Patents

Literature

471results about "Gas discharge connecting/feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS20100180934A1Flow on effectReduce softeningAddress electrodesConductive layers on insulating-supportsTe elementAntimony

Owner:RESONAC CORP

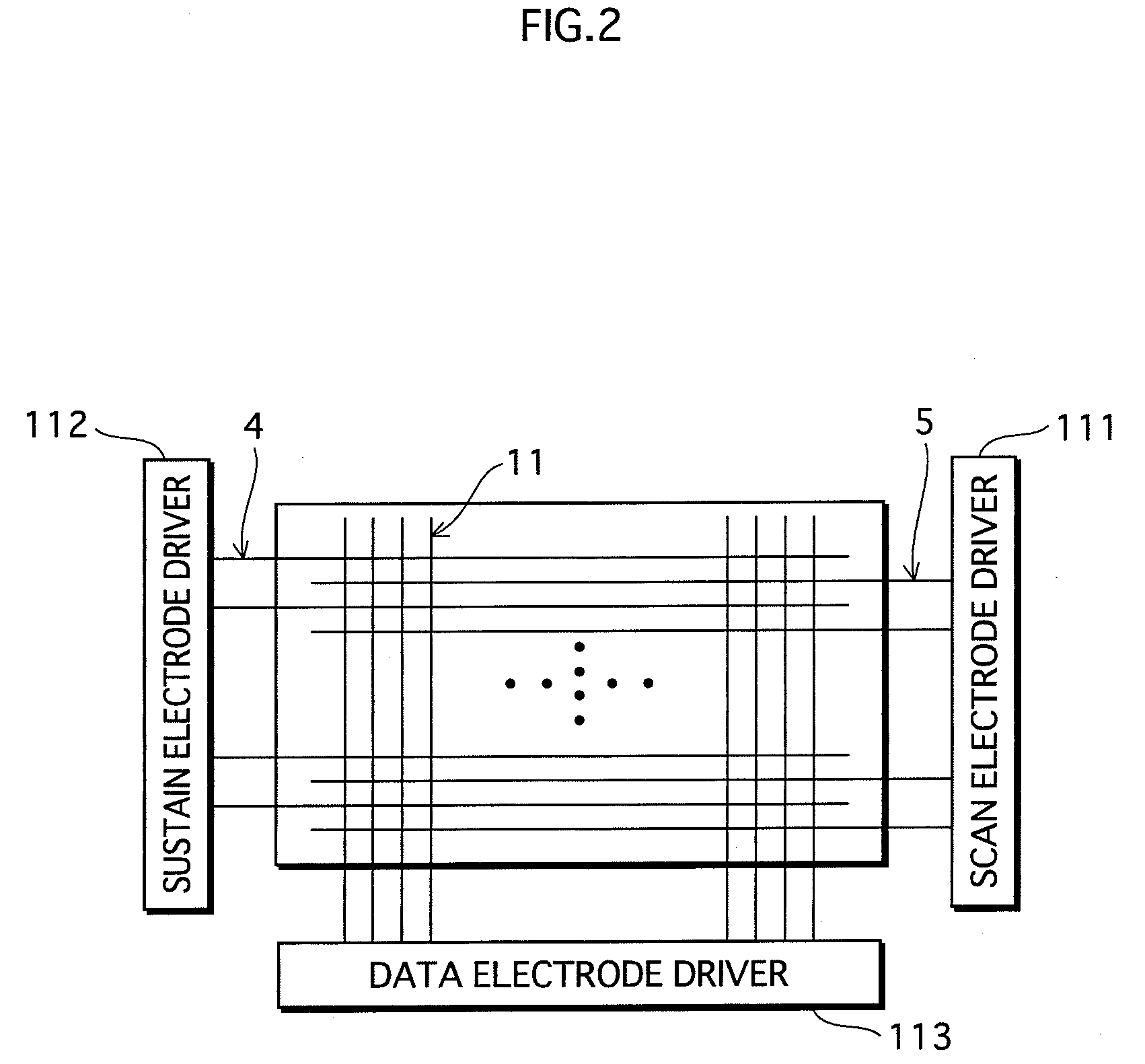

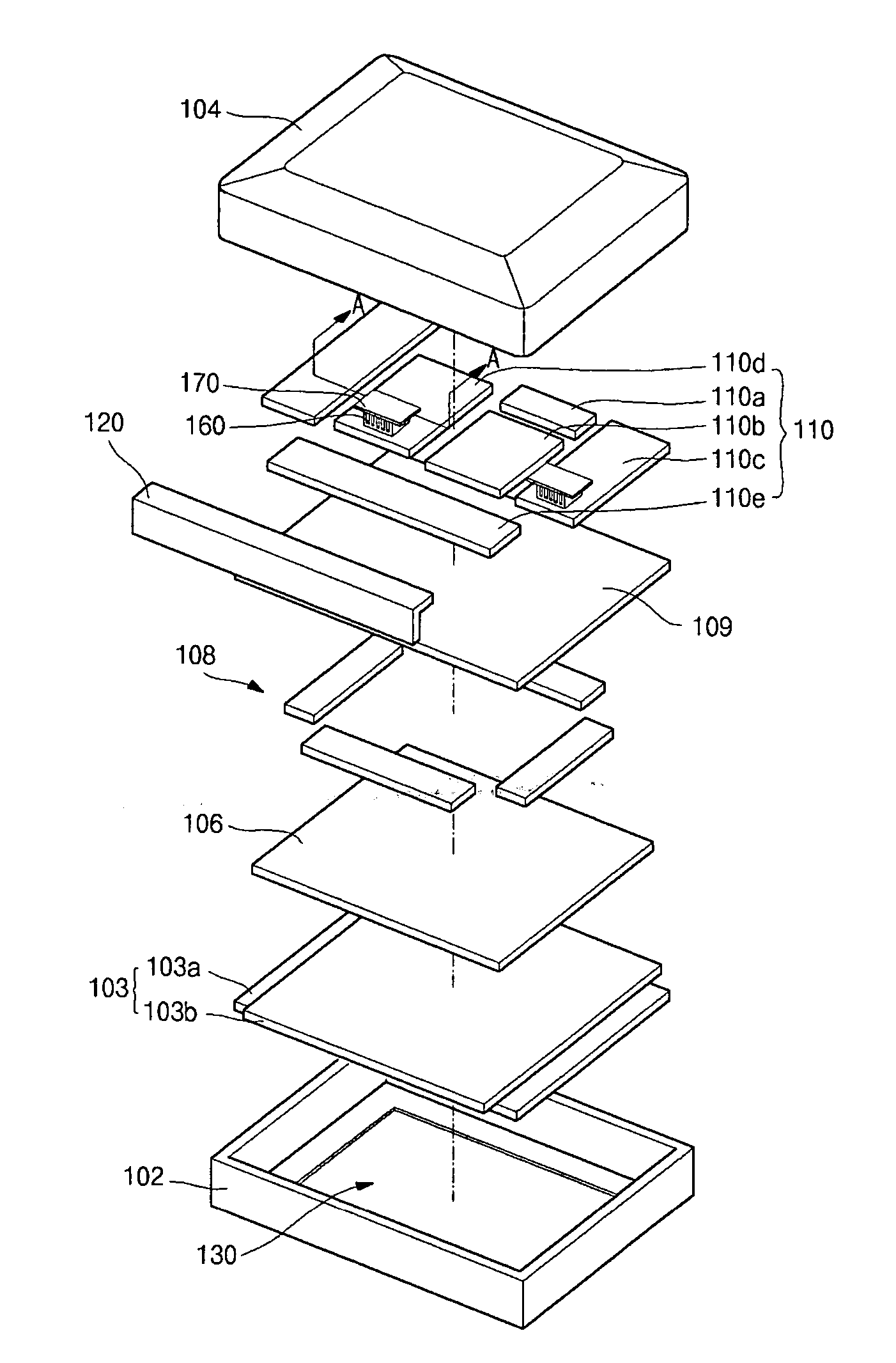

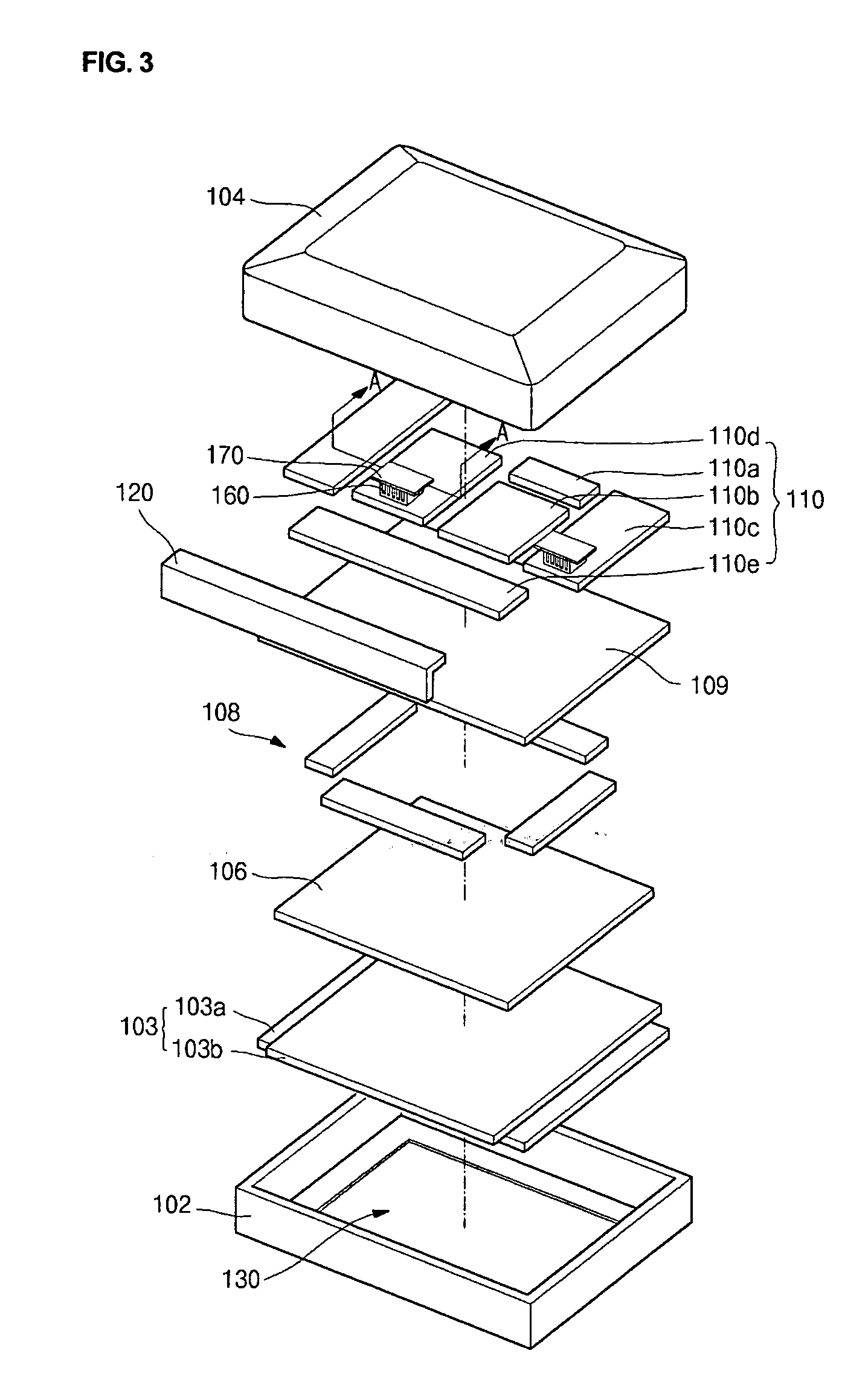

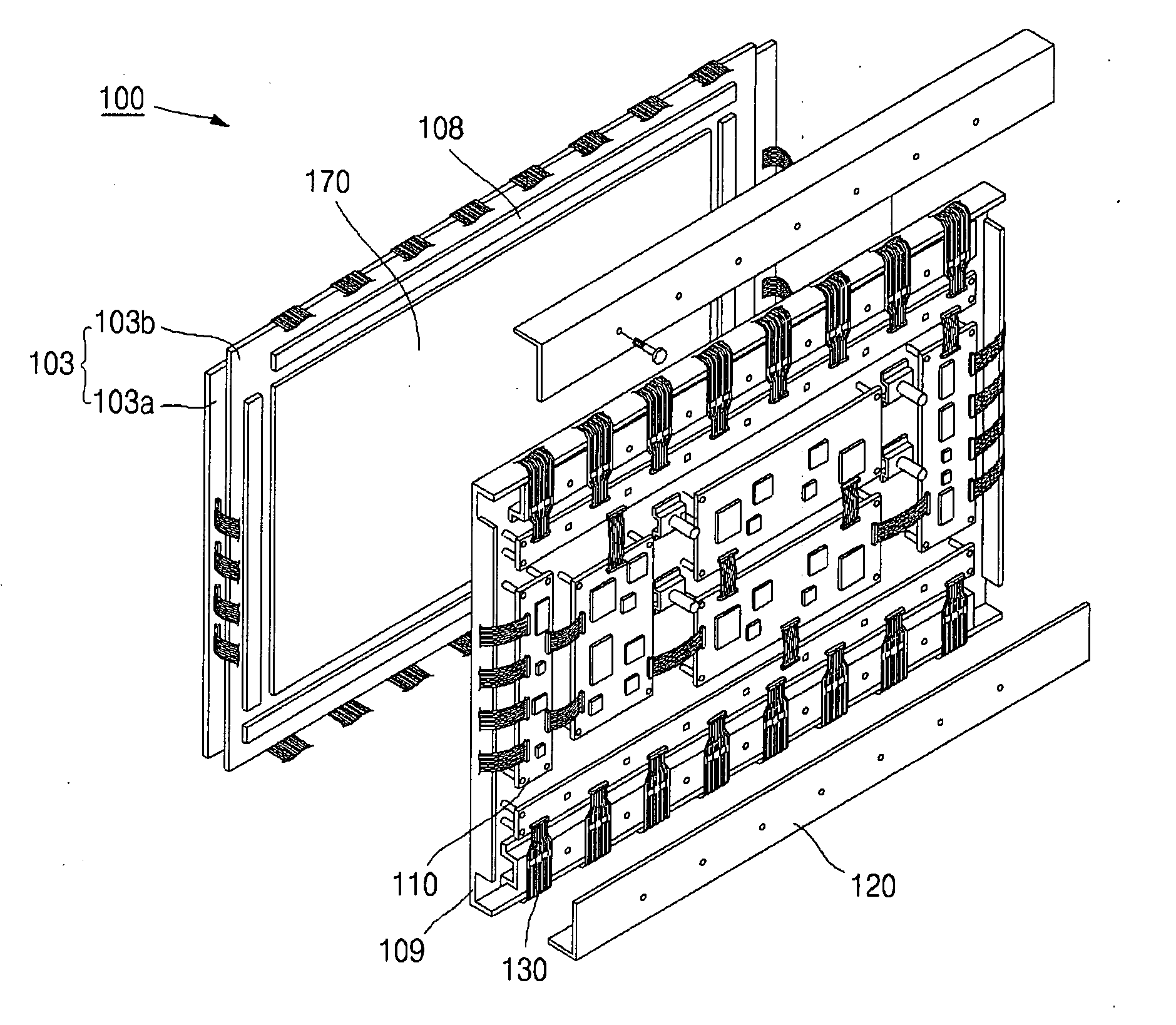

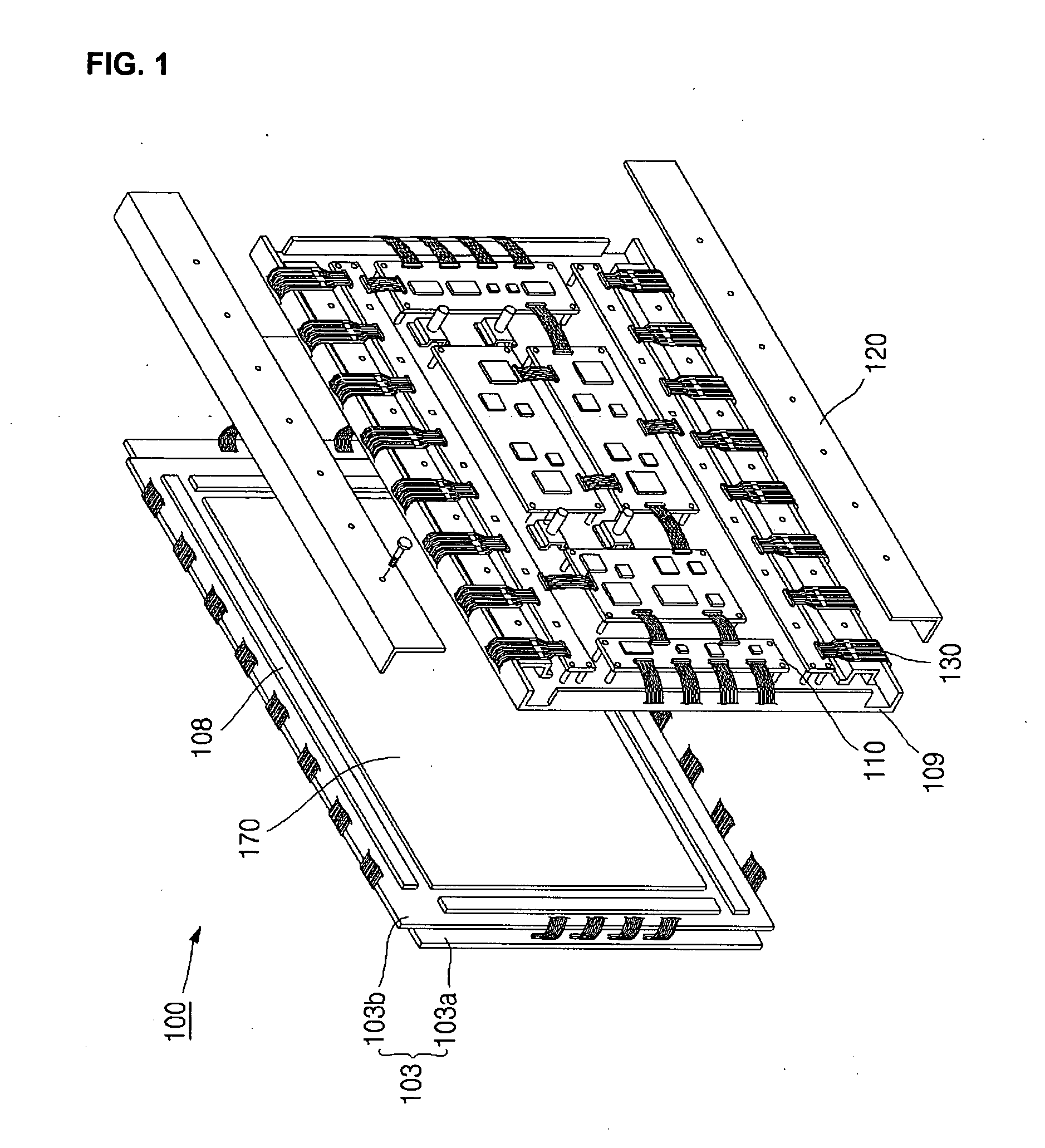

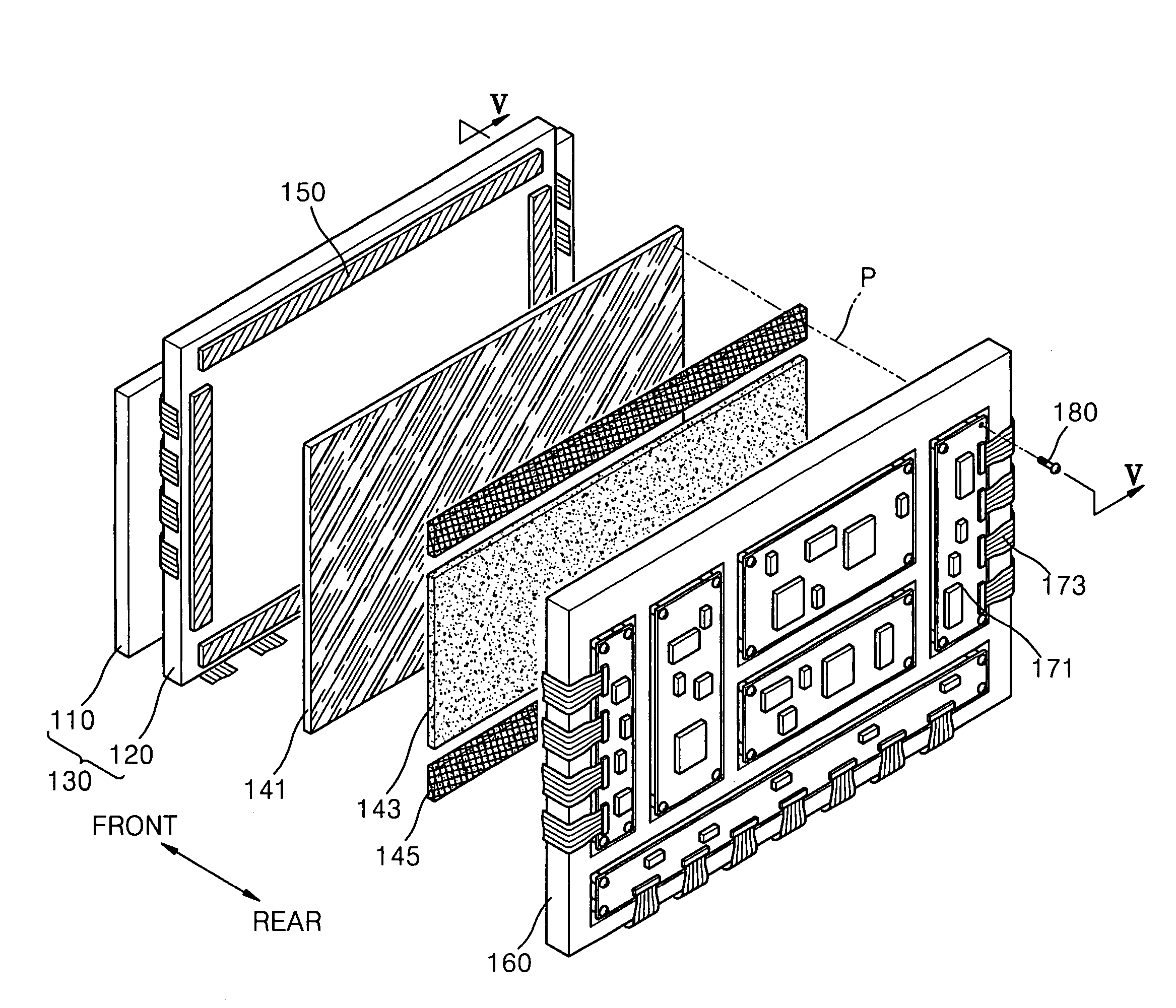

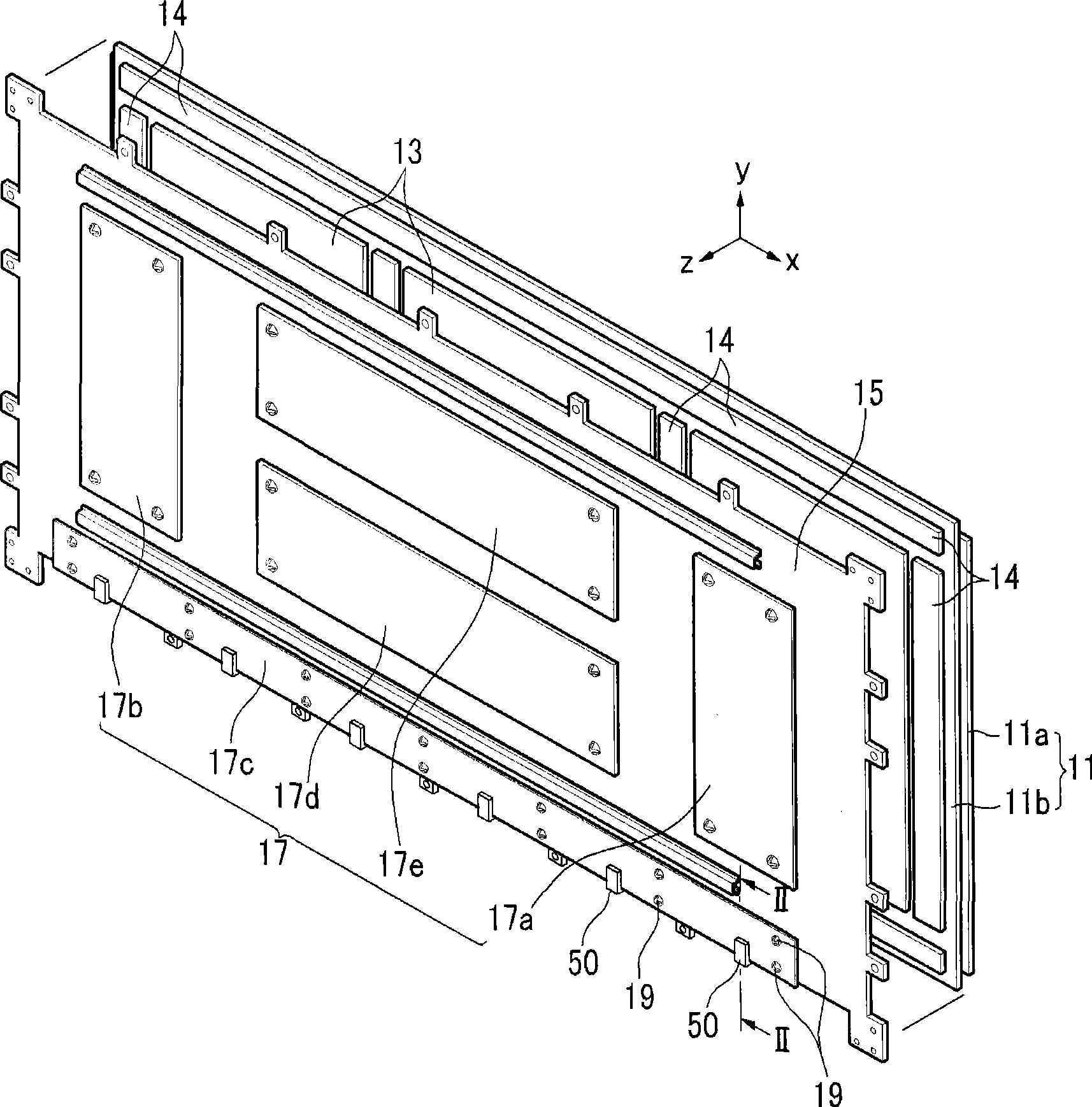

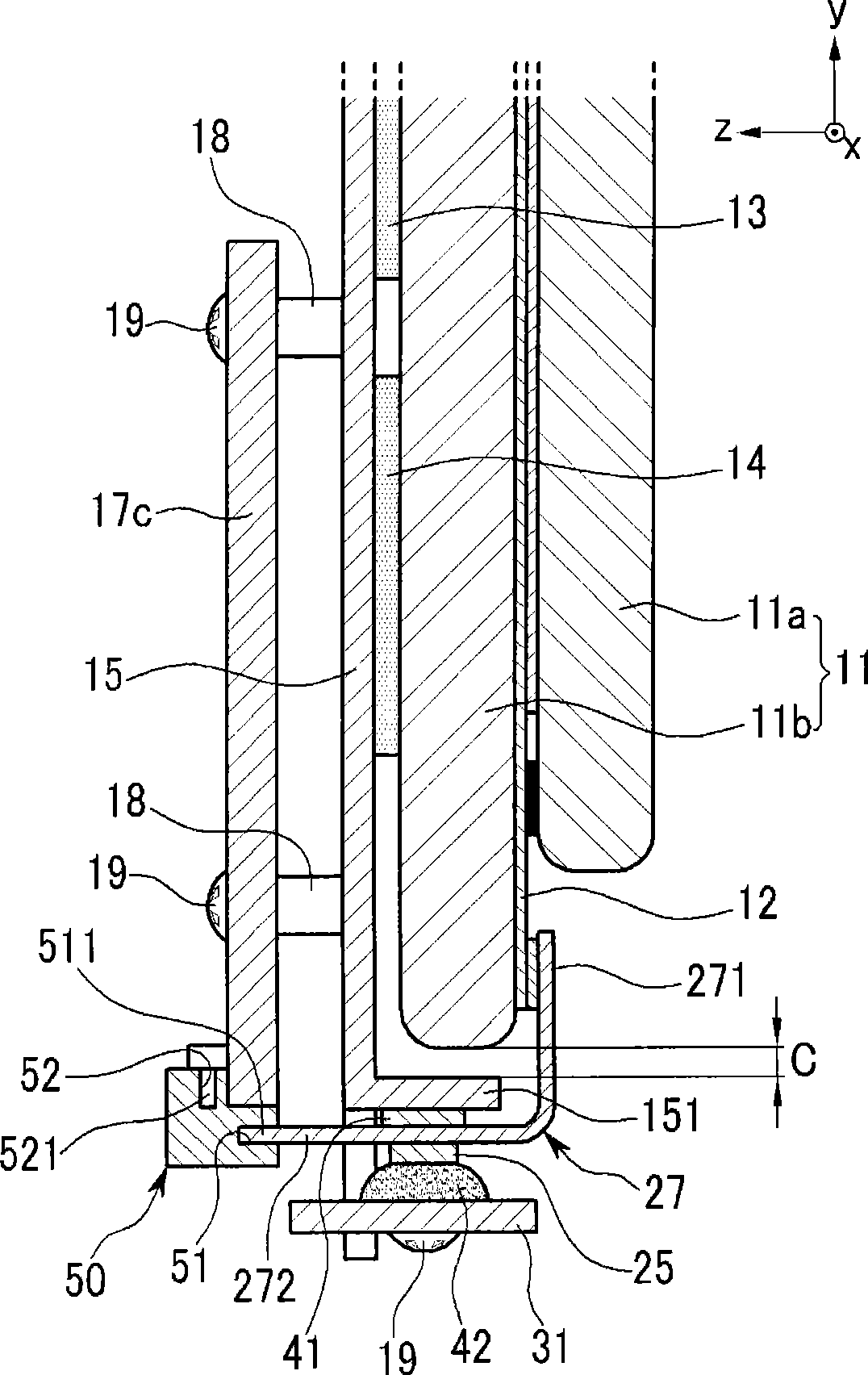

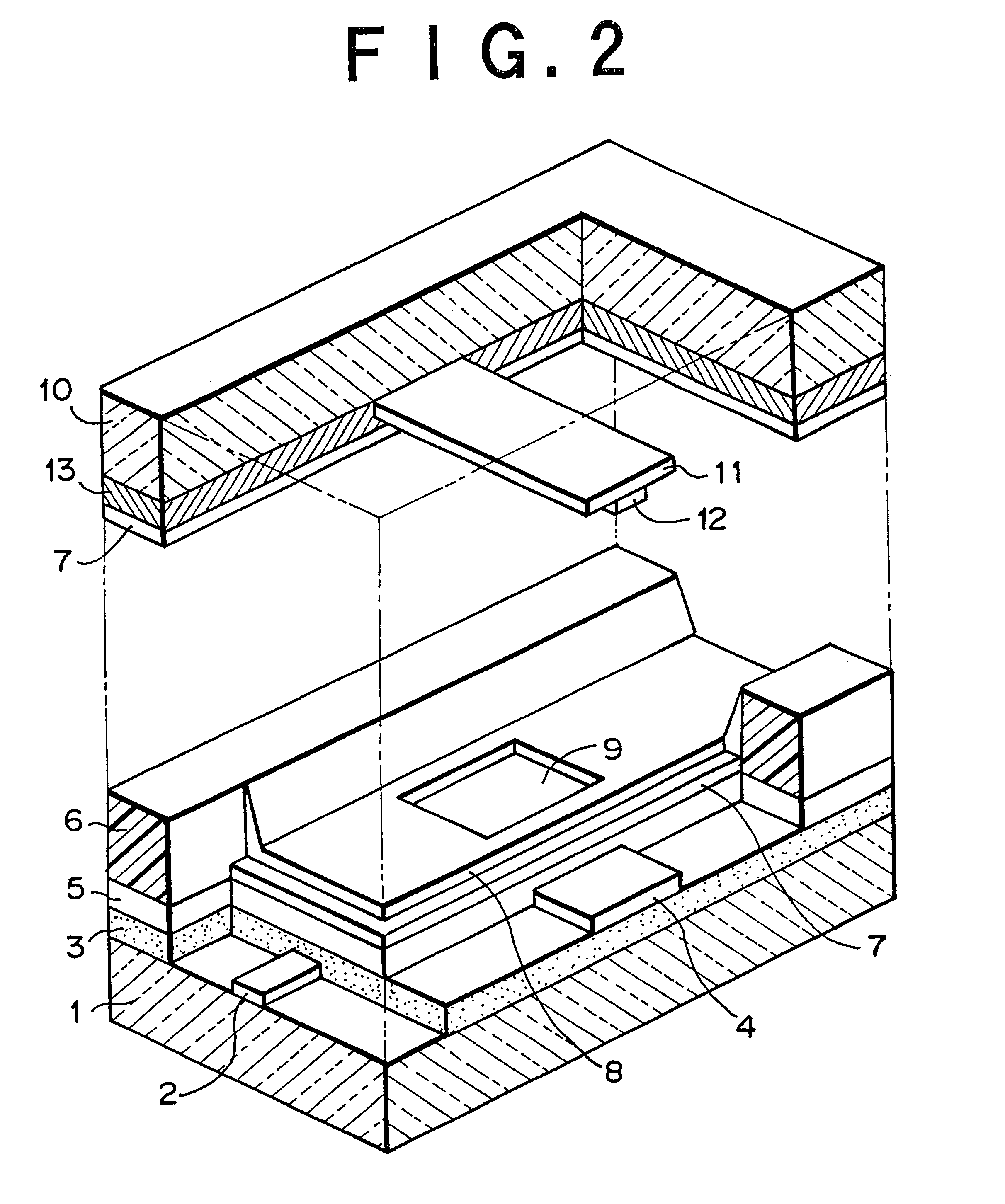

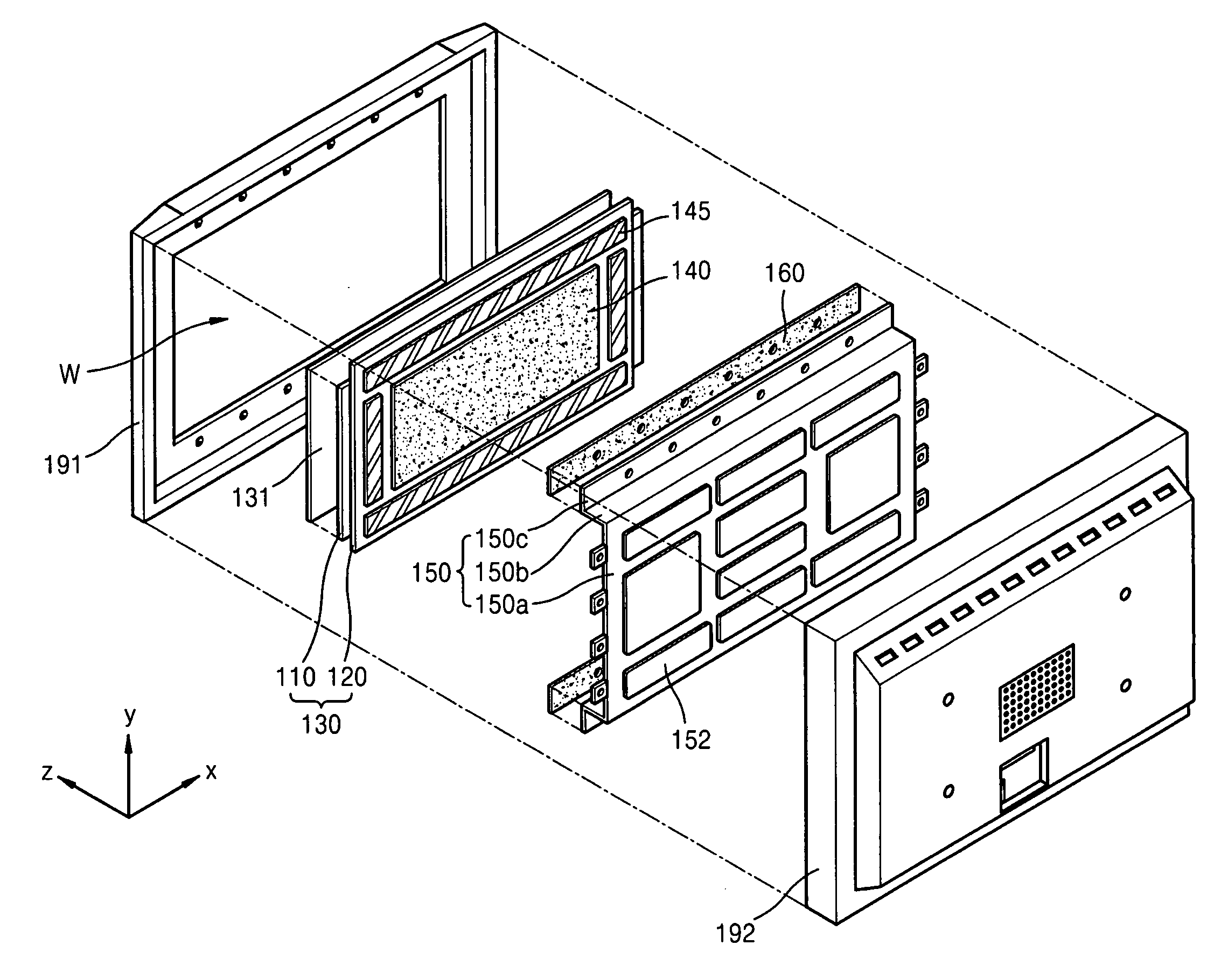

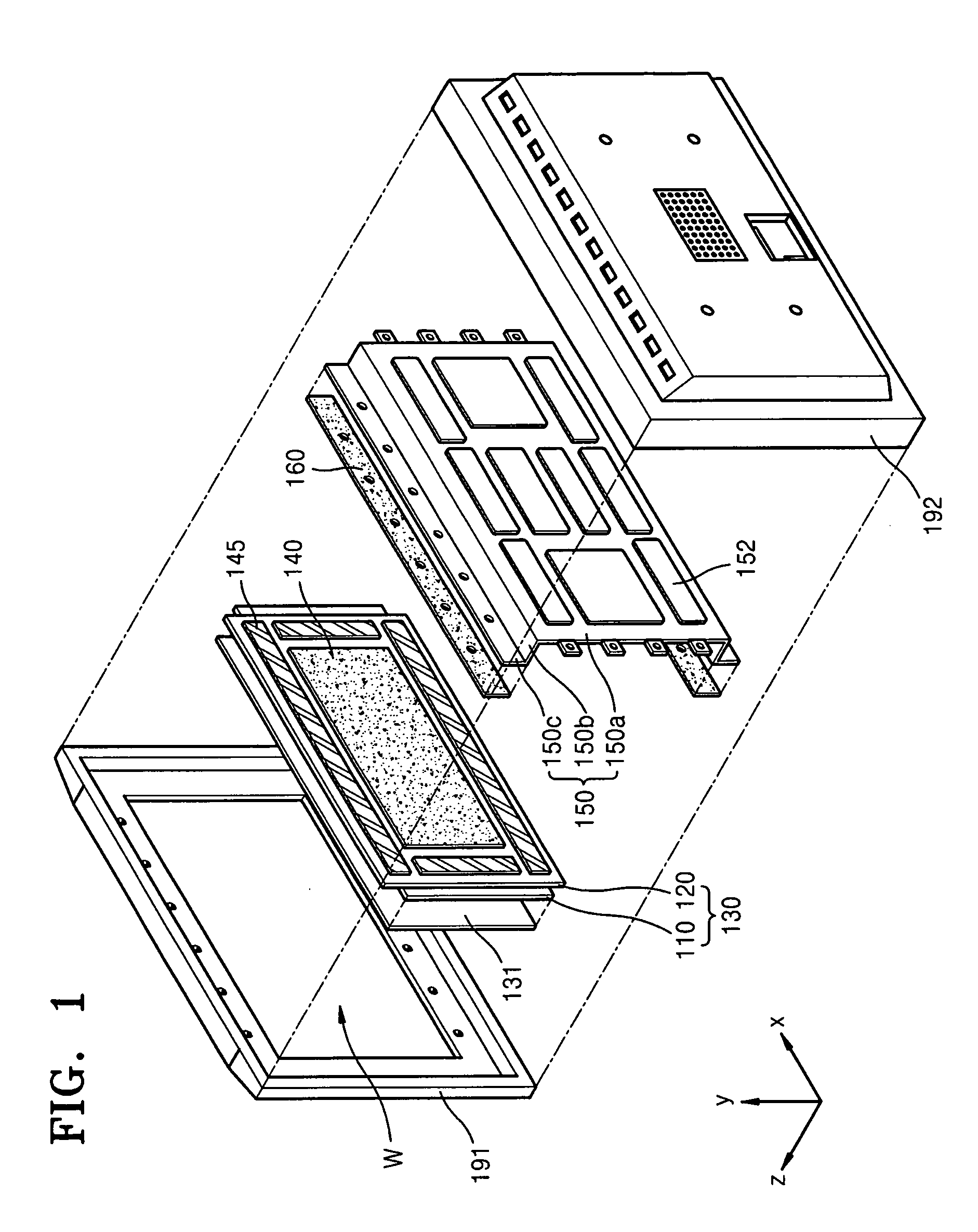

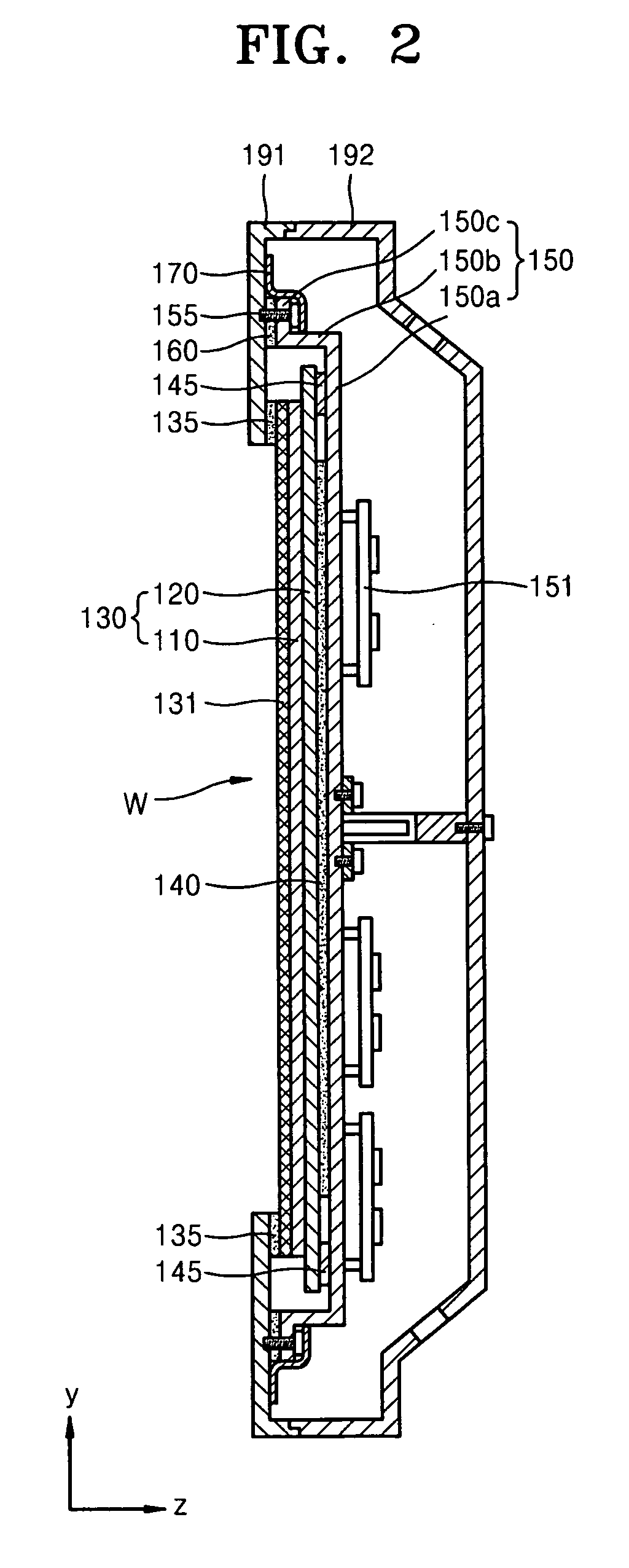

Plasma display panel device

InactiveUS20070258199A1Improve discharge performanceGood electrical functionalitySubstation/switching arrangement detailsGas discharge vessels/containersThin metalEngineering

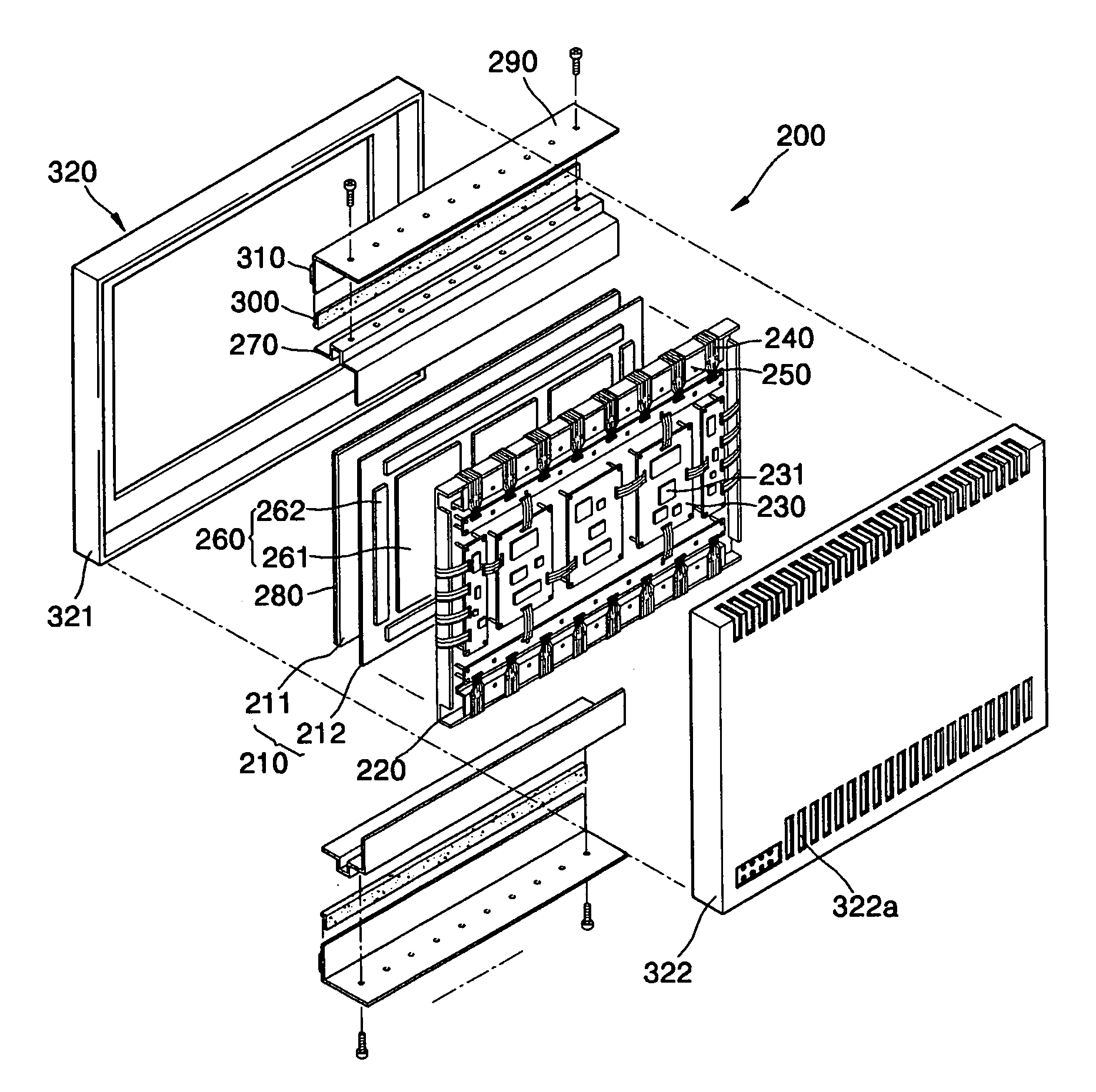

A plasma display panel device including a panel to display an image, a chassis base coupled to a rear surface of the panel, a thin metal plate interposed between the panel and the chassis base, a plurality of driving boards applying an electrical signal to discharge electrodes patterned within the panel, and a case to house the panel, the chassis base, the thin metal plate, and the driving boards. The chassis base is in the shape of a frame, so that the manufacturing costs of the chassis base are drastically reduced.

Owner:SAMSUNG SDI CO LTD

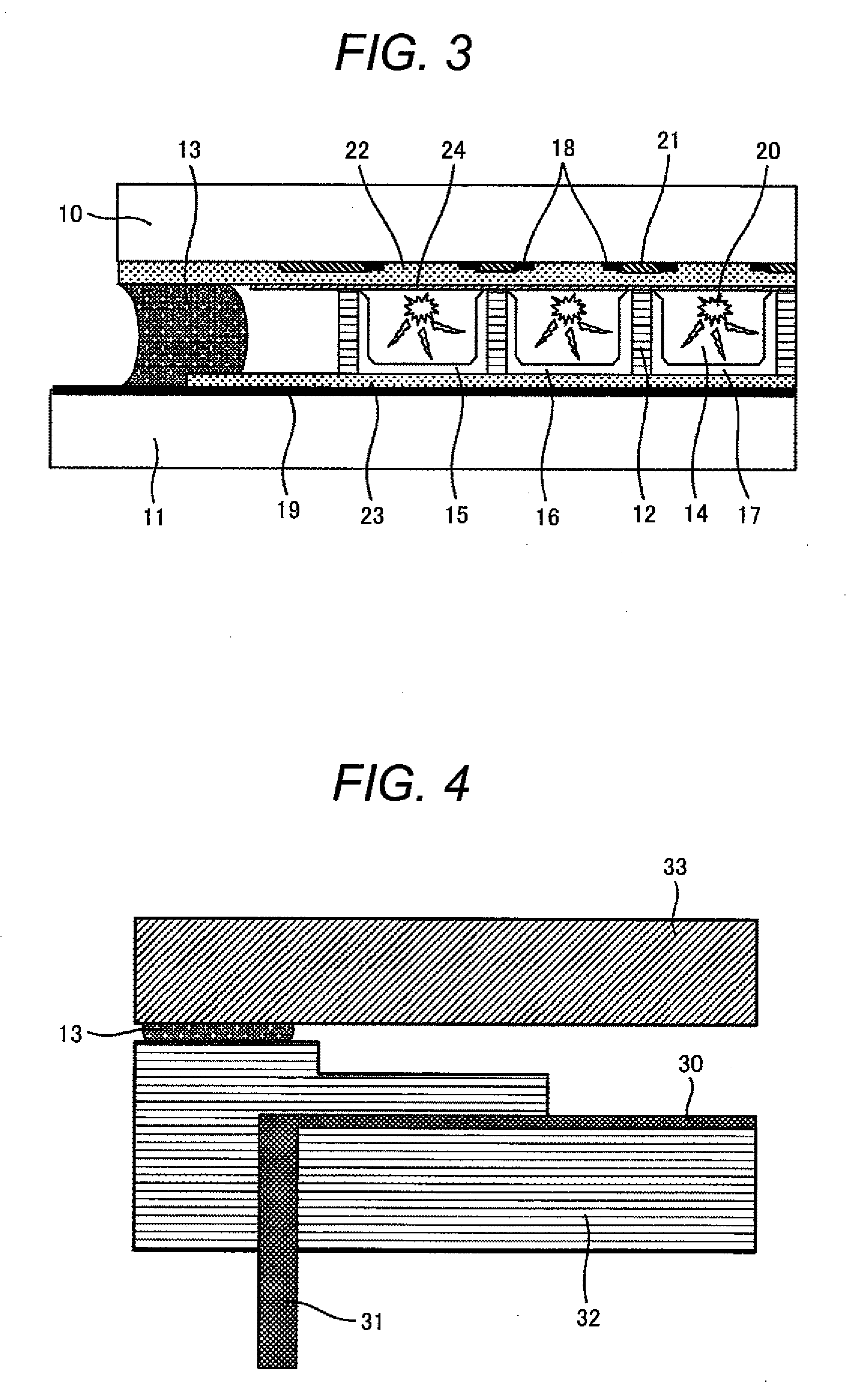

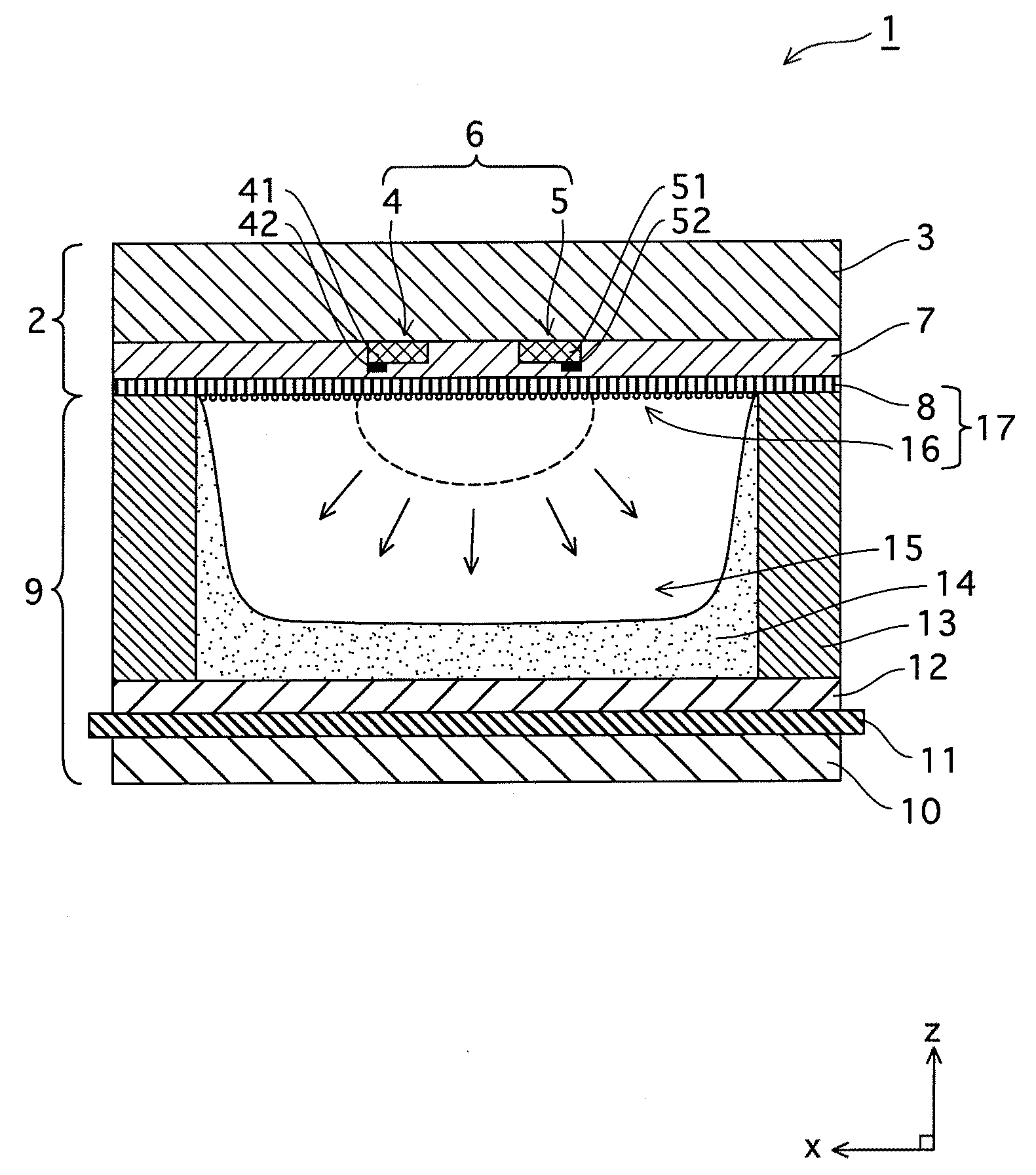

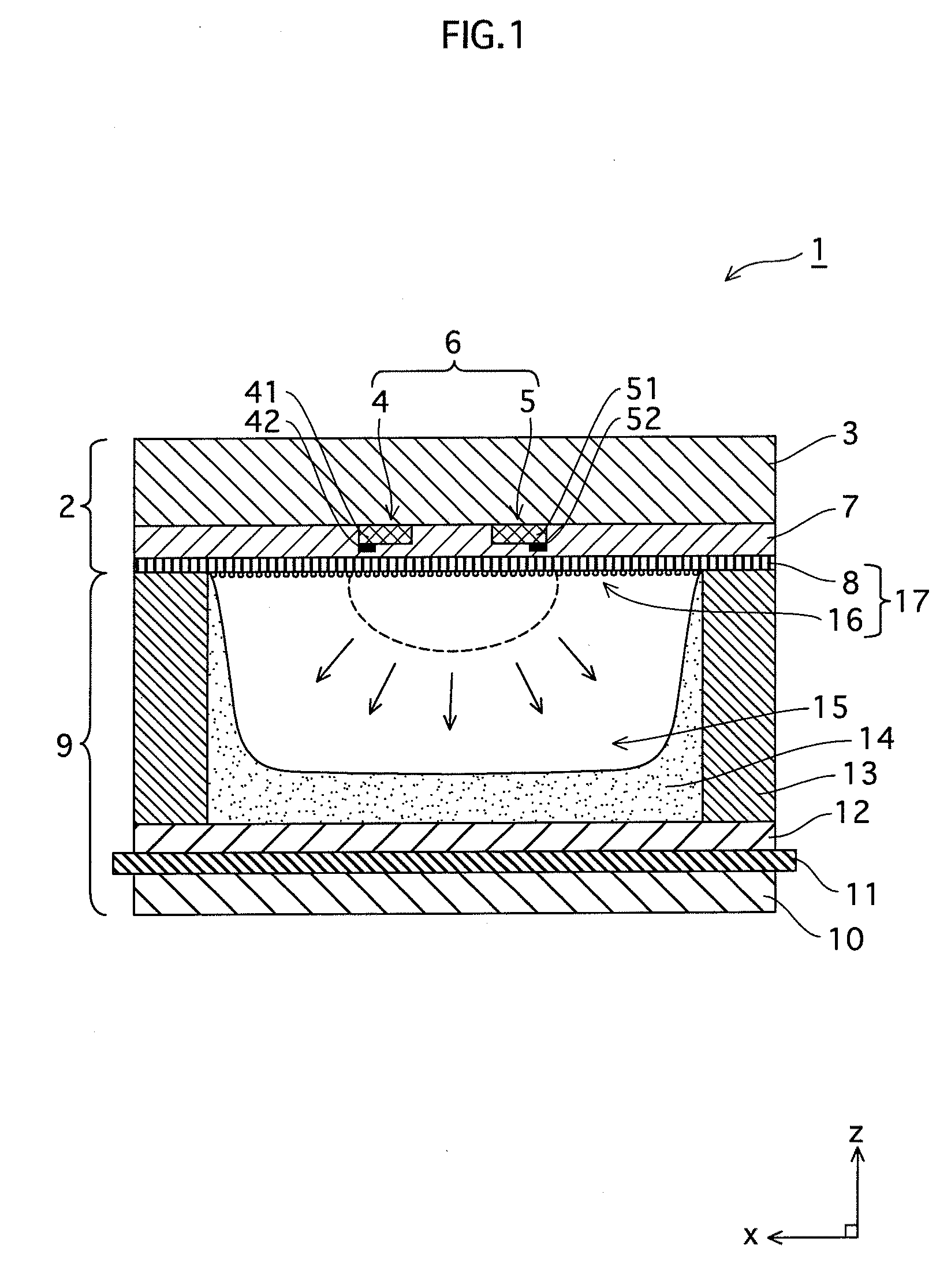

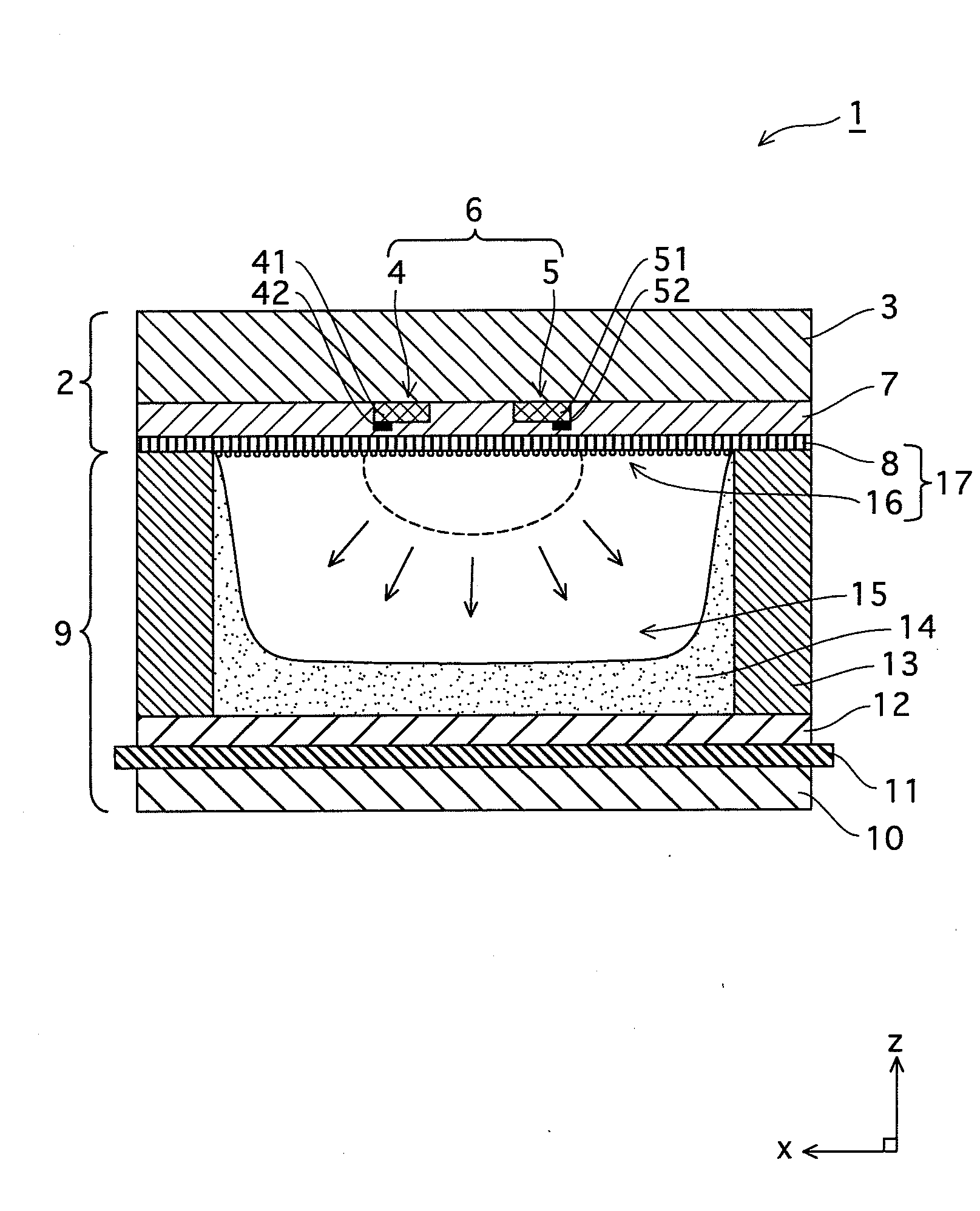

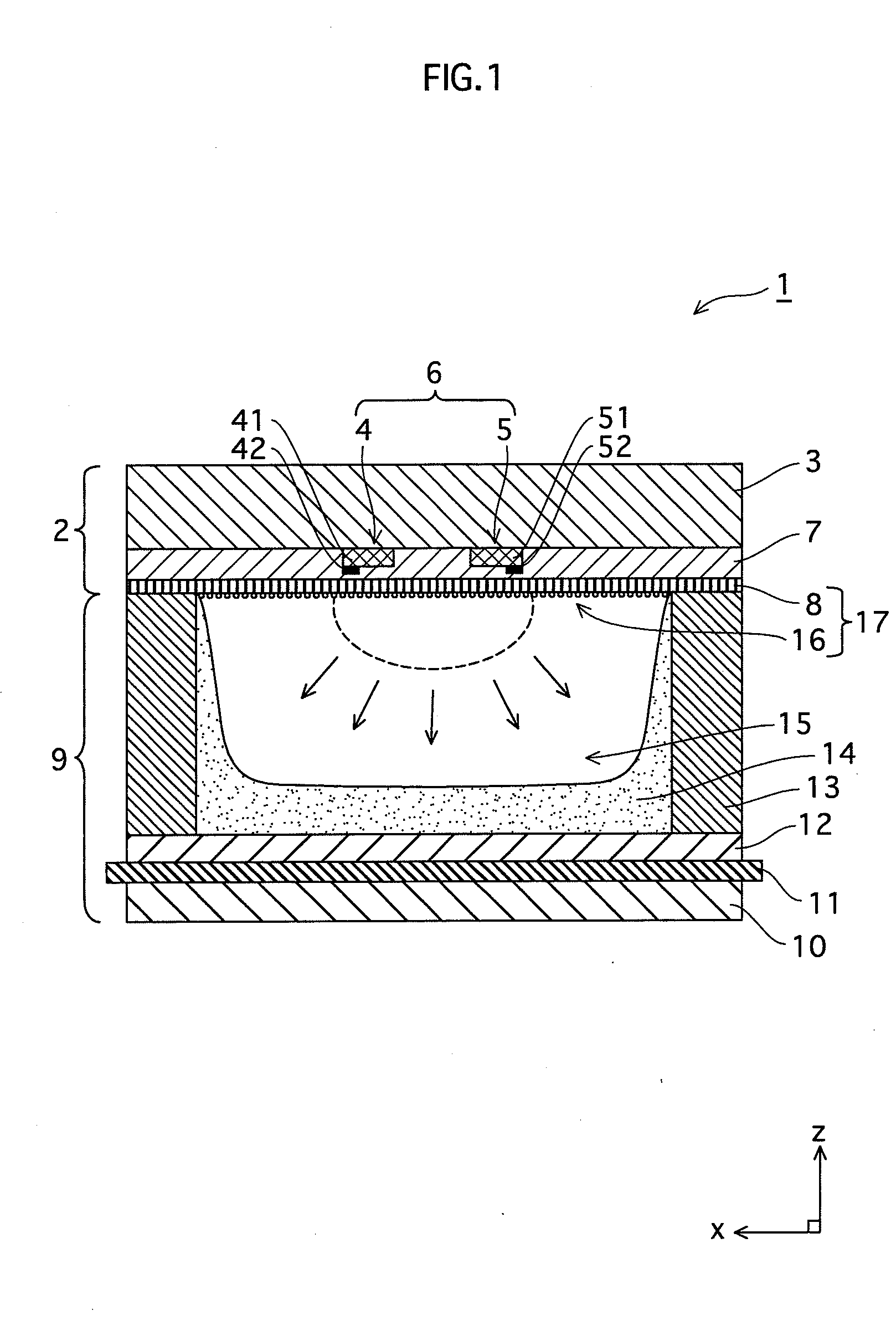

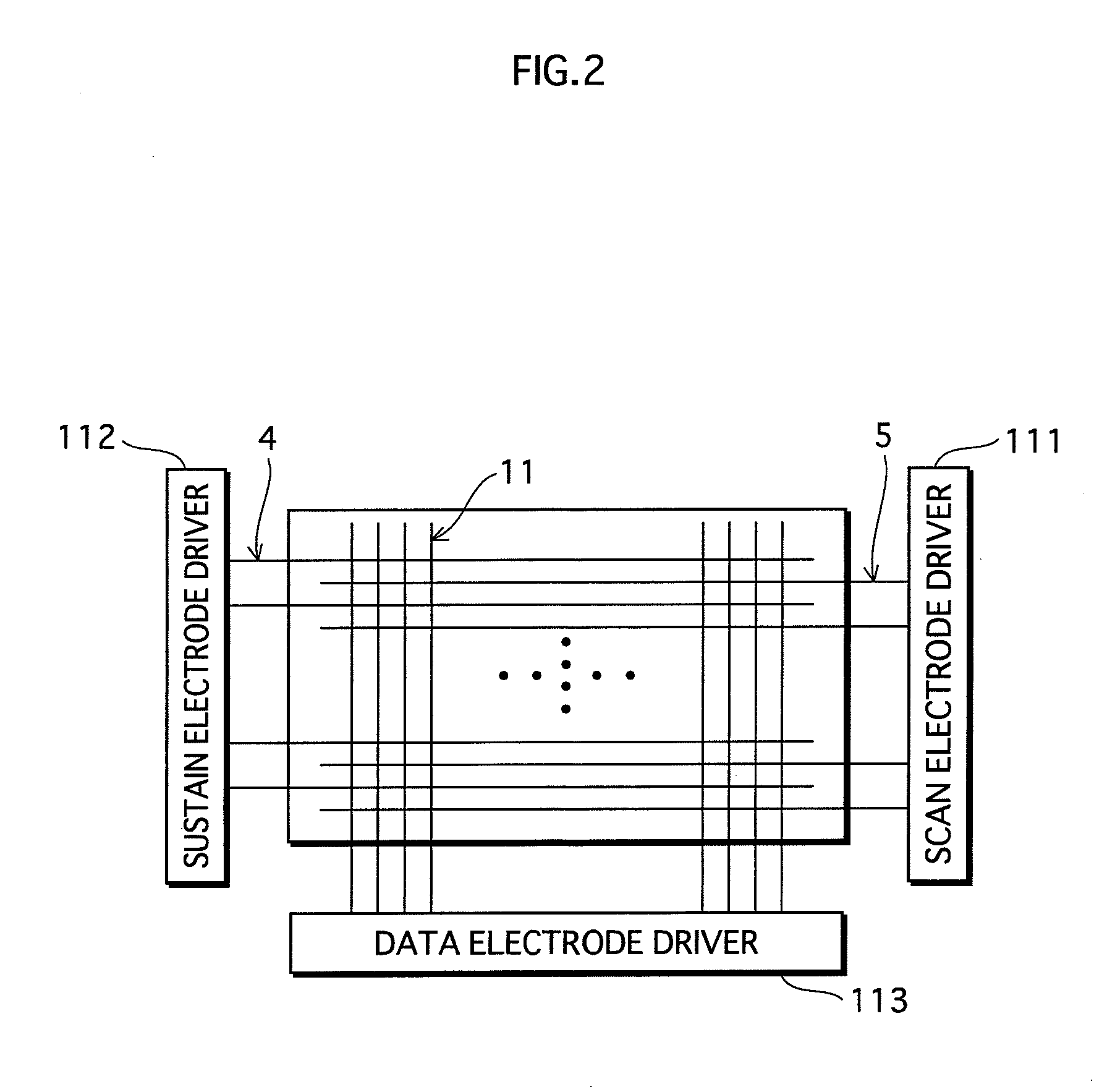

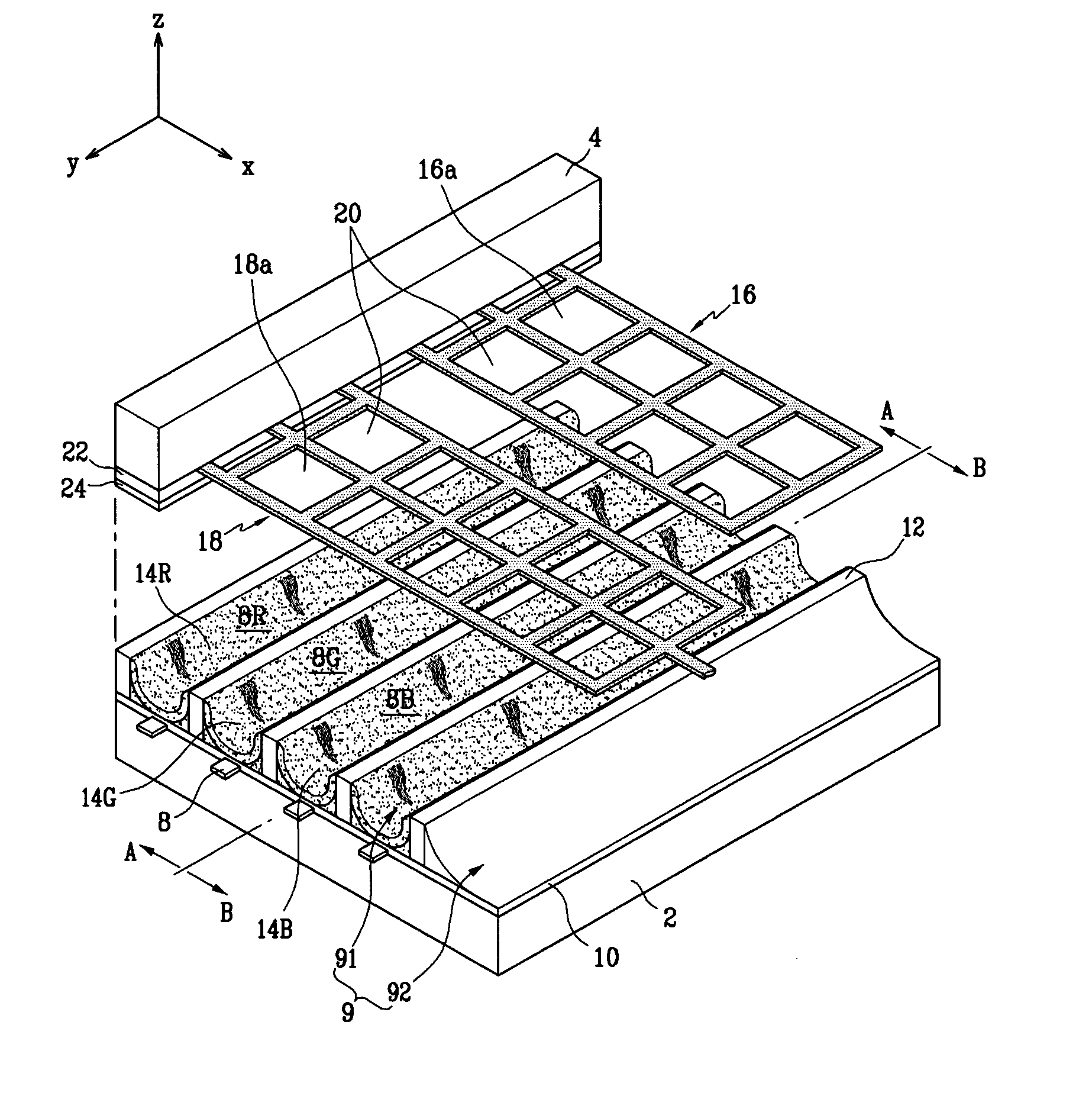

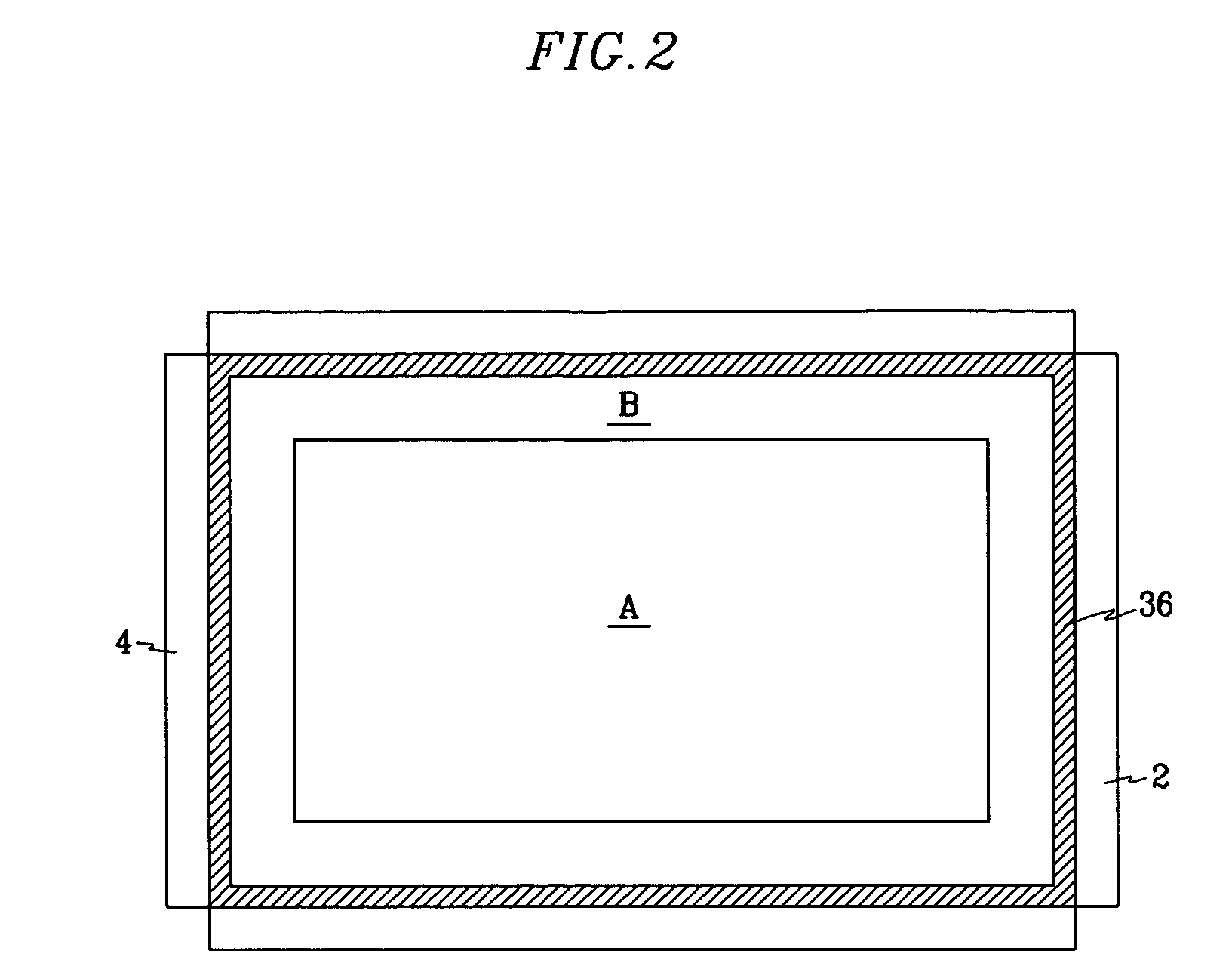

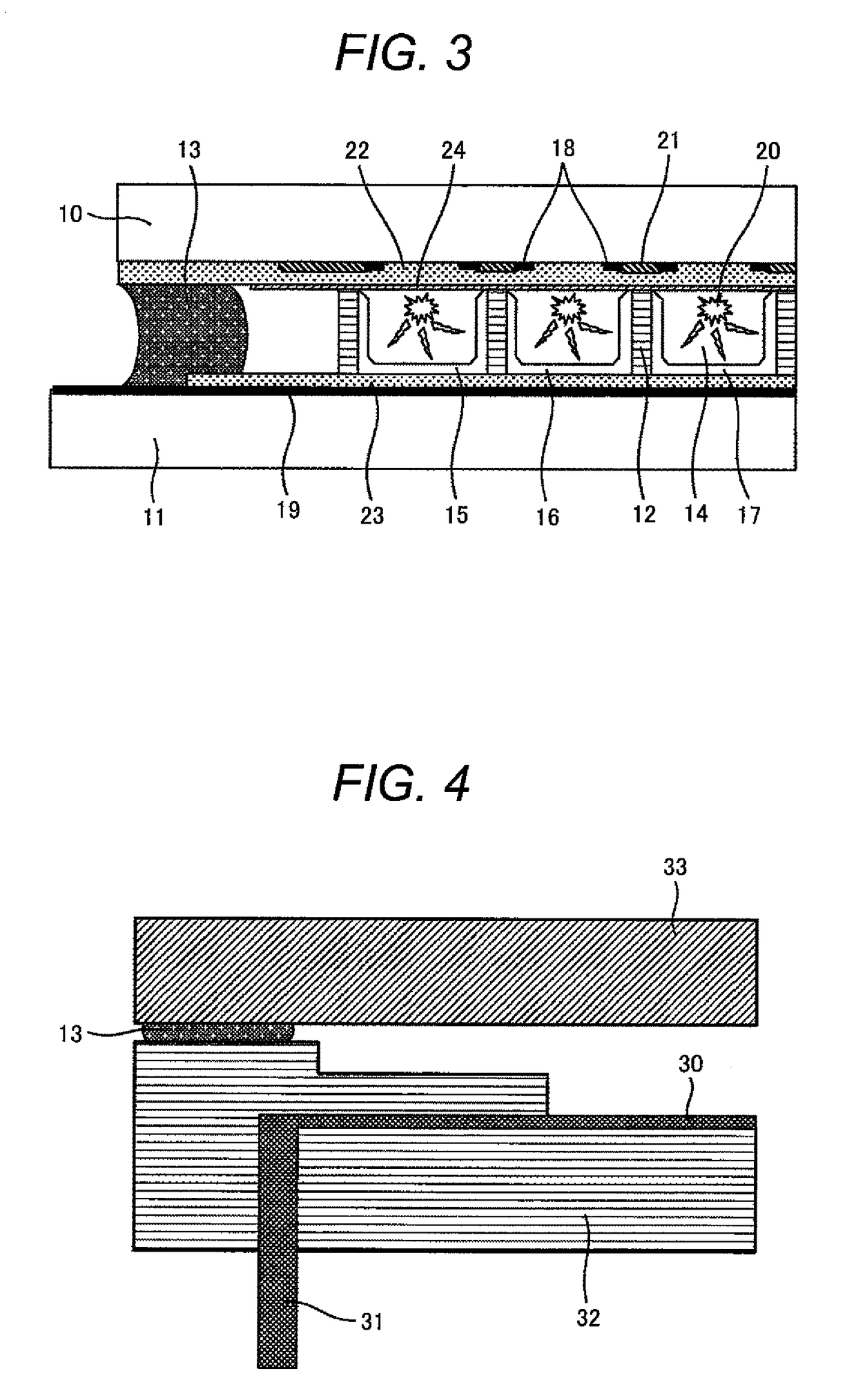

Plasma display panel and method for manufacturing the same

ActiveUS20090140652A1Large secondary electron emission coefficientLaunch evenlyTube/lamp screens manufactureAddress electrodesLow voltagePlasma display

“Discharge delay” and “dependence of discharge delay on temperatures” are solved by improving a protective layer, thus a PDP can be driven at a low voltage. Furthermore, the PDP can display excellent images by suppressing “dependence of discharge delay on space charges.” Liquid-phase magnesium alkoxide (Mg (OR)2) or acetylacetone magnesium ate whose purity is 99.95% or more is prepared, and is hydrolyzed by adding a small amount of acids to the solution. Thus, a gel of magnesium hydroxide that is a magnesium oxide precursor is formed. Burning the gel in atmosphere at 700° C. or more produces powder containing MgO particles 16a-16d having the NaCl crystal structure with (100) and (111) crystal faces or with (100), (110) and (111) crystal faces. By pasting the powder on a dielectric layer 7 or a surface layer 8, the MgO powder 16 is formed so as to serve as the protective layer.

Owner:PANASONIC CORP

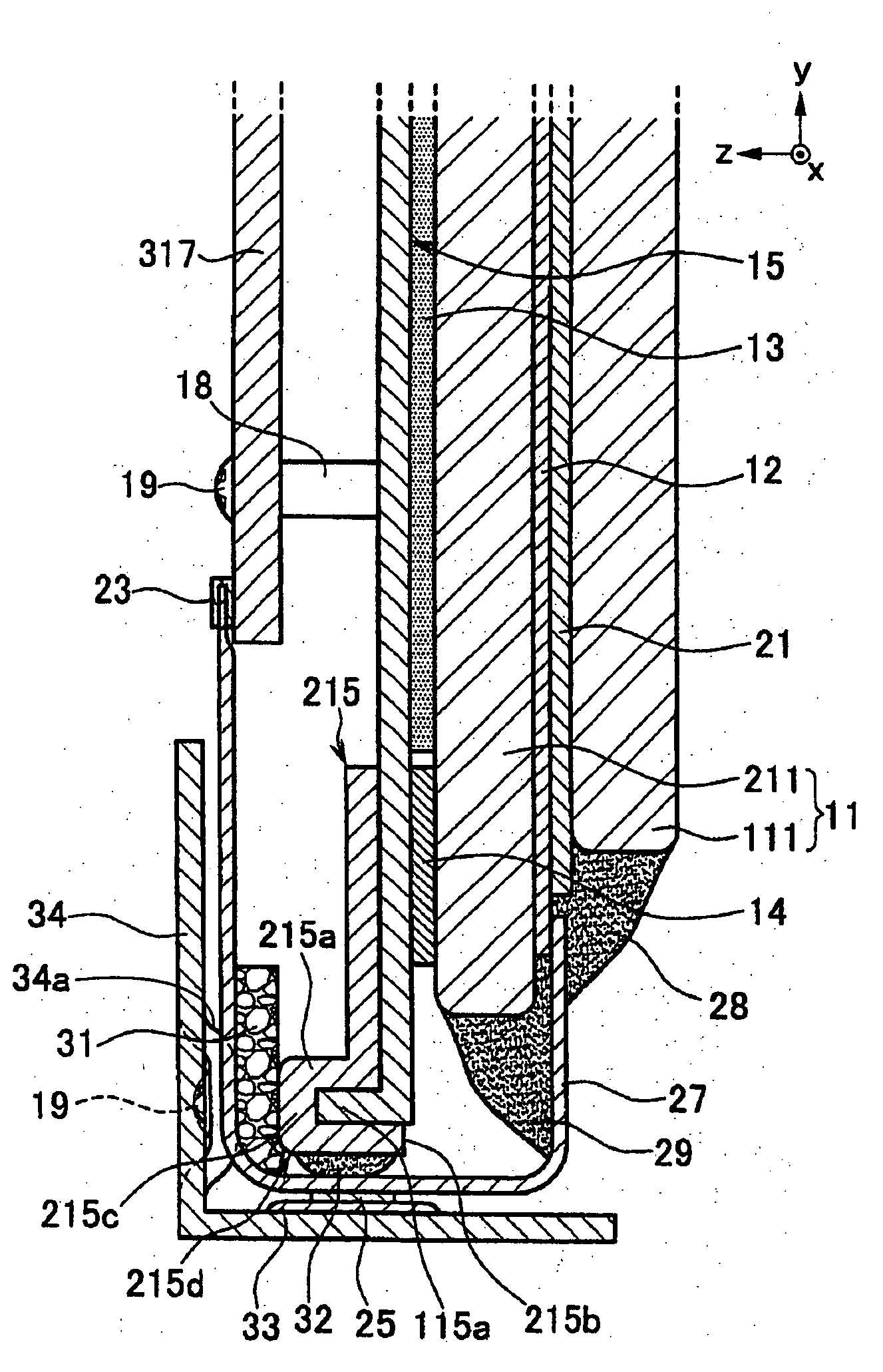

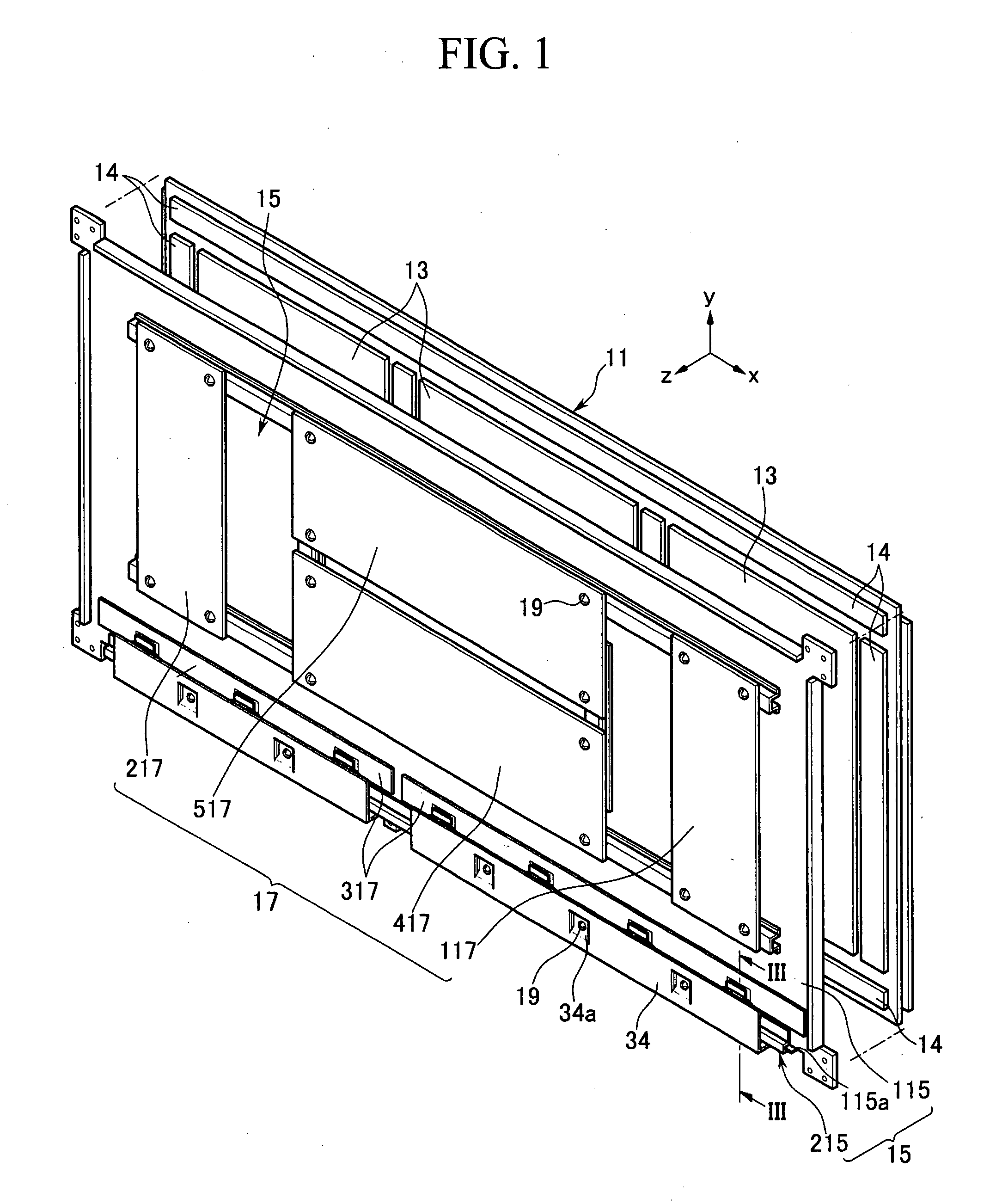

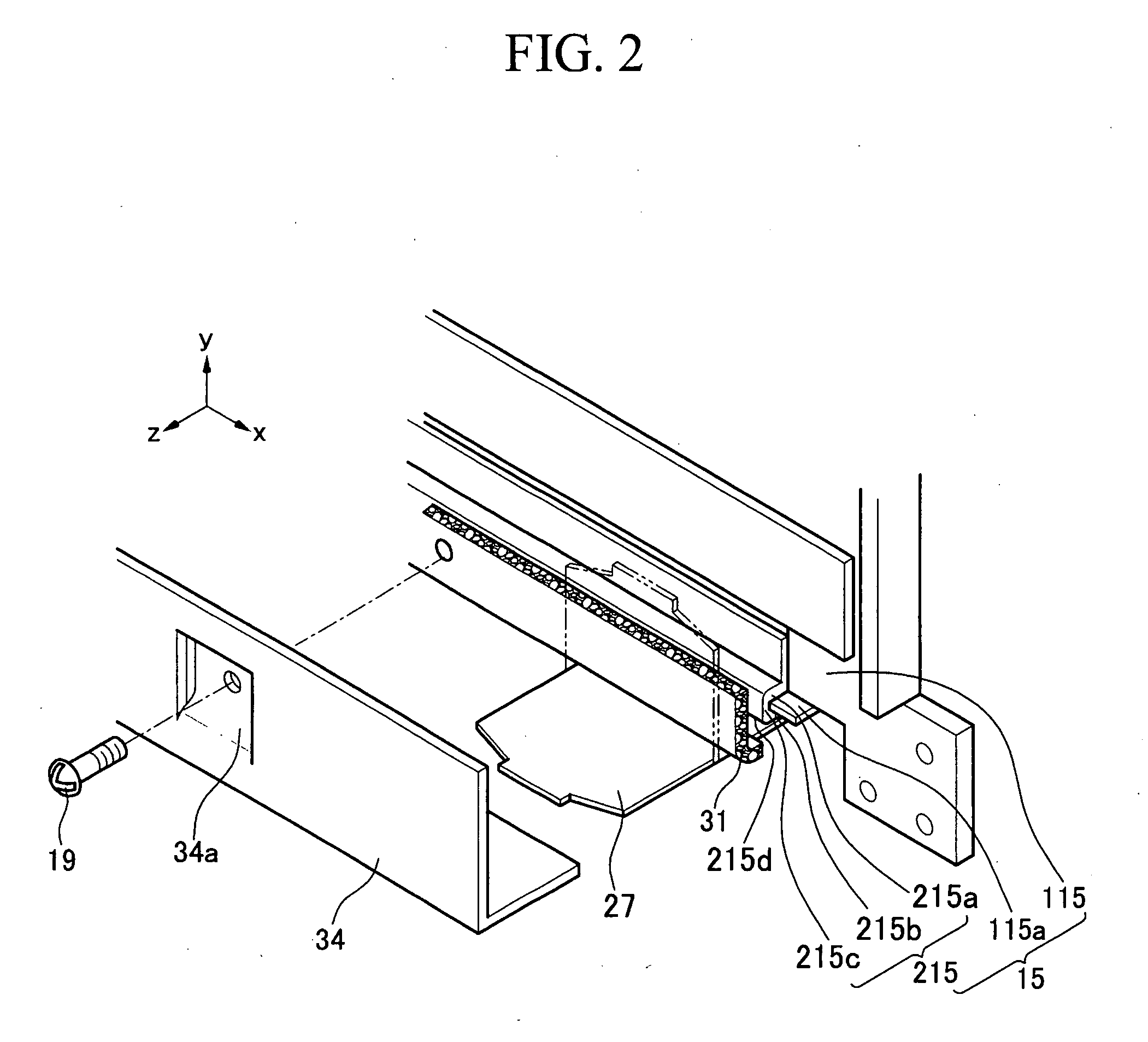

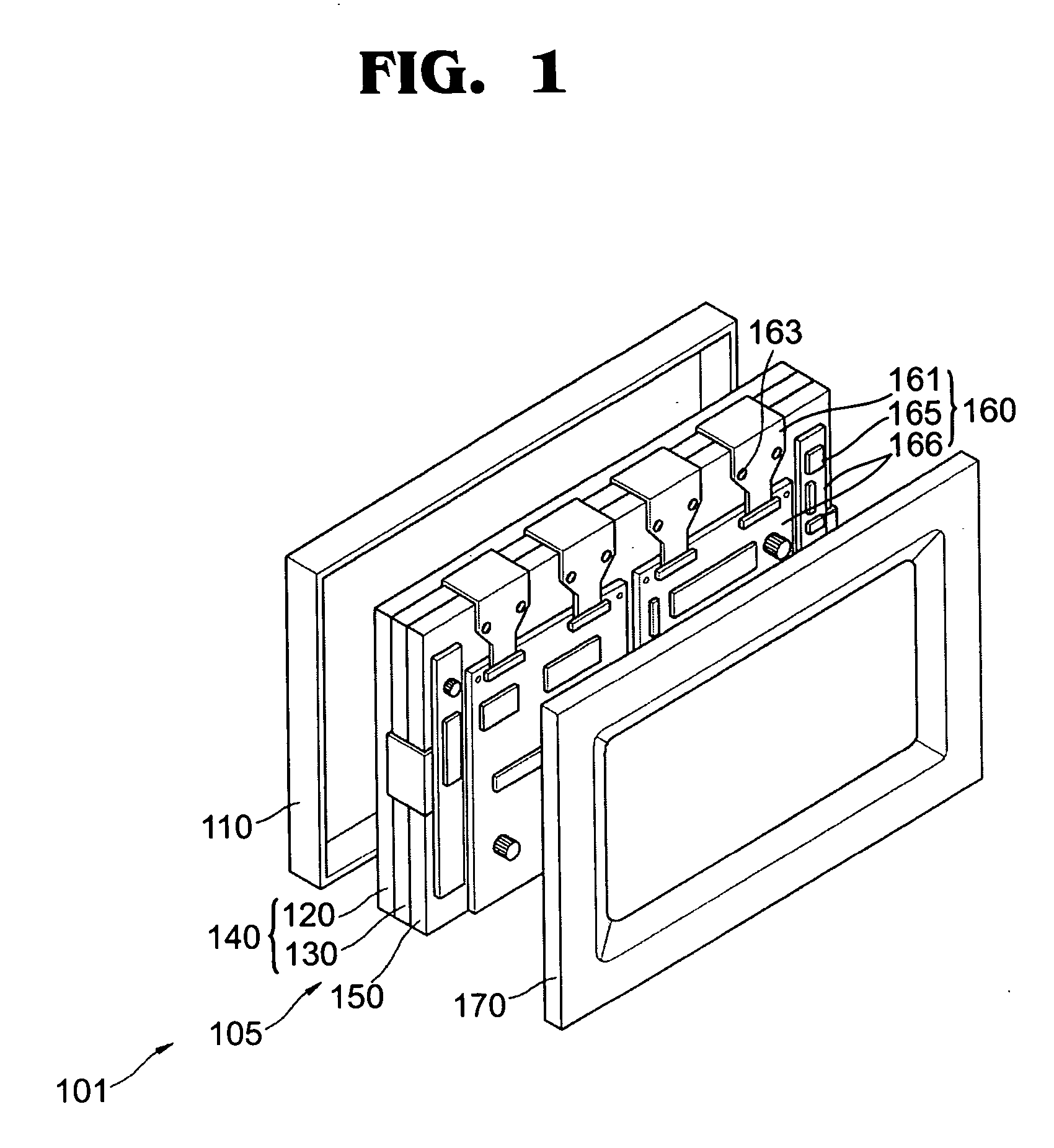

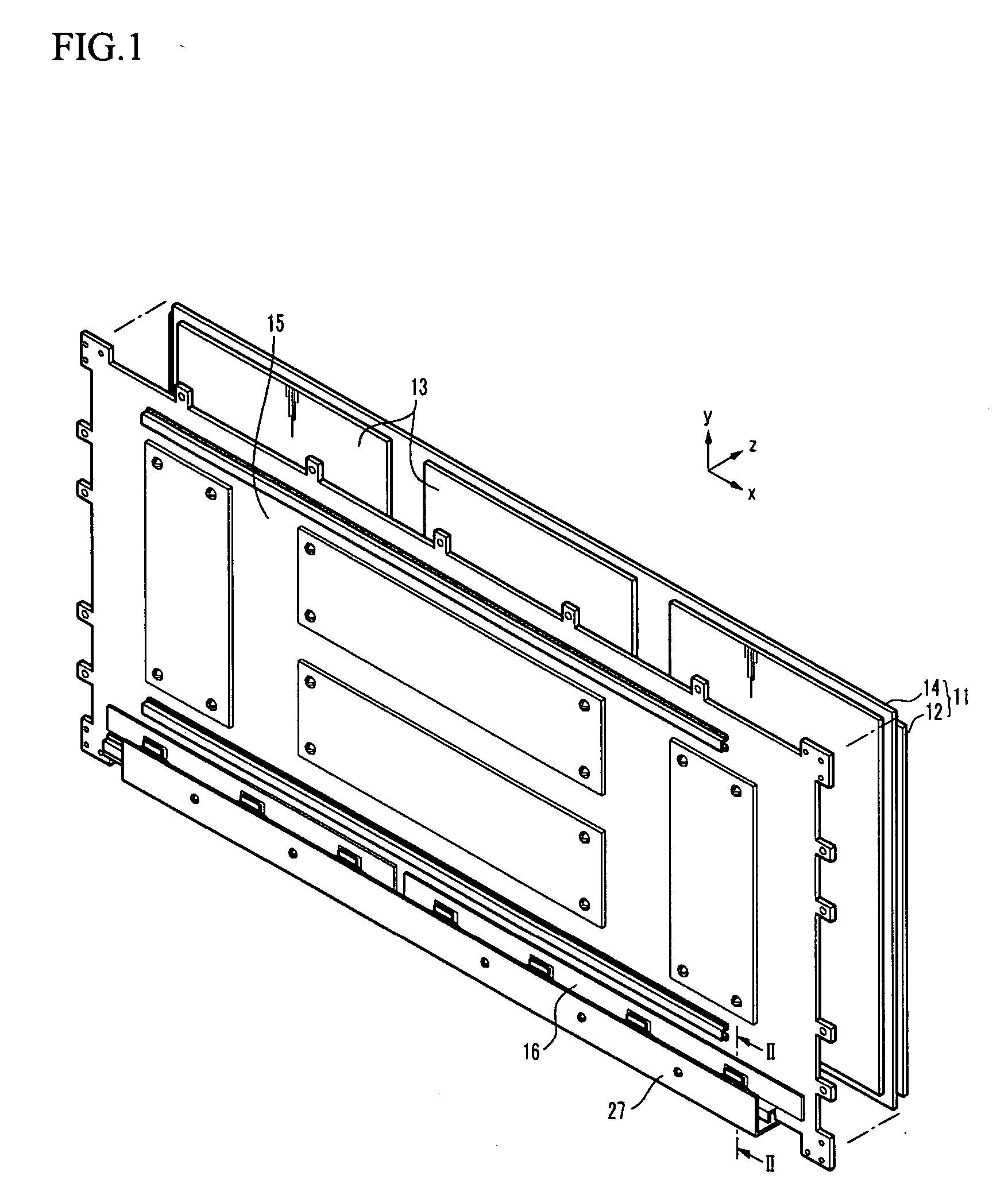

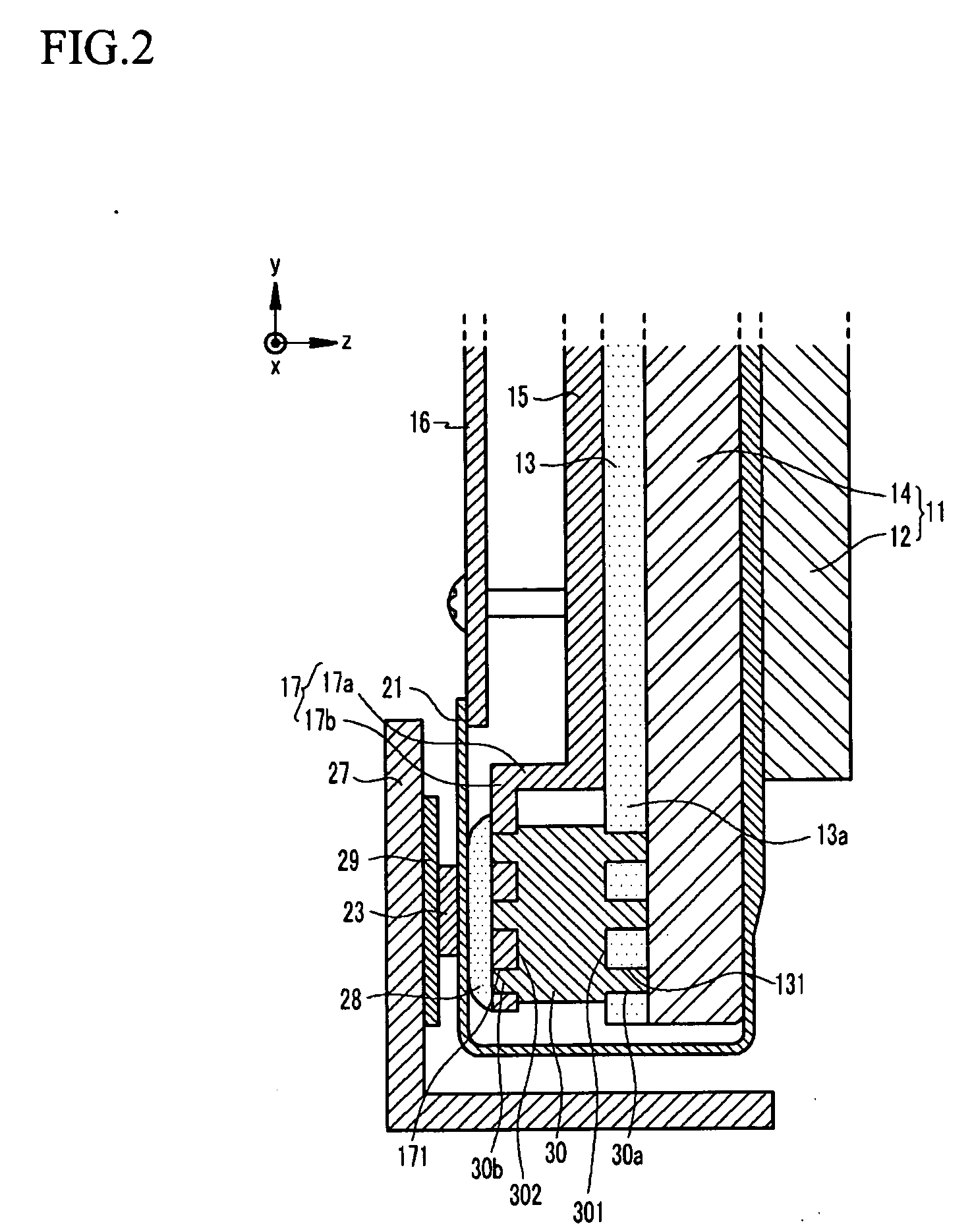

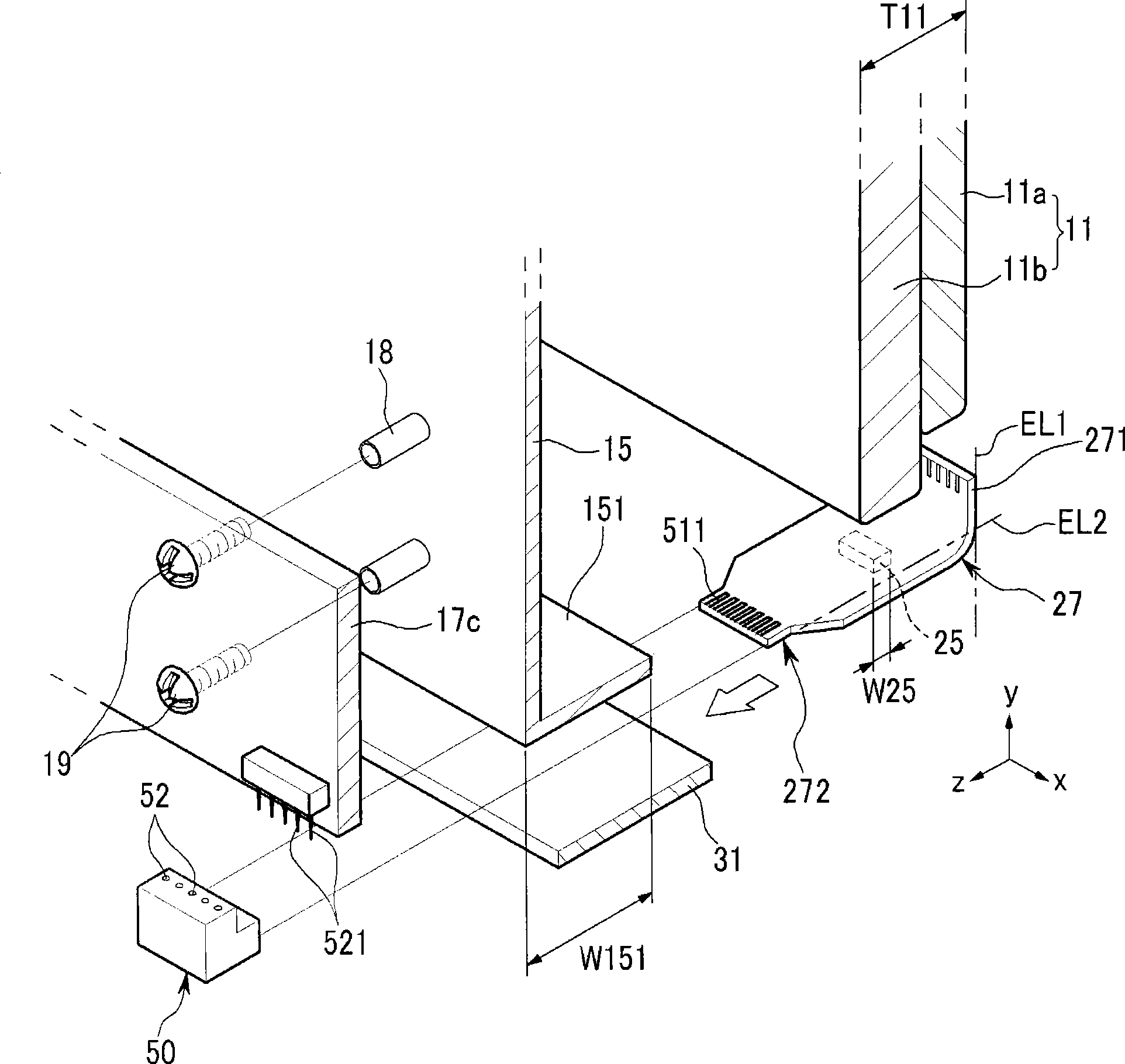

Plasma display device

InactiveUS20080186662A1Reduce noise transferAvoid problemsMagnetic/electric field screeningGas discharge vessels/containersDisplay devicePrinted circuit board

A design for a plasma display device that attenuates noise generated in a flexible printed circuit (FPC) so that the noise does not reach the chassis base, the FPC connecting a printed circuit board assembly to electrodes within the plasma display panel. The plasma display device includes a spacer made out of non woven fabric and located between the FPC and the chassis.

Owner:SAMSUNG SDI CO LTD

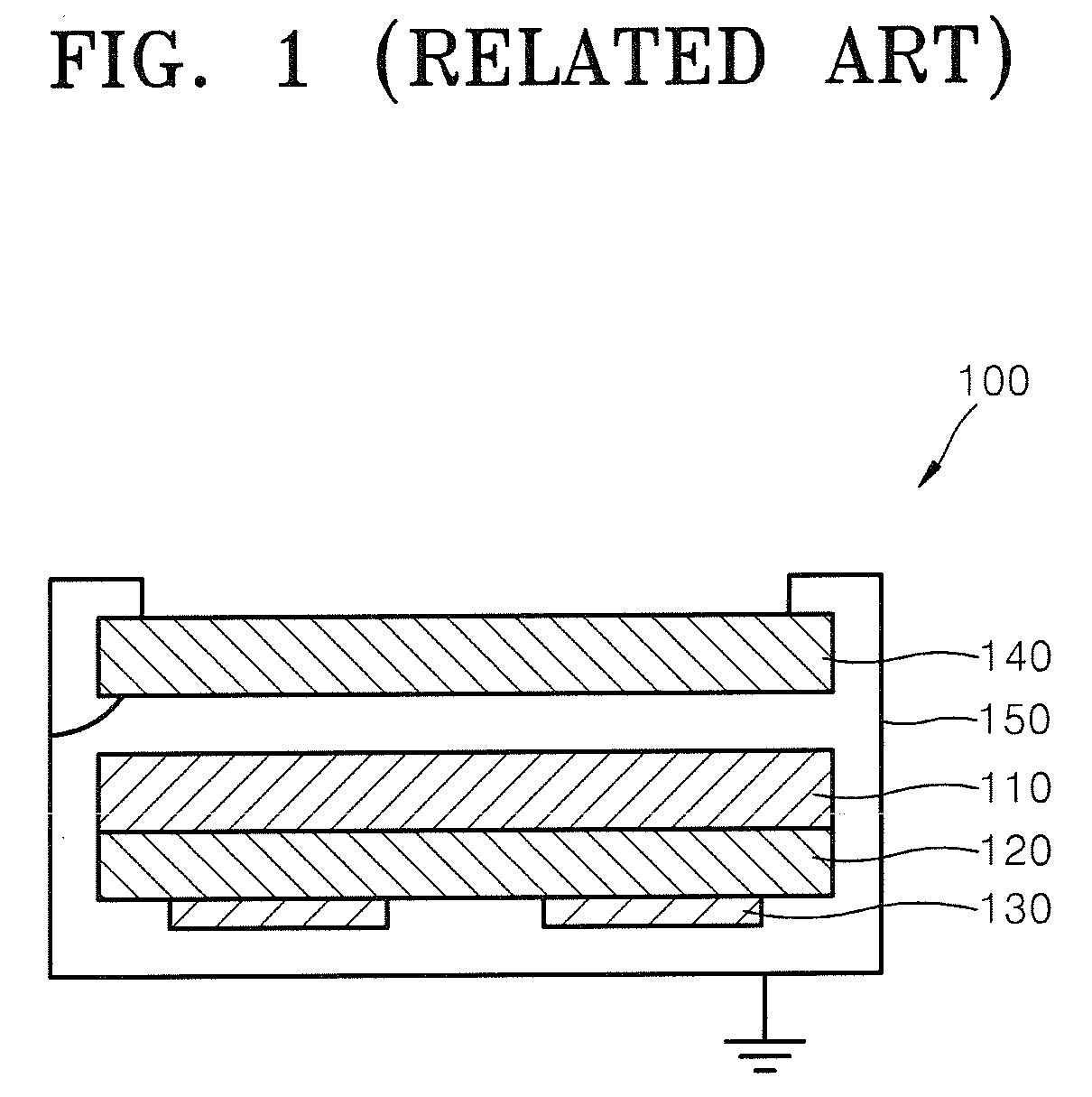

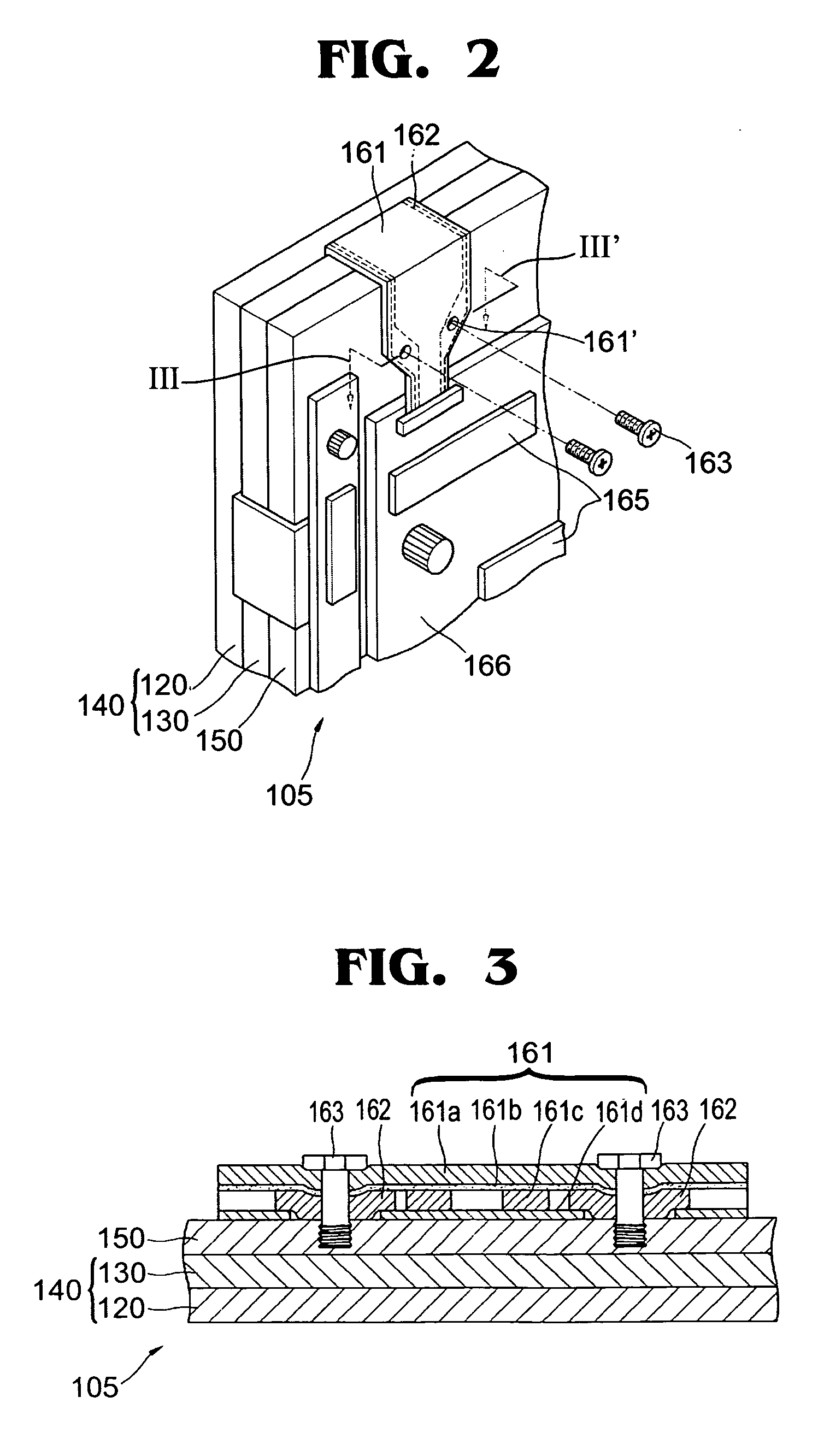

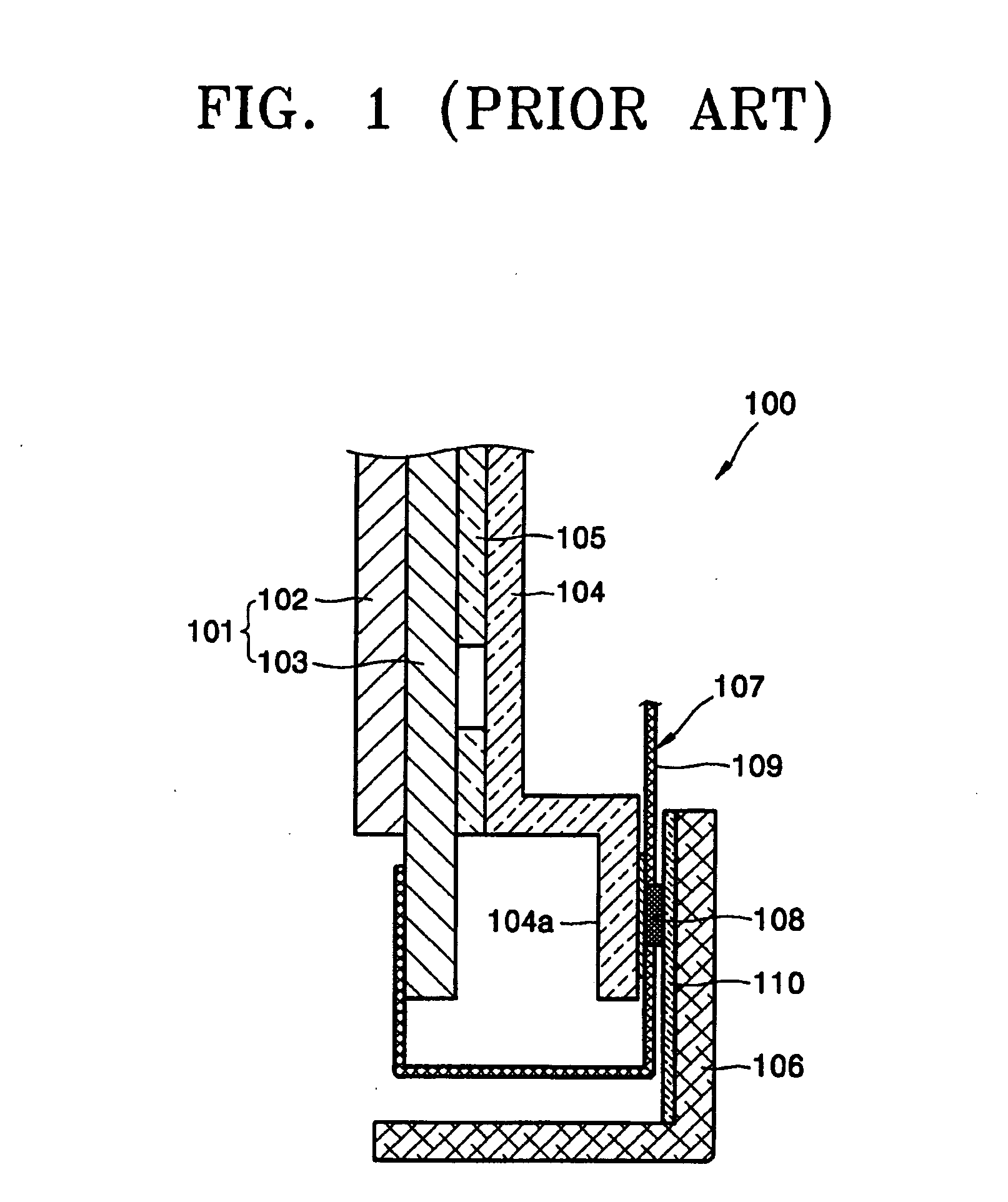

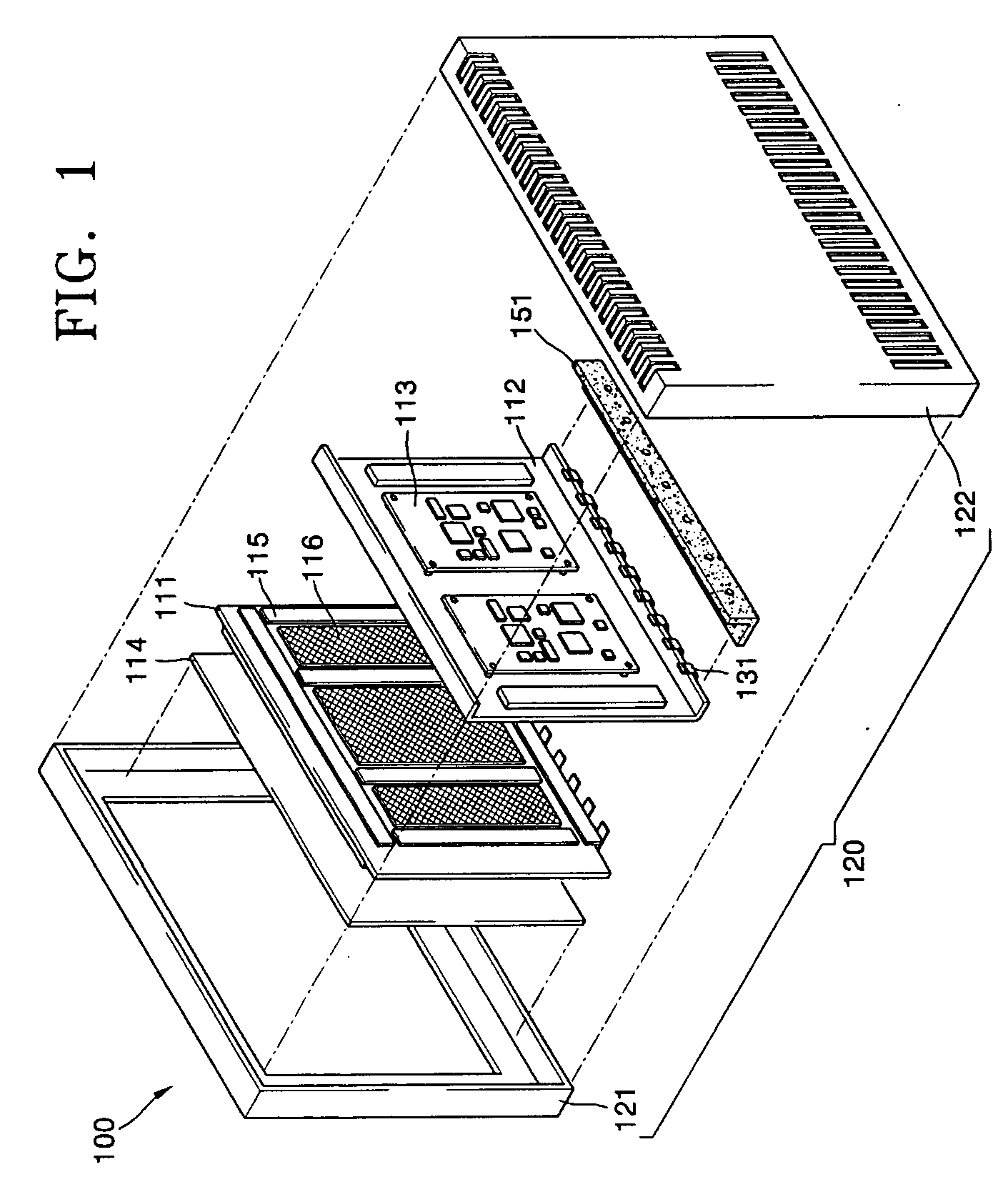

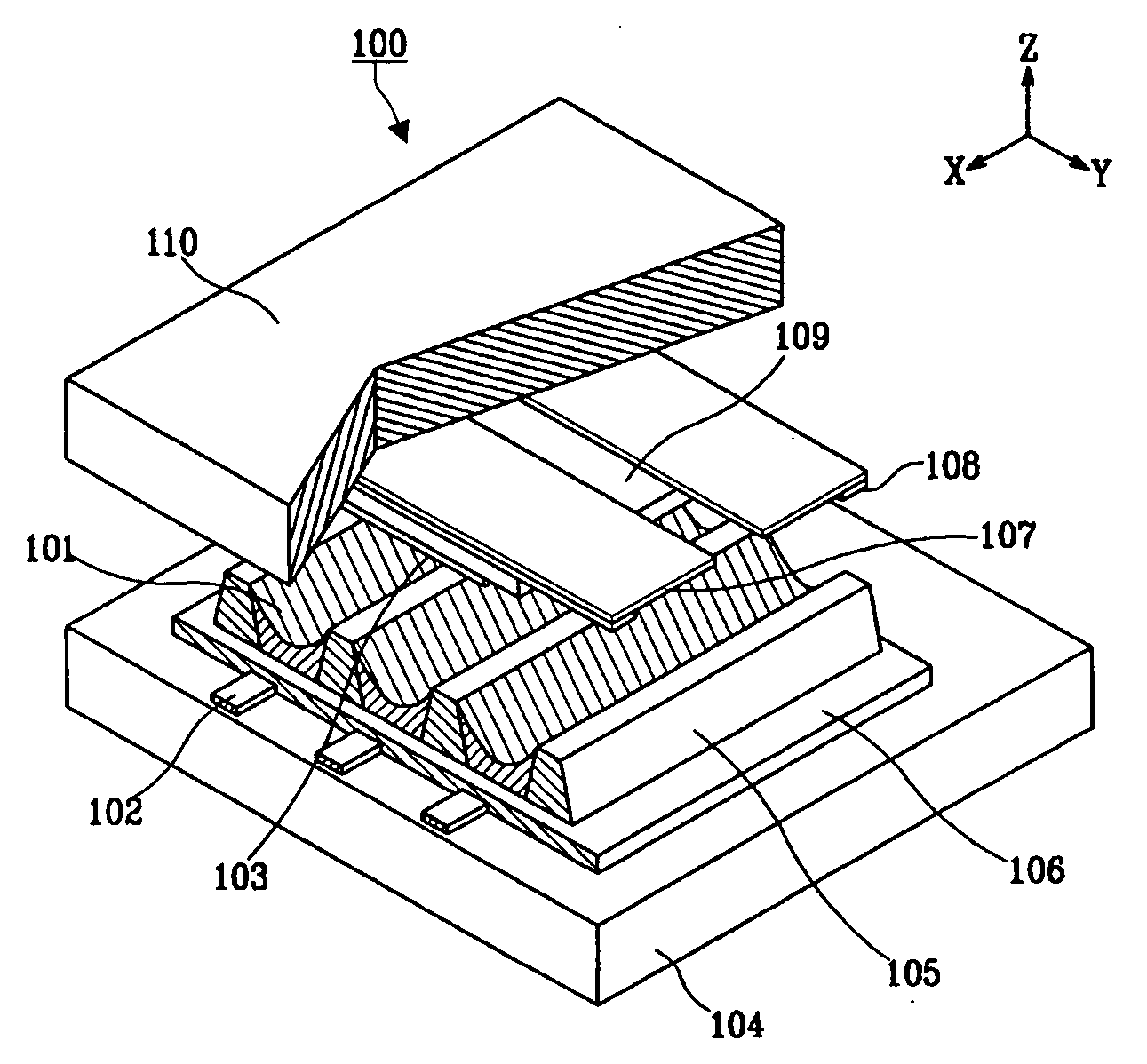

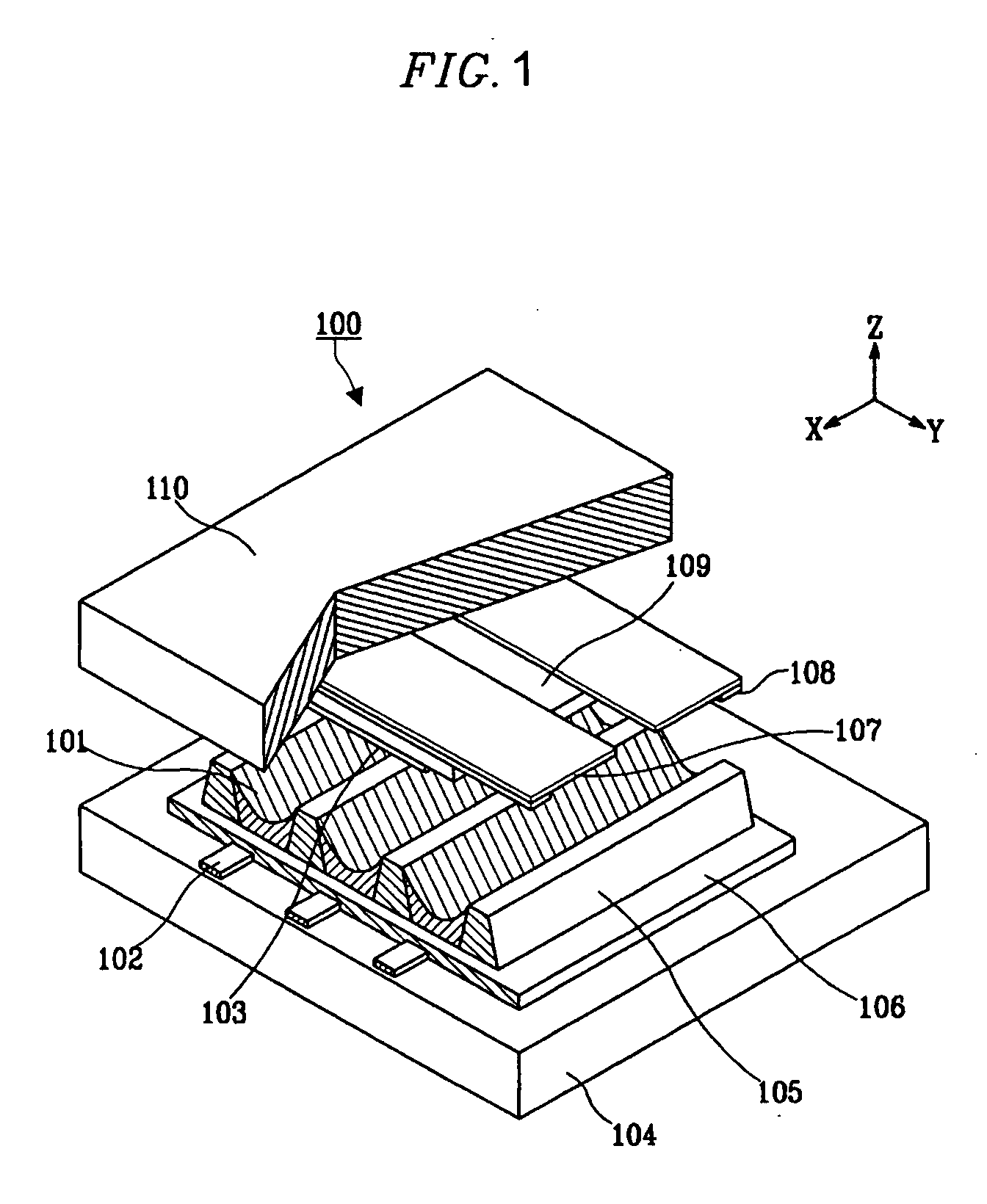

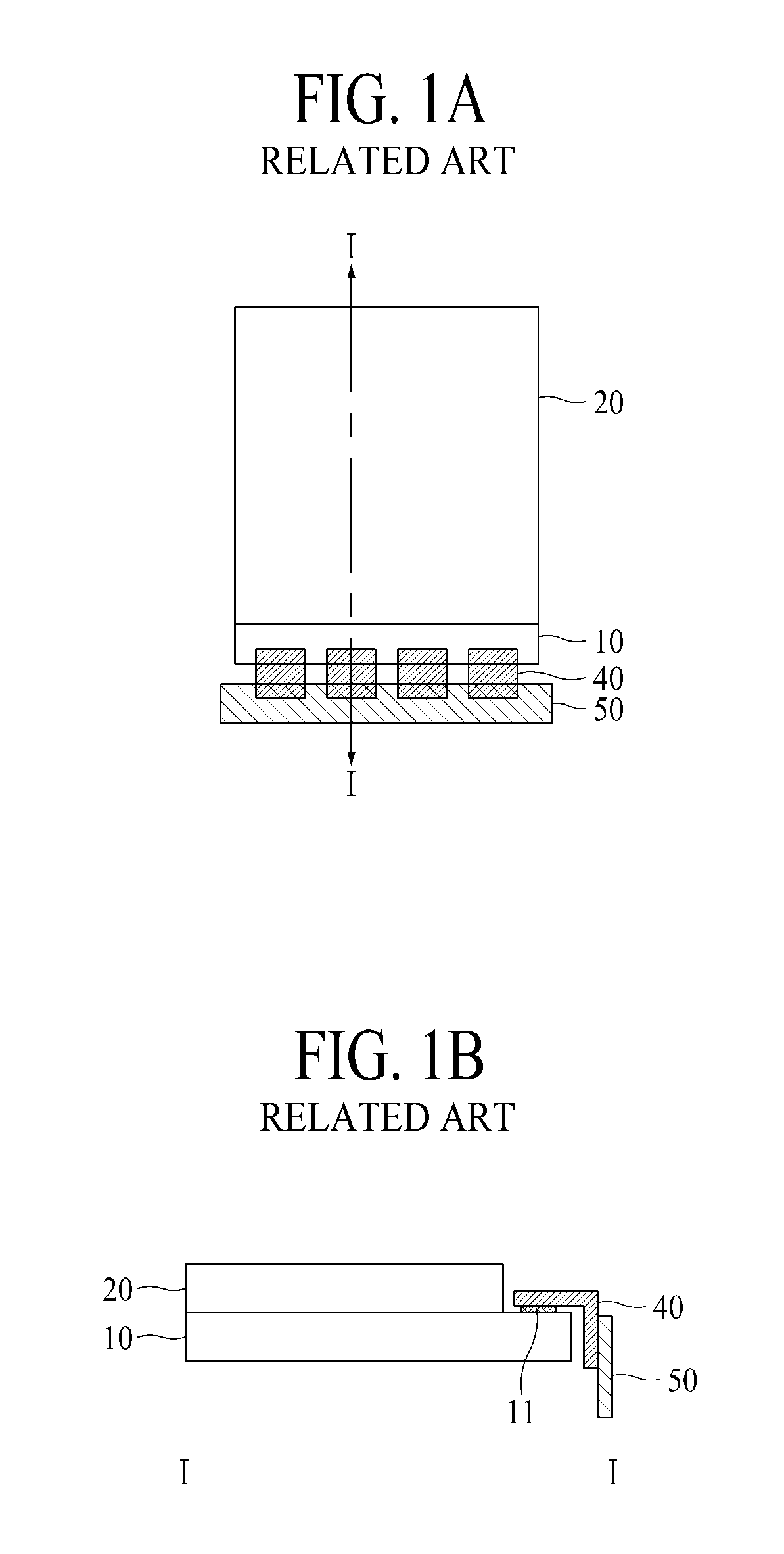

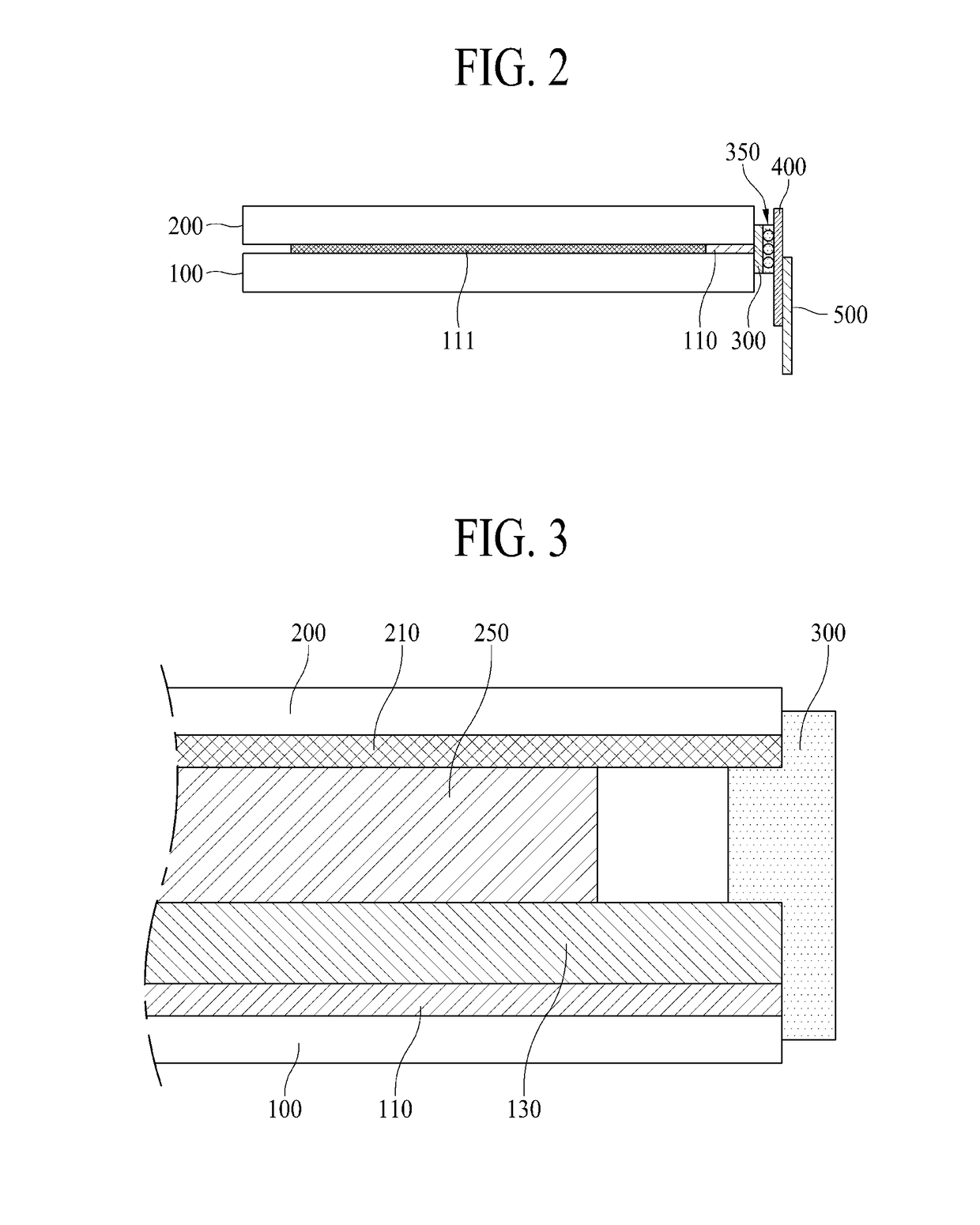

Plasma display apparatus

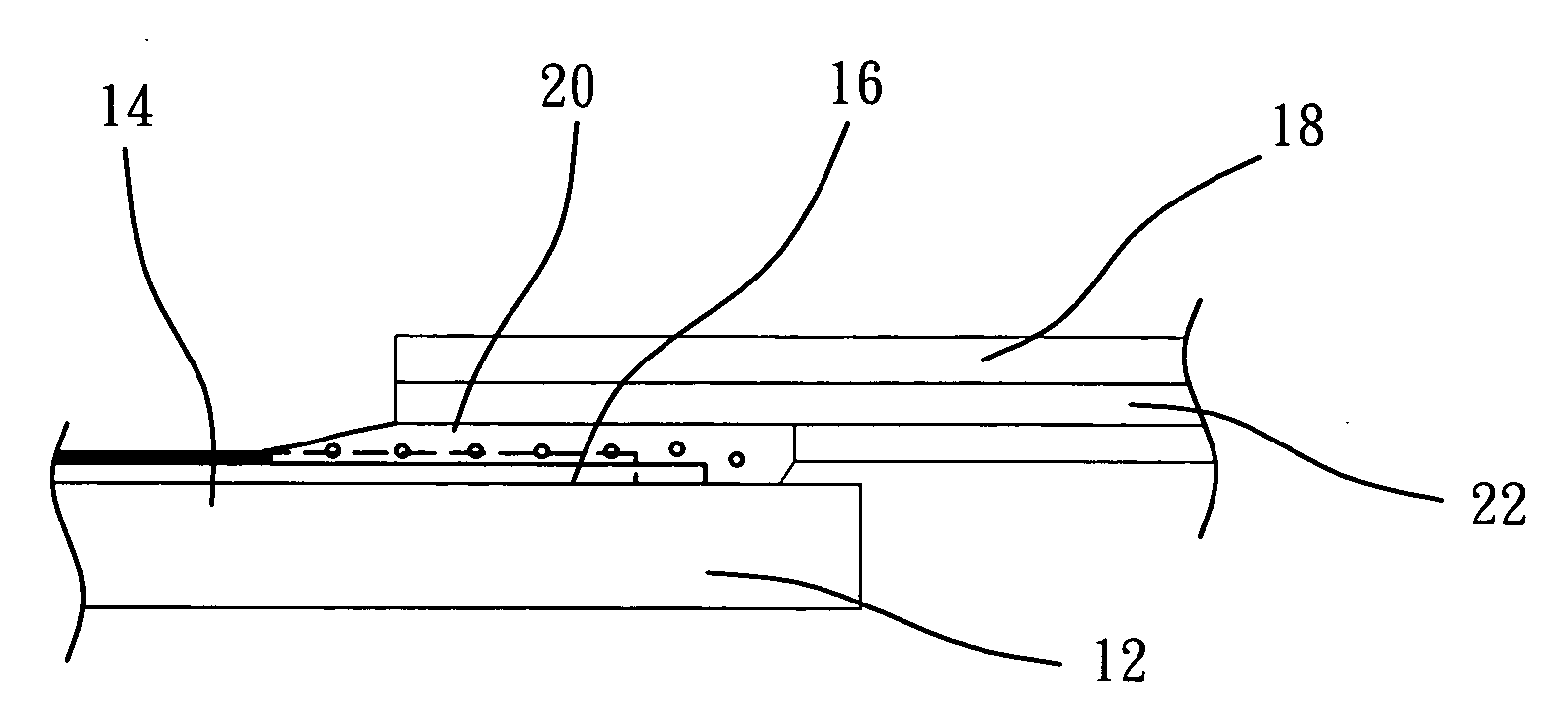

InactiveUS20050088093A1Television system detailsGas discharge connecting/feedingPlasma displayDriving circuit

The present invention provides an improved plasma display apparatus which is configured to prevent electrical shorts in a connection between a plasma display panel (PDP and a driving circuit. In one embodiment the plasma display apparatus includes a plasma display panel, and a chassis base positioned proximate and proceeding substantially parallel the plasma display panel. The chassis base has a surface contacting the plasma display panel, and an opposite surface on which the driving circuit is mounted. A connector electrically connects the plasma display panel to the driving circuit unit. At least one spacer member is disposed between the chassis base and the connector to space the chassis base and the connector from each other with a gap.

Owner:SAMSUNG SDI CO LTD

Plasma display panel and method for manufacturing the same

InactiveUS20090146566A1Increase dependenceLarge secondary electron emission coefficientTube/lamp screens manufactureAddress electrodesLow voltageSpace charge

“Discharge delay” and “dependence of discharge delay on temperatures” are solved by improving a protective layer, thus a PDP can be driven at a low voltage. Furthermore, the PDP can display excellent images by suppressing “dependence of discharge delay on space charges.” Liquid-phase magnesium alkoxide (Mg(OR)2) or acetylacetone magnesium ate whose purity is 99.95% or more is prepared, and is hydrolyzed by adding a small amount of acids to the solution. Thus, a gel of magnesium hydroxide that is a magnesium oxide precursor is formed. Burning the gel in atmosphere at 700° C. or more produces powder containing MgO particles 16a-16d having the NaCl crystal structure with (100) and (111) crystal faces or with (100), (110) and (111) crystal faces. By pasting the powder on a dielectric layer 7 or a surface layer 8, the MgO powder 16 is formed so as to serve as the protective layer.

Owner:PANASONIC CORP

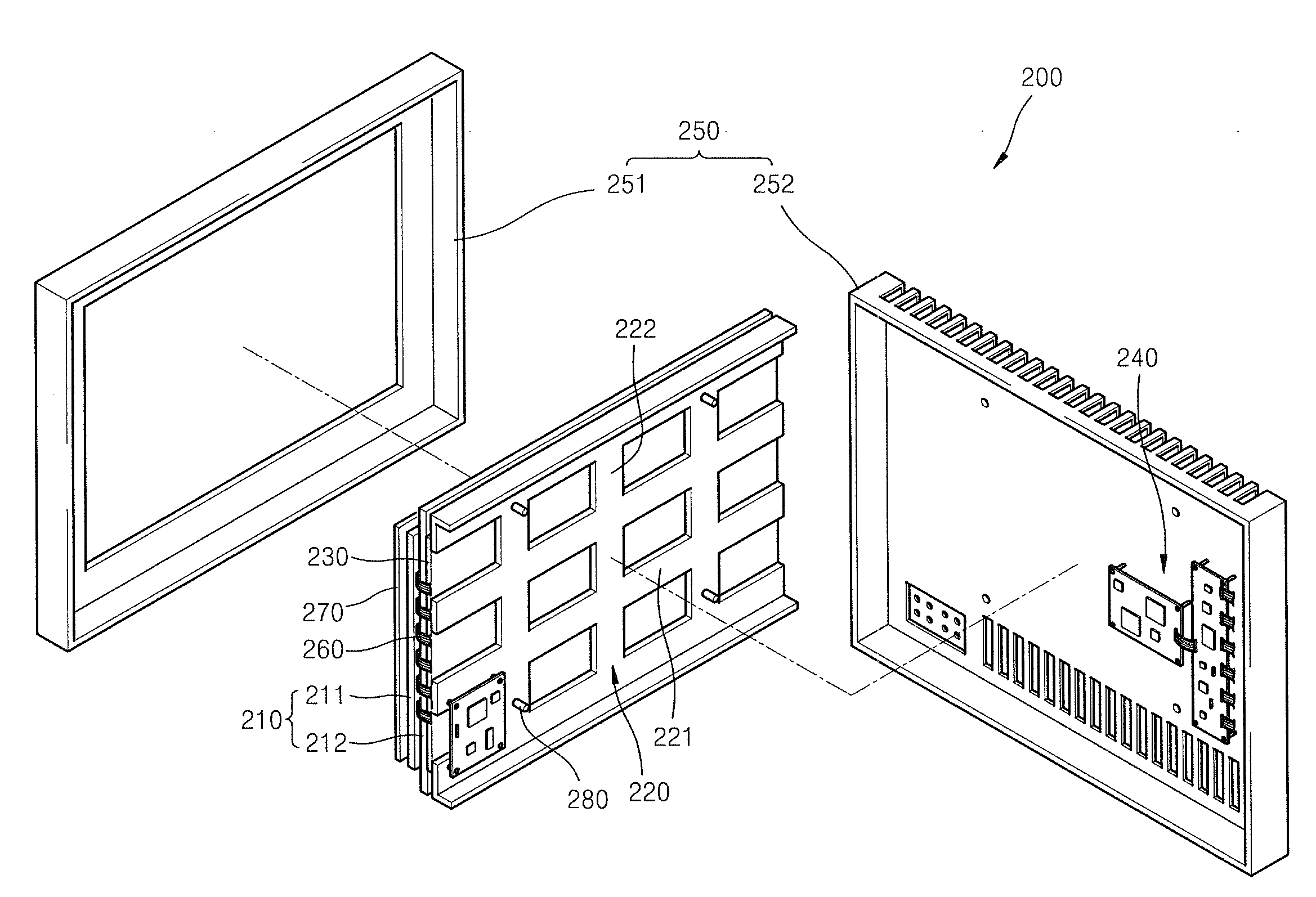

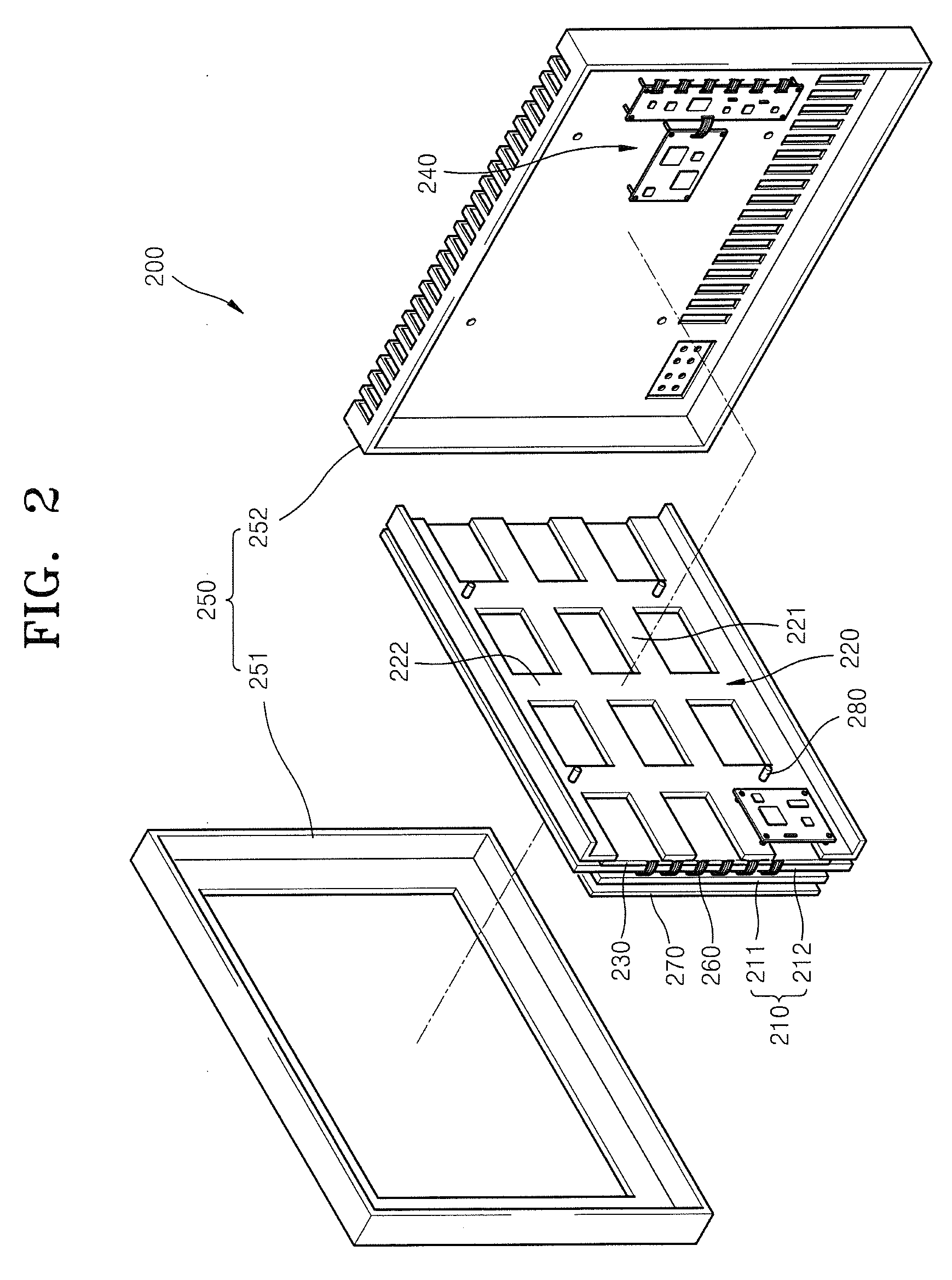

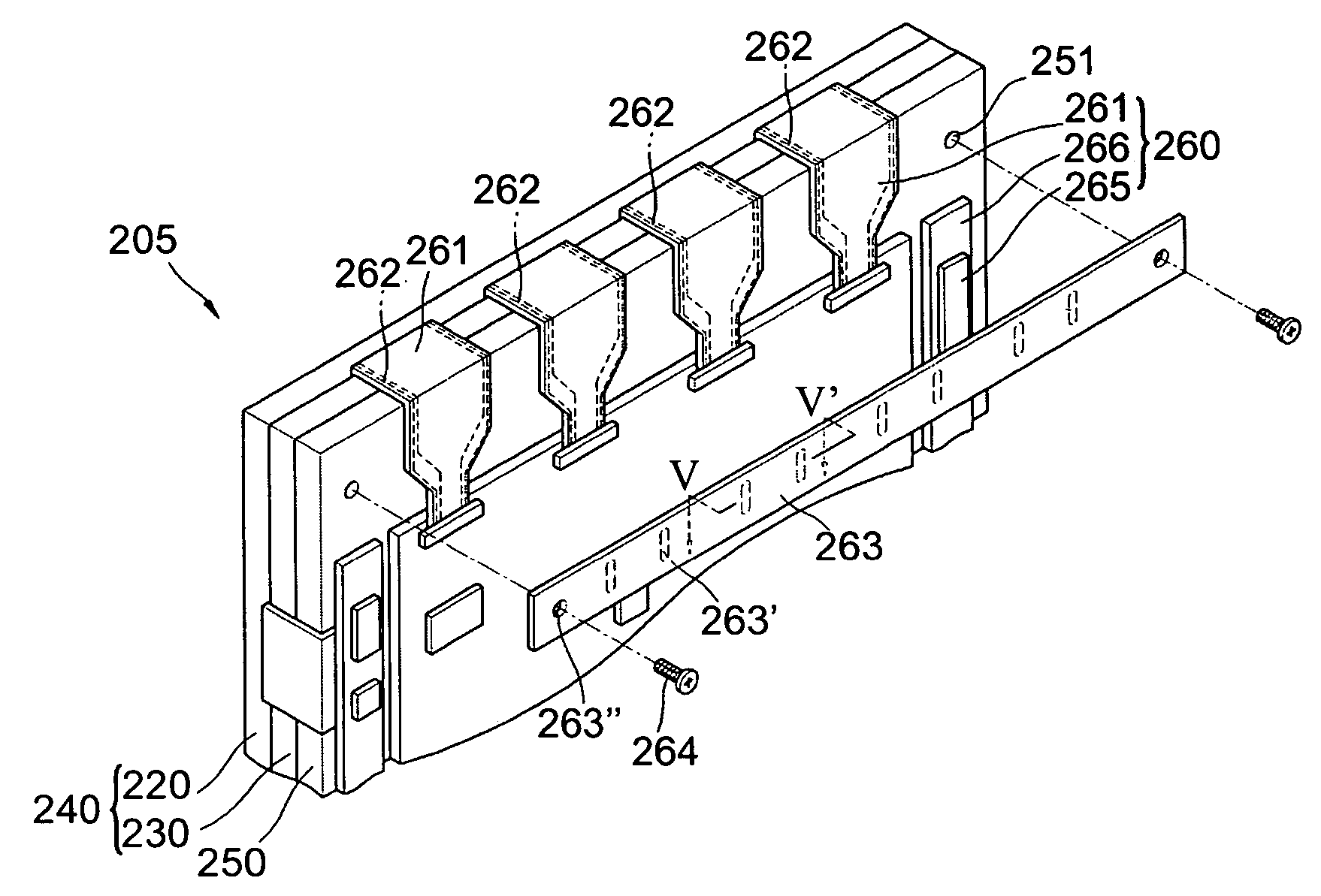

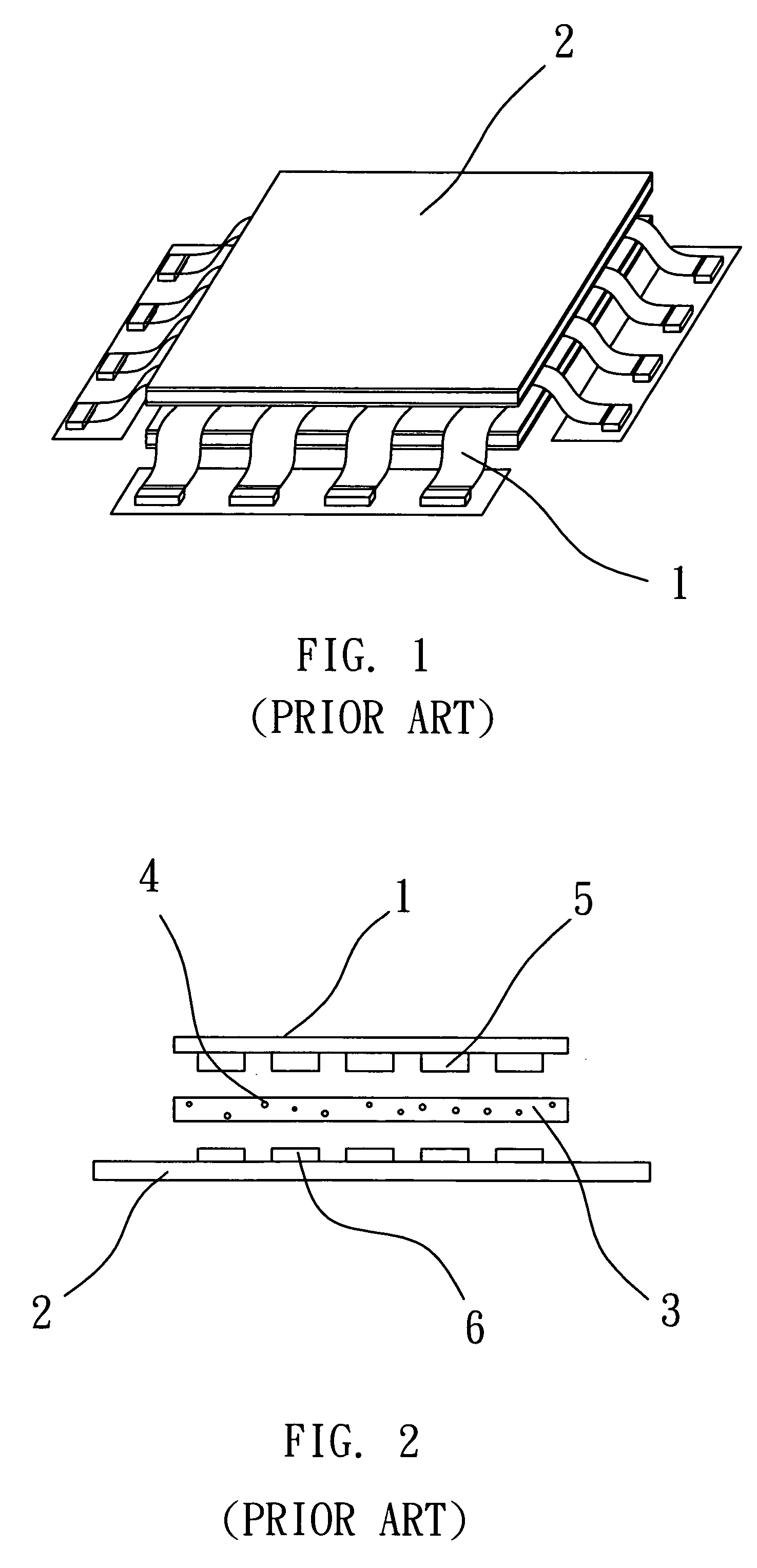

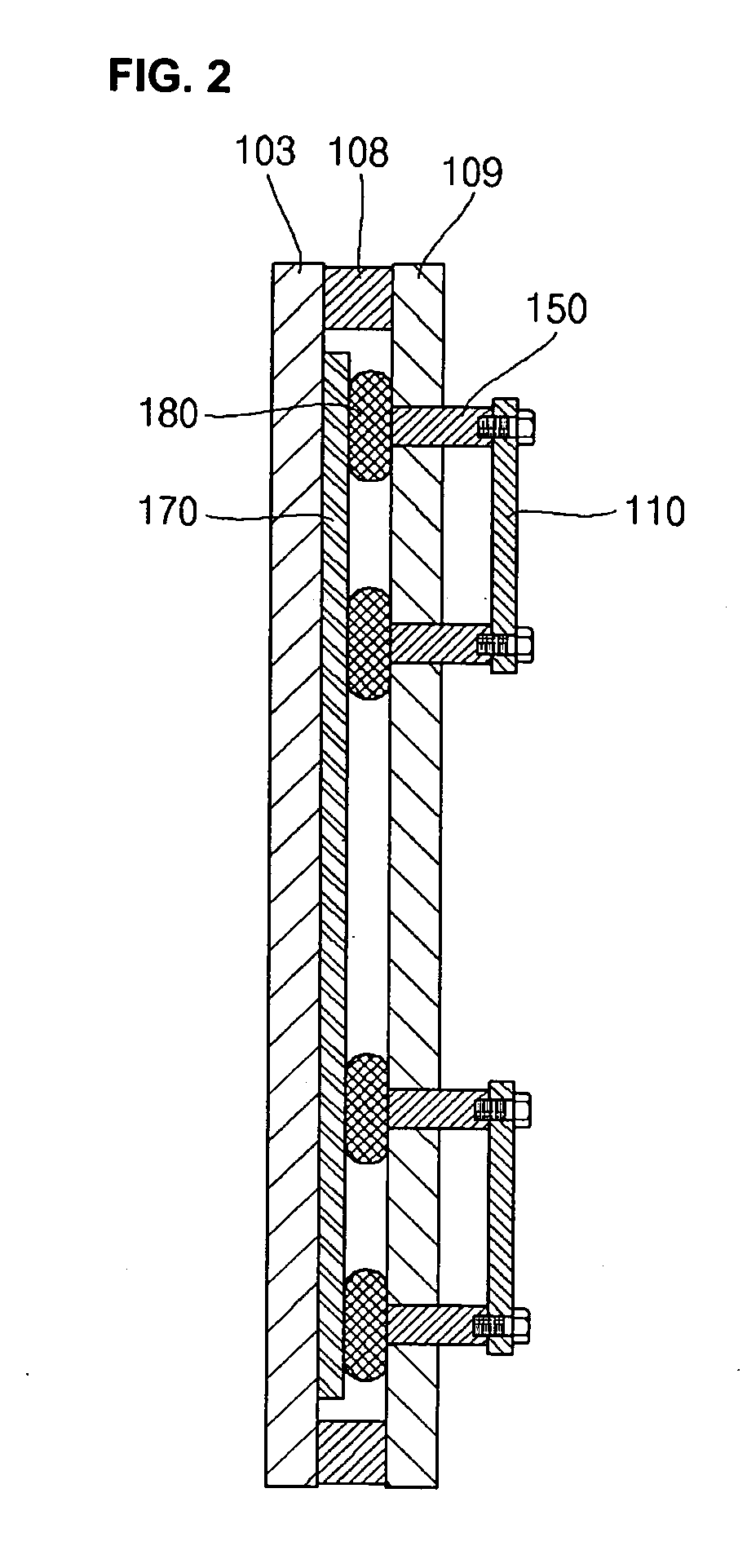

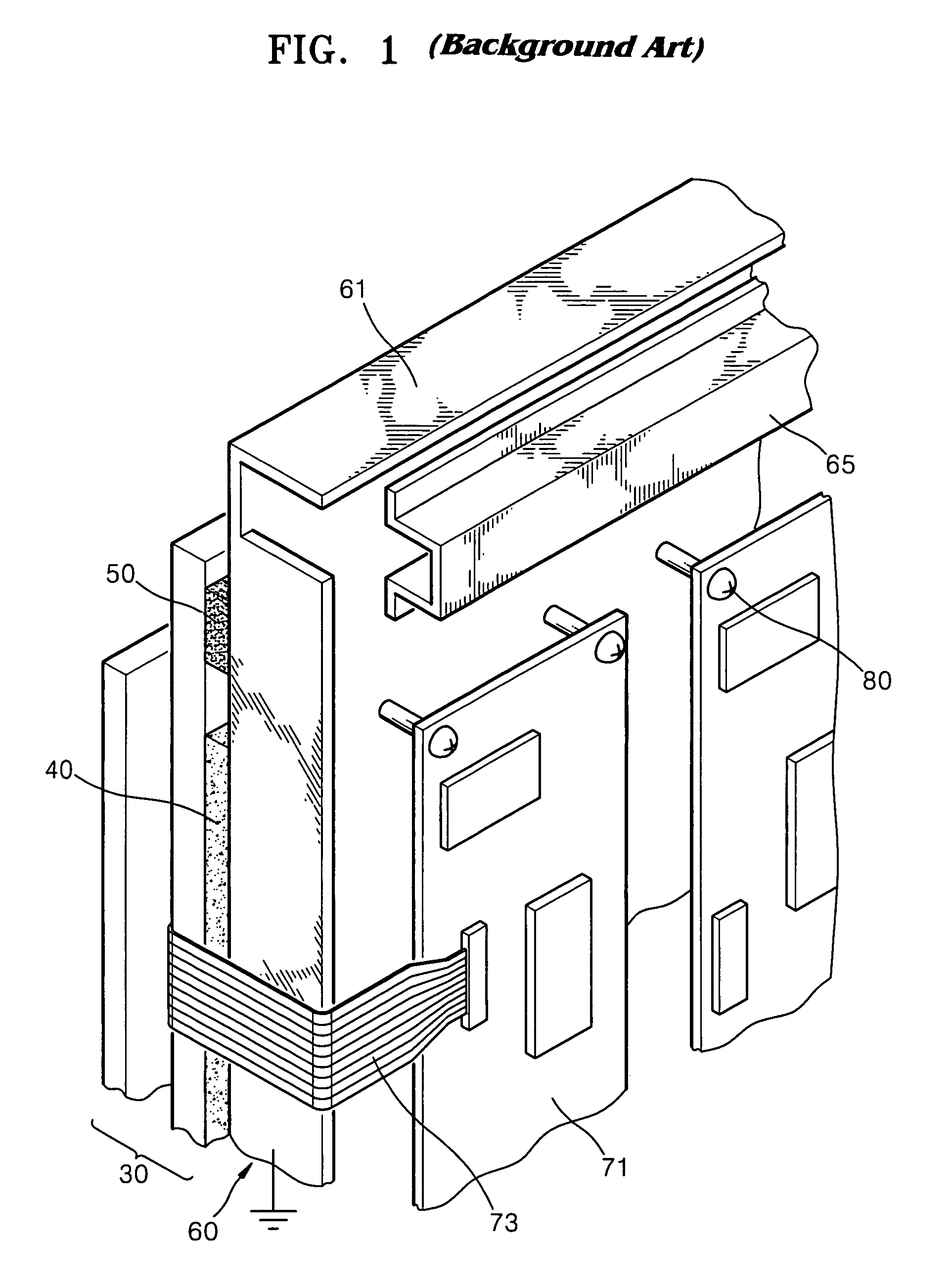

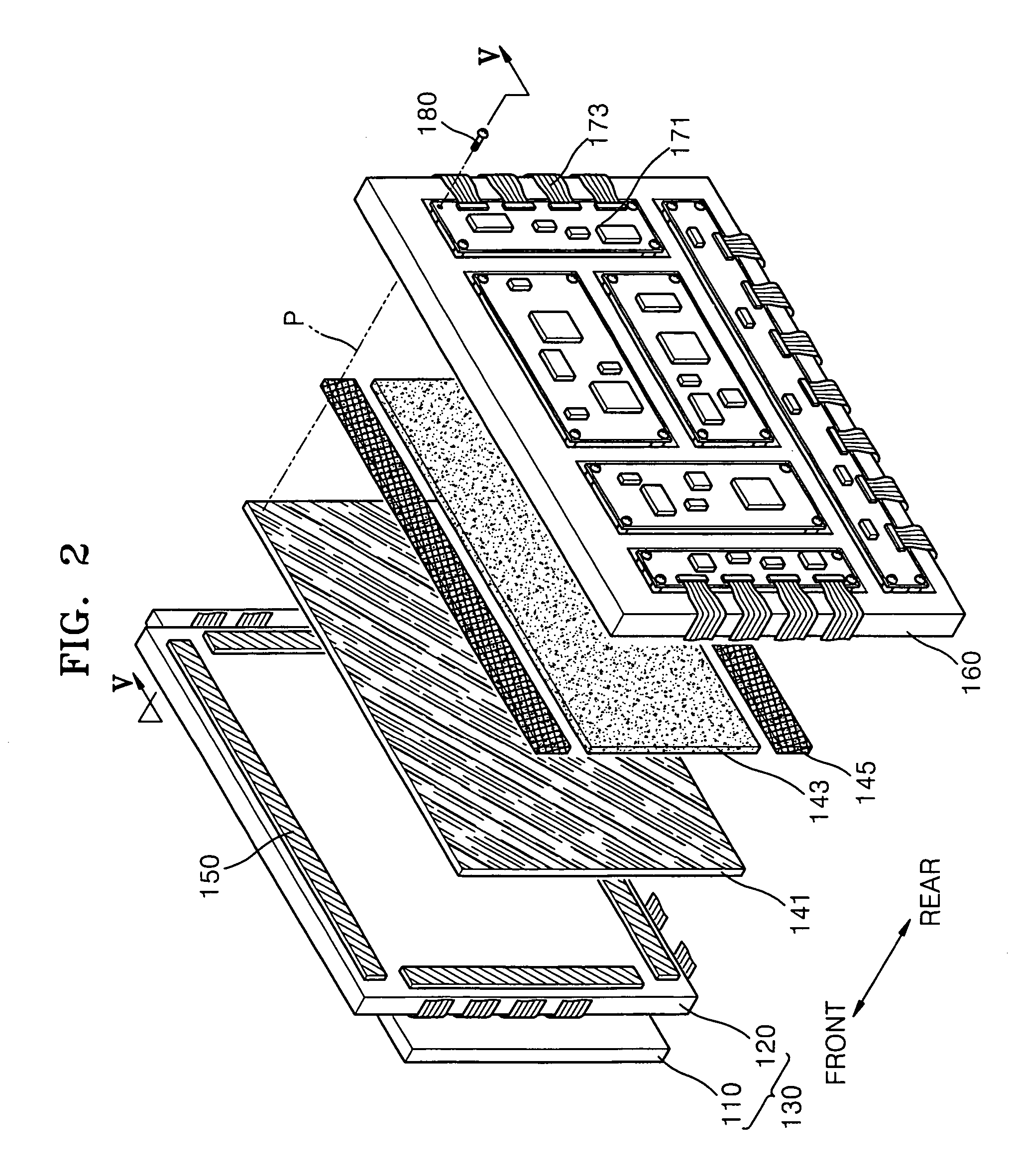

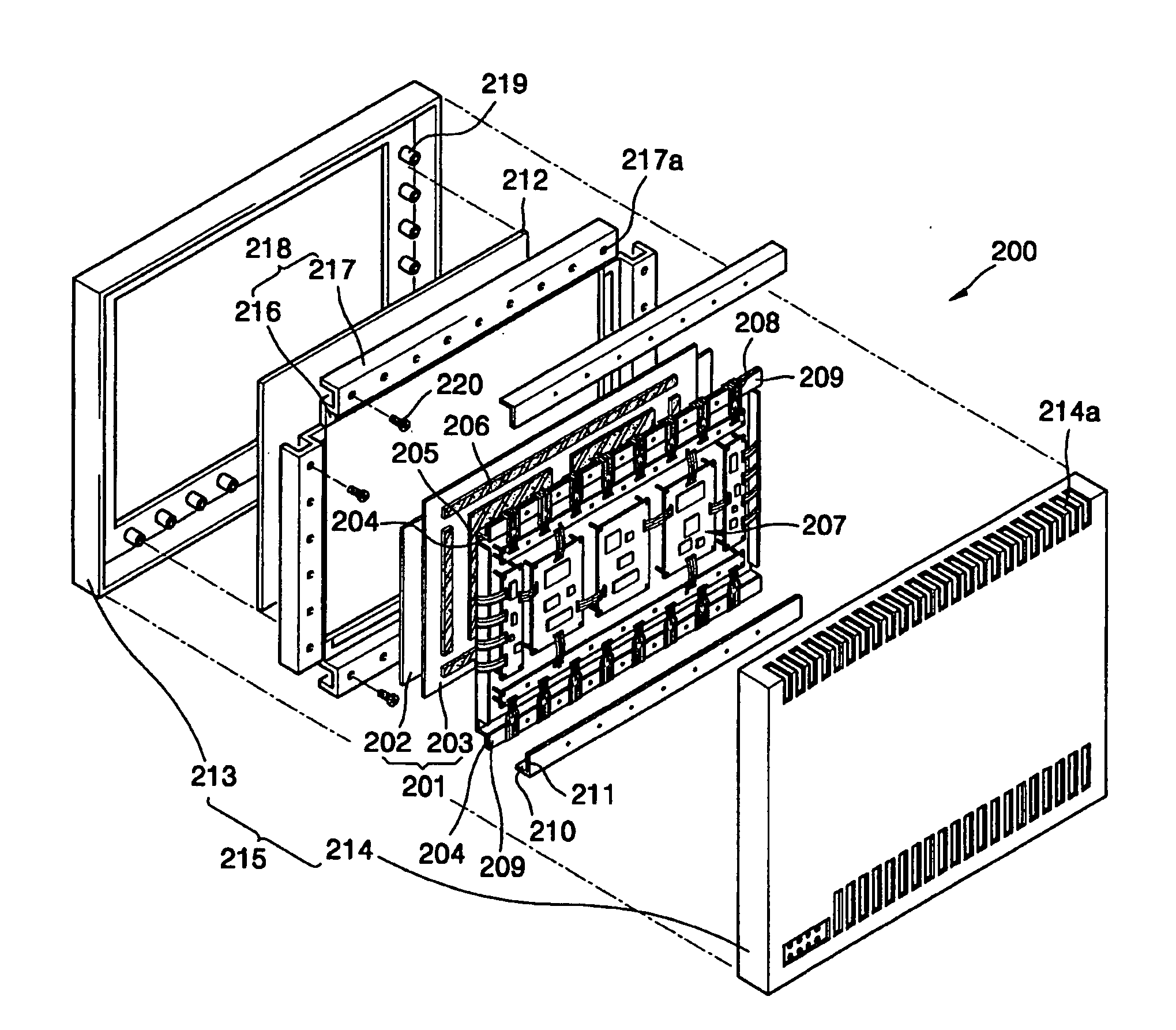

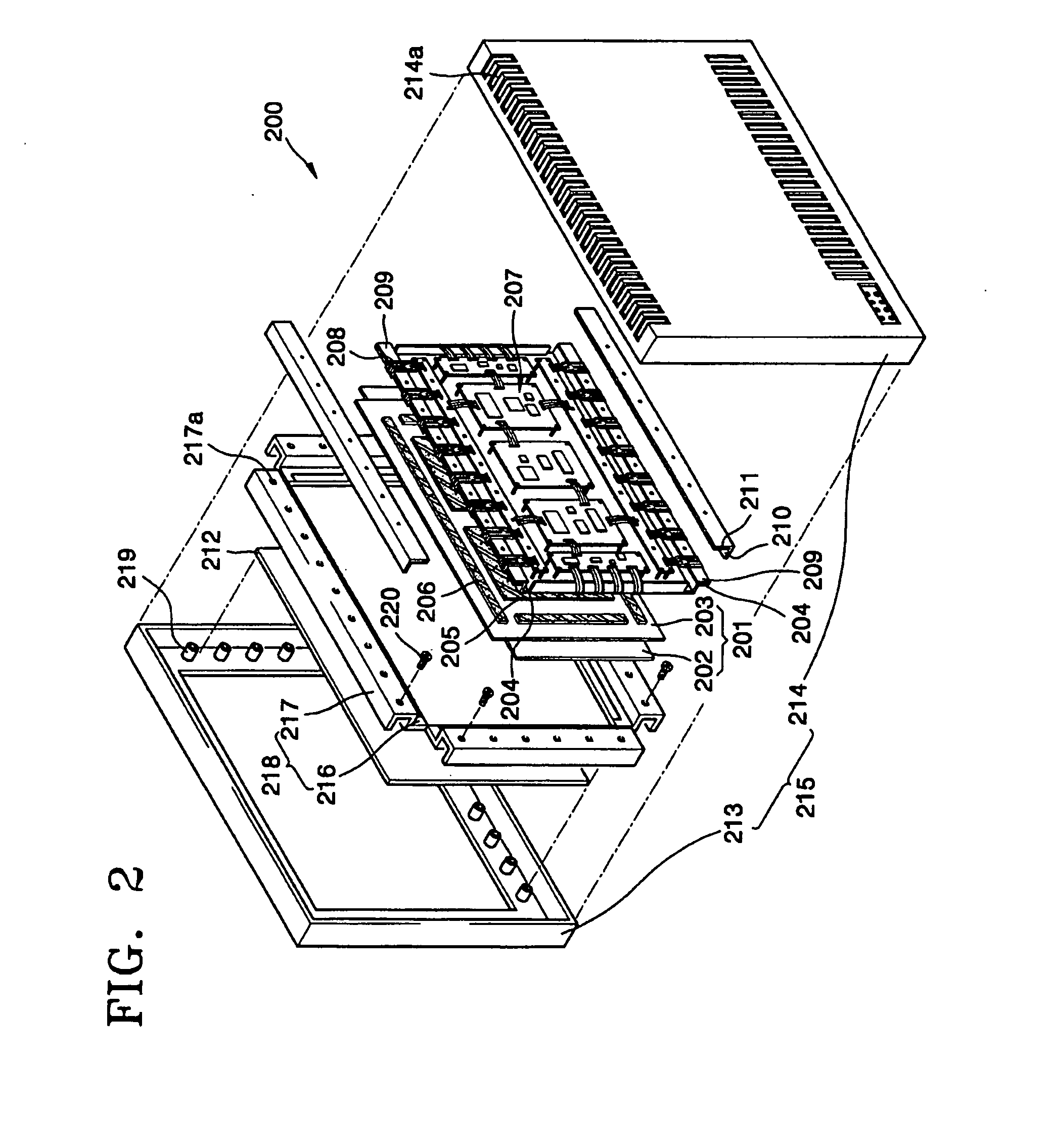

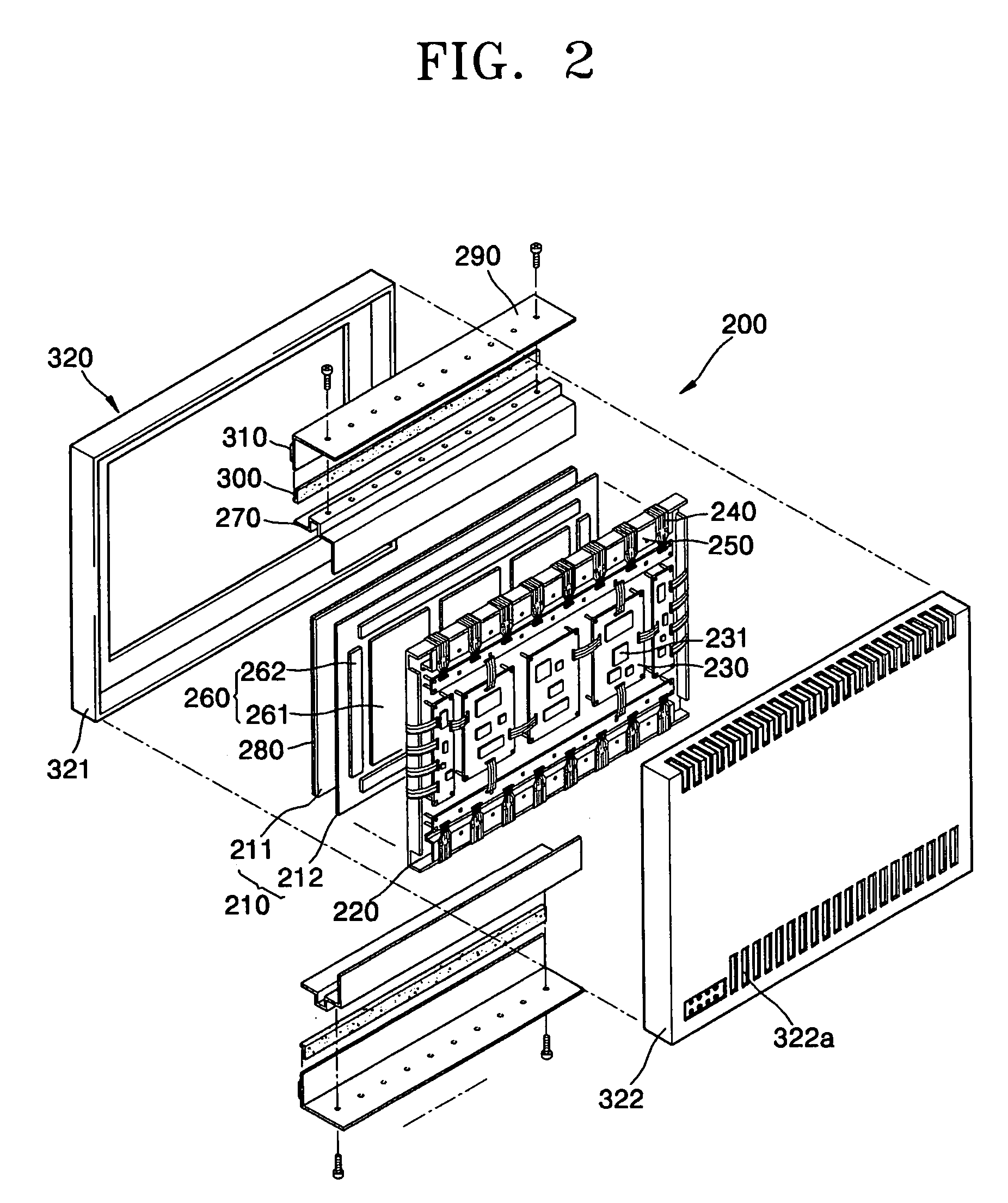

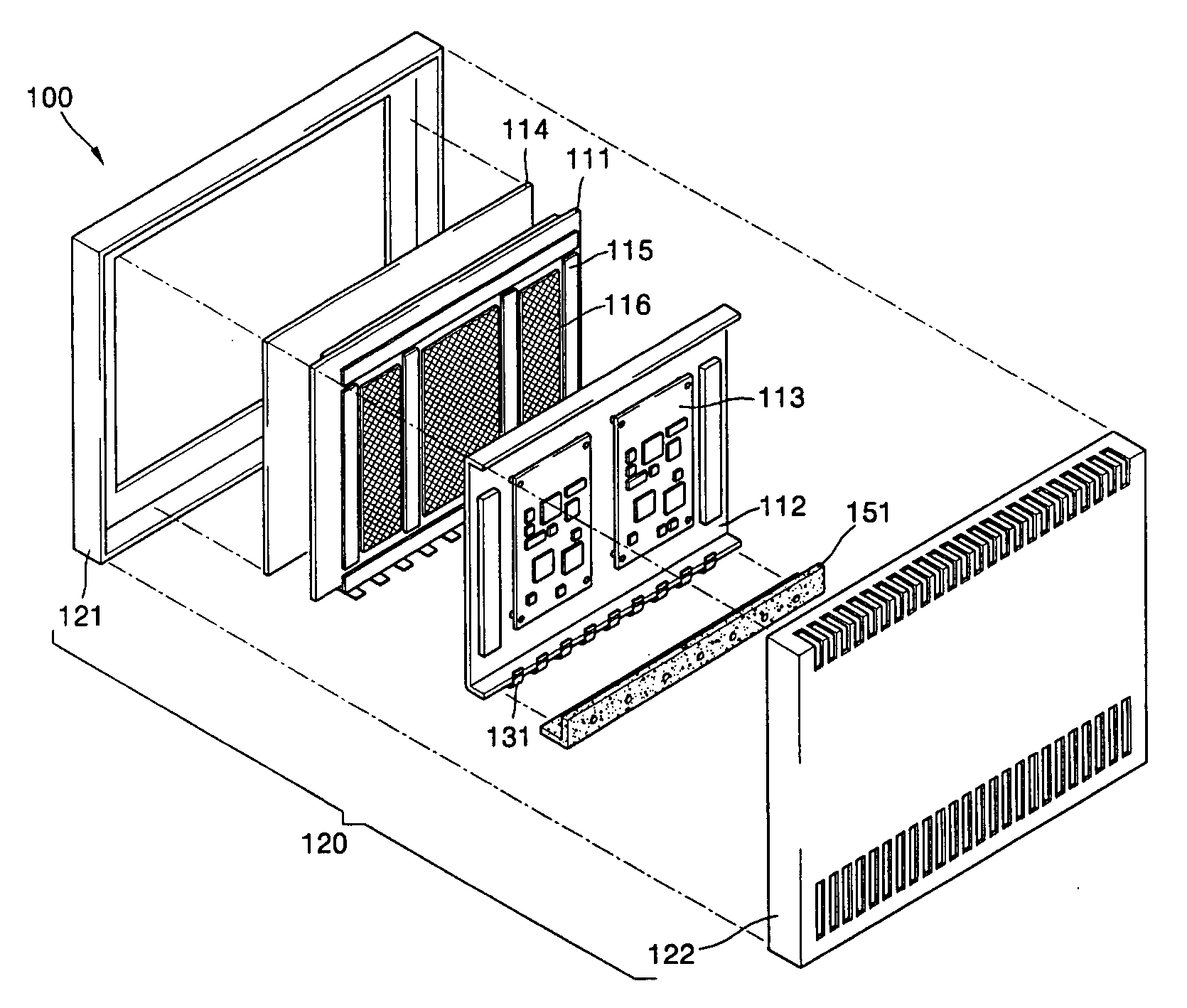

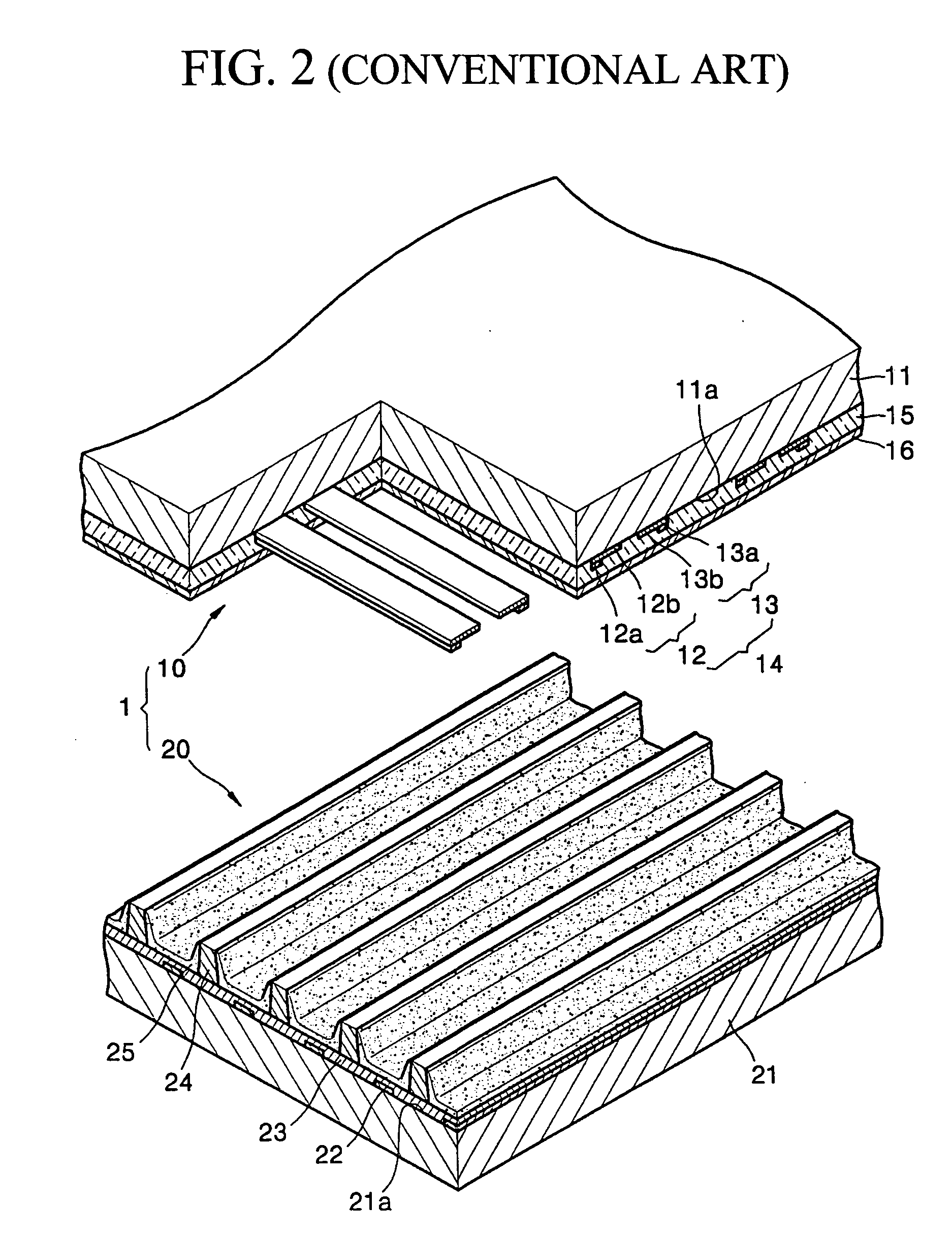

Plasma display module

InactiveUS20050111175A1Improved grounding structureDrive stabilityTelevision system detailsMagnetic/electric field screeningPlasma displayBackplane

A plasma display module constructed with a chassis base; a plasma display panel supported by the chassis base in front of the chassis base to display an image; a circuit board on which a plurality of circuit devices that drive the plasma display panel are mounted, supported by the chassis base behind the chassis base; and a connection cable electrically connecting the circuit board and the plasma display panel, and directly grounded to the chassis base. Therefore, the module will be electrically stable when driven because of its grounding structure, and is suitable for providing images of high resolution.

Owner:SAMSUNG SDI CO LTD

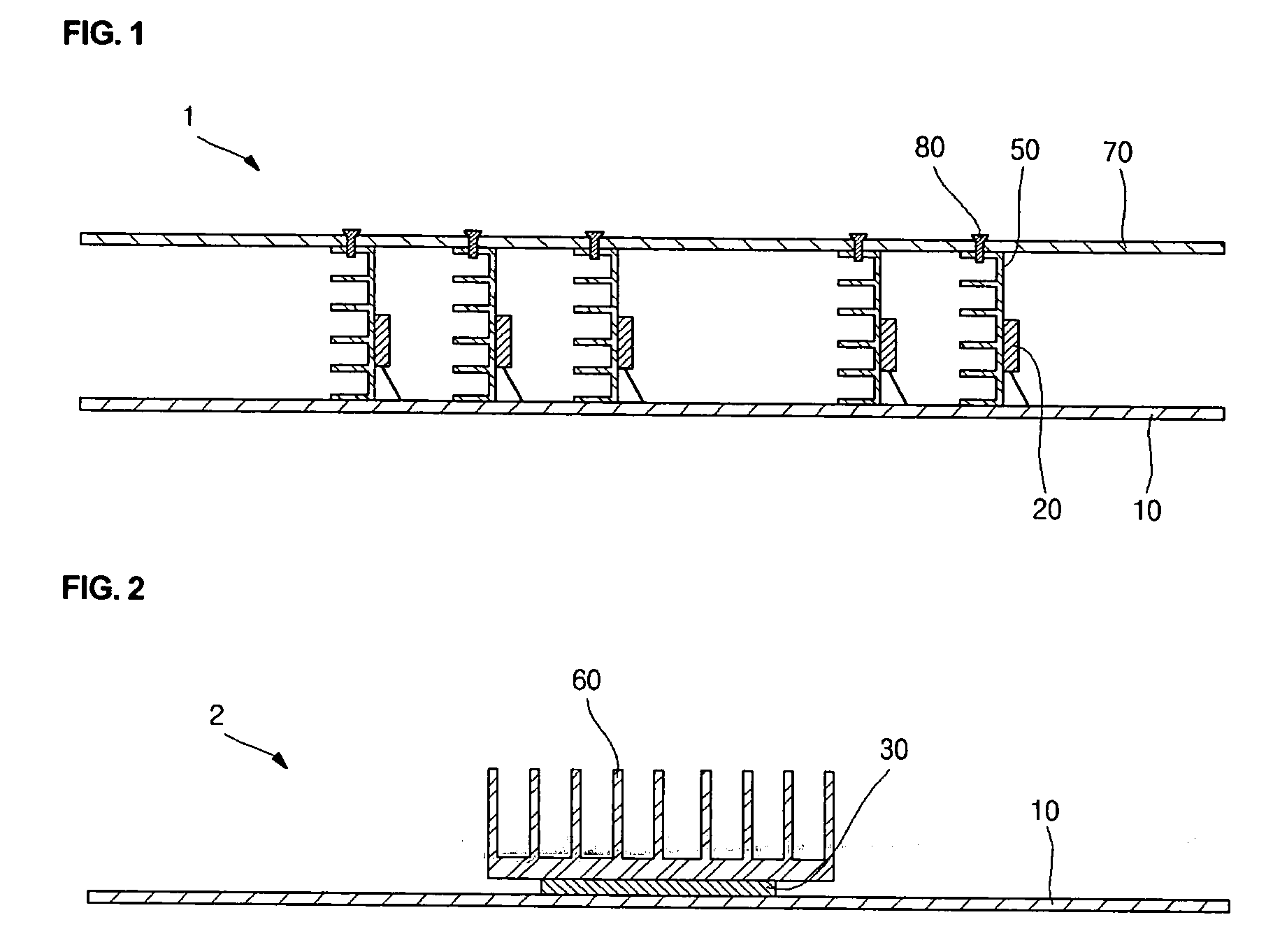

Circuit assembly and flat display having the same

InactiveUS20060268511A1Improve cooling efficiencyReduce noisePrinted circuit aspectsGas discharge connecting/feedingDisplay deviceEngineering

A circuit assembly includes a mount having a circuit element mounted thereon; a heat sink for absorbing and discharging heat generated from the circuit element around, the heat sink mounted on the circuit element on a surface opposite the mount and a noise isolator for isolating noise generated from the circuit board, the noise isolator mounted on the heat sink. The heat sink may include a base portion in surface contact with the circuit element and a top portion in surface contact with the noise isolator. A plurality of fins may be positioned between and parallel to the base and top portions. A plurality of fins may be positioned between and perpendicular to the base and top portions. The top portion may be co-extensive with the base portion, or may only extend past the base portion.

Owner:SAMSUNG SDI CO LTD

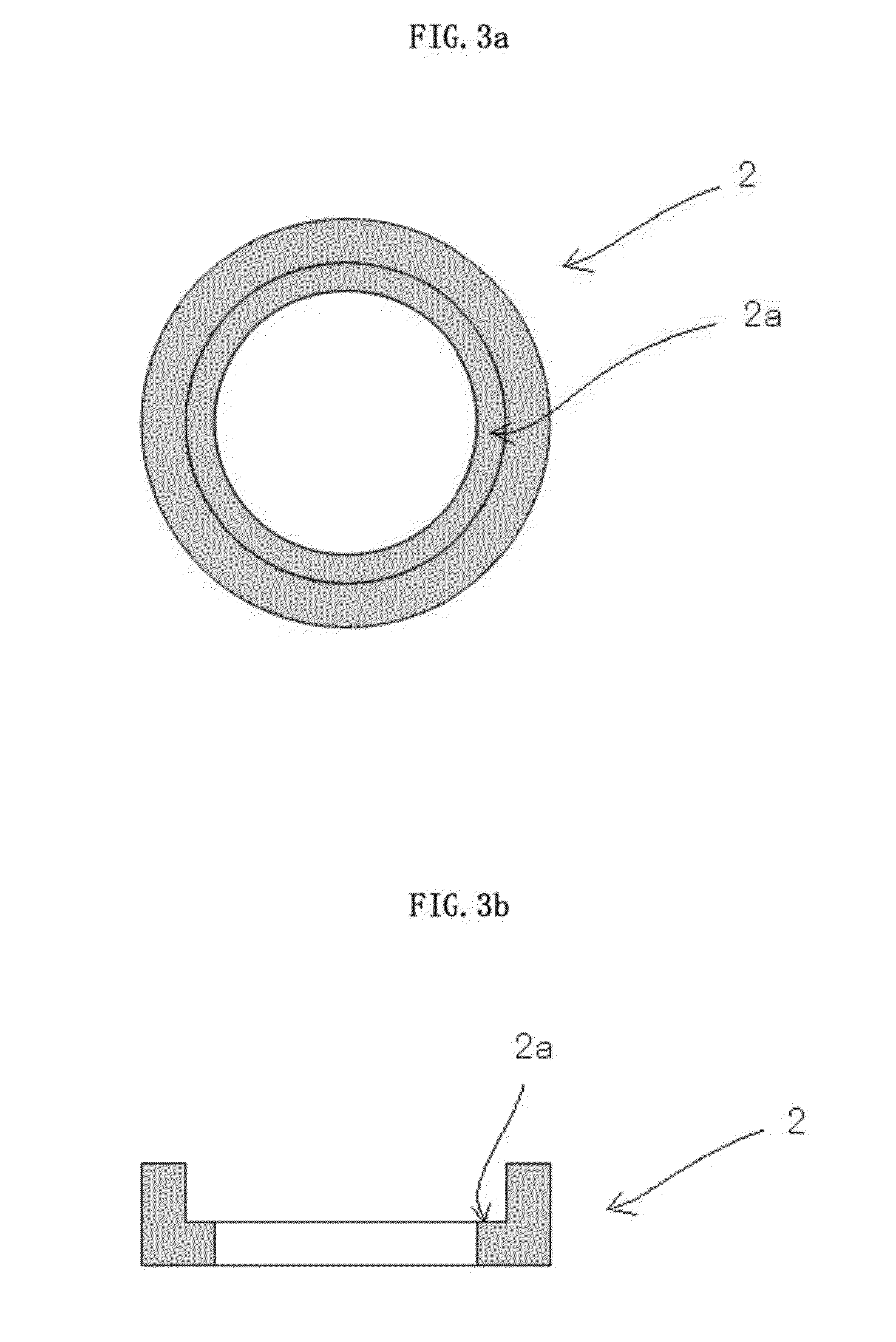

Method and the plasma display panel with an improvement of overflow effect of anisotropic conductive adhesive film

InactiveUS20060146262A1Prolong lifeGood overflow effectGas discharge connecting/feedingPrinted circuit aspectsAnisotropic conductive filmDisplay board

A method to improve the effect of the overflow of the anisotropic conductive film has the steps of providing guide blocks on electrodes of a panel or on a flexible printing circuit (FPC) or on both of them, and then processing a bonding process of the flexible printing circuit (FPC) to melt a conductive film between the flexible printing circuit (FPC) and the panel. The melted conductive film is restricted by the guide blocks to flow to the electrodes and to cover them.

Owner:CHUNGHWA PICTURE TUBES LTD

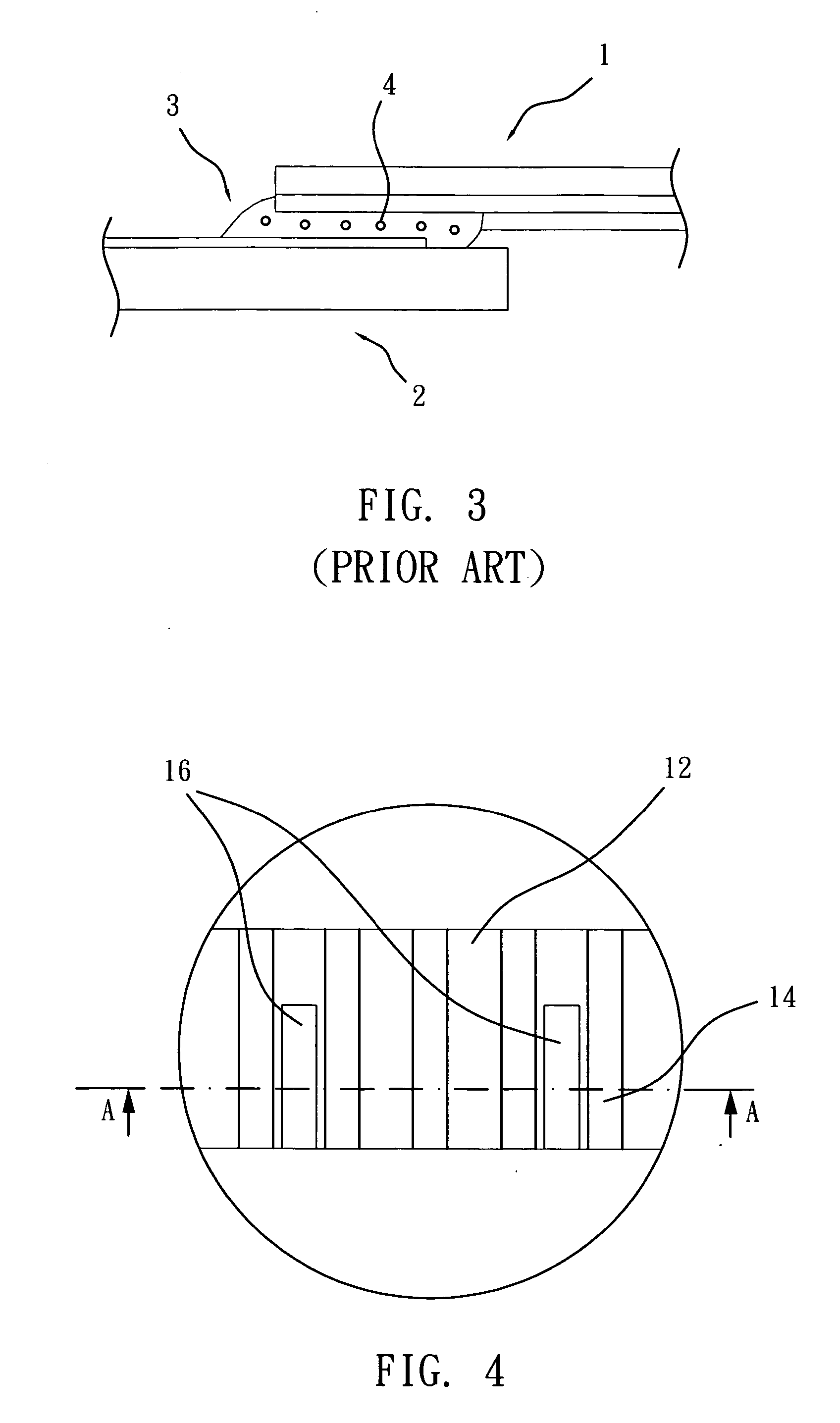

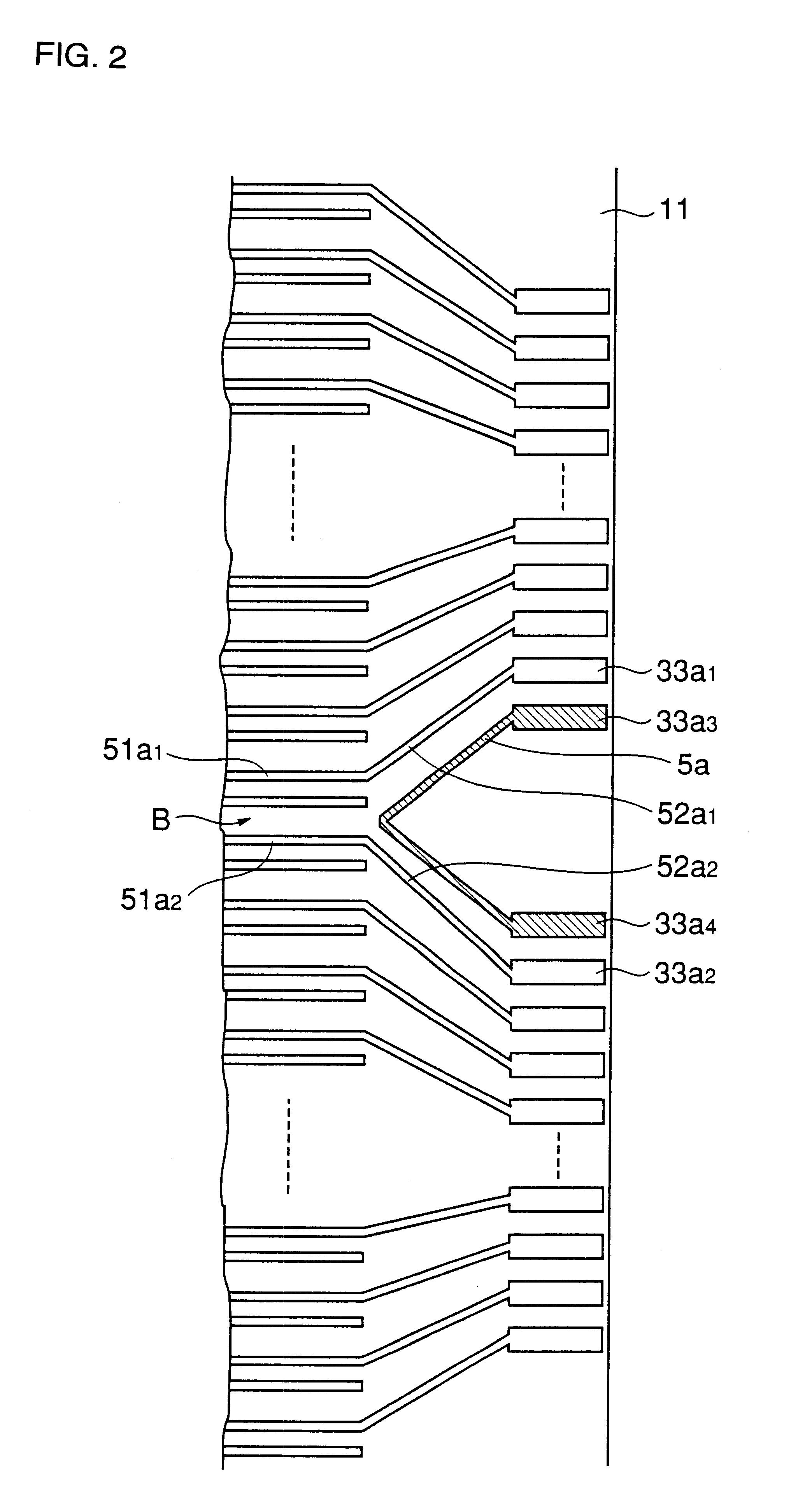

Electrode structure of display panel and electrode forming method using dummy electrode

InactiveUS6680759B2Eliminate unevennessControl flowAddress electrodesSustain/scan electrodesEngineeringLead electrode

An electrode structure of a display panel includes a plurality of electrodes formed on a substrate constituting the display panel, the electrodes including display electrode portions provided in almost parallel in a central part of the substrate and oblique lead electrode portions converged in a predetermined number for each block from the display electrode portions to reach terminal portions at an end of the substrate, and a dummy electrode provided between two oblique lead electrode portions extending in different directions in a block boundary portion for limiting a flow of an etching solvent into the block boundary portion during etching when the electrodes are formed.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

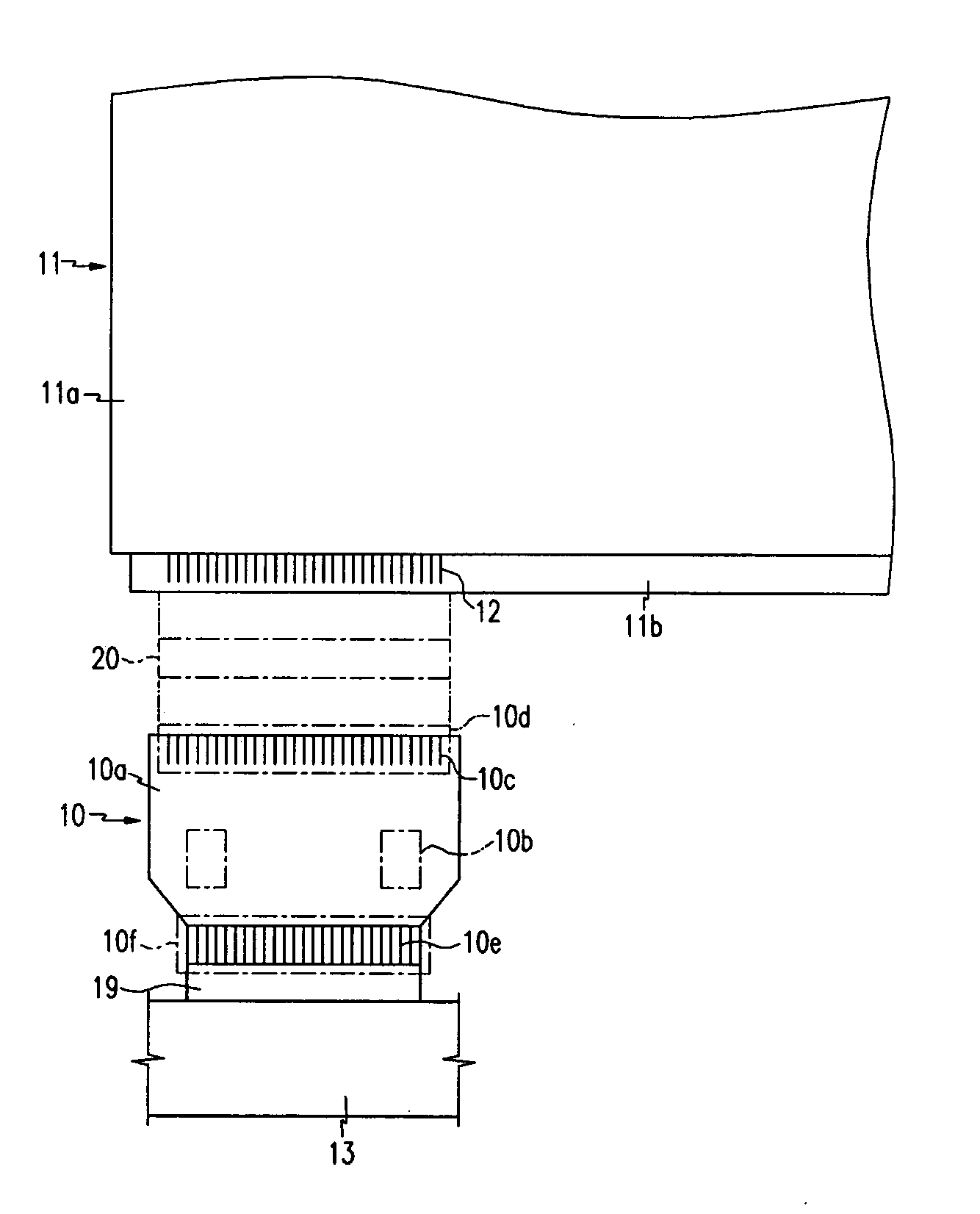

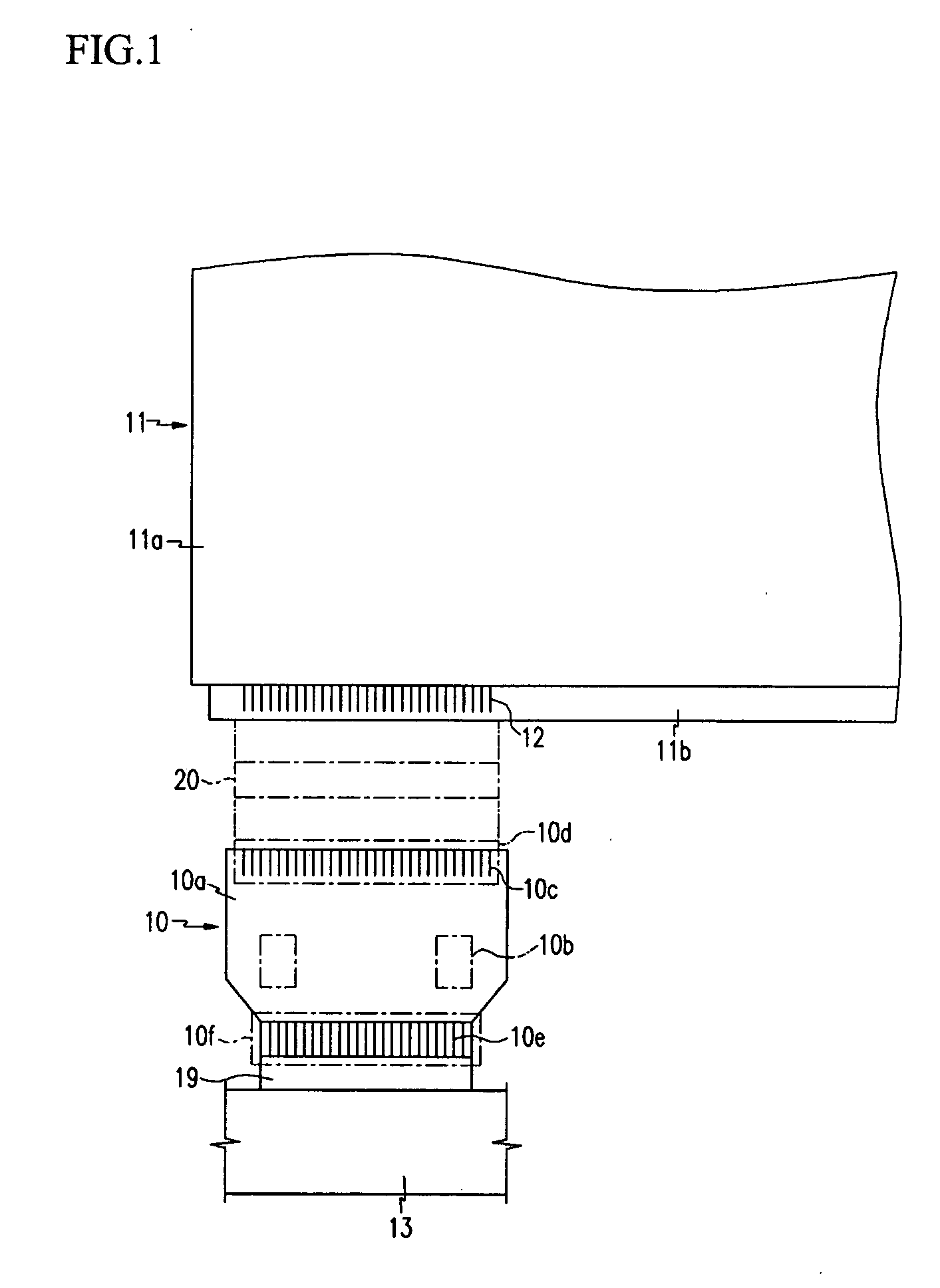

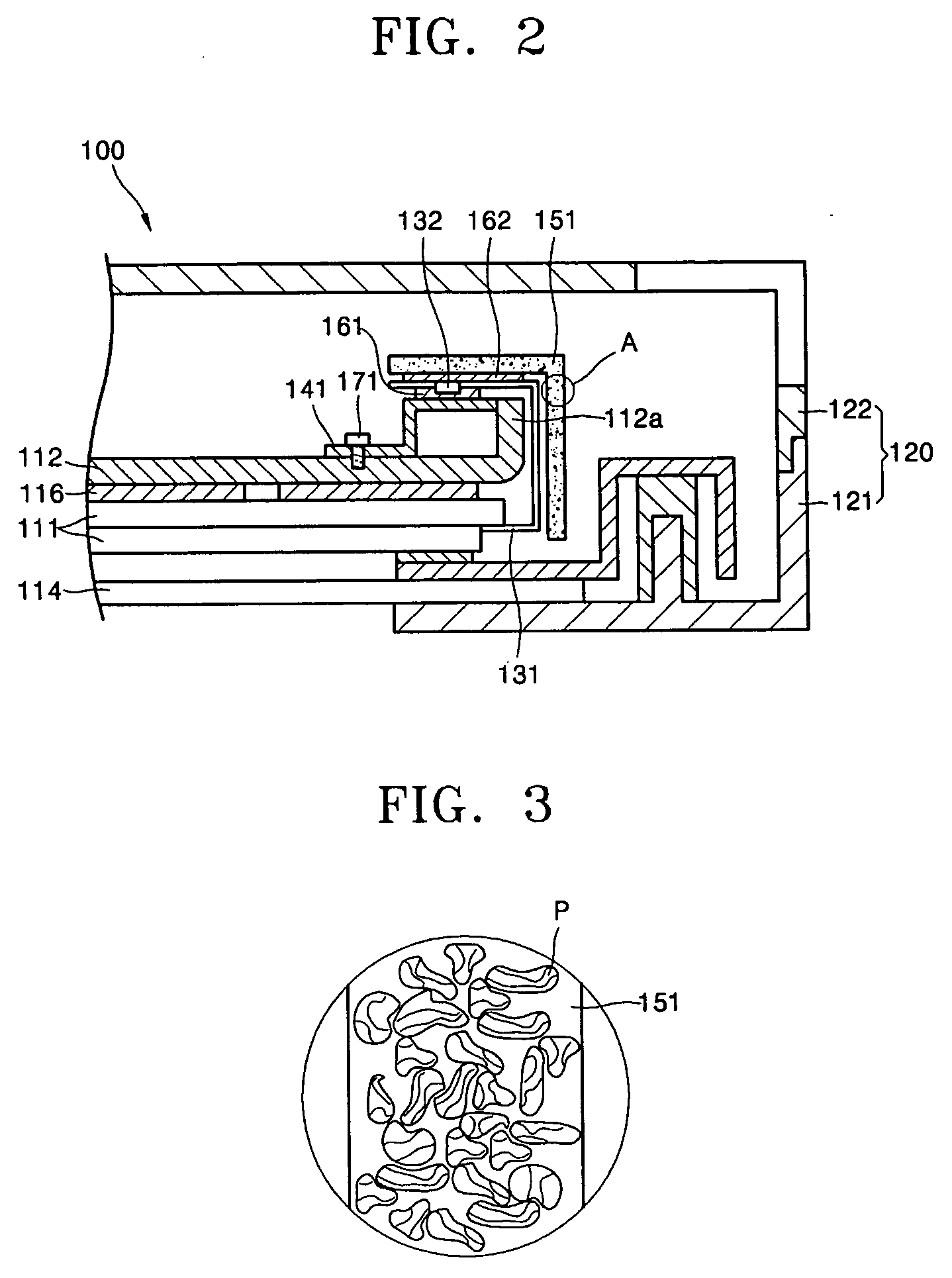

Flat display apparatus

InactiveUS20070002535A1Reduce weightReduce noiseGas discharge connecting/feedingCooling/ventilation/heating modificationsEngineeringSynthetic resin

A flat display apparatus includes a panel for displaying images, a conductive sheet attached to a back surface of the panel, a chassis base for supporting the panel, the chassis base being disposed at a back of the panel while spaced at a predetermined distance from the conductive sheet, and made from synthetic resin and a circuit portion for operating the panel, the circuit portion having a ground portion electrically connected to the conductive sheet. Accordingly, since the conductive sheet is attached to the back surface of the panel and is electrically connected to the ground portion of the circuit portion, the circuit portion can be securely grounded.

Owner:SAMSUNG SDI CO LTD

Plasma display device

InactiveUS20060187641A1Efficiently dissipatedStatic indicating devicesGas discharge connecting/feedingDisplay devicePrinted circuit board

A display device that efficiently dissipates high temperature heat generated from a driver IC of a driver IC package. The display device includes a display panel, a chassis base having the display panel on a first surface, the printed circuit board assembly mounted at a second surface of the chassis base the second surface being opposite to the first surface, and a driver IC package having a driver IC connected to an electrode of the display device and the printed circuit board assembly. Additionally, the display device may include a thermal conduction sheet inserted between the display device and the chassis base and having an extension portion formed at a position corresponding to the driver IC, and a thermal conduction member formed between the extension portion of the thermal conduction sheet and the chassis base.

Owner:SAMSUNG SDI CO LTD

Highly productive method of producing plasma display panel

InactiveUS6860780B2Inhibit deteriorationHigh light-emitting efficiency and color purityAddress electrodesSustain/scan electrodesPhosphorEngineering

A method for producing a plasma display panel that has a front substrate and a back substrate disposed to face each other. A pre-baking phosphor layer containing a phosphor and an organic binder is formed on at least one of surfaces of the front substrate and the back substrate that are to face each other. A sealing material that softens with heat is applied to the peripheral region of at least one of the surfaces of the front and back substrates that are to face each other. The front and back substrates are disposed to face each other in a stack. The front and back substrates are heated to burn out the organic binder while supplying a dry gas containing oxygen to an internal space that is formed between the front and back substrates.

Owner:PANASONIC CORP

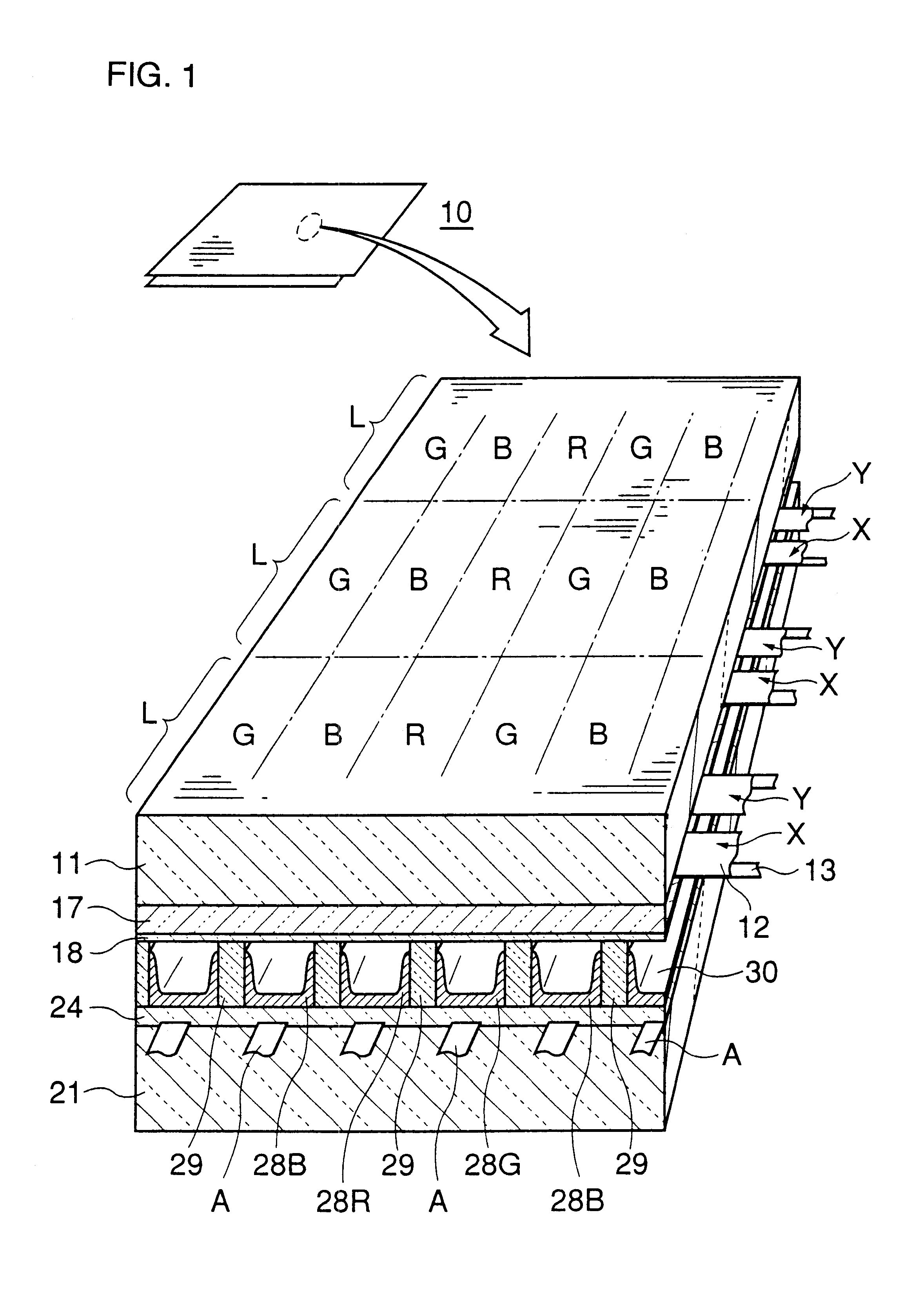

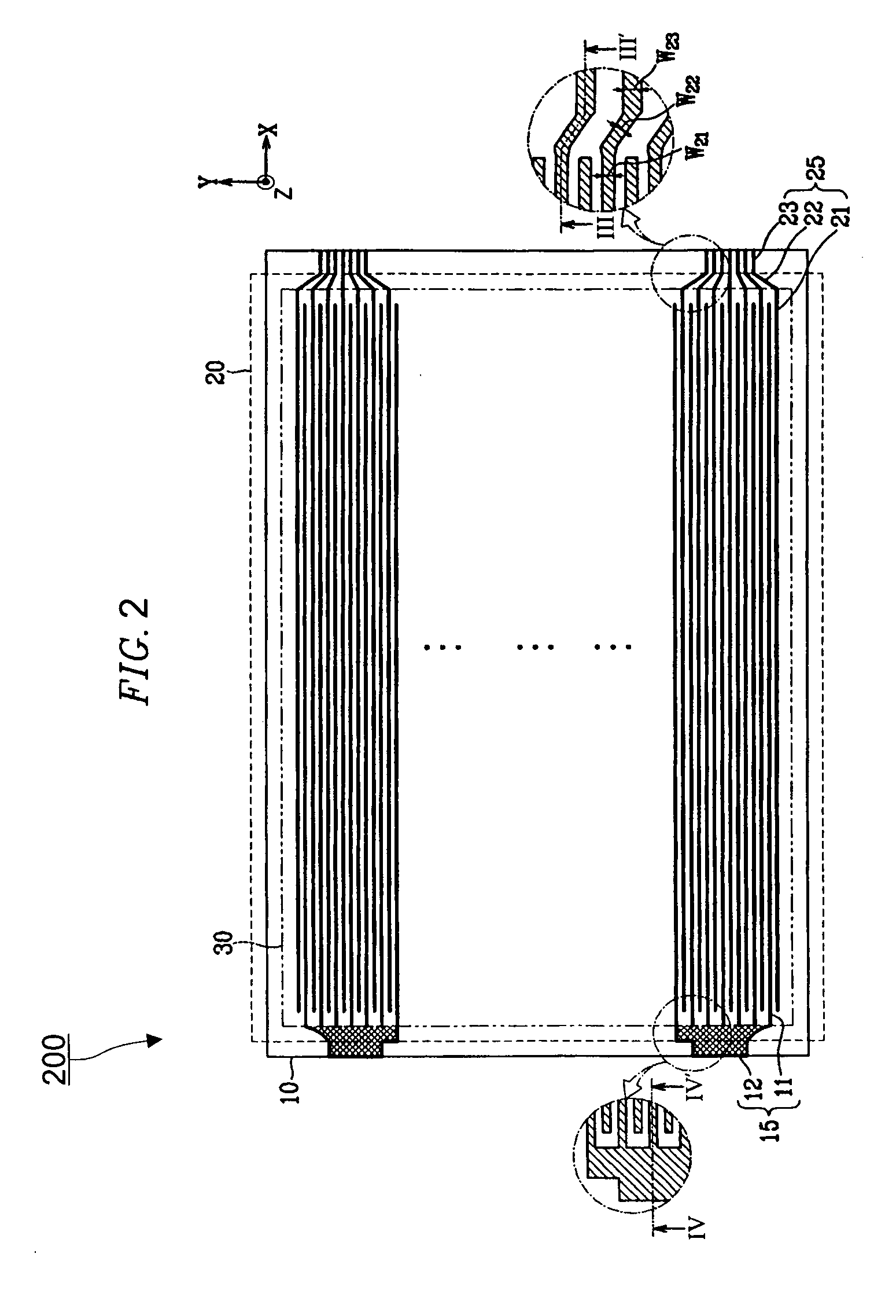

Plasma display panel

A plasma display panel includes a pair of substrates that are arranged opposite to each other, each having a display region to display an image and a non-display region not to display an image. Barrier ribs are located in a space between the substrates for forming a plurality of discharge cells. Phosphor layers are formed in the discharge cells. Address electrodes are formed on one of the substrates. First and second electrodes are formed on the other substrate so as to extend in a direction orthogonal to the address electrodes and are spaced apart from each other to form discharge gaps in the discharge cells. The first and second electrodes extend into the non-display region with different lengths from each other.

Owner:SAMSUNG SDI CO LTD

Plasma display module

InactiveUS7436654B2Added strength and rigidityGas discharge vessels/containersDigital data processing detailsPlastic materialsEngineering

A plasma display module having an improved grounding structure suitable for manufacturing a lightweight and slim plasma display module. The plasma display module includes: a chassis base formed of a plastic material; a plasma display panel disposed in front of the chassis base to display images; a plurality of circuit substrates disposed on a rear surface of the chassis base to drive the plasma display panel; a grounding member which is disposed corresponding to the circuit substrates so that the chassis base is disposed between the grounding member and the circuit substrates and is formed of a conductive material so that the grounding member can provide a ground voltage to the circuit substrates grounded to the grounding member; and a screw member that electrically connects the circuit substrates to the grounding member through the chassis base and fixes the circuit substrates to the chassis base.

Owner:SAMSUNG SDI CO LTD

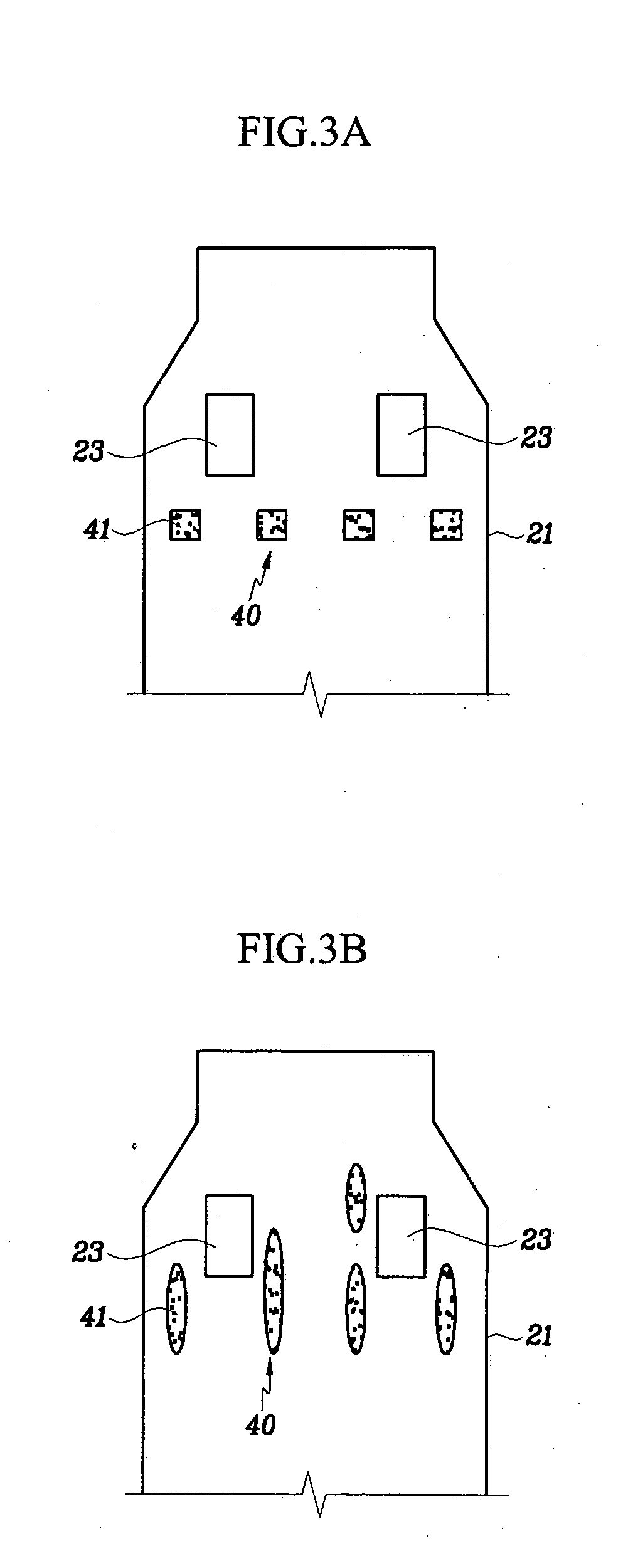

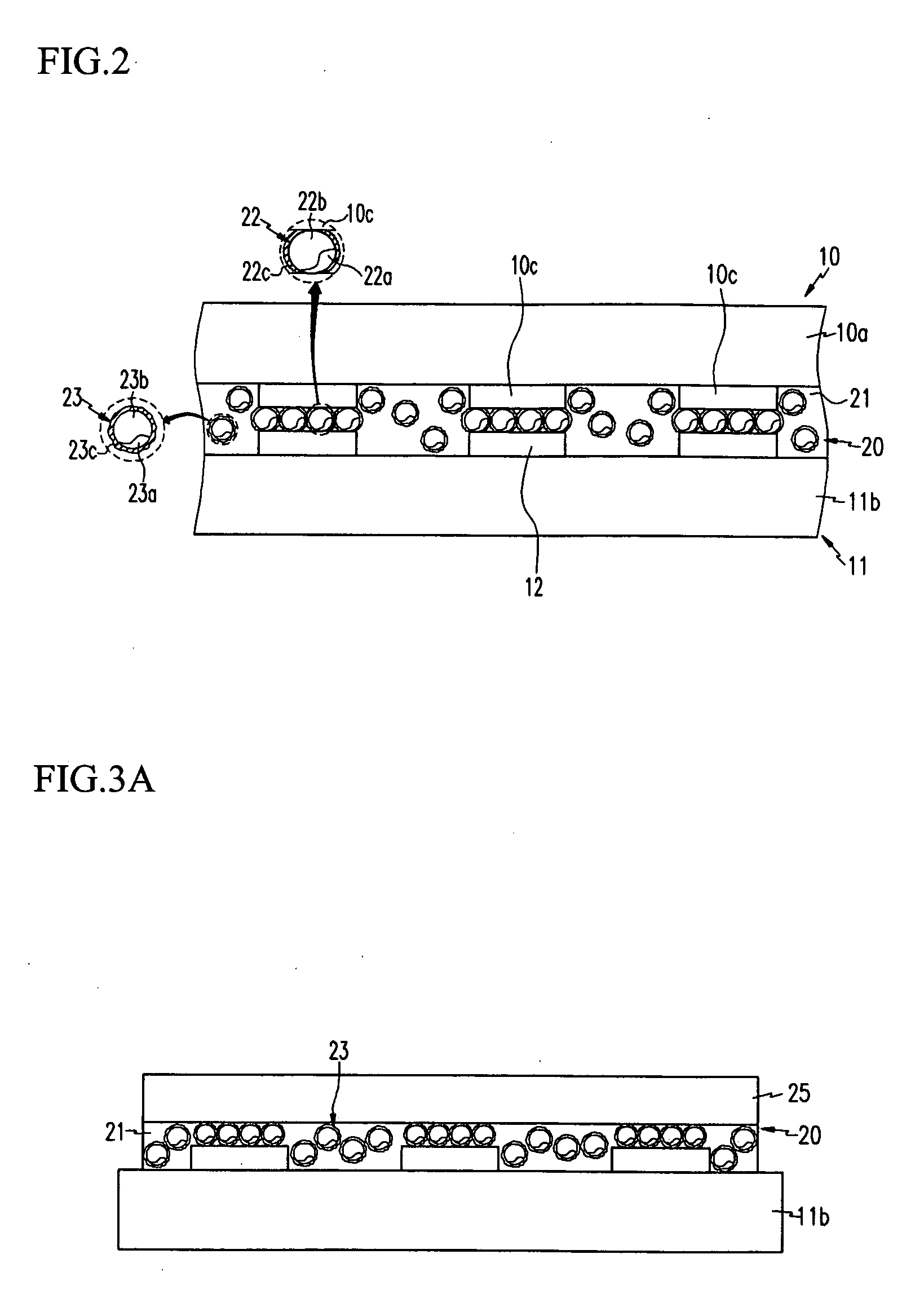

Interconnector, method for manufacturing a plasma display device using the same, and a plasma display device with the same

InactiveUS20050110406A1Strengthen interconnectionAlternating current plasma display panelsPrinted circuits structural associationsInterconnectorEngineering

A plasma display device may include a plasma display panel, a driving circuit portion for driving the plasma display panel, a connecter for electrically connecting electrodes of the plasma display panel with the driving circuit portion, and an interconnecter for electrically connecting the connecter with the plasma display panel. The interconnecter may include an adhesive layer, a plurality of conductive pellets, and a plurality of non-conductive pellets dispersed in the adhesive layer. The conductive pellets may be positioned substantially within a first region where the wiring of the connecter overlaps the electrodes of the plasma display panel. The non-conductive pellets may be positioned substantially at least at a second region other than the first region in the adhesive layer.

Owner:SAMSUNG SDI CO LTD

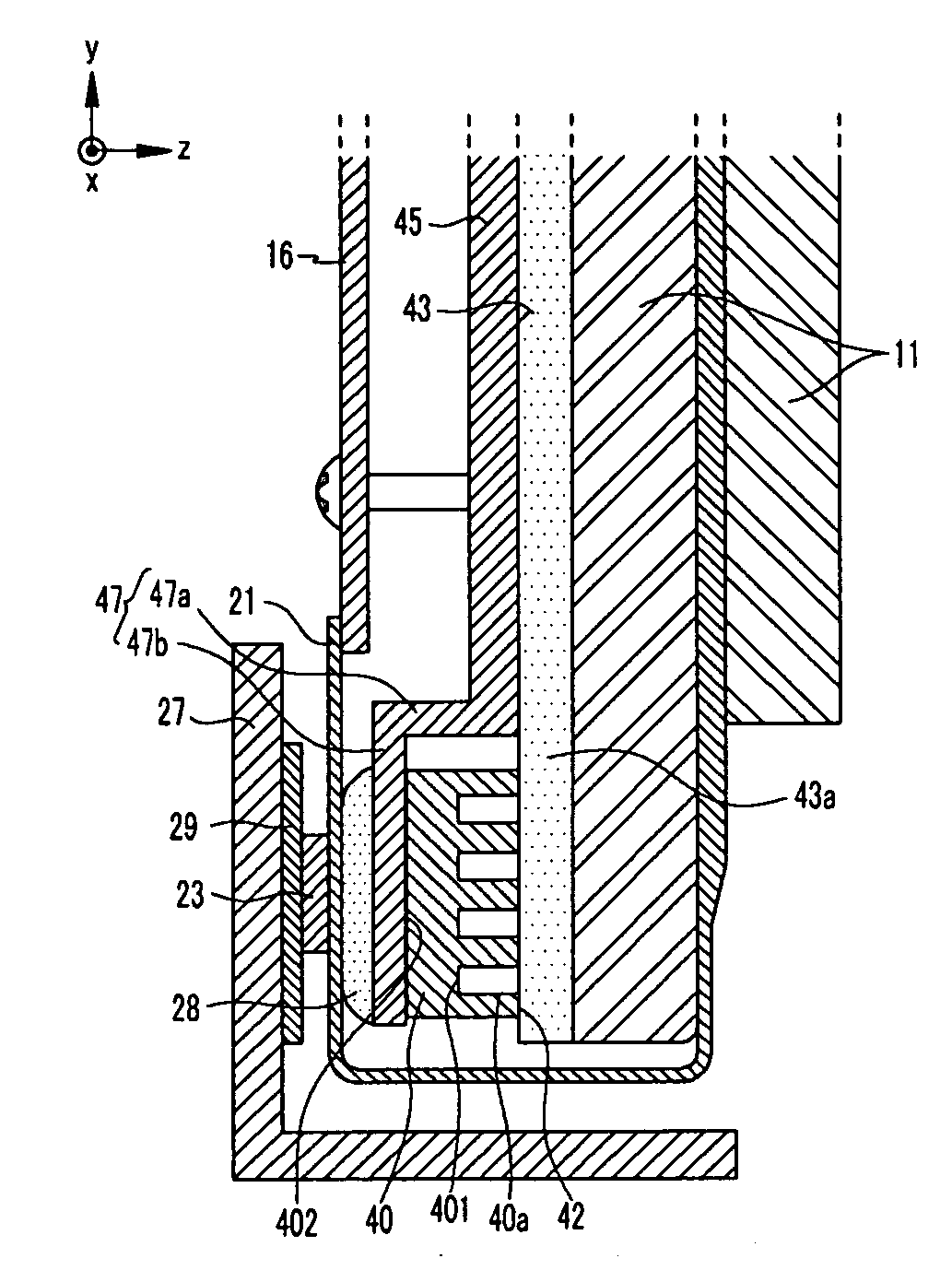

Plasma display device

InactiveCN101447147AShorten the lengthReduce manufacturing costMagnetic/electric field screeningPrinted circuit detailsManufacturing cost reductionElectricity

The invention provides a plasma display device. In one embodiment, the plasma display device includes a plasma display panel, a chassis base), a printed circuit board assembly, and a flexible printed circuit. The chassis base supports the plasma display panel. The printed circuit board assembly is disposed at one side of the chassis base. The flexible printed circuit electrically connects an electrode of the plasma display panel and the printed circuit board assembly. The flexible printed circuit crosses an extension plane of the printed circuit board assembly at a predetermined angle and is connected to the printed circuit board assembly. One embodiment of the invention lowers manufacturing costs and reduces EMI by shortening a length of a flexible printed circuit.

Owner:SAMSUNG SDI CO LTD

Plasma display panel assembly

InactiveUS20060098398A1Prevent short-circuitingDissipate quicklyDigital data processing detailsSemiconductor/solid-state device detailsEngineeringIntegrated circuit

A plasma display panel (PDP) assembly including a PDP, a chassis base supporting the PDP, a driving circuit unit, a tape carrier package electrically coupling the PDP with the driving circuit unit, and including a driving integrated circuit (IC), and a short circuit preventive unit arranged between the chassis base and the tape carrier package and preventing the tape carrier package from short-circuiting.

Owner:SAMSUNG SDI CO LTD

Low softening point glass composition, bonding material using same and electronic parts

ActiveUS8470723B2Reduce softeningAddress electrodesConductive layers on insulating-supportsBismuthAntimony

Owner:RESONAC CORP

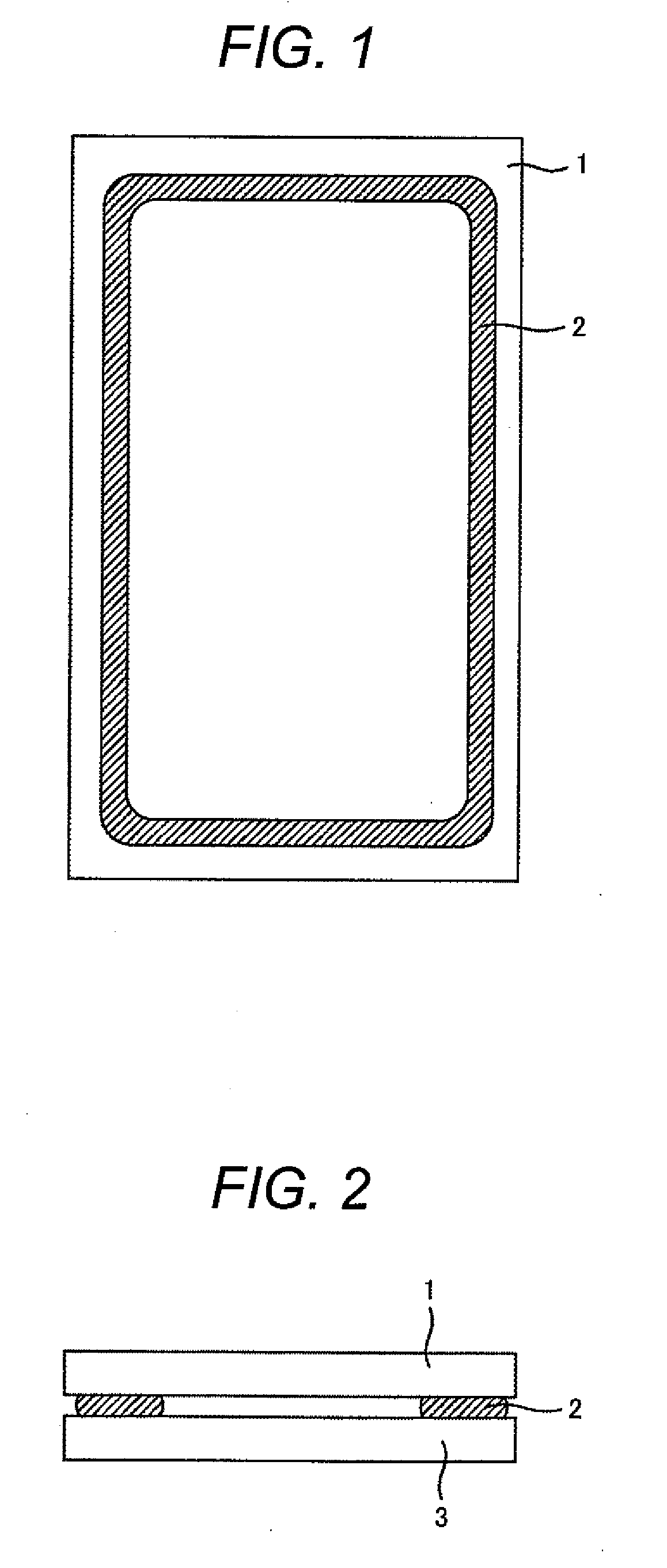

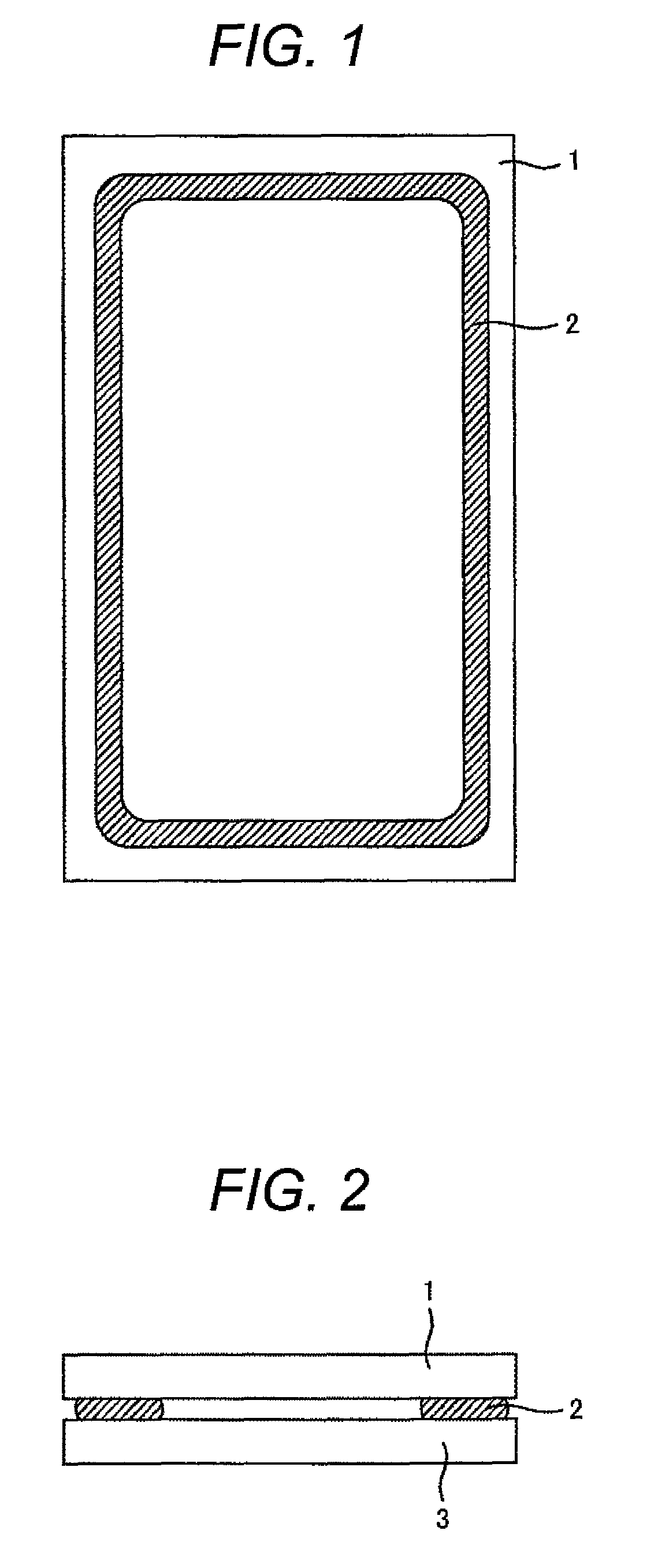

Manufacturing method of hermetic container and image display apparatus

InactiveUS20110265518A1Low viscosityReduce the differenceCathode-ray/electron-beam tube vessels/containersGas discharge vessels/containersViscosityElectrical and Electronics engineering

A manufacturing method of a hermetic container includes the steps of sandwiching a frame-like sealing material between a first glass substrate and a second glass substrate, irradiating first local heating light to a first region of the sealing material, and sealing the first glass substrate and the second glass substrate to each. The sealing is performed by irradiating, on a boundary between the first region of the sealing material and a second region of the sealing material which is adjacent to the first region and on which the first local heating light is not irradiated, second local heating light to heat and melt a portion of the second region adjacent to the boundary, during a period that viscosity of the sealing material at a portion of the first region adjacent to the boundary is equal to or lower than 1018 Pa·sec.

Owner:CANON KK

Thin display device and plasma display

InactiveUS20060197718A1Inhibition is effectiveSimple and inexpensive configurationStatic indicating devicesGas discharge vessels/containersDisplay deviceEngineering

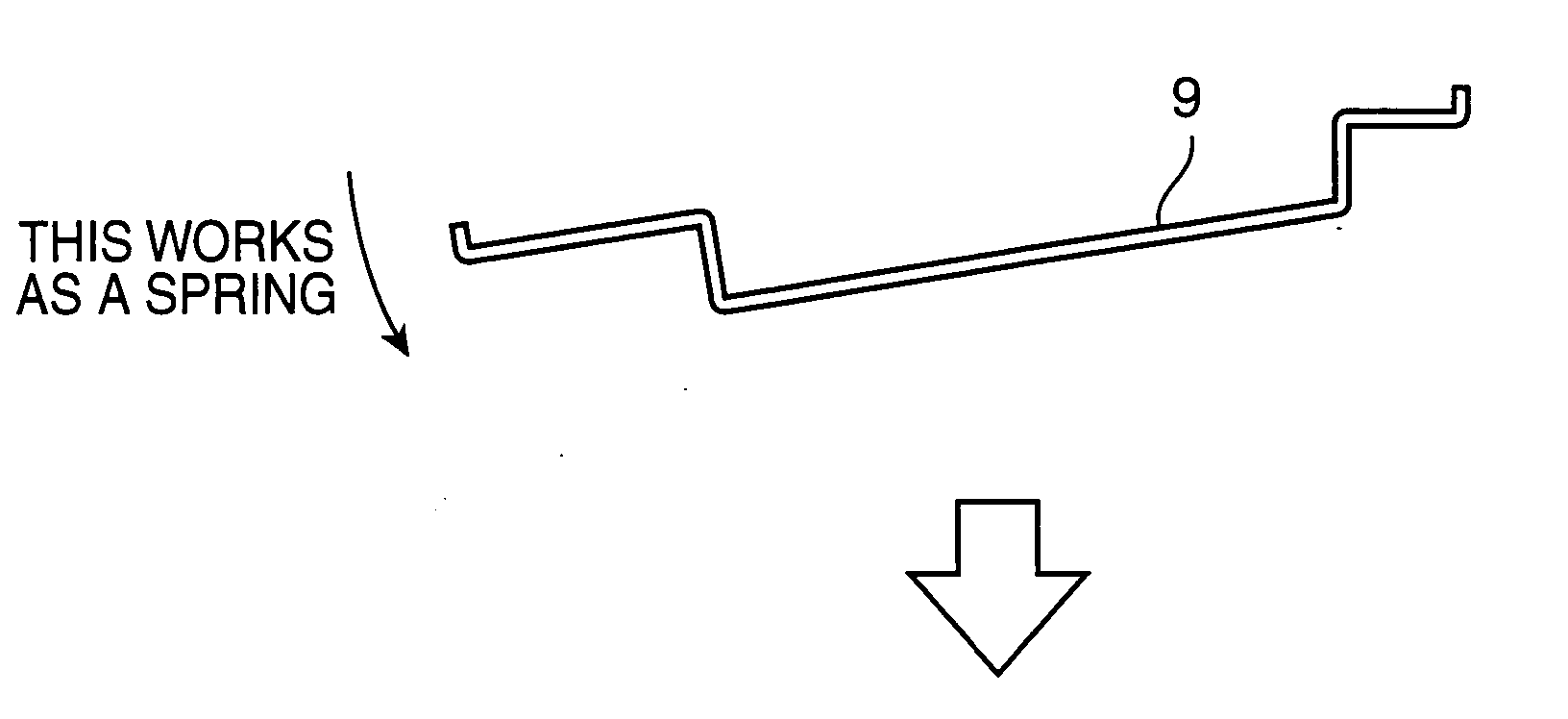

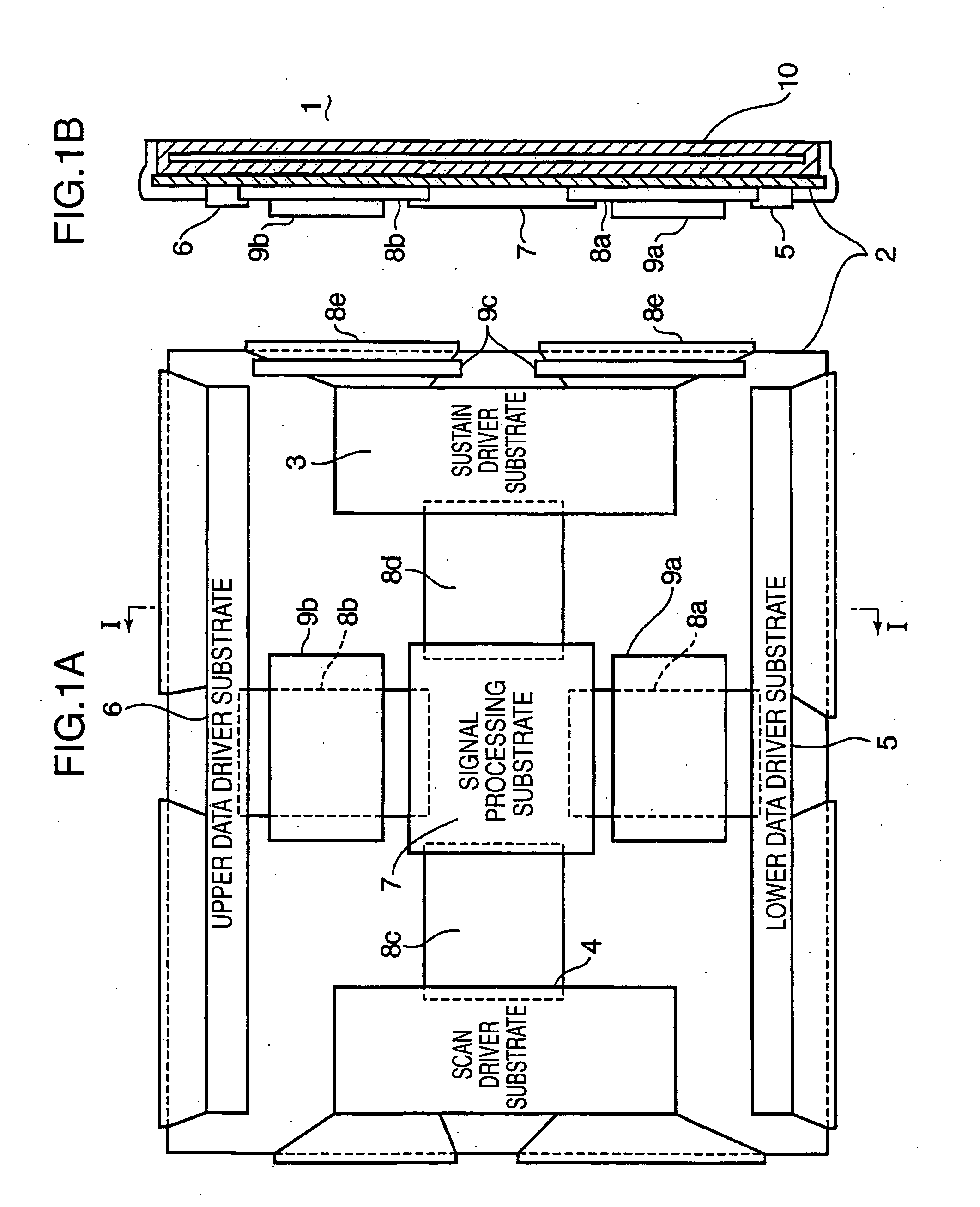

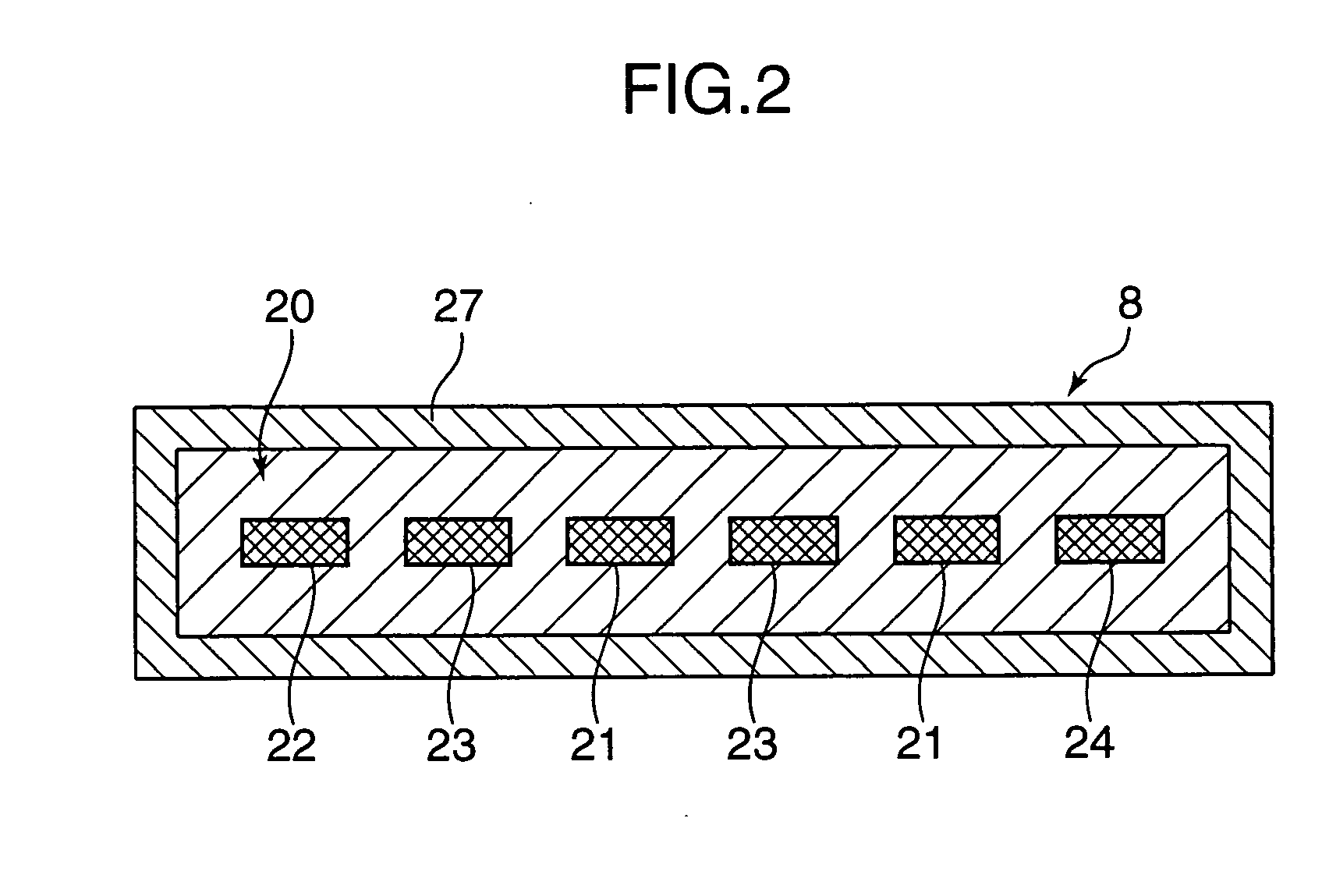

A flat-panel display unit is provided which includes: a PDP 10; an aluminum chassis 2 that is attached to the PDP 10; an upper data driver substrate 6 and a signal processing substrate 7 that are attached to the aluminum chassis 2; and a flexible cable 8 that connects the substrates 6, 7 electrically. Between the substrates 6, 7, a pressing plate 9 fixes at least one part of the flexible cable 8, so that the space between the flexible cable 8 and the aluminum chassis 2 remains unchanged. Thereby, a stray capacitor can be stably formed using the insulating material of the flexible cable 8, and a high-frequency noise can be effectively reduced.

Owner:PANASONIC CORP

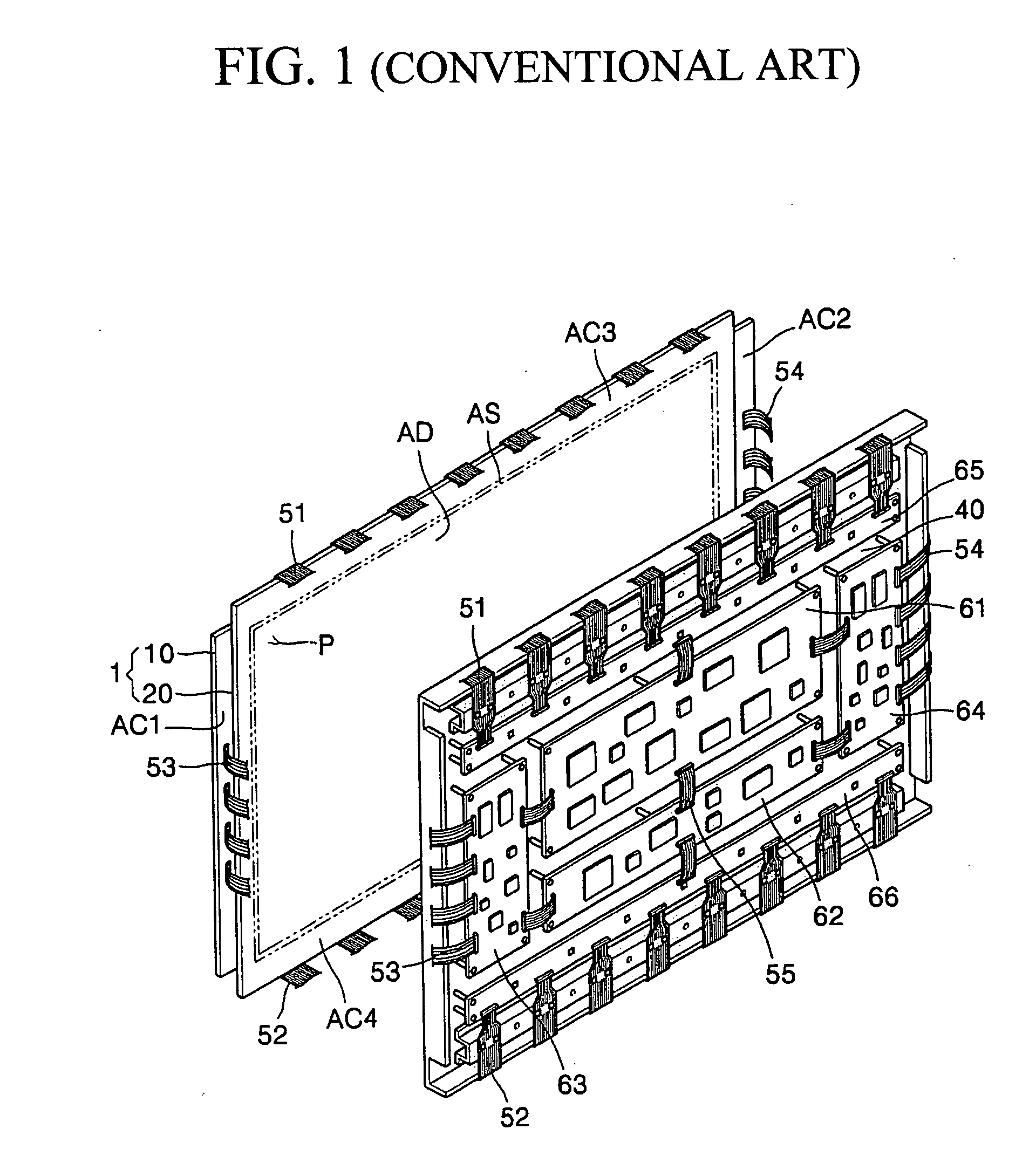

Plasma display panel (PDP) assembly

InactiveUS20060132946A1High strengthStable electrical groundingMagnetic/electric field screeningGas discharge connecting/feedingElectricityEngineering

A Plasma Display Panel (PDP) assembly includes: a panel assembly including a front panel and a rear panel disposed to face the front panel; a chassis base adapted to support the panel assembly; driving circuit units adapted to be attached to the chassis base; flexible printed cables adapted to have both ends electrically connected to terminals of electrodes of the panel assembly and connectors of the driving circuit units, to transmit an electrical signal; a filter assembly adapted to be attached to an exterior surface of the filter assembly; protection units adapted to be attached to the filter assembly, to ground the filter assembly, and to dissipate heat generated during an operation of the panel assembly; and a case adapted to accommodate the panel assembly, the chassis base, the driving circuit units, the flexible printed cables, the filter assembly, and the protection unit.

Owner:SAMSUNG SDI CO LTD

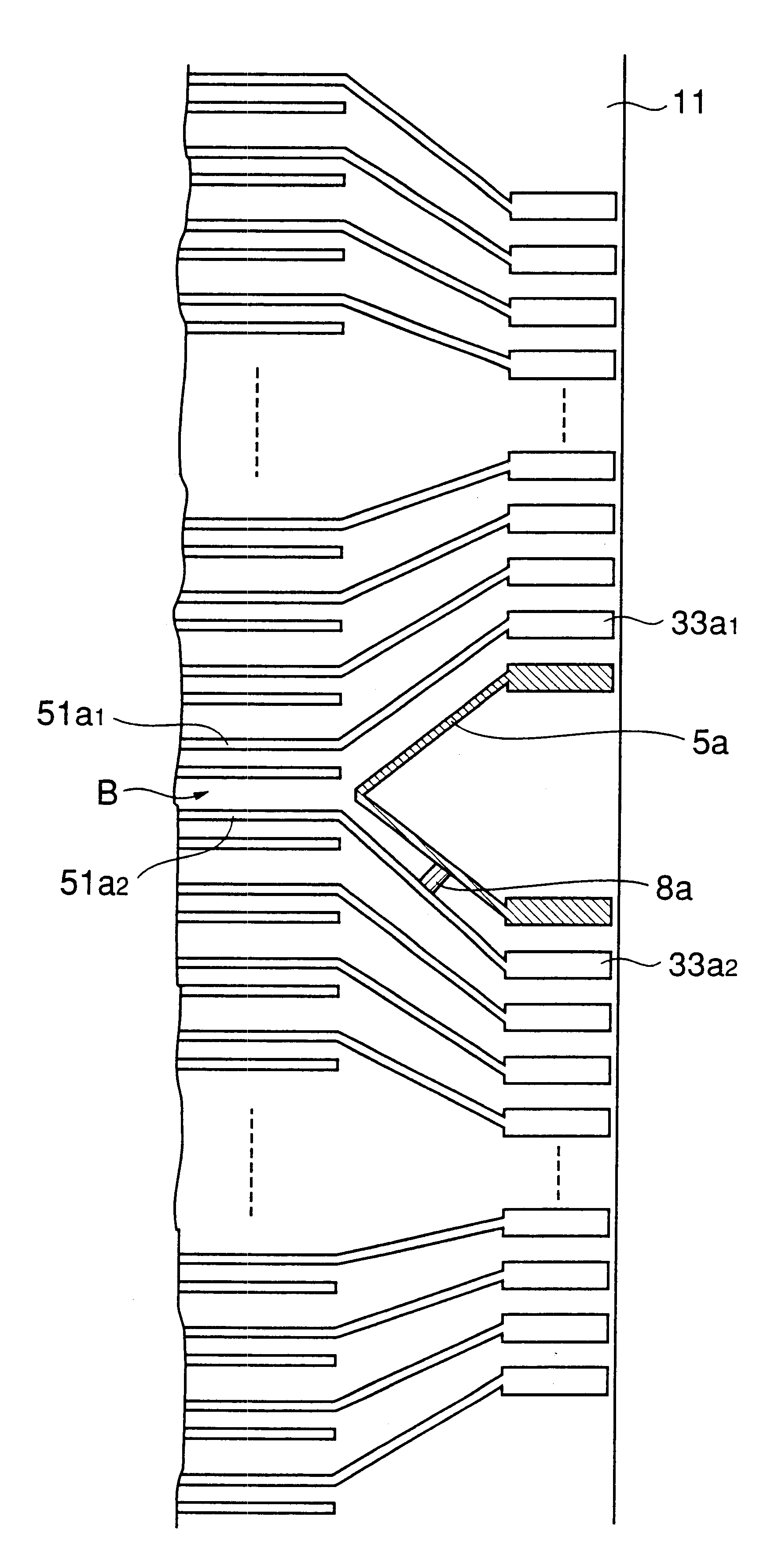

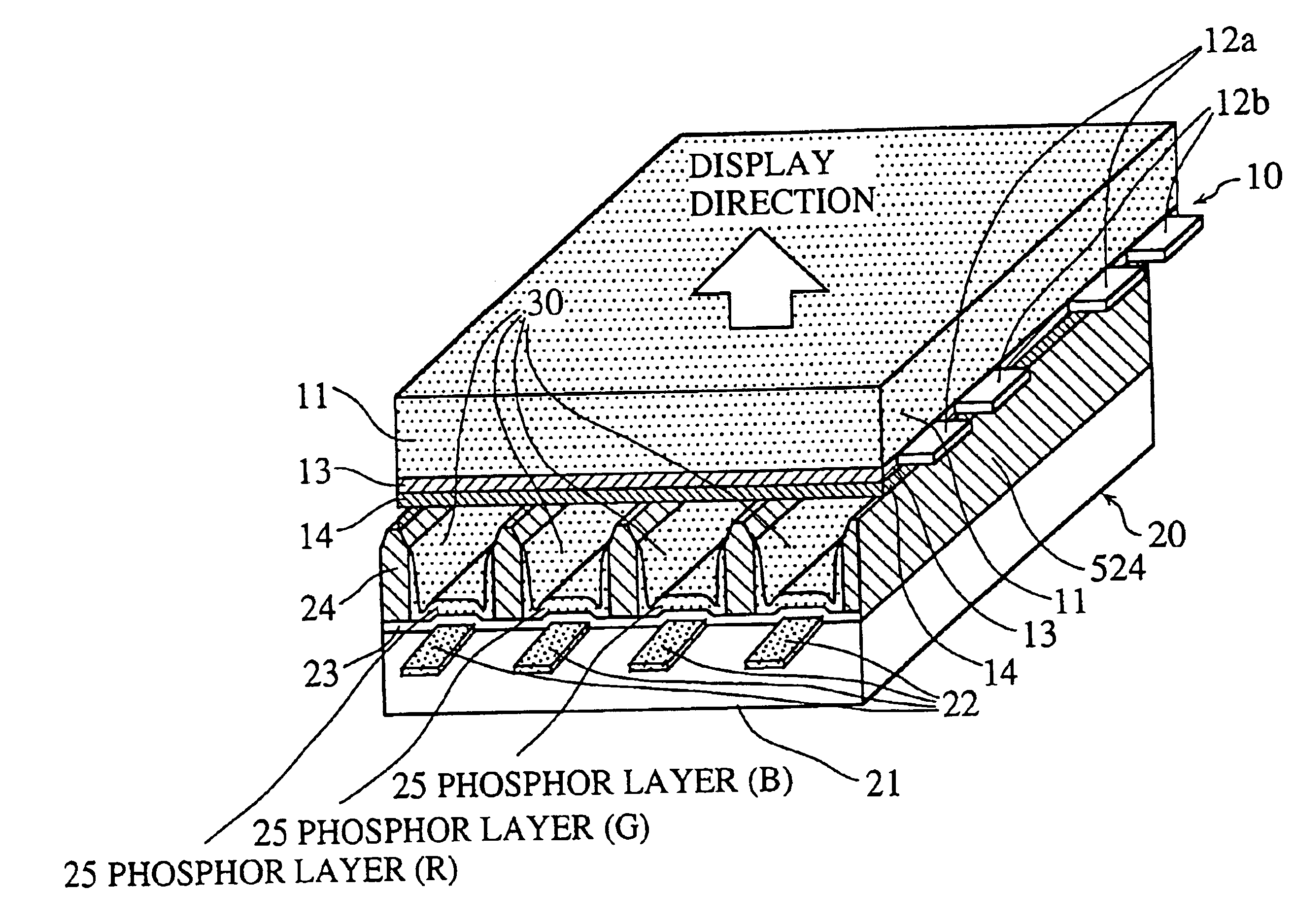

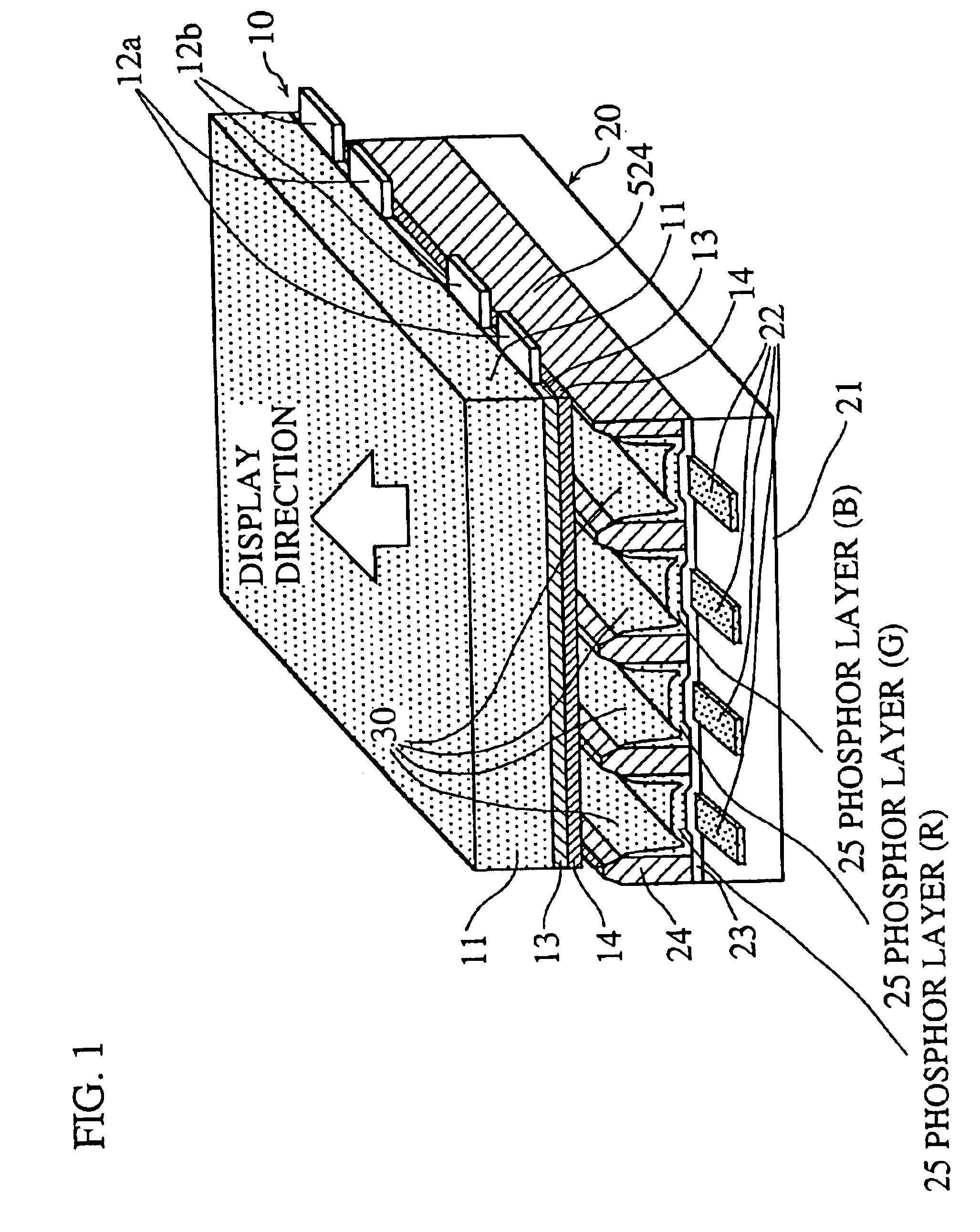

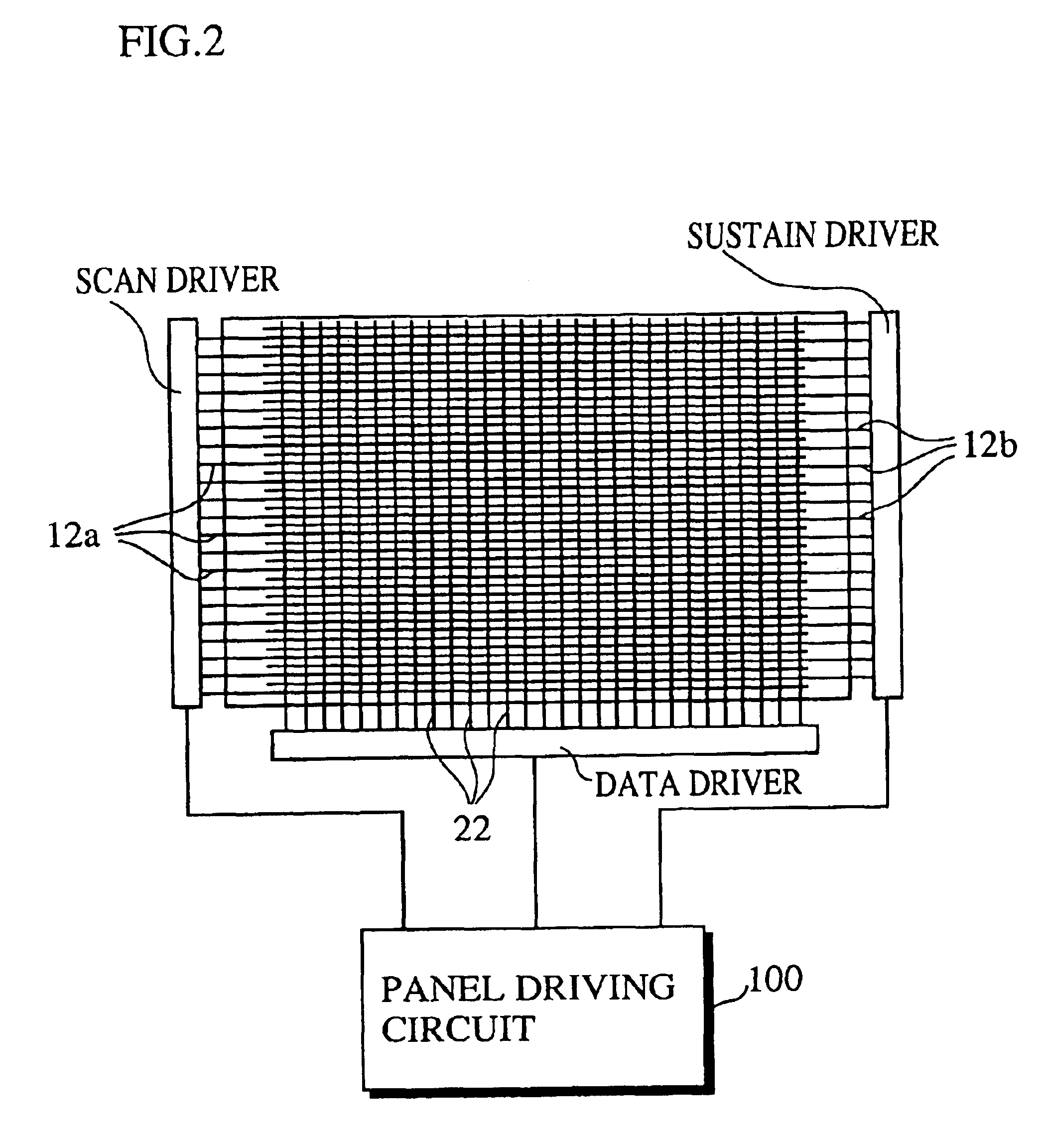

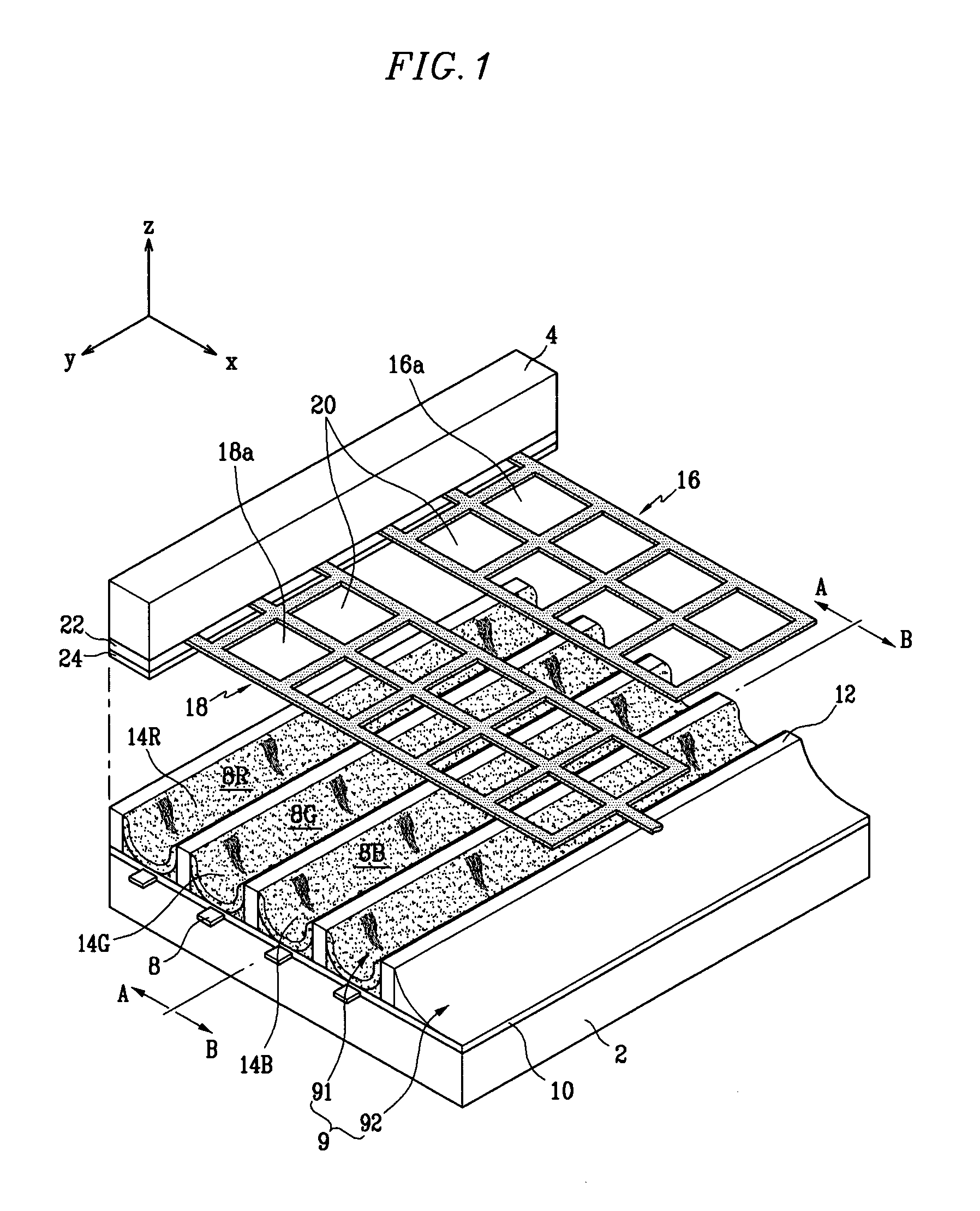

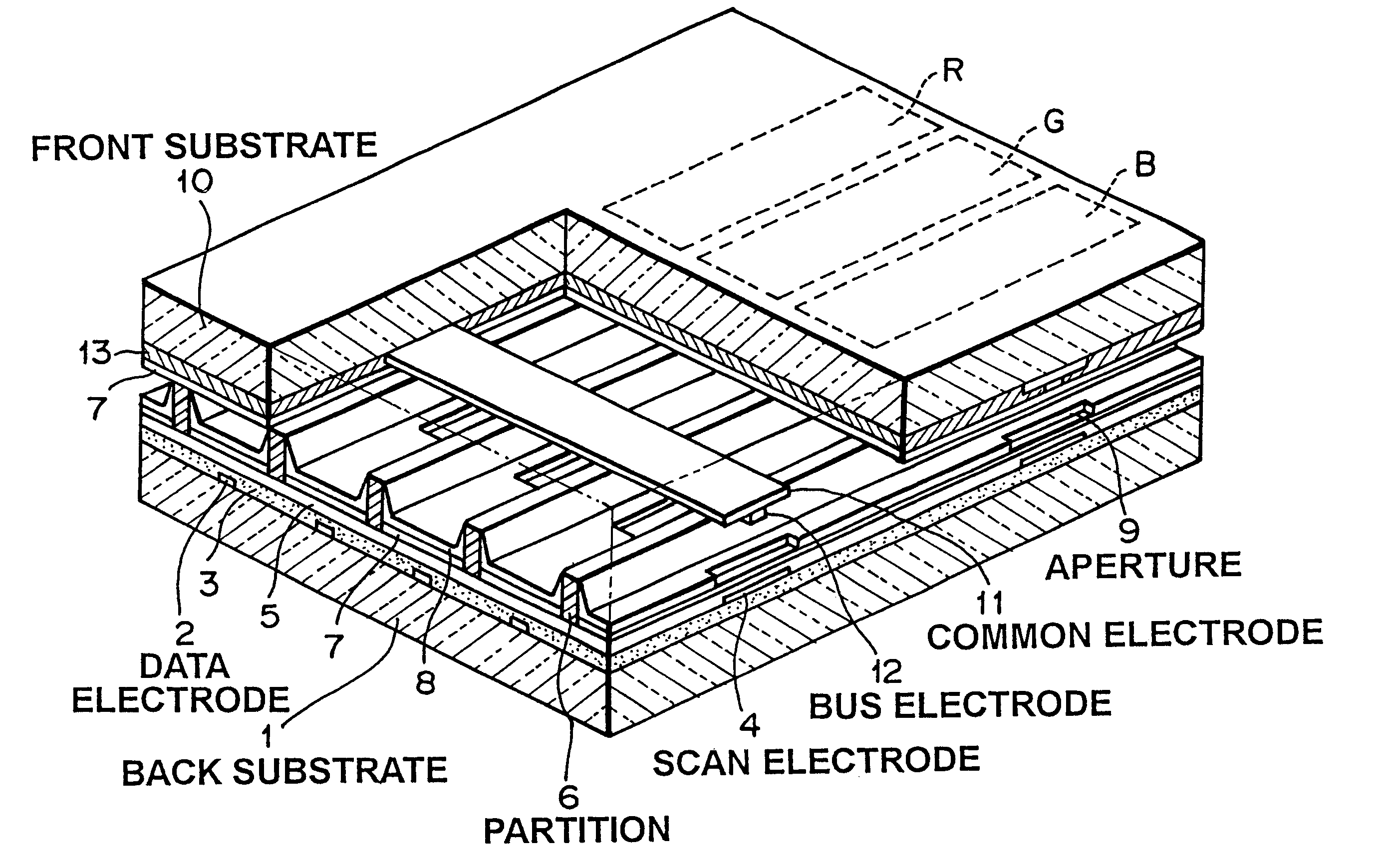

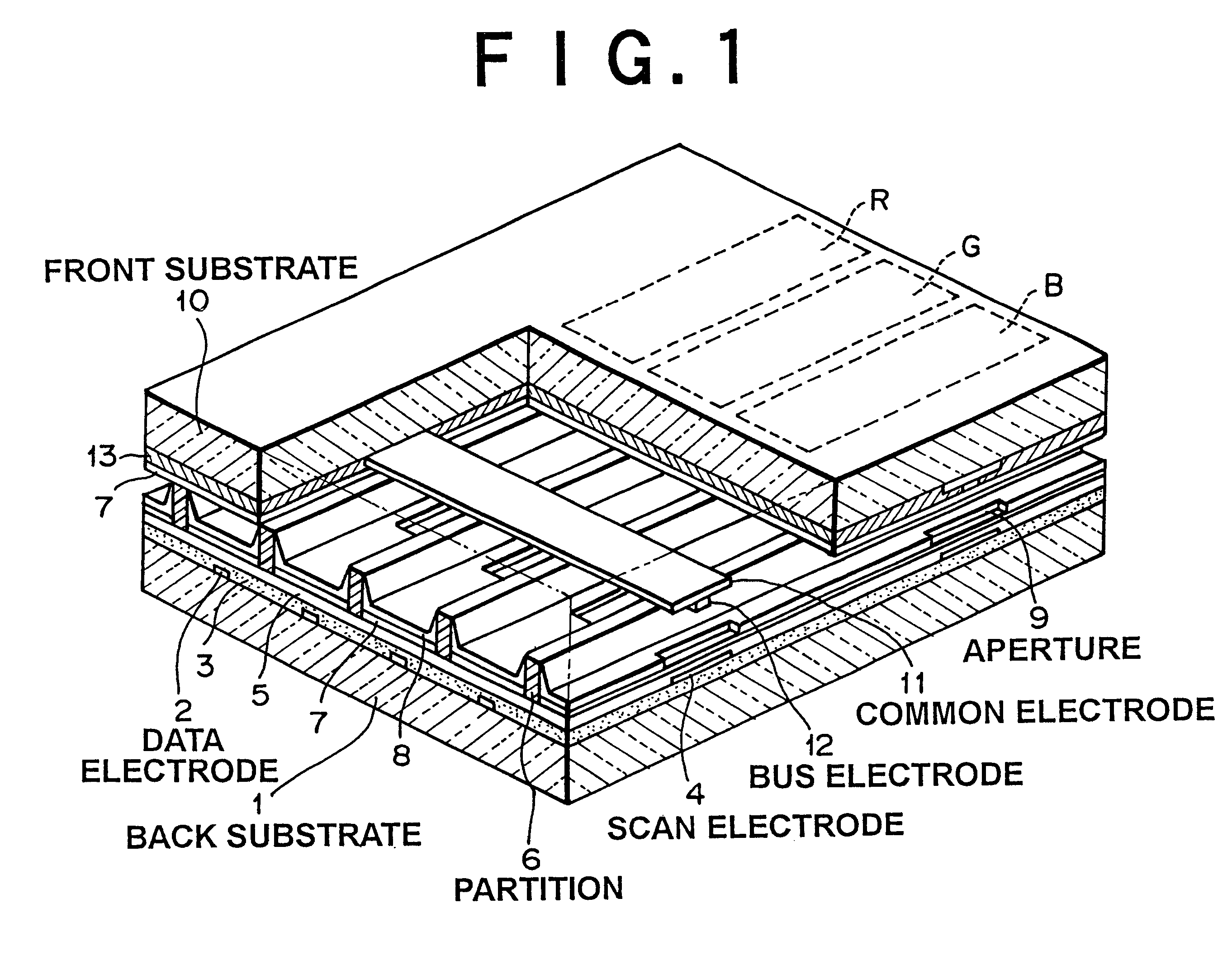

Apparatus, manufacturing method and driving method of plasma display panel

To provide a plasma display panel which improves the write characteristics, luminous luminance, and luminous efficiency and which has a longer life. On a back glass substrate, data electrodes are formed in the substrate column direction. Over the data electrodes, a dielectric layer is formed. On the dielectric layer, scan electrodes are formed in a substrate row direction. Over the scan electrodes, a dielectric layer is formed. On the dielectric layer, partitions are formed in the substrate column direction. On the dielectric layer including the partitions, a protection layer and a fluorescent material layer are formed. On the other hand, on a front glass substrate, common electrodes and bus electrodes electrically connected to the common electrodes are formed in the substrate row direction so as to be opposed to the scan electrodes. Over the common electrodes and the bus electrodes, a dielectric layer and a protection layer are formed.

Owner:PIONEER CORP

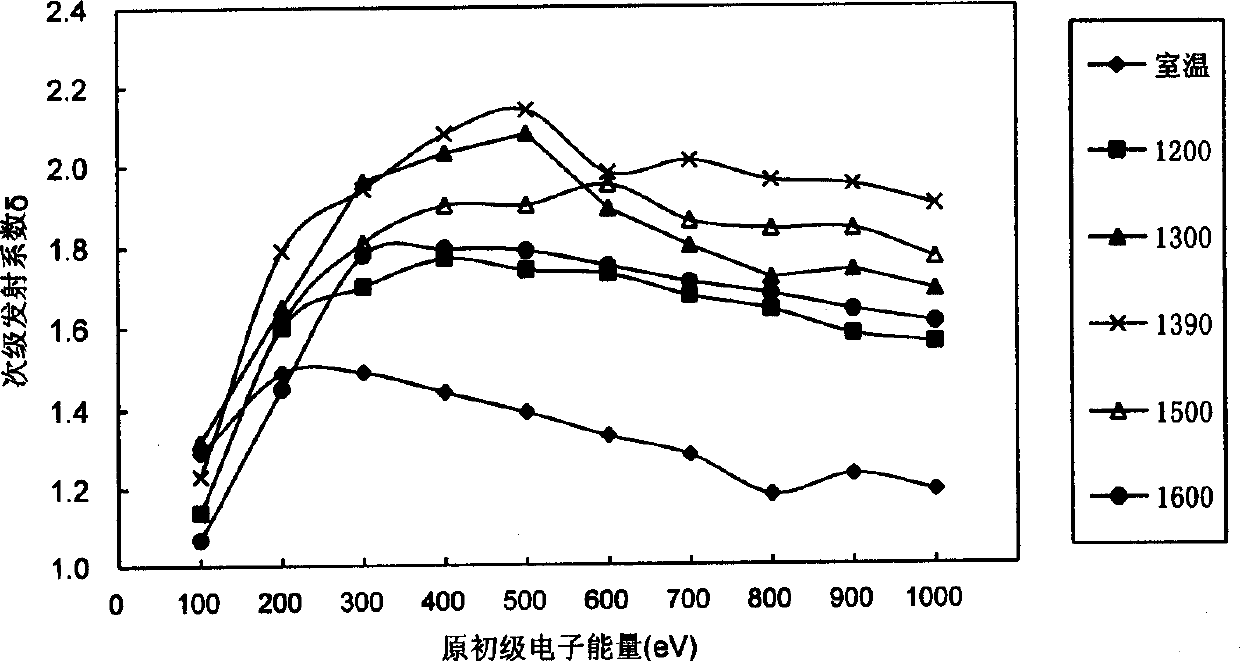

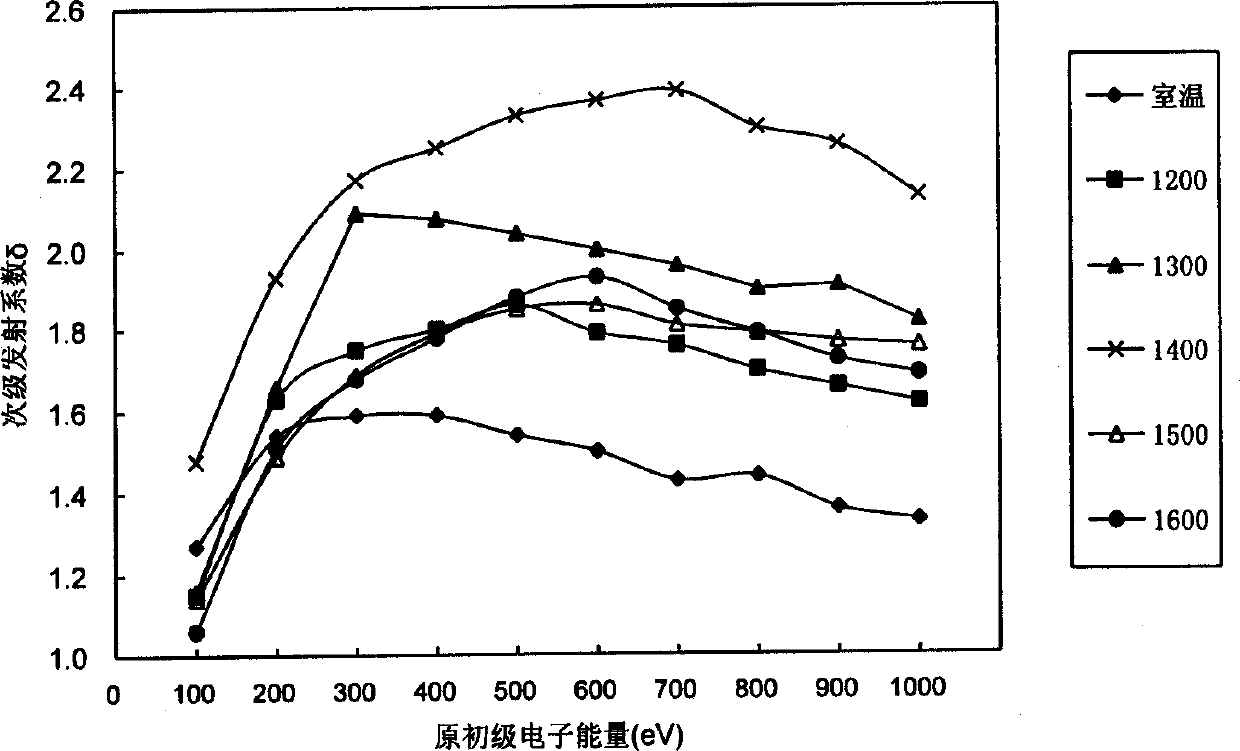

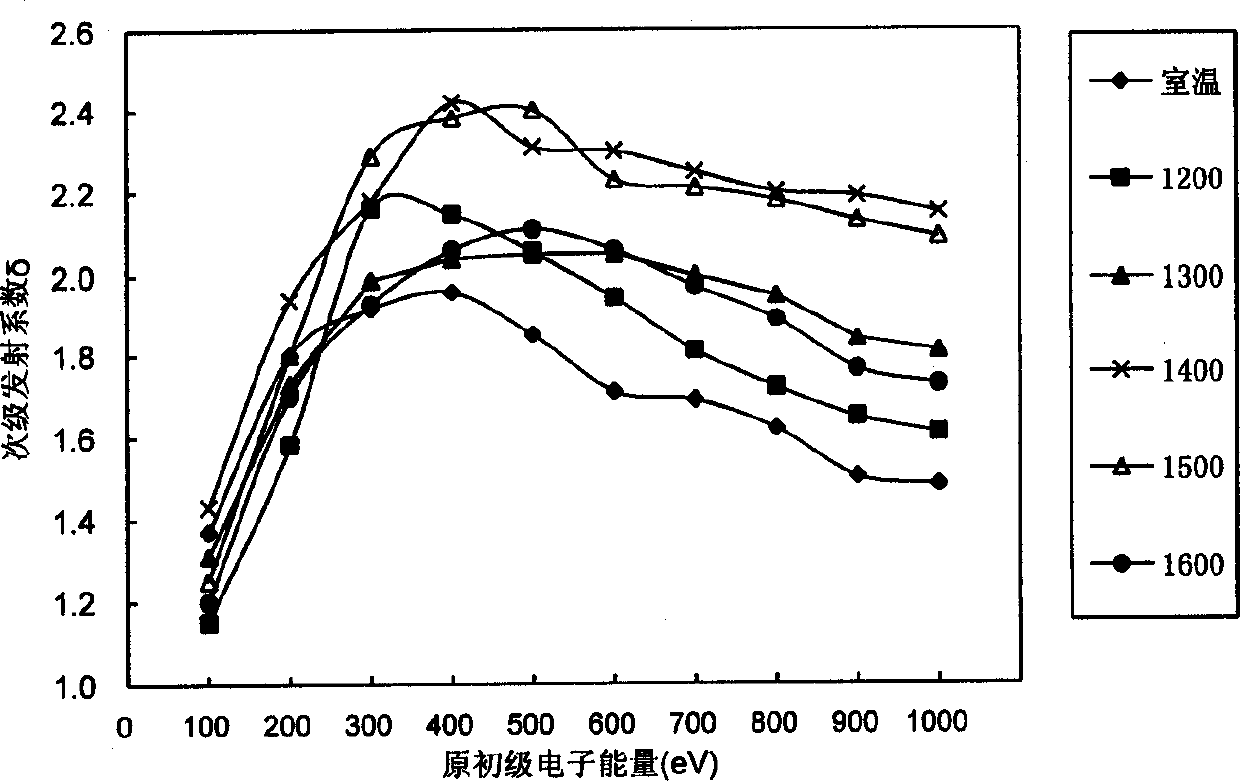

Secondary-emission rare earth-molybdenum material and its preparing process

InactiveCN1360079AImprove machinabilityThe secondary emission coefficient is constantMagnetronsGas discharge connecting/feedingHigh resistanceSecondary emission

A two-element rare-earth / molybdenum material as secondary emission material is characterized by that it contains La2O3 and Y2O3 in a weight ratio of 1:3, and is preapred through adding La2O3 and Y2O3in the form of aqueous solution of their nitrates to molybdenum oxide or Mo powder, treating in hydrogen at 500-550 deg.C for 1-5 hr, reducing at 800-1000 deg.C, and powder metallurgy to obtain said secondary emission material, which has advantages of high emission coefficient, stability and mechinability and high resistance to expose in atomosphere.

Owner:BEIJING UNIV OF TECH

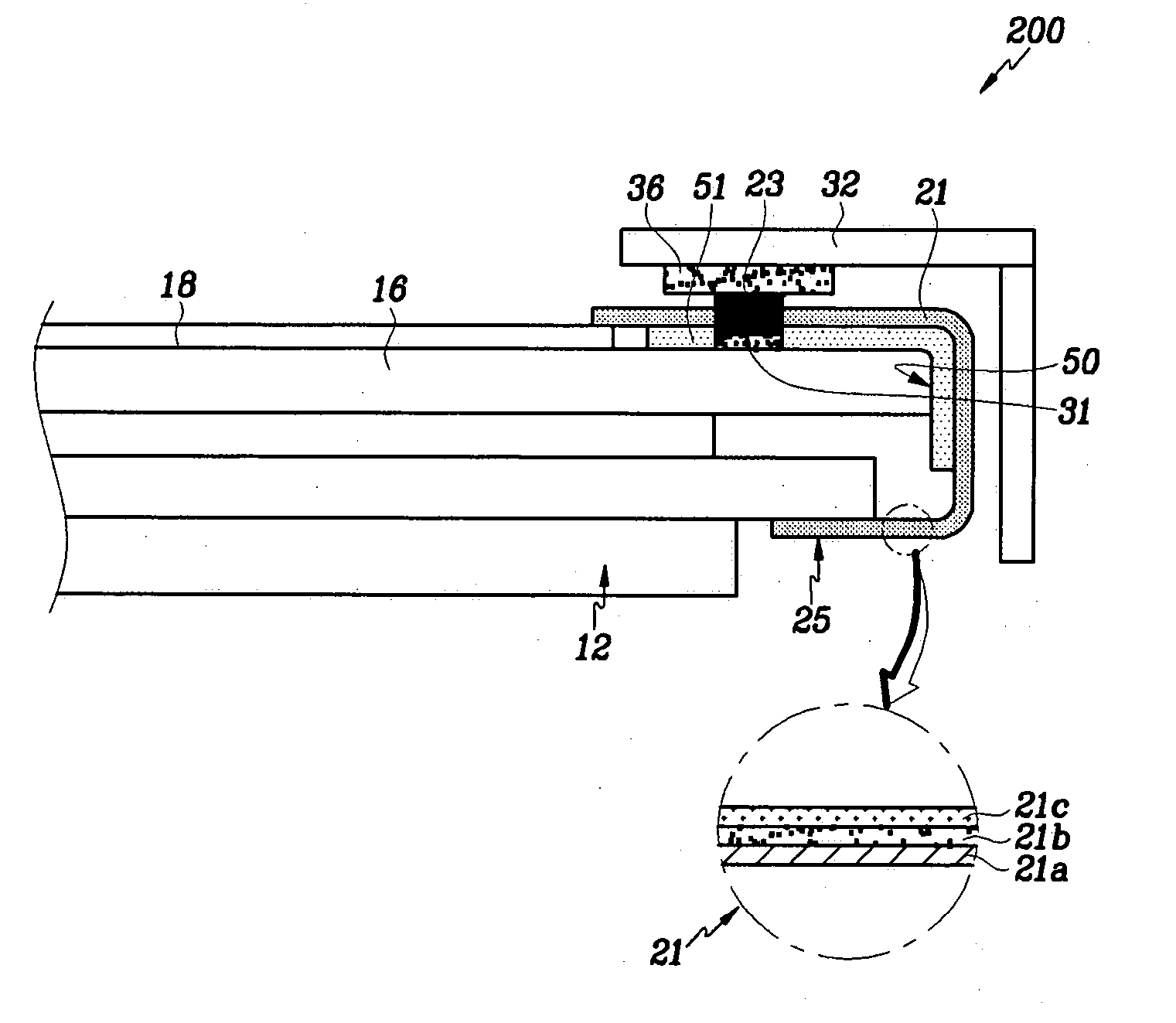

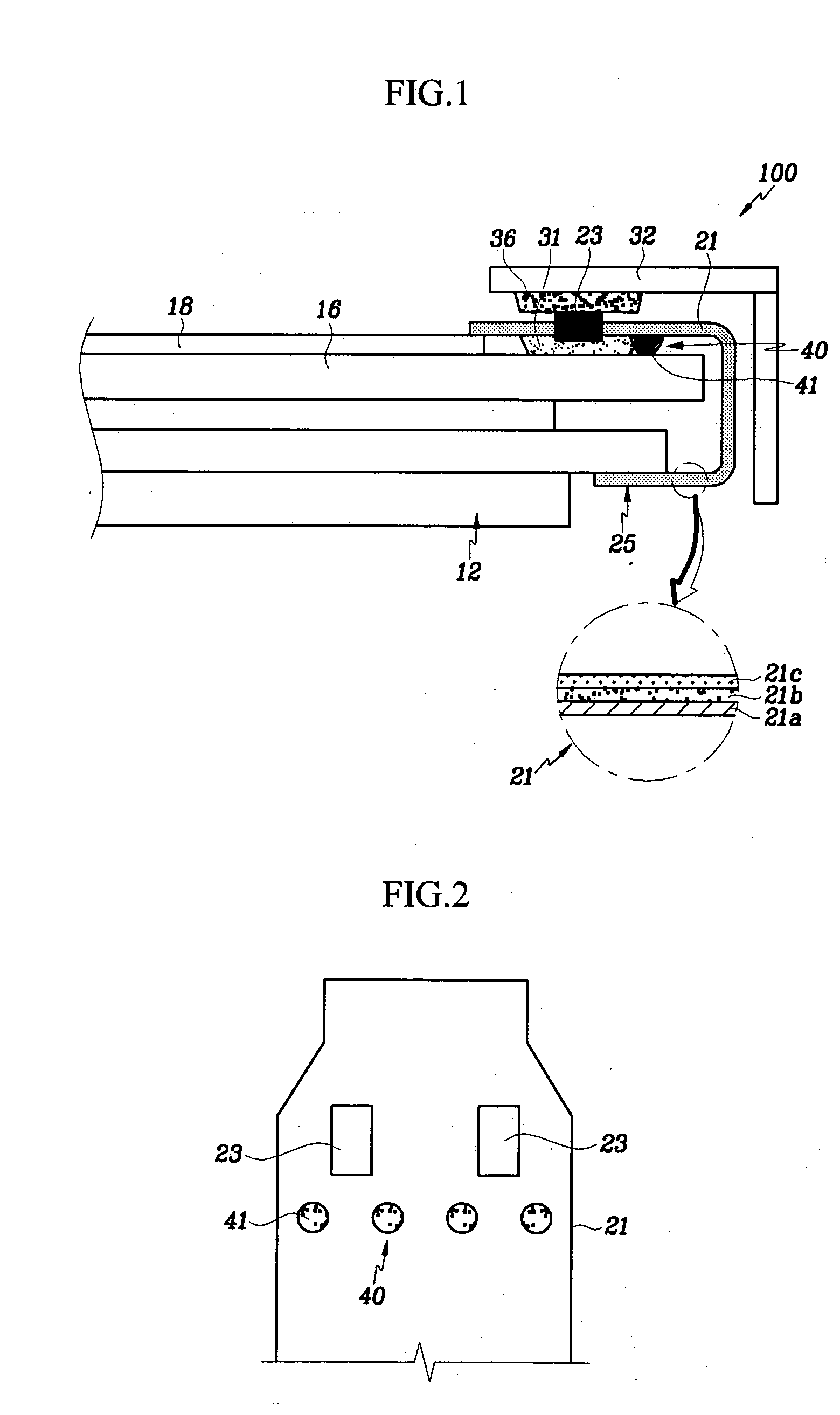

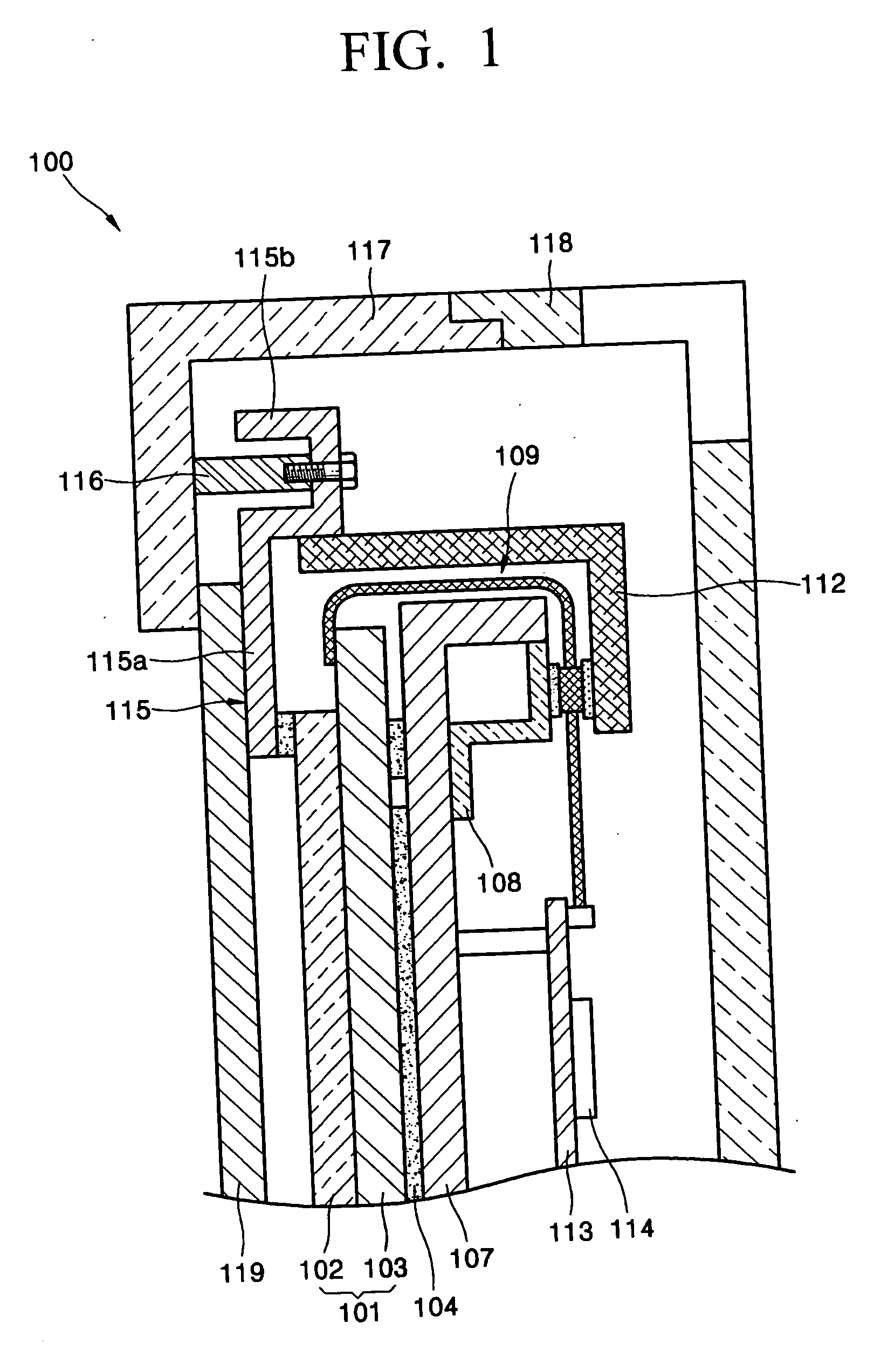

Plasma display apparatus

InactiveUS20080298003A1Emission reductionStatic indicating devicesMagnetic/electric field screeningEngineeringFlange

A plasma display apparatus includes a front case coupled to a rear case, the front and rear cases facing each other, a plasma display panel between the front and rear cases, and a chassis attached to the front case, the chassis being between the plasma display panel and the rear case, and the chassis including, a base unit parallel to the plasma display panel, at least one flange unit on the front case, the flange being parallel to the base unit and spaced apart from the base unit, and at least one shielding unit connecting the base unit with the flange unit, the shielding unit covering sides of the plasma display panel.

Owner:SAMSUNG SDI CO LTD

Plasma display apparatus

InactiveUS20050099106A1Prevent heat transferEfficiently dissipatedTelevision system detailsMagnetic/electric field screeningPlasma displayElectrical and Electronics engineering

A plasma display apparatus includes: a panel on which images are displayed; a circuit board for driving the panel; a chassis base for supporting the panel and the circuit board; a case for accommodating the panel, the circuit board and the chassis base; a signal transfer unit, on which at least one device is mounted, for transmitting electrical signals between the panel and the circuit board by connecting the panel to the circuit board; and a porous protection plate having a plurality of pores, and disposed on an outer surface of the signal transfer unit. In accordance with a further feature of the invention, the case includes a front cabinet disposed in front of the panel, and a porous back cover having a plurality of pores, said porous back cover being disposed on a rear surface of the circuit board and being coupled to the front cabinet.

Owner:SAMSUNG SDI CO LTD

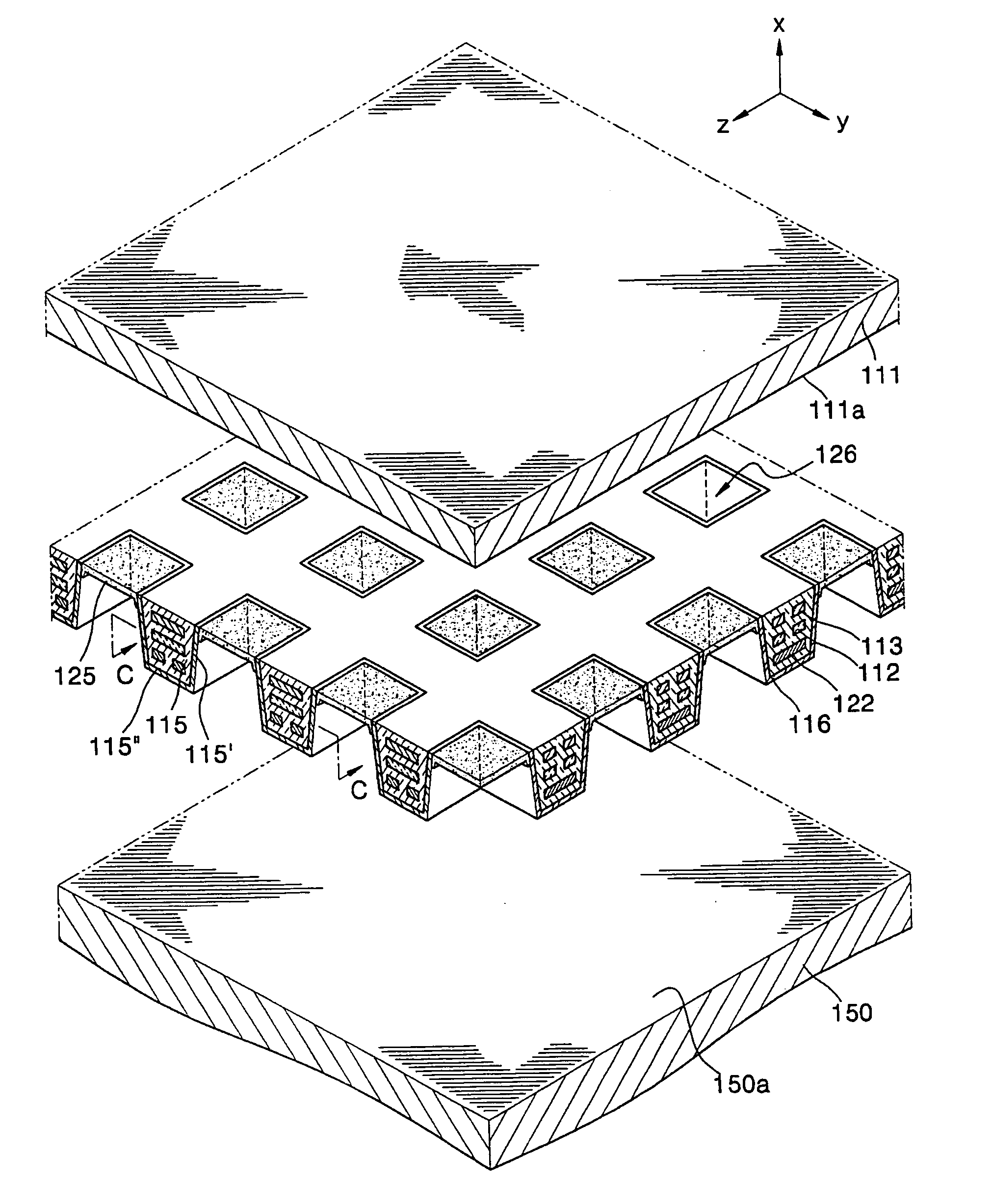

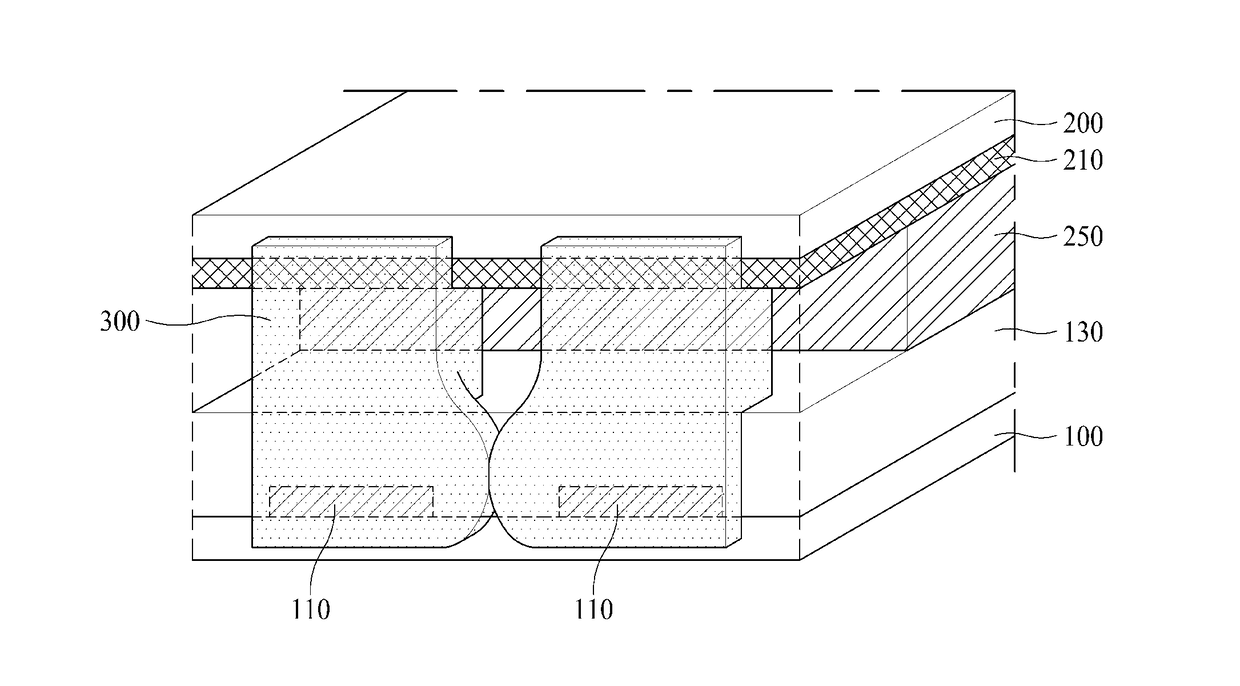

Plasma display module and method of manufacturing the same

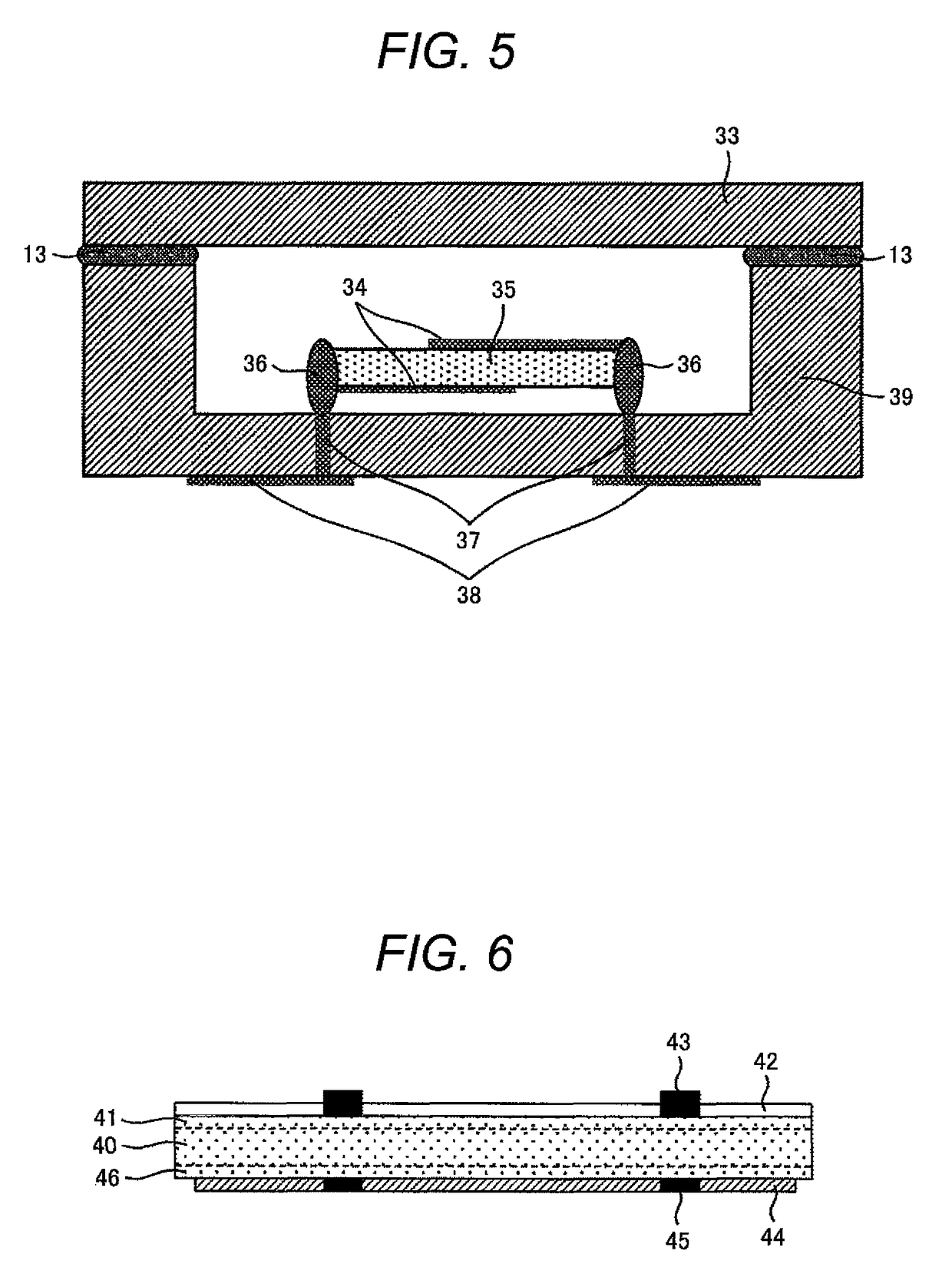

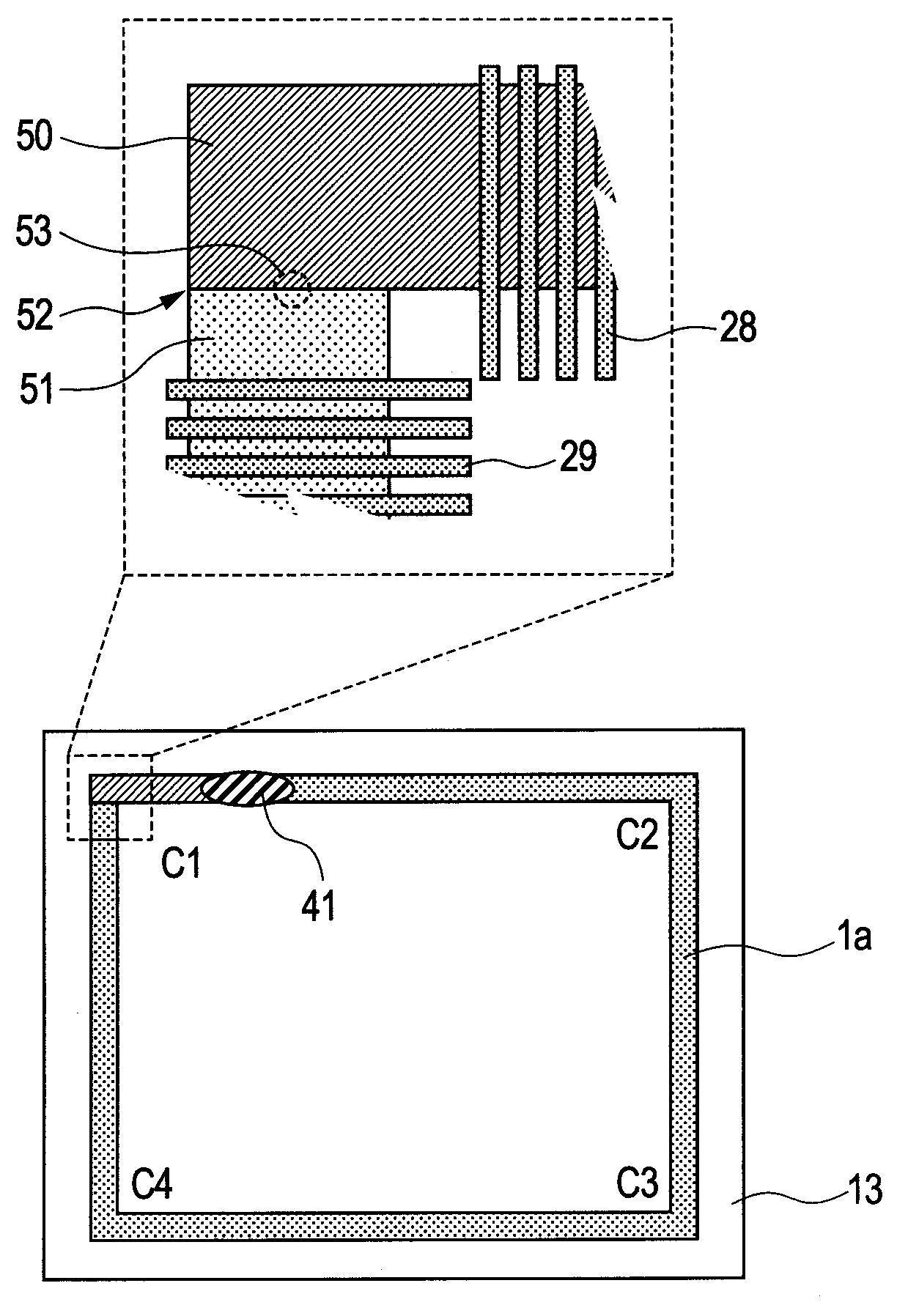

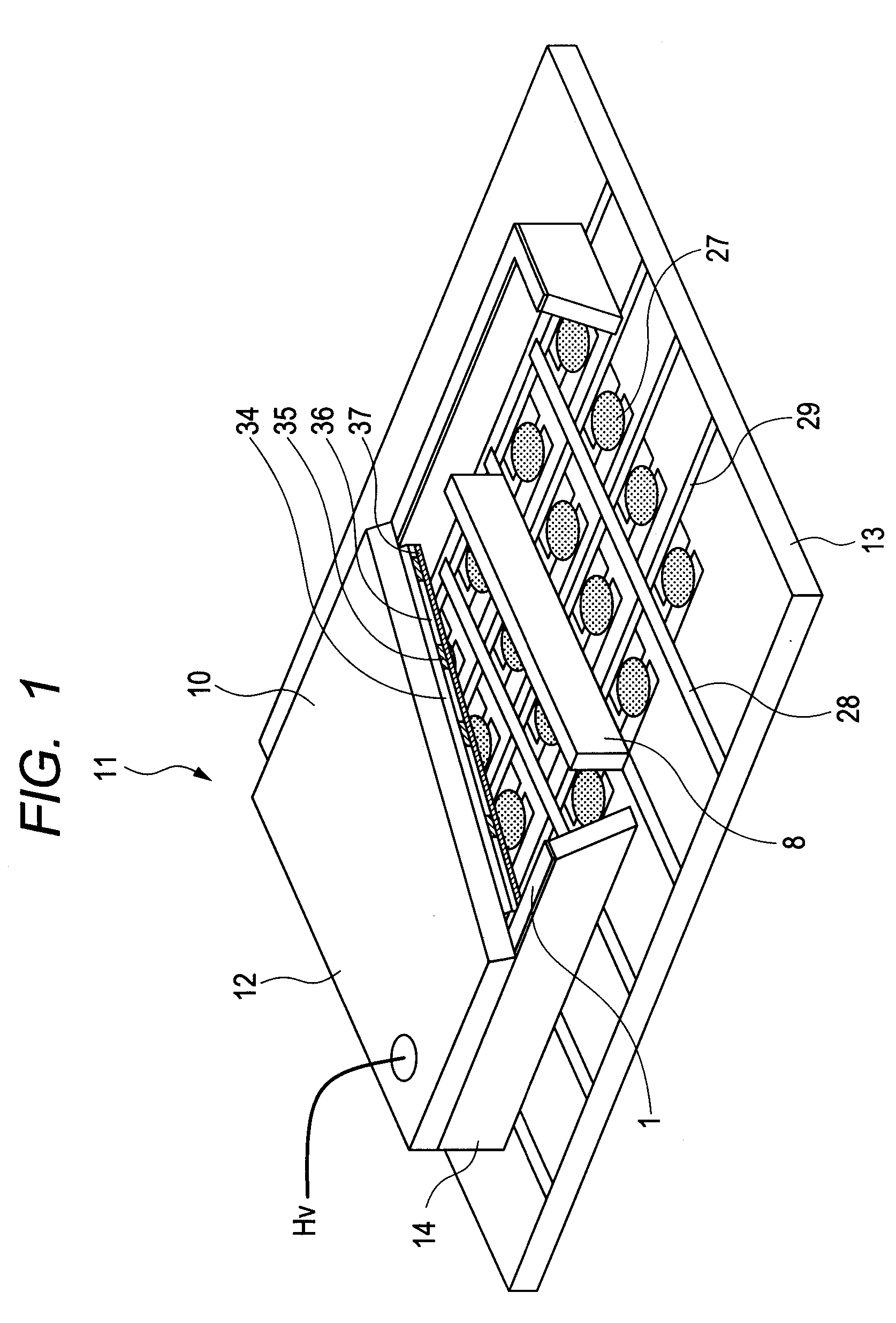

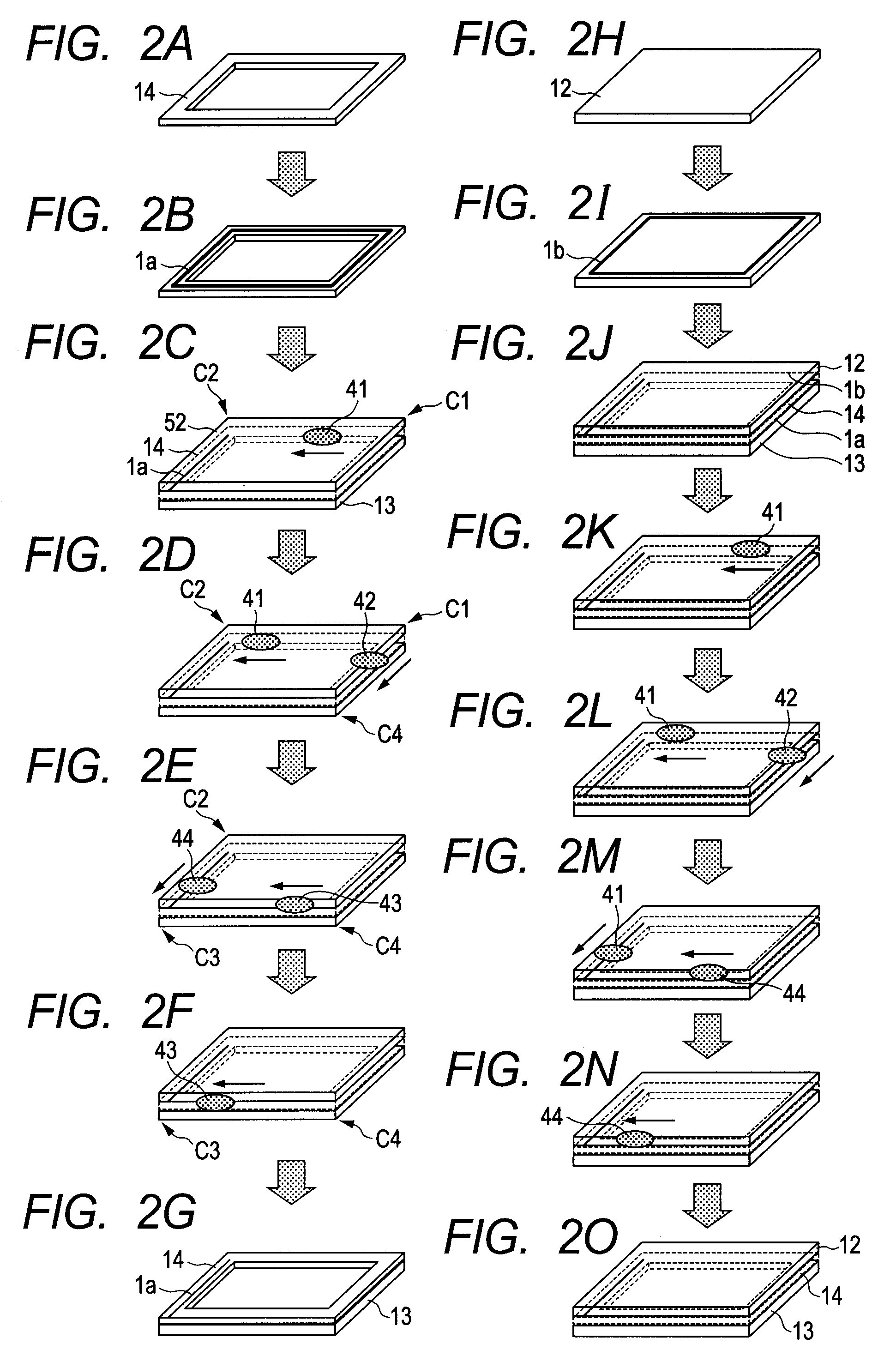

InactiveUS20050264198A1Improve emission efficiencyQuick buildGas discharge electrodesGas discharge connecting/feedingFailure rateEngineering

A plasma display module that can improve the emission efficiency of light, generate a discharge quickly, reduce an address voltage, and be manufactured at lower costs and failure rates, includes a substrate formed of a transparent insulator, a chassis base disposed on a rear side of the substrate, a plurality of barrier ribs formed of a dielectric disposed between the substrate and the chassis base and define discharge cells together with the substrate and the chassis base, a plurality of front discharge electrodes formed in the barrier ribs that surround the discharge cell, a plurality of rear discharge electrodes spaced apart from the front discharge electrodes and formed in the barrier ribs to surround the discharge cell, a fluorescent layer disposed in the discharge cell, a discharge gas filled in the discharge cell, and a plurality of circuit substrates that apply electrical signals to the electrodes by disposing on a rear side of the chassis base.

Owner:SAMSUNG SDI CO LTD

Plasma display panel

InactiveUS20050077823A1Small widthSimple designSustain/scan electrodesGas discharge connecting/feedingDisplay deviceEngineering

A plasma display panel that has electrode extending to a periphery thereof with a thickness and width that varies from the thickness and width of other electrode portions to enhance electrode resistance efficiency and discharge characteristics. That is, the electrodes in the display extend through a display area where visible images are generated into a non-display area around the display area where a connection to a driving circuit is made. The electrodes are designed to have varying widths and thicknesses that vary depending on whether the electrode is inside the display area or is outside the display area.

Owner:SAMSUNG SDI CO LTD

Tablet and exhaust pipe integrated with tablet

InactiveUS20120128904A1Increase productivityDegree of improvementGas filling substance selectionCathode-ray/electron-beam tube vessels/containersFilling ratioBismuth

A tablet comprises a bismuth-based glass and a refractory filler, wherein: (1) the bismuth-based glass comprises, as a glass composition, in terms of mass %, 70 to 90% of Bi2O3, 2 to 12% of B2O3, 0 to 5% of Al2O3, 1 to 15% of ZnO, 0 to 10% of BaO, and 0 to 8% of CuO+Fe2O3; (2) the tablet comprises 1 to 25 vol % of alumina as the refractory filler; and (3) the filling ratio of the tablet is 71% or more.

Owner:NIPPON ELECTRIC GLASS CO LTD

Display device

ActiveUS20170082888A1Reduce border areaGas discharge connecting/feedingPrinted circuit manufactureDisplay deviceElectrode

A display panel according to various embodiments comprises: a first substrate and a second substrate facing each other; a first pad and a second pad between the first substrate and the second substrate at an end of the first substrate; a first connection electrode on a side face of the first pad and a second connection electrode on a side face of the second pad; an insulating layer disposed on a top face of the first substrate and disposed on at least a portion of a top face of the first and second pads; and at least one spread prevention hole in the insulating layer between the first and second pads.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com