Patents

Literature

1254results about "Sidewalk pavings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

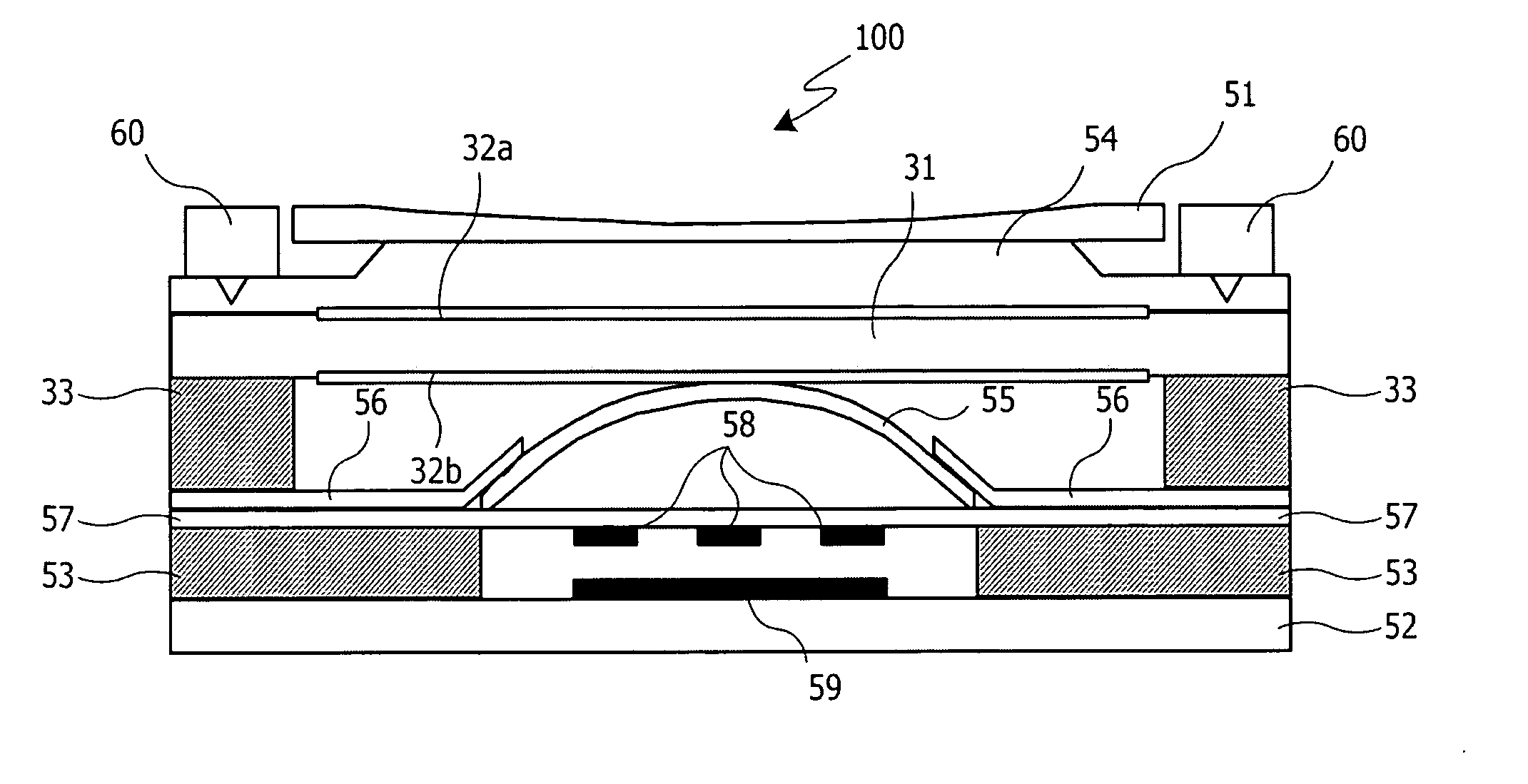

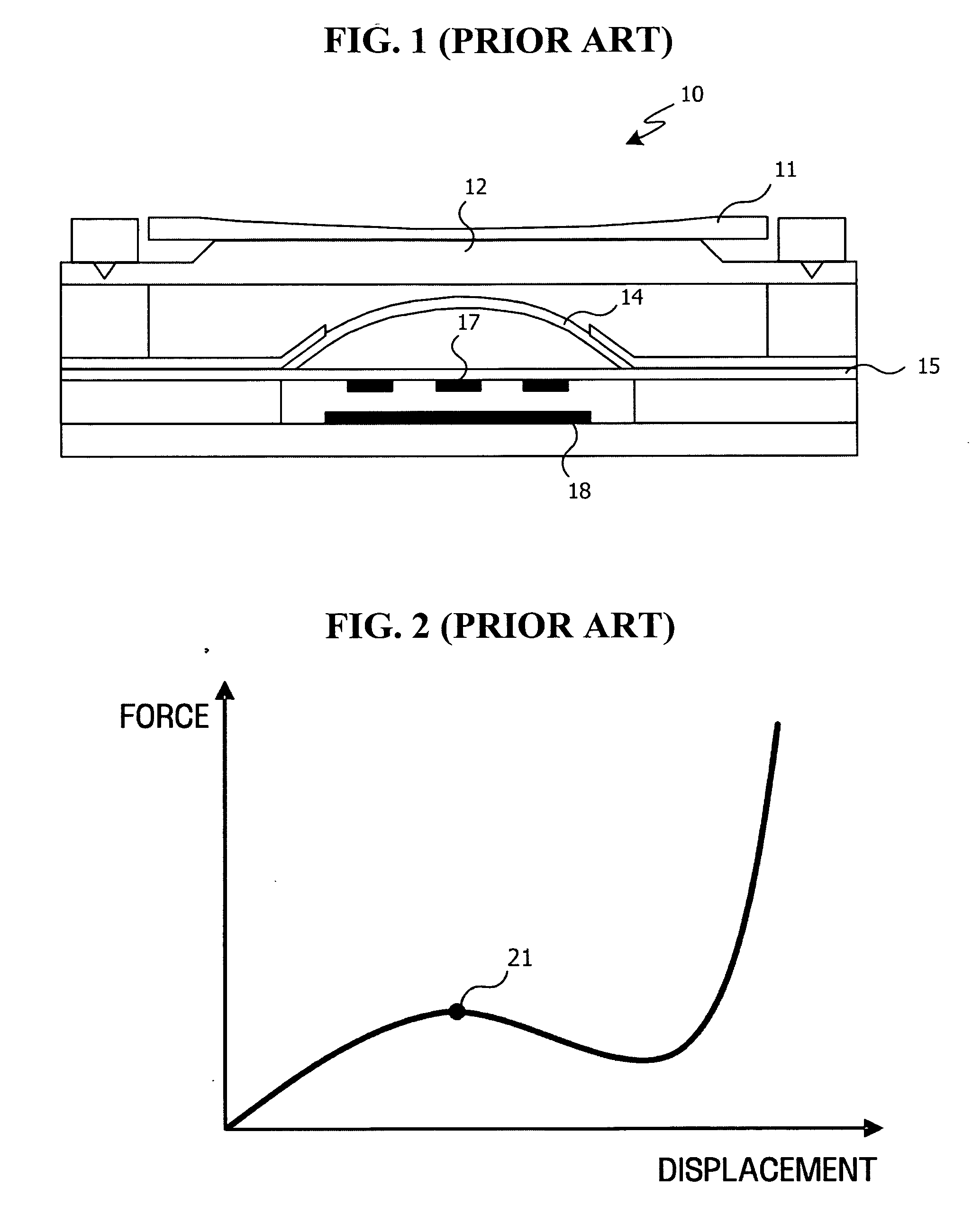

Haptic button and haptic device using the same

InactiveUS20070152974A1Easy to operateInput/output for user-computer interactionSingle unit pavingsActive polymerEngineering

A haptic button providing various stimulations to a user according to a current application and a haptic device using the same are provided. The haptic button includes an electro-active polymer having a flat shape, a pair of electrodes contacting two sides of the electro-active polymer, an electric circuit applying a predetermined voltage to the pair of electrodes, and a sensor sensing a button input from a user, wherein stimulation provided from the electro-active polymer to the user is changed by changing a waveform of the voltage according to a current application status.

Owner:SAMSUNG ELECTRONICS CO LTD

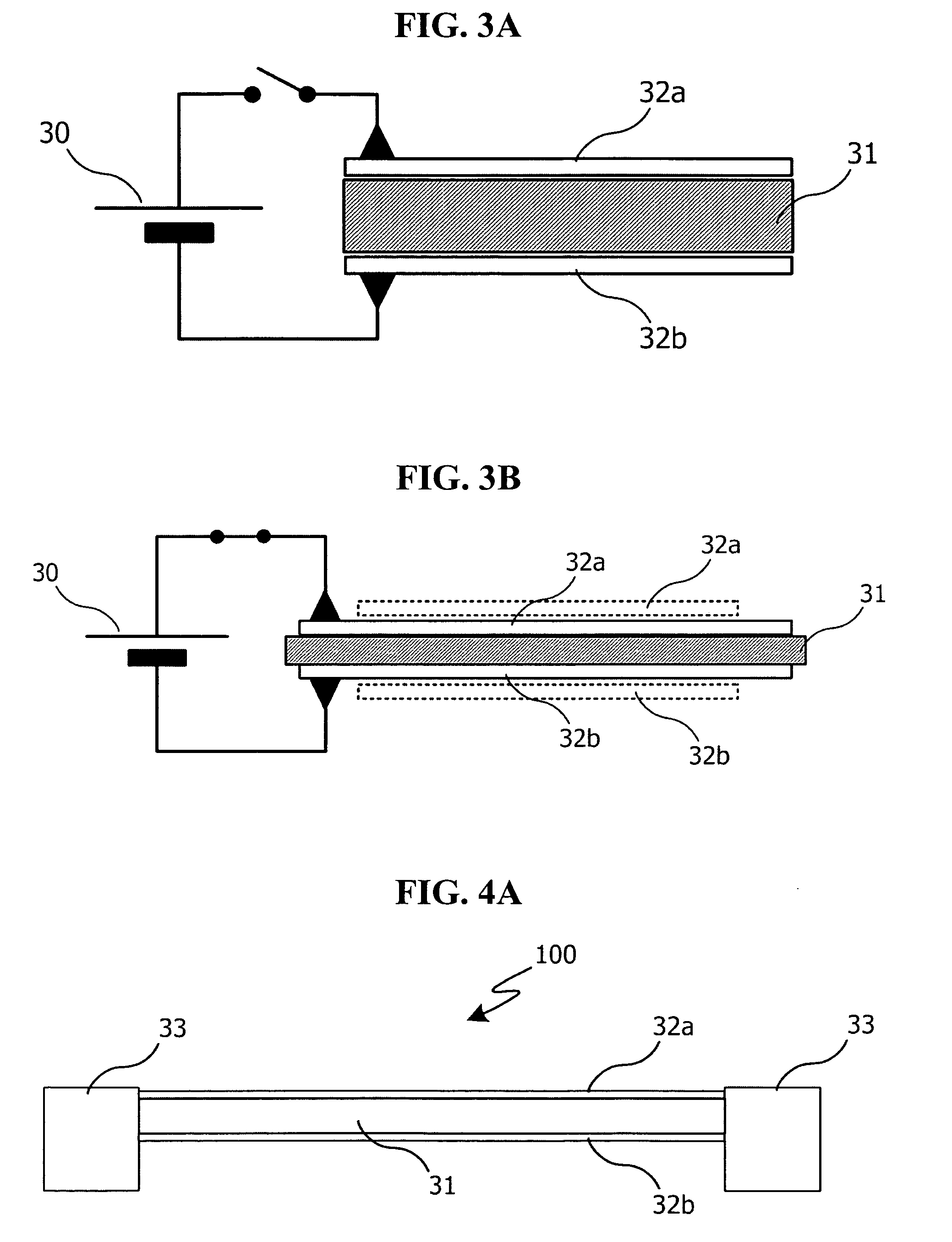

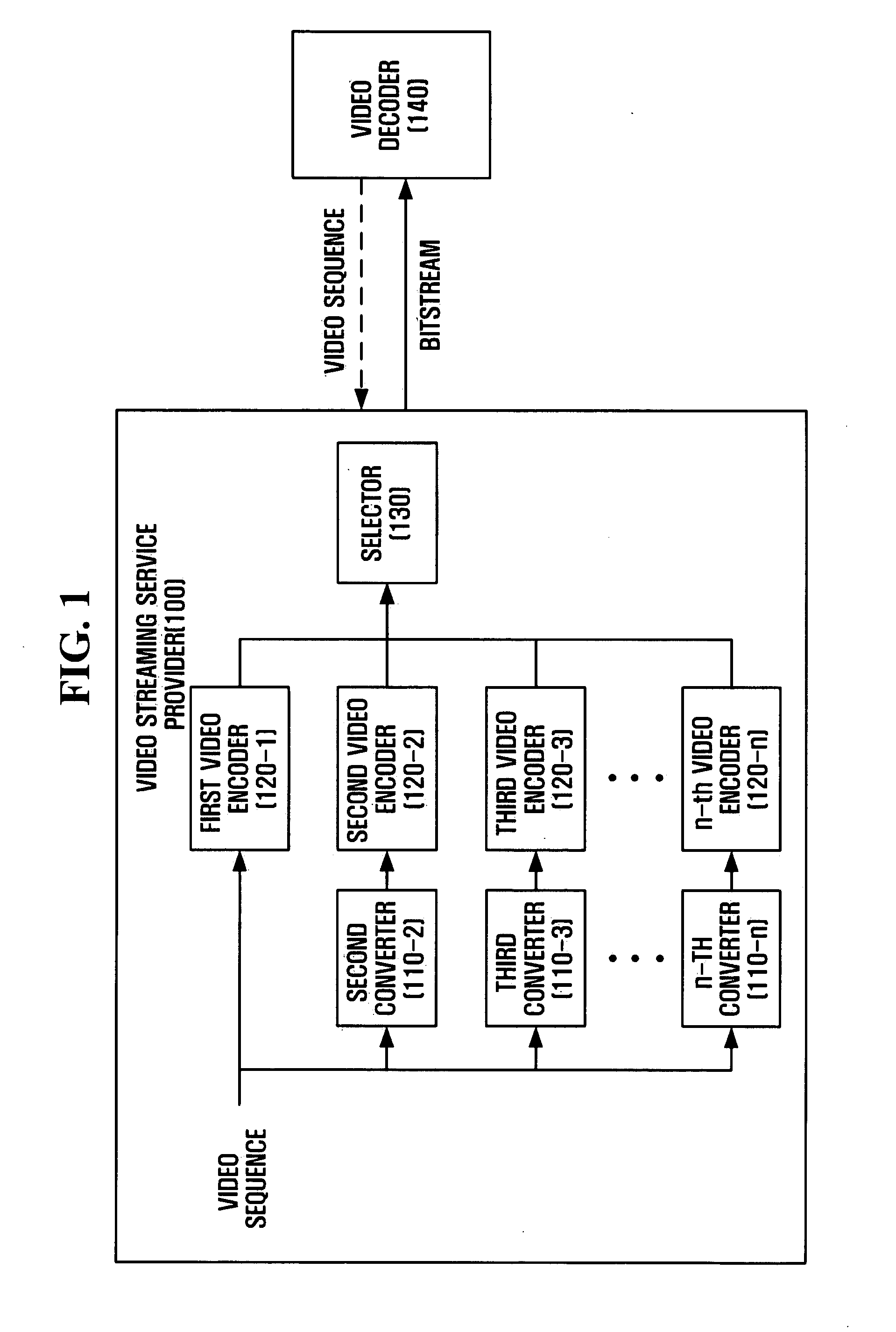

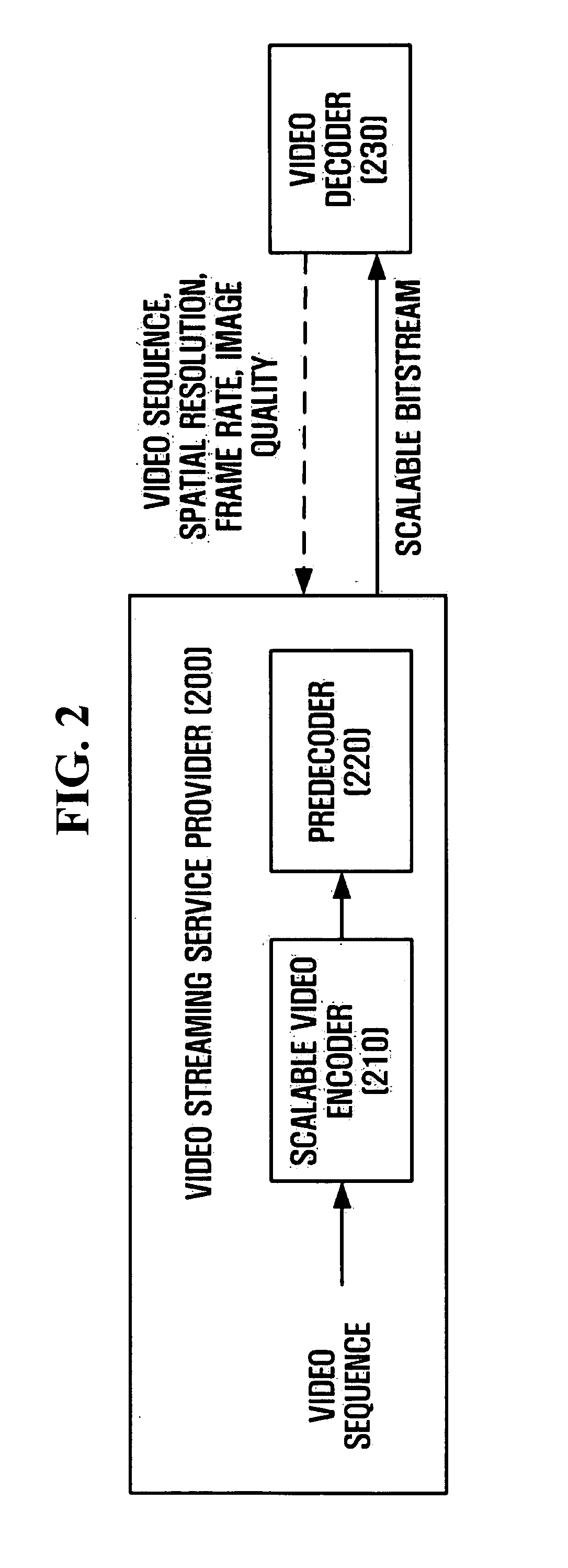

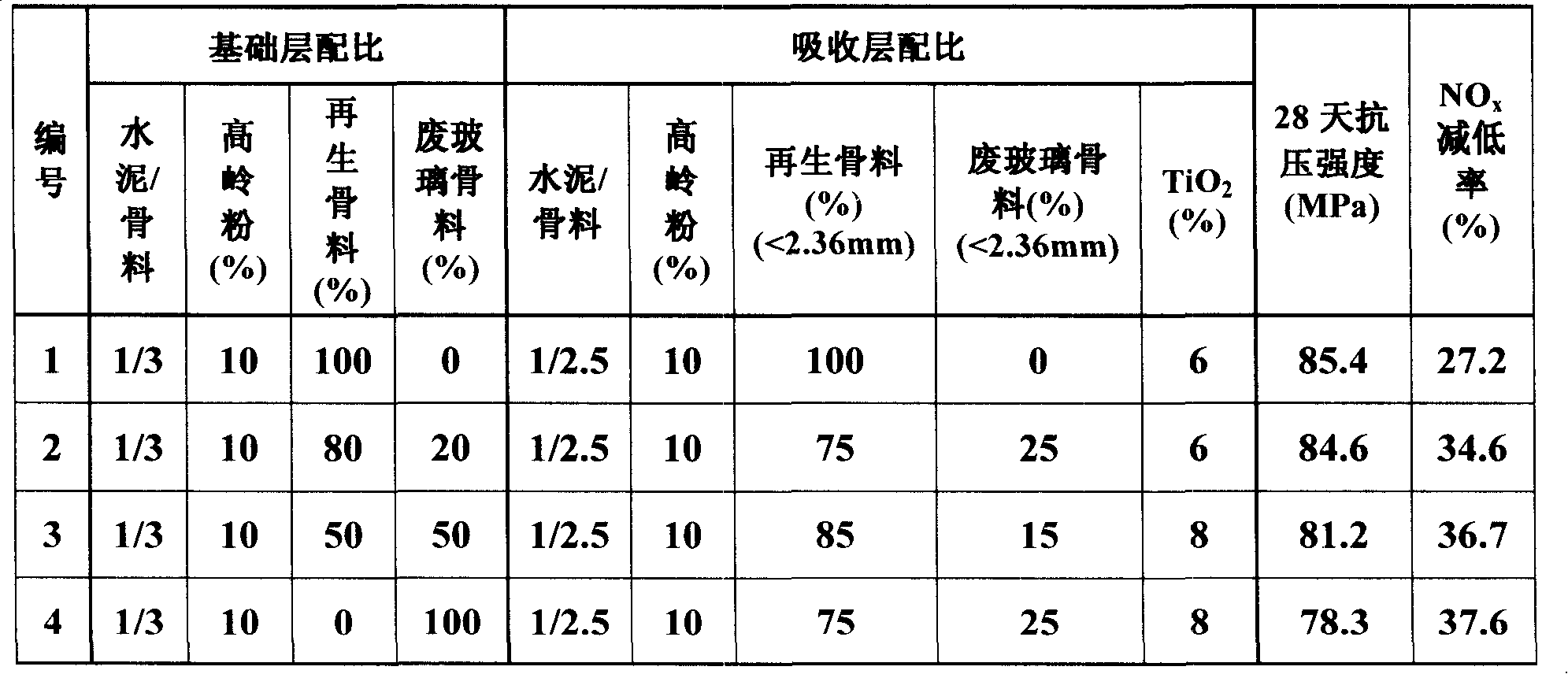

Method and apparatus for video coding, predecoding, and video decoding for video streaming service, and image filtering method

ActiveUS20050195899A1Improve efficiencyImprove image qualityPulse modulation television signal transmissionPicture reproducers using cathode ray tubesComputer graphics (images)Video encoding

A method and apparatus for video encoding, predecoding, and video decoding for video streaming services. The video encoding method includes encoding first and second video sequences into first and second bitstreams using scalable video coding, wherein at least one of resolution, frame rate, and image quality of the second video sequence is different from that of the first video sequence, and combining the first and second bitstreams into a super bitstream.

Owner:SAMSUNG ELECTRONICS CO LTD

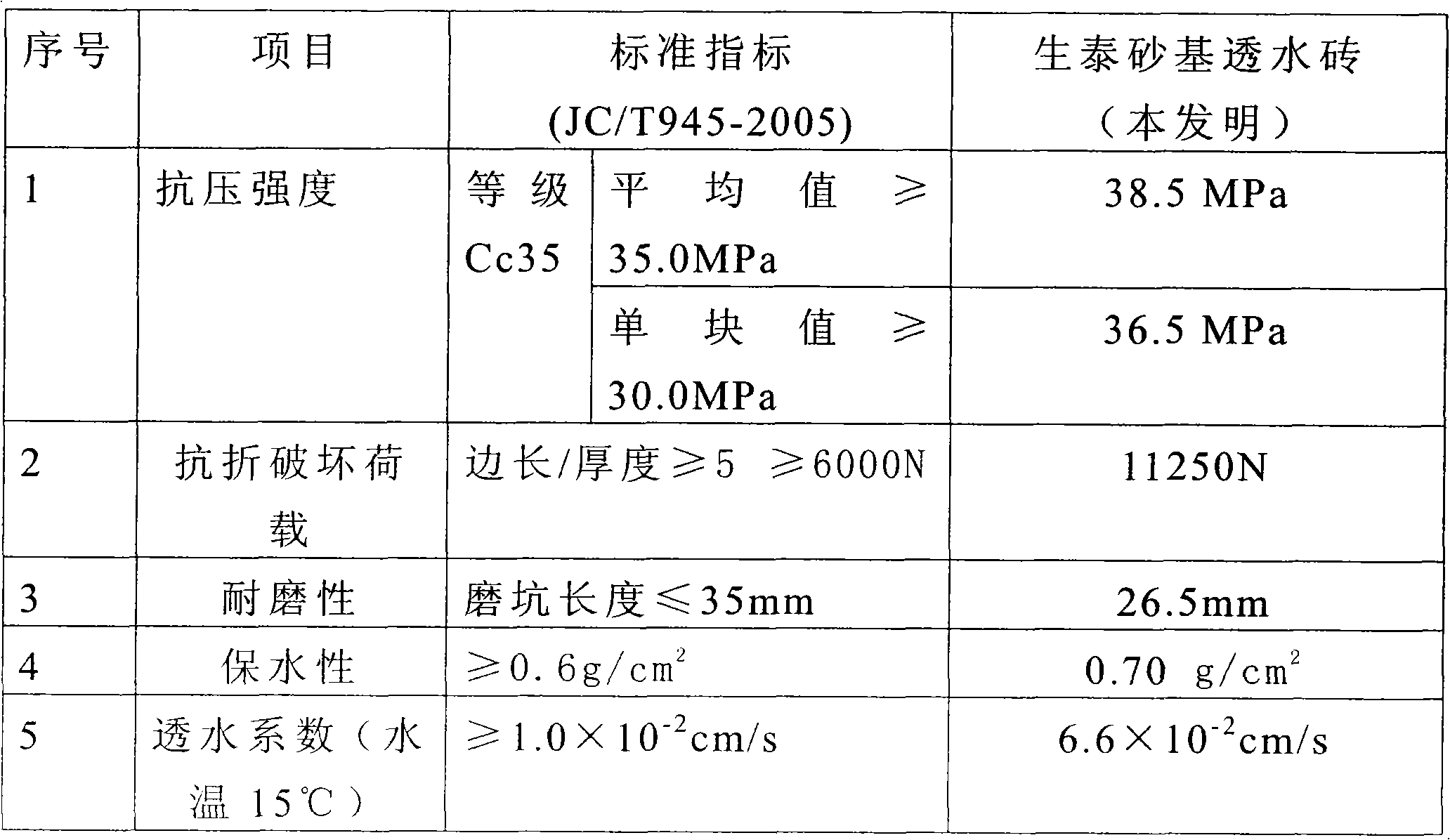

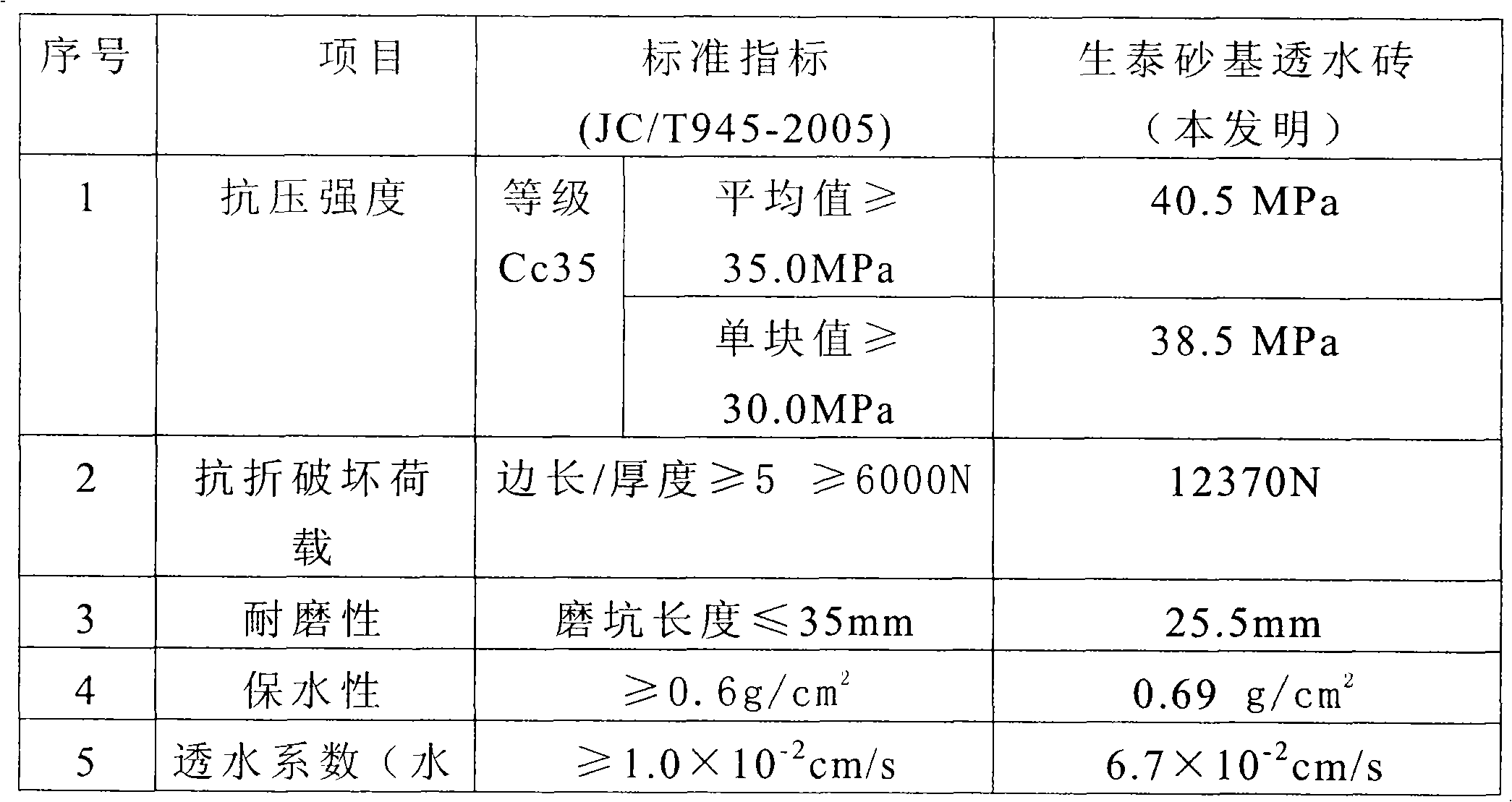

Composite water permeable brick

InactiveCN1966861AGood water permeabilityLow costSingle unit pavingsClimate change adaptationBrickAdhesive

A composite water permeable brick comprises water permeable surface and base closely combined together with aggregate and adhesive coating the aggregate, with the adhesive of the said water permeable surface including at least hydrophilicity adhesive. It can keep fine water permeability, with the brick surface fine and close and reduced in cost.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

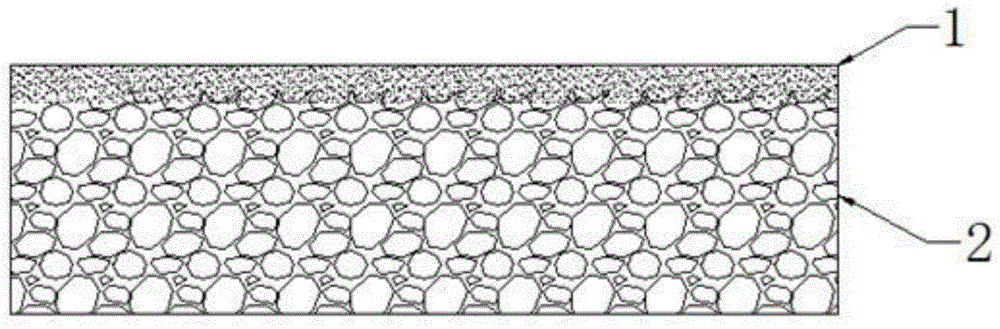

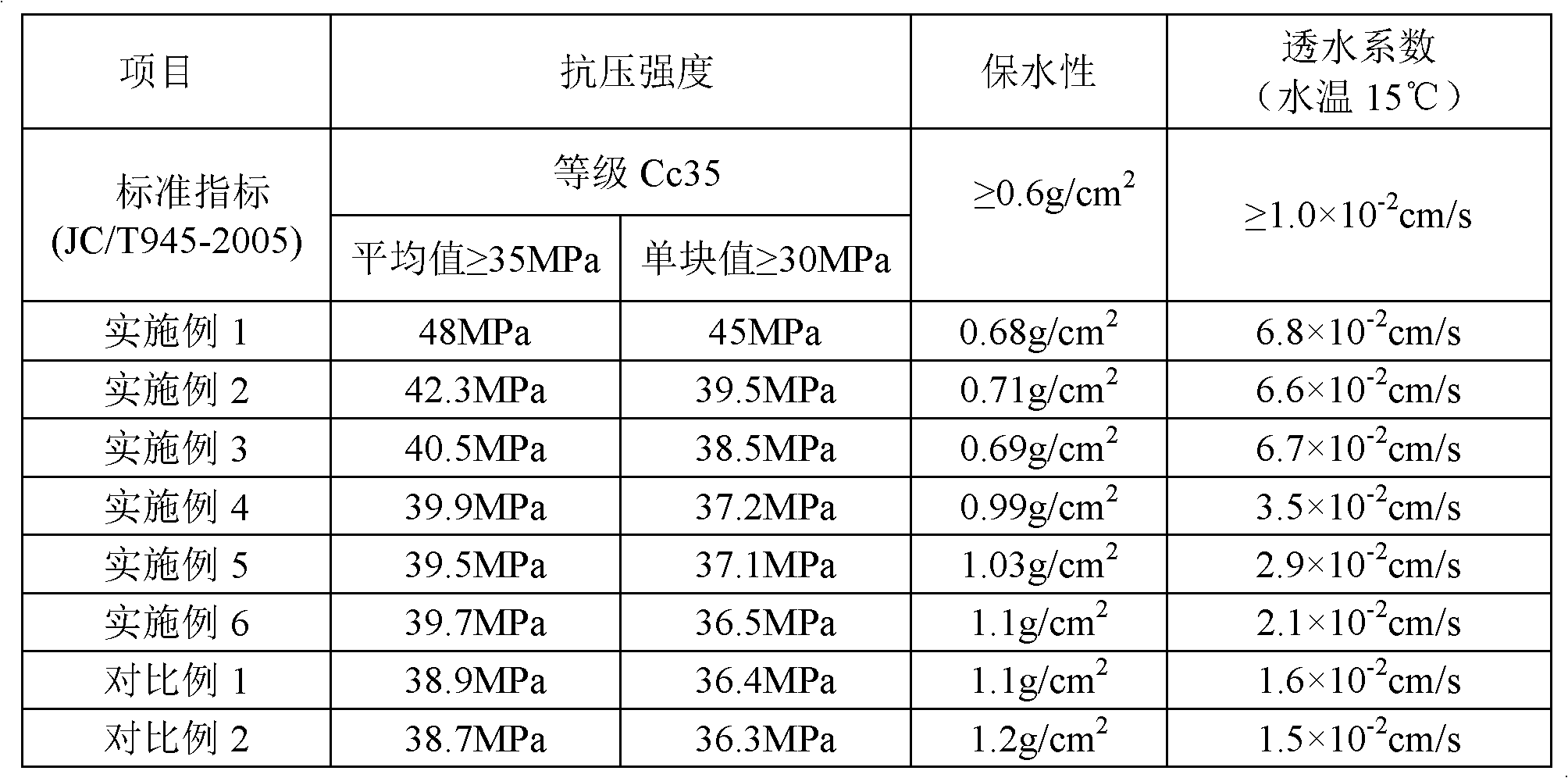

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

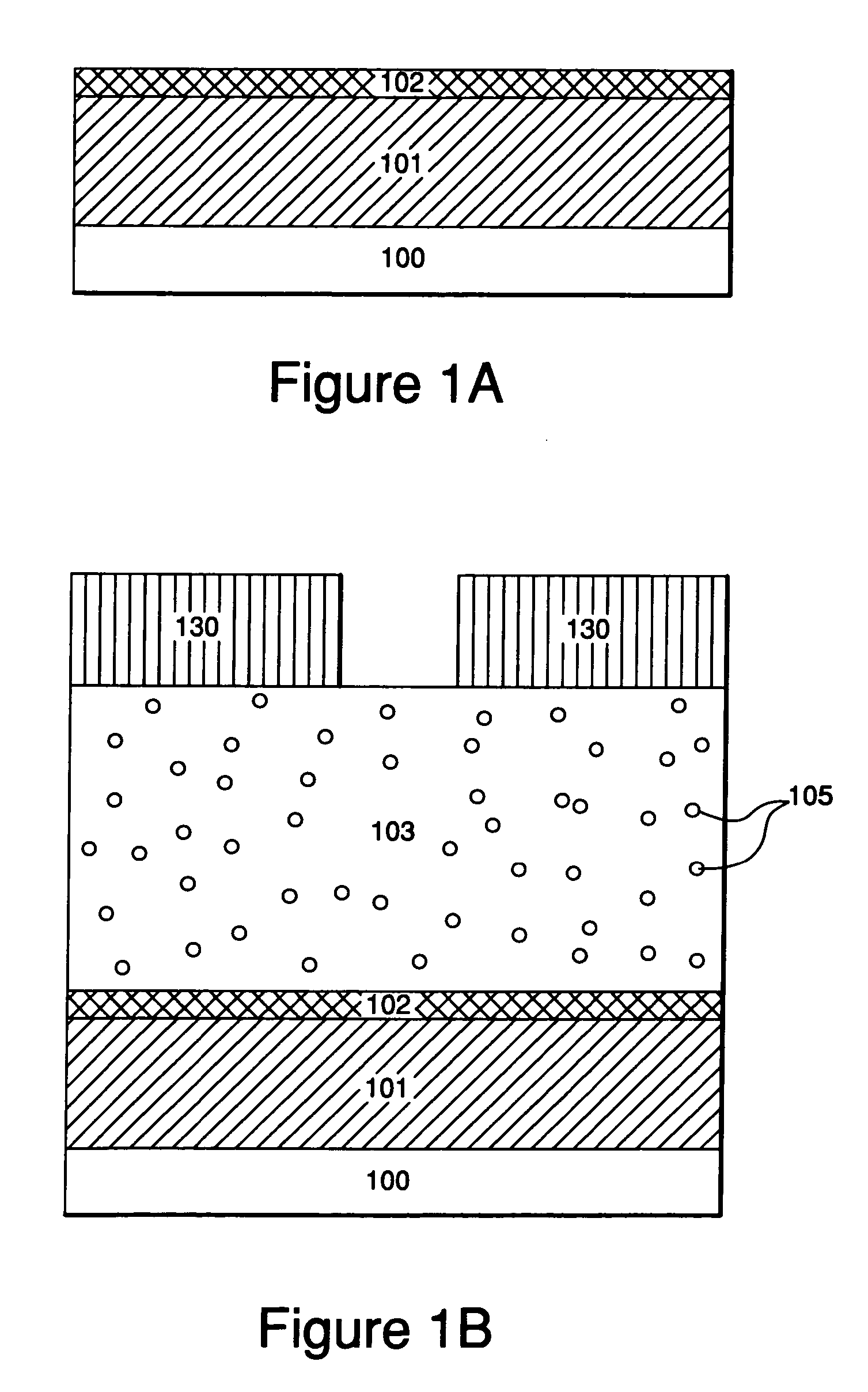

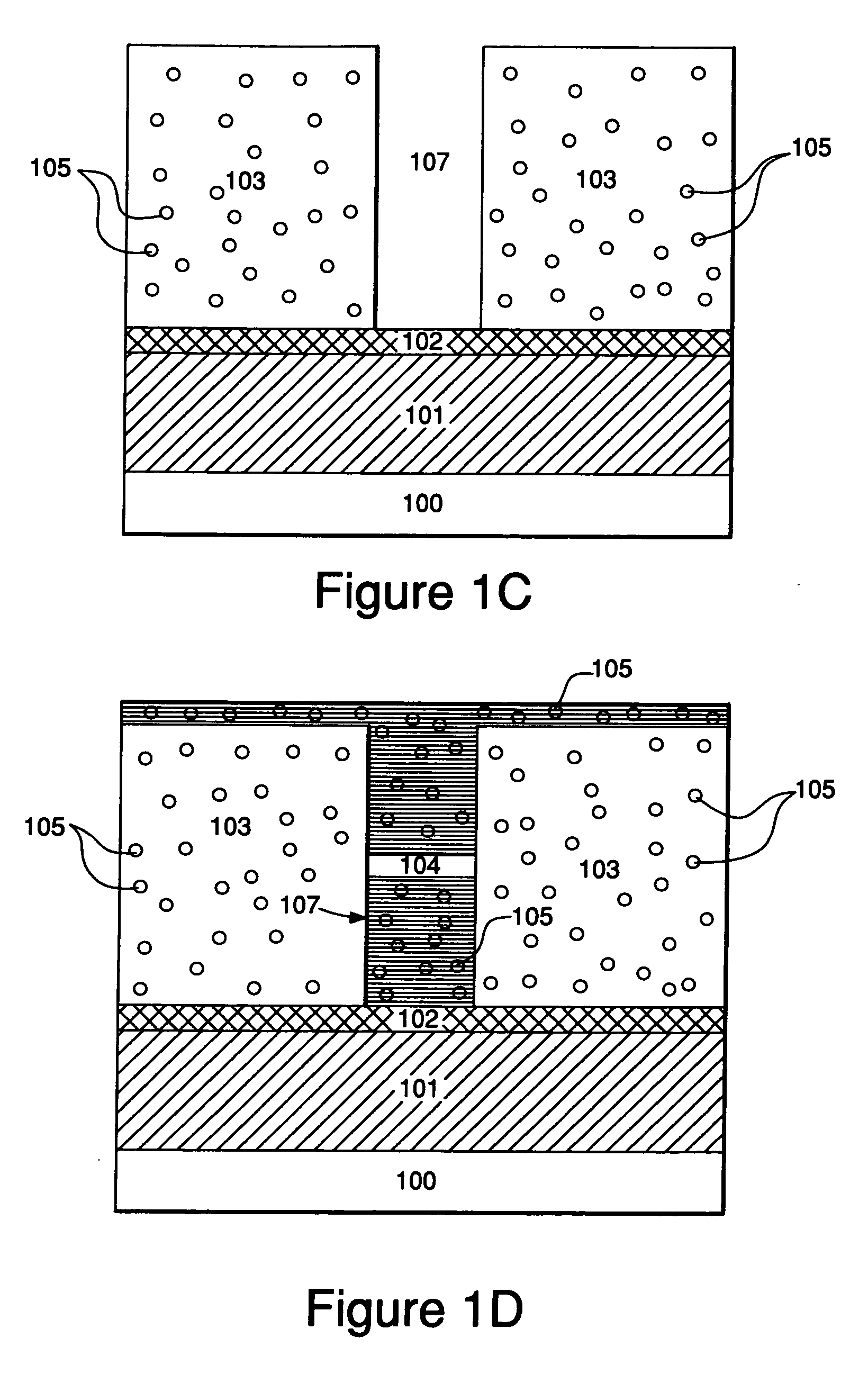

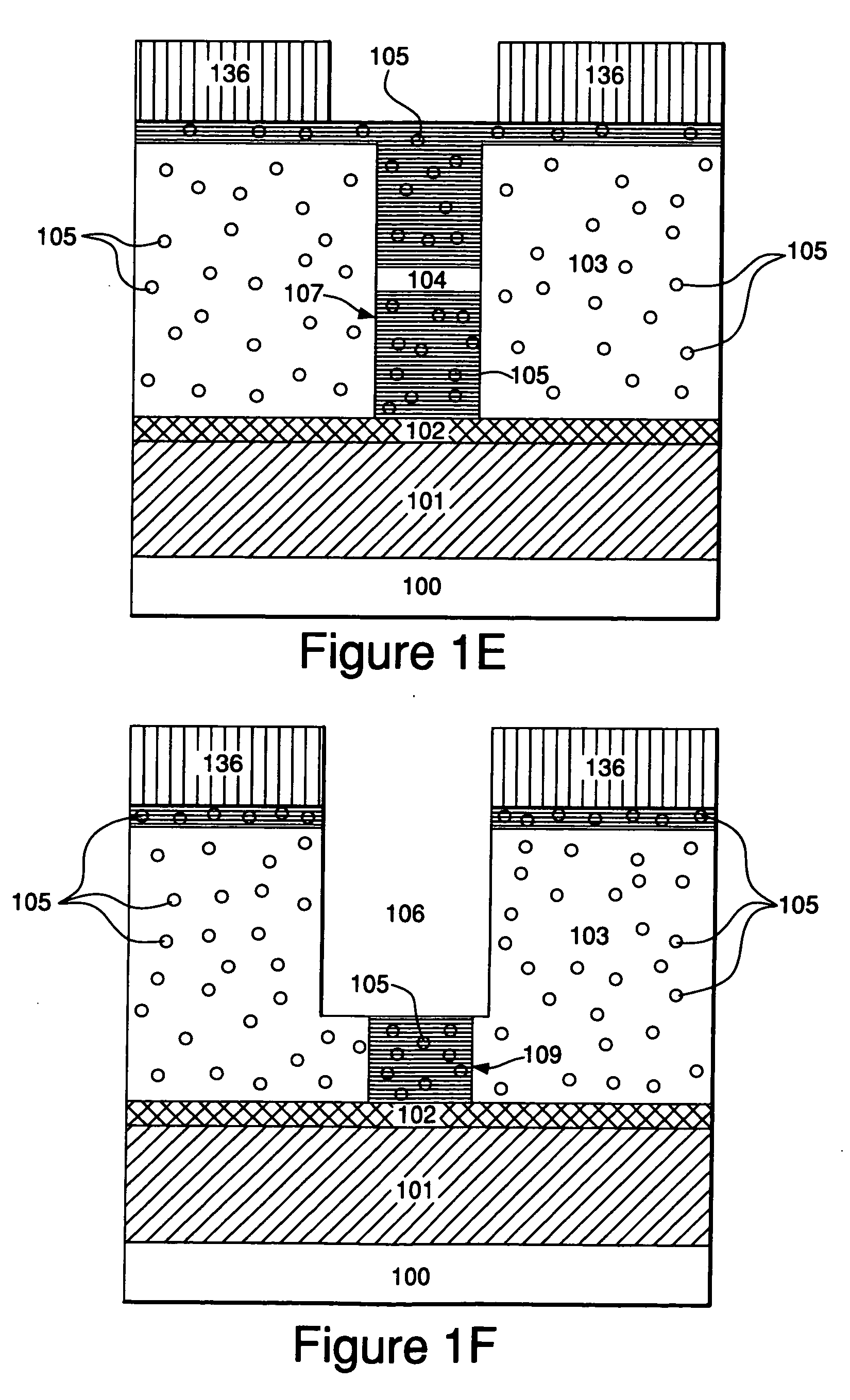

Method for defining a feature on a substrate

An improved method of forming a feature in a semiconductor substrate is described. The method comprises the steps of forming a porous dielectric layer on a substrate; removing a first portion of the porous dielectric layer to form a first etched region; filling the first etched region with a porous sacrificial light absorbing material having dry etch properties similar to those of the porous dielectric layer; removing a portion of the porous sacrificial light absorbing material and a second portion of the porous dielectric layer to form a second etched region; and removing the remaining portions of the porous sacrificial light absorbing material by employing a process, wherein the porous sacrificial light absorbing material has an etch rate greater than that of the porous dielectric layer in the process.

Owner:VERSUM MATERIALS US LLC

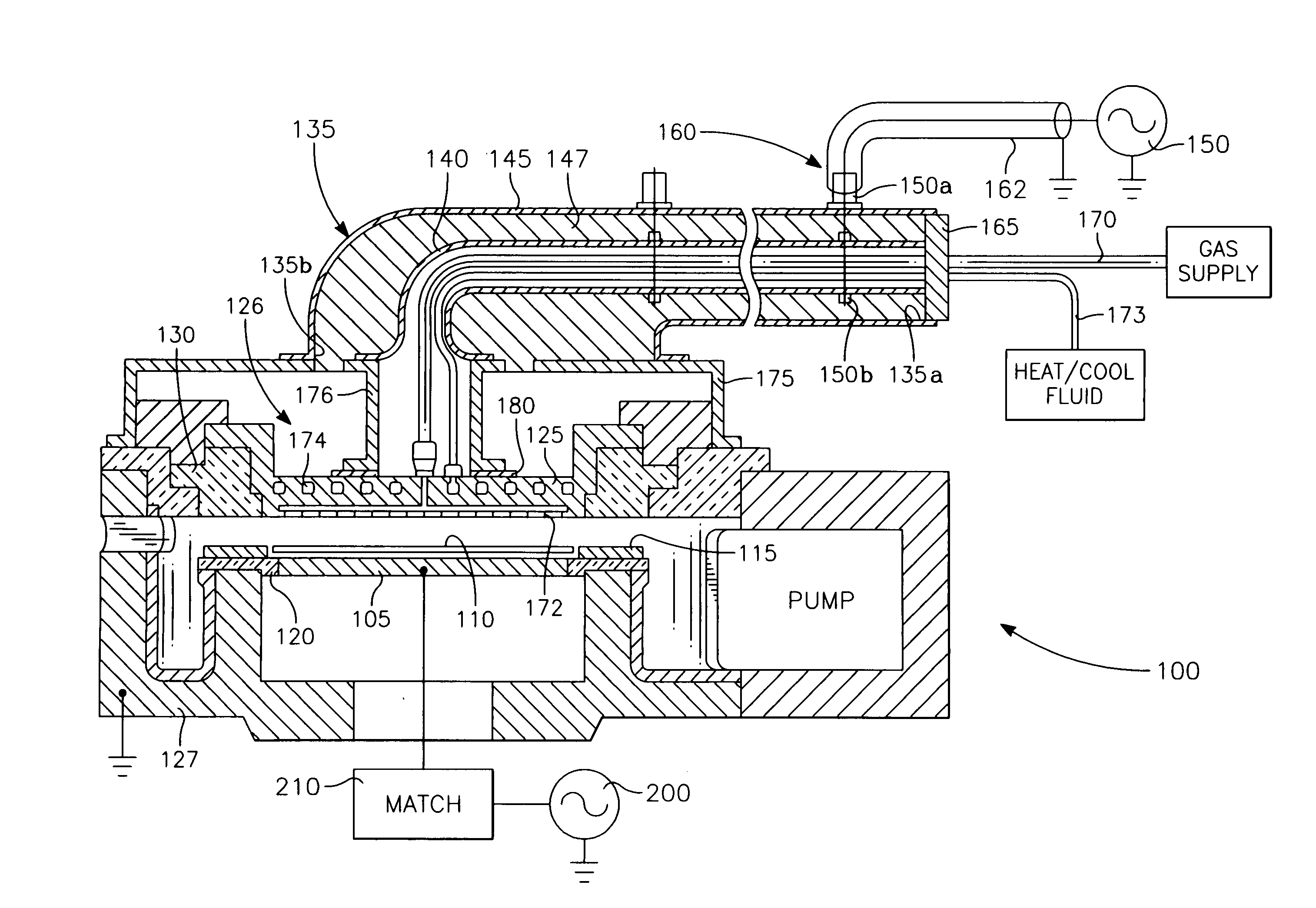

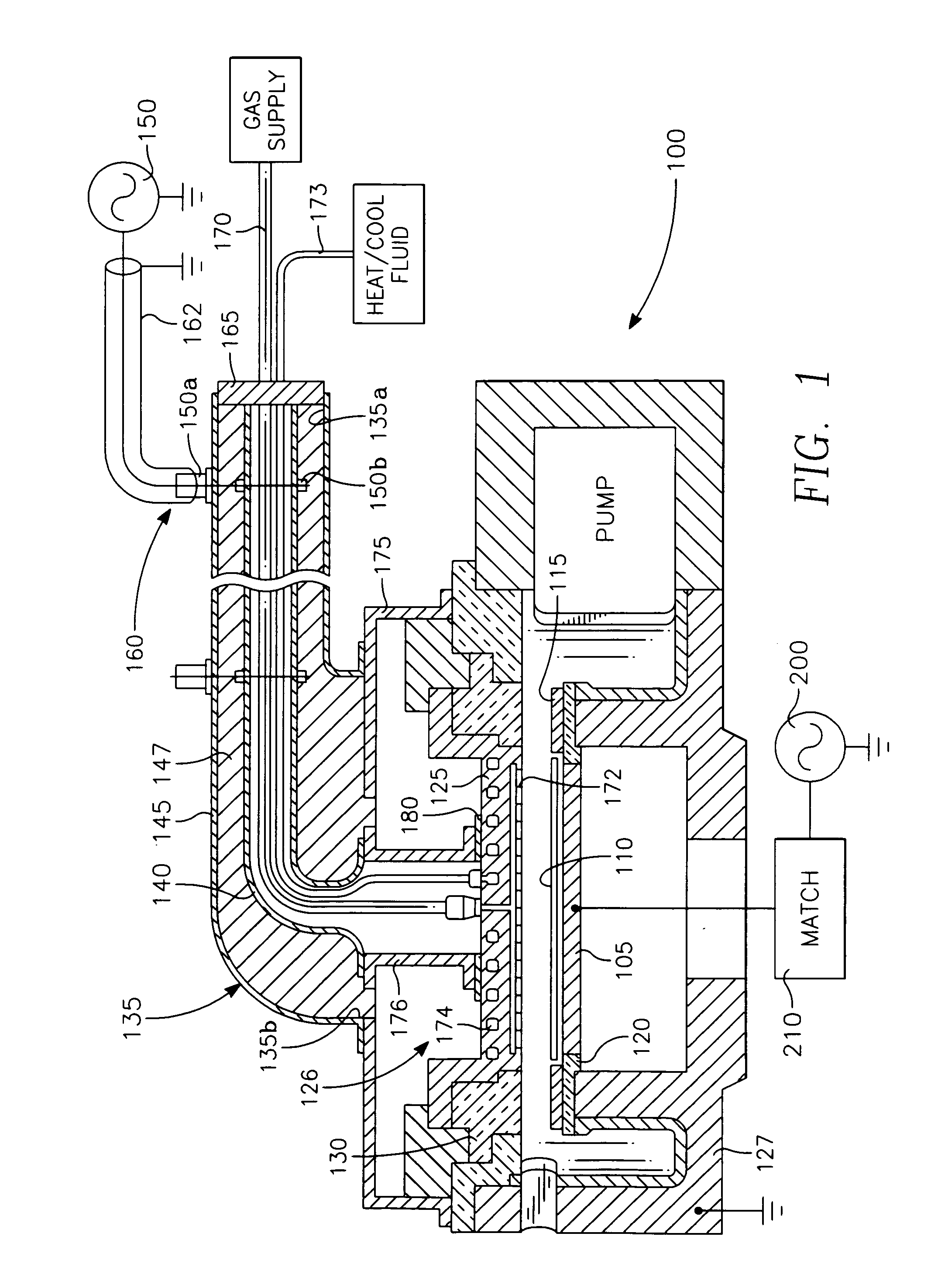

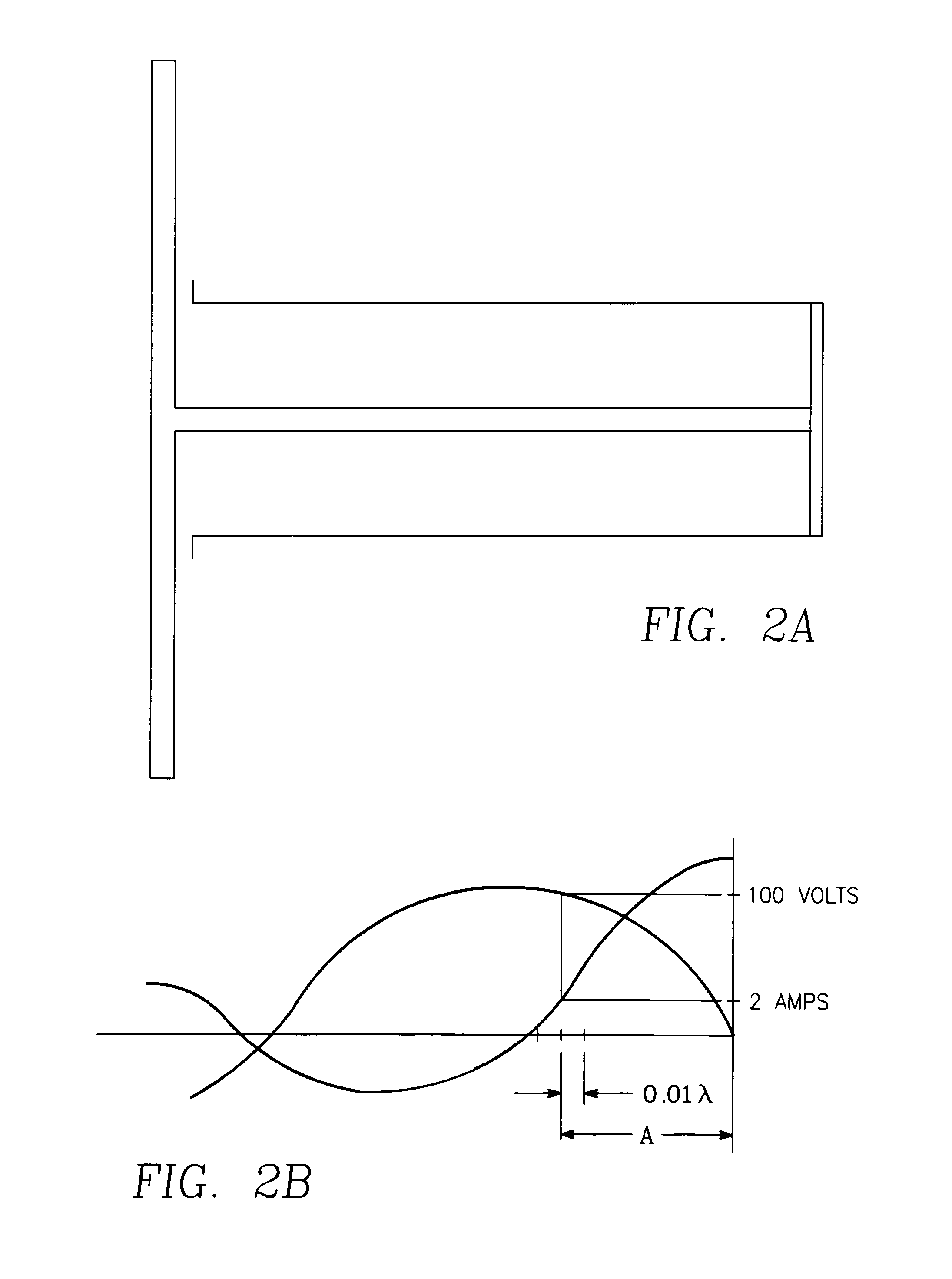

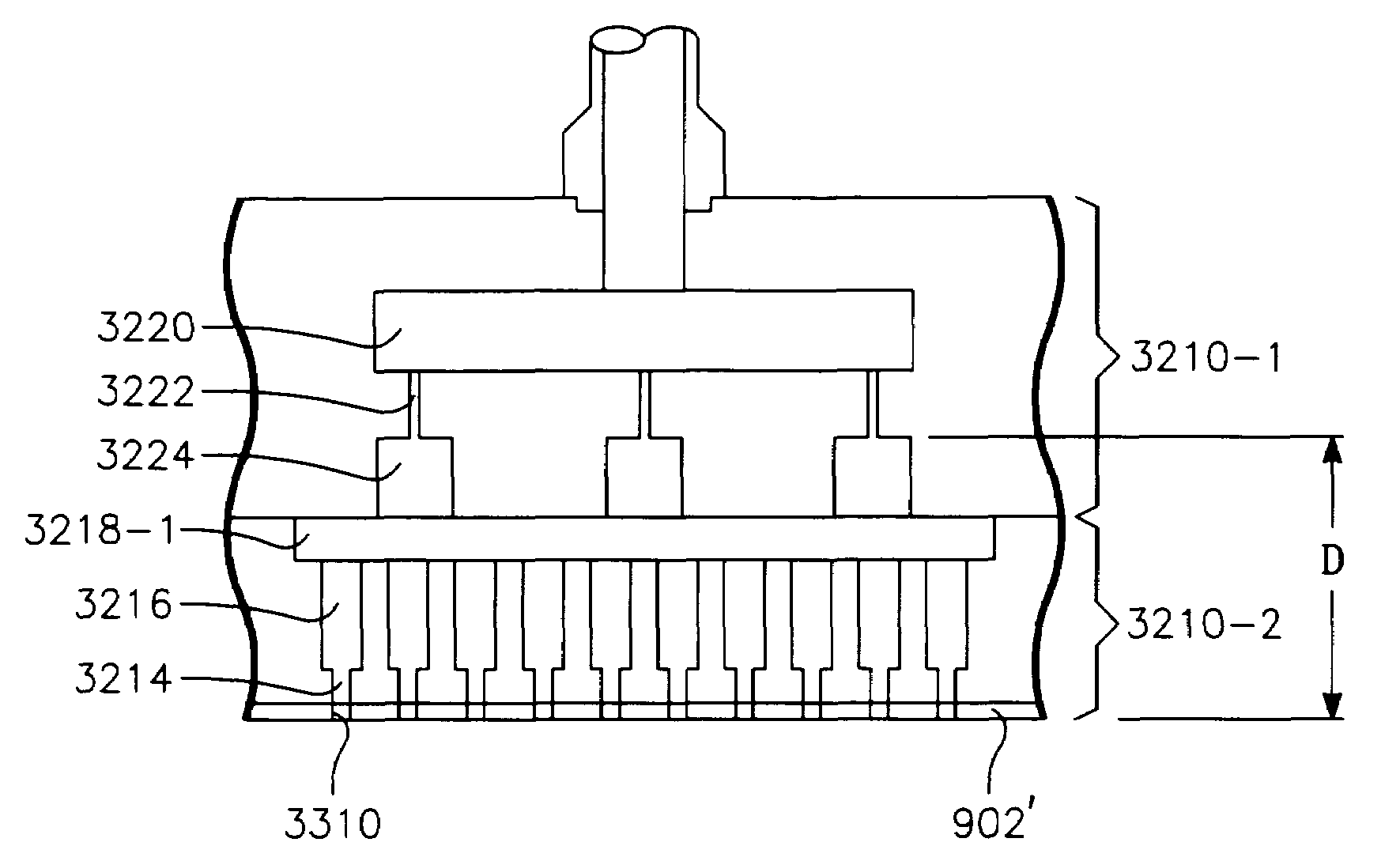

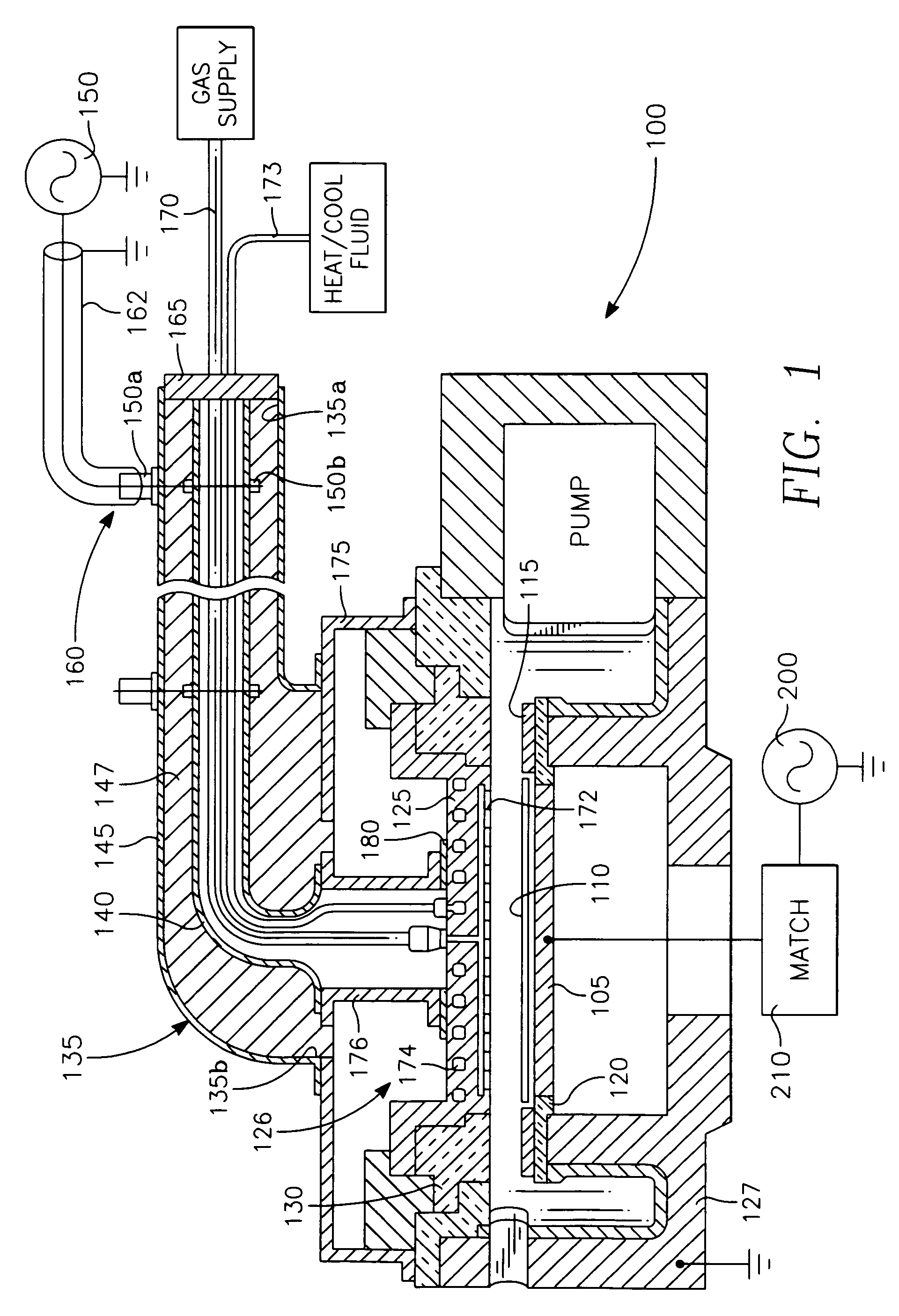

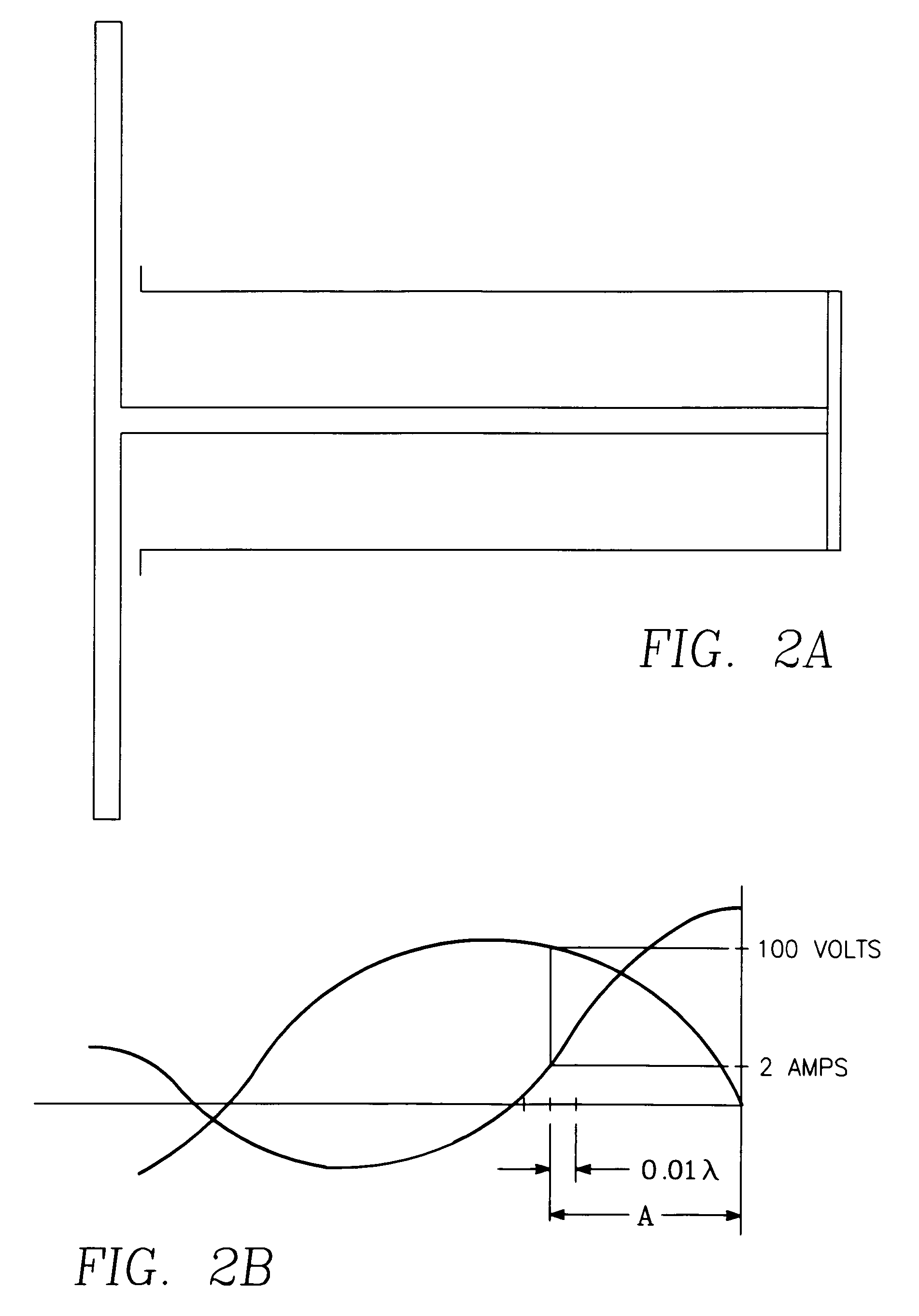

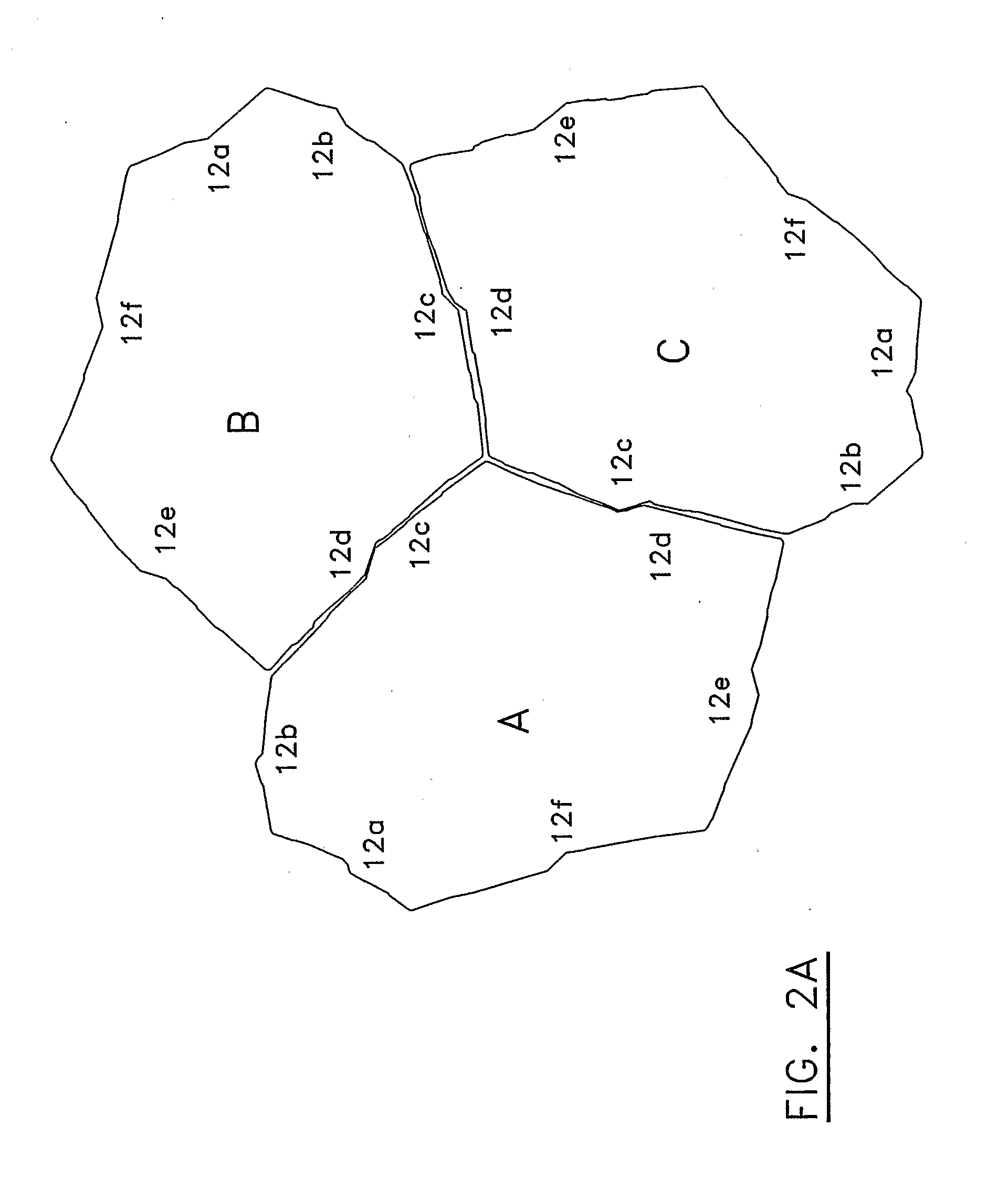

Plasma reactor overhead source power electrode with low arcing tendency, cylindrical gas outlets and shaped surface

An overhead gas distribution electrode forming at least a portion of the ceiling of a plasma reactor has a bottom surface facing a processing zone of the reactor. The electrode includes a gas supply manifold for receiving process gas at a supply pressure at a top portion of the electrode and plural pressure-dropping cylindrical orifices extending axially relative to the electrode from the gas supply manifold at one end of each the orifice. A radial gas distribution manifold within the electrode extends radially across the electrode. Plural axially extending high conductance gas flow passages couple the opposite ends of respective ones of the plural pressure-dropping orifices to the radial gas distribution manifold. Plural high conductance cylindrical gas outlet holes are formed in the plasma-facing bottom surface of the electrode and extend axially to the radial gas distribution manifold.

Owner:APPLIED MATERIALS INC

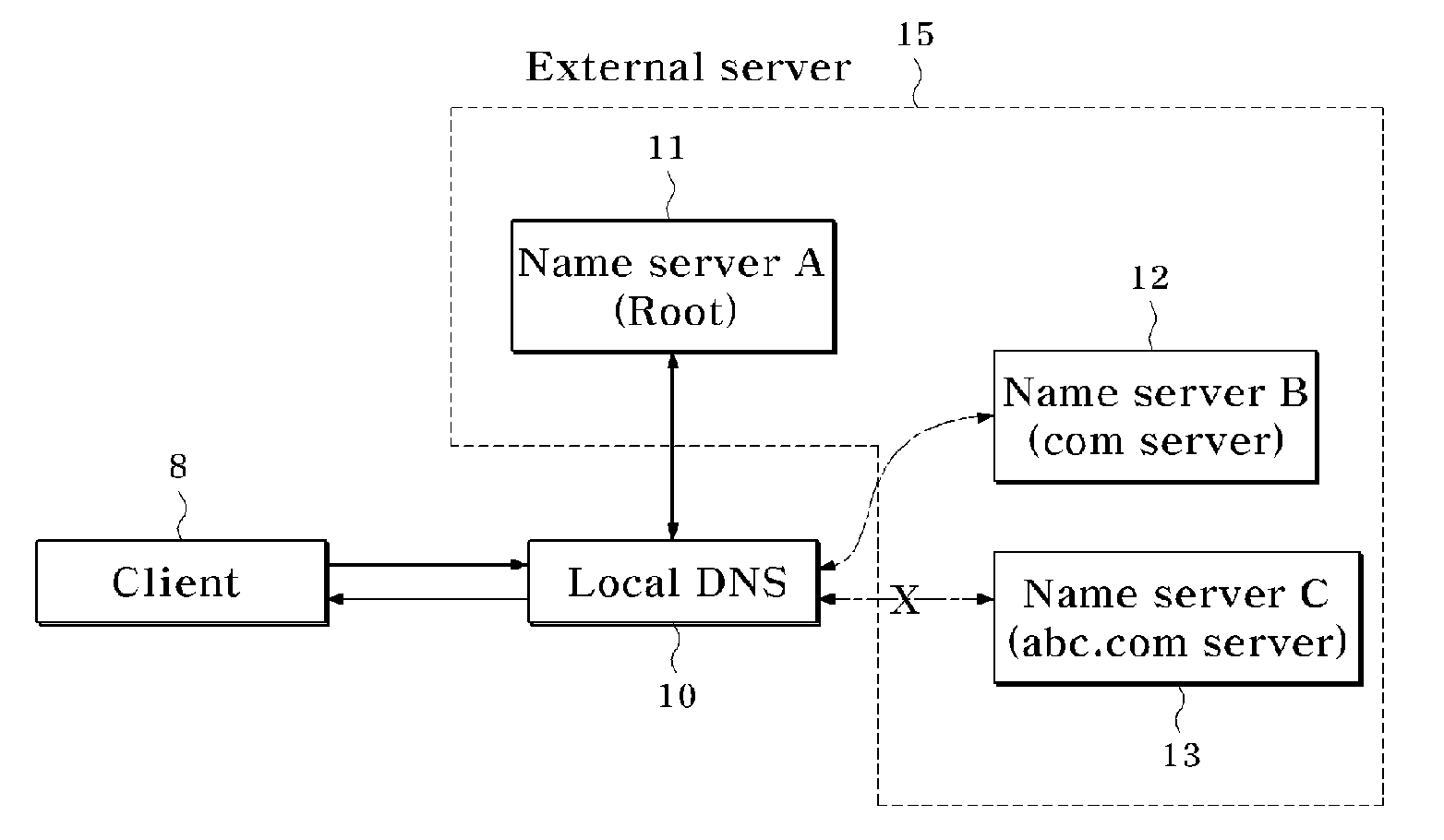

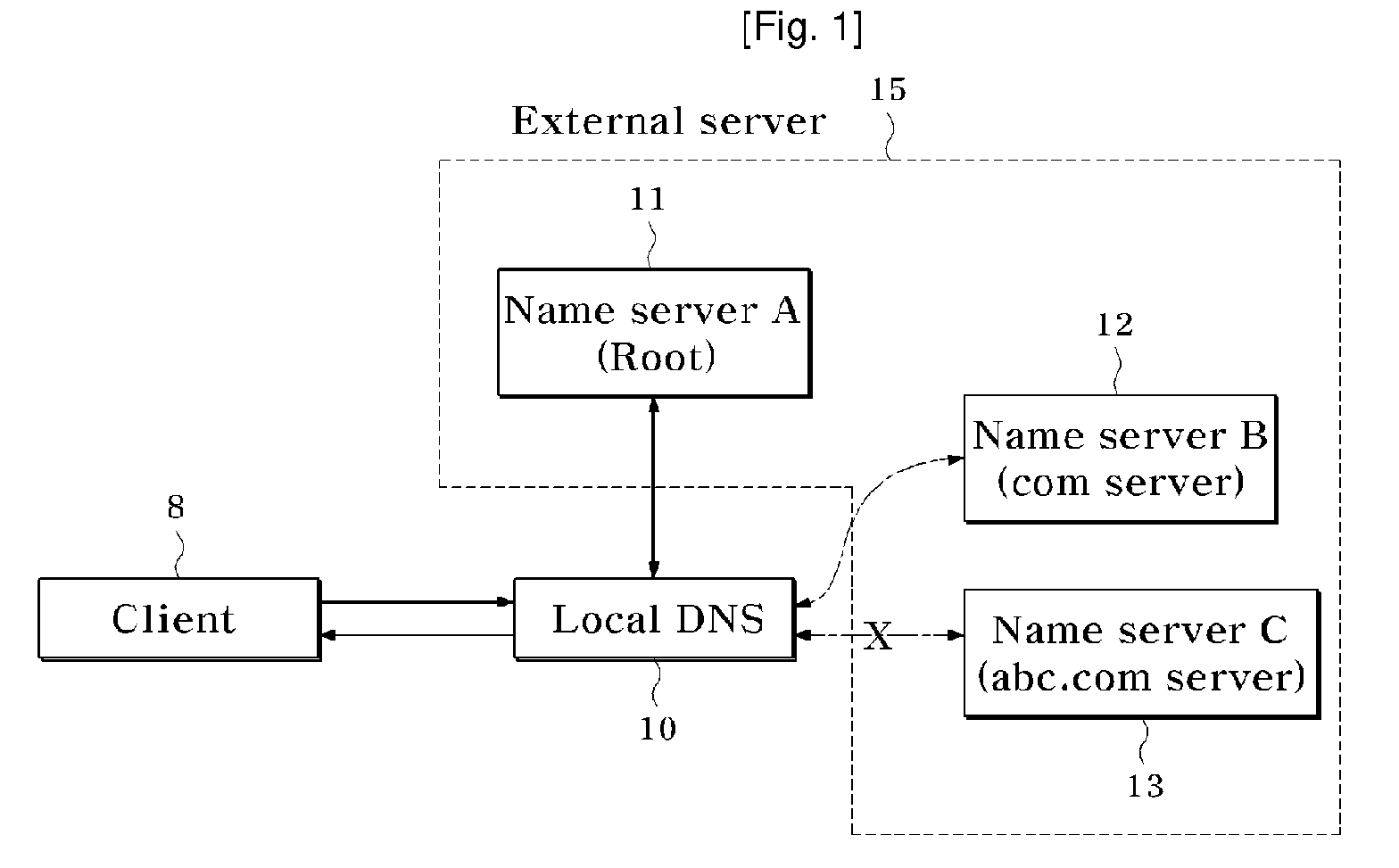

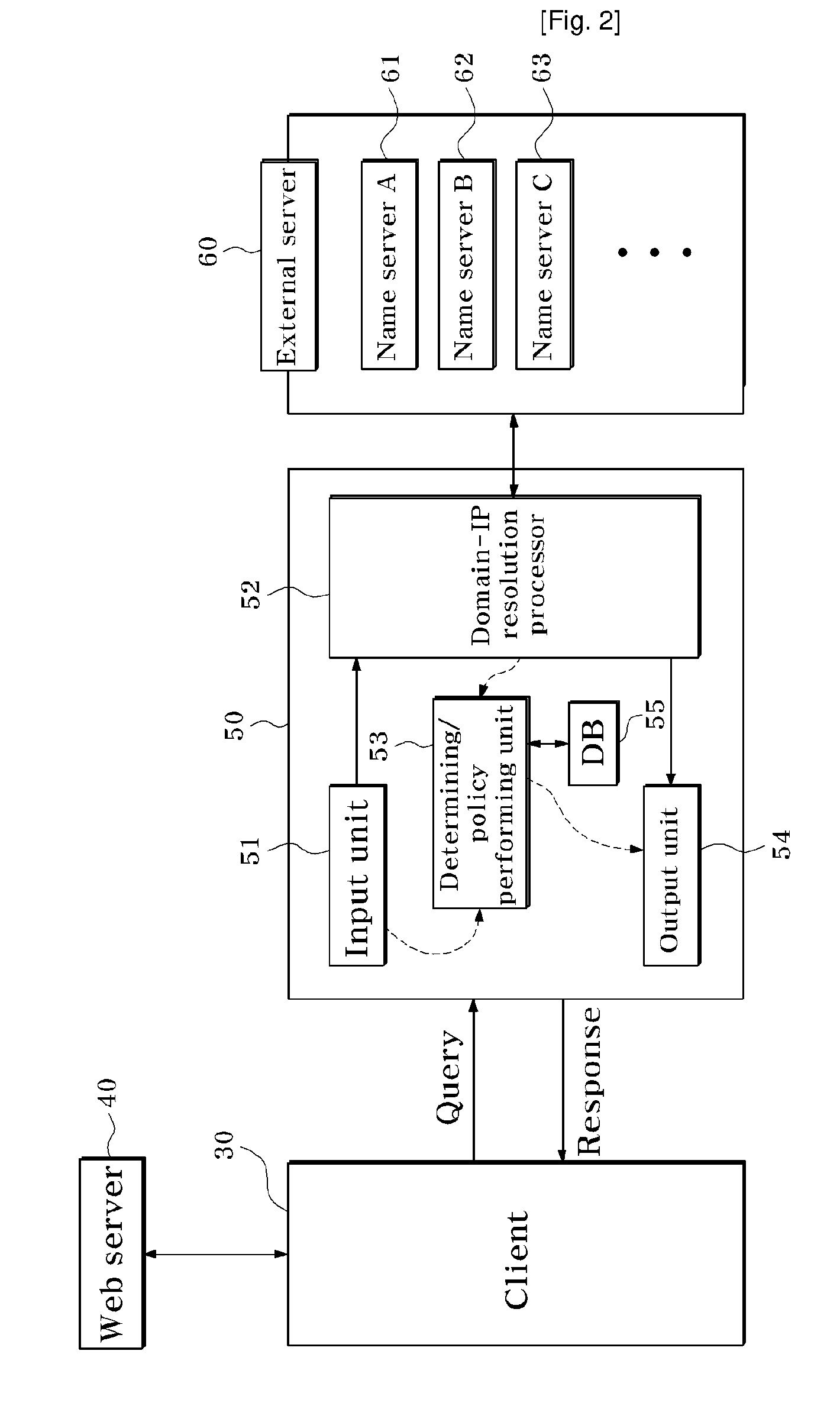

Local Domain Name Service System and Method for Providing Service Using Domain Name Service System

InactiveUS20090055929A1Quality improvementImprove system performanceSingle unit pavingsMemory loss protectionDomain nameClient-side

Provided is a local domain name system for querying an external server for a client-requested domain name and providing desired data to a user. A determination is made as to whether a special policy is to be applied to a client-input query through a test task. When a special policy is to be applied to the query, the special policy is performed to provide additional service to the client.

Owner:NETPIA COM

Plasma reactor overhead source power electrode with low arcing tendency, cylindrical gas outlets and shaped surface

An overhead gas distribution electrode forming at least a portion of the ceiling of a plasma reactor has a bottom surface facing a processing zone of the reactor. The electrode includes a gas supply manifold for receiving process gas at a supply pressure at a top portion of the electrode and plural pressure-dropping cylindrical orifices extending axially relative to the electrode from the gas supply manifold at one end of each the orifice. A radial gas distribution manifold within the electrode extends radially across the electrode. Plural axially extending high conductance gas flow passages couple the opposite ends of respective ones of the plural pressure-dropping orifices to the radial gas distribution manifold. Plural high conductance cylindrical gas outlet holes are formed in the plasma-facing bottom surface of the electrode and extend axially to the radial gas distribution manifold.

Owner:APPLIED MATERIALS INC

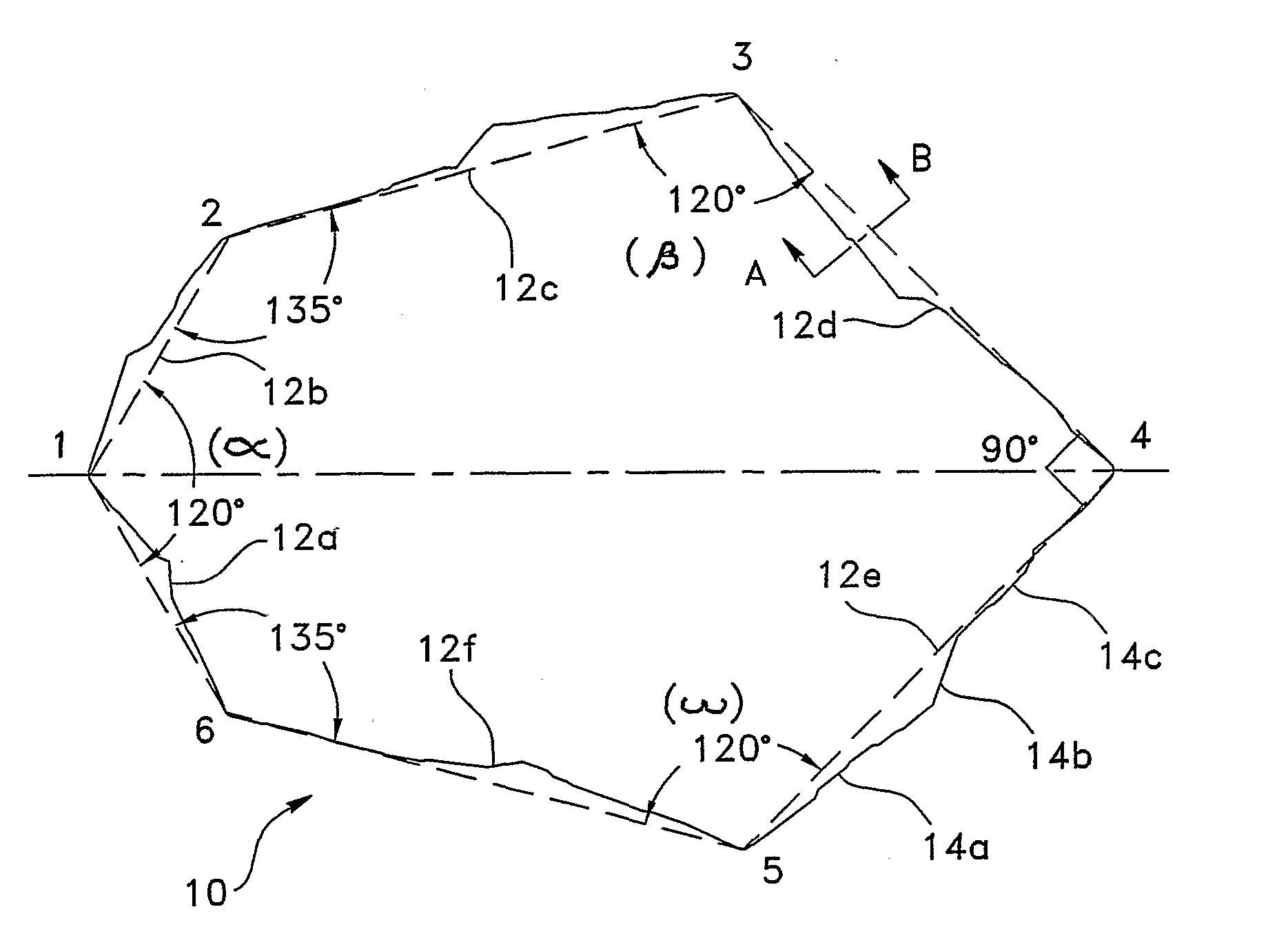

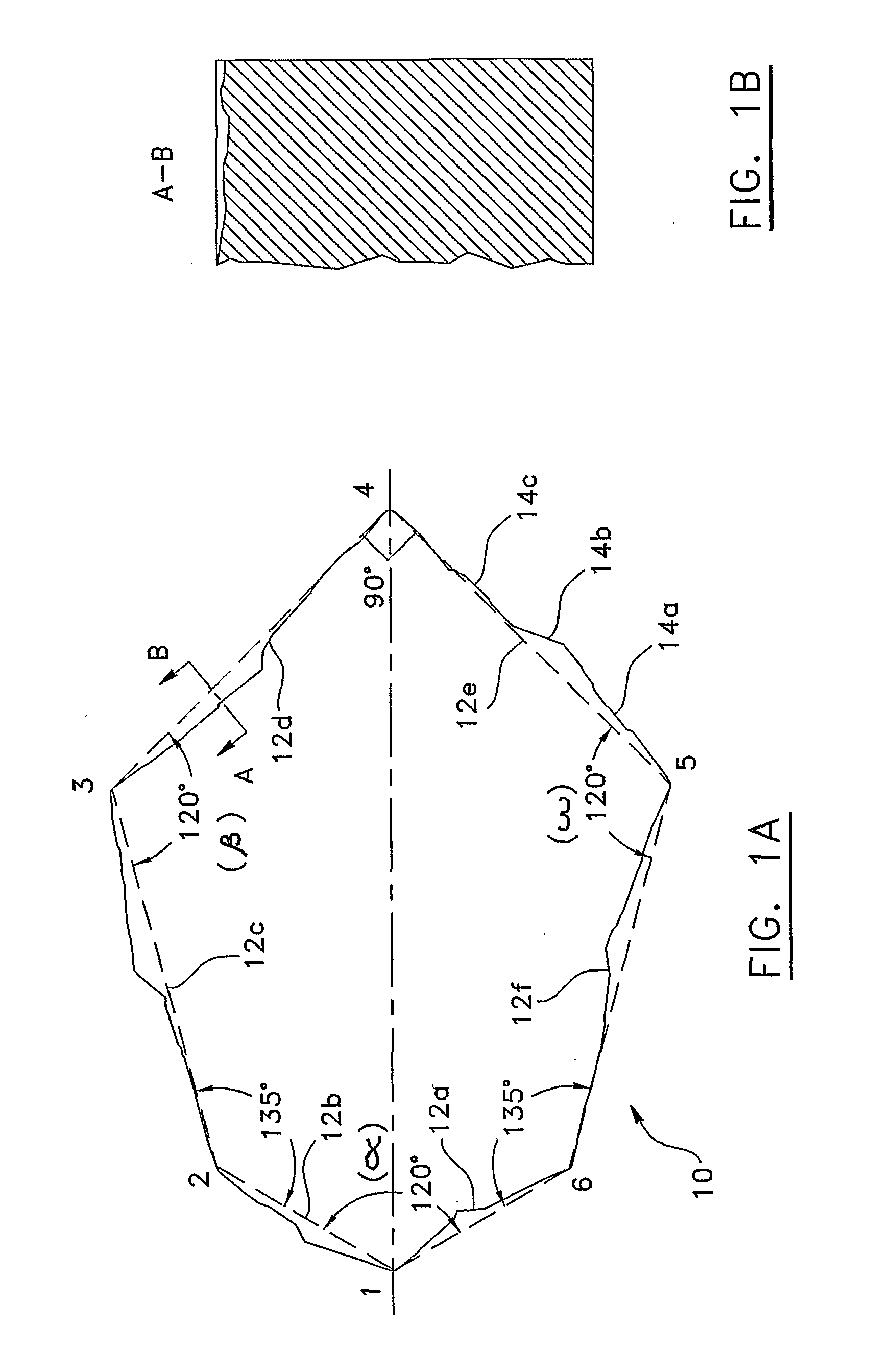

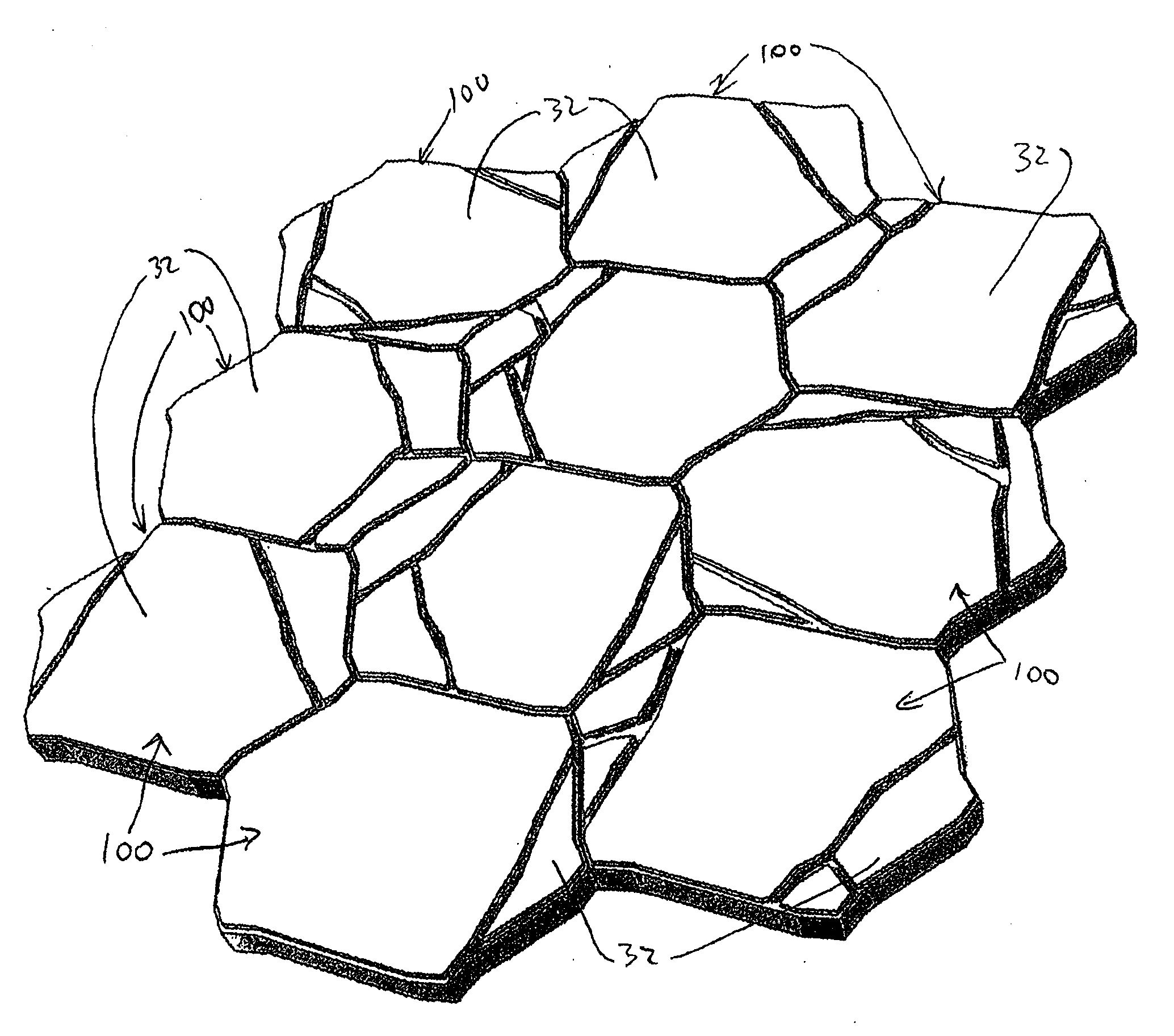

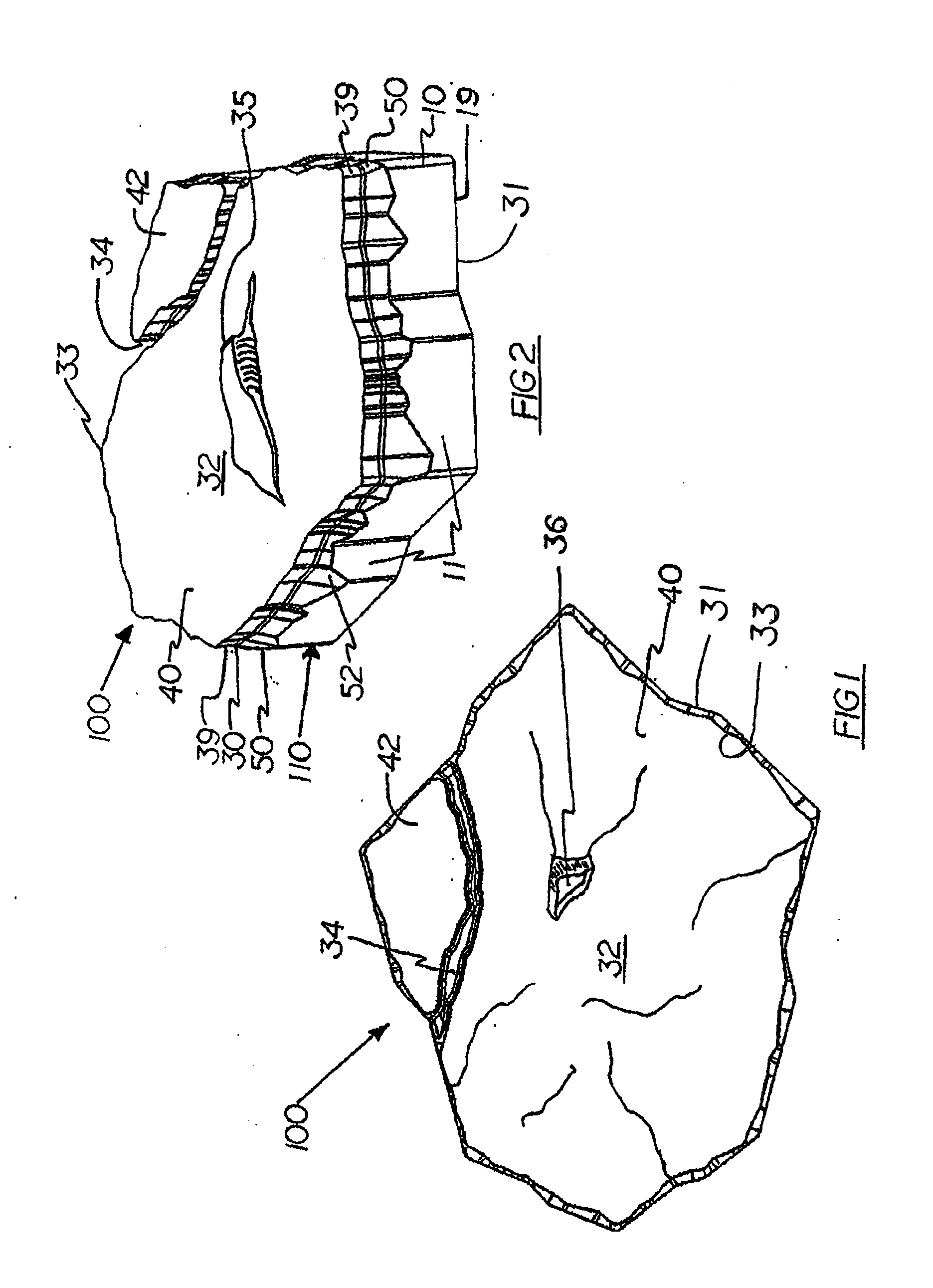

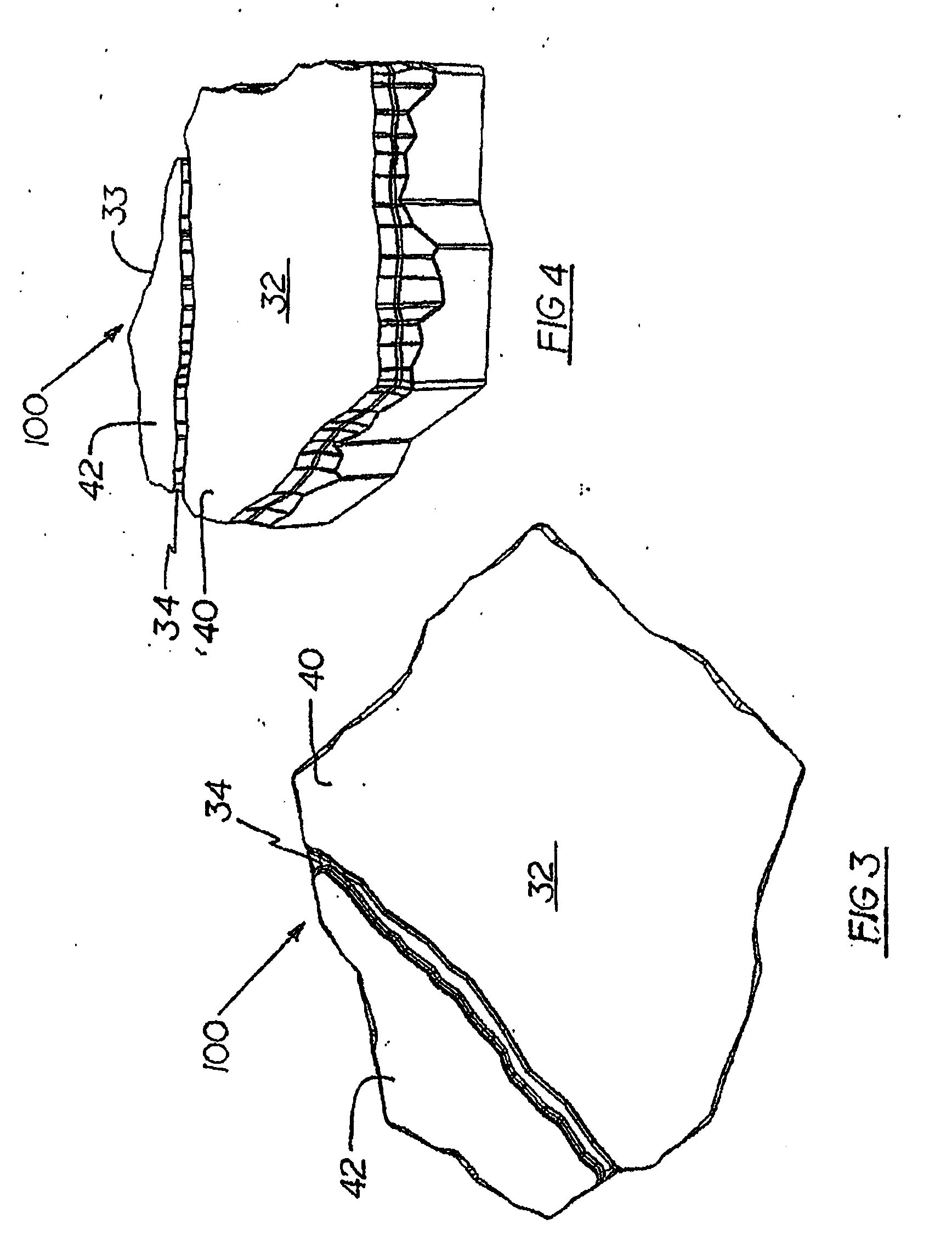

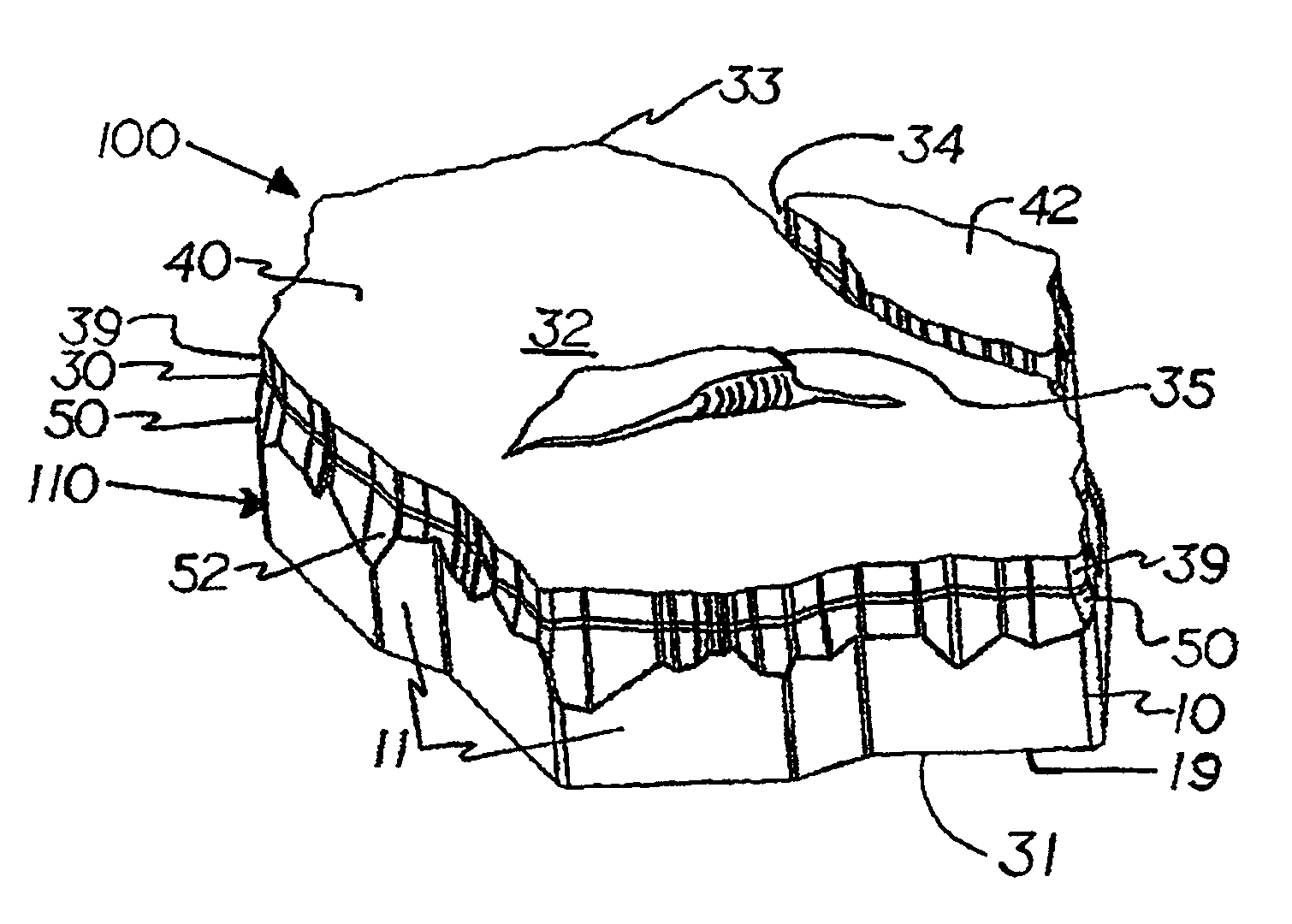

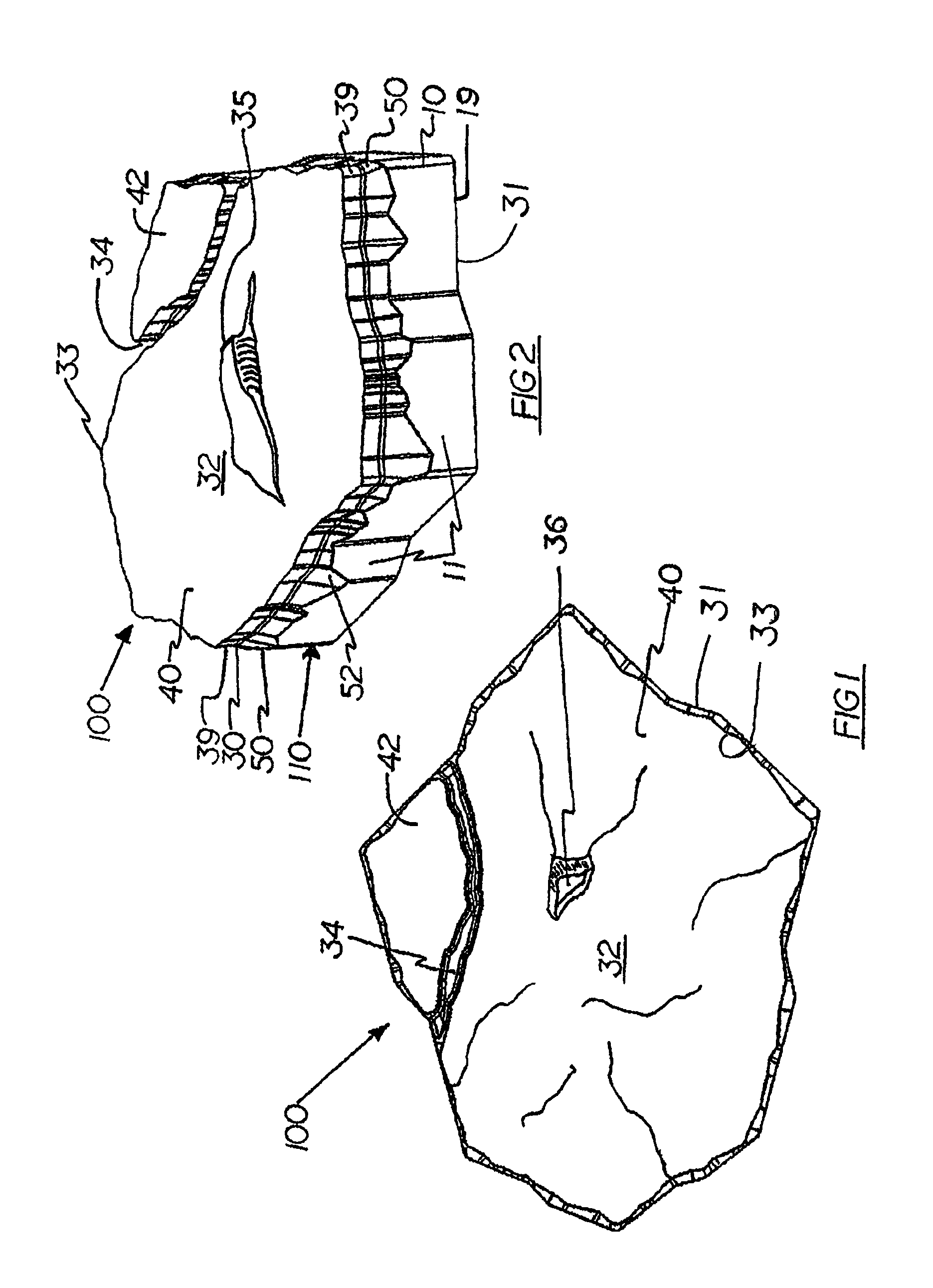

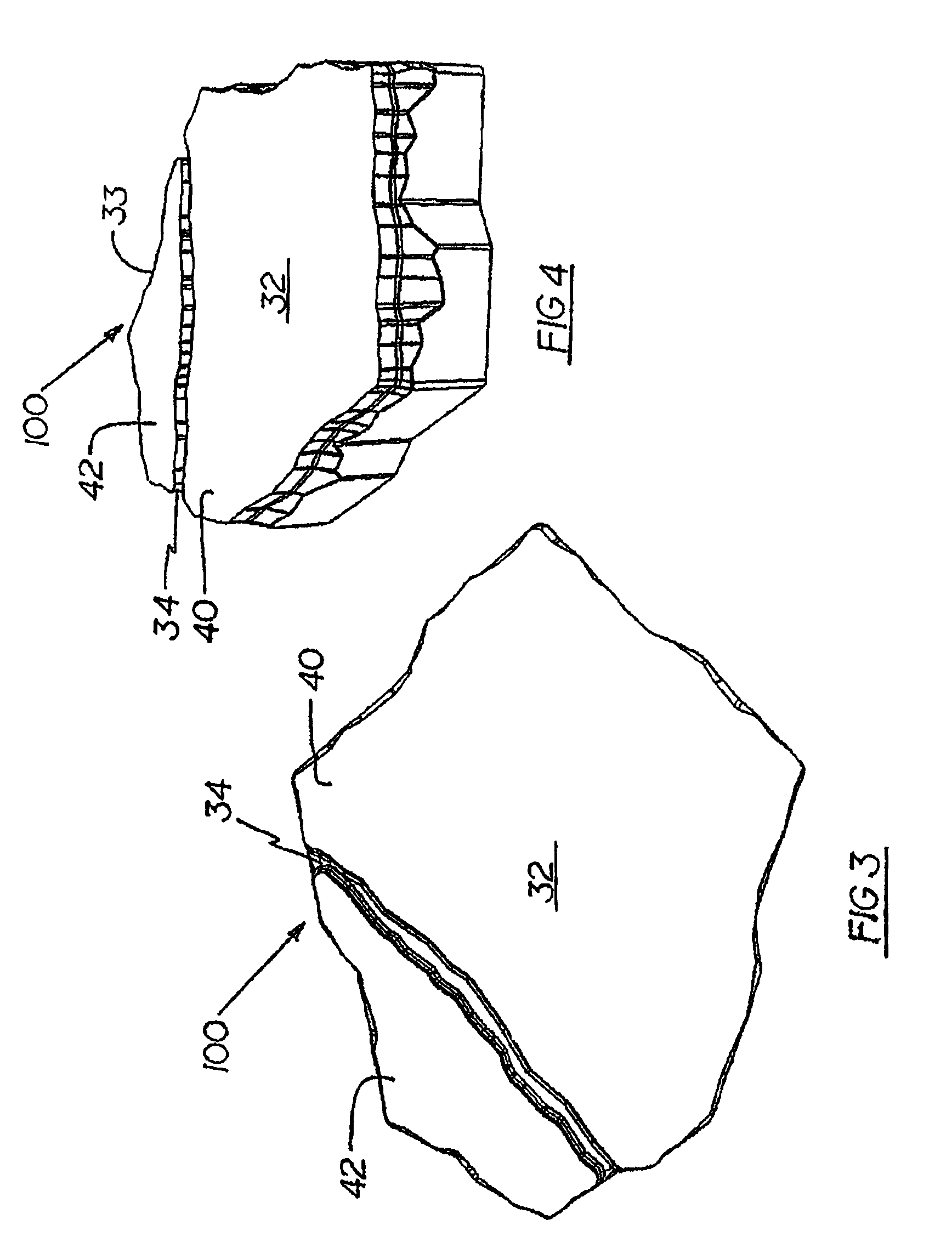

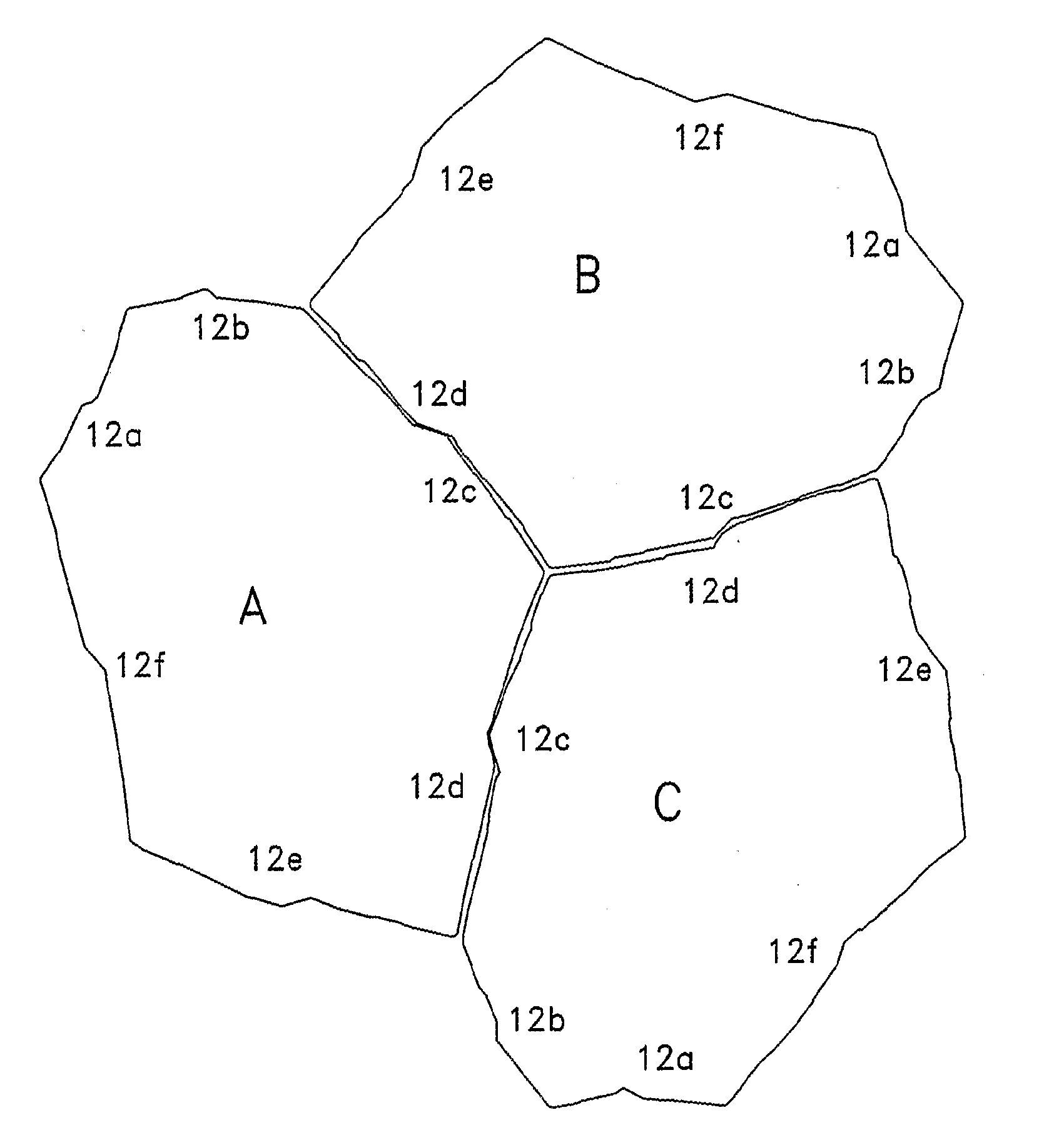

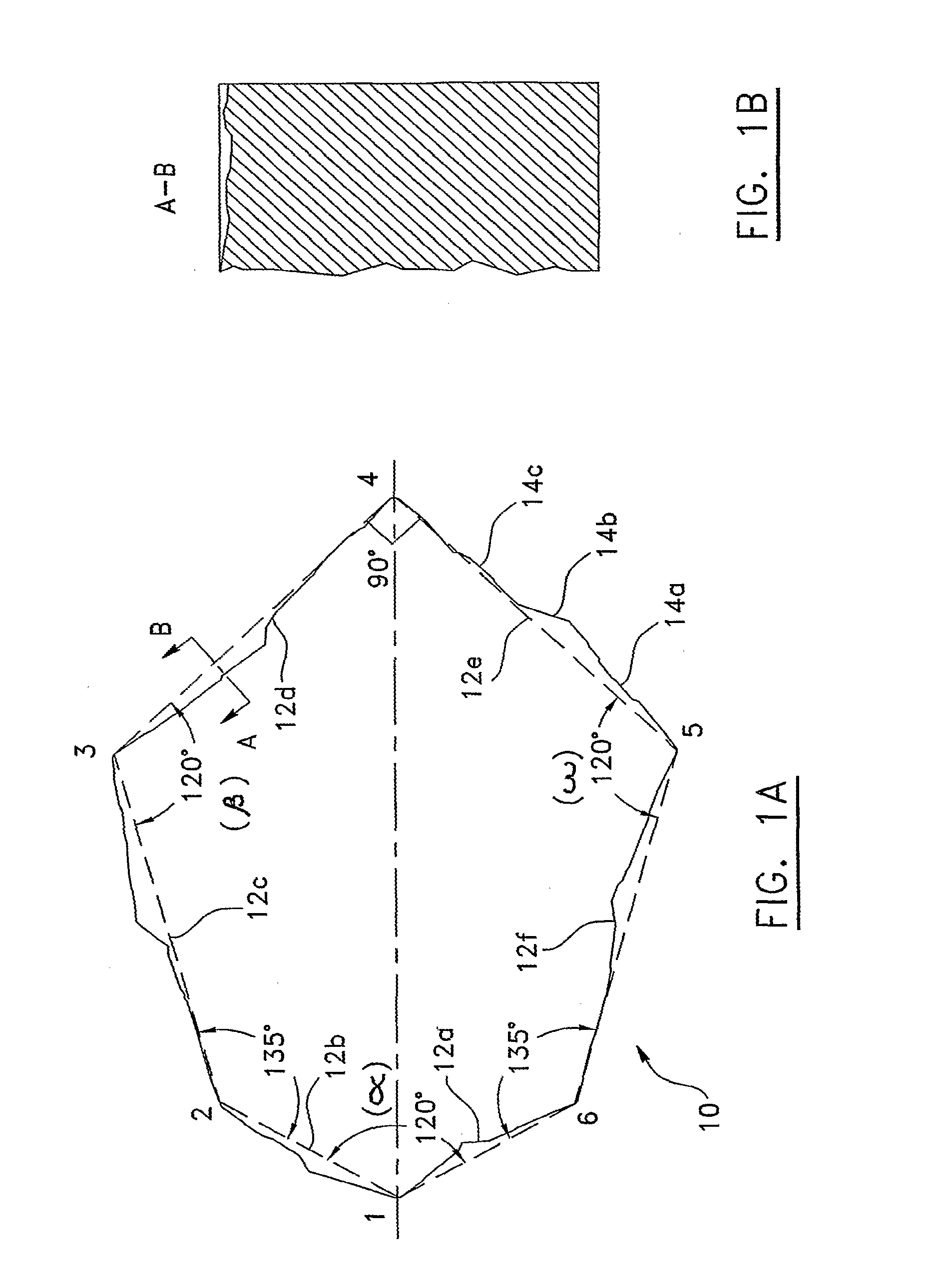

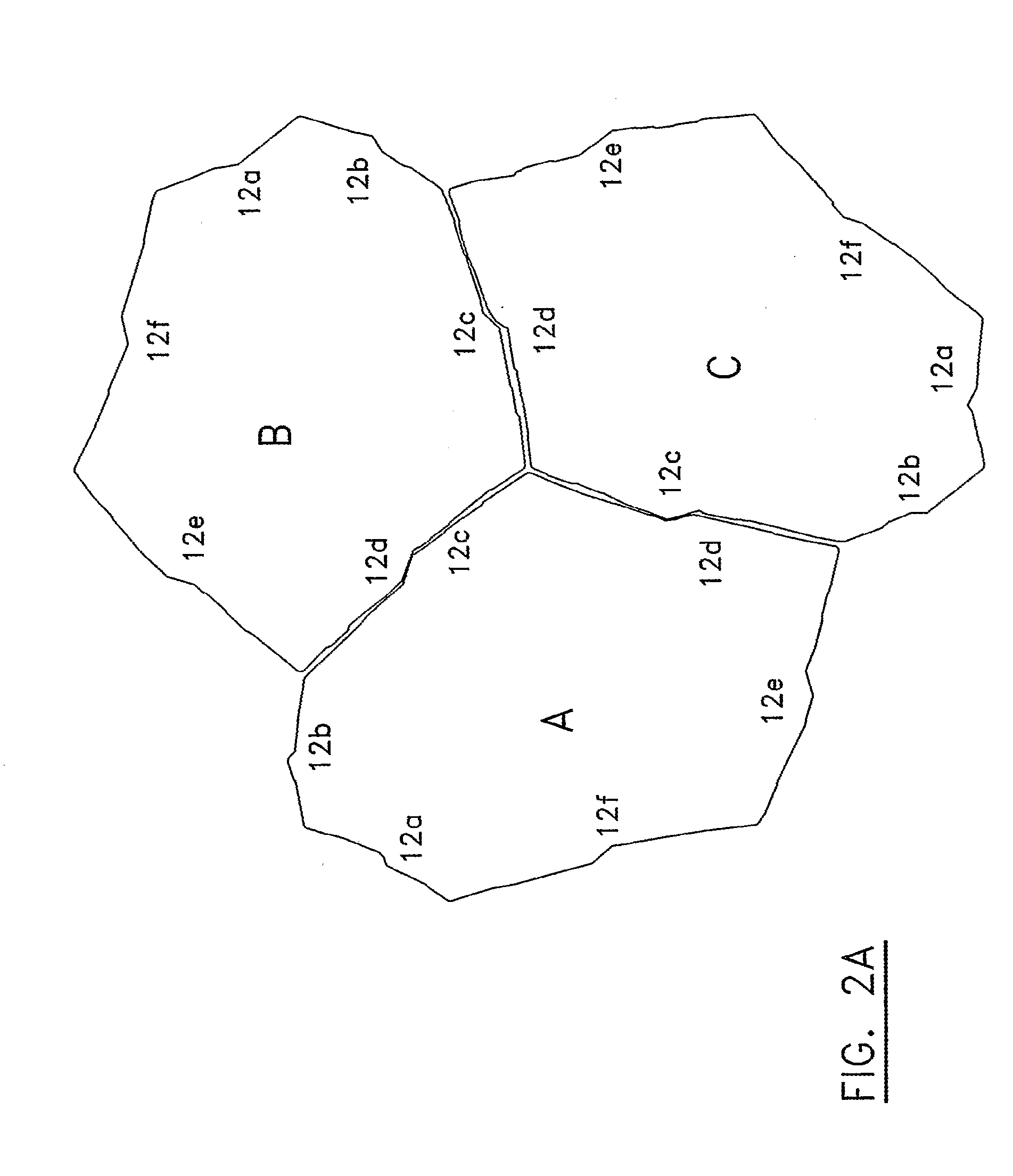

Artificial Flagstone For Providing A Surface With A Natural Random Look

InactiveUS20070217865A1Natural lookEnd result is extremely stableCovering/liningsNatural patternsMechanical engineeringIrregular shape

An artificial flagstone for use in combination with other similar flagstones for covering a surface with a natural random look, the flagstone having a generally hexagonal body comprising a first, second, third, fourth, fifth and sixth consecutive vertices; a first pair of generally congruent irregularly-shaped first and second sides extending radially from the first vertex and being rotationally spaced from each other by an angle α of approximately 120°; a second pair of generally congruent irregularly shaped third and fourth sides extending radially from the third vertex and being rotationally spaced from each other by an angle β of approximately 120°; a third pair of generally congruent irregularly shaped fifth and sixth sides extending radially from the fifth vertex and being rotationally spaced from each other by an angle ω of approximately 120°; wherein the sides of each of the first, second and third pair of sides have at least one split deviation along their length and are respectively rotational images of each other, whereby in use in combination with other flagstones, each one of the sides is matingly engageable with the sides of an equivalent pair of sides of a neighbouring flagstone.

Owner:OLDCASTLE BUILDING PROD CANADA INC

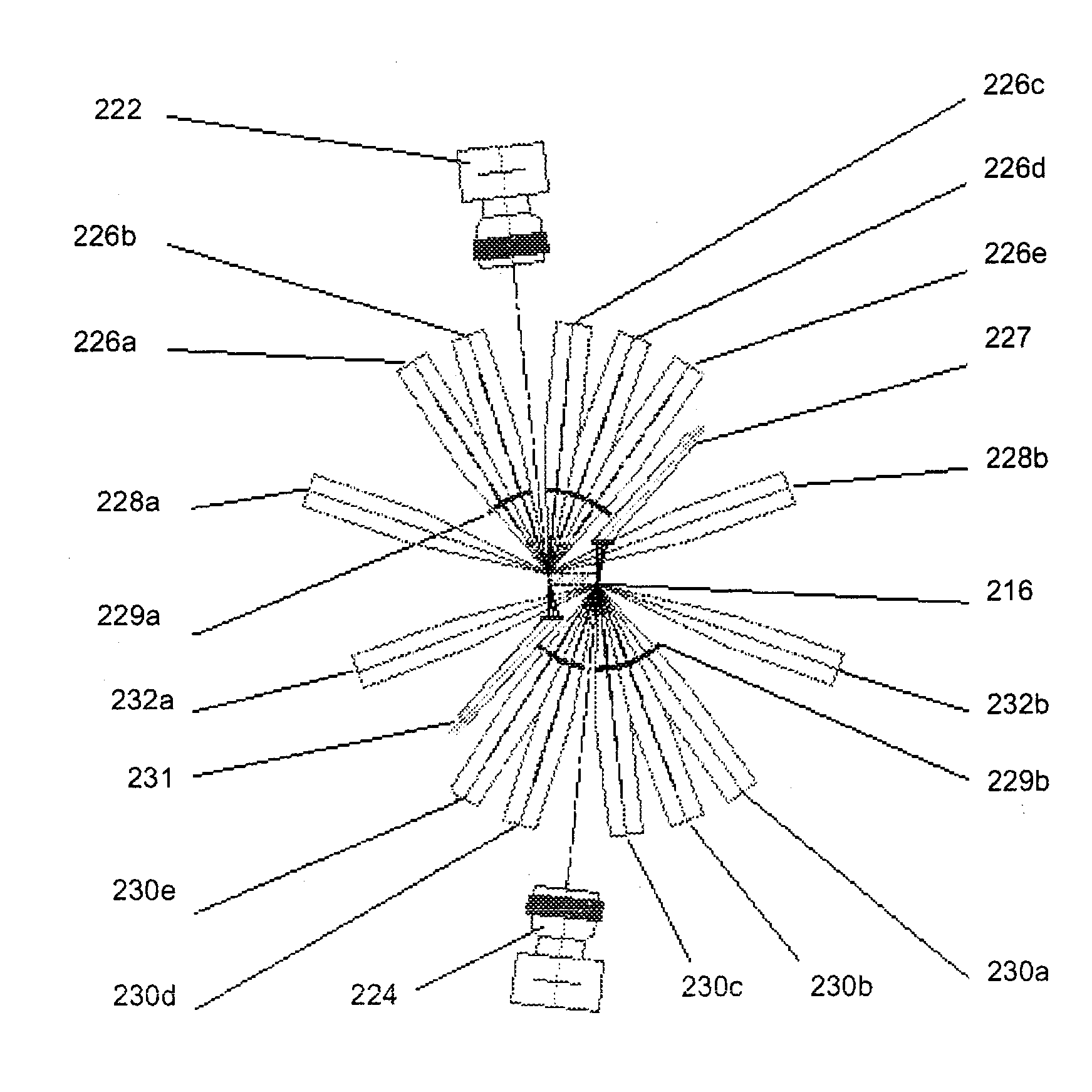

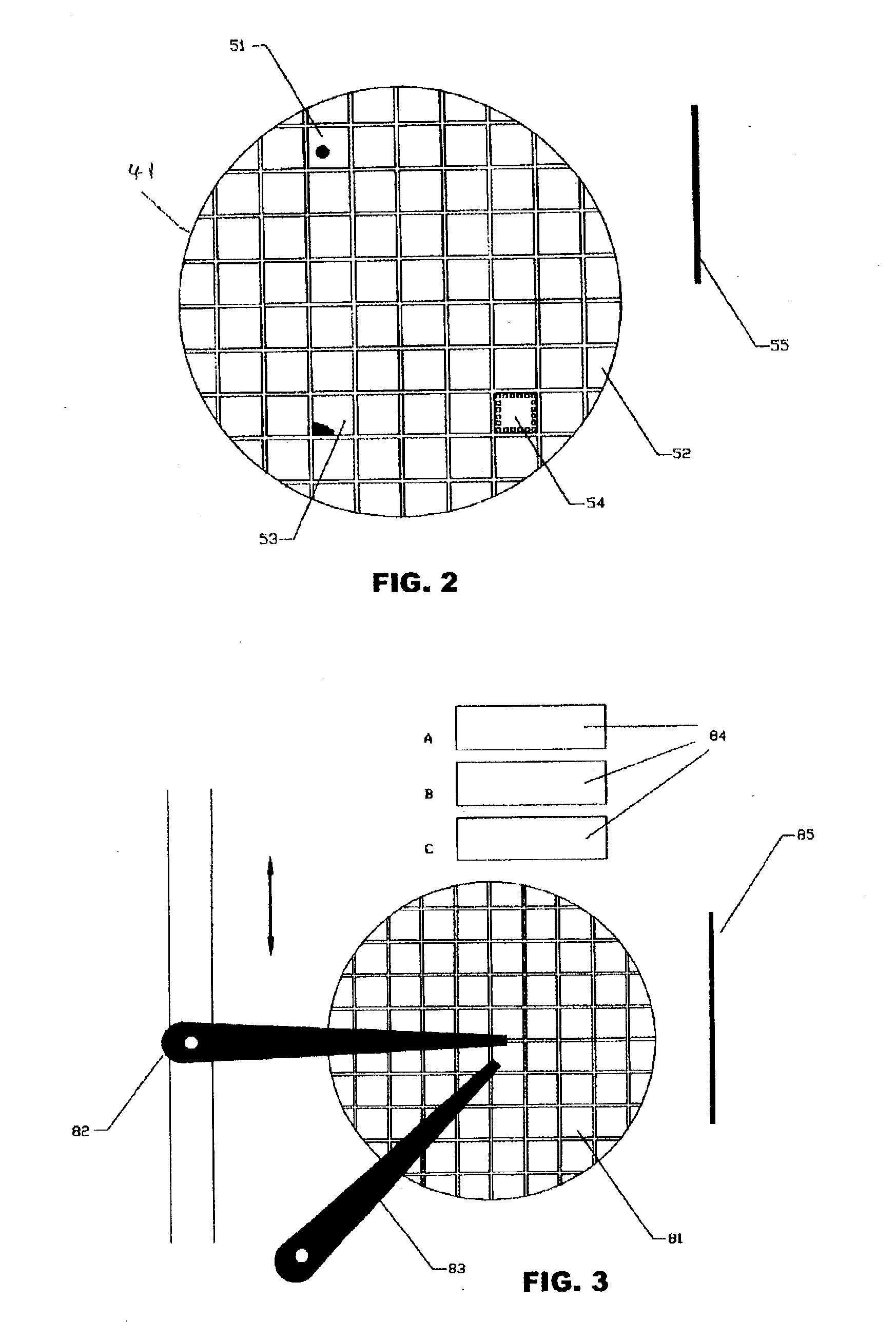

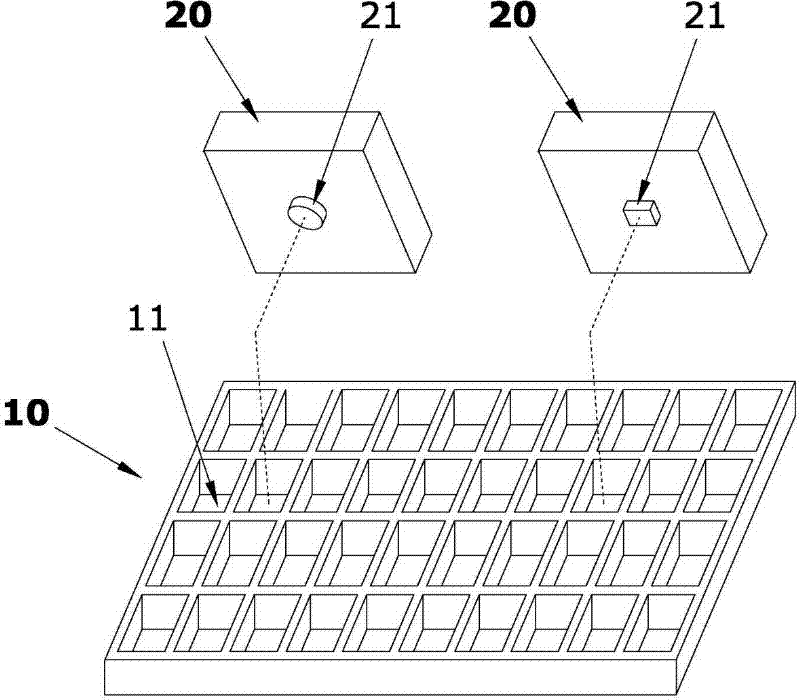

Inspecting an array of electronic components

InactiveUS20040156539A1Overcome disadvantagesImage enhancementImage analysisElectronic componentBiomedical engineering

The invention provides an apparatus and method for inspecting an array of electronic components. The apparatus comprises a scanning device adapted to capture images of at least one surface of each of the respective components, whereby to inspect said surface. The scanning device may be a line scanning device.

Owner:ASM ASSEMBLY AUTOMATION LTD

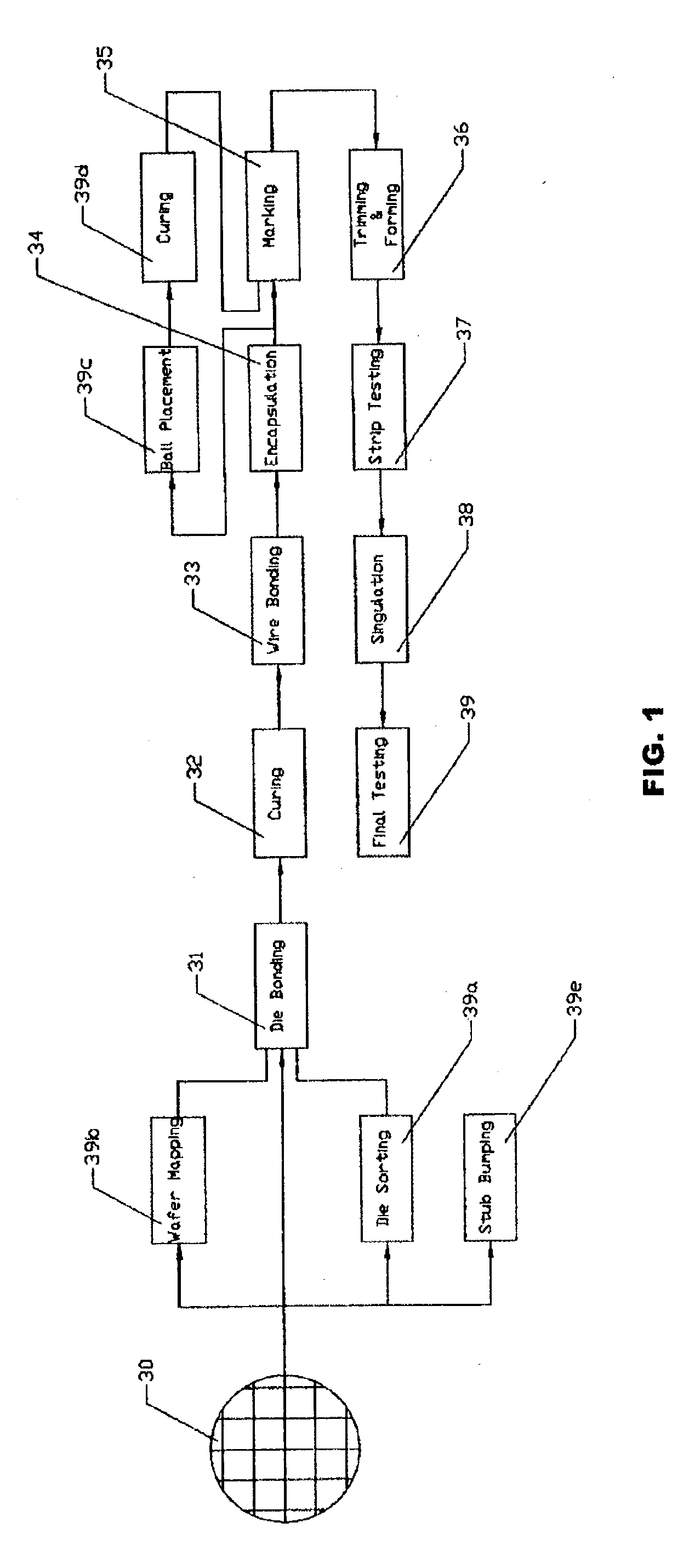

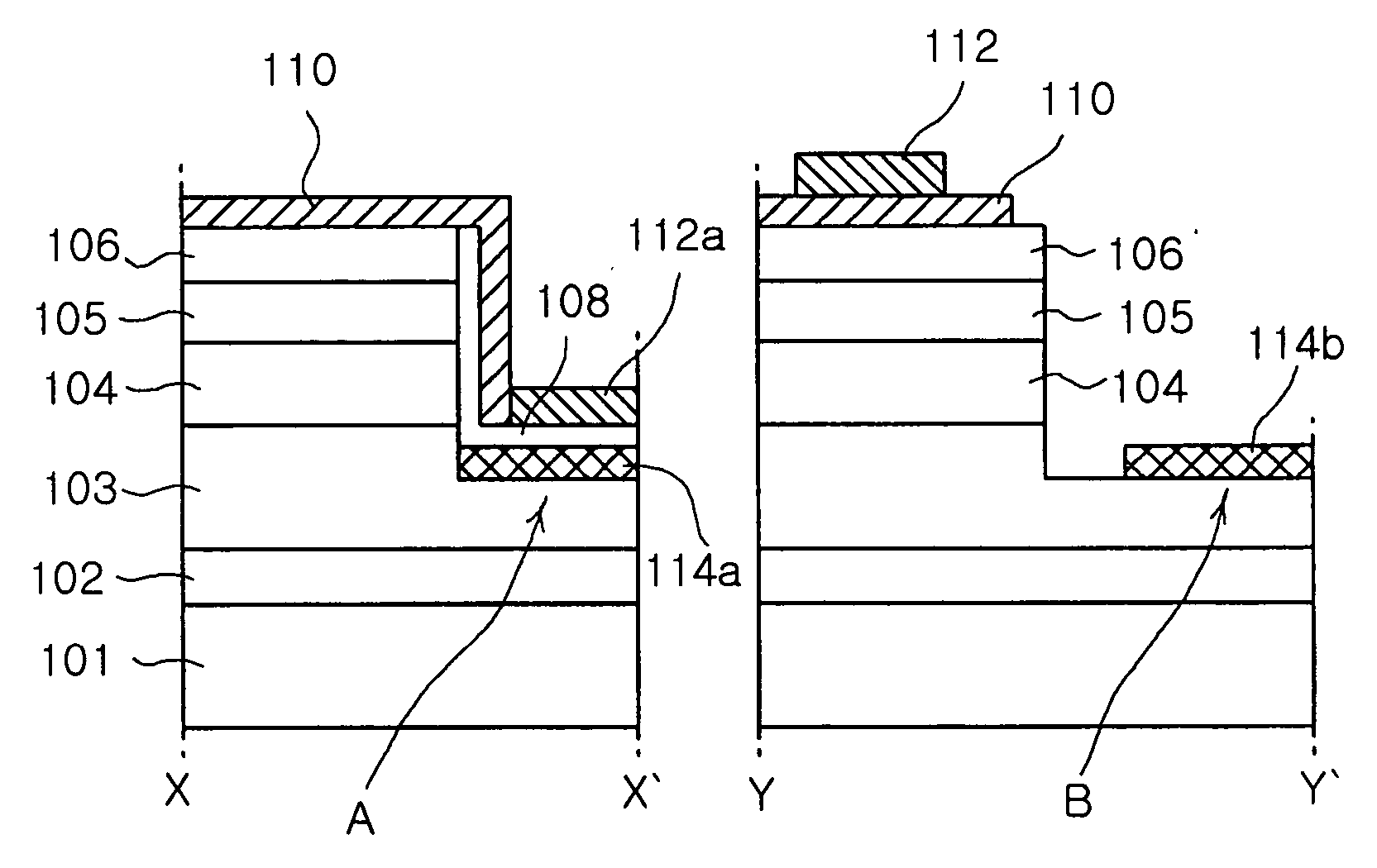

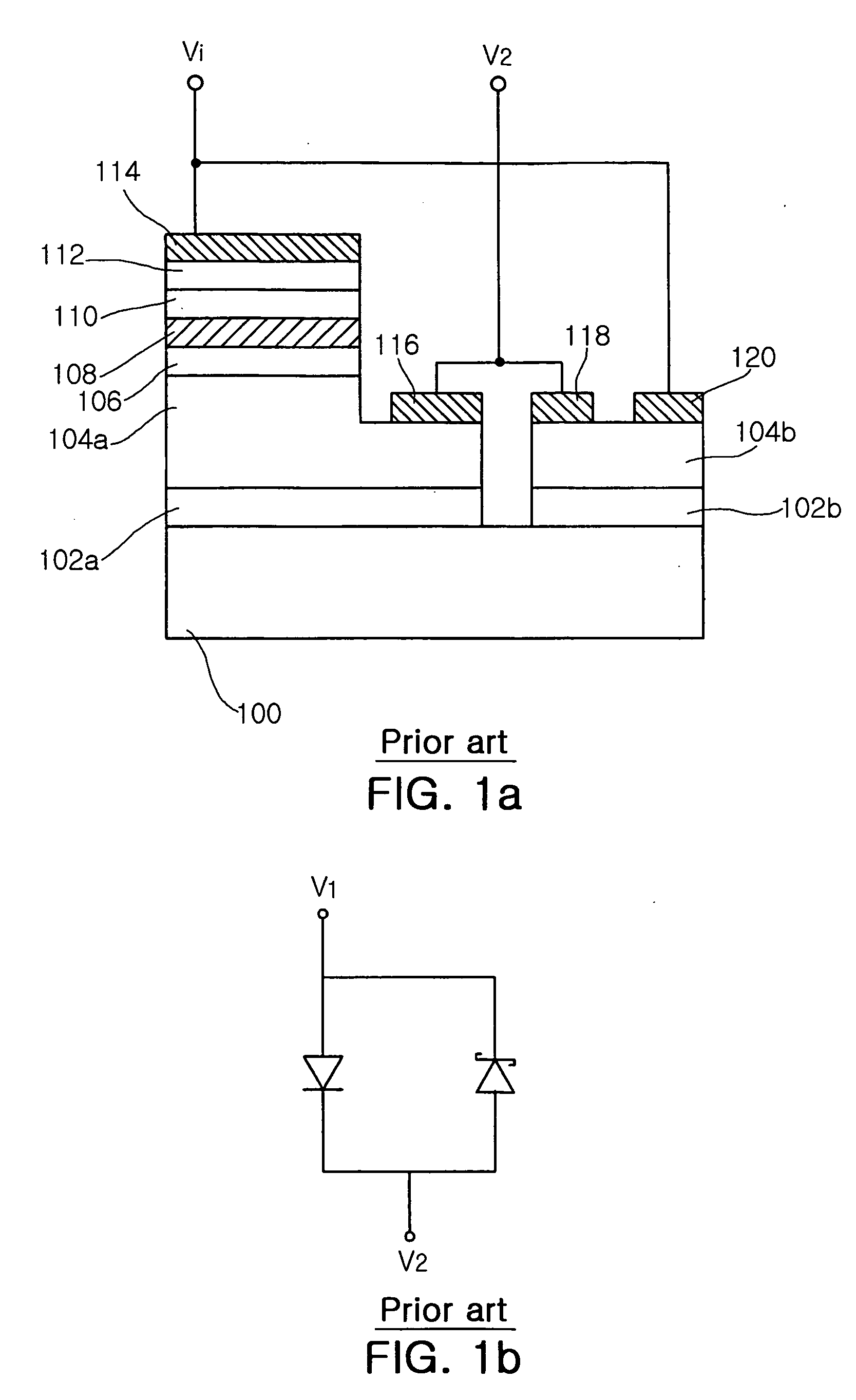

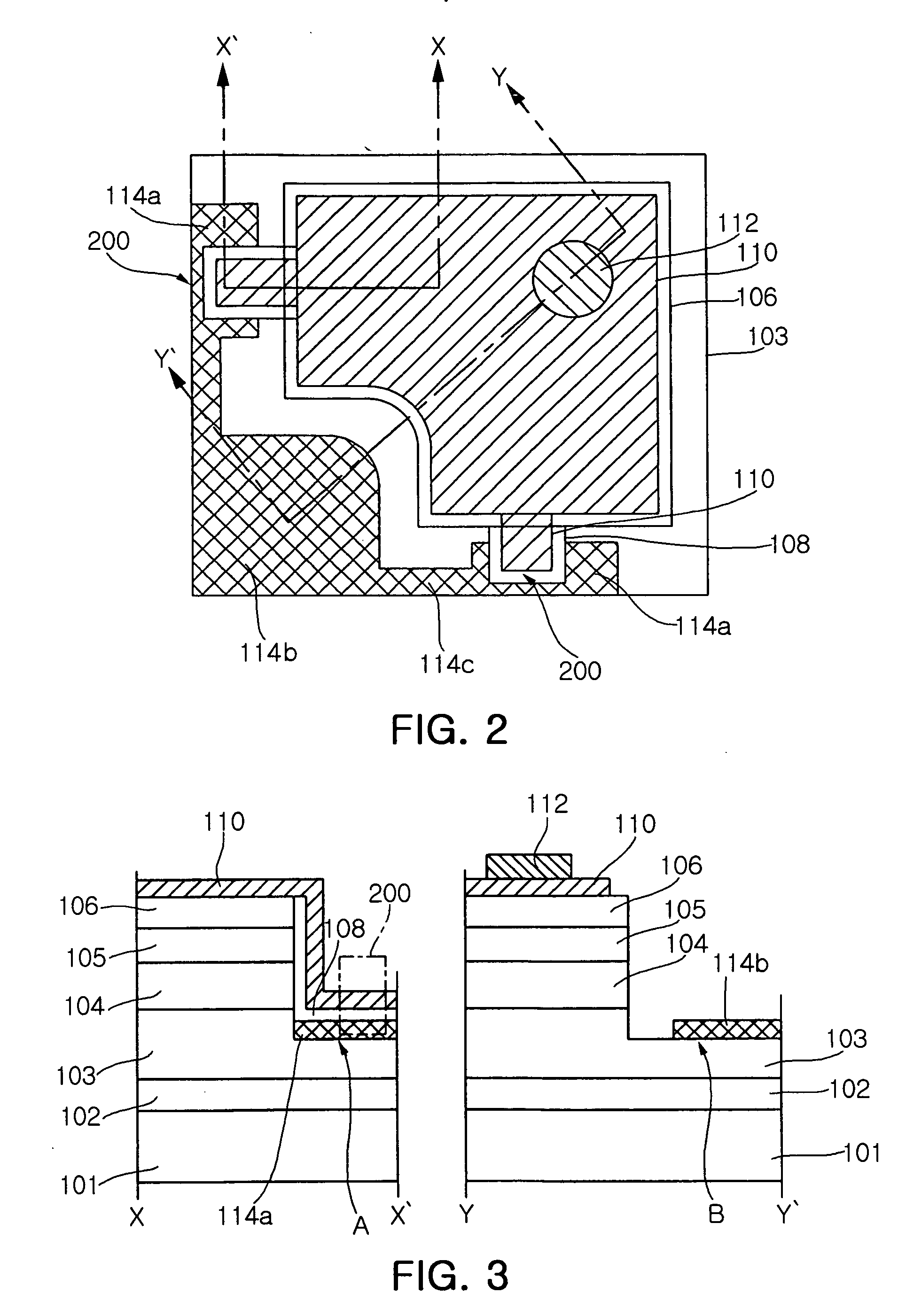

Gallium nitride-based light emitting device having ESD protection capacity and method for manufacturing the same

InactiveUS20060157718A1Improve toleranceImprove equipment reliabilitySidewalk pavingsSolid-state devicesGallium nitrideActive layer

A gallium nitride-based light emitting device, and a method for manufacturing the same are disclosed. The light emitting device comprises an n-type GaN-based clad layer, an active layer, a p-type GaN-based clad layer and a p-side electrode sequentially stacked on a substrate. The device further comprises an n-side electrode formed on one region of the n-type GaN-based clad layer, and two or more MIM type tunnel junctions formed on the other regions of the n-type GaN-based clad layer. Each of the MIM type tunnel junctions comprises a lower metal layer formed on the GaN-based clad layer so as to contact the n-type GaN-based clad layer, an insulating film formed on the lower metal layer, and an upper metal layer formed on the insulating film. The device is protected from reverse ESD voltage, so that tolerance to reverse ESD voltage can be enhanced, thereby improving reliability of the device.

Owner:SAMSUNG ELECTRONICS CO LTD

Cement concrete permeable brick, permeable road and production methods thereof

InactiveCN101671987AComply with quality deviationMitigate the heat island effectSingle unit pavingsClimate change adaptationPondingBrick

The invention relates to a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. At present, most of urban construction adopting the rigid hardened ground has the problems of dust blowing at a fine day, water accumulation and impermeable ground at a rainy day, no groundwater level supplement, no relief of urban heat island effect, and the like. The invention aims to develop a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. The cement concrete permeable brick is formed by pressing and molding a base material layer and a surface material layer, and both the base material layer and the surface material layer contain cement, sand, stone, water adsorbing resin, asphalt powder, diffusant and a water reducing agent. The production method of the permeable brick is realized by molding the permeable brick by a computer full-automatic building block forming machine; and the production method of the cement concrete permeable road is realized by directly pressing the cement concrete permeable road through a road roller. The invention can achieve the aims of water adsorption, water retention, permeability and practicability, can be widely used for a highway, an airport runway, a roadway, a footway, a square, garden construction, and the like and solve the problem of road icing.

Owner:SHAANXI SUNSHINE RAIN ECOLOGICAL TECH

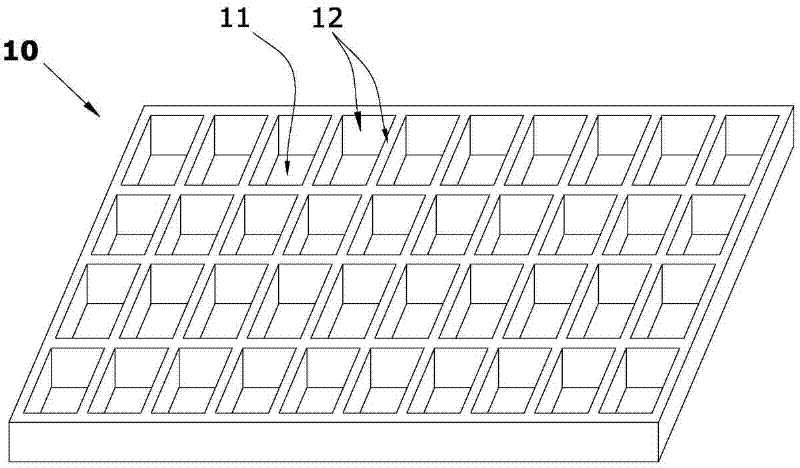

Concrete void former

A void former comprises a core assembly having at least two body members. The body members are removably coupled together to define the desired shape of a void to be formed in a concrete slab. After the void has been formed in the concrete slab, the body members may be selectively removed from the void.

Owner:DAYTON SUPERIOR CORP

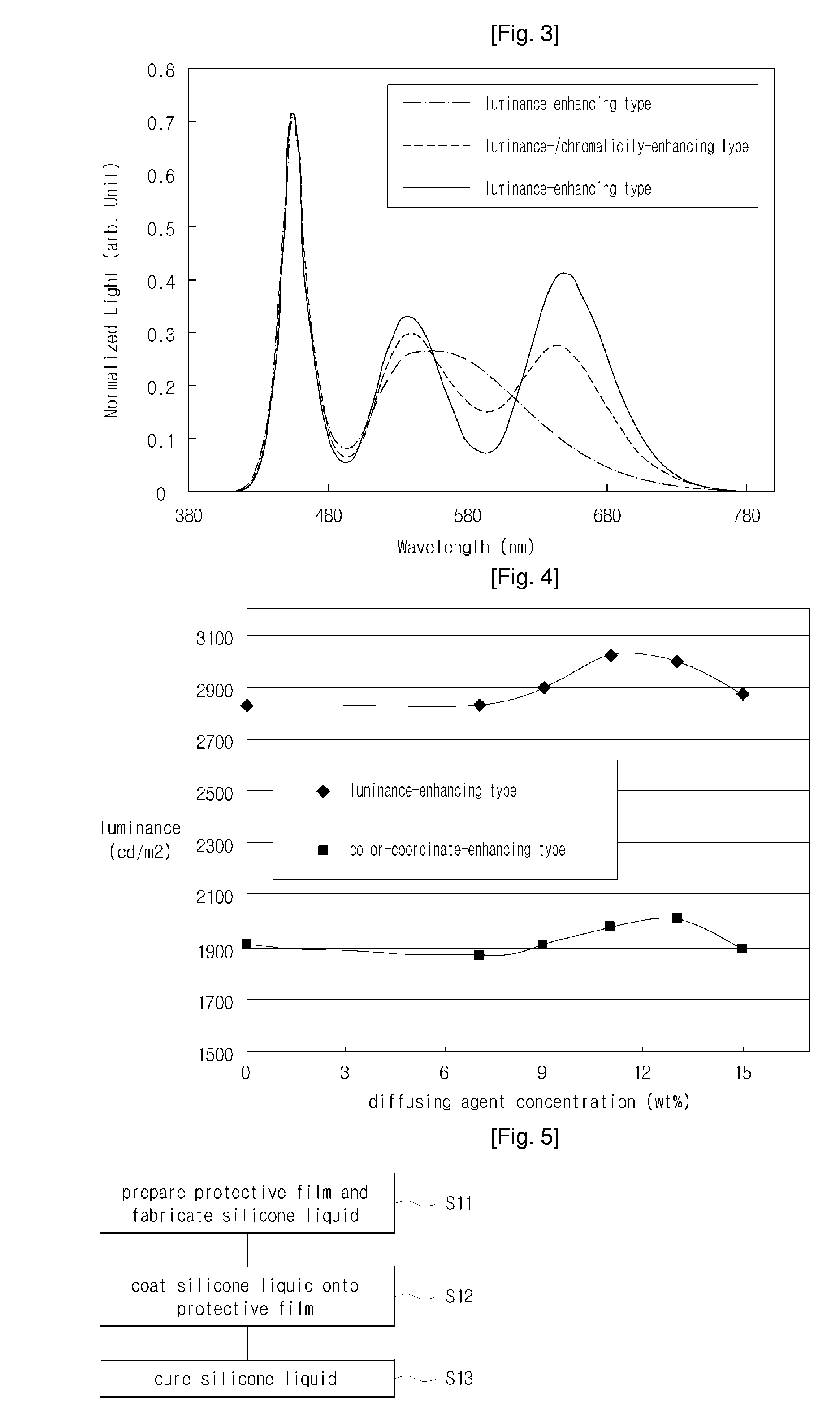

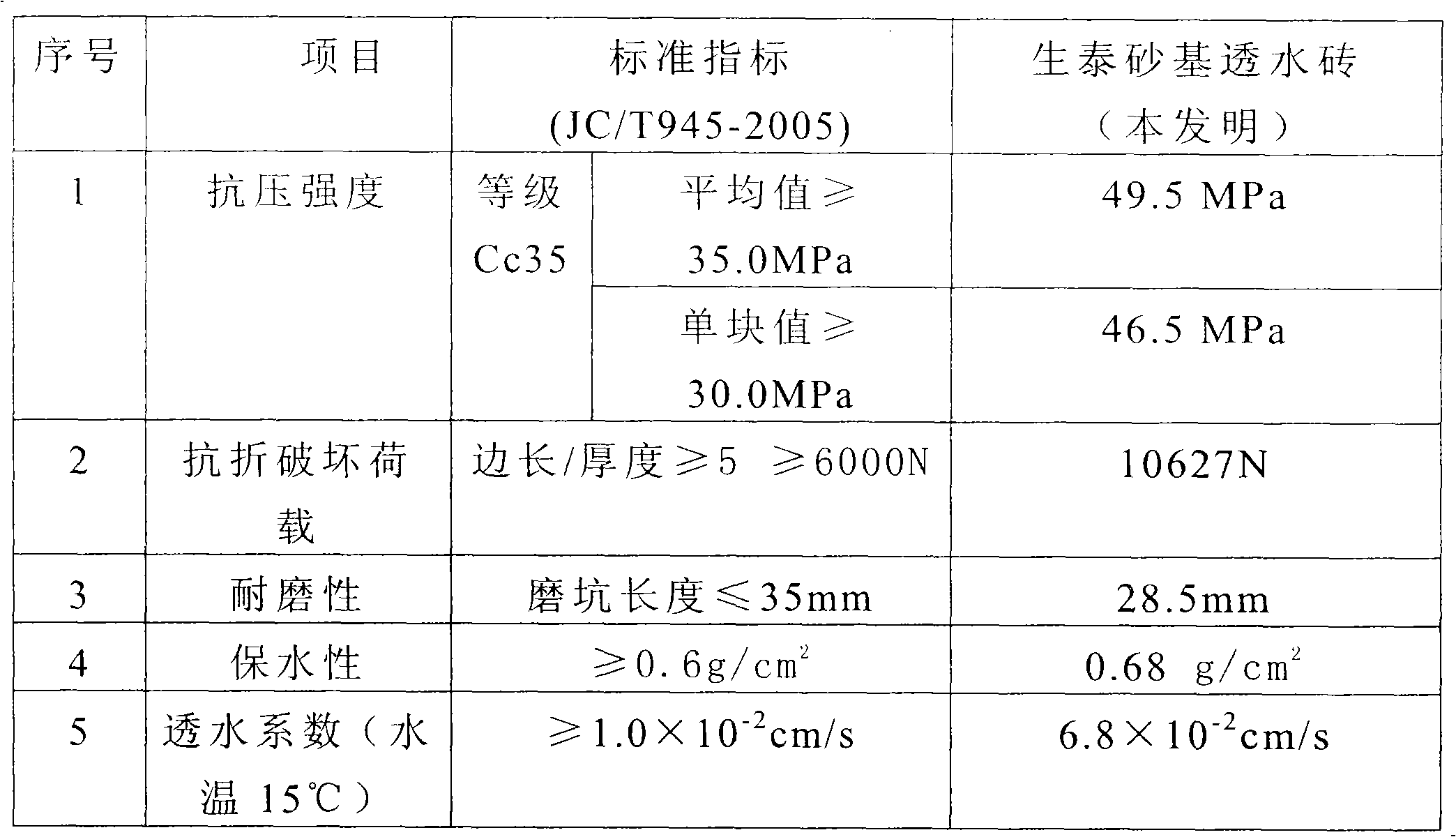

Photoluminescent Sheet

ActiveUS20090212257A1Improve the immunityUneven levelDischarge tube luminescnet screensSidewalk pavingsPhotoluminescencePhosphor

A photoluminescent sheet is disclosed. A photoluminescent sheet that includes a matrix resin layer, which is a thermosetting resin; a phosphor, which is included in the matrix resin layer and which converts the wavelength of light emitted from a blue LED; a curing agent, which is included in the matrix resin layer and which cures liquid thermosetting resin; and an additive, which is included in the matrix resin layer and which disperses the phosphor uniformly within the matrix resin layer, can implement white light from light having wavelengths corresponding to blue color.

Owner:SUZHOU LEKIN SEMICON CO LTD

Weather resistance permeable material and application thereof

ActiveCN101665340ANo pollution in the processGood weather resistanceIn situ pavingsSolid waste managementEpoxyWater cycling

The invention relates to a weather resistance permeable material, comprising aggregate and binding agent, wherein, the aggregate is one of natural quartz sand, coal ash, smelting waste residue, artificial quartz sand or the arbitrary combination thereof; the grain diameter of the aggregate is 0.07 mm-1.6 mm; the binding agent is epoxy resin, polyurethane resin and acrylic acid resin with good weather resistance or the arbitrary combination thereof; the weather resistance is effectively improved by selecting the binding agent with good weather resistance and adding light stabilizer and antioxidant; and the water permeability of materials is effectively improved by selecting hydrophilic reactive resin with good water permeability and adding hydrophilic inorganic material in the aggregate. The application of the weather resistance permeable material is as follows: the above raw materials can be mixed to manufacture permeable prefabricated pieces used for road surfacing or rain water collecting and water filtering, and can also be directly paced on the road surface to form a permeable road surface, thus promoting full utilization of rain water resources and improving urban water circulation.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Artificial stone

ActiveUS20110067333A1Enhance natural appearanceLarge widthCovering/liningsNatural patternsRepeat patternEngineering

An artificial stone is disclosed for use in creating a covering for a supporting surface. The artificial stone includes a body for placement on the supporting surface, which is shaped for mating engagement with like stones with intermediate perimeter joints to produce a continuous surface covering. The stone has a facing surface on the body, which facing surface has a contour defining a surface area and is subdivided by at least one simulated joint into a major surface portion and at least one minor surface portion. The major surface portion is free of simulated joints and extends over at least about 60% of the total surface of the facing surface. The stone further includes at least one perimeter recess in the body for generating a gap between the stone and another like stone in mating engagement therewith, which gap is wider than adjacent the adjoining perimeter joint. Stones of this construction can easily be arranged in a regular, repeated pattern to generate a continuous covering for the supporting surface with the surface of the resulting covering having an irregular, natural appearance. The irregular top contours of the stones, the uneven division of the facing surface and the perimeter recesses and the resulting gaps between mating stones simulate the appearance of a natural stone surface covering for walkways, roadways, pavements or walls.

Owner:OLDCASTLE BUILDING PROD CANADA INC

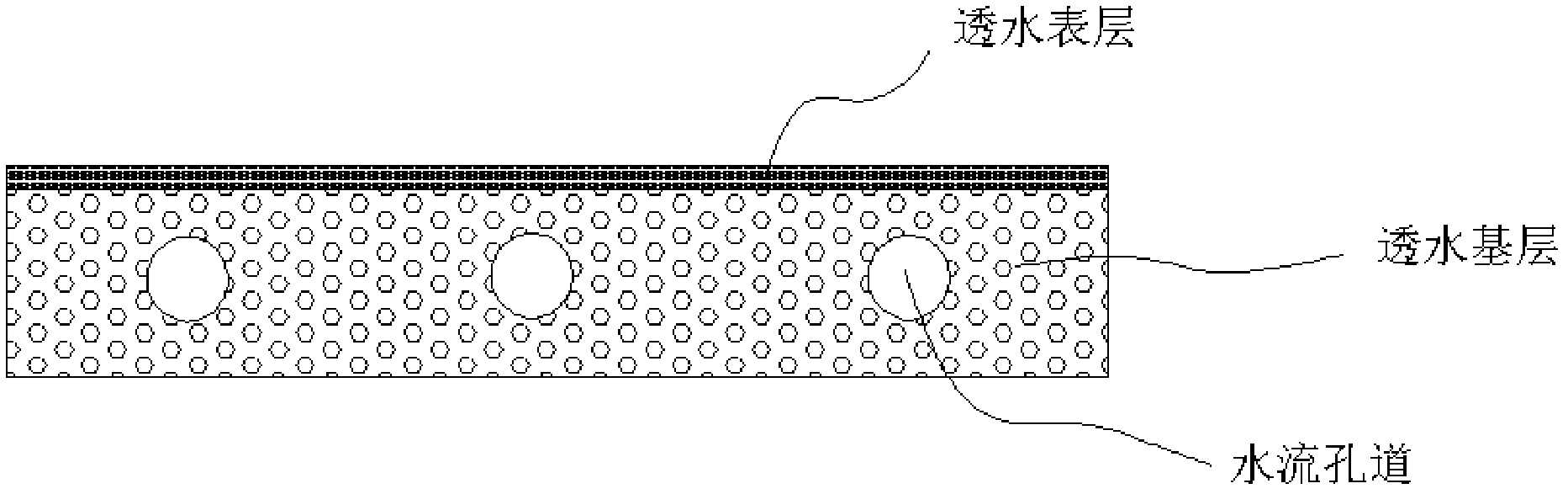

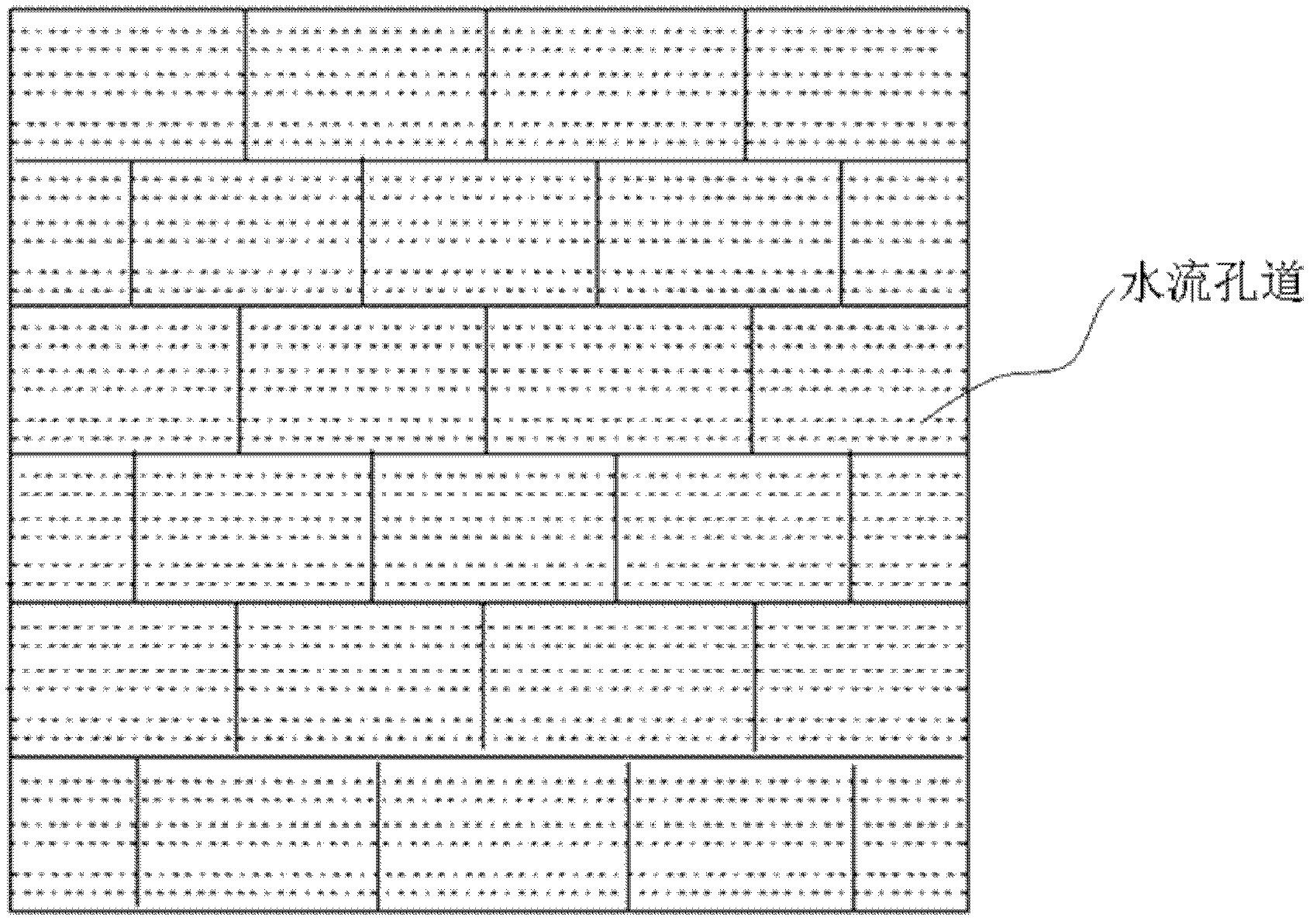

Water permeable brick

ActiveCN103132423AStrong drainageImprove drainage capacitySingle unit pavingsSidewalk pavingsSurface layerBrick

The present invention provides a water permeable brick, which comprises a water permeable base layer and a water permeable surface layer covering on the water permeable base layer, wherein the water permeable base layer is formed through curing a mixture containing a first aggregate and a first binder, the water permeable surface layer is formed through curing a mixture containing a second aggregate and a second binder, and the second binder contains a hydrophilic binder. The water permeable brick further comprises at least a water flow pore channel positioned inside the water permeable base layer, wherein the water flow pore channel penetrates through both side surfaces of the water permeable base layer. The water permeable brick has excellent water permeability, and can not cause foundation loosing.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

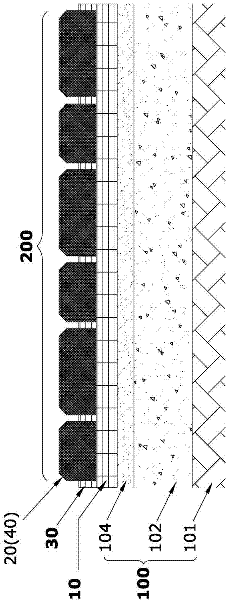

Semi-flexible structure permeable street and pavement method thereof

InactiveCN102433819AQuickly restore water permeabilityQuick installationSingle unit pavingsSidewalk pavingsArchitectural engineeringEngineering

The invention relates to a semi-flexible structure permeable street and a pavement method thereof. The structure of the street comprises a fully-permeable multilayer pavement structure roadbed or a drainage multilayer pavement structure roadbed, a permeable grid plate cushion paved on the roadbed, and a street surface layer paved on the permeable grid plate cushion. By paving the permeable cushion formed by the linked pavement of permeable grid plates on the fully-permeable multilayer pavement structure roadbed or the drainage multilayer pavement structure roadbed, the semi-flexible structure permeable street which is constructed on condition that the permeable grid plate structure is reasonably designed, the manufacturing material of the permeable grid plate cushion is reasonably selected and the unit structure of the street surface layer is reasonably designed has the advantages of good permeability and strong water storage capability, and the surface layer and the permeable grid plate cushion of the street have a good combination degree and are easy to disassemble, replace and maintain.

Owner:苏鸣

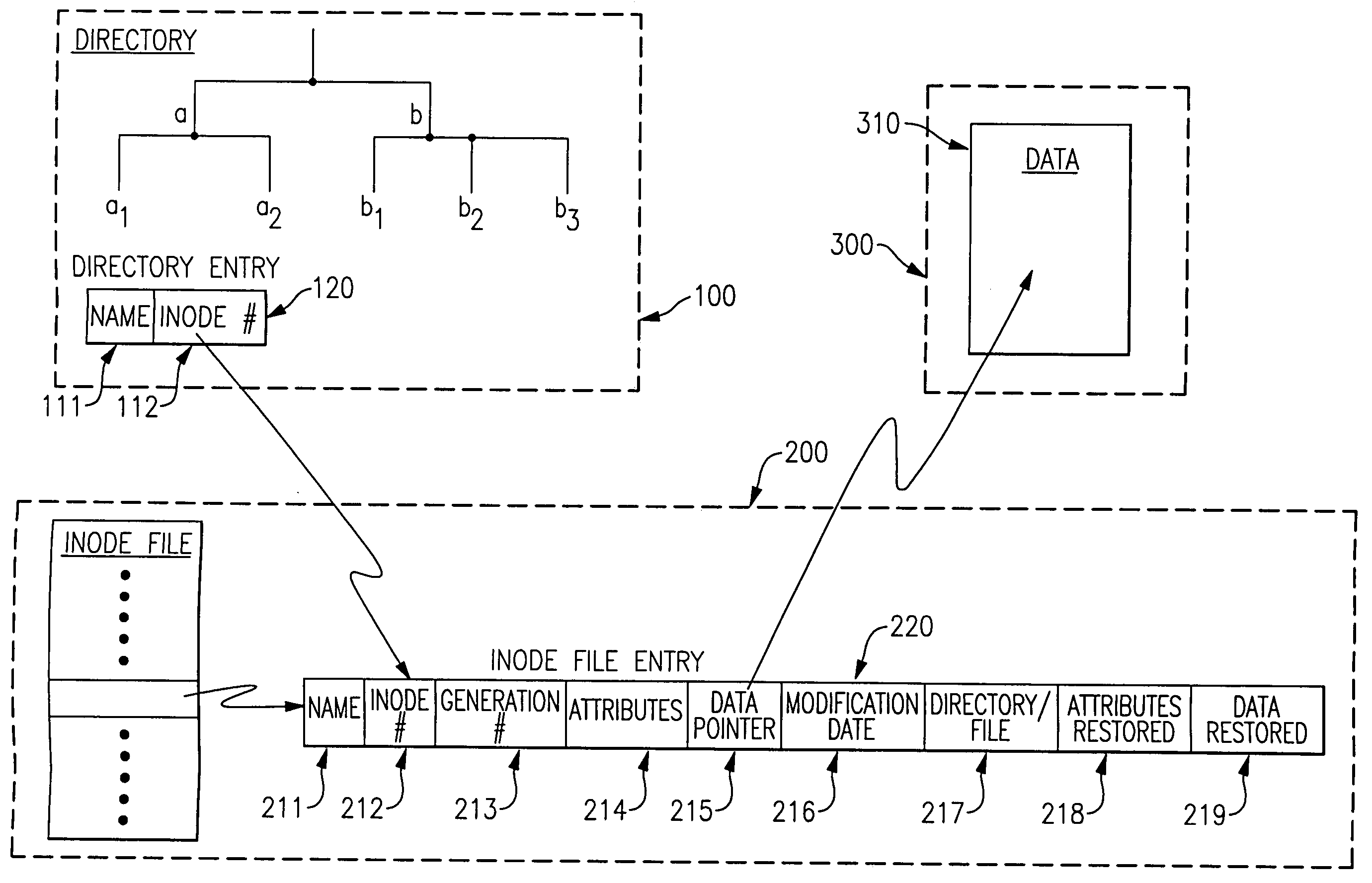

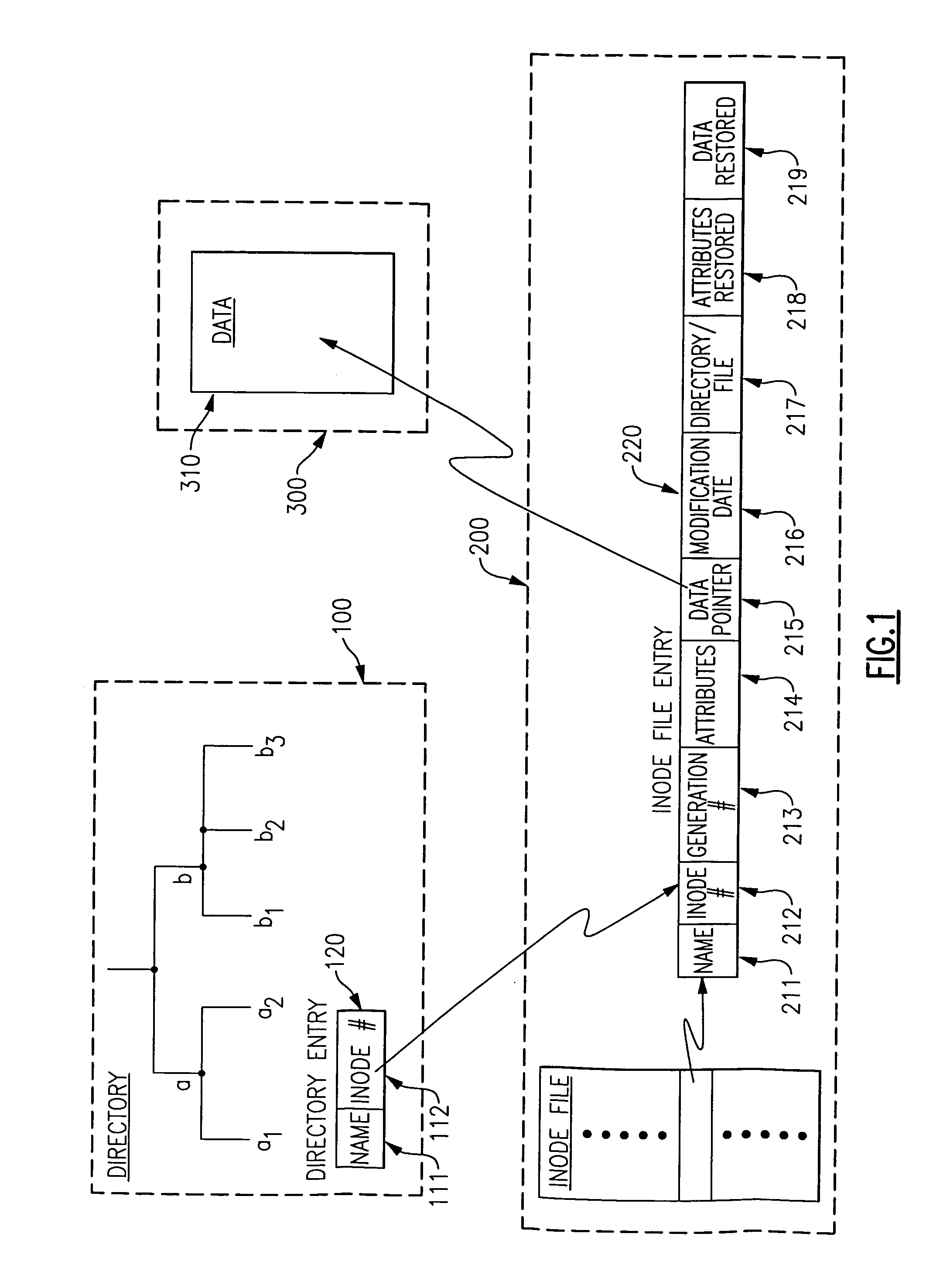

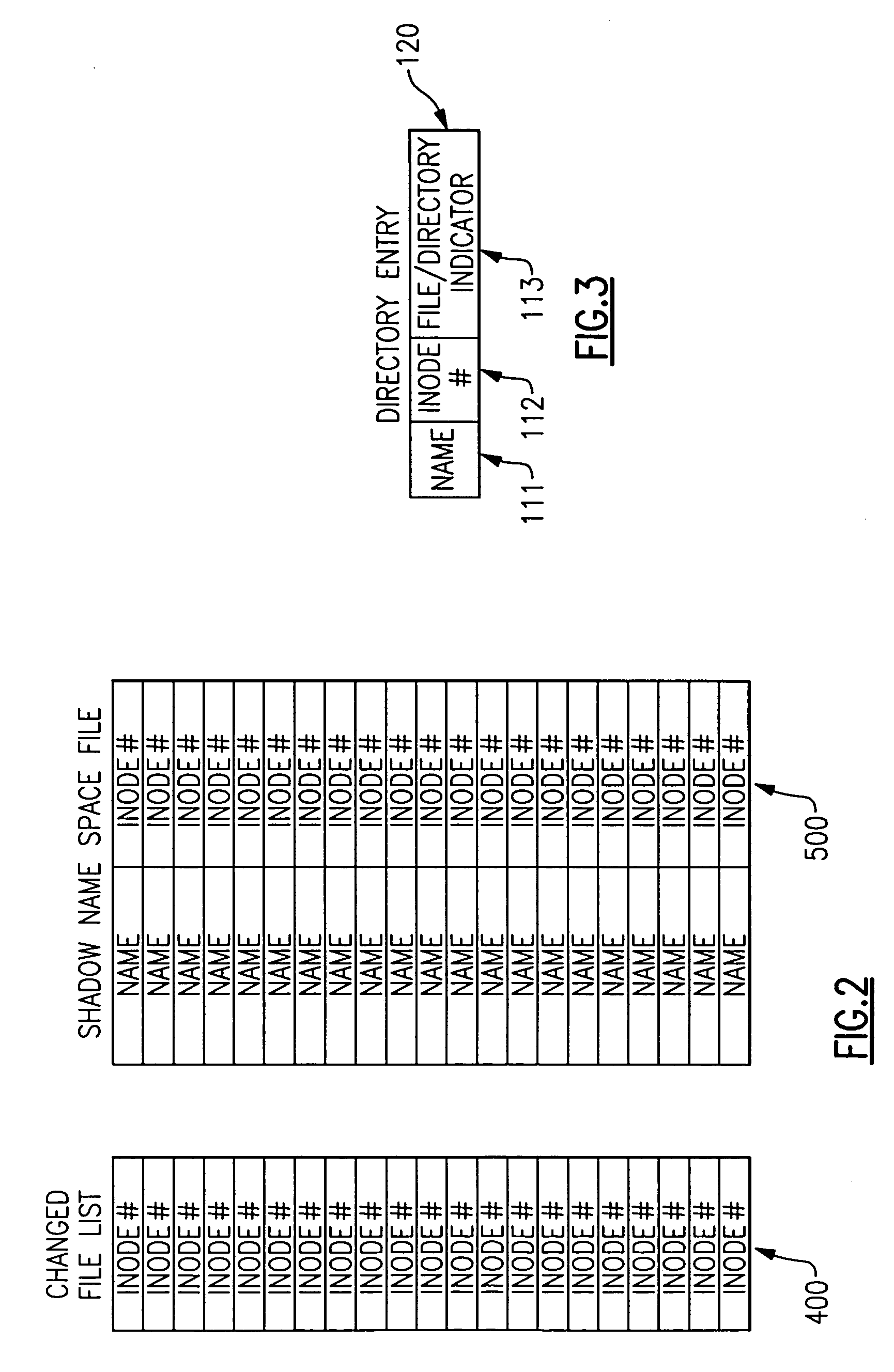

Rapid restoration of file system usage in very large file systems

ActiveUS7234077B2Improve facilitiesIncrease flexibilityData processing applicationsInput/output to record carriersFlash file systemFile system

File system restoration is made more flexible through the use of indicators of individual file restoration status throughout the restoration process. Such indicators are particularly useful in the restoration of large file systems where, for example, the number of files may range upwards of several hundred million. Since file system restoration for large systems takes such a relatively long time, the present invention provides various degrees of individual file access even as the restoration process is being carried out. During file system restoration times, file access may be full or limited to a file's attributes. Most advantageously, the present invention is capable of providing full, dynamically driven (on-demand) file access even during file system restoration operations.

Owner:IBM CORP

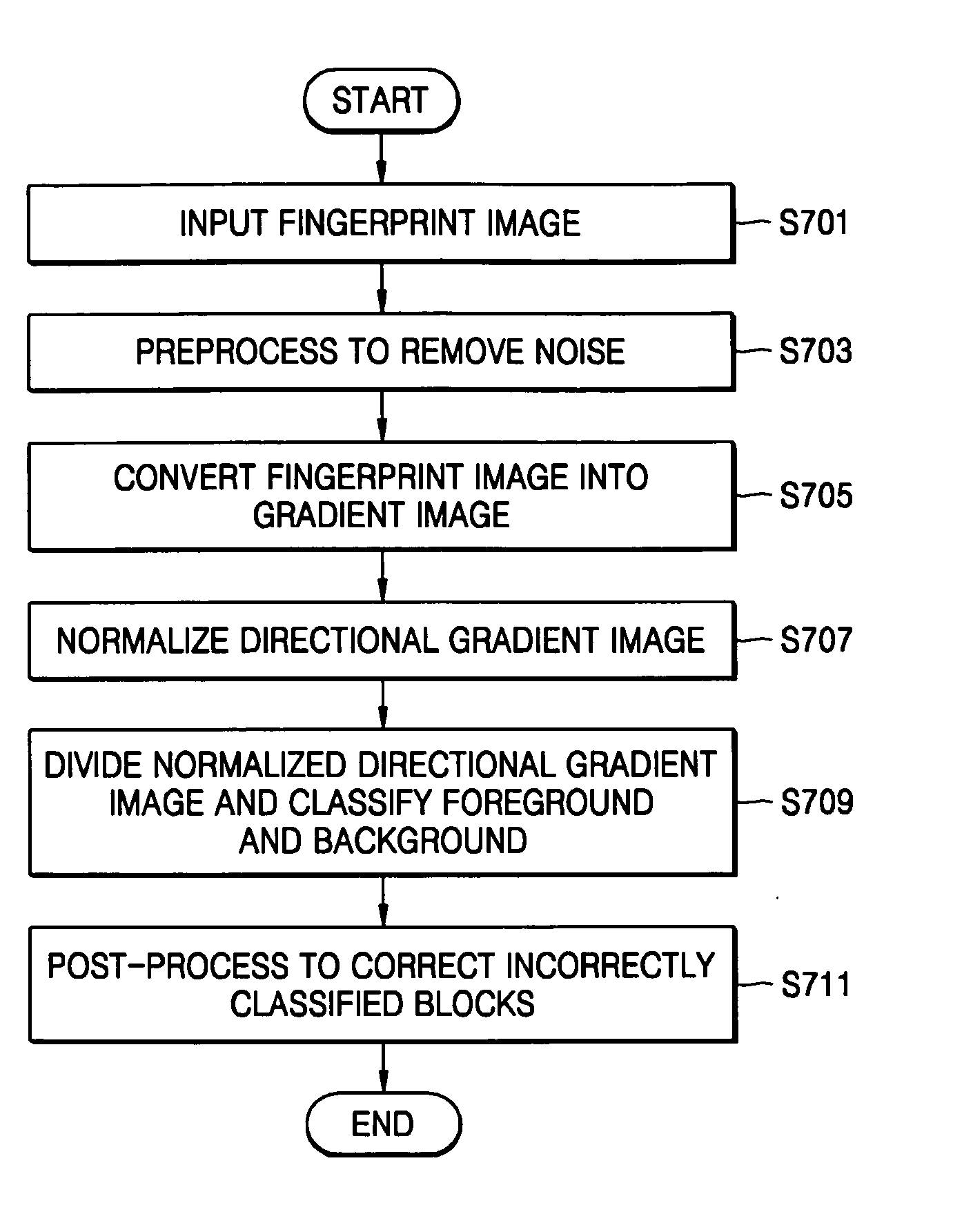

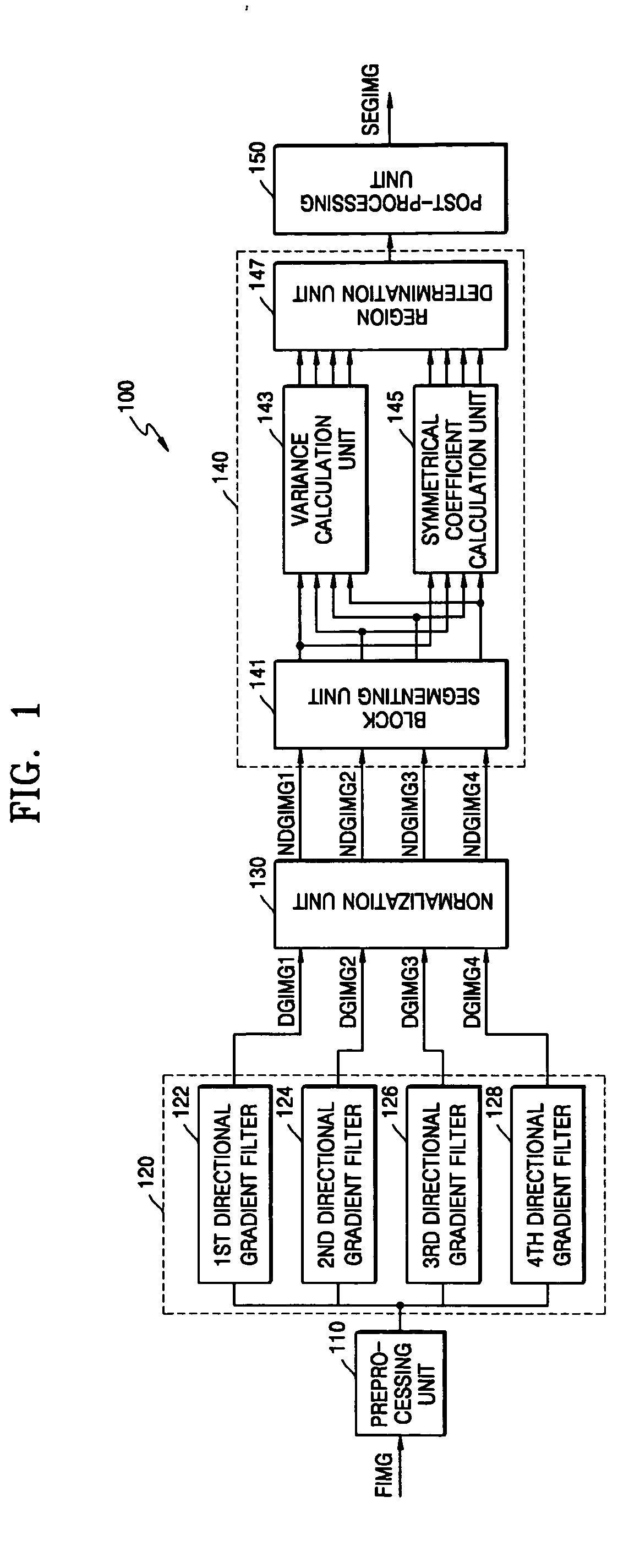

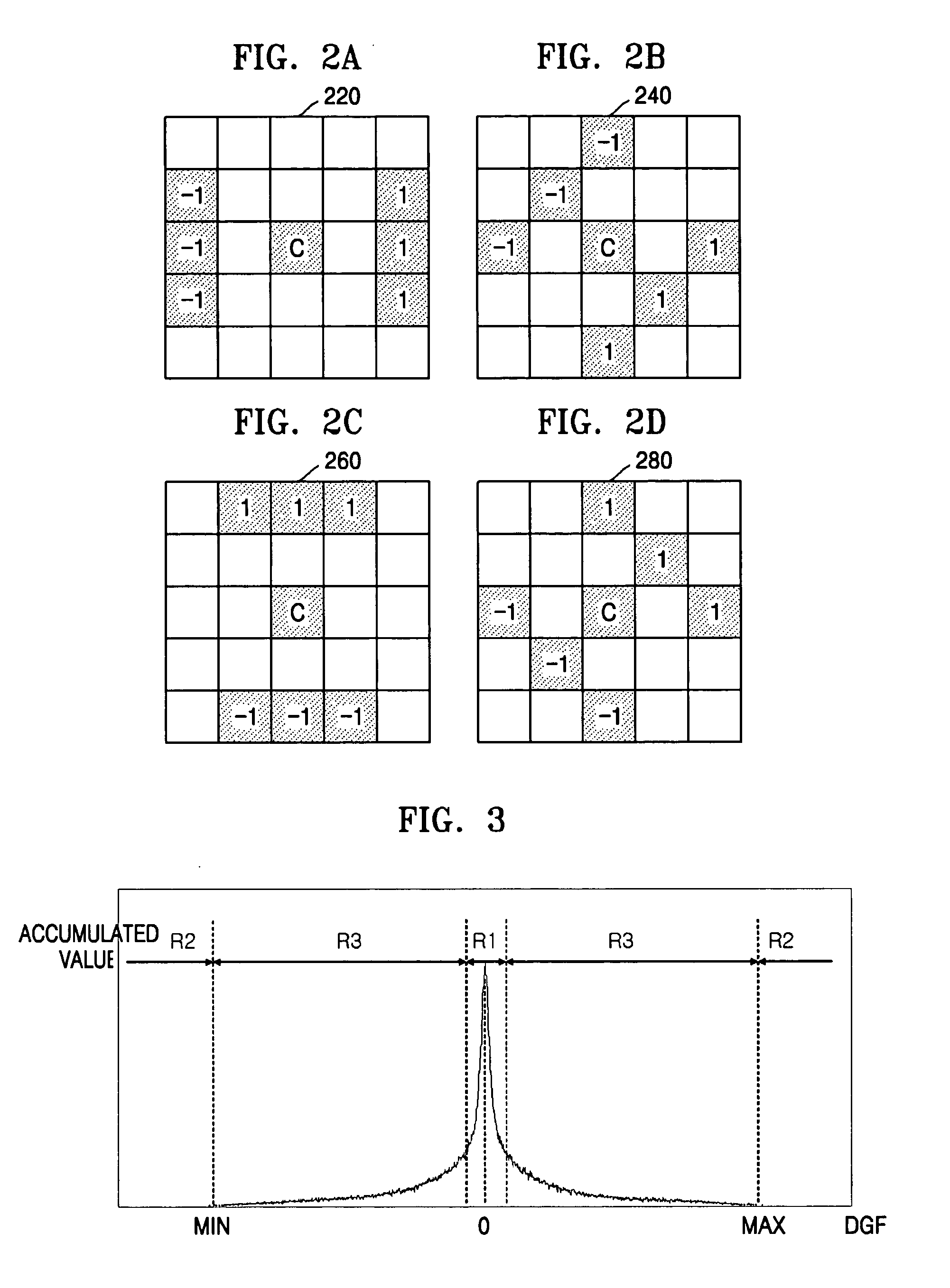

Fingerprint region segmenting apparatus, directional filter unit and methods thereof

A fingerprint region segmenting apparatus and methods thereof The fingerprint region segmenting apparatus may include at least one directional filter receiving an input fingerprint image and filtering the input fingerprint image to generate at least one directional image, a normalization unit normalizing the at least one directional image and a region classification unit dividing the normalized at least one directional image into a plurality of blocks and classifying each of the plurality of blocks. In an example, the classification for each of the plurality of blocks may be one of a foreground of the input fingerprint image and a background of the input fingerprint image. In an example method, a fingerprint may be segmented by segmenting a fingerprint image into a plurality of regions based on a plurality of directional images, each of the plurality of directional images associated with a different angular direction.

Owner:SAMSUNG ELECTRONICS CO LTD

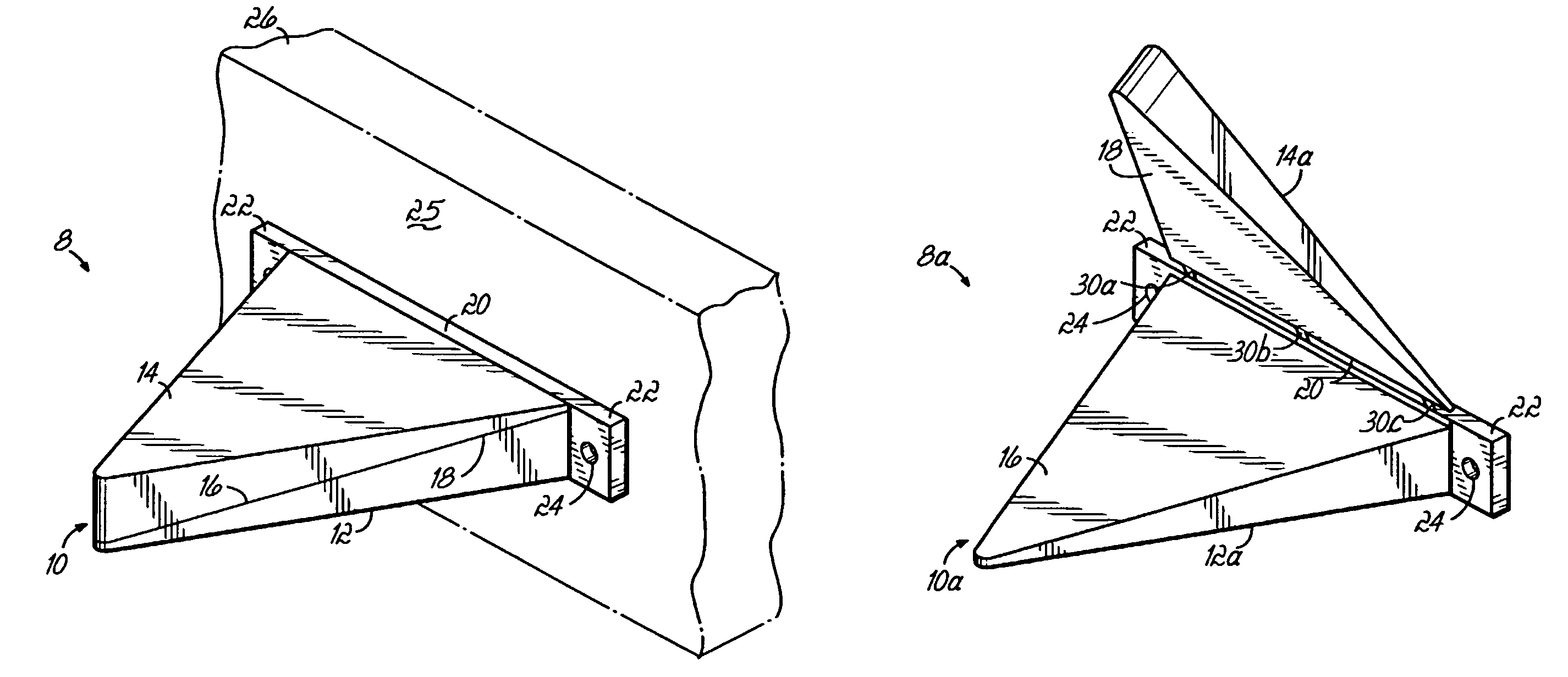

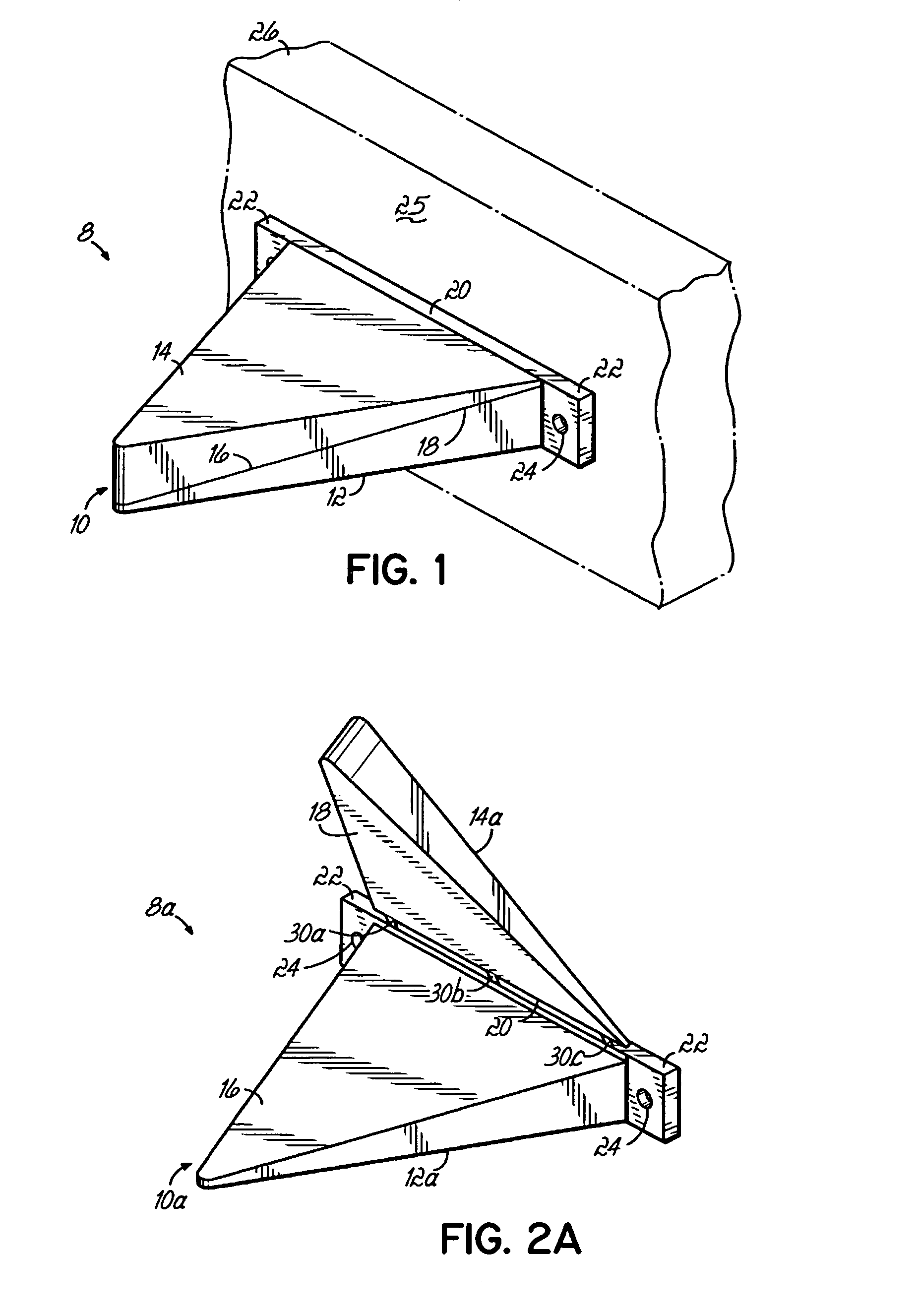

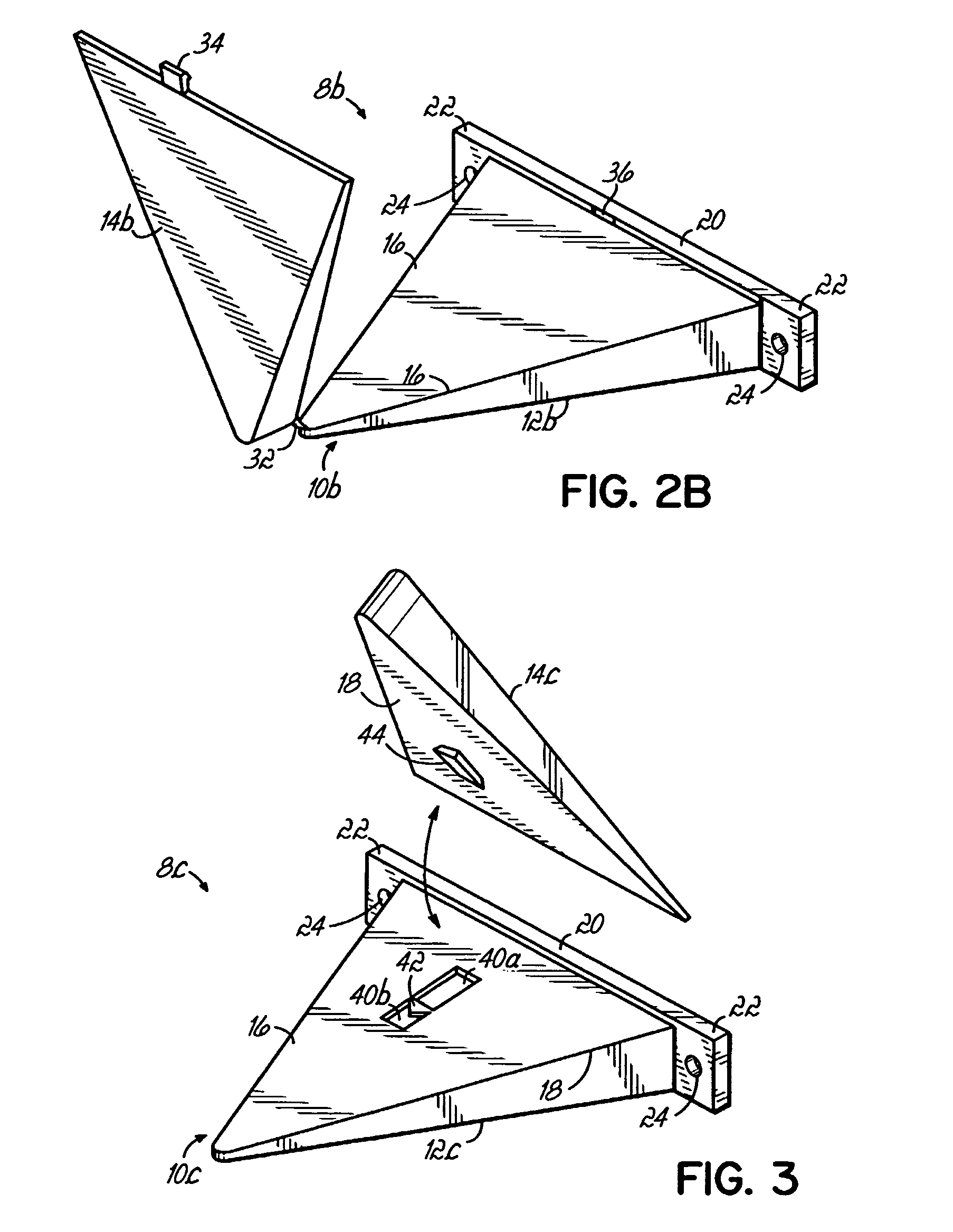

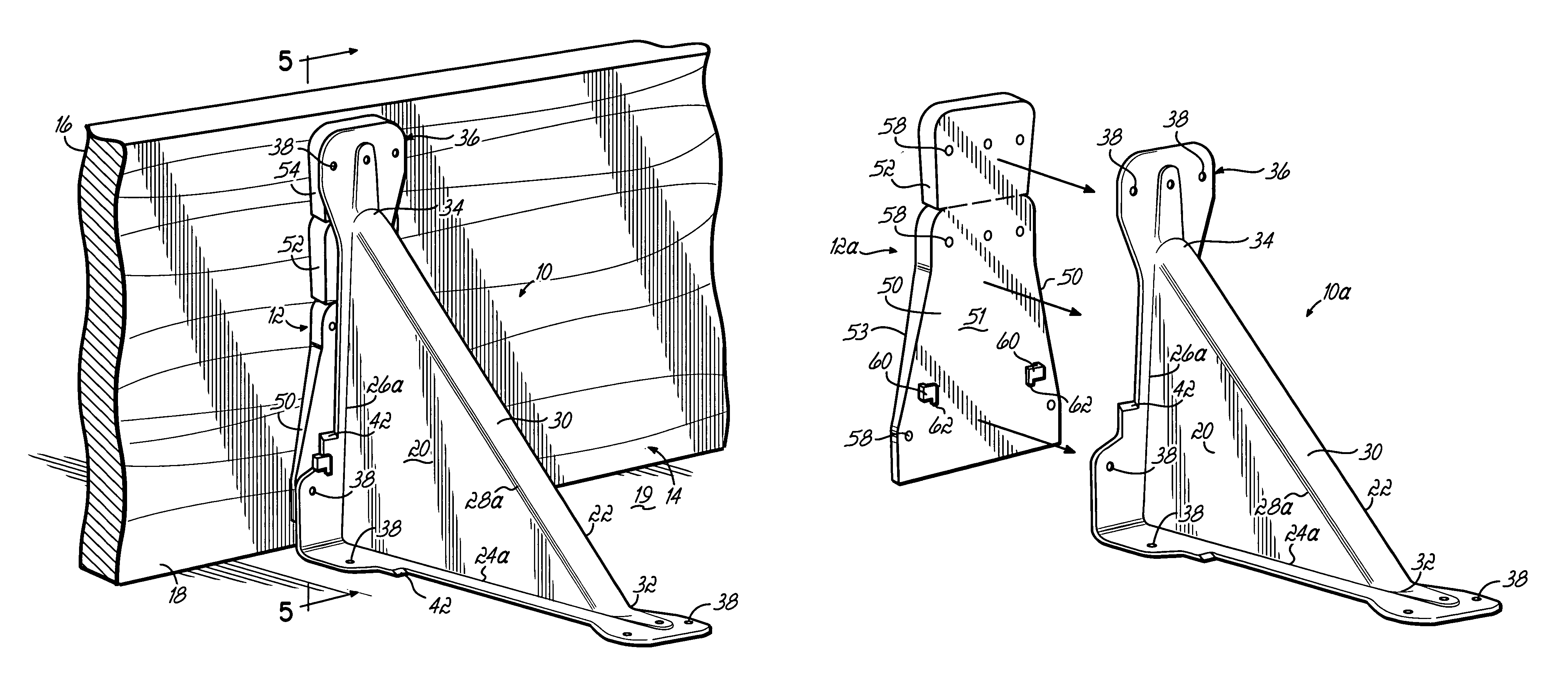

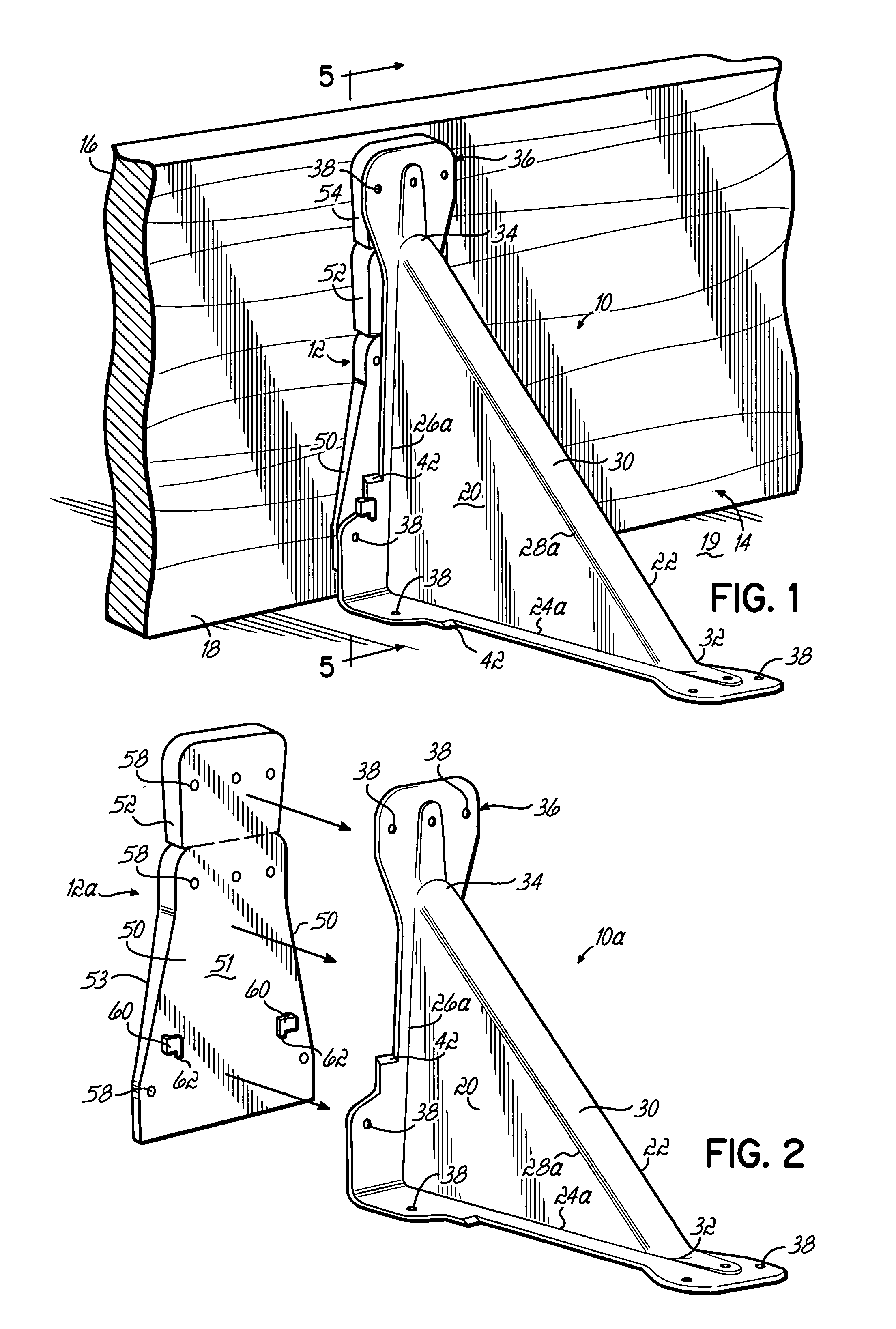

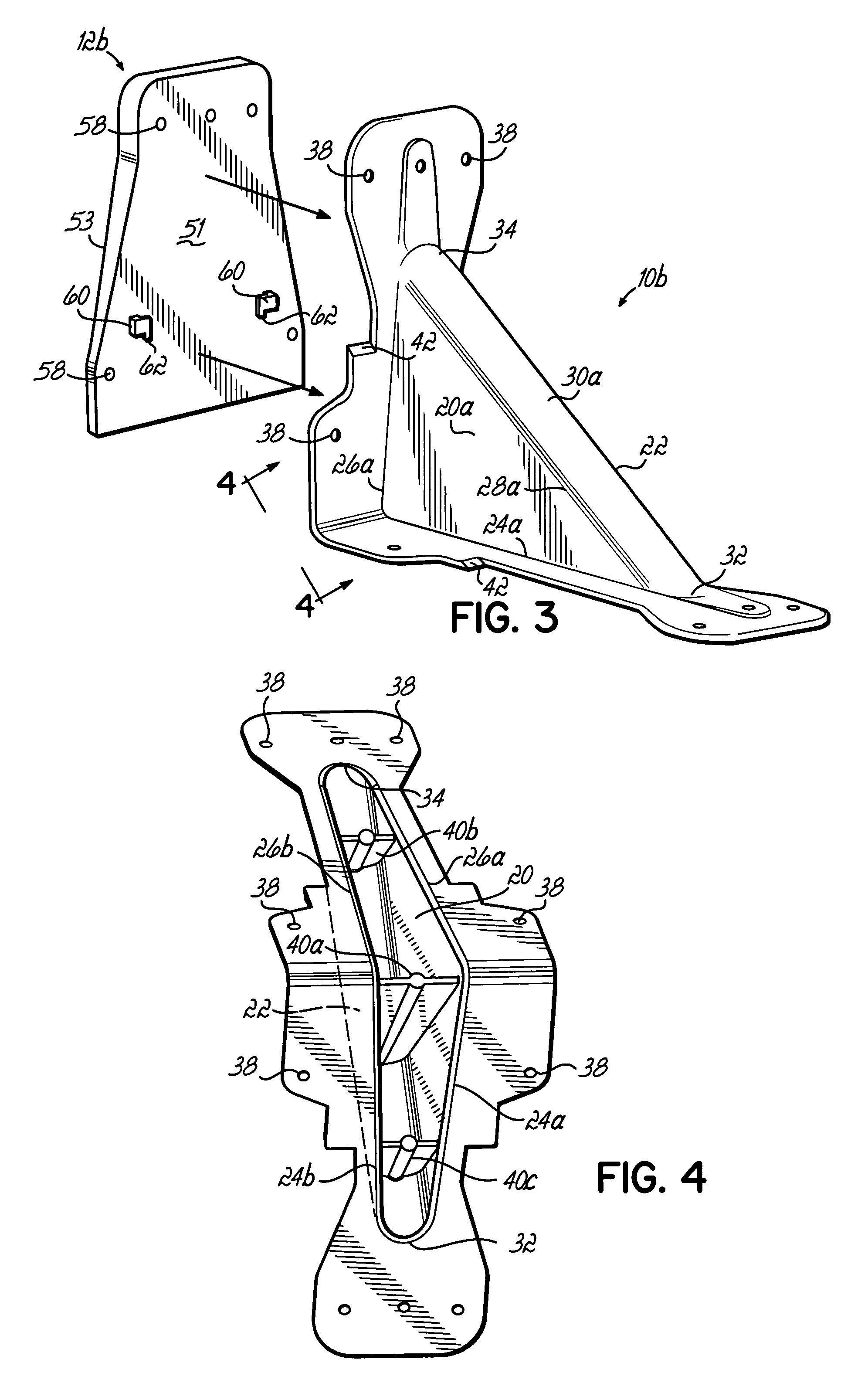

Concrete form brace and battering wedge

A brace for securing concrete forms to a base has first and second triangularly-shaped sidewalls and a back wall extending between corresponding side edges of the sidewalls. A peripheral flange extends outwardly from the side edges of the sidewalls and the ends of the back wall and has apertures for facilitating fastening of the brace to the concrete forms and a casting surface. Advantageously, the brace can be formed as a unitary, molded component. A battering wedge is selectively attachable to the side edges of the sidewalls and cooperates with the brace to facilitate tilting the concrete form at an angle to the casting surface. The battering wedge is selectively frangible to permit use with braces of varying size.

Owner:DAYTON SUPERIOR CORP

Artificial stone

Owner:OLDCASTLE BUILDING PROD CANADA INC

Artificial flagstone for providing a surface with a natural random look

ActiveUS20100236174A1Natural lookThe result is stableCovering/liningsNatural patternsEngineeringMechanical engineering

An artificial flagstone for use in combination with other similar flagstones for covering a surface with a natural random look, the flagstone having a generally hexagonal body comprising a first, second, third, fourth, fifth and sixth consecutive vertices; a first pair of generally congruent irregularly-shaped first and second sides extending radially from the first vertex and being rotationally spaced from each other by an angle α of approximately 120°; a second pair of generally congruent irregularly shaped third and fourth sides extending radially from the third vertex and being rotationally spaced from each other by an angle β of approximately 120°; a third pair of generally congruent irregularly shaped fifth and sixth sides extending radially from the fifth vertex and being rotationally spaced from each other by an angle ω of approximately 120°; wherein the sides of each of the first, second and third pair of sides have at least one split deviation along their length and are respectively rotational images of each other, whereby in use in combination with other flagstones, each one of the sides is matingly engageable with the sides of an equivalent pair of sides of a neighbouring flagstone.

Owner:OLDCASTLE BUILDING PROD CANADA INC

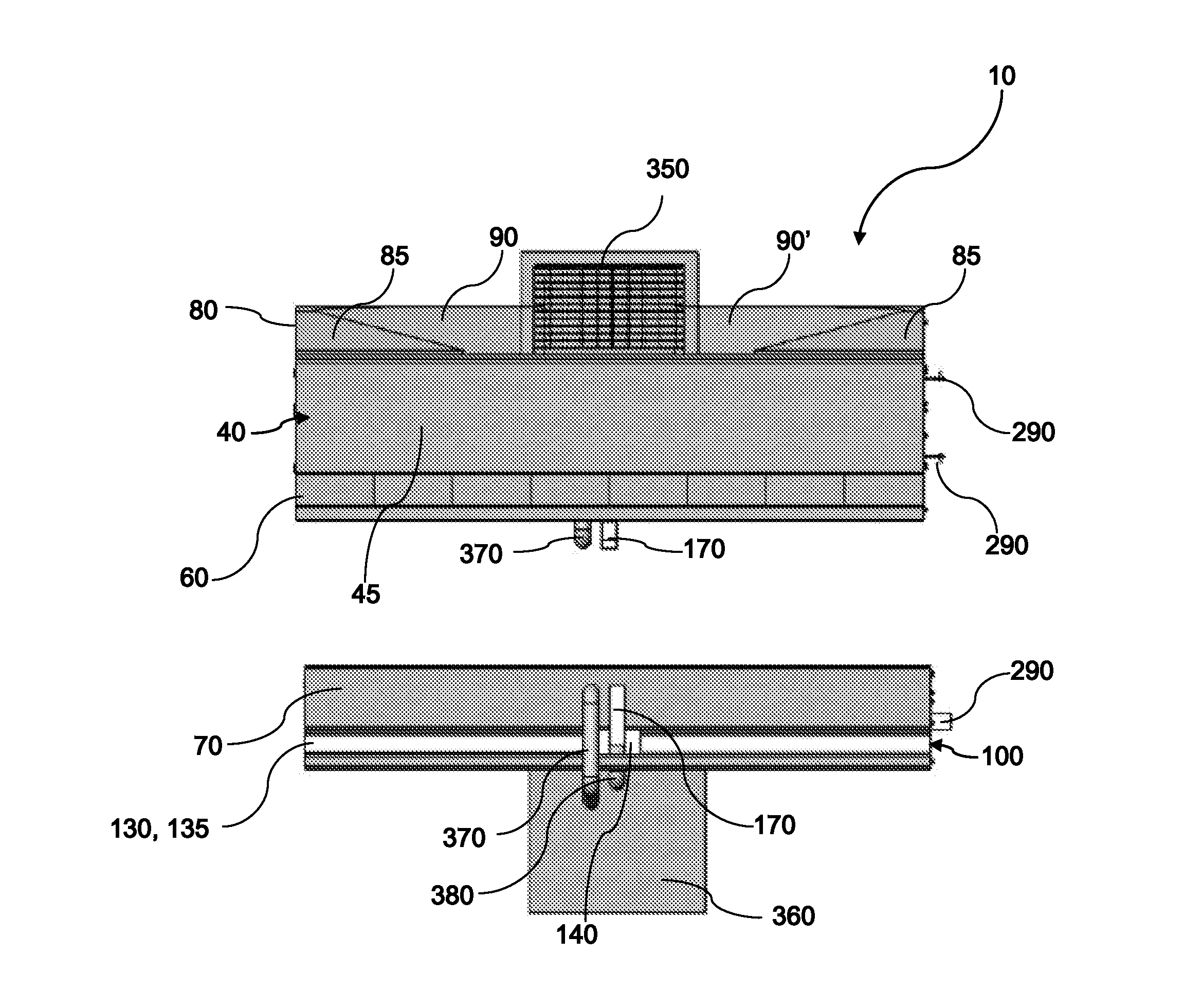

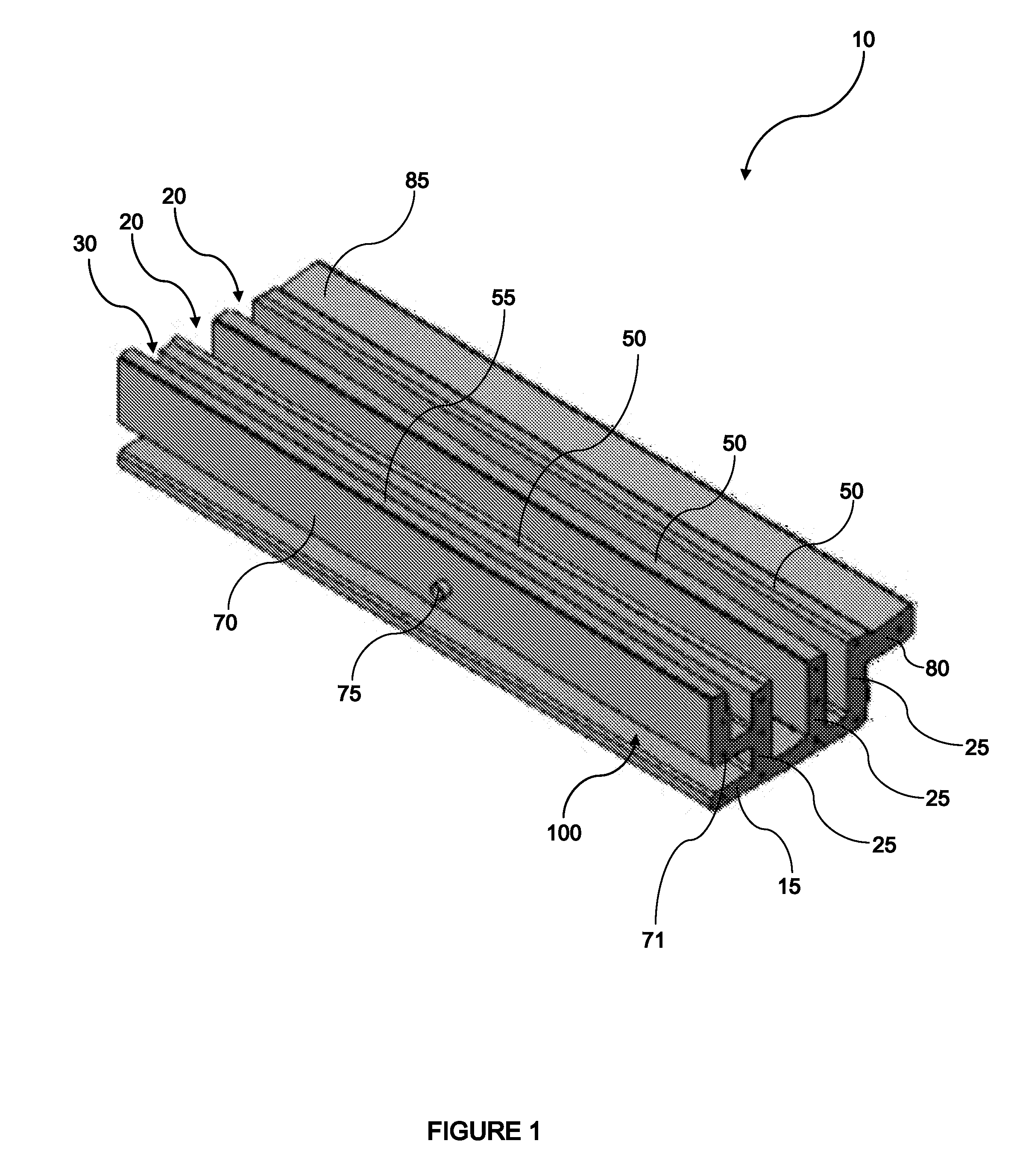

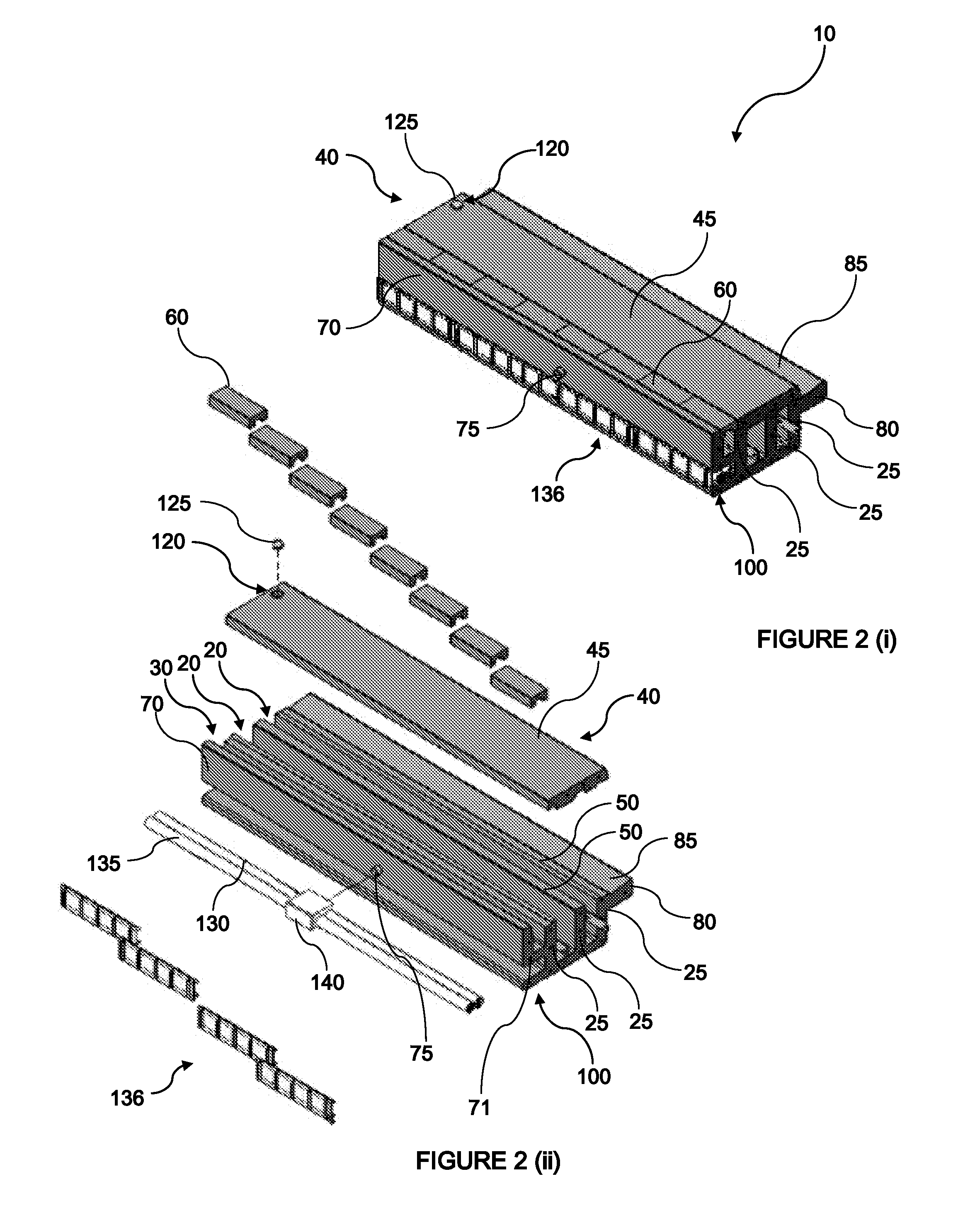

Modular Ducting Section Adapted for Laing End-To-End and Side by Side Forming a Networked Utilities Ducting System and Rain and Run-Off Water Management System

ActiveUS20130121761A1Cost-effectiveLow-cost installationCable installations in surface ductsGround-workCycloneRoad surface

The invention integrates the functionality of: kerbs, gutters, pathways, into a surface accessible networked utility ducting system and a a rain and run-off water management system.It is comprised of a base section formed a combination of one or more open topped utility access channels, an open topped water catchment channel, a slopped flange and one or more open sided access and or open topped feeder line distribution channels.The invention includes features for the isolation of electric power channels from contact with other utilities such as gas, water, or communications.The invention includes features for, integration with existing stormwater systems such as overflow points.The invention provides utilities access pathway all the way to an end users premises with minimal need for digging or disturbance of footpaths or paved surfaces this is a major improvement upon the prior art which tranforms the economics of surface accessible utility ducting systems.The invention includes covers, which are interchangeable, may take various forms, such as a pavement and kerb, a driveway ramp or a wheel chair access ramp. This allows the invention to be economically adapted to changes in kerb requirements as changes to the pathways and kerbs occur along their length and as requirements change over time, this solves the problems associated with the prior art which can not be readily adapted to all the variations found in kerbs and gutters along the length of the kerb and pavement or as they occur over time.The invention enables rain and run-off water to be isolated from contamination and managed to preserve its value and usefulness.The invention lowers the cost of, and, increases the speed, of new service deployment thereby overcoming the major economic barriers to market entry of new distributed utility services.The invention is to be manufactured in most cases as precast modules. The channels, lids, access boxes are linked by flexible interstitial joints which enable the system so formed to change direction to conform with the contours of the landscape in which it is located. In most cases the material of construction will be a dense, reinforced material such as concrete. When so constructed the invention will resist the effects of earthquakes, cyclones, flooding, tornados, and tsunamis.

Owner:DIXON GUY ANDREW COTTERILL

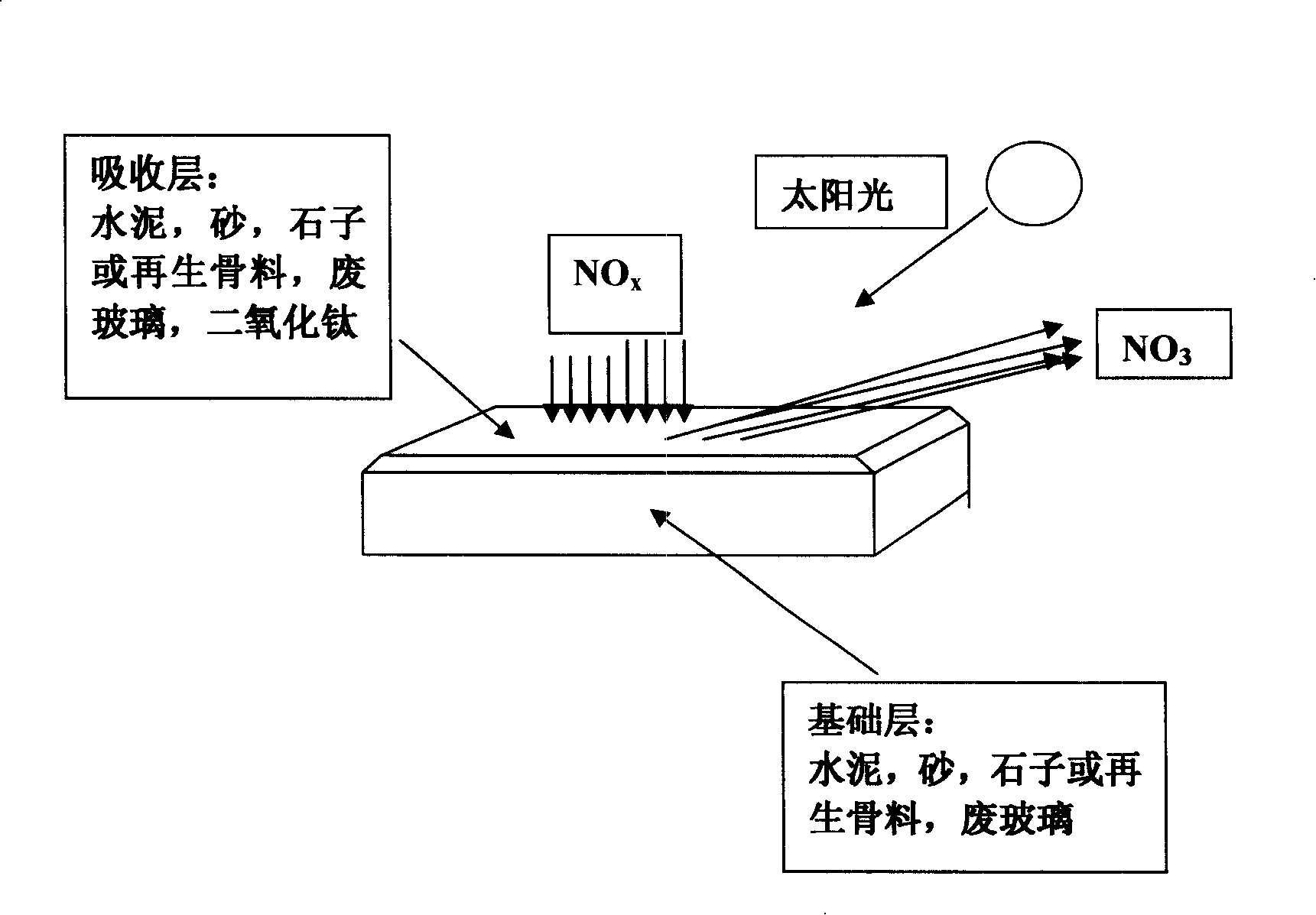

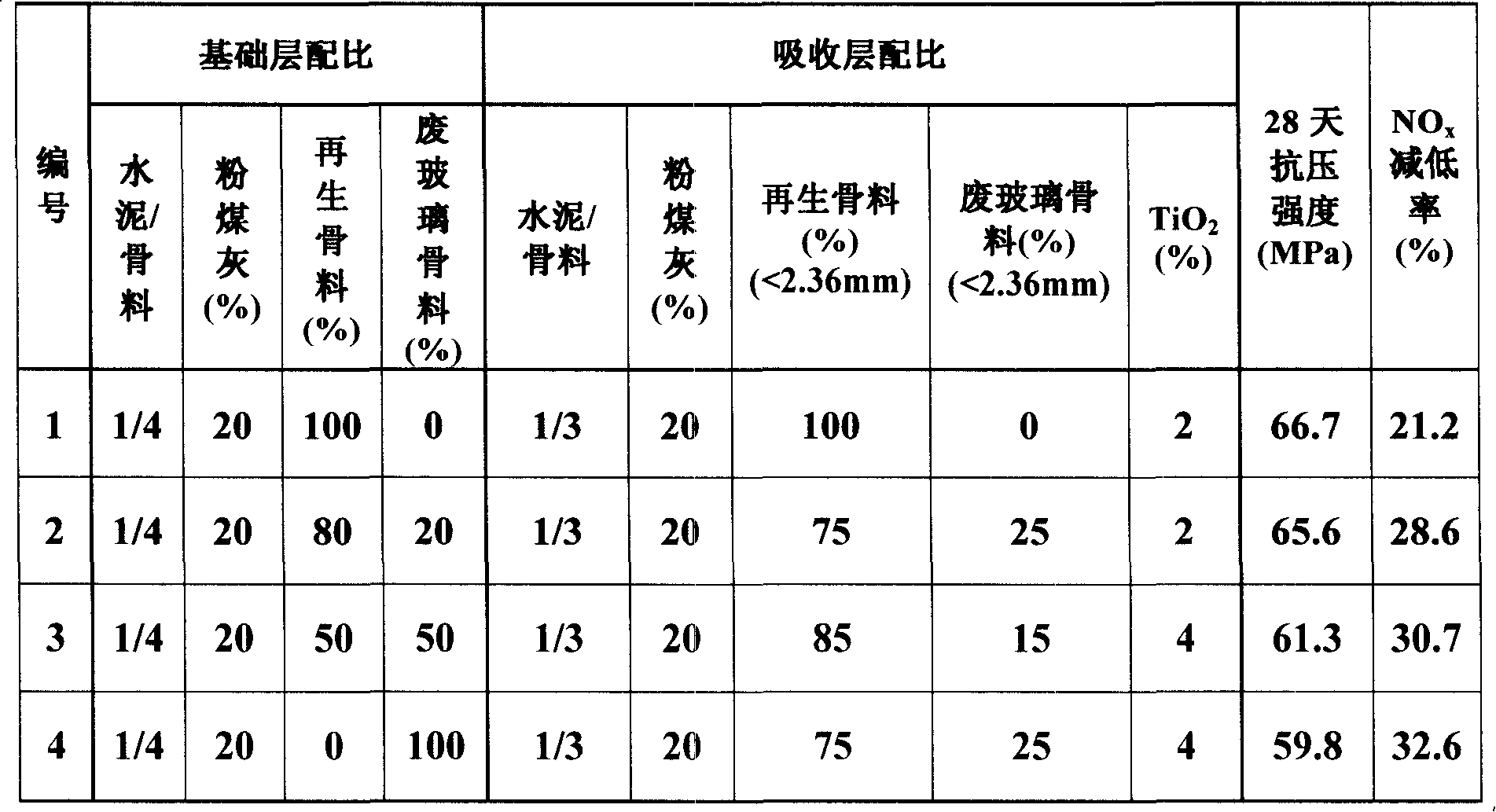

Concrete paving brick capable of purifying air and method for manufacturing the same

The invention provides a concrete paving brick capable of clarifying air produced by using building waste and recycled glass and the manufacturing method thereof. The paving brick comprises an absorption layer and a foundation layer, the absorption layer comprises cement, aggregate, titanium oxide and coal ash or kaolinite powder, the aggregate of the absorption layer comprises recycled aggregate, waste glass aggregate and sand or stones; the foundation layer comprises cement, aggregate and coal ash or kaolinite powder, the aggregate of the foundation layer comprises recycled aggregate, waste glass aggregate and sand or stones. The paving brick of the invention has good function of absorbing exhaust gas and good strength.

Owner:THE HONG KONG POLYTECHNIC UNIV

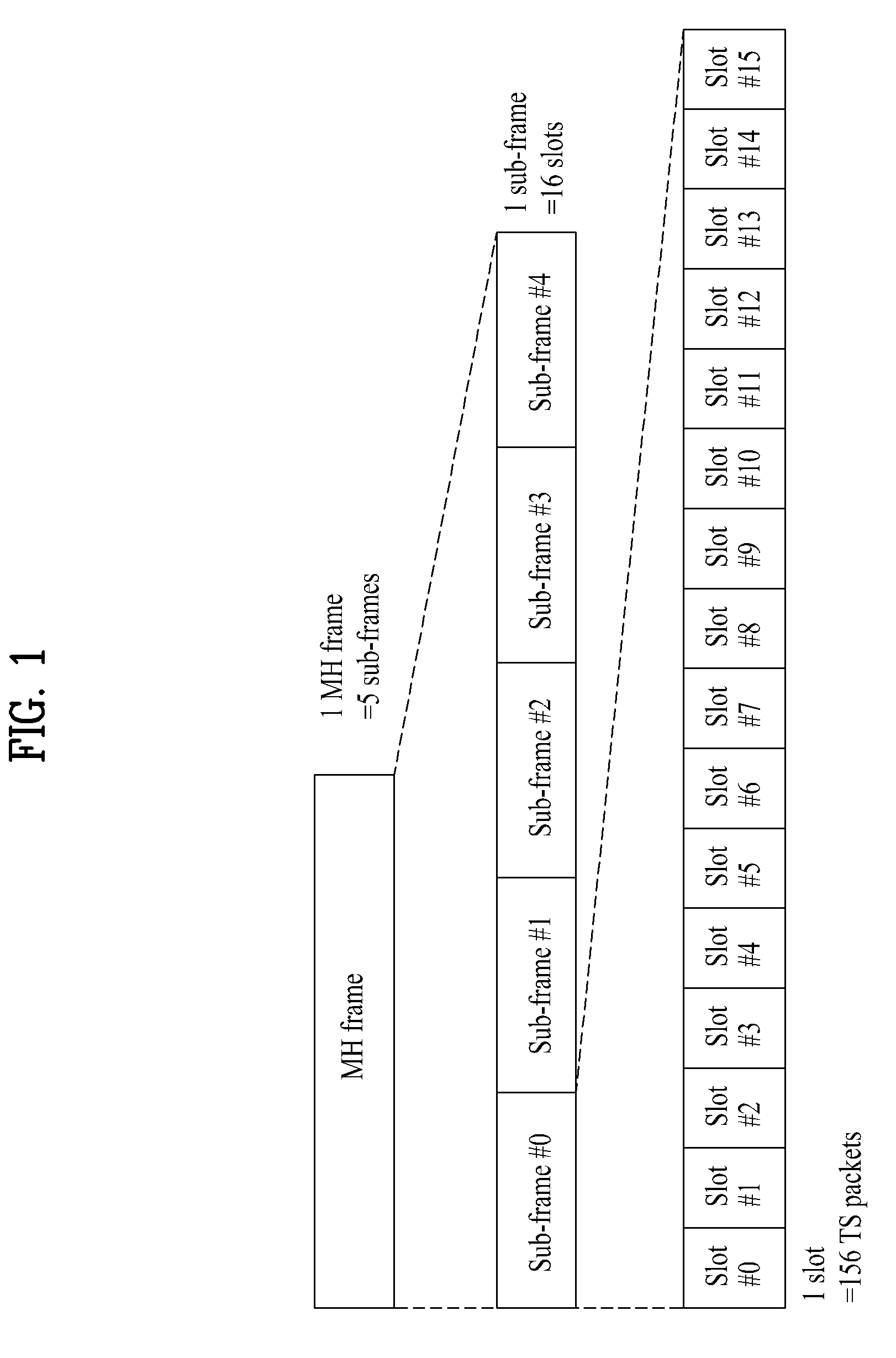

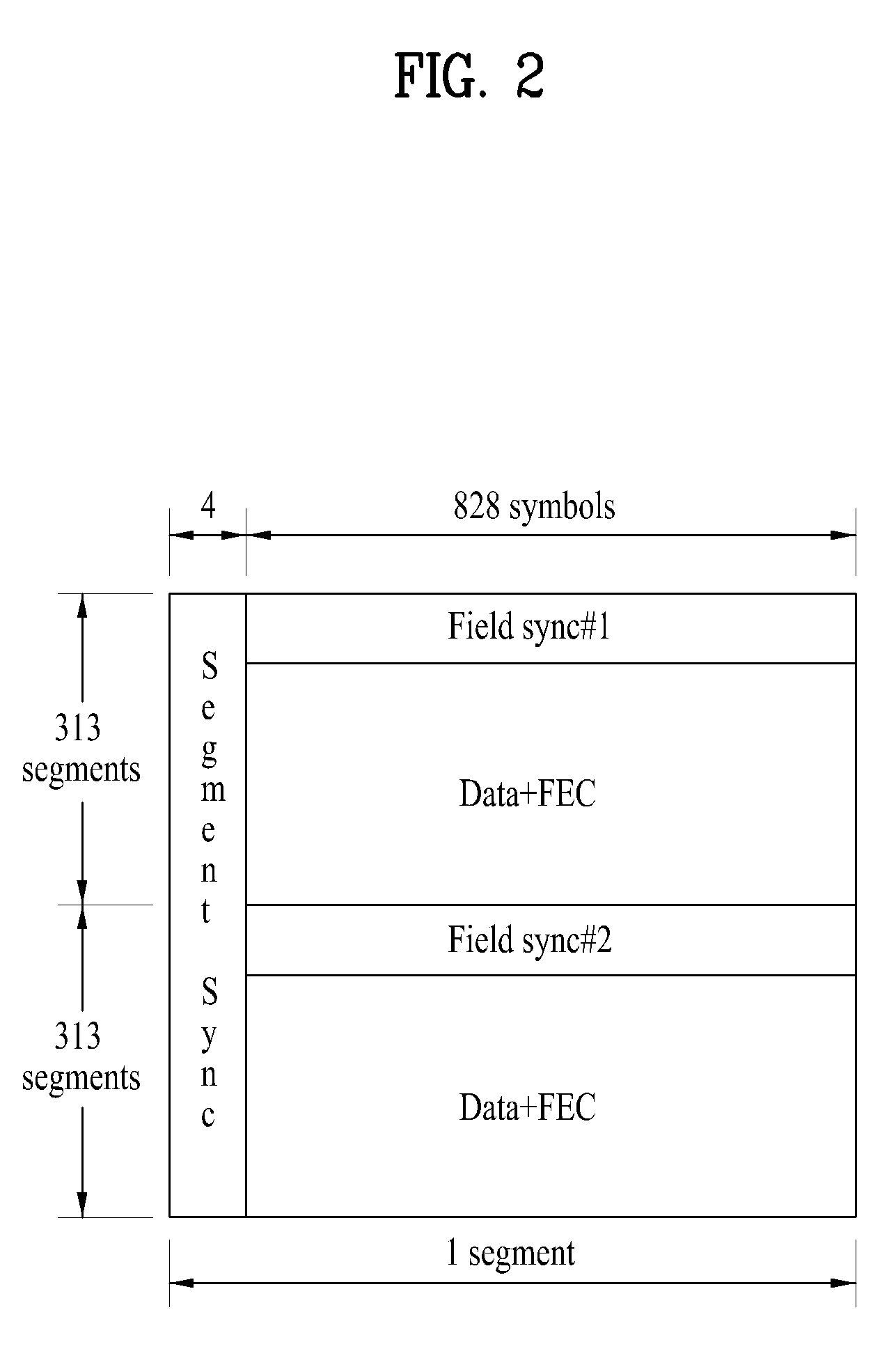

Digital broadcasting system and method of processing data in the digital broadcasting system

ActiveUS20090228764A1Improve reception performanceMaintain compatibilityError correction/detection using convolutional codesSidewalk pavingsData packMobile business

Owner:LG ELECTRONICS INC

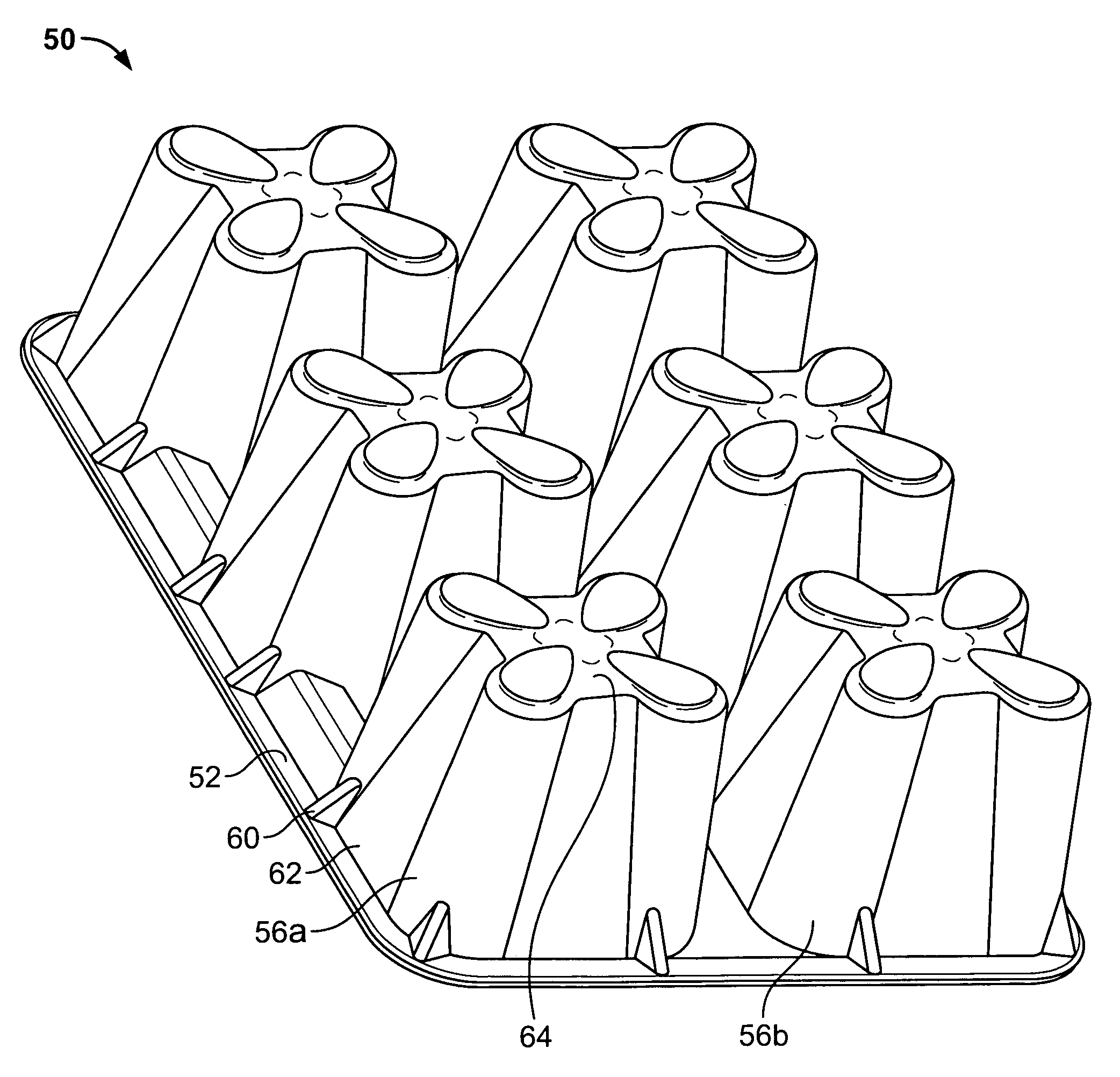

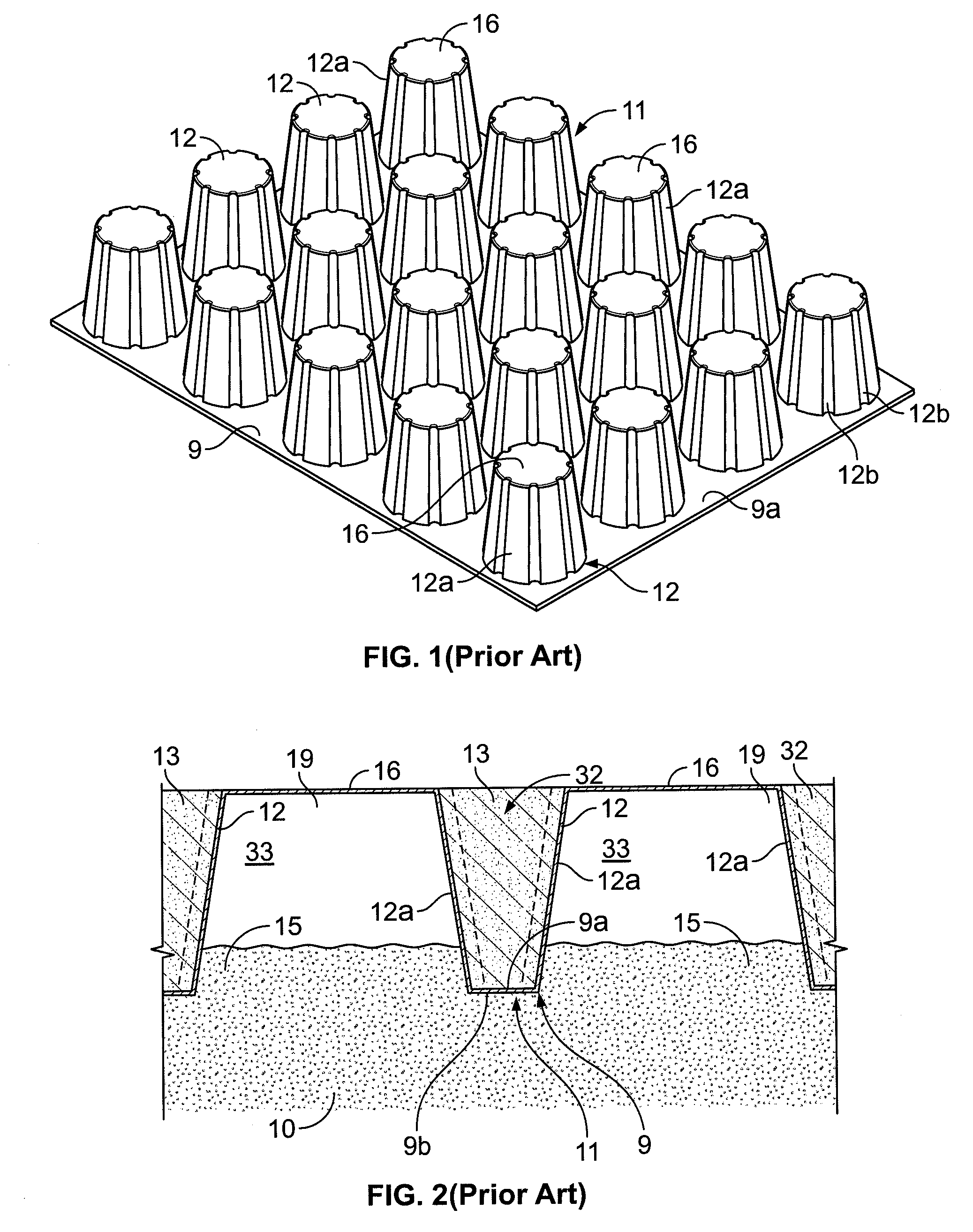

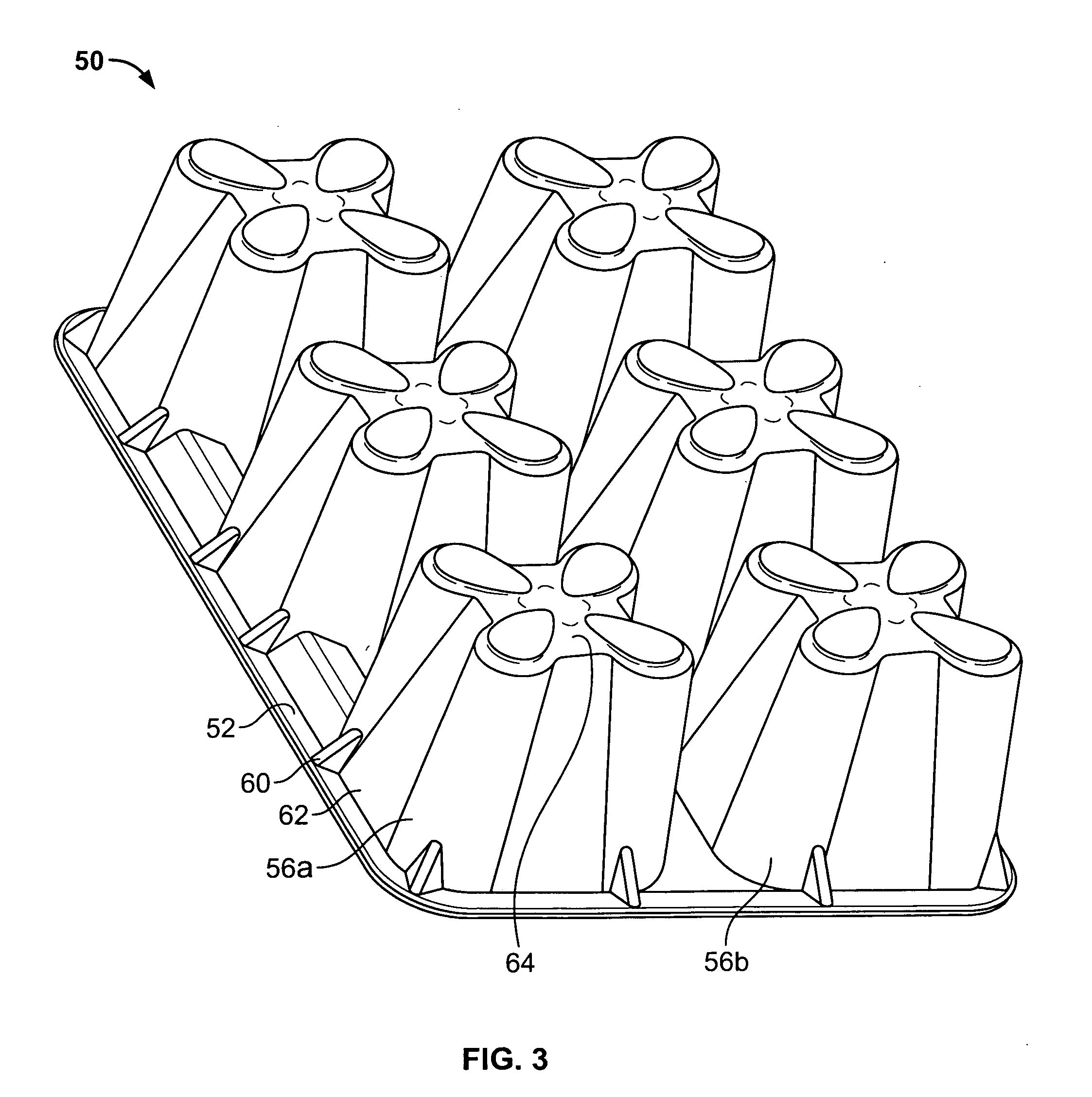

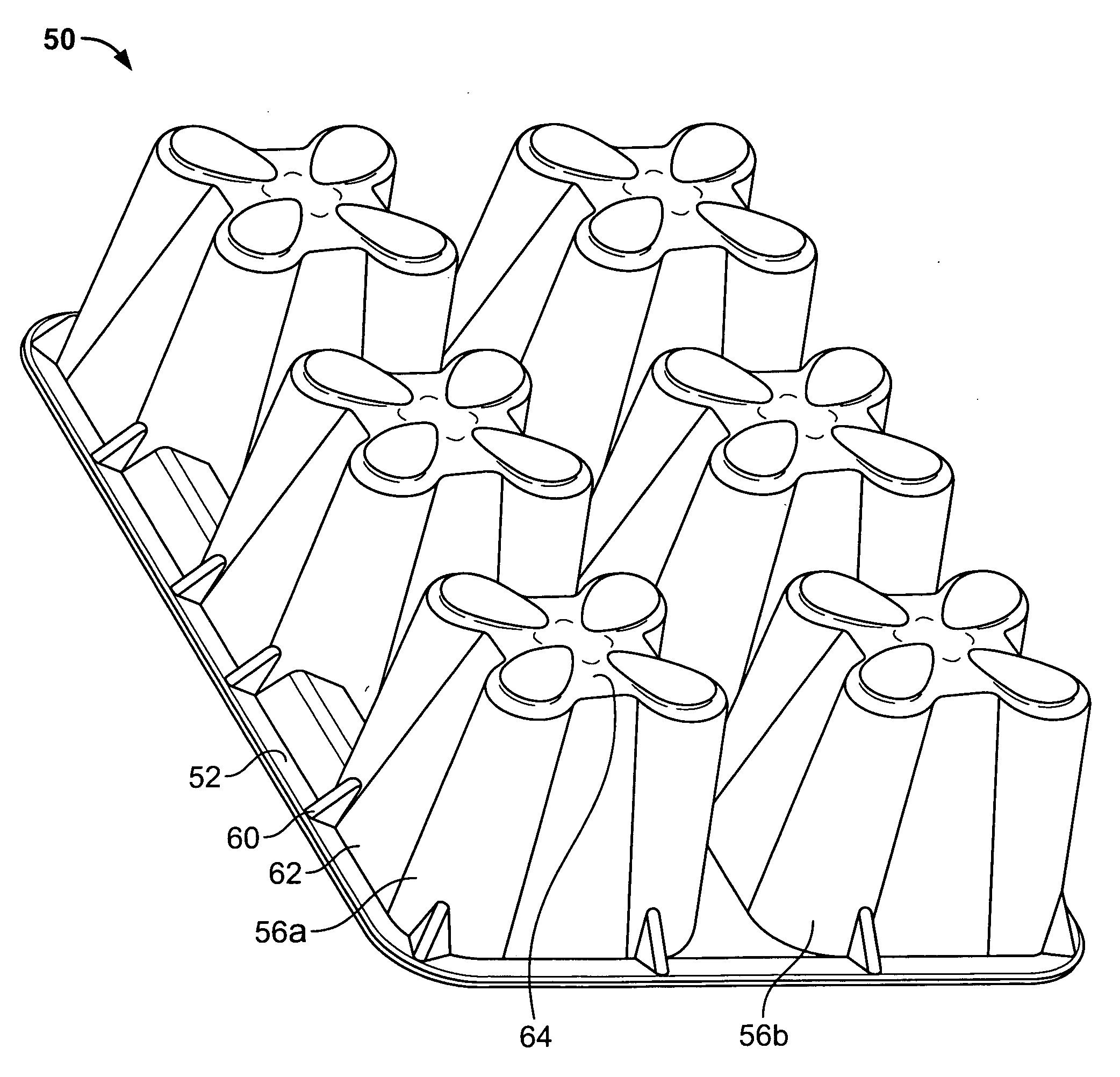

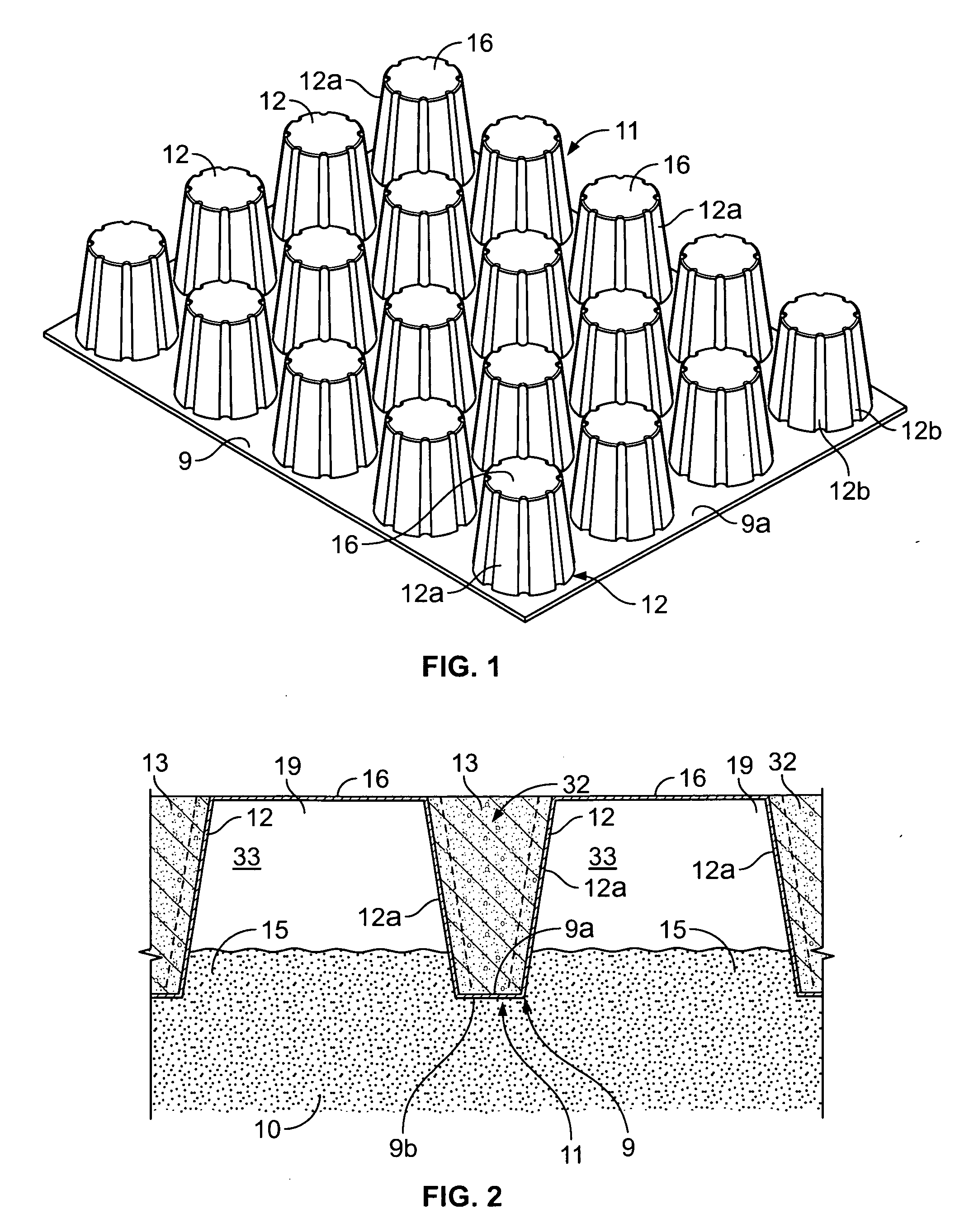

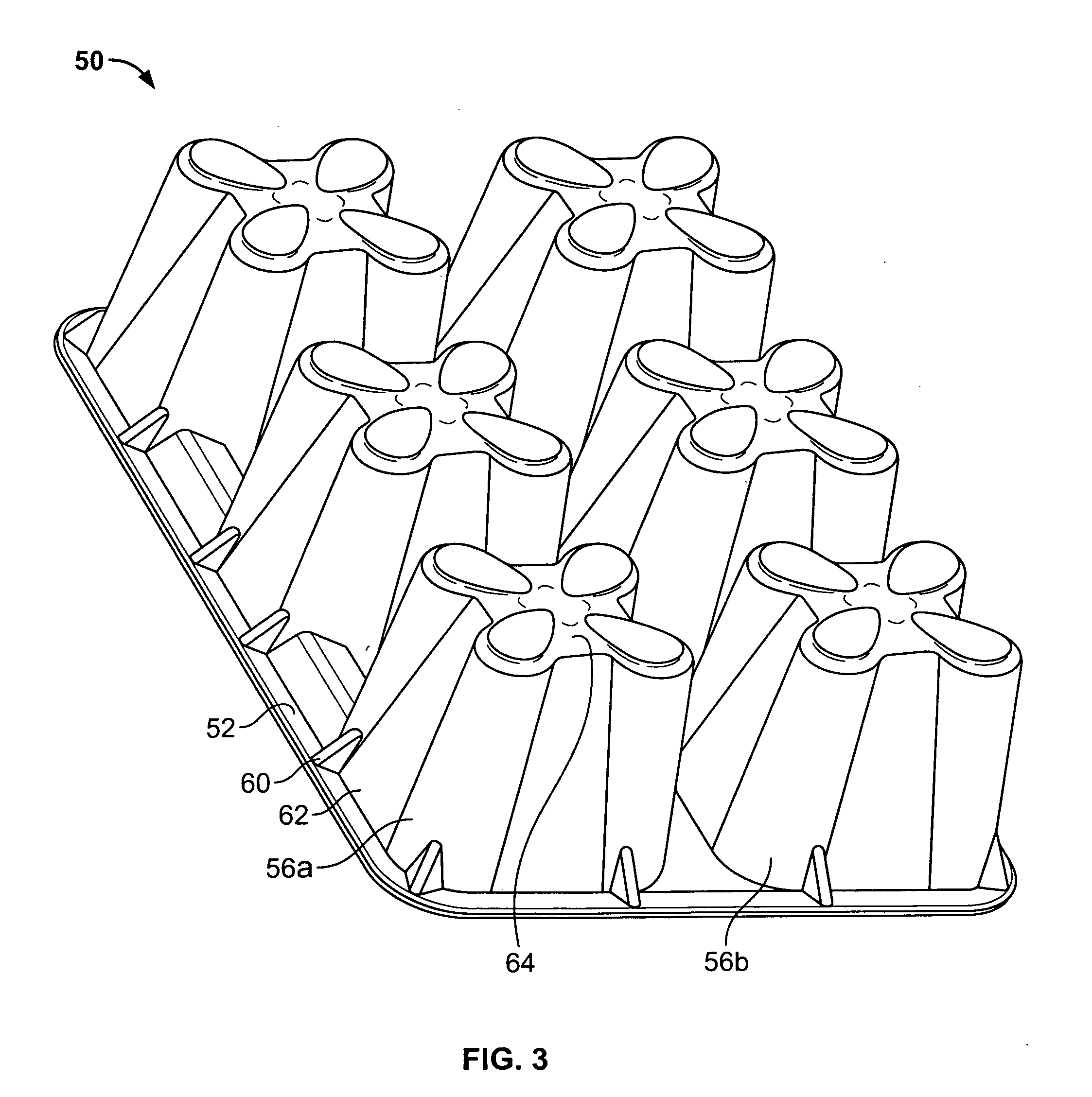

Former for pavement-like sites

ActiveUS7771814B2Increase ratingsReduce labor costsArtificial flowers and garlandsWood working apparatusWood fibreEngineering

A former, process for making same, process for using same, and resulting pavement-like site, where the former is a one-time use structure made of wood fiber or paper pulp molded into a rigid shape and defining a plurality of hollow peak-like structures extending from a base sheet. Each peak is substantially closed at its extremity away from the base sheet and open at the extremity at the base sheet. This former is used for installing combination pavement and dirt / gravel surfaces such as those known under the tradename Grasscrete®.

Owner:SUSTAINABLE PAVING SYST

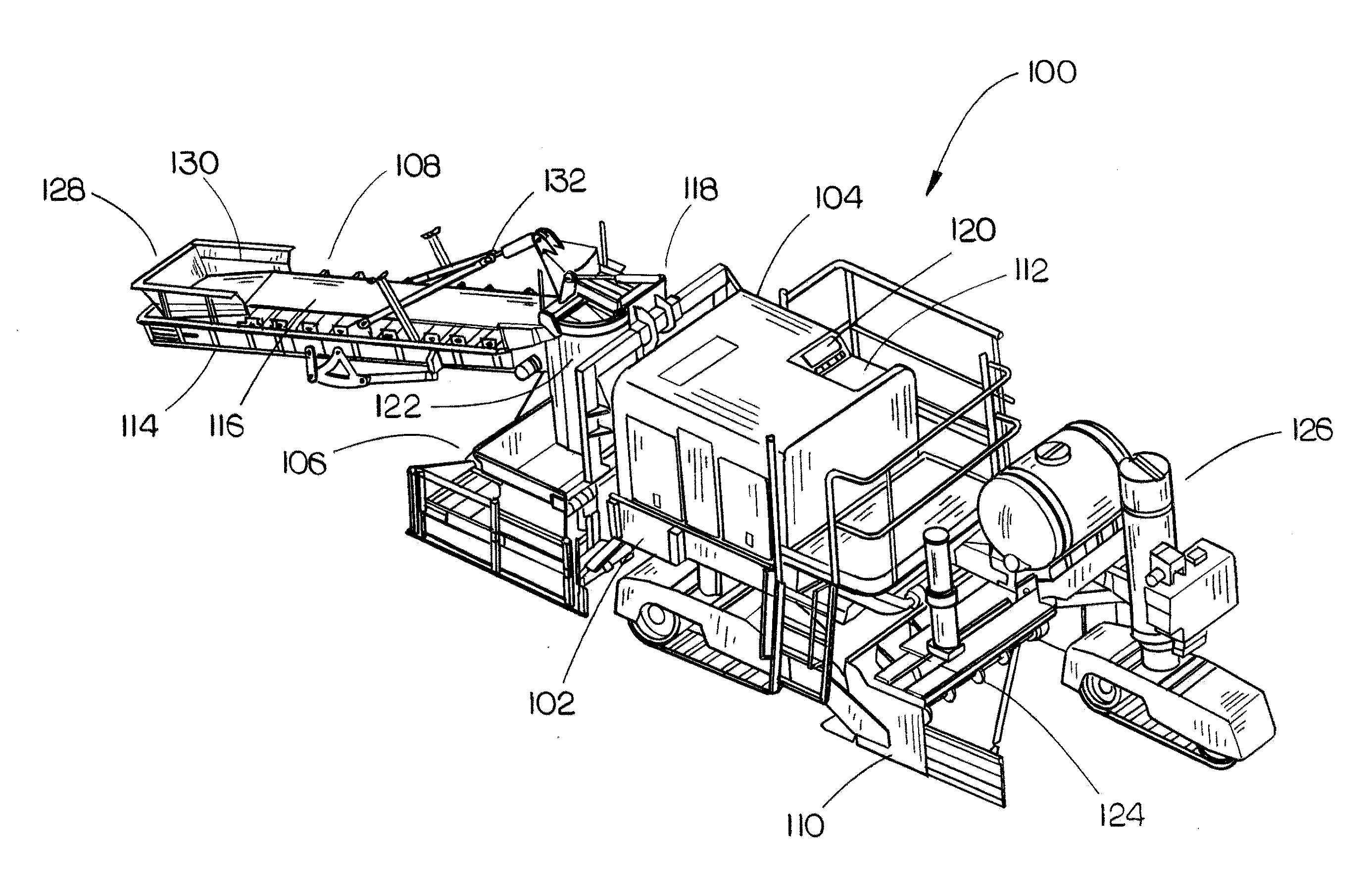

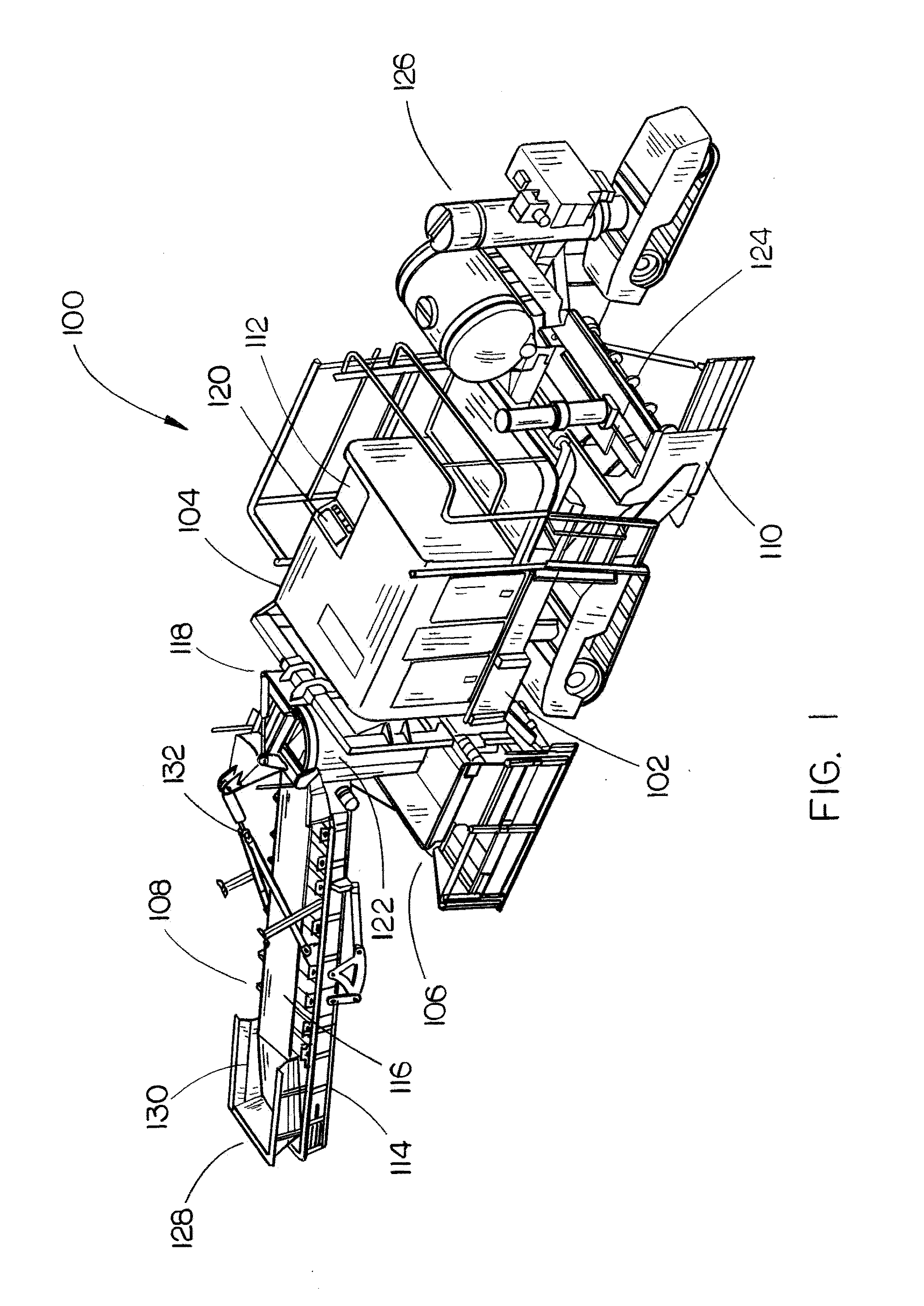

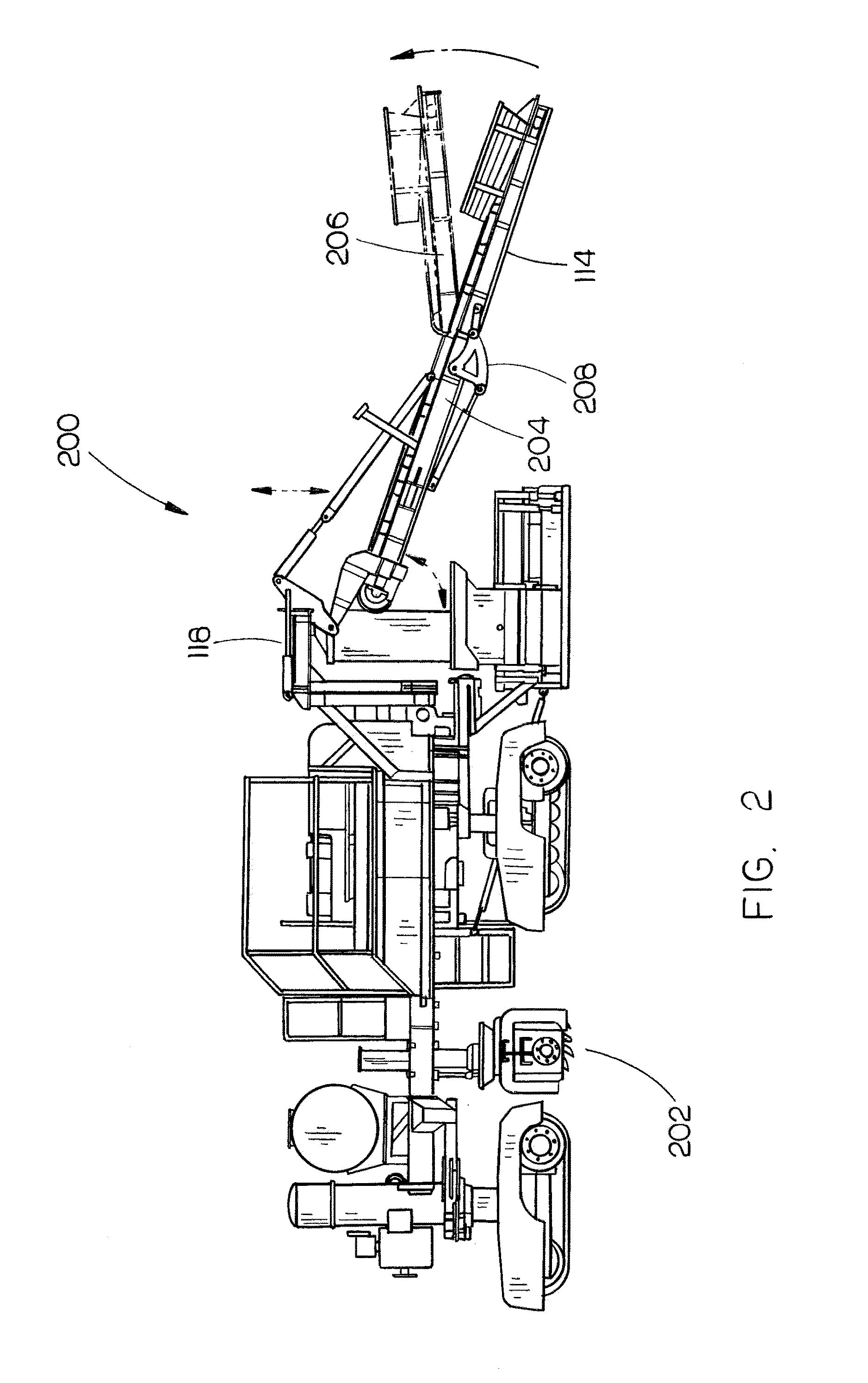

Adjustable Width Trail Paver

An adjustable width trail paver comprising a prime mover, an adjustable width paver, moveable and controllable materials conveyor, a controller, a base mold, and a trimmer; the control having pivot, tilt, raise, and fold features to move or control the materials conveyor around obstacles along the path to be paved; a prime mover with hydraulically telescoping frame; an adjustable width paver having interchangeable molds or hydraulically expanding pressure compensated side plates; and, methods for achieving continuous paving near or around obstacles along a path to be paved utilizing the adjustable width trail paver.

Owner:GOMACO

Former for pavement-like sites, method of making same, method of using same, and resulting pavement-like site

ActiveUS20080113161A1Improve productivityReduce labor costsArtificial flowers and garlandsWood working apparatusWood fibreRoad surface

A former, process for making same, process for using same, and resulting pavement-like site, where the former is a one-time use structure made of wood fiber or paper pulp molded into a rigid shape and defining a plurality of hollow peak-like structures extending from a base sheet. Each peak is substantially closed at its extremity away from the base sheet and open at the extremity at the base sheet. This former is used for installing combination pavement and dirt / gravel surfaces such as those known under the tradename Grasscrete®.

Owner:SUSTAINABLE PAVING SYST

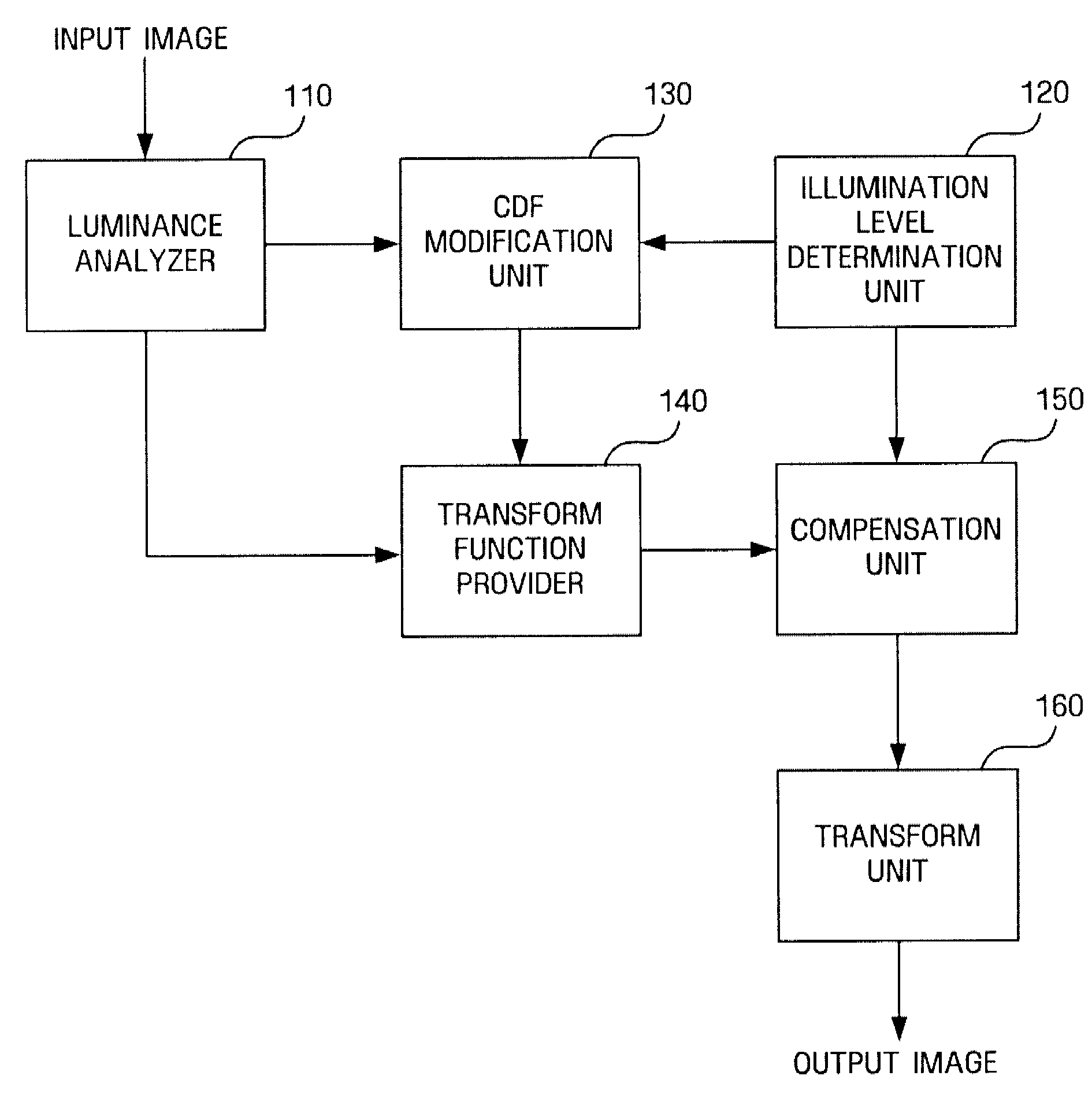

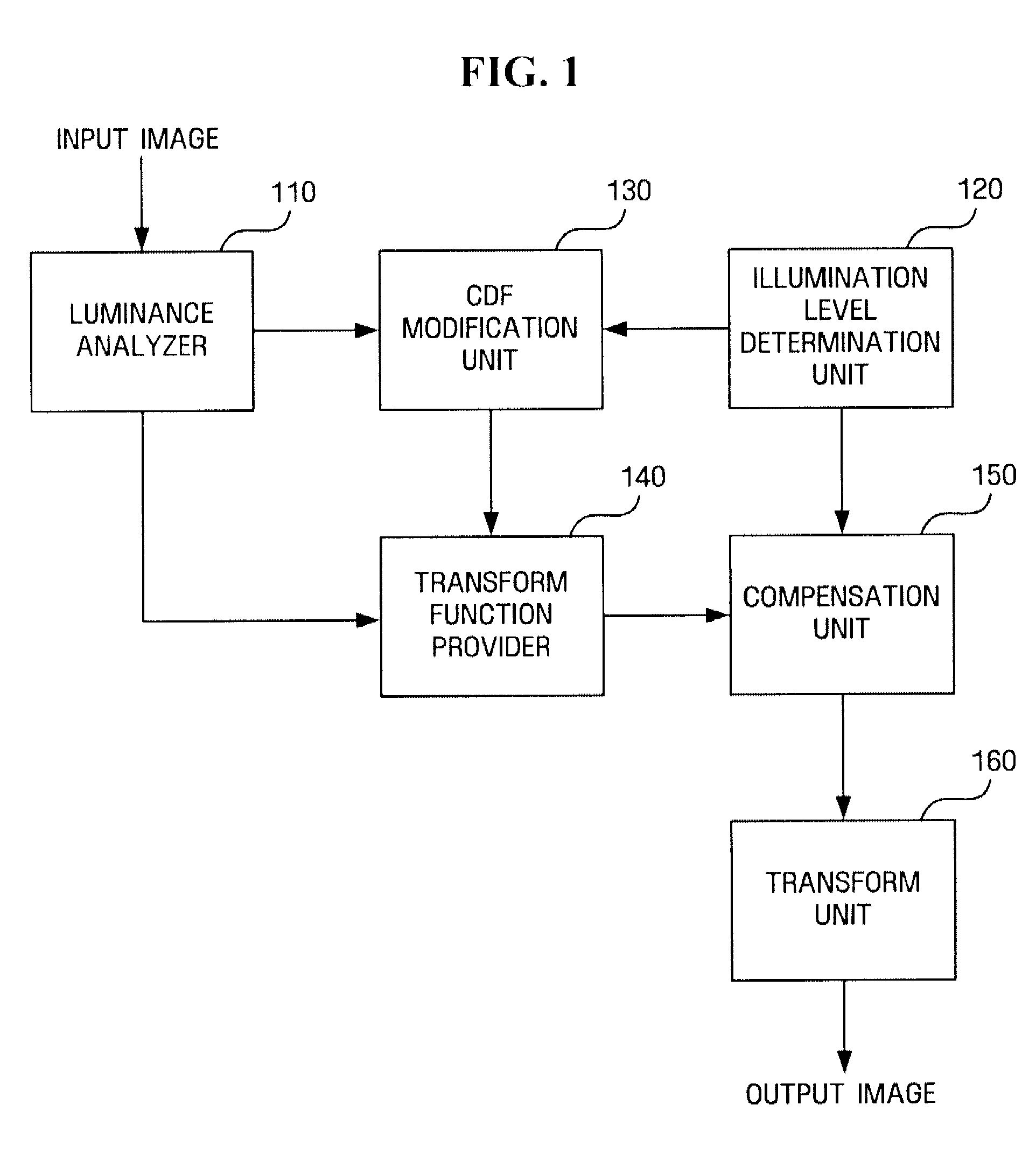

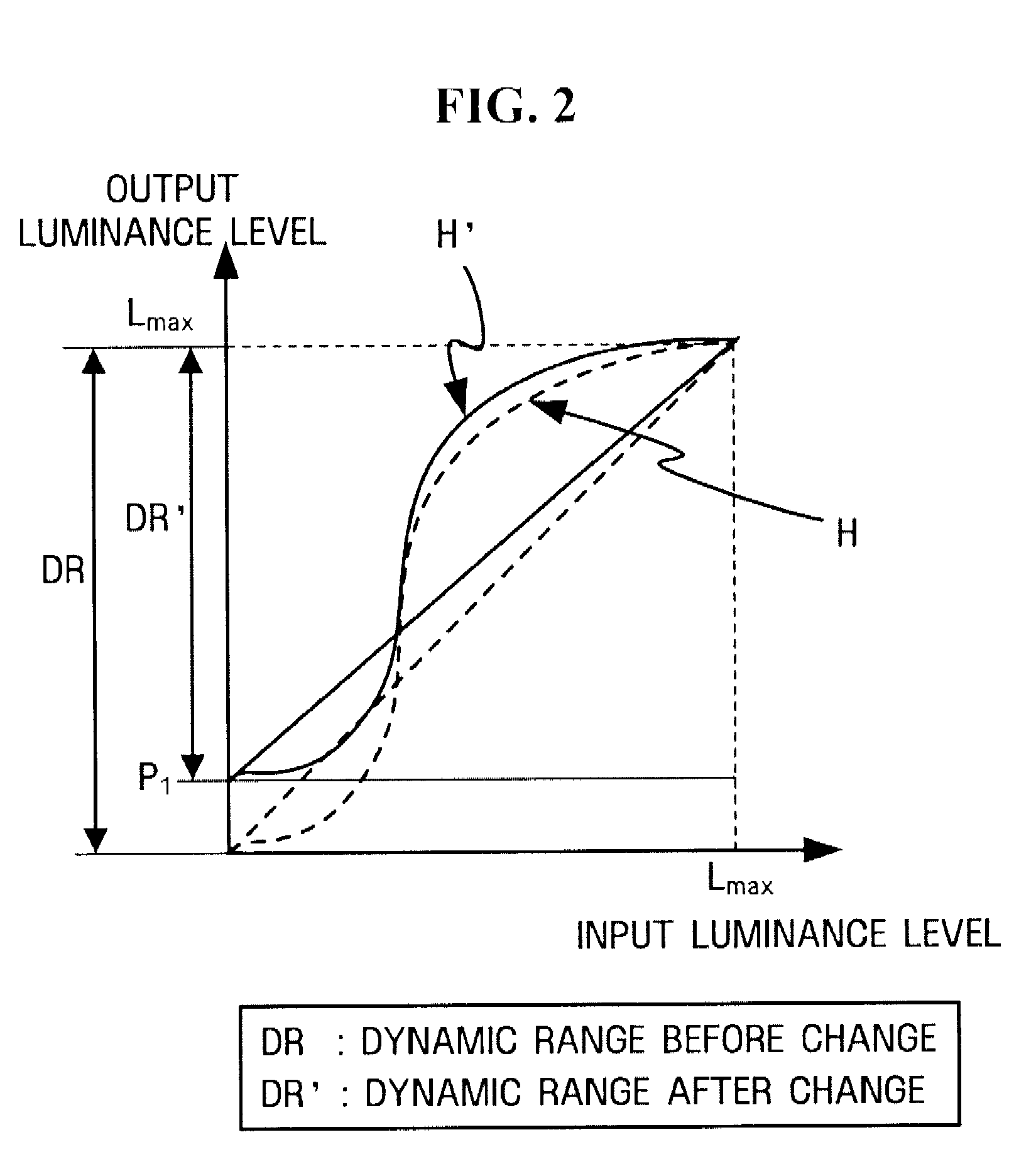

Method and apparatus for controlling contrast

InactiveUS20080037868A1Increase contrastPreventing excessive contrastImage enhancementTelevision system detailsTransformerComputer science

A method and apparatus for contrast control is provided. The apparatus includes a cumulative density function which provides a second cumulative density function modified from a first cumulative density function based on a first luminance histogram of an input image; a transformer function provider which provides a transform function based on the first cumulative density function and the second cumulative density function; a compensation unit which compensates the transform function based on a predetermined illumination level; and a transform unit which transforms a luminance distribution of the input image based on the compensated transform function.

Owner:SAMSUNG ELECTRONICS CO LTD

Popular searches

Walking aids Cathode-ray tube indicators Electric switches Tactile feedback Picture reproducers with optical-mechanical scanning Picture reproducers using projection devices Picture reproducers using solid-state color display Paving details Television signal transmission by single/parallel channels Digital video signal modification

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com