Patents

Literature

187 results about "Secondary emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary emission in physics is a phenomenon where primary incident particles of sufficient energy, when hitting a surface or passing through some material, induce the emission of secondary particles. The term often refers to the emission of electrons when charged particles like electrons or ions in a vacuum tube strike a metal surface; these are called secondary electrons. In this case, the number of secondary electrons emitted per incident particle is called secondary emission yield. If the secondary particles are ions, the effect is termed secondary ion emission. Secondary electron emission is used in photomultiplier tubes and image intensifier tubes to amplify the small number of photoelectrons produced by photoemission, making the tube more sensitive. It also occurs as an undesirable side effect in electronic vacuum tubes when electrons from the cathode strike the anode, and can cause parasitic oscillation.

Secondary-emitter sensor position indicator

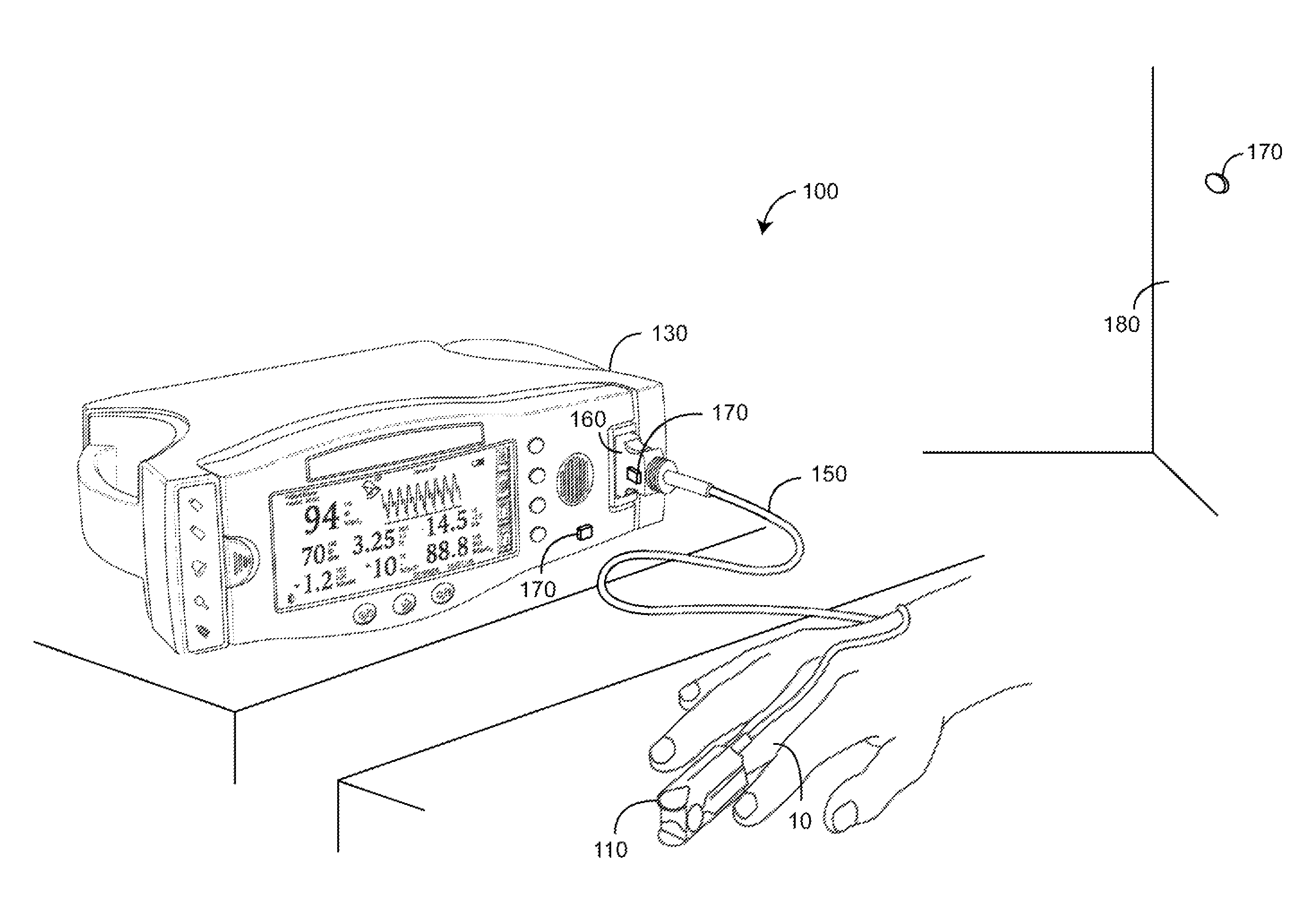

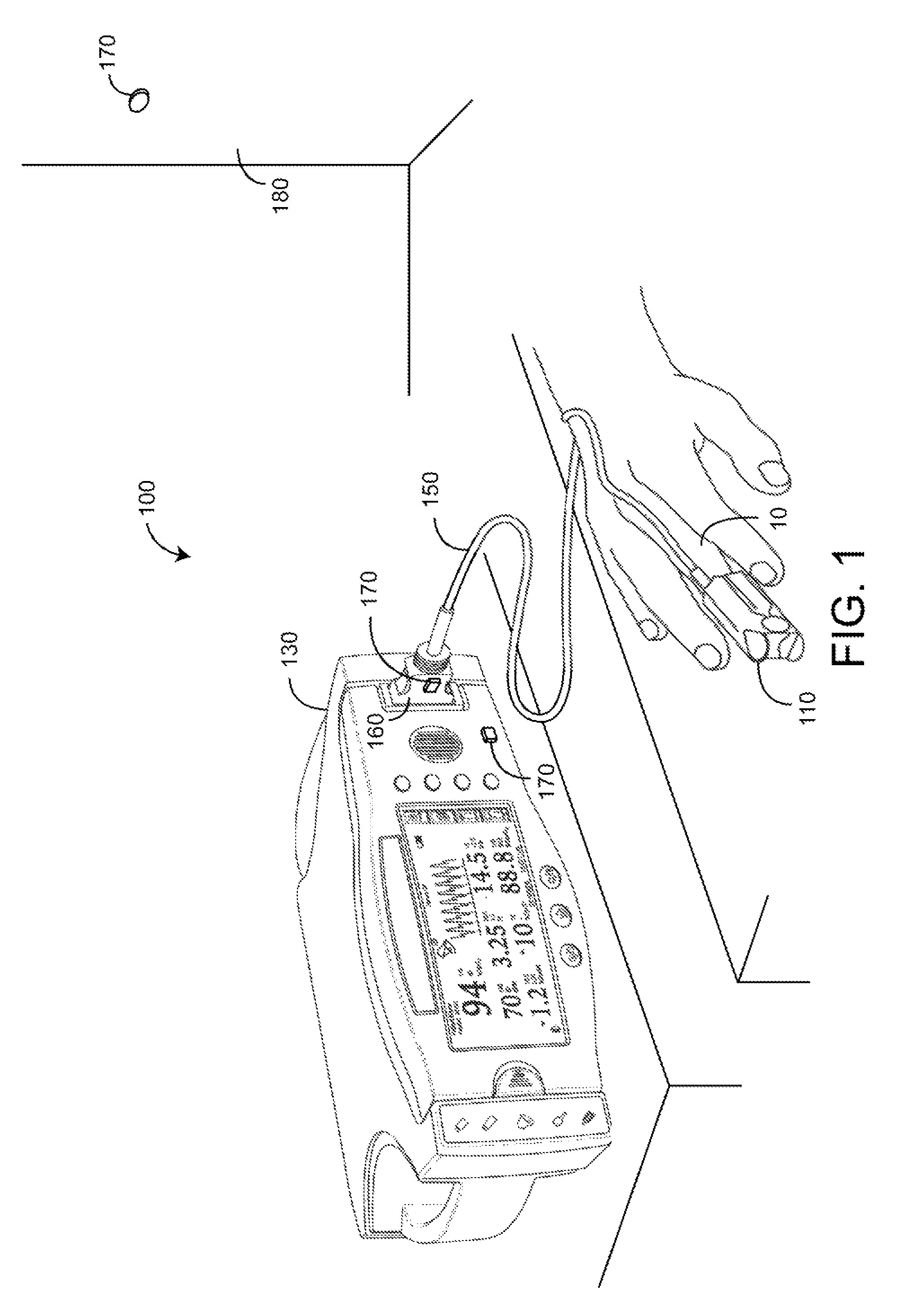

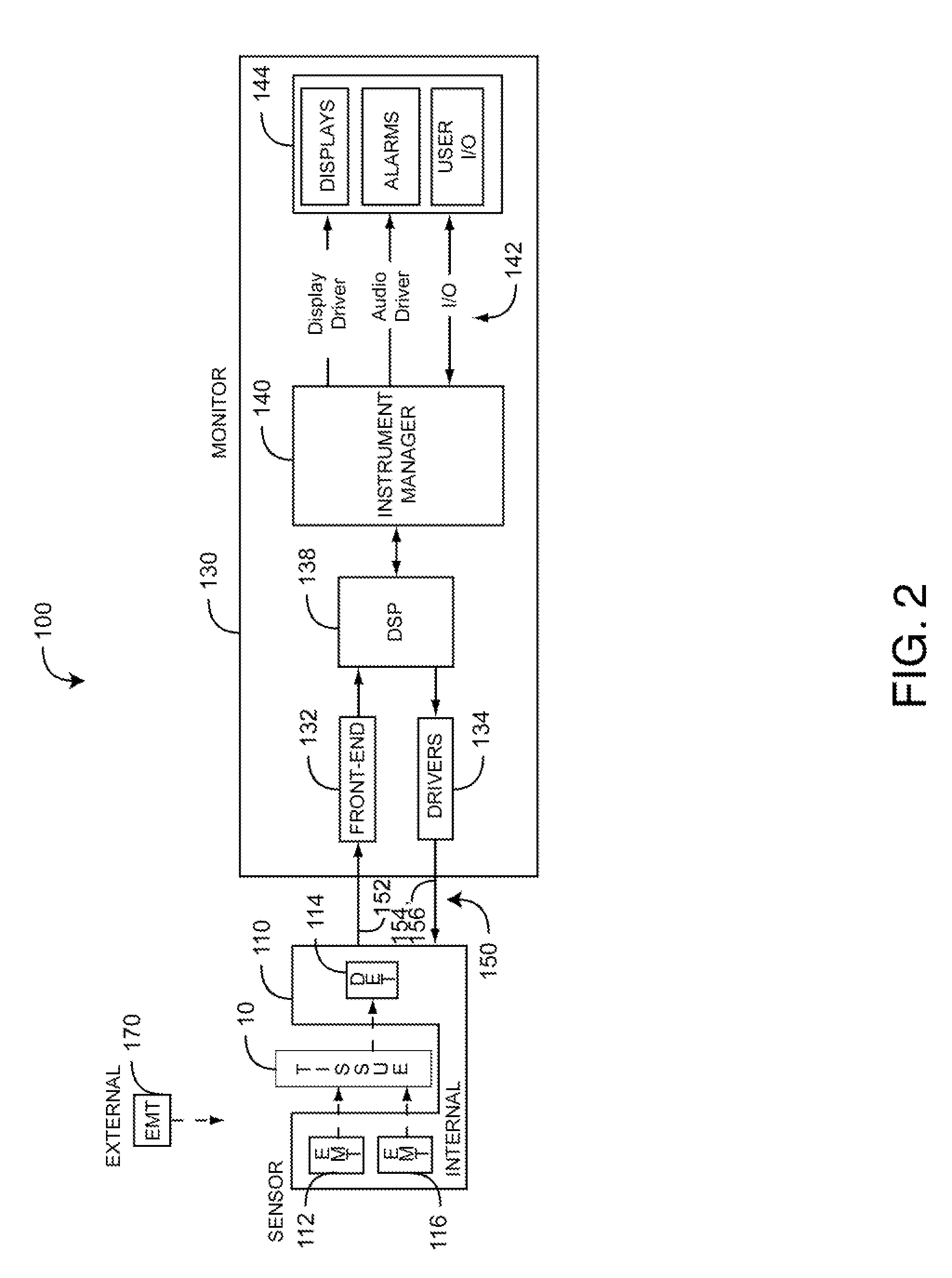

A secondary-emitter sensor position indicator has primary emitters that transmit light having primary wavelengths and at least one secondary emitter that transmits light having at least one secondary wavelength. A detector outputs a sensor signal in response to received light. An attachment assembly, in a sensor-on condition, positions the emitters and detector relative to a tissue site so that the sensor signal is substantially responsive to the primary wavelength light after attenuation by pulsatile blood flow within the tissue site and is negligibly responsive to the secondary wavelength light. The attachment assembly, in a sensor out-of-position condition, positions the secondary emitter relative to the tissue site so that the sensor signal is at least partially responsive to the secondary wavelength.

Owner:JPMORGAN CHASE BANK NA

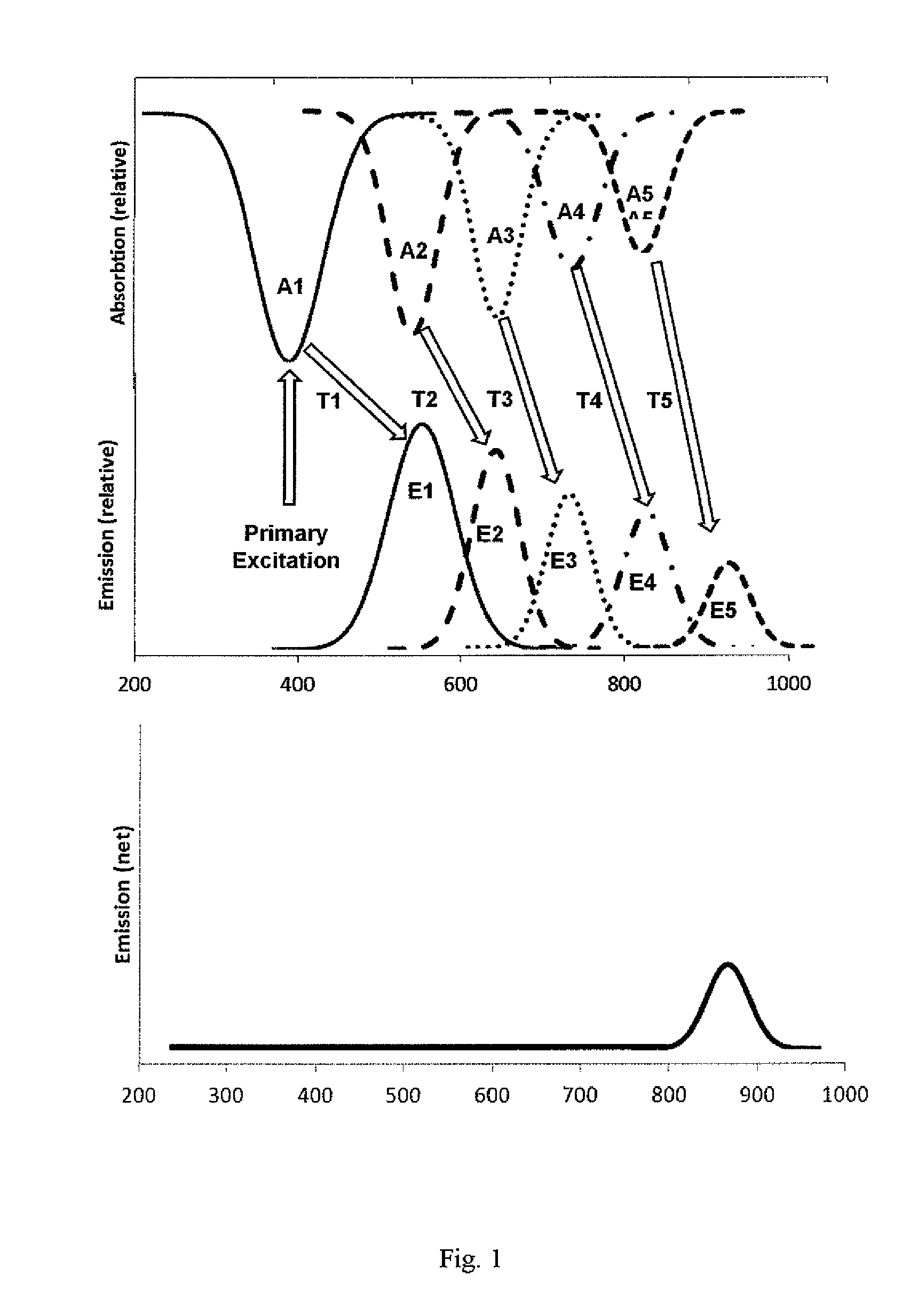

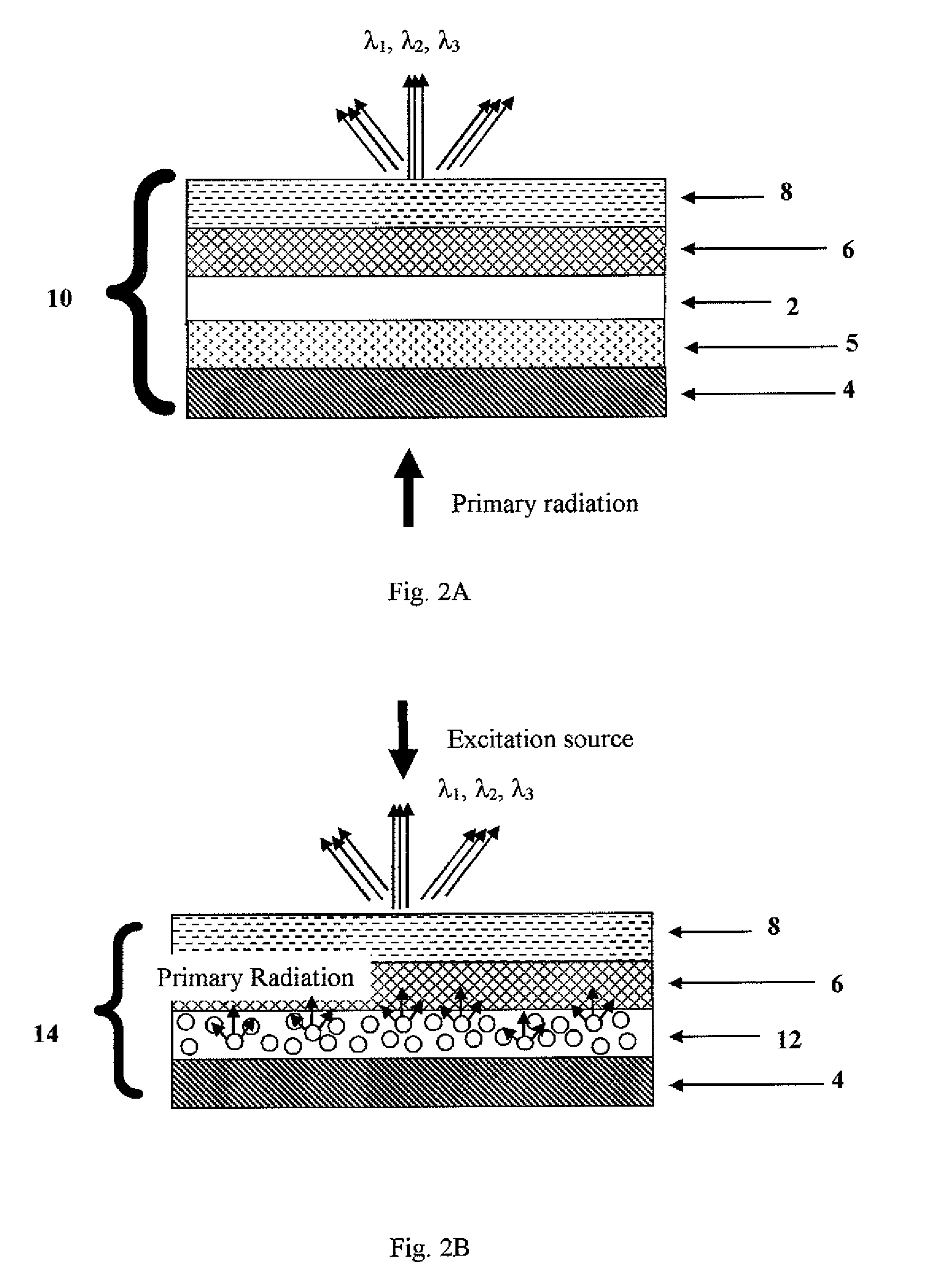

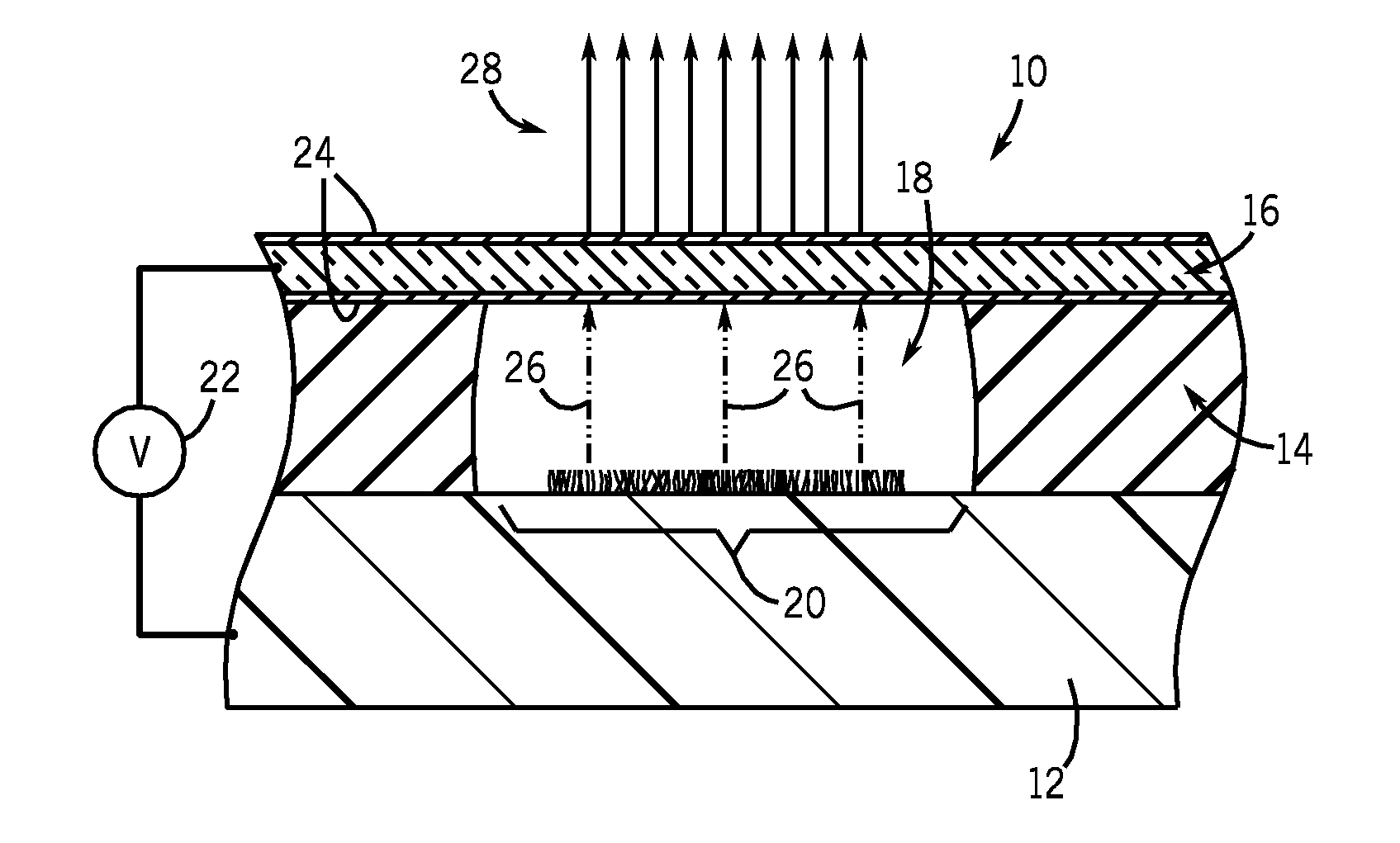

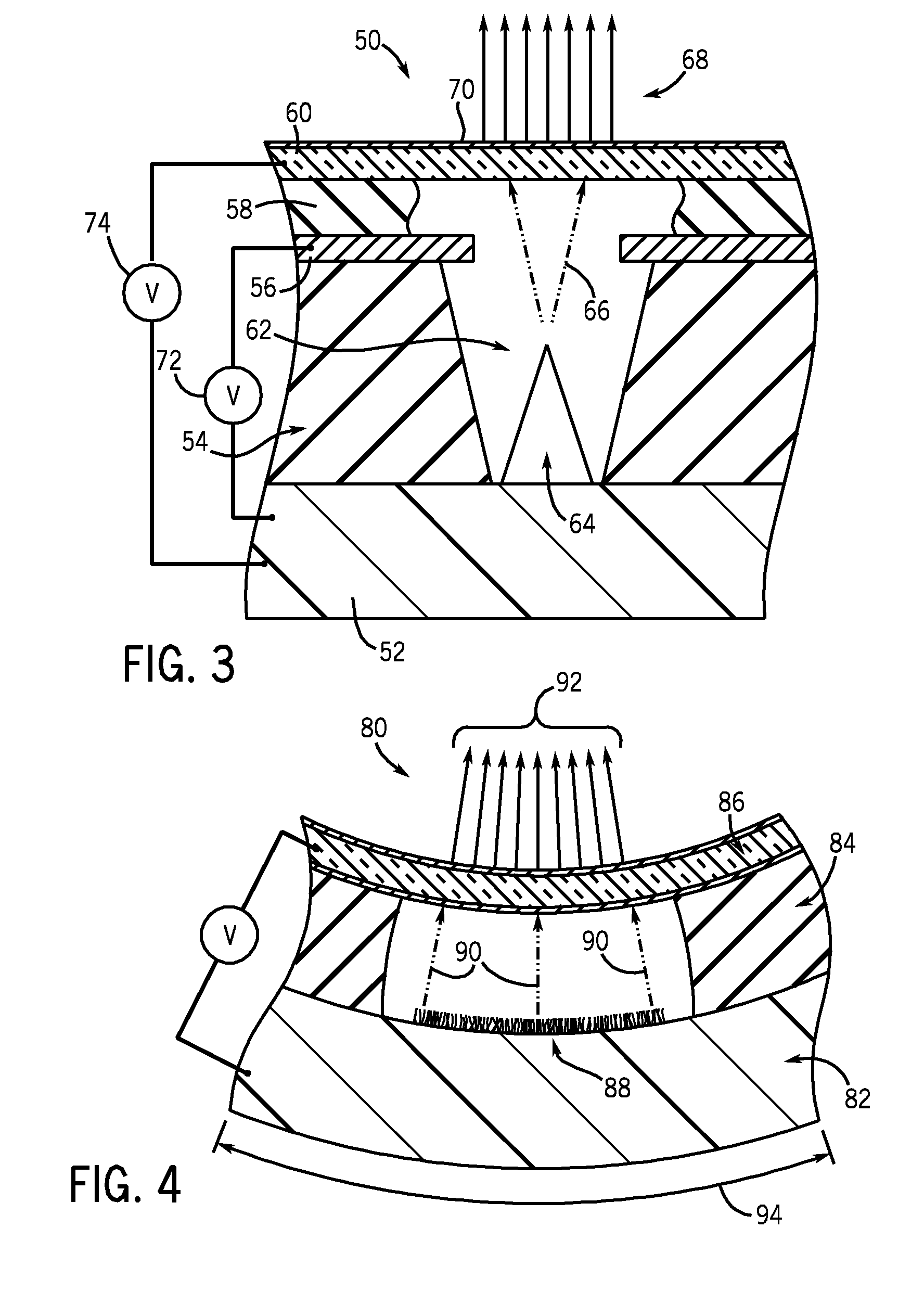

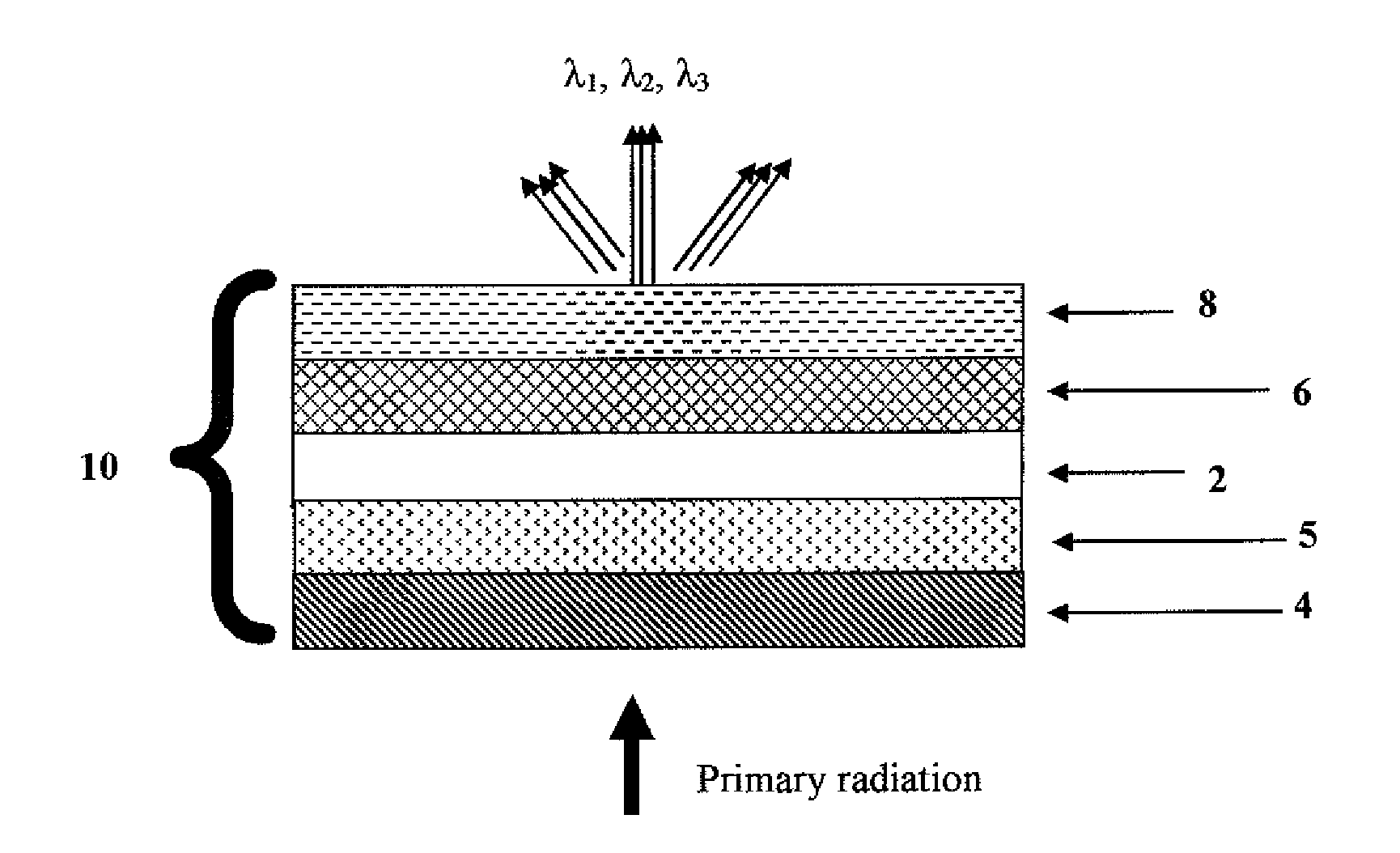

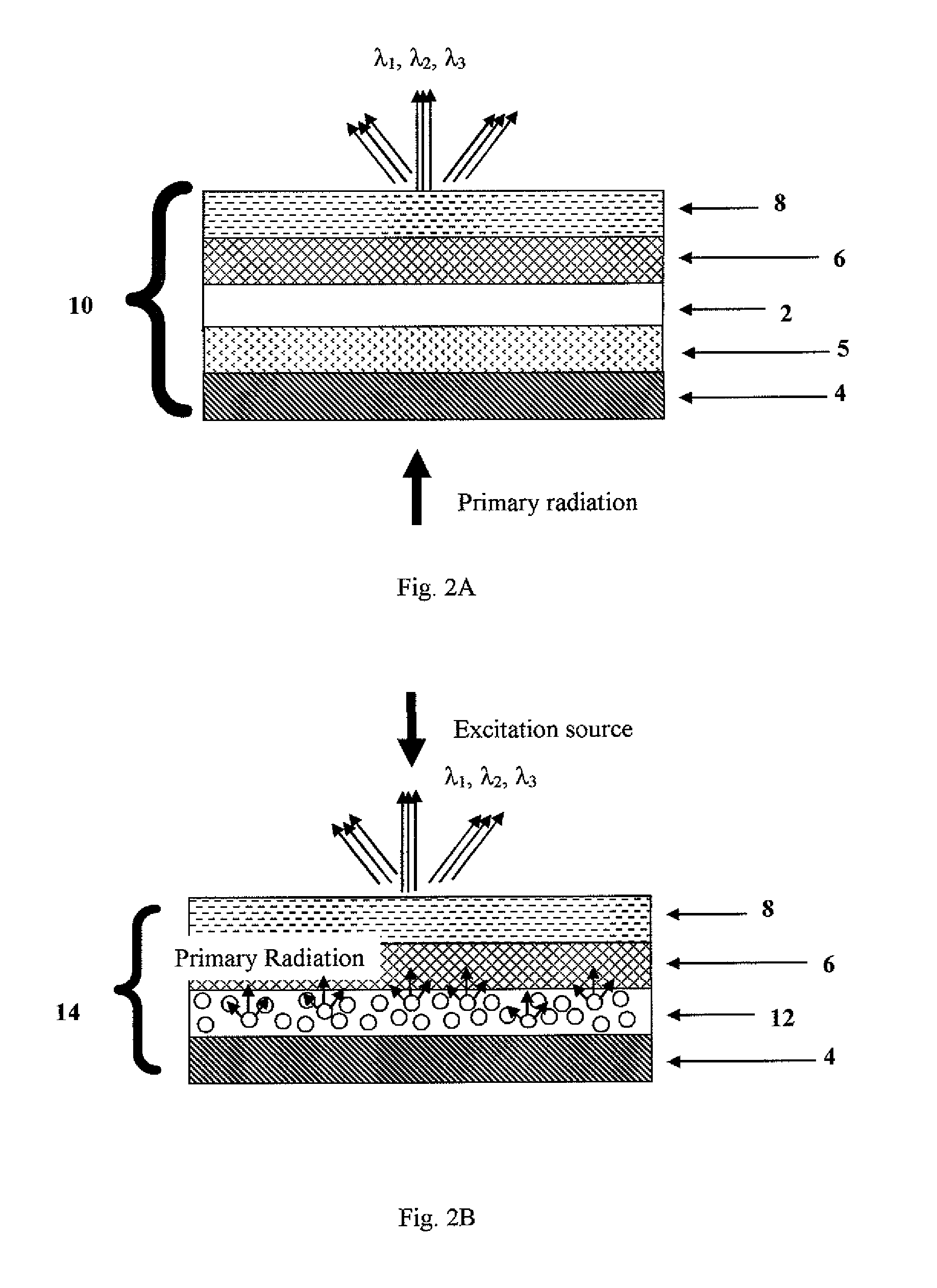

Photolytically and environmentally stable multilayer structure for high efficiency electromagnetic energy conversion and sustained secondary emission

ActiveUS8519359B2Increases photolytic and thermal stabilityEnhanced light scatteringPhotometryLuminescent dosimetersSecondary emissionPhotoluminescence

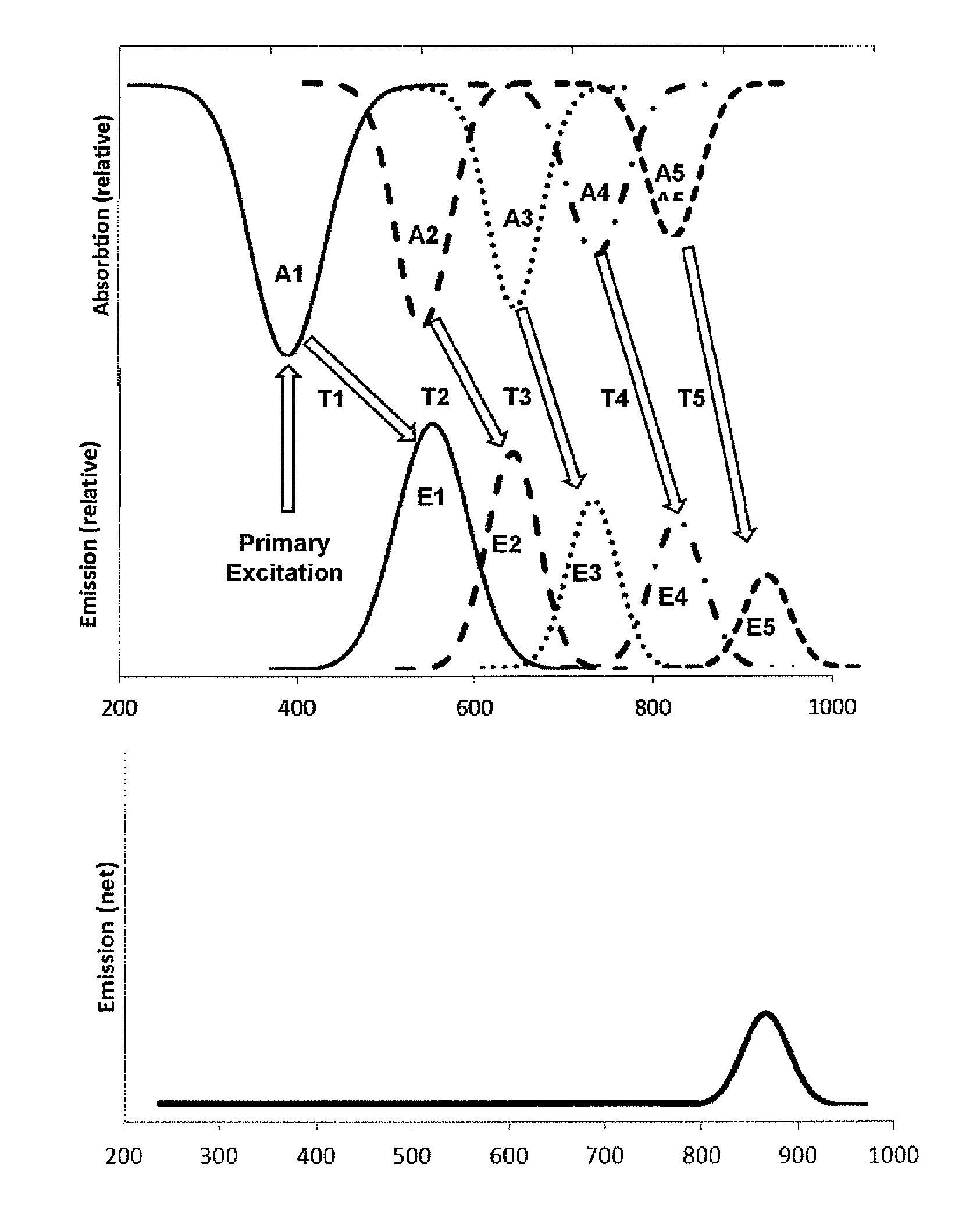

Disclosed is a method for converting a primary electromagnetic radiation to a longer output wavelength that includes providing an energy conversion layer having a first photoluminescent material and a second photoluminescent material, exposing the energy conversion layer to the primary electromagnetic radiation, and transferring at least a portion of absorbed energy from the first photoluminescent material to the second photoluminescent material by dipolar coupling, such that the second photoluminescent material subsequently emits the longer output wavelength.

Owner:PERFORMANCE INDICATOR LLC

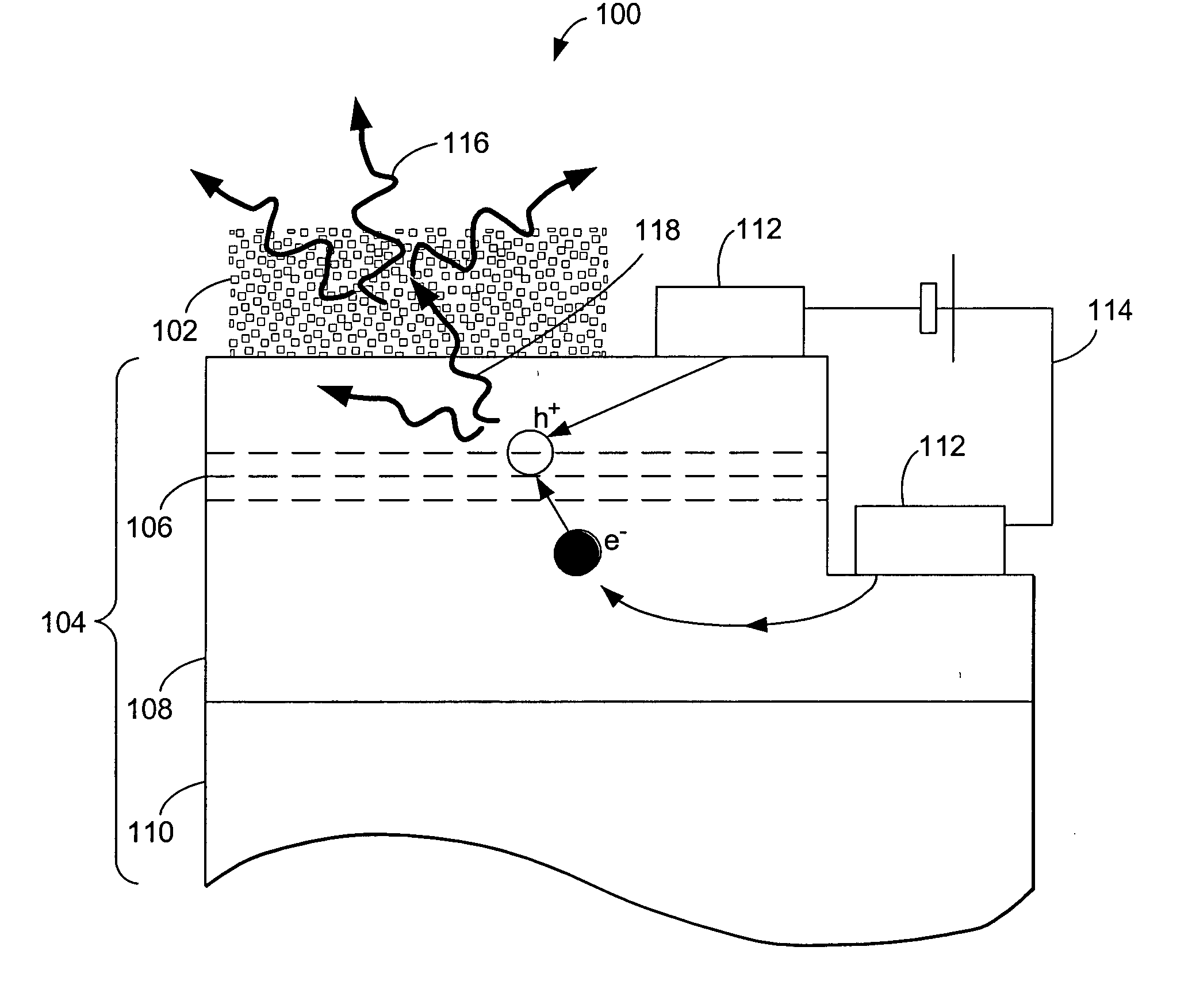

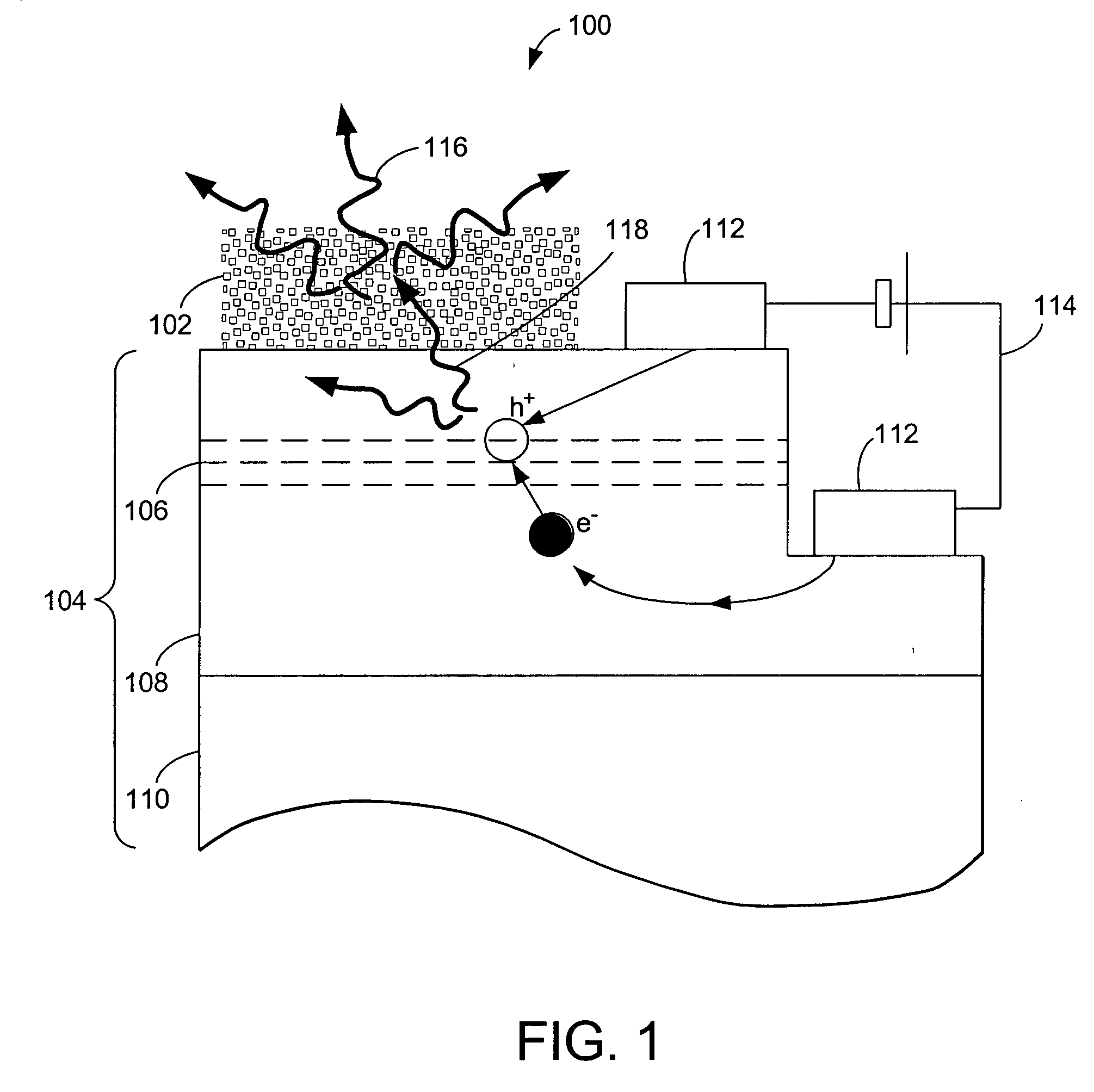

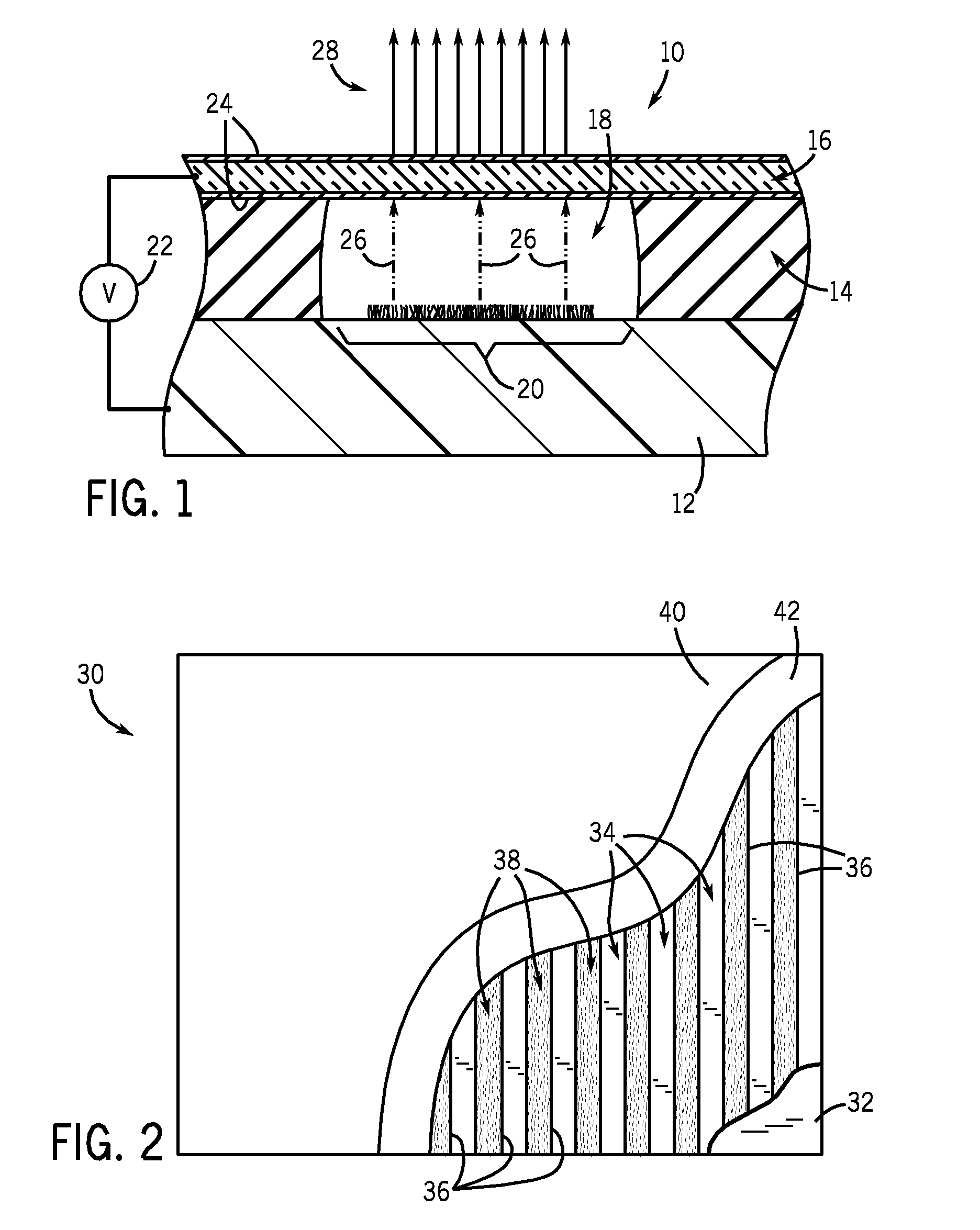

Photonic structures for efficient light extraction and conversion in multi-color light emitting devices

InactiveUS20070085100A1Improve light extraction efficiencyEfficient excitationSemiconductor/solid-state device manufacturingNanoopticsPhotonic crystalSecondary emission

Owner:RGT UNIV OF CALIFORNIA

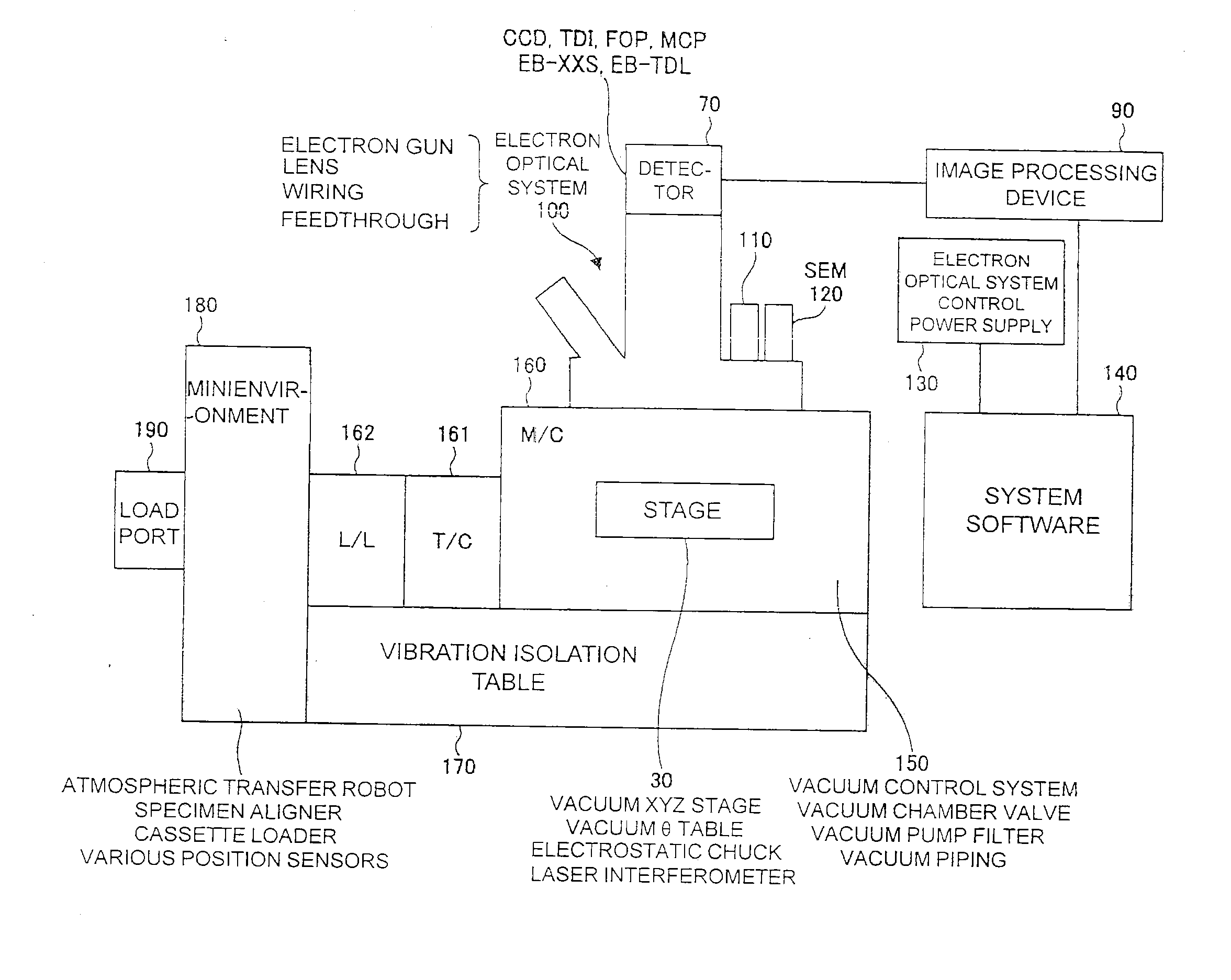

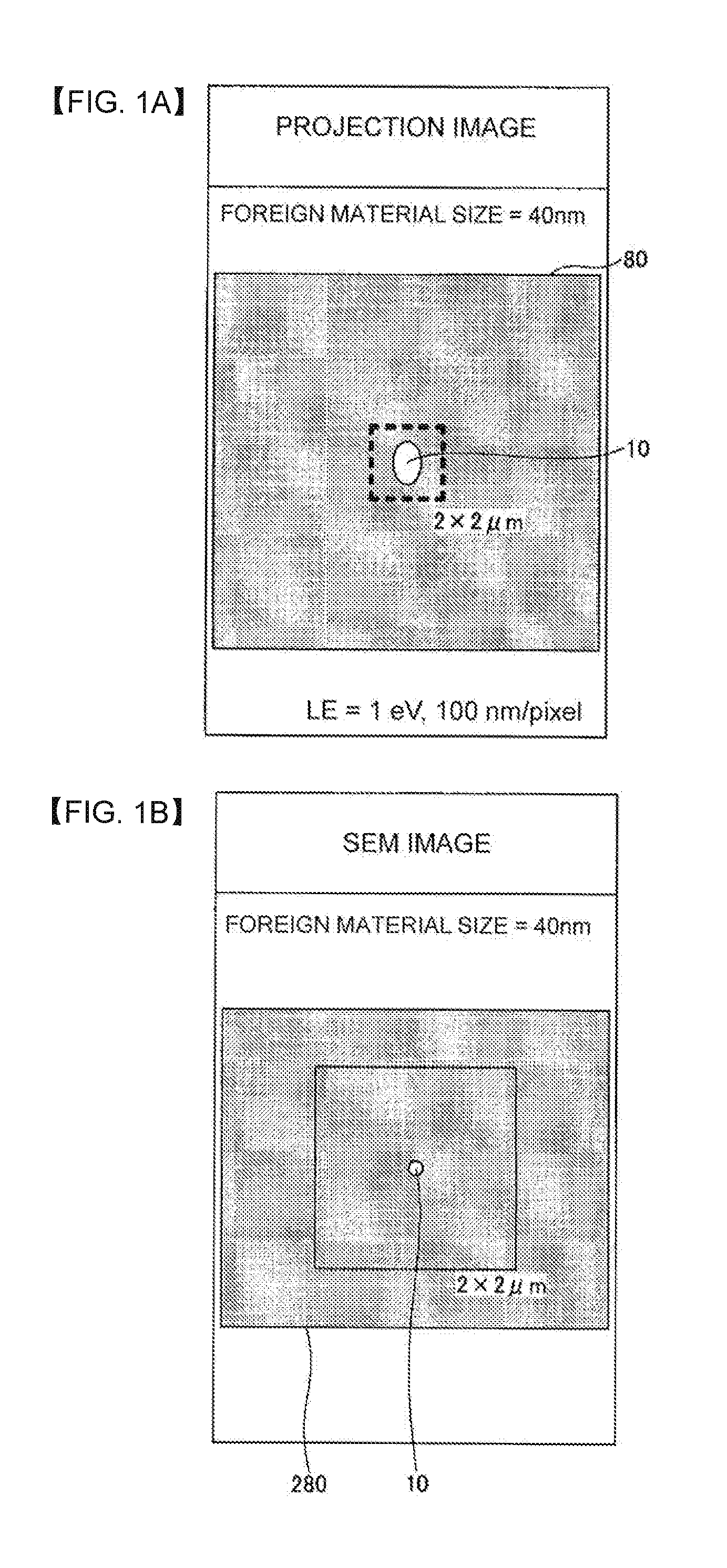

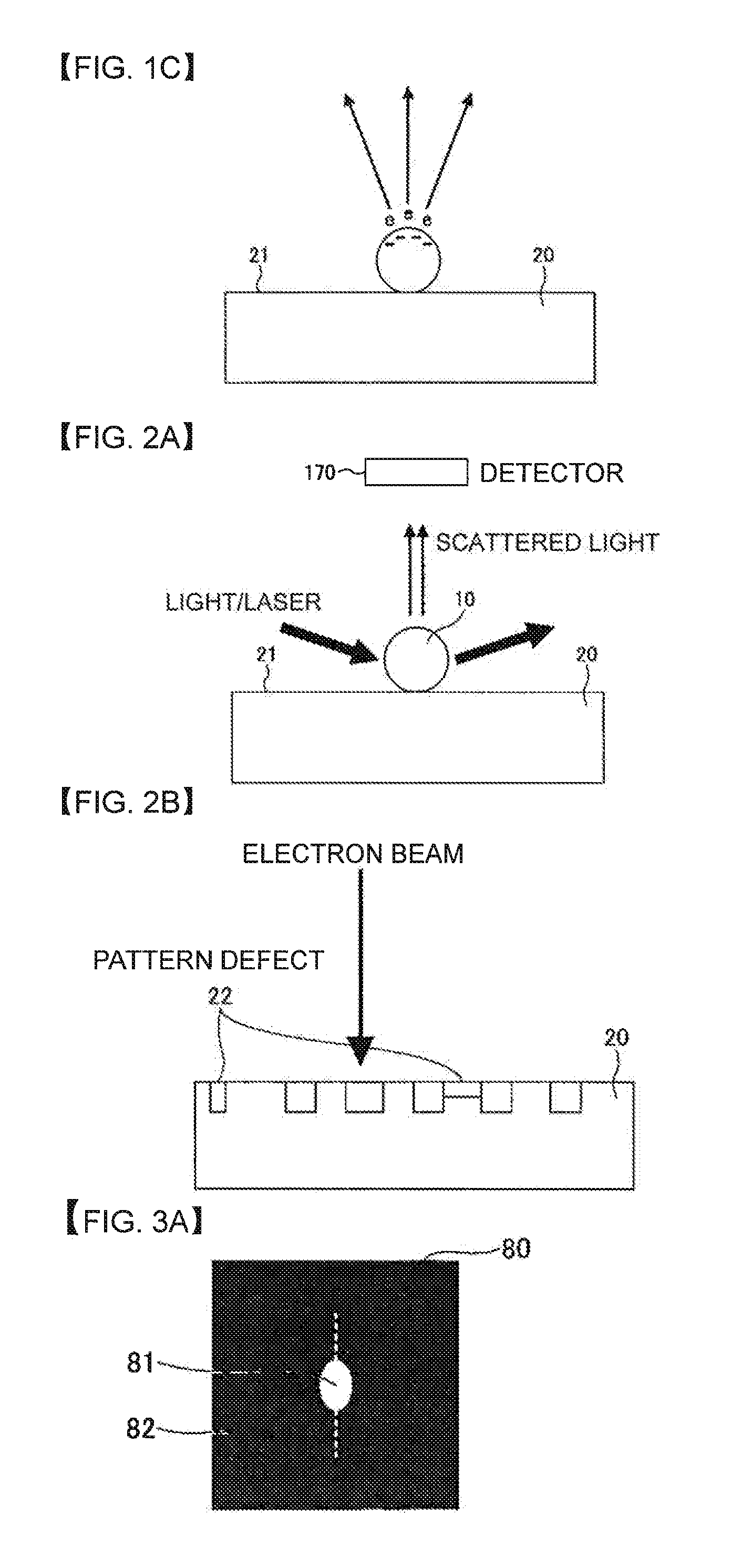

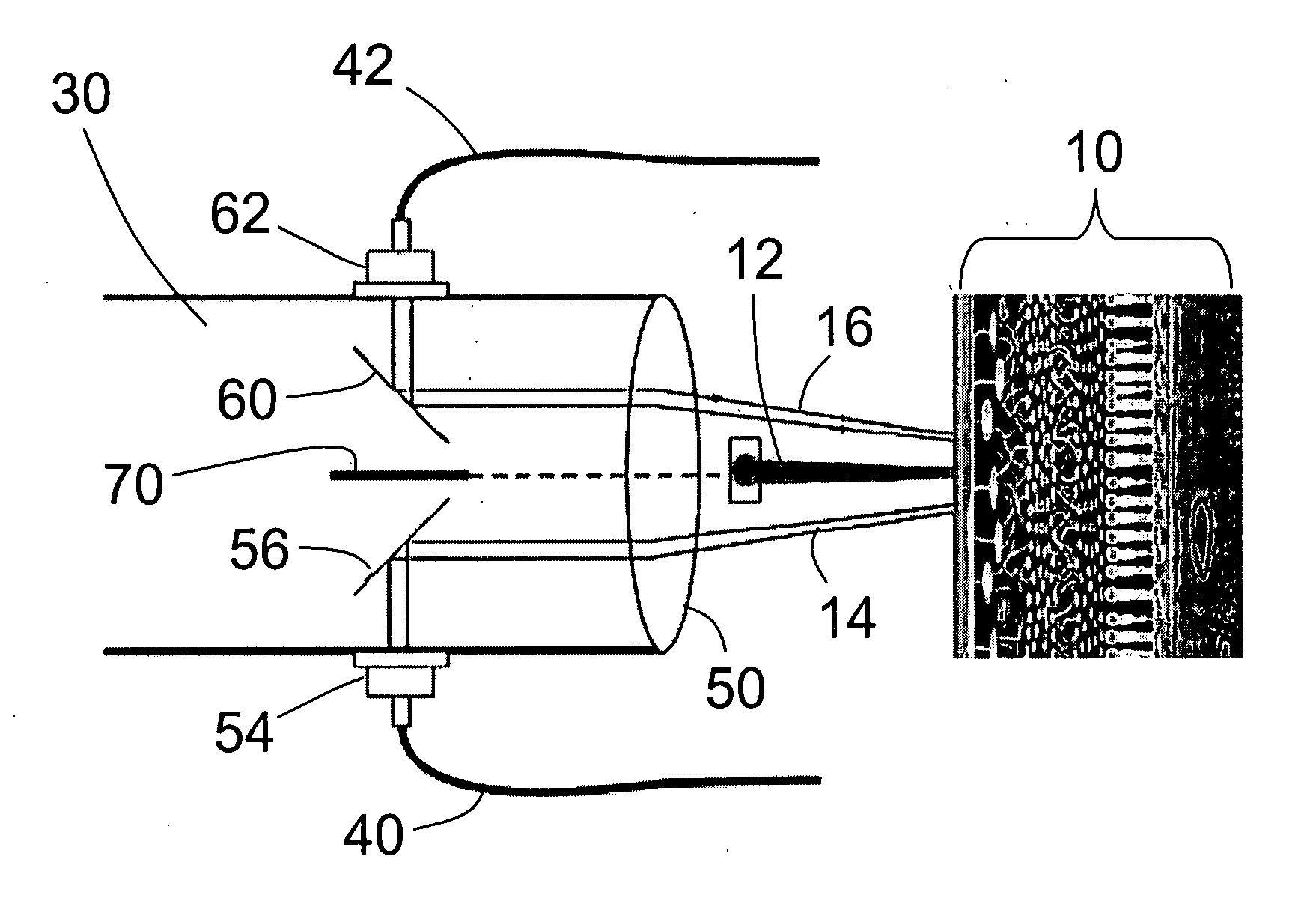

Specimen observation method and device, and inspection method and device using the method and device

ActiveUS20110155905A1Material analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementForeign matterPerformed Observation

A technique capable of improving the ability to observe a specimen using an electron beam in an energy region which has not been conventionally given attention is provided. This specimen observation method comprises: irradiating the specimen with an electron beam; detecting electrons to be observed which have been generated and have obtained information on the specimen by the electron beam irradiation; and generating an image of the specimen from the detected electrons to be observed. The electron beam irradiation comprises irradiating the specimen with the electron beam with a landing energy set in a transition region between a secondary emission electron region in which secondary emission electrons are detected and a mirror electron region in which mirror electrons are detected, thereby causing the secondary emission electrons and the mirror electrons to be mixed as the electrons to be observed. The detection of the electrons to be observed comprises performing the detection in a state where the secondary emission electrons and the mirror electrons are mixed. Observation and inspection can be quickly carried out for a fine foreign material and pattern of 100 nm or less.

Owner:EBARA CORP

Optical Communication Systems and Methods

ActiveUS20150132004A1Reduce distractionsImprove optical communicationElectromagnetic transmission optical aspectsSecondary emissionEngineering

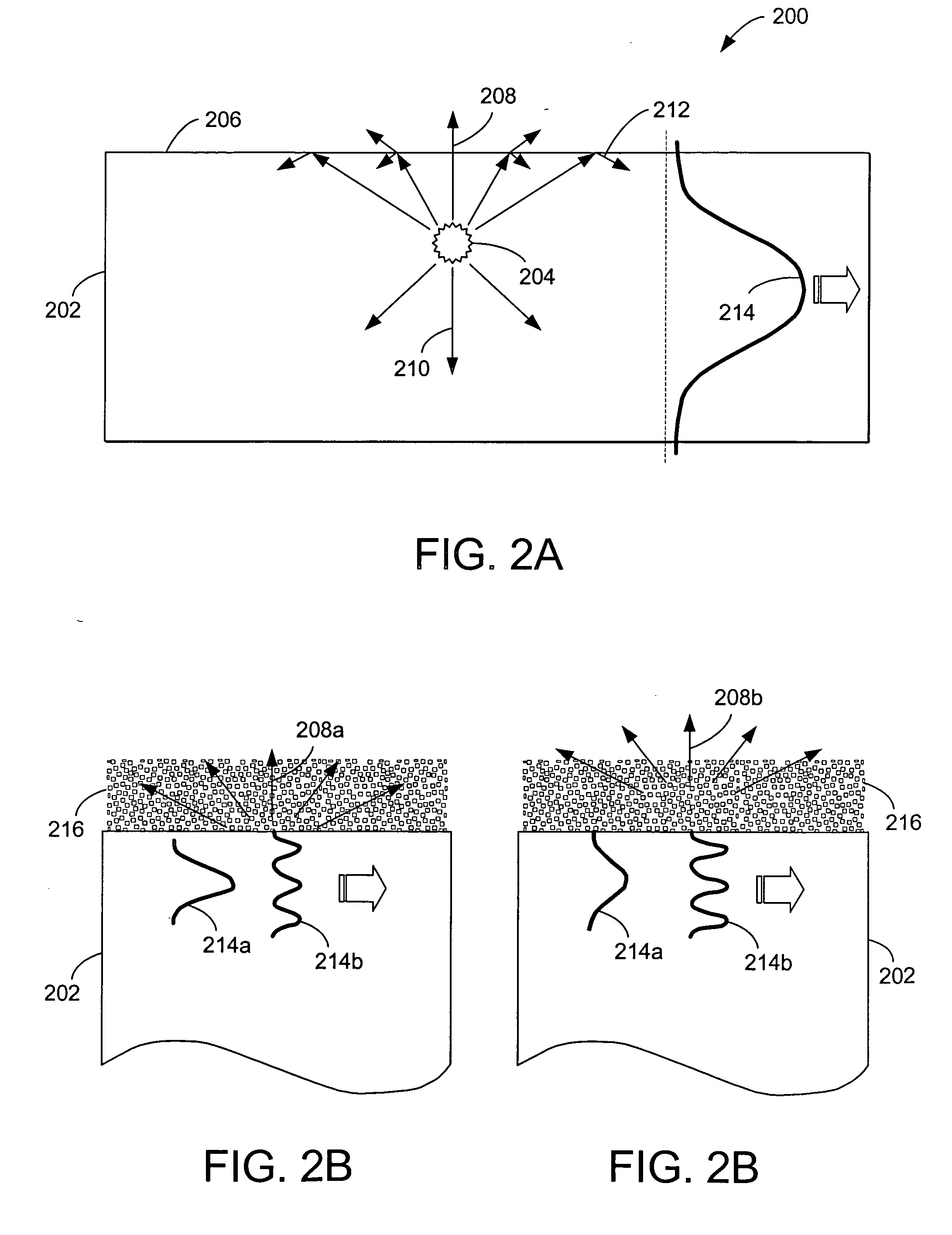

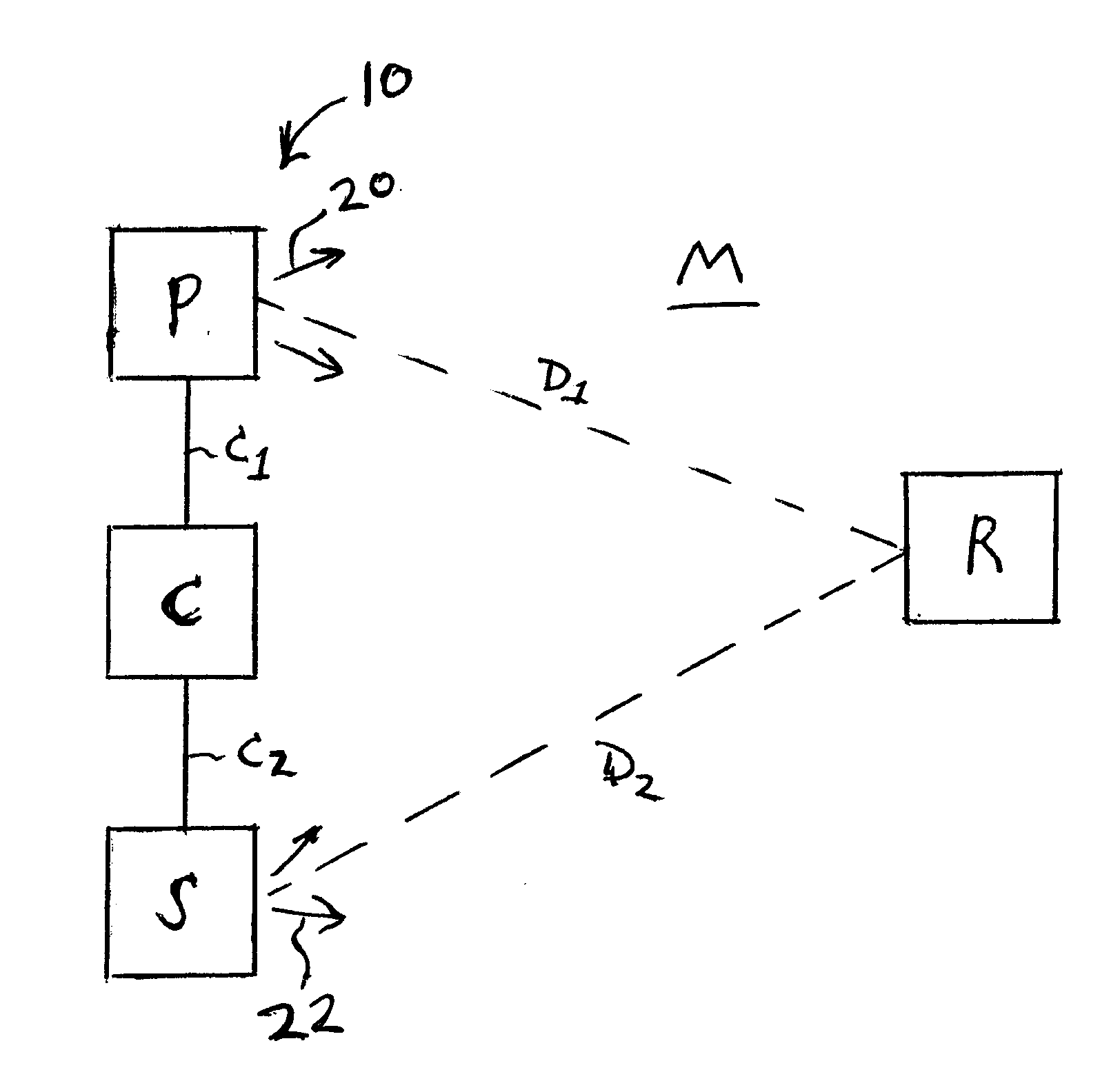

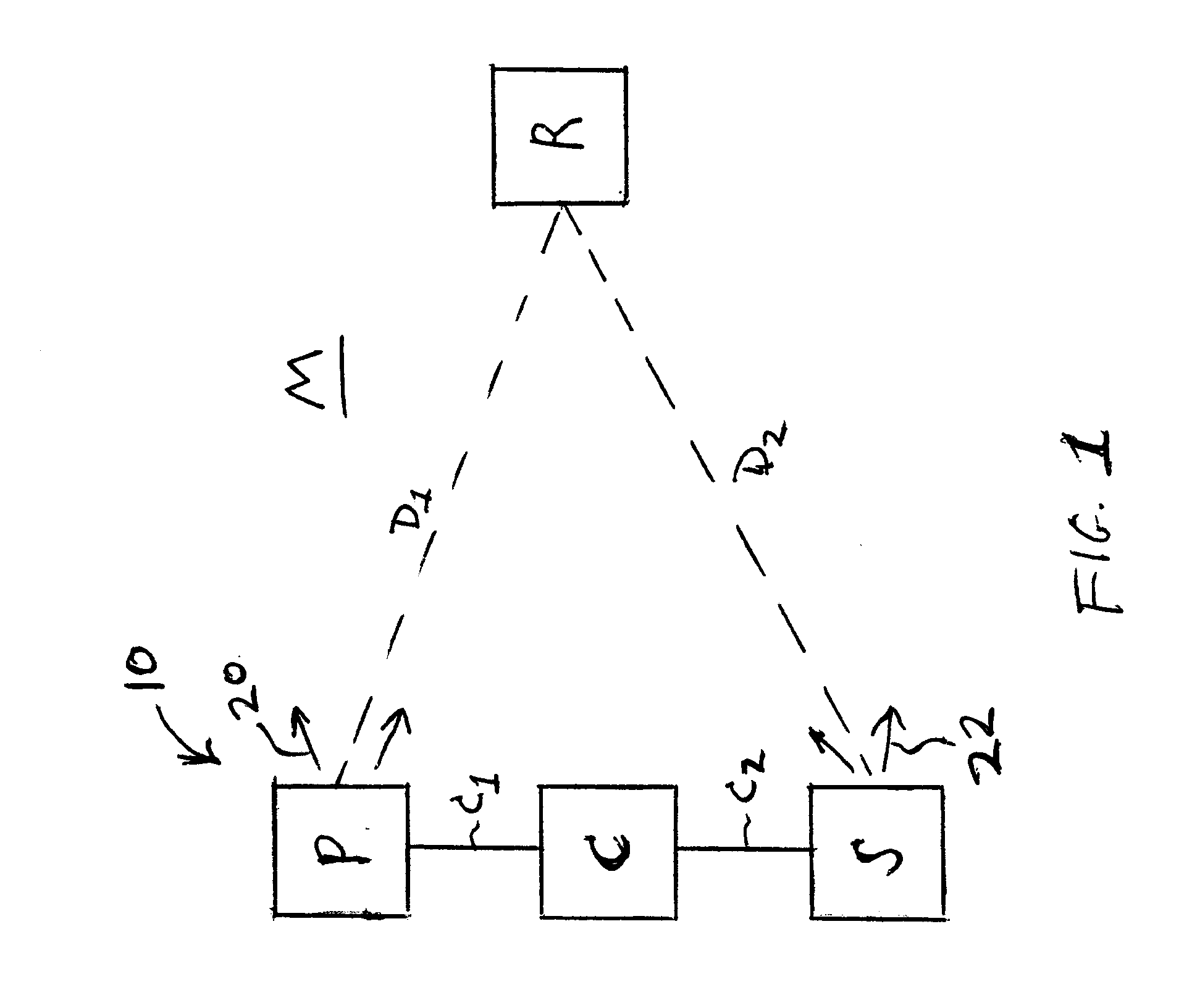

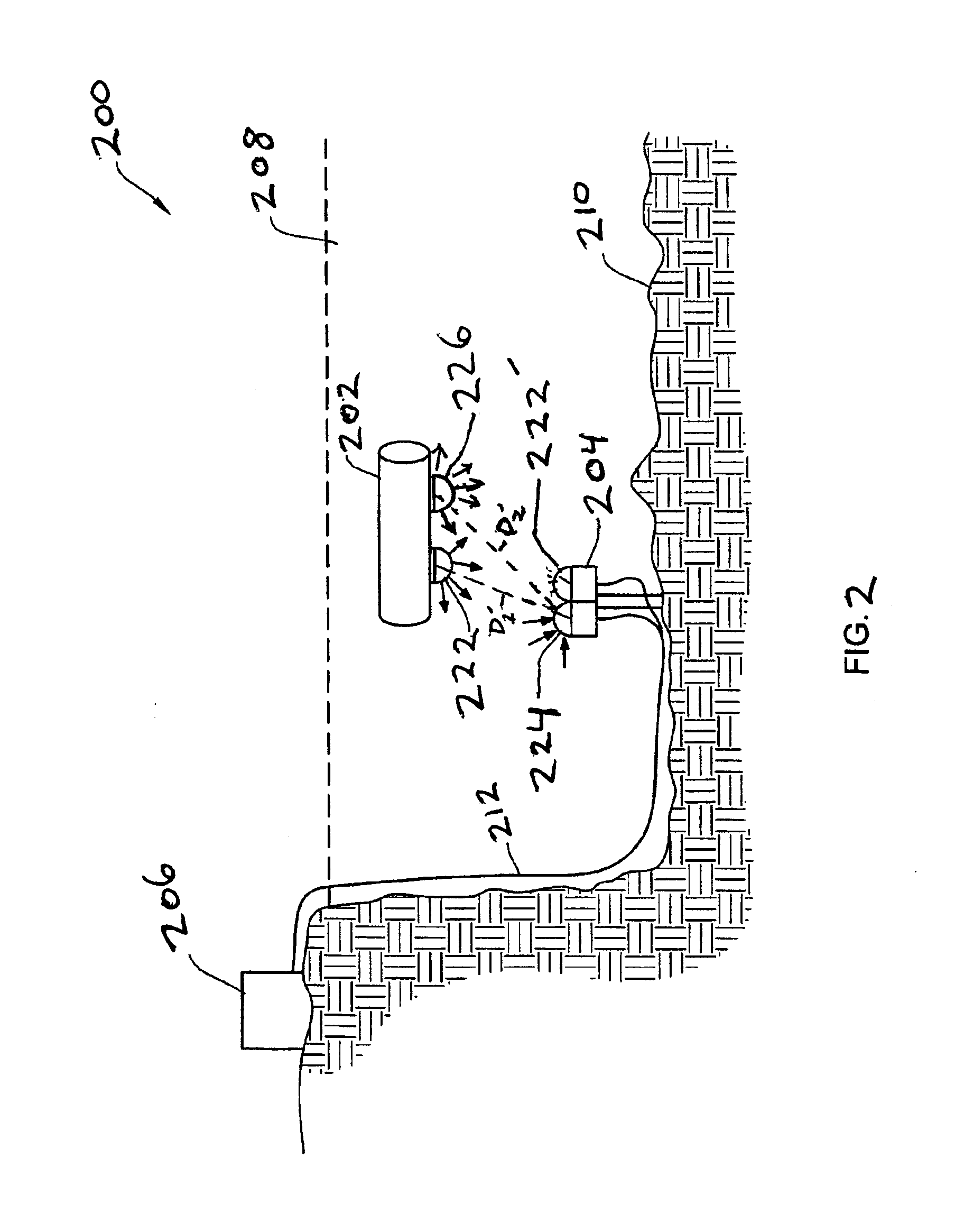

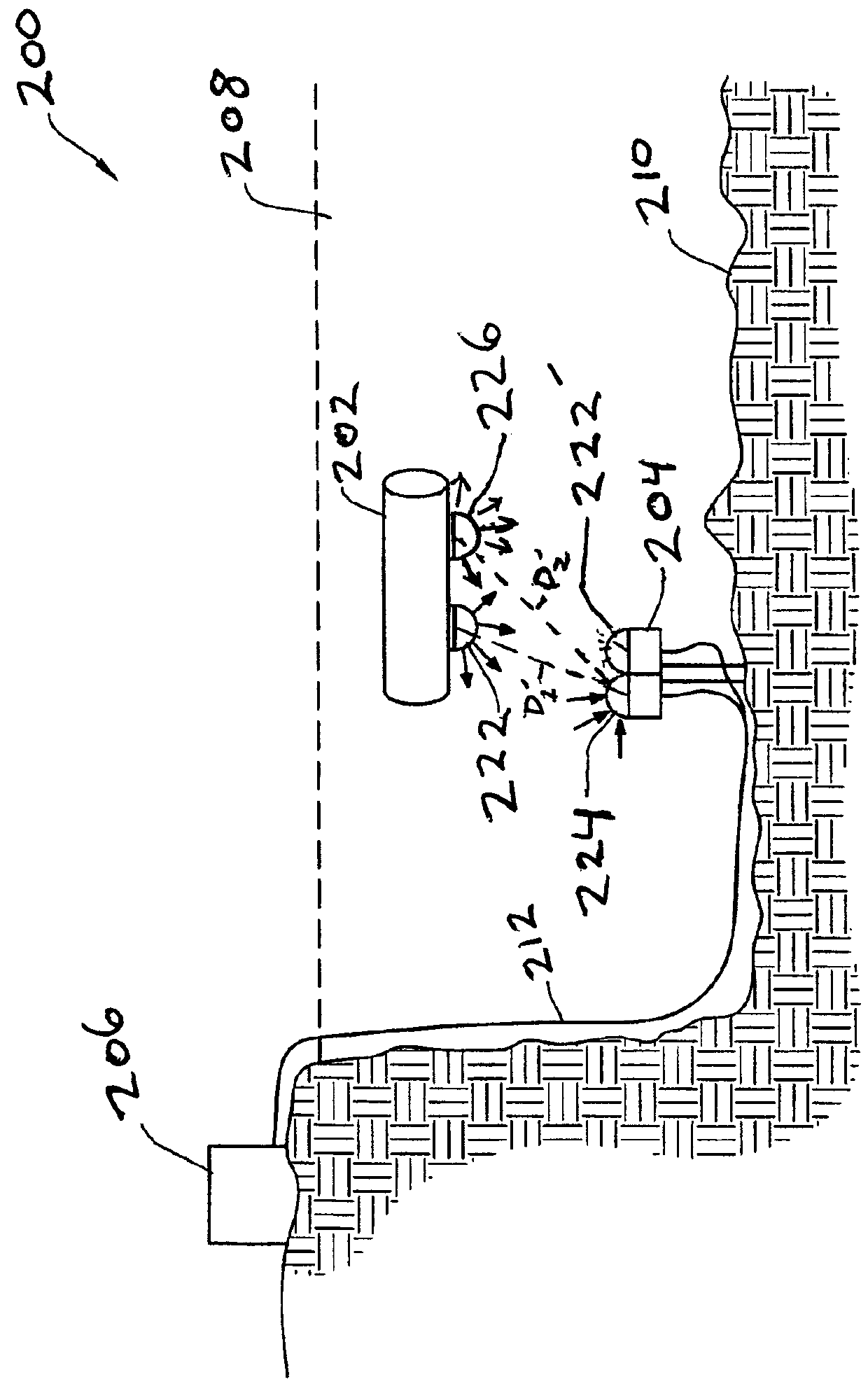

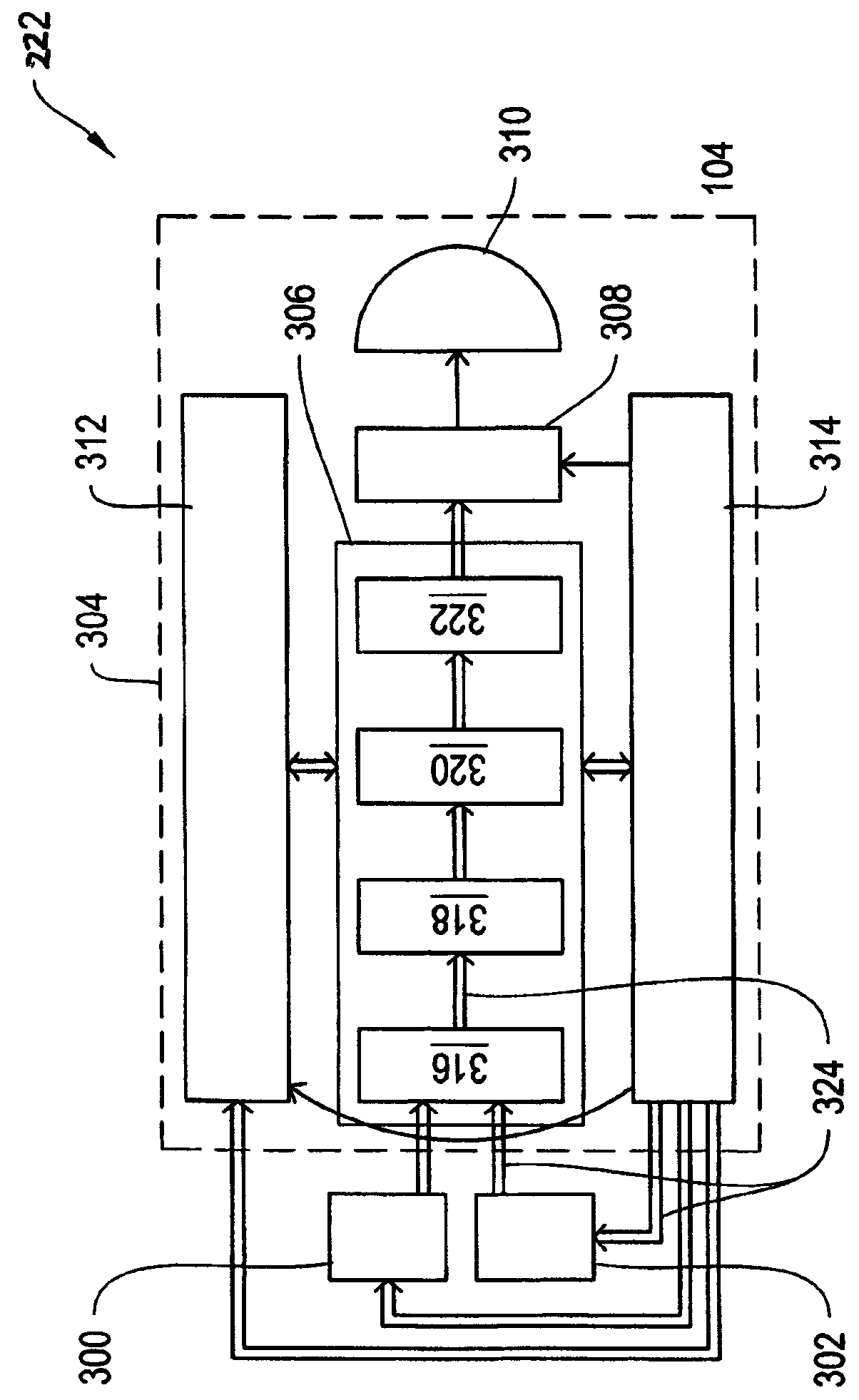

A system and method to broadcast an optical signal through an amorphous medium, including a primary emitter capable of producing a primary optical signal during at least one broadcast period and capable of transmitting the primary optical signal through the amorphous medium. A secondary emitter, separate from the primary emitter and in operation during at least a portion of the broadcast period, produces a secondary emission detectable by a detector during the broadcast period. A signal entrainment controller, in communication with the primary emitter and the secondary emitter, synchronizes the secondary emitter with the primary emitter to generate a resultant signal of higher intensity than the primary signal by itself.

Owner:WOODS HOLE OCEANOGRAPHIC INSTITUTION

X-ray generation using secondary emission electron source

InactiveUS20080187093A1Harsh operating environmentEasy to operateMaterial analysis using wave/particle radiationRadiation/particle handlingElectron currentSecondary emission

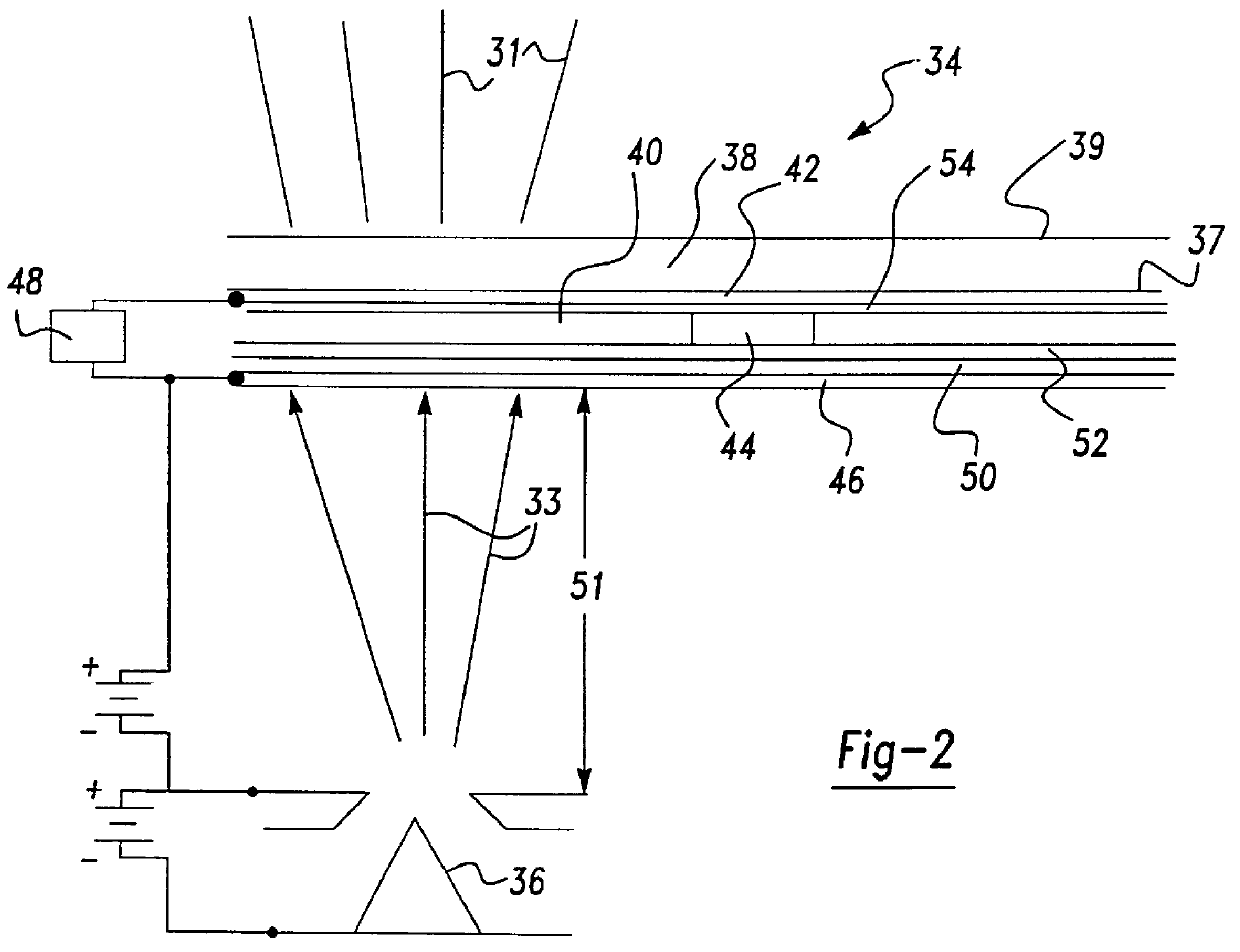

A method and apparatus are provided for generating high frequency electromagnetic energy using a secondary emission electron source. An x-ray source is therefore provided having a primary electron emitter, a secondary emission member, and an anode. The primary electron emitter provides a primary electron current directed to the secondary emission member. The secondary emission member then generates a secondary electron current which causes x-ray generation when impinging upon the anode.

Owner:GENERAL ELECTRIC CO

Photolytically and Environmentally Stable Multilayer Structure for High Efficiency Electromagnetic Energy Conversion and Sustained Secondary Emission

ActiveUS20120080613A1Increases photolyticImprove thermal stabilityLayered productsLuminescent dosimetersSecondary emissionLength wave

A multilayer structure for sustained conversion of a primary electromagnetic radiation into another electromagnetic radiation characterized by a spectrum of a higher average wavelength is disclosed. Also disclosed are methods of creating and using the inventive multilayer structure.

Owner:PERFORMANCE INDICATOR LLC

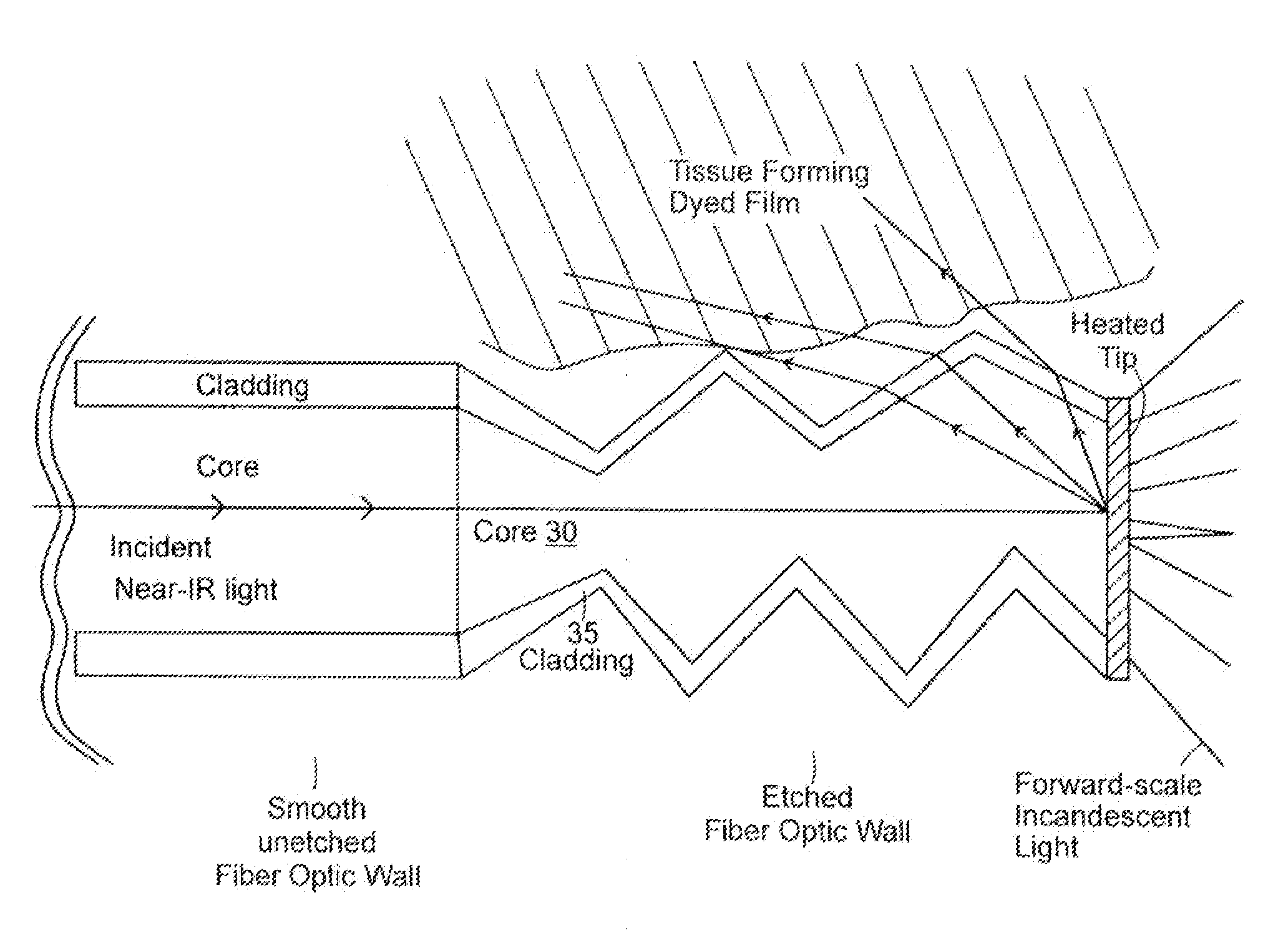

Use of secondary optical emission as a novel biofilm targeting technology

InactiveUS20110070552A1Without harming healthy dental structure and tissueMore processedDental implantsTeeth fillingFiberBiofilm

Owner:NOMIR MEDICAL TECH

Method for treating odors produced by drying sewage sludge

InactiveCN102068878AReduce usageAvoid temperature riseDispersed particle separationSecondary emissionChemical reaction

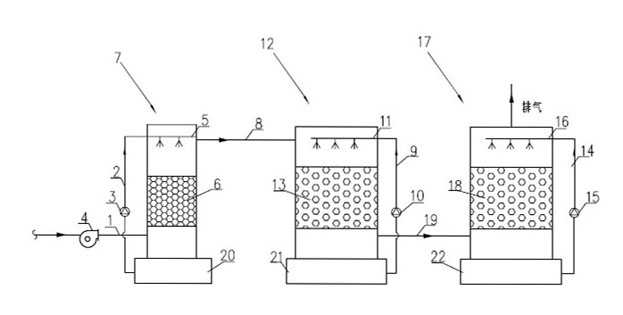

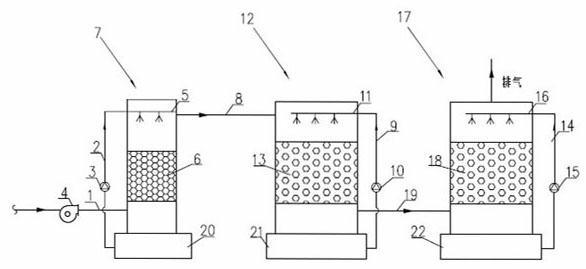

The invention discloses a method for treating odors produced by drying sewage sludge. The method comprises the following steps: (1) delivering odors exhausted by a sewage sludge drying system to a pretreatment tower through a fan to be rinsed with clean water, wherein the components soluble in water in the odors are absorbed by the clean water, and the odors are cooled at the same time; (2) rinsing the pretreated odors in a primary spraying tower, wherein the acid gases and volatile organic compound gases in the odors are subjected to chemical reaction with the spraying solution with strong oxidability and alkalinity in the primary spraying tower and are absorbed; (3) rinsing the remaining gases after treatment in the step (2) in a secondary spraying tower, wherein alkaline gases in the gases are subjected to neutralization reaction with the acid spraying solution in the secondary spraying tower and are absorbed; and (4) exhausting the tail gases after treatment in the step (3) through an exhaust pipe. After the odors produced by drying the sewage sludge are treated by the method disclosed by the invention, the obtained tail gases can reach the secondary emission standard in the Emission Standards for Odor Pollutants (GB14554-93).

Owner:广州中洲环保科技有限公司

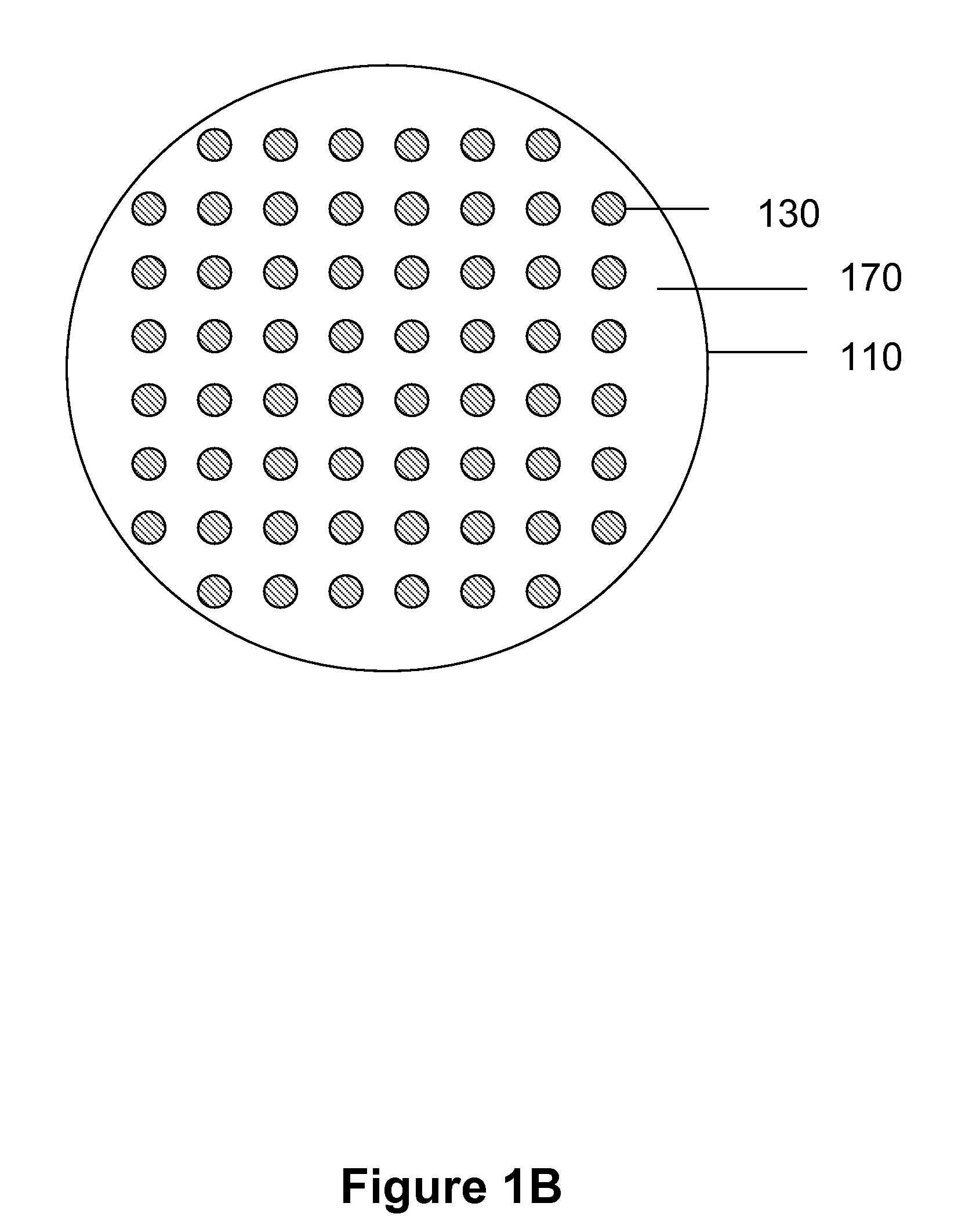

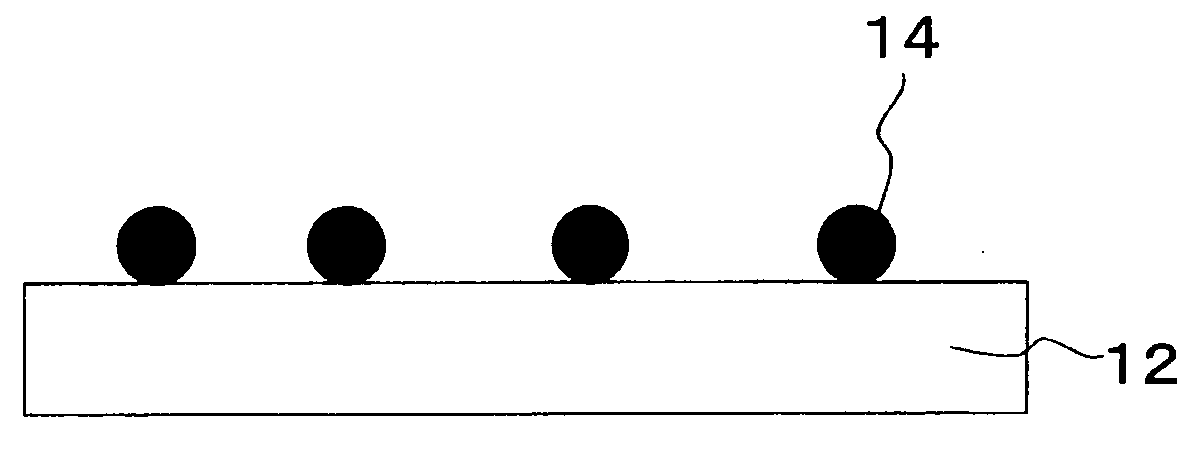

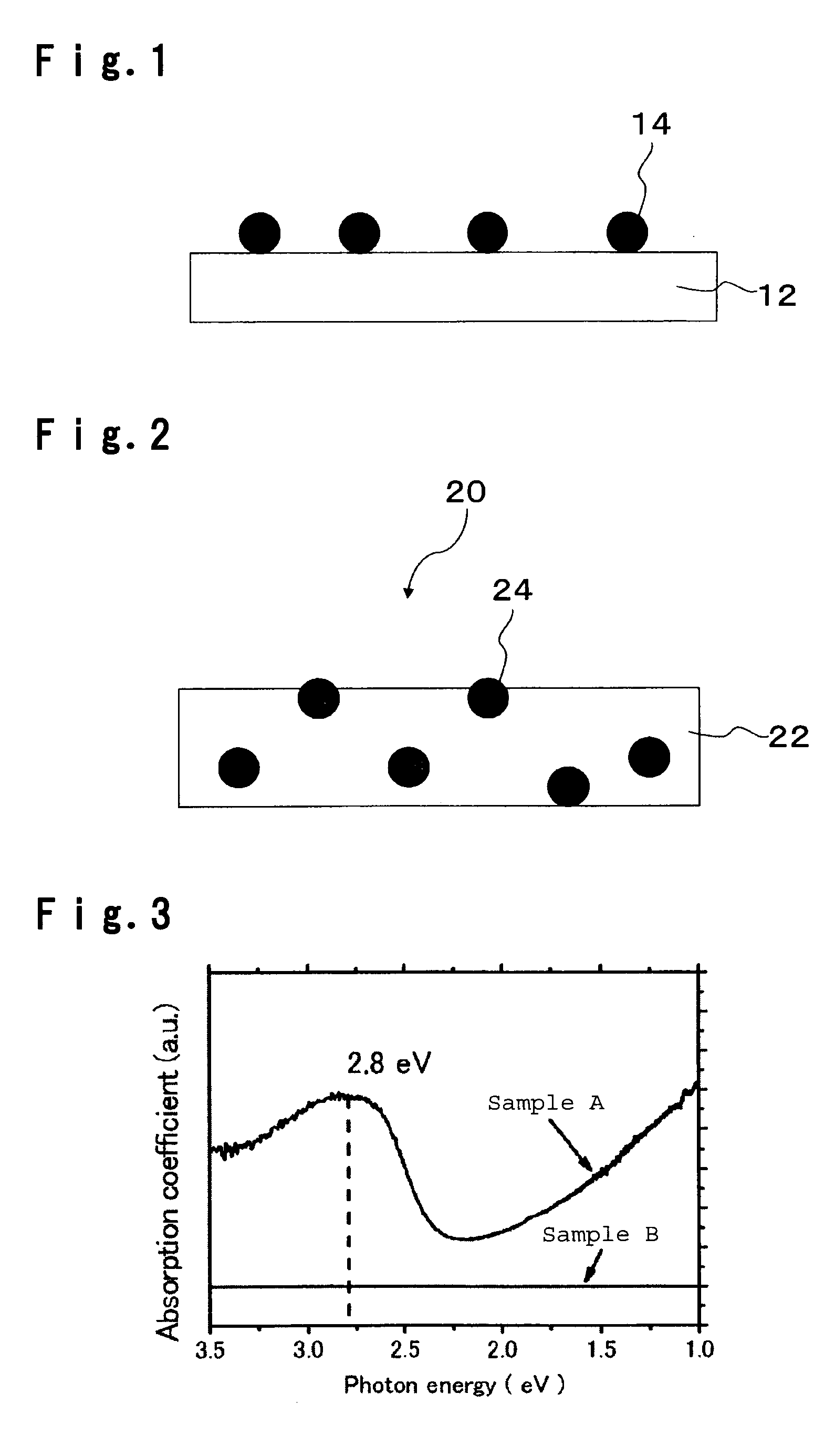

Nanopillar arrays for electron emission

The present invention provides systems, devices, device components and structures for modulating the intensity and / or energies of electrons, including a beam of incident electrons. In some embodiments, for example, the present invention provides nano-structured semiconductor membrane structures capable of generating secondary electron emission. Nano-structured semiconductor membranes of this aspect of the present invention include membranes having an array of nanopillar structures capable of providing electron emission for amplification, filtering and / or detection of incident radiation, for example secondary electron emission and / or field emission. Nano-structured semiconductor membranes of the present invention are useful as converters wherein interaction of incident primary electrons and nanopillars of the nanopillar array generates secondary emission. Nano-structured semiconductor membranes of this aspect of the present invention are also useful as directed charge amplifiers wherein secondary emission from a nanopillar array provides gain functionality for increasing the intensity of radiation comprising incident electrons.

Owner:WISCONSIN ALUMNI RES FOUND

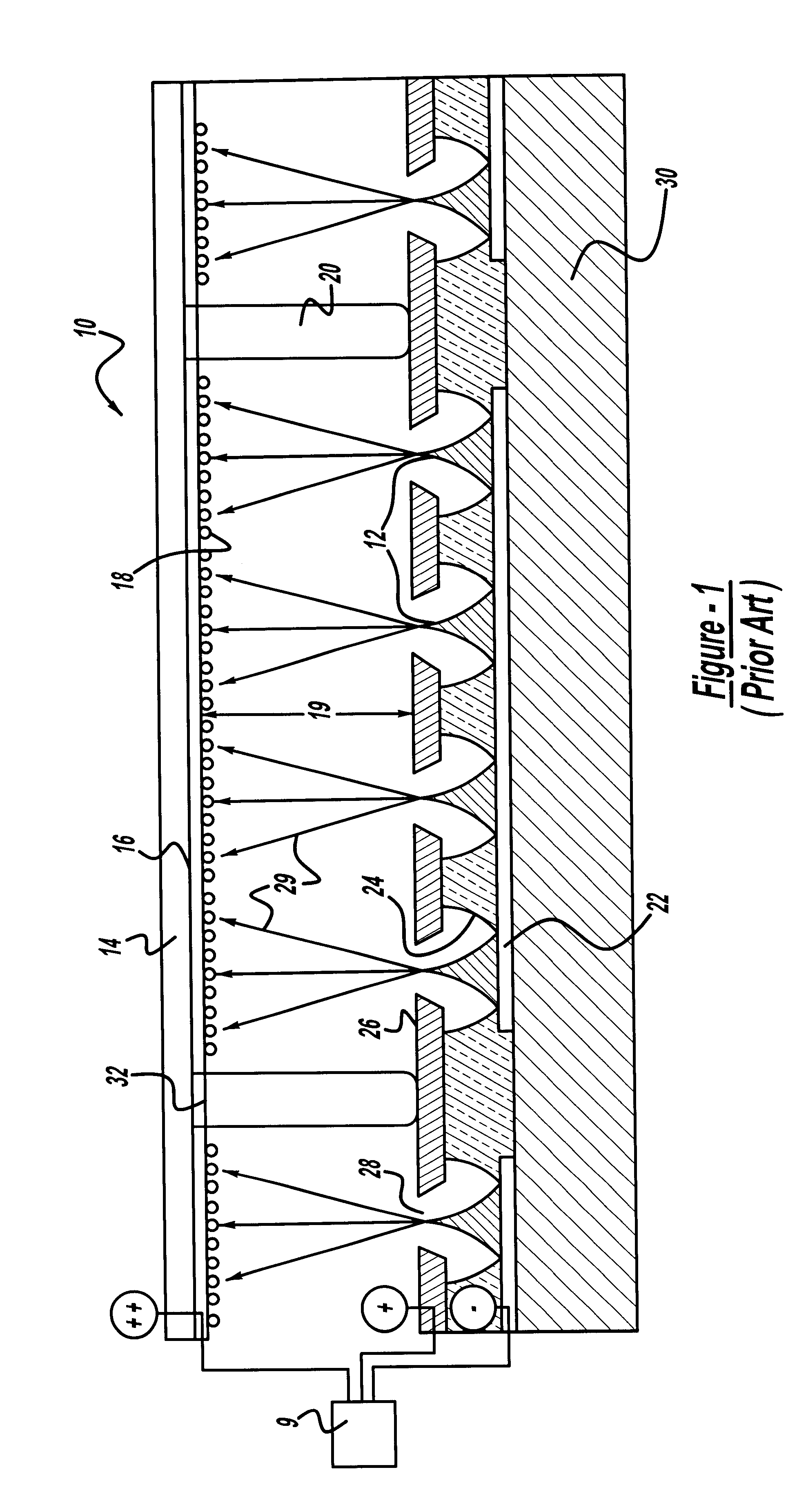

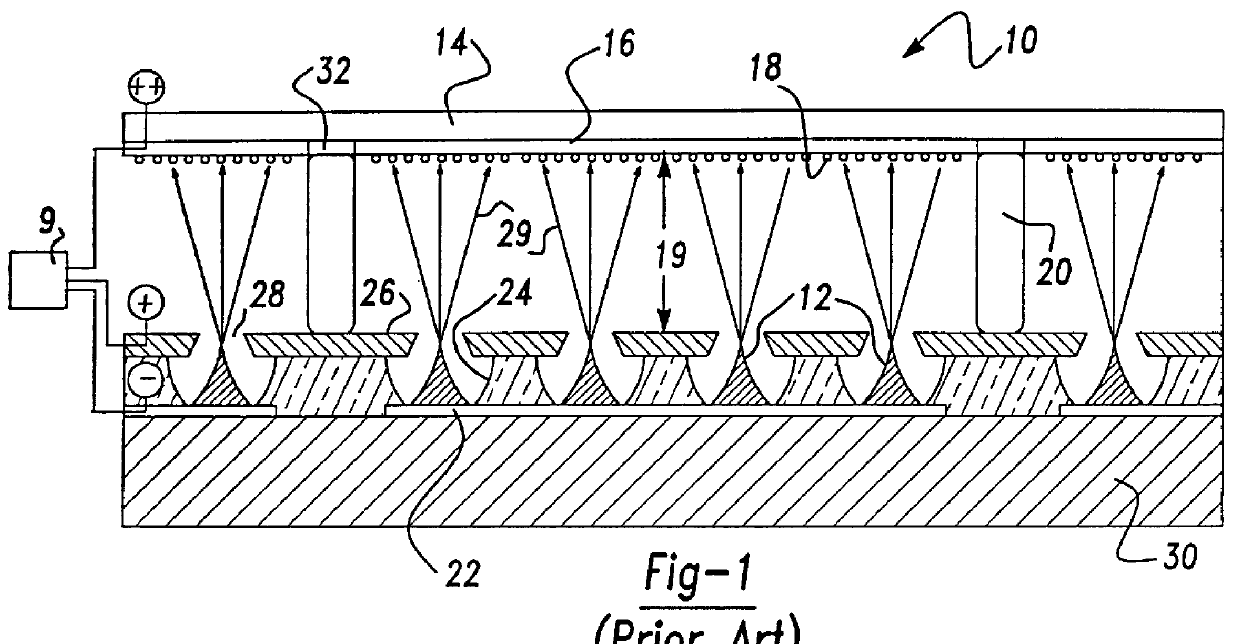

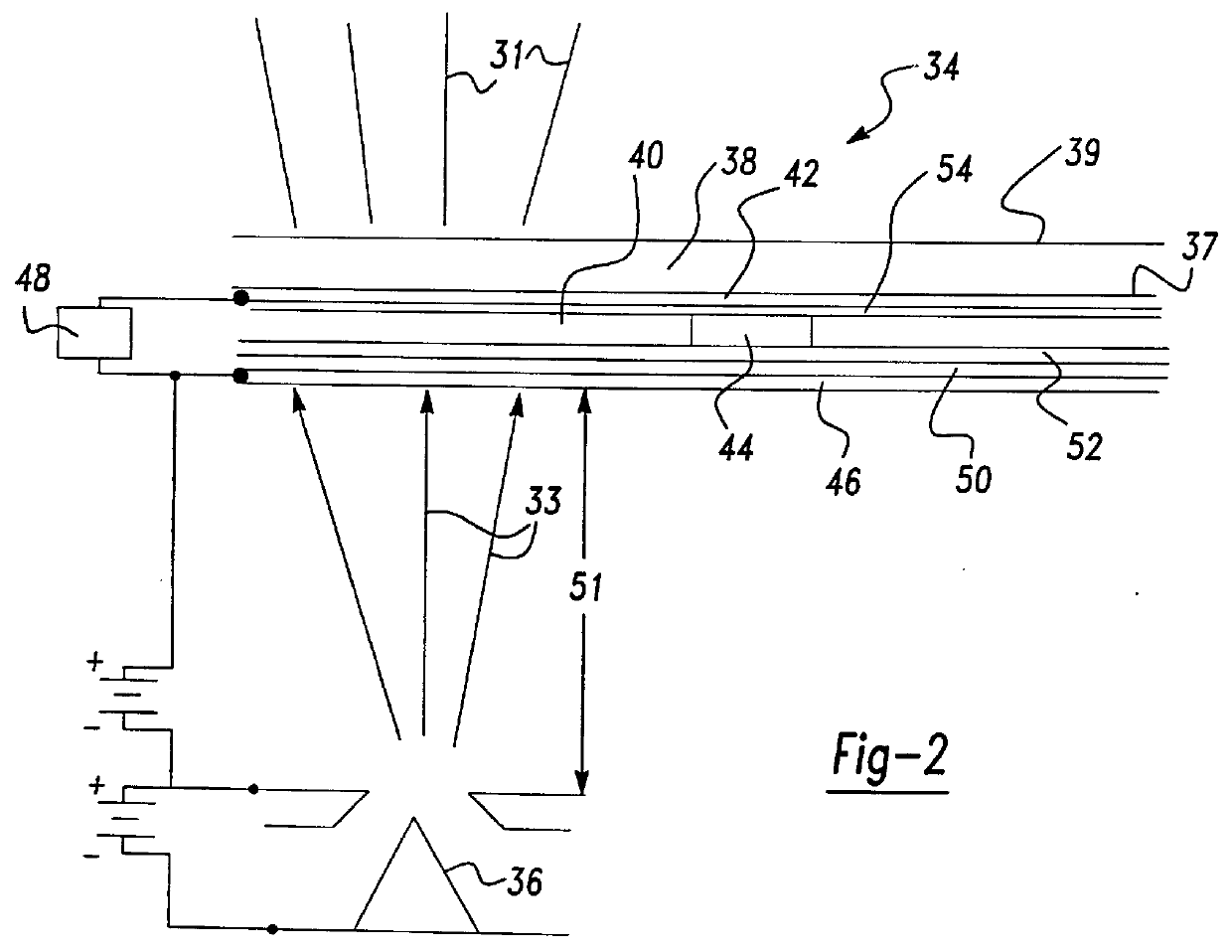

Electron amplification channel structure for use in field emission display devices

InactiveUS6323594B1Improve efficiencyExcellent optical propertiesDischarge tube luminescnet screensElectrode and associated part arrangementsSecondary emissionElectron source

Cathodoluminescent field emission display devices features an electron amplification structure for generating secondary electron emissions. The electron amplification structure includes a channel structure having a bottom wall coupled to at least one side wall, thereby defining a channel cavity, and at least one protrusion extending from the side wall into the channel cavity. Furthermore, a primary electron source or emitter is provided for generating primary electron emission into the channel cavity, whereby secondary emissions of electrons are produced when the protrusion is bombarded by electrons within the channel structure. The use of a narrow channel in the electron amplification structure reduces the possibility that a returning ion will strike the emitter, and thus decreases cathode emitter tip erosion.

Owner:ST CLAIR INTPROP CONSULTANTS

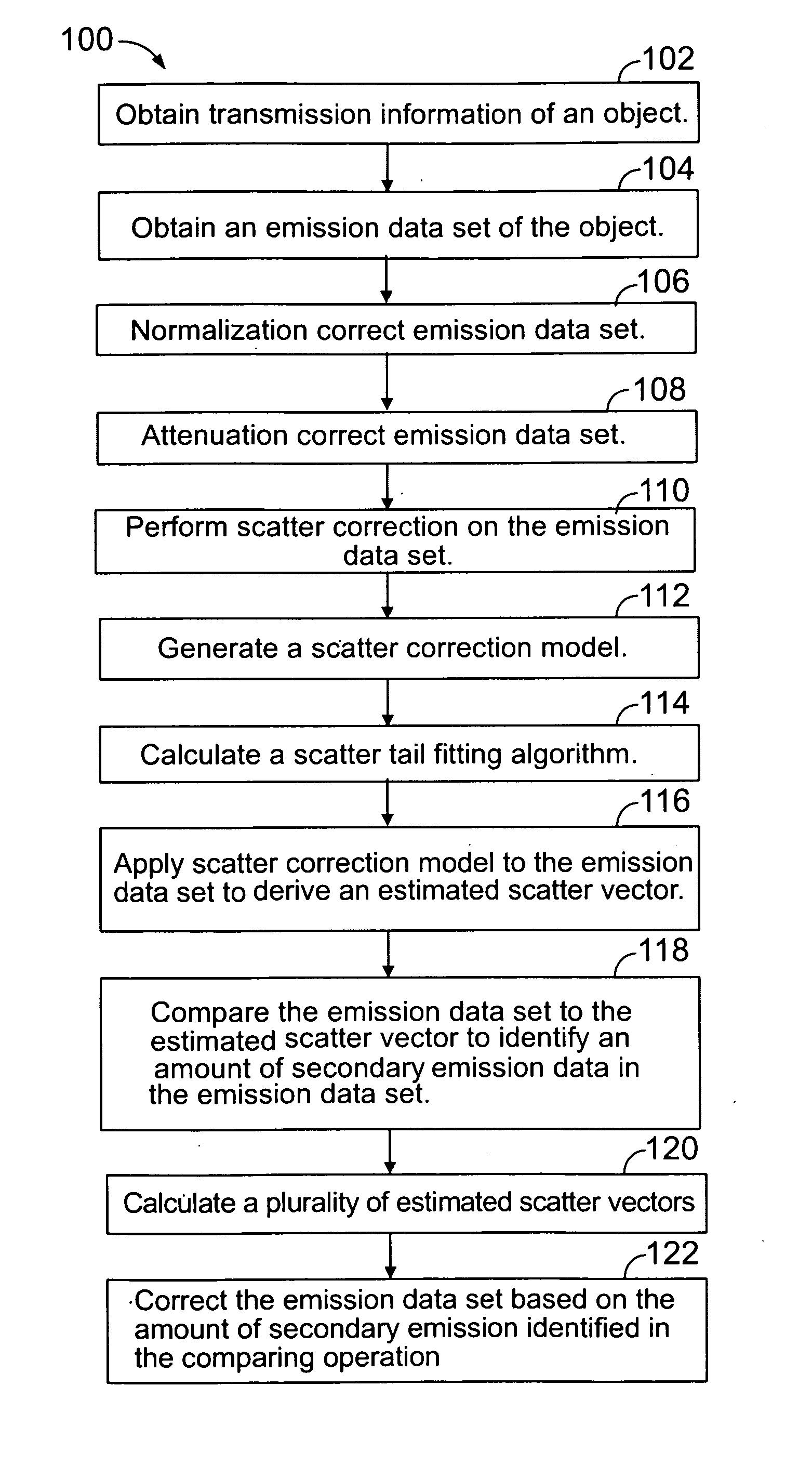

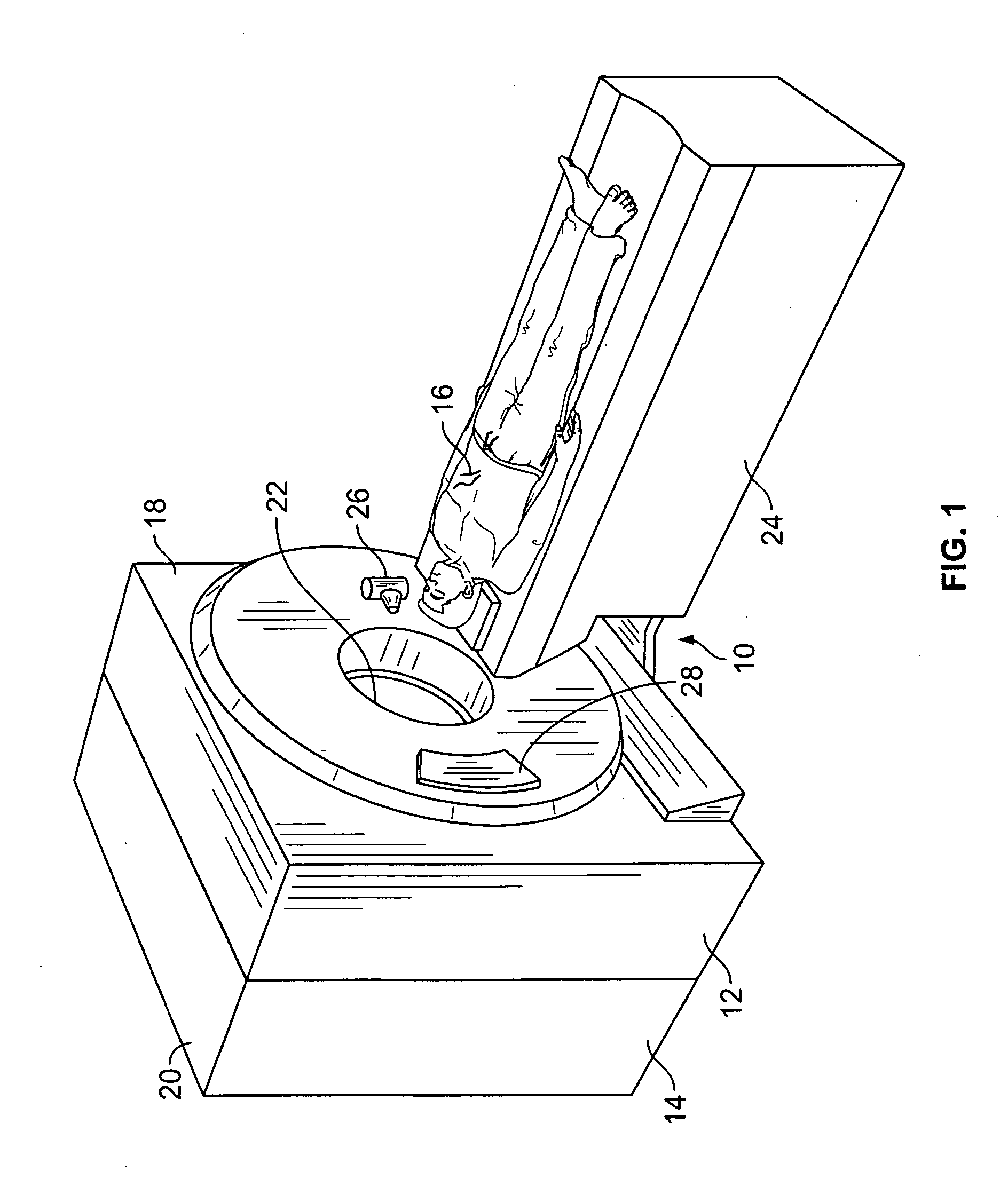

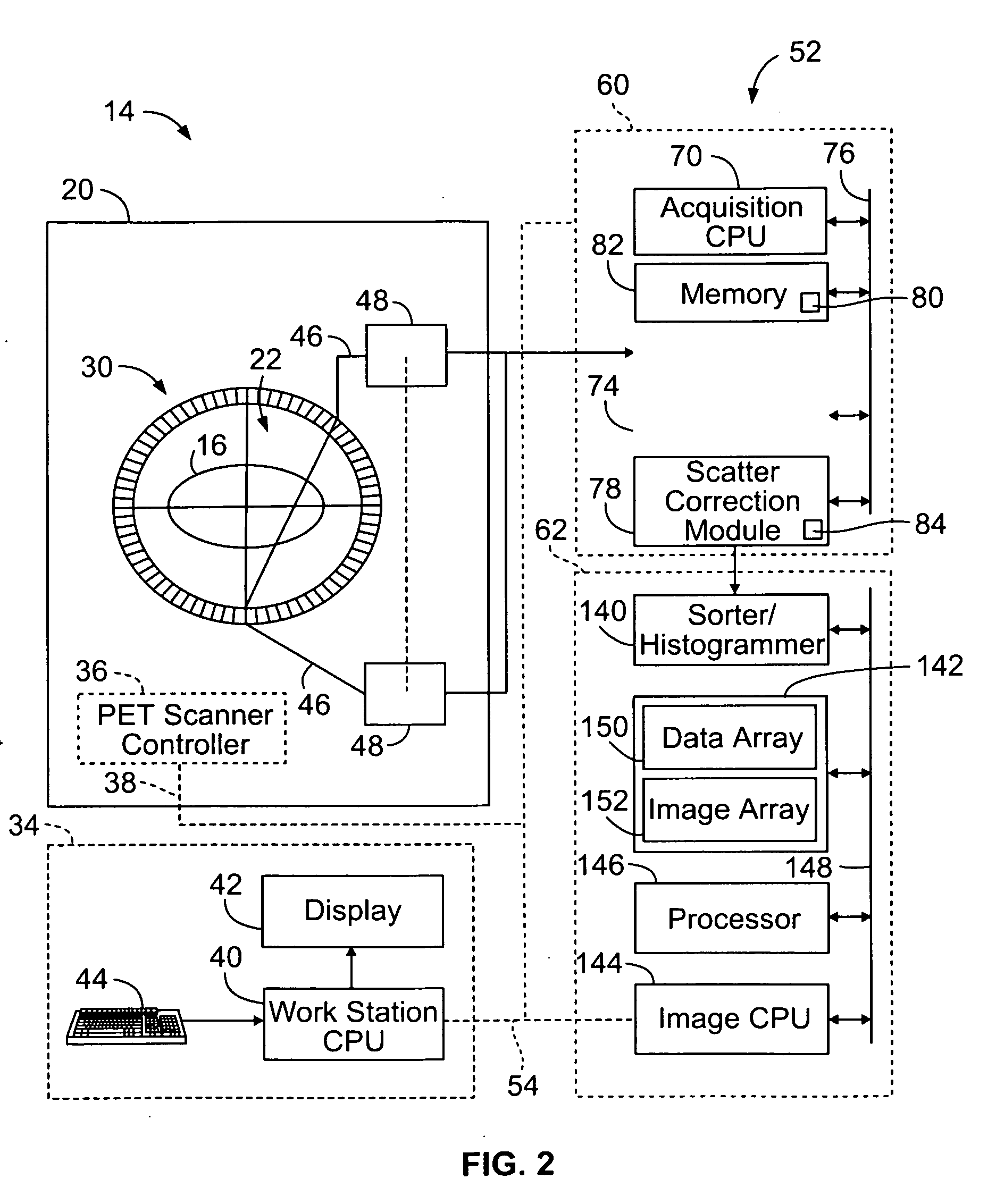

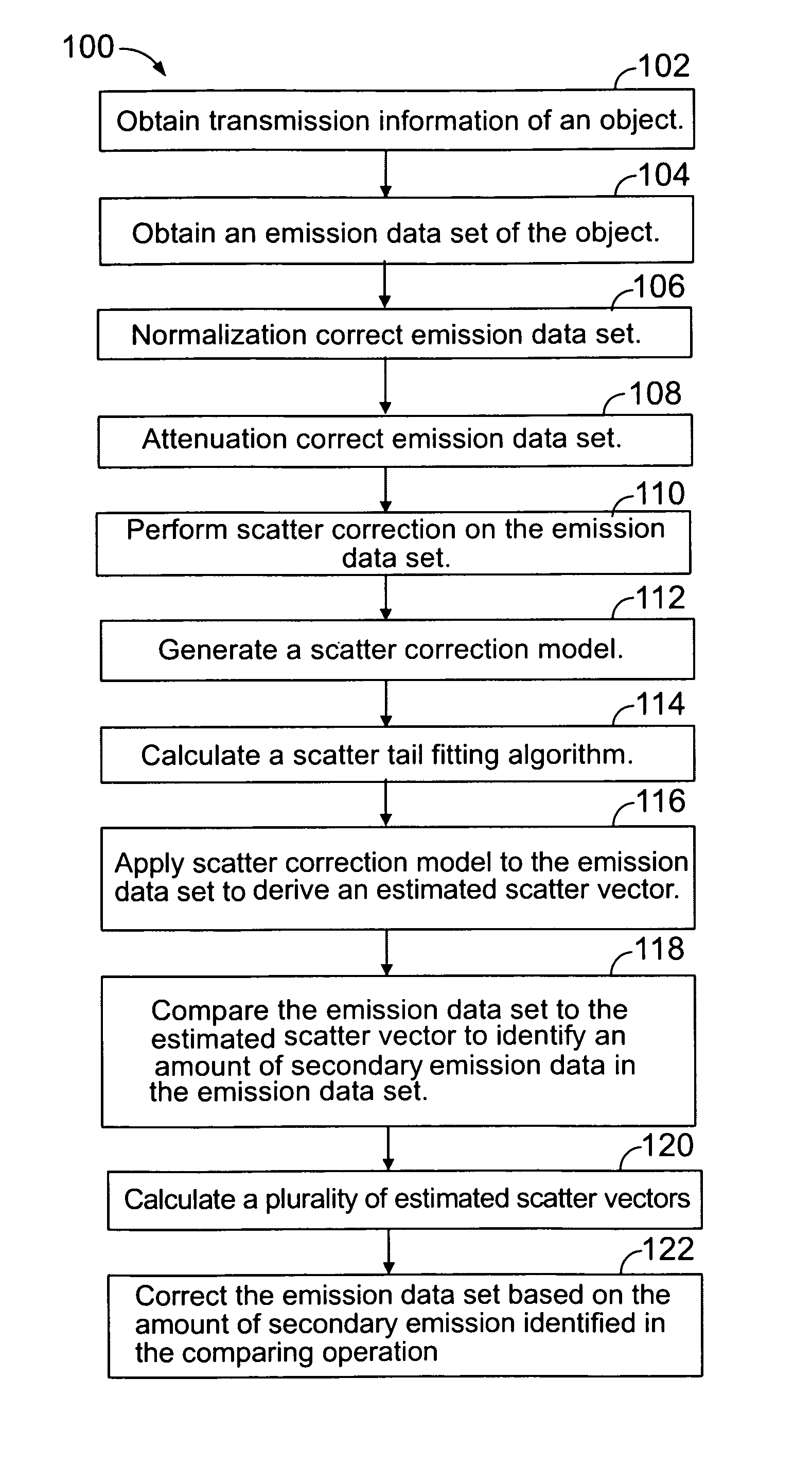

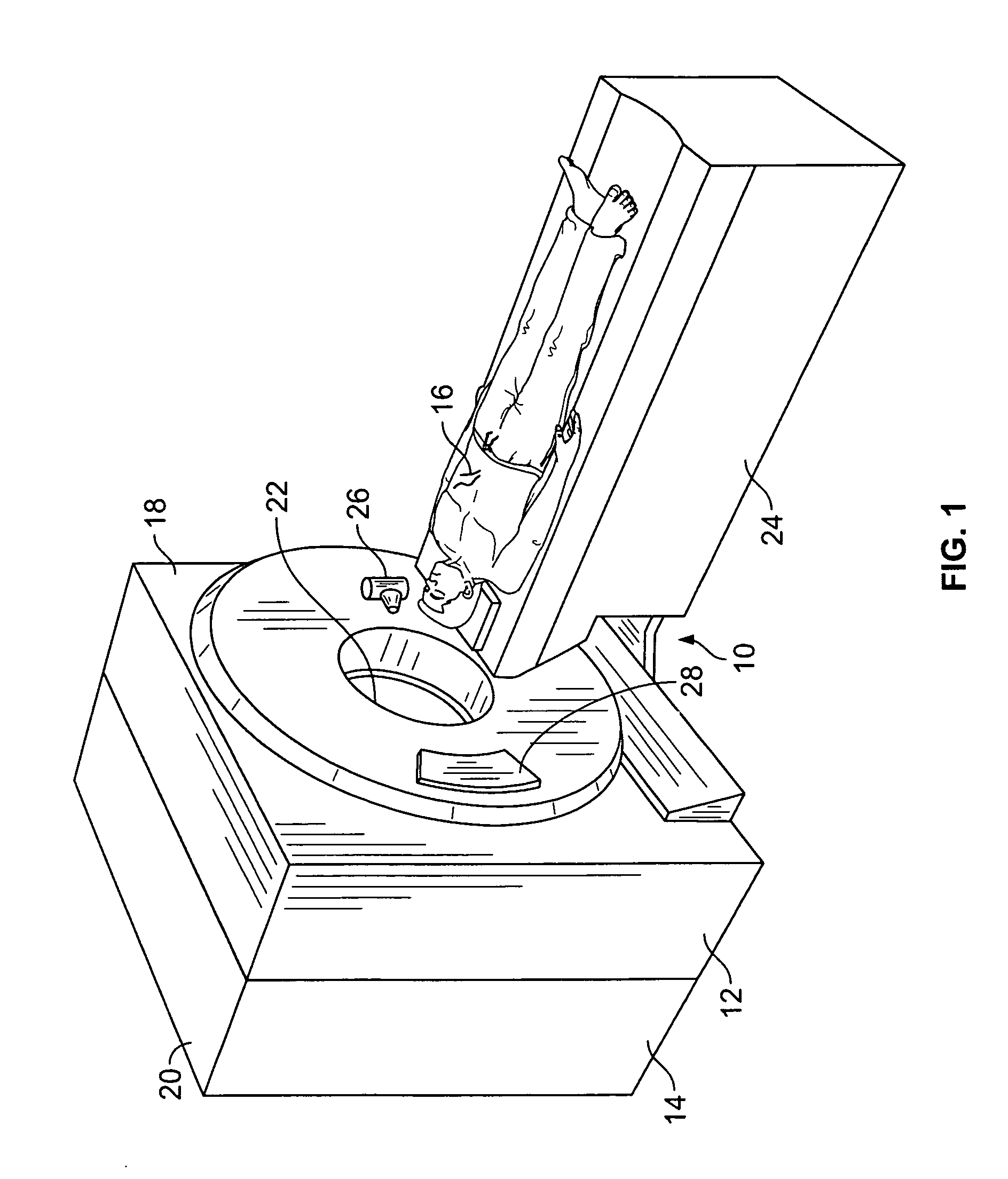

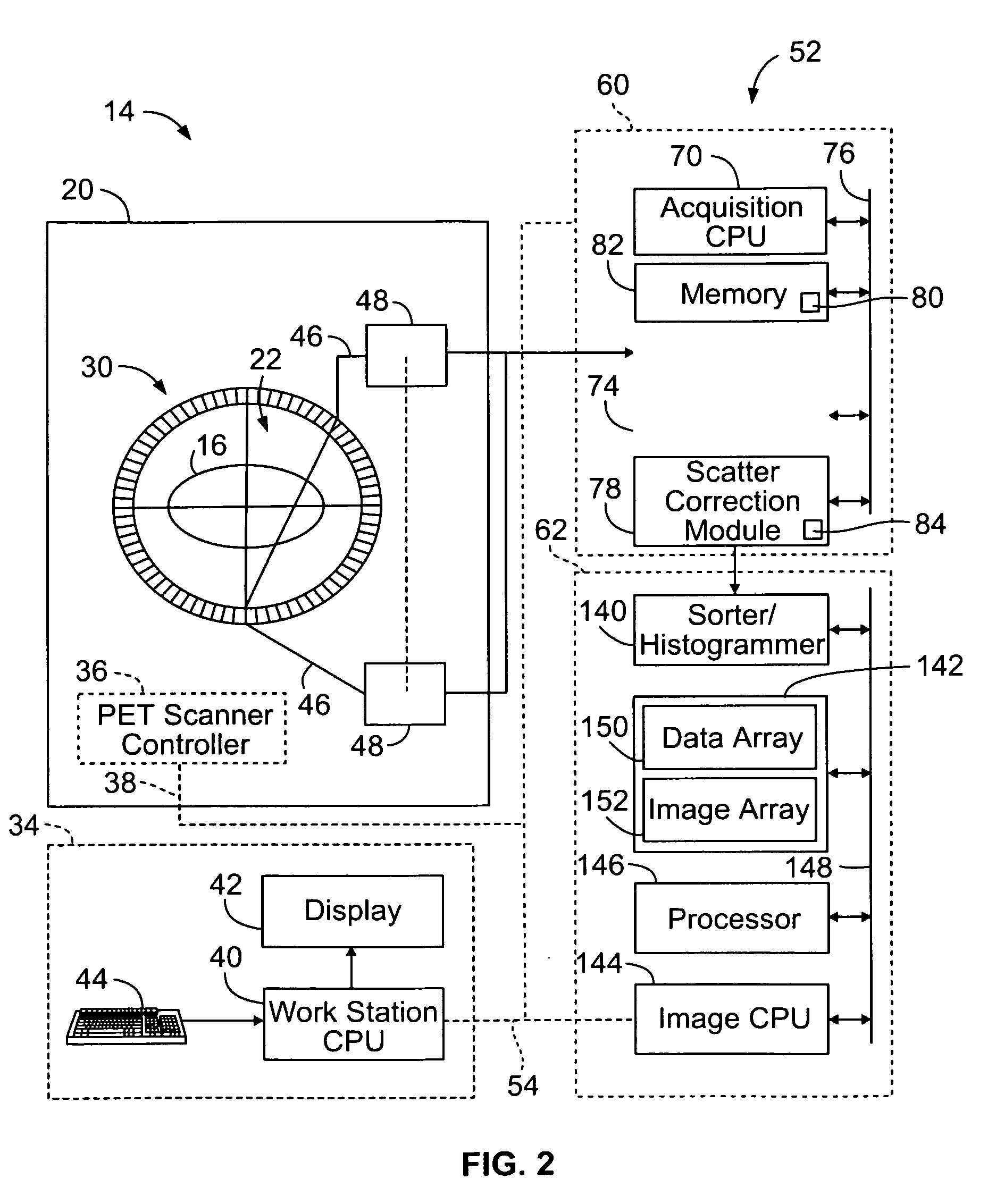

Method and system for scatter correction

ActiveUS20100116994A1Material analysis by optical meansHandling using diaphragms/collimetersData setSecondary emission

A method and apparatus are provided for correcting primary and secondary emission data. The method includes obtaining an emission data set having primary and secondary emission data representative of primary and secondary emission particles emitting from a region of interest and applying a scatter correction model to the emission data set to derive an estimated scatter vector. The method also includes comparing the emission data set to the estimated scatter vector to identify an amount of secondary emission data in the emission data set and correcting the emission data set based on the amount of secondary emission data identified in the comparing operation.

Owner:GENERAL ELECTRIC CO

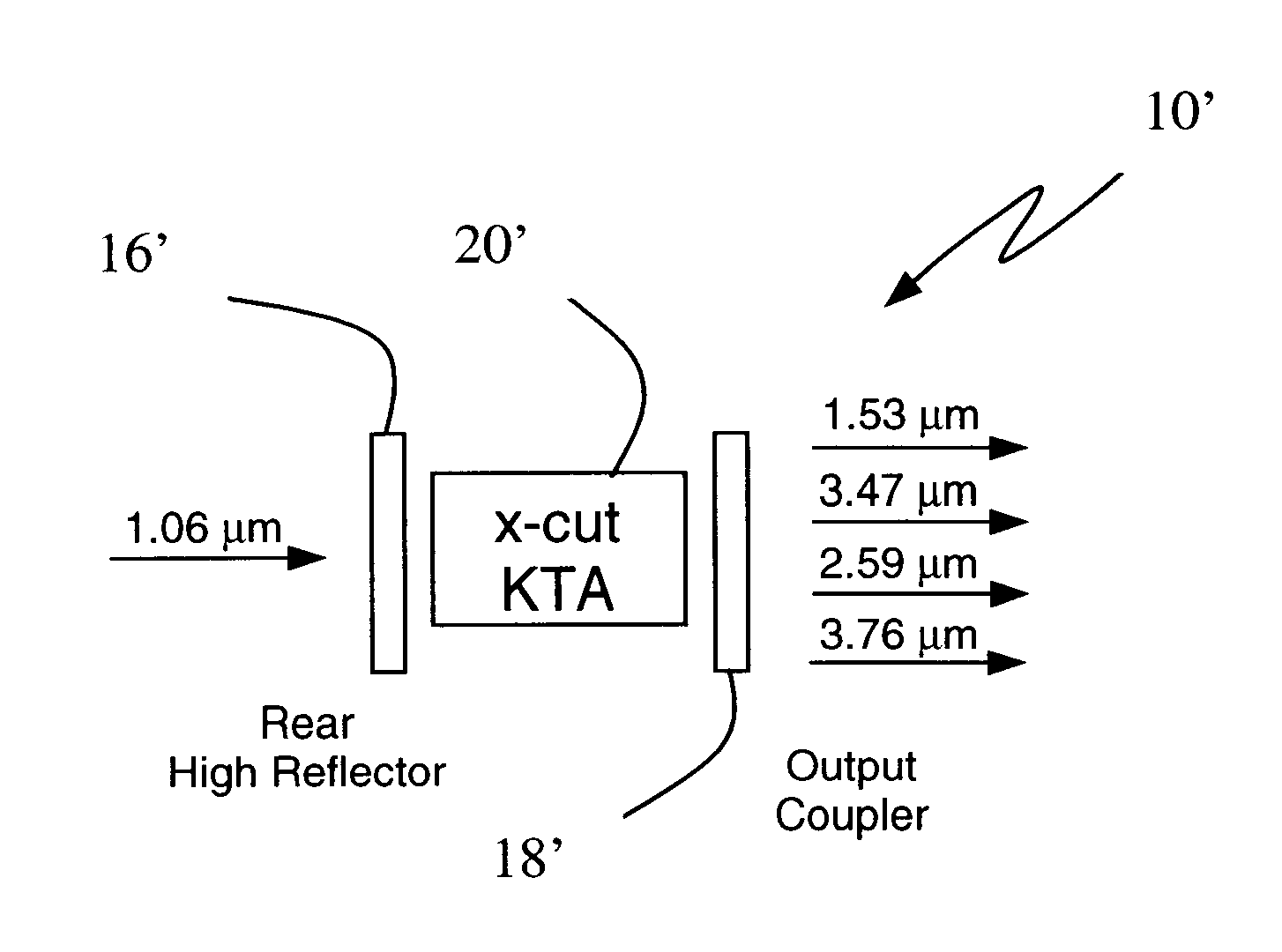

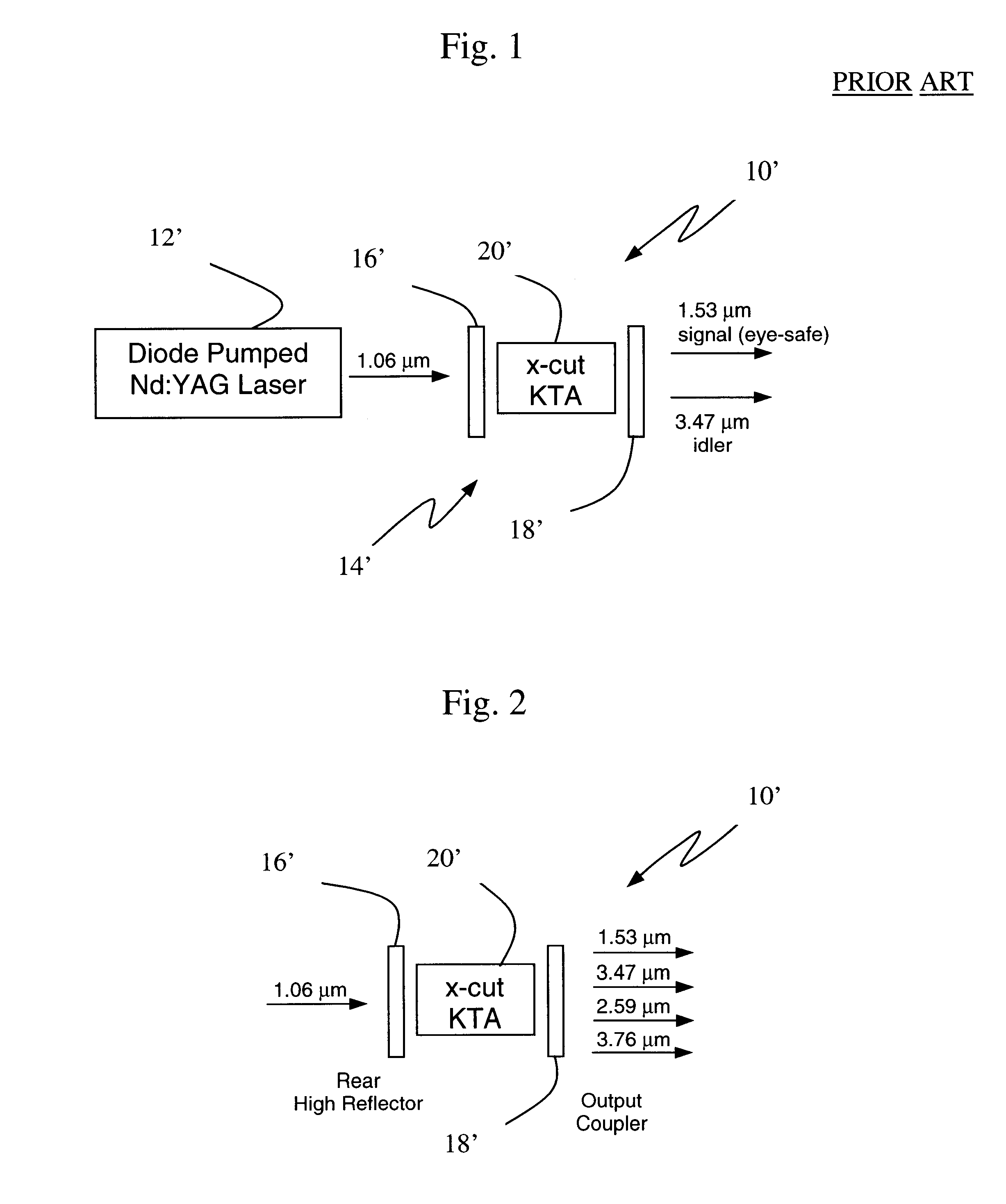

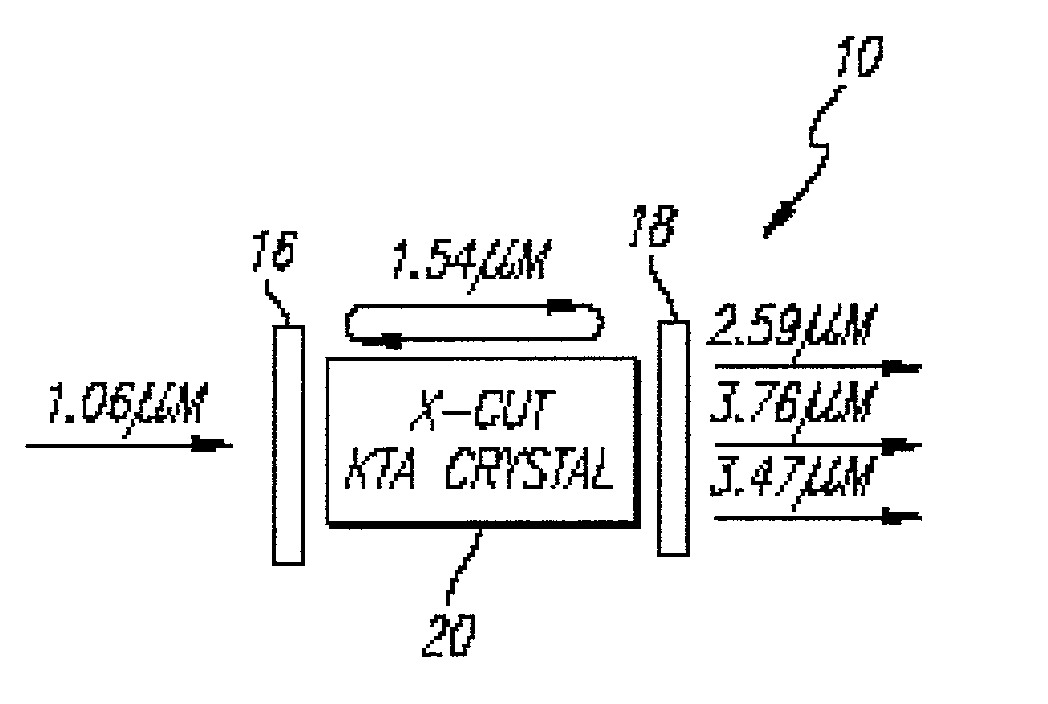

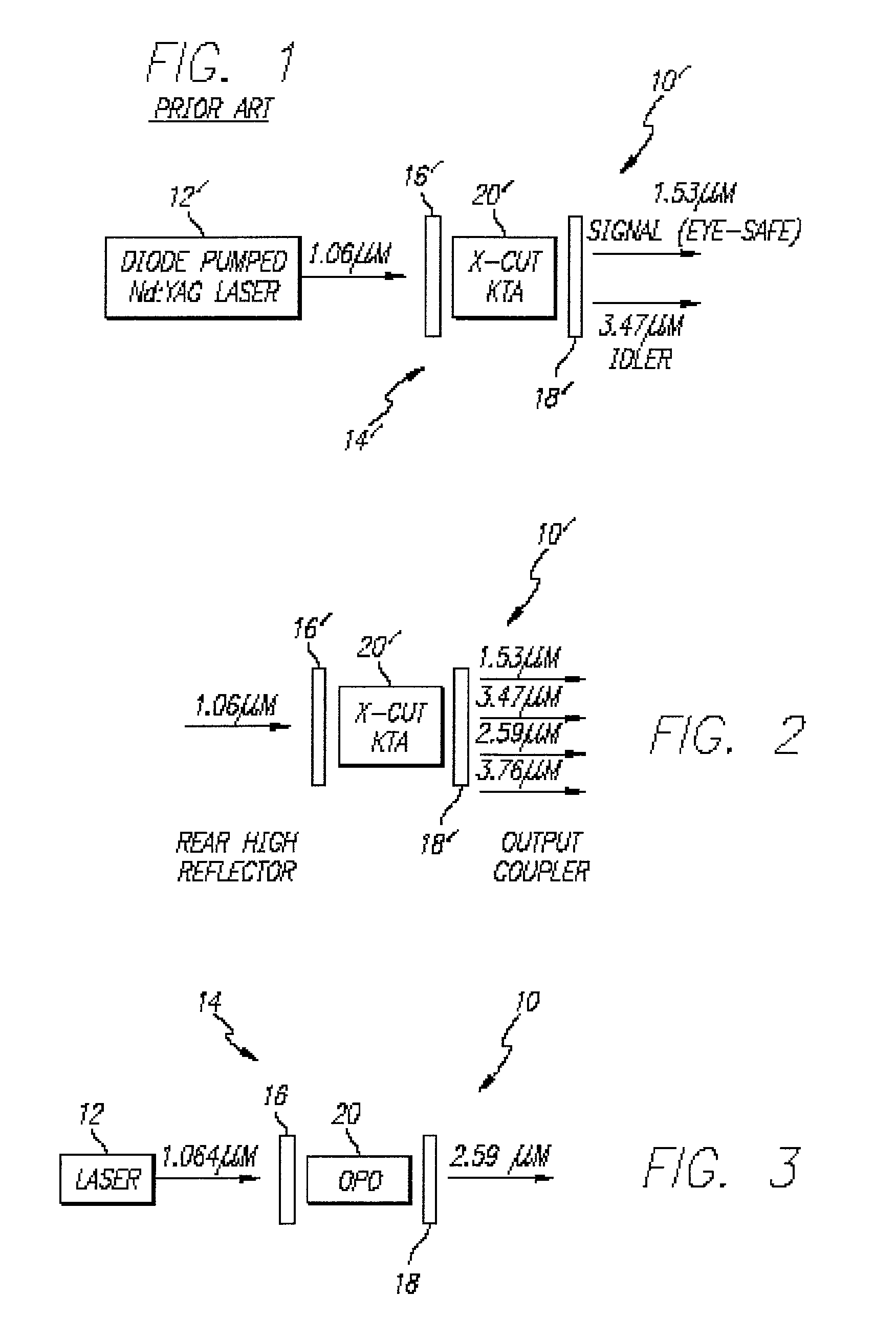

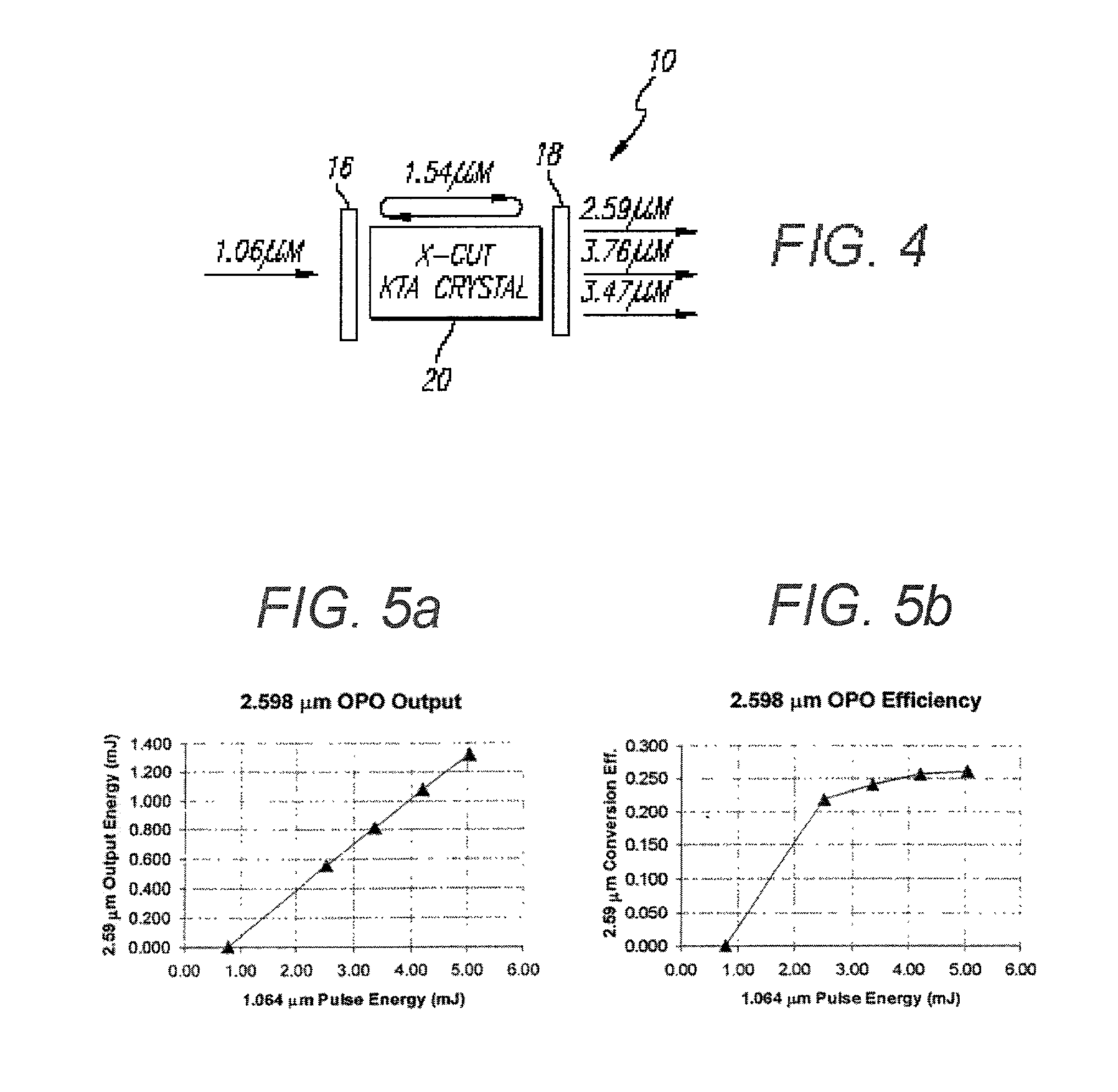

Monolithic serial optical parametric oscillator

InactiveUS6344920B1Optical resonator shape and constructionLight demodulationEnergy transferSecondary emission

An arrangement (10) for efficiently shifting energy received at a first wavelength and outputting the shifted energy at a second wavelength. The arrangement (10) includes a laser (12) and an optical parametric oscillator (14) of unique design. The oscillator (14) is constructed with a energy shifting crystal (20) and first and second reflective elements (16) and (18) disposed on either side thereof. Light from the laser (12) at a fundament frequency is shifted by the crystal and output at a second wavelength. The second wavelength is a primary emission and induces a secondary emission of energy in the crystal. A novel feature of the invention is a coating applied on the reflective elements (16 and / or 18) for minimizing the secondary emission. This constrains the energy to be output by the arrangement (10) at the wavelength of the desired primary emission. In the alternative, the arrangement (10) may be optimized to output one or more of the secondary emissions.

Owner:RAYTHEON CO

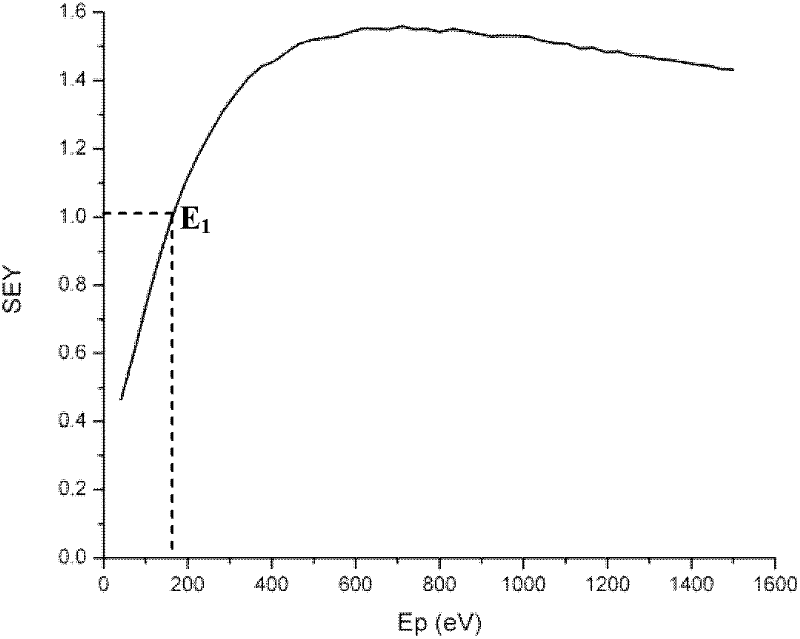

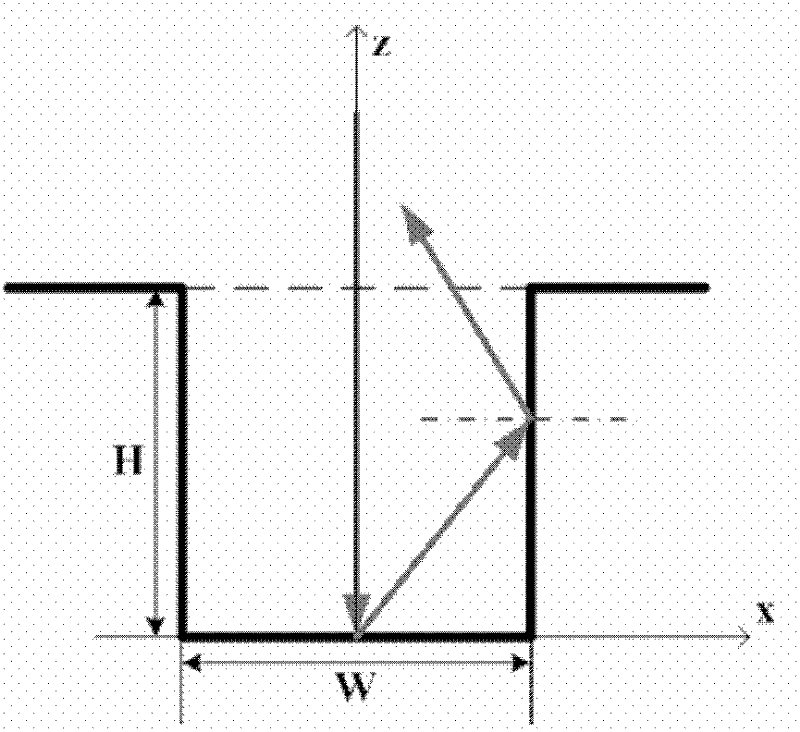

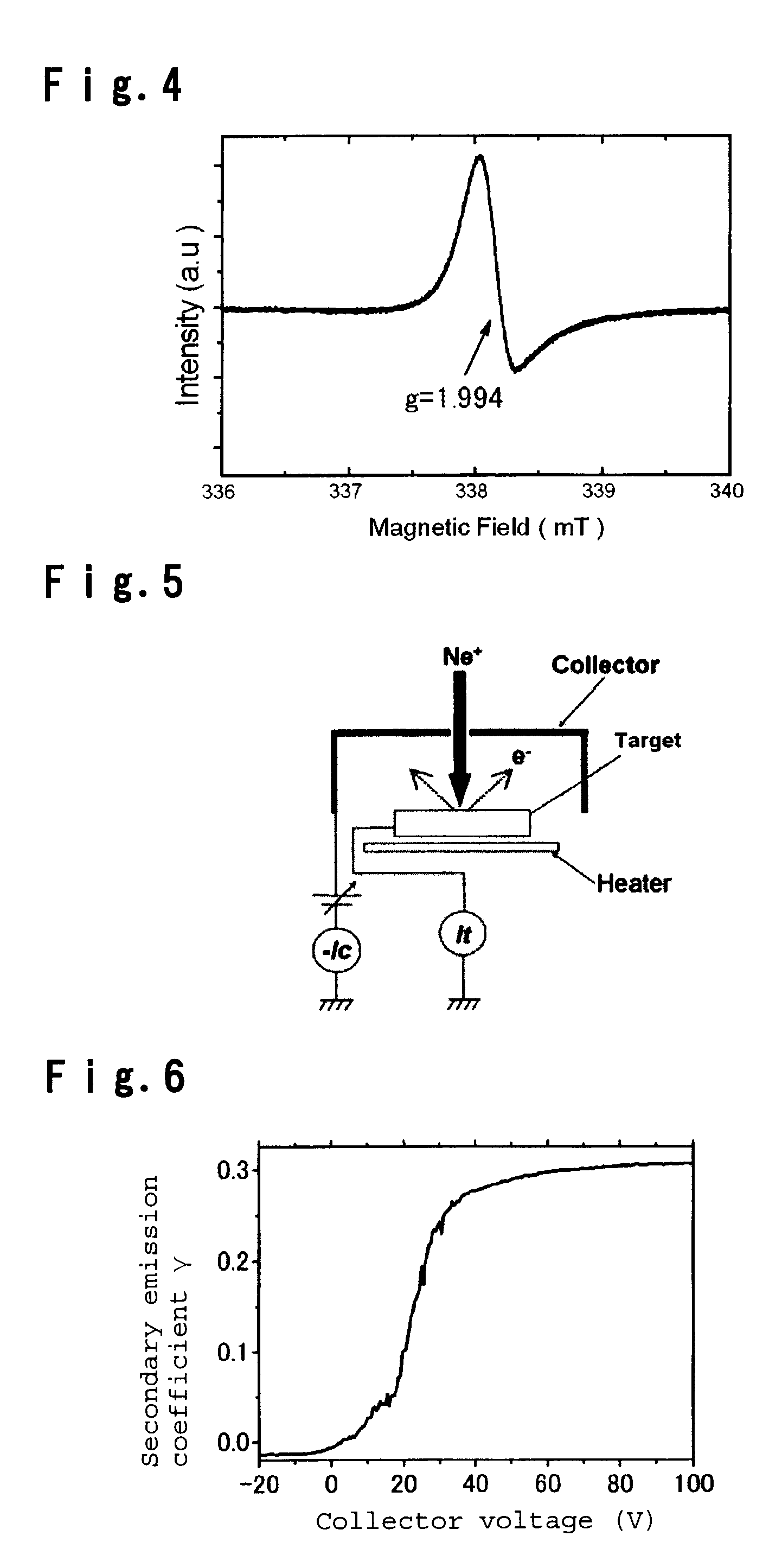

Method for restraining secondary emission of surface nano-structure of microwave component

InactiveCN102515085ARaise the microdischarge thresholdAvoid negative effectsDecorative surface effectsChemical vapor deposition coatingPorosityElectrical conductor

A method for restraining the secondary emission of a surface nano-structure of a microwave component comprises the following steps that: a metal nano-structure is formed on a good conductor layer of a microwave component basal body; different test conditions are selected, and comprise the porosity, depth-to-width ratio and shape of the nano-structure; a Monte-Carlo simulation is utilized to simulate the collision and absorption processes of an electron which enters the nano-structure and the collision, absorption and escape processes of a secondary electron which is produced by the electron, and the secondary emission yield of a single nano-structure is theoretically obtained; and according to the principle of secondary emission yield, various surface treatment technologies are utilized to adjust the shape, depth-to-width ratio and porosity of the surface nano-structure of the microwave component, so the secondary emission yield is the minmum. The method can greatly improve the micro discharge threshold of the microwave component which undergoes the electrochemical silvering surface treatment; and the secondary electron trap structure with high depth-to-width ratio is easier to realize, the influence on surface roughness can be neglected to a certain extent, and negative effects which are caused by restraining the secondary emission yield (SEY) of the current large roughness structure surface are solved.

Owner:XI AN JIAOTONG UNIV +1

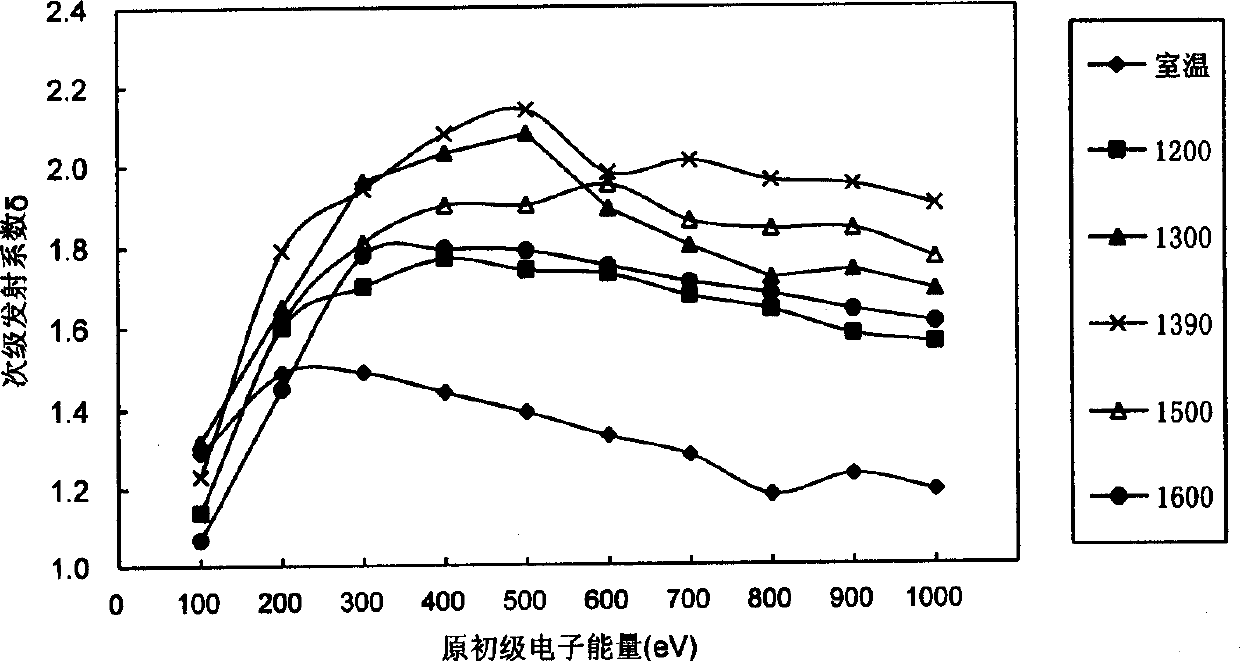

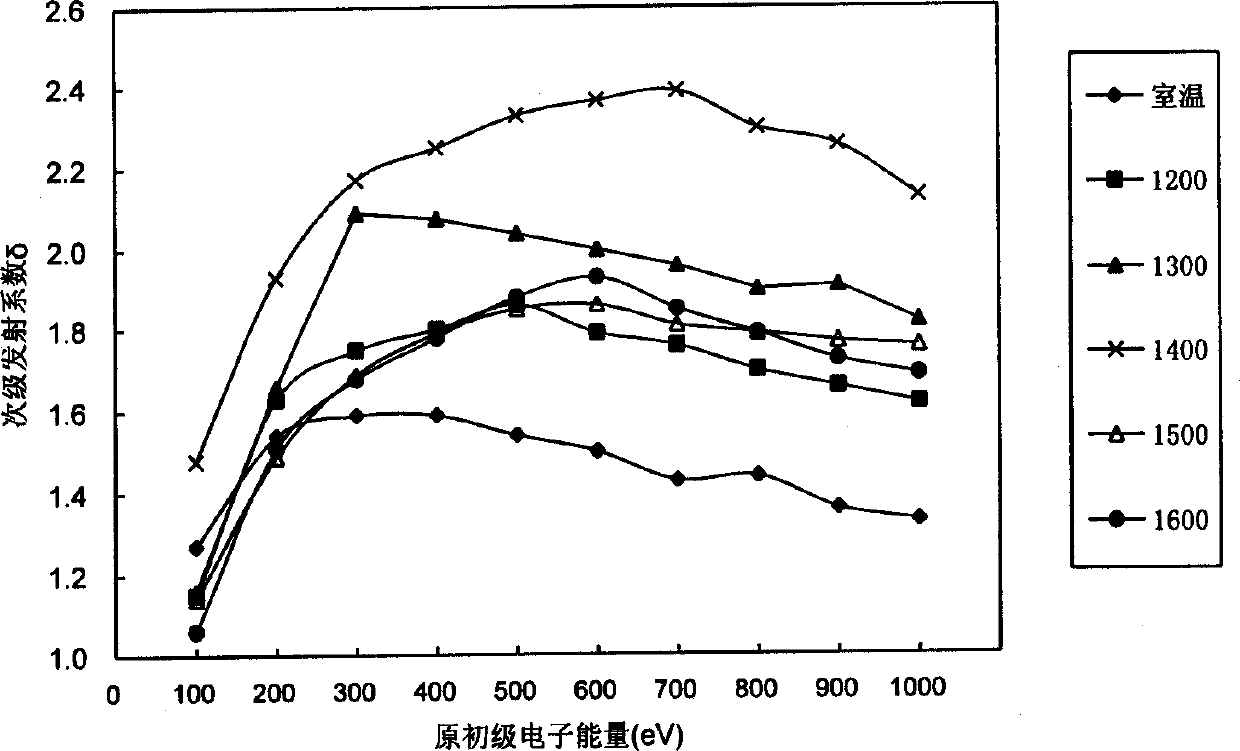

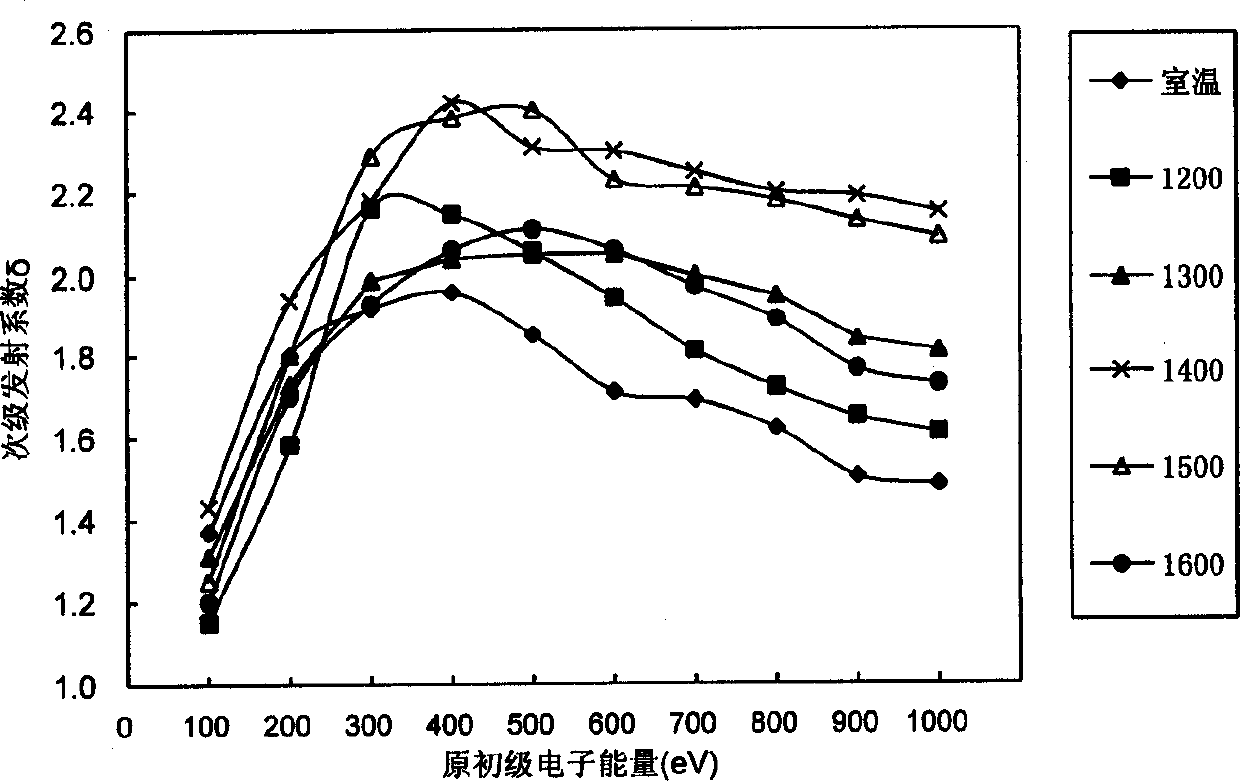

Secondary-emission rare earth-molybdenum material and its preparing process

InactiveCN1360079AImprove machinabilityThe secondary emission coefficient is constantMagnetronsGas discharge connecting/feedingHigh resistanceSecondary emission

A two-element rare-earth / molybdenum material as secondary emission material is characterized by that it contains La2O3 and Y2O3 in a weight ratio of 1:3, and is preapred through adding La2O3 and Y2O3in the form of aqueous solution of their nitrates to molybdenum oxide or Mo powder, treating in hydrogen at 500-550 deg.C for 1-5 hr, reducing at 800-1000 deg.C, and powder metallurgy to obtain said secondary emission material, which has advantages of high emission coefficient, stability and mechinability and high resistance to expose in atomosphere.

Owner:BEIJING UNIV OF TECH

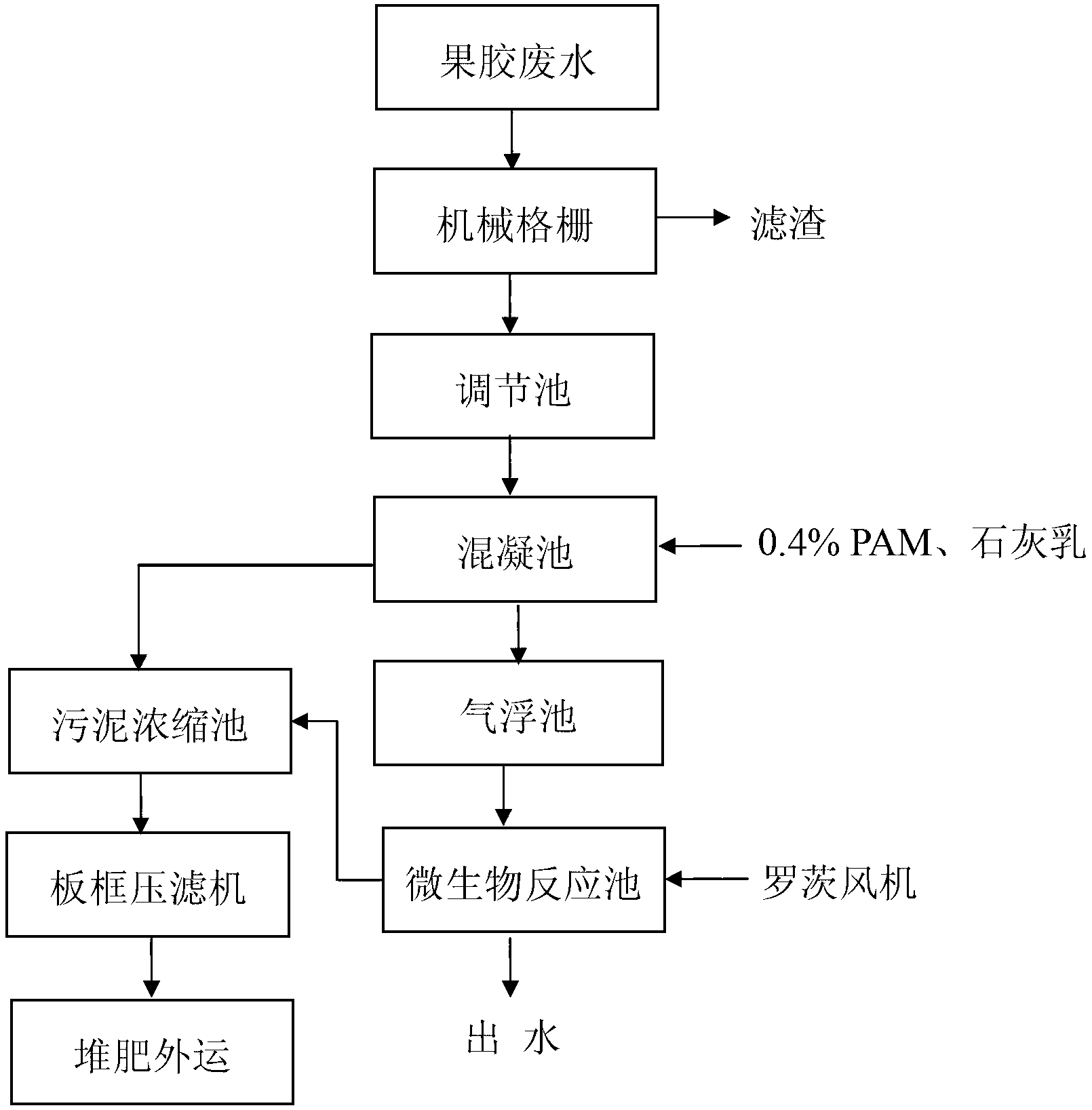

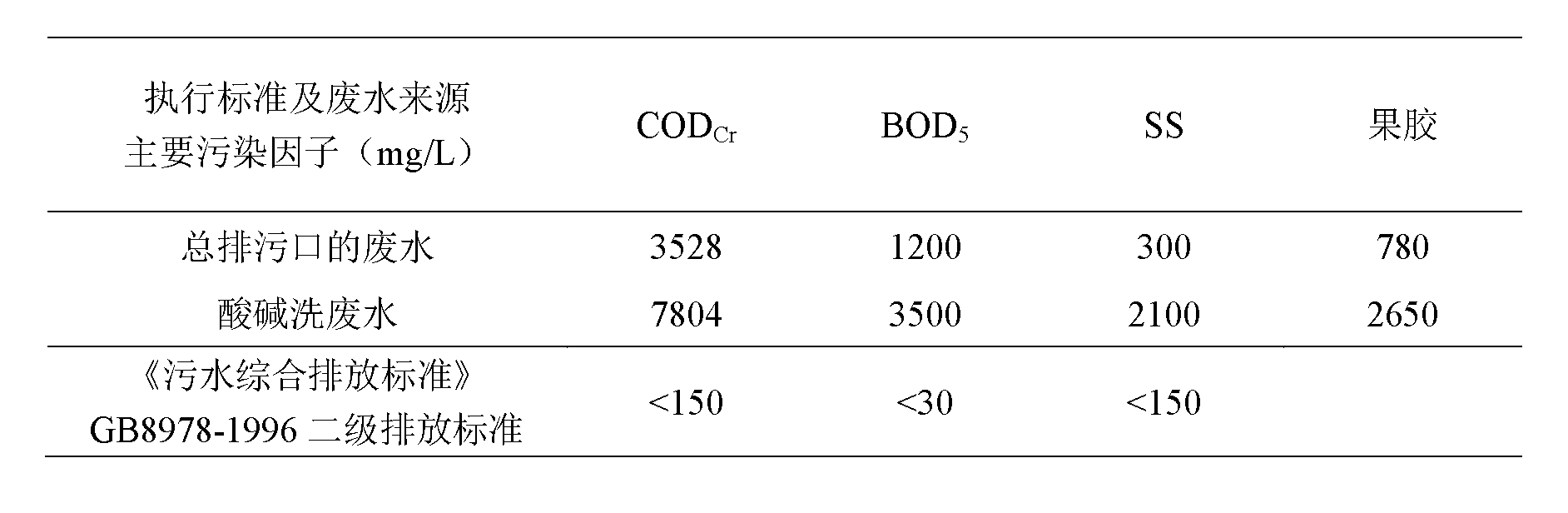

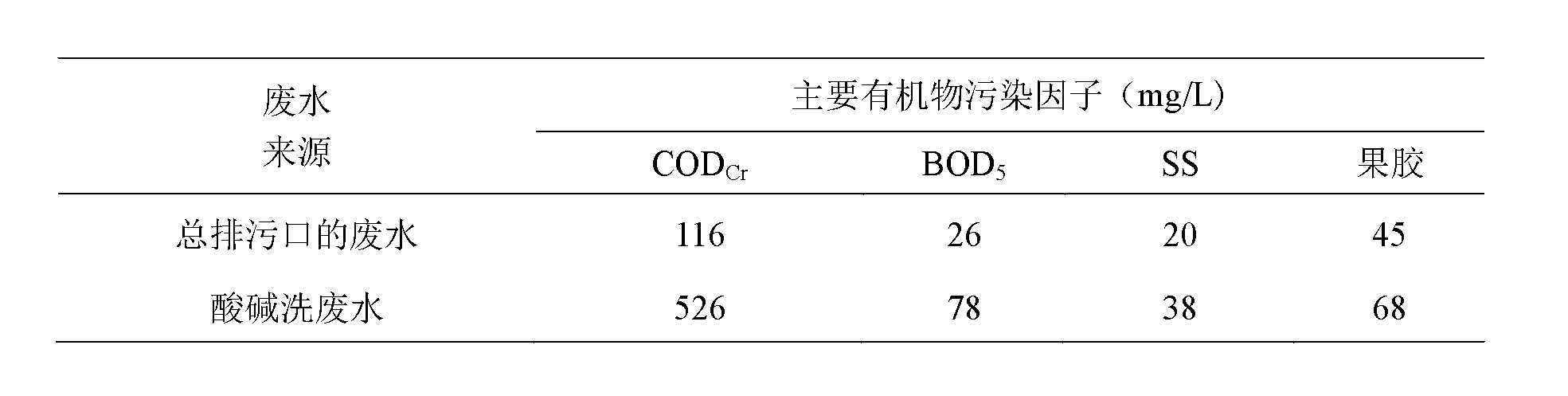

Method for treating canned citrus petal pectin wastewater

InactiveCN103304107AReduce contentAvoid secondary pollutionMultistage water/sewage treatmentPectinaseSecondary emission

The invention discloses a method for treating canned citrus petal pectin wastewater. By employing the method for combining mechanical bar screen and coagulating sedimentation, aerated air floatation and microbial advanced treatment, a mature strain of fungus penicillium simplicissimum is added into a microbial reaction pool in the microbial advanced treatment process, the pectin in the wastewater is degraded into low molecular weight organic matter galacturonic acid and methyl galacturonase under the catalytic action of pectinase generated by the mature strain of penicillium simplicissimum, and the highest degradation efficiency of the penicillium simplicissimum on the pectin is 97.4 percent; meanwhile, the penicillium simplicissimum has a good effect on the degradation of the CODCr in the wastewater, and the highest degradation efficiency on the CODCr is 89.9 percent; moreover, according to the process flow, the wastewater is extremely low in organic content and viscosity, the GB8978-1996 secondary emission standard of the integrated wastewater discharge standard is achieved, and emission on standard is realized. The process has the advantages that the energy consumption is low, the process is easy to operate, secondary pollution is not caused, and the like.

Owner:HUNAN UNIV

Optical communication systems and methods

ActiveUS9231708B2Reduce distractionsFacilitate communicationElectromagnetic transmission optical aspectsCommunications systemSecondary emission

A system and method to broadcast an optical signal through an amorphous medium, including a primary emitter capable of producing a primary optical signal during at least one broadcast period and capable of transmitting the primary optical signal through the amorphous medium. A secondary emitter, separate from the primary emitter and in operation during at least a portion of the broadcast period, produces a secondary emission detectable by a detector during the broadcast period. A signal entrainment controller, in communication with the primary emitter and the secondary emitter, synchronizes the secondary emitter with the primary emitter to generate a resultant signal of higher intensity than the primary signal by itself.

Owner:WOODS HOLE OCEANOGRAPHIC INSTITUTION

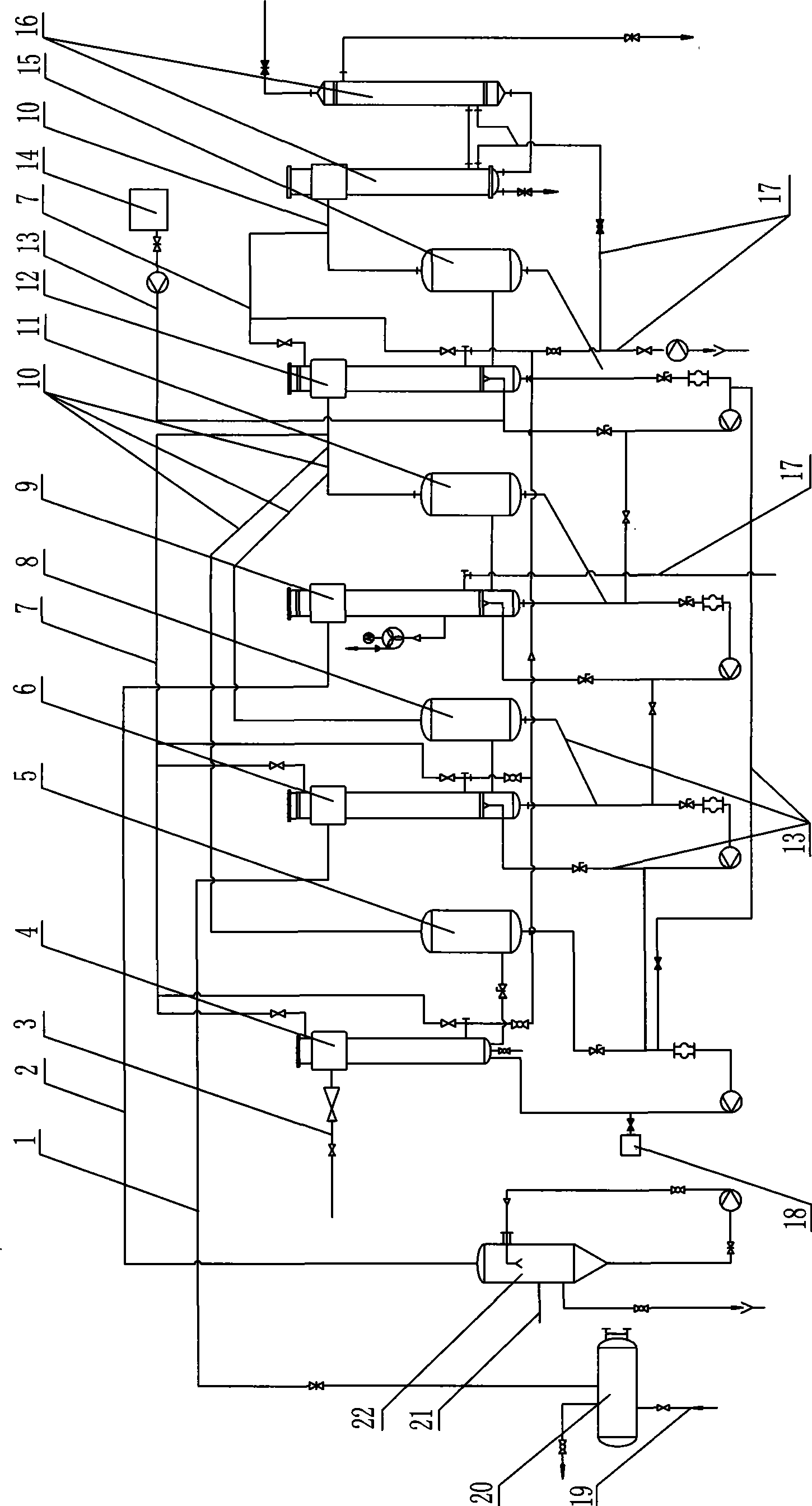

Method and equipment for utilizing waste heat from corn starch production

The invention belongs to the corn starch production technology field by a wet method, particularly relates to a use method of dry waste heat in the production process of corn starch and equipment thereof. The technical proposal of the invention is as follows: the waste heat use equipment in the production of corn starch comprises a fourth-effect evaporator, a washing tower, a flash evaporator, a corn steep liquor can and a corn soak solution can; the fourth-effect evaporator comprises a first-effect heating room, a first-effect separator, a second-effect heating room, a second-effect separator, a third-effect heating room, a third-effect separator, a fourth-effect heating room, a fourth-effect separator, and a condenser which are connected by pipelines; only the first-effect heating room is supplied with fresh steam; the second-effect heating room and the third-effect heating room respectively use secondary emission of a tube bundle and the tube bundle, and heat of condensed water by air drying for heating; and the fourth-effect heating room uses the waste heat and secondary steam of the first-effect heating room, the second-effect heating room and the third-effect heating room for heating. The invention can reduce the amount of fresh steam, and is a measure which can not be ignored for saving energy, reducing consumption, and increasing benefits of the enterprise.

Owner:山东华义玉米科技有限公司

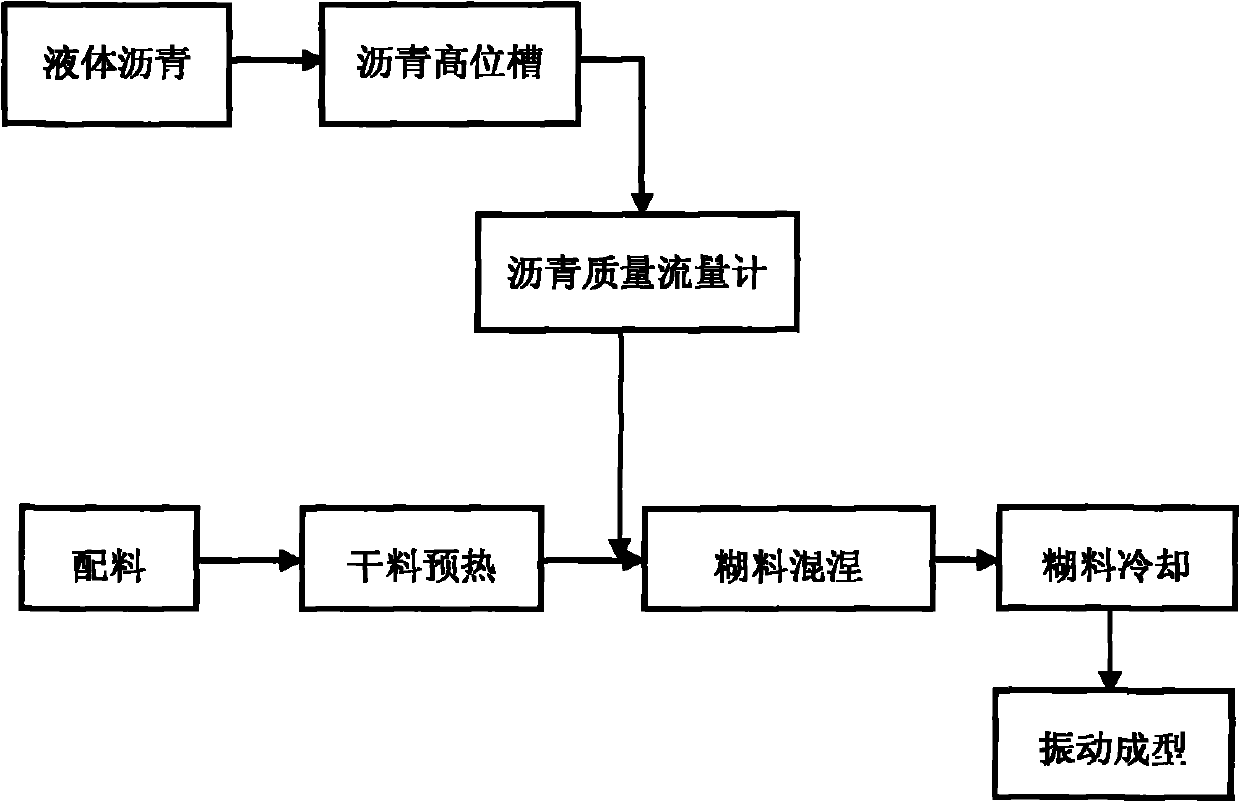

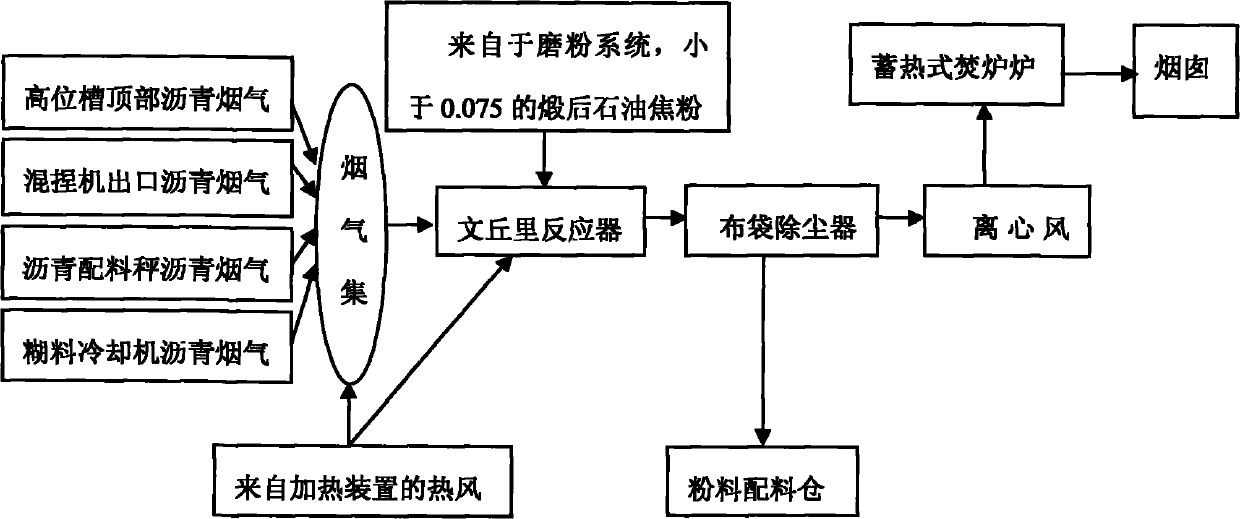

Method for treating asphalt gas efficiently and harmlessly

InactiveCN102000483ACollect completeEfficient collectionDispersed particle filtrationSecondary emissionBenzanthracenes

The invention discloses a method for treating asphalt gas efficiently and harmlessly. The method comprises the following steps of: performing reaction adsorption on the asphalt gas and calcined petroleum coke powder in a Venturi reactor; collecting dust and coke tar from the gas in a bag-type duster remover for recycle; after removing the coke tar and dust-containing steam in the asphalt gas, performing burning treatment by using a regenerative combustion furnace, wherein the burning temperature is higher than 800 DEG C and the burning time is 1 to 2 seconds; and decomposing polycyclic aromatic hydrocarbons such as benzopyrene, benzanthracene and carbazole in the gas after the burning treatment for effectively removing harmful substances of the polycyclic aromatic hydrocarbons such as the benzopyrene, the benzanthracene and the carbazole, wherein the harmful substance content of the treated gas is below 5 mg / m<3>. By using the method, the harmful substances of the polycyclic aromatic hydrocarbons such as the benzopyrene, the benzanthracene, the carbazole and the like are removed effectively; and the harmful substance content of the gas after the treatment is below 5 mg / m<3> which is far below a national secondary emission standard.

Owner:YUNNAN YUANXIN CARBON CO LTD

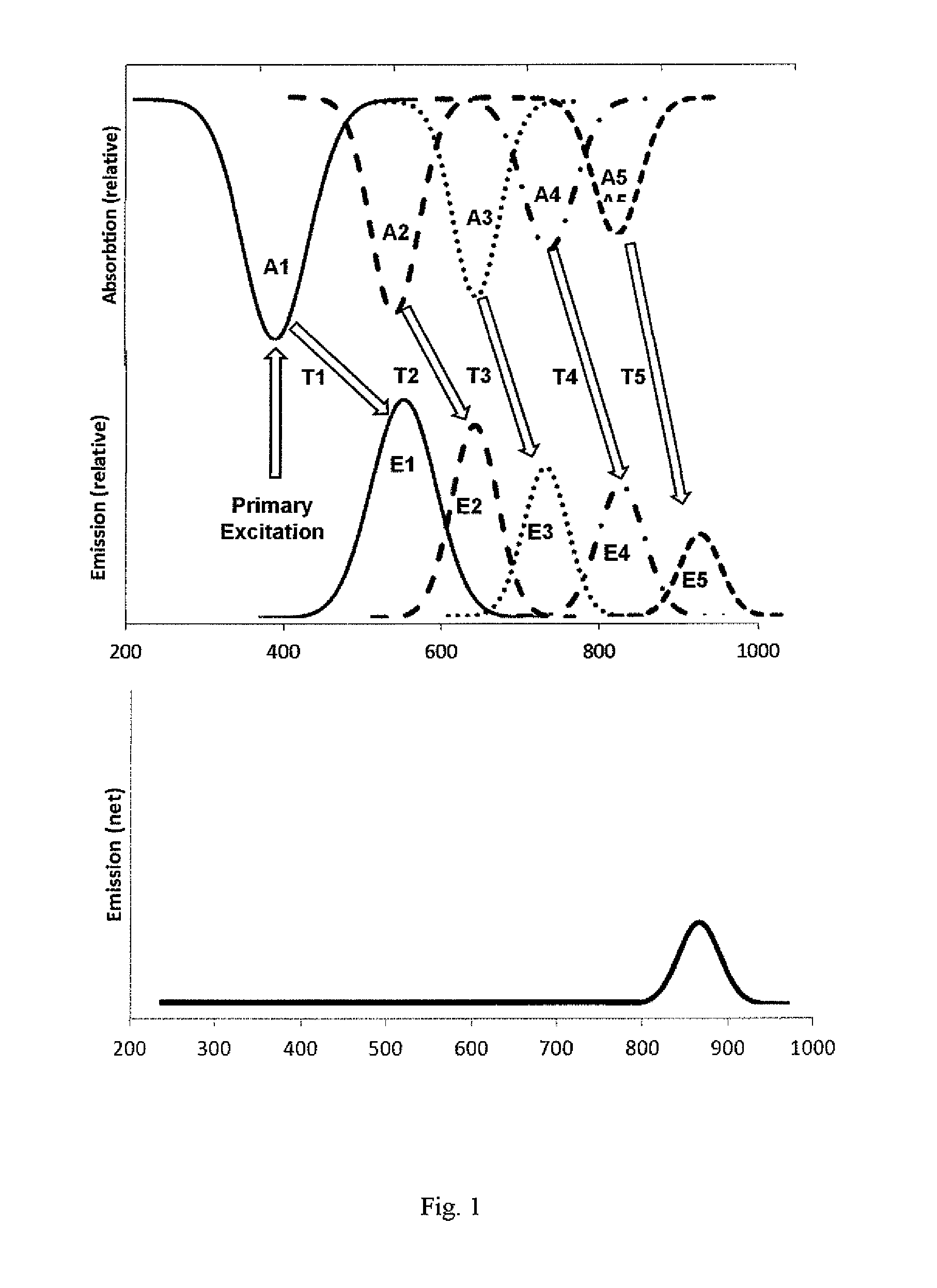

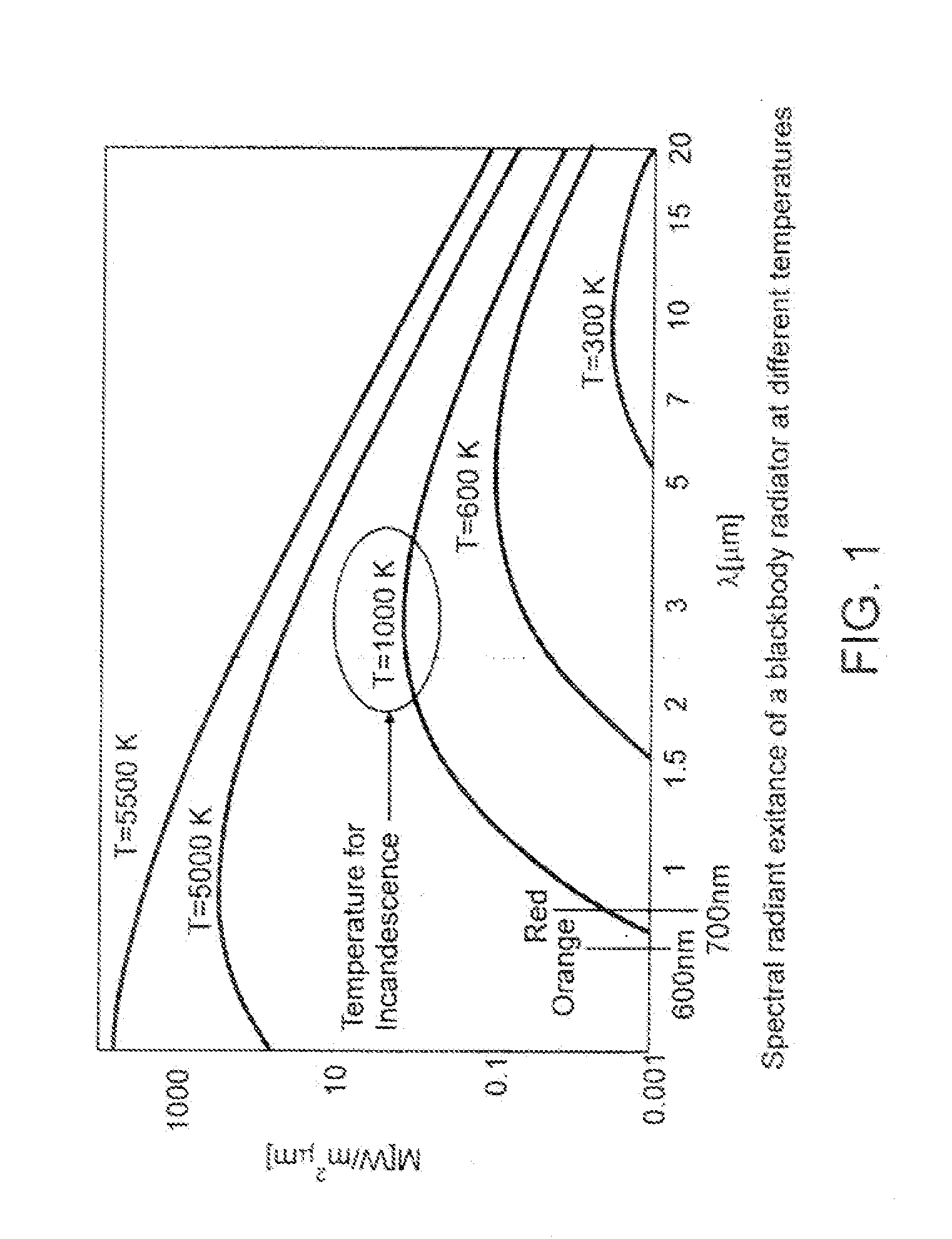

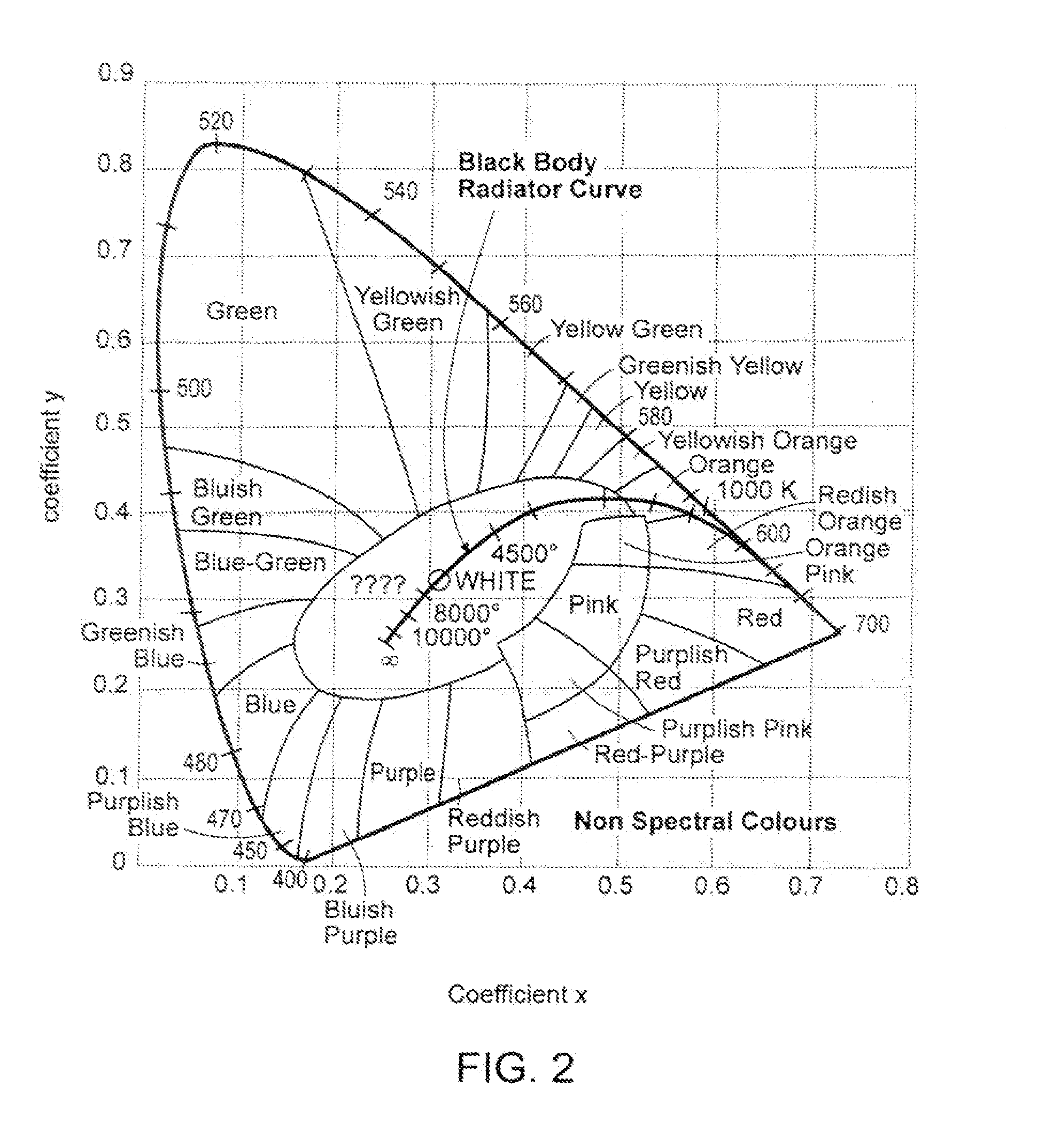

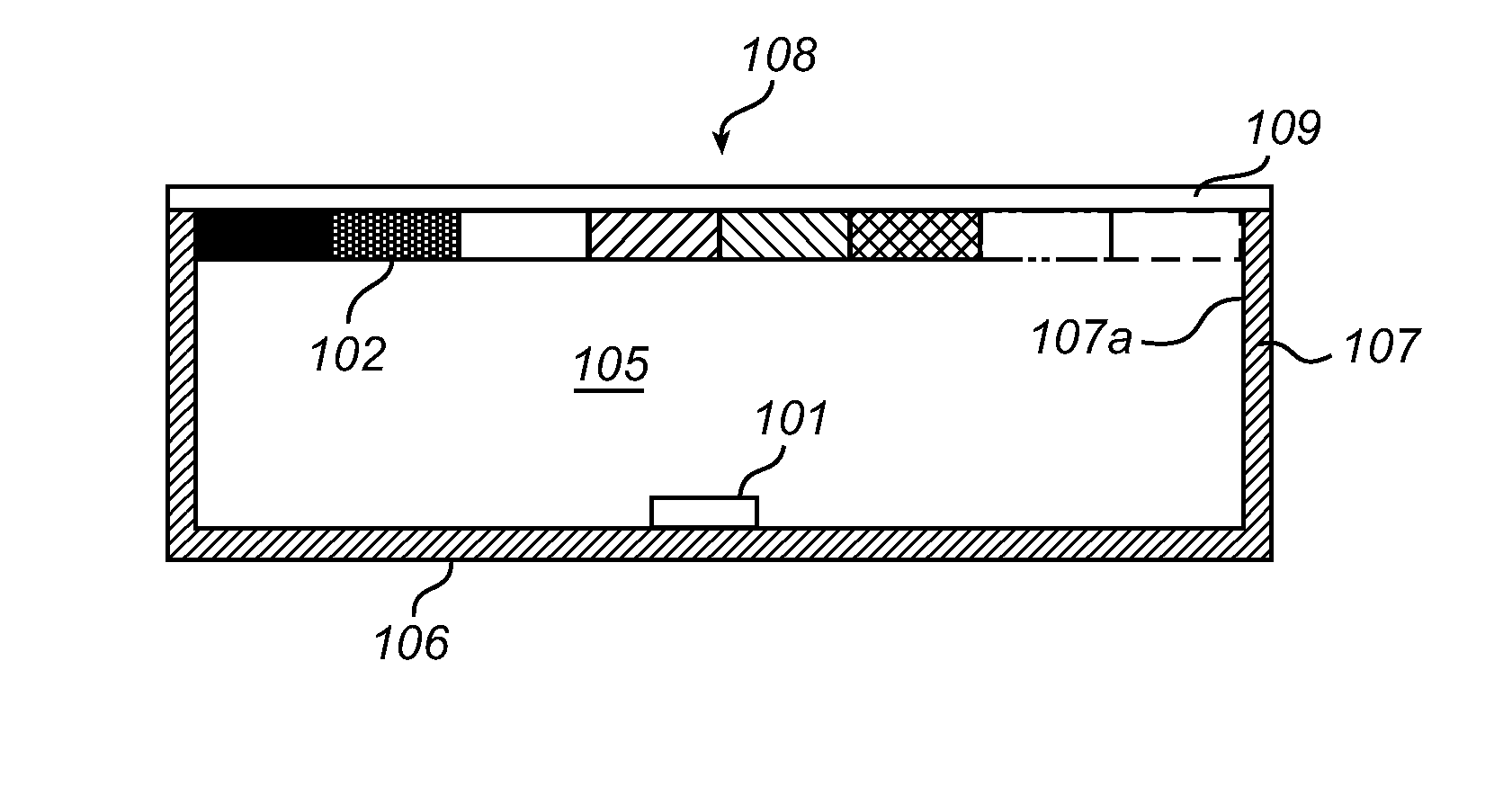

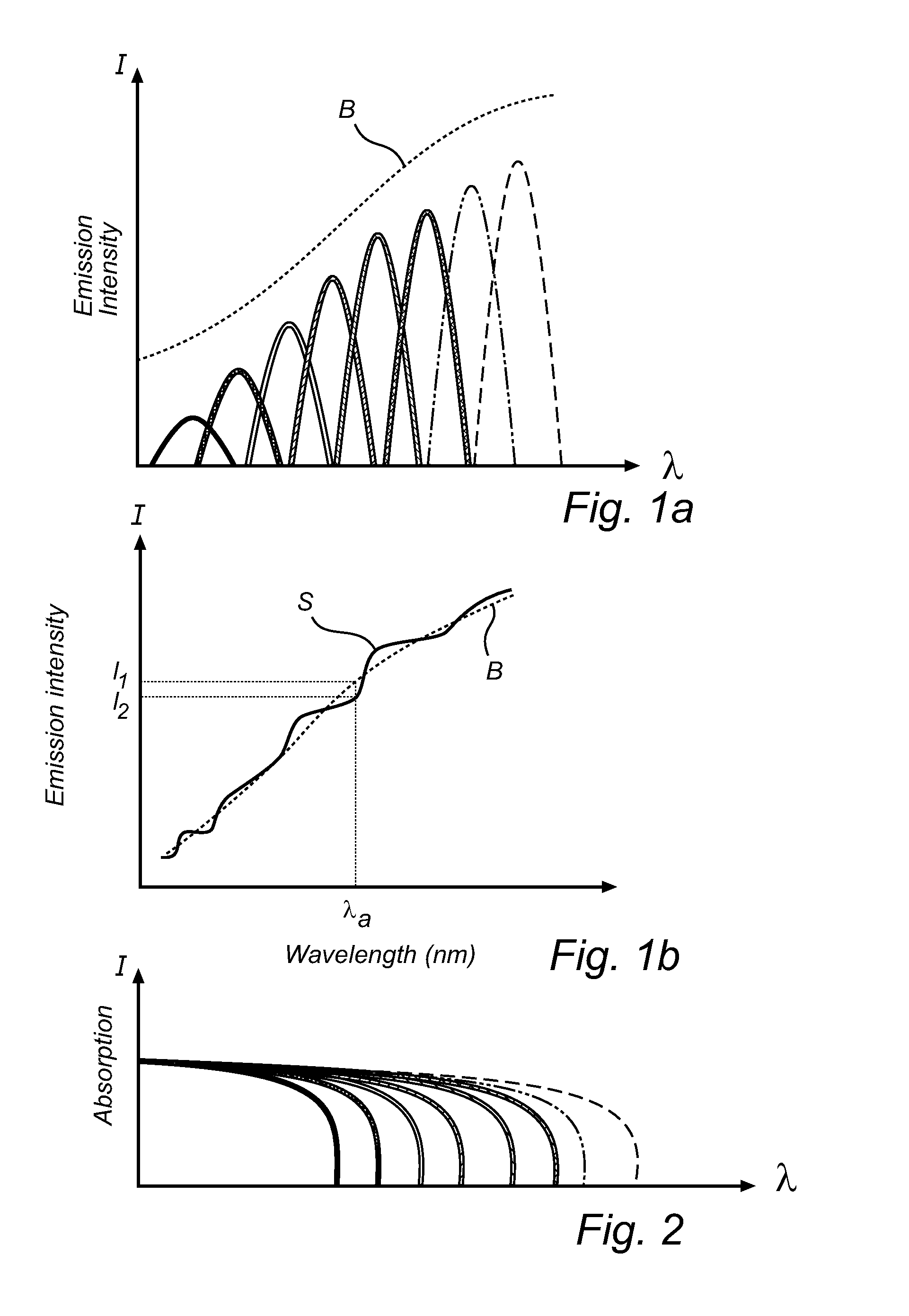

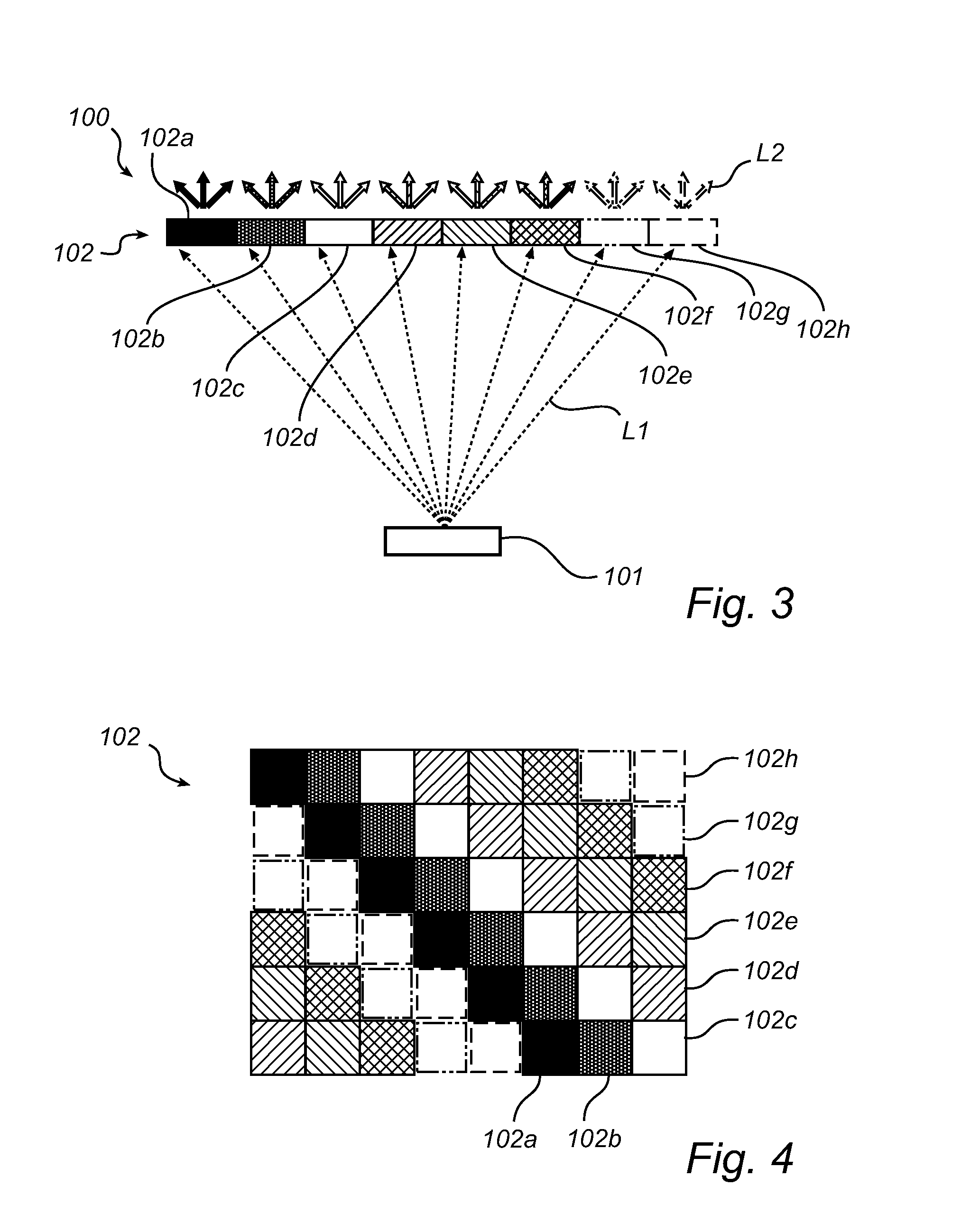

Full spectrum light emitting arrangement

ActiveUS20150176777A1Guaranteed continuous outputAvoid secondary emissionsPlanar light sourcesPoint-like light sourceSecondary emissionFull-spectrum light

A light emitting arrangement is provided, comprising:—a solid state light source (101) adapted to emit primary light (L1); and—a wavelength converting member (102) comprising a plurality of wavelength converting domains (102a, 102b, 102c, etc) for converting primary light into secondary light (L2), each wavelength converting domain thereby providing a sub-range of the total light output spectrum, wherein at least some of said wavelength converting domains are arranged as an array and comprise quantum dots, wherein different wavelength converting domains comprise quantum dots having different secondary light emission ranges providing different sub-ranges of the total light output spectrum, and wherein a sub-range provided by each wavelength converting domain overlaps or is contiguous with at least one other sub-range provided by another wavelength converting domain. By arranging materials having different wavelength conversion properties in different domains, preferably in a plane, re-absorption of secondary emission can be avoided.

Owner:LUMILEDS

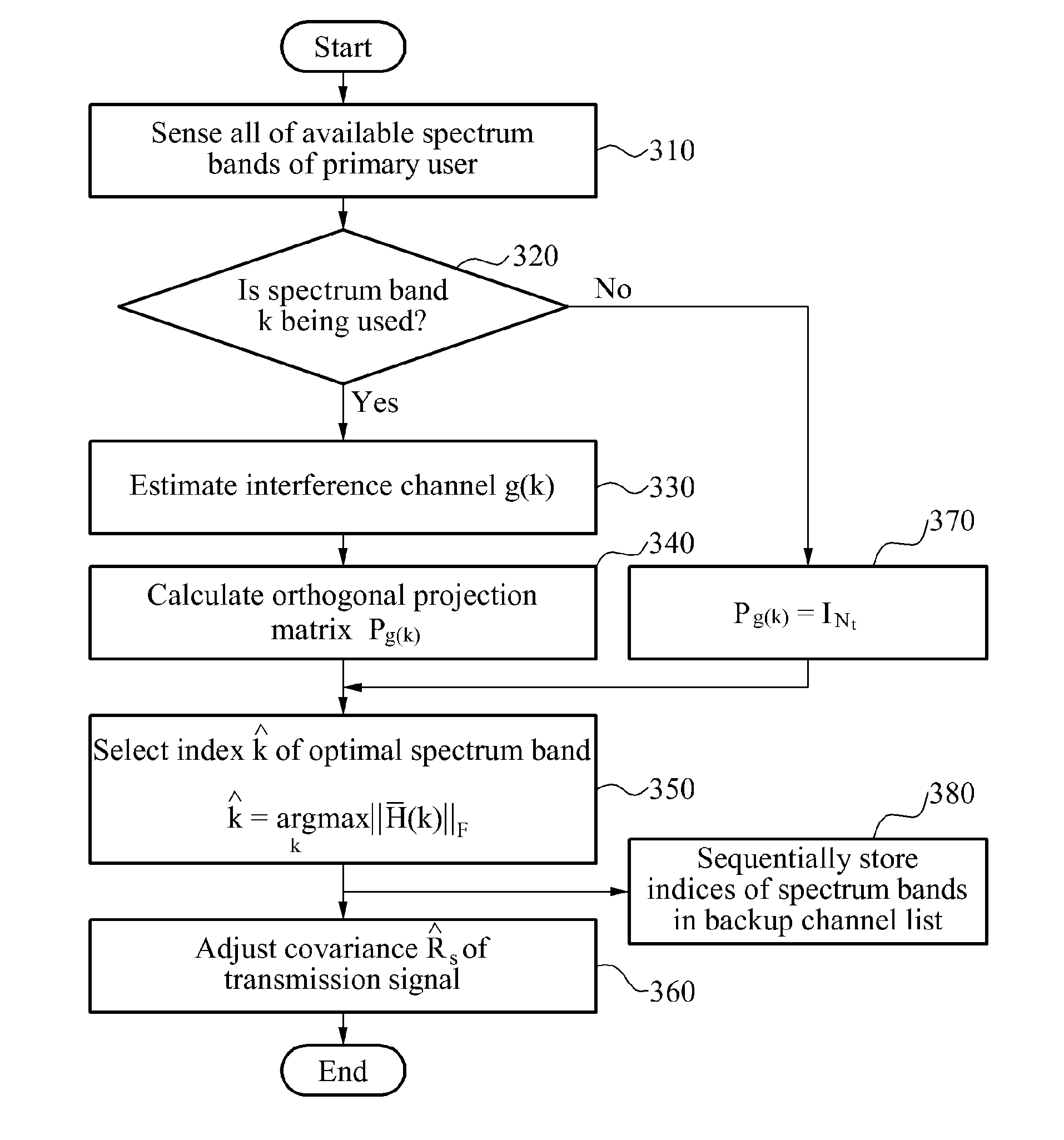

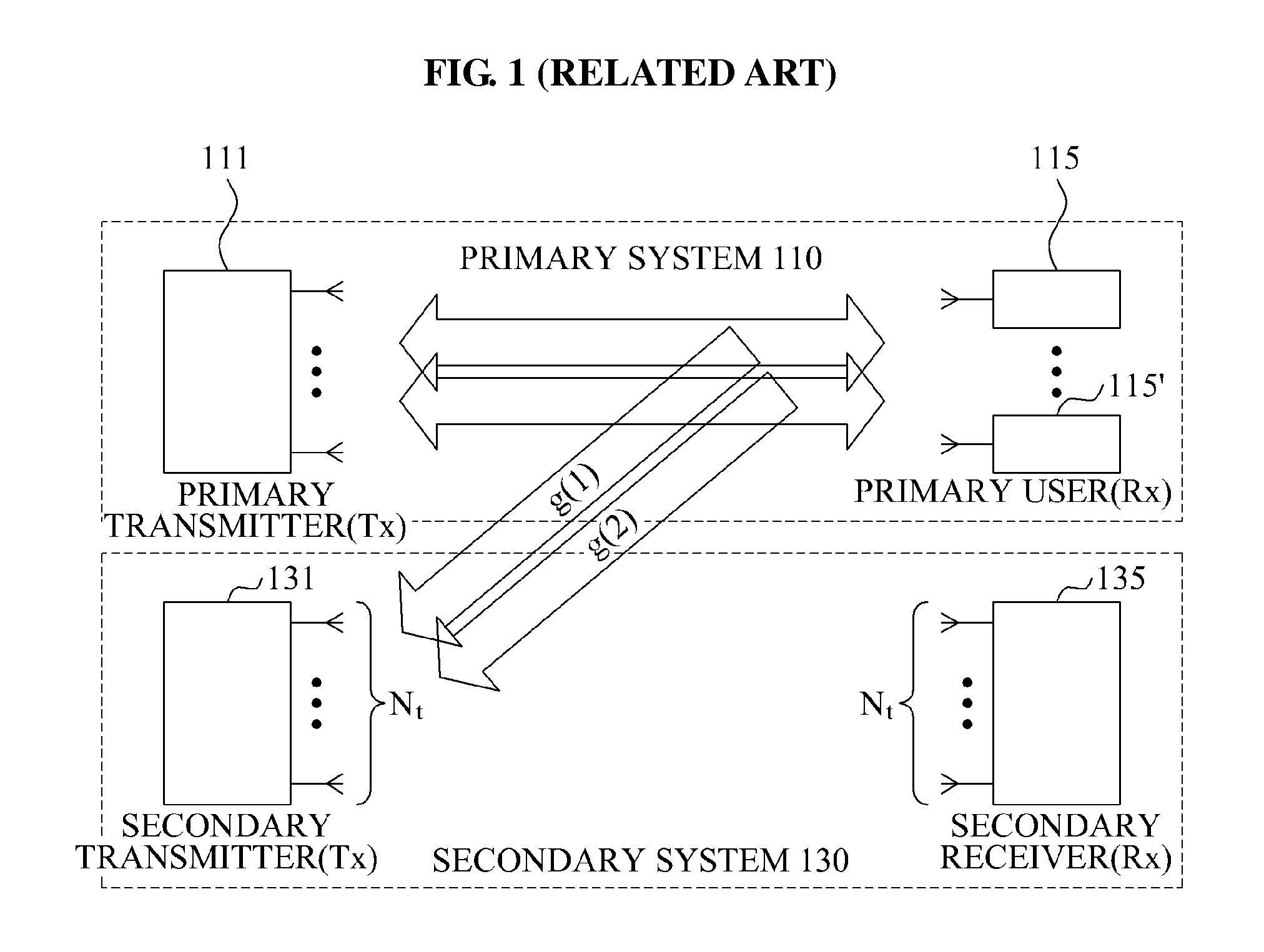

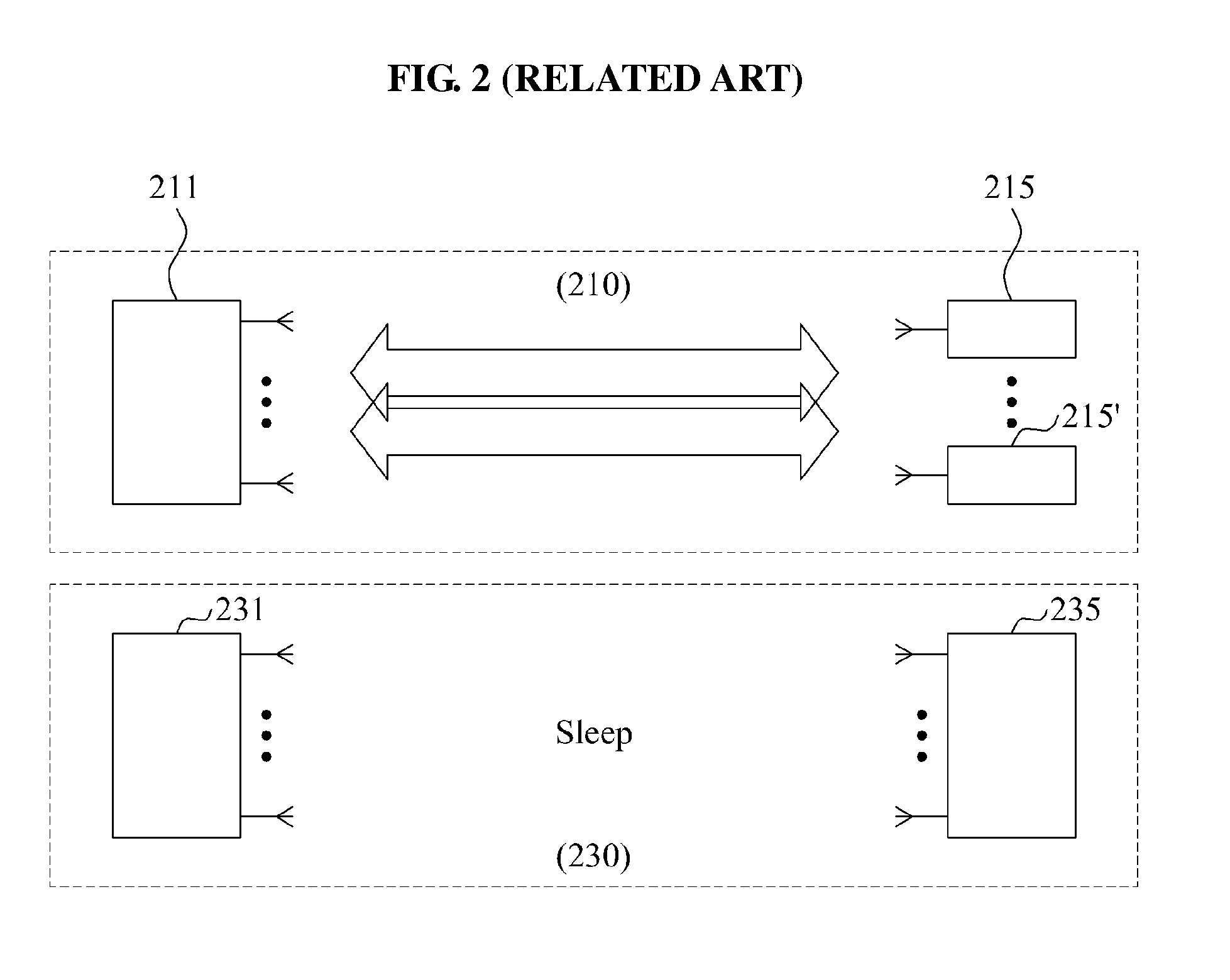

Secondary transmitter included in cognitive radio communication system and communication method of the secondary transmitter

InactiveUS20120288021A1Broaden the spectral widthIncrease capacitySite diversitySpectral gaps assessmentHat matrixFrequency spectrum

Provided is a communication method of a secondary transmitter included in a multiple-antenna based multiple input multiple output (MIMO) cognitive radio communication system, the method including: estimating an interference channel between the secondary transmitter and a primary user in each of at least one first spectrum band that is being used in a primary system; calculating an orthogonal projection matrix to cancel interference with respect to the primary user from the interference channel; calculating an effective channel between the secondary transmitter and a secondary receiver based on the to orthogonal projection matrix; and selecting an index of an optimal spectrum band from the at least one first spectrum band based on the orthogonal projection matrix and the effective channel.

Owner:ELECTRONICS & TELECOMM RES INST

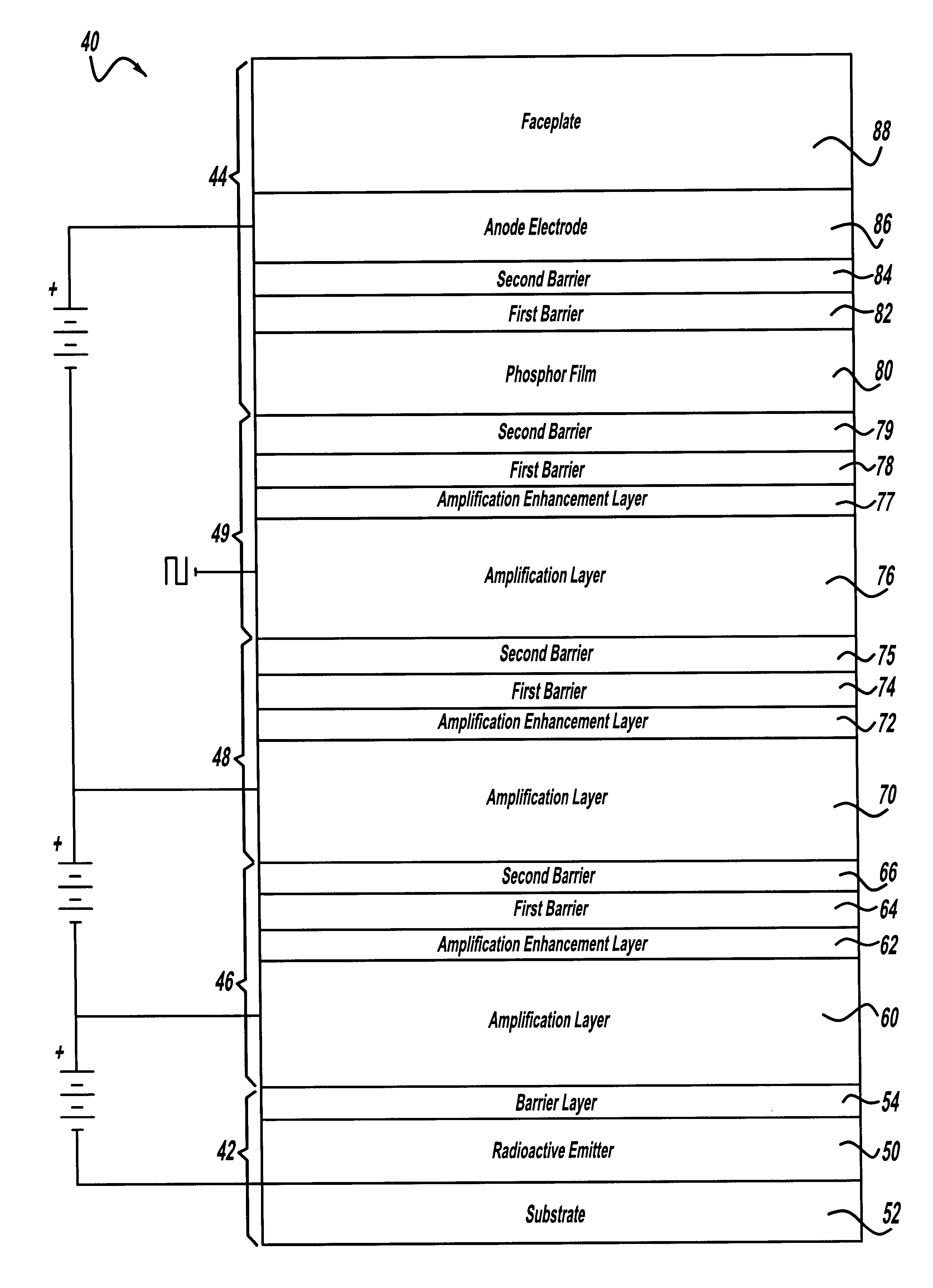

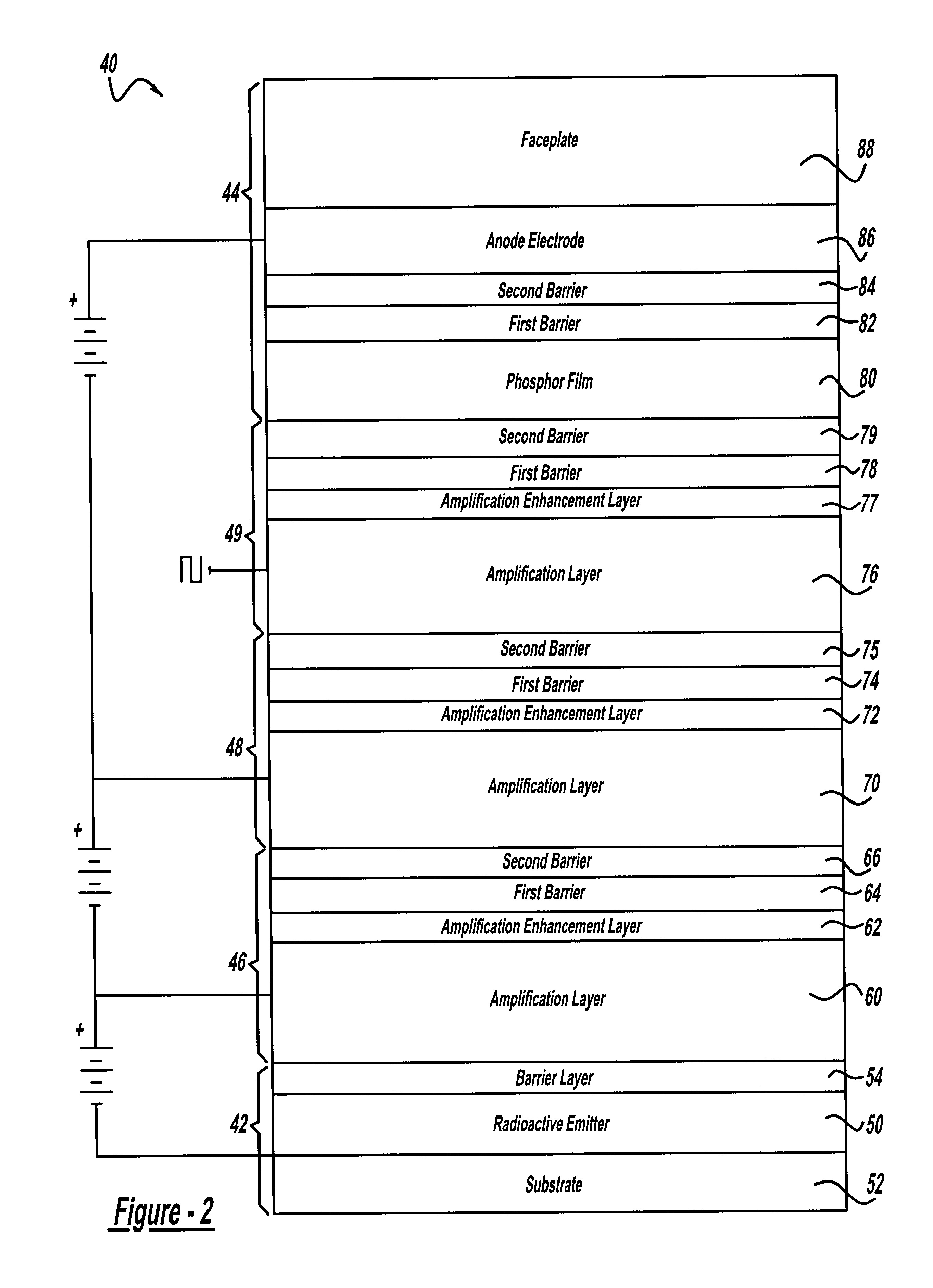

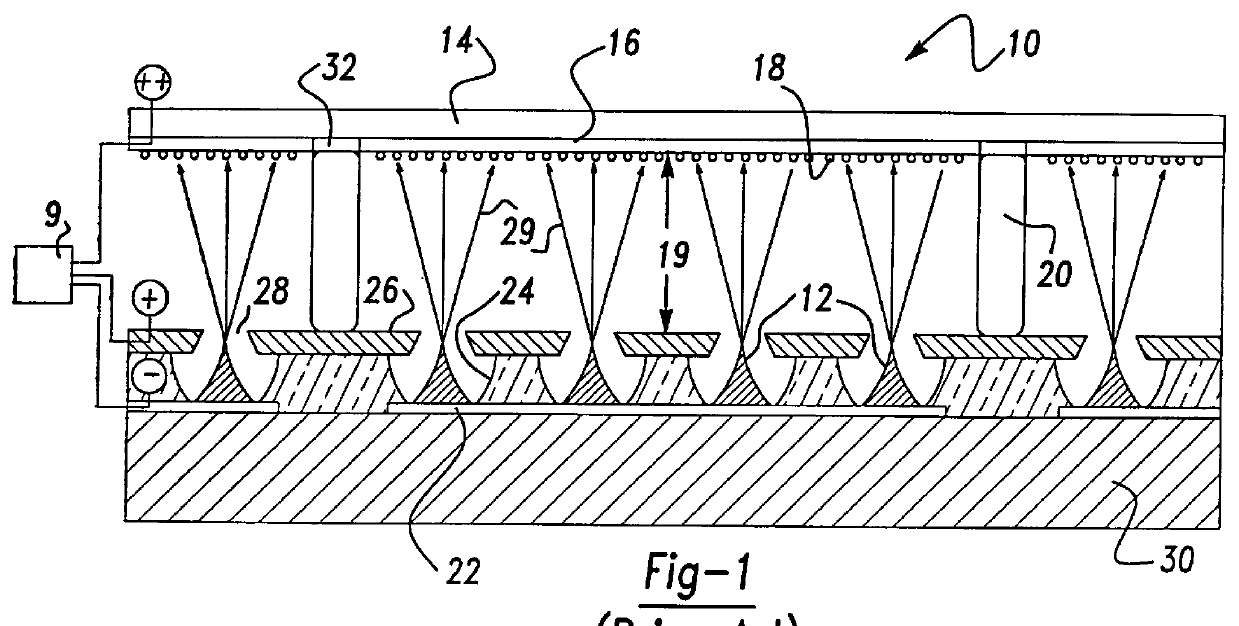

Field emission display devices

InactiveUS6087766AImprove efficiencyExcellent optical propertiesDischarge tube luminescnet screensElectrode and associated part arrangementsSecondary emissionDisplay device

Cathodoluminescent field emission display devices feature phosphor biasing, amplification material layers for secondary electron emissions, oxide secondary emission enhancement layers, and ion barrier layers of silicon nitride, to provide high-efficiency, high-brightness field emission displays with improved operating characteristics and durability. The amplification materials include copper-barium, copper-beryllium, gold-barium, gold-calcium, silver-magnesium and tungsten-barium-gold, and other high amplification factor materials fashioned to produce high-level secondary electron emissions within a field emission display device. For enhanced secondary electron emissions, an amplification material layer can be coated with a near mono-molecular film consisting essentially of an oxide of barium, beryllium, calcium, magnesium or strontium. Use of a high amplification factor film as a phosphor biasing electrode, and variability of the phosphor biasing potential to achieve brightness or gray scale control are further described in the disclosure.

Owner:ST CLAIR INTPROP CONSULTANTS

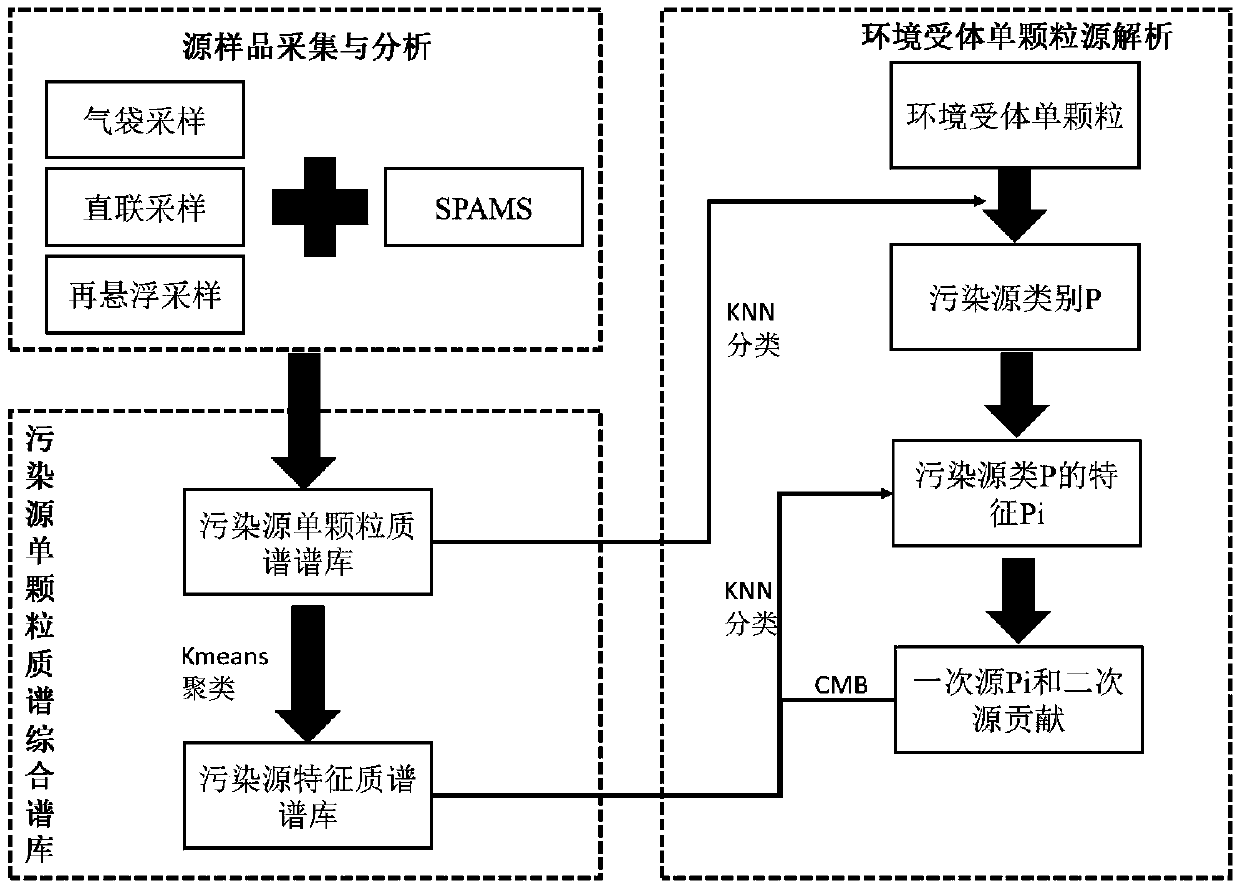

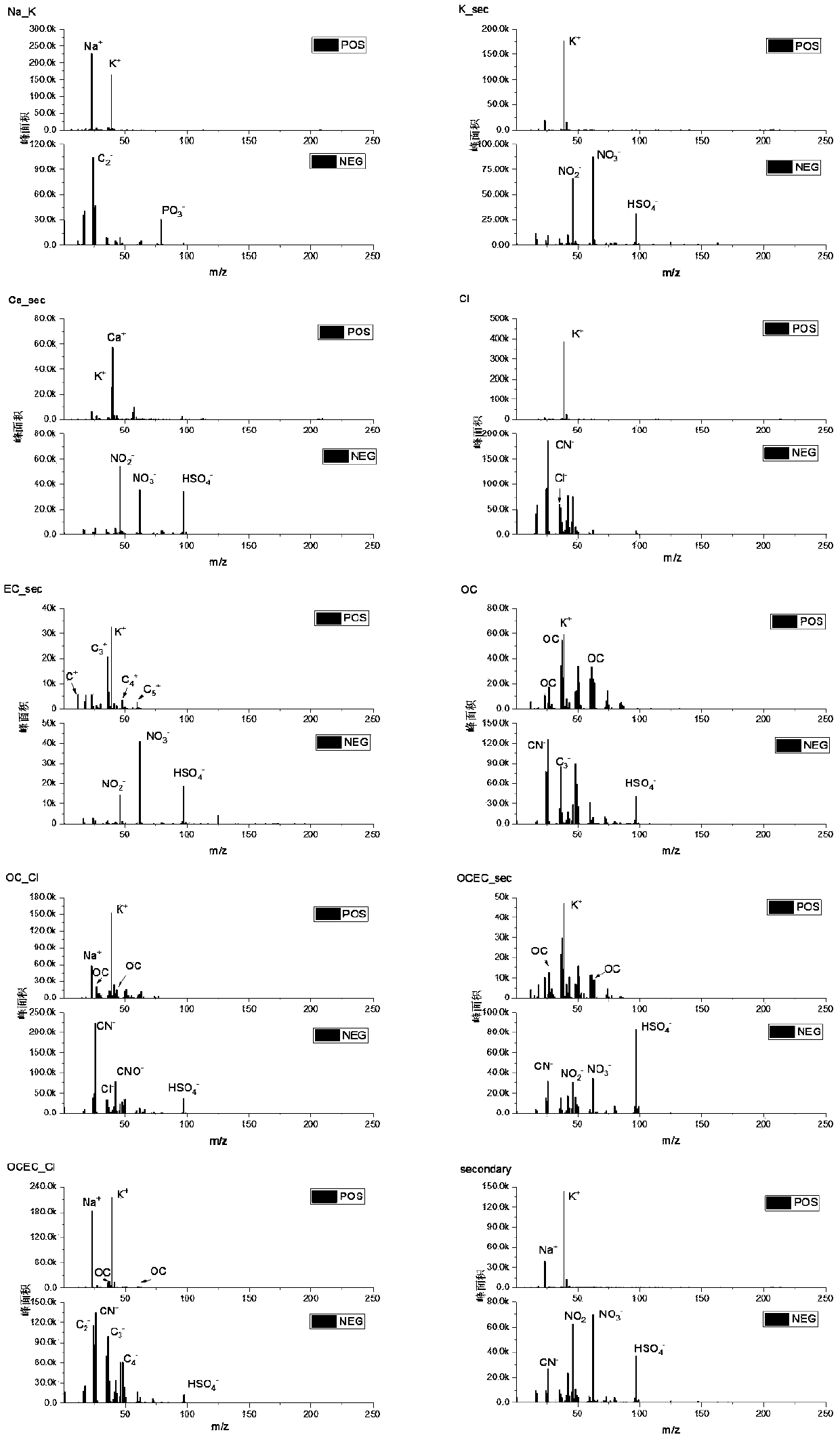

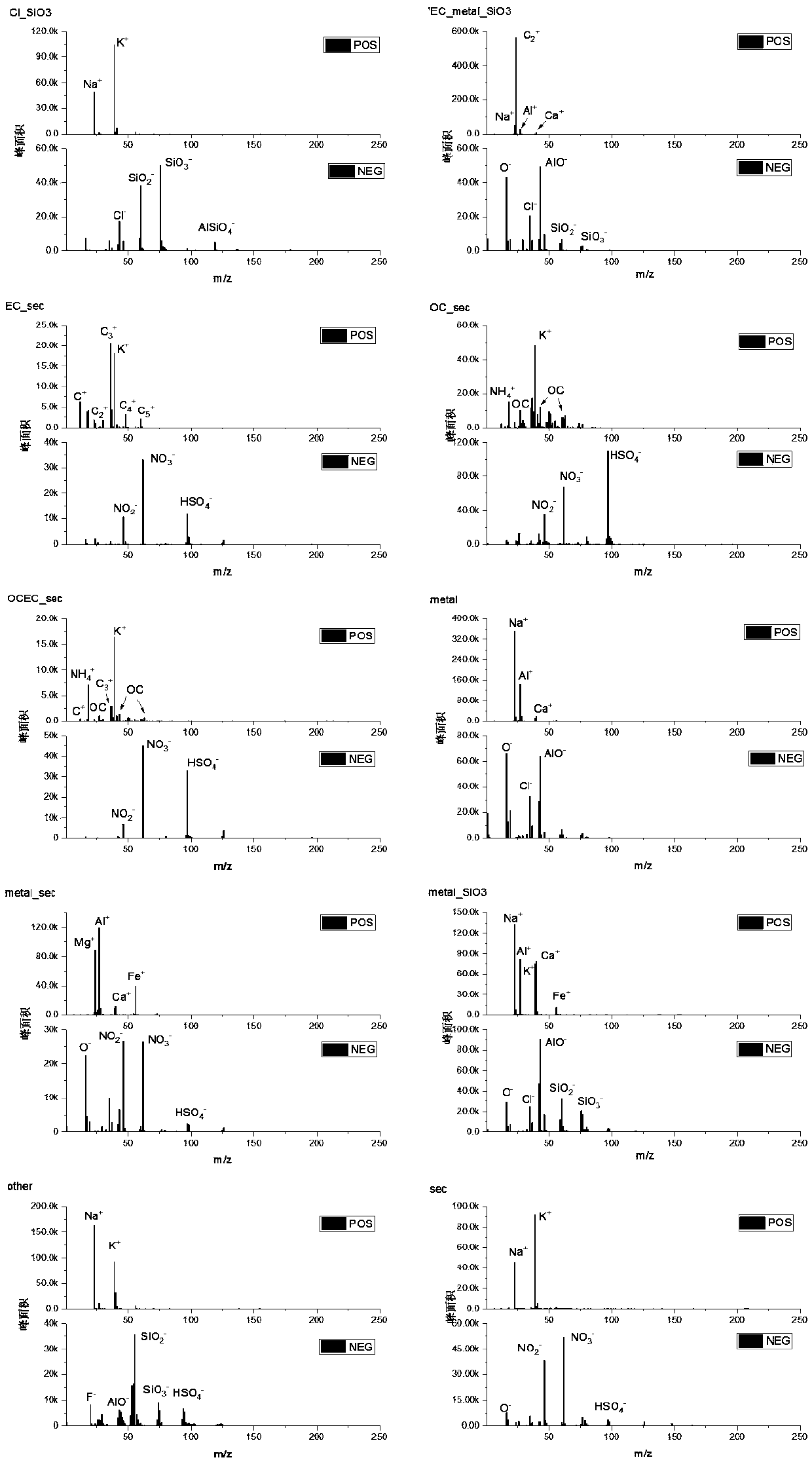

Method for performing particle source analysis by using single-particle aerosol mass spectrometer

InactiveCN108680473AImprove time resolutionHigh particle size resolutionCharacter and pattern recognitionParticle size analysisSecondary emissionNear neighbor

The invention provides a method for performing particle source analysis by using a single-particle aerosol mass spectrometer and relates to the field of atmospheric particle source analysis. Accordingto the method, a KNN (K Nearest Neighbor) classifier and a CMB (Cosmic Microwave Background) source analysis model are combined, single-particle mass spectrometry information of the pollution sourceas well as environmental receptor single-particle mass spectrometry characteristic and particle size information are fully utilized, the contribution of the primary emission source and secondary emission source of the particles on single environmental receptor particle can be rapidly solved, and refined source analysis results with high time resolution and high particle size resolution can be obtained. The method has excellent popularization and application prospects.

Owner:NANKAI UNIV

Plasma display panel and its production process

InactiveUS20080265774A1Improve discharge performanceSolve low luminous efficiencyAlternating current plasma display panelsVessels or leading-in conductors manufactureDischarge efficiencySecondary emission

For a PDP, a panel having favorable discharge properties such a high discharge efficiency and a short discharge delay, being chemically stable and capable of electric power saving, is desired.A plasma display panel comprising a front substrate and a rear substrate facing each other via a discharge space, discharge electrodes formed on at least one of the front substrate and the rear substrate, a dielectric layer covering the discharge electrodes, and a protective layer covering the dielectric layer, wherein the protective layer contains a Mayenite compound, and the secondary emission coefficients when Ne and Xe are used as excited ions at an accelerating voltage of 600 V, are respectively at least 0.05 at a secondary electron collector voltage at which secondary electrons can be sufficiently captured.

Owner:ASAHI GLASS CO LTD

Monitoring of retinal temperature during laser therapy

InactiveUS20060084948A1Good reproducibilityLow retinal irradiancesLaser surgerySurgical instrument detailsSecondary emissionTherapeutic Devices

In a laser eye treatment apparatus, a probe light source generates a secondary emitted light emanating from a treatment area of retinal tissue that is irradiated by a treatment light source. An optical detector detects the secondary emitted light. A processor statistically analyzes the secondary emitted light to determine a temperature of the treatment area of retinal tissue.

Owner:ROVATI LUIGI +1

Field emission display devices

InactiveUS6084345ALow costImprove efficiencyDischarge tube luminescnet screensElectrode and associated part arrangementsSecondary emissionDisplay device

Cathodoluminescent field emission display devices feature phosphor biasing, amplification material layers for secondary electron emissions, oxide secondary emission enhancement layers, and ion barrier layers of silicon nitride, to provide high-efficiency, high-brightness field emission displays with improved operating characteristics and durability. The amplification materials include copper-barium, copper-beryllium, gold-barium, gold-calcium, silver-magnesium and tungsten-barium-gold, and other high amplification factor materials fashioned to produce high-level secondary electron emissions within a field emission display device. For enhanced secondary electron emissions, an amplification material layer can be coated with a near mono-molecular film consisting essentially of an oxide of barium, beryllium, calcium, magnesium or strontium. Use of a high amplification factor film as a phosphor biasing electrode, and variability of the phosphor biasing potential to achieve brightness or gray scale control are further described in the disclosure.

Owner:ST CLAIR INTPROP CONSULTANTS

Method and system for scatter correction

ActiveUS8017914B2Material analysis by optical meansHandling using diaphragms/collimetersData setSecondary emission

Owner:GENERAL ELECTRIC CO

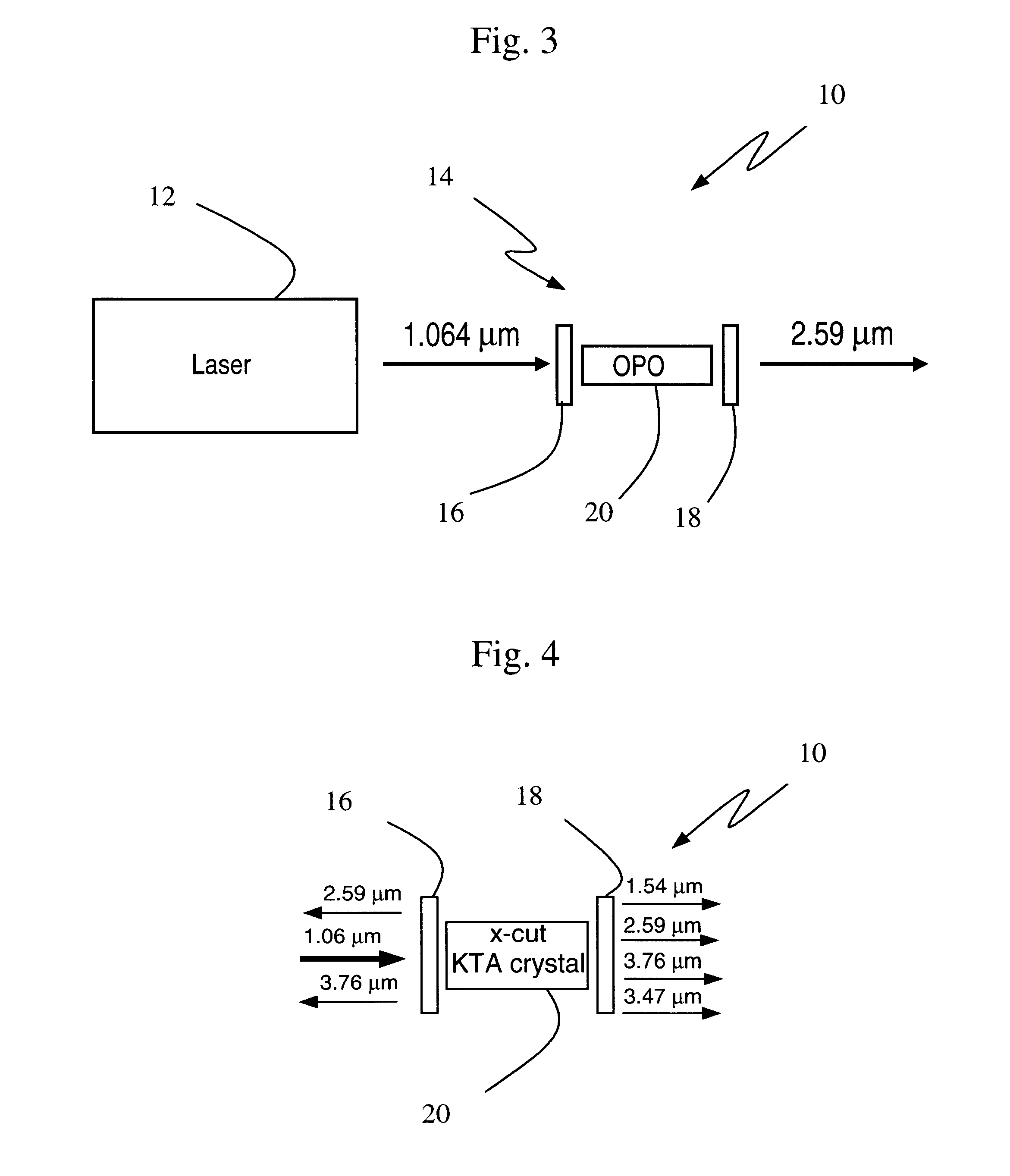

Efficient angle tunable output from a monolithic serial KTA optical parametric oscillator

InactiveUS20020048077A1Optical resonator shape and constructionLight demodulationSecondary emissionFundamental frequency

An arrangement (10) for efficiently shifting energy received at a first wavelength and outputting the shifted energy at a second wavelength. The arrangement (10) includes a laser (12) and an optical parametric oscillator (14) of unique design. The oscillator (14) is constructed with an energy shifting crystal (20) and first and second reflective elements (16) and (18) disposed on either side thereof. Light from the laser (12) at a fundamental frequency is shifted by the crystal and output at a second wavelength. The second wavelength is a secondary emission of energy induced by a primary emission generated by the first wavelength in the crystal. A novel feature of the invention is a coating applied on the reflective elements (16 and / or 18) for containing the primary emission and enhancing the secondary emission. This constrains the energy to be output by the arrangement (10) at the wavelength of the desired secondary emission.

Owner:RAYTHEON CO

Wireless power supply desktop

ActiveCN102048367AEnabling complete wireless power deliveryEasy to manageElectromagnetic wave systemCircuit arrangementsSecondary emissionElectrical battery

The invention relates to the technical field of radio transmission, in particular to a desktop which is made by the principles of electromagnetic resonance and resonance derivative ring and has the function of wireless power supply. An electrical energy transmitting module is embedded into the desktop, and a plurality of resonance derivation rings are placed around the transmitting module; when the transmitting module transmits electrical energy, the resonance derivation rings absorb part of energy from the transmitting module to perform secondary transmission to transmit the energy to different electrical appliances on the desktop by gradient; an electrical energy receiving module is respectively placed in the electrical appliances such as a display, a sound box, a desk lamp, a keyboard,a mouse and the like on the desktop, and the electrical energy receiving modules respectively receive energy from the desktop and supply power to the different electrical appliances, so that power wires or batteries various devices on the desktop are , wireless power supply the electrical appliances on the desktop is realized, the desktop becomes clean, tidy and safe, and the electrical appliances are convenient to manage, clean and use.

Owner:深圳市德赛工业研究院有限公司

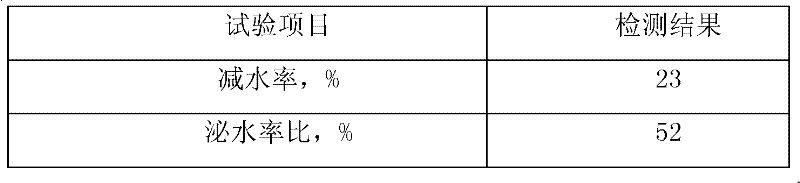

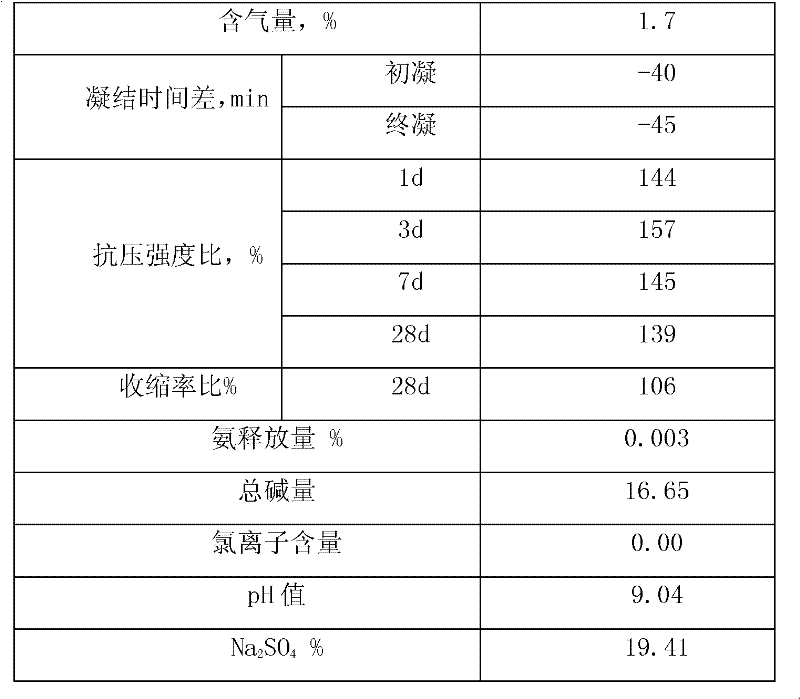

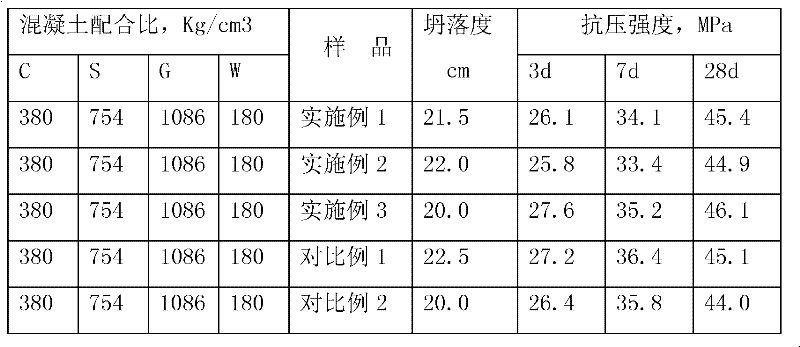

Preparation method for synthetizing high efficiency water reducing agent by 2-naphthol waste water

The invention relates to a preparation method for synthetizing a high efficiency water reducing agent by 2-naphthol waste water. The invention belongs to the technical field of concrete water reducing agents. According to the preparation method for synthetizing the high efficiency water reducing agent by the 2-naphthol waste water, the proportion of crude naphthalene to concentrated sulfuric acid to naphthol waste water to formaldehyde is (1:0.8)-(1.0:0.1)-(0.9:0.5)-0.8. The preparation method for synthetizing the high efficiency water reducing agent by the 2-naphthol waste water comprises the following process flows of: 1-, sulfonating: heating to melt crude naphthalene, adding the concentrated sulfuric acid when the temperature rises to 130-160 DEG C, and reacting for 2-2.5 hours at the temperature of 160-165 DEG C; 2-, hydrolyzing: cooling reactants to 90-110 DEG C, adding naphthol waste liquor and hydrolyzing for 0.5-1 hour; 3-, condensation: dropwise adding the formaldehyde at the temperature of 95-115 DEG C and reacting for 3-6 hours; and (4) neutralizing: adding liquid caustic soda to neutralize a condensation compound to regulate a pH value to be 7-9 to obtain a water reducing agent product. The preparation method for synthetizing the high efficiency water reducing agent by the 2-naphthol waste water has the advantages that the production process is simple, the operation is convenient, the process control is easy, waste is turned into wealth, and thereby, secondary emission cannot be generated, and the economic value and the social benefit are high and the like.

Owner:天津市飞龙砼外加剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com