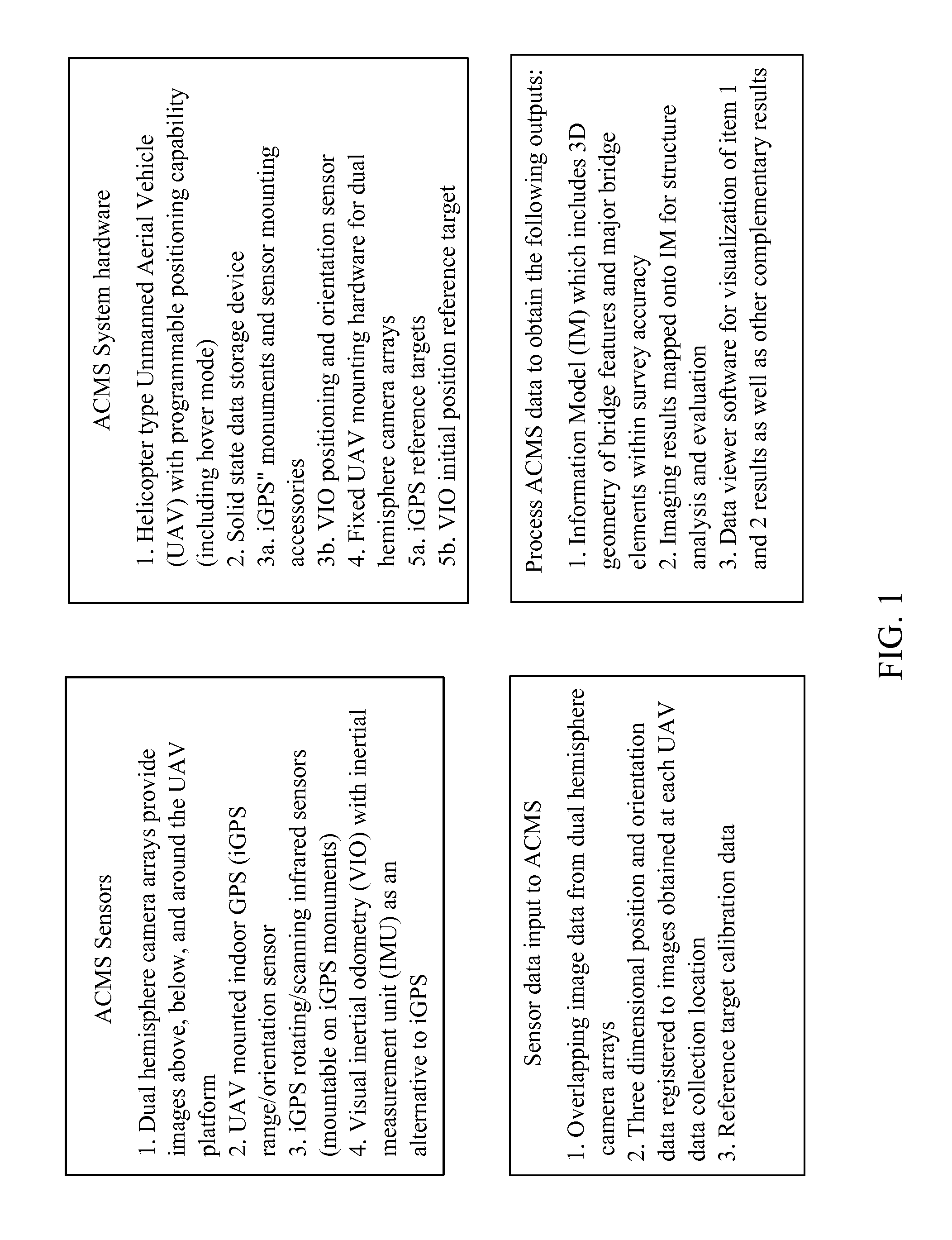

System and Method of Automated Civil Infrastructure Metrology for Inspection, Analysis, and Information Modeling

A system and method of automated civil infrastructure metrology for inspection, analysis, and information modeling utilizes an unmanned aerial vehicle (UAV) equipped with a position tracking system and digital cameras to capture a plurality of images of a structure to be inspected. The UAV is flown in a scan pattern around the structure while continually capturing images of the structure while position and orientation data is also recorded and linked for each of the images. Image processing and pattern recognition software algorithms are used to analyze the images and create an information model of the structure which is then used to carry out a virtual inspection of the structure in a three dimensional software environment.

Owner:SCOTT MICHAEL L

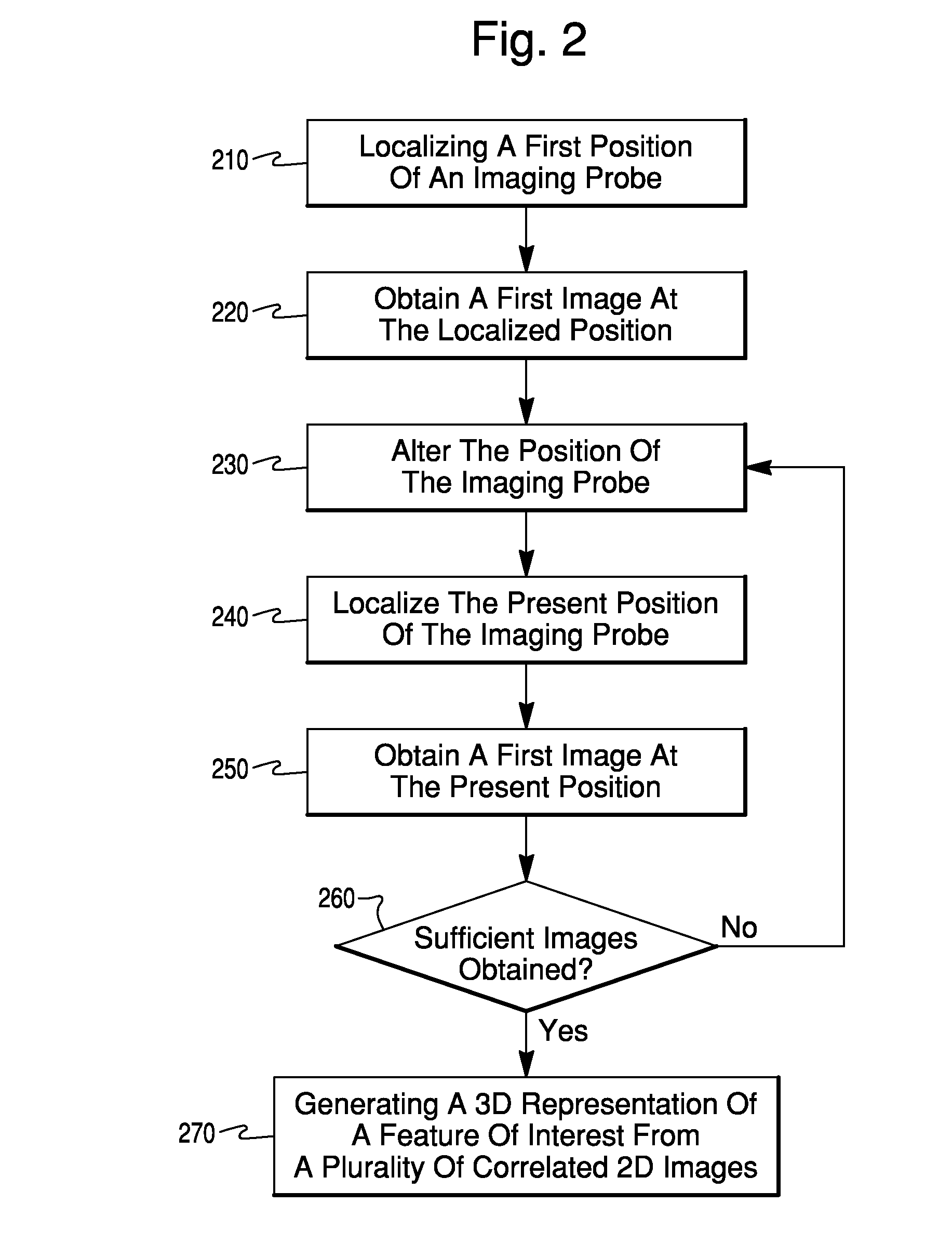

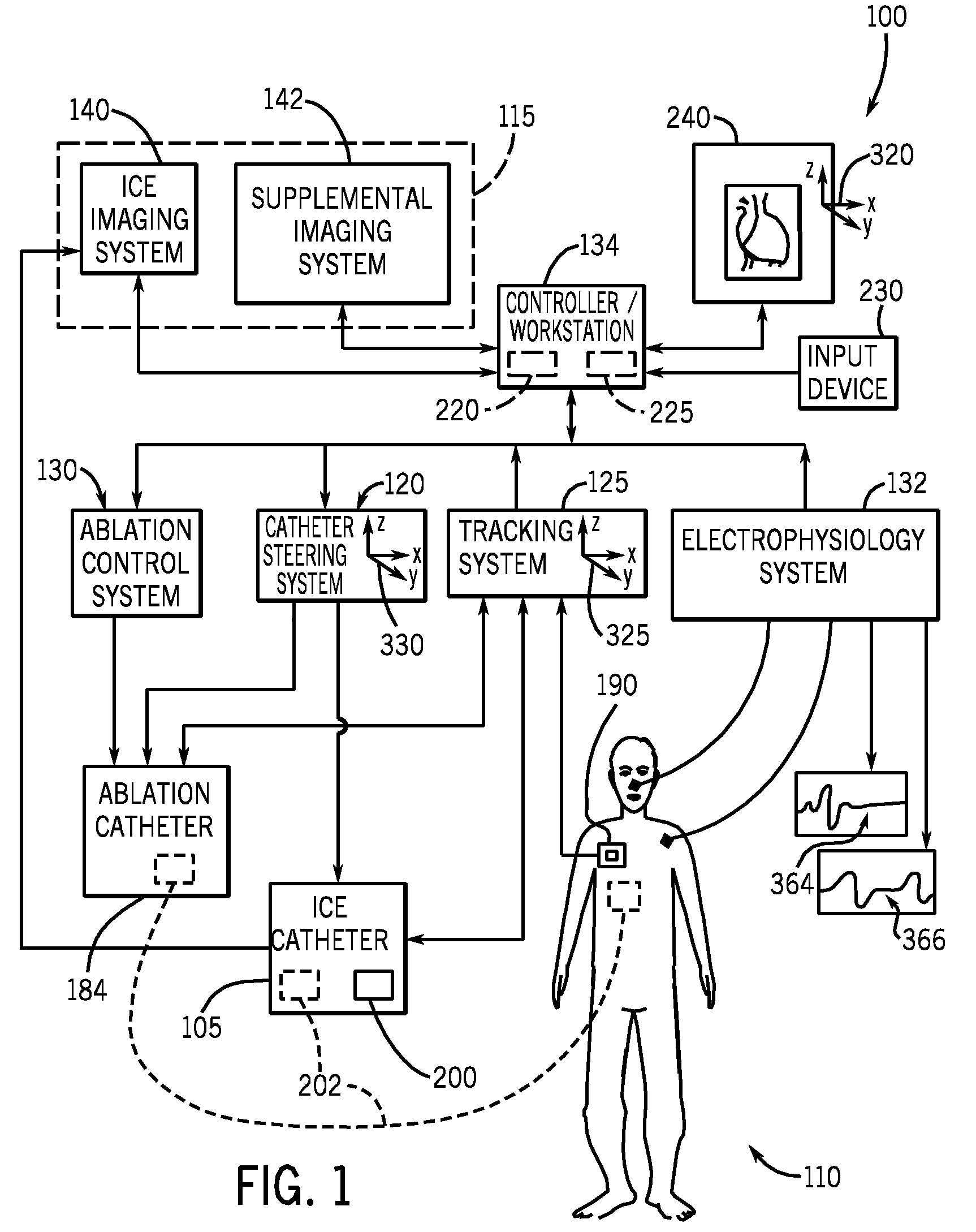

Intracardiac echocardiography image reconstruction in combination with position tracking system

ActiveUS20080287803A1Reduce health risksExpand field of viewUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsSonification3d image

A system and method to display a four-dimensional (4D) model of an imaged anatomy is provided. The system comprises a controller, and an imaging system including an imaging probe in communication with the controller. The imaging probe can acquire generally real-time, 3D image data relative to a direction of image acquisition along an imaging plane. The system also includes a tracking system in communication with the controller. The tracking system includes at least one tracking element integrated with the imaging probe. The system is operable to process the generally real-time, 3D image data acquired by the imaging probe relative to generally real-time tracking information acquired by the tracking system so as to display the 4D model of the imaged anatomy.

Owner:GENERAL ELECTRIC CO

Systems and methods for determining a location of an object

ActiveUS20070018811A1Improve accuracyHigh position resolutionElectric signal transmission systemsDigital data processing detailsMobile vehicleLocation tracking

A system for determining a location of an object. The system includes an object location tracker and a computer system. The object location tracker is configured for attachment to a mobile vehicle and includes an object identification reading device and a position-tracking device. The object identification reading device senses object identification indicia on the object, such as RF ID tags, bar codes, etc., as the mobile vehicle moves around an environment in which the object is situated. The position-tracking device computes the location of the object location tracker as the mobile vehicle moves throughout environment. The computer system associates the sensed object identification indicia of the object, as determined by the reading device, with a location in the environment based on the position of the object location tracker in the environment, as determined by the position-tracking device, when the reading device senses the object identification indicia. The mobile vehicle may include its own mobility system, such as a forklift or an autonomous robotic device, or the mobile vehicle may be, for example, a pushcart that is pushed around the environment.

Owner:PINC SOLUTIONS

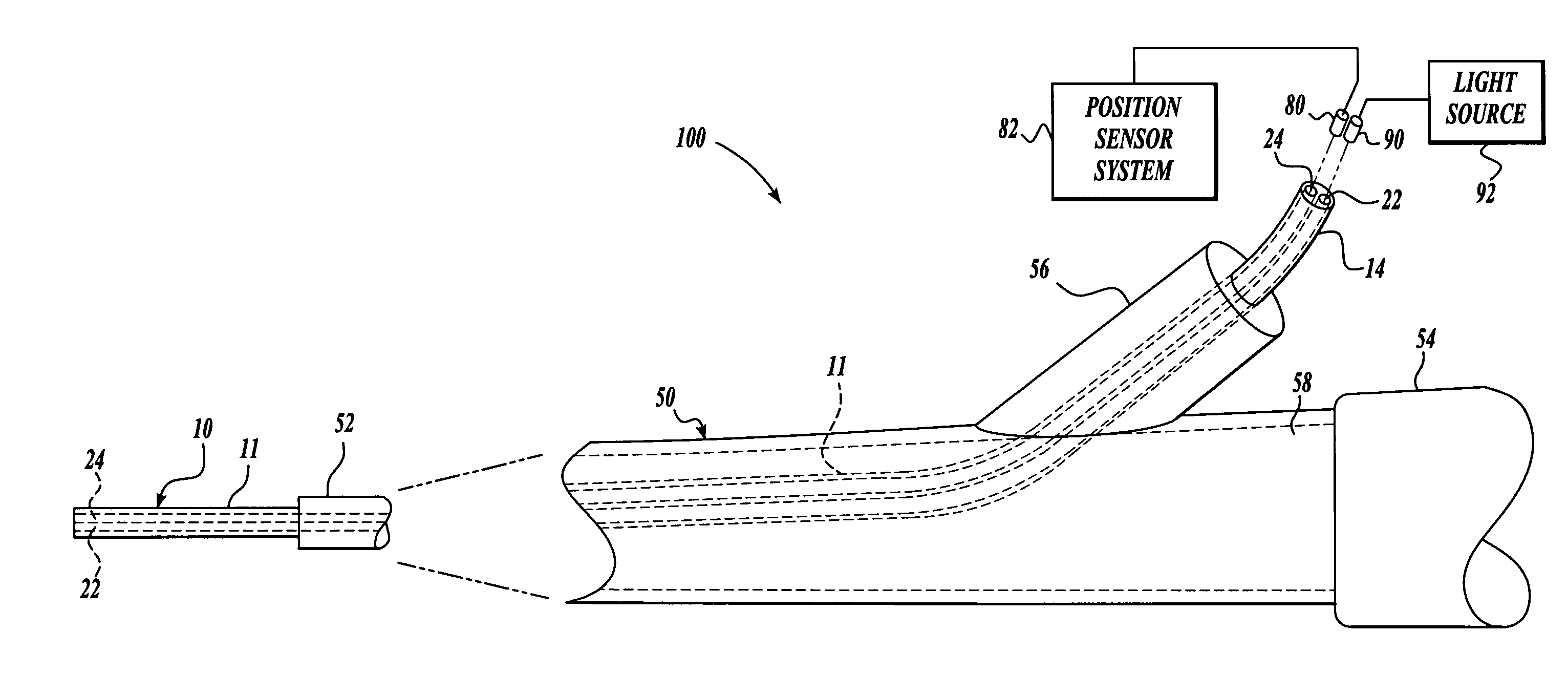

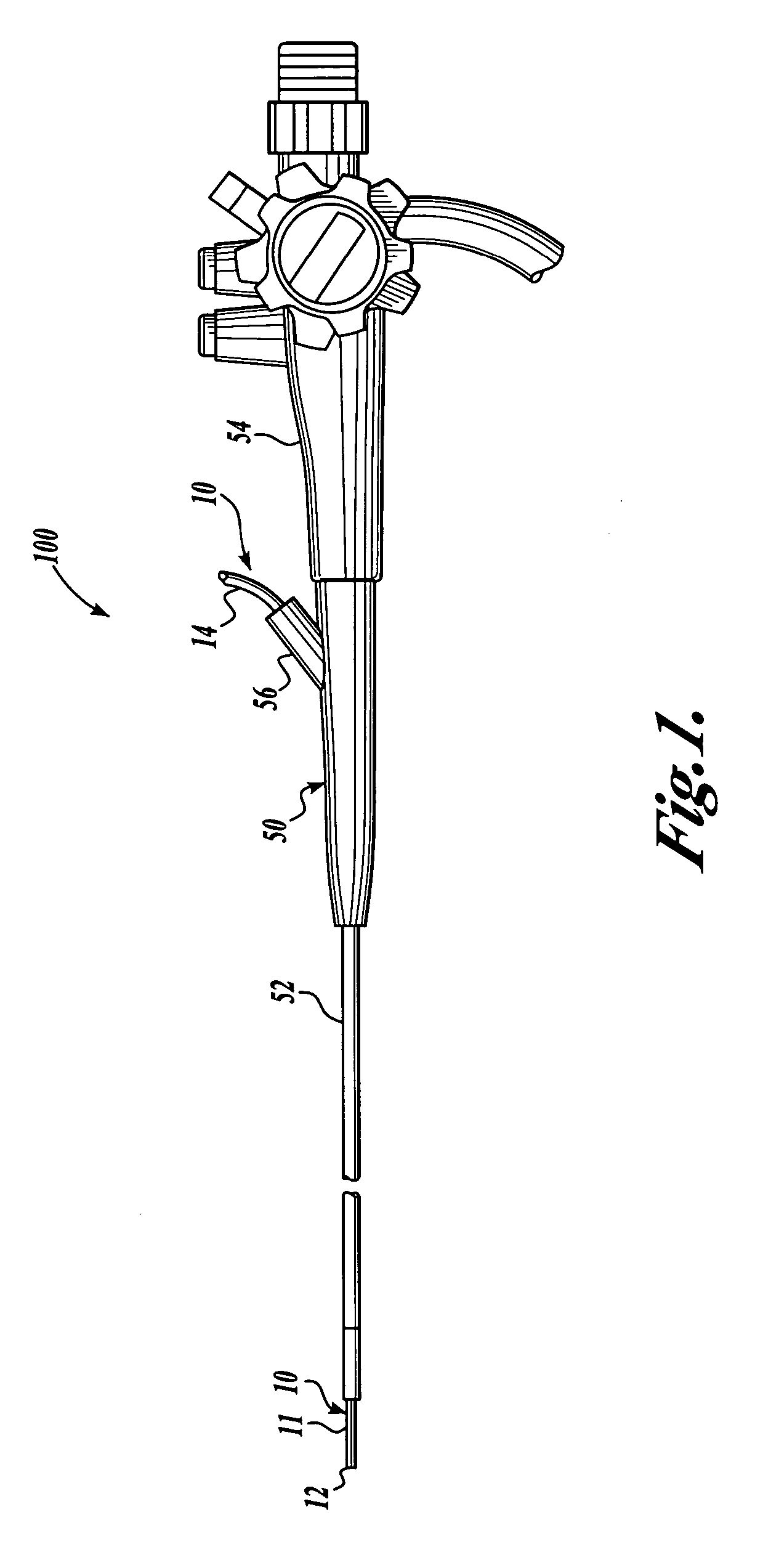

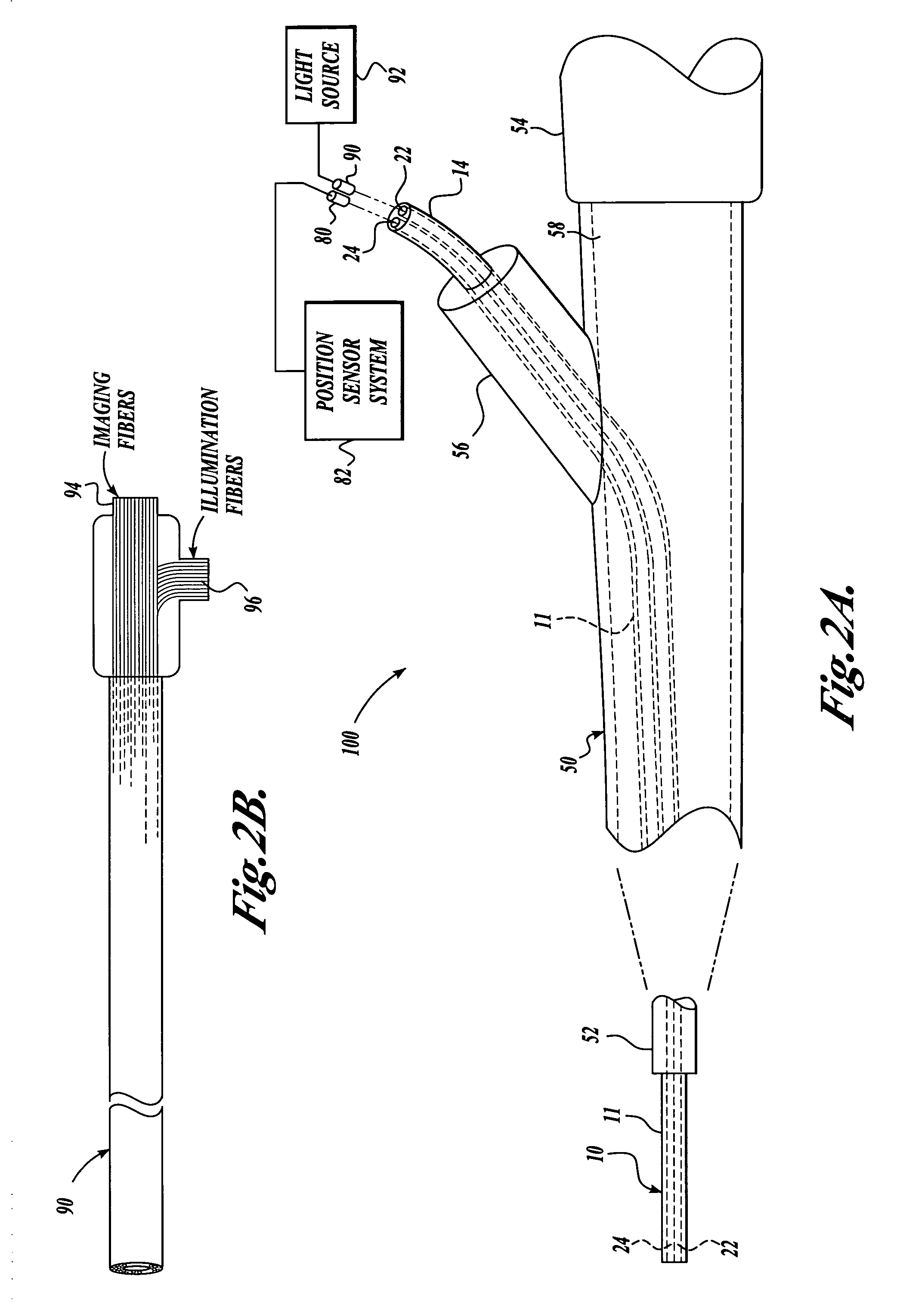

Vision catheter having electromechanical navigation

The present invention is a visualization system including a small gauge vision catheter that is designed to be stand-alone or received within an instrument channel of a larger endoscope. The vision catheter has imaging means disposable within an imaging channel, a working channel, and an electromagnetic sensor element insertable into the working channel of the catheter to provide position tracking. The working channel of the catheter also provides access for therapeutic and diagnostic tools.

Owner:BOSTON SCI SCIMED INC

Position tracking device

InactiveUS7532201B2Precision therapyOrgan movement/changes detectionSurgeryOn boardLocation tracking

A position tracking device is disclosed combining one or more optical sensors in a housing with a medical device. The medical device may be an insertion device or one that produces radiant energy. The device may utilize an on-board processor or an external processor to track position data generated by the optical sensors and correlate the treatment regime of the medical device. Alternative embodiments and methods of use are also described.

Owner:LIPOSONIX

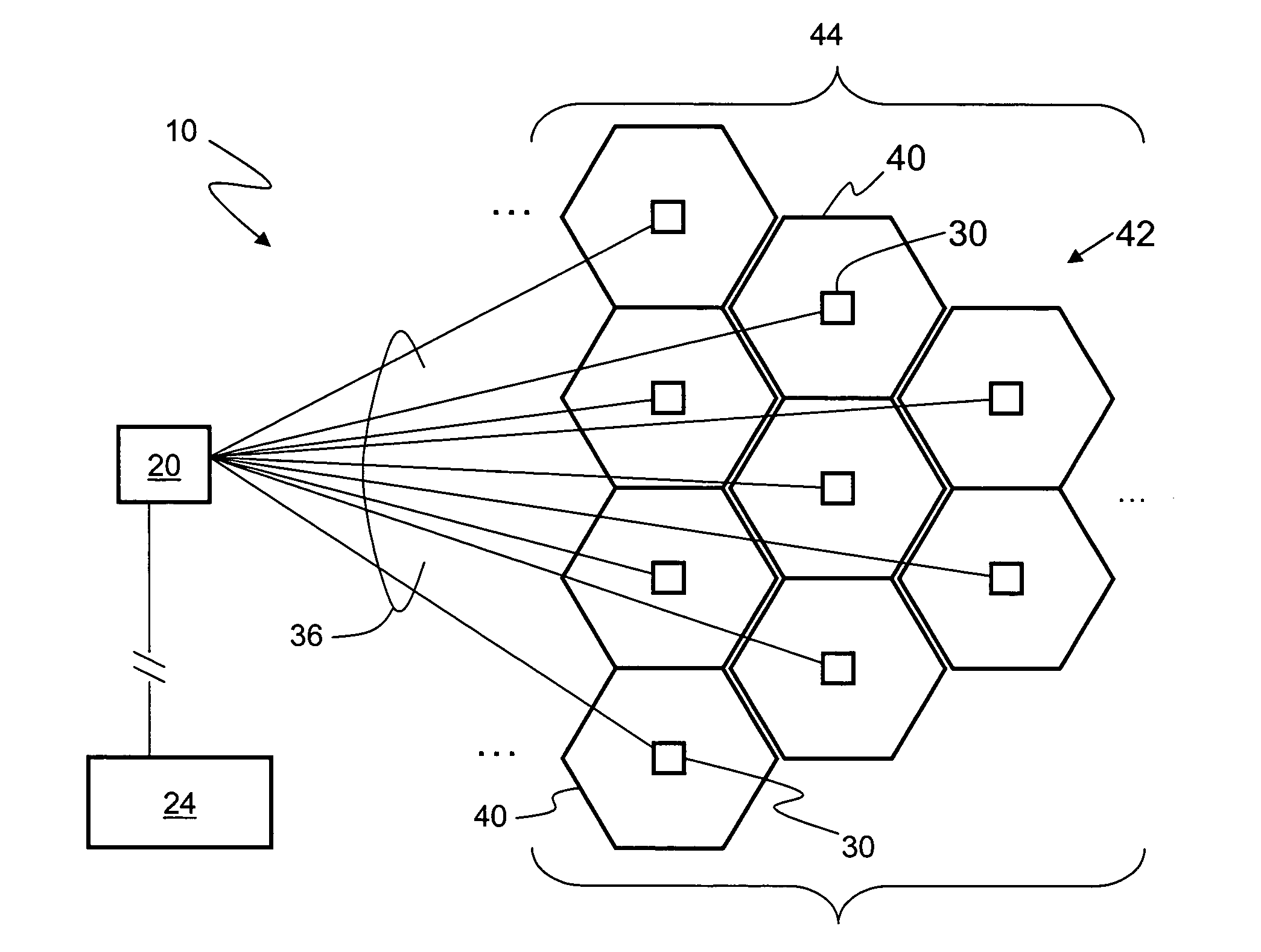

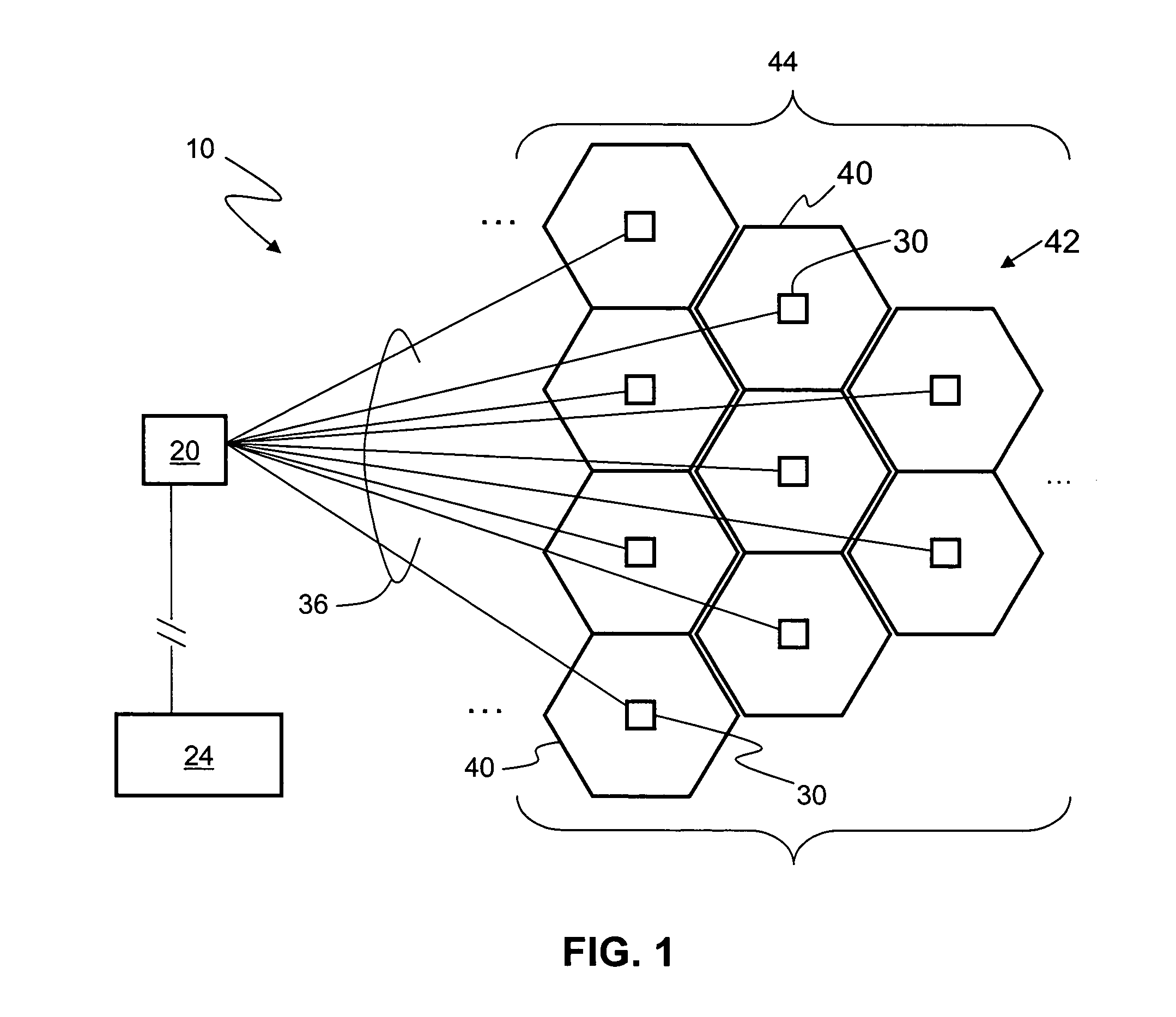

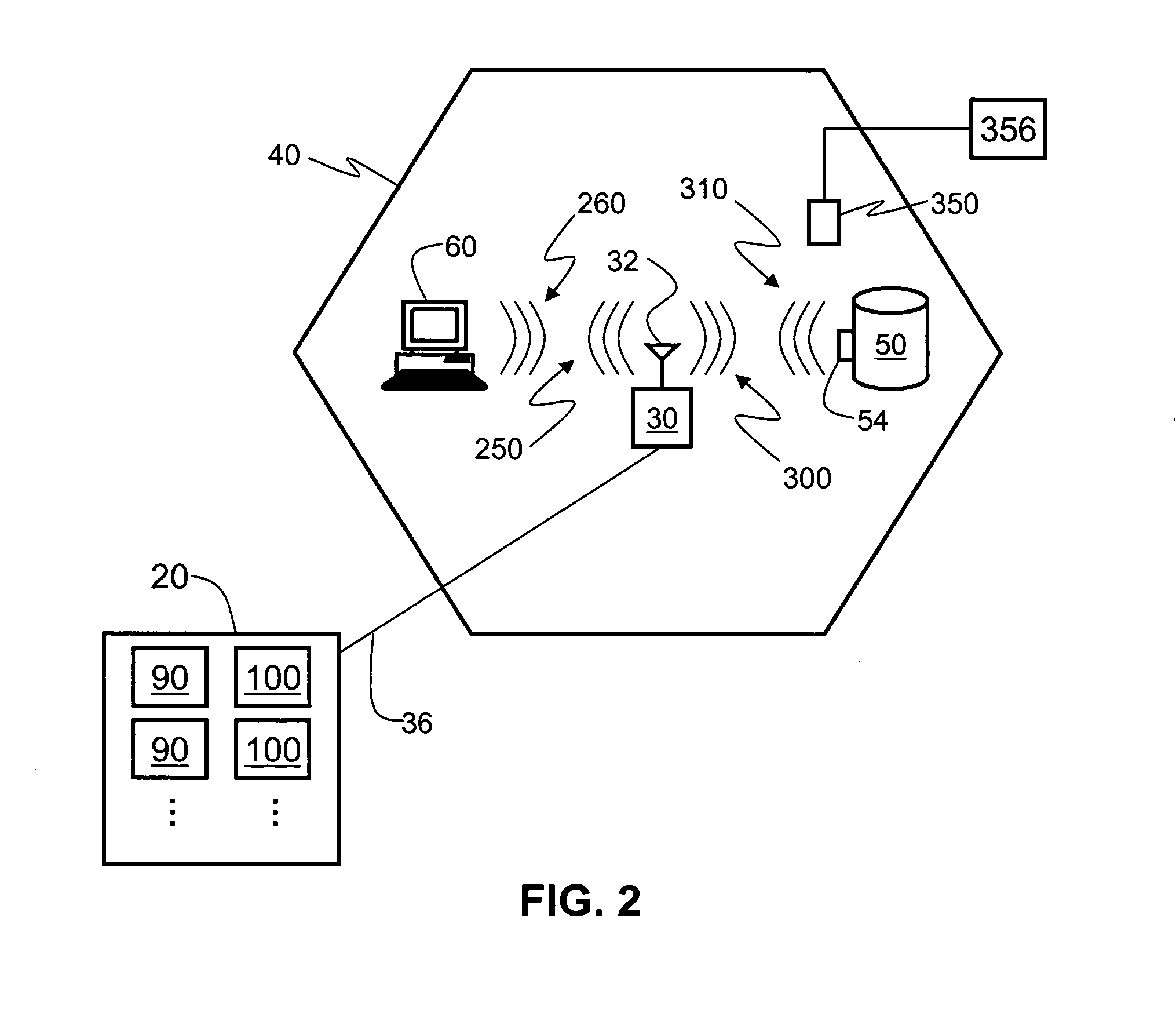

Wireless picocellular RFID systems and methods

InactiveUS20070257796A1Near-field in RFIDElectric/electromagnetic visible signallingElectronic taggingLocation tracking

The wireless radio-frequency identification (RFID) picocellular system includes a central control station optically coupled to one or more electrical-optical (E-O) access point devices that generate the individual picocells. The central control station includes service units that provide conventional wireless cellular services, and further includes one or more RFID reader units. The E-O access point devices are adapted to receive electromagnetic RFID tag signals from RFID tags within the associated picocell and transmit optical RFID tag signals to the central control station, which converts the optical RFID tag signals to electrical RFID tag signals, which are then received by the one or more RFID reader units. The system allows for large numbers of RFID tags in the picocellular coverage area to be quickly read and the information stored. The relatively small size of picocells allows for high-precision locating and position tracking of items without the need for manually scanning RFID tags with an RFID reader.

Owner:CORNING OPTICAL COMM LLC

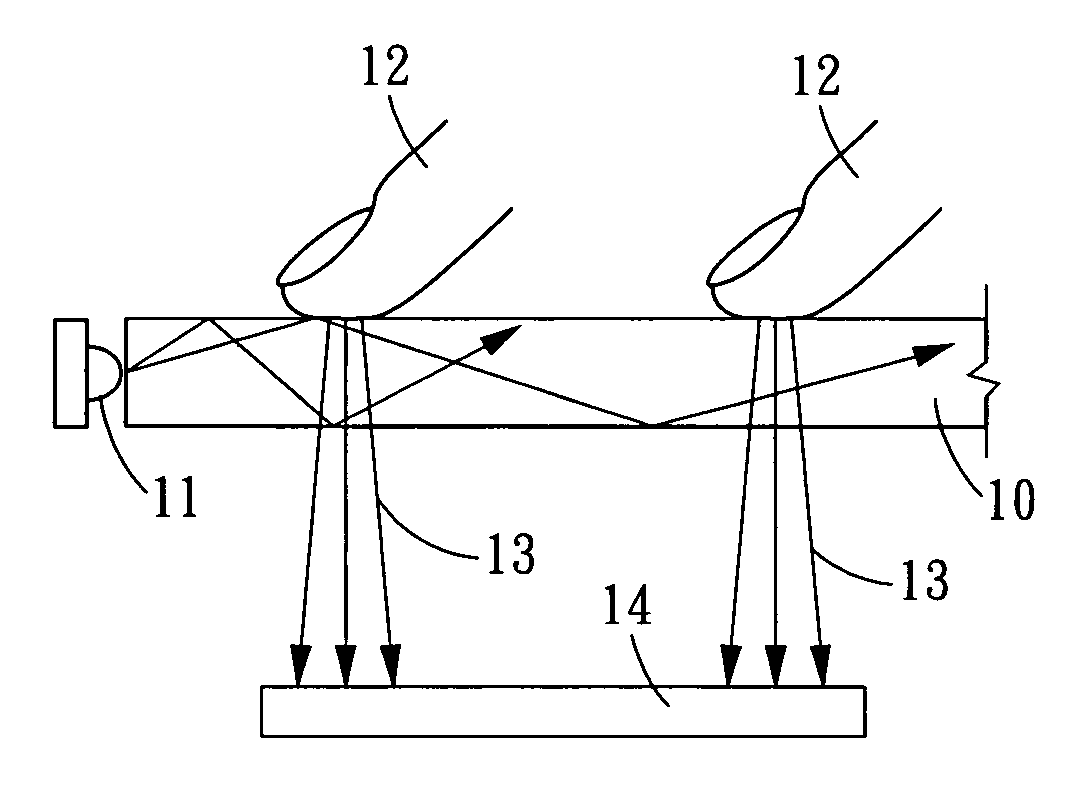

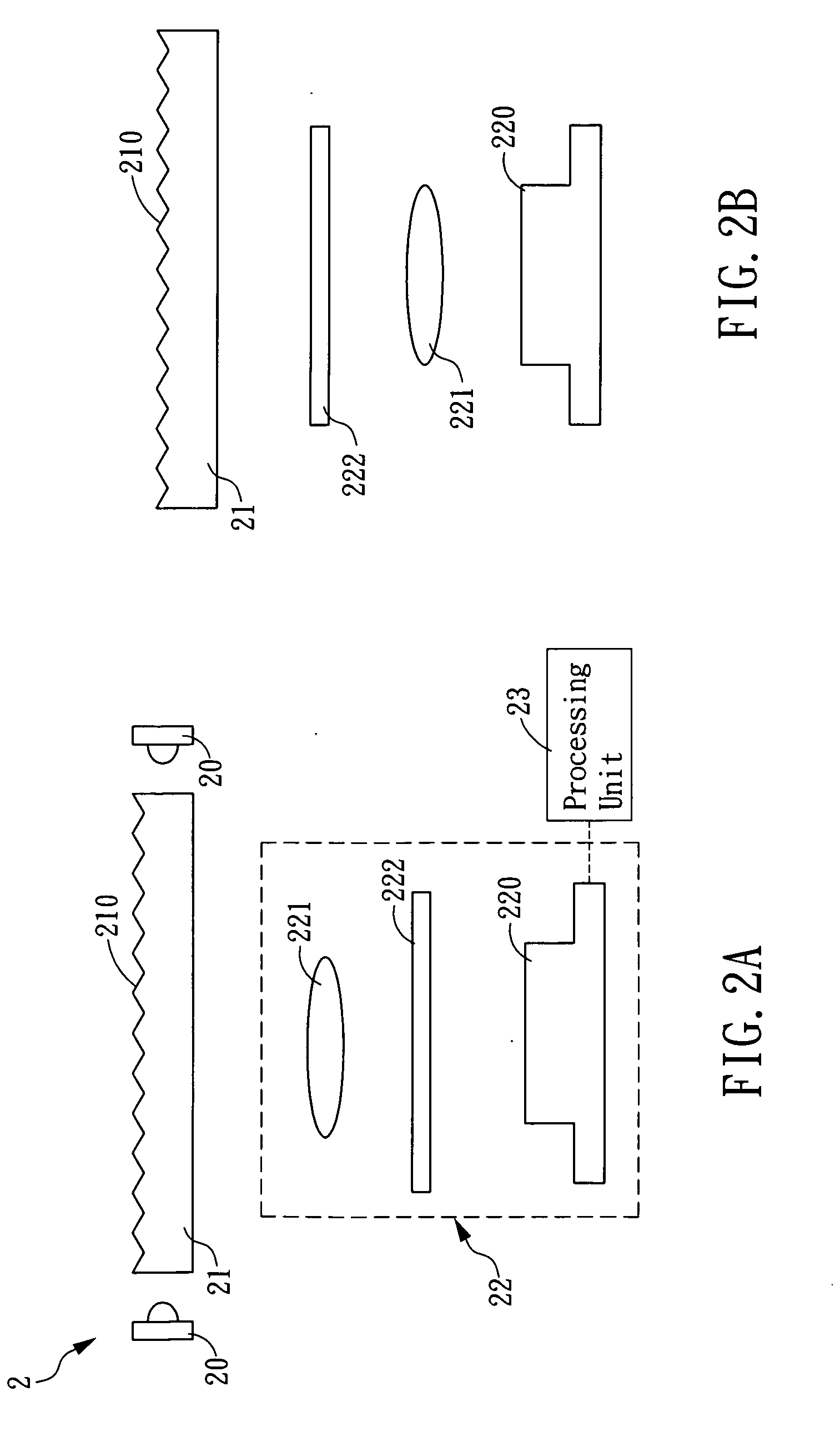

Multi-touch position tracking apparatus and interactive system and image processing method using the same

InactiveUS20090267919A1Input/output processes for data processingTotal internal reflectionImaging processing

The present invention provides a multi-touch position tracking technique and an interactive system and a multi-touch interactive image processing method using the same. In the present invention, a light guide element is designed to comprise frustrating structures to frustrate total internal reflection (TIR) so that the light beam therein can be dispersed to form a dispersed optical field distribution. The dispersed optical field is used to respond a physical relation between an object and the light guide element.

Owner:IND TECH RES INST

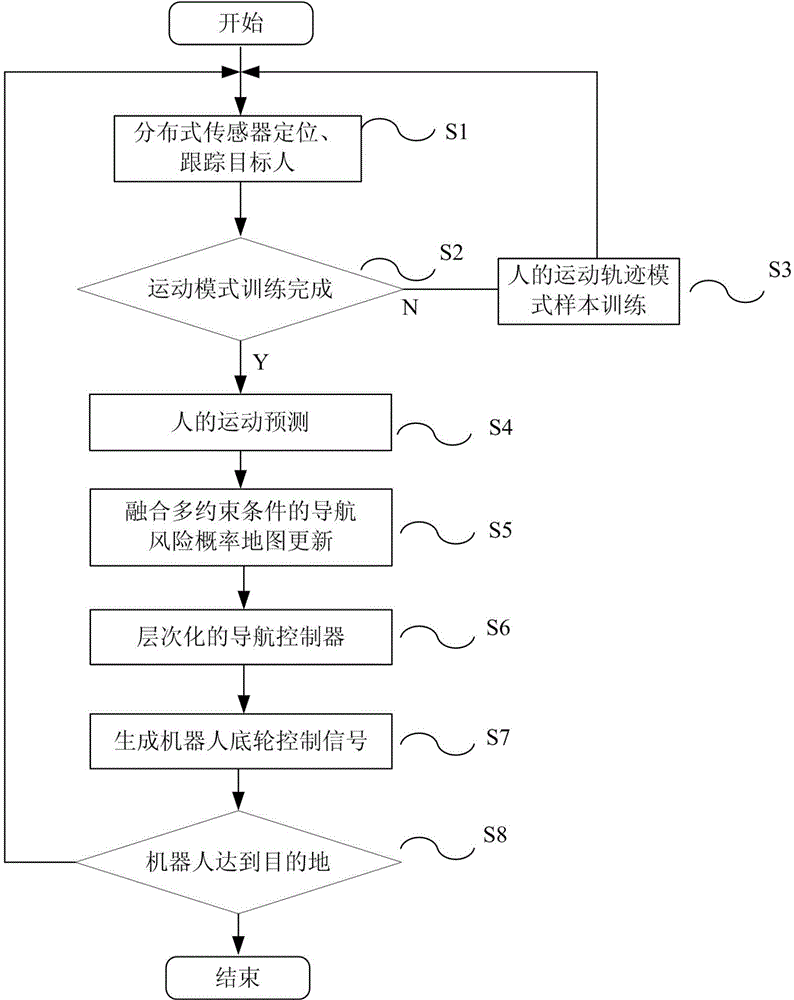

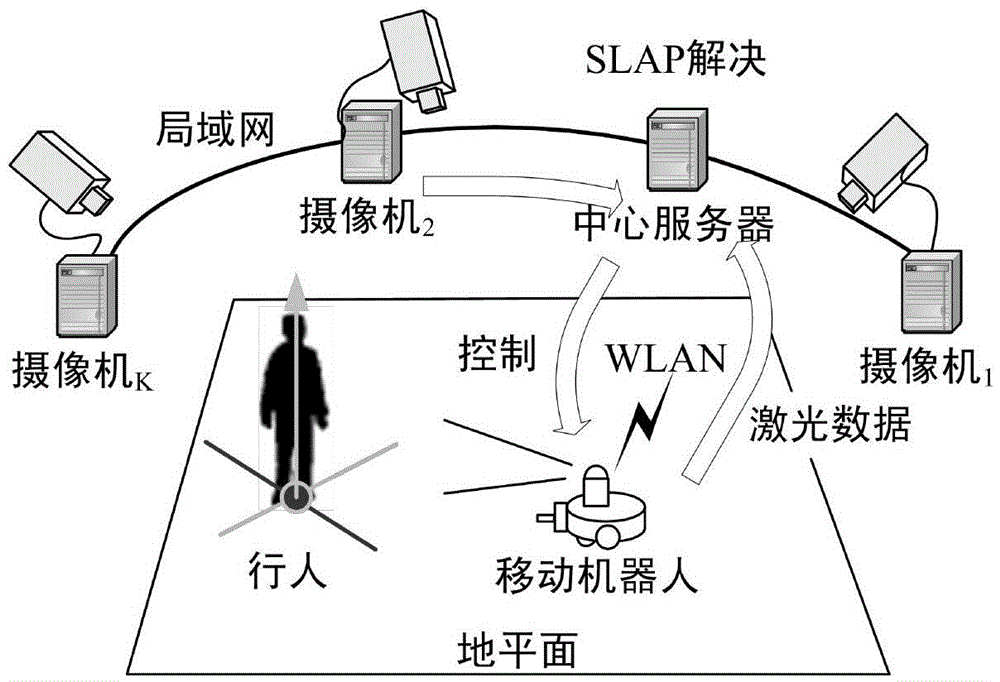

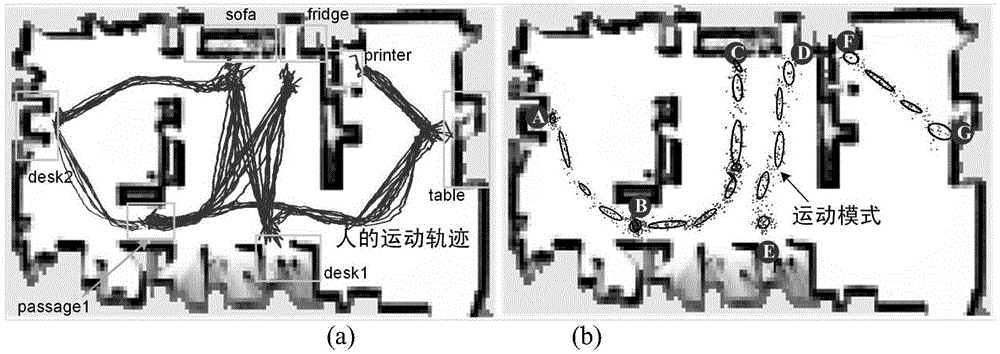

Service mobile robot navigation method in dynamic environment

InactiveCN103558856AEnsure predictabilityImprove securityPosition/course control in two dimensionsLocation trackingLaser sensor

The invention relates to the technical field of mobile robot autonomous navigation and discloses a service mobile robot navigation method in a dynamic environment. The service mobile robot navigation method in the dynamic environment includes the following steps that firstly, position tracking of people can be achieved by utilizing multiple global cameras and robot vehicle-mounted laser sensors in an indoor environment; secondly, the moving mode of people under a specific indoor environment site is trained according to collected samples, and the moving trend of people is predicated; thirdly, a current position and a predicated position of people are merged with an environment static obstacle raster map, and a navigation risk probability map is generated; fourthly, a robot navigation movement controller of a global route planning-local obstacle avoidance control gradational structure is adopted to control robot navigation behavior, and safe and efficient navigation behavior of a robot under a complex dynamic environment where the robot coexists with people is ensured through controlling.

Owner:SOUTHEAST UNIV

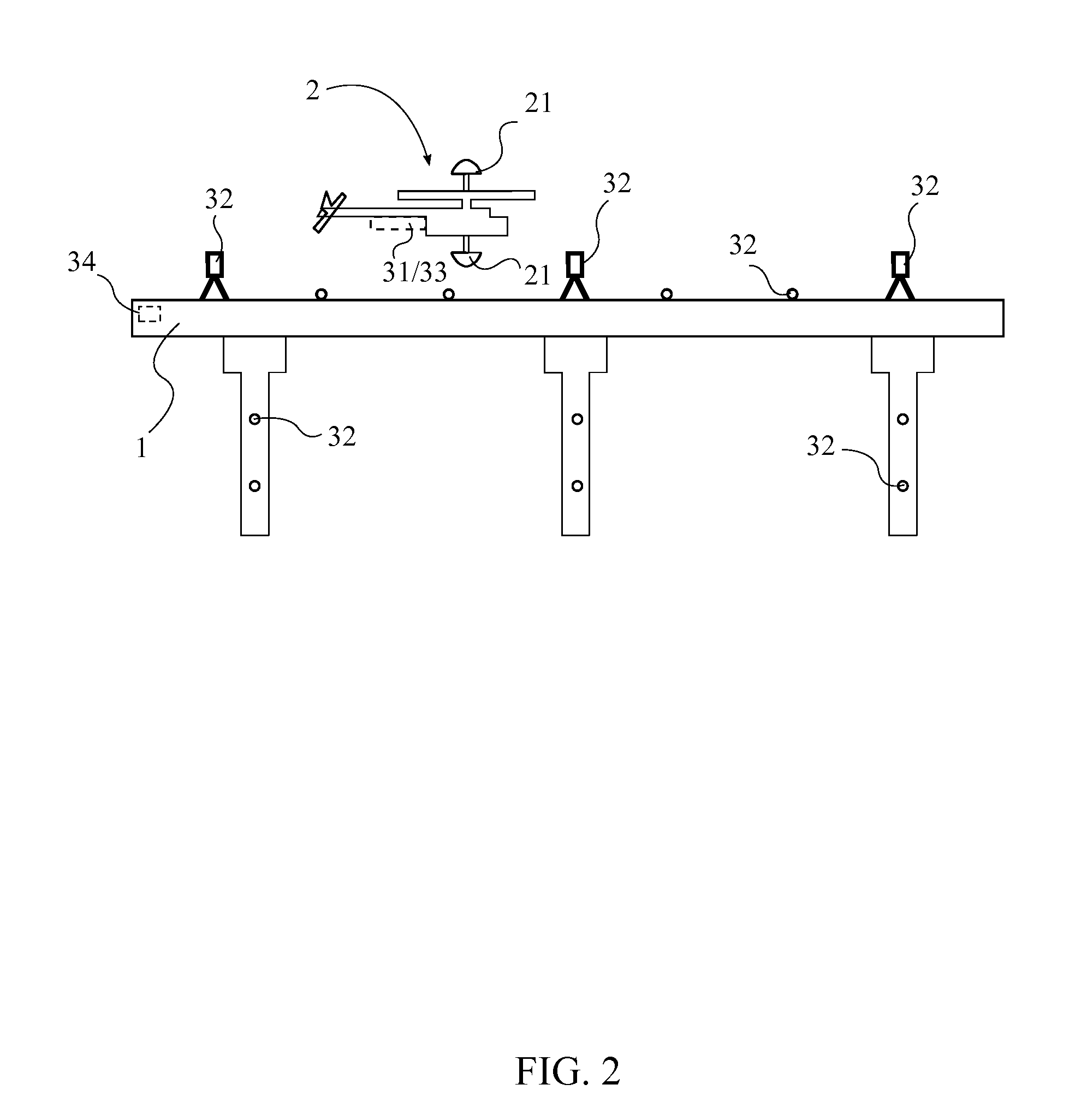

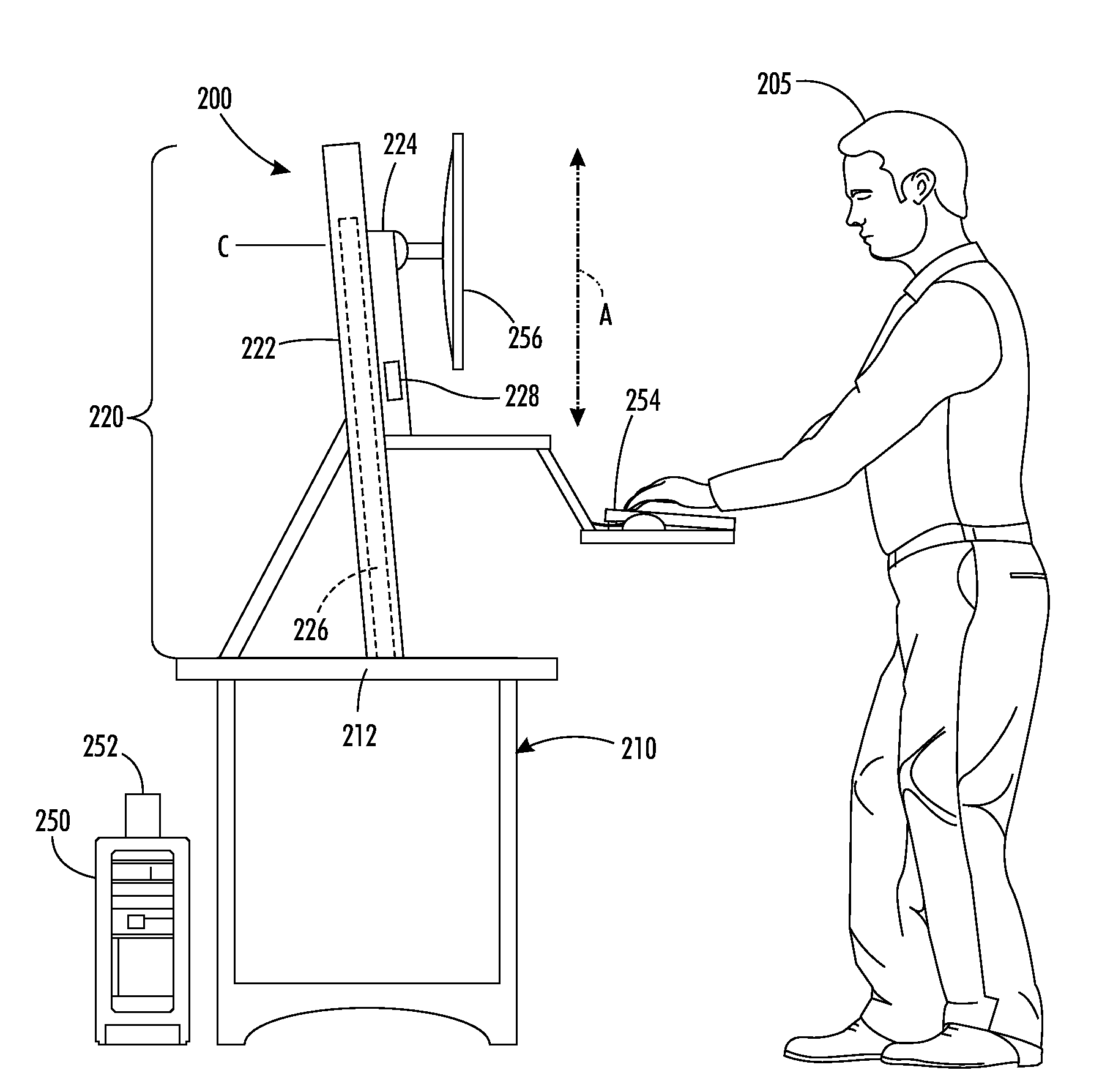

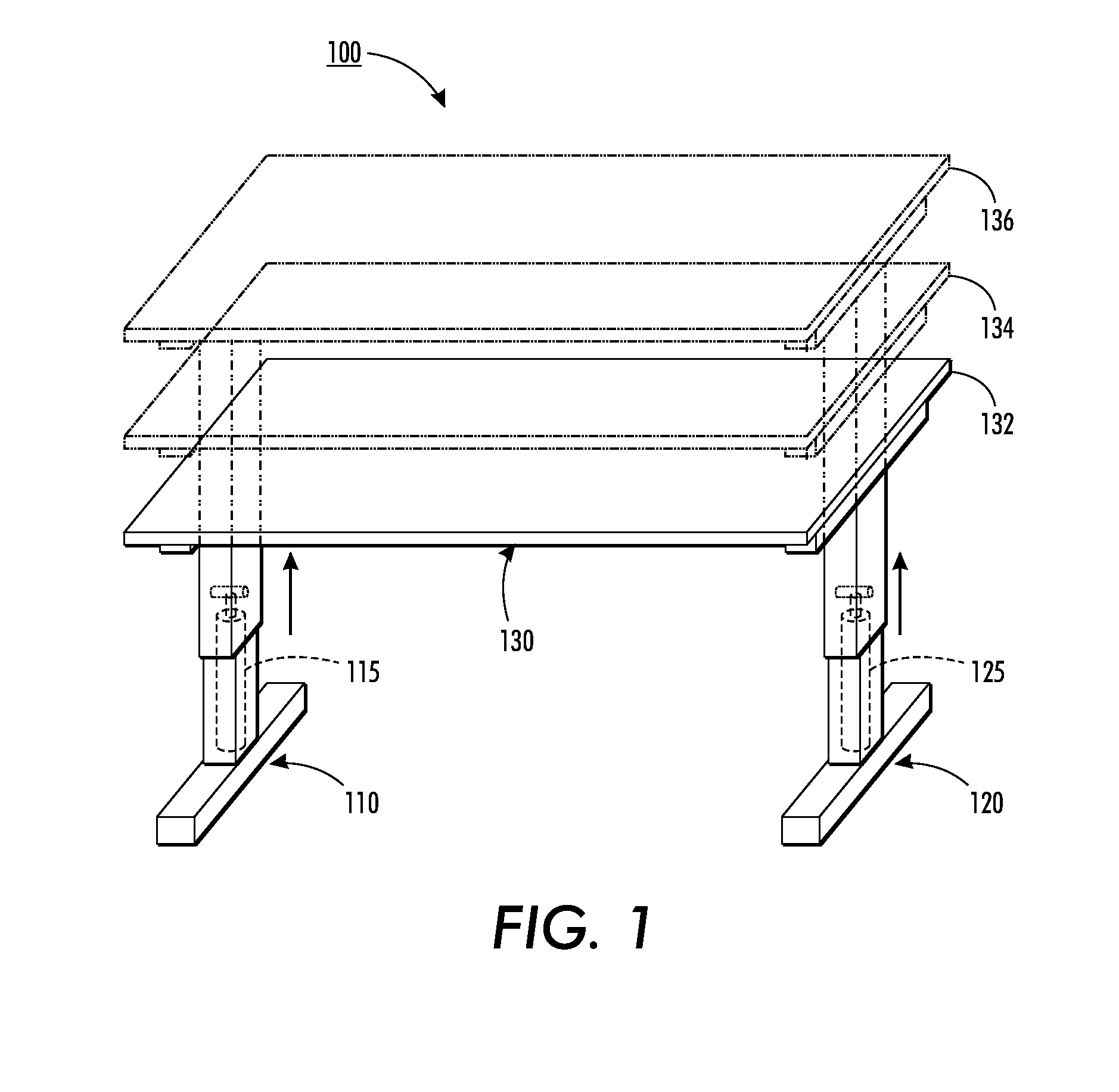

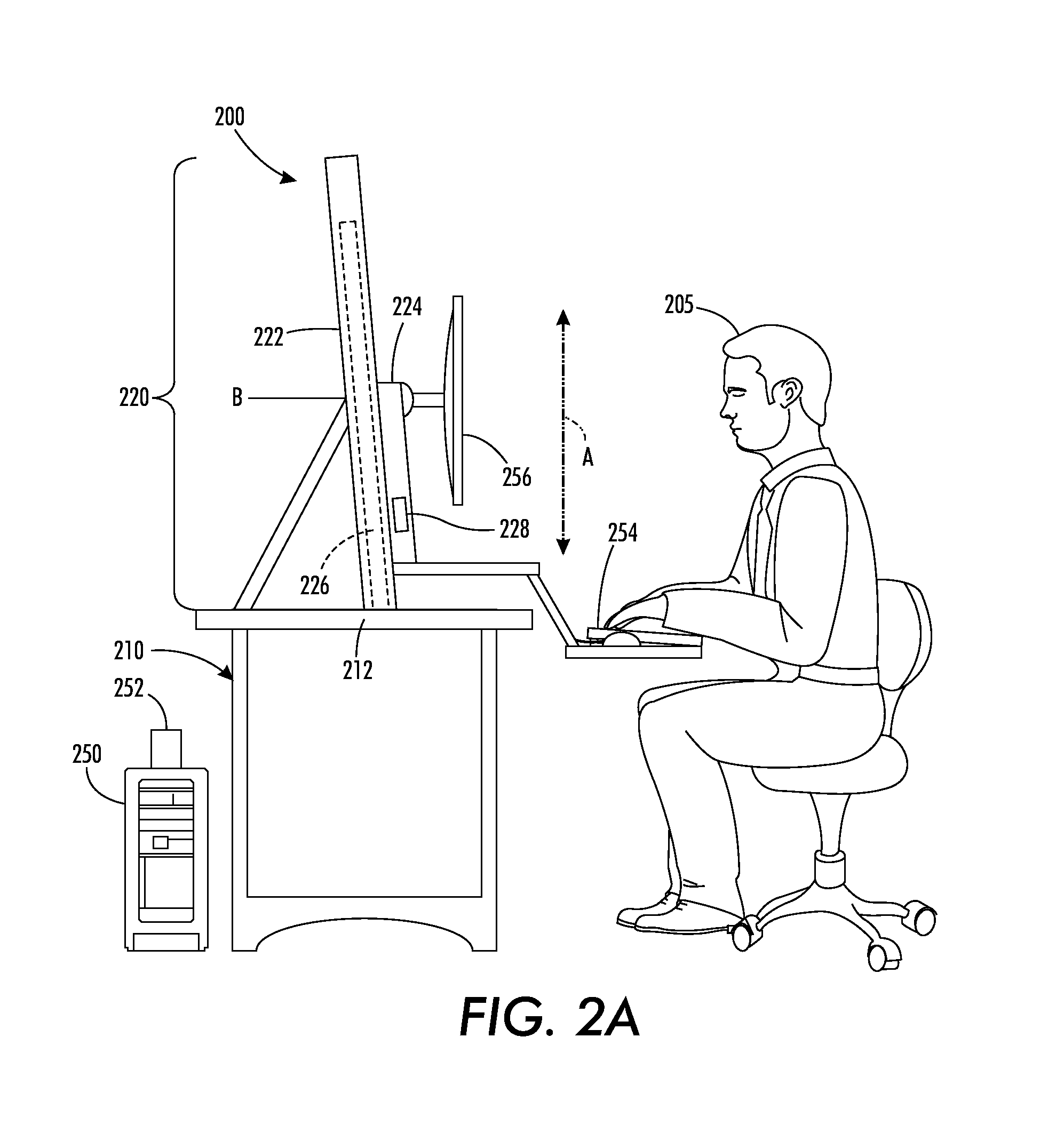

Systems and methods for implementing automated workstation elevation position tracking and control

ActiveUS20140137773A1Accurately tracks timeRealize automatic adjustmentOffice tablesOffice automationAutomatic controlStanding Positions

A system and method are provided for implementing an automated workstation elevation position tracking and control scheme. Software running on the user's computer generates reminders and / or to forces an individual to periodically readjust the height of the workstation in a manner that promotes standing while at work. A current position, and an elapsed time that the workstation has been at the current position, is detected with an objective of providing pre-programmed routine or random automated reminders to a user to change the current position of the workstation from one elevation state to the other. The software tracks the percent of time that a user is standing and optionally compares this with a pre-defined goal. Automatic control via the user workstation, of workstation elevator actuators is provided in a manner that makes it easier, or otherwise unavoidable, for the user to initiate repositioning from a sitting to a standing position.

Owner:MILLERKNOLL INC

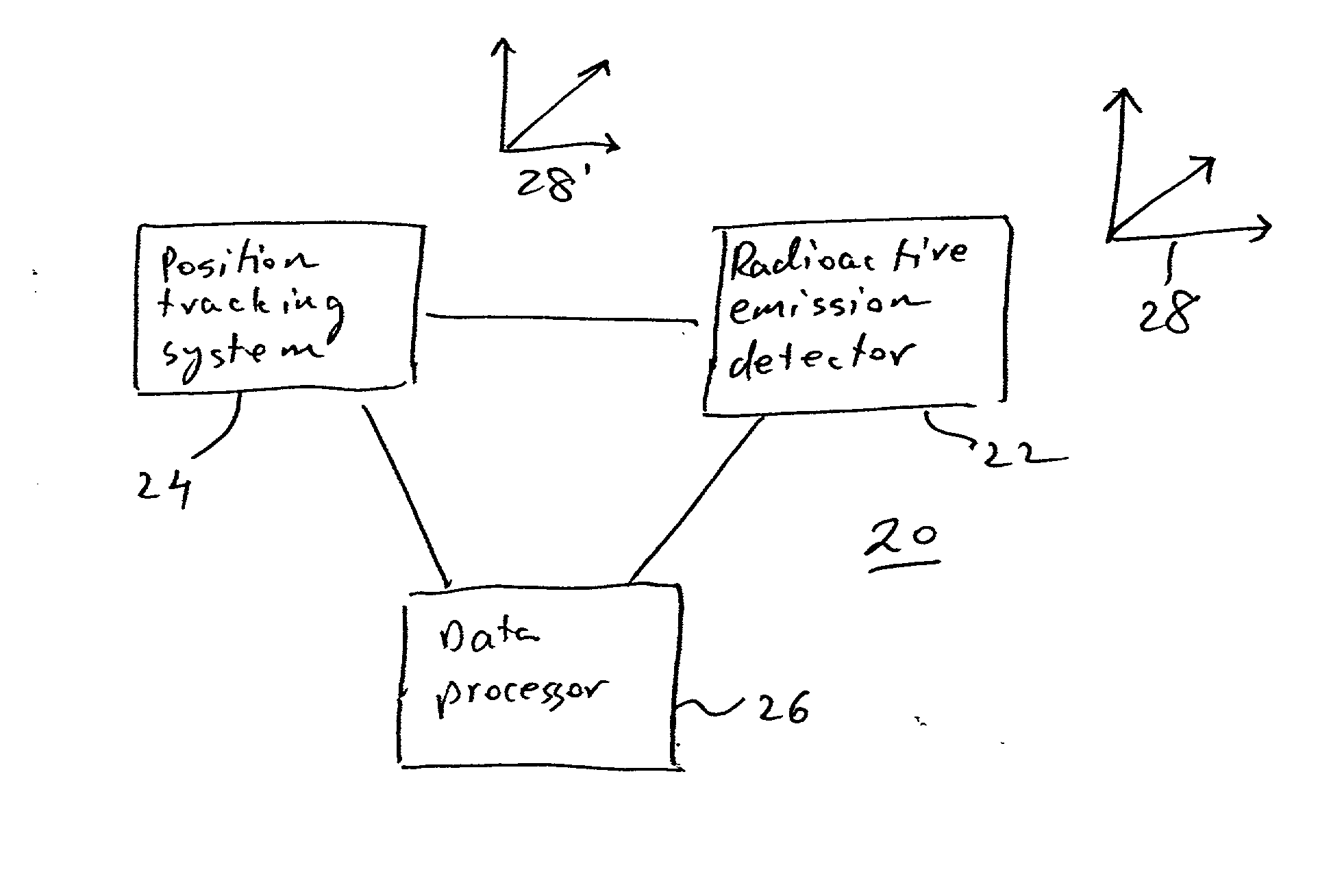

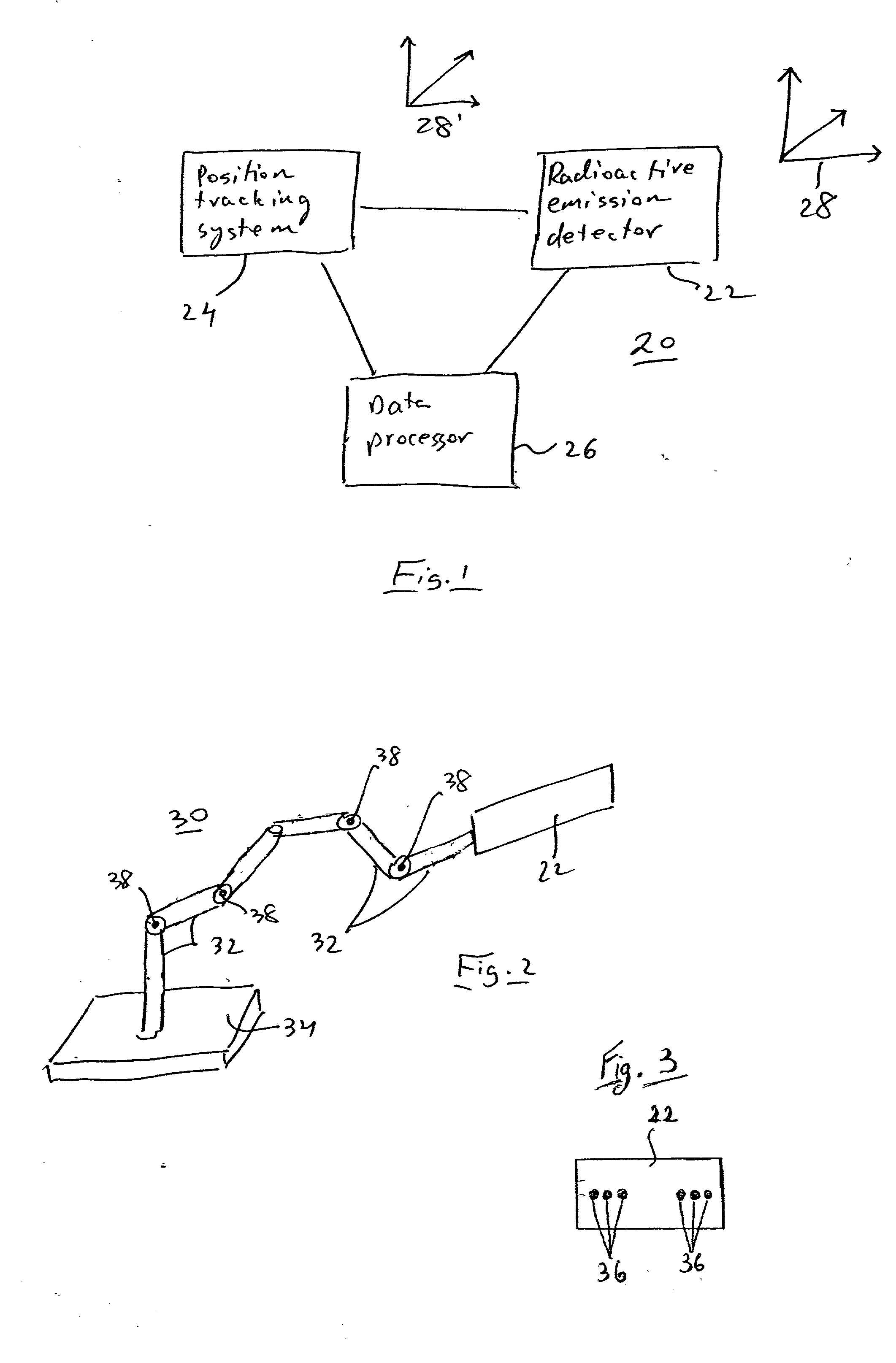

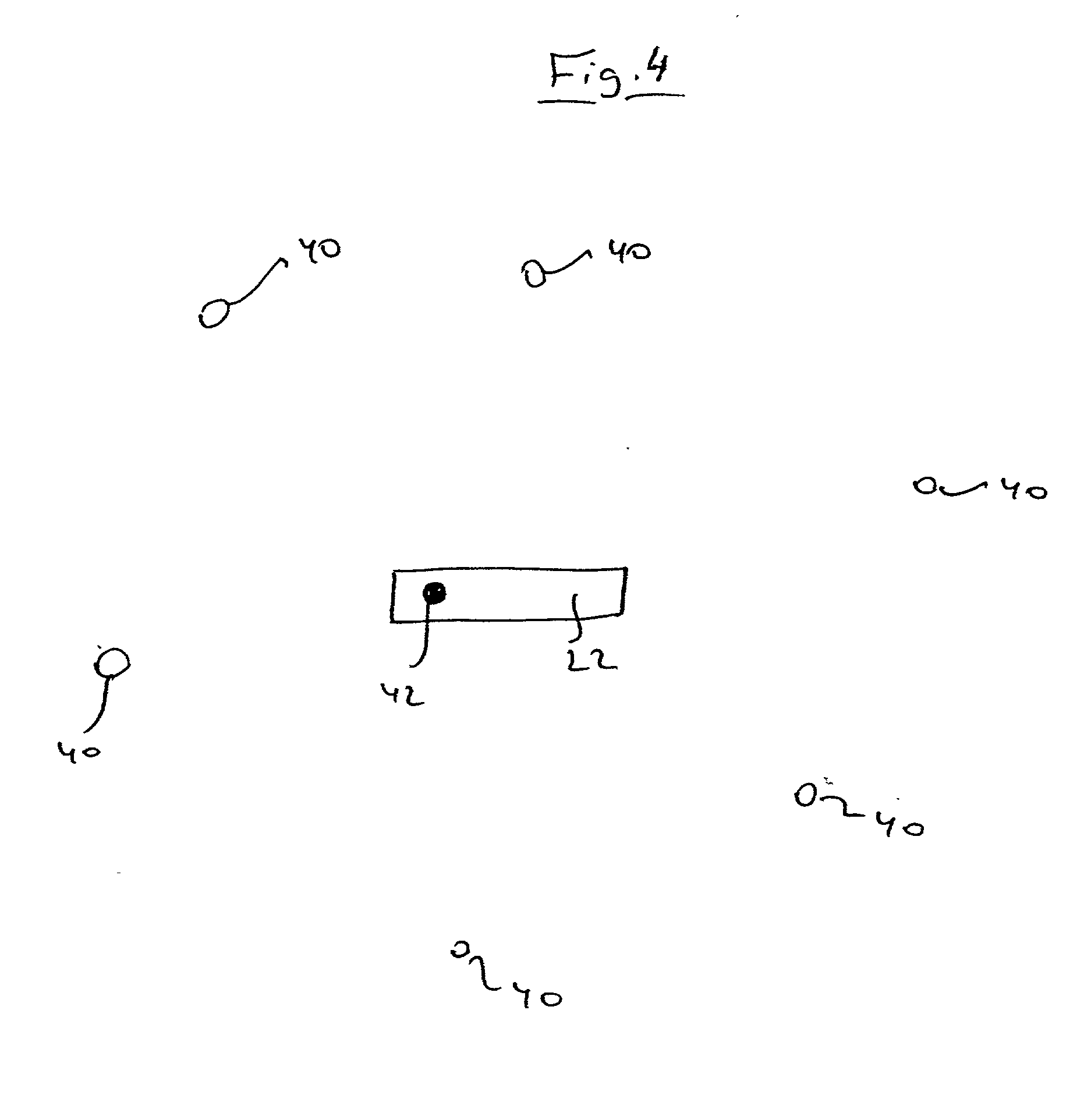

Radioactive emission detector equipped with a position tracking system and utilization thereof with medical systems and in medical procedures

ActiveUS20050055174A1Surgical navigation systemsDigital computer detailsLocation trackingEngineering

a system for calculating a position of a radioactivity emitting source in a system-of-coordinates, the system comprising (a) a radioactive emission detector; (b) a position tracking system being connected to and / or communicating with the radioactive emission detector; and (c) a data processor being designed and configured for receiving data inputs from the position tracking system and from the radioactive emission detector and for calculating the position of the radioactivity emitting source in the system-of-coordinates.

Owner:SPECTRUM DYNAMICS MEDICAL LTD

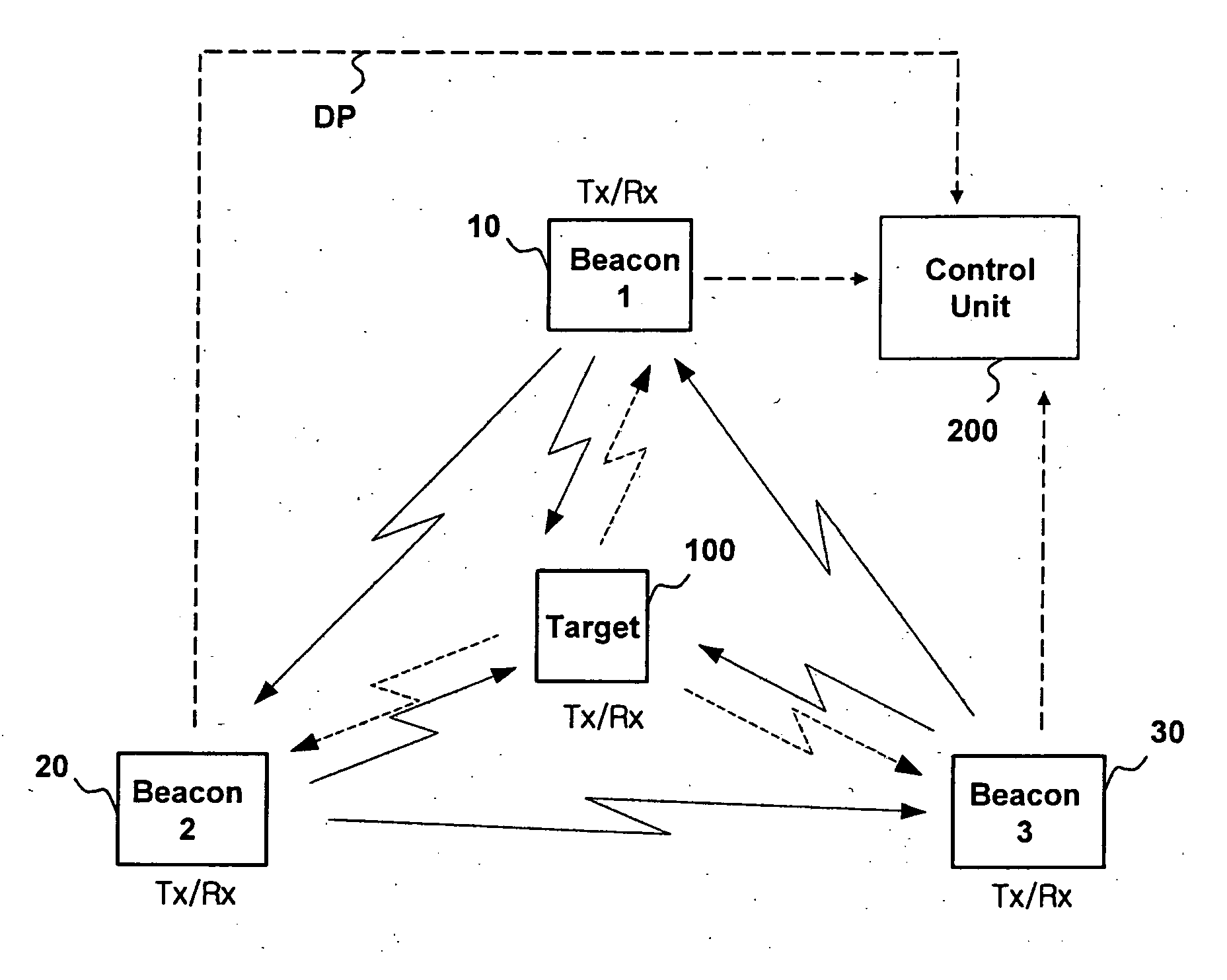

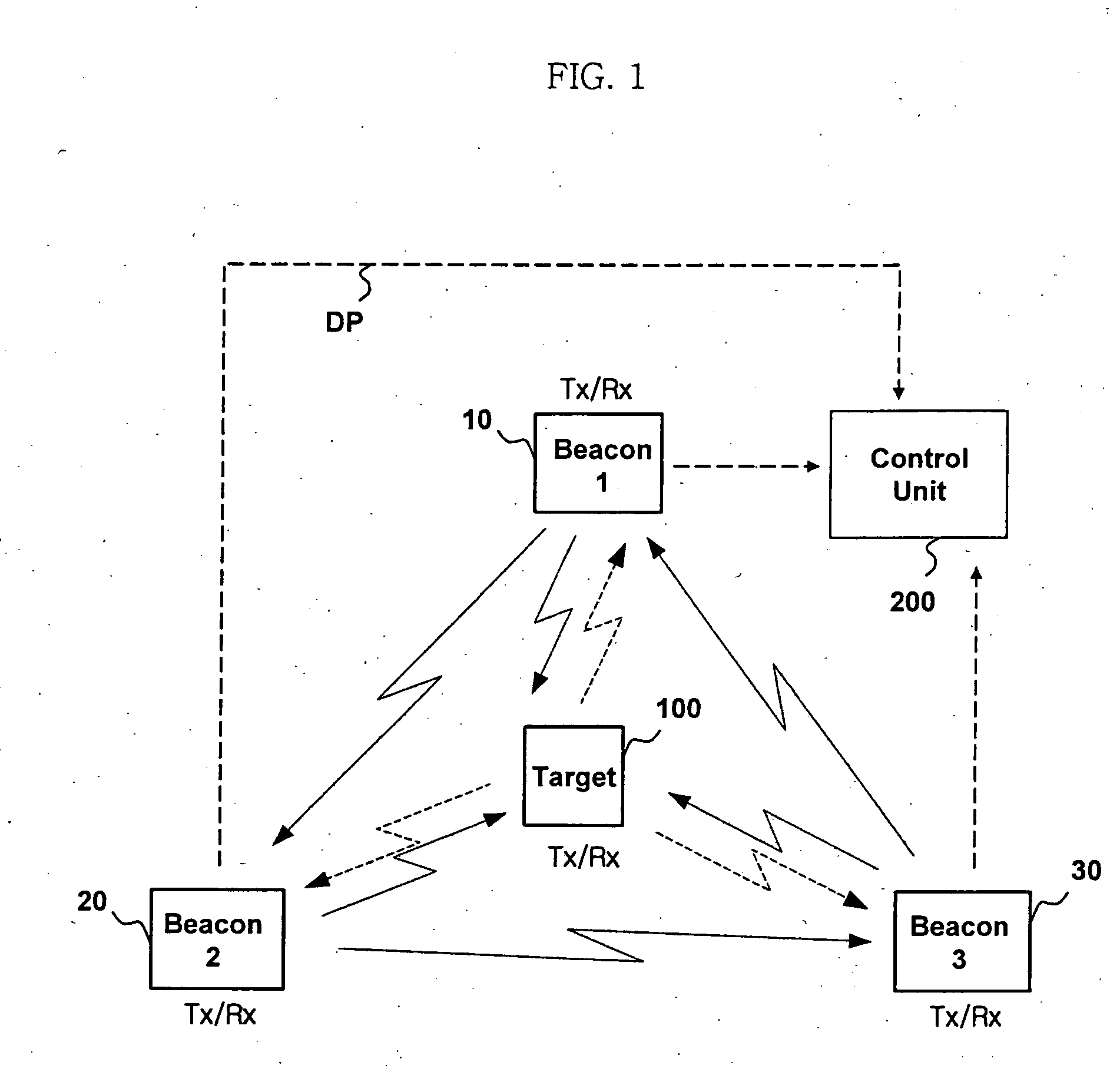

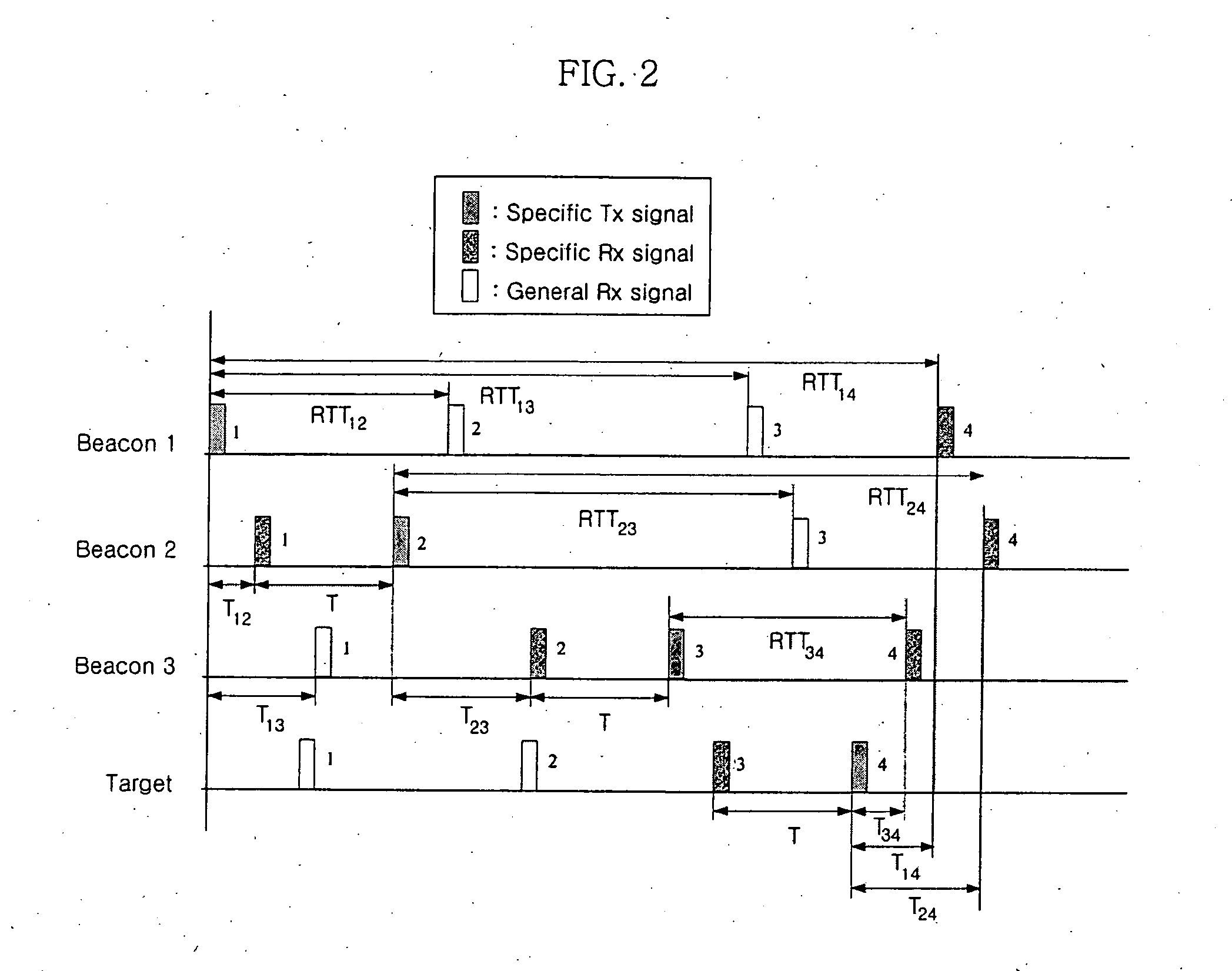

System and method for asynchronous wireless positioning by ordered transmission

ActiveUS20050282558A1High-precision position trackingPrecise time synchronizationRadio wave direction/deviation determination systemsBeacon systemsEngineeringWireless positioning

Disclosed is a wireless positioning system and method that can perform a high-precision position tracking. The wireless positioning system includes a target device that is an object of wireless positioning, beacon devices and a processing unit. The beacon devices transmits wireless signals and sense reception time points of the wireless signals transmitted from the other beacon devices and the target device and received at time points after the transmission of the wireless signal. The target device receives the wireless signal transmitted from at least one of the beacon devices, and then transmits the wireless signal to the beacon devices. The processing unit obtains the position of the target device by calculating distances between the beacon devices and the target device using information about the reception time points of the wireless signals sensed by the respective beacon devices.

Owner:KOREA ELECTROTECH RES INST

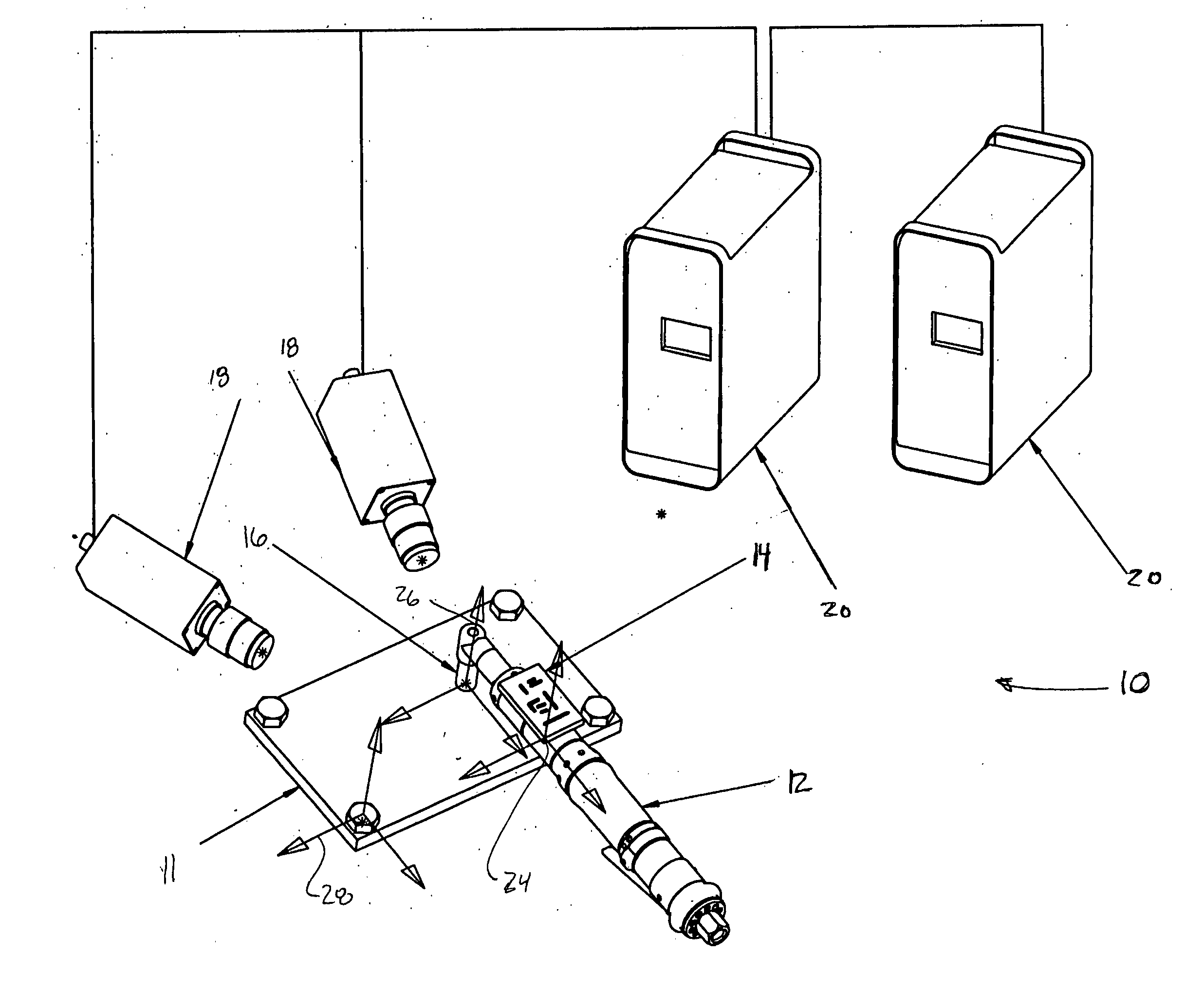

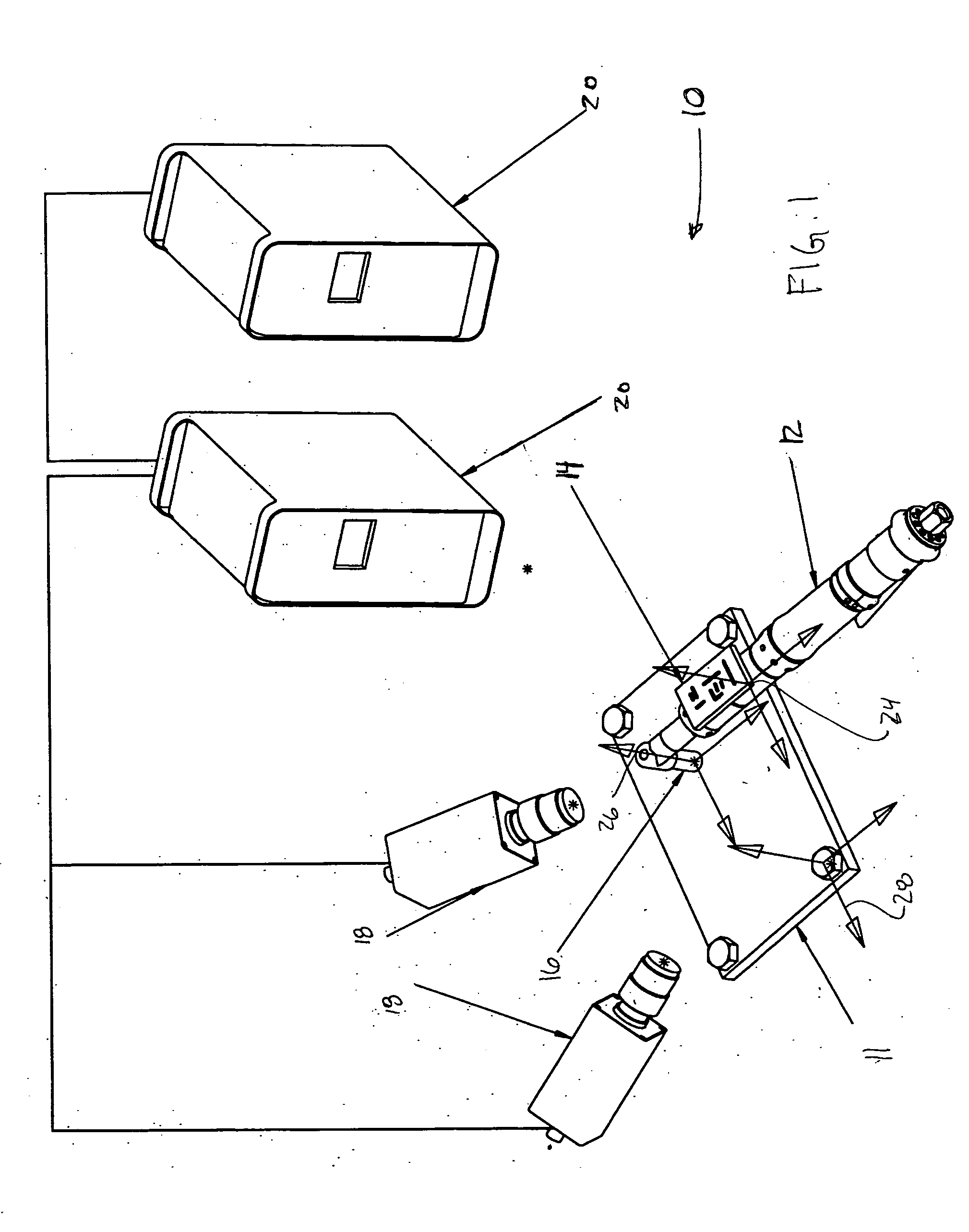

Vision-based position tracking system

The invention is directed to a tracking system for tracking the use of an object on a work piece within a predetermined work space comprising a target, at least one video imaging source and a computer. The target is attached to the object and calibrated to derive an “Object Tracking Point”. Each target has a predetermined address space and a predetermined anchor. At least one video imaging source is arranged such that the work piece is within the field of view. Each video imaging source is adapted to record images within its field of view. The computer is for receiving the images from each video imaging source and comparing the images with the predetermined anchor and the predetermined address, calculating the location of the target and the tool attached thereto in the work space relative to the work piece.

Owner:RADIX CO LTD

GPS position tracking method with variable updating rate for power conservation

ActiveUS20060211430A1Low possible update rateReduce power consumptionPosition fixationSubstation equipmentMaximum errorUser input

A system and method in which the position update rate is adaptively modified, based on previous position measurements. By adjusting the update rate based on velocity predictions from two or more position fixes, a lower update rate may be used without exceeding the maximum error. Lowering the update rate reduces power consumption in the UE, providing longer battery operation. The updating method may comprise periodically repeating the velocity prediction and periodically adjusting the update rate responsive thereto. The update rate may be adjusted using additional information such as an acceleration prediction, a minimum update rate, or a preferred error. In some embodiments a model for user movement may be used to provide more accurate predictions, for example, stationary, walking, jogging, city driving, and freeway driving. The updating method may comprise receiving user input regarding the maximum position error.

Owner:QUALCOMM INC

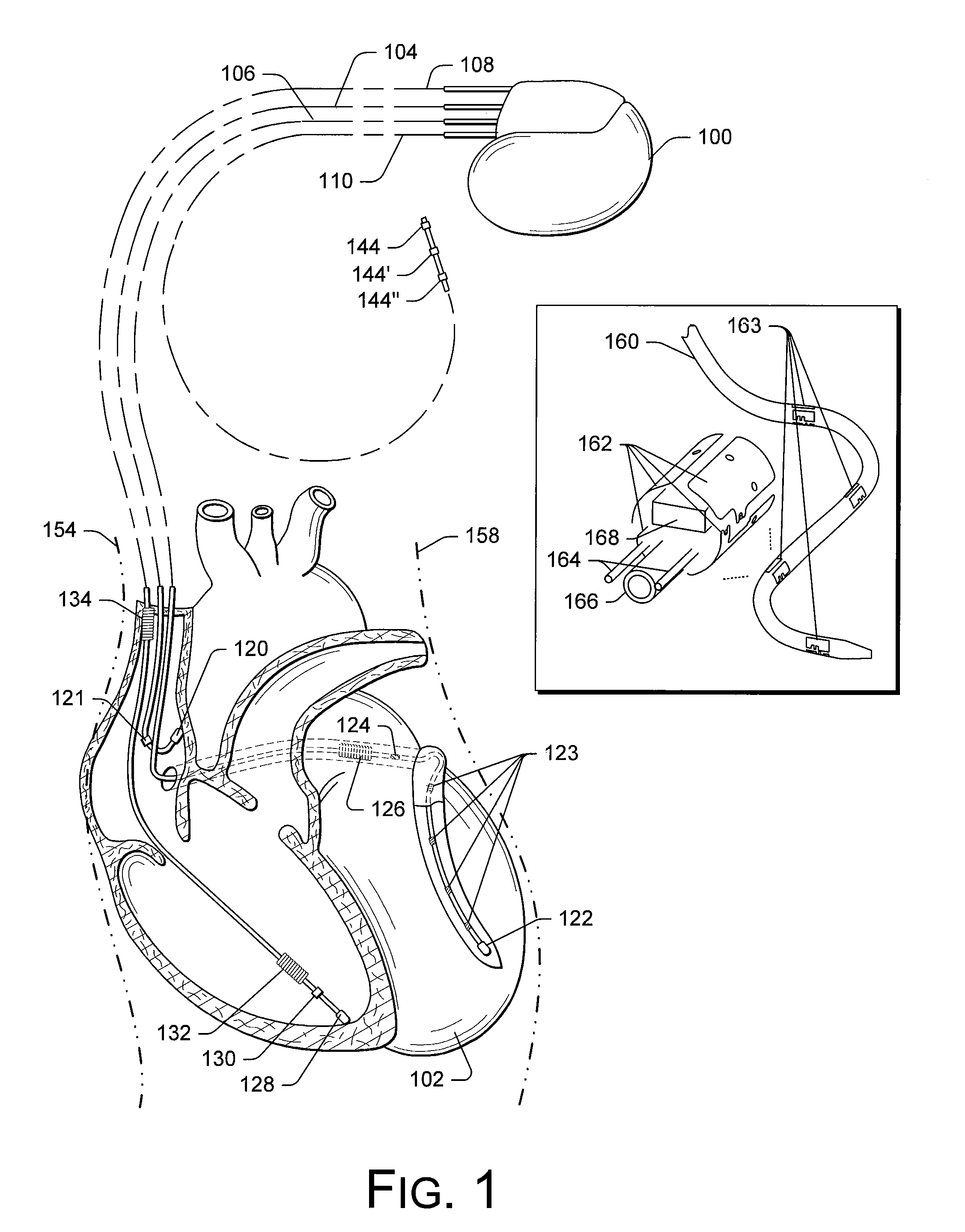

Cardiac Resynchronization Therapy Optimization Using Vector Measurements Obtained From Realtime Electrode Position Tracking

An exemplary method includes selecting a first pair of electrodes to define a first vector and selecting a second pair of electrodes to define a second vector; acquiring position information during one or more cardiac cycles for the first and second pairs of electrodes wherein the acquiring comprises using each of the electrodes for measuring one or more electrical potentials in an electrical localization field established in the patient; and determining a dyssynchrony index by applying a cross-covariance technique to the position information for the first and the second vectors. Another method includes determining a phase shift based on the acquired position information for the first and the second vectors; and determining an interventricular delay based at least in part on the phase shift.

Owner:PACESETTER INC

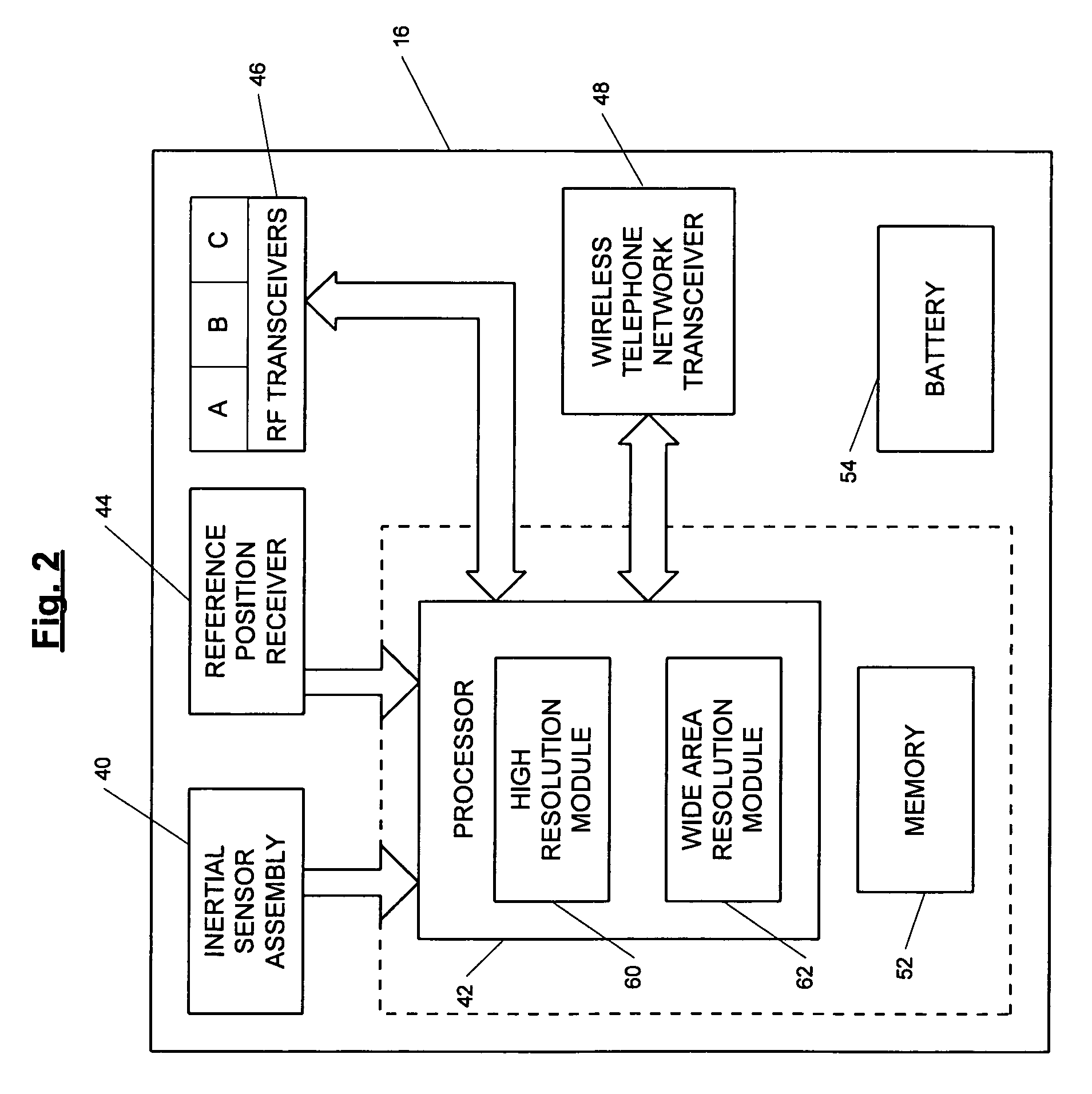

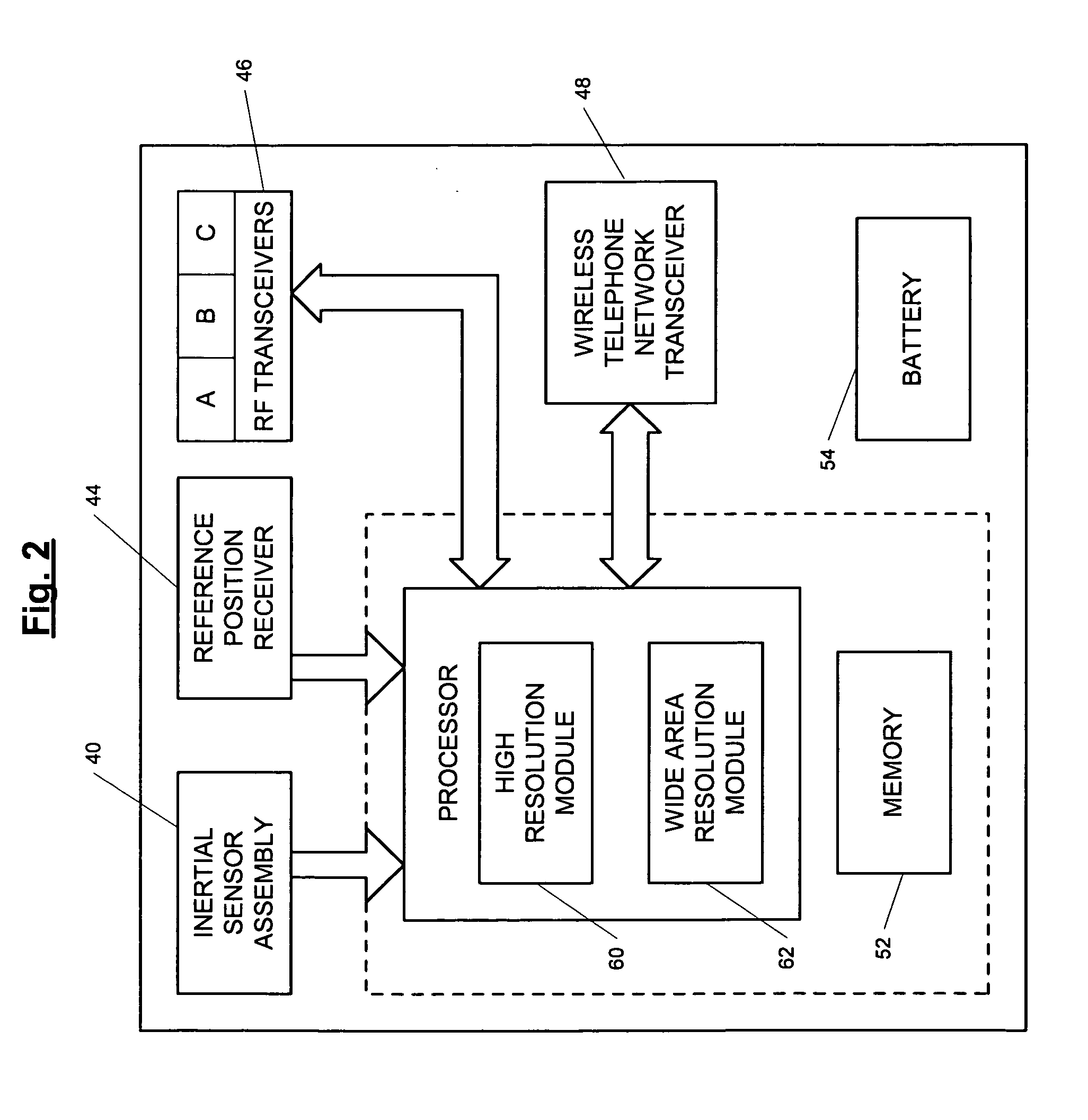

Position-tracking system

ActiveUS7236091B2High position resolutionImprove accuracyRoad vehicles traffic controlElectric/electromagnetic visible signallingObject basedTransceiver

A position-tracking system for tracking the position of an object is disclosed. According to various embodiments, the tracking system includes a tracking device that is connected to or otherwise affixed to the object to be tracked. The tracking device may include, among other things, an inertial sensor assembly, radio transceivers and a processor. The position tracking system may also include a host processing system that is in communication with the tracking device. The position tracking system may provide variable-resolution position information based on the environment in which the object is moving. In a “wide resolution” area, the system may compute a general position for the object based on a wireless telephone network Cell-ID / map correlation architecture. In a high-resolution area, greater position resolution may be realized from the combination of a wireless aiding system and inputs from the inertial sensors. In the high-resolution mode, the system may exploit distinct patterns of motion that can be identified as motion “signatures” that are characteristic of certain types of motion. Kinematic (or object movement) models may be constructed based on these motion signatures and the position tracking system may estimate the state of the object based on the kinematic model for the current mode of the object. Adaptive and cascaded Kalman filtering may be employed in the analysis to more accurately estimate the position and velocity of the object based on the motion pattern identified.

Owner:PINC SOLUTIONS

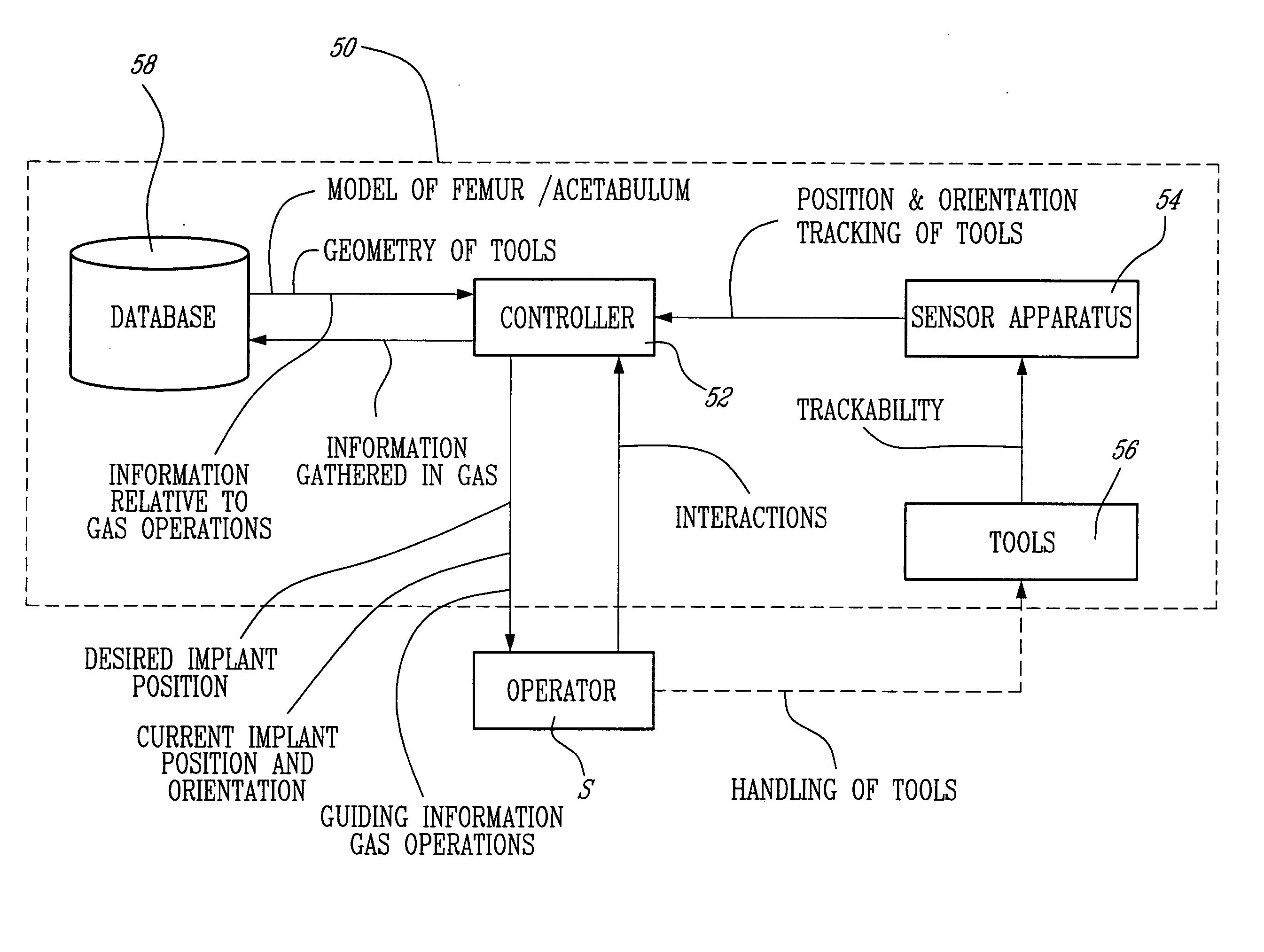

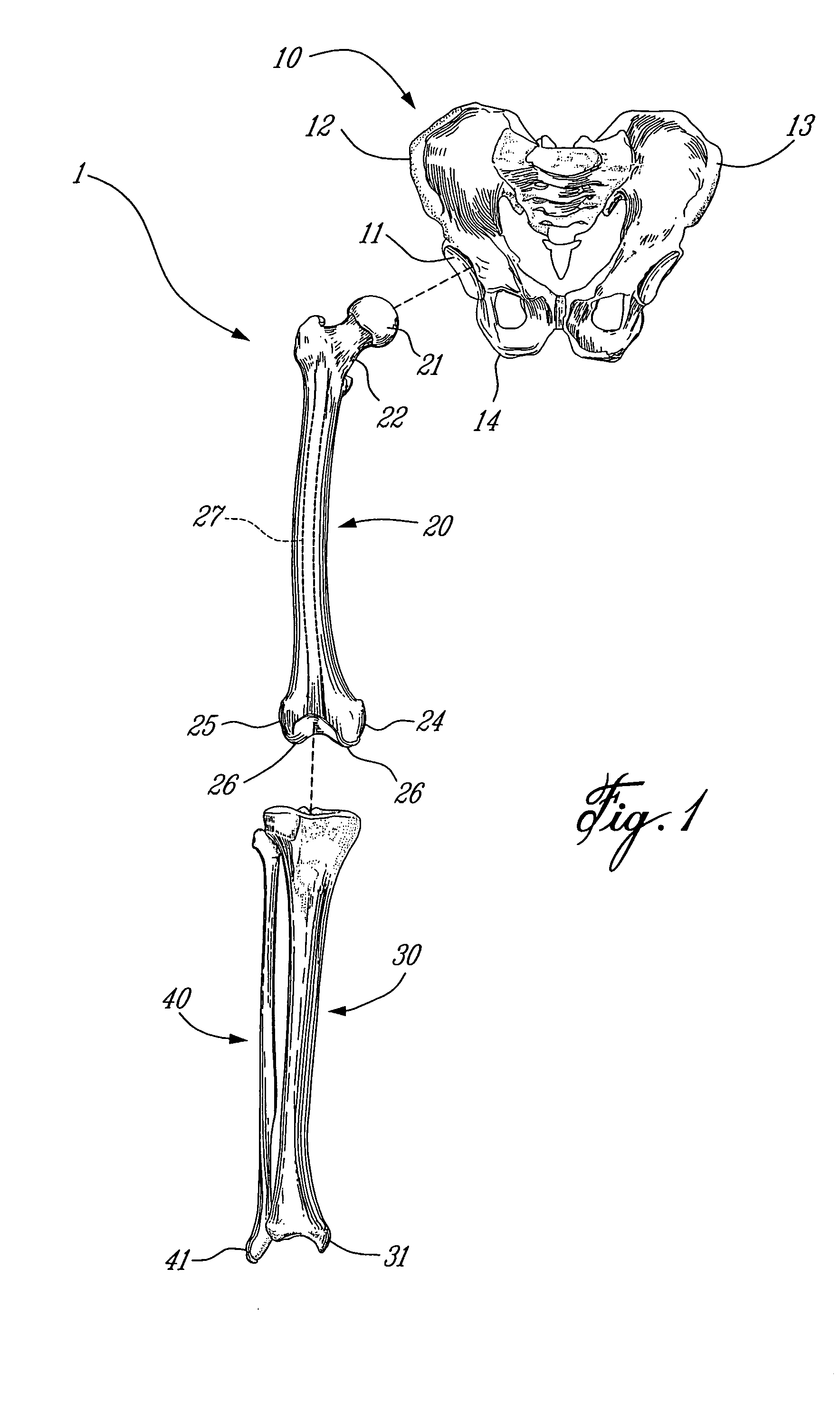

Apparatus for digitizing intramedullary canal and method

InactiveUS20050021043A1Joint implantsDiagnostic recording/measuringComputer-assisted surgeryComputer-aided

An apparatus for obtaining an axis of an intramedullary canal of an exposed bone with a position tracking system in computer-assisted surgery, comprising a detectable device trackable in space for position and orientation. A stem portion is secured to the detectable device so as to be tracked for position and orientation. The stem portion has a leading end insertable in an intramedullary canal of the bone through an opening in the bone, and is adapted to be handled by a following end thereof. A tip portion is provided at the leading end of the stem portion. The tip portion is positionable in a determined way with respect to a surface of the intramedullary canal, such that reference points with respect to the intramedullary canal are calculable as a function of the position and orientation of the detectable device. The reference points are related to define an axis of the intramedullary canal. A method is provided for digitizing the intramedullary canal axis.

Owner:ORTHOSOFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com