Patents

Literature

857 results about "Sulfurous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfurous acid (also sulphurous acid) is the chemical compound with the formula H₂SO₃. There is no evidence that sulfurous acid exists in solution, but the molecule has been detected in the gas phase. The conjugate bases of this elusive acid are, however, common anions, bisulfite (or hydrogen sulfite) and sulfite. Sulfurous acid is an intermediate species in the formation of acid rain from sulfur dioxide.

Corn refining process

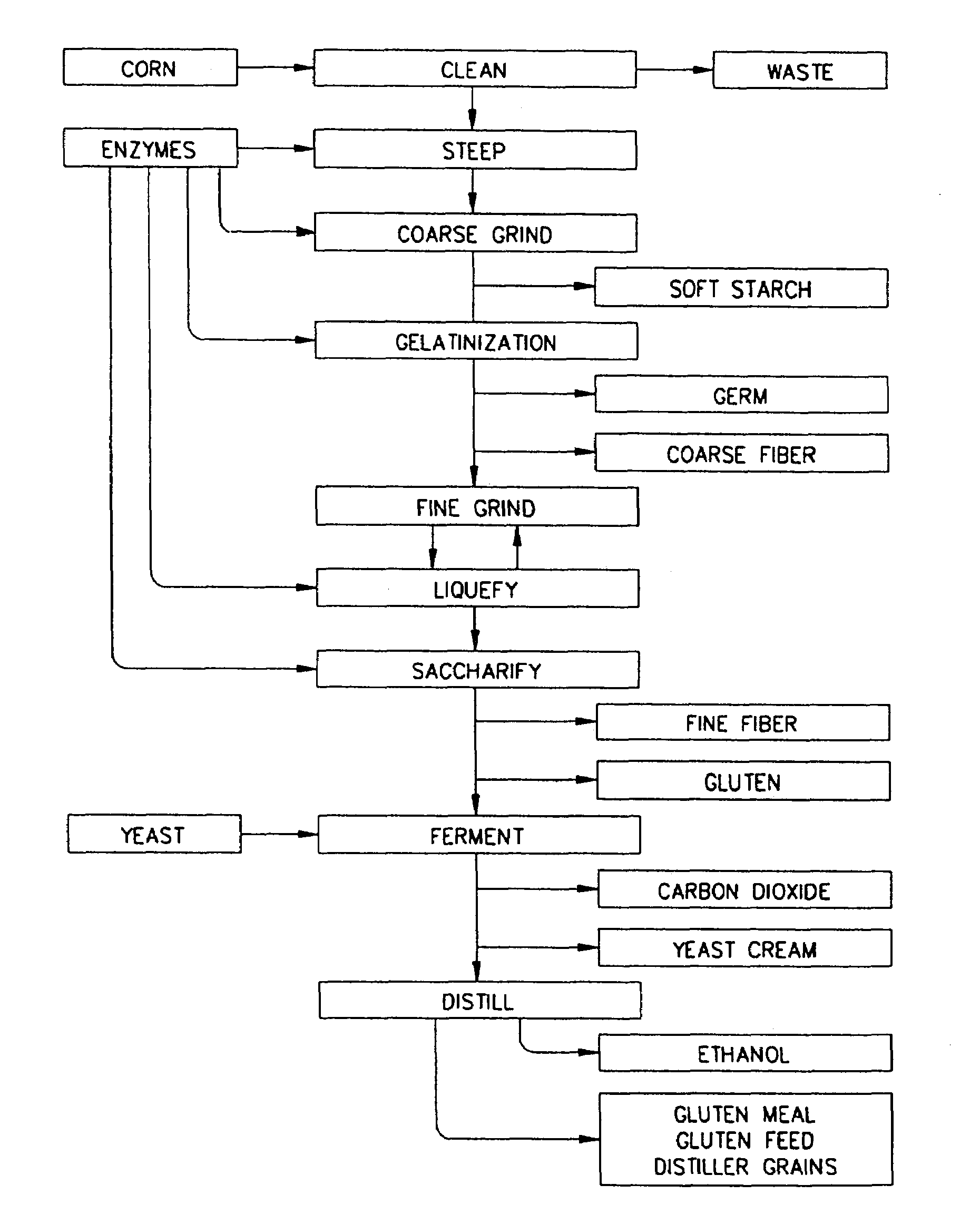

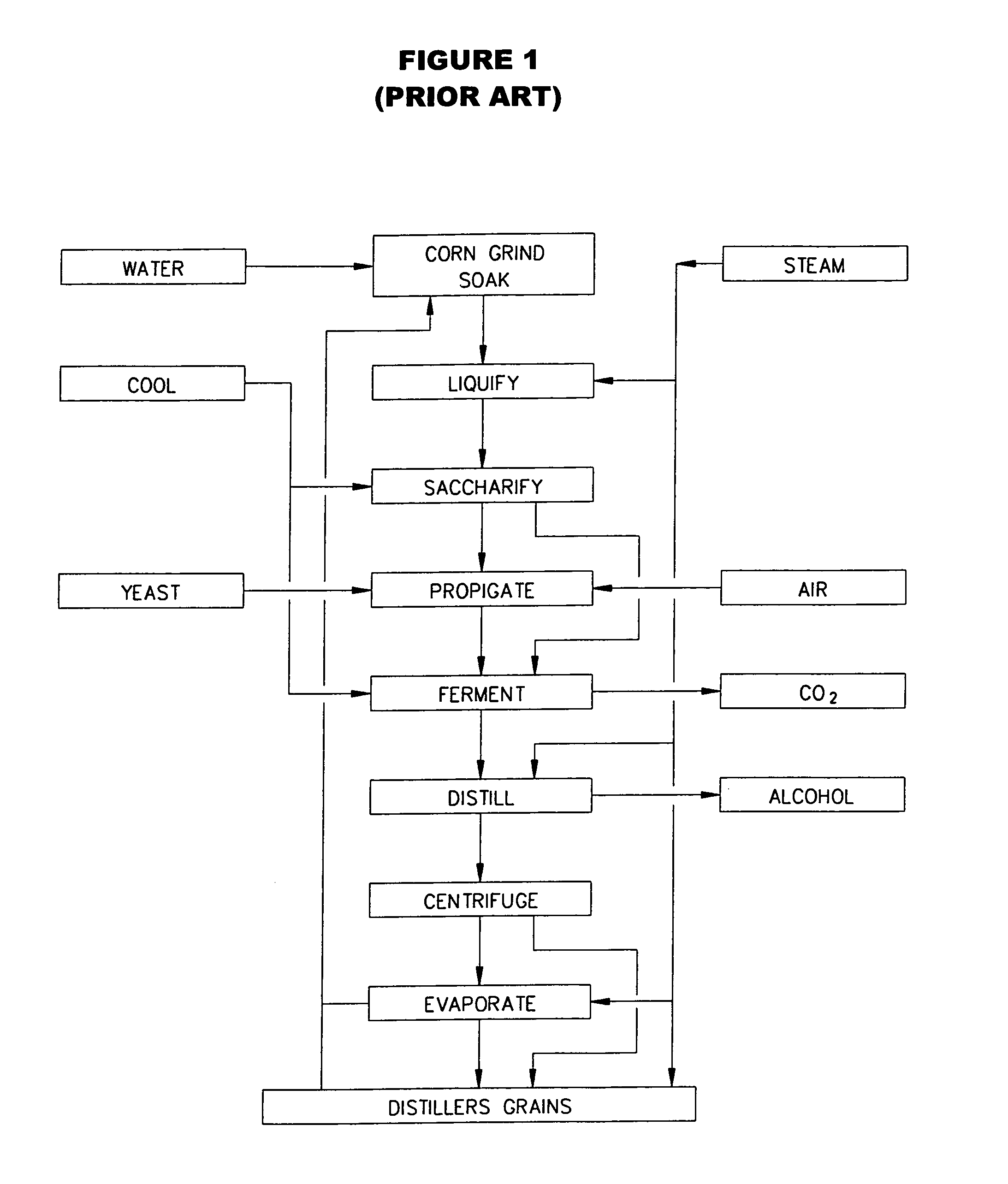

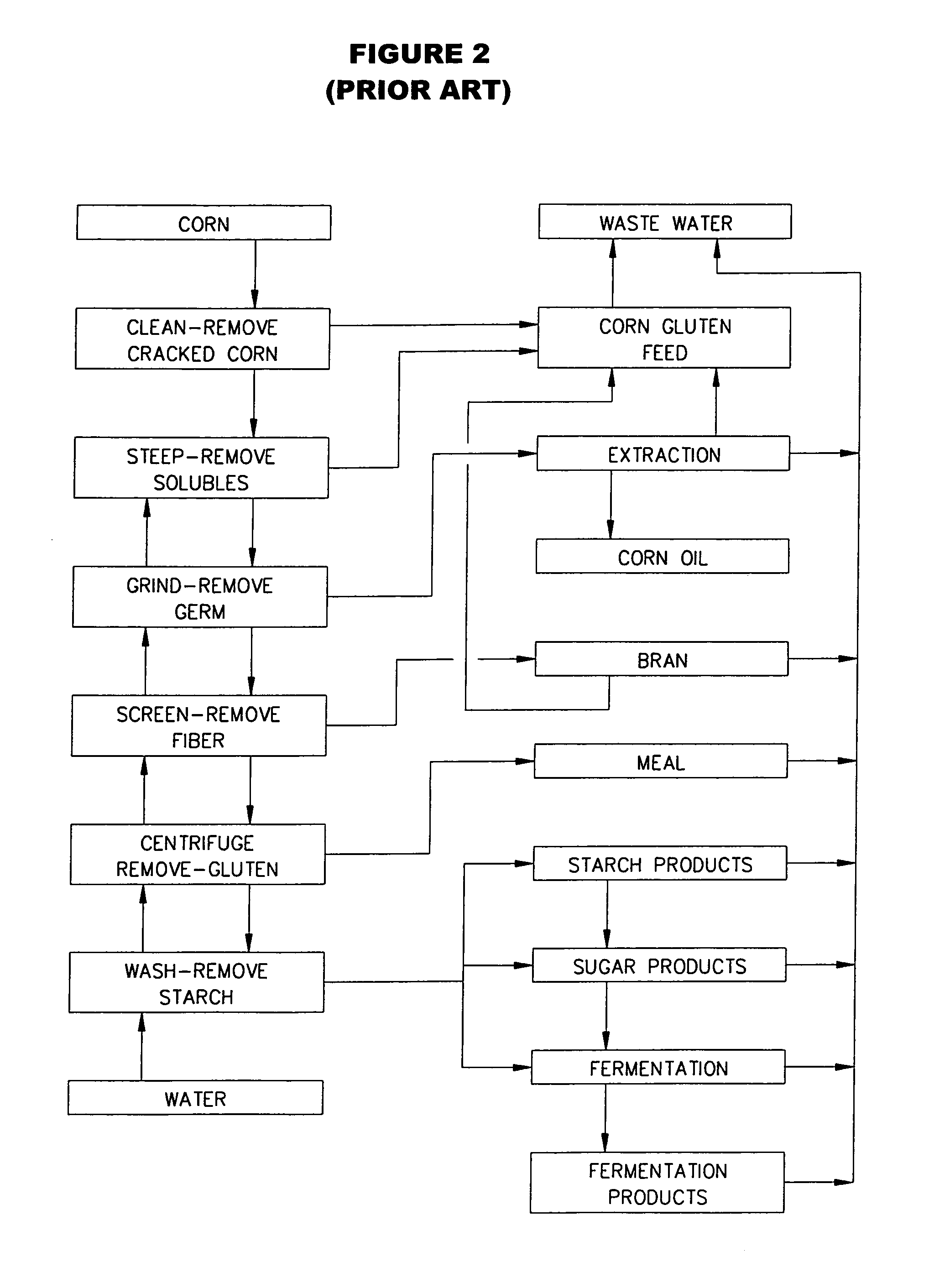

InactiveUS7452425B1Quickly and efficiently producedAvoid large quantitiesJuice extractionBiofuelsSteepingSlurry

A grain containing starch, such as corn, is refined. The grain is steeped in water at a temperature of about 125 to 160° F., which water is essentially free of sulfurous acid and contains recycled enzymes from downstream processes, in a counter-current steeping reactor for about 10 to 20 hours to produce an aqueous slurry of steeped grain having a moisture content of about 40 to 50 percent. The various components of the grain are then separated and the starch is converted to ethanol.

Owner:LANGHAUSER ASSOC

Medicinal compositions with relieved bitterness

InactiveUS6576677B1Alleviate bad tasteGrowth inhibitionPowder deliveryDispersion deliveryD-SorbitolAntioxidant

The present invention provides a composition alleviated in a bitter taste or the like of a medicament. The present invention relates to a composition comprising a basic medicament having an unpleasant taste and polyvinylpyrrolidone and / or copolyvidone; or a method for alleviating an unpleasant taste of a basic medicament having the unpleasant taste by adding polyvinylpyrrolidone and / or copolyvidone. The present invention further provides a composition comprising (1) a basic medicament, (2) polyvinylpyrrolidone and / or copolyvidone, and (3) propylene glycol and / or D-sorbitol; a composition comprising (1) a basic medicament, (2) polyvinylpyrrolidone and / or copolyvidone, and (4) an antioxidant; and a composition comprising (1) a basic medicament, (2) polyvinylpyrrolidone and / or copolyvidone, and (5) a colorant or flavor containing a sulfuric acid or sulfurous acid group.

Owner:EISAI CO LTD

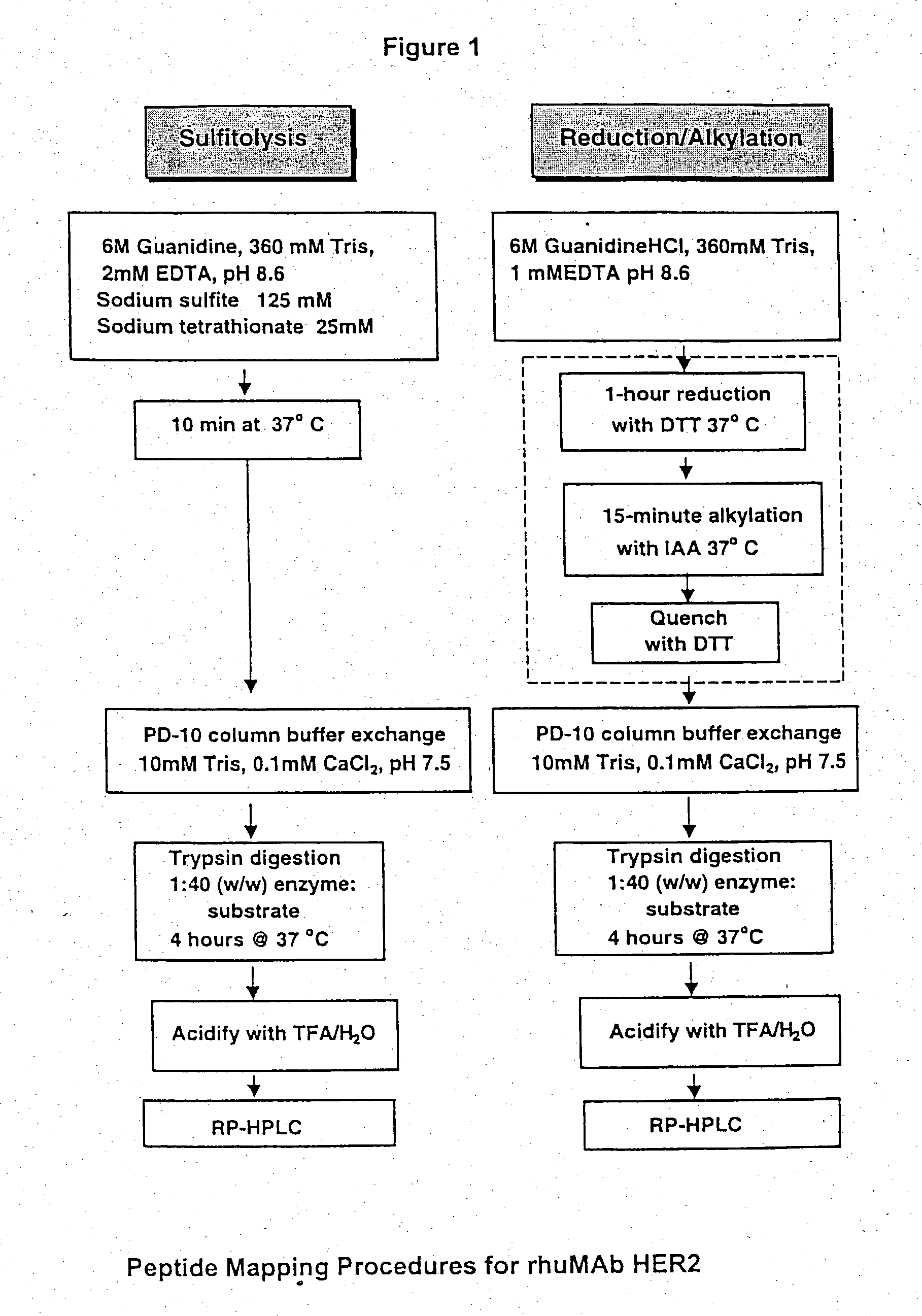

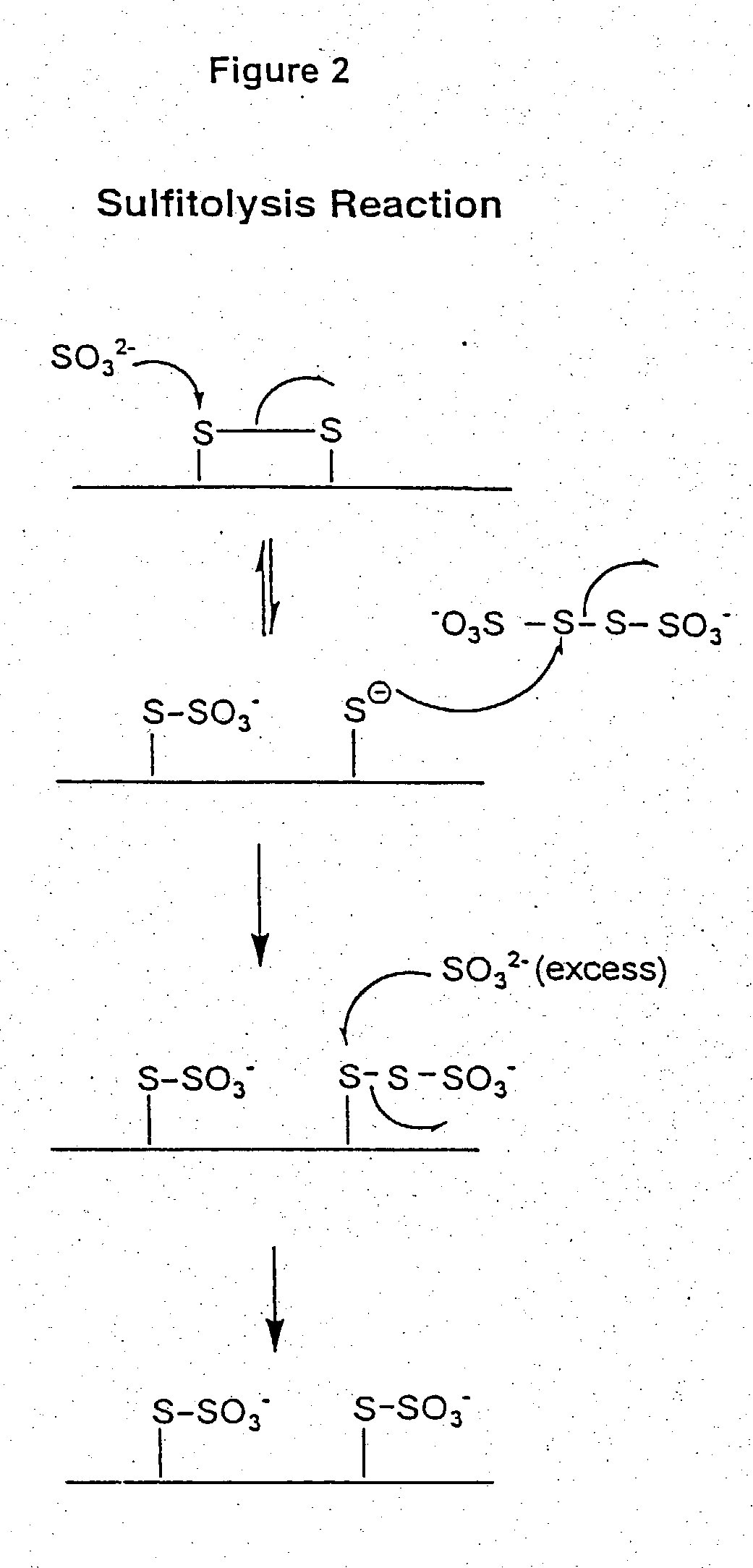

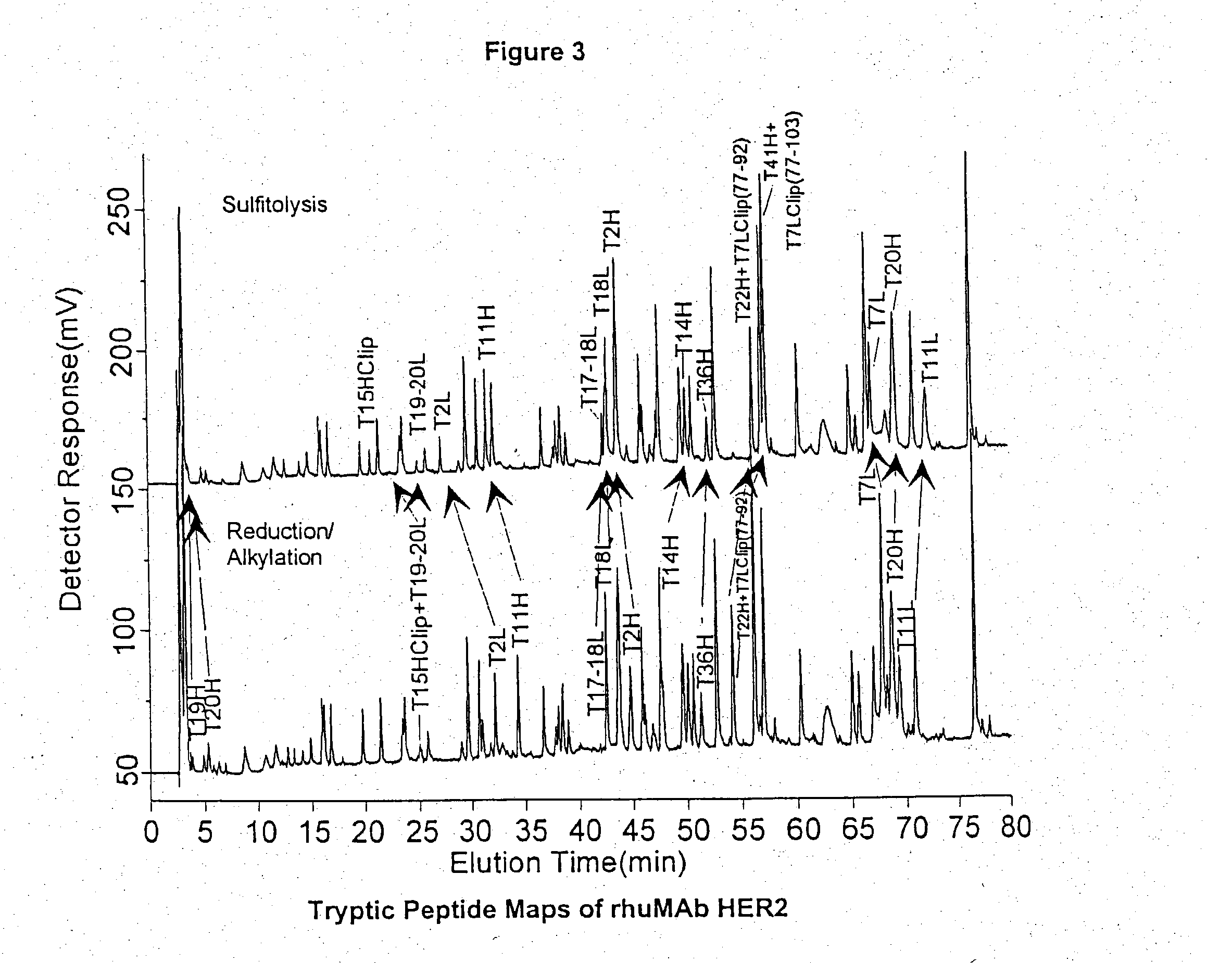

Use of sulfitolysis in high performance peptide mapping

InactiveUS20030175845A1Microbiological testing/measurementBiological testingCrystallographyCysteine thiolate

Owner:GENENTECH INC

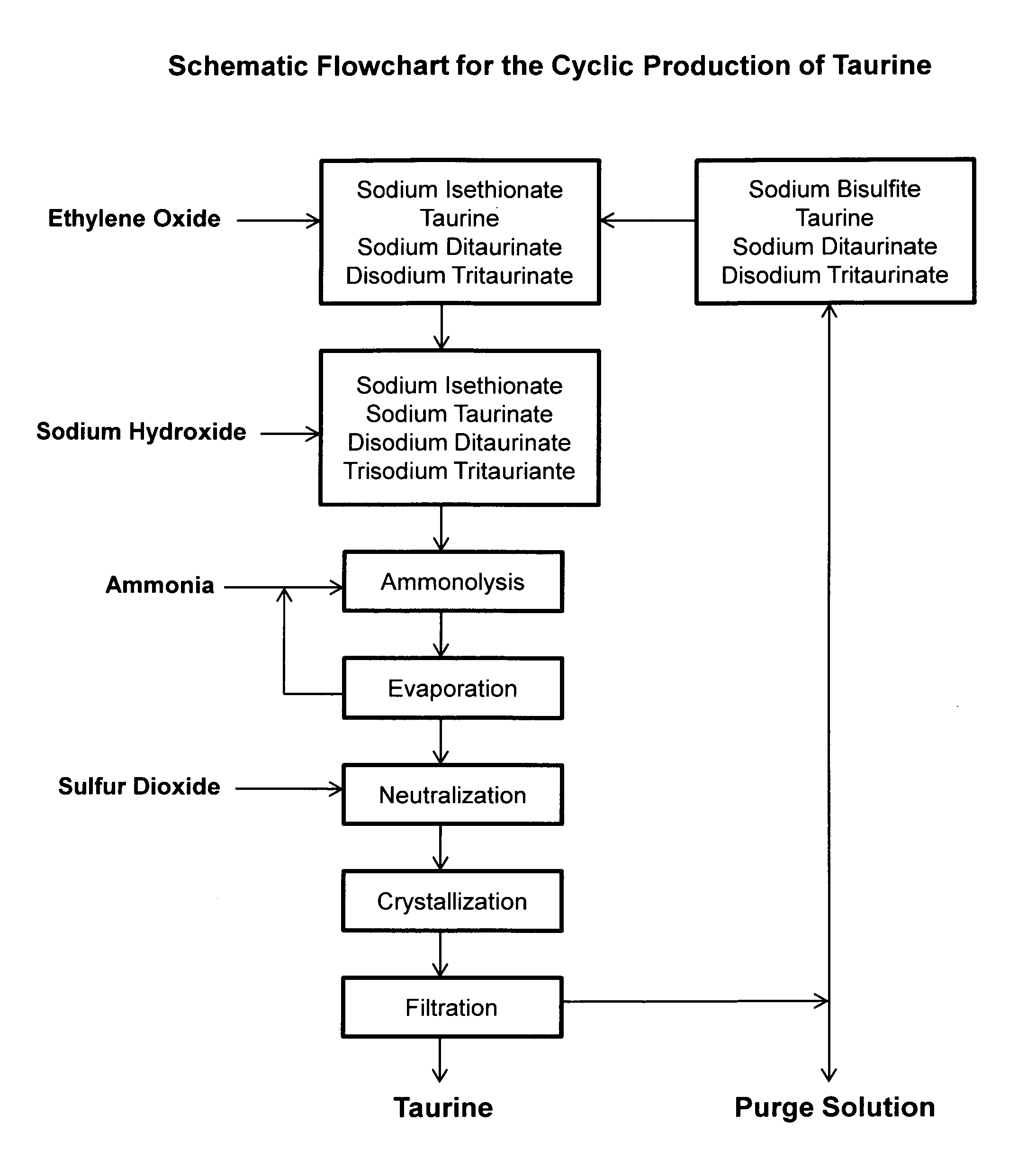

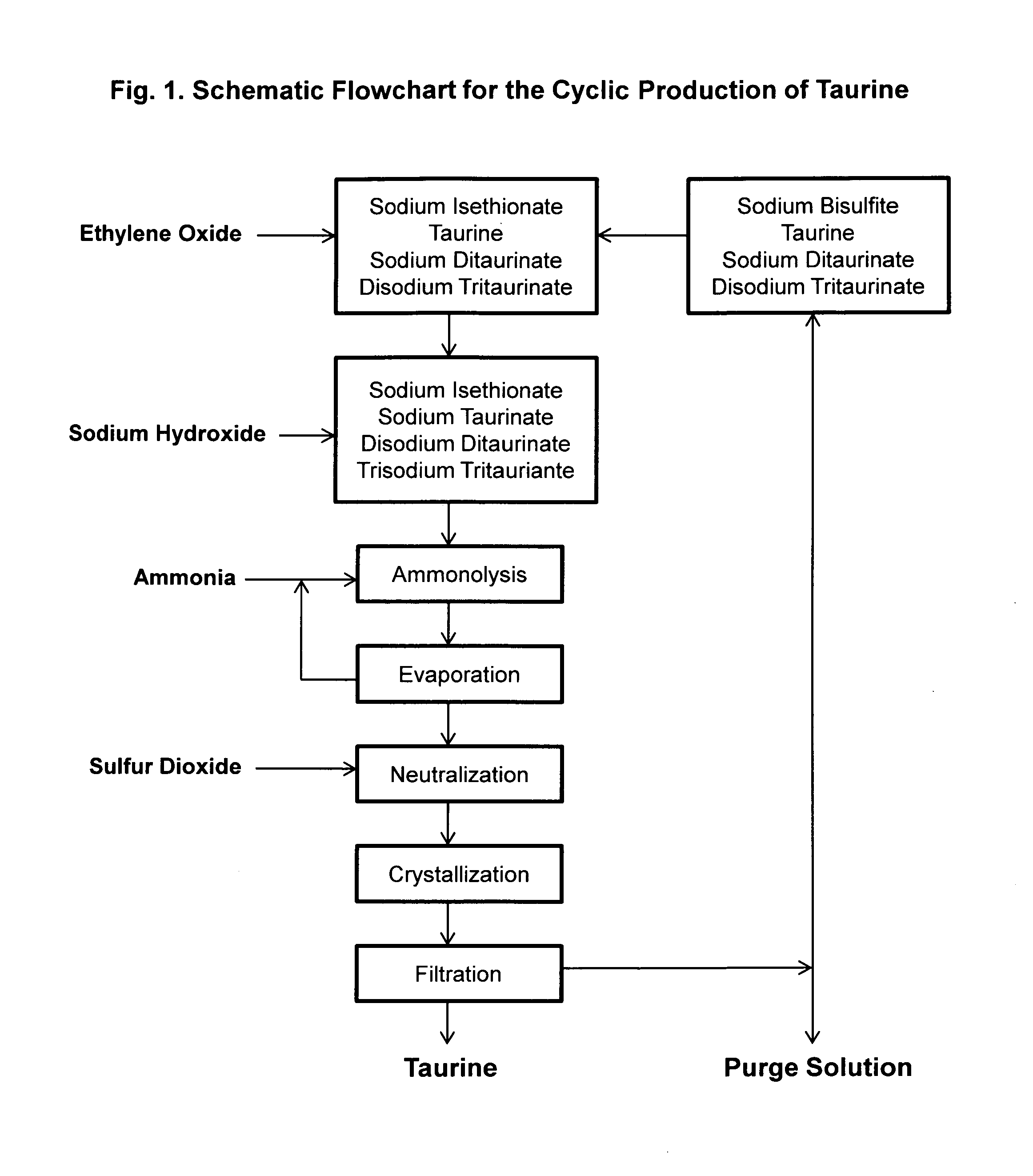

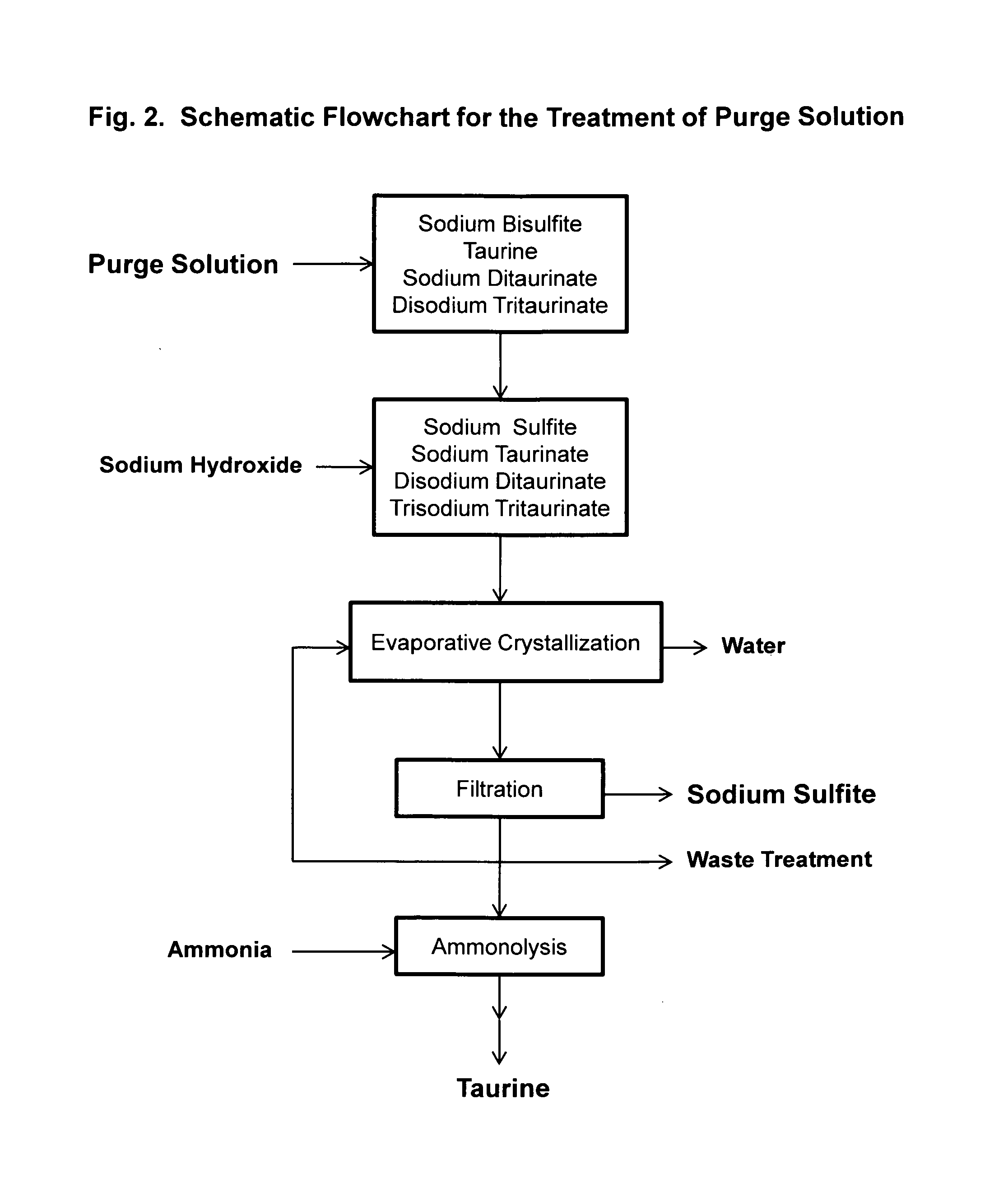

Cyclic process for the production of taurine from ethylene oxide

ActiveUS9061976B1Organic compound preparationSulfonic acids salts preparationCyclic processSodium dithionite

The present invention discloses a cyclic process for the production of taurine from ethylene oxide in a high yield of greater than 95% by continuously converting the byproducts of the ammonolysis reaction, sodium ditaurinate and sodium tritaurinate, to sodium taurinate. The cyclic process is completed by using sulfur dioxide or sulfurous acid to neutralize sodium taurinates to recover taurine and to regenerate sodium bisulfite, which is then reacted with ethylene oxide.

Owner:VITAWORKS IP LLC

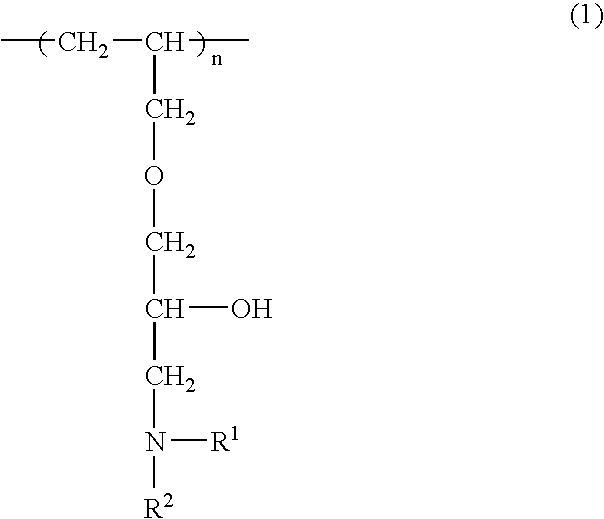

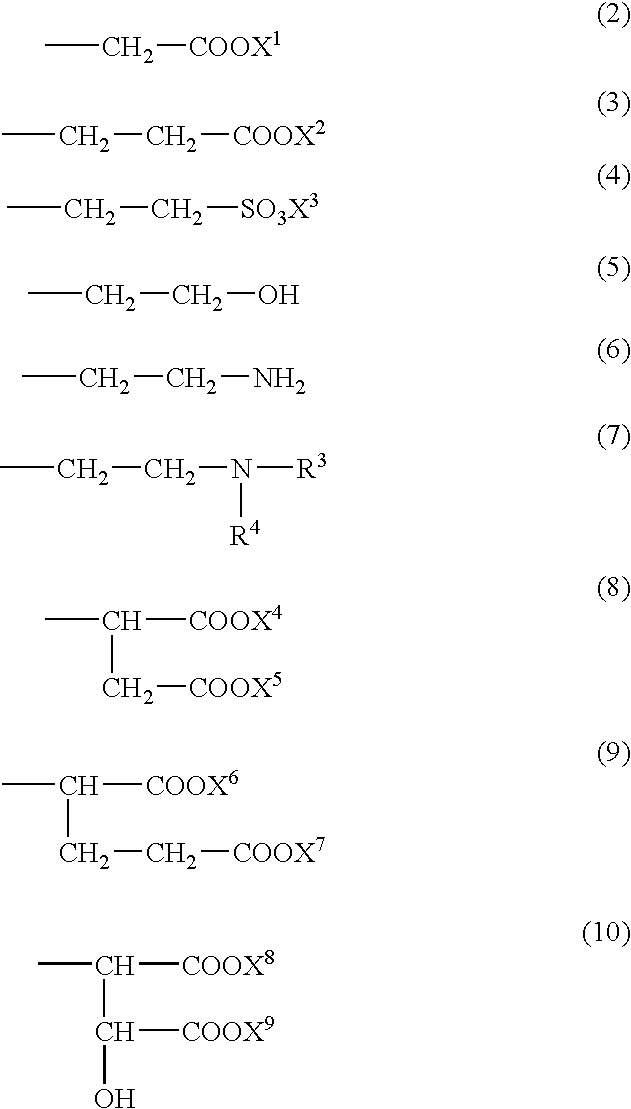

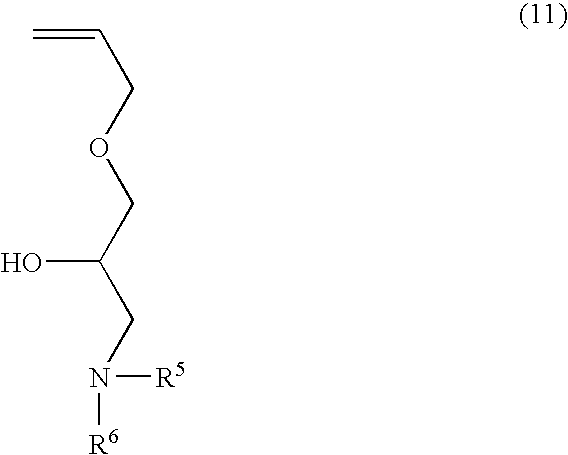

Amino Group-Containing Water-Soluble Copolymer

ActiveUS20080262192A1Improve quality performanceGood dispersionTransportation and packagingFibre treatmentSulfiteWater soluble

Owner:NIPPON SHOKUBAI CO LTD

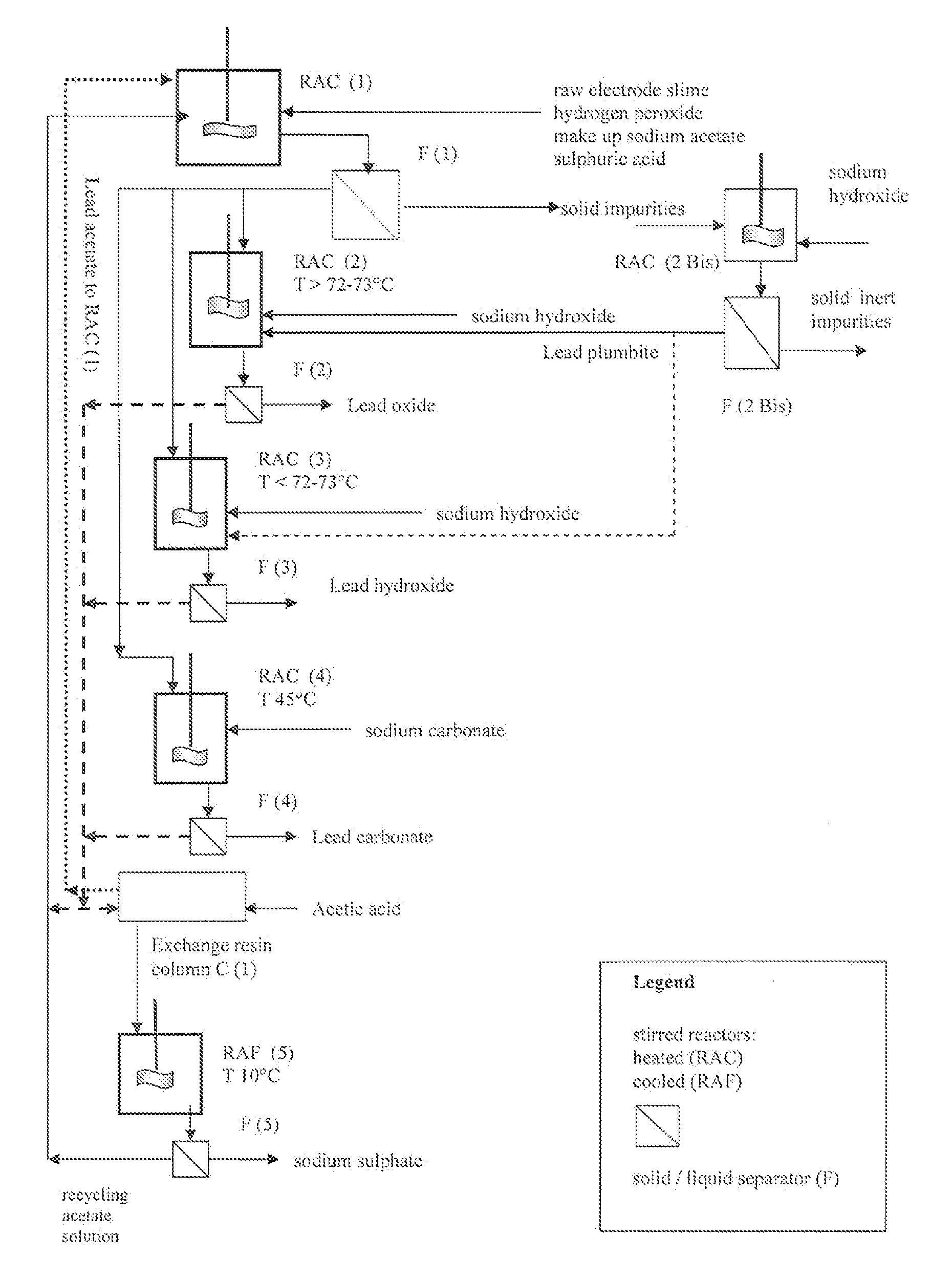

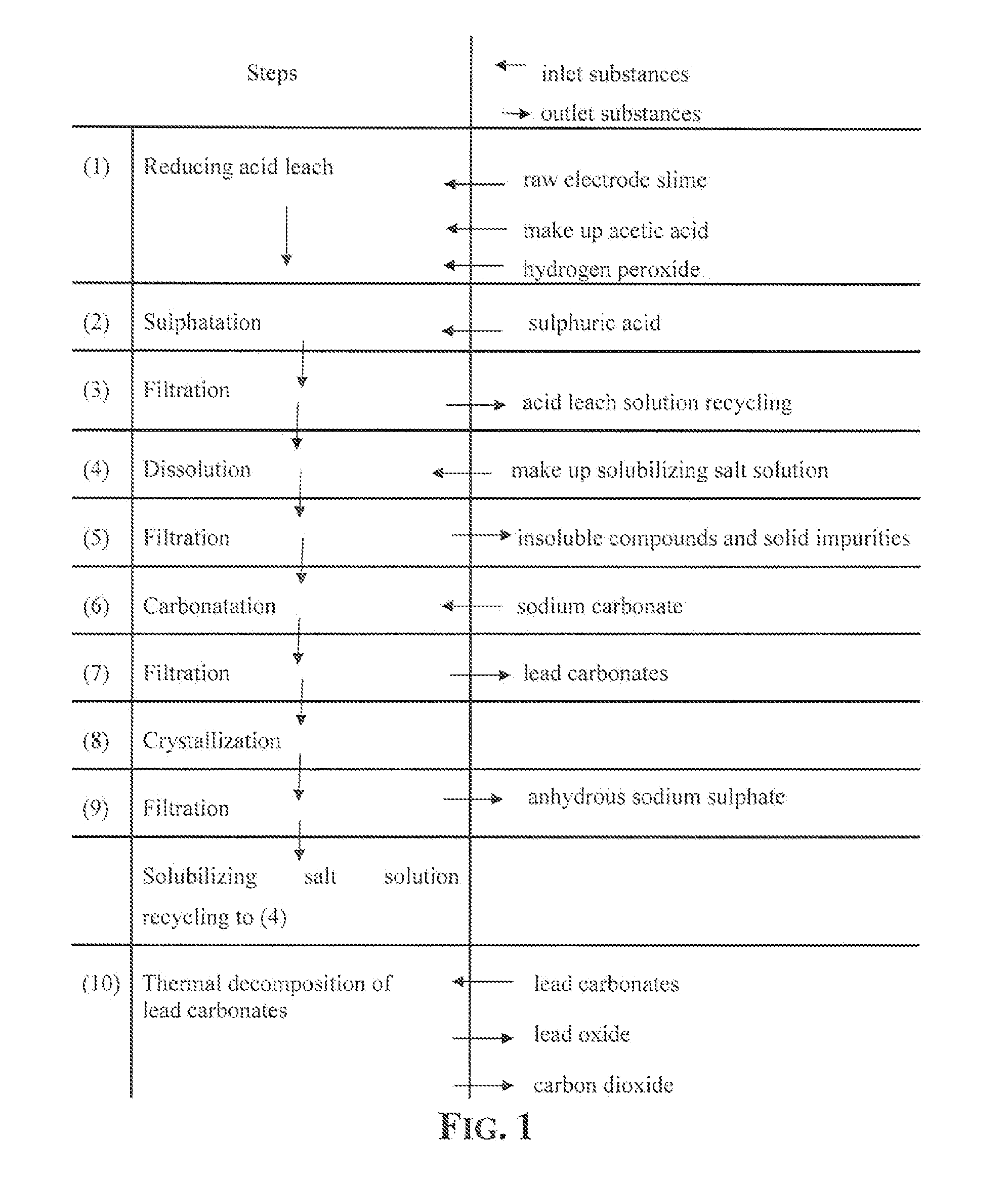

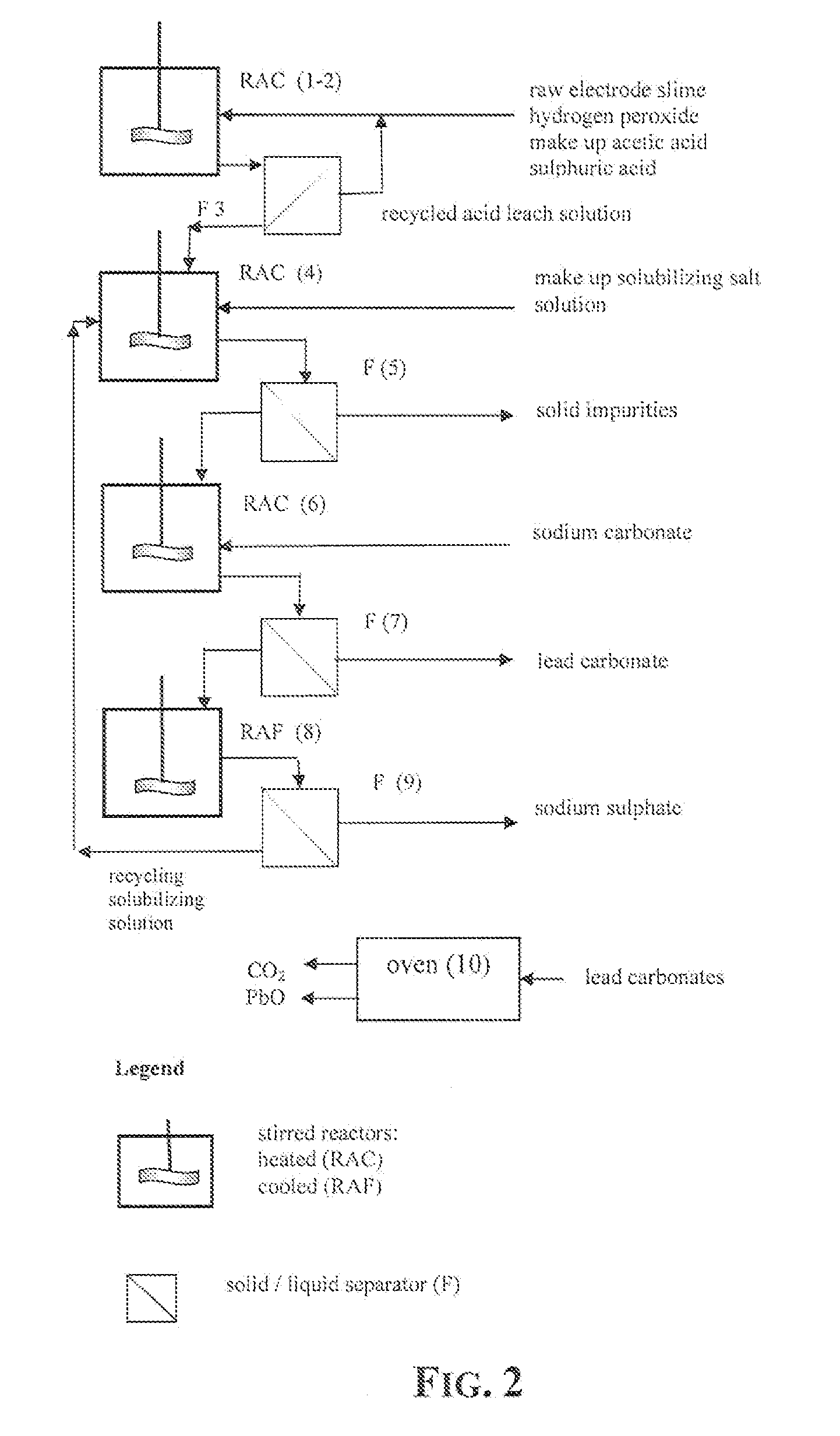

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

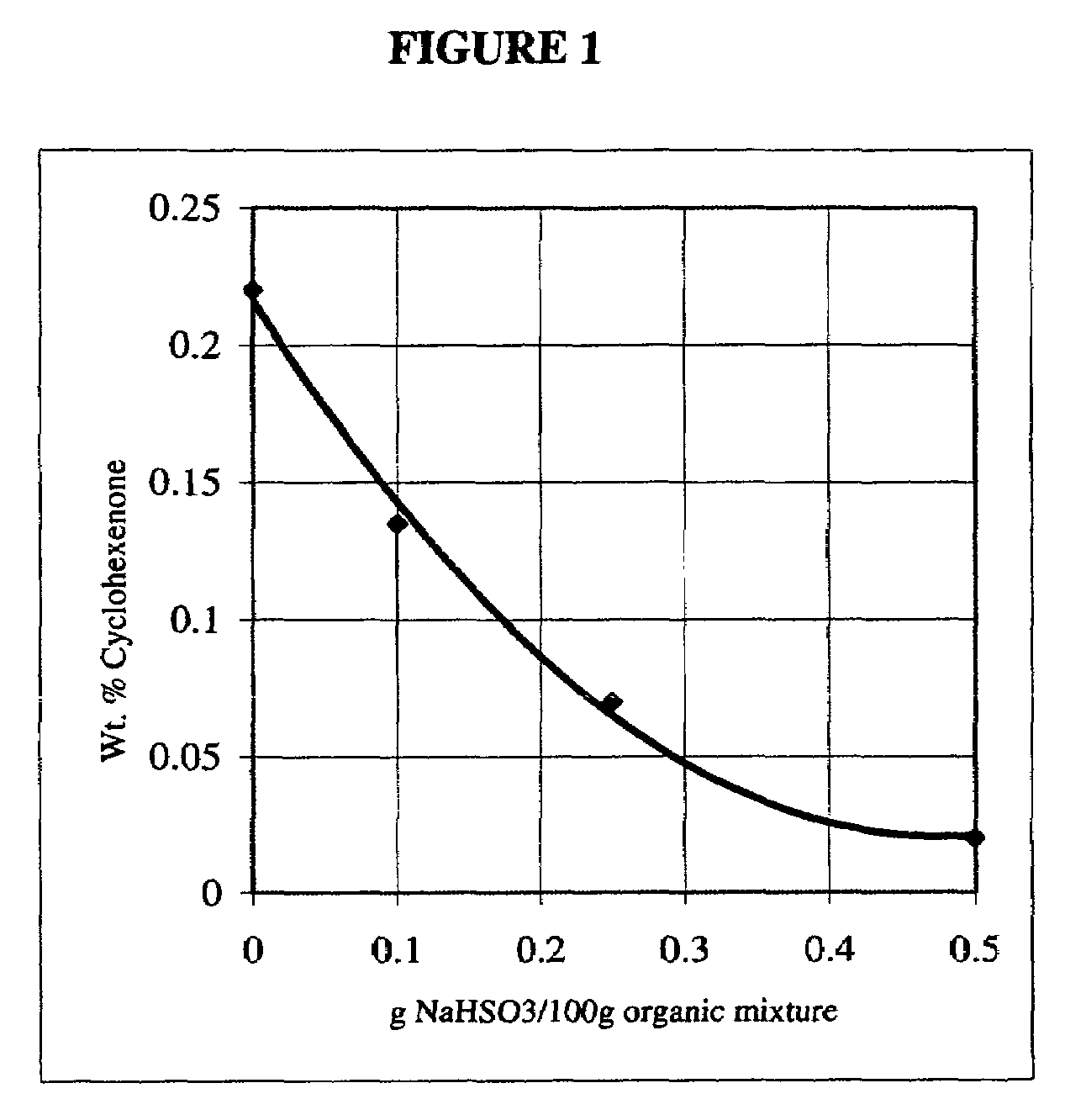

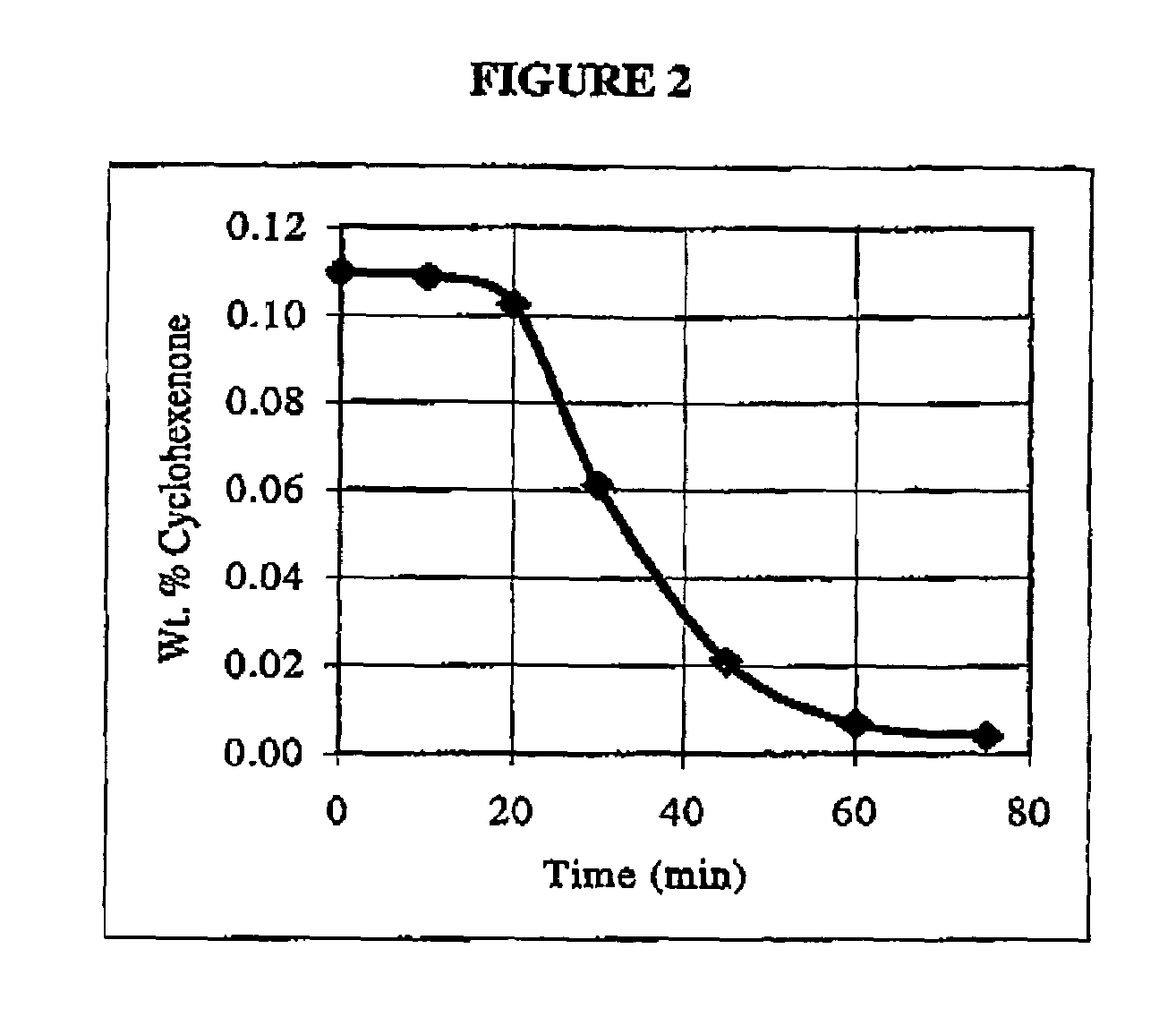

Method for reducing cyclohexenone content of a cyclohexenone-containing organic mixture

A method for reducing the concentration of cyclohexenone in a cyclohexenone containing organic mixture is disclosed. The method includes contacting an organic mixture comprising cyclohexenone with an effective amount of at least one of sulfurous acid, a salt of sulfurous acid, an alkali hydroxide, or a mixture of two or more of these compounds.

Owner:INVISTA NORTH AMERICA R L

Aquatic vegetable anti-staling agent

The invention relates to an aquatic vegetable preservative, which comprises citric acid, calcium chloride, sodium tripolyphosphate and vitamin C solution; the quality percentage concentration of the components are that: citric acid accounts for 0.15 percent to 0.2 percent; calcium chloride accounts for 0.5 percent; sodium tripolyphosphate accounts for 0.3 percent to 0.5 percent ; and vitamin C occupies 0.15 percent to 0.2 percent. The invention can be used in the refreshment of fresh lotus seeds, fresh water bamboo and fresh lotus root. The preservation methods are that: firstly, after the processing of sterilization, the fresh lotus seeds, fresh water bamboo and fresh lotus root are soaked for 15 minutes by the chlorine dioxide in a certain concentration; secondly, the dried fresh lotus seeds, fresh water bamboo and fresh lotus root are soaked and sterilized for 2 hours by the preservative in a certain percentage, and then the free water on which is drained; thirdly, a vacuum packaging or modified atmosphere packaging can be implemented for the materials, and then is arranged in the environment under 0 DEG C to 5 DEG C for storage; the shelf life for the aquatic vegetable is more than or equal to 60 days. After the toxicity test, the preservative is in a relative non-toxic level. The invention has the advantages of safety and high efficiency without sulfite components.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Scavenger for aldehyde(s) and a manufacturing method of a woody panel using the same

InactiveUS20090130474A1Ease of evaluationImprove trapping efficiencyOrganic chemistrySulfate/bisulfate preparationScavengerRoom temperature

Regarding the scavenger for aldehyde(s) used at the time of manufacturing a woody panel using woody materials and formaldehyde-based binders, the scavenger for aldehyde(s) without lowering of trapping properly even when a surface of said woody panel is sanded and having an excellent trapping property of trapping formaldehyde is provided. Further, the method of manufacturing a woody panel using a scavenger for aldehyde(s) and a woody panel are provided.At least one kind of compound for trapping aldehyde(s) being solid at a room temperature is included and said compound for trapping aldehyde(s) is defined to be a powdery scavenger for aldehyde(s) having a property of generating acidic gas, in particular, sulfurous acid gas by heating and said compound for trapping aldehyde(s) is added to a binder or woody materials followed by a hot press, thereby manufacturing a woody panel.

Owner:IPPOSHA OIL INDS

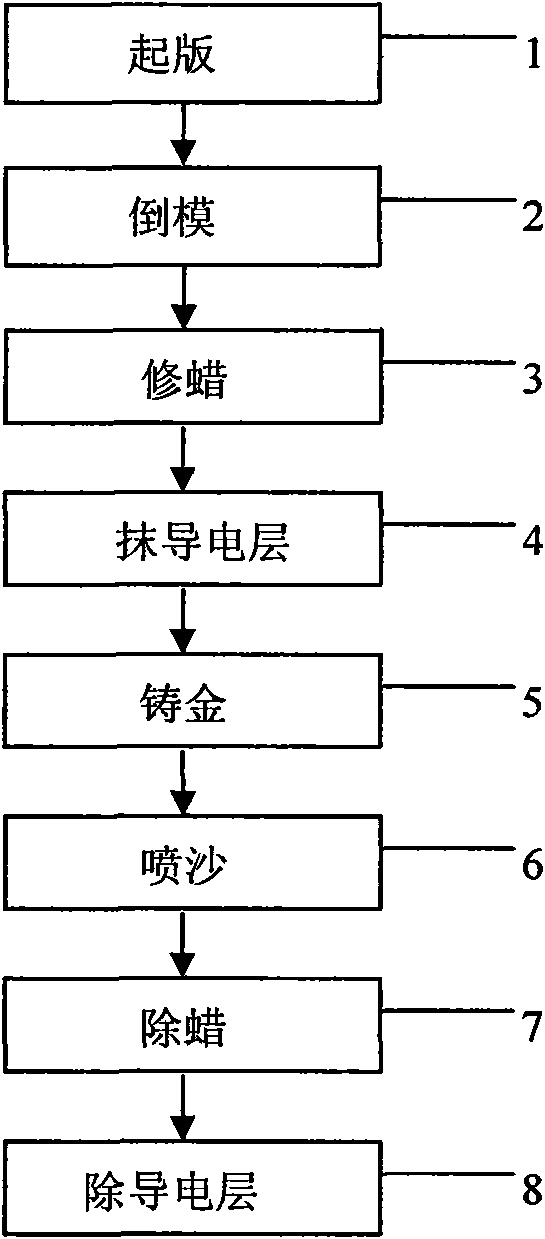

Method for electroforming hard gold product

InactiveCN101560676AIncrease in sizeHigh hardnessElectroforming processesChemical structurePotassium

The invention relates to a method for electroforming hard gold products. The method comprises the following steps: template picking, mould pouring, wax repairing and electric conducting layer coating are carried out to obtain a wax mould of a gold product to be processed, and a layer of electric conductive oil is coated on the surface of the wax mould; and a titanium net is taken as anode in the gold electroforming step, the wax mould coated with the electric conductive oil is put in an electrotyping bath as cathode, the electroforming solution is put in the electrotyping bath and includes sulfurous acid gold potassium, ammonium sulfite and potassium citrate, wherein the sulfurous acid gold potassium is combined with the ammonium sulfite, a trivalent gold ion is reduced into a univalent gold ion, the univalent gold ion generates close crystal grains, the close crystal grains are combined through the potassium citrate to form complexing gold through PH buffer solution, the gold is deposited on the wax mould to form a casting gold layer, and the half-finished product is prepared; and the wax film in the half-finished product and the electric conductive layer are removed in the wax removal step and the electric conductive layer removal step to obtain the finished product. The volume and the hardness of the gold product are changed by using the variation of the chemical structure of the gold ion, so that the hardness, the volume and the toughness of the gold product meet the standards simultaneously.

Owner:武汉金凰珠宝股份有限公司

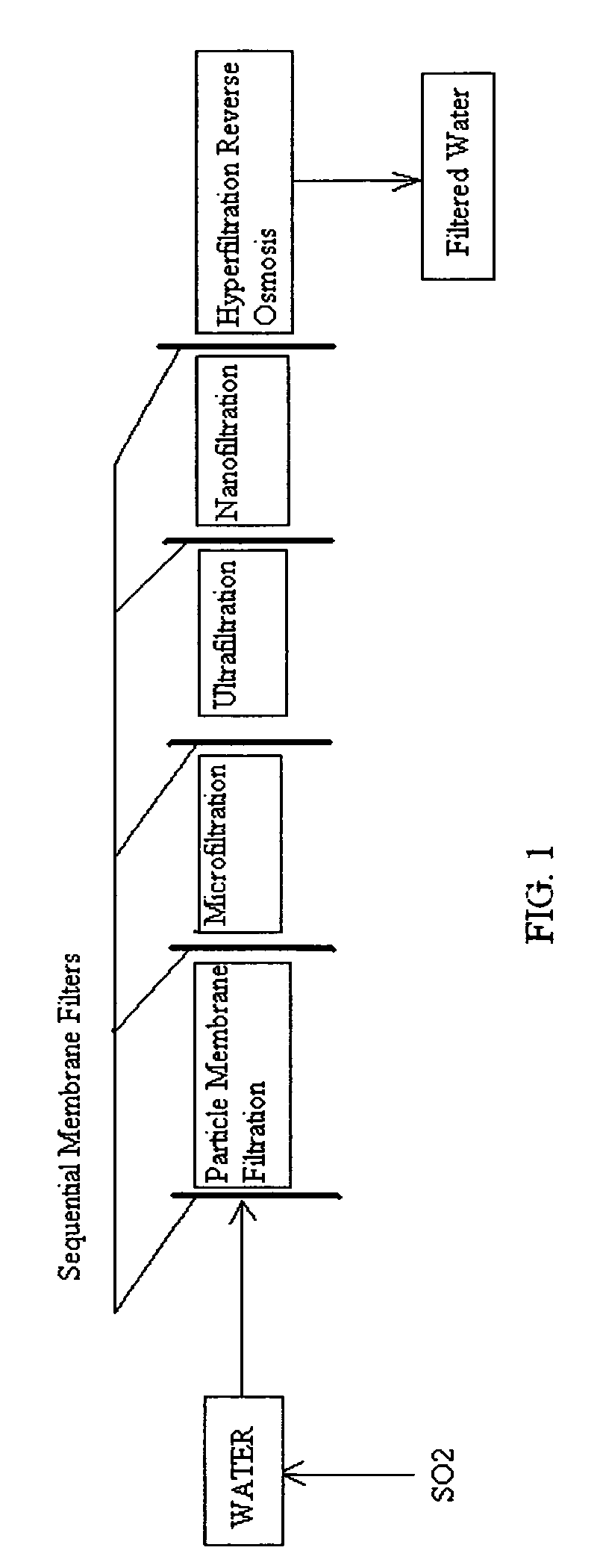

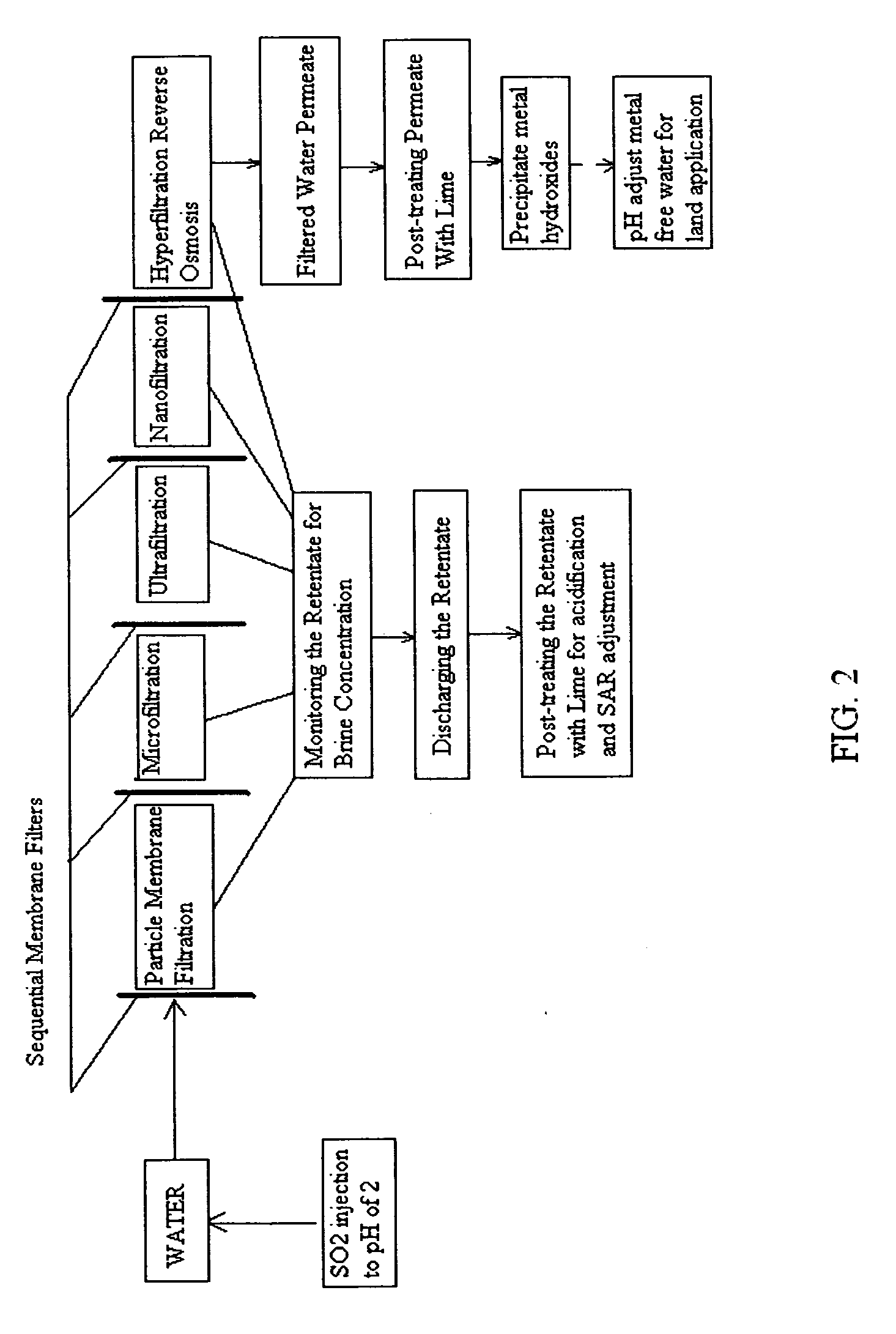

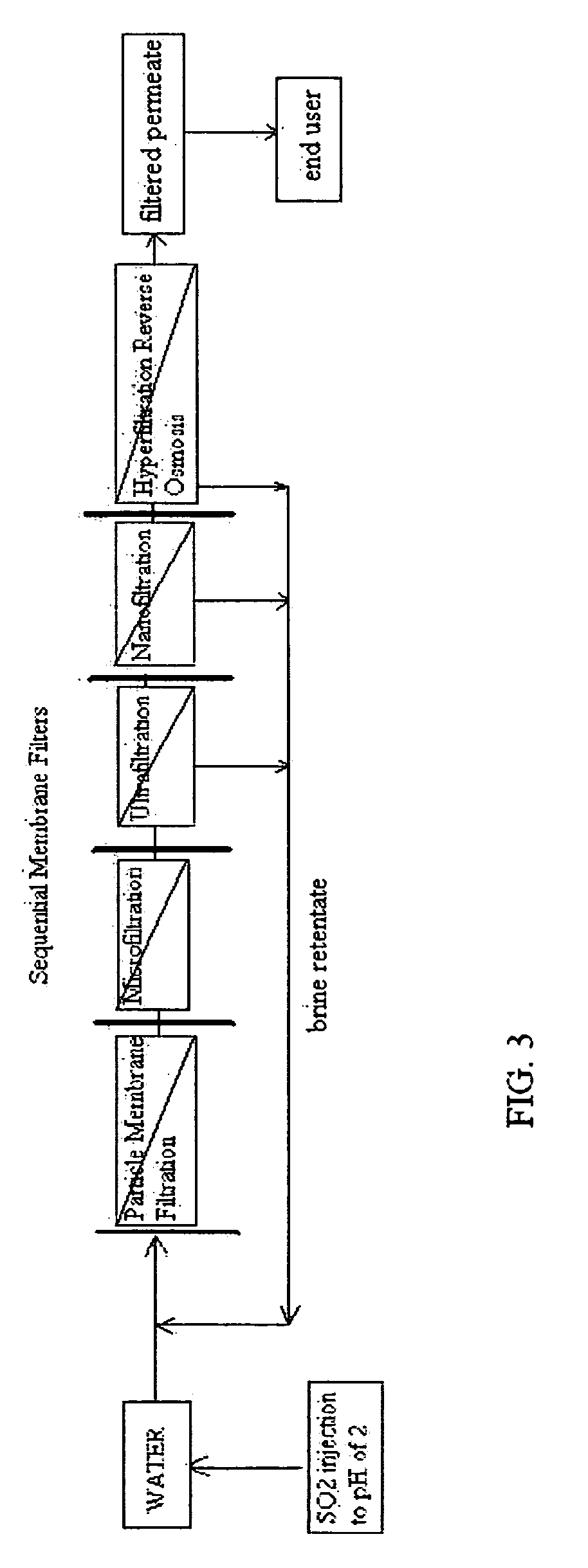

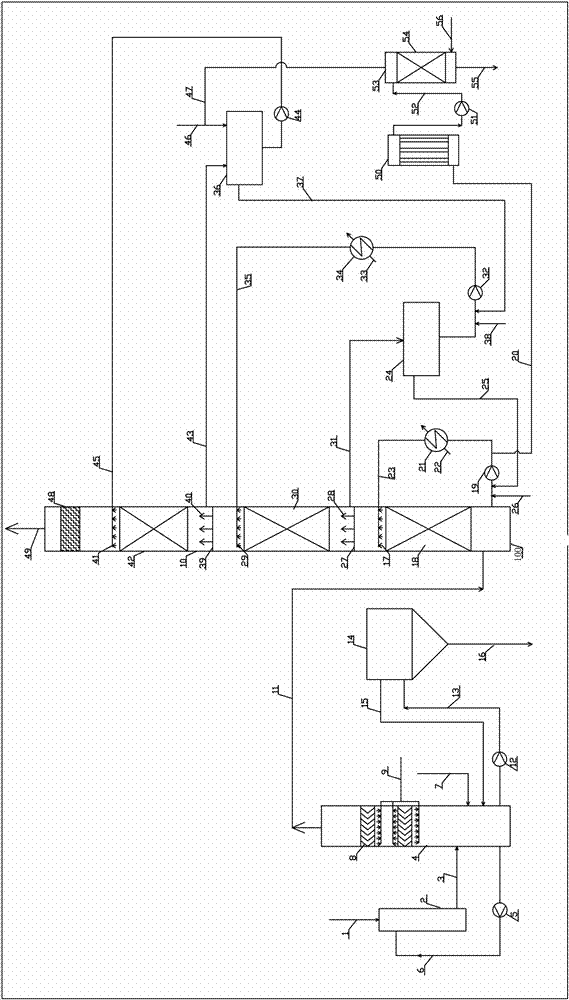

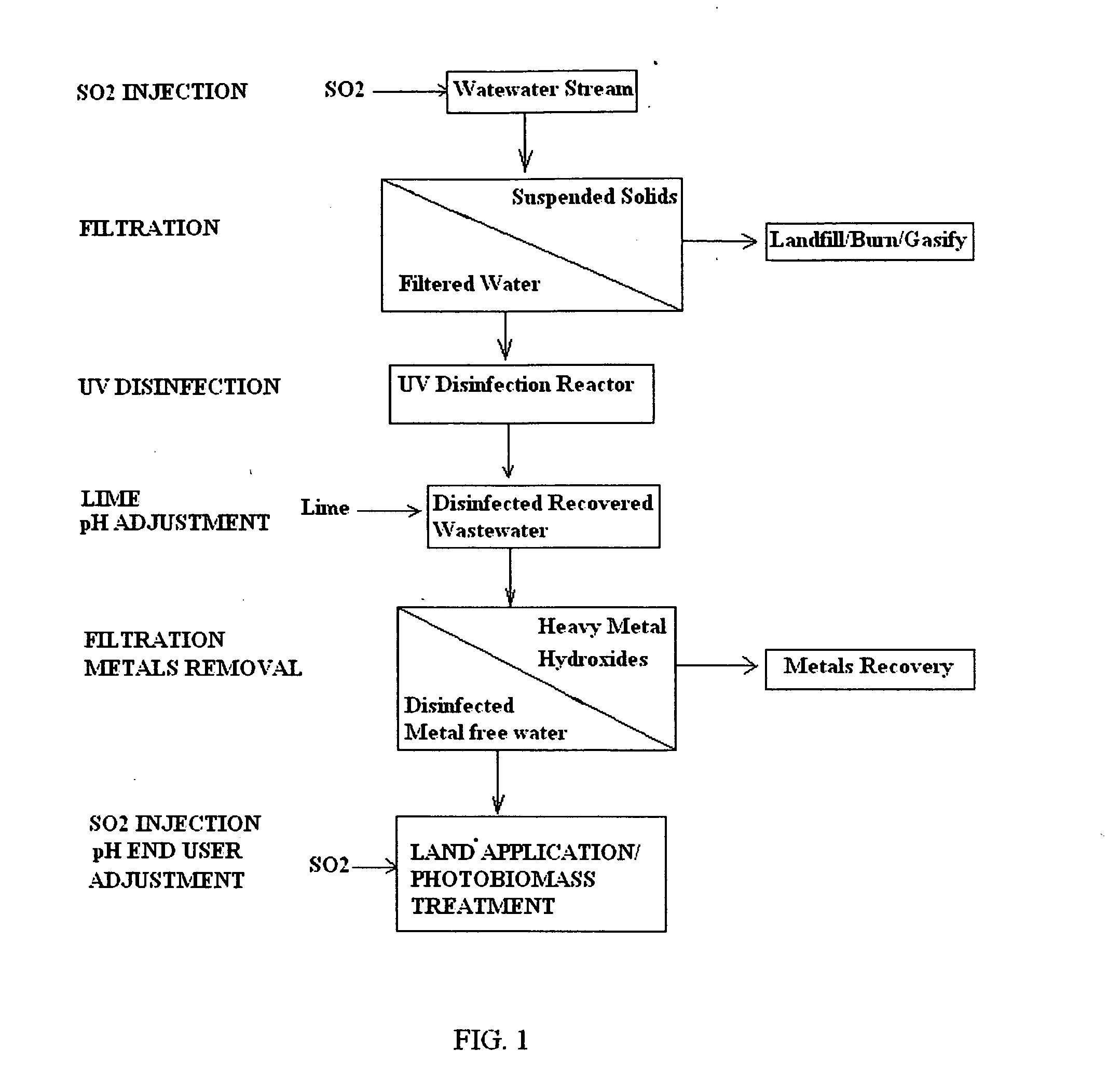

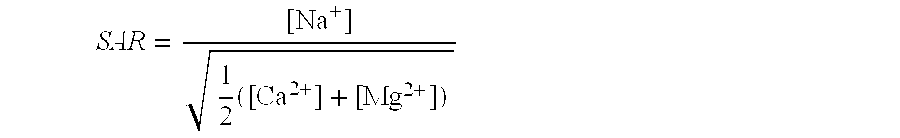

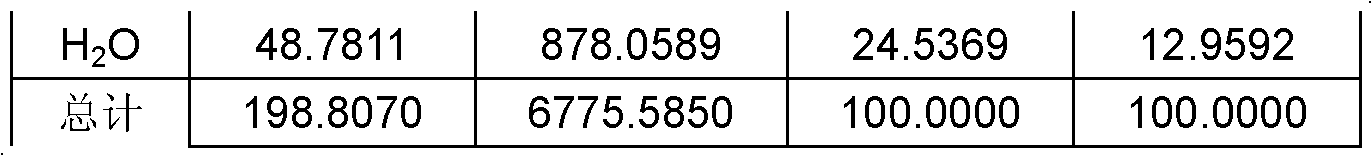

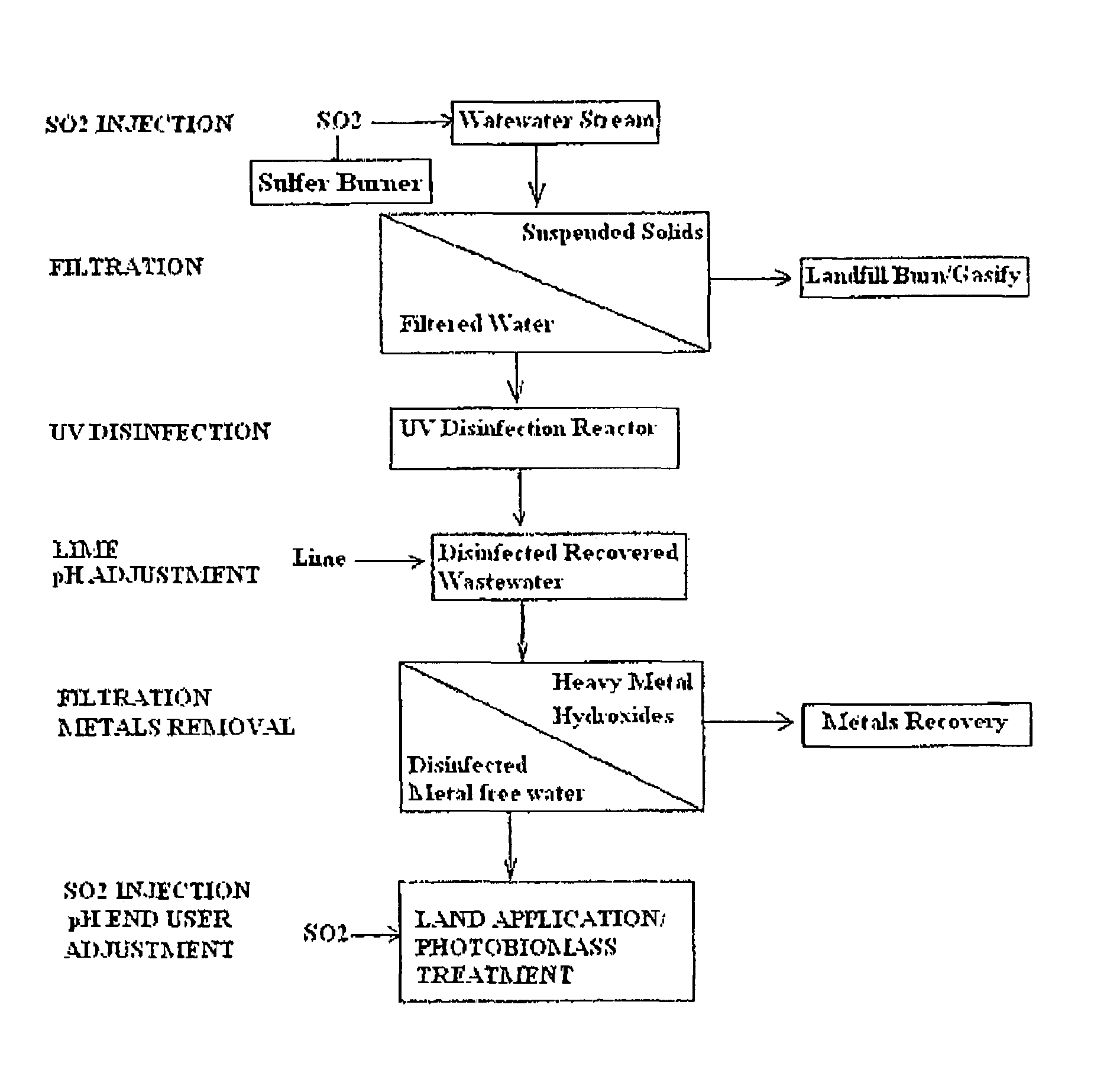

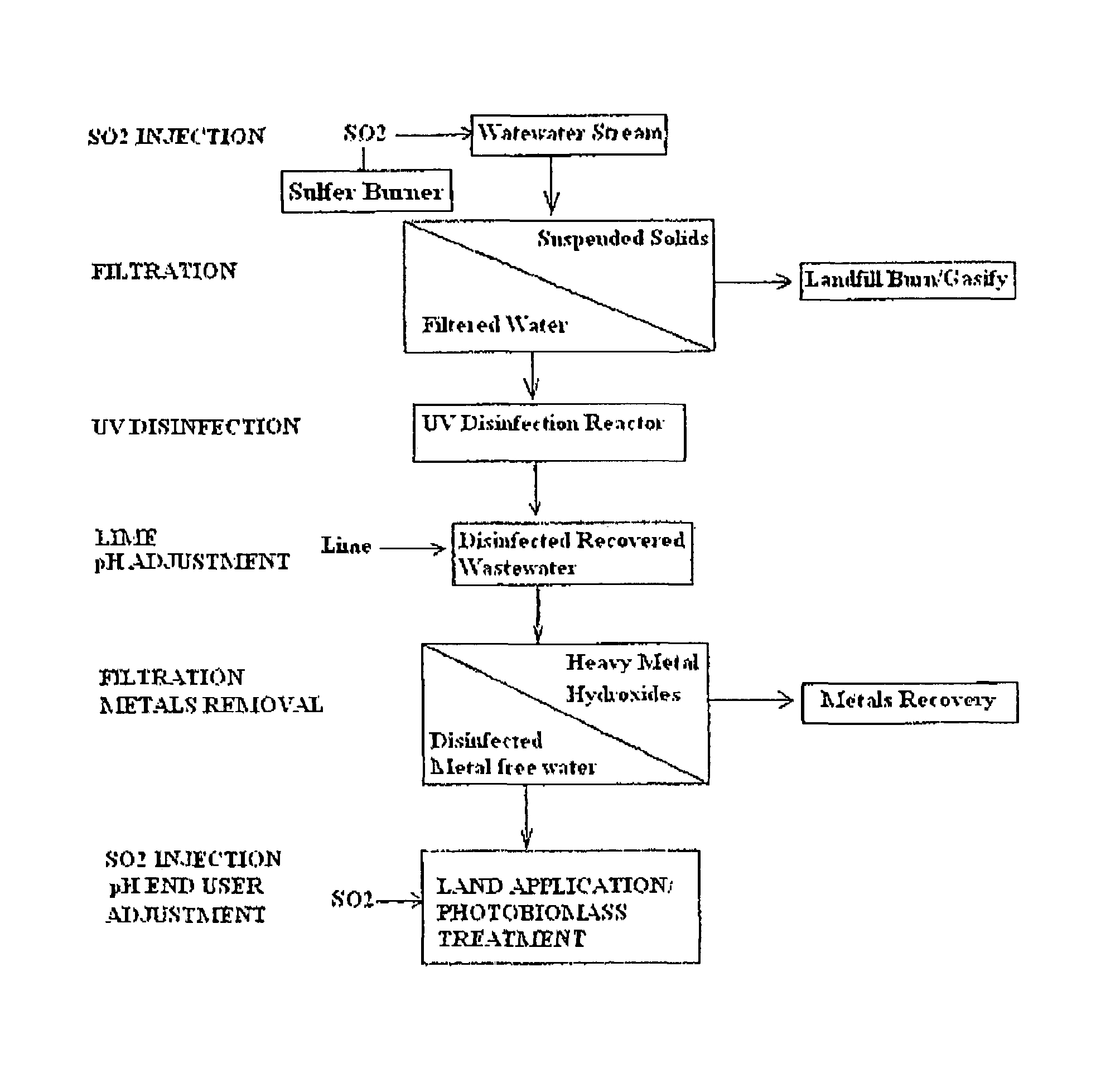

Pre-treatment reverse osmosis water recovery method for brine retentate metals removal

ActiveUS20100193436A1Minimize adhesionPrevent bacterial growthMembranesOther chemical processesRecovery methodPretreatment method

A pre-treatment method for cleaning and maintaining reverse osmosis membrane filters by injecting sulfurous acid into waters with suspended solids in a liquid fraction to be filtered to form sulfurous acid (H2SO3) to acid leach heavy metals into the liquid fraction, reduce alkalinity and mineral scaling, add sufficient SO2 as a biocide to attack bacteria and other micro organisms to prevent membrane fouling, reduce iron to prevent iron deposit build-up, scavenge and remove dissolved oxygen prior to filtration to prevent membrane oxidation, and then sequentially filtering the acidified water through membrane filters to create a metal free permeate and a brine retentate, which can be pH adjusted to remove the heavy metals as metal hydroxide precipitates.

Owner:EARTH RENAISSANCE TECH

Production technology of mulberry daret

The invention is a mulberry dry red wine producing process, including the producing flow: crushing and pulping mulberry->batching->prefermenting->separating and discharging residues-> after-fermenting->primary pouring in kettle->sealing->secondary pouring in kettle->sealing-> tertiary pouring in kettle->sealing->clarifying->mixing->freezing, where the batching: adding in sugar, sulfurous acid, pectase, and crude mulberry pulp; putting the raw pulp in kettles, adding in yeast and fermenting; the separating and discharging residues: discharging clear juice at first and the filtering the rest pulp; combining the juice and the fermentation liquor to enter in the after-fermenting working procedure, and making pouring-in-kettle thrice and making top-layer wine extraction; adopting glutin to clarify the extract. It contains 6-9 percent alcohol. It maintains the natural color of the mulberry, showing prunosus in color, its color is dazzlingly beautiful, sparkling and through-transparent, and it is tasty and refreshing, and pure and nice.

Owner:云南桑立科技发展有限公司

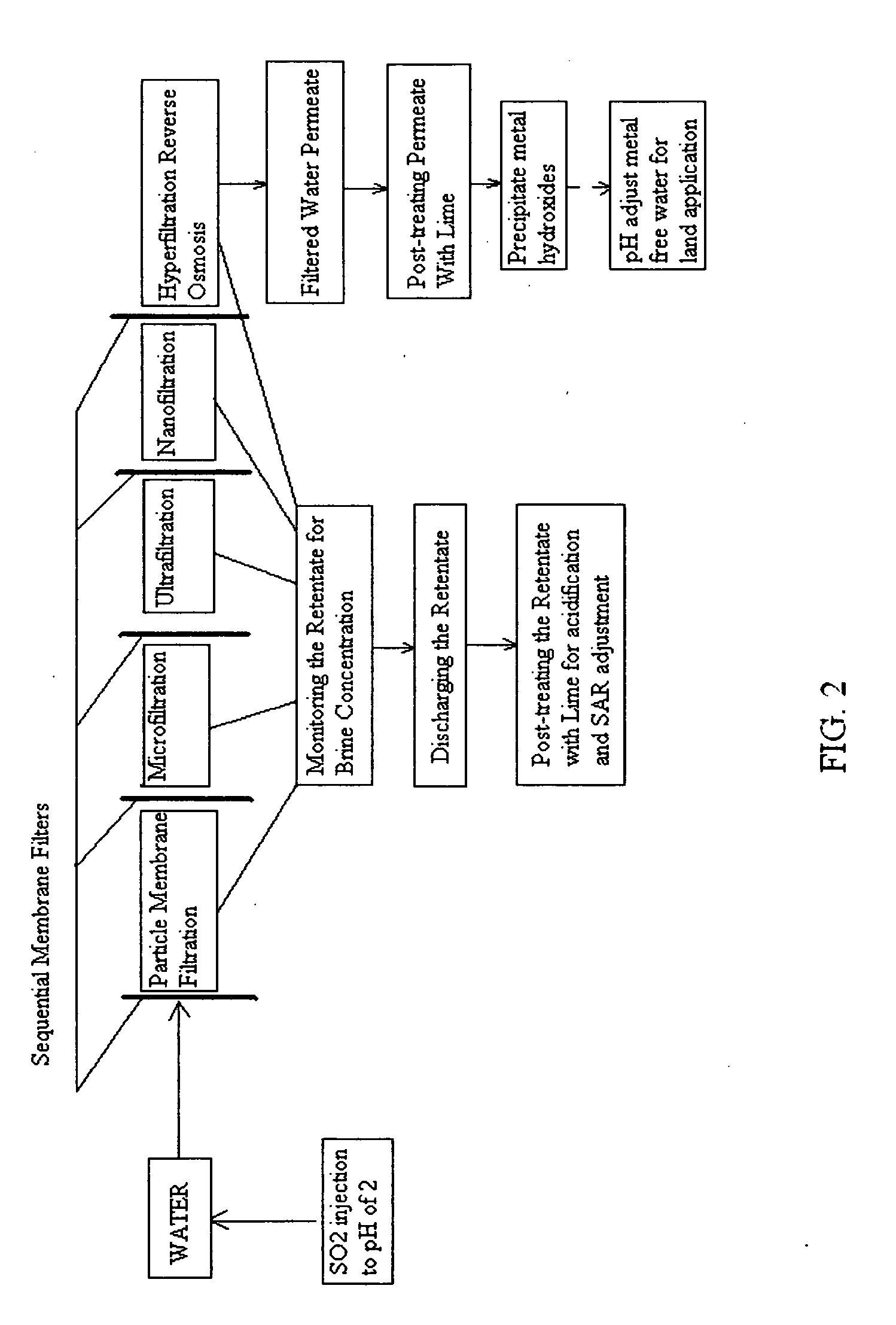

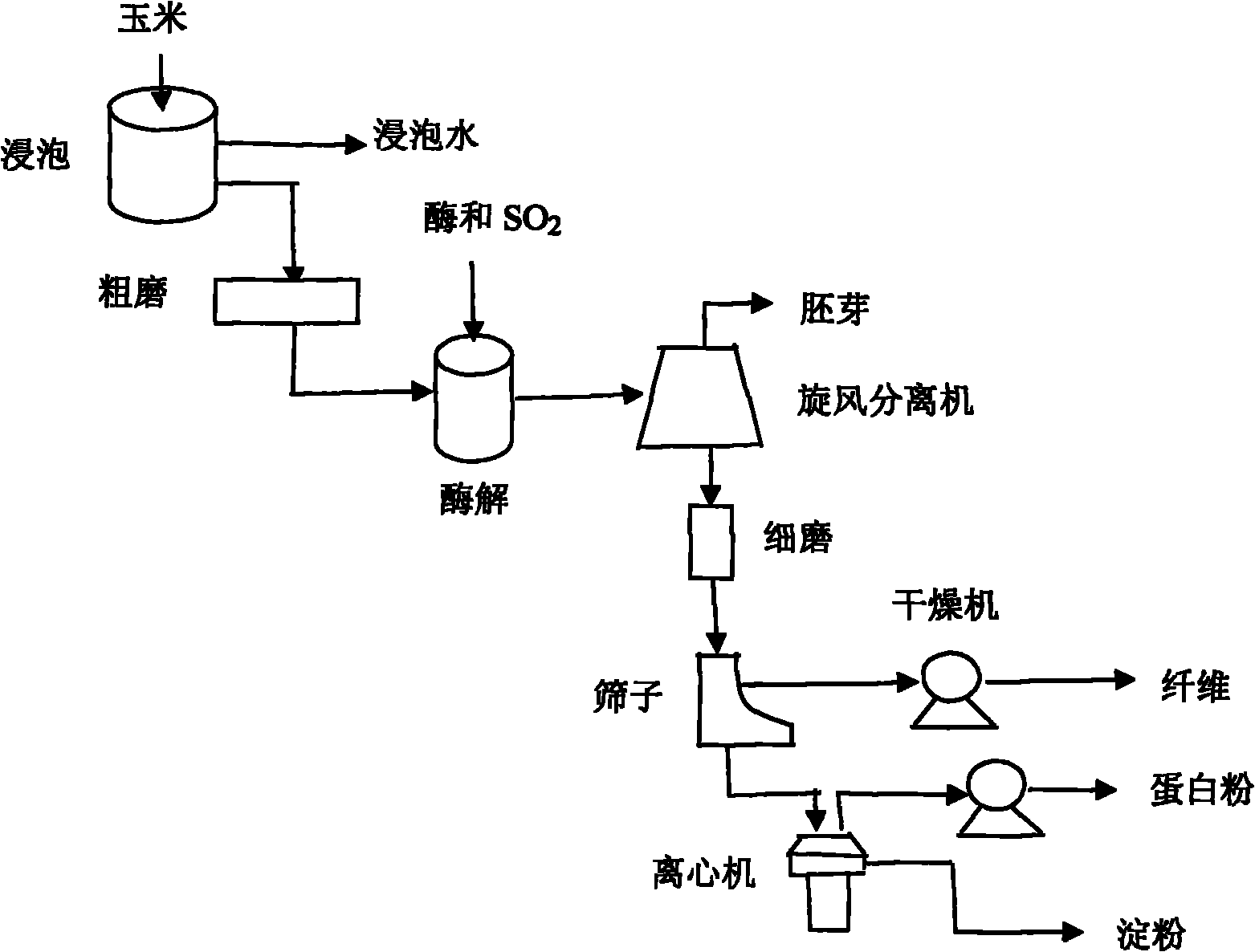

Tech. of closed water circulation in maize starch prodn. process

InactiveCN1792221AReduce water consumptionGuarantee product qualityProteins working-up by texturisingVegetable proteins working-upFiberEvaporation

A closed-loop cyclic utilization technology for the technological water in the procedure of preparing corn starch is disclosed. After the technological water is used to prepare sulfurous acid and immerse corn grains in it, it flows in technological water pool behind evaporation, condensing and regulating pH value. The technological water is also used for coarse grinding, fine grinding, and washing germinal buds and fibers. After two-stage air-floating separation, the water containing bran flows in protein depositing tank. The supernatant is drained in technological water pool and the protein deposit is recovered.

Owner:鲁洲生物科技(山东)有限公司

Brewing technique of blueberry wine

The invention belongs to the technical field of a direct fermentation method for preparing fruit juice wine, and relates to a brewing technique of blueberry wine. The fermentation technique comprises the following steps: (1) picking; (2) selecting; (3) freezing; (4) crushing; (5) adding pectinase; (6) carrying out primary sugar content adjustment; (7) while adding a yeast to carry out controlled-temperature fermentation, carrying out secondary sugar content adjustment, and carrying out general circulation; (8) terminating fermentation; (9) separating skin and slag; (10) adding sulfurous acid, and sealing the tank; (11) filtering; (12) fining and filtering; (13) freezing and filtering; and (14) tempering, filtering with a membrane and filling. In the step (3), the blueberries are cooled to 7-10 DEG C. The brewing method provided by the invention solves the problem of utilization of skin and slag; and the prepared blueberry wine has the advantages of favorable color, excellent scent, high yield and high overall quality.

Owner:CHINA AGRI UNIV

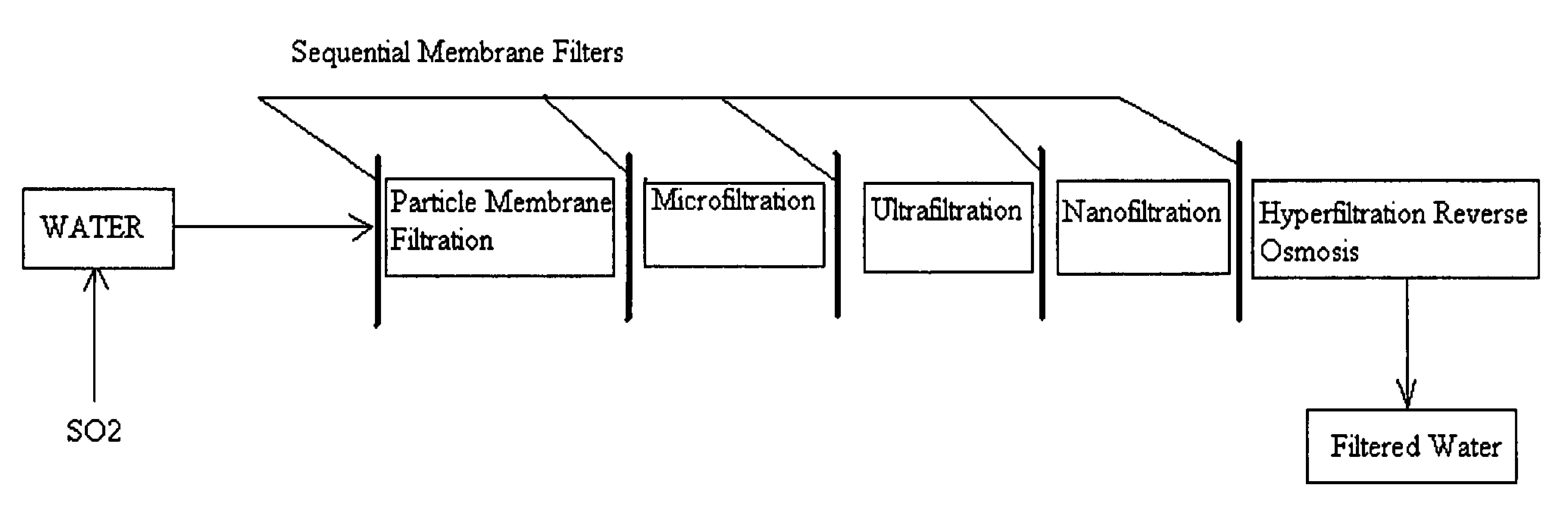

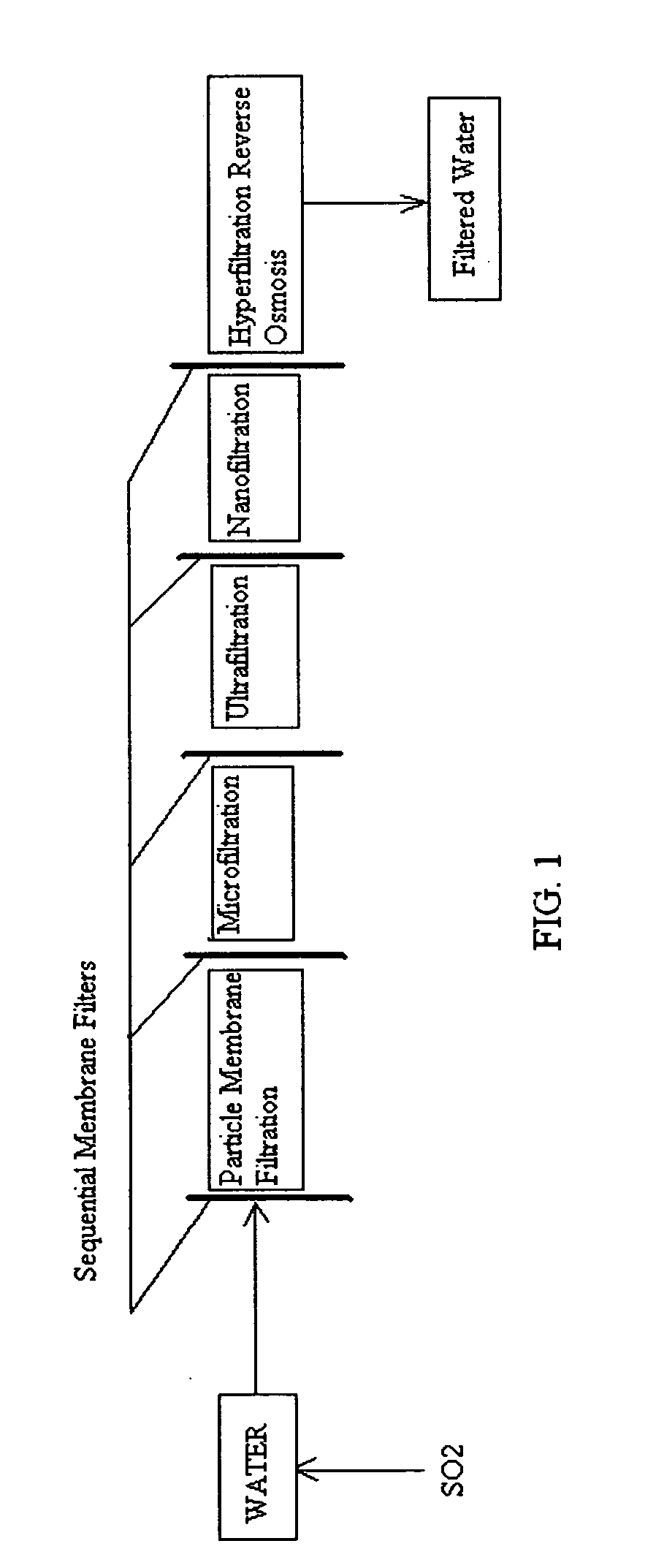

Reverse osmosis water recover method

ActiveUS20100018921A1Avoid applicationPrevent water infiltrationMembranesSedimentation separationMicroorganismFiltration

A method for cleaning and maintaining reverse osmosis membrane filters by injecting sulfurous acid into water to form sulfurous acid (H2SO3), and then sequentially filtering the acidified water through membrane filters to reduce alkalinity and mineral scaling, add sufficient SO2 as a biocide to attack bacteria and other micro organisms to prevent membrane fouling, reduce iron to prevent iron deposit build-up, scavenge and remove dissolved oxygen prior to filtration to prevent membrane oxidation, and prevent concentrated salts within the retentate from precipitating out of solution during transport for land application.

Owner:EARTH RENAISSSANCE TECH

Method for desulfurizing high-sulphur boiler flue gas to prepare high-purity ammonium bisulfite

ActiveCN102755823ASimple processLow investment costCombination devicesAmmonium sulfitesIon exchangeDust control

The invention relates to a method for removing and recycling SO2 in high-sulphur boiler flue gas and discloses a method utilizing ammonia water as material and recycling desulfuration to prepare ammonium bisulfite with high SO2 / NH3 value and high purity. The method comprises the steps of (1) performing dry dedusting on high-sulphur boiler flue gas, and cooling through wet dust collection, (2) utilizing ammonia water as absorbents to absorb SO2 in flue gas in a triple tandem desulfurizing absorption tower, controlling the absorbing temperature through an exterior circulation cooling mode, preparing ammonium bisulfite solution with high SO2 / NH3 value, and discharging with standard level after water scrubbing and demisting, (3) removing high chemical valence insoluble heavy metal ions such as ferric iron through microfiltration, and (4) removing heavy metal ions through chelating ion exchange resins to obtain products. According to the method, the concentration of SO2 in flue gas after desulfurization is low, SO2 in high-sulphur boiler flue gas is effectively recycled, and ammonium bisulfite solution with high SO2 / NH3 value and high purity is prepared.

Owner:JIANGSHAN TAIGE CHEM

Acidification pre-treatment for UV water disinfection

ActiveUS20110243665A1Efficient inactivationEliminate needWater/sewage treatment by irradiationOther chemical processesPretreatment methodFiltration

A pre-treatment method injecting sulfur dioxide into waters containing suspended solids to undergo ultra violet disinfection to form sulfurous acid (H2SO3) to self-agglomerate and precipitate solids from the wastewater for settling or filtration removal and provide acid to reduce bicarbonate and mineral scaling and microbial buildup on ultraviolet light tubes to improve their performance.

Owner:EARTH RENAISSANCE TECH

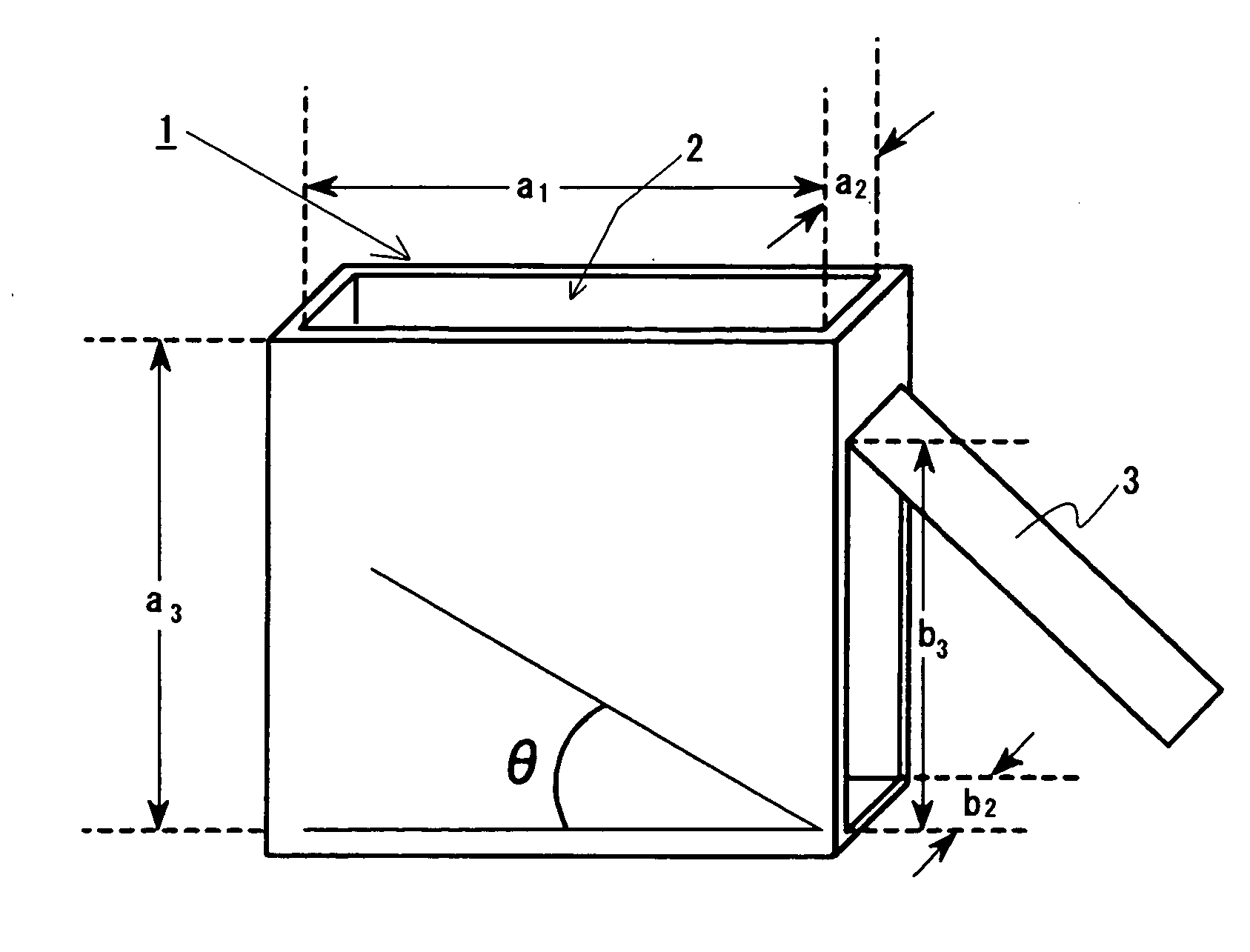

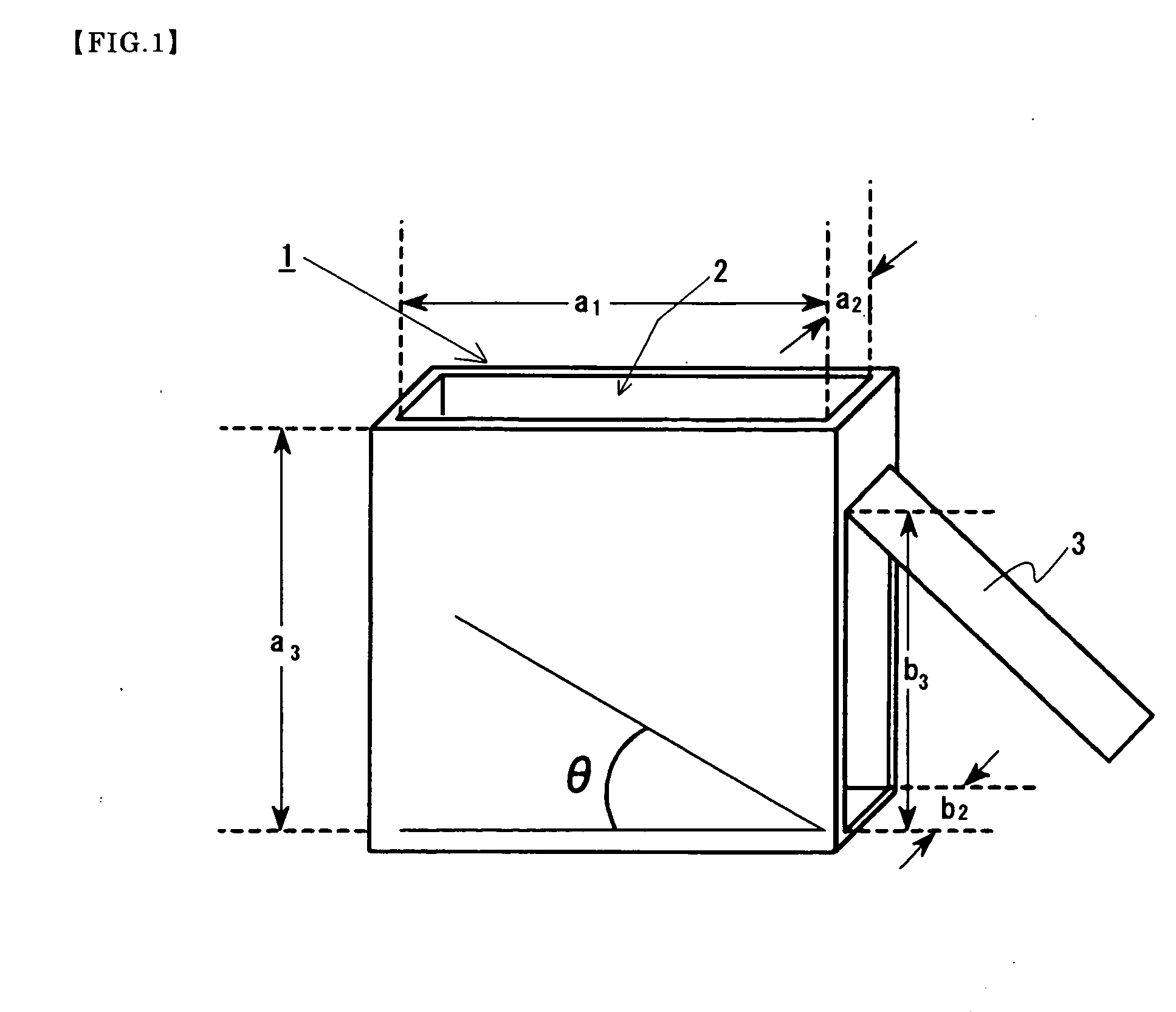

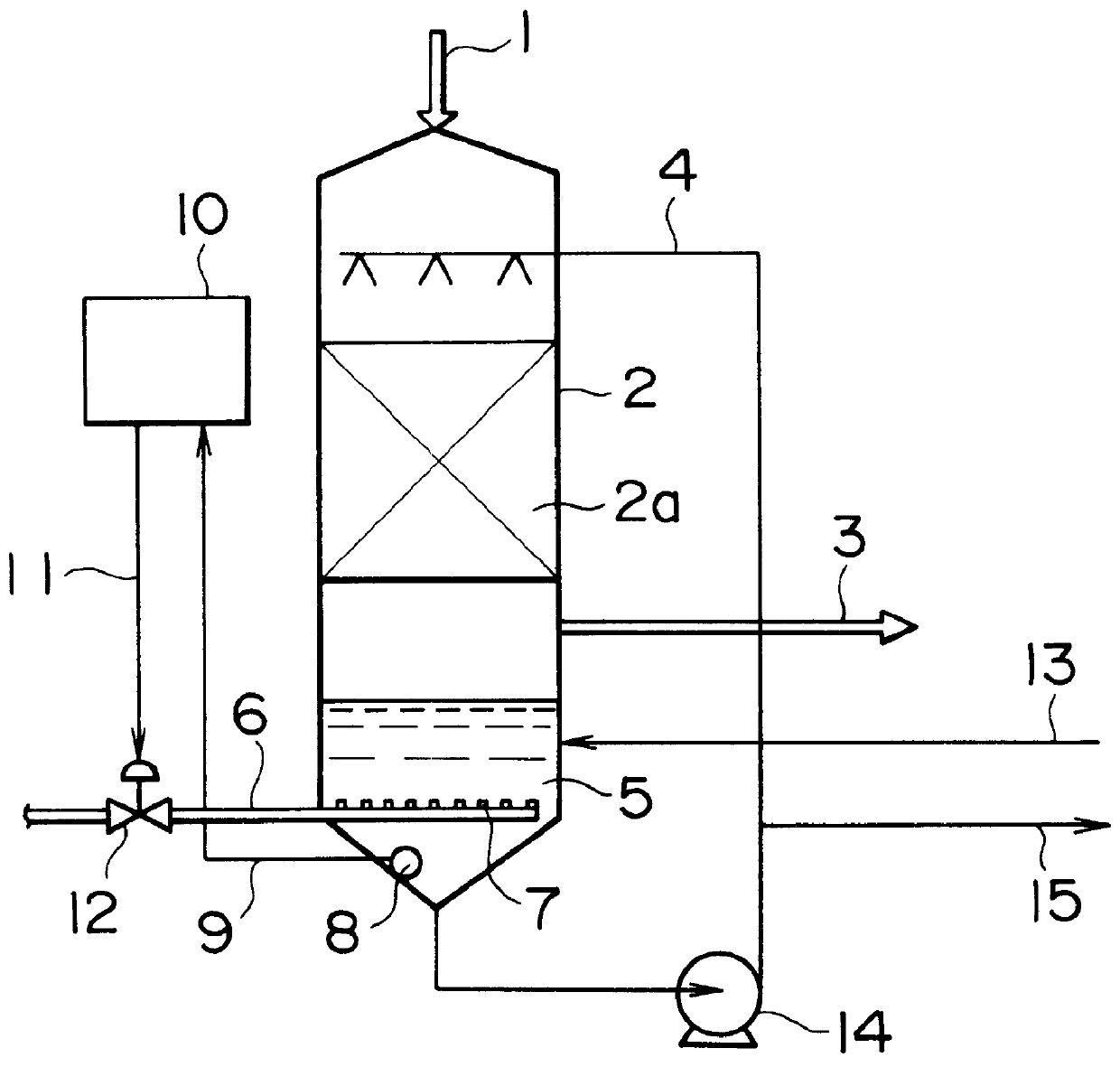

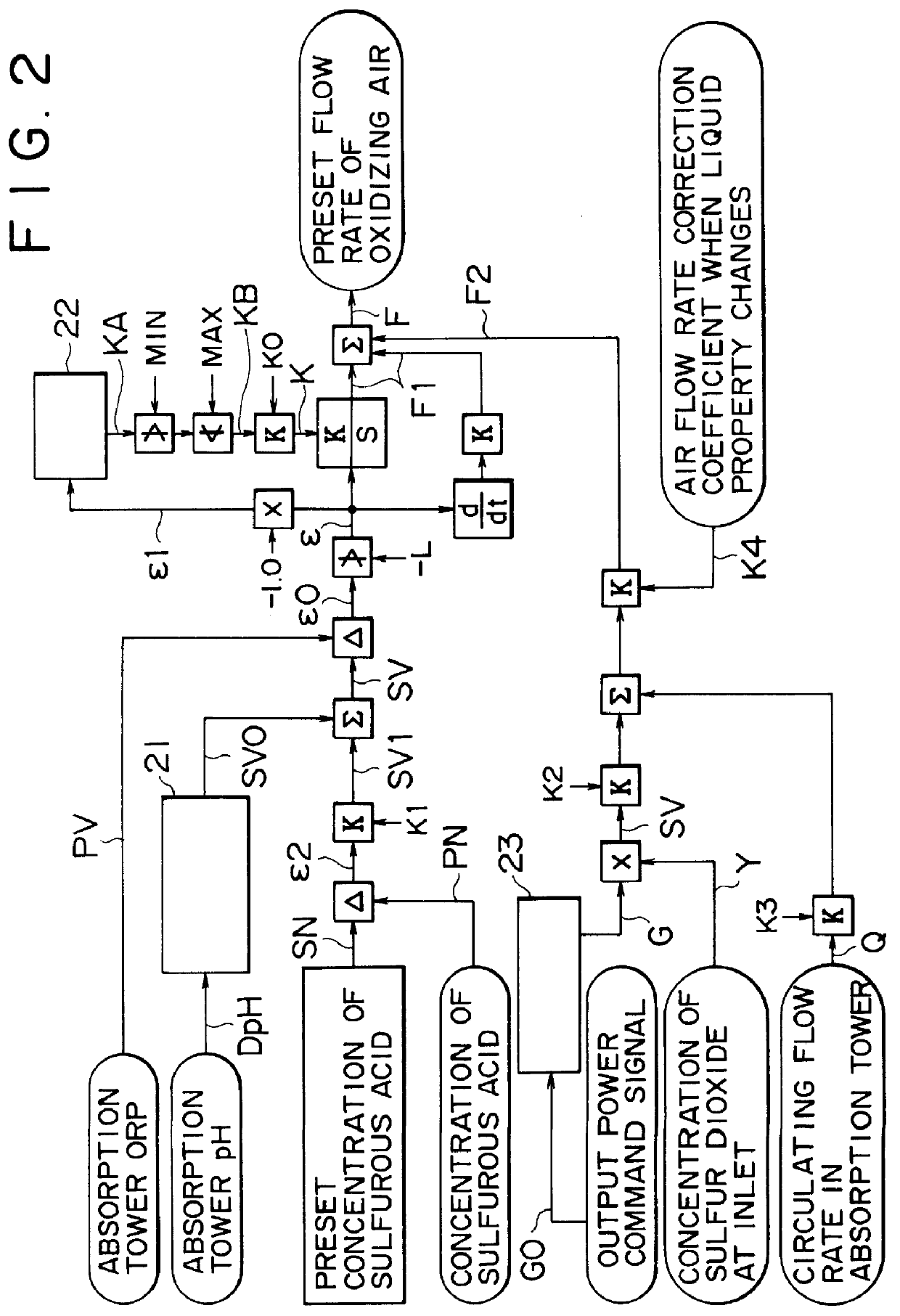

Method for controlling oxidation in flue gas desulfurization

There is provided a method for flue gas desulfurization which is capable of conducting minute control of oxidation and which is capable of maintaining the concentration of sulfurous acid in an absorbent liquid within a proper range in a highly reliable and efficient manner, even in the case where an abrupt change occurs in the operational conditions of the system. In the method for controlling the oxidation in flue gas desulfurization, the value of proportional sensitivity K in the feed back control process, which is based primarily on the oxidation-reduction potential, is increased depending on the deviation epsilon in a region where the detected oxidation reduction potential value PN is below the target oxidation reduction potential value SN in correspondence with the characteristic change of the oxidation-reduction potential against the concentration of sulfurous acid.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Sulfonium salt, resist composition, and patterning process

ActiveUS8173354B2Promote divisionImprove responseOrganic chemistryOrganic compound preparationResistLithographic artist

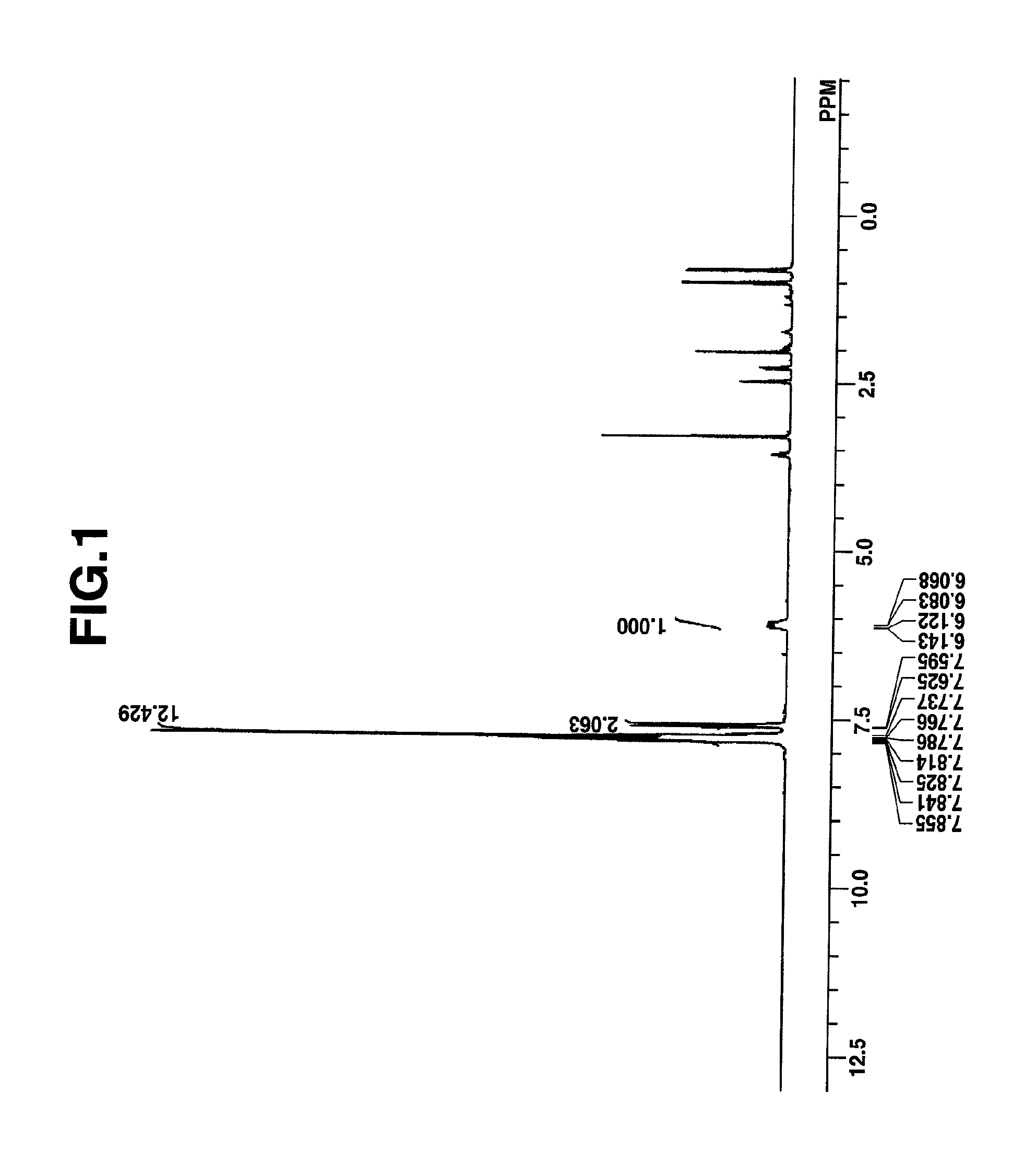

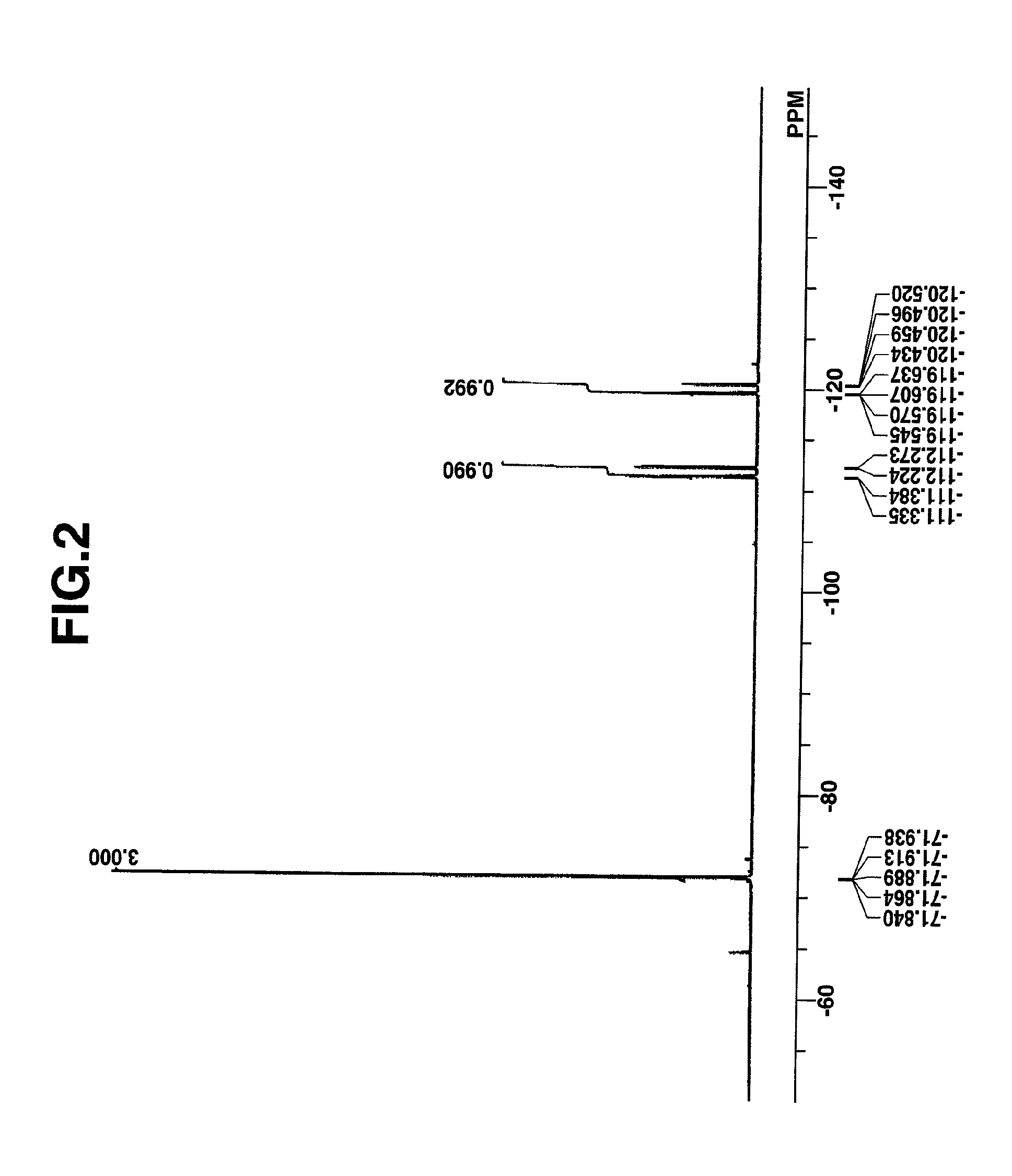

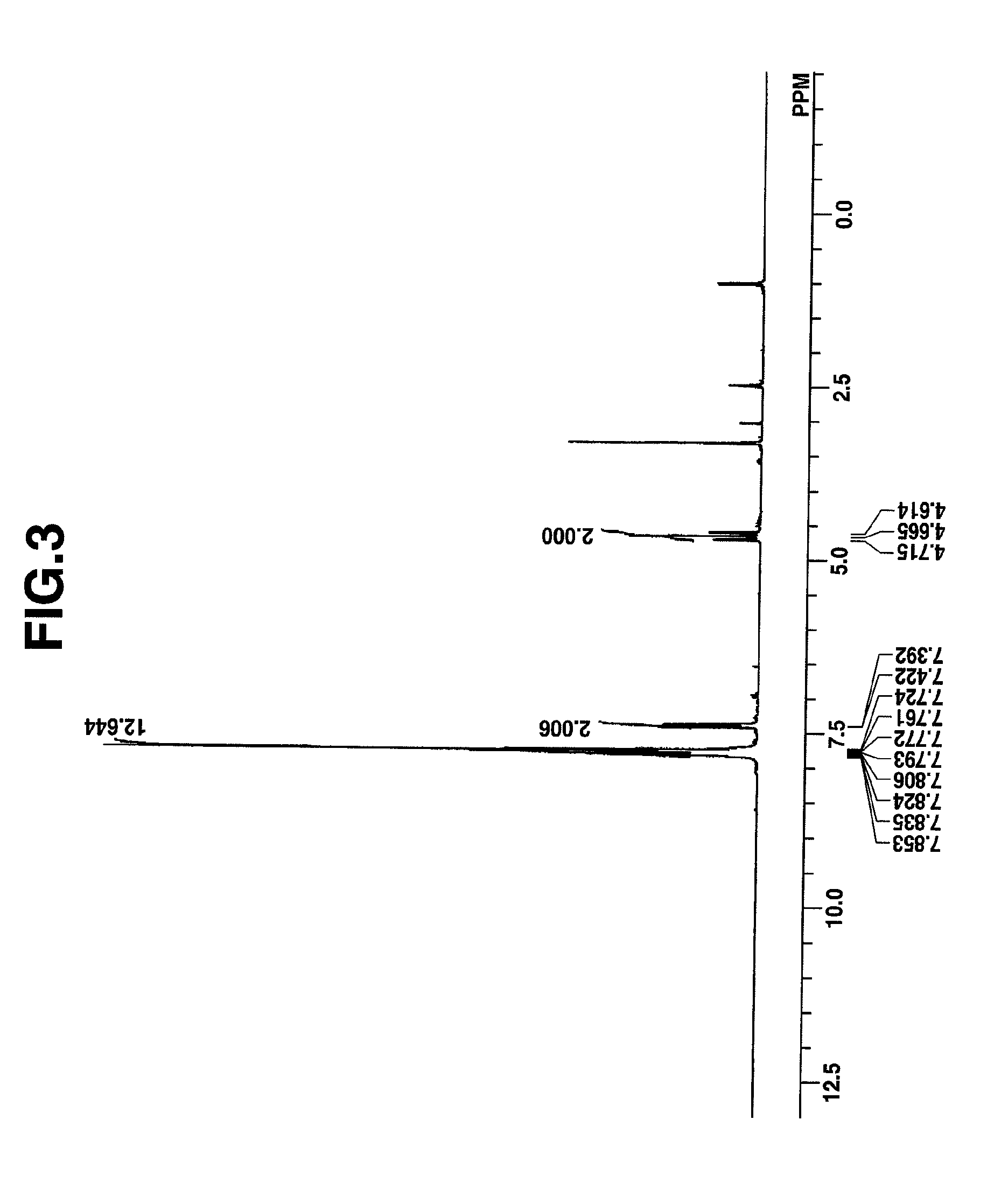

A sulfonium salt having a triphenylsulfonium cation and a sulfite anion within the molecule is best suited as a photoacid generator in chemically amplified resist compositions. Upon exposure to high-energy radiation, the sulfonium salt generates a sulfonic acid, which facilitates efficient scission of acid labile groups in chemically amplified positive resist compositions. Because of substantial non-volatility under high vacuum conditions in the EB or EUV lithography, the risk of the exposure tool being contaminated is minimized.

Owner:SHIN ETSU CHEM IND CO LTD

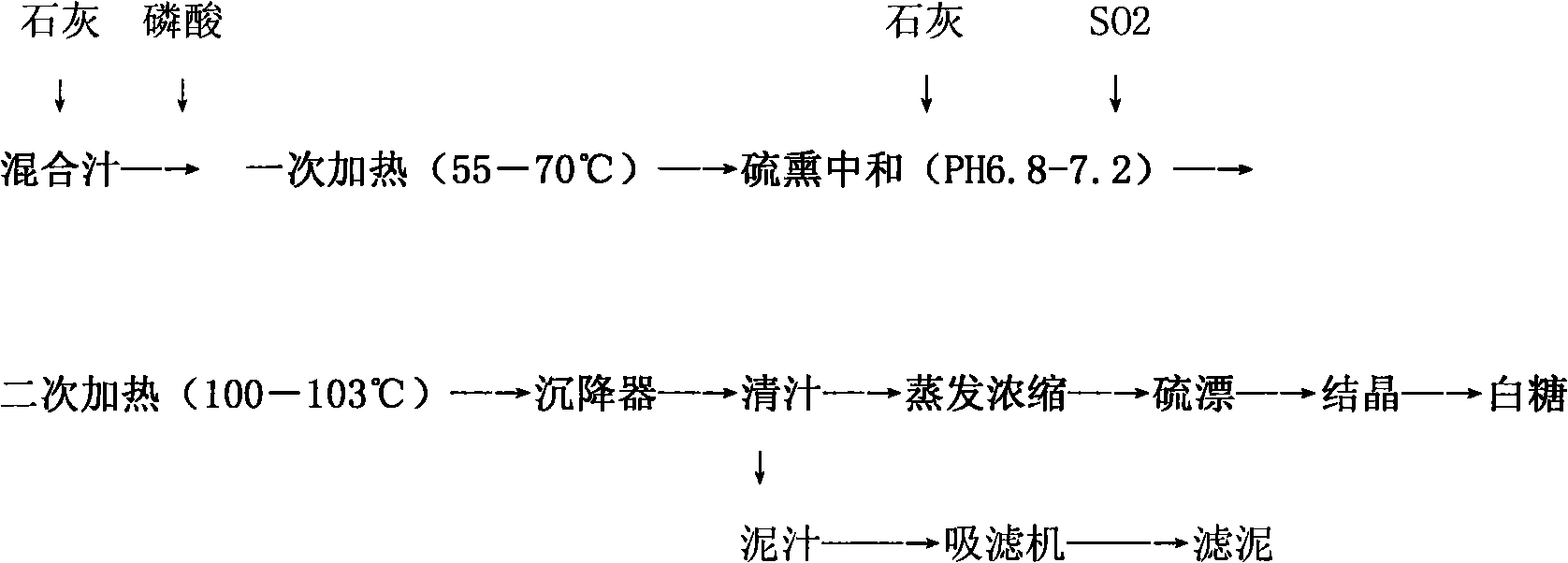

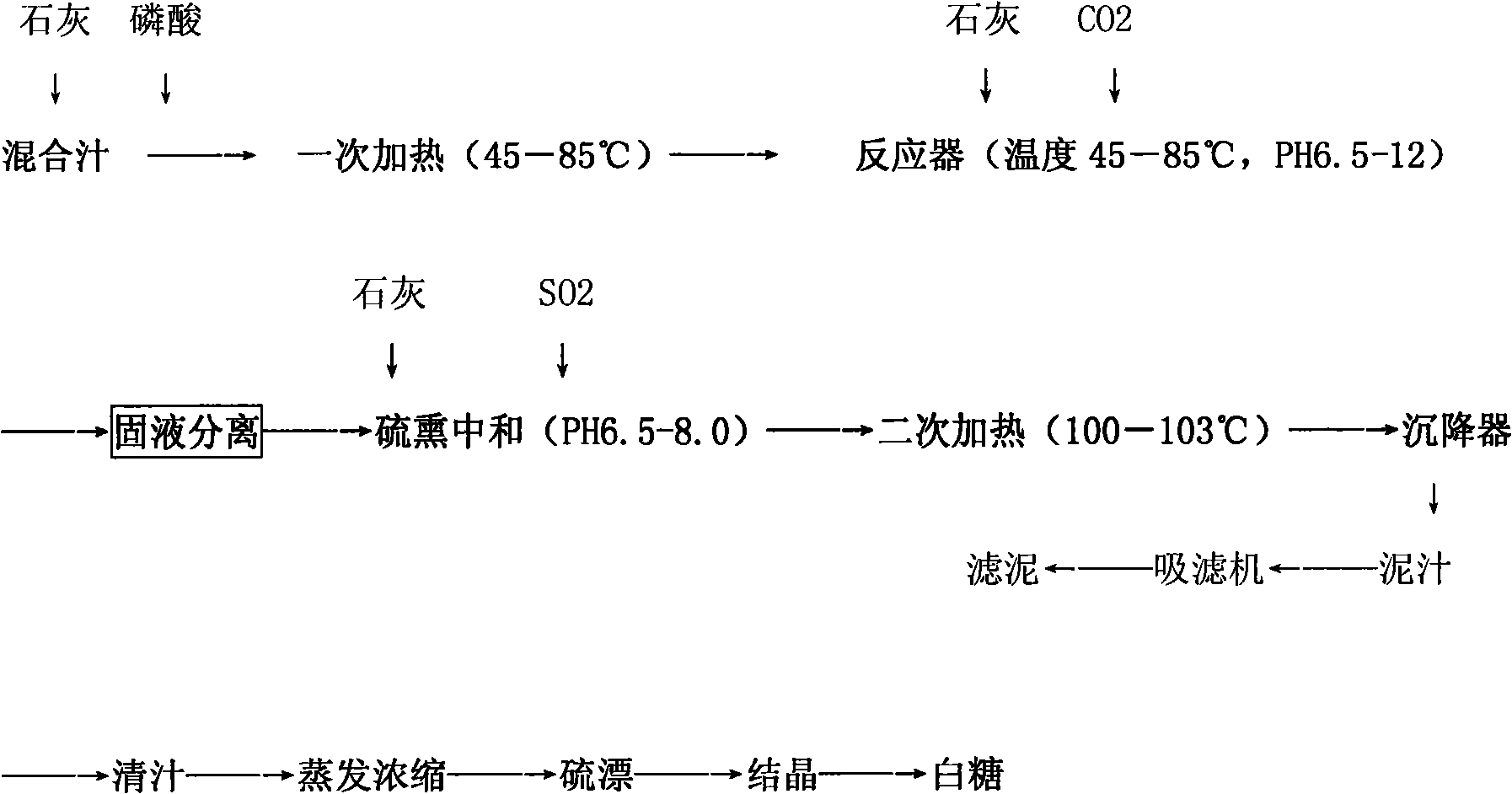

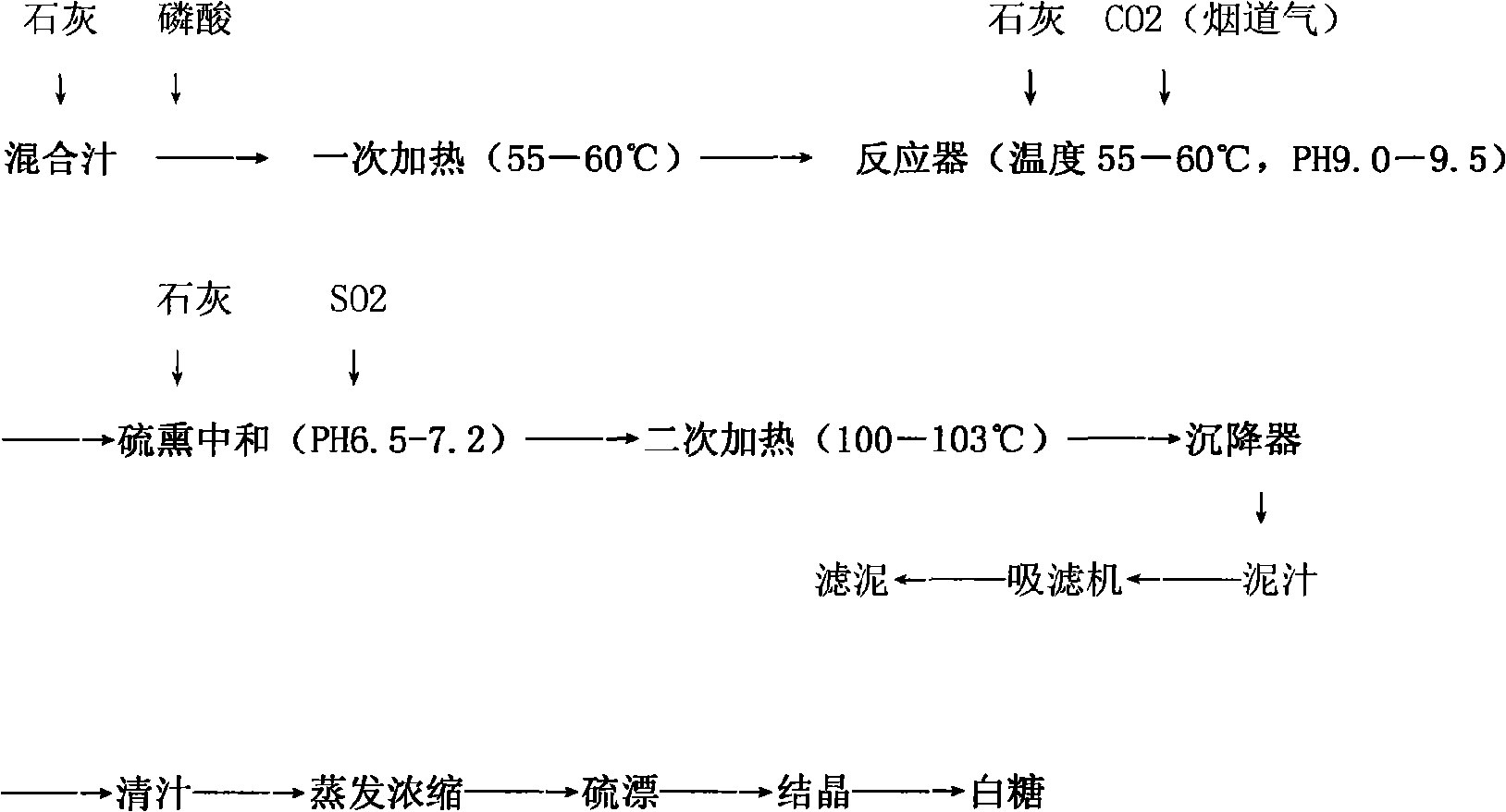

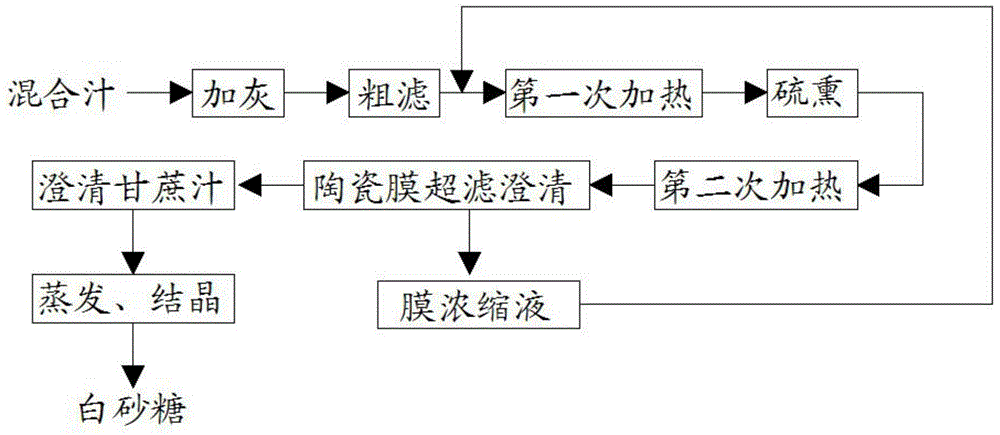

Clarification method for sugarcane juice

InactiveCN101280344AEmission reductionReduce residual sulfur dioxidePurification using alkaline earth metal compoundsSugar caneCarbonation

The invention discloses a clarification method for cane expressed juice, which is an improvement for sulfurous acid method manufacturing technique of a cane sugar factory. The cane juice is conveyed into a reactor after the first heating, and carbonation is performed through adding lime and carbon dioxide; solid-liquid separation can be performed to the carbonation cane juice to remove solid impurity, and the stoving liming neutralization treatment is performed to the obtained clear juice taking sulfur dioxide and lime as clarificant; the stoving liming neutralization treatment can be also performed to the turbid carbonation cane juice directly taking sulfur dioxide and lime as clarificant. The stoving liming neutralization cane juice is conveyed into a settler after the second heating, and the clear juice and the mud juice are separated. The clarification method has the advantages that the brenstone use level is reduced, the production cost is saved, the sulfur dioxide residual in white sugar is decreased greatly, the product quality is improved, the carbon dioxide discharge amount is reduced, the clear juice purity is increased by 1 to 1.5, the white granulated sugar color value is reduced by twenty percent, and therefore the environment problem does not exist.

Owner:南宁苏格尔科技有限公司

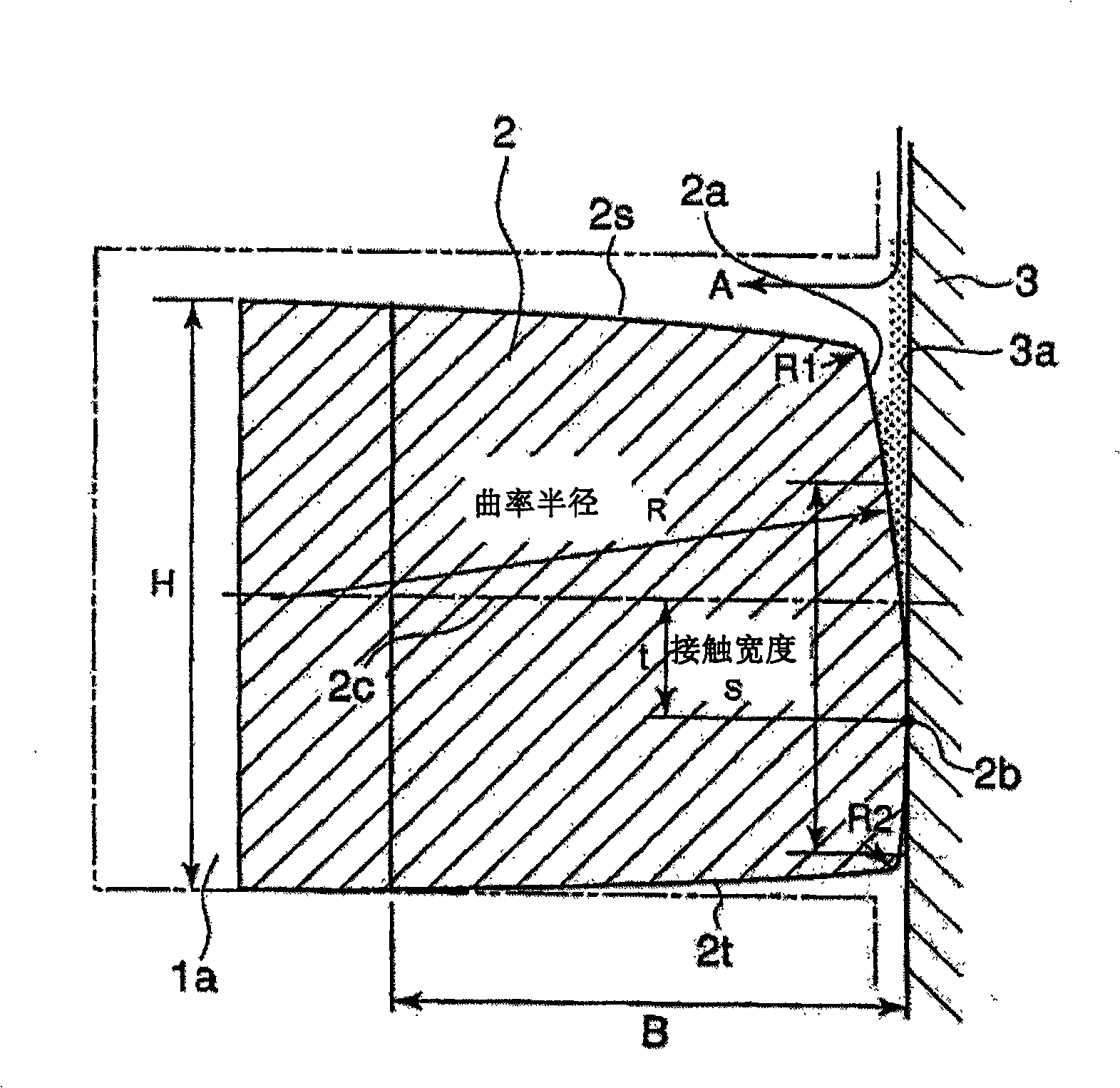

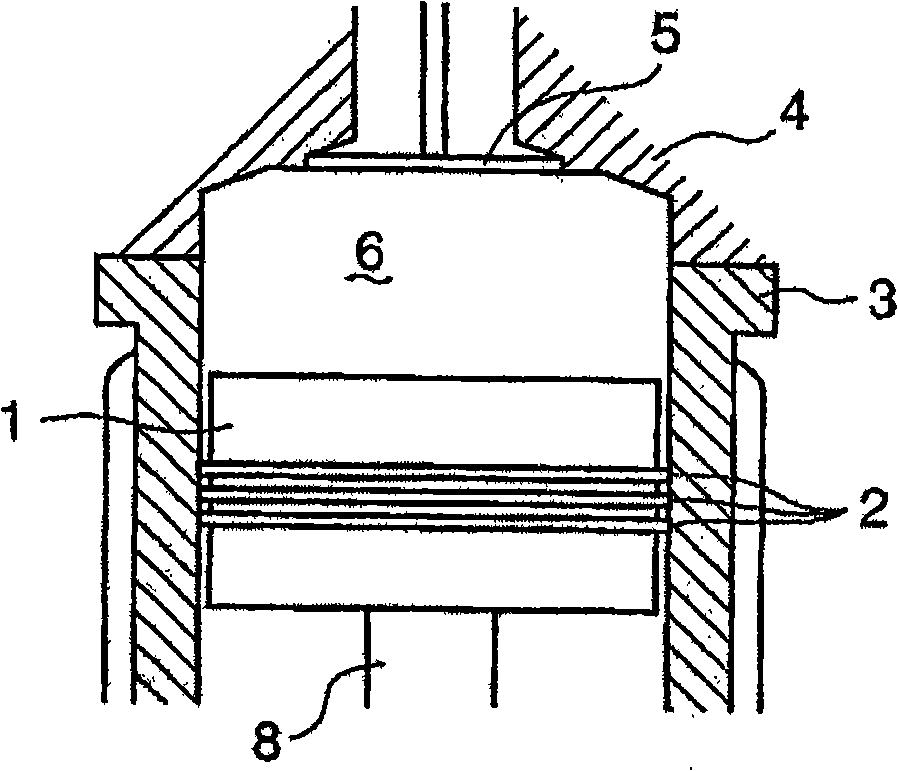

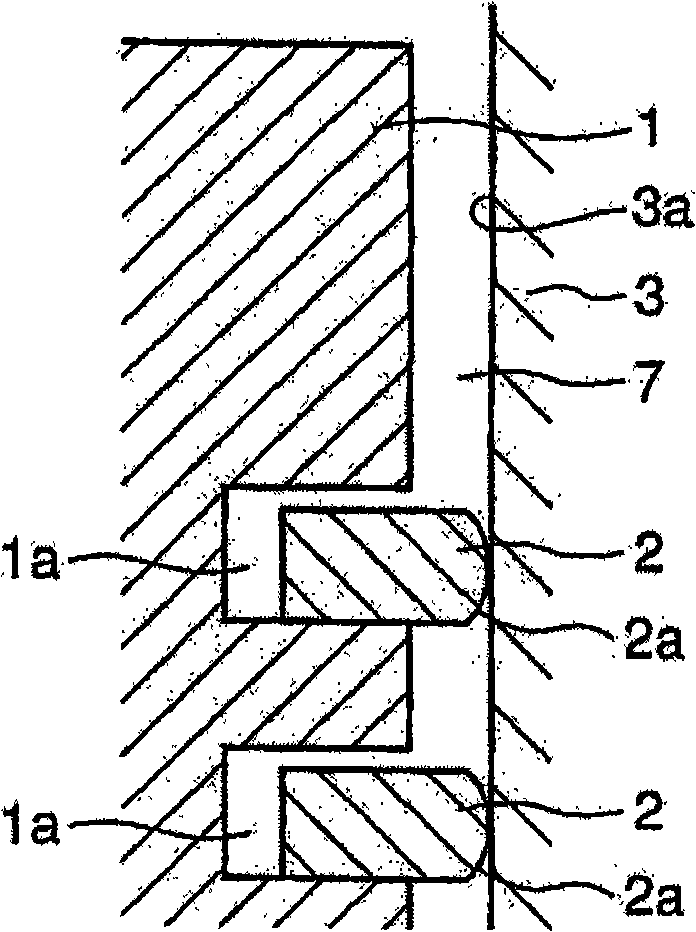

Piston ring of reciprocating engine

The invention provides a piston ring for a reciprocating motion internal combustion engine which can increase gas sealing performance, prevent increase of blow-by gas quantity due to deficiency gas sealing capability between outer circumferential surface of the piston ring and sliding surface of a cylinder sleeve, prevent pollution increase of a inner surface portion of the piston ring due to blow-by gas quantity increase and prevent increase of circumference of a sliding surface 3a of the cylinder sleeve 3 corroded by sulfuric acid due to sulfurous acid gas contained in the blow-by gas by maximatily increasing a first curved surface radius R of outer circumferential surface of the piston ring, and can reduce contact pressure. The outer circumferential surface of the piston ring contacted with the sliding surface of the cylinder sleeve is formed to a curved surface with radius of curvature R along axial direction, which is characterized in that the radius of curvature R of the outer circumferential surface is set from 1.18D to 1.35D relative to cylinder inner diameter D of engine.

Owner:MITSUBISHI HEAVY IND LTD +1

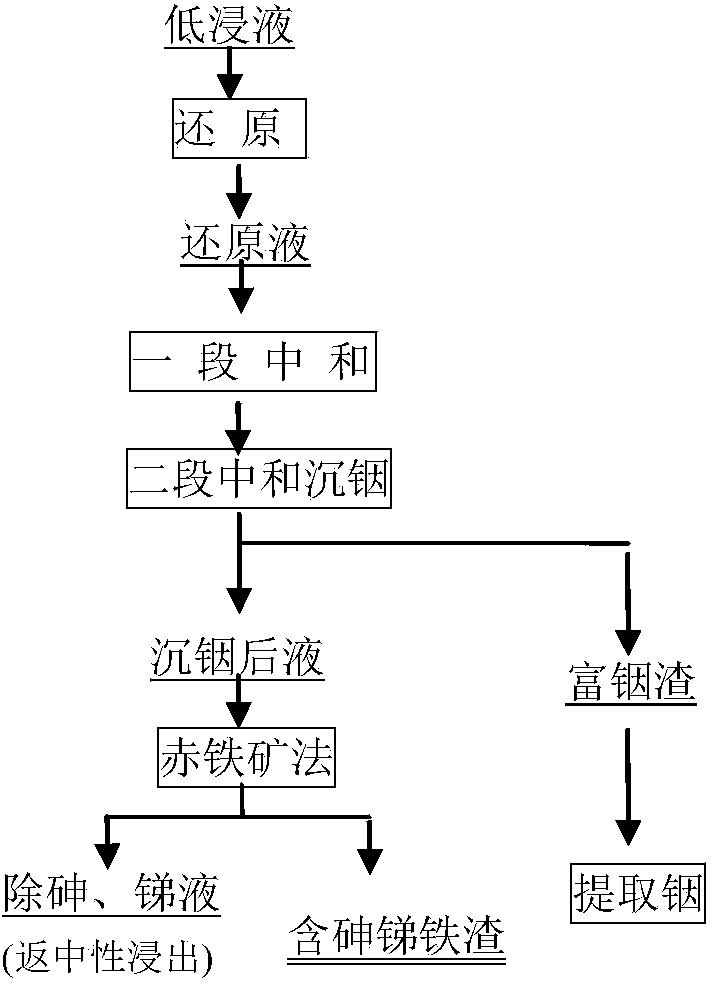

Method for removing arsenic and antimony from zinc smelting leach liquor

InactiveCN103911512AEfficient use ofStable physical and chemical propertiesProcess efficiency improvementIndium metalPregnant leach solution

The invention discloses a method for removing arsenic and antimony from zinc smelting leach liquor, and relates to a method for removing arsenic and antimony from a solution produced during zinc smelting by purifying. The method is characterized by comprising the following steps: comprehensively recovering valuable components of zinc, indium, iron and the like by purifying in an arsenic and antimony removing process consisting of pre-reduction, neutralization of precipitated indium and a hematite process under the condition that zinc smelting low-acid leach liquor is taken as a raw material; turning high-valence iron into low-valence iron by taking zinc concentrate, zinc sulfite, sulfur dioxide and the like as reducing agents in the low-acid leach liquor, wherein the content of high-valence iron (Fe<3+>) in the reduced liquor is lower than 2g / L; performing two-stage neutralization by using lime, limestone, secondary zinc oxide, calcined sand and zinc oxide to regulate the pH value of reduced liquor to 4.0-5.4 in order to enrich indium precipitate; and removing arsenic and antimony from indium-precipitated liquor to fulfill the aim of efficiently cleaning and purifying the solution. The method has the advantages of high indium metal recovery rate, high arsenic and antimony removing rates, small residue amount, stable performance and environmental friendliness.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

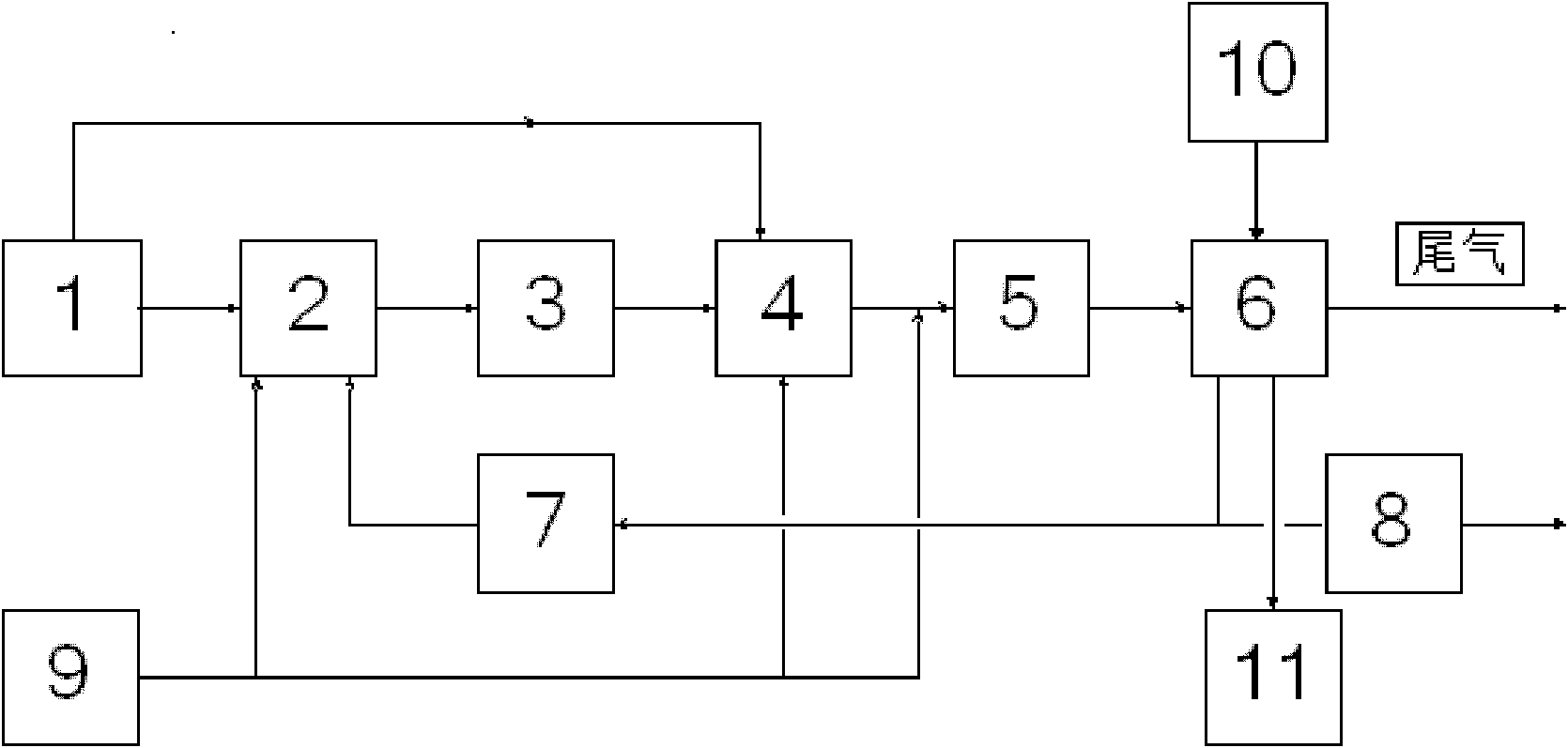

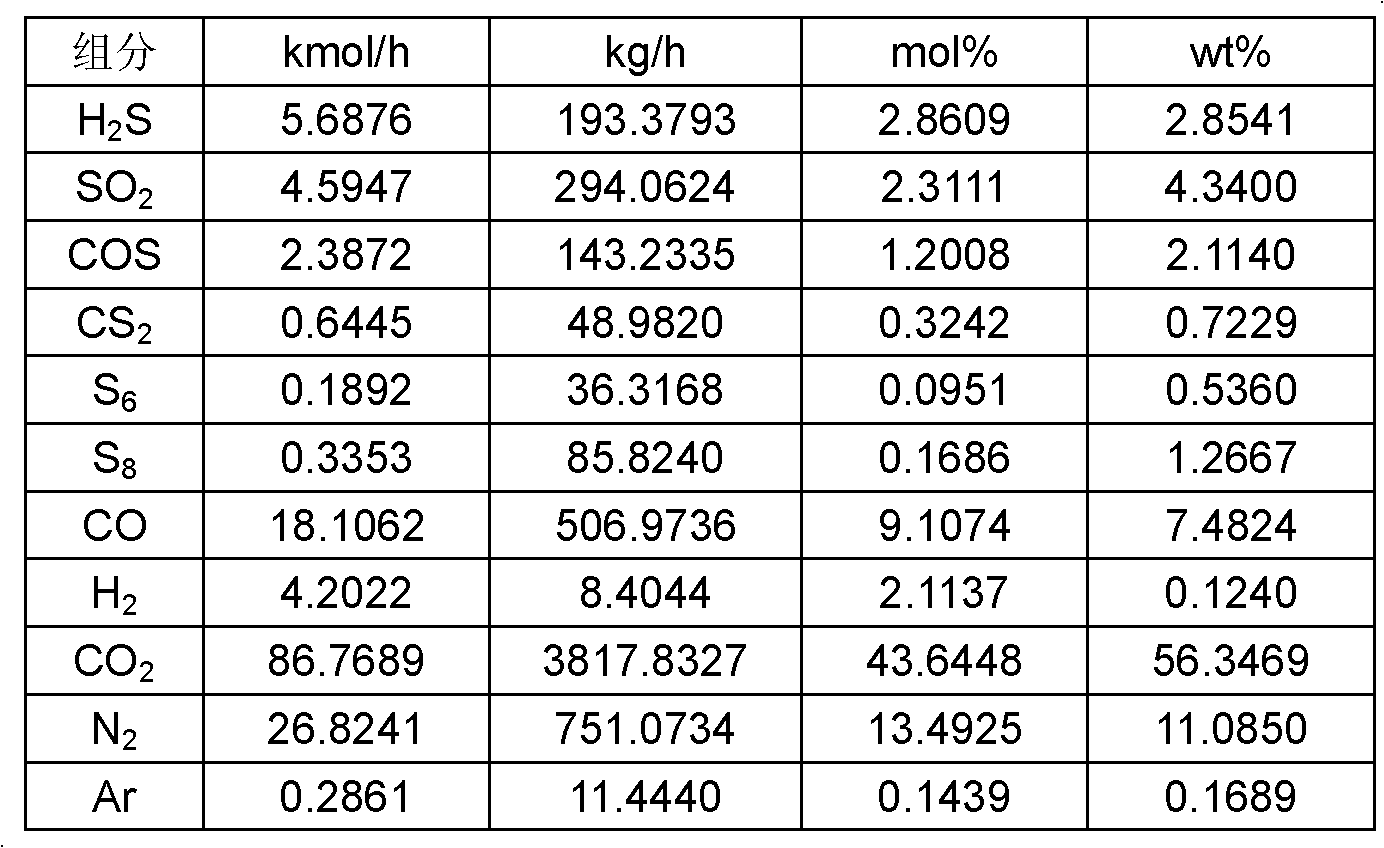

Processing method of acid gas

InactiveCN102198365AAchieve recyclingAchieve further pyrolysis recoveryDispersed particle separationSulfur preparation/purificationSulfurSulfurous acid

The invention relates to a processing method of acid gas, comprising the steps of: burning the acid gas; reacting the burned acid gas with oxygenous gas to obtain the acid gas containing SO3 and SO2; reacting the acid gas containing SO3 and SO2 with water to obtain sulphuric acid and sulphurous acid, and conveying tail gas downstream for processing; and directly recovering the sulphuric acid and the sulphurous acid, or returning to the step of burning the acid gas. The technical scheme provided by the invention is simple to operate; by use of the technical scheme, the acid gas can be effectively purified, the sulfur recovery rate is increased, the processing procedure of the acid gas is simplified, and the operation difficulty is reduced; and the processing method of the acid gas is suitable for large-scale application.

Owner:BEIJING FUNGHAN ENG CONSULTING

Acidification pre-treatment for UV water disinfection

A pre-treatment method injecting sulfur dioxide into waters containing suspended solids to undergo ultra violet disinfection to form sulfurous acid (H2SO3) to self-agglomerate and precipitate solids from the wastewater for settling or filtration removal and provide acid to reduce bicarbonate and mineral scaling and microbial buildup on ultraviolet light tubes to improve their performance.

Owner:EARTH RENAISSANCE TECH

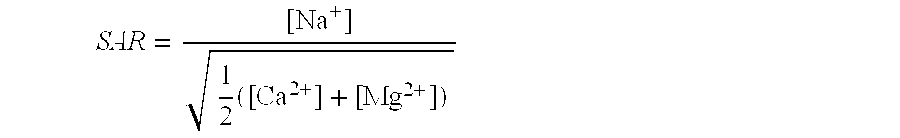

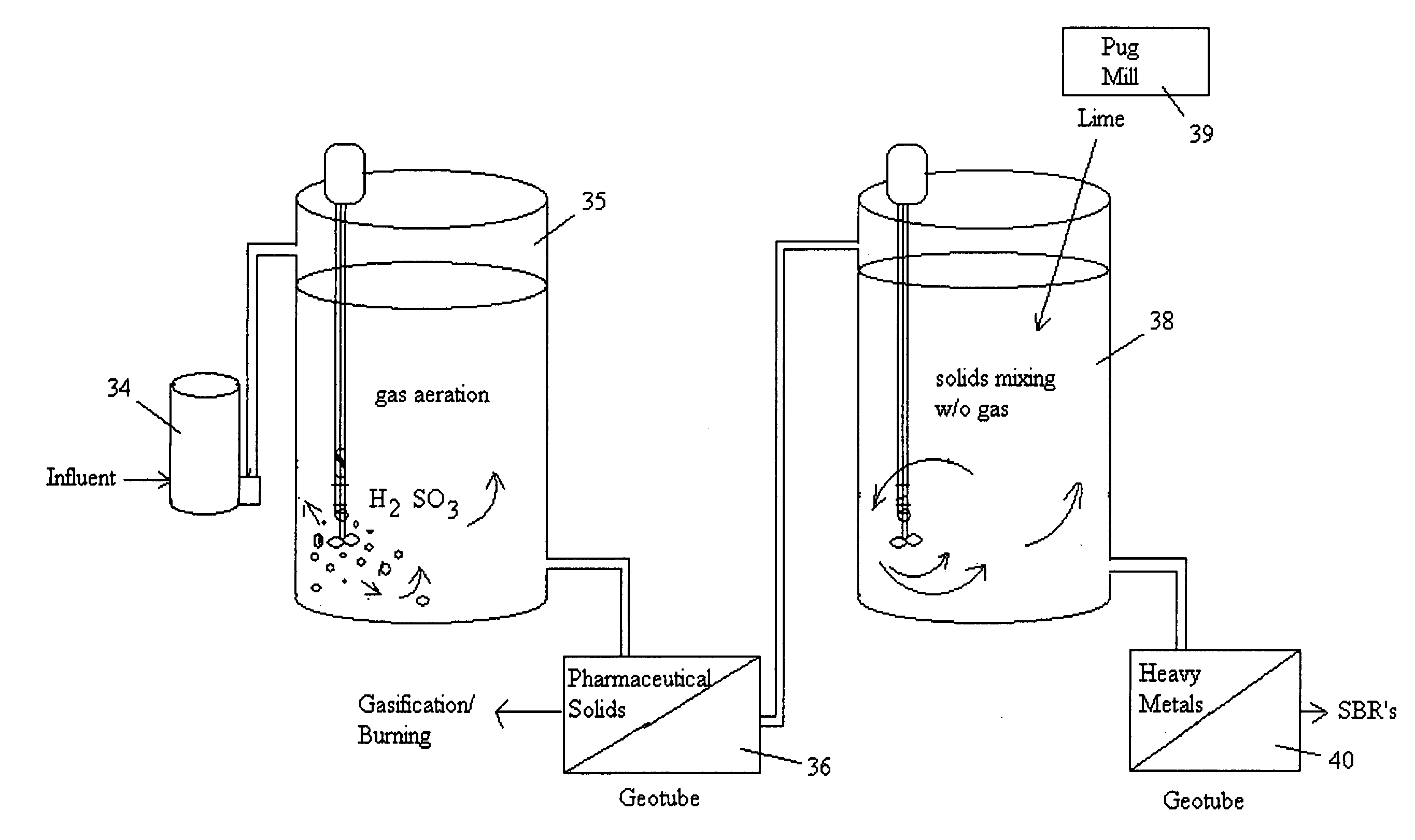

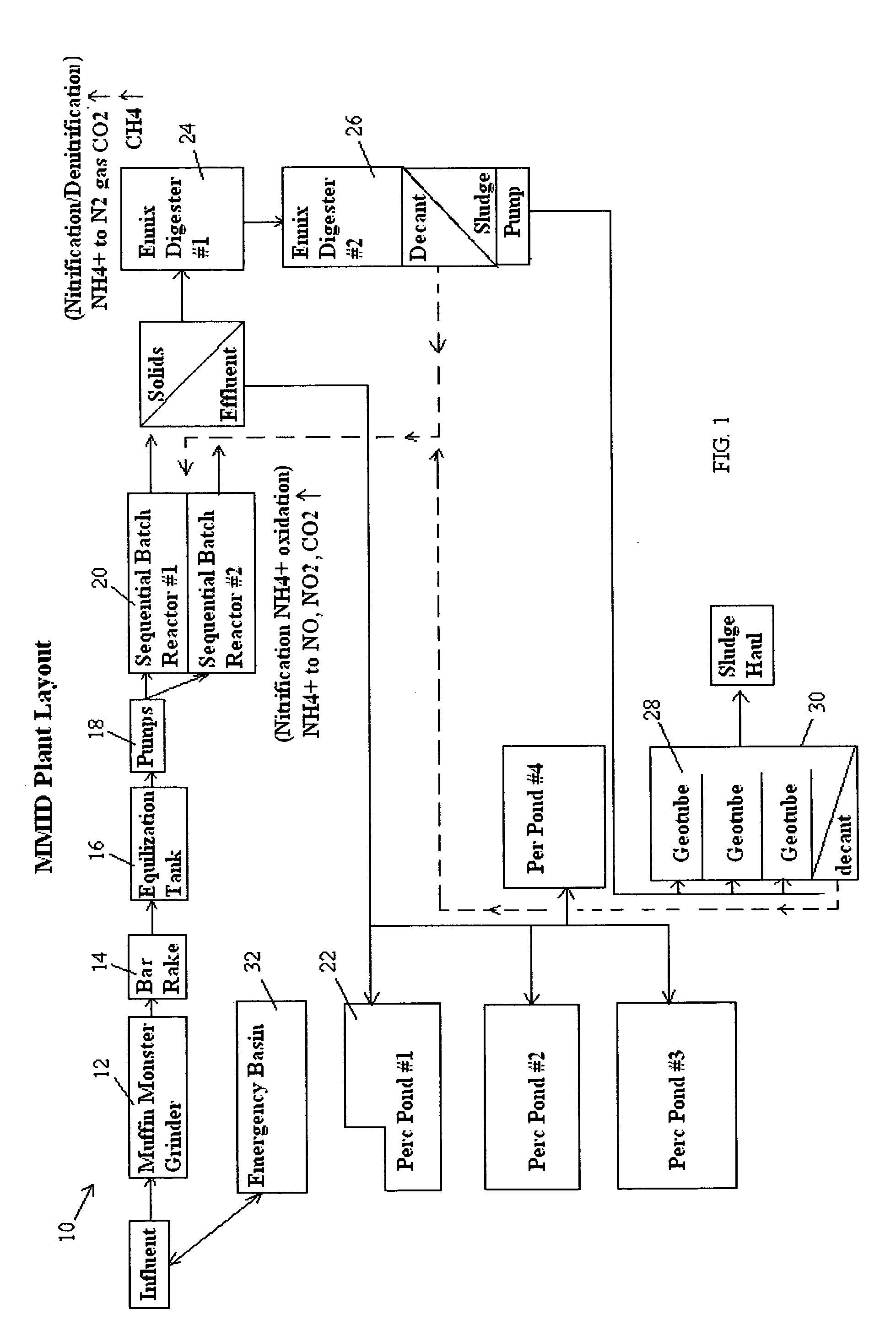

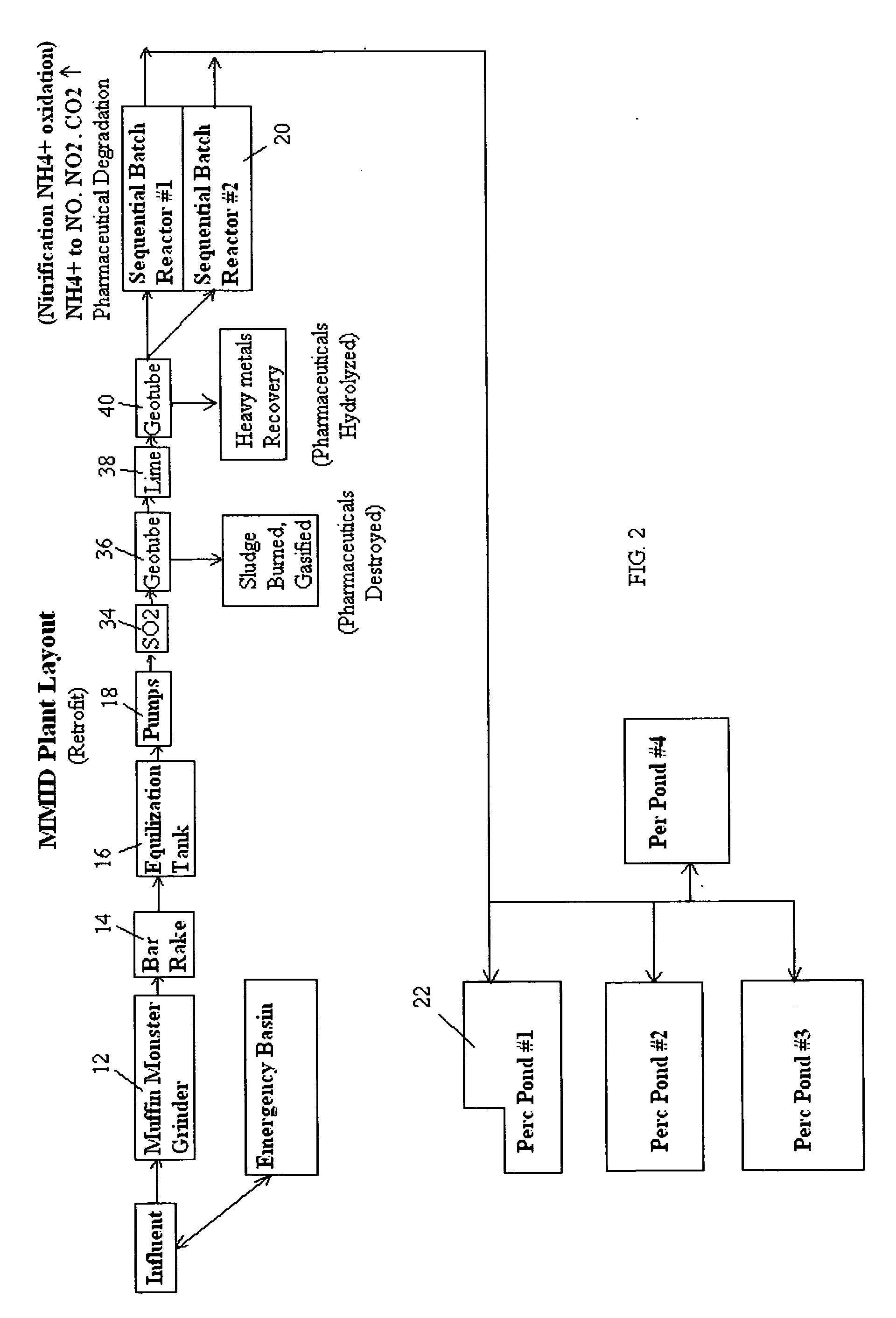

Treatment method reducing wastewater influent chemical/pharmaceuticals before biological reduction to enhance sewage treatment

ActiveUS20120006742A1Installation economyRaise the pHWater treatment parameter controlSpecific water treatment objectivesPretreatment methodWastewater

A sulfurous acid / alkalinization pre-treatment method for wastewaters to condition and remove a number of chemicals / pharmaceuticals and heavy metals before the recovered treated influent undergoes further biological reduction via anaerobic and aerobic digestion.

Owner:EARTH RENAISSANCE TECH

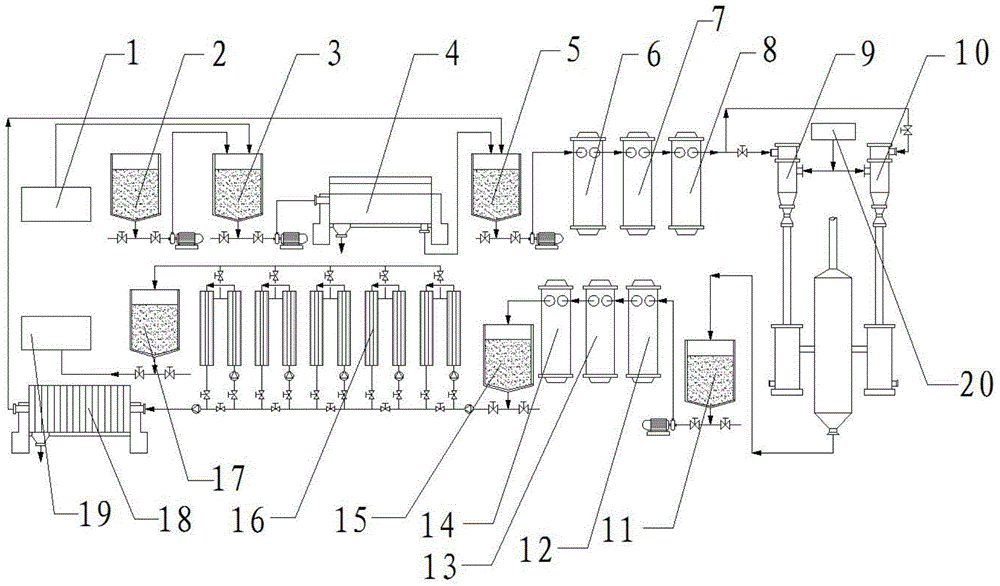

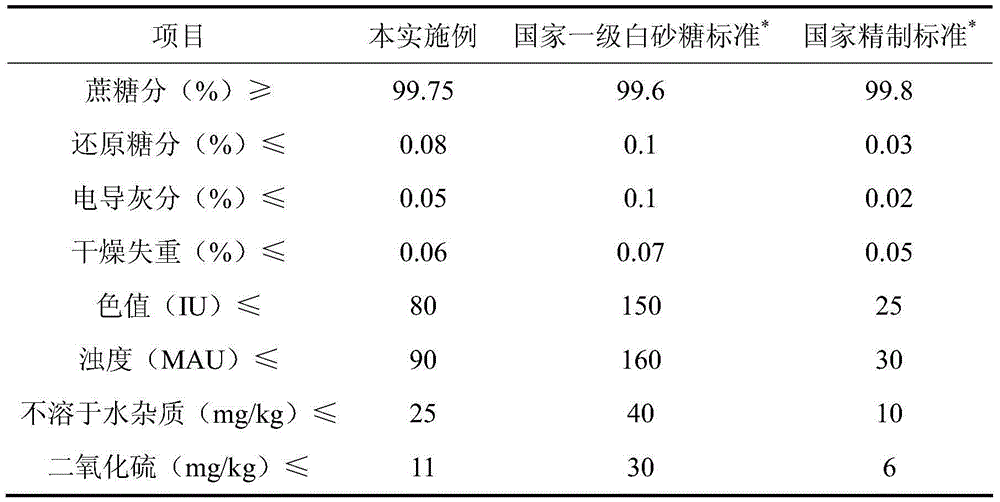

Sugar manufacture clarification process

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

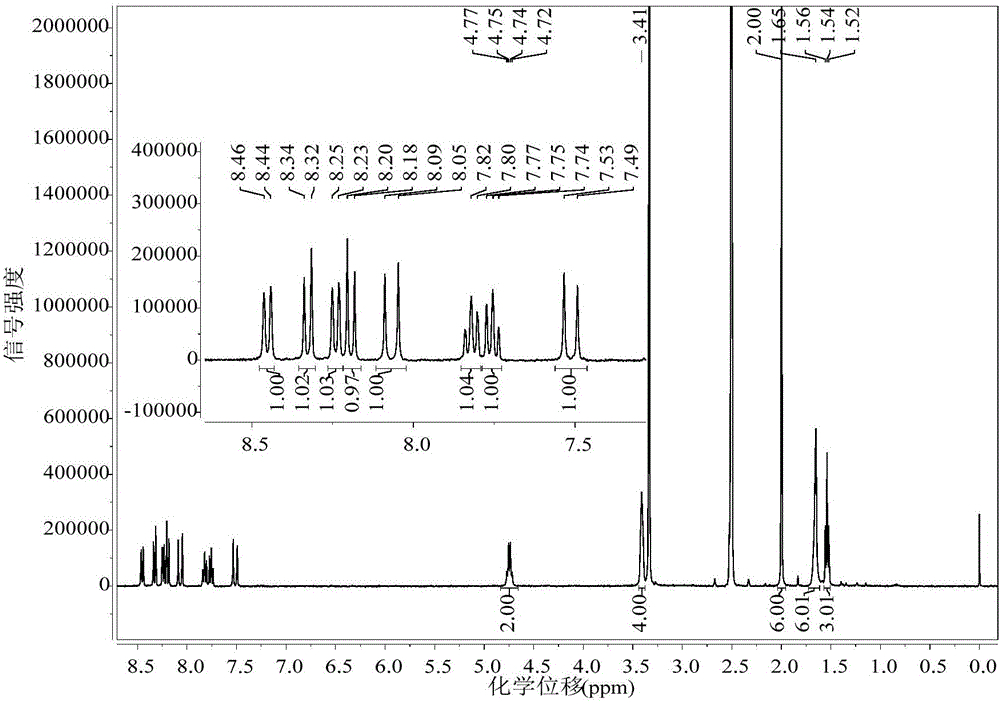

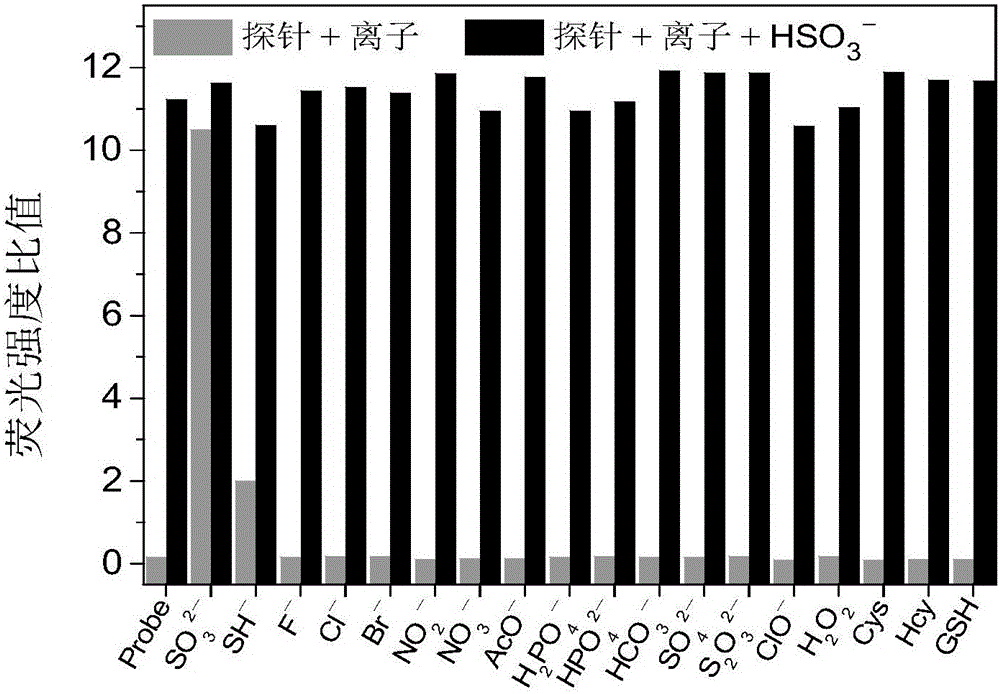

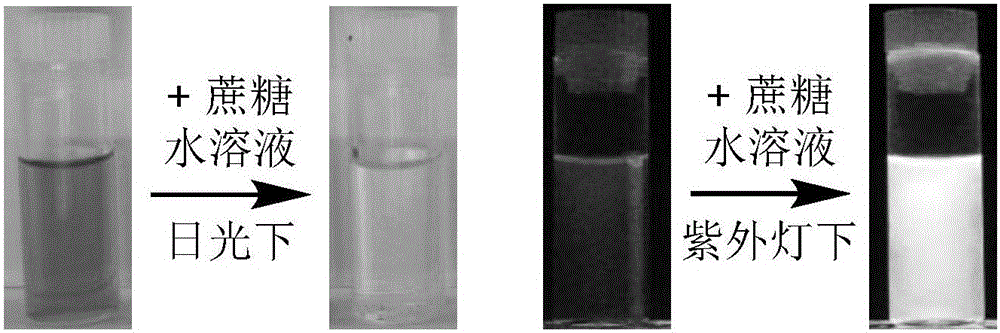

Fluorescent probe used for sulfite or bisulphate and preparation method and application thereof

InactiveCN105733566AShort response timeHigh measurement sensitivityOrganic chemistryFluorescence/phosphorescenceQuinolineLinearity

A class of fluorescent probes for the detection of sulfite (hydrogen) salts, consisting of benzoindole quaternary ammonium salts, and the molecule has the following structure: Wherein: R is a kind of in alkyl, aryl, nitro, ester group and ether group of 1-18 carbons independently or at the same time, or benzene, naphthalene, anthracene, pyrene, pyridine, pyrrole, indole, One of coumarin, fluorescein, carbazole, rhodamine, fluorene and quinoline and derivatives thereof; n is 0-20; X ‑ for F ‑ , Cl ‑ , Br ‑ or I ‑ , + is a positive charge. The advantages of the invention are: the fluorescent probe has good selectivity to sulfite, and the fluorescence intensity of the fluorescent probe solution and the concentration of sulfite are in the range of 0-8×10 ‑6 The linear relationship in the molar / liter range is good, showing good practical applicability; the fluorescent probe has a short response time, high detection sensitivity, simple molecular structure, and simple synthesis method, which makes it extremely easy for practical application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

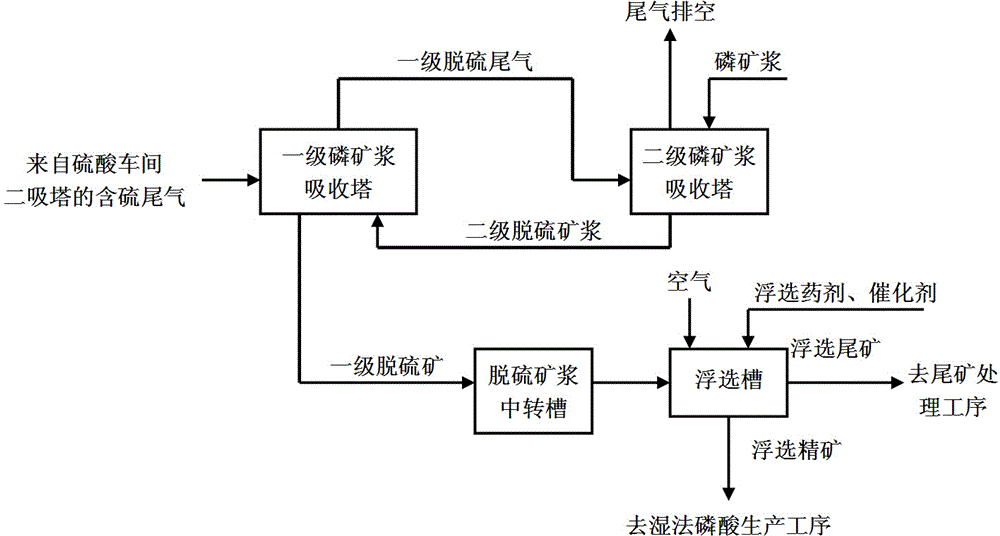

Method for removing sulfur dioxide in sulfuric acid tail gas

InactiveCN104667728AReduce manufacturing costImprove desulfurization effectDispersed particle separationSolid separationPhysical chemistryPhosphorite

The invention relates to a method for removing sulfur dioxide in sulfuric acid tail gas. The method comprises the following steps: (1) by using phosphoric ore pulp with the solid content of 20-60% as sulfuric acid tail gas, carrying out circulating scrubbing to the phosphoric ore pulp in a sulfuric acid tail gas scrubbing tower for absorbing sulfur dioxide in tail gas; and (2) absorbing sulfur dioxide in sulfuric acid tail gas at normal temperature by phosphoric ore pulp without heating or cooling, wherein most of sulphurous acid in absorption liquid is catalyzed-oxidized into sulfuric acid in an absorption process due to iron, manganese and other elements in phosphorite. The method has the remarkable effects that firstly, the production cost is low; secondly, the desulphurization effect is remarkable; thirdly, phosphorite flotation and sulphurous acid oxidization can be carried out in the same device by one step; and fourthly, the desulfuration operation is associated with the reverse flotation of the phosphorite, and wastes are turned into wealth.

Owner:KUNMING CHUAN JINNUO CHEM IND

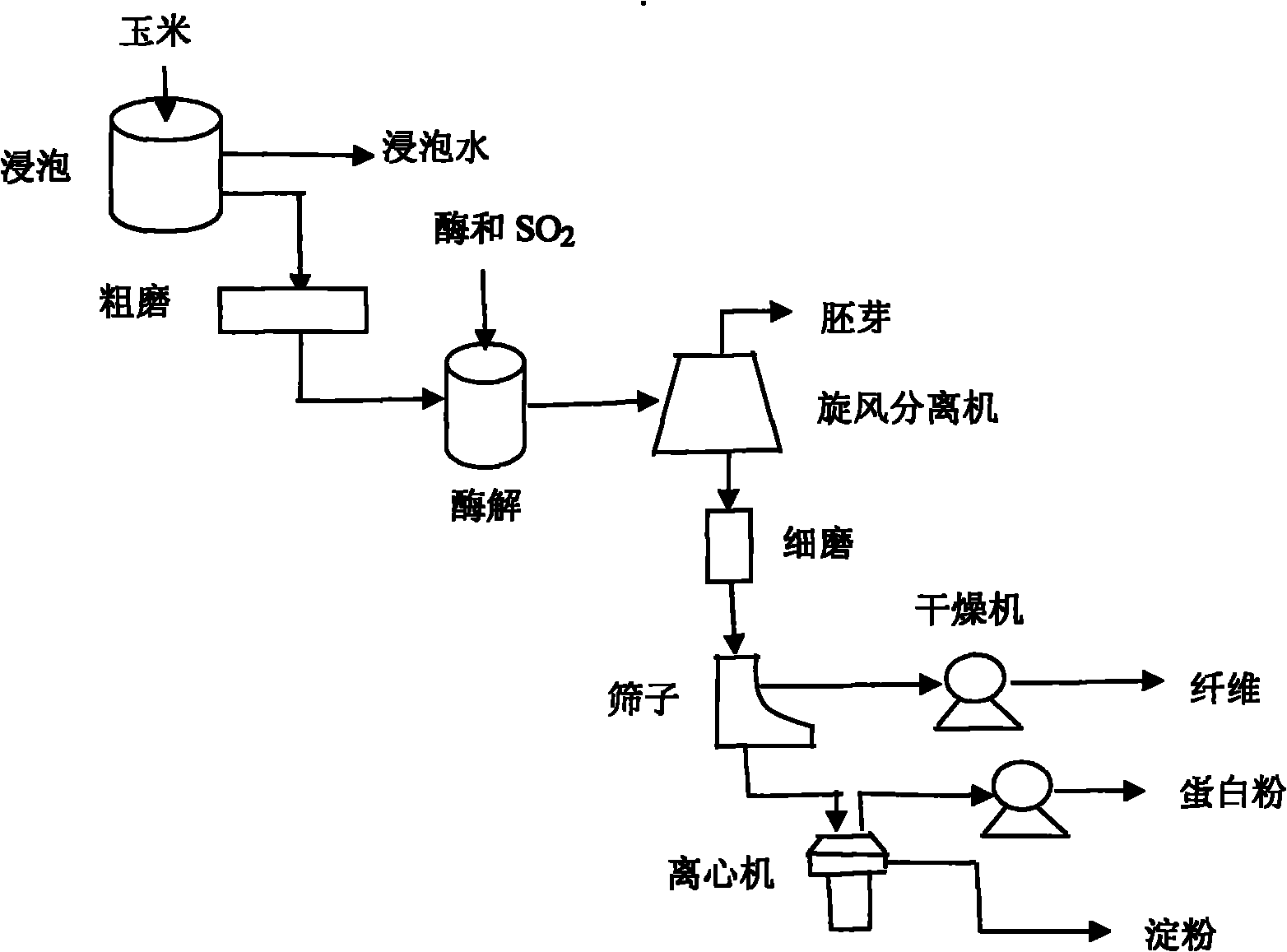

Soaking technology for preparing corn starch

The invention relates to a soaking technology for preparing corn starch, belonging to the technical field of grain deep processing. The technological steps comprise: 1. soaking: corn grains are soaked in water to soften embryos; 2. pulp grinding: the soaked corn grains are coarsely ground to obtain corn pulp; 3. enzymolysis: one of acid protease and pepsin is added in the obtained corn pulp after coarse grinding to conduct enzymolysis to the corn pulp, and SO2 is fed at the same time to mainly take the effect of inhibiting activities of microorganisms on the premise that the enzymatic activity is not affected; and 4. fine grinding, separation and drying to obtain starch finished product. Through shortening soaking time and reducing the used amount of SO2, the invention has the advantages that the corrosion of equipment, the underground water pollution, the residual sulfurous acid in the product and the like are obviously reduced, the obstacles restricting enzyme to enter endosperm to react with protein particles are eliminated, the total soaking time is only 8-12h, the soaking time is shortened, the cost is reduced, the effect is good, and the popularization value and the application value are high.

Owner:山东福田糖醇有限公司

Production method of persimmon wine

ActiveCN102604778ABright colorThere is less mold on the surfaceMicroorganism based processesAlcoholic beverage preparationAlcoholEnzyme

The invention discloses a production method of persimmon wine, which comprises the following steps: 1) choosing fresh persimmons, spraying the surface of the fresh persimmons with an alcoholic solution, and sealing to thoroughly ripen and soften the persimmons; 2) breaking to obtain a persimmon pulp, adding sulfurous acid to sterilize, and then adding activated saccharomyces cerevisiae, activatedpectase and dissolved tartaric acid, and agitating uniformly and performing preliminary fermentation; 3) separating the preliminarily fermented persimmon pulp to obtain persimmon juice, and adding tartaric acid into the persimmon juice to adjust the pH value of the persimmon juice; 4) performing secondary fermentation; 5) adjusting the alcohol degree, the residual sugar, the total acid concentration and the concentration of free sulfur dioxide, and ageing; and 6) adjusting the concentration of free sulfur dioxide, filtering, sterilizing and filling to obtain the persimmon wine. According to the production method disclosed by the invention, white granulated sugar is not added in the fermentation process, and water is not additionally added in the whole production process, so that the fermented persimmon wine is intense in taste and balanced in wine, and in addition, the smell and the taste of the persimmon wine are enriched by using grape brandy to adjust the alcohol degree of the persimmon wine.

Owner:XIAN YUSHAN WINE ESTATE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com