Backlight device and liquid crystal display

a backlight device and liquid crystal display technology, applied in the direction of illuminated signs, display means, instruments, etc., can solve the problems of deteriorating image quality affecting the uniformity of luminance on the screen of liquid crystal display including the means, and affecting the uniformity of luminance on the screen of liquid crystal display, so as to prevent luminance on the diffuser plate, maintain the constant distance between the diffuser plate and the light source, and achieve uniformity. uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

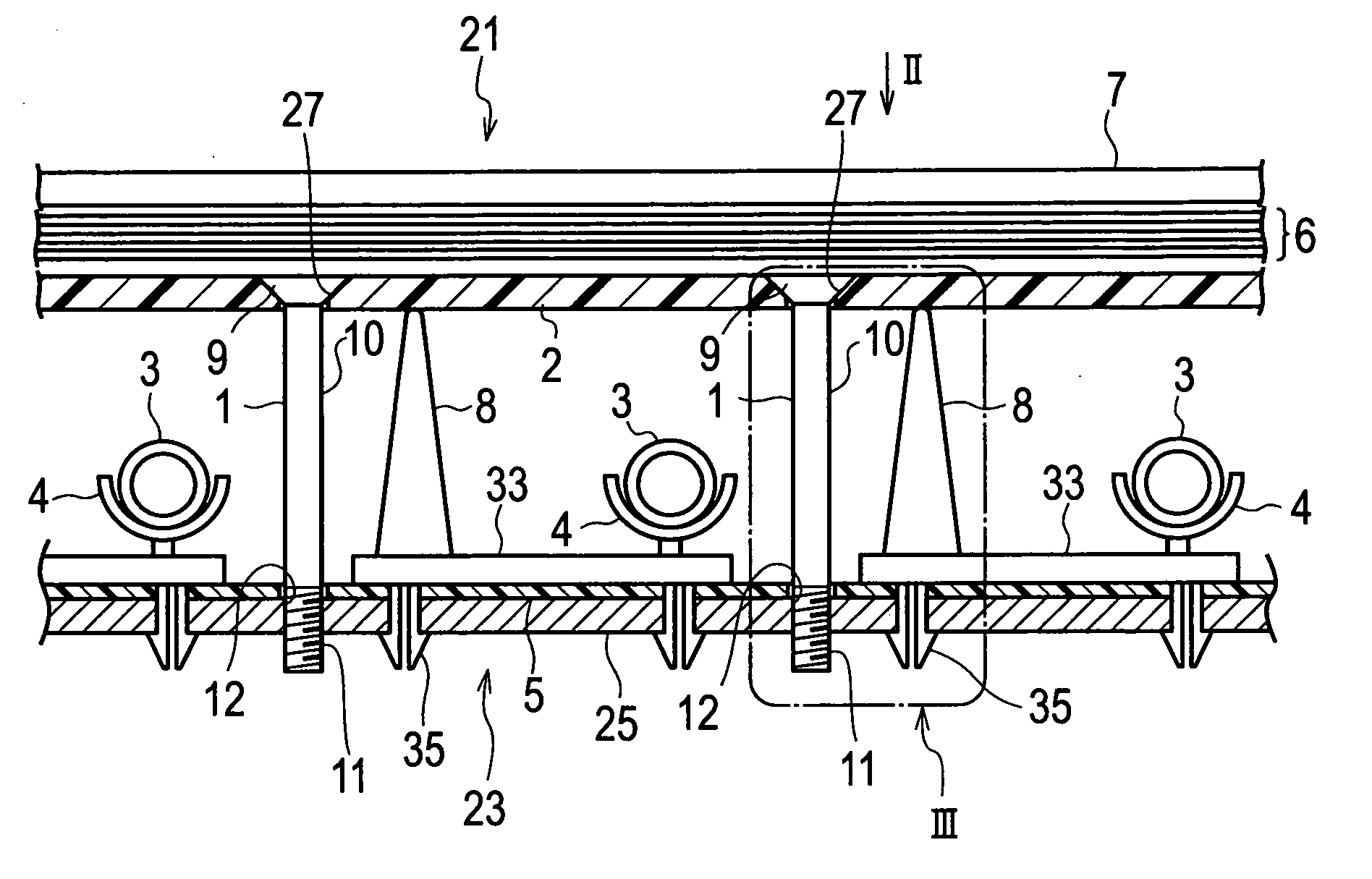

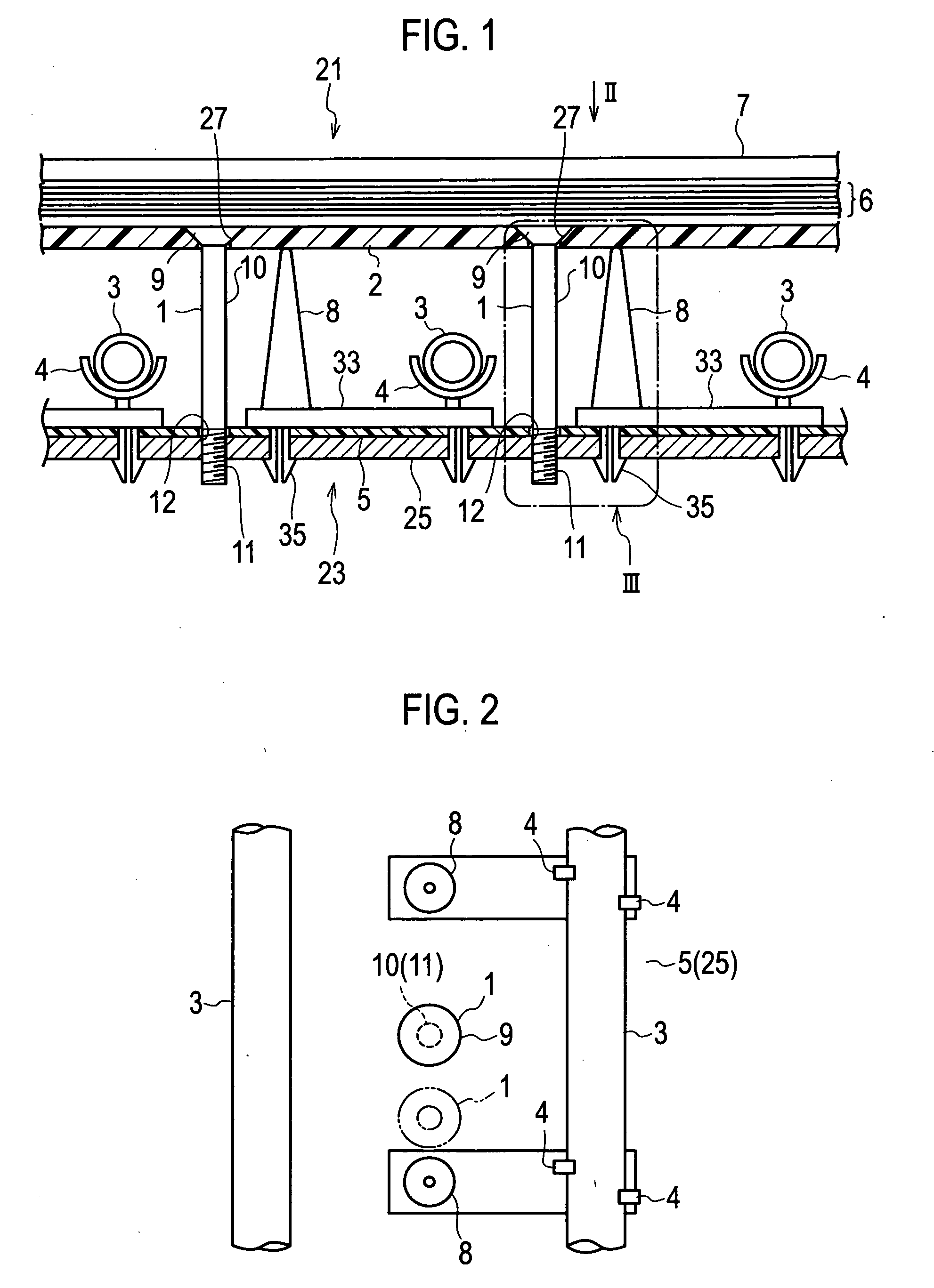

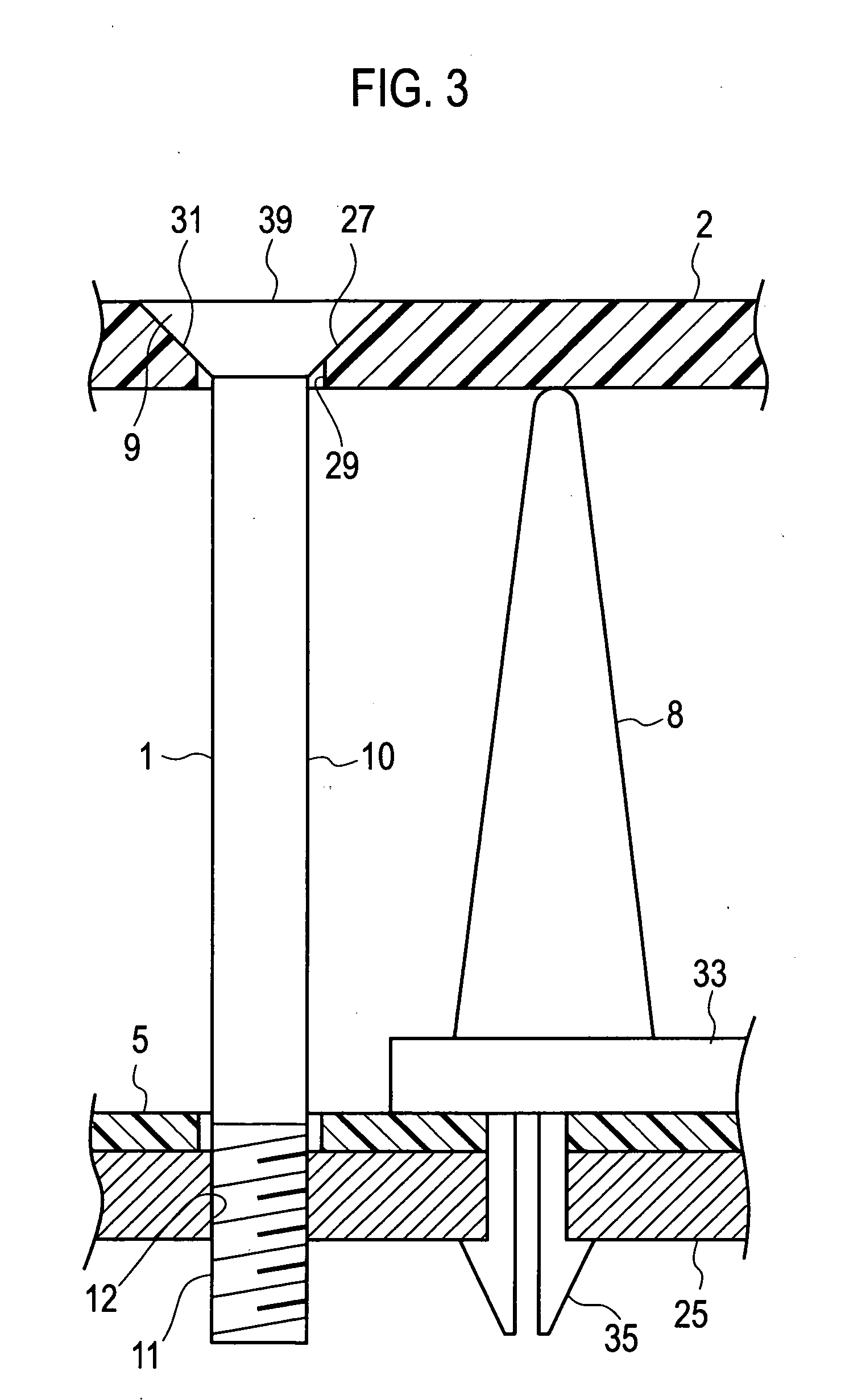

first exemplary embodiment

[0069]A liquid crystal display 21 includes optical sheets 6, a liquid crystal panel 7 and a backlight device 23. Each optical sheet 6 is composed of a polarized reflection film or the like and arranged in front of a diffuser plate 2 of the backlight device 23. The liquid crystal panel 7 is arranged in front of the optical sheets 6. Light emitted from the backlight device 23 passes though the diffuser plate 2 and the optical sheets 6 to illuminate the liquid crystal panel 7. The liquid crystal display 21 drives the liquid crystal panel 7 using a driving device or the like (not shown), and modulates light emitted from the backlight device 23 to carry out gradation process, which allows various images to be displayed thereon. It is noted that the upper side of FIG. 1 corresponds to a front side of the liquid crystal display 21 and the lower side of FIG. 1 corresponds to a rear side of the liquid crystal display 21.

[0070]The backlight device 23 includes fixing members 1, the diffuser pl...

second exemplary embodiment

[0105]A liquid crystal display 101 includes a liquid crystal panel 102 and a backlight device 103. The liquid crystal panel 102 is arranged as a display unit in the front of the liquid crystal display 101 (a viewed side, a display surface side, or a front side of the liquid crystal display 101). The backlight device 103 illuminates the liquid crystal panel 102. It is noted that the upper side of FIG. 7 corresponds to the front side of the liquid crystal display 101 and the lower side of FIG. 7 corresponds to a rear side of the liquid crystal display 101.

[0106]The backlight device 103 includes optical sheets 104, supporting members 105, a housing (open case) 1031, a diffuser plate 1032, a reflector sheet (reflector member) 1033, CCFLs 1034 and lamp holders 1035.

[0107]The housing 1031 has one open surface. The diffuser plate 1032 is a light diffuser plate for diffusing light emitted from the CCFLs 1034 and arranged on the one open surface to close the housing 1031. The diffuser plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com