Method for removing impurities from sorgo

An impurity removal and sweet sorghum technology, which is applied in the extraction of juice from sugar cane, sucrose production, sugar production, etc., can solve the problems of high energy consumption, large sugar loss, low impurity removal rate, etc., and achieves reduced operating costs and residual Small amount and relatively small loss of sugar

Active Publication Date: 2012-06-13

兴储世纪科技股份有限公司

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

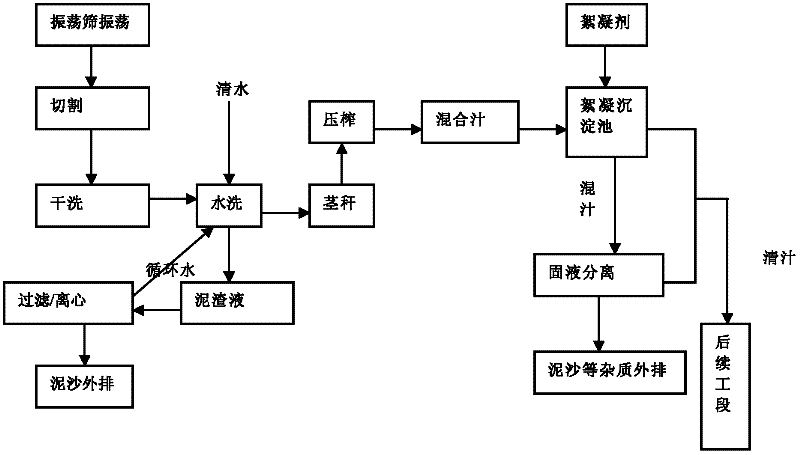

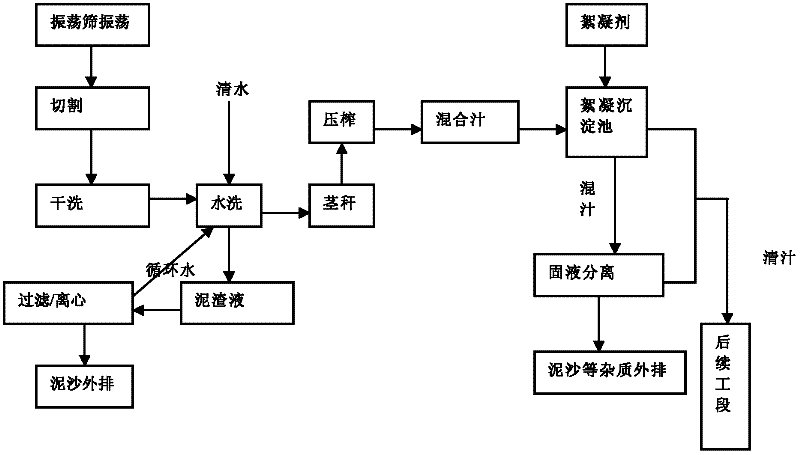

[0005] In order to improve the problem of low impurity removal rate and high sugar loss in the prior art, especially the problem of excessive energy consumption, the present invention effectively utilizes pretreatment, such as initial sand removal by oscillation, and subsequent negative pressure absorption after cutting Such methods effectively remove the impurities of sweet sorghum stalks while ensuring the minimum loss of sugar, and greatly save energy consumption

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The source of equipment used in this embodiment is shown in Table 1:

[0028] Table 1

[0029] equipment

[0030] Three Roll Press

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for removing impurities from sorgo. The method comprises the following steps of: cutting: cutting sorgo straws into 10-30cm; dry-cleaning: conveying the cut material into a disperser for dispersing and extracting at negative pressure at the same time; water-cleaning: conveying the dried-cleaned material by a link plate, wherein the dried-cleaned material is sprayed and rinsed 3-4 times according to the water volume of 0.05-0.3t in each ton of straws; squeezing: squeezing the rinsed material to produce mixed sugar juice; and flocculating: adding a flocculating agent to the mixed sugar juice for carrying out flocculating reaction, and feeding the flocculated supernatant juice into a subsequent working section. The method disclosed by the invention realizes removal of the impurities in the sorgo straws with a simple and efficient method, is beneficial to reducing the influence on the subsequence process, has a simple process and greatly-reduced operation cost and ensures that relative loss of sugars in the materials is little.

Description

technical field [0001] The invention relates to a sweet sorghum impurity removal method, in particular to a simple and efficient sweet sorghum impurity removal method with little sugar loss. Background technique [0002] As a non-grain crop, sweet sorghum stalks can be used as raw materials for the production of fuel ethanol, opening up a new path for the development of clean energy; however, sediment will inevitably be introduced during harvesting and transportation, which will bring great impact to subsequent production. Difficulties, such as: (1) a large amount of sediment and serious equipment loss; (2) a large amount of sediment will cause pipeline blockage and affect subsequent production. At the same time, the sugar content in the leaves and sheaths of sweet sorghum is low, the extraction value is small, and the equipment loss is large during pressing. Therefore, it is of great practical significance to find an economical, simple, efficient and less sugar loss treatm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C13B10/02C13B20/00C13B5/00C13B5/02

Inventor XIE SHUANGPINGLING FENGWANG XIAODONGCAO JUNWEI JUNQI XIAOBAOCHEN YONGZHANG MENG

Owner 兴储世纪科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com