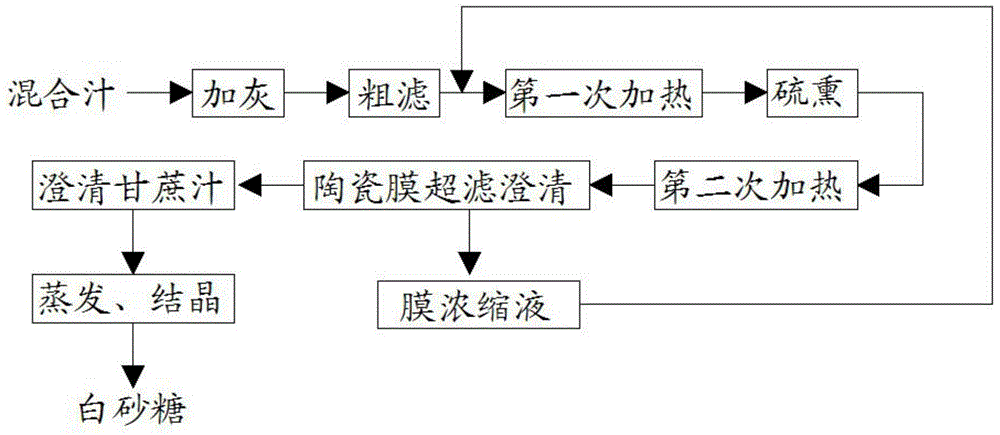

Sugar manufacture clarification process

A process, sugarcane juice technology, applied in the field of sugar clarification process, can solve the problems of high sulfur content in finished sugar, high color value of finished sugar, poor clarification effect, etc., and achieve high production capacity, high separation efficiency and less auxiliary equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

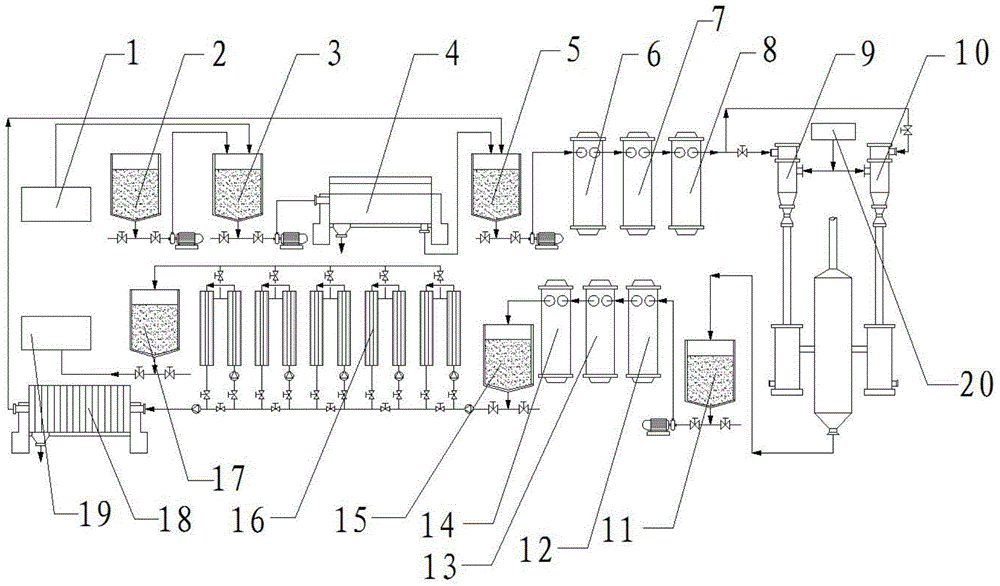

Method used

Image

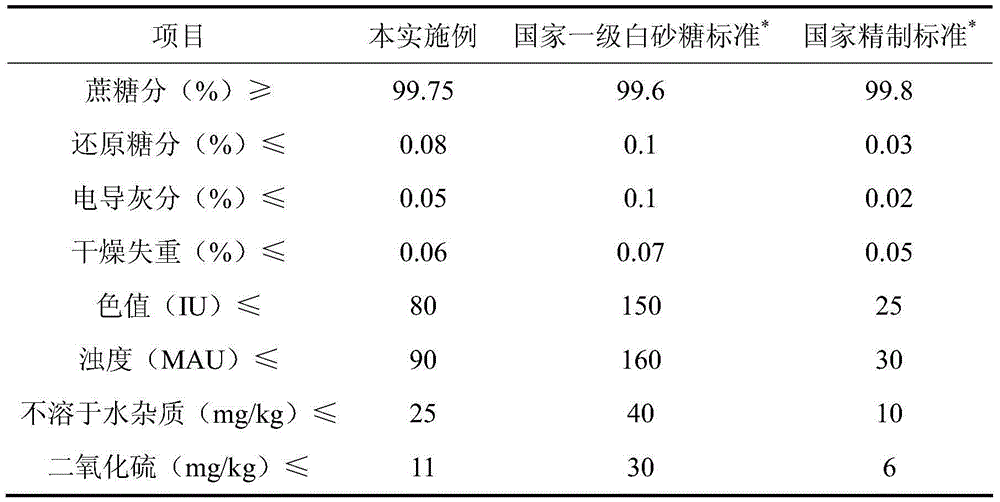

Examples

Embodiment 1

[0033] A sugar clarification process, comprising the steps of:

[0034] (1) Liming: adding milk of lime with a concentration of 8.0 ° Be to the mixed juice of the sugarcane sugar factory, adjusting the pH value of the sugarcane juice to 7.6, preventing the sucrose in the sugarcane juice from converting under acidic conditions, resulting in the loss of sucrose, and obtaining limed cane juice;

[0035] (2) Coarse filtration: Utilize a decanter centrifuge with an aperture of 50.0 μm to filter the ash-added sugarcane juice to obtain the coarsely filtered sugarcane juice;

[0036] (3) The first heating: heat the coarsely filtered sugarcane juice to 55°C with a tube-and-tube heat exchanger, which is beneficial to the sulfur fumigation process of the next step on the SO 2 The absorption of sugarcane juice is obtained by heating for the first time;

[0037] (4) Sulfur fumigation: Utilize the sulfur fumigation device to carry out sulfur fumigation to the sugarcane juice heated for th...

Embodiment 2

[0050] A sugar clarification process, comprising the steps of:

[0051] (1) Liming: adding milk of lime with a concentration of 8.5 ° Be to the mixed juice of the sugarcane sugar factory, adjusting the pH value of the sugarcane juice to 7.5, preventing the sucrose in the sugarcane juice from converting under acidic conditions, resulting in the loss of sucrose, and obtaining limed cane juice;

[0052] (2) Coarse filtration: Utilize a decanter centrifuge with an aperture of 150.0 μm to filter the ash-added sugarcane juice to obtain the coarsely filtered sugarcane juice;

[0053] (3) The first heating: heat the coarsely filtered sugarcane juice to 65°C with a tube-and-tube heat exchanger, which is beneficial to the sulfur fumigation process of the next step on the SO 2 The absorption of sugarcane juice obtained by heating for the first time;

[0054] (4) Sulfur fumigation: Utilize the sulfur fumigation device to carry out sulfur fumigation to the sugarcane juice heated for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com