Patents

Literature

35395 results about "Brick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brick is building material used to make walls, pavements and other elements in masonry construction. Traditionally, the term brick referred to a unit composed of clay, but it is now used to denote rectangular units made of clay-bearing soil, sand, and lime, or concrete materials. Bricks can be joined together using mortar, adhesives or by interlocking them. Bricks are produced in numerous classes, types, materials, and sizes which vary with region and time period, and are produced in bulk quantities. Two basic categories of bricks are fired and non-fired bricks.

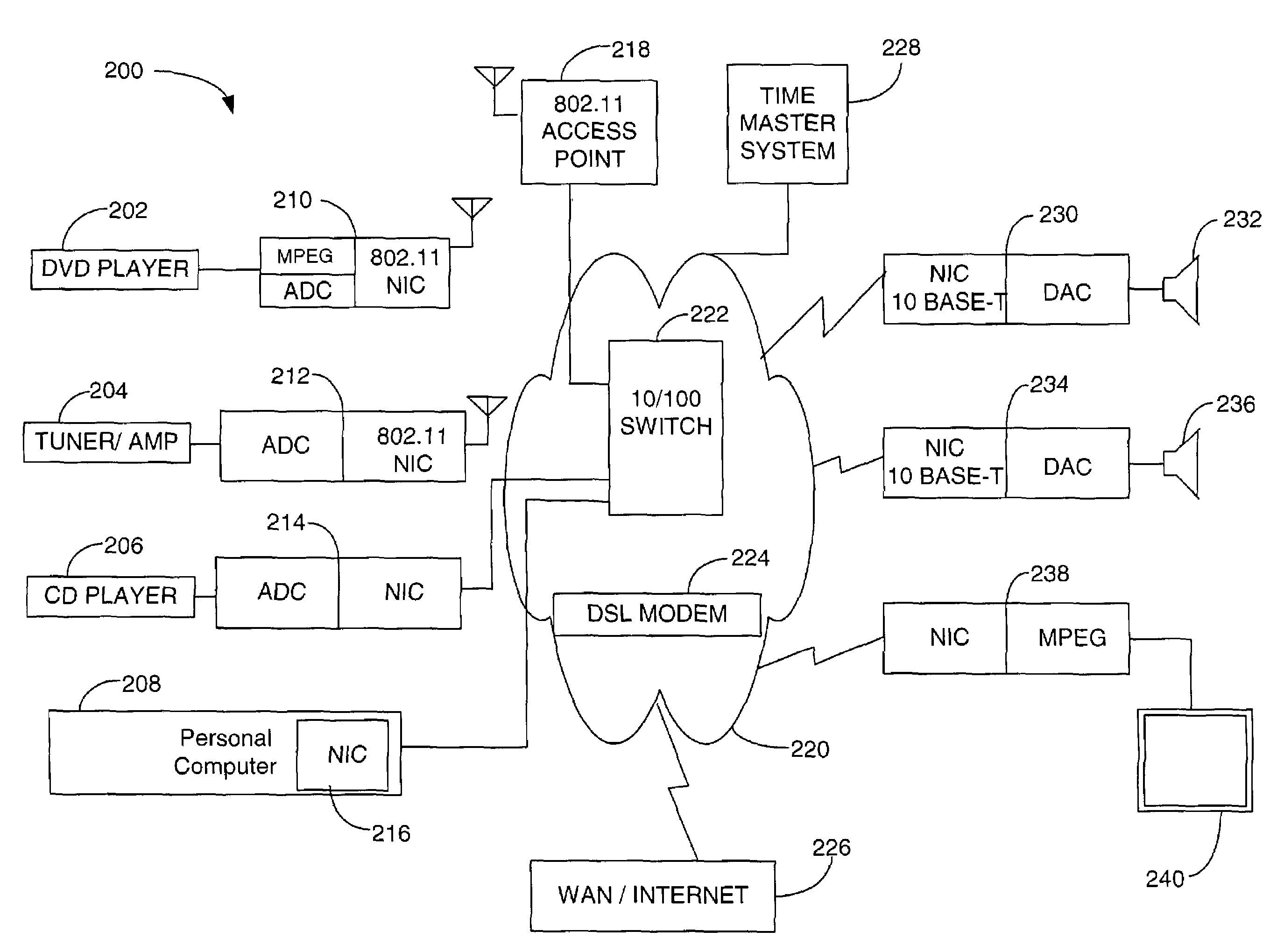

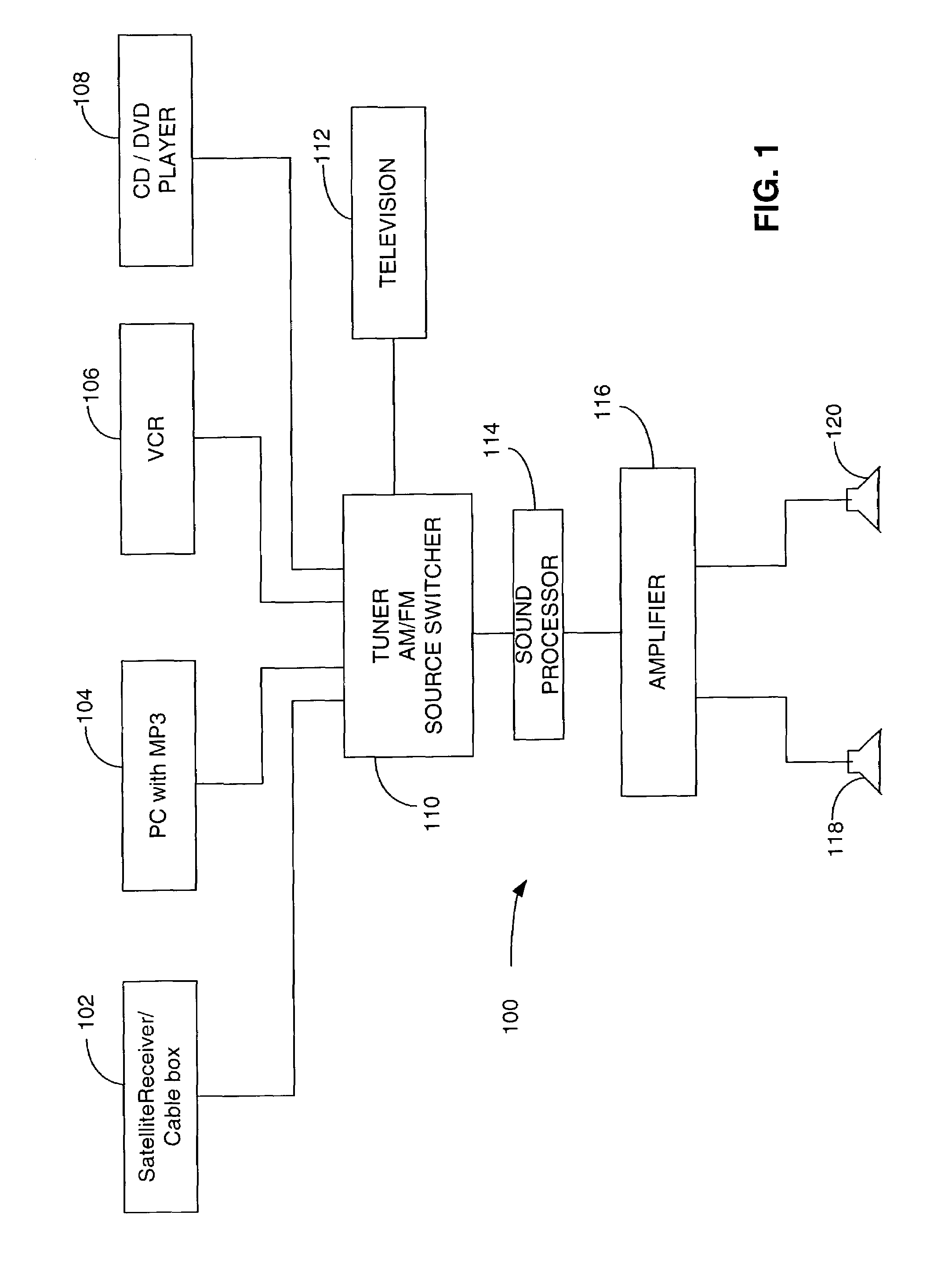

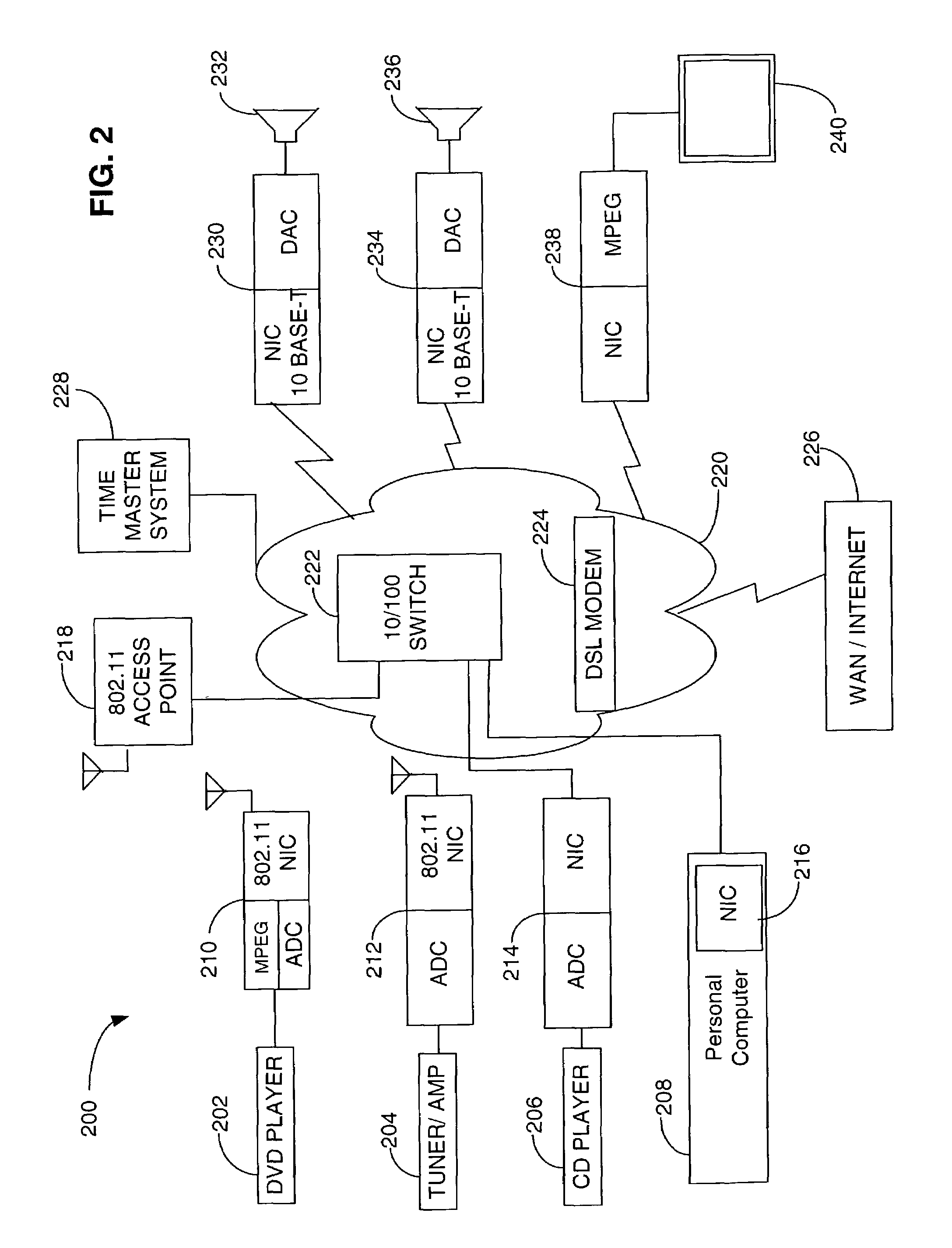

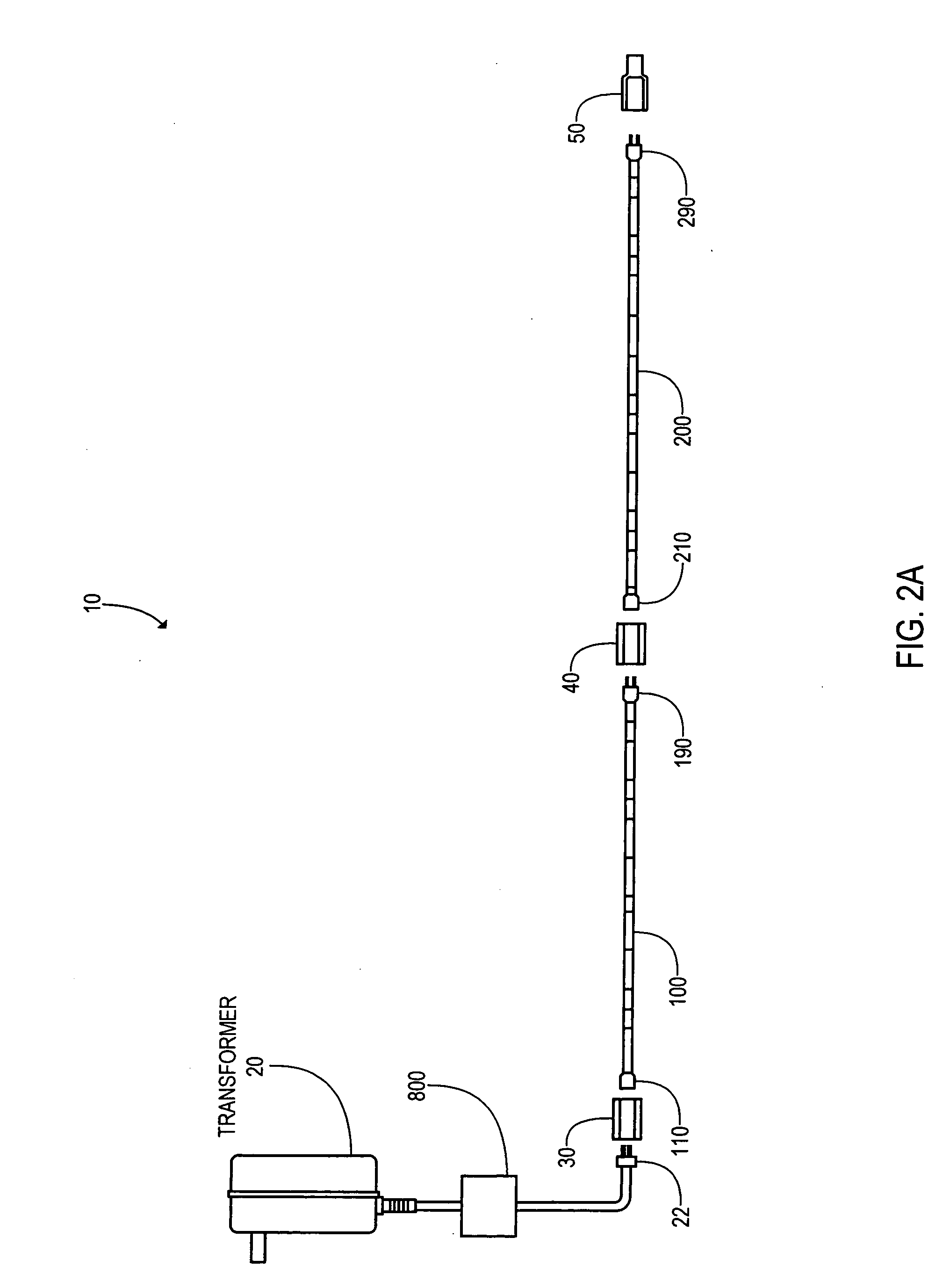

Method and system for disaggregating audio/visual components

ActiveUS7295548B2Improve user experiencePlural information simultaneous broadcastTwo-way working systemsComputer networkBrick

The present invention is directed to a method and system for disaggregating and connecting A / V components, and communicating A / V content stream information. An A / V stream from a source device is packaged for transmission over an IP network to one or more output devices. A brick device enables the integration of legacy A / V systems into the network supported A / V system. The brick device operates to provide analog signal and IP protocol conversion, along with the synchronization of received A / V stream data packets. The rendering and play of the A / V stream content on multiple output devices is synchronized to overcome distortions and other network idiosyncrasy and to facilitate a pleasant user experience.

Owner:MICROSOFT TECH LICENSING LLC

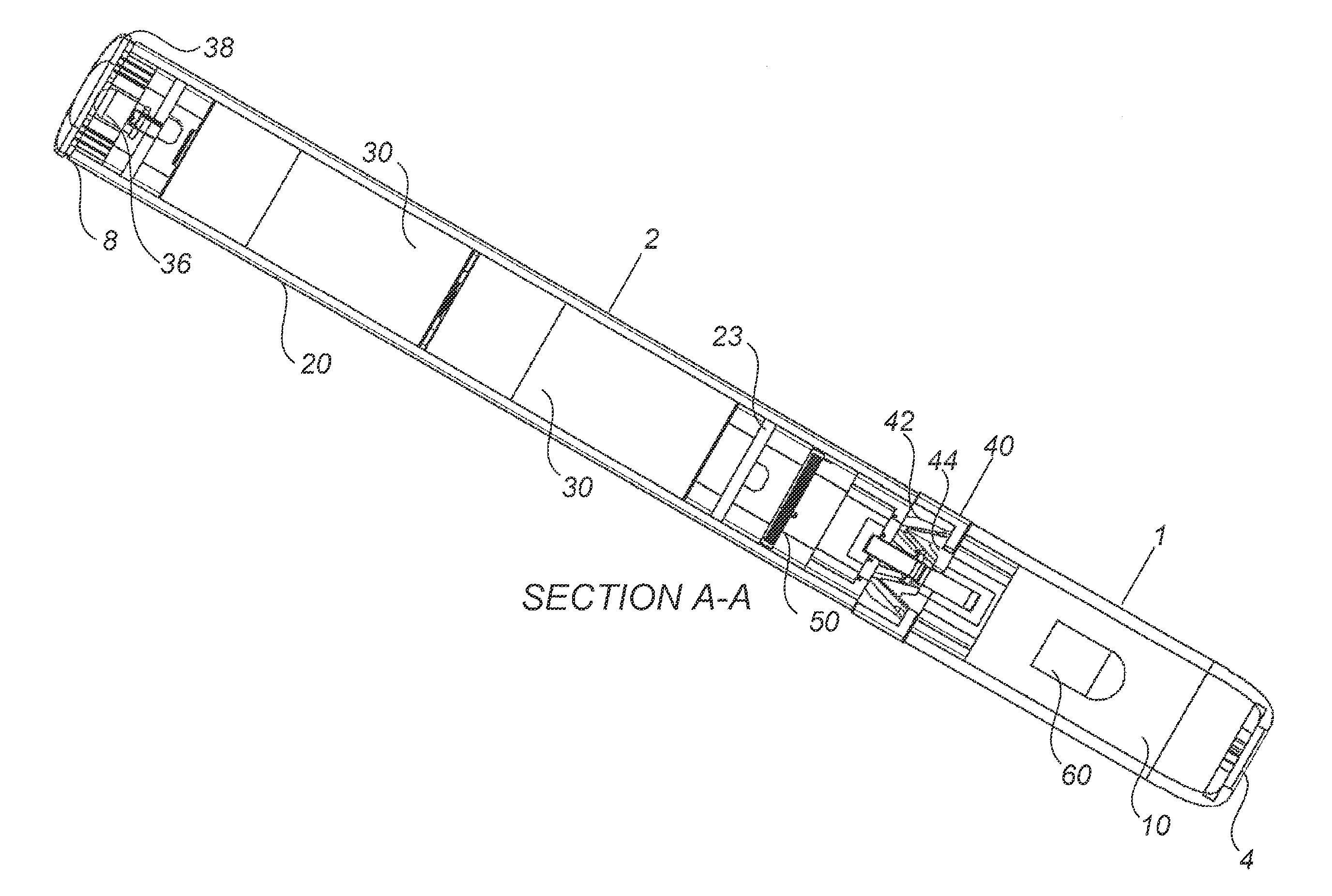

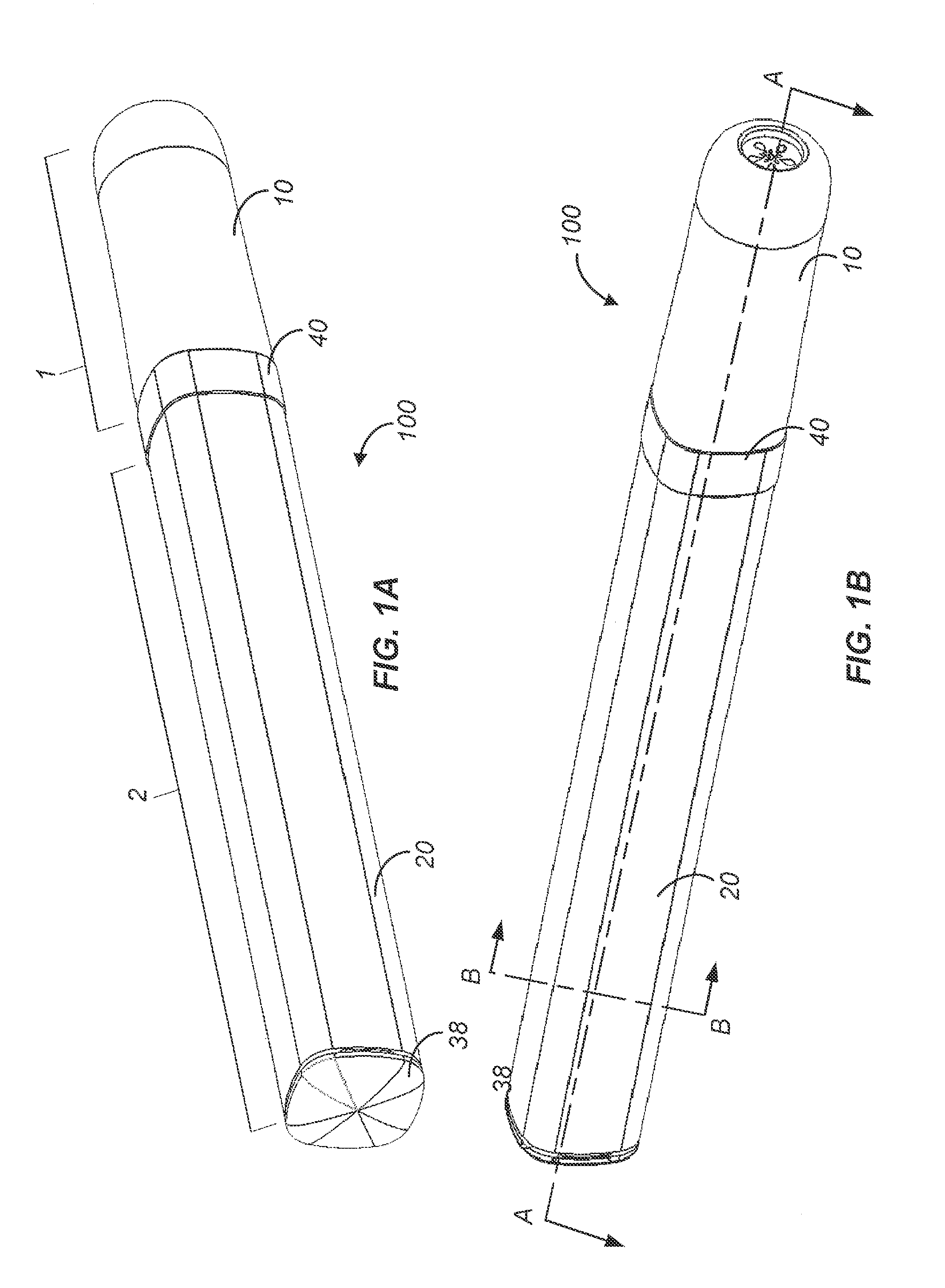

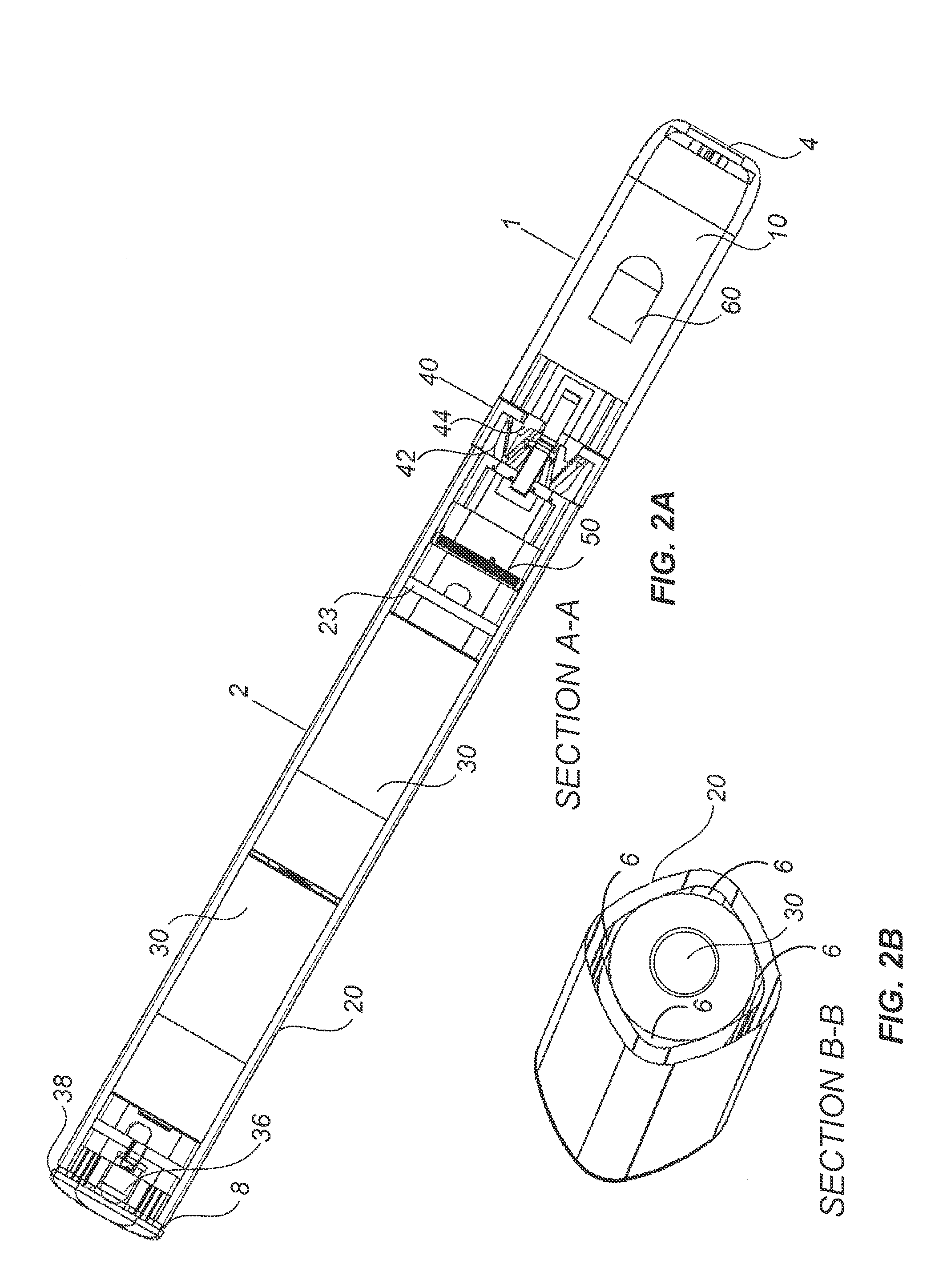

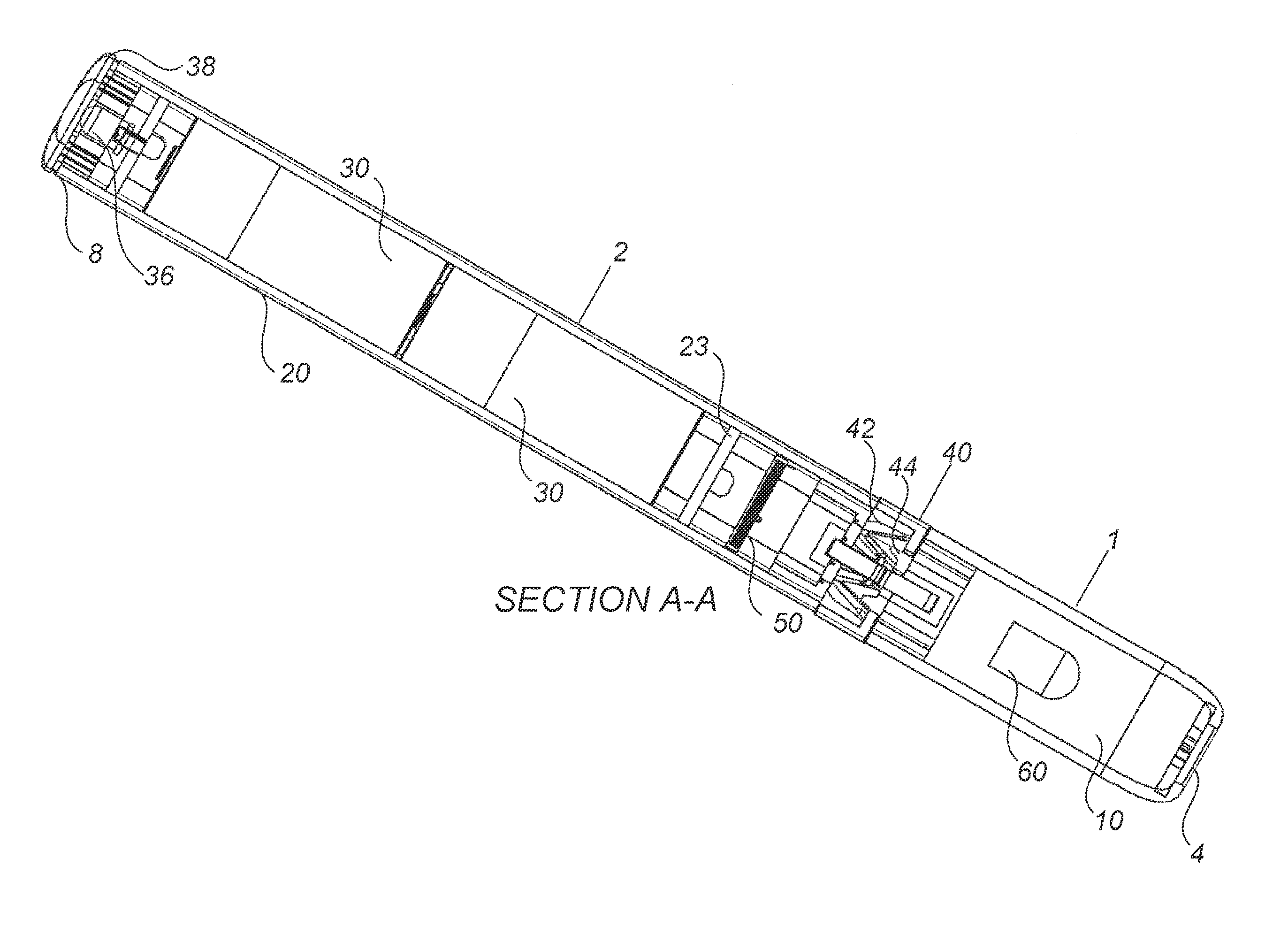

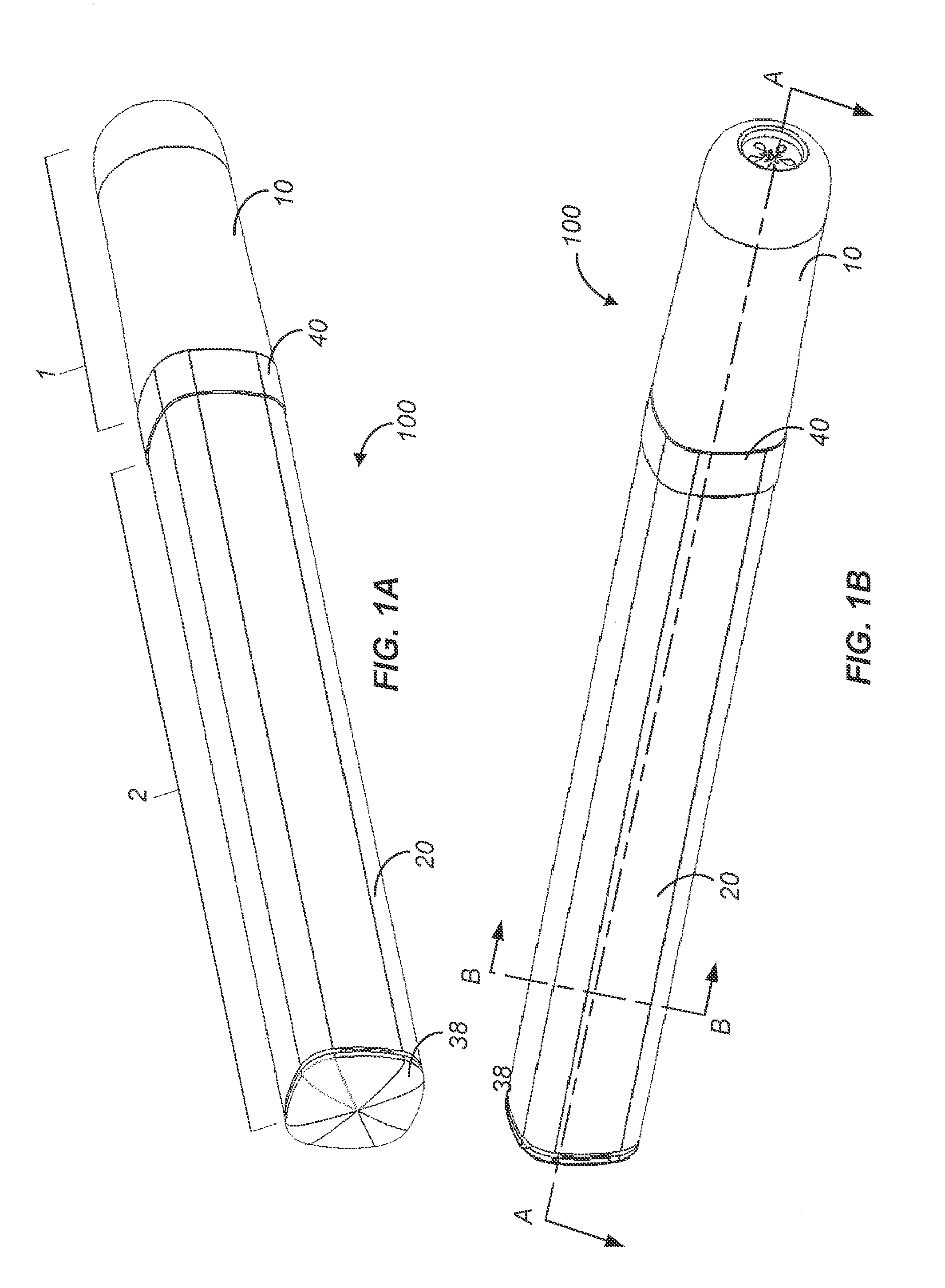

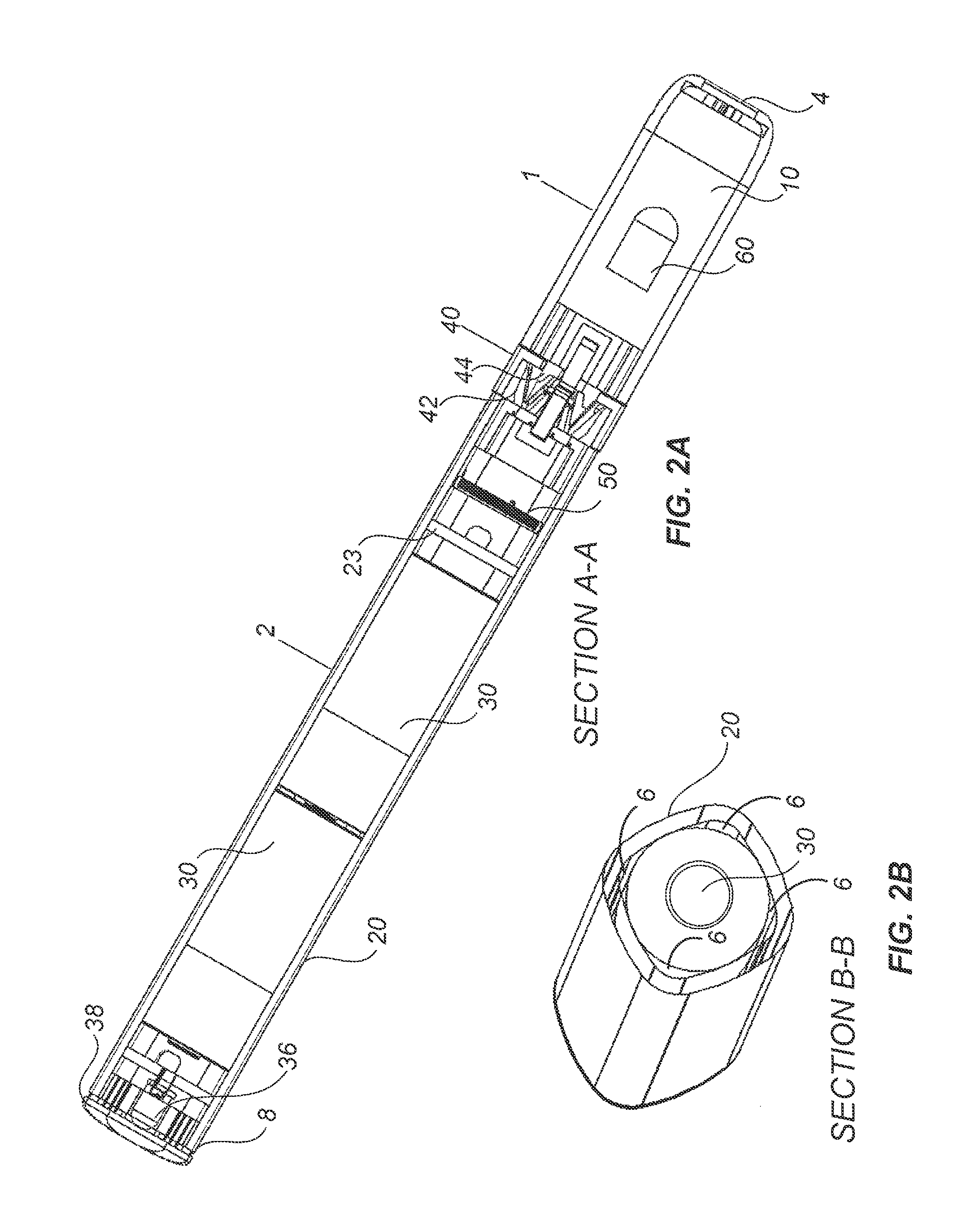

Electronic vaporizing device and methods for use

InactiveUS20130298905A1Increase heatImproved vaporizing capabilityTobacco devicesInhalatorsCelluloseBrick

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE

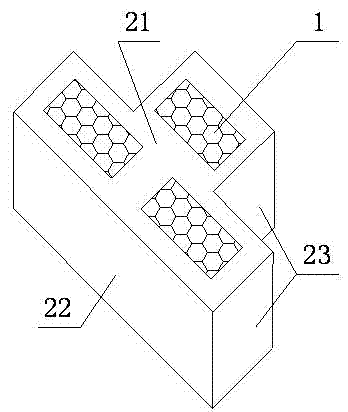

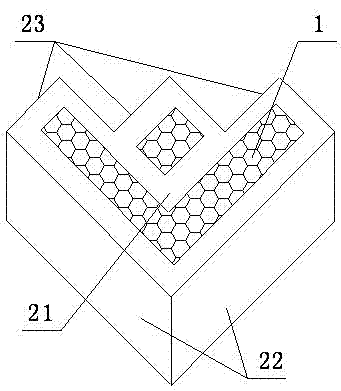

Self-insulation wall with high energy conservation property

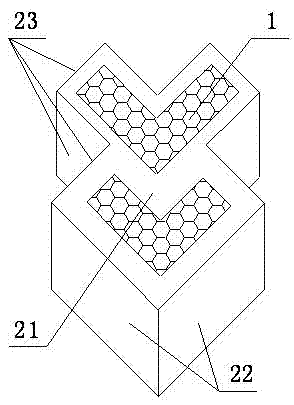

The invention discloses a self-insulation wall with a high energy conservation property, and belongs to the field of building wall materials. The self-insulation wall with the high energy conservation property is mainly characterized in that building blocks of a self-insulation wall body are shaped like a T, building blocks of a self-insulation right-angle wall corner are in a flower shape and a scissor shape, building blocks of a self-insulation T-shaped wall corner are provided with either a T-shaped top with a handle or a T-shaped bottom with a handle, when the wall body is built, one of every two horizontally adjacent self-insulation wall bricks is placed in a T shape, the other one is placed in a reverse T shape, when the right-angle wall corner is built, the flower-shaped and scissor-shaped building blocks of the self-insulation right-angle wall corner are alternatively placed, and when the T-shaped wall corner is built, the building blocks, provided with either the T-shaped top with the handle or the T-shaped bottom with the handle, of the self-insulation T-shaped wall corner are alternatively placed. The self-insulation wall with the high energy conservation property has the advantage of improving the energy conservation property.

Owner:SHANDONG UNIV OF SCI & TECH

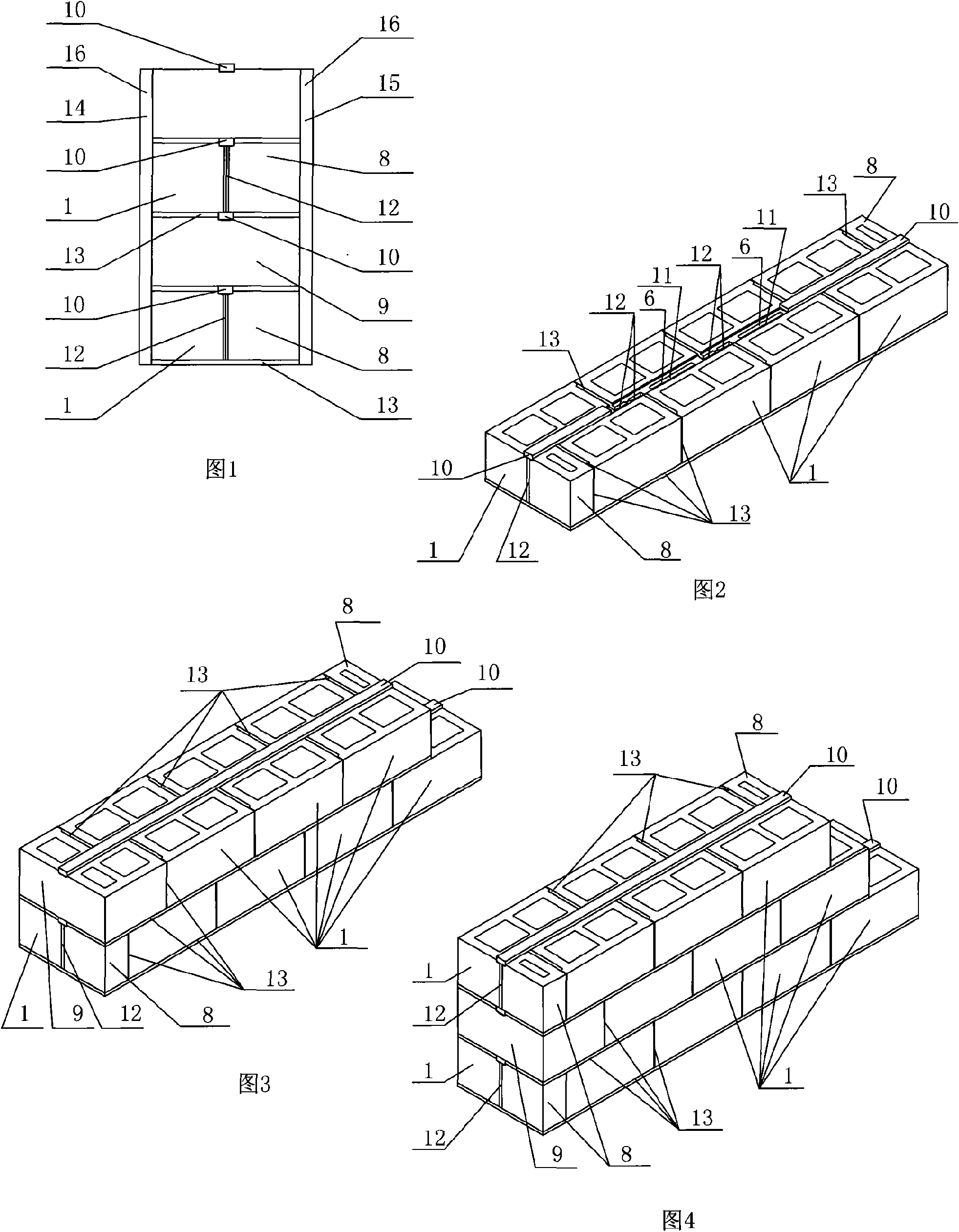

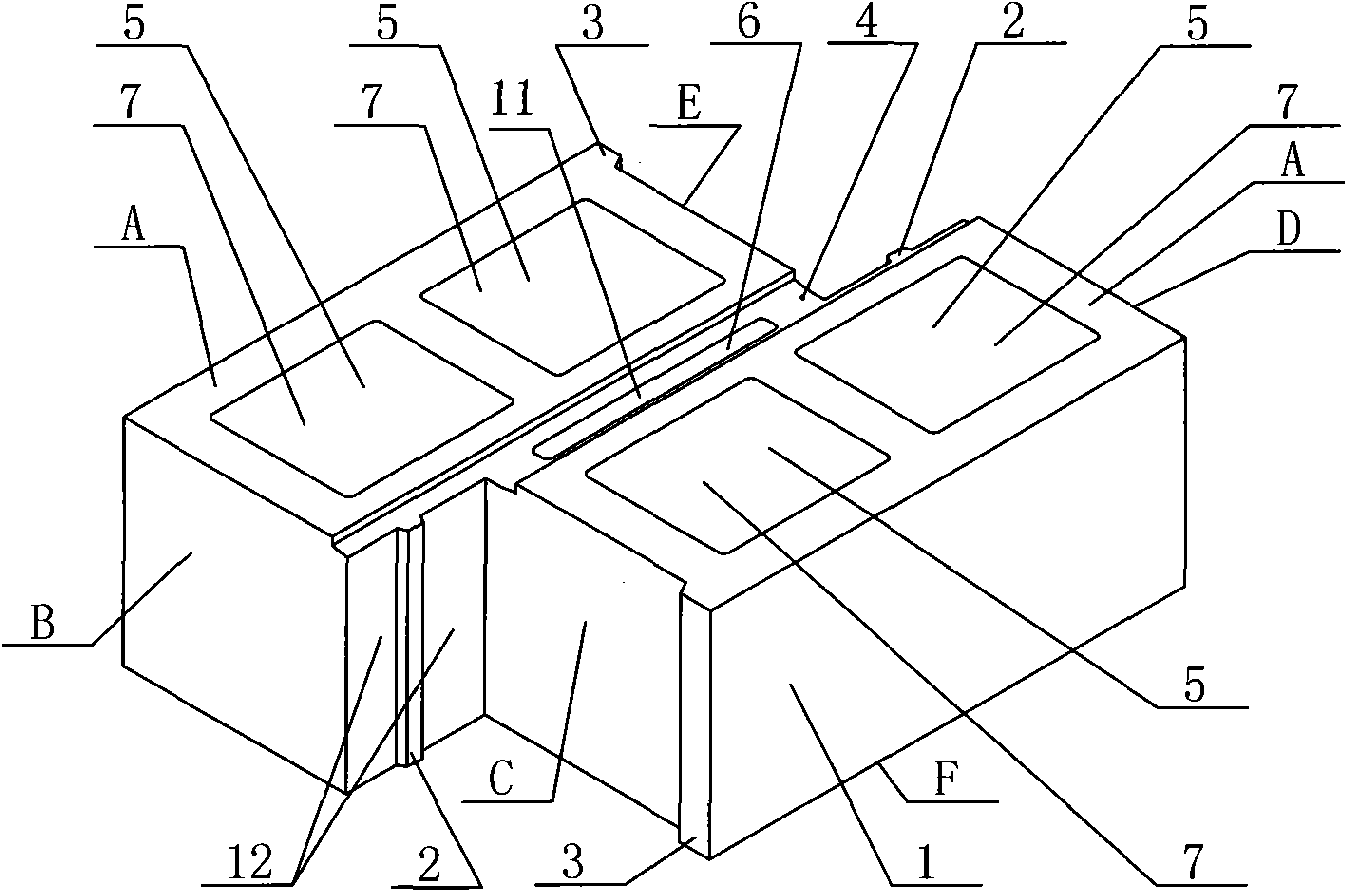

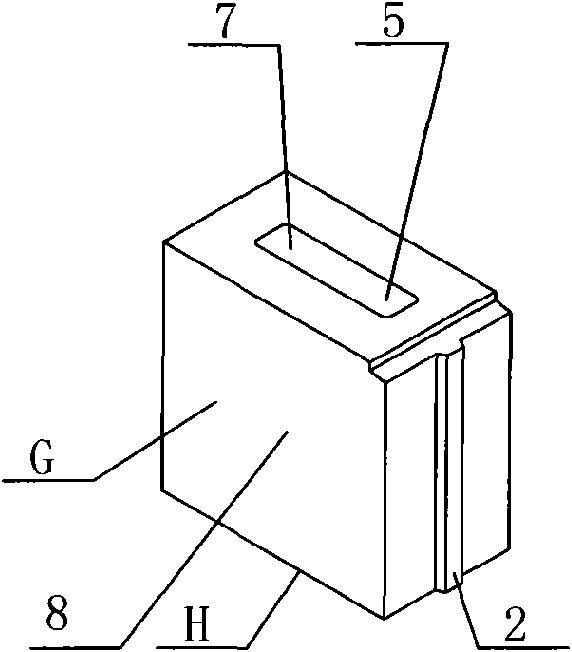

Technical method for building self-insulating and energy-saving wall with Z-shaped energy-saving building blocks

In the invention, the same clad bricks are laid in the forward direction, and a positioning convex platform 2 and a longitudinal positioning convex platform 3 are used for realizing transverse and longitudinal self-locking positioning, thereby naturally ensuring the designed thickness and surface smoothness of the wall, forming a combined still air layer 12 which is 9mm to 10mm wide and vertical to the ground, and further blocking heat bridges in vertical bricklaying seams. The cavity of a 28-30mm-wide groove 4 in the horizontal bricklaying seam between two clad bricks is filled with a broken bridge insulation board 10 which is as wide as the groove and has a thickness of 15mm; the broken bridge insulation board 10 is used for sealing a long-strip groove still air layer 11 and the combined still air layer 12 and cutting off the heat bridges in the horizontal bricklaying seams; the exposed part of broken bridge insulation board with a height of 10mm, is used for controlling the coating thickness of anti-crack masonry mortar 13 to be even and uniform. When the self-insulating and energy-saving wall is built, Z-shaped energy-saving building blocks 1 of the upper clad bricks and the lower bricks are laid in a staggered manner so as to cut off heat bridges in vertical bricklaying seams. The structure of the invention, with a reasonable thickness, can satisfy the requirement of saving 50 percent of energy in various regions, or even higher requiremets without an internal or external insulating layer of walls. Simultaneously, the structure is easy to build and the formation of the block shape effectively ensures the thickness of walls and the smoothness of wall surfaces. The thermal insulation function of the still air layer with a thickness of 10mm to 12mm strengthens the heat insulation effect. The insulation boards (28-30mm wide and 15mm thick) between the two clad bricks is capable of cutting off the heat bridge effects.

Owner:康玉范

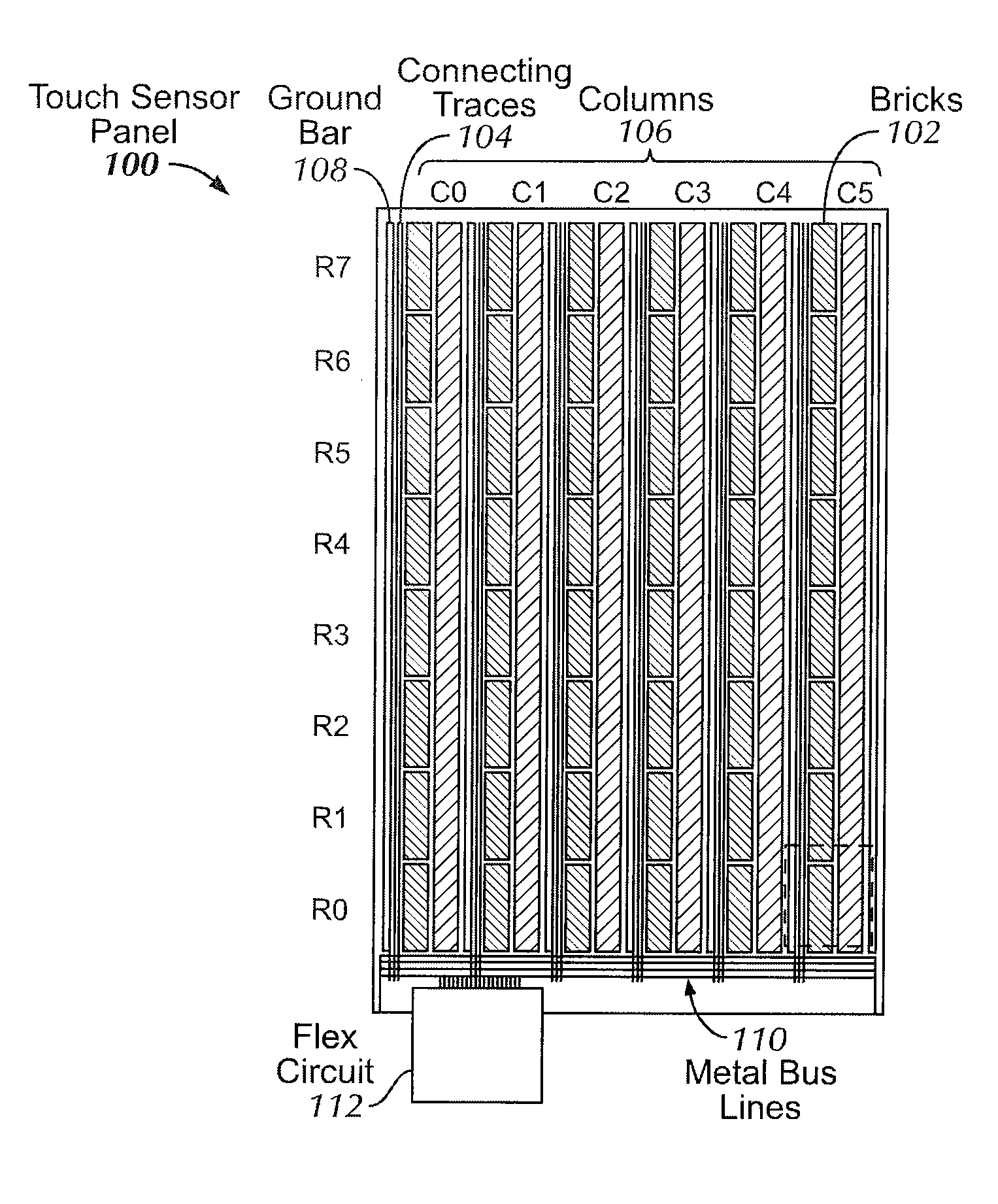

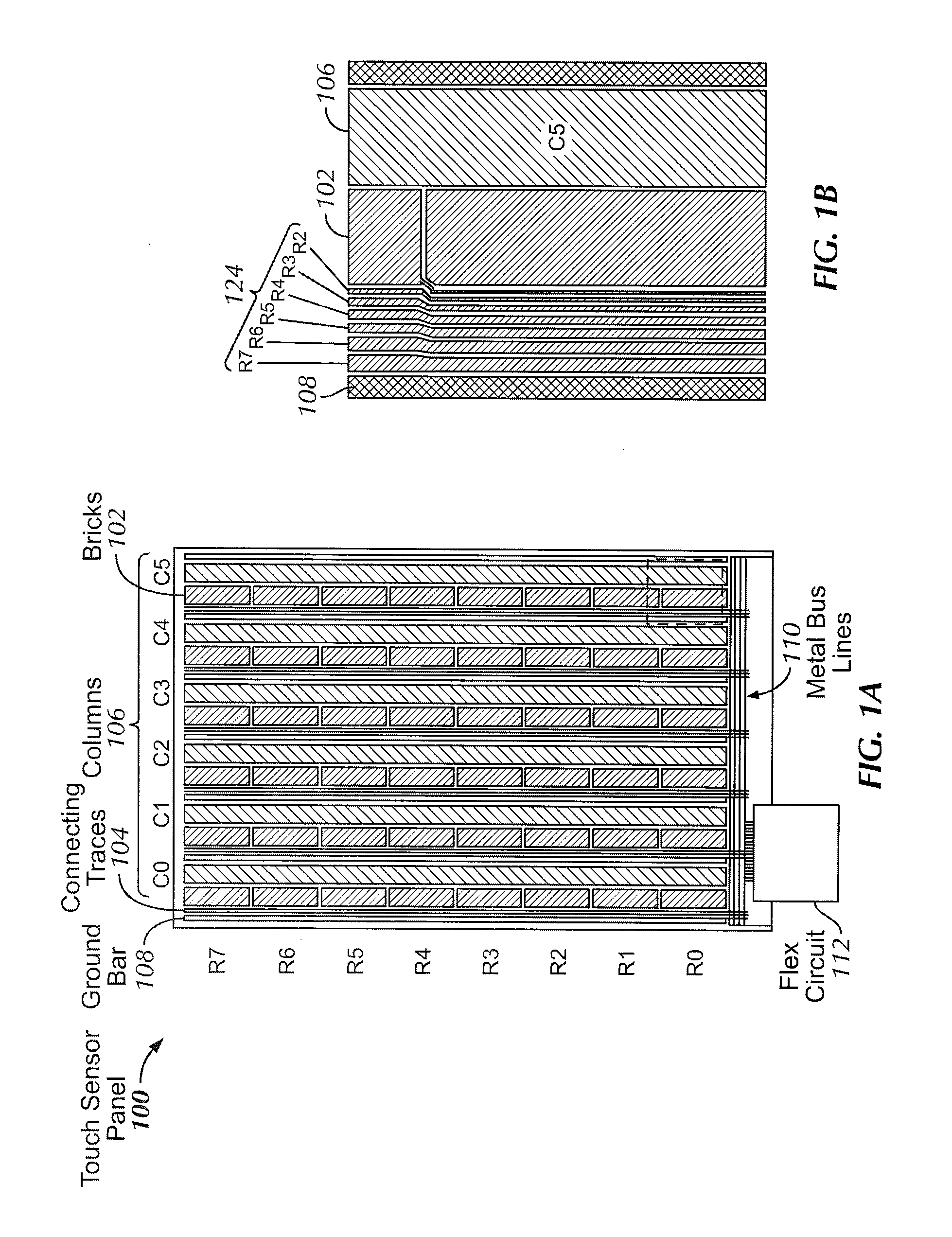

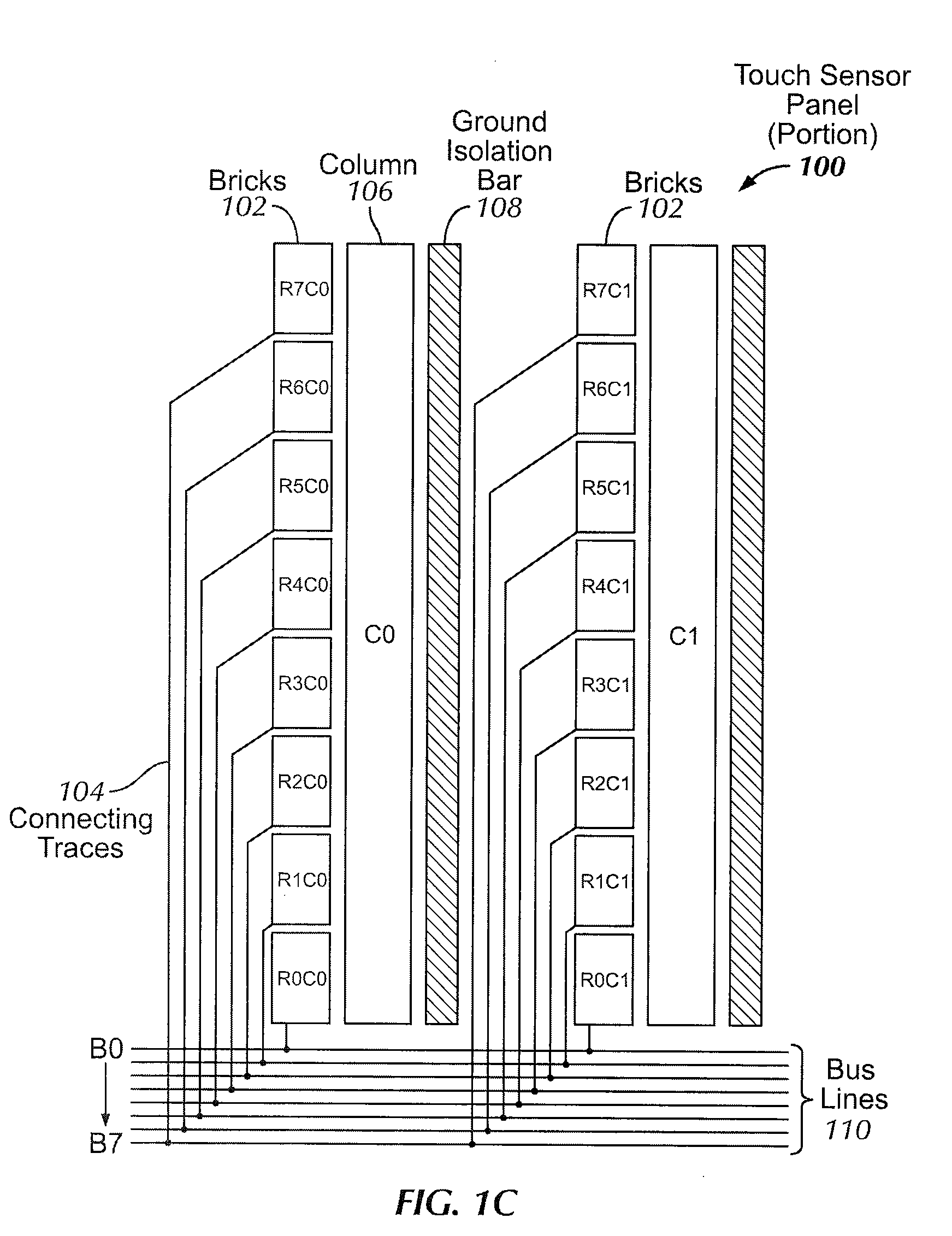

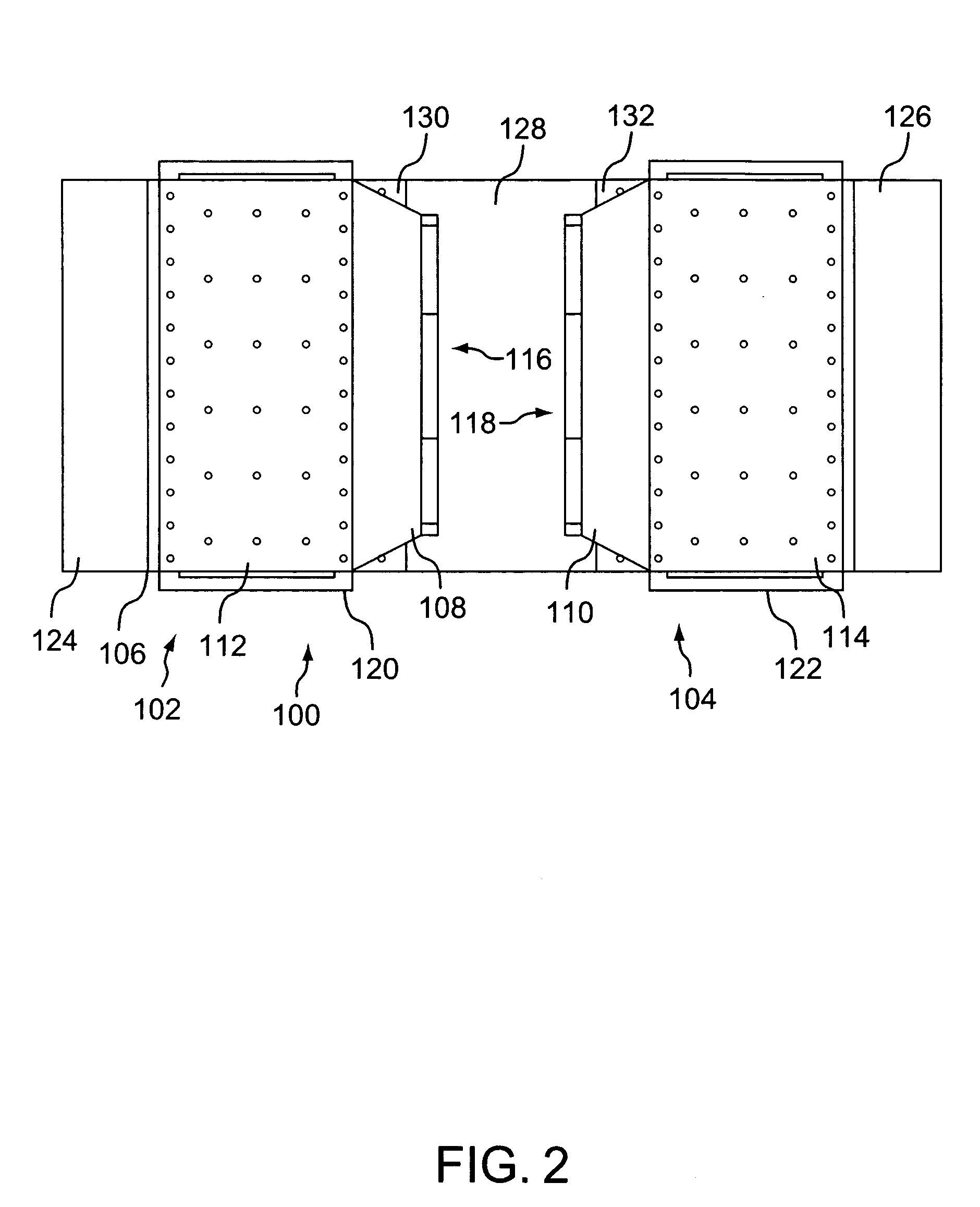

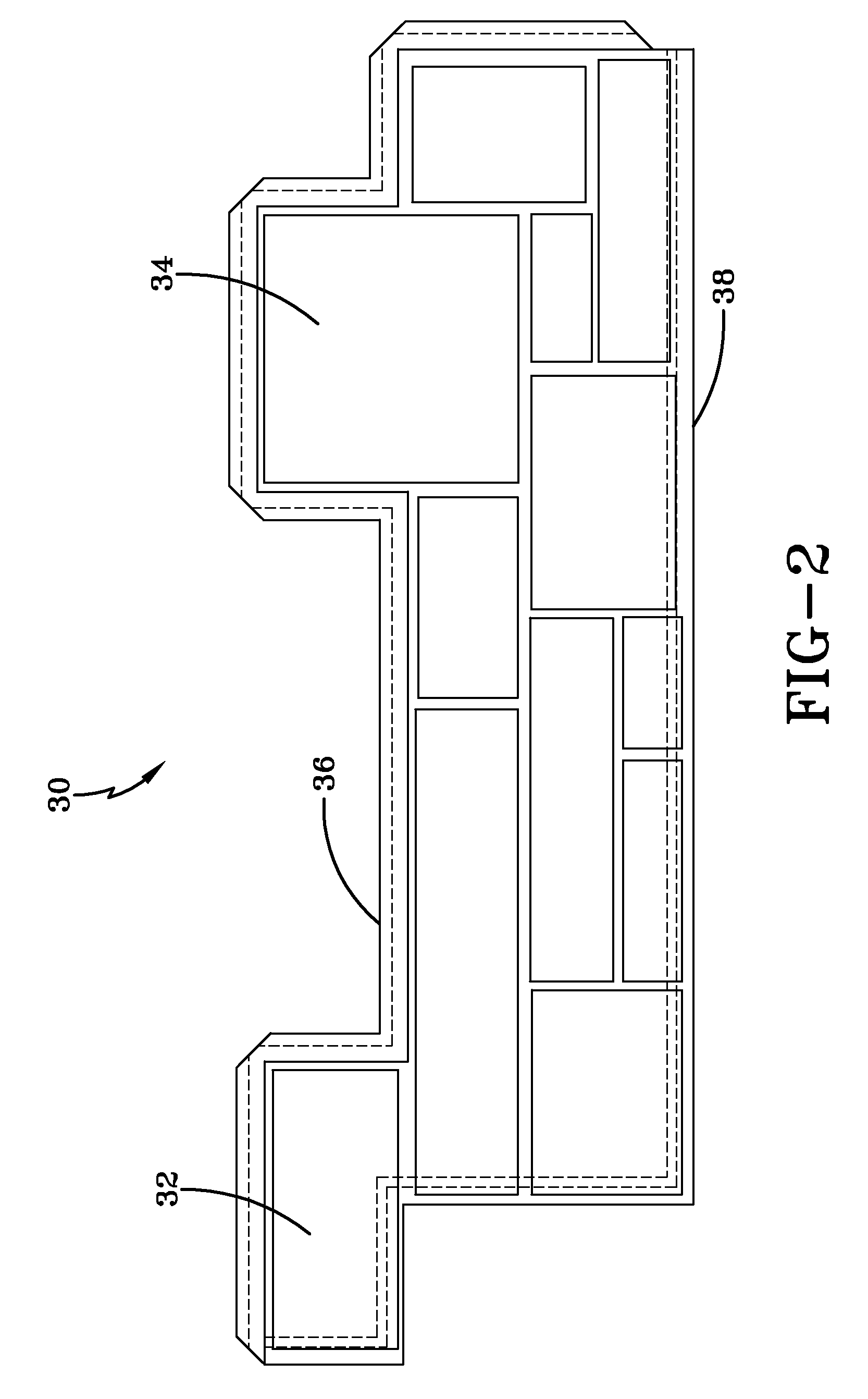

Brick Layout and Stackup for a Touch Screen

ActiveUS20090314621A1Reduce dynamic range budgetDifficult to makeElectronic switchingInput/output processes for data processingSensor arrayBrick

A touch sensor panel is disclosed having an array of co-planar single-layer touch sensors fabricated on a single side of a substrate. The sense (or drive) lines can be fabricated in a single strip as columnar or zig-zag patterns in a first orientation, and the drive (or sense) lines can be fabricated as rows of polygonal (e.g. brick-shaped or pentagonal) conductive areas in a second orientation. Each sense (or drive) line in the first orientation can be coupled to a separate metal trace in the border area of the touch sensor panel, and each polygonal area in the second orientation can also be coupled to a metal trace in the border area of the touch sensor panel. The metal traces can allow both the row and column lines to be routed to the same edge of the substrate for flex circuit attachment.

Owner:APPLE INC

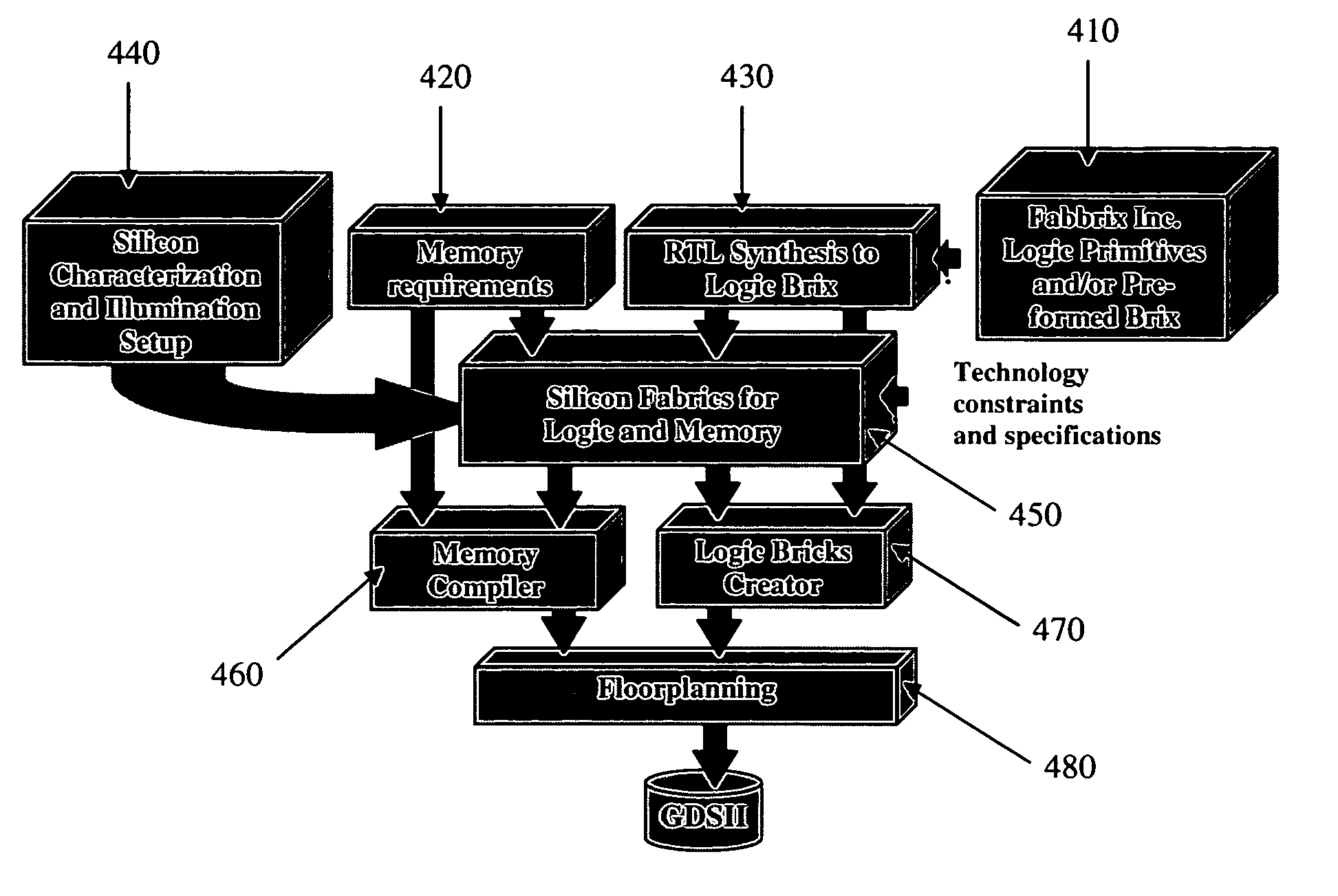

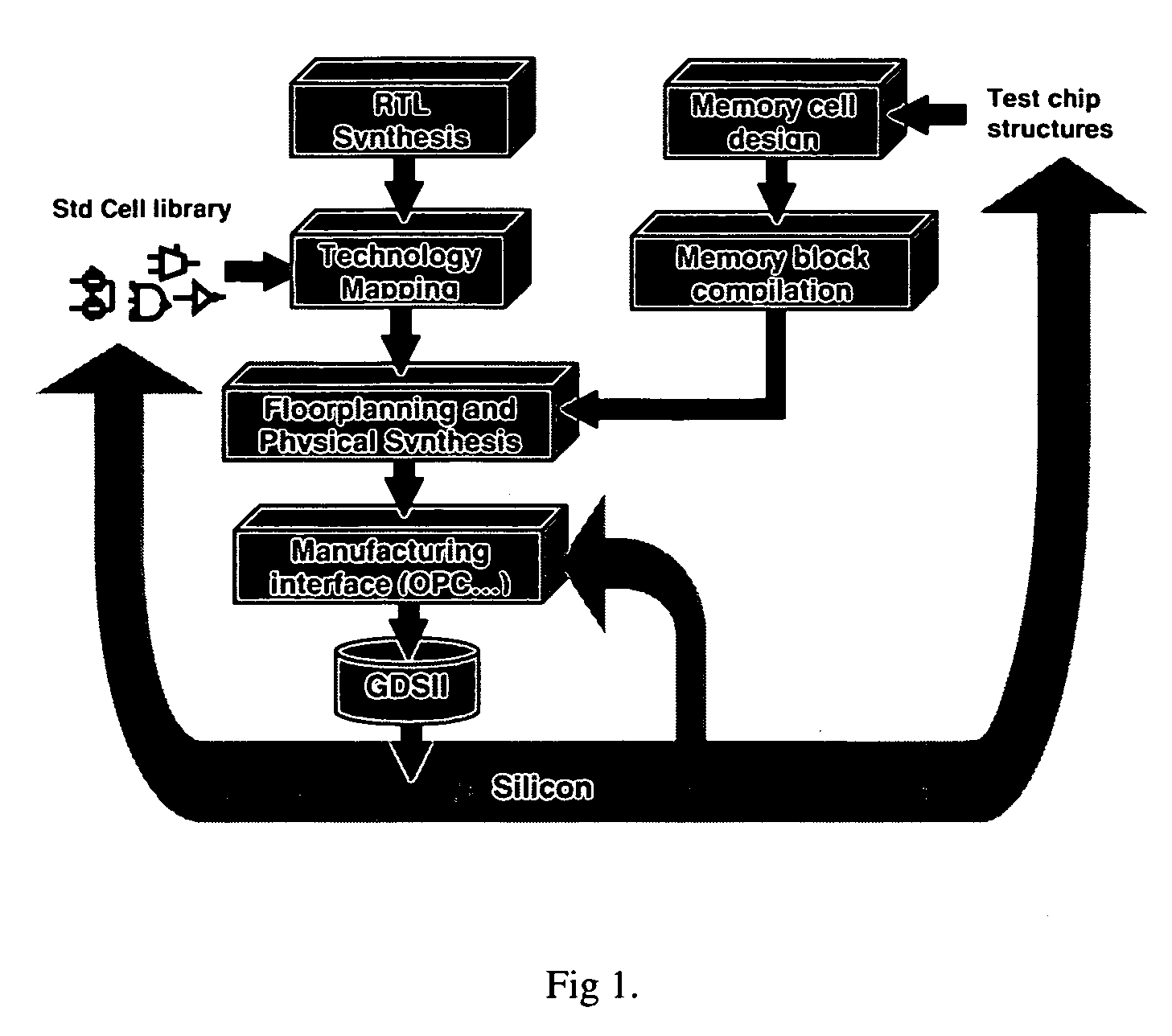

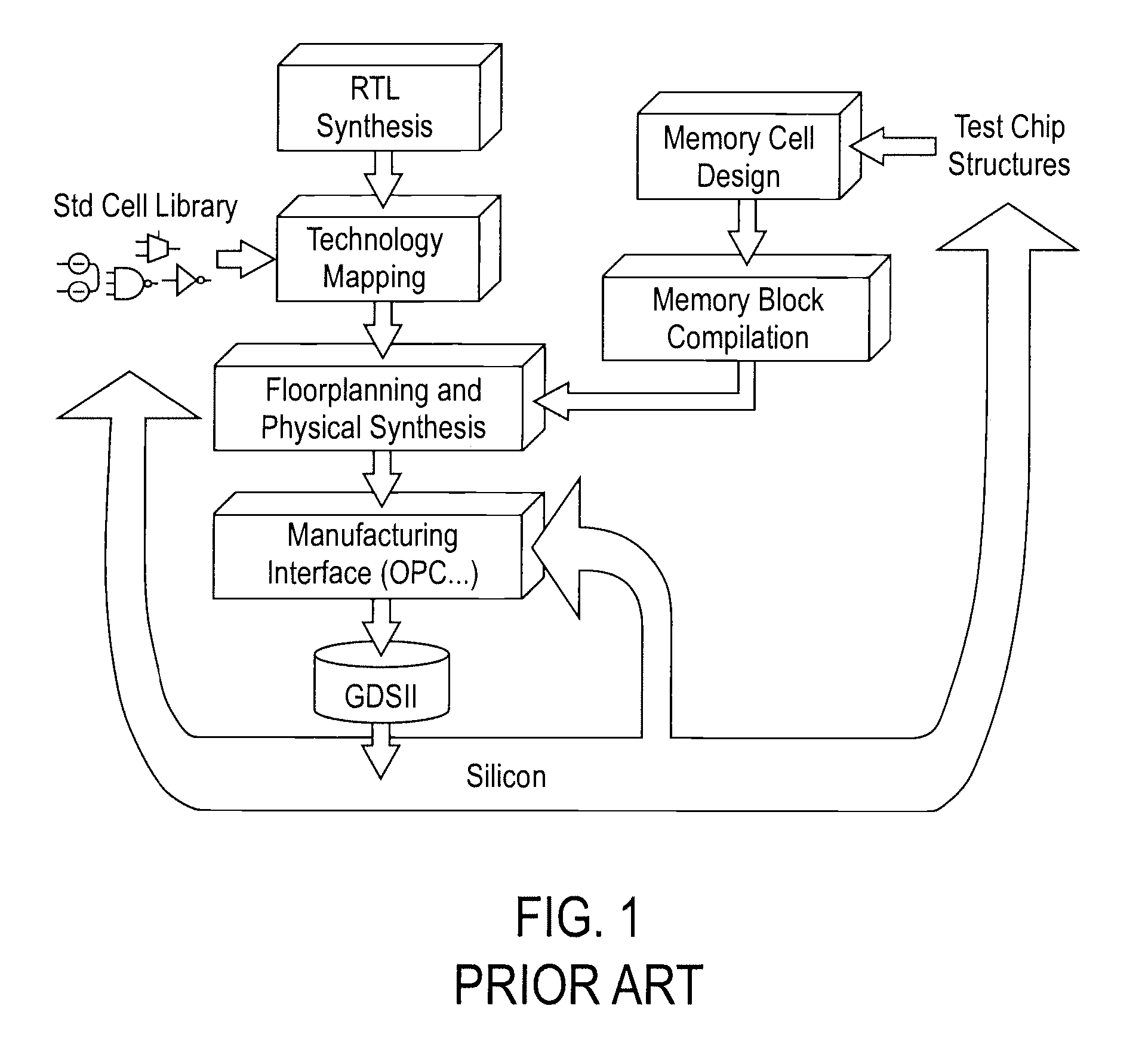

Method and process for design of integrated circuits using regular geometry patterns to obtain geometrically consistent component features

ActiveUS20060112355A1CAD circuit designSpecial data processing applicationsComputer architectureBrick

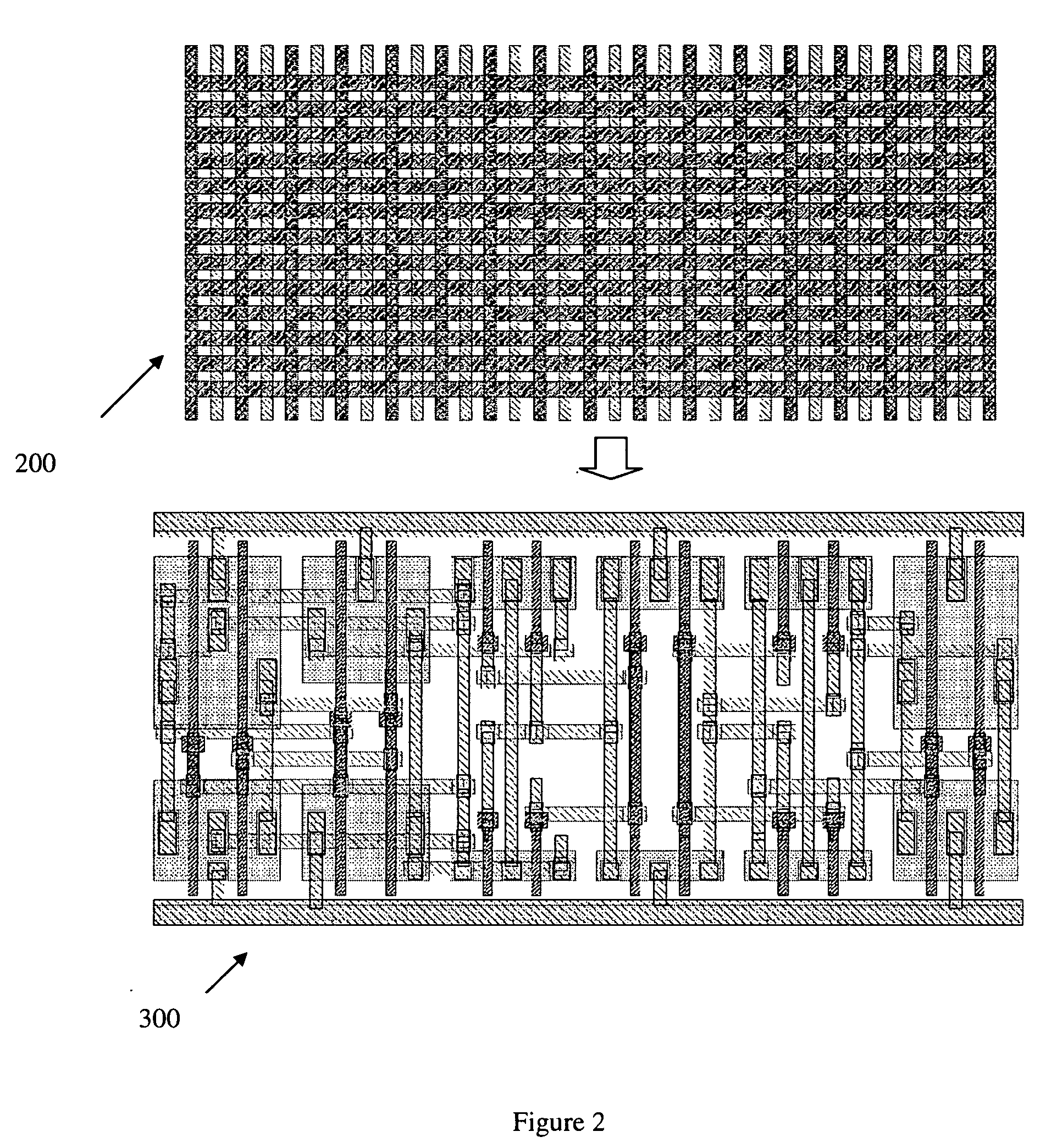

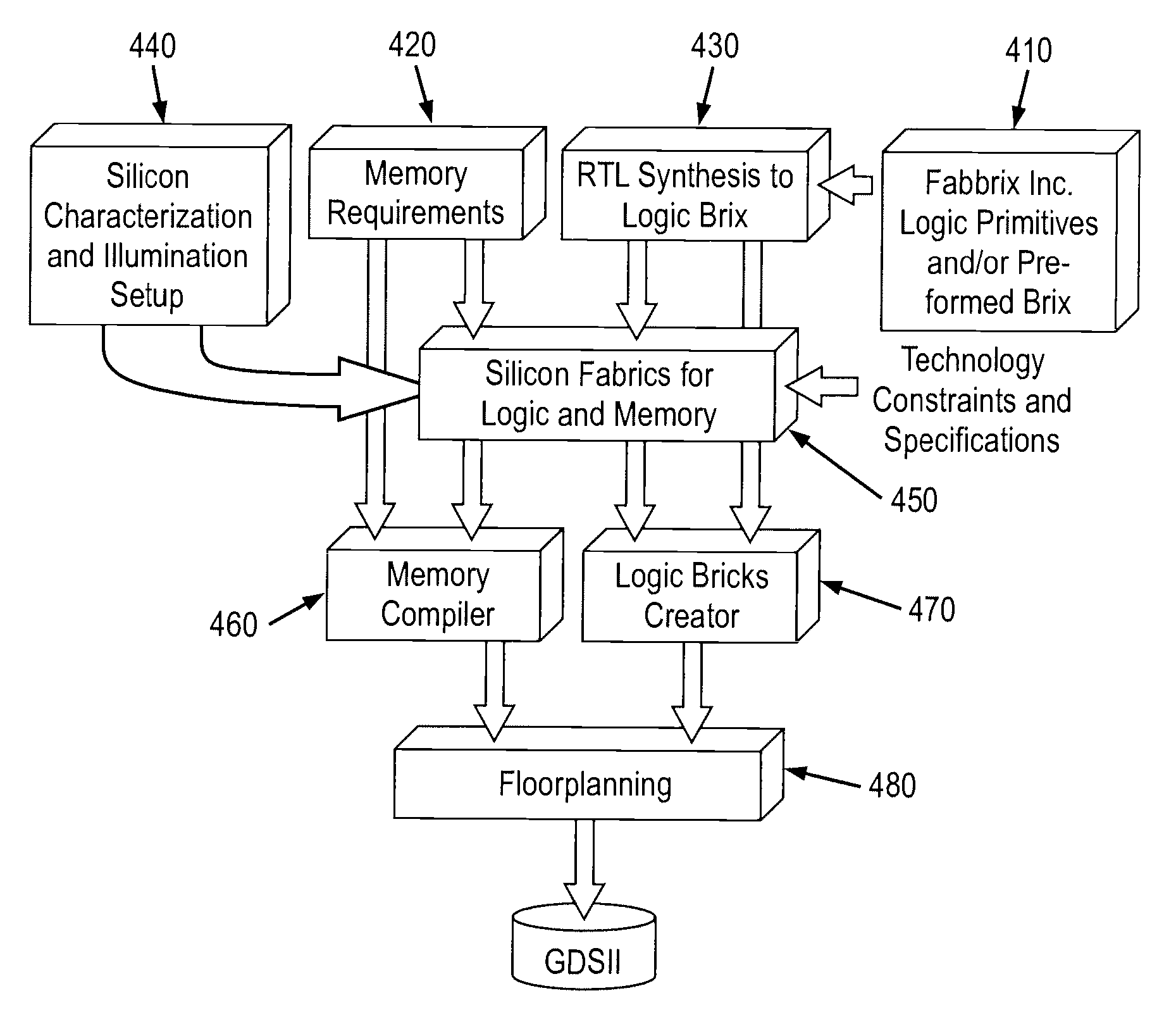

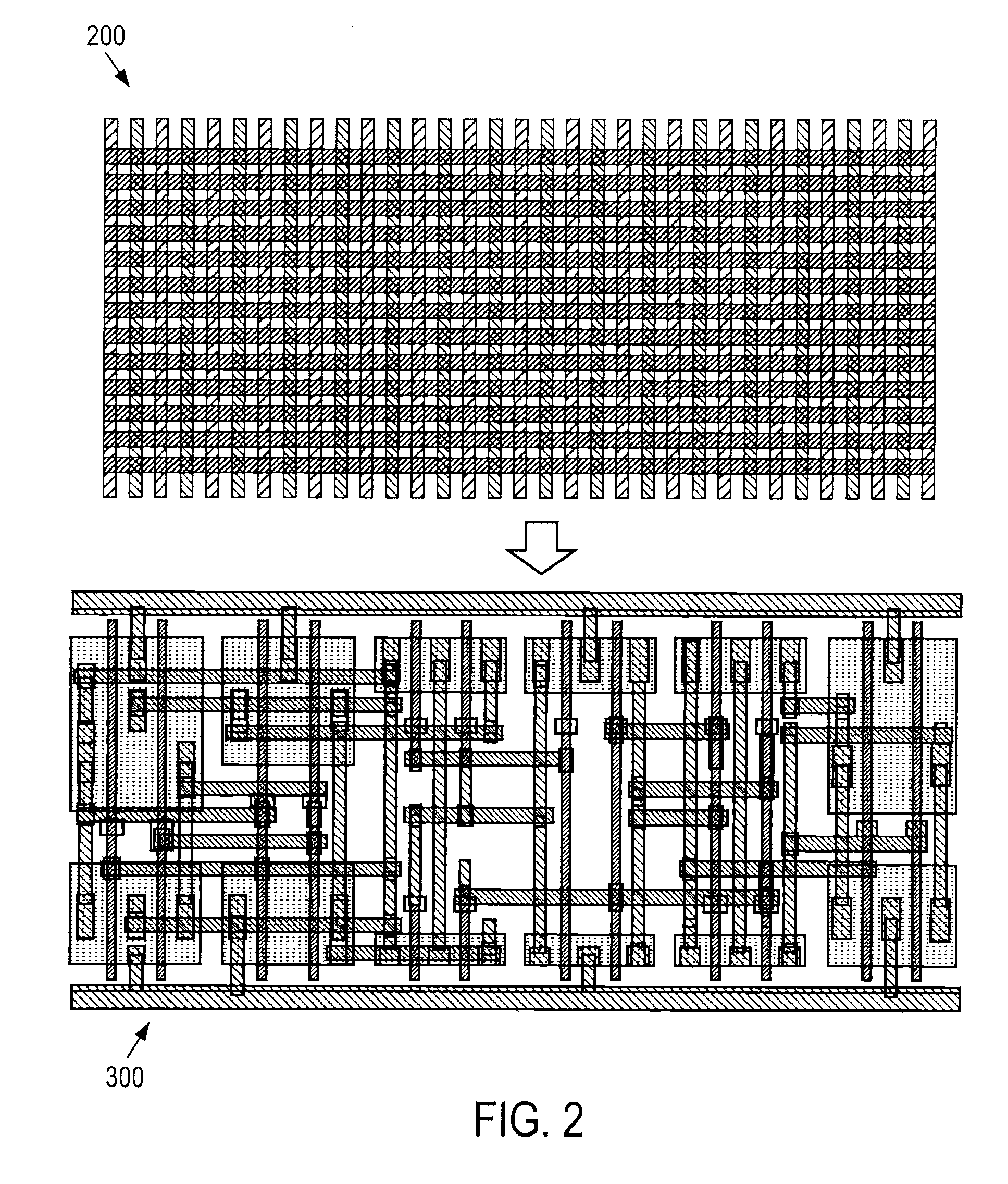

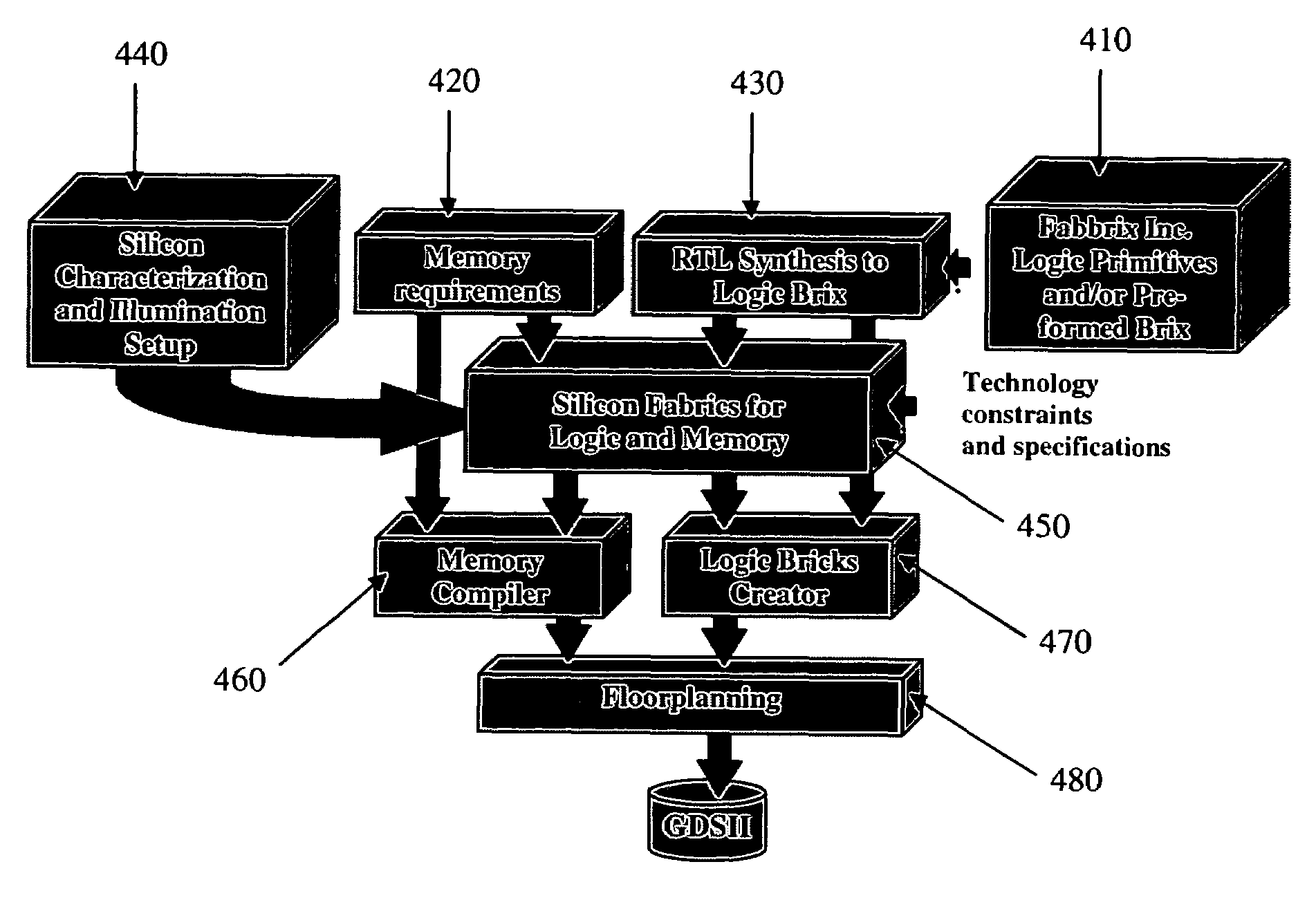

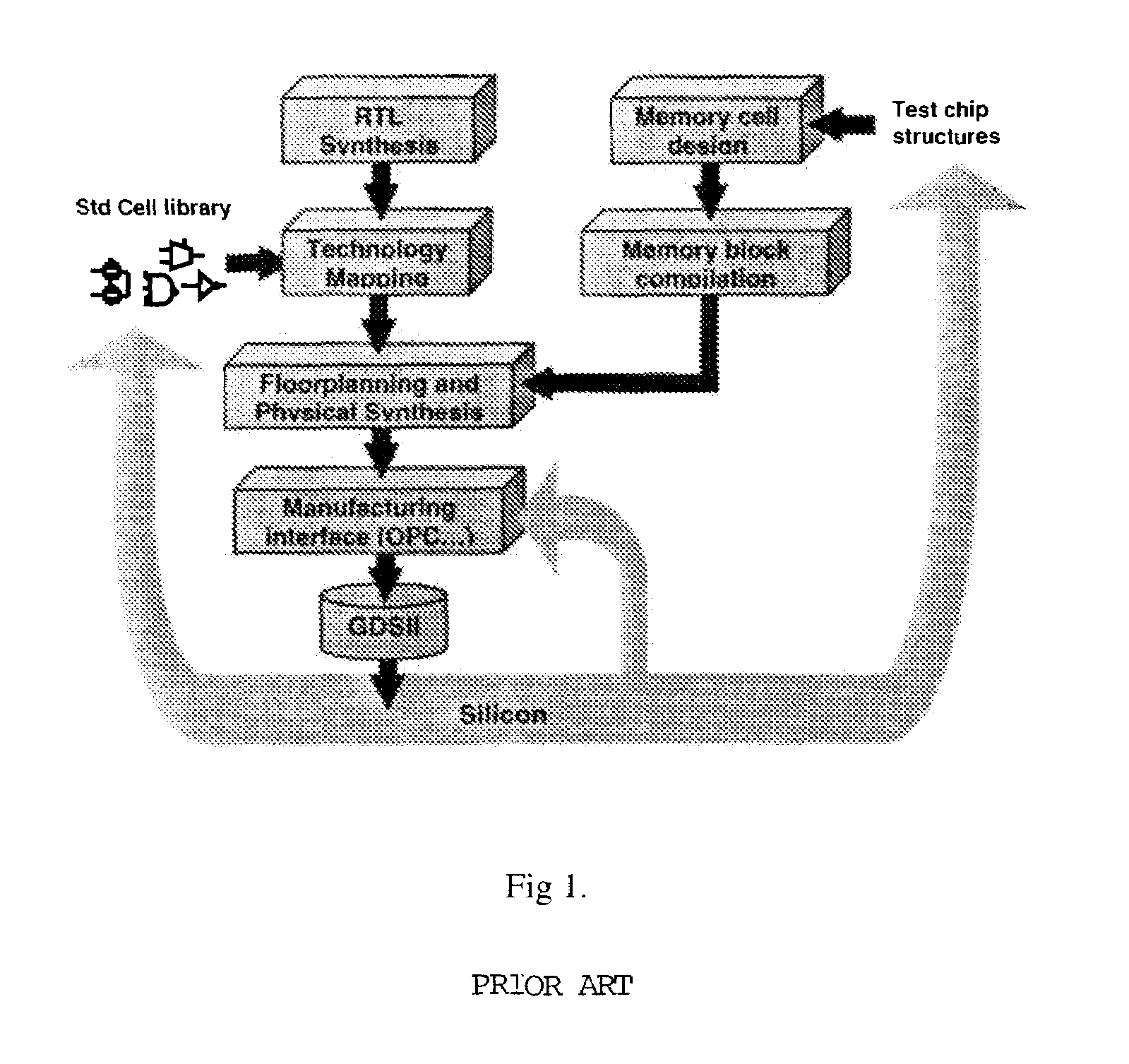

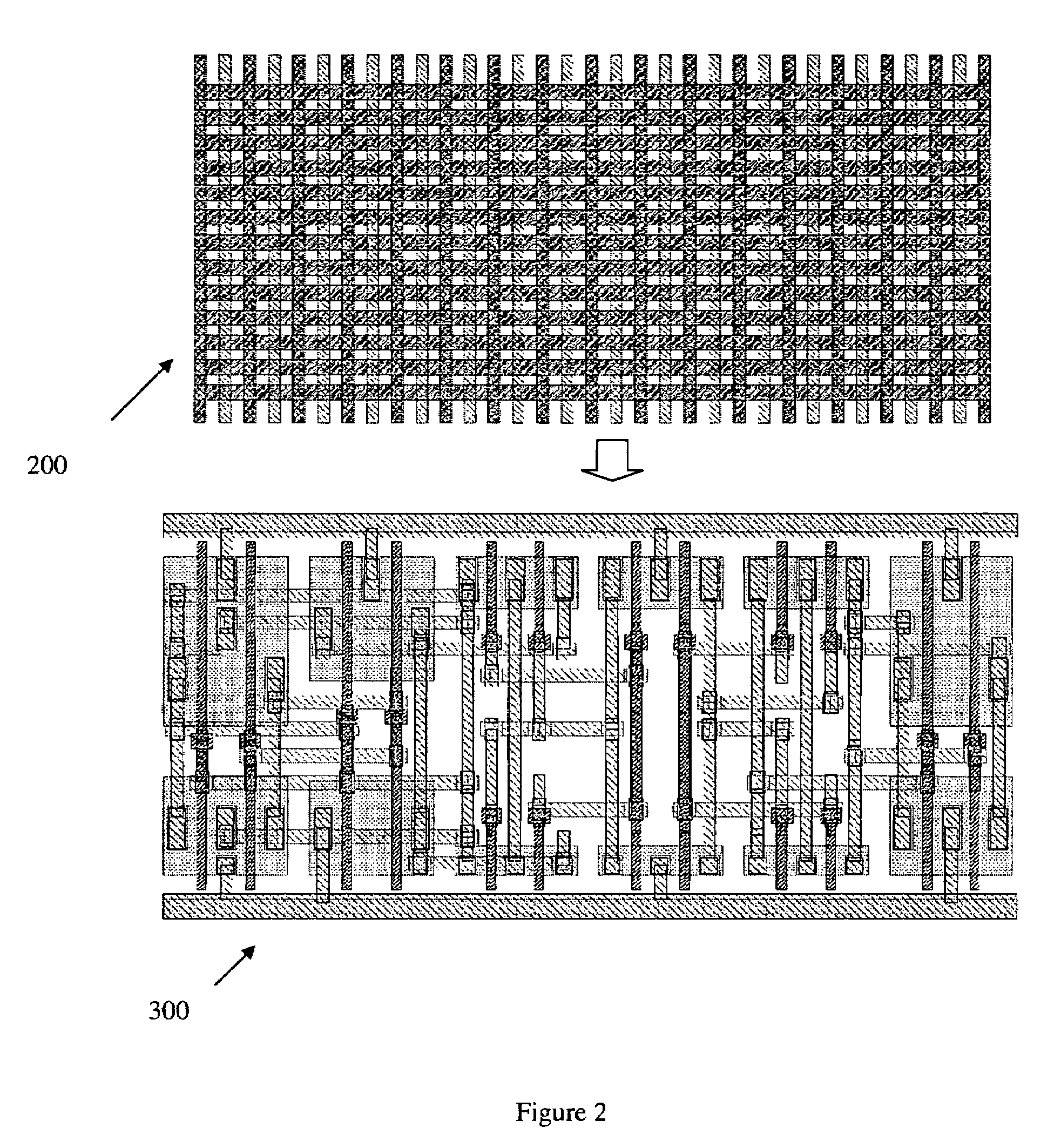

The invention provides a method and process for designing an integrated circuit based on using the results from both 1) a specific set of silicon test structure characterizations and 2) the decomposition of logic into combinations of simple logic primitives, from which a set of logic bricks are derived that can be assembled for a manufacturable-by-construction design. This implementation of logic is compatible with the lithography settings that are used for implementation of the memory blocks and other components on the integrated circuit, particularly by implementing geometrically consistent component features. The invention provides the ability to recompile a design comprised of logic and memory blocks onto a new geometry fabric to implement a set of technology-specific design changes, without requiring a complete redesign of the entire integrated circuit.

Owner:PDF SOLUTIONS INC

Method and process for design of integrated circuits using regular geometry patterns to obtain geometrically consistent component features

InactiveUS20080098334A1CAD circuit designOriginals for photomechanical treatmentComputer architectureBrick

The invention provides a method and process for designing an integrated circuit based on using the results from both 1) a specific set of silicon test structure characterizations and 2) the decomposition of logic into combinations of simple logic primitives, from which a set of logic bricks are derived that can be assembled for a manufacturable-by-construction design. This implementation of logic is compatible with the lithography settings that are used for implementation of the memory blocks and other components on the integrated circuit, particularly by implementing geometrically consistent component features. The invention provides the ability to recompile a design comprised of logic and memory blocks onto a new geometry fabric to implement a set of technology-specific design changes, without requiring a complete redesign of the entire integrated circuit.

Owner:PDF SOLUTIONS INC

Method and process for design of integrated circuits using regular geometry patterns to obtain geometrically consistent component features

The invention provides a method and process for designing an integrated circuit based on using the results from both 1) a specific set of silicon test structure characterizations and 2) the decomposition of logic into combinations of simple logic primitives, from which a set of logic bricks are derived that can be assembled for a manufacturable-by-construction design. This implementation of logic is compatible with the lithography settings that are used for implementation of the memory blocks and other components on the integrated circuit, particularly by implementing geometrically consistent component features. The invention provides the ability to recompile a design comprised of logic and memory blocks onto a new geometry fabric to implement a set of technology-specific design changes, without requiring a complete redesign of the entire integrated circuit.

Owner:PDF SOLUTIONS INC

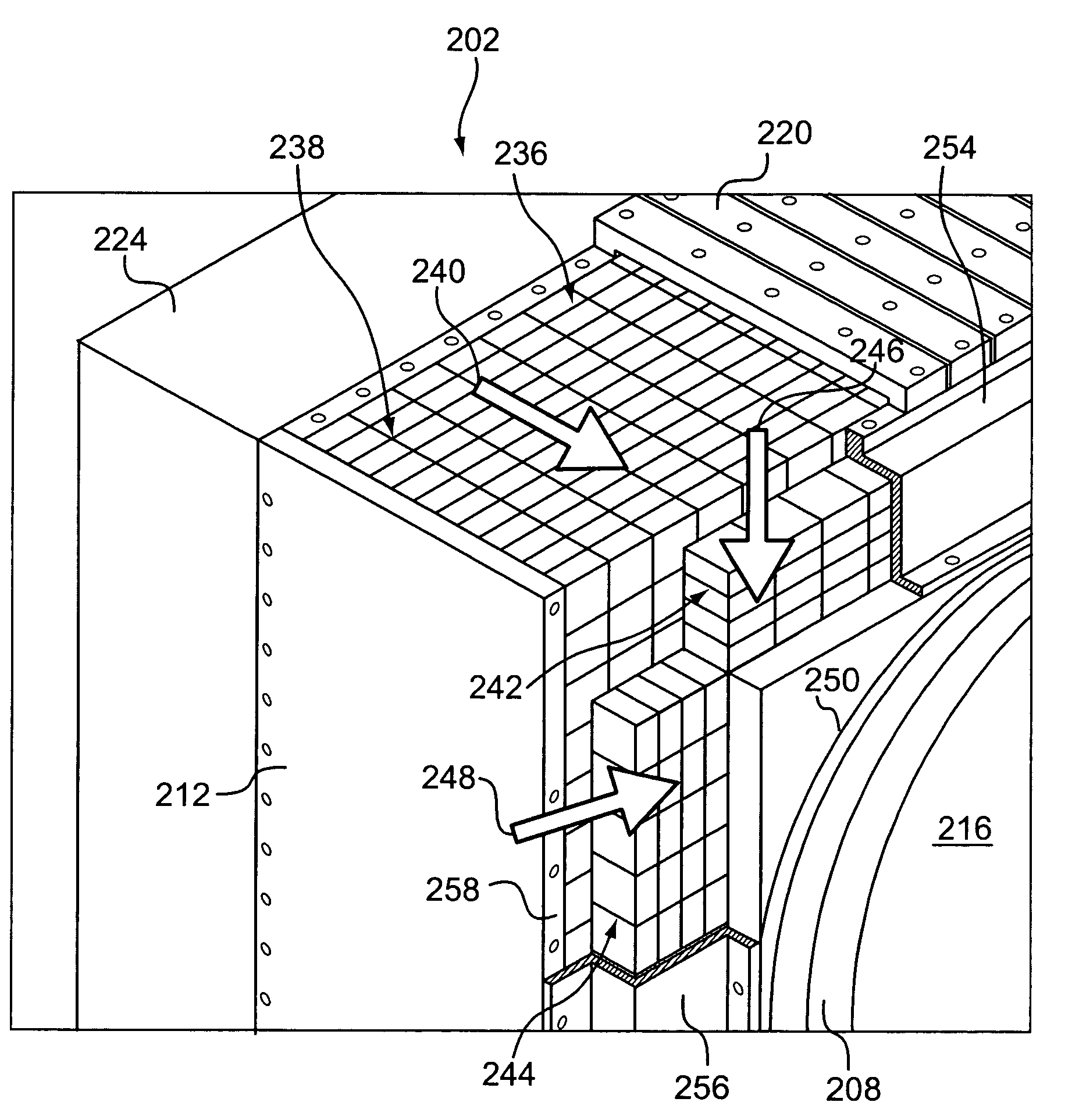

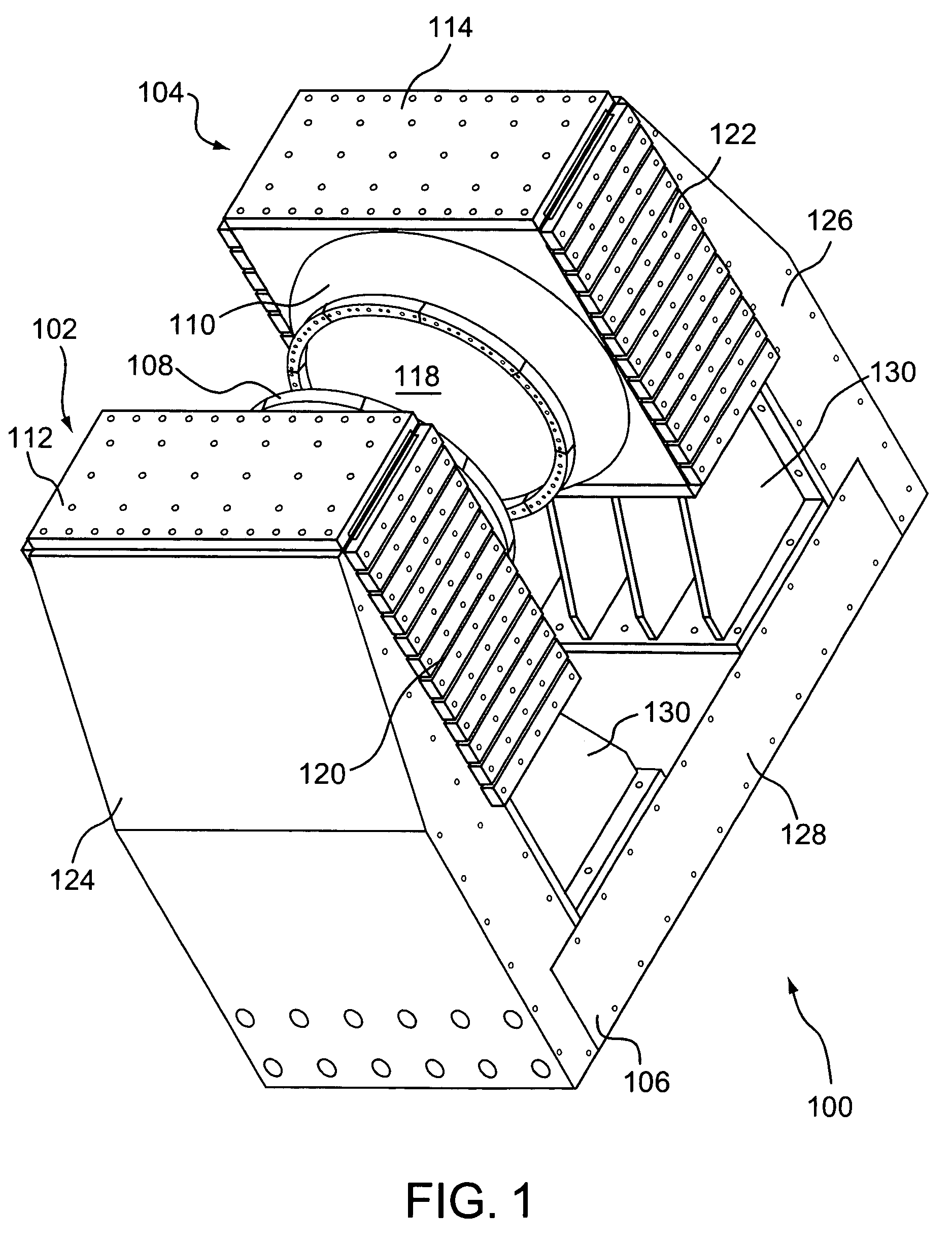

Magnet structure

A magnet structure produces a field within a magnet gap. The field is provided at least in part by a pair of permanent magnets that are fixed in place by a frame. The frame fixes a magnet assembly that is adapted to hold the magnetic material composing the permanent magnets, such that the quantity of the magnetic material can be adjusted to suit the particular application. The magnetic material can be provided in the form of discrete magnetic elements, such as magnetic “bricks”. The frame also functions as the flux collector and return. Accordingly, the general geometry of the magnet structure is fixed, and the amount of magnetic material, and therefore the magnetic field strength, is adjustable.

Owner:FONAR

Electronic vaporizing device and methods for use

Devices and methods for vaporizing active ingredients of a selected substance for inhalation using a portable vaporization device are provided herein. In certain aspects, the device includes a portable power source, a heating portion, an inhalation sensor, a temperature sensor, a distal light source, and a grinding portion. In response to an inhalation by a user, the power source energizes a heating element of the heating portion so as to heat air flow to a desired vaporization temperature within a few seconds of detecting inhalation, using convection and radiative heating. The device may include a receptacle for receiving a cartridge containing a pre-prepared substance, such as a liquid, gel, powder, or solid brick, and a grinding portion to allow a user to grind intact portions of cellulose-based material into smaller pieces to facilitate vaporization by manually rotating portions of the device relative to each other.

Owner:UPTOKE LLC

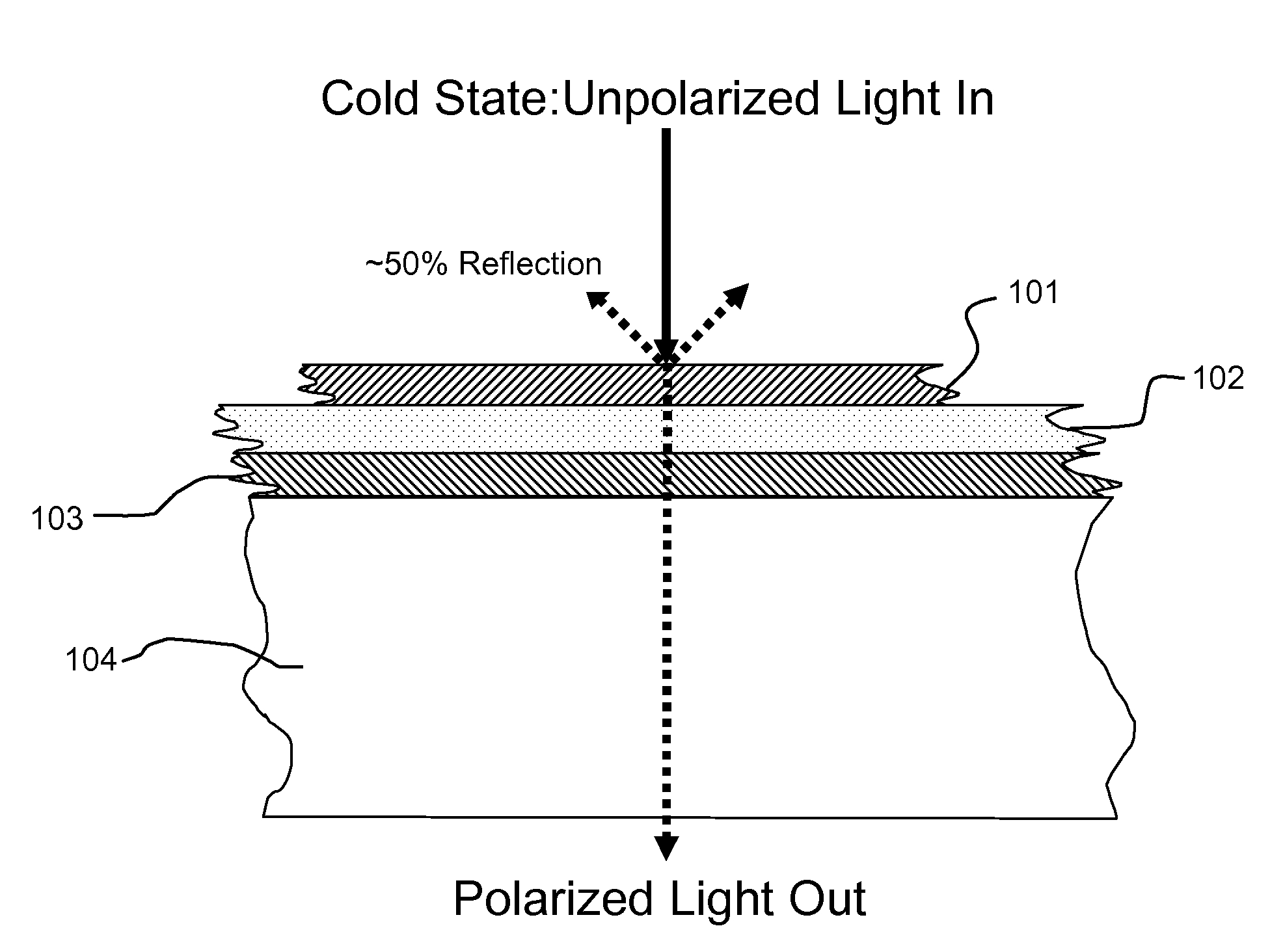

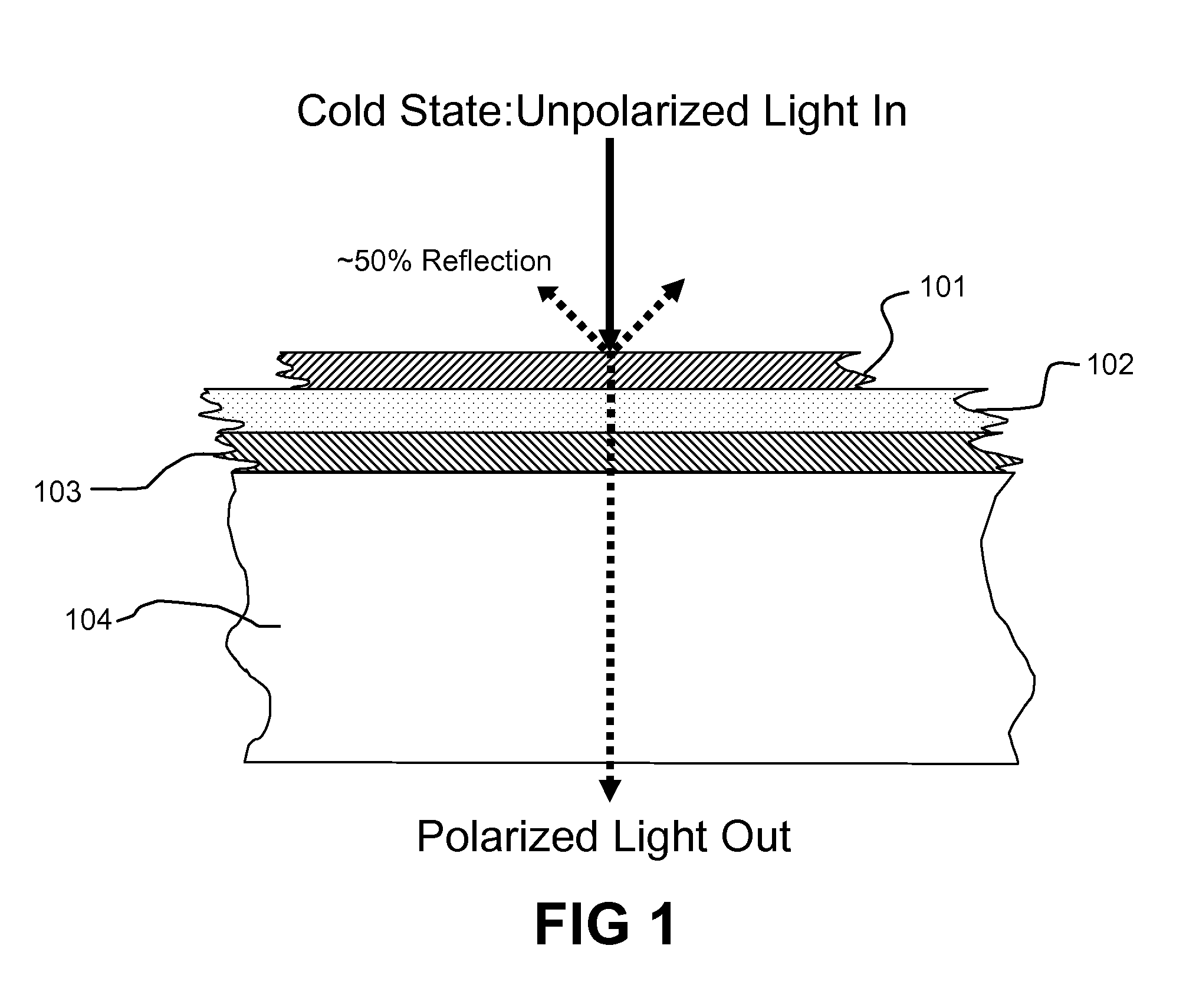

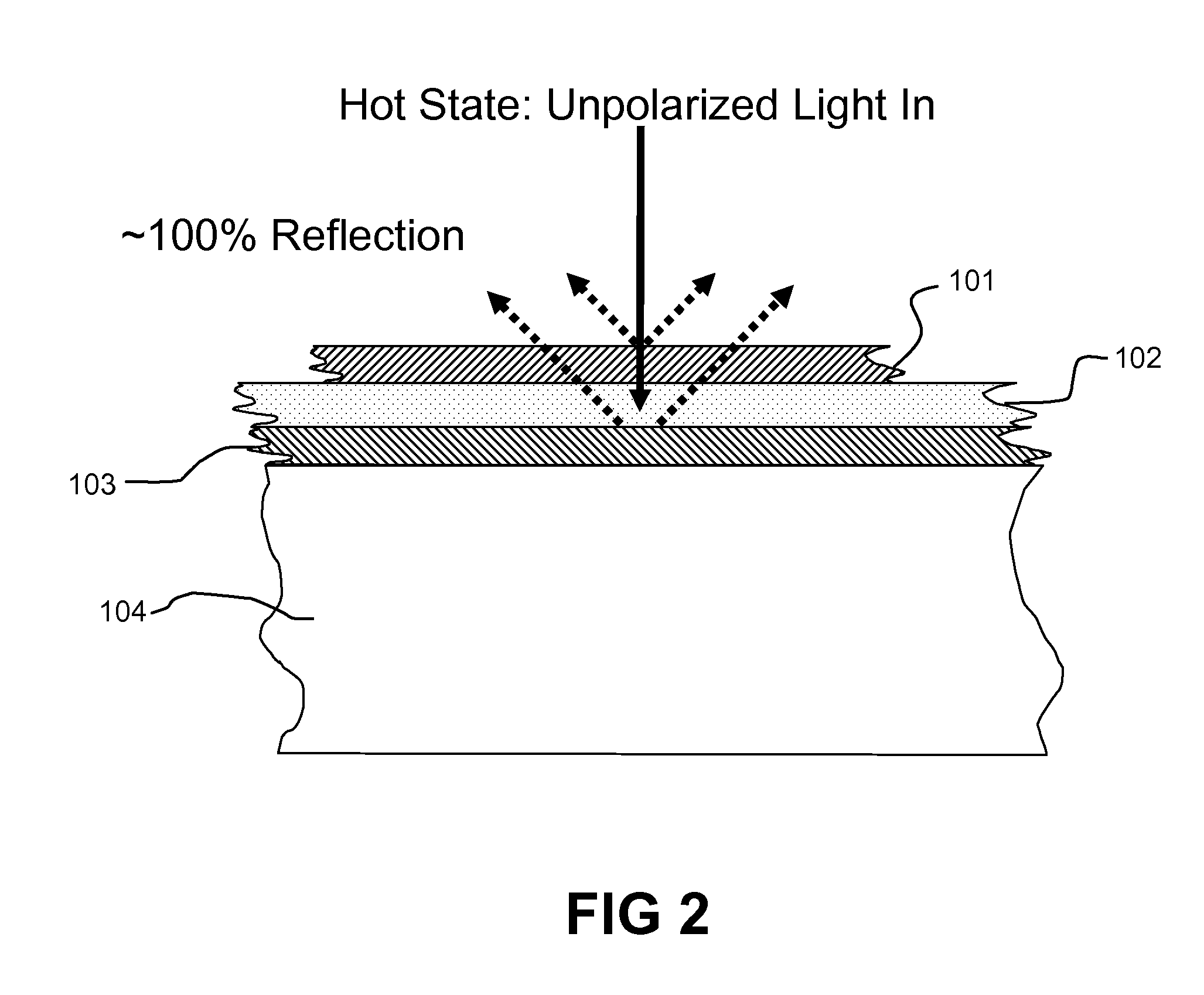

Thermally Switched Reflective Optical Shutter

The thermally switched reflective optical shutter is a self-regulating “switchable mirror” device that reflects up to 100% of incident radiant energy above a threshold temperature, and reflects up to 50% of incident radiant energy below a threshold temperature. Control over the flow of radiant energy occurs independently of the thermal conductivity or insulating value of the device, and may or may not preserve the image and color properties of incoming visible light. The device can be used as a construction material to efficiently regulate the internal temperature and illumination of buildings, vehicles, and other structures without the need for an external power supply or operator signals. The device has unique aesthetic optical properties that are not found in traditional windows, skylights, stained glass, light fixtures, glass blocks, bricks, or walls. The device can be tailored to transmit sufficient visible light to see through in both the transparent and reflective states, while still providing significant control over the total energy transmission across the device.

Owner:RAVENBRICK

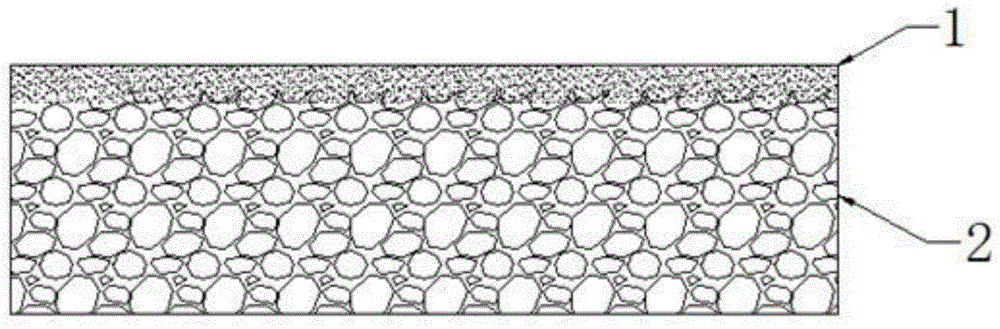

Ceramsite water permeable brick and preparation method thereof

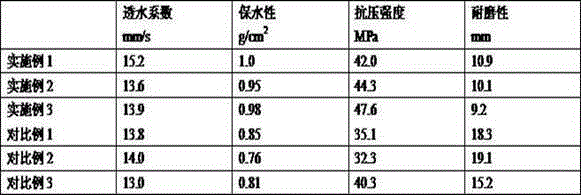

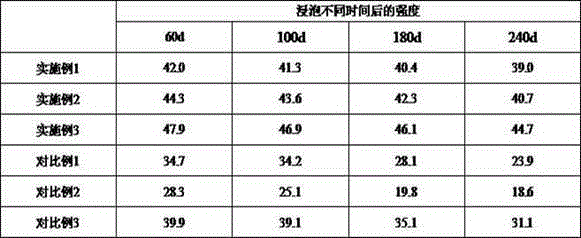

The invention provides a ceramsite water permeable brick, which comprises the following components by weight: 80-100 parts of ceramsite, 10-15 parts of silicon sand, 20-40 parts of cement, a setting accelerator accounting for 2-4% of the weight of the ceramsite, and a water reducing agent accounting for 2-4% of the weight of the ceramsite. According to the invention, silicon sand dust made ceramsite is combined with a small quantity of cement, the setting accelerator, the water reducing agent and a silicon sand fabric to manufacture the ceramsite water permeable brick. One the one hand, the water permeable brick has a beautiful appearance, and on the other hand it combines the lightweight and high strength characteristics of ceramsite. At the same time, ceramsite is round stone rather than polygonal, and usually the gap between round objects is larger than that between polygonal objects, so that the prepared water permeable brick has good permeability effect. The water permeable brick prepared by the method has compressive strength of greater than or equal to 30Mpa and a permeability coefficient of greater than or equal to 0.05cm / s, and the other properties of the brick meet the JCT945-2005 industrial standard.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

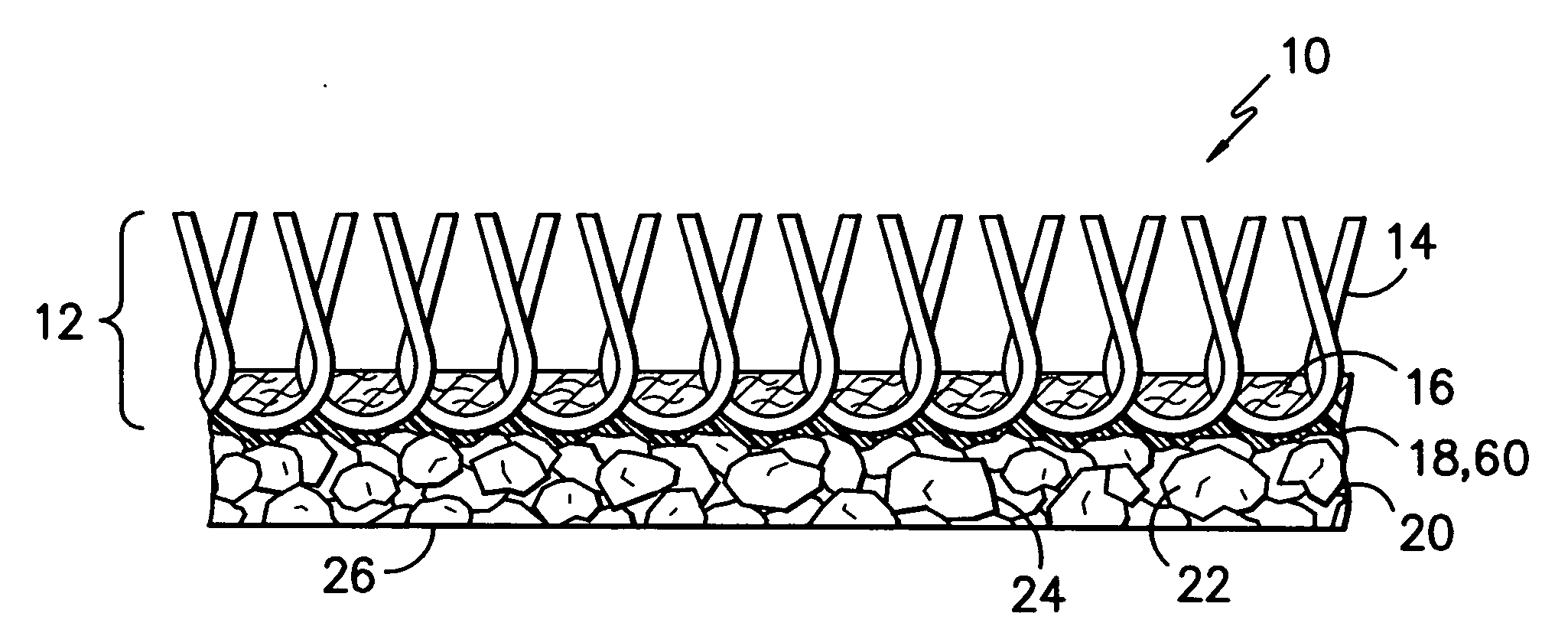

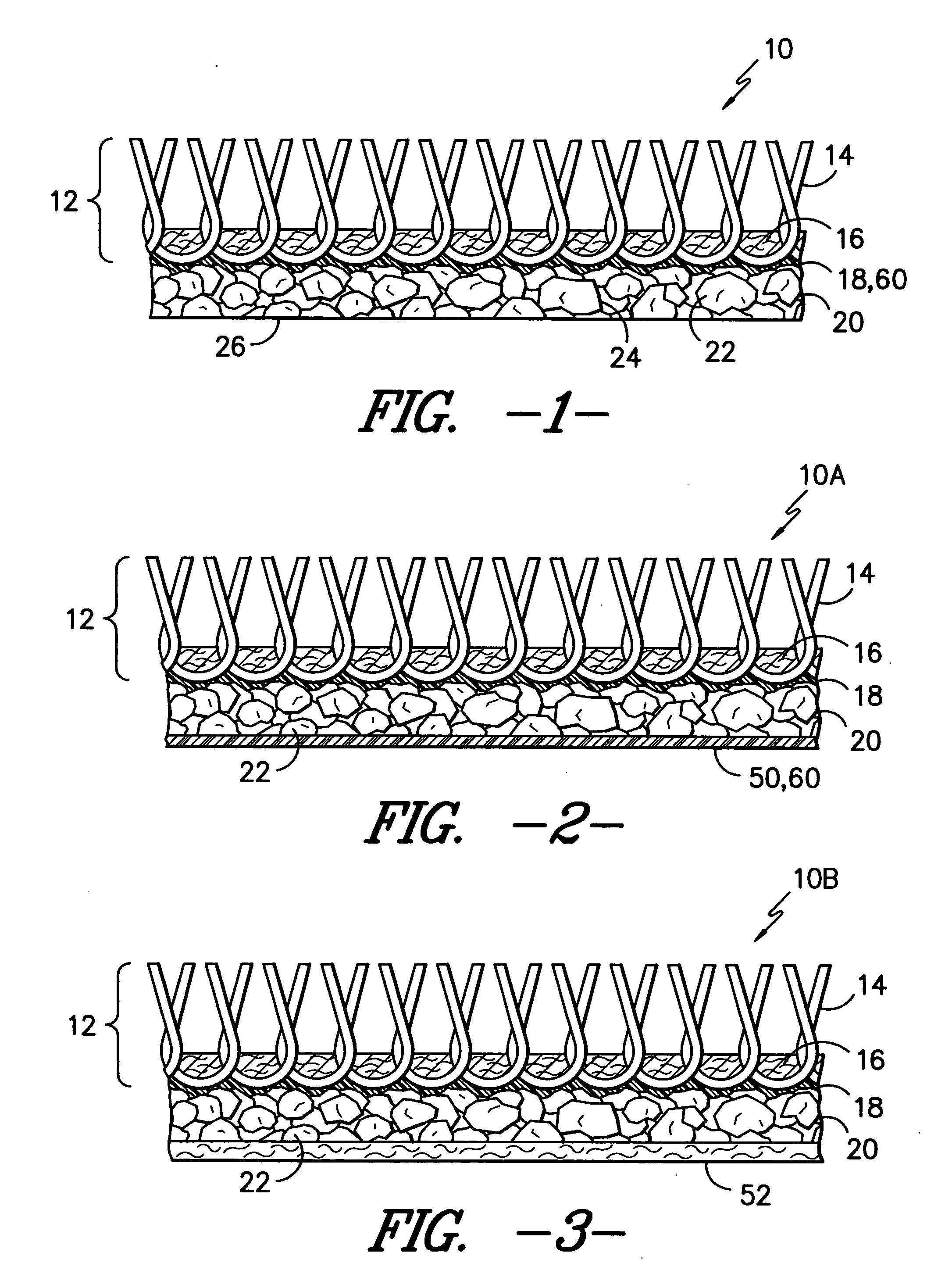

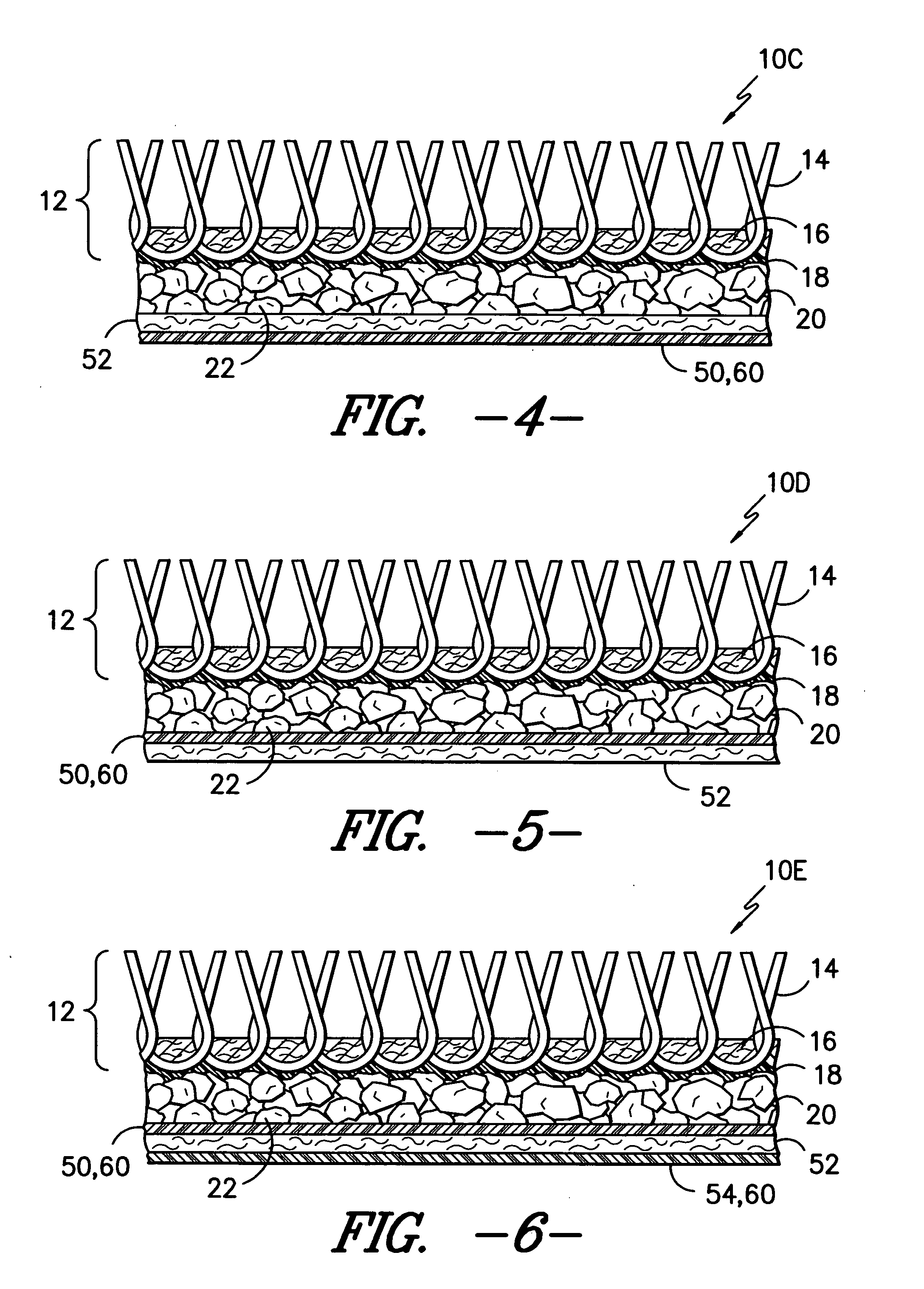

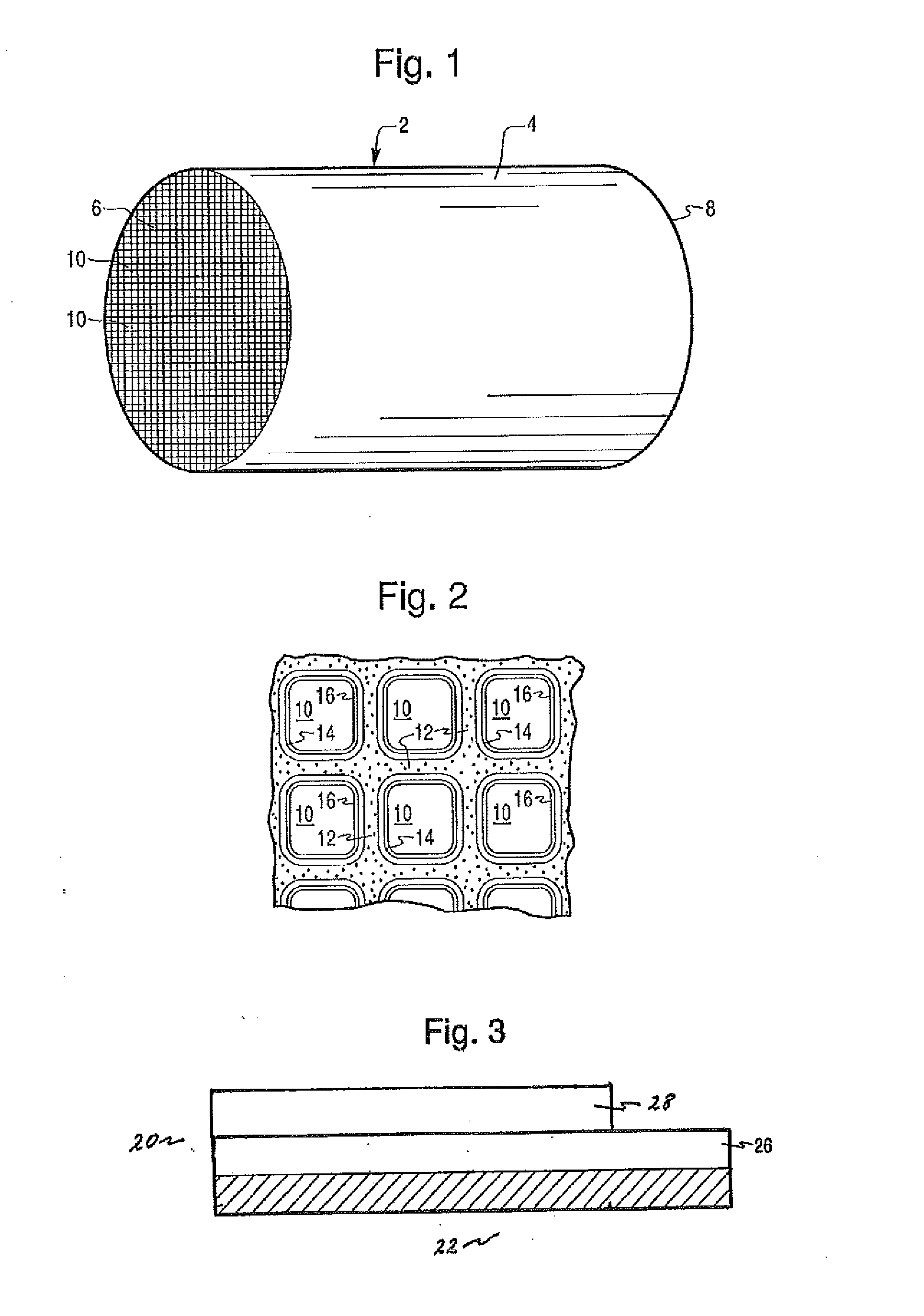

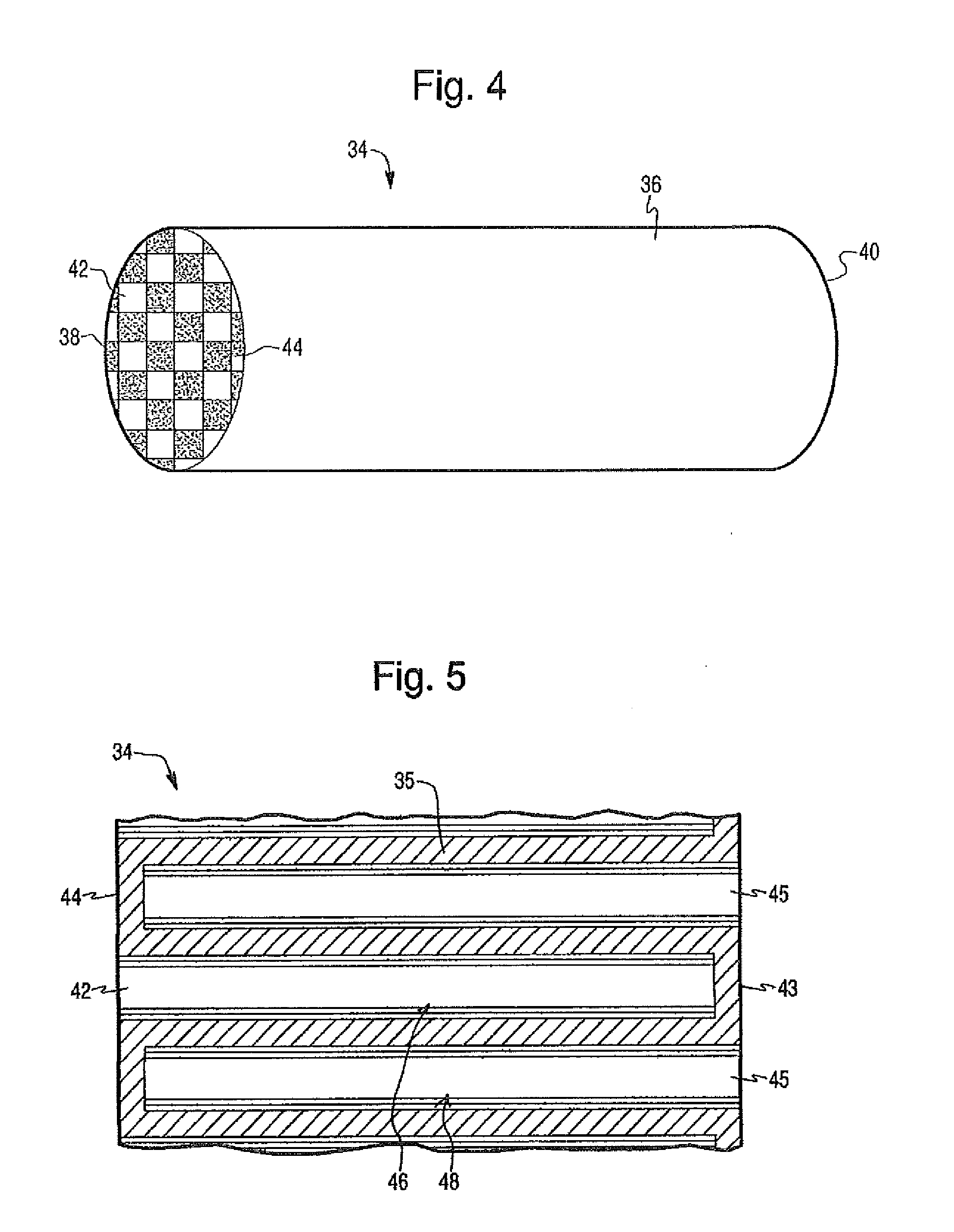

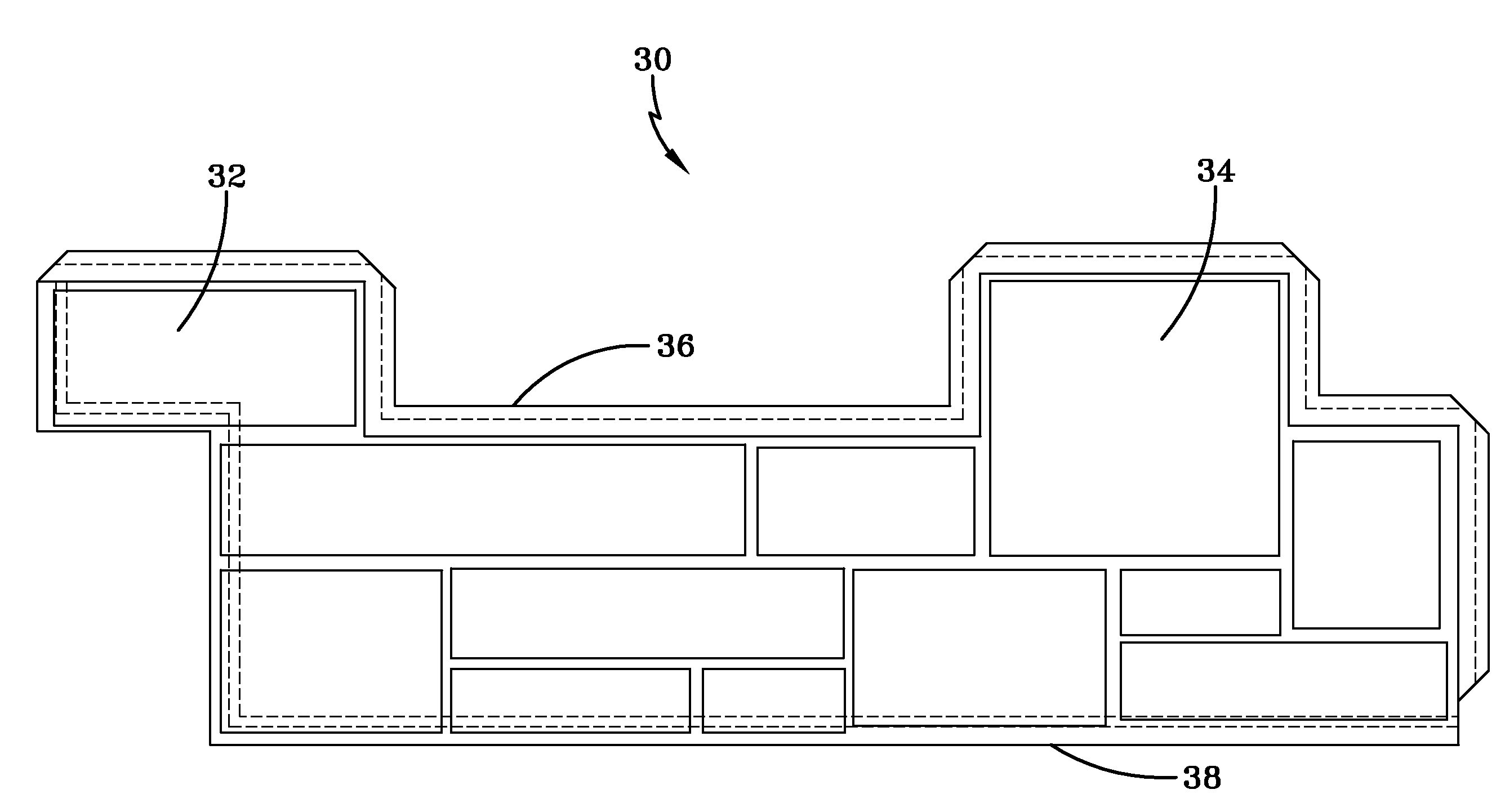

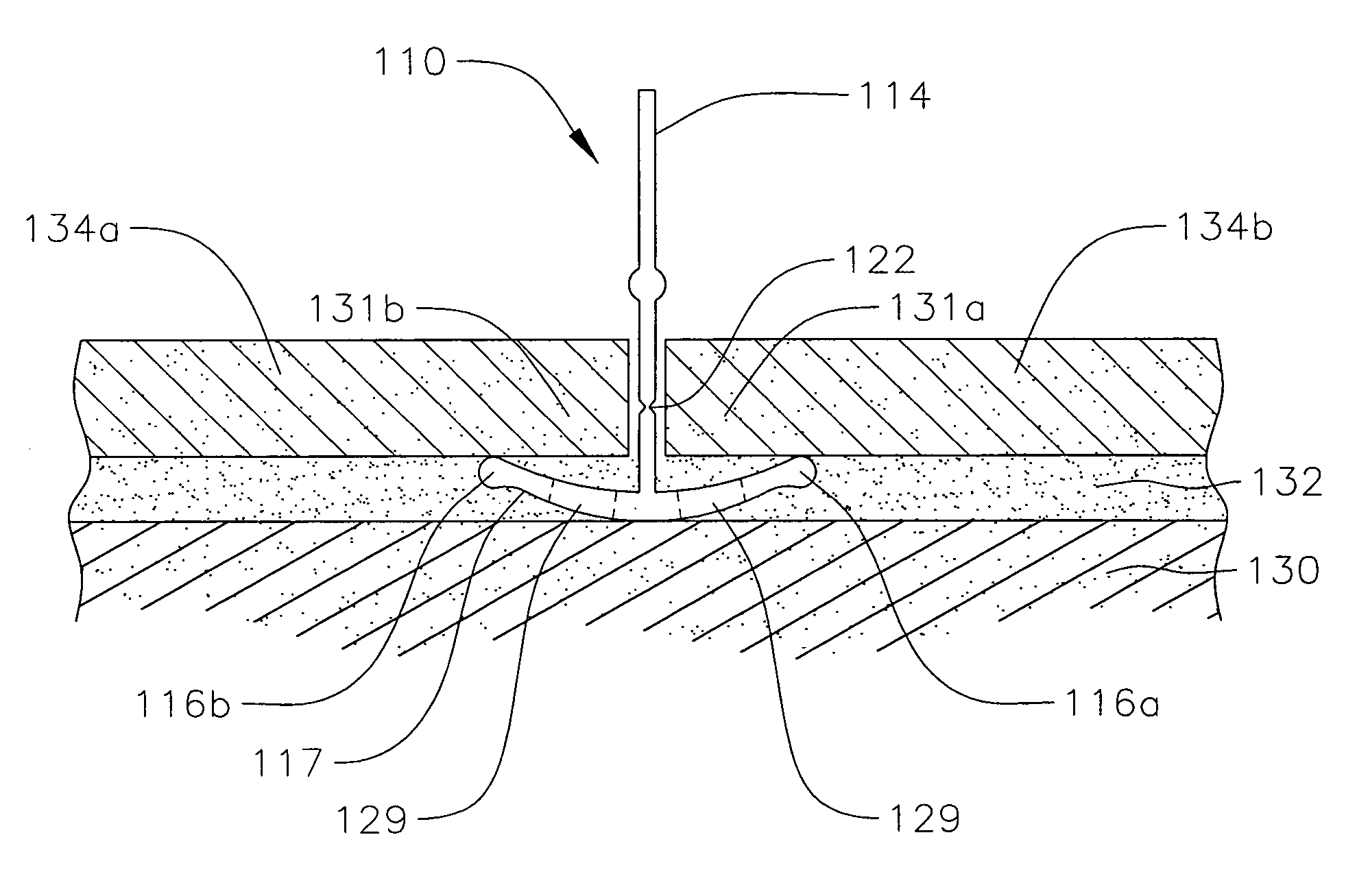

Carpet tile and related methods

InactiveUS20070275207A1Increase lateral gripReduce creepLamination ancillary operationsBristleBrickEngineering

Carpet tile, carpet tiles, or modular flooring include a carpet face or show surface in overlying relation to a backing of or including adjoined particle elements. In particular, but not exclusively, the carpet tiles incorporate a carpet surface or carpet face, having, for example, a pile or non-pile surface. In one embodiment, the carpet of the carpet tile has a tuft bind or precoat layer, such as a urethane precoat, disposed in overlying relation to a resilient backing formed from a mass, mixture, or slurry, for example, of particles or crumbs, bonded together in adjoined relation by a binder. One or more optional stabilizing and / or backing layers may be included. Methods of making such carpet tiles are also provided.

Owner:HIGGINS KENNETH B +1

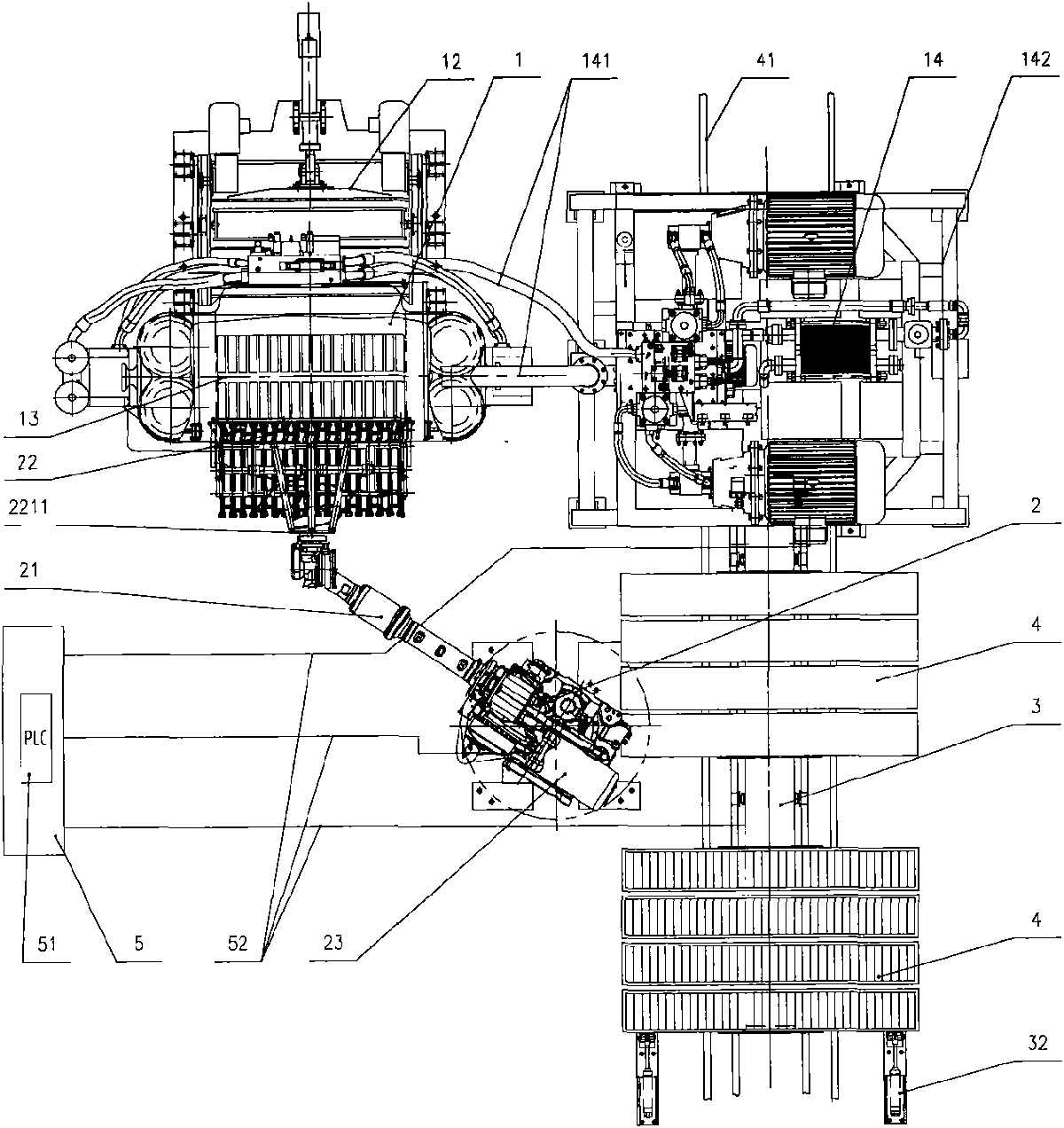

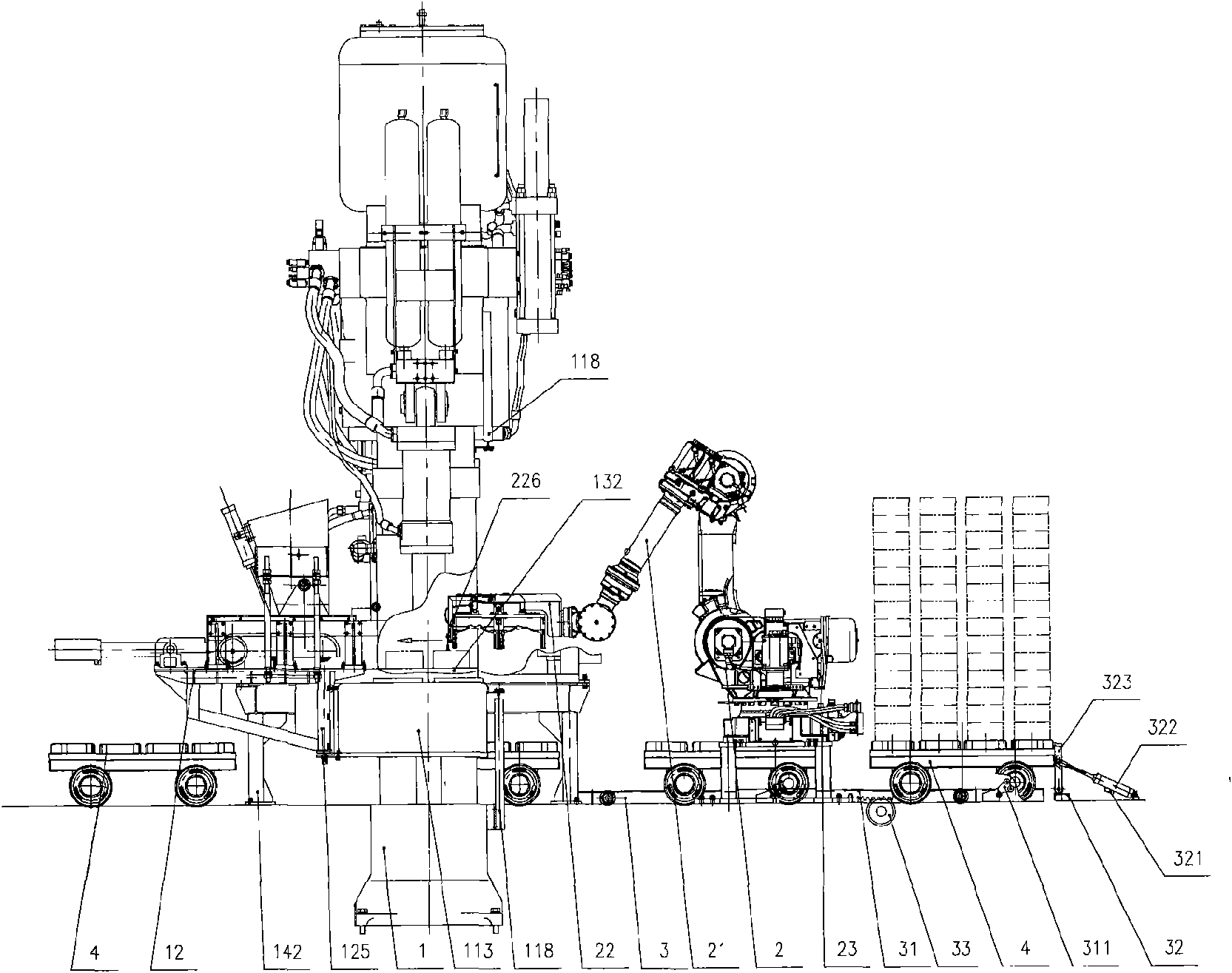

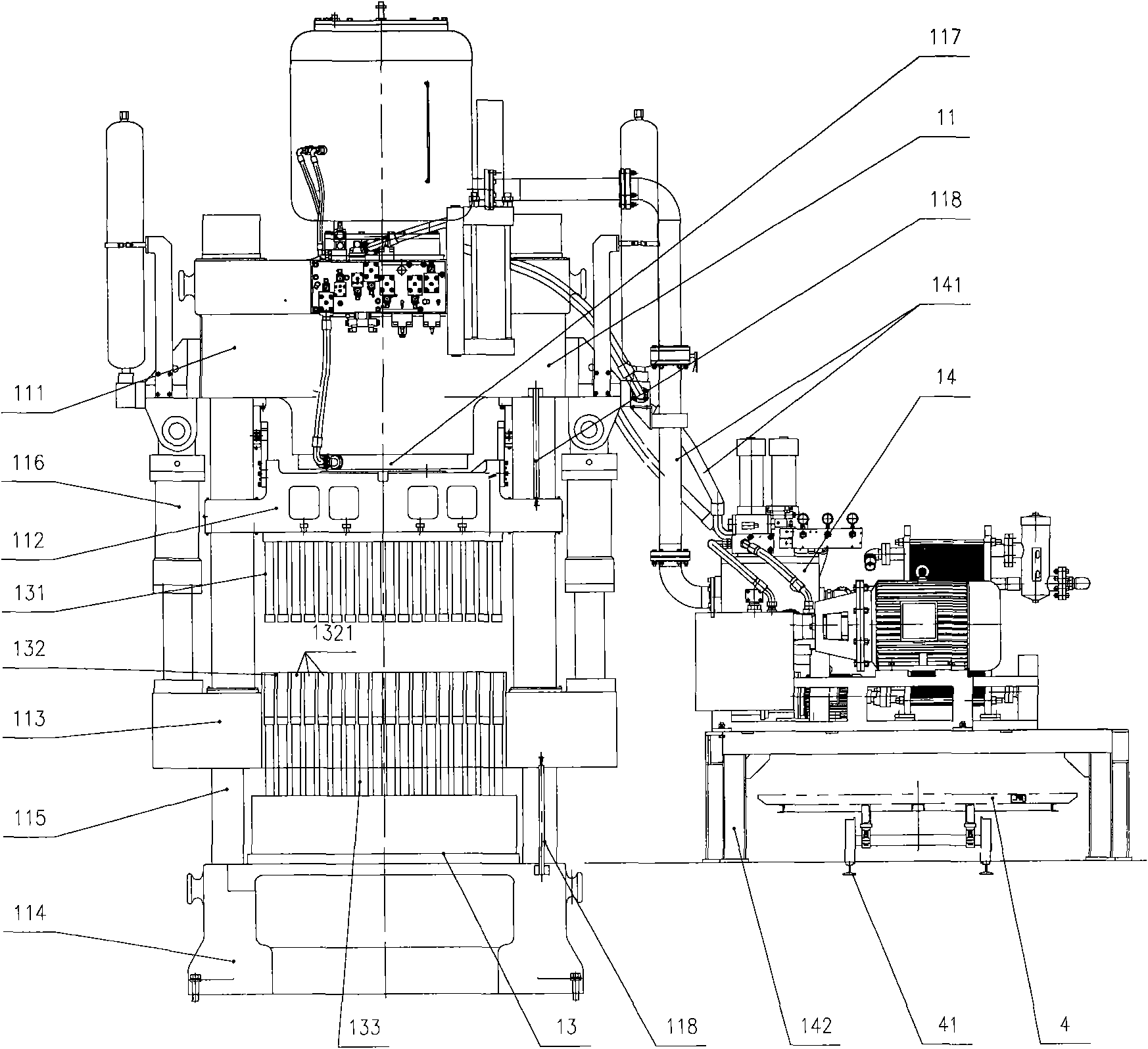

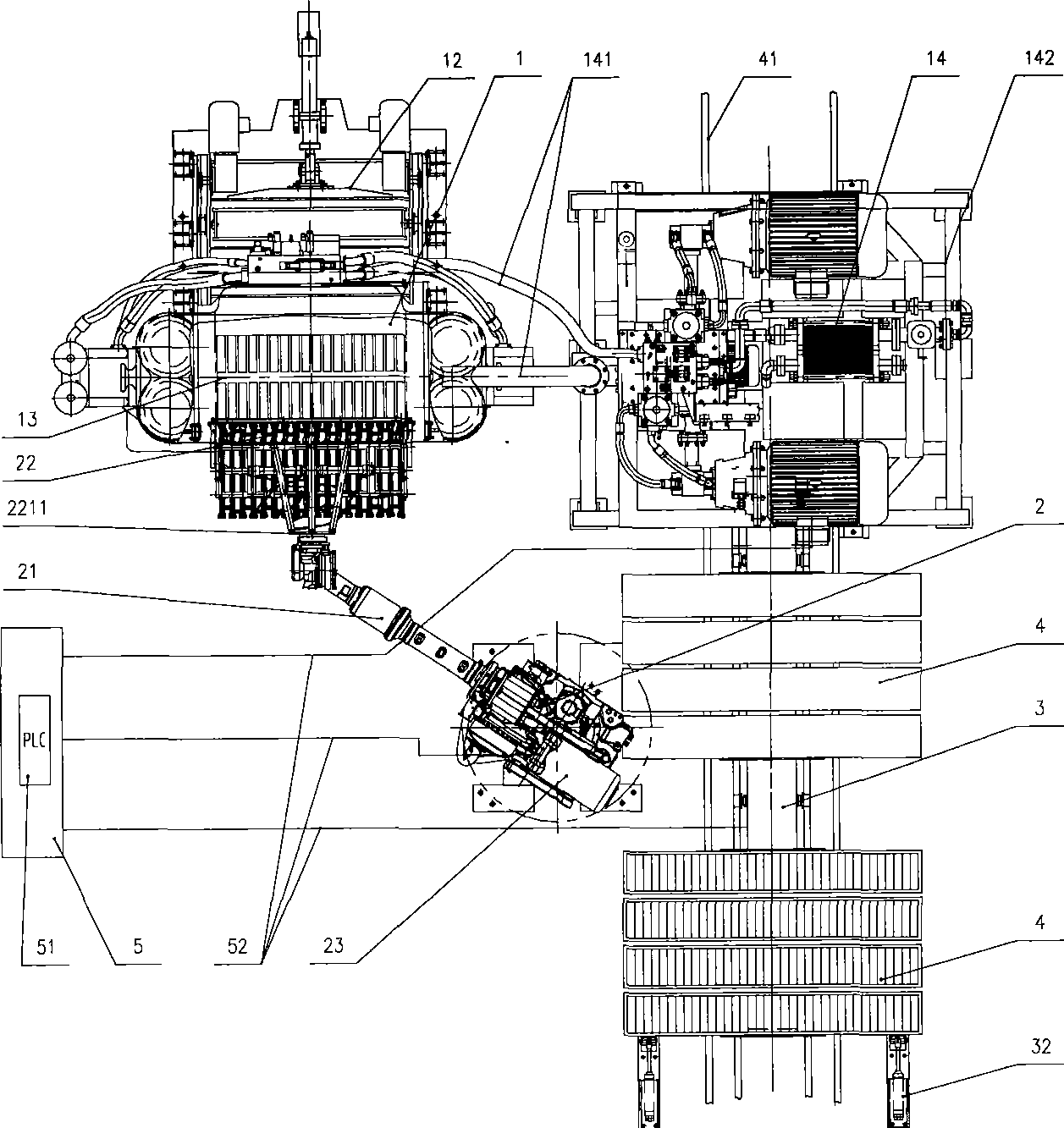

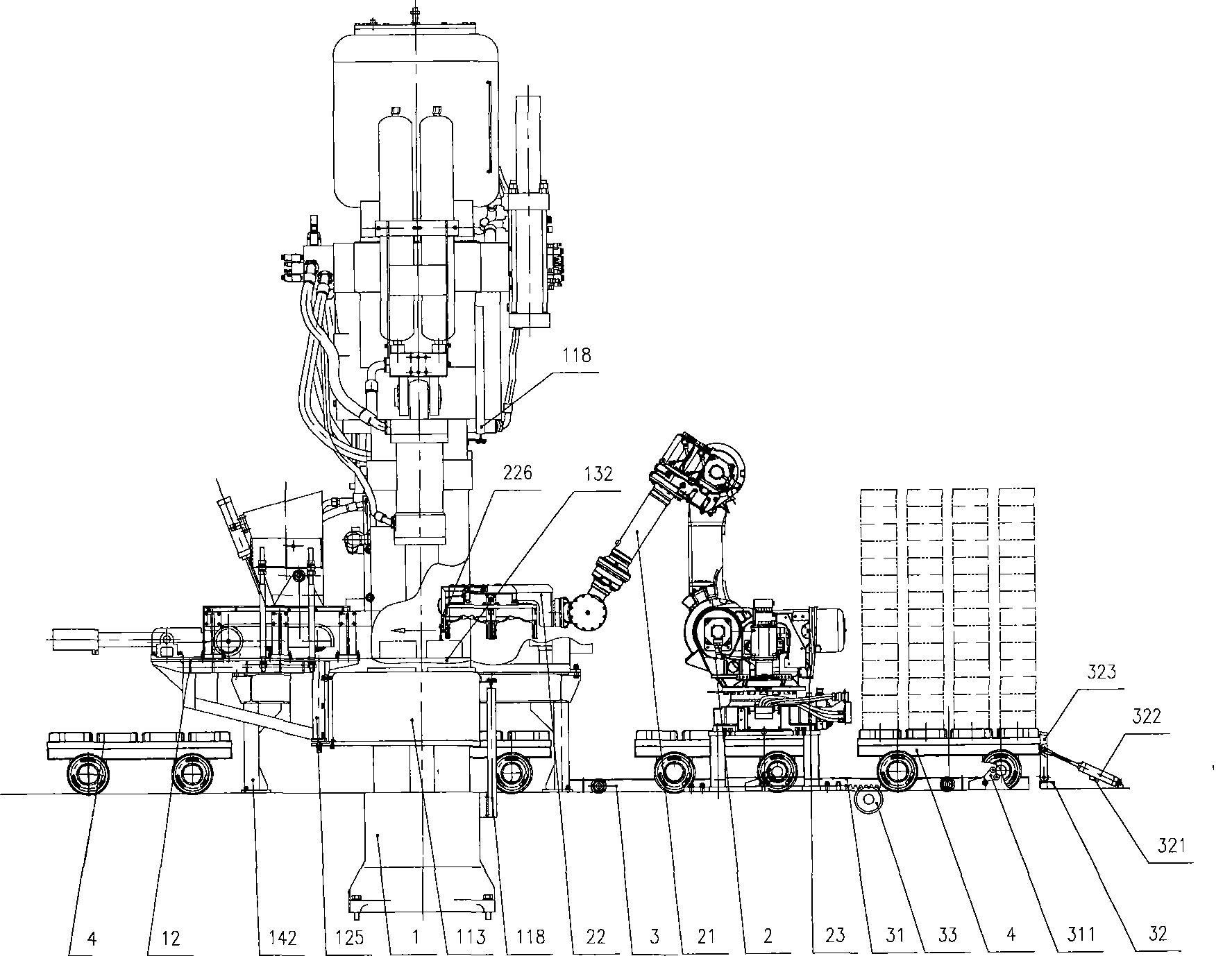

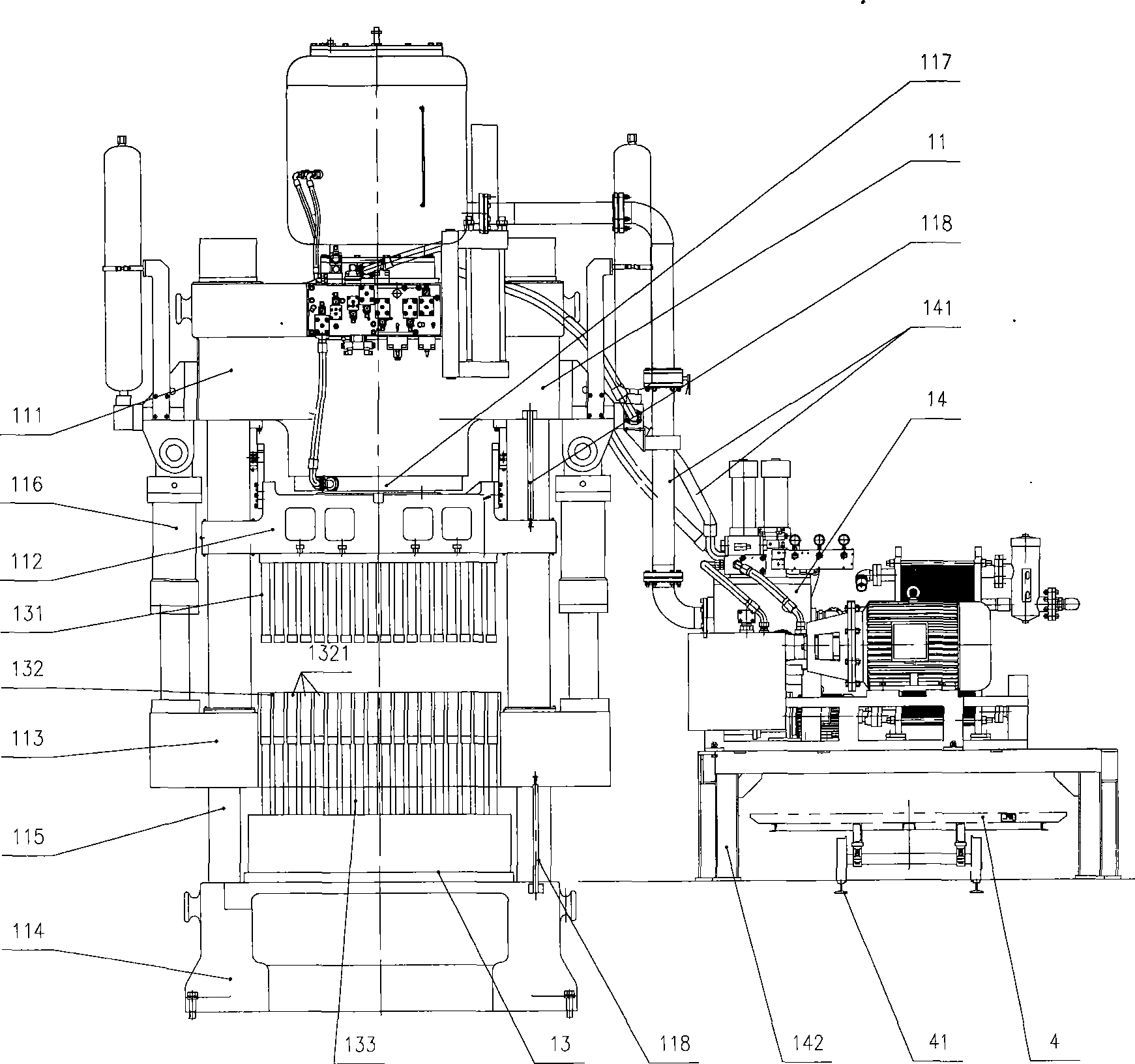

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833AEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

Composite water permeable brick

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833BEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

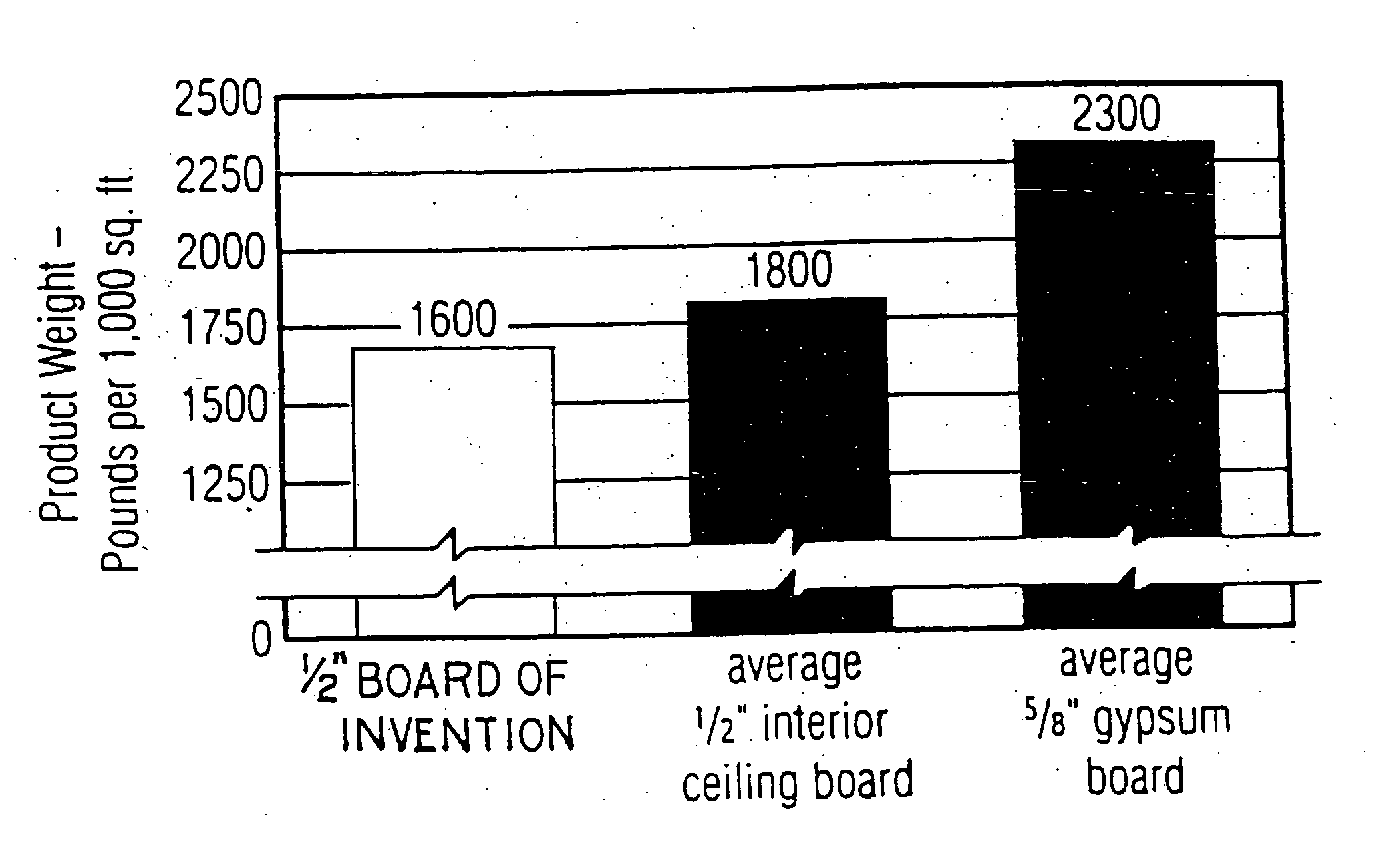

Gypsum-containing board and tile, and method for producing same

InactiveUS20050019618A1Improve the immunitySave a lot of costLiquid surface applicatorsConstruction materialO-Phosphoric AcidBrick

A method for producing a set gypsum-containing product comprising an interlocking matrix of set gypsum wherein said method comprises applying to said set gypsum one or more enhancing materials selected from the group consisting of phosphoric acid; condensed phosphoric acids, each of which comprises 2 or more phosphoric acid units; and salts or ions of condensed phosphates, each of which comprises 2 or more phosphate units, and monobasic salts or monovalent ions of orthophosphates.

Owner:UNITED STATES GYPSUM CO

Corrosion resistant water permeable brick

ActiveCN105016765AHigh permeability coefficientHigh compressive strengthCeramicwareCompressive resistanceBrick

The present invention relates to a corrosion resistant water permeable brick, and belongs to the technical field of building materials. The corrosion corrosion resistant water permeable brick comprises 20-25wt% of Portland cement, 1.0-1.2wt% of anhydrite powder, 15.0-20.0wt% of slag pellets, 10-12wt % of cenospheres, 1.5-2.1wt% of admixtures, and the balance of quartz sand. Under the premise that the porosity and water permeability coefficient of the corrosion resistant water permeable brick are significantly higher than that of a water permeable brick, the compressive strength of the corrosion resistant water permeable brick is still higher than that of the conventional water permeable brick, the corrosion resistant water permeable brick has good corrosion resistance, and service life is significantly increased.

Owner:江苏溧阳建设集团有限公司

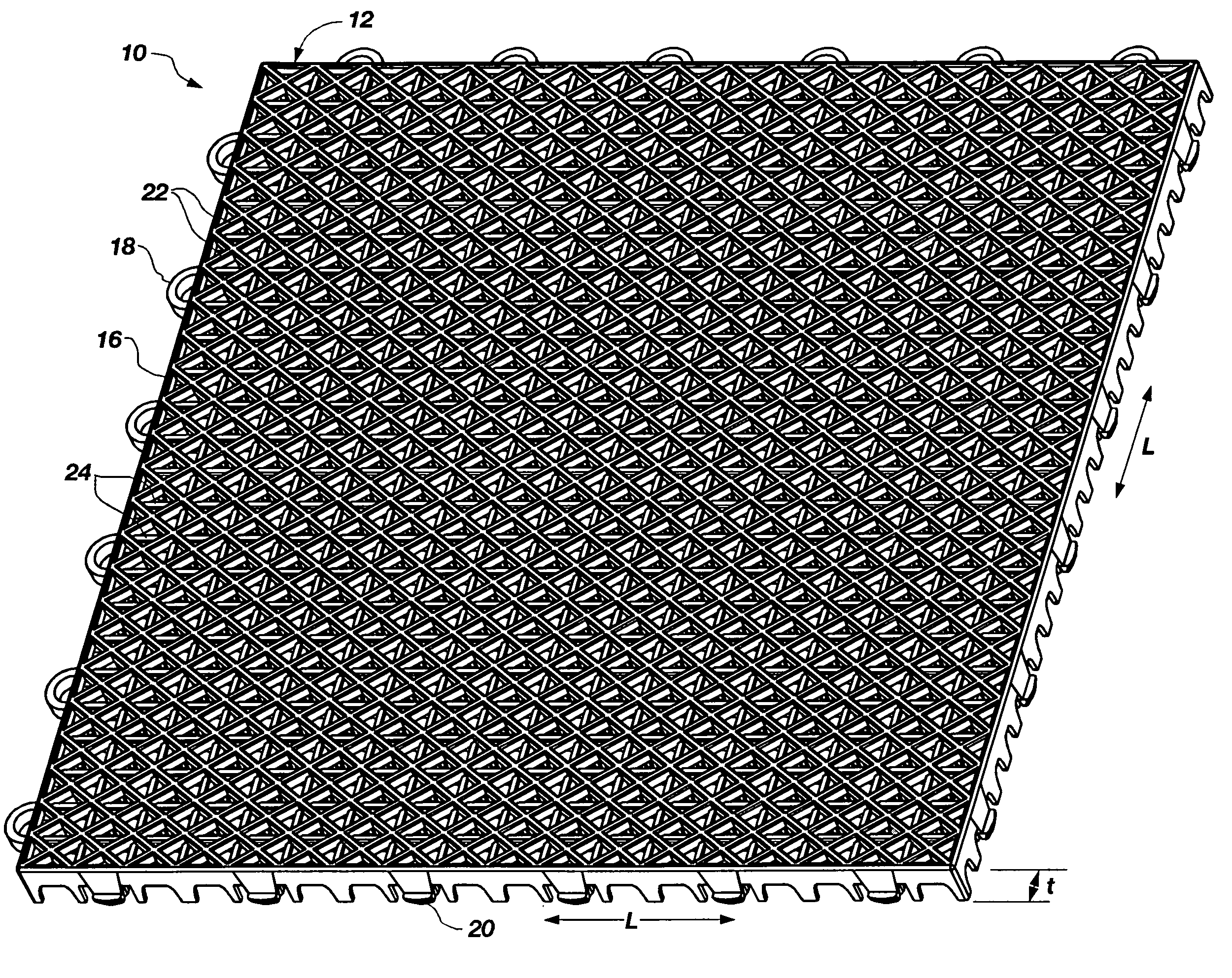

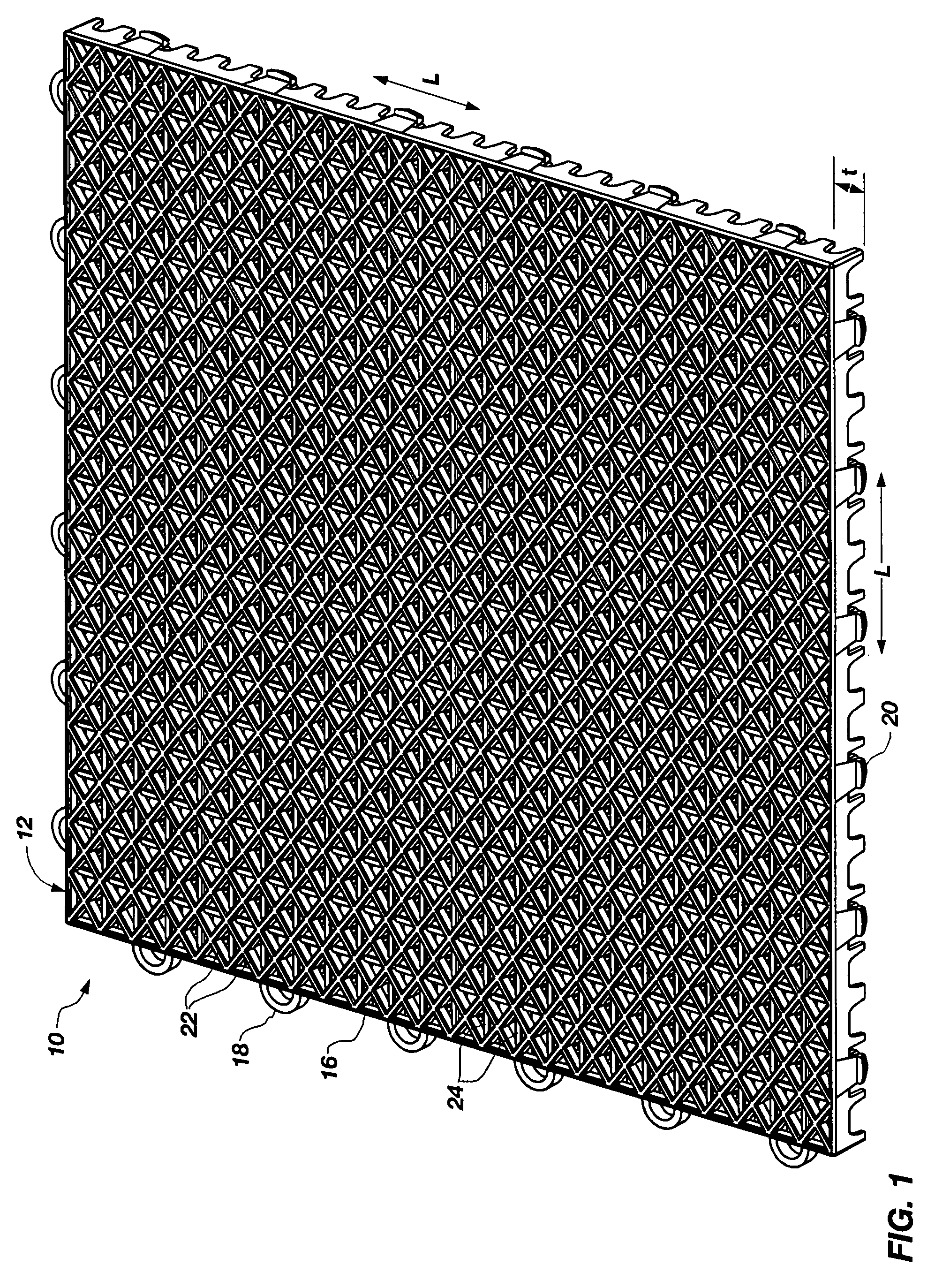

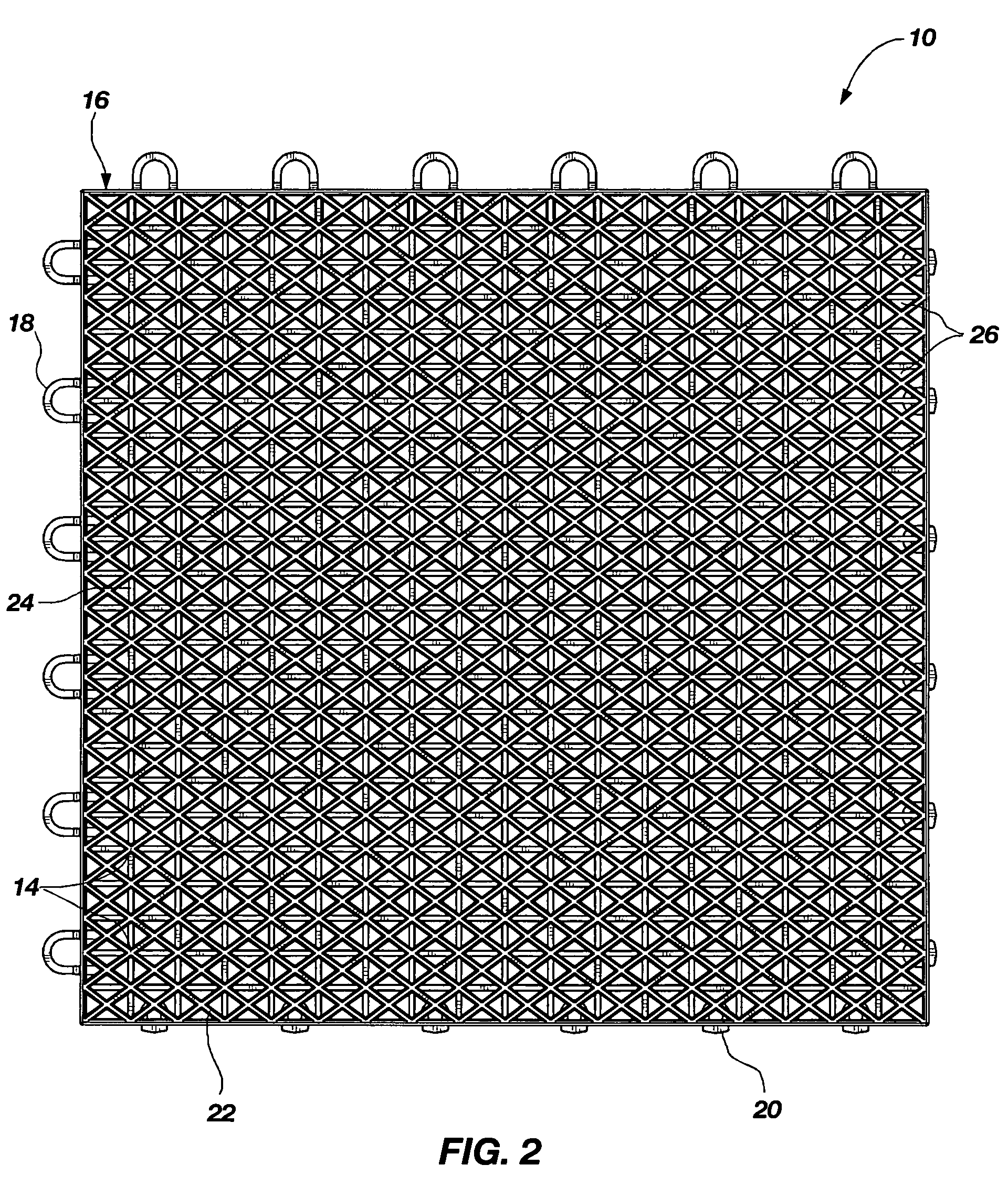

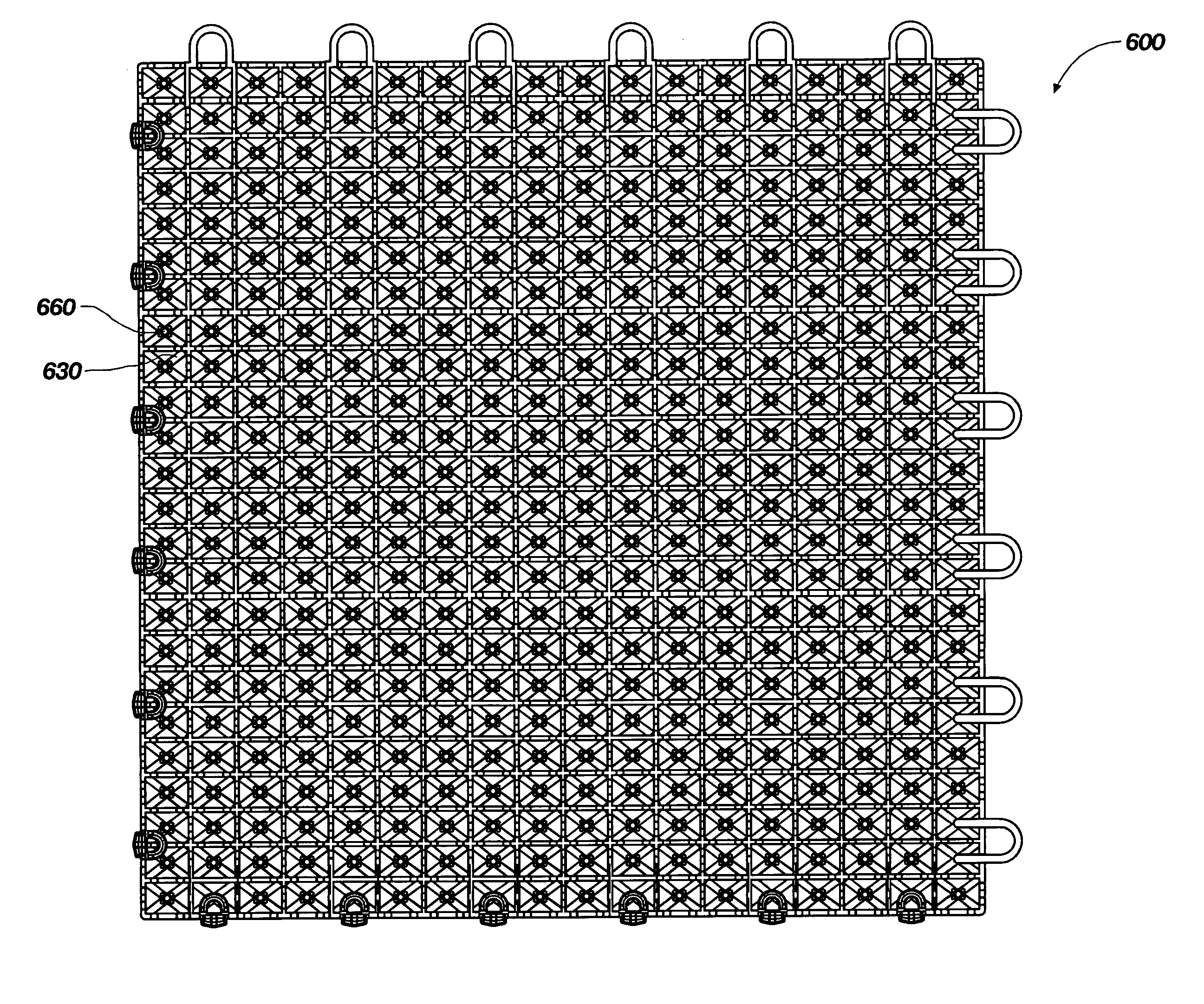

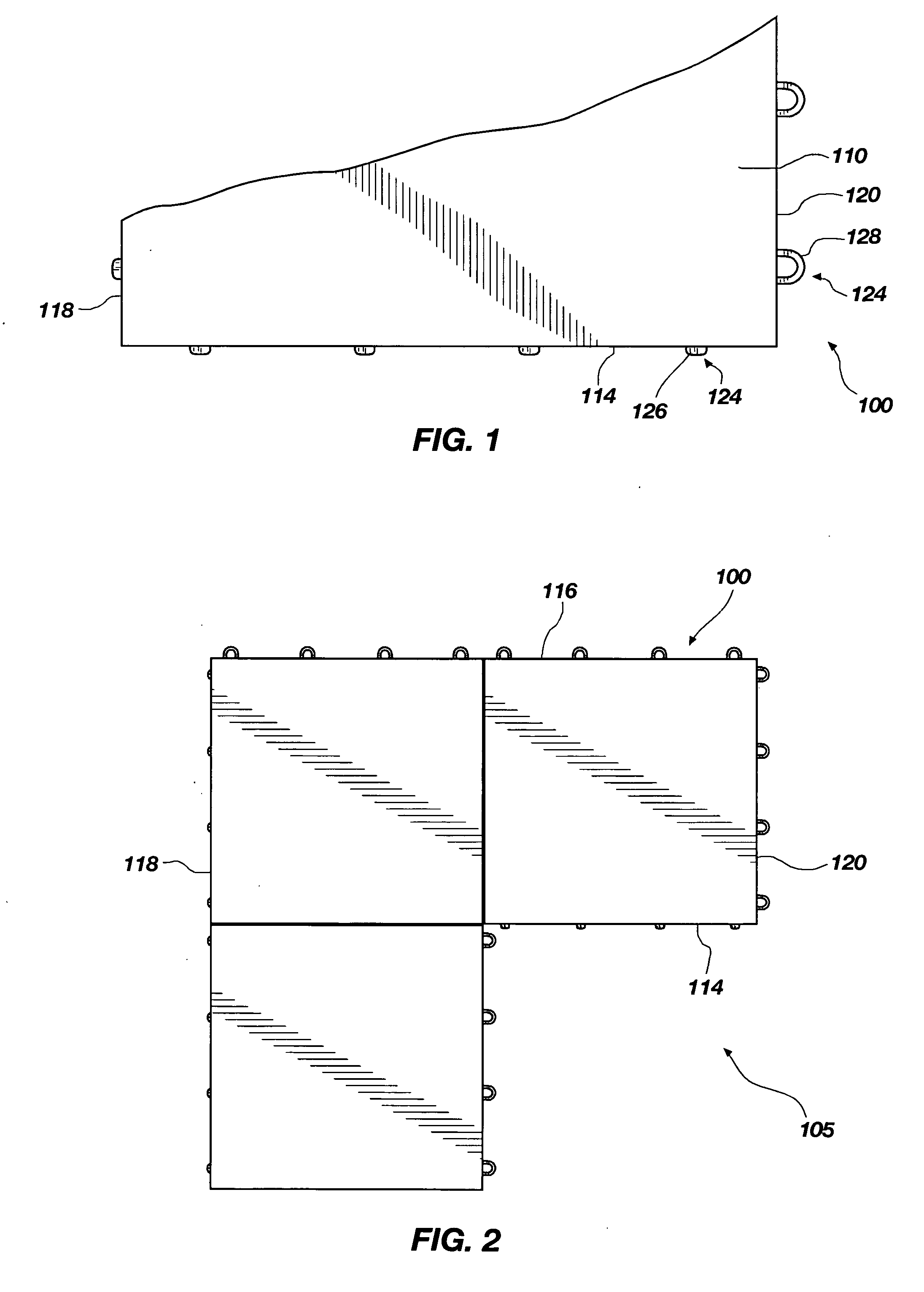

Tile with multiple-level surface

A grid-top floor tile for outdoor use includes a polymer tile having a grid-type top surface with multiple levels, such as a bi-level surface having an upper lattice and a lower lattice oriented generally transverse to the upper lattice. The multiple levels of the surface are preferably integrally formed with one another and provide drainage gaps therethrough. In a bi-level surface configuration, the lower lattice has a top surface below a top surface of the upper lattice, so as to draw residual moisture below the top surface of the upper lattice. The tile further includes a support structure, configured to support the tile on a support surface and provide drainage pathways beneath the top surface. The tile still further comprises various reinforcement members on each of the loop and pin connectors used to interlock the tiles when forming a flooring assembly.

Owner:CONNOR SPORT COURT INT

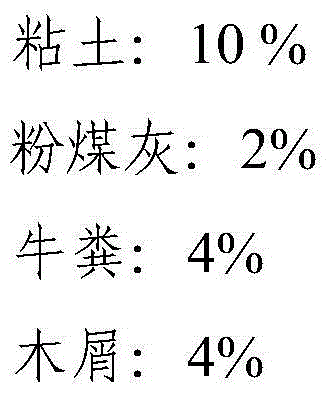

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

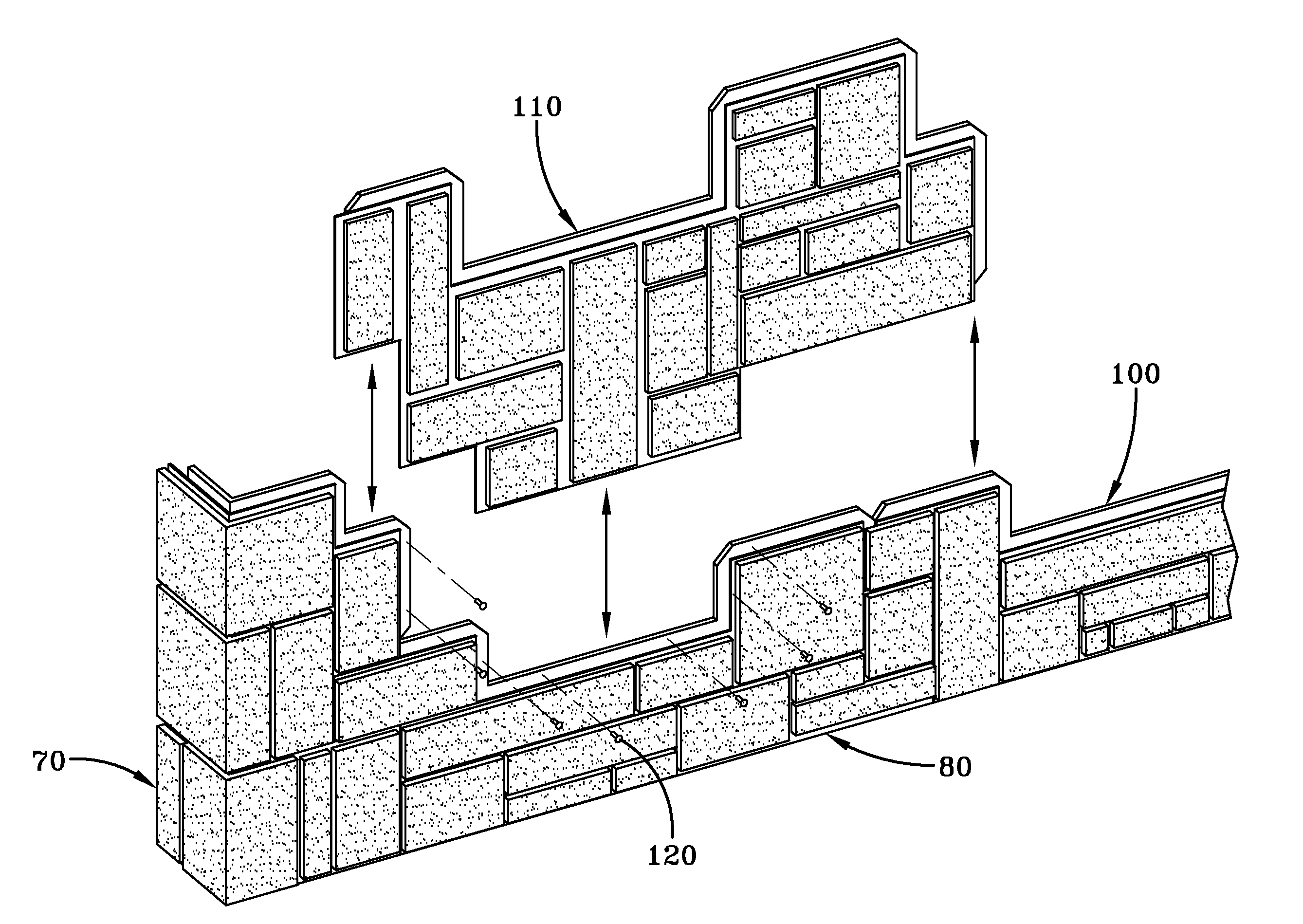

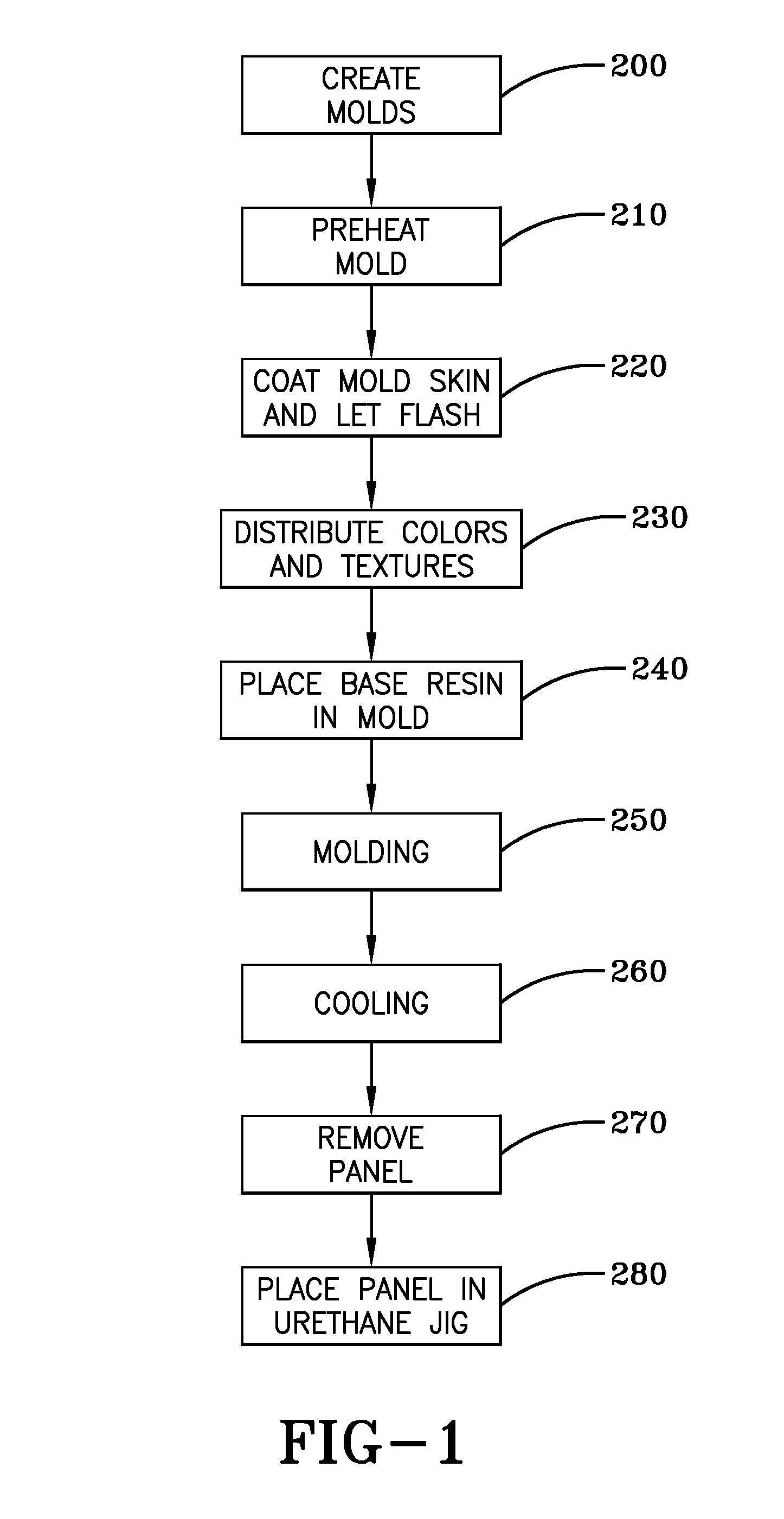

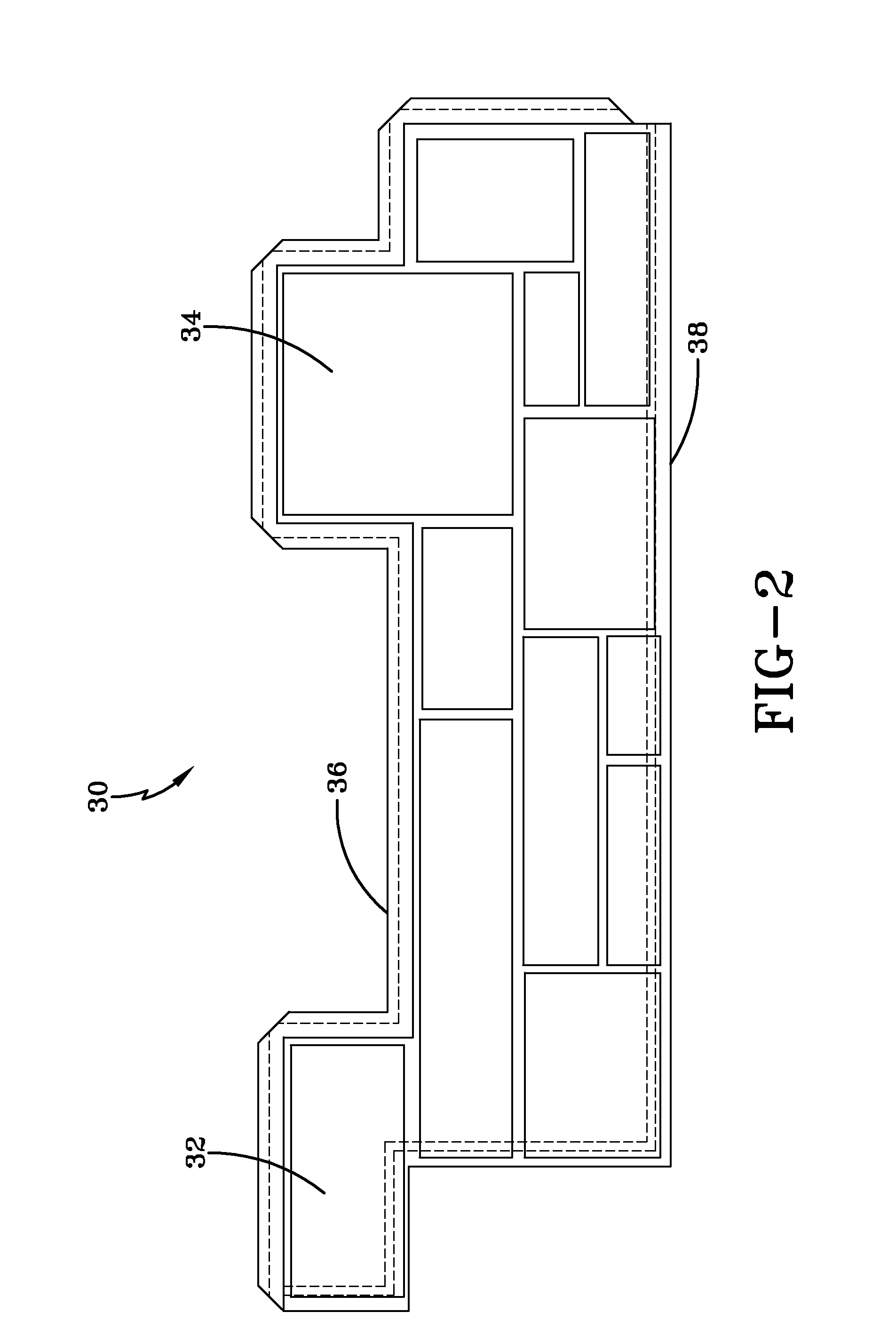

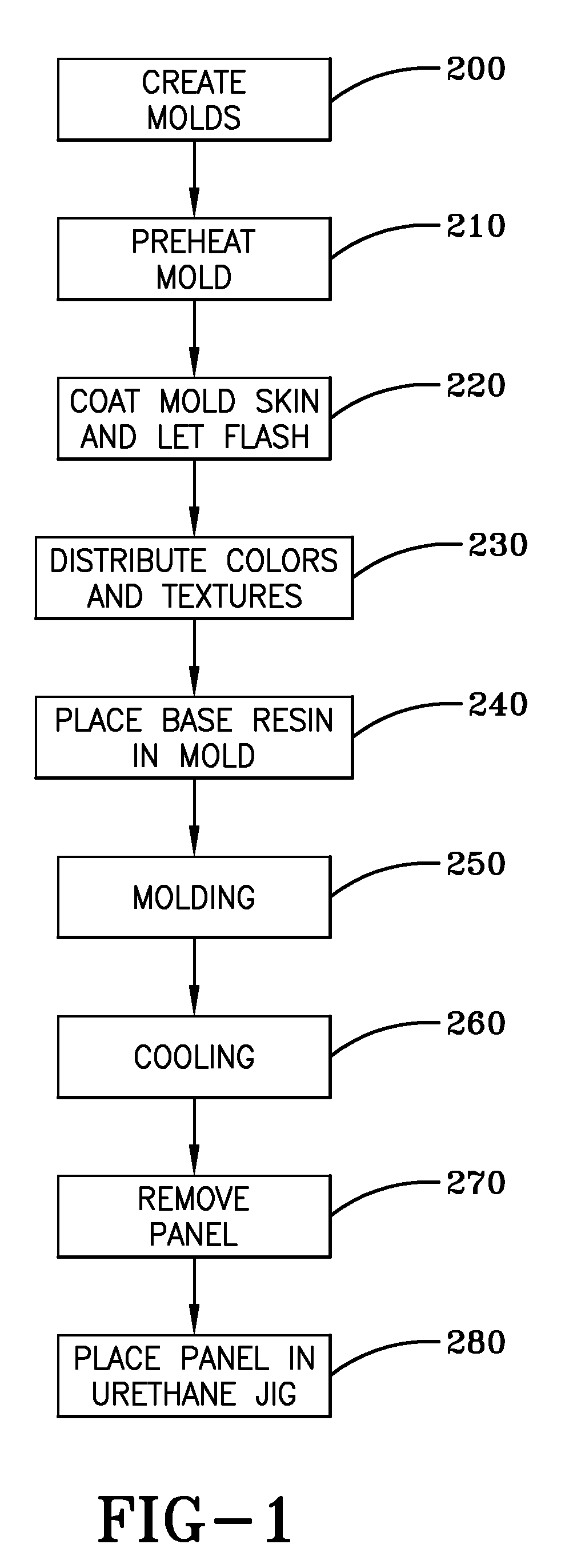

Foaming of simulated stone structures

InactiveUS20090056257A1Improve insulation performanceImprove sound insulationConstruction materialCovering/liningsBrickThermal insulation

Simulated stone, masonry, and brick textured products such as siding having a foam backing or with the hollow parts injected with foam or molded with foam in one or more steps, obtained when specially selected materials are properly admixed and formed via molding techniques. The foam backing is applied to the product in either a one or two step process. The foam backing may be used on panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearance of conventional building and construction materials including, but not limited to, stone, brick, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. The foam backing provides improves thermal insulation, improved sound reduction, improved rigidity, and improved dimensional stability. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

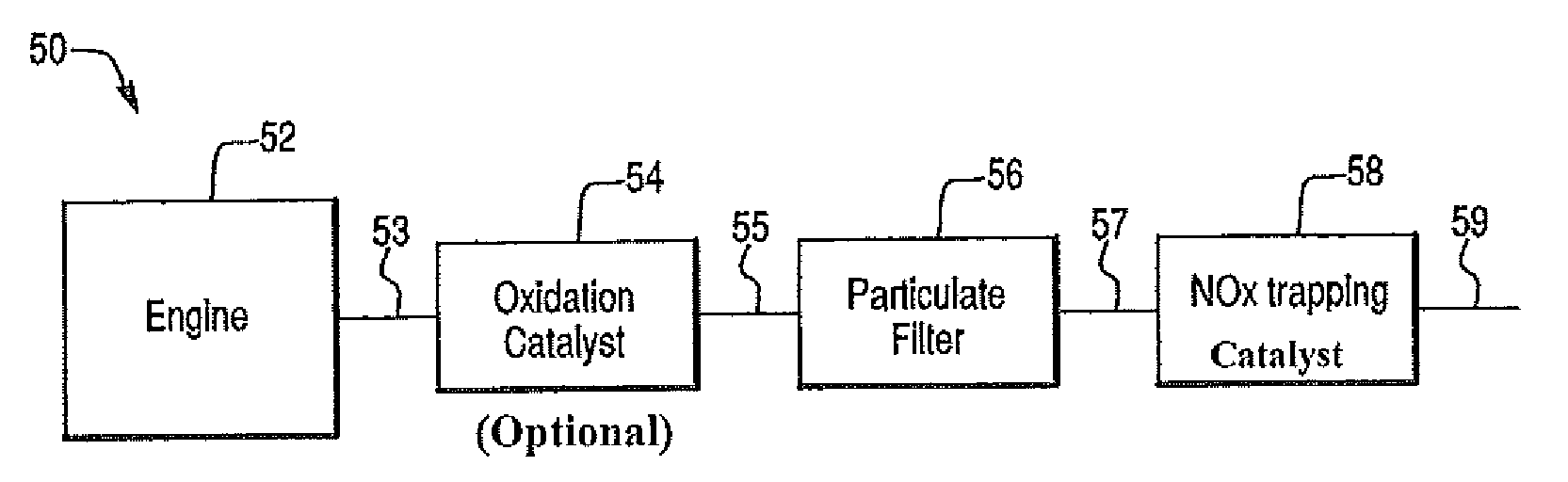

NOx Adsorber Catalyst with Superior Low Temperature Performance

The lean NOx trap catalyst composition of the present invention comprises distinct layers, or zone configuration or multi-brick arrangement. The top layer, front zone or front brick is free of any alkali or alkaline earth NOx trapping components. The under layer, rear zone or rear brick may contain any desirable NOx trapping component in contact with a precious metals group catalyst (e.g., Pt). Catalysts of this invention show wide temperature operation window with superior low temperature performance.

Owner:BASF CORP

Composition of fillers with plastics for producing superior building materials

InactiveUS20090062413A1Minimize limitationEasy to assembleCovering/liningsSolid waste managementChemical LinkageBrick

The use of high aspect fillers in the production of simulated stone, masonry and brick textured products such as cladding, siding, panels, or other building and construction materials. High aspect fillers increase the dimensional stability, rigidity, thermal and sound insulation. The high aspect fillers may be included into a matrix polymer with or without chemical bonding. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:CRANE BUILDING PRODS

Modular tile with controlled deflection

A modular tile configured to interlock with multiple tiles to form a modular floor covering over a floor. The tile includes a top surface having a periphery defining side walls extending downward from the top surface, the side walls having a coupling portion configured to couple with other tiles adjacent thereto to form the modular floor covering. The tile also includes a bottom side, opposite the top surface, having a support grid including an array of downward extending polymeric post structures, at least some of the post structures including at least one resilient end portion with a radial end surface configured to be positioned against the floor to facilitate controlled deflection of the post structures. The post structures may comprise primary and secondary post structures, with the secondary post structures limiting the deflection of the primary post structures.

Owner:CONNOR SPORT COURT INT

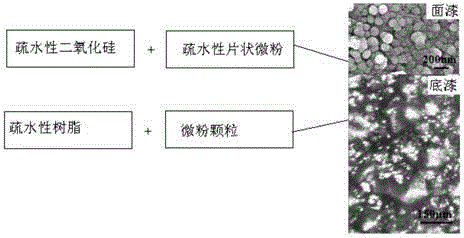

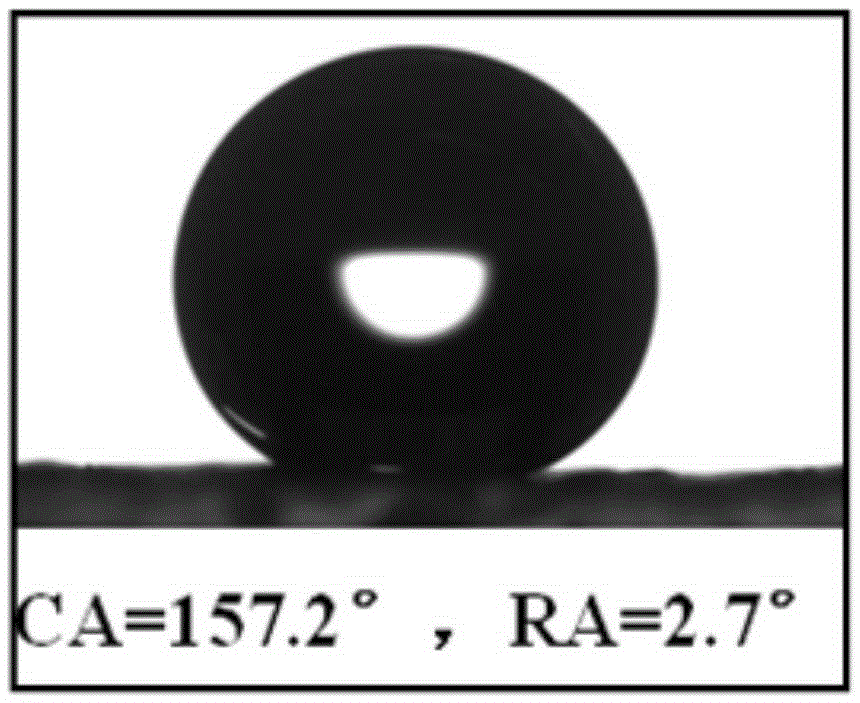

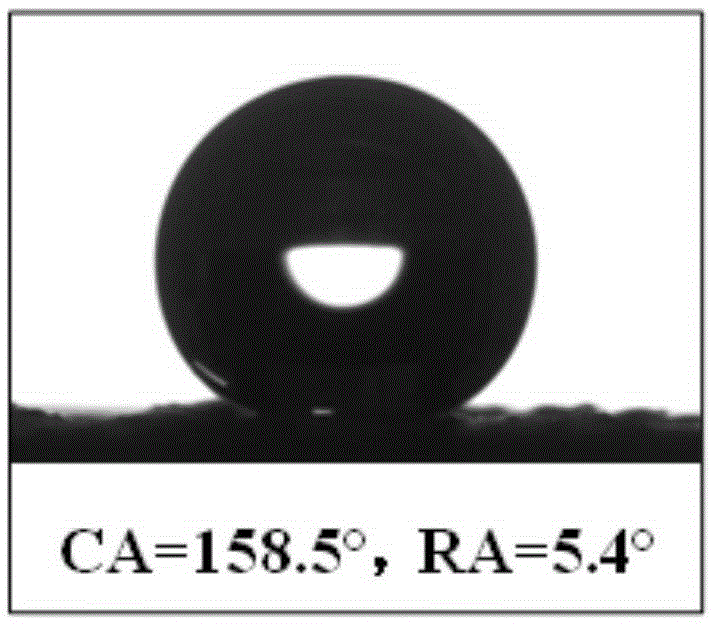

Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

The invention discloses a highly-wear-resistant super-hydrophobic composite coating and a preparation method thereof. The preparation method includes the steps that the surface of a base is coated with hydrophobic resin primer containing compound micropowder through a brush coating or spray coating method, the surface of the resin primer is sprayed with hydrophobic organic / inorganic hybrid nano-paint after semi-curing, and the highly-wear-resistant super-hydrophobic composite coating is obtained after complete curing. The highly-wear-resistant super-hydrophobic composite coating and the preparation method thereof have the advantages that equipment and the process are simple, operation is easy and cost is low, and have the industrial mass production prospect. The prepared super-hydrophobic composite coating can be applied to various hard / soft bases such as glass, copper, aluminum, stainless steel, exterior wall tiles, wood, paper and cloth and can bear damage of external force such as sanding.

Owner:SOUTHEAST UNIV

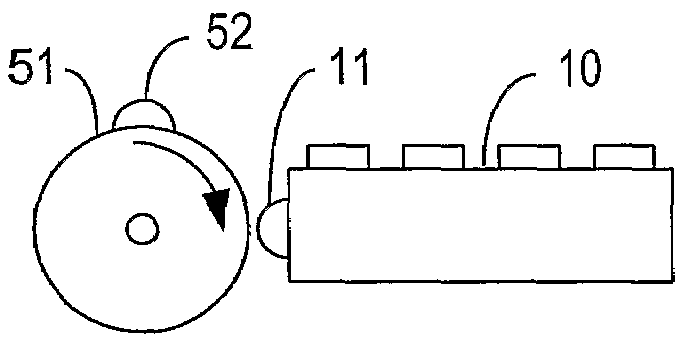

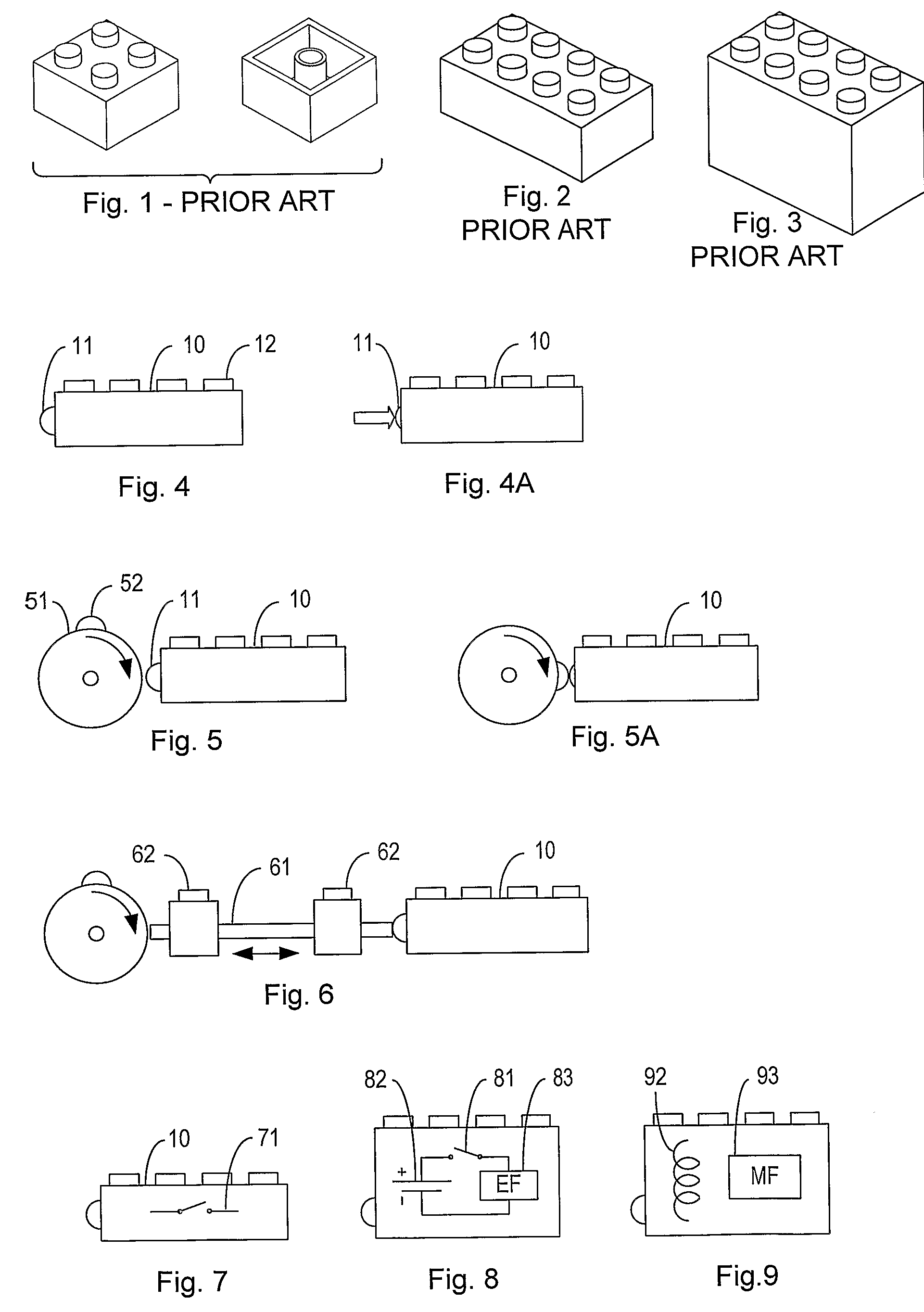

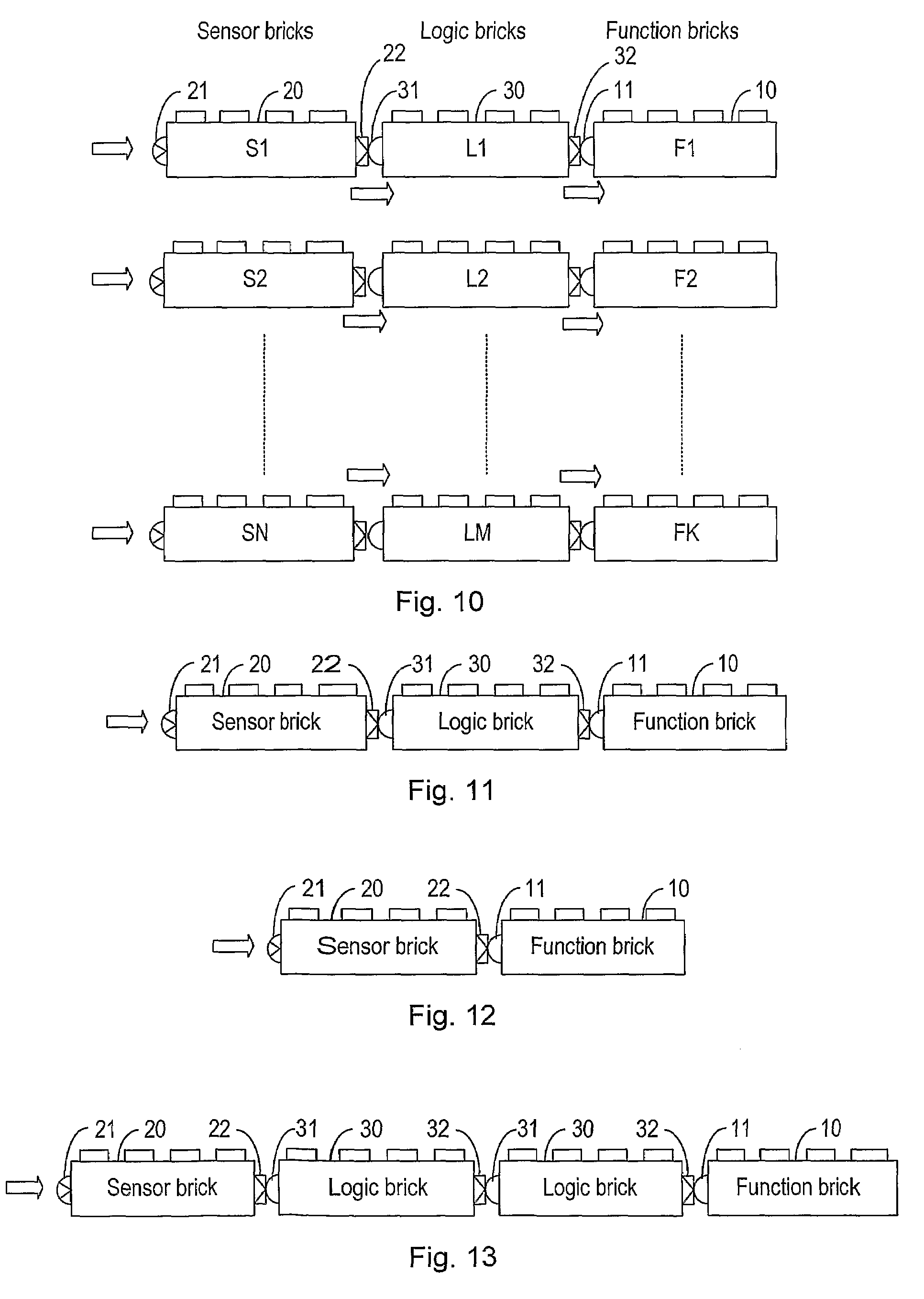

Toy building system with function bricks

A toy building system with function bricks adapted to perform a function in response to a mechanical trigger action; sensor bricks with a sensor adapted to produce an output in response to a mechanical trigger action; and logic bricks with an input responsive to a sensor brick output and adapted to perform a logic function on the sensor brick output and to produce a logic output. The sensor brick output and the logic brick output are arranged in a first uniform manner relative to the coupling means, and the sensor output action and the logic output action are of uniform physical nature. The logic brick input and the function brick input are arranged in a second uniform manner relative to the coupling means. The function brick input is responsive to a logic brick output and adapted to perform the function in response to a logic brick output.

Owner:LEGO AS

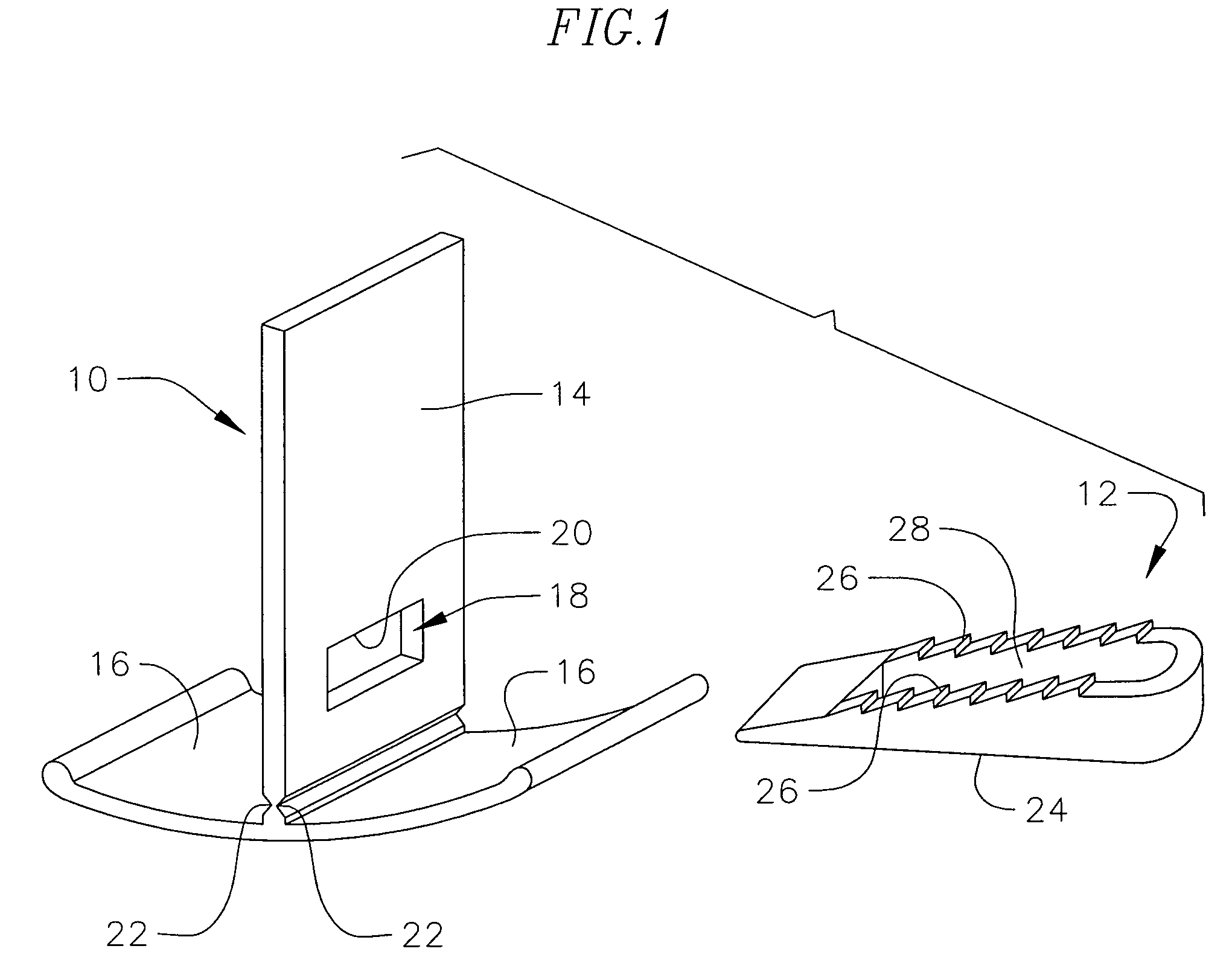

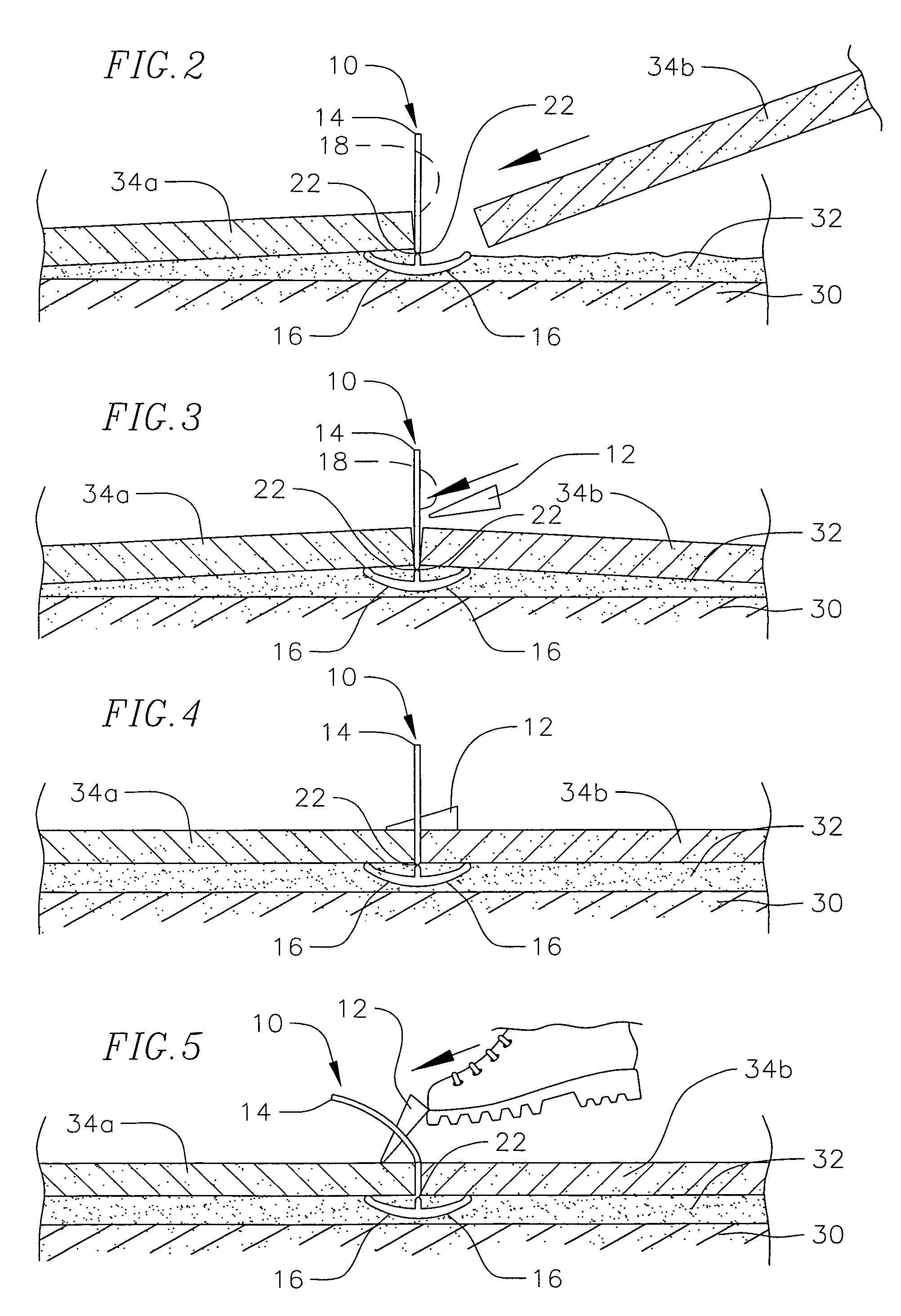

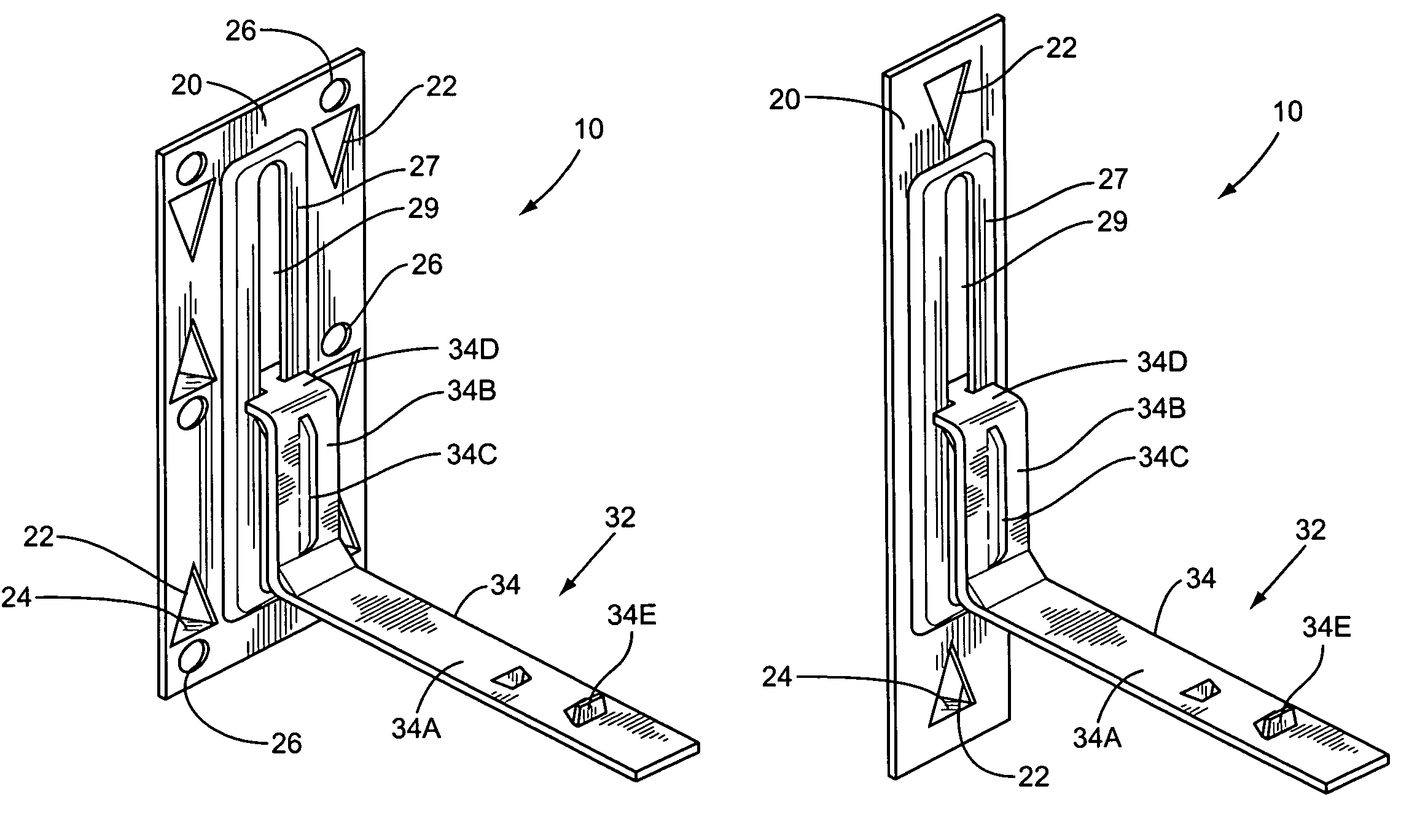

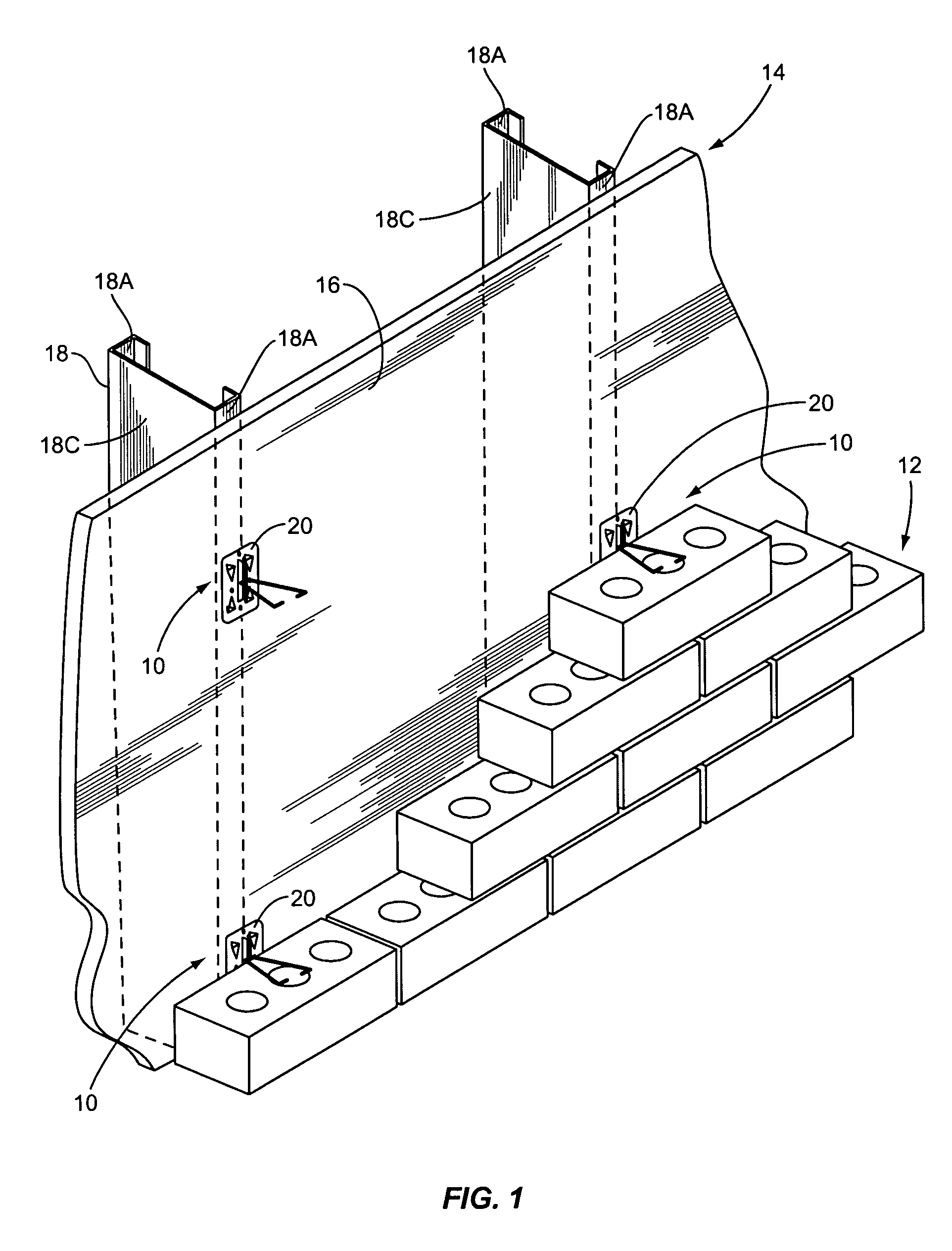

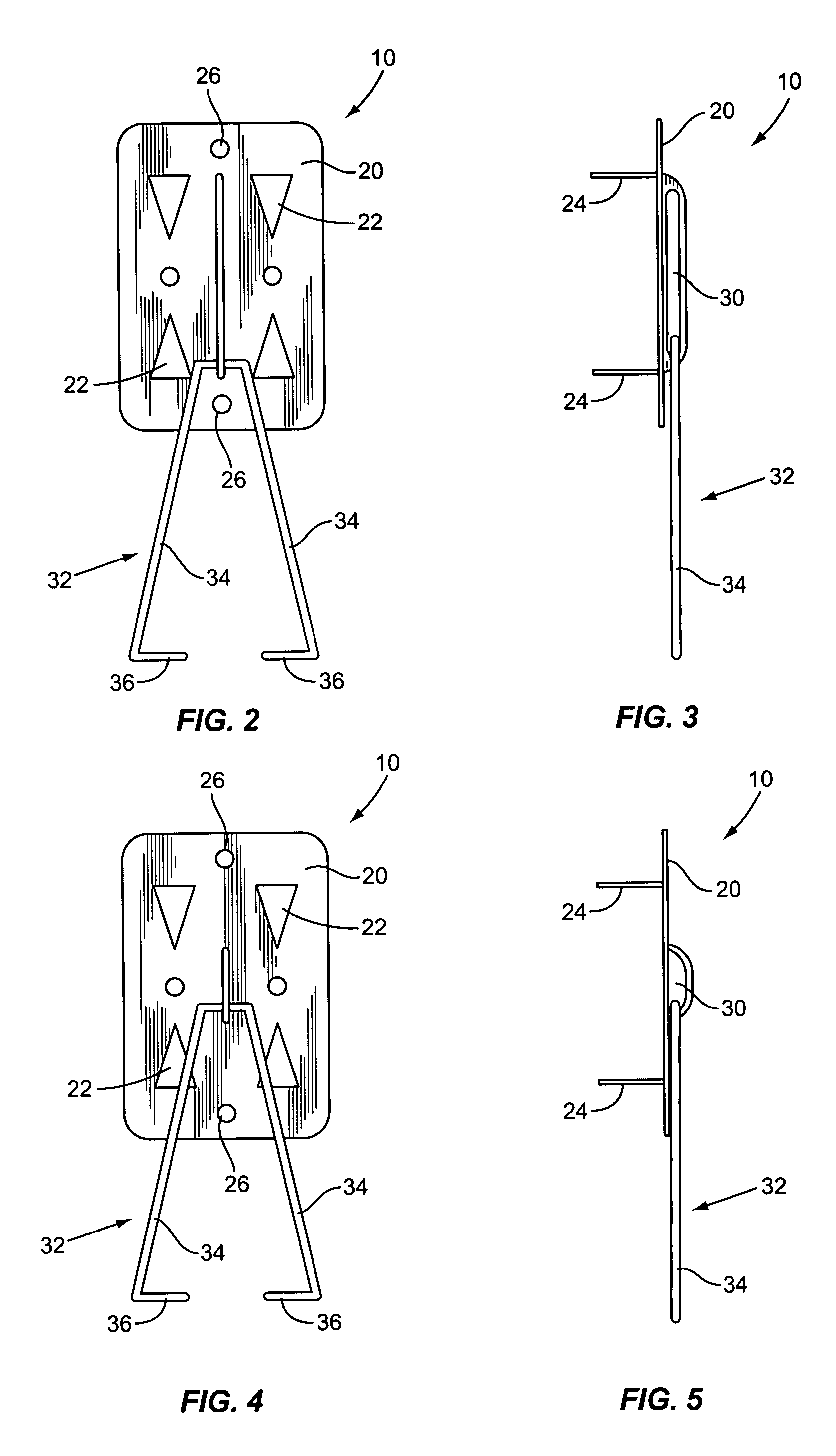

Brick tie

A brick tie for interconnecting a brick wall with a back-up wall comprised of a plurality of spaced apart studs and a wall board secured to the studs wherein each stud includes a pair of opposed side flanges and a web formed between the flanges. The brick tie includes a plate having a series of spikes projecting from a backside. The spikes are adapted to be pushed into and through a portion of the wallboard so as to at least partially support the plate on the wallboard. Further, the plate is positioned on the wallboard such that it aligns with one side flange of a stud. Further, the brick tie includes a series of fasteners that are extended through the plate, through the wallboard and into the side flange of the stud. A loop or tie holder is secured or formed on the front of the plate. A tie is at least partially confined in the loop and the loop is of such a size that the tie can be vertically adjusted within the loop when the plate is secured to the wallboard. When the brick tie is secured to the back-up wall, the tie projects outwardly from the plate and extends between two layers of brick or block so as to anchor or secure the brick or block wall to the back-up wall.

Owner:THE STEEL NETWORK

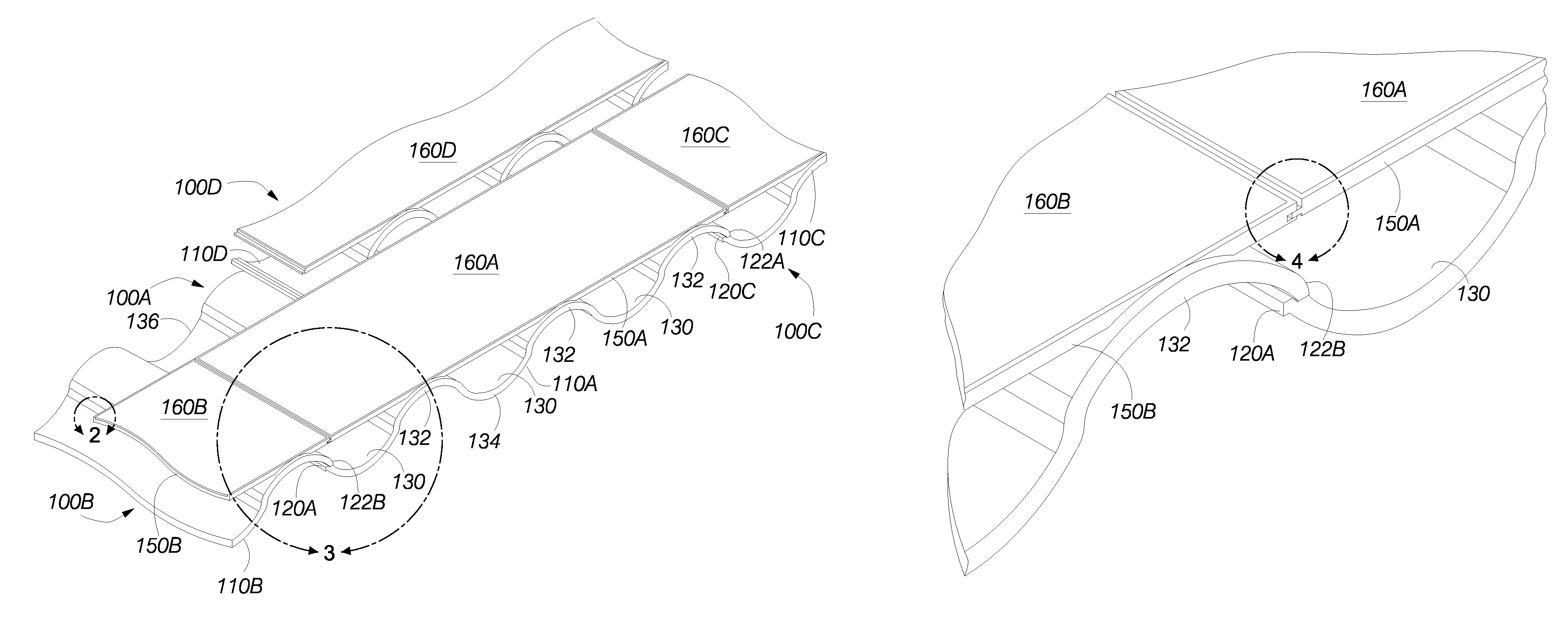

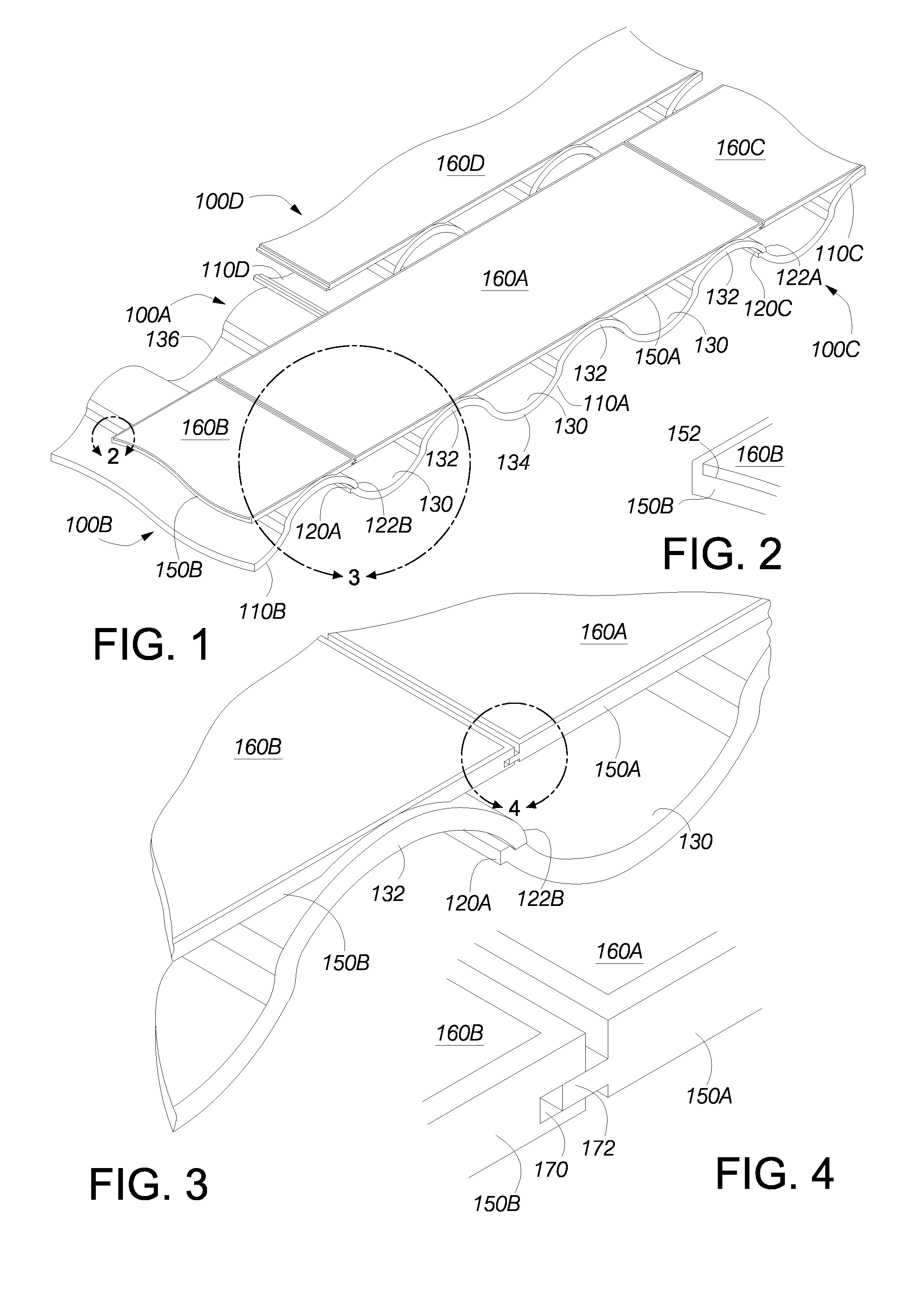

Profile roof tile with integrated photovoltaic module

Owner:LUMETA LLC

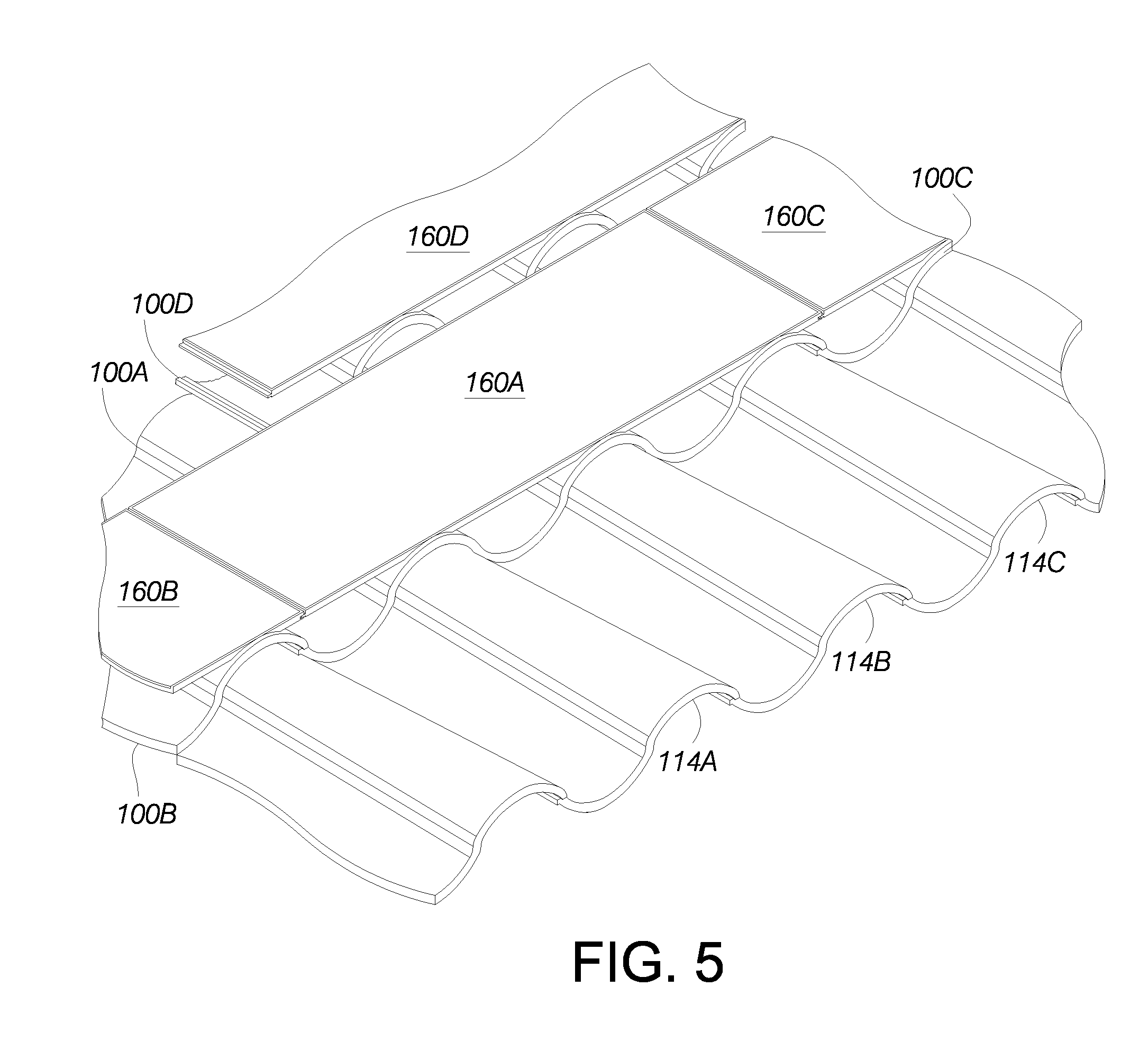

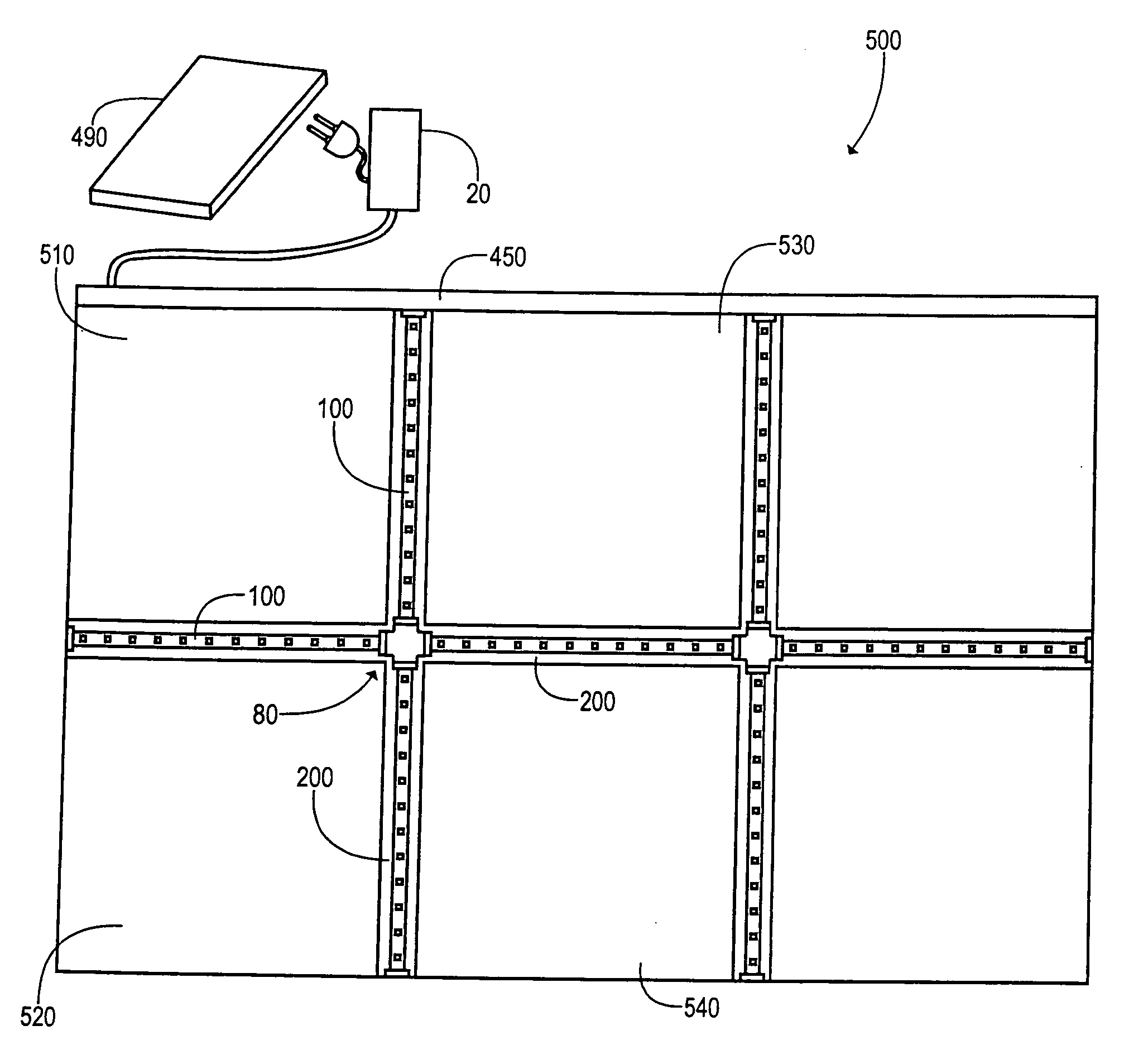

LED lighting for glass tiles

InactiveUS20090147504A1Easy to removeEasy to replaceCovering/liningsPoint-like light sourceBrickSurface layer

Devices, apparatus, systems, and methods of installing LED (light emitting diodes) for glass tiles and glass blocks. The LEDs can be housed in flexible strips having flexible bendable transparent housing sleeves with ends that can interconnect by male and female ends to one another with various types of interconnectors. Each separate sleeve can house up to 33 LEDs in a transparent plastic sleeve. A transparent connector sleeve can be slid over the interconnected ends and heat shrunk in place. The glass tiles can be laid out to uniform joints spacings between the glass tiles of approximately 3 / 16 of an inch. The LED strips can be placed on a surface layer of transparent grout that has been laid in the joint spacing, followed by a top layer of transparent grout. The transparent grout can be removable grout and include clear Silicon. The LED strips can have peel and stick back layers with adhesive backing that allows mounting to the lower surface. The LED strips can be placed with glass tiles, and other types of tiles such as but not limited to ceramic tiles, stone tiles and the like, as well as with glass blocks. Splitter(s) can be used to run parallel runs of LED strips at different spaced apart locations.

Owner:NEW HORIZON DESIGNS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com