Patents

Literature

303results about "Juice extraction from sugarcane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrialized production method of primitive brown sugar

ActiveCN103993106ARetract lowPromote recoverySugar crystallisationPurification by physical meansSlagMicrofiltration

The invention discloses an industrialized production method of primitive brown sugar. The method comprises the steps of with cane sugar factory mixed juice as a raw material, adding lime milk to regulate the pH value to 5.8-6.6; sieving and filtering; heating, floating and removing floating slag; removing impurities through microfiltration; evaporating and concentrating to obtain syrup with the concentration of 60-65-degree Bx; boiling sugar at the temperature of 125-130 DEG C at normal pressure to obtain syrup with the concentration of 95-98-degree Bx; sanding and forming to realize industrialized production of the primitive brown sugar. When used for producing brown sugar, the industrialized production method disclosed by the invention is safe and reliable in production process, high in mechanization degree, capable of realizing large-scale production of the primitive brown sugar and stable in product quality.

Owner:GUANGXI UNIV +1

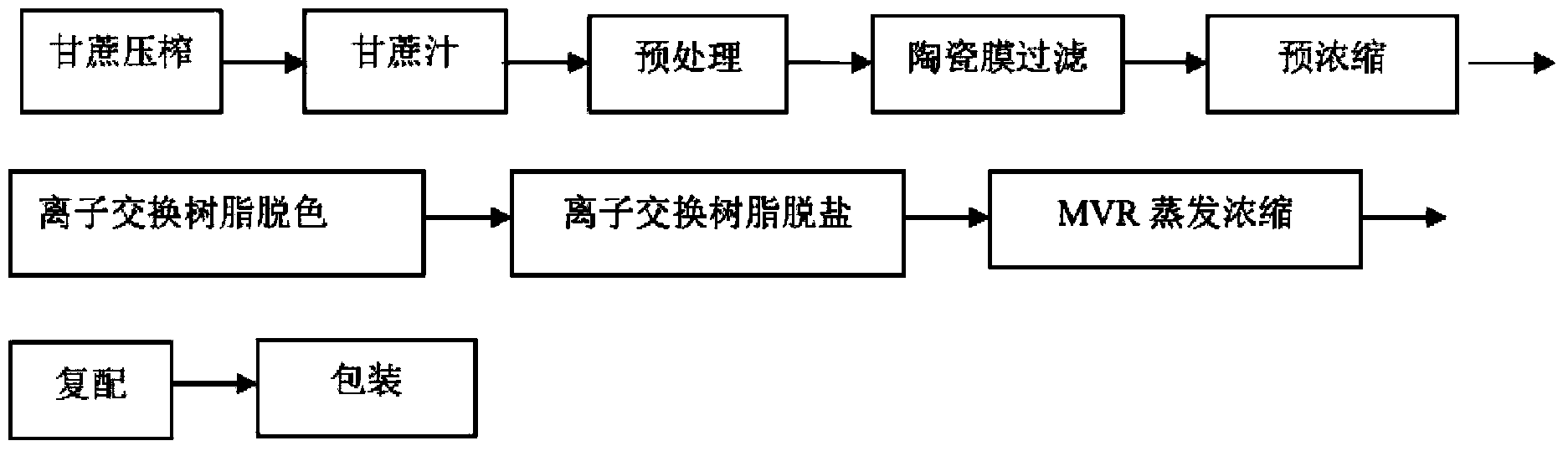

Technology for refining saccharose

ActiveCN103725802ANo color reversionOptimal production process parametersSugar crystallisationPurification using ion-exchange materialsInorganic saltsSucrose

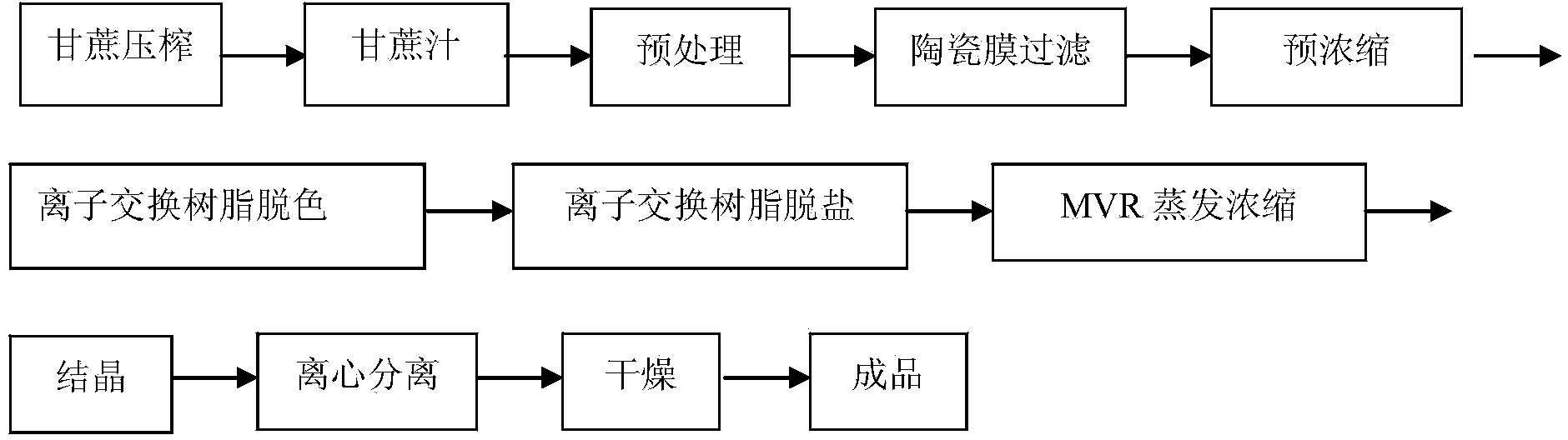

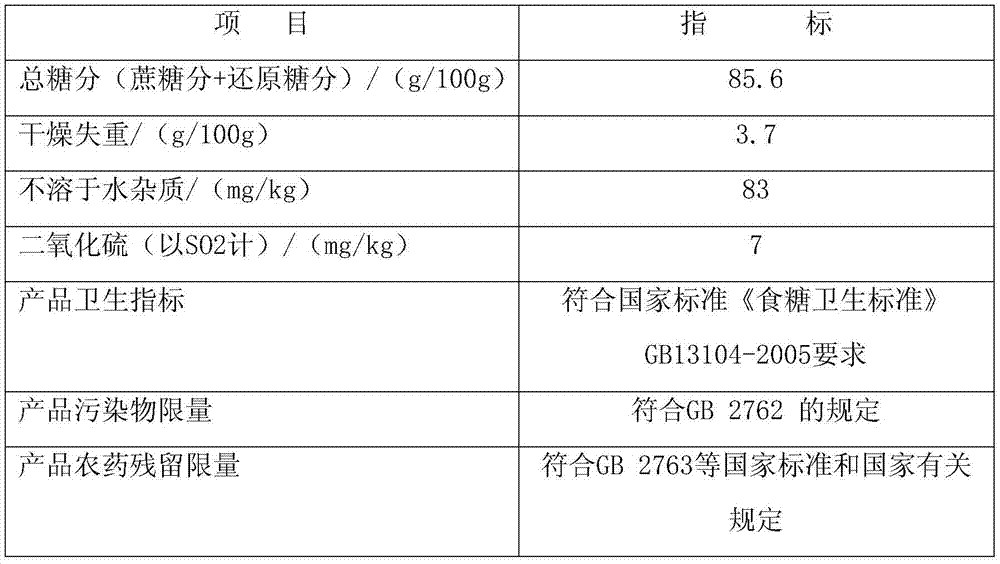

The invention discloses a technology for refining saccharose. The technology comprises specific steps of juicing, pretreating, micro-filtering by a membrane, pre-concentrating, decoloring through ion exchange, desalting, evaporating and concentrating through MVR (mechanical vapor recompression), crystallizing, separating through centrifuging, and drying so as to obtain the saccharose crystal. The technology has the advantages that ceramic microfiltration substitutes for sedimentation by sheet frames and lime, so that the step of ultrafiltration is saved; due to concentration by the membrane, the evaporation capacity of evaporation and concentration equipment is reduced, the energy consumption is lowered, and part of inorganic salt is removed; the technology of decoloring and removing impurities through ion exchange substitutes for the technology of stoving, so that the problem of residual sulphur in the saccharose is solved, and the quality of the product is improved; the manner of ion exchange can effectively remove the salt in cane juice; energy consumption is effectively lowered due to the MVR; by adopting the membrane concentration and separation and ion exchange equipment, the floor space of the equipment is reduced, and investment of capital construction is lowered.

Owner:JIANGSU JIUWU HITECH

Method for producing raw juice brown sugar

The invention relates to a method for producing raw juice brown sugar and belongs to the technical field of food processing. The invention aims at solving the technical problem of providing a method for producing raw juice brown sugar with higher quality. The method for producing the raw juice brown sugar comprises the following steps: a, juicing sugarcane, and sieving, so as to obtain raw juice after sieving and screening residue; b, heating the raw juice after sieving, eliminating formed floating condensation products, so as to obtain clear juice, and filtering, so as to obtain filtrate I; c, standing the filtrate I for 2-3 hours, and removing fine silt impurities at the bottom layer, so as to obtain sugar juice clear liquid; d, evaporating and concentrating the sugar juice clear liquid obtained in the step c into syrup with the brix of 85-90 degree Bx, then carrying out sugar boiling to obtain massecuite, sanding, and moulding, so as to obtain lump sugar; or evaporating and concentrating the sugar juice clear liquid obtained in the step c into clear syrup with the brix of 55-60 degree Bx, and then carrying out sugar boiling at normal pressure, so that liquid brown sugar with the concentration of 68-78 degree Bx is obtained.

Owner:MIYI HUASENTY CO LTD

Originally ecological black sugar processing method

ActiveCN104805225ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

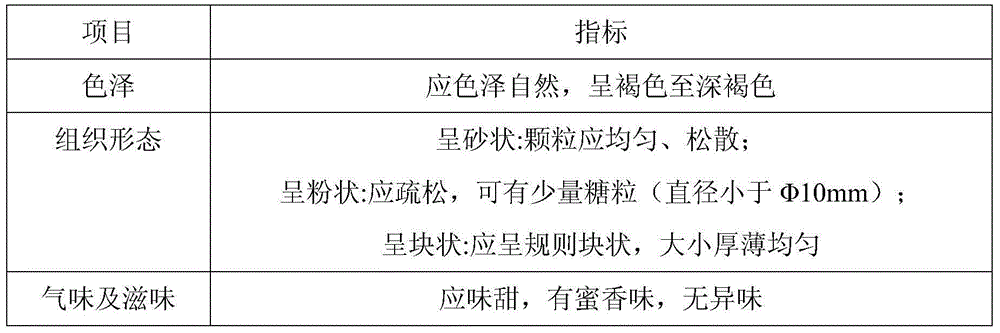

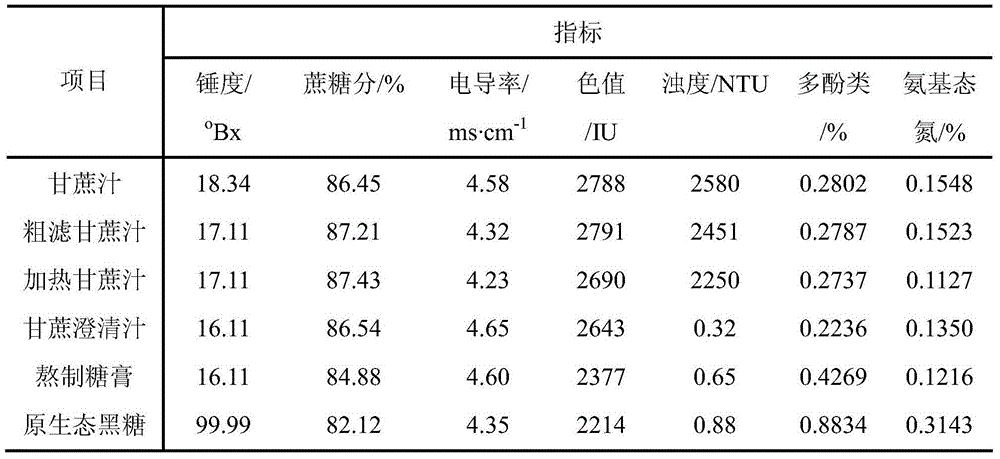

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

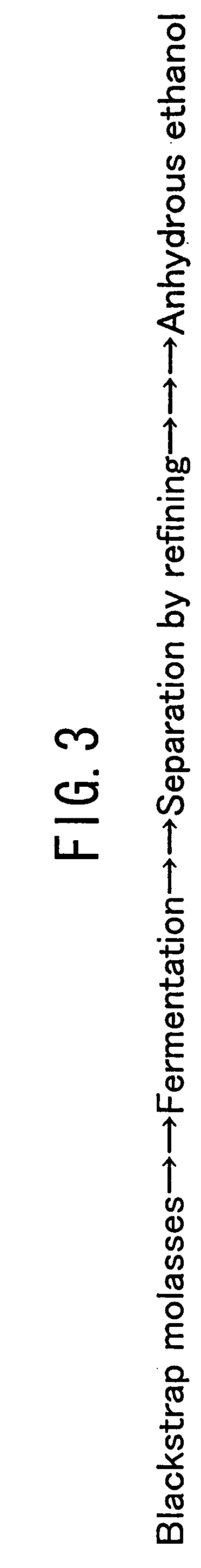

Method for producing sugar and a useful material

InactiveUS20060035355A1Increase volumeReduce productionBiofuelsSugar crystallisationBiotechnologyEngineering

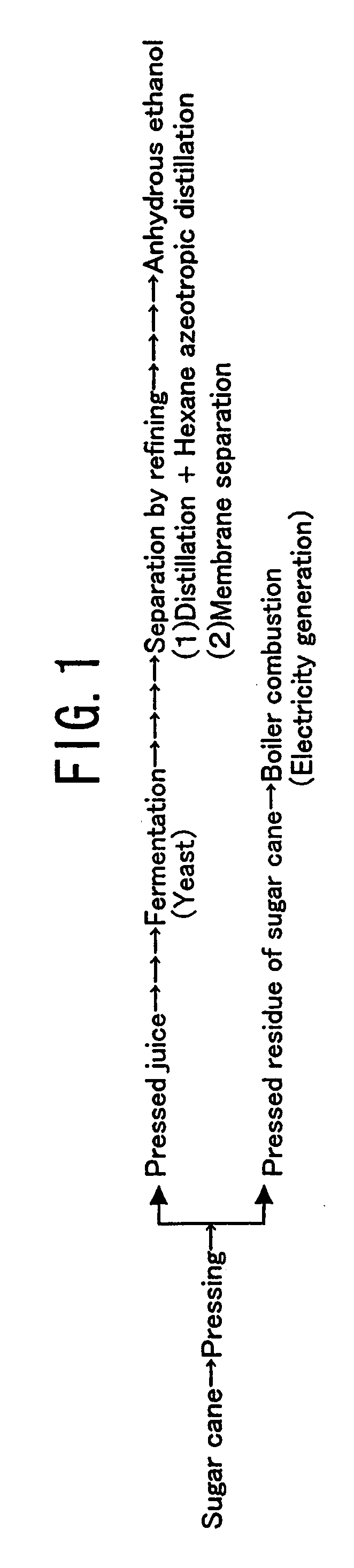

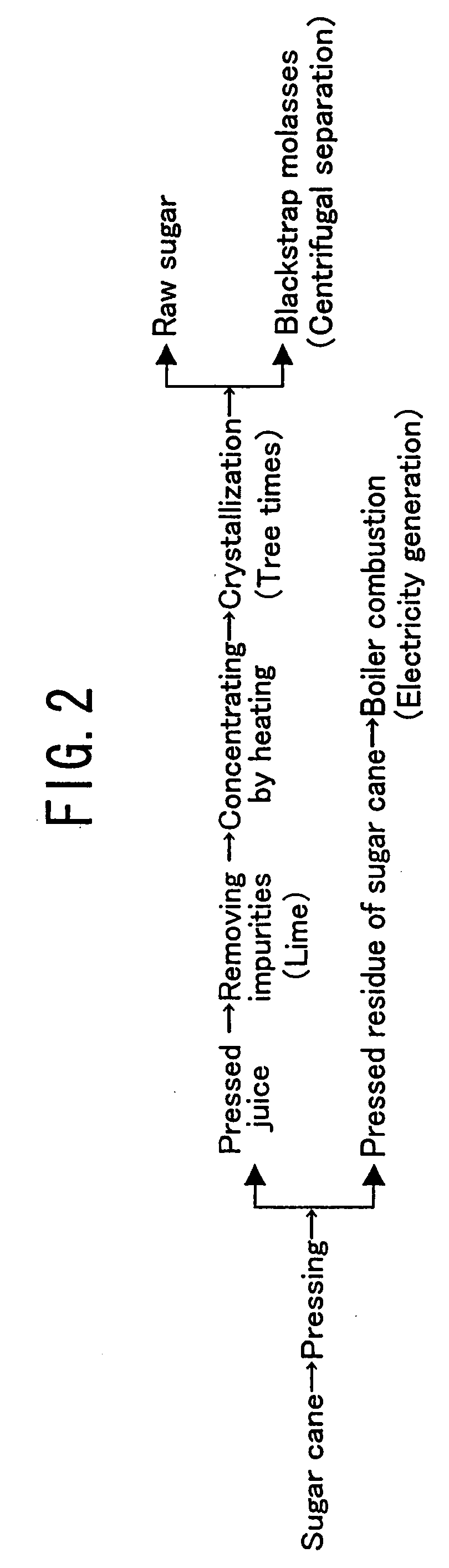

An object of the present invention is to provide a method for producing sugar and ethanol from sugar cane, in which almost all of energy to be consumed in the production processes of the sugar, the ethanol and the like can be supplied by the energy obtained by burning a pressed residue of sugar cane, yet without decreasing the sugar amount to be produced. The present invention provides a method for producing sugar and a useful material from sugar cane, comprising the steps of: (a) producing from sugar cane a pressed juice and pressed residue of sugar cane; (b) producing sugar and blackstrap molasses from said pressed juice; and (c) generating an energy and a useful material by using said pressed juice, said blackstrap molasses and said pressed residue of sugar cane as source materials that have been obtained from said steps (a) and (b), wherein said sugar cane contains an amount of 15% or greater by mass of fiber component in its cane stem region and provides a dry matter yield amount per unit area of 40 t / ha / year or higher; and 90% or more of energy required for all of the steps of said production method is obtained from energy generated by burning said pressed residue of sugar cane.

Owner:ASAHI BREWERIES LTD

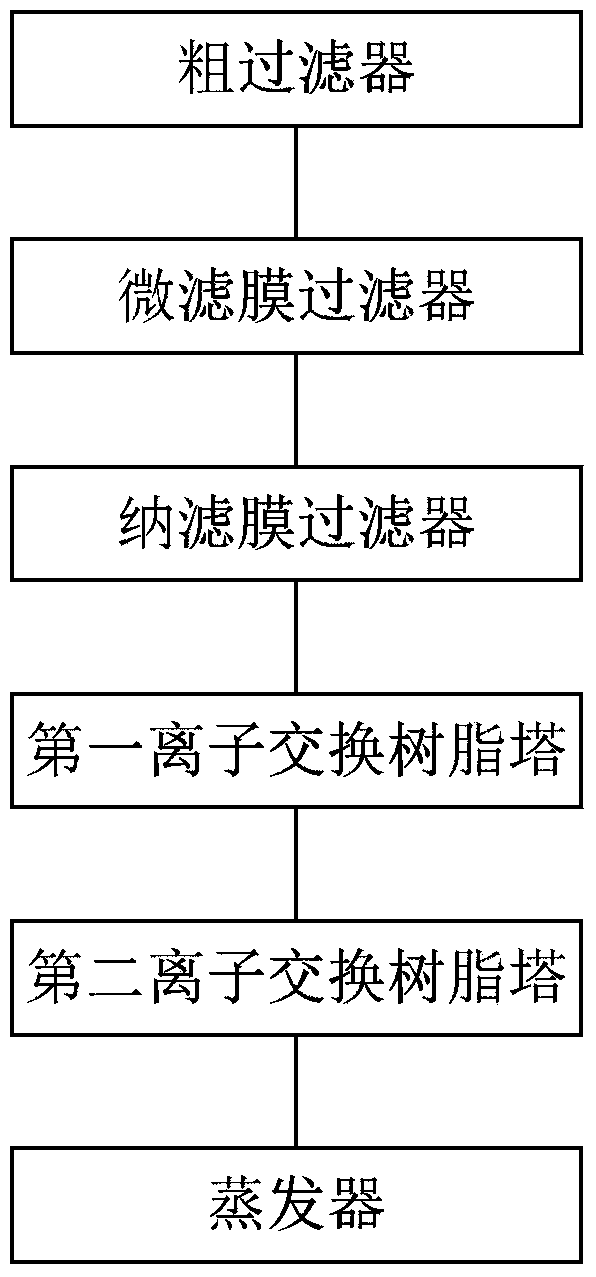

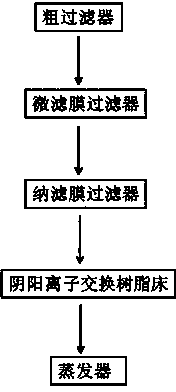

Production technique and device of directly edible edible syrup

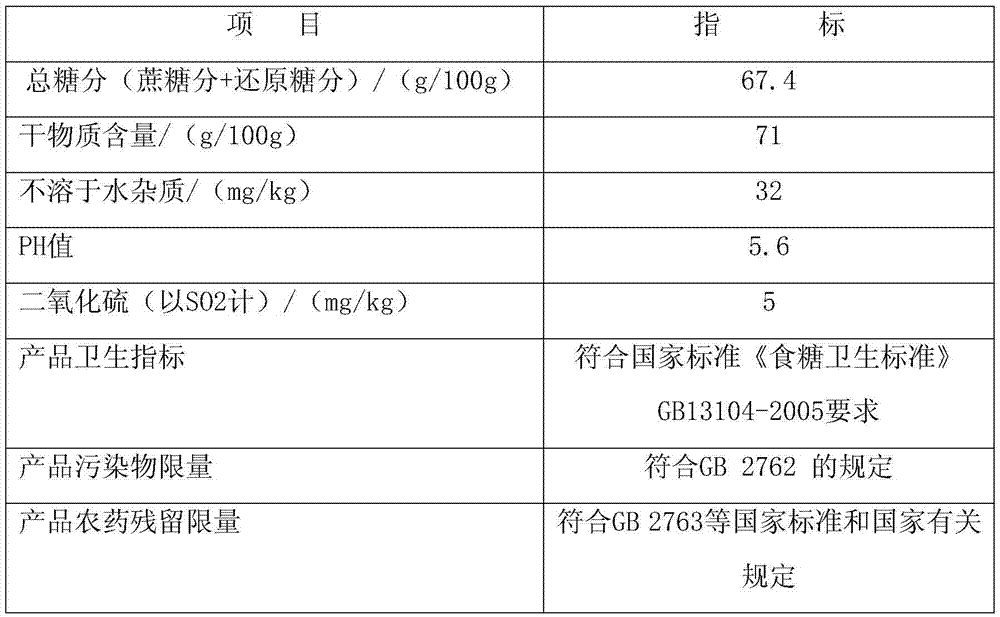

ActiveCN103710469ALow chroma valueHigh desalination ratePurification using ion-exchange materialsPurification by physical meansSucroseMicrofiltration membrane

The invention relates to a production technique and device of directly edible syrup. The method comprises the following steps: pressing sugar cane with a juice press to obtain a sugar cane juice; prefiltering the sugar cane juice through a coarse filter, and filtering with a microfiltration membrane to obtain a sucrose juice clear solution; concentrating the sucrose juice clear solution through a nanofiltration membrane to obtain a concentrated solution; sending the concentrated solution into a first ion exchange resin tower to obtain a first permeation solution; sending the first permeation solution into a second ion exchange resin tower to obtain a second permeation solution; and concentrating the second permeation solution in an evaporator to obtain a refined concentrated solution, adding additives and uniformly mixing to obtain the syrup. The product produced by the production technique provided by the invention has the advantages of low chromatic value, high desalting rate and high yield.

Owner:JIANGSU JIUWU HITECH

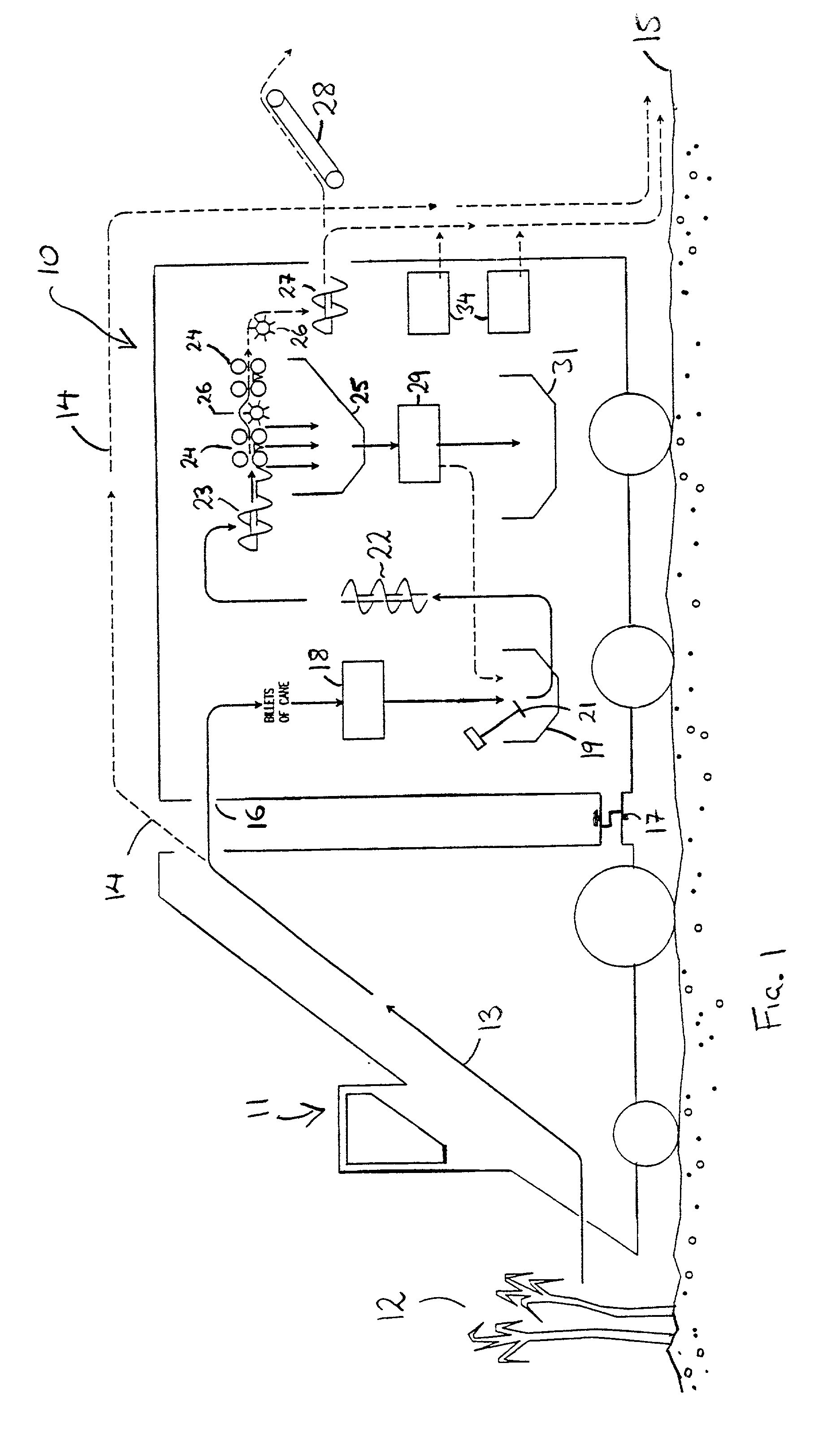

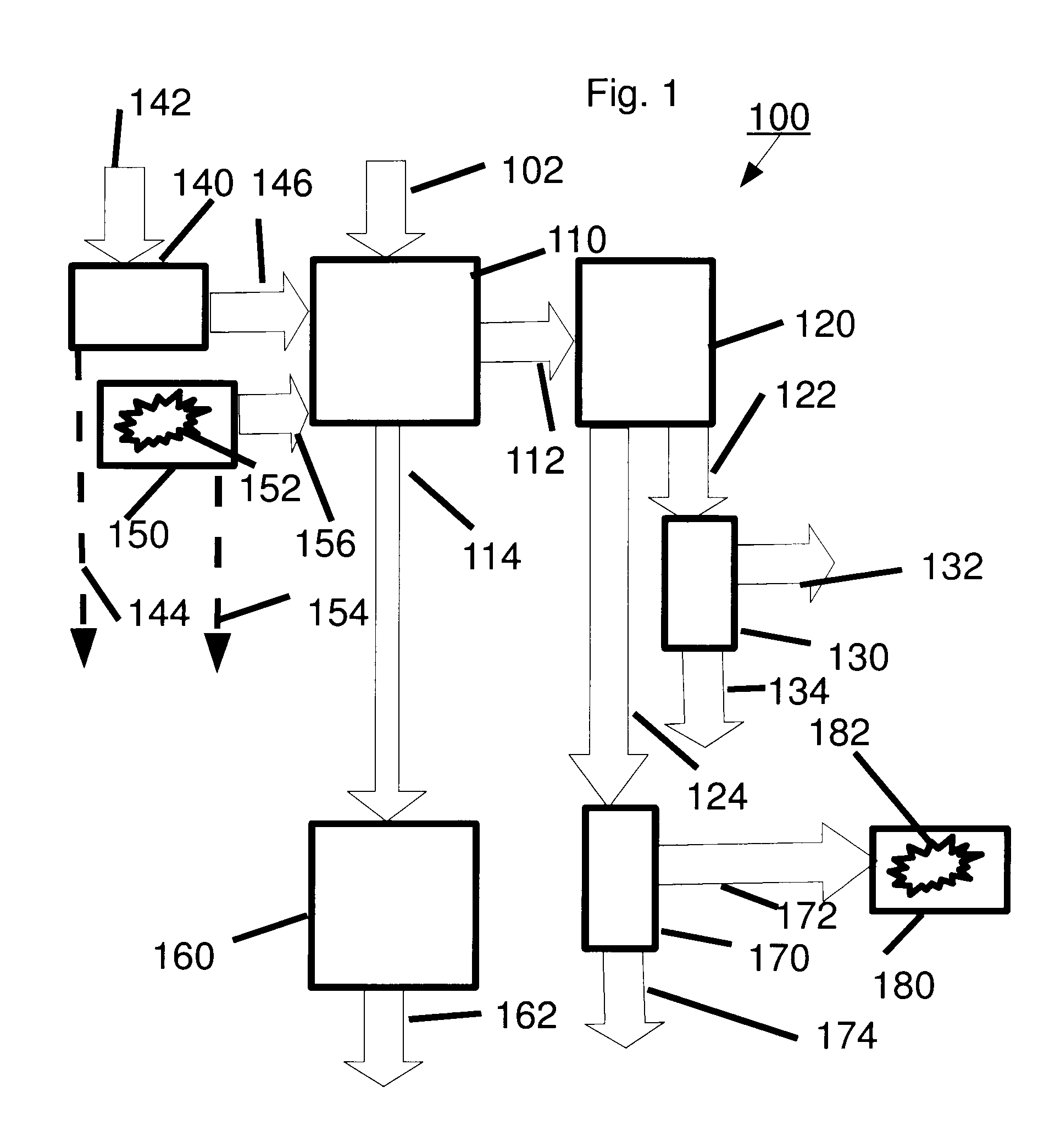

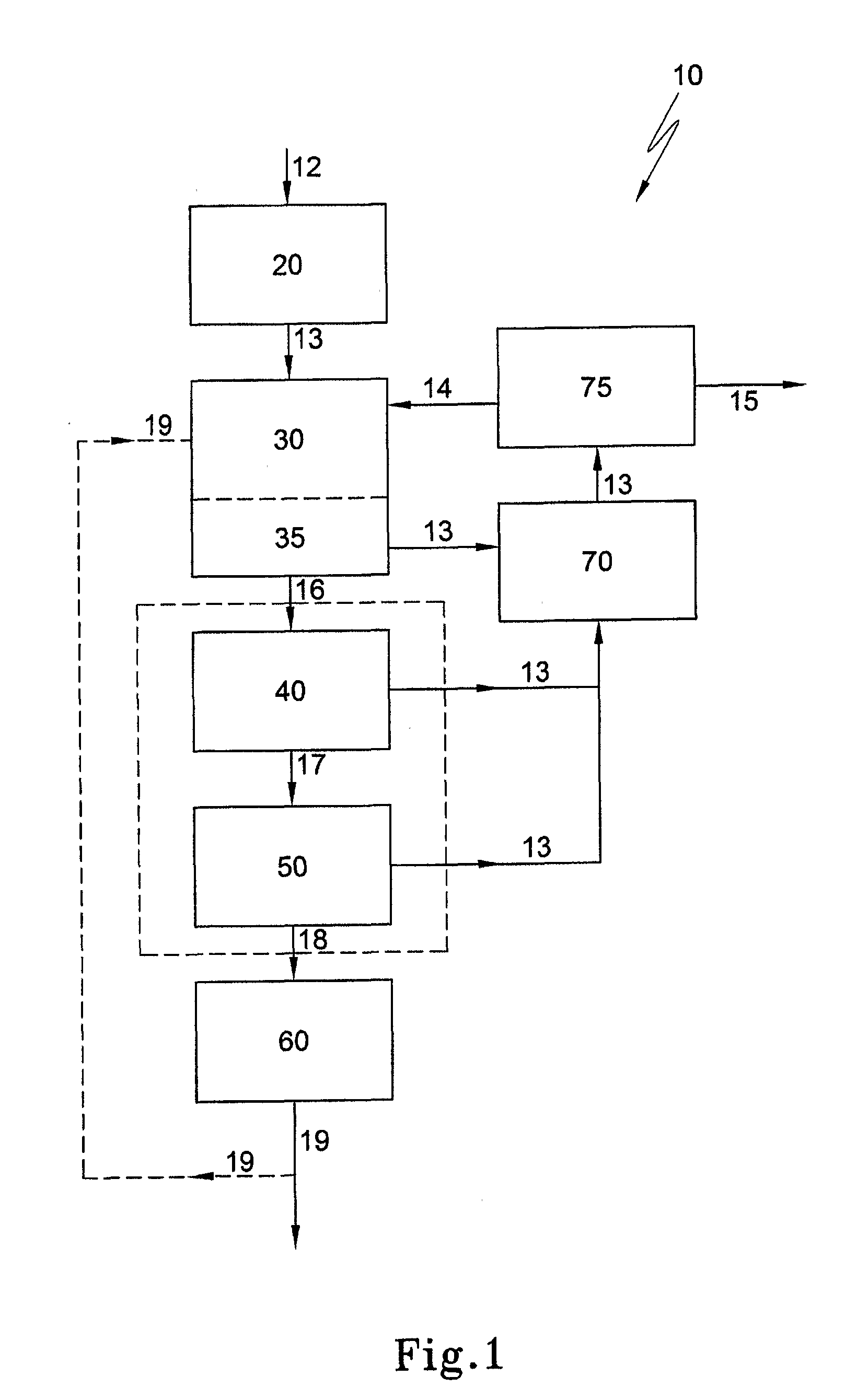

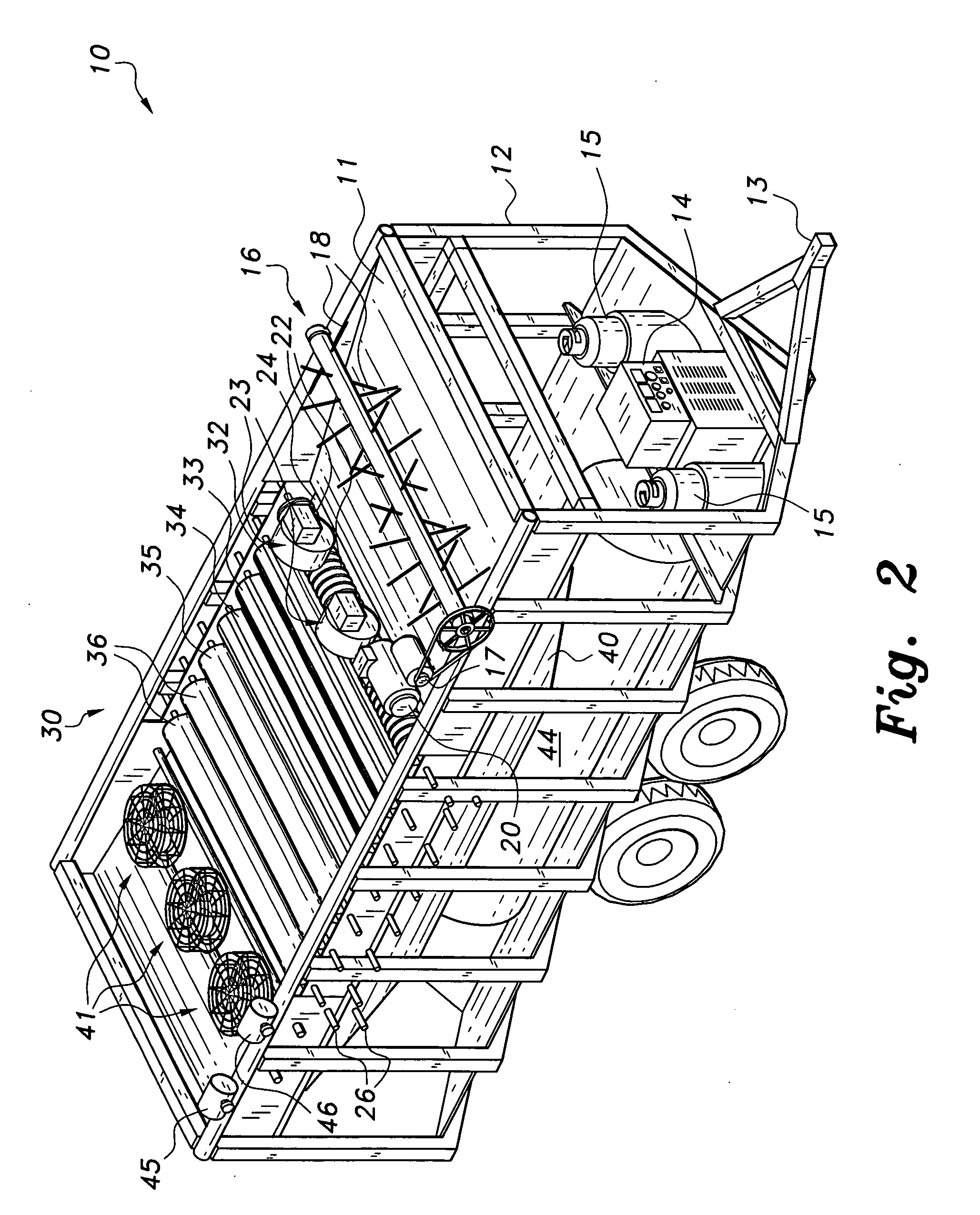

In-field sugar cane processor

An apparatus and method for extracting sugar-containing juice from sugar-containing plant matter, such as sugar cane. The apparatus is adapted to be installed in or near the field in which the plant matter is to be harvested. The apparatus comprises an inlet means for receiving the plant matter, a comminuting means for finely comminuting the received plant matter, and a separating means for separating the sugar-containing juice from the finely comminuted plant matter. Use of the apparatus at or near the site of harvest reduces the quantity of fibrous material transported to the sugar mill. It also allows return to the field of much of the fibrous matter that is at present lost in the harvesting process.

Owner:BIOMASS TECH PTY LTD

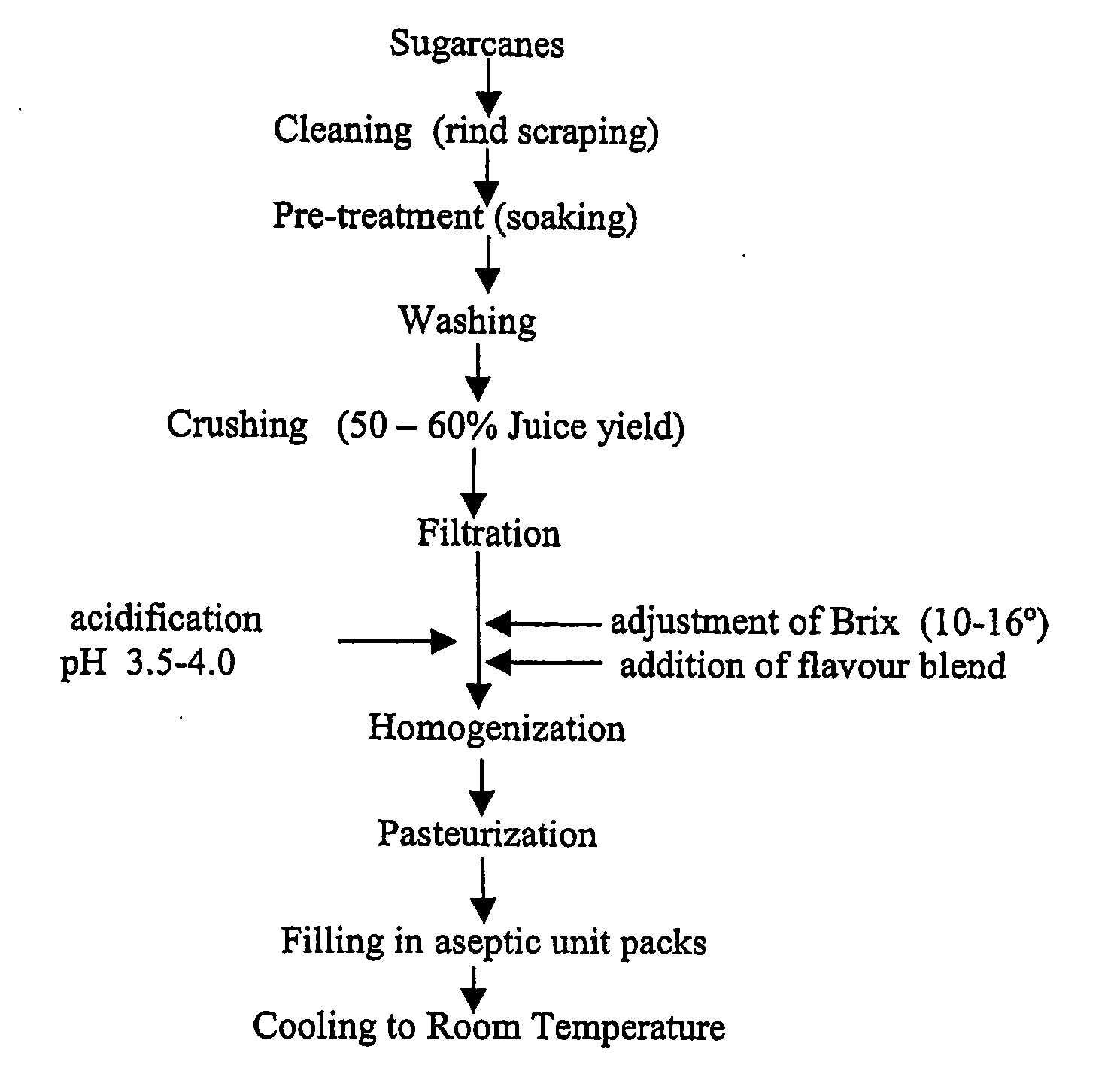

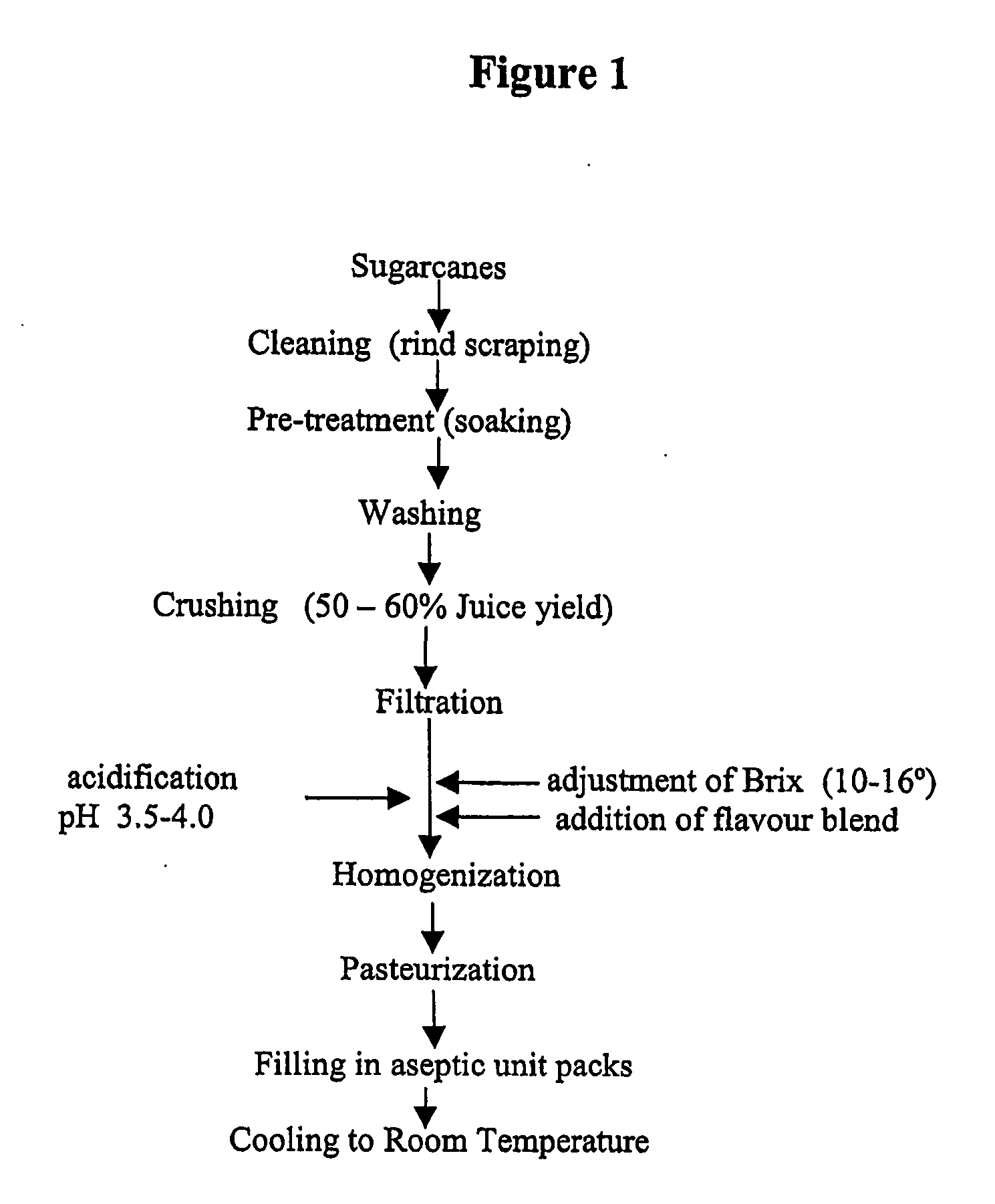

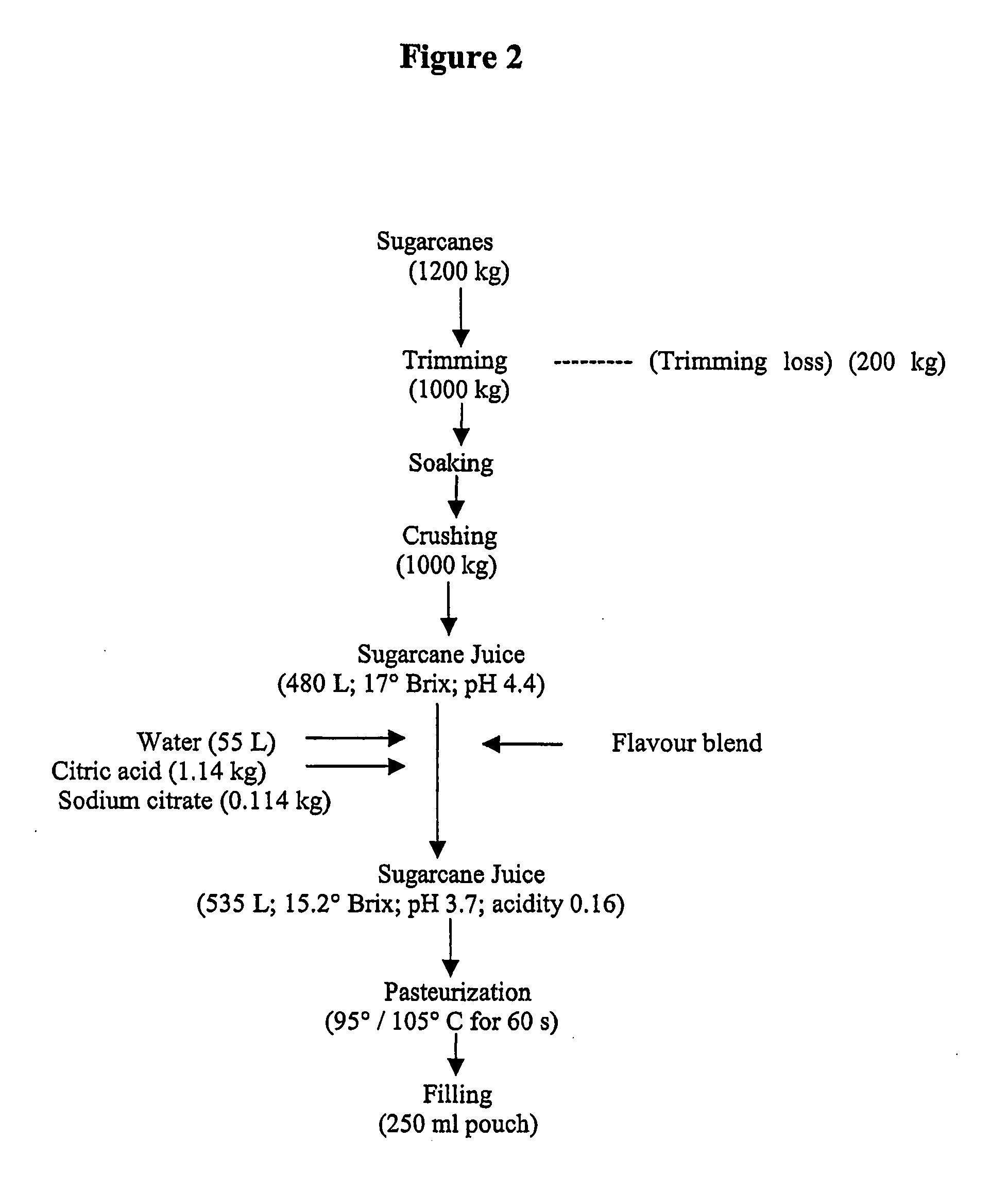

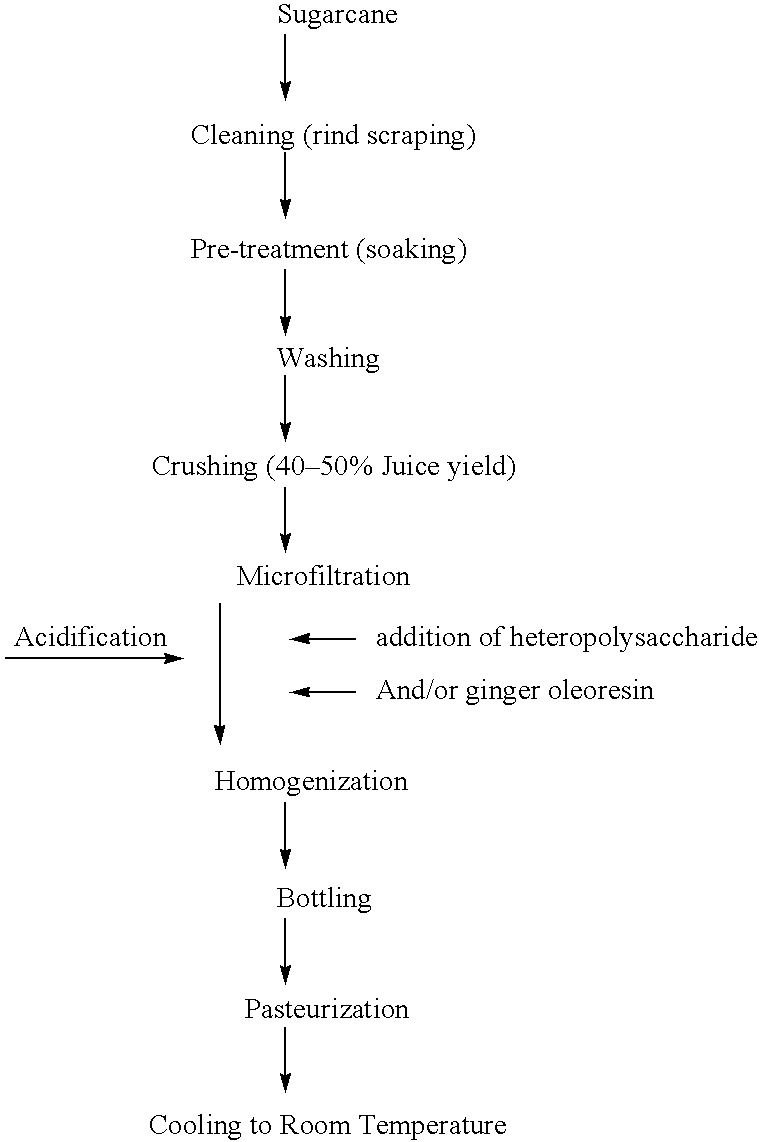

Flavored sugarcane juice in aseptic unit packs

InactiveUS20060083835A1Increase aromaFood preservationPurification by physical meansSoluble solidsChemistry

The present invention provides a method wherein flavored sugarcane juice containing 18-20% soluble solids and can be preserved after suitable dilution in aseptic unit packs.

Owner:COUNCIL OF SCI & IND RES

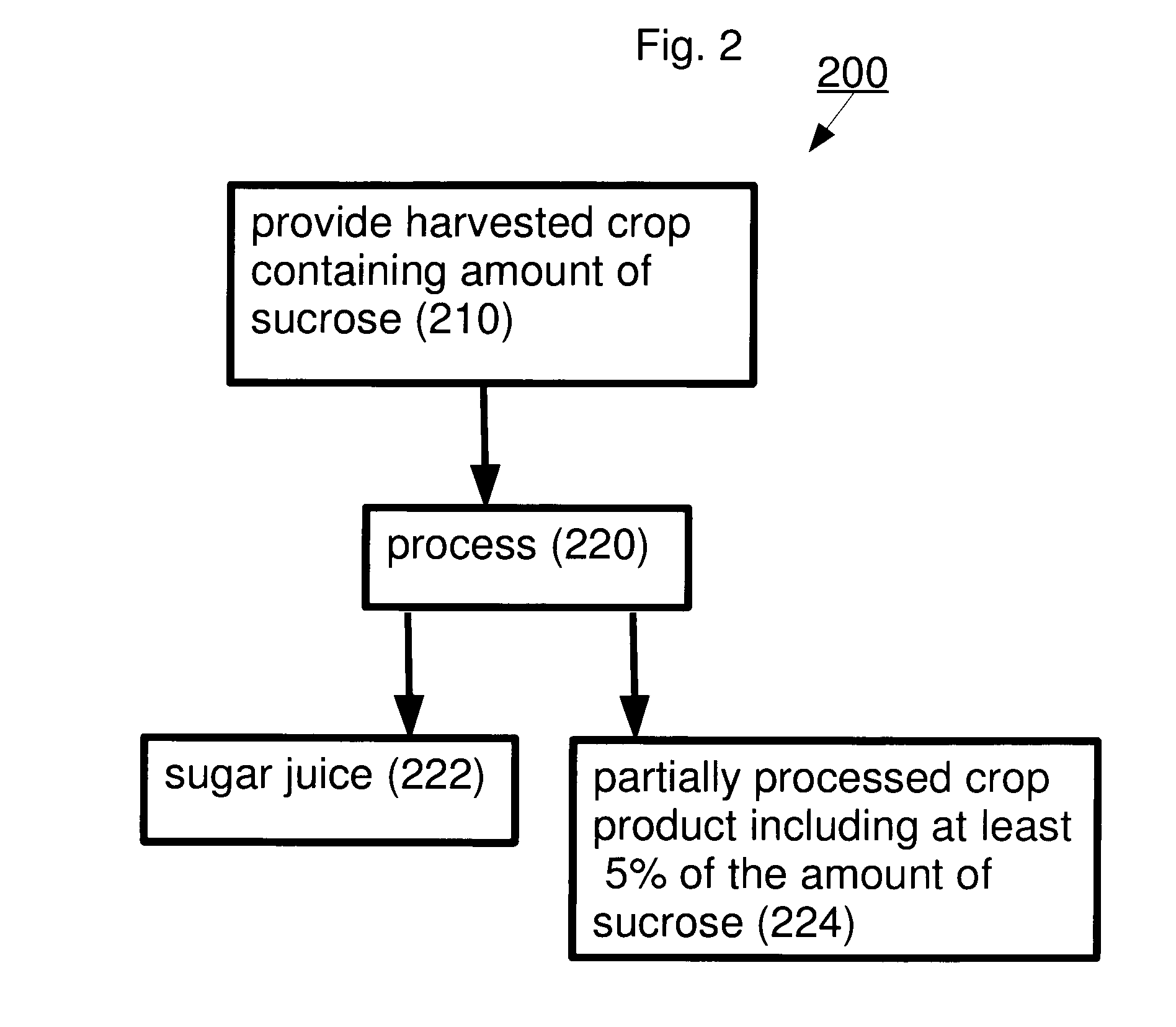

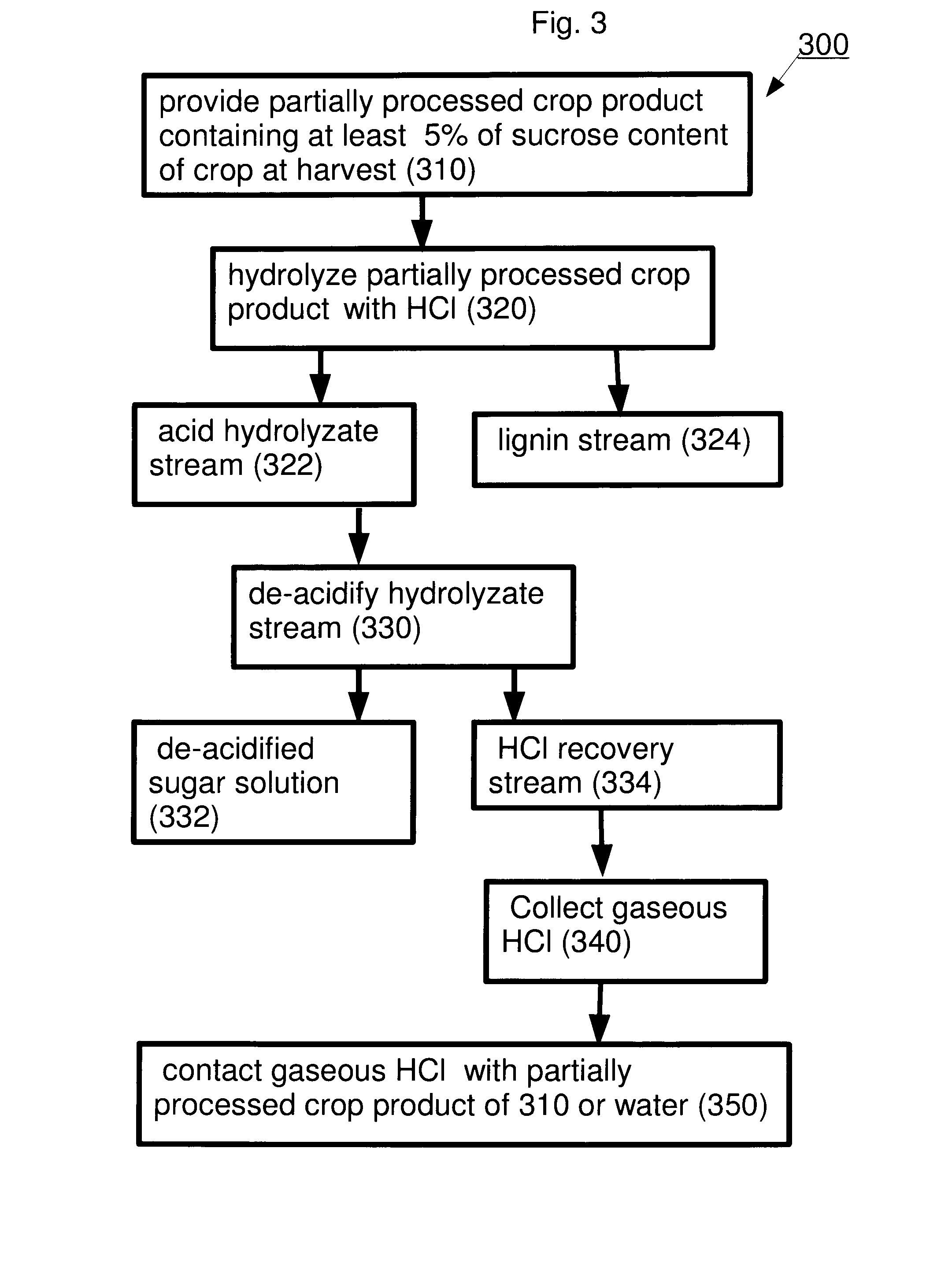

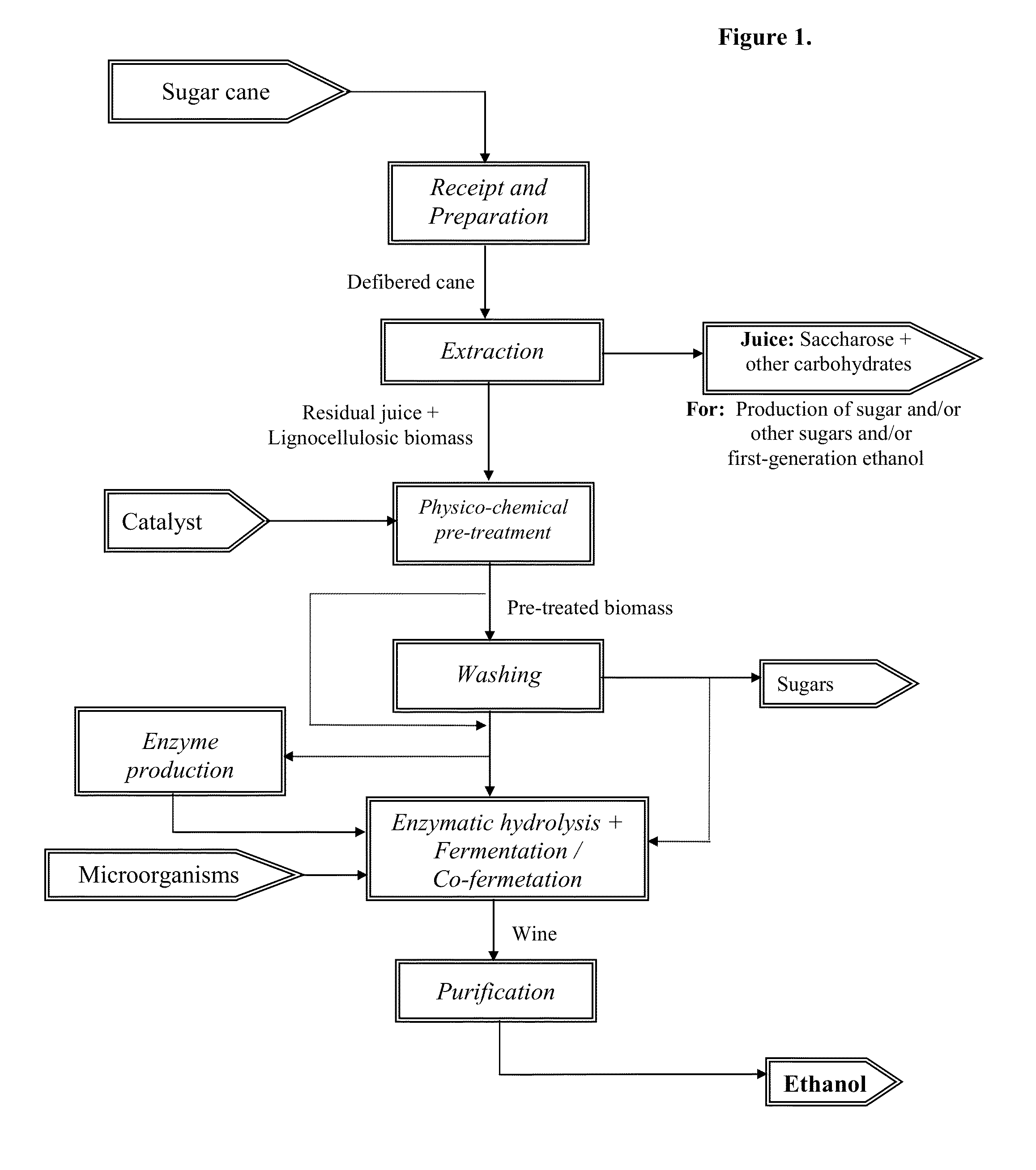

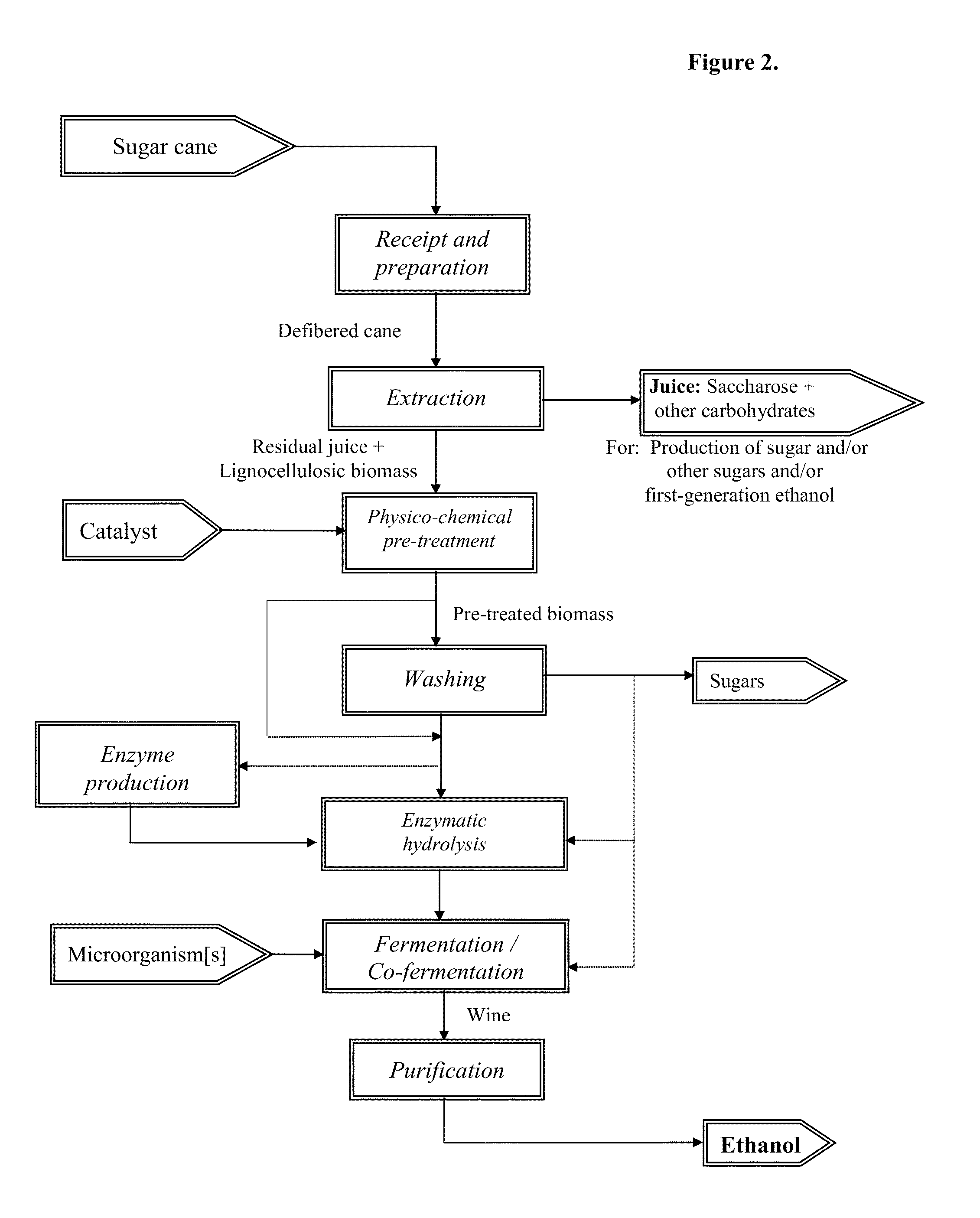

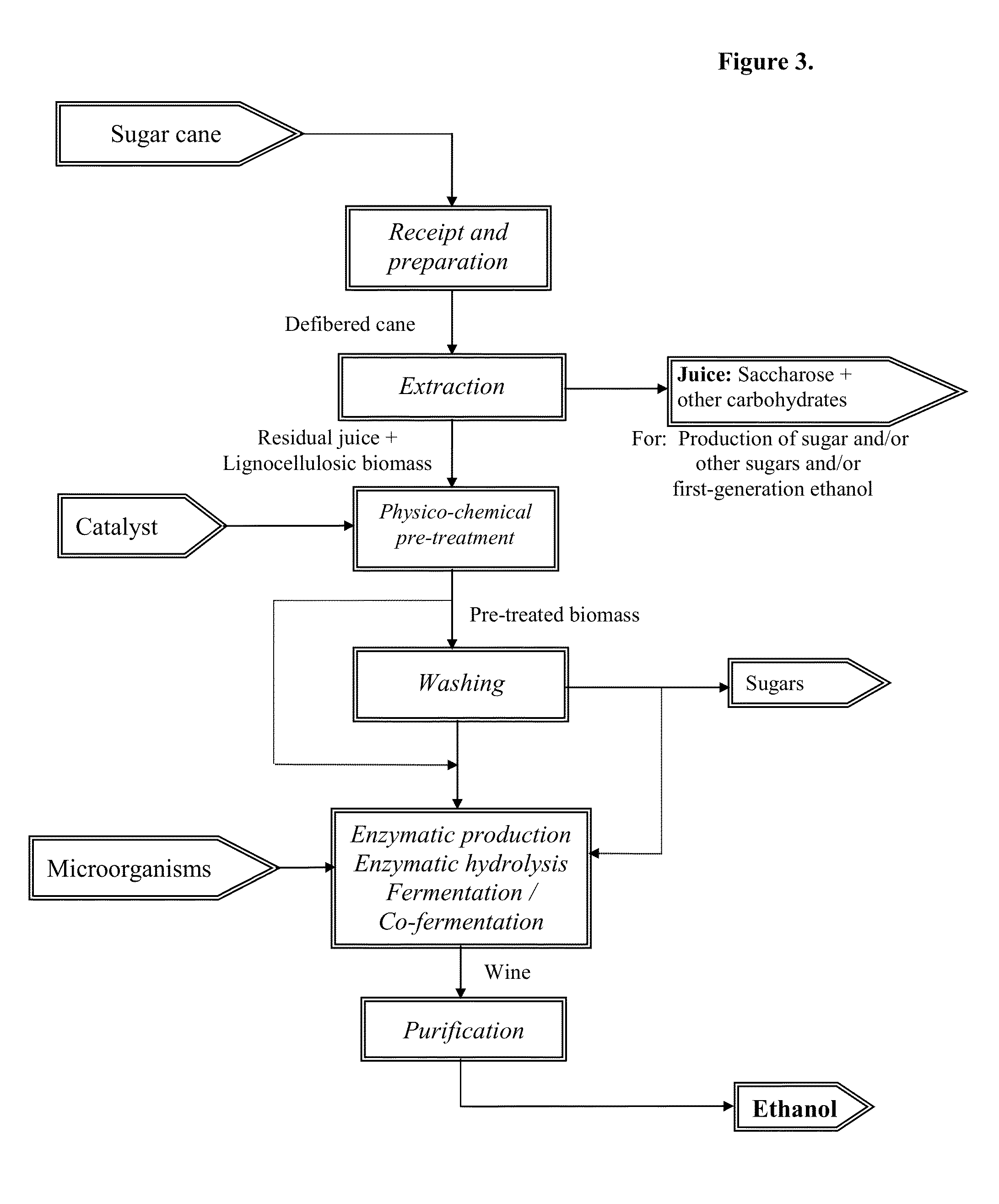

Method for processing vegetable biomass

The present invention relates to an energy-efficient process for the treatment of plant biomass, particularly sugar cane, for the production of carbohydrates and ethanol, using physico-chemical and extraction techniques, as well as very simple milling configurations, thereby minimizing energy consumption during extraction of the cane juice.The biomass treated and obtained through this process, when subjected to a fermentation process for the production of ethanol, increases the yield of the process in comparison with that of traditional sugar cane. It can also be used for the production of enzymes, animal feedstuffs, and other useful products.

Owner:CTC CENT DE TECHA CANAVIEIRA

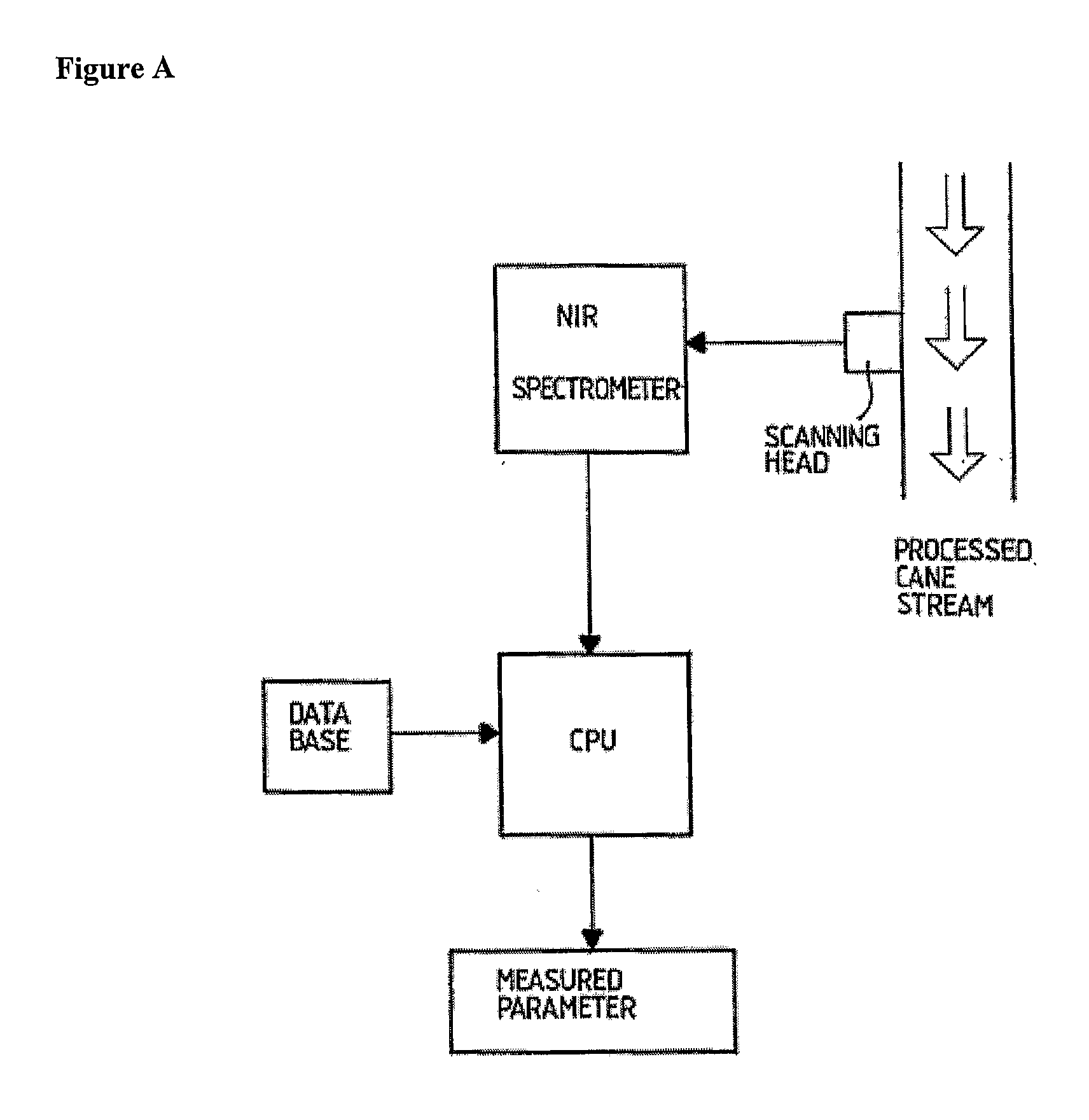

Process for the Manufacture of Sugar and Other Food Products

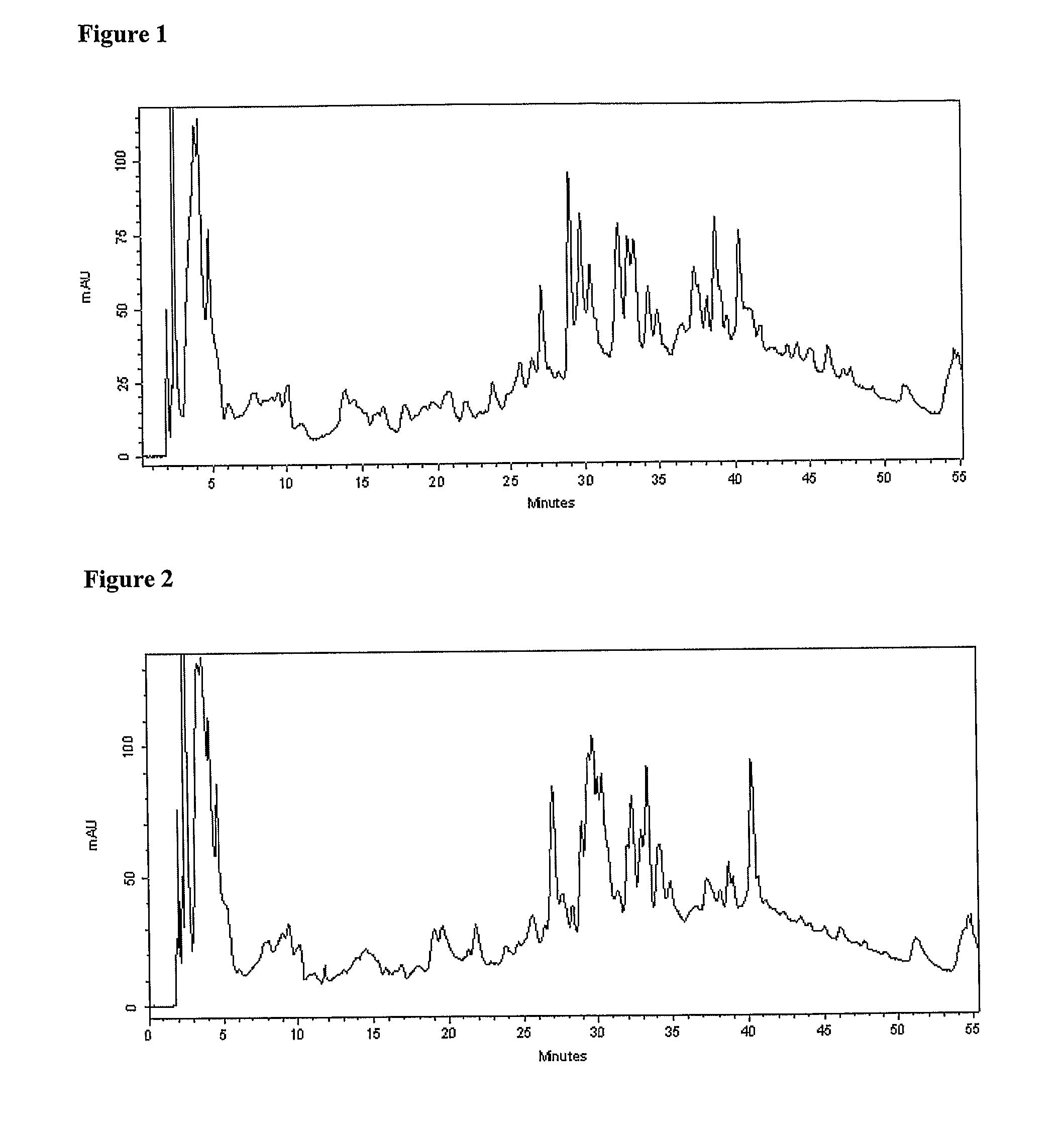

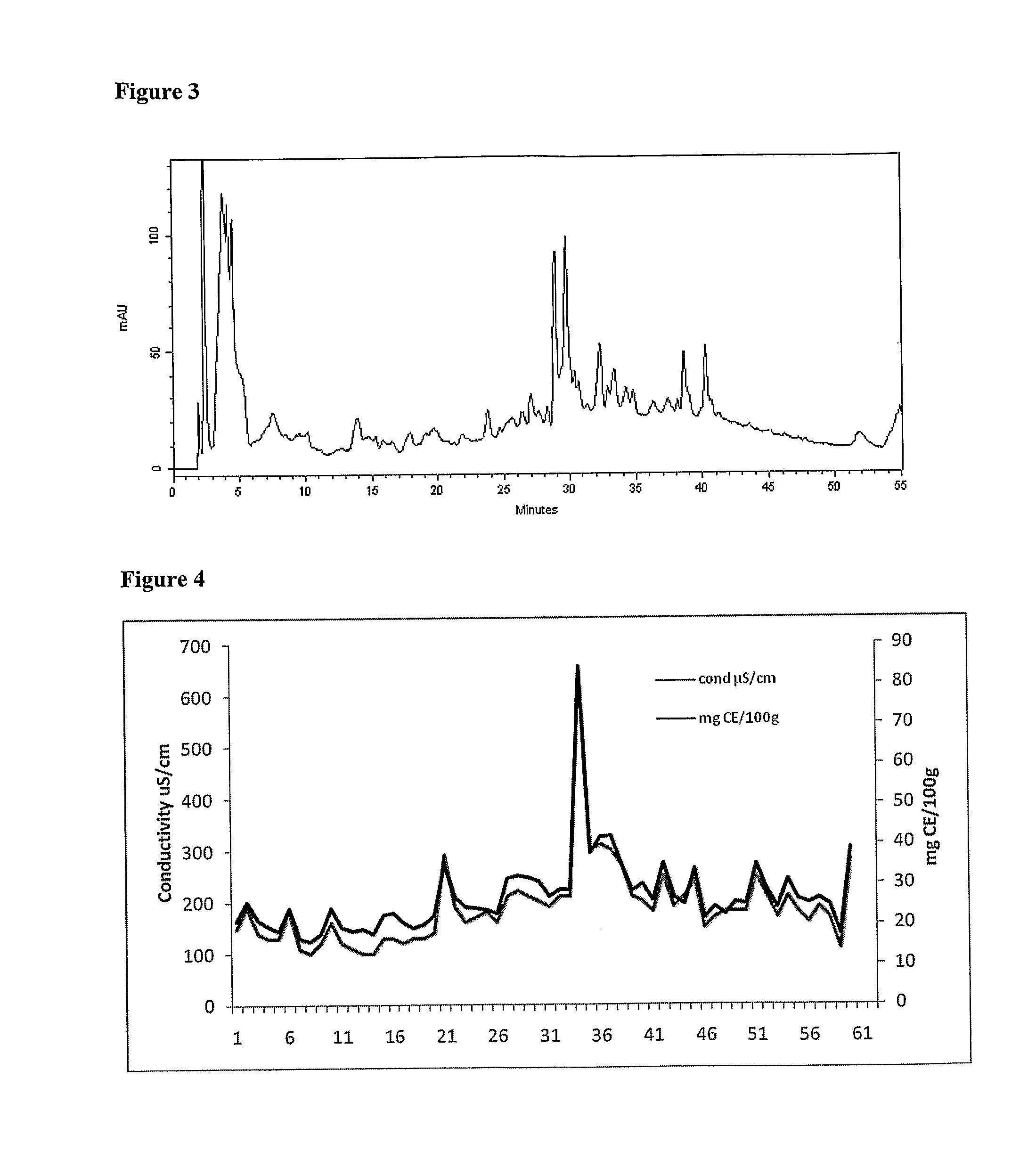

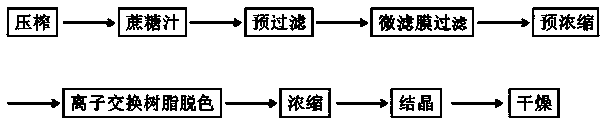

InactiveUS20100285186A1Rapid quantitativeRapid Qualitative DetectionSugar productsAviculturePhytochemicalSugar

A process for manufacturing of sugar products having desired levels of specific phytochemicals comprising the steps of: preparing a primary sugar product; analysing said primary sugar product for its phytochemical profile using an analytical method selected from the group consisting of near infrared spectroscopy, electrical conductivity, and combinations thereof; comparing said profile; treating said primary sugar product, if required, to achieve a final sugar product having desired levels of specific phytochemicals.

Owner:HORIZON SCI

Production process and device of golden sugar

InactiveCN104004860AHigh desalination rateHigh yieldSugar crystallisationPurification using ion-exchange materialsSucroseIon-exchange resin

The invention provides a production process and a production device of golden sugar. The production process comprises the following steps: pressing sugarcane or beets to obtain cane sugar juice; pre-filtering the cane sugar juice through a coarse filter and feeding the pre-filtered crane sugar juice into a microfiltration membrane for filtering to obtain clear cane sugar juice; pre-concentrating the clear cane sugar juice to obtain a pre-concentrated solution; feeding the pre-concentrated solution into ion exchange resin for desalting to obtain a permeation solution; feeding the permeation solution into an evaporator for concentrating to obtain cane sugar concentrated liquid; heating the cane sugar concentrated liquid to be oversaturated, adding crystal seeds, naturally cooling and crystallizing, and centrifuging the obtained crystals to obtain golden sugar crystals; drying the golden sugar crystals to obtain a finished product of the golden sugar. The production device comprises the coarse filter, a microfiltration membrane filter, a nanofiltration membrane filter, an anion exchange resin bed, a cation exchange resin bed and the evaporator which are connected in sequence. The production method provided by the invention is capable of continuously producing high-quality golden sugar, the chromatic value of the obtained product is 800-3,000, the desalting rate is high, and the yield is high.

Owner:JIANGSU JIUWU HITECH

Method for preparing concentrated sugarcane juice

ActiveCN101985666AQuality assuranceGuarantee quality and safetySugar juice boiling/evaporationSugar juice purificationChemical reactionPhosphate

The invention discloses a method for preparing concentrated sugarcane juice. In the traditional method for preparing the concentrated sugarcane juice, phosphoric acid and lime water are added after sugarcane is squeezed into juice to generate a chemical reaction to generate phosphate, so that impurities are precipitated out from the sugarcane juice. The concentrated sugarcane juice prepared by the traditional method is deep in color, reddish and astringent due to the residual phosphate radical and lime water in the sugarcane juice and enzyme and pigment in the sugarcane. In the method, any additives and other chemical medicaments are not added in the preparation process, so the quality safety of products is guaranteed, the nutrient and the flavor of the sugarcane juice are maintained to the utmost extent, the concentrated sugarcane juice prepared by the method has good color and luster and rich flavor and is fresh, sweet and delicious, and the problem that the concentrated sugarcane juice is off-color and has bad mouthfeel for a long time due to the influence of the pigment, the enzyme, the lime and the phosphoric acid is solved.

Owner:TIANYE INNOVATION

Process for directly producing high quality white sugar from sugarcane

InactiveCN1699603AImprove qualityLight colorSugar juice boiling/evaporationJuice extraction from sugarcaneElectrolysisPhosphoric acid

The present invention discloses a process in which high quality white sugar is directly produced from sugarcane. The first step of the process is low temperature phosphorus floatation method to remove most insolubles and parts of organic colloids, obtaining clean solution. The second step is to further increase the quality of the cane solution, this step has the following three alternative methods depending on the actual situations: 1) blowing sulphur dioxide in lime milk and decolourant, and heating and precipitation separating, 2) blowing carbon dioxide which is produced from alcohol fermentation, and precipitating by adding lime milk, followed by phosphoric acid gas floatation separation. 3) treating with electrolysis method. Adopting the present invitation, the clean solution has the properties of light color and high purity. The quality of the product of white sugar meets the standard of 'beverage sugar'. The production rate and digestion recycle rate are obviously higher than that of the conventional sulfurous acid process. Therefore, the present technology has good economic efficiency. The equipment investment and production cost is low.

Owner:霍汉镇

Process for the production of invert liquid sugar

InactiveUS20040255934A1Purification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

Process for preparation of brown sugar from sugarcane

InactiveCN105063239AReduce cokingLow boiling pointSugarcane cuttingLiquid solutions solvent extractionBoiling pointEvaporation

The invention provides a process for preparation of brown sugar from sugarcane. The process includes: juicing, ethanol extraction, heating and impurity removal, and mixed boiling four steps. According to the invention, by means of extracting the residual sugar in the squeezed residue through ethanol, sugar in sugarcane can be transformed maximumly, also the sugarcane juice is firstly boiled, black foams in the juice is removed by filtering, and the filtrate is mixed with a sugar-containing ethanol solution, thus not only lowering the boiling point of the solution, reducing sugar coking, but also accelerating the evaporation of water and ethanol in the solution, and speeding up sugar making. Experiments show that the sugar making time of the process is in the range of 4-4.5. The brown sugar prepared by the process provided by the invention completely adopts physical method, is not added with any chemical, and the sugar product is very healthy.

Owner:GUANGXI NANNING PAITENG TECH

Biological degradant for reducing viscosity and starch content in sugar pressing industry

InactiveCN101805803AIncrease production capacityLow viscosityJuice extraction from sugarcaneAmylasePectinase

The invention relates to a biological degradant for reducing viscosity and starch content in the sugar pressing industry, which is characterized by comprising the following ingredients by weight percent: 12-20 percent of glucanase, 8-12 percent of pectinase, 10-15 percent of xylanase, 15-25 percent of amylase, 5-10 percent of protease, and 20-25 percent of purified water. The biological degradant for reducing viscosity and starch content in the sugar pressing industry effectively degrades macromolecular viscous substances, such as pectin, starch, glucan, hemicellulose and the like brought by raw materials in sugarcane juice, reduces blocking risks, obviously reduces the content of starch in finished sugar, improves the quality of finished white sugar, shortens the time of boiling the sugar, saves the production cost, simultaneously reduces sucrose content to be brought into waste molasses by the macromolecular substances, and improves productivity.

Owner:吴鹏 +2

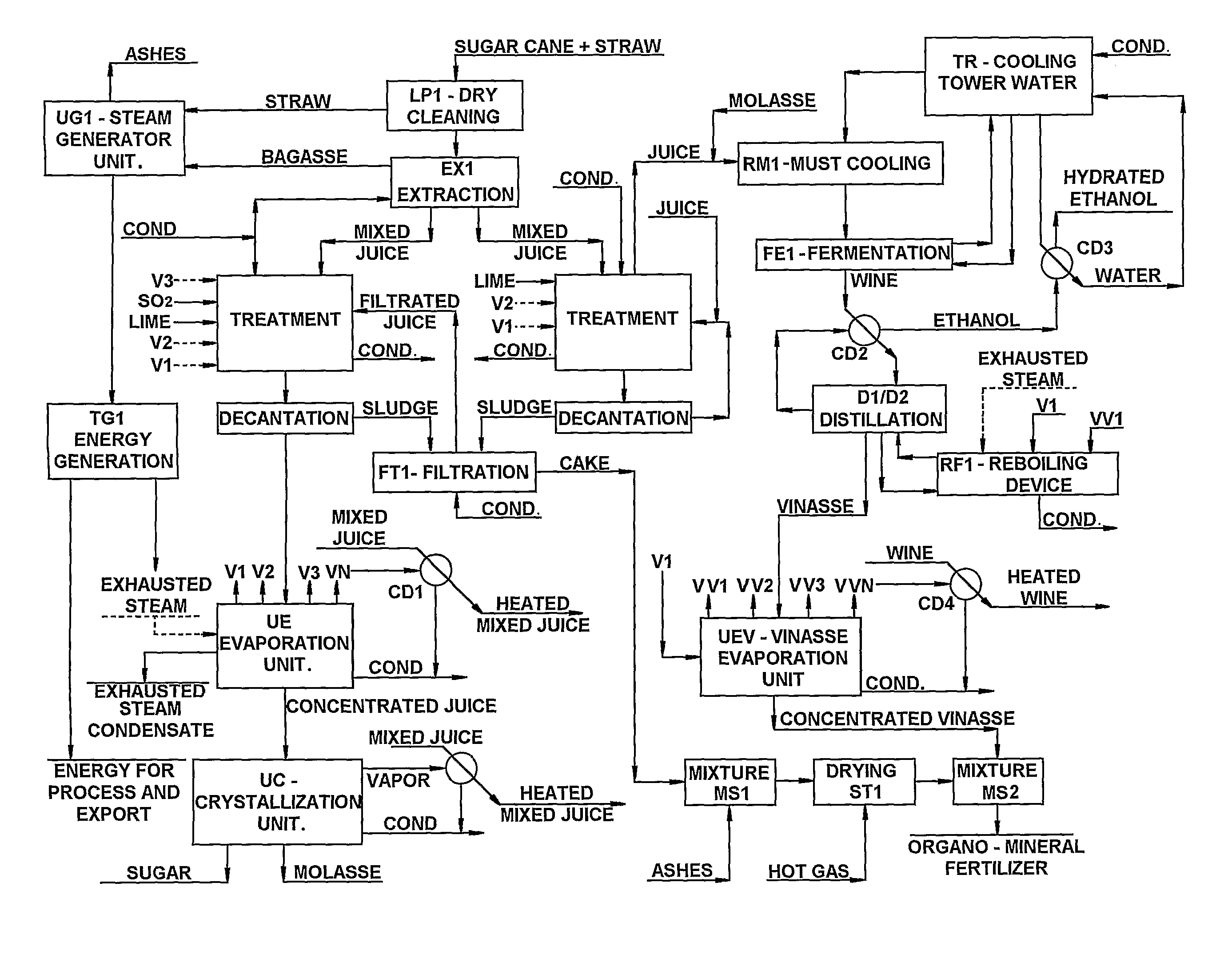

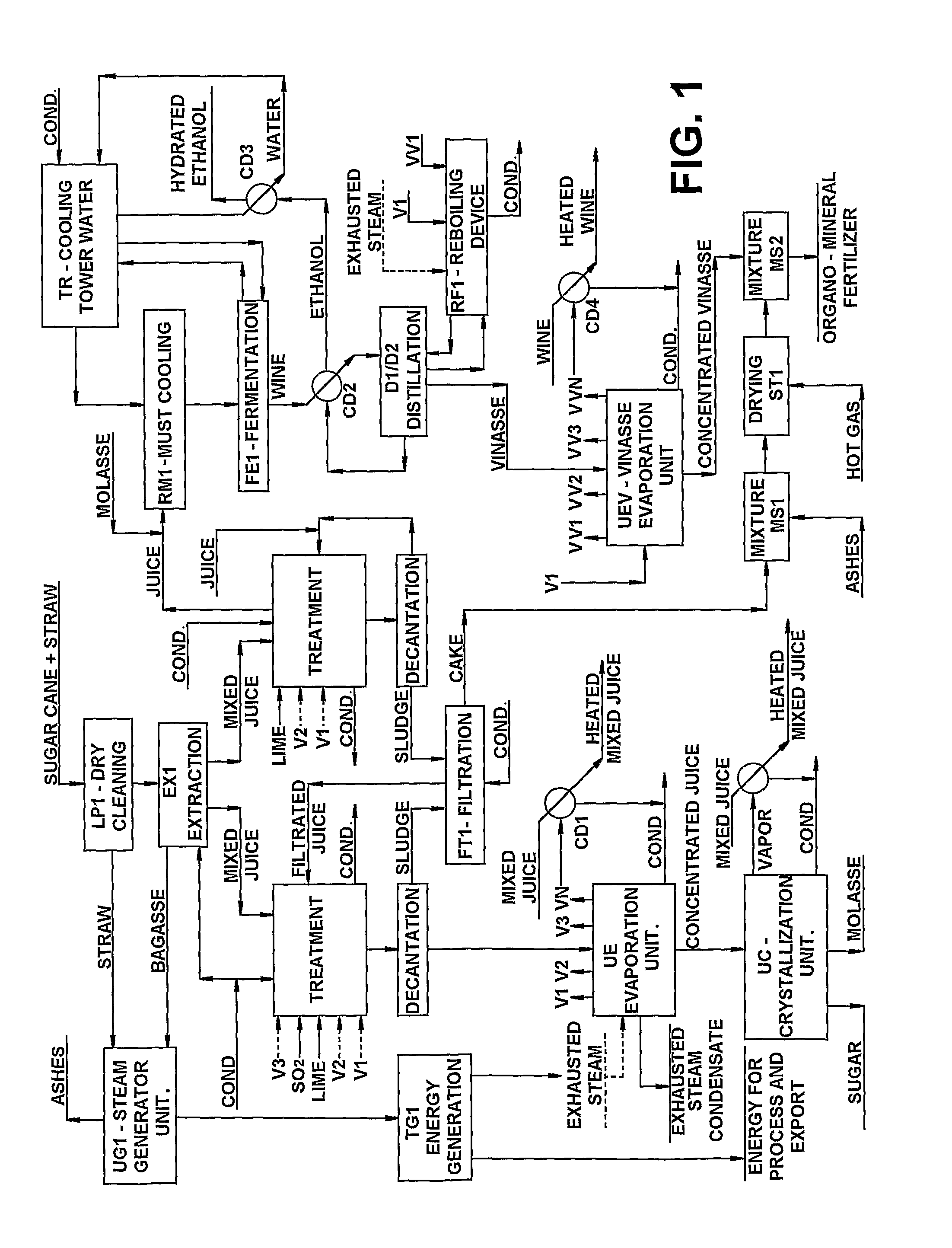

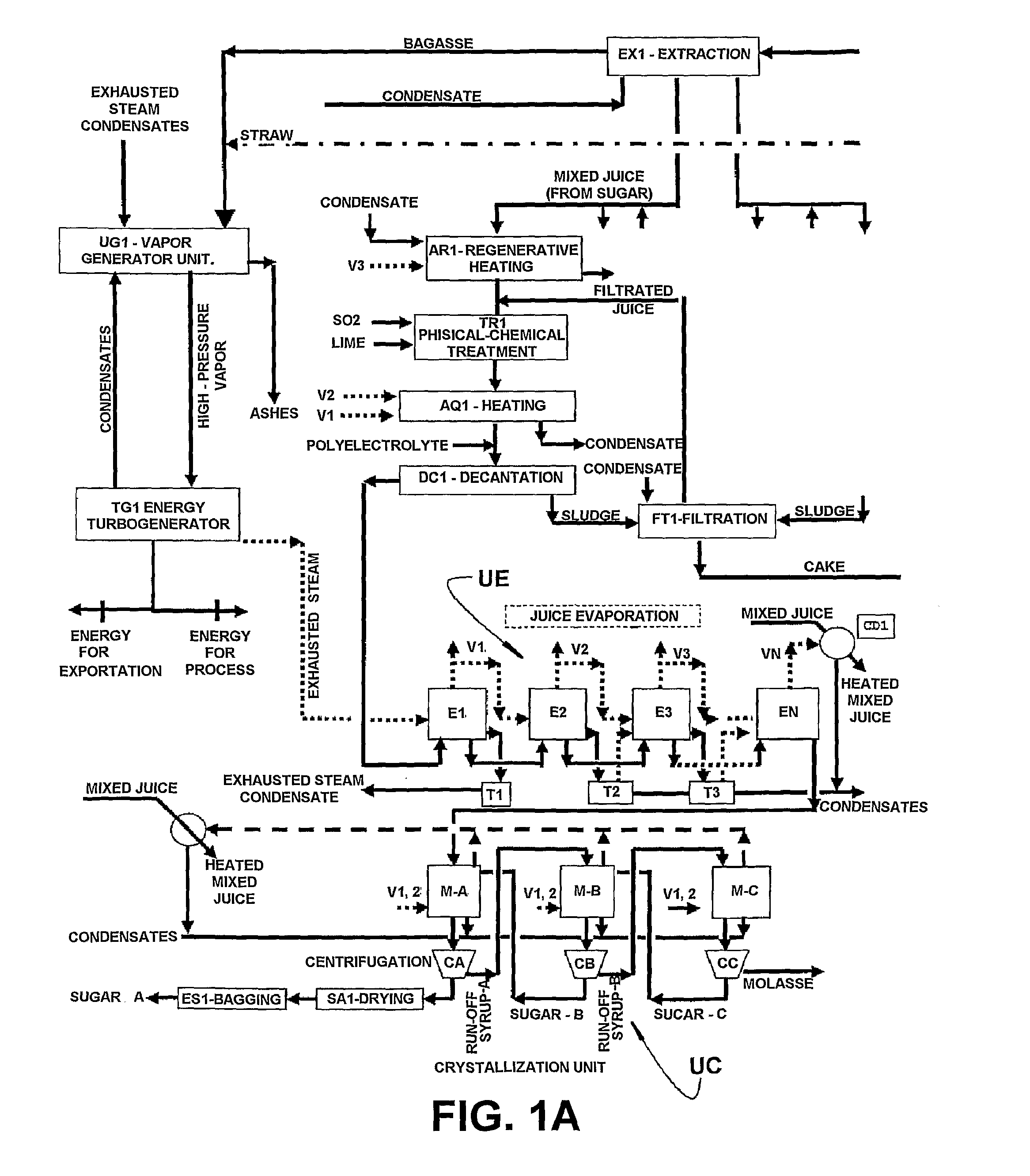

Process for the recovery of water and energy from the processing of sugar cane in sugar and ethanol production mills

ActiveUS20110232343A1Reduce consumptionEconomic savingsBio-organic fraction processingSugar crystal separationThermal energyCooling tower

A process is proposed for recovery of water in the sugar cane processing in production mills of sugar and alcohol or only alcohol (ethanol). In the process, the thermal energy available in the exhausted steam from the electric energy generation turbines is transferred to the different mixed juice processing phases, with the reuse of the exhausted steam condensates in the boilers and of the other condensates, after using thermal energy, for imbibition, in the juice extraction phase, for cooling in the process, after passing through cooling towers, for other industrial uses and for possible treatment or use in the irrigation out of the productive system in the mill

Owner:DEDINI S A IND DE BASE

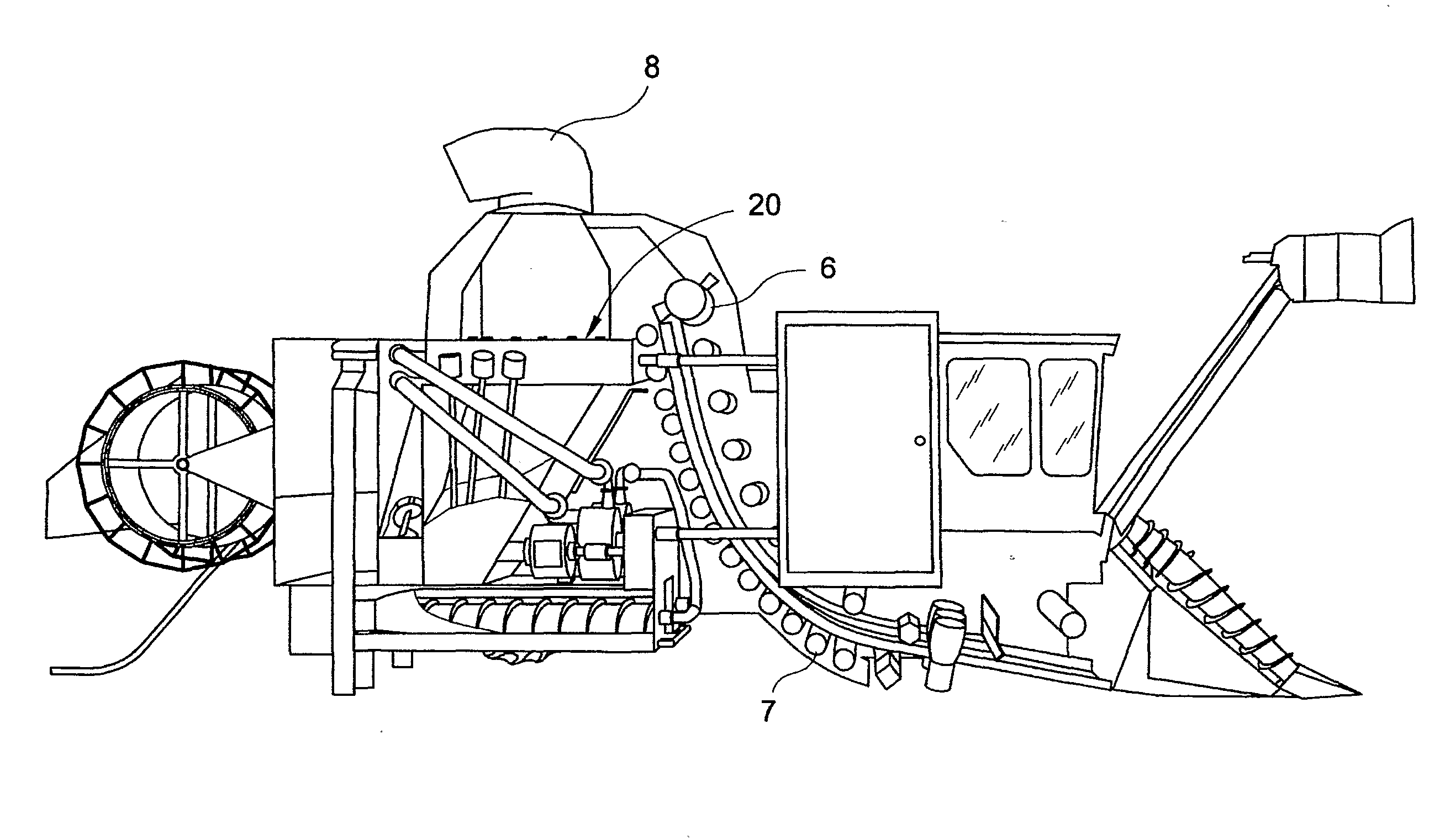

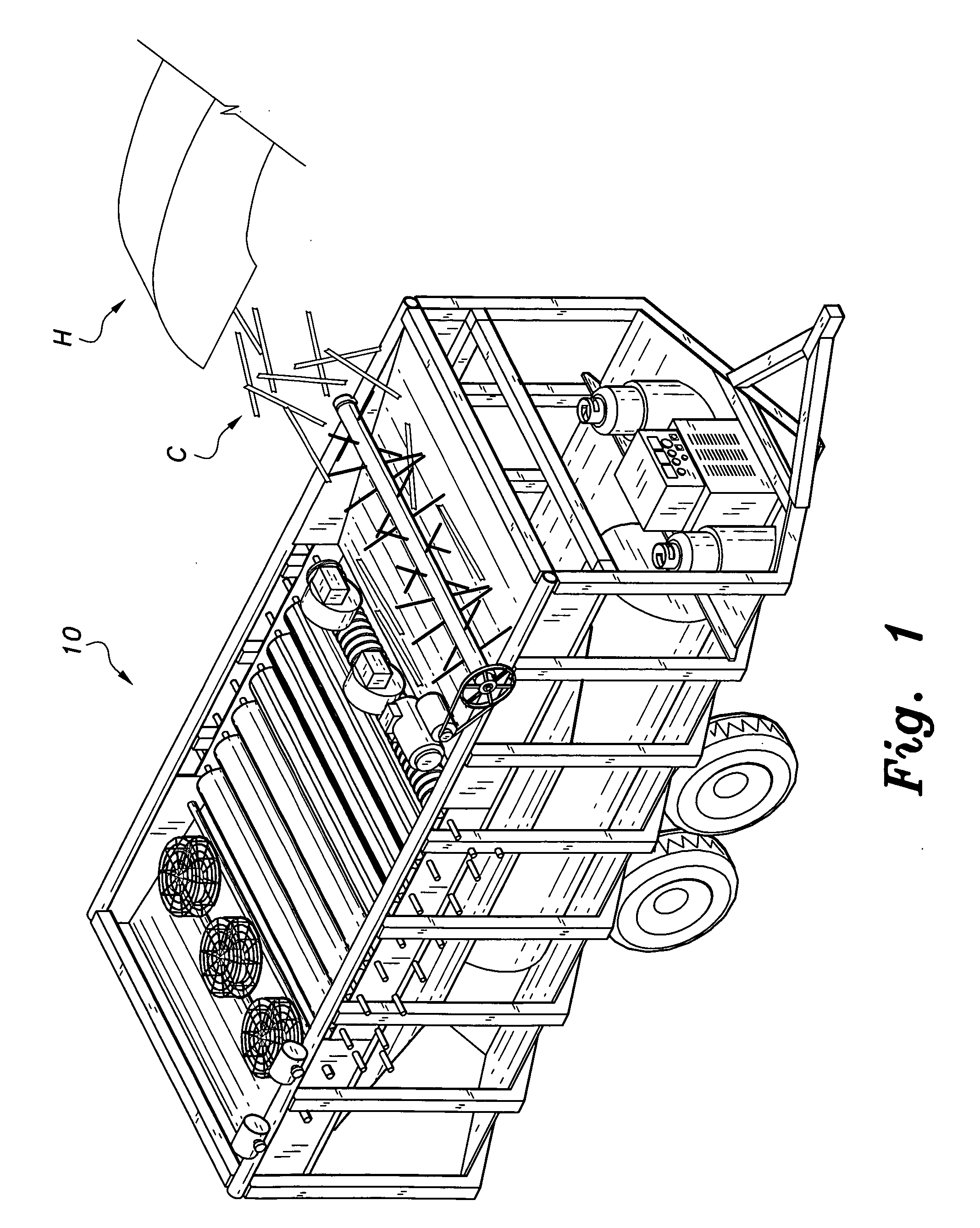

Biomass Processor

ActiveUS20090241944A1Facilitated releaseIncrease shear forcePressurized chemical processSugarcane cuttingFiberBiomedical engineering

Owner:BIOMASS TECH PTY LTD

Production of high fruit-sugar syrup from sweet kaoliang stalks

Sorgo is a kind of high photosynthetic efficiency C4 vegetable and one of the crops with the highest output of biography. It has a long planting history in China and can be planted massively in both southern and northern part of our country due to its strong resistance and excellent adaptability. Since the sweetness of high fructose syrup is higher than sucrose, the former is a perfect natural sweetener. Corn is the main raw material of high fructose syrup in China, and the producing process includes such steps like braising and cooking, glycosylation and isomerization. Since the price of corn is relatively high and the price of sucrose is low, the production cost is relatively high, which has a certain influence with its development. However, if crushing and squeezing the culms of Sorgo, the product includes mainly the sucrose and glucose with the sugar brix of 18%-28%. Because it neední»t such complex steps as adding water and size mixing, braising and cooking and glycosylation, applying this method in the production of high fructose syrup can predigest the producing technics, shorten the producing process, reduce the investment on facilities and reduce the producing cost, and thus this method has some practical value.

Owner:XINJIANG UNIVERSITY

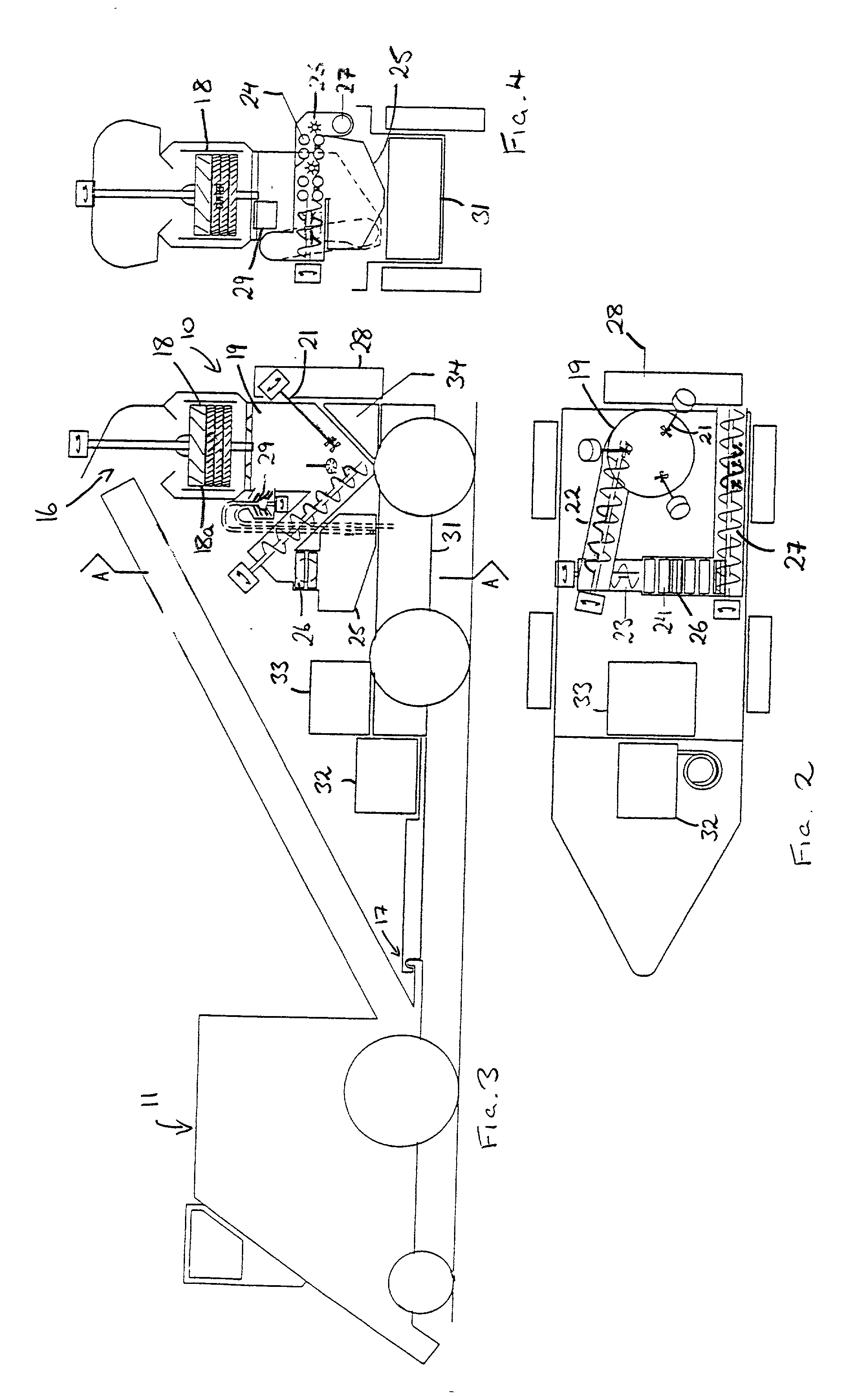

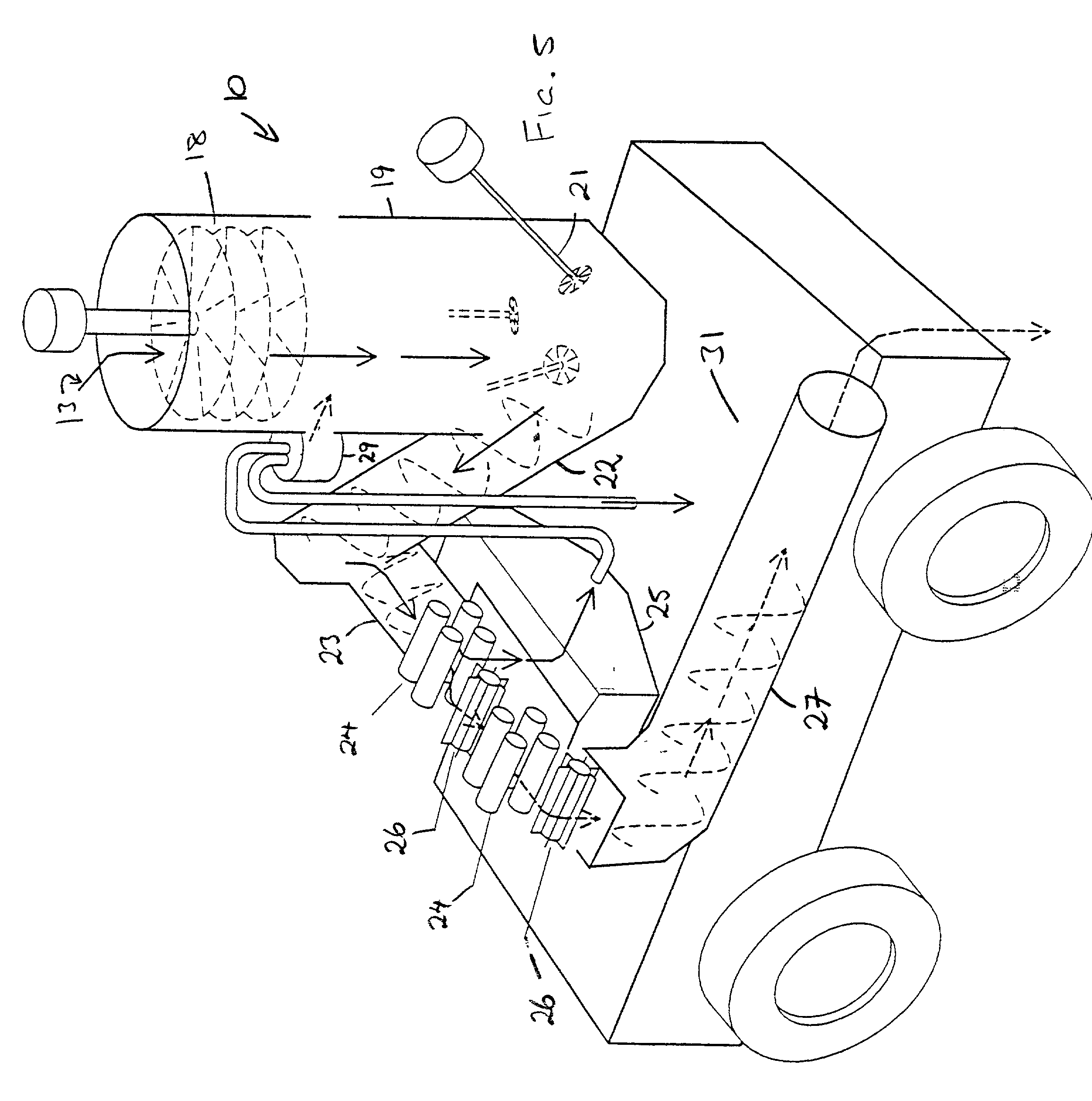

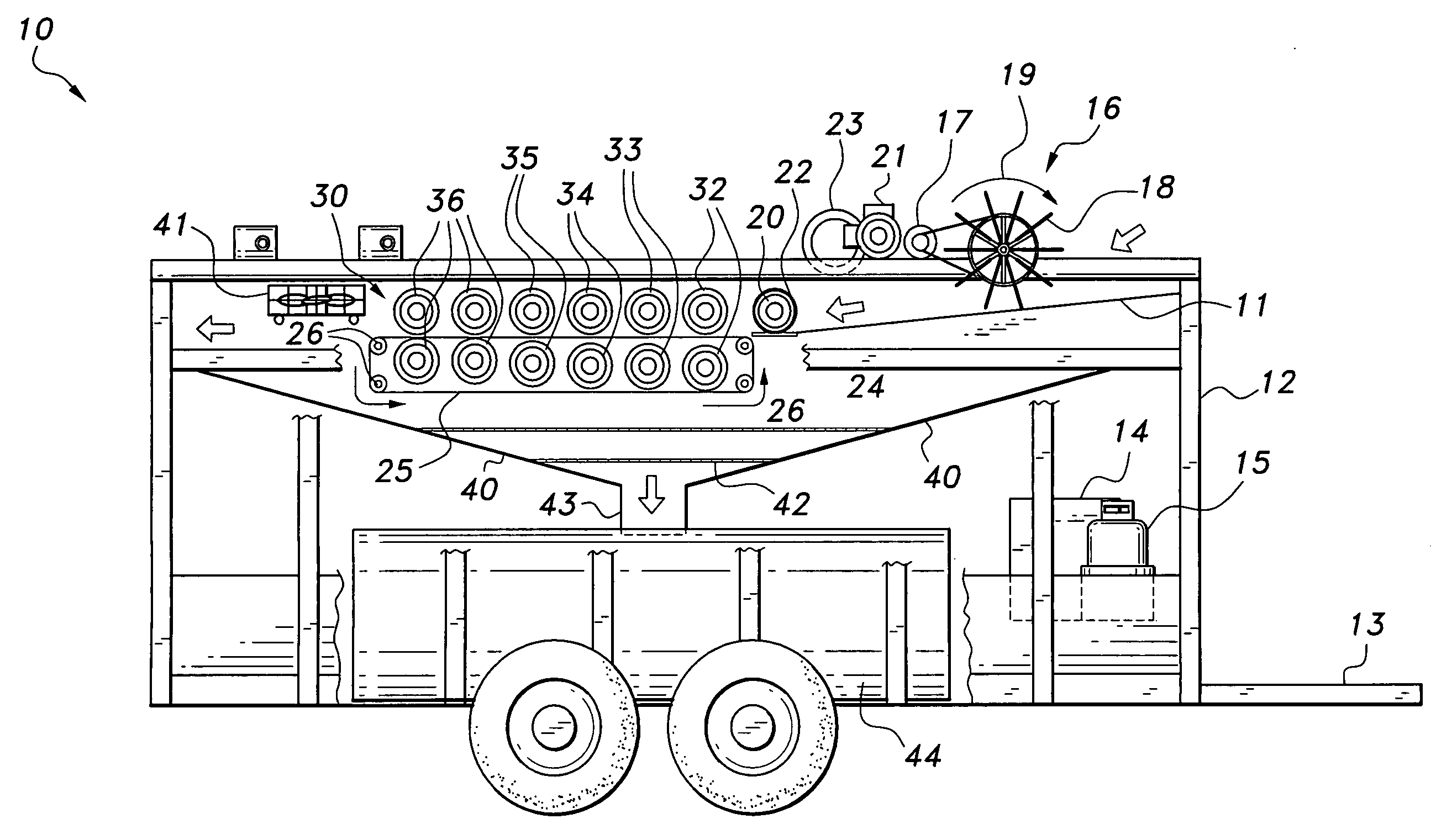

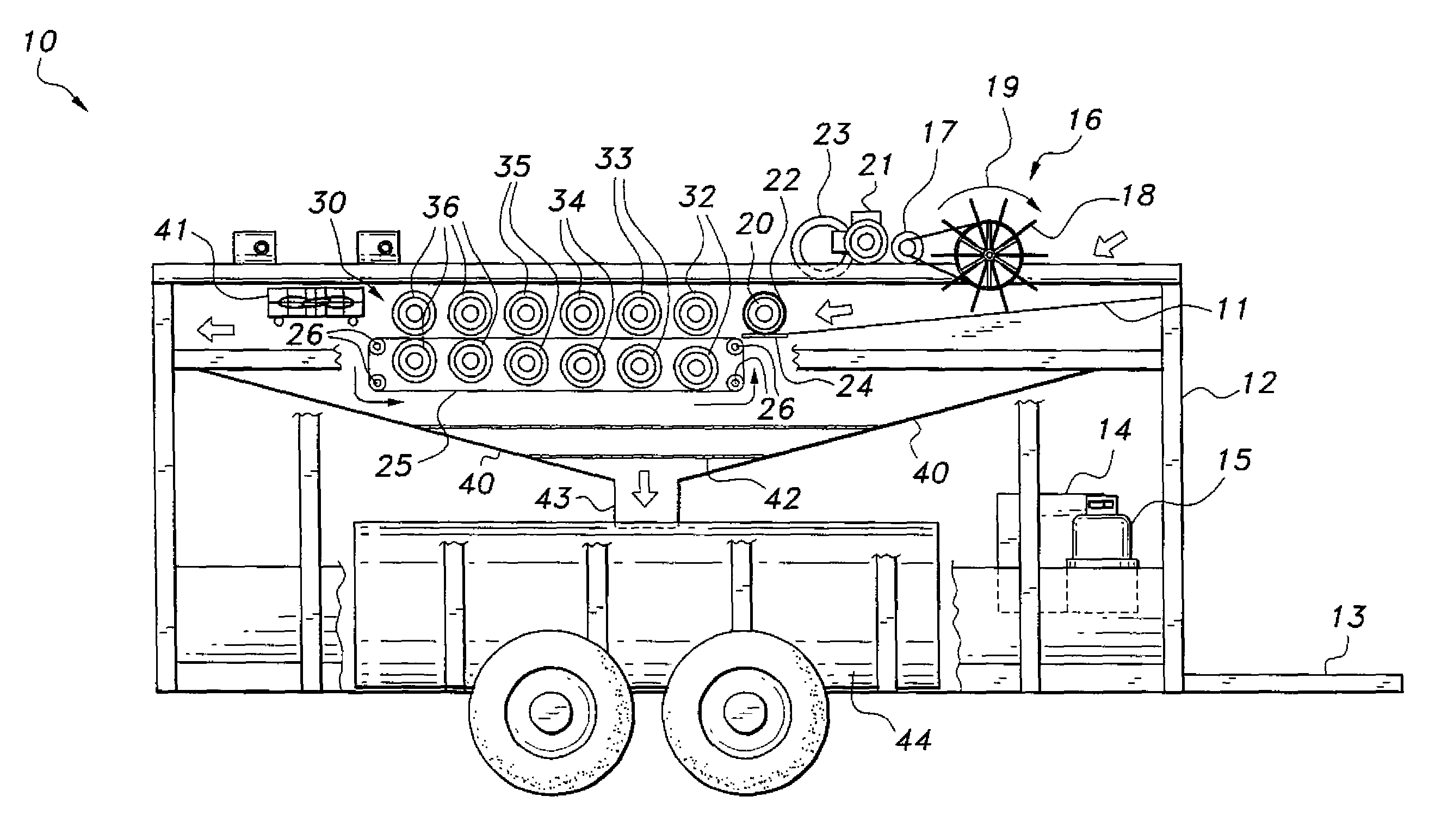

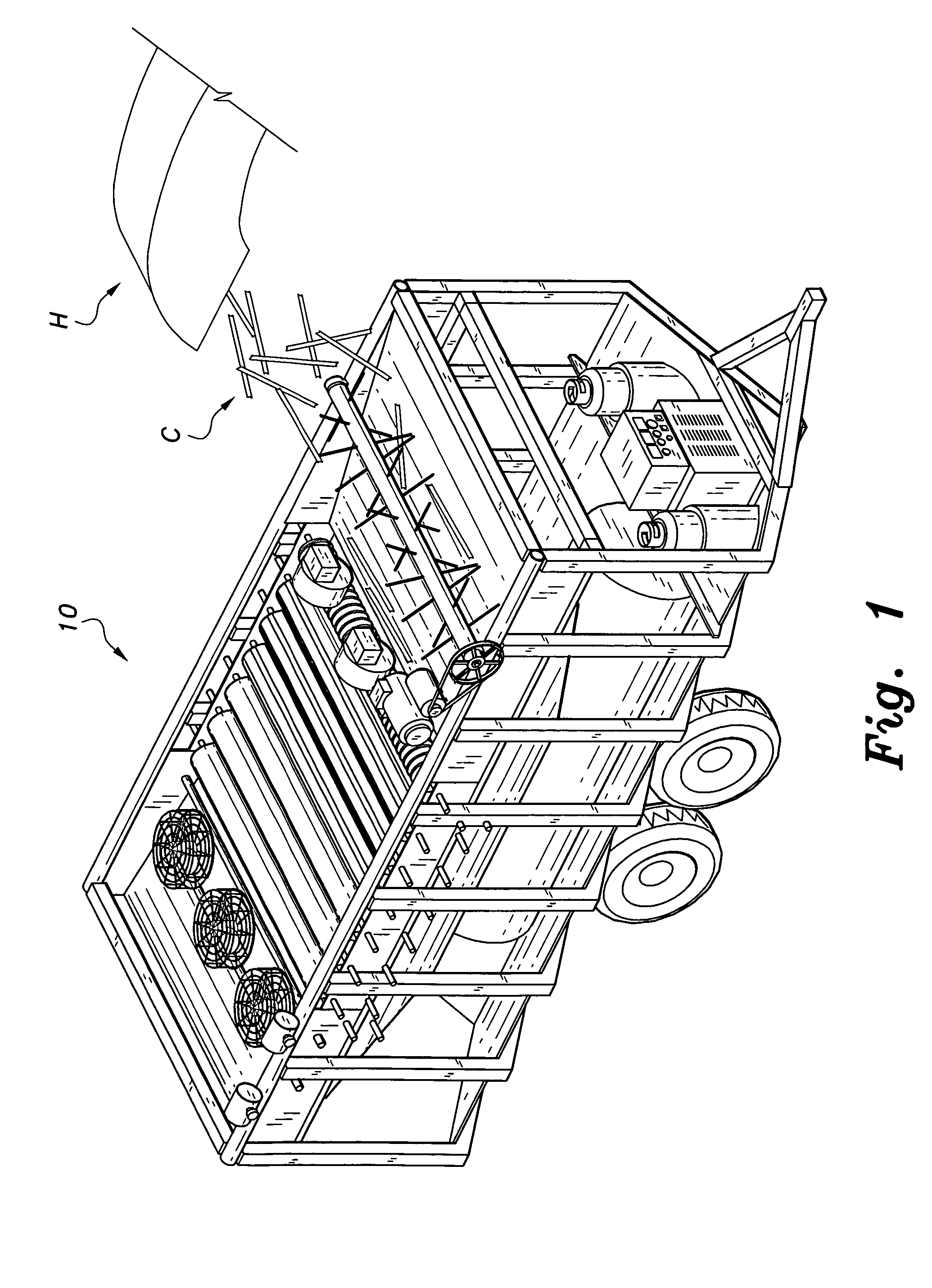

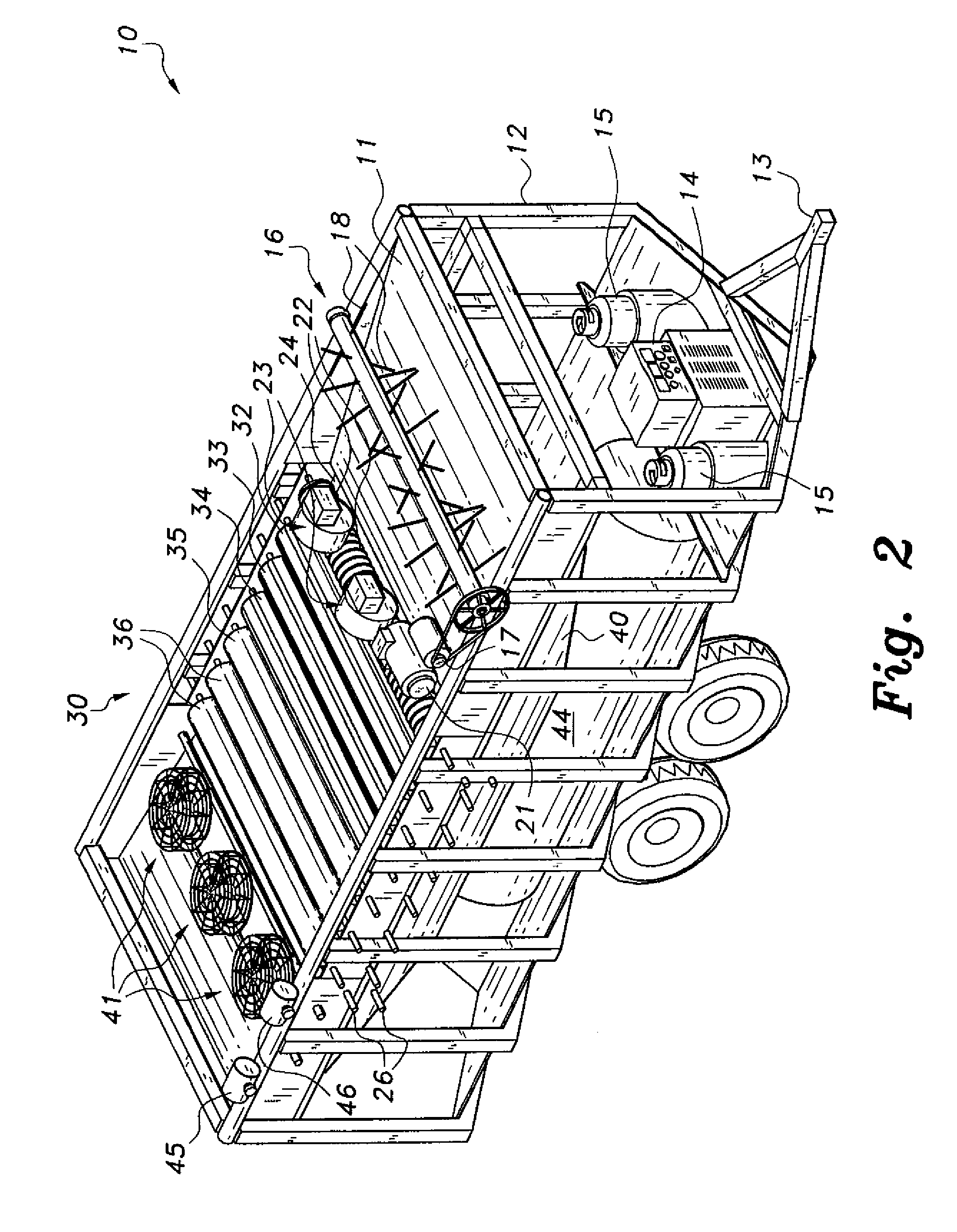

Cane juice extractor

ActiveUS20100307483A1Readily apparentPressurized chemical processJuice extraction from sugarcanePulp and paper industryTruck

The cane juice extractor includes a wagon that may be hitched to or towed alongside a harvesting machine or combine for application in-field. The wagon includes a frame having an upper deck and a lower deck. The upper deck includes an inlet side where harvested cane may be fed for juice extraction and an outlet side for disposing the pulp. Rotating feeders feed the cane to a cutting station on the upper deck. The cutting station comminutes the cane into billets that are carried by an endless belt through a series of compression roller sets. Each set of rollers compress the cut cane down to smaller dimensions to extract the juice. A chute disposed between the upper and lower decks collects the juices and funnels them into a juice storage tank on the lower deck. The pulp is expelled from the outlet side to the field.

Owner:STEGEMAN JOSEPH

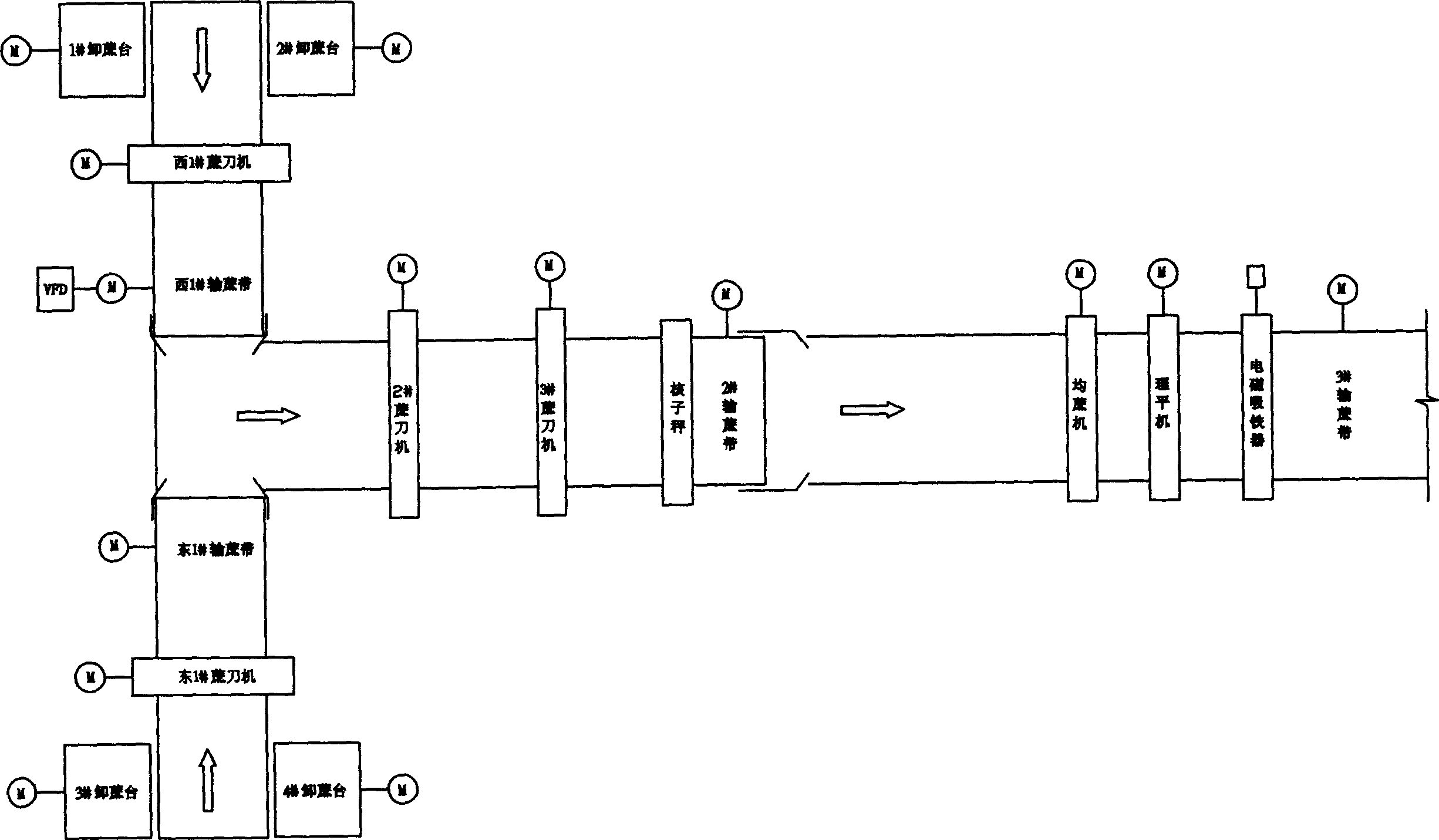

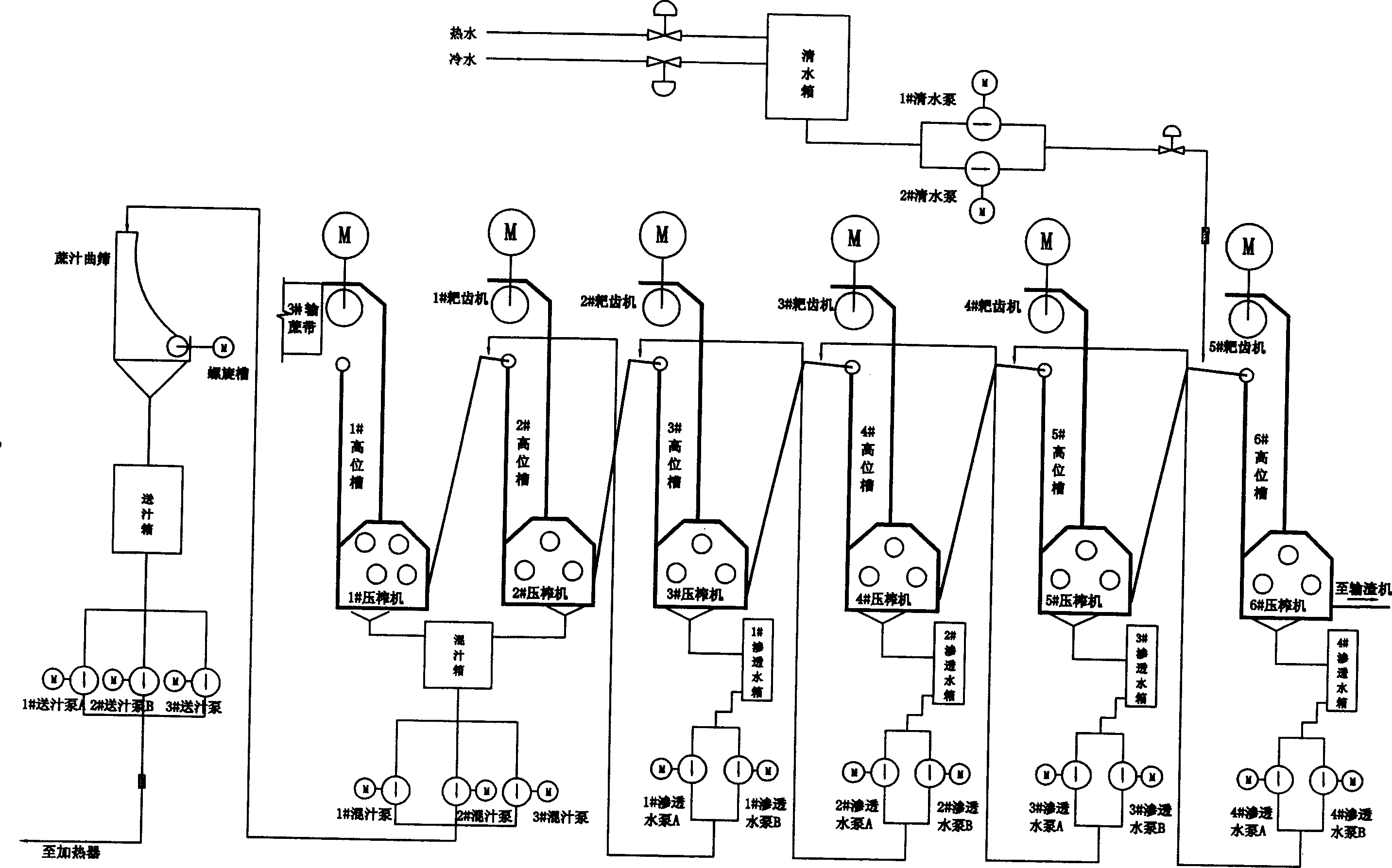

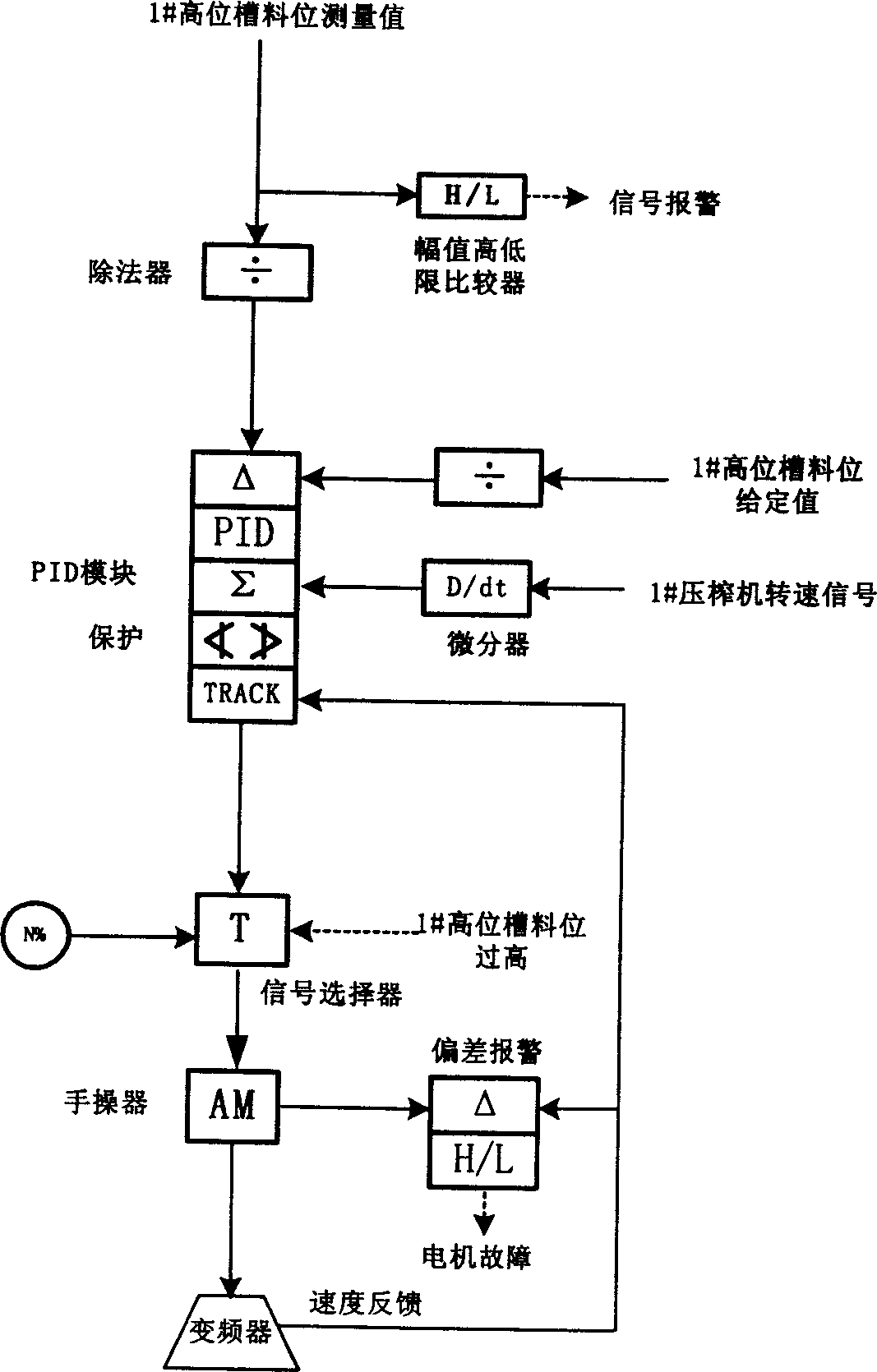

Auto controlling system of sugar cane press

InactiveCN1560280AImprove equalization performanceImprove stabilityAdaptive controlJuice extraction from sugarcaneAuto regulationAutomatic control

The invention discloses a sugarcane-press automatic control system, including automatic regulation of sugarcane feeding, pressing, and analogue quantities of water-permeating system, artificially setting the speed of the first-stage presser, regulating the speed of the last-stage sugarcane feed belt to keep the stability of the material level of the first-stage elevated bunker, regulating the speeds of the other sugarcane feed belts at different stages to synchronize with the last-stage sugarcane feed belt, regulating the speeds of the other pressers at different stages to keep the stability of the same-stage elevated bunkers, regulating the aperture of the feed baffles of the first- and last- stage elevated bunkers to protect the pressers and avoid the overlarge torsions; according to sugarcane amount, regulating the flow of clear water, and keeping the level and temperature of the clear water box; regulating the addition of permeating water at different stages to keep the balance. It can enhance the uniformity, stability and safety of sugarcane feeding, pressing and permeating, ensure high-efficiency crushing of sugarcane.

Owner:BEIJING HOLLYSYS +1

Process for the production of invert liquid sugar

InactiveUS6916381B2Reduce amountFew stepsPurification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

Portable squeezing machine for plant stalk

InactiveCN101585243AReduce volumeAchieve reusePressesJuice extraction from sugarcanePlant stalkNutrition

The present invention discloses a portable squeezing machine for plant stalk, including a large pressing chamber with one to seven clapboards inside to divide the large pressing chamber into two to eight small pressing chambers, a cross rod is arranged above the large pressing chamber, the middle part of the cross rod is connected with a screw thread guide screw driven by a motor to move up and down, a connecting rod locating on the lower end of the cross rod is connected with a pressing plate facing to the small pressing chamer, the quantity of the connecting rods and the pressing plates are equal to that of the small pressing chambers. The invention has a simple structure, a small volume, and may be used in a field or a side hill directly, it is capable of harvesting the crops and squeezing the plant stalk at the same time, and the squeezed nutrition sweet juice is directly processed for sugar cook, wine brewing or beverage; it is capable of reusing resource; the volume of the plant stalk after squeezing is reduced greatly, which reduces a work intensity for carrying the stalk greatly. The invention is suitable for squeezing grain series plants such as rice, wheat, corn, Chinese sorghum, sweet potato and the like, oil series plants such as rape-seed oil, earthnut and the like, and fruit series plants such as bananas, tomatoes and the like.

Owner:周云培

Squeezing method of sugarcane

InactiveCN103540689AReduce leachingImprove squeeze extraction rateJuice extraction from sugarcaneChemistry

The invention discloses a squeezing method of sugarcane. The squeezing method comprises following steps: peel of sugarcane is removed; sugarcane is cut and smashed, and is squeezed using a squeezer so as to obtain squeeze residue and squeeze juice; the squeeze juice is filtered using a filter vat so as to obtain filtrate and filter residue; the squeeze residue and the filter residue are collected for further processing, are heated in water, are cooked at a temperature of 40 to 45 DEG C, and then are cooled and filtered so as to obtain a liquid and a mixed residue; a complex enzyme preparation is added into the mixed residue; the mixed residue is immersed fully in the complex enzyme preparation for 2 to 3h, and then is squeezed using a squeezer so as to obtain squeeze juice; the filtrate, the liquid and the squeeze juice are collected, and are sieved using a 80 to 100 meshes sieve so as to obtain refined sugarcane juice. According to the squeezing method, after the first time of squeezing, the residue is cooked so as to increase juice yield; the residue are mixed and are subjected to enzymolysis so as to obtain more juice; the complex enzyme preparation is sprayed on the sugarcane residue, so that squeezing yield of sugarcane is increased more than 3%.

Owner:梅秀芳

Cane juice extractor

The cane juice extractor includes a wagon that may be hitched to or towed alongside a harvesting machine or combine for application in-field. The wagon includes a frame having an upper deck and a lower deck. The upper deck includes an inlet side where harvested cane may be fed for juice extraction and an outlet side for disposing the pulp. Rotating feeders feed the cane to a cutting station on the upper deck. The cutting station comminutes the cane into billets that are carried by an endless belt through a series of compression roller sets. Each set of rollers compress the cut cane down to smaller dimensions to extract the juice. A chute disposed between the upper and lower decks collects the juices and funnels them into a juice storage tank on the lower deck. The pulp is expelled from the outlet side to the field.

Owner:STEGEMAN JOSEPH

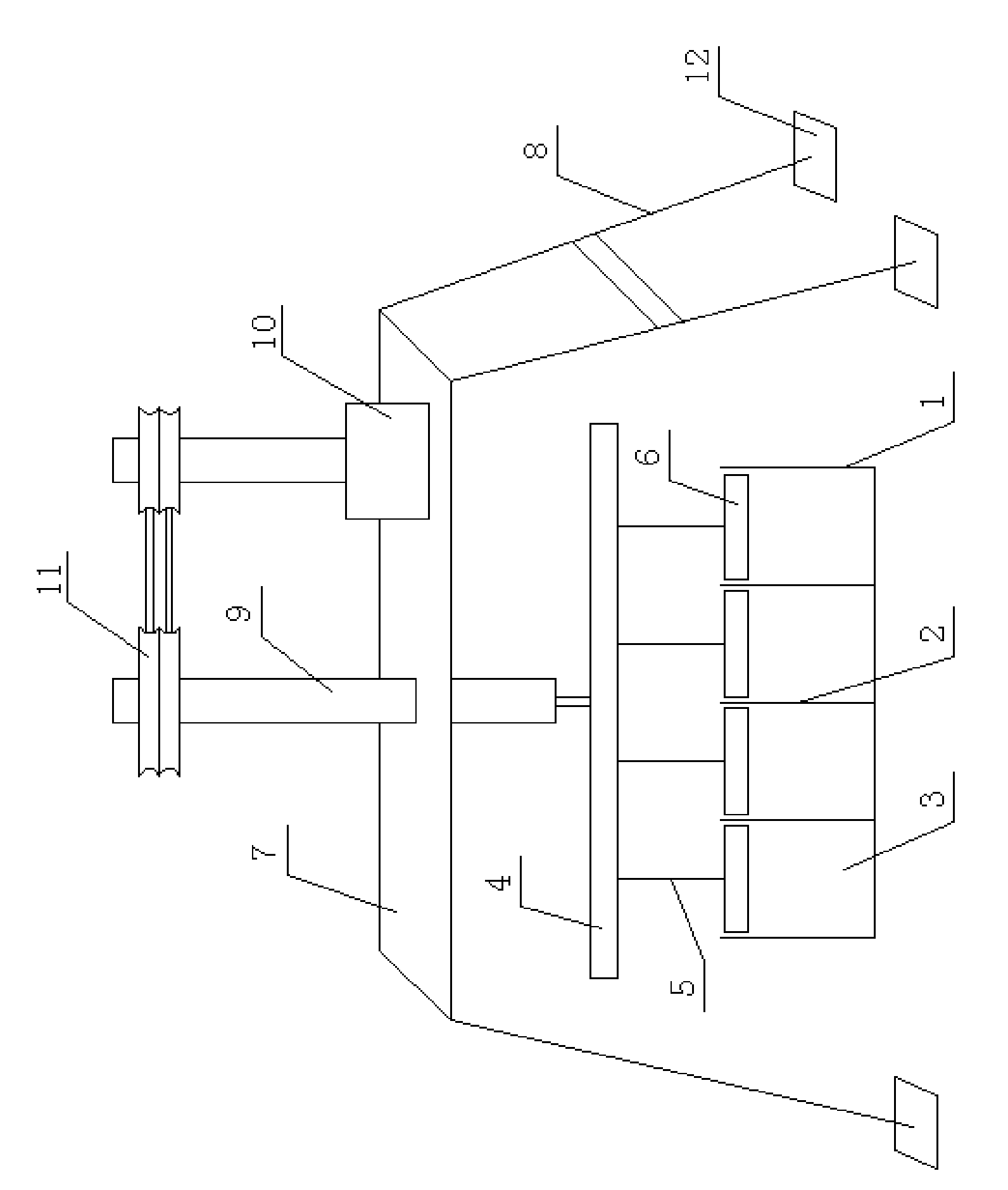

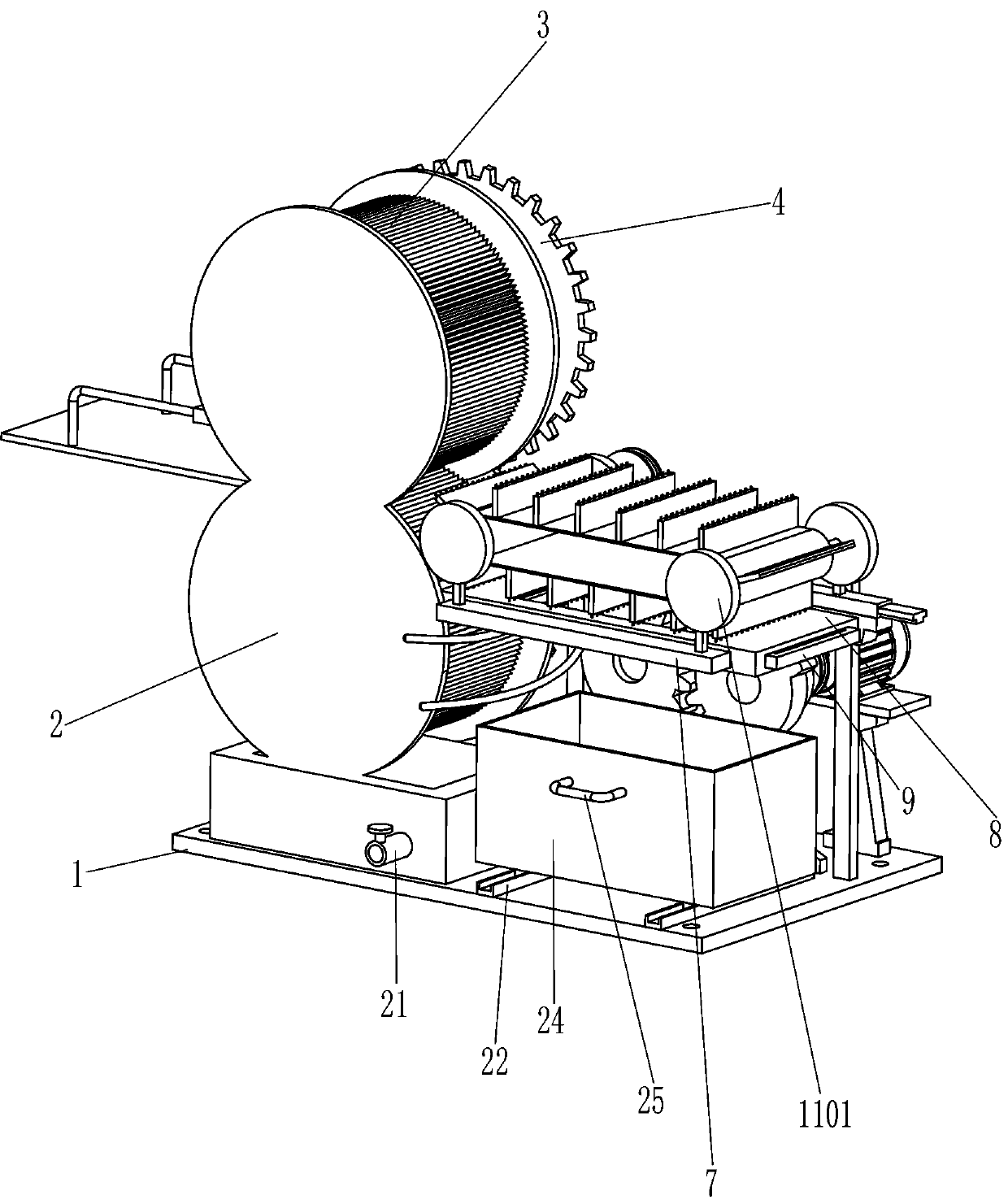

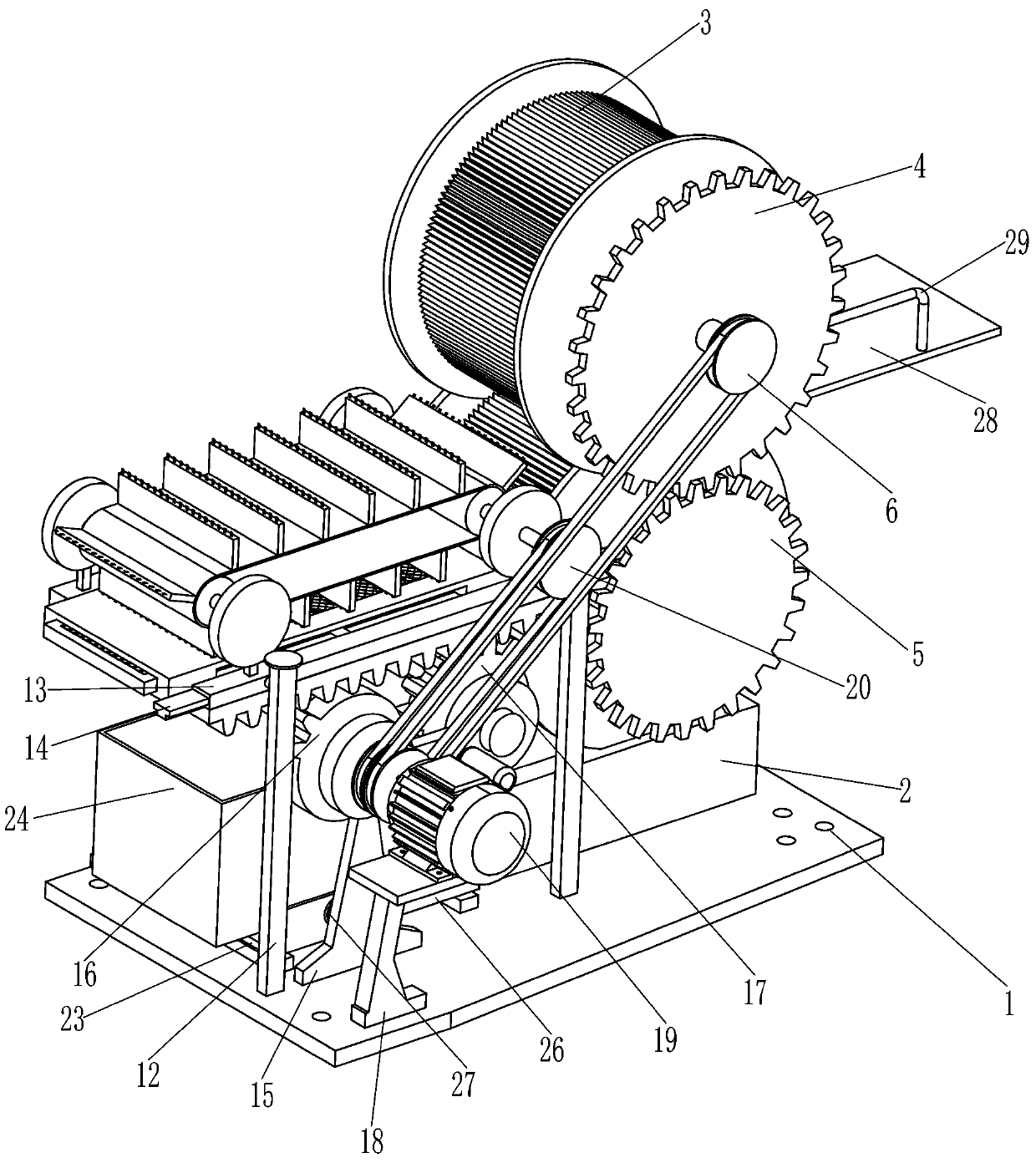

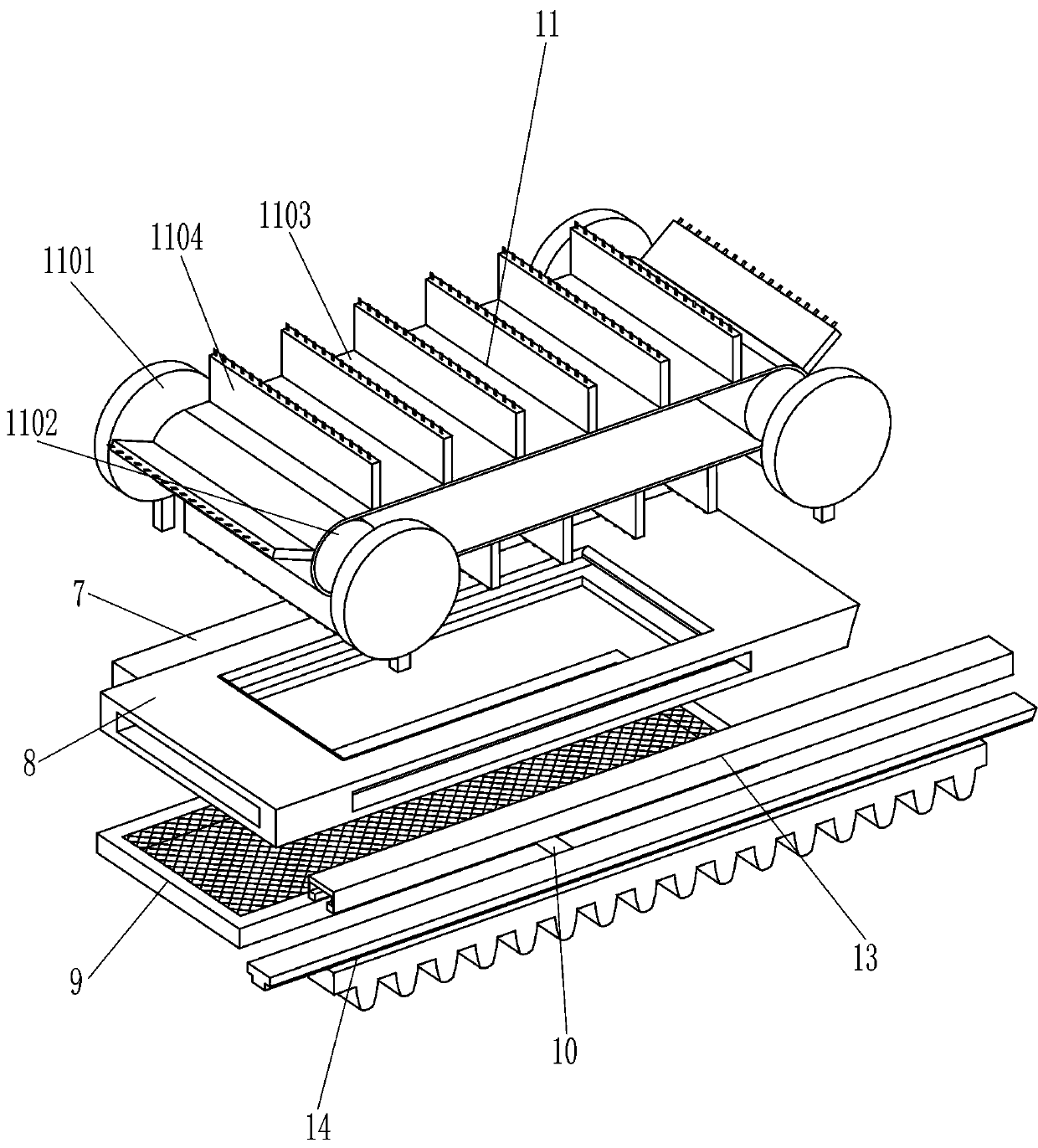

Sugarcane juicing equipment capable of automatically classifying residues

InactiveCN111251648AEasy to sieveSmooth recycling processSievingScreeningBiochemical engineeringProcess engineering

The invention relates to sugarcane juicing equipment, in particular to sugarcane juicing equipment capable of automatically classifying residues. The technical problem of the invention is how to provide the sugarcane juicing equipment capable of automatically classifying the residues, in which bagasse can be automatically screened, and the sorted bagasse can be conveniently packed and cleaned. Thesugarcane juicing equipment capable of automatically classifying residues comprises a bottom plate, a collecting frame and the like; and a collecting frame is arranged on the top of the bottom plate.Through cooperation of a screen plate and devices on the screen plate, bagasse can be conveniently screened by the equipment, so that the subsequent bagasse recycling process is more smoothly carriedout, and the resource utilization rate is increased.

Owner:陈丽平

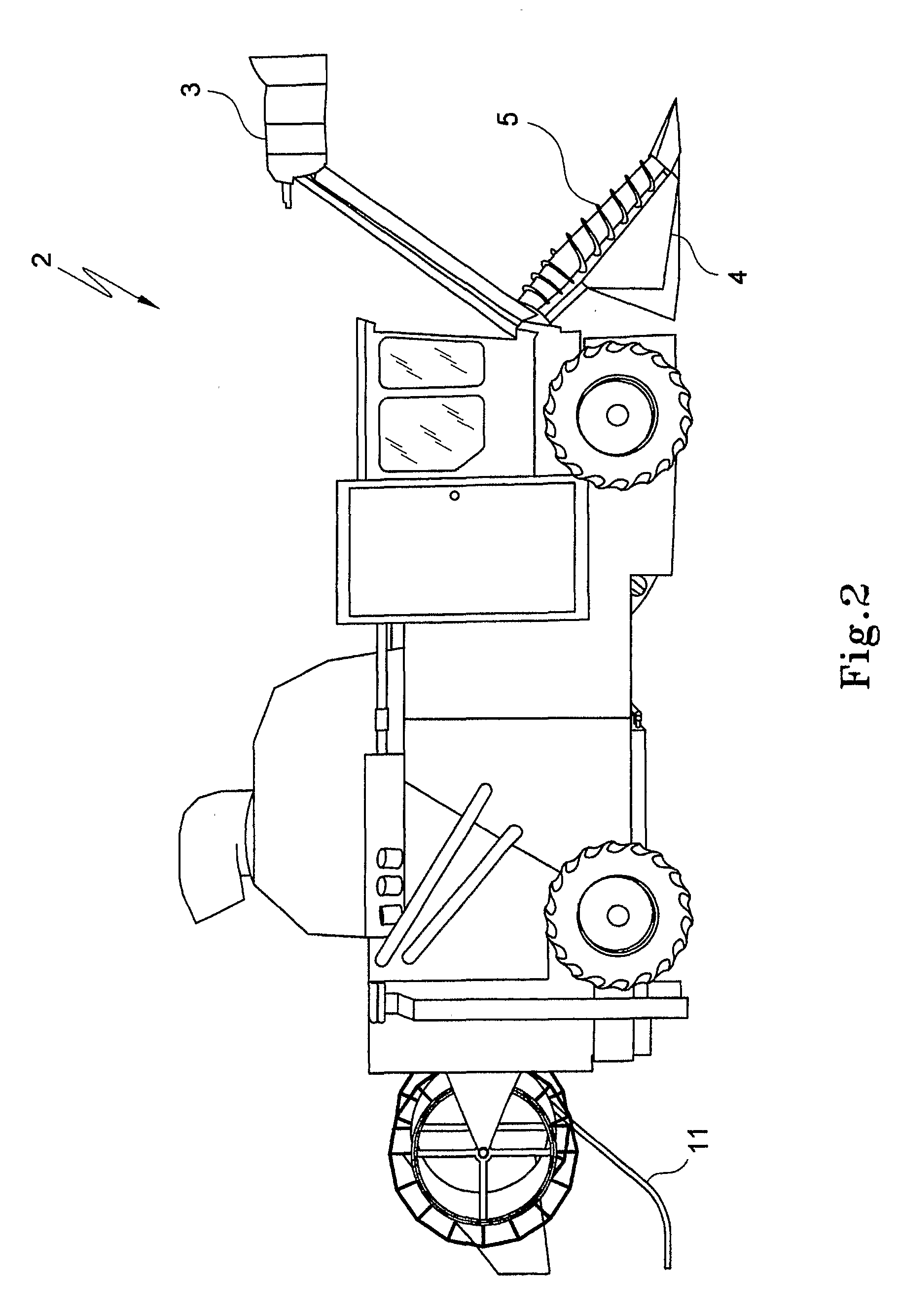

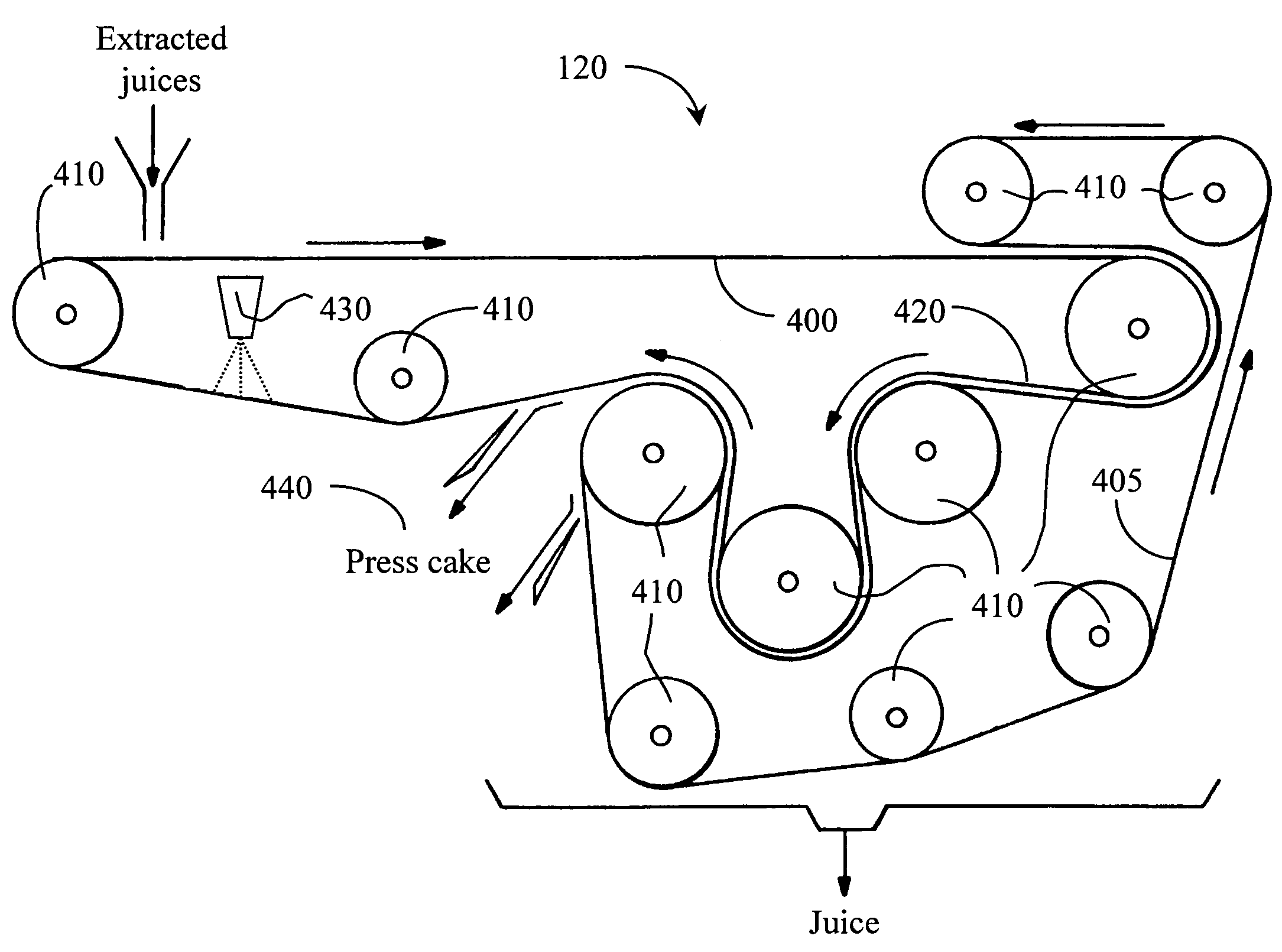

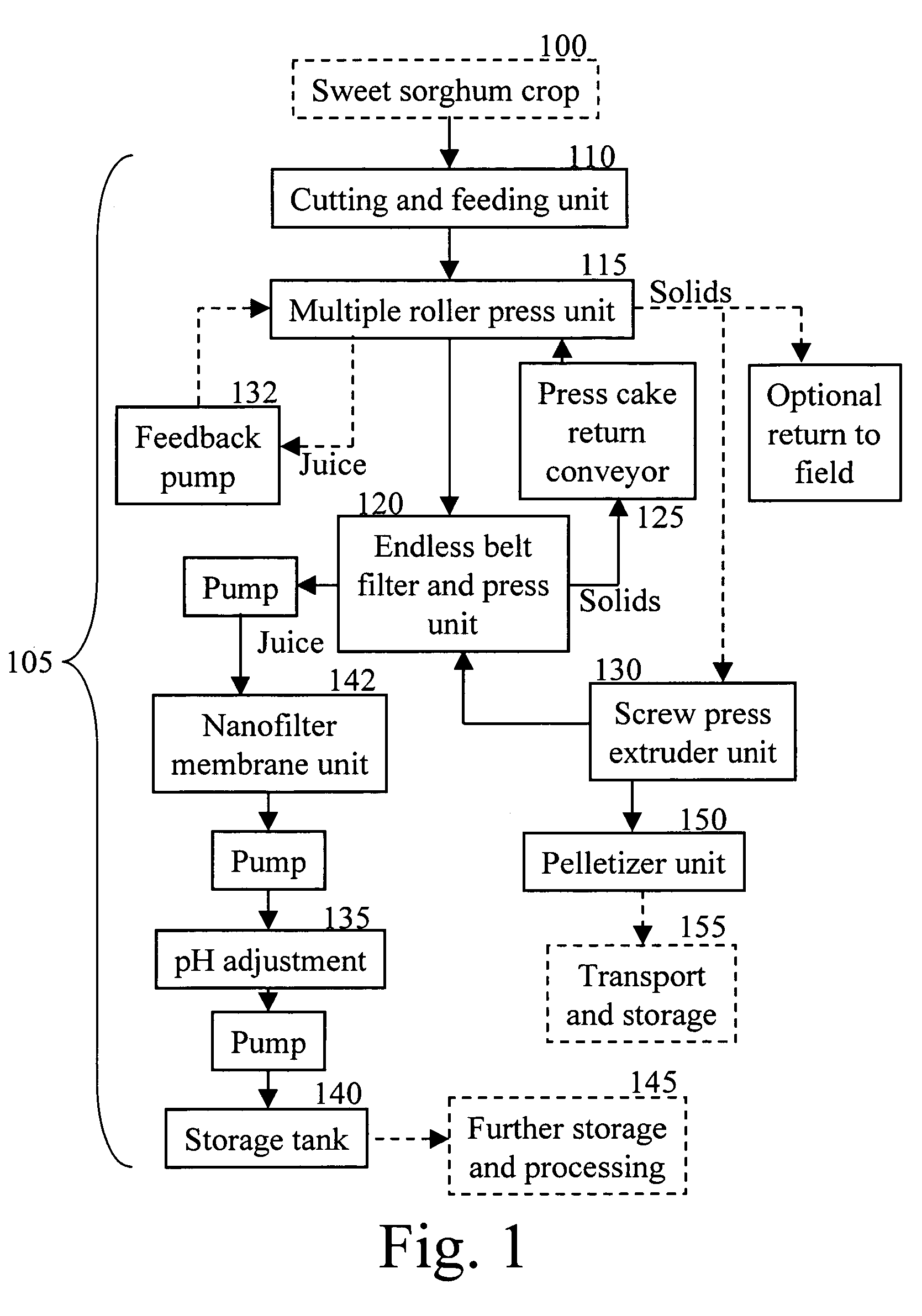

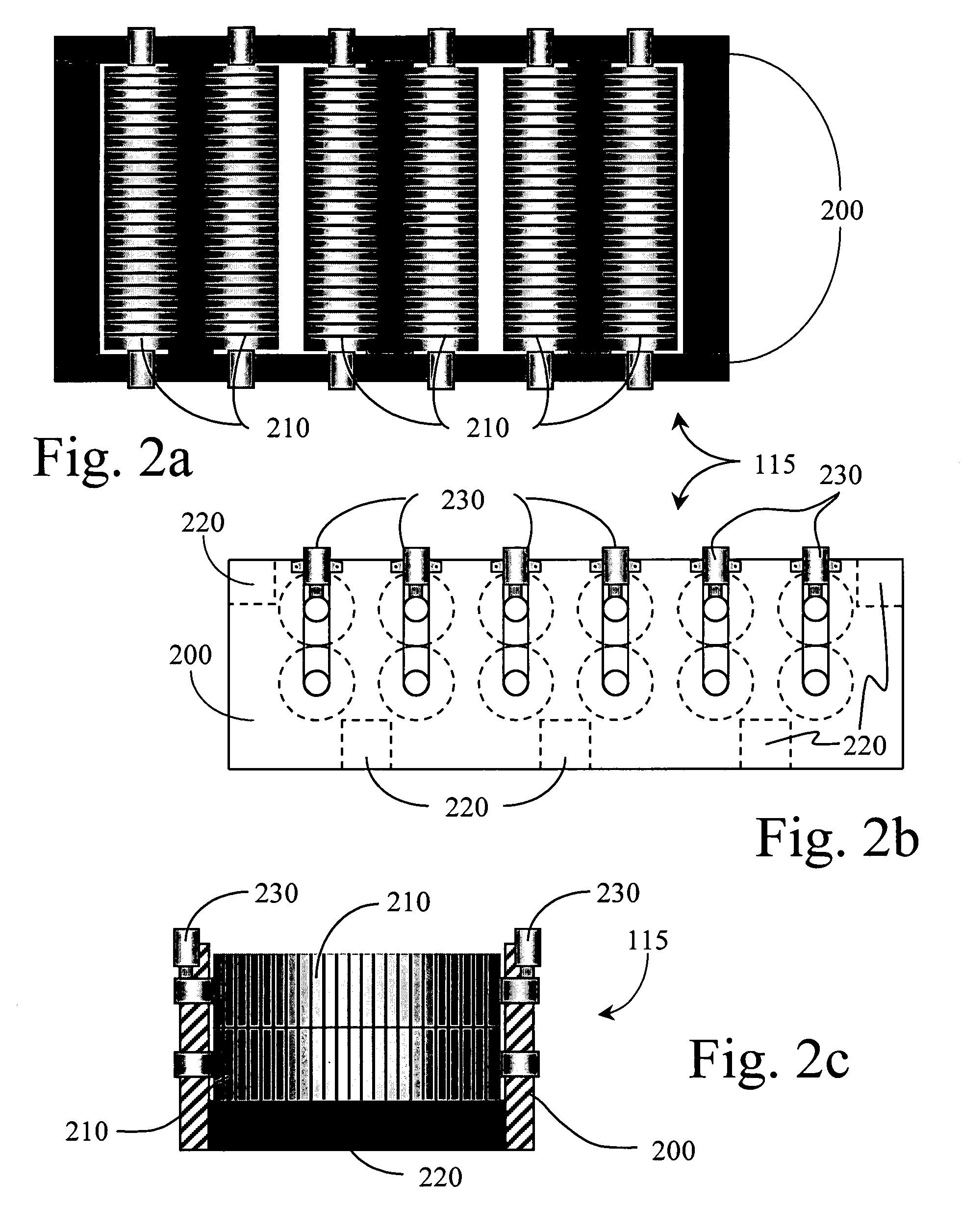

Field harvester for sweet sorghum

Present-day harvest methods for sweet sorghum are labor intensive, and / or require that large quantities of matter be removed to a central location for processing. A field harvester for sweet sorghum would cut the crop and reduce it to its separated juice and solids in the field. A cutter / feeder unit cuts the crop off and feeds it into a multiple roller press where most of the juice is removed. An optional screw press may be used to further remove juices from the solids. The solids are filtered from the juice using an endless belt filter press unit. The pH of the juice may be adjusted by the addition of some acid to inhibit bacterial action. The solids may optionally be pelletized for use as livestock feed or for fuel. The juice is temporarily stored on the harvester in a mounted or pull-behind tank before it is transferred, ultimately, to a nearby storage / processing location.

Owner:MCCLUNE LEE F

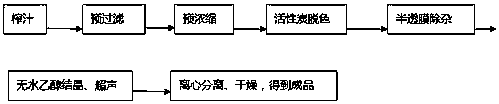

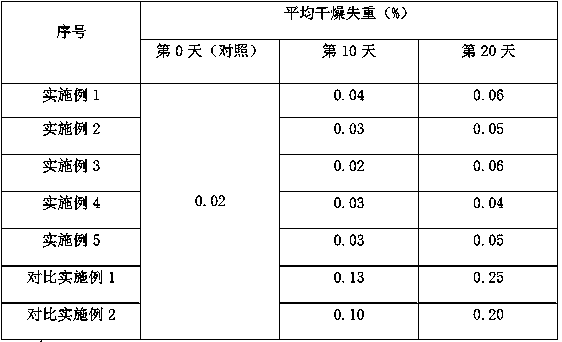

Refining method for medicinal sucrose

InactiveCN108203739ASignificant progressLow pricePurification using adsorption agentsSugar crystallisationSucroseSaccharum

The invention discloses a refining method for medicinal sucrose. The refining method comprises the following concrete steps: juicing of sucrose, pre-filtration, pre-concentration, decoloring with activated carbon, re-filtering, impurity removal via a semi-permeable membrane, purification and crystallization, centrifugation, drying, etc. The refining method has the advantages that an activated carbon process is employed for decoloring, so production cost is greatly reduced compared with an ion exchange decoloring process, the problem of residual sulfur in sucrose produced by using a sulfur fumigation process is avoided, and product quality is improved; a semi-permeable membrane process is employed for impurity removal, so impurities in sucrose can be effectively removed; and through subsequent purification and ultrasonic crystallization, the prepared medicinal sucrose reaches standards prescribed in Chinese Pharmacopeia and meets medicinal requirements, the particle size of the sucroseis controlled in a range of 30 to 100 nm, and the prepared medicinal sucrose has moisture resistance and hygroscopicity.

Owner:HUNAN ER KANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com