Patents

Literature

2113results about "Sustain/scan electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

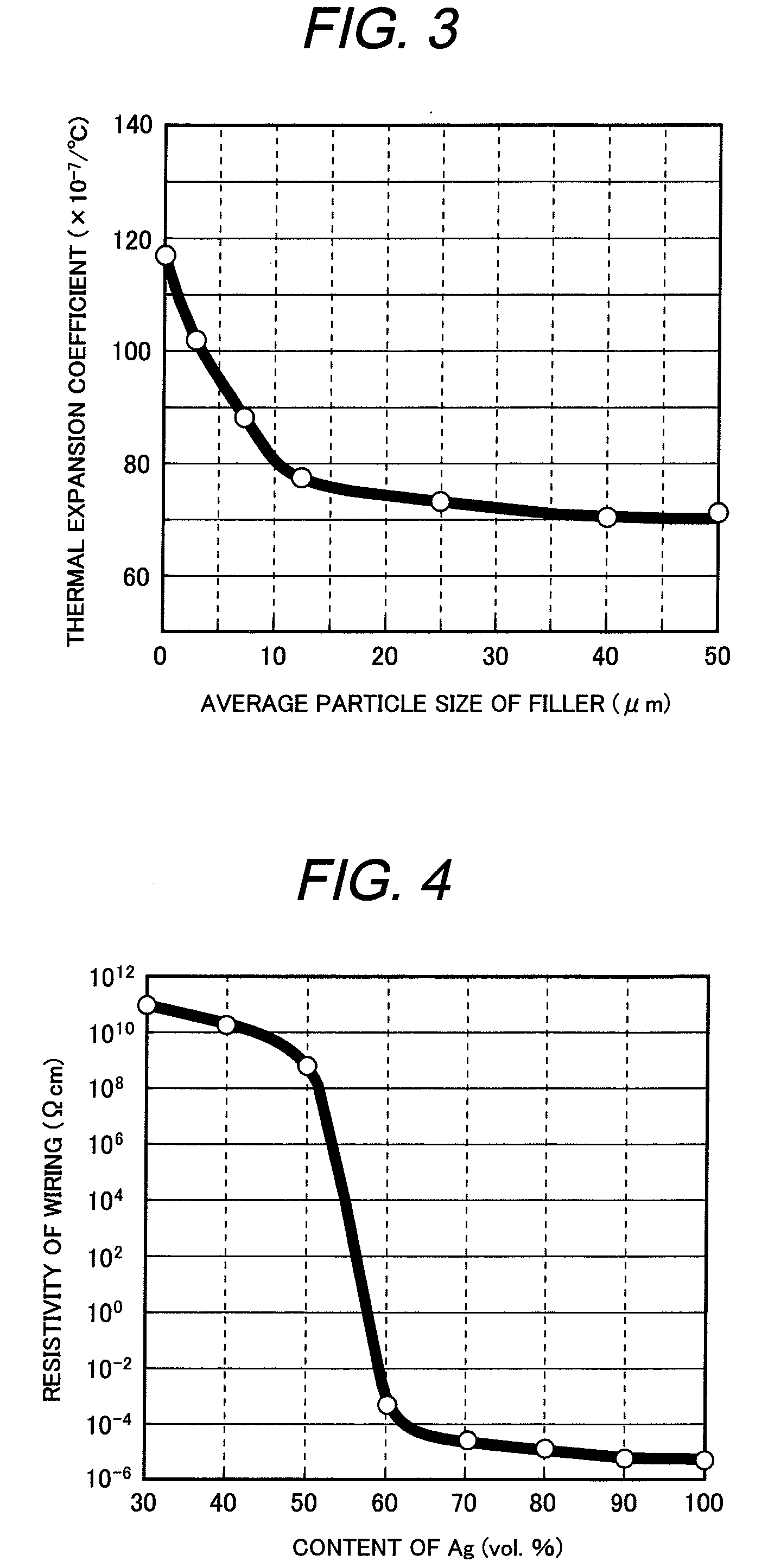

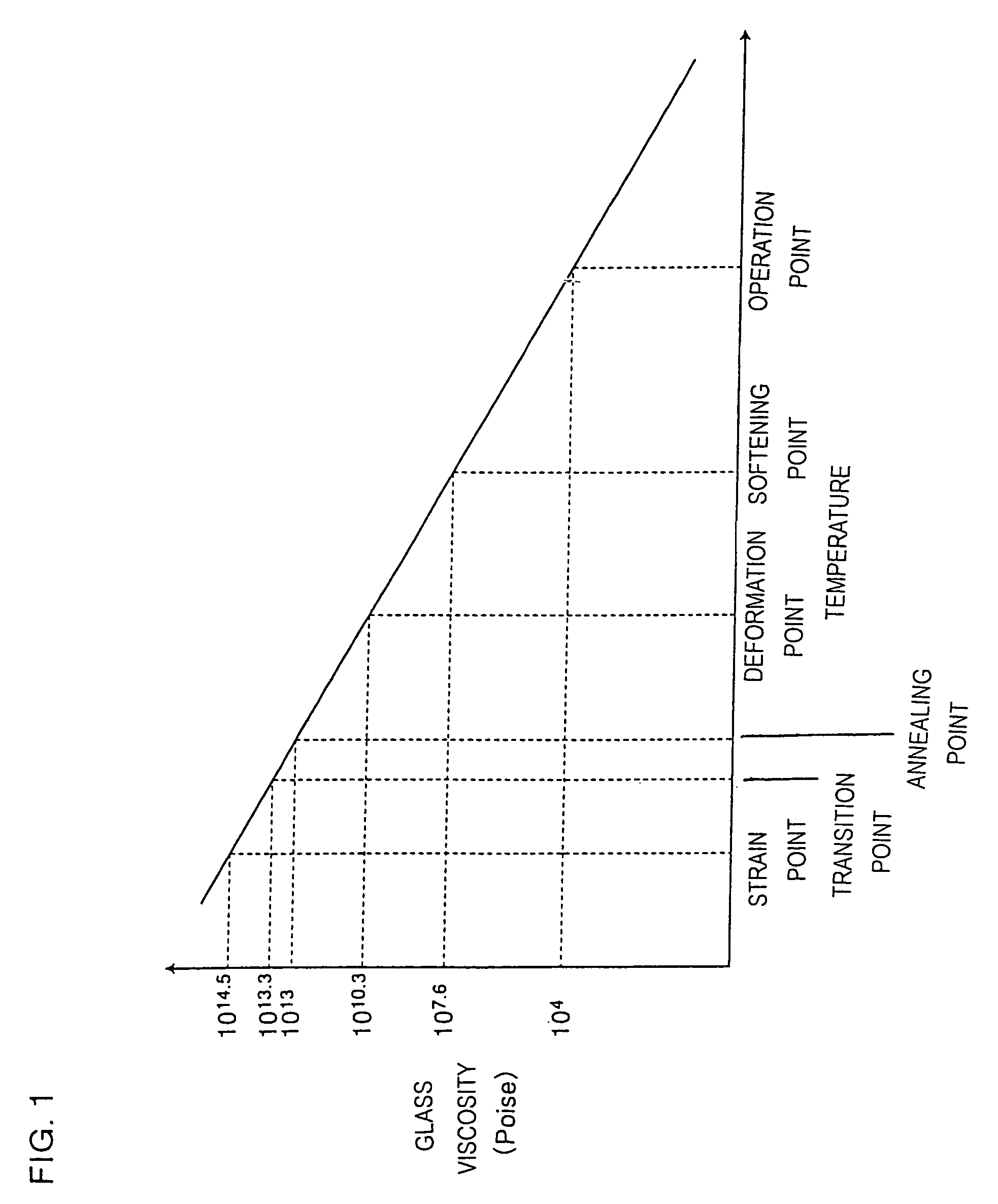

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS20100180934A1Flow on effectReduce softeningAddress electrodesConductive layers on insulating-supportsTe elementAntimony

Owner:RESONAC CORP

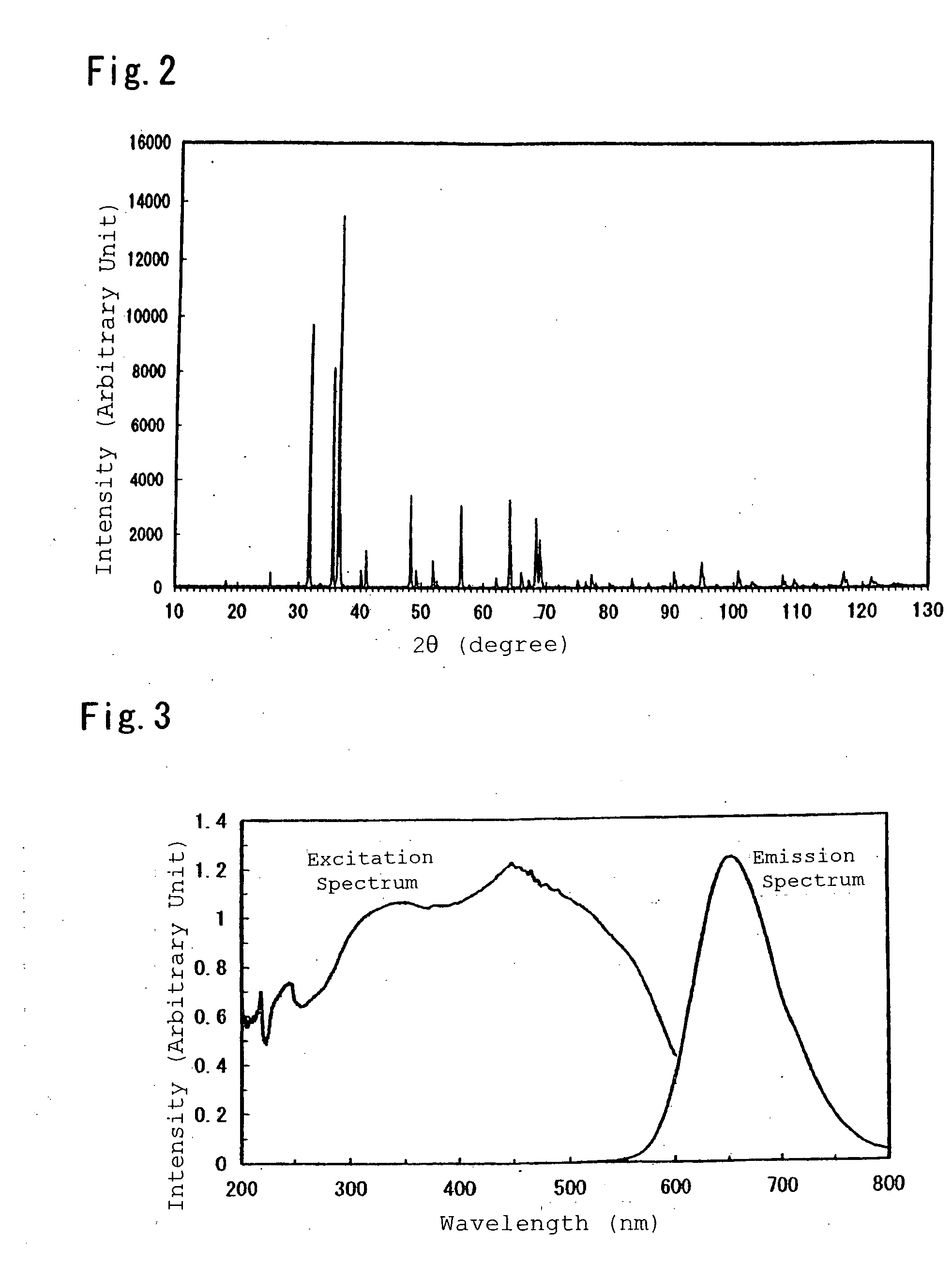

Light emitting device

InactiveUS20050264161A1Effective lightingIncrease brightnessSustain/scan electrodesDischarge tube luminescnet screensDisplay deviceUltraviolet lights

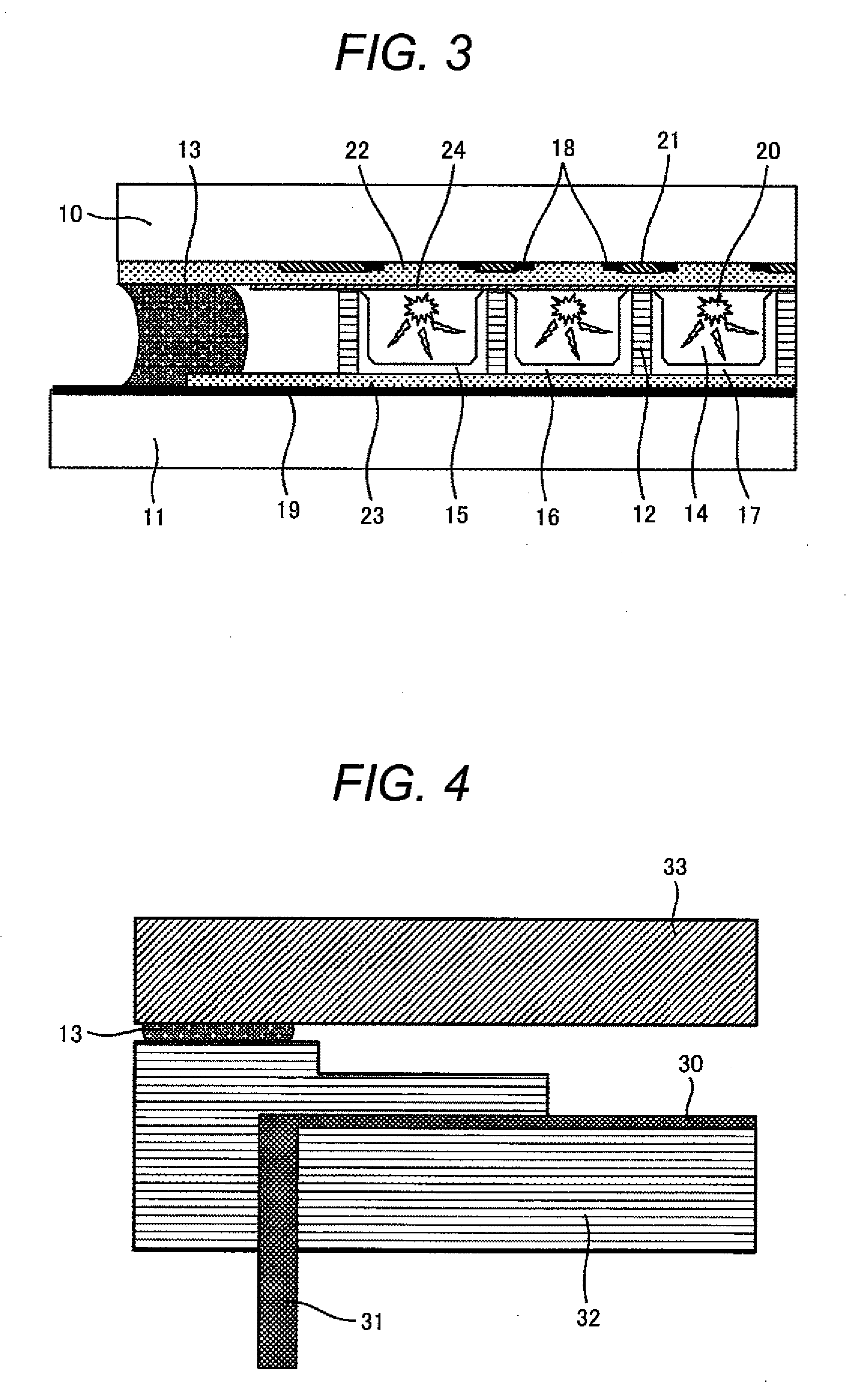

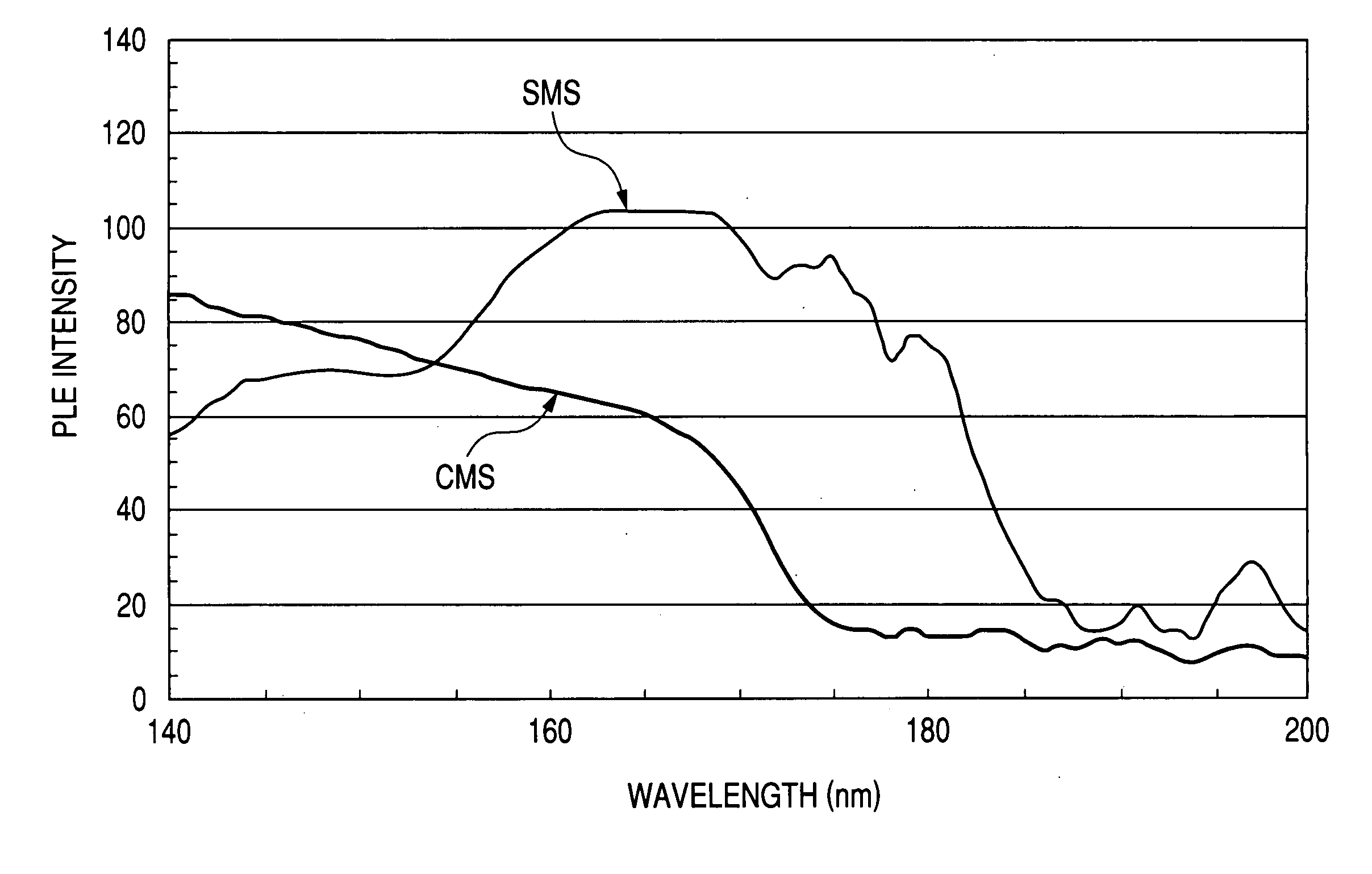

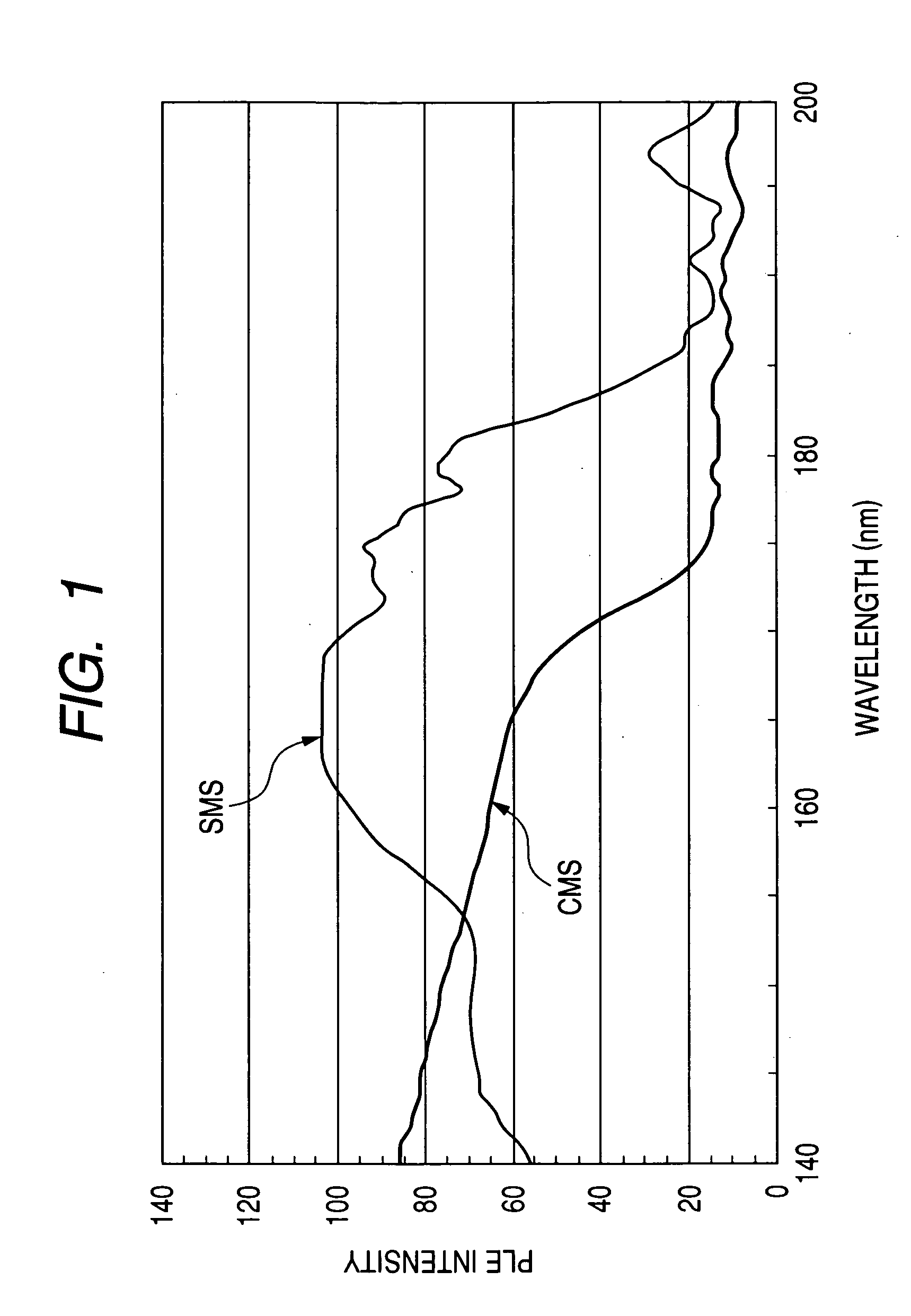

A blue-emitting phosphor is optimized by controlling mole fractions typically of Mg and Si in Sr3-eMgbSi2cO8d:Eue or by further including an optimal amount of at least one additional component such as Ba or Ca. The resulting phosphor exhibits a higher brightness and a higher color purity upon excitation by ultraviolet light emitted as a result of discharge of xenon gas. The optimized phosphor is incorporated into light emitting devices such as lamps and PDPs, and further into display devices.

Owner:HITACHI LTD

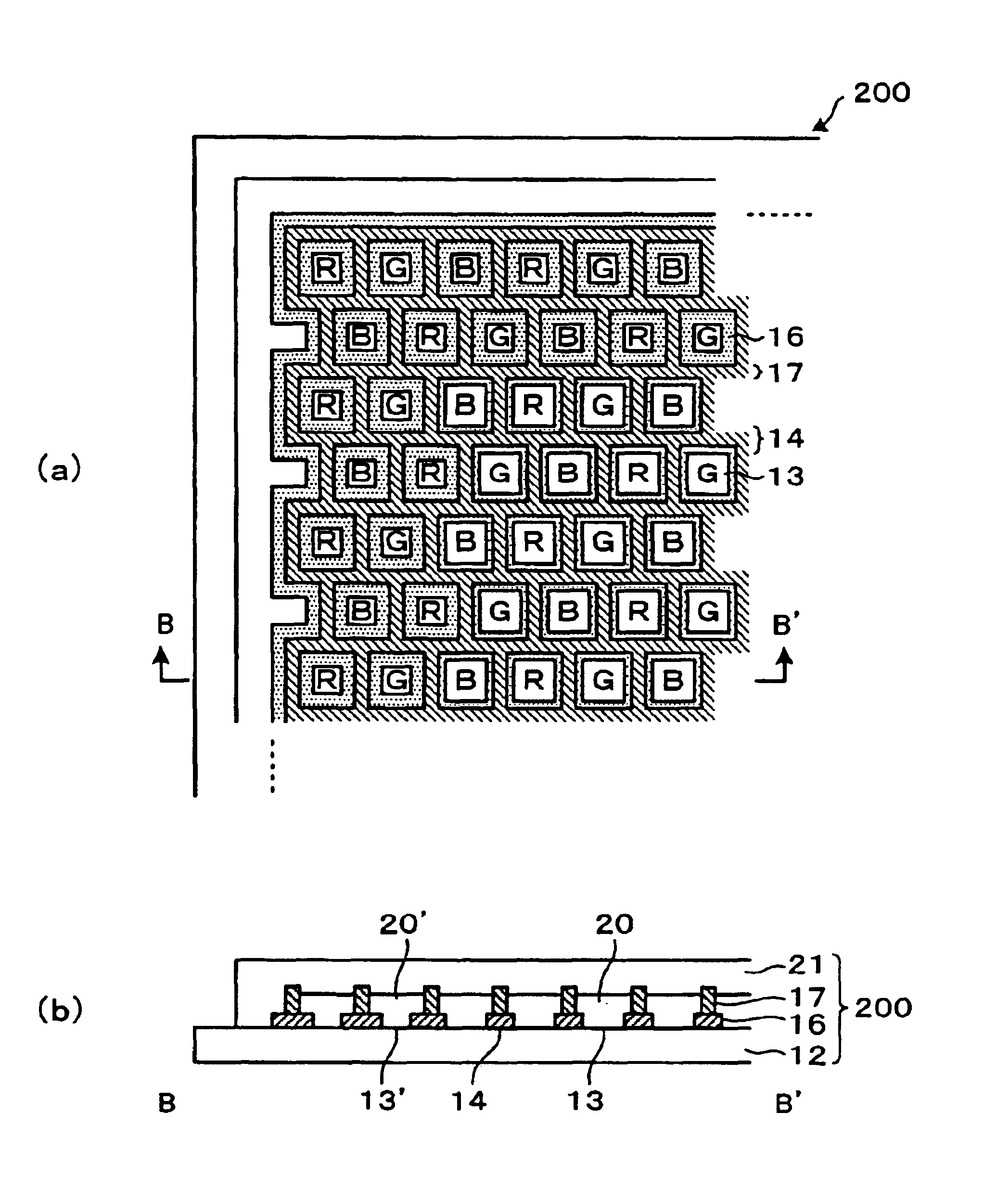

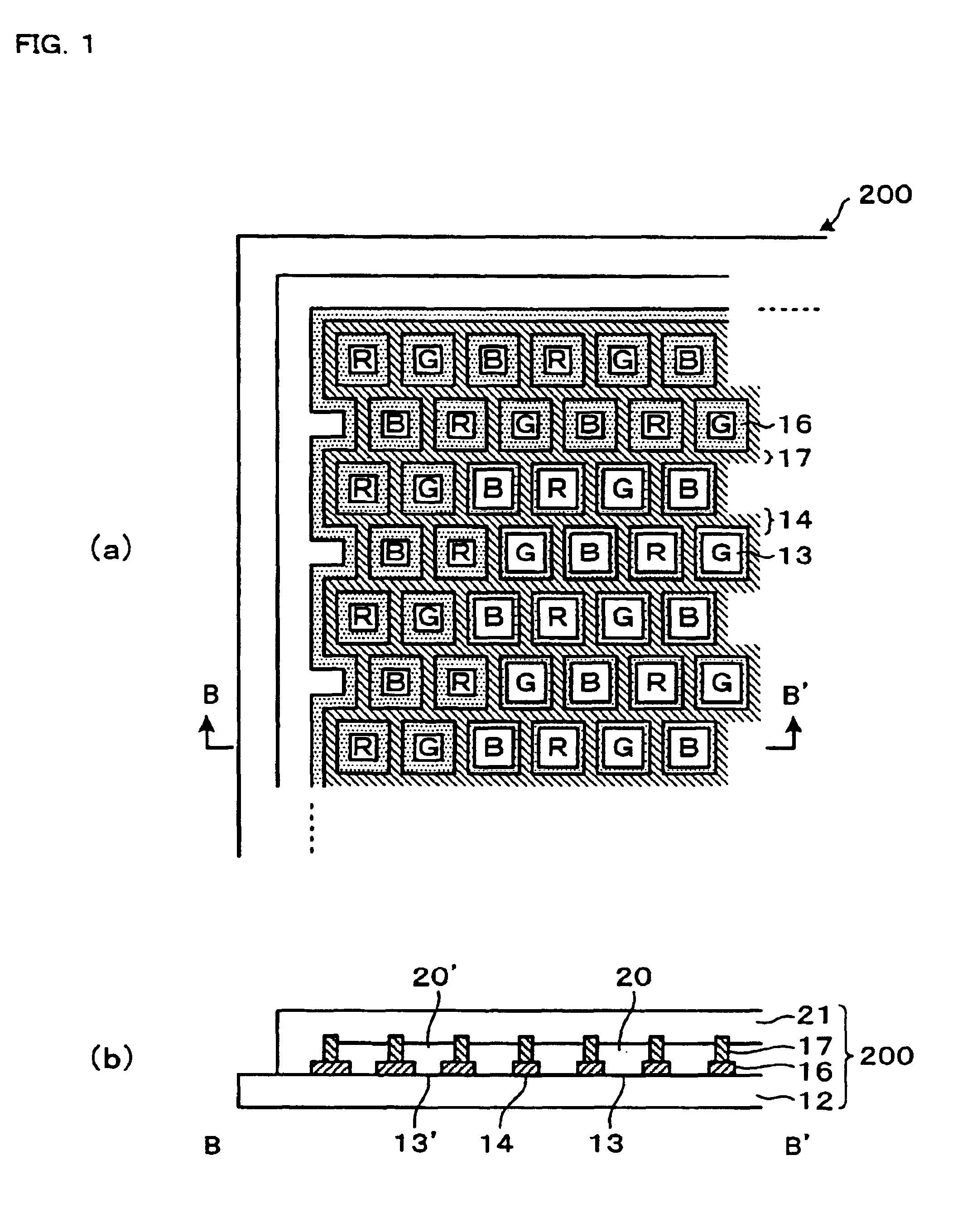

Color filter and electro-optical device

InactiveUS6887631B2Difference in qualityEvenly distributedAddress electrodesSustain/scan electrodesTectorial membraneColor gel

Owner:KATEEVA

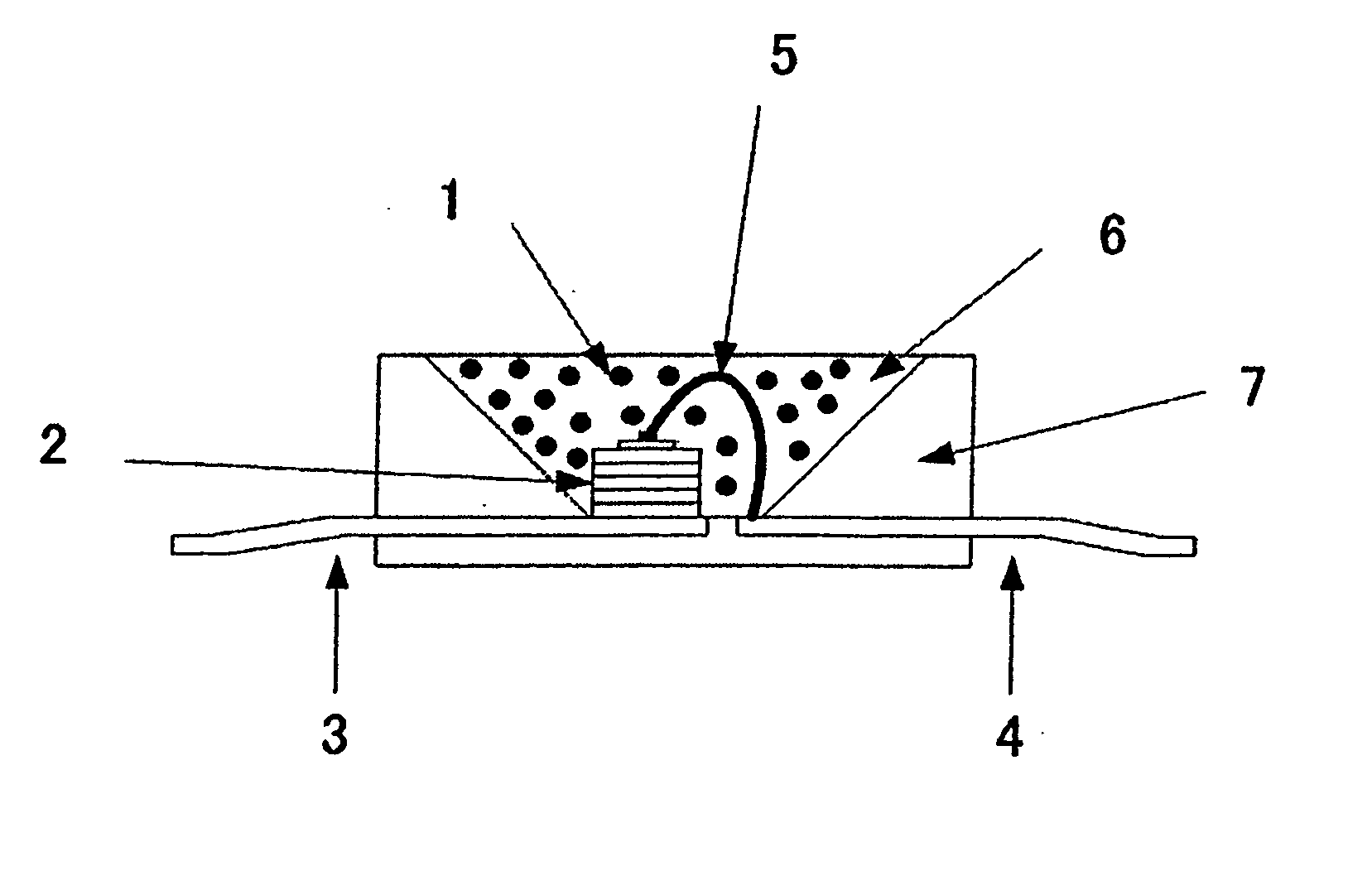

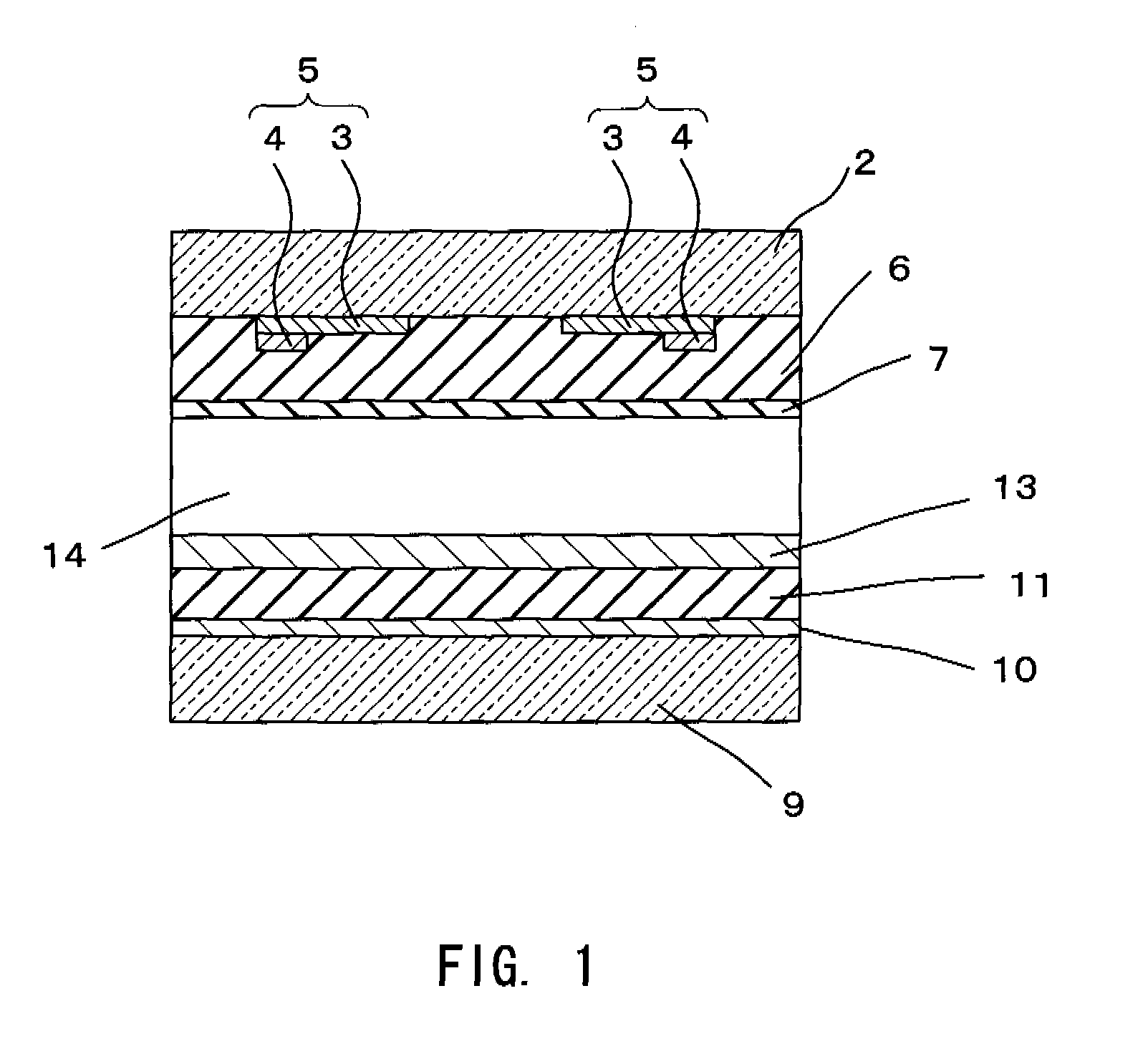

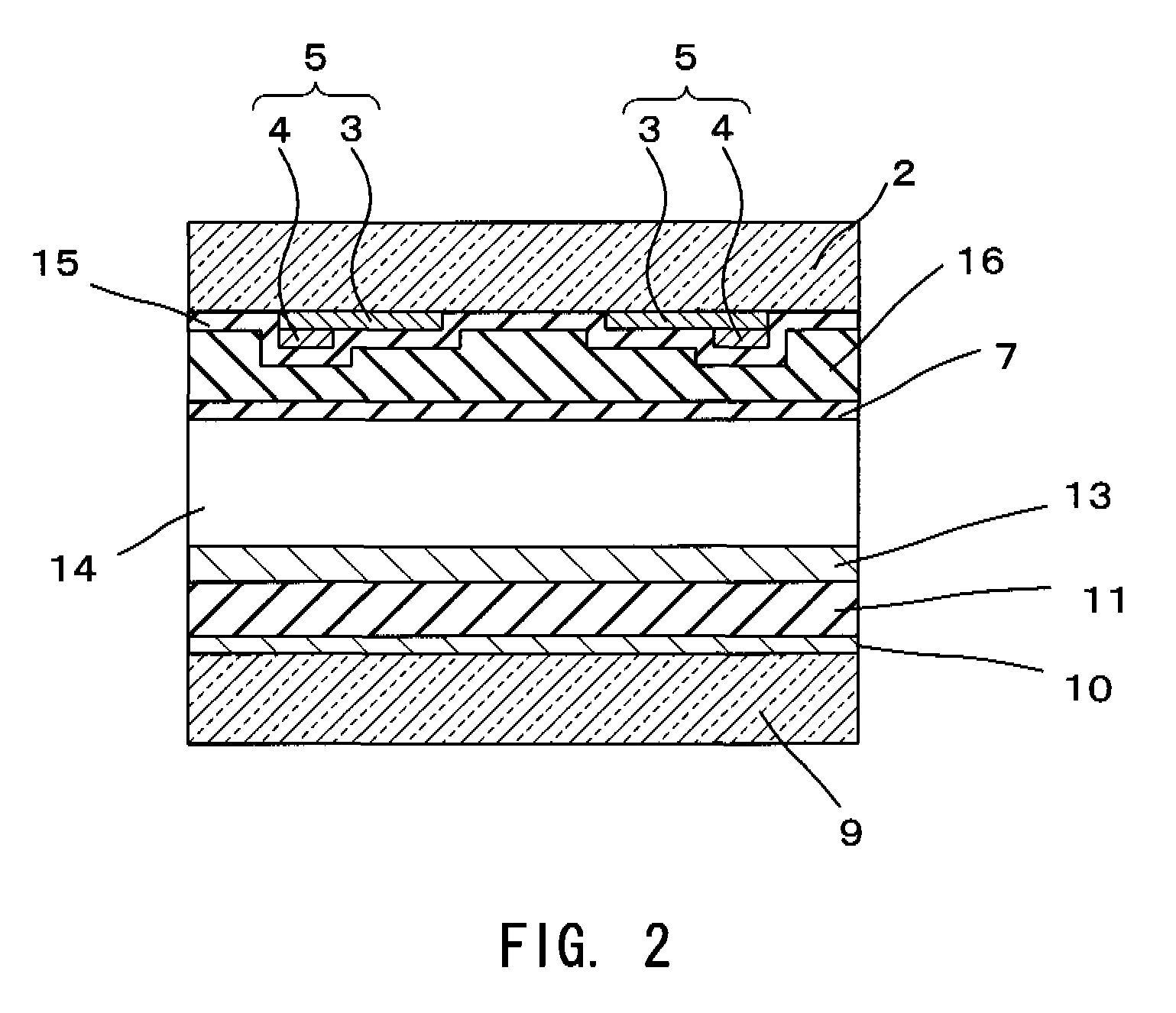

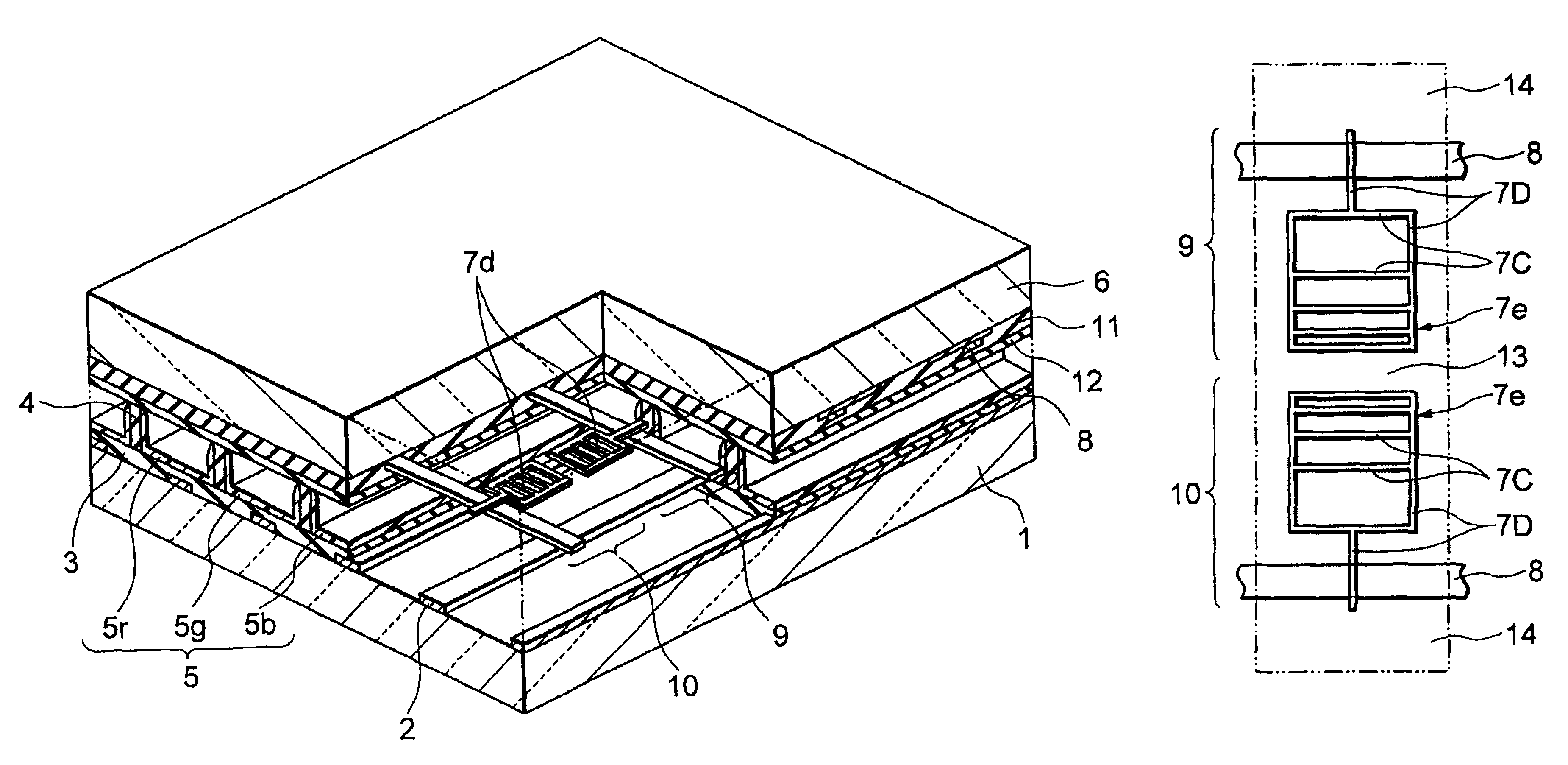

Photo-curable electrically conductive composition and plasma display panel having electrodes formed by use of the same

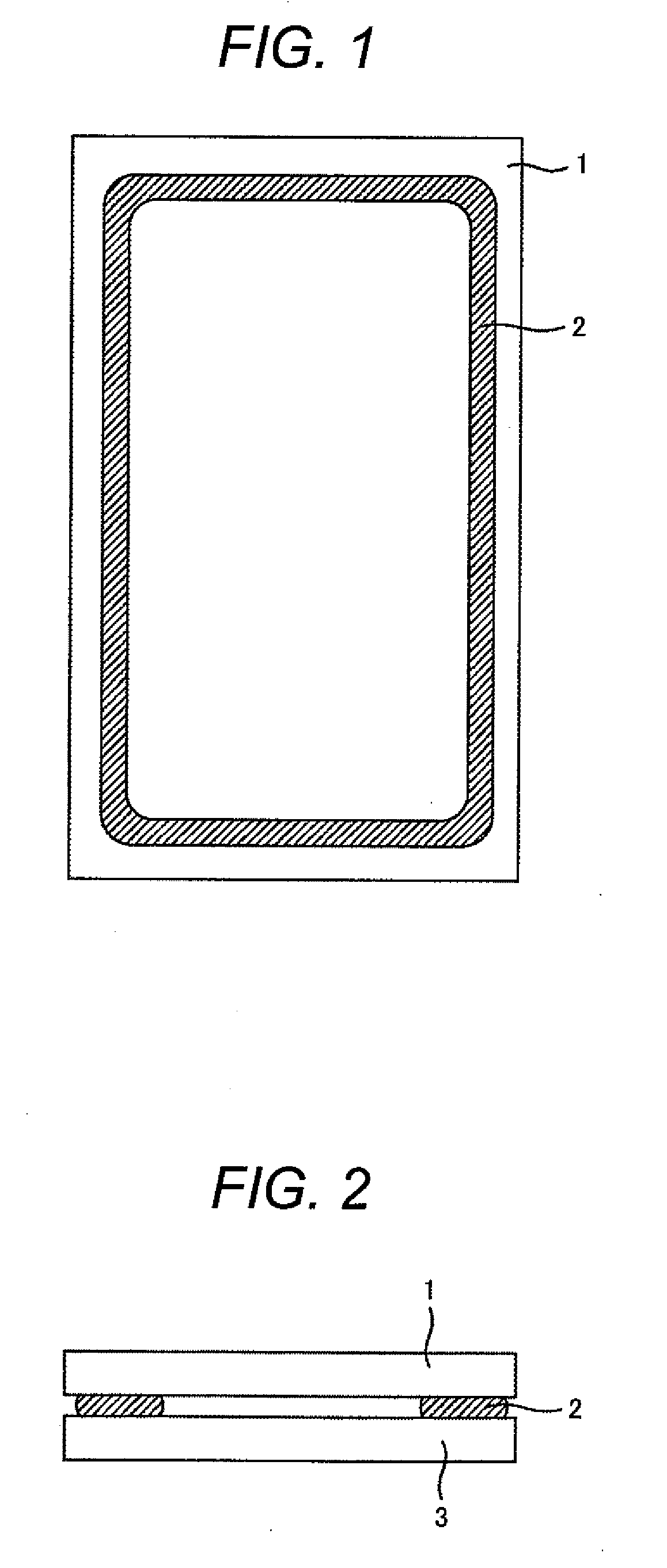

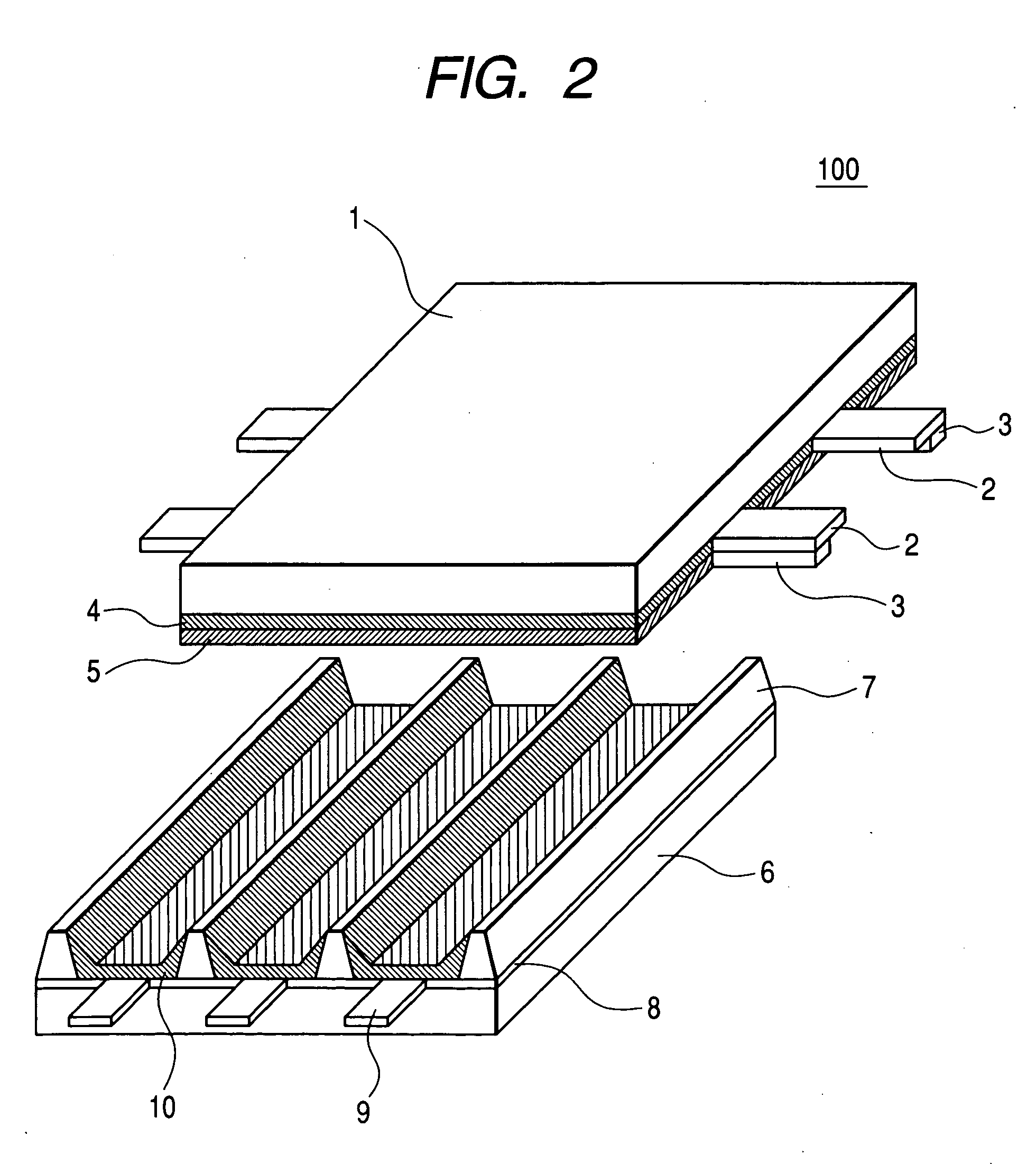

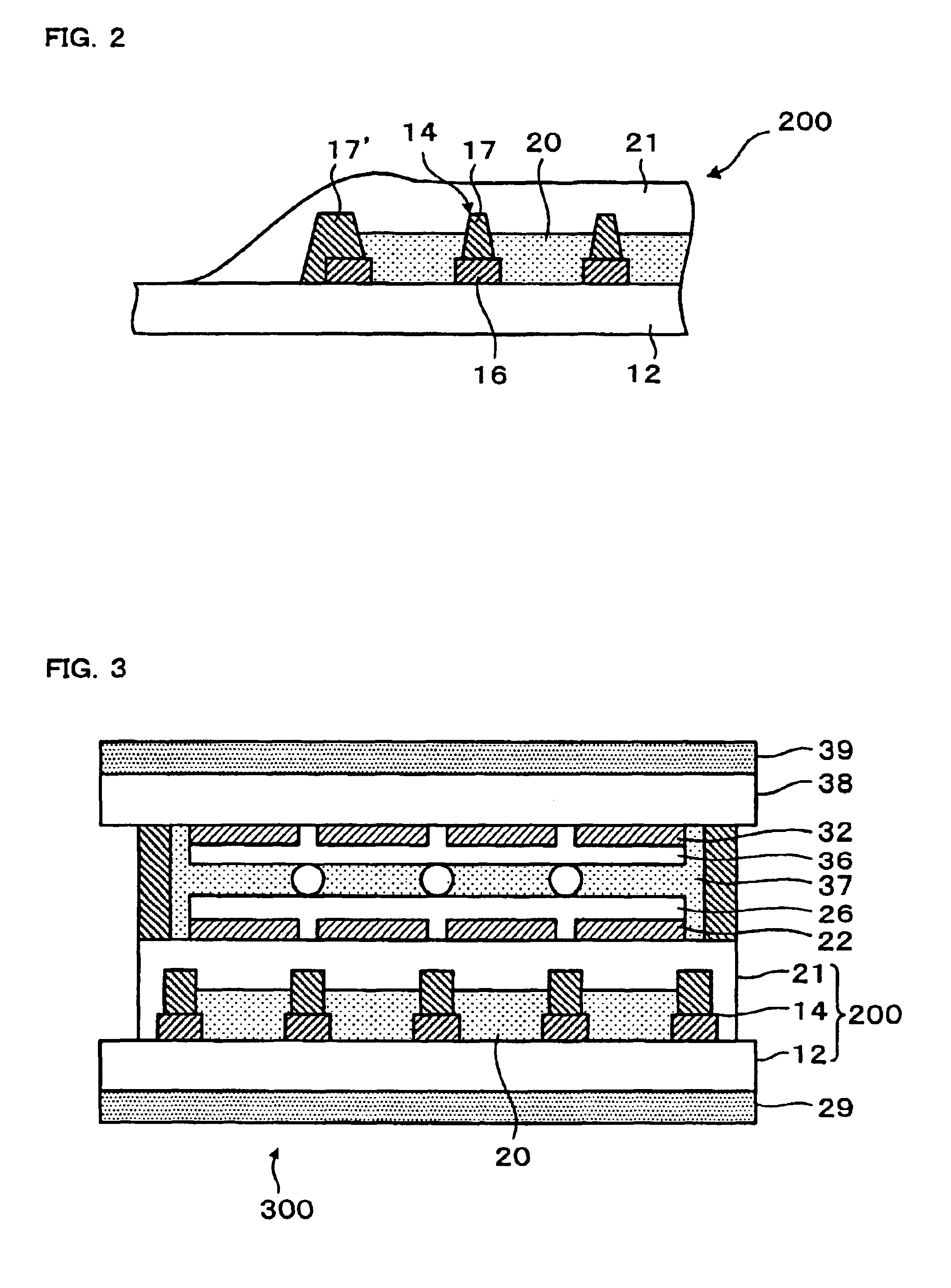

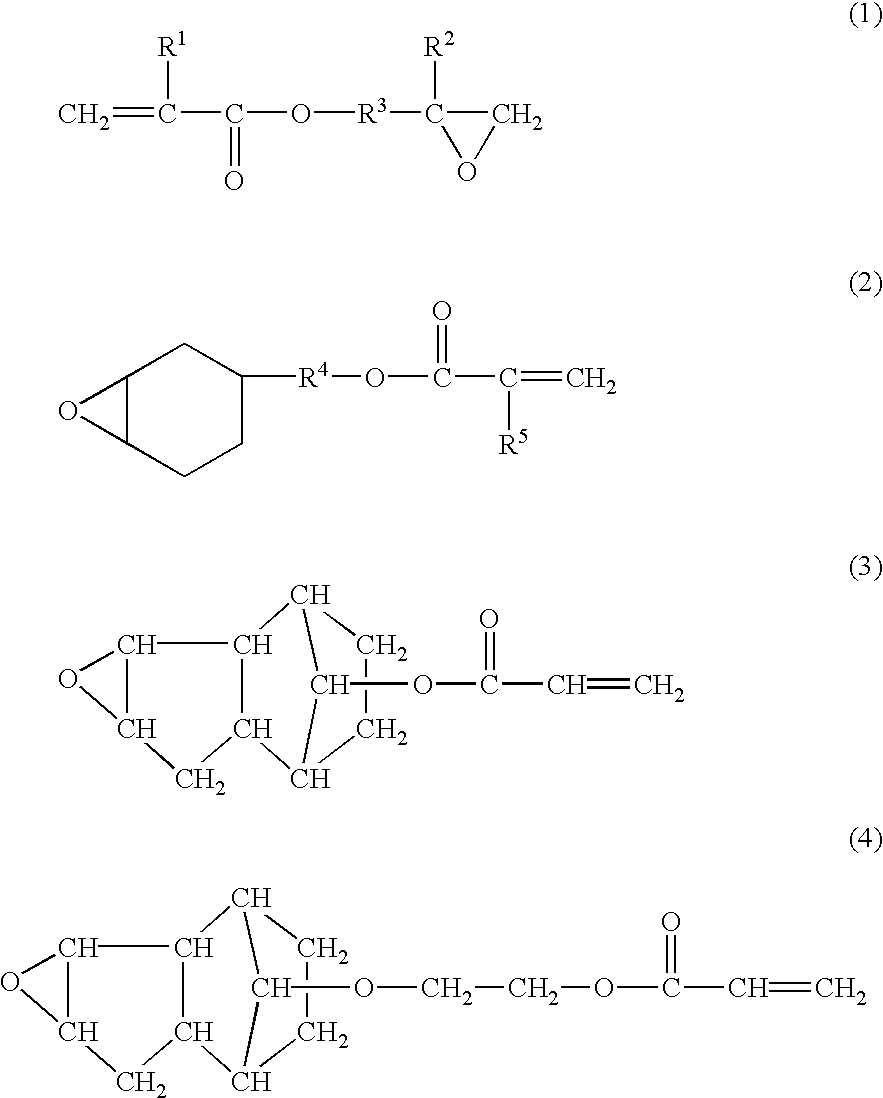

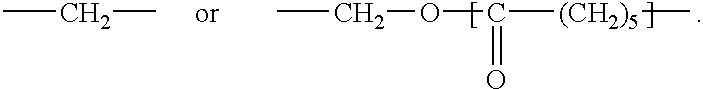

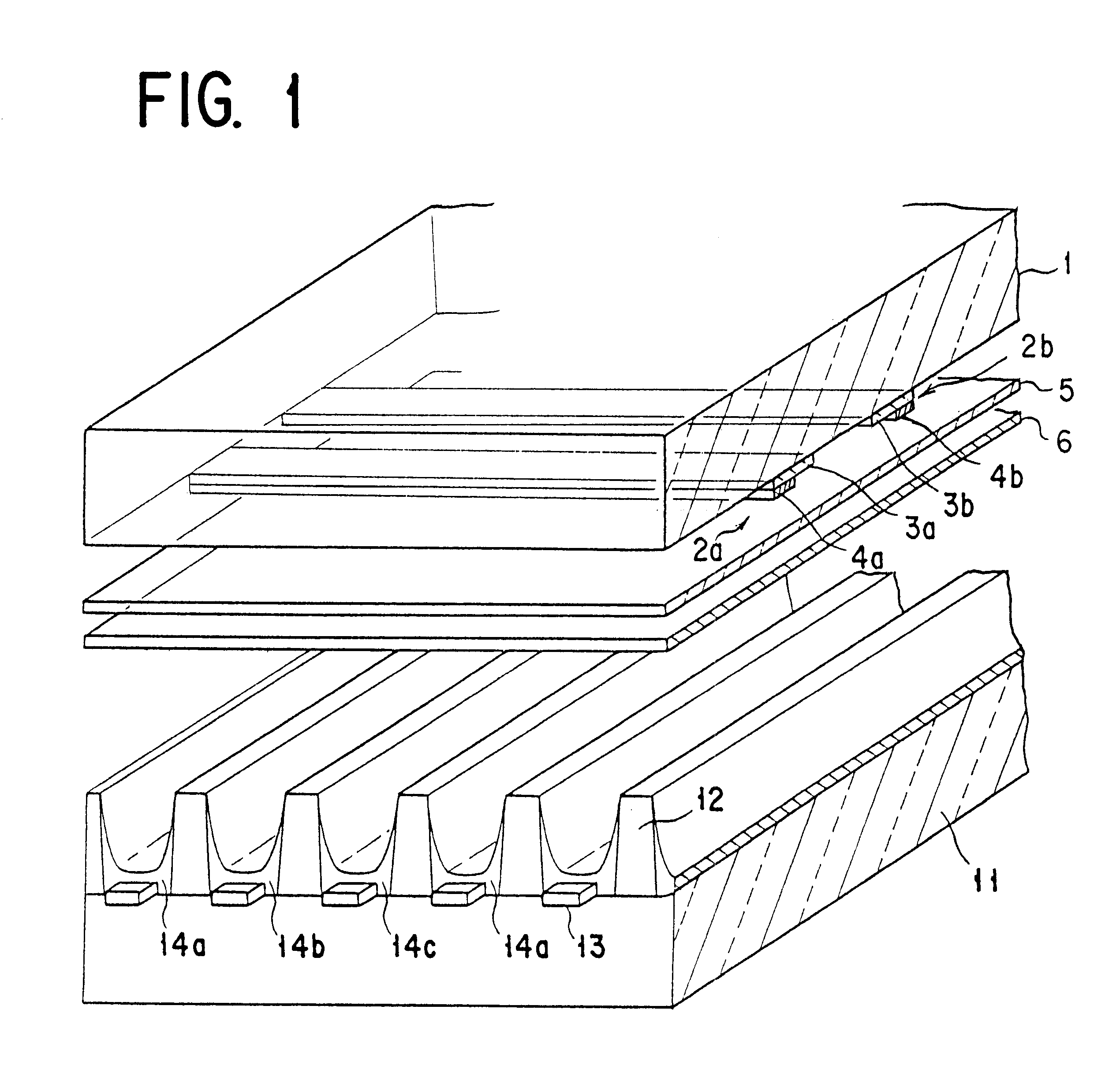

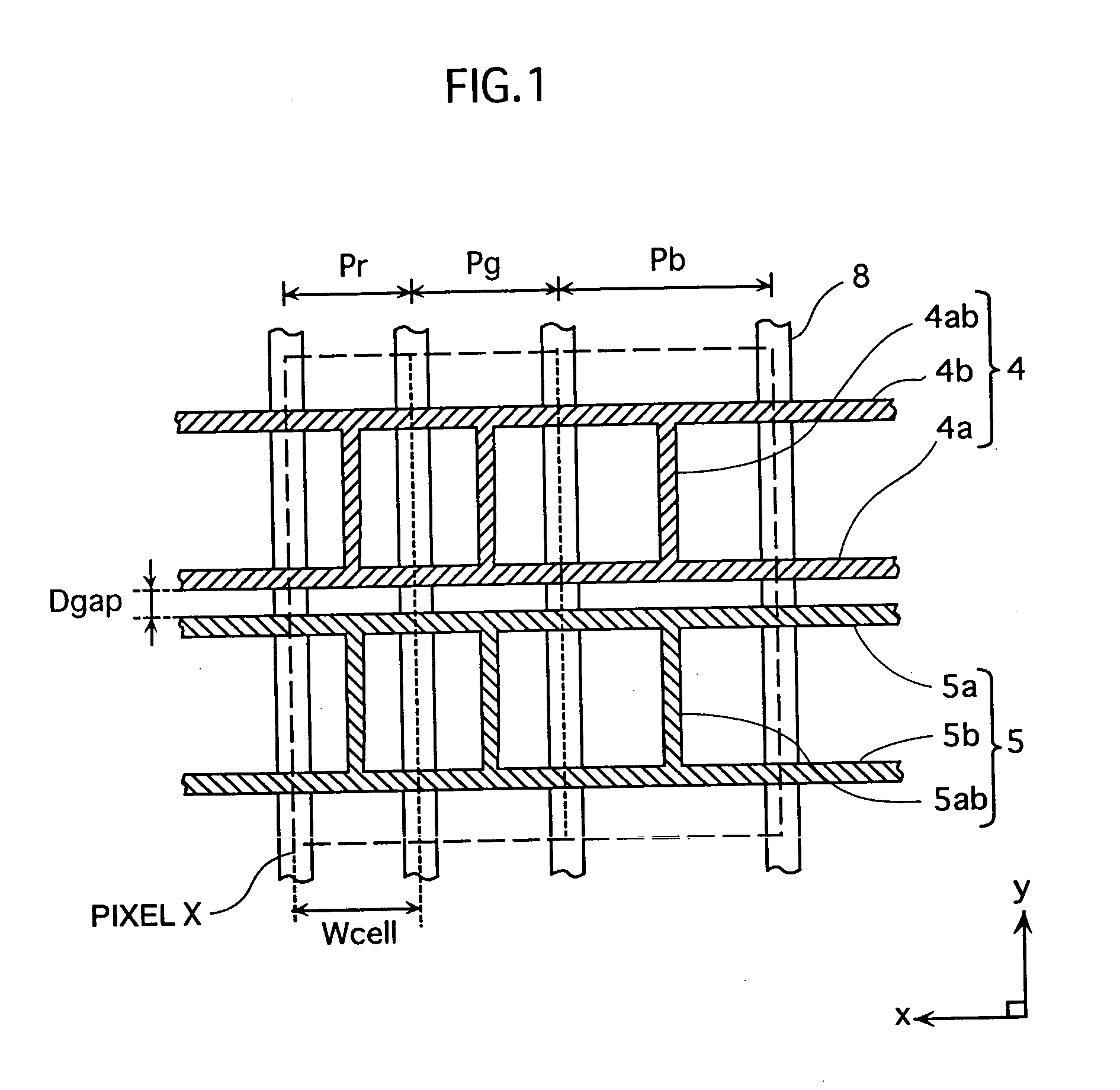

There is provided a photo-curable, electrically conductive composition which is capable of forming a lower layer (black layer) electrode circuit satisfying both the sufficient conductivity and blackness after calcination in the formation of an electrode on a front substrate of a plasma display panel (PDP). The composition comprises, in the first fundamental mode thereof, (A) electrically conductive black fine particles having a specific surface area of more than 20 m2 / g,(B) anorganic binder, (C) a photopolymerizable monomer, and (D) a photopolymerization initiator, and in the second mode further comprises (E) inorganic fine particles besides the above components. The lower layer (black layer) electrode circuit of bus electrodes (4a, 4b) of the PDP is formed by applying such a photo-curable, electrically conductive composition on transparent electrodes (3a, 3b) of a front glass substrate (1), exposing the applied layer to light according to a predetermined pattern, and subjecting the layer to development and calcination.

Owner:TAIYO INK MFG

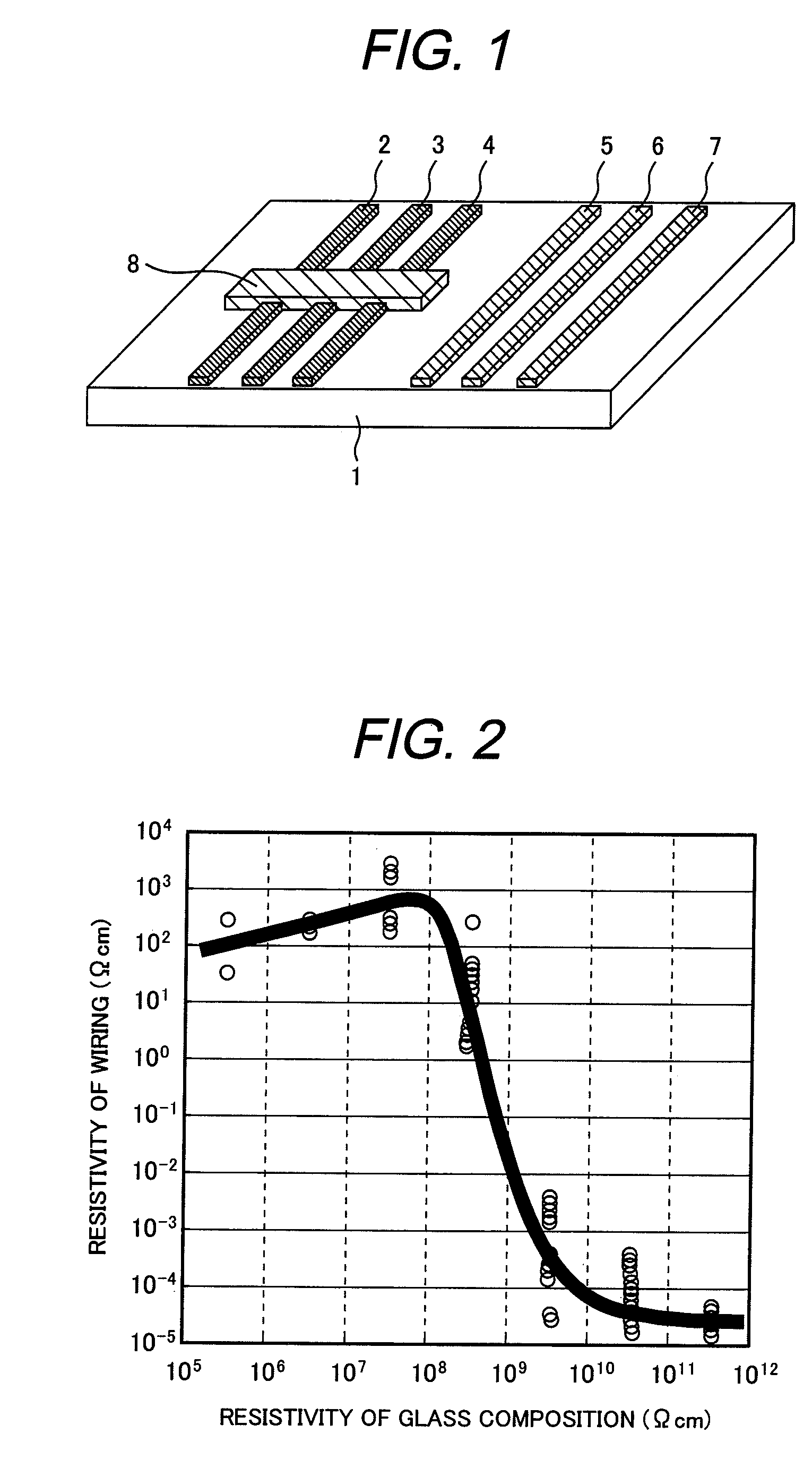

Glass composition and its applications

InactiveUS20090199897A1Reduce the temperatureLow air tightness requirementsConductive layers on insulating-supportsSustain/scan electrodesVanadium oxideMaterials science

Owner:HITACHI POWDERED METALS COMPANY

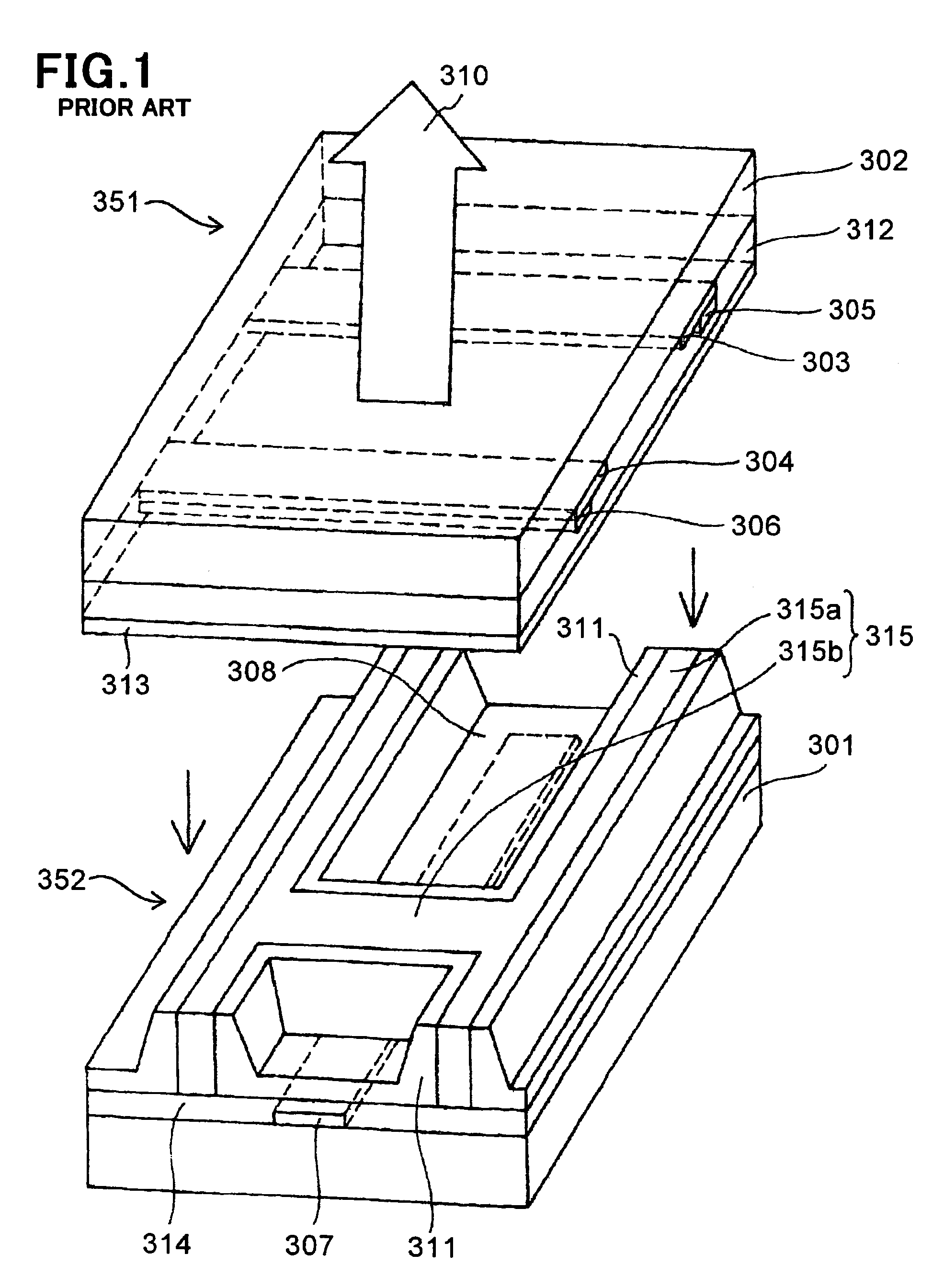

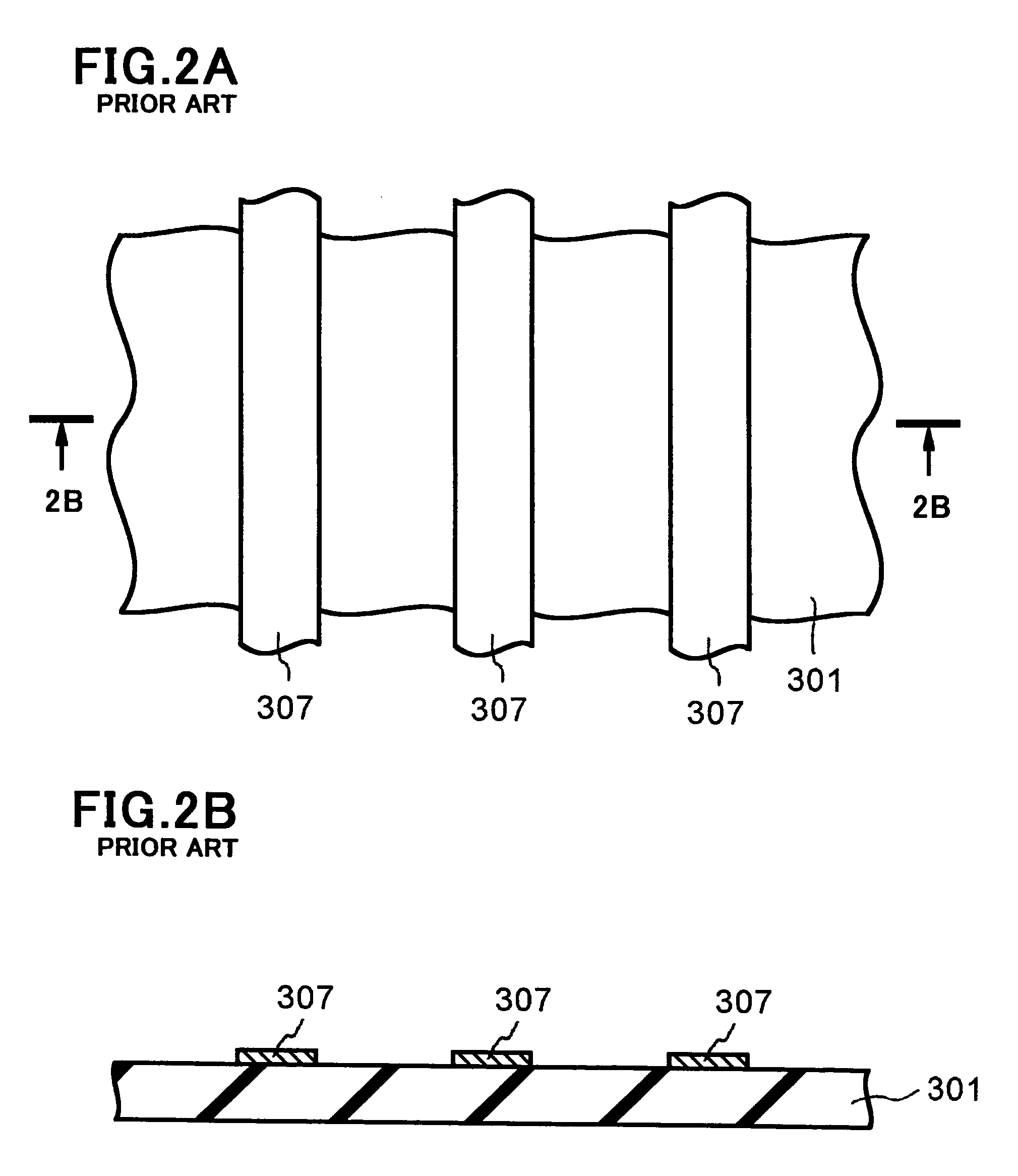

Gas dischargeable panel

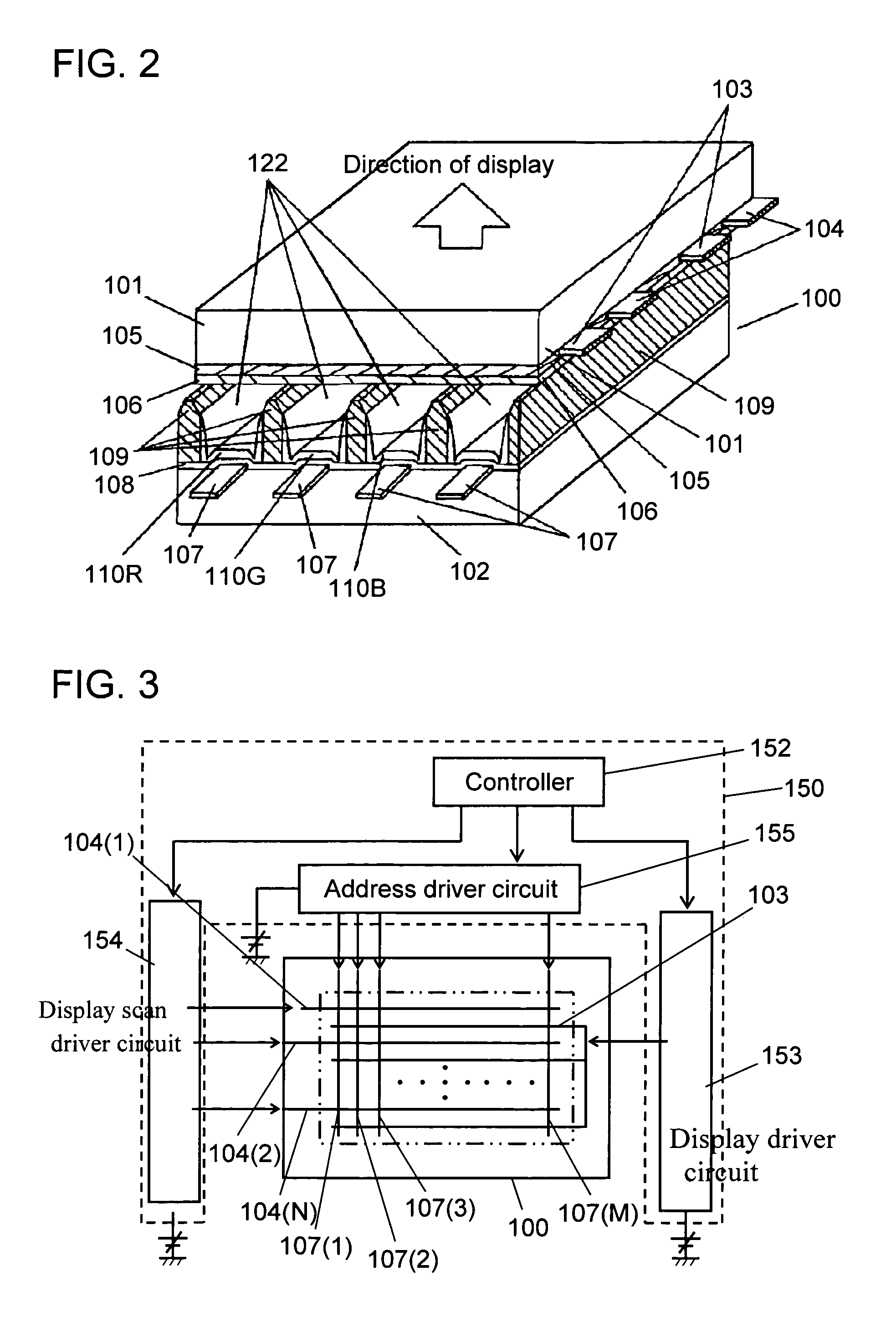

InactiveUS20040032215A1Illumination efficiency is highImprove reflectivityAddress electrodesSustain/scan electrodesElectrode pairElectrical and Electronics engineering

A gas discharge panel includes a first substrate and a second substrate. A plurality of display electrode pairs which are each made up of a sustain electrode and a scan electrode are formed on the first substrate, and the first substrate and the second substrate are set facing each other with a plurality of barrier ribs in between so as to form a plurality of cells. In this gas discharge panel, at least one of the sustain electrode and the scan electrode includes: a plurality of line parts; and a discharge developing part which makes a gap between adjacent line parts smaller in areas corresponding to channels between adjacent barrier ribs than in areas corresponding to the barrier ribs.

Owner:PANASONIC CORP

Electrode and method of manufacture

InactiveUS7557507B2Avoid breakingSustain/scan electrodesAlternating current plasma display panelsElectrical conductorLine width

An electrode on a substrate of a plasma display panel has a relatively narrow bus line conductor at an intersection with a pad, and a line width of the pad being wider than a line width of the bus line conductor and substantially narrower than a line width of a wider section of the pad, which avoids a break in the electrode when the electrode is fired at an elevated temperature.

Owner:AU OPTRONICS CORP

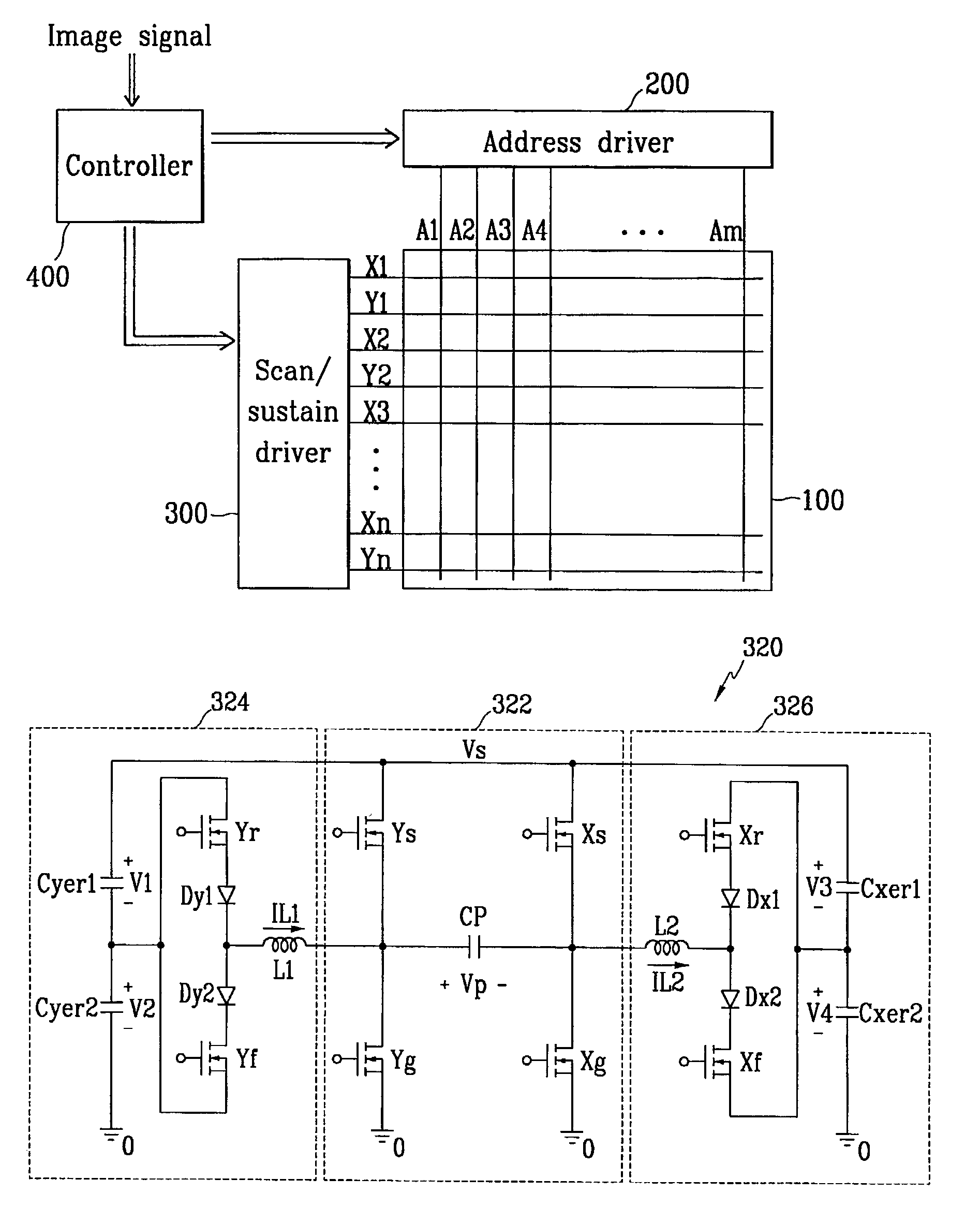

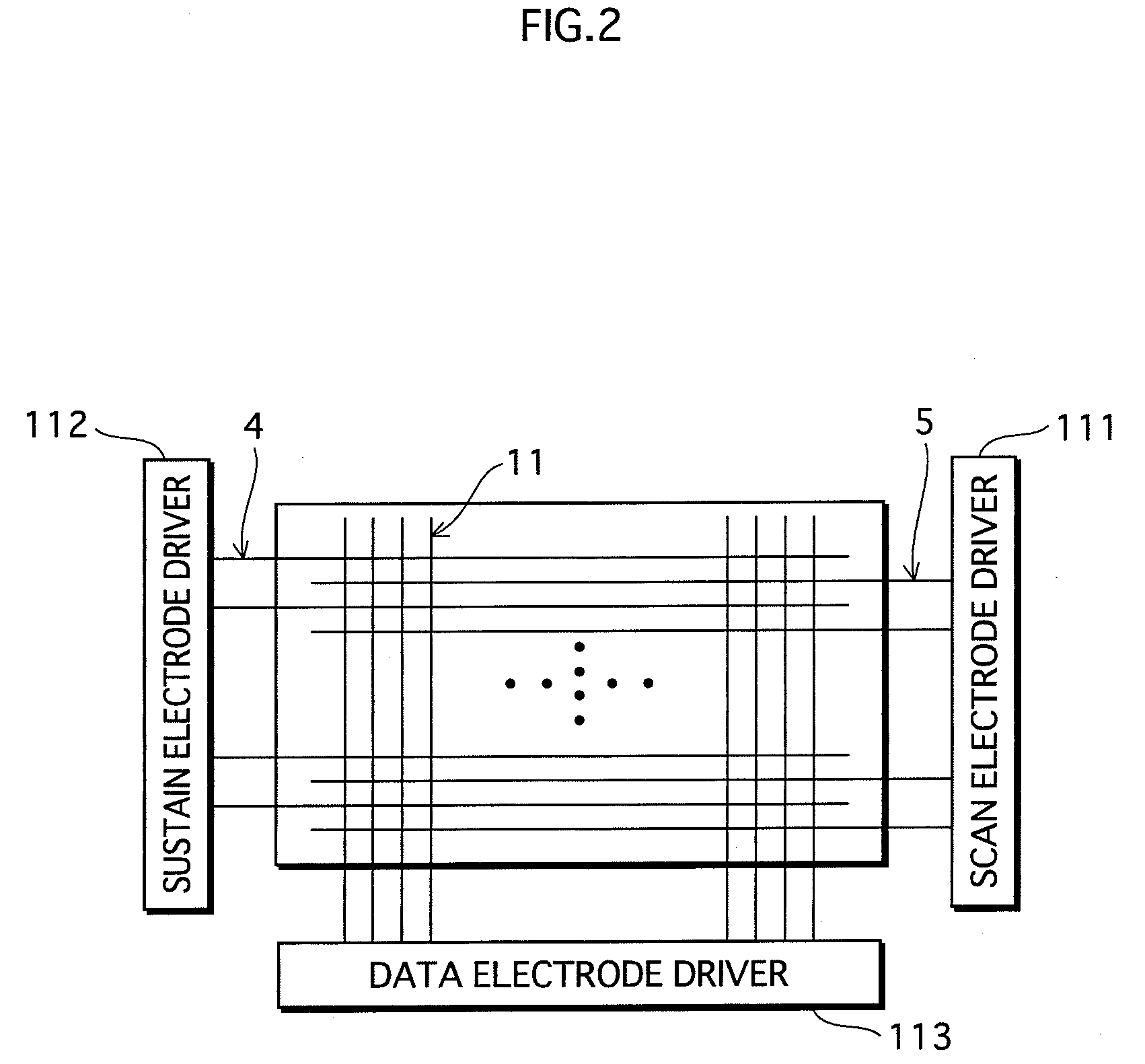

Plasma display panel, and apparatus and method for driving the same

InactiveUS7027010B2Total current dropShorten the timeAddress electrodesSustain/scan electrodesStored energyTerminal voltage

A PDP driving apparatus includes a sustain discharge unit including a first switch and a second switch connected between a first voltage and second voltage and having a contact connected to one terminal of a panel capacitor, and a third switch and a fourth switch connected between the voltages and having a contact connected to other terminal of the panel capacitor, for maintaining either terminal voltage at the first voltage or the second voltage; and a charge / discharge unit including a first inductor and a second inductor connected to the terminals of the panel capacitor, for boosting a current to a level to store energy in the first inductor and the second inductor while either terminal voltage of the panel capacitor is maintained at the sustain discharge voltage, and inverting the polarity of either terminal voltage using the stored energy.

Owner:SAMSUNG SDI CO LTD

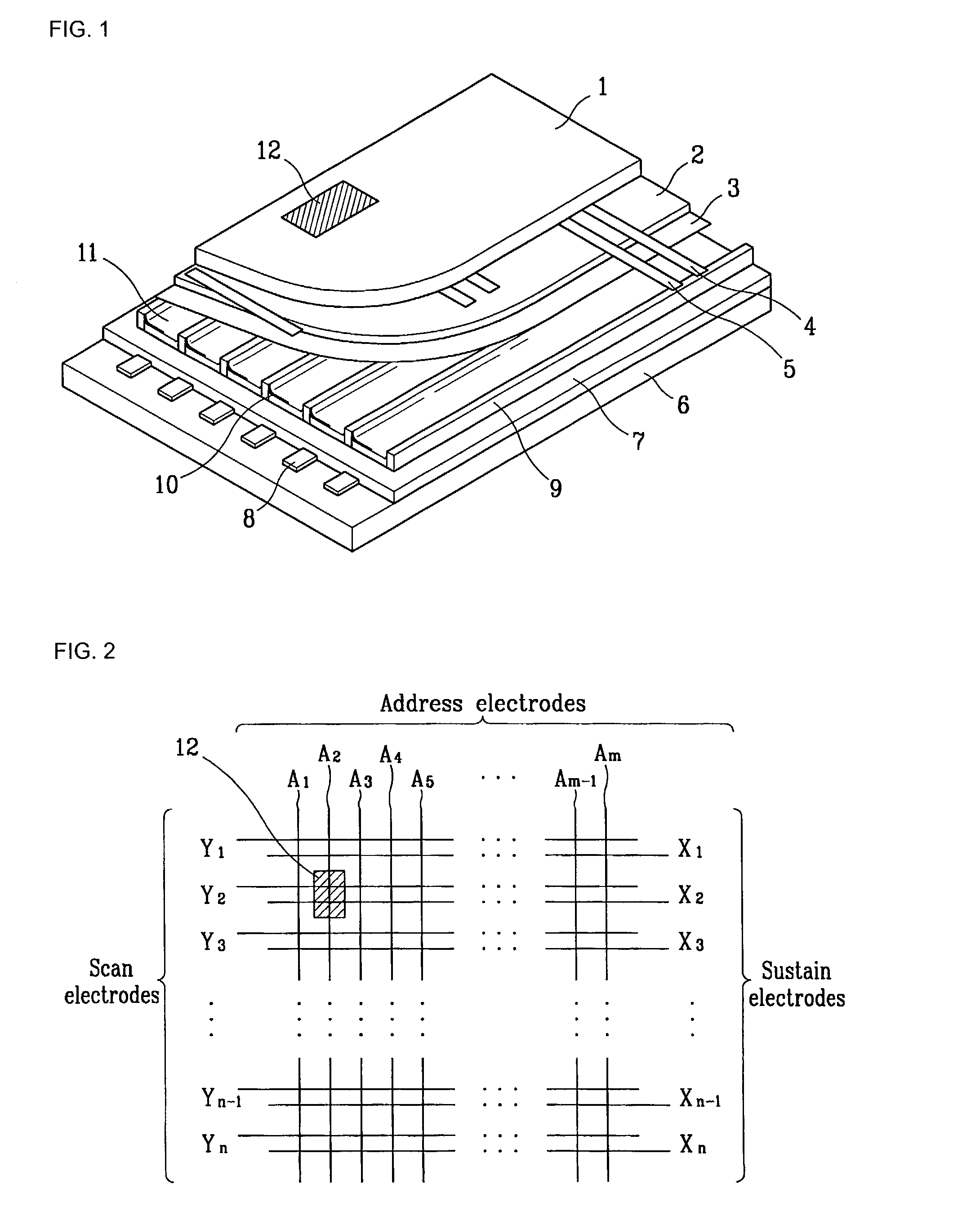

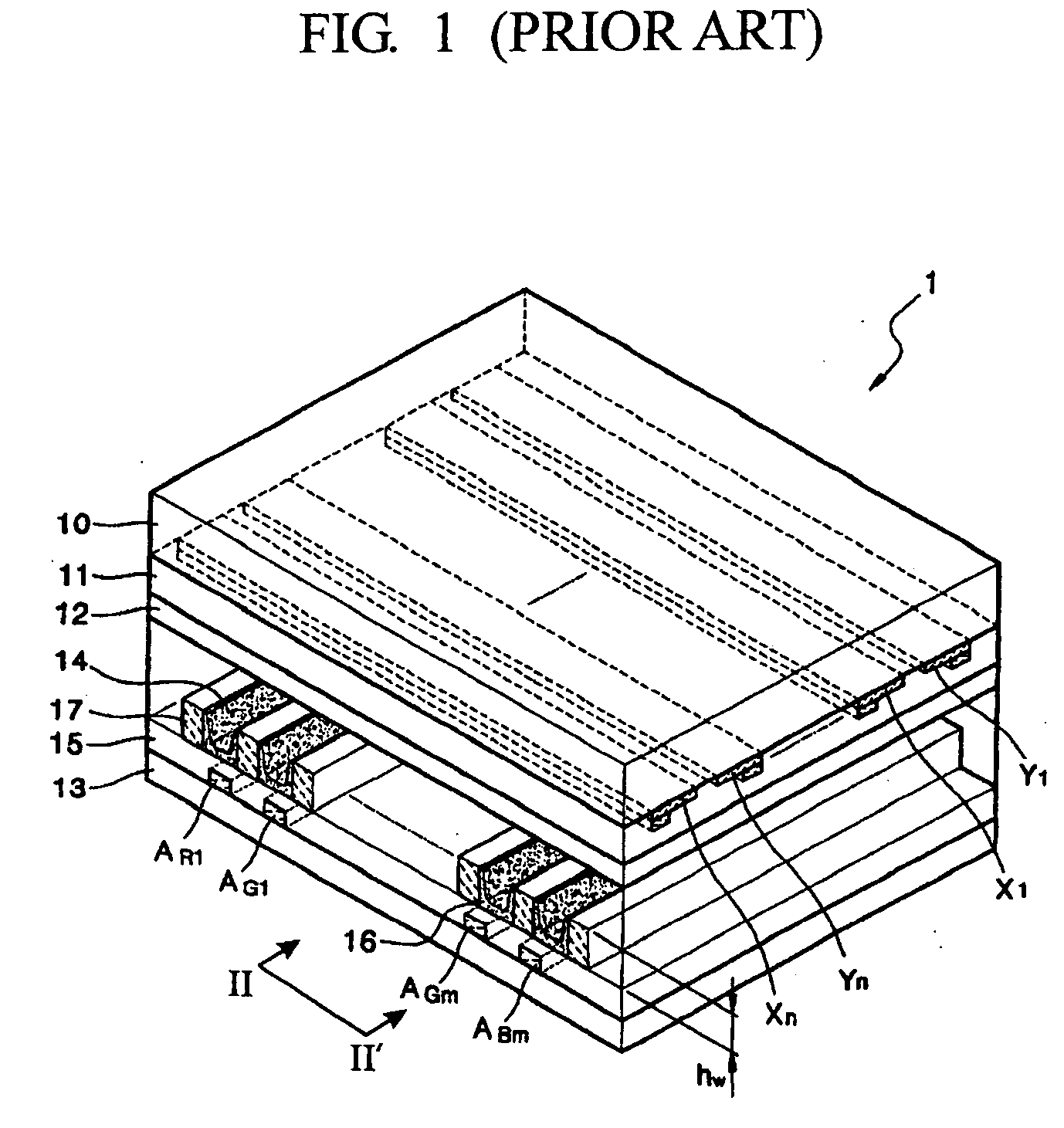

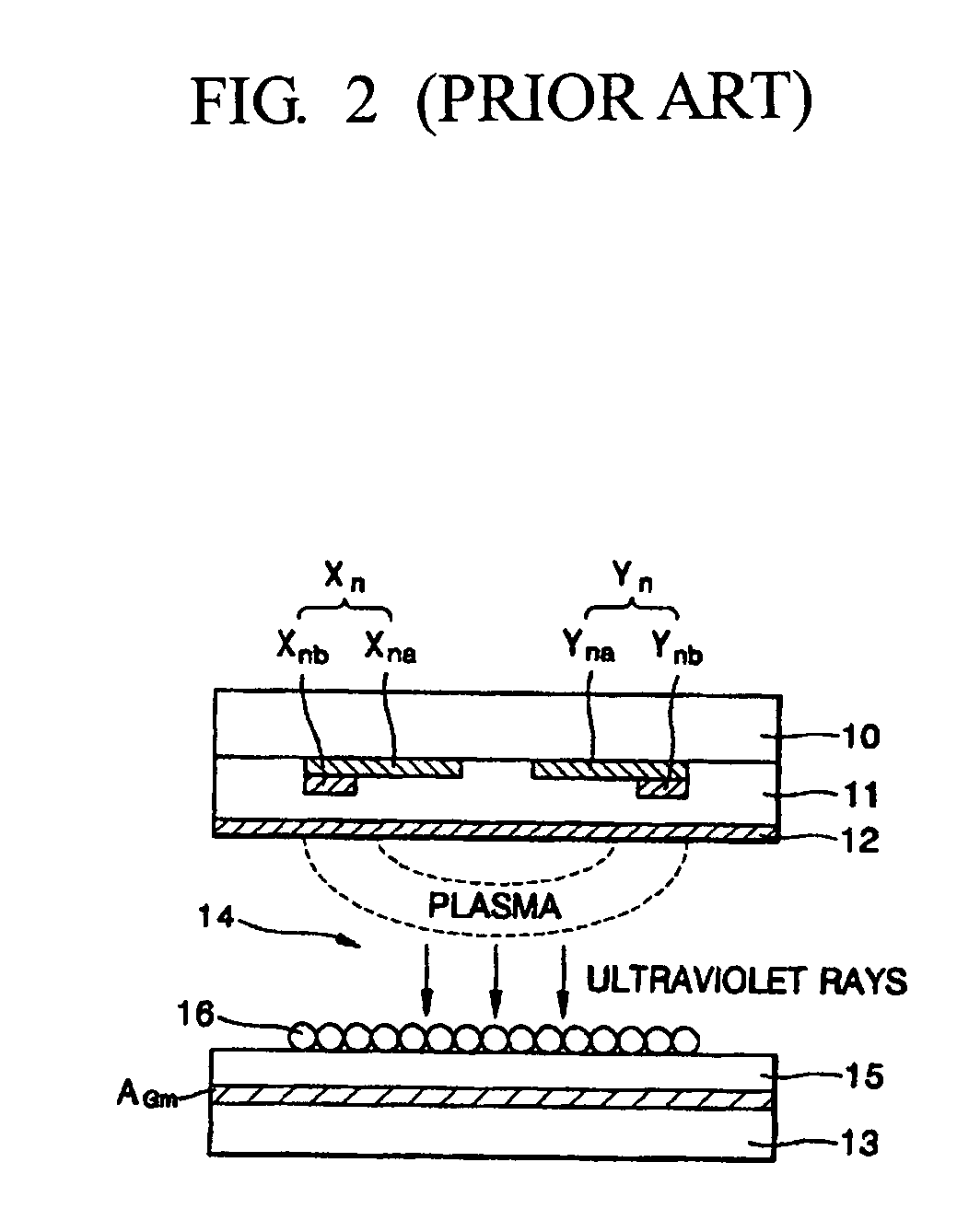

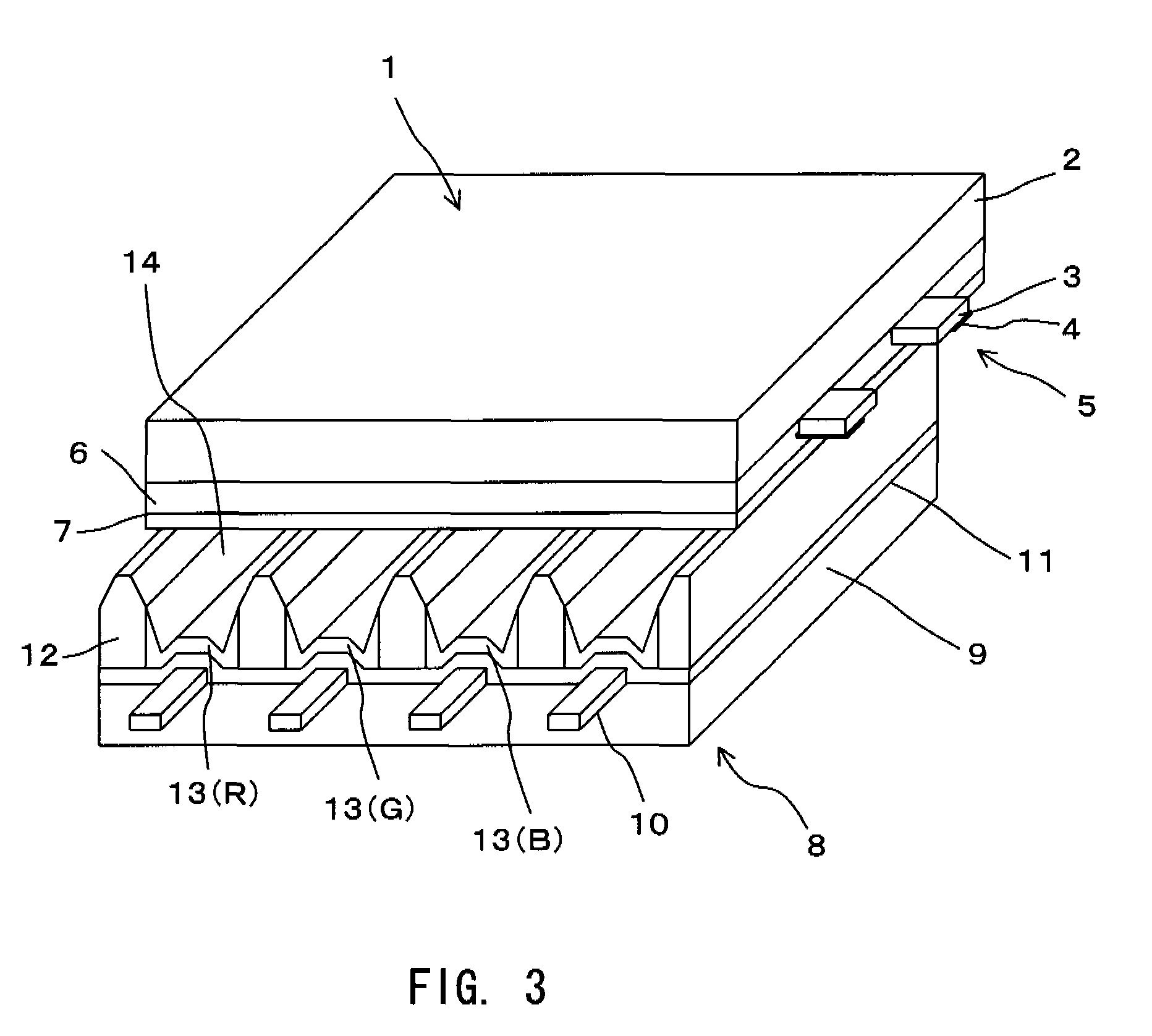

Plasma display panel

InactiveUS7239085B2Suppress brightness changesReduce brightnessAddress electrodesSustain/scan electrodesFluorescencePhosphor

A plasma display panel includes a first substrate, and a second substrate facing the first substrate. The first substrate includes a transparent substrate, a scanning electrode and a common electrode both formed on the transparent substrate, and a dielectric layer covering the transparent substrate, the scanning electrode and the common electrode therewith. The second substrate includes an electrically insulating substrate, data electrodes formed on the electrically insulating substrate, partition walls formed on the electrically insulating substrate, and a phosphor layer covering the electrically insulating substrate and the data electrodes therewith between adjacent partition walls. The phosphor layer includes a blue-phosphor layer composed of phosphor which emits a blue light. The blue-phosphor layer is composed of a mixture of two or more phosphors each of which emits a blue light and has an initial brightness and variation of brightness with the lapse of time both different from one another.

Owner:PANASONIC CORP

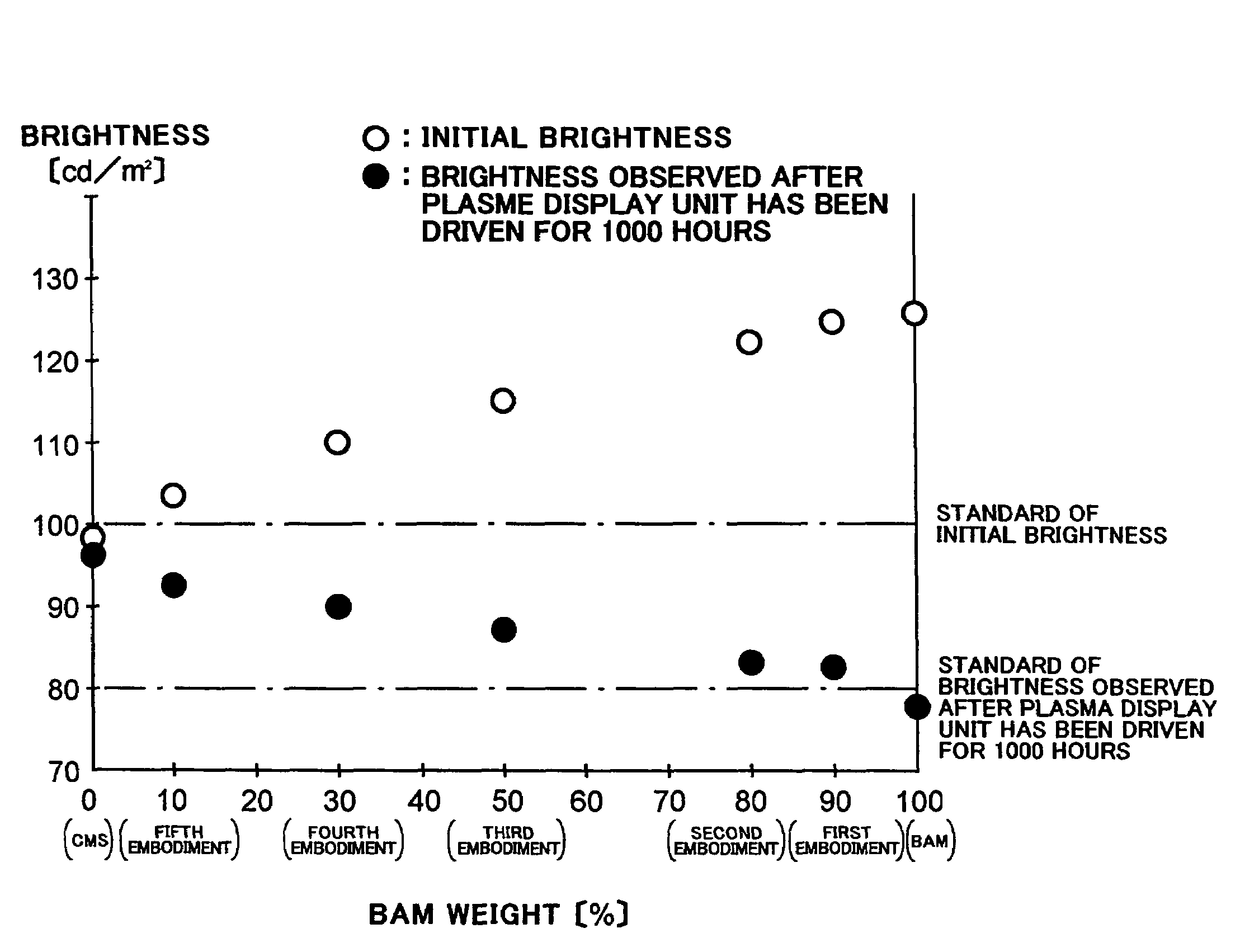

Plasma display unit, phosphor and process for producing phosphor

InactiveUS7208102B2Inhibition of adsorptionDecrease in luminanceAddress electrodesSustain/scan electrodesPhosphorFluorescence

A plasma display device exhibits suppressed luminance degradation of a phosphor, a suppressed change in chromaticity and improved discharge characteristics as a result of suppression of adsorption of water or hydrocarbon-containing gas on a surface of a blue phosphor. A blue phosphor layer used in the plasma display device is formed of a compound expressed by Ba1−XMgAl10O17:EuX or Ba1−x−ySryMgAl10O17:EuX and includes at least one element that is selected from Nb, Ta, Pr, P, As, Sb, Bi and Tm which substitutes for a part of its Al or Mg element.

Owner:PANASONIC CORP

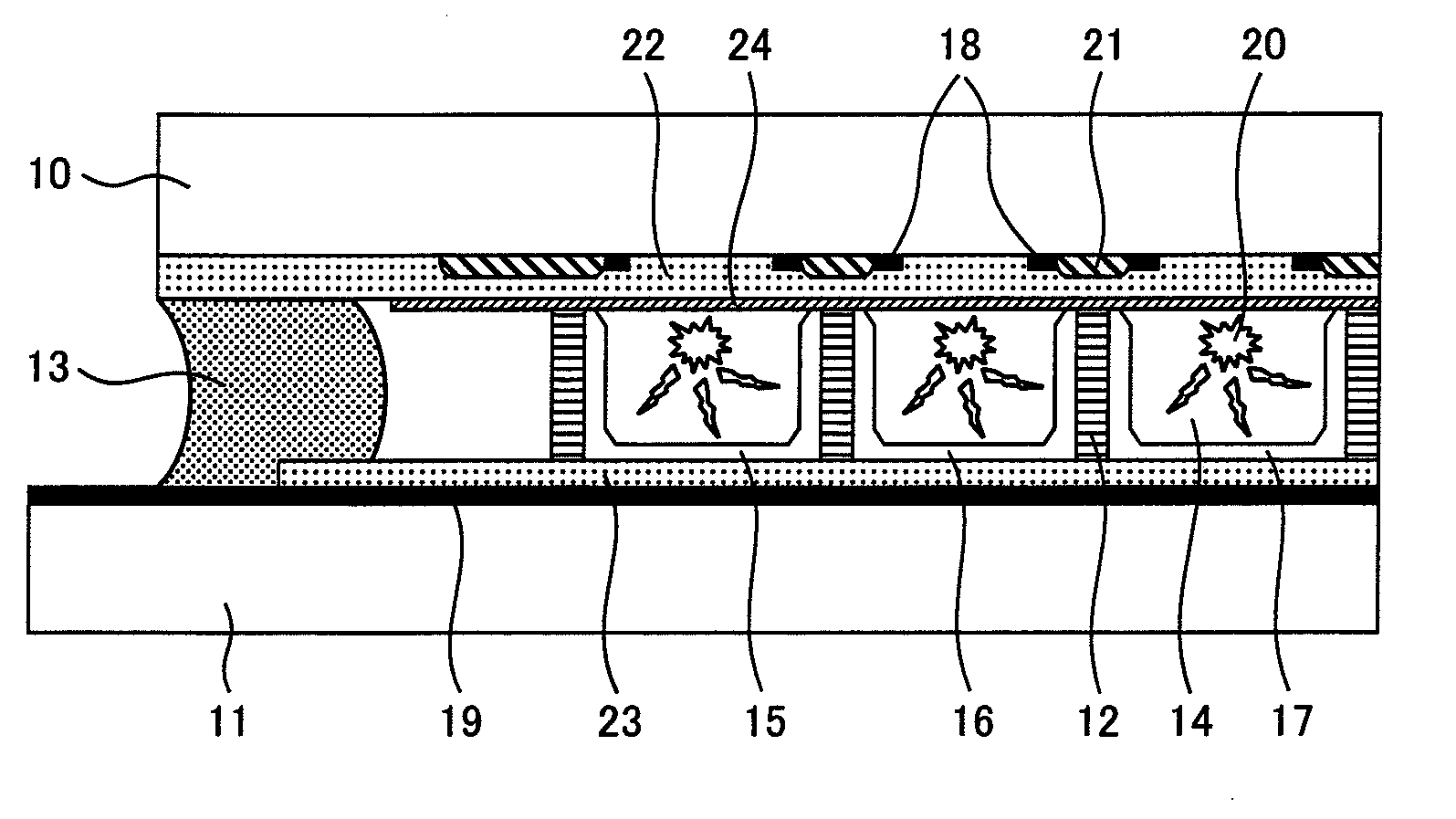

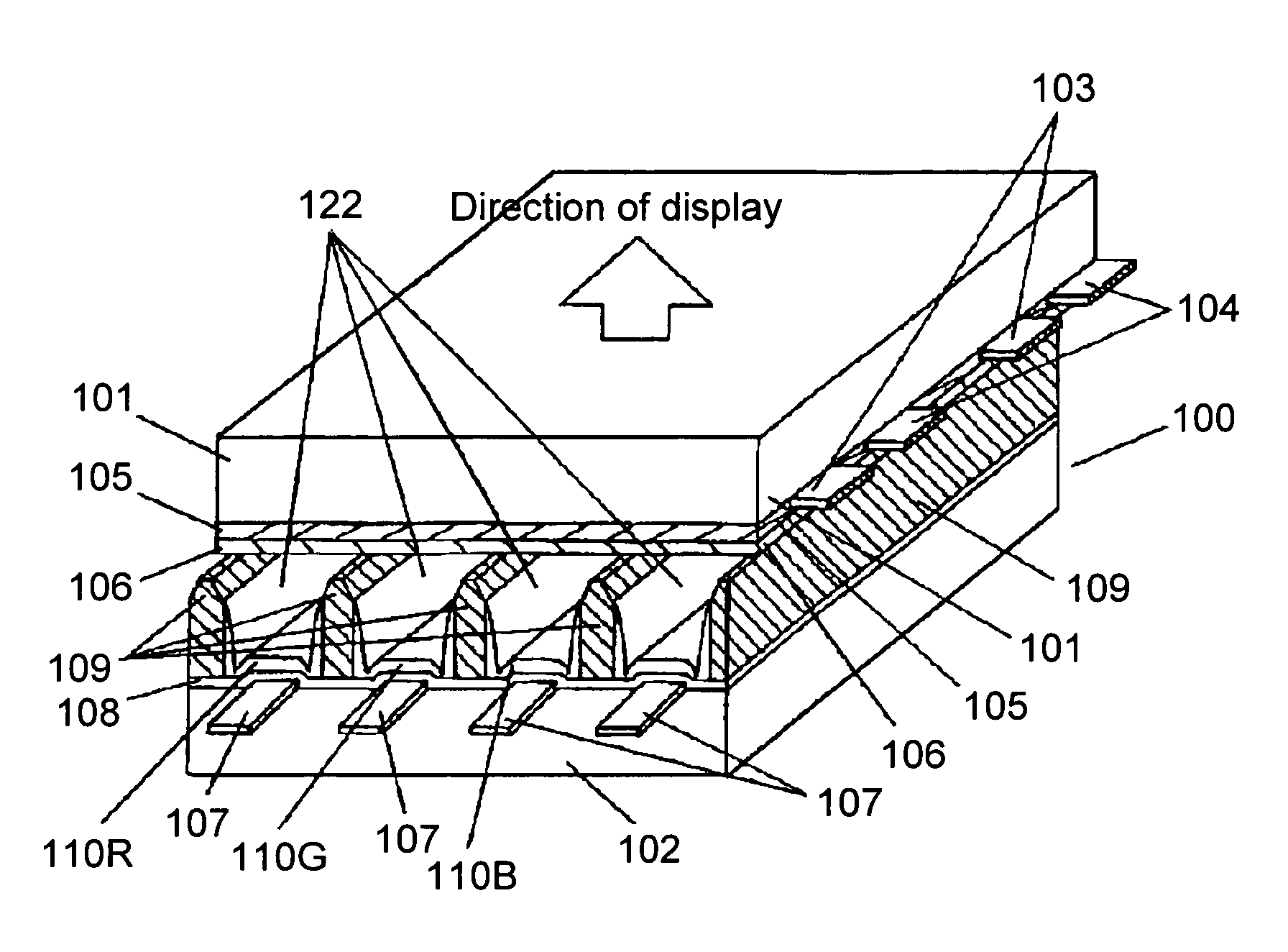

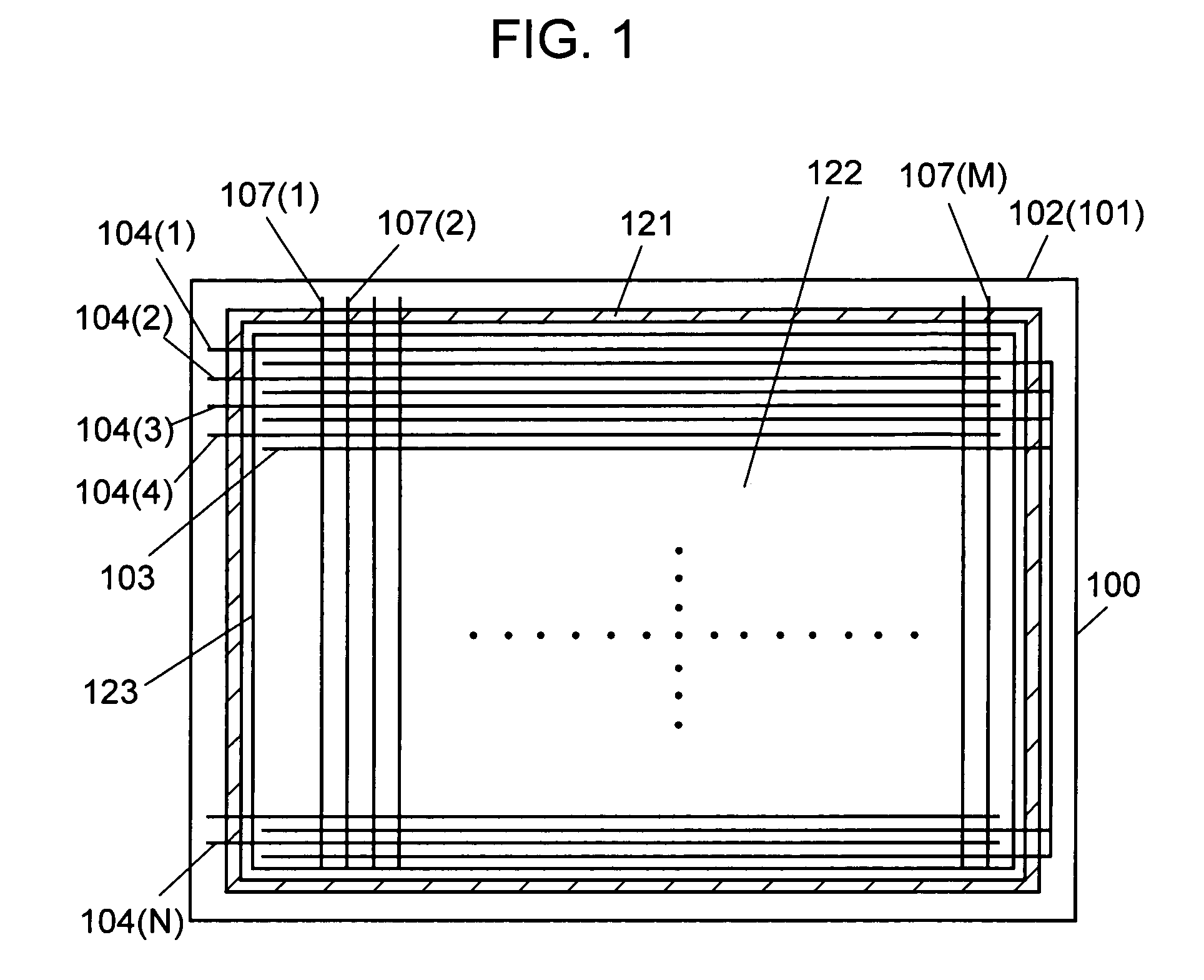

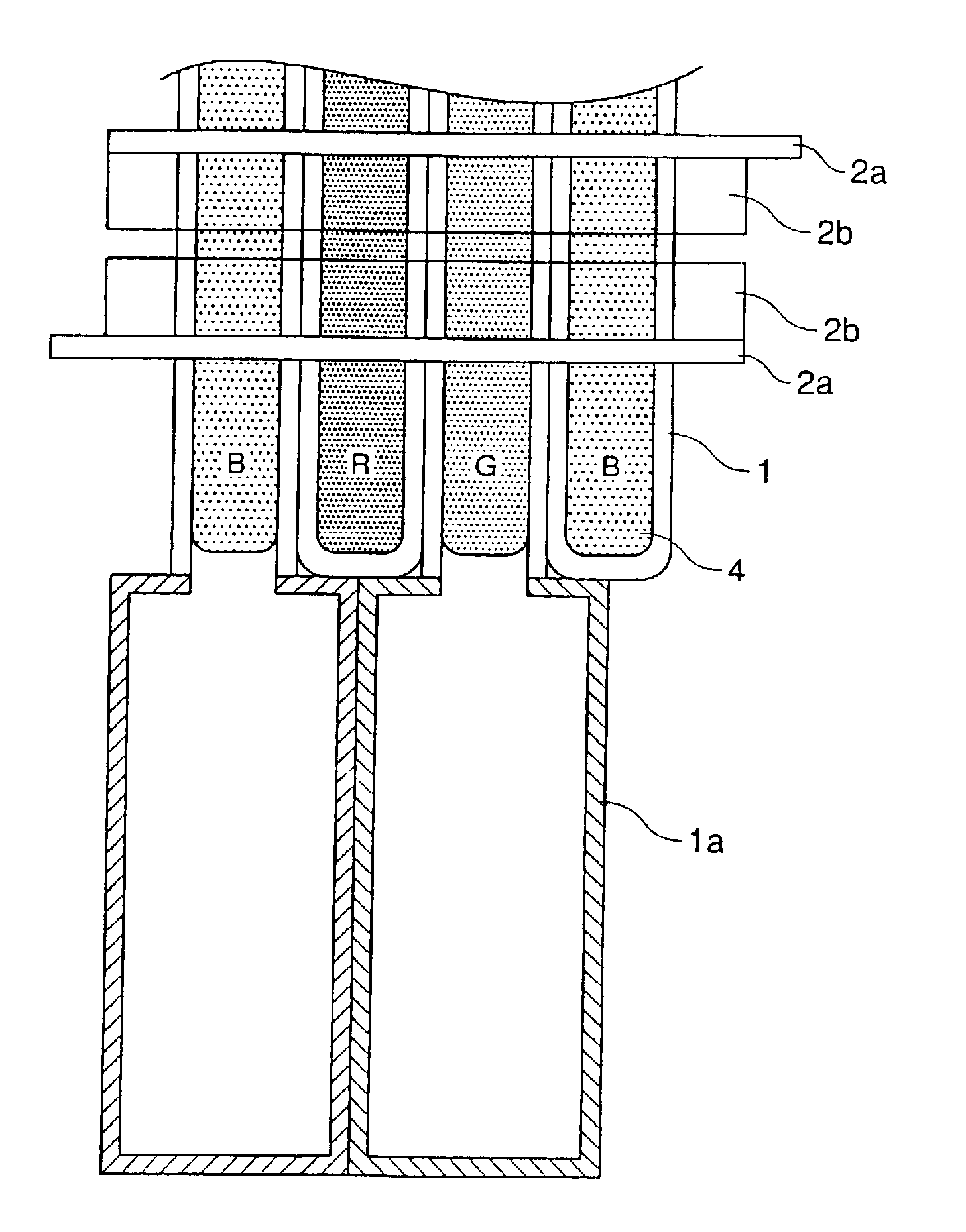

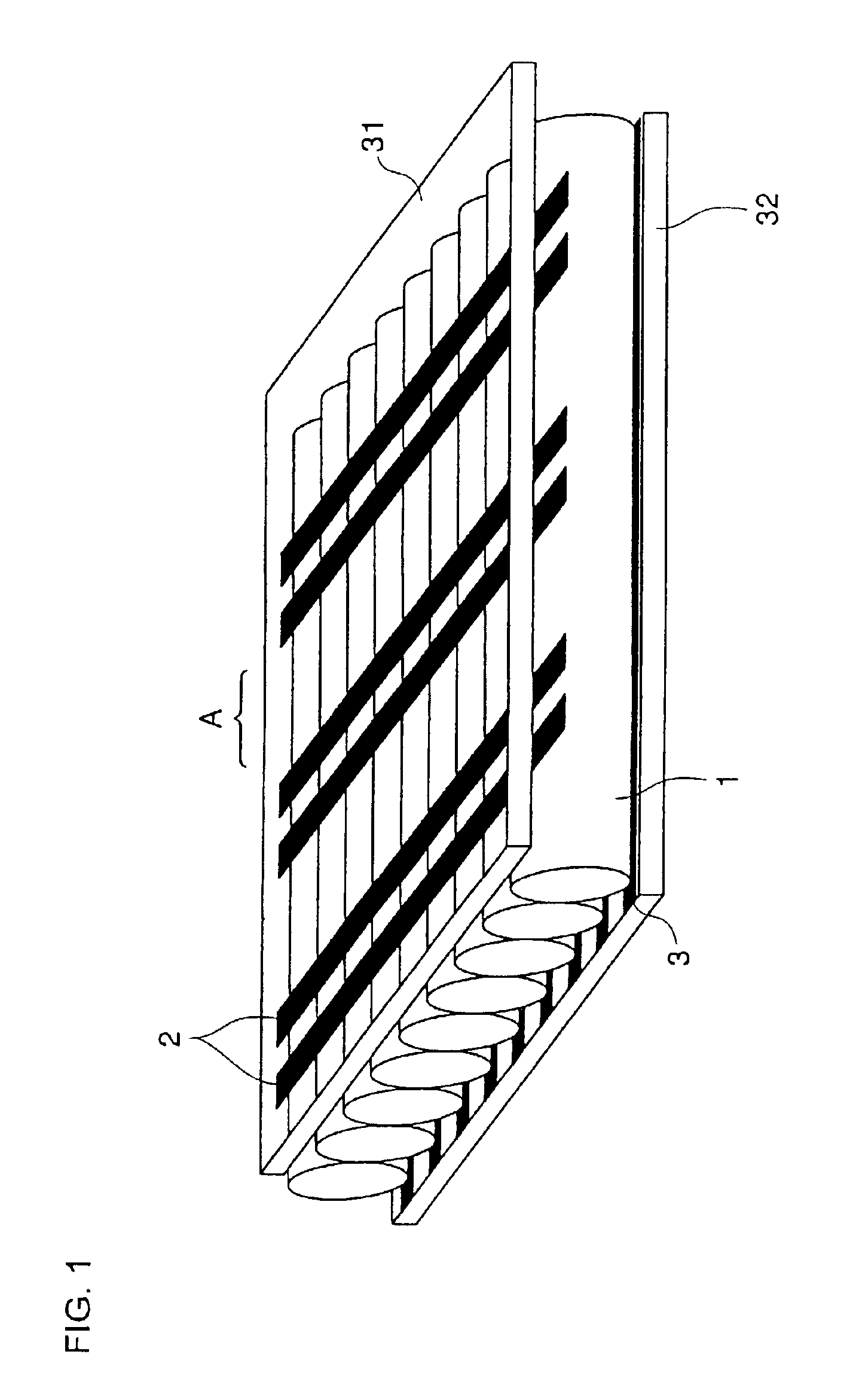

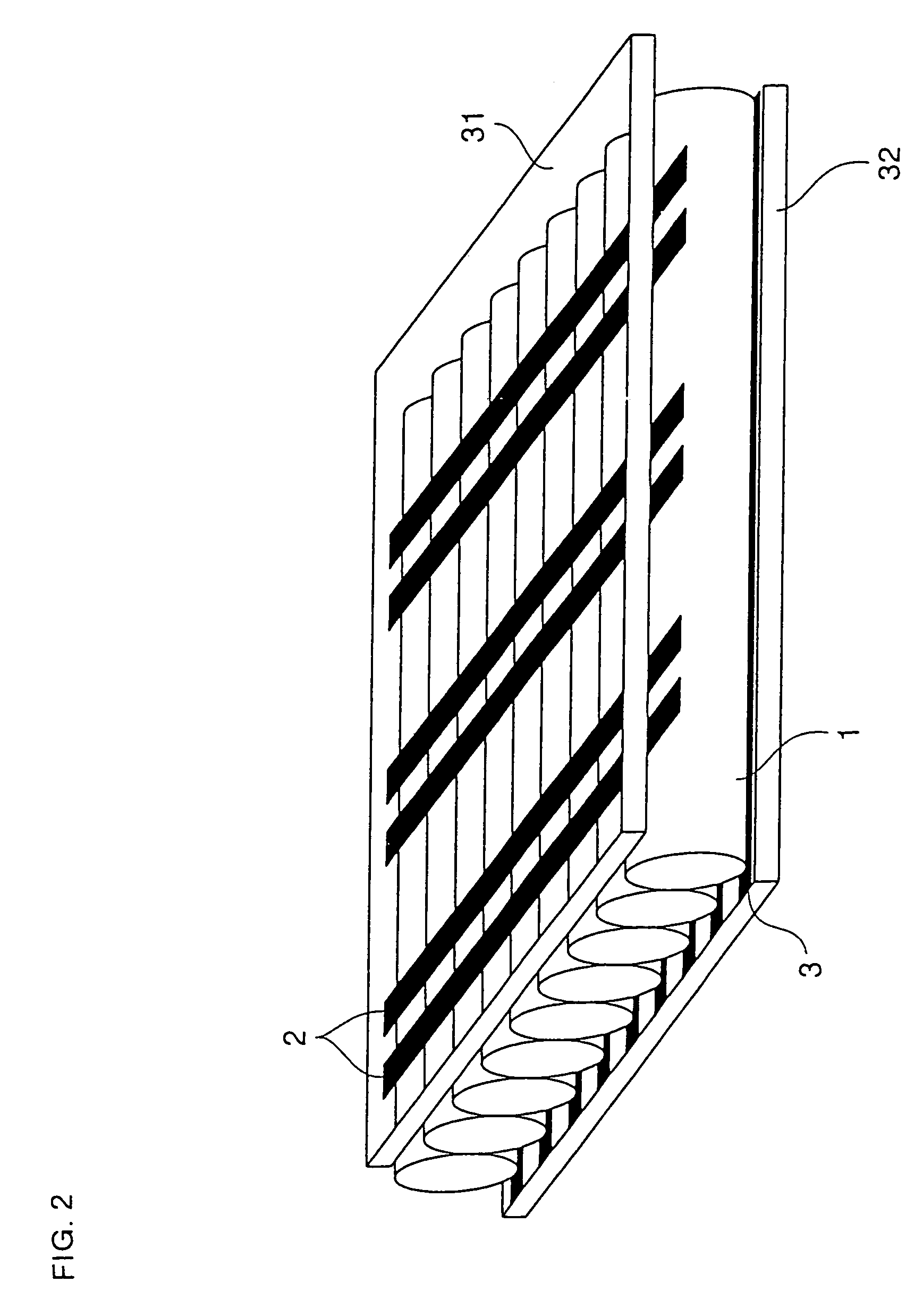

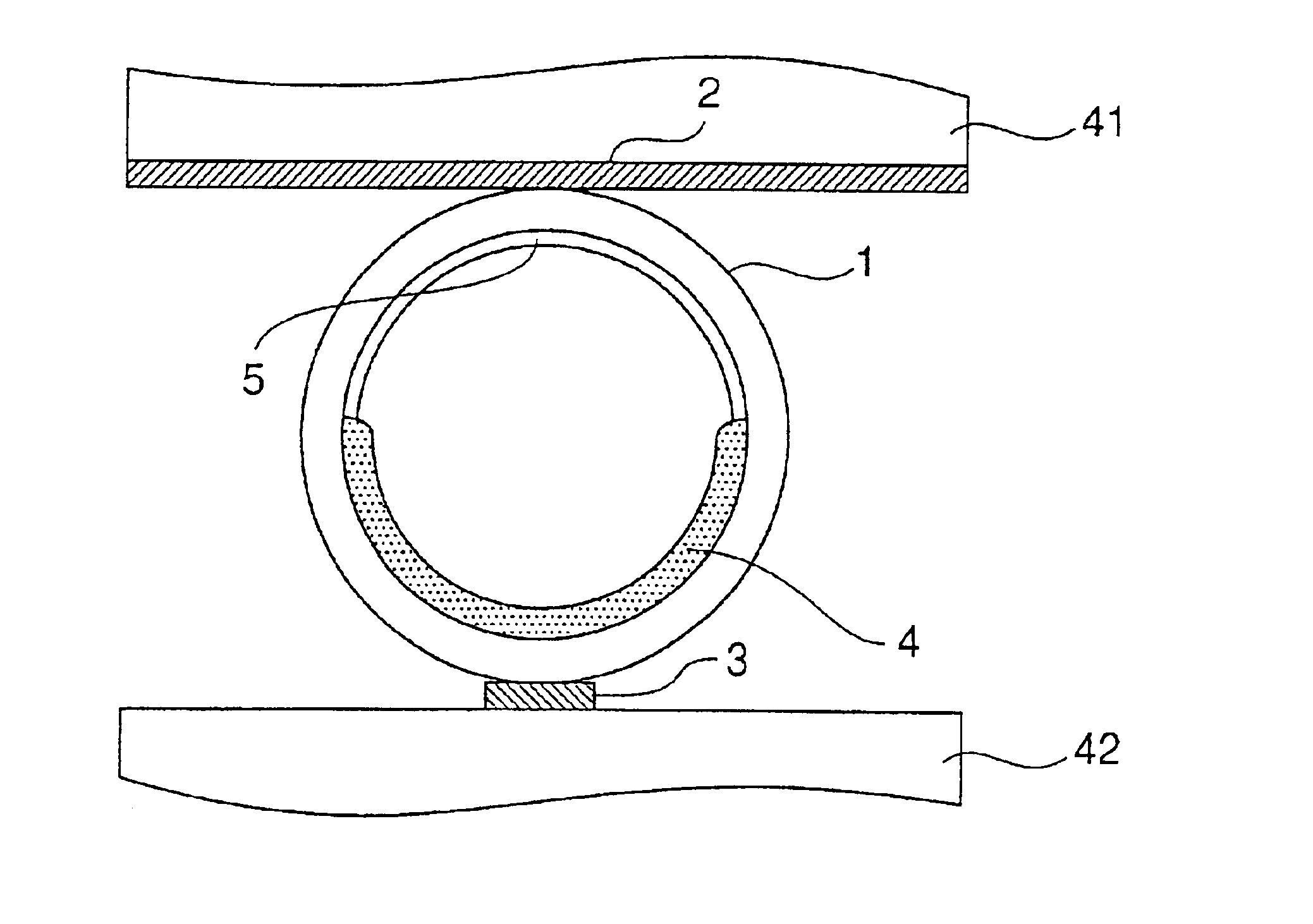

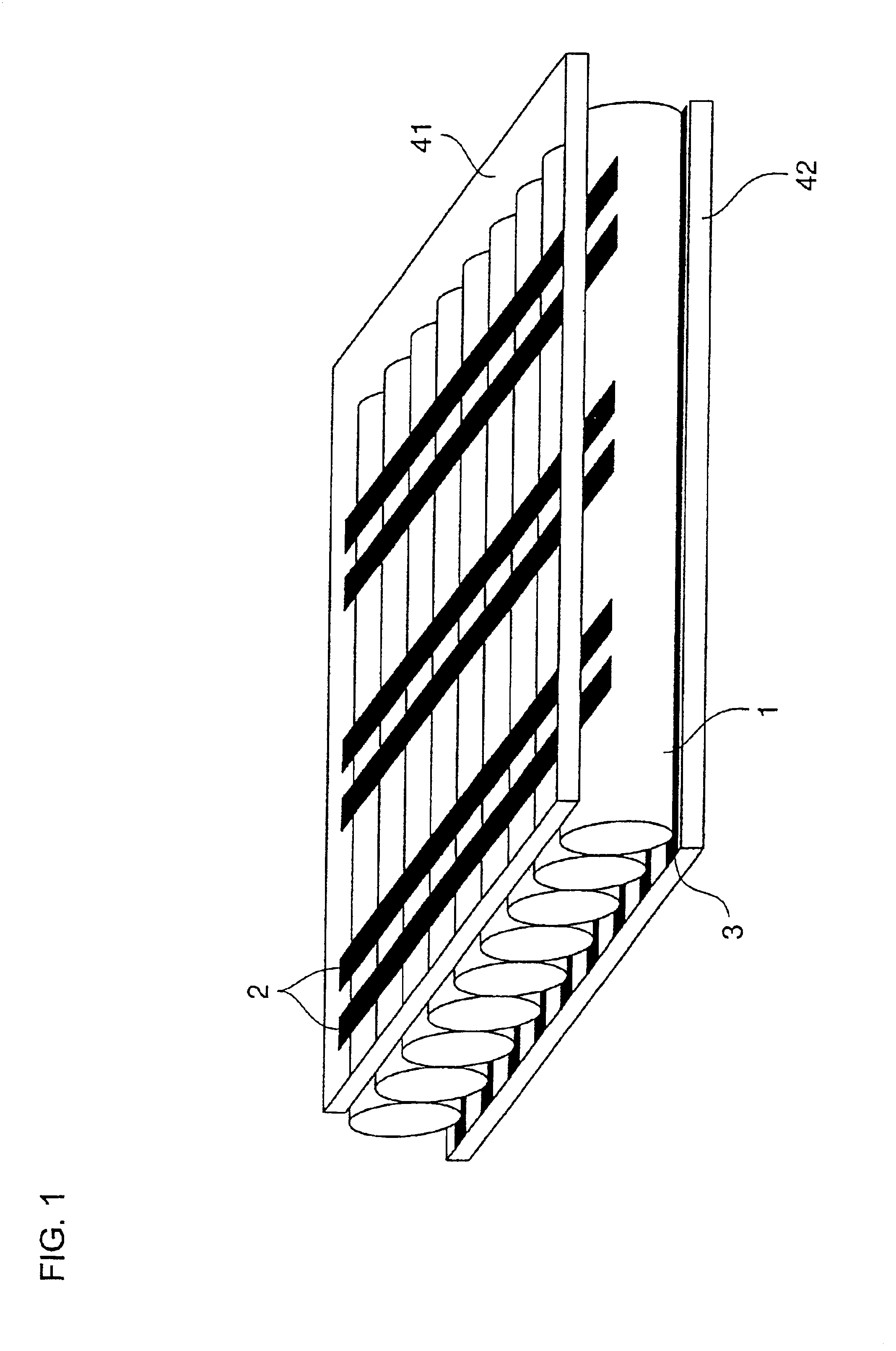

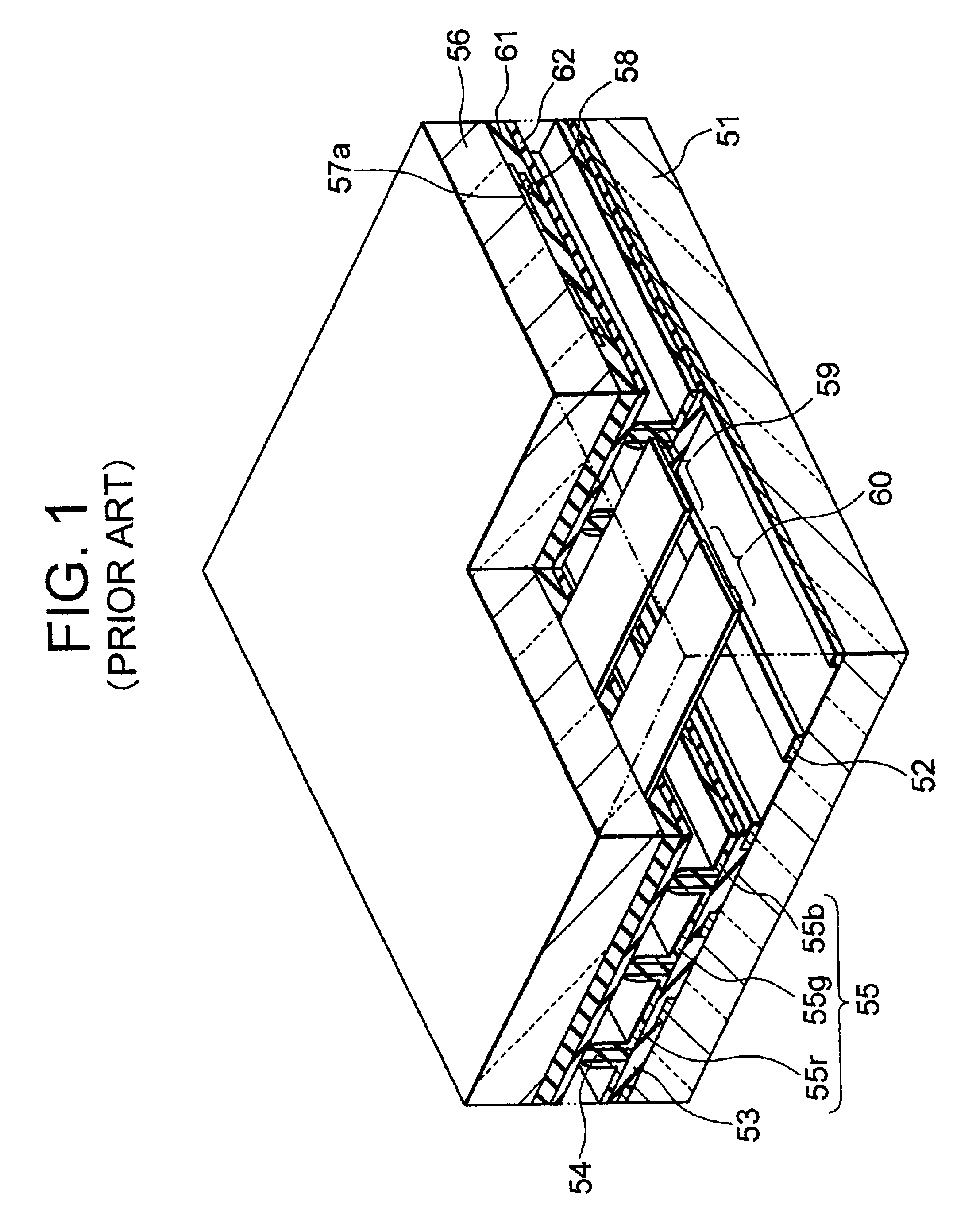

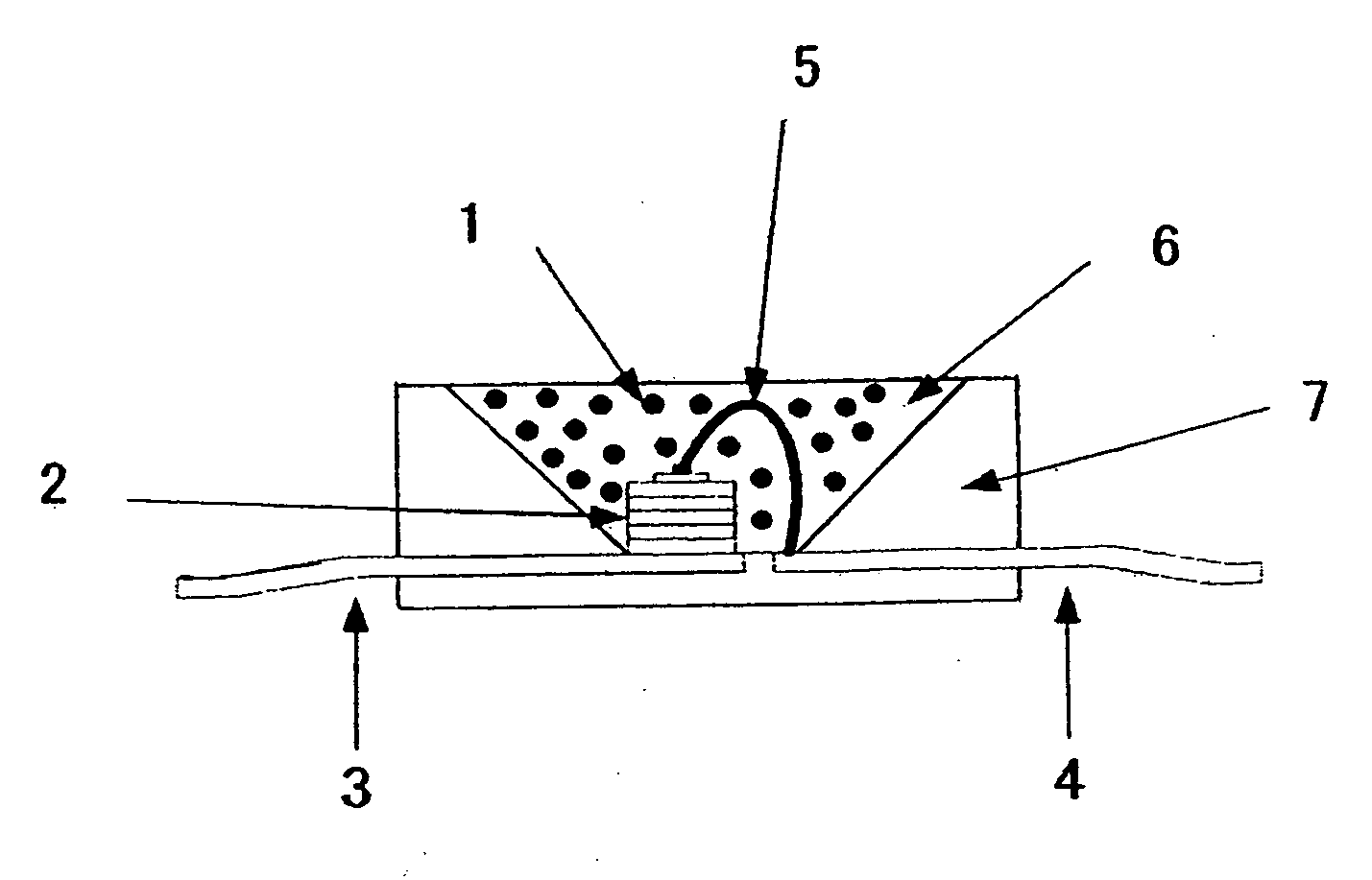

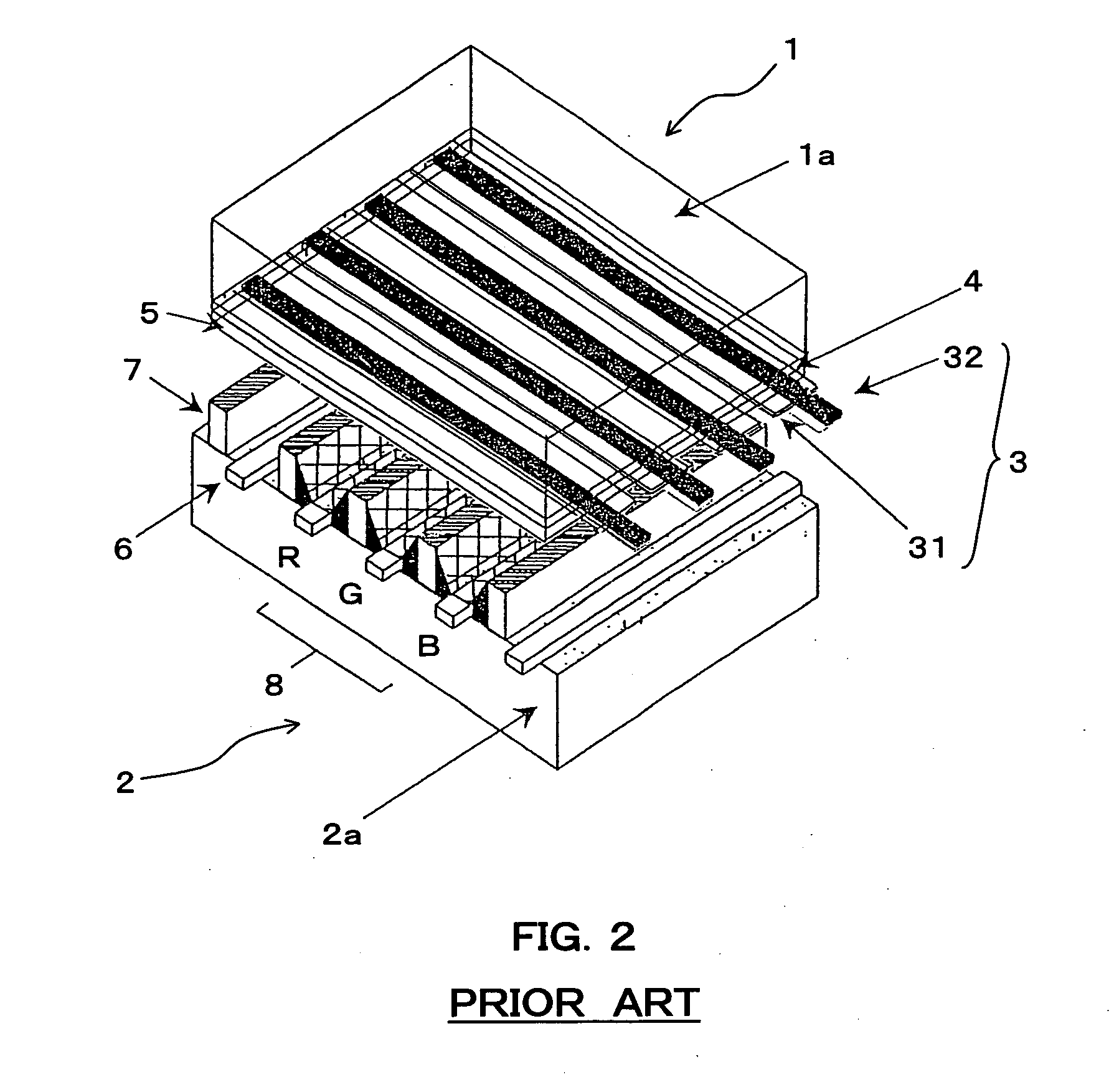

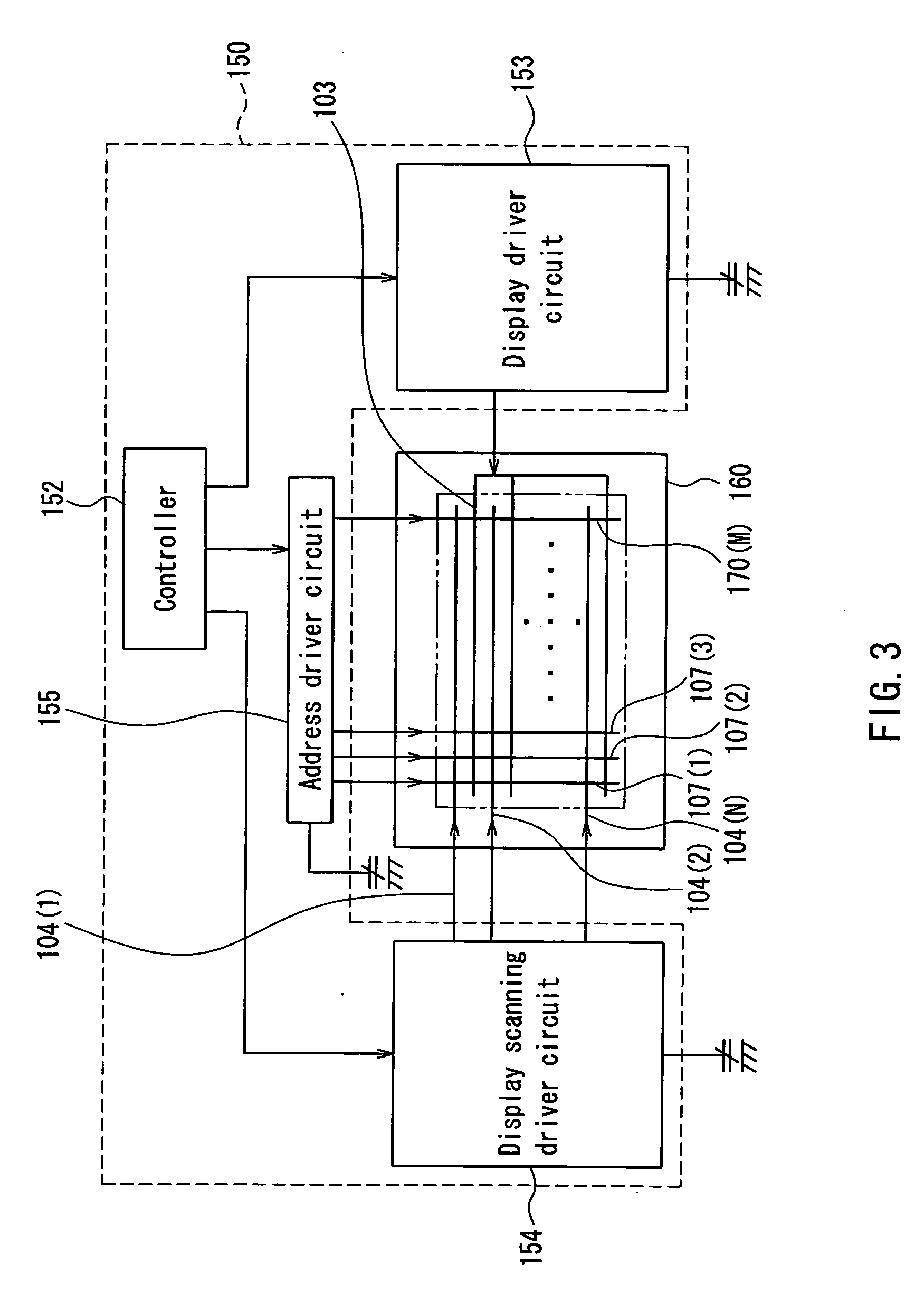

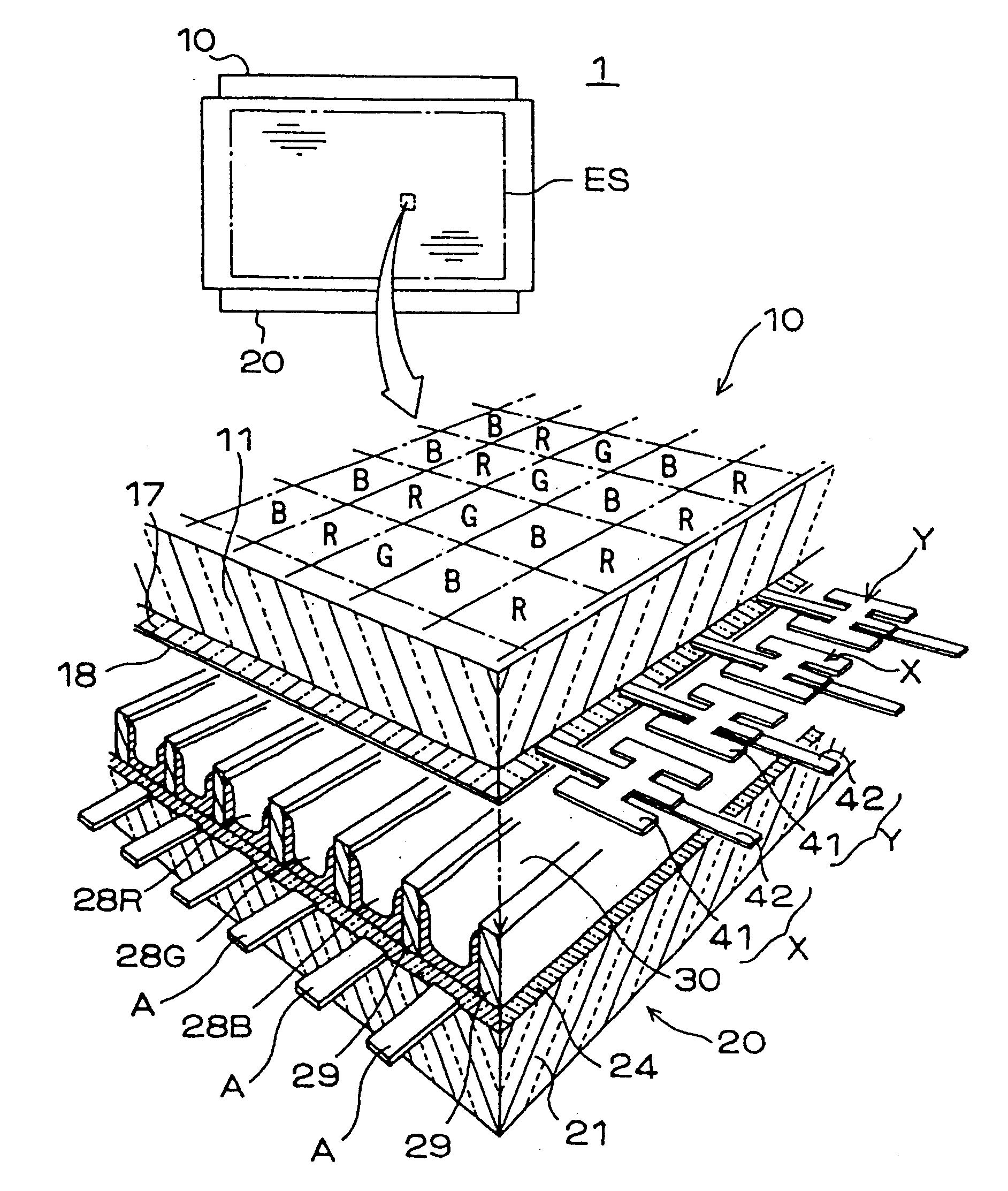

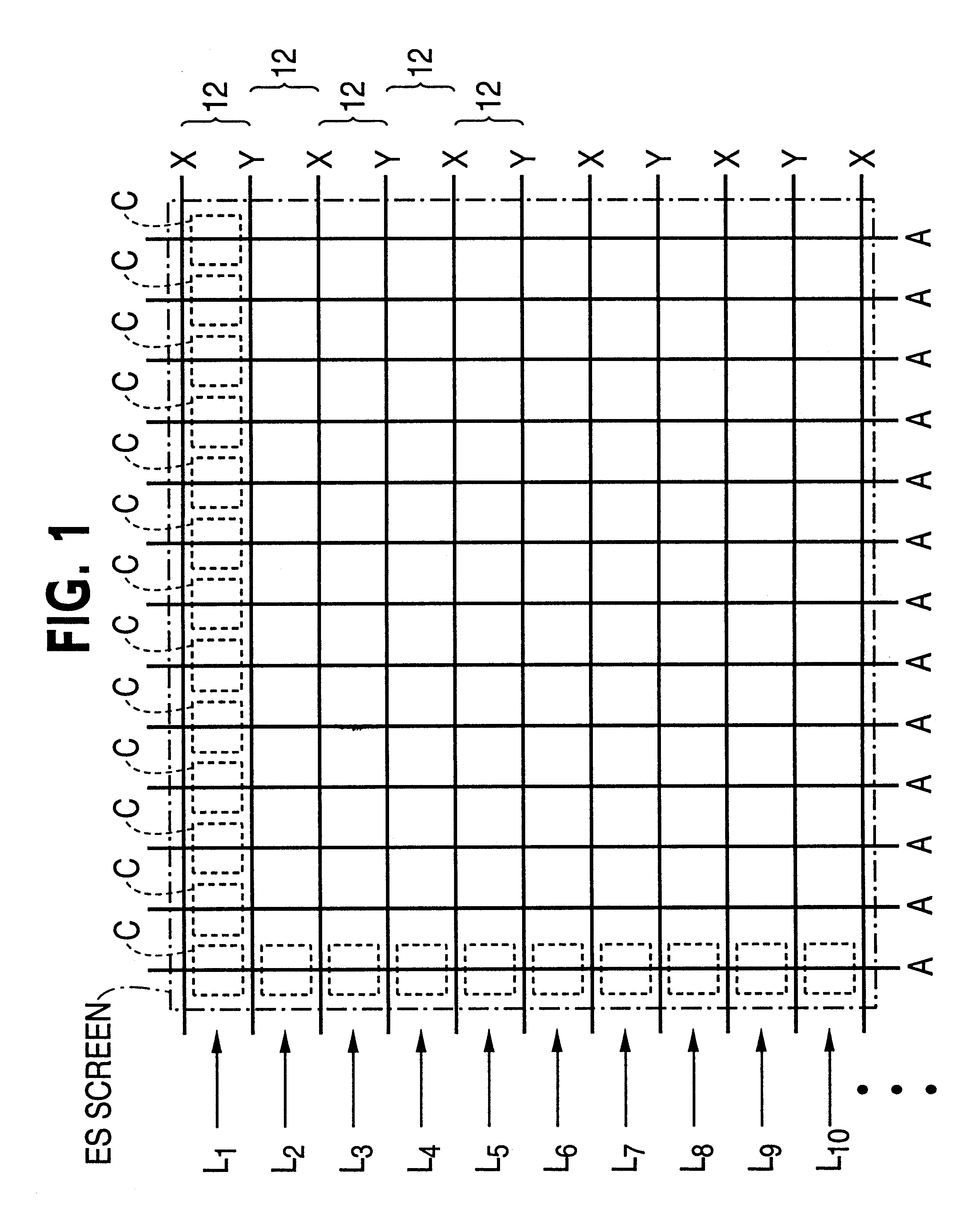

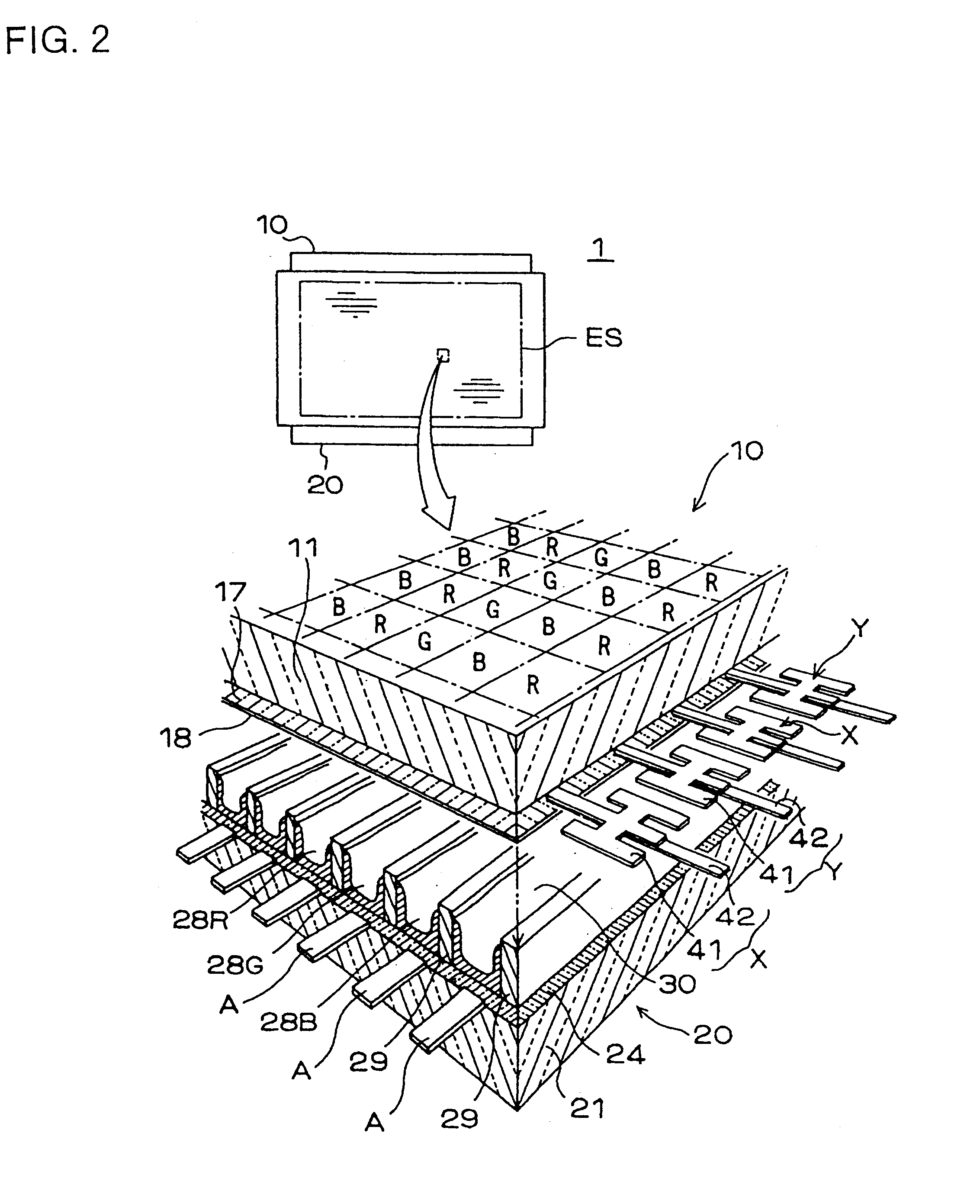

Display device employing gas discharge tubes arranged in parallel between front and rear substrates to comprise a display screen, each tube having a light emitting section as part of the display screen and a cleaning section connected to the light emitting section but displaced from the display screen

InactiveUS7049748B2Deterioration of discharge characteristic is preventedInhibit deteriorationAddress electrodesSustain/scan electrodesFluorescencePhosphor

A gas discharge tube has a phosphor layer formed and a discharge gas enclosed within an elongated tube which is to serve as the gas discharge tube. The gas discharge tube includes a light-emitting section and a cleaning section for cleaning the discharge gas. The cleaning section is connected to the light-emitting section.

Owner:SHINODA PLASMA

Plasma display panel

InactiveUS20050116646A1Reduce distanceIncrease speedAddress electrodesSustain/scan electrodesLow voltagePlasma display

A plasma display panel capable of being fast driven with low voltage by reducing a distance between an address electrode and a Y electrode. The plasma display panel includes a pair of substrates, discharge electrodes, and an address electrode. The substrates are arranged at a predetermined interval to face each other and form a plurality of discharge spaces between facing surfaces of the substrates. The discharge electrodes are arranged at predetermined intervals between the substrates. The address electrode is arranged a predetermined distance apart from the discharge electrodes in a direction where the substrates are arranged, and defines each of the discharge spaces in cooperation with the discharge electrodes.

Owner:SAMSUNG SDI CO LTD

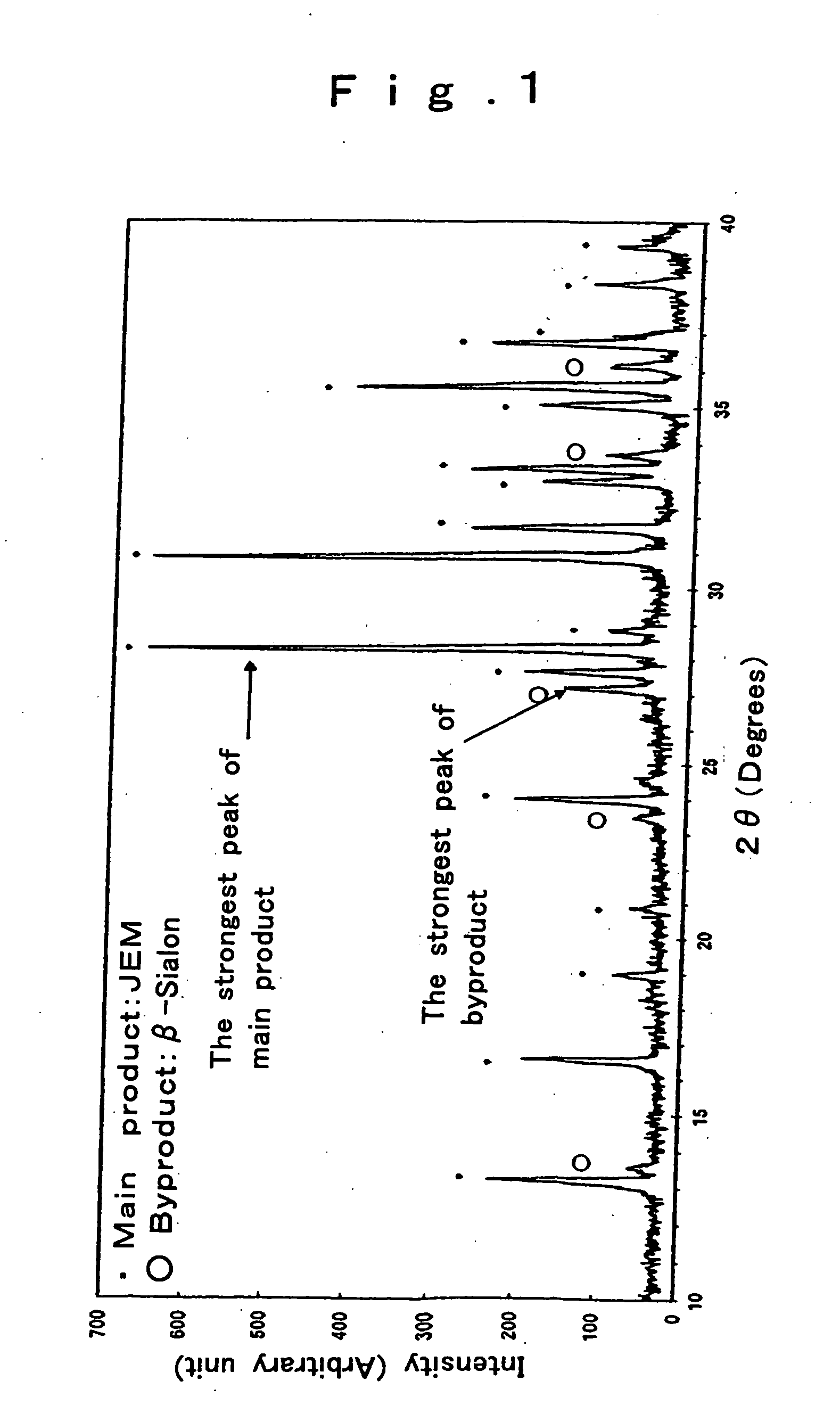

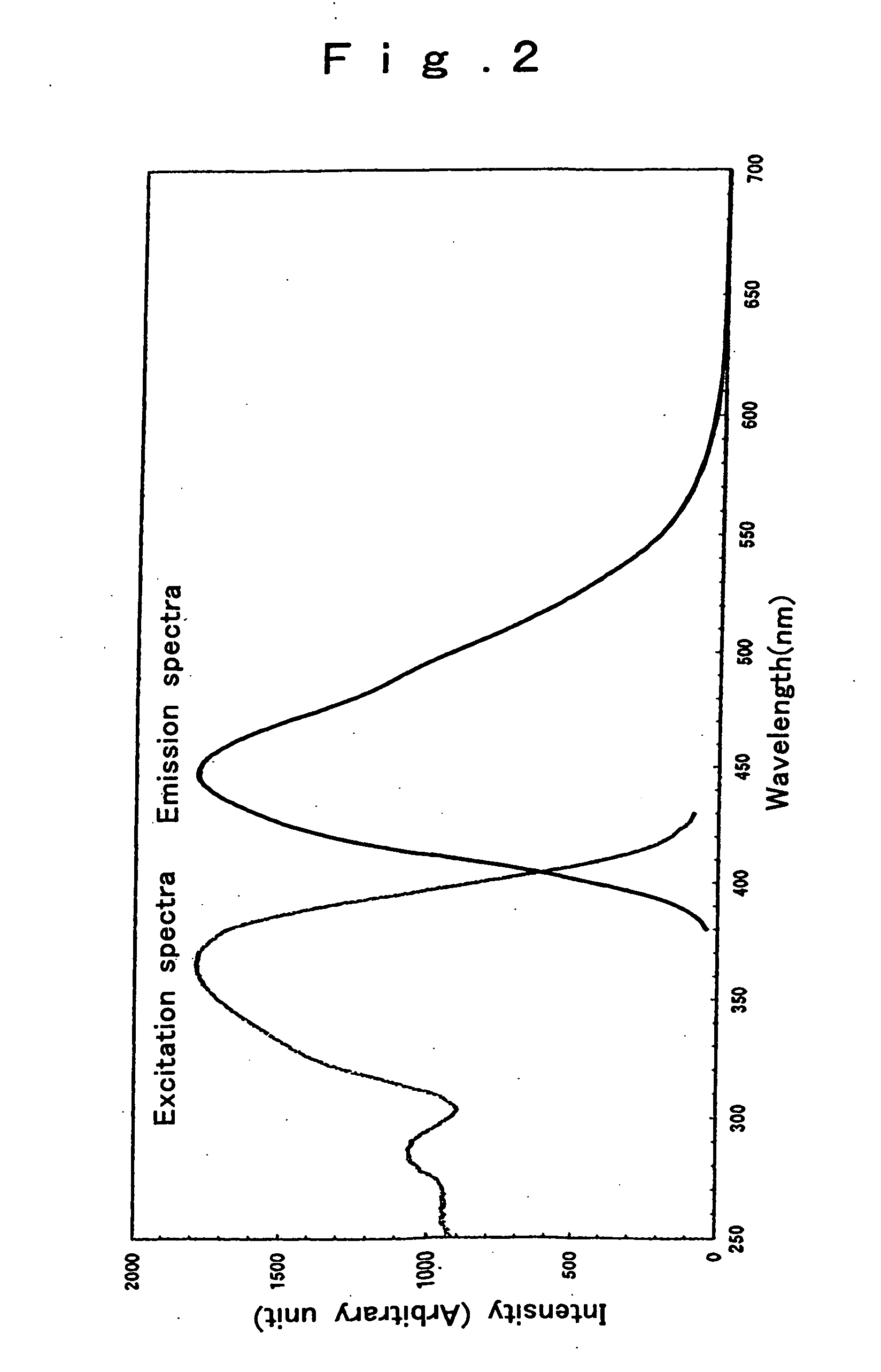

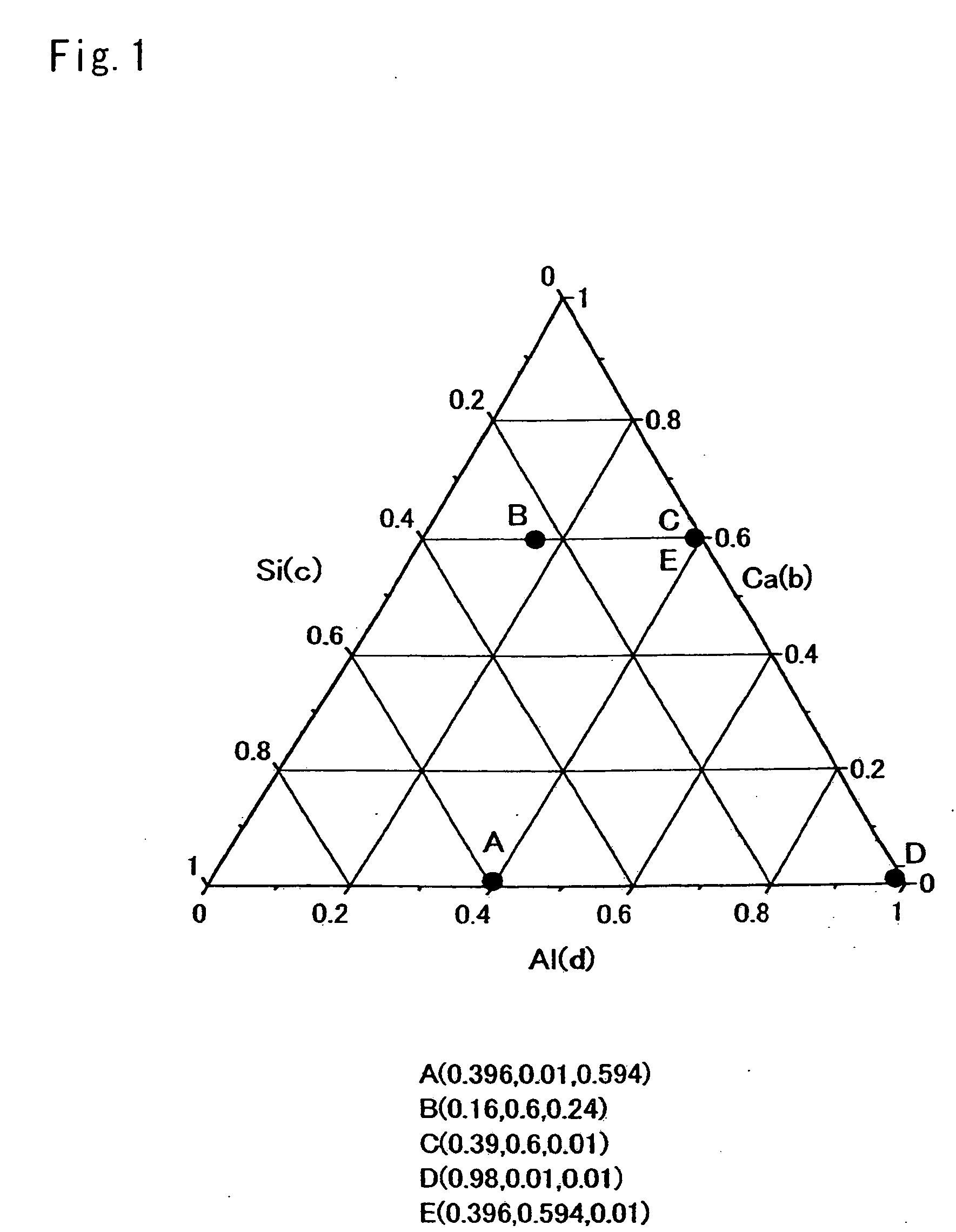

Oxynitride phosphor and light-emitting instrument

InactiveUS20070018567A1Increase brightnessReduced in material deterioration and luminance dropAddress electrodesSustain/scan electrodesRare-earth elementPhosphor

The invention has for its object the provision of an oxynitride fluorescent material has higher emission luminance than conventional rare earth element-activated sialon fluorescent materials. To this end, an oxynitride fluorescent material is designed in such a way as to contain as the primary constituent a JEM phase represented by a general formula MA1(Si6−zAlz)N10−zOz wherein M is one or two or more elements selected from the group consisting of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu. For instance, this fluorescent material has a fluorescent spectrum maximum emission wavelength of 420 nm to 500 nm inclusive and an excitation spectrum maximum emission excitation wavelength of 250 nm to 400 nm inclusive.

Owner:NAT INST FOR MATERIALS SCI

Glass composition for covering electrodes and glass paste containing the same

InactiveUS20060276322A1Improve reliabilityImprove pressure resistanceSustain/scan electrodesGas discharge fillingPolymer chemistryElectrode

Owner:PANASONIC CORP

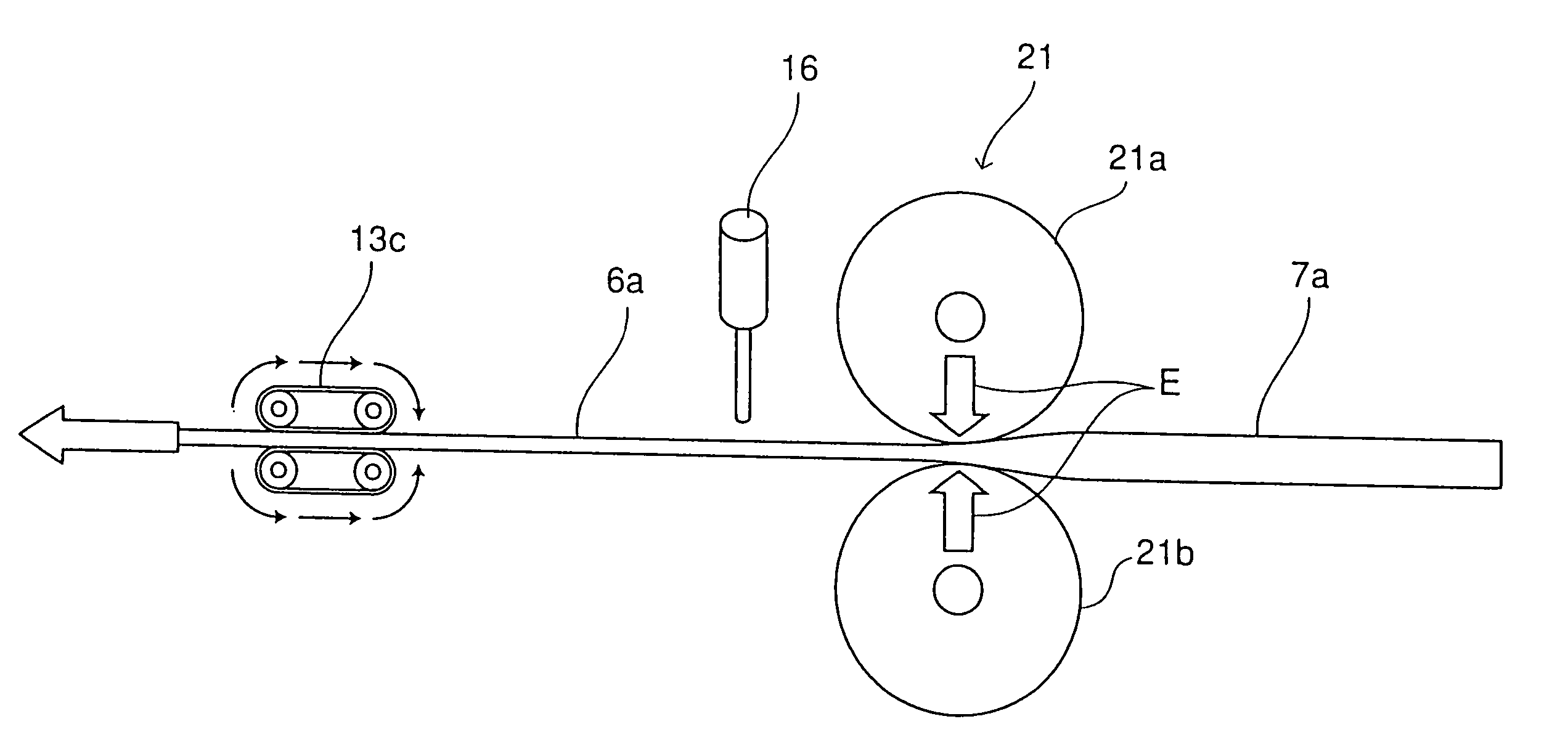

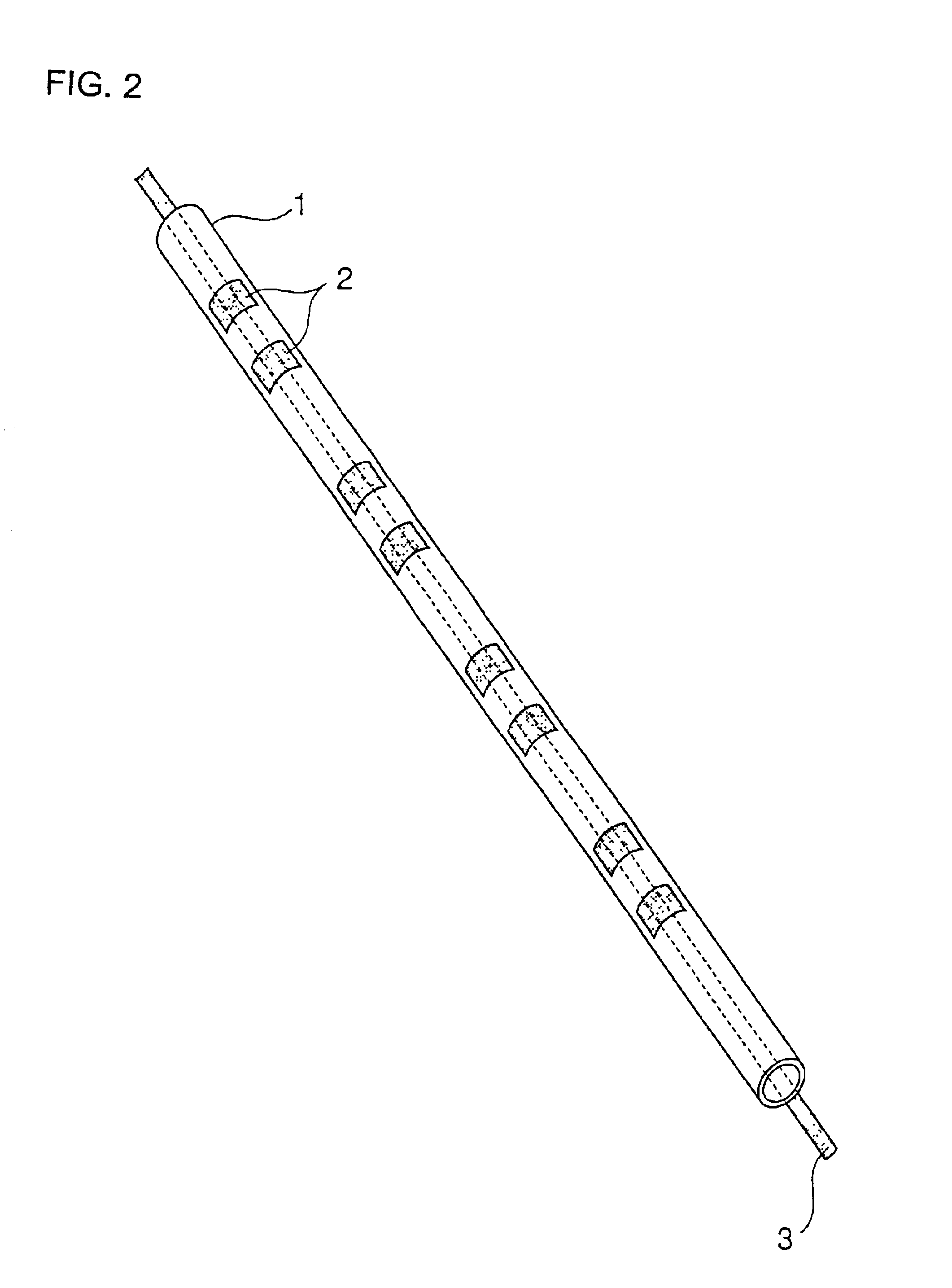

Method for forming phosphor layer of gas discharge tube and method for fabricating phosphor layer supporting member

InactiveUS6969292B2Well formedHigh yieldAddress electrodesSustain/scan electrodesFluorescencePhosphor

A phosphor layer is formed efficiently in a gas discharge tube by drawing a mother material to fabricate a supporting member which is insertable in a small glass tube used for a gas discharge tube, forming a phosphor layer on the supporting member, and inserting and placing the supporting member in the small glass tube.

Owner:SHINODA PLASMA

Method of forming phosphor layer of gas discharge tube

InactiveUS6857923B2Quality improvementExtended service lifeAddress electrodesSustain/scan electrodesFluorescencePhosphor

A method of forming a phosphor layer of a gas discharge tube provided with the phosphor layer on an internal surface of an elongated tubular vessel forming a discharge space. The method includes the steps of introducing a slurry of phosphor powder and a binding resin dispersed in a medium into the tubular vessel, holding the tubular vessel sideways to deposit the phosphor powder and the binding resin in the tubular vessel, and removing the medium from the tubular vessel, thereby forming a phosphor layer on one side of the internal surface of the tubular vessel.

Owner:SHINODA PLASMA

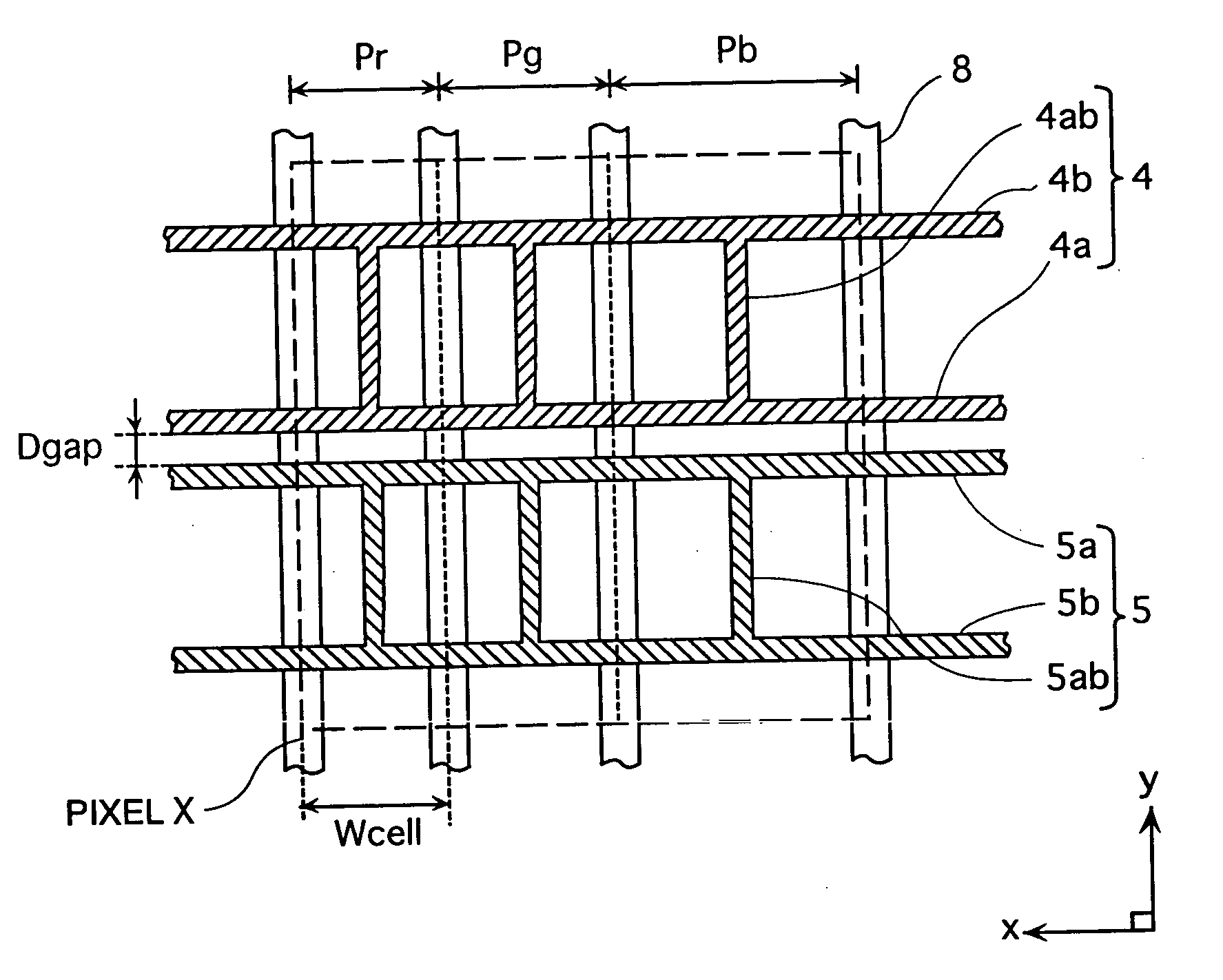

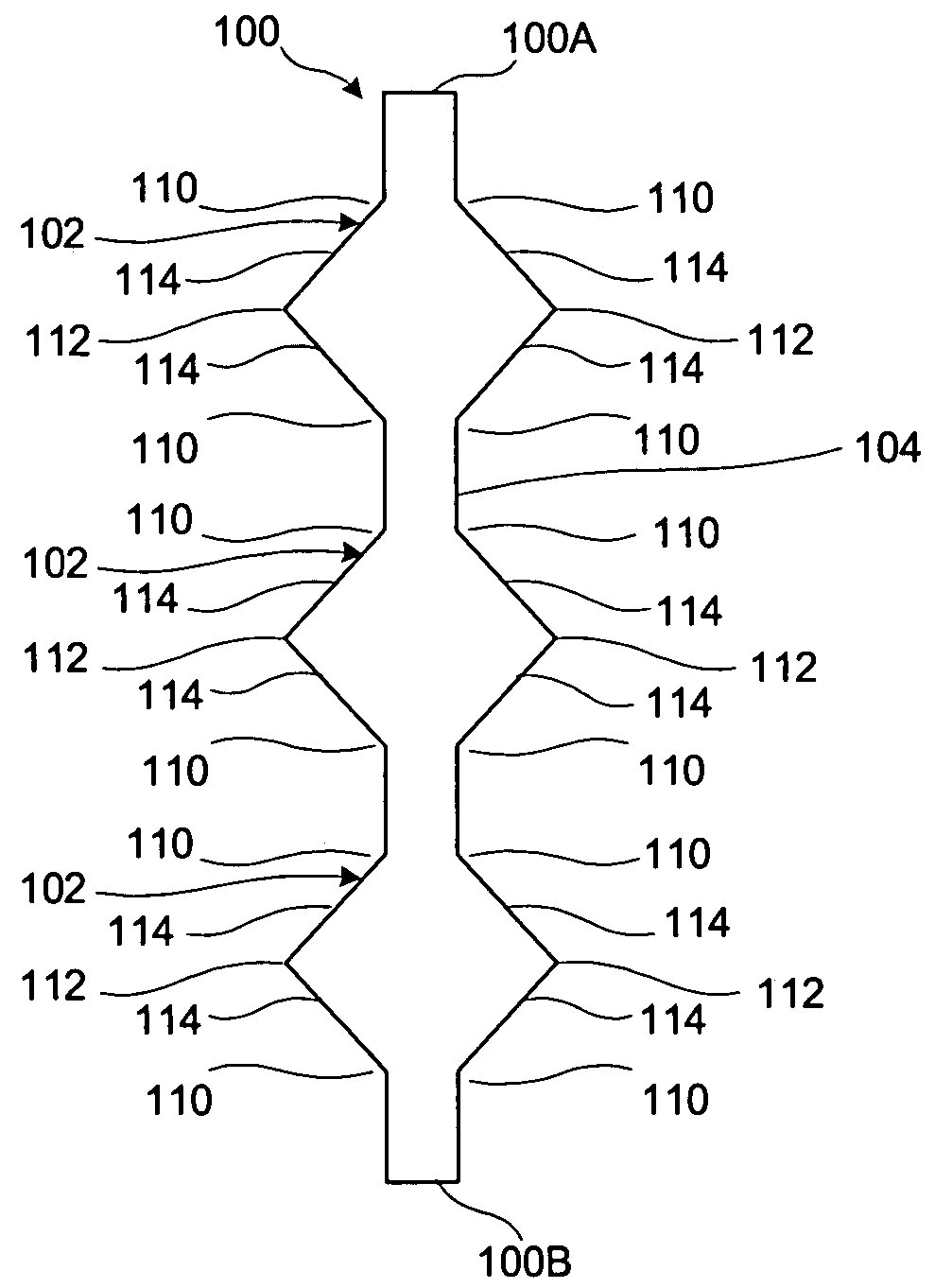

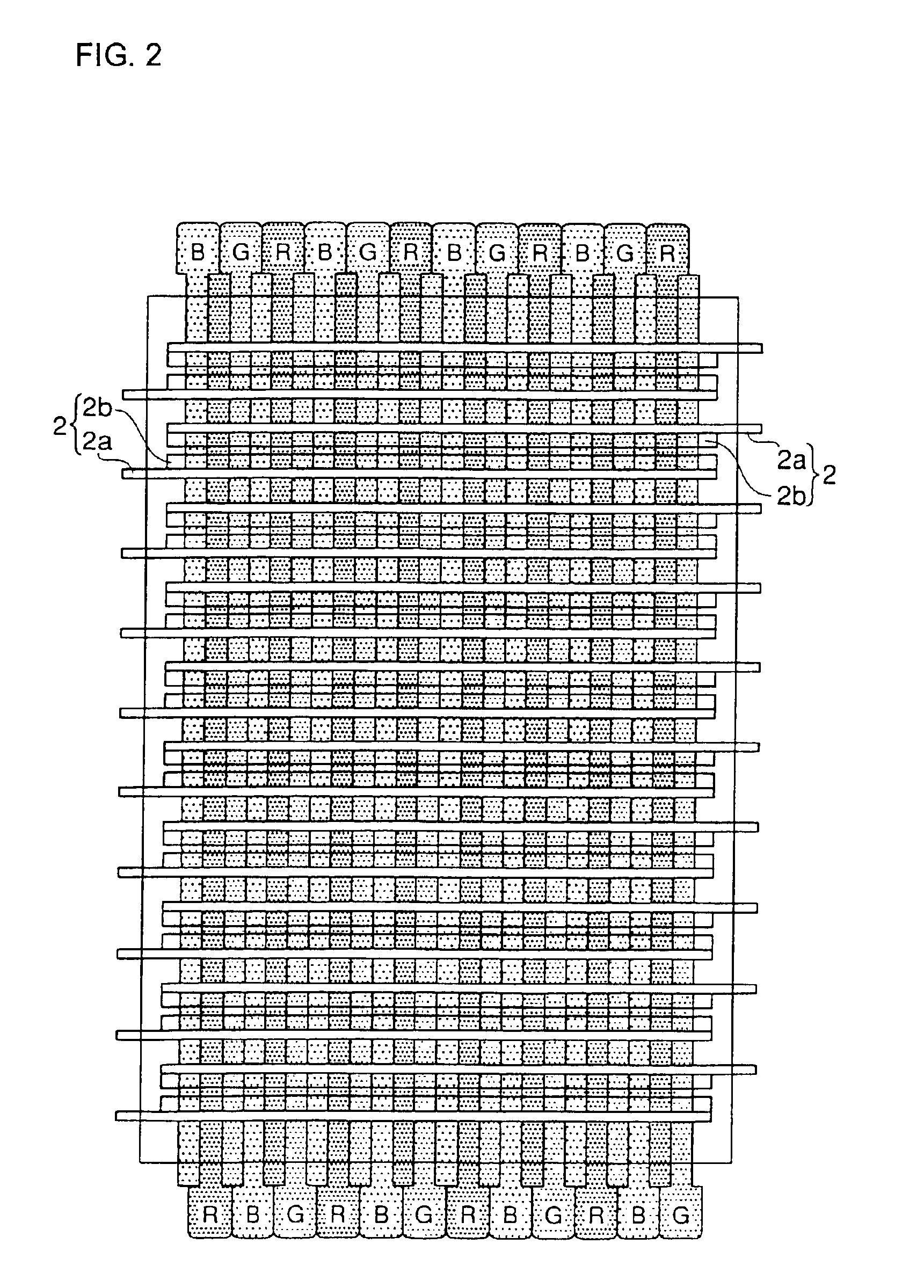

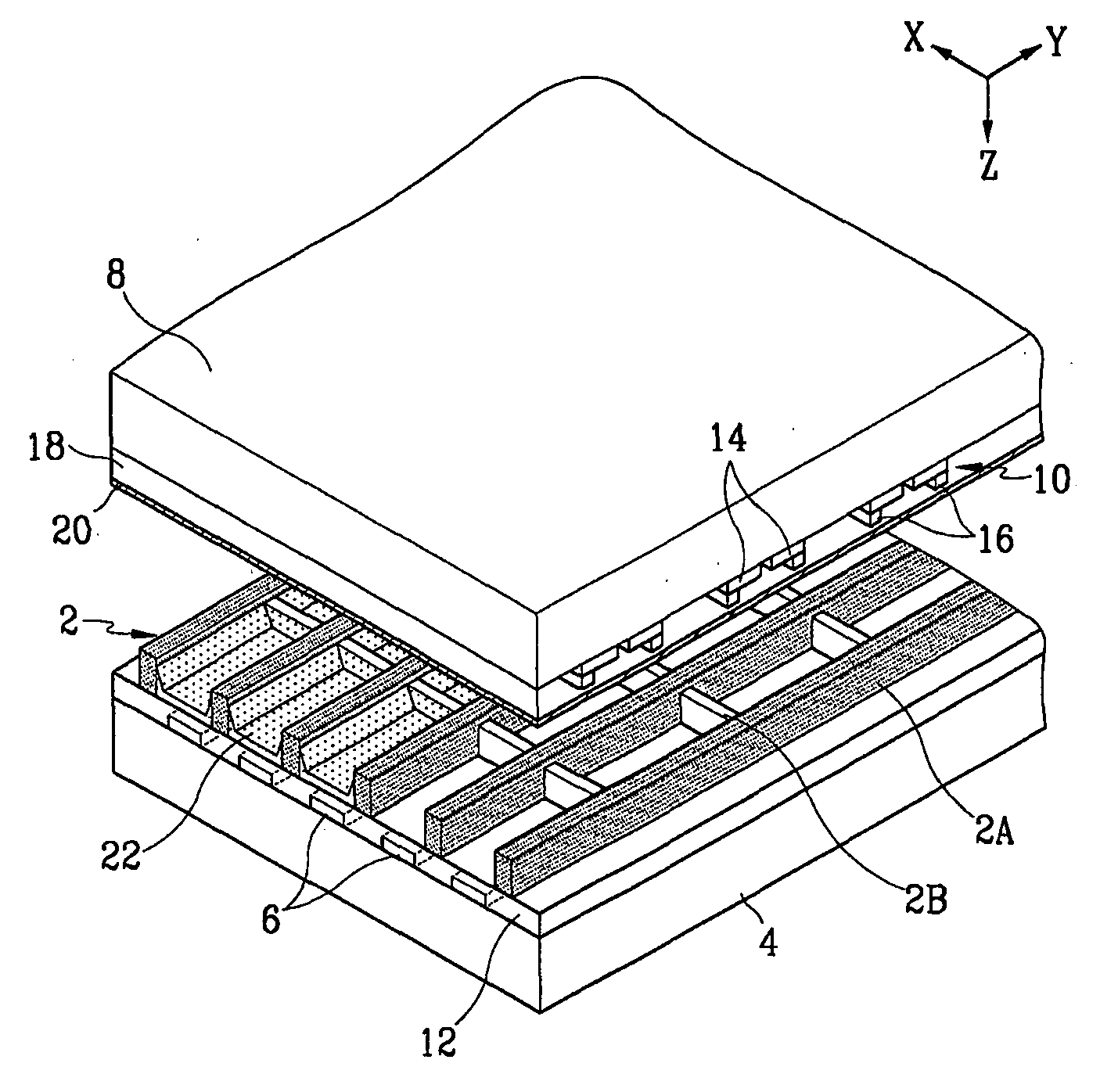

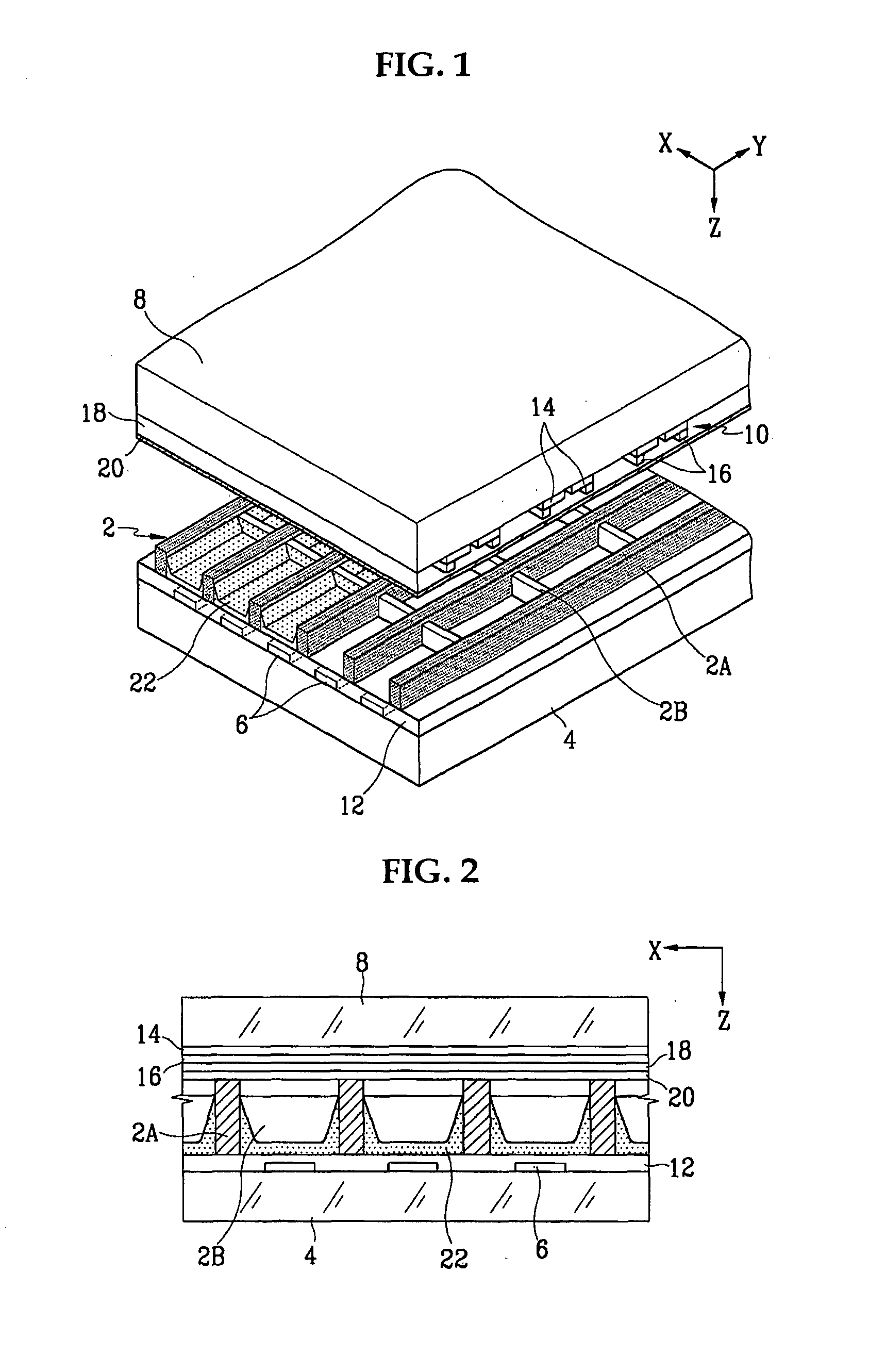

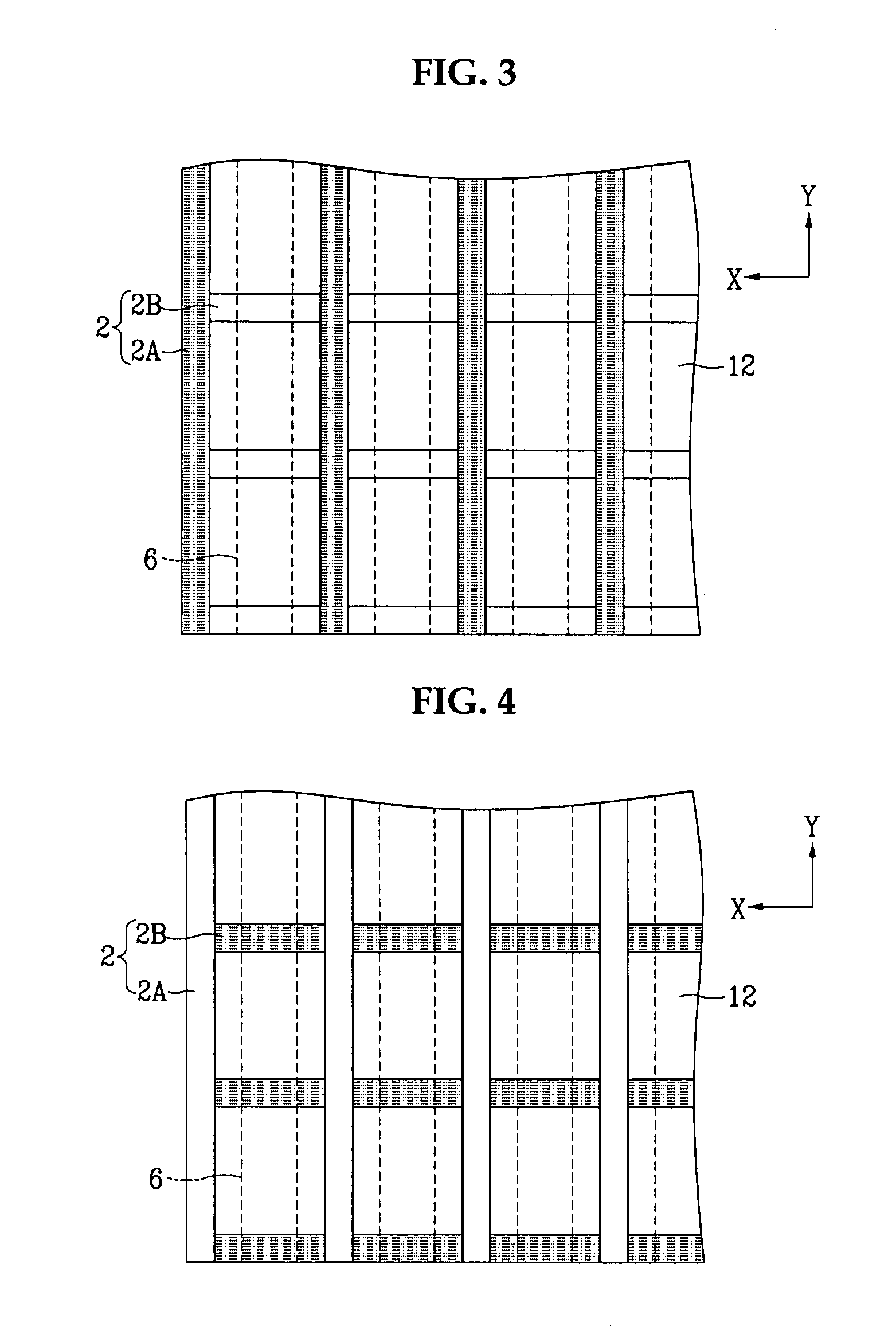

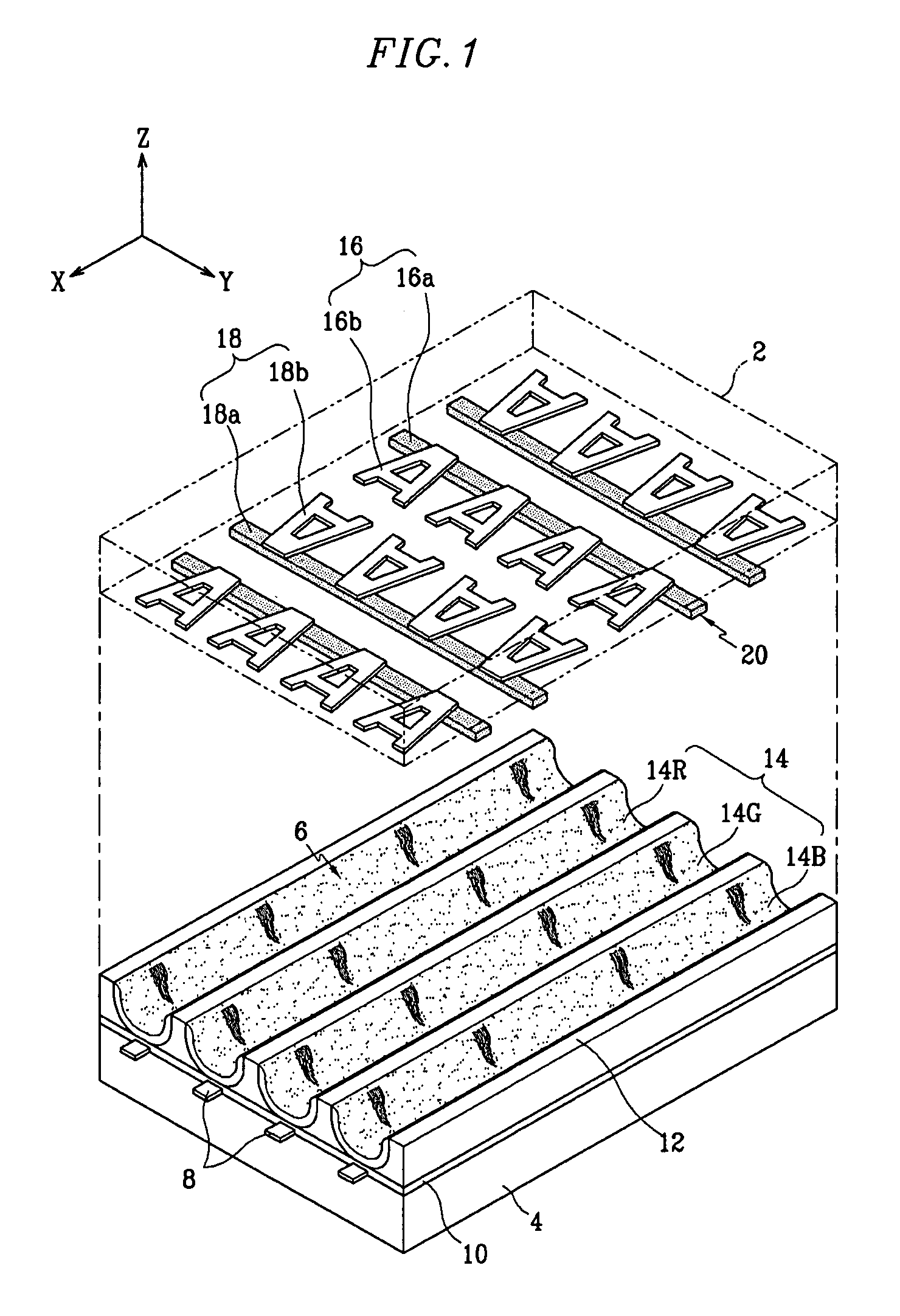

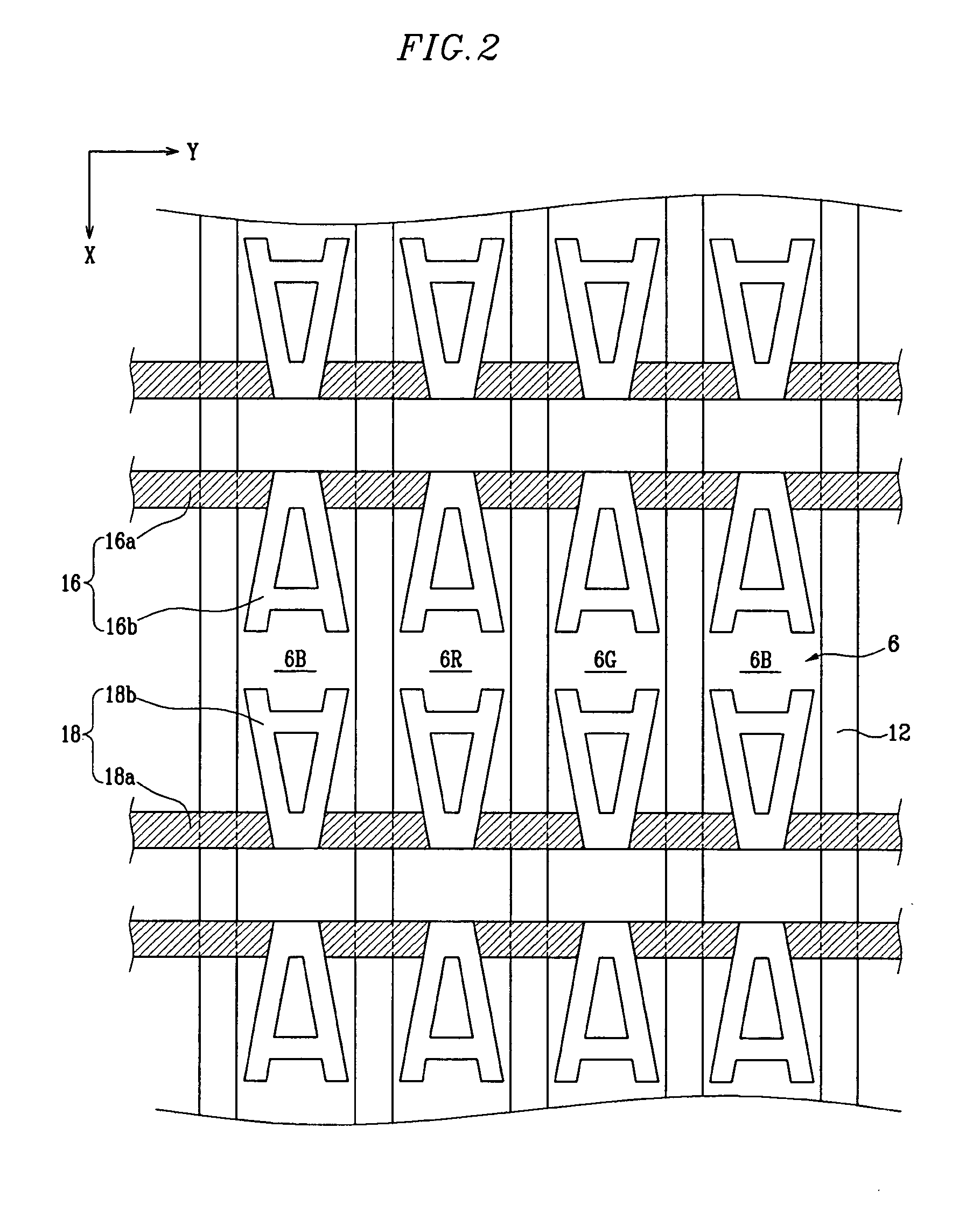

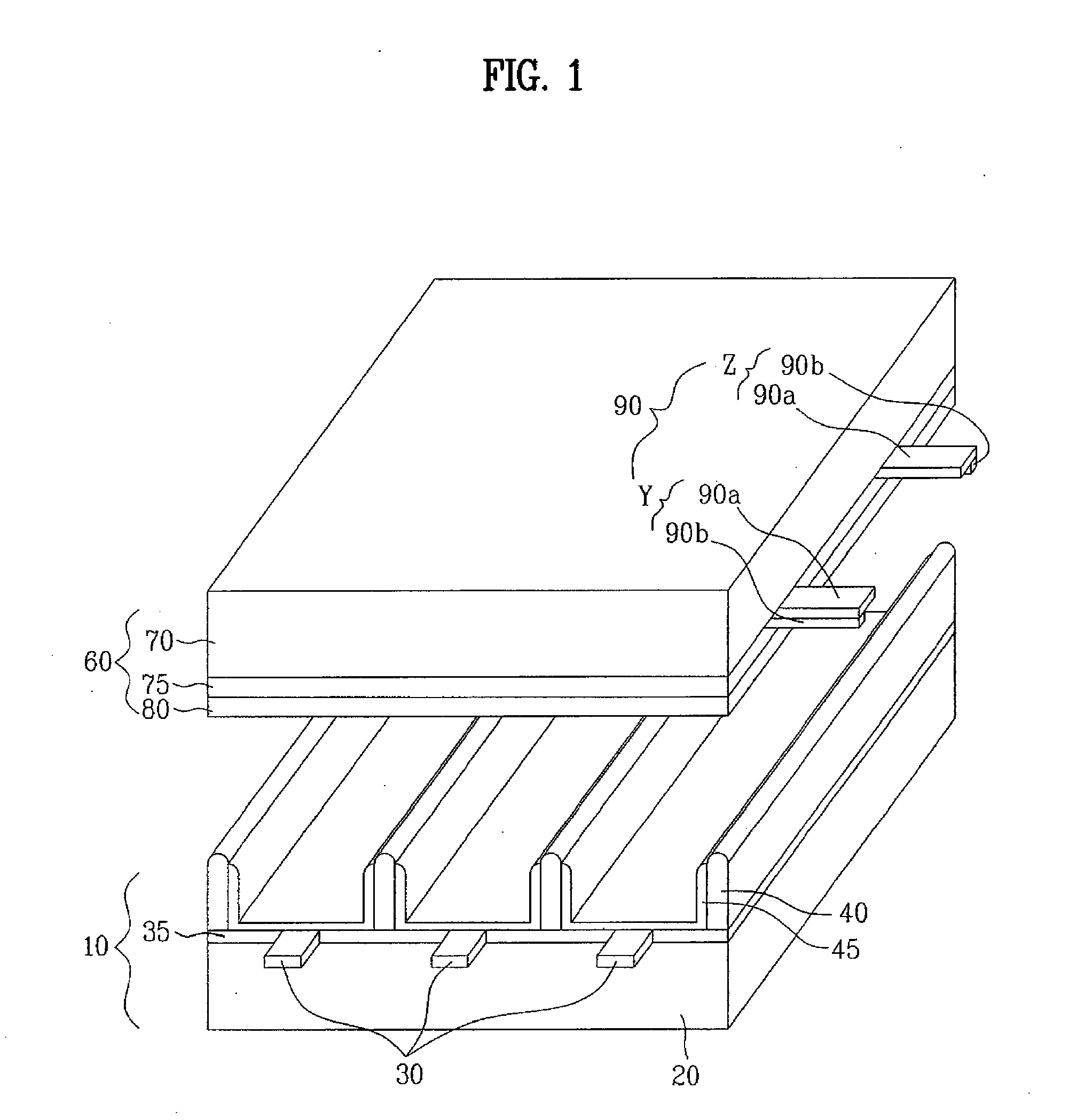

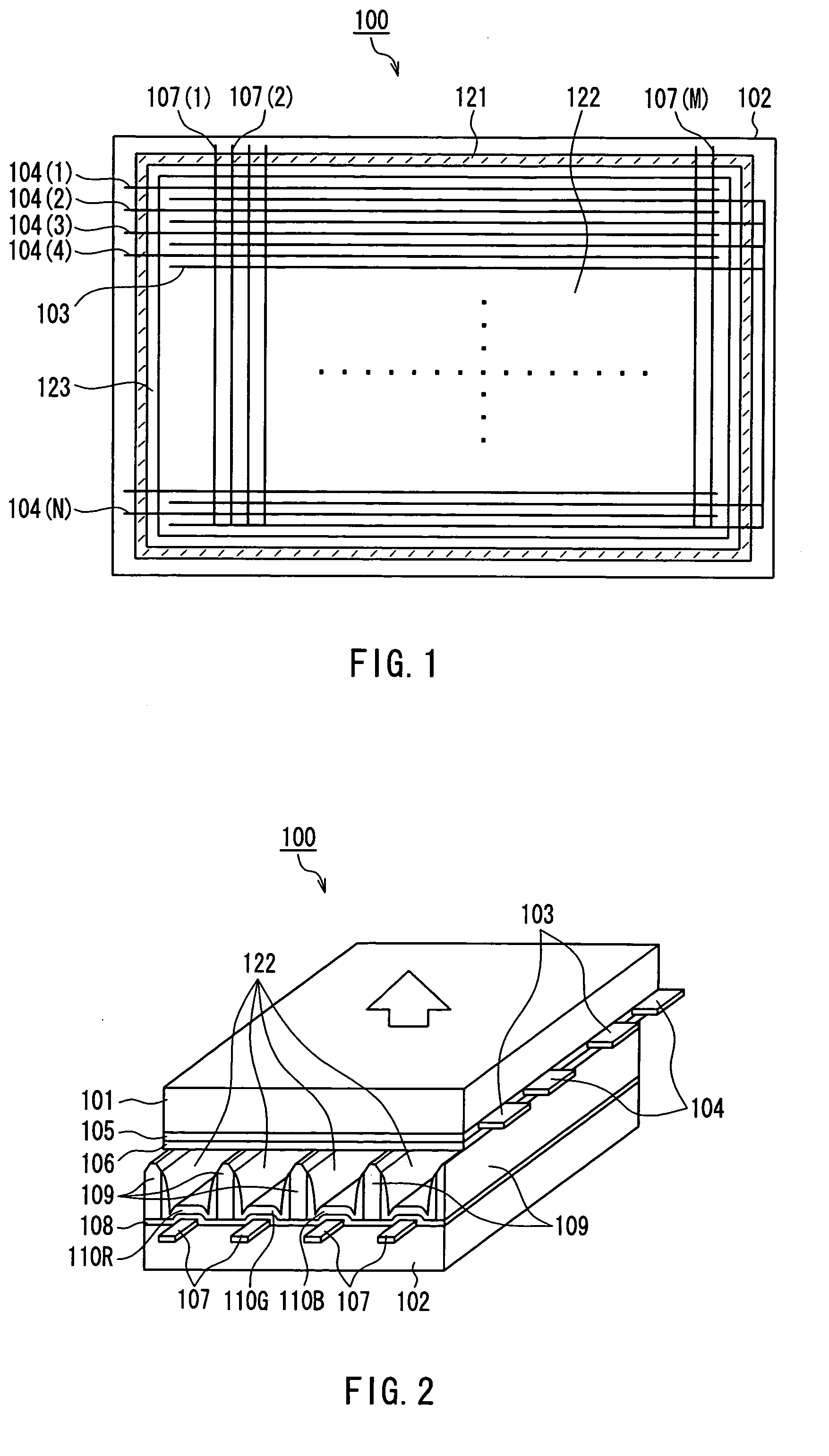

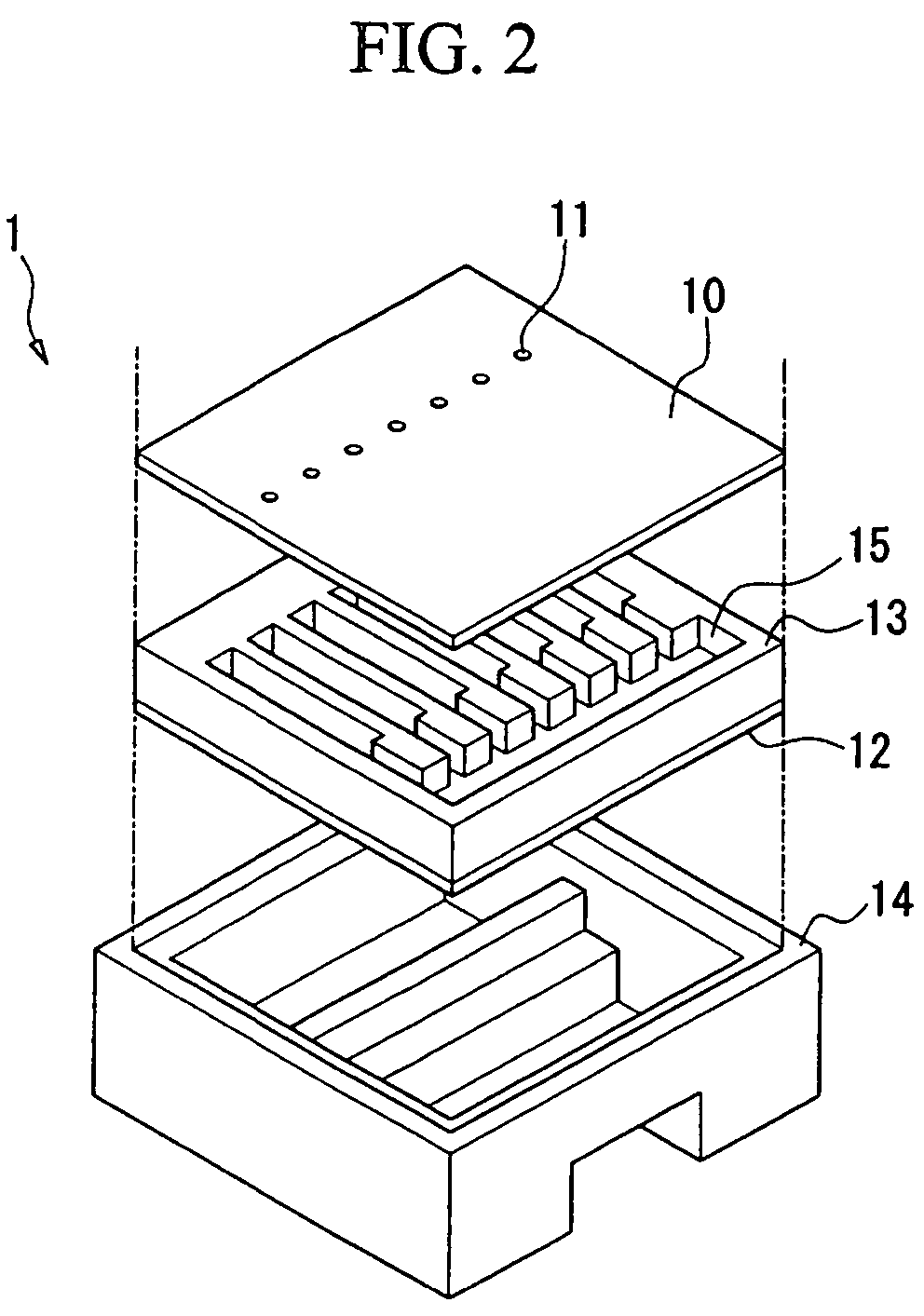

Plasma display panel having an improved plane electrode structure

InactiveUS6819046B2Wide operation marginReduce power consumption rateAddress electrodesSustain/scan electrodesPlanar electrodeFixed ratio

The PDP disclosed herein has a plurality of thin wire electrodes extending in the row direction, which are laid out in such a way as to widen the interval at a fixed ratio (2 times) from the discharge gap section toward the non-discharge gap section as well as to shorten the lengths of those row direction thin wire electrodes in steps with a fixed difference (approximately 20 mumxleft / right) from the cell's vertical center axis toward the partition walls. They are connected by thin wire electrodes that extend in the column direction to form antenna-shaped plane electrodes and the thin wire electrodes that extend in the column direction from the center of the antenna-shaped plane electrodes and the bus electrodes that extend in the row direction are connected to form a sustaining electrode pair (scan electrode and common electrode).

Owner:PIONEER CORP

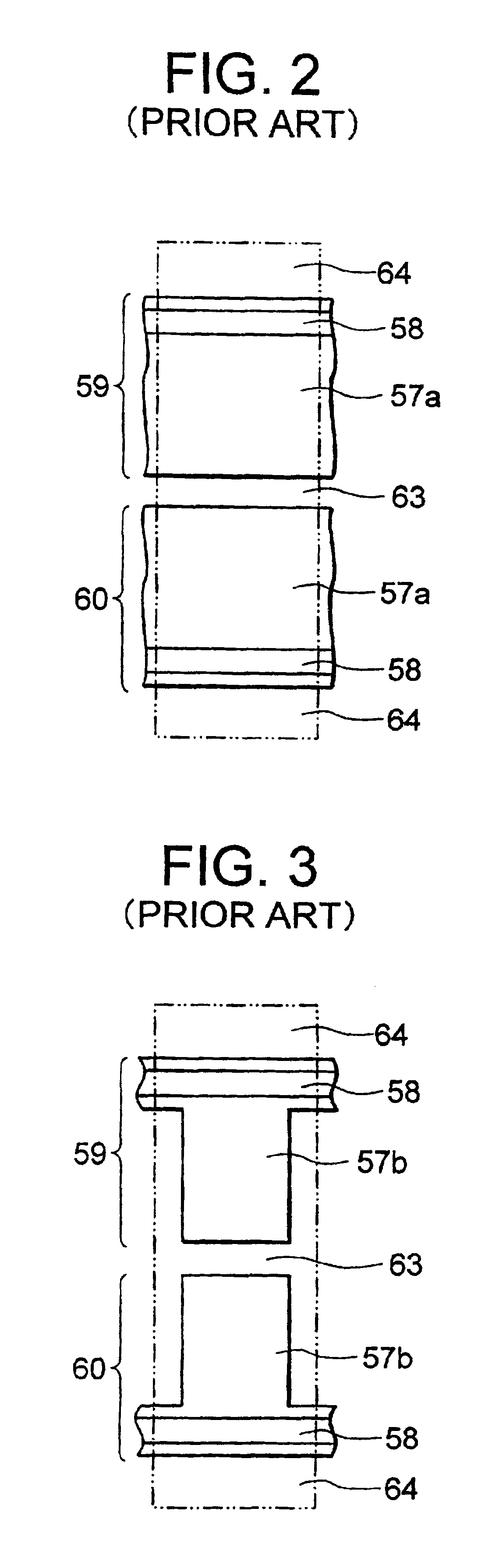

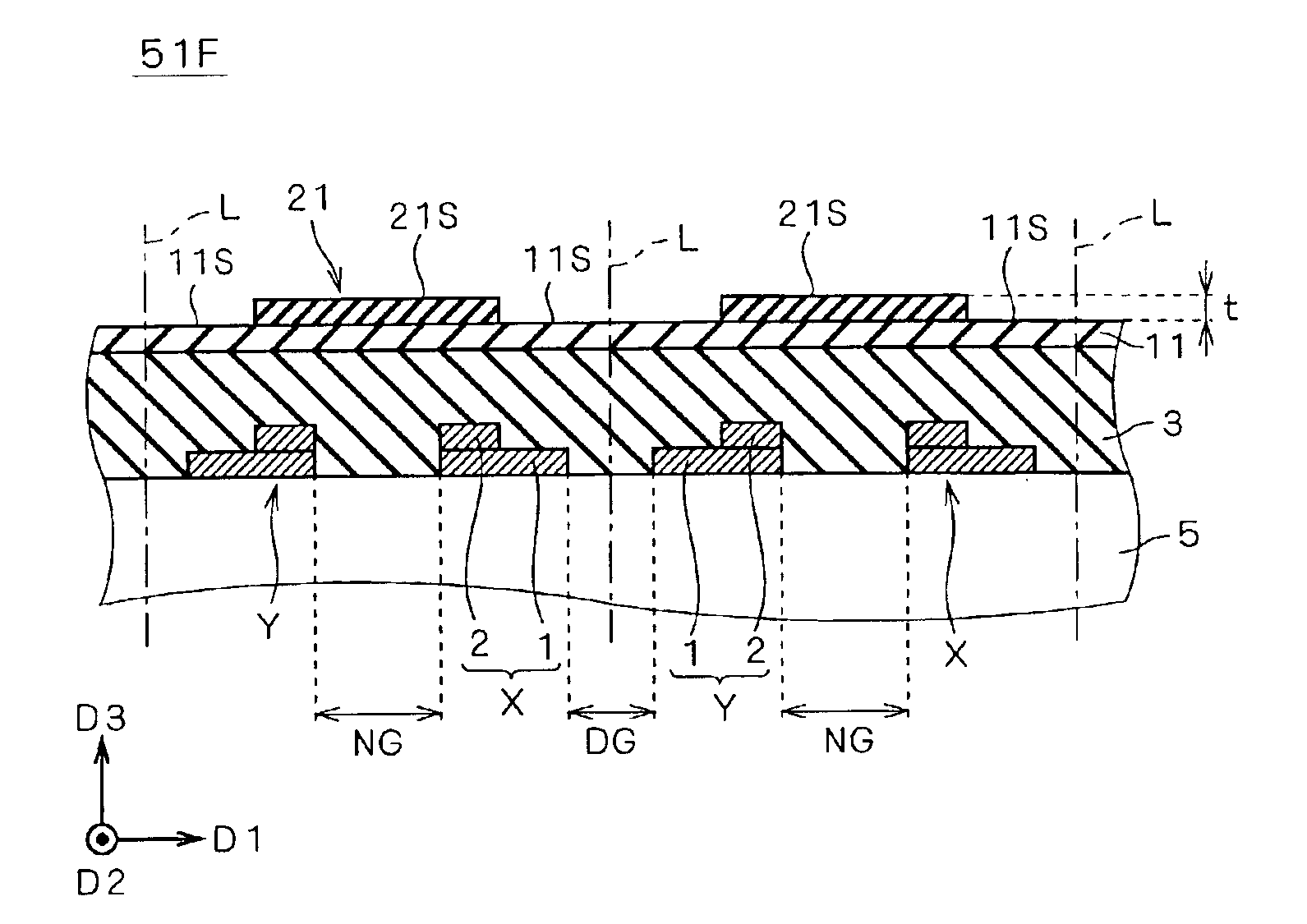

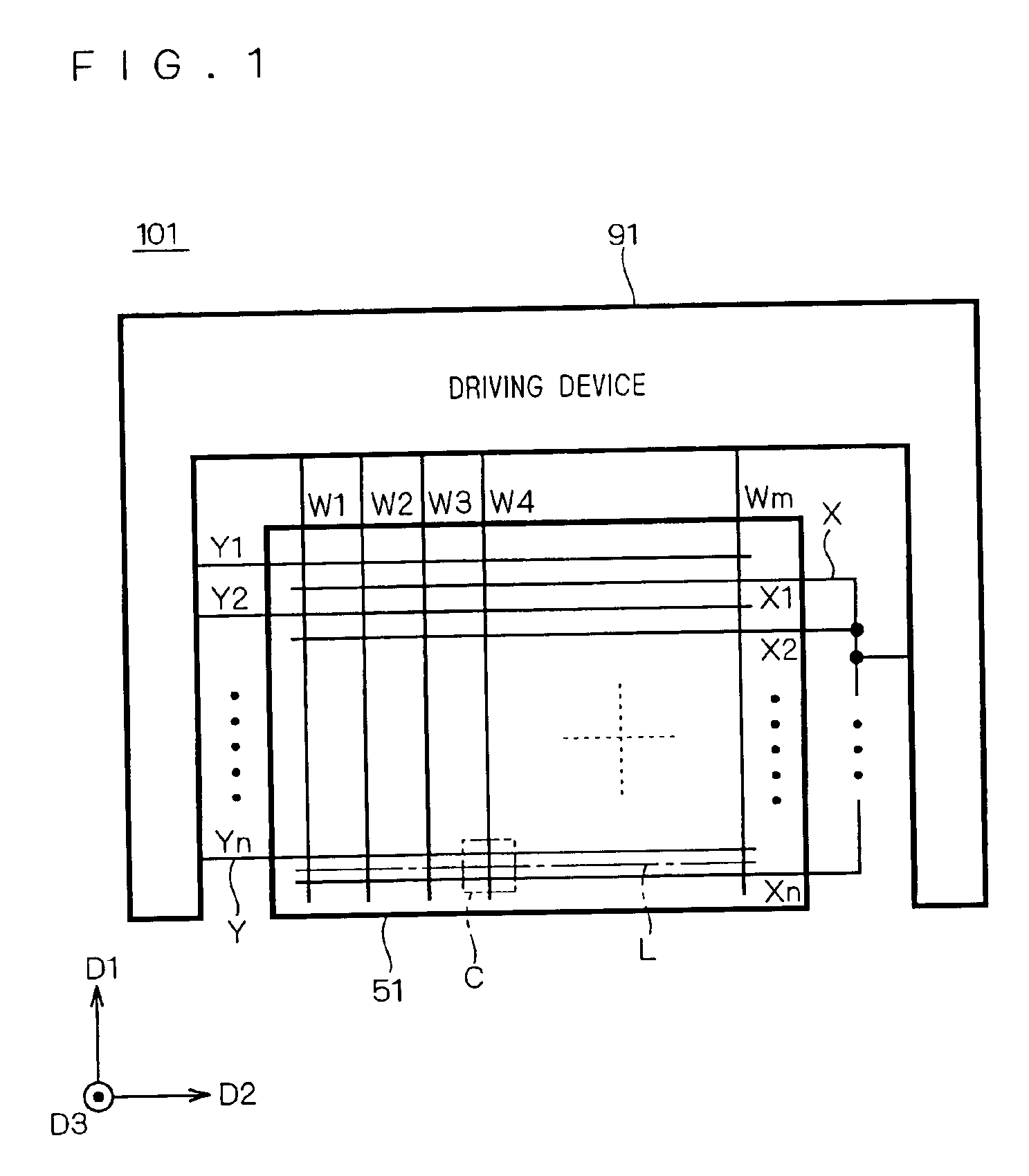

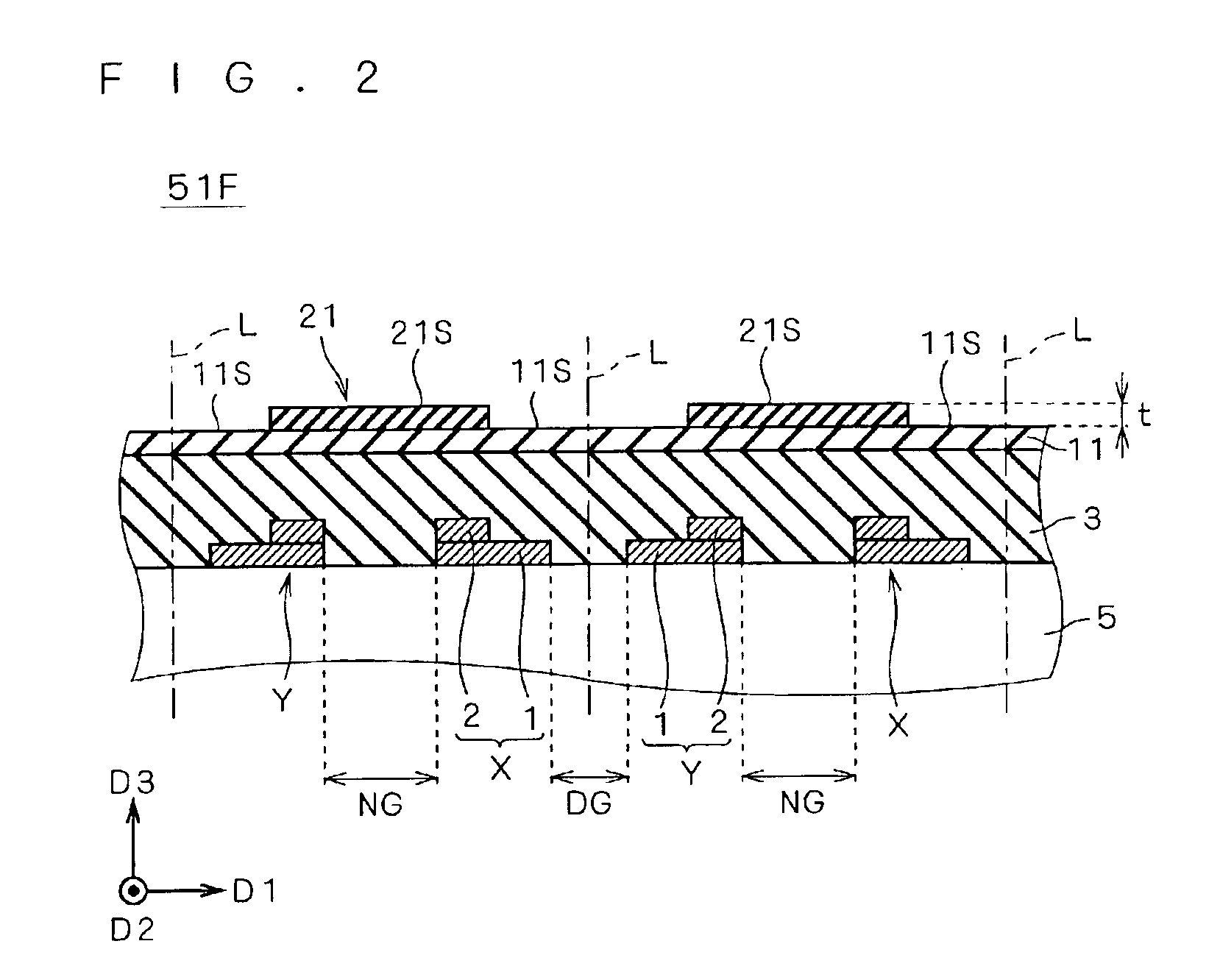

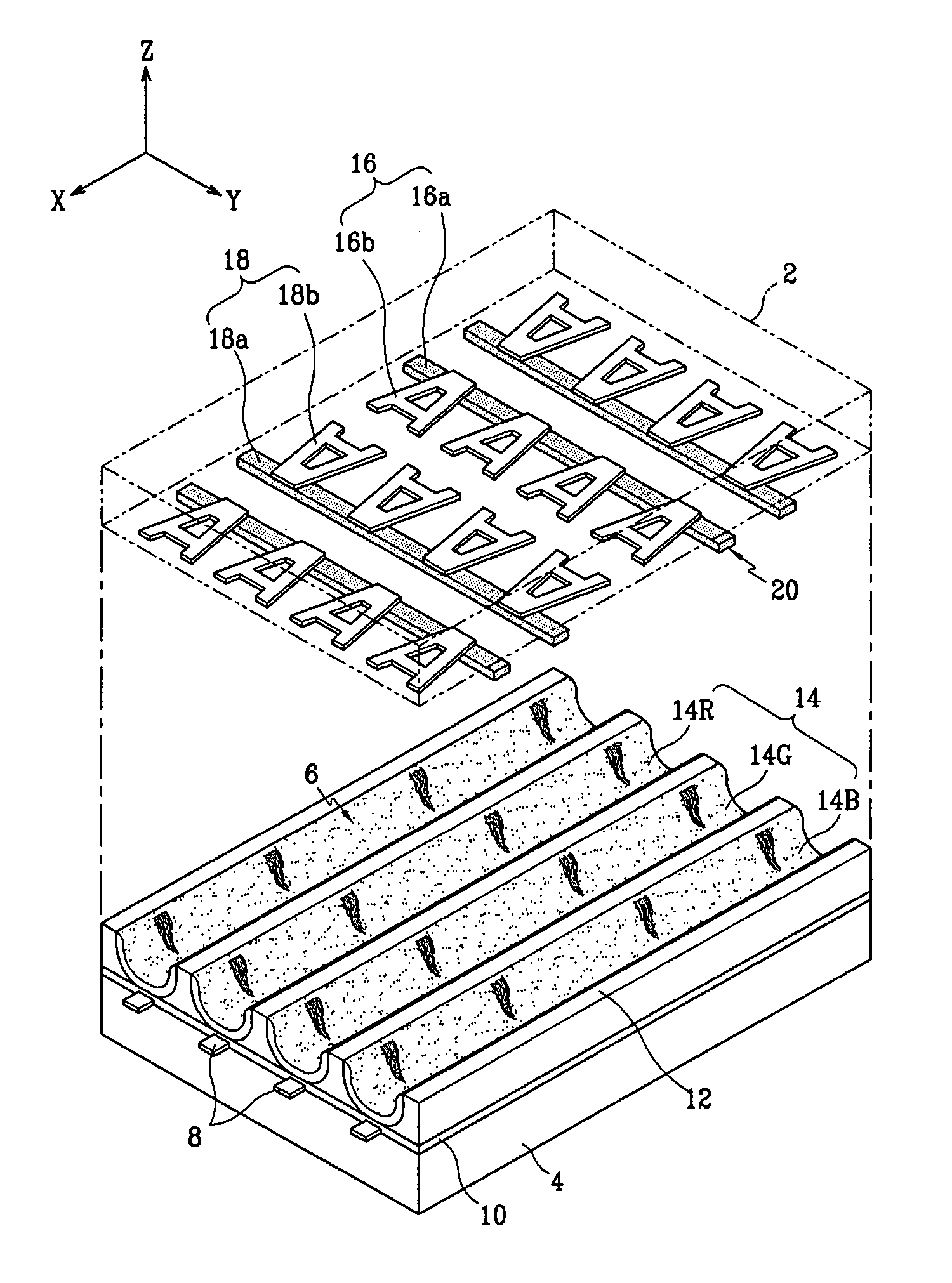

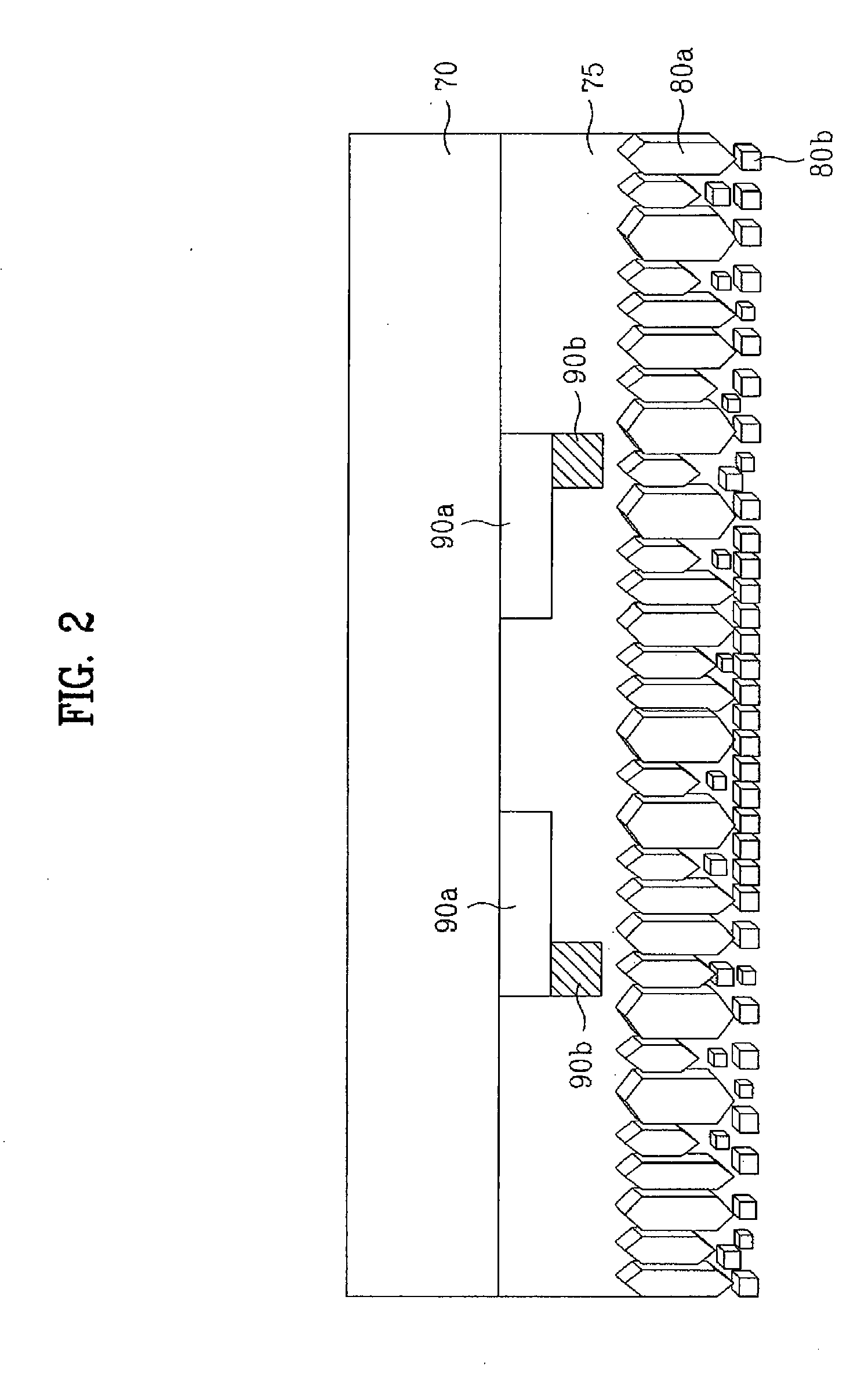

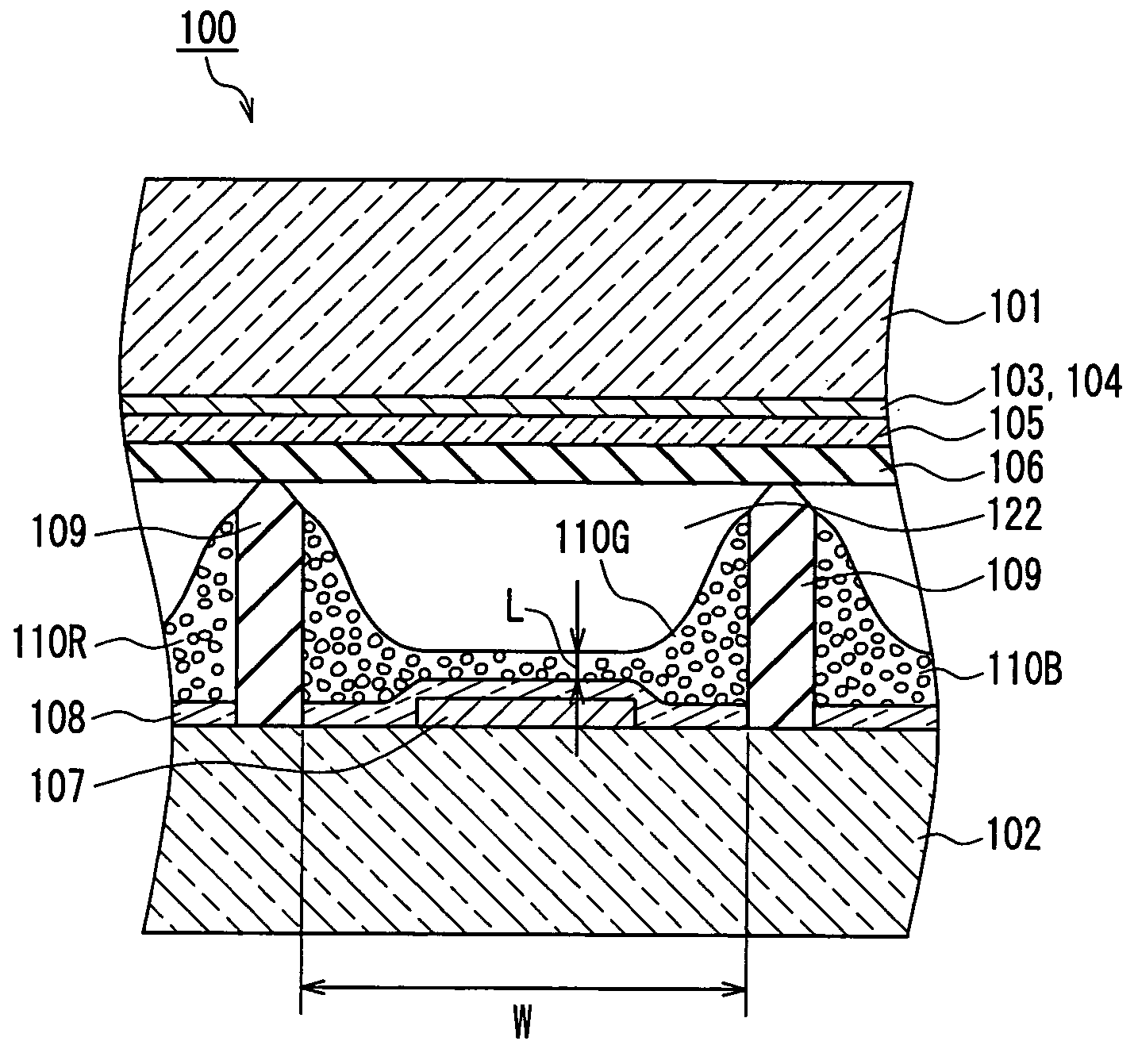

Plasma display panel and plasma display device

InactiveUS6856305B2Increase in minimum sustain pulse voltageAddress electrodesSustain/scan electrodesPotential differenceDisplay device

A discharge inert film (22) is made of an aggregate of fine particles not substantially containing any inorganic binder. Each of sustain discharge electrodes (XB, YB) includes a plurality of discharge gap adjoining portions (a), a bus portion (b) and a plurality of bridge-building portions (c). The bus portion (b) adjoins the electrode pair gap portion (NG), extending along a second direction (D2). Each of bridge-building portions (c) extends towards a discharge gap portion (DG). The bridge-building portions (c) are connected to the discharge gap adjoining portions (a), respectively, and these adjoining portions (a) adjoin the discharge gap portion (DG) and are arranged therealong. The film (22) is so disposed as not to cover the discharge gap adjoining portions (a). When a surface discharge is generated between the sustain discharge electrodes (X, Y) during a reset period, the potential difference between the electrodes (X, Y) is gradually increased.

Owner:MITSUBISHI ELECTRIC CORP

Phosphor and Light Emitting Instrument

ActiveUS20080303409A1Without luminance deteriorationLong wavelengthSustain/scan electrodesDischarge tube luminescnet screensPhosphorRare earth

The present invention aims at providing a chemically stabilized inorganic phosphor which emits orange light or red light at wavelengths longer than the conventional rare-earth activated sialon phosphor and which has a higher luminance.The solving means resides in an inorganic phosphor design represented by a composition formula MaAbDcEdNeOfXg and containing: an M element (M is one kind or two or more kinds of element(s) selected from Mn, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu); a divalent A element (A is one kind or two or more kinds of element(s) selected from Mg, Ca, Sr, and Ba); a trivalent E element (E is one kind or two or more kinds of element(s) selected from B, Al, Ga, and In); a tetravalent D element (D is one kind or two or more kinds of element(s) selected from Si, Ge, and Sn); nitrogen; oxygen (including an oxygen absent condition); and another X element (including an X absent condition); wherein the parameters a, b, c, d, e, f, and g included in the equation are adjusted to and set at particular regions to provide an inorganic phosphor which emits orange light at wavelengths of 570 nm or longer or red light at wavelengths of 600 nm or longer with excellent color rendering property.

Owner:NAT INST FOR MATERIALS SCI

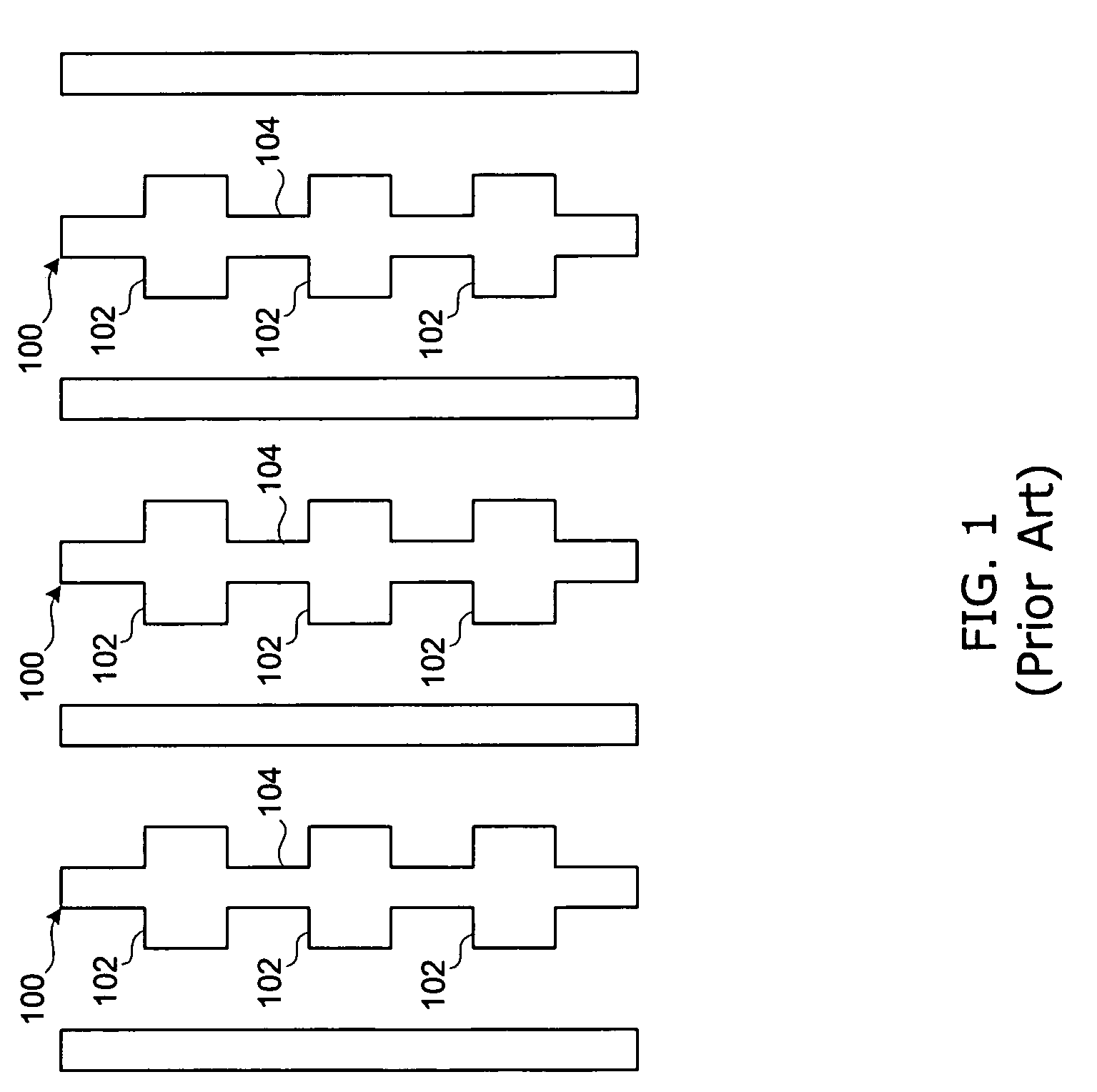

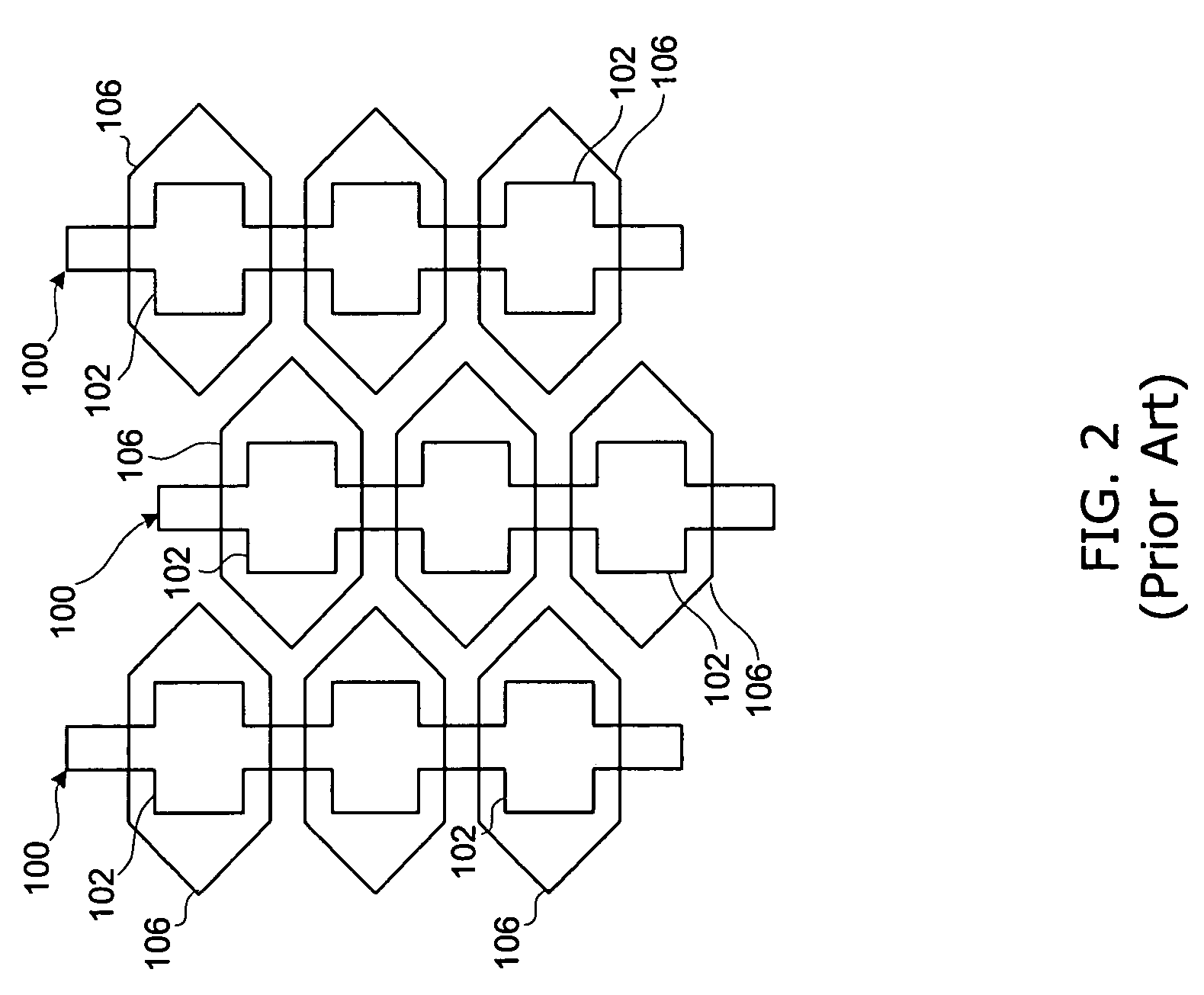

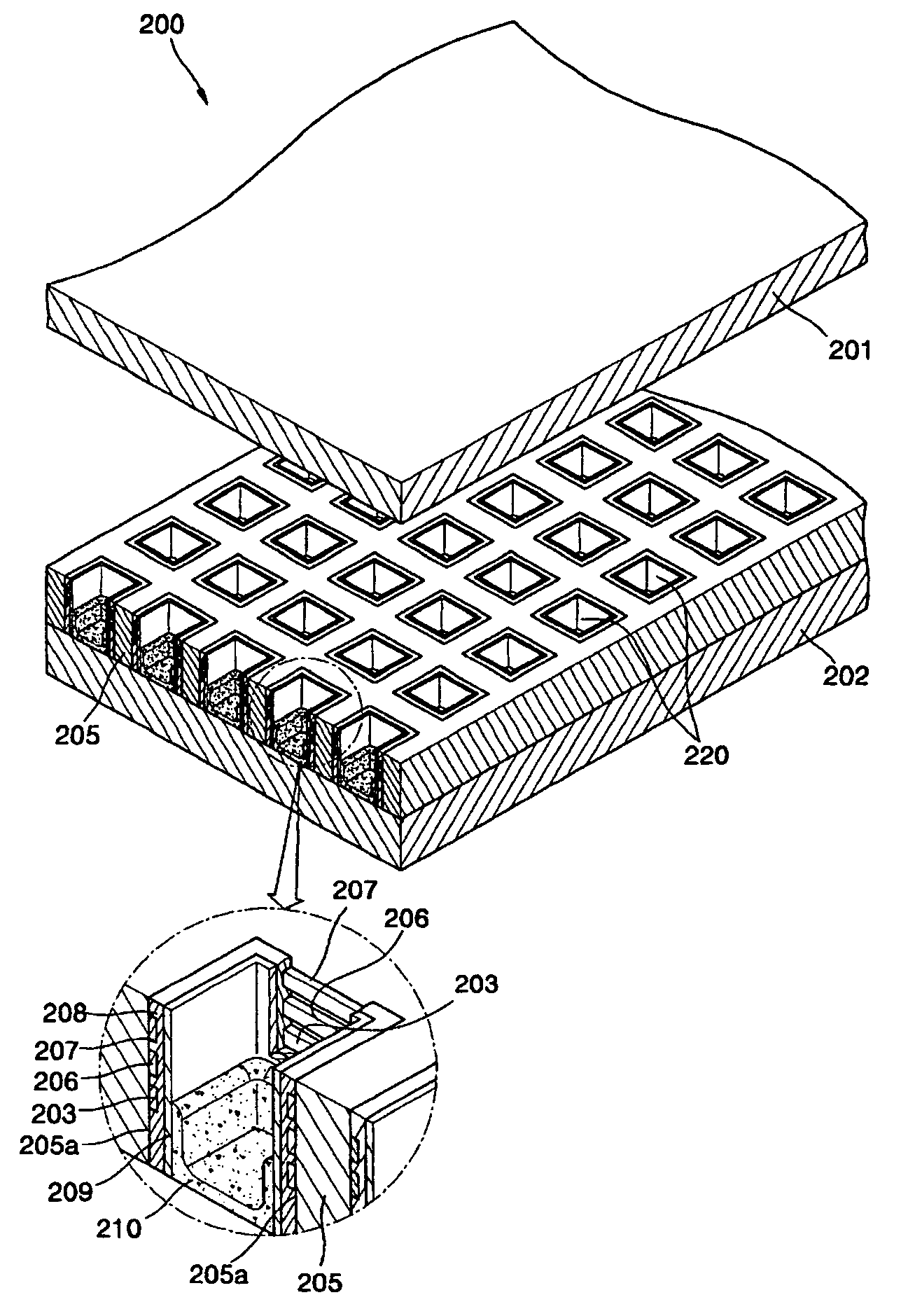

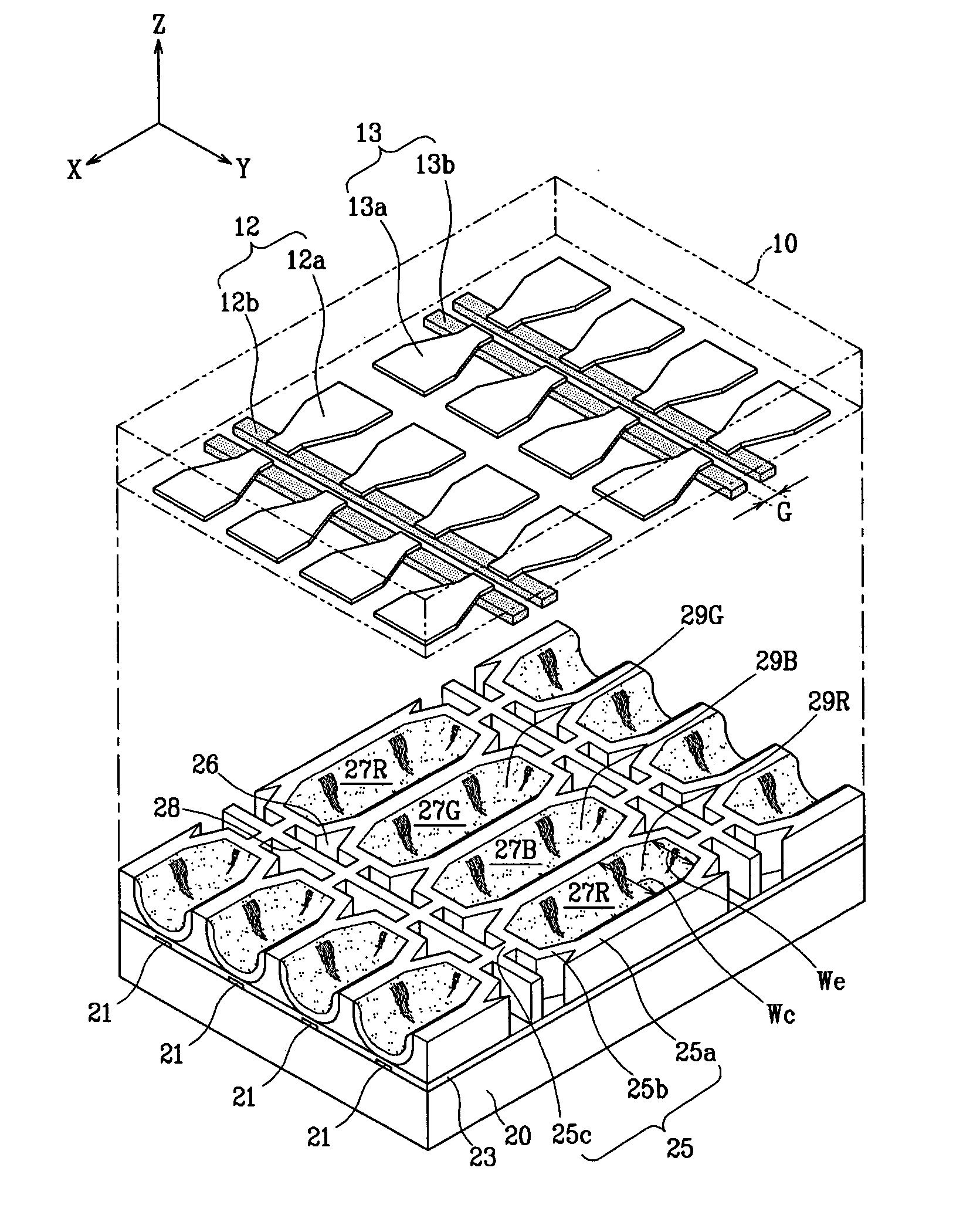

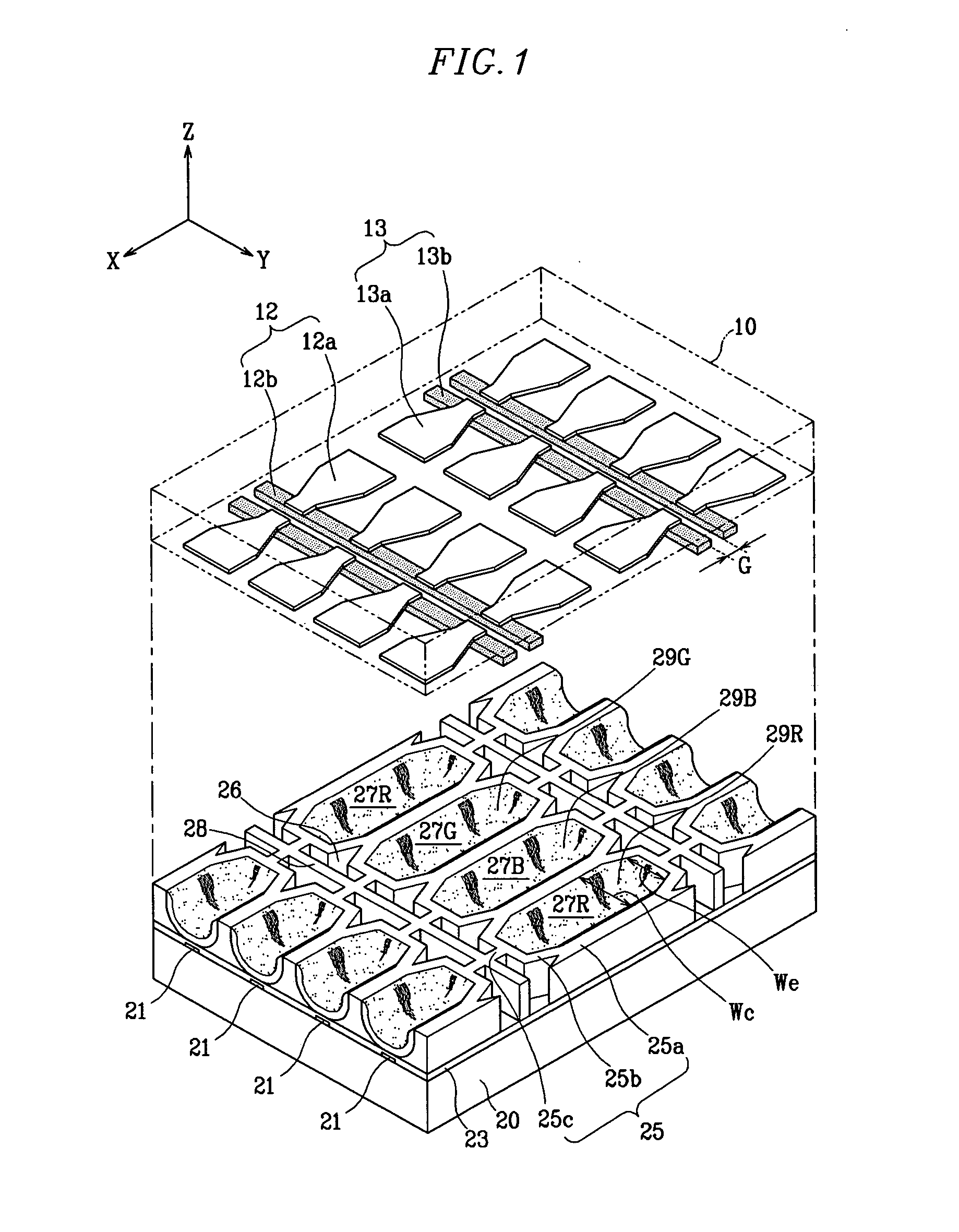

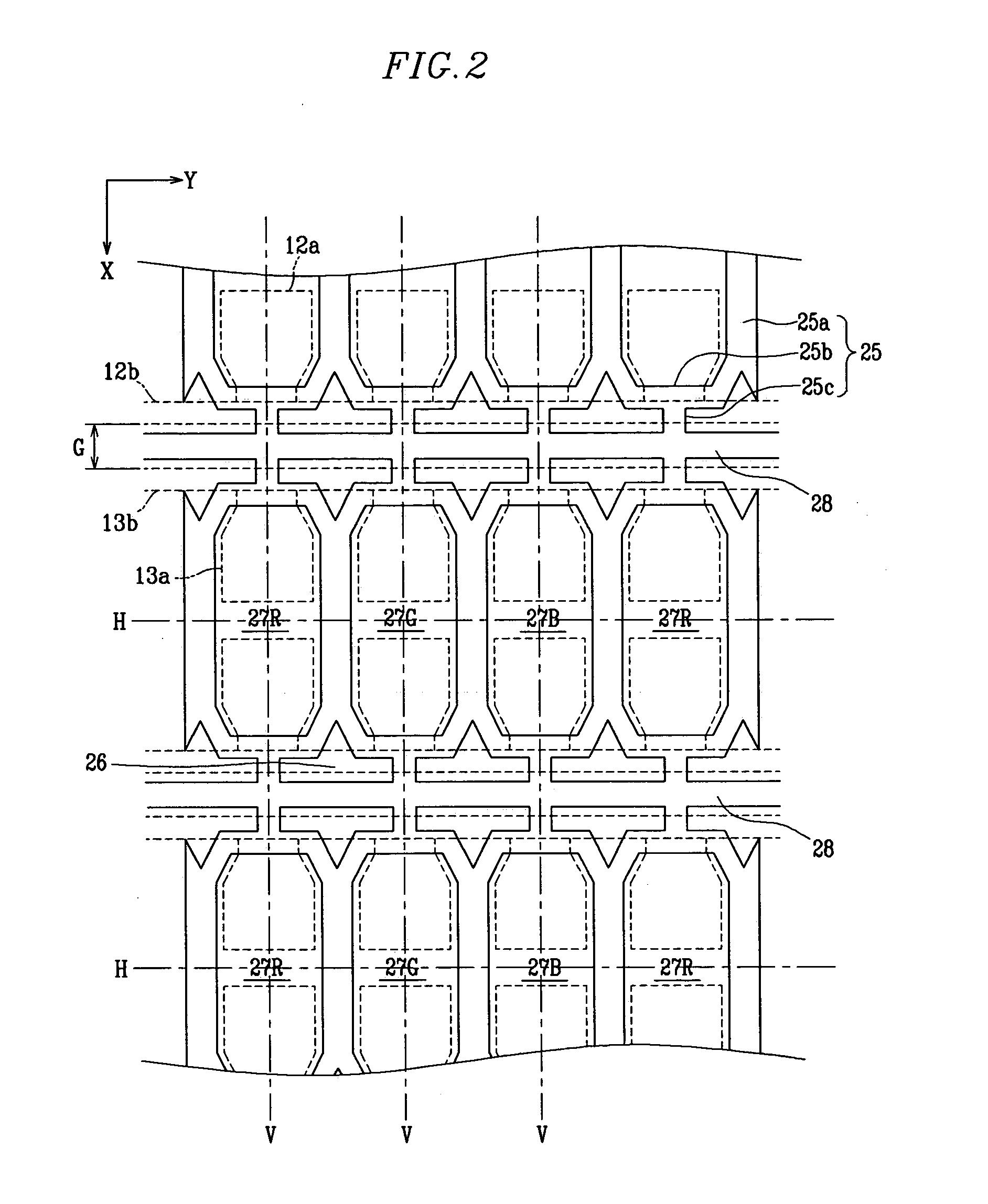

Plasma display panel including barrier ribs and method for manufacturing barrier ribs

InactiveUS20040000873A1Increase contrastImprove efficiencyAddress electrodesSustain/scan electrodesEngineeringProtection layer

The present invention provides a plasma display panel and a method for manufacturing barrier ribs for the plasma display panel. The plasma display panel includes first and second substrates that have a predetermined gap therebetween. A plurality of parallel address electrodes are formed on the first substrate. A dielectric layer is formed on the first substrate covering the address electrodes and barrier ribs are formed on the dielectric layer in a lattice pattern. Discharge sustain electrodes are formed on the second substrate which is perpendicular to the address electrodes, and a transparent dielectric layer and a protection layer are formed on the second substrate covering the discharge sustain electrodes. The barrier ribs are, for example, first and second barrier rib members which are formed respectively in the same direction as the address electrodes and the discharge sustain electrodes. Either or both the first barrier rib members or the second barrier rib members are made of a non-transparent material.

Owner:SAMSUNG SDI CO LTD

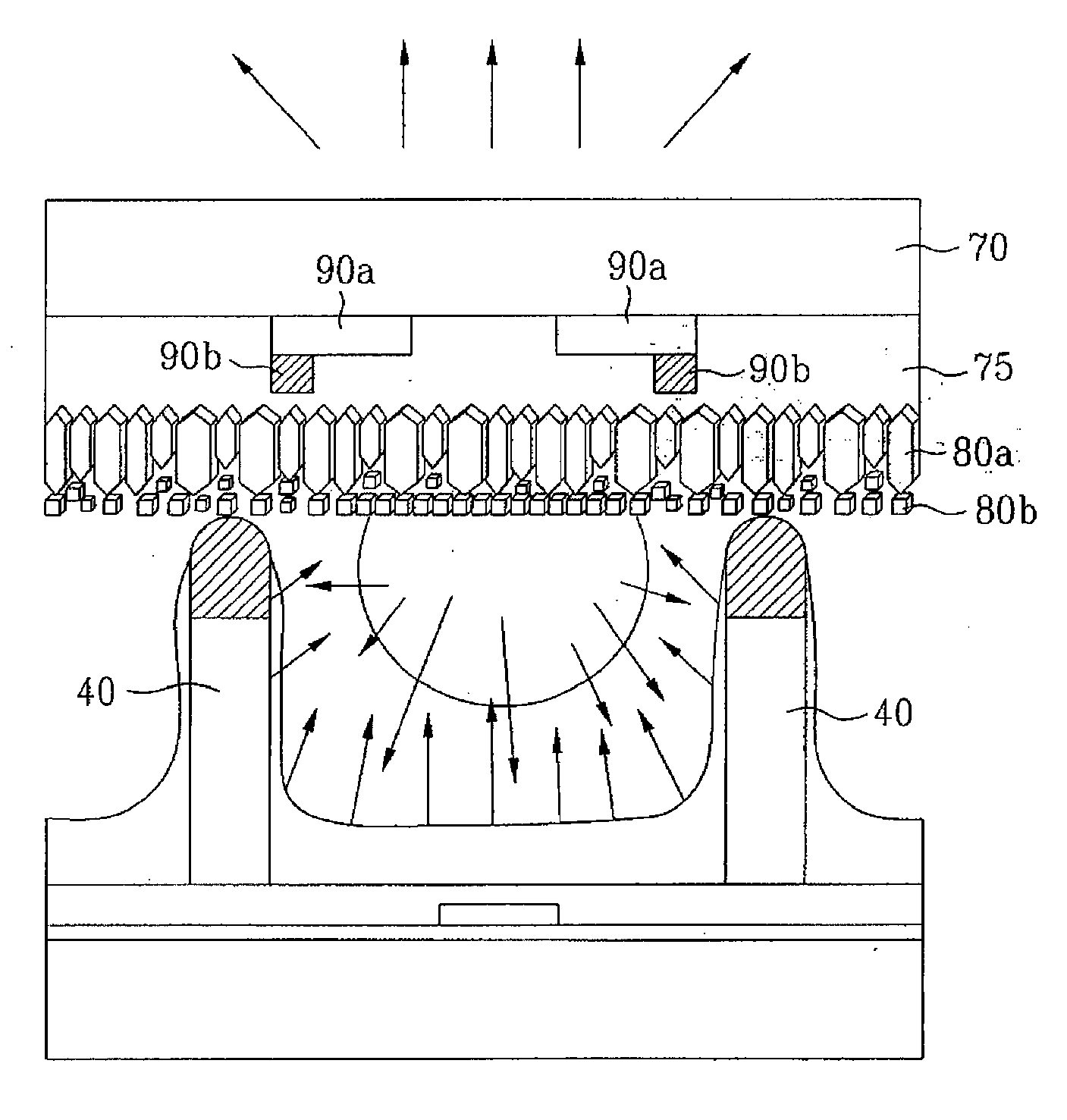

Plasma display panel

InactiveUS20050029939A1Improve discharge efficiencyIncreased formationSustain/scan electrodesAlternating current plasma display panelsPhosphorPlasma display

A plasma display panel. A first substrate and a second substrate are provided opposing one another with a predetermined gap therebetween. Address electrodes are formed on the second substrate. Barrier ribs are mounted between the first substrate and the second substrate defining a plurality of discharge cells. Phosphor layers are formed within the discharge cells. Discharge sustain electrodes are formed on the first substrate. The discharge sustain electrodes include bus electrodes that extend such that a pair of the bus electrodes is provided for each of the discharge cells, and protrusion electrodes extending from each of the bus electrodes such that a pair of opposing protrusion electrodes is formed within an area corresponding to each discharge cell. A distal end of each protrusion electrode includes an indentation such that a gap is formed between the pair of opposing protrusion electrodes, and an aperture is formed in each protrusion electrode.

Owner:SAMSUNG SDI CO LTD

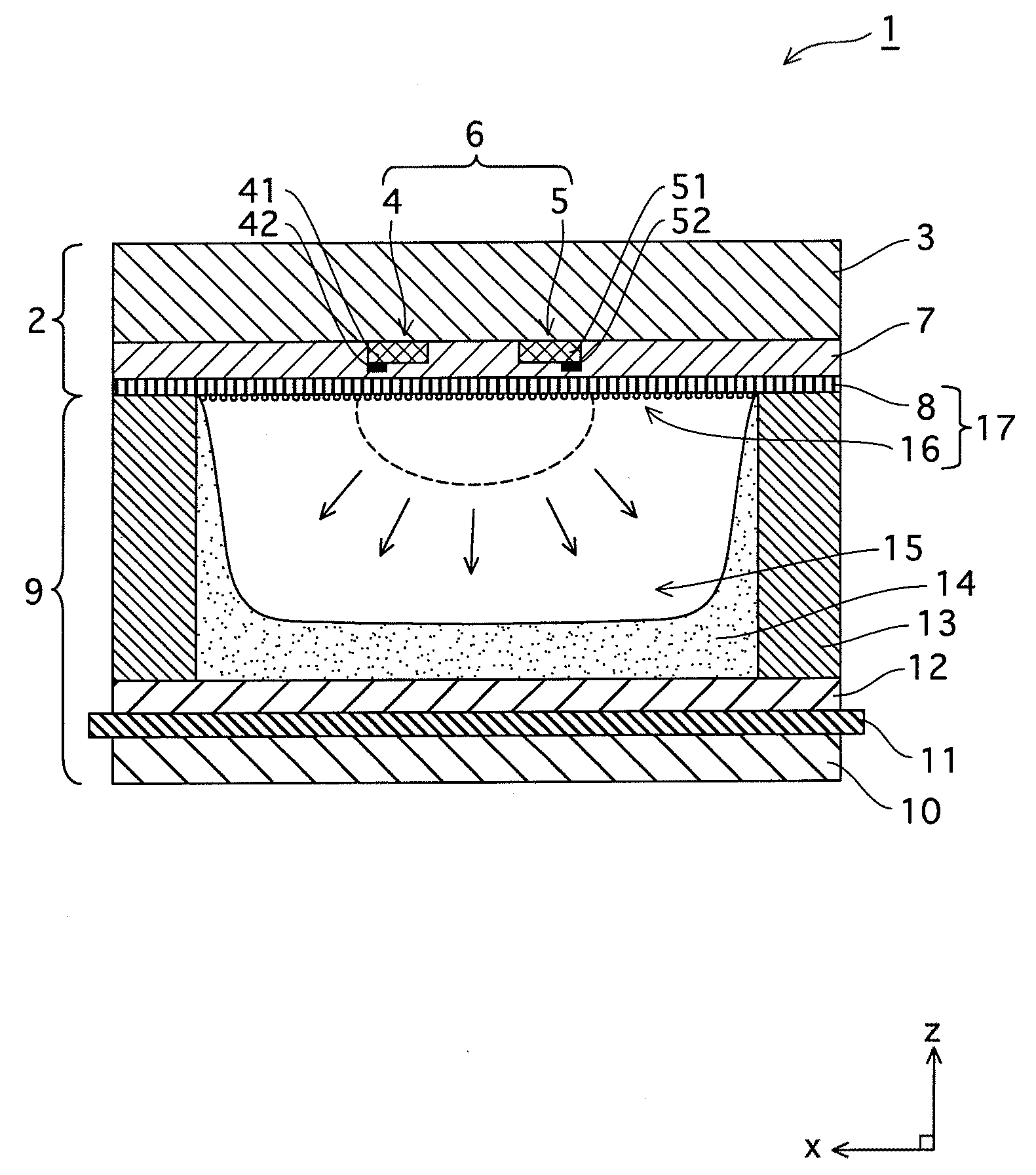

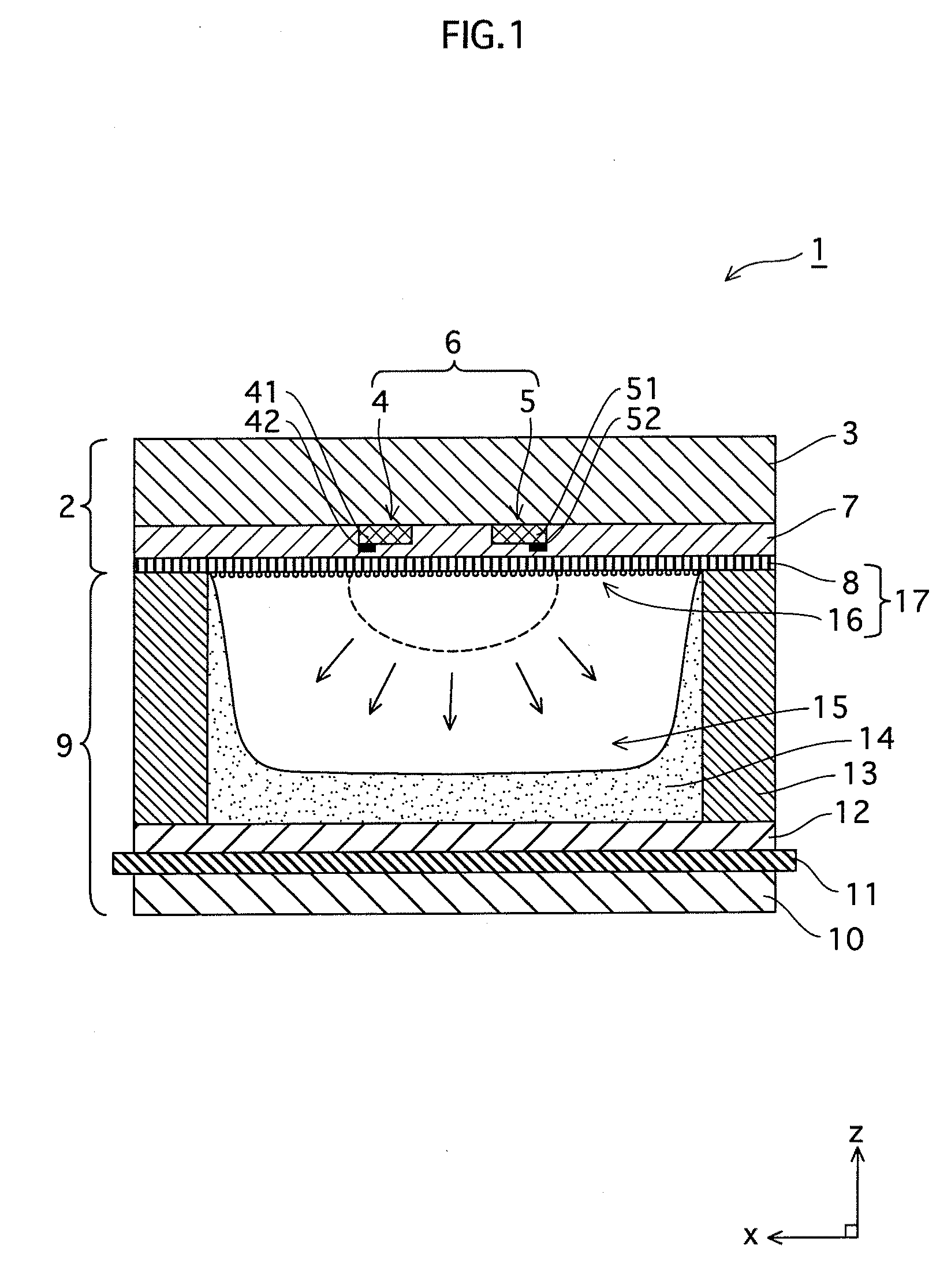

Plasma display panel and method for manufacturing the same

ActiveUS20090140652A1Large secondary electron emission coefficientLaunch evenlyTube/lamp screens manufactureAddress electrodesLow voltagePlasma display

“Discharge delay” and “dependence of discharge delay on temperatures” are solved by improving a protective layer, thus a PDP can be driven at a low voltage. Furthermore, the PDP can display excellent images by suppressing “dependence of discharge delay on space charges.” Liquid-phase magnesium alkoxide (Mg (OR)2) or acetylacetone magnesium ate whose purity is 99.95% or more is prepared, and is hydrolyzed by adding a small amount of acids to the solution. Thus, a gel of magnesium hydroxide that is a magnesium oxide precursor is formed. Burning the gel in atmosphere at 700° C. or more produces powder containing MgO particles 16a-16d having the NaCl crystal structure with (100) and (111) crystal faces or with (100), (110) and (111) crystal faces. By pasting the powder on a dielectric layer 7 or a surface layer 8, the MgO powder 16 is formed so as to serve as the protective layer.

Owner:PANASONIC CORP

Plasma display panel

InactiveUS20070126361A1Reduce voltageImproves contrast and jitter characteristicSustain/scan electrodesGas discharge vessels/containersTectorial membraneEngineering

Disclosed is a plasma display panel with improved discharge characteristics. The plasma display panel comprises an upper panel and a lower panel integrally joined to the upper panel through barrier ribs wherein the upper panel includes a dielectric layer, a first protective film formed on one surface of the dielectric layer and composed of columnar magnesium oxide crystal particles, and a second protective film formed on the first protective film and composed of hexahedral magnesium oxide crystal particles.

Owner:LG ELECTRONICS INC

Plasma display panel

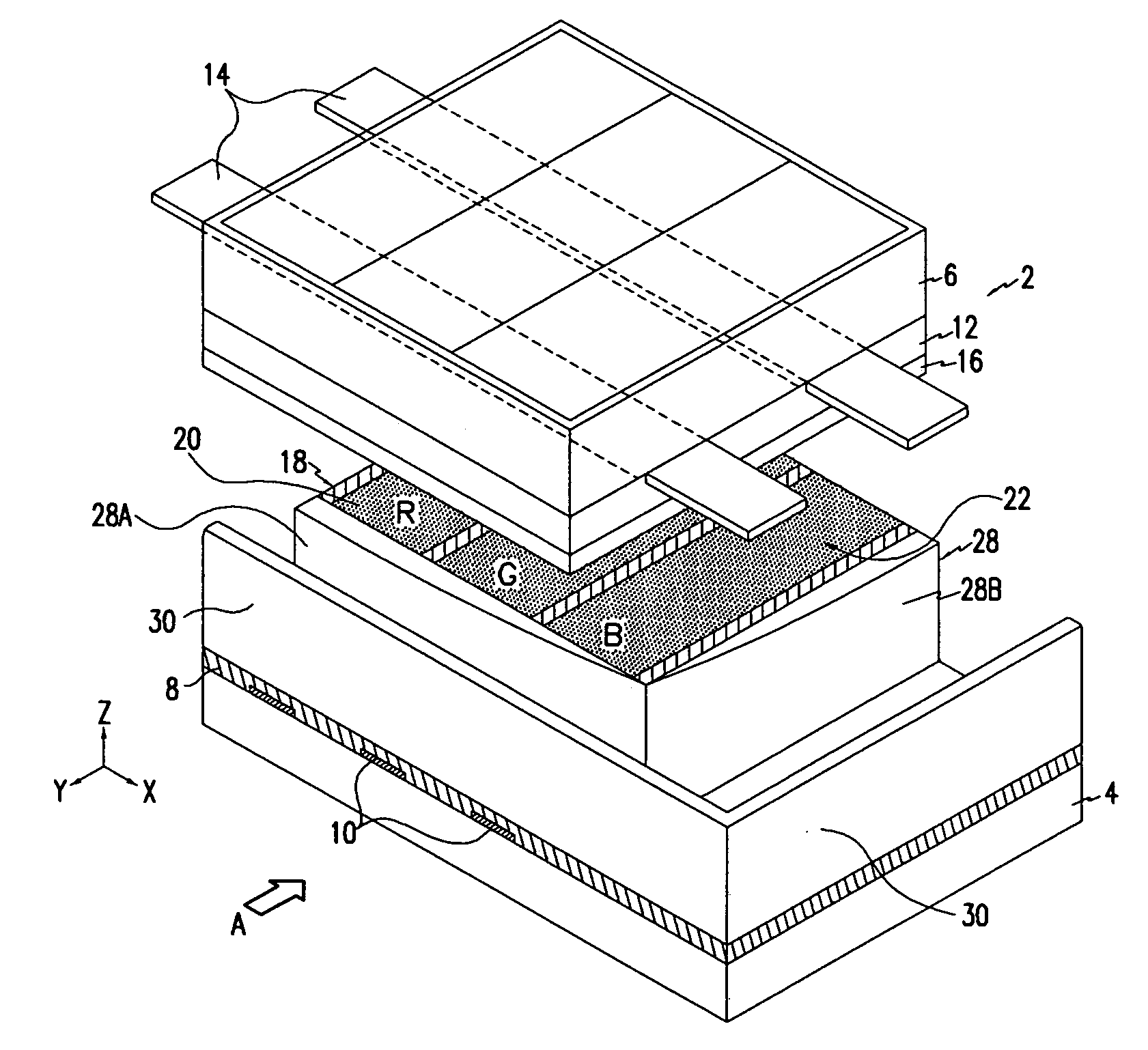

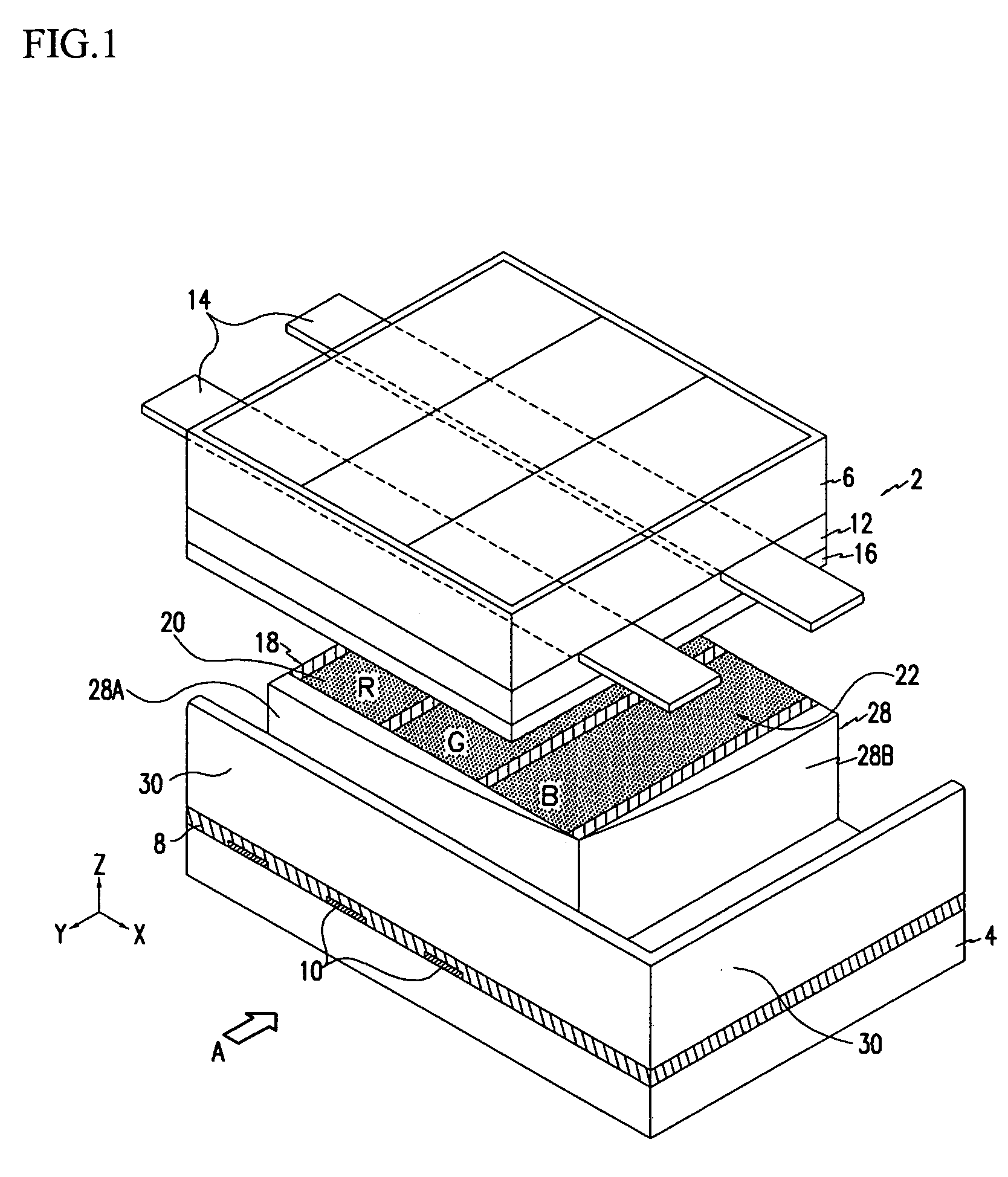

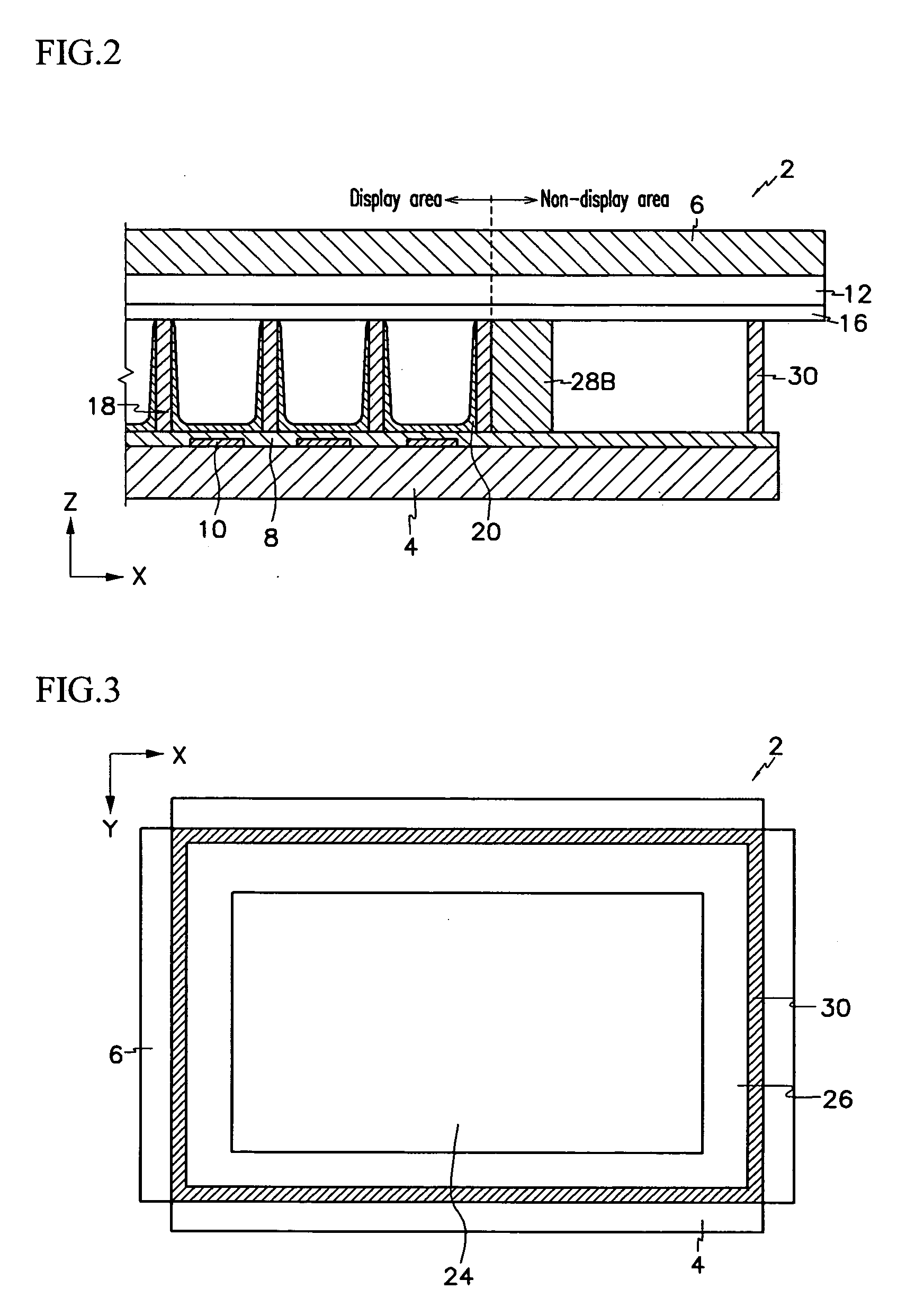

InactiveUS20040201351A1Improve structural strengthMinimize damageAddress electrodesSustain/scan electrodesPhosphorEngineering

A plasma display panel includes first and second substrates spaced apart from each other at a distance while proceeding substantially parallel to each other. The first and the second substrates have a display area and a non-display area. A plurality of address electrodes are formed on the first substrate, and covered by a dielectric layer. Main barrier ribs are arranged between the substrates to form discharge cells. Phosphor layer is formed with the discharge cells. A plurality of discharge sustain electrodes are formed on the surface of the second substrate facing the first substrate, and covered by a dielectric layer. Reinforcing barrier ribs are arranged at the non-display area while surrounding the display area, and connected to the main barrier ribs with an outer structure curved toward the outside of the substrates.

Owner:SAMSUNG SDI CO LTD

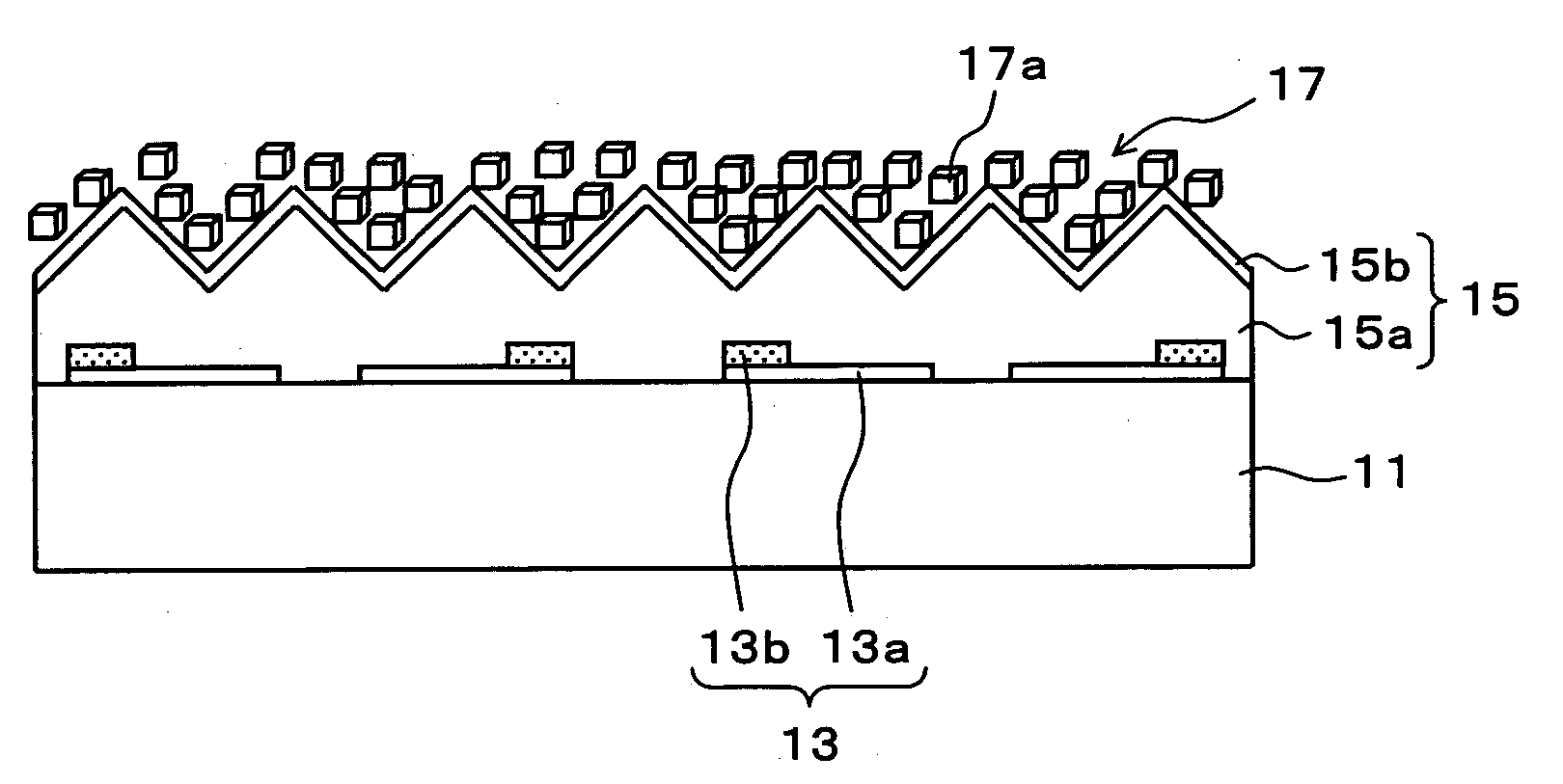

Method for producing substrate assembly for plasma display panel, and plasma display panel

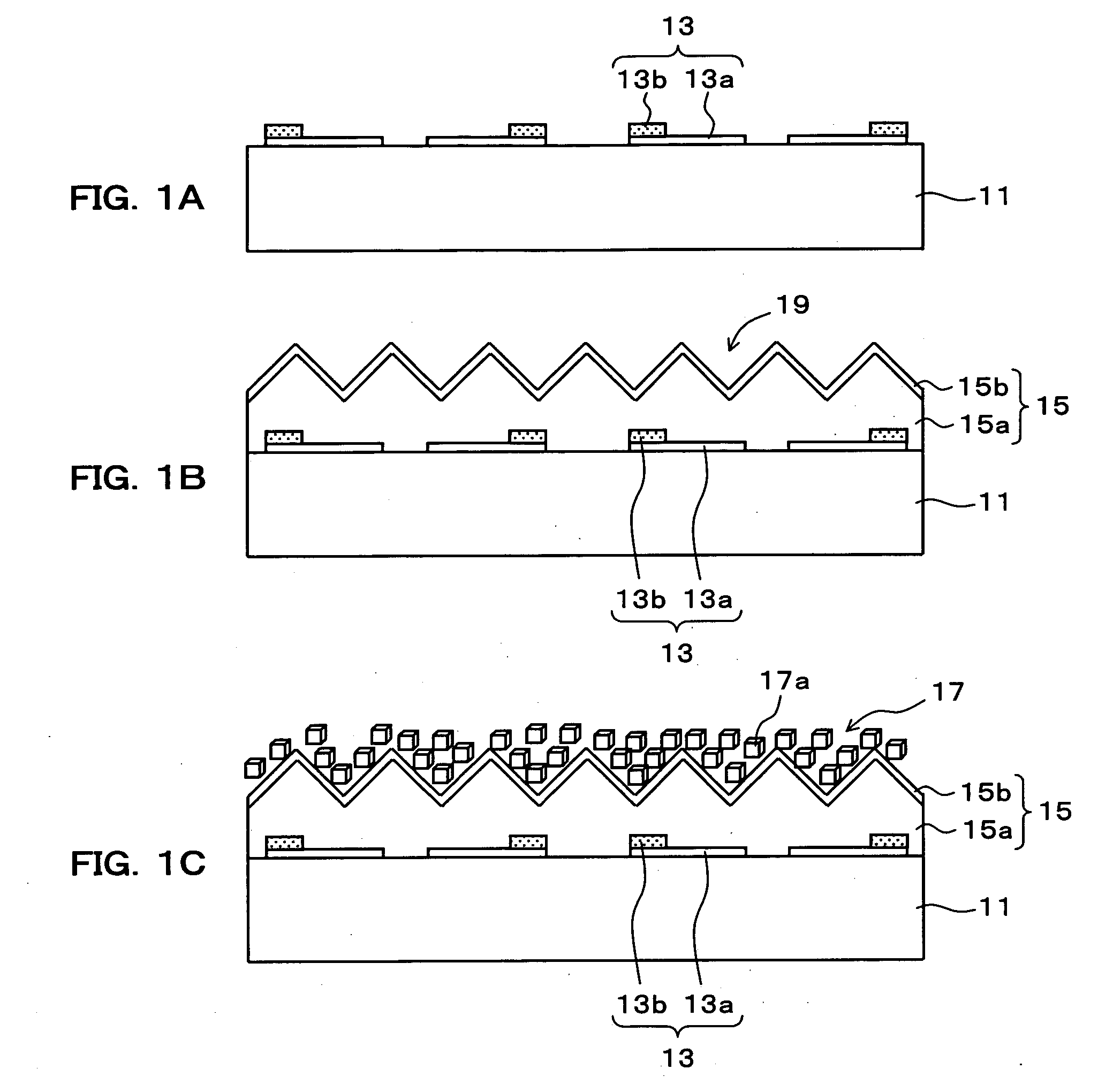

InactiveUS20080049382A1Form evenlyAddress electrodesSustain/scan electrodesRough surfaceOptoelectronics

A method for producing a substrate assembly for a plasma display panel includes the steps of applying a suspension to a dielectric layer covering display electrodes formed on a substrate, the suspension containing a dispersion medium and a large number of magnesium oxide crystals dispersed in the dispersion medium, and thereafter evaporating the dispersion medium to form a layer of the magnesium oxide crystals on the dielectric layer, wherein the dielectric layer has a rugged surface structure having uniformly-dispersed projections and depressions, the rugged surface structure being capable of trapping the magnesium oxide crystals.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

Phosphor and plasma display device

InactiveUS20050062417A1Excellent initial characteristicDeterioration in brightnessSustain/scan electrodesDischarge tube luminescnet screensAluminateAlkaline earth metal

Phosphor and a plasma display device are provided whose deterioration in brightness of phosphors and a degree of change in chromaticity are alleviated and whose discharge characteristics are improved and that has excellent initial characteristics. Phosphor of the present invention is an alkaline-earth metal aluminate phosphor containing an element M (where M denotes at least one type of element selected from the group consisting of Nb, Ta, W and B). In this phosphor, a concentration of M in the vicinity of a surface of the phosphor particles is higher than the average concentration of M in the phosphor particles as a whole. A plasma display device according to the present invention includes a plasma display panel in which a plurality of discharge cells in one color or in a plurality of colors are arranged and phosphor layers are arranged so as to correspond to the discharge cells in colors and in which light is emitted by exciting the phosphor layers with ultraviolet rays. The phosphor layers include blue phosphor, where the afore-mentioned phosphor is used as the blue phosphor.

Owner:PANASONIC CORP

Plasma display panel with various electrode projection configurations

InactiveUS6495957B2Reduce the burden onPrevented from expandingAddress electrodesSustain/scan electrodesEngineeringElectrode pair

A plasma display panel includes a plurality of row electrodes defining rows of a screen. The row electrodes are arranged at intervals so that adjacent row electrodes are capable of serving as an electrode pair for generating a surface discharge. Each of the row electrodes includes a belt-shaped base extending along the full length of the screen in a direction of the rows and protrusions extending from the base toward an adjacent row electrode in every column.

Owner:HITACHI PLASMA PATENT LICENSING

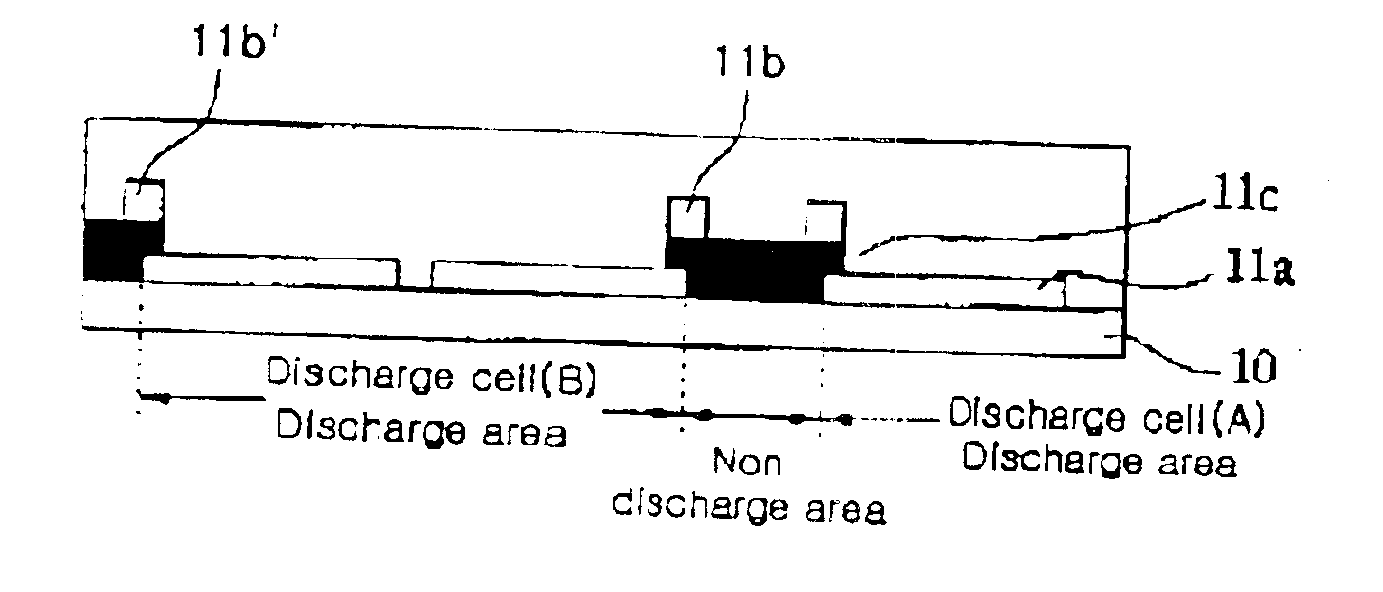

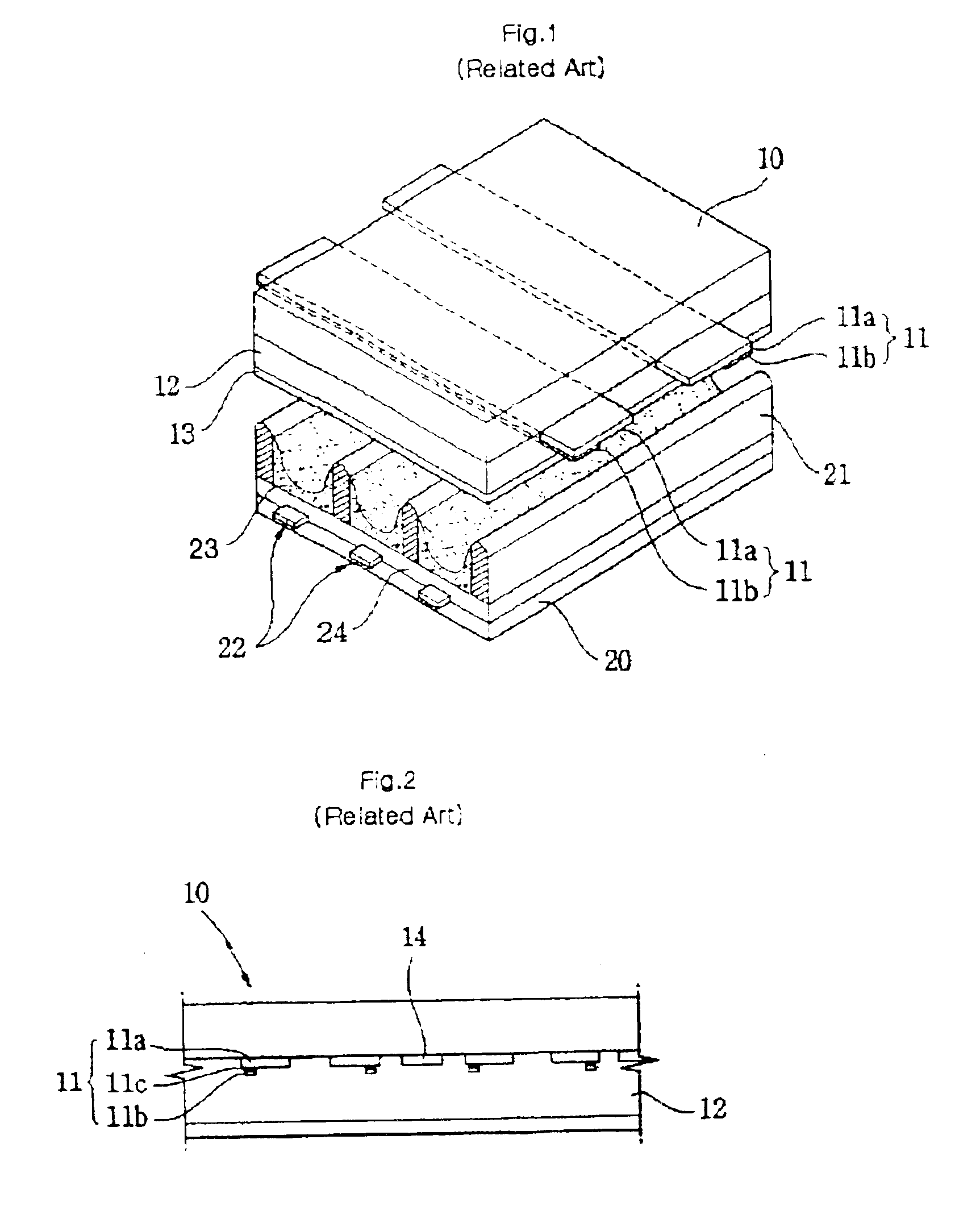

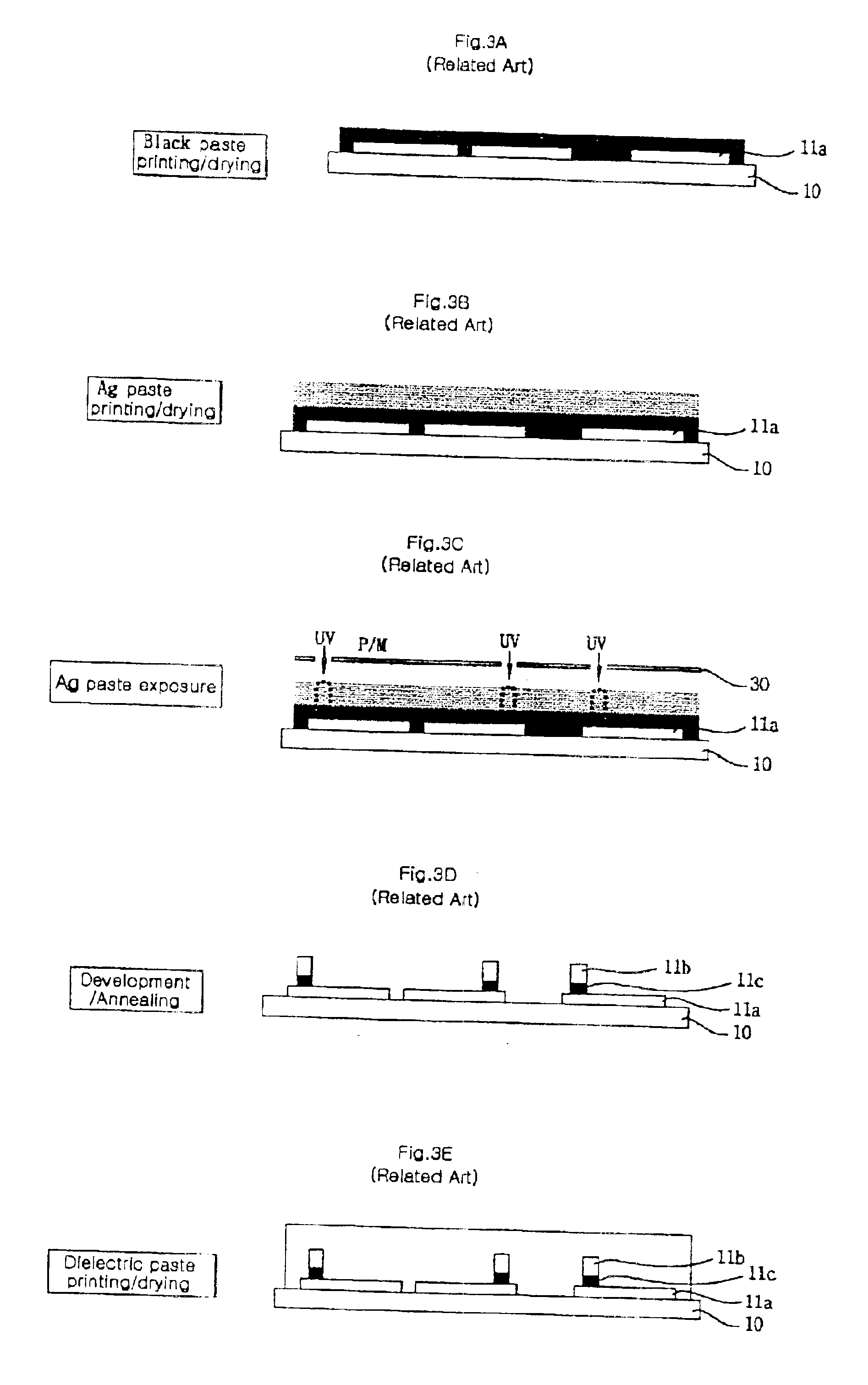

Plasma display panel and manufacturing method thereof

InactiveUS6838828B2Simple manufacturing processIncrease brightnessTube/lamp screens manufactureAddress electrodesEngineeringBrightness perception

The present invention relates to plasma display panel and manufacturing method thereof to simplify the manufacturing steps and reduce cost of production. In the present invention, a black layer formed between a transparent electrode and a bus electrode is formed together with a black matrix at the same time. In this case, the black layer is formed together with the black matrix in one. Cheap nonconductive oxide is used as a black powder of a black layer. Specifically, in case the black layer and the black matrix are formed in one, the bus electrode is shifted to a non-discharge area to improve the brightness of the plasma display panel.

Owner:LG ELECTRONICS INC

Plasma display panel

InactiveUS20050001551A1Maximize discharge efficiencyImprove efficiencyAddress electrodesSustain/scan electrodesPhosphorPlasma display

A plasma display panel. A first substrate and a second substrate are provided opposing one another with a predetermined gap therebetween. Address electrodes are formed on the second substrate. Barrier ribs are mounted between the first substrate and the second substrate, the barrier ribs defining a plurality of discharge cells and a plurality of non-discharge regions. Phosphor layers are formed within each of the discharge cells. Discharge sustain electrodes are formed on the first substrate. The non-discharge regions are formed in areas encompassed by discharge cell abscissas that pass through centers of adjacent discharge cells and discharge cell ordinates that pass through centers of adjacent discharge cells, the non-discharge regions having a width that is at least as large as a width of an end of barrier ribs. Also, a transverse barrier rib is formed extending between each pair of adjacent rows of discharge cells.

Owner:SAMSUNG SDI CO LTD

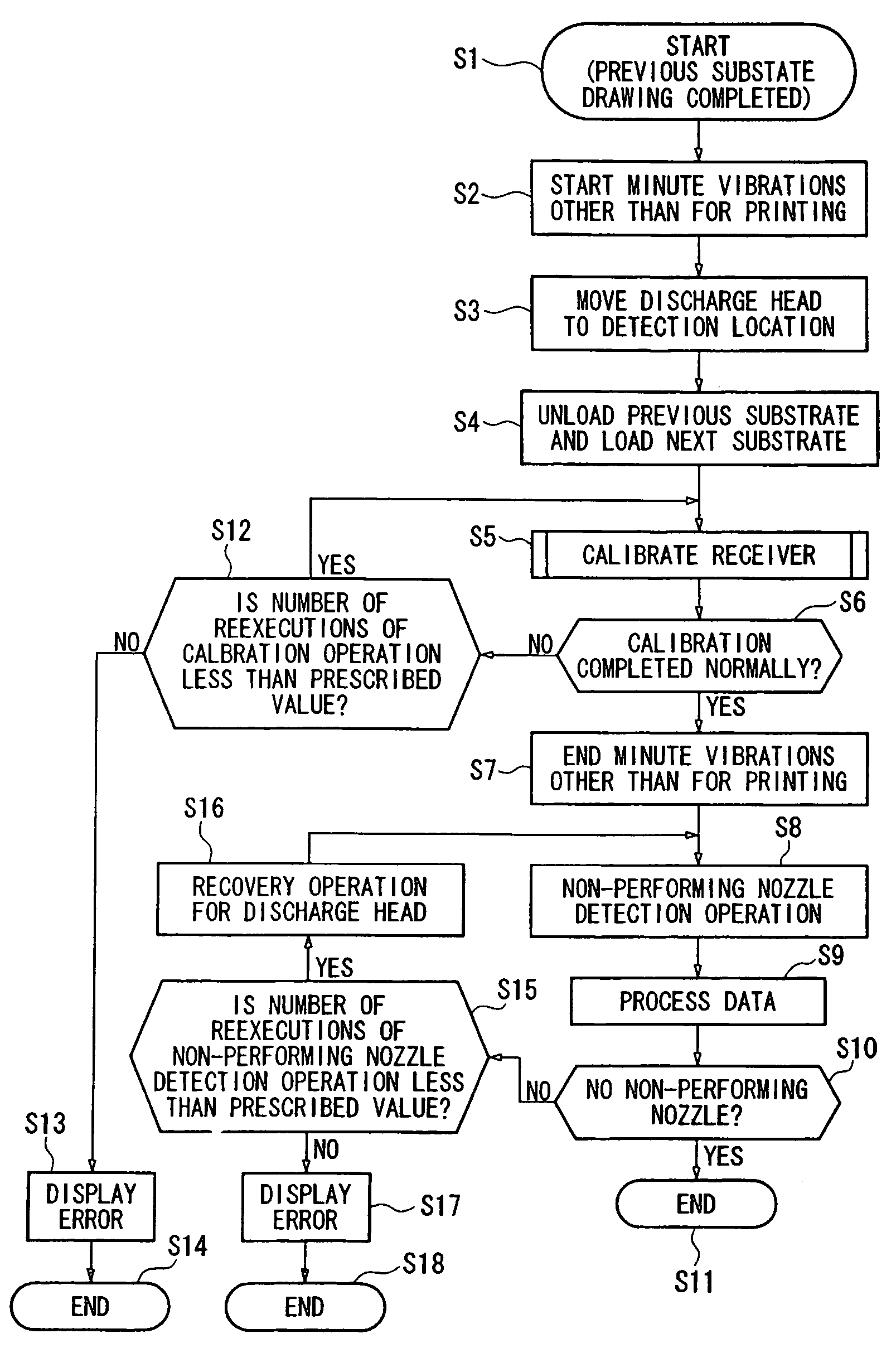

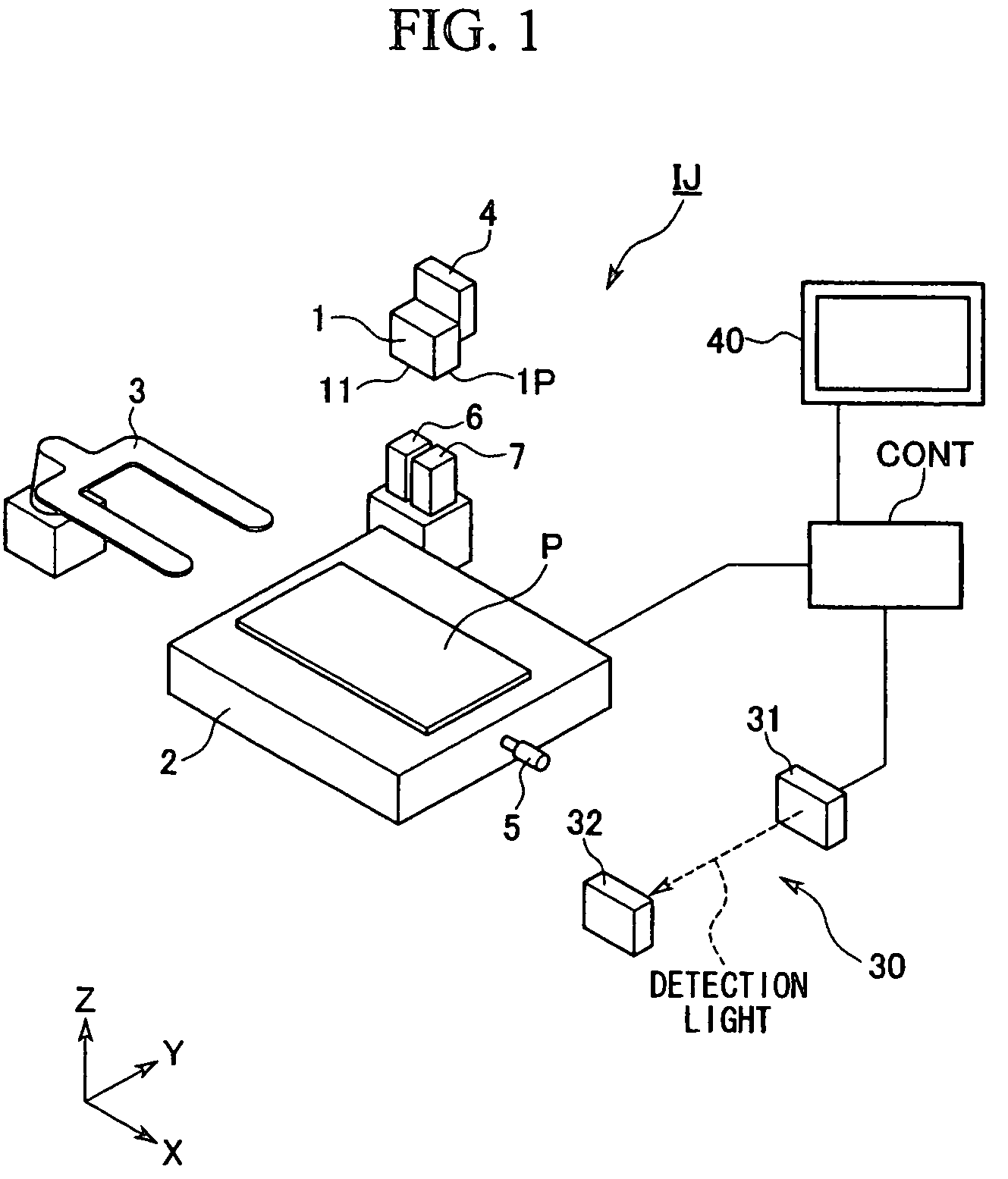

Device manufacturing apparatus, device manufacturing method, and electronic equipment

InactiveUS7461912B2Improve efficiencyLow costAddress electrodesLiquid surface applicatorsManufactured apparatusEngineering

A device manufacturing apparatus includes a discharge head discharging a droplet containing a functional material, a stage supporting a substrate on which the droplet is discharged, and which is capable of moving relative to the discharge head, a carrier carrying the substrate, a detector detecting a discharge condition of the droplet which is discharged from a discharge nozzle formed in the discharge head, and a controller executing a detection operation by the discharge device during a carrying operation of the substrate.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com