Method and equipment for utilizing waste heat from corn starch production

A corn starch and equipment technology, which is applied in the field of drying waste heat in the production process of corn starch, can solve the problems of unutilized waste heat, consumption of large steam and heat, waste, etc., and achieves saving money, saving energy and reducing consumption, and increasing benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

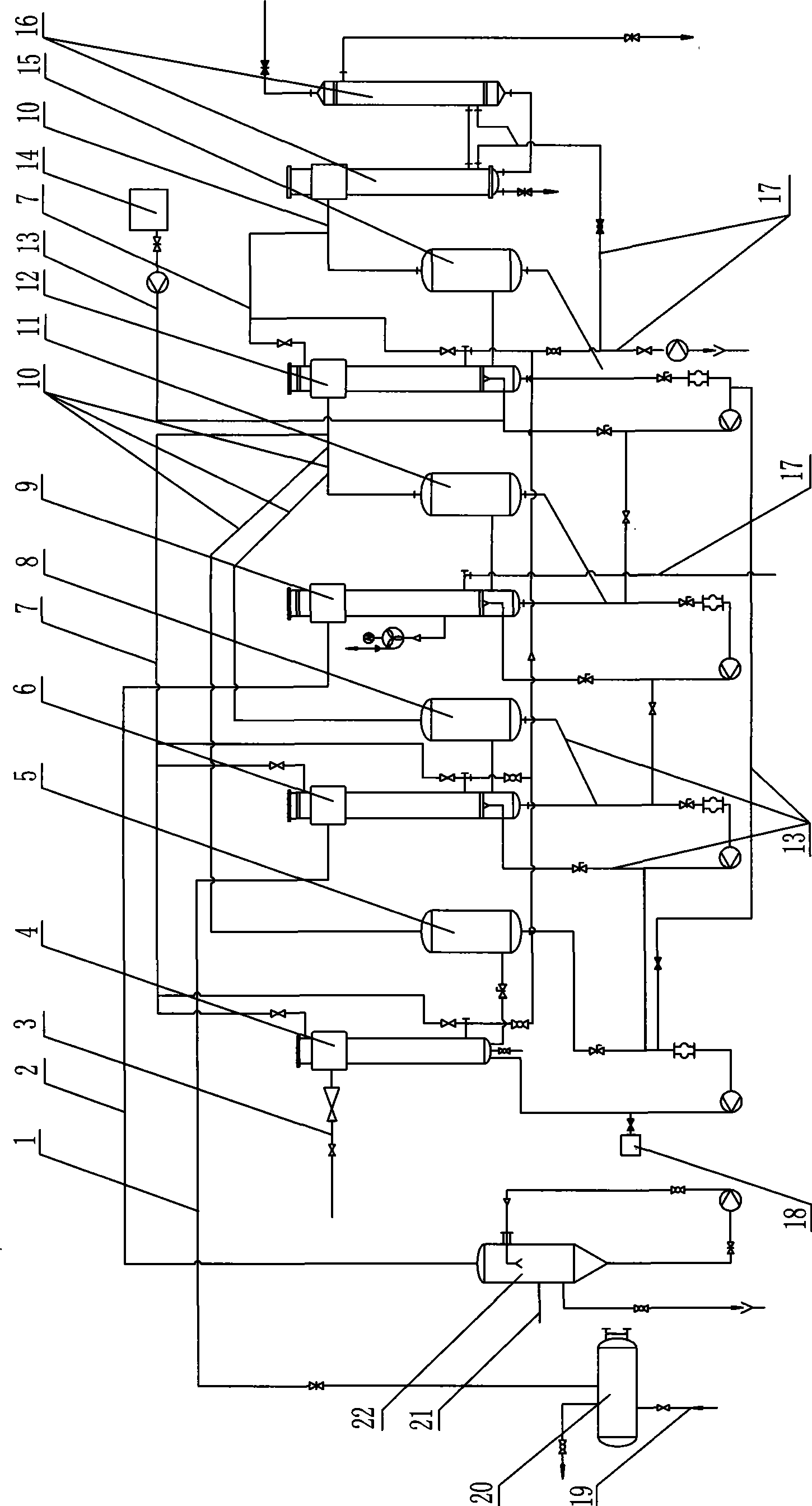

[0018] according to figure 1 As shown, the waste heat utilization equipment in the production of cornstarch comprises a four-effect evaporator, a washing tower 22, a flash evaporator 20, a corn steep liquor tank 18 and a corn steeping liquid tank 14, and the described four-effect evaporator comprises a pipe-connected Effect heating chamber 4, first effect separator 5, second effect heating chamber 6, second effect separator 8, third effect heating chamber 9, three effect separator 11, four effect heating chamber 12, four effect separator 15 and condenser 16 , the first-effect heating chamber 4 is connected to the fresh steam pipeline 3, the lower part of the scrubber 22 is connected to the secondary exhaust gas pipeline 21 of the tube bundle, and the upper part of the scrubber 22 is heated by the steam pipeline 2 produced by the secondary exhaust gas of the tube bundle. Chamber 9 is connected, and the lower part of the flash evaporator 20 is connected with the tube bundle and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com