Connection structure with display module

A display module and connection structure technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of increasing production cost, increasing production difficulty, large thickness of liquid crystal screen, etc., and achieve light and thin connection structure , minus the complexity, save the effect of unnecessary cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

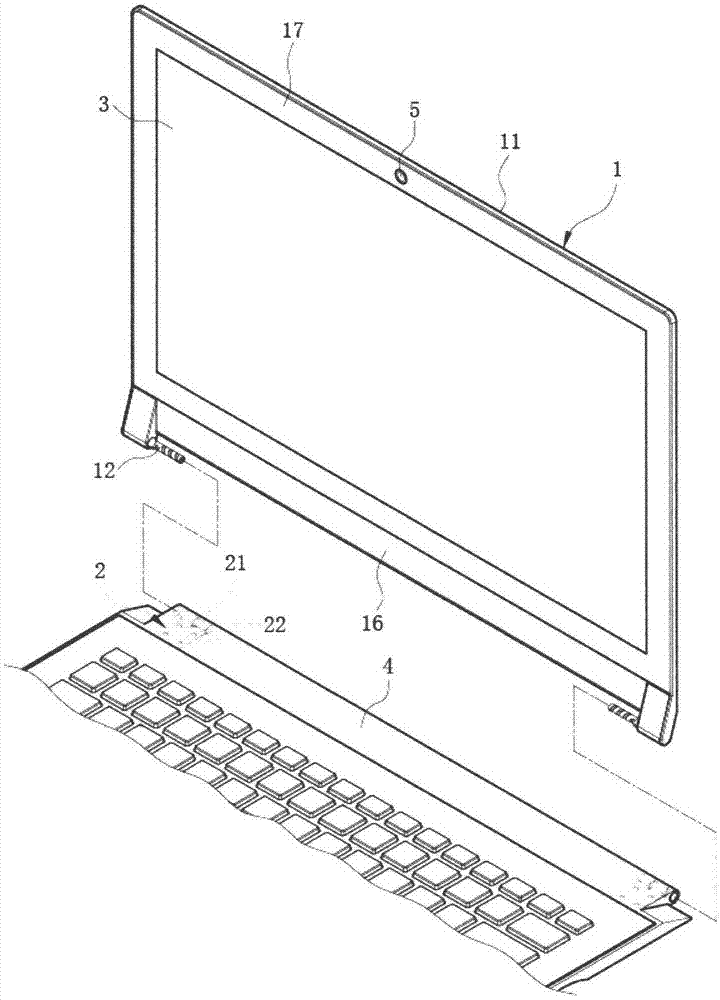

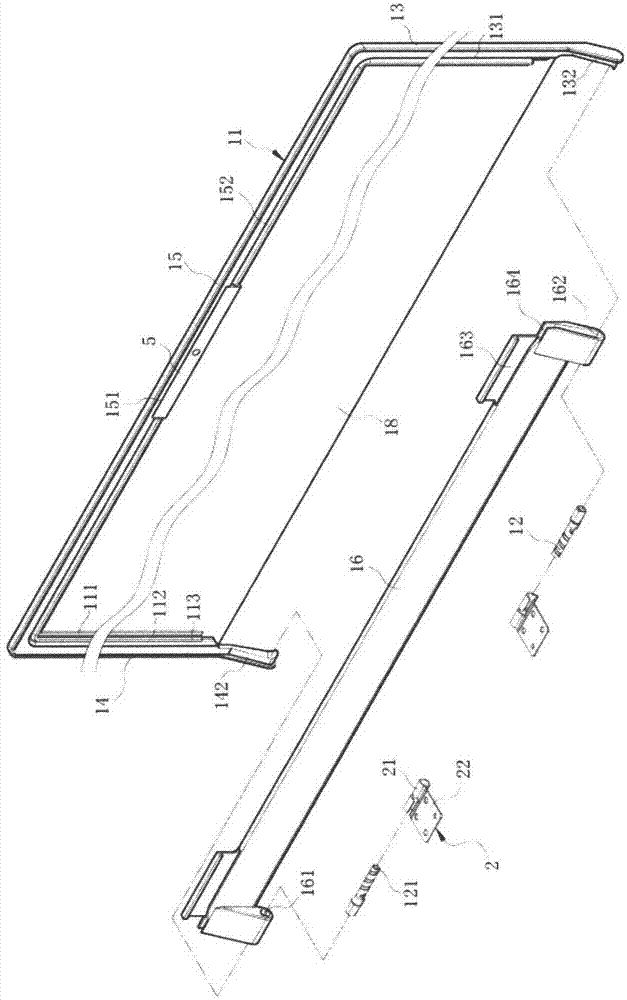

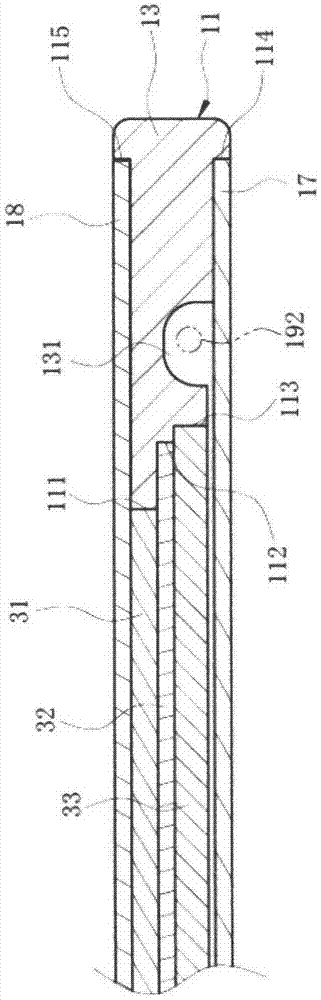

[0023] Examples, see figure 1 and figure 2 As shown, there is a connecting structure of the display module, which is used to connect the display module 3 to the base 4 . The base 4 is the host part of the notebook computer. The connection structure containing the display module includes a first bearing seat 1 and a second bearing seat 2 . The first bearing seat 1 includes an assembly part 11 and at least one shaft 12 connected with the assembly part 11 . The shaft 12 has a bore 121 axially inside. The assembly part 11 includes a first extension frame 13 connected to the shaft 12 and parallel to each other, a second extension frame 14, and a second extension frame 14 arranged between the first extension frame 13 and the second extension frame 14. Top frame 15 and a bottom frame 16. The top frame 15 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com