Patents

Literature

56results about "Sugarcane cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparation of brown sugar from sugarcane

InactiveCN105063239AReduce cokingLow boiling pointSugarcane cuttingLiquid solutions solvent extractionBoiling pointEvaporation

The invention provides a process for preparation of brown sugar from sugarcane. The process includes: juicing, ethanol extraction, heating and impurity removal, and mixed boiling four steps. According to the invention, by means of extracting the residual sugar in the squeezed residue through ethanol, sugar in sugarcane can be transformed maximumly, also the sugarcane juice is firstly boiled, black foams in the juice is removed by filtering, and the filtrate is mixed with a sugar-containing ethanol solution, thus not only lowering the boiling point of the solution, reducing sugar coking, but also accelerating the evaporation of water and ethanol in the solution, and speeding up sugar making. Experiments show that the sugar making time of the process is in the range of 4-4.5. The brown sugar prepared by the process provided by the invention completely adopts physical method, is not added with any chemical, and the sugar product is very healthy.

Owner:GUANGXI NANNING PAITENG TECH

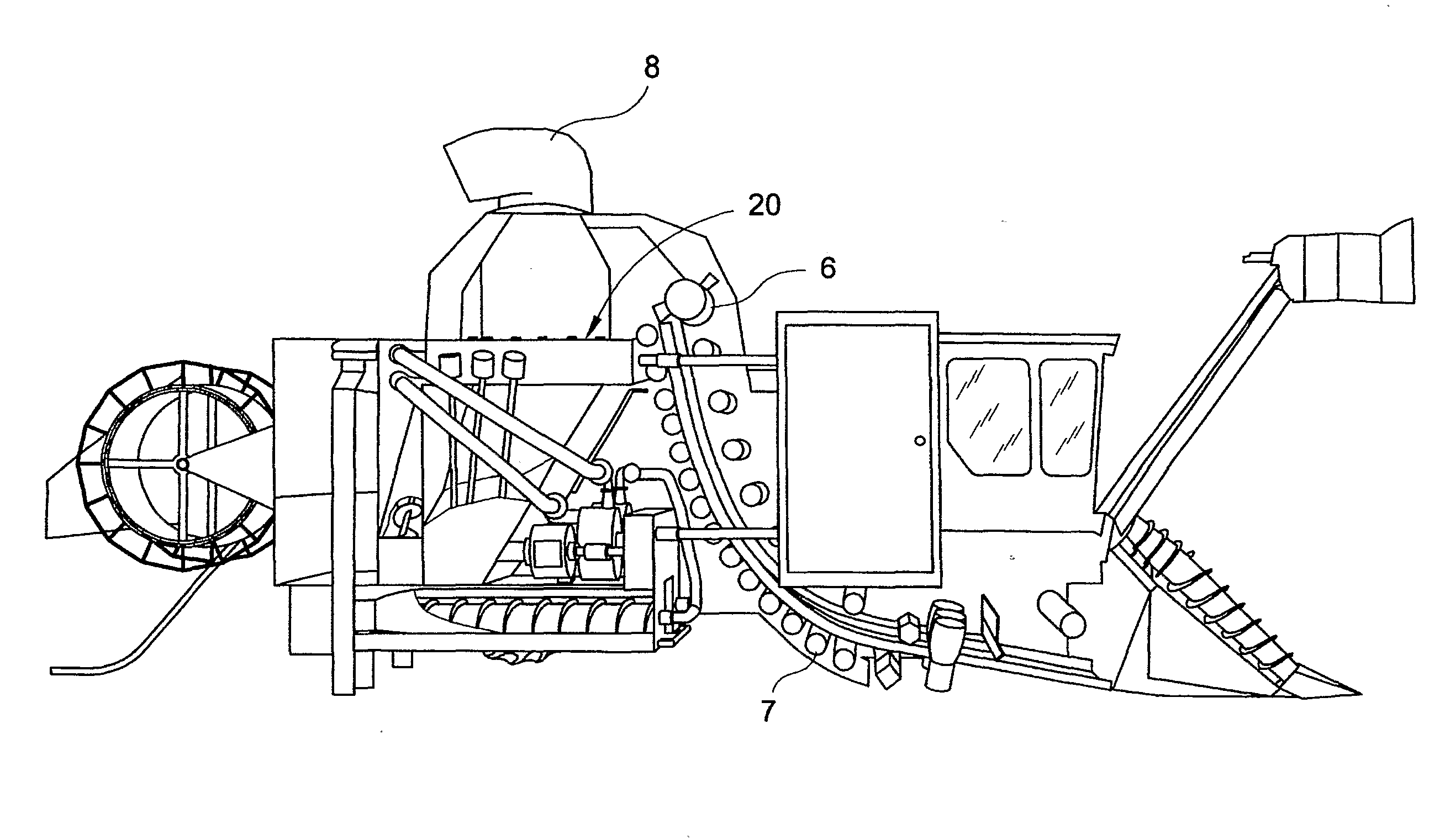

Biomass Processor

ActiveUS20090241944A1Facilitated releaseIncrease shear forcePressurized chemical processSugarcane cuttingFiberBiomedical engineering

Owner:BIOMASS TECH PTY LTD

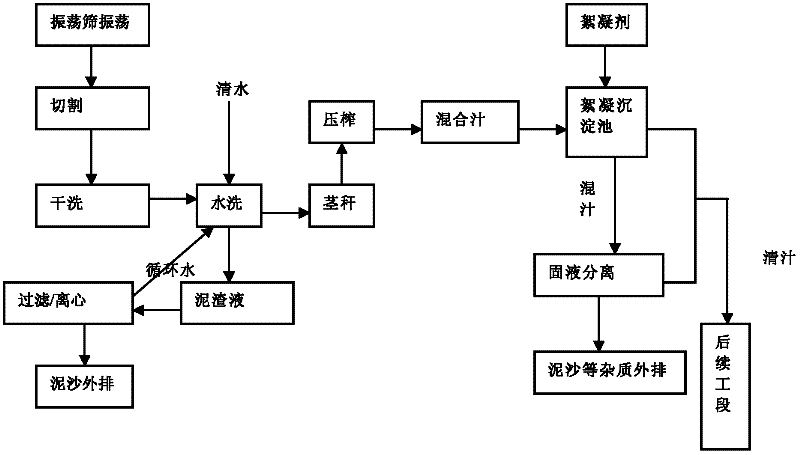

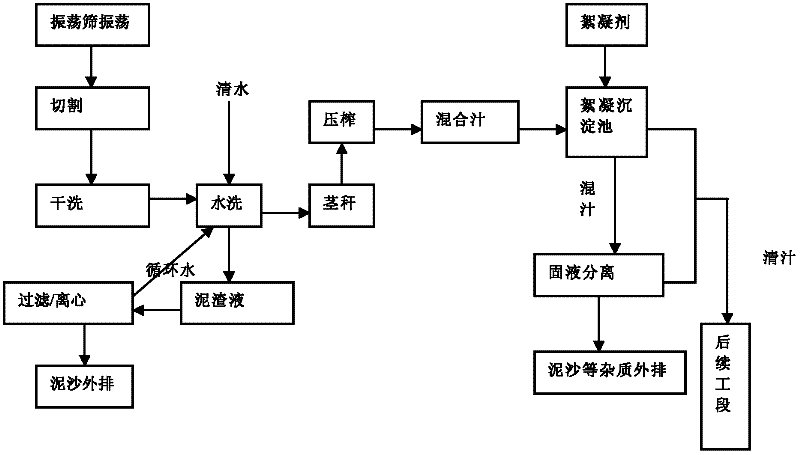

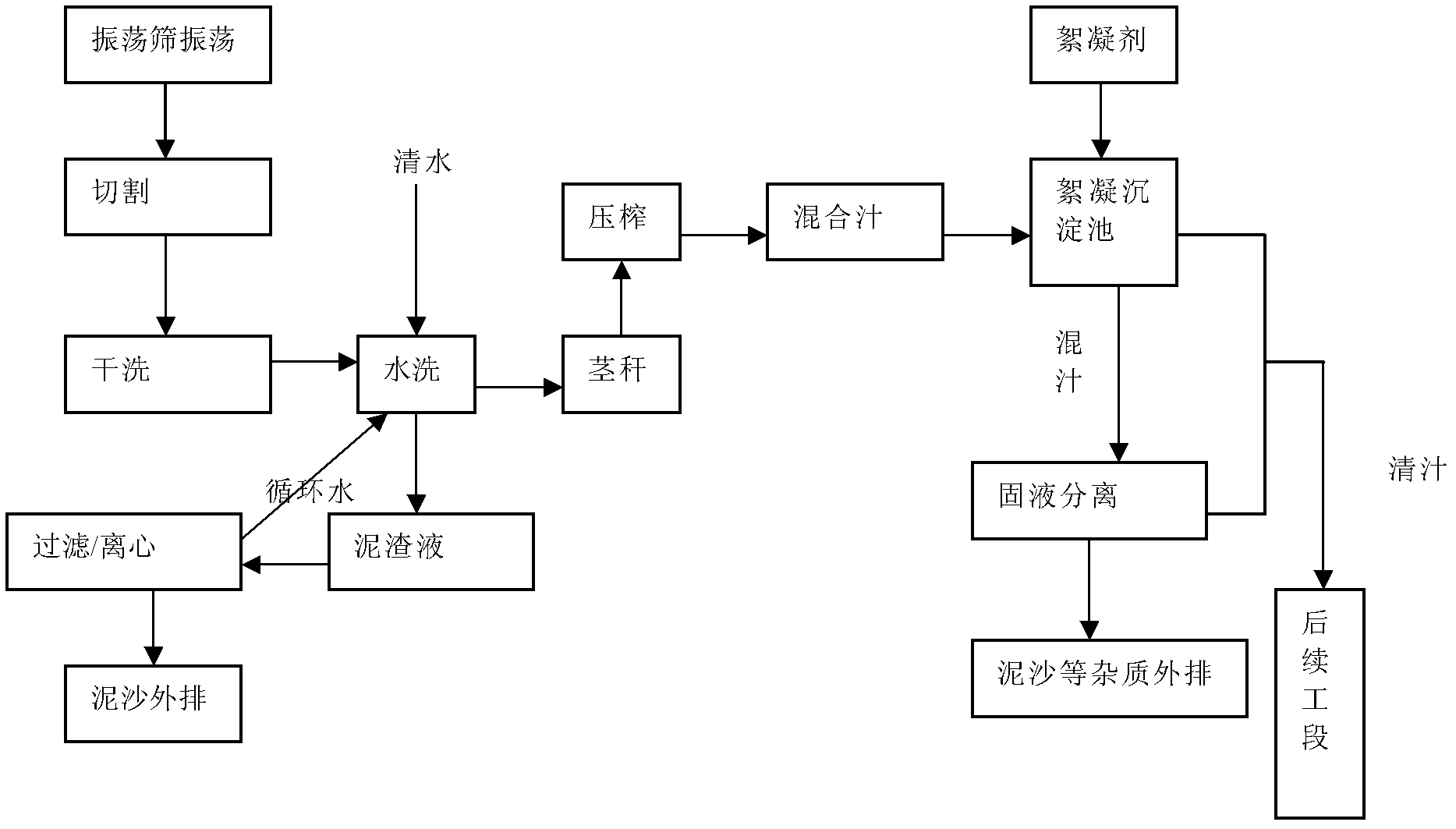

Method for removing impurities from sorgo

ActiveCN102492780ASimple processLow running costSugarcane cuttingSugar juice purificationWater volumeSugar

The invention provides a method for removing impurities from sorgo. The method comprises the following steps of: cutting: cutting sorgo straws into 10-30cm; dry-cleaning: conveying the cut material into a disperser for dispersing and extracting at negative pressure at the same time; water-cleaning: conveying the dried-cleaned material by a link plate, wherein the dried-cleaned material is sprayed and rinsed 3-4 times according to the water volume of 0.05-0.3t in each ton of straws; squeezing: squeezing the rinsed material to produce mixed sugar juice; and flocculating: adding a flocculating agent to the mixed sugar juice for carrying out flocculating reaction, and feeding the flocculated supernatant juice into a subsequent working section. The method disclosed by the invention realizes removal of the impurities in the sorgo straws with a simple and efficient method, is beneficial to reducing the influence on the subsequence process, has a simple process and greatly-reduced operation cost and ensures that relative loss of sugars in the materials is little.

Owner:兴储世纪科技股份有限公司

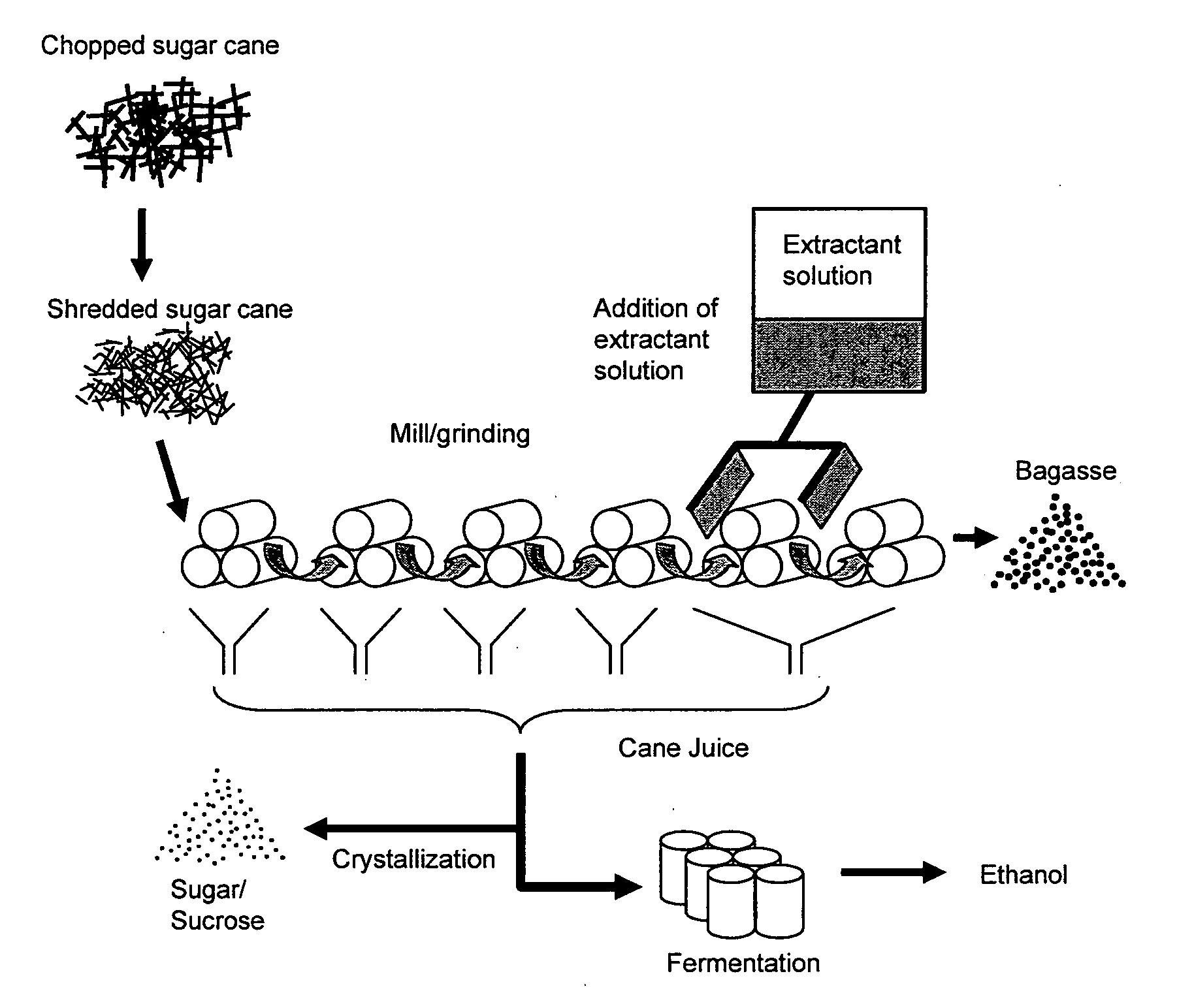

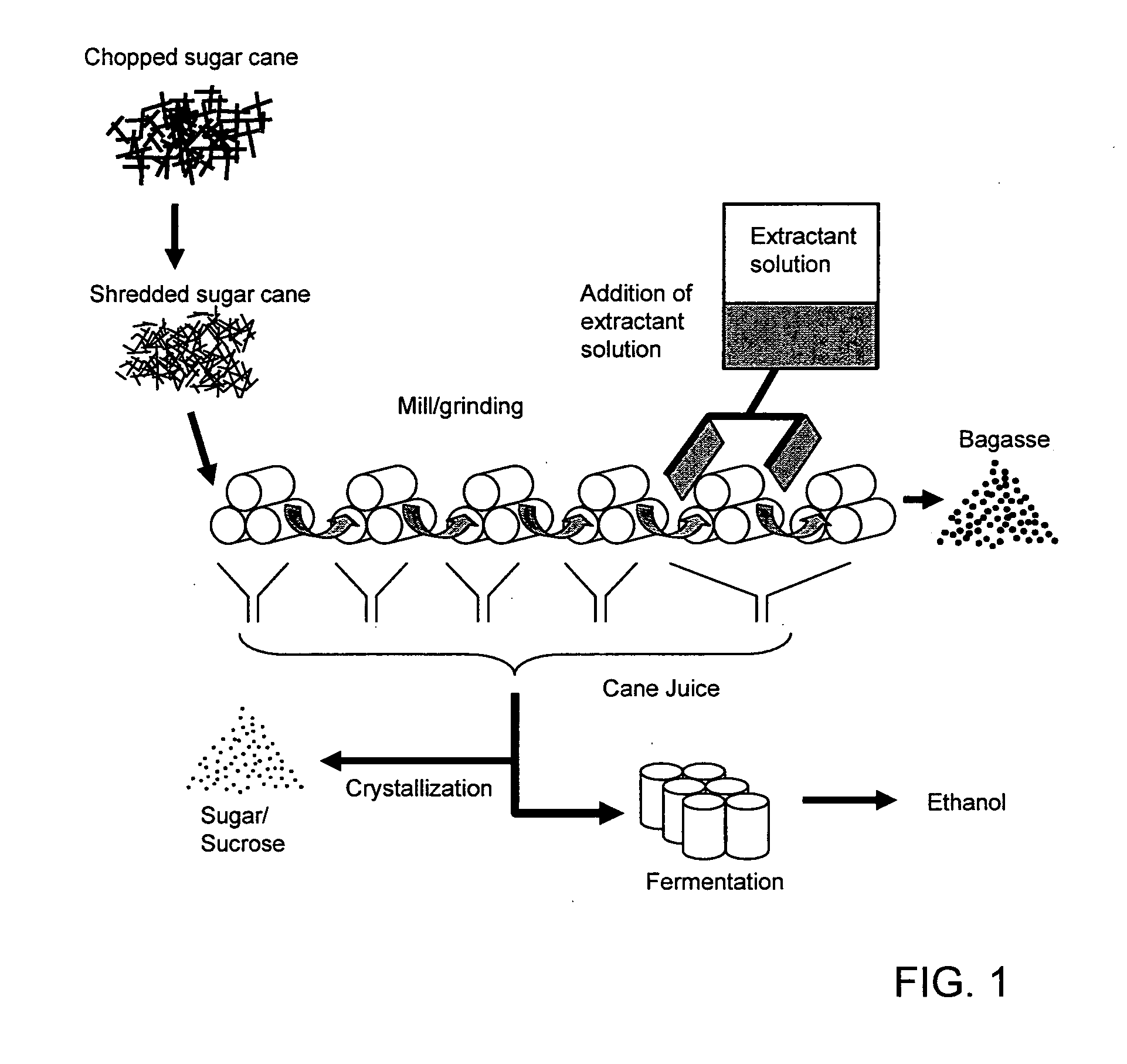

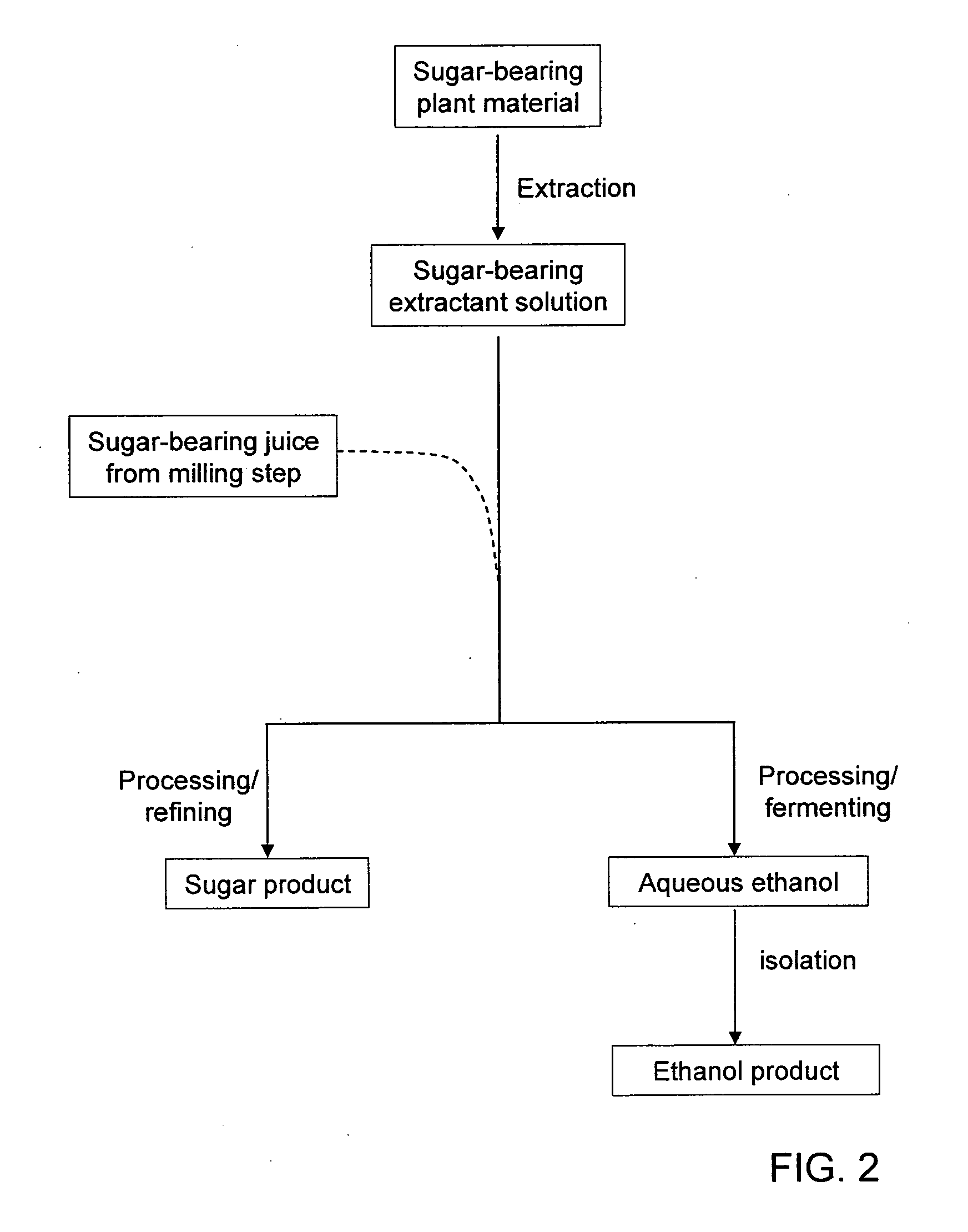

Processes for Extraction of Sugar From Sugar-Bearing Plant Material

The invention provides processes for the extraction of sugar from sugar-bearing plant material such as sugar cane. Accordingly, in one aspect of the invention, a process for extracting sugar from sugar-bearing plant material comprises contacting the sugar-bearing plant material with an extractant solution comprising water and a surfactant; and separating the extractant solution from the sugar-bearing plant material. One example of a suitable surfactant is a poly(alkylene oxide) polymer such as a poly(propylene oxide) polymer, a poly(ethylene oxide) polymer, or a poly(propylene oxide) / (ethylene oxide) copolymer.

Owner:DOW BRASIL SUDESTE IND

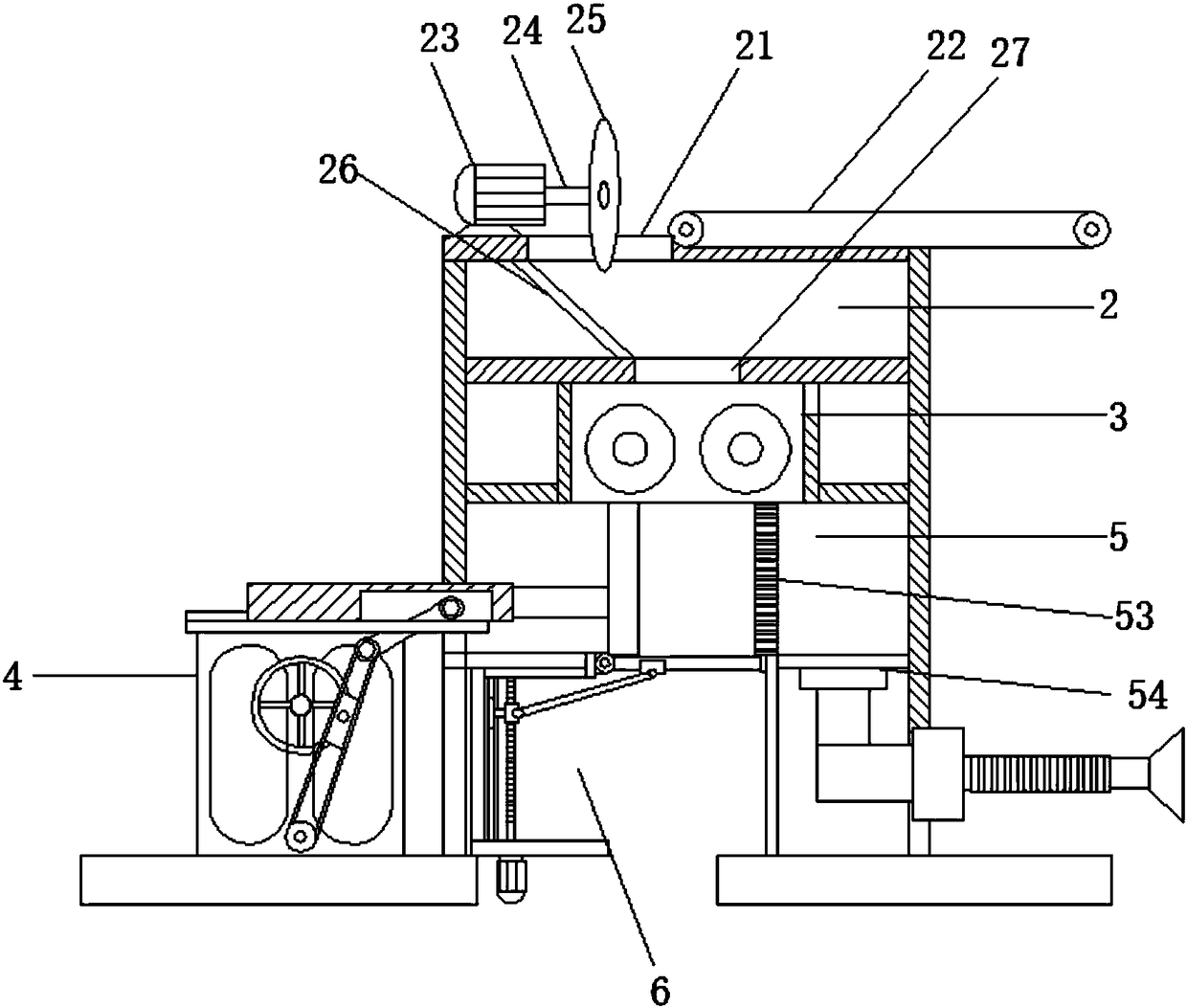

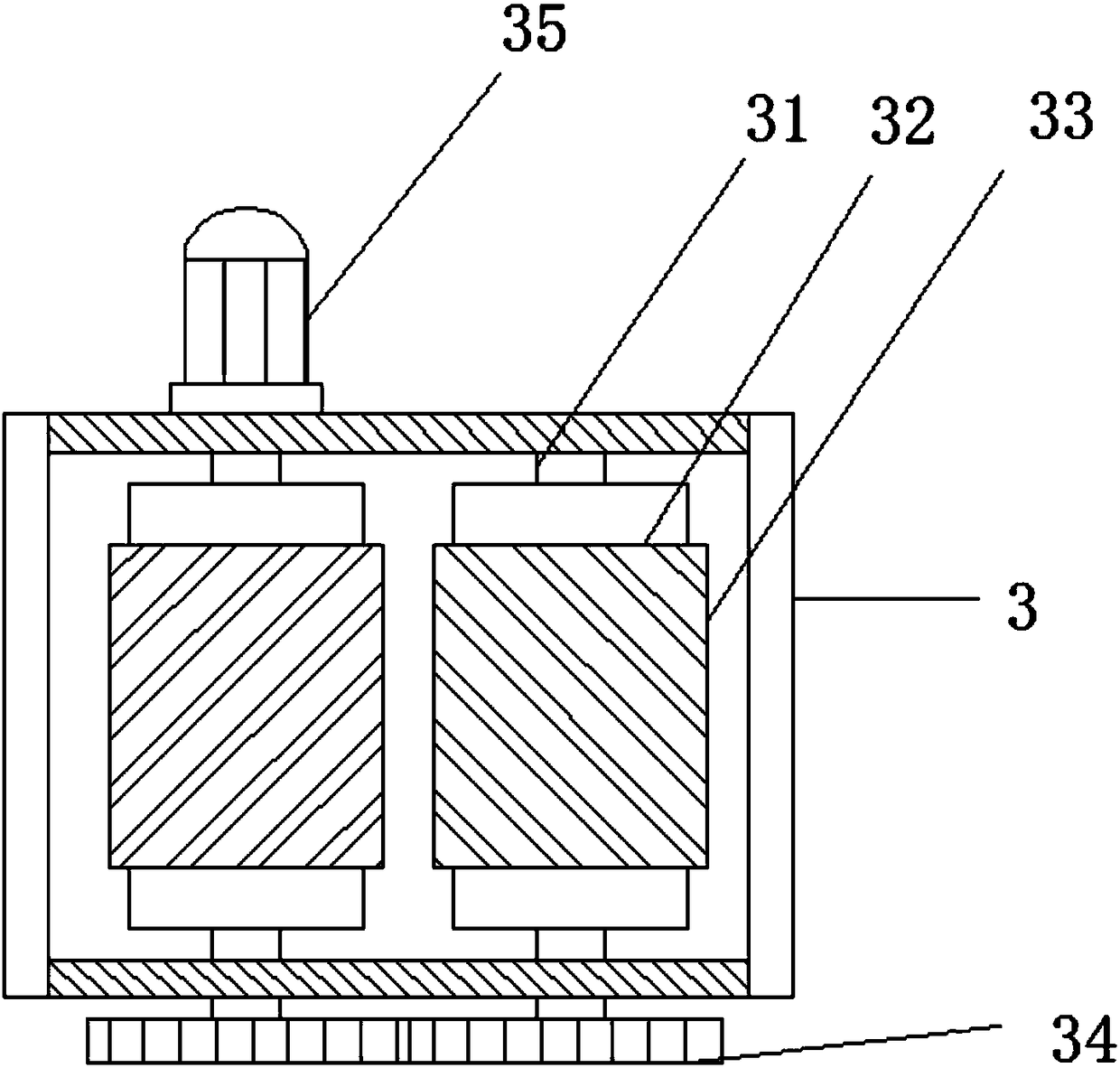

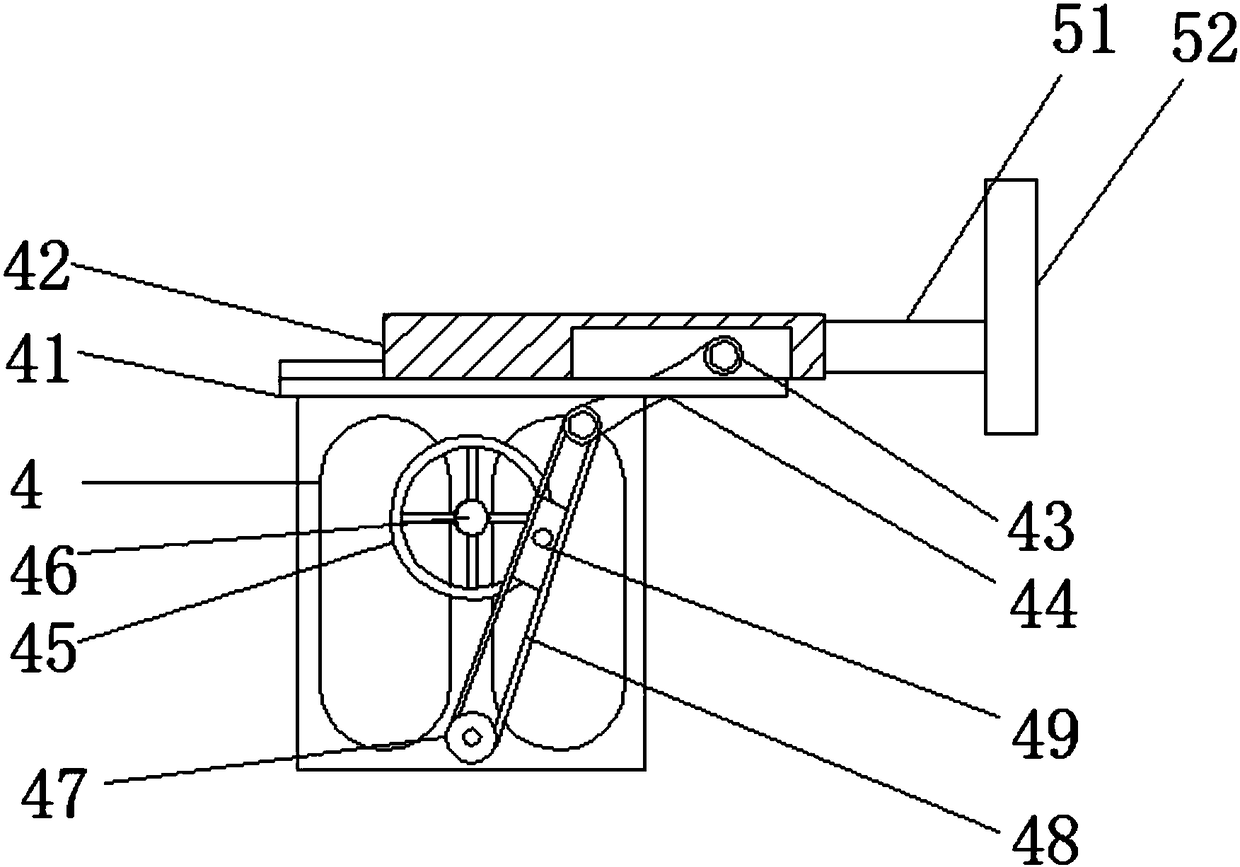

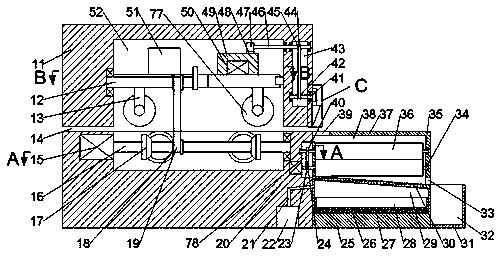

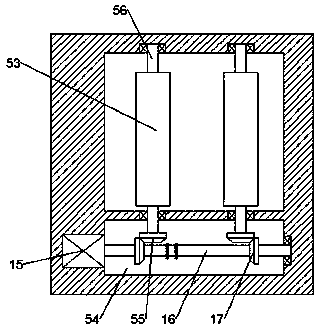

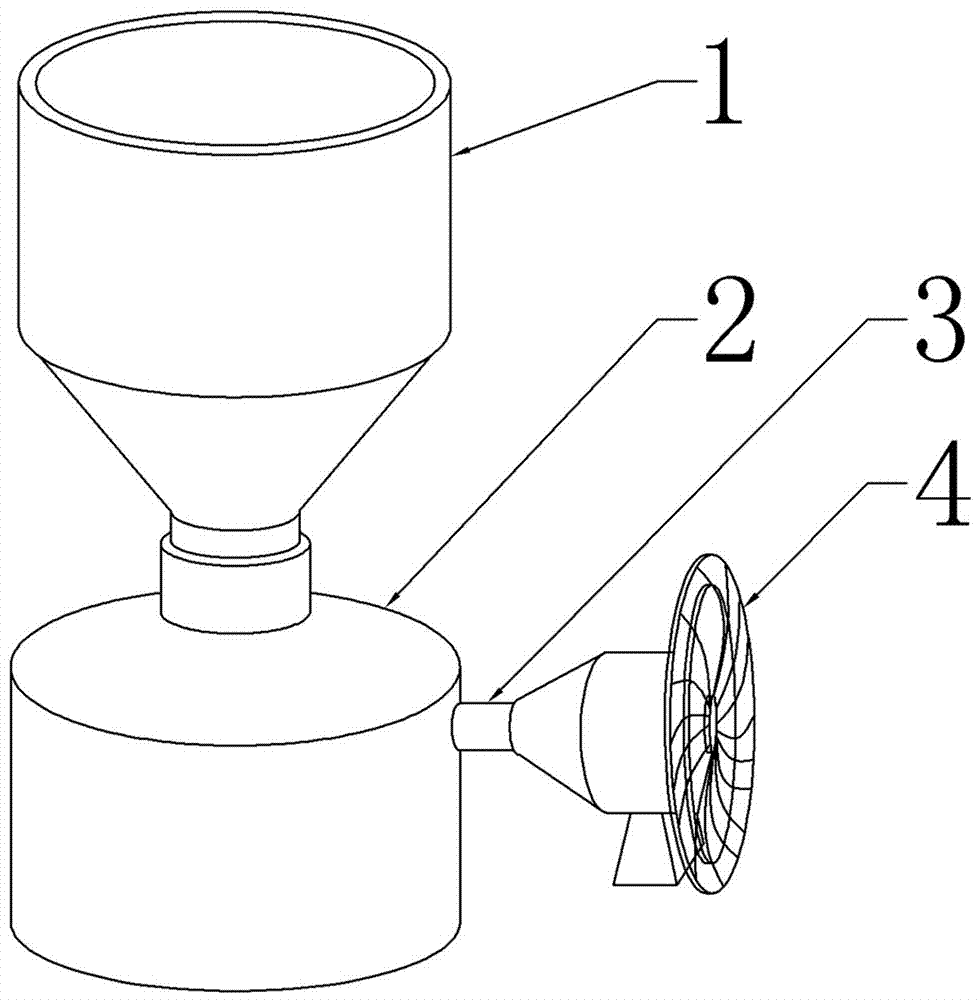

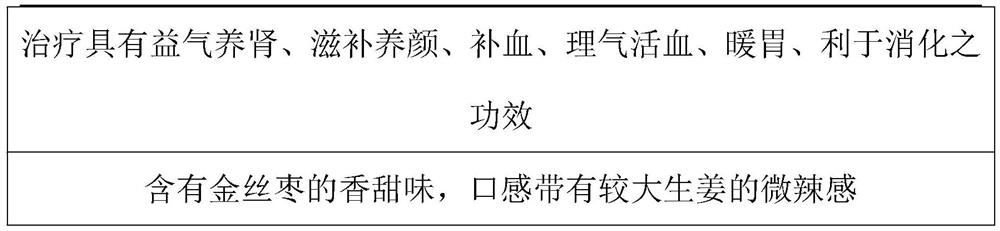

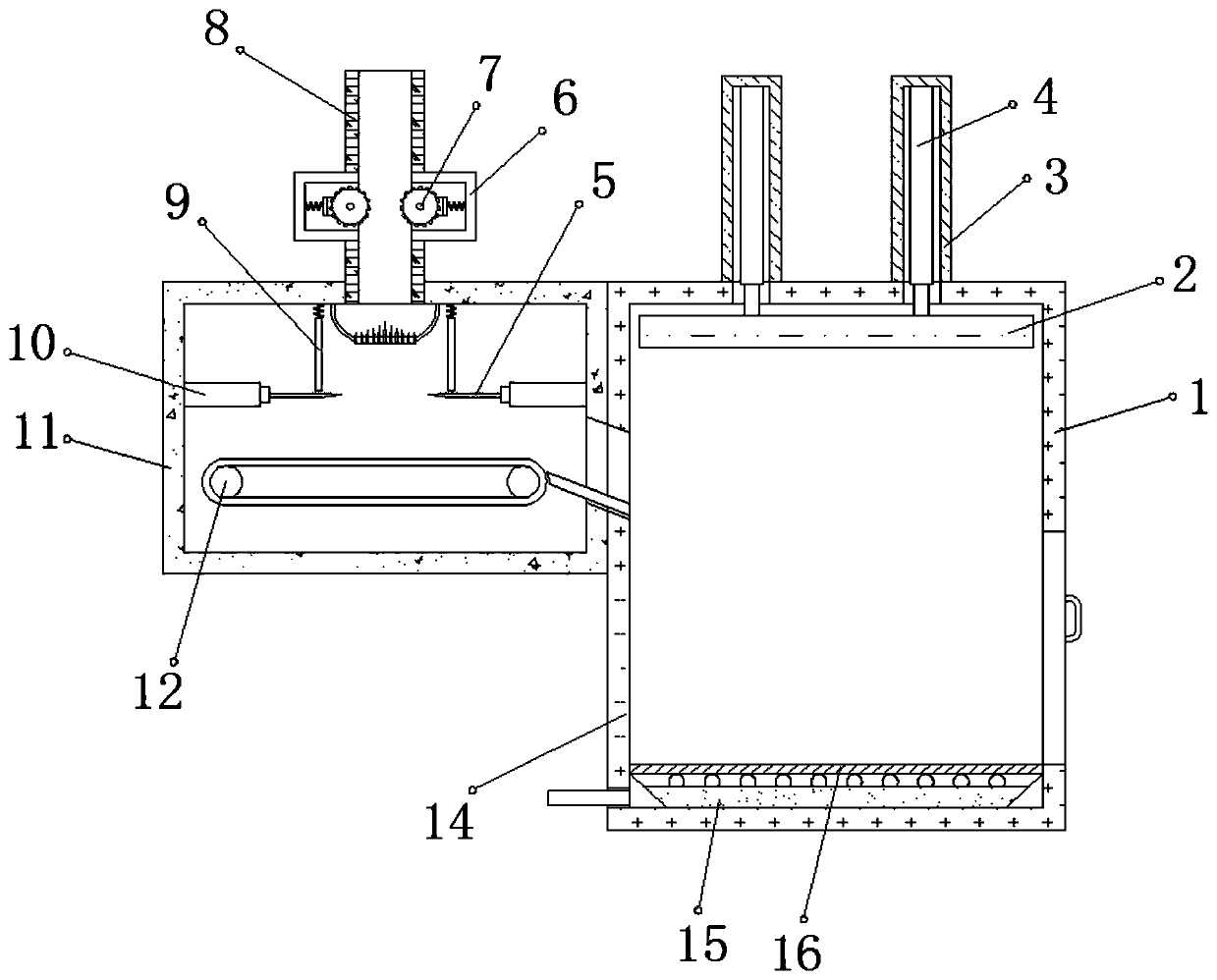

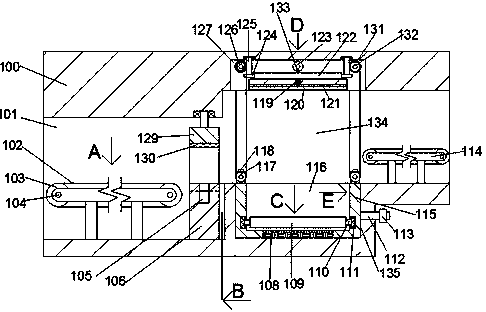

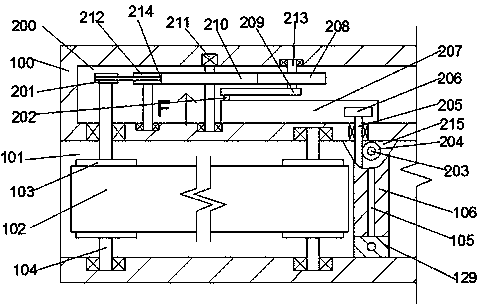

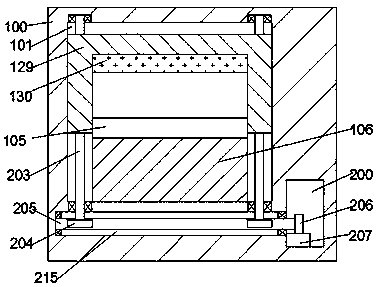

Extrusion juice squeezing device for sugarcane

PendingCN108546787AEfficient dischargeEasy to handleSugarcane cuttingSugarcane shreddingEngineeringMechanical engineering

The invention discloses an extrusion juice squeezing device for sugarcane. The extrusion juice squeezing device comprises a machine frame, wherein a material conveying cavity, a crushing cavity, an extrusion cavity and a material discharging cavity are formed in the machine frame; a transmission frame is arranged at the back side of the machine frame; a slide groove is formed in a top plate of thetransmission frame; a movable plate is arranged on the slide groove; a movable shaft is transversely arranged in an inner cavity of the movable plate; a transmission block is arranged on the movableshaft; the middle position of the transmission frame is provided with a transmission disc through a rotating shaft; the bottom end of the transmission frame is provided with a fixed shaft bolt; a slide rail is connected between the tail end of the transmission block and the fixed shaft bolt; a slide block is arranged in the slide rail; the slide block is connected with an outer disc of a transmission disc through a locking bolt; a push rod is arranged at the front end of the movable plate; the push rod extends into the extrusion cavity; the front end of the push rod is provided with an extrusion plate. The operation stroke of a crank connecting rod mechanism is shorter than the return stroke, so that the high-impact force during the extrusion in each time is maintained; the extrusion juicesqueezing effect is ensured.

Owner:孙明

Method for refining sugar through sugar refining apparatus

The invention discloses a method for refining sugar through a sugar refining apparatus. The sugar refining apparatus comprises a cleaning box, and further comprises a cleaning mechanism, wherein a cleaning cavity is formed in the cleaning box, the cleaning mechanism is arranged in the cleaning cavity, a drive cavity is arranged in the front side of the cleaning cavity, a drive mechanism is arranged in the drive cavity and comprises a drive motor, a rightwards output shaft of the drive motor is connected with a drive rod, and a drive main bevel gear on the drive rod controls a main cleaning brush in the cleaning cavity to rotate. The sugar refining apparatus is simple in structure and convenient to operate, is an integral machine with functions of cleaning, cutting, pressing and distilling,and can complete sugar refining without multiple devices in the prior art; since sugarcane is cleaned automatically, a great amount of labor force is saved, sugarcane cleaning amount is increased, and the sugar refining speed of the whole apparatus is increased; a distilling mechanism and a filtering mechanism in the apparatus can treat filter residues and distilled moisture.

Owner:义乌市绿美生物科技有限公司

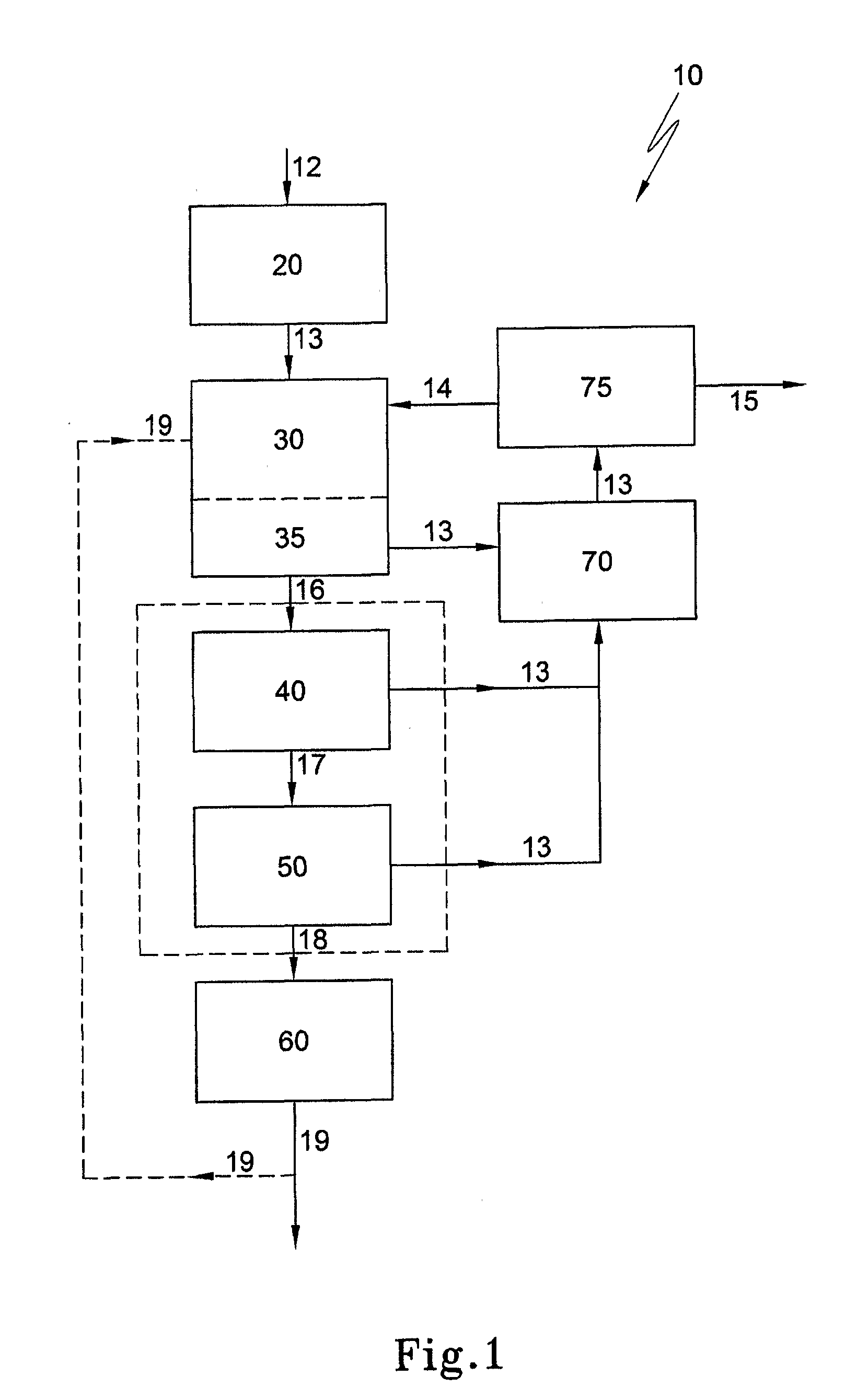

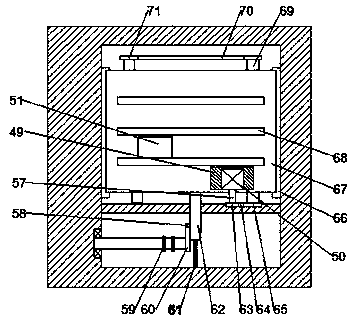

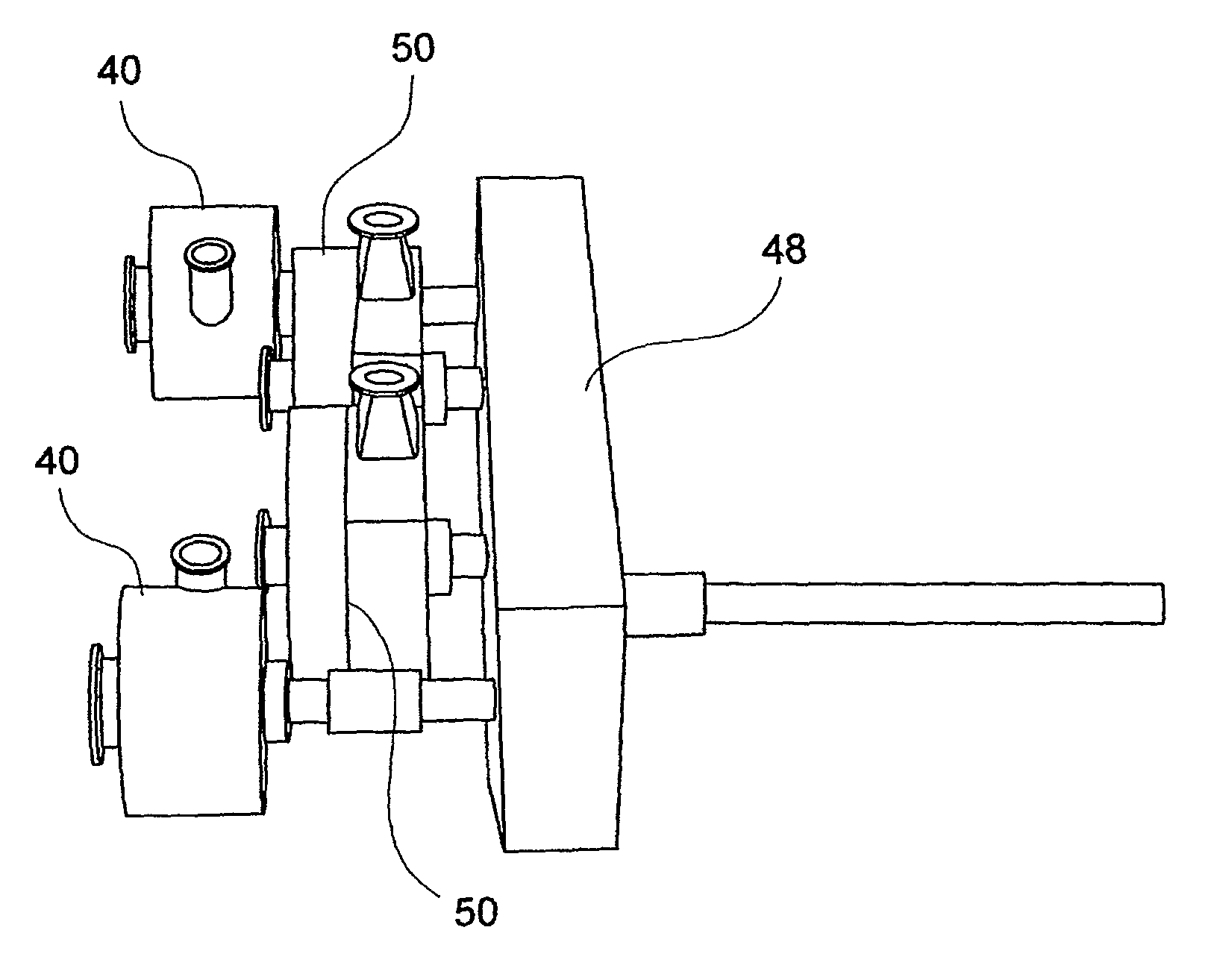

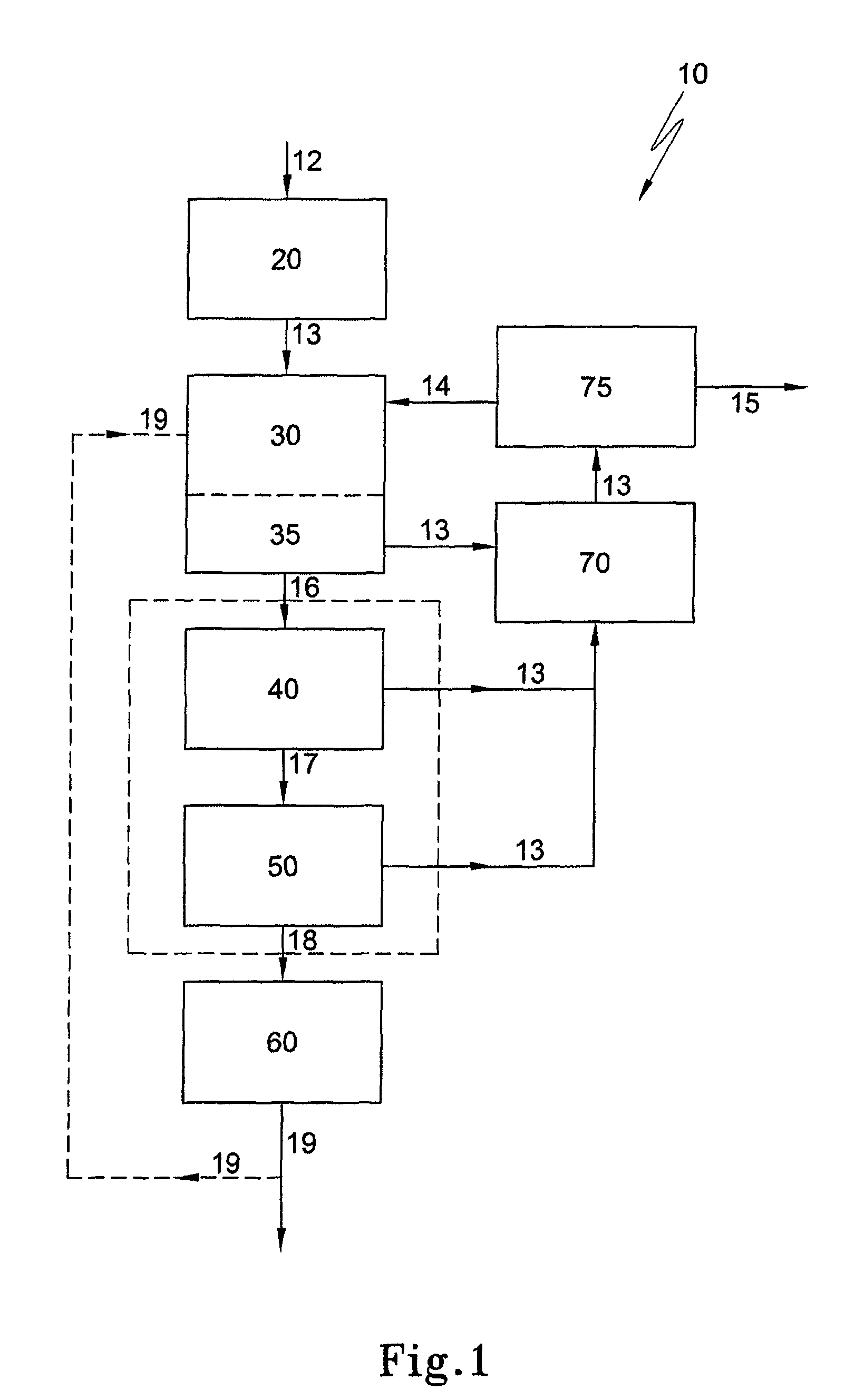

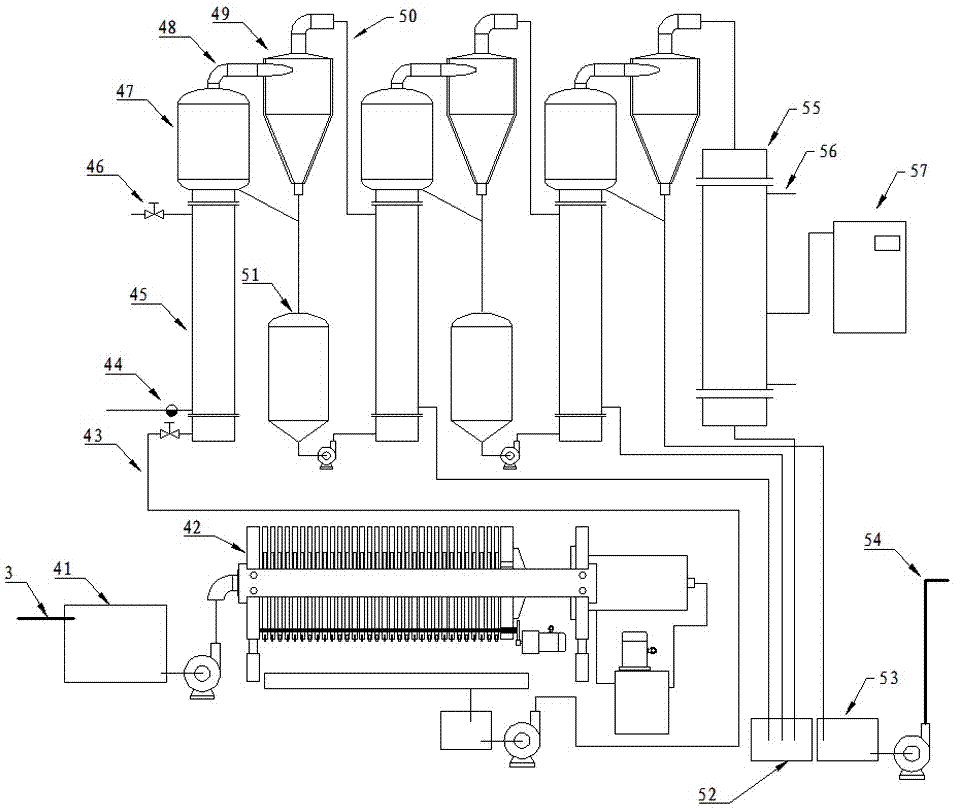

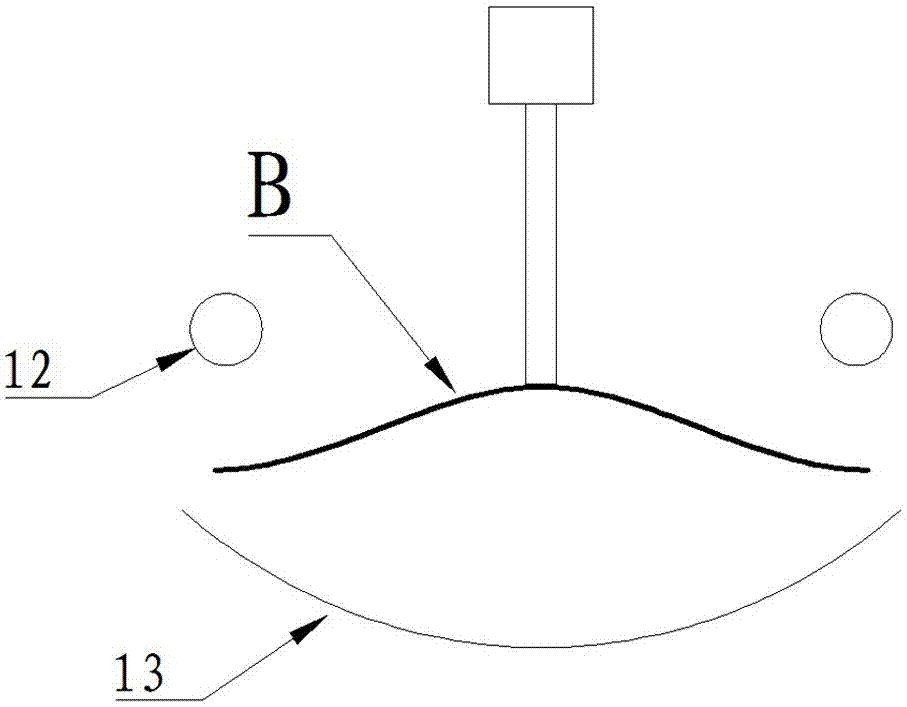

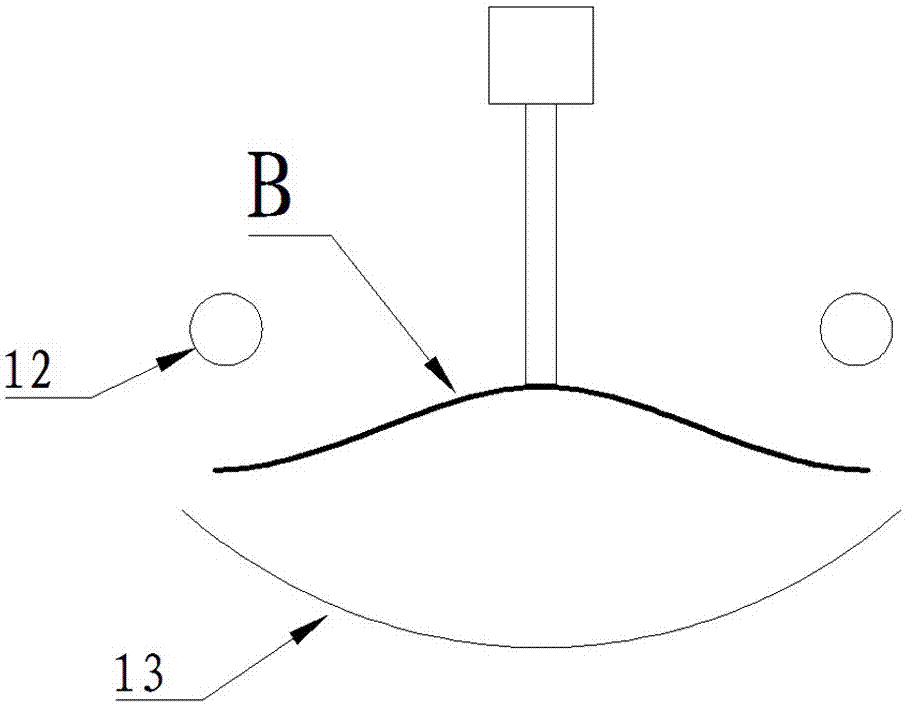

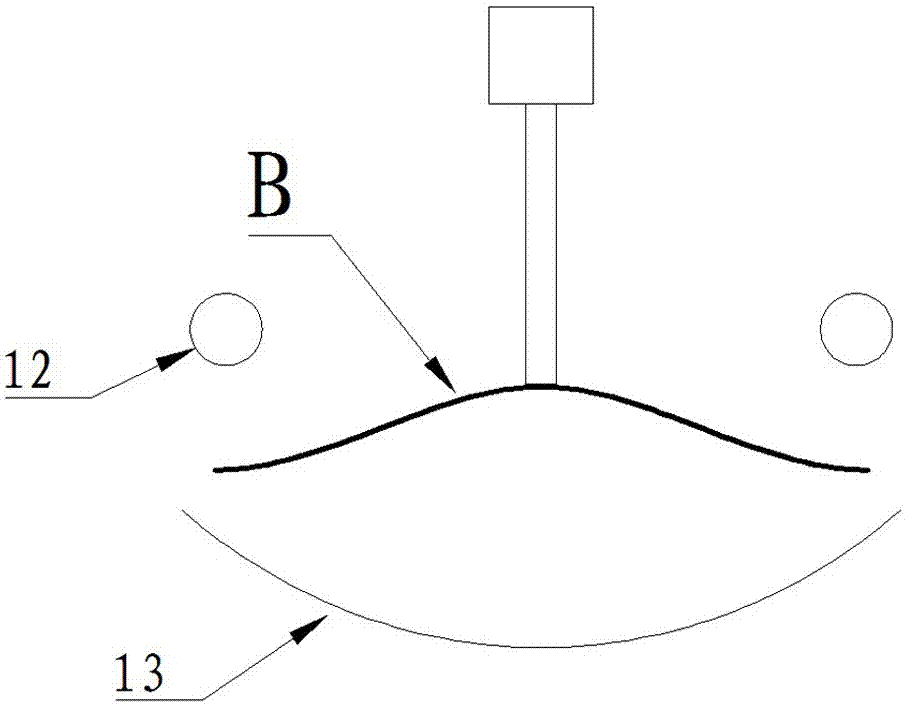

Biomass processor

ActiveUS7959736B2Facilitated releaseFacilitates at least partial releasePressurized chemical processSugarcane cuttingFiberBiomedical engineering

A process (10) and apparatus (2) for extracting juice from a fibrous material. The process (10) comprises a step of feeding the fibrous material (13) into a receiving chamber (30) having a fluid contained therein. The fibrous material (13) is then combined with the fluid in the receiving chamber (30) to form a first fluid mixture. The first fluid mixture is then passed through at least one cell disruptor device (40) to facilitate at least partial release of juice from the fibrous material into the first fluid mixture, thereby forming a second fluid mixture having a relatively higher released juice content than said first fluid mixture with relatively finely disrupted fibrous material suspended therein. The second fluid mixture is then collected.

Owner:BIOMASS TECH PTY LTD

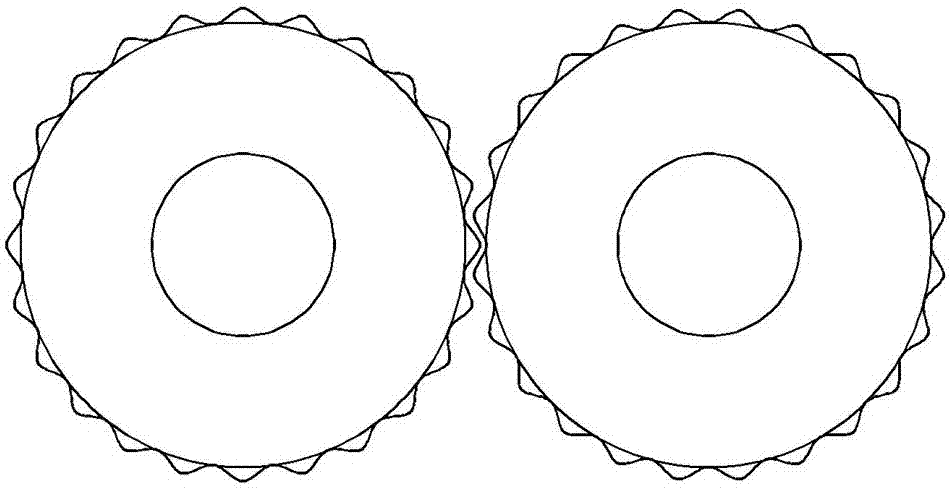

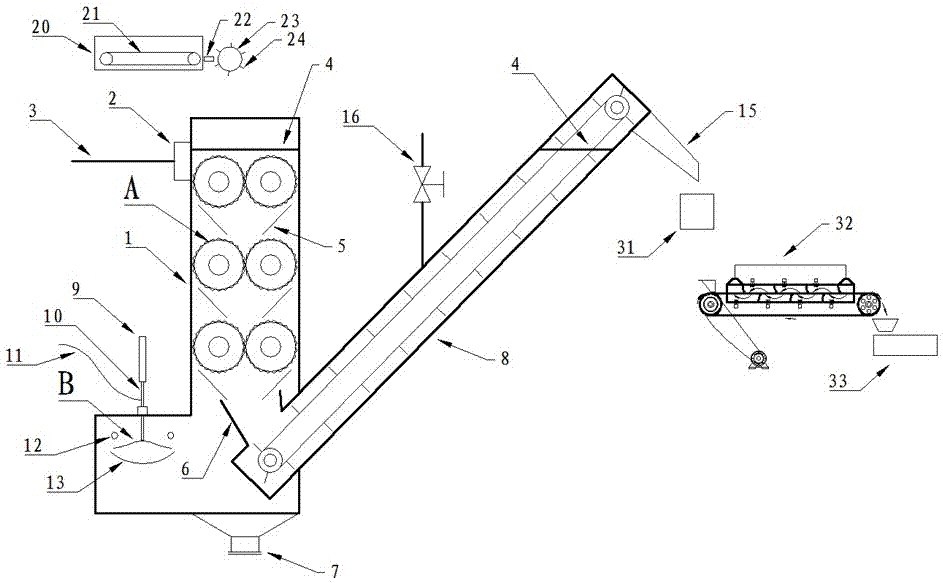

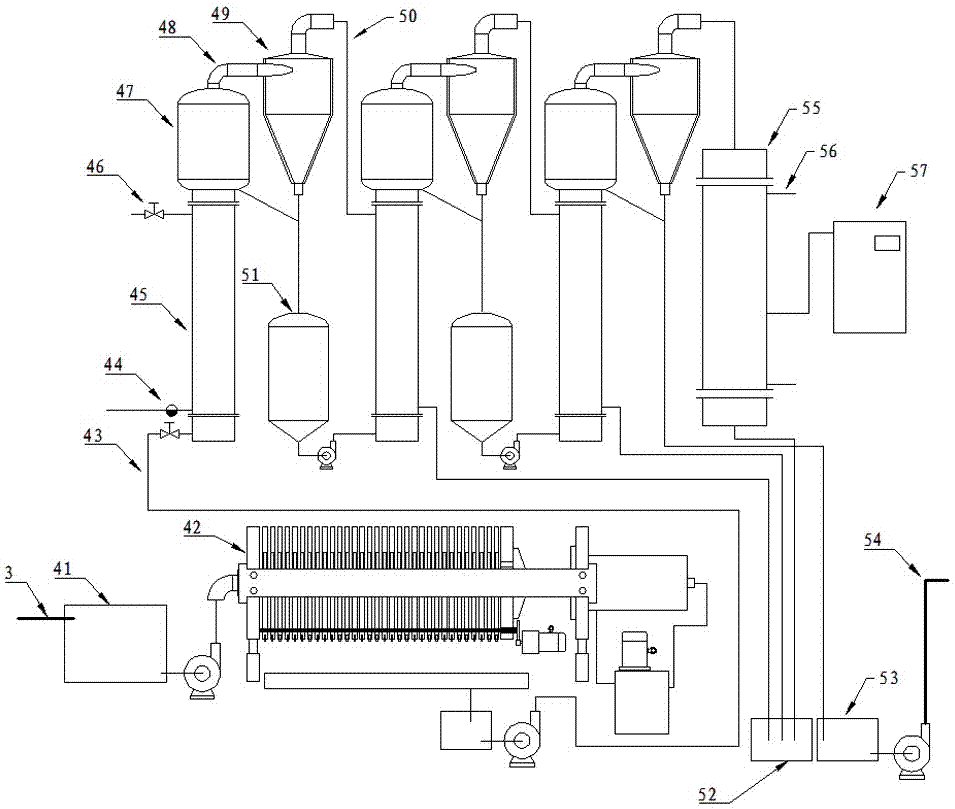

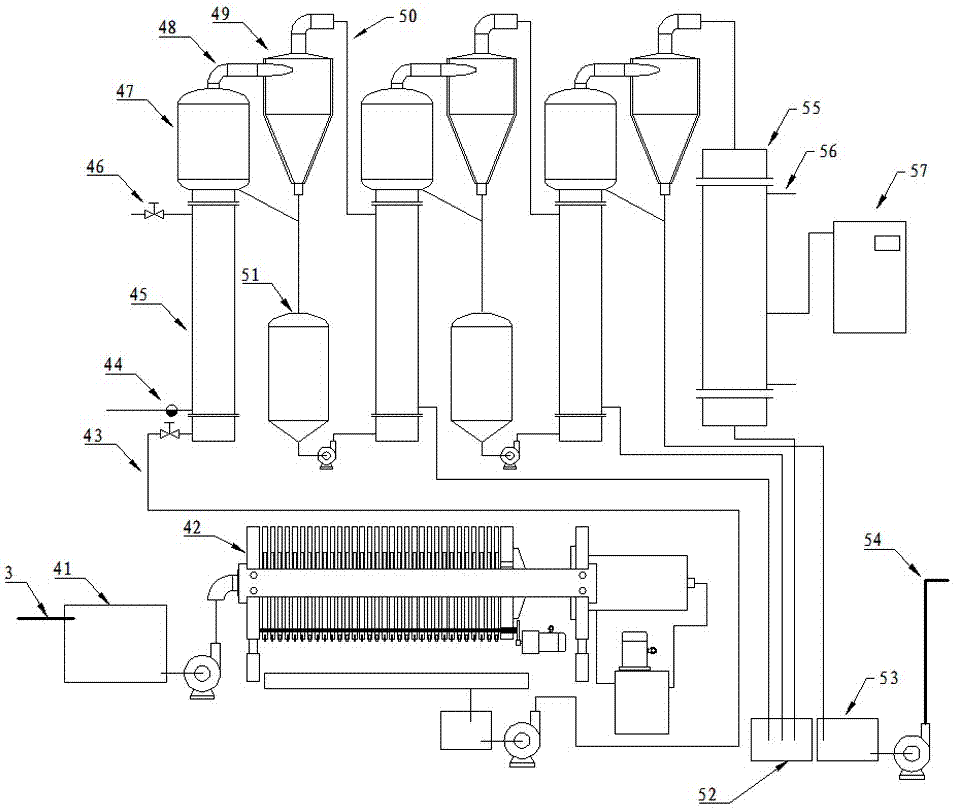

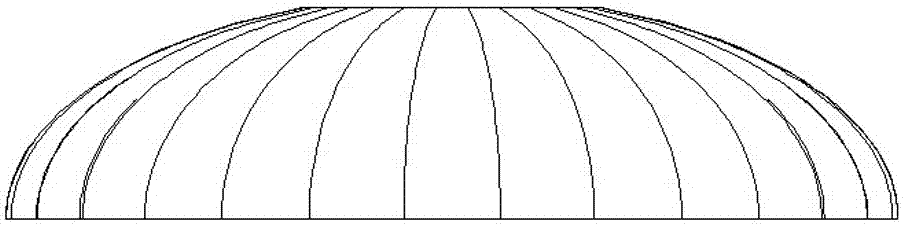

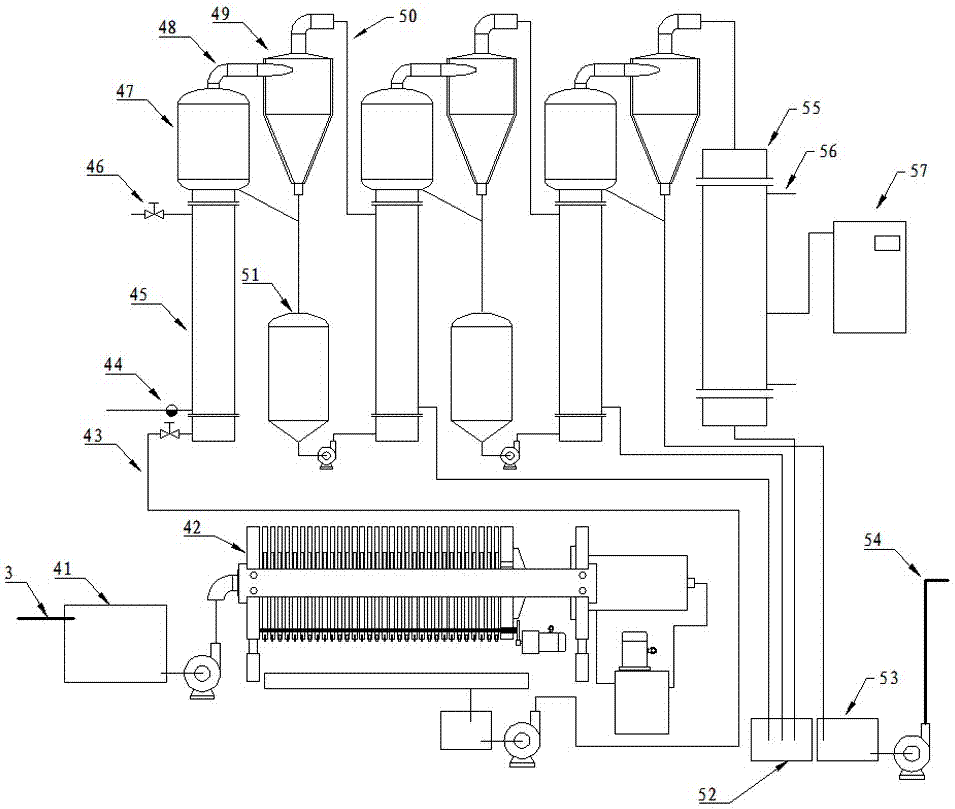

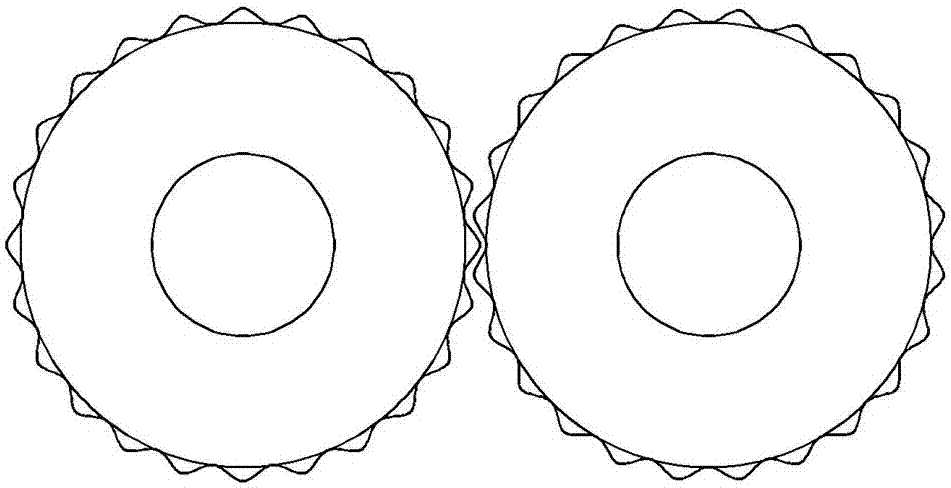

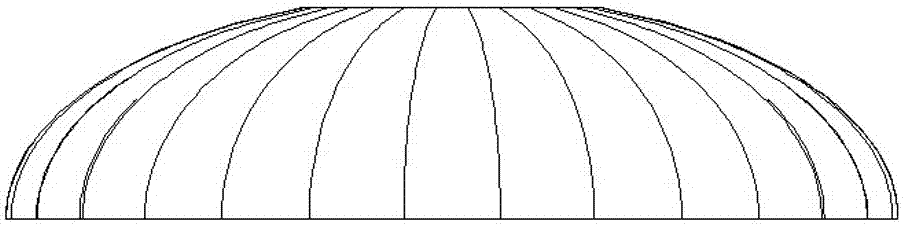

Sugarcane bagasse treatment device with straw cutting machine and carbon-making molding machine

InactiveCN107299161AContinuous and reliable biteExtrusion compression ratio is largeSolid waste disposalTransportation and packagingThree levelMolding machine

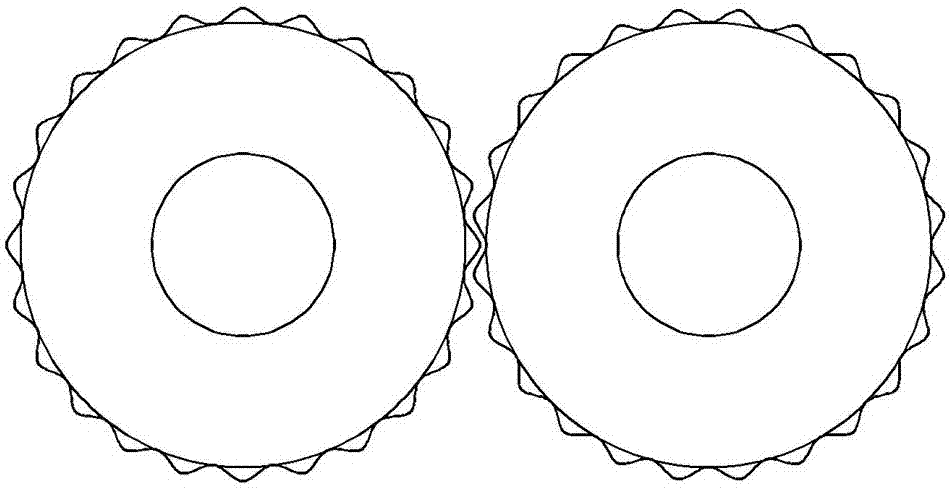

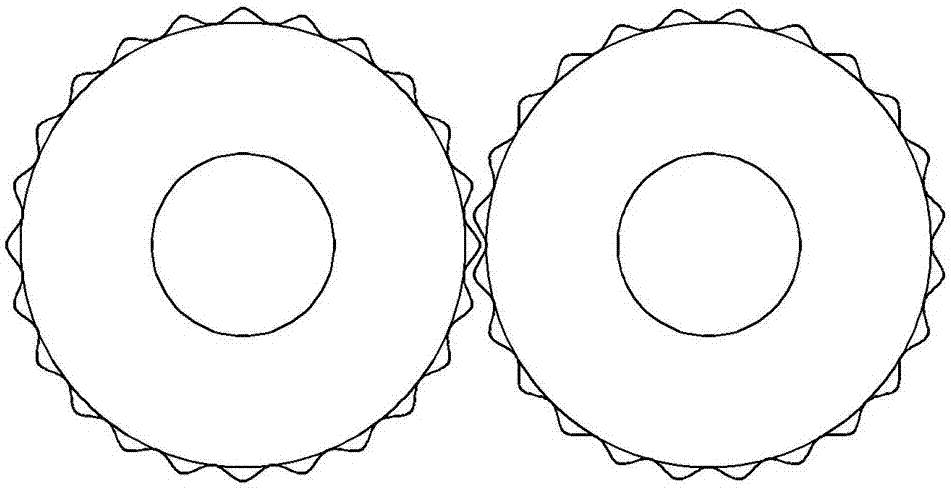

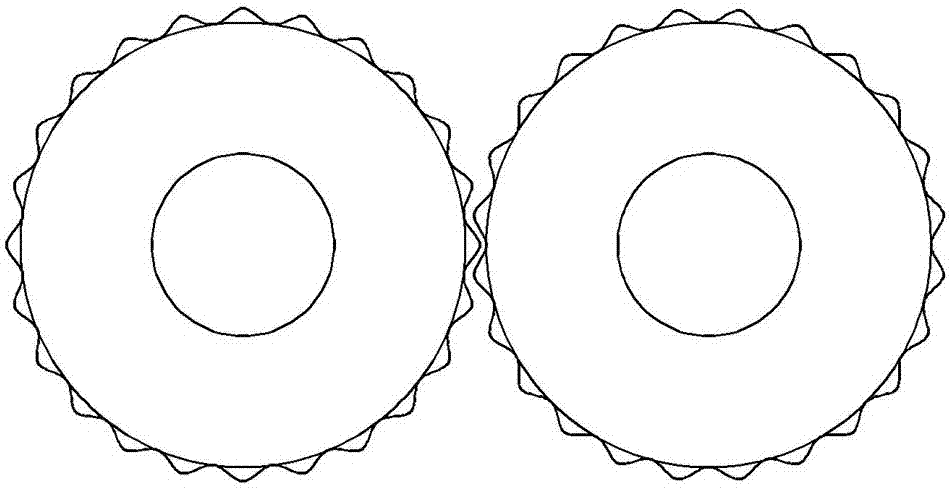

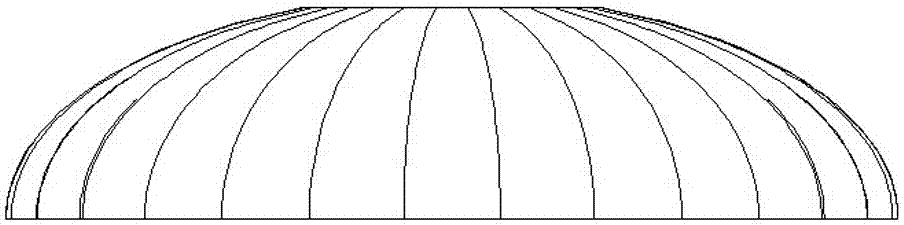

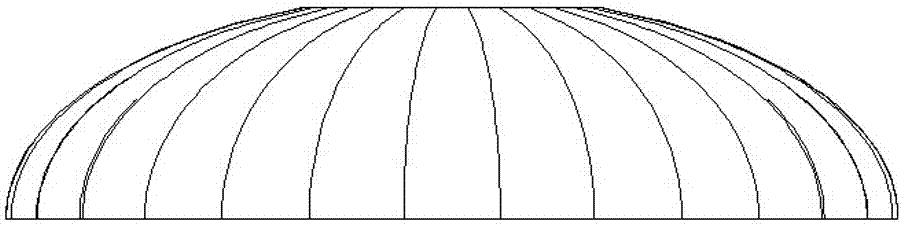

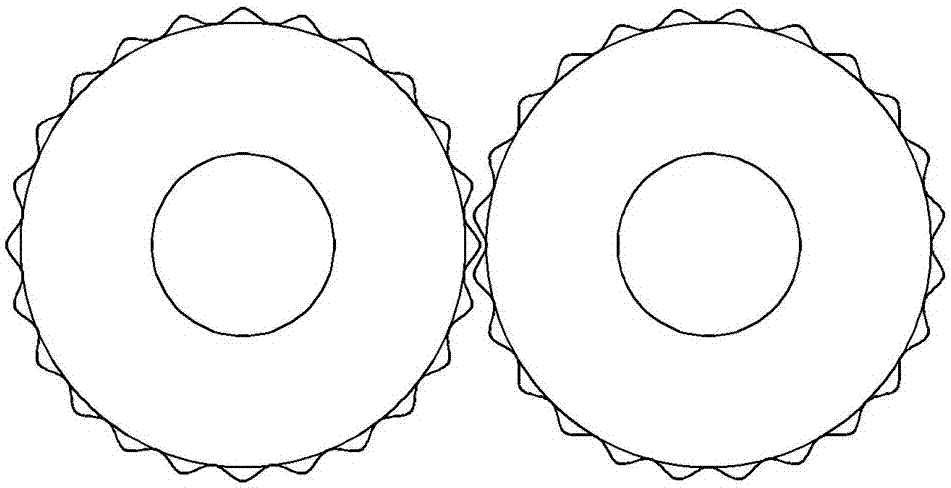

The invention discloses a sugarcane bagasse treatment device with a straw cutting machine and a carbon-making molding machine. The straw cutting machine is arranged above a device body; three levels of counter-rotation cosine rollers are arranged inside the device body, and surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with a dryer through a centrifugal machine; a discharging end of the dryer is connected with a mechanized carbon-making molding machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube rising-film evaporation concentration device; a cosine gel tray pulse aeration device is arranged in the device body; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers, the cosine gel tray pulse aeration device and the mechanical ultrasonic vibration exciter of the sugarcane bagasse treatment device disclosed by the invention all have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:熊小媚

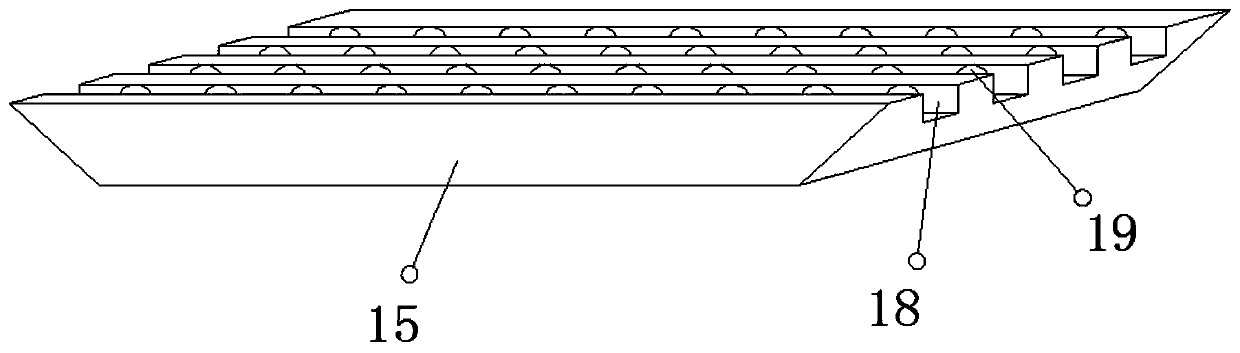

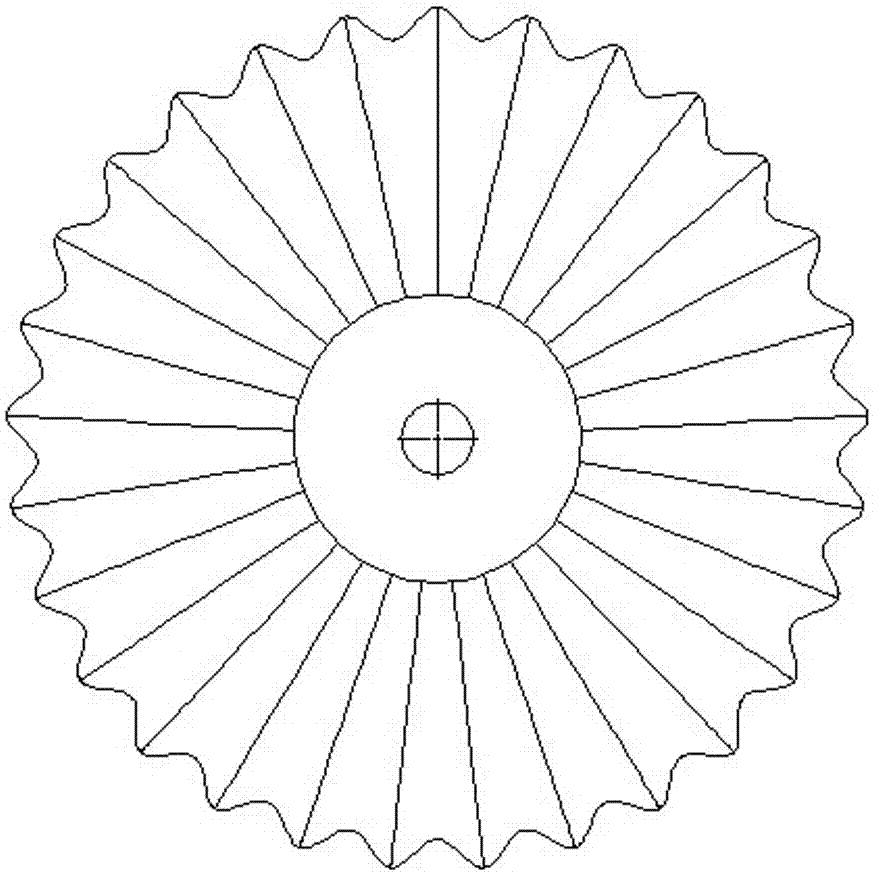

Cosine roller type bagasse processing device provided with cutter and made carbon former

InactiveCN107312877AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree stageInlet valve

The invention discloses a cosine roller type bagasse processing device provided with a cutter and a made carbon former. The bagasse cutter is arranged above the body of the processing device; three-stage counter rotating cosine rollers are arranged in the body, the surface of every counter rotating cosine roller is a continuous cosine curved surface, a bagasse guiding chute is arranged below every stage counter rotating cosine roller, the last stage guiding chute is connected with the hopper of a bagasse elevator, the discharging chute of the elevator is connected with a drying machine through a centrifuge, and the discharging end of the drying machine is connected with the machine-made carbon former; the elevator is provided with a water inlet valve, the upper part of the body is provided with a filter and a liquid discharging tube, and the liquid discharging tube is connected with a triple-effect long tube rising membrane evaporation concentrator; and a cosine plastic plate pulse aerator is arranged in the body. The three-stage counter rotating cosine rollers and the cosine plastic plate pulse aerator have distinct characteristics, and can cooperatively promote the leaching extraction of sugar, and the device has a working principle and technical effects which cannot be foreseen by technical personnel in the field, and has high practical application values.

Owner:段少海

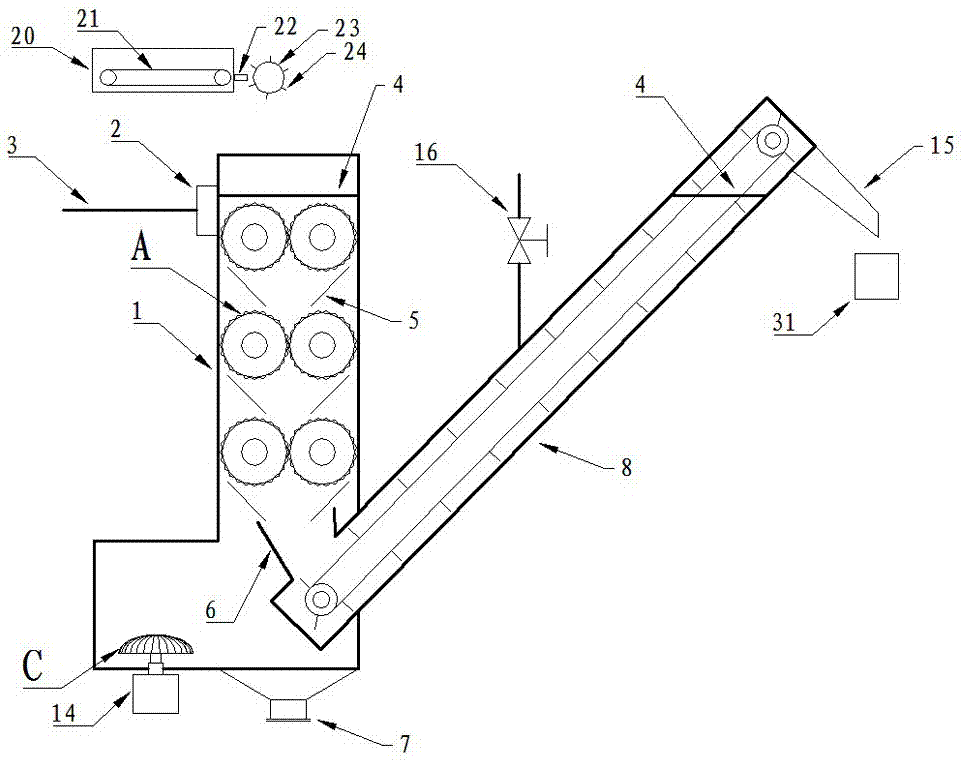

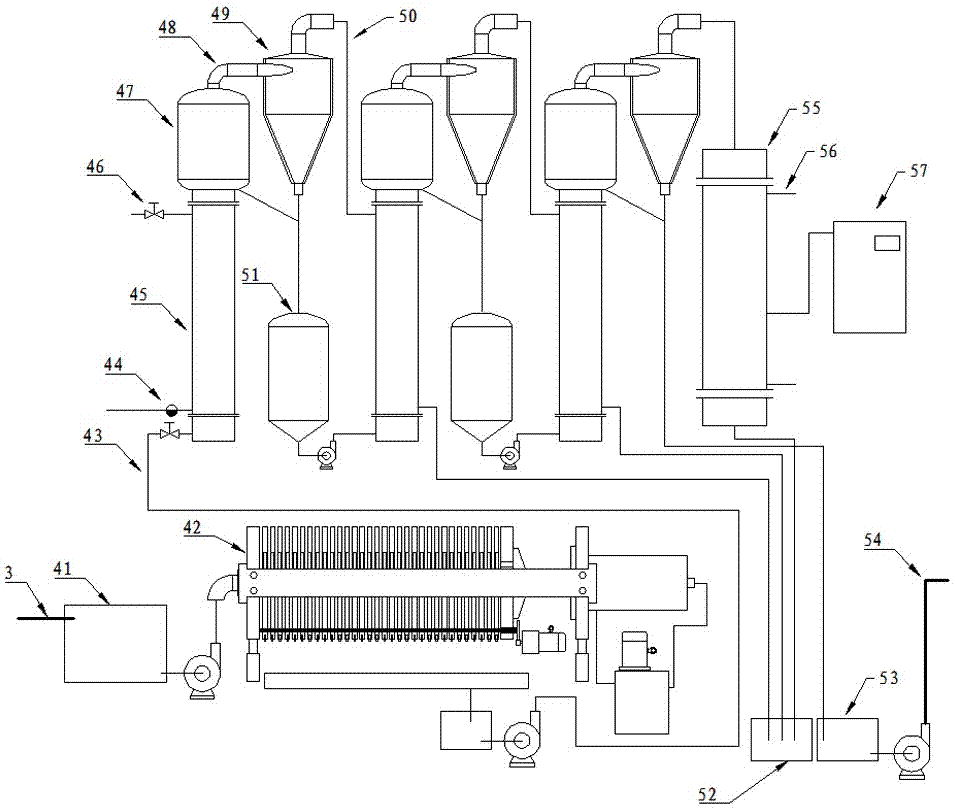

Energy-saving environment-friendly multifunctional sugar making equipment

InactiveCN106337092AExtract thoroughlySave waterSugarcane cuttingSugar juice purificationSprayerElectric machinery

The invention discloses energy-saving environment-friendly multifunctional sugar making equipment. The equipment comprises a case, a water tank, a centrifugal box and a sugar water tank. A conveying belt is arranged in the case, a sprayer is arranged at the top end in the case and connected with a water pump at the top of the case, a hydraulic machine is arranged at one side of the water pump, and the hydraulic machine is connected with a cutter in the case through a hydraulic rod. A plurality of compression rollers are arranged at one side of the cutter, one end of each compression roller is connected with a belt disc through the conveying belt, and the belt disc is in transmission connection with a dive motor at the top of the case. A discharging opening is formed in one side of the case, the centrifugal box is arranged on one side of the discharging opening, and a roller is arranged in the centrifugal box. According to the energy-saving environment-friendly multifunctional sugar making equipment, water resources for cleaning sugar making raw materials can be reused after being filtered in the sugar making process, the sugar making raw materials obtained after cutting and rolling are subjected to centrifugal dewatering again, and sugar in the sugar making theory can be extracted more thoroughly.

Owner:吴海珍

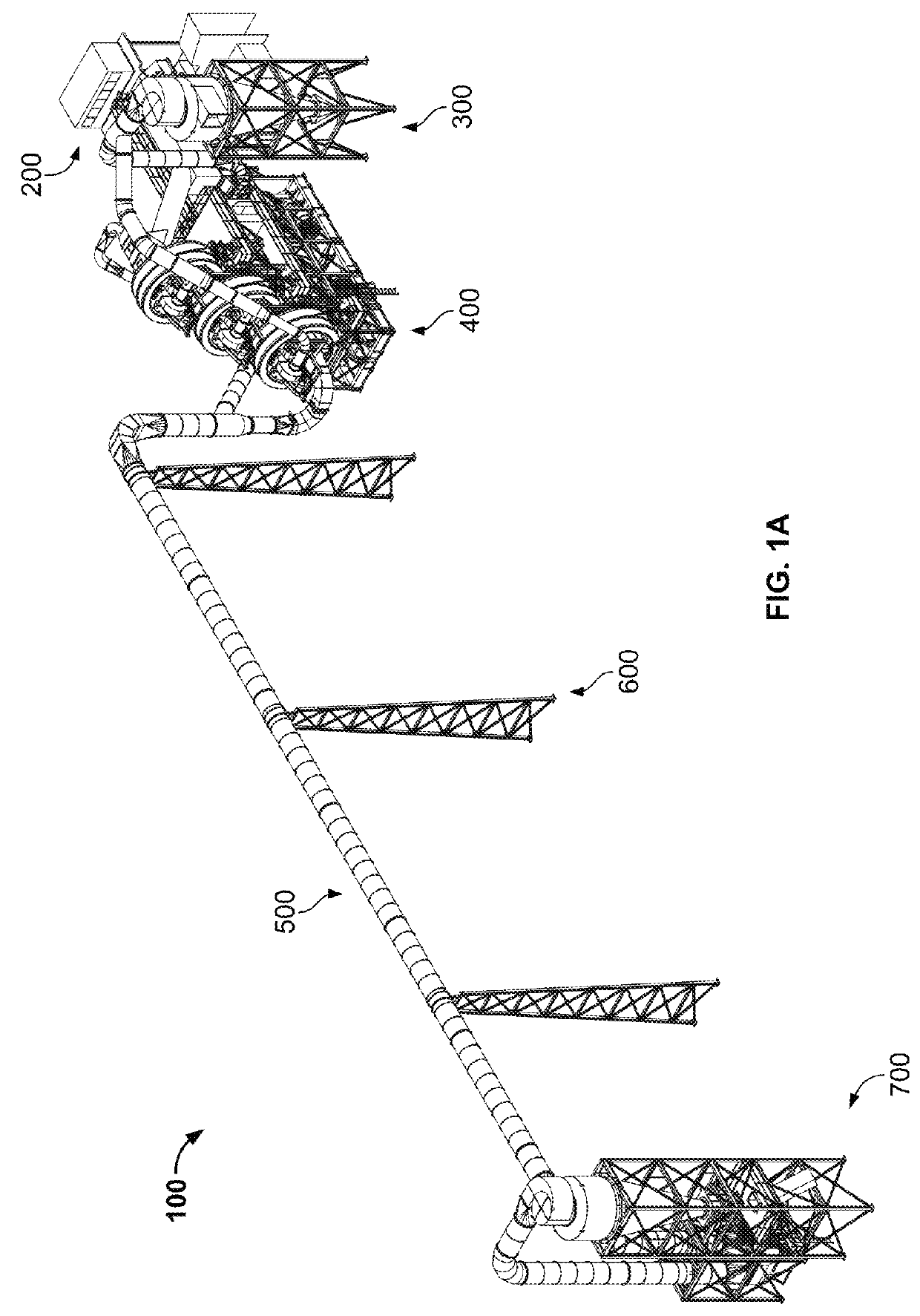

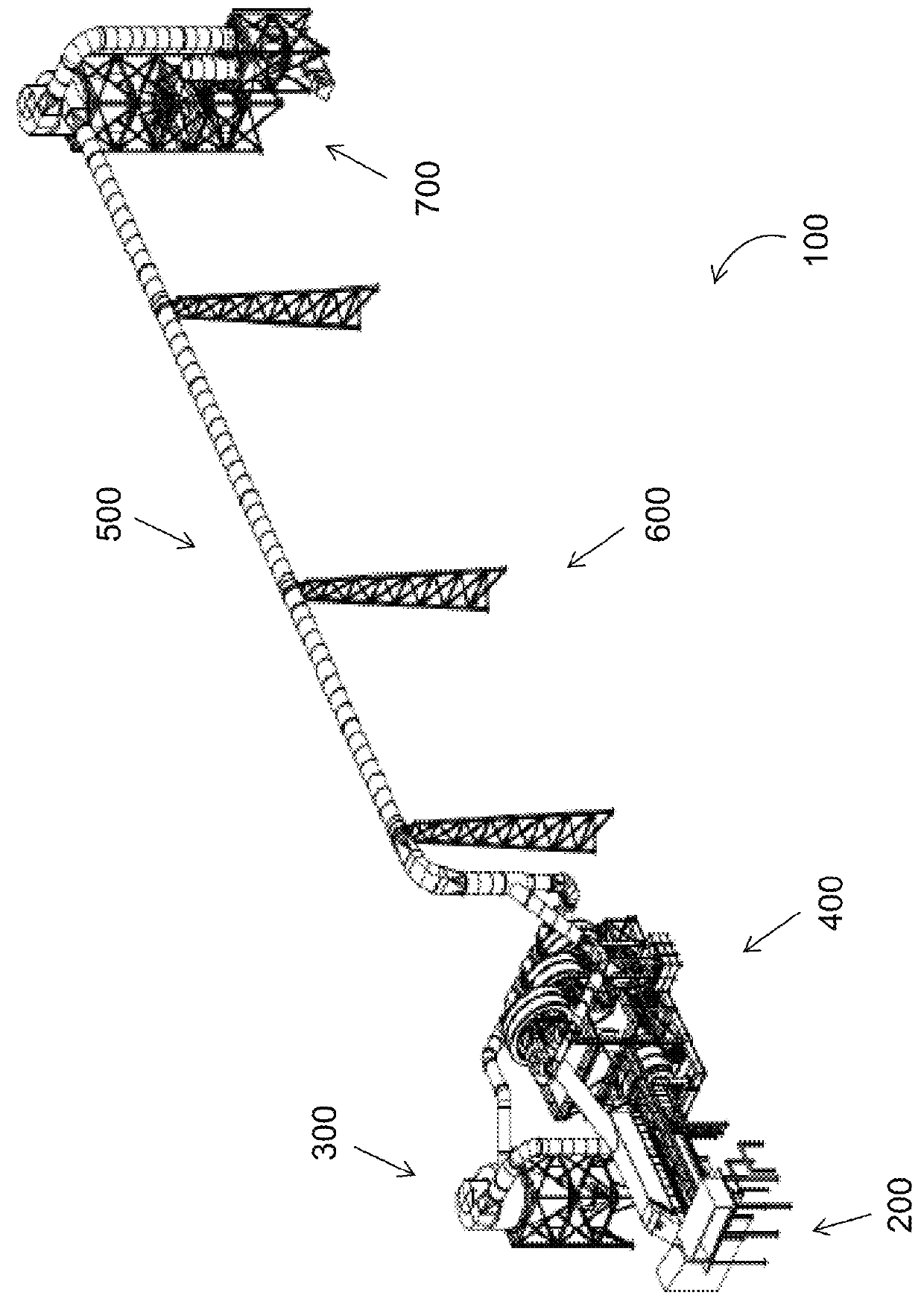

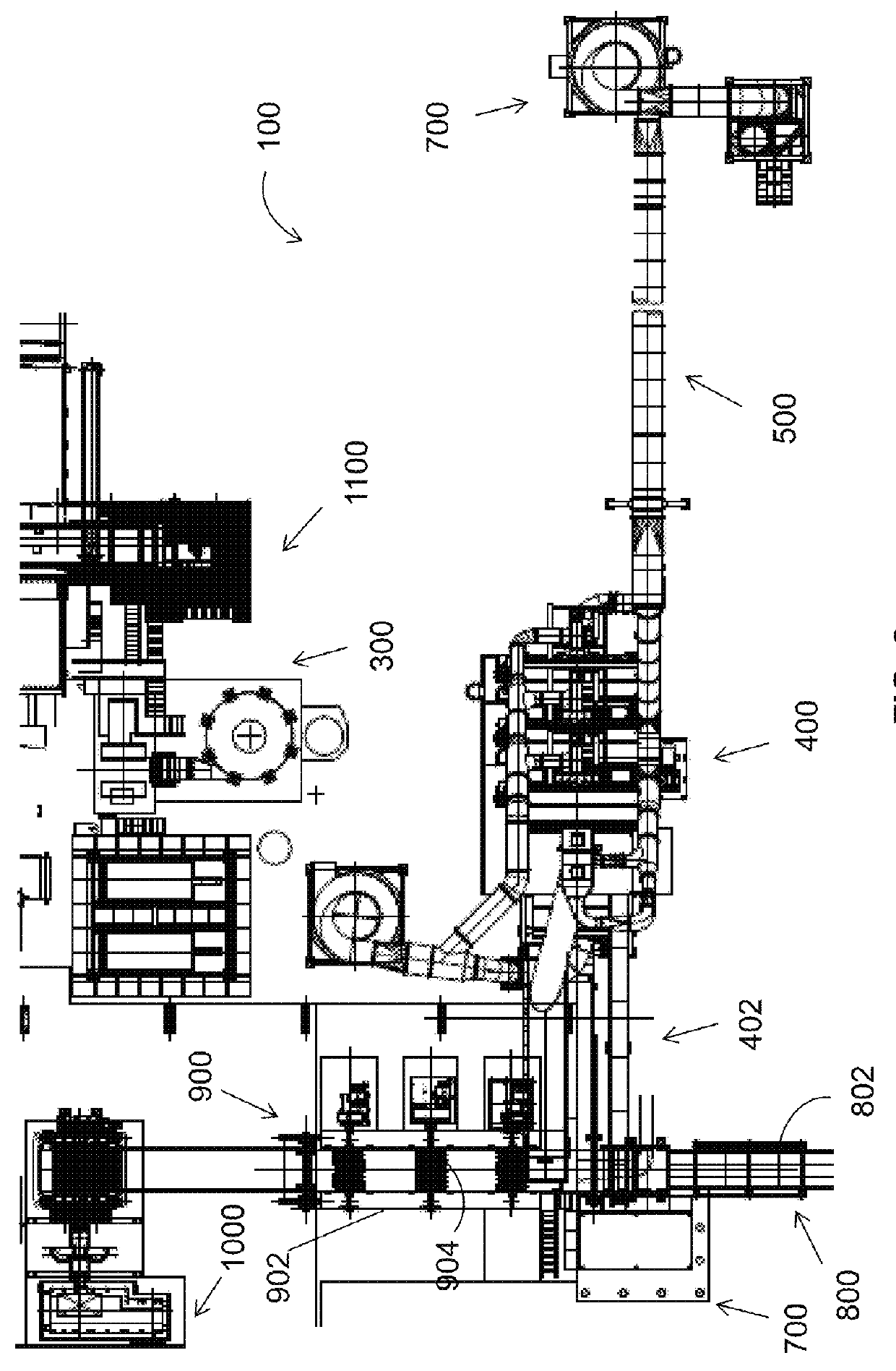

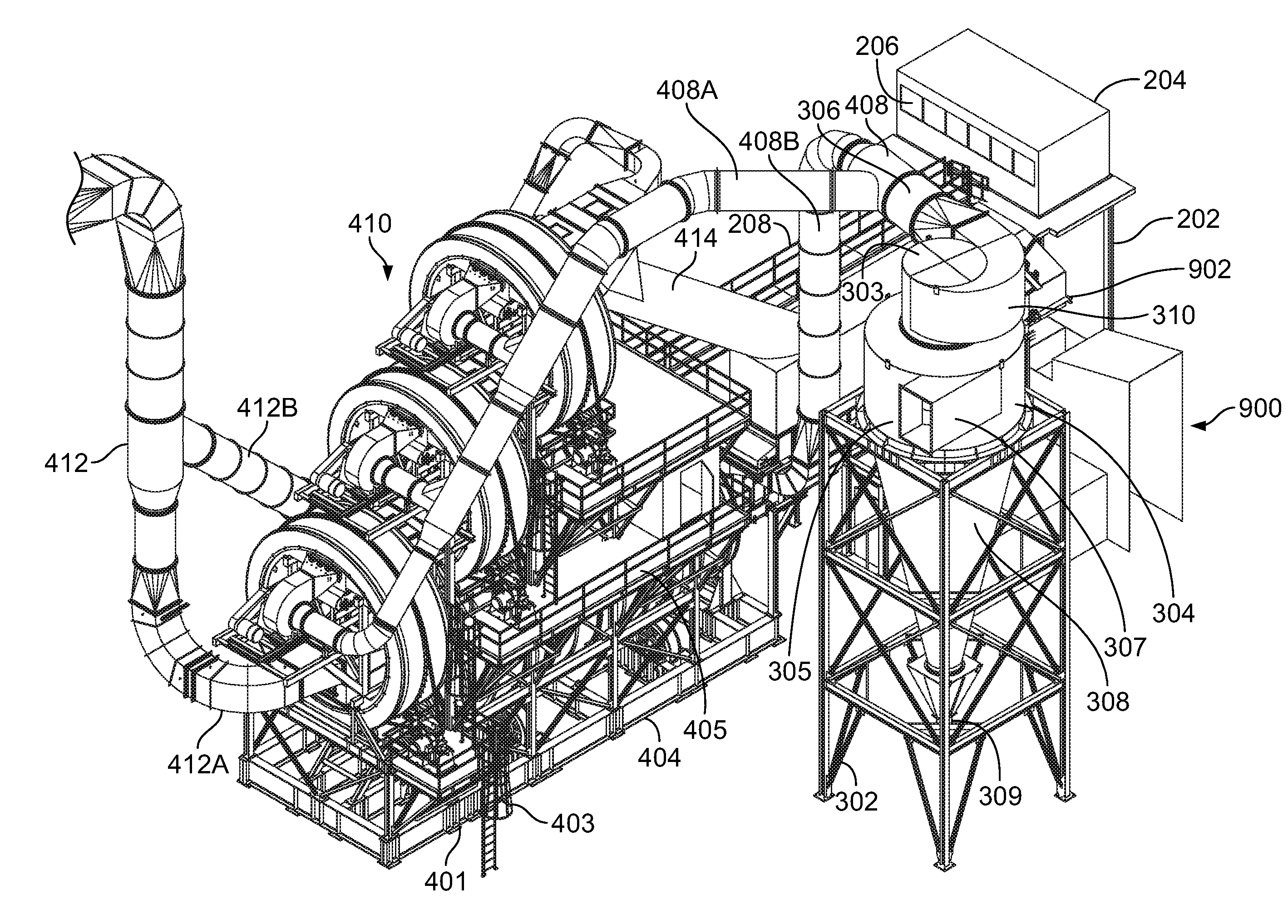

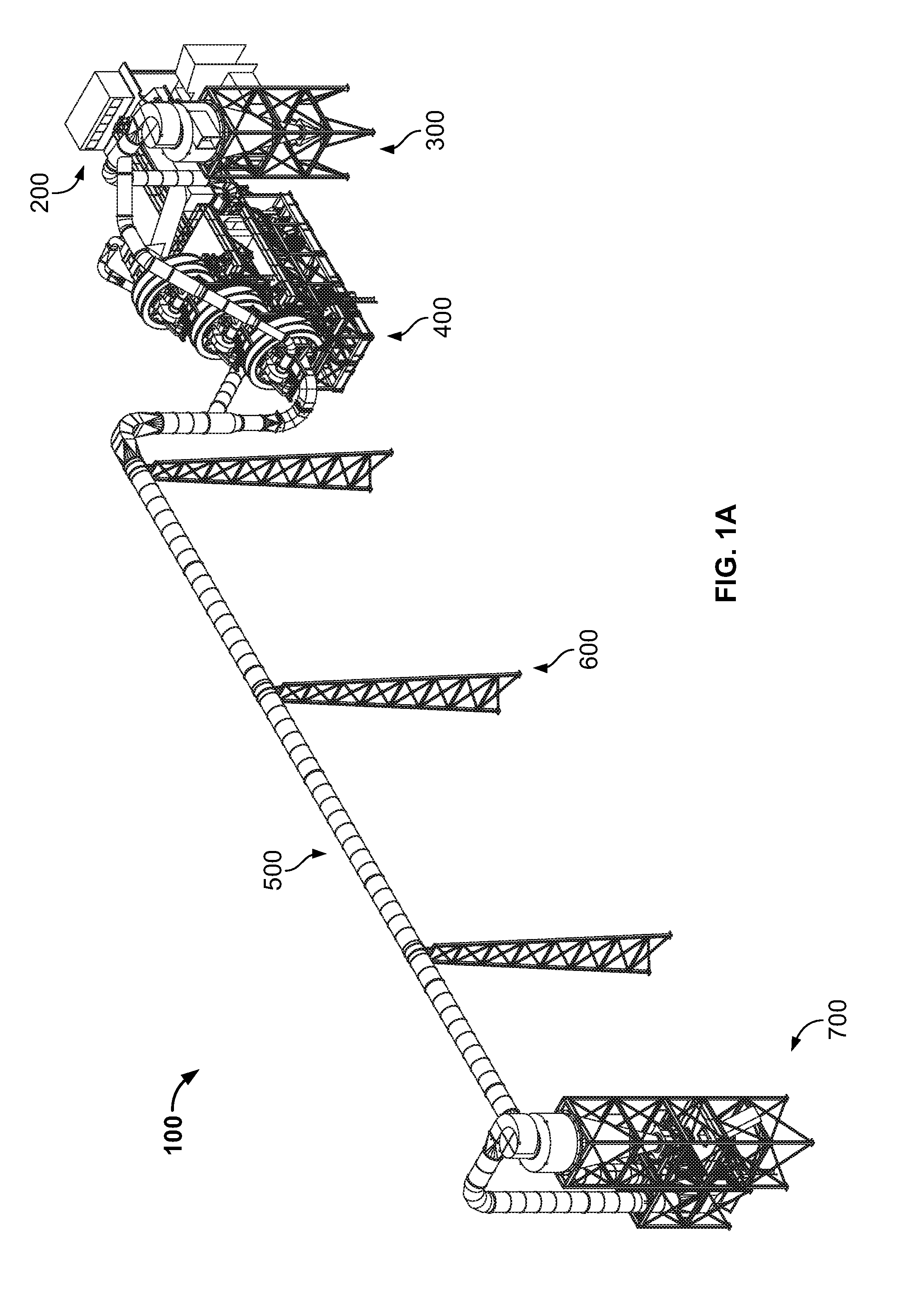

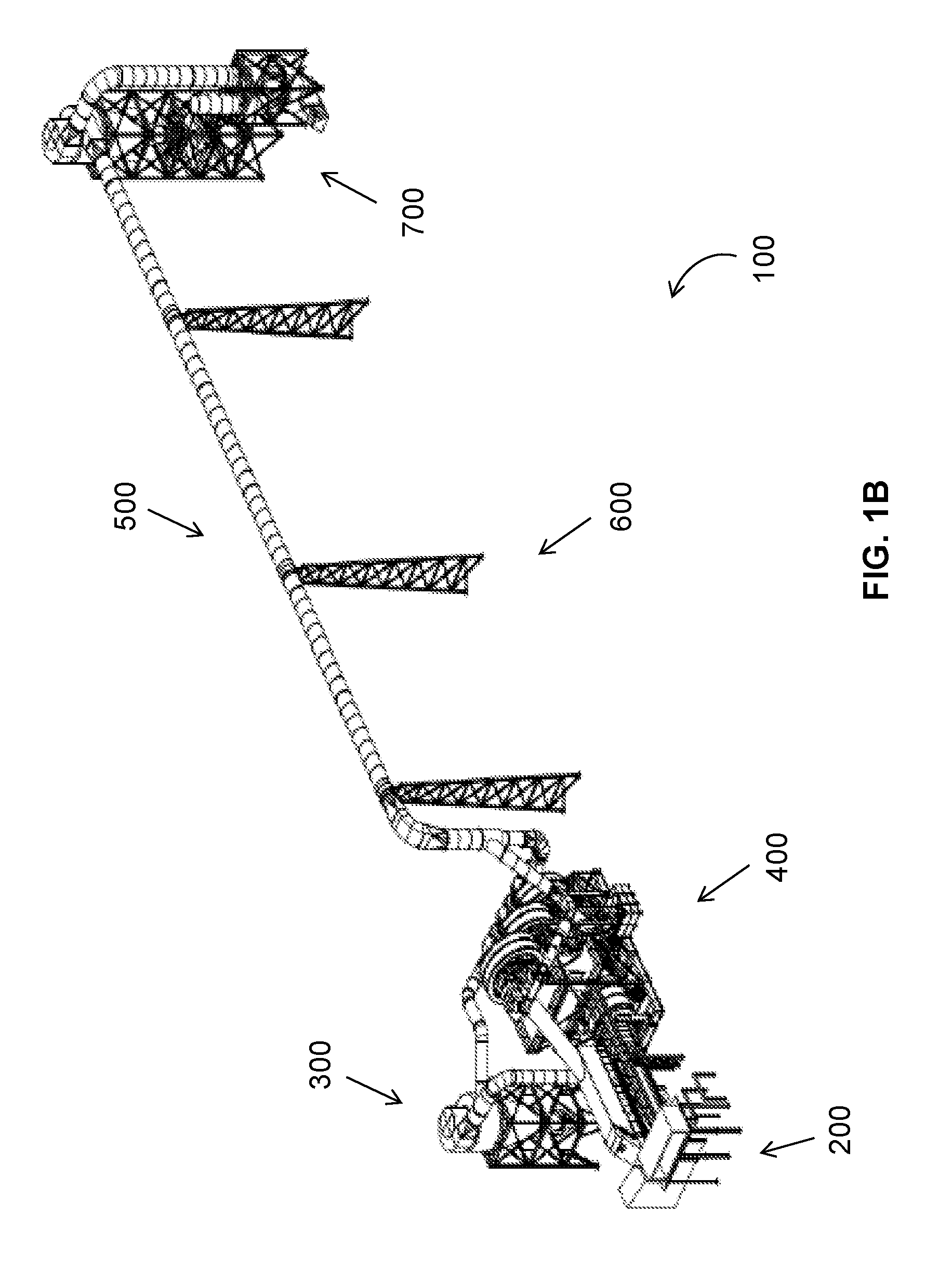

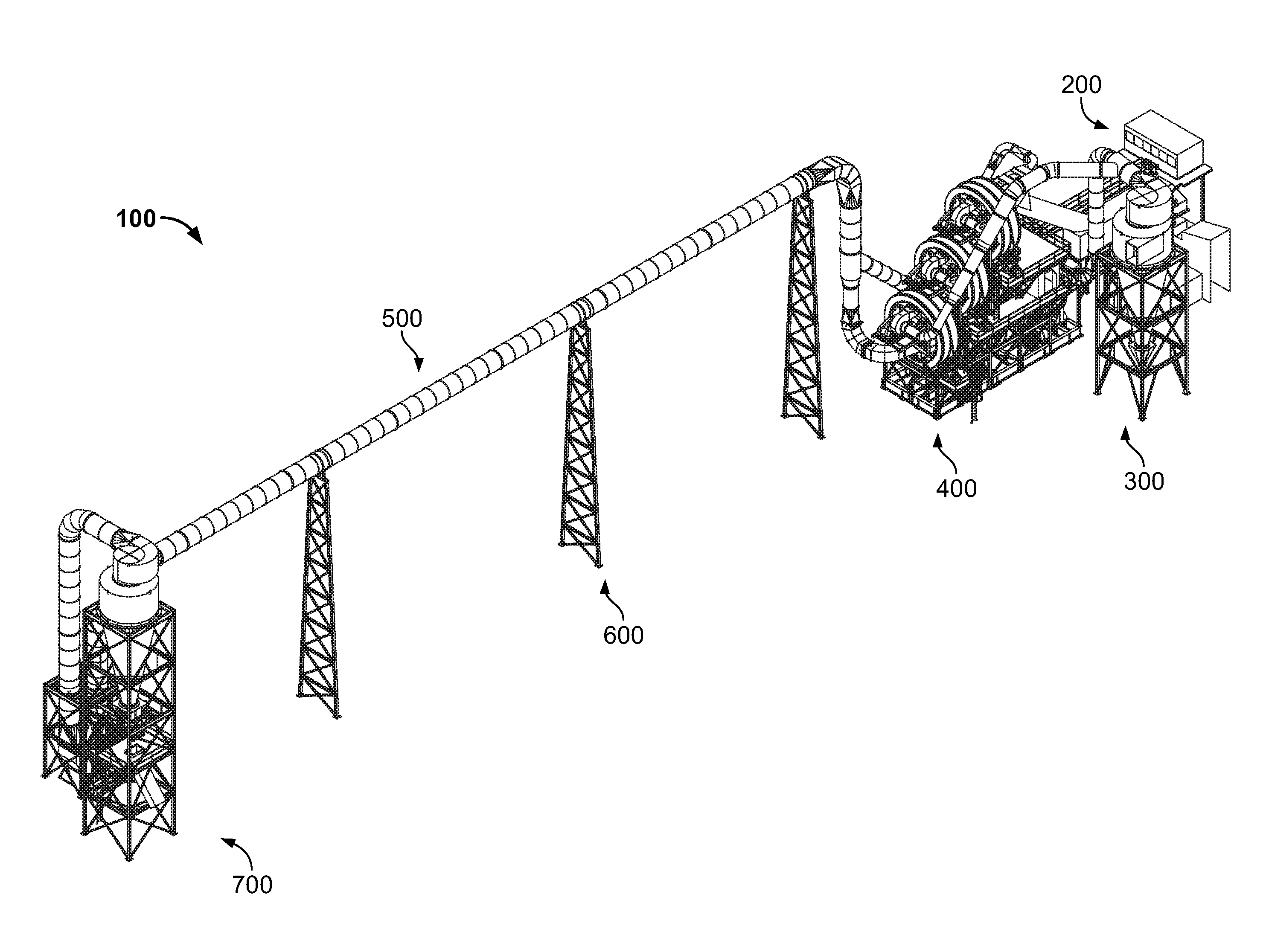

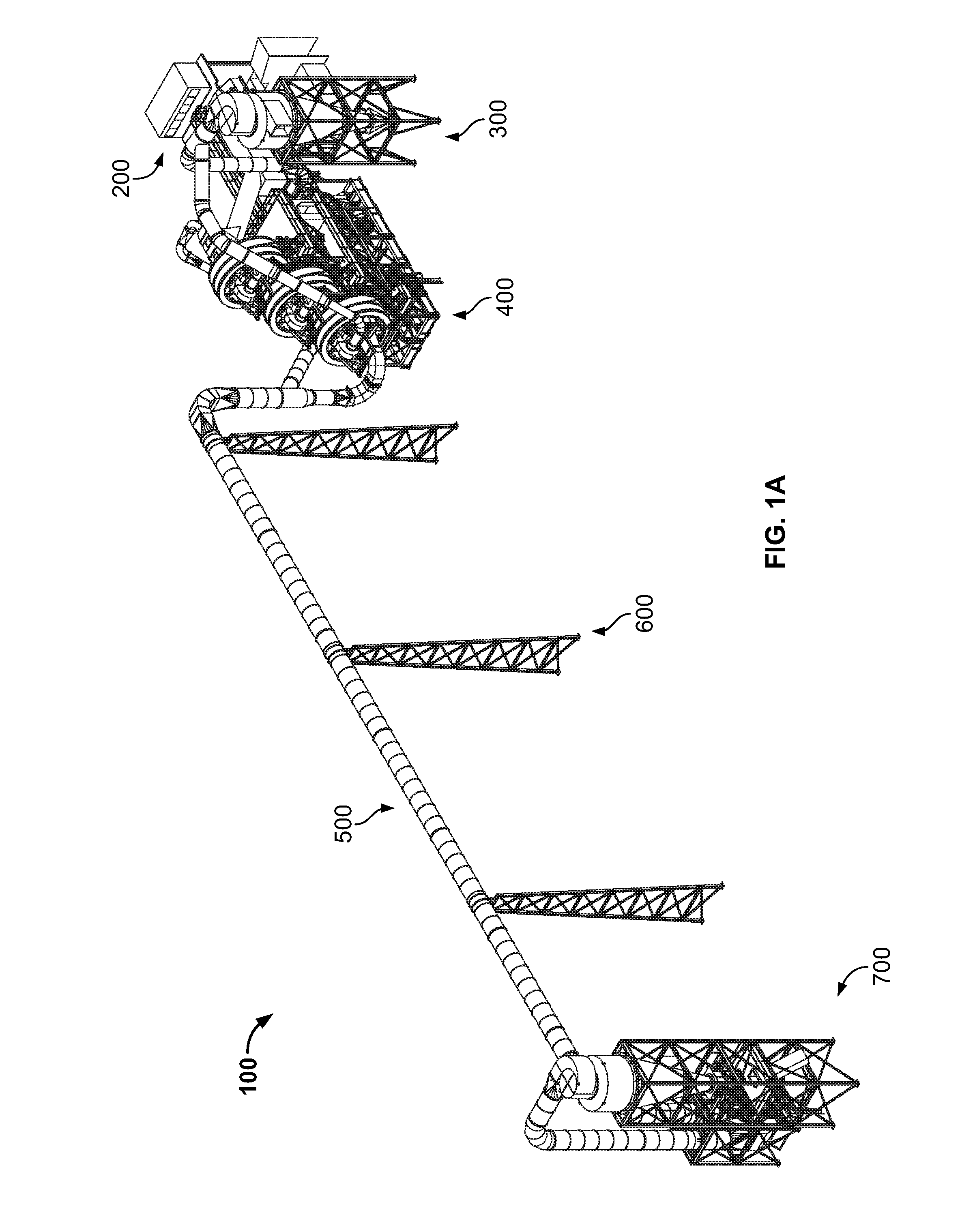

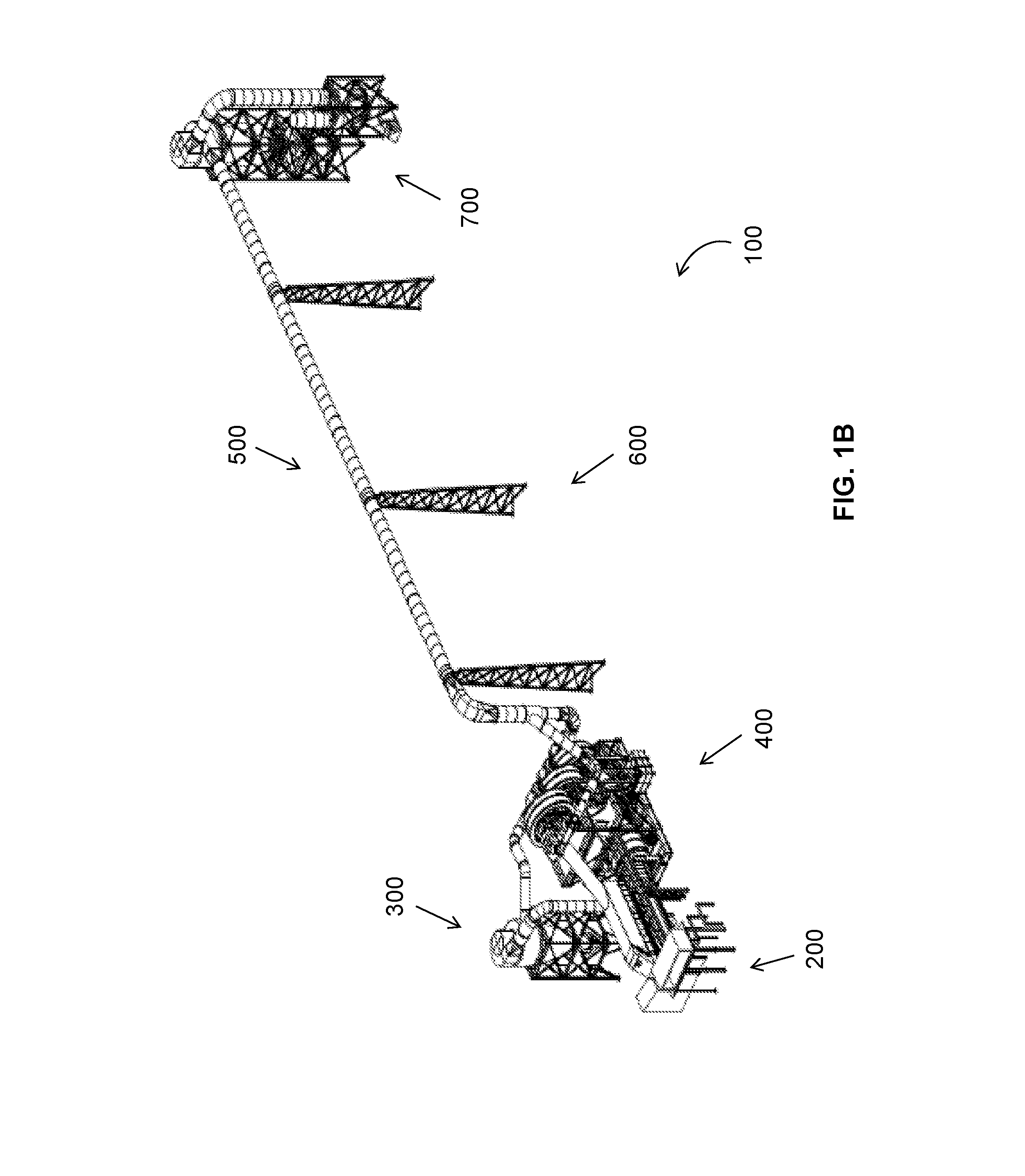

Technologies for material separation

A technology for material separation is provided. The technology enables an output of a first material from a rotary lifter. The technology enables a direction of a fluid stream onto the first material in flight based on the output of the first material such that the first material is separated into at least a second material and a third material. The technology enables a conveyance of the second material away from the rotary lifter. The technology enables a removal of the third material via a vacuum port.

Owner:AMERICAN BIOCARBON

Brown sugar processing technology

InactiveCN107338334AHigh purityPromote leachingSugar productsSugarcane cuttingRotary evaporatorEvaporation

The invention discloses a brown sugar processing technology in the field of brown sugar processing. The brown sugar processing technology comprises steps as follows: sugarcanes are frozen, crushed in the environment at the temperature lower than or equal to 15 DEG C and then extruded by weight, and sugarcane juice obtained through extrusion is collected and filtered by filter paper; the sugarcane juice is subjected to vacuum concentration by a rotary evaporator at the temperature of 50-60 DEG C for 1-1.5 h, and a sugarcane thick liquid is obtained; the sugarcane thick liquid obtained after the vacuum concentration is put in a pot for heating and boiling, and a boiled liquid is obtained; finally, the boiled liquid is coagulated. According to the scheme, filtering time is shortened in a freezing manner, the vacuum concentration is performed before boiling, so that evaporation time of moisture in the sugarcane juice is shortened, and the processing efficiency is remarkably improved.

Owner:贵州省习水县淋滩红糖厂

Technologies for cyclonic material separation

A technology for material separation is provided. The technology enables an output of a first material from a rotary lifter. The technology enables a direction of a fluid stream onto the first material in flight based on the output of the first material such that the first material is separated into at least a second material and a third material. The technology enables a conveyance of the second material away from the rotary lifter. The technology enables a removal of the third material via a vacuum port.

Owner:AMERICAN BIOCARBON

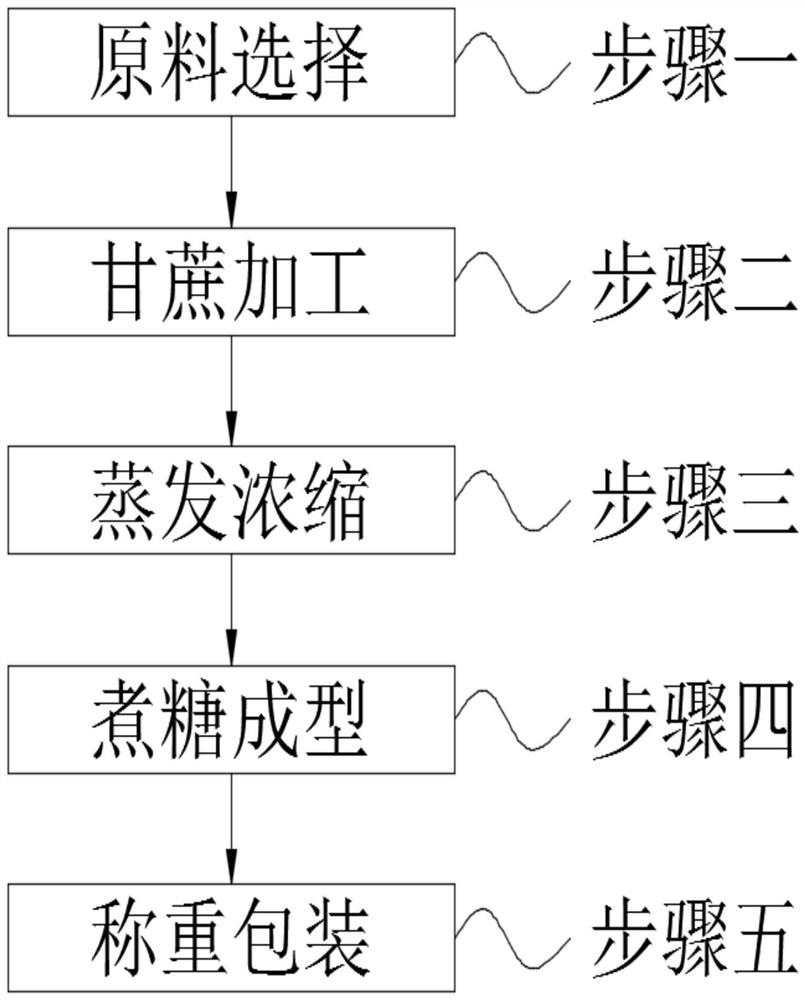

Ancient method and modern method combined brown sugar making process

PendingCN112029912ASimple preparation processLess impuritiesSugarcane cuttingPurification by physical meansProcess engineeringCane

The invention discloses an ancient method and modern method combined brown sugar making process. The process comprises the steps of step 1, raw material selection; step 2, sugarcane processing; step 3, evaporation and concentration; step 4, boiling sugar and molding; step 5, weighing and packaging; In the step 1, purple sugarcane which is uniform in thickness, bright in skin, frosted, dark in color and relatively straight is manually selected; and dry shells of the selected sugarcanes are peeled off , then protruding parts on sugarcane nodes are peeled off, and then drip washing with clear water is performed. The ancient method and modern method combined brown sugar making process is simple to operate, and the purity of clear sugarcane juice is greatly improved by utilizing decoction of the ancient method and clarification and filtration of the modern lime milk carbonation method, so that impurities of the brown sugar are reduced, the purity of the brown sugar is improved, and the brown sugar is high in nutritional value and favorable for users to eat. The ancient method and modern method brown combined brown sugar making process is cheap in raw materials, simple in process and suitable for large-scale mass production, and the brown sugar production efficiency is improved.

Owner:宜章县丰乐古方红糖有限公司 +1

Mechanical ultrasonic type sugarcane bagasse treatment device with straw cutting machine and centrifugal machine

InactiveCN107299158AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree levelInlet valve

The invention discloses a mechanical ultrasonic type sugarcane bagasse treatment device with a straw cutting machine and a centrifugal machine. A sugarcane bagasse straw cutting machine is arranged above a device body of a leaching device; three levels of counter-rotation cosine rollers are arranged inside the device body, and surfaces of the counter-rotation cosine rollers are continuous cosine curved surfaces; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation cosine rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with the centrifugal machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube rising-film evaporation concentration device; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation cosine rollers and the mechanical ultrasonic vibration exciter of the mechanical ultrasonic type sugarcane bagasse treatment device disclosed by the invention both have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:李小兰

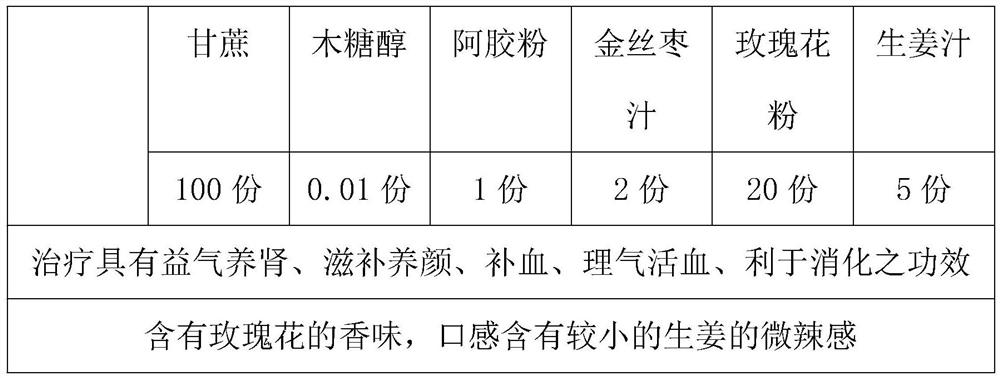

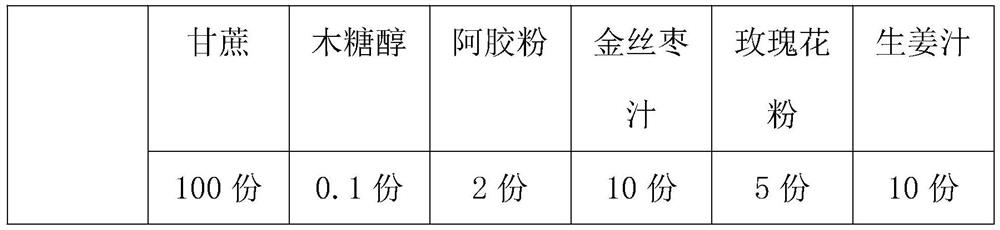

Ancient brown sugar and preparation method thereof

InactiveCN112646936AImprove Qi and kidneyLower sugar contentSugar productsSugarcane cuttingBiotechnologyColla corii asini

The invention relates to the technical field of ancient brown sugar processing, in particular to ancient brown sugar and a preparation method thereof, and the ancient brown sugar comprises the following components: 100 parts of sugarcane, 0.01-0.1 part of xylitol, 1-2 parts of donkey-hide gelatin powder, 2-10 parts of golden-silk jujube juice, 5-20 parts of rose flower powderand 5-10 parts of ginger juice. The ancient brown sugar has the beneficial effects that the donkey-hide gelatin powder, the golden-silk jujube juice and the rose flower powder are added into the ancient brown sugar, and the effects of tonifying qi, nourishing kidney, enriching blood, replenishing essence and promoting digestion are improved through mutual cooperation of the effects of the components.

Owner:武汉点溪园生态景观发展有限公司

Cane sugar purification device for sugarcane processing

PendingCN110512031AWith preprocessing functionAchieving processing powerSugarcane cuttingSugar raw material preprocessing knivesEngineeringSugar

The invention discloses a cane sugar purification device for sugarcane processing. The cane sugar purification device comprises a squeezing box, wherein a fixed shell is arranged on the outer wall ofthe top of the squeezing box; a hydraulic oil cylinder is arranged on the inner wall of the top of the fixed shell; a downward pressing plate is arranged at one end, extending into the squeezing box,of the hydraulic oil cylinder; a pretreatment box is arranged on the top of one outer sidewall of the squeezing box; a feeding pipe is inserted into the outer wall of the top of the pretreatment box;a slitting net plate is arranged on the inner wall of the top of the pretreatment box; first electric telescopic rods are arranged on the tops of two inner side walls of the pretreatment box correspondingly; cutting knife plates are arranged at one ends of the two first electric telescopic rods correspondingly; a conveying mechanism is connected to the bottoms of two inner side walls of the pretreatment box through bearings; and a feeding opening is formed in one inner side wall of the pretreatment box. The cane sugar purification device has the function of slitting and sectioning sugarcane for pretreatment, is convenient and efficient, and achieves integration of pretreatment, conveying and squeezing.

Owner:湖南志辉知识产权有限公司

Technologies for material separation

A technology for material separation is provided. The technology enables an output of a first material from a rotary lifter. The technology enables a direction of a fluid stream onto the first material in flight based on the output of the first material such that the first material is separated into at least a second material and a third material. The technology enables a conveyance of the second material away from the rotary lifter. The technology enables a removal of the third material via a vacuum port.

Owner:AMERICAN BIOCARBON

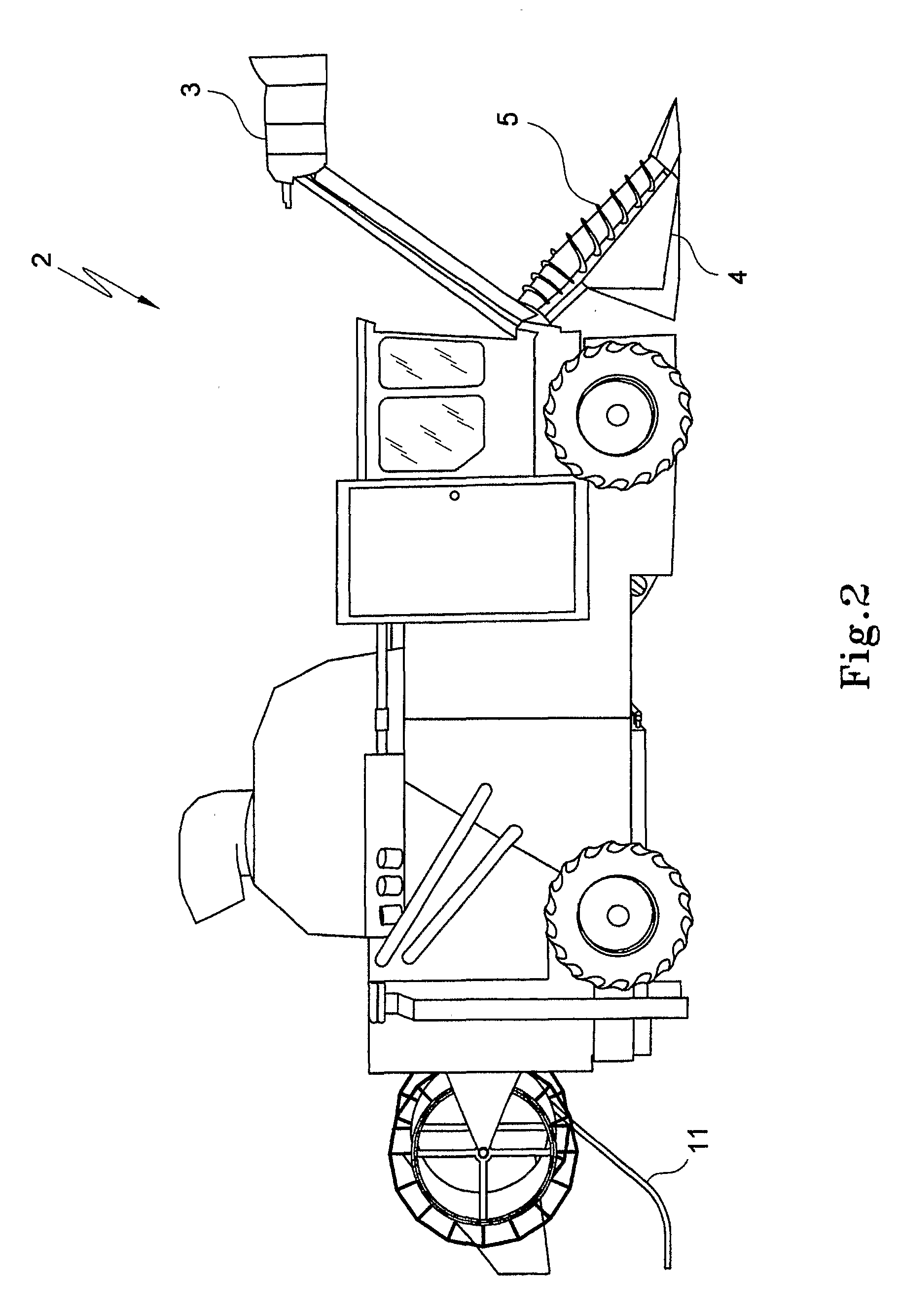

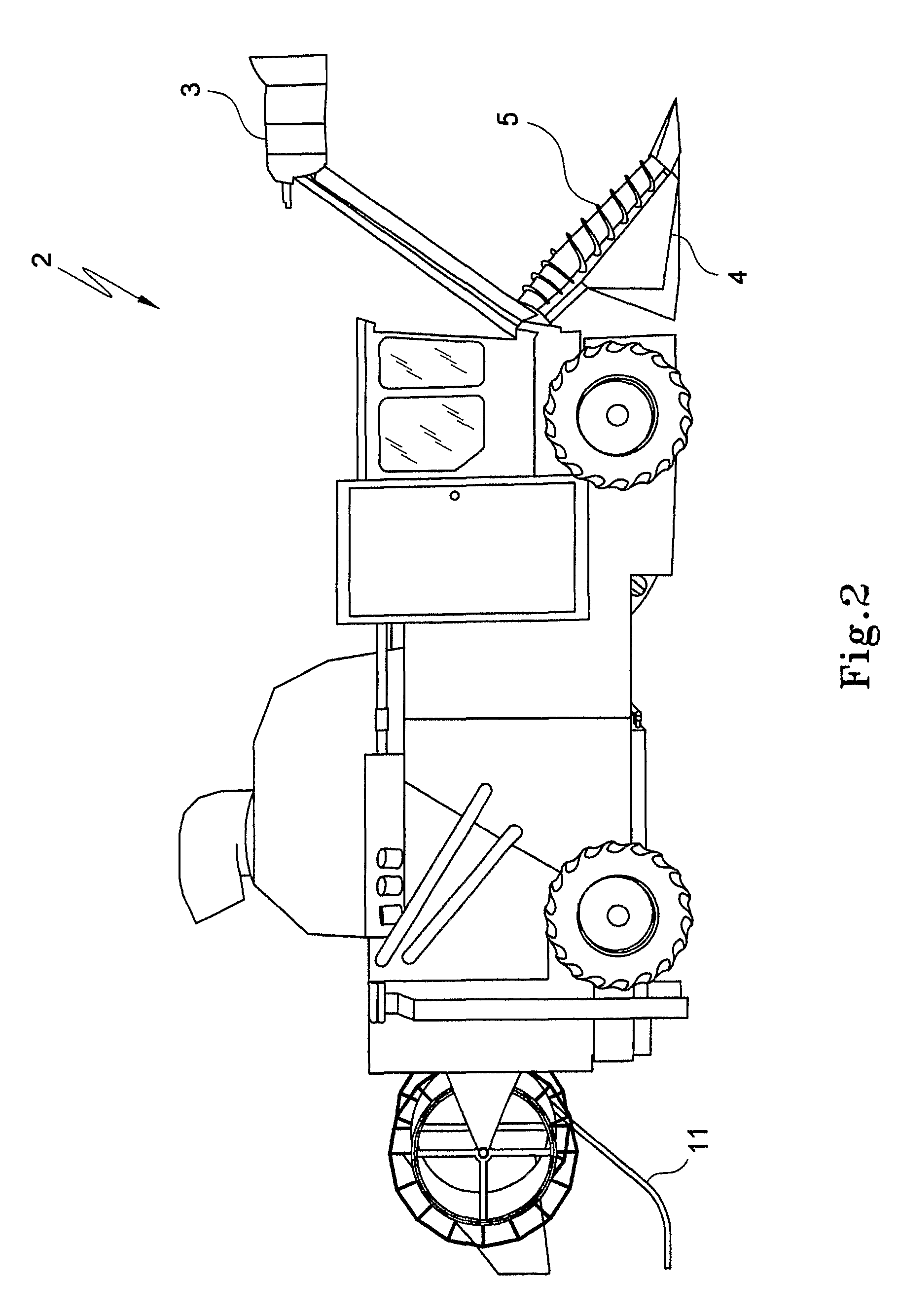

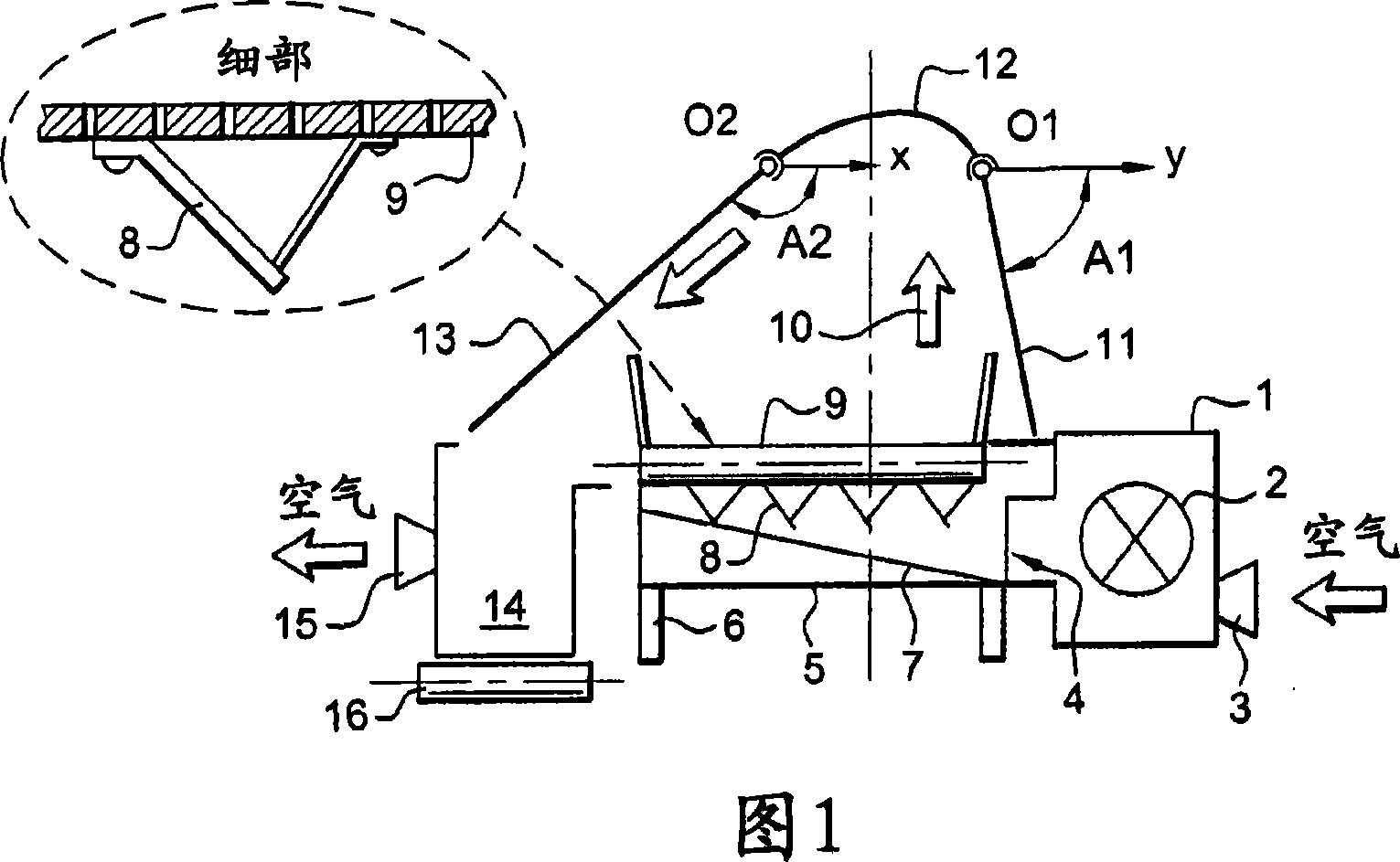

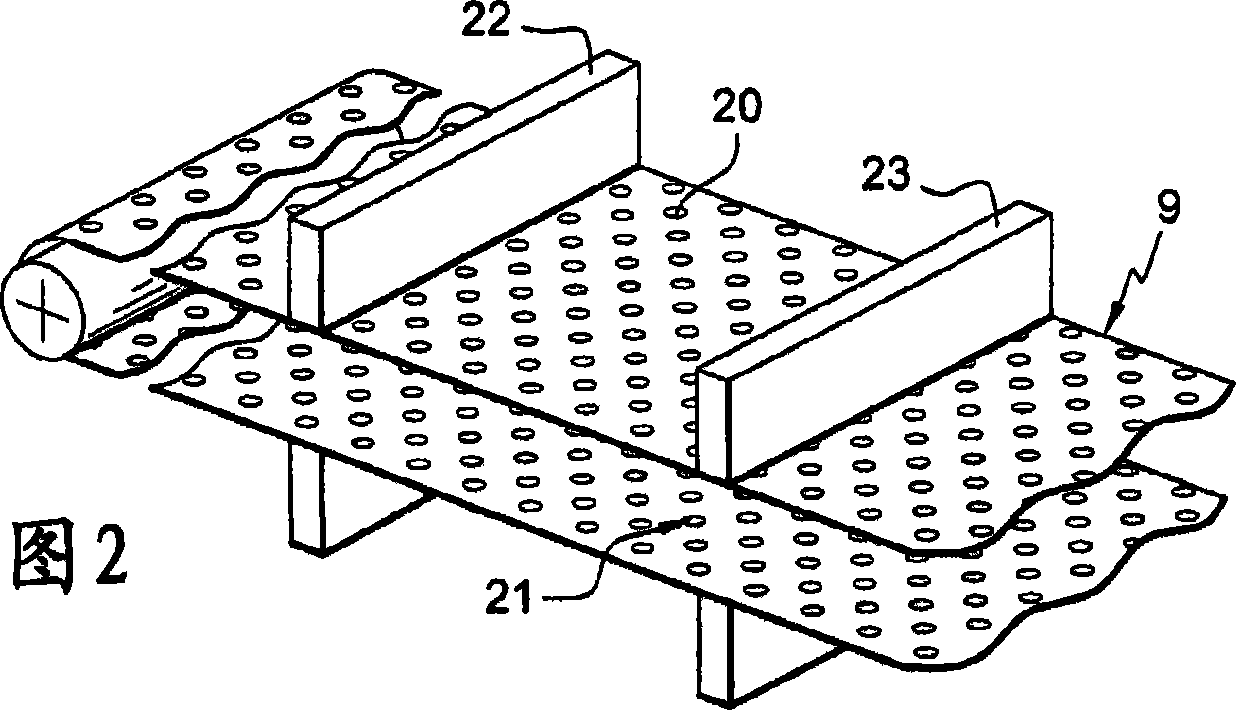

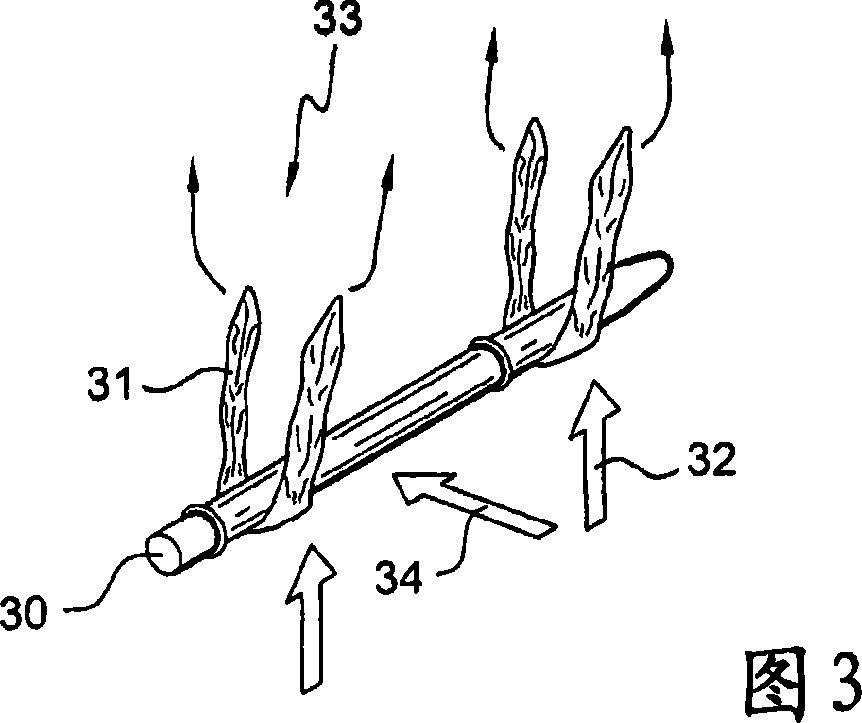

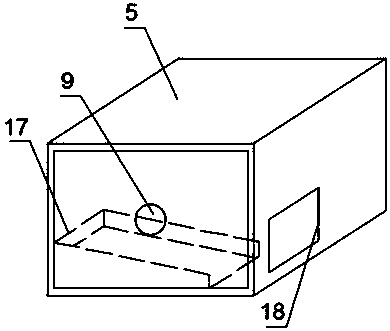

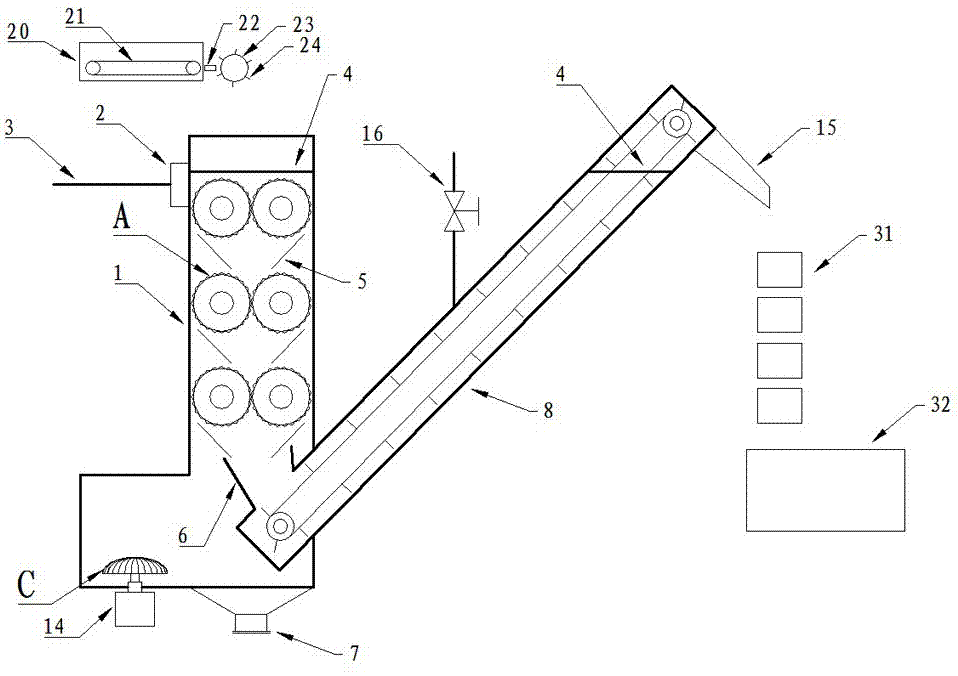

Method for removing straw from agriculture products and a straw removing device for carrying out said method

InactiveCN101080502AReduce volumeImprove overall processing efficiencyHarvestersSugarcane cuttingEngineeringSugar cane

The invention relates to a straw removing method, in particular for removing leaves and other vegetable wastes form agriculture products such as corn stalks or sugar canes. Said invention also relates to a straw removing device for carrying out said method. The inventive device comprises at least one transfer conveyor (9) carrying processable agriculture products, an air blow device (1, 2, 3) across the transfer conveyor and, finally, a ventilation bell (11, 12, 13) for orienting (10) an airflow and / or vegetable wastes transported thereby, for separating useless vegetable wastes (A2) as agriculture product leaves and to transfer said wastes to a receptacle area (14).

Owner:ODDEIS SA

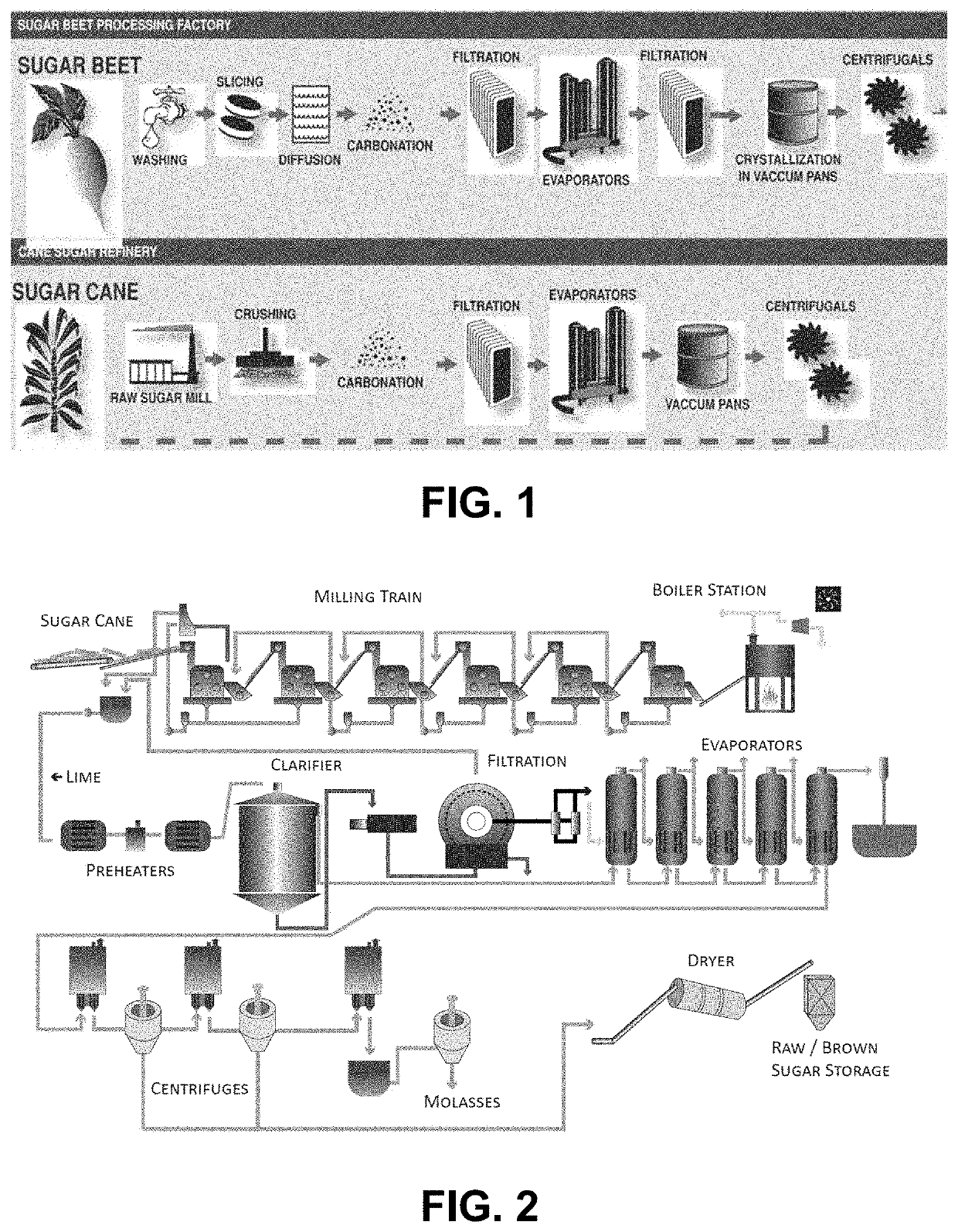

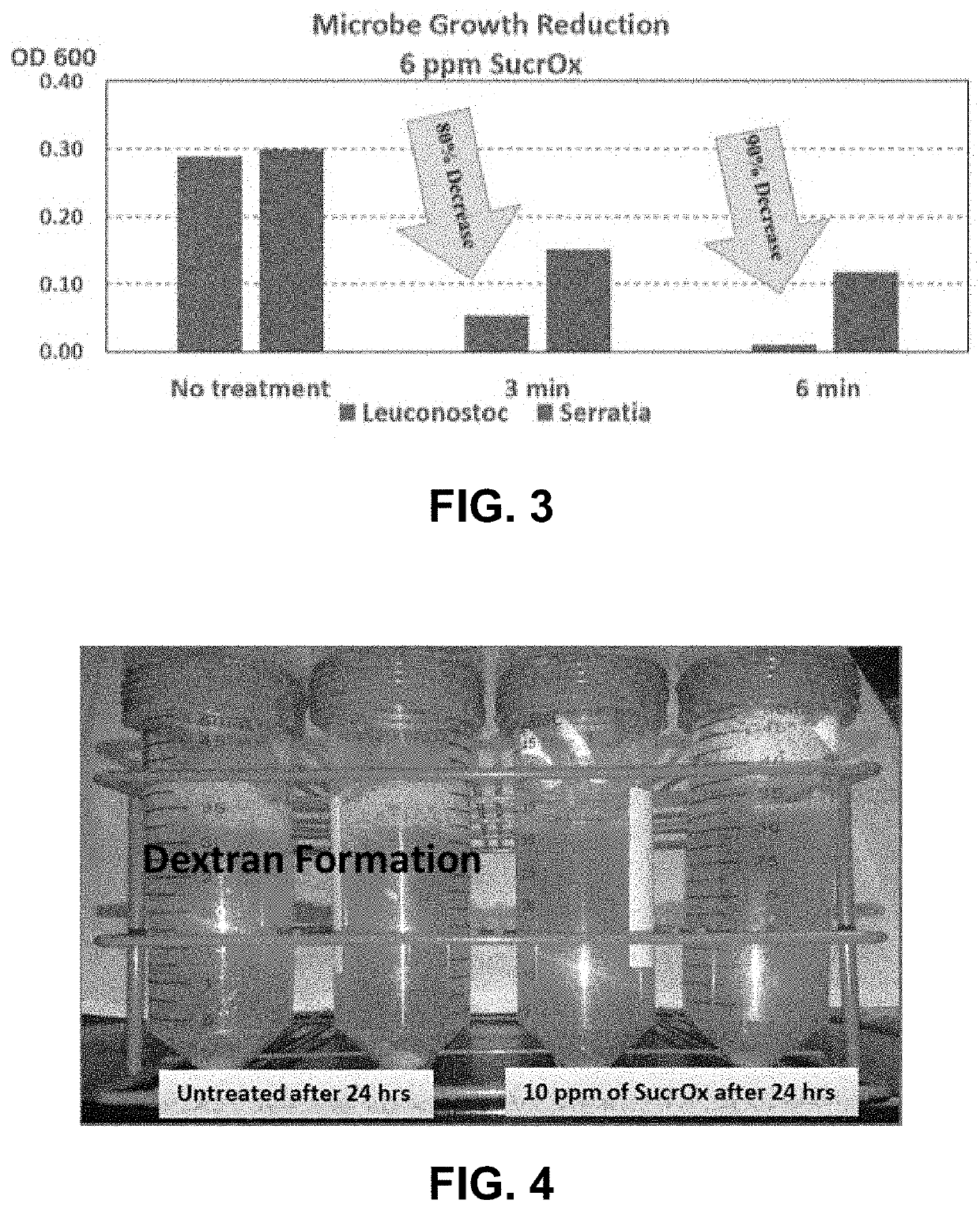

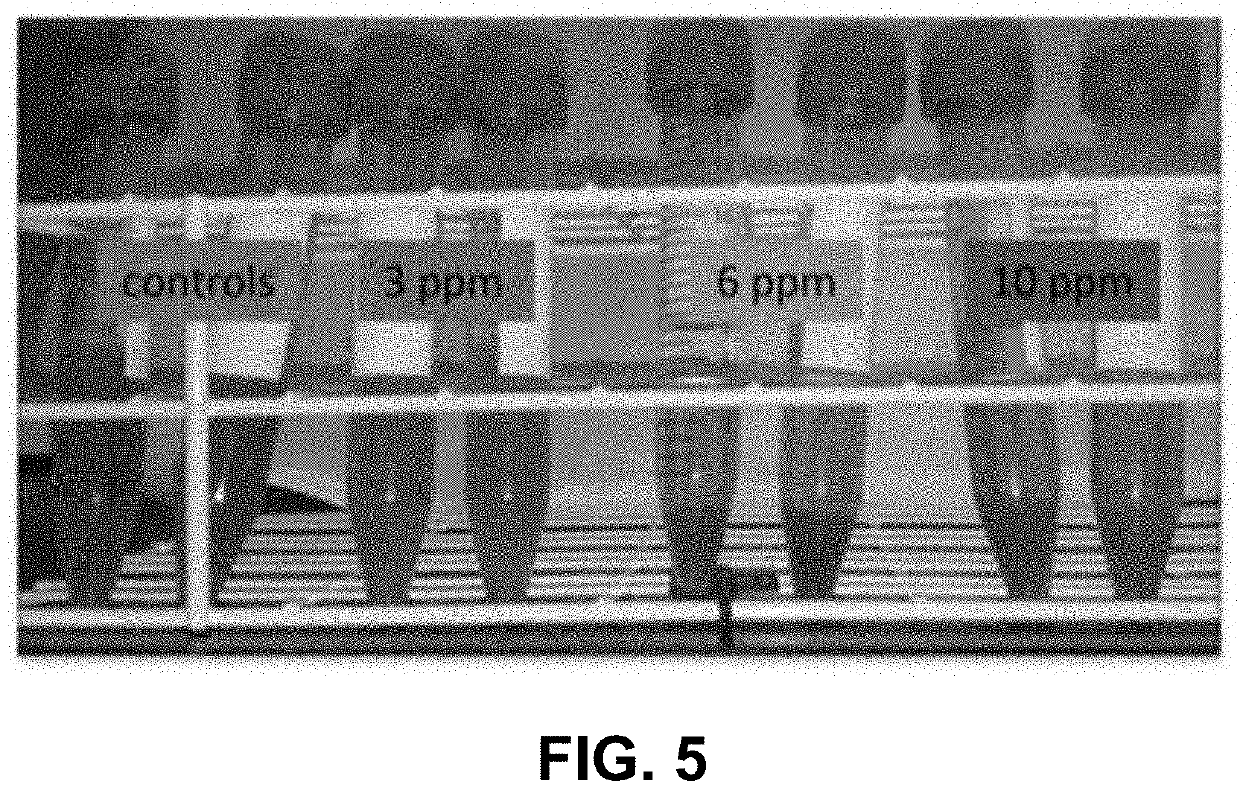

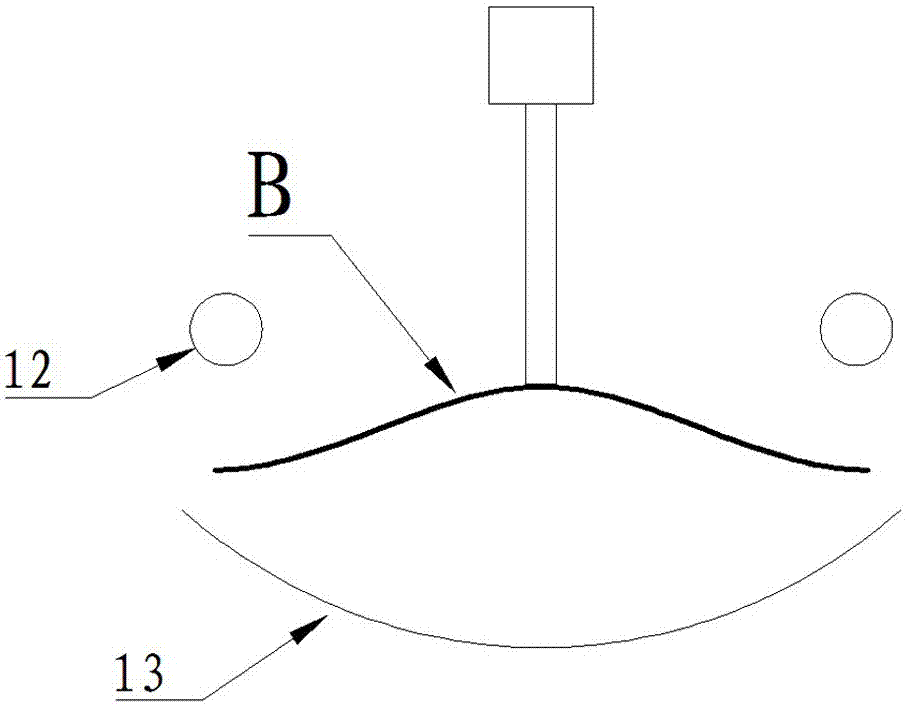

Systems and methods comprising permanganate for improved preservation and yield of crops and related goods

ActiveUS20210062278A1Reduce turbidityReduction of exopolysaccharidesFruit and vegetables preservationSugarcane cuttingFruit juicePermanganate salt

Preferred embodiments of the present invention comprise the optional application of concentrations of an aqueous permanganate solution, such as an approximately 0.01% to approximately 50% liquid permanganate solution and preferably comprising approximately 20% sodium permanganate dosed at approximately 1 ppm to approximately 100 ppm to harvested sugar crops, such as sugarcane, sugar beets, and sweet sorghum, at one or more of the sugar processing steps for the crops. The steps where the liquid sodium permanganate may optionally be applied include at a sugar crop cutting step, a sugar crop conveying step, a sugar juice extraction step, a sugar juice clarifying step, and a clarifier muds filtration step. The application of liquid sodium permanganate in the processing of sugar from sugar crops results in reduced equipment fouling, reduced loss in juice purity, reduced scale formation, decreased turbidity in clarified juices, increased sugarcane processing rates, reduced sugar crop production costs, increased sugar product yield, and increased production capacity.

Owner:CARUS CORP

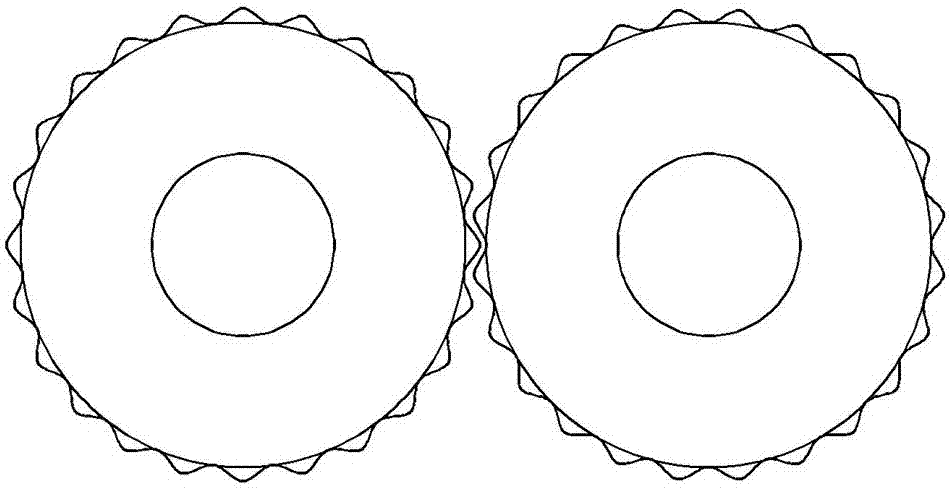

Contra-rotating roller type bagasse leaching device with chopping machine and carbon making molding machine

InactiveCN107262515AContinuous and reliable biteExtrusion compression ratio is largeSugar productsTransportation and packagingThree levelMolding machine

The invention discloses a contra-rotating roller type bagasse leaching device with a chopping machine and a carbon making molding machine. The contra-rotating roller type bagasse leaching device is characterized in that the chopping machine is arranged above a body of the contra-rotating roller type bagasse leaching device; three levels of cylindrical contra-rotating rollers are arranged inside the body, a bagasse guide groove is formed in a position below each level of contra-rotating rollers, a hopper of a bagasse elevator is connected with the last level of guide groove, a drying machine is connected with a discharge groove of the elevator by a centrifugal machine, and the carbon making molding machine is connected with a discharge end of the drying machine; a water inlet valve is arranged on the elevator, and a filter and a liquid outlet tube are arranged on the upper portion of the body; a cosine plastic plate pulse aeration device is arranged in the body, and a mechanical ultrasonic vibration exciter is arranged at the left lower corner of the body. The contra-rotating roller type bagasse leaching device has the advantages that the three levels of contra-rotating rollers, the cosine plastic plate pulse aeration device and the mechanical ultrasonic vibration exciter have distinct characteristics, accordingly, leaching and extracting of sugar can be synergistically promoted, working principles and technical effects which are difficult to foresee by technicians in the field can be realized, and the contra-rotating roller type bagasse leaching device has high practical application value.

Owner:罗小英

Mechanical ultrasonic bagasse leaching device provided with cutter

InactiveCN107312893AFor smooth cuttingEasy to disassemble and maintainSugarcane cuttingPurification by physical meansInlet valveEngineering

The invention discloses a mechanical ultrasonic bagasse leaching device with a guillotine cutter. A bagasse cutter is arranged above the body of the leaching device; a three-stage counter-rotating cosine roller is arranged inside the body, and the surface of the counter-rotating cosine roller is It is a continuous cosine surface, and there is a bagasse guide groove under each counter-rotating cosine roller. The last stage guide groove is connected to the hopper of the bagasse elevator, and the discharge chute of the elevator is connected to the bagasse temporary storage tank; There is a water inlet valve, a filter and a liquid outlet pipe are arranged on the upper part of the body; a mechanical ultrasonic exciter is installed at the lower left corner of the body. Both the three-stage counter-rotating cosine drum and the mechanical ultrasonic exciter of the present invention have distinctive features, can synergistically promote the leaching and extraction of sugar, have working principles and technical effects that are difficult for those skilled in the art to foresee, and have strong practical application value .

Owner:蒋霞

Mechanical ultrasonic type bagasse treatment device with cutter and pulping machine

InactiveCN107254557AFor smooth cuttingEasy to disassemble and maintainSugarcane cuttingSugar raw material preprocessing knivesThree stageInlet valve

The invention discloses a mechanical ultrasonic bagasse processing device with a guillotine cutter and a pulping machine. A bagasse guillotine cutter is arranged above the body of the leaching device; The surface of the cosine drum is a continuous cosine curved surface, and each stage of the counter-rotating cosine drum is provided with a bagasse guide groove. The last stage of the guide groove is connected to the hopper of the bagasse elevator. Storage tank; the elevator is provided with a water inlet valve, the upper part of the body is provided with a filter and a liquid outlet pipe, and the liquid outlet pipe is connected to the triple-effect long-tube rising film evaporation and concentration device; the lower left corner of the body is provided with a mechanical ultrasonic vibration exciter. The three-stage counter-rotating cosine cylinder and the mechanical ultrasonic vibration exciter of the present invention have distinct characteristics, can synergistically promote the leaching and extraction of sugar, have working principles and technical effects that are difficult to foresee by those skilled in the art, and have strong practical application value .

Owner:李小兰

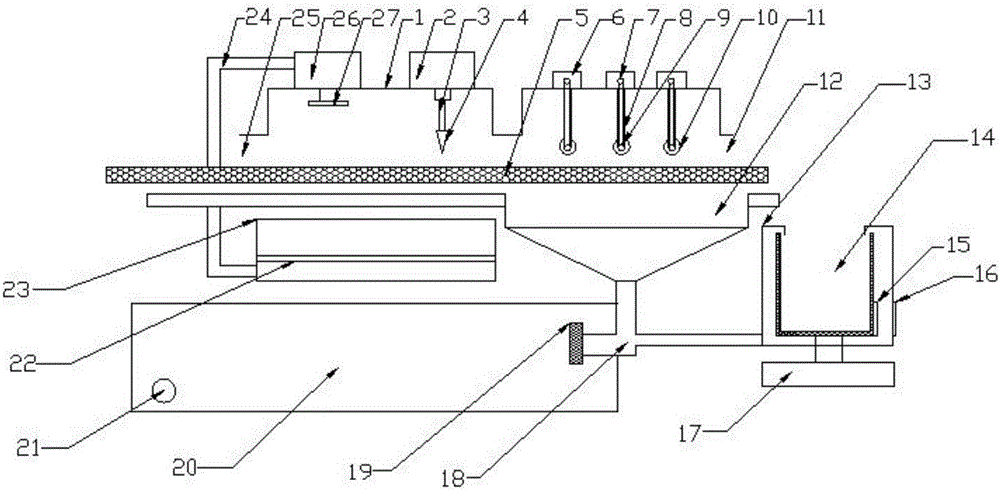

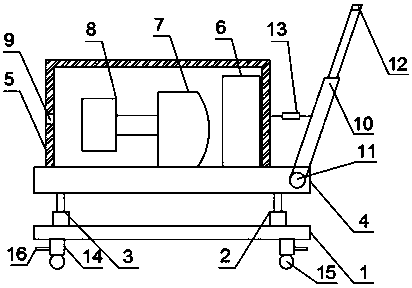

Sugarcane cutting machine for sugar production

InactiveCN108754034AAddressing Structural ComplexitySolve structural volumeSugarcane cuttingPulp and paper industryMotor shaft

The invention relates to a sugarcane cutting machine for sugar production. The sugarcane cutting machine comprises a base, wherein a first telescopic rod and a second telescopic rod are symmetricallyarranged at the surface of the base; a worktable is arranged at the surfaces of the top ends of the first telescopic rod and the second telescopic rod; a machine cover is arranged at the surface of the worktable; a storage battery, a stepless variable-speed motor and a revolving knife are sequentially arranged in the machine cover; the stepless variable-speed motor is connected with the revolvingknife through a motor shaft; one side surface of the machine cover is provided with an inlet; a pull rod is arranged at one end of the worktable; the worktable is connected with a pull rod through a rotary shaft; a pull handle is arranged at the top end of the pull rod; one end, near the revolving tool, of the machine cover is provided with a slide groove; the opposite surface of the slide grooveis provided with a collecting port. The sugarcane cutting machine for sugar production has the advantages that the worktable can be descended with certain height by a lifting device at the surface ofthe base when the worktable is not used, so that the occupation space is reduced; the pull rod with a reset function is arranged at one end of the worktable, so that the worktable can be moved to anyposition and be fixed by the pull rod when the sugarcane cutting machine is not used.

Owner:梁廷洲

Mechanical ultrasonic bagasse leaching device provided with cutter and pulper

InactiveCN107312883AFor smooth cuttingEasy to disassemble and maintainTransportation and packagingSolid waste disposalThree stageInlet valve

The invention discloses a mechanical ultrasonic bagasse leaching device provided with a cutter and a pulper. The bagasse cutter is arranged above the body of the leaching device; three-stage counter rotating cosine rollers are arranged in the body, the surface of every counter rotating cosine roller is a continuous cosine curved surface, a bagasse guiding chute is arranged below every stage counter rotating cosine roller, the last stage guiding chute is connected with the hopper of a bagasse elevator, and the discharging chute of the elevator is connected with a bagasse temporary storage tank; the elevator is provided with a water inlet valve, and the upper part of the body is provided with a filter and a liquid discharging tube; and the bottom left corner of the body is provided with a mechanical ultrasonic vibration exciter. The three-stage counter rotating cosine rollers and the mechanical ultrasonic vibration exciter have distinct characteristics, and can cooperatively promote the leaching extraction of sugar, and the device has a working principle and technical effects which cannot be foreseen by technical personnel in the field, and has high practical application values.

Owner:蒋霞

Sucrose extraction equipment

InactiveCN109988871AReduce mass productionReduce filtration processSugarcane cuttingSucroseWork productivity

The invention discloses sucrose extraction equipment. The equipment comprises a pretreatment box; a conveying cavity with a leftward opening is fixedly arranged in the pretreatment box; a conveying rod which is symmetrical from left to right is rotationally arranged on the front end wall and the rear end wall of the conveying cavity; conveying wheels are fixedly arranged on the outer surface of the conveying rod, and the conveying wheels are connected with each other through a conveying belt; a rotating cavity is formed in the rear end wall of the conveying cavity; and a rotating assembly is arranged in the rotating cavity. The equipment is simple in structure and is convenient to use. Manual participation is reduced by adopting an automatic working mode, so that labor cost is reduced, working efficiency and quality of the equipment are improved, and batch production of sucrose is realized. Through a high-efficiency sugarcane pretreatment procedure, the procedures are ordered and simplified, the impurity filtering procedure in subsequent production is effectively reduced, working efficiency and quality of sucrose production are improved, and reliability of equipment is improved.

Owner:杭州诚娇服饰有限公司

Method for removing impurities from sorgo

ActiveCN102492780BAchieve removalSimple processSugarcane cuttingSugar juice purificationWater volumeSugar

The invention provides a method for removing impurities from sorgo. The method comprises the following steps of: cutting: cutting sorgo straws into 10-30cm; dry-cleaning: conveying the cut material into a disperser for dispersing and extracting at negative pressure at the same time; water-cleaning: conveying the dried-cleaned material by a link plate, wherein the dried-cleaned material is sprayed and rinsed 3-4 times according to the water volume of 0.05-0.3t in each ton of straws; squeezing: squeezing the rinsed material to produce mixed sugar juice; and flocculating: adding a flocculating agent to the mixed sugar juice for carrying out flocculating reaction, and feeding the flocculated supernatant juice into a subsequent working section. The method disclosed by the invention realizes removal of the impurities in the sorgo straws with a simple and efficient method, is beneficial to reducing the influence on the subsequence process, has a simple process and greatly-reduced operation cost and ensures that relative loss of sugars in the materials is little.

Owner:兴储世纪科技股份有限公司

Counter-rotation roller type sugarcane bagasse treatment device with straw cutting machine and carbon-making molding machine

InactiveCN107299166AContinuous and reliable biteExtrusion compression ratio is largeTransportation and packagingSolid waste disposalThree levelMolding machine

The invention discloses a counter-rotation roller type sugarcane bagasse treatment device with a straw cutting machine and a carbon-making molding machine. The straw cutting machine is arranged above a device body of a leaching device; three levels of counter-rotation rollers are arranged inside the device body, and the counter-rotation rollers are cylindrical; sugarcane bagasse guiding slots are formed in lower parts of the three levels of counter-rotation rollers; the last level of guiding slot is connected with a hopper of a sugarcane bagasse lifting machine; a discharging groove of the lifting machine is connected with a dryer through a centrifugal machine; a discharging end of the dryer is connected with a mechanized carbon-making molding machine; the lifting machine is provided with a water inlet valve; an upper part of the device body is provided with a filter and a liquid outlet pipe; the liquid outlet pipe is connected with a triple-effect long-tube rising-film evaporation concentration device; a cosine gel tray pulse aeration device is arranged in the device body; a mechanical ultrasonic vibration exciter is arranged at a left lower corner of the device body. The three levels of counter-rotation rollers, the cosine gel tray pulse aeration device and the mechanical ultrasonic vibration exciter of the counter-rotation roller type sugarcane bagasse treatment device disclosed by the invention all have distinctive characteristics; the leaching extraction of sugars can be promoted in a cooperation manner; the device has a working principle and a technical effect which are difficultly predicted by technicians in the field, and has a stronger practical application value.

Owner:吴贻湖

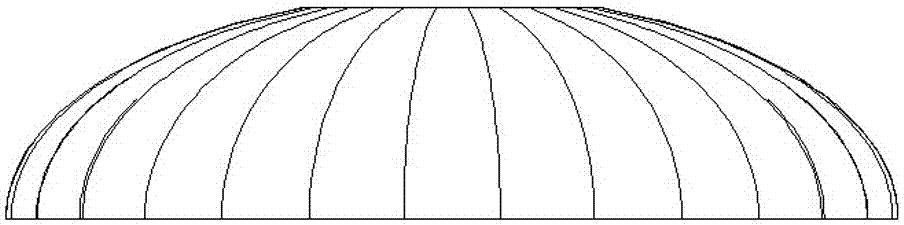

Bagasse leaching device provided with feeding groove and carbonizing forming machine

InactiveCN107282609AContinuous and reliable biteExtrusion compression ratio is largeSugar productsSolid waste disposalThree stageInlet valve

The invention provides a bagasse leaching device provided with a feeding groove and a carbonizing forming machine, and the bagasse feeding groove is arranged above the machine body of the leaching device; three-stage opposite rotation cosine rollers are arranged inside the machine body, the surfaces of the opposite rotation cosine rollers are continuous cosine curved surfaces, bagasse guide grooves are arranged below each-stage opposite rotation cosine rollers, the last-stage guide grooves are connected with a hopper of a bagasse hoist, and a discharge groove of the hoist is connected with a drying machine by a centrifugal machine; a discharge end of the drying machine is connected with the carbonizing forming machine; a water inlet valve is arranged on the hoist, and a filter and a liquid outlet pipe are arranged at the upper part of the machine body; a cosine rubber disk pulse aeration device is arranged in the machine body, and a mechanical ultrasonic vibration exciter is arranged at the left bottom of the machine body. According to the bagasse leaching device provided with the feeding groove and the carbonizing forming machine, the three-stage opposite rotation cosine rollers, the cosine rubber disk pulse aeration device and the mechanical ultrasonic vibration exciter have distinct characteristics, leaching extraction of sugar can be promoted synergistically, and the leaching device has the working principle and the technical effect which are difficult to predict by the technical staff in this field and has a higher practical application value.

Owner:谢瑶

Method for manually preparing brown sugar pieces

InactiveCN106350612ASimple preparation processEasy to implementSugar productsSugarcane cuttingHigh concentrationAdditive ingredient

The invention refers to a handmade method for slices of brown sugar, comprising the steps of chopping and pressing sugarcane, boiling the liquid of sugarcane after pressing to syrup; using quick lime as coagulator and adding coagulator after liquid of sugarcane is boiled to syrup; cooling the high concentration of syrup and molding; cutting the syrup into slices according to requirements, packing the slices according to quantity and getting the finished goods. By the implementation of the method, the whole making process of slices of brown sugar just costs around two hours. The finished slices of brown sugar almost reserve all ingredients in liquid of sugarcane, except the function as sugar, the slices of brown sugar also contain vitamin and trace elements, such as iron, zinc, manganese, chrome etc, the nutritious ingredients are higher than brown sugar and white sugar. At the same time, the slices of brown sugar, made by the handmade method, is totally made by physical method without adding any chemical, so the sugar related products are very healthy. In addition, the product cost is low and market prospect is wide.

Owner:黄爱红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com