Patents

Literature

3909results about "Safety devices for lifting equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

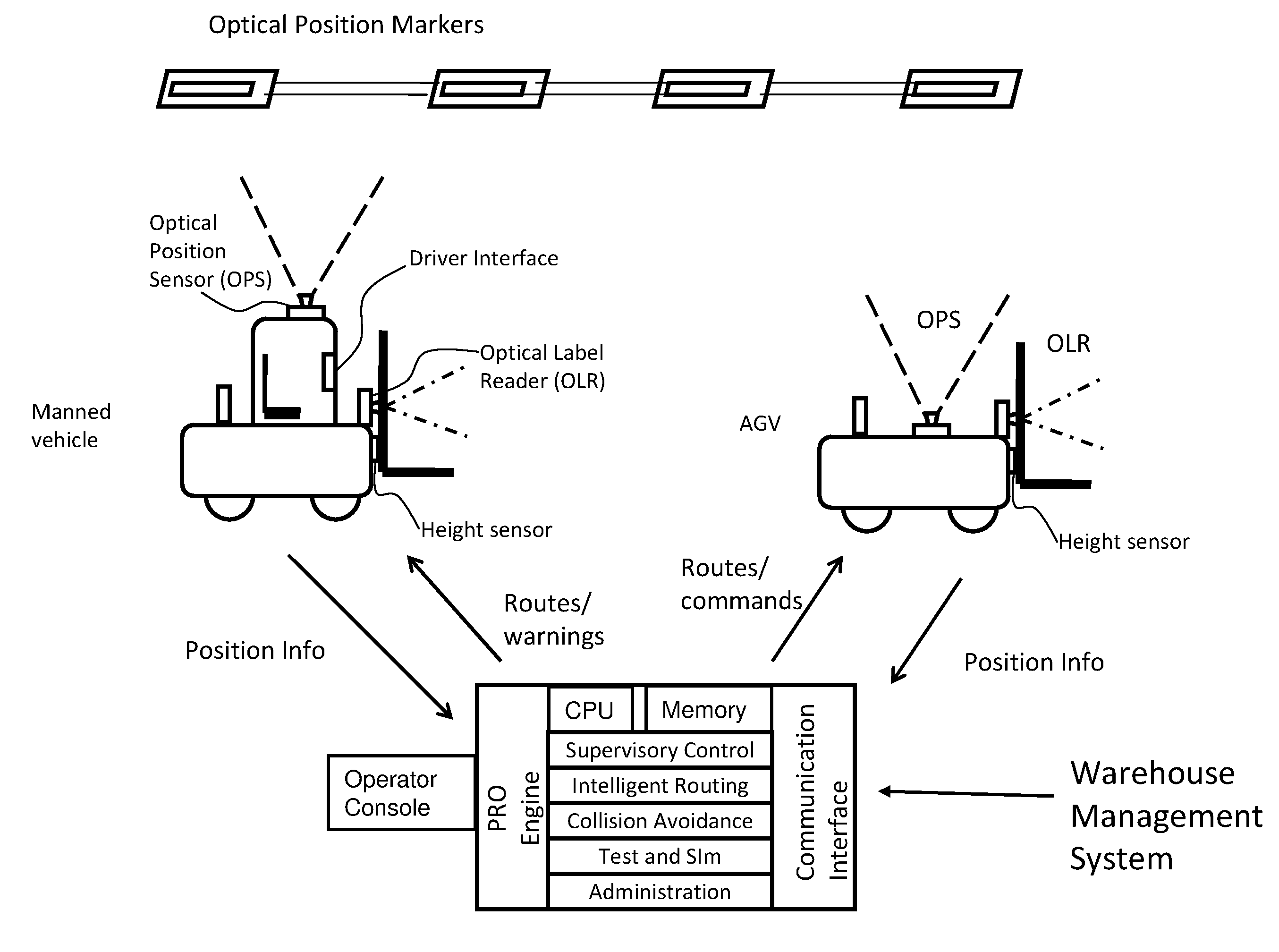

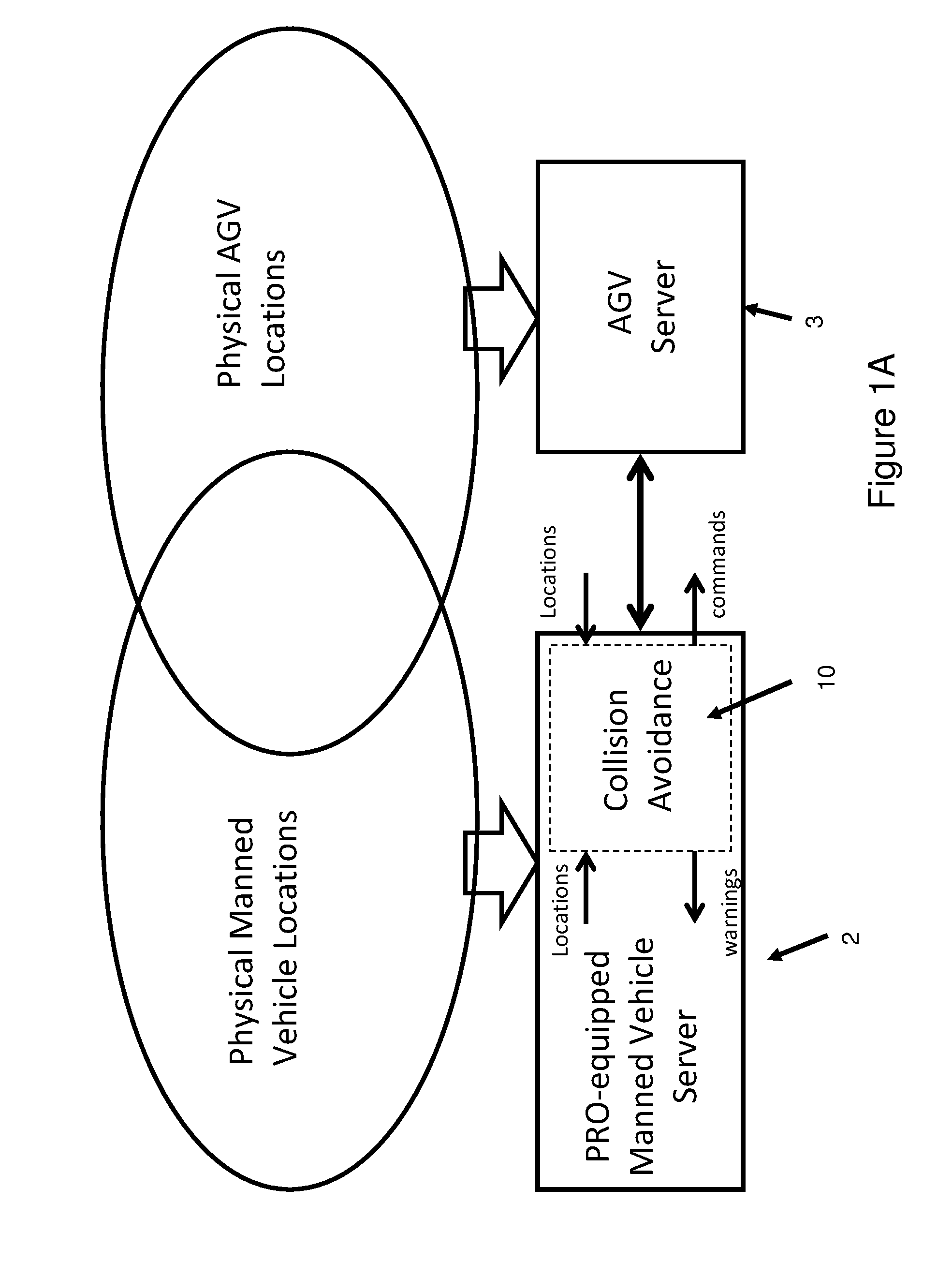

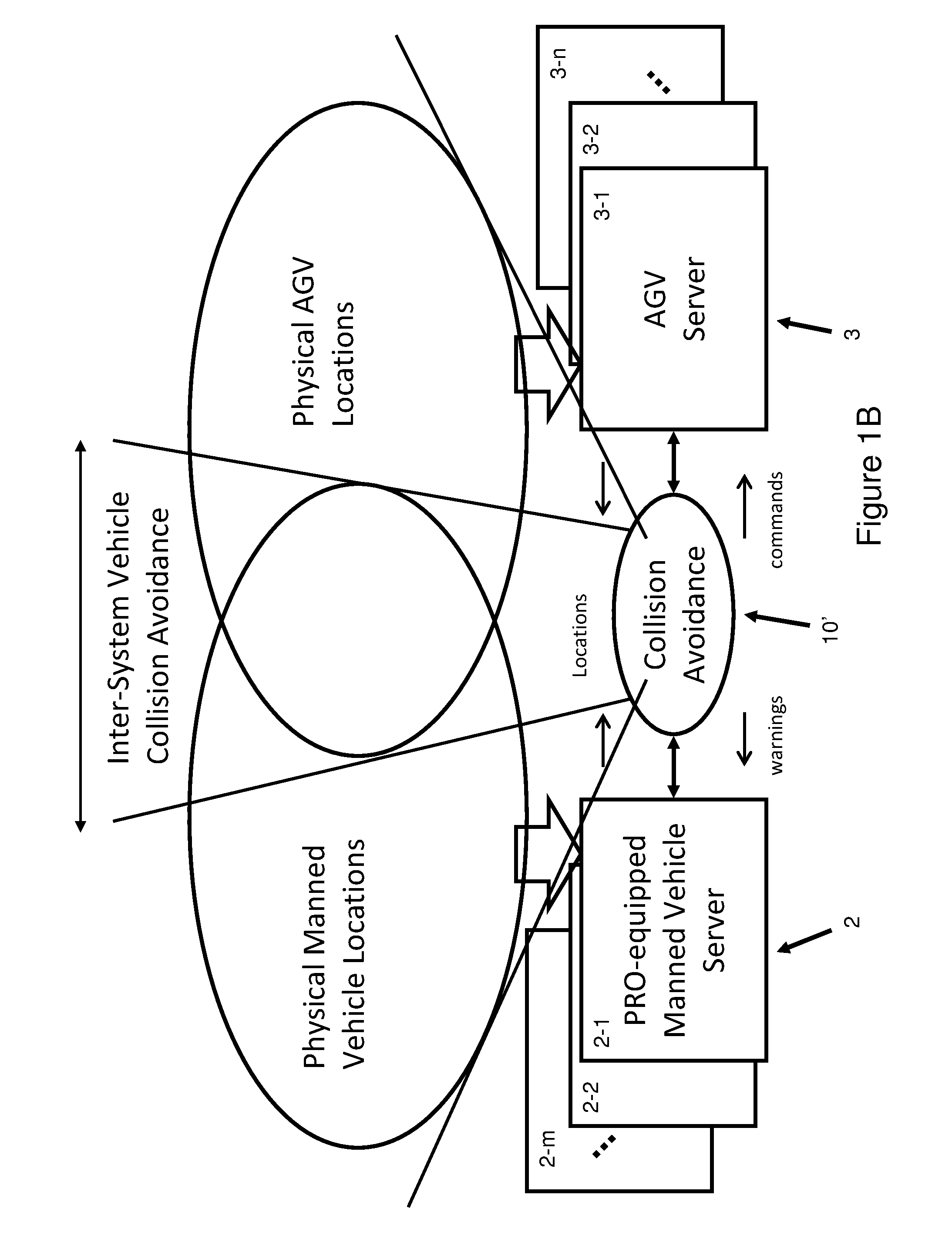

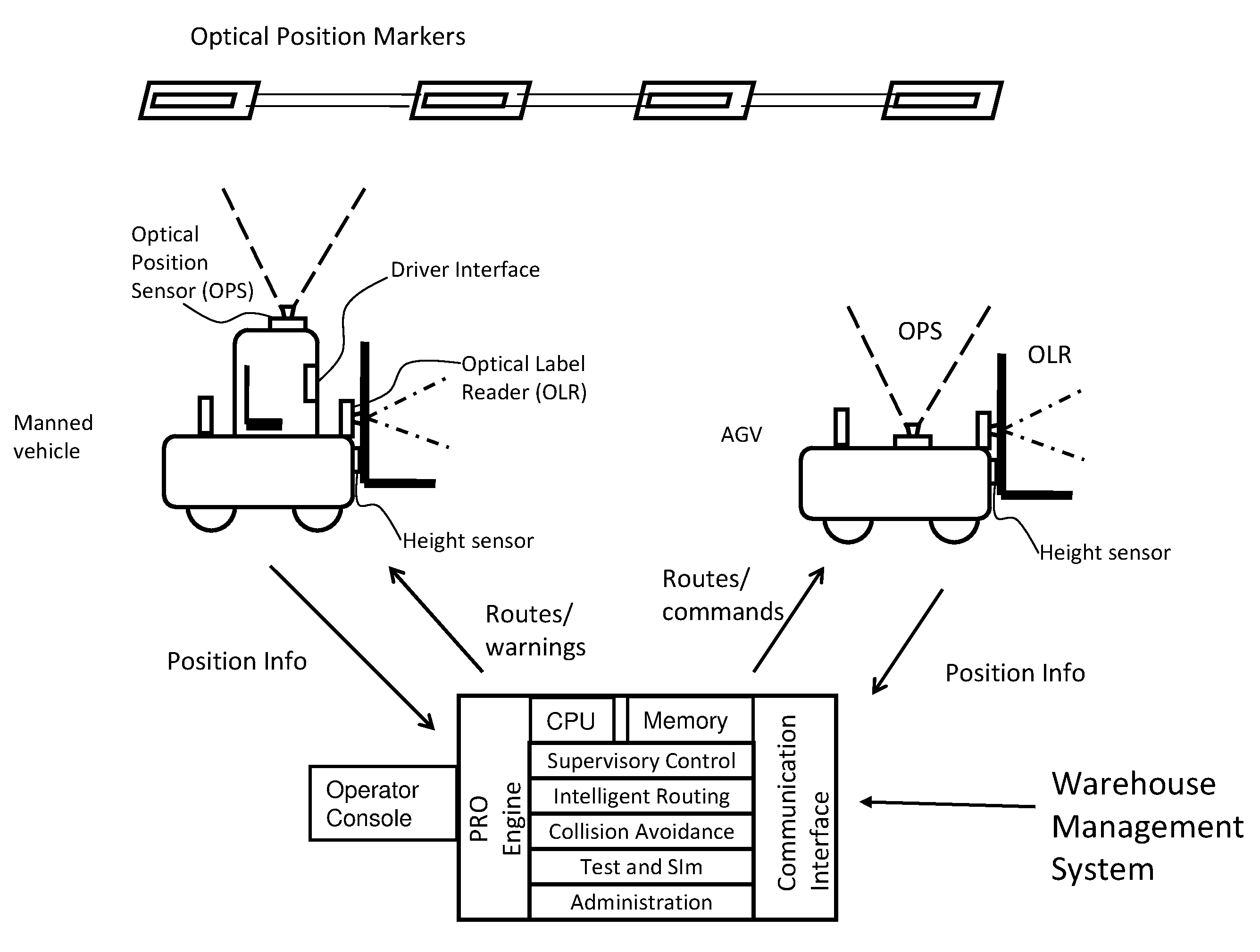

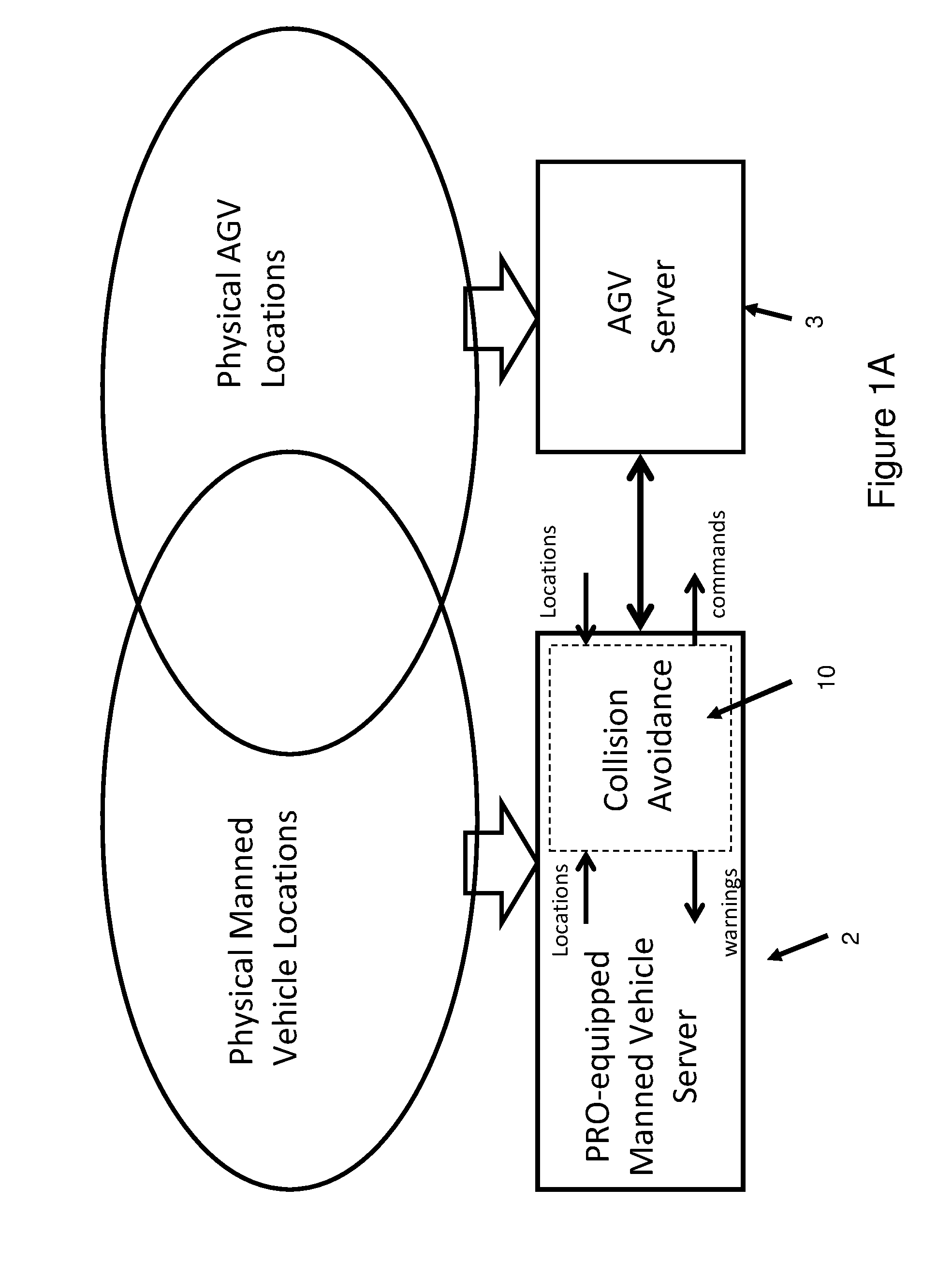

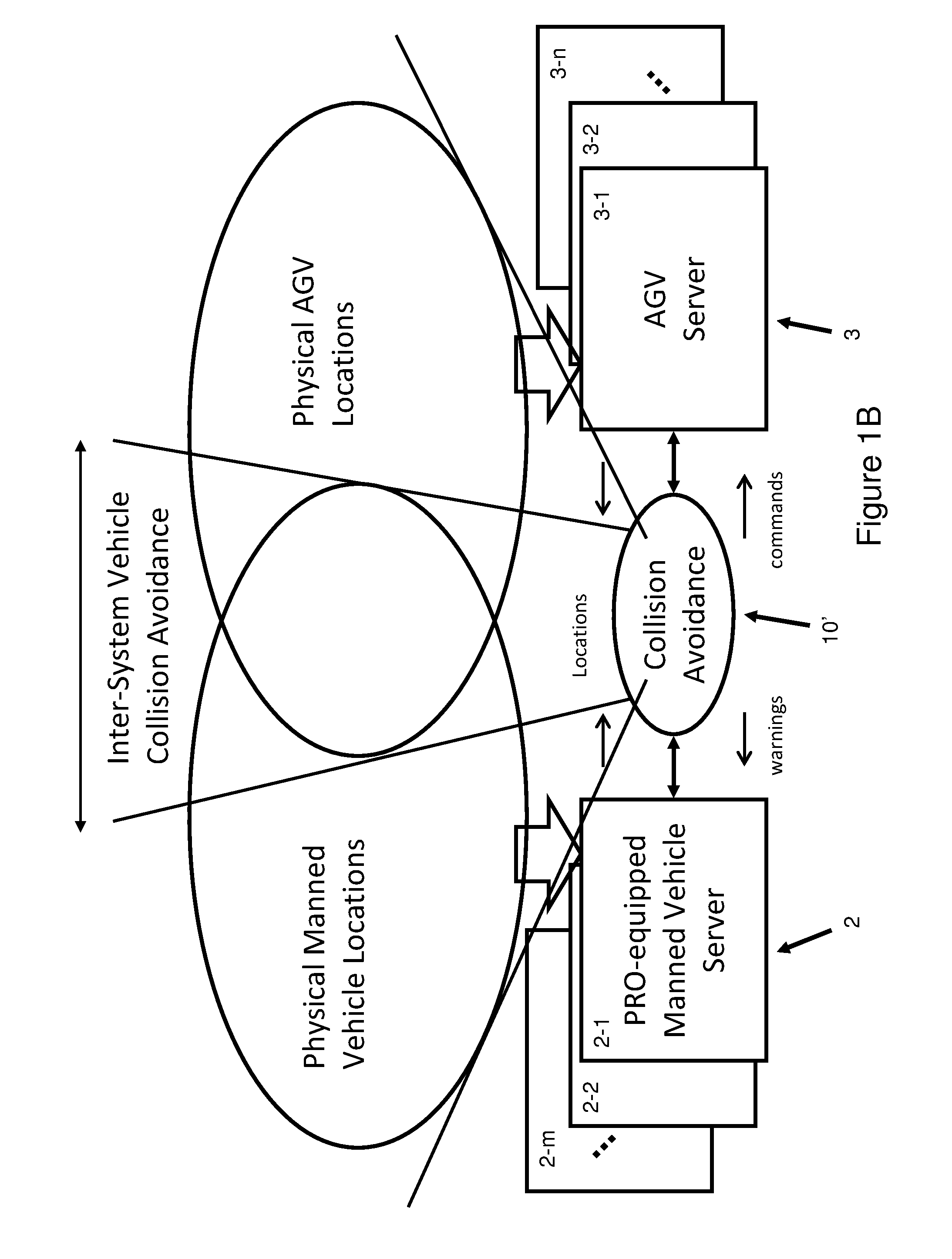

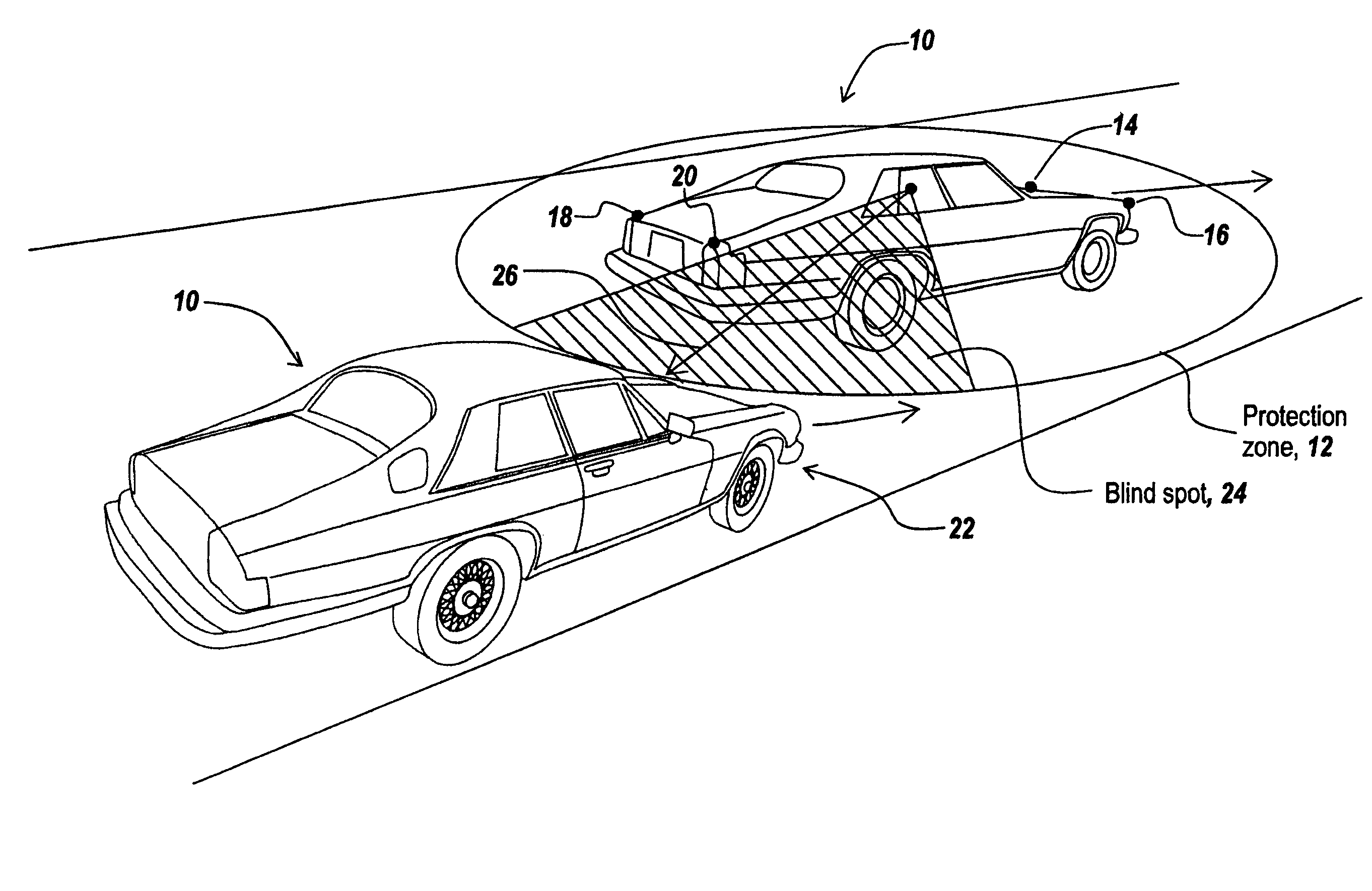

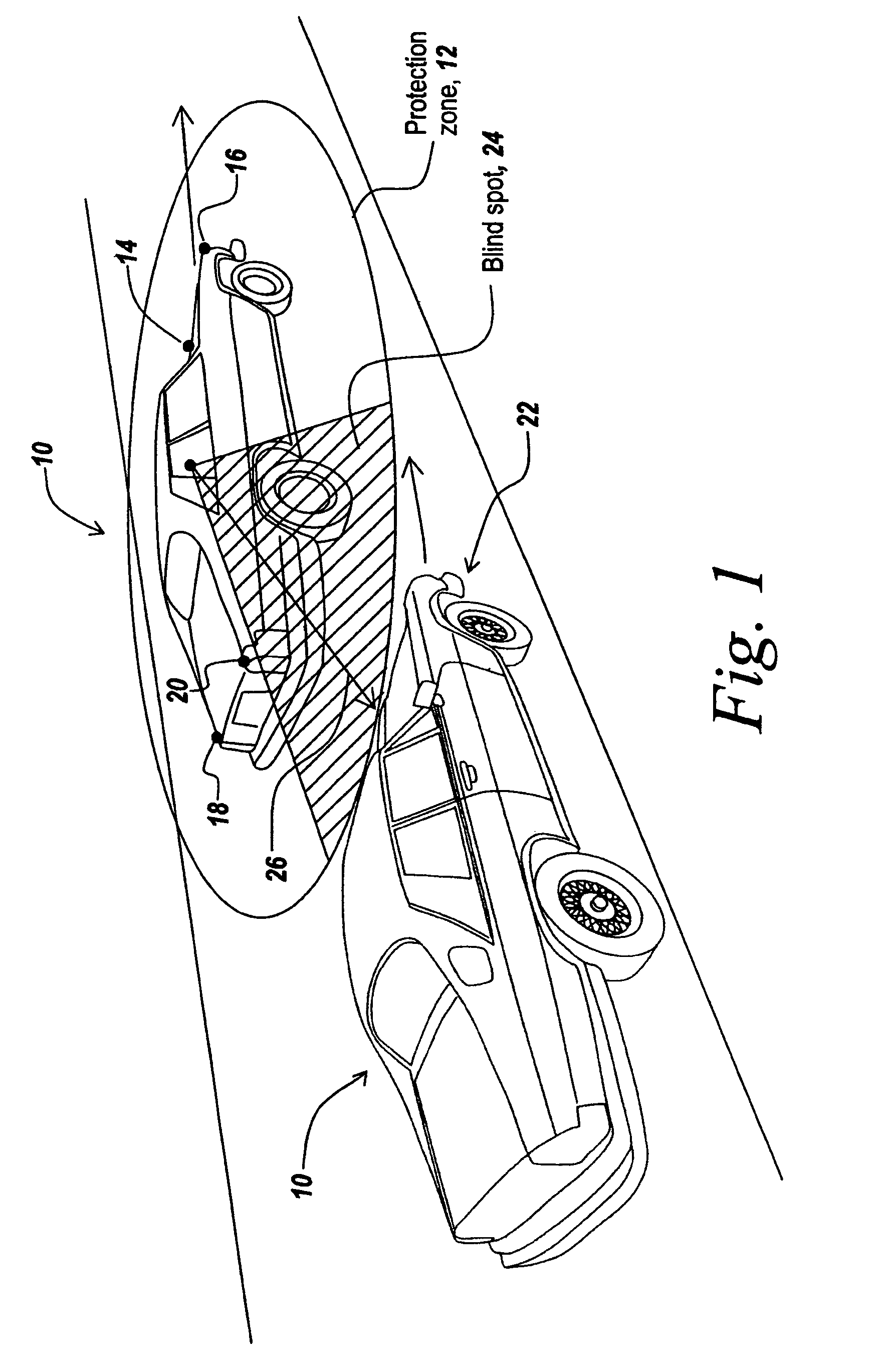

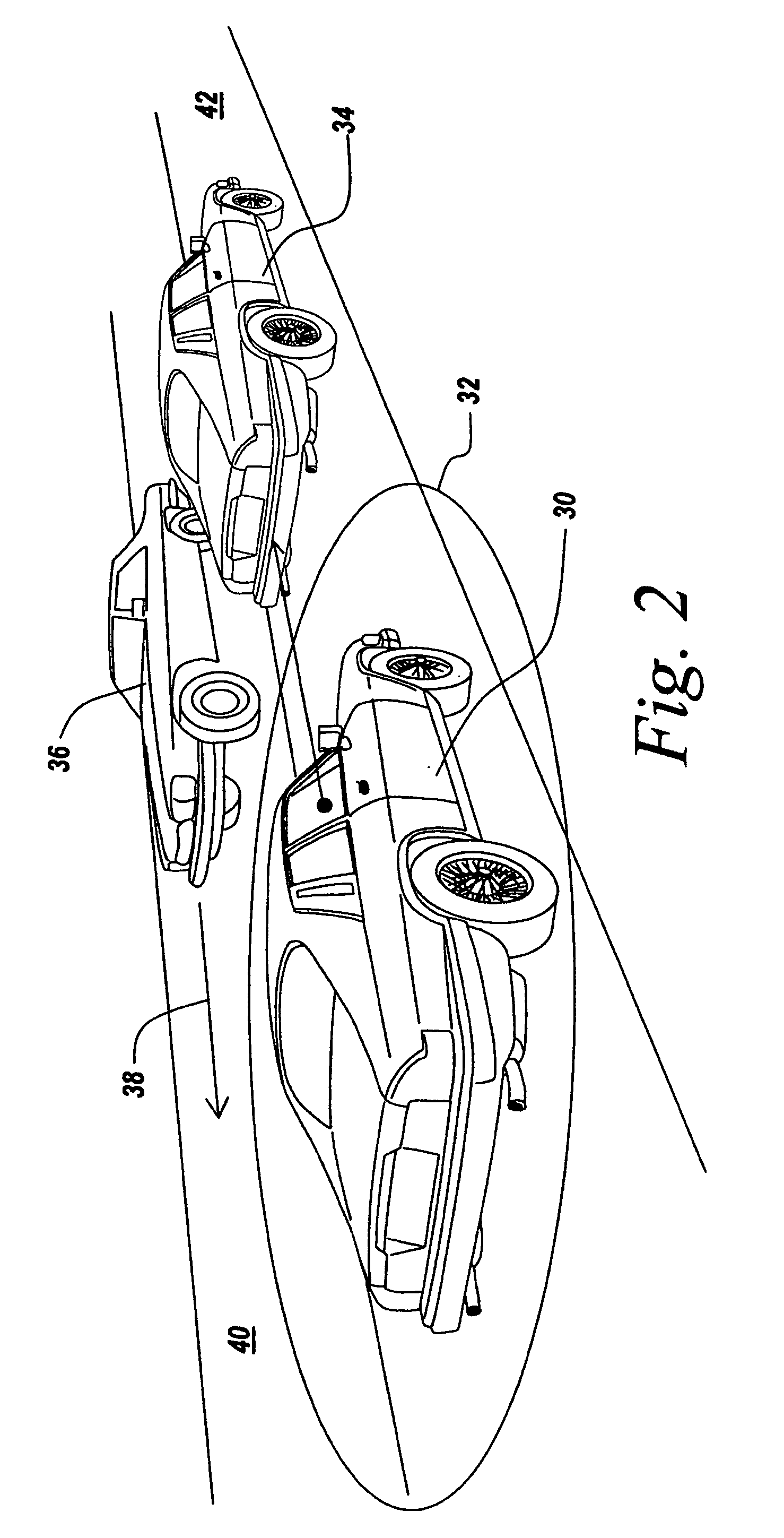

Method and apparatus for collision avoidance

ActiveUS20110093134A1Safety devices for lifting equipmentsDigital data processing detailsMobile vehicleLocation tracking

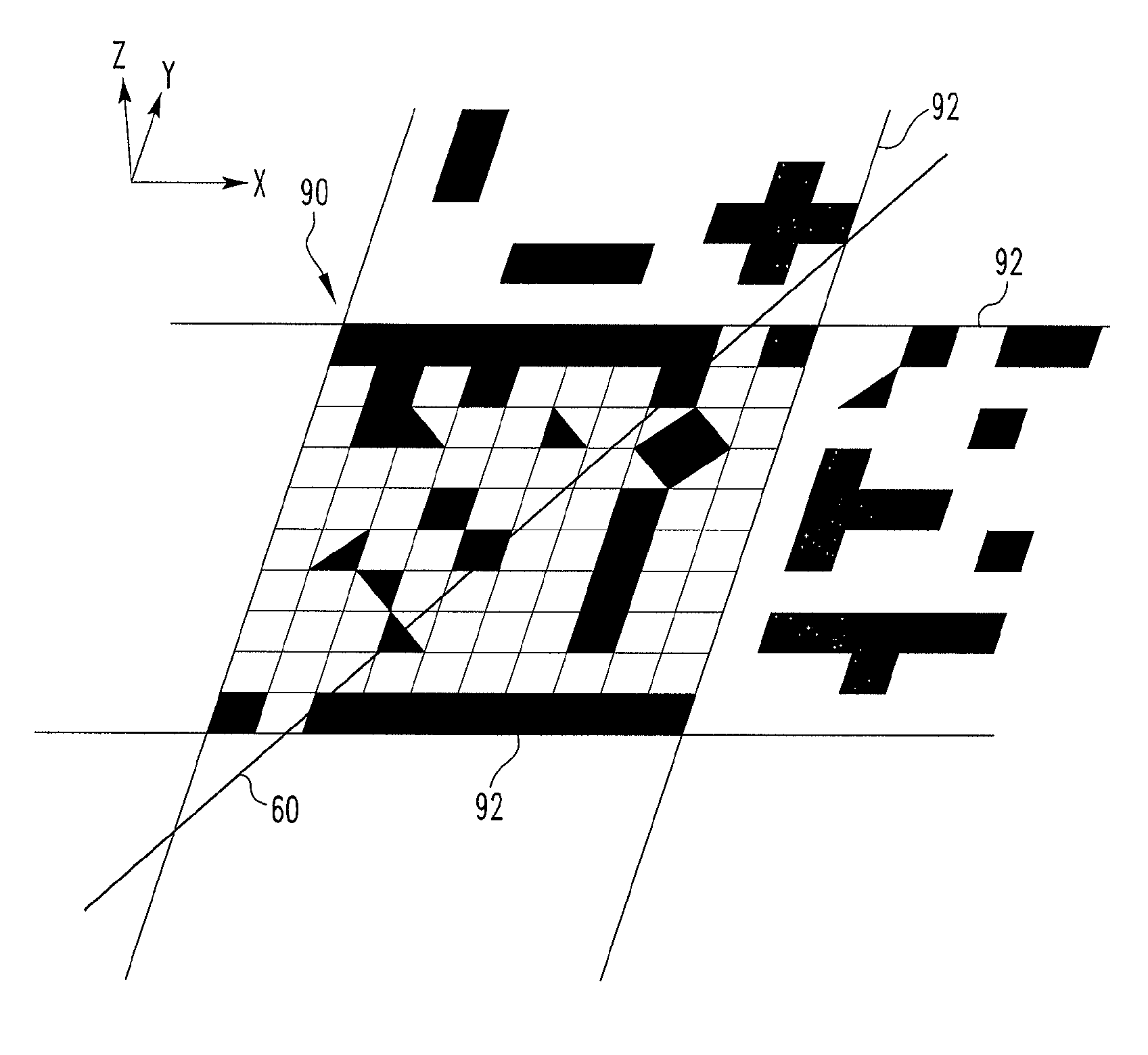

A method and apparatus for avoiding collisions of moving vehicles in an environment that utilizes a position and rotational orientation system to track vehicle locations within a preconfigured operational zone, the method comprising using position tracking data to calculate a predicted trajectory and safety zone of each vehicle for a predetermined prediction time period and determining potential areas of intersection with vehicles to predict collisions.

Owner:TOTALTRAX

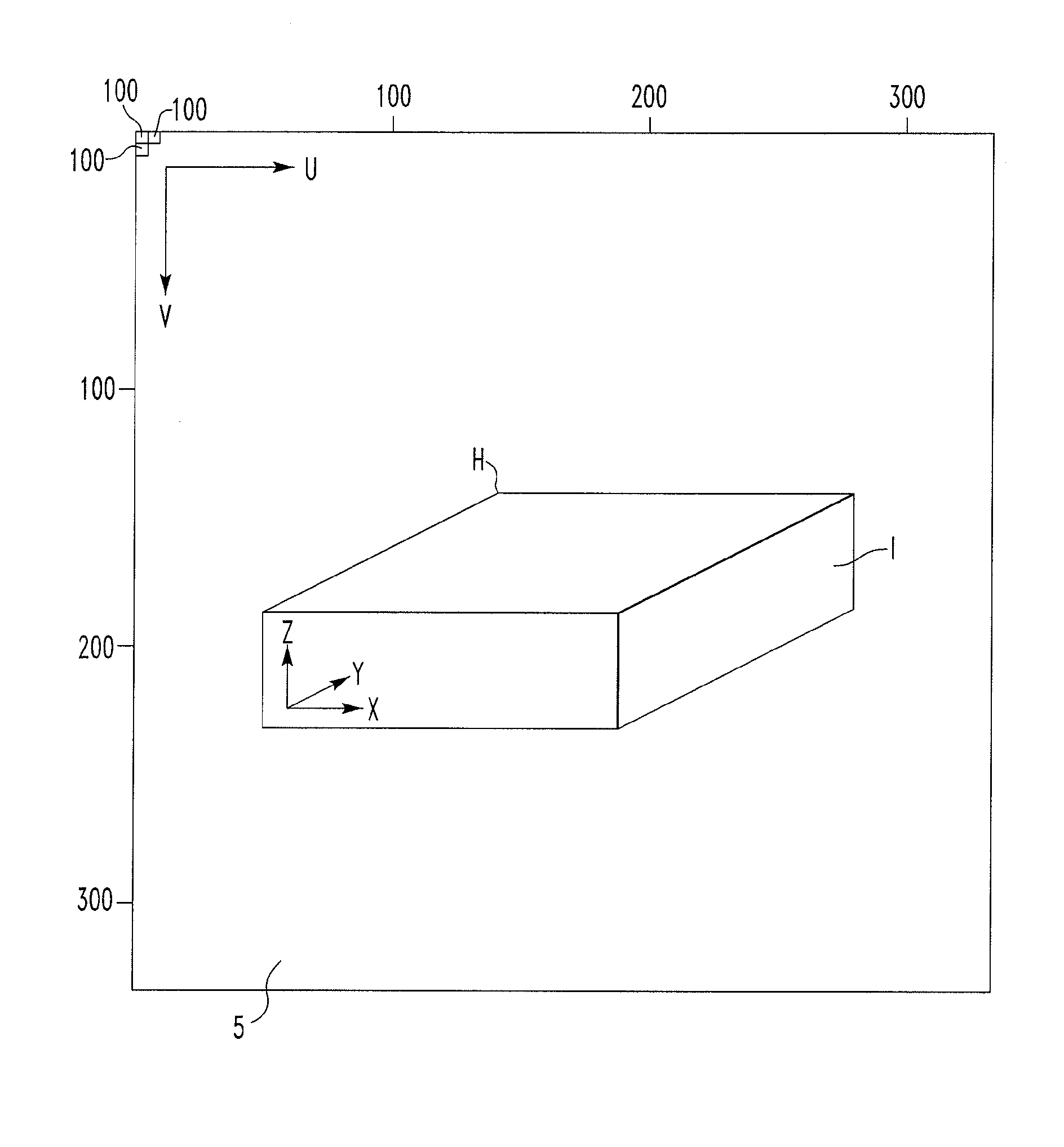

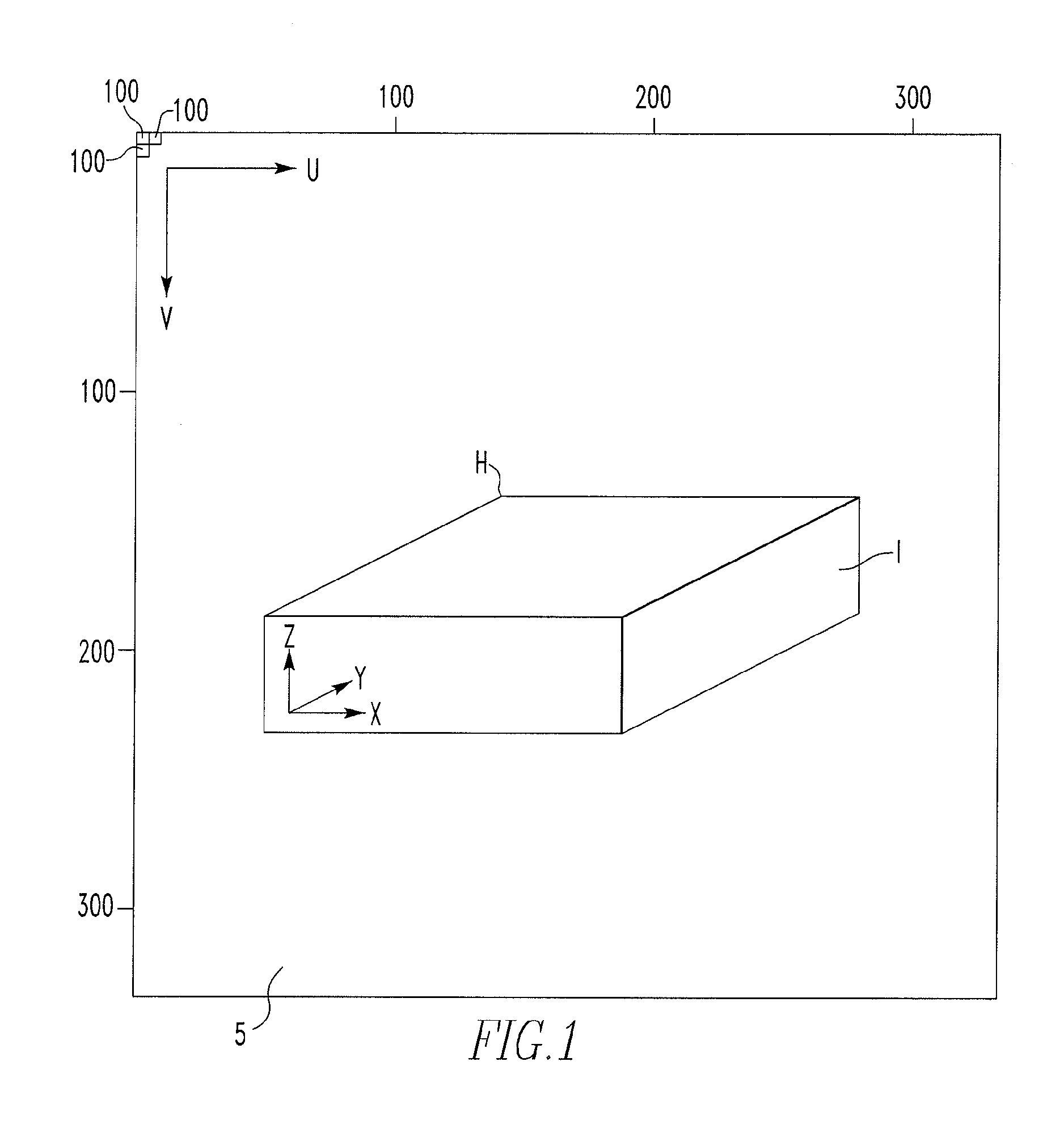

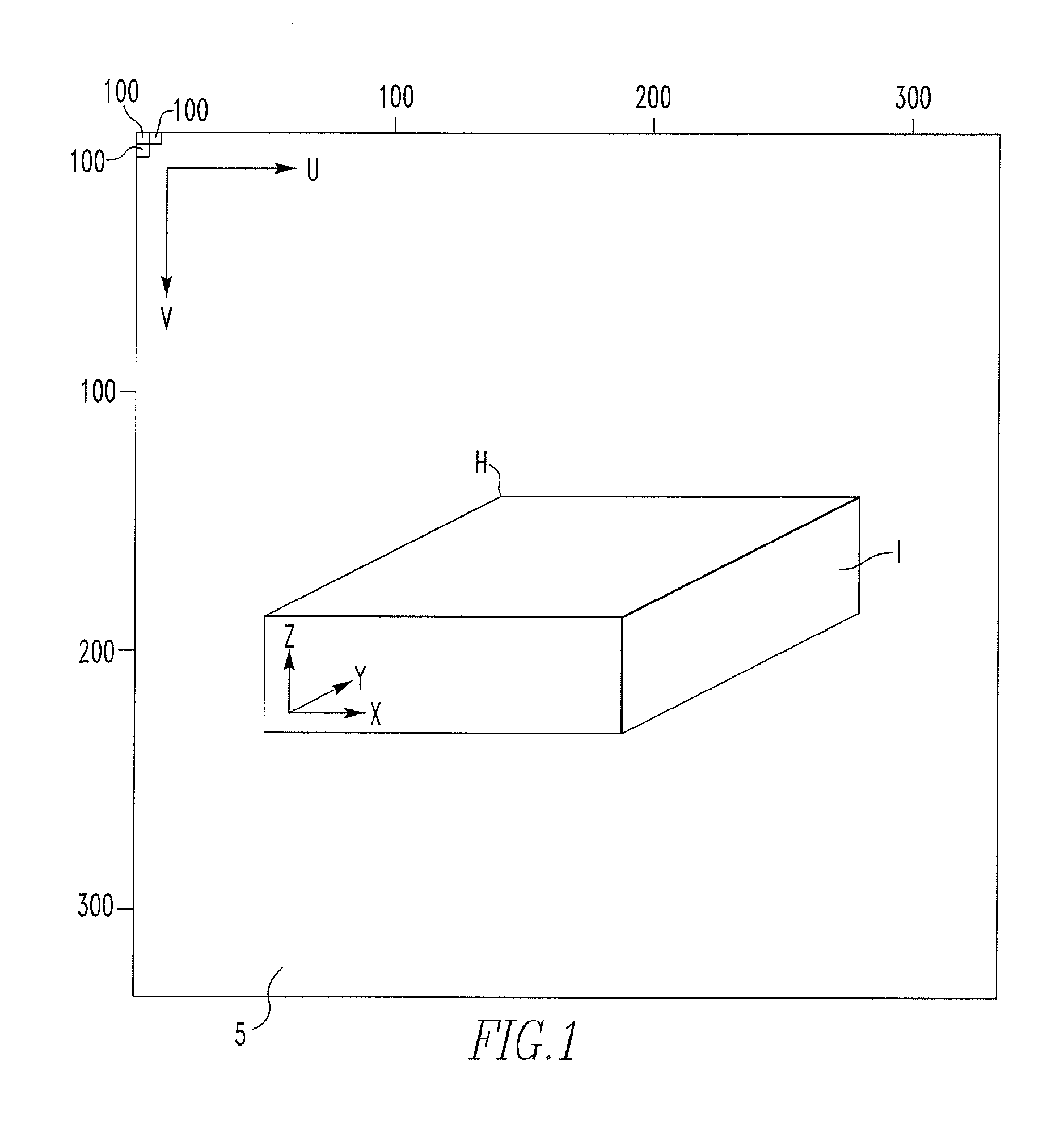

Dimensional Detection System and Associated Method

InactiveUS20110286007A1Clear visionSafety devices for lifting equipmentsCharacter and pattern recognitionData setLight beam

An improved dimensional detection system is portable and can be used to characterize a workpiece. The dimensional detection system employs as few as a single focused light source and as few as a single camera along with a calibration data set to convert the illuminated pixels of an image of a beam on the workpiece into a cloud of real world points in space on an outer surface of the workpiece. The cloud of points can be processed to characterize the workpiece, such as by determining the right hexahedron that would encompass all of the real world points in space and which could be used to determine a dimensional weight of the workpiece.

Owner:LTS SCALE CO LLC

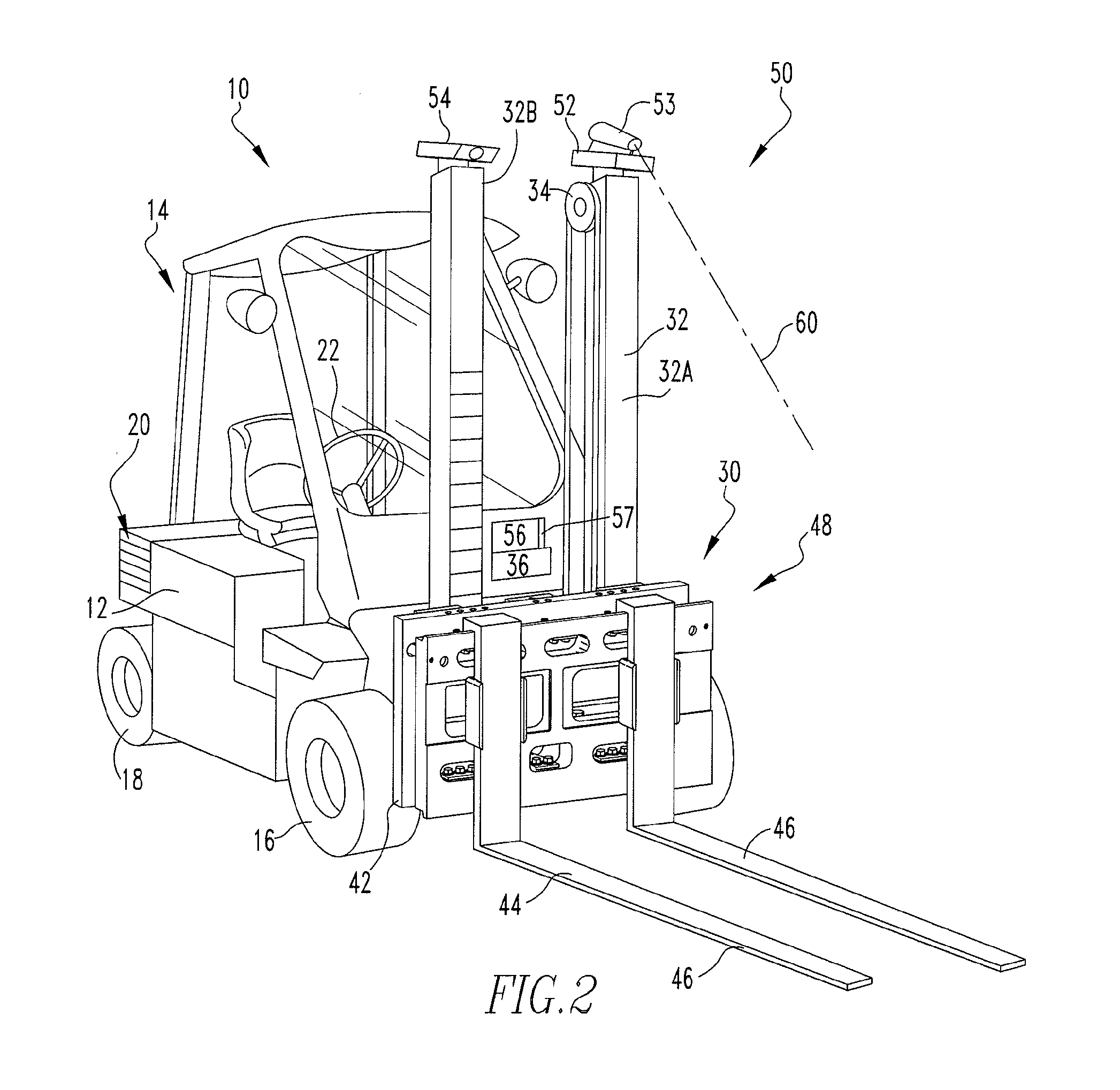

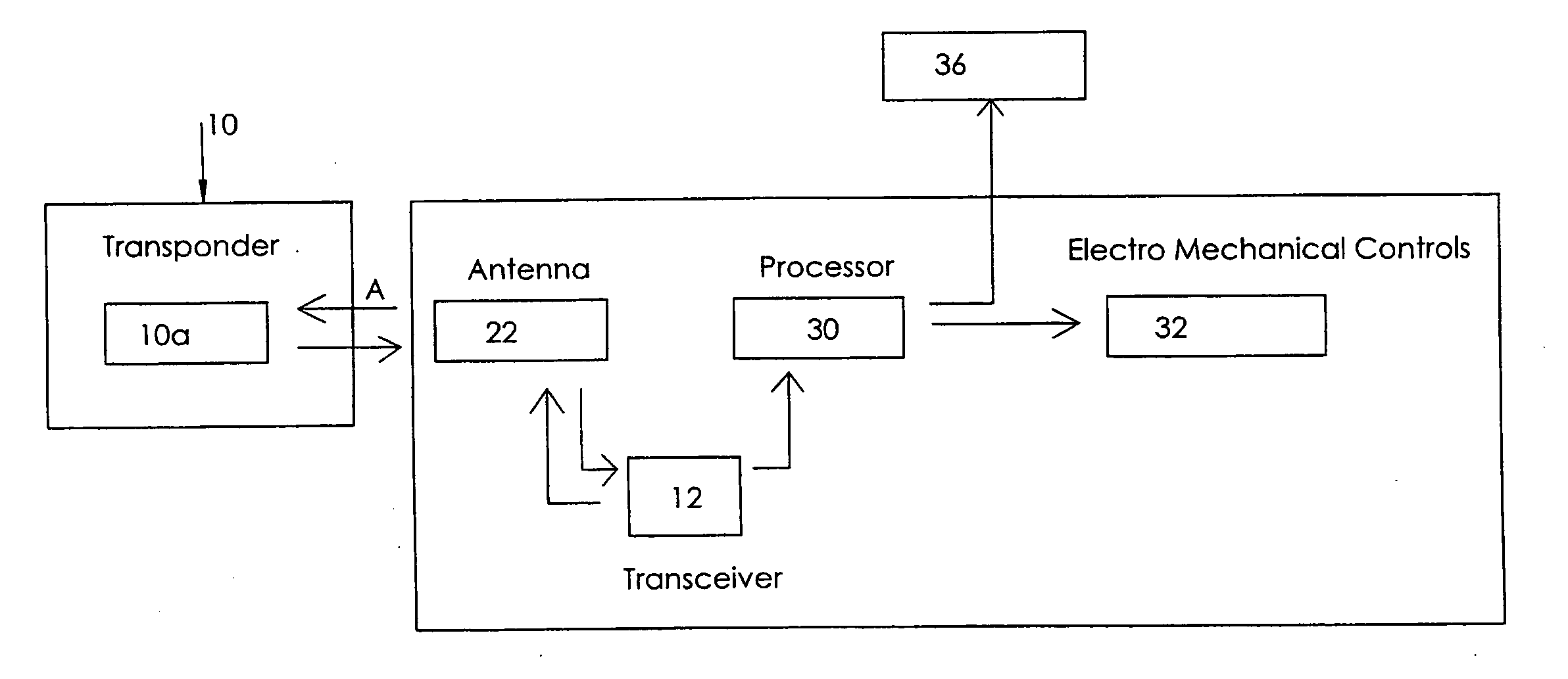

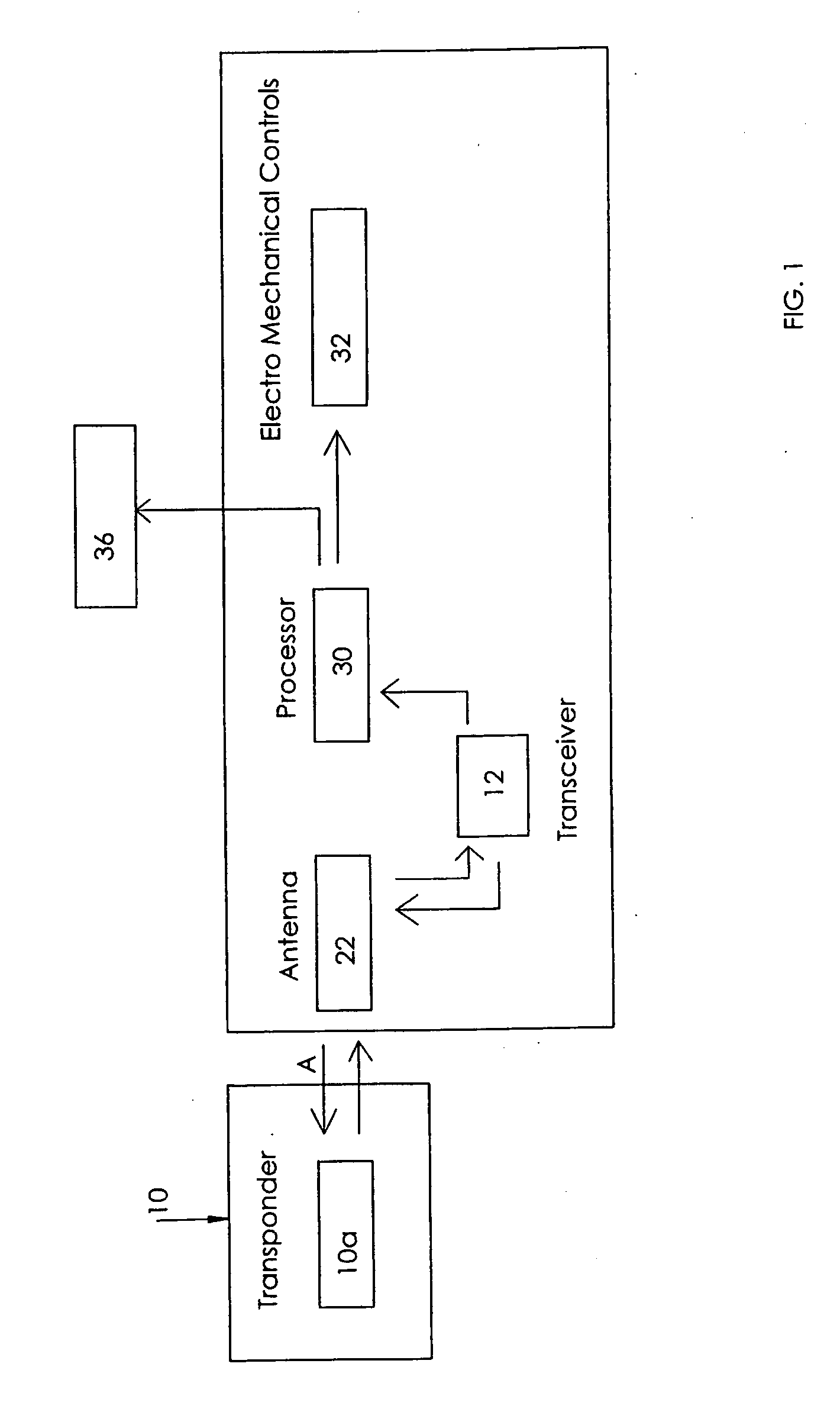

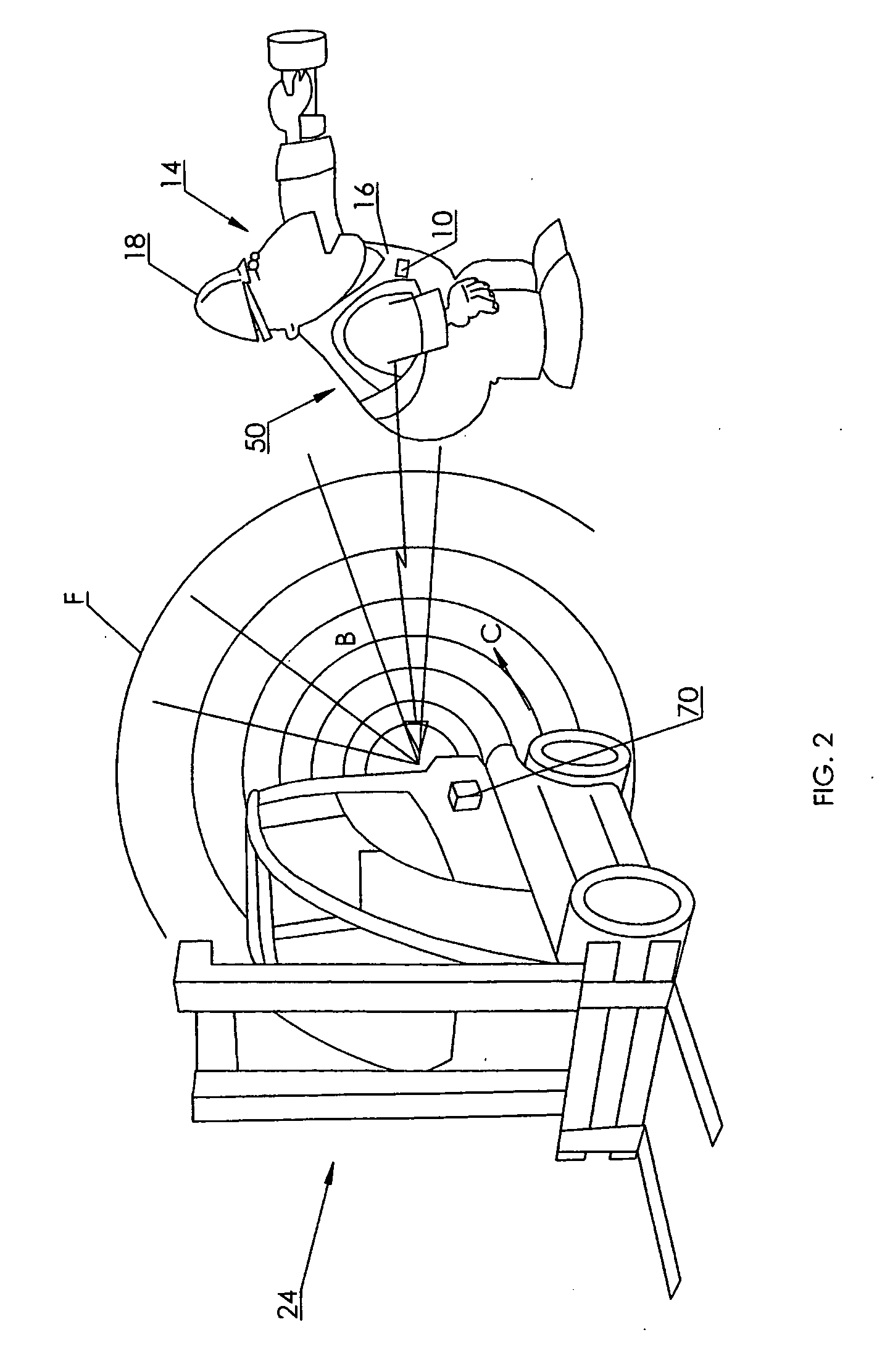

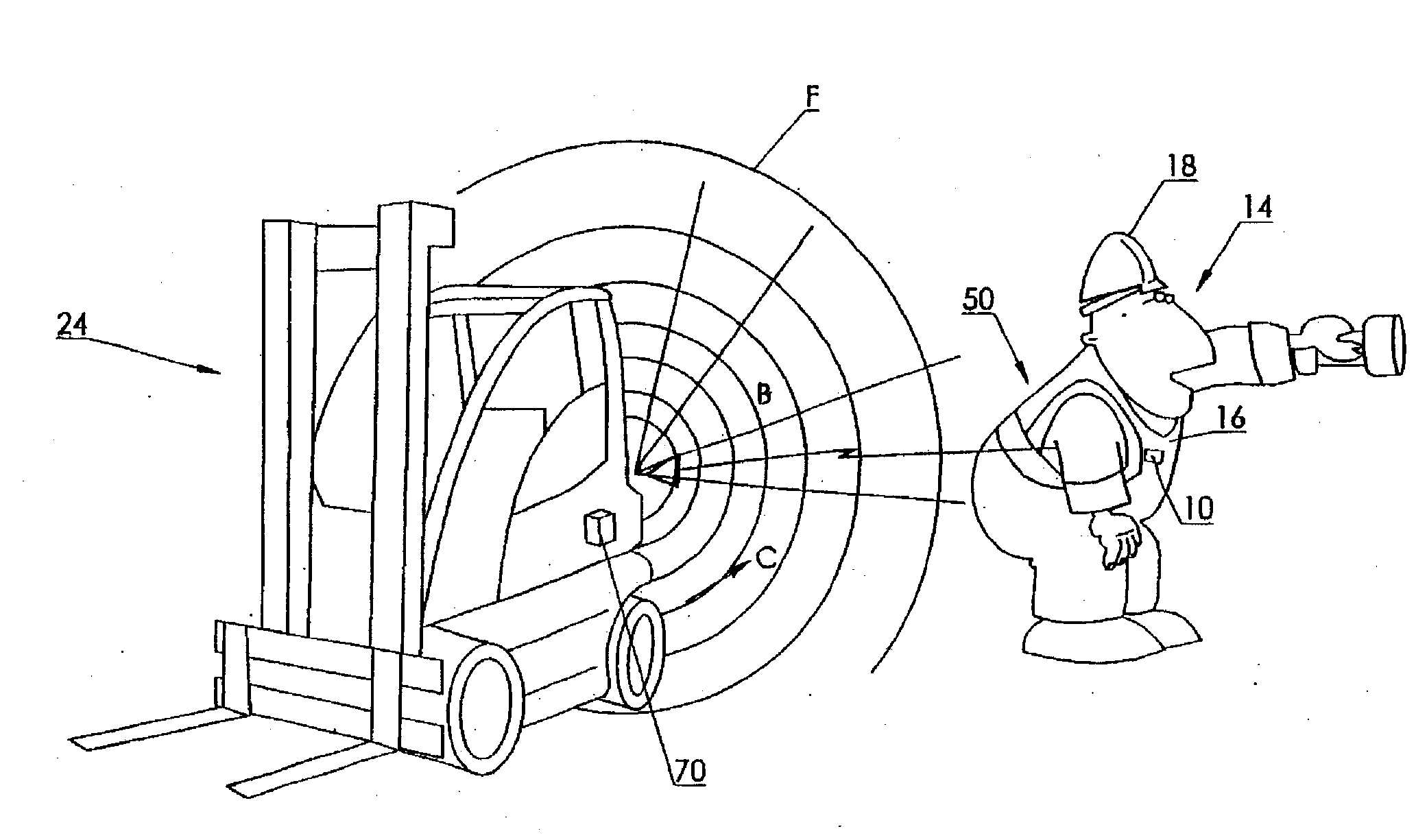

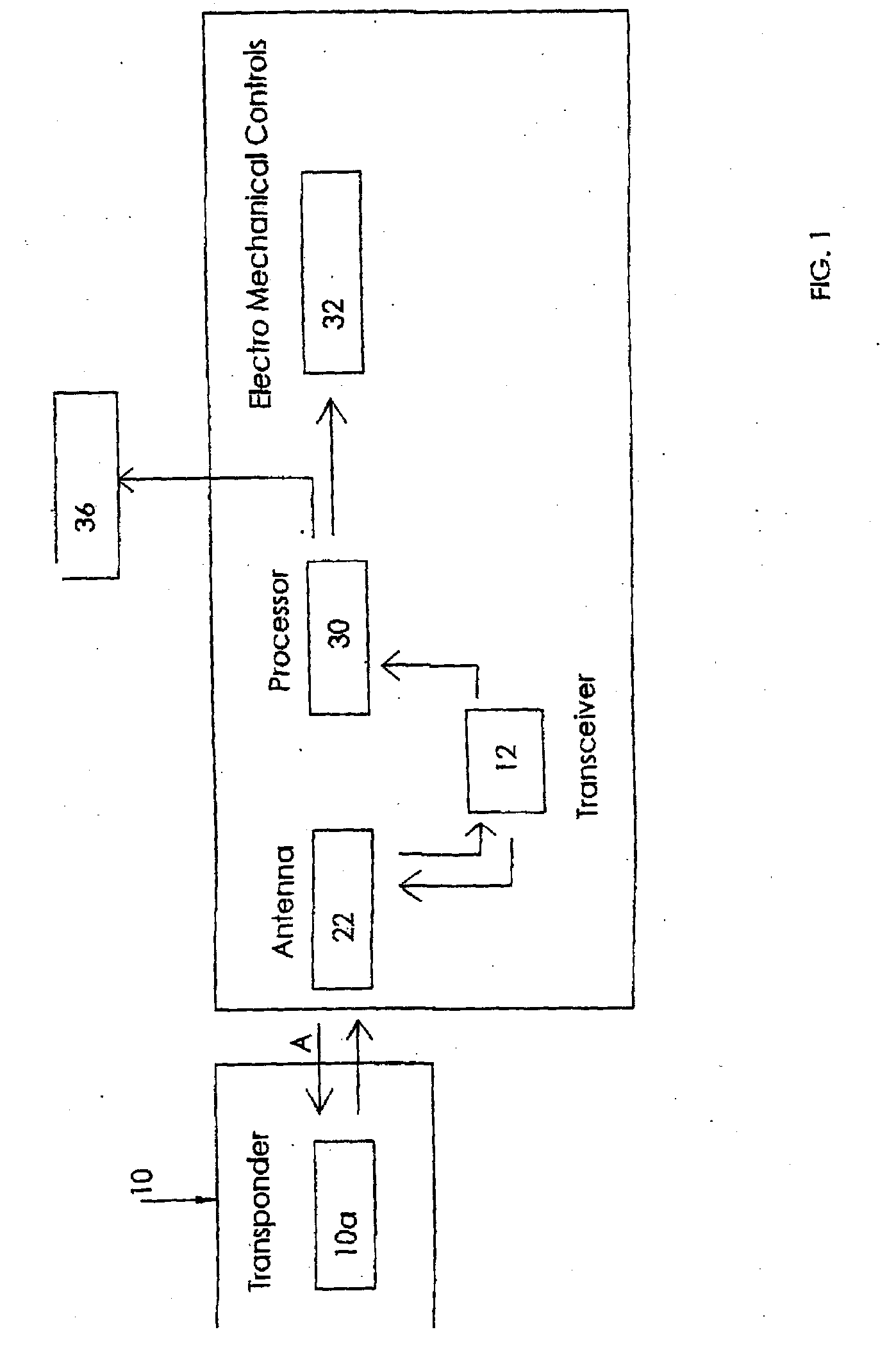

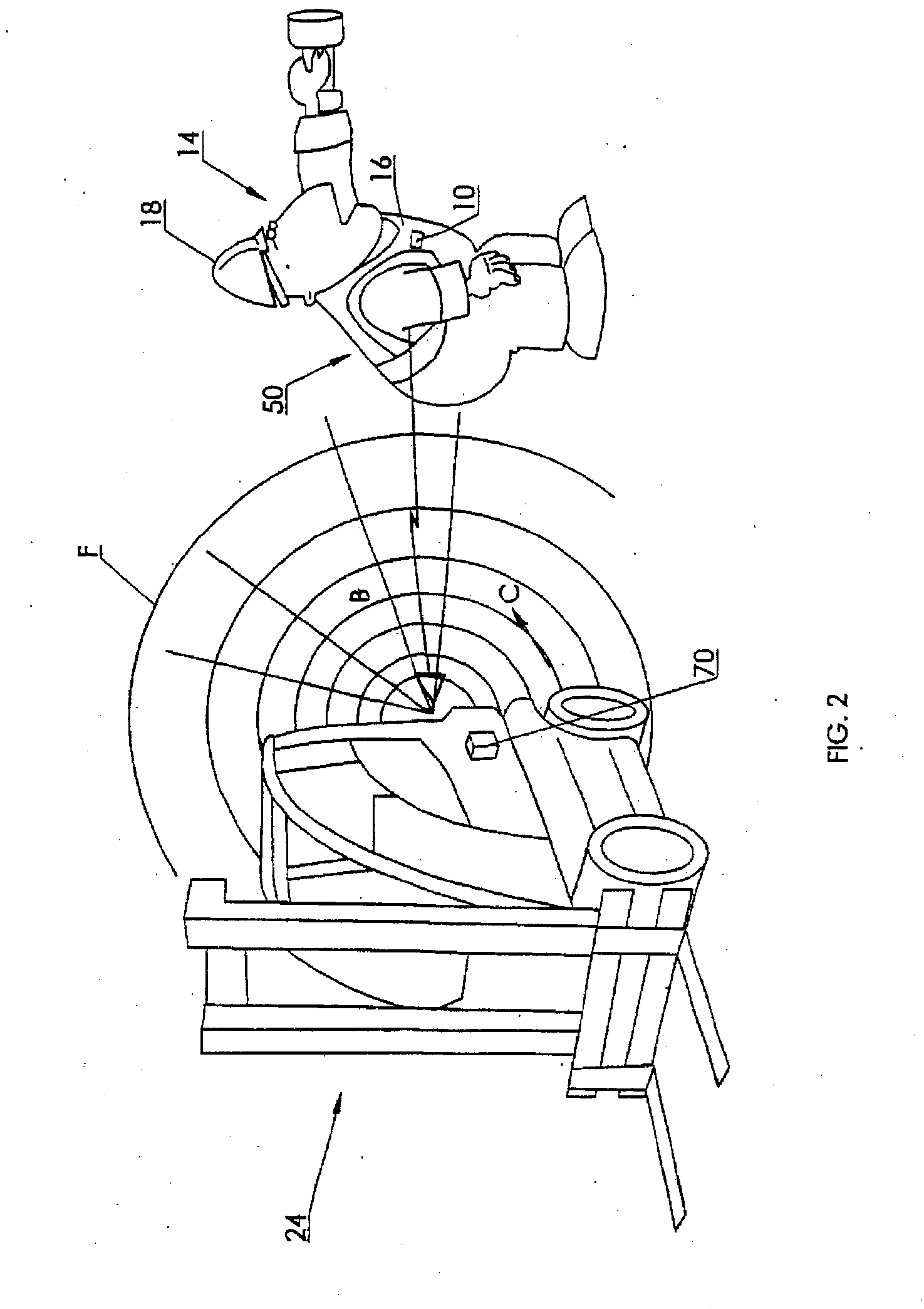

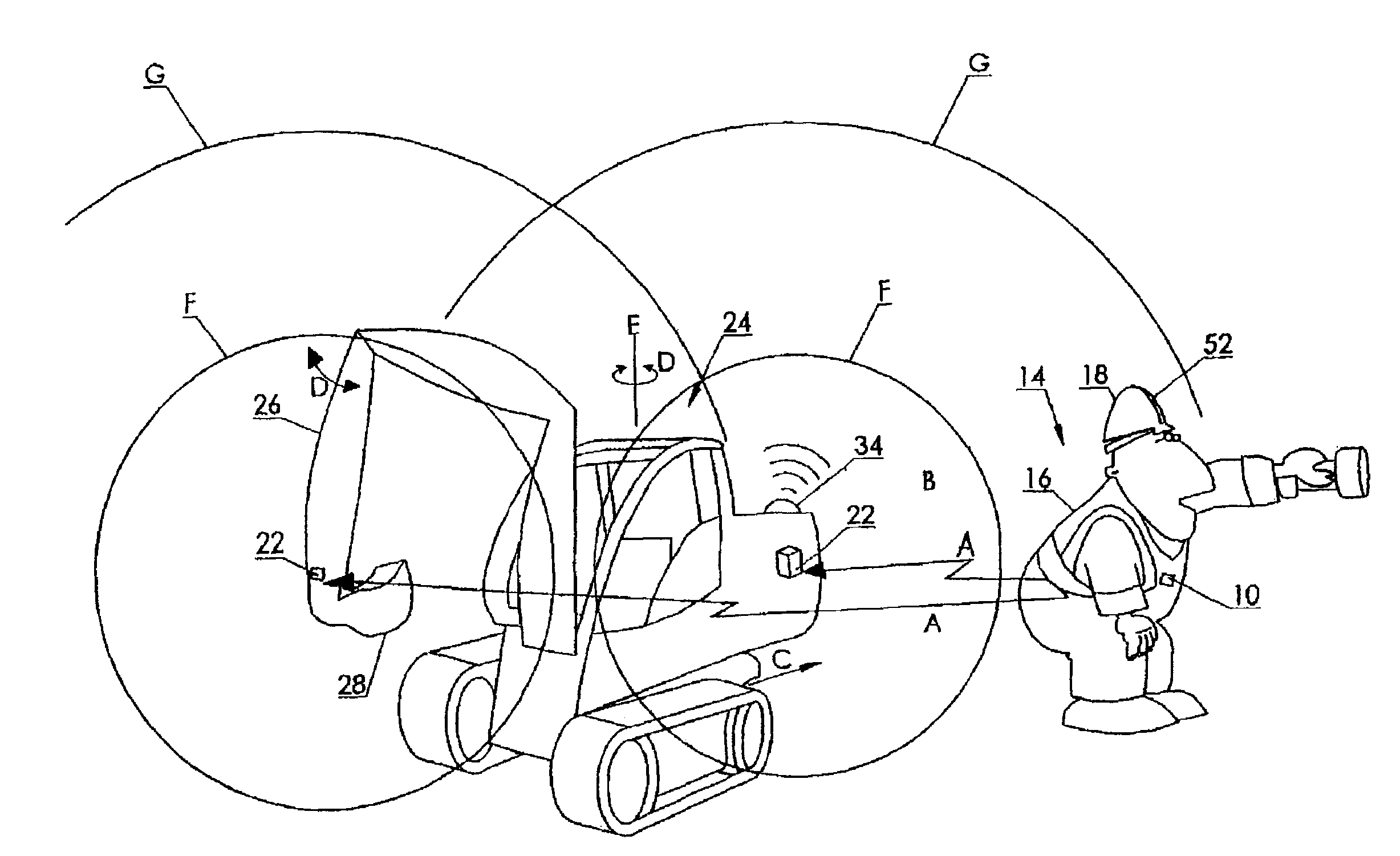

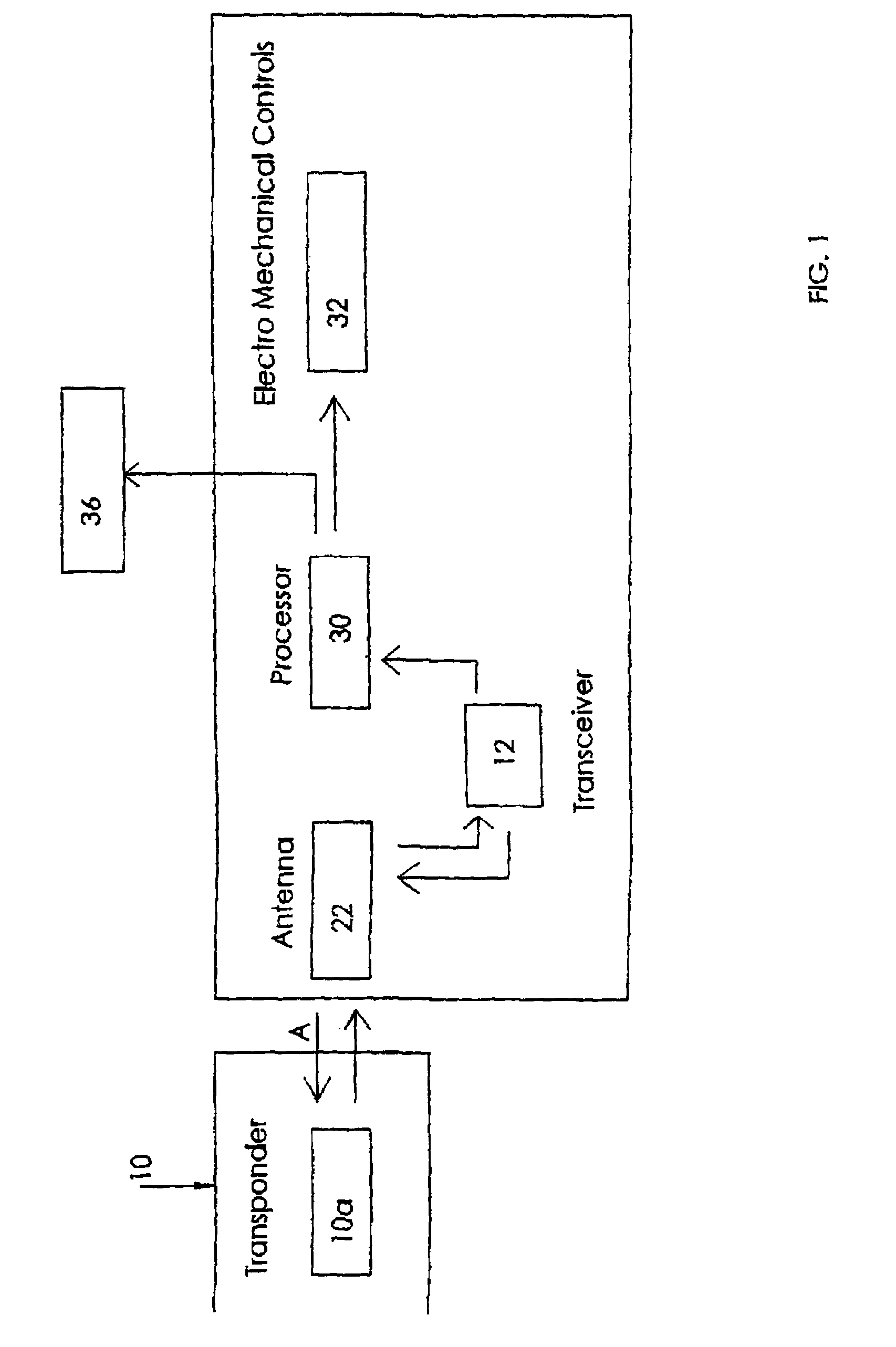

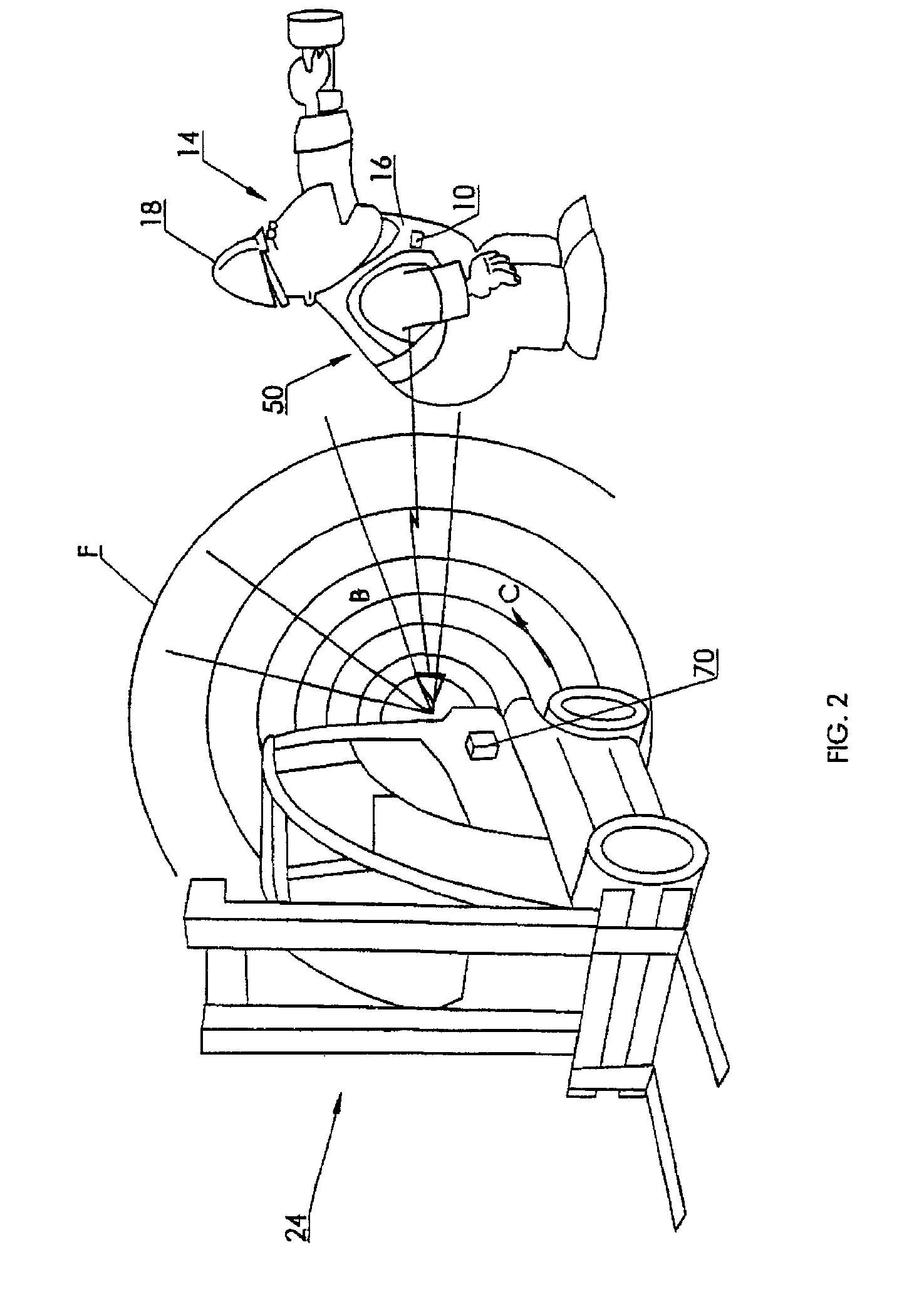

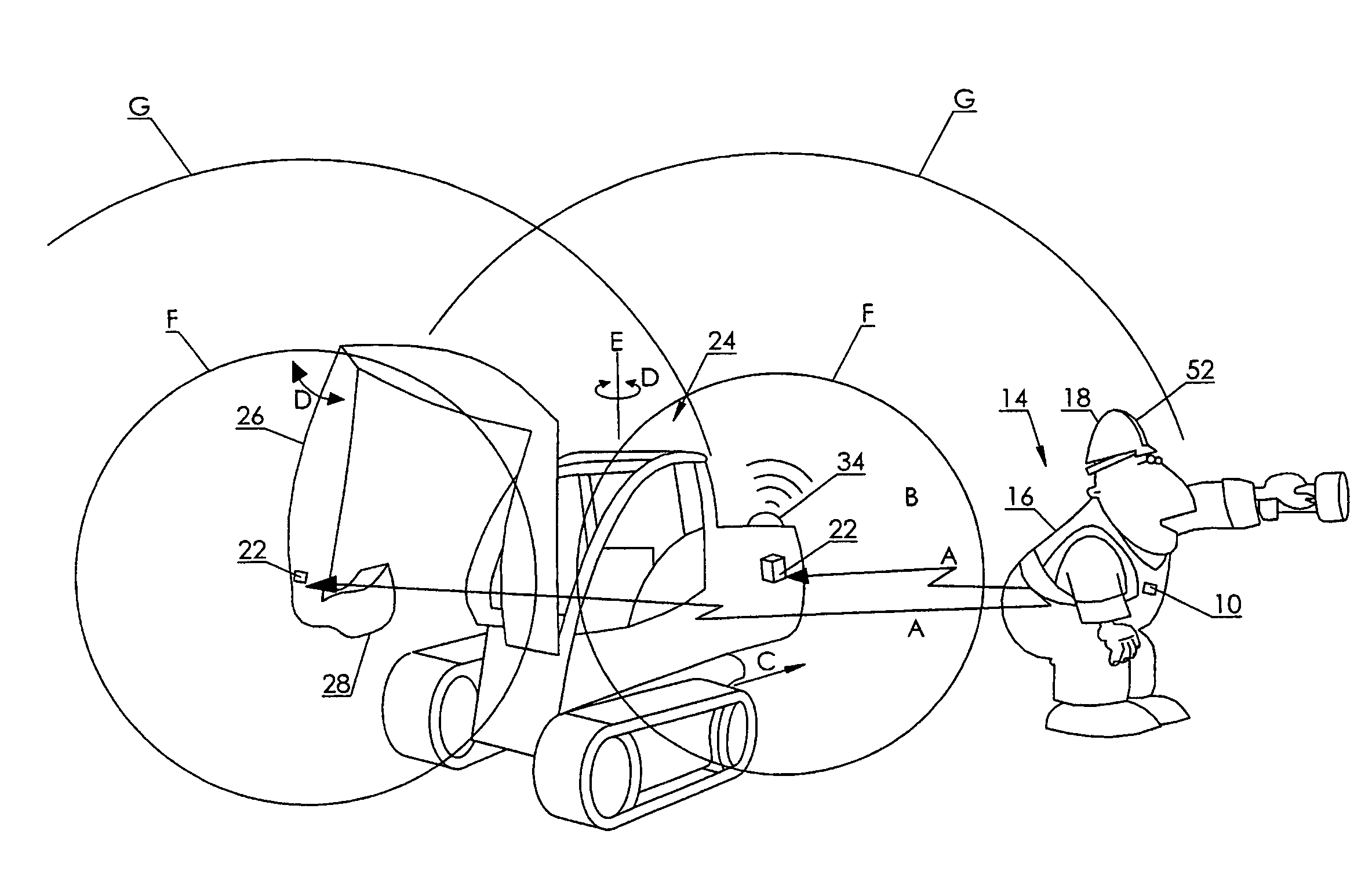

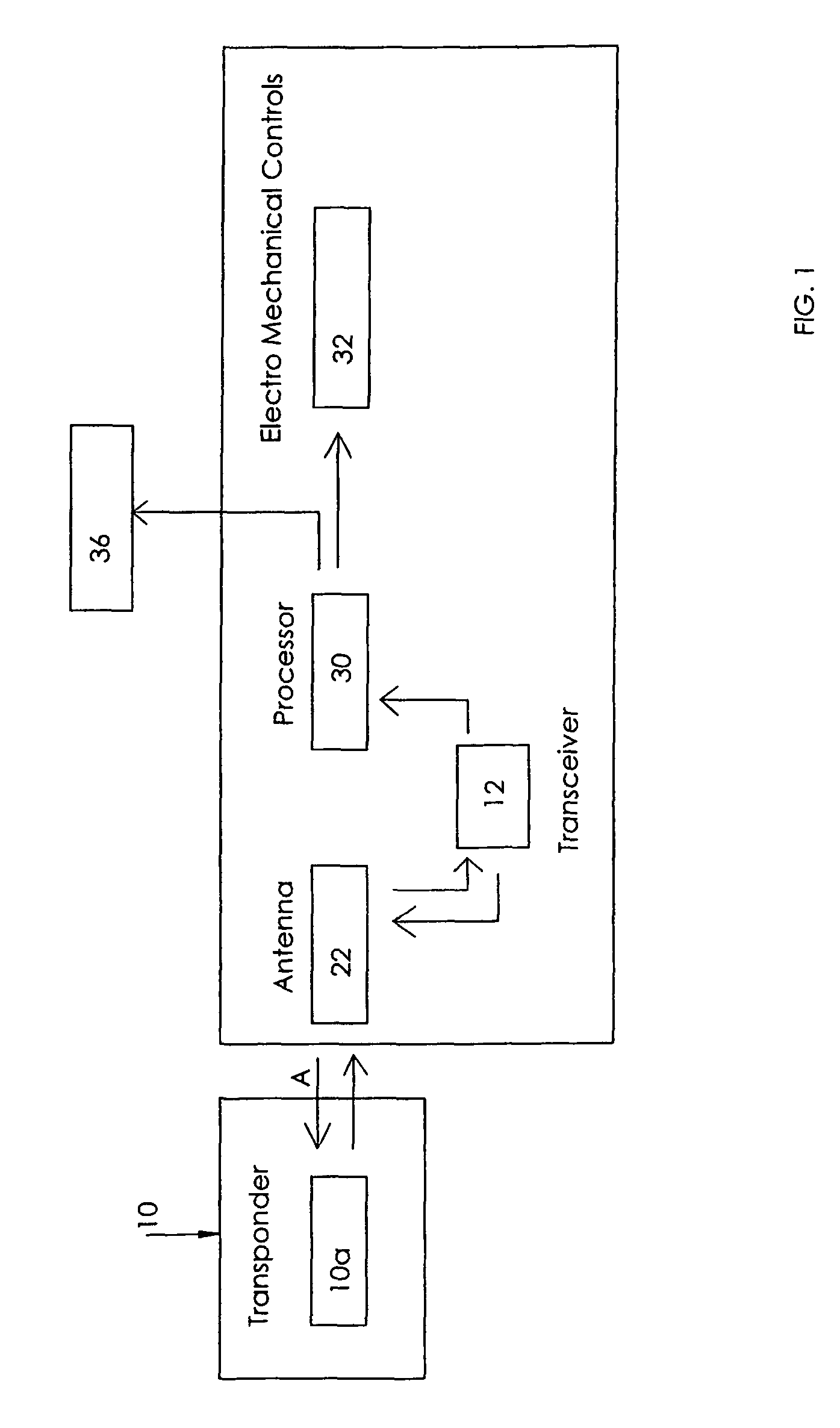

Radio frequency identification based personnel safety system

InactiveUS20080018472A1Safety devices for lifting equipmentsEngineering safety devicesEngineeringStops device

Disclosed is a method and apparatus for selectively immobilizing equipment to ensure the safety of a proximate worker. The apparatus comprises an article of clothing wearable by the proximate worker, a sensor and a stopping means for stopping the movement of a portion of the equipment in response to the sensing. The article of clothing has a RFID tag having an antenna distributed about the article so as to substantially surround a worker wearing the article of clothing. The sensor senses the proximity of the RFID tag to a portion of the equipment. The method comprises sensing the proximity of the RFID tag to a portion of the equipment and stopping the movement of a portion of the equipment in response to the sensing.

Owner:PSST MOBILE EQUIP - RICHARD SHERVEY

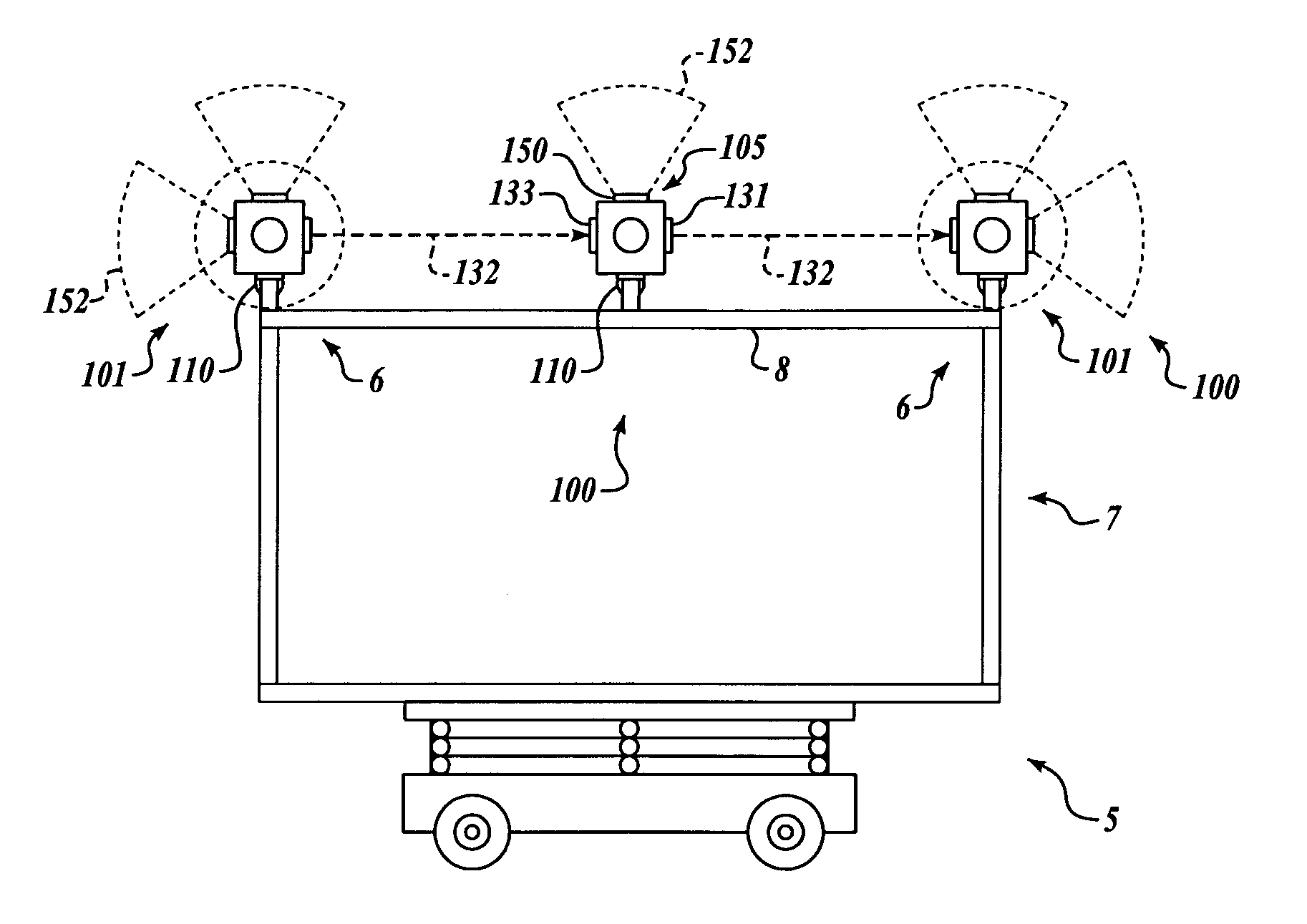

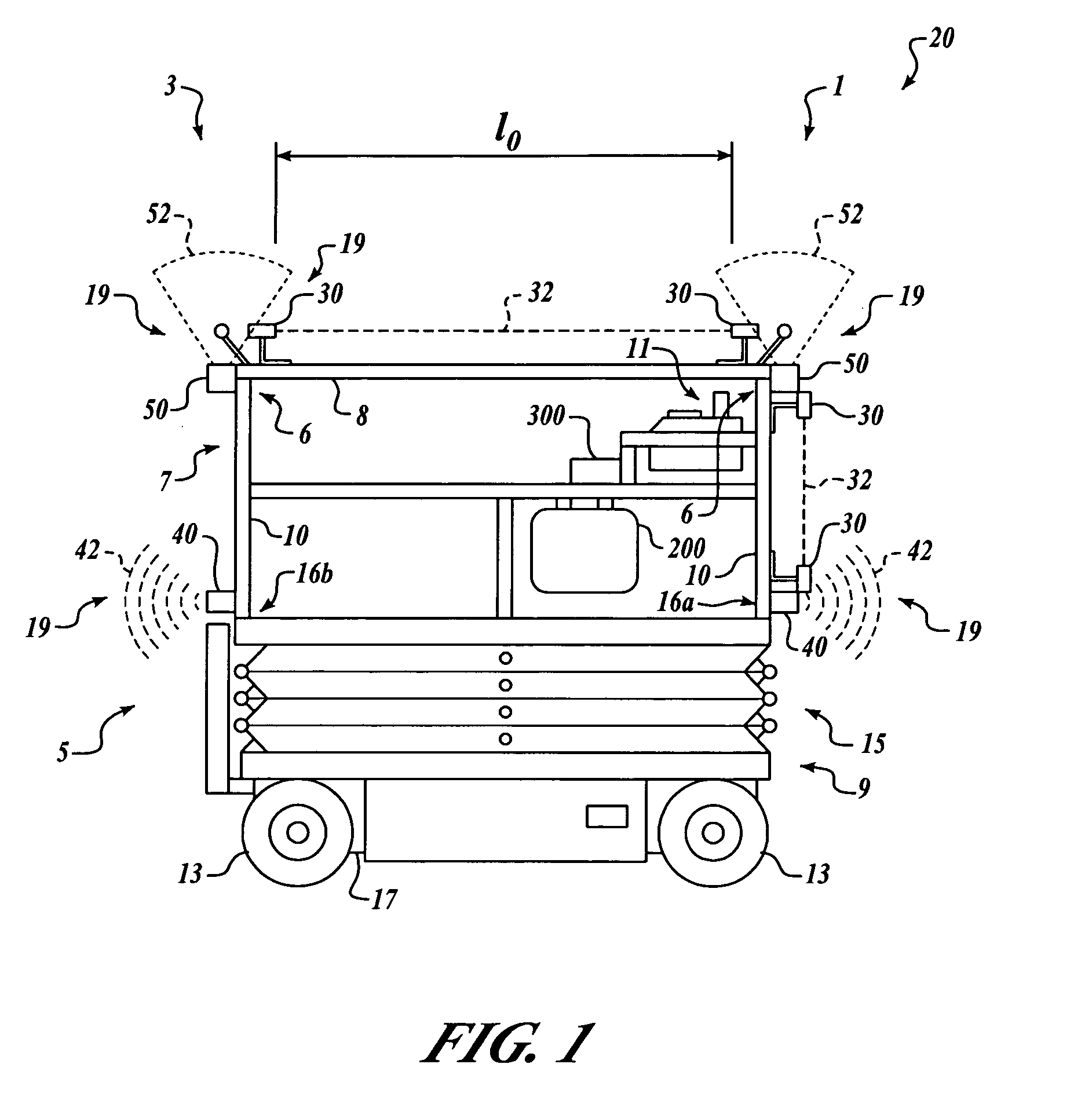

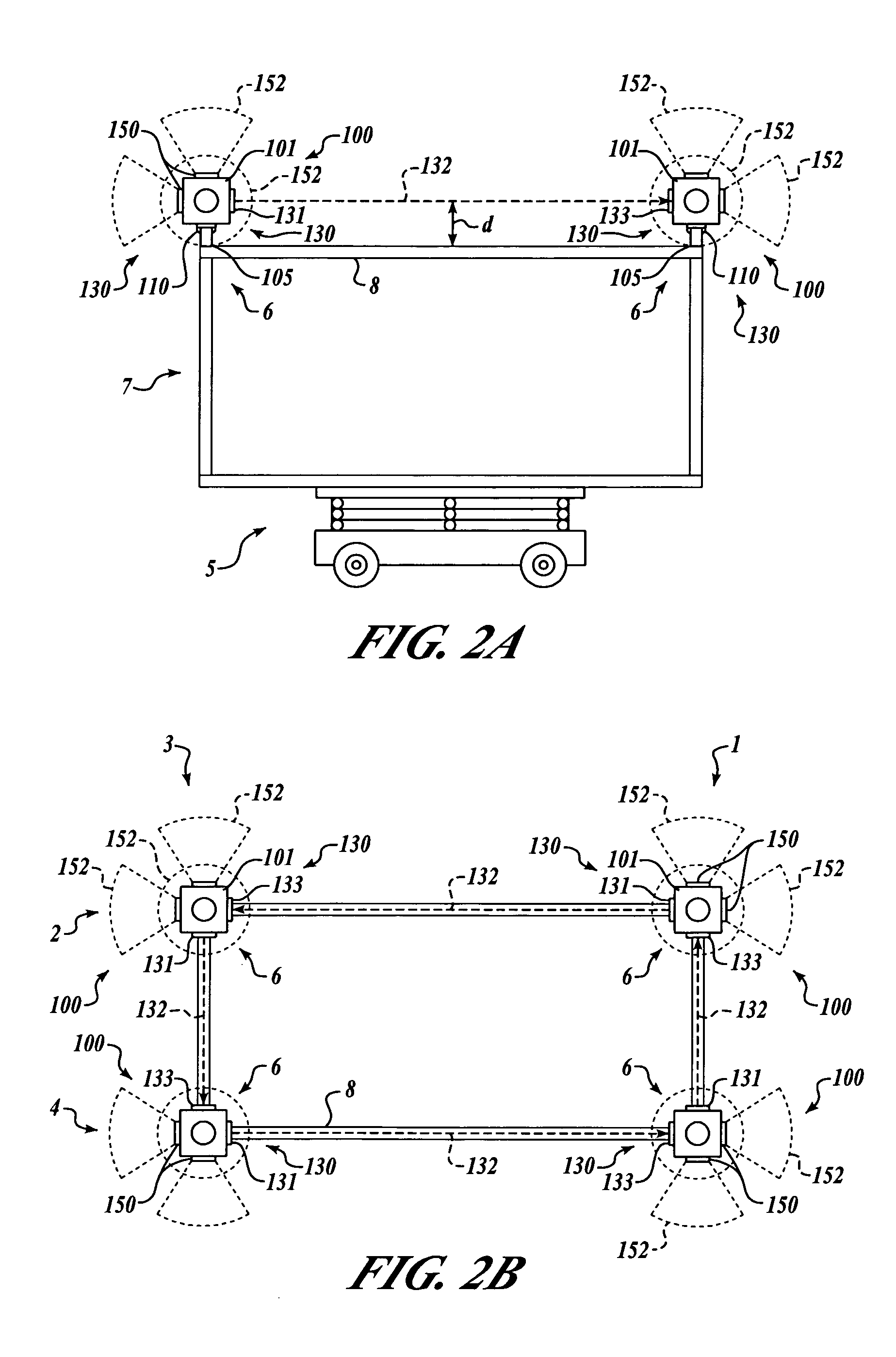

Personnel safety utilizing time variable frequencies

InactiveUS20100289662A1High noiseIncrease resistanceSafety devices for lifting equipmentsEngineering safety devicesOmnidirectional antennaDirectional antenna

A system to improve safety of workers who are in proximity to mobile machines includes a machine mountable radio-frequency identification reader that wirelessly monitors radio-frequency identification tags worn by workers moving relative to and in proximity to a mobile machine when the reader is mounted on the machine. The reader includes a processor and an antenna front-end which is switchable between an omni-directional antenna or at least one directional antenna. The omni-directional antenna is mountable so as to monitor a machine circumference completely around the mobile machine. Each directional antenna is mountable so as to monitor only either a front or a back of the mobile machine relative to the machines direction of motion.

Owner:PSST MOBILE EQUIP - RICHARD SHERVEY +1

Dimensional detection system and associated method

InactiveUS8134717B2Clear visionSafety devices for lifting equipmentsCharacter and pattern recognitionData setLight beam

An improved dimensional detection system is portable and can be used to characterize a workpiece. The dimensional detection system employs as few as a single focused light source and as few as a single camera along with a calibration data set to convert the illuminated pixels of an image of a beam on the workpiece into a cloud of real world points in space on an outer surface of the workpiece. The cloud of points can be processed to characterize the workpiece, such as by determining the right hexahedron that would encompass all of the real world points in space and which could be used to determine a dimensional weight of the workpiece.

Owner:LTS SCALE CO LLC

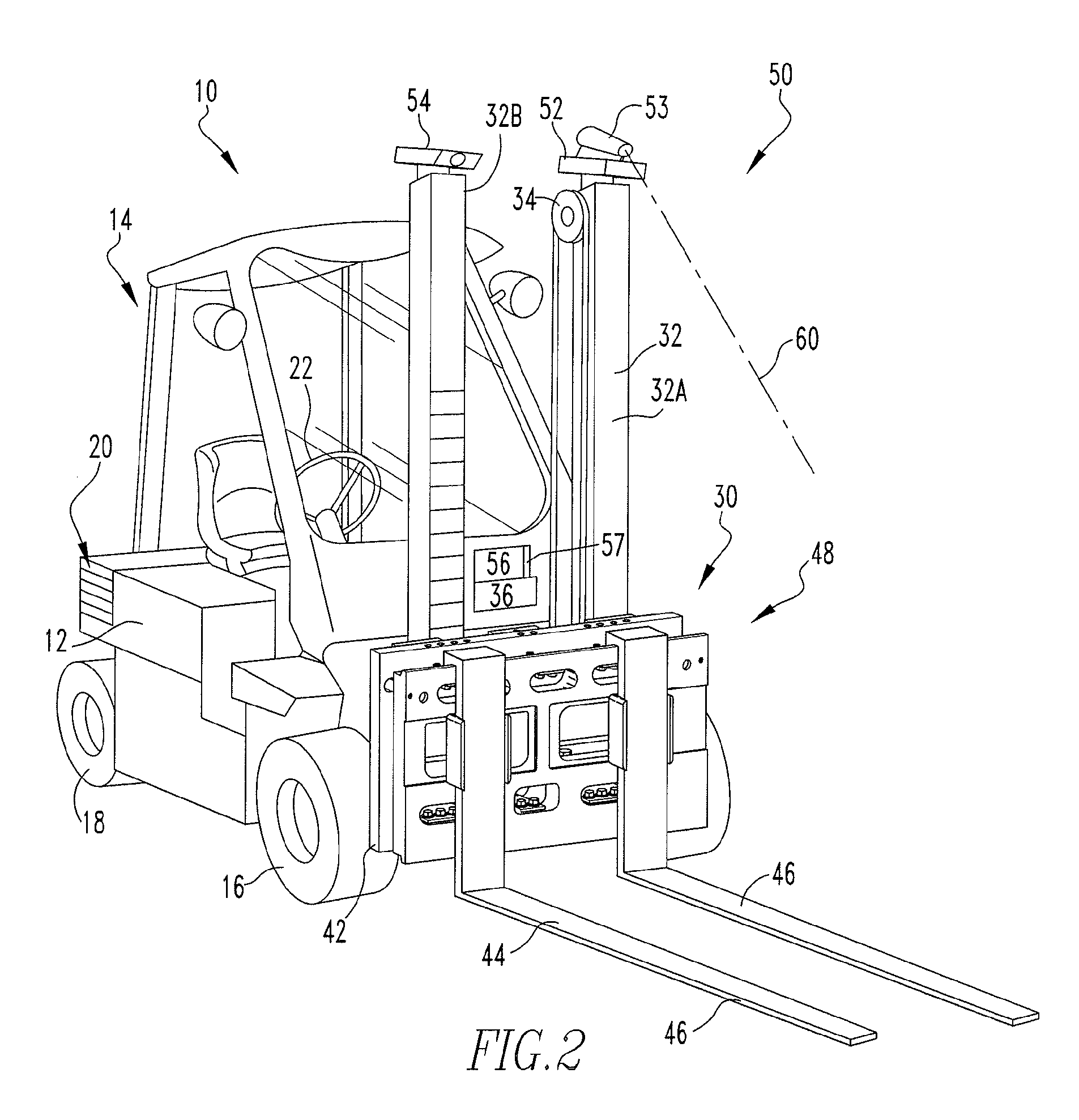

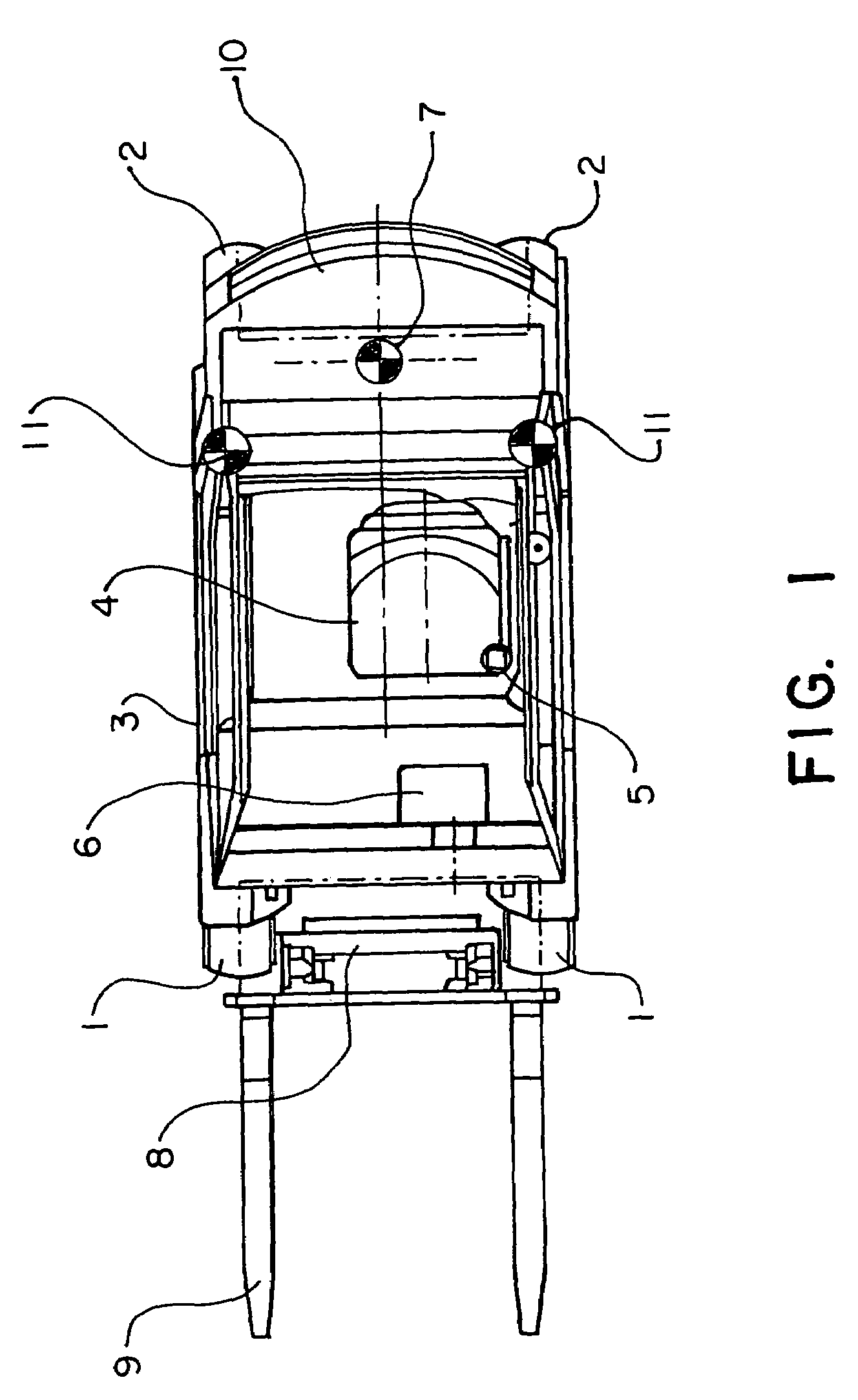

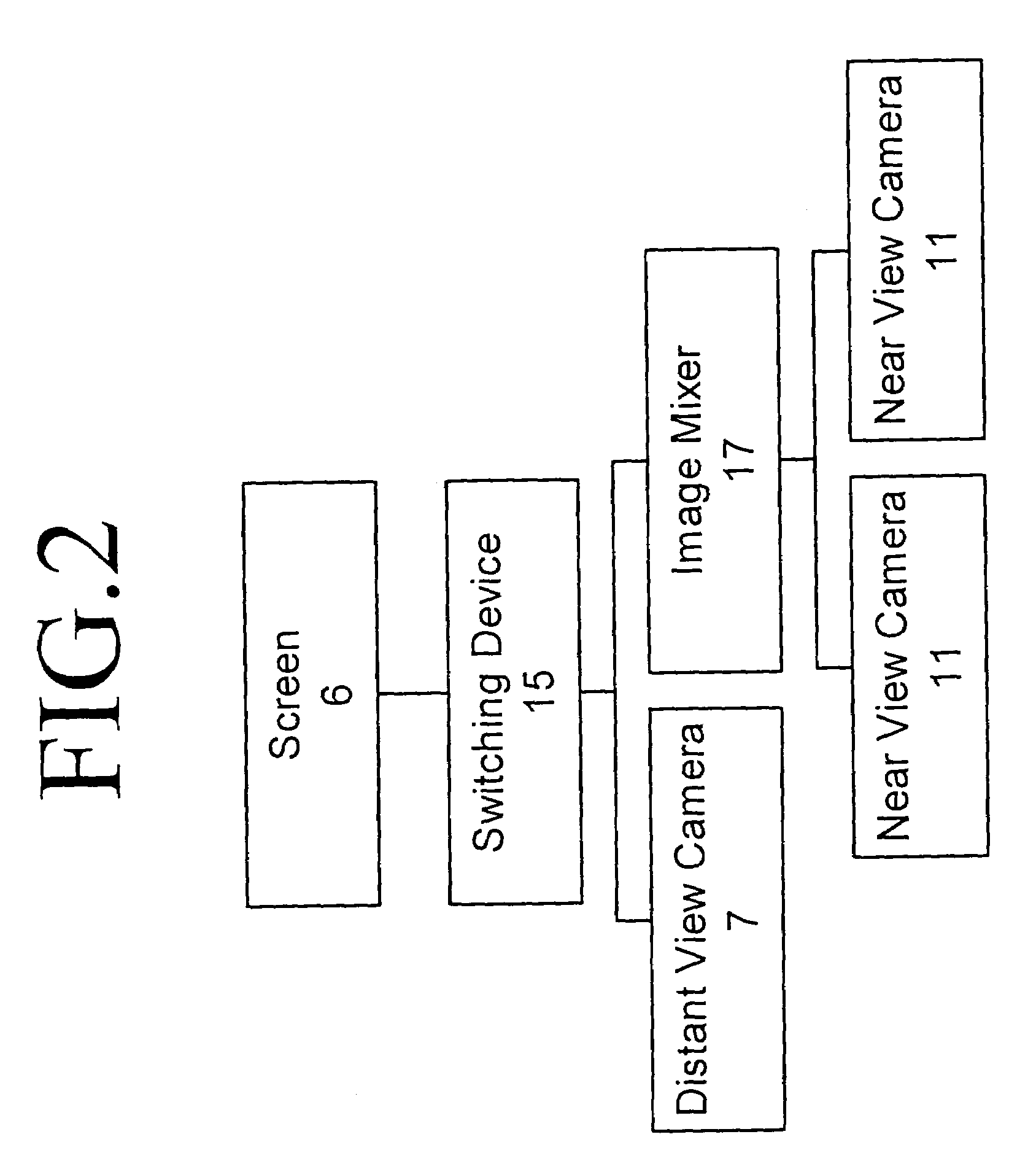

Industrial truck with a camera device

InactiveUS7629996B2Interfere with installationActive connectionSafety devices for lifting equipmentsColor television detailsDriver/operatorEngineering

An industrial truck, in particular a fork lift truck, has a driver's seat that is oriented in the forward direction, at least one screen that is located in the vicinity of the driver's seat, a first camera pointing toward the rear of the industrial truck and at least one additional camera that is directed toward the rear. The first camera is provided to view a distant area and the additional camera is provided to view a near area behind the industrial truck. The image taken with the first camera and / or the image taken with the additional camera can be displayed on the screen. There are advantageously two additional cameras to view the near area.

Owner:STILL GMBH

Personnel safety utilizing time variable frequencies

InactiveUS8248263B2High noiseIncrease resistanceSafety devices for lifting equipmentsEngineering safety devicesOmnidirectional antennaDirectional antenna

A system to improve safety of workers who are in proximity to mobile machines includes a machine mountable radio-frequency identification reader that wirelessly monitors radio-frequency identification tags worn by workers moving relative to and in proximity to a mobile machine when the reader is mounted on the machine. The reader includes a processor and an antenna front-end which is switchable between an omni-directional antenna or at least one directional antenna. The omni-directional antenna is mountable so as to monitor a machine circumference completely around the mobile machine. Each directional antenna is mountable so as to monitor only either a front or a back of the mobile machine relative to the machine's direction of motion.

Owner:PSST MOBILE EQUIP - RICHARD SHERVEY +1

Lift collision avoidance system

ActiveUS7194358B2Safety devices for lifting equipmentsAnti-collision systemsControl theoryCollision avoidance system

The present invention is directed to systems, devices and methods for avoiding collisions and detecting objects proximate to a surface. In one embodiment, a system for collision avoidance includes at least one sensor adapted to sense an object above a lift device and a controller linked to the at least one sensor and linked to the drive components of the device and adapted to interrupt operation of the lift drive when the lift device approaches or touches the object. In another aspect of the invention, at least one controller is linked between at least one hand control and at least one drive adapted to move a lift device, the controller being adapted to interrupt operation of the drive when the lift device approaches or touches an object.

Owner:THE BOEING CO

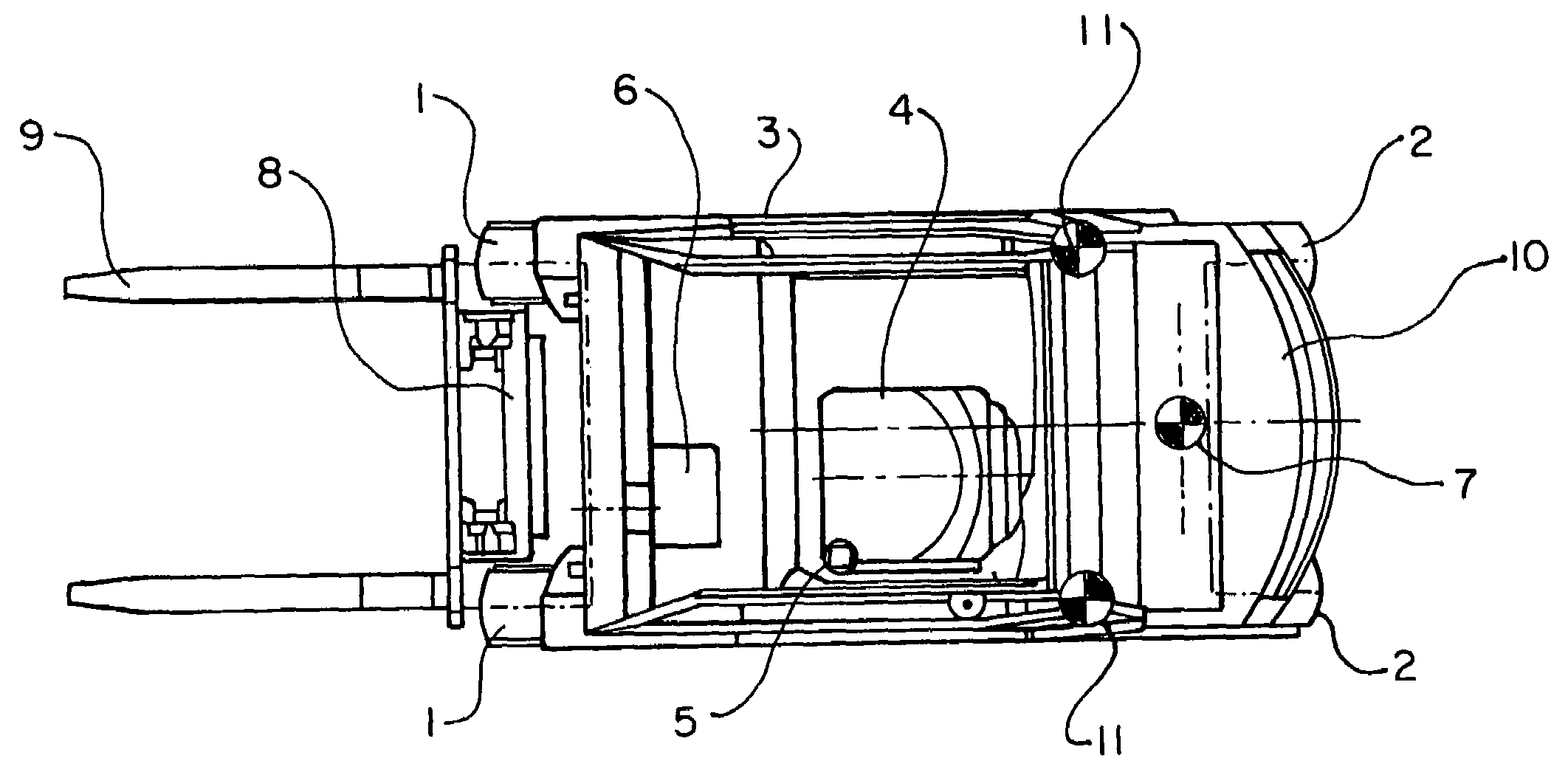

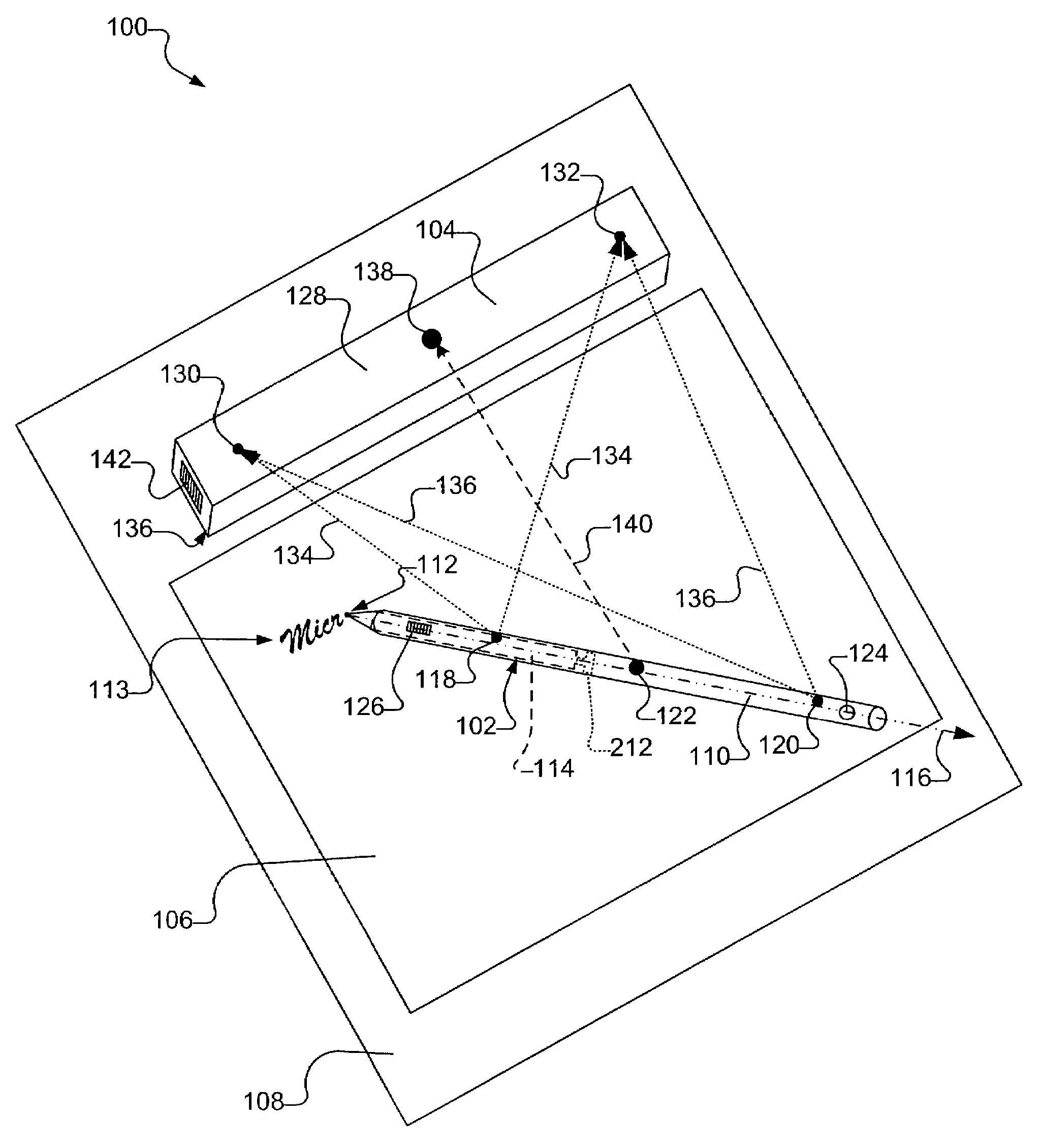

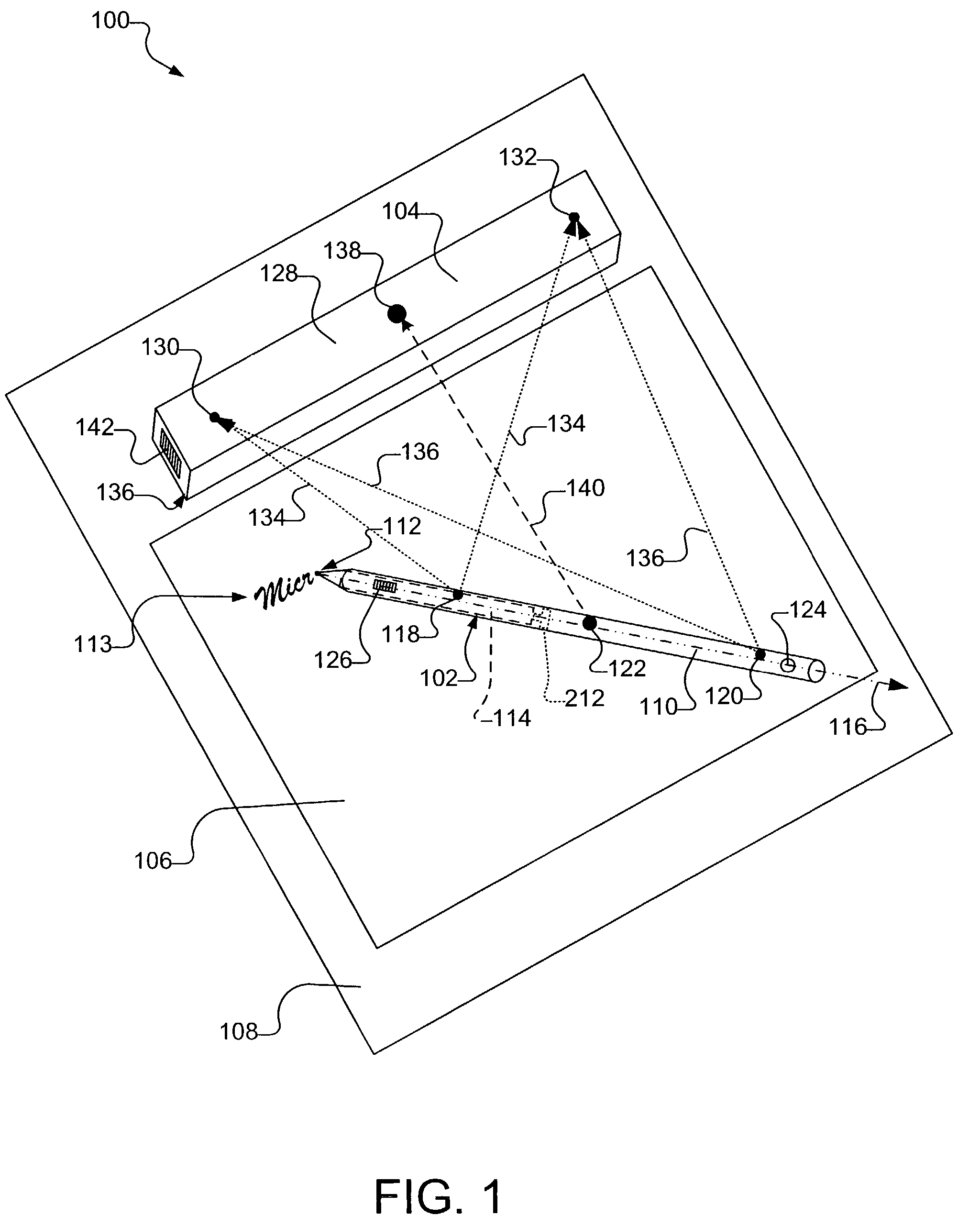

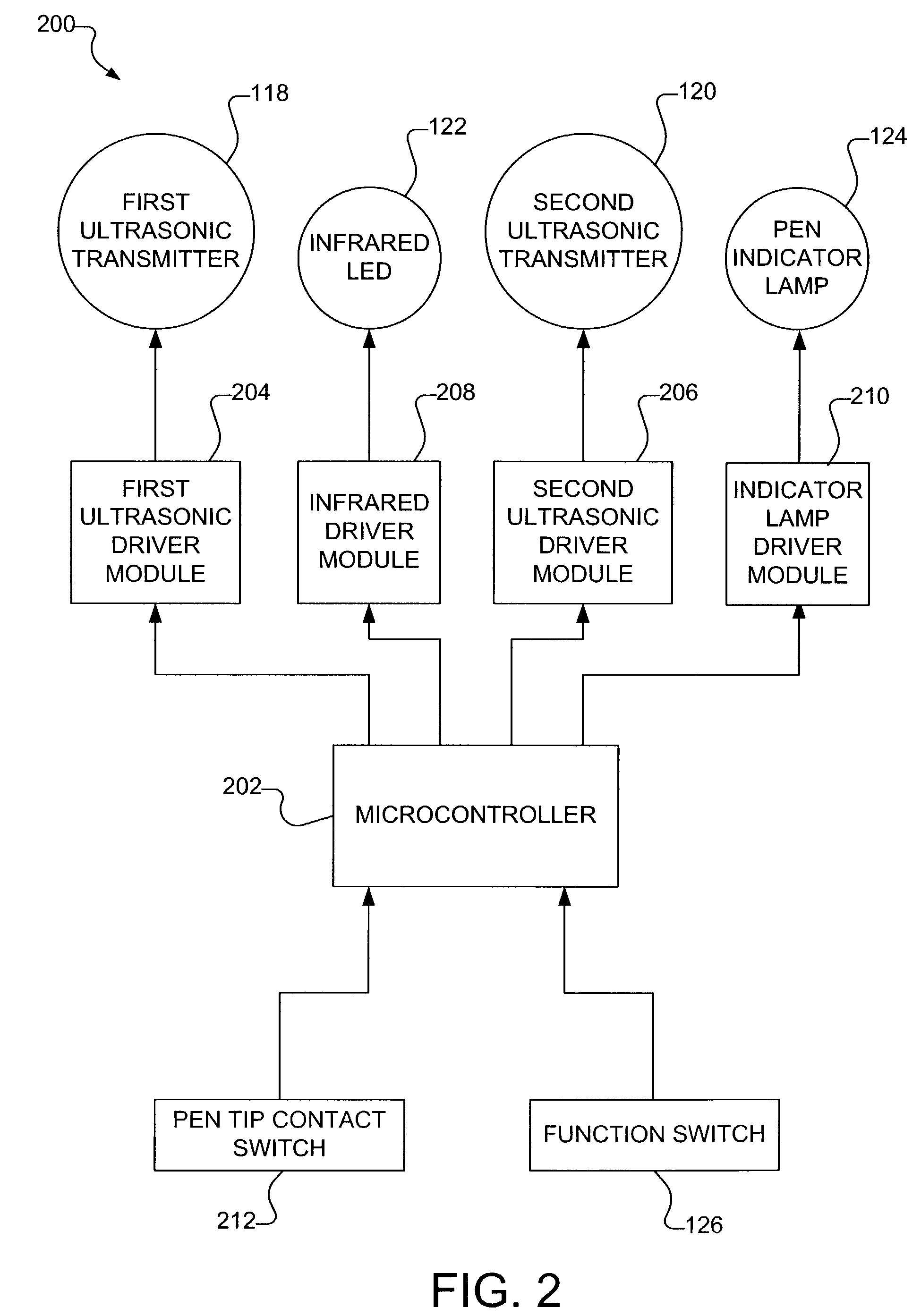

Determining the location of the tip of an electronic stylus

InactiveUS7489308B2Accurate locationSafety devices for lifting equipmentsTransmission systemsElectromagnetic launchEngineering

An electronic stylus system includes an electronic stylus and base receiving unit. The electronic stylus includes a first ultrasonic transmitter, a second ultrasonic transmitter, an electromagnetic transmitter, and a writing tip. The base receiver unit includes a first ultrasonic receiver, a second ultrasonic receiver, and an electromagnetic receiver. The ultrasonic receivers of the base unit are operable to receive signals transmitted by the ultrasonic transmitters of the electronic stylus. Similarly, the electromagnetic receiver of the base unit is operable to receive signals transmitted by the electromagnetic transmitter of the stylus. The location of the tip of the electronic stylus relative to a given reference point is determined using the locations of two ultrasonic transmitters relative to the two ultrasonic receivers.

Owner:MICROSOFT TECH LICENSING LLC

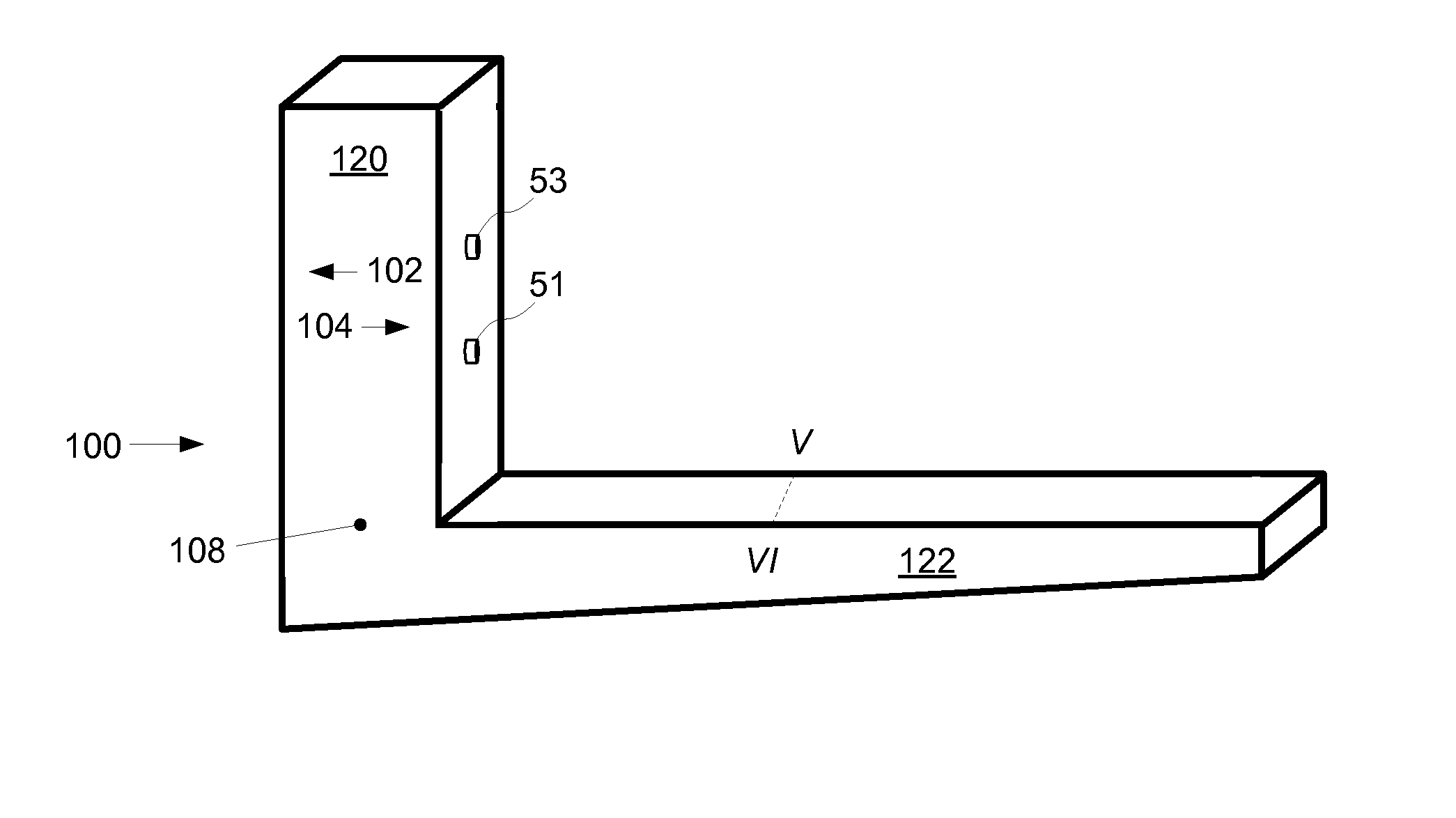

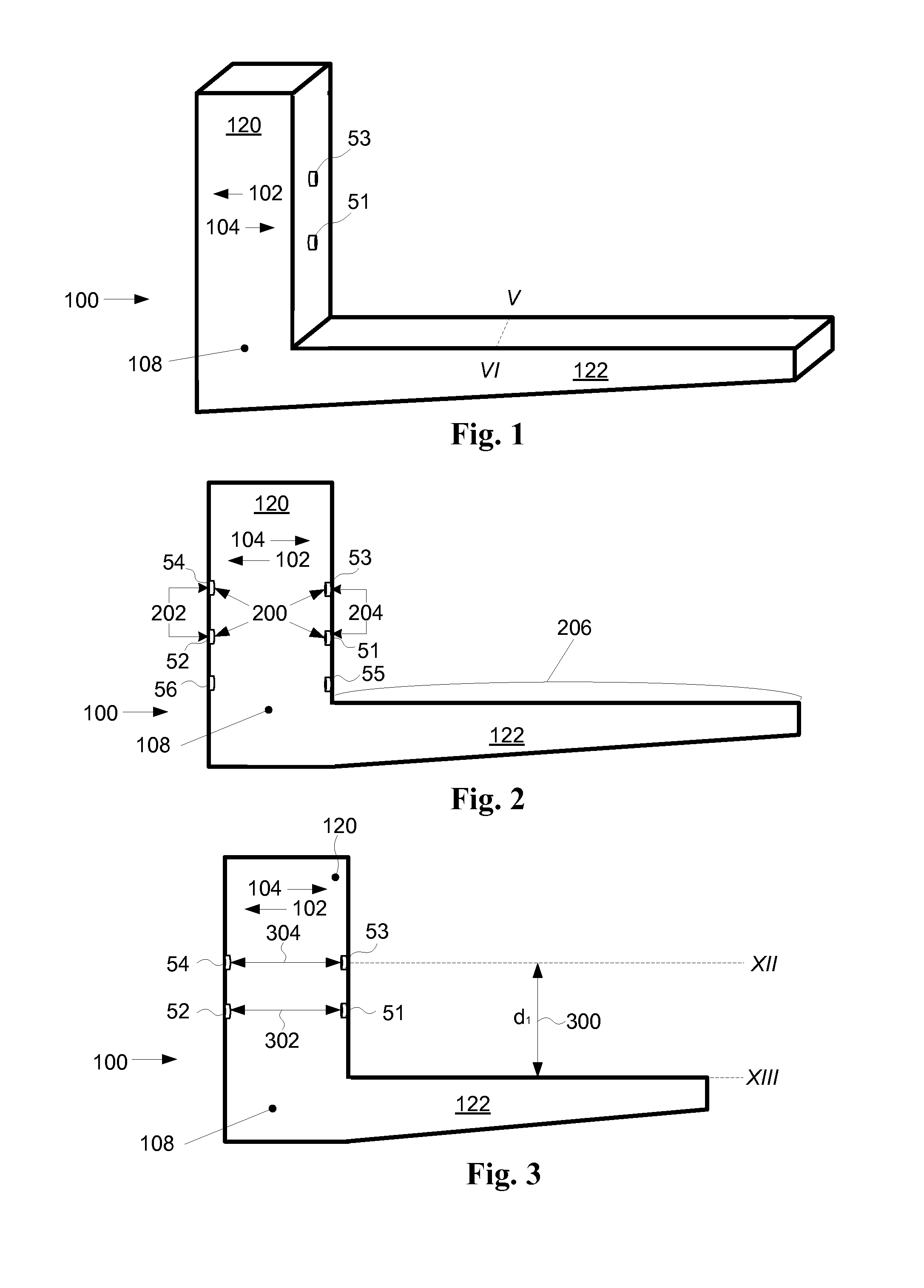

System and method to measure force or location on an l-beam

InactiveUS20160187186A1Improve accuracyAvoid problemsSafety devices for lifting equipmentsConveyorsEngineeringProduct image

Force and location sensing systems and methods are disclosed. A method comprises bending a L-beam at an initially unknown location on a force-supporting portion of the L-beam, the L-beam substantially having a tension side and a compression side, measuring a first local stress at a first location on the tension side, measuring a second local stress at a second location on the tension side, measuring a third local stress at a third location on the compression side, and measuring a fourth local stress at a fourth location on the compression side. A weight-sensing storage system capable of tracking removed items is disclosed with a product image captured via a camera, a plurality of sensors on an L-beam, a first signal from the plurality of sensors indicating a first state prior to change of the product image, and a second signal indicating lower strain on the L-beam than the first signal.

Owner:COLEMAN NATE J +1

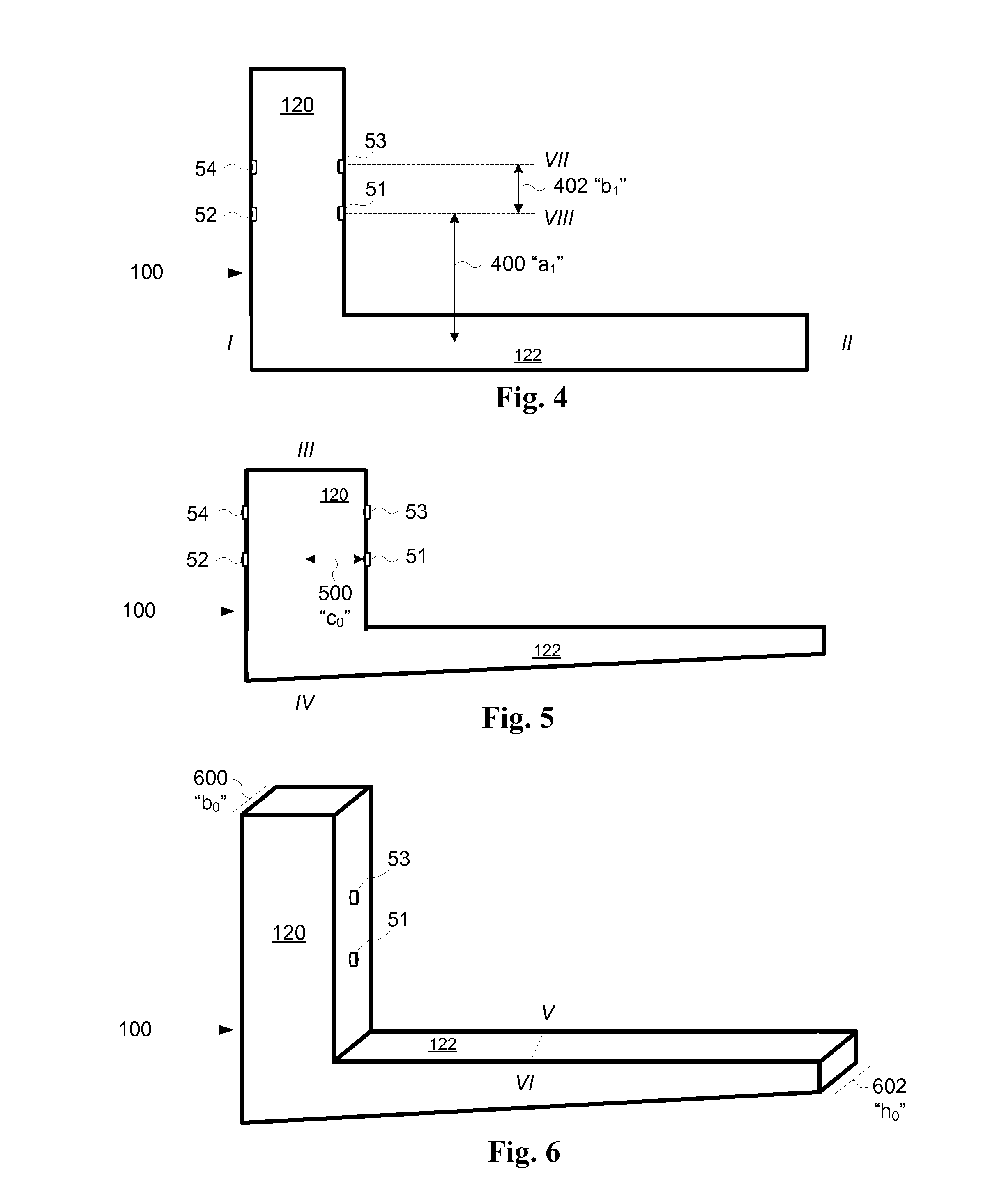

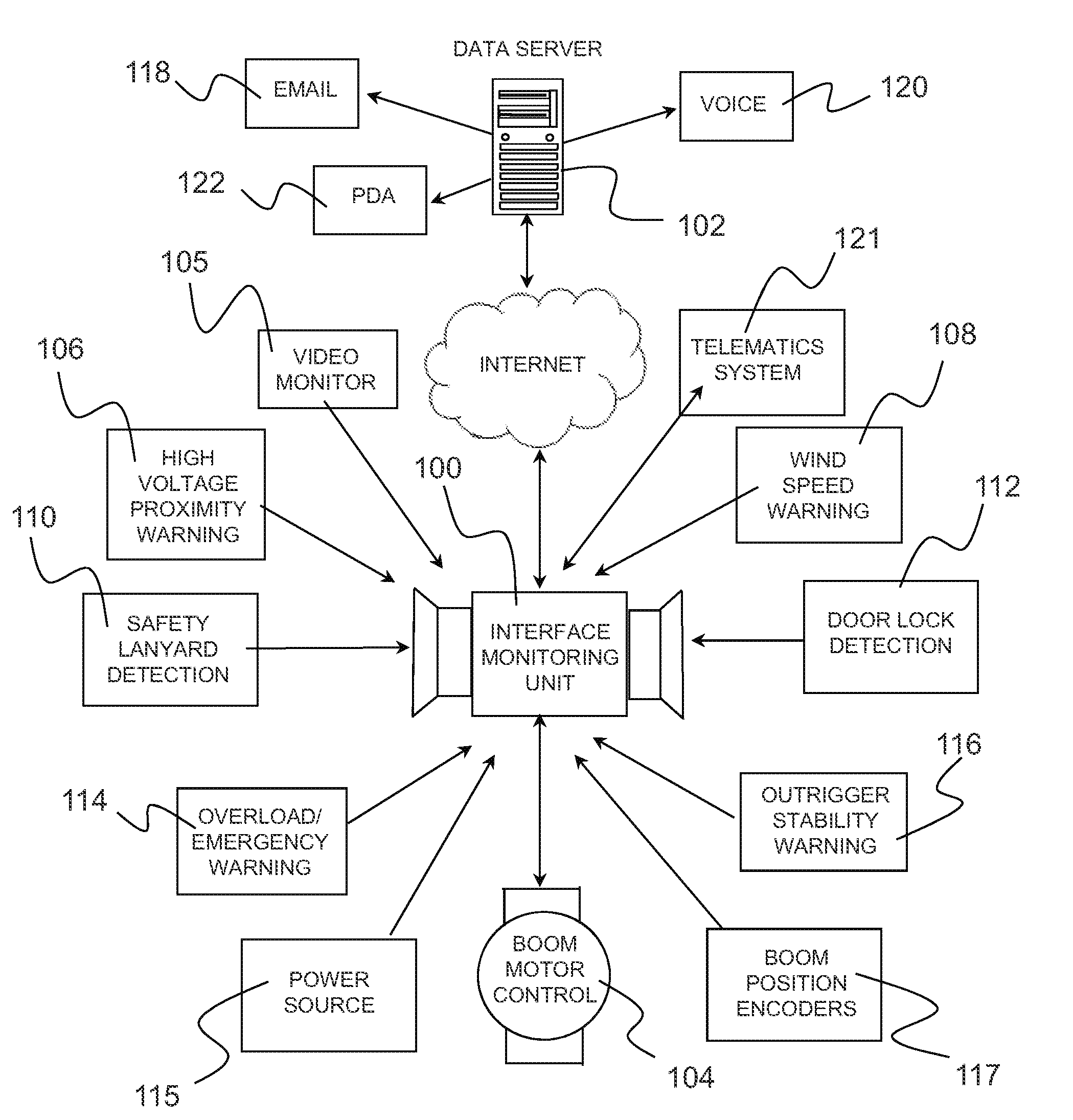

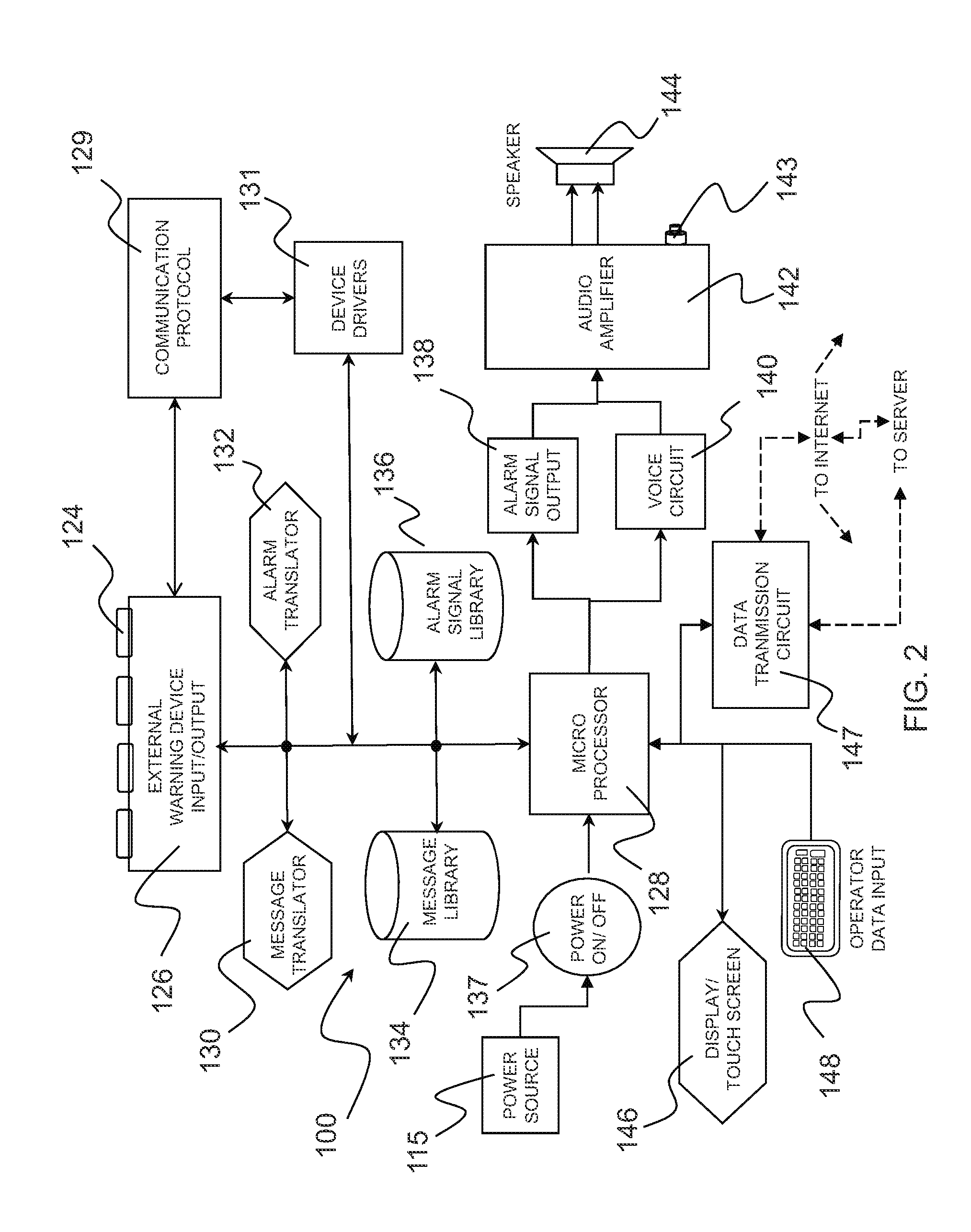

Warning and message delivery and logging system utilizable in the monitoring of fall arresting and prevention devices and method of same

ActiveUS20120217091A1Allow accessEasy to useSafety devices for lifting equipmentsDigital data processing detailsMessage deliveryWarning system

An active interface monitoring and warning system for fall arresting / prevention devices delivering specific fault condition messages to individuals who are subject to accidental falls or other safety hazards when performing construction or the like or when operating elevating construction machinery such as aerialift work platforms and the like. The invention further provides a data logging system to record and transmit operational conditions, fault conditions and safety infractions.

Owner:O E M CONTROLS INC +1

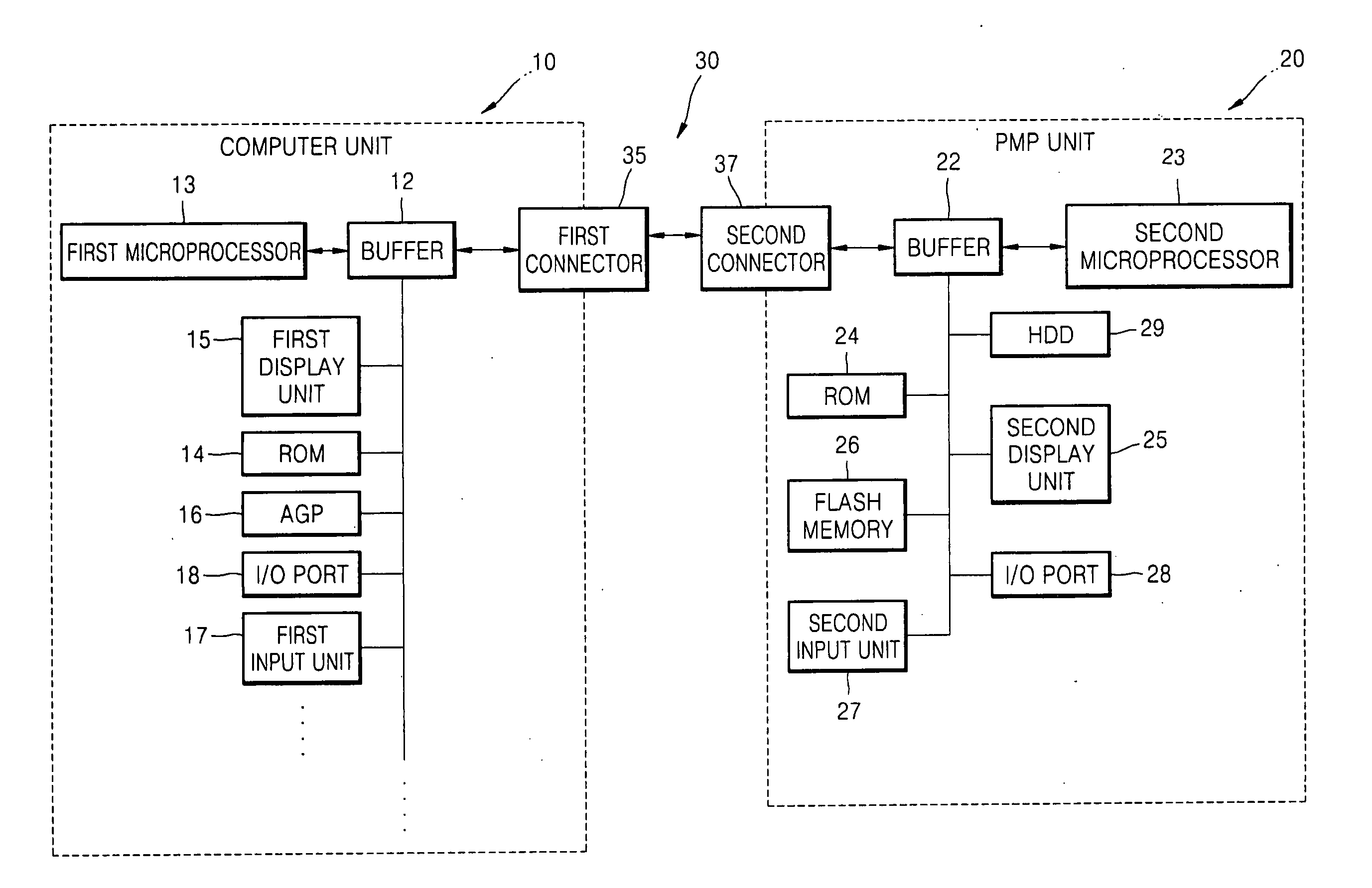

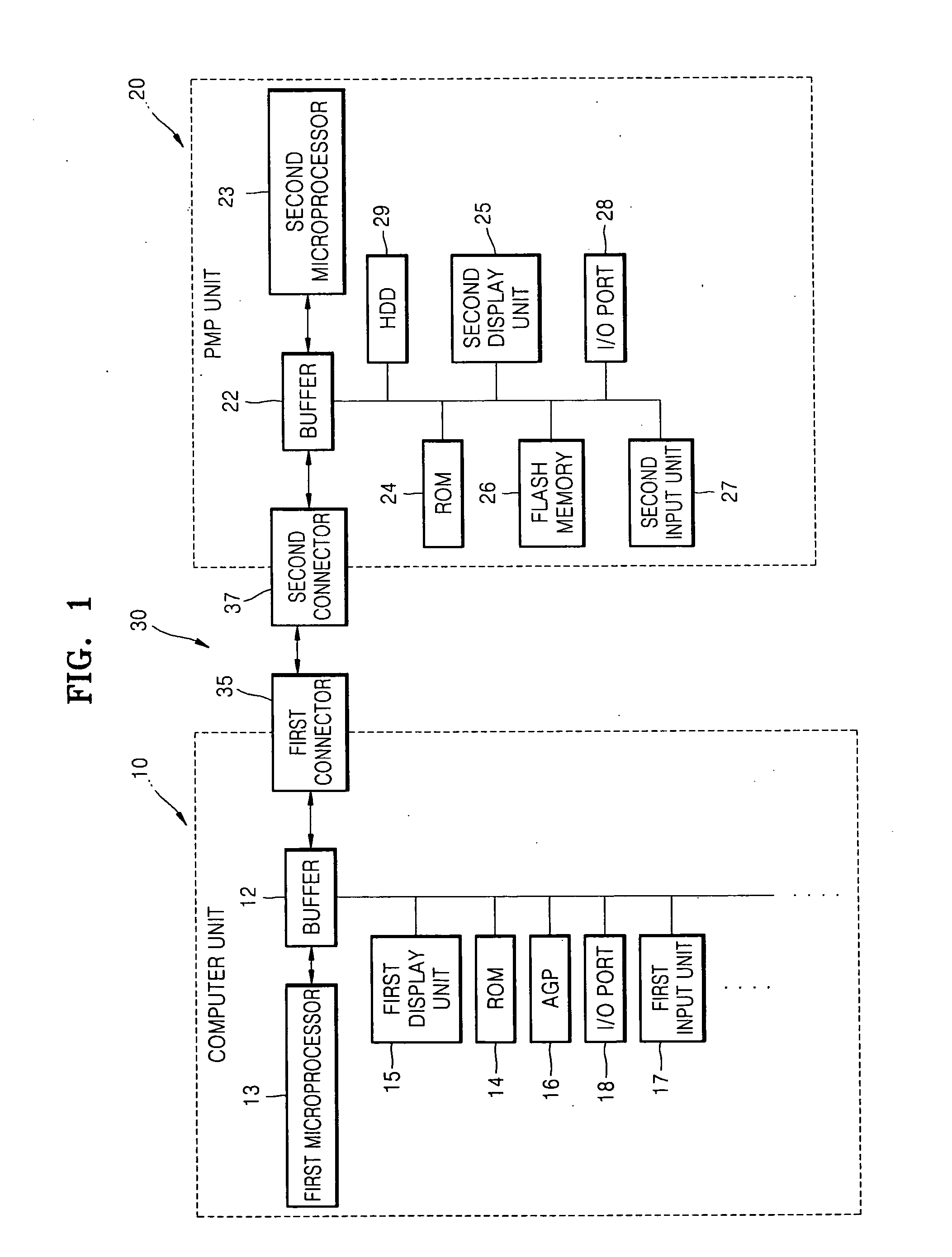

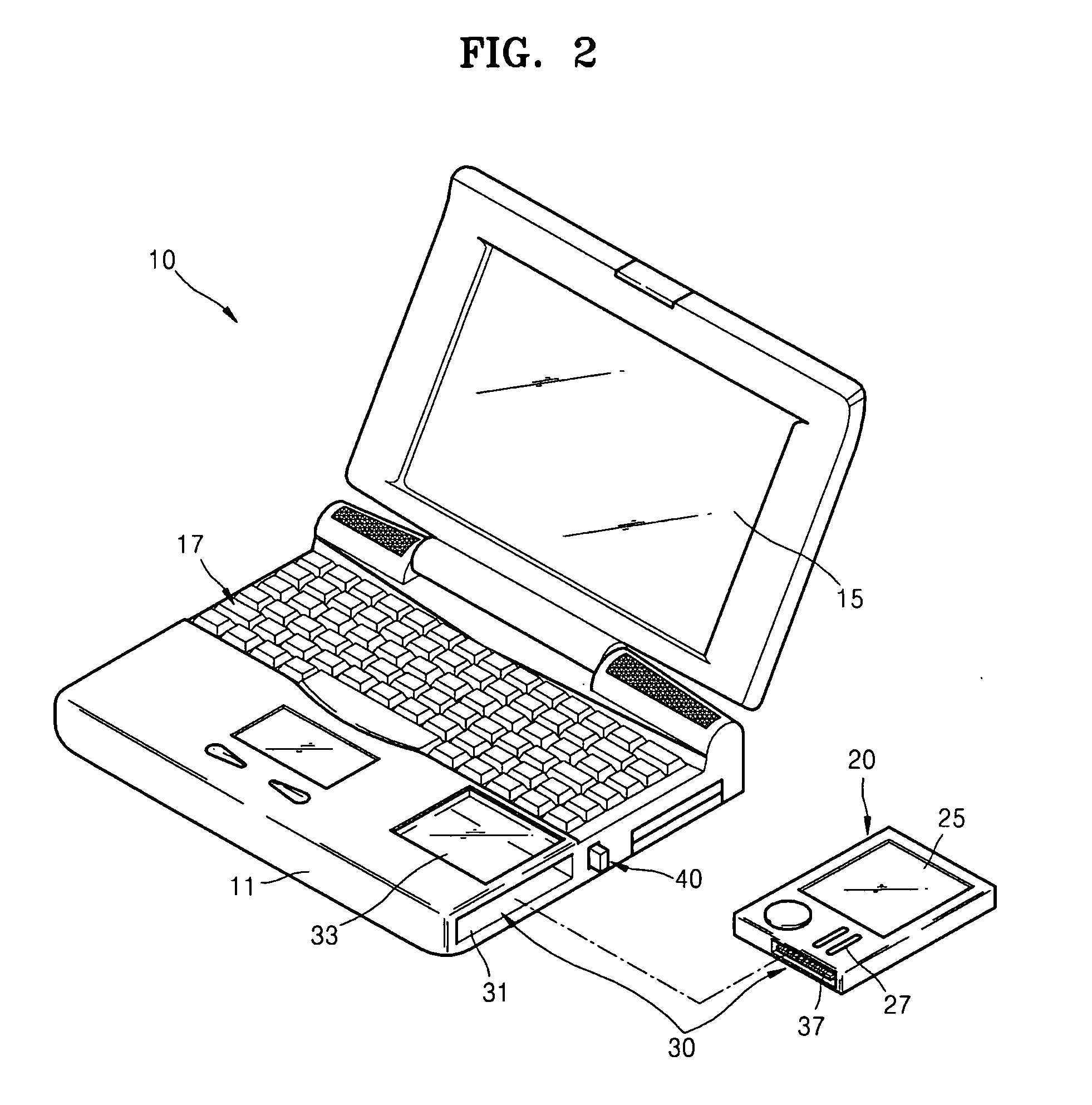

Digital multimedia device

InactiveUS20070198760A1Safety devices for lifting equipmentsDigital data processing detailsHard disc driveOperational system

A digital multimedia device capable of functioning as both a portable multimedia player (PMP) and a notebook computer is provided. The digital multimedia device includes: a computer unit including a body, a first processor included in the body to operate a first operating system (OS), a first display unit for displaying image information processed by the first processor, and a first input unit; a PMP unit including a second processor to operate a second operating system, a hard disk drive (HDD) for storing programs and data, a second display unit for displaying image information processed by the second processor, and a second input unit; and a docking unit disposed in the computer unit and the PMP unit for docking the PMP unit to the computer unit, wherein, when the PMP unit is docked with the computer unit, the computer unit shares the HDD with the PMP unit to perform processing operations, and the PMP unit operates independently or in association with the computer unit.

Owner:SAMSUNG ELECTRONICS CO LTD

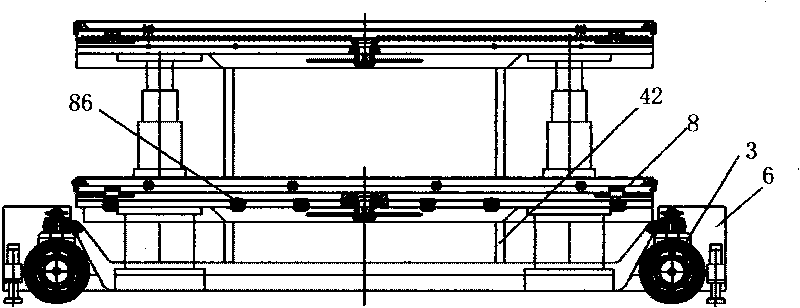

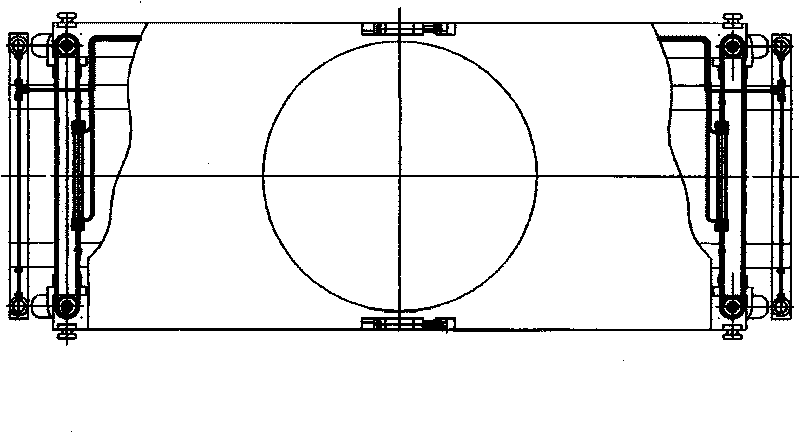

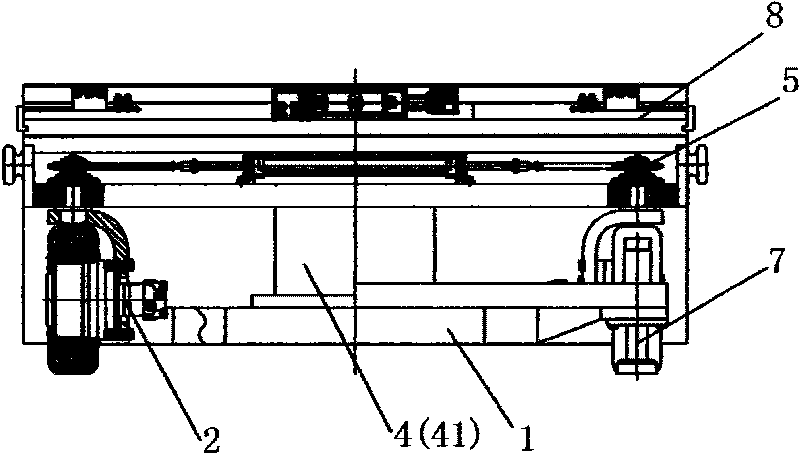

Fully automatic mobile hydraulic lifting platform machine

InactiveCN101708816ASuit one's needsLift freelySafety devices for lifting equipmentsProduction lineControl system

The invention discloses a fully automatic mobile hydraulic lifting platform machine. The machine comprises a chassis, a travelling drive device, a lifting device, hydraulic and electrically controlled systems and a charging device, wherein the lower surface of the chassis is provided with wheels, the travelling drive device and a braking device, the lifting device, the hydraulic system, a steering system, a operation system, a control system, the charging device and a foot device are arranged on the chassis, the chassis and a platform are provided with a safety device and a measurement system, and the lifting device is provided with a floating platform device. The machine of the invention can bear the rated weight according to the demand; and the travelling mechanism thereof can realize forth-back travelling and left-right travelling, 90 degrees of translation and crab motion, and the lifting platform device can move longitudinally and transversely, rotates and go up and down freely. Owning to various movement choices, the degrees of mechanization and automation are high, and the machine can change according to different conditions and accurately and timely position the installation position of the chassis, thus increasing the efficiency, ensuring the satisfy and satisfying the demand of the railway vehicle manufacture and assembly production line.

Owner:EZHOU CITY HEQIANG MACHINERY DEV

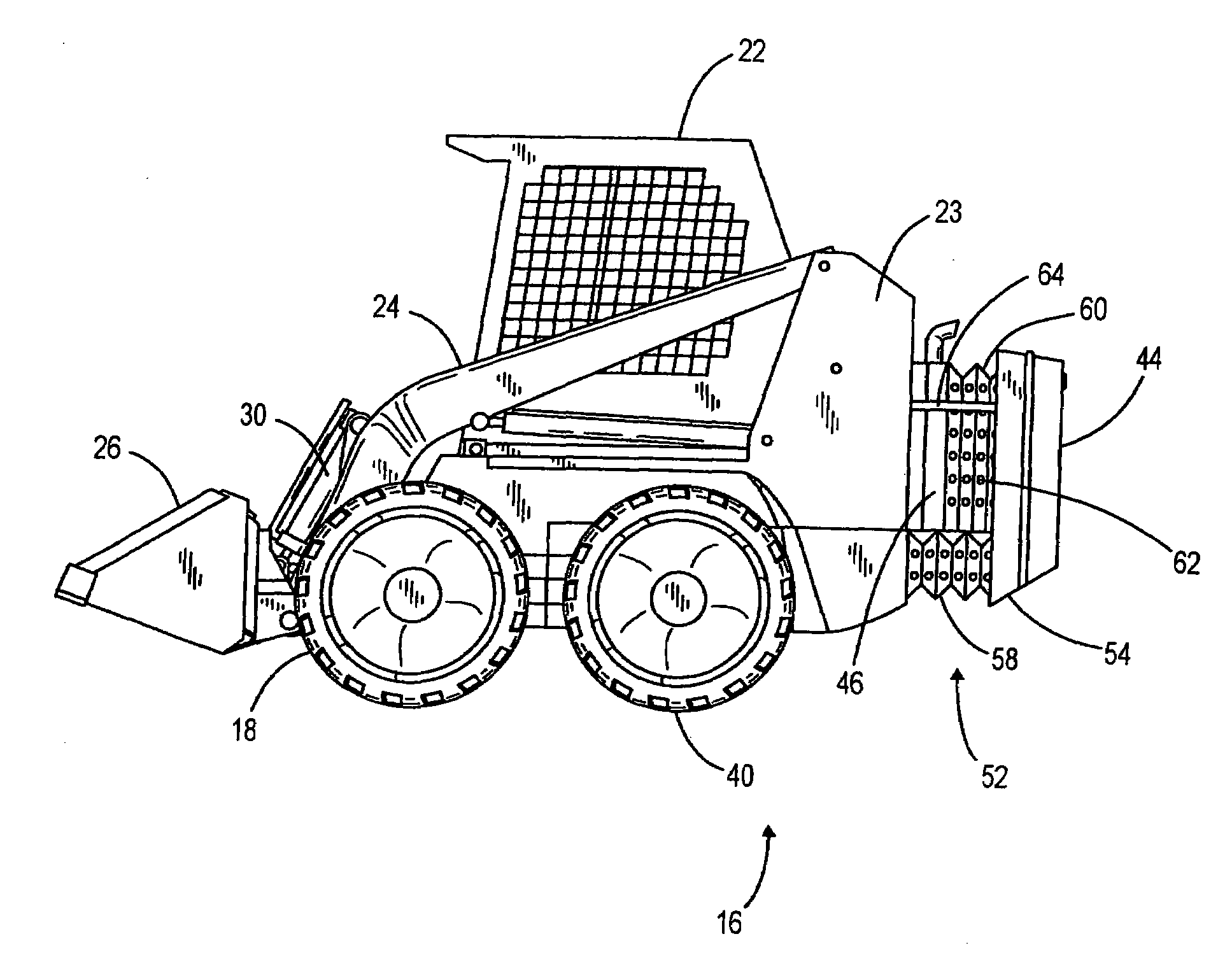

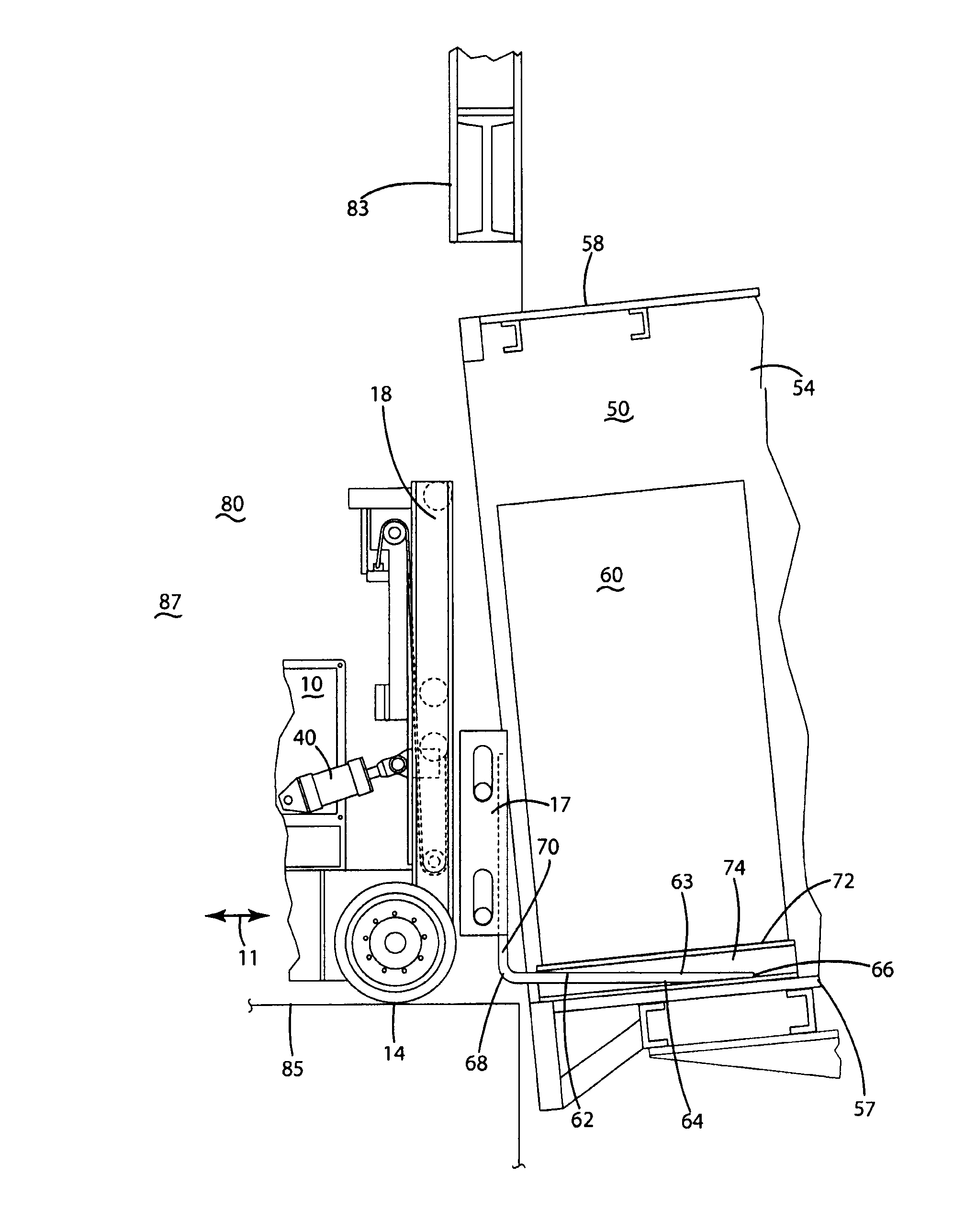

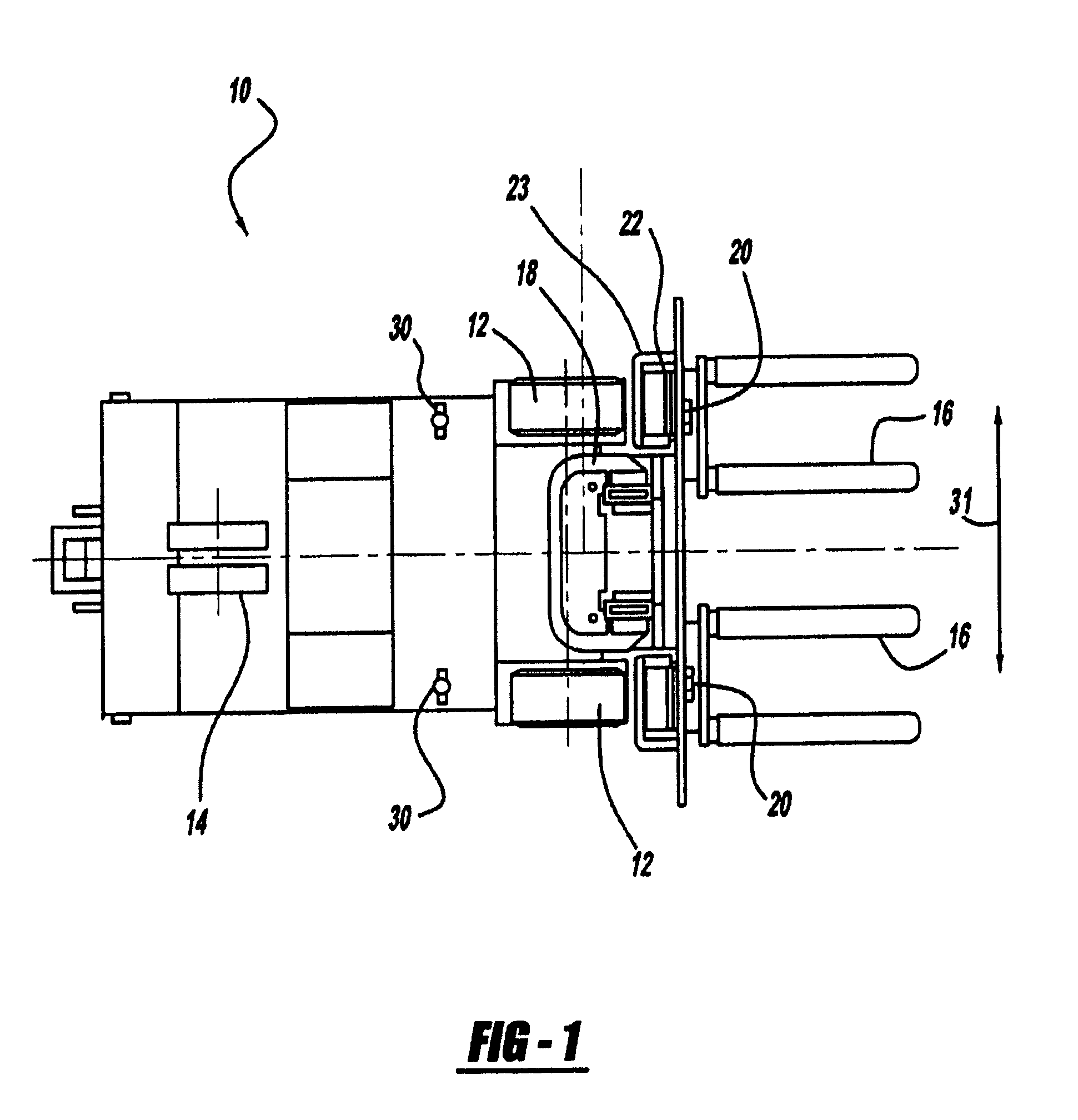

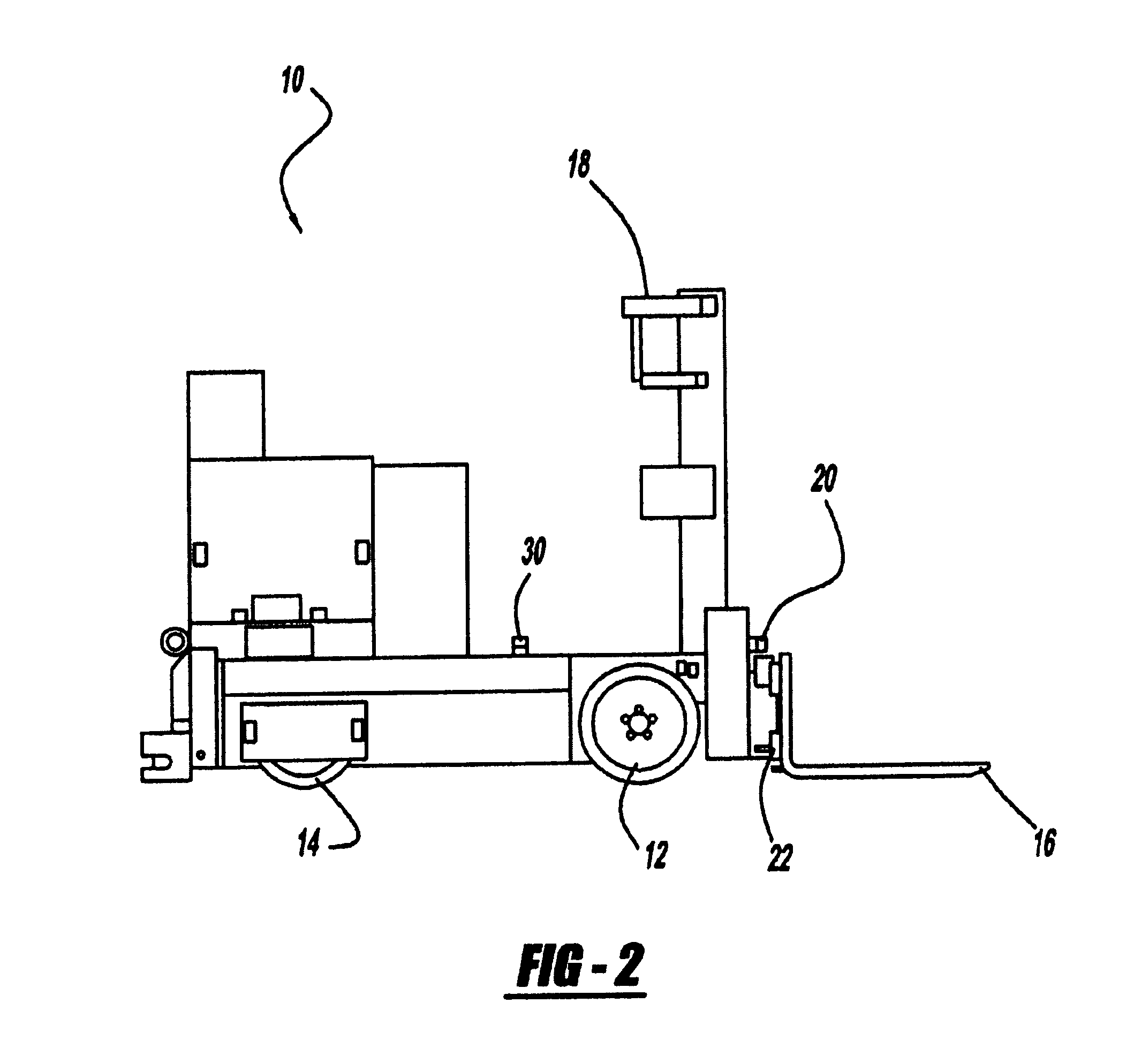

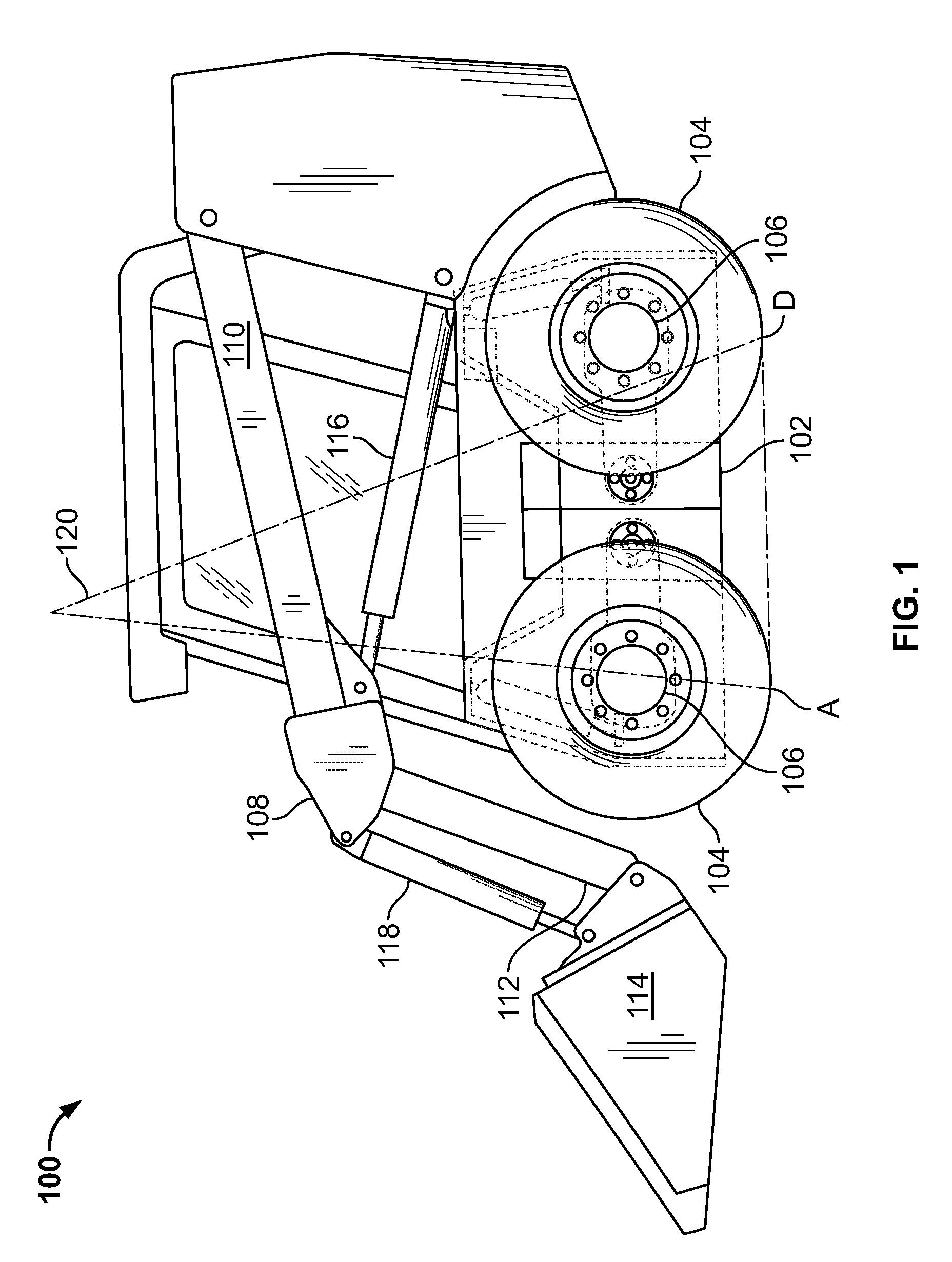

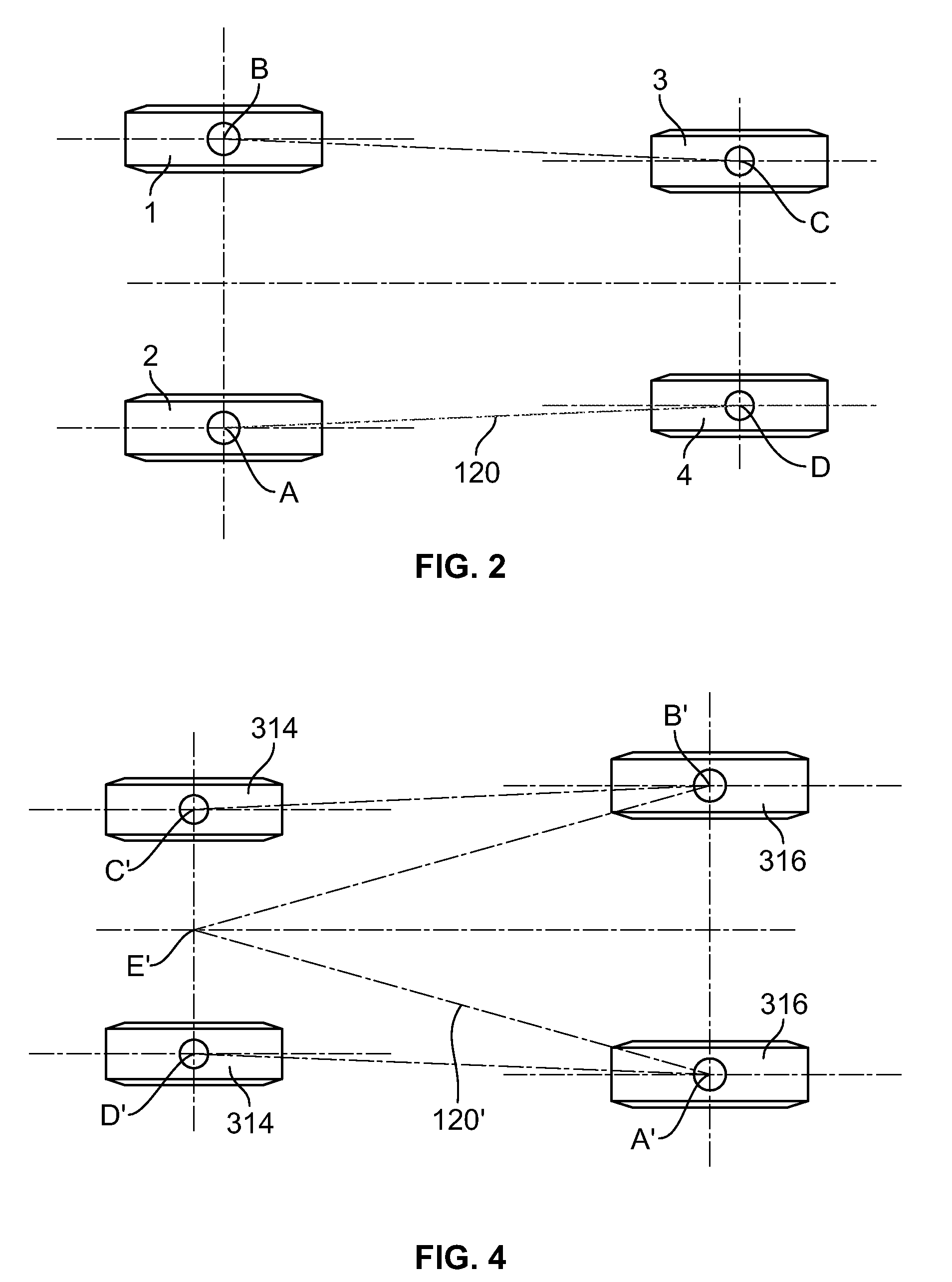

Extendable frame work vehicle

ActiveUS20090038186A1Improve versatilityImprove securitySafety devices for lifting equipmentsAuxillary drivesHydraulic motorVehicle frame

An extendable frame work vehicle offering enhanced versatility, safety and effectiveness. The vehicle includes an adjustable frame with front and rear portions that extend or retract with respect to each other. The front portion is supported by a first pair of wheels and said rear portion is supported by a second pair of wheels. Each wheel is independently driven and steered. The vehicle also includes an engine mounted on the rear portion of the frame. Incorporated into the vehicle is an electro-hydraulic assembly which enables extension and retraction of the adjustable frame. The assembly includes a sensor-responsive microprocessor controller, at least one hydraulic pump, at least one hydraulic drive motor, and at least one valve network.

Owner:EXTENDQUIP LLC

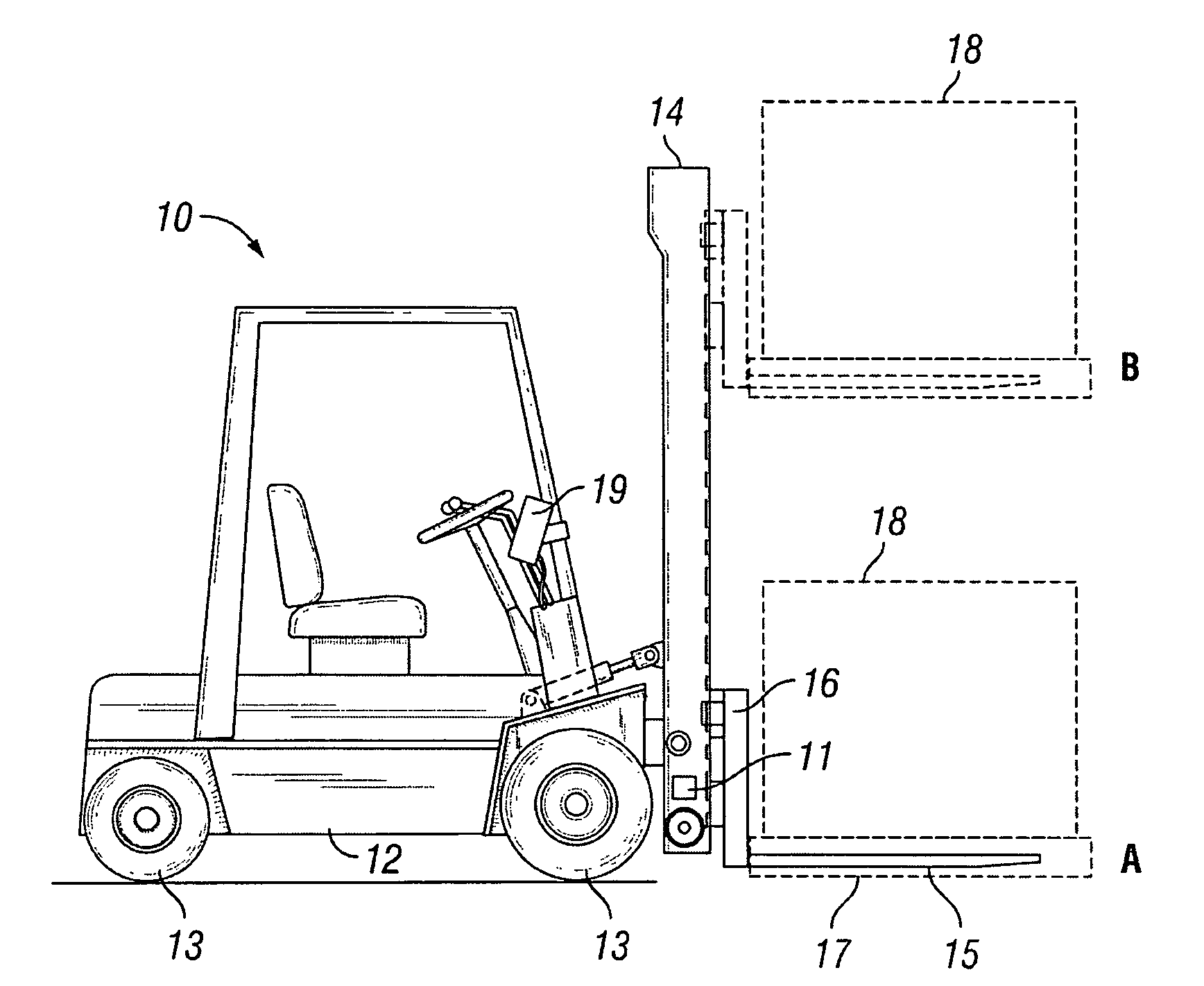

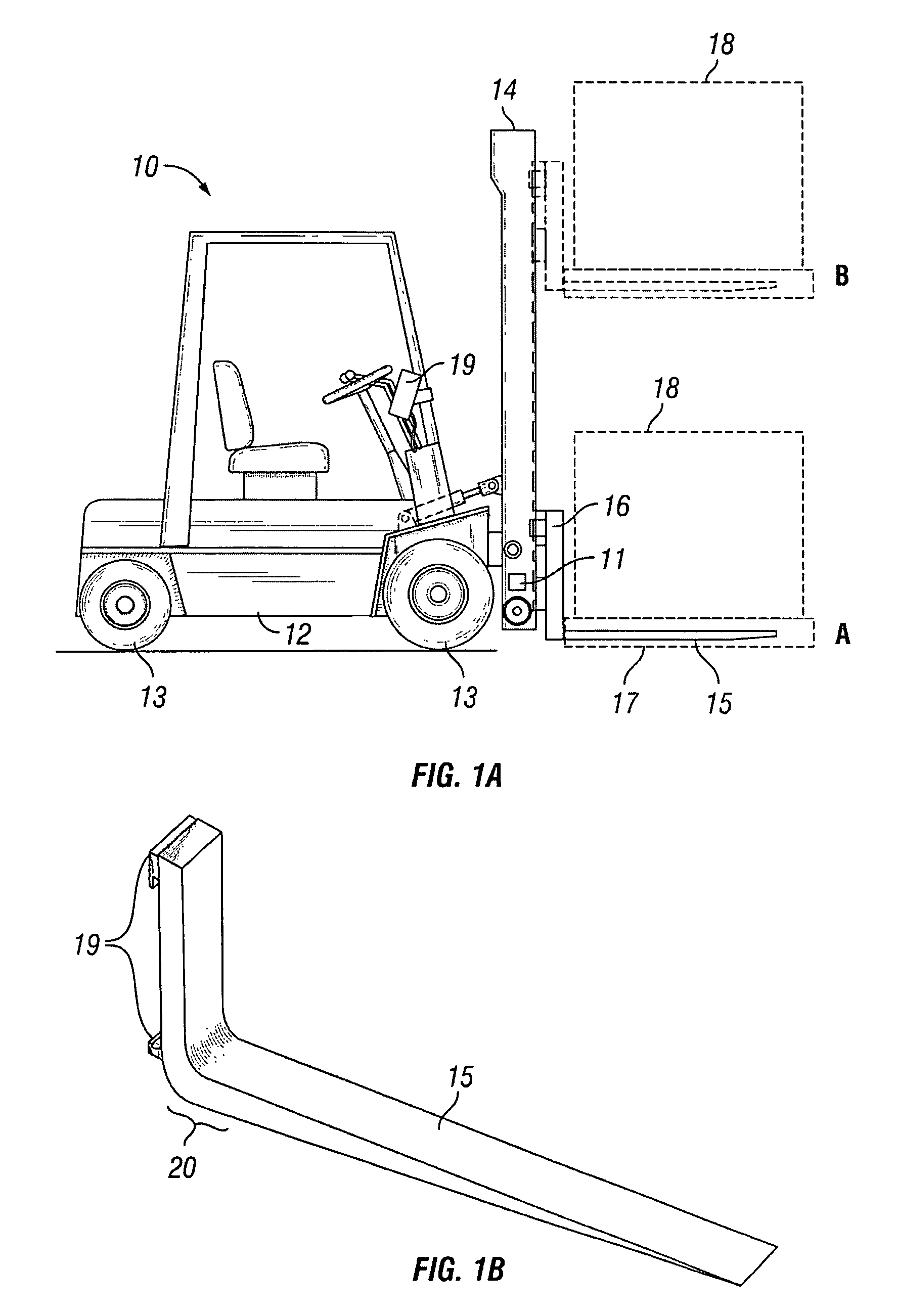

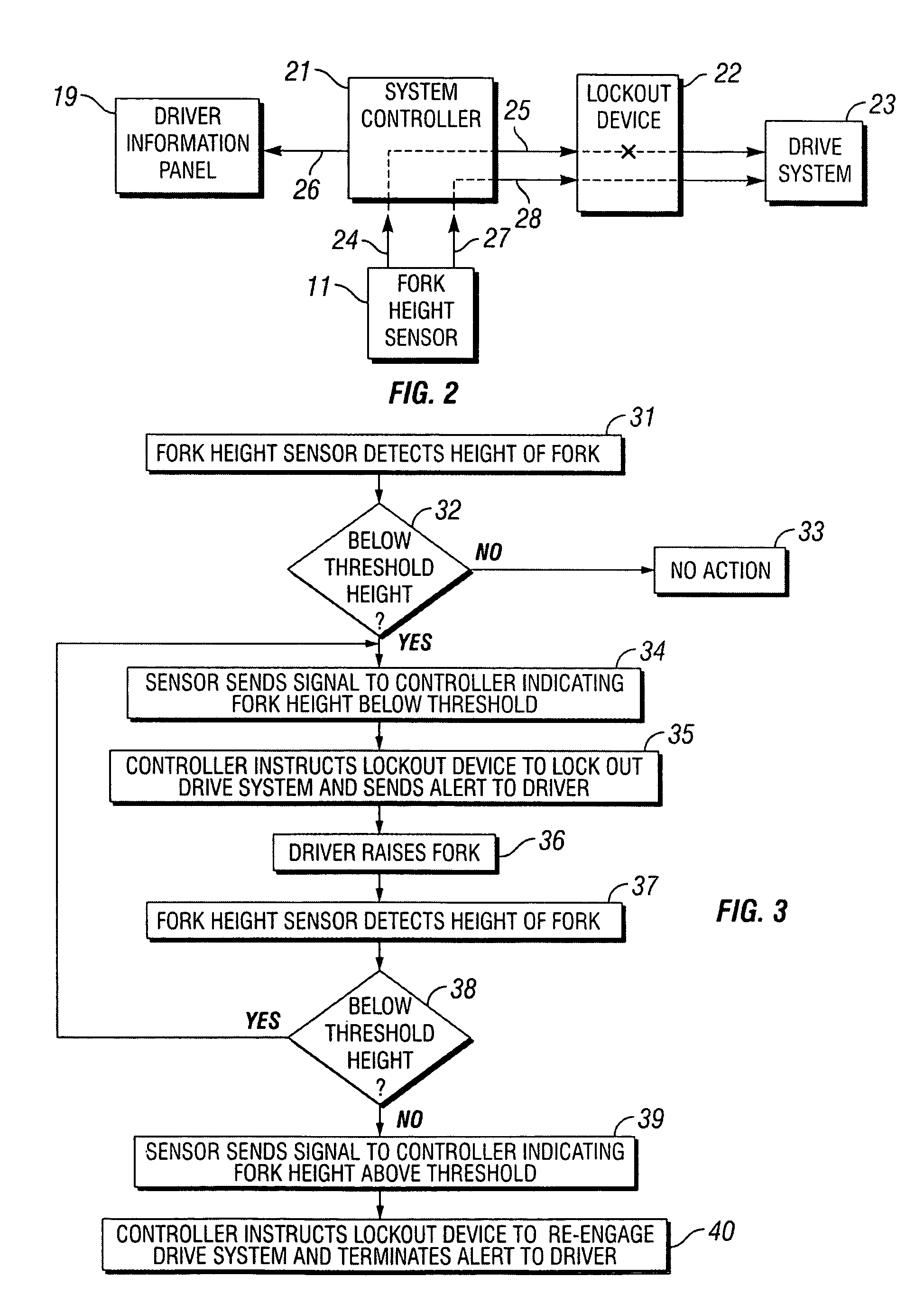

Forklift safety sensor and control system

InactiveUS7287625B1Preventing unsafe wearEliminate the problemSafety devices for lifting equipmentsVehicle with raised loading platformGround contactDriver/operator

A forklift safety sensor and control system for preventing unsafe wear on the bottom surface of the fork. A fork height sensor detects when the fork is below a predefined threshold height at which the bottom surface is in close proximity to the ground or is in contact with the ground. The sensor sends a height signal to a system controller. In response, the controller sends a lockout signal to a lockout device, which prevents the forklift's drive mechanism from moving the forklift relative to the ground. The controller may also send an alert to the driver. When the fork is raised above the threshold height, the lockout is removed.

Owner:HARRIS BRIAN L

Extendable frame work vehicle having lift member movable in a true vertical fashion

ActiveUS20090206589A1Improve versatilityImprove effectivenessSafety devices for lifting equipmentsVehicle body stabilisationHydraulic motorVehicle frame

An extendable frame work vehicle offering enhanced versatility, safety and effectiveness. The vehicle includes an adjustable frame with front and rear portions that extend or retract with respect to each other. The front portion is supported by a first pair of wheels and said rear portion is supported by a second pair of wheels. Each wheel is independently driven and steered. The vehicle also includes an engine mounted on the rear portion of the frame. Incorporated into the vehicle is an electro-hydraulic assembly which enables extension and retraction of the adjustable frame. The assembly includes a sensor-responsive microprocessor controller, at least one hydraulic pump, at least one hydraulic drive motor and at least one valve network.

Owner:EXTENDQUIP LLC

Automatic transport loading system and method

ActiveUS7980808B2Easy and efficient endEfficient and effectiveRailway vehiclesNavigation by speed/acceleration measurementsGuidance systemTransport engineering

A method and system for automatically loading and unloading a transport is disclosed. A guidance system follows a travel path to a position near the transport and then a sensor profiles a transport so that a transport path is determined for an AGV to follow into the transport to place a load and for exiting the transport upon placement of the load.

Owner:JERVIS B WEBB INT CO

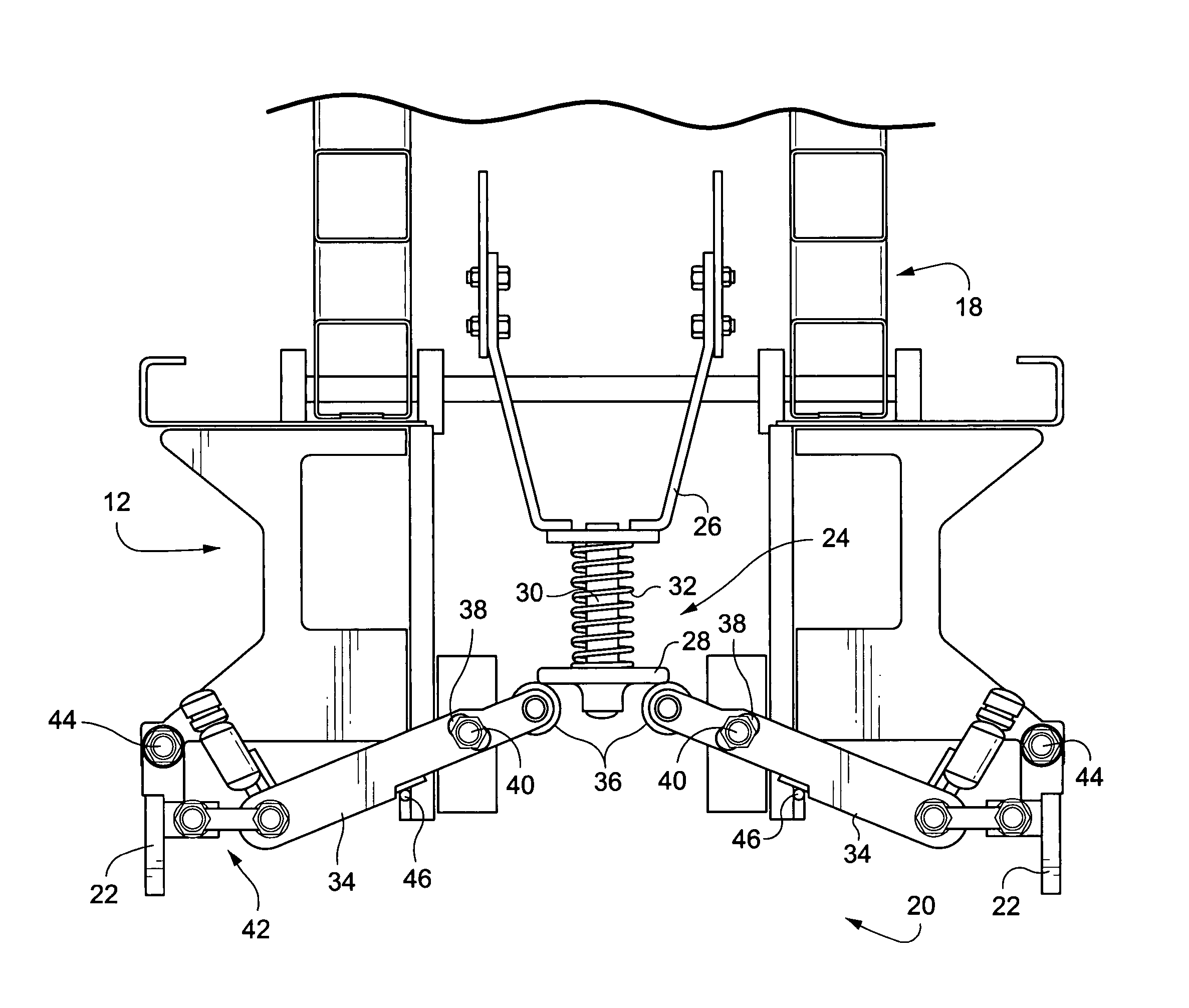

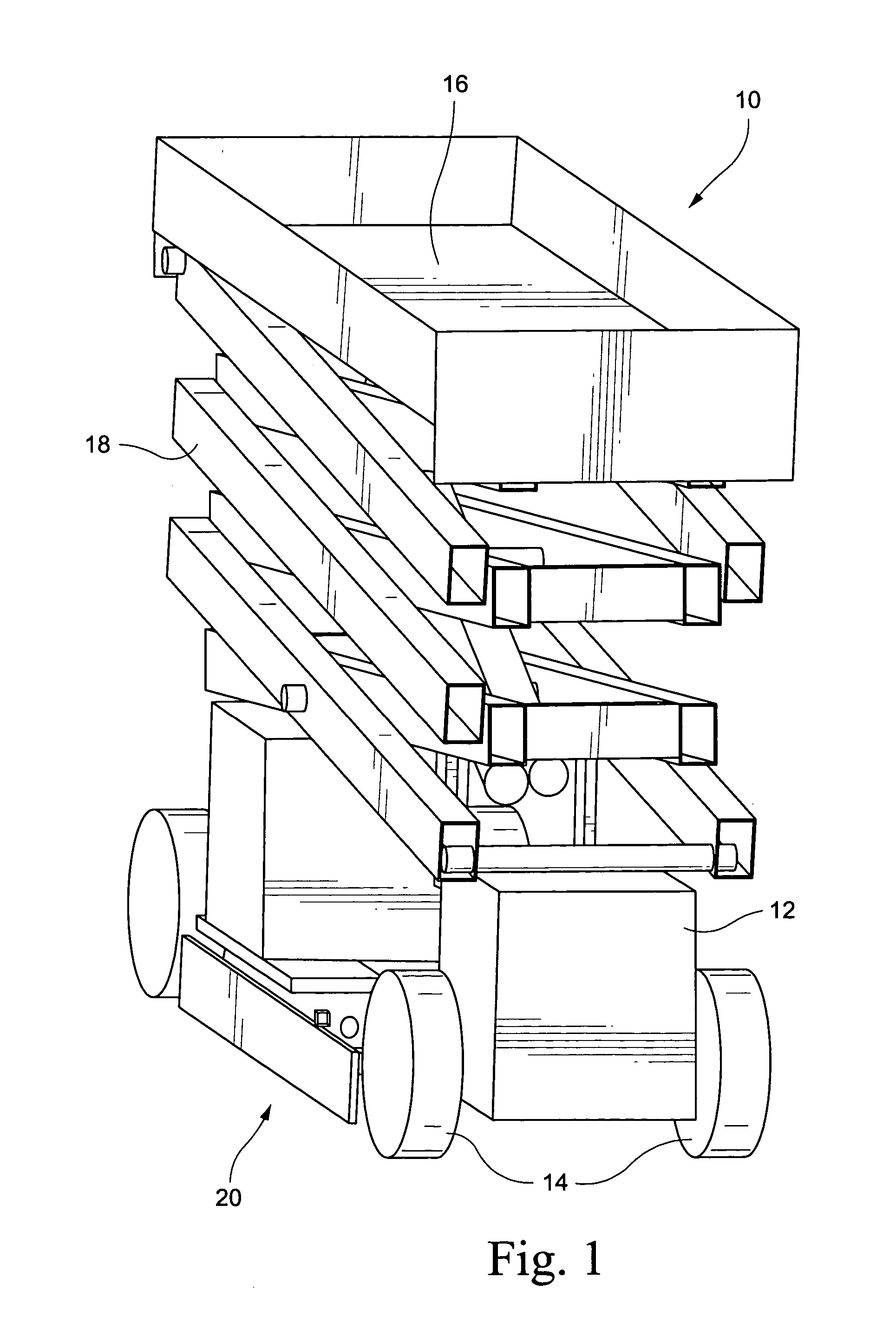

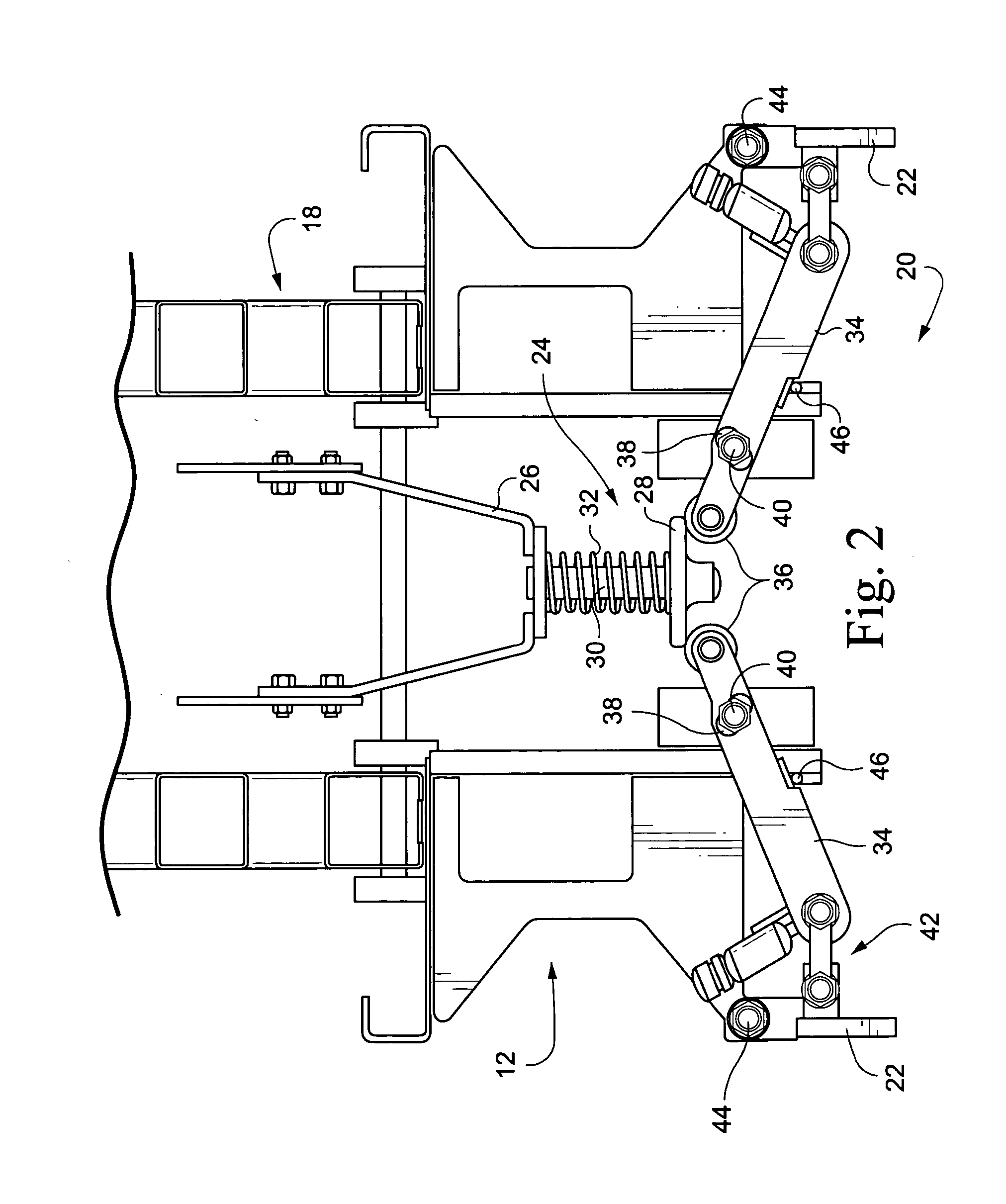

Pothole protection mechanism

ActiveUS20050224290A1Guaranteed uptimeSafety devices for lifting equipmentsPedestrian/occupant safety arrangementProtection mechanismEngineering

A pothole protection mechanism provides additional support for the vehicle in the event a wheel is driven into a hole while the platform is elevated. The mechanism includes an extendible and retractable pothole protection bar. A five-bar mechanism serves to actuate the pothole protection bar based on a position of the vehicle lifting section. The construction of the mechanism serves to prevent a crushing hazard while deploying the bar and tolerates fixed objects on the ground while raising the bar.

Owner:JLG IND INC

Method and apparatus for collision avoidance

ActiveUS8346468B2Analogue computers for vehiclesSafety devices for lifting equipmentsMobile vehicleTime segment

Owner:TOTALTRAX

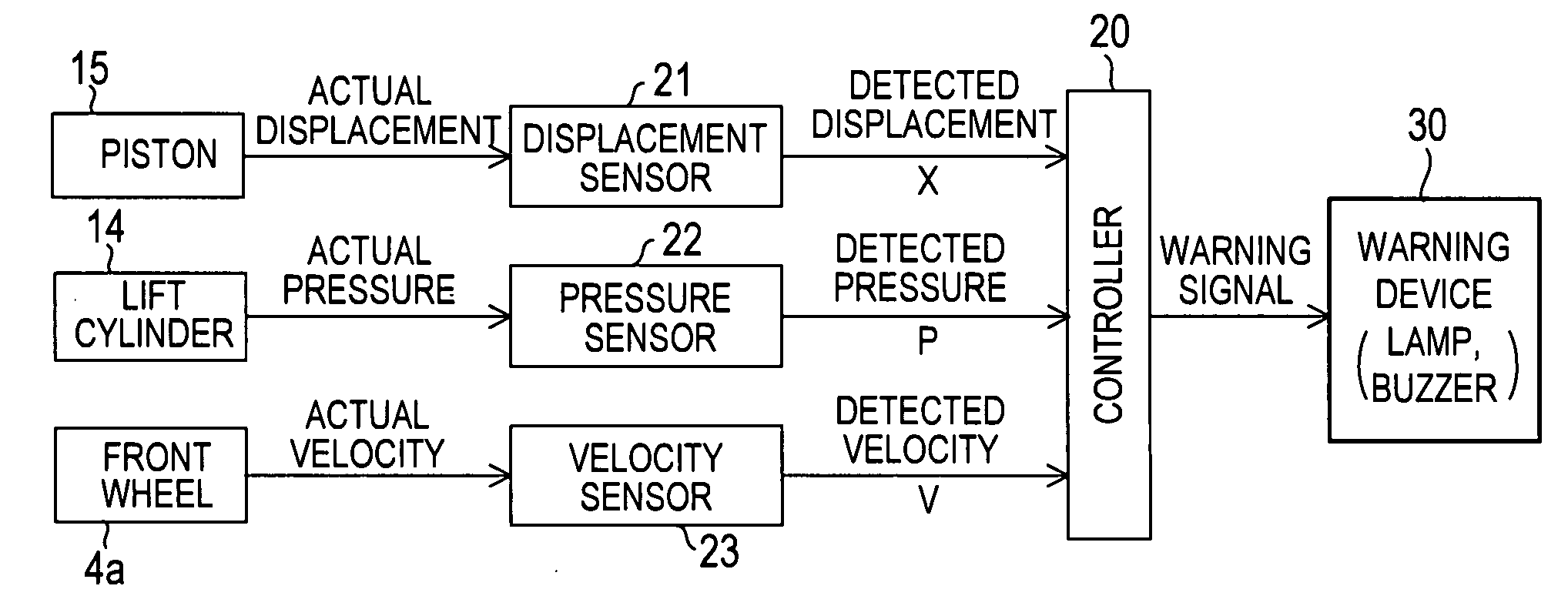

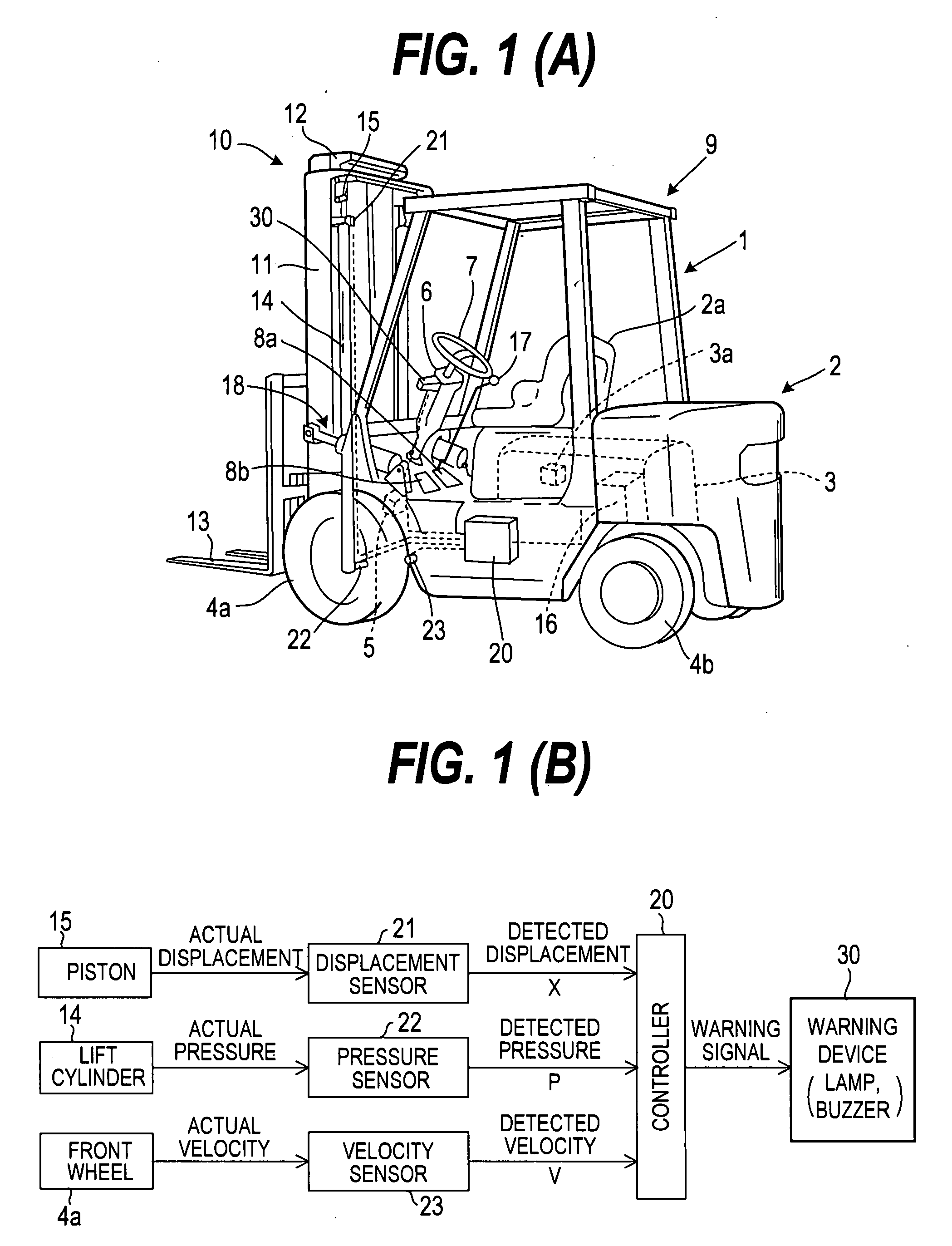

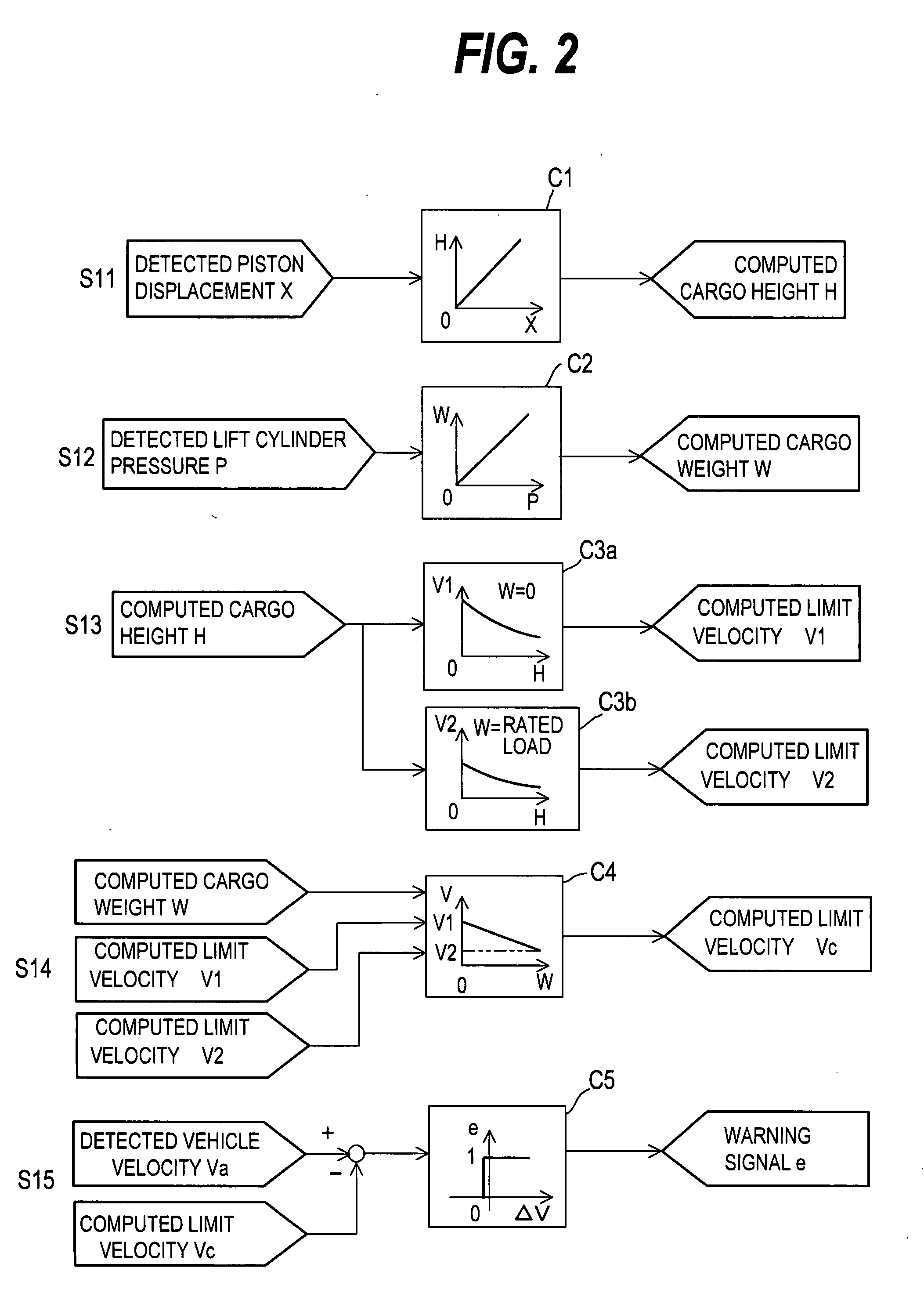

Overturning prevention device for forklift vehicle

InactiveUS20100063682A1Reduce the overall heightAvoid overall overturningAnalogue computers for trafficSteering initiationsControl theoryPiston

A subject of the present invention is to provide an overturning prevention apparatus for a forklift with various means. A cargo height H is calculated from a piston displacement detected by a displace sensor 21 and a cargo weight W is calculated by pressure P detected by a pressure sensor 22. A controller 20 detects a limit speed V1 in the case of non-cargo weight and a limit speed V2 in the case of the maximum cargo weight. By linearly interpolating the limit speeds V1 and V2, limit velocity Vc in the case that the cargo weight is W by utilizing a minimum turning radius memorized in the controller as a turning radius. If an actual velocity Va measured by a velocity sensor 23 is reached to the limit velocity Vc, the warning device 30 is actuated for warning an operator.

Owner:MITSUBISHI HEAVY IND LTD

Electronically controlled valve for a materials handling vehicle

A materials handling vehicle is provided comprising: a base; a carriage assembly movable relative to the base; at least one cylinder coupled to the base to effect movement of the carriage assembly relative to the base; and a hydraulic system to supply a pressurized fluid to the cylinder. The hydraulic system includes an electronically controlled valve coupled to the cylinder. The vehicle further comprises control structure to control the operation of the valve such that the valve is closed in the event of an unintended descent of a carriage assembly in excess of a commanded speed.

Owner:CROWN EQUIP CORP

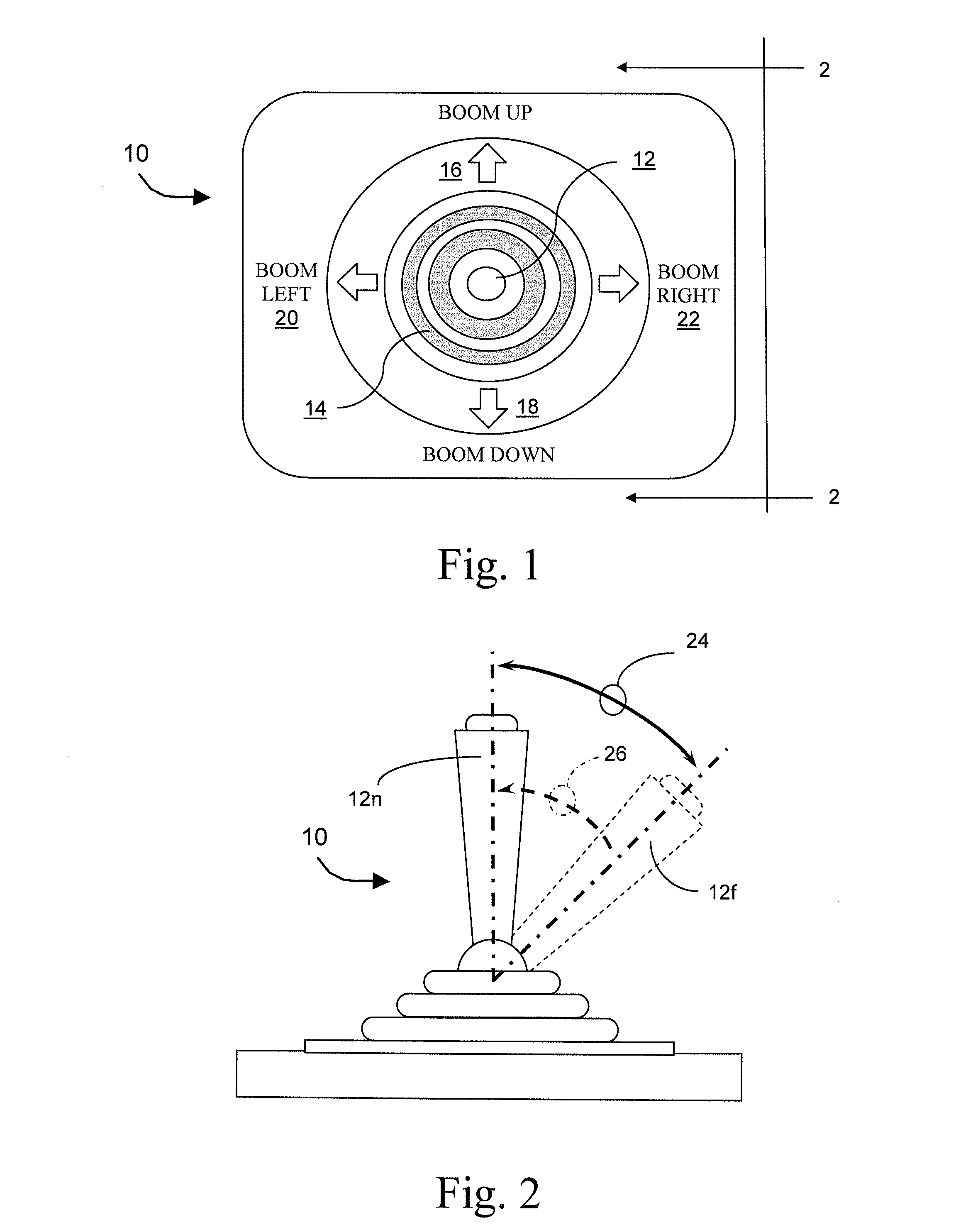

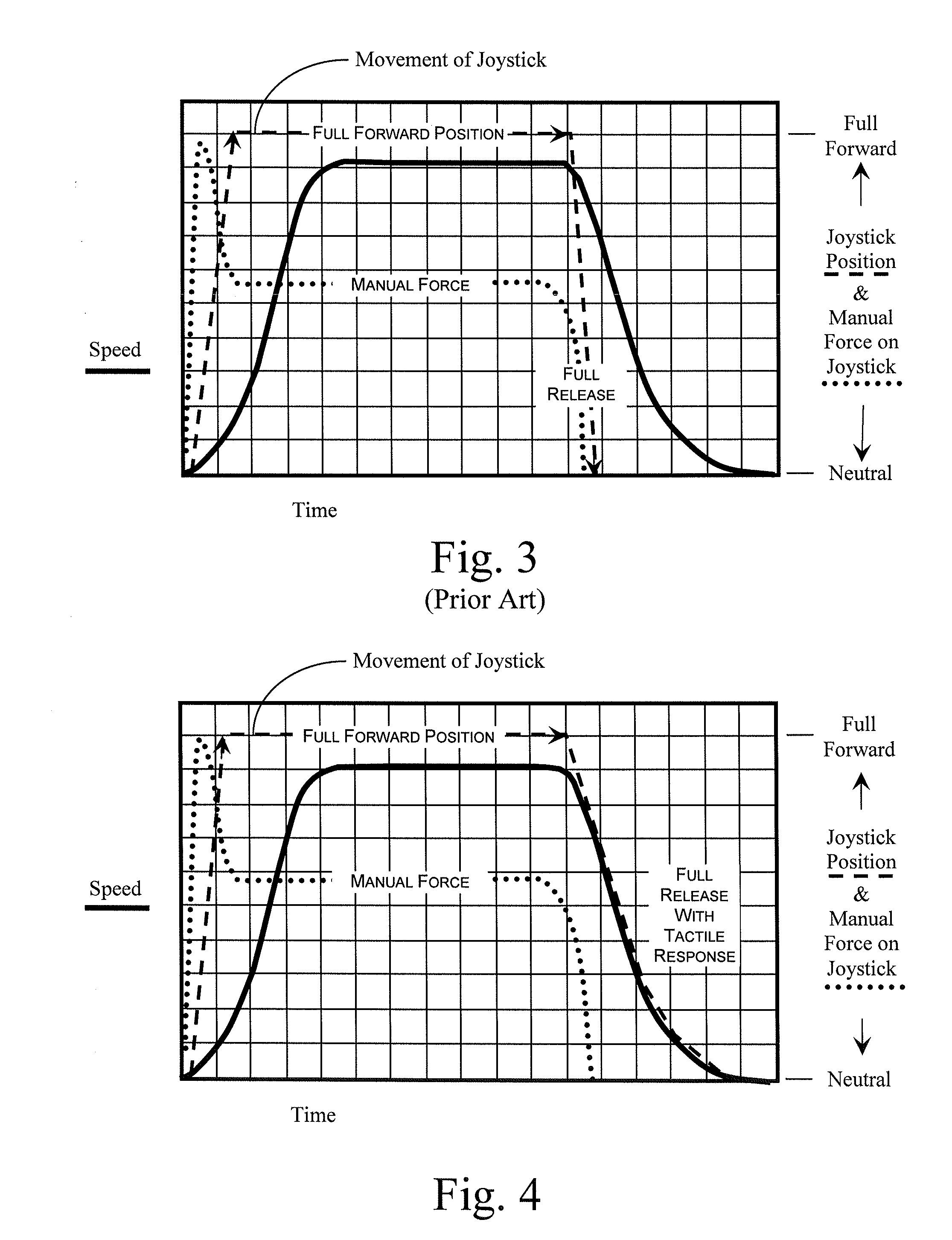

Tactile Feedback for Joystick Position/Speed Controls

ActiveUS20160179128A1Minimize complexityReduce unnecessary costsManual control with multiple controlled membersControlling membersJoystickActuator

A joystick controller is disclosed for controlling movement of a boom lift platform, the controller having actuators or the like that provide one or more forms of tactile feedback that are intuitively interpreted and adjusted by the user of the joystick motion control, the joystick being neutrally-biased to effect a null movement when the joystick is positioned in a neutral position, but also being adapted with at least one form of tactile feedback by which the joystick controller conveys information about the boom lift's operation to the joystick operator, such as through resistive force or through vibrations or the like.

Owner:ENOVATION CONTROLS

Radio frequency identification based personnel safety system

InactiveUS8115650B2Safety devices for lifting equipmentsEngineering safety devicesStops deviceEmbedded system

Disclosed is a method and apparatus for selectively immobilizing equipment to ensure the safety of a proximate worker. The apparatus comprises an article of clothing wearable by the proximate worker, a sensor and a stopping means for stopping the movement of a portion of the equipment in response to the sensing. The article of clothing has a RFID tag having an antenna distributed about the article so as to substantially surround a worker wearing the article of clothing. The sensor senses the proximity of the RFID tag to a portion of the equipment. The method comprises sensing the proximity of the RFID tag to a portion of the equipment and stopping the movement of a portion of the equipment in response to the sensing.

Owner:PSST MOBILE EQUIP - RICHARD SHERVEY

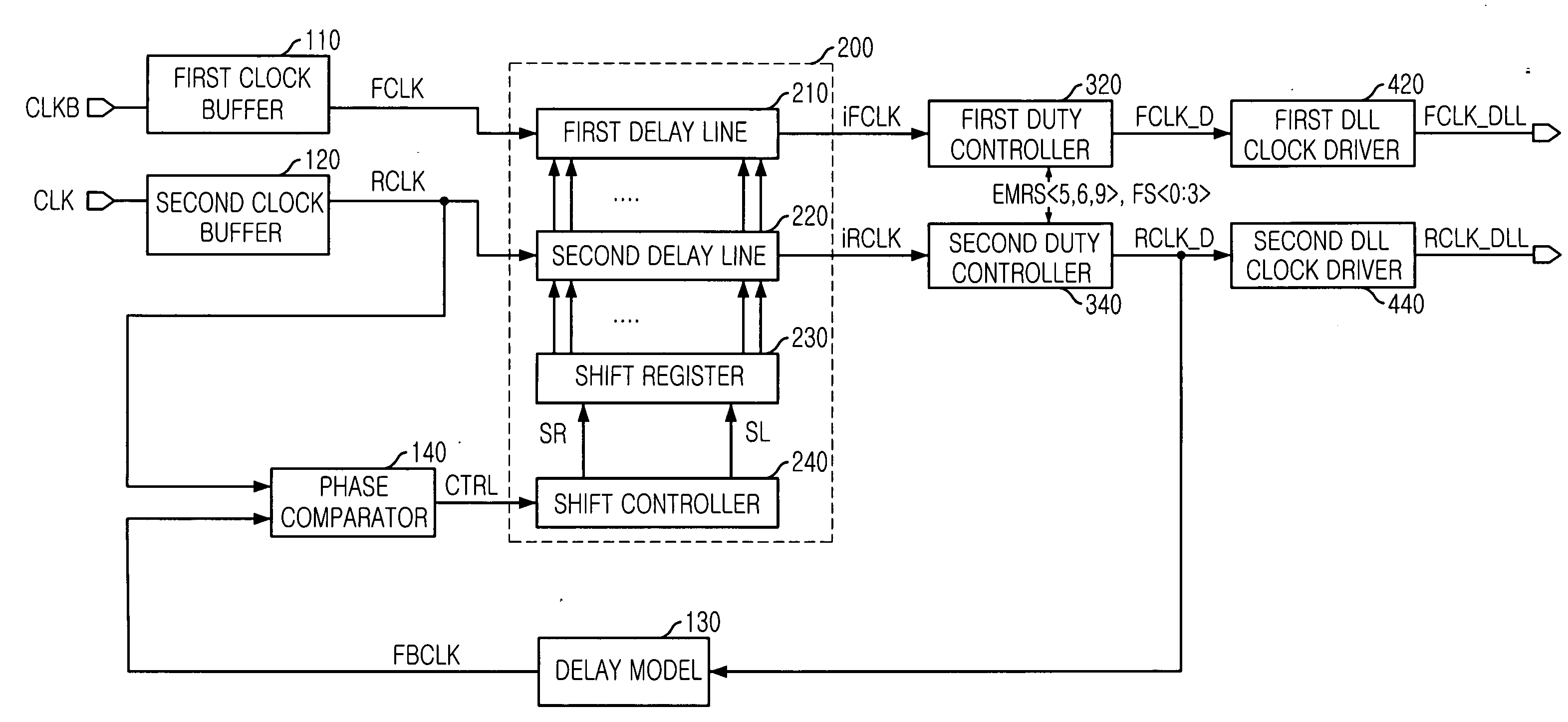

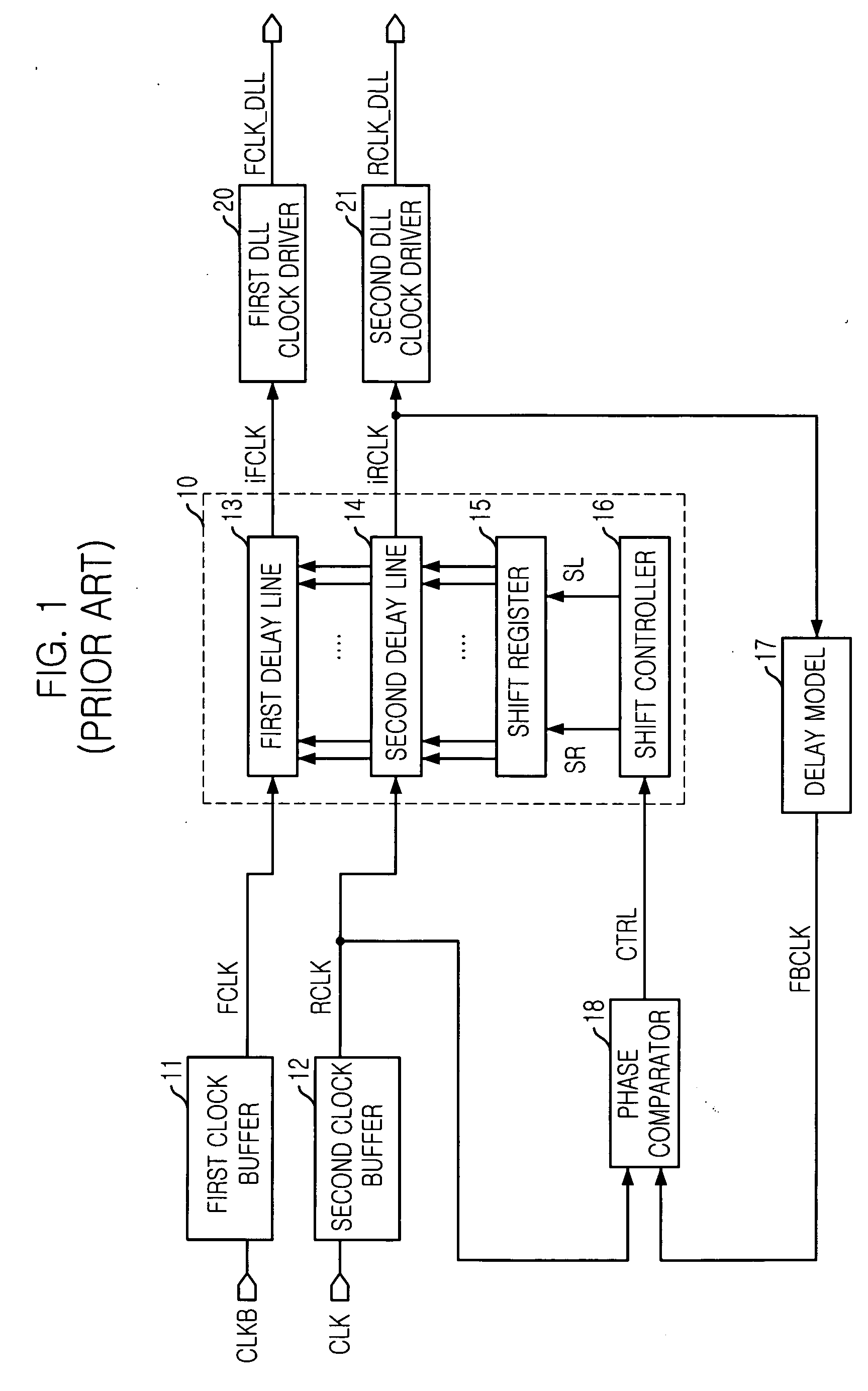

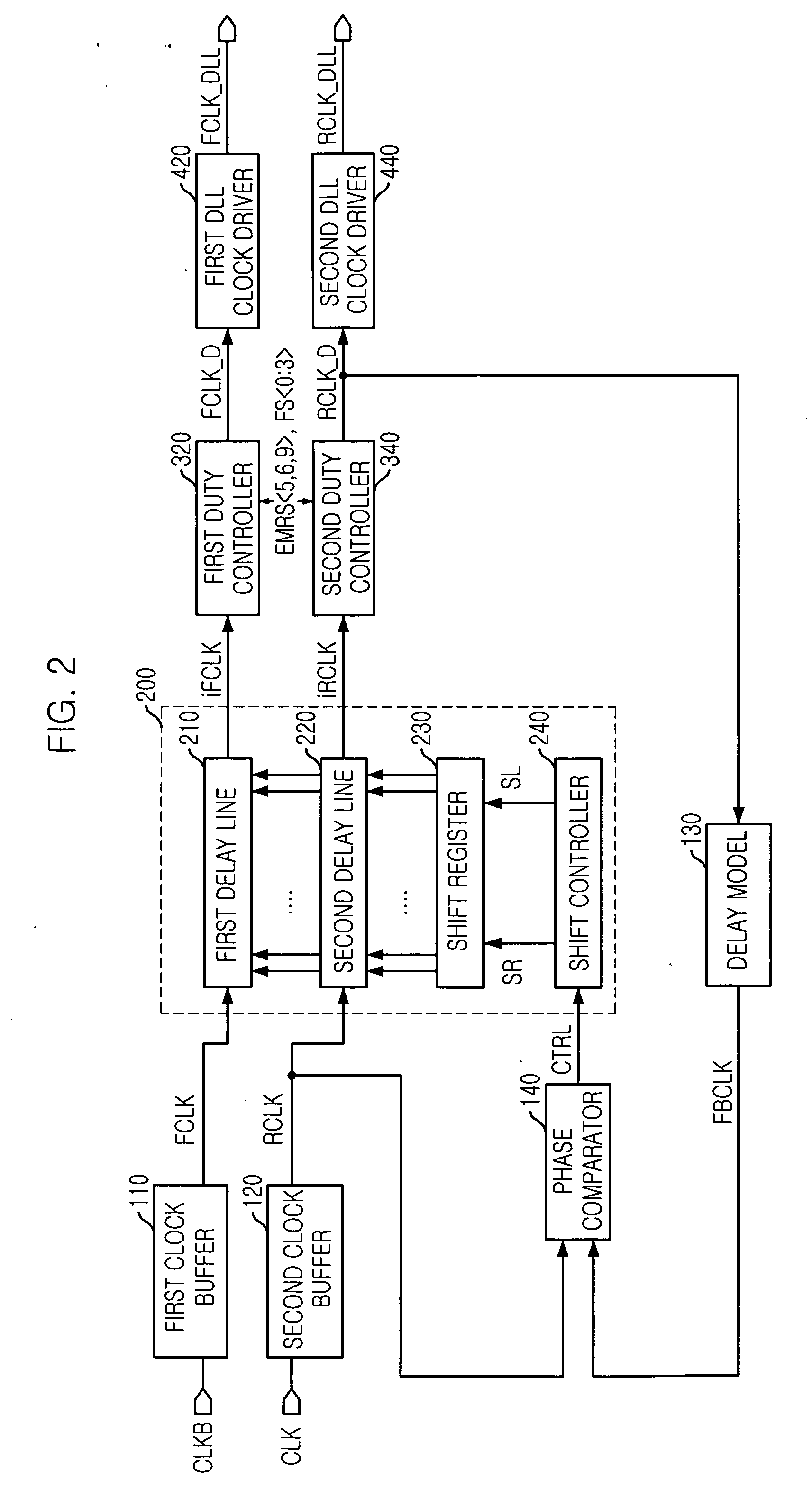

Delay locked loop for controlling duty rate of clock

ActiveUS20060197565A1Safety devices for lifting equipmentsPulse automatic controlShift registerDelay-locked loop

There is provided a DLL capable of controlling a duty rate of a clock by a fuse option or an EMRS input. The DLL includes a first clock buffer, a second clock buffer, a first delay line, a second delay line, a shift register, a first duty control unit, a second duty control unit, a first DLL driver, a second DLL driver, a delay model, a phase comparator, and a shift control unit. In the DLL, a first duty control unit and a second duty control unit control each duty rate of the output clocks of a first and a second delay lines respectively through the EMRS input or the fuse option. Therefore, it is possible to control the duty rate of DLL clocks through the EMRS input or the fuse option.

Owner:SK HYNIX INC

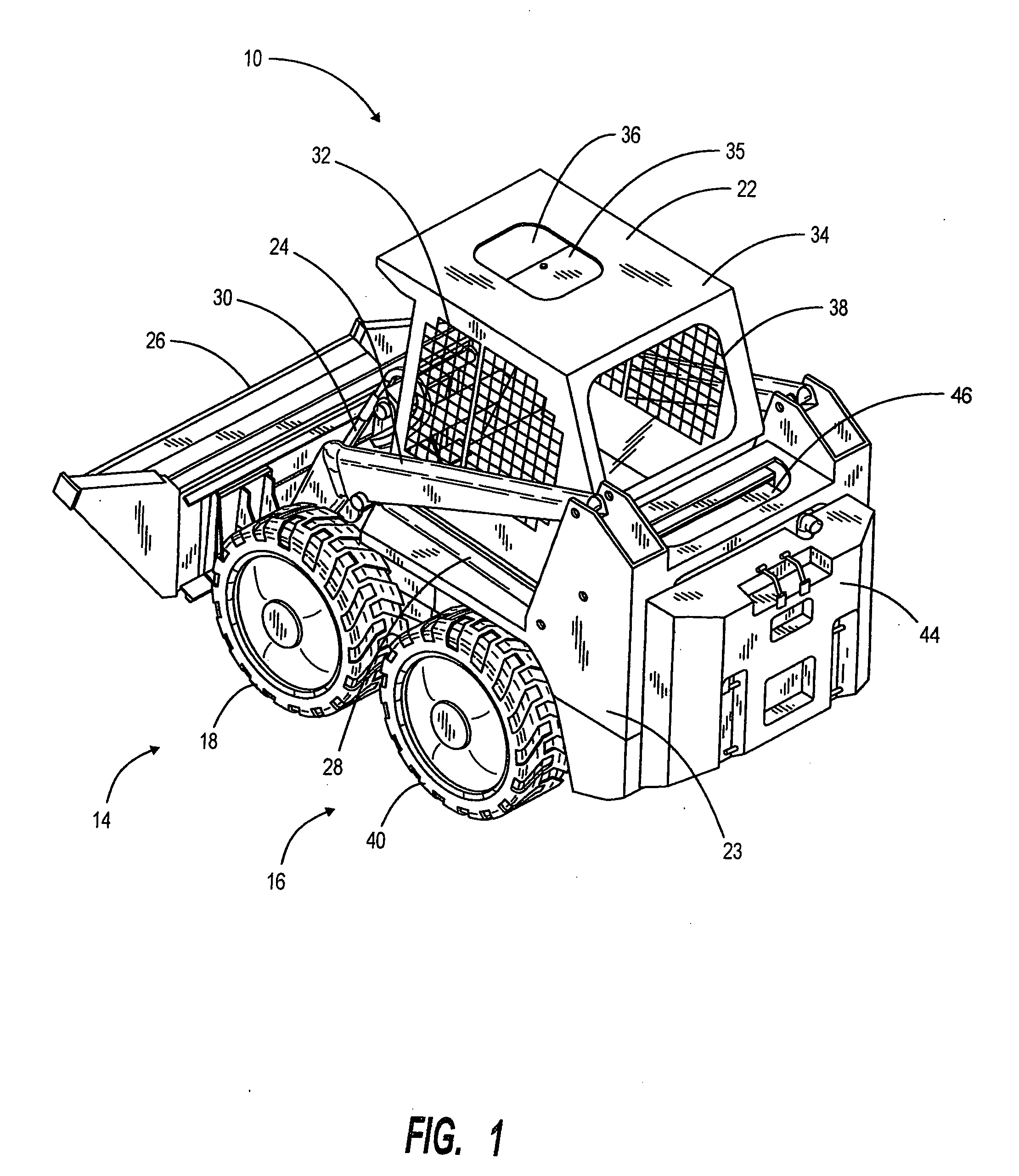

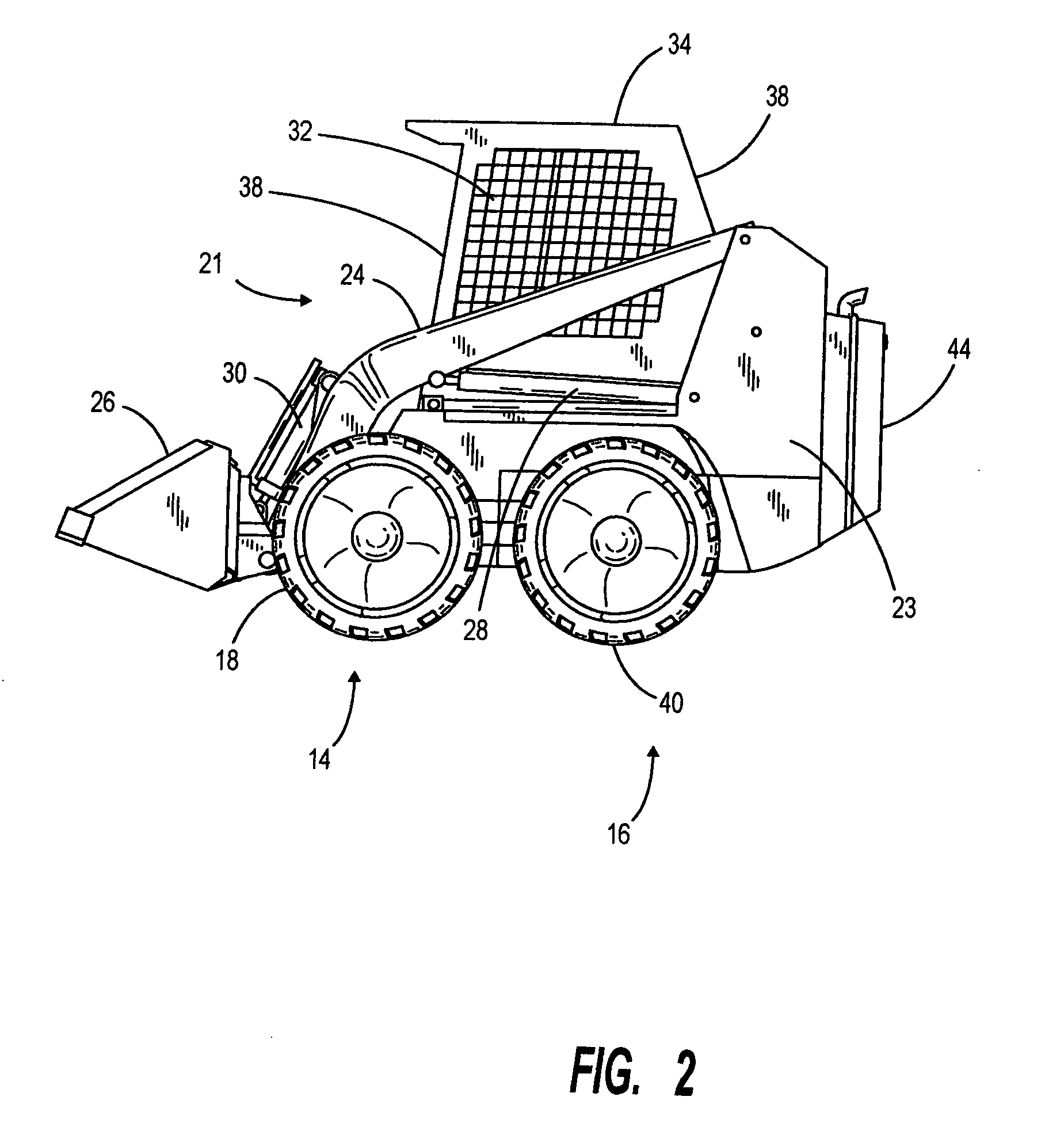

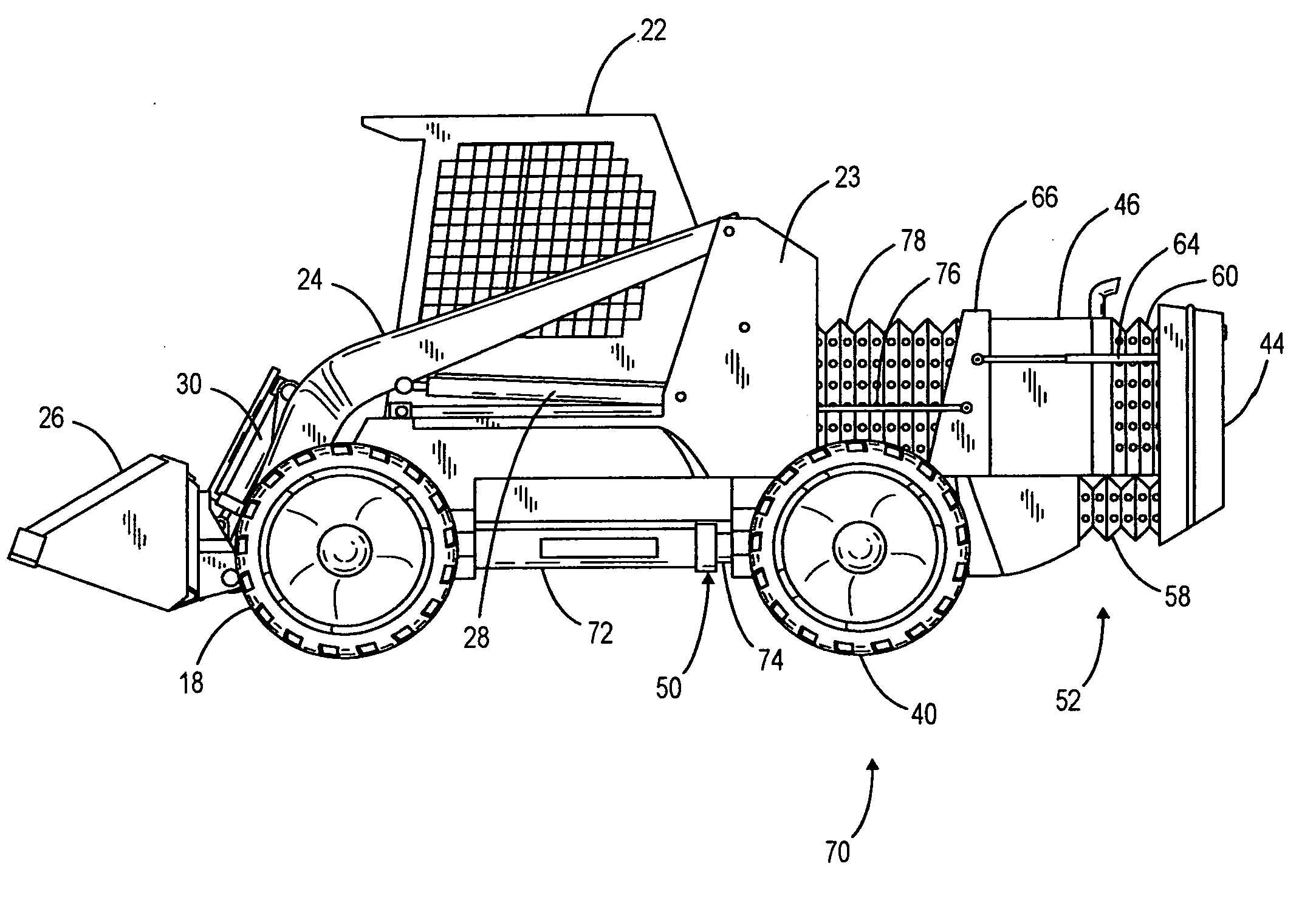

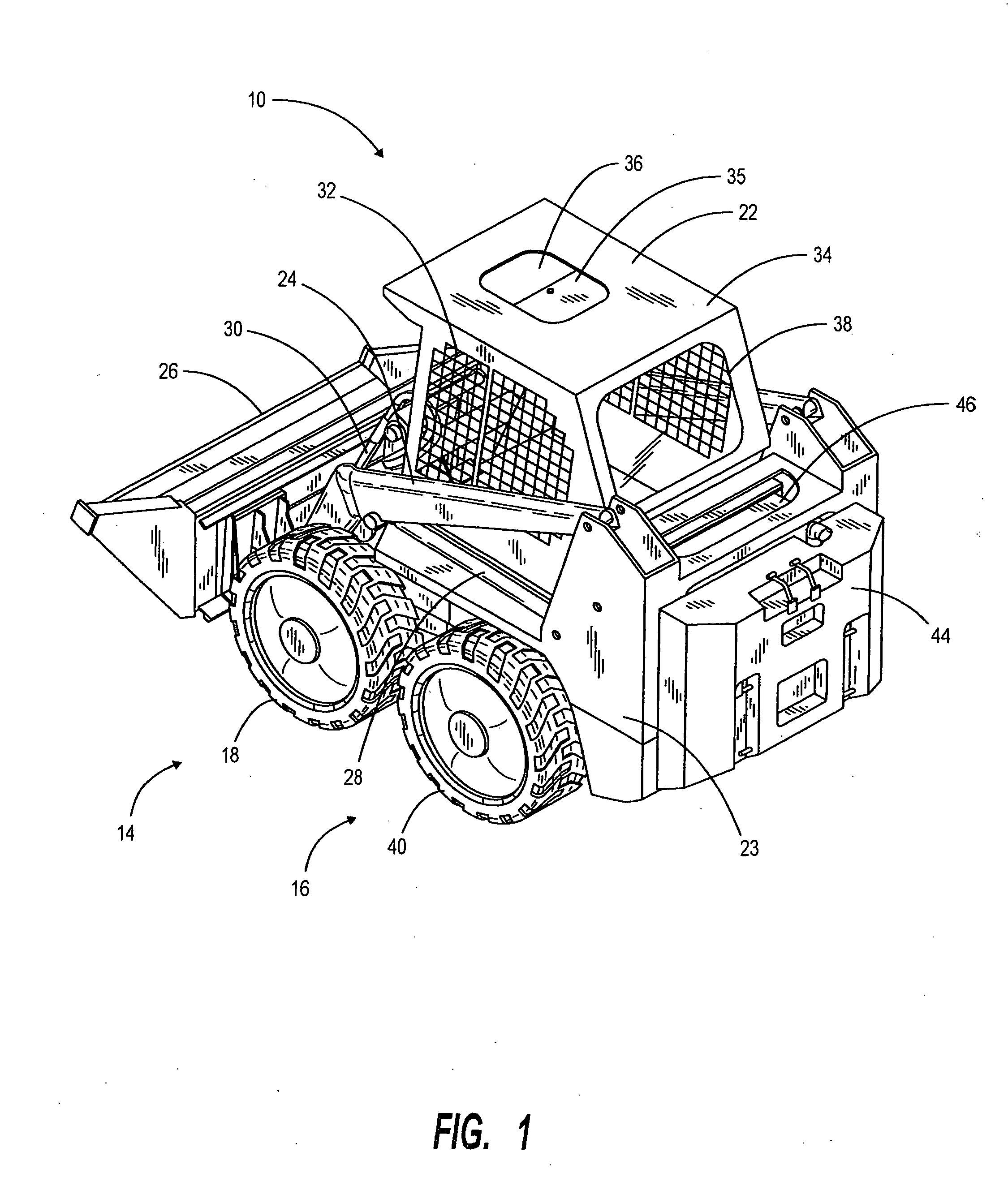

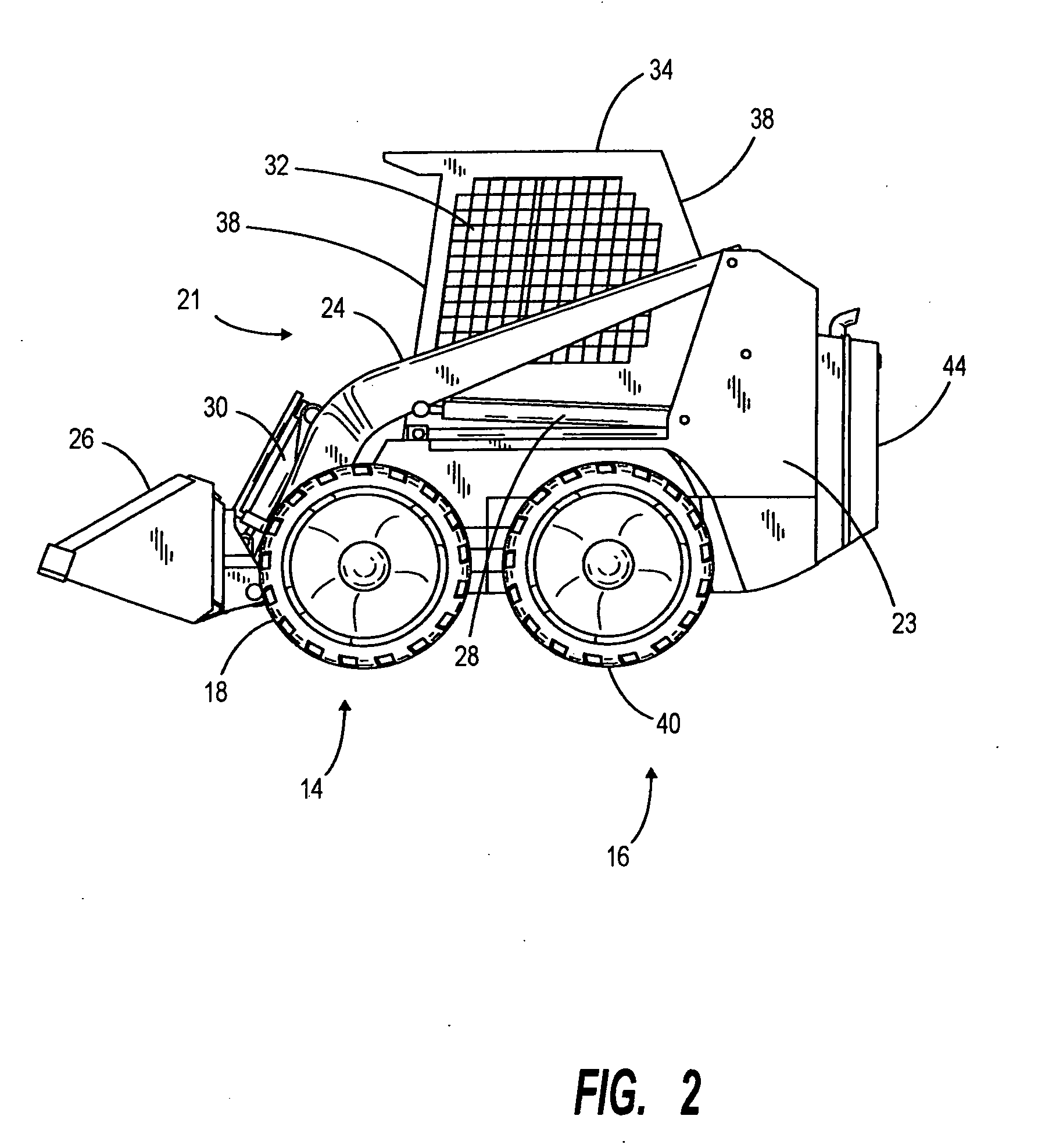

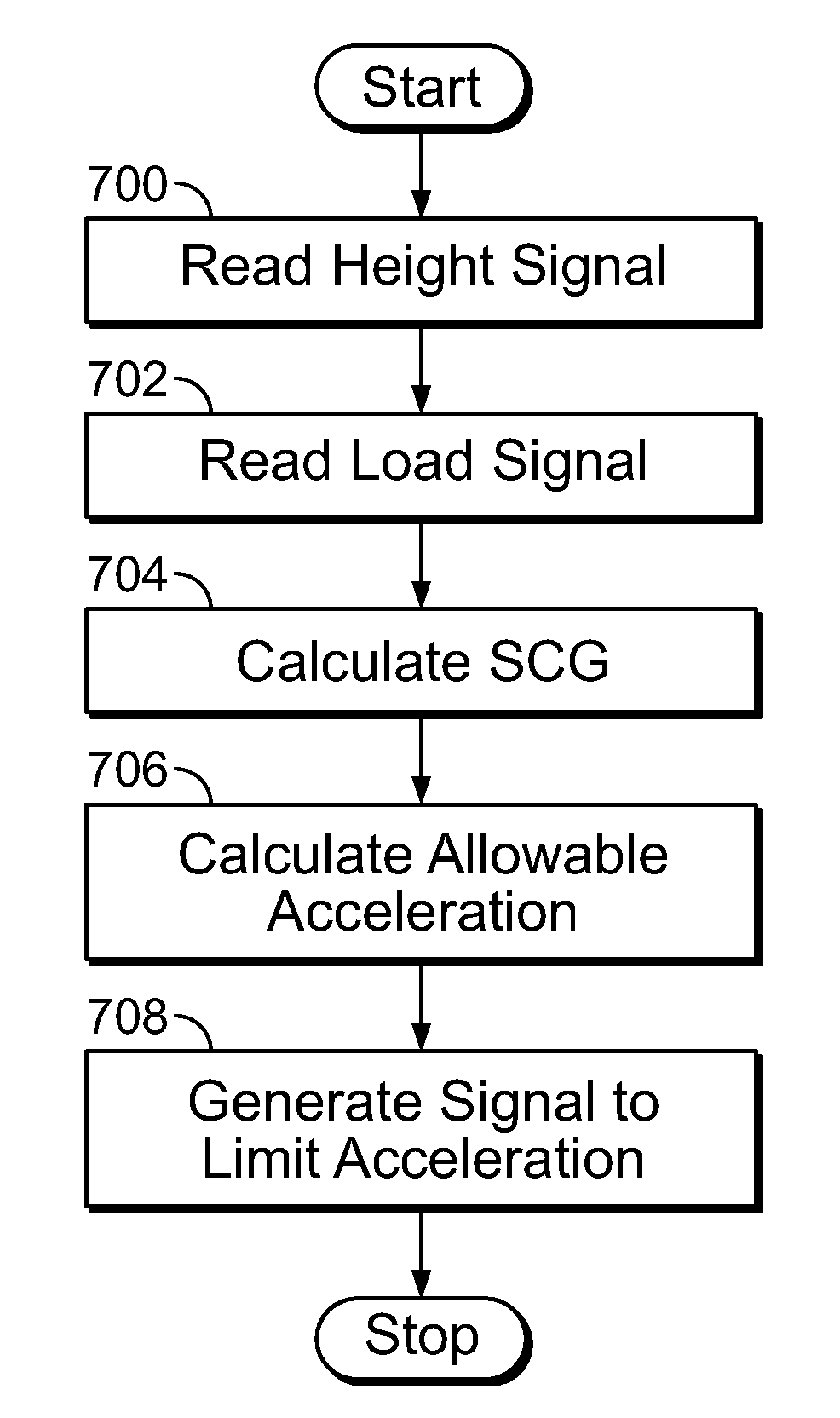

Acceleration control for vehicles having a loader arm

InactiveUS20100204891A1Safety devices for lifting equipmentsAnalogue computers for trafficControl systemLoading arm

A control system for a vehicle having a loader arm, such as a skid steer loader, telescopic handler, wheel loader, backhoe loader or forklift, reads a load height sensor, a load weight sensor; dynamically calculates the static center of gravity of the combined vehicle and load; calculates the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon; and limits the acceleration of the vehicle to less than the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon.

Owner:CNH IND AMERICA LLC

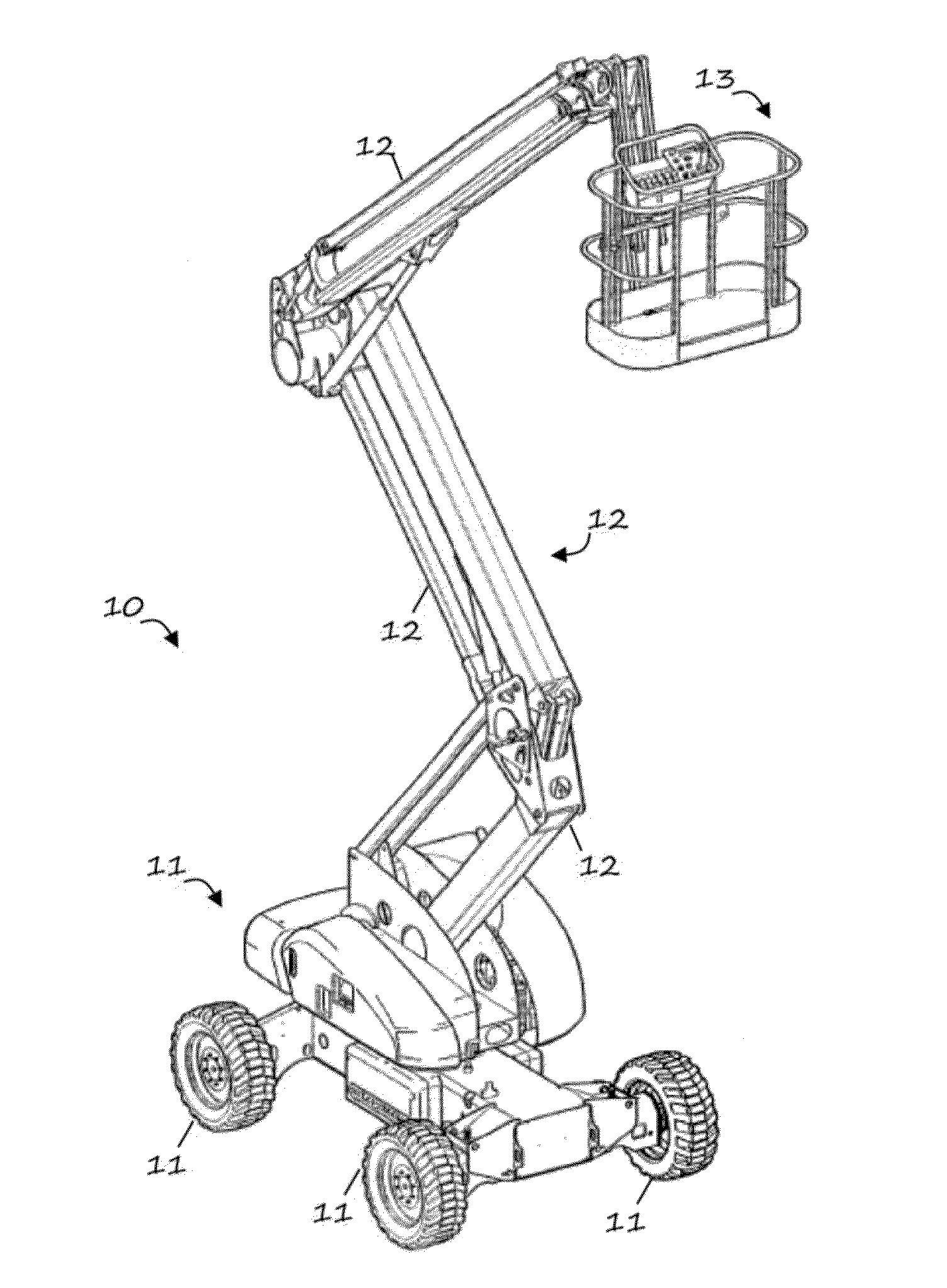

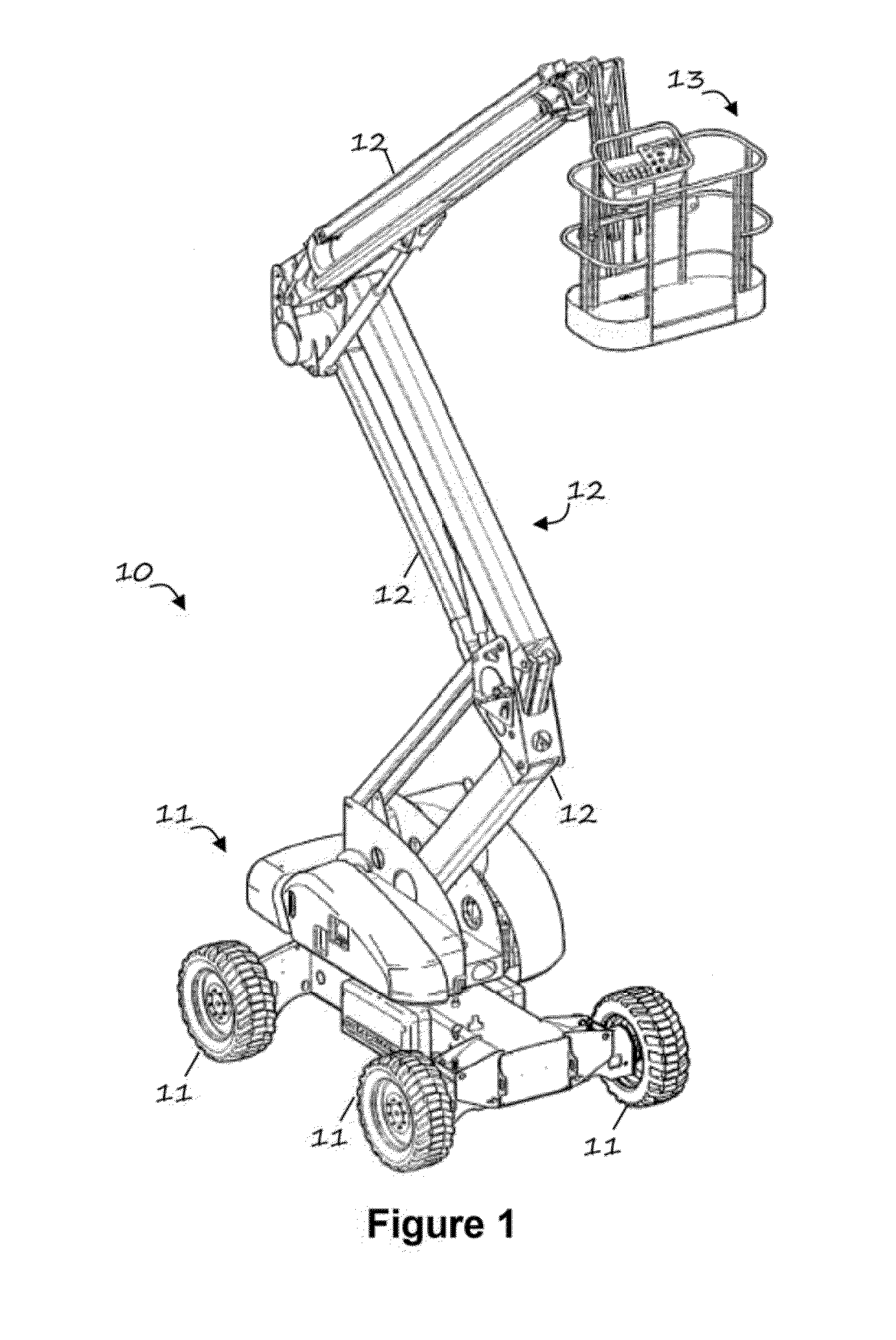

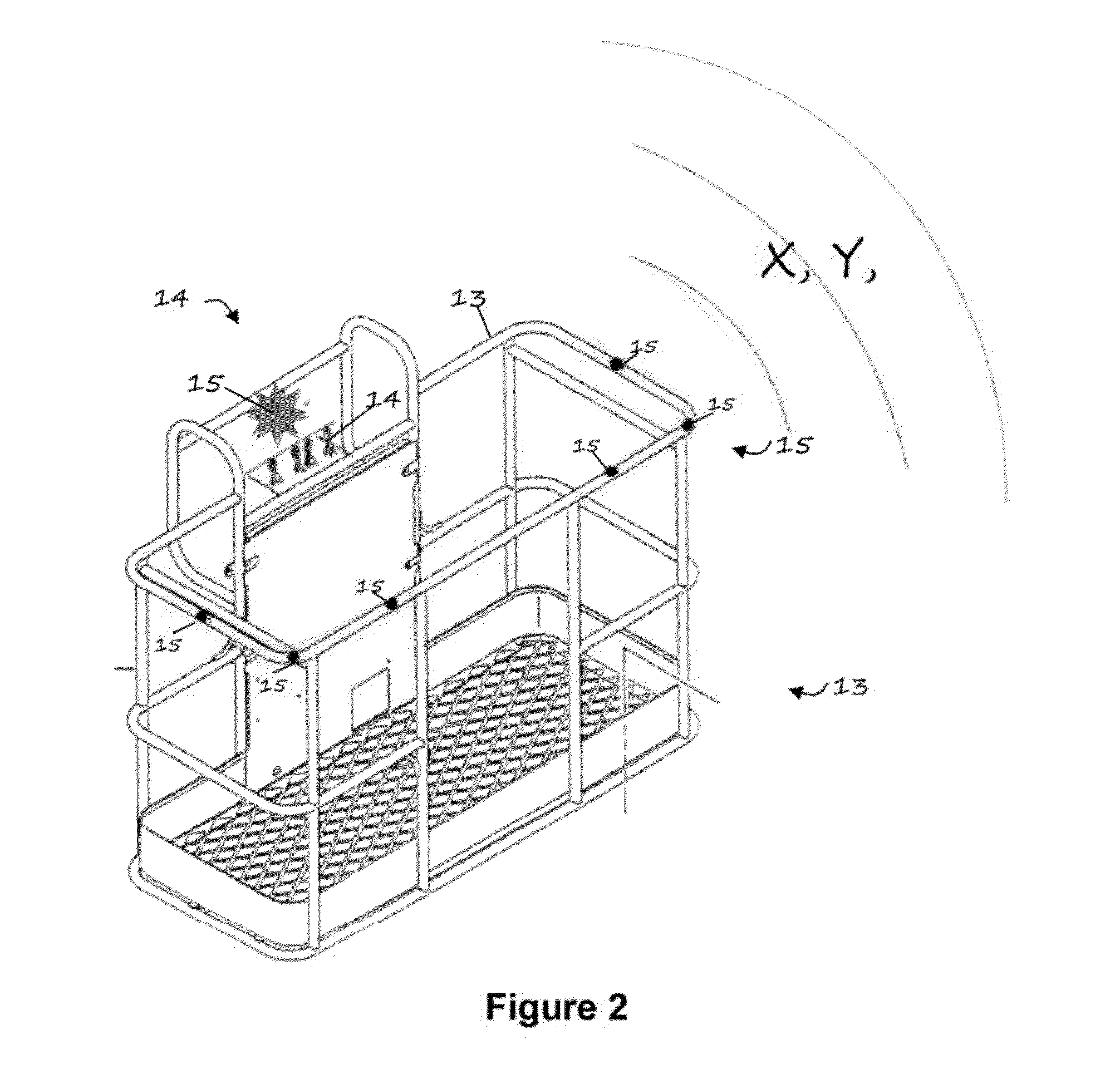

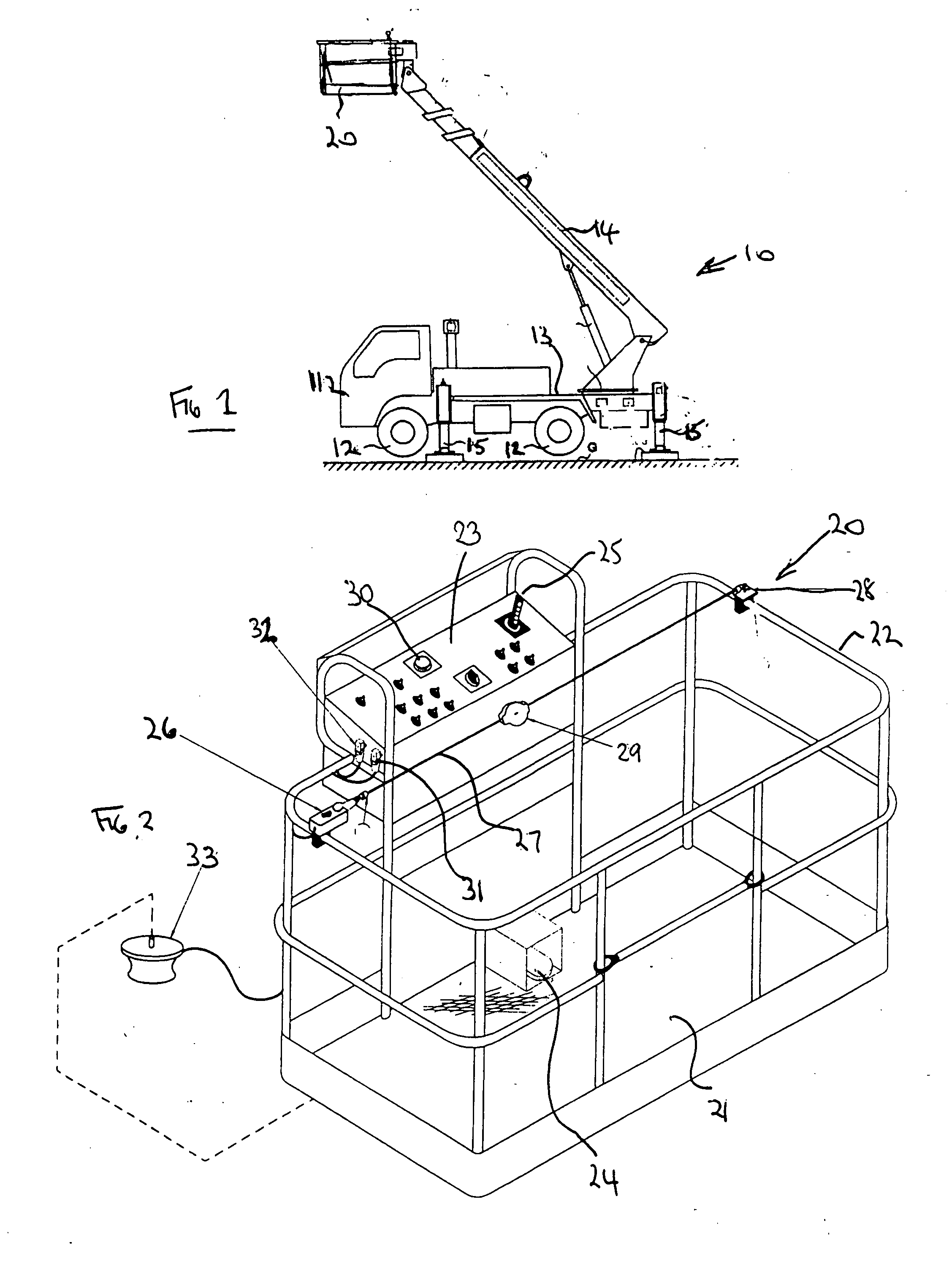

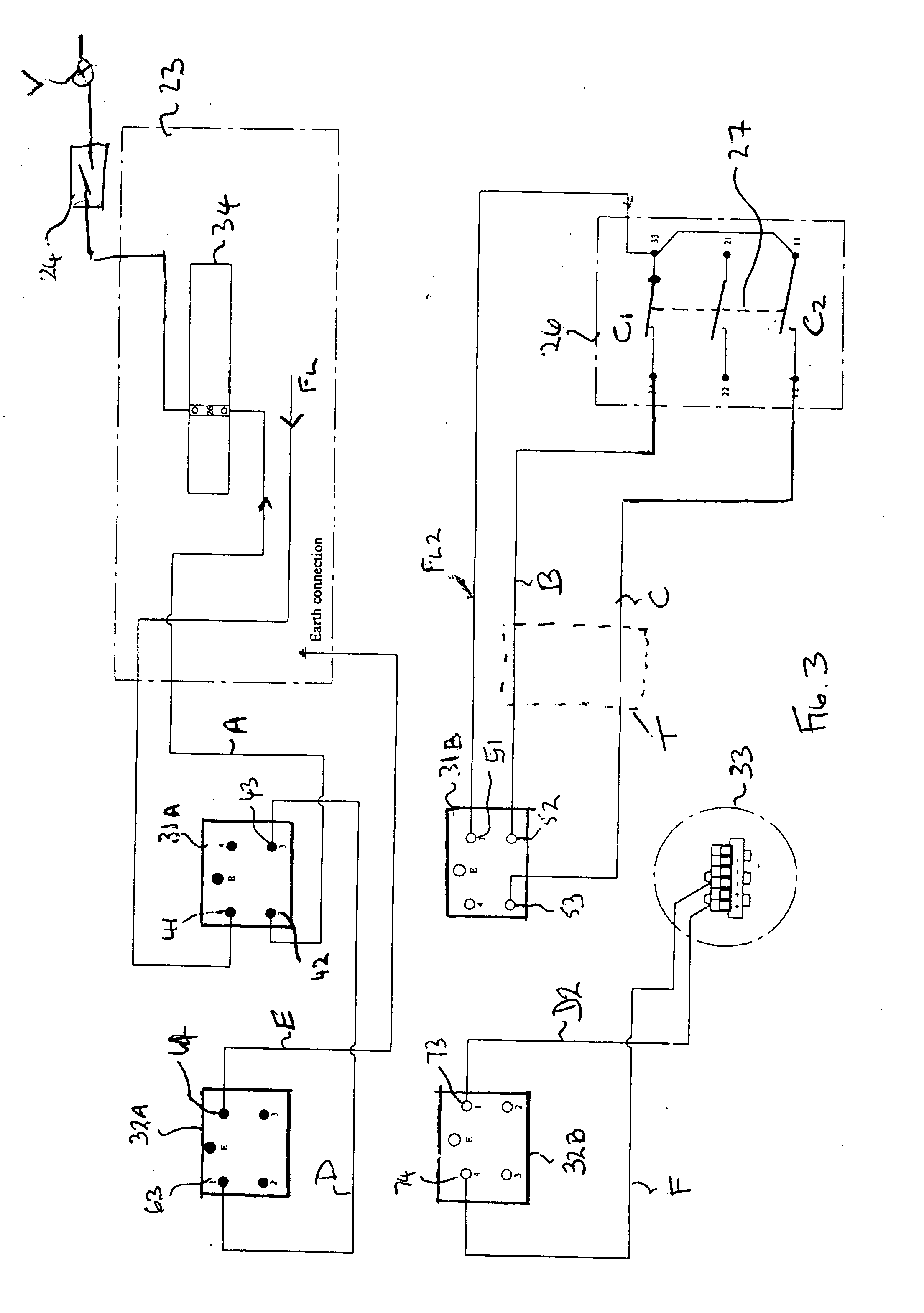

Safety device for an aerial lift, a method of operation thereof, an aerial lift having the safety device, a kit of parts and a method of installation thereof for providing the safety device in an aerial lift

InactiveUS20130153333A1Easy to installInhibit the ability of operators on the platformSafety devices for lifting equipmentsWindow cleanersAerial liftEngineering

An aerial lift, a kit of parts for installing a safety device in the aerial lift and a method includes a moveable platform having a control panel operable to manoeuvre the platform provided near a first side of the platform and a proximity sensing means that remotely senses the presence of off-platform objects within a sensing zone opposite the control panel. A further method averts an accident when operating an aerial lift by remotely sensing whether or not an off-platform object is present in a sensing zone of proximity, and if an object is sensed in the sensing zone, signalling an alarm and / or shutting down the aerial lift to stop further movement of the platform.

Owner:SAFETY ZONE

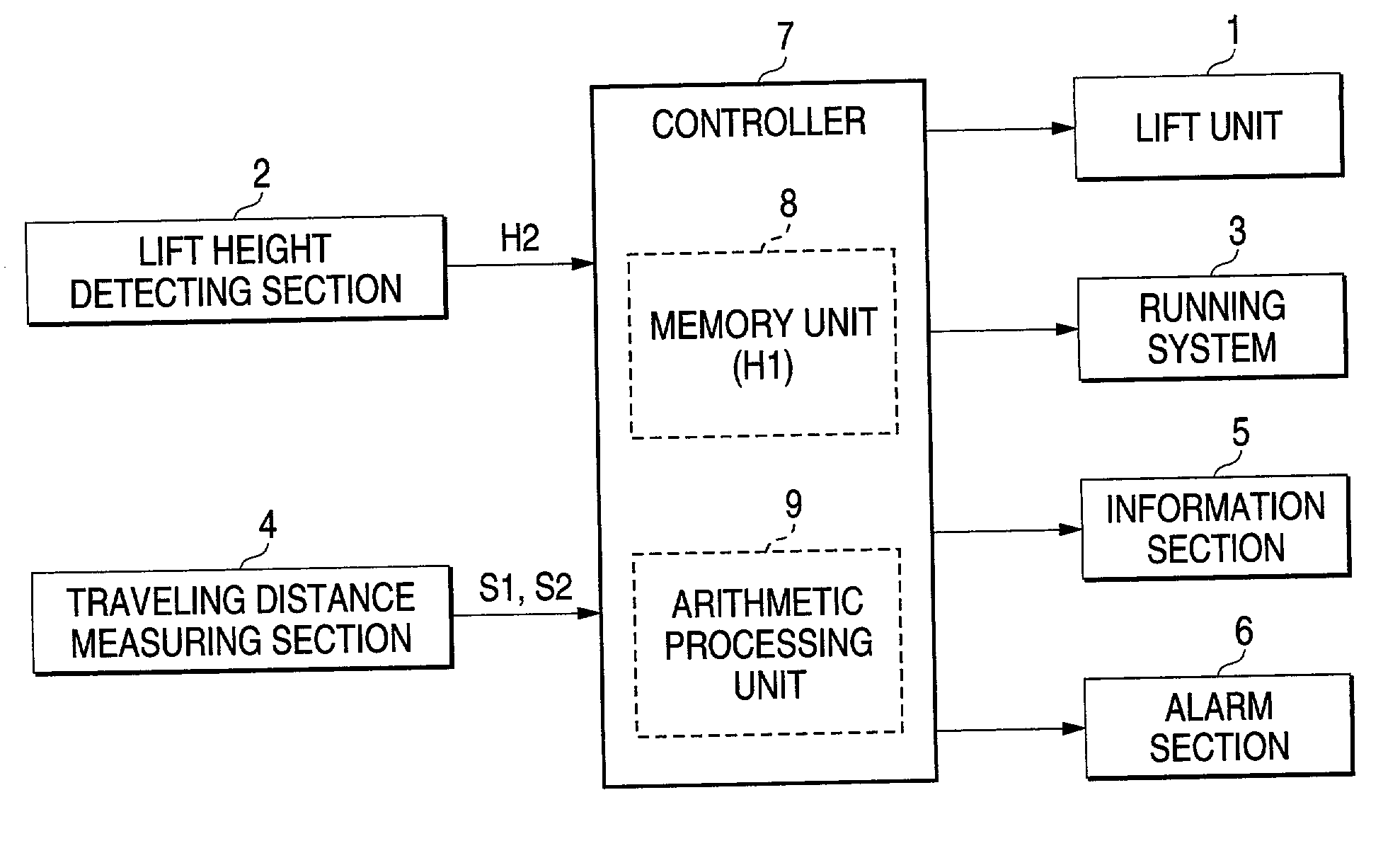

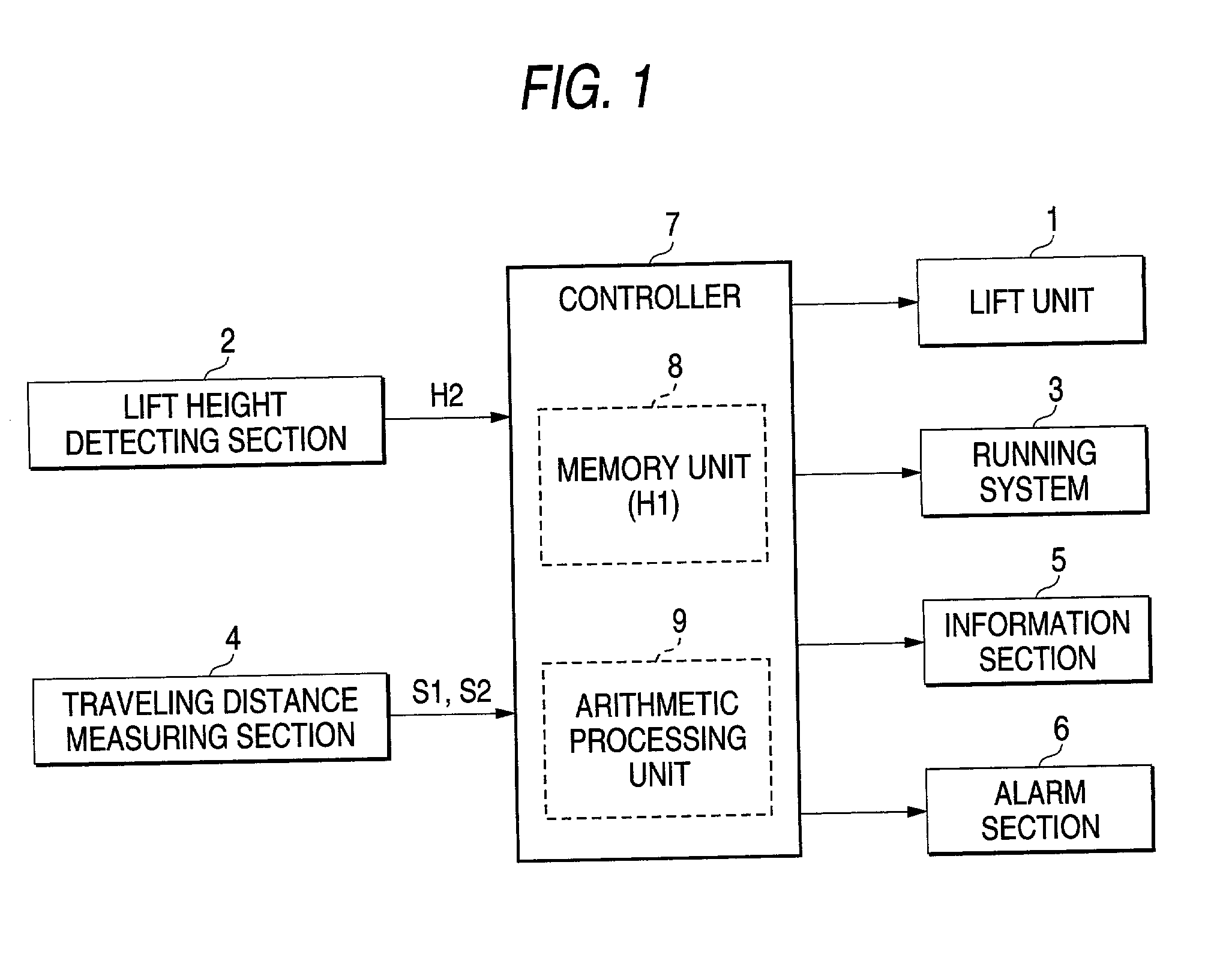

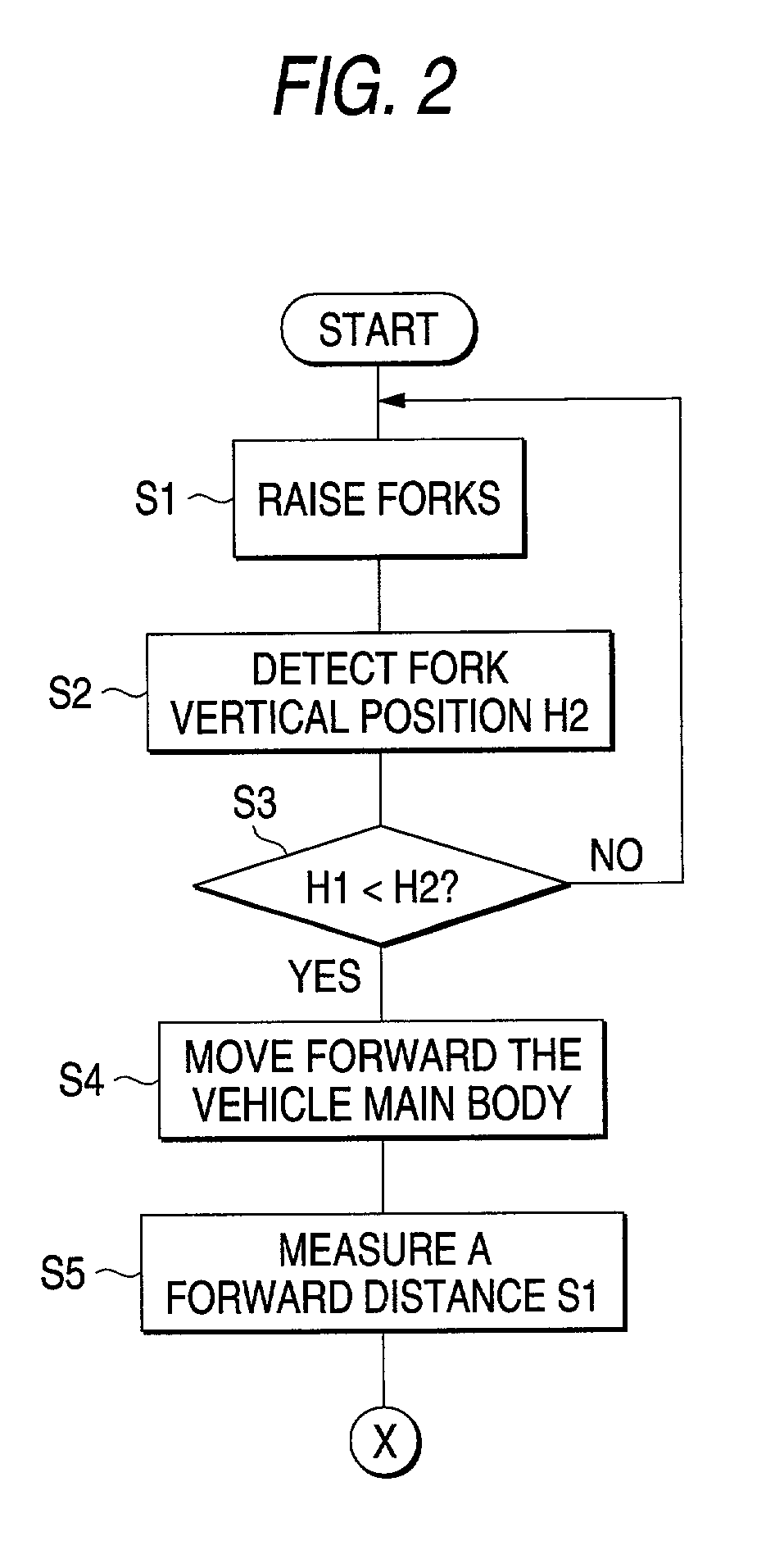

Cargo handling vehicle

InactiveUS20030024132A1Safety devices for lifting equipmentsWalking sticksMovement controlMotion control

A cargo handling vehicle comprises cargo carriers 21, a lift unit 1, a vehicle main body 24, and a running system 3, and the cargo handling vehicle further comprises a lift height detecting section 2 for detecting the vertical position of the cargo carriers 21, a traveling distance measuring section 4 for measuring a forward distance S1 covered by the vehicle main body 24 which starts its forward movement after the cargo carriers 21 are started to be raised and a rearward distance S2 covered by the vehicle main body 24 which starts its rearward movement after having completed its forward movement, and a movement control section 9 for prohibiting the lowering movement of the cargo carriers 21 until a rearward distance to be covered by the vehicle main body 24 which starts its rearward movement in a state in which the vertical position H2 of the raised cargo carriers 21 exceeds a preset reference height H1 becomes equal to or greater than the forward distance covered by the vehicle main body 24.

Owner:NIPPON YUSOKI

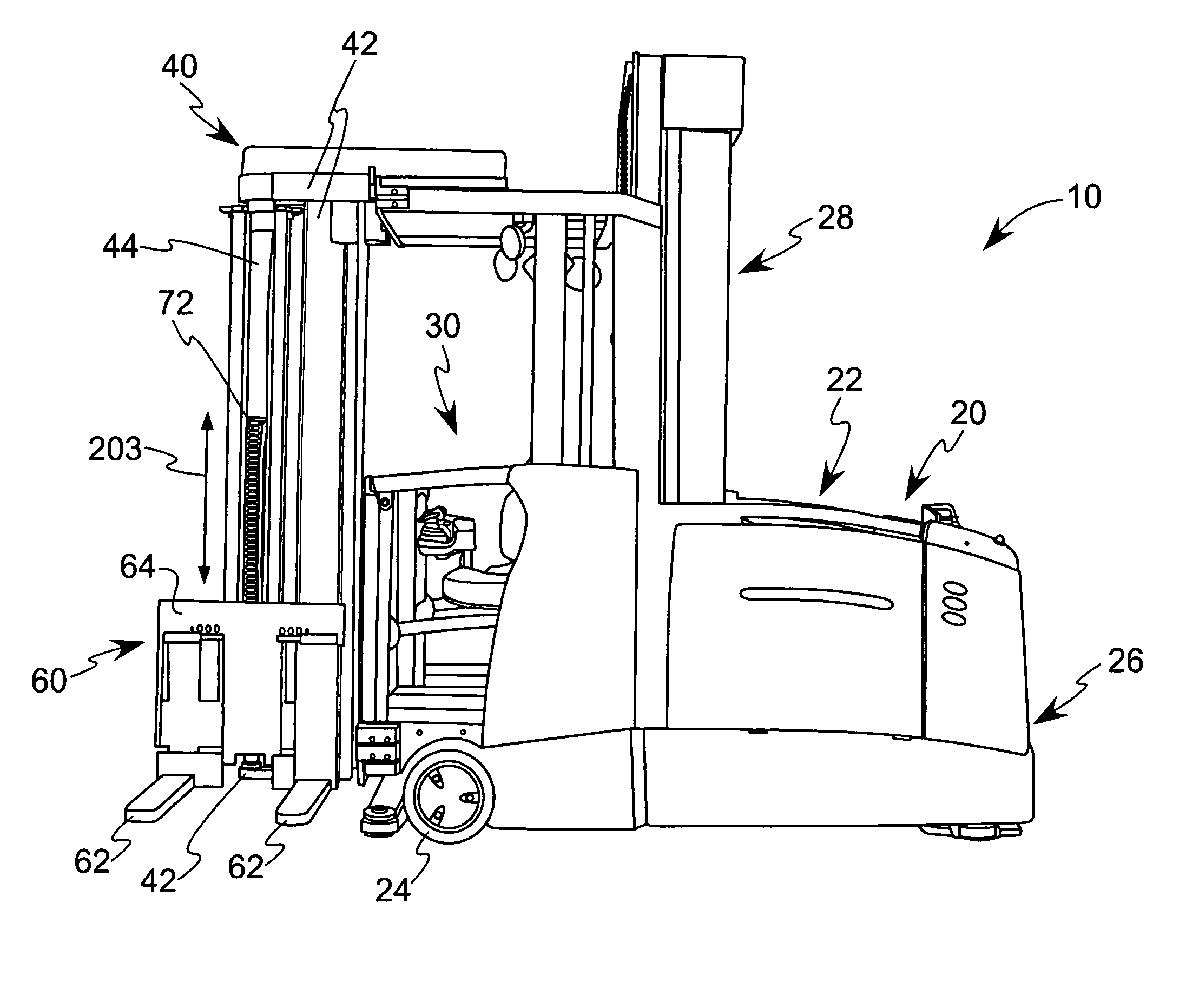

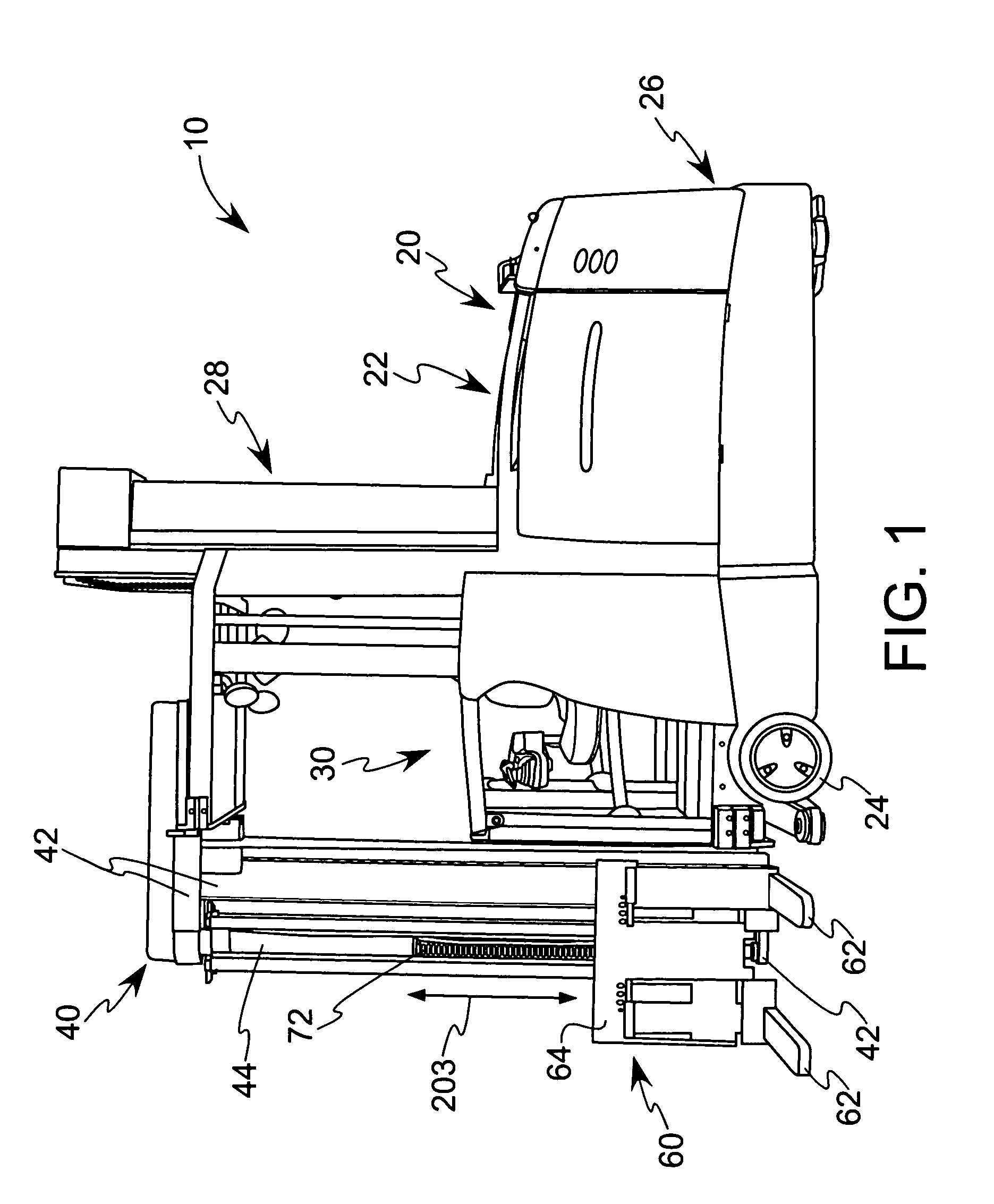

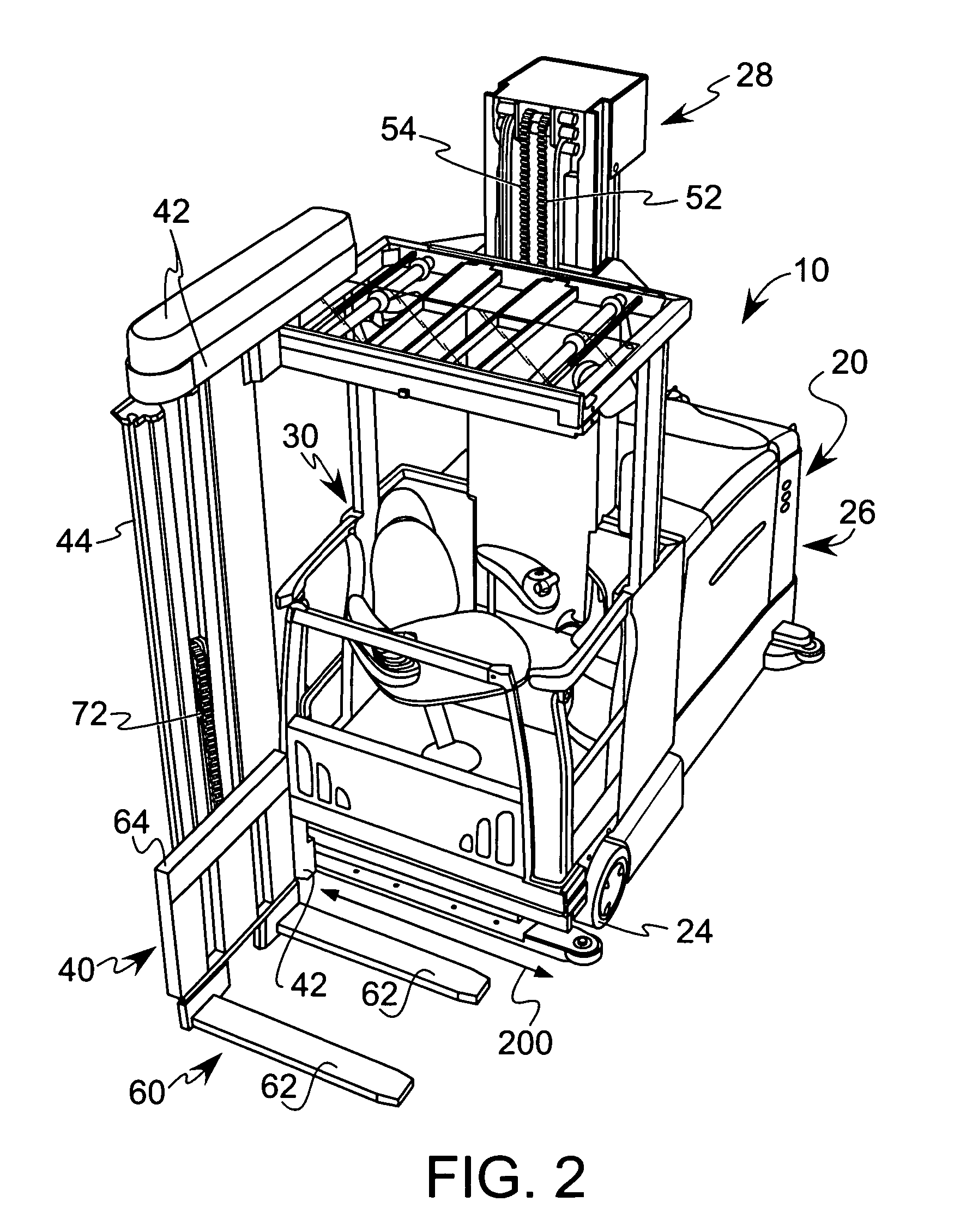

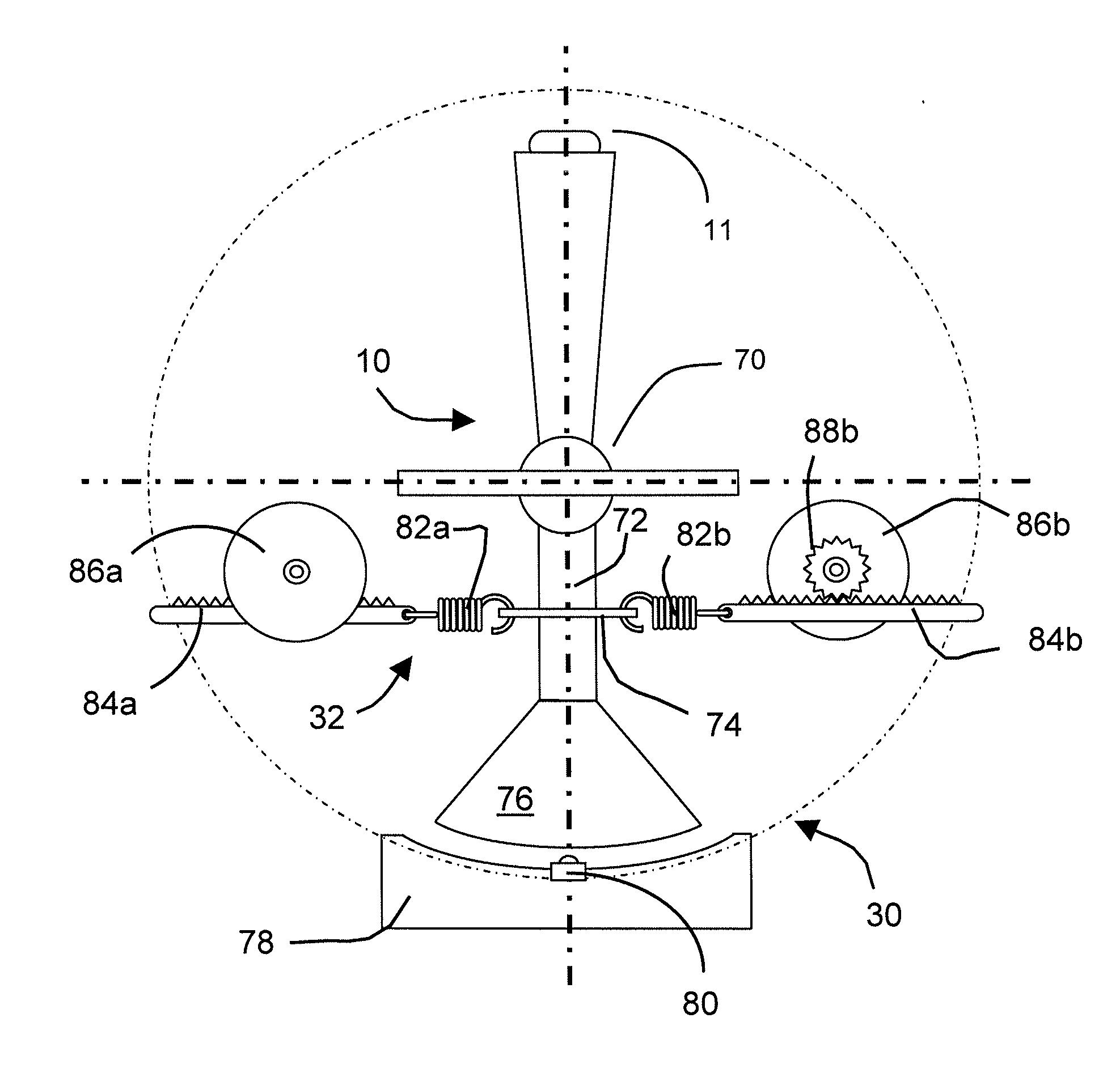

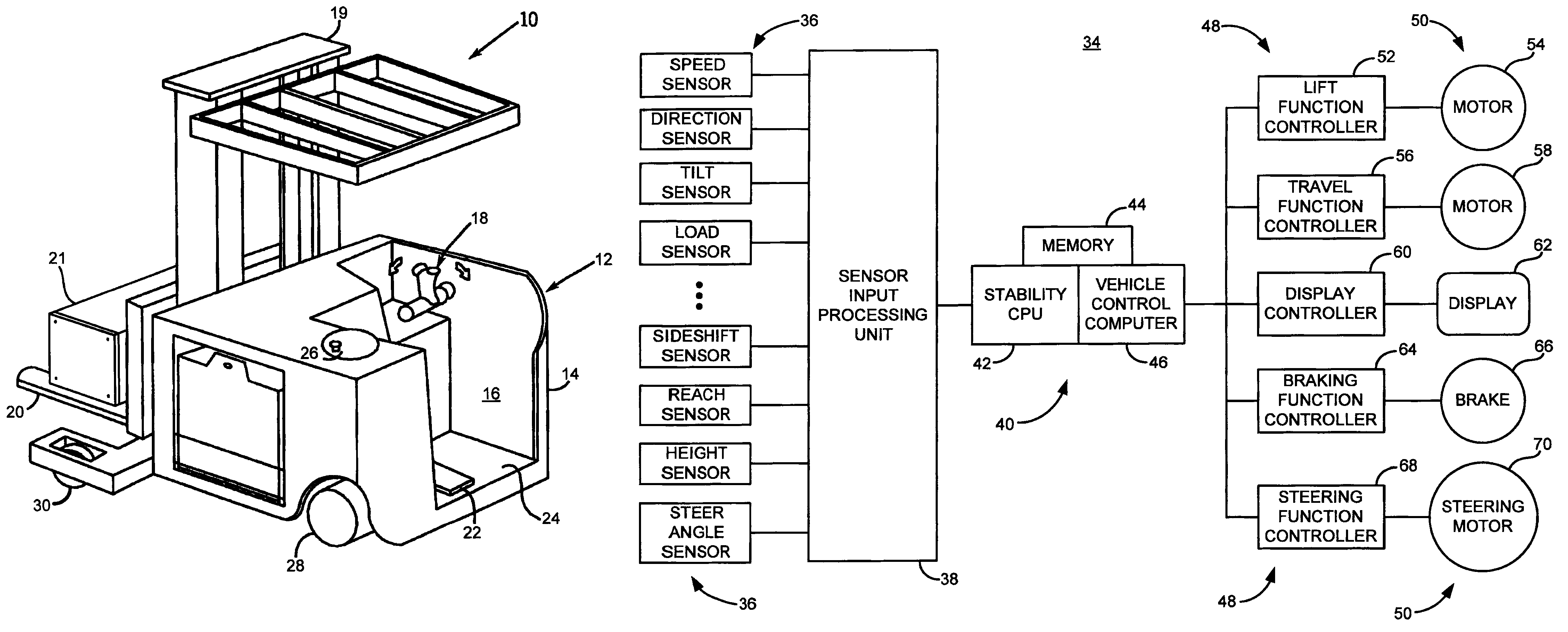

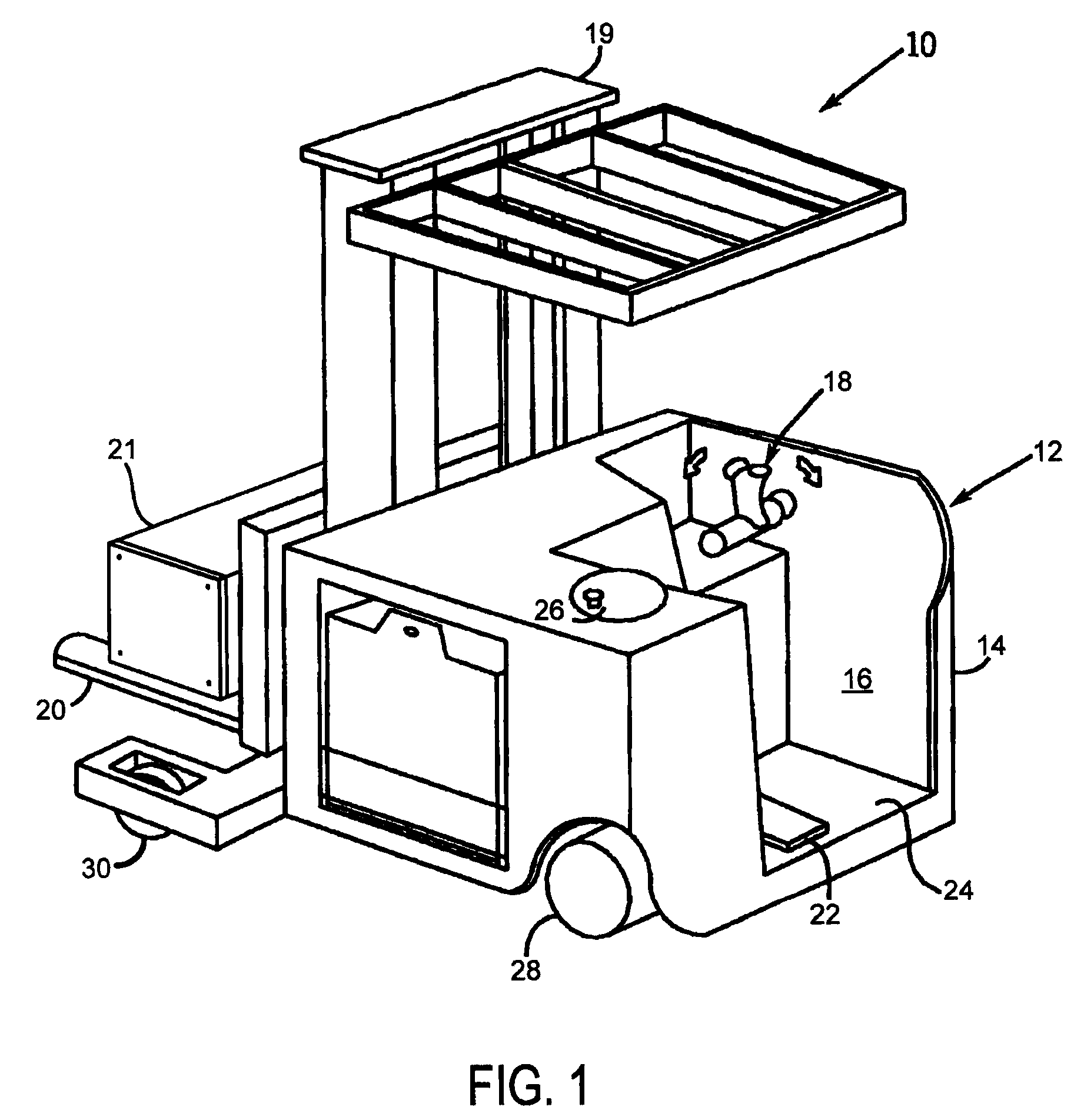

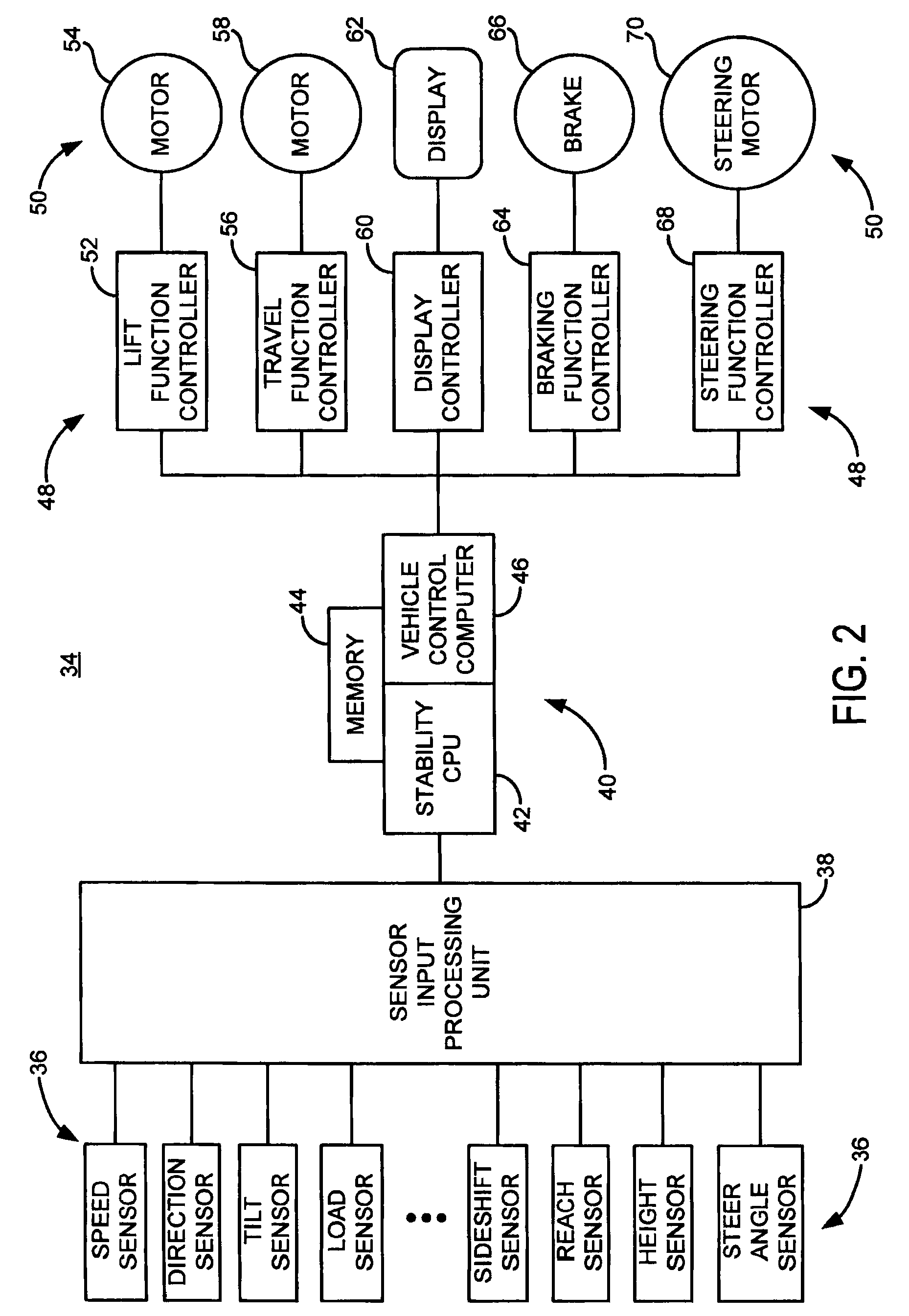

System and method for dynamically maintaining the stability of a material handling vehicle having a vertical lift

ActiveUS8140228B2Improve material stabilityMaintain dynamic stabilitySafety devices for lifting equipmentsAnalogue computers for trafficWheelbaseMaintaining vehicles

Owner:RAYMOND LTD

Use of E-field sensors for situation awareness/collision avoidance

ActiveUS7397351B1Sure easyEliminate false alarmSafety devices for lifting equipmentsOptical signallingElectric field sensorEngineering

Owner:III HLDG 1

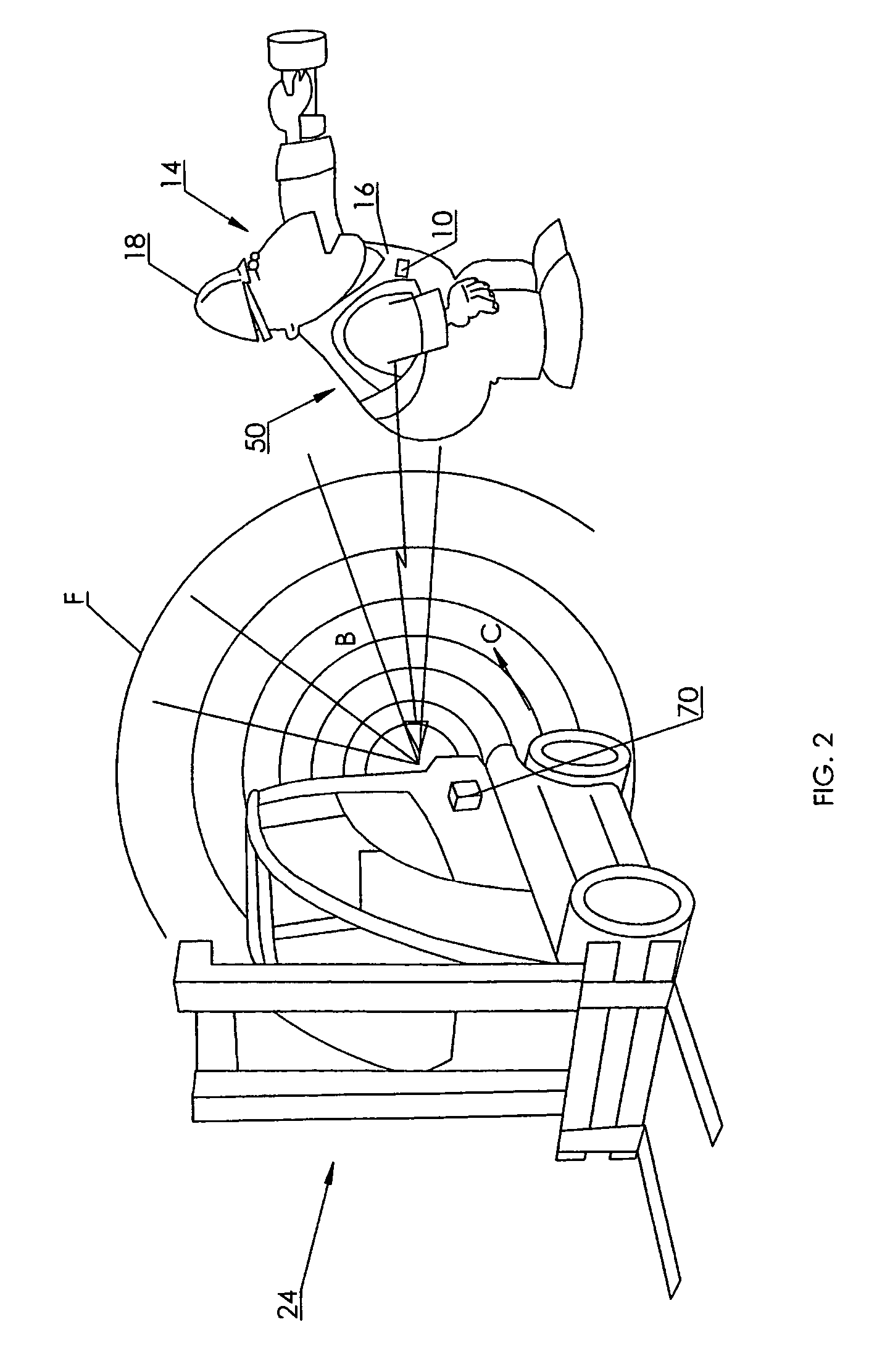

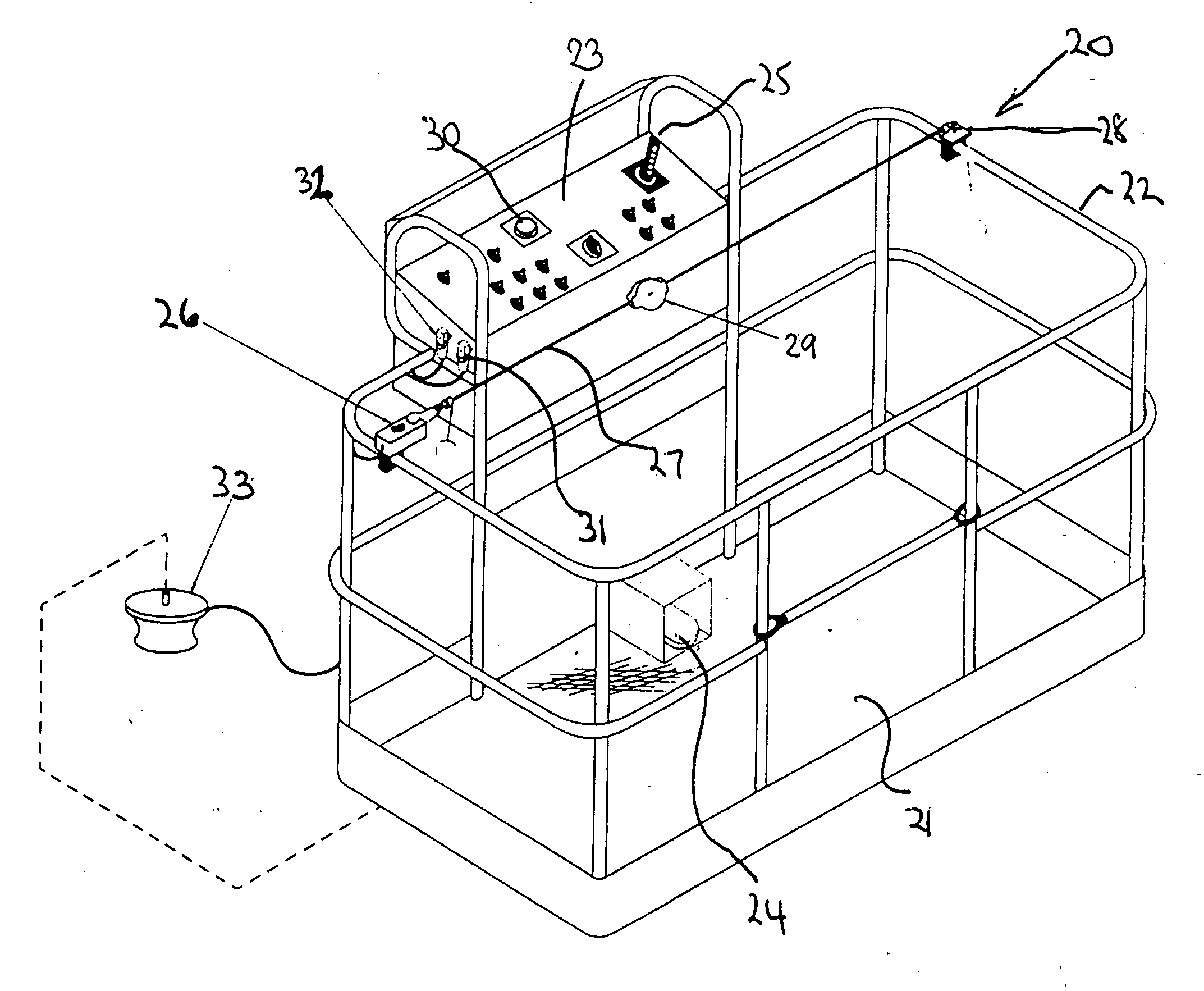

Aerial lift with safety device

ActiveUS20090260920A1Avoid changeSafety devices for lifting equipmentsBuilding support scaffoldsAerial liftControl theory

A safety device for an aerial lift (10) having a basket (20) with controls (23) which permit an operator to manoeuvre the basket (20), and a foot operable safety switch (24) which activates the controls (23), the safety device comprising an auxiliary safety switch (24) operated by a trip cord (27) arranged proximate to the controls (23) and which is connected in series with the foot safety switch (24) so that in the event that the cord is distorted the auxiliary switch (26) prevents activation of the control panel (23) and may additionally operate an alarm.

Owner:NATIONWIDE PLATFORMS LTD

Popular searches

Vehicle position/course/altitude control Complex mathematical operations Vehicles Analogue processes for specific applications Position/direction control Using optical means Electric signalling details Burglar alarm by hand-portable articles removal Electric/electromagnetic visible signalling Individual entry/exit registers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com