Patents

Literature

570 results about "Luminance distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

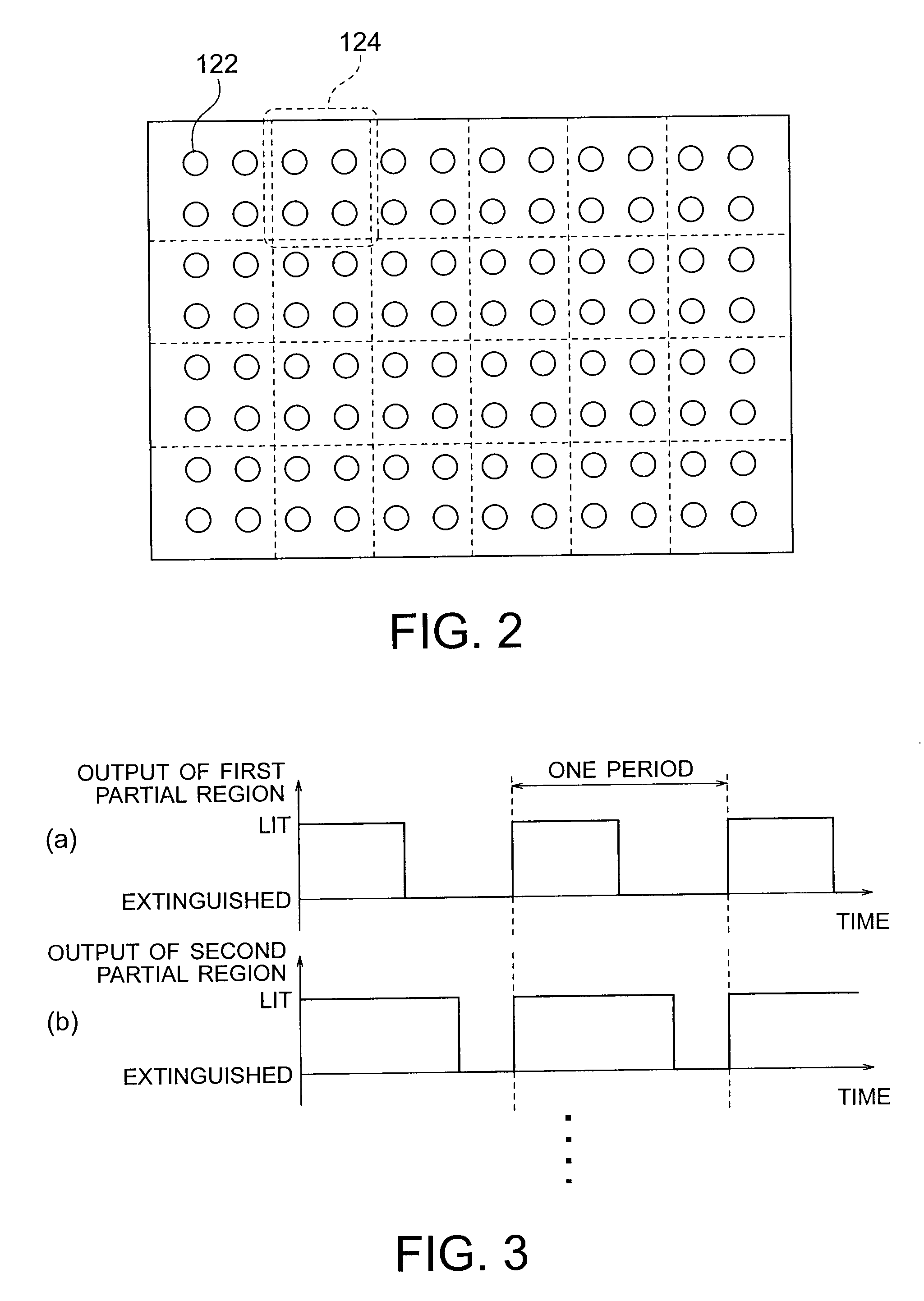

Liquid crystal display apparatus

ActiveUS20050184952A1Increase contrastLess irregularityStatic indicating devicesNon-linear opticsLiquid-crystal displayEffect light

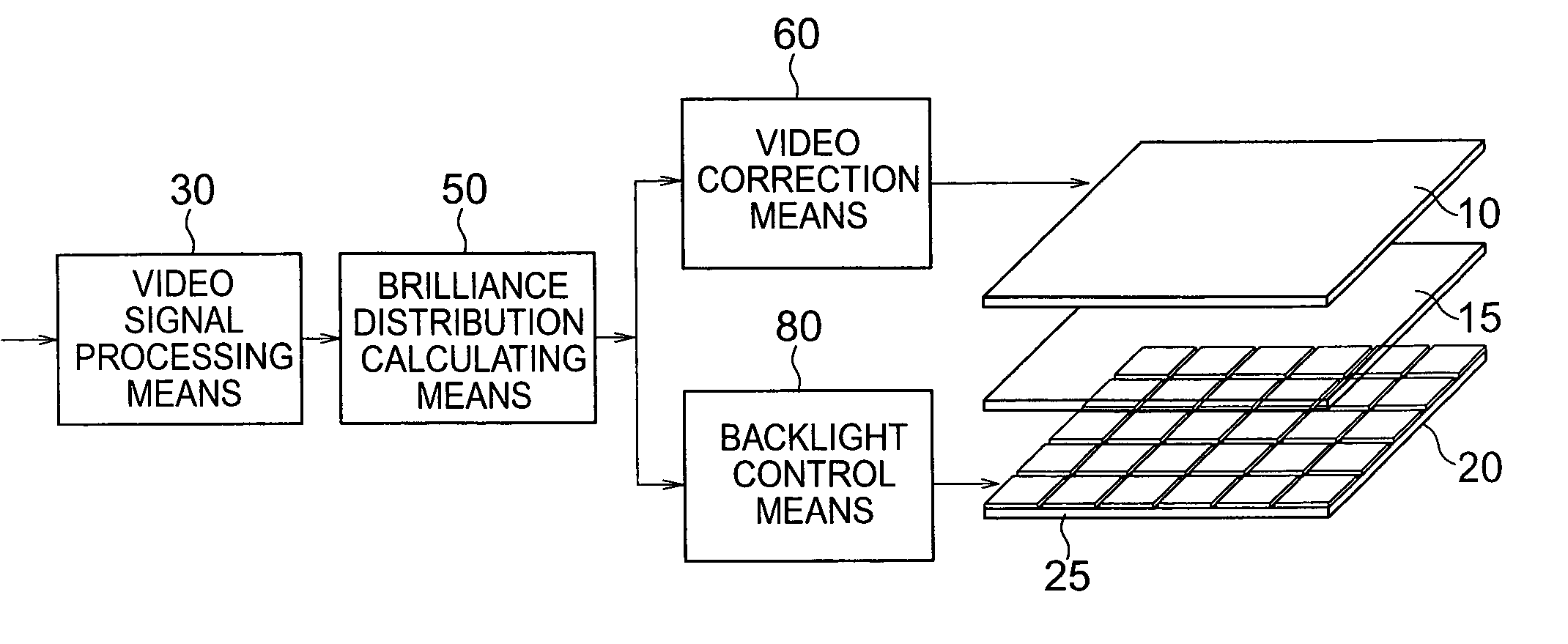

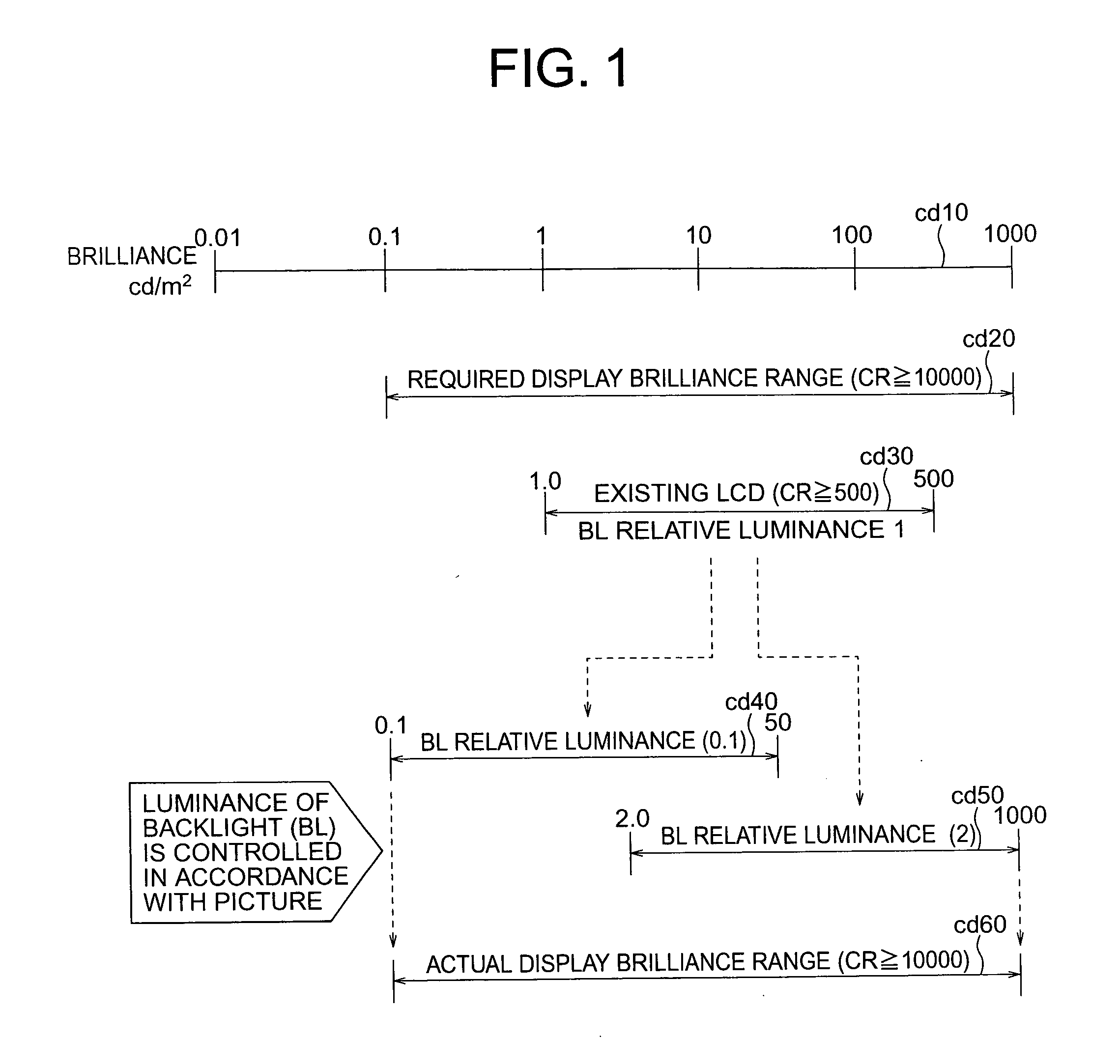

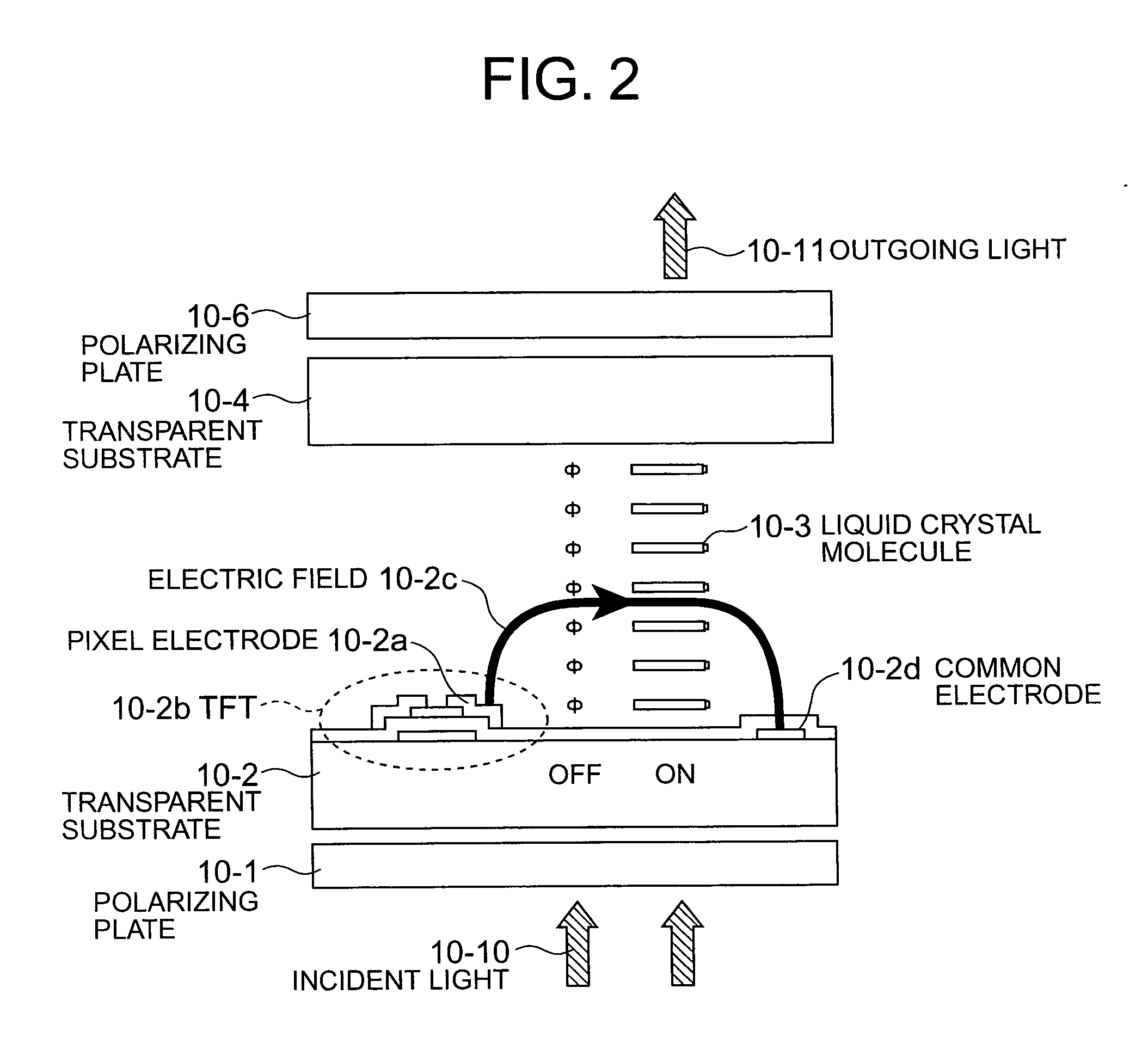

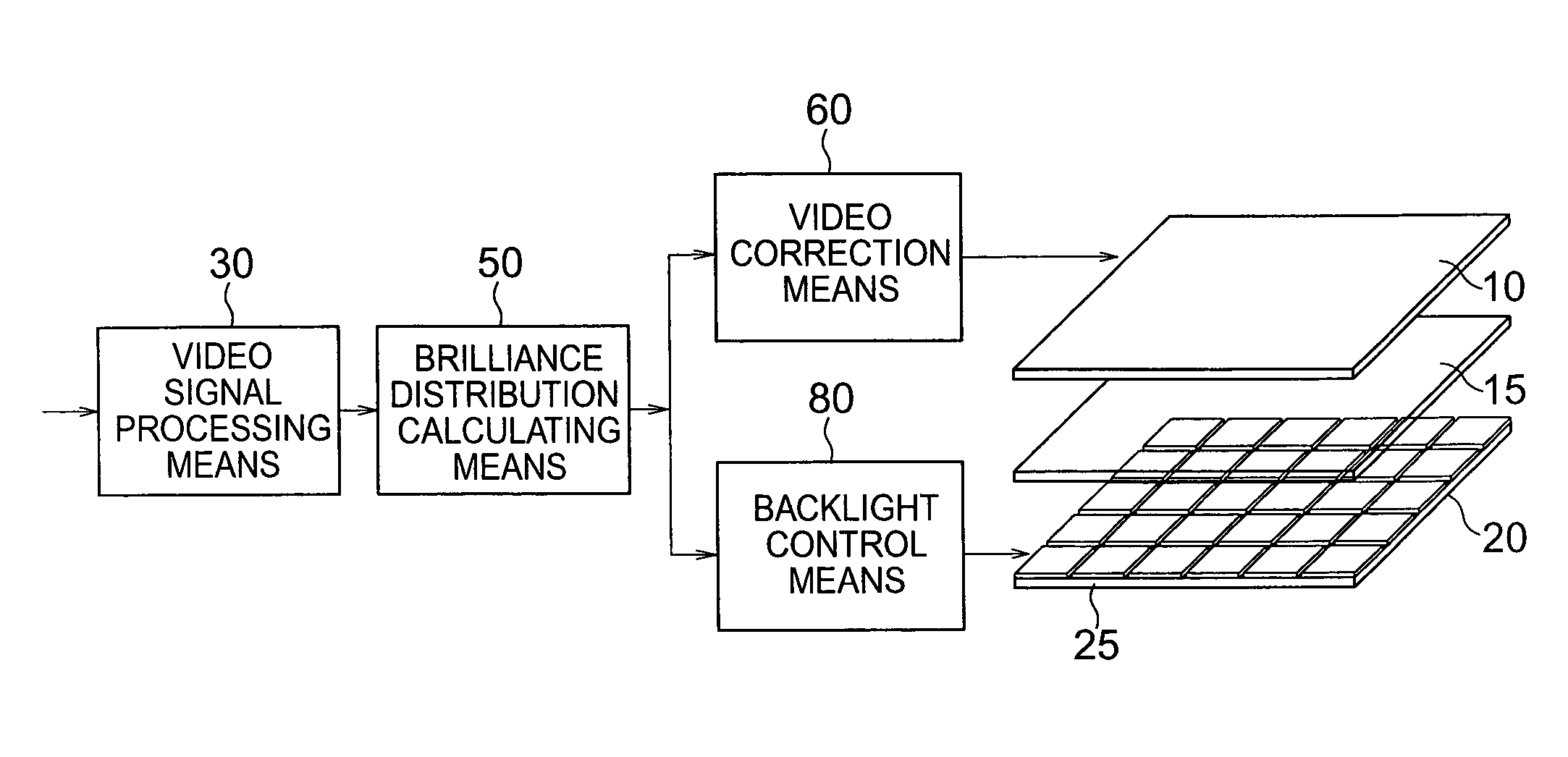

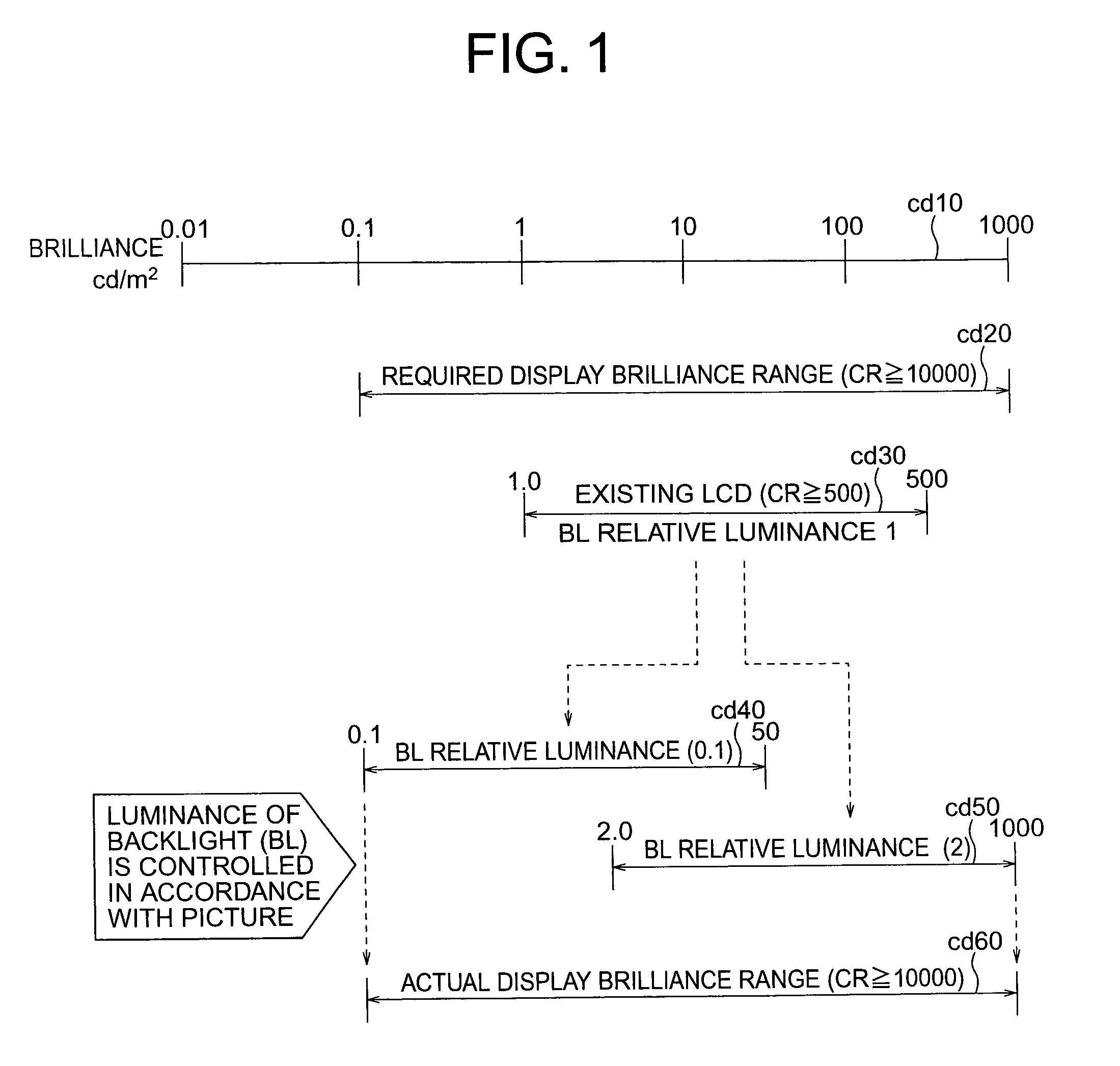

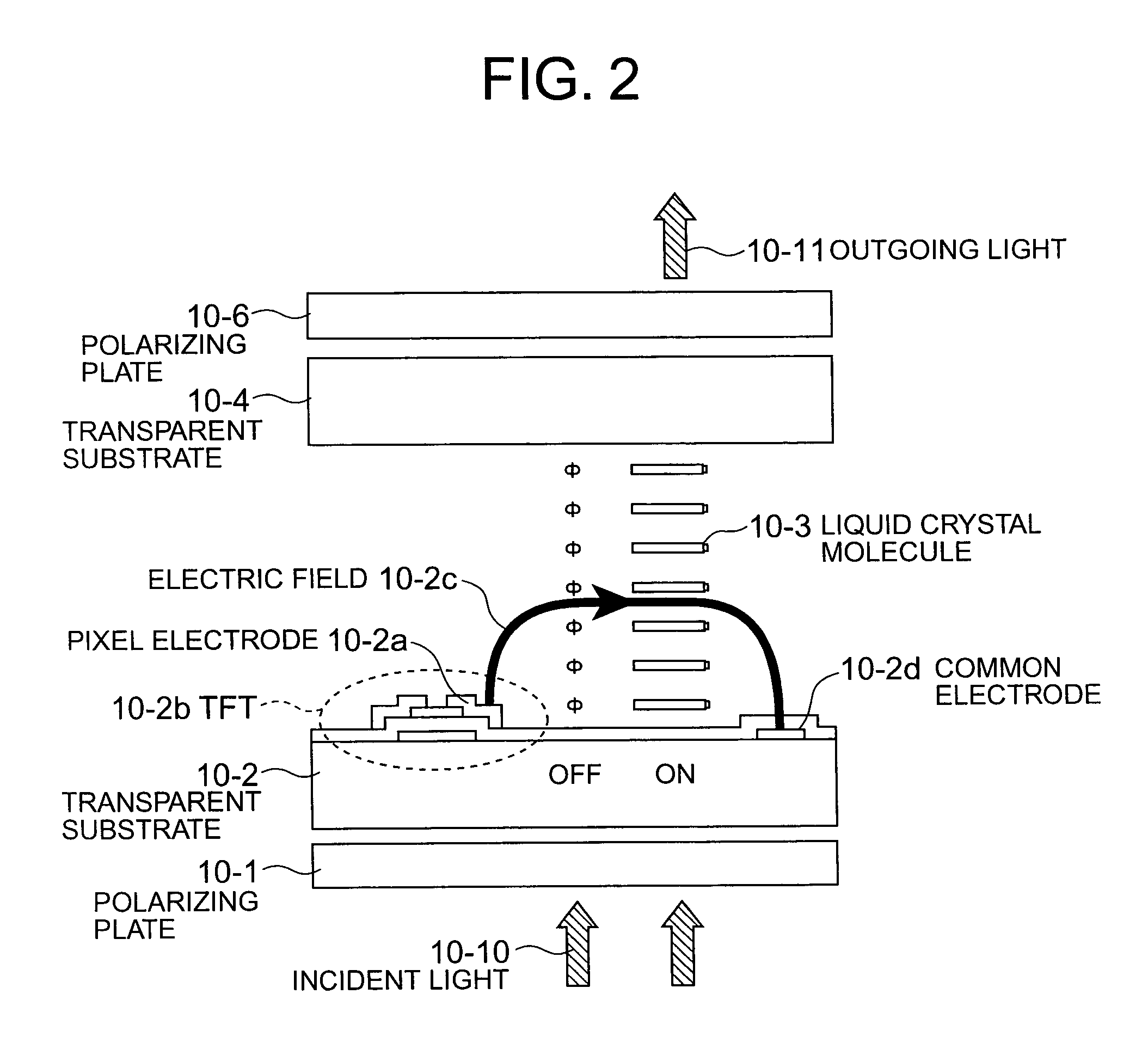

The video display apparatus has a light modulation device for forming a picture in accordance with a video signal and a lighting unit for irradiating, on the light modulation device, illumination light necessary to cause it to display the picture. In the apparatus, the lighting unit irradiates the illumination light in sequence of individual plural illumination light source partitive areas, a luminance distribution calculating unit calculates luminance distributions of video signals corresponding to the plural partitive areas to determine illumination light luminance levels of the individual partitive areas, an illumination controller controls rays of the illumination light of individual areas of the lighting unit on the basis of determination by the luminance distribution calculating unit, and a video corrector corrects the video signal inputted to the light modulation device on the basis of the determination by the luminance distribution calculating unit.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

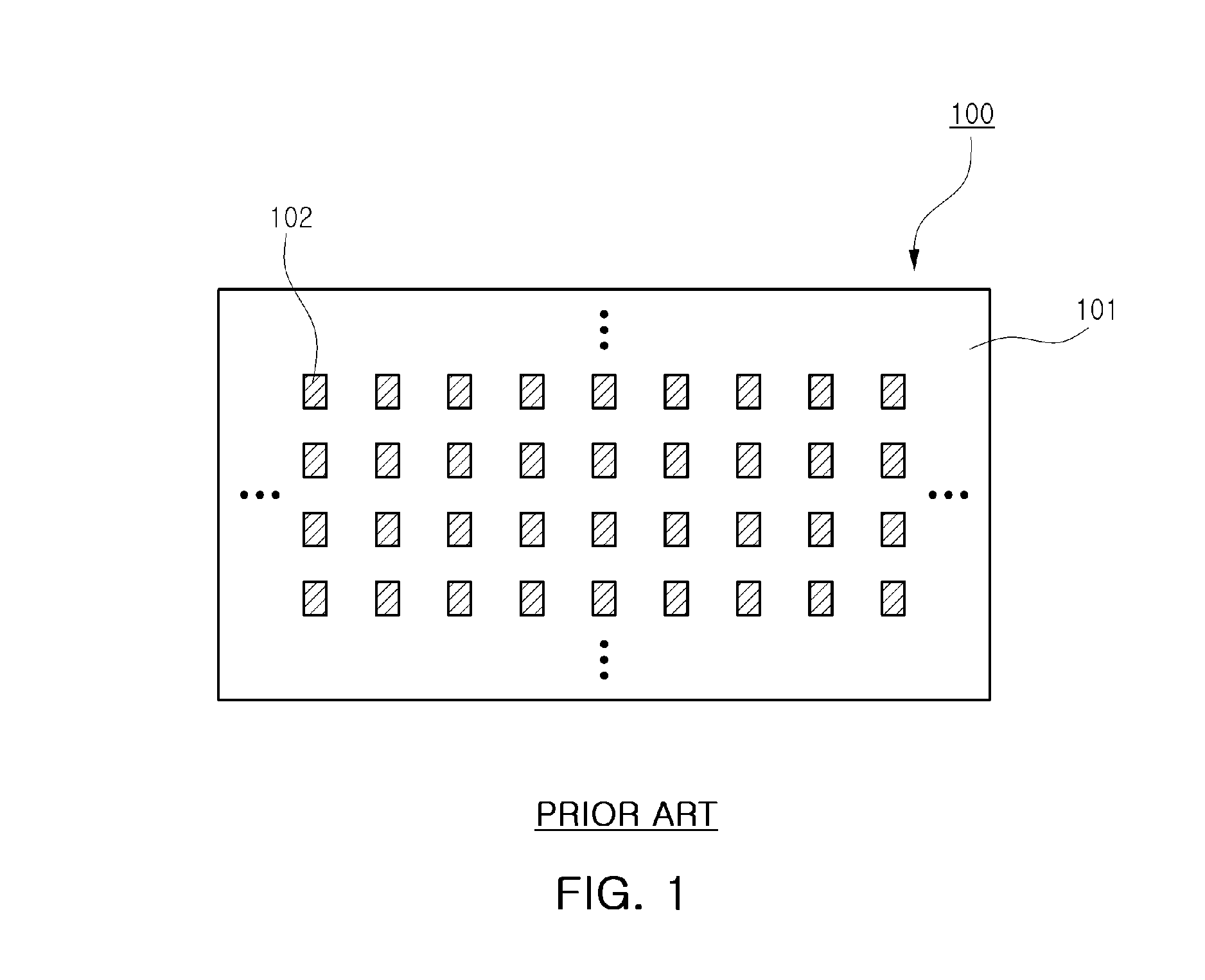

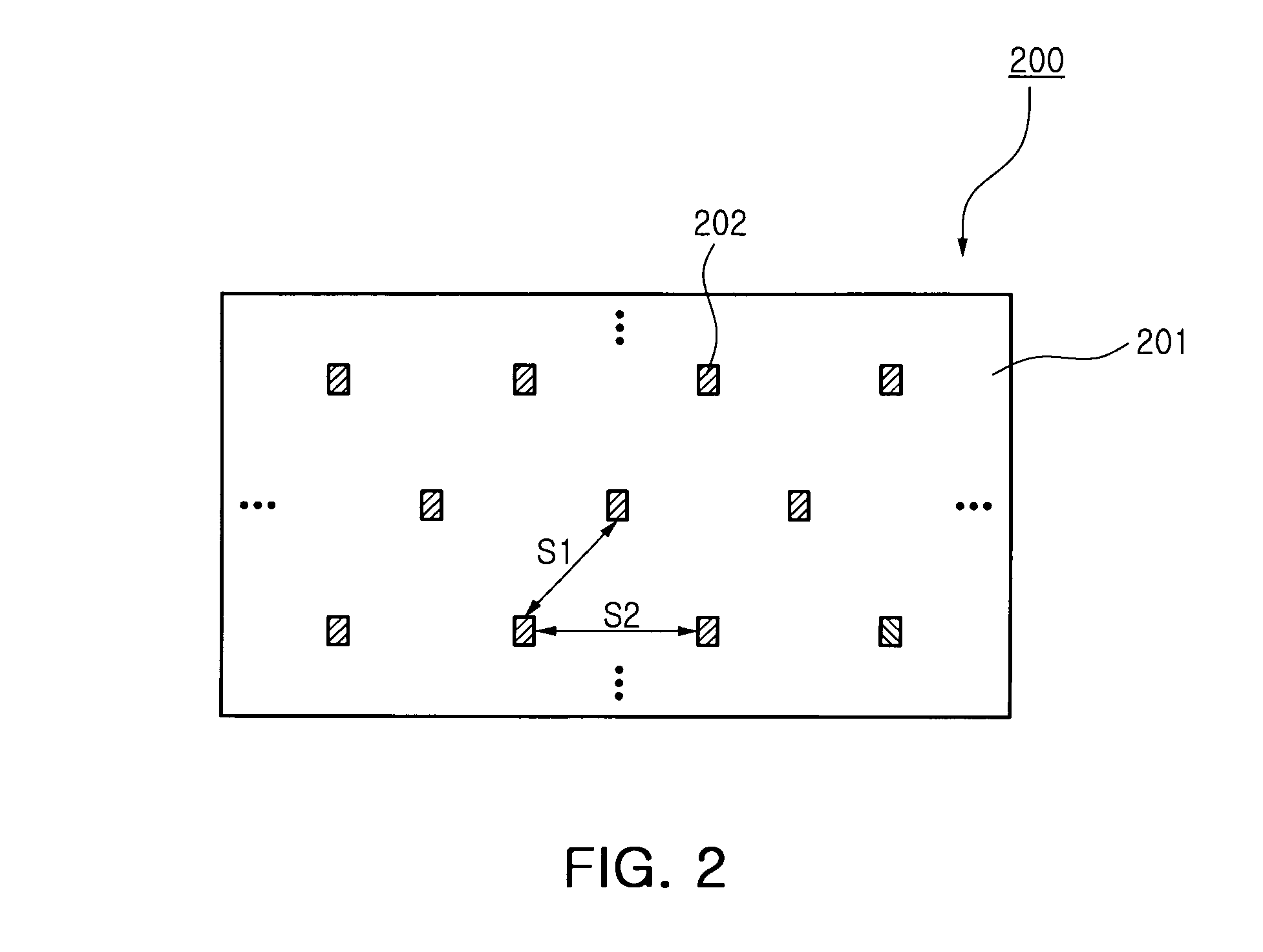

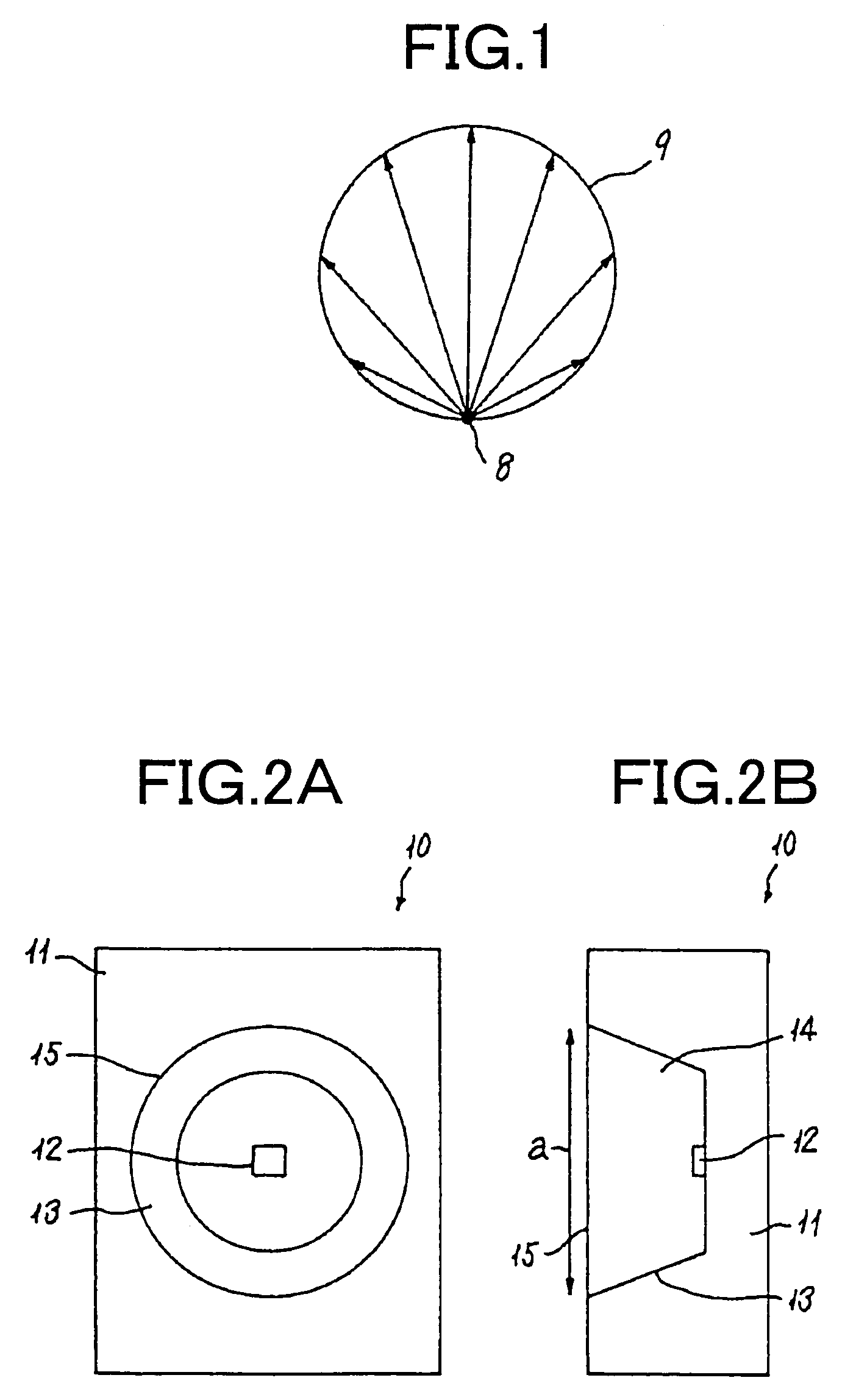

Plane light source and LCD backlight unit having the same

ActiveUS7940350B2Reduce in quantityImprove efficiencyLighting support devicesNon-linear opticsLight emitting deviceLightness

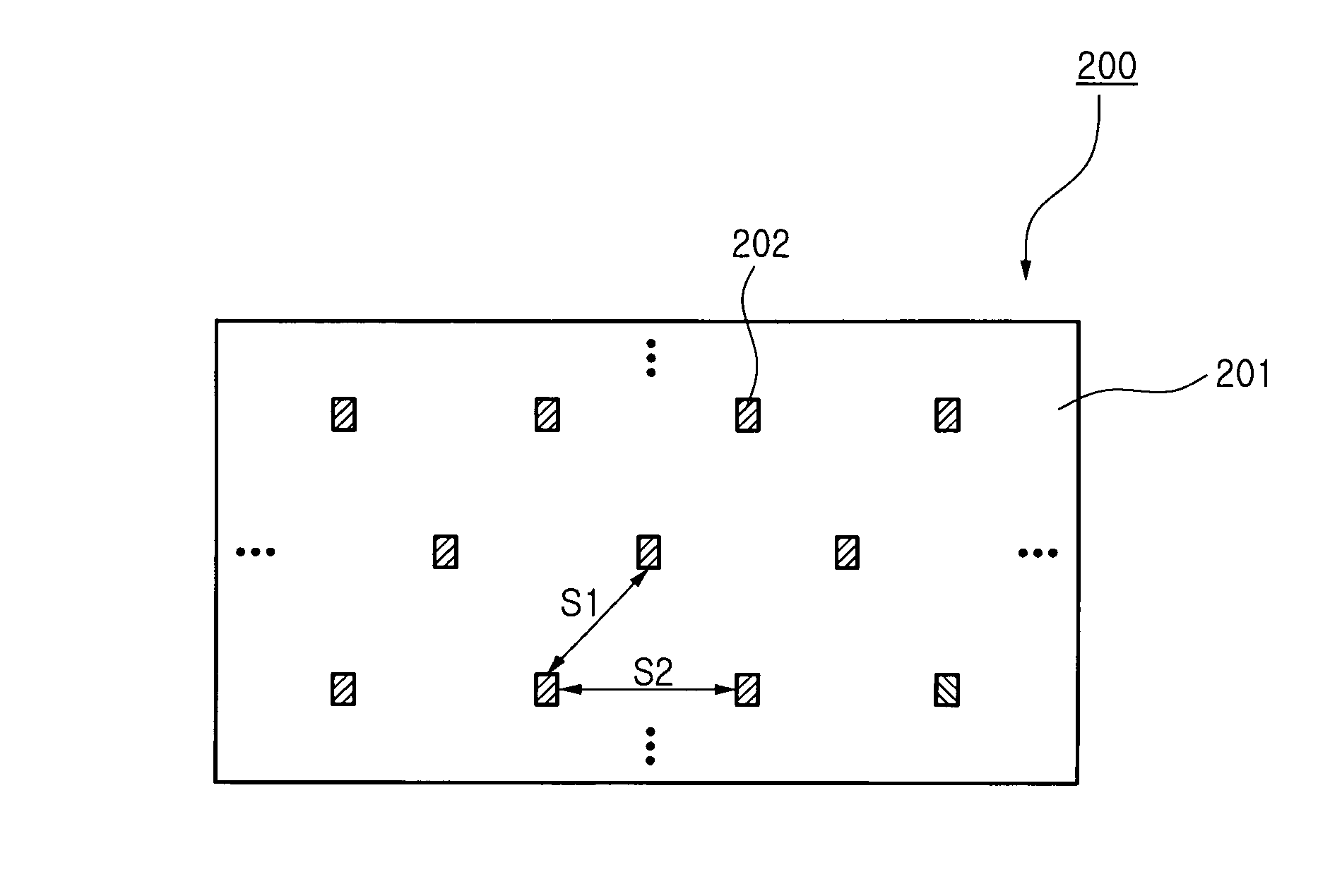

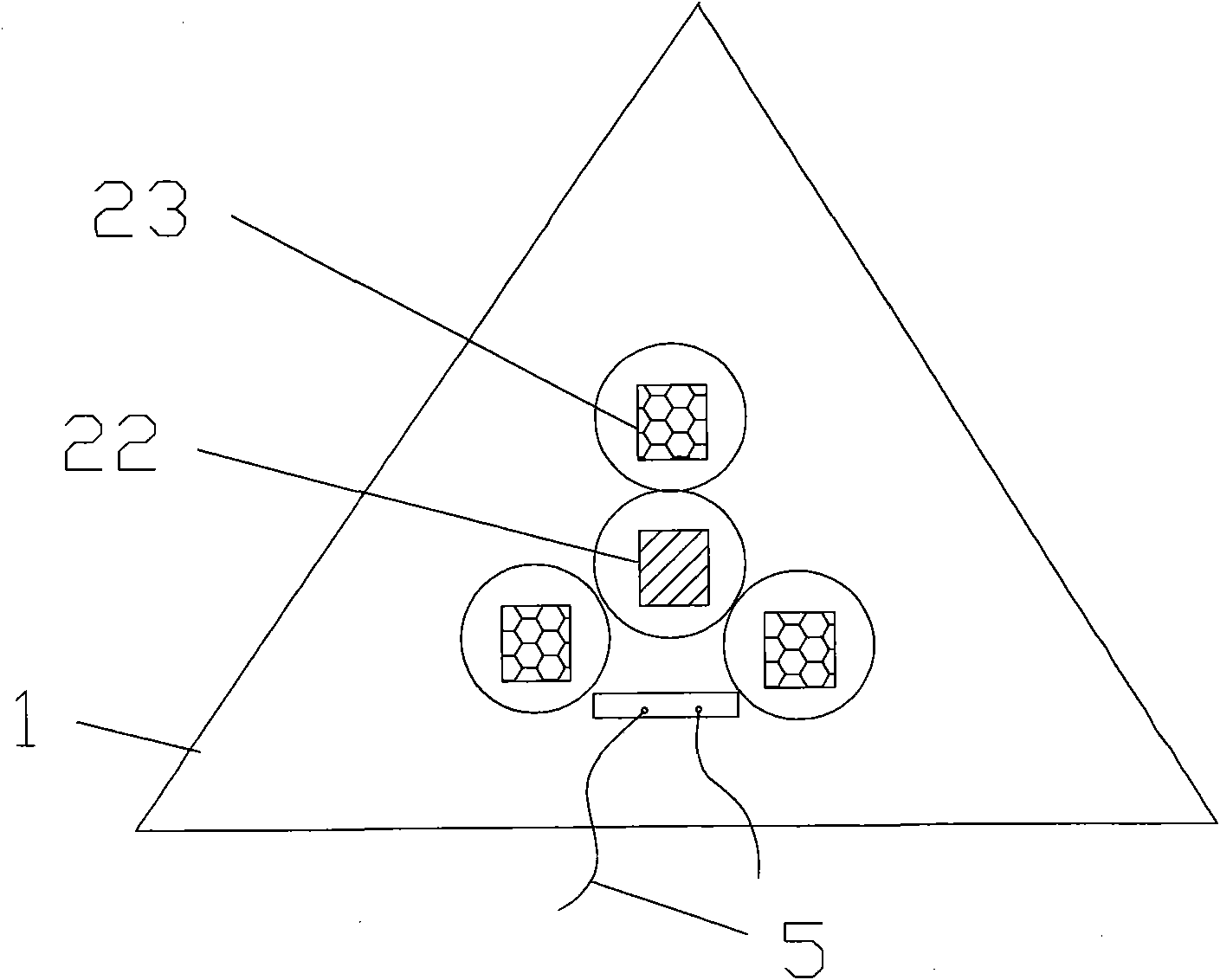

There are provided a plane light source and an LCD backlight unit having the same. A plane light source having a plurality of light emitting devices arranged in a light emitting device matrix having rows and columns at a substrate according to an aspect of the invention includes a first matrix having a plurality of light emitting devices arranged in rows and columns; and a second matrix having a plurality of light emitting devices arranged in rows and columns, each of the light emitting devices located within a quadrangle formed by four neighboring light emitting devices included in the first matrix, wherein a pitch S between one light emitting device included in the light emitting device matrix and another light emitting device most adjacent to the one light emitting device satisfies the following equation to obtain uniform luminance distribution at a position distant from a light emitting surface of the light emitting device by an optical length l,S≤l2×tan(θ2+α),Equationwhere −π / 18≦α≦π / 18 is satisfied, and θ is an orientation angle of the light emitting device.

Owner:SAMSUNG ELECTRONICS CO LTD

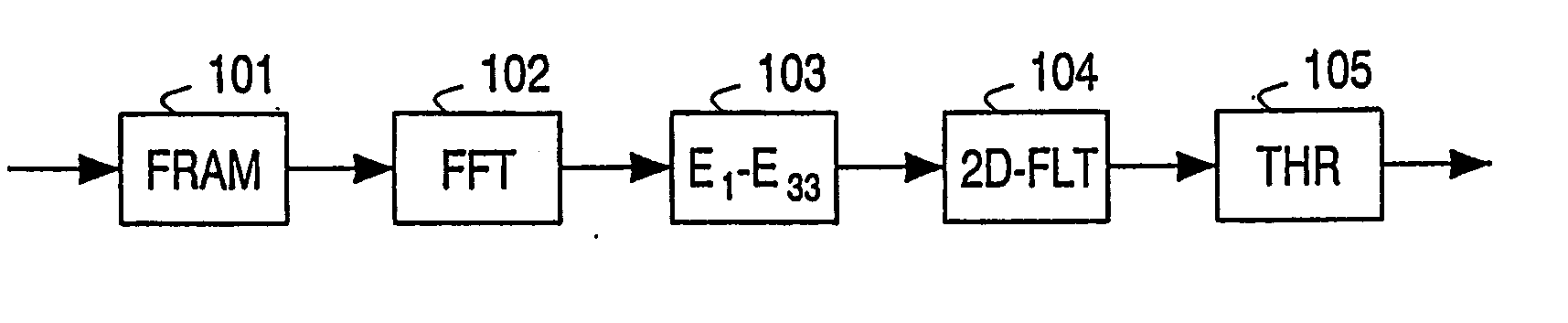

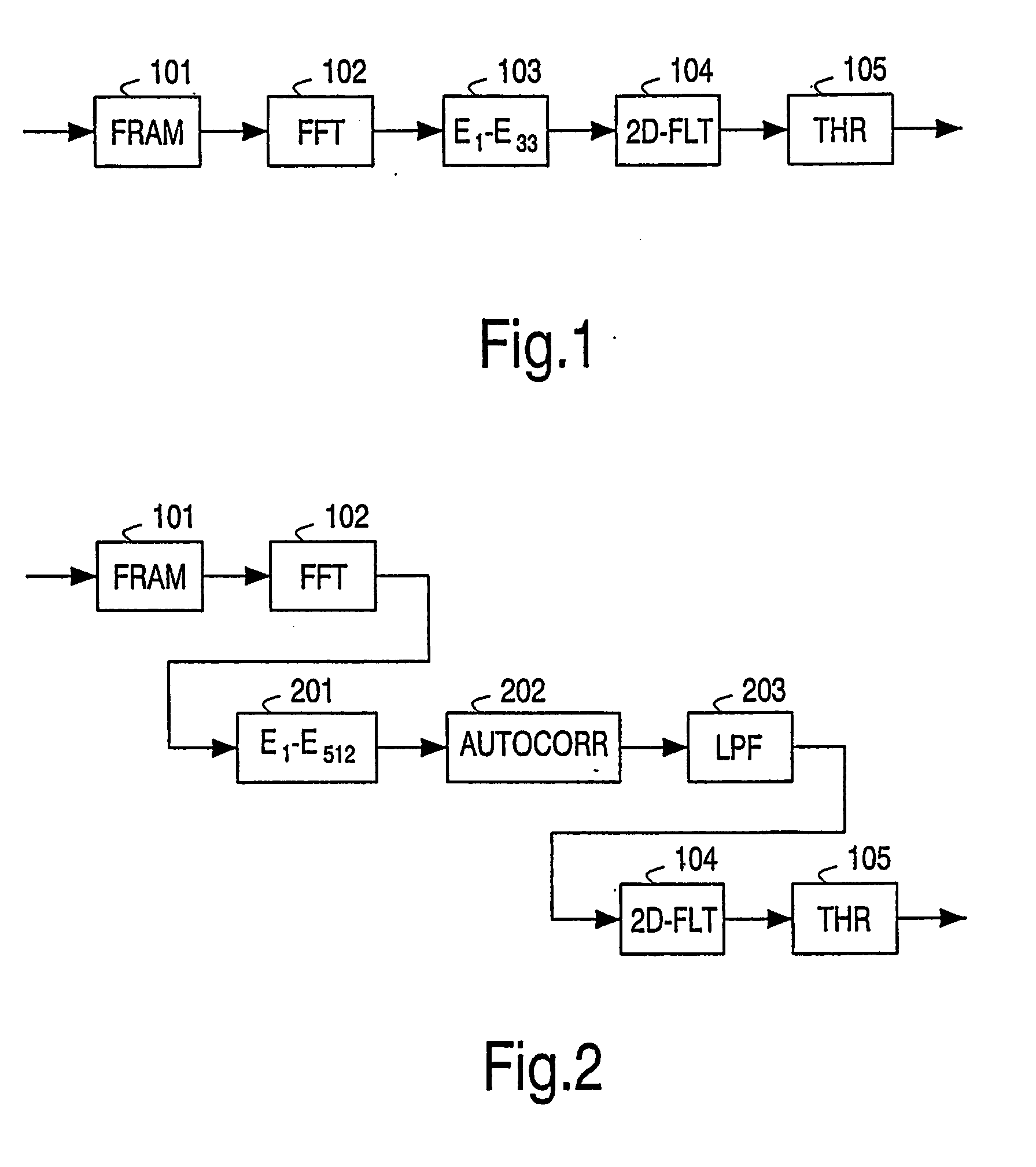

Fingerprint extraction

InactiveUS20060041753A1Electrophonic musical instrumentsUser identity/authority verificationFrequency spectrumCorrelation function

Fingerprints are bit strings extracted from a media signal (e.g. an audio or video clip) to identify said media signal. Typically, they are derived from a perceptual property of the signal, for example, the spectral energy distribution of an audio fragment or the luminance distribution of a video image. A method and arrangement for extracting a fingerprint is here disclosed which is robust with respect to shifts of the perceptual property. Such shifts occur, inter alia, when the fingerprint is derived from a logarithmically mapped spectral energy distribution of an audio signal and said audio signal is subjected to speed changes. According to the invention, the fingerprint is not derived from the perceptual property as such, but from its auto-correlation function.

Owner:GRACENOTE

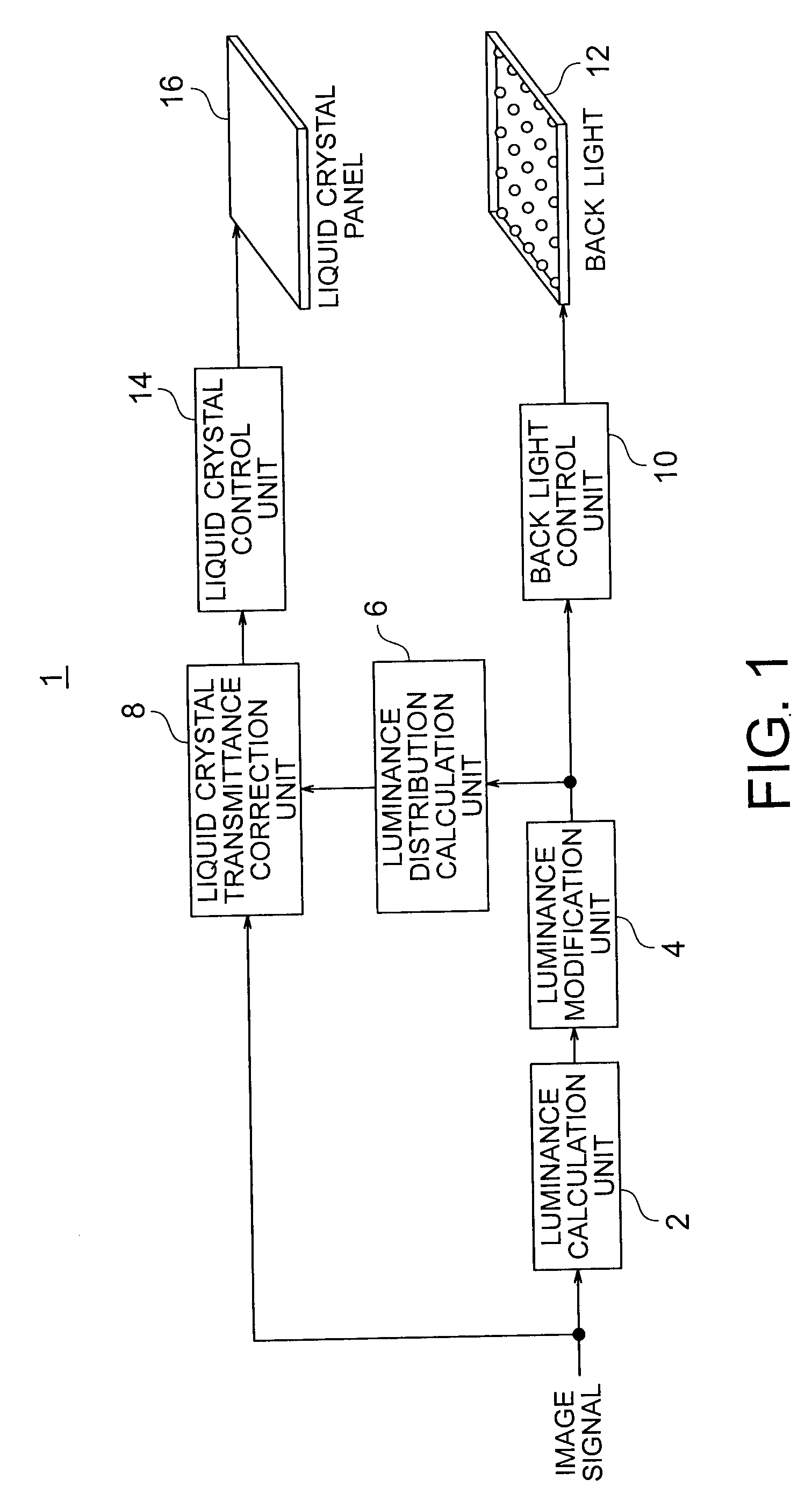

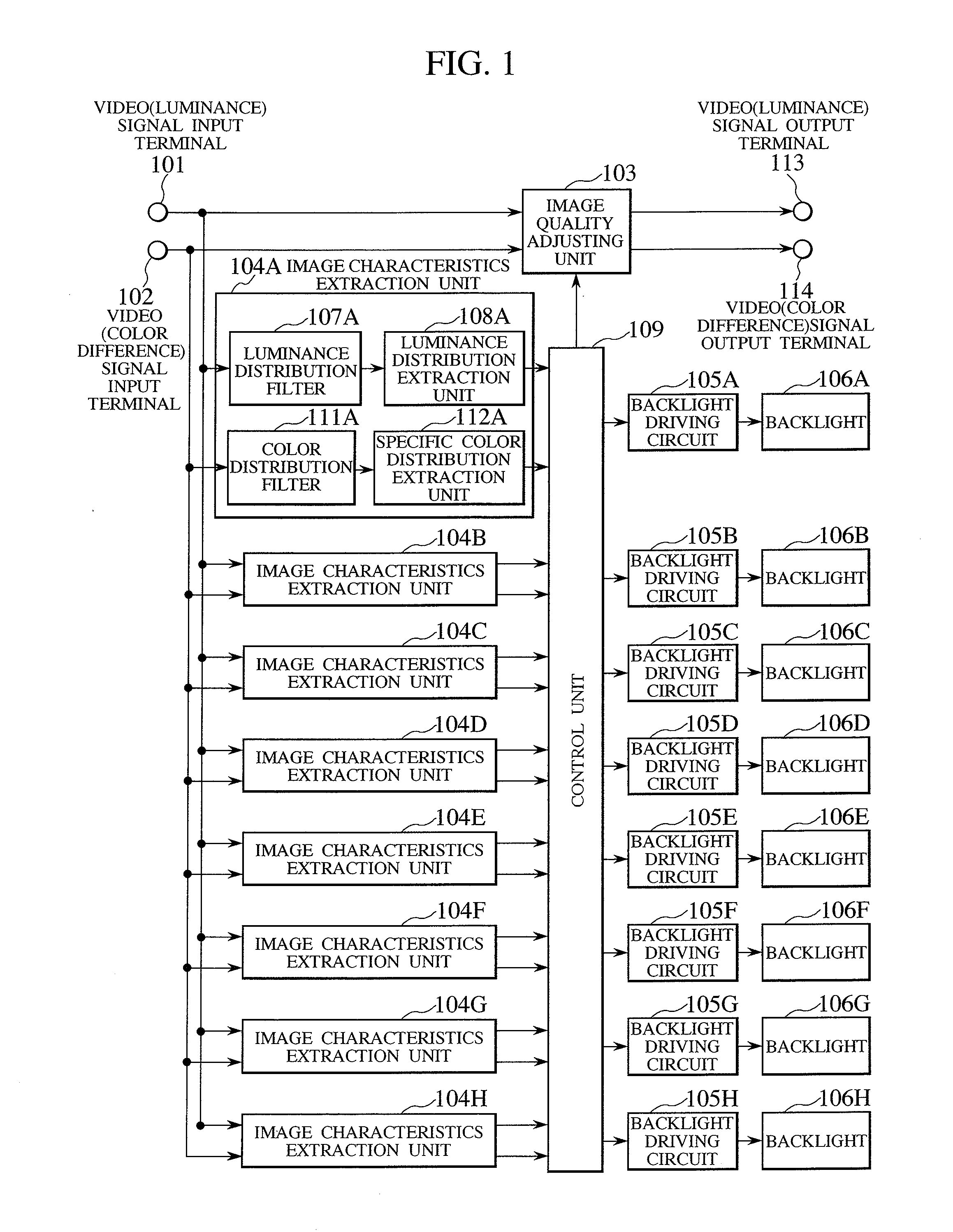

Liquid crystal display apparatus with luminance distribution calculating, backlight controller, and video correction to improve display contrast ratio

ActiveUS7460103B2Wide display luminance rangeSufficient contrast ratioStatic indicating devicesNon-linear opticsDisplay contrastEffect light

The video display apparatus has a light modulation device for forming a picture in accordance with a video signal and a lighting unit for irradiating, on the light modulation device, illumination light necessary to cause it to display the picture. In the apparatus, the lighting unit irradiates the illumination light in sequence of individual plural illumination light source partitive areas, a luminance distribution calculating unit calculates luminance distributions of video signals corresponding to the plural partitive areas to determine illumination light luminance levels of the individual partitive areas, an illumination controller controls rays of the illumination light of individual areas of the lighting unit on the basis of determination by the luminance distribution calculating unit, and a video corrector corrects the video signal inputted to the light modulation device on the basis of the determination by the luminance distribution calculating unit.

Owner:JAPAN DISPLAY INC +1

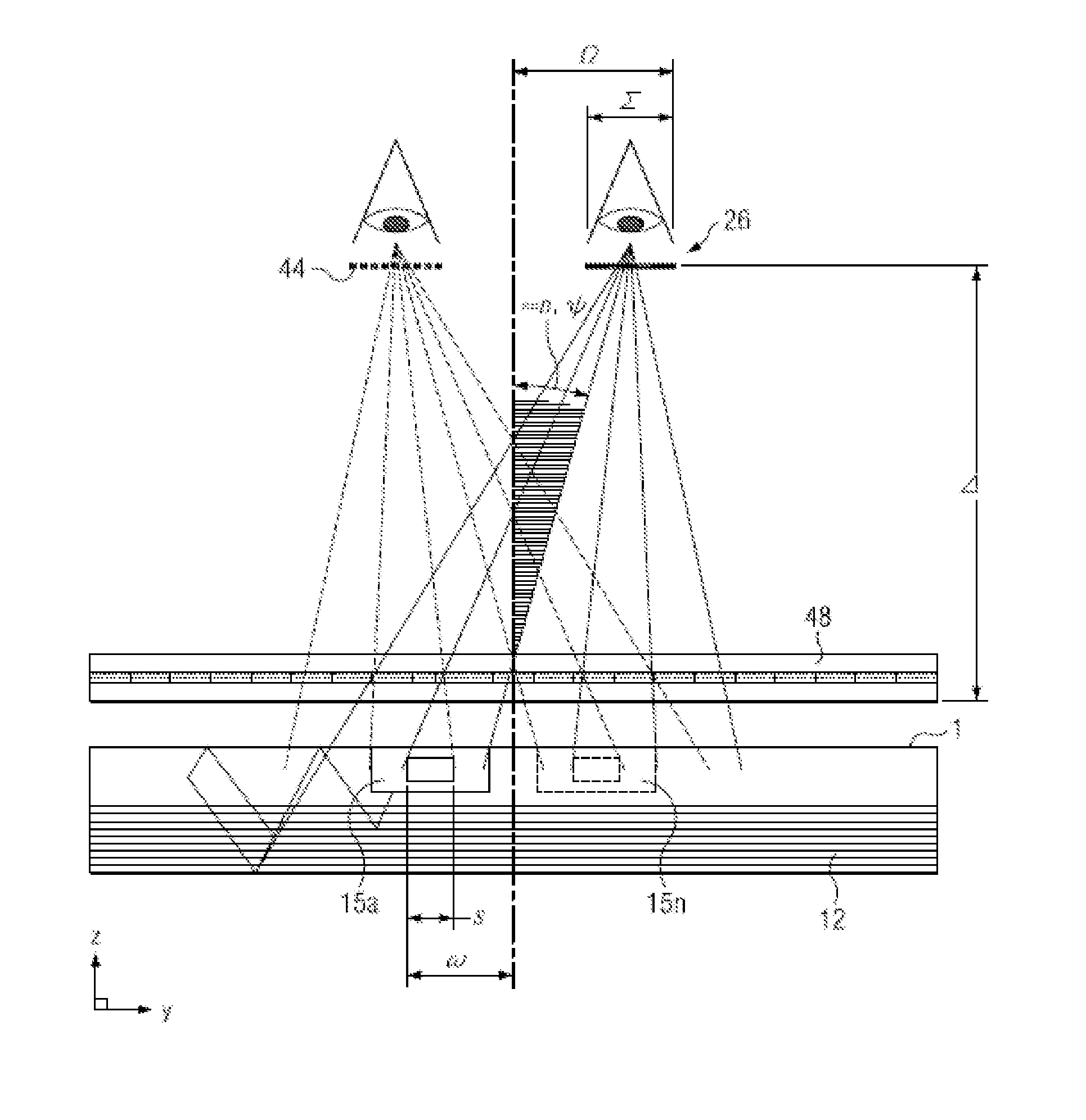

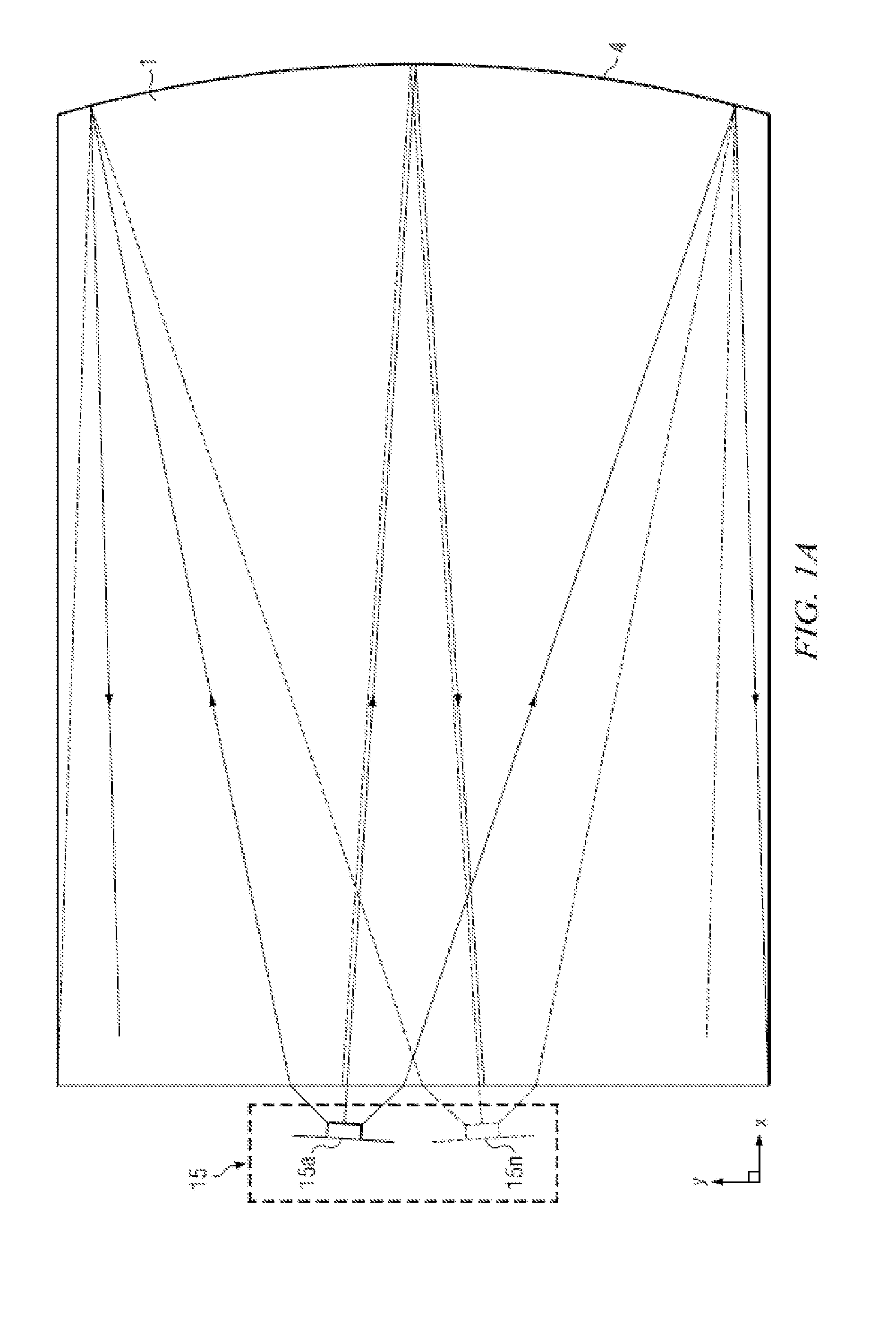

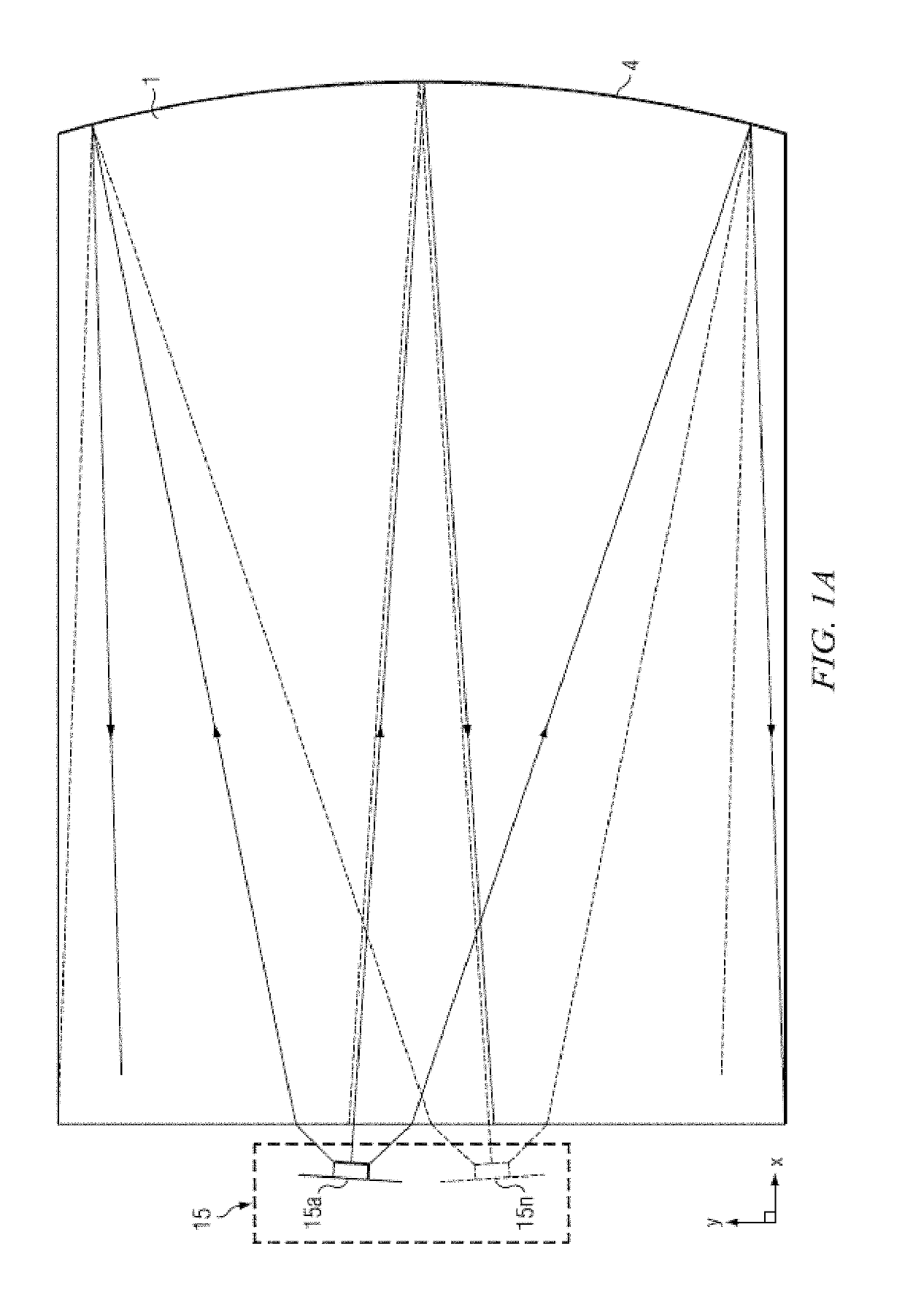

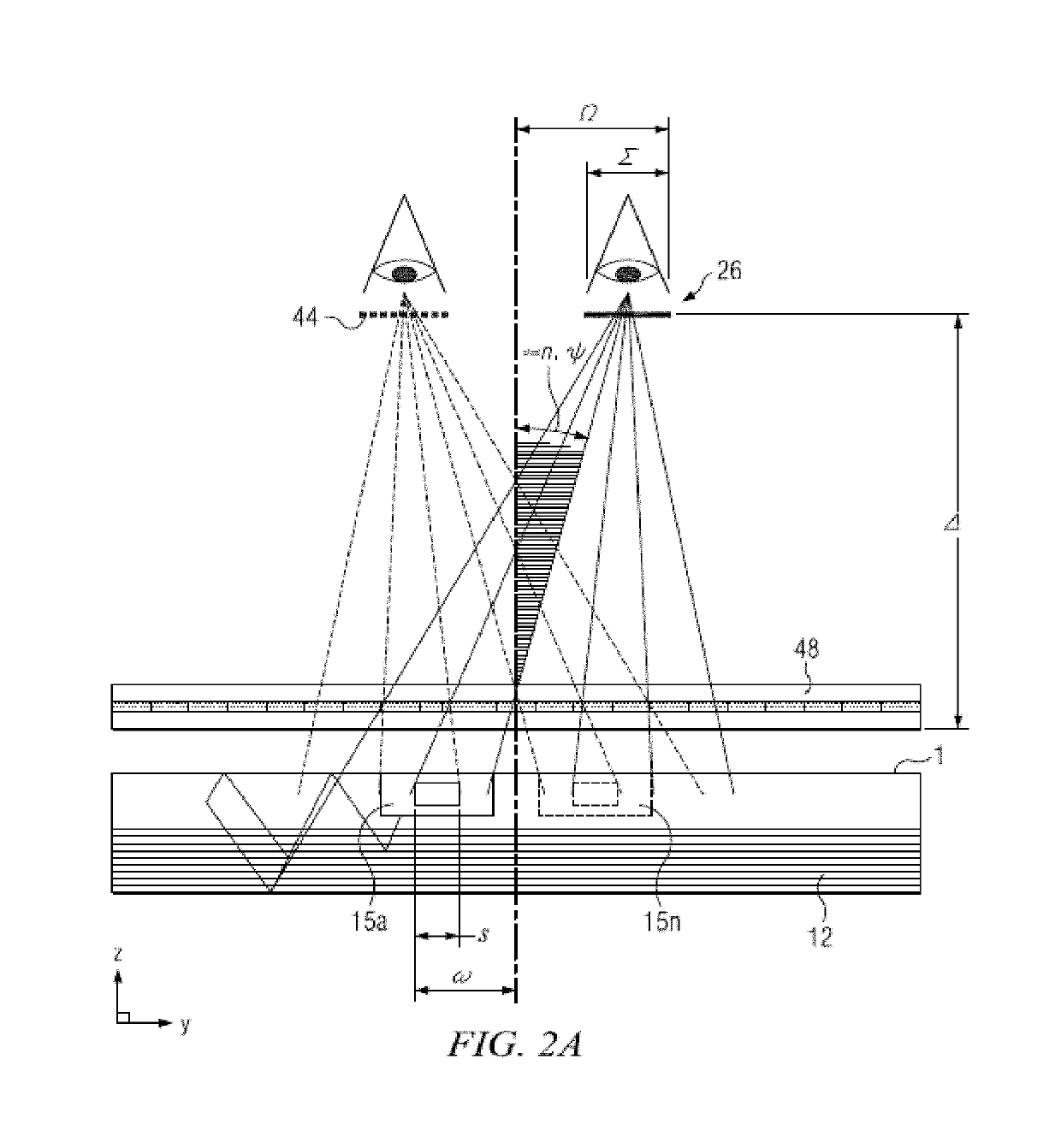

Controlling light sources of a directional backlight

InactiveUS20140009508A1Viewing comfortReduce power consumptionMechanical apparatusCathode-ray tube indicatorsLuminous intensityImaging quality

Disclosed is an imaging directional backlight including an array of light sources, and a control system arranged to provide variable distribution of luminous fluxes, scaled inversely by the width associated with the respective light sources in the lateral direction, across the array of light sources. The luminous intensity distribution of output optical windows may be controlled to provide desirable luminance distributions in the window plane of an autostereoscopic display, a directional display operating in wide angle 2D mode, privacy mode and low power consumption mode. Image quality may be improved and power consumption reduced.

Owner:REALD SPARK LLC

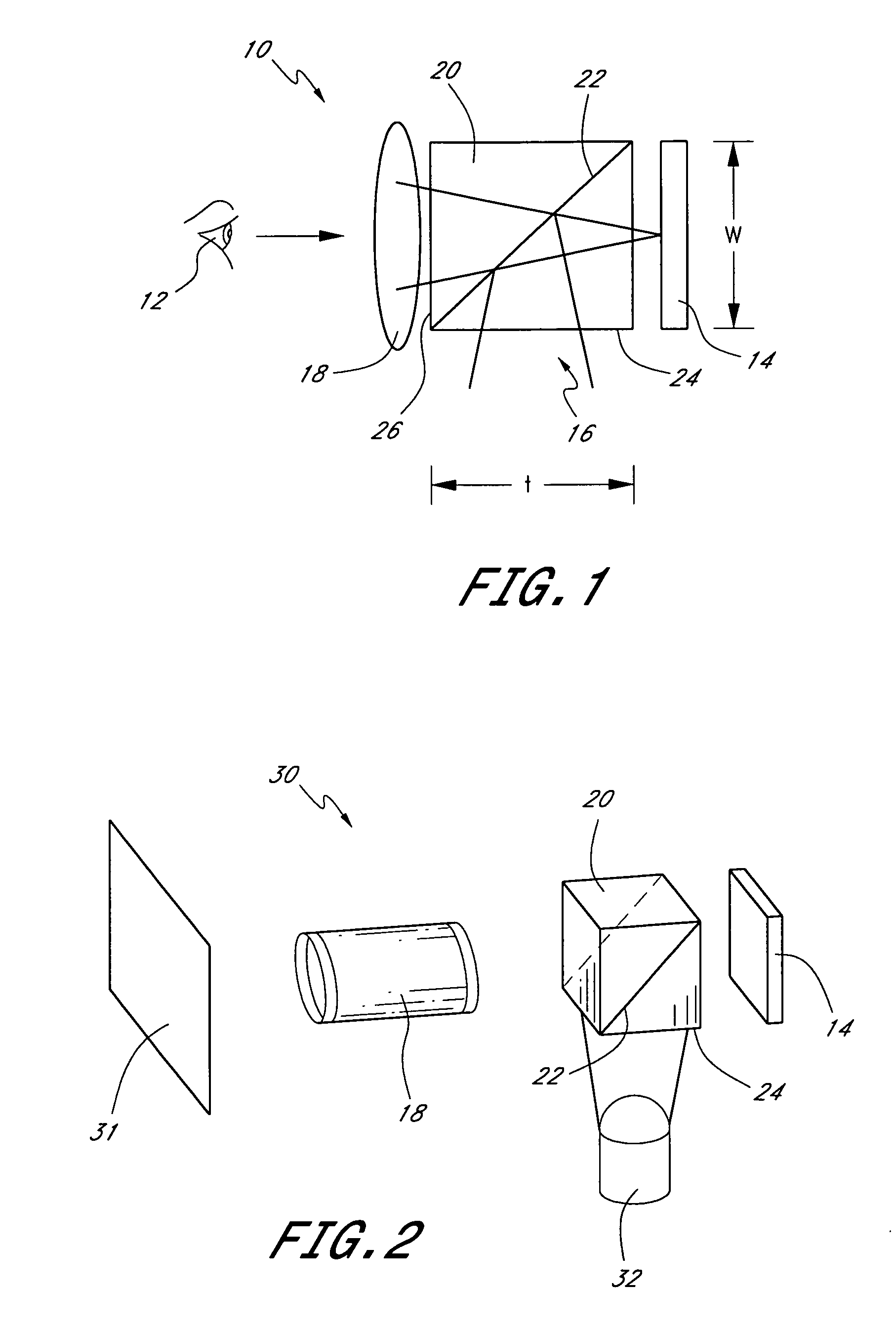

Light distribution apparatus and methods for illuminating optical systems

ActiveUS20050018308A1Constant brightnessEasy to divergeDiffusing elementsColor television detailsFiberSpatial light modulator

Various embodiments involving structures and methods for illumination can be employed, for example, in projectors, head-mounted displays, helmet-mounted displays, back projection TVs, flat panel displays as well as other optical systems. Certain embodiments may include prism elements for illuminating, for example, a spatial light modulator. Light may be coupled to the prism in some cases using fiber optics or lightpipes. The optical system may also include a diffuser having scatter features arranged to scatter light appropriately to produce a desired luminance profile. Other embodiments are possible as well.

Owner:SYNOPSYS INC

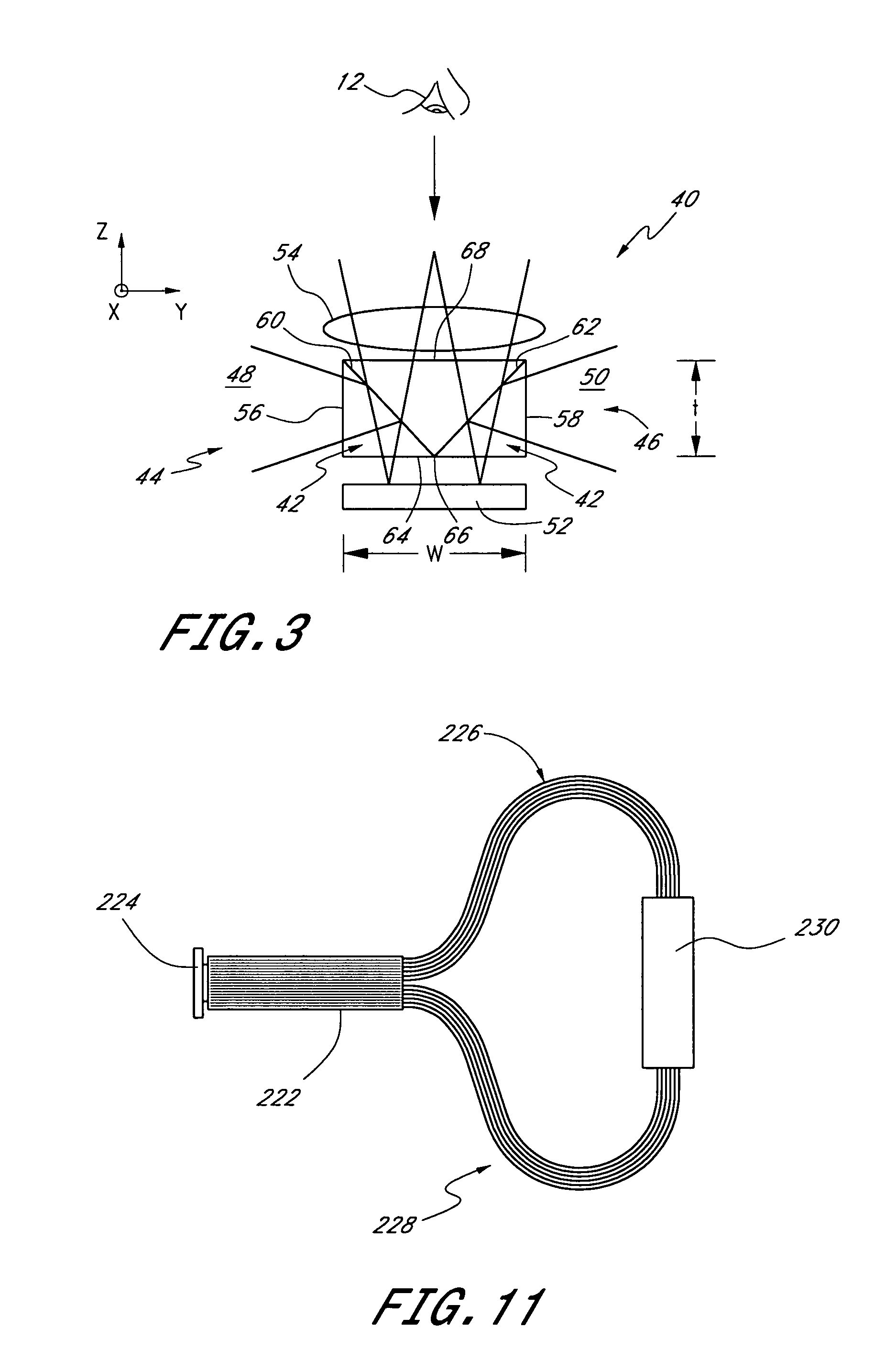

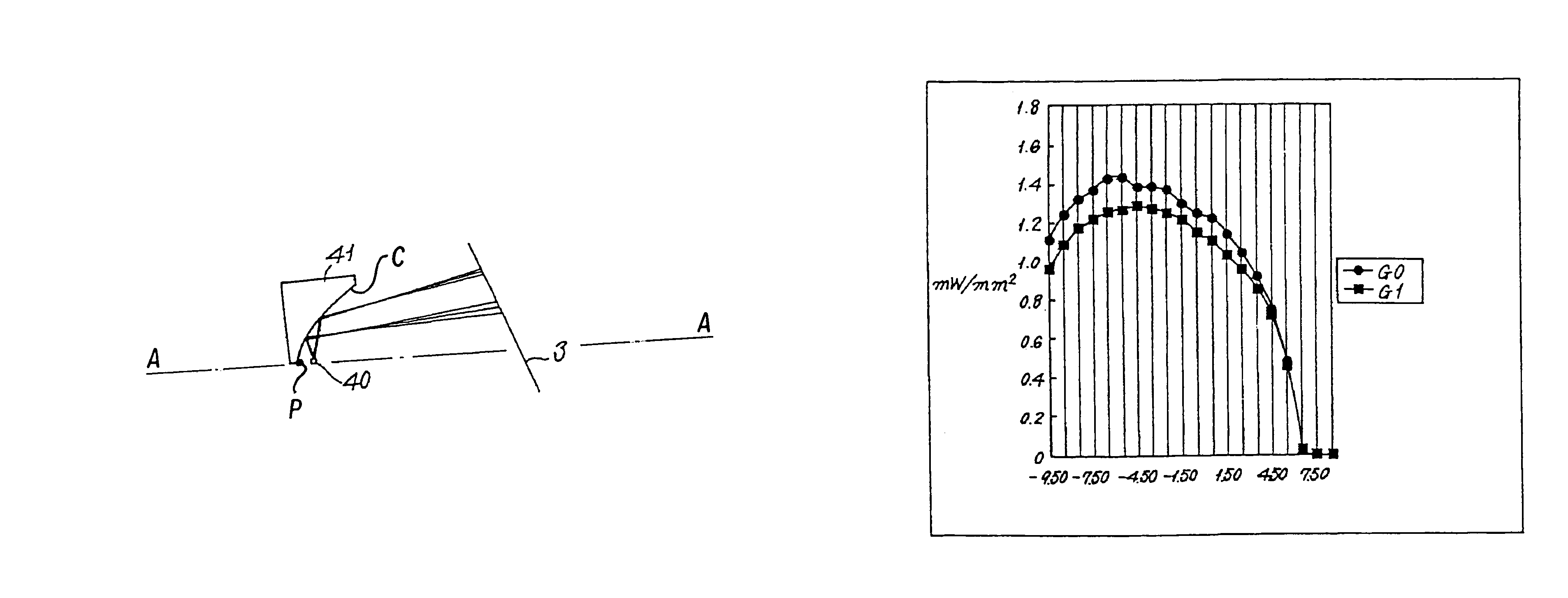

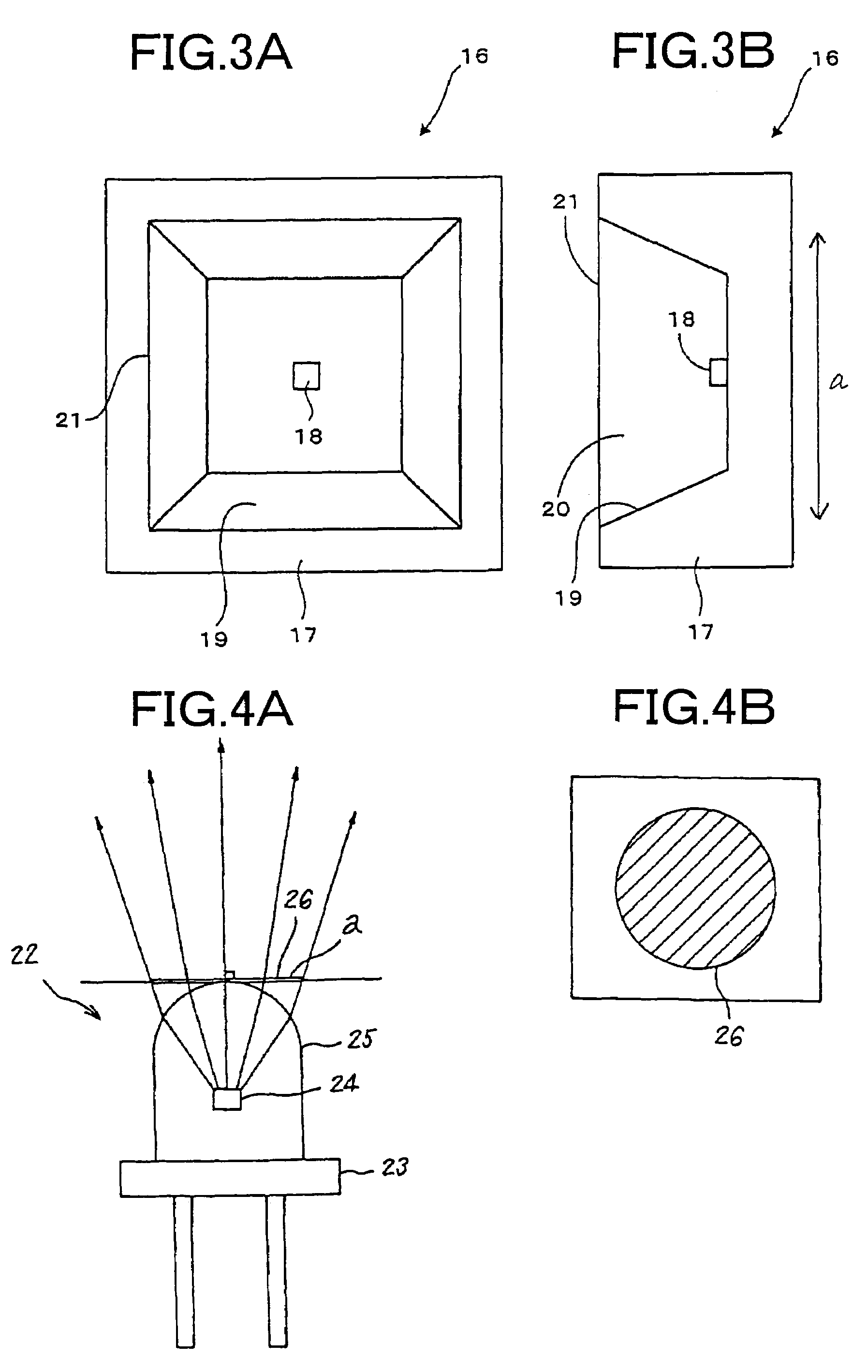

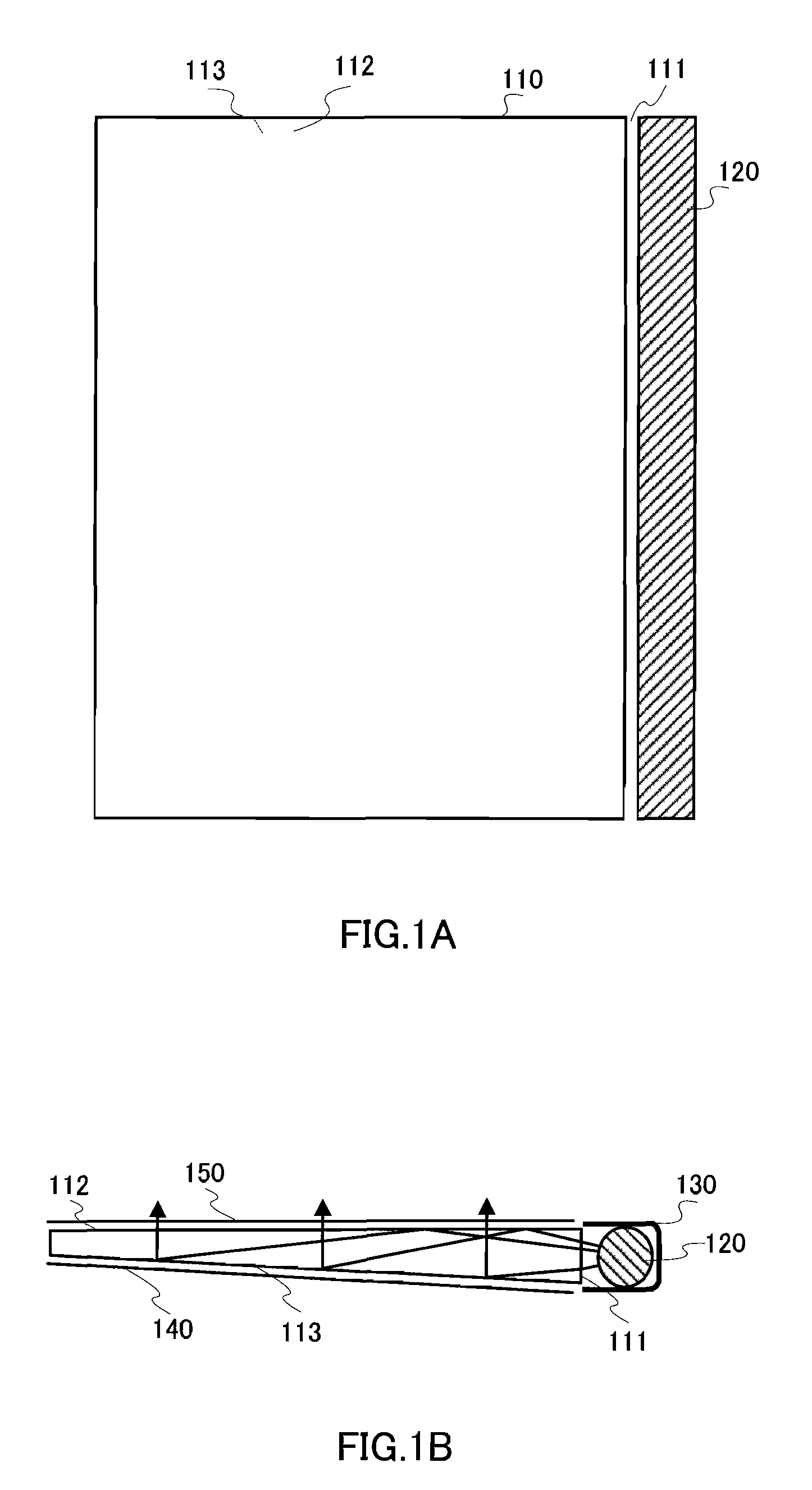

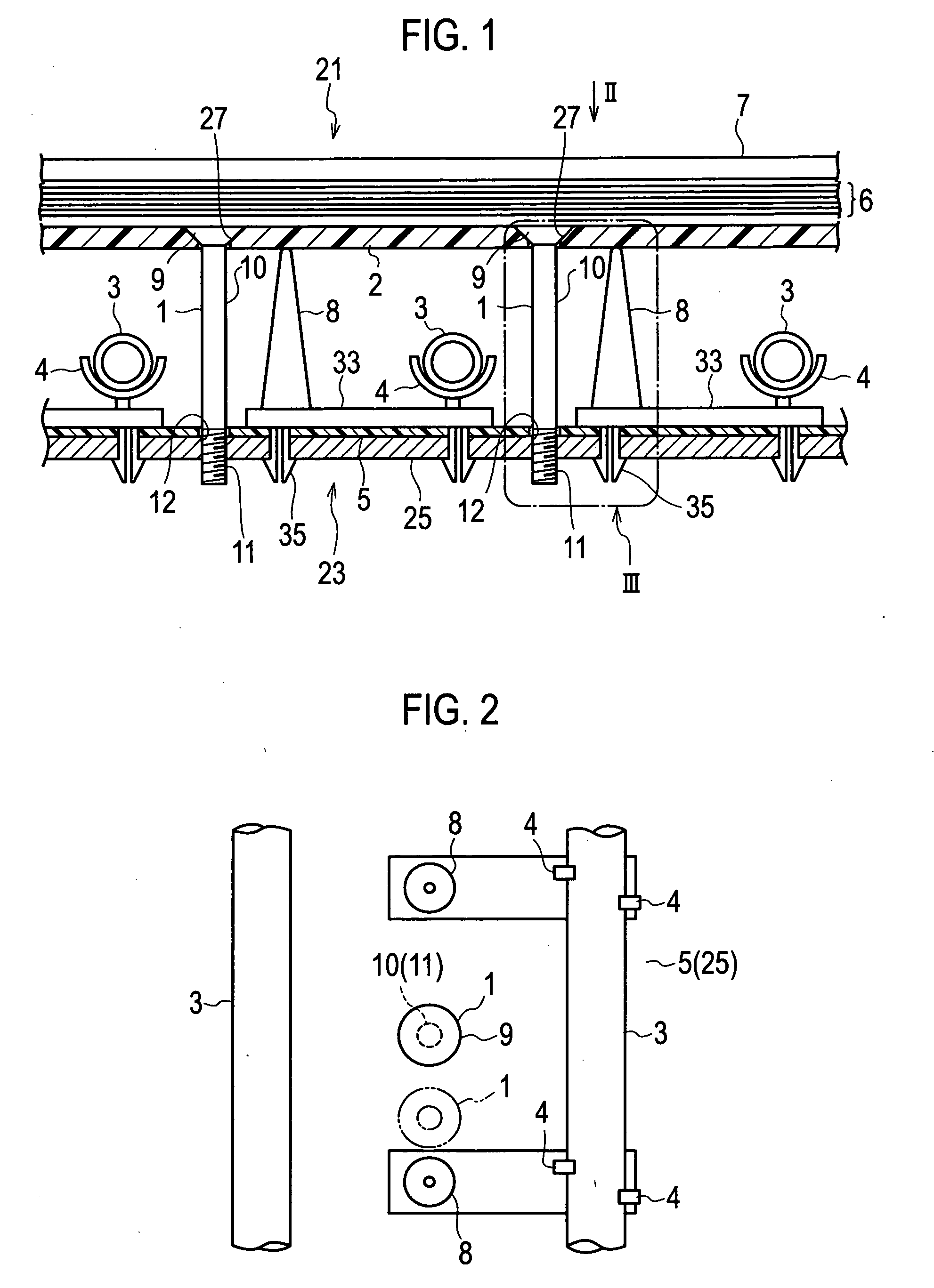

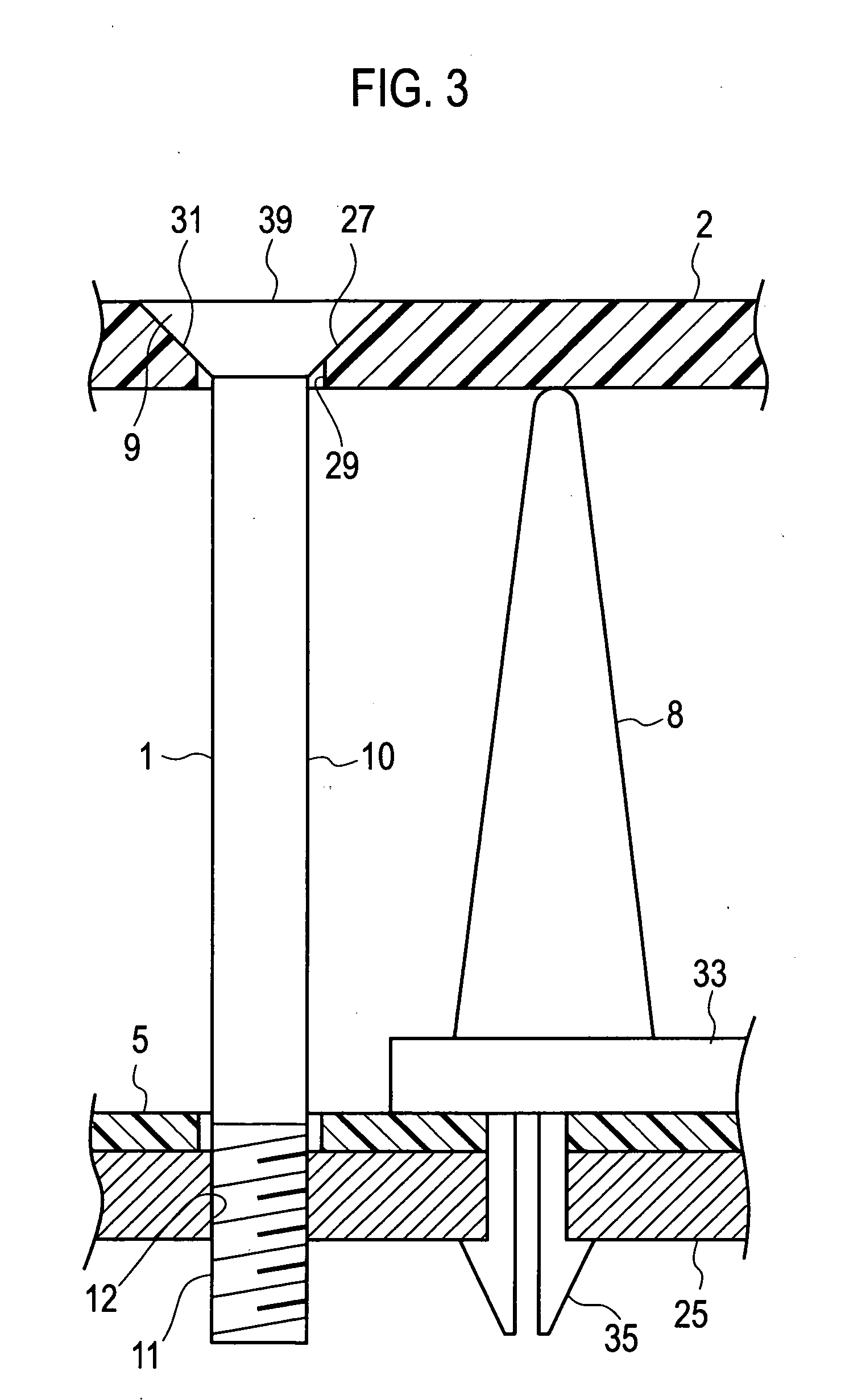

Lighting device, image-reading device, color-document reading apparatus, image-forming apparatus, projection apparatus

A lighting device includes an illumination face having a length and a width; a light-emitting element having a light-ray-releasing face the maximum length of which is equal to or less than the width of the illumination face; and a light-source unit that has an optical element which changes the direction of light rays released from the light-emitting element to be directed to the illumination face. The optical element has a concave-face reflecting unit having a cross section that is shaped into a quadratic curve or a pseudo quadratic curve, which is placed at least on one portion thereof, and a luminance distribution on the illumination face has a flat portion that is equal to or not less than a predetermined width.

Owner:RICOH KK

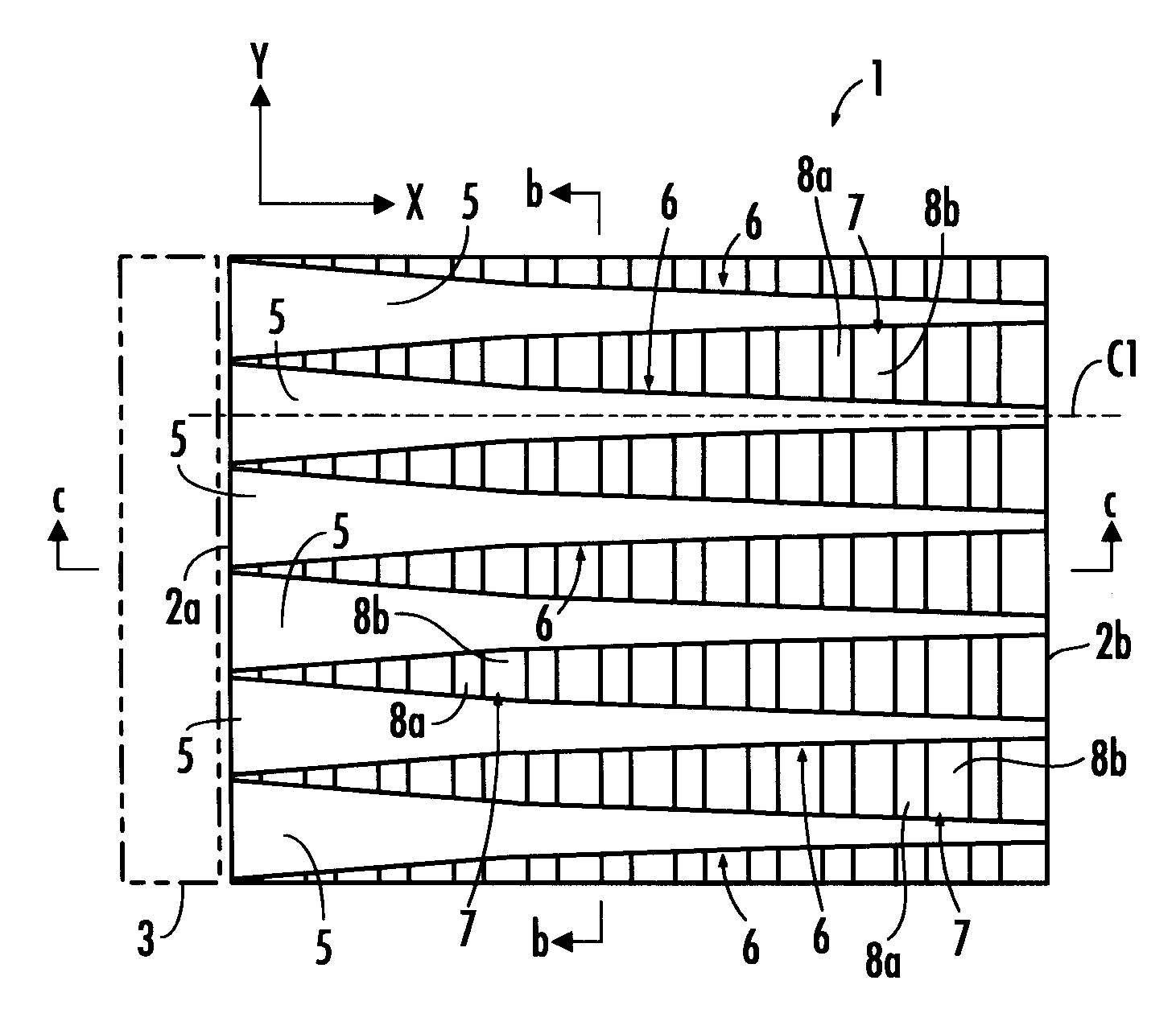

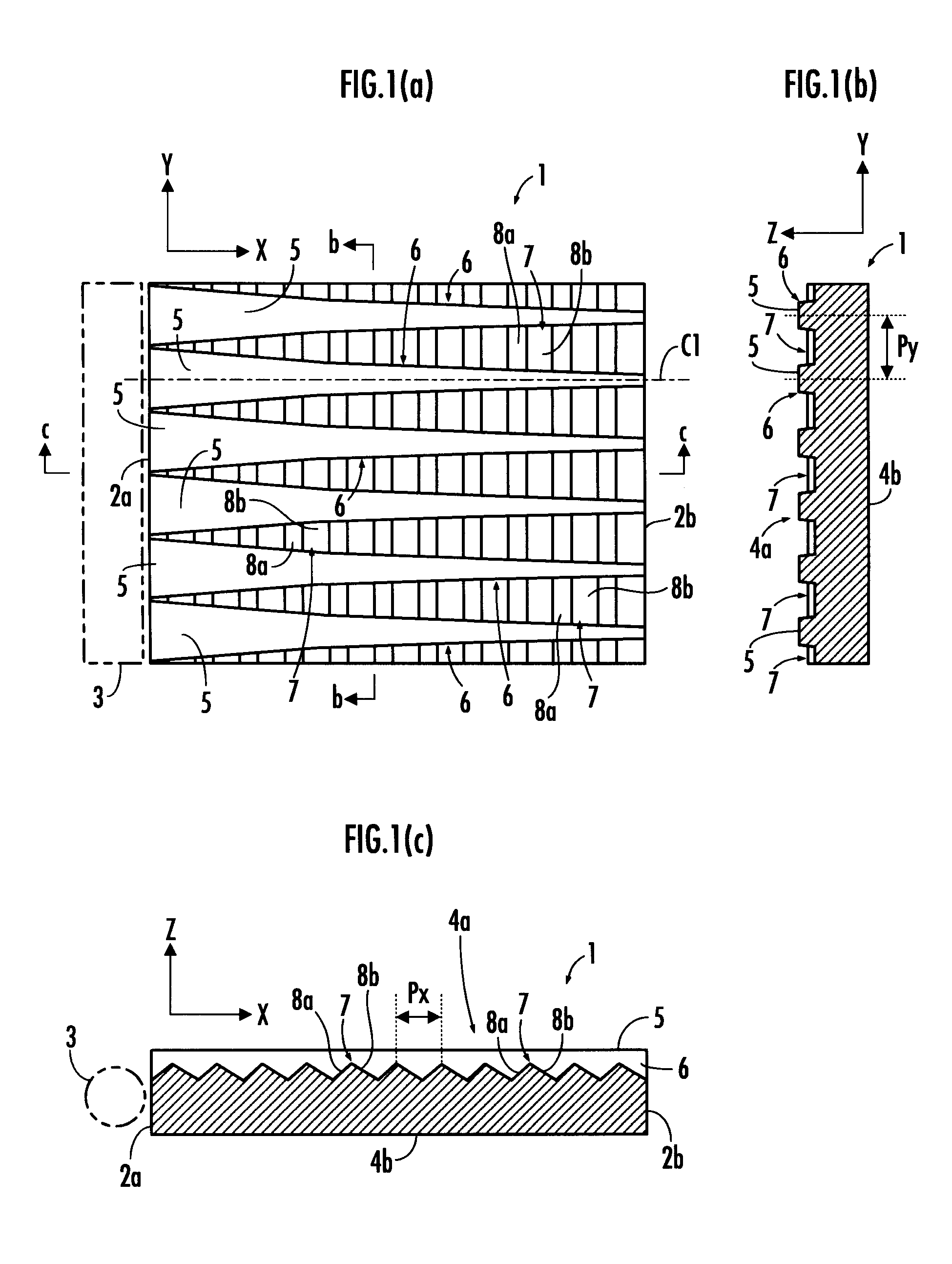

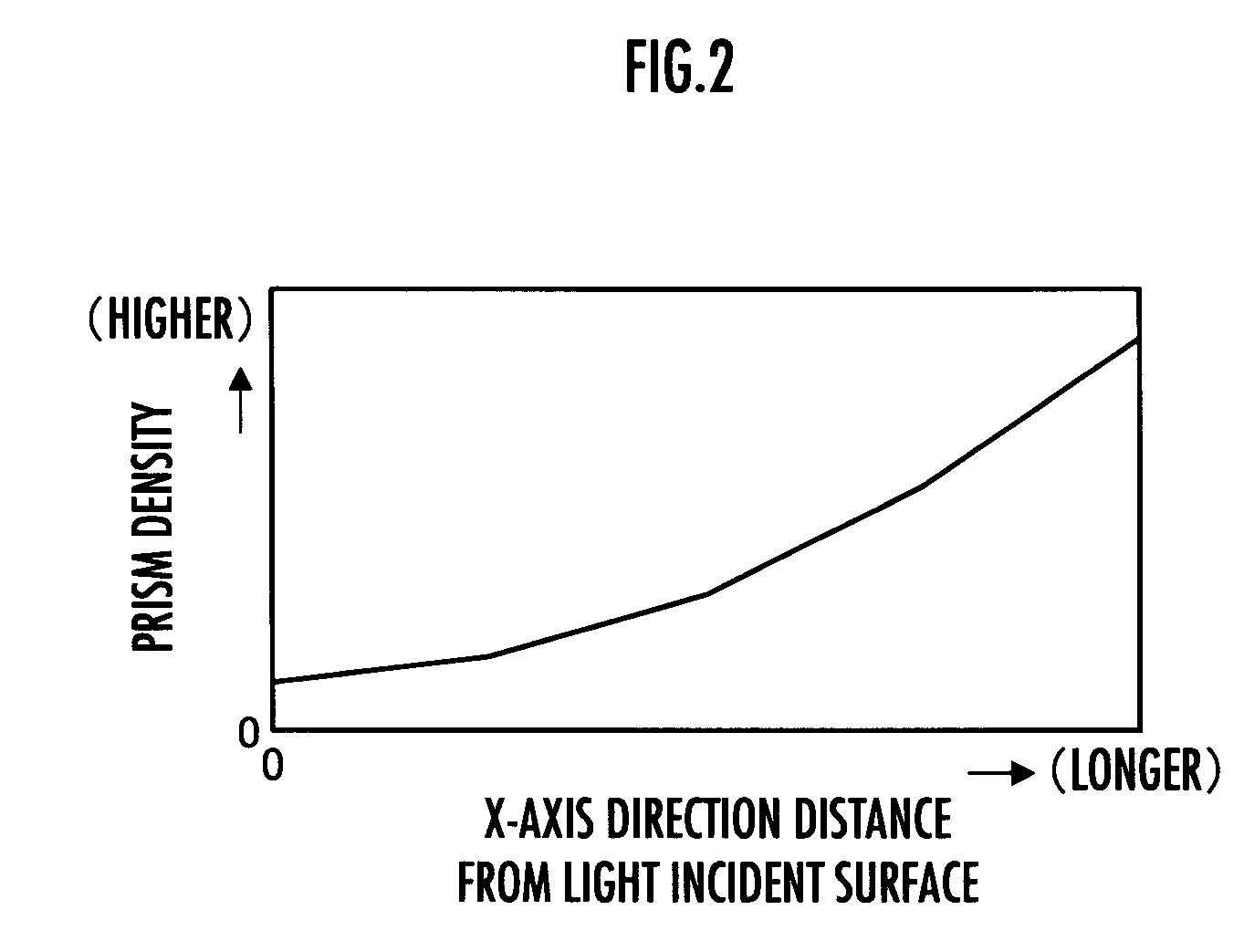

Light guide plate for surface light source

ActiveUS20090086509A1Preventing situationEfficient emissionsShow cabinetsImpedence networksDistribution controlLight guide

A plurality of mirror surfaces (5), which extend in a direction (X-axis direction) perpendicular to a light incident surface (2a), are formed side by side in a longitudinal direction (Y-axis direction) of the light incident surface (2a) on a light distribution control surface (4a) of both surfaces (4a, 4b) of a light guide plate (1) in a thickness direction (Z-axis direction) thereof, and a plurality of prisms (7) extending in the Y-axis direction are formed side by side in the X-axis direction in areas other than the mirror surfaces (5). The mirror surfaces 5 are formed in such a way that Y-axis direction widths thereof vary in the X-axis direction. This enables the setting of the light distribution characteristics and luminance distribution of emitted light, which are viewed in two directions, namely a longitudinal direction of the light incident surface of the light guide plate and the direction perpendicular to the light incident surface, to target light distribution characteristics and luminance distribution.

Owner:STANLEY ELECTRIC CO LTD

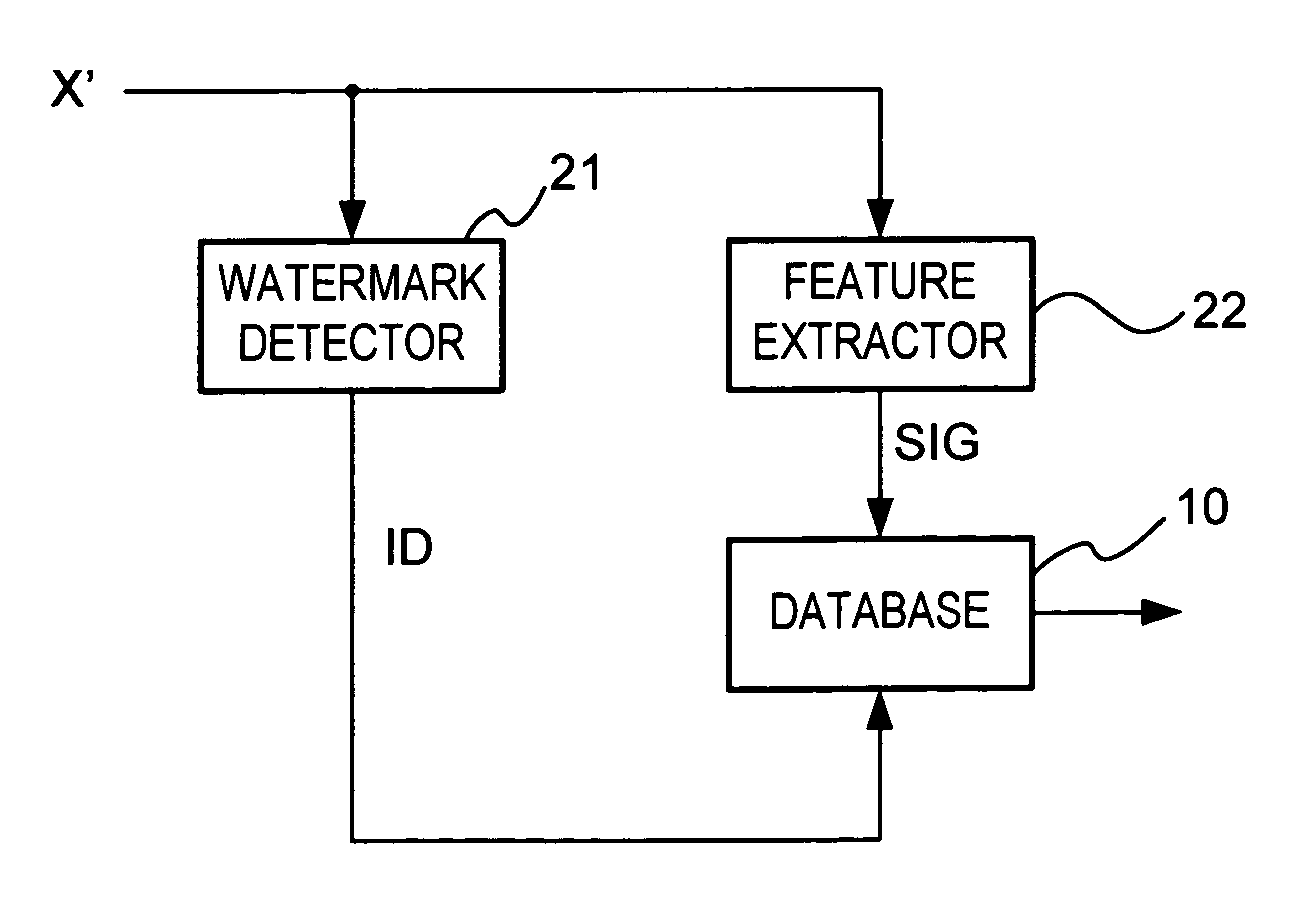

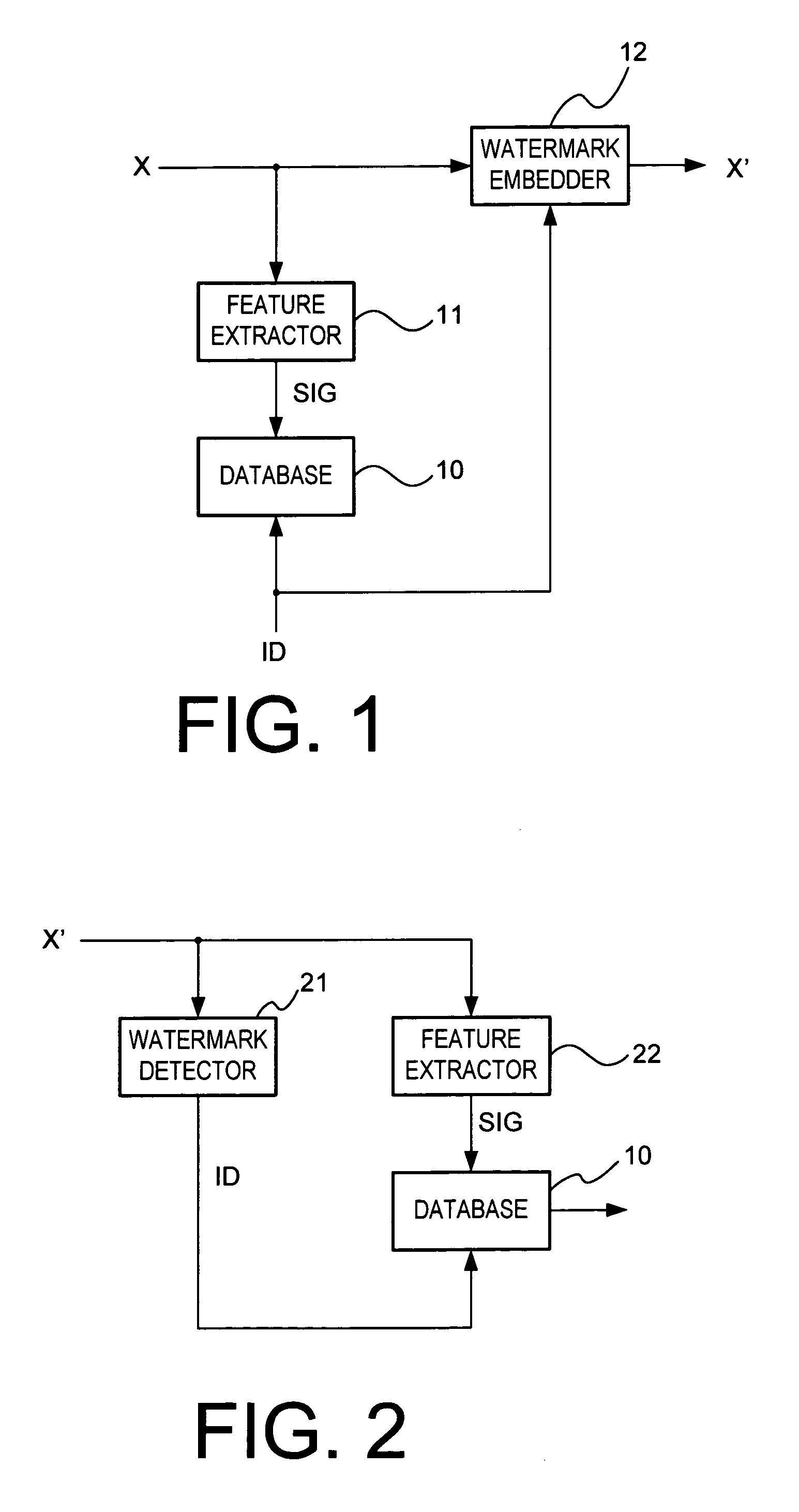

Content monitoring

InactiveUS7168083B2Improve robustness and efficiencyReduce complexityDigital data information retrievalBroadcast systems characterised by watermarksFeature extractionData mining

A method and arrangement are disclosed for distributing multimedia content such that that the actual distribution of said content can be monitored in an efficient and reliable manner. The invention combines the extensiveness of feature extraction and the robustness of watermarking. Characteristic features of the content, e.g. luminance distribution, are extracted (11) to constitute a signature (SIG) of the content. In addition, a watermark is embedded (12) having a payload representing an index (ID) in a database (10) in which the content to be monitored is stored. The watermark serves as an index for limiting the database search needed for monitoring the signatures.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

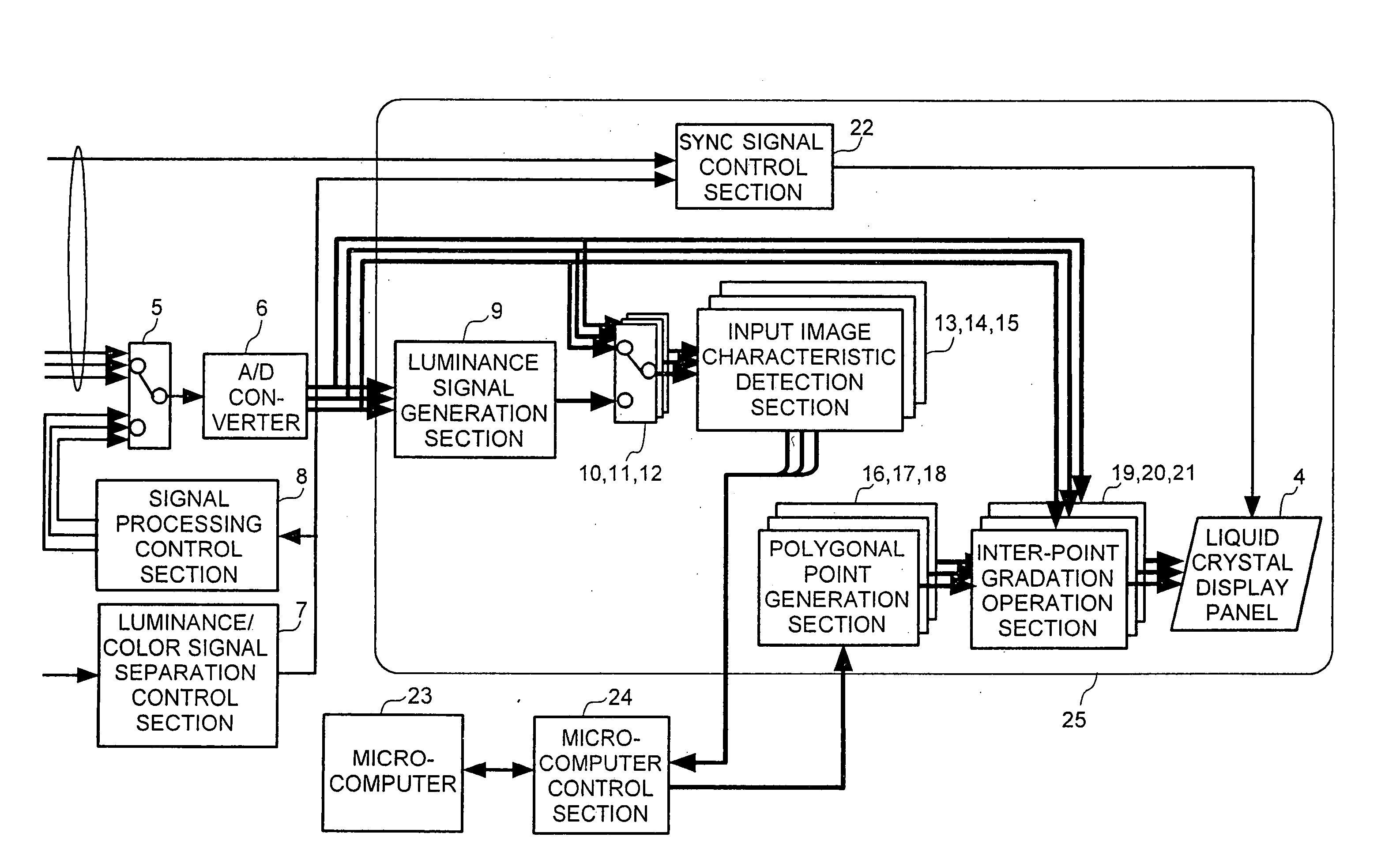

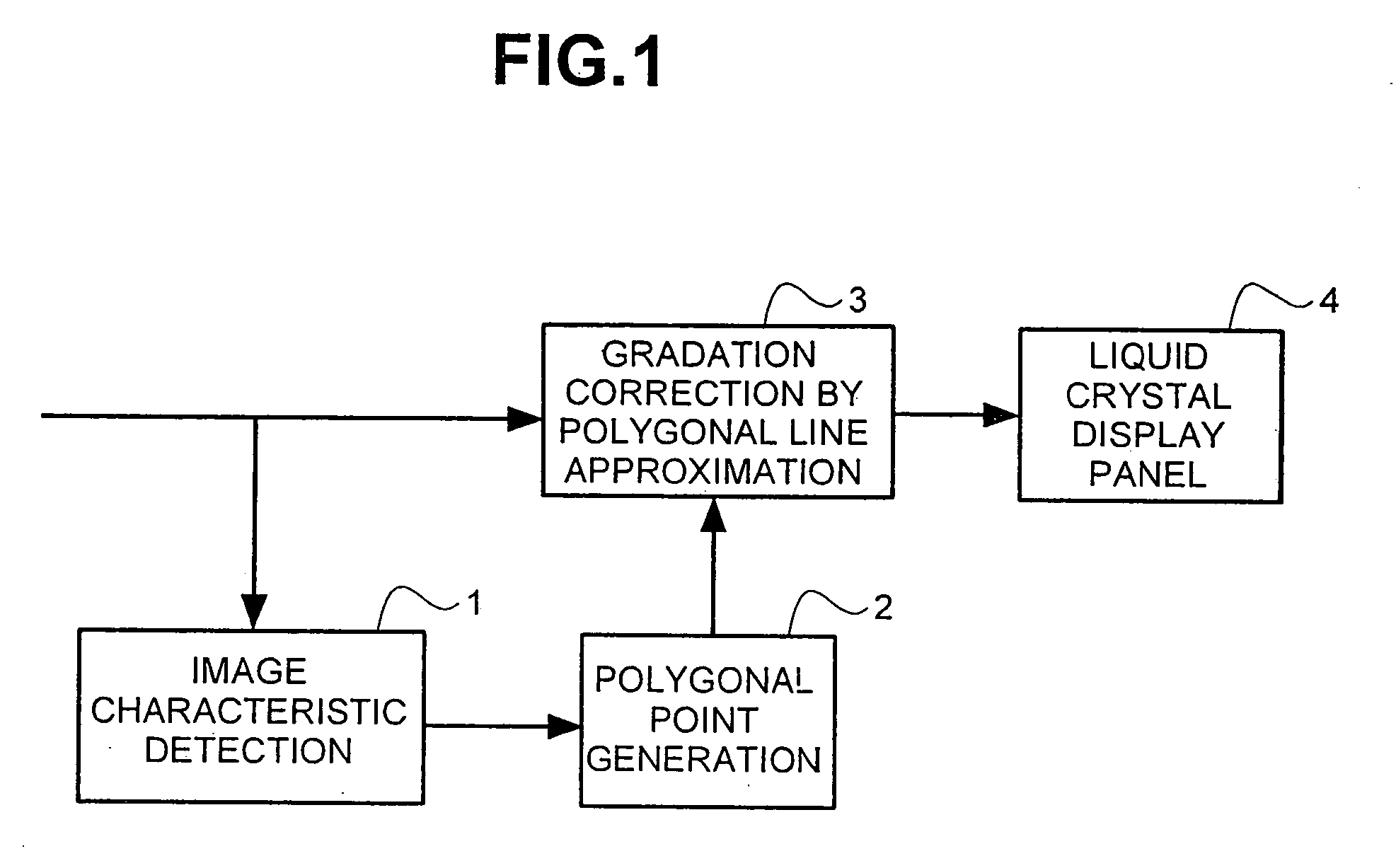

Liquid crystal display device for displaying video data

InactiveUS20050122287A1Clear imagingImprove efficiencyTelevision system detailsColor signal processing circuitsLiquid-crystal displayDisplay device

A liquid crystal display device for displaying video data having a detection circuit for detecting a luminance distribution based on video data which is inputted, the luminance distribution being indicative of generation frequency of gradations in each of divided region which includes a plurality of gradations. The display device includes a determination circuit for determining at least one of a plurality of divided regions of higher generation frequency of gradation than that of other divided regions based on the luminance distribution, a correction circuit for correcting the video data so as to make a luminance characteristic of the at least one of the plurality of divided regions of higher generation frequency of gradation more abrupt than a luminance characteristic of the other divided regions, and a liquid crystal display panel for displaying the corrected video data. A width of the divided region is changeable.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

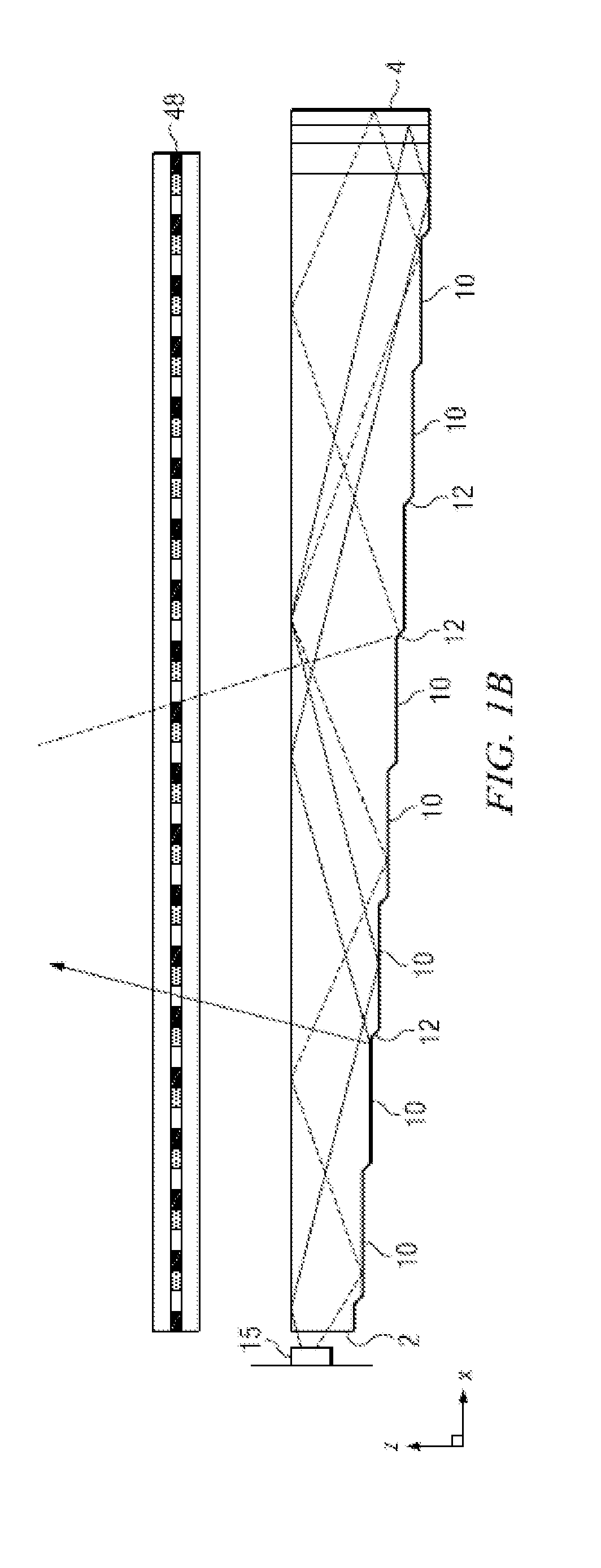

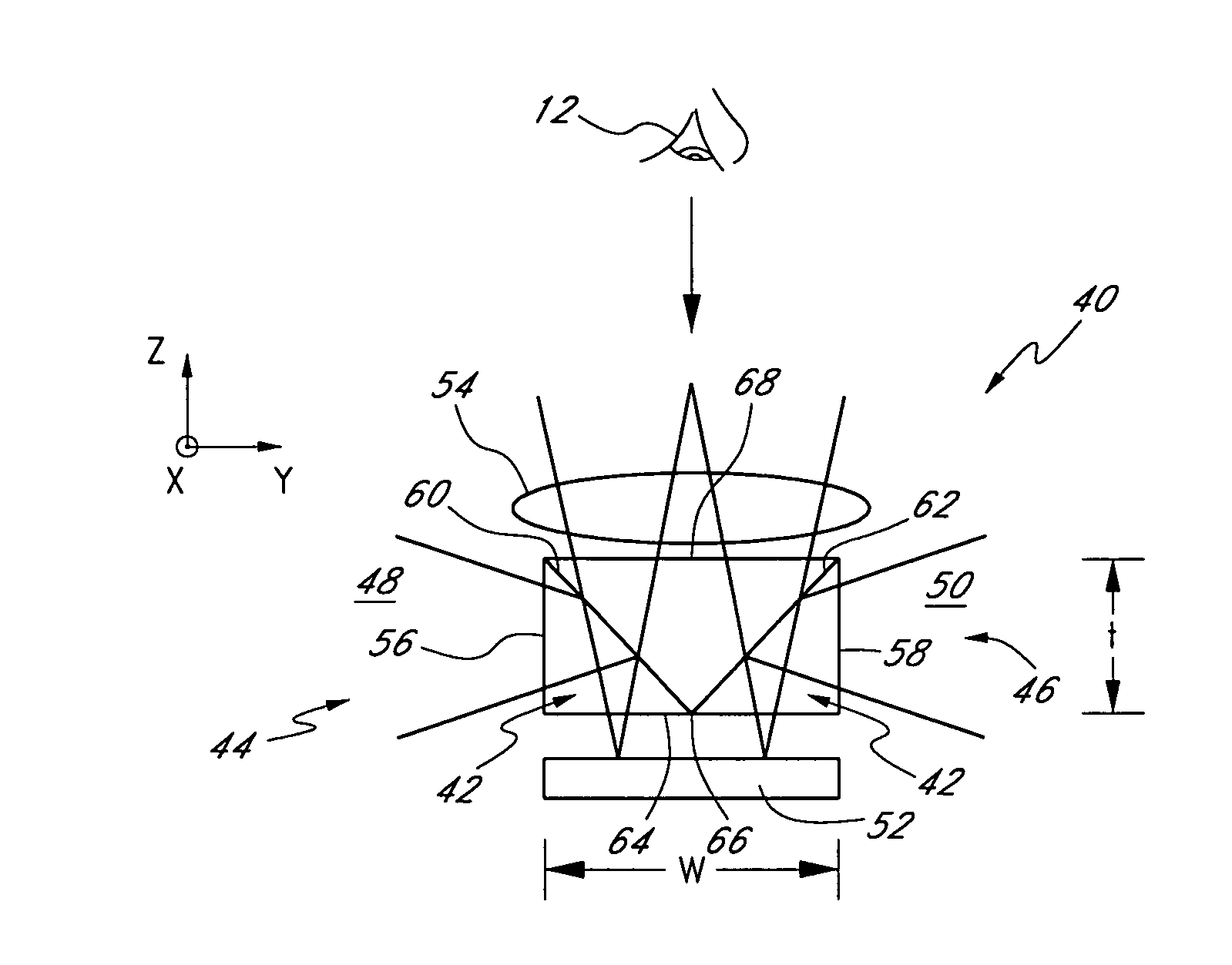

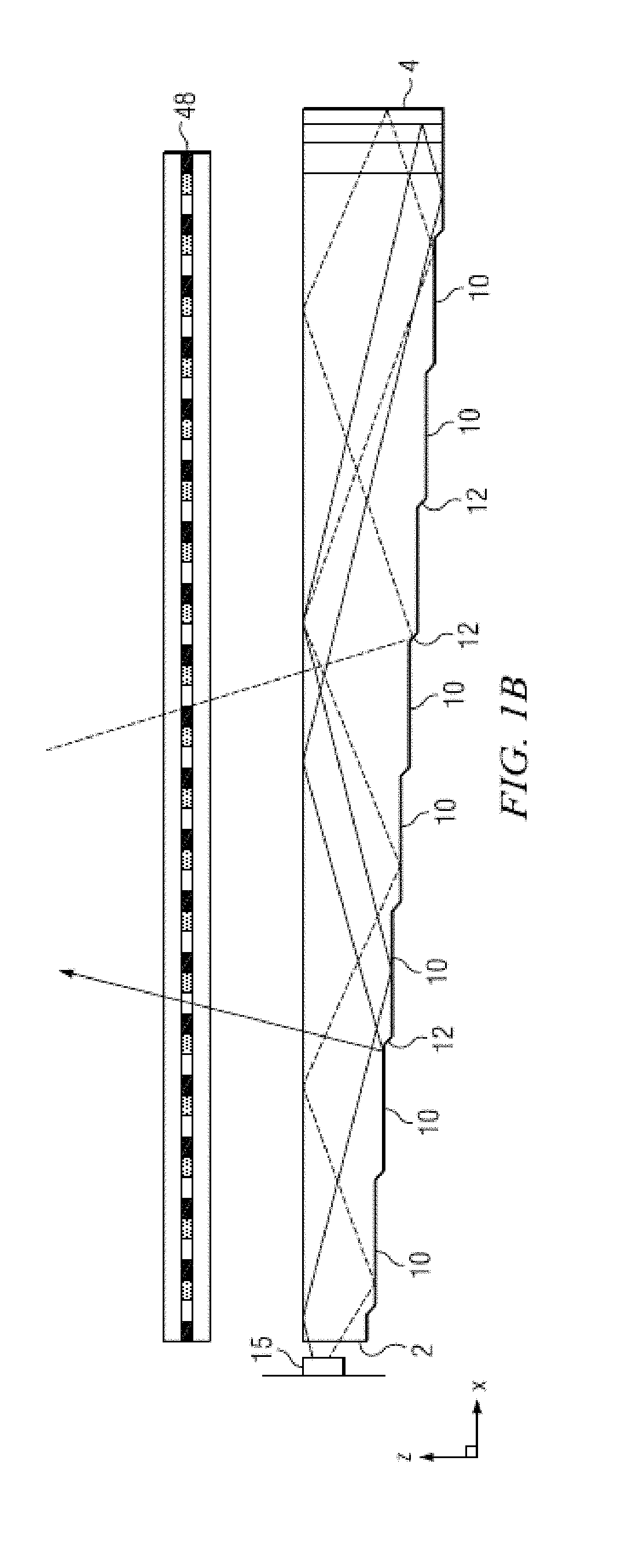

Privacy display apparatus

ActiveUS20190215509A1Operational savingHigh luminance operationMechanical apparatusDiffusing elementsDirect illuminationLiquid crystal

An imaging directional backlight apparatus including a waveguide, a light source array, for providing large area directed illumination from localized light sources. The waveguide may include a stepped structure, in which the steps may further include extraction features optically hidden to guided light, propagating in a first forward direction. Returning light propagating in a second backward direction may be refracted, diffracted, or reflected by the features to provide discrete illumination beams exiting from the top surface of the waveguide. The directional backlight may be arranged to switch between at least a first wide angular luminance profile mode and a second narrow angular luminance profile mode. The directional backlight is arranged to illuminate an LCD with a bias electrode arranged to switch liquid crystal directors in black state pixels between a first wide angular contrast profile mode and a second narrow angular contrast profile mode. Performance of privacy operation for off-axis snoopers is enhanced in comparison to displays with only directional backlights or switchable contrast properties.

Owner:REALD SPARK LLC

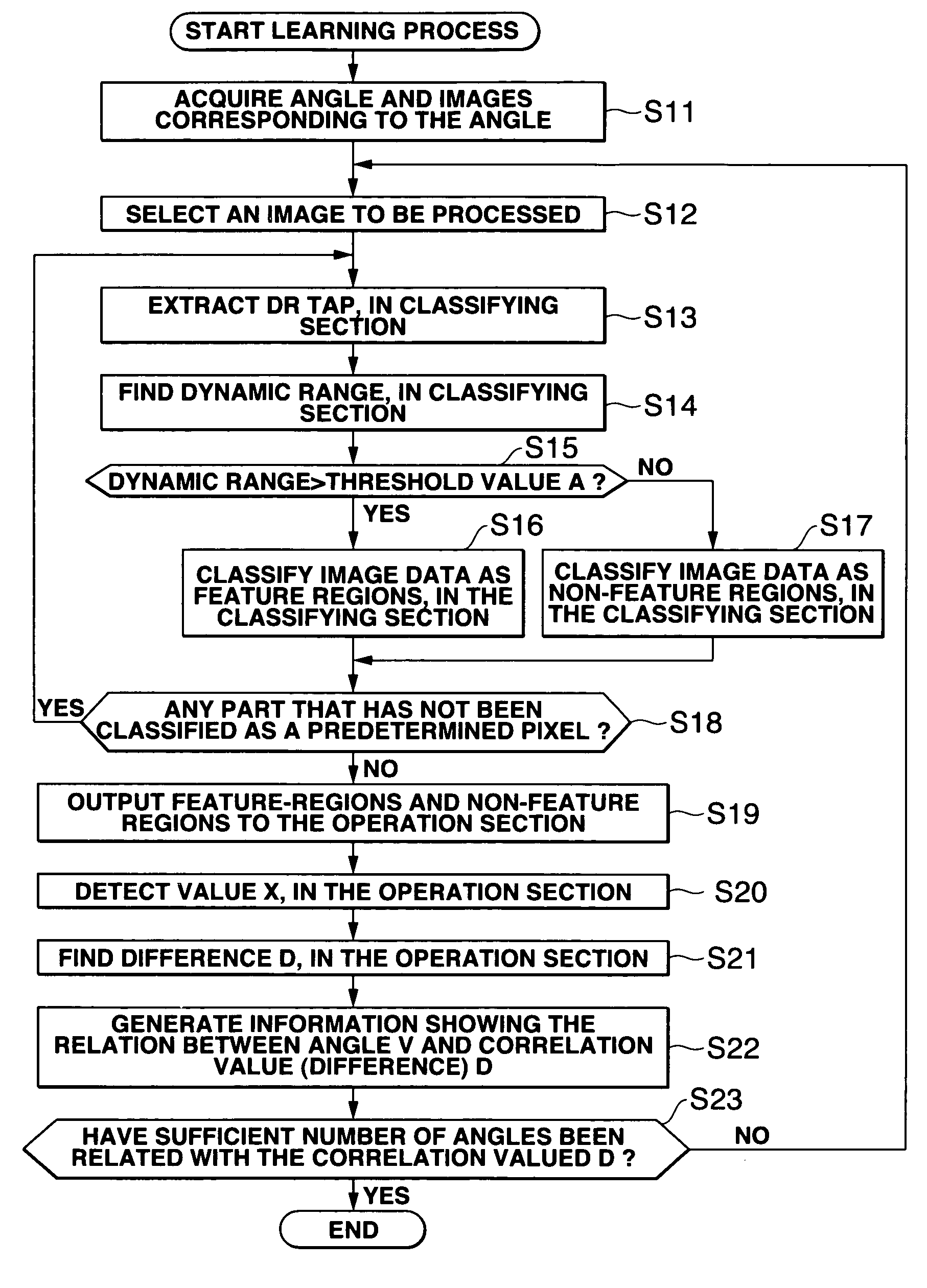

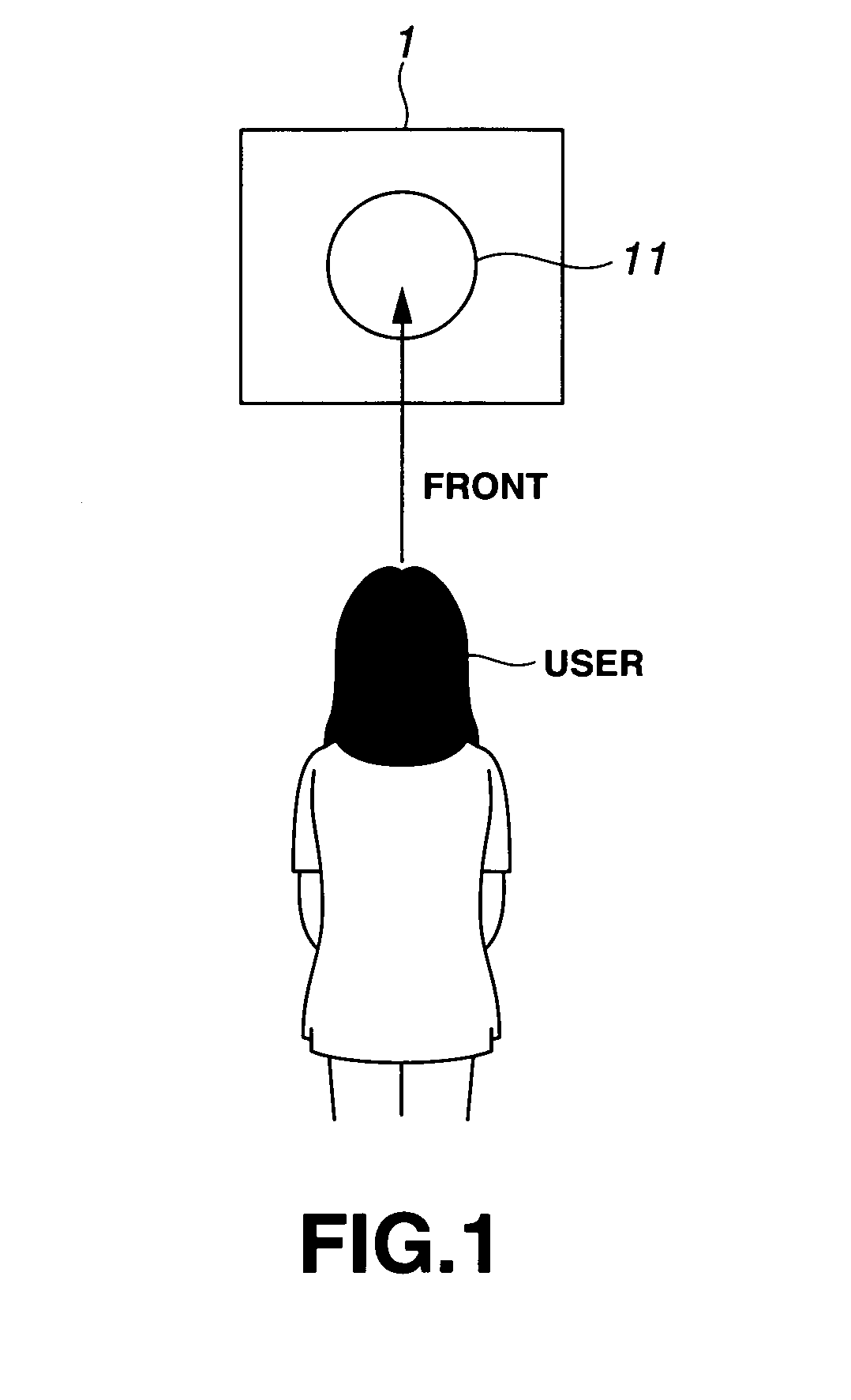

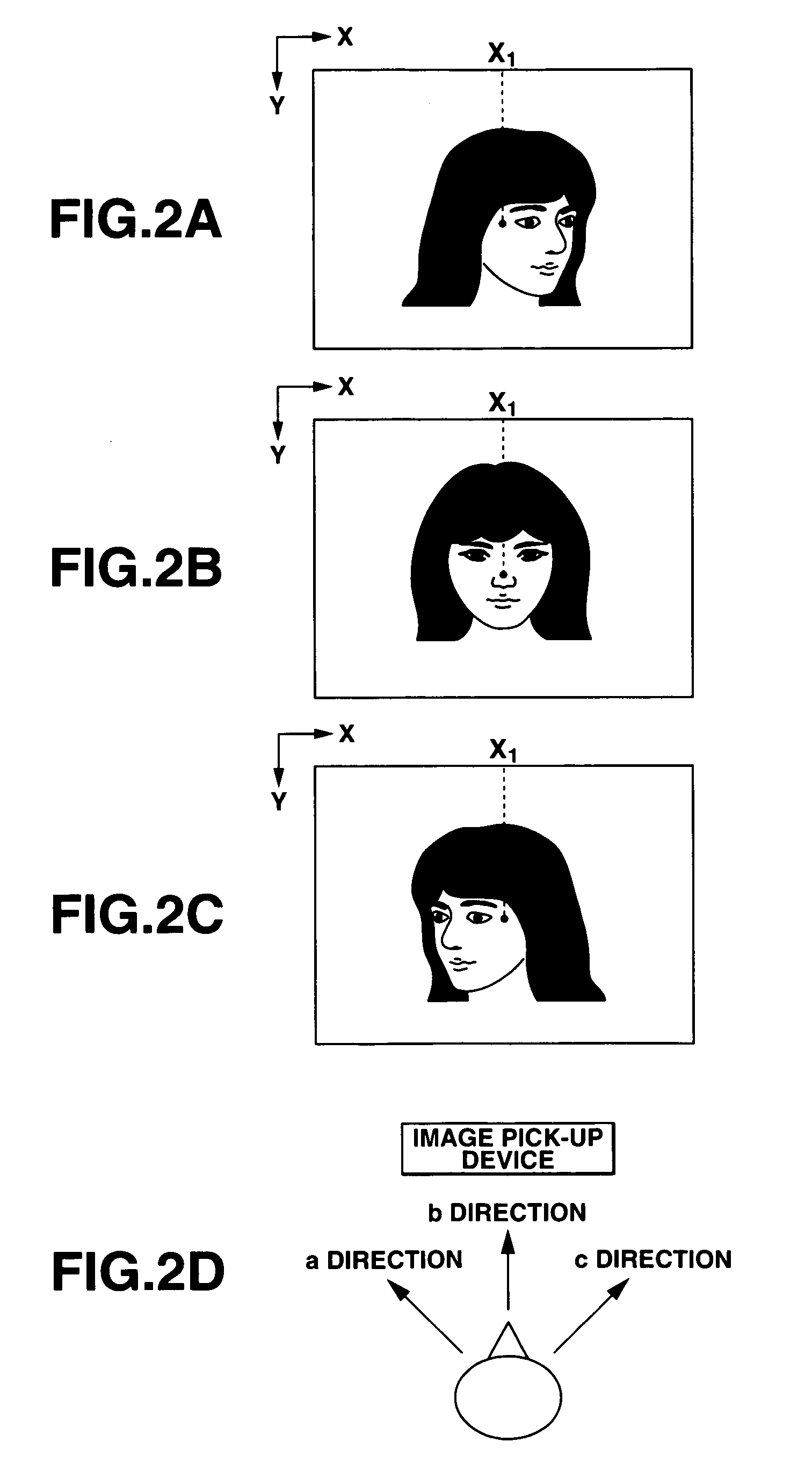

Image processor, image processing method, and recorded medium

InactiveUS6965693B1Reliable detectionImage analysisCharacter and pattern recognitionImaging processingGravity center

A feature region is extracted from the image region of an object, in accordance with the luminance distribution of pixels adjacent to a predetermined pixel that exists in the image region of the object (S31 to S34). A gravity-center correlation value is calculated, which shows the correlation between the gravity center of the feature region and the gravity center of the image region of the object (S35 and S36). The orientation of the object is determined from the gravity-center correlation value (S37).

Owner:SONY CORP

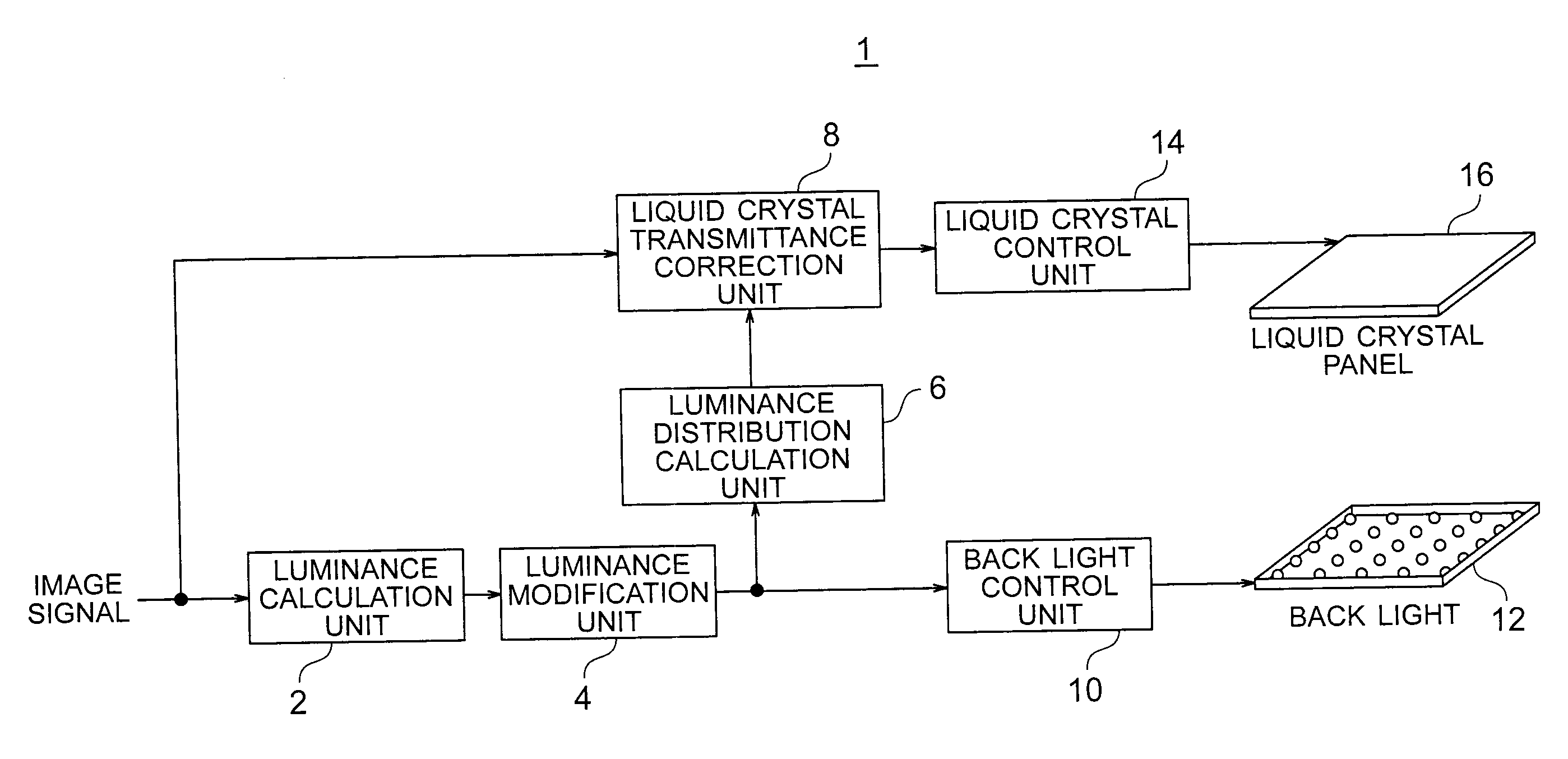

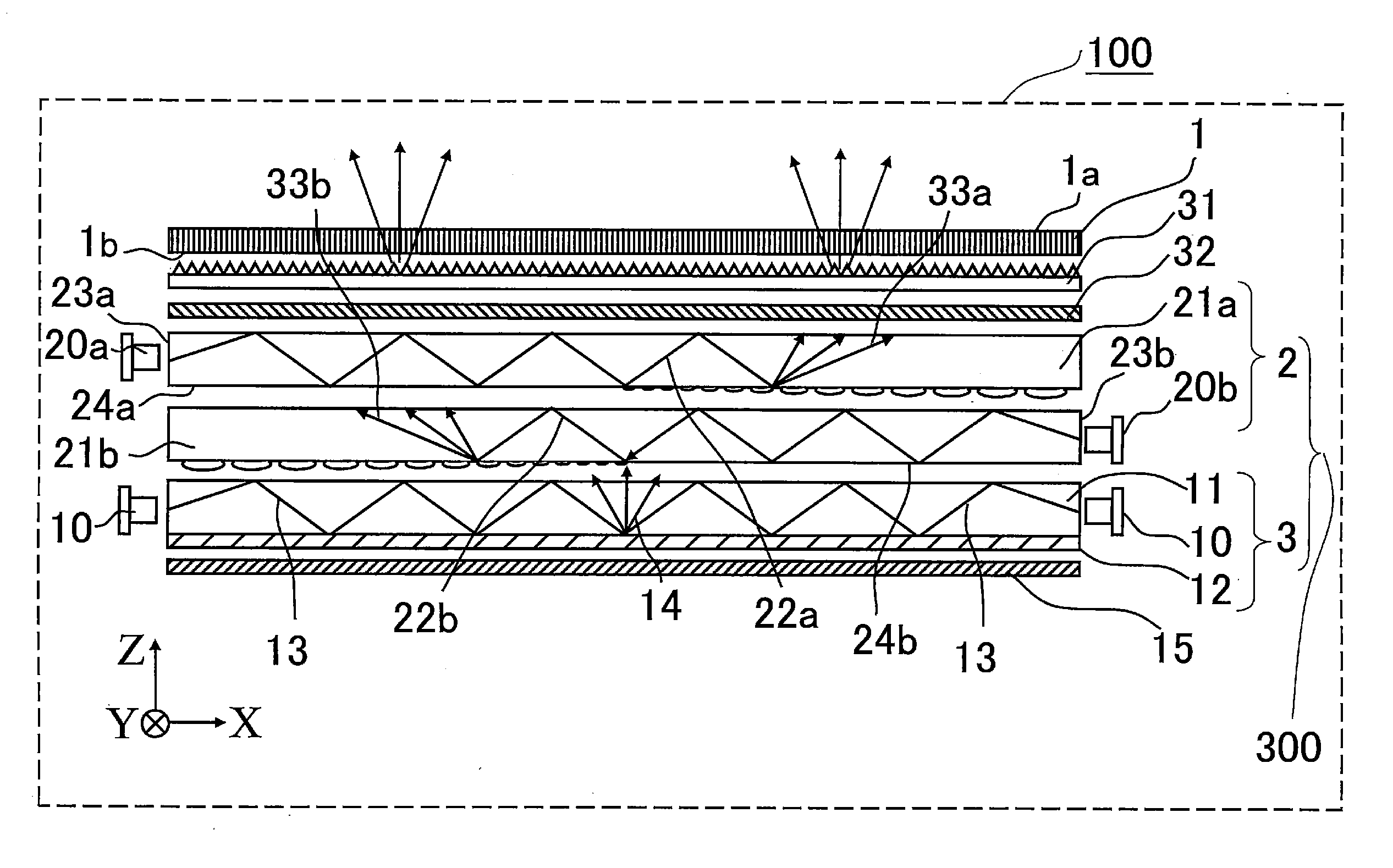

Image display apparatus and image display method

ActiveUS20090140975A1Suppression of uneven brightnessCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayOptical transmittance

An image display apparatus includes: a luminance modification unit configured to modify the luminance setting value so as to make a luminance difference between adjacent partial regions of a back light smaller; a luminance distribution calculation unit configured to calculate a predicted value of luminance distribution of light incident on a liquid crystal panel from the back light on the basis of the modified luminance setting value; a liquid crystal transmittance correction unit configured to correct an optical transmittance of the image signal at each pixel of the liquid crystal panel on the basis of the image signal and the luminance distribution; a back light control unit configured to control the back light on the basis of the modified luminance setting value; and a liquid crystal control unit configured to control the liquid crystal panel so that the transmittance of the image signal becomes the corrected optical transmittance.

Owner:HISENSE VISUAL TECH CO LTD

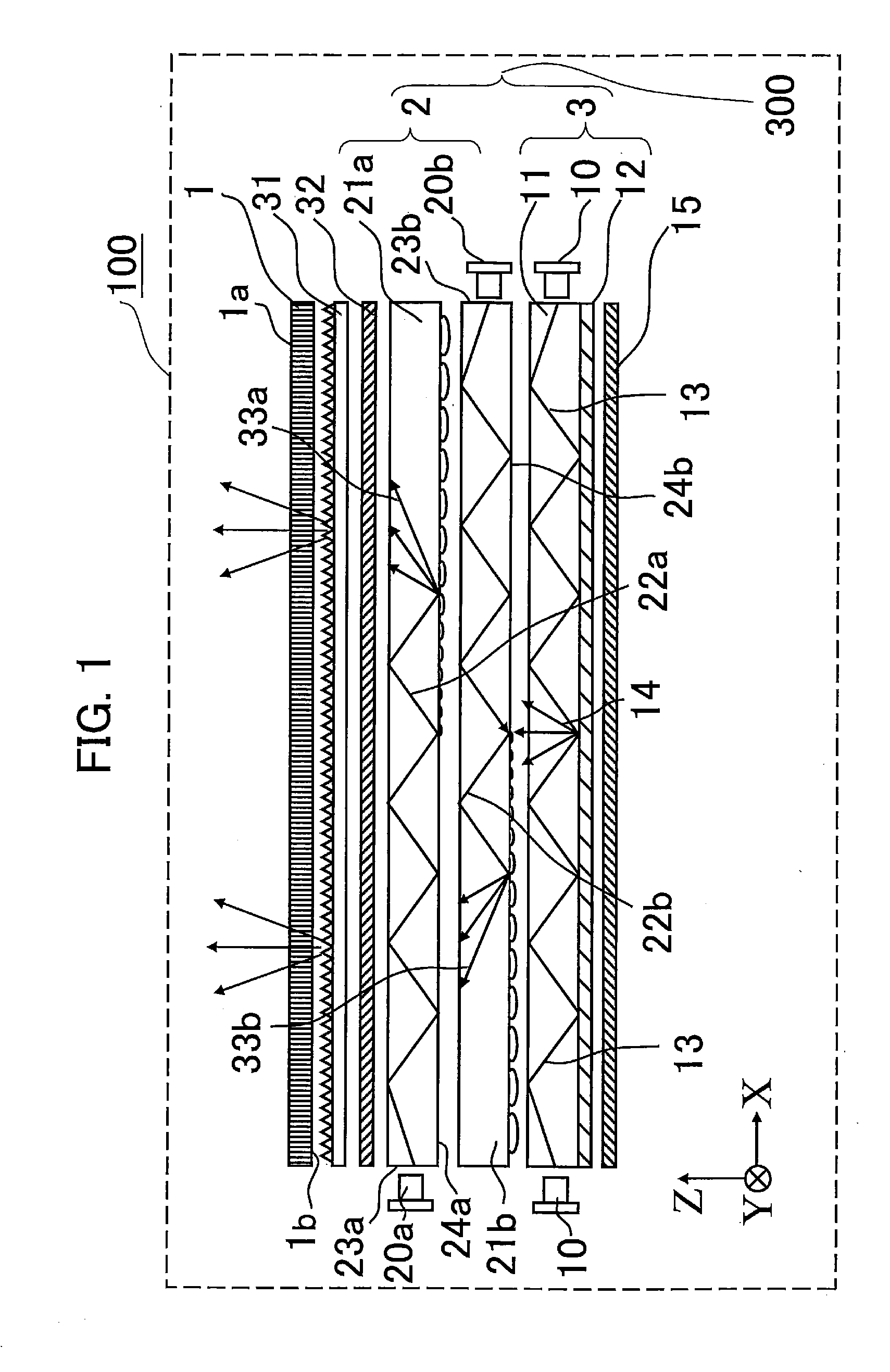

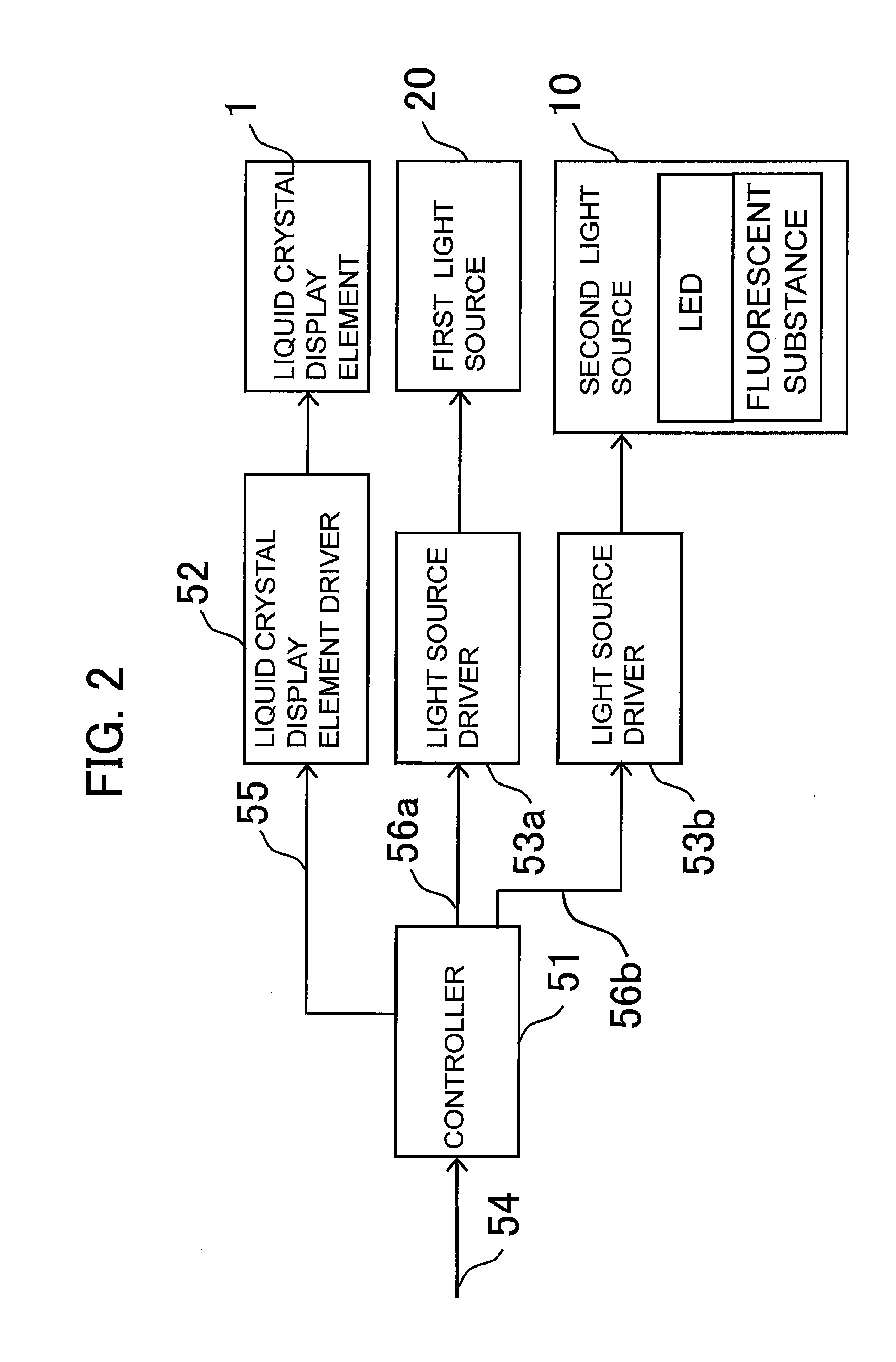

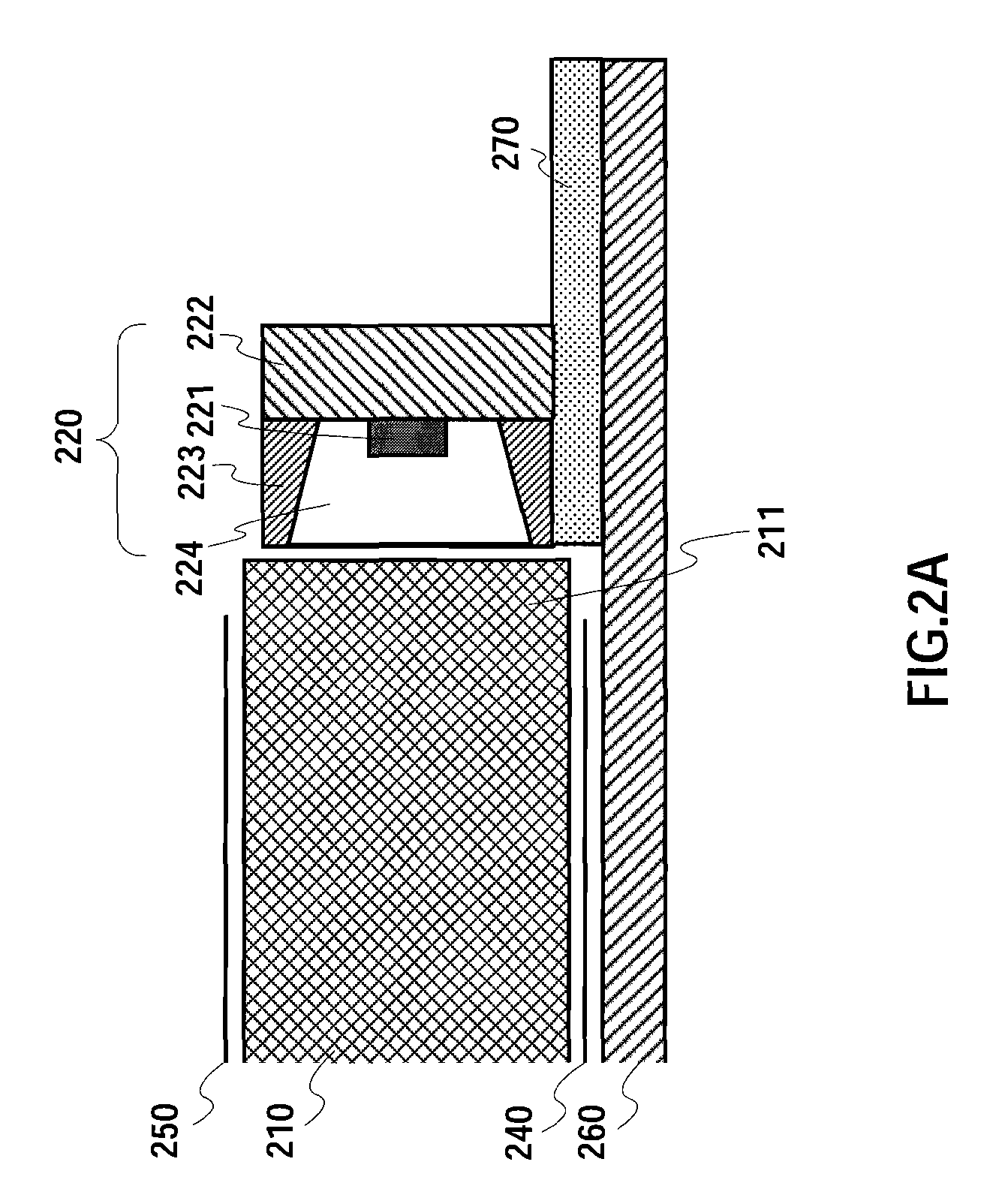

Backlight device and liquid crystal display apparatus

InactiveUS20130033901A1Suppress power consumptionExtended range of color reproductionMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayDivergence angle

A planar light source device includes a first light source for emitting a first light ray having a punctate spatial luminance distribution; a second light source for emitting a second light ray; a first spatial luminance distribution conversion portion for changing the first light ray to a linear spatial luminance distribution; a second spatial luminance distribution conversion portion for changing a spatial luminance distribution of the first and second light rays to a planar spatial luminance distribution; wherein the first light ray is a laser light; the second light ray has a divergence angle larger than the divergence angle of the first light ray when the first light ray is emitted from the first light source; and a slow-axis direction of the first light ray entering the second spatial luminance distribution conversion portion is parallel to an outgoing direction of the planar light.

Owner:MITSUBISHI ELECTRIC CORP

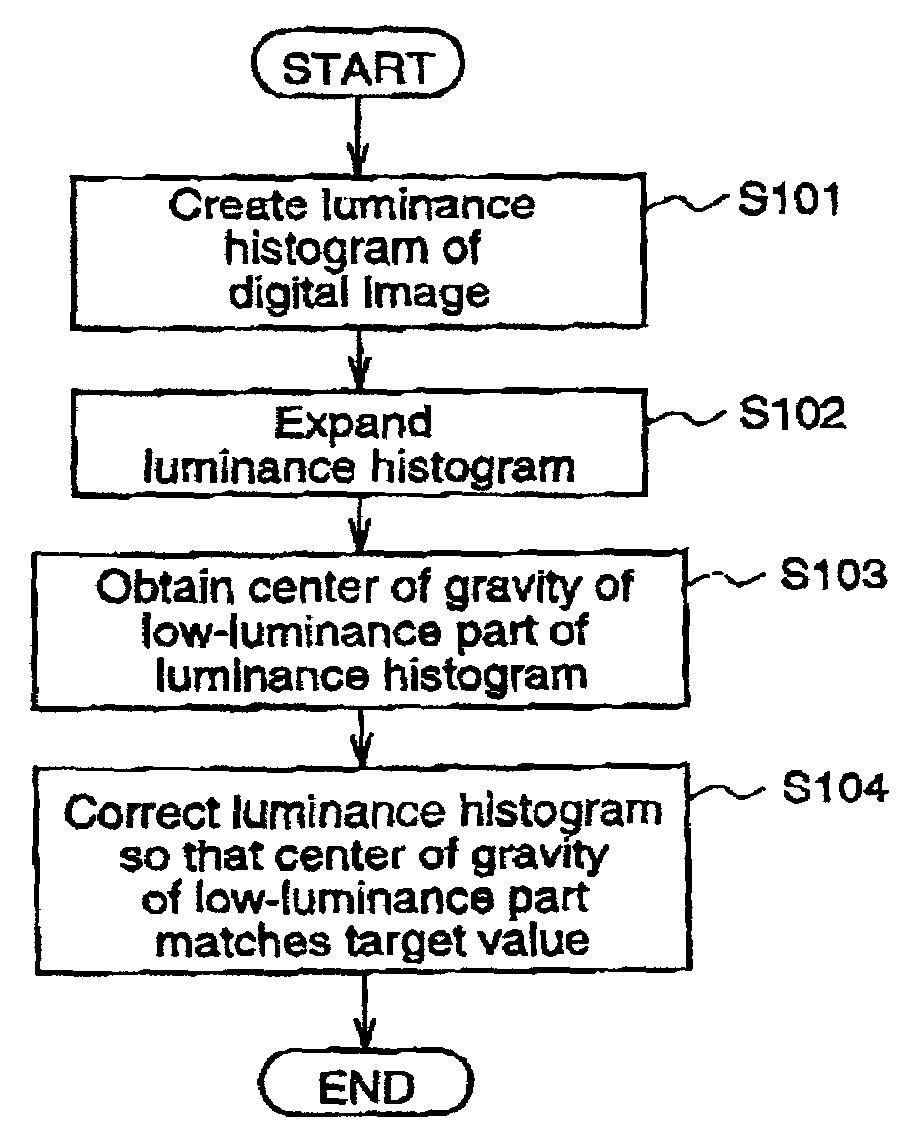

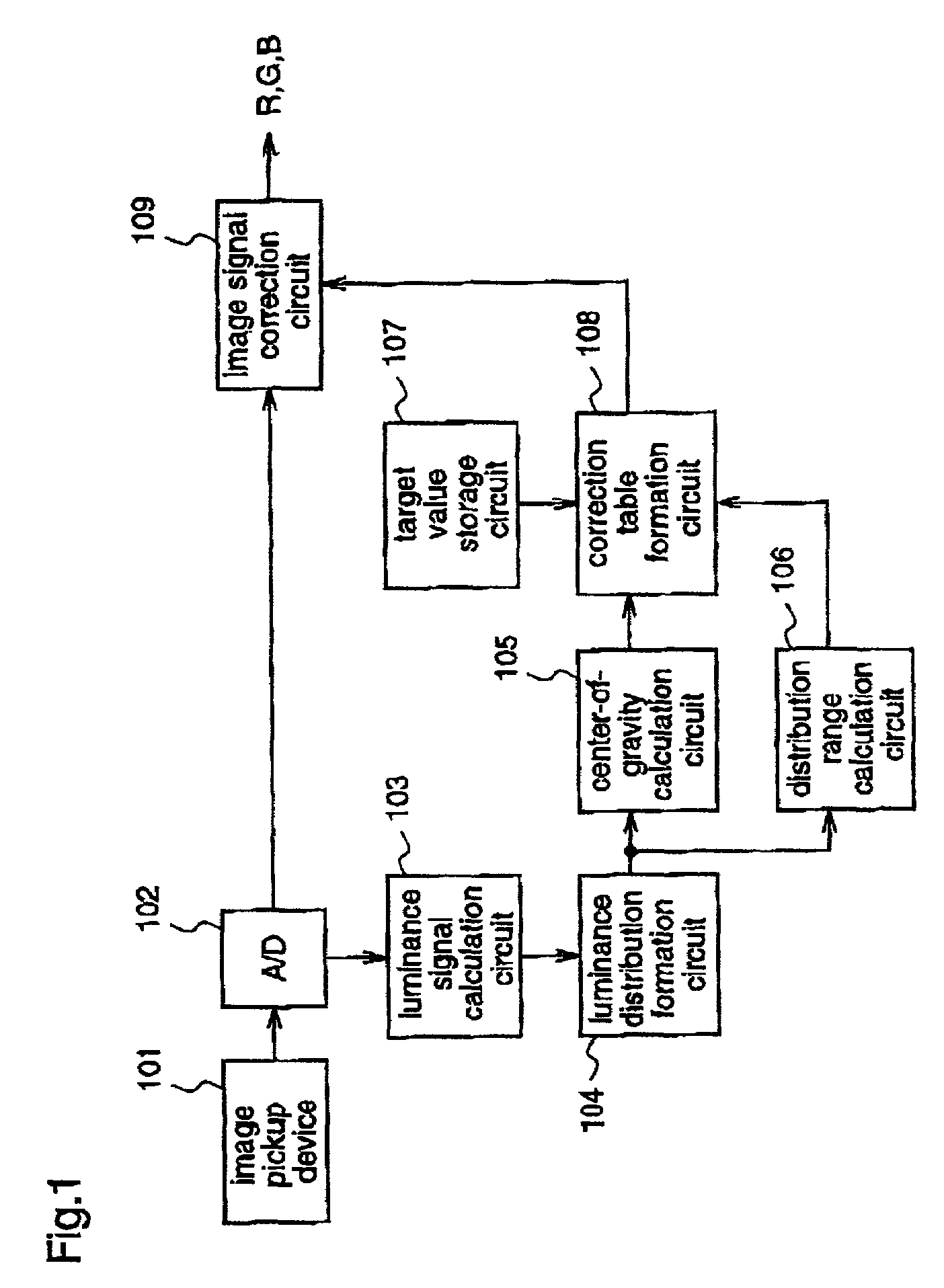

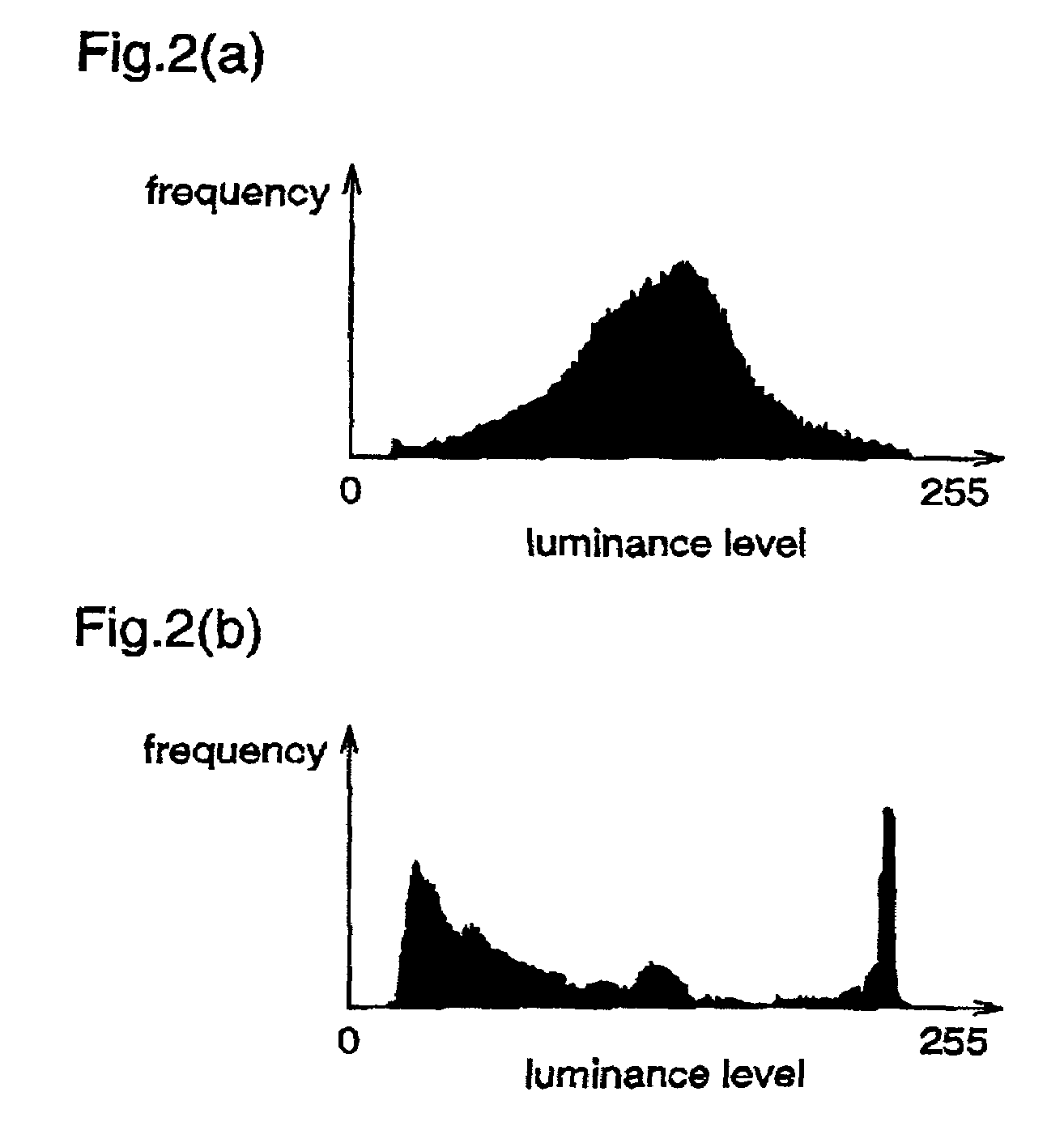

Automatic tone correction apparatus, automatic tone correction method, and automatic tone correction program storage mediums

InactiveUS7142712B2Corrected satisfactorilyOptimize contrastImage enhancementDigitally marking record carriersComputer scienceCorrection method

An automatic tone correction apparatus comprises a luminance distribution formation circuit for forming a luminance histogram of an input image; a center-of-gravity calculation circuit for calculating the center of gravity of a low-luminance part of the luminance histogram; a distribution range calculation circuit for calculating a maximum value and a minimum value on an input luminance level axis; a target value storage circuit for holding a luminance correction target value; a correction table formation circuit for forming a correction table for expanding the luminance distribution and, simultaneously, correcting the luminance histogram so that the center of gravity matches the luminance correction target value; and an image signal correction circuit for performing tone correction on the basis of the correction table. Therefore, whether the input image is a forward-light image or a back-lighted image, the apparatus performs tone correction using the same processing.

Owner:PANASONIC CORP

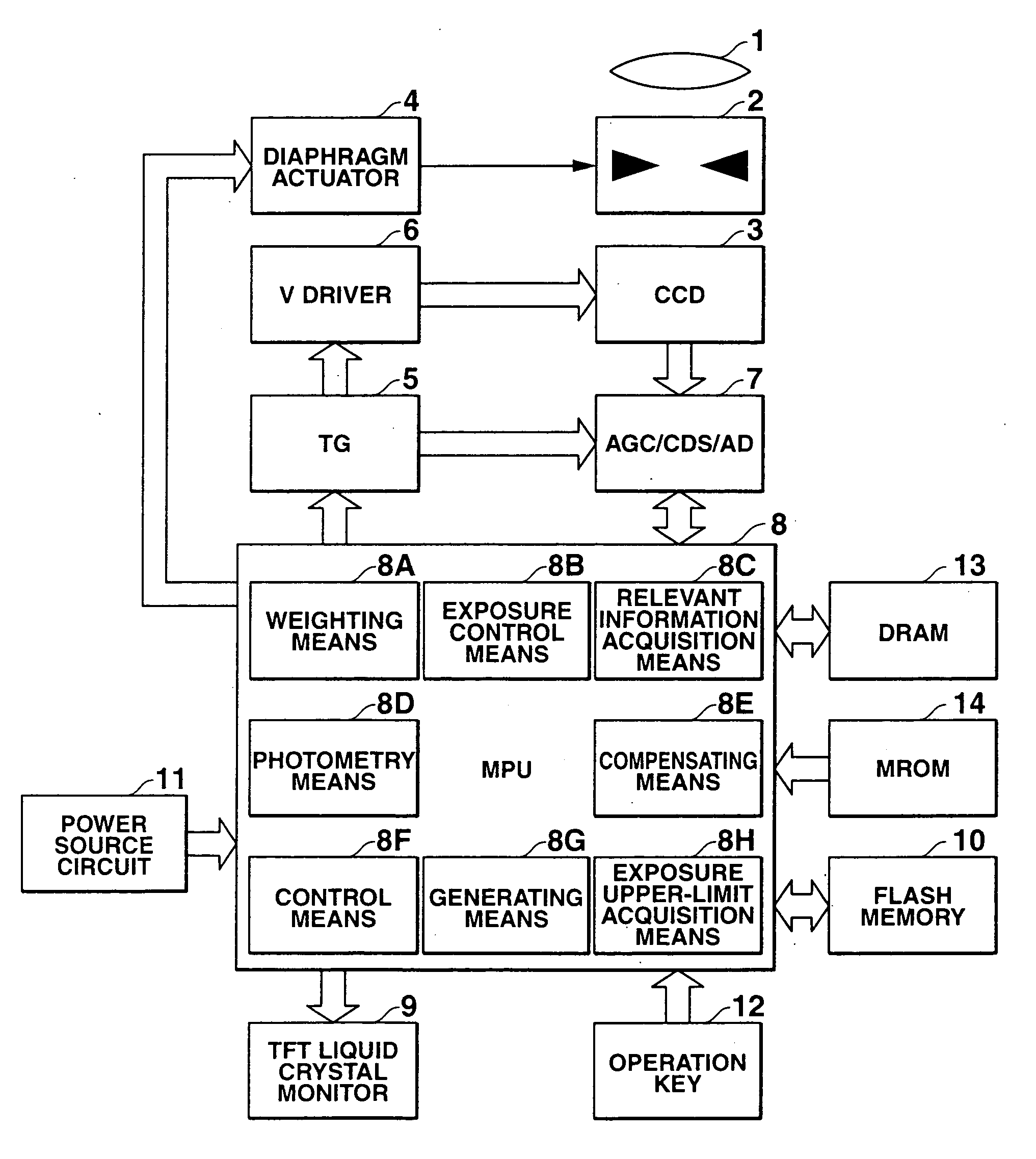

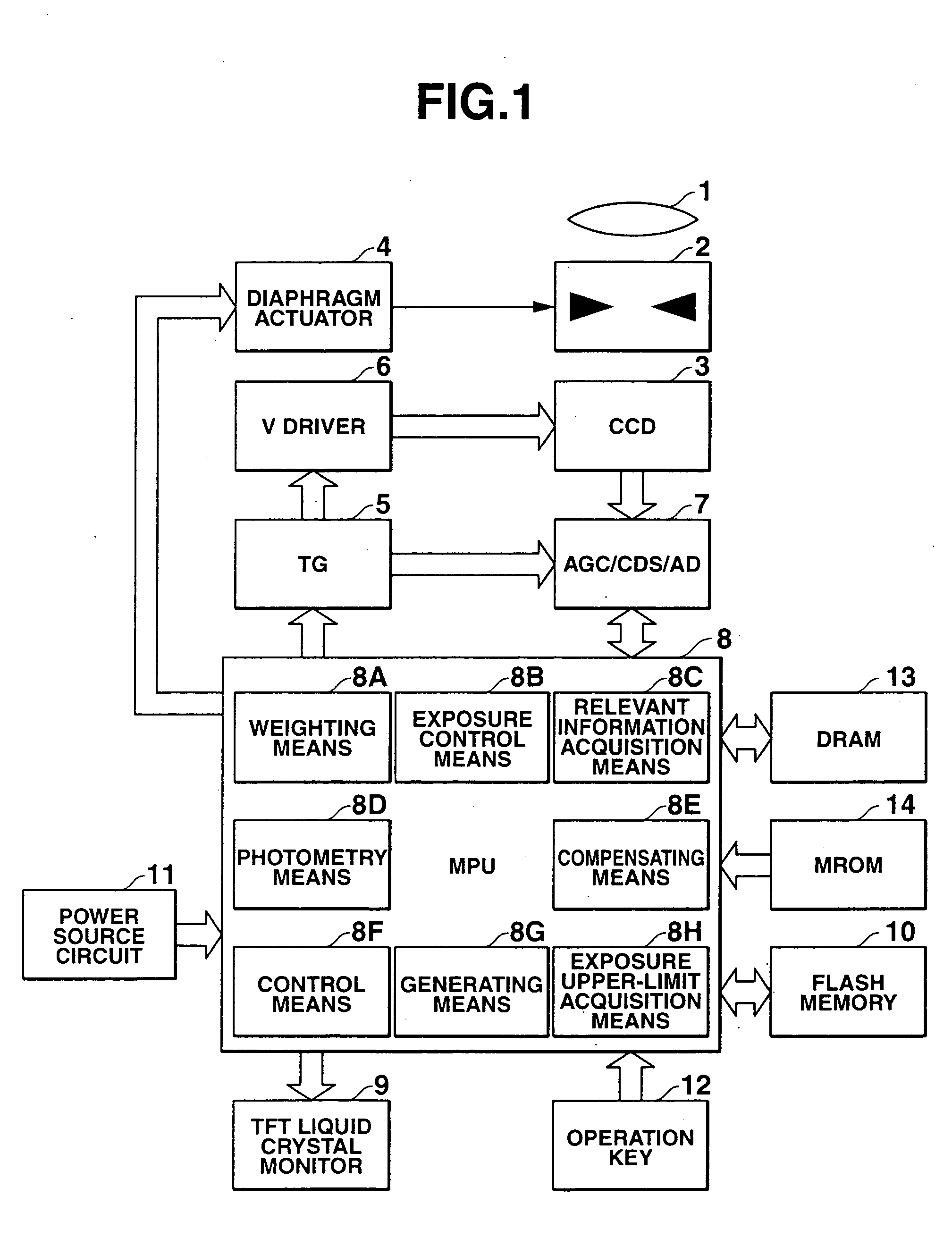

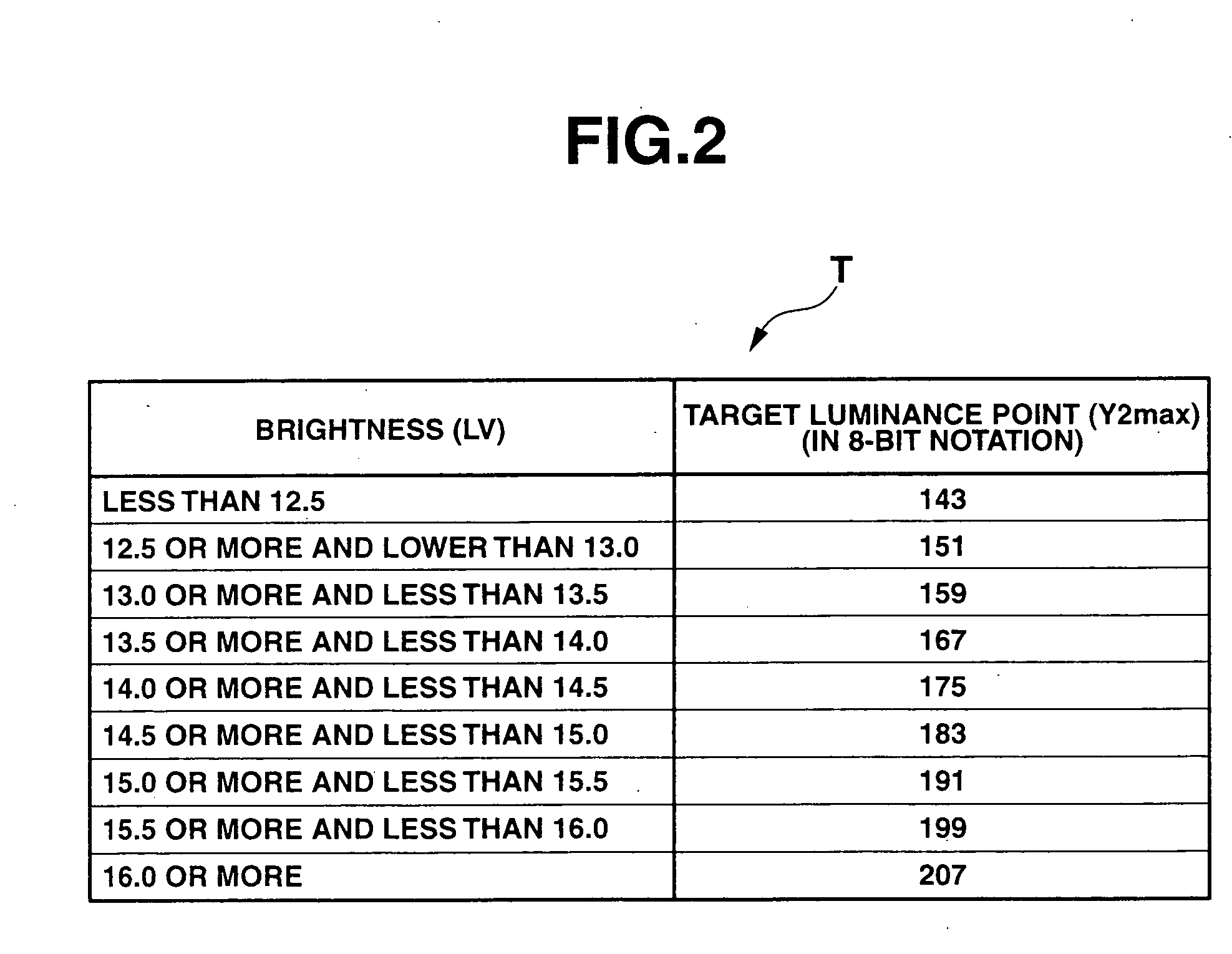

Image capturing device

ActiveUS20090073287A1Wide dynamic rangeGood brightness levelTelevision system detailsColor signal processing circuitsImaging qualityComputer science

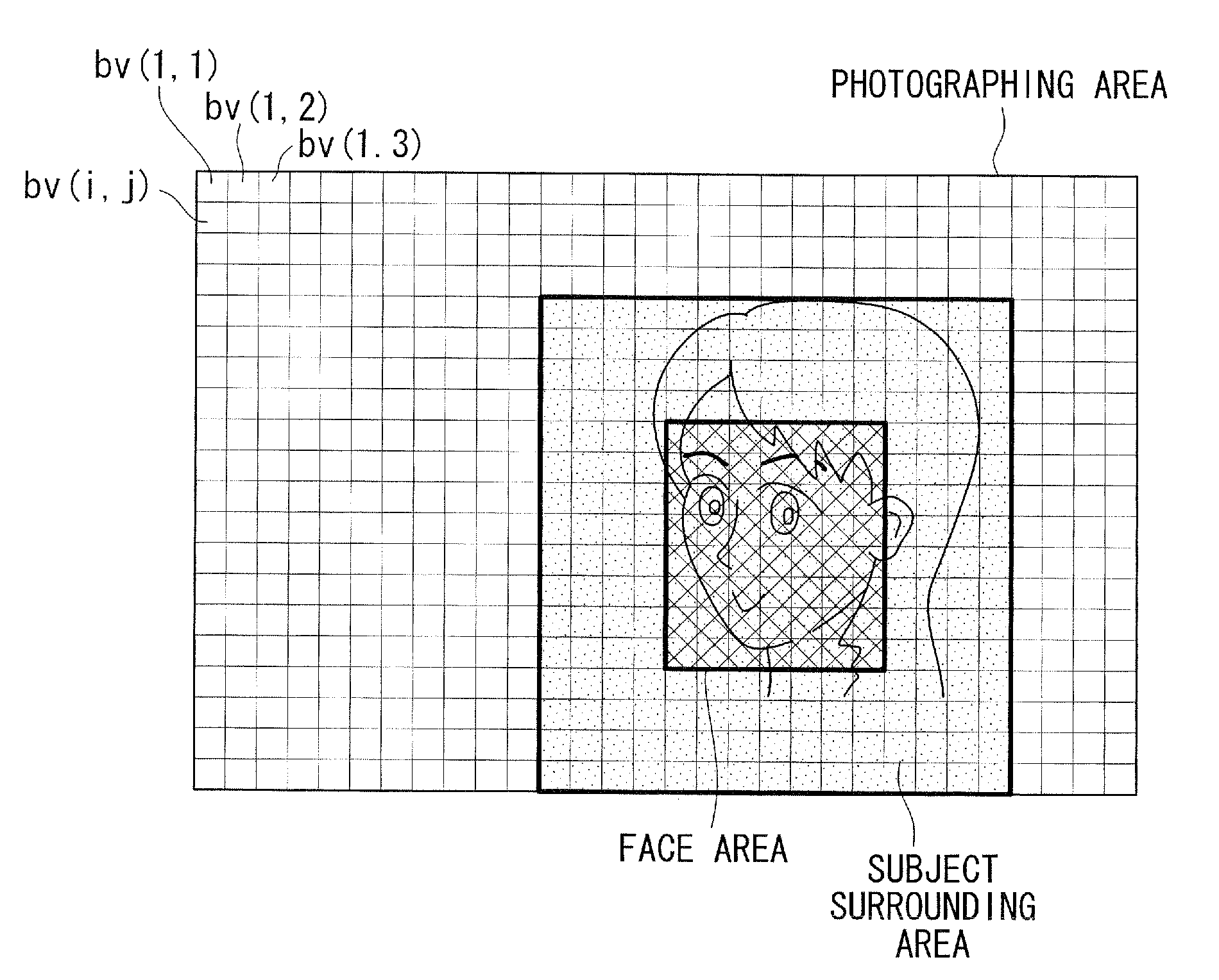

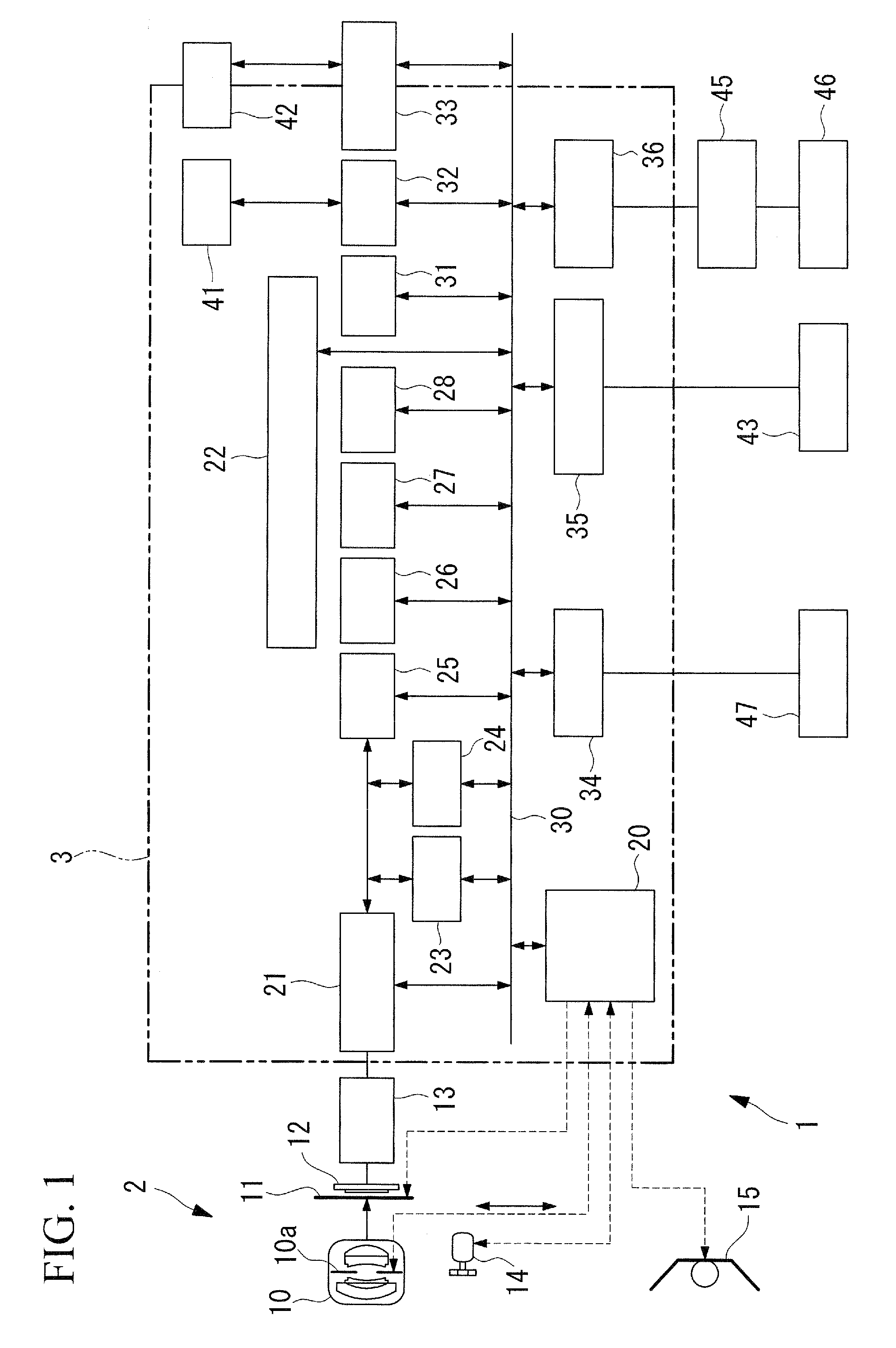

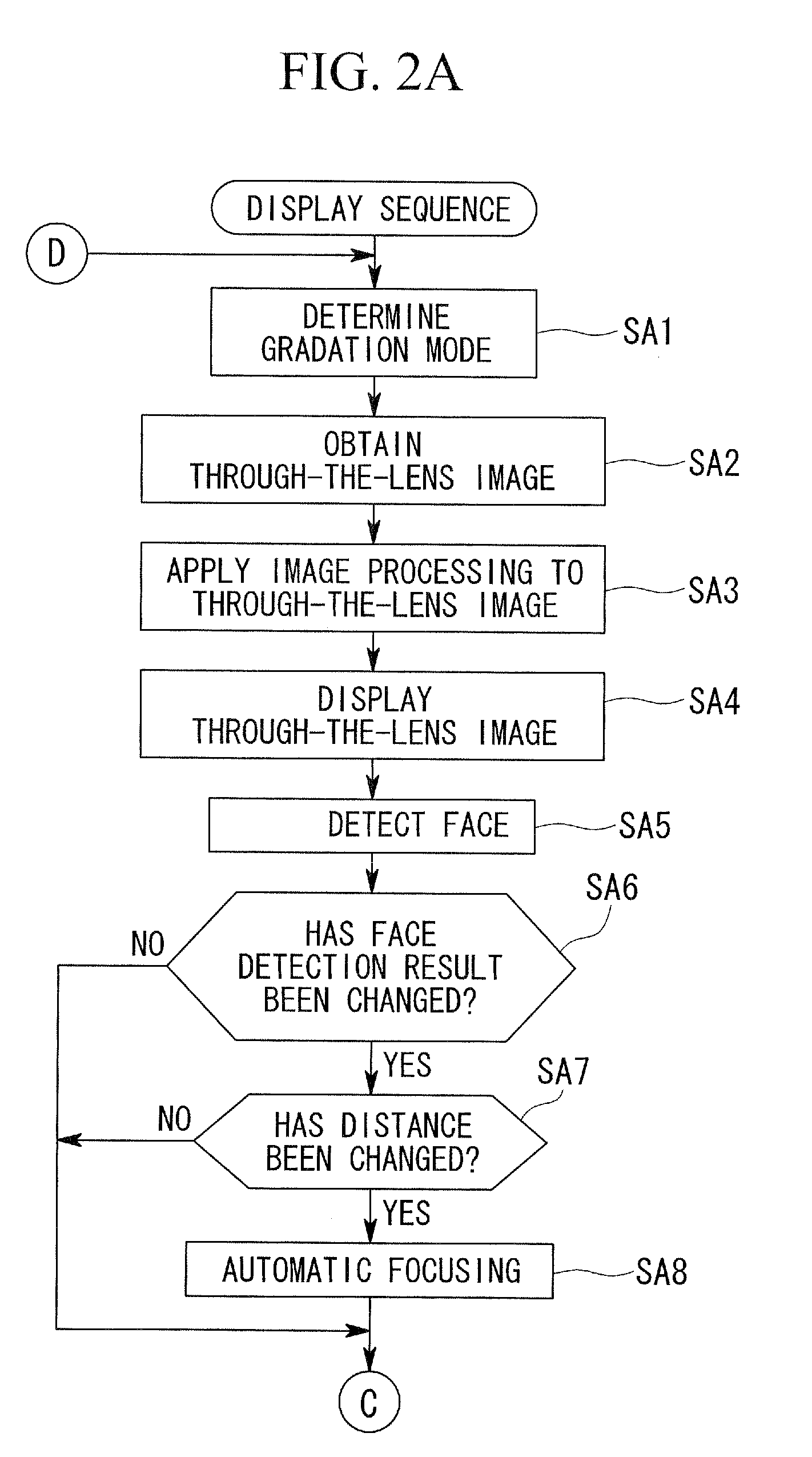

An image having the image quality desired by a photographer is provided by minimizing overexposure or underexposure, making the dynamic range wide, and specifying an optimum brightness level for a main subject. An image capturing device includes a subject detecting unit which detects a main subject in an image obtained before actual photographing; a subject luminance information acquiring unit which obtains luminance information; a luminance distribution calculating unit which calculates a luminance distribution of each of multiple areas; a target luminance calculating unit which determines a target luminance; a target luminance correcting unit which corrects the target luminance; and an exposure condition determining unit which determines an exposure condition for the actual photographing, in which the target luminance correcting unit includes a criterial range determining unit which determines the criterial range; and a correction amount determining unit which determines a correction amount by using the difference between the target luminance and the luminance of the main subject.

Owner:OLYMPUS CORP

Image processing system

InactiveUS20100134688A1Reduce inaccuracyReduce needImage enhancementImage analysisGraphicsImaging processing

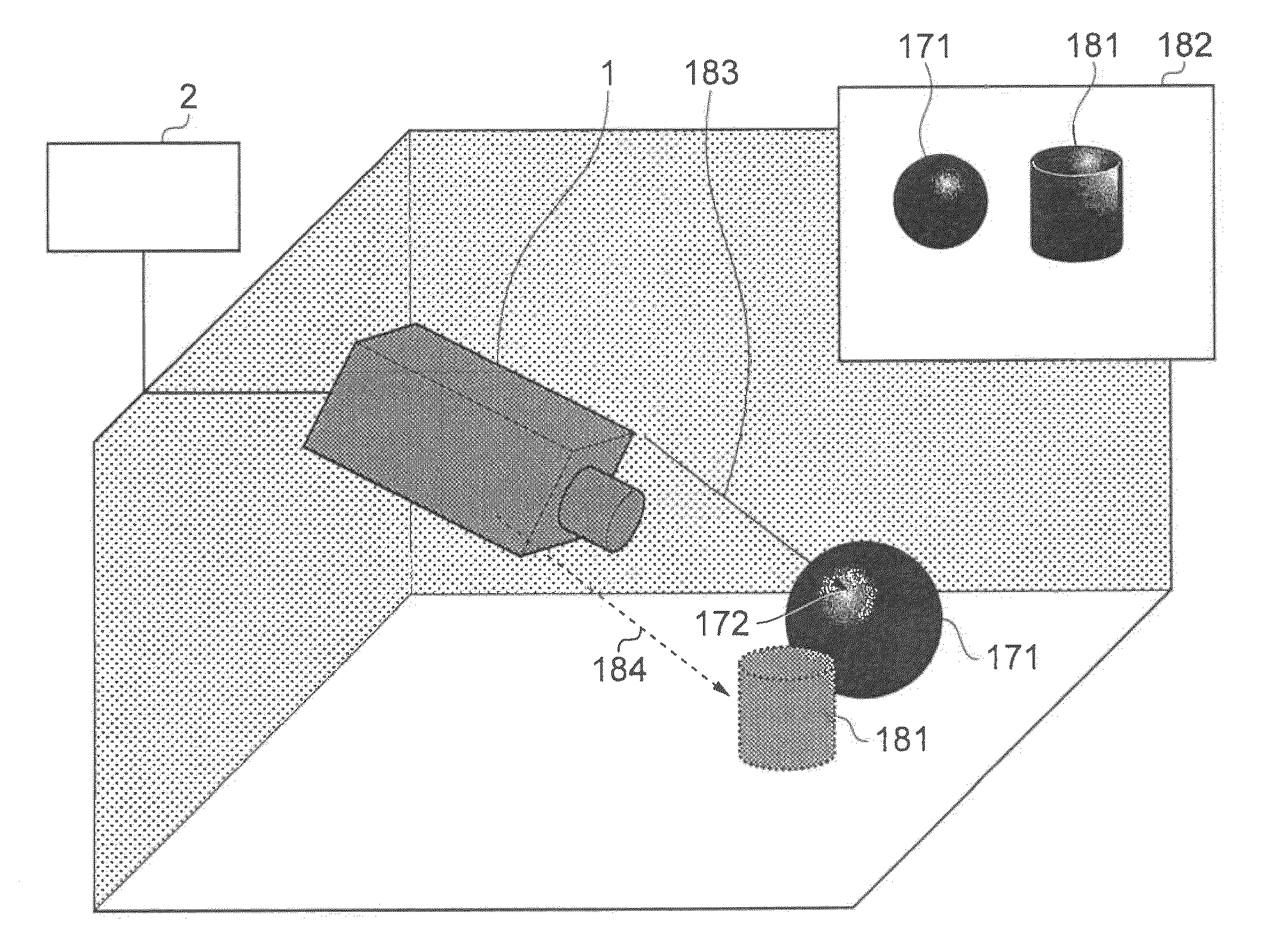

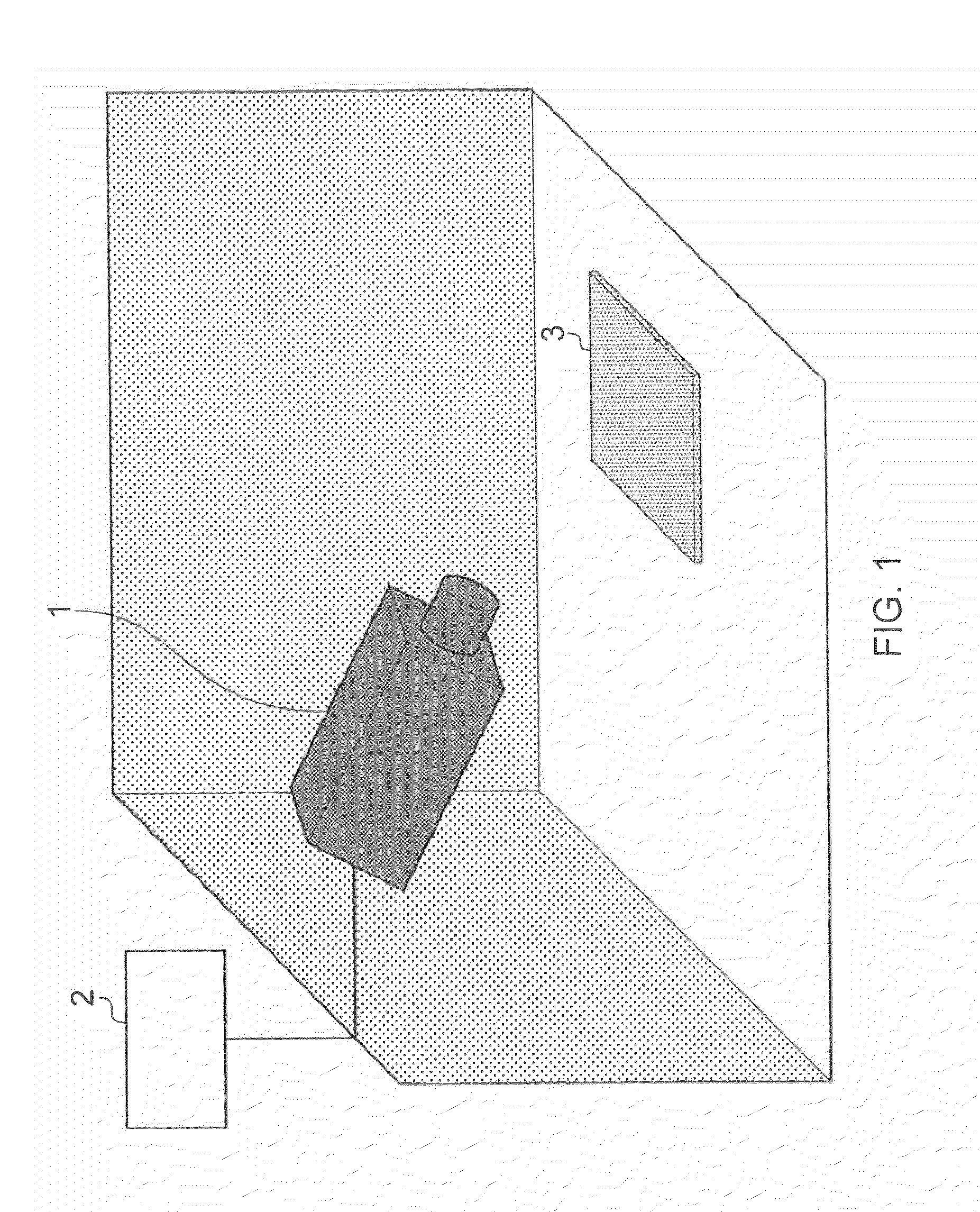

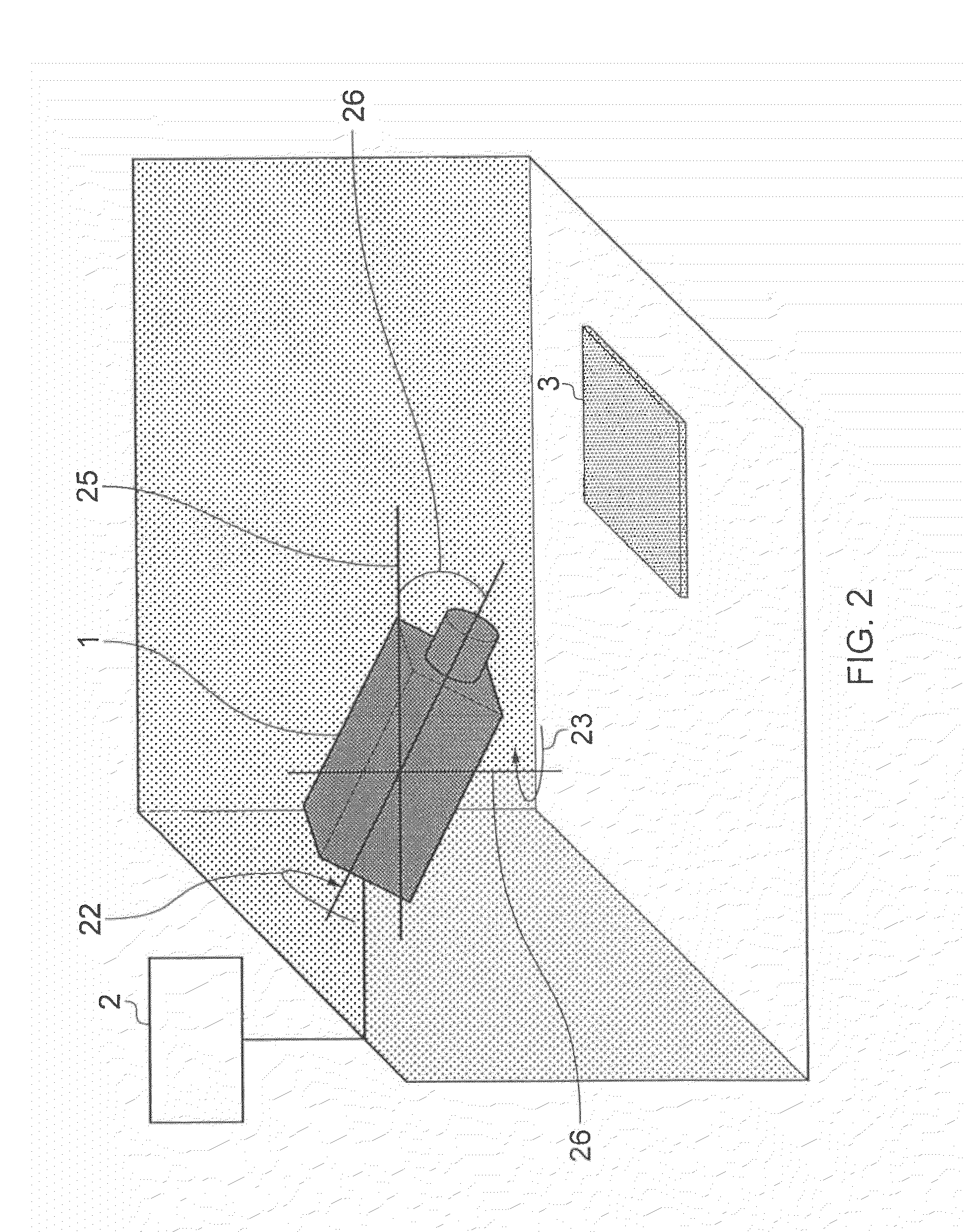

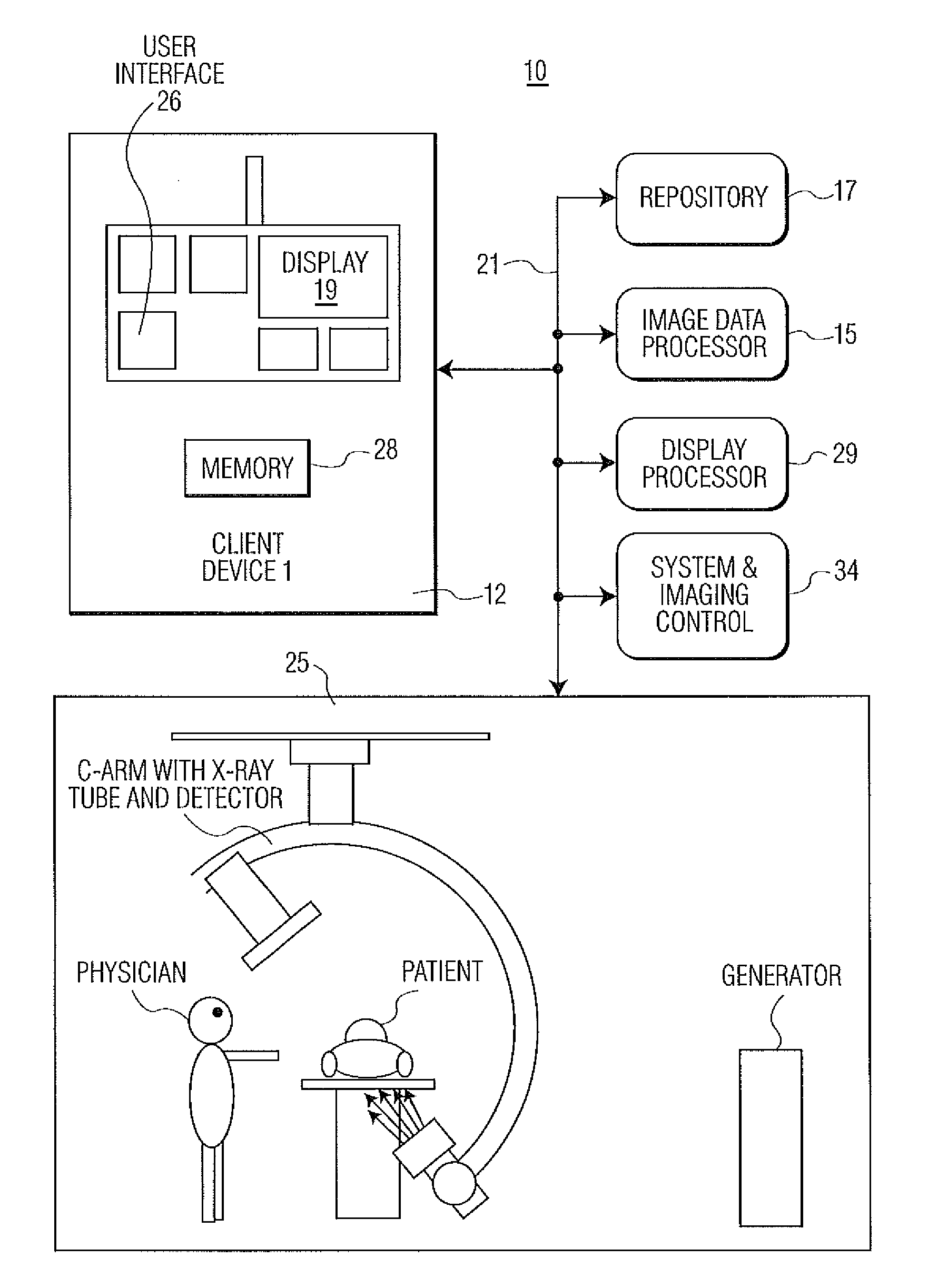

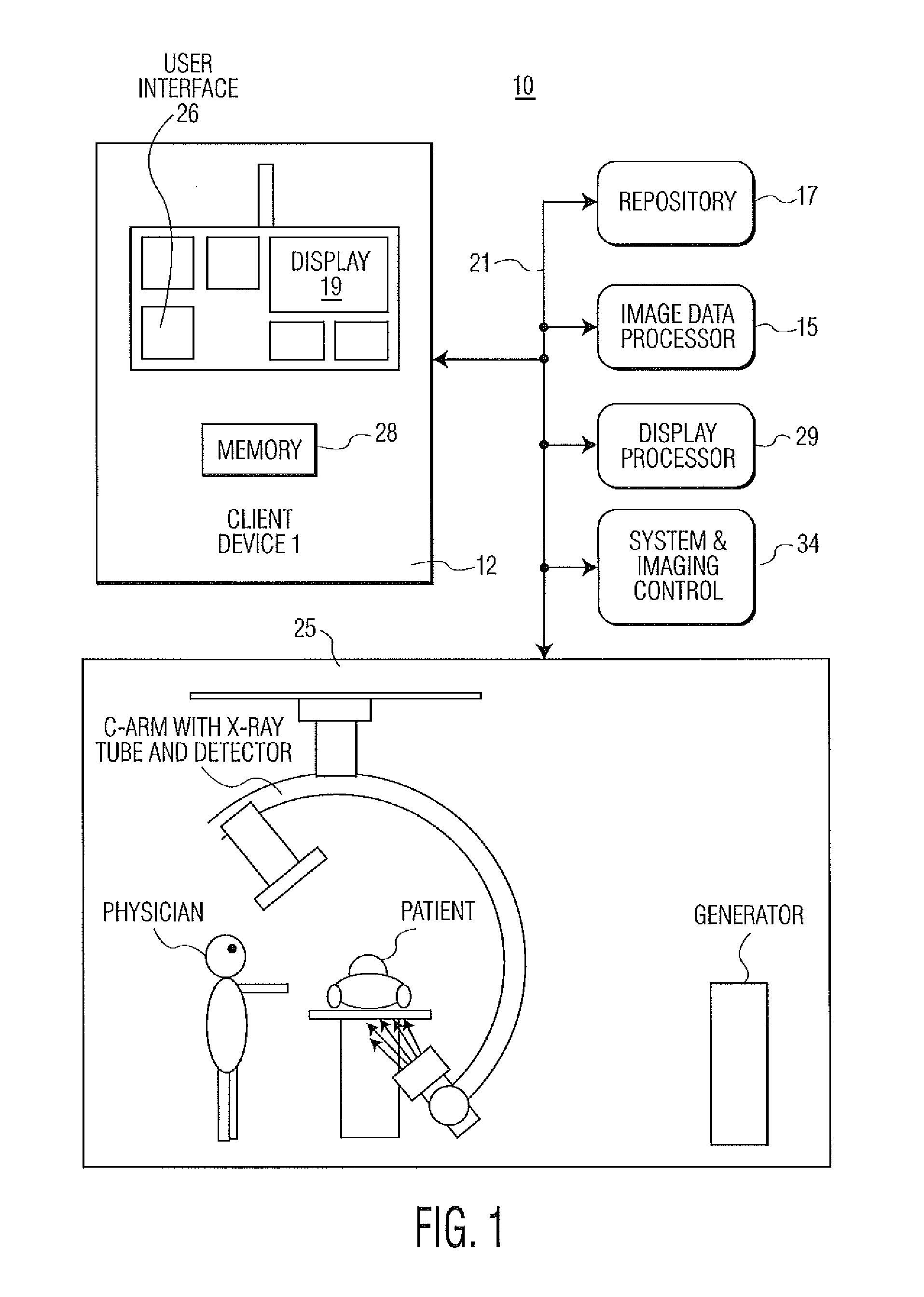

A computer graphics generation system combines video images of a scene captured by a camera with one or more rendered computer generated objects. The system comprises a camera which is arranged to generate an image signal representative of a scene including a reference object of a predetermined shape, and an image processor. The image processor is arranged in operation to identify the reference object from the image signal, to detect a luminance distribution across a surface of the reference object by estimating a luminance magnitude at a plurality of surface points on the surface of the reference object, and to estimate a direction of light incident on the reference object derived from the detected luminance distribution across the surface of the reference object by calculating the average of a plurality of luminance vectors, each luminance vector corresponding to one of the surface points and comprising a luminance magnitude of the corresponding surface point and a luminance direction corresponding to a direction perpendicular to the surface at the corresponding surface point, wherein the luminance distribution across the surface of the reference object is detected for luminance above a threshold clipping level. Accordingly a reduction in the “wobble” of the computer generated objects in the scene can be achieved and a more stable image provided from the image light direction estimation.

Owner:SONY CORP

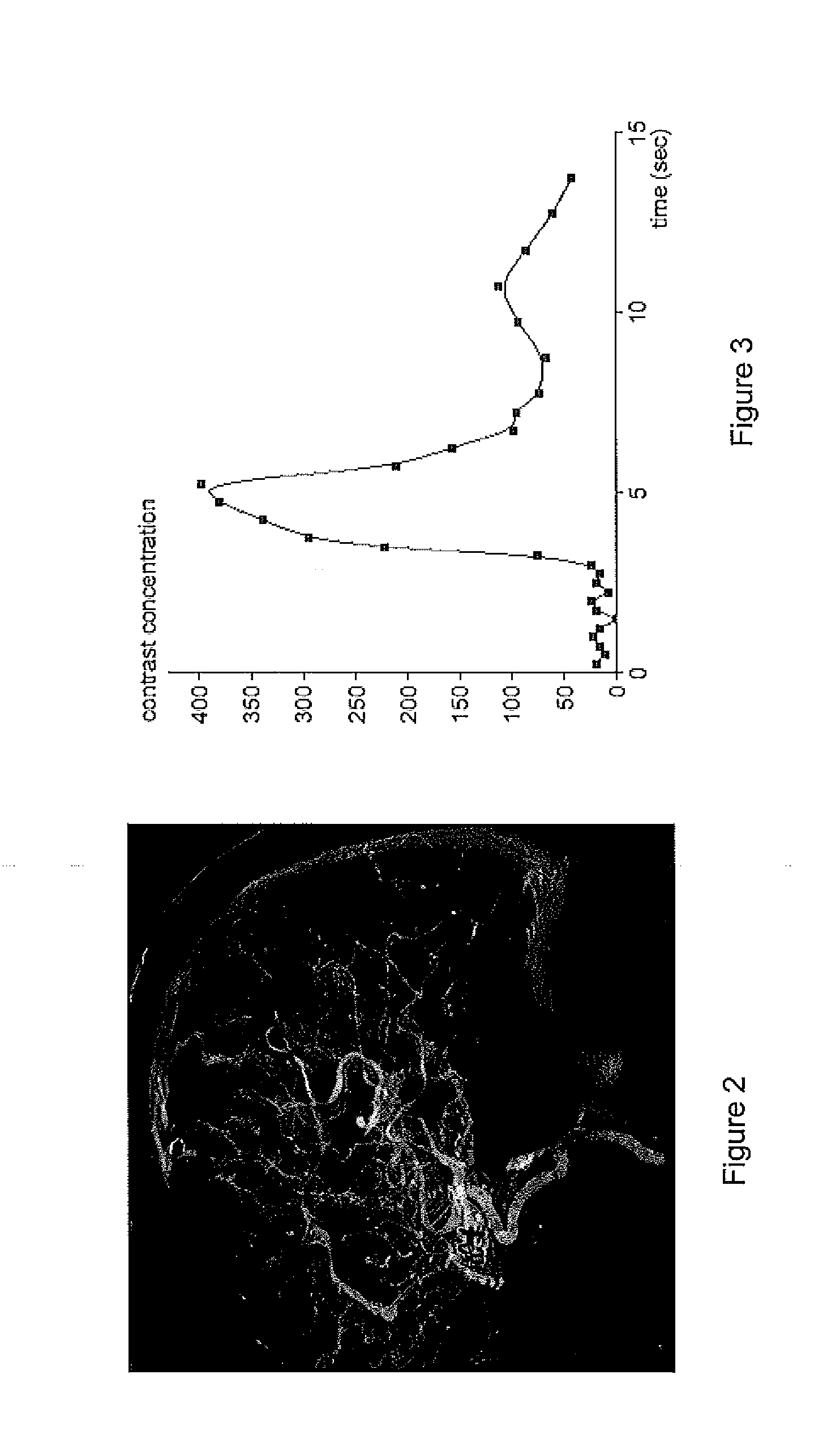

System for Providing Digital Subtraction Angiography (DSA) Medical Images

A method generates a two dimensional (2D) medical image through a three dimensional (3D) imaged volume of patient anatomy at a desired position, by storing 3D image data representing a 3D imaging volume including vessels in the presence of a contrast agent. The 3D image data comprises, data identifying multiple voxels representing multiple individual volume image element luminance values and luminance distribution data for individual voxels of a vessel in the 3D image data. For multiple individual voxels of a 2D image, the method determines composite luminance distribution data of an individual voxel in the 2D image by combining luminance distribution data of the 3D image data of multiple identified voxels substantially lying on a projection line from a source point to the individual voxel and generating data representing the 2D image using the determined composite luminance distribution data of the multiple individual voxels.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

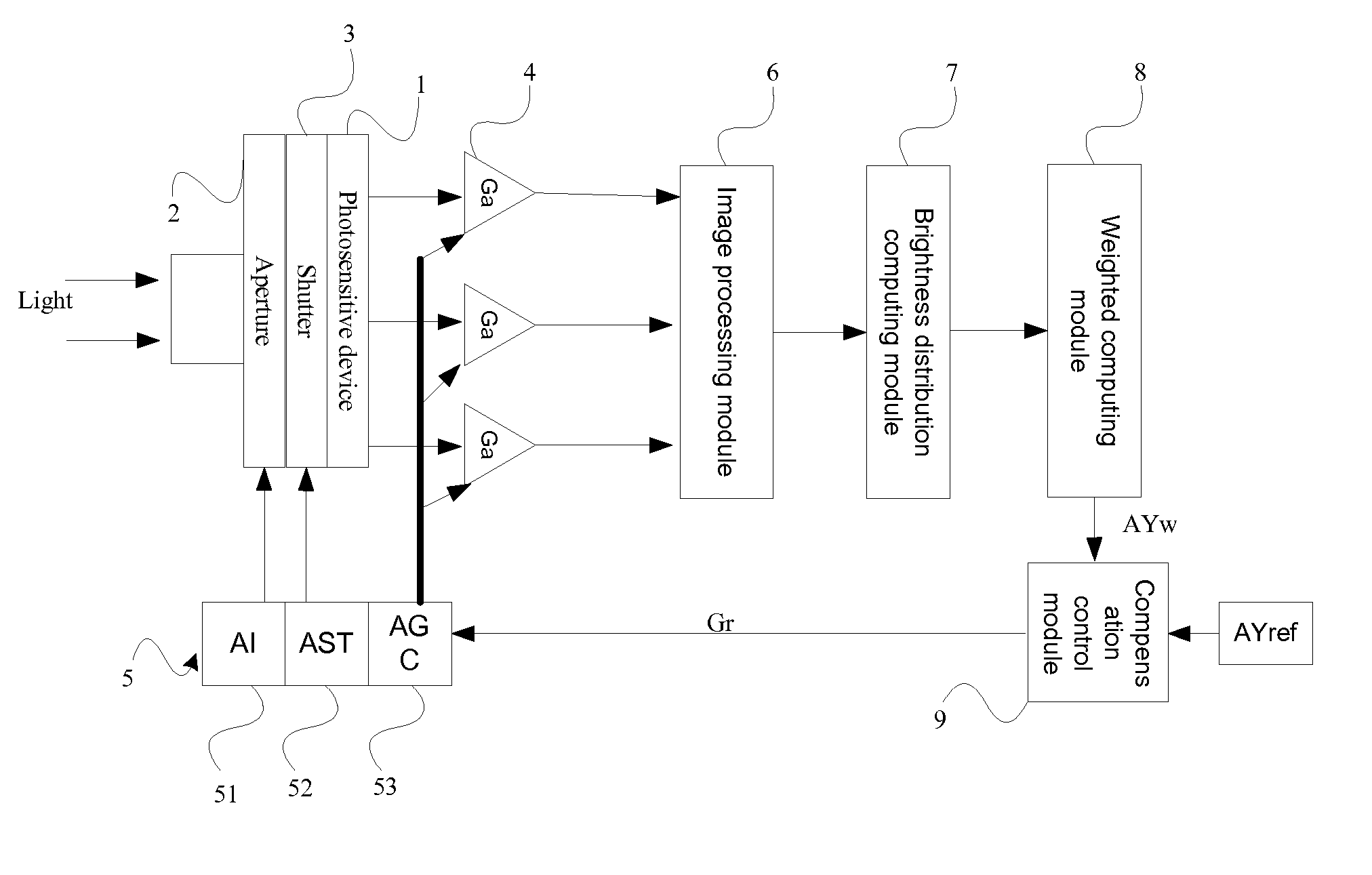

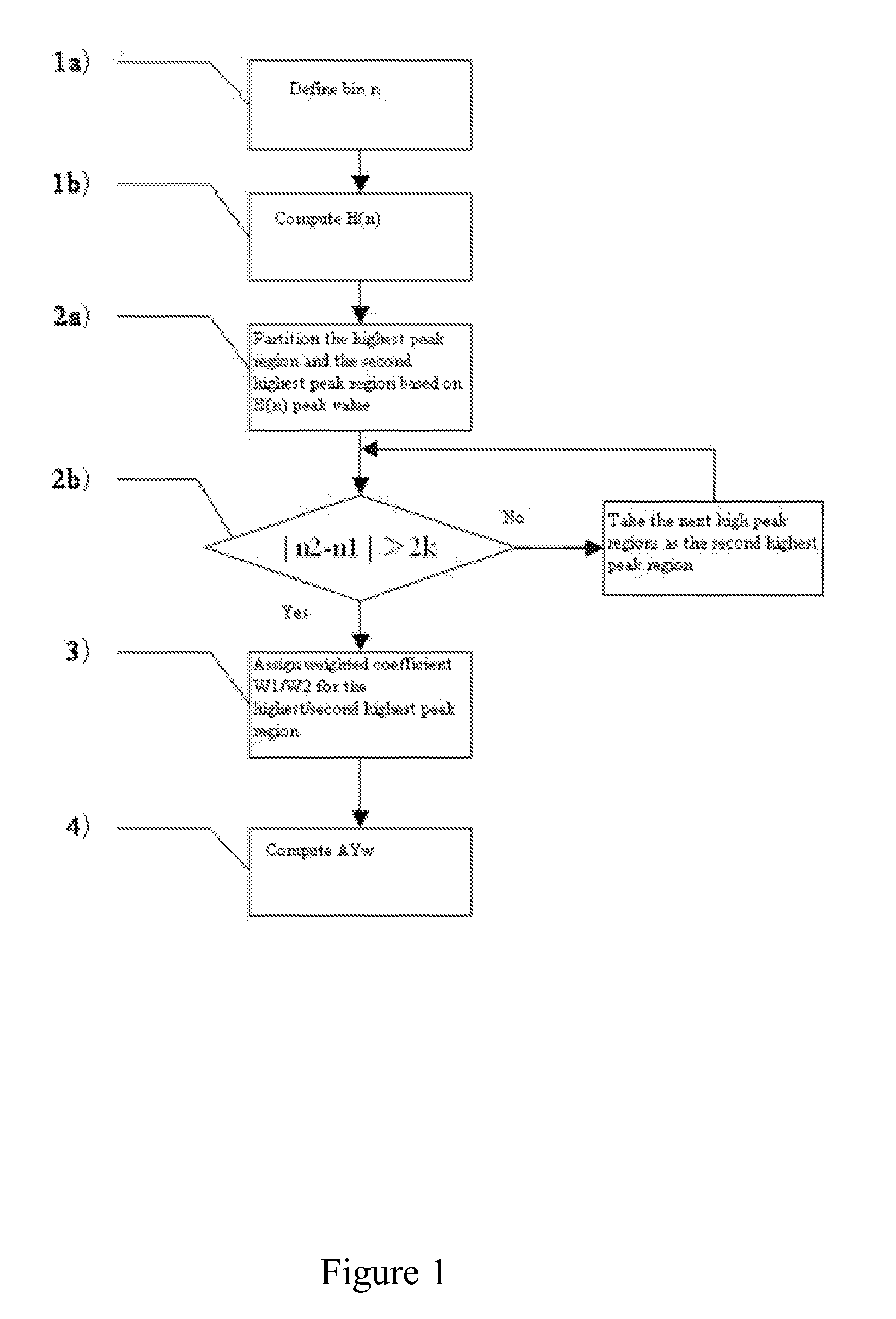

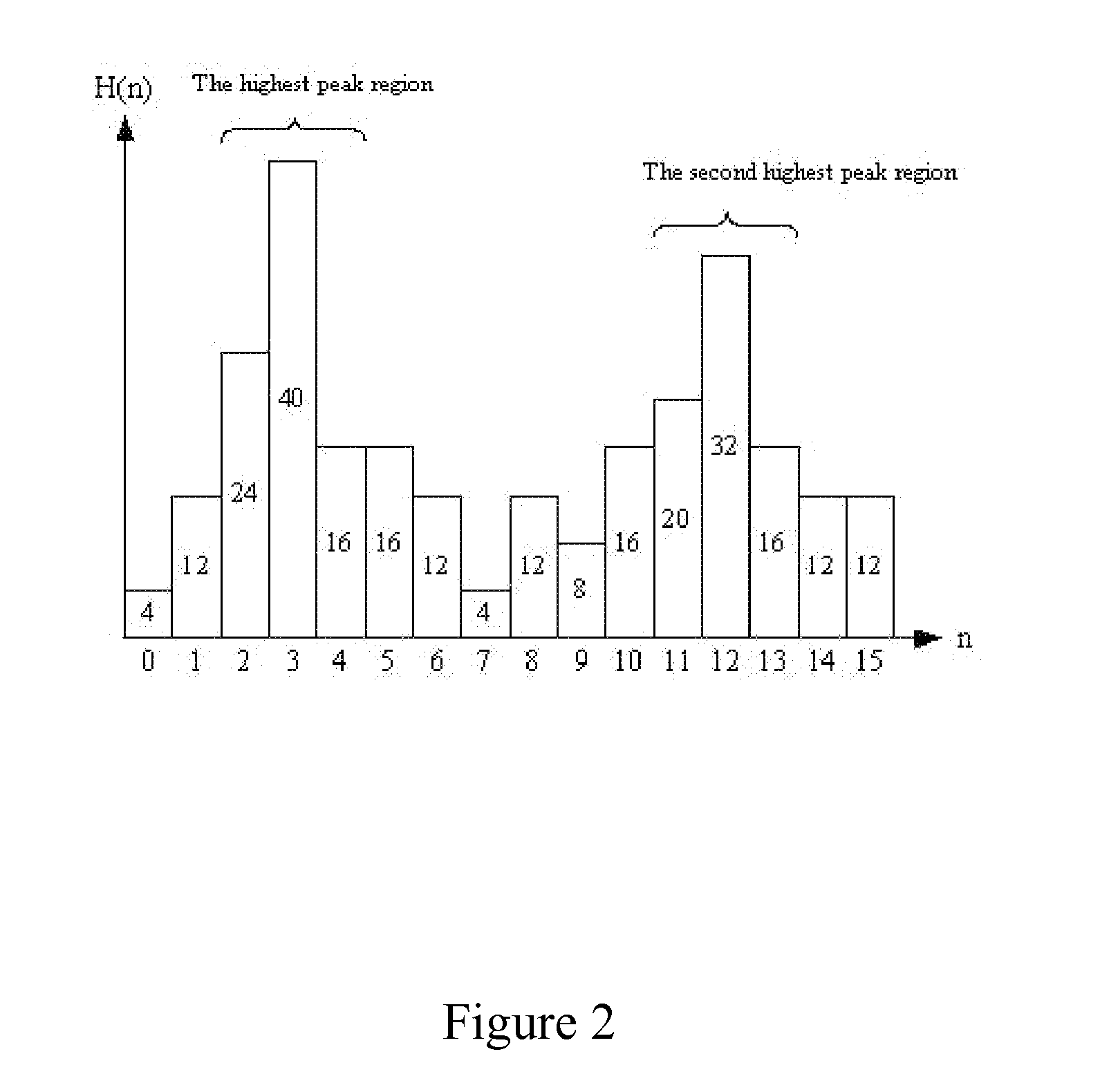

Method For Acquiring And Controlling Automatic Exposure Control Parameters And Imaging Device

ActiveUS20070263097A1Universal adaptabilityTelevision system detailsColor signal processing circuitsWeight coefficientExposure control

The present invention discloses a method for acquiring automatic exposure control parameters and a method for controlling automatic exposure control parameters and an imaging device. The core idea is to take the brightness weighted average value obtained according to brightness distribution weighted statistics of the image as the exposure control parameter. Then through adjusting the weighted coefficient of pixels in different brightness regions, control the influence of the pixel concentrated brightness regions on the brightness average value. Because the brightness distribution is the basis for determining weighted statistics, the control method of the present invention is not influenced by the scene assumption. Rather it can be universally adapted to a variety of different scenes, and the exposure control effect is not influenced by the position of scenes in the actual bright region / dark region and block distribution.

Owner:HUAWEI TECH CO LTD

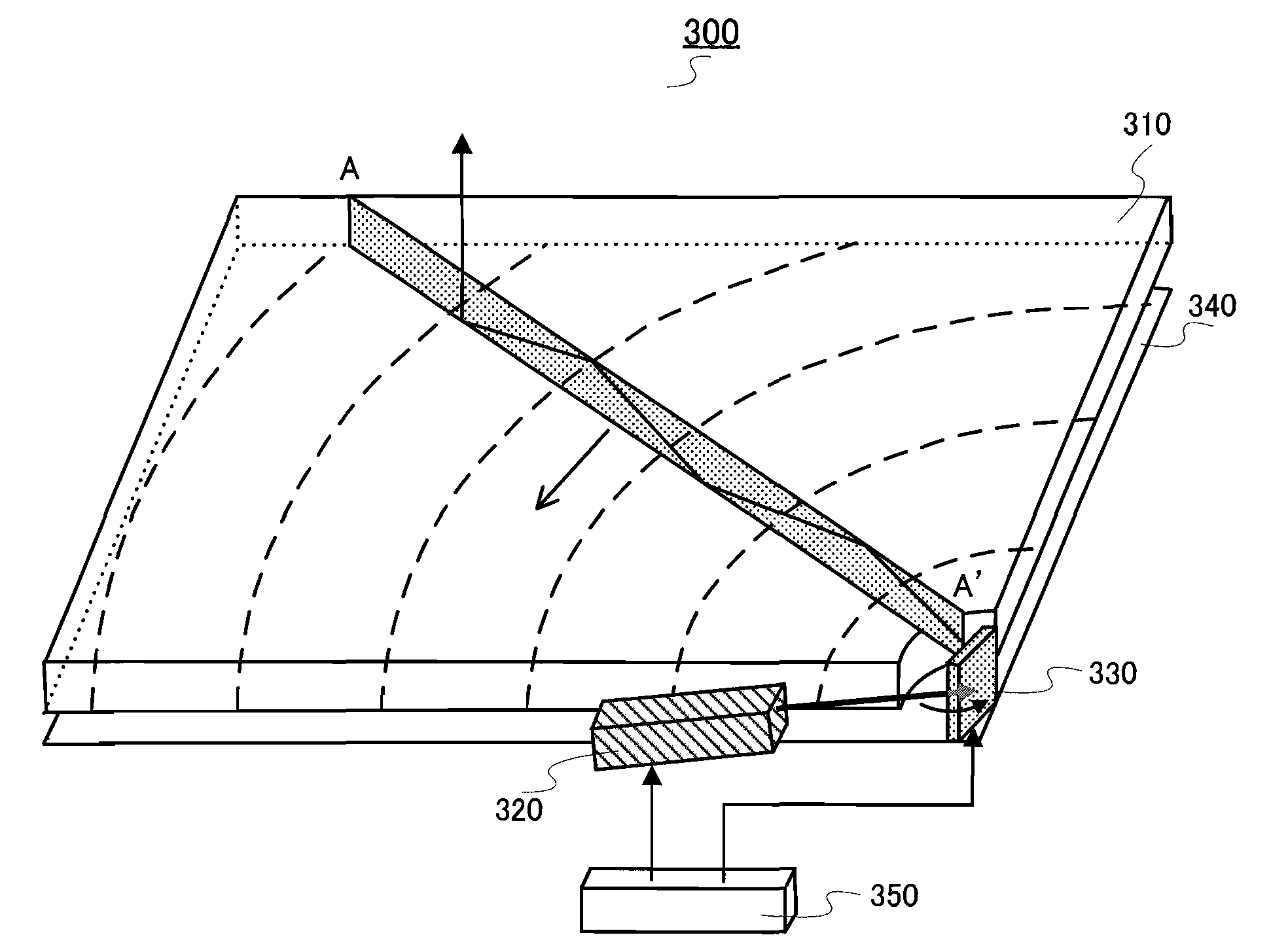

Planar light source device and liquid crystal display device

InactiveUS20090207342A1Simple configurationSemiconductor laser optical deviceCharacter and pattern recognitionLiquid-crystal displayLight guide

Provided is a planar light source device (300) having a planar light source with uniform luminance distribution by using a laser light source for outputting a beam-like luminous flux. The planar light source device (300) applies a laser beam from the side surface of a light guide plate (310) through a scanning mirror (330) and periodically scans the entire light guide plate. At that time, a light output (P(t)) of the laser light source (320) is modulated in synchronization with the scanning cycle so that the output is proportional to the temporal differentiation dS / dt of a scanning area (S(t)) from a search start within a scanning period. Thus, changes of the scanning speed and scanning length with time are eliminated and planar lighting with uniform luminance can be performed.

Owner:GK BRIDGE 1

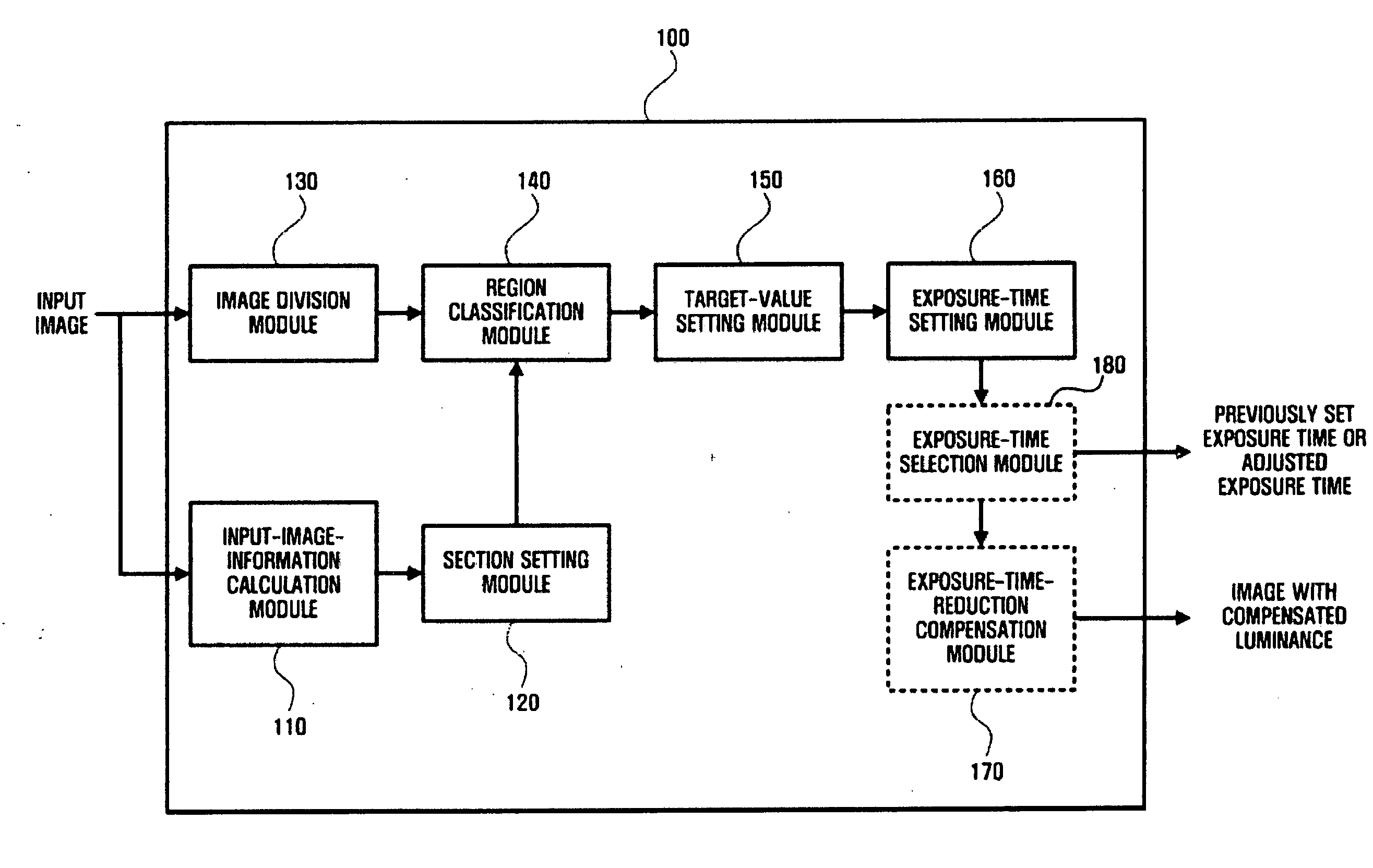

Method, medium, and apparatus for setting exposure time

ActiveUS20090073306A1Avoid it happening againReduce exposure timeTelevision system detailsTelevision system scanning detailsImage segmentationComputer vision

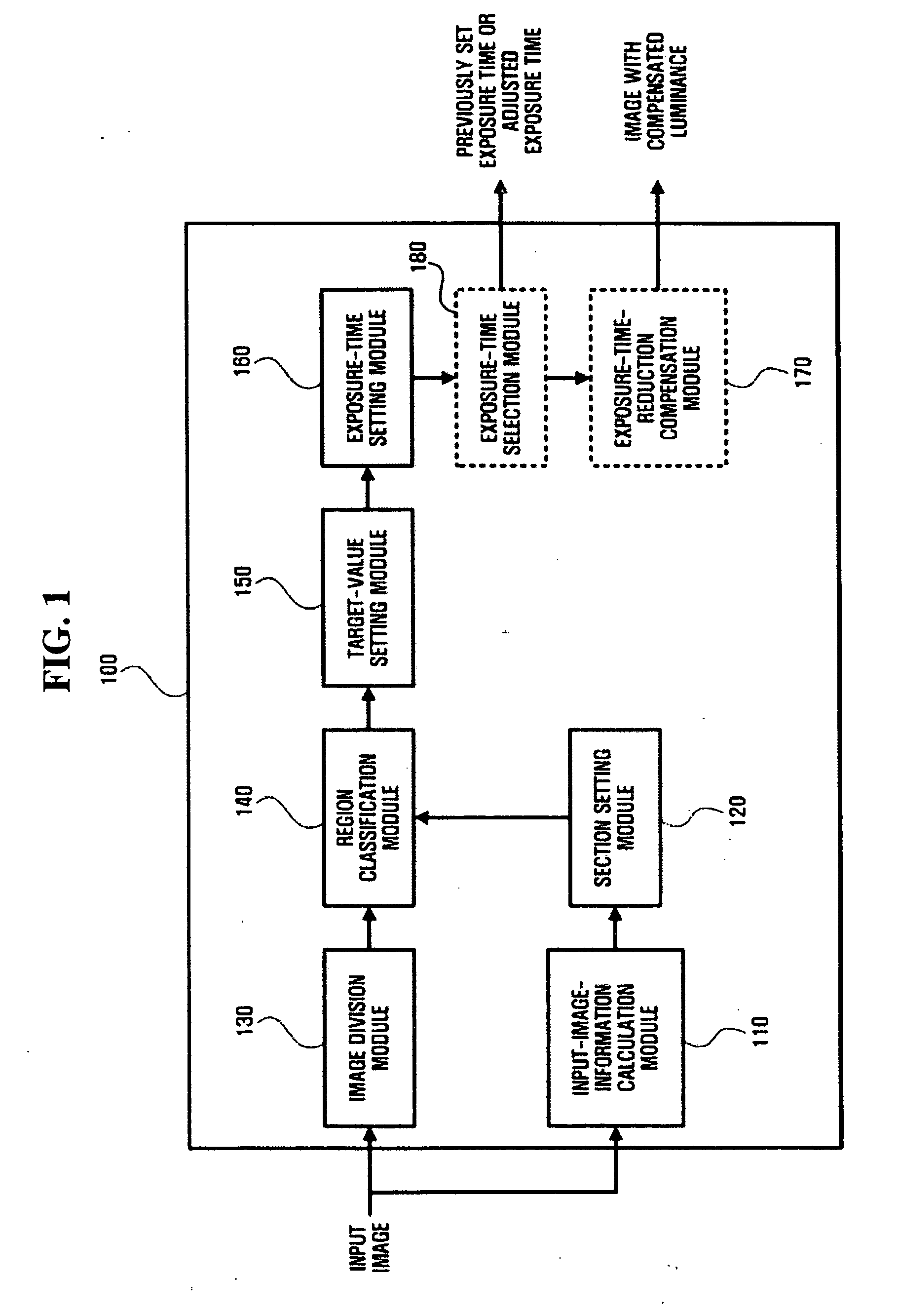

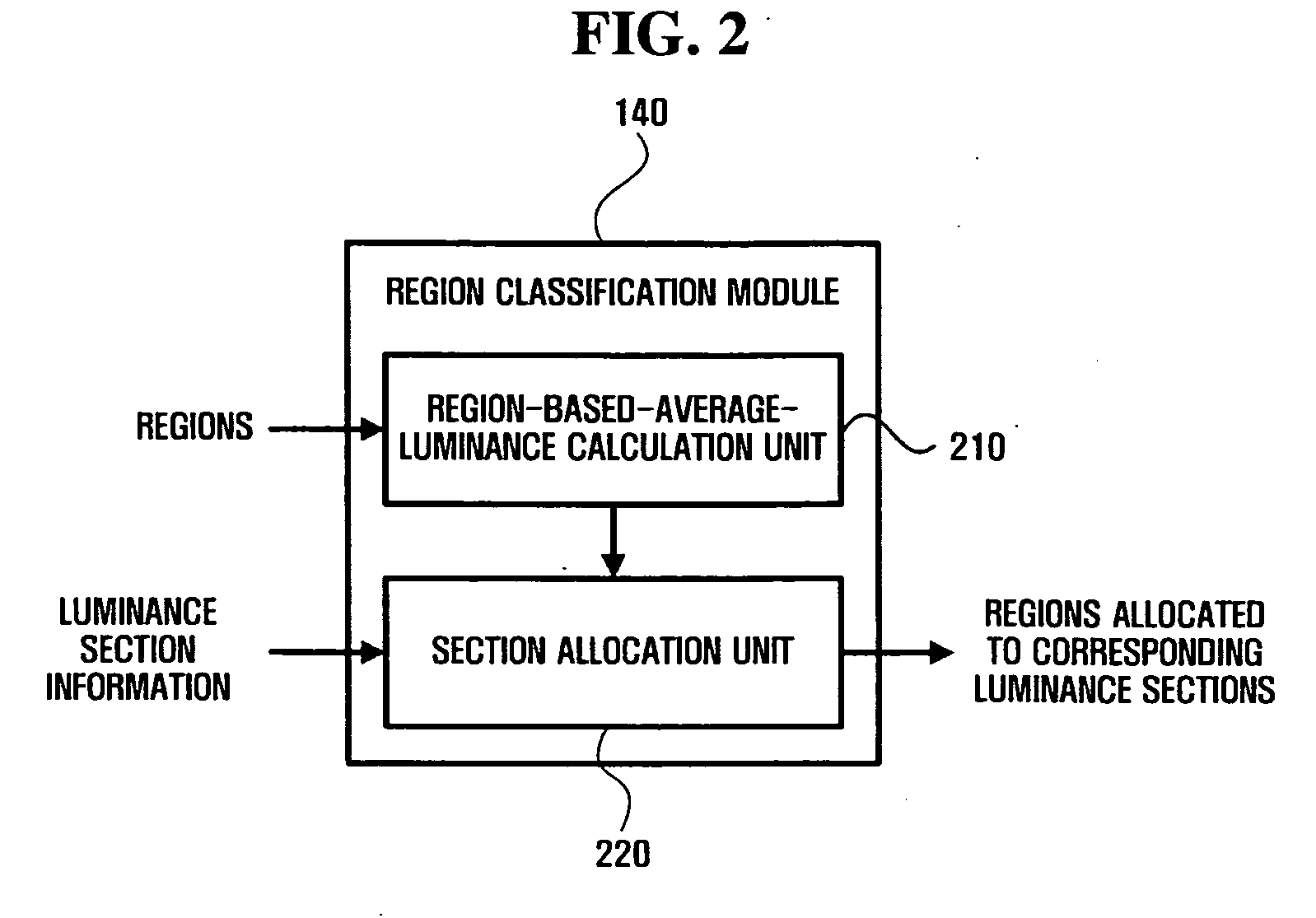

A method, medium, and apparatus for setting an exposure time is provided. The apparatus includes a section setting module which sets one or more luminance sections based on a luminance distribution of an input image, an image division module which divides the input image into two or more regions, a region classification module which classifies the regions into the luminance sections, and an exposure-time setting module which sets an exposure time for each of the regions with reference to a target luminance value, the target luminance value being set based on the results of the classification performed by the region classification module.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Method for manufacturing color temperature tunable LED lamp and LED lamp

InactiveCN101592291AHigh color rendering indexImprove luminous efficiencyLine/current collector detailsPoint-like light sourceMaterial typeColor rendering index

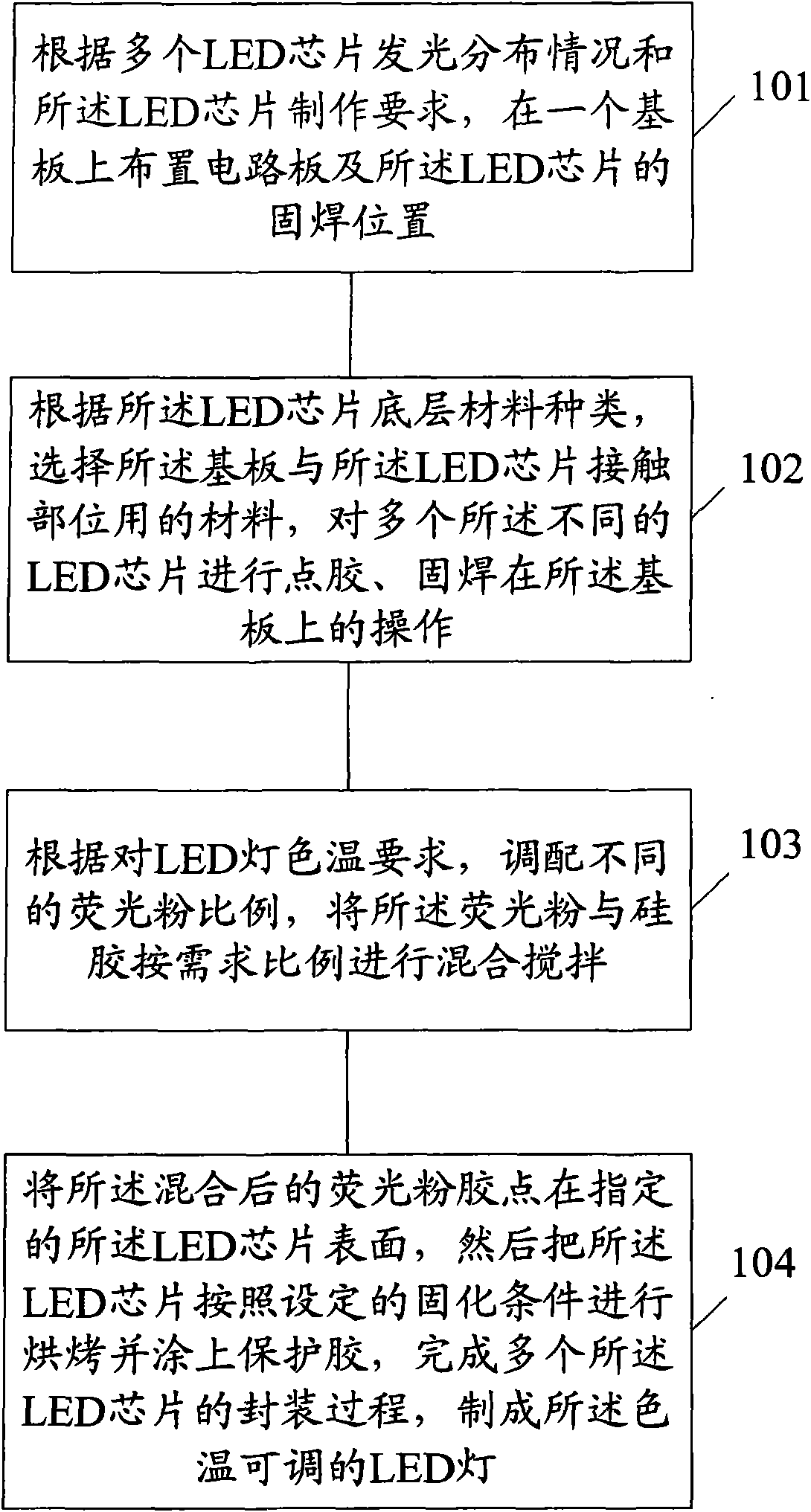

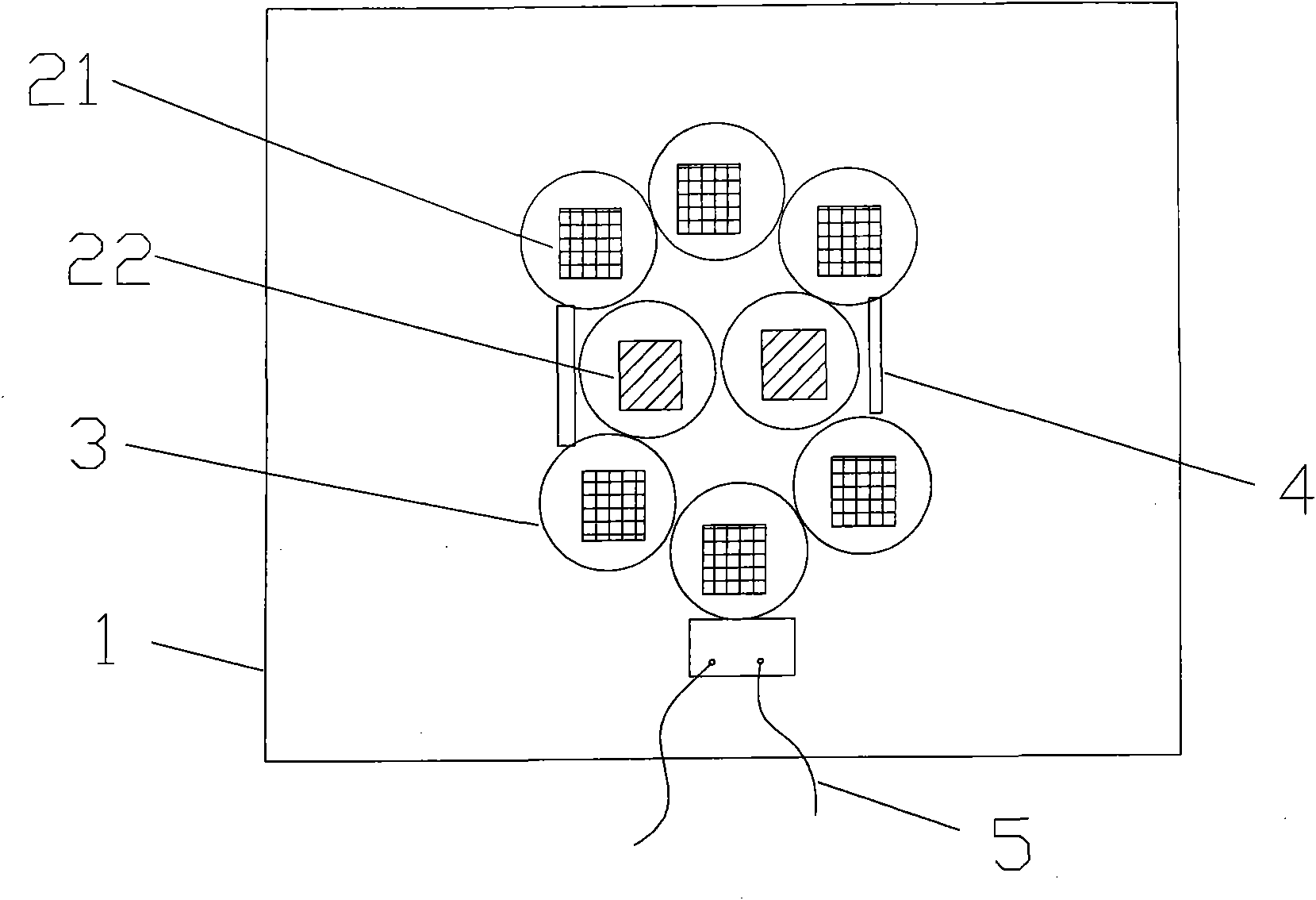

The invention discloses a method for manufacturing a color temperature tunable LED lamp and the LED lamp. The method comprises the following steps: distributing a circuit board and fixed welding positions of LED chips on a substrate according to the luminance distribution conditions and manufacturing requirements of a plurality of LED chips; selecting a material for contact positions of the substrate and the LED chips according to material types of base layers of the LED chips, and carrying out adhesive dispensing and fixed welding on the substrate; blending different proportions of fluorescent powder according to the color temperature requirement of the LED lamp, and mixing and stirring the fluorescent powder and silica gel according to the required proportion; dispensing the mixed fluorescent powder gel on the surfaces of the LED chips; and baking the LED chips, coating with protective adhesive, and completing the encapsulation process of the plurality of LED chips. The manufacturing method has advanced process and easily controlled flow. The color temperature tunable LED lamp has good color rendering index and high luminous efficiency, and the color rendering index and the luminous efficiency cannot be reduced because of the change of the color temperature.

Owner:GUANGDONG SEEDCOM ELECTRICAL & LIGHTING +1

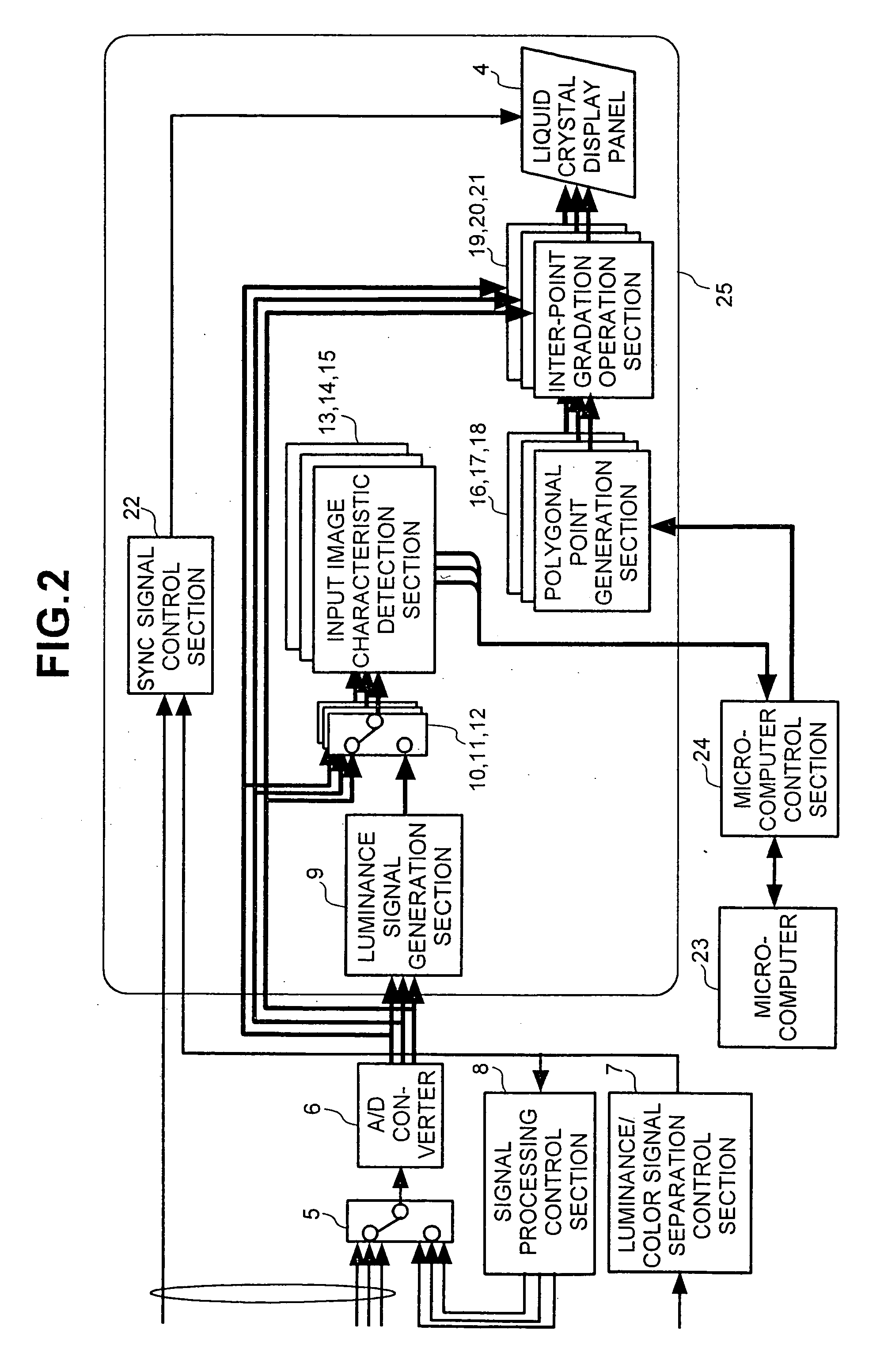

Video signal processing apparatus, TV receiver using the same, and video signal processing method

ActiveUS20050128358A1Improve picture qualityReduce noiseTelevision system detailsColor television detailsControl circuitComputer science

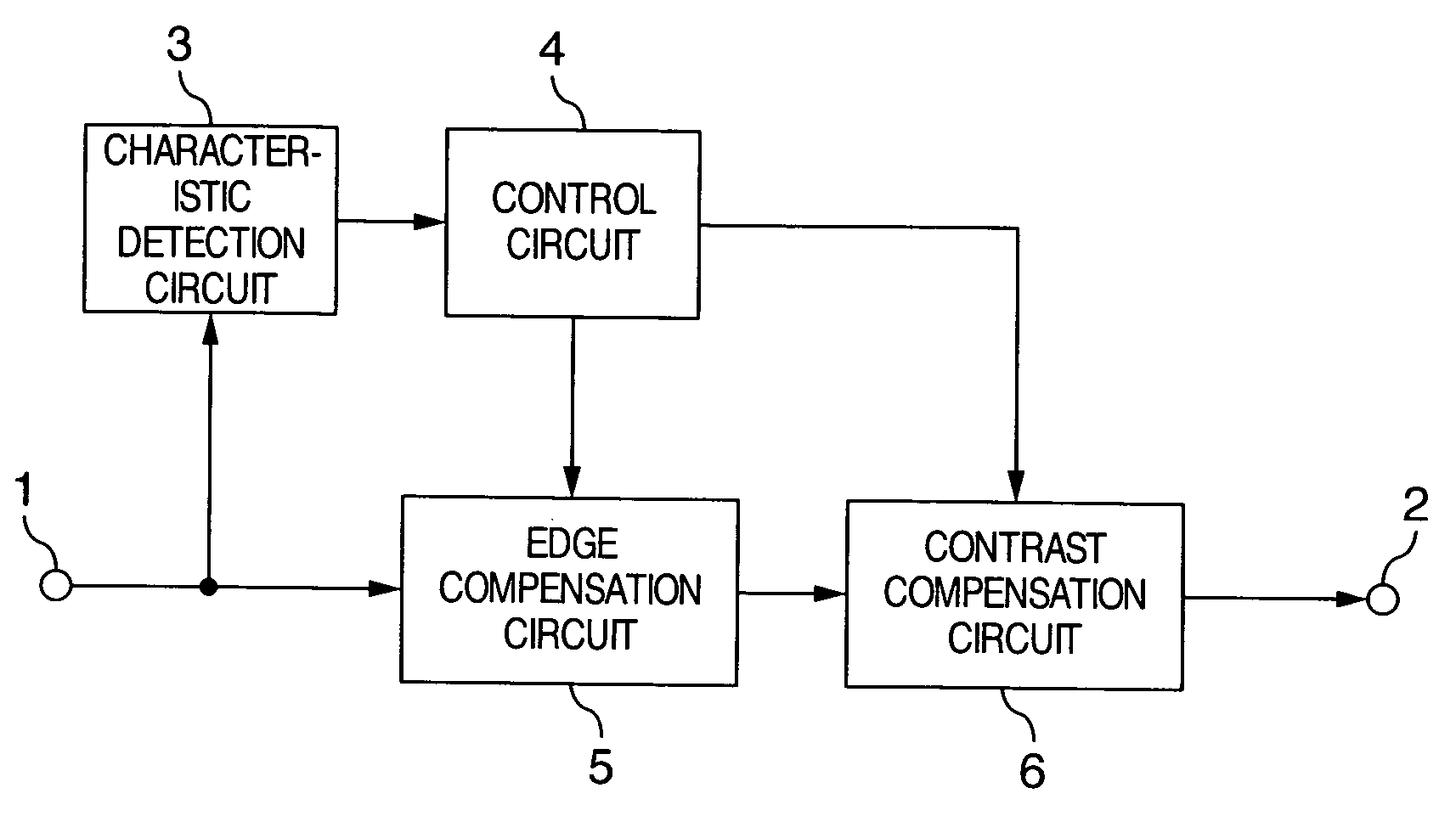

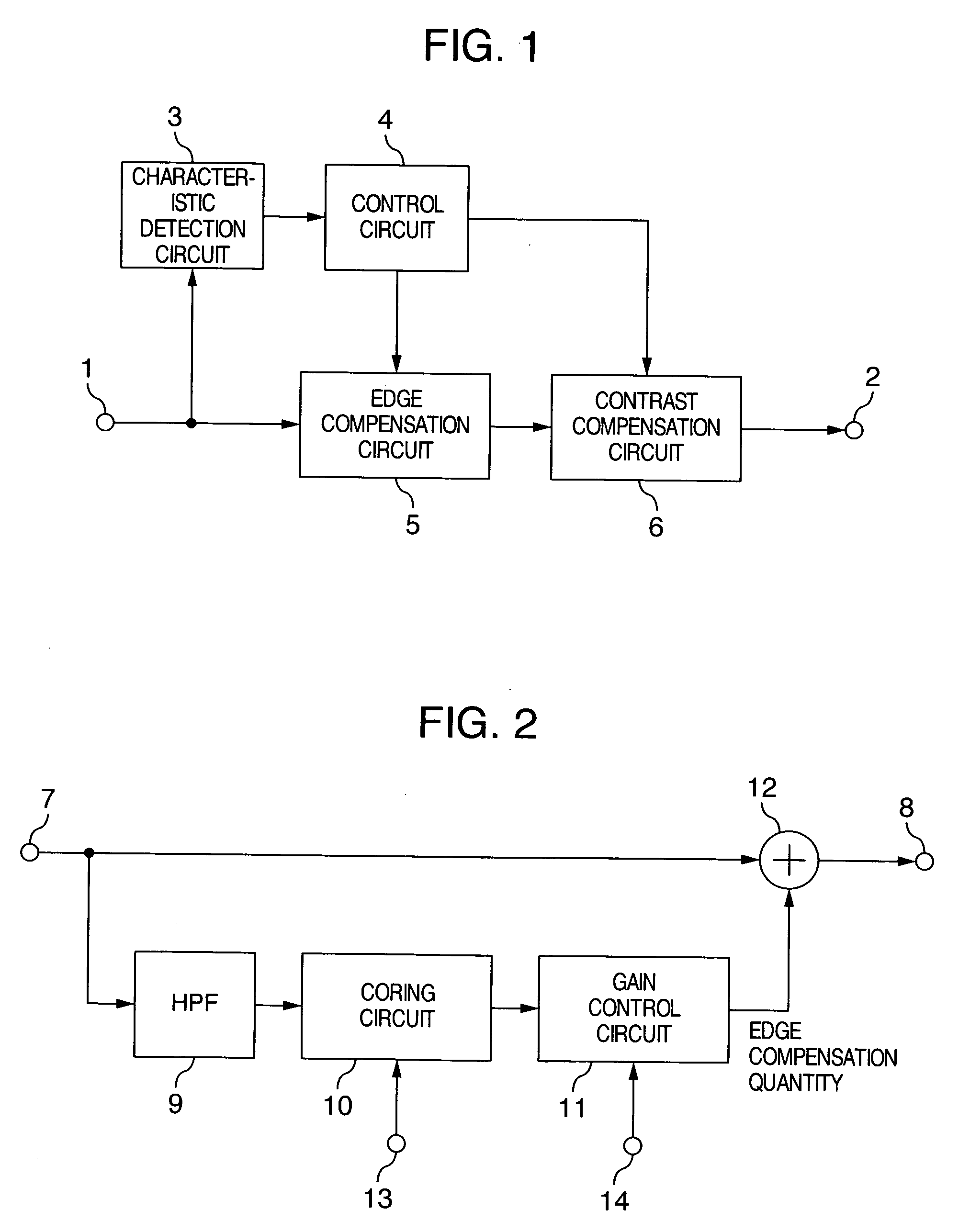

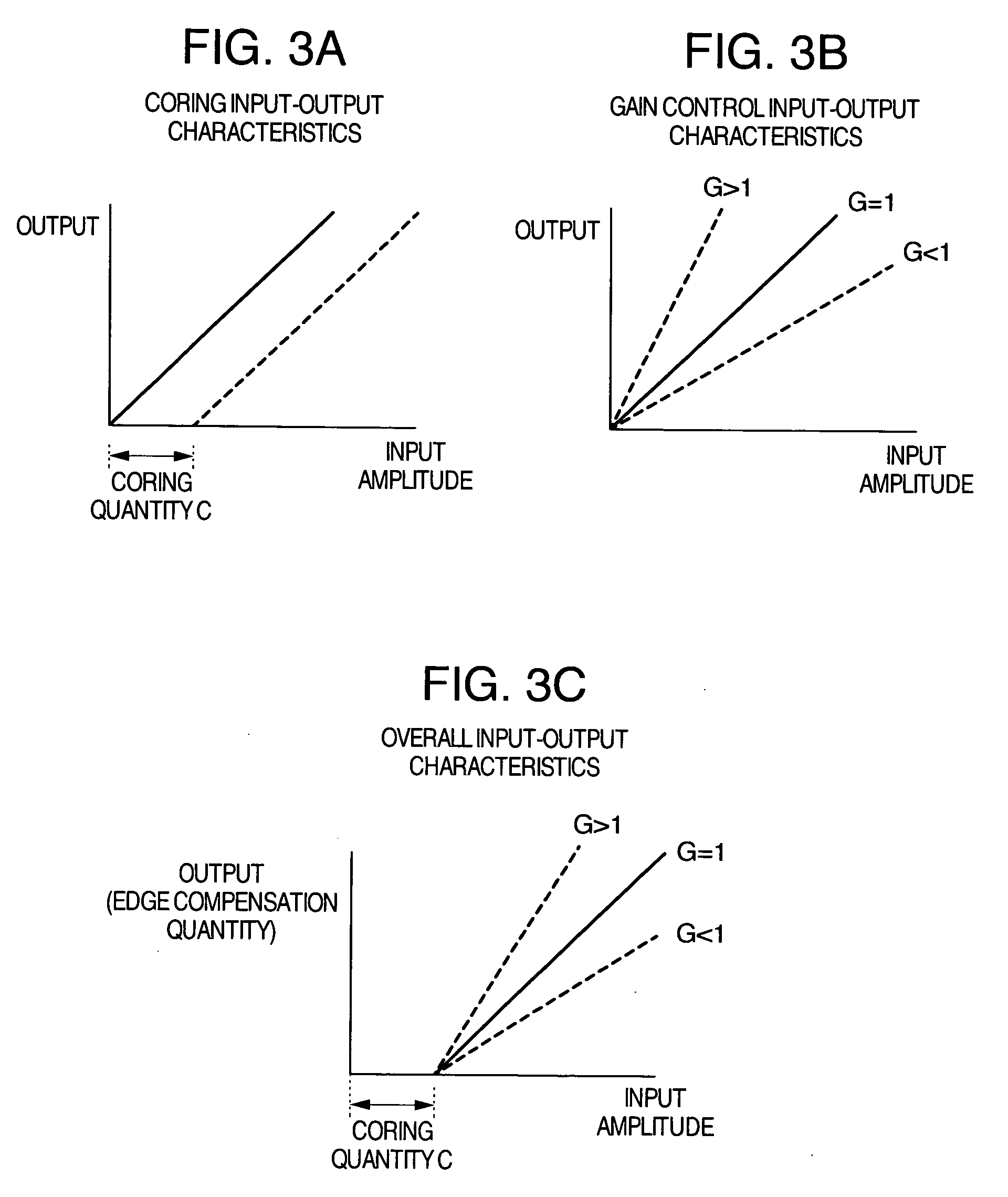

A video signal processing apparatus includes a characteristic detection circuit for detecting luminance distribution corresponding to one frame of a video signal, a contrast compensation circuit for compensating contrast of the video signal, an edge compensation circuit for compensating an edge portion of the video signal, and a control circuit for determining a luminance range to be controlled on the basis of the luminance distribution detected by the characteristic detection circuit, and controlling the contrast compensation circuit and edge compensation circuit to conduct predetermined compensation on the video signal belonging to the luminance range. The control circuit controls the contrast compensation circuit to increase contrast for the video signal in the luminance range as compared with the video signal in other regions, and controls the edge compensation circuit to make an edge compensation quantity for the video signal in the luminance range smaller as compared with other regions.

Owner:MAXELL HLDG LTD

Image pickup apparatus, exposure control method, and computer program installed in the image pickup apparatus

InactiveUS20060044459A1Limited brightnessTelevision system detailsColor television detailsReference imageExposure control

Immediately before regular image pickup, a reference image is taken through exposure control by center-weighted photometry. A histogram indicative of a luminance distribution of all pixels is generated on the basis of luminance information of the reference image. Then, a luminance point in the histogram where the accumulated number of pixels from the high-luminance side is equal to a half of the total number of pixels is obtained, and a difference is calculated between the luminance point and a luminance point (“118”) when the brightness is uniform in the reference image. At the time of regular image pickup, proper exposure determined in response to the brightness of the subject when the reference image is taken is compensated with the previously calculated difference, and exposure control for the compensated proper exposure is performed.

Owner:CASIO COMPUTER CO LTD

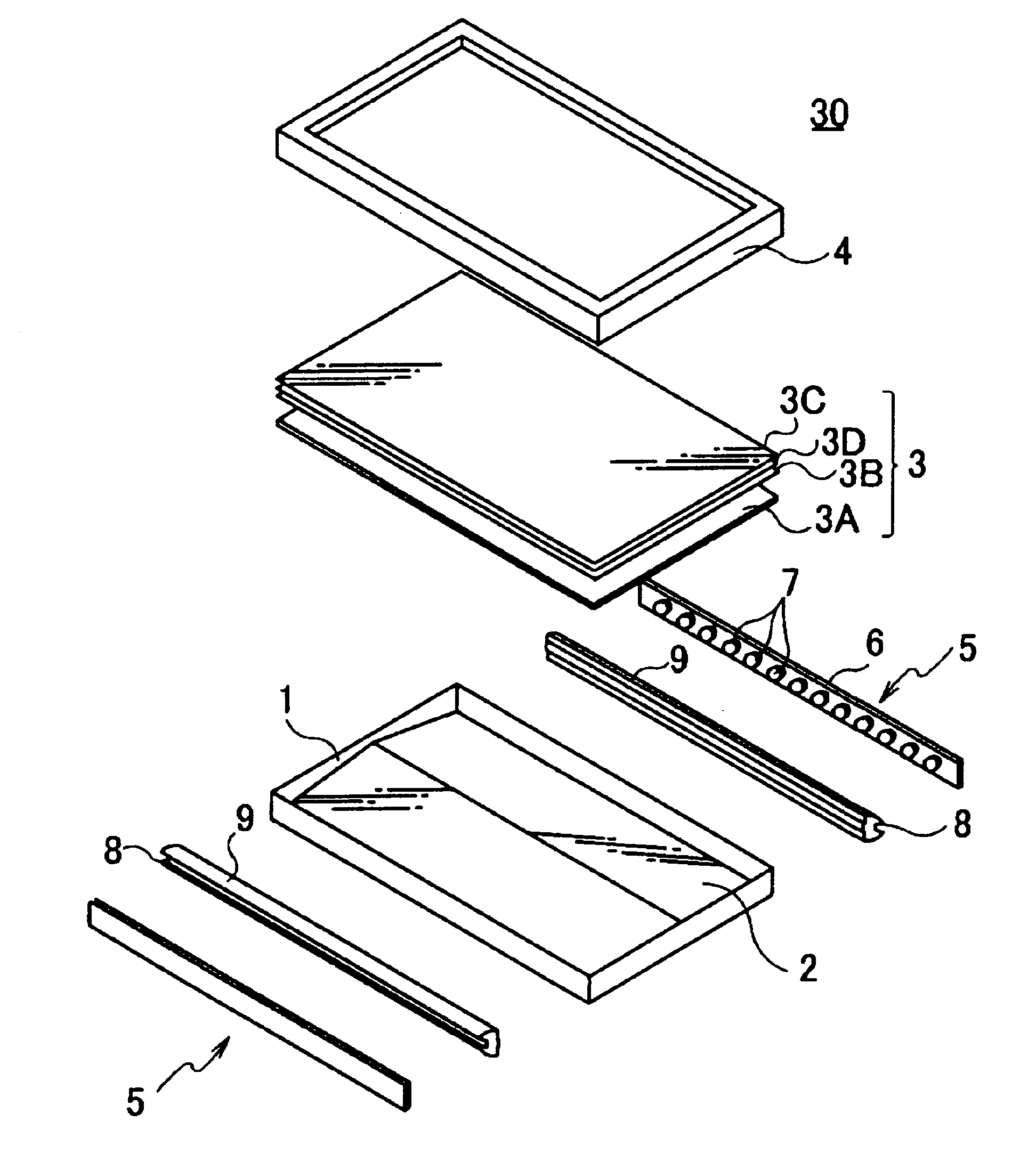

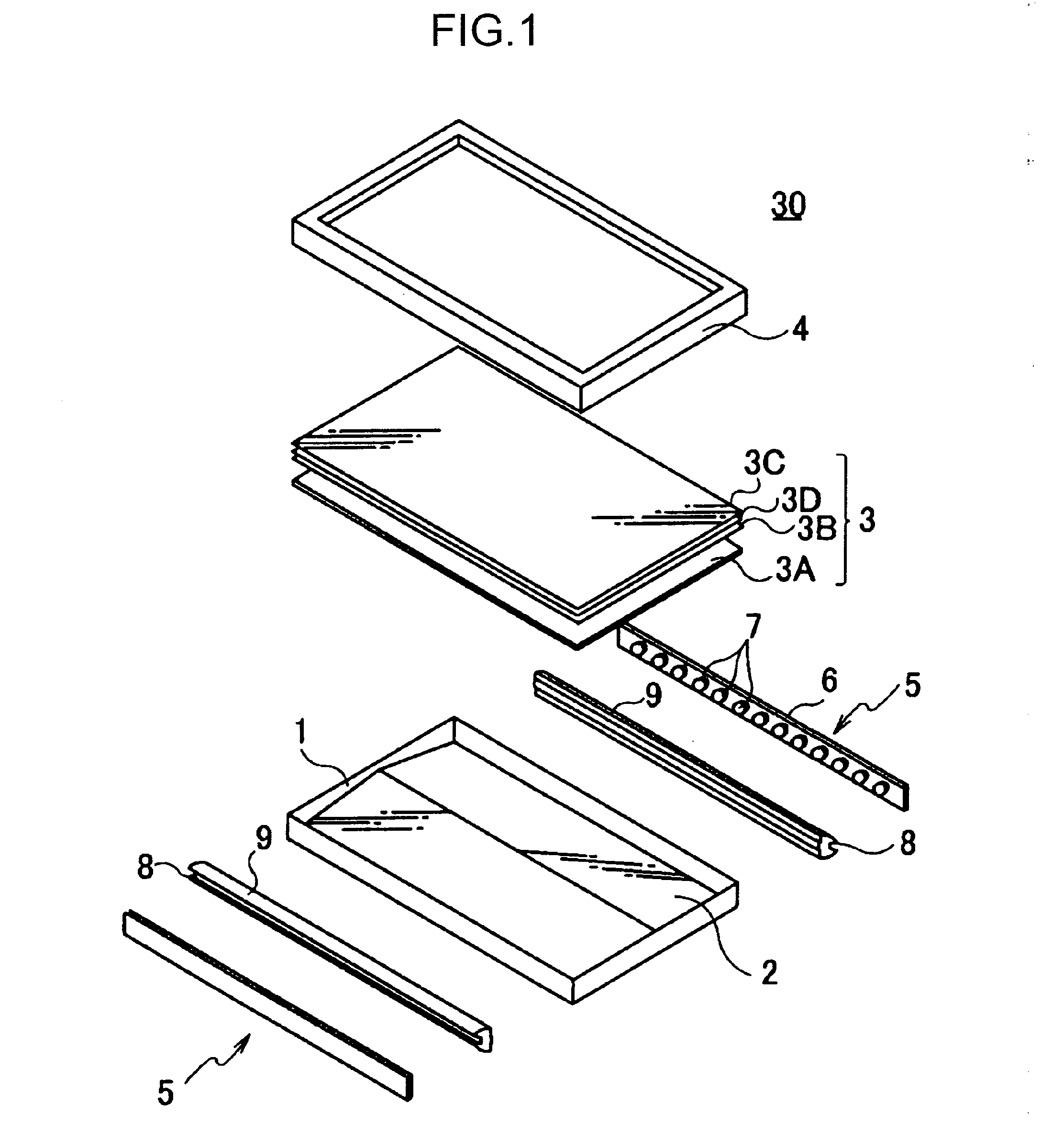

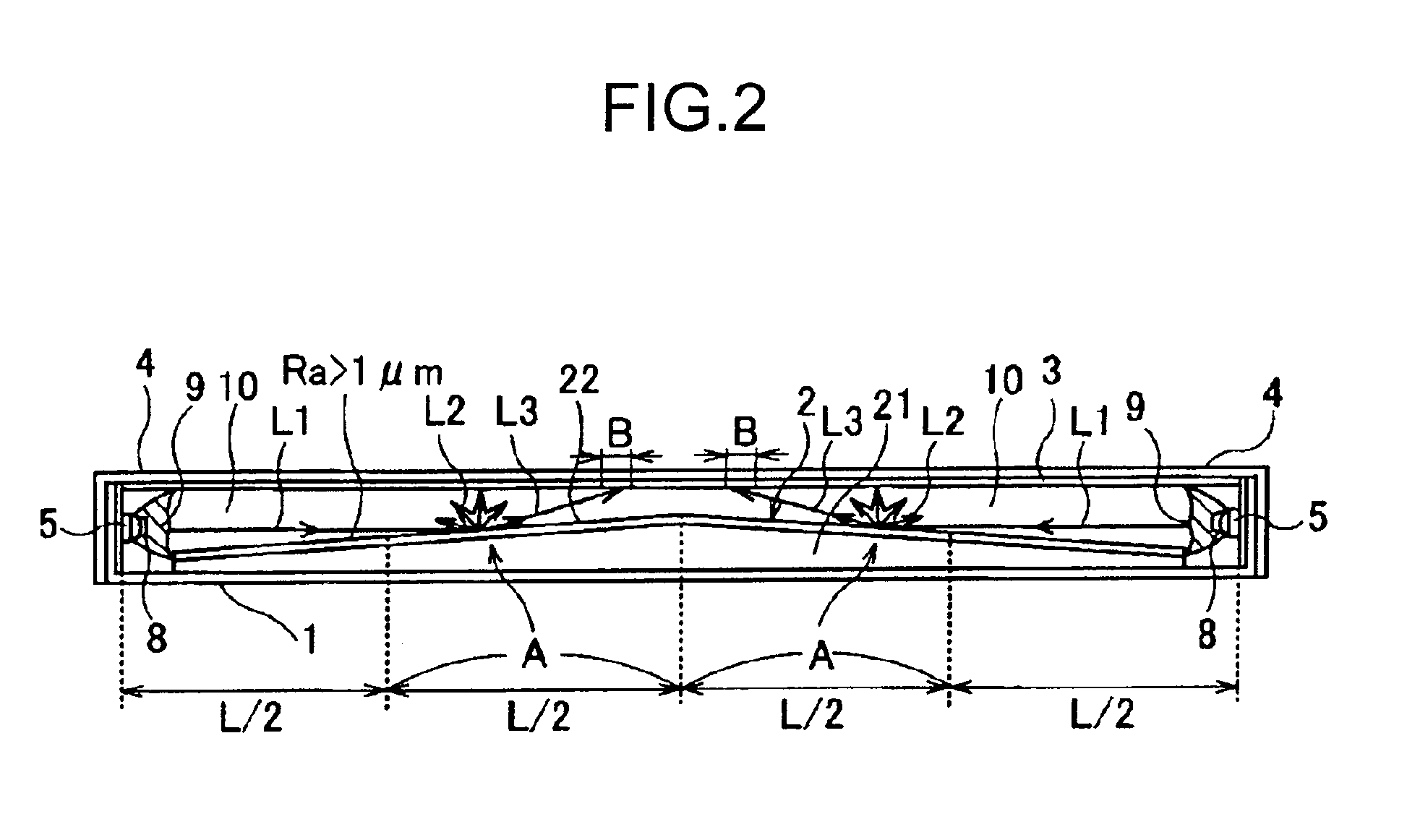

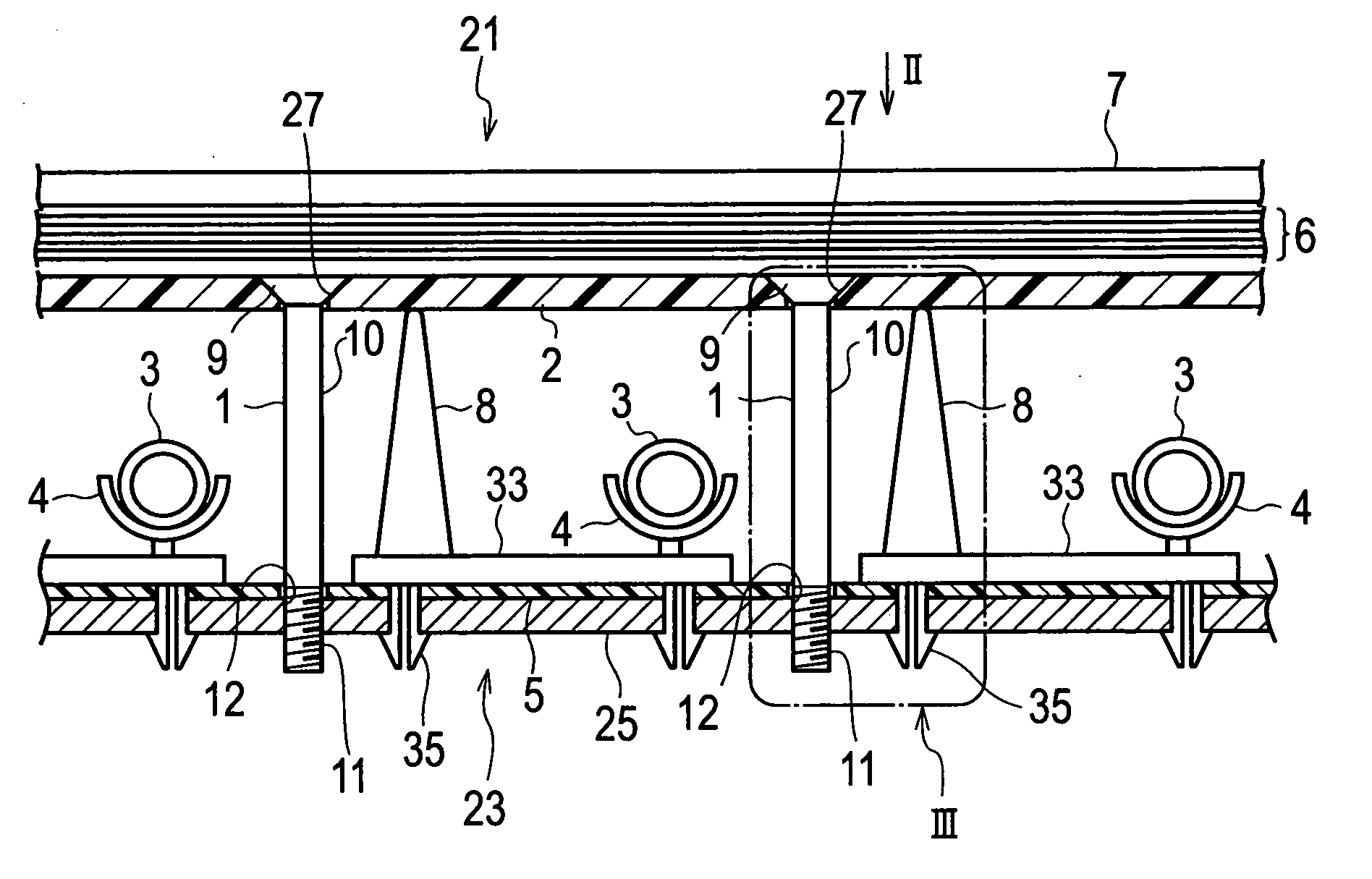

Hollow type planar illuminatng device

InactiveUS20100208490A1Reduce directivity angleImprove diffusion abilityPoint-like light sourcePlanar/plate-like light guidesLight guideSurface roughness

Provided is a hollow type planar illuminating device having uniform luminance distribution over the entire light emitting surface. A reflecting surface member (2) is arranged on the bottom side of a hollow unit case (1), a light emitting surface member (3) is arranged on the side facing the reflecting surface member of the unit case, and a space sandwiched between the reflecting surface member and the light emitting surface member of the unit case is permitted to be a hollow light guide space (10). An LED light source unit (5) wherein many LEDs are mounted in a row on a wiring board is arranged adjacent to the both sides or one side of the hollow light guide space so that light is emitted to the hollow light guide space. Between the LED light source unit and an end surface of the hollow light guide space, a light collecting lens (9) is arranged. The light collecting lens reduces the directivity angle of light emitted from the LED light source unit in the device thickness direction. Thus, a hollow type planar illuminating device (30) is formed. The surface roughness (Ra) of the surface of the reflecting surface member (2) facing the hollow light guide space (10) is set to satisfy the inequalities of 1 μm<RA<10 μm.

Owner:HARISON TOSHIBA LIGHTING CORP

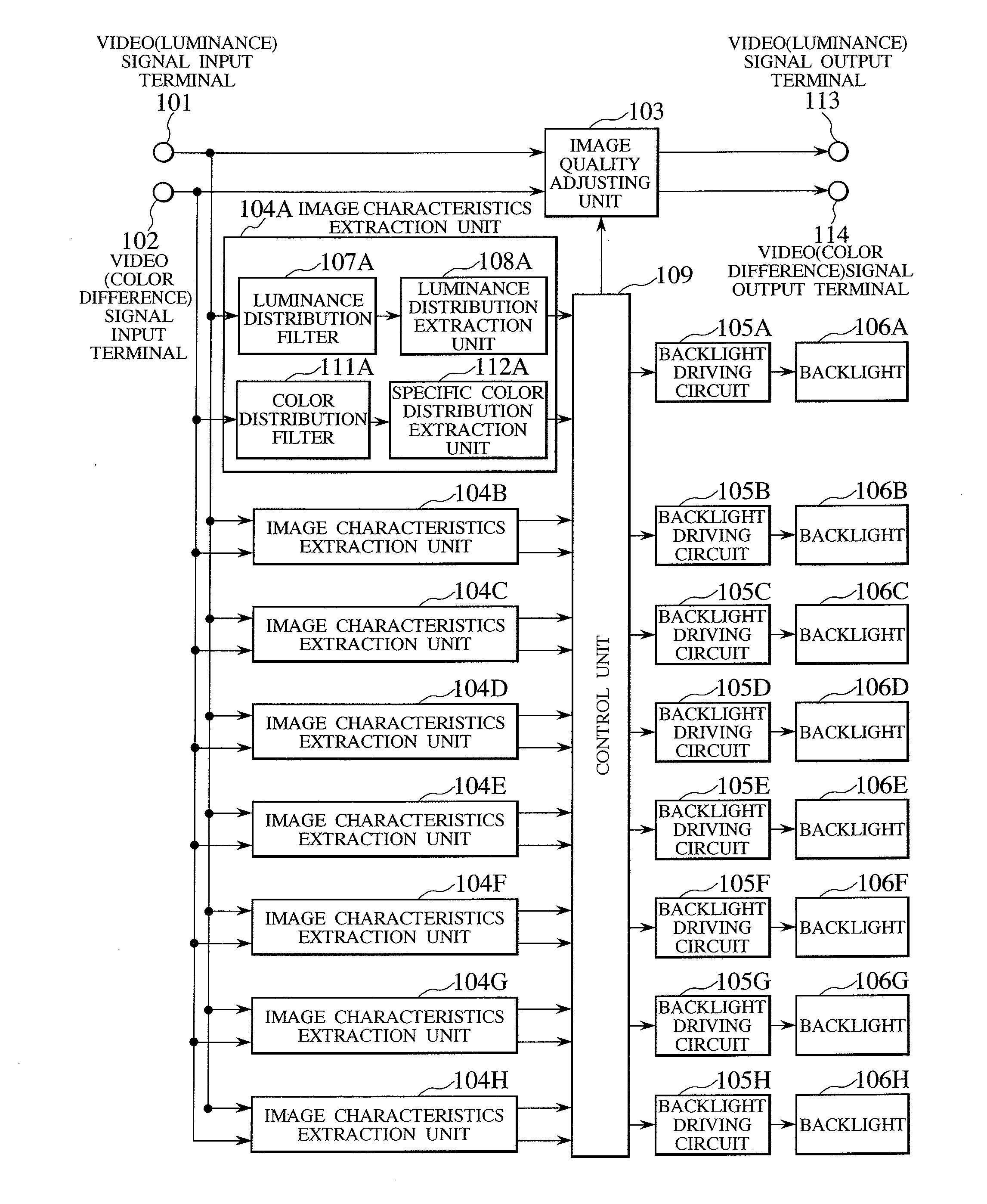

Liquid crystal display apparatus and luminance control method thereof

InactiveUS20080297463A1Increase contrastReduced characteristicsTelevision system detailsColor signal processing circuitsLiquid-crystal displaySignal on

For the purpose of suppressing untrue black with the change in luminance of video, which is displayed as the same object, being reduced to improve the contrast, there is provided a liquid crystal display apparatus that is capable of: extracting the pixel frequency distribution of an input video signal on a luminance level basis, and extracting the pixel frequency distribution of specific color from a color-difference signal of input video in a screen area, the color-difference signal being determined from the luminance distribution of a plurality of backlights; on the basis of the result of the extraction, determining the control amount of the luminance of the plurality of backlights, and the correction amount of the luminance of a liquid crystal panel, on a screen area basis; controlling the luminance of the plurality of backlights on the basis of the control amount of the luminance; and at the same time, controlling the luminance of the input video signal on the basis of the correction amount of the luminance.

Owner:HITACHI LTD

Image processing system, projector, program, information storage medium and image processing method

InactiveUS6939011B2Reduce the impactReduce impactTelevision system detailsGeometric image transformationImaging processingPeak value

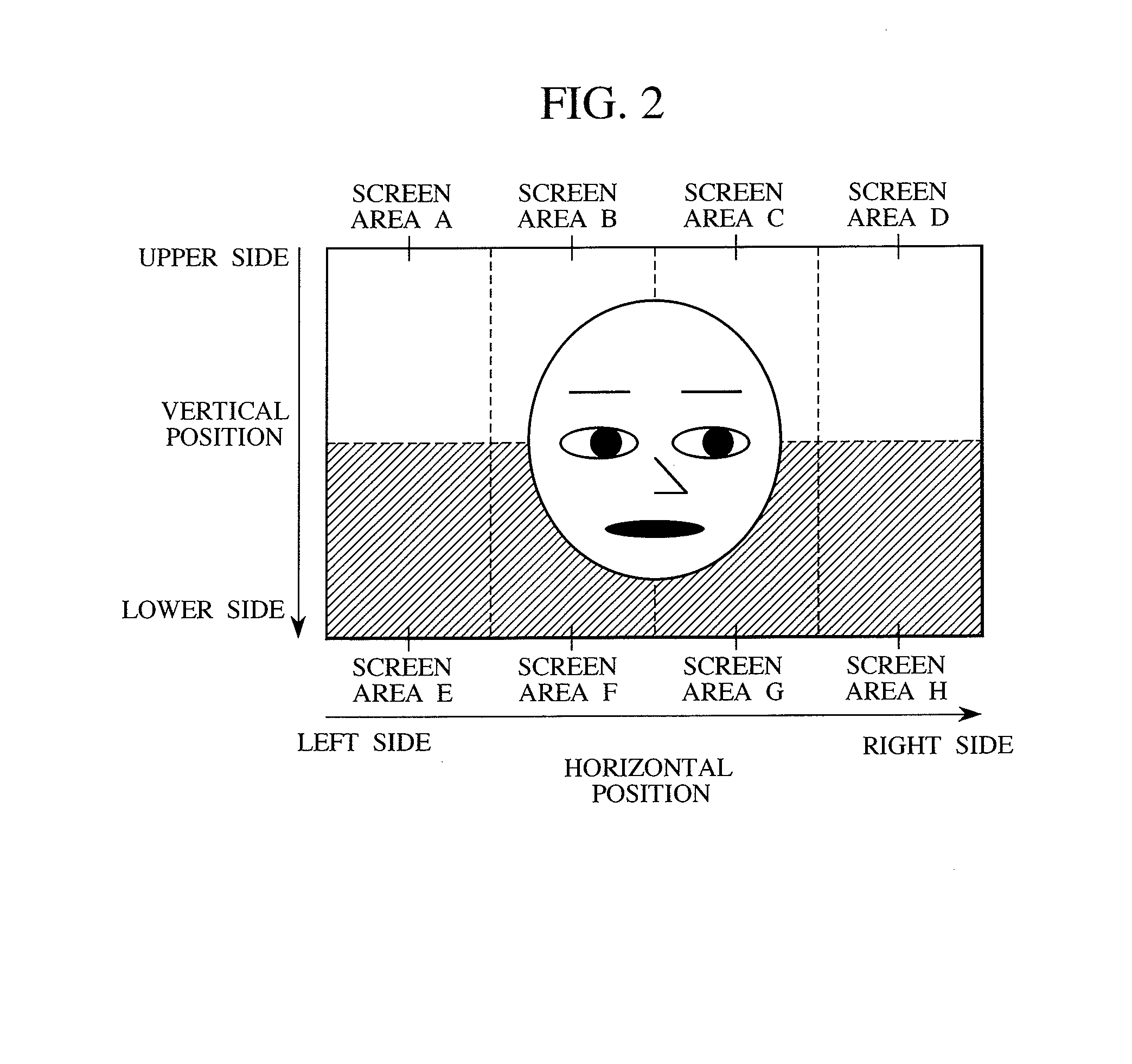

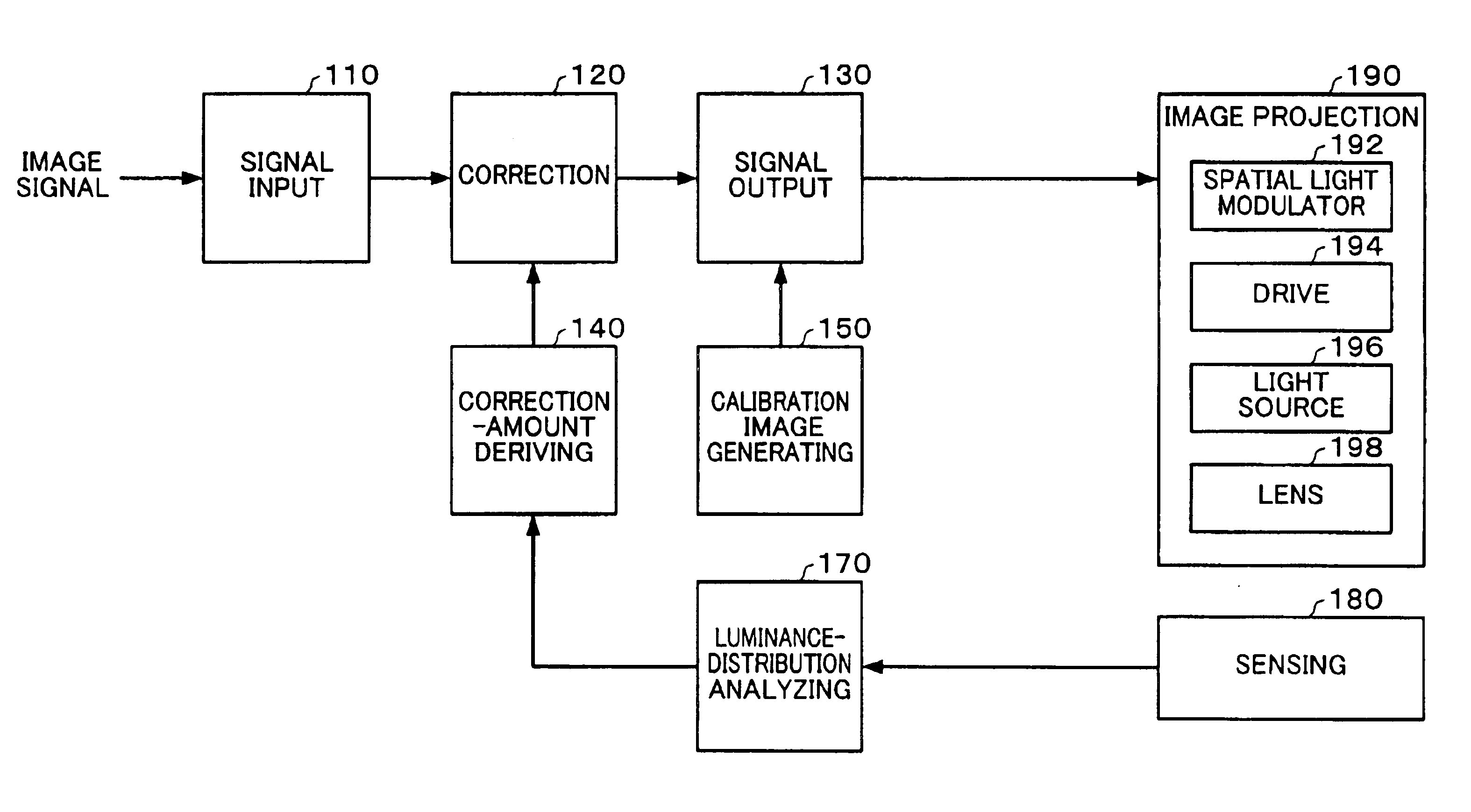

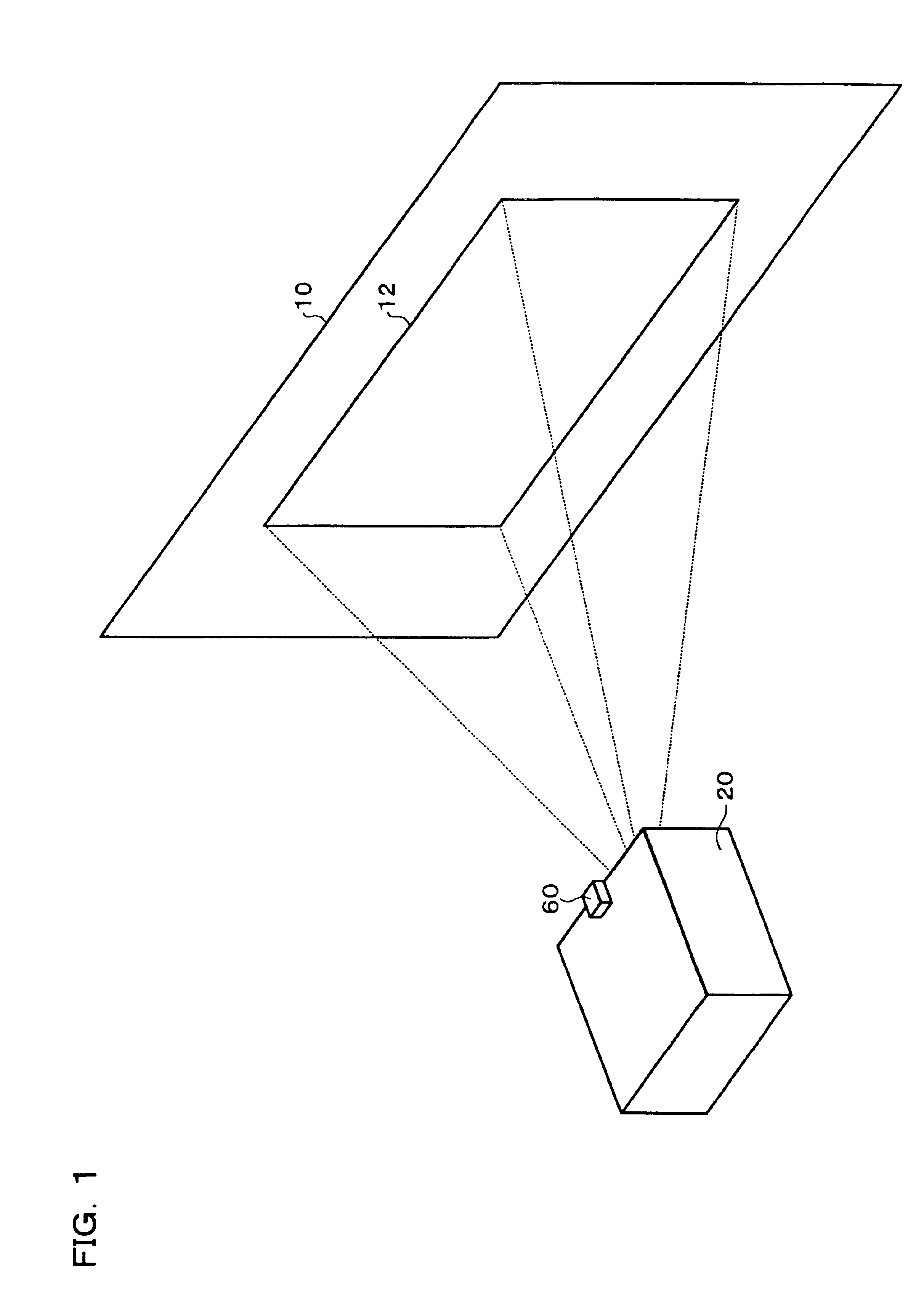

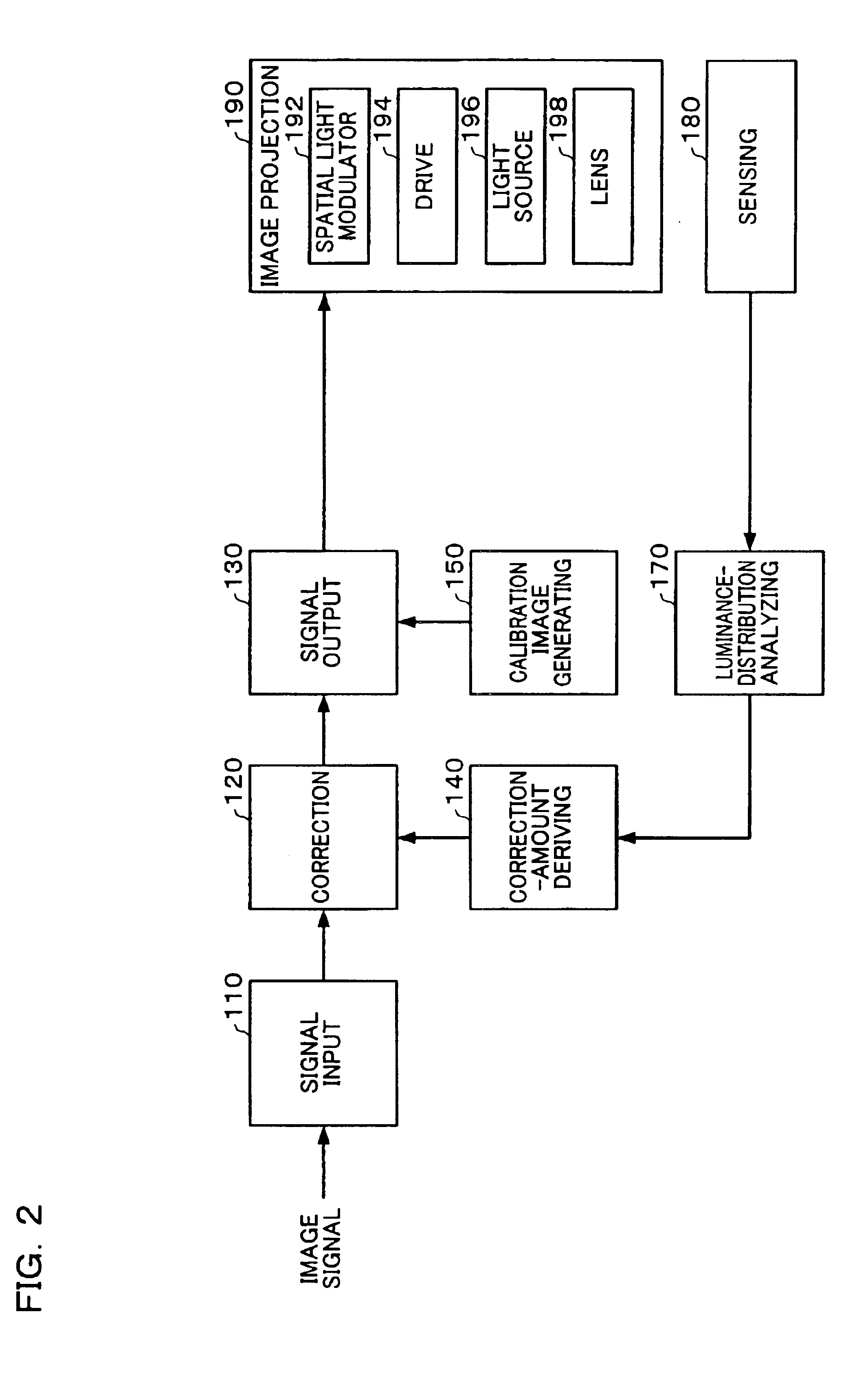

To provide an image processing system and the like which can more exactly correct the distortion in an image by reducing the influence of color in an area onto which the image is projected, a projector is provided with a correction section which corrects image signals to adjust a distortion of an image; an image projection section which projects an image based on the image signals; a sensing section which senses the projected image to generate sensing information; a luminance-distribution analyzing section which generates coordinate information indicating a peak position which is the brightest position in the sensed projected image, based on the total luminance value for each pixel line forming the sensed projected image based on the sensing information; and a correction-amount deriving section which determines the distortion in the projected image and derives the amount of correction for the correcting section, based on the coordinate information.

Owner:SEIKO EPSON CORP

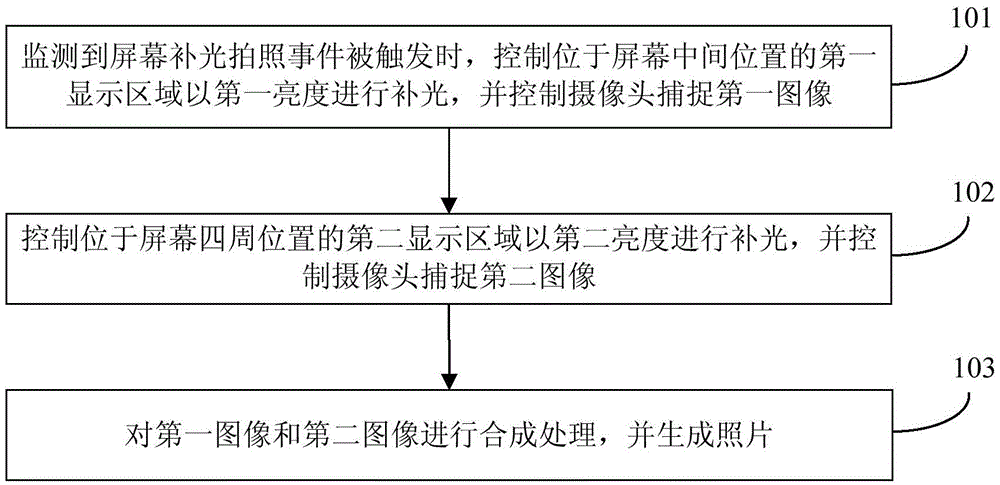

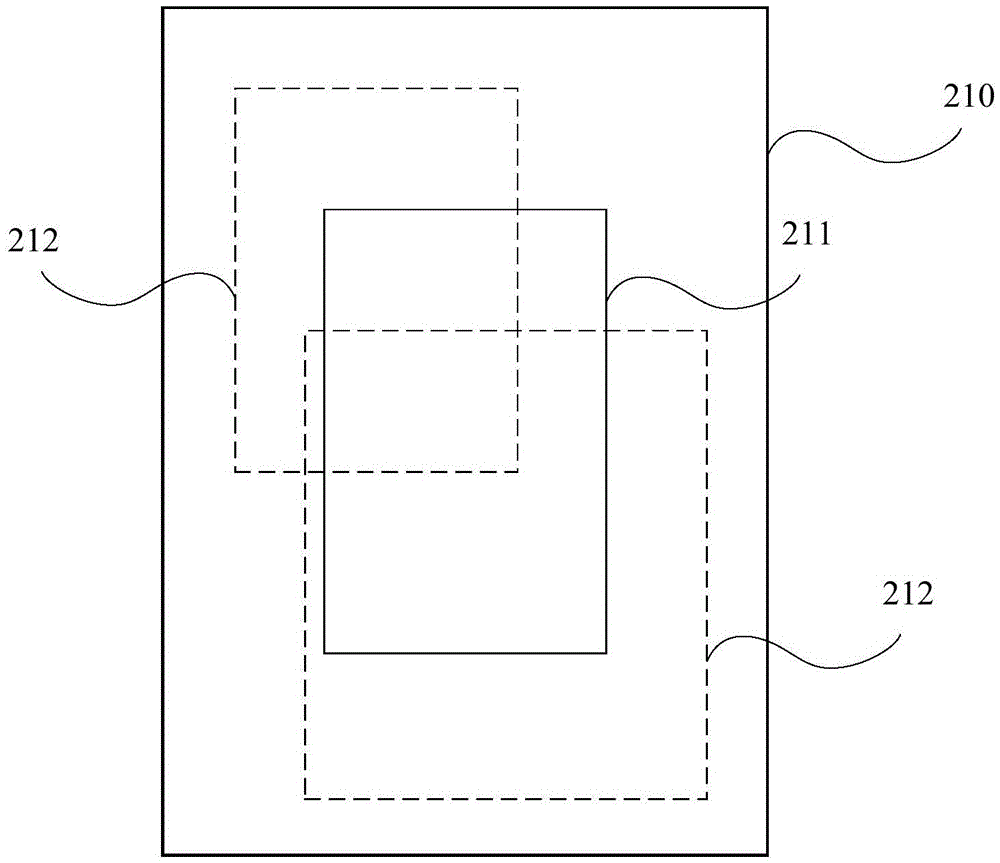

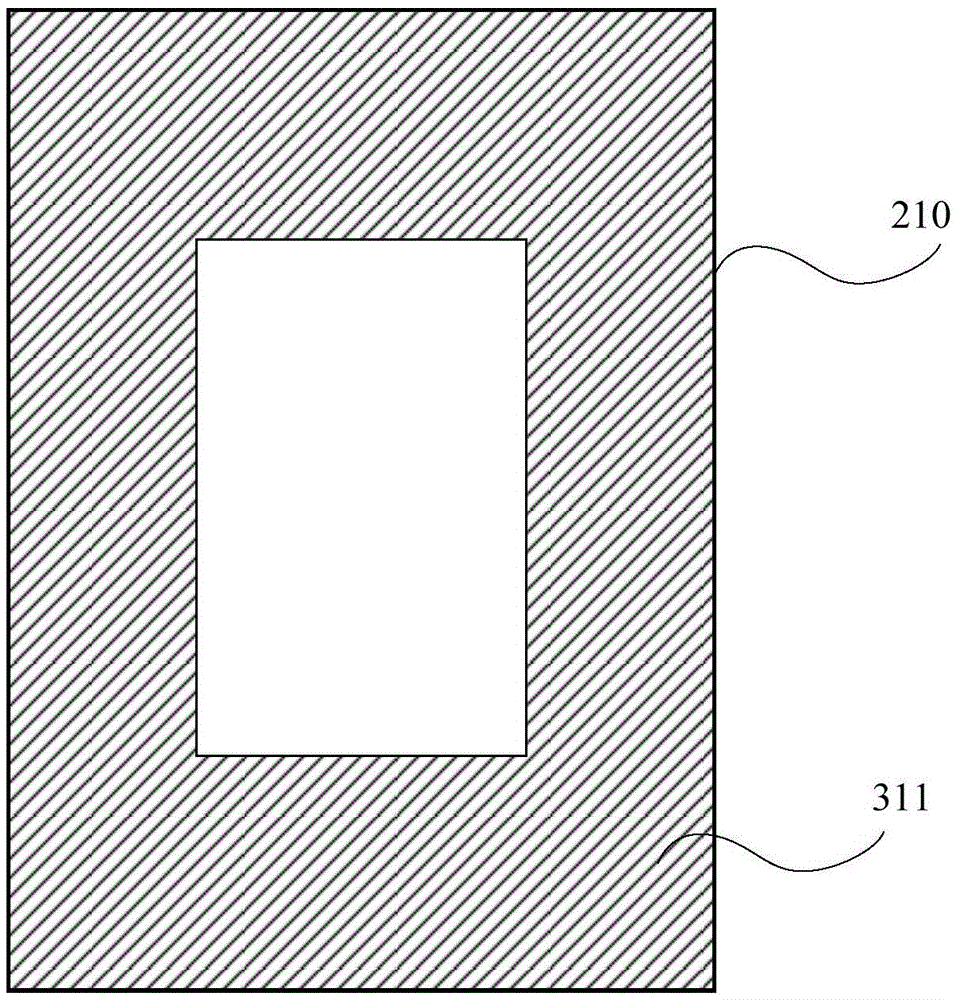

Photographing method and device based on screen light compensation and mobile terminal

ActiveCN105554411AReasonable brightness distributionImprove experienceTelevision system detailsColor television detailsComputer graphics (images)Computer terminal

The embodiment of the invention discloses a photographing method and a photographing device based on screen light compensation and a mobile terminal. The method comprises the steps of when monitoring that a screen light compensation a photographing event is triggered, controlling a first display area in the middle position of a screen to compensate light with first luminance, and controlling a camera to capture a first image; controlling a second display area in the periphery of a screen to compensate light with second luminance, and controlling a camera to capture a second image, wherein the second luminance is higher than the first luminance; combining the first image with the second image, and then generating a photograph. By using the photographing method provided by the embodiment of the invention, light compensation and image capture are respectively performed on a human face and a background in a framing range, the photograph synthesized according to the two captured images is reasonable in luminance distribution, the photographing effect based on screen light compensation can be effectively improved, and the user experience can be enhanced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Color fusion method of night vision weak light image and infrared image based on color transfer

The invention discloses a color fusion method of a night vision low-light image and an infrared image based on color transfer. The present invention first linearly fuses visible light and infrared images to obtain the , , and components of the gray-scale fused image. Utilize the brightness and color distribution of the reference image to adjust the gray-scale fusion image, and adjust the adjusted image data from YUV space back to RGB space to obtain the final color fusion image. The fusion image obtained by the method of the present invention and the color reference The brightness distribution of the image is similar and has a good visual effect.

Owner:ZHEJIANG SCI-TECH UNIV

Backlight device and liquid crystal display

InactiveUS20100208161A1Luminance can be restrainedLack of uniformityIlluminated signsNon-linear opticsLiquid-crystal displayTransmittance

A backlight device includes a housing, a light source, a diffuse plate and a fixing member. The housing has an open surface. The light source is arranged in the housing. The diffuser plate is arranged on the open surface of the housing and allows light emitted from the light source to pass therethrough while diffusing the light. The fixing member prevents the diffuser plate from bending in a direction in which light passes through the diffuser plate. A part of the fixing member has transmittance adjusted to substantially equalize luminance distribution of light passed through the diffuser plate.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com