Patents

Literature

35results about How to "Reduce unnecessary costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

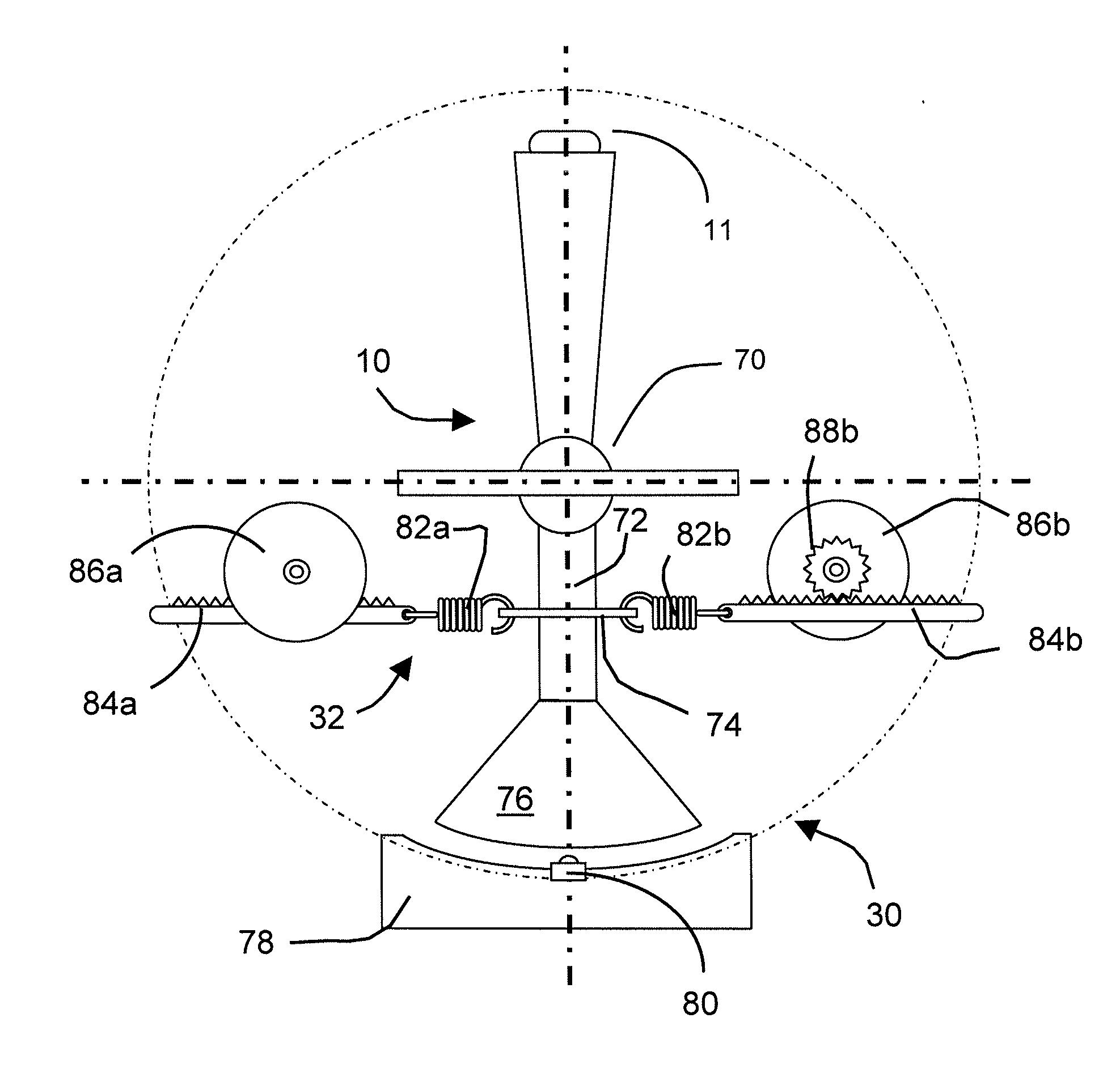

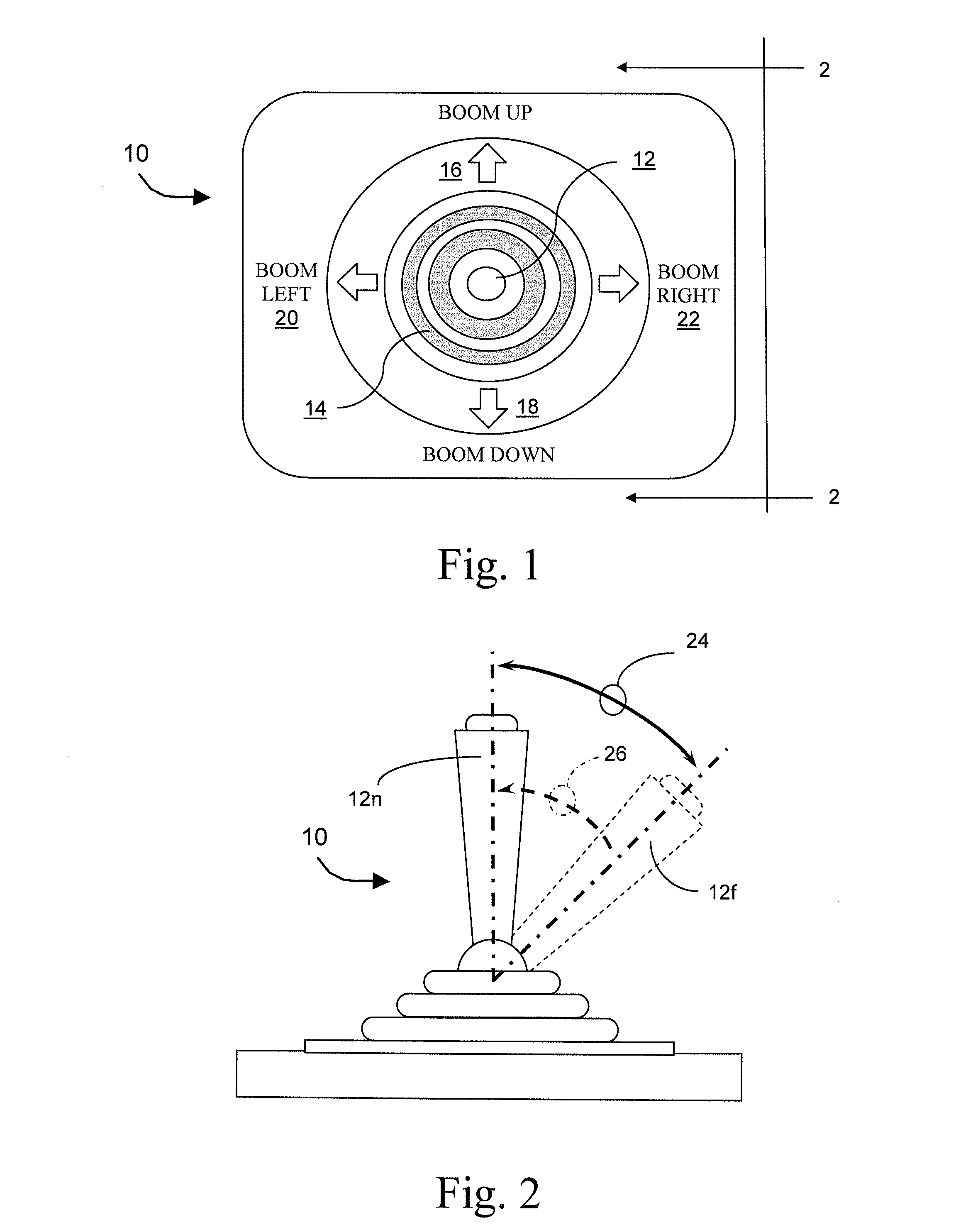

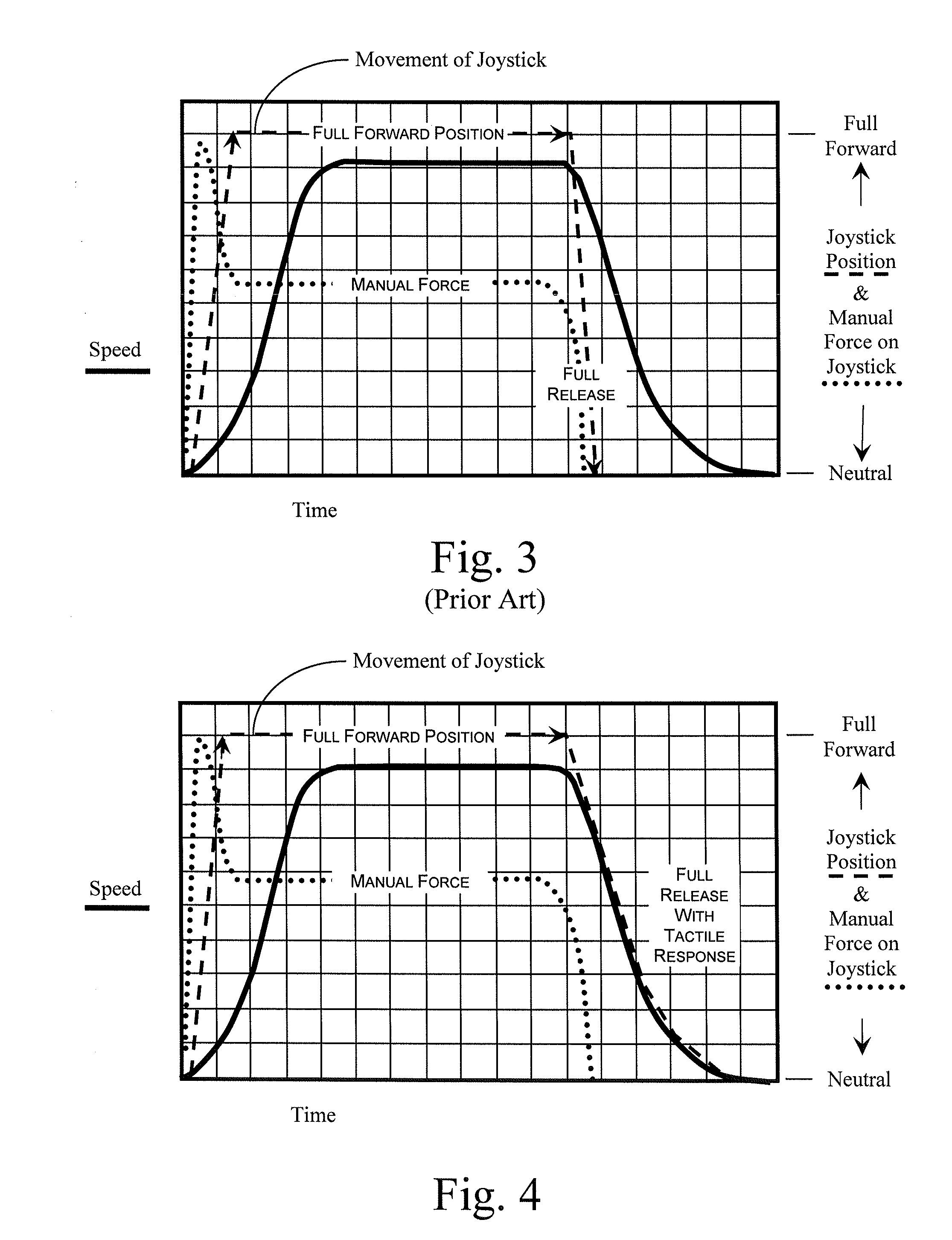

Tactile Feedback for Joystick Position/Speed Controls

ActiveUS20160179128A1Minimize complexityReduce unnecessary costsManual control with multiple controlled membersControlling membersJoystickActuator

A joystick controller is disclosed for controlling movement of a boom lift platform, the controller having actuators or the like that provide one or more forms of tactile feedback that are intuitively interpreted and adjusted by the user of the joystick motion control, the joystick being neutrally-biased to effect a null movement when the joystick is positioned in a neutral position, but also being adapted with at least one form of tactile feedback by which the joystick controller conveys information about the boom lift's operation to the joystick operator, such as through resistive force or through vibrations or the like.

Owner:ENOVATION CONTROLS

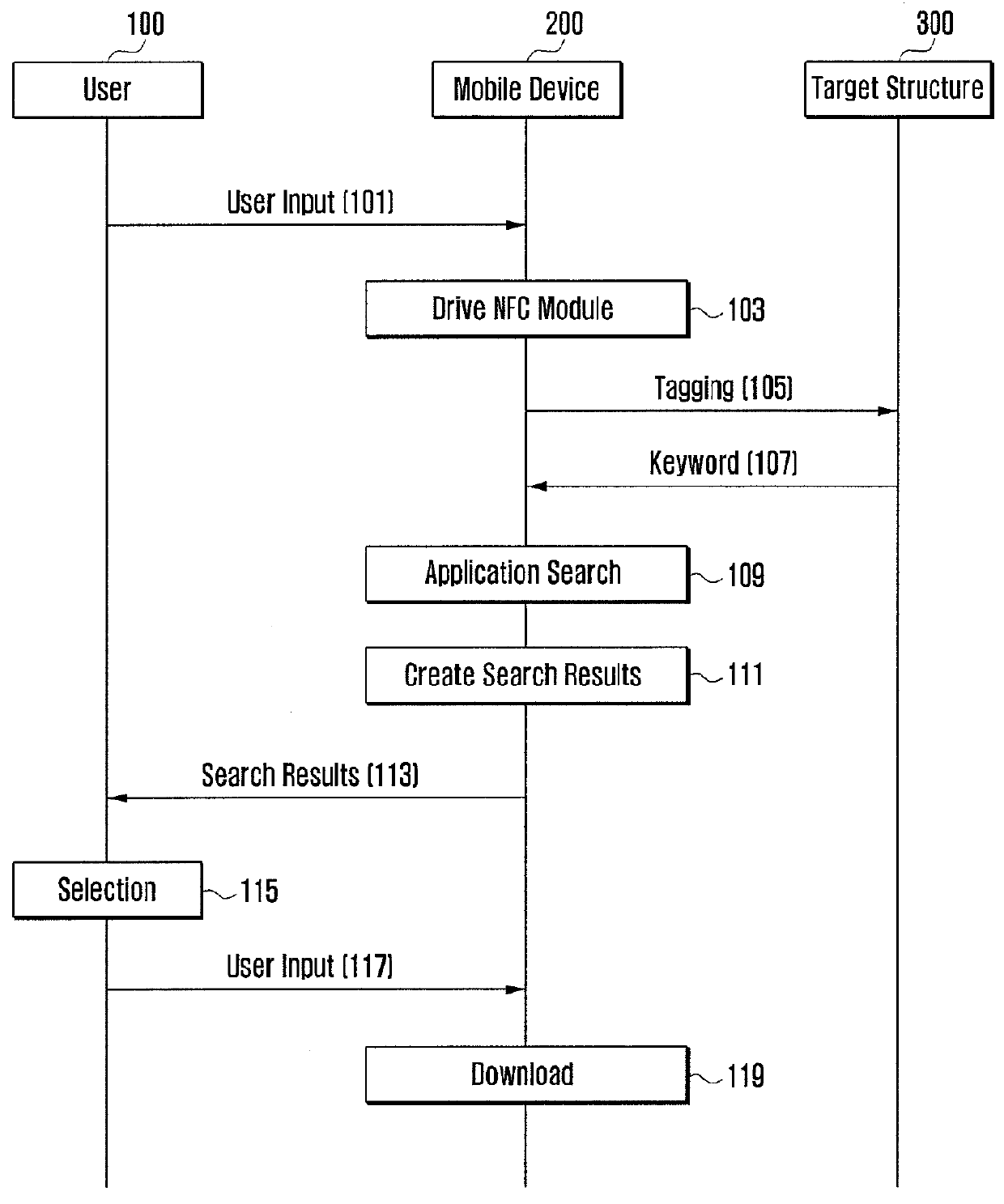

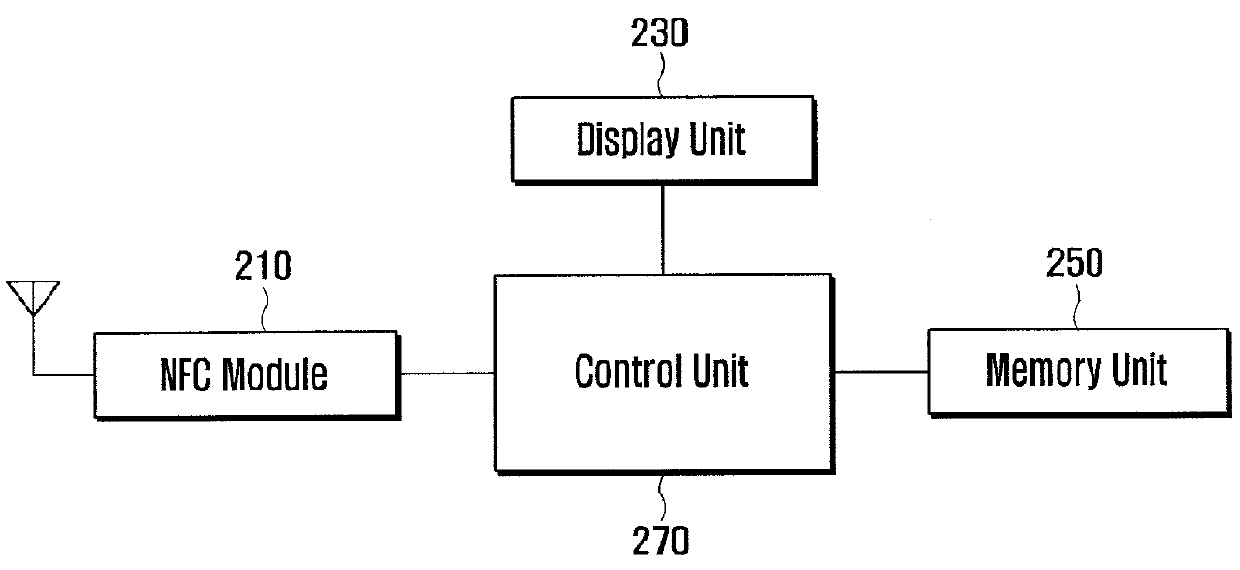

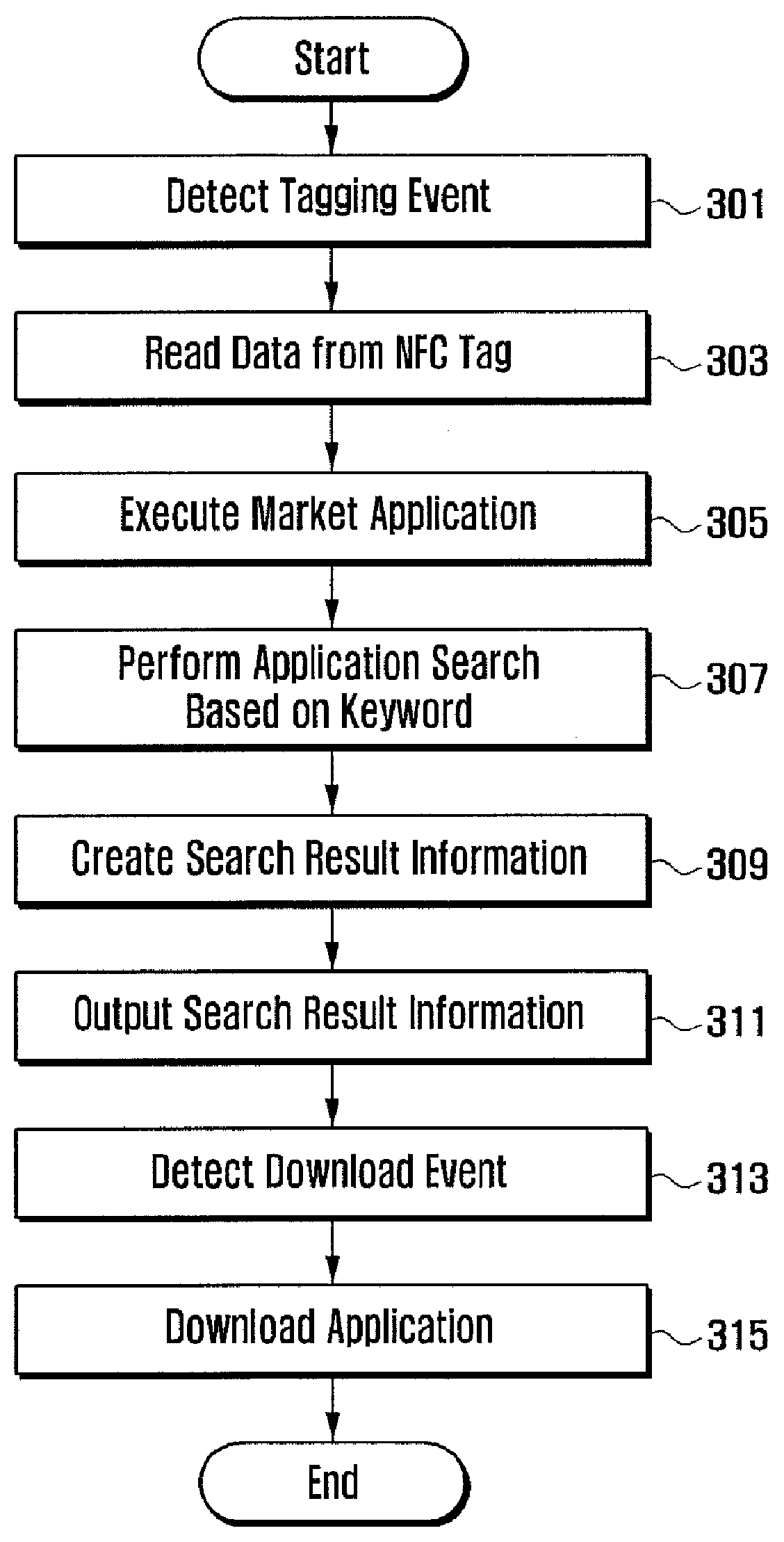

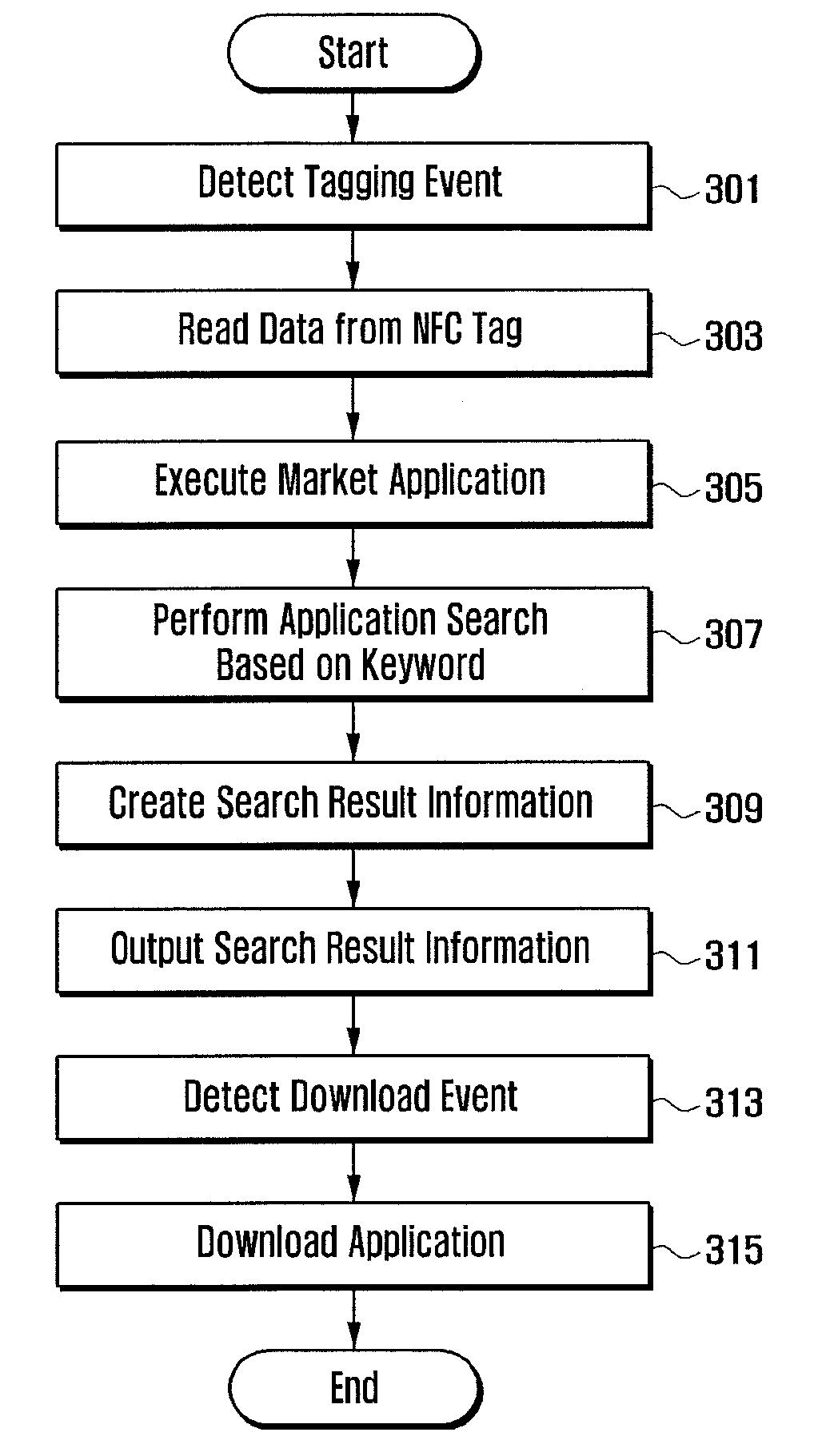

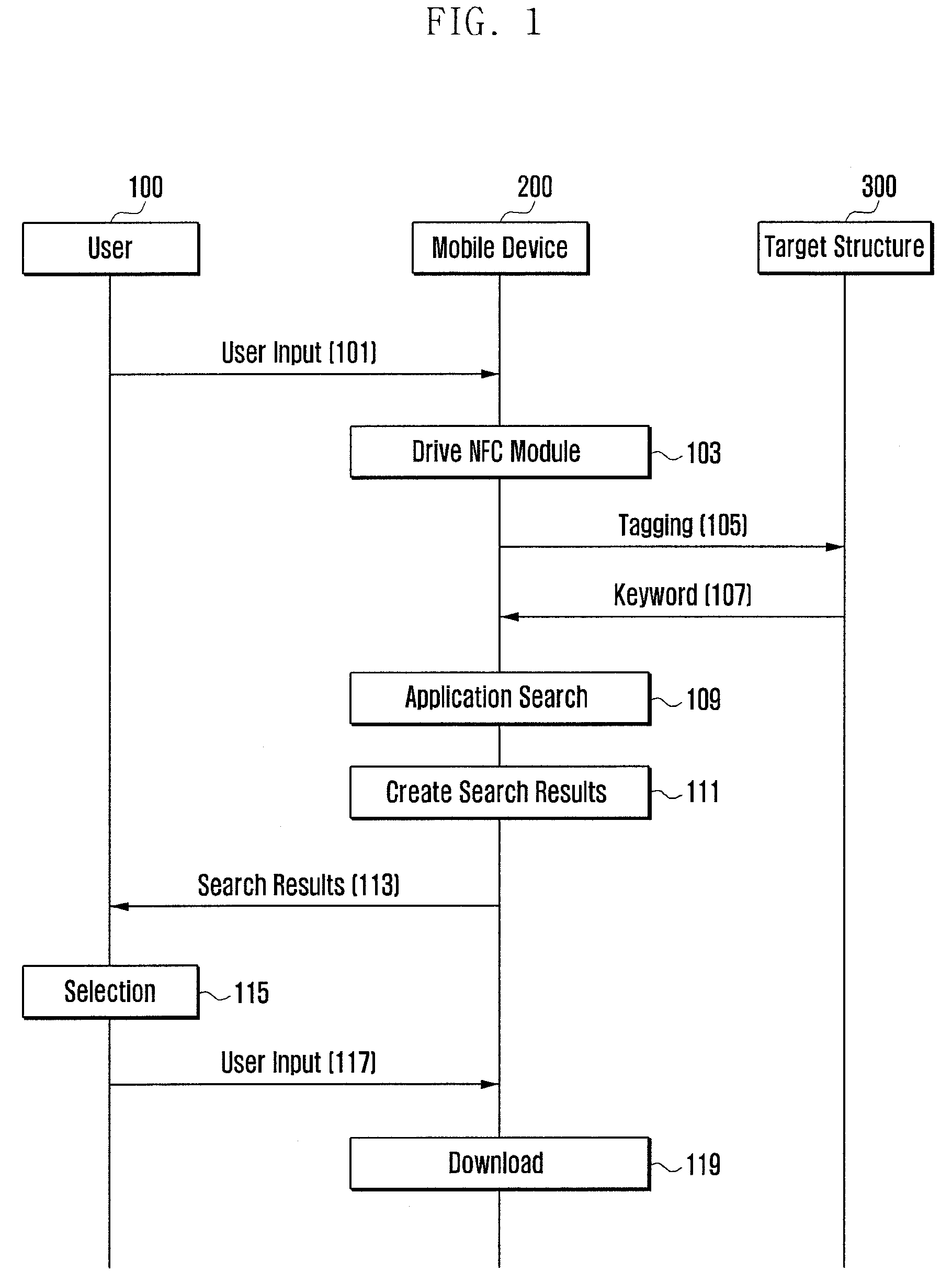

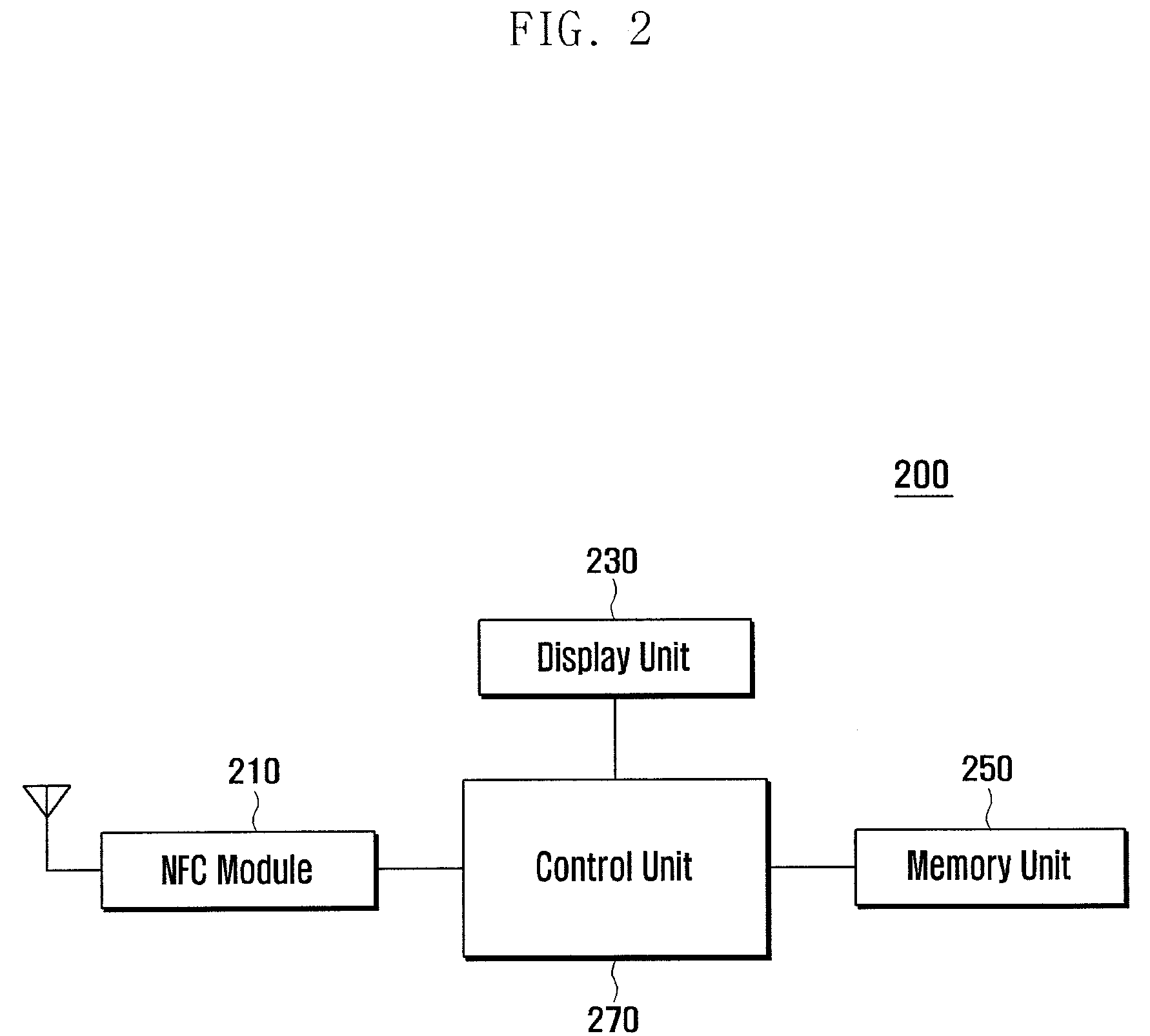

Method and system for acquiring application in mobile device

ActiveUS20120220282A1Intuitive acquisitionReduce unnecessary costsService provisioningNear-field for read/write/interrrogation/identification systemsStructure of Management InformationMobile device

A method, system and mobile device for searching for and acquiring a desired application by using Near Field Communication (NFC) regardless of time and location are provided. In the method, the mobile device reads a keyword from an NFC tag of a target structure in response to a tagging event between the mobile device and the NFC tag. Then the mobile device performs an application search using the keyword, and downloads a specific application found using the keyword.

Owner:SAMSUNG ELECTRONICS CO LTD

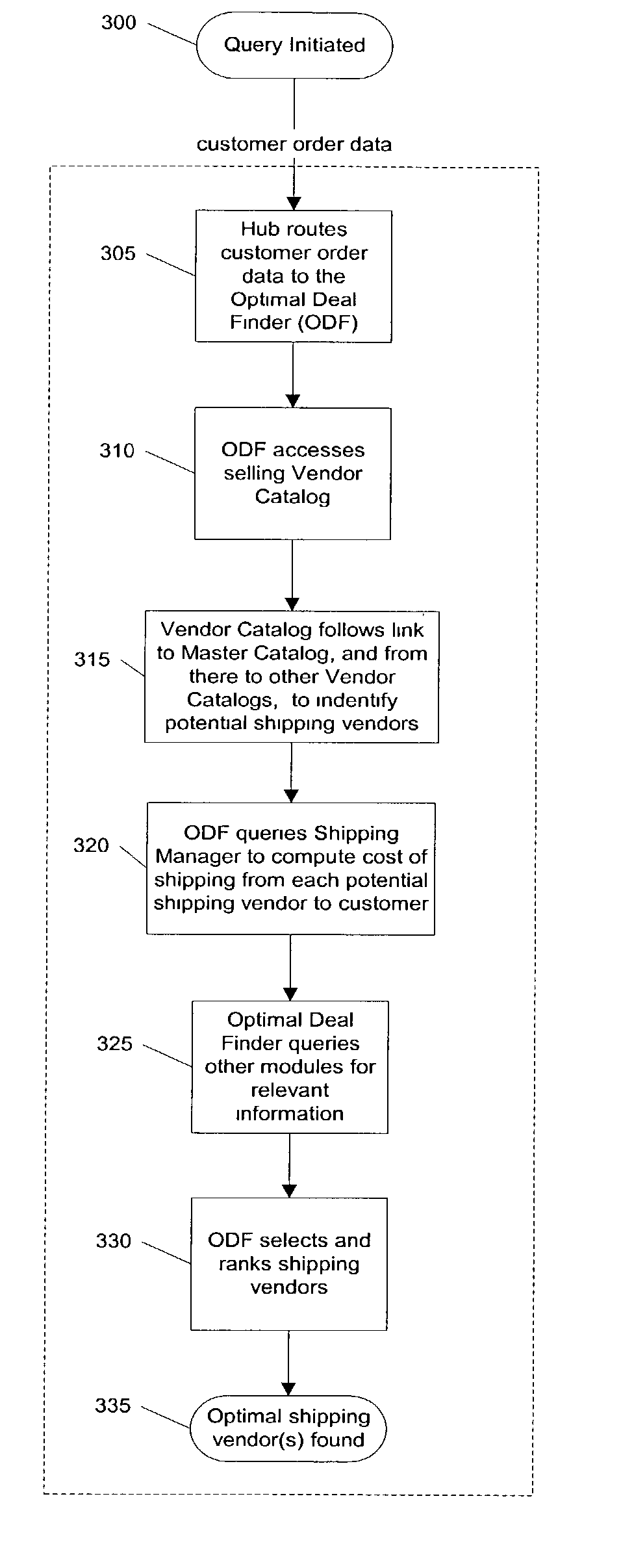

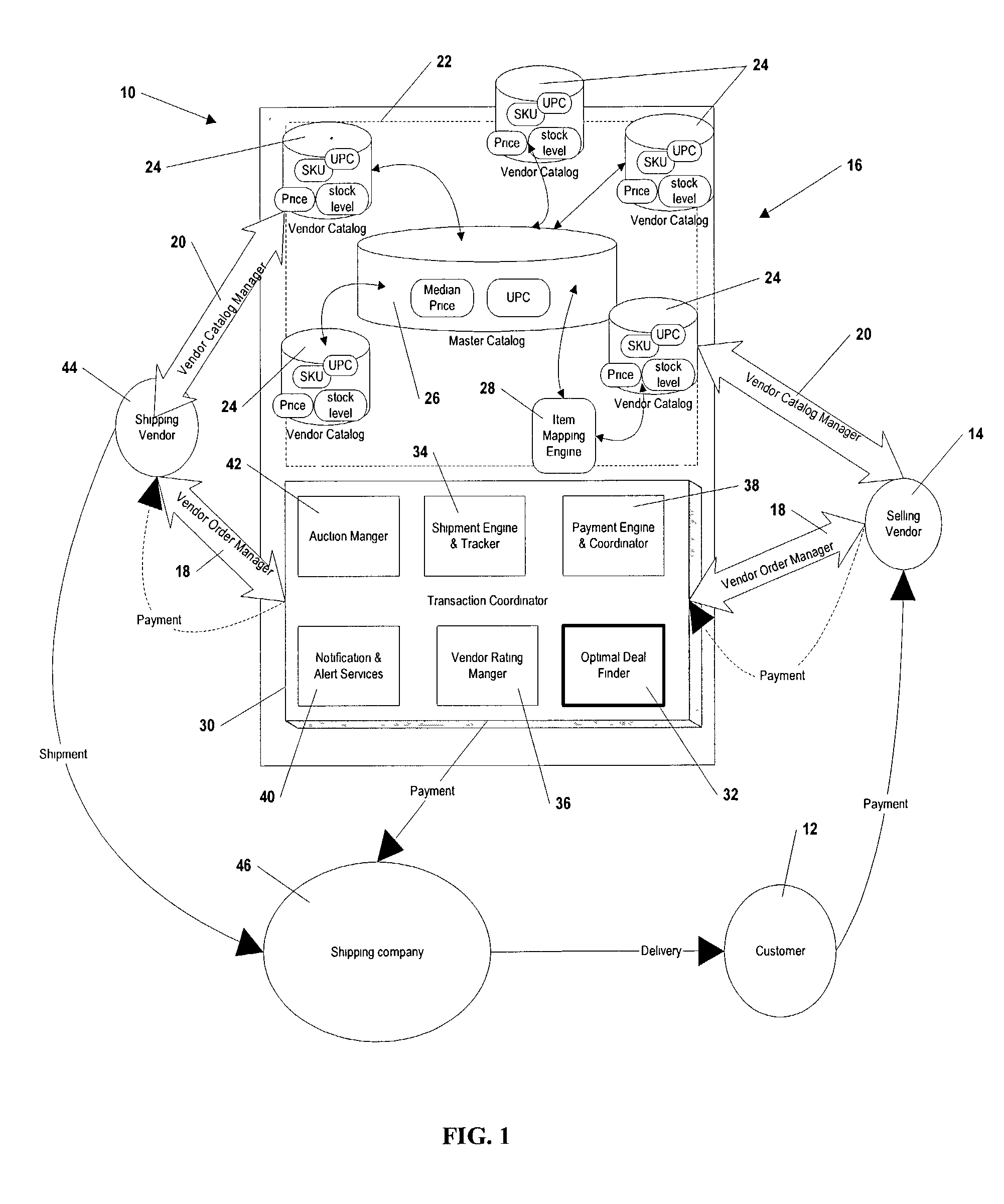

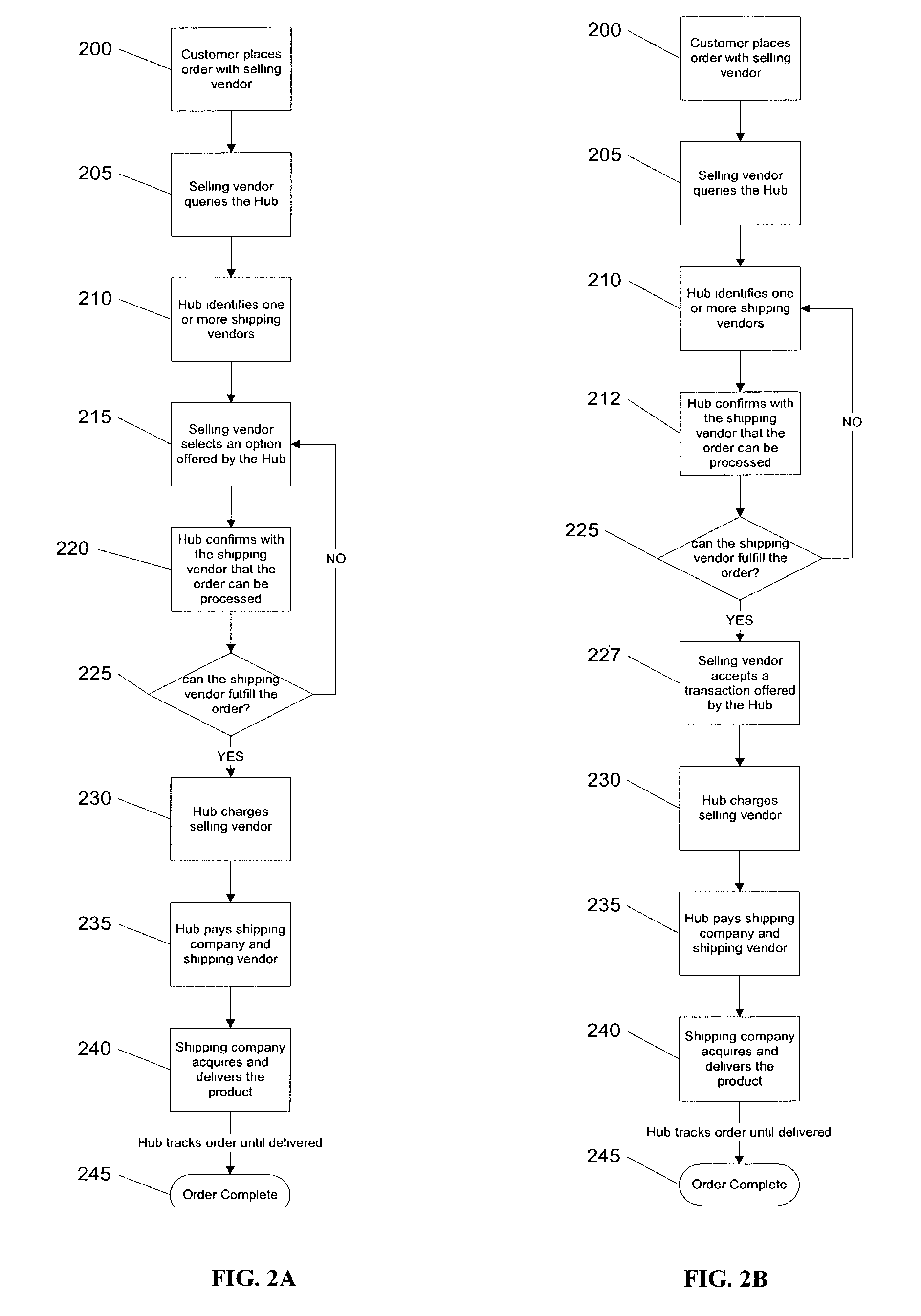

Method for optimizing a business transaction

ActiveUS7212991B2Reduce unnecessary costsOptimize various aspectBuying/selling/leasing transactionsLogisticsRelevant informationWorld Wide Web

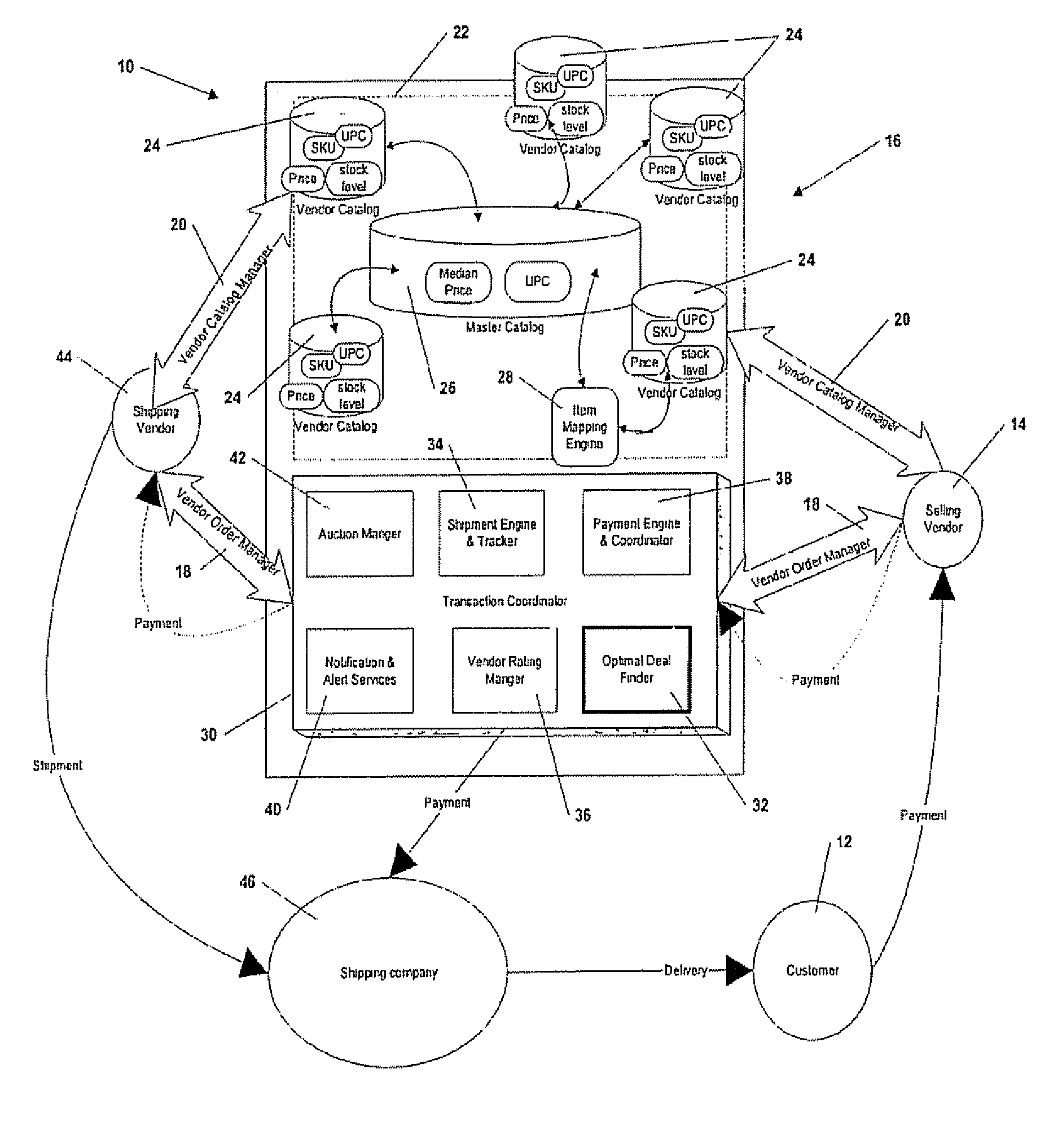

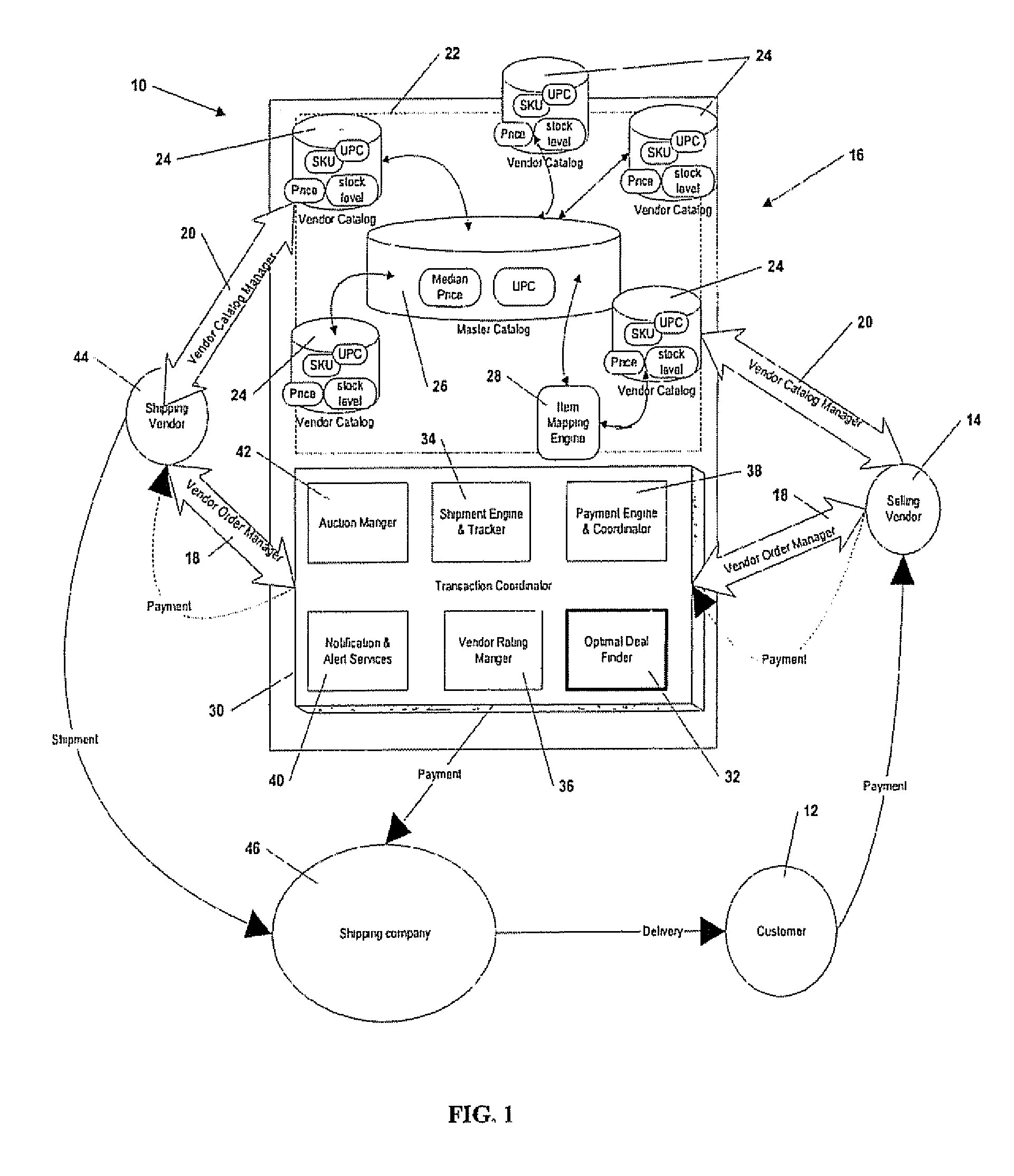

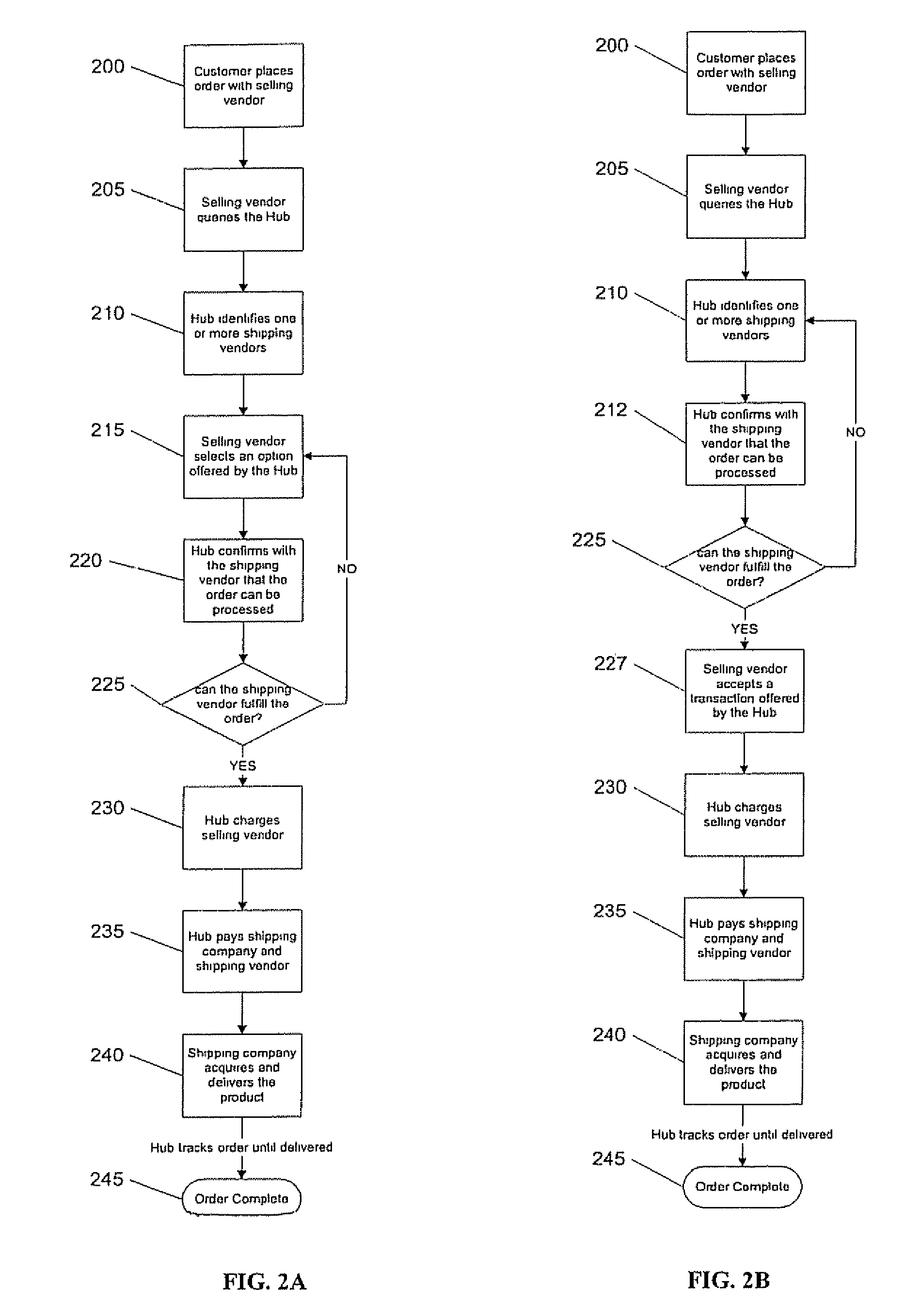

A system for coordinating business transactions between multiple vendors of consumer products, referred to herein as selling vendors and shipping vendors. This system includes an electronic device for allowing a consumer to access a selling vendor's website, at least one server connected to the selling vendor's website for receiving purchase-related information from the consumer and sending and receiving information to and from the system, at least one server connected to the shipping vendor's business network for receiving and sending communications from and to the system, and a transaction coordination hub connected to the selling vendor's server and the shipping vendor's server for coordinating transactions between the selling vendor and the shipping vendor. The transaction coordination hub further includes a catalog subcomponent for storing detailed vendor-related data and a transaction coordinator software subcomponent for coordinating transactions between the selling vendors and the shipping vendors.

Owner:FORMULA LABS

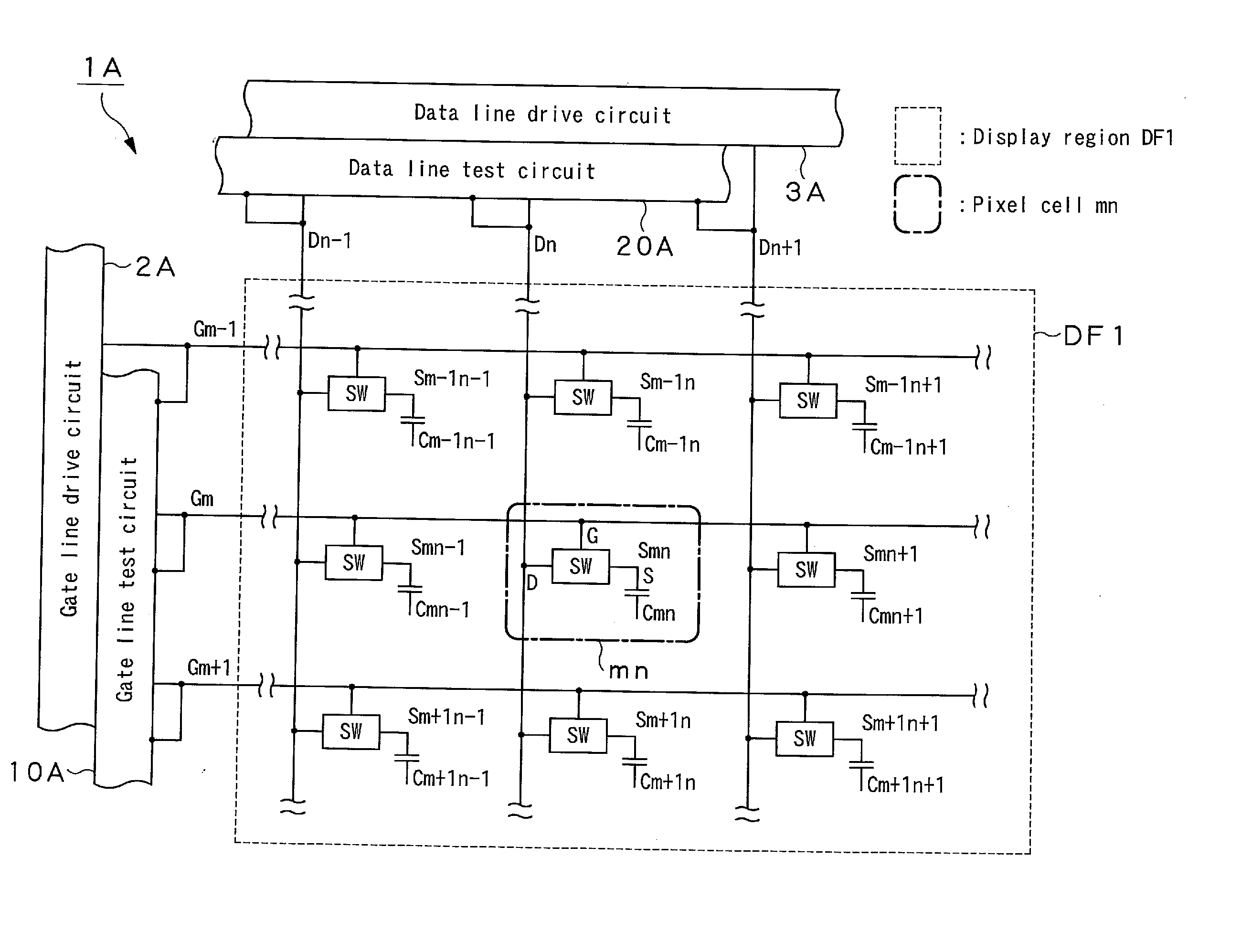

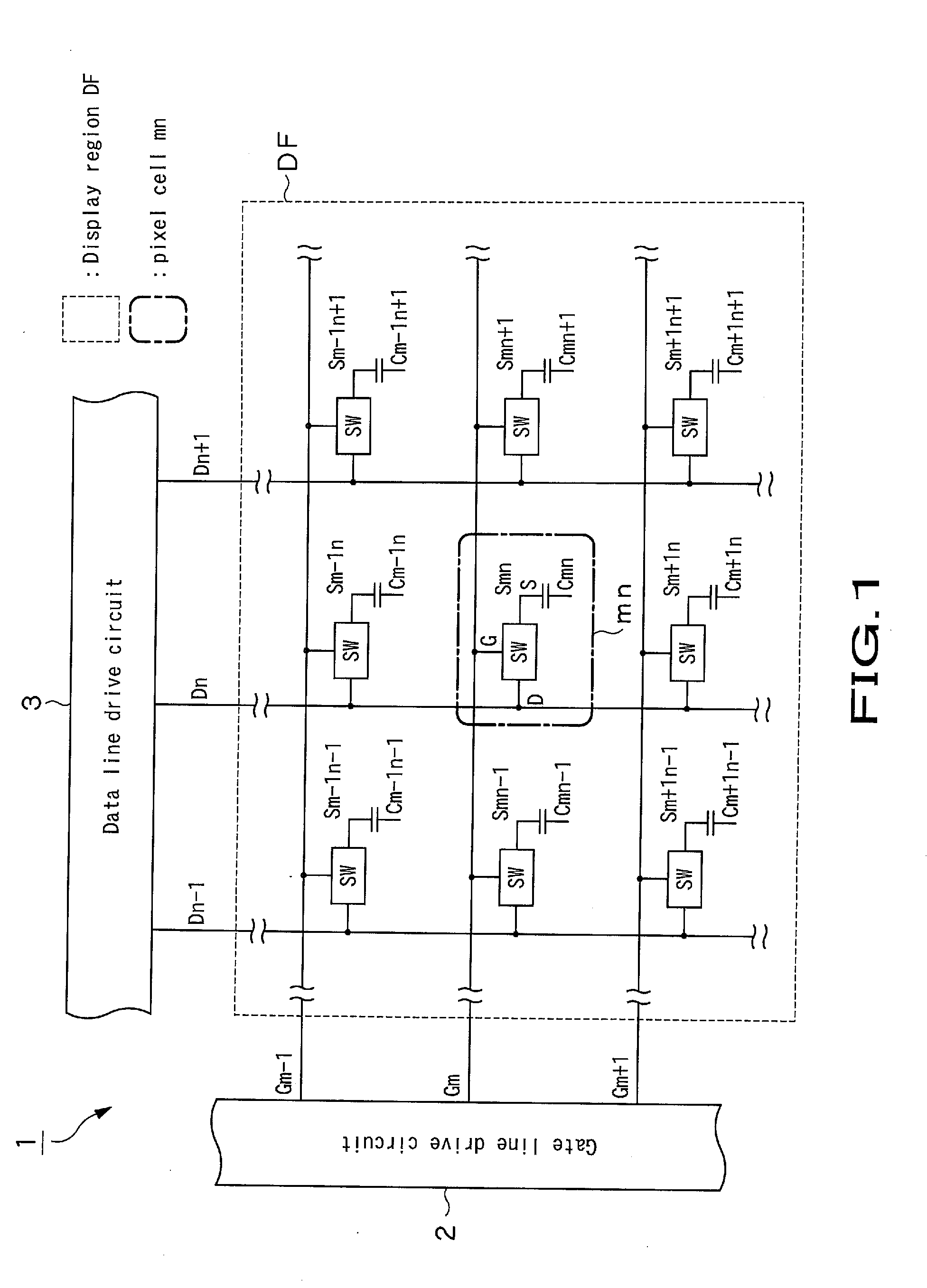

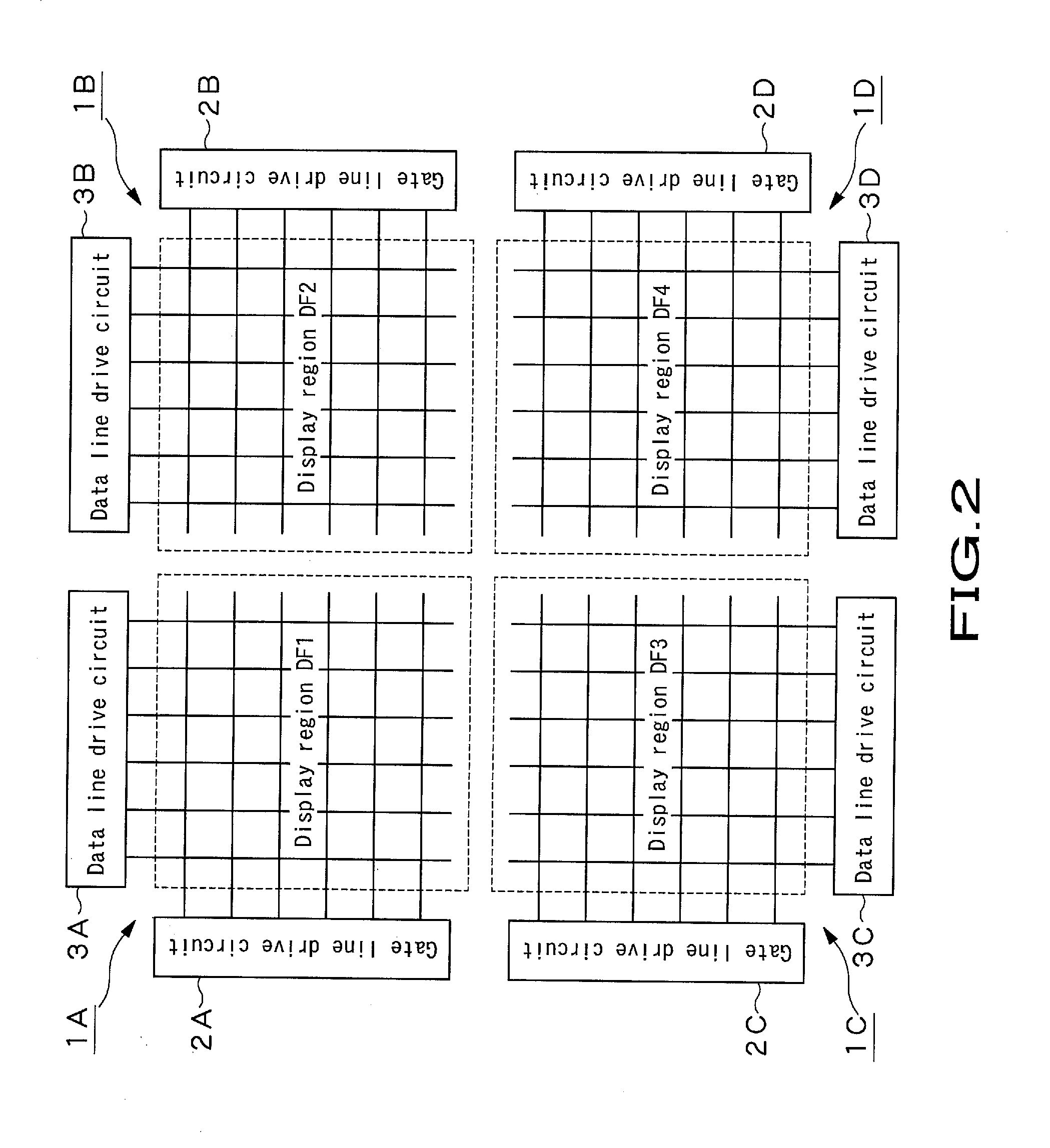

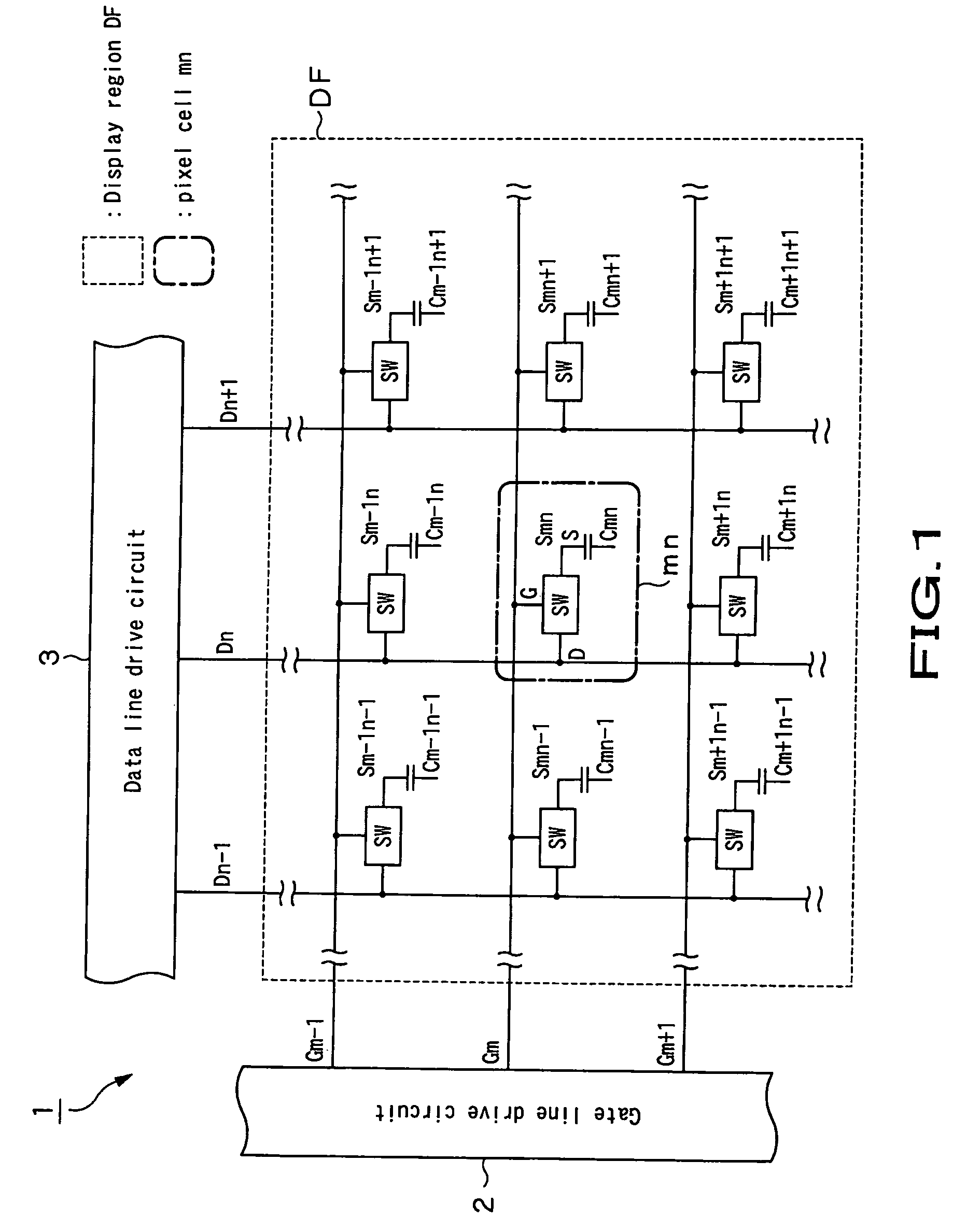

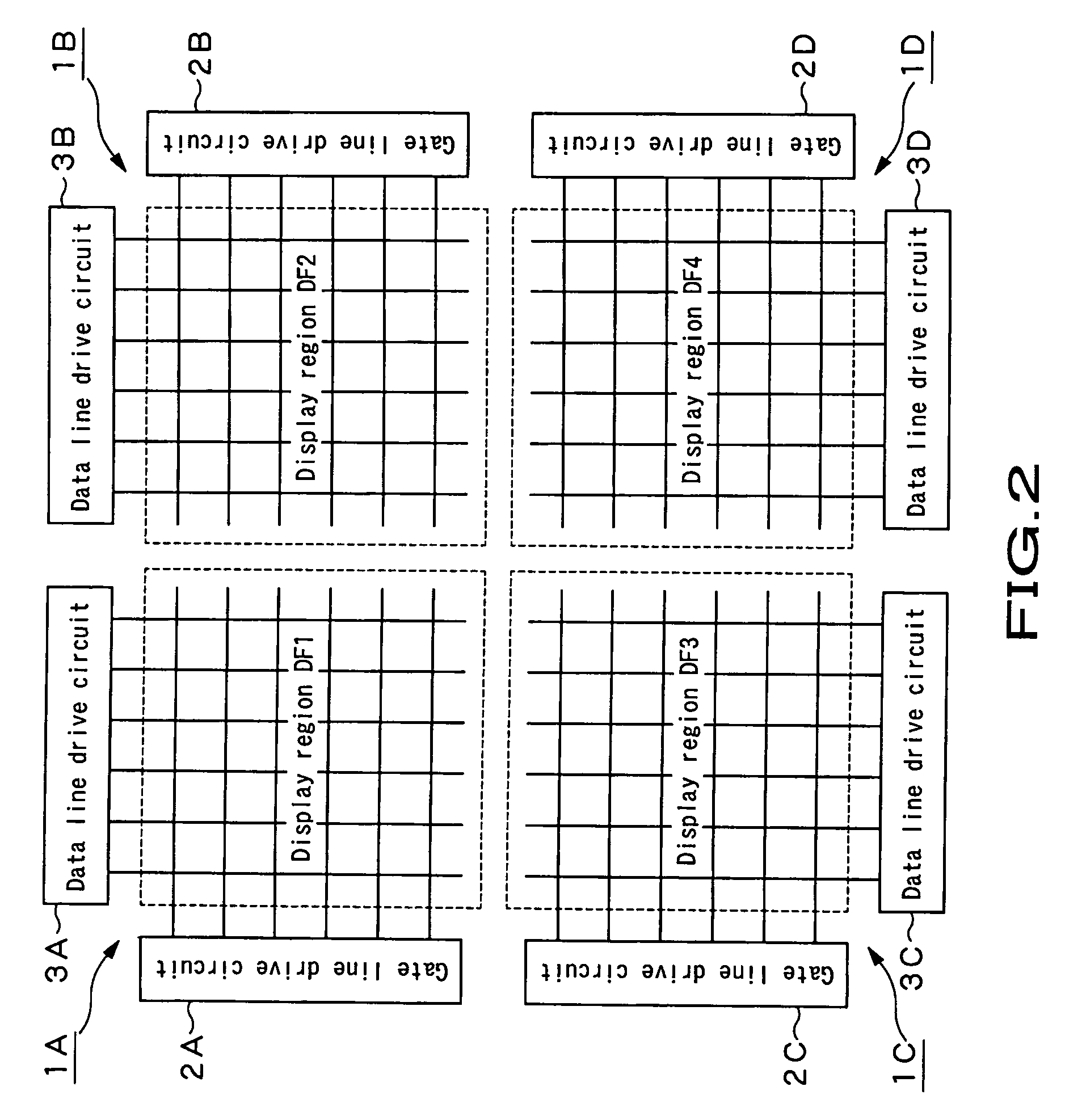

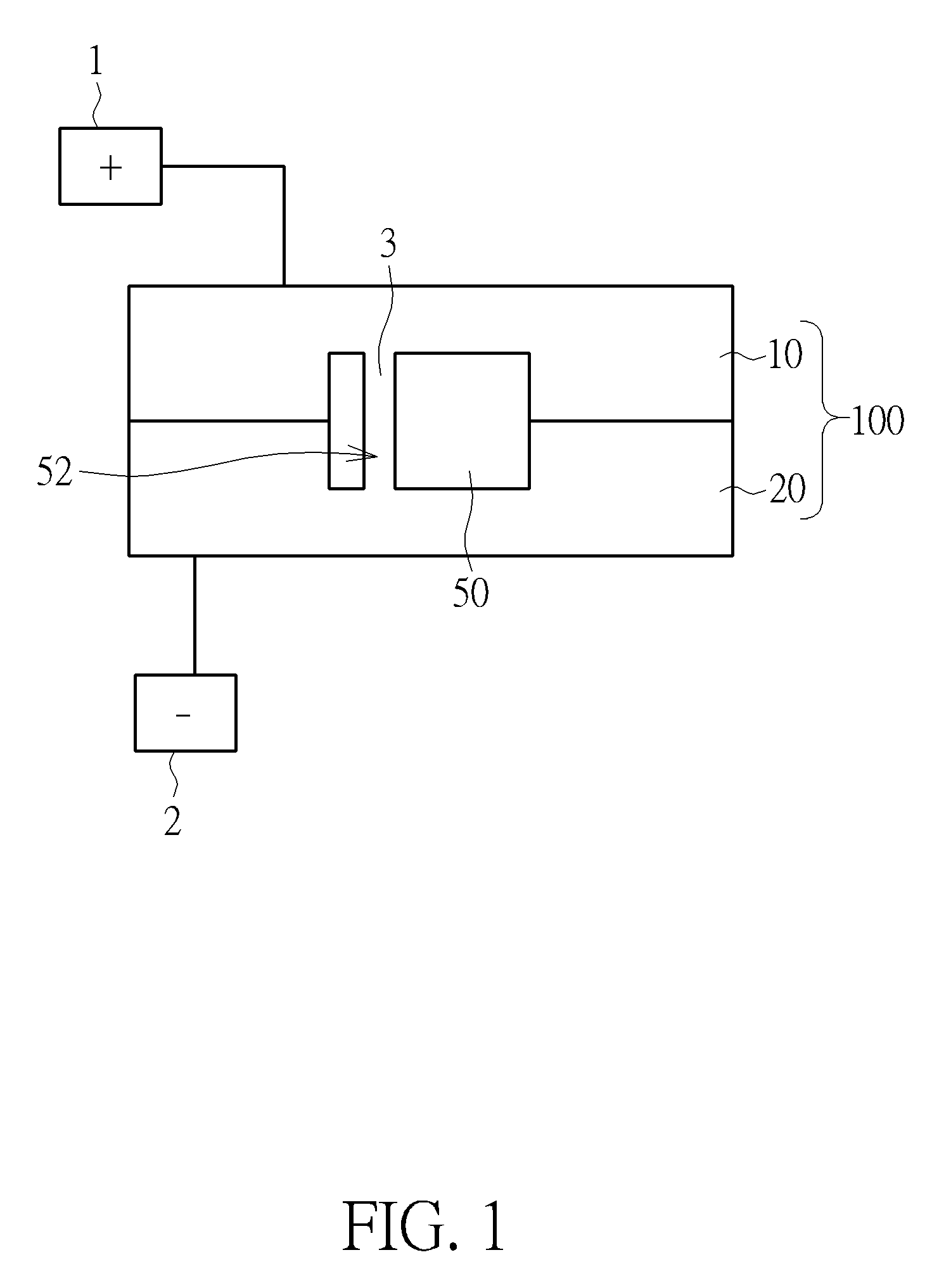

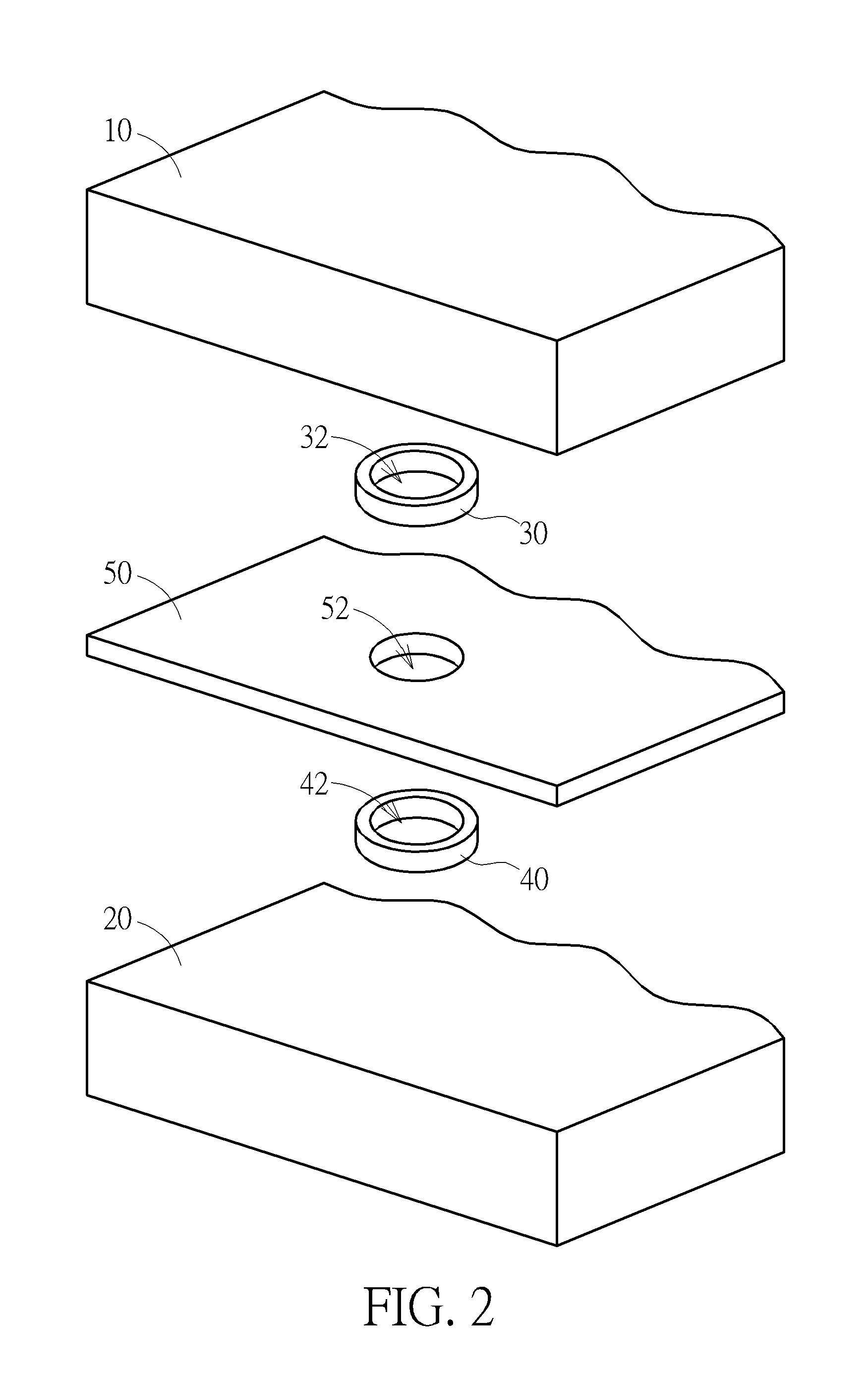

Display apparatus and inspection method

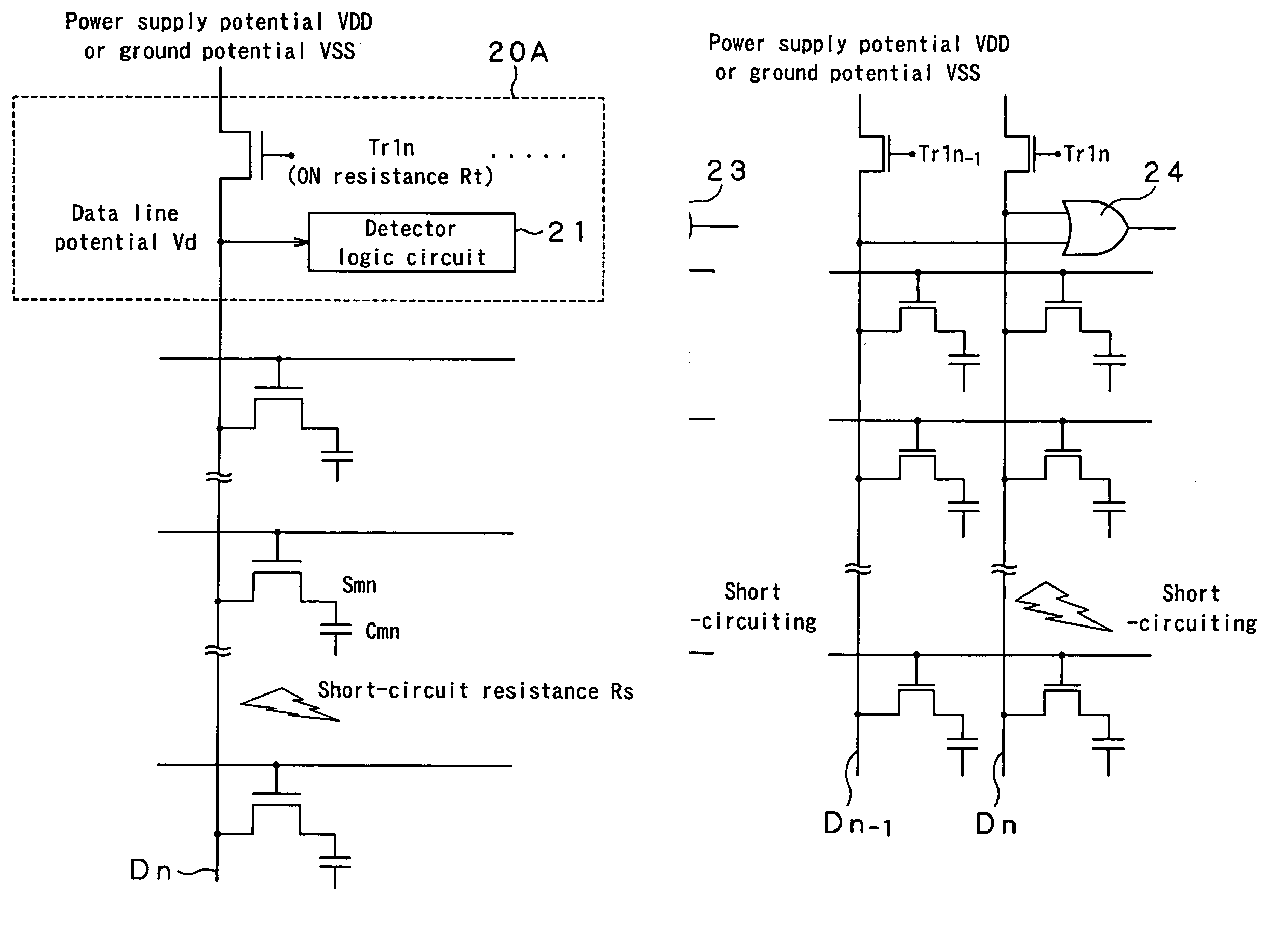

ActiveUS20060226866A1Easily short-circuitedEasy to testStatic indicating devicesVisual presentationHigh resistanceElectrical resistance and conductance

The test circuit of a display apparatus according to the invention detect short-circuiting in each of the data lines Dn by inputting the electric potential Vd of the data line Dn connected to the corresponding one of high resistance first short-circuiting detecting resistors Tr1n connecting a predetermined electric potential and the data line Dn to the corresponding one of first detector logic circuits and binarizing and outputting the input electric potential Vd of the data line Dn by referring to a predetermined threshold value and also detect short-circuiting in each of the gate lines Gm by inputting the electric potential of the gate line Gm connected to the corresponding one of high resistance second short-circuiting detecting resistors connecting a predetermined electric potential and the gate line Gm to the corresponding one of second detector logic circuits and binarizing and outputting the input electric potential of the gate line by referring to a predetermined threshold value. The defects (short-circuits) produced in the process of manufacturing the display apparatus can be inspected by a simple technique.

Owner:SONY CORP

Automated Transaction Coordinator

ActiveUS20070250398A1Optimize various aspectExtending the market outreach of its membersBuying/selling/leasing transactionsLogisticsCustomer orderOperating system

A method is disclosed for optimizing a business transaction between a selling vendor and a shipping vendor The method includes receiving a query from a selling vendor. The query includes customer order data. The method also includes identifying at least one possible shipping vendor based on the customer order data and determining shipping information for each of the at least one possible shipping vendors. The method further includes selecting a preferred shipping vendor from among the at least one possible shipping vendors and completing the transaction between the selling vendor and the shipping vendor

Owner:FORMULA LABS

Display apparatus and inspection method

ActiveUS7145358B2Easily short-circuitedEasy to testStatic indicating devicesVisual presentationElectrical resistance and conductanceHigh resistance

The test circuit of a display apparatus according to the invention detect short-circuiting in each of the data lines Dn by inputting the electric potential Vd of the data line Dn connected to the corresponding one of high resistance first short-circuiting detecting resistors Trln connecting a predetermined electric potential and the data line Dn to the corresponding one of first detector logic circuits and binarizing and outputting the input electric potential Vd of the data line Dn by referring to a predetermined threshold value and also detect short-circuiting in each of the gate lines Gm by inputting the electric potential of the gate line Gm connected to the corresponding one of high resistance second short-circuiting detecting resistors connecting a predetermined electric potential and the gate line Gm to the corresponding one of second detector logic circuits and binarizing and outputting the input electric potential of the gate line by referring to a predetermined threshold value. The defects (short-circuits) produced in the process of manufacturing the display apparatus can be inspected by a simple technique.

Owner:SONY GRP CORP

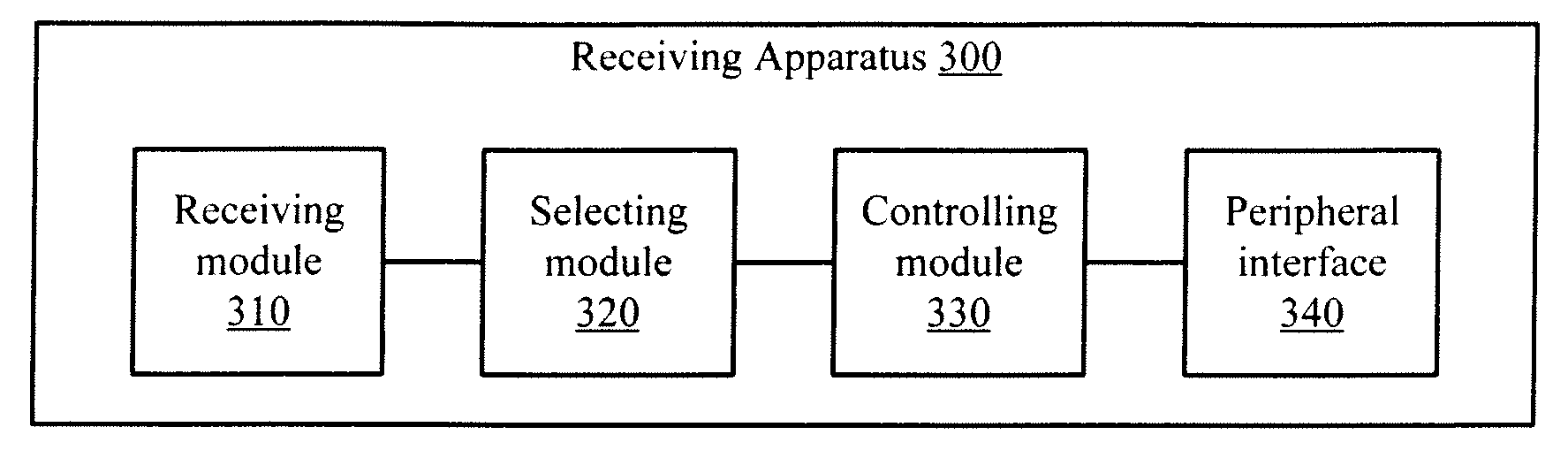

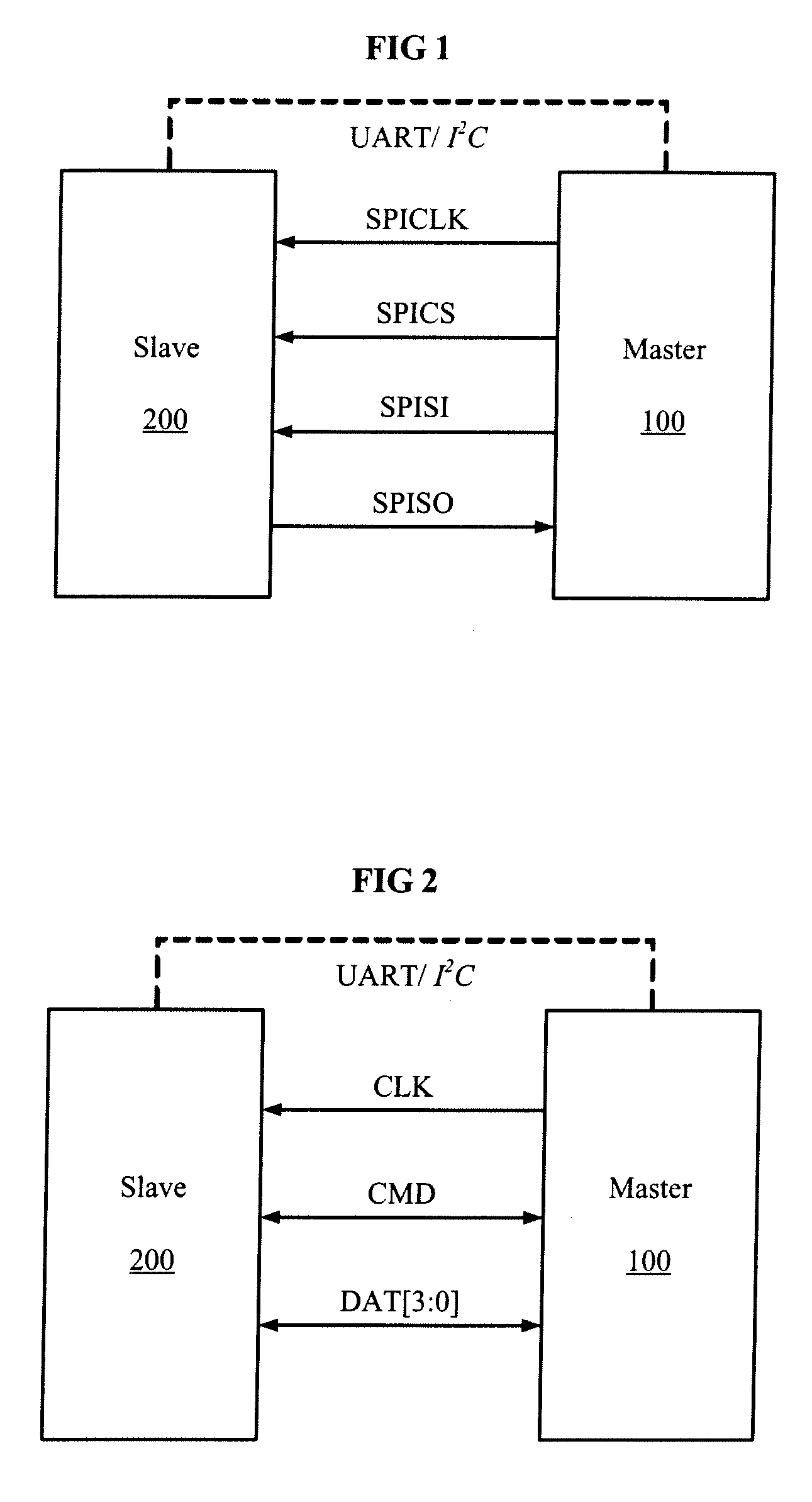

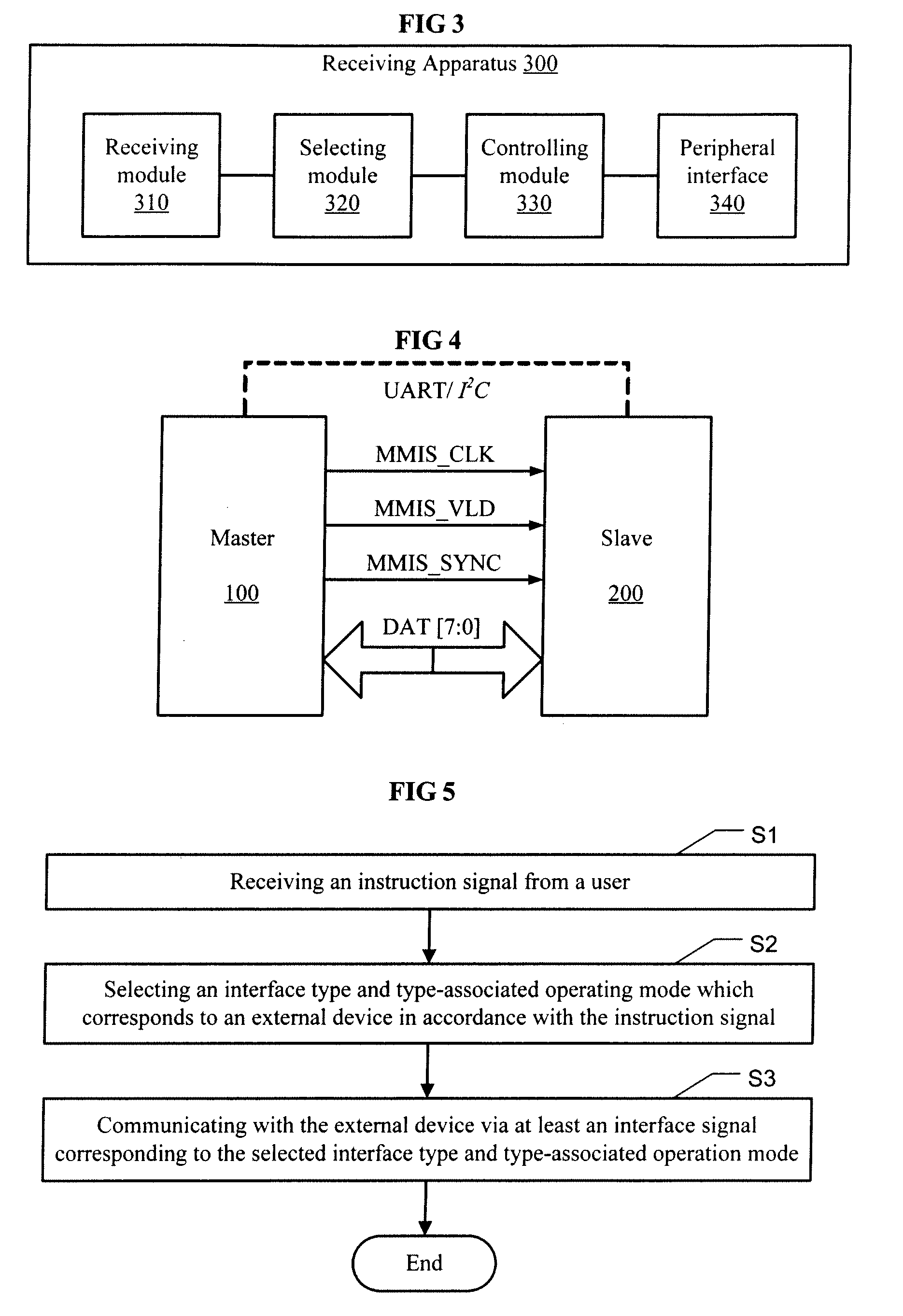

Peripheral Interface, Receiving Apparatus and Data Communication Method Using the Same

InactiveUS20080235411A1Small sizeReduce unnecessary costsElectric digital data processingComputer hardwareMultiplexing

Peripheral interface(s), a receiving apparatus and a data communication method using the same are disclosed. According to an embodiment of the present invention, a peripheral interface comprises one or more pins for multiplexing at least two types of interfaces, wherein the pins transmit interface signals corresponding to an interface type and type-associated operating mode which are selected from those multiplexed by the pins. According to another embodiment, a receiving apparatus comprises: a peripheral interface for multiplexing at least two types of interfaces; a receiving module for receiving an instruction signal; a selecting module for selecting an interface type and type-associated operating mode which corresponds to an external device to be connected, based on the instruction signal; a controlling module for controlling the peripheral interface to communicate with the external device via at least one interface signal corresponding to the selected interface type and type-associated operating mode.

Owner:INNOFIDEI TECHNOLOGIES INC

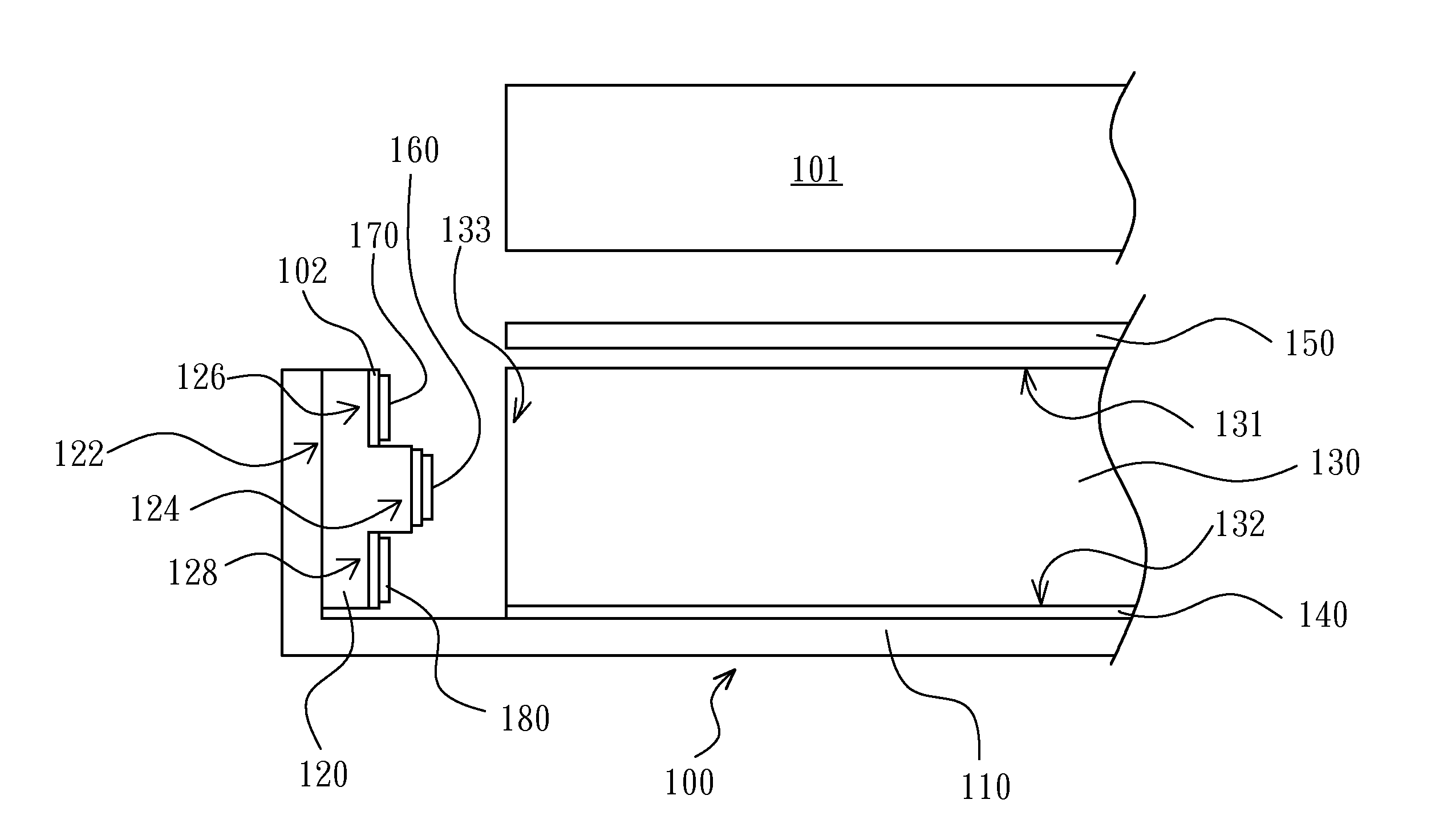

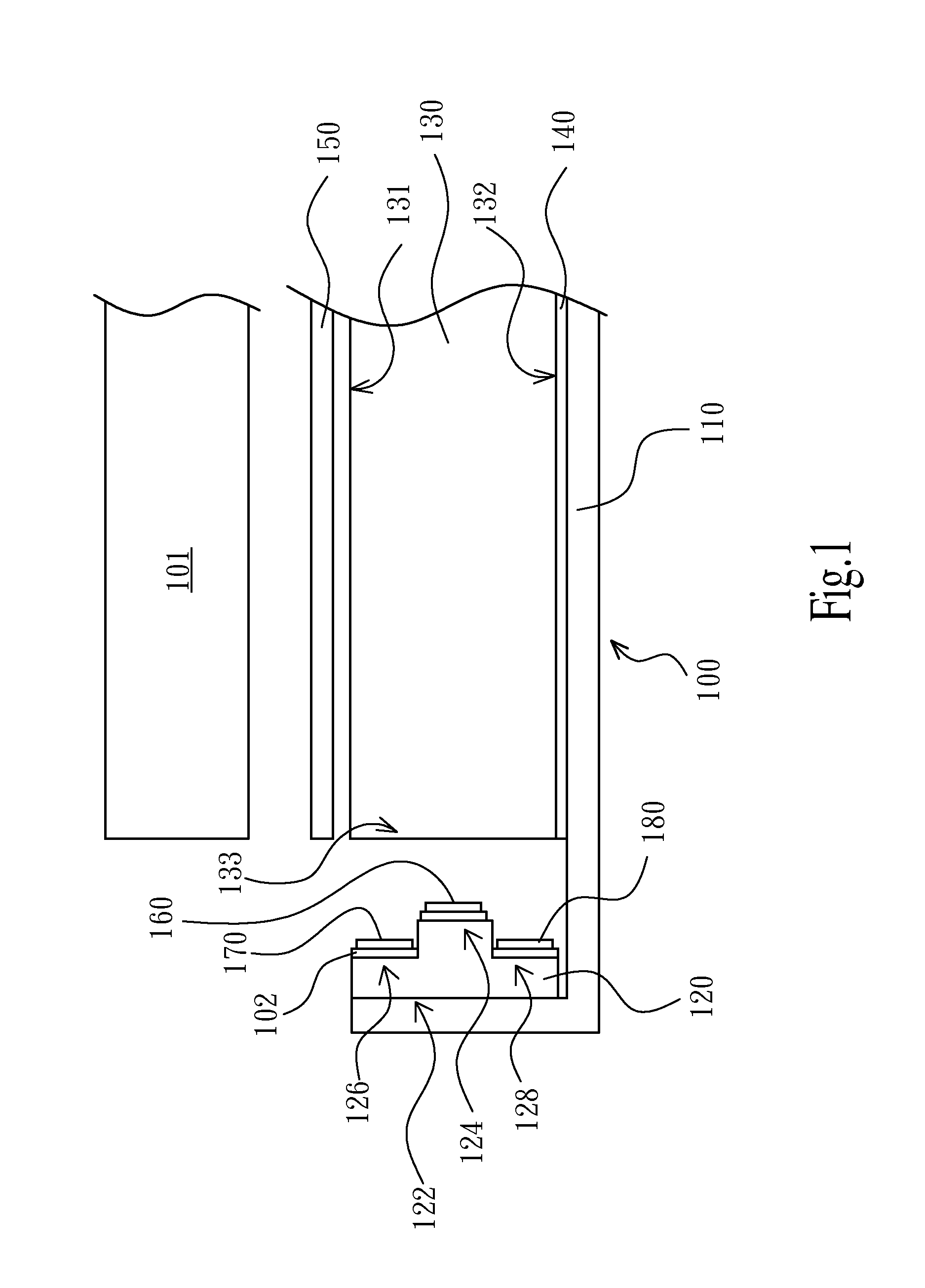

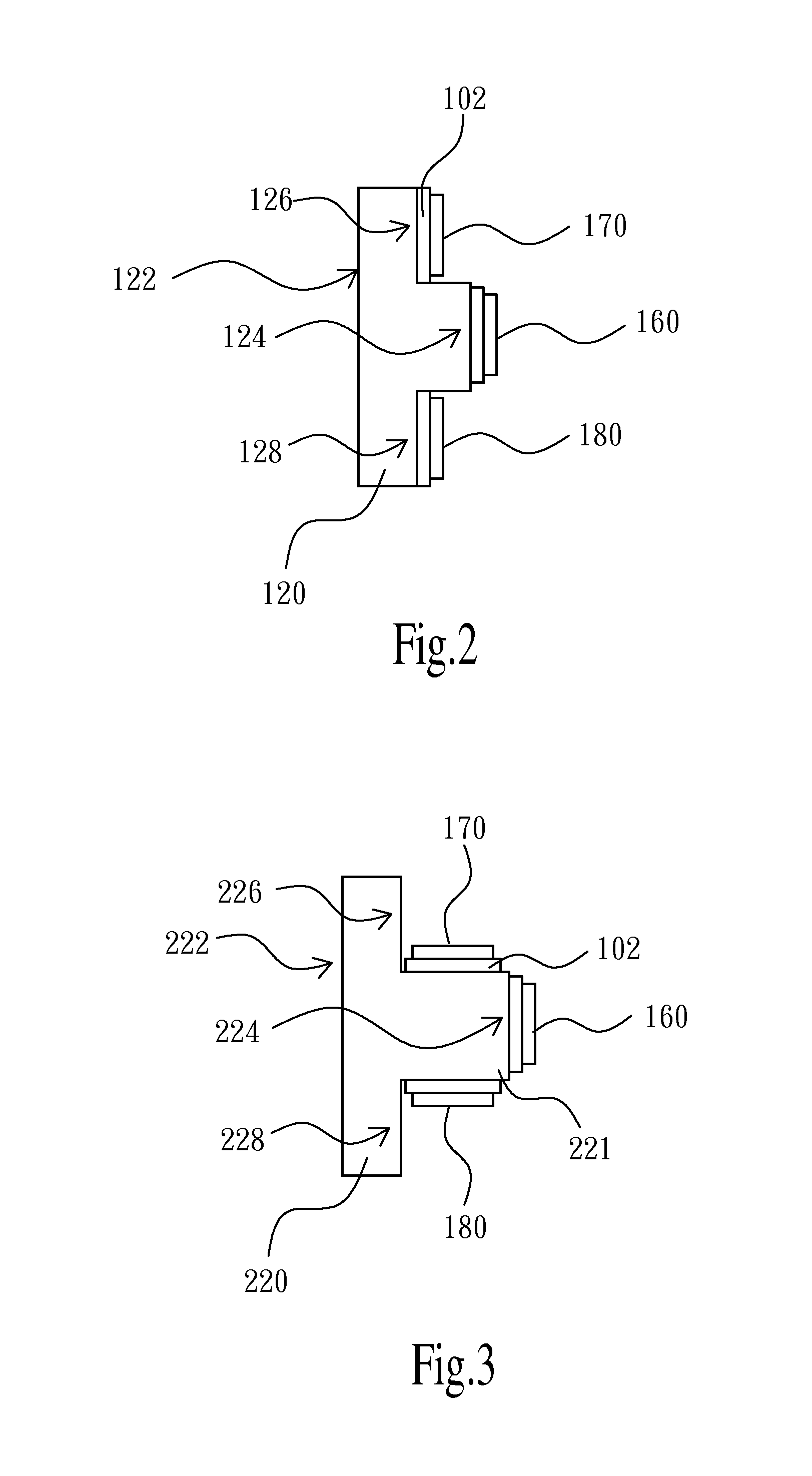

Backlight module and display apparatus

ActiveUS20120020113A1Reduce energy consumptionReduce unnecessary costsPlanar/plate-like light guidesReflectorsLight guideLight-emitting diode

The present invention provides a backlight module and a display apparatus. The backlight module comprises a light guide plate, a base, a first light emitting diode and a second light emitting diode. The base is disposed at one side of the light guide plate. The first light emitting diode is disposed on a first arrangement surface of the base. The second light emitting diode is disposed on the second arrangement surface of the base. The distance between the first light emitting diode and the bottom surface is longer than the distance between the second light emitting diode and the bottom surface. The present invention can improve color shifting defect and coupling effect of the light emitting diodes.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

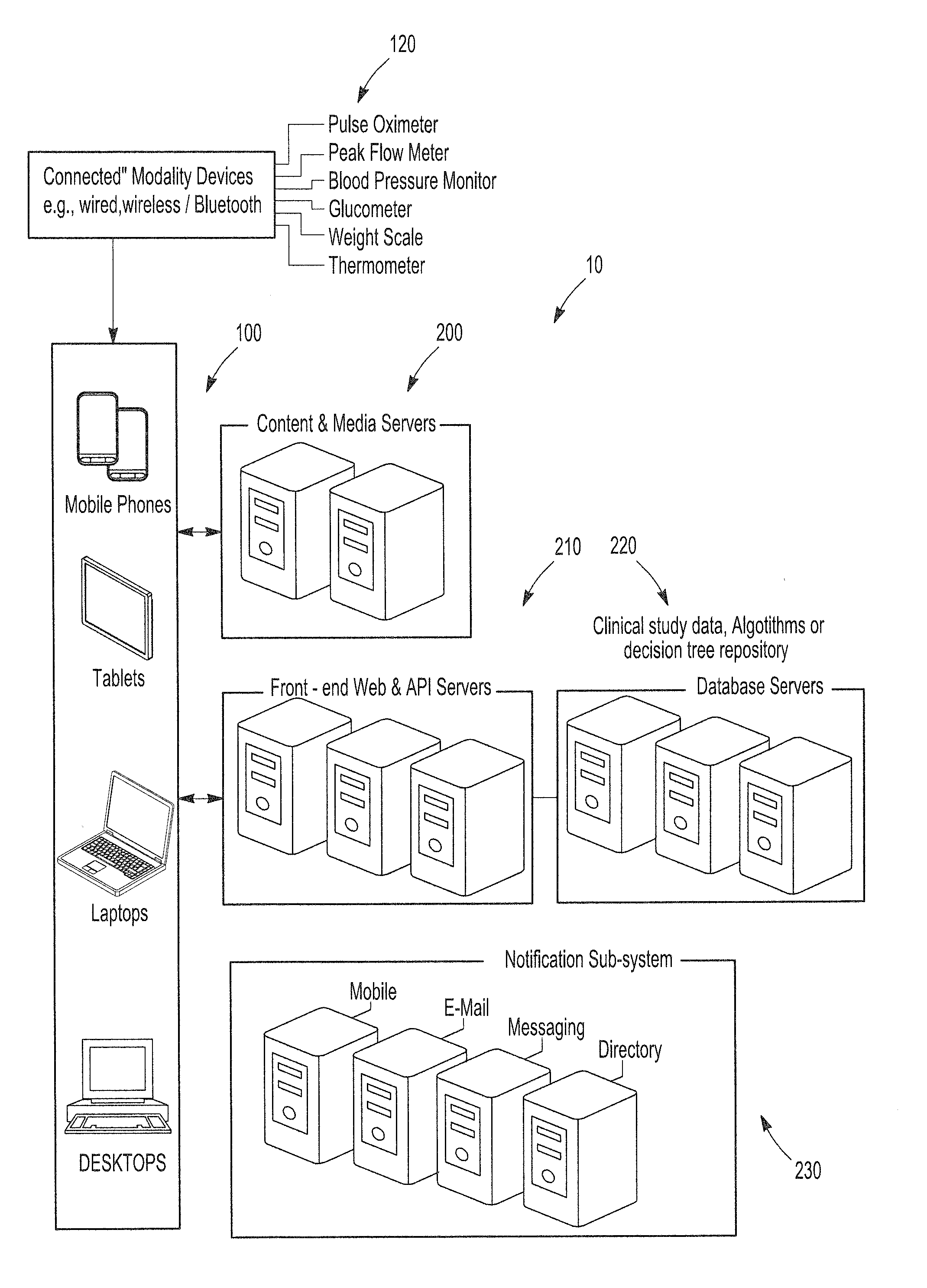

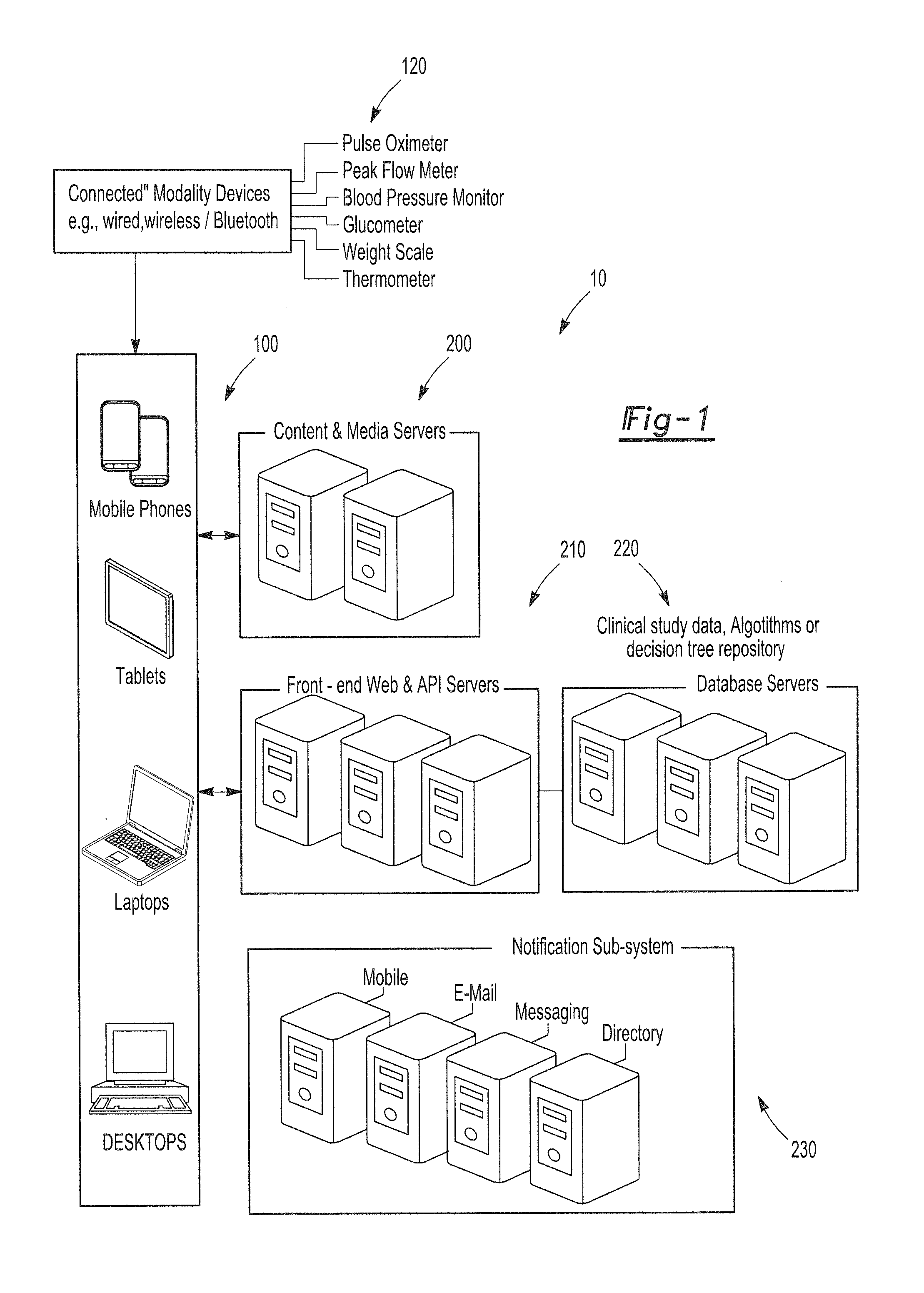

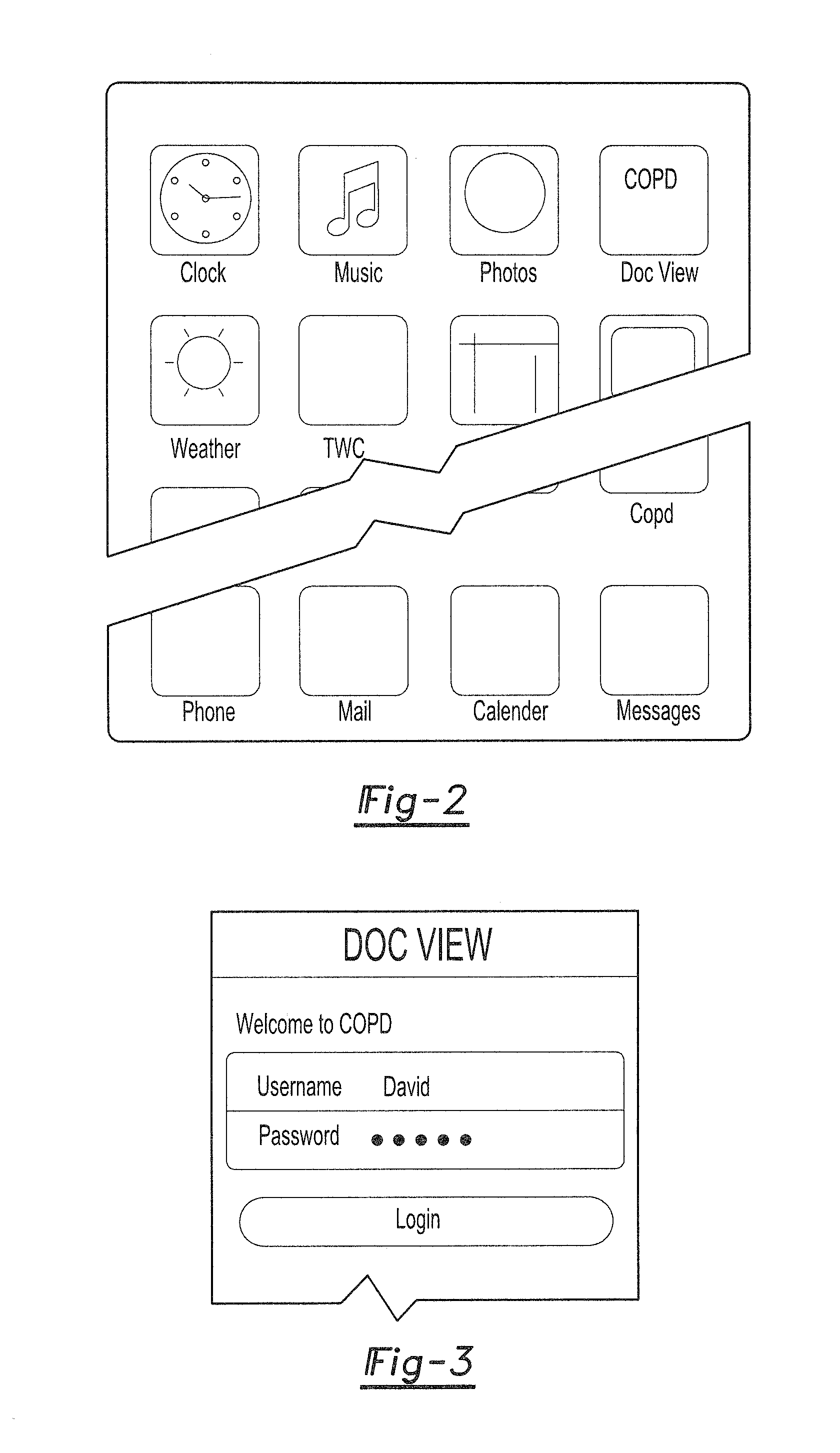

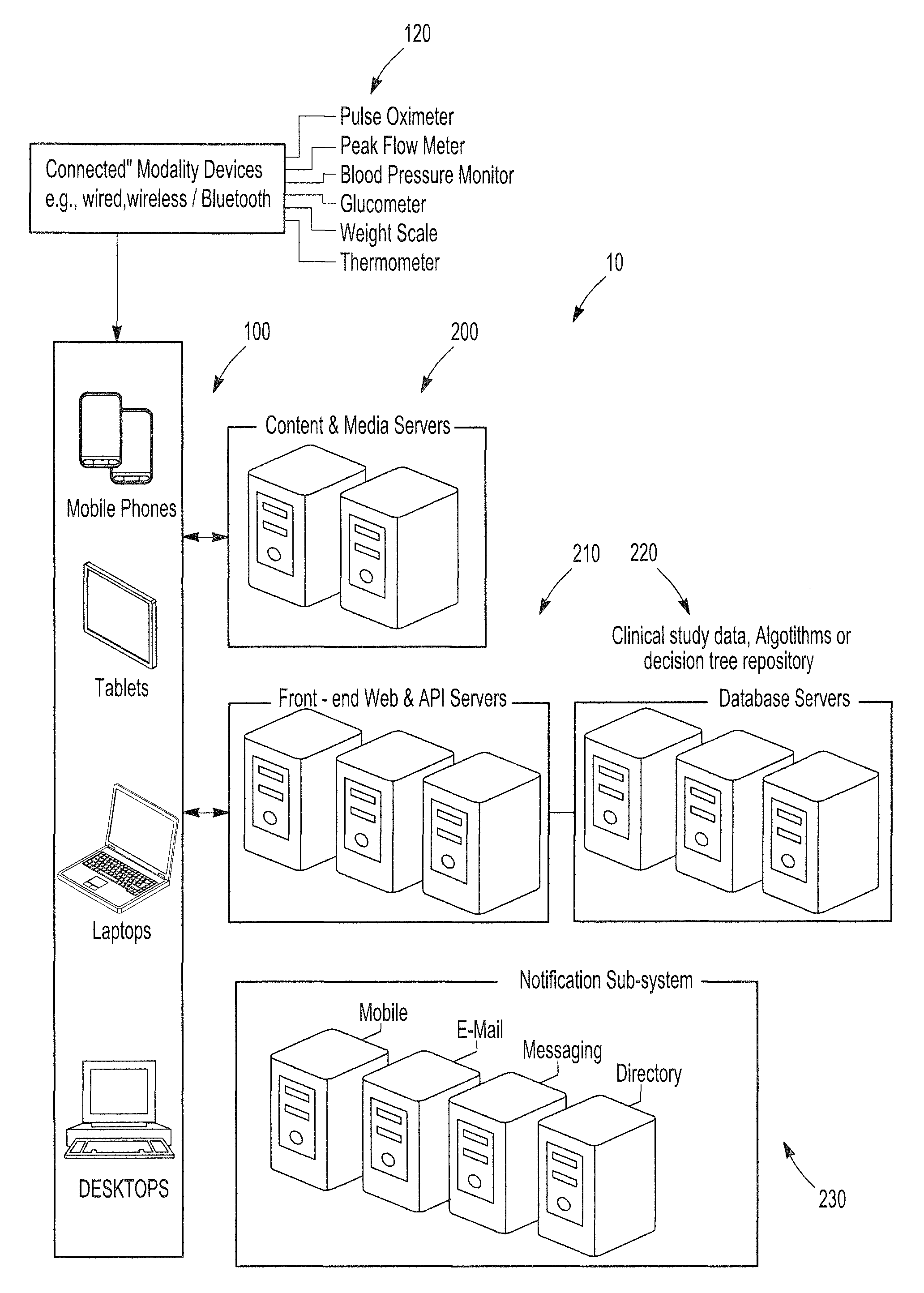

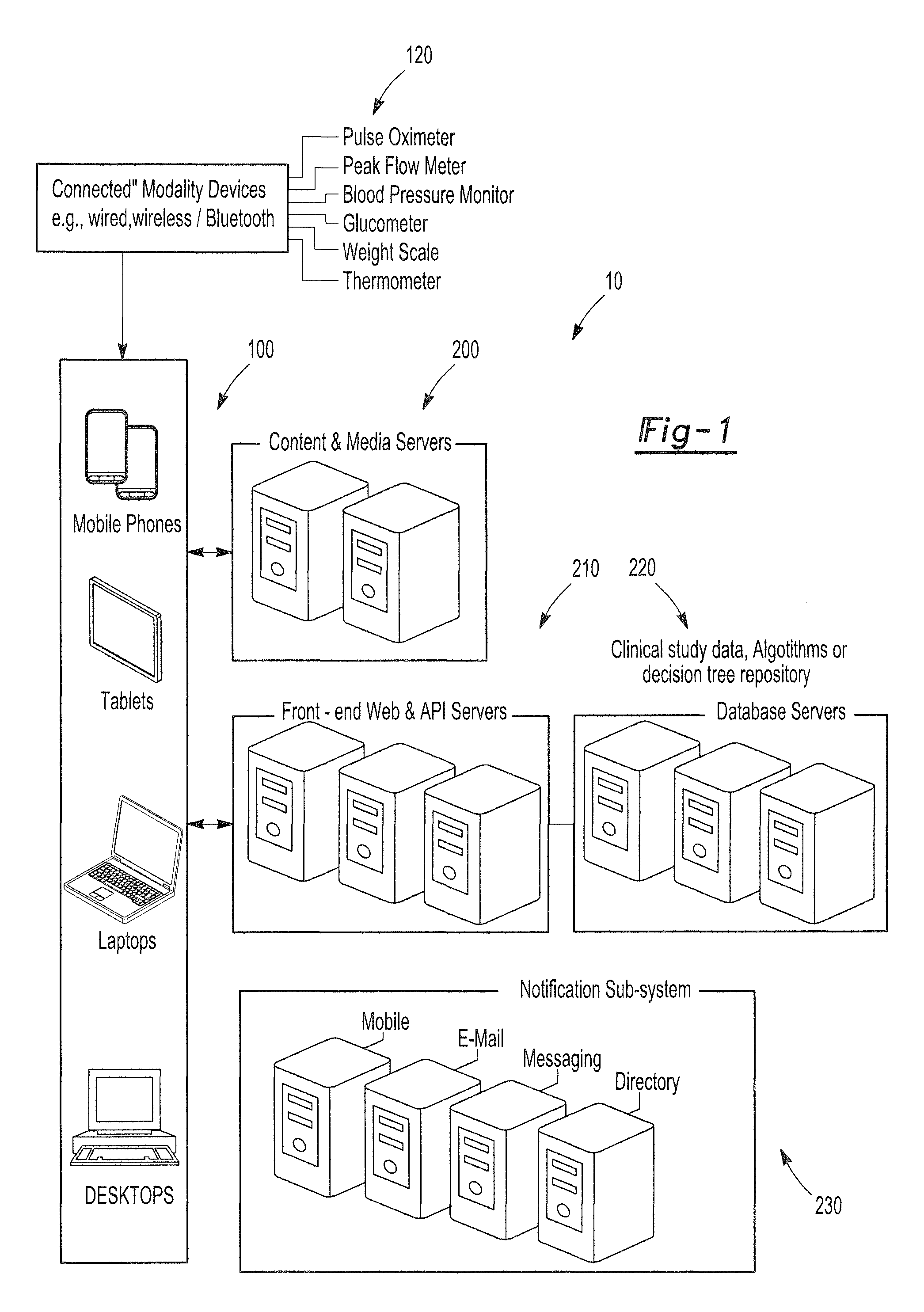

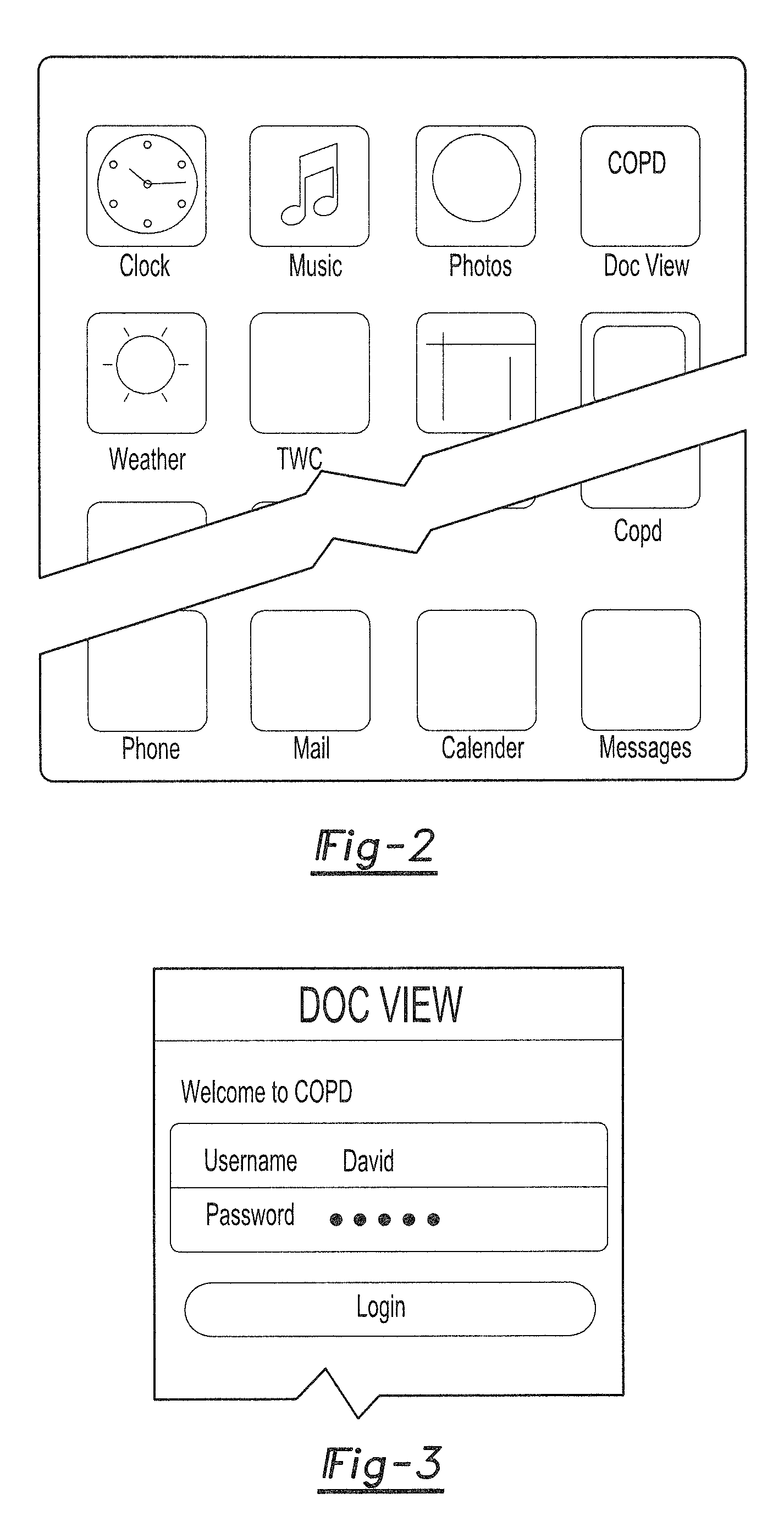

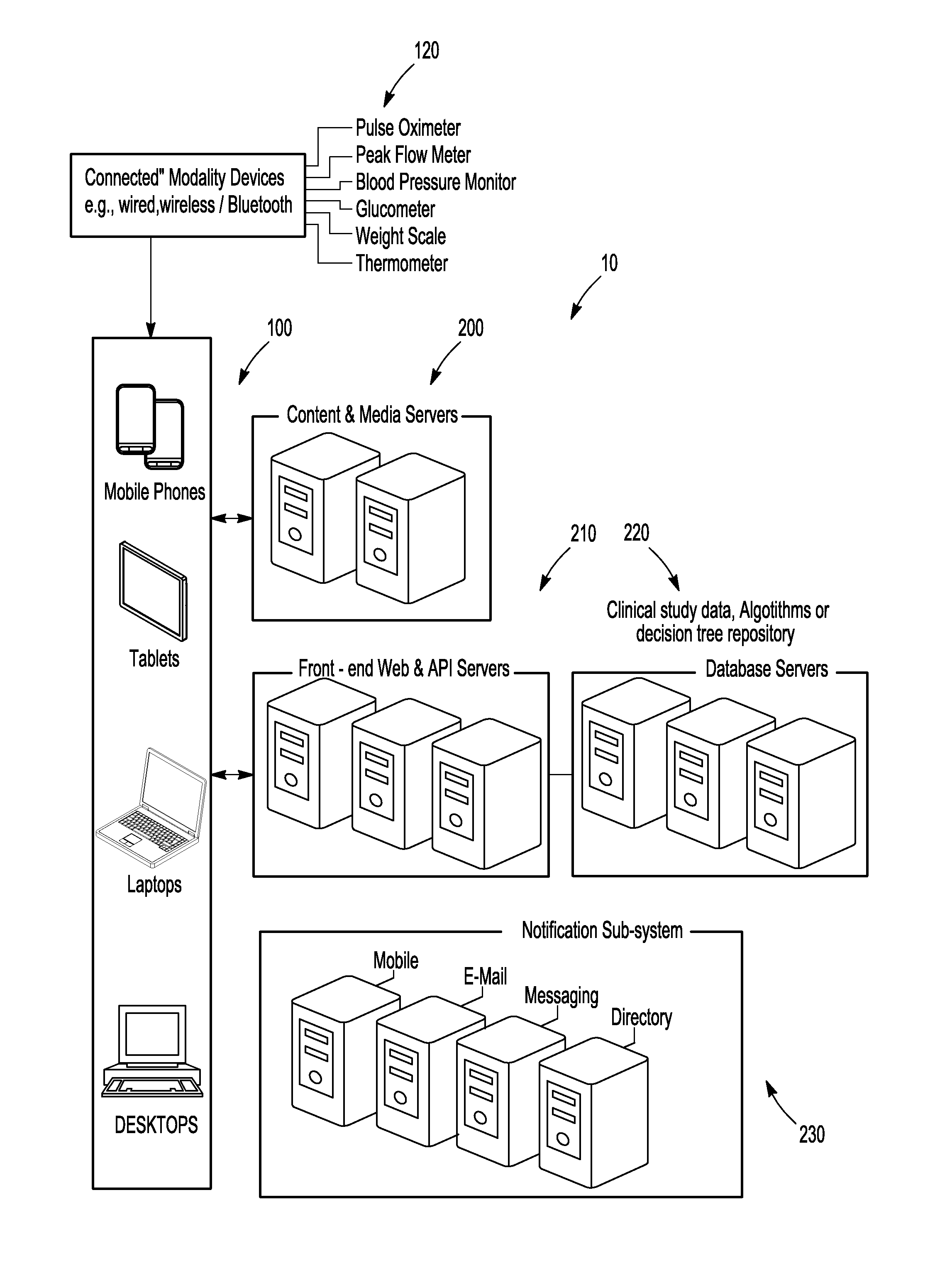

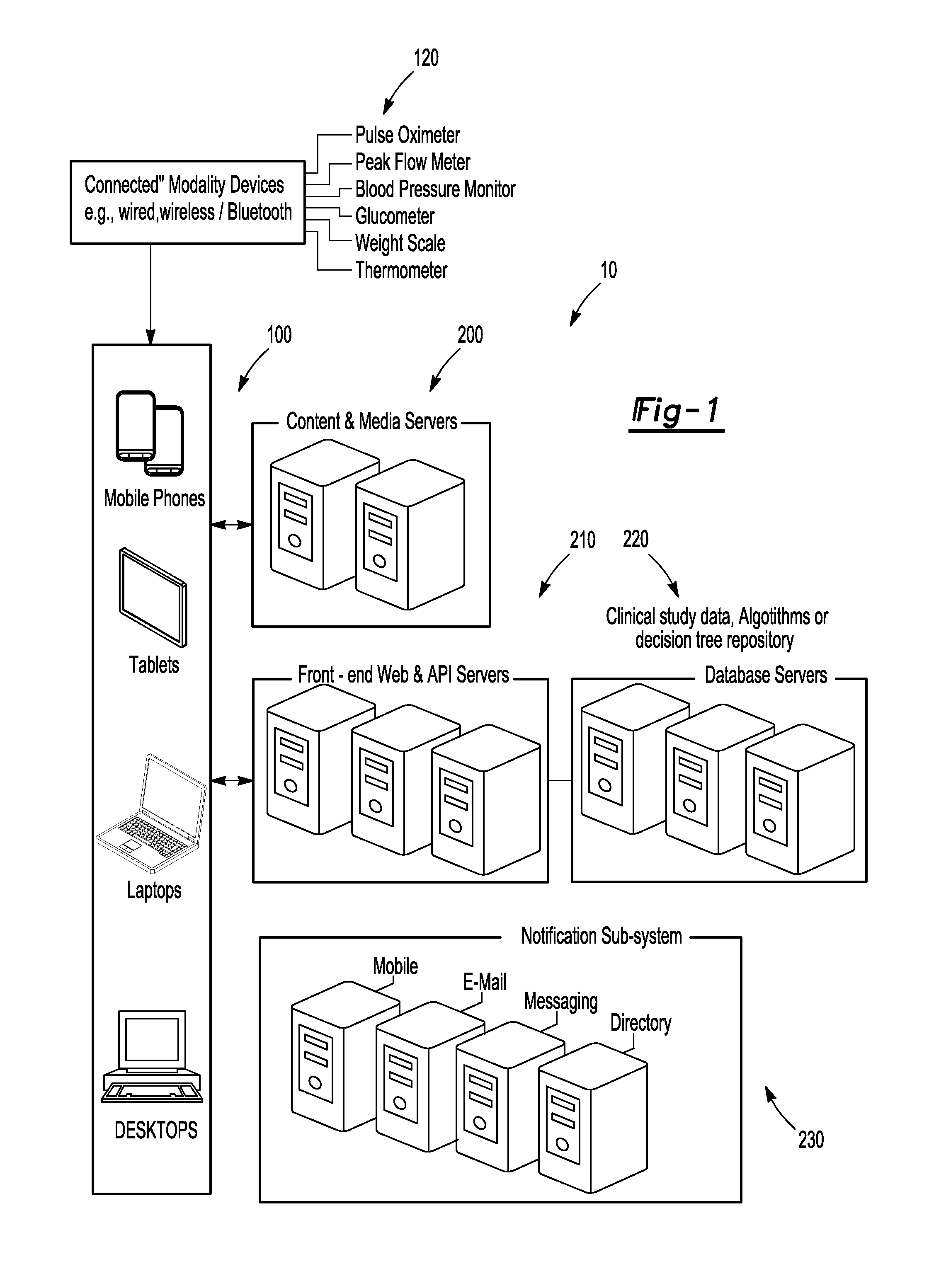

Interactive medical device monitoring and management system

InactiveUS20140062694A1Reduce unnecessary costsLower cost of careMedical automated diagnosisAlarmsThird partyMedical equipment management

A system for improving medical device management for a patient is also provided. The system can include a portable wireless device having an ECU, memory and an interactive remote patient monitoring module (IRPMM) for at least one medical device. The IRPMM has a medical device data request module that is operable to request and receive medical device data input from the at least one medical device. The medical device data can be input by the patient, or in the alternative, be automatically received without input from the patient. The IRPMM also has a medical device data supply module receives medical device information from an outside third party and provides the medical device information to the patient.

Owner:DOCVIEW SOLUTIONS

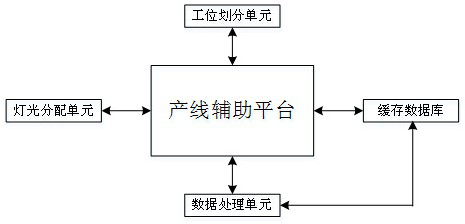

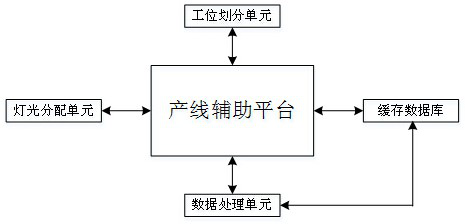

Industrial production line auxiliary supervision system based on digital twinning

ActiveCN113298371AImprove efficiencyLow costElectrical apparatusEnergy saving control techniquesProcess engineeringManufacturing line

The invention discloses an industrial production line auxiliary supervision system based on digital twinning, and relates to the technical field of industrial production line auxiliary supervision. The technical problem that in the prior art, real-time station planning cannot be carried out on a production line, and consequently the cost of workers is increased is solved. Stations on the industrial production line are divided through a station dividing unit; the orders set by the industrial production line are analyzed, and the demand rhythm of a customer is obtained through the specific value calculation of the available time and the predicted production piece number; preset station number SLi of the corresponding industrial production line is acquired through a formula; and according to the production sequence, a coefficient set is constructed for the process key coefficients of the corresponding industrial production line, and weight assignment is carried out on subsets in the coefficient set; the number of stations is analyzed according to orders, the labor cost is strictly controlled while the orders are completed, the unnecessary cost of production is reduced; meanwhile, the interval length of the stations is calculated in real time, and the efficiency of a production line is made to be the highest at the most energy-saving speed through a conveying belt.

Owner:EAST CHINA UNIV OF TECH

Interactive medical device monitoring and management system

InactiveUS9183720B2CostReduce unnecessary costsTelemedicineComputer-assisted medical data acquisitionThird partyMedical equipment management

A system for improving medical device management for a patient is also provided. The system can include a portable wireless device having an ECU, memory and an interactive remote patient monitoring module (IRPMM) for at least one medical device. The IRPMM has a medical device data request module that is operable to request and receive medical device data input from the at least one medical device. The medical device data can be input by the patient, or in the alternative, be automatically received without input from the patient. The IRPMM also has a medical device data supply module receives medical device information from an outside third party and provides the medical device information to the patient.

Owner:DOCVIEW SOLUTIONS

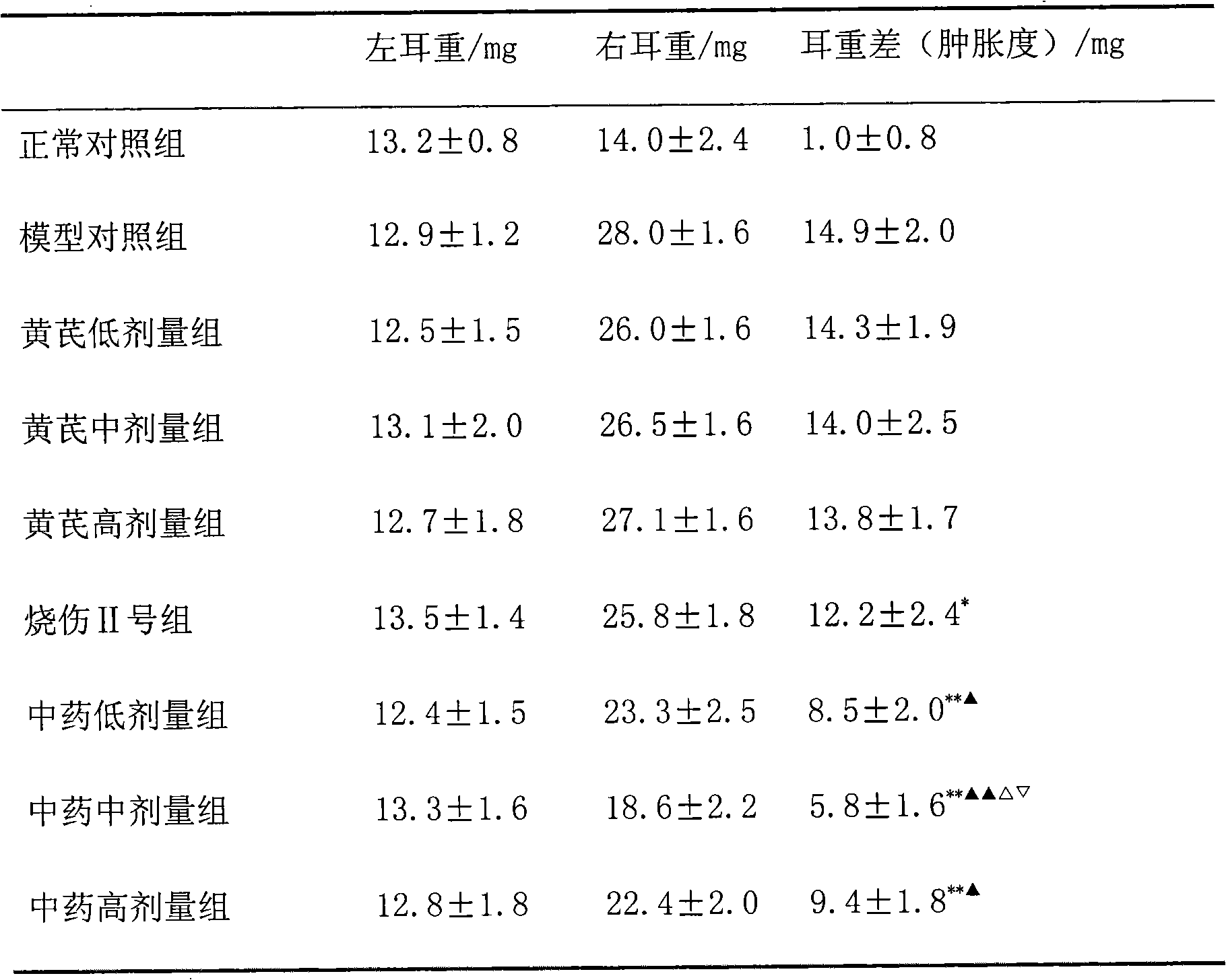

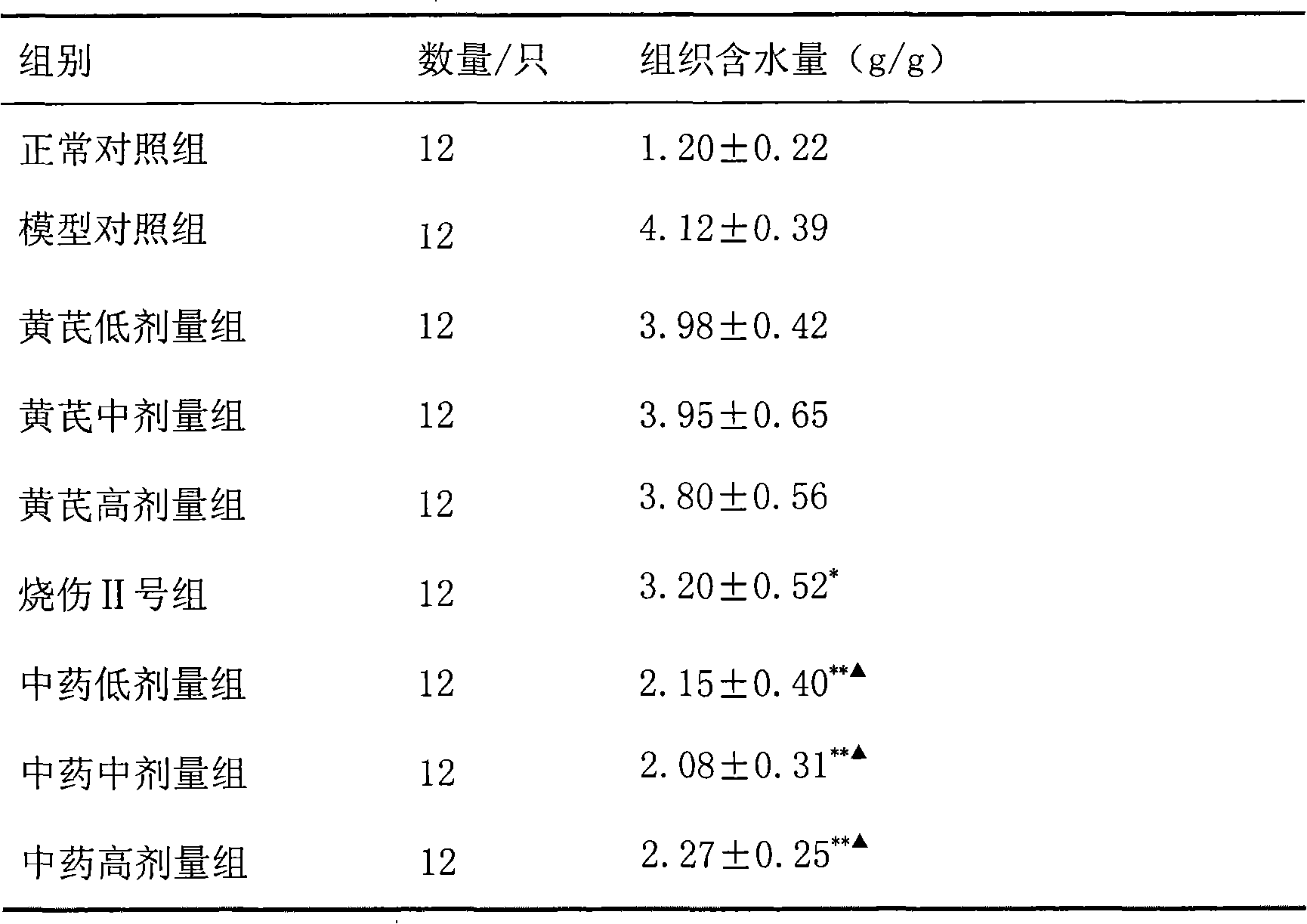

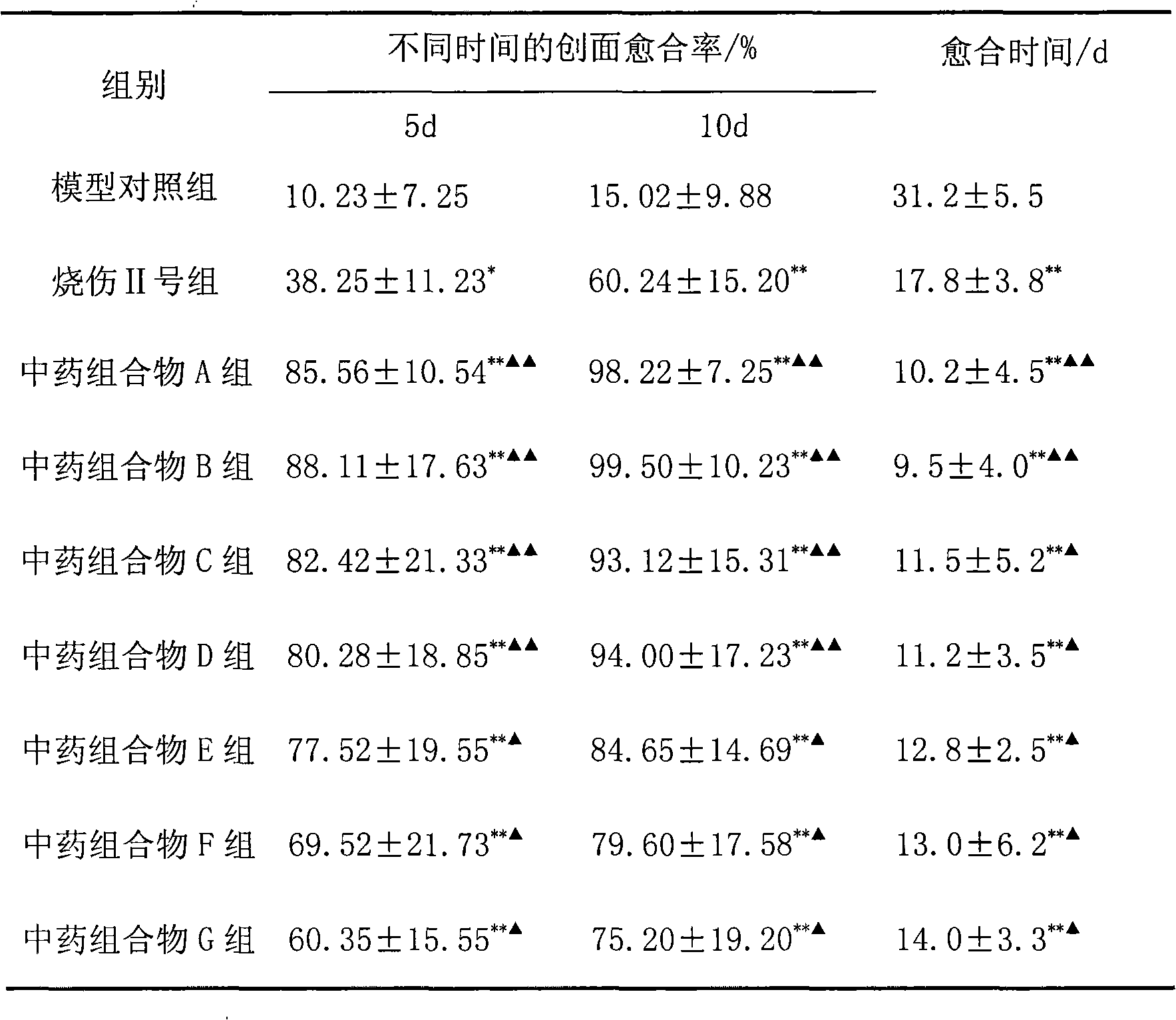

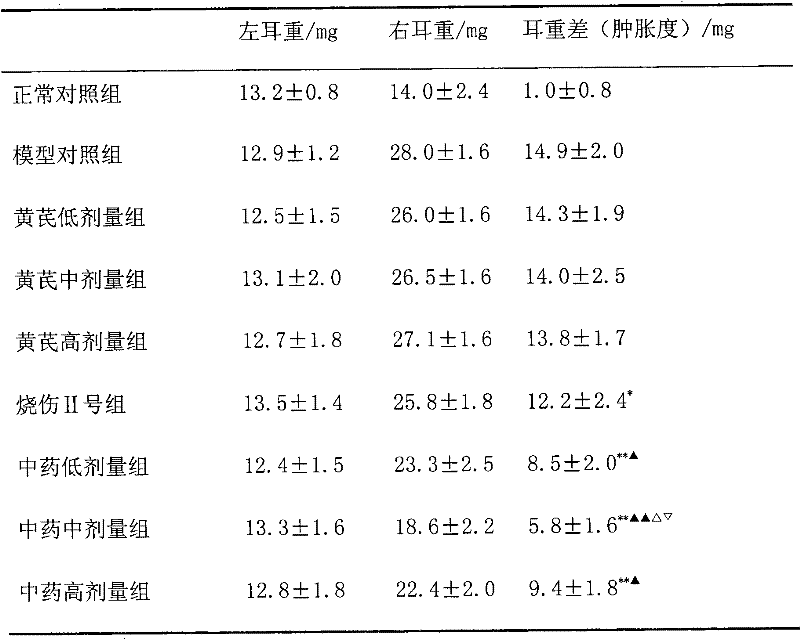

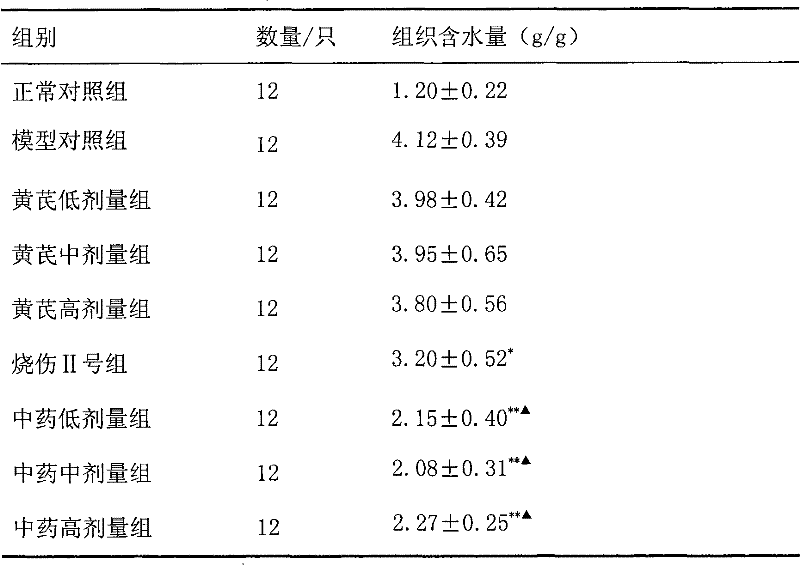

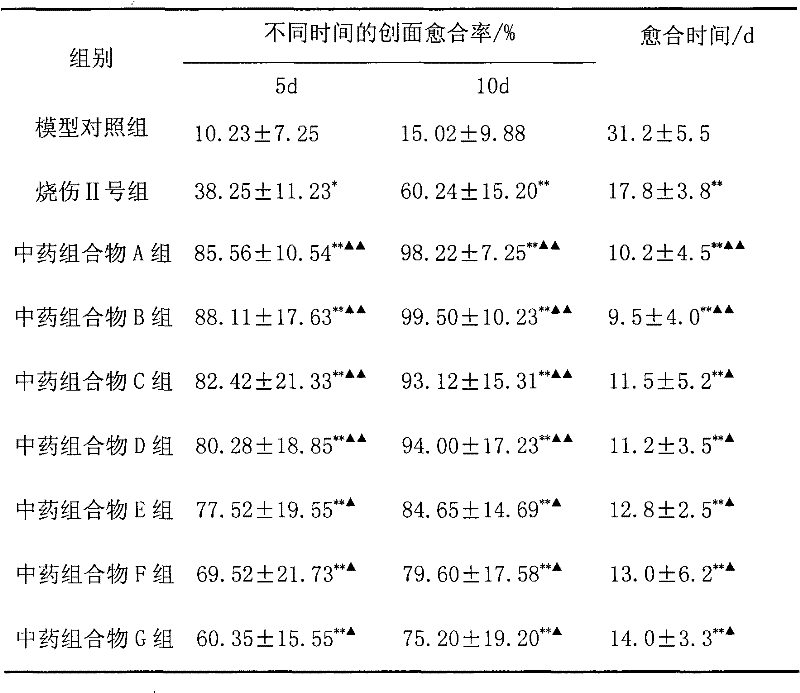

Chinese medicinal composition for treating burn and scald and application thereof

InactiveCN102106920AShorten healing timeReduce exudationDermatological disorderPlant ingredientsWound healingCure rate

The invention belongs to the field of Chinese medicine, in particular relates to a Chinese medicinal composition for treating burn and scald and the application thereof, and solves the problems that the cure rate of the burn and the scald is improved, the healing time of the wound surface is shortened and scars on the wound surface of burn and scald are reduced. The invention provides the Chinese medicinal composition for treating the burn and the scald, which is prepared from phellodendron amurense, milkvetch root and elm bark, and has the efficacies of clearing away heat and toxic material, reducing swelling and alleviating pain, inhibiting and eliminating bacteria, reducing seepage of body liquid, removing necrosis and promoting granulation, improving the local blood supply and promoting the wound healing. The Chinese medicinal composition has high cure rate and short healing time, almost has no scar in treating the burn and scald, and can be used for treating decubitus.

Owner:王斌

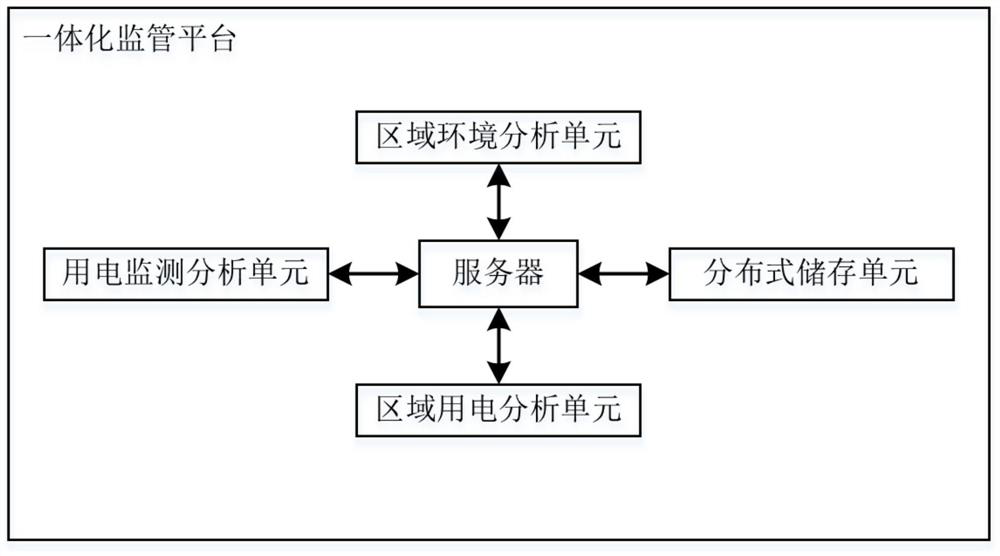

Wind and light storage integrated supervision system based on smart energy consumption

PendingCN114386866AImprove rationalityImprove effectivenessTechnology managementResourcesElectric consumptionPower usage

The invention discloses a wind and light storage integrated supervision system based on smart energy consumption, relates to the technical field of supervision, solves the technical problem that the stored electric quantity of each power consumption area cannot be reasonably matched in the prior art, and judges the power consumption and frequency of each area so as to analyze the power consumption intensity of each power consumption area. Electric energy is stored according to the power consumption intensity, and the situation that the electric energy storage amount corresponding to an area with high power consumption intensity does not meet the requirement is prevented; the electric energy storage corresponding to each type of power utilization area is analyzed, so that the situation that the electric energy storage of the high-intensity power utilization area cannot meet the requirement and consequently the power utilization efficiency is reduced is avoided, and meanwhile, the situation that the electric energy storage of the low-intensity power utilization area exceeds the requirement and consequently the storage cost is wasted is avoided; and the power transmission and the power consumption cost consumption of each power consumption area are judged, so that a processing mode of reasonably selecting the residual electric quantity is carried out for each power consumption area, and the unnecessary cost of regional power consumption is reduced on the whole.

Owner:浙江容大电力工程有限公司

Method and system for acquiring application in mobile device

ActiveUS8594649B2Intuitive acquisitionReduce unnecessary costsService provisioningNear-field for read/write/interrrogation/identification systemsStructure of Management InformationMobile device

A method, system and mobile device for searching for and acquiring a desired application by using Near Field Communication (NFC) regardless of time and location are provided. In the method, the mobile device reads a keyword from an NFC tag of a target structure in response to a tagging event between the mobile device and the NFC tag. Then the mobile device performs an application search using the keyword, and downloads a specific application found using the keyword.

Owner:SAMSUNG ELECTRONICS CO LTD

Interactive remote disease monitoring and management system

InactiveUS9076315B2Reduce unnecessary costsLower cost of careTelemedicineMedical automated diagnosisCaregiver personDisease monitoring

Owner:DOCVIEW SOLUTIONS

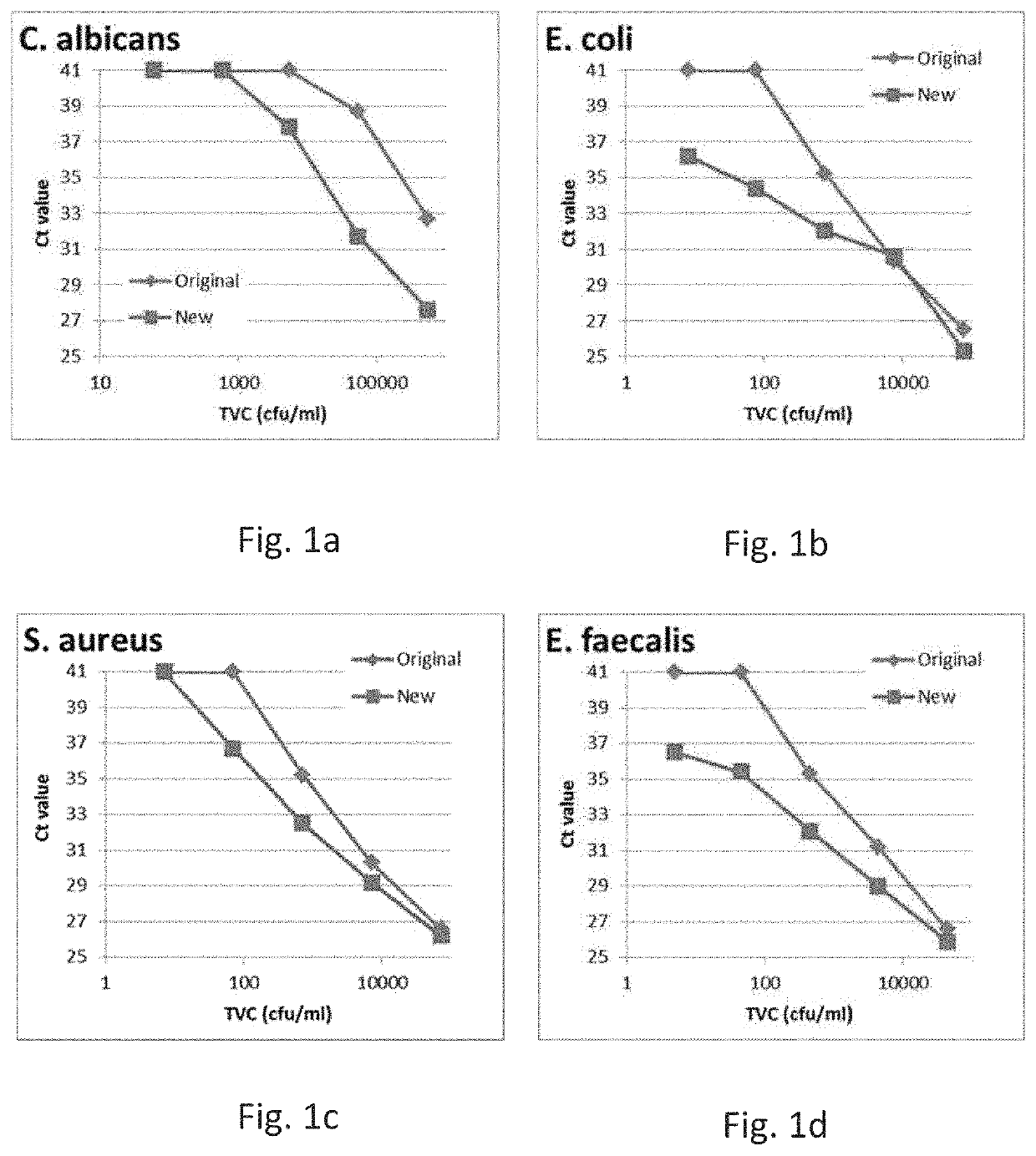

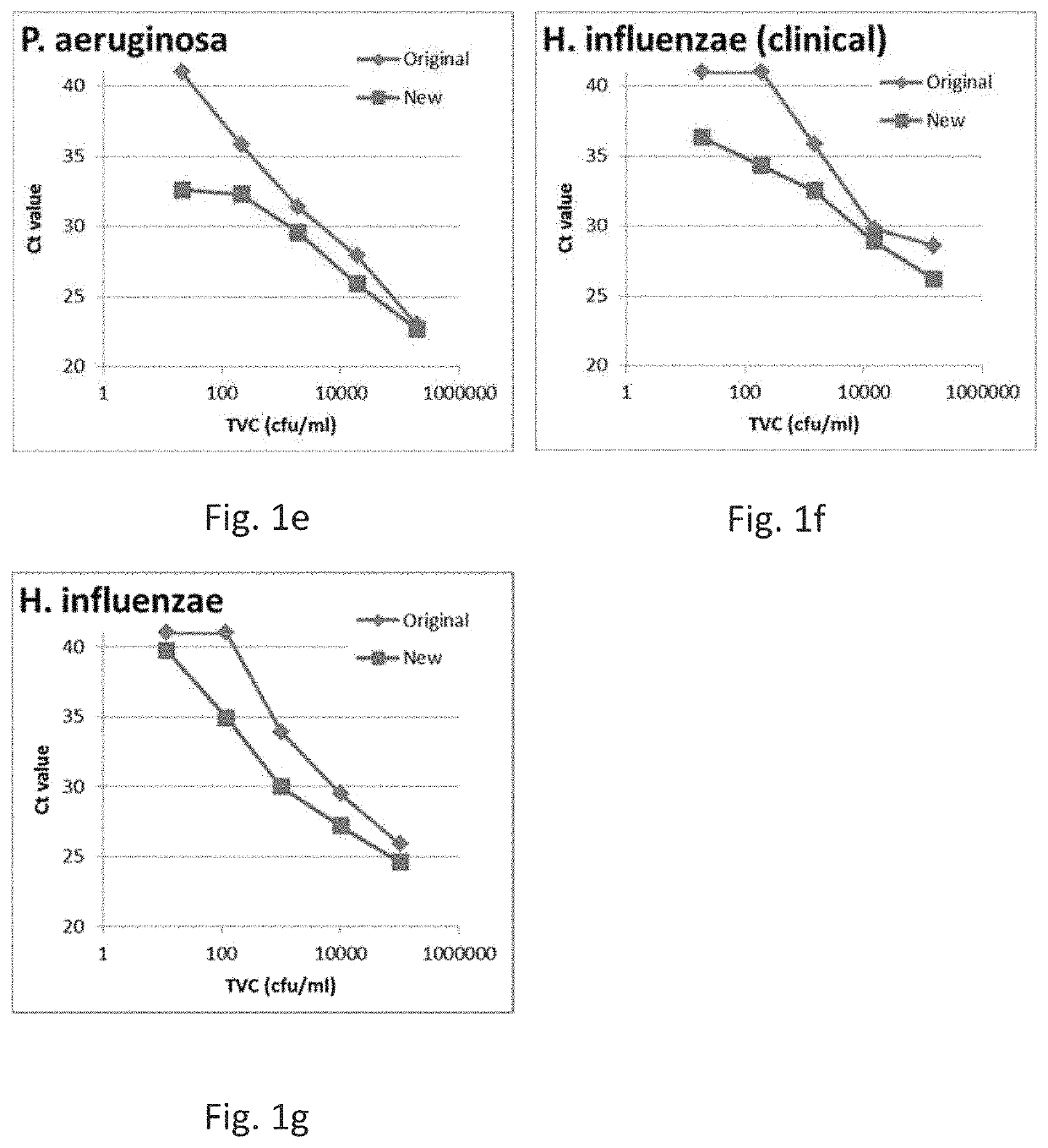

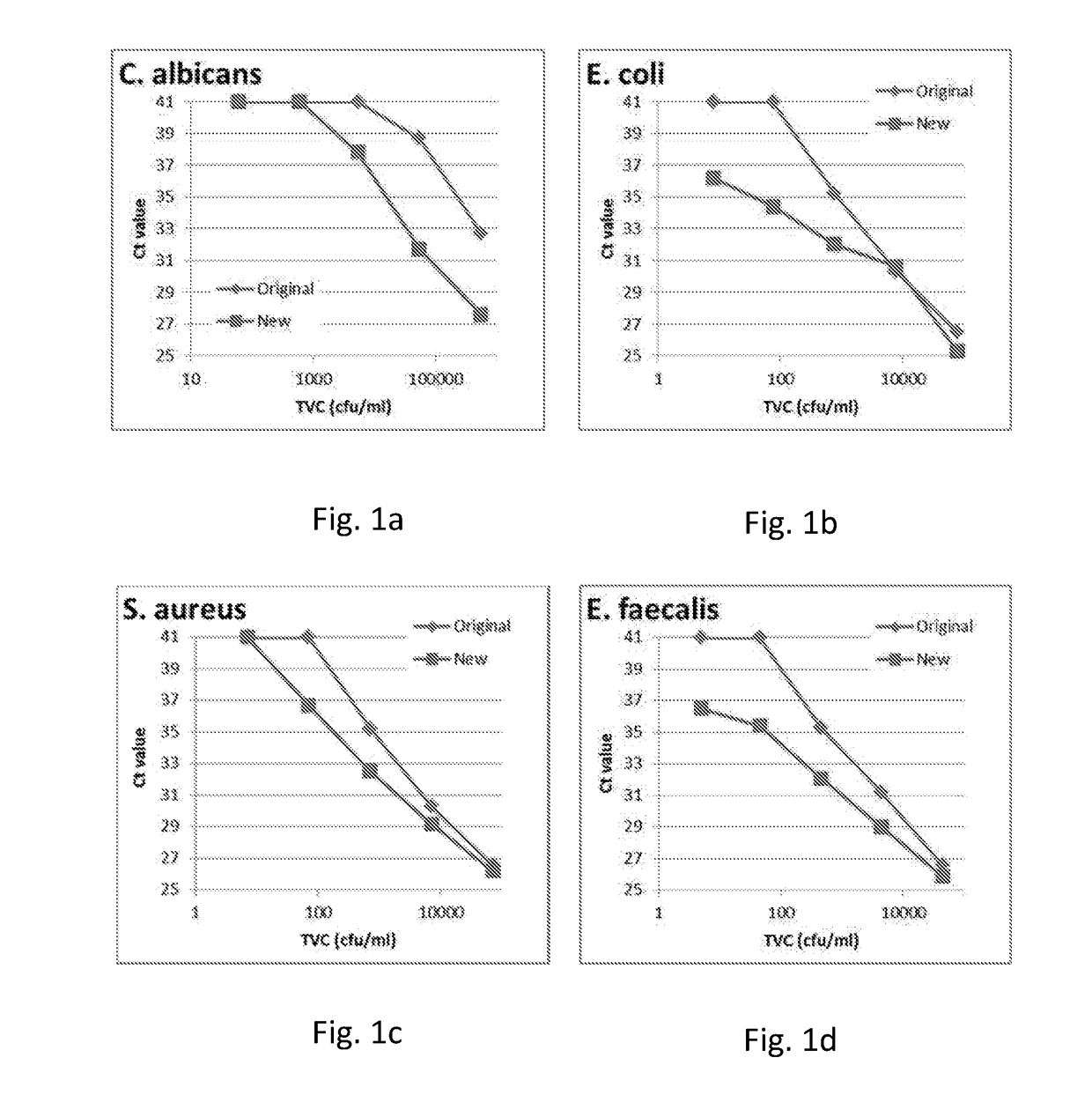

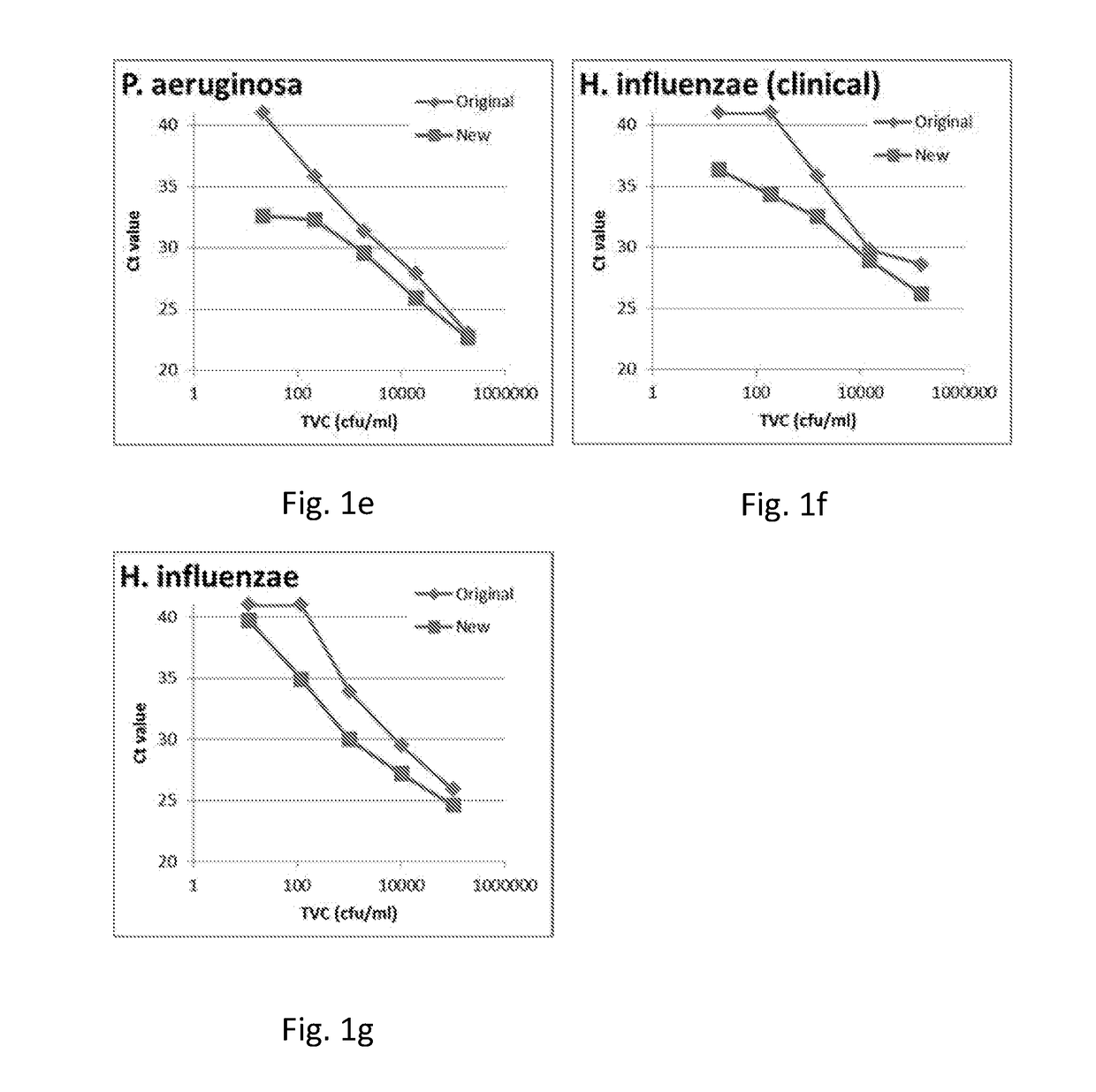

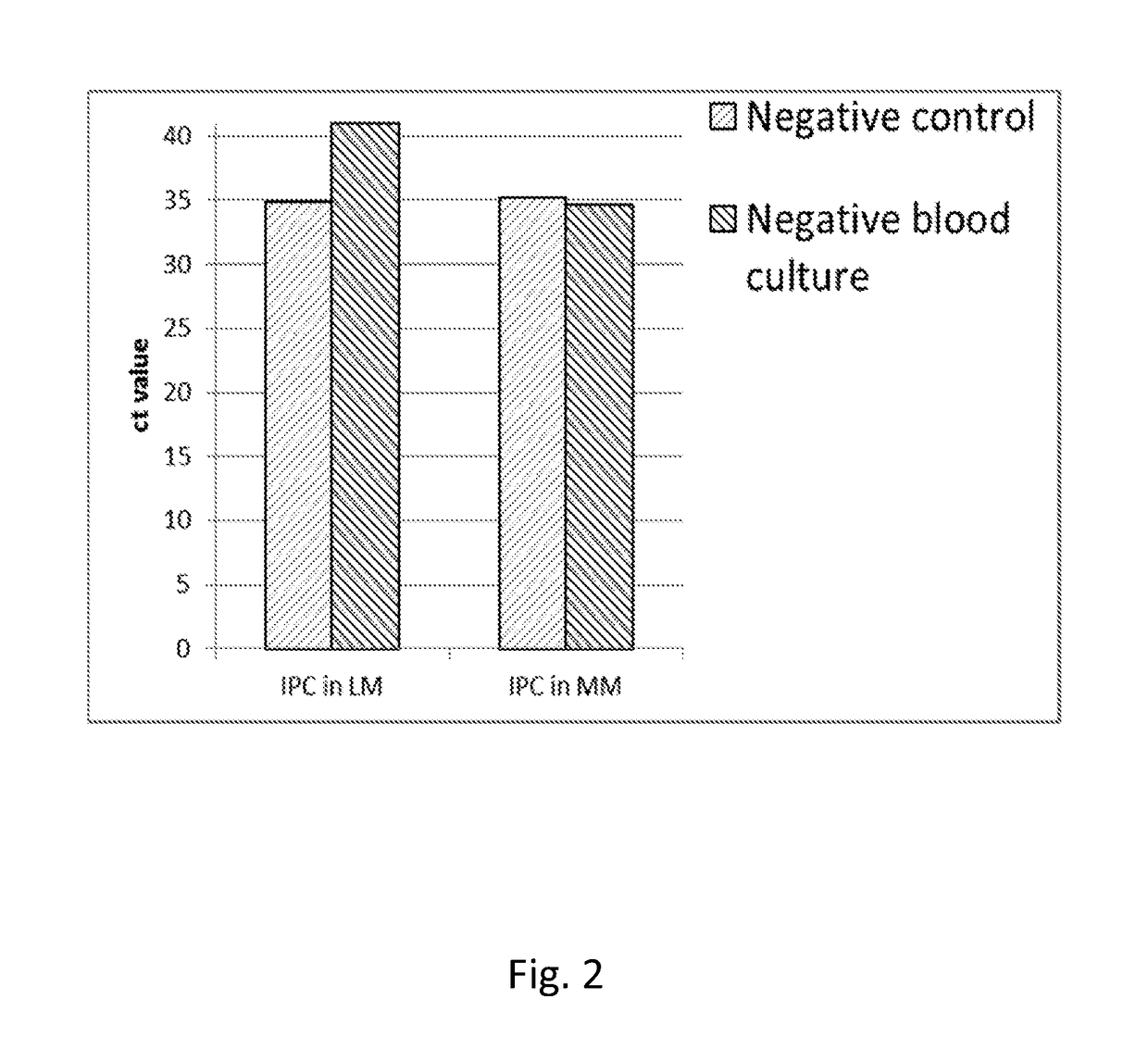

Method and kit of detecting the absence of micro-organisms

ActiveUS10793917B2Reduce unnecessary costsImprove degradation rateMicrobiological testing/measurementBiological material analysisIndicator microorganismsOrganism

Methods of detecting the absence or presence of a micro-organism in a sample comprising: contacting the sample with a nucleic acid molecule which acts as a substrate for nucleic acid modifying activity of the micro-organism in the sample, incubating the thus contacted sample under conditions suitable for nucleic acid modifying activity; and specifically determining the absence or presence of a modified nucleic acid molecule resulting from the action of the nucleic acid modifying activity on the substrate nucleic acid molecule to indicate the absence or presence of the micro-organism. Corresponding kits are also provided.

Owner:MOMENTUM BIOSCI

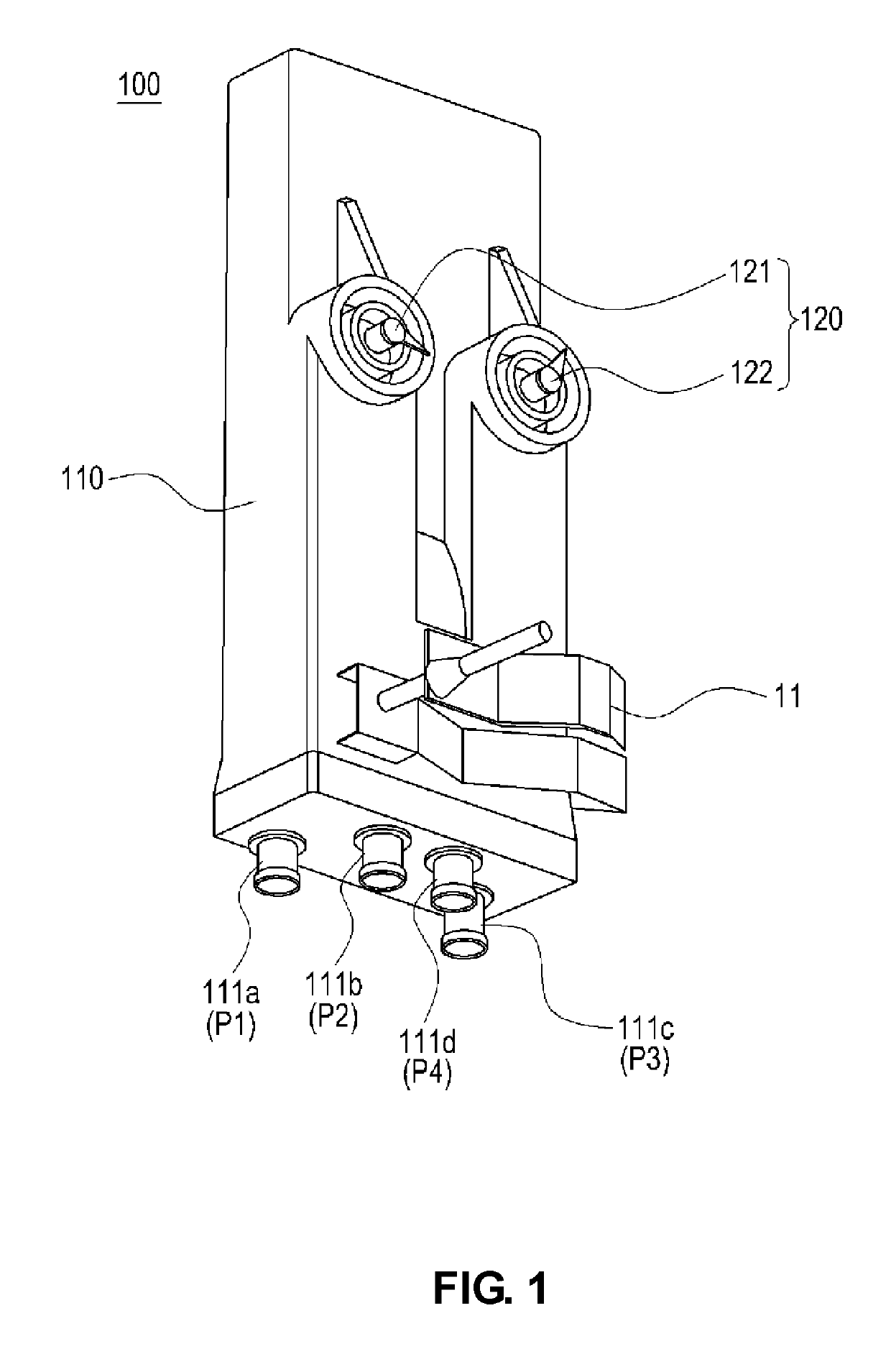

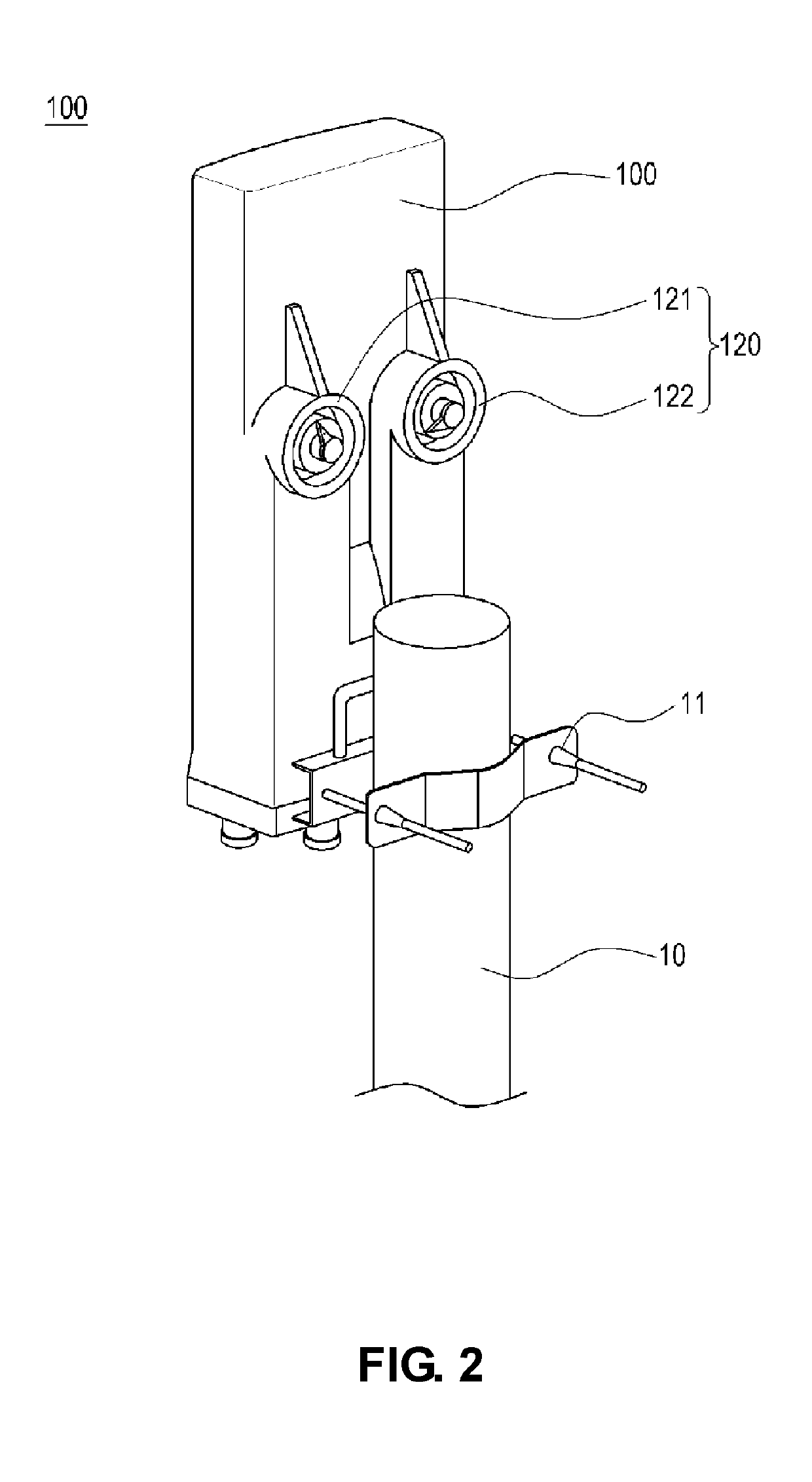

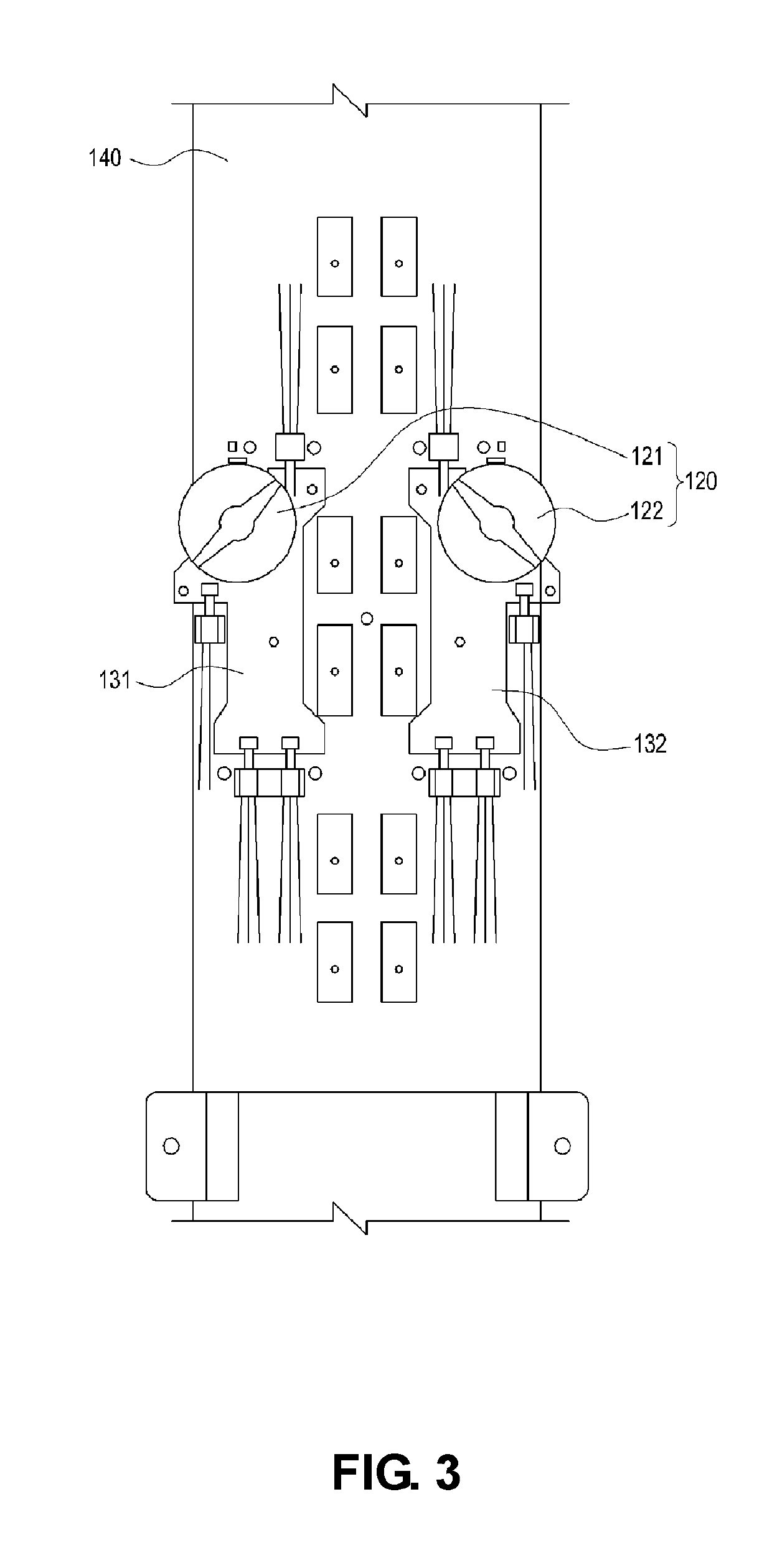

Compact antenna apparatus for mobile communication system

ActiveUS10403974B2Easy to adjustMinimize error rangeAntenna supports/mountingsRadiating element housingsDirect couplingEngineering

A compact antenna apparatus for a mobile communication system includes: a radome having at least one frequency band radiating element provided therein; at least one phase shifter portion which is provided in an inner side of the radome and which is connected to the radiating element to adjust a tilting angle of the radiating element; and a rotary knob portion which is provided so as to be exposed to the outside of the radome and which is directly coupled to the phase shifter portion to drive a phase shifter.

Owner:KMW INC

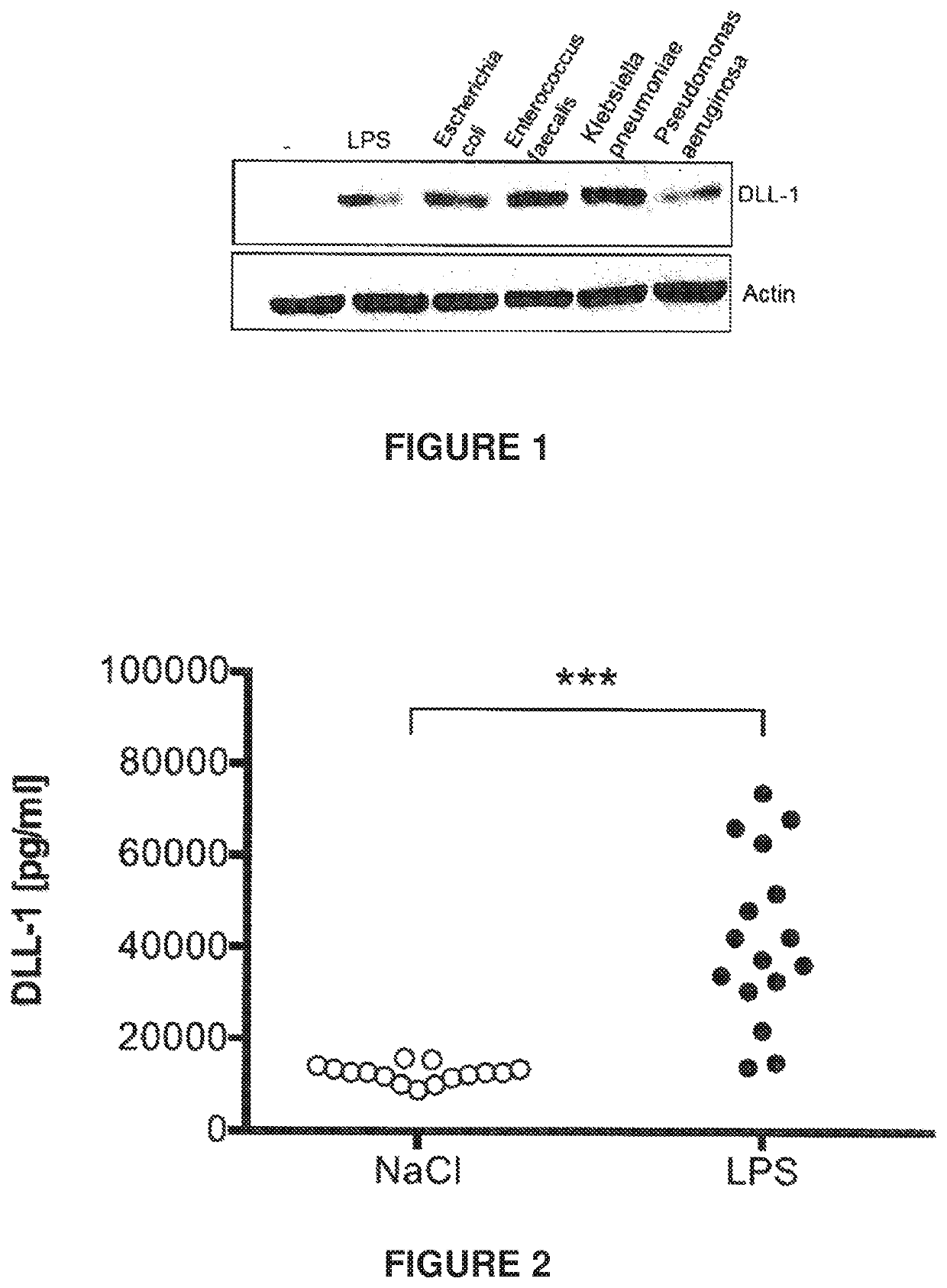

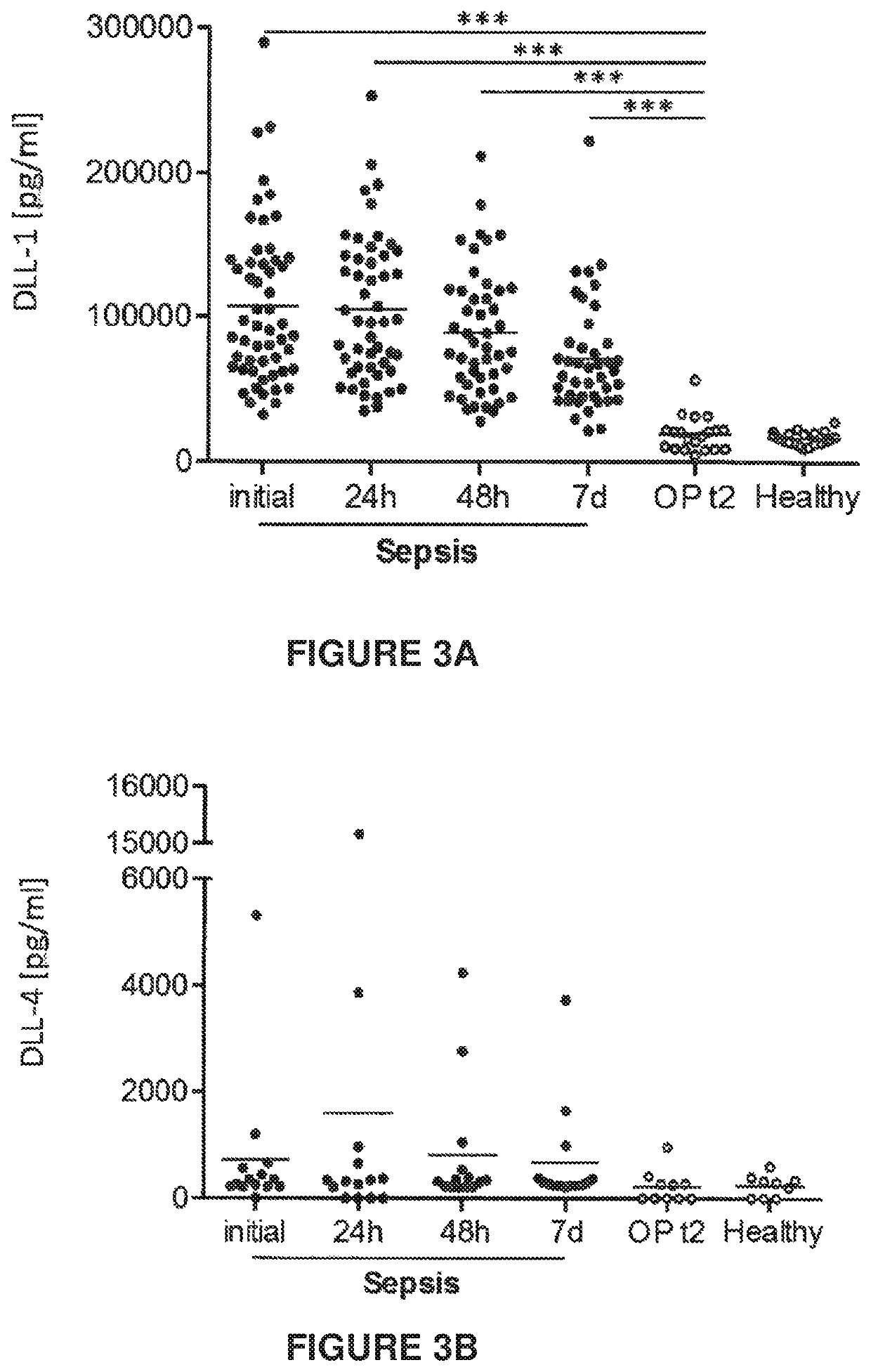

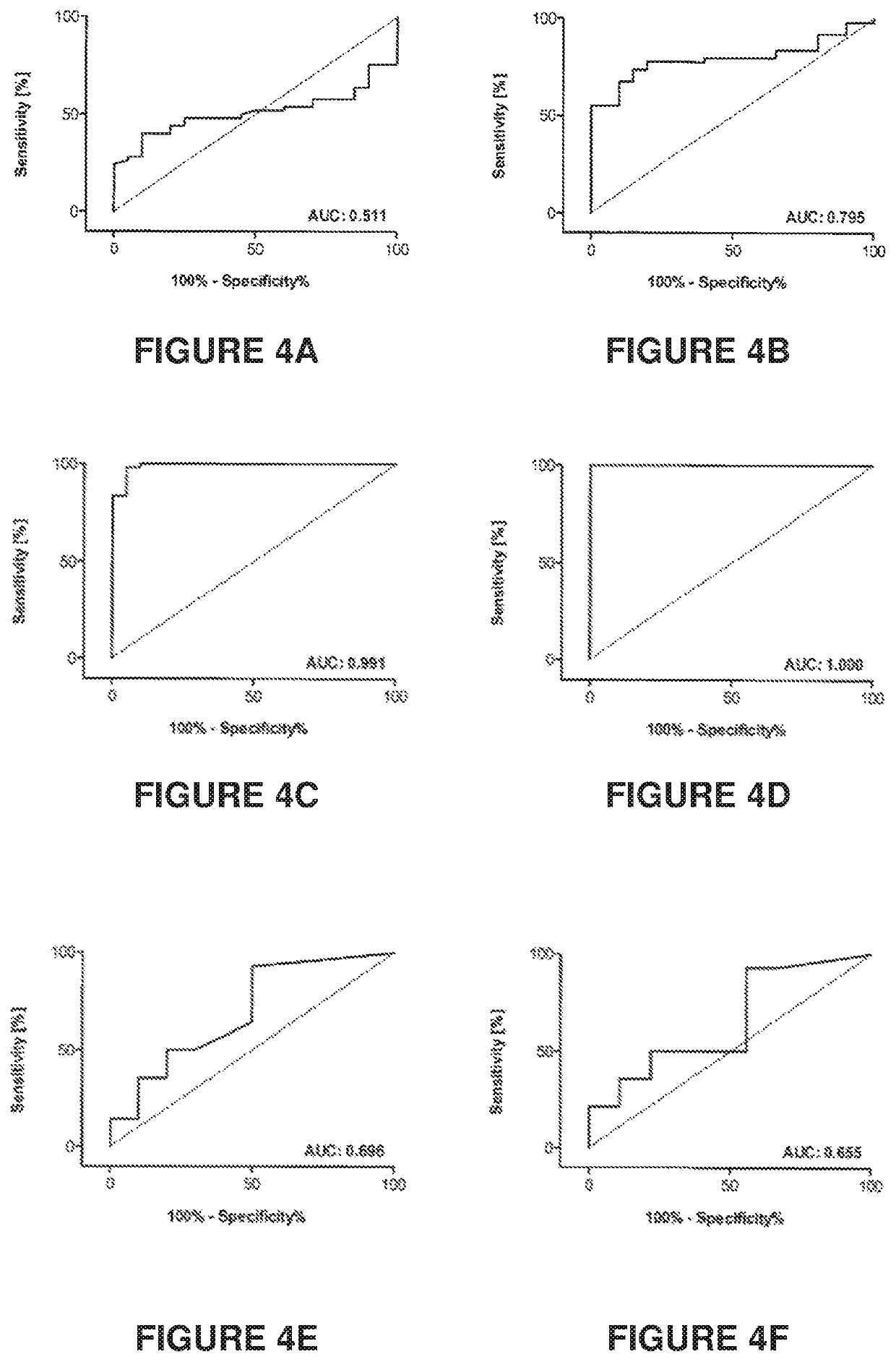

Delta-like ligand 1 for diagnosing severe infections

ActiveUS11181532B2Improve reliabilityImproved disease outcomeMicrobiological testing/measurementDisease diagnosisNucleotideSerious infection

The invention refers to a method for in vitro diagnosis of a severe infection comprising determining delta-like ligand 1 protein or a nucleotide sequence coding for delta-like ligand 1 protein in a biological sample wherein an elevated level of expression of delta-like ligand 1 protein or a nucleotide sequence coding for delta-like ligand 1 protein is indicative of a severe infection; and the use of delta-like ligand 1 protein as a biomarker for in vitro diagnosis of a severe infection such as sepsis.

Owner:UNIVERSITY OF HEIDELBERG

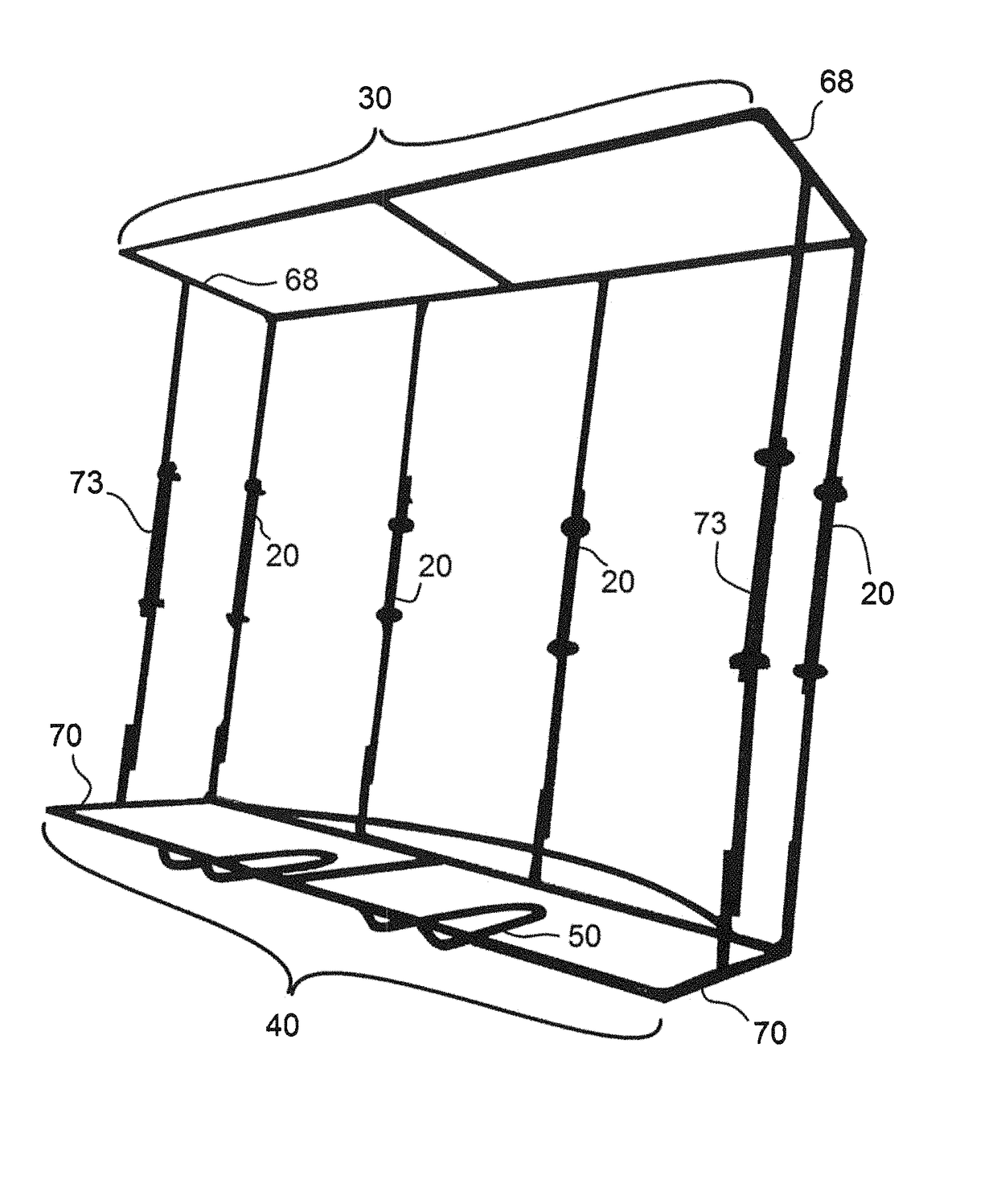

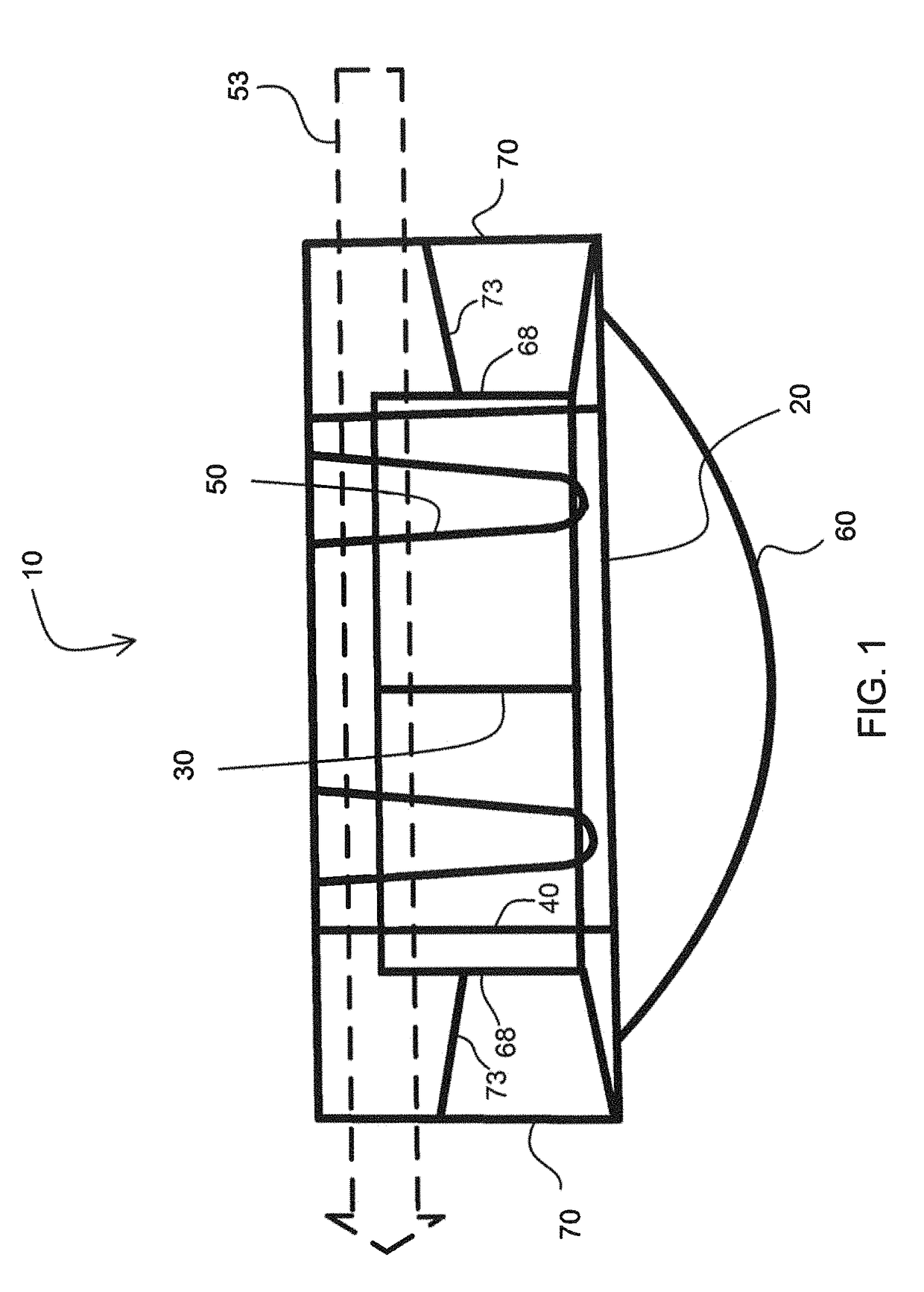

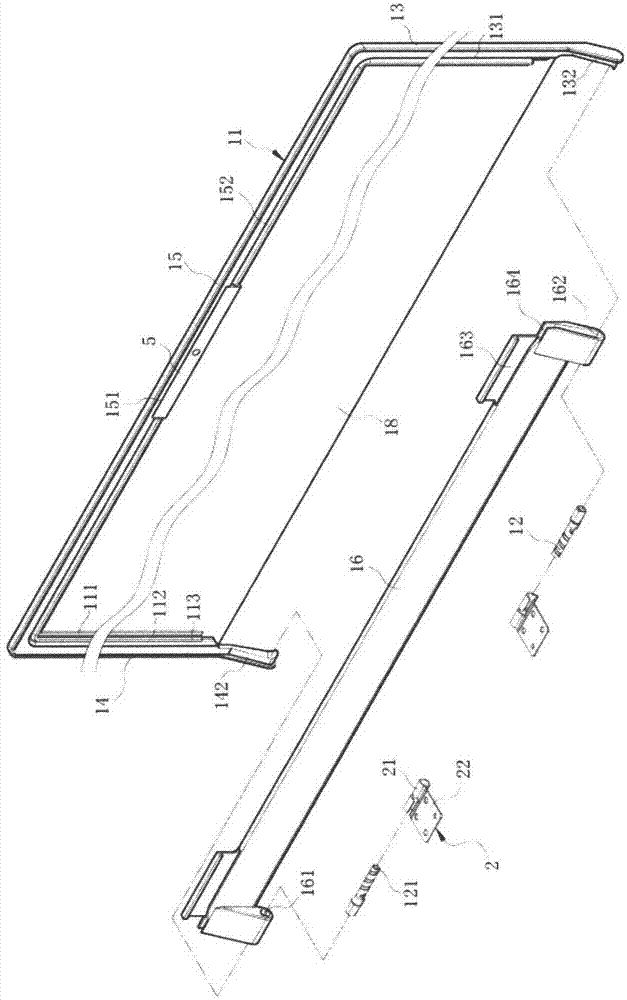

Apparatus, method and system for harvesting, handling and packing berries picked directly from the plant

Method for packing harvested berries directly into clamshell packages during hand harvesting by a harvester. The harvester utilizes a new open-topped harvesting apparatus that has a plurality of bottom assemblies for supporting a shipping tray that contains a plurality of clamshell packages. The open-topped harvesting apparatus further includes a plurality of front and rear end wall assemblies affixed perpendicular to the bottom assembly. A first side wall assembly is affixed perpendicular to the bottom assemblies and affixed to the plurality of end wall assemblies. A second side wall assembly is affixed perpendicular to the bottom assemblies and affixed to the end wall assemblies. The second side wall has two belt notch-like loops for allowing the carrier to be secured on a harvester's belt; and the second side wall further including an arch-shaped side supporter for maintaining the bottom assemblies substantially horizontal to the ground when worn by the harvester.

Owner:NATURIPE BERRY GROWERS

Method and Kit of Detecting the Absence of Micro-Organisms

ActiveUS20170240957A1Reduce unnecessary costsImprove degradation rateMicrobiological testing/measurementBiological material analysisIndicator microorganismsOrganism

Methods of detecting the absence or presence of a micro-organism in a sample comprising: contacting the sample with a nucleic acid molecule which acts as a substrate for nucleic acid modifying activity of the micro-organism in the sample, incubating the thus contacted sample under conditions suitable for nucleic acid modifying activity; and specifically determining the absence or presence of a modified nucleic acid molecule resulting from the action of the nucleic acid modifying activity on the substrate nucleic acid molecule to indicate the absence or presence of the micro-organism. Corresponding kits are also provided.

Owner:MOMENTUM BIOSCI

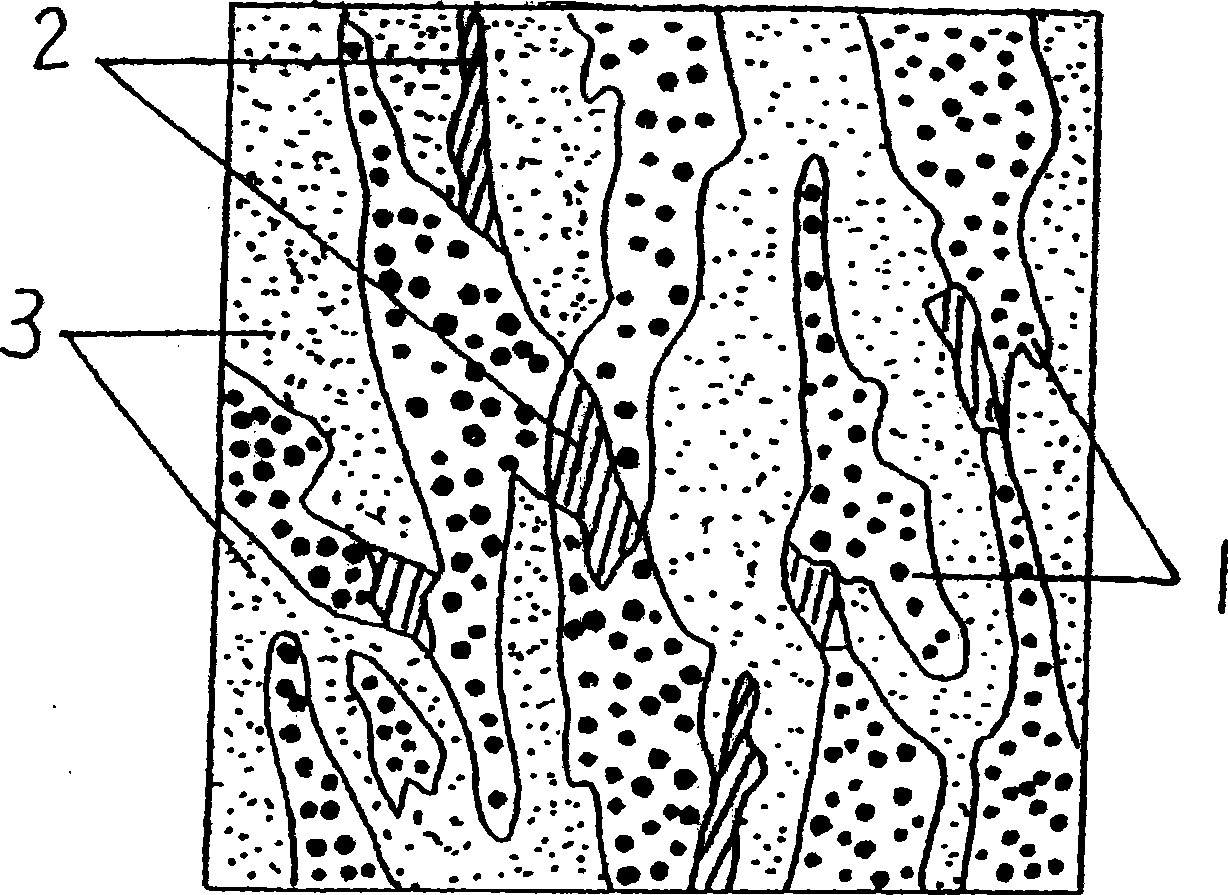

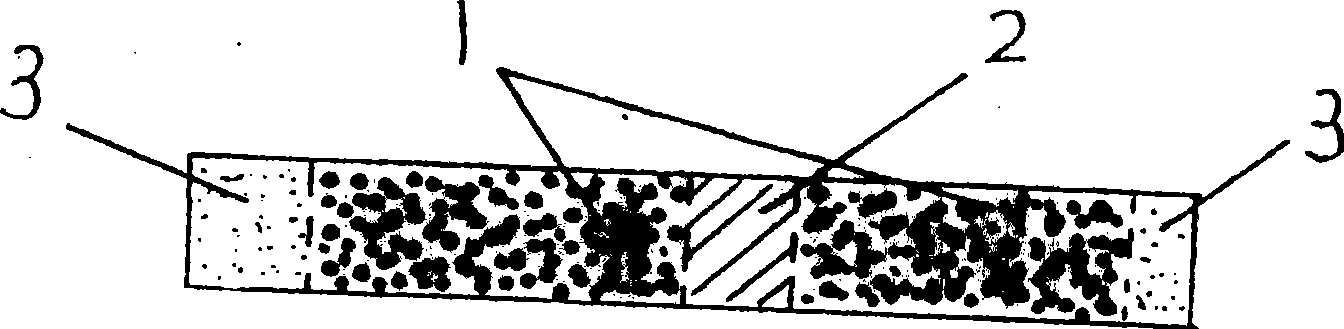

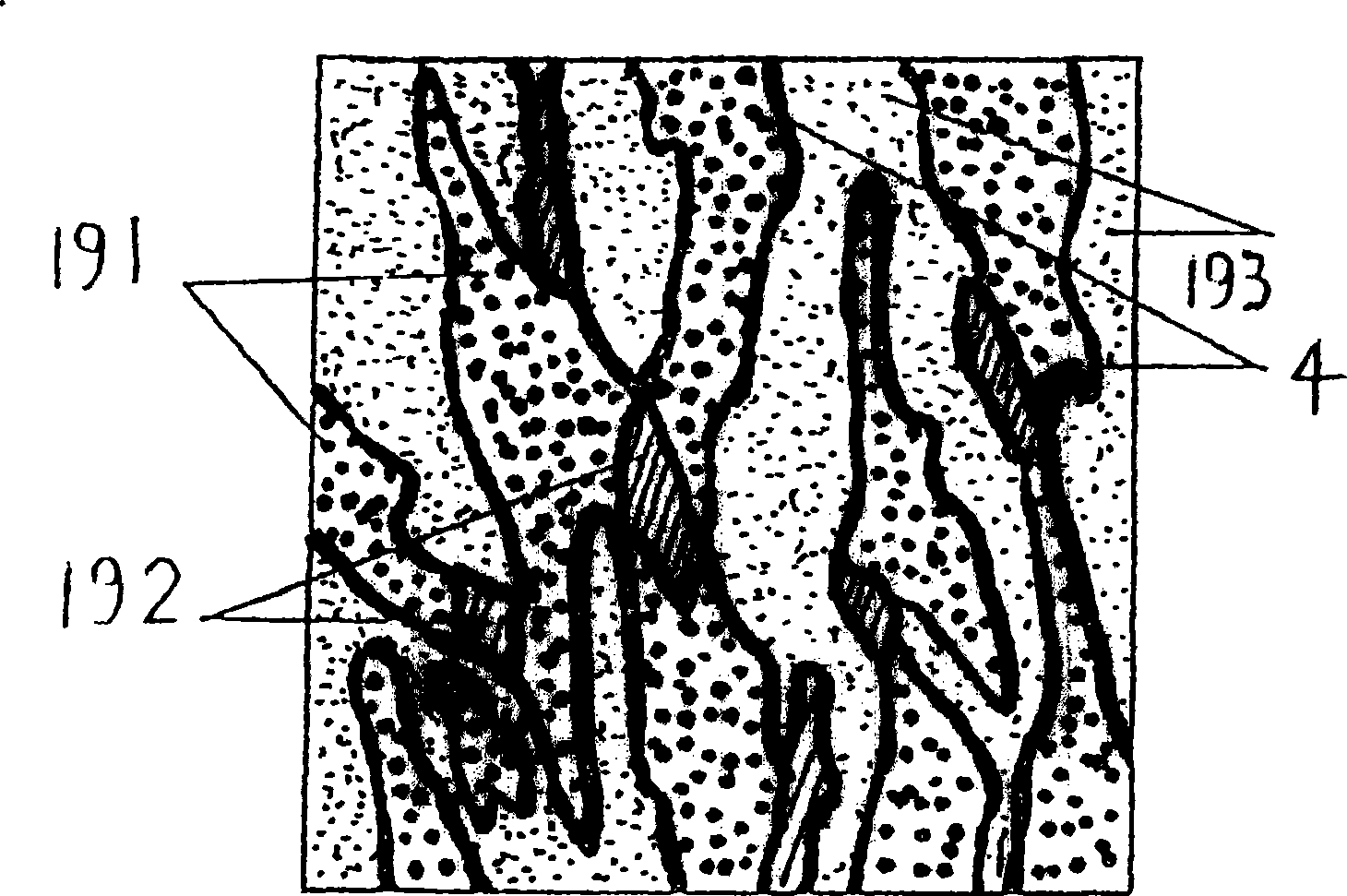

Method and device for making ceramic products with three-dimensional blank colored pattern

The invention relates to a device for producing three-dimensional blank colorful pattern ceramic product and relative method. Wherein, the device can apply the production of ceramic ornament plate, which comprises a punching compressor, a upper punch head of punching mould, a platform of punching mould, a lower mould core of punching mould, a feeding vehicle which can move forwards and backwards, a pattern mould grid, and a plate-drawing device moving at the lower part of said patter mould grid. Said plate-drawing device is flat while its upper surface is a plane tightly contacting the lower part of pattern mould grid to support the colorful ceramic brick powder of colorful pattern powder area. And the blank colorful pattern product has at least two color areas with distinguished colors and at least 1-10000 shapes of pattern designed by the shape of said patter mould grid.

Owner:杨德宁

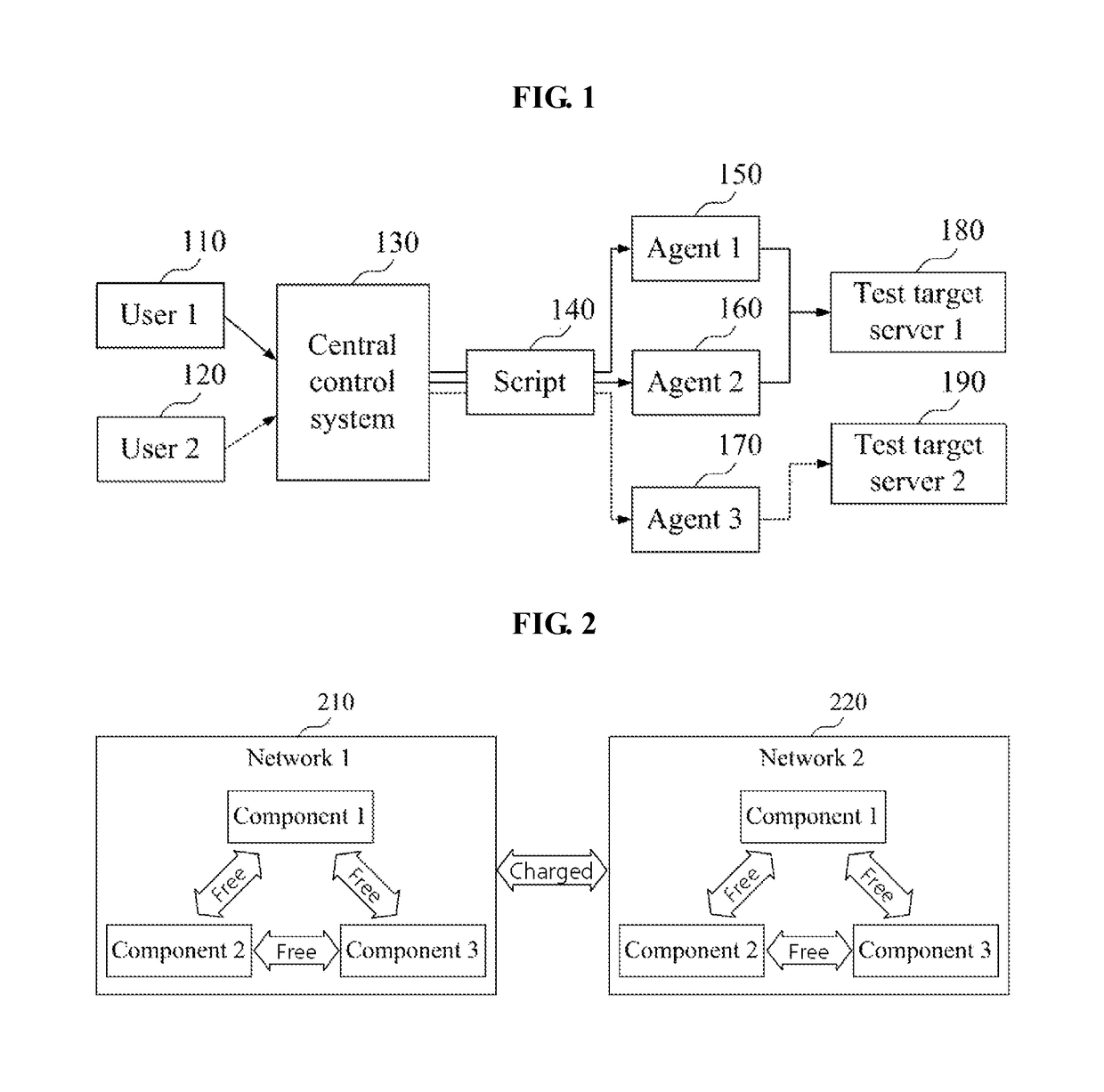

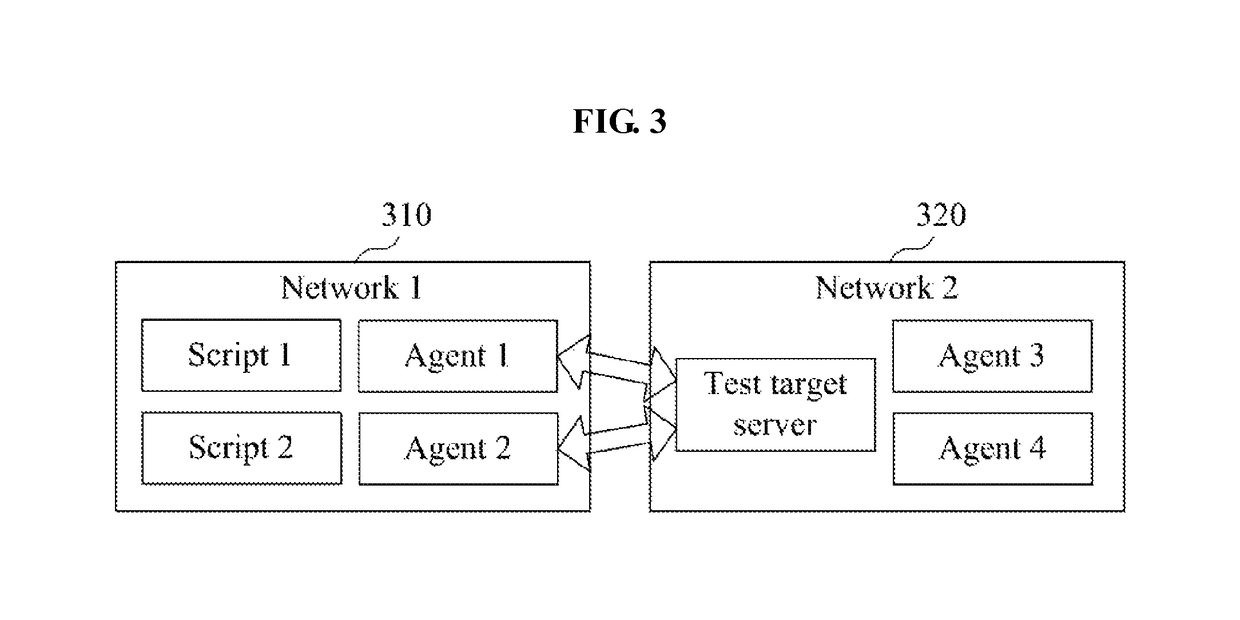

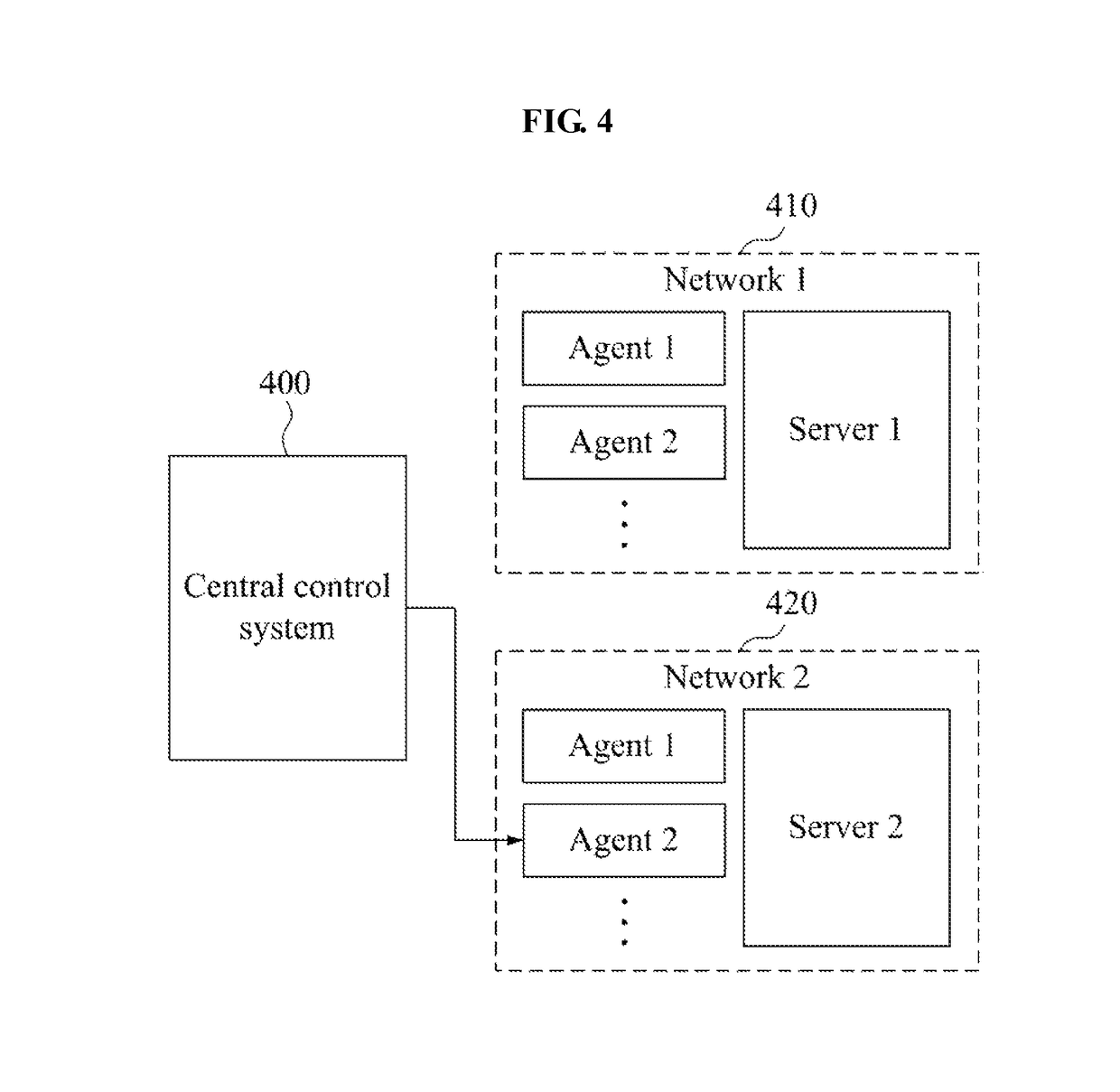

Test system for reducing performance test cost in cloud environment and test method therefor

ActiveUS10230613B2InhibitionReduce variationDetecting faulty computer hardwareMultiple digital computer combinationsUser inputComputer science

A test method includes selecting at least one agent included in a selected network based on network information input from a user, the selected network corresponding to the network information; receiving target server information; verifying whether a server corresponding to the target server information is present in the selected network based on the network information and the target server information; and transferring the target server information to the selected at least one agent.

Owner:NAVER CLOUD CORP

A digital twin-based auxiliary supervision system for industrial production lines

ActiveCN113298371BImprove efficiencyLow costElectrical apparatusEnergy saving control techniquesProcess engineeringWorkstation

The invention discloses a digital twin-based industrial production line auxiliary supervision system, relates to the technical field of industrial production line auxiliary supervision, and solves the technical problem in the prior art that the production line cannot be planned in real time, resulting in increased labor costs. , divide the stations on the industrial production line through the station division unit, analyze the orders set up on the industrial production line, calculate the ratio of the available time to the estimated number of production pieces to obtain the customer's demand beat, and obtain the corresponding time through the formula The preset number of stations in the industrial production line SLi; according to the production sequence, construct the coefficient set of the process key coefficients corresponding to the industrial production line, and assign weights to the subsets in the coefficient set; analyze the number of stations according to the order, and complete the order At the same time, the labor cost is strictly controlled to reduce unnecessary production costs. At the same time, the interval length of the stations is calculated in real time, so that the conveyor belt can maximize the efficiency of the production line at the most energy-saving speed.

Owner:EAST CHINA UNIV OF TECH

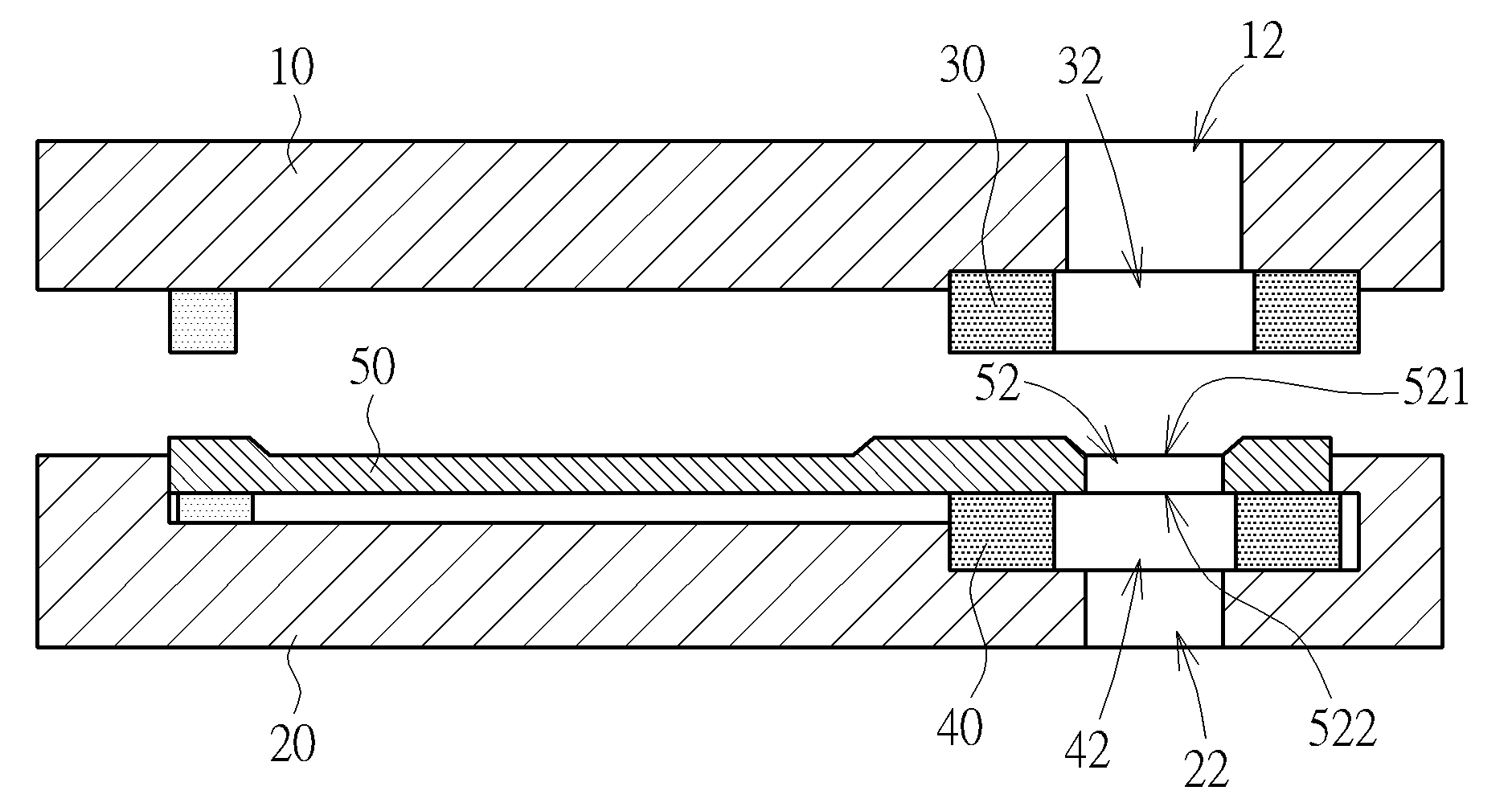

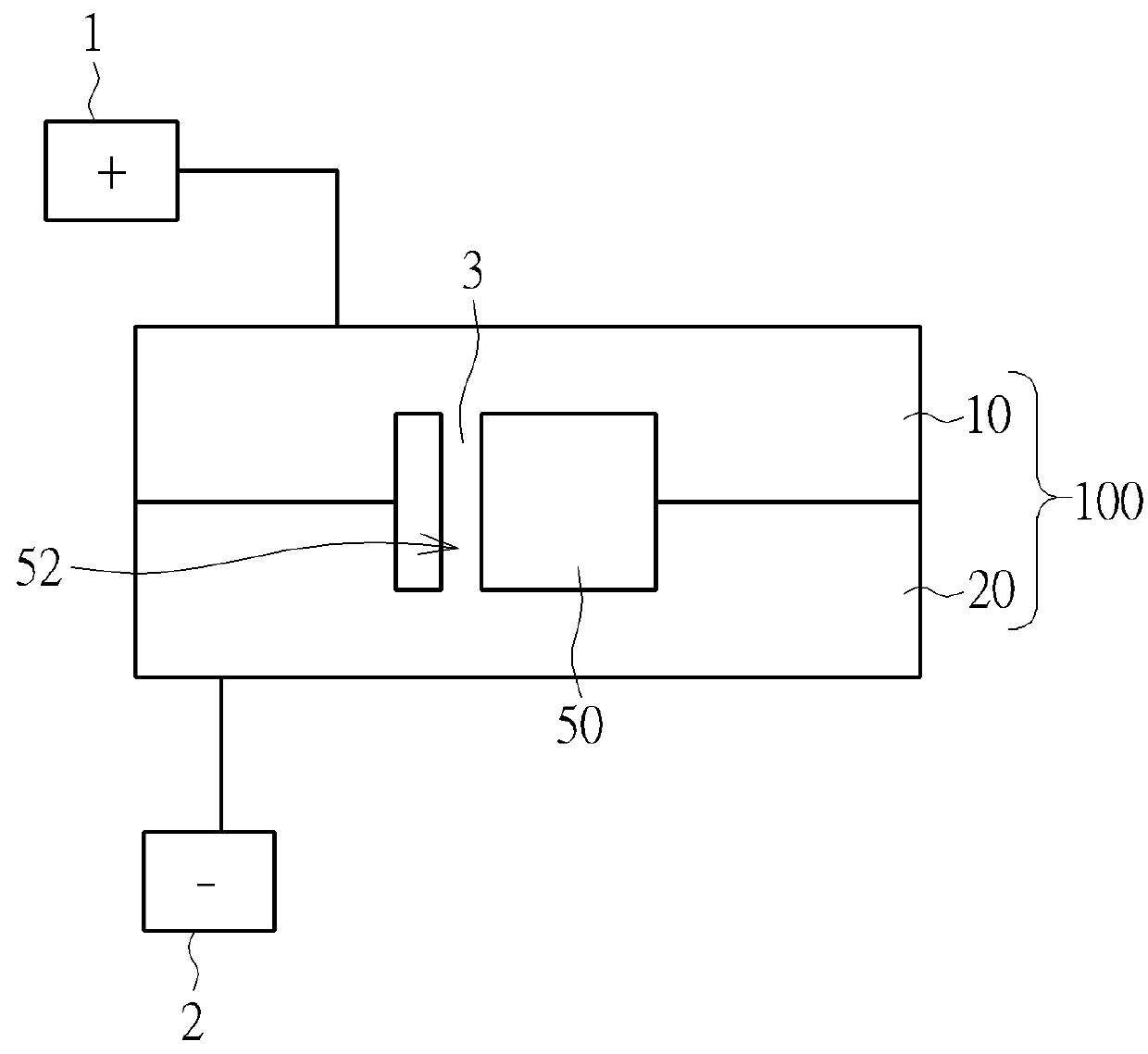

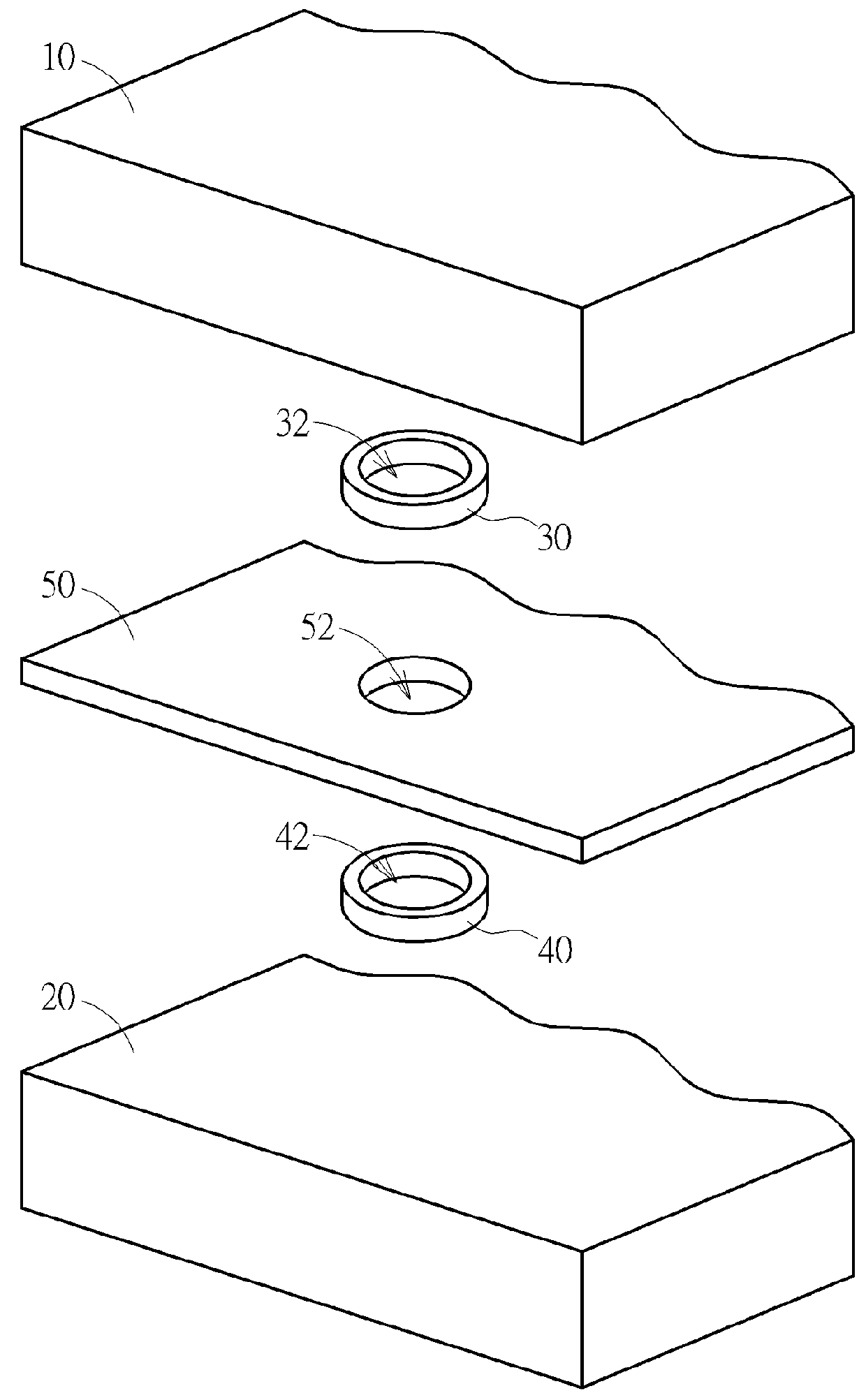

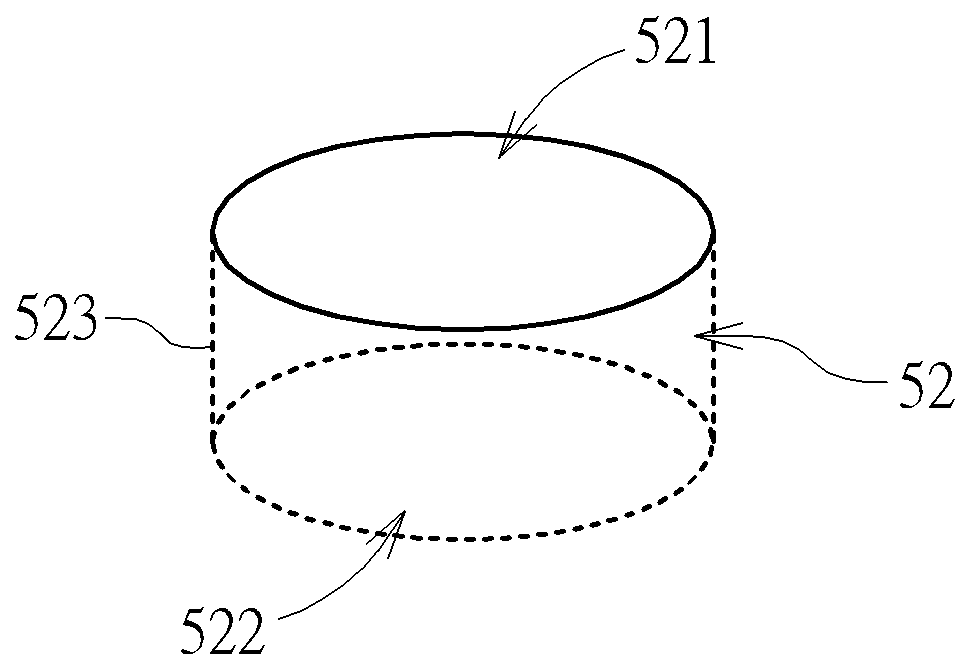

Electroplating equipment capable of gold-plating on a through hole of a workpiece

The electroplating equipment disposes a hollow first ring between a first mold and a through hole of a workpiece, and a hollow second ring between a second mold and the through hole of the workpiece, such that the first ring and the second ring provide substantially equivalent channel as the openings of the through hole when the first mold and the second mold are set to hold tight the workpiece. The first ring and the second ring, along with an injection channel of the first mold and a recycling channel of the second mold and the through hole of the workpiece, form a seamless flow channel for an electroplating fluid to flow and be electroplated on the wall of the through hole.

Owner:MIN AIK PRECISION IND

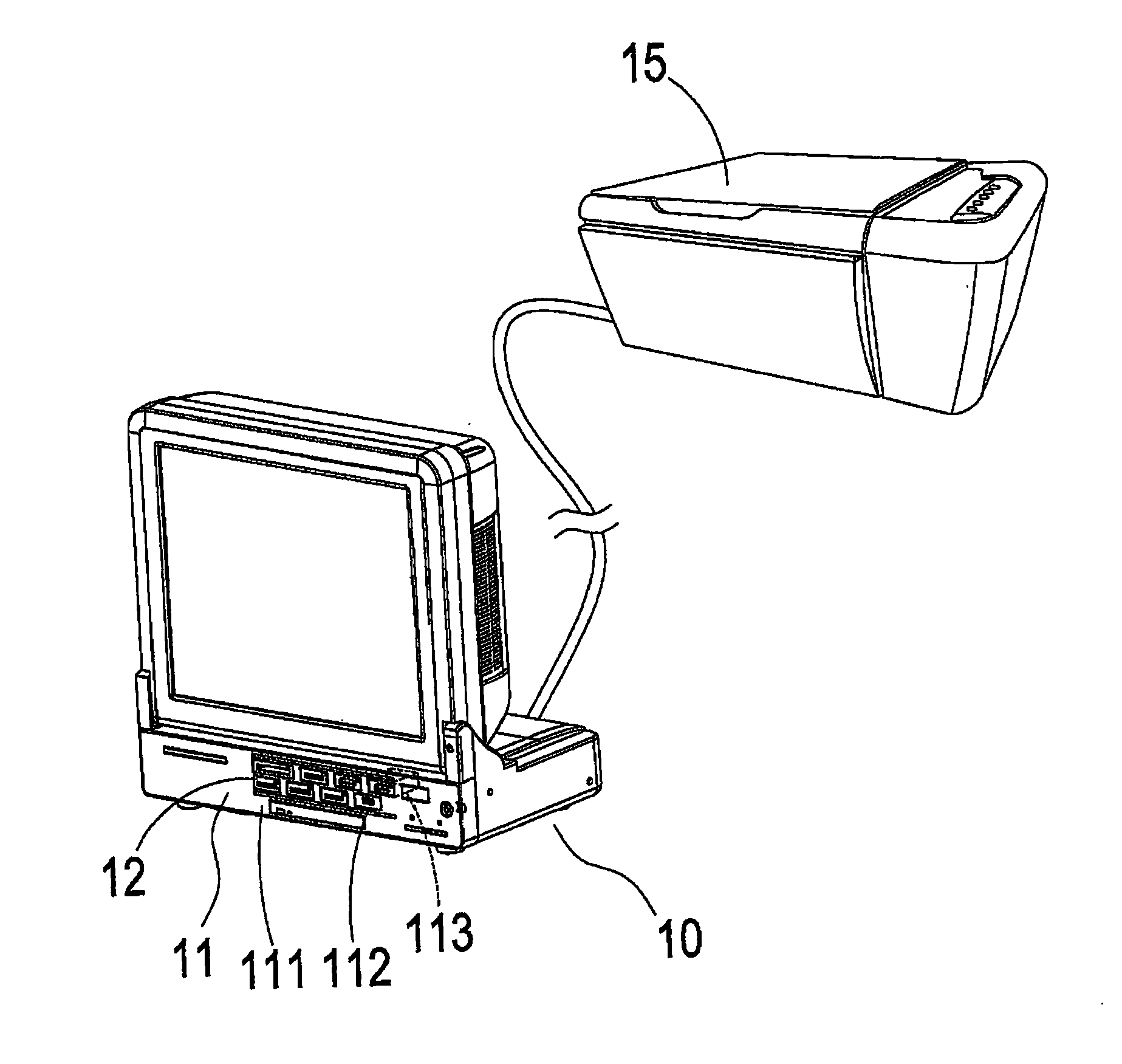

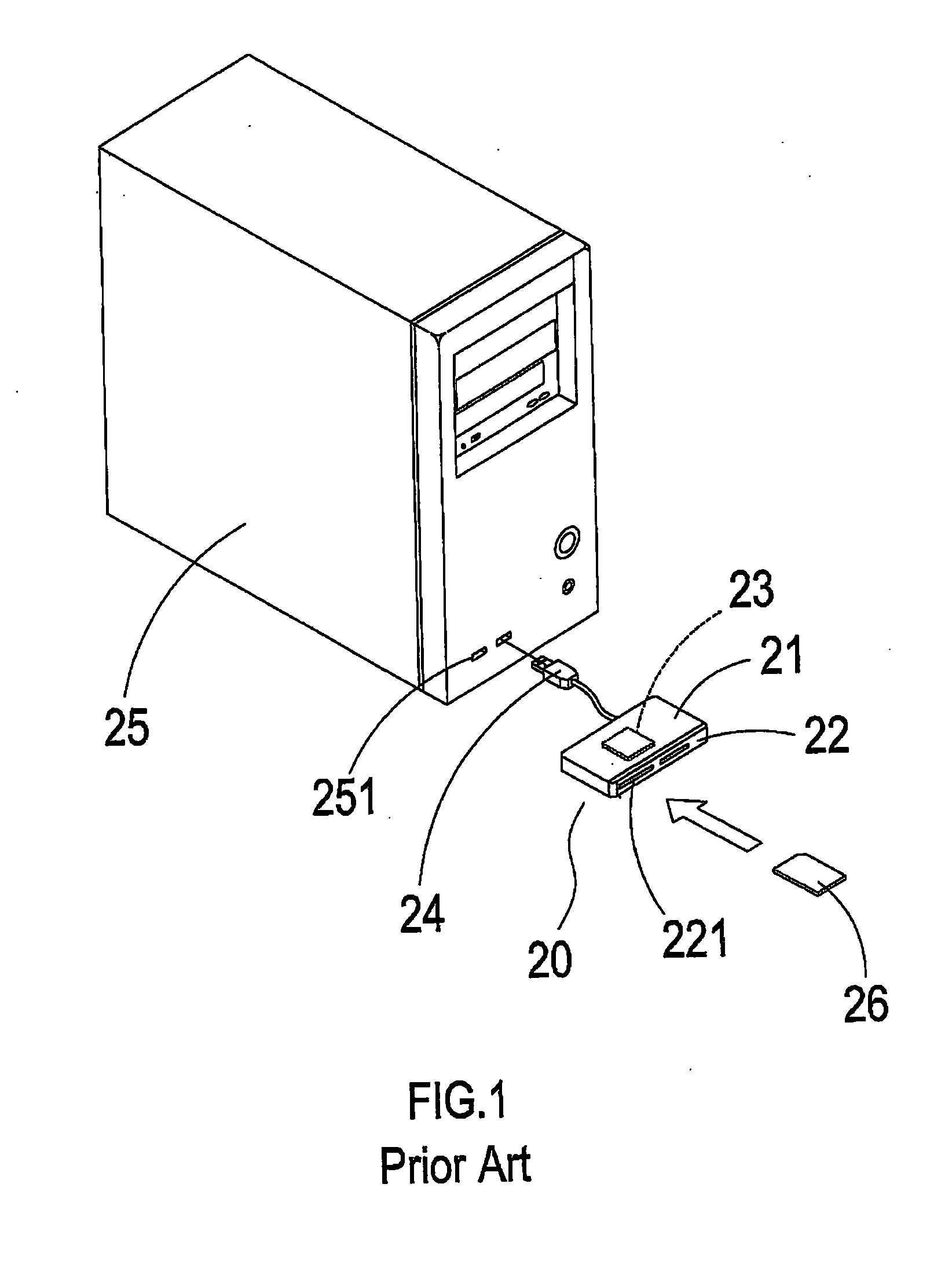

Card reader

InactiveUS20110102993A1Improve acceleration performanceShorten the timeCoupling device detailsSensing record carriersExtensibilityEngineering

A card reader includes a housing, an interior of which is defined with plural holding slots accommodating interface units respectively. The interface units are connected respectively with control units which are primarily a single chip. The interface units are storage devices, such as MS, CF, SD, XD, USB, microSD or M2. The housing is further provided with a cover board on which are disposed with perforations at locations corresponding to the interface units. When a user is to replace, update or repair the card reader, he or she can take down the cover board and then perform a respective operation to the interface unit to be replaced, updated or repaired independently, without removing other interface units together. Therefore, time and labor works can be reduced, expandability is high, and an unnecessary cost spent can be saved.

Owner:HEISEI ELECTRONICS CO LTD

Chinese medicinal composition for treating burn and scald and application thereof

InactiveCN102106920BReduce exudationEnhanced inhibitory effectDermatological disorderPlant ingredientsWound healingCure rate

The invention belongs to the field of Chinese medicine, in particular relates to a Chinese medicinal composition for treating burn and scald and the application thereof, and solves the problems that the cure rate of the burn and the scald is improved, the healing time of the wound surface is shortened and scars on the wound surface of burn and scald are reduced. The invention provides the Chinesemedicinal composition for treating the burn and the scald, which is prepared from phellodendron amurense, milkvetch root and elm bark, and has the efficacies of clearing away heat and toxic material,reducing swelling and alleviating pain, inhibiting and eliminating bacteria, reducing seepage of body liquid, removing necrosis and promoting granulation, improving the local blood supply and promoting the wound healing. The Chinese medicinal composition has high cure rate and short healing time, almost has no scar in treating the burn and scald, and can be used for treating decubitus.

Owner:王斌

Electroplating equipment capable of gold-plating on a through hole of a workpiece

InactiveUS20160032476A1Simple procedureReduce unnecessary costsCellsTanksElectroplatingMaterials science

The electroplating equipment disposes a hollow first ring between a first mold and a through hole of a workpiece, and a hollow second ring between a second mold and the through hole of the workpiece, such that the first ring and the second ring provide substantially equivalent channel as the openings of the through hole when the first mold and the second mold are set to hold tight the workpiece. The first ring and the second ring, along with an injection channel of the first mold and a recycling channel of the second mold and the through hole of the workpiece, form a seamless flow channel for an electroplating fluid to flow and be electroplated on the wall of the through hole.

Owner:MIN AIK PRECISION IND

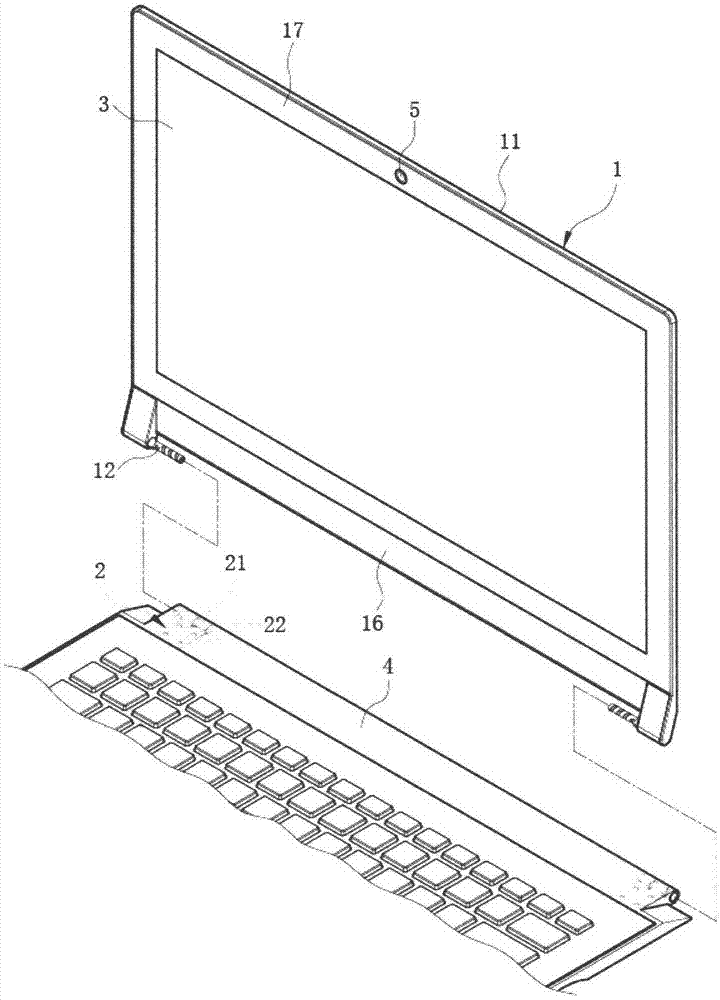

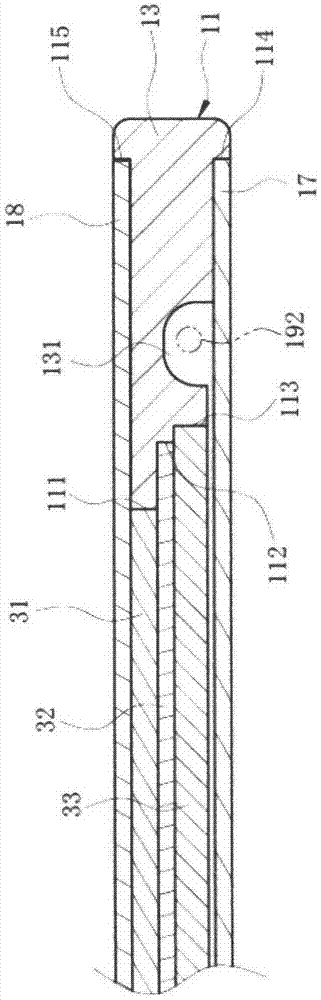

Connection structure with display module

The invention discloses a connection structure containing a display module. The connection structure is used for enabling the display module to be connected on a base, wherein the display module comprises a first optical lamina and a second optical lamina which are mutually parallel. The connection structure containing the display module comprises a first bearing seat and a second bearing seat, wherein the first bearing seat is provided with an assembling portion, a first positioning groove and a second positioning groove which are respectively matched with the first optical lamina and the second optical lamina are arranged on the inner side of the assembling portion, and the bottom portion of the assembling portion is provided with at least one shaft lever; and meanwhile, the second bearing seat comprises a pivot joint portion and a connecting portion, the pivot joint portion is matched with the shaft lever, and the connecting portion is matched with the base. After the adoption of the structure, the connection structure containing the display module has the advantages of low production difficulty, little production cost, and small thickness.

Owner:KUNSHAN WANHER PRECISION ELECTRON

Biotechnological method for the production of acrylamide and new bacterial strain

ActiveUS10975401B2Improved, effective and rapid culture protocolIncrease heightBacteriaFermentationBiotechnologyAcrylonitrile

A bacterial strain of Rhodococcus biphenylivorans named Palladio 22 and registered at the BCCM-LMG Bacteria Collection under registration number LMG P-29520. A method is provided for the production of acrylamide following hydration of acrylonitrile using a biomass of the bacterial strain.

Owner:COLUMBIA

Biotechnological Method for the Production of Acrylamide and Relative New Bacterial Strain

ActiveUS20190127768A1Improved, effective and rapid culture protocolIncrease heightBacteriaMicroorganism based processesBacteroidesAcrylonitrile

A bacterial strain of Rhodococcus biphenylivorans named Palladio 22 and registered at the BCCM-LMG Bacteria Collection under registration number LMG P-29520. A method is provided for the production of acrylamide following hydration of acrylonitrile using a biomass of the bacterial strain.

Owner:COLUMBIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com