Patents

Literature

720 results about "Corn steep liquor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corn steep liquor is a by-product of corn wet-milling. A viscous concentrate of corn solubles which contains amino acids, vitamins and minerals, it is an important constituent of some growth media. It was used in the culturing of Penicillium during research into penicillin by American microbiologist Andrew J. Moyer. It is an excellent source of organic nitrogen.

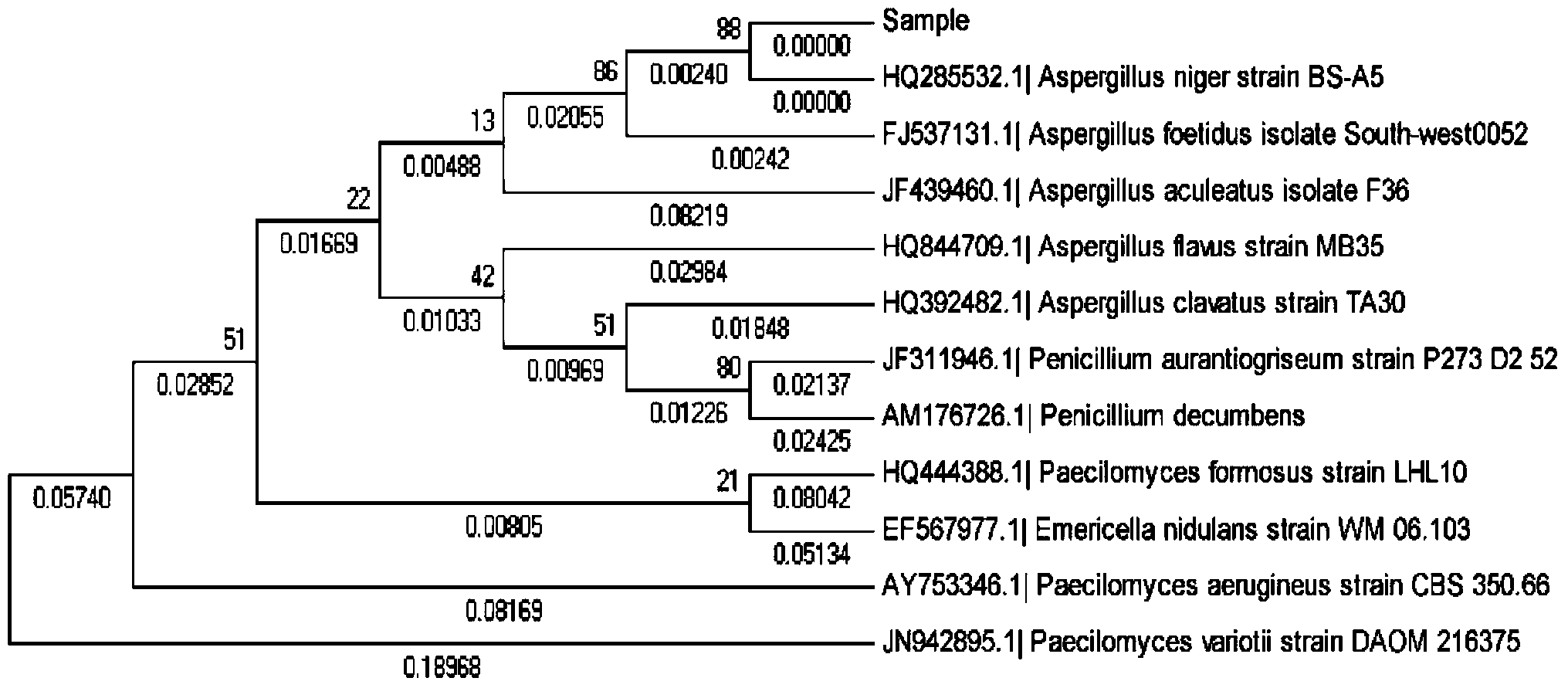

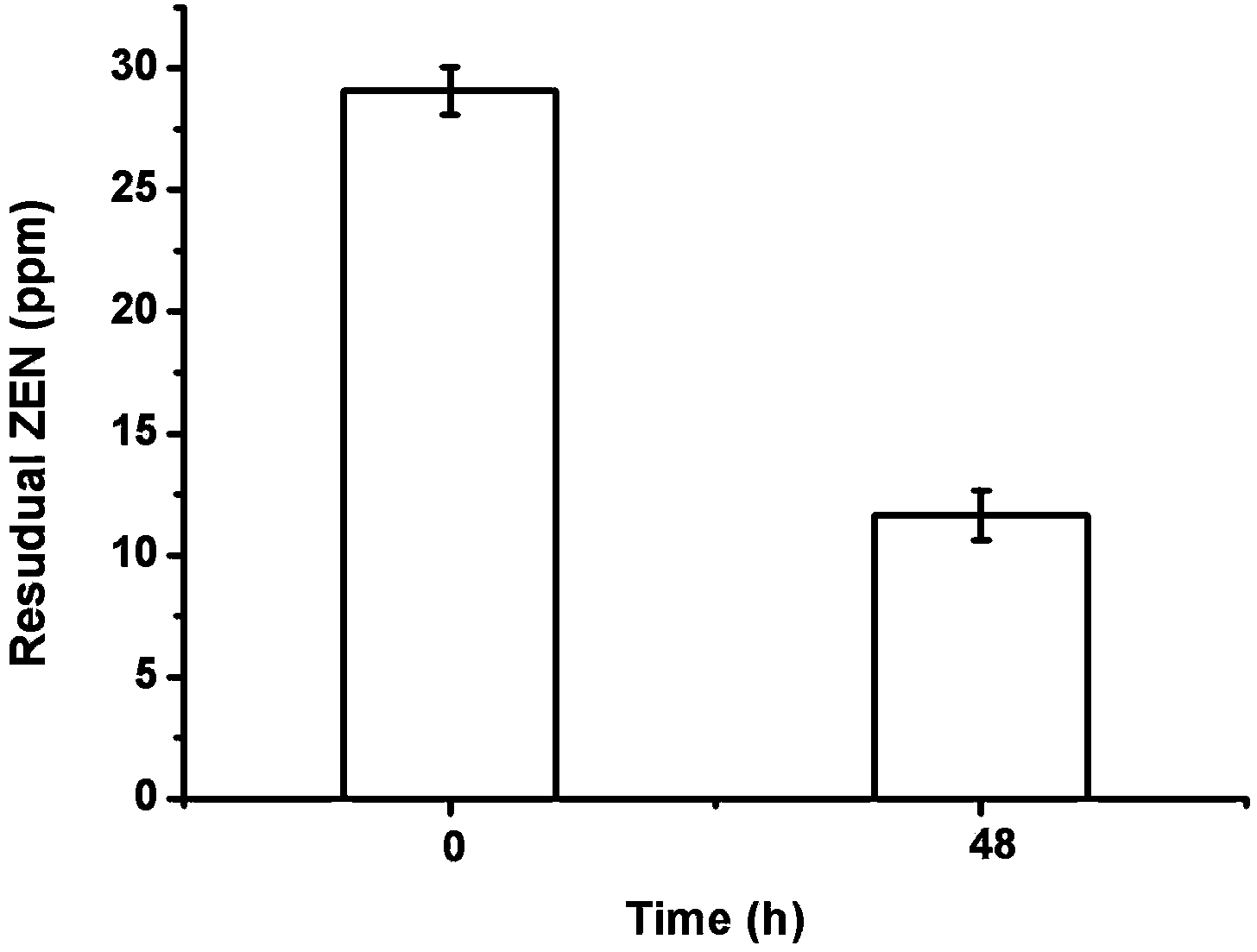

Food-grade aspergillus niger strain and application of strain in zearalenone degradation

ActiveCN103937681AReduce contentPromote degradationFungiMicroorganism based processesToxinAspergillus niger

The invention discloses a food-grade aspergillus niger strain FS-Z1 which is separated out from sauce grains and capable of preventing and treating zearalenone toxin. The collection number of the food-grade aspergillus niger strain FS-Z1 is CCTCC NO: M 2013703. The strain has excellent degradation effect on the zearalenone and the degradation rate reaches 89.56%. Besides, animal experiments in rats verify that the zearalenone in the corn steep liquor degraded by using an aspergillus niger fermentation liquor has no toxicity.

Owner:JIANGNAN UNIV

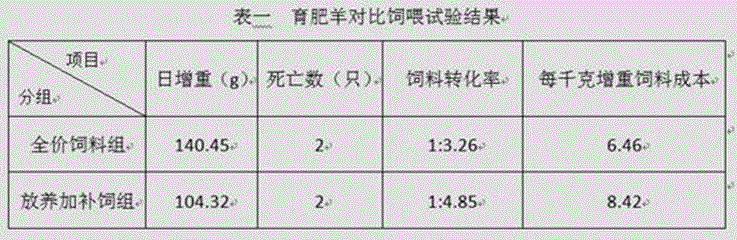

Novel feed for cattle and sheep and preparation method of novel feed

ActiveCN103141699ALow costStrong price advantageAnimal feeding stuffIsomaltooligosaccharideFeed conversion ratio

The invention belongs to the field of animal feed processing and particularly relates to a novel feed for cattle and sheep and a preparation method of the novel feed. The novel feed is prepared by processing byproducts, namely corn steep liquor, corn bran, corn gluten meal, saccharified liquid residues and yeast bodies on a production line of isomaltooligosacharide, as well as corn stalks, a compound premix for the cattle and the sheep, and corn flour; the produced complete feed meets cattle and sheep production requirements, and solves he problems of poor utilization of the byproducts and environment pollution during the production of the isomaltooligosacharide; and besides, the processed complete feed for the cattle and the sheep is low in cost, complete in nutrition, good in palatability, high in feed conversion rate and very suitable to be used for the large-scale captive breeding of the cattle and the sheep, so that not only is the culture benefit increased, and simultaneously the problem that the cattle and the sheep scramble food with pigs and poultry is solved.

Owner:BAOLINGBAO BIOLOGY

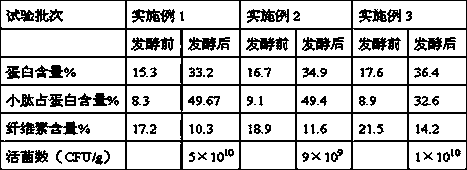

Technology for fermenting and decomposing protein feed with protease in two steps by using probiotics

InactiveCN101720853AReduce consumptionLess bacteriaAnimal feeding stuffBiotechnologyNutrient solution

The invention relates to technology for fermenting and decomposing protein feed with protease in two steps by using probiotics, which is characterized in that the protein is fermented and decomposed with protease of aerobic fermentation matter in the anaerobic condition, soybean dregs, cotton dregs, vegetable dregs meal, wheat bran and other vegetable protein raw materials are sterilized at high temperature and then are aerobically fermented for 24-36h, feather meal and other animal protein raw materials are aerobically fermented for 20-26h, the inoculating temperature is controlled at 60-80 DEG C, the fermented materials are not dried and are directly mixed with fresh raw materials, corn steep liquor and other nutrient solution are added or not added; lactic acid bacillus are inoculated to the mixture, and water is supplemented to the mixture until the water content of the mixture reaches 40-60 percent, the mixture is compacted and sealed to be anaerobically fermented for 1-3d above 20 DEG C or 2-5d below 20 DEG C, and the mixture is dried after being fermented and decomposed with protease.

Owner:李军训

Origin fermentation method and origin fermentation product prepared by same

ActiveCN104152514AShort fermentation timeSimple stepsCosmetic preparationsToilet preparationsAdditive ingredientUltrafiltration

The invention relates to the field of biological fermentation and in particular relates to an origin fermentation method and an origin fermentation product prepared by the same. The origin fermentation method comprises the following steps: acquiring fresh leaves, pulping and crushing to obtain a leaf slurry; placing the leaf slurry into a fermentation tank, adding sterilized ammonium sulphate, ammonium dihydrogen phosphate, ammonium hydrogen carbonate and an aqueous solution of corn steep liquor dry powder into a fermentation tank so as to be fermented; carrying out cell breakage, ultrafiltration, low-temperature drying and concentrating on a fermentation product, and packaging, so that the origin fermentation product is obtained. The origin fermentation method provided by the invention has the advantages that fresh leaves are crushed, bacteria and enzymes carried by the leaves are directly utilized for carrying out fermentation, no organic solvent, saccharifying enzyme or yeast is added in a fermentation process, the fermentation time is short, main ingredients of the obtained origin fermentation product are active substances beneficial to skin, such as micromolecule plant proteins, plant growth factors, plant activity auxin and part of cell growth factors, and the quality of the obtained origin fermentation product is high.

Owner:北京翰若生物科技有限公司

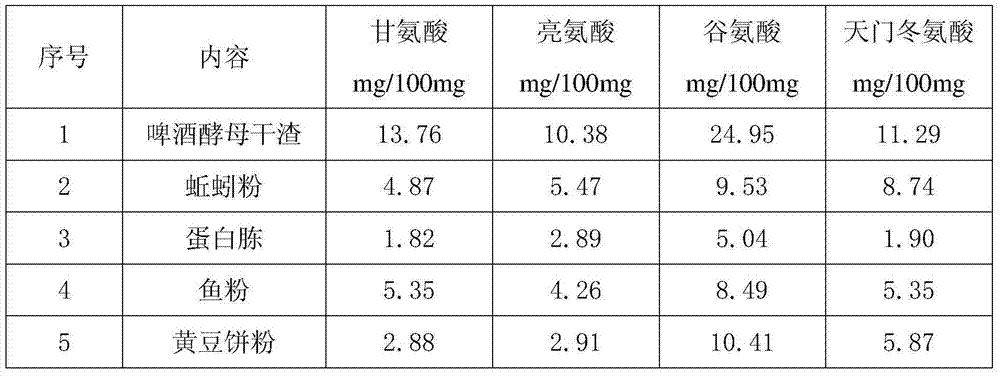

Method for preparing glutamic acid fermentation organic nitrogen additive from glutamic acid fermentation waste thalli

InactiveCN101979627ASolve pollutionIncrease valueMicroorganism based processesFermentationCombined methodFeed additive

The invention relates to a method for preparing a glutamic acid fermentation organic nitrogen additive from glutamic acid fermentation waste thalli, which solves the problem that environment can be polluted by directly discharging fermented waste thalli or economic benefit is low when the fermented waste thalli are prepared into a feed additive in the conventional glutamic acid production. The glutamic acid fermentation waste thalli are taken as raw materials; protein hydrolyzate is obtained by enzymatic hydrolysis, acid hydrolysis or an enzymatic hydrolysis and acid hydrolysis combined method; and the hydrolyzate is concentrated or dried to prepare the organic nitrogen additive for fermentation. For the organic nitrogen additive prepared by the method, the protein recovery rate of the glutamic acid fermentation waste thalli reaches 93 percent; the prepared organic nitrogen additive can be recycled for glutamic acid fermentation and replaces yeast extract, peptone, corn steep liquor and other organic nitrogen additives which are used in the conventional glutamic acid production, so environmental pollution can be reduced and the added value of the organic nitrogen additive can be greatly improved; and the organic nitrogen additive has great significance for the comprehensive utilization of the glutamic acid fermentation waste thalli.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Heat-stress-resistant fermented feed for laying hen and preparation method thereof

InactiveCN104304819ARelieve heat stressImprove micro-ecological environmentAnimal feeding stuffAdditive ingredientCorn steep liquor

The invention discloses heat-stress-resistant fermented feed for a laying hen. The heat-stress-resistant fermented feed is prepared from the following raw materials: corn, soybean meal, cottonseed meal, apple pomace, chili meal, corn steep liquor sprayed corn husk, wheat bran, bacteria liquid, compound premixed feed and water, wherein the bacteria liquid is prepared from enterococcus aureus, bacillus subtilis, saccharomyces cerevisiae, brown sugar and water. The preparation method of the heat-stress-resistant fermented feed comprises the following steps: crushing the raw material, mixing the dried material, preparing the bacteria liquid, secondarily mixing the wet feed, and conducting anaerobic fermentation. The heat-stress-resistant fermented feed disclosed by the invention has the following benefits: the main essential nutrients in the fermented feed are approximate to that of complete feed for the laying hen and comprise active beneficial bacteria, gamma-aminobutyric acid, organic acid and other active factors; the feed can be added to the daily ration of the laying hen based on the rate of 5-15% to obviously improve the laying rate of the laying hen, the feed-gain ratio, the broken egg rate and the oxidation resistance, synergistically give play to multiple action of the beneficial bacteria on microecologic control to bacterial flora in the gastrointestinal tract, nerve regulation to the central nervous system by the neurotransmitter, and buffering of the organic acid to respiratory alkalosis due to high temperature, and obviously resist against the heat stress due to high temperature in summer for the laying hen.

Owner:ANHUI SCI & TECH UNIV

Preparation method of microecological fermented feed by utilizing byproducts of corn deep-processing as raw materials

InactiveCN103829036AIncrease feed intakeImprove utilization efficiencyAnimal feeding stuffBiotechnologyRhizopus

The present invention relates to a preparation method of a microecology fermented feed by utilizing byproducts of corn deep-processing as raw materials. The preparation method includes: 1, selecting three probiotics of bacillus subtilis, aspergillus oryzae and rhizopus, obtaining a second stage seed by slant culture, first stage seed culture in a shake flask and second stage culture in a shake flask, and carrying out complex formulation according to a certain proportion; 2, selecting three probiotics of lactic acid bacteria, candida utilis and flavor yeast, obtaining a second stage seed by slant culture, first stage seed culture in a shake flask and second stage culture in a shake flask, and carrying out complex formulation according to a certain proportion; 3, reasonably proportioning to prepare a fermentation medium by utilizing the by-products of the corn deep-processing, such as corn bran, embryo cake, corn steep liquor and gluten meal, as raw materials; 4, inoculating the formulated probiotics of the step 1 in a solid state fermentation medium to perform aerobic fermentation, inoculating the formulated probiotics of the step 2 to perform anaerobic fermentation after aerobic fermentation for a while, drying after the fermentation, to obtain the microecological feed. The preparation method has high comprehensive utilization efficiency. The microecological feed has high active proteins, lactic acid and functional small peptides, and is a high quality health care feed which is easily absorbed by body.

Owner:郑州市中食农产品加工研究院

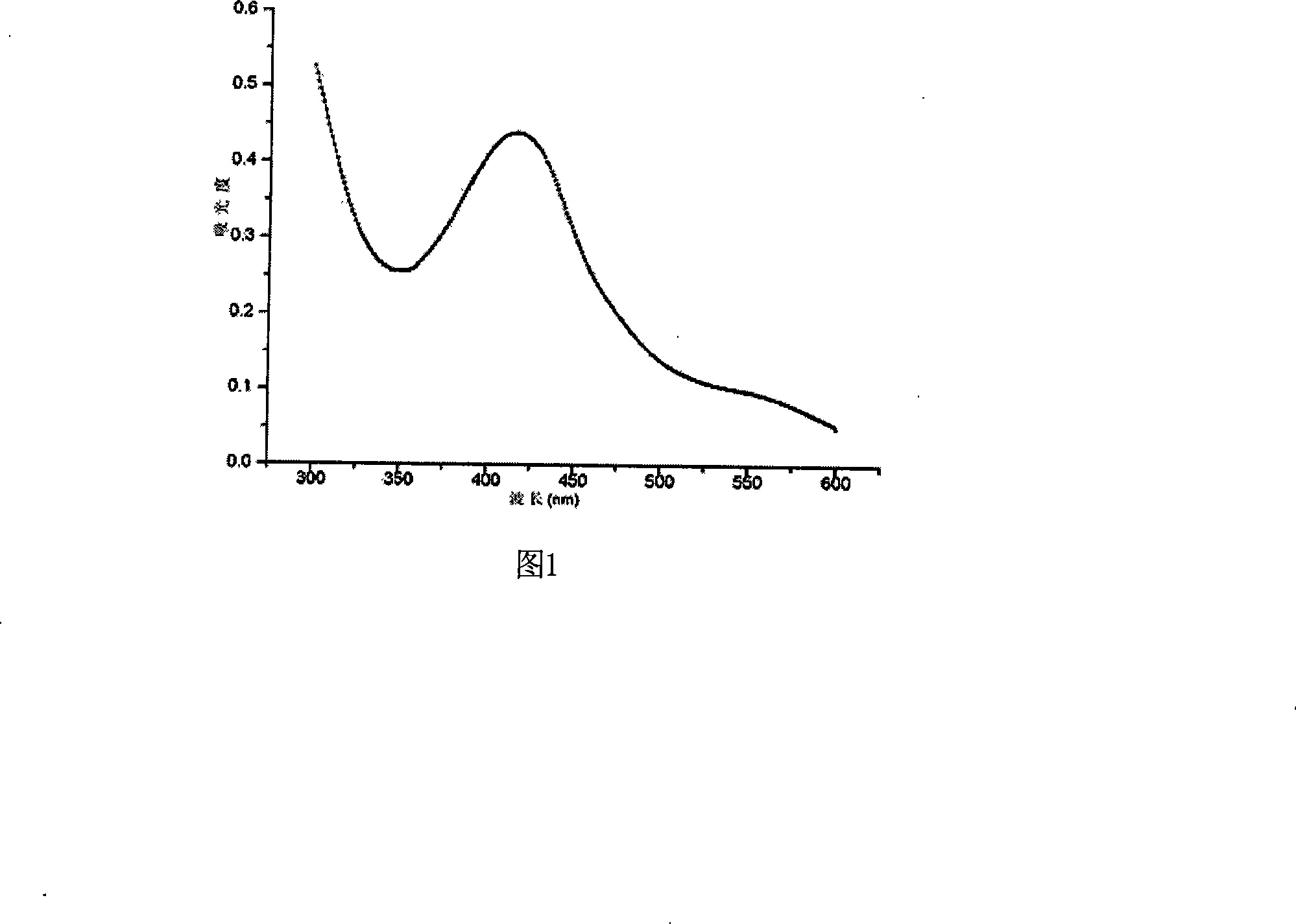

Monascus mutant and method for preparing flavochrome by fermenting the same

The invention relates to a monascus mutant and a method for fermenting to get yellow pigment, the Monascus anka mutant MYM2 is reserved in Chinese micro-organism culture preservation management committee normal microorganism center on November 30th, 2007, and preservation number is CGMCC2275. The method for fermenting the monascus mutant to get yellow pigment comprises the following steps: utilizing a fluid medium whose pH value us 3-4.5 to be a fermentation medium, utilizing ammonia sulfate and maize milk to be main nitrogen source, utilizing grape-sugar and soluble starch to be main carbon source, fermenting for 3-10 days under 25-35 DEG C, and the rotating speed of a shaking table is 160-300r / min. Yellow pigment which is got through fermenting has very strong tinctorial power, which can resist high temperature, and the yellow pigment is stable to metal ion, which is stable under wide pH value, and the yellow pigment mainly is liposolubility yellow pigment, which can be used in a complex way with other coloring matters.

Owner:SOUTH CHINA UNIV OF TECH

Fermentation preparation method for edible fungus probiotics health-care drink

ActiveCN103932344AGood health valueHigh nutritional valueFood thermal treatmentLactobacillusBiotechnologyFruit juice

The invention provides a fermentation preparation method for an edible fungus probiotics health-care drink. The method comprises the following steps: adding proper amounts of sugar, albumen powder, inorganic salt, gelatinized corn steep liquor, fruit juice and water to obtain a mixture, wherein edible fungus mycelium homogenate or fruiting body powder is used as a raw material, filing a fermentation tank with the mixture, performing steam sterilization, cooling, and fermenting according to the following stages: (1) introducing sterile air into the fermentation liquor, wherein the tank pressure is 0.04-0.08MPa, inoculating a bacillus subtilis seed solution, wherein the compression-ventilation ratio is 0.5-1.0, the temperature is 26-30 DEG C, the stirring rotating speed is 150-220r / min, and fermenting for 24-36 hours; (2) raising the temperature to 34-40 DEG C, wherein the stirring rotating speed is 180-260r / min, and ventilating and fermenting for 8-16 hours; (3) stopping ventilating, closing all connected valves on the fermentation tank, raising the temperature to 46-50 DEG C, wherein the stirring rotating speed is 200-250r / min, and fermenting for 5-10 hours; and (4) inoculating a lactic acid bacteria seed solution, wherein the temperature is 40-44 DEG C, the stirring rotating speed is 150-200r / min, fermenting for 4-6 hours, reducing the temperature to 30-35 DEG C, inoculating a bifidobacterium seed solution, wherein the stirring rotating speed is 100-180r / min, and fermenting for 6-10 hours, so as to obtain a viable type health-care drink containing bacillus subtilis and lactic acid bacteria after the fermentation is ended.

Owner:湖北九公堂生物科技有限公司

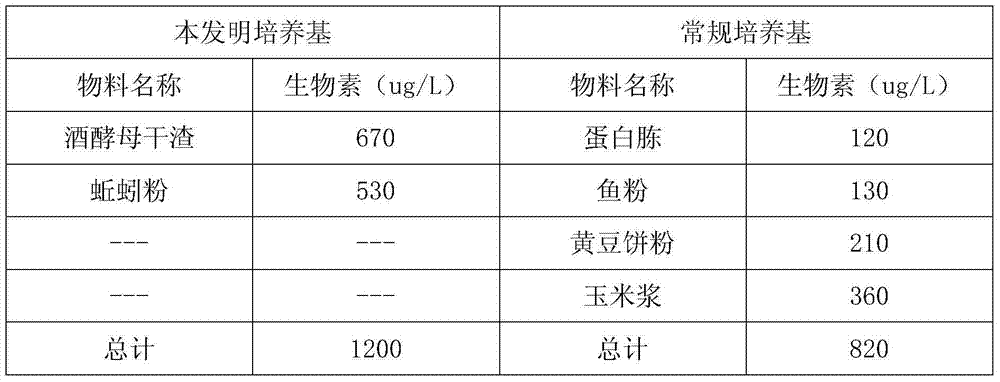

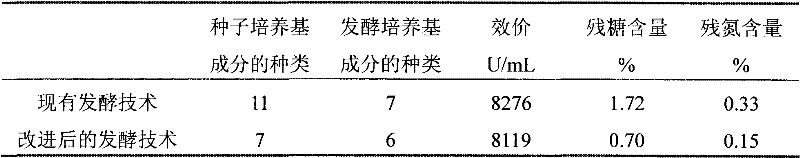

Culture medium for fermentation production of spectinomycin through streptomyces spectabilis and fermentation method

ActiveCN103484509AReduce dosageReduce typesMicroorganism based processesFermentationBiotechnologySpectinomycin

The invention relates to a culture medium for fermentation production of spectinomycin through streptomyces spectabilis and a fermentation method. A primary seed culture medium, a secondary seed culture medium and a fermentation culture medium all contain corn oil, maltose, beer yeast dry residues and earthworm meal. According to the invention, maltose replaces glucose, beer yeast dry residues and earthworm meal replace fish meal, peptone, soybean cake meal and corn steep liquor, and the culture medium formula is optimized, so that the problem of high costs of raw materials is solved, the environmental effect on the source of the raw materials is reduced to the utmost extent, sufficient supply of the raw materials is guaranteed, and stable and efficient production of spectinomycin is realized. Meanwhile, the culture medium can improve the fermentation unit and shorten the fermentation period.

Owner:宁夏泰瑞制药股份有限公司

Preparation method of Se-enriched nutrient corn beverage

The invention discloses a preparation method of Se-enriched nutrient corn beverage, which is characterized by comprising the following steps of: using fresh sweet corn as raw material, conducting controlled hydrolyzing on fresh sweet corn steep liquor starch liquid by using amylase and maltogenic amylase, then using Lactobacillus acidophilus and Se-enriched beer yeast to carry two-stage fermentation on corn liquid, and obtaining a novel Se-enriched natural corn beverage product with rich health care functional factors and good taste.

Owner:ZHEJIANG UNIV

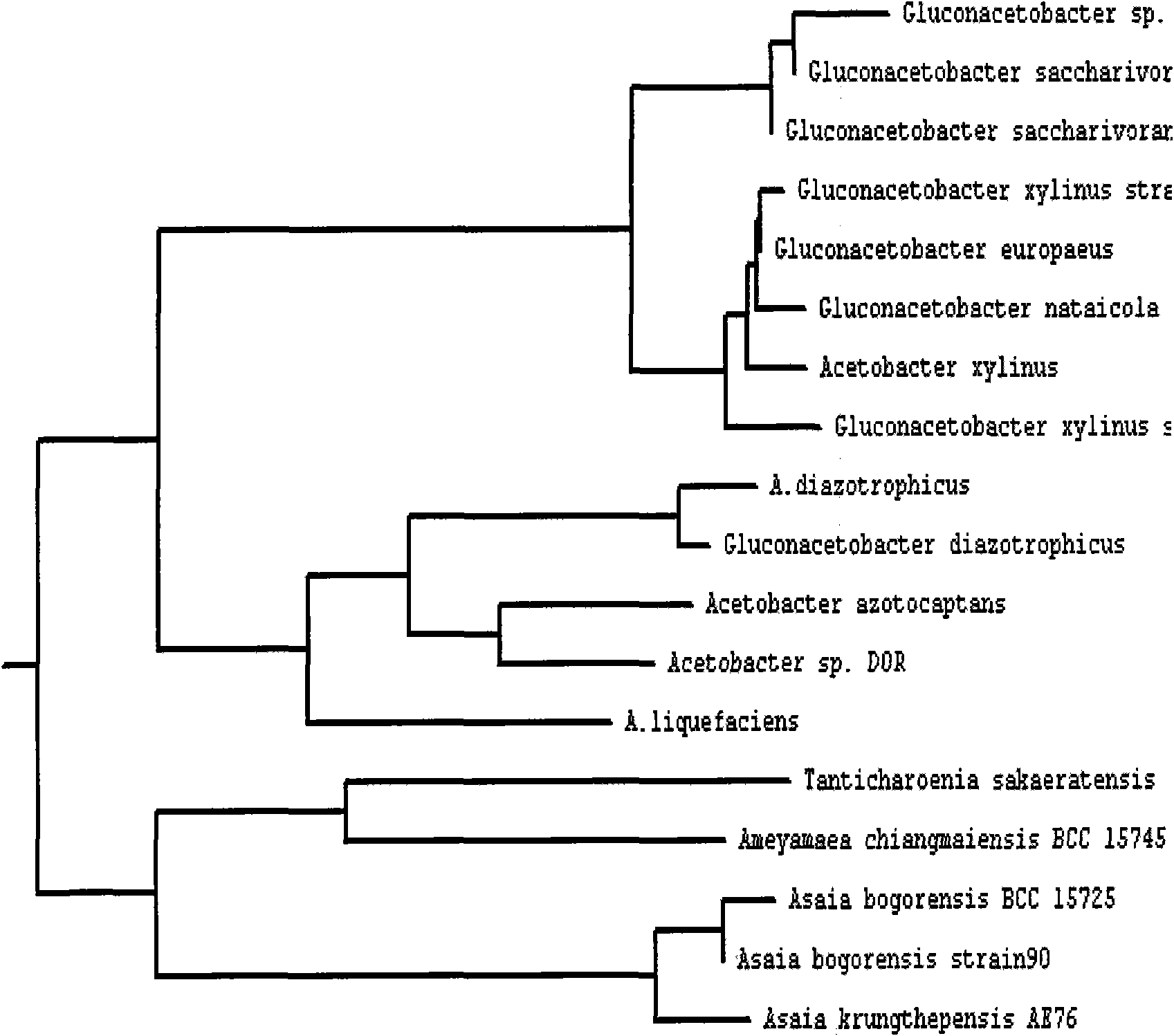

Strain of gluconacetobacter and application thereof

InactiveCN101591626AFlexible culture conditionsWide growthBacteriaMicroorganism based processesSucroseSaccharum

The invention discloses a strain of gluconacetobacter SC-01 (Gluconacetobacter sp.SC-01) and application thereof and relates to the strain of the gluconacetobacter and a method for producing bacterial cellulose by utilizing the gluconacetobacter. The strain is inoculated into a seed culture medium and subjected to shaking culture by a shaker for 24 hours at a temperature of between 25 and 35 DEG C; and the strain with 10 percent of inoculation amount is inoculated into a fermentation medium, stood at the constant temperature of between 25 and 35 DEG C and cultured for 10 days or subjected to shaking culture for 5 days. The cellulose is separated, purified and dried. A carbon source of the culture medium is one or more of glucose, mannitol, sucrose, galactose, fructose or xylose; and a nitrogen source is one or more of yeast powder, peptone or dry powder of corn steep liquor. The strain still has high yield of the bacterial cellulose in low pH environment and is suitable for large-scale industrialized fermenting production. The bacterial cellulose obtained by the gluconacetobacter has the characteristics of ultra-pureness, ultra-fineness, high crystallization degree, strong hygroscopicity, degradability, high mechanical strength and the like.

Owner:NANKAI UNIV

Process for producing propionate

InactiveCN102703530AIncrease productionShorten fermentation timeMicroorganism based processesFermentationBiotechnologyPropionate

The invention discloses a microbial fermentation culture medium and a process for producing propionate by using the fermentation culture medium. According to the fermentation process, the fermentation culture medium in which corn steep liquor dry powder and soybean meal are taken as an organ nitrogen source is used, so that the fermentation time is shortened, and the yield of the propionate is also improved; and raw materials are industrial by-products, so that the cost is saved, and the environment problem is also solved.

Owner:沈阳科纳提克生物科技有限公司

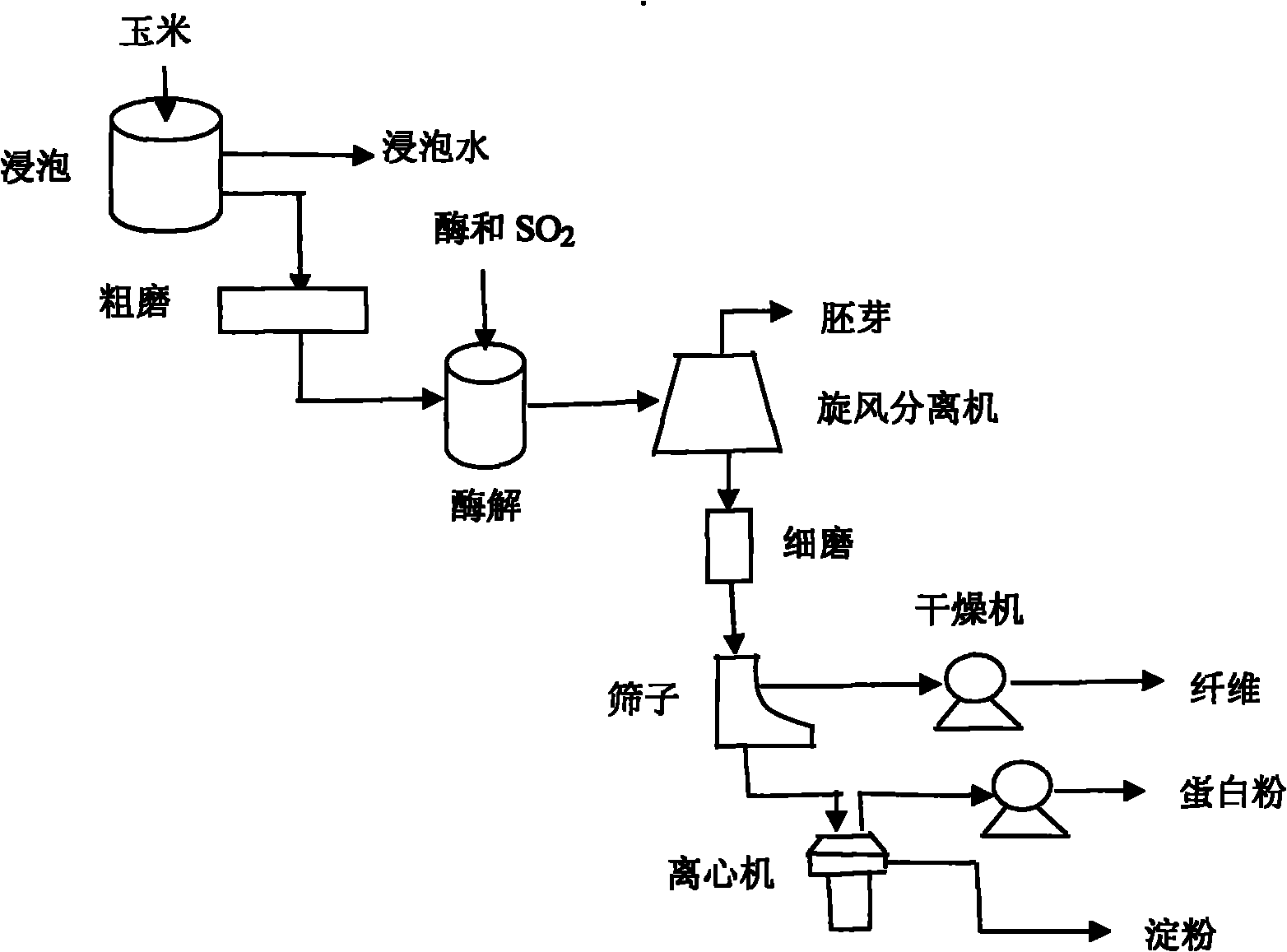

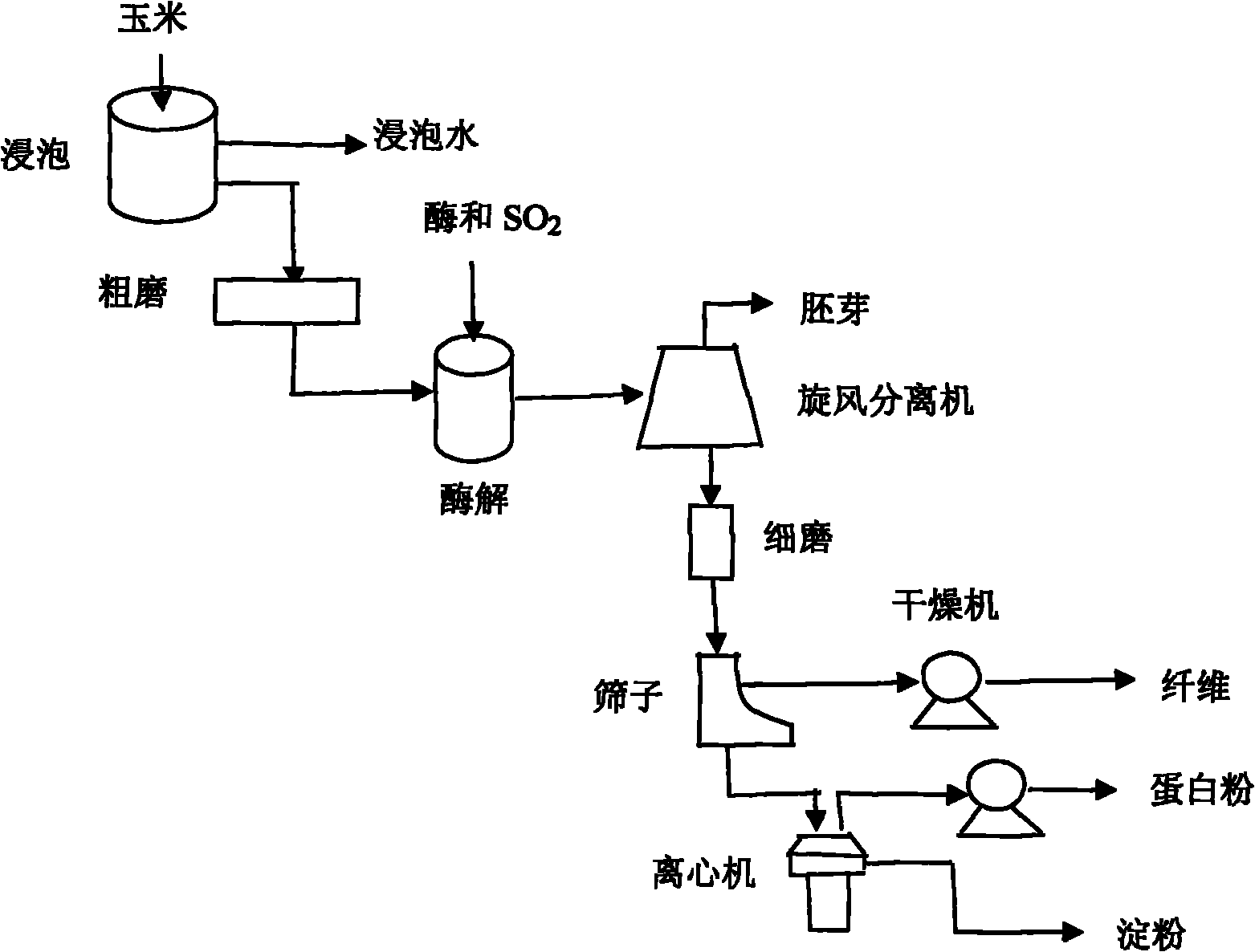

Soaking technology for preparing corn starch

The invention relates to a soaking technology for preparing corn starch, belonging to the technical field of grain deep processing. The technological steps comprise: 1. soaking: corn grains are soaked in water to soften embryos; 2. pulp grinding: the soaked corn grains are coarsely ground to obtain corn pulp; 3. enzymolysis: one of acid protease and pepsin is added in the obtained corn pulp after coarse grinding to conduct enzymolysis to the corn pulp, and SO2 is fed at the same time to mainly take the effect of inhibiting activities of microorganisms on the premise that the enzymatic activity is not affected; and 4. fine grinding, separation and drying to obtain starch finished product. Through shortening soaking time and reducing the used amount of SO2, the invention has the advantages that the corrosion of equipment, the underground water pollution, the residual sulfurous acid in the product and the like are obviously reduced, the obstacles restricting enzyme to enter endosperm to react with protein particles are eliminated, the total soaking time is only 8-12h, the soaking time is shortened, the cost is reduced, the effect is good, and the popularization value and the application value are high.

Owner:山东福田糖醇有限公司

Fermented fresh fructus momordicae wine and brewing process thereof

The invention provides a fermented fresh fructus momordicae wine and a method for making the same. The fermented fresh fructus momordicae wine is produced via primary fermentation, secondary fermentation and ageing of fermenting strains by using fresh fructus momordicae mash as a raw material and using cane sugar, corn steep liquor, citric acid and clean water as auxiliary materials. The fruit wine has the advantages of golden, clear, transparent and bright color, full-bodied, fresh and soft taste, coexistence of bouquet and fruit flavor, full and complete wine body and nobleness and elegance. The alcohol content can be formed as high caloric sugar and other contents in fructus momordicae are degraded by microorganisms during brewing. The fructus momordicae wine has good biological activity as the loss of sweet mogrosides, flavone, VC and other active ingredients is small, thereby guaranteeing the health efficacy of the fructus momordicae. Fresh fructus momordicae wines with different flavors and alcohol contents can be brewed by preferring strains with different fermenting characteristics for fermentation so as to meet requirements of different consumers. The method has the advantages of simple manufacturing technique, short fermenting period, high production yield and low manufacturing cost.

Owner:桂林亦元生现代生物技术有限公司

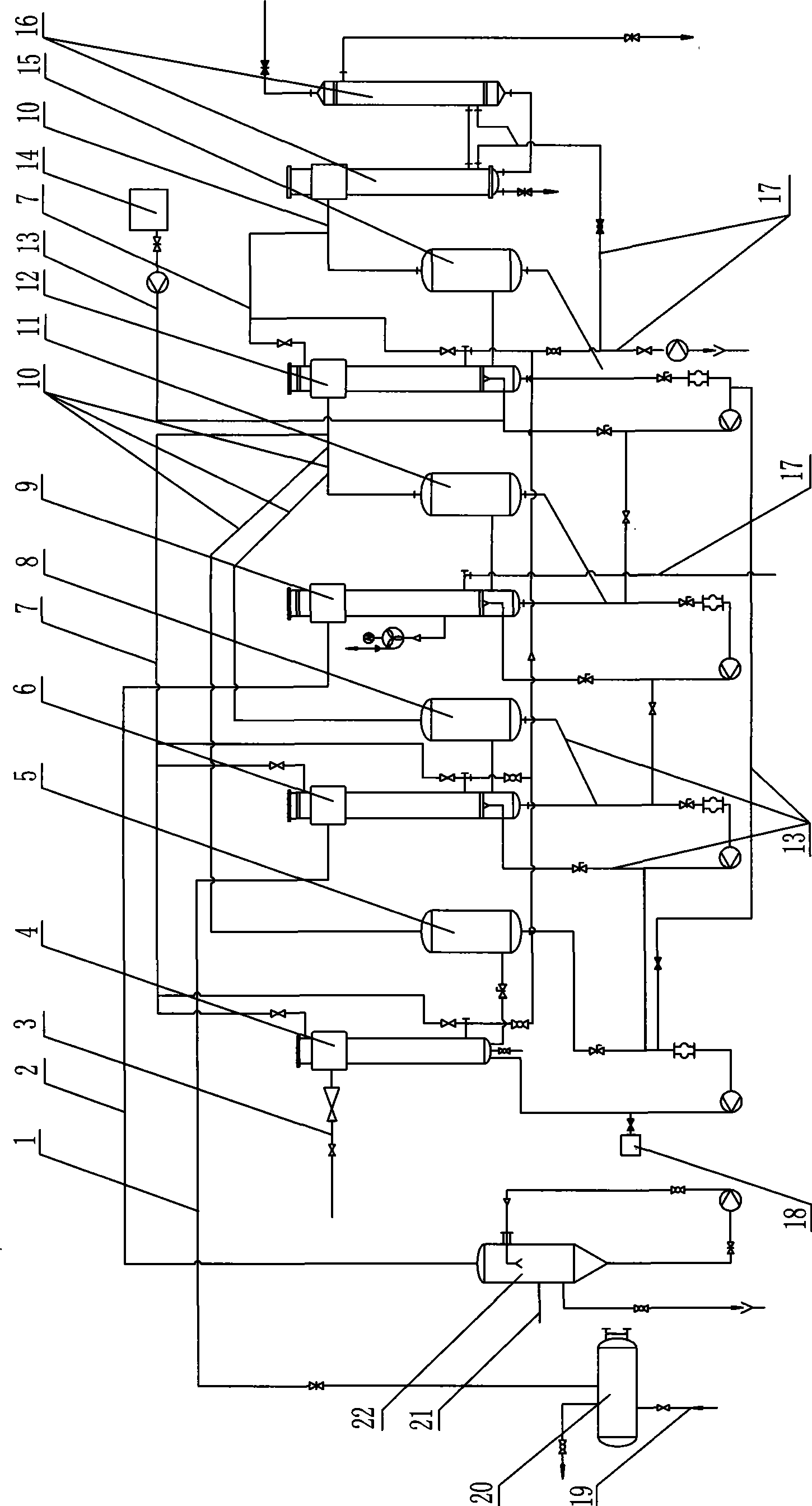

Method and equipment for utilizing waste heat from corn starch production

The invention belongs to the corn starch production technology field by a wet method, particularly relates to a use method of dry waste heat in the production process of corn starch and equipment thereof. The technical proposal of the invention is as follows: the waste heat use equipment in the production of corn starch comprises a fourth-effect evaporator, a washing tower, a flash evaporator, a corn steep liquor can and a corn soak solution can; the fourth-effect evaporator comprises a first-effect heating room, a first-effect separator, a second-effect heating room, a second-effect separator, a third-effect heating room, a third-effect separator, a fourth-effect heating room, a fourth-effect separator, and a condenser which are connected by pipelines; only the first-effect heating room is supplied with fresh steam; the second-effect heating room and the third-effect heating room respectively use secondary emission of a tube bundle and the tube bundle, and heat of condensed water by air drying for heating; and the fourth-effect heating room uses the waste heat and secondary steam of the first-effect heating room, the second-effect heating room and the third-effect heating room for heating. The invention can reduce the amount of fresh steam, and is a measure which can not be ignored for saving energy, reducing consumption, and increasing benefits of the enterprise.

Owner:山东华义玉米科技有限公司

Single cell protein fodder and preparation process thereof

InactiveCN1449673AWide variety of sourcesLow priceFungiFood processingBiotechnologySingle-cell protein

The present invention relates to a kind of single cell protein feed and its production process. Its technical scheme is characterized by that it uses grain or by-product produced by milling engineering as solid culture medium, adds the corn steep liquor and lysine waste liquor, uses any one of zymophyte, candida, distillers' yeast, torula yeast and baidy enzyme or their any combination to make inoculation. Said invention is extensive in raw material source, and its cost is low, and the gross protein value of said feed is up to 35-55%, and it is easily absorbed by livestock and fowl.

Owner:JILIN HUANYU FODDER

Technology for processing black corn milk beverage

The invention discloses a technology for processing a black corn milk beverage. The technical scheme is that the technology comprises the following steps of: selecting fresh black corncobs which are black, impurity-free and 60 to 70 percent mature, cleaning, performing centrifugal dehydration, crushing until the fineness is not less than 80 meshes, mixing materials and water in a ratio of 1: 10, heating and boiling for 20 minutes, adding 1 percent of alpha-amylase into black corn steep liquor, keeping the temperature at the temperature of between 90 and 95 DEG C for 20 minutes, cooling, adjusting the pH value until the solution is slightly acid, adding 0.1 percent of saccharifying enzyme, keeping the temperature at 55 to 60 DEG C to ensure that the solution is fully saccharified, roughly filtering a hot saccharified liquid by using a kieselguhr filter, finely filtering by using a sheet filter, adding 8 to 10 percent of granulated sugar, transferring correction liquor into a high-pressure homogenizer, homogenizing under the pressure of 20MPa, sterilizing at the temperature of 100 DEG C for 6 to 8 minutes, and bottling at the temperature of between 70 and 75 DEG C.

Owner:杨绪明

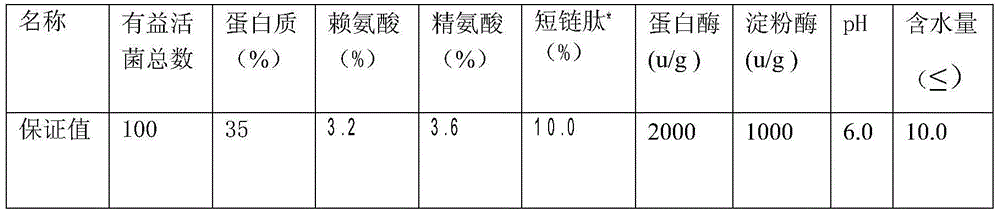

Production method for functional amino-acid humic-acid microecological preparation for aquatic animal and poultry

The invention discloses a production method for a functional amino-acid humic-acid microecological preparation for aquatic animal and poultry. The production method comprises: employing arginine concentrated-bacterial-liquid wet powder, humic acid powder, corn-steep-liquor dry powder, soybean meal and wheat bran as fermentation raw materials, and employing bacillus subtilis, bacillus licheniformis, saccharomyces cerevisiae and lactobacillus acidophilus as beneficial microbial flora; separately performing single-colony separation, solid seed culture and liquid seed culture on the four microorganisms, mixing seed liquids of the four microorganisms, performing solid piling fermentation, and introducing air for aerobic solid fermentation, so as to obtain the microecological preparation. By employing the arginine concentrated-bacterial-liquid wet powder, humic acid powder and corn-steep-liquor dry powder as the main fermentation raw materials, the product is high in content of protein, amino acids, short-chain peptide and compound enzyme. The product is abundant in nutrition, good in disease-preventing disease-controlling effect, and obvious in growth promoting effect of cultured animals. The product also is capable of improving culture environment and purifying water quality, and is a green high-quality functional microecological preparation for aquatic animal and poultry.

Owner:辽宁威兰生物技术有限责任公司

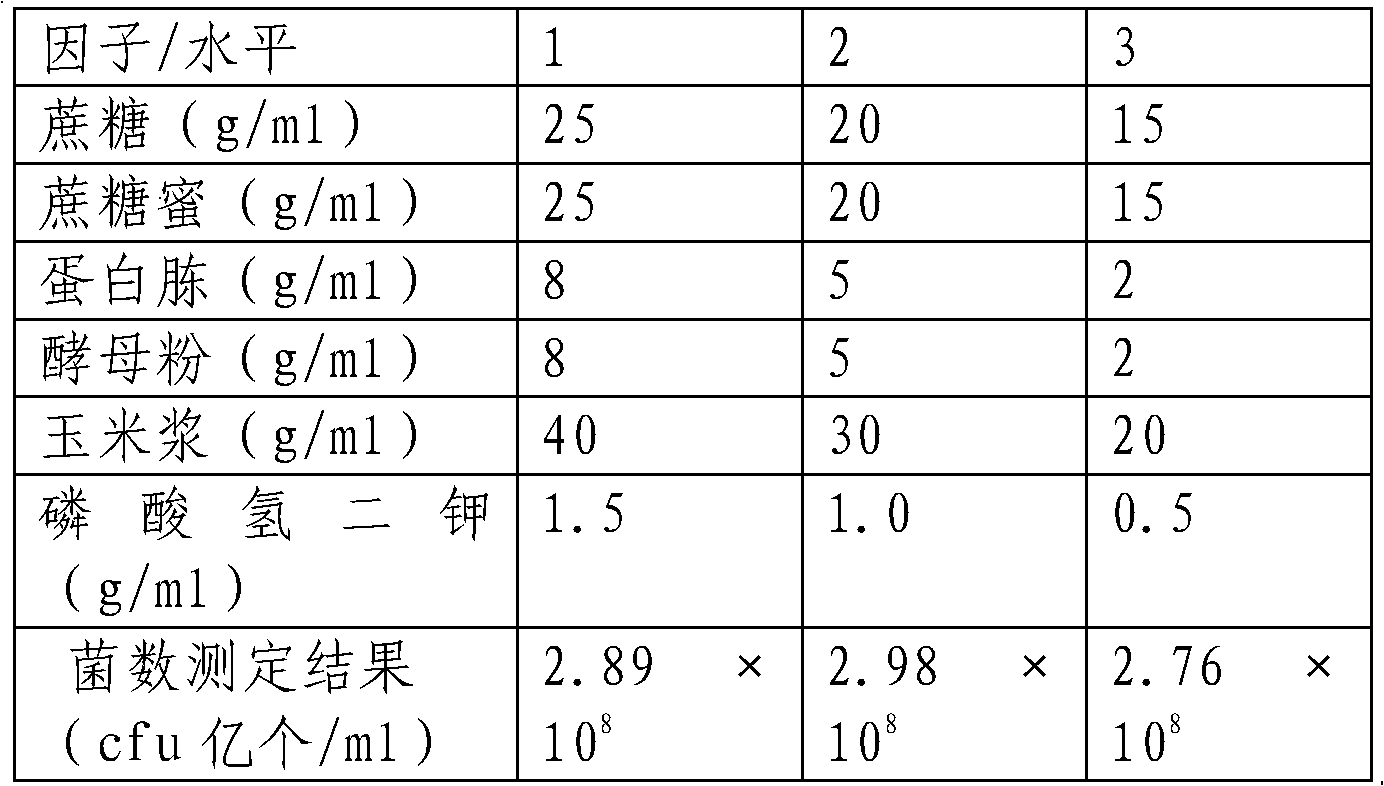

Method for producing glutamic acid through double-feeding fermentation optimization of corn steep liquor and glucose

ActiveCN103243132AFast growthImprove adaptabilityMicroorganism based processesFermentationBiotechnologyDouble-time

The invention discloses a method for producing glutamic acid through double-feeding fermentation optimization of corn steep liquor and glucose, which comprises the following steps of: in fermentation culture of glutamic acid, initially adding 1-10g / L of glucose to a fermentation culture medium, and initially adding 1-10g / L of corn steep liquor; after the fermentation culture starts, starting feeding the corn steep liquor and glucose at the same time, wherein 5-19g / L of corn steep liquor is fed and completely added within 5-10 hours since the fermentation starts, and the total amount of the corn steep liquor is 15-20g / L; feeding the concentrated solution of glucose until the fermentation is over; maintaining the amount of residual sugar in the fermentation culture medium at 0.05-10g / L; and controlling the pH value of the liquid ammonia in the whole process of fermentation to 6.8-7.3. The method disclosed by the invention effectively increases the growth speed of thalli and shortens the adaptation period in the initial stage of thallus fermentation and the thallus doubling time, thus shortening the overall fermentation time and reducing the overall production cost of glutamic acid.

Owner:山东祥维斯生物科技股份有限公司

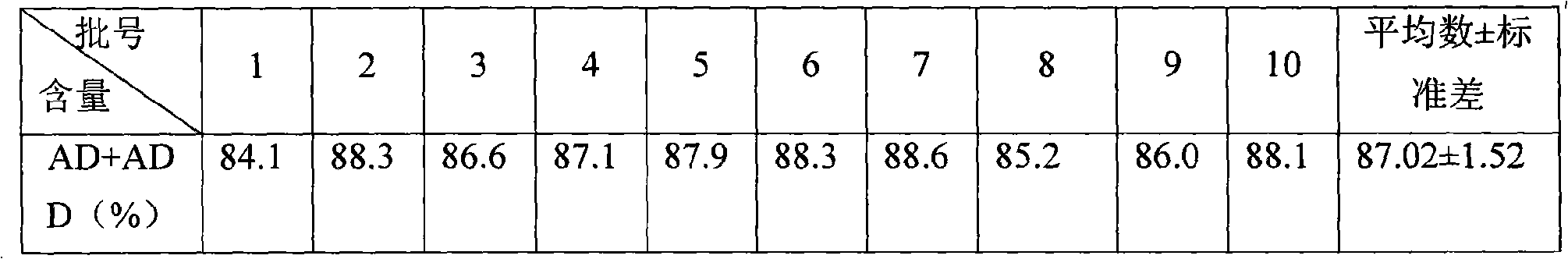

Novel bacteriological culture medium

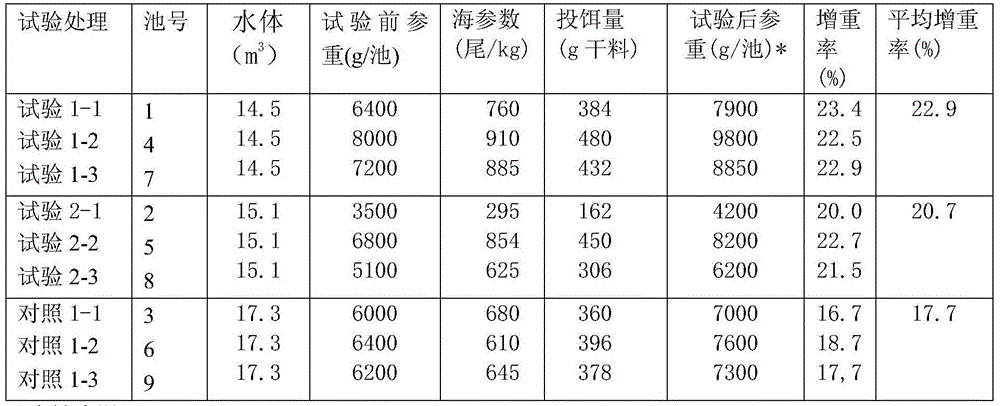

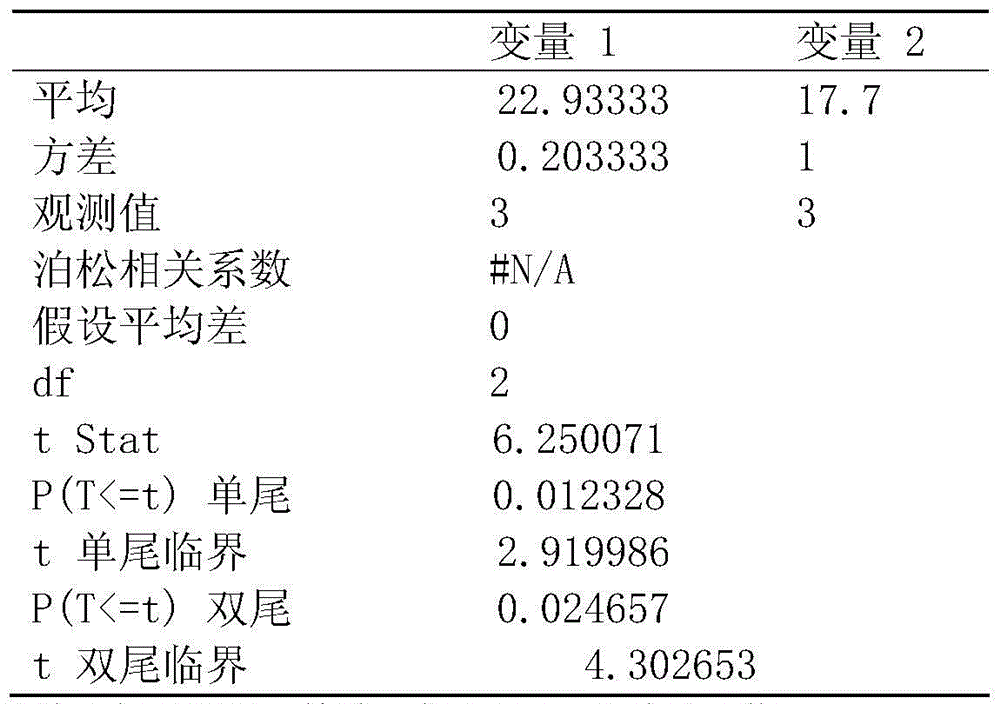

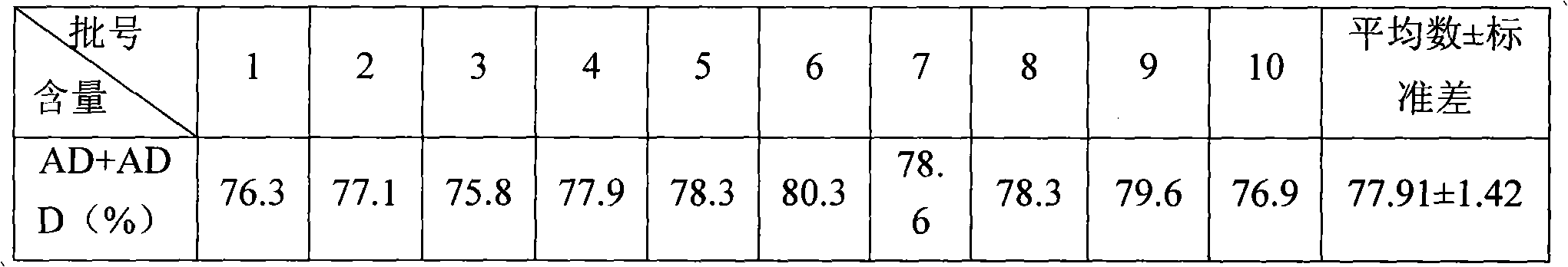

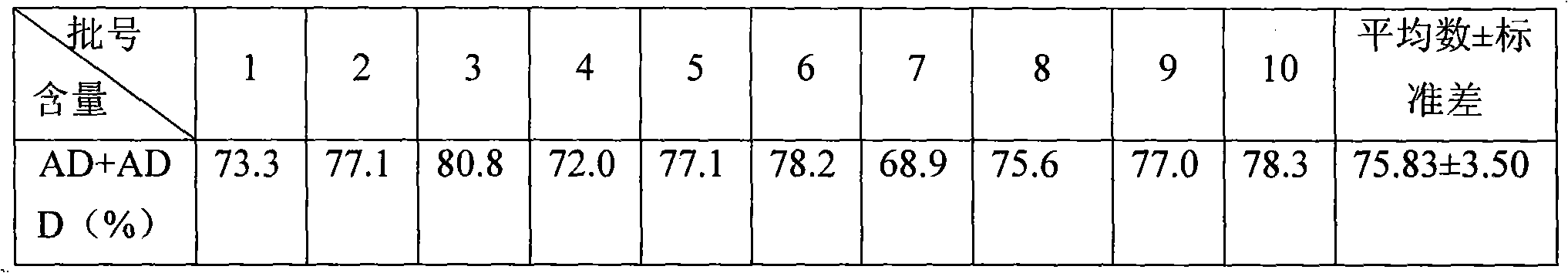

The invention provides a novel bacteriological culture medium, which is used in a fermenting process for converting phytosterin into AD and ADD by adopting athrobacter nicotinovorans, mycobacteria ornocardia, contains corn steep liquor and inorganic salt, and contains 5 to 50ml of the corn steep liquor per liter preferably. The culture medium can improve the conversion ratio of biofermentation.

Owner:TIANJIN JINYAO GRP

Method for producing high-energy high-protein feed by fermenting and decomposing polysaccharide in corn steep liquor

InactiveCN102178034AHigh energyImprove digestion utilizationFood processingAnimal feeding stuffBiotechnologyMetabolite

The invention relates to a method for producing a high-energy high-protein feed by fermenting and decomposing polysaccharide in corn steep liquor, which comprises the following steps of: respectively carrying out amplification culture on bacillus subtilis, bacillus licheniformis, yeasts and aspergillus oryzae and then adding the obtained product into a seeding tank to cultivate for 60-72 hours to obtain a composite bacterial liquid; mixing and heating the corn steep liquor and water, then adding xylanase, glucanase, protease and fatty acid enzyme into a mixed solution and carrying out heat preservation and fermentation on the mixed solution; adding ammonium sulfate, urea, monopotassium phosphate, magnesium sulfate and caramel into the fermented mixed solution; after uniformly mixing, regulating the pH value into the range of 5.5-6.5; then adding the composite bacterial liquid into the mixed solution, stirring the mixture, filling oxygen into the mixture and fermenting the mixture; and after the mixture is fermented well, spraying the mixture on bran or bean pulp, drying after uniformly stirring, grinding the dried mixture into powder with granularity of less than 2mm, and packaging to obtain the high-protein feed. In the method, the polysaccharide can be sufficiently decomposed. The method has high speed and high efficiency on the aspect of transformation. After being decomposed, a product contains various beneficial microorganism viable bacteria, digestive enzymes, metabolites and small molecule substances which can be sufficiently adsorbed by animals.

Owner:河南宏翔生物科技有限公司

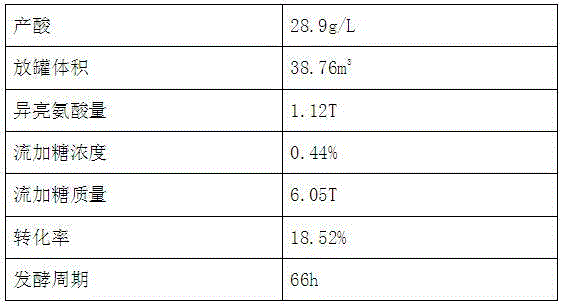

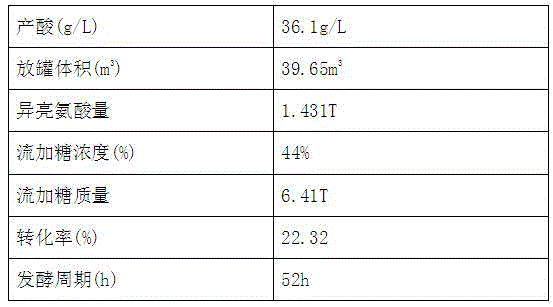

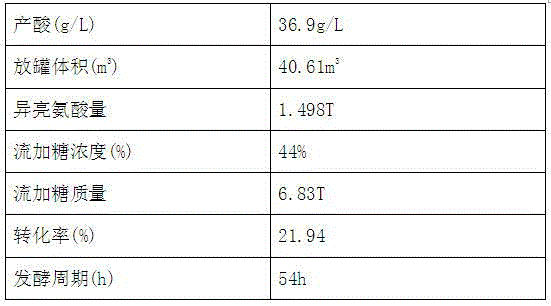

Fermentation method for improving yield of isoleucine

The invention discloses a fermentation method for improving the yield of isoleucine. The fermentation method comprises the following steps: culturing microorganisms, fermenting, separating fermentation liquor, carrying out ion exchange on fermentation supernatant, deaminizing with a deamination tower, decolorizing with activated carbon and crystallizing by evaporating. Because the corn steep liquor which serves as a hydrolysis liquor in the culture medium and accounts for 40% of the total weight of the culture medium replaces the hydrochloric acid adopted by the traditional method to regulate the pH value, the corrosion of the hydrochloric acid to the stainless steel tank is avoided. In addition, because biotin and VB1 are used as growth factors in the process, the viscosity of the fermentation liquor can be reduced, the respiratory metabolism of the microorganisms can be promoted, and the down-stream finished product can be extracted easily. By adopting the fermentation method disclosed by the invention, a good fermentation index can be achieved, the yield of the isoleucine which is a metabolite can be improved significantly, the average yield of the isoleucine can be up to 36.9g / L and can be increased by 30% compared with that of the metabolite isoleucine obtained by adopting the original method, the conversion rate of the metabolite isoleucine can be increased by 2-4%, and the fermentation cycle can be shortened by 10 hours.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

Fermentation method of erythromycin fermentation liquid

ActiveCN102409071AReduce typesDemand reductionMicroorganism based processesFermentationBiotechnologyNutrients substances

The invention discloses a fermentation method of erythromycin fermentation liquid, comprising the following steps of: inoculating streptomyces erythreus (producing bacterium) spores, culturing in a slant culture medium, performing three-stage seed intermediate culture, then inoculating into a sterilized culture medium, introducing sterile air and stirring, adding nutrient substances, and culturing. According to the invention, by optimizing the culture medium and improving the fermentation method, the utilization ratios of raw material such as glucose, soybean meal, corn steep liquor and the like are improved, the kinds and consumption of raw and auxiliary materials for fermentation are reduced, and the bioavailability of the raw and auxiliary materials is high.

Owner:YILI CHUANNING BIOTECH CO

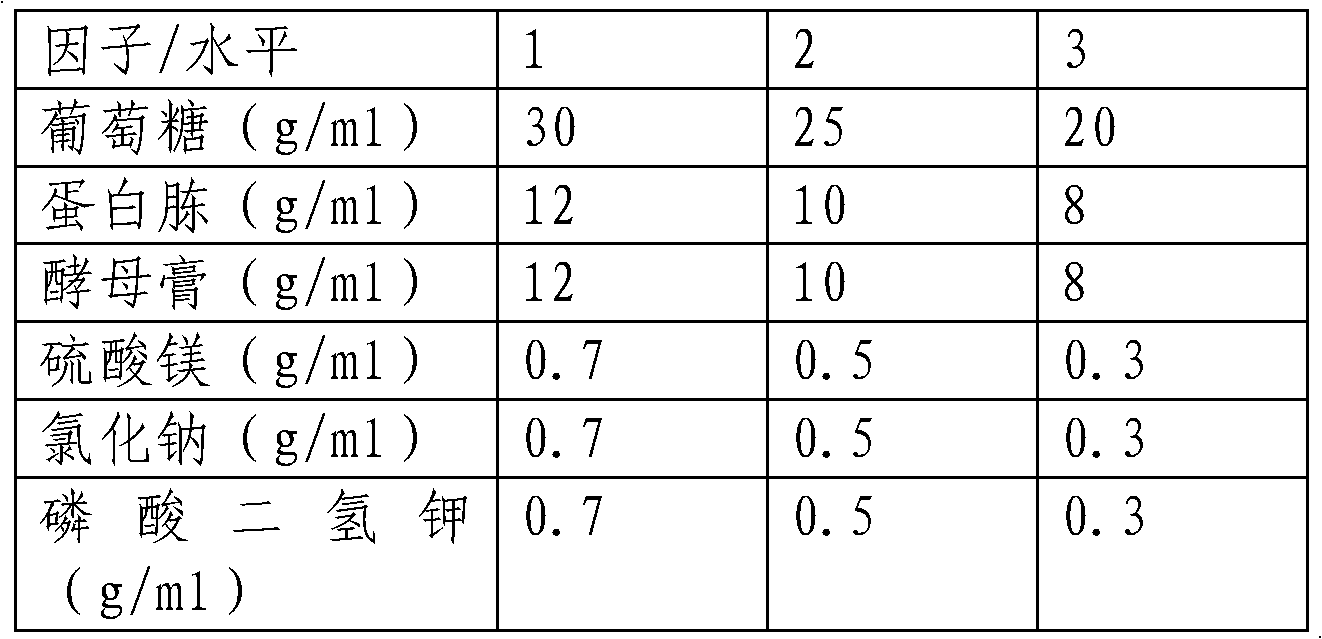

Production of saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation used for feed

The invention relates to a microbe preparation, and concretely relates to a production method of a saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation used for feed, the production method is characterized in that concentrated saccharomyces cerevisiae mother liquor containing saccharomyces cerevisiae greater than or equal to 50 hundreds million / ml and the concentrated lactobacillus acidophilus mother liquor with high density containing lactobacillus acidophilus greater than or equal to 100 hundreds million / ml are mixed according to 1:1 with the volume ratio, and the composite microbe preparation product containing saccharomyces cerevisiae greater than or equal to 50 hundreds million / ml and containing lactobacillus acidophilus greater than or equal to 100 hundreds million / ml. The saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation takes glucose, cane sugar, cane sugar honey and corn steep liquor as main fermentation raw materials, the fermental cultivation can be carried out at 30-34 DEG C, the product bacteria number is high, the quality is good, pH value is between 5.0-6.6, and the quality guarantee period is 18 monthes. The saccharomyces cerevisiae and lactobacillus acidophilus composite microbe preparation used for feed has simple production technology and good product application effect, can purify the culture environment, and can be used in the culture industries such as aquatic product and livestock and poultry.

Owner:辽宁威兰生物技术有限责任公司

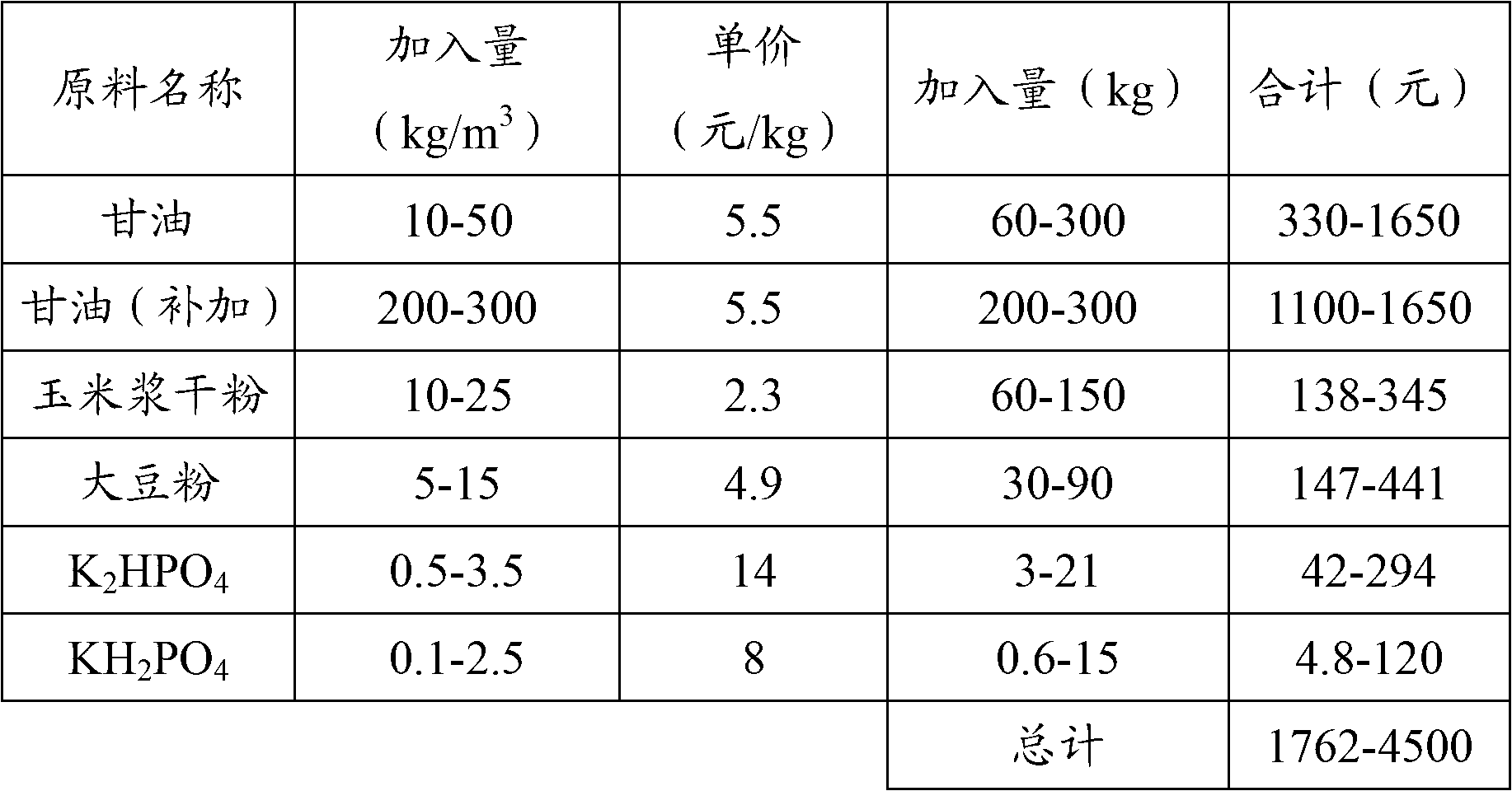

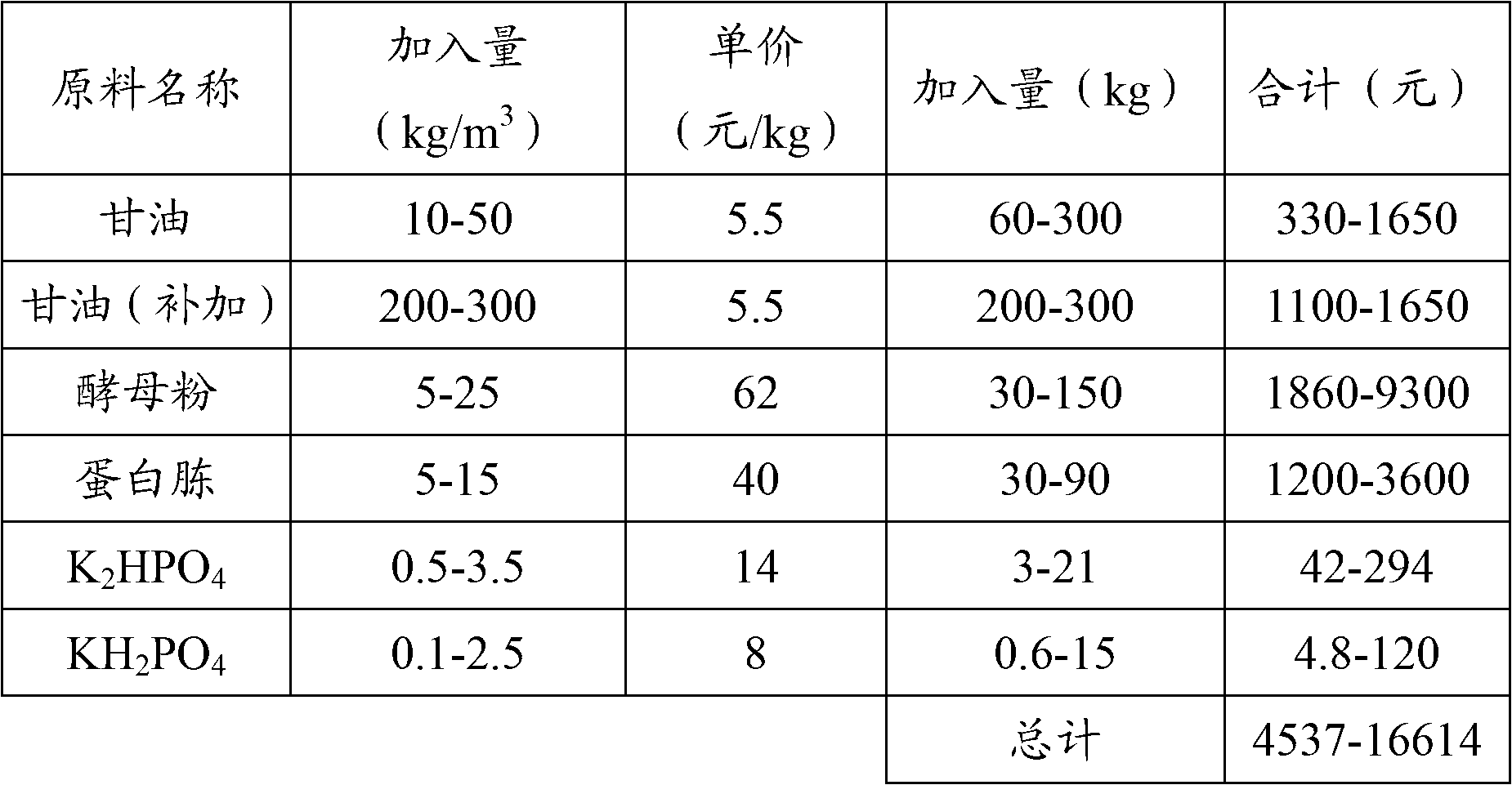

Method for producing 1,3-propylene glycol through fermentation via recombinant microbes

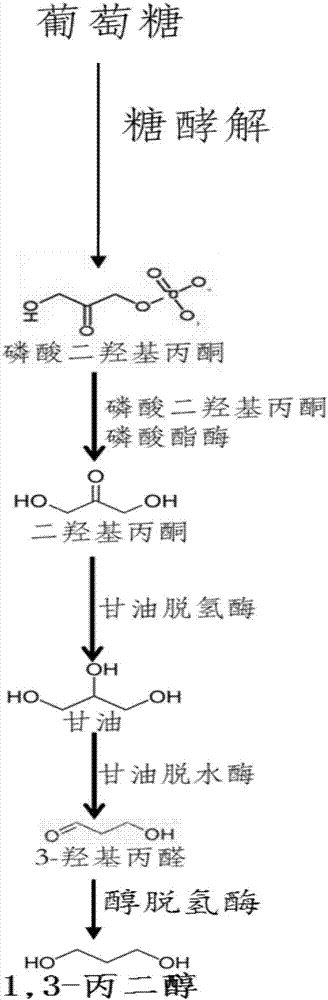

PendingCN106906248AAddressing Biosecurity IssuesLow costMicroorganism based processesFermentationPhosphoric acidBacterial strain

The invention provides a method for producing 1,3-propylene glycol through fermentation via recombinant microbes. According to the invention, an endogenous dihydroxypropanone phosphatein phosphatase gene hdpA is over-expressed in Corynebacterium glutamicum to reinforce removal of phosphoric acid from dihydroxypropanone phosphatein so as to produce dihydroxypropanone; exogenous glycerol dehydrogenase is introduced to convert dihydroxypropanone into glycerin; and glycerin finally produces 1,3-propylene glycol under the action of exogenous glycerol dehydratase and an activator thereof and alcohol dehydrogenase. Corynebacterium glutamicum can use different cheap raw materials for fermentation, and cheap corn steep liquor can be used as a nutritional component to replace expensive yeast powder, so cost for raw materials is further reduced, and the problems in biosecurity and tolerance of the bacterial strain to a substrate and a product are overcome; and thalli obtained in the process of fermentation can be used as a product for a feed additive. The method provided by the invention produces few by-products and can further simplify the separating process of 1,3-propylene glycol.

Owner:GUANGDONG TSINGDA SMART BIOTECH CO LTD

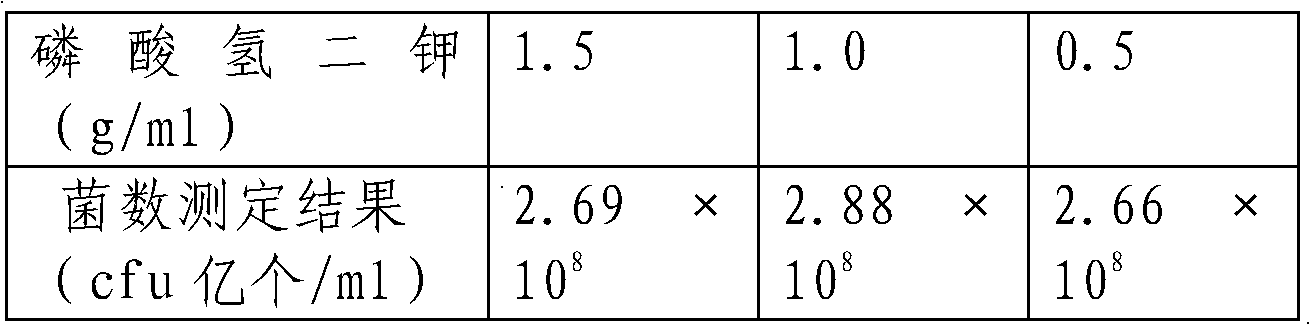

Production method of lactobacillus micro-ecological preparation for cultivation water regulation

InactiveCN101353636AReduce investmentAchieve re-useBacteriaMicroorganism based processesCulture fluidAdditive ingredient

The invention discloses a production method of lactobacillus microecologics which is used for regulating and controlling culture water quality, comprising the following steps of: (1) tube culture; (2) shaking culture; (3) seed tank culture; and (4) fermentor culture: culture solution in the seed tank is inoculated into the fermentor filled with culture solution, and placed for culturing of 24 to 36 hours at the temperature of 25 to 35 DEG C; when the final pH of the fermenting liquid is 3.0 to 4.0 and the density of the lactobacillus is 5 billion / ml, the fermentation is stopped; the pH of the culture solution of the step (3) and the step (4) is 5.5 to 6.5; the culture solution comprises the following ingredients in 1L of water by weight portion: 3 to 5 portions of molasses, 3 to 5 portions of yeast extract, 0.8 to 1 portion of corn steep liquor, 0.1 to 0.3 portion of KH2PO4, 0.3 to 0.5 portion of MgSO4, 3 to 5 portions of NaCl, 8 to 10 portions of glucose and 0.8 to 1 portion of peptone; the method adopts a totally open culture mode to carry out the production of lactobacillus microecologics which is used for regulating and controlling the culture water quality, and is characterized by little equipment investment, little energy consumption, simple technique and low production cost.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for preparing drug residue free feed for feeding live pigs

InactiveCN101912056AReduce respiratory consumptionReduce heat dissipationFood processingAnimal feeding stuffDaidzeinInhalation

The invention discloses a method for preparing drug residue free feed for feeding live pigs. The method comprises the steps of: preparing 1 part of bacterial strain, 0.1 part of lower polyxylose and 0.2 part of daidzein by mass, adding 10 parts of water, stirring for 30-45 minutes, and preserving the water temperature at 20-35 DEG C; preparing 100 parts of feed and 20 parts of corn steep liquor by mass and adding into a cone type stirrer together, loading into a plastic bag with a reducing valve after stirring to be uniform, stacking at a warehouse for fermentation, unpacking the plastic bag after 72 hours, pouring out, drying, and packaging. In the invention, the raw materials need no strict sterilization and can be directly inoculated and cultured, inhalation consumption is very low without exceeding 1.0 percent generally, the heat radiated during fermentation is lower, the operation is easy to control, the production process is simplified, the production cost is reduced, the equipment investment is low, a feed factory can be used for carrying out granulation production without increased cost on a feeding farm, thereby being easy to popularize.

Owner:张留医

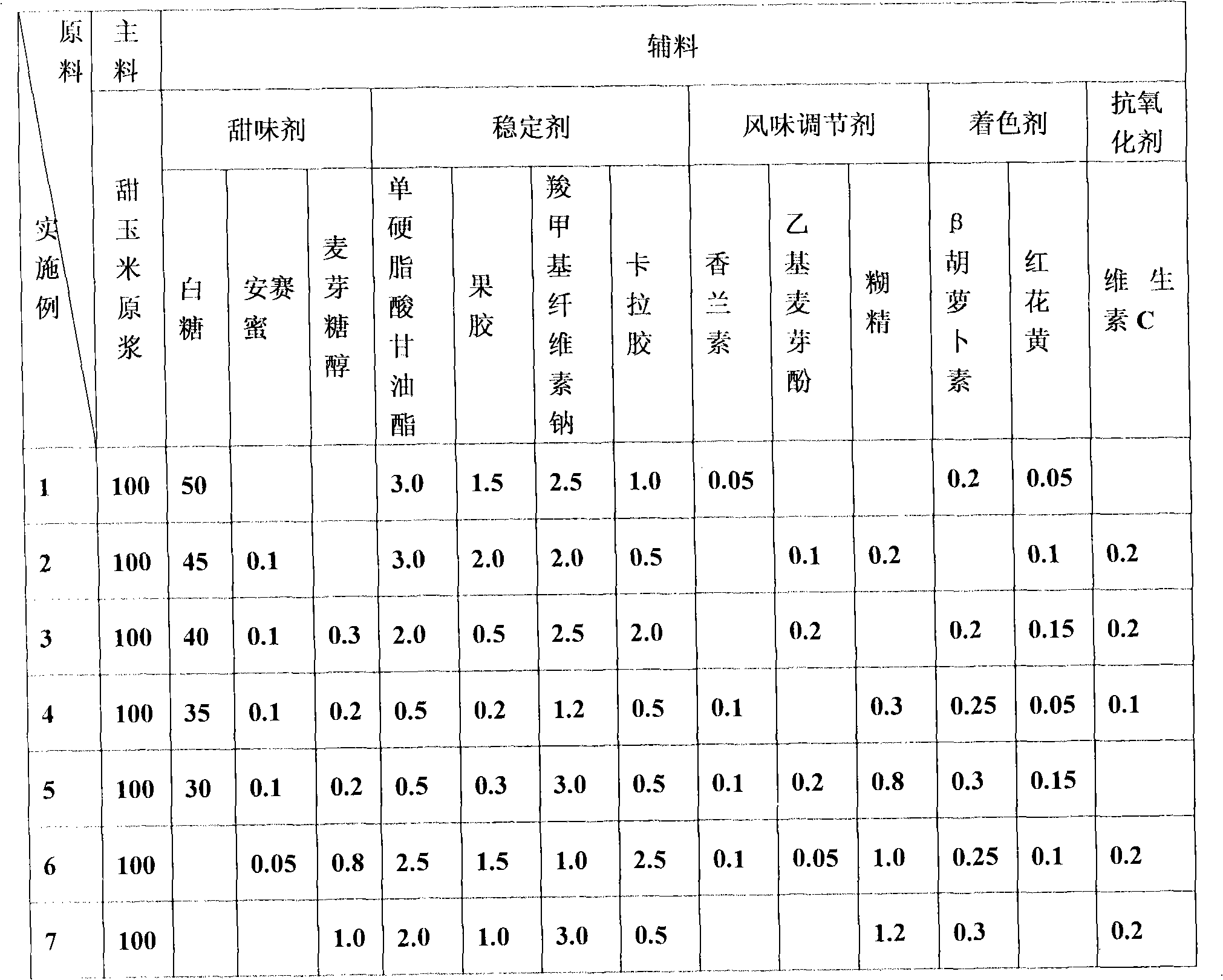

Method for processing maize milk beverage by using gold corn

InactiveCN101548785AFully maintain the fragranceFully maintain the tasteFood preparationAdditive ingredientCorn steep liquor

The present invention provides a method for processing maize milk beverage by using gold corn. The method includes steps as follows: mixing corn plasmogen and sweetening agent, stabiliser, flavour regulating agent, colorant, miscible liquid of anti-oxidant and water by emulsive solubilization, then heating to 72-75 deg c for gelatinization process in a seal heat preserving tank, processing vacuum out gas desaeration to the prepared liquid under environment of negative 0.03-0.05MPa, designing savory, adding water and constant volume, homogeneous with 20-30MPa under temperature 75-80 deg c, then filling and sealing under temperature 65-80 deg c, finally, elevated temperature sterilizing for obtaining the maize milk beverage. The maize milk beverage prepared by the method has advantages of even product plasmogen, stabile structure, flavour and component from damage, and keeping delicate fragrance fully, and can avoid phenomenon of demixing, deposition, false gelatine.

Owner:HUBEI DAOHUAXIANG GREEN FOOD

Method for preparing feedstuff yeast from maize peel hydrolysis solution

InactiveCN101054559AReduce generationHigh yieldFungiAnimal feeding stuffEvaporationSimulated moving bed

The present invention relates to method for preparing feedstuff yeast using corn husk hydrolyzed liquor as material. Acid is separated and recovered from the hydrolyzed liquor adopting simulated moving bed chromatogram separation system. The normal neutralization is substituted. The method is : mixing corn-soaking water, corn husk hydrolyzed liquor for preparing culture medium, carrying out three-stage culture at bevel medium, and ferment culture, concentration and evaporation, spray drying for preparing feedstuff yeast. The inventive medium is enriched with nitrogen source, carbon, inorganic salt, microelement and vitamin, growth factor etc. The inventive method can ensure the feedstuff yeast nutrient integrity, and substitute for the fish powder in fowl and stock breeding and effectively reduce the cost. The present invention promote the additive value of product, reduce the environmental pollution.

Owner:SHANDONG LUZHOU FOOD GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com