Patents

Literature

351results about "Sugar juice boiling/evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrialized production method of primitive brown sugar

ActiveCN103993106ARetract lowPromote recoverySugar crystallisationPurification by physical meansSlagMicrofiltration

The invention discloses an industrialized production method of primitive brown sugar. The method comprises the steps of with cane sugar factory mixed juice as a raw material, adding lime milk to regulate the pH value to 5.8-6.6; sieving and filtering; heating, floating and removing floating slag; removing impurities through microfiltration; evaporating and concentrating to obtain syrup with the concentration of 60-65-degree Bx; boiling sugar at the temperature of 125-130 DEG C at normal pressure to obtain syrup with the concentration of 95-98-degree Bx; sanding and forming to realize industrialized production of the primitive brown sugar. When used for producing brown sugar, the industrialized production method disclosed by the invention is safe and reliable in production process, high in mechanization degree, capable of realizing large-scale production of the primitive brown sugar and stable in product quality.

Owner:GUANGXI UNIV +1

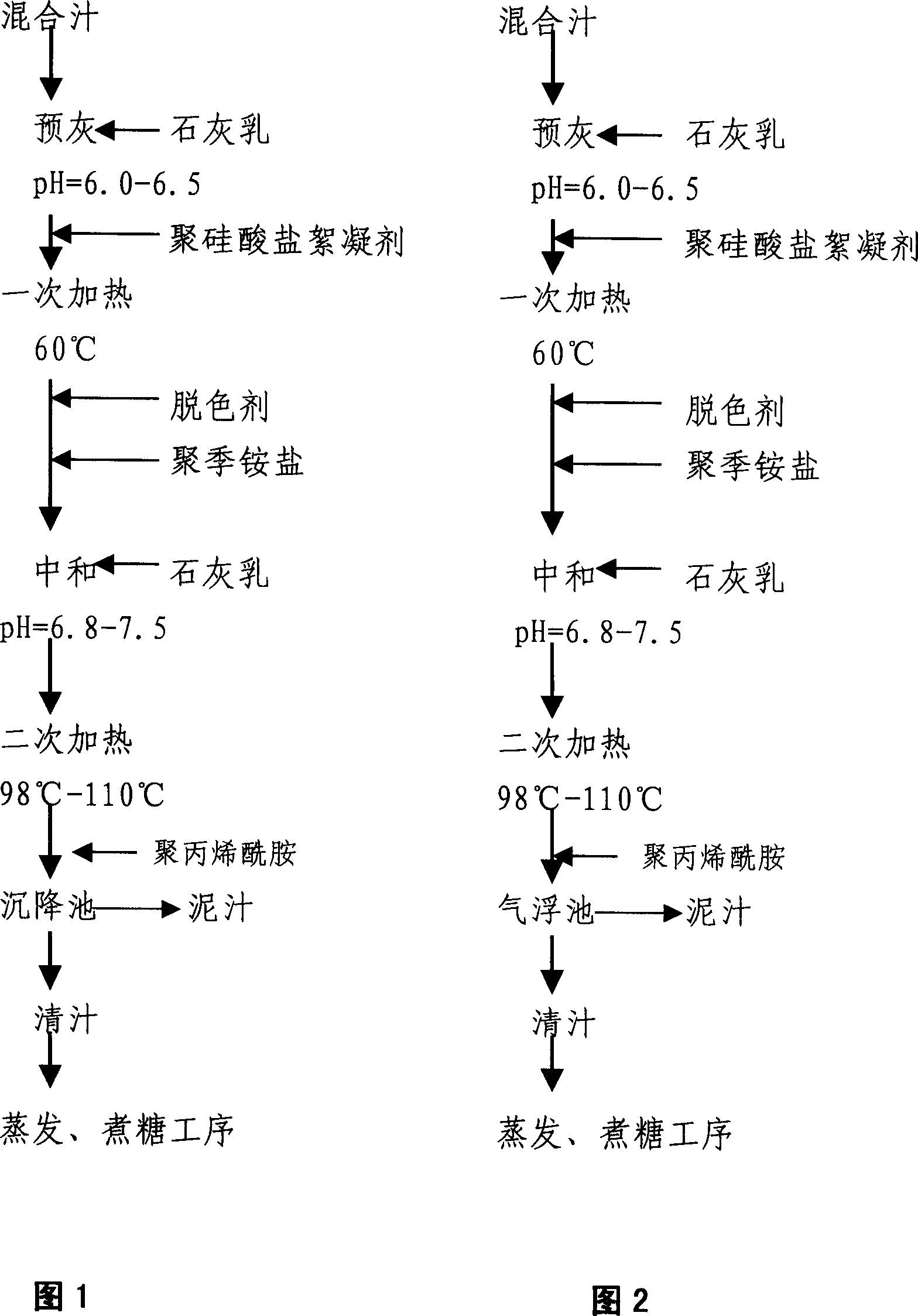

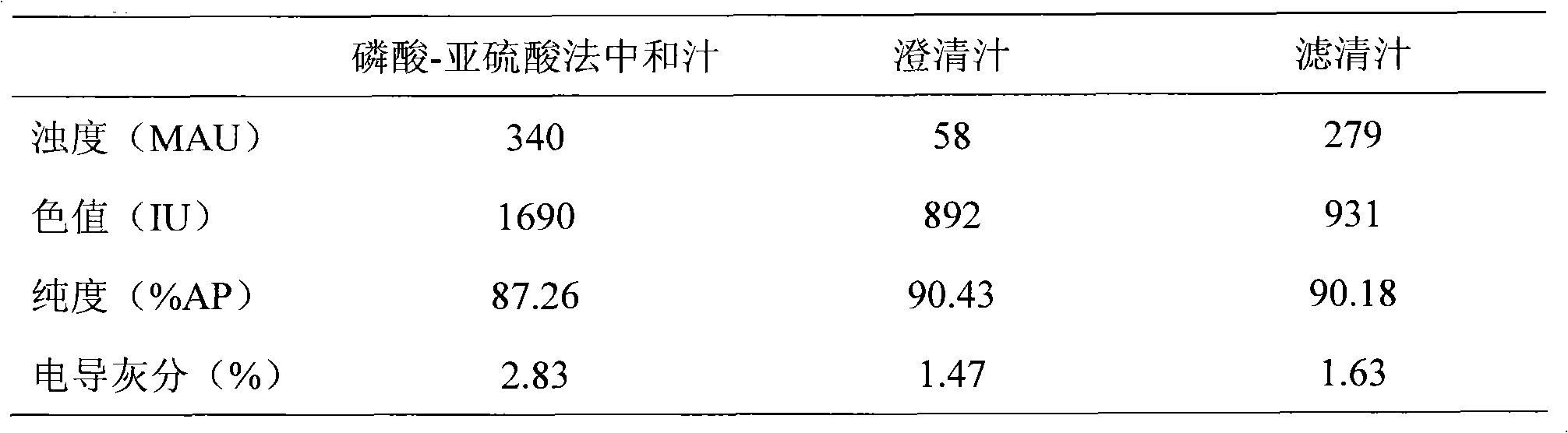

New clarification technique for refining sugar from sugar cane

InactiveCN101003842AHigh purityShort processPurification using alkaline earth metal compoundsSugar juice boiling/evaporationSulfurPhosphoric acid

This invention provides a new process for clarifying sugar produced from sugarcane. The process comprises: (1) adding inorganic decolorant, poly (quaternary ammonium salt), polysilicate coagulant and polyacrylamide into sugarcanejuice, heating, adding lime suspension to neutralize, heating, and separating clear juice and mud slurry in a precipitation pool or a flotation pool; (2) evaporating the clear juice, concentrating, boiling, crystallizing, and separating to obtain sugar product. Compared with traditional phosphoric acid / sulphurous acid process, the process has such advantages as simple process flow, light clear juice color, high sugar quality, saved phosphoric acid resources, and clean production.

Owner:刘和清

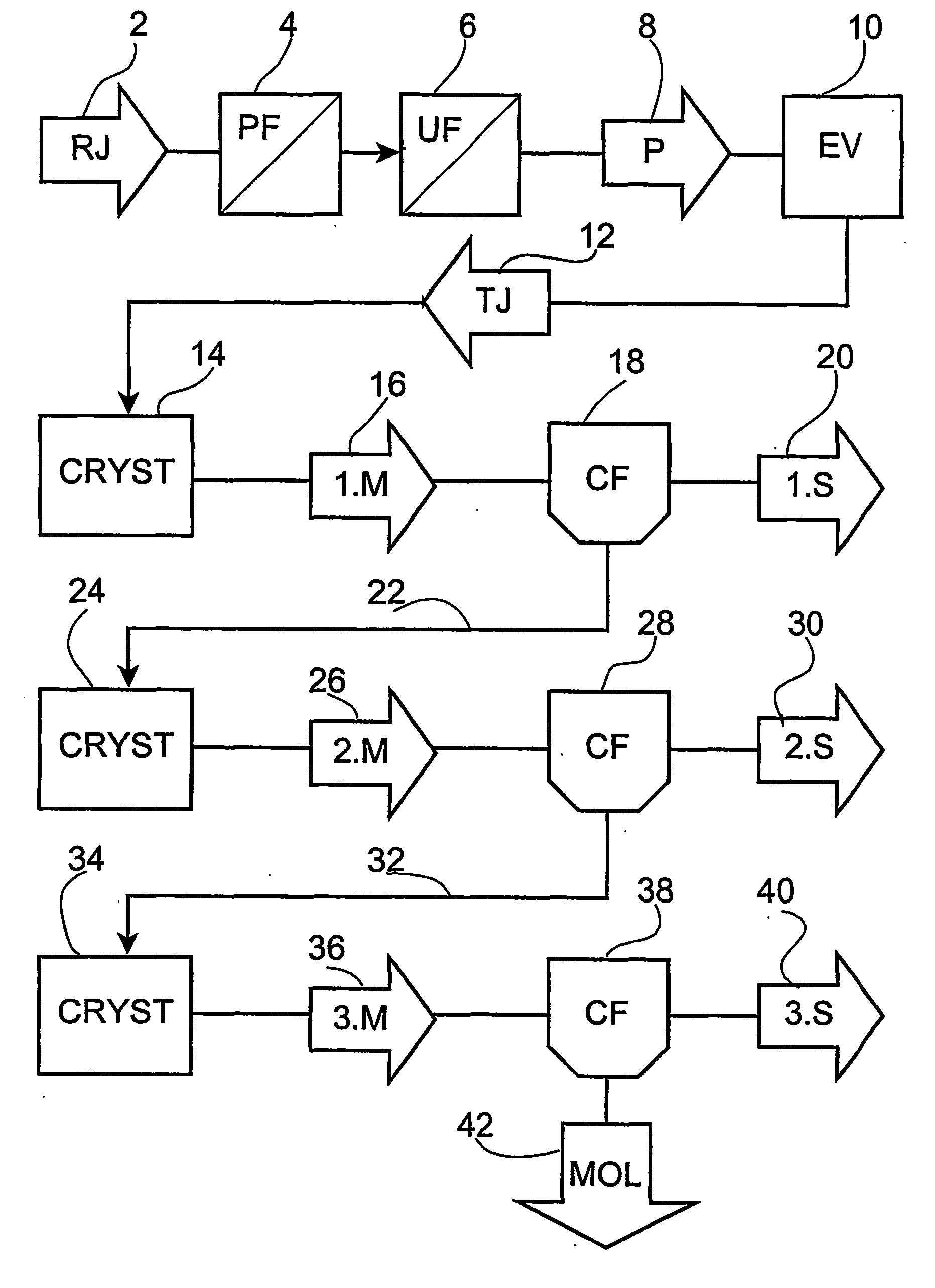

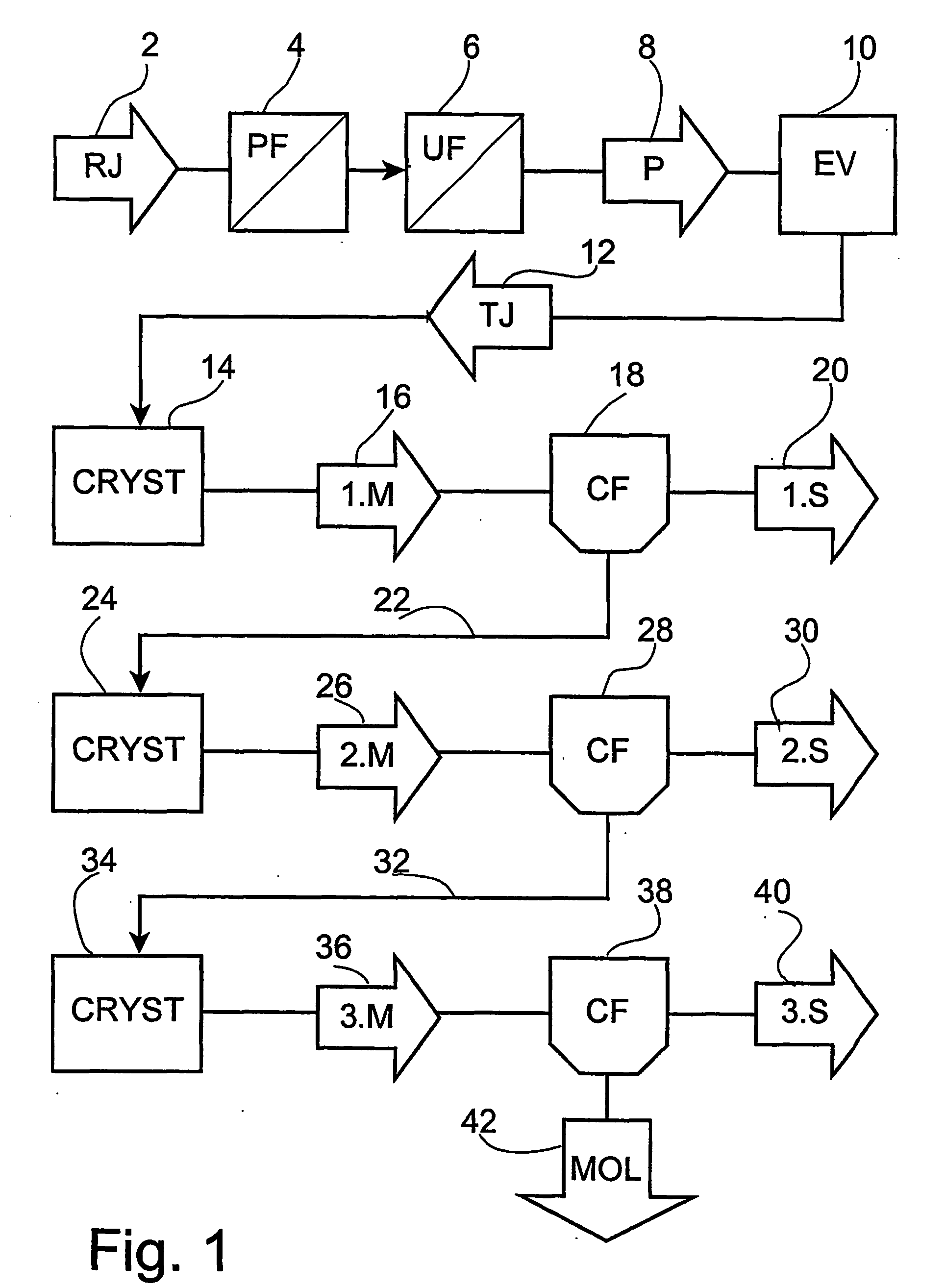

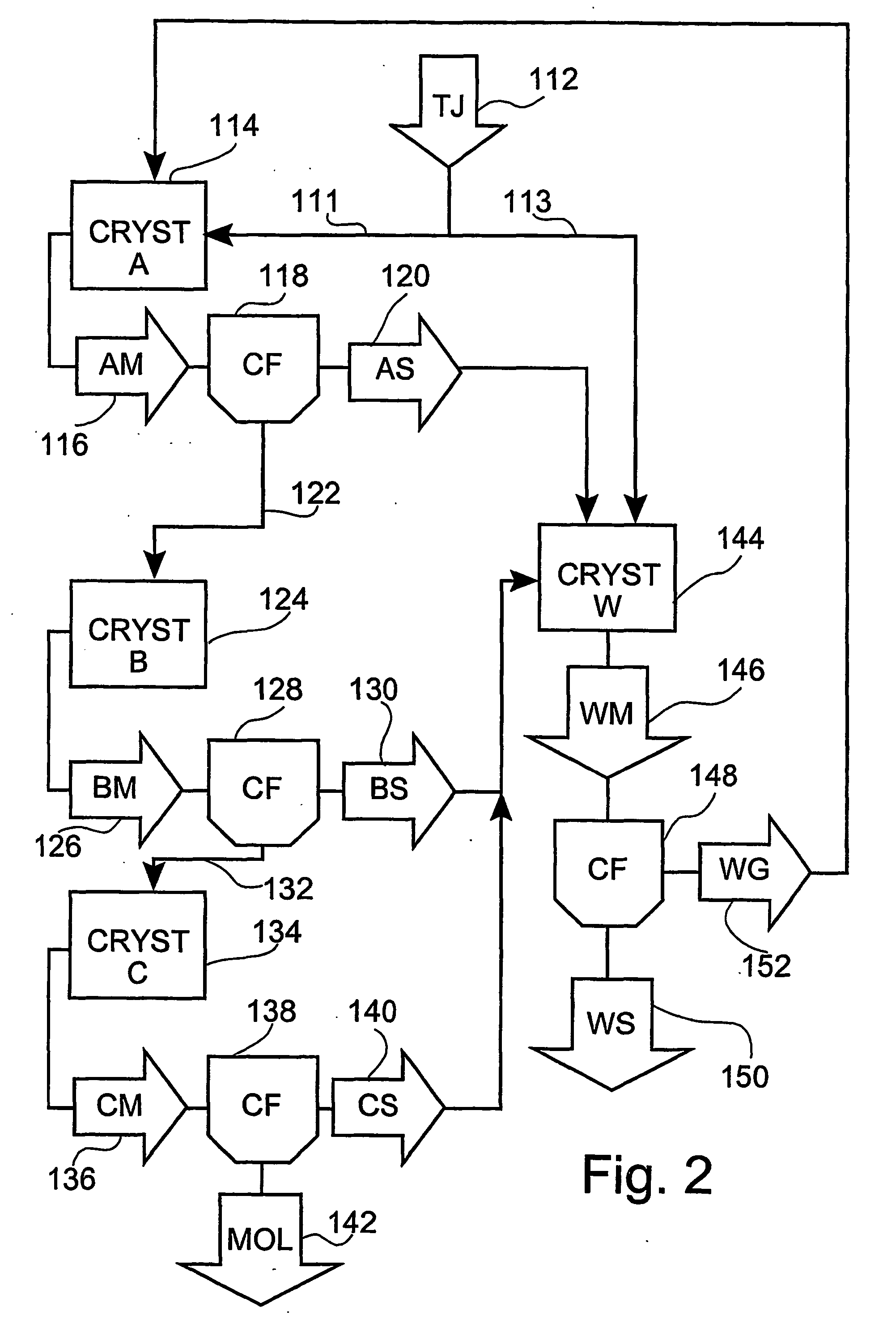

Process for the preparation of white and brown sugar from sugar beets

InactiveUS20040231663A1Avoid the needEasy to mergeSugar productsSugar crystal separationBiotechnologySugar

A process for the preparation of white and brown sugar from raw diffuser beet juice. The juice is purified by membrane filtration at 70-95° C. on a filter having a molecular weight cut-off between 2,000 and 500,000 Dalton and evaporated to a dry matter content of between 60 and 80% by weight under vacuum to a thick juice. A conventional multi-step evaporative crystallisation of the thick juice gives crops of white and brown sugar crystals. The brown sugar obtained have valuable organoleptic properties.

Owner:AS DE DANSKE SUKKERFABRIKKER

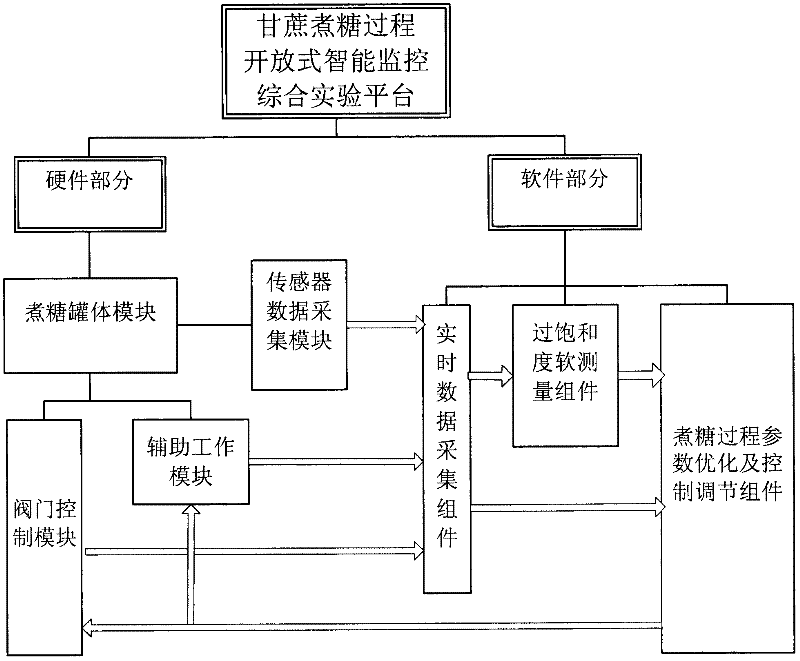

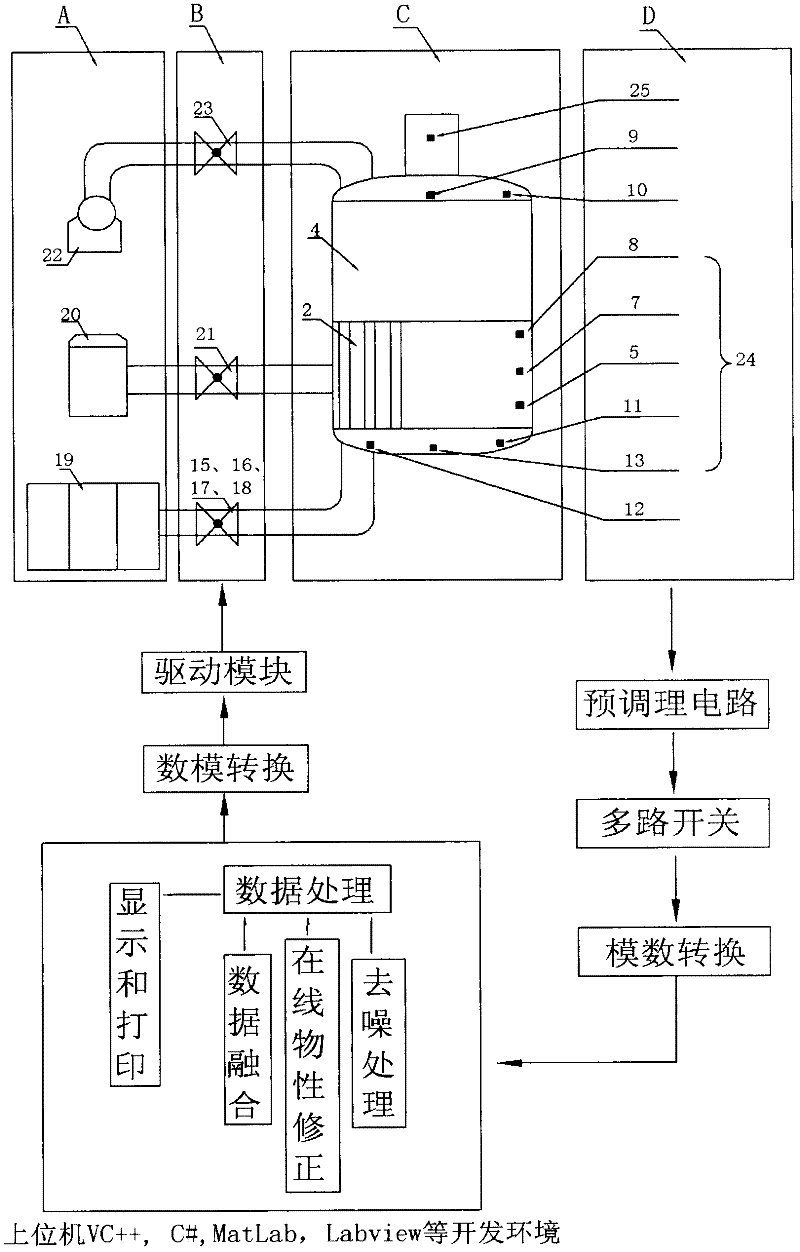

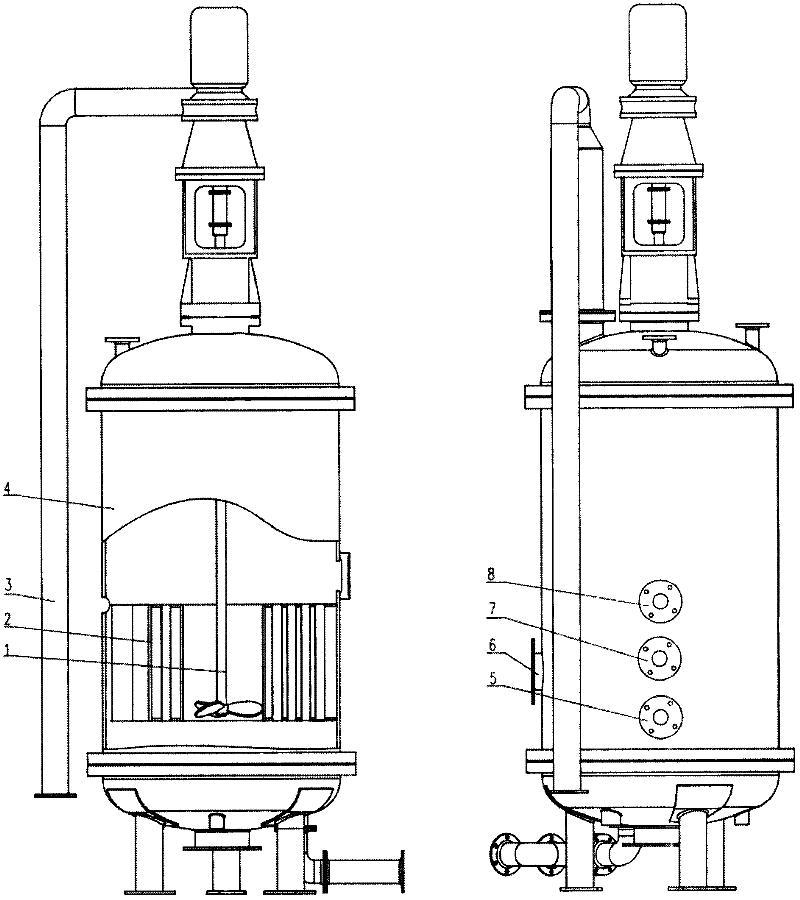

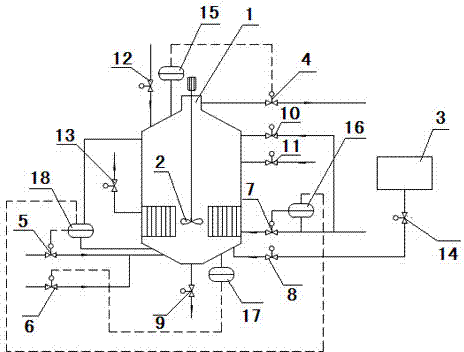

Open type intelligent monitoring comprehensive experiment platform in sugarcane sugar boiling process

ActiveCN102505048AReduce volumeLess materialSugar juice boiling/evaporationTotal factory controlArea networkReal-time data

The invention relates to an open type intelligent monitoring comprehensive experiment platform in the sugarcane sugar boiling process. The open type intelligent monitoring comprehensive experiment platform consists of a hardware part and a software part, wherein the hardware part comprises a sugar boiling tank body module, an auxiliary work module, a sensor data collecting module and a valve control module, the software part comprises a real-time data collecting assembly, a supersaturation degree soft measuring assembly and a sugar boiling process dynamic parameter optimizing and control regulation assembly, and the hardware part and the software part are connected with each other through a Mod bus and a controller area network (CAN) bus. The platform is used for scientific research, various kinds of monitoring method optimizing research are developed under various actual work conditions in the sugar boiling process, and the practical monitoring technology is provided in the actual sugar boiling process. The experiment platform can also be used as a comprehensive experiment teaching platform for students specialized in measuring control and sugar making, and relative comprehensive and design research teaching method research is developed.

Owner:GUANGXI UNIV

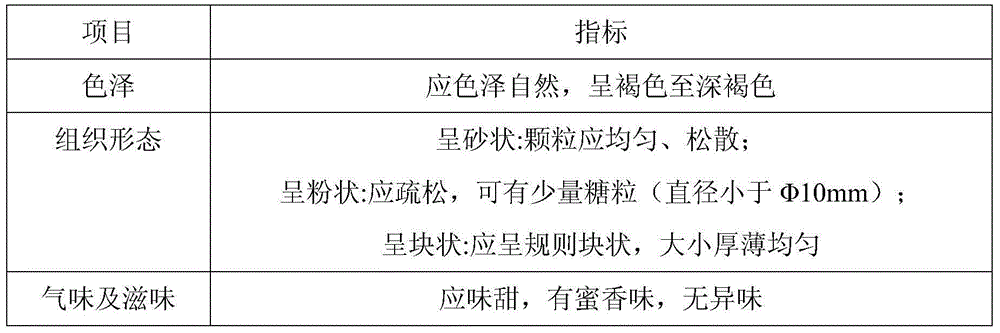

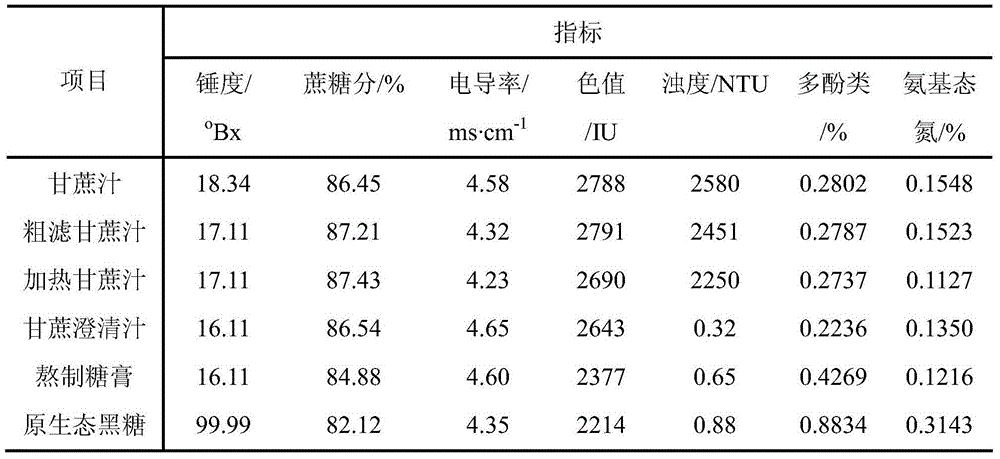

Originally ecological black sugar processing method

ActiveCN104805225ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

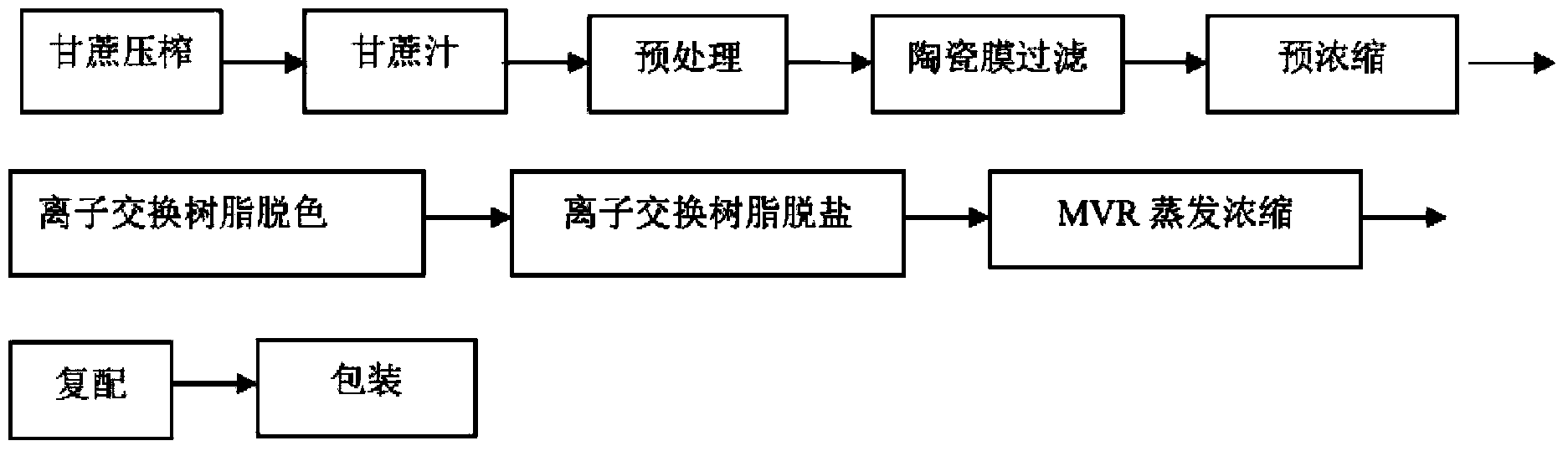

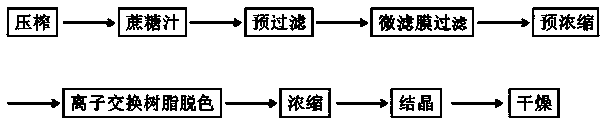

Production technique and device of directly edible edible syrup

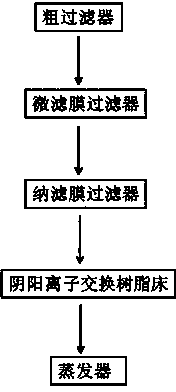

ActiveCN103710469ALow chroma valueHigh desalination ratePurification using ion-exchange materialsPurification by physical meansSucroseMicrofiltration membrane

The invention relates to a production technique and device of directly edible syrup. The method comprises the following steps: pressing sugar cane with a juice press to obtain a sugar cane juice; prefiltering the sugar cane juice through a coarse filter, and filtering with a microfiltration membrane to obtain a sucrose juice clear solution; concentrating the sucrose juice clear solution through a nanofiltration membrane to obtain a concentrated solution; sending the concentrated solution into a first ion exchange resin tower to obtain a first permeation solution; sending the first permeation solution into a second ion exchange resin tower to obtain a second permeation solution; and concentrating the second permeation solution in an evaporator to obtain a refined concentrated solution, adding additives and uniformly mixing to obtain the syrup. The product produced by the production technique provided by the invention has the advantages of low chromatic value, high desalting rate and high yield.

Owner:JIANGSU JIUWU HITECH

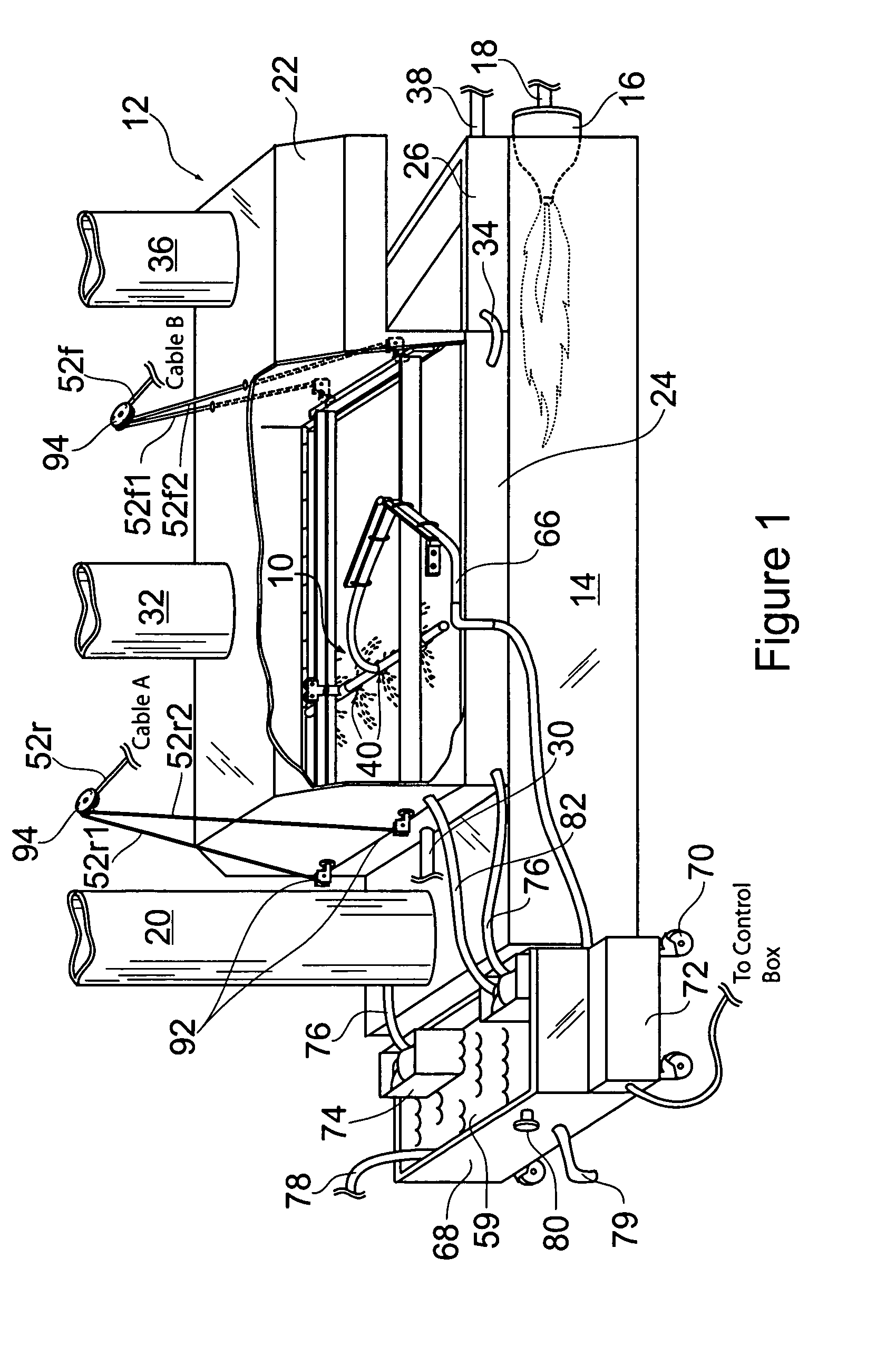

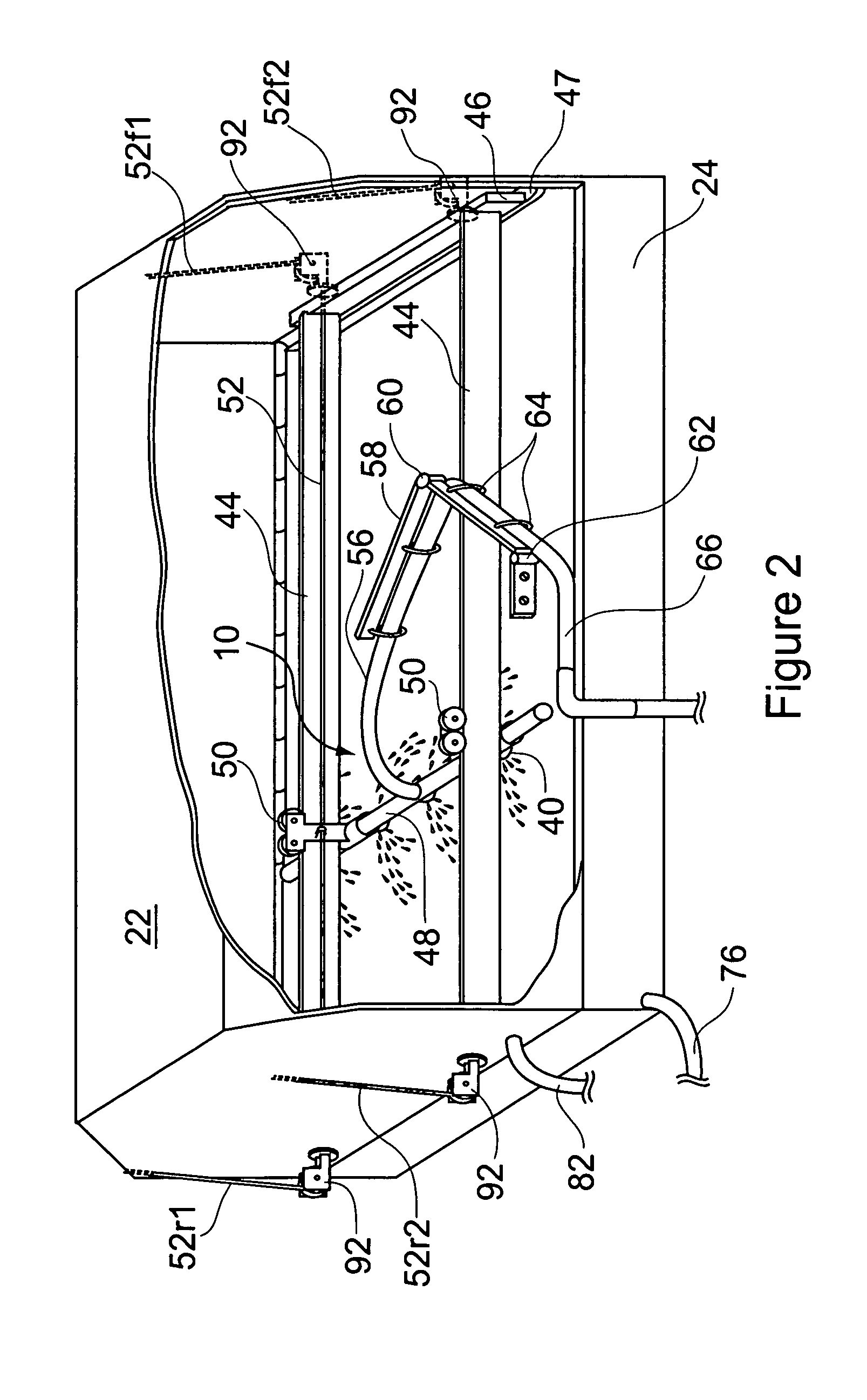

Centrifugal separation apparatus and method of using the same

InactiveUS6267899B1Water/sewage treatment by centrifugal separationSugar crystal separationCentrifugationEngineering

Centrifugation separations apparatus including centrifugation means having an inlet, a liquids discharge and a solids discharge, a deflector operatively associated with the solids discharge, wherein the solids discharge is adapted to operatively discharge solids being discharged from the centrifugation means at a trajectory and the deflector is adapted to interrupt the trajectory to decelerate and change the direction of travel of the solids, or wherein the deflector is operatively associated with the solids discharge and cooperable with solids being discharged from the solids discharge whereby buildup of solids on the deflector is substantially prevented, or wherein the solids discharge includes a lip configuration which causes the trajectories of the discharging crystals to be relatively independent of their size and / or their residual syrup / moisture content, or including support means, such as a spider like construction having one or more webs substantially parallel to the angular motion of the solids being discharged from the solids discharge, operatively supporting the centrifugation means whereby the impact area for solids discharged from the solids discharge may be minimized, or including blending means operatively associated with the solids discharge for blending solids discharged from the centrifugation separations apparatus.

Owner:STG FCB HLDG

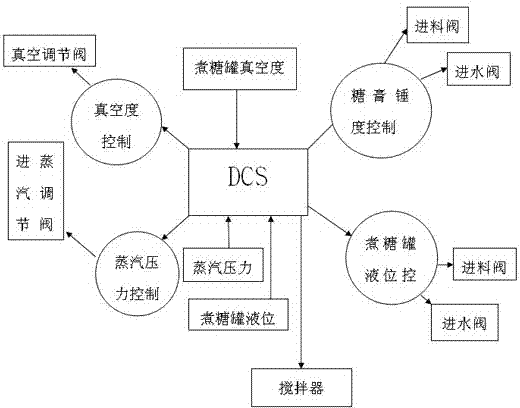

Sugar boiling automatic control device

ActiveCN102925593AImprove reliabilityImprove efficiencySugar juice boiling/evaporationThermodynamicsAutomatic control

The invention provides a sugar boiling automatic control device and relates to a device for controlling several main parameters of a sugar boiling pot automatically. The sugar boiling automatic control device comprises a vacuum control module, a massecuite brix control module, a heating steam pressure control module and a sugar boiling pot liquid level control module. The vacuum control module measures vacuum of the sugar boiling pot through a transmitter and uses a distributed control system (DCS) for regulating a condenser inlet circulating water regulating valve so as to control the vacuum. The massecuite brix control module measures brix of syrupy through a brix meter and controls a feed valve, a water inlet valve and sugar boiling time through the DCS. The heating steam pressure control module measures steam pressure of the sugar boiling pot through a pressure transmitter and uses a DCS for controlling amount of heating steam entering the sugar boiling pot. The sugar boiling pot liquid level control module measures liquid level of the syrupy of the sugar boiling pot through a liquid level transmitter and controls a feed valve and a water inlet valve of the sugar boiling pot through the DCS. The sugar boiling automatic control device achieves full-automatic sugar boiling, effectively improves reliability and economic benefit of sugar boiling control, greatly reduces consumption of water and steam, reduces faulty operation, lowers accident rate, and improves sugar output.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

Small brown sugar preparation method

InactiveCN106435043AGreat tastePure tasteSugar productsSugar juice boiling/evaporationFlavorBoiling process

Provided is a small brown sugar preparation method. The method comprises the steps of squeezing sugar cane juice, boiling the juice in a series of pots, controlling the flame in the direction air stove, granulating, and putting the granule sugar in different models for cooling and shape forming to acquire the purely manual brown sugar of different flavors and different shapes. The detailed method comprises the steps of firstly preparing sugar cane juice, then boiling the sugar can juice, at last conducting the shape forming of the brown sugar. The method applies the series pots and direct air stove. The series pot uses five consecutive pots to boiling the sugar cane juice in sequence for multiple cycles. The direct air stove is used to control the heating degree and heating duration to make the heating process to be stable and orderly in the boiling process. The small brown sugar of various shapes processed by various models is both beautiful and attractive. Different spices are positioned under each model to greatly enhance the mouthfeel of the small brown sugar in the tea serving.

Owner:何启华

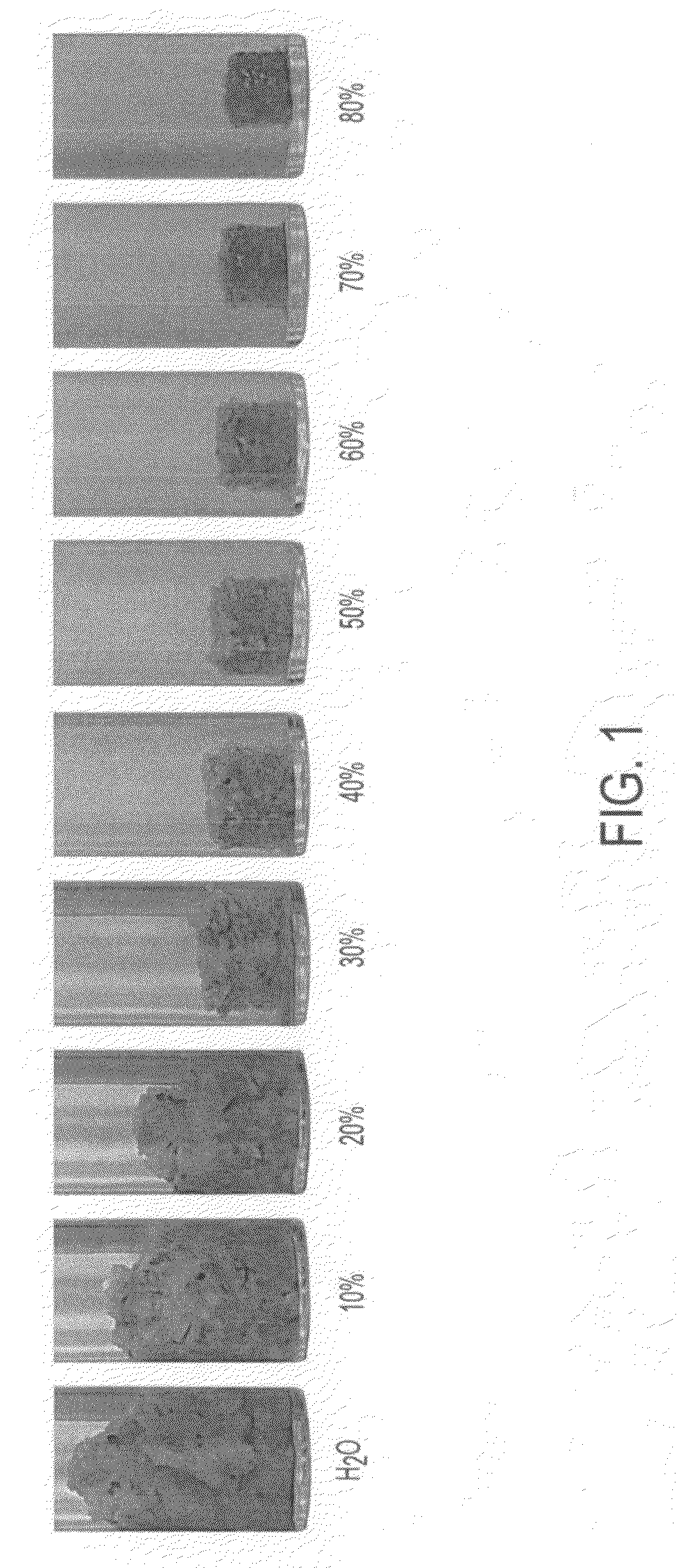

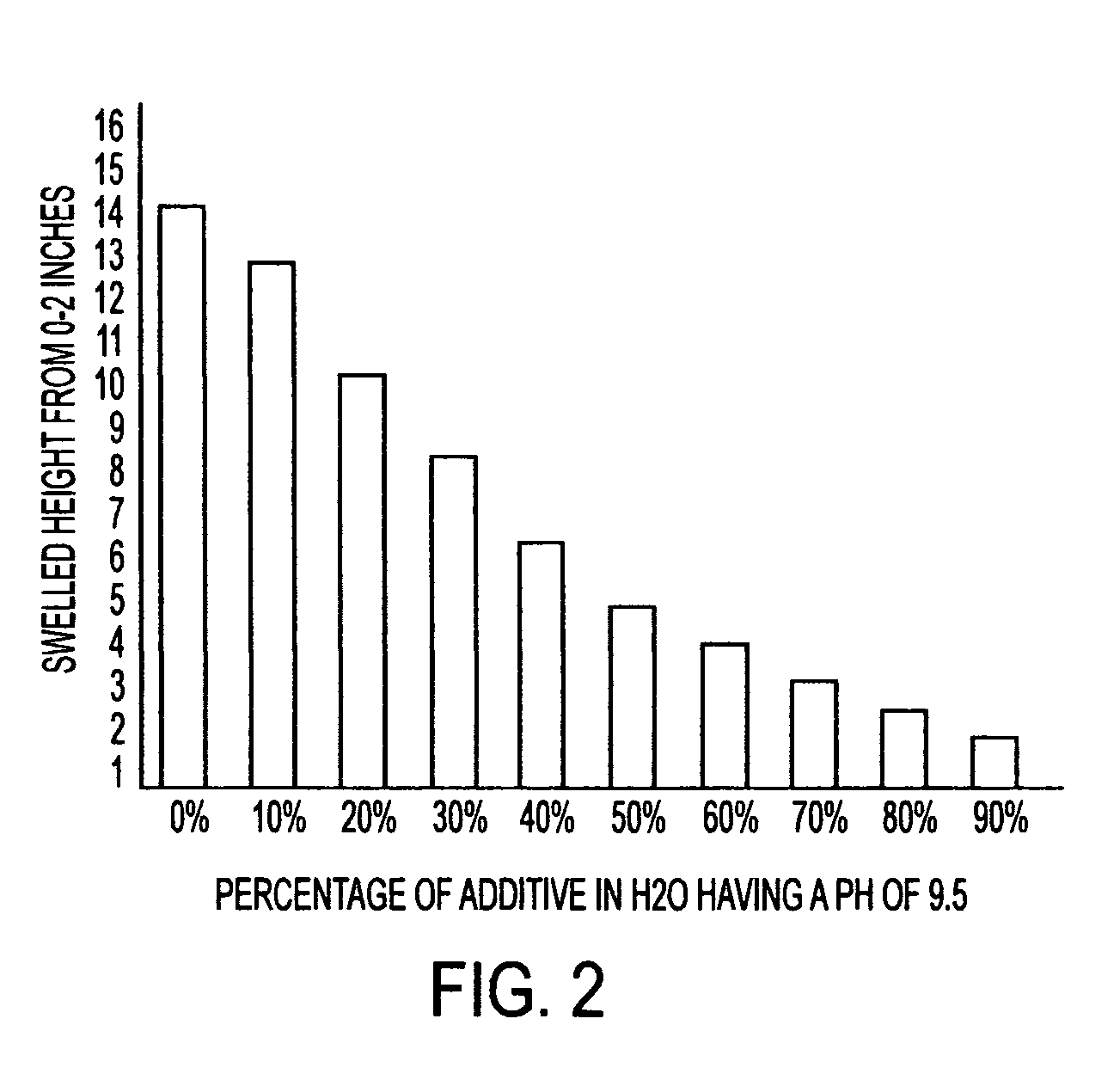

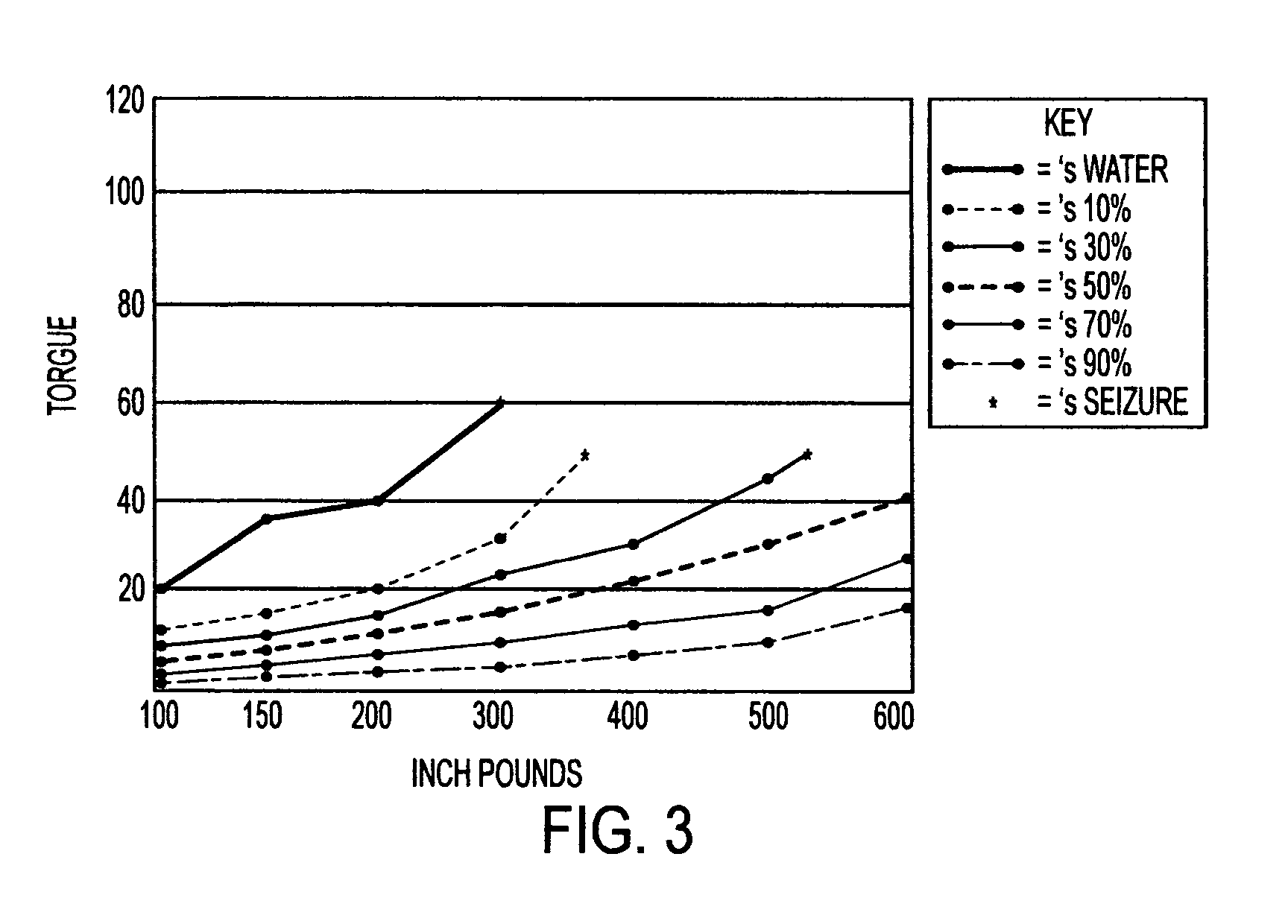

Drilling fluid additive containing syrups

ActiveUS7763570B1Present inventionReduce coefficient of frictionSugar productsFlushingLiquid mediumGolden syrup

A drilling fluid additive is provided and the additive consist of: syrup solids in the amount from about 30 to about 90% by weight of total volume of the additive and a liquid medium in the amount from about 10 to about 70% by weight of total volume of the additive, said syrup solids are derived from a group consisting essentially of agave syrup, barley syrup, sugar syrup, beets syrup, birch syrup, rice syrup, cane syrup, chocolate syrup, coconut syrup, corn syrup, date syrup, fruit syrup, golden syrup, high fructose corn syrup, karo syrup, citrus fruit syrup, maple syrup, molasses, Muscavado syrup, palm syrup, rice syrup, sorghum syrup, Turbinado syrup, vanilla syrup and mixtures and blends thereof.

Owner:MUD MASTERS ACQUISITION CORP

Sugar manufacture clarification process

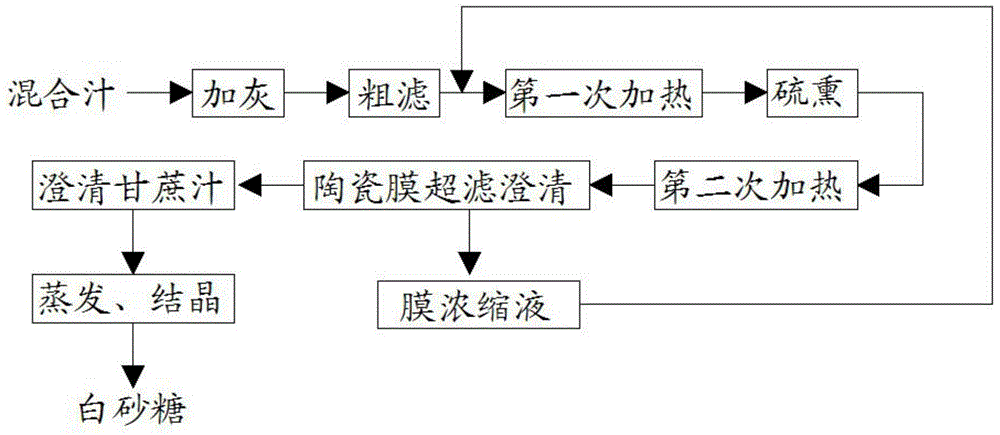

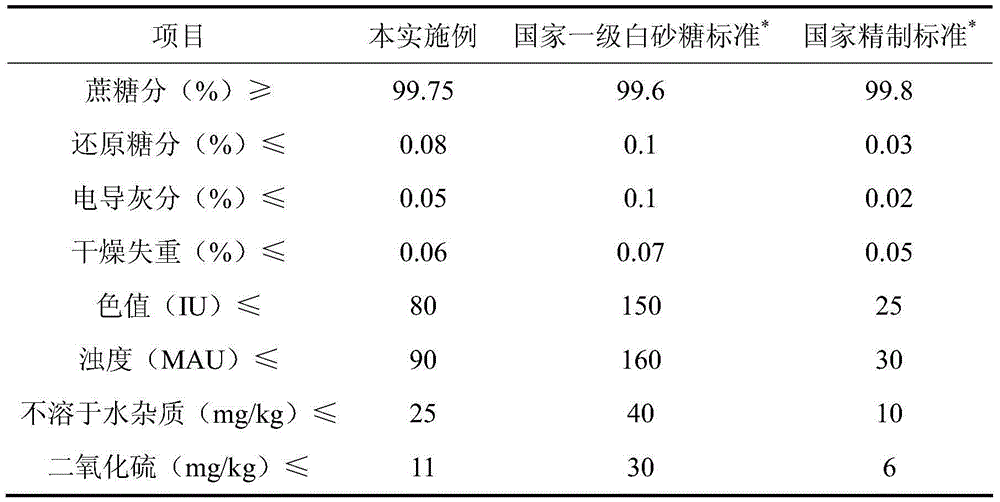

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

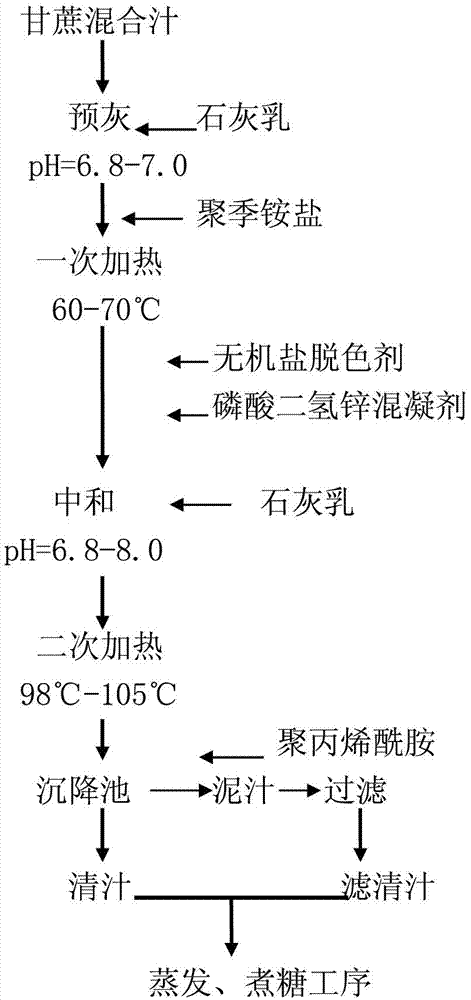

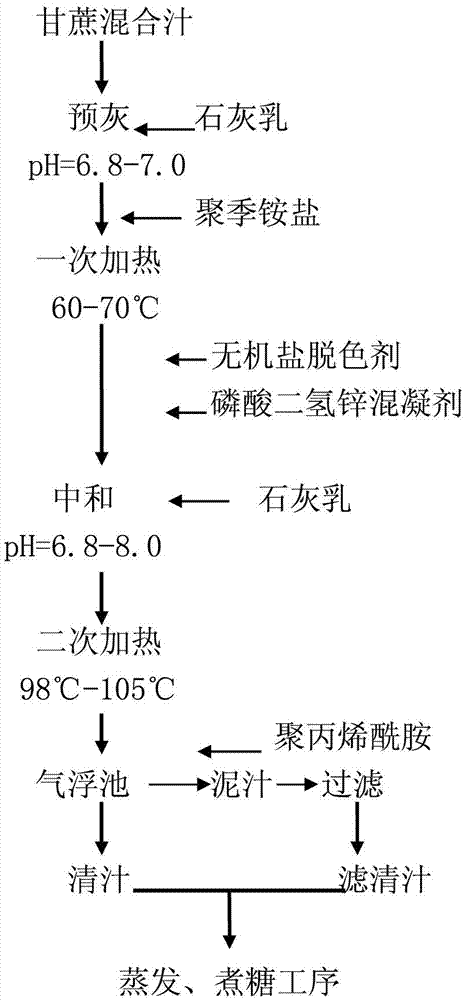

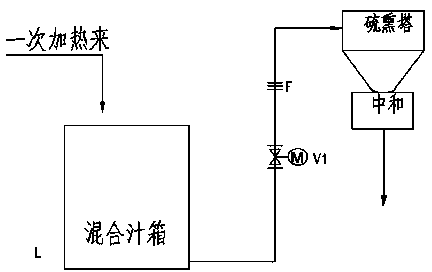

New sugaring and clarifying process of low-sulfur low-phosphorus sugarcane

ActiveCN103114156ASave resourcesShort processSugar productsPurification using alkaline earth metal compoundsPhosphatePhosphoric acid

The invention provides a new sugaring and clarifying process of low-sulfur low-phosphorus sugarcane. The process comprises the following steps of: respectively adding an inorganic salt decoloring agent, polyquaternium and a zinc dihydrogen phosphate coagulant into the mixed sugarcane juice, feeding the mixed juice into a sedimentation tank or a floatation tank to separate out clear juice and mud juice after performing primary heating, the neutralization by adding lime milk and secondary heating; and obtaining a finished product of sugar after the clear juice is evaporated, concentrated, sugar boiled, crystallized and purged. Compared with the existing phosphate-sulfite clarification method, the new sugaring and clarifying process of low-sulfur low-phosphorus sugarcane disclosed by the invention has the advantages of short process flow, low tone and good quality of the clear juice and good thermal stability, and is capable of saving the resources of lime, sulphur and phosphoric acid, shortening the process flow, improving the product quality and realizing the cleaned production by removing the sulphitation process and device.

Owner:广西糖业集团防城精制糖有限公司

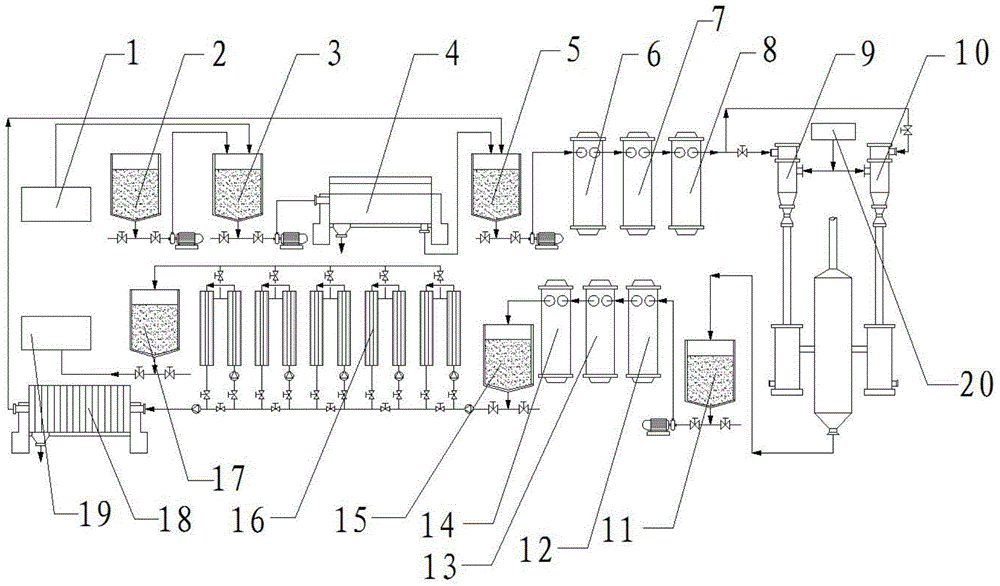

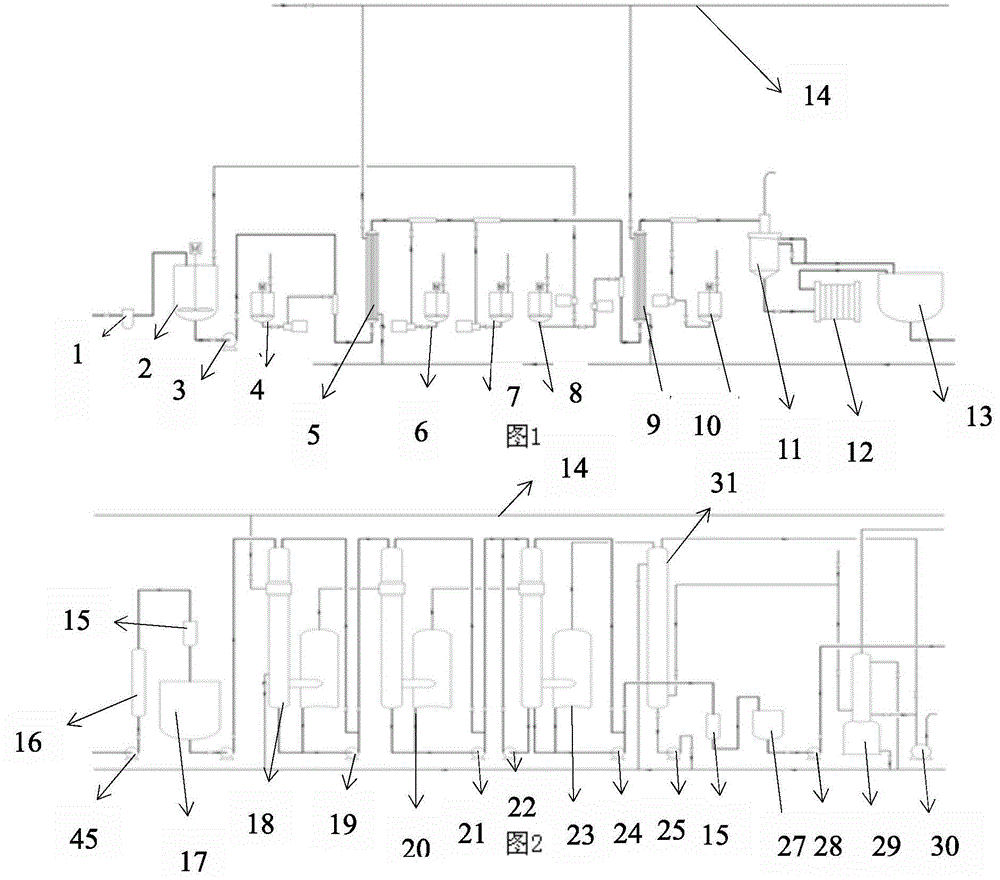

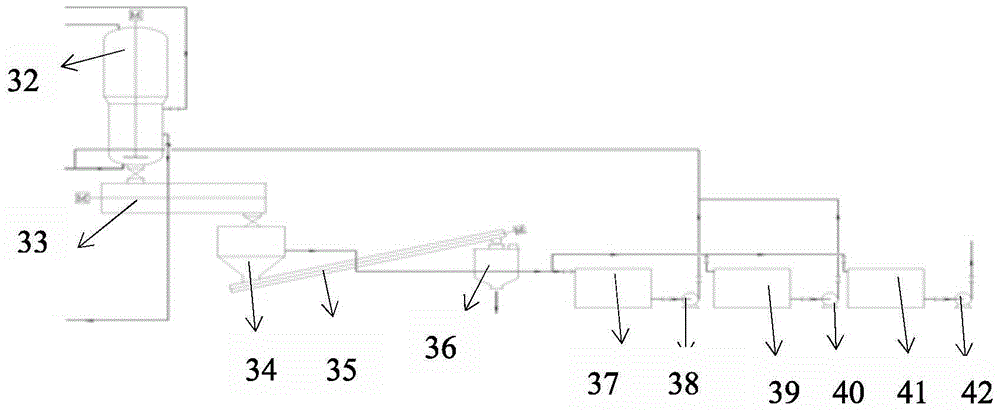

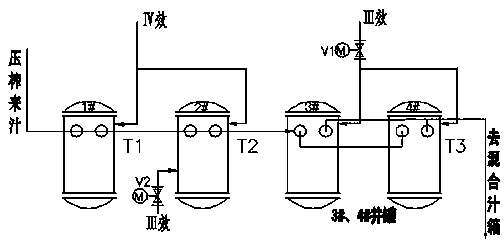

Cane sugar manufacture production system

InactiveCN103981291ALow investment costReduce manufacturing costSucrose extractionSugar juice boiling/evaporationIndustrial equipmentSettling basin

The invention discloses a cane sugar manufacture production system. The production system is characterized by comprising a cleaning system, a discoloring system, an evaporation system, a sugar boiling system and a purging and drying system; the system device comprises a pipeline filter, a mixed juice tank, a mixed juice pump, a static mixer, a heater, a rapid settling basin, a dosing storage tank, a filter press, a falling film evaporator, a condenser, a discoloring column, a bag filter, a sugar boiling crystallizing tank, a syrup tank, a help-crystallization box, a purging box, a conveyor, a drying machine, a gas-liquid separator, a honey jar, a clear juice pump, a syrup pump, a circulating pump and a vacuum pump. According to the cane sugar manufacture production system, a stove drying system and a carbonation system in the original sugar refining design are canceled, a novel process is adopted, novel industrial equipment is introduced, and the system can serve as a scientific research platform for performing a novel cane sugar manufacture process or an industrial production line for producing raw sugar, primary white granulated sugar, high-grade sugar and refined sugar.

Owner:GUANGXI UNIV +1

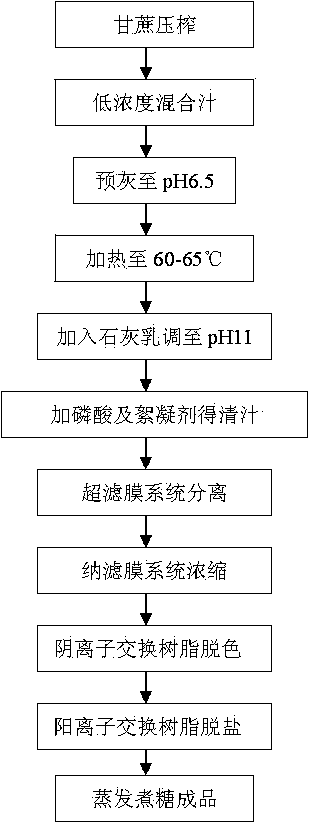

Process for producing high-safety white granulated sugar

InactiveCN103468832AReduce consumptionReduce power consumptionSugar juice boiling/evaporationSugar juice purificationUltrafiltrationPhosphoric acid

The invention relates to a process for producing high-safety white granulated sugar. The process comprises the following steps of squeezing sugarcane to obtain a mixed juice, pre-liming the mixed juice until the pH value is 6.5, carrying out once heating on the mixed juice until the temperature is 60-65 DEG C, adding lime milk until the pH value is 11, adding phosphoric acid and a polyacrylamide flocculating agent so as to obtain a clear juice, carrying out separation by utilizing an ultrafiltration membrane system, carrying out concentration by using a nanofiltration membrane system, carrying out decoloration by utilizing anion exchange resin, carrying out desalination by utilizing cation exchange resin, and evaporating to obtain a finished product. According to the process, a low-temperature strong-base process is combined with membrane separation, membrane concentration and ion exchange techniques so as to produce sulfur-free organic sugar, so that the problems of existence of sulfur in the product, complex process procedure, low production efficiency, sugar yield and clear juice clarity, serious environmental pollution, low economic benefit and the like in the prior art are solved.

Owner:云南省轻工业科学研究院有限公司

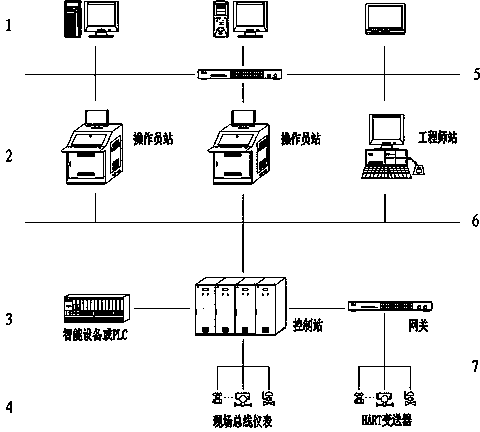

Automatic control system for clarification and evaporating process of sugar refinery

InactiveCN103365274ARealize fully automatic controlAvoid churnSugar juice boiling/evaporationTotal factory controlSteam pressureAutomatic control

The invention provides an automatic control system for a clarification and evaporating process of a sugar refinery. The automatic control system comprises six subsystems, namely a mixed juice heating and uniform-pumping automatic-control system, a neutralizing juice heating and uniform-pumping automatic-control system, a clear juice heating and uniform-pumping automatic-control system, waste steam and live steam pressure-reducing temperature-reducing automatic-control system, an I-V-effect evaporation tank syrup liquid level control and last-effect syrup brix control system and a production dispatching management system. The whole automatic control system structure is divided into four levels, namely a field instrument layer, a control station, an engineer station and an operator station, and an information management layer from bottom to top. The whole system forms the four-level structure through the six subsystems to automatically control the production process. According to the system, sugar enterprises can achieve the operating target of the production process, namely five stabilities, different levels of managers can master industrial site conditions any time and anywhere across the regions, and the fully-automatic control for the clarification and evaporating process of the sugar refinery and the cross-region real-time production management are realized.

Owner:广西宏智科技有限公司

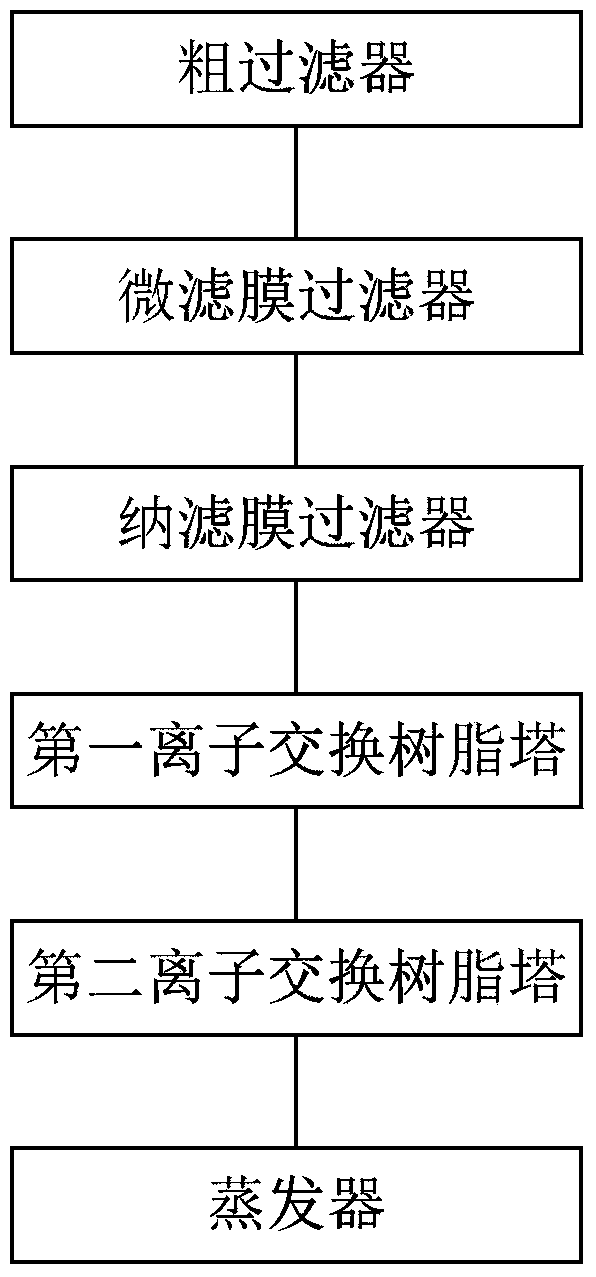

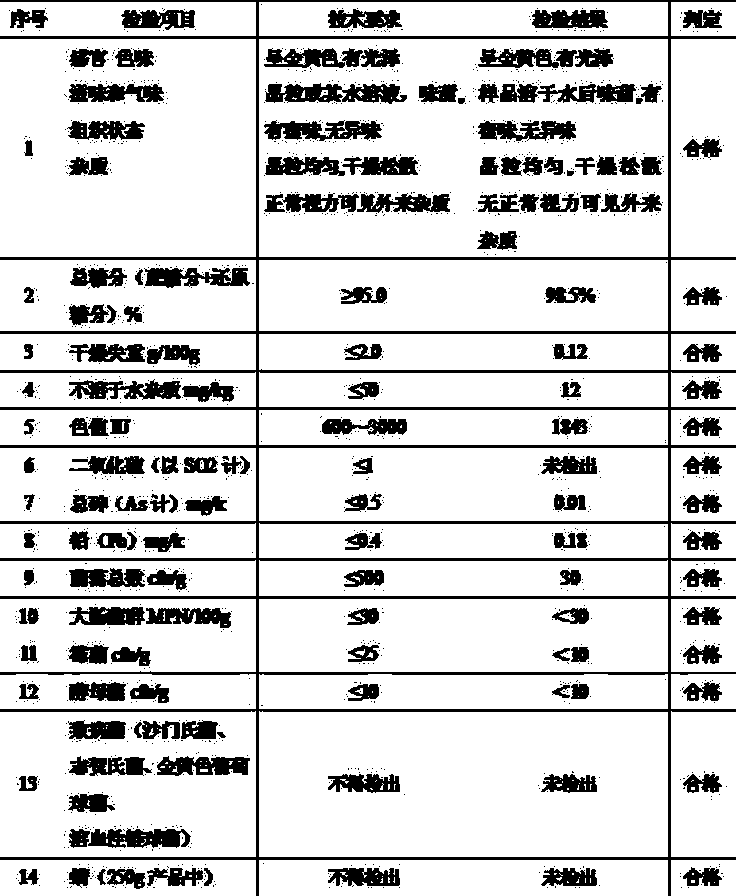

Production process and device of golden sugar

InactiveCN104004860AHigh desalination rateHigh yieldSugar crystallisationPurification using ion-exchange materialsSucroseIon-exchange resin

The invention provides a production process and a production device of golden sugar. The production process comprises the following steps: pressing sugarcane or beets to obtain cane sugar juice; pre-filtering the cane sugar juice through a coarse filter and feeding the pre-filtered crane sugar juice into a microfiltration membrane for filtering to obtain clear cane sugar juice; pre-concentrating the clear cane sugar juice to obtain a pre-concentrated solution; feeding the pre-concentrated solution into ion exchange resin for desalting to obtain a permeation solution; feeding the permeation solution into an evaporator for concentrating to obtain cane sugar concentrated liquid; heating the cane sugar concentrated liquid to be oversaturated, adding crystal seeds, naturally cooling and crystallizing, and centrifuging the obtained crystals to obtain golden sugar crystals; drying the golden sugar crystals to obtain a finished product of the golden sugar. The production device comprises the coarse filter, a microfiltration membrane filter, a nanofiltration membrane filter, an anion exchange resin bed, a cation exchange resin bed and the evaporator which are connected in sequence. The production method provided by the invention is capable of continuously producing high-quality golden sugar, the chromatic value of the obtained product is 800-3,000, the desalting rate is high, and the yield is high.

Owner:JIANGSU JIUWU HITECH

Method for preparing concentrated sugarcane juice

ActiveCN101985666AQuality assuranceGuarantee quality and safetySugar juice boiling/evaporationSugar juice purificationChemical reactionPhosphate

The invention discloses a method for preparing concentrated sugarcane juice. In the traditional method for preparing the concentrated sugarcane juice, phosphoric acid and lime water are added after sugarcane is squeezed into juice to generate a chemical reaction to generate phosphate, so that impurities are precipitated out from the sugarcane juice. The concentrated sugarcane juice prepared by the traditional method is deep in color, reddish and astringent due to the residual phosphate radical and lime water in the sugarcane juice and enzyme and pigment in the sugarcane. In the method, any additives and other chemical medicaments are not added in the preparation process, so the quality safety of products is guaranteed, the nutrient and the flavor of the sugarcane juice are maintained to the utmost extent, the concentrated sugarcane juice prepared by the method has good color and luster and rich flavor and is fresh, sweet and delicious, and the problem that the concentrated sugarcane juice is off-color and has bad mouthfeel for a long time due to the influence of the pigment, the enzyme, the lime and the phosphoric acid is solved.

Owner:TIANYE INNOVATION

Process for directly producing high quality white sugar from sugarcane

InactiveCN1699603AImprove qualityLight colorSugar juice boiling/evaporationJuice extraction from sugarcaneElectrolysisPhosphoric acid

The present invention discloses a process in which high quality white sugar is directly produced from sugarcane. The first step of the process is low temperature phosphorus floatation method to remove most insolubles and parts of organic colloids, obtaining clean solution. The second step is to further increase the quality of the cane solution, this step has the following three alternative methods depending on the actual situations: 1) blowing sulphur dioxide in lime milk and decolourant, and heating and precipitation separating, 2) blowing carbon dioxide which is produced from alcohol fermentation, and precipitating by adding lime milk, followed by phosphoric acid gas floatation separation. 3) treating with electrolysis method. Adopting the present invitation, the clean solution has the properties of light color and high purity. The quality of the product of white sugar meets the standard of 'beverage sugar'. The production rate and digestion recycle rate are obviously higher than that of the conventional sulfurous acid process. Therefore, the present technology has good economic efficiency. The equipment investment and production cost is low.

Owner:霍汉镇

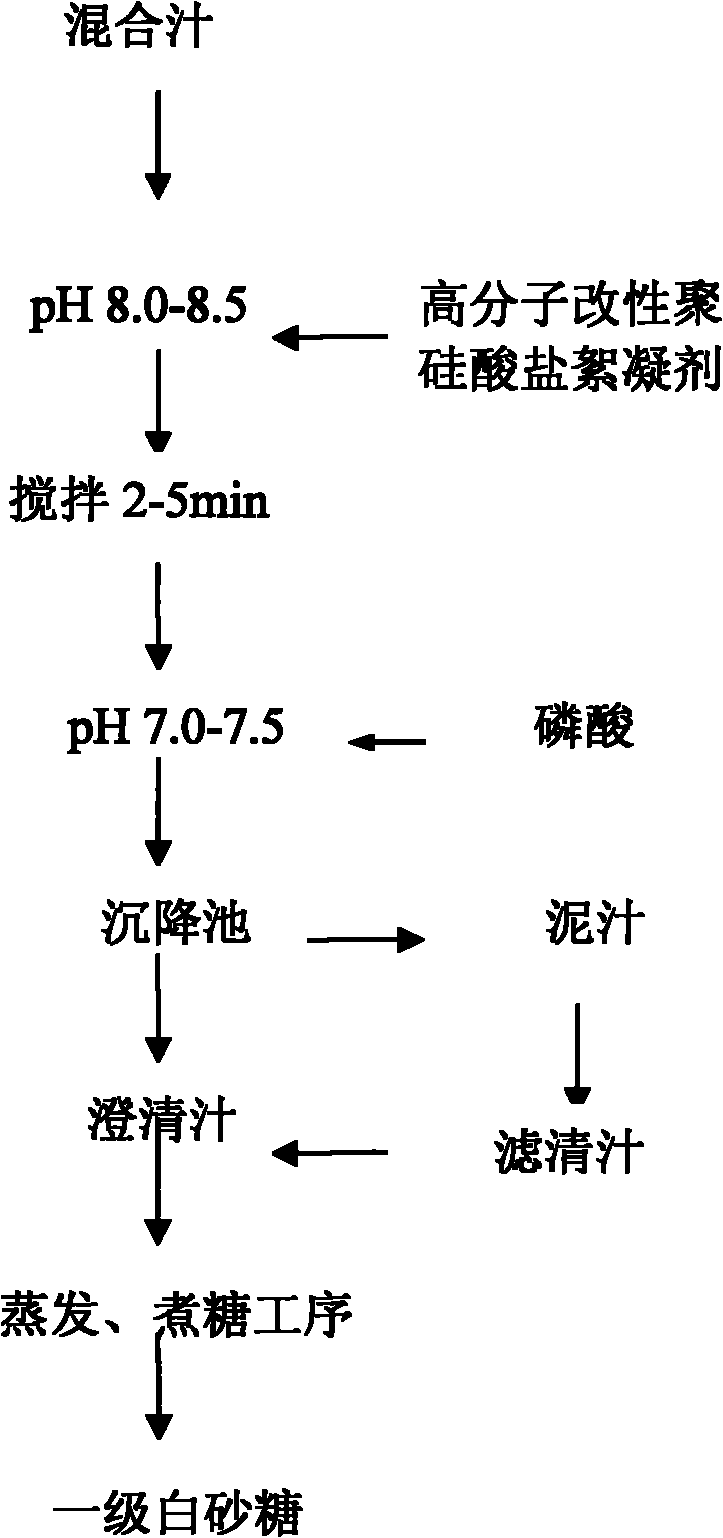

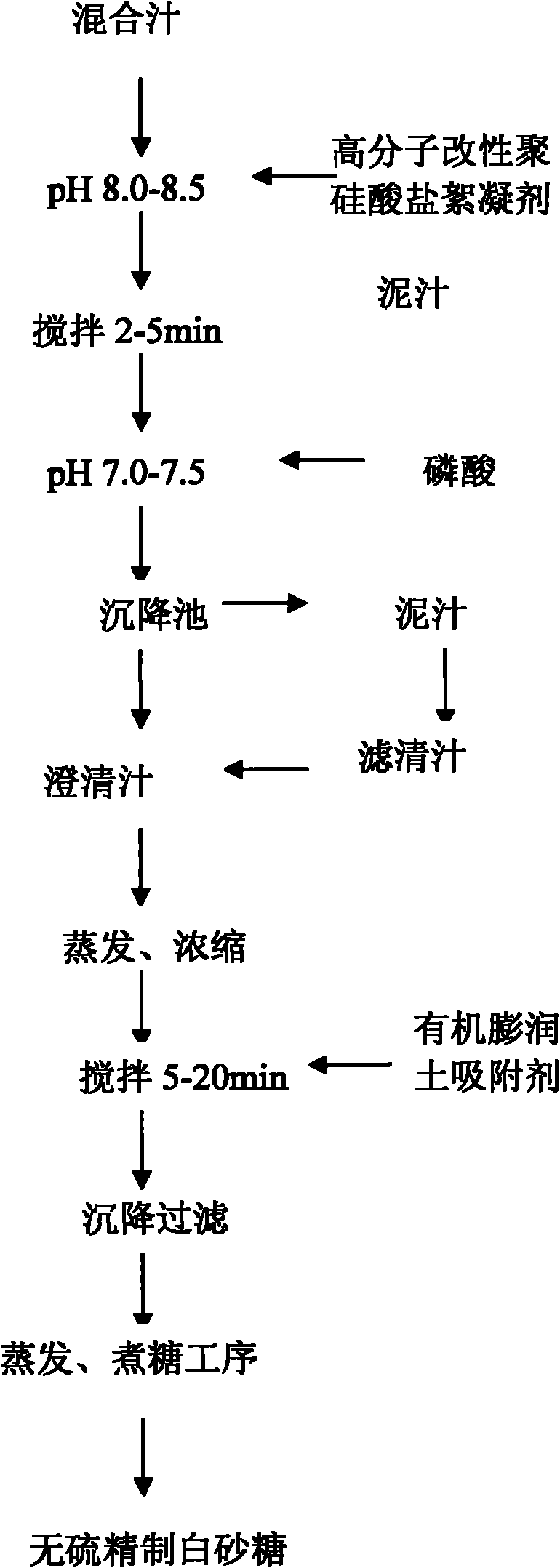

Method for producing high-quality white granulated sugar by clarifying syrup

InactiveCN102021250AReduce color valueHigh purityPurification using adsorption agentsPurification using alkaline earth metal compoundsSulfurPhosphoric acid

The invention relates to a method for producing high-quality white granulated sugar by clarifying syrup. The method comprises the following steps of: heating the syrup; adding lime milk; adjusting the pH value to be between 8.0 and 8.5; adding anionic inorganic gel serving as a flocculating agent in an amount which accounts for 0.01 to 0.05 percent of the amount of the syrup; keeping the pH value at 8.0 to 8.5 for about 2 minutes; adding phosphoric acid to reduce the pH value to be between 7.0 and 7.5; pouring the syrup into a sedimentation tank or a floatation tank to separate clarified juice and mud juice out; filtering the mud juice by using filtering cloth or a vacuum filter, and mixing the filtered clarified juice and the separated clarified juice; and evaporating, concentrating, boiling sugar, crystallizing and extracting the sugar to obtain the white granulated sugar of above first class; or evaporating and concentrating to obtain the syrup, adding organic bentonite in an amount which accounts for 0.2 to 1 percent of the amount of the syrup, stirring, adsorbing for 5 to 20 minutes, filtering by using the filtering cloth, boiling, crystallizing and extracting the sugar to directly produce sulfur-free refined sugar. The method has the advantages of good clarification effect, high clear juice purity, short process flow, high process operation safety and low labor intensity.

Owner:杨鲁昆

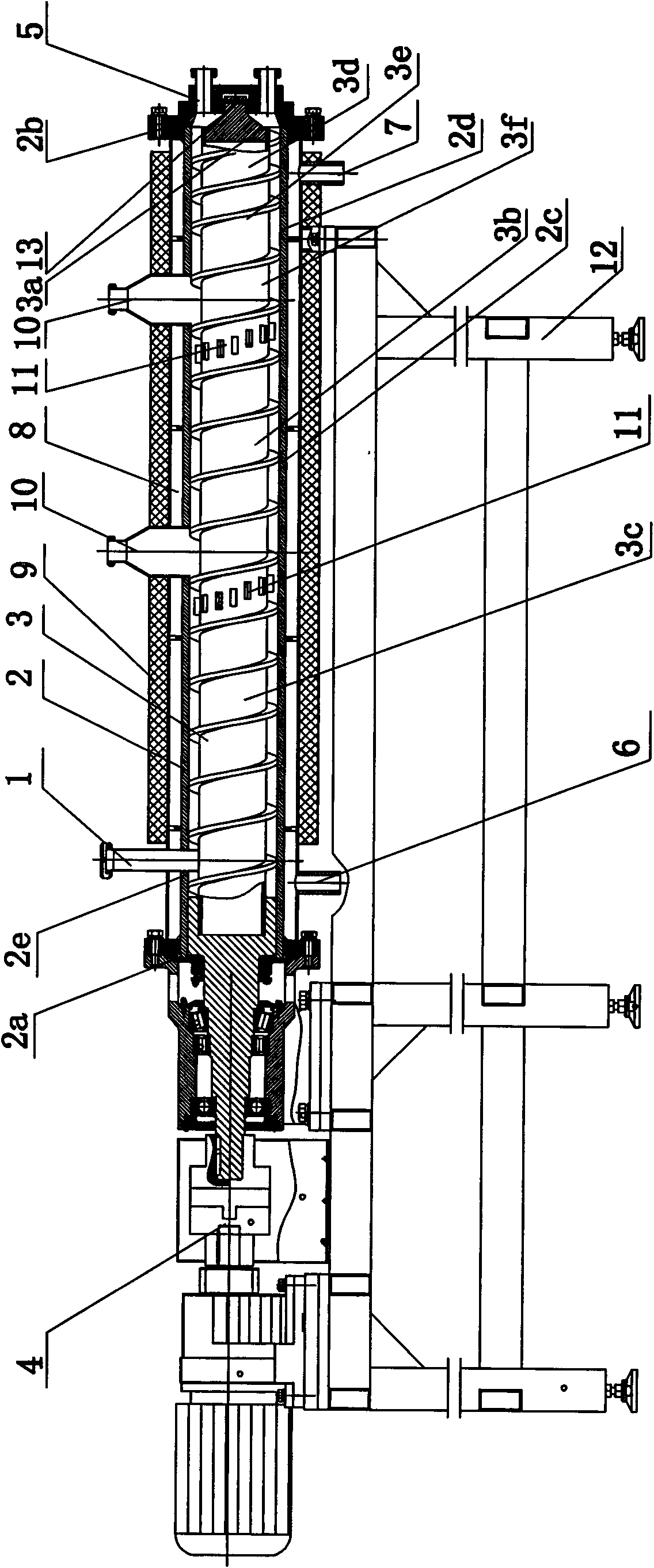

Continuous cooking machine

ActiveCN101660008ABoil concentrated short mixing timeSuitable for industrial continuous productionSugar juice boiling/evaporationEngineeringMechanical engineering

The invention relates to a continuous cooking machine which is characterized by comprising a conveying circular pipe, a screw rod, a power mechanism and an extrusion spray head, wherein the side faceof the front section of the conveying circular pipe is provided with more than one feed inlet, the screw rod is arranged in the conveying circular pipe in a rotation way, the external diameter of thescrew threads of the screw rod is matched with the internal diameter of the conveying circular pipe, the power mechanism is fixed at the front end of the conveying circular pipe and drives the screw rod to rotate, the extrusion spray head is fixed at the back end head of the conveying circular pipe, a heating jacket provided with a medium inlet and a medium outlet is arranged on the outer side wall of the conveying circular pipe, a heat preservation layer is arranged on the outer side wall of the heating jacket, and the middle section and the tail section of the conveying circular pipe are provided with steam extraction discharge openings. Compared with the prior art, the invention has the advantages of continuous completion of cooking, concentration and conveying and short time of cooking, concentration and mixing, is suitable for industrialized continuous production and ensures the uniformity of the product quality.

Owner:黎泽荣

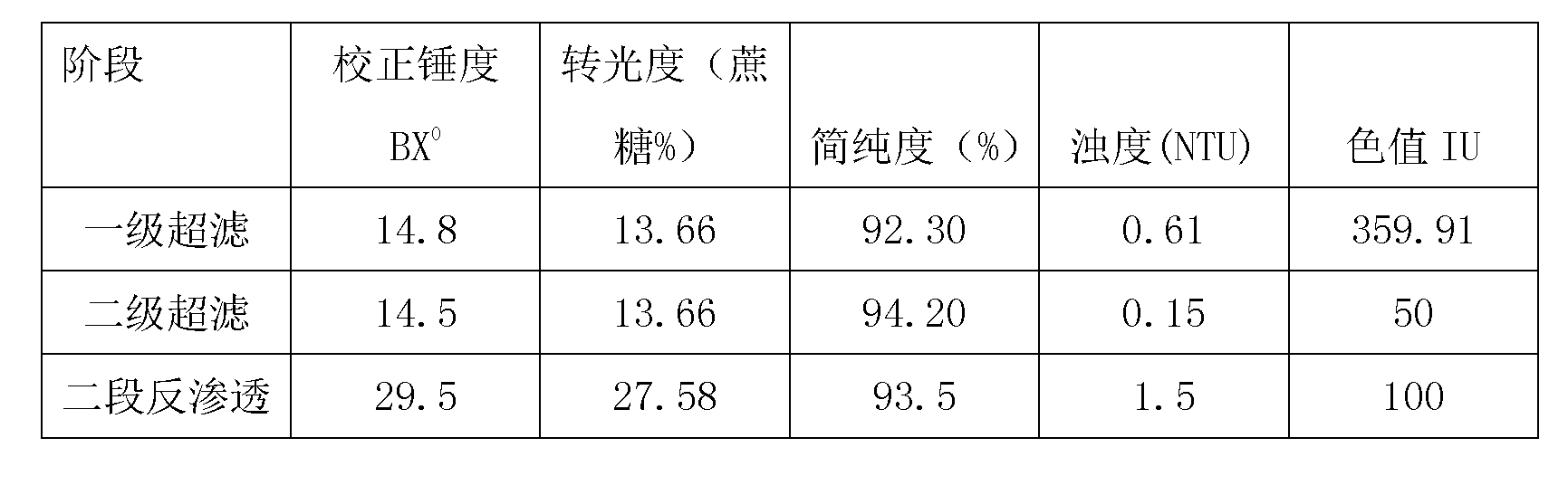

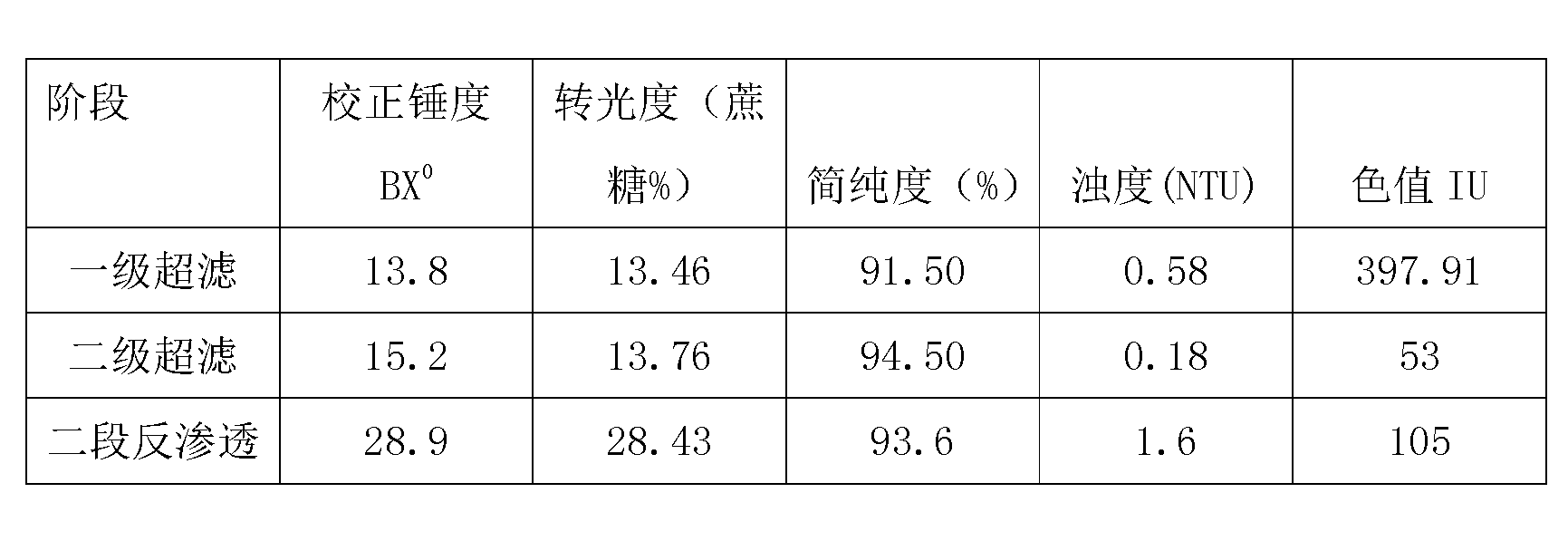

Method for treating sugarcane mixed clear juice

ActiveCN103194545AReduce energy consumptionLow running costPurification by physical meansSugar juice boiling/evaporationMembrane methodSugar

The invention discloses a treatment technology for sugarcane mixed clear juice, and in particular relates to a membrane method for treating the sugarcane mixed clear juice. The method comprises the following steps of: filtering the mixed clear juice through a first stage ultrafiltration membrane; filtering the obtained clear liquor through a second stage ultrafiltration membrane; evaporating the strong liquor filtered by the first stage ultrafiltration membrane for preparing sugar; mixing the mixed clear juice and the strong liquor filtered by the second stage ultrafiltration membrane and filtering by the first stage ultrafiltration membrane; and concentrating the thin liquor filtered by the second stage ultrafiltration membrane by a membrane concentration device so as to obtain a concentrated solution and plain water, wherein the molecular weight cutoff of the first stage ultrafiltration membrane is 50000-100000 Dalton, and the molecular weight cutoff of the second stage ultrafiltration membrane is 1000-20000 Dalton. The method has the advantages that the energy consumption can be greatly lowered, the equipment has low operating cost and long service life, the quality of the product is improved sharply, the degree of automation is higher and the method is more environment-friendly.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

Process for the production of invert liquid sugar

InactiveUS20040255934A1Purification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

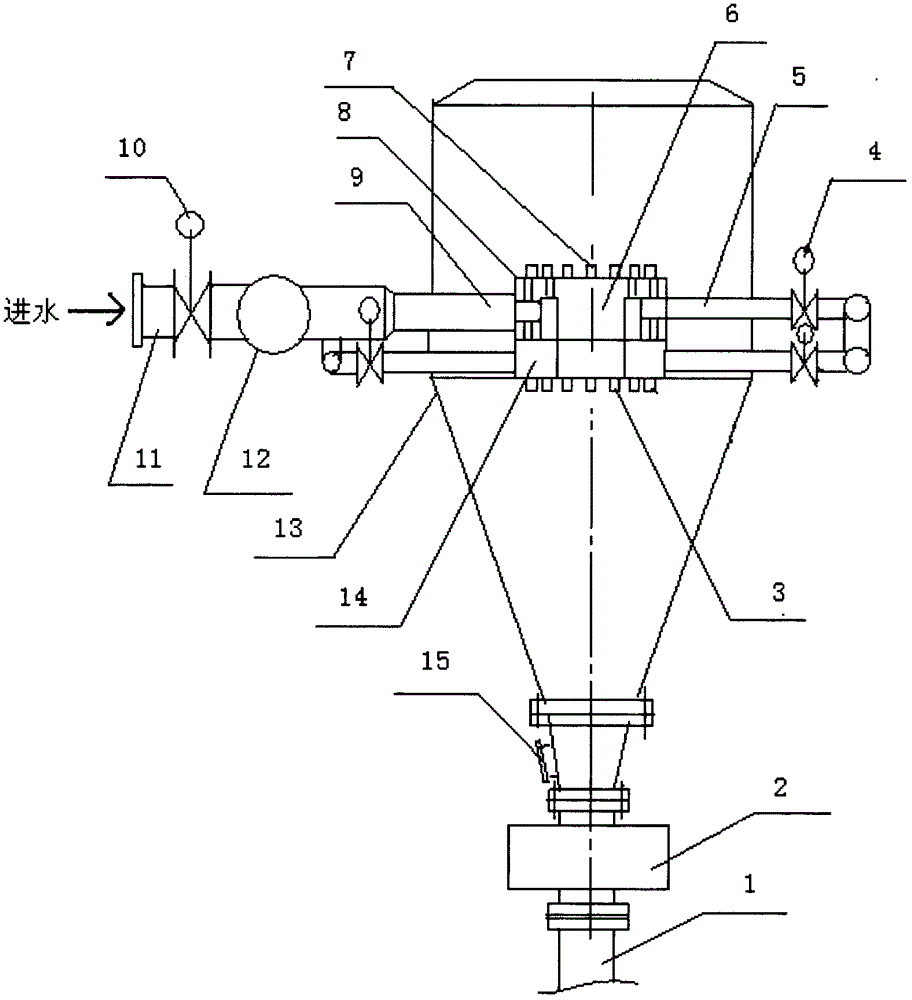

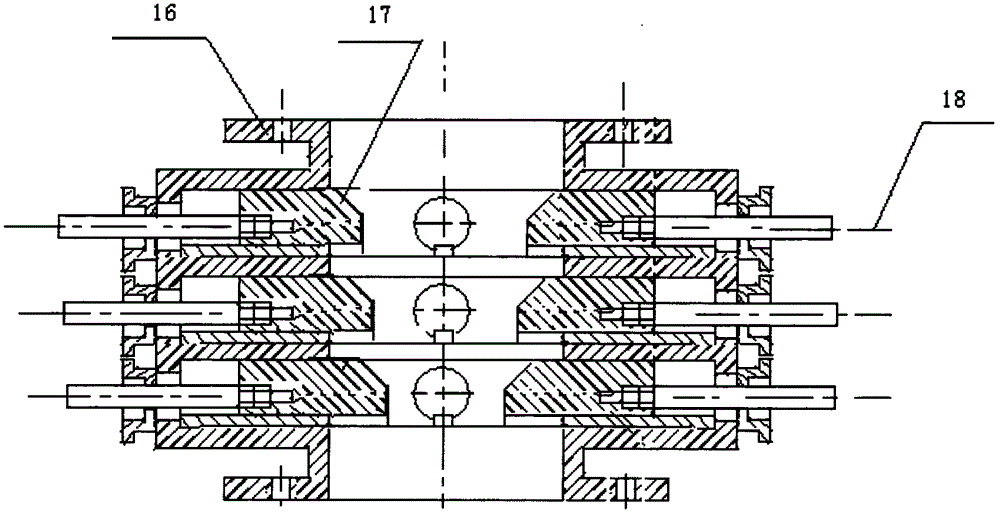

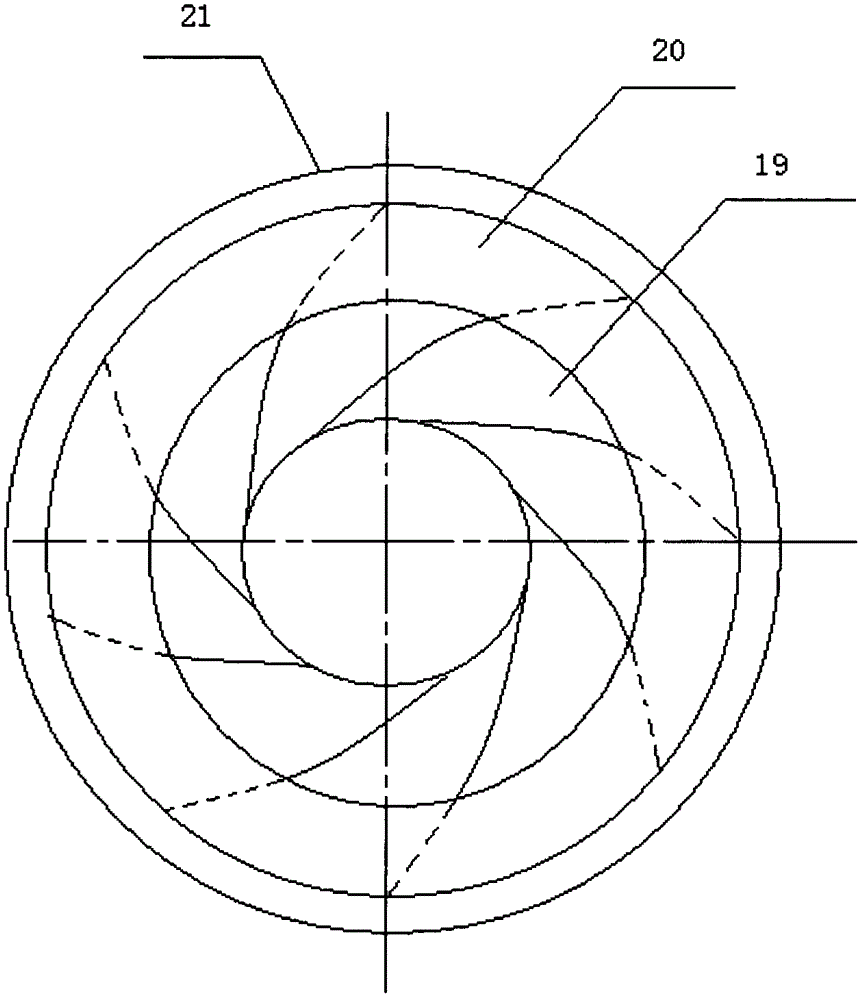

Novel water jet condenser with multiple closed water chambers and jet flow control valve

The invention discloses a novel water jet condenser with multiple closed water chambers and a jet flow control valve used in a sugar refinery. The water jet condenser is characterized in that a water chamber of the condenser is divided into an opened big water chamber and a plurality of closed small water chambers; each water chamber is respectively provided with a jet nozzle and a spray nozzle; a plurality of closed small water chambers are respectively controlled by a plurality of pneumatic or electric butterfly valves installed on the outside of the condenser; the lower part of the condenser is provided with a monolayer or multilayer jet flow control valve for making the size of the central round aperture of a jet flow passage keep a coaxial change; the jet nozzle and the spray nozzle in each water chamber are respectively cooperated with the monolayer or multilayer jet flow control valve to control the water supply amount of the condenser, so that a high vacuum degree of the condenser can be always kept in the production.

Owner:NANNING MAST SUGAR MACHINE EQUIP MFG CO LTD

Method for producing original ecologic colored sugar product

ActiveCN103757142ARetain trace elementsClearing away heat and promoting body fluidSugar dryingPurification using alkaline earth metal compoundsBiotechnologyO-Phosphoric Acid

The invention discloses a method for producing an original ecologic colored sugar product. The method comprises the following steps: preliming a mixture juice obtained by extruding sugarcanes till the pH value is 7.0-7.2, adding 100-150PPM (Parts Per Million) of phosphoric acid, subsequently performing primary heating, further adding lime milk into the heated mixture juice till the pH value is 7.6-8.2, adding activated calcium carbonate to fulfill, further performing dreg-foam separation to obtain floating clear juice, adding phosphoric acid and lime milk into the floating clear juice till the pH value is 8.4-8.6, wherein the addition amount of the phosphoric acid is 50-100PPM, subsequently performing secondary heating to obtain a neutral juice, sinking the neutral juice to separate a clear juice and a mud juice, filtering the mud juice by using a filter to obtain a filtrate, combining the filtrate with the clear juice, heating for three times, evaporating, filtering in rotational flow, boiling the sugar to crystallize, prompting crystal, purging, drying, deironing and the like so as to obtain the original ecologic colored sugar product. The method is low in production cost and preserves activated sugarcane antioxidant substances to the maximum extent, and the sugar product is safe to eat, good in environment-friendly effect and has good population values and social and economic benefits.

Owner:GUANGXI DUAN YONGXIN SUGAR CO LTD

Process for preparation of brown sugar from sugarcane

InactiveCN105063239AReduce cokingLow boiling pointSugarcane cuttingLiquid solutions solvent extractionBoiling pointEvaporation

The invention provides a process for preparation of brown sugar from sugarcane. The process includes: juicing, ethanol extraction, heating and impurity removal, and mixed boiling four steps. According to the invention, by means of extracting the residual sugar in the squeezed residue through ethanol, sugar in sugarcane can be transformed maximumly, also the sugarcane juice is firstly boiled, black foams in the juice is removed by filtering, and the filtrate is mixed with a sugar-containing ethanol solution, thus not only lowering the boiling point of the solution, reducing sugar coking, but also accelerating the evaporation of water and ethanol in the solution, and speeding up sugar making. Experiments show that the sugar making time of the process is in the range of 4-4.5. The brown sugar prepared by the process provided by the invention completely adopts physical method, is not added with any chemical, and the sugar product is very healthy.

Owner:GUANGXI NANNING PAITENG TECH

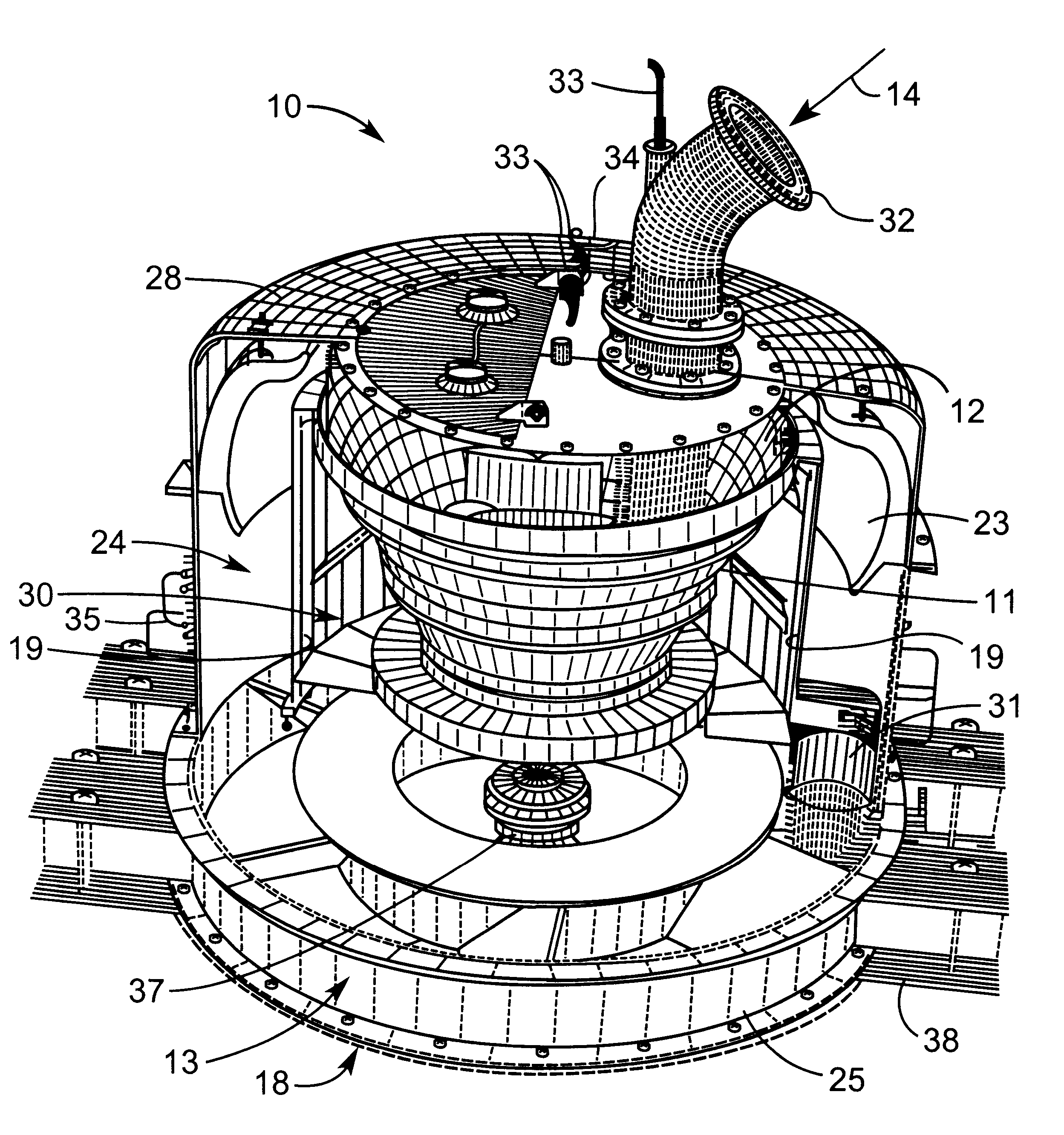

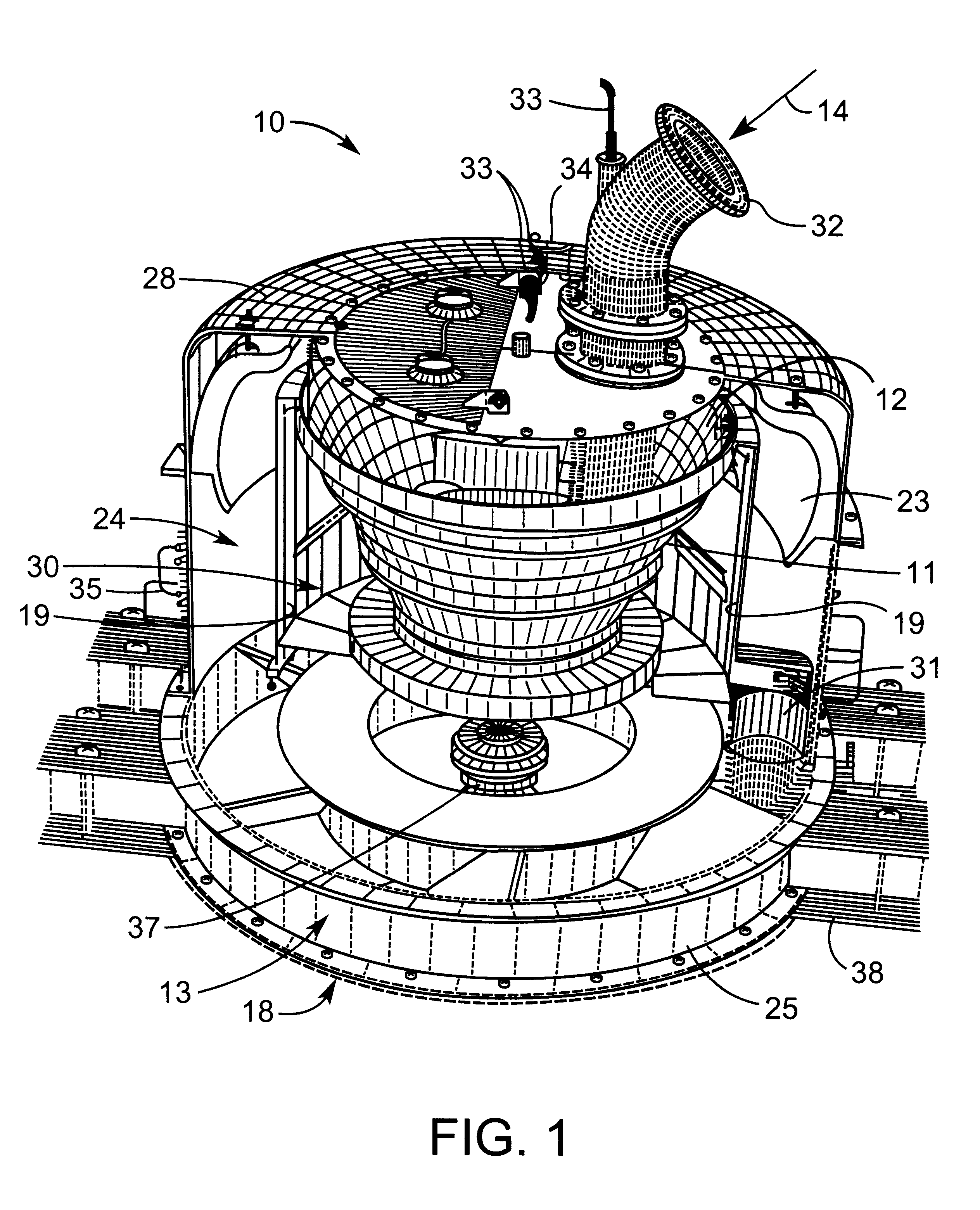

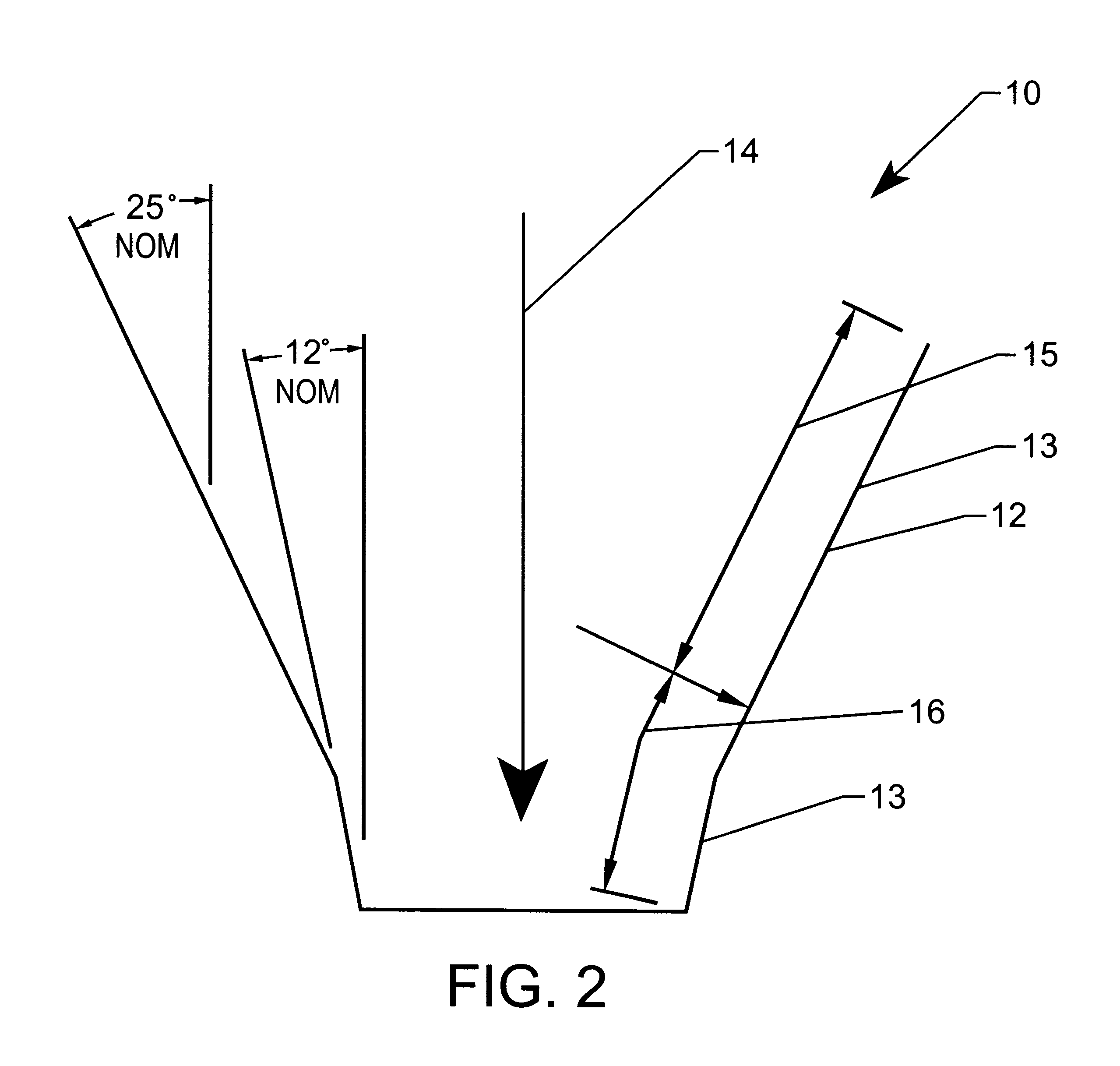

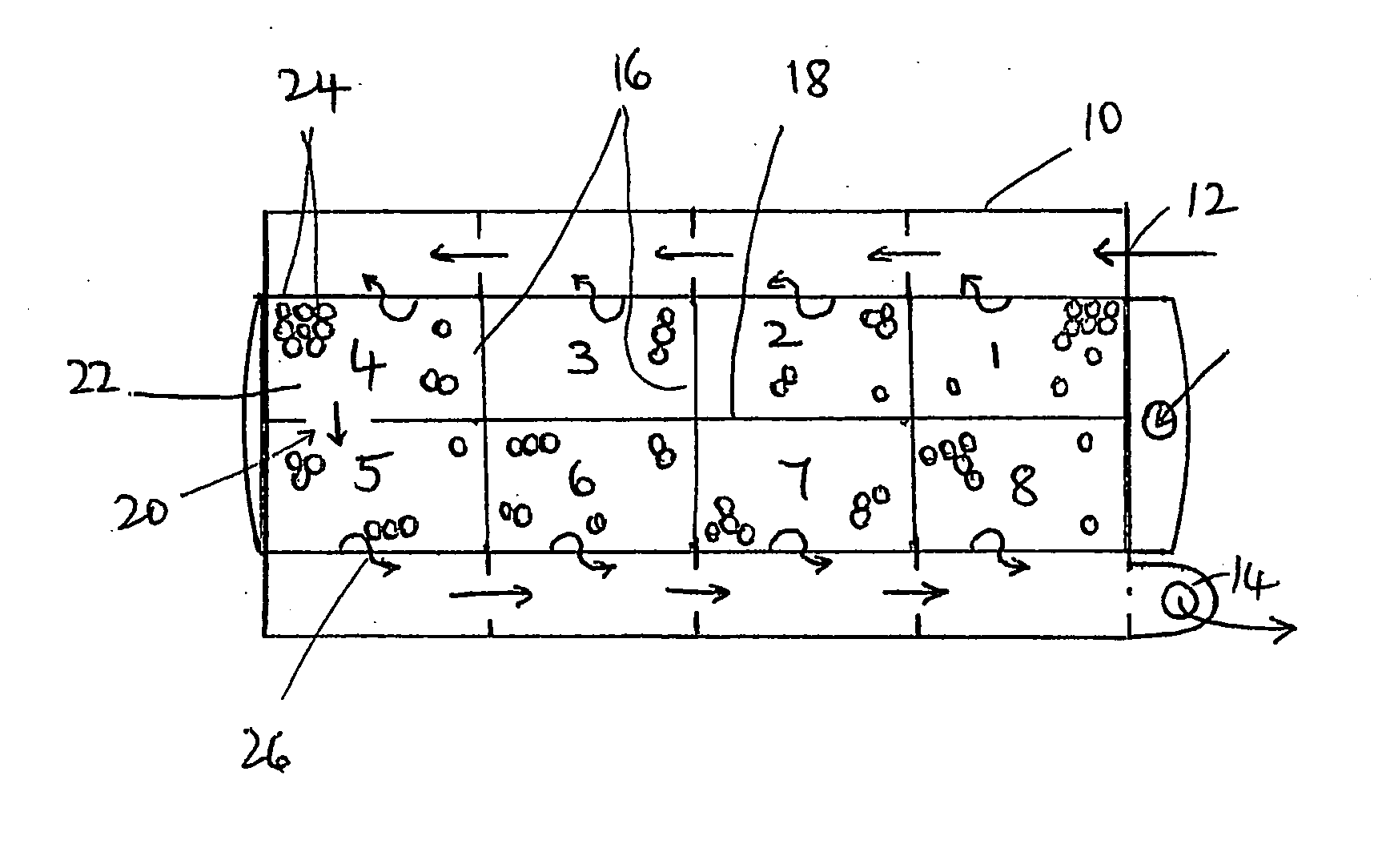

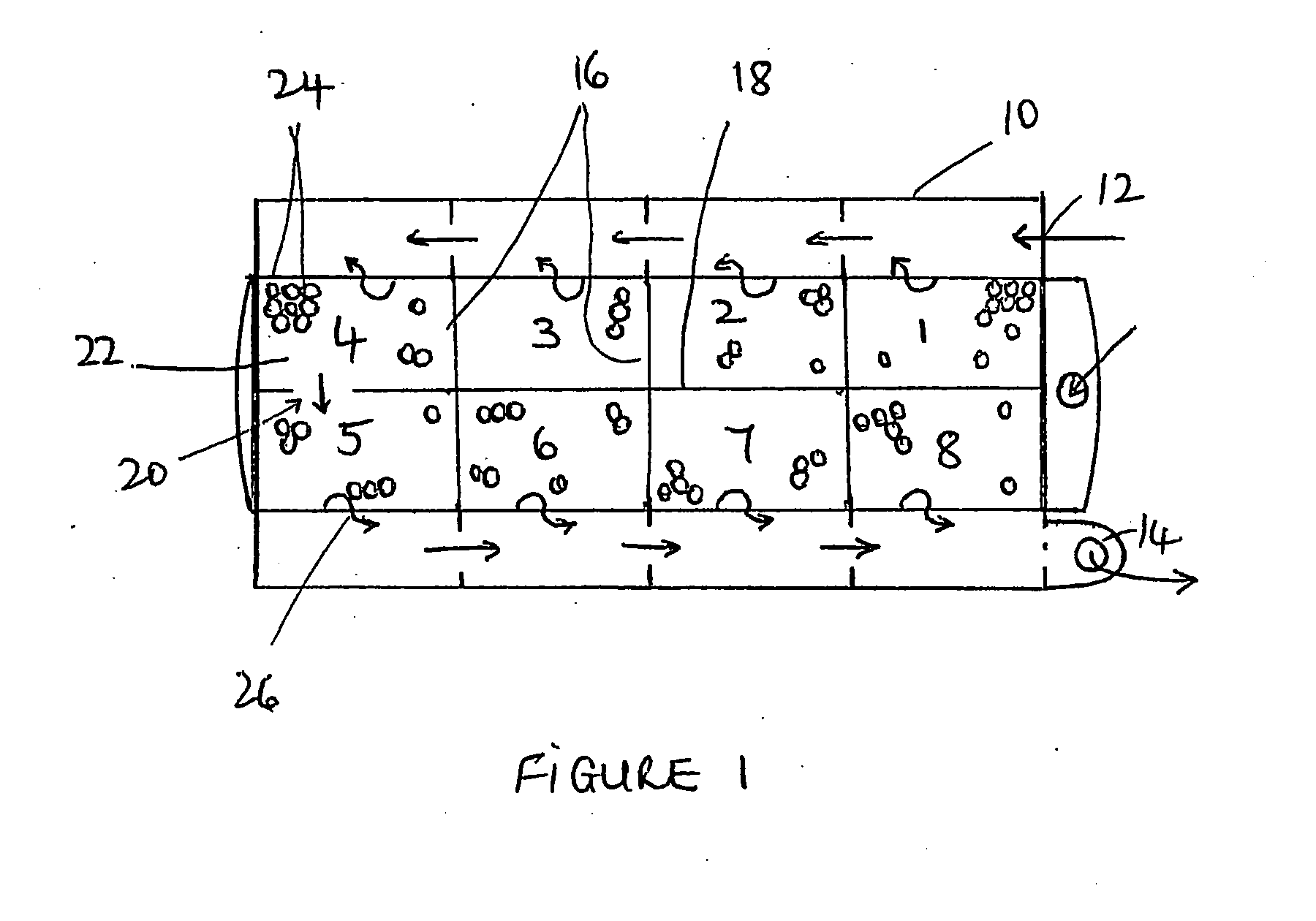

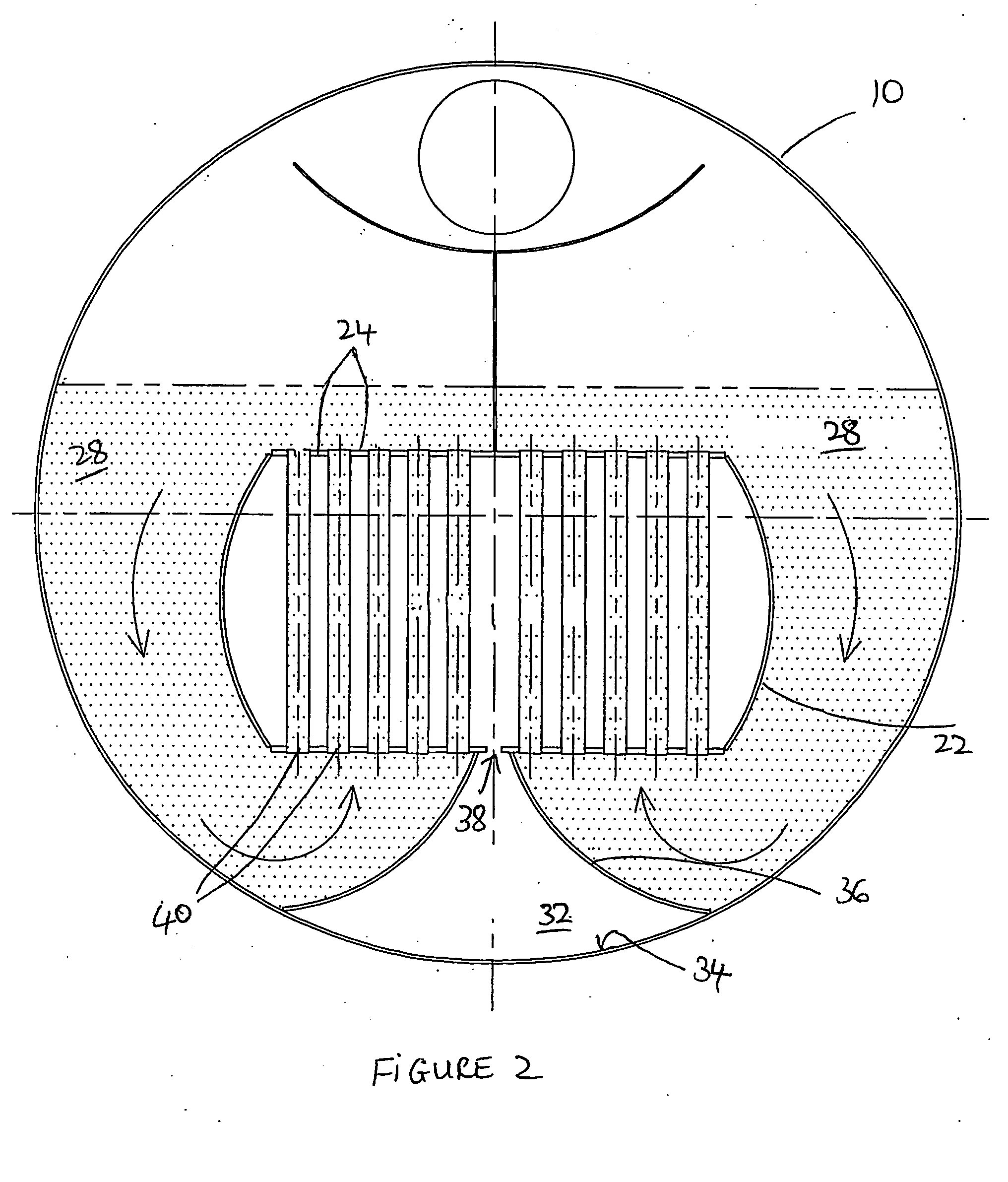

Continuous pan crystalliser

InactiveUS20040177846A1Prevent solidificationLow densitySugar crystallisationSugar juice boiling/evaporationEngineeringVolumetric Mass Density

A continuous pan crystalliser for use in the sugar industry includes a heated zone in the form of a steam chamber (32) below a calandria (22). The heated zone heats massecuite in the area below the calandria in the pan and reduces massecuite density and viscosity and promotes the vigorous circulation required for even crystal growth.

Owner:MOOR BRUCE STCLAIR

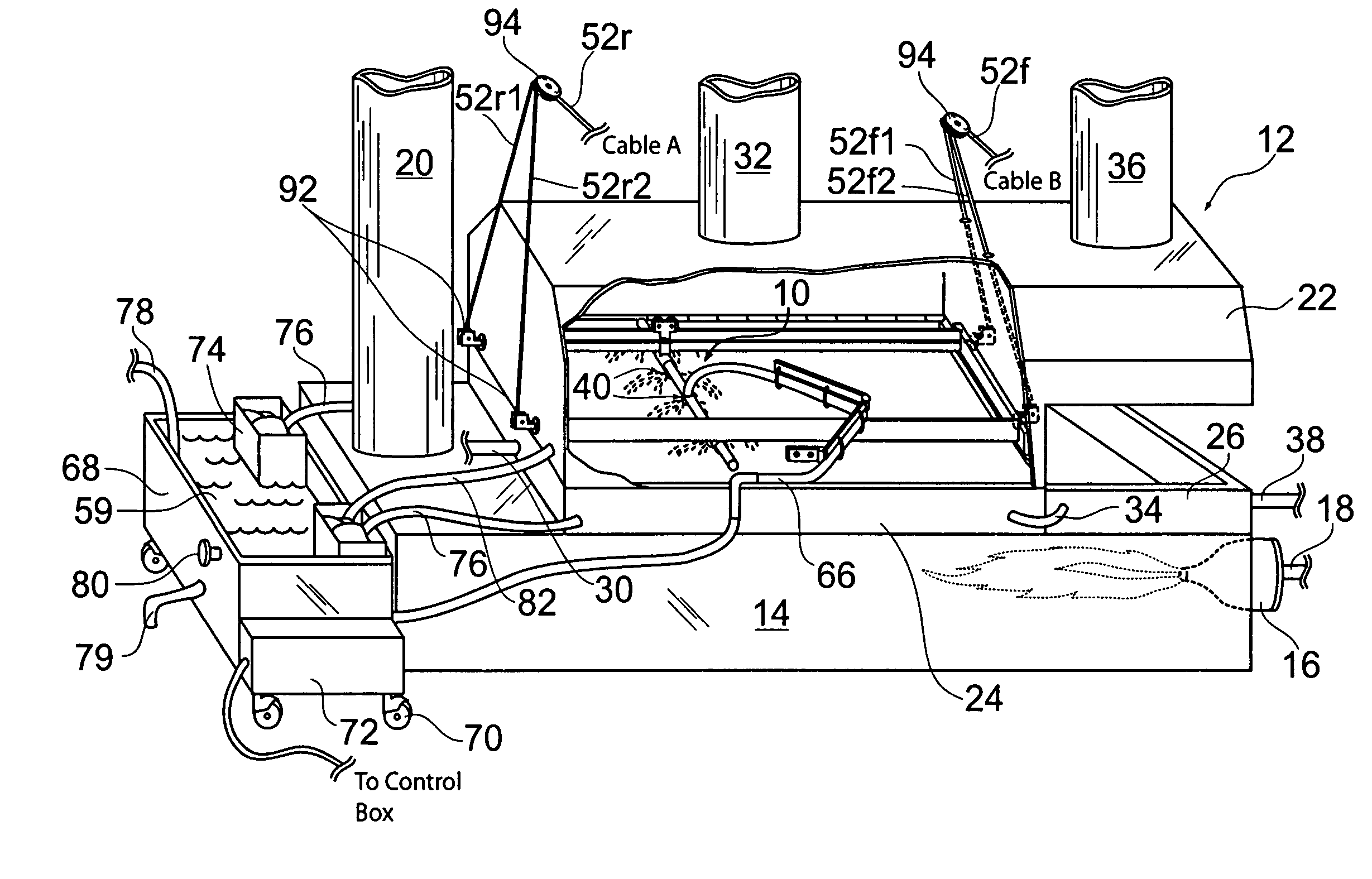

Flue pan washer for maple sugar evaporator

InactiveUS20080029129A1Pressurized chemical processBoiler cleaning apparatusSpray nozzlePulp and paper industry

The present invention is directed to an automatic washer system mounted within a maple sugar evaporator above the rear flue pan for removing niter and sediment built up during the boiling of sap. The evaporator comprises a furnace, a steam hood, a pan and a nozzle for washing the pan. The steam hood extends over the furnace. The pan is mounted to the furnace and under the steam hood. The nozzle is mounted over the pan. Cleaning fluid is sprayed from the nozzle to clean the pan by an automated process.

Owner:MANN DAVID SHRADER

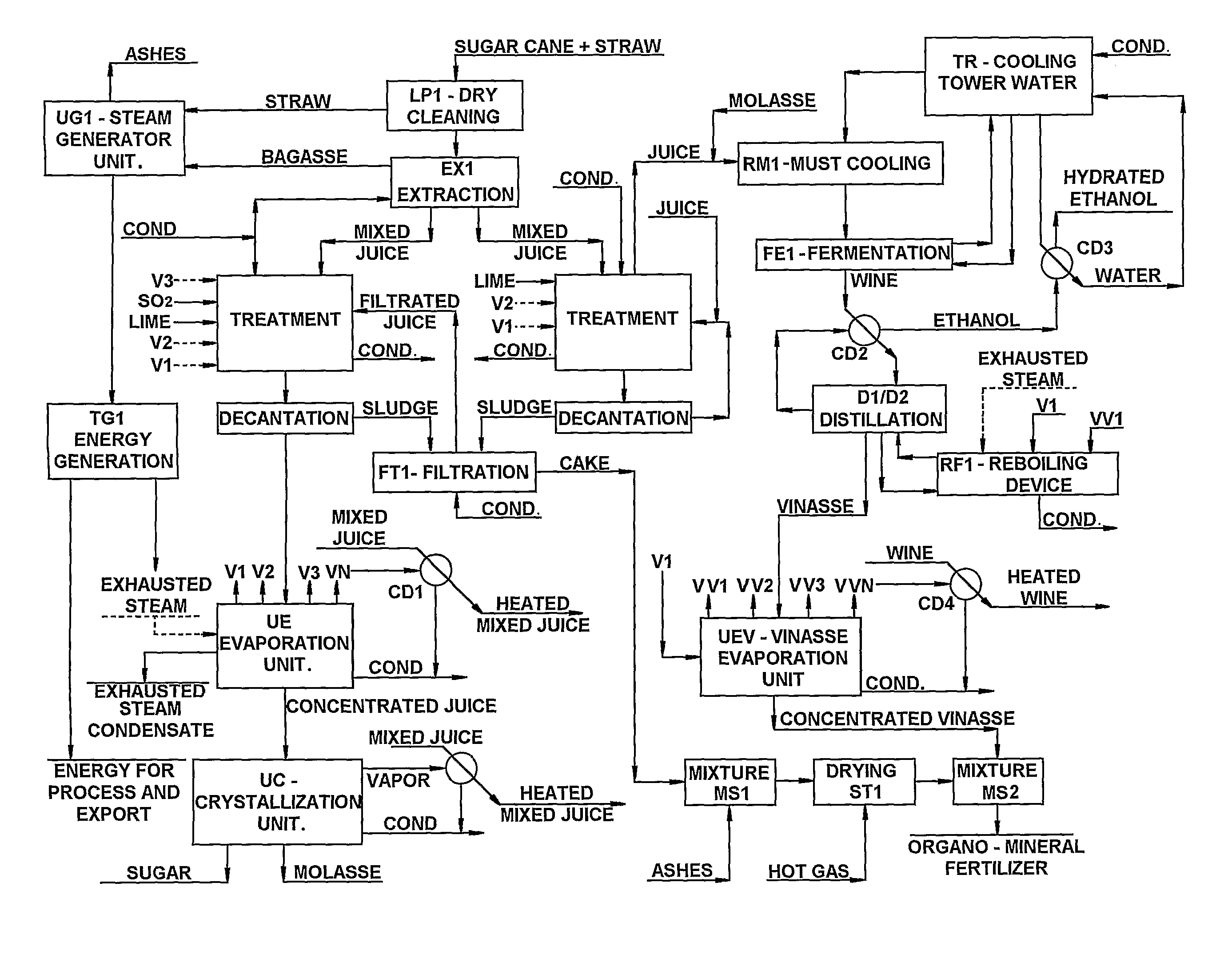

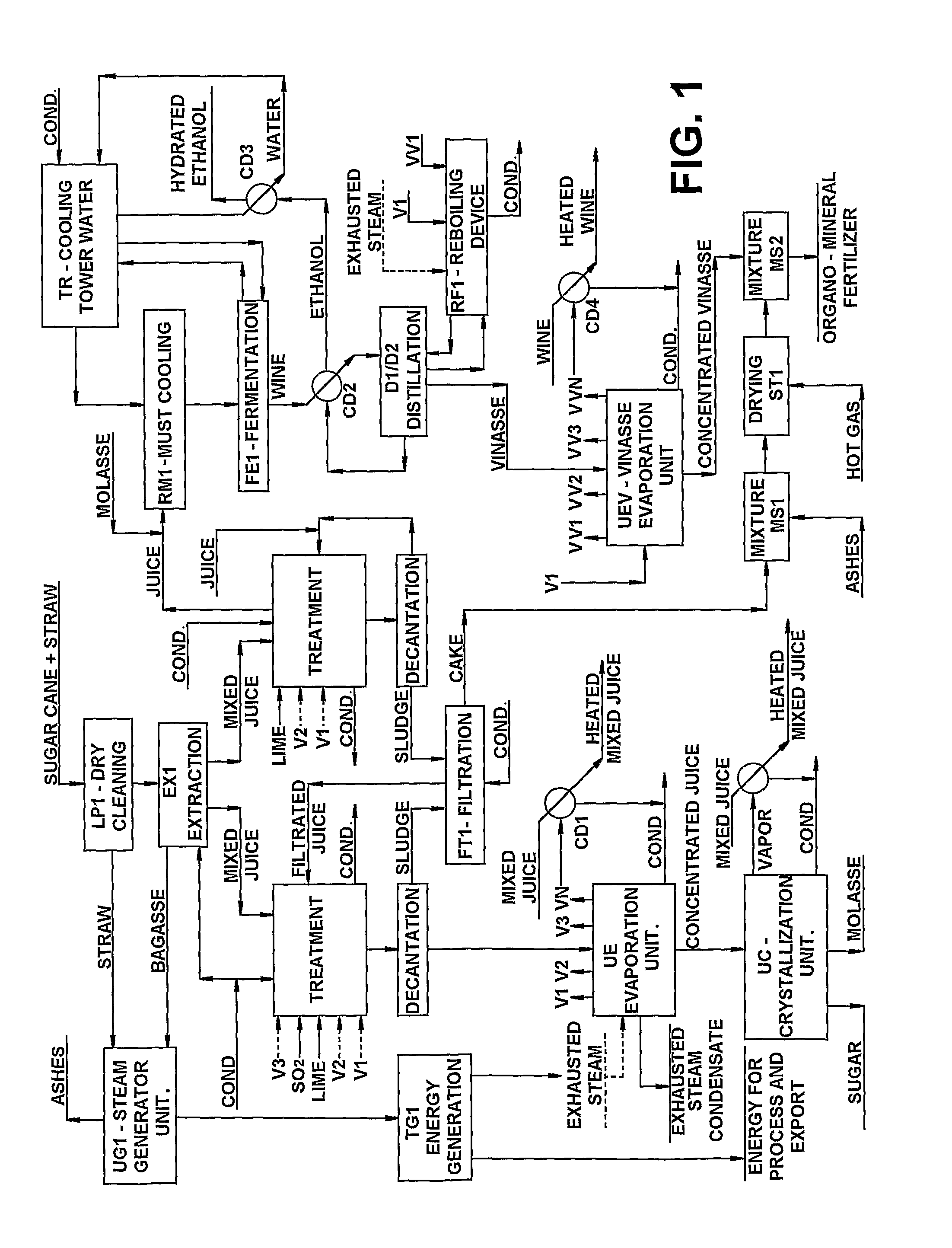

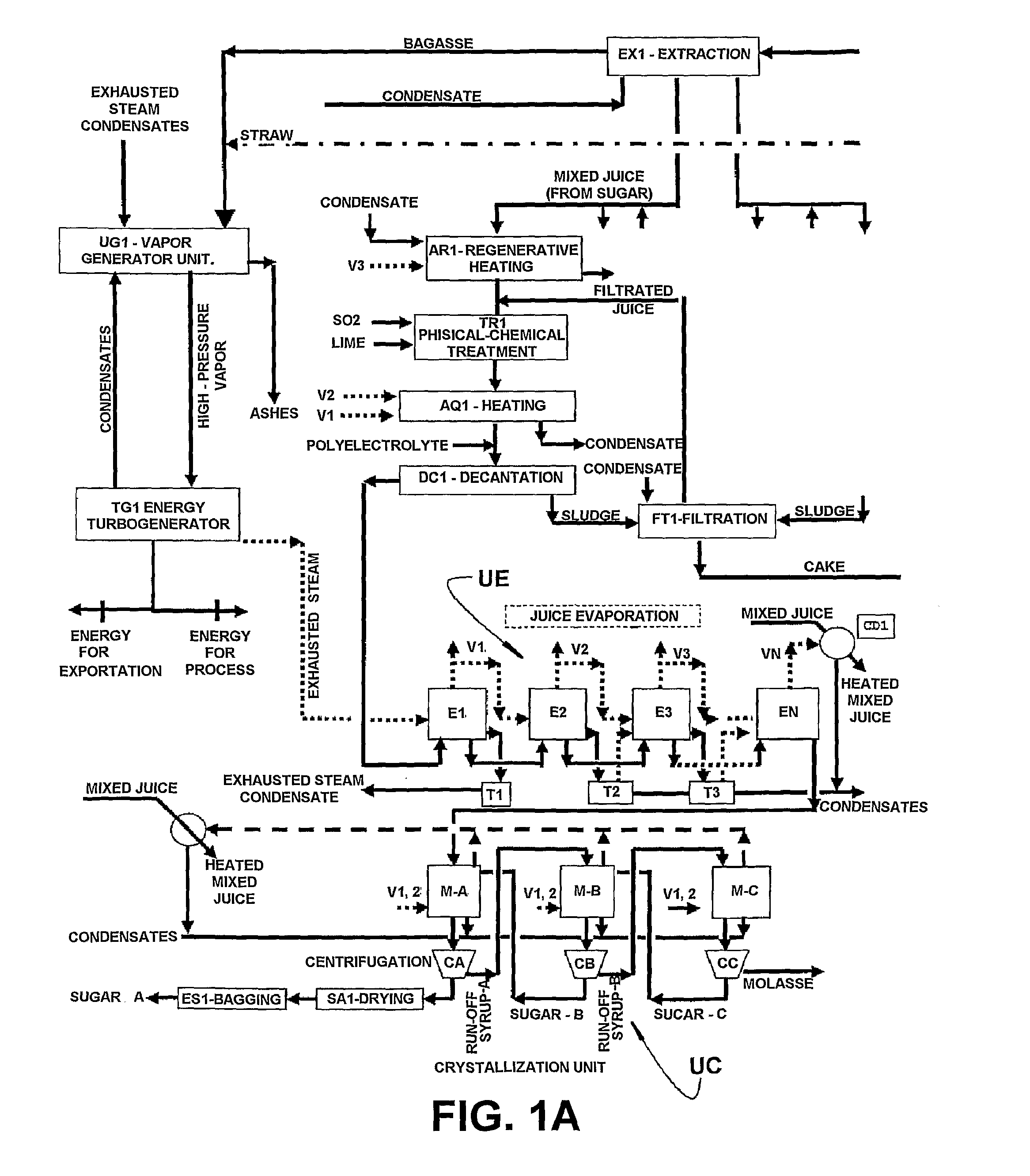

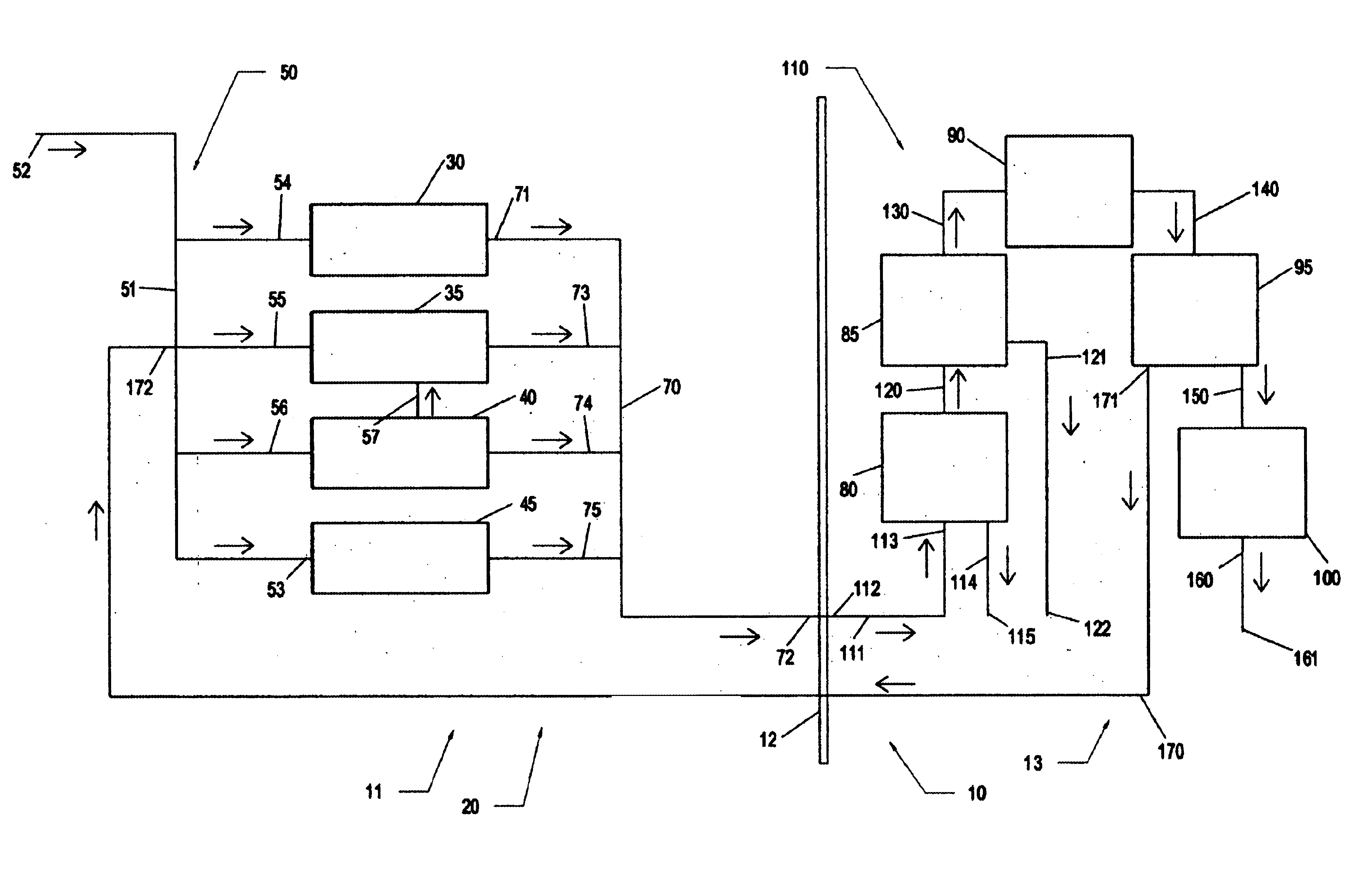

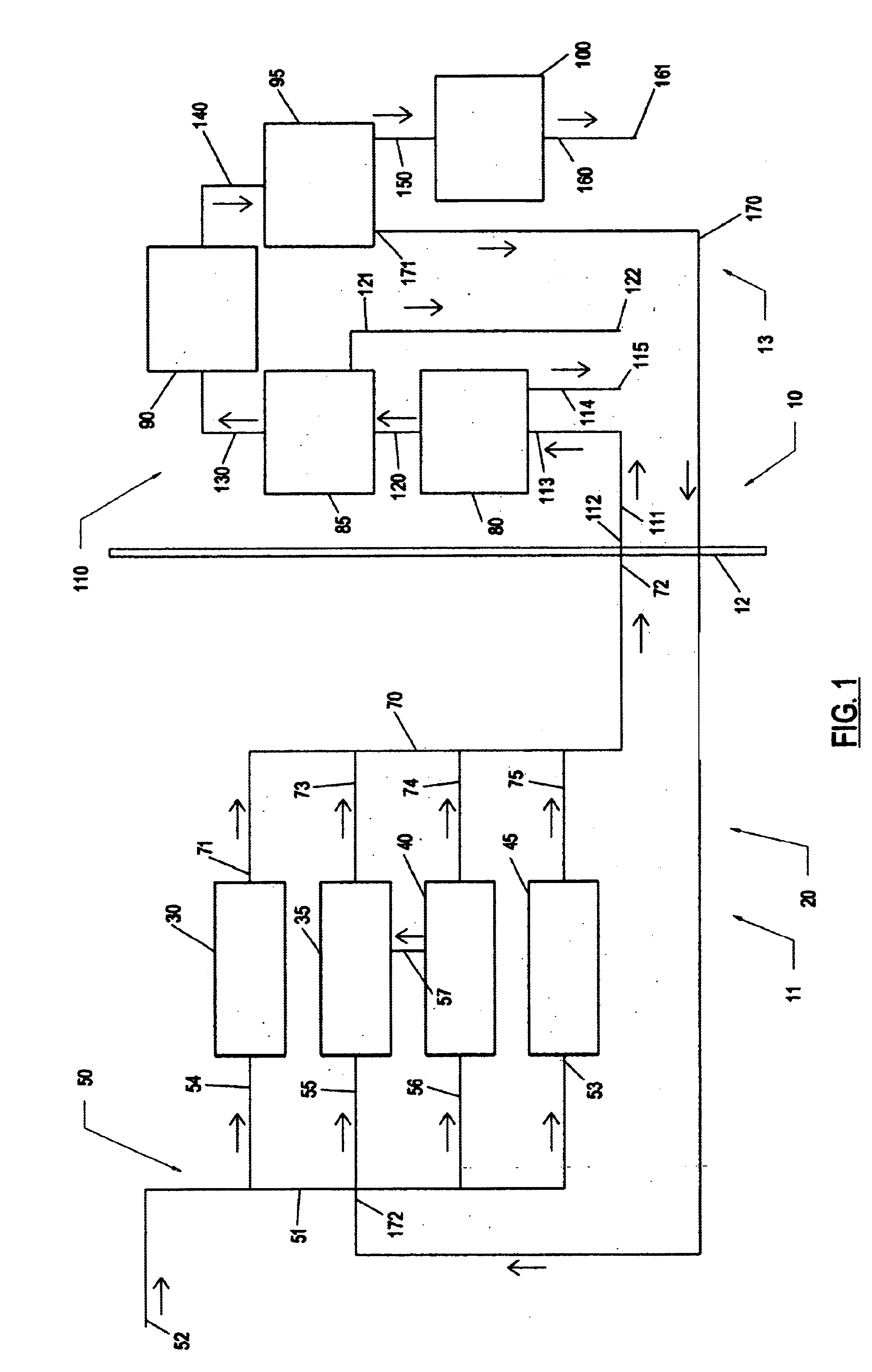

Process for the recovery of water and energy from the processing of sugar cane in sugar and ethanol production mills

ActiveUS20110232343A1Reduce consumptionEconomic savingsBio-organic fraction processingSugar crystal separationThermal energyCooling tower

A process is proposed for recovery of water in the sugar cane processing in production mills of sugar and alcohol or only alcohol (ethanol). In the process, the thermal energy available in the exhausted steam from the electric energy generation turbines is transferred to the different mixed juice processing phases, with the reuse of the exhausted steam condensates in the boilers and of the other condensates, after using thermal energy, for imbibition, in the juice extraction phase, for cooling in the process, after passing through cooling towers, for other industrial uses and for possible treatment or use in the irrigation out of the productive system in the mill

Owner:DEDINI S A IND DE BASE

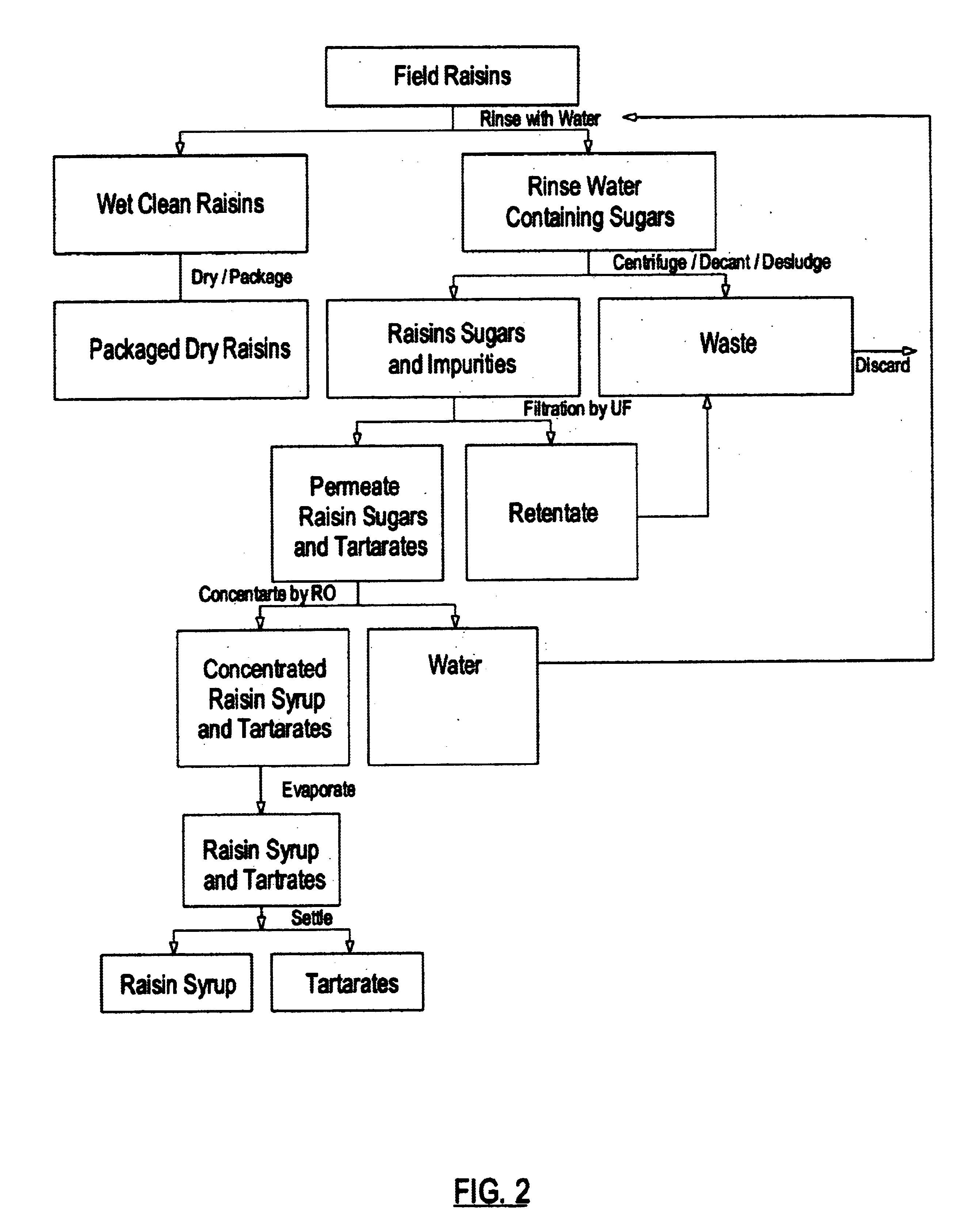

Method and apparatus for producing a work product

InactiveUS6736903B2Low costReduce the ratioPressurized chemical processSugar crystal separationReverse osmosisEngineering

A method for producing a work product including the steps of receiving a first fluid composed of a liquid, a target substance and at least one residual substance; passing the first fluid through a first work station for separating the residual substance from the first fluid to produce a secondary fluid substantially composed of the liquid and the target substance; and treating the secondary fluid to reduce the proportion of the liquid relative to the target substance in the secondary fluid to form the work product. An apparatus for producing a work product including an intake conduit adapted to receive a first fluid, composed substantially of water, a sugar substance and residual substances, from a rinsing system for raisins or the like; a first processing station adapted to remove the residual substances from the first fluid to form a second fluid, composed substantially of water and the sugar substance; and a second processing station adapted to treat the second fluid by reverse osmosis, nanofiltration, or the like to reduce the proportion of water relative to the sugar substance in the second fluid to form the work product.

Owner:SUNSHIE RAISIN CORP

Process for the production of invert liquid sugar

InactiveUS6916381B2Reduce amountFew stepsPurification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com