Soaking technology for preparing corn starch

A technology of corn starch and process, applied in the field of grain deep processing, can solve the problems of sulfurous acid residue, equipment corrosion, long soaking time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

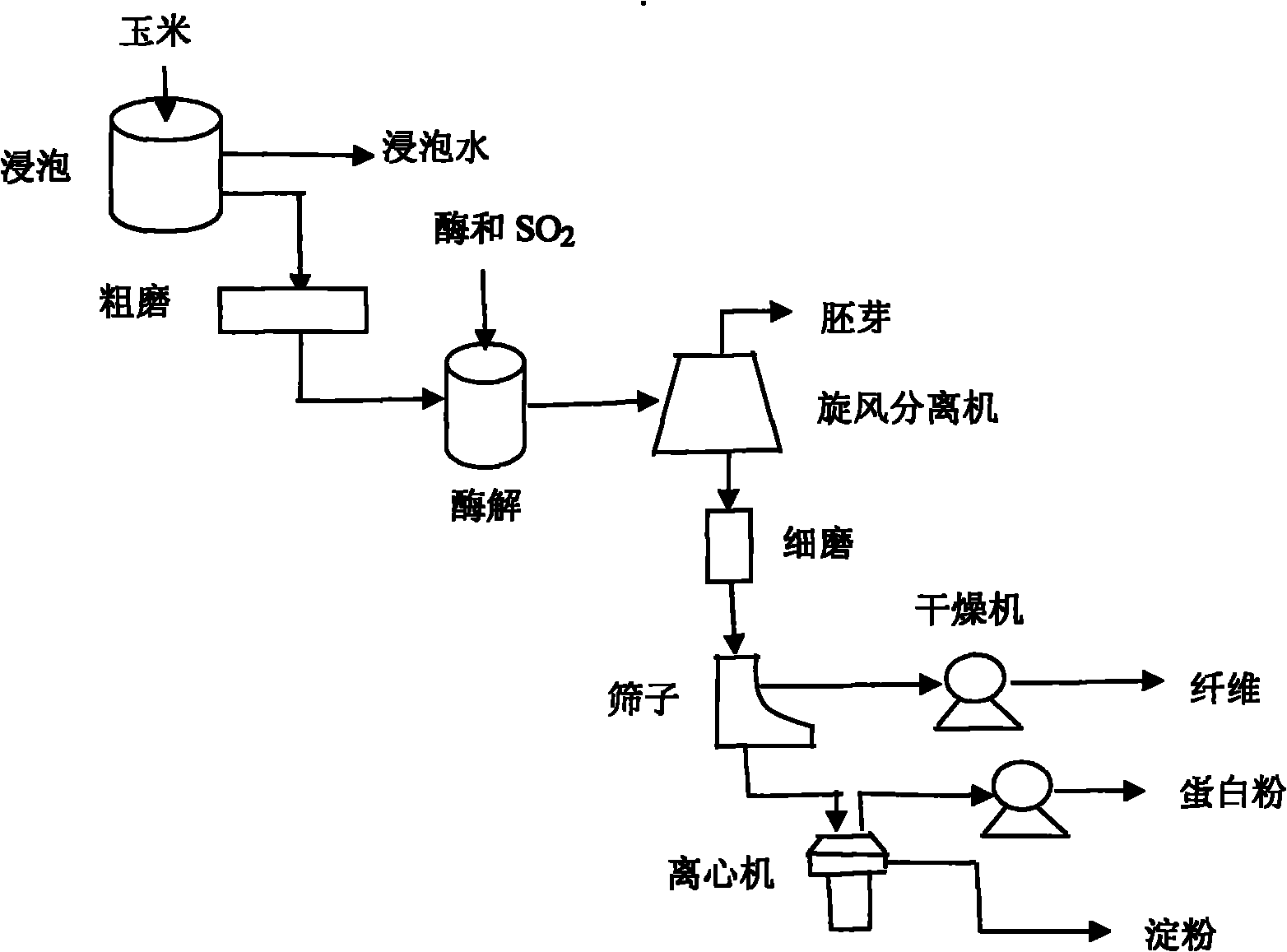

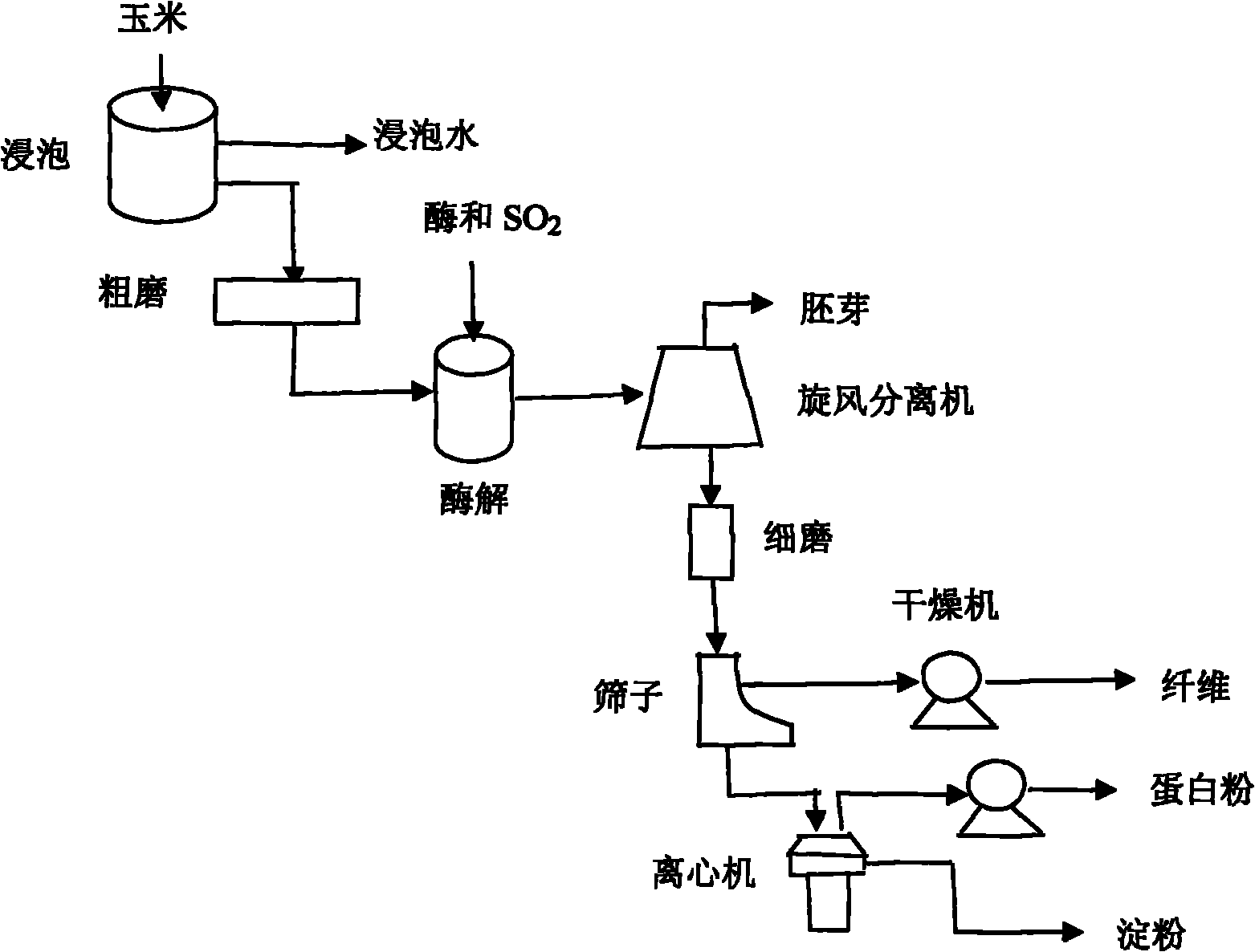

Method used

Image

Examples

Embodiment 1

[0016] Soak 100g corn in water at 48°C for 6 hours, coarsely grind the soaked corn, and then add SO 2 0.06g, 0.5g of acid protease, and adjust the pH to 4.0, at 25°C for 4 hours, stirring constantly. The enzymatically hydrolyzed corn steep liquor is degermed, finely ground, sieved, centrifuged, dried and other steps to obtain starch products.

Embodiment 2

[0018] Soak 100g corn in water at 50°C for 4 hours, coarsely grind the soaked corn, and then add SO 2 0.02g, 0.3g of acid protease, and adjust the pH to 4.5, at 63°C for 2 hours, stirring constantly. The enzymatically hydrolyzed corn steep liquor is degermed, finely ground, sieved, centrifuged, dried and other steps to obtain starch products.

Embodiment 3

[0020] Soak 100g corn in water at 45°C for 7 hours, coarsely grind the soaked corn, and then add SO 2 0.041g, 0.25g of pepsin, and adjust the pH to 3.5, at 50°C for 3h, with constant stirring. The enzymatically hydrolyzed corn steep liquor is degermed, finely ground, sieved, centrifuged, dried and other steps to obtain starch products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com