Patents

Literature

71results about "Purification by oxidation/reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

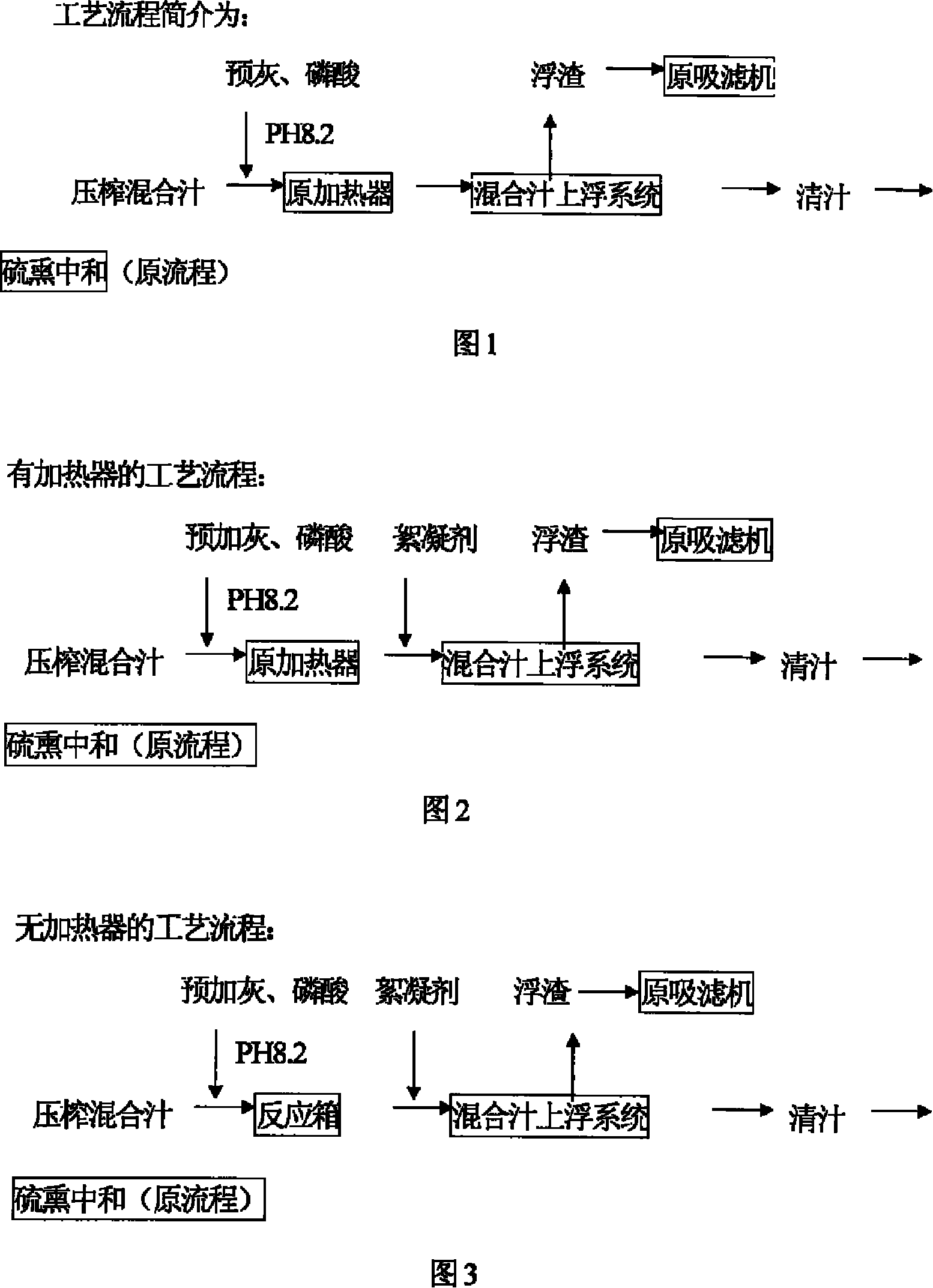

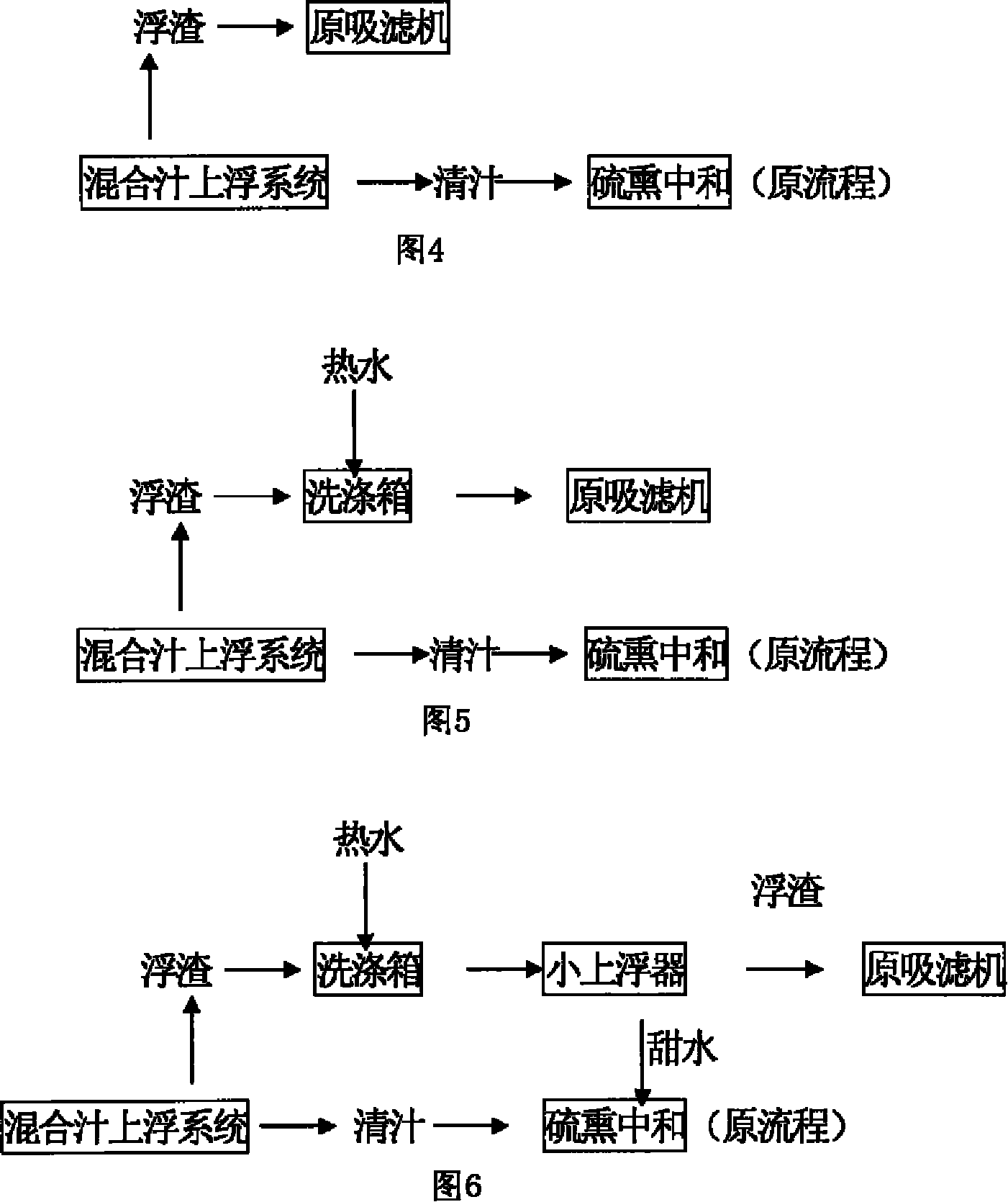

Clarification method of flue gas saturated with mixed liquid

ActiveCN101358250AImprove product qualityHigh purityPurification by oxidation/reductionPhosphateFlue gas

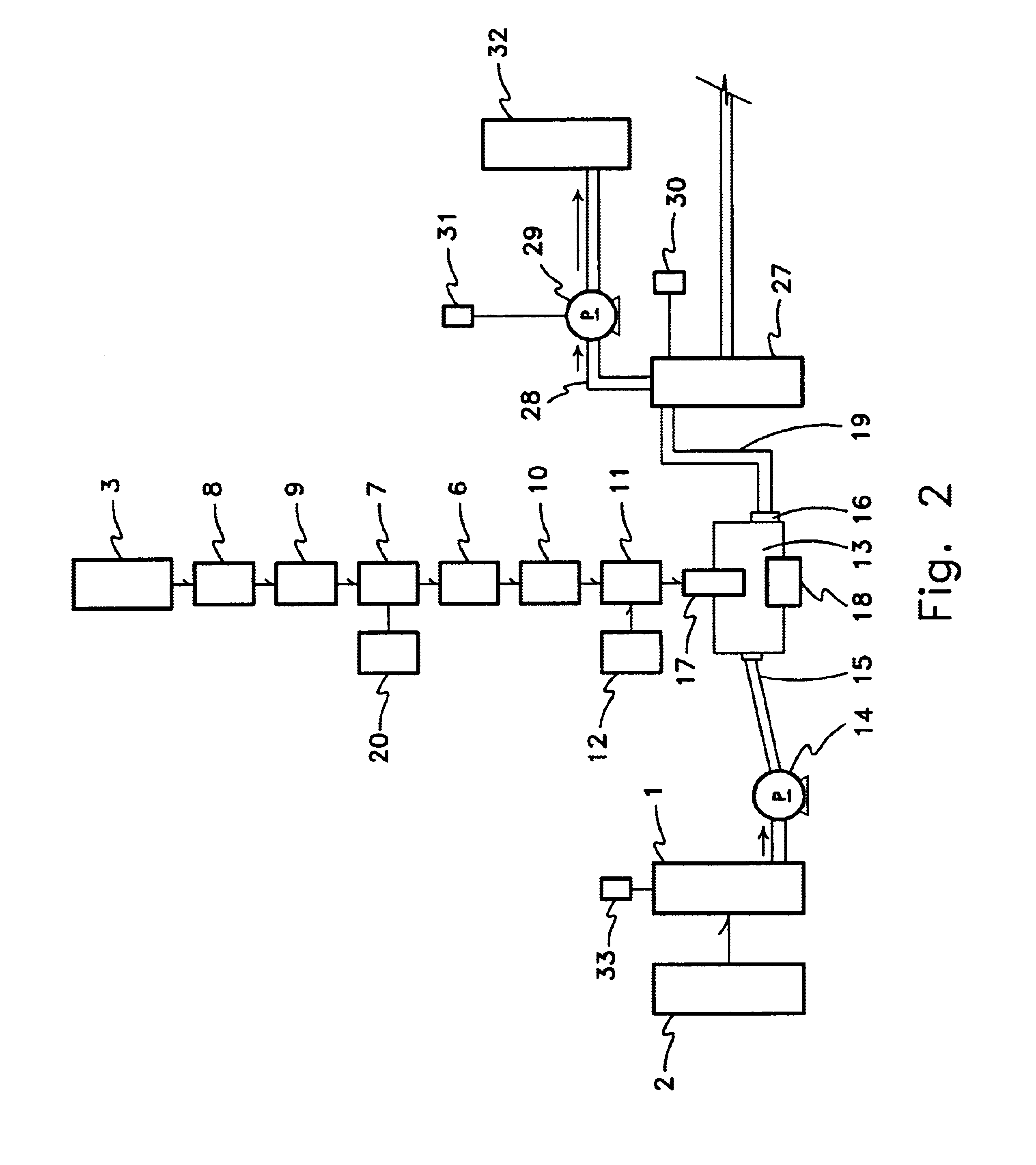

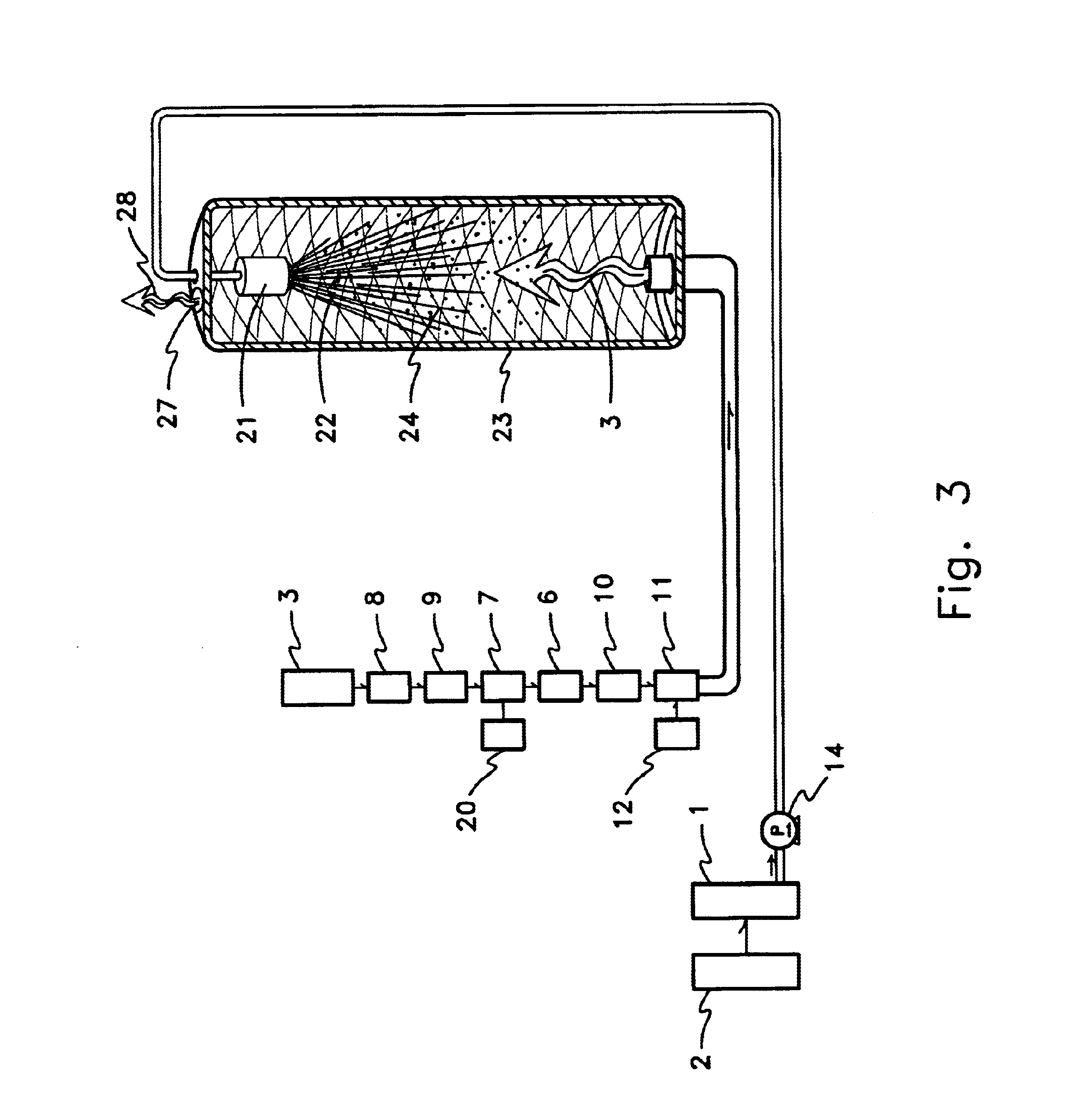

The invention discloses a flue gas saturation mixed juice settling method, which is that flue gas is adopted to carry out the saturation pretreatment of mixed juice on the basis of the phosphate sulfite method before the sulfur fumigation of the mixed juice is carried out; then the mixed juice is treated by the floating treatment to remove part of impurities and reducing sugar to enable the mixed juice to reach an ideal effect, at the same time, the utilization of the flue gas can reduce the using amount of phosphate and sulfur and the production amount of filter mud is reduced to achieve the purposes of improving the sugar boiling recovery, lowering the intensity of sulfitation and the using amount of the phosphate and improving the product quality.

Owner:GUANGXI LAIBIN YONGXIN XIAOPINGYANG SUGAR IND CO LTD

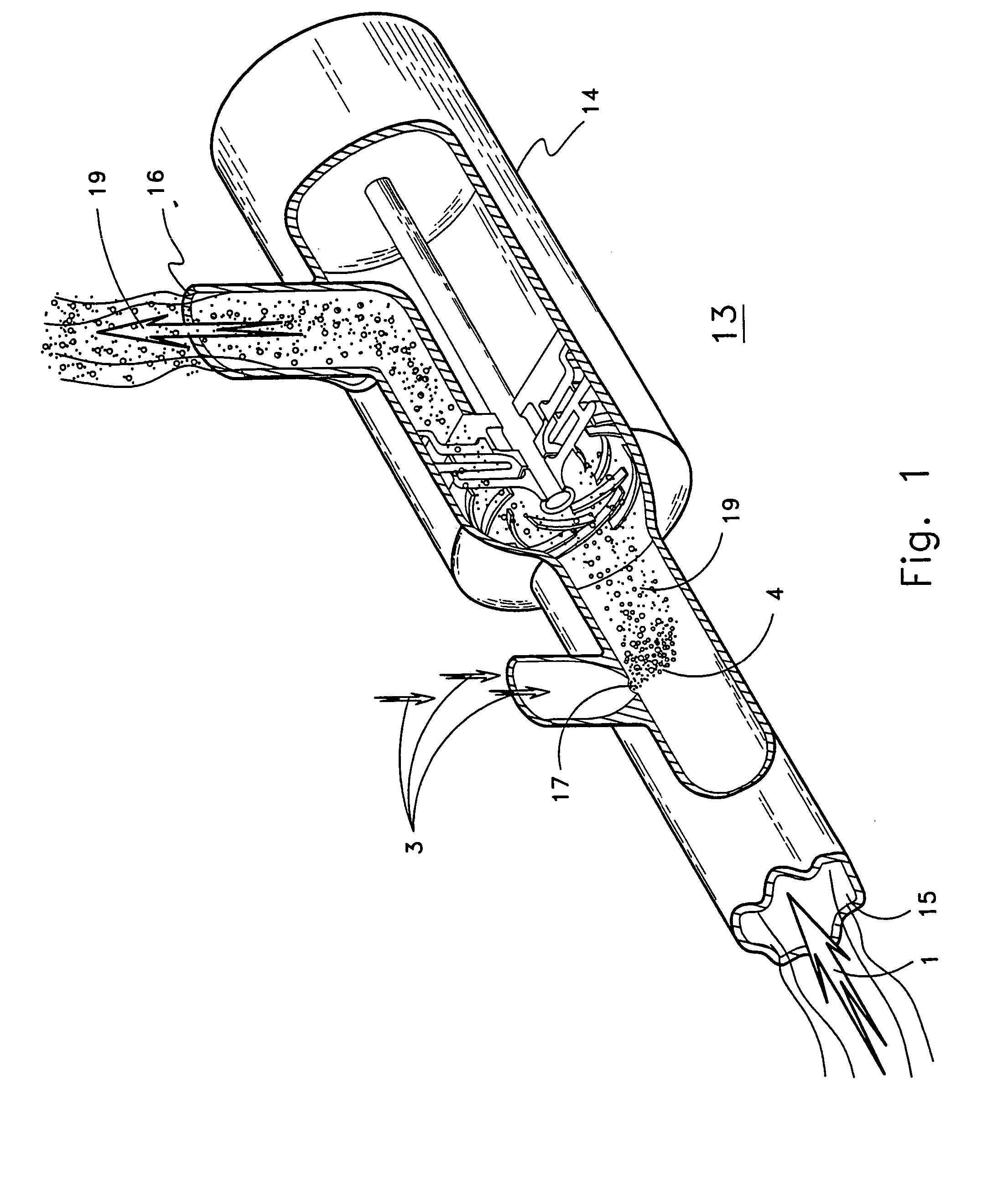

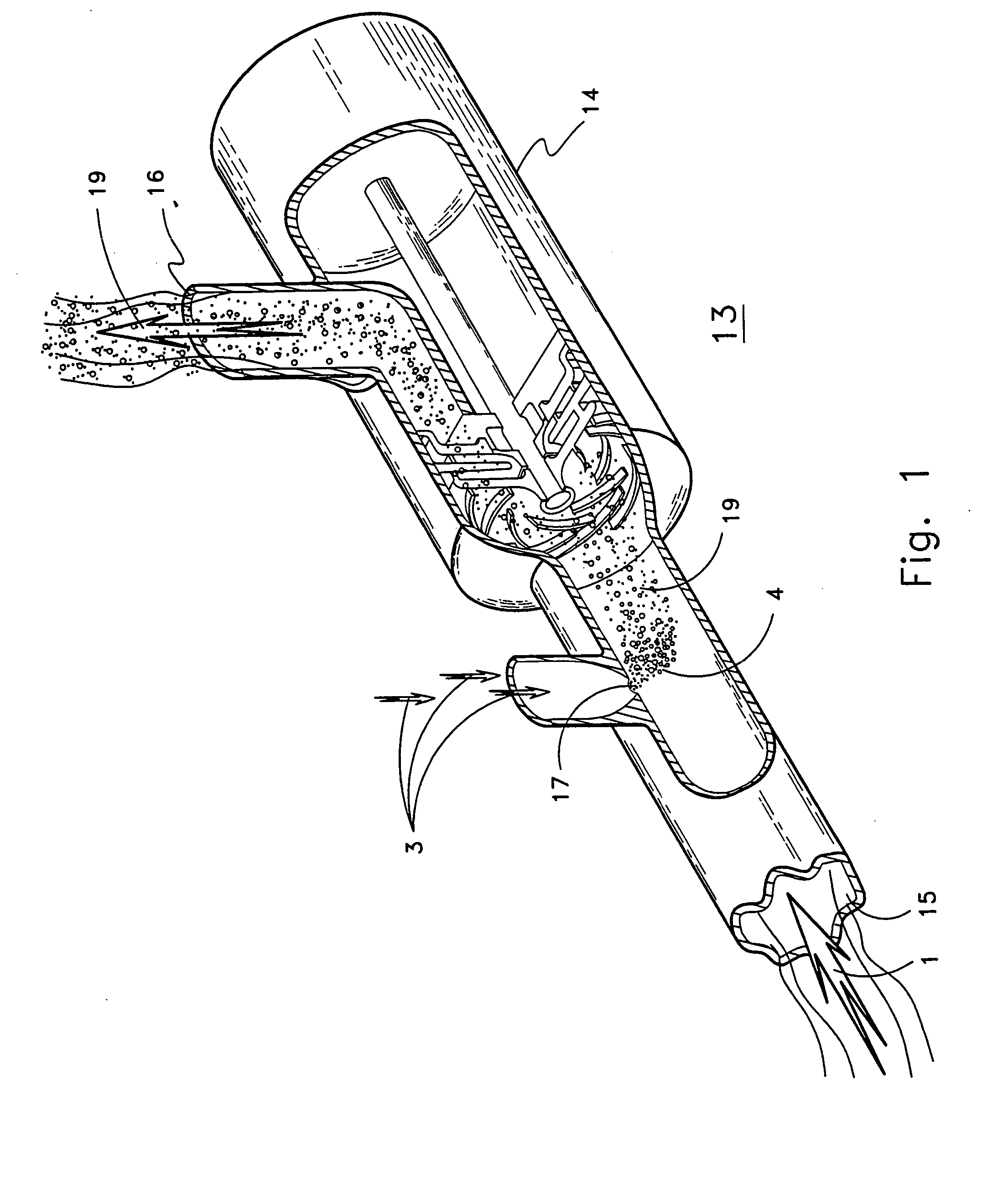

Method for Obtaining White Sugar from Cane Juice

InactiveUS20120216799A1Requires low equipmentReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsFruit juicePhosphoric acid

The invention relates to a method for obtaining white sugar from cane juice, characterized in that it involves: obtaining sugar colors of between 300 and 150 ICUMSA units, with a sulphite content no greater than 5 ppm and an ash content no greater than 0.2% in the case of white sugar and in the case of refined sugar with colors less than 40 UI, less than 5 ppm sulphites and less than 0.04% ash, using fewer chemical products and devices and comprising the formation of reducing sugars; as well as optimizing the production time, reducing deterioration, making the process and the chemical products more efficient and preventing SO2 contamination. The method is characterized in that it simplifies the traditional method of obtaining white sugar using elemental sulfur, eliminating prealkalinization and sulphiting and the respective machinery and equipment and reducing the number of chemical products, such as lime, phosphoric acid, sulfur and activated carbon, in order to aggregate only sodium metabisulphite optionally complemented with monosodium phosphate in juice with pH values of 4 to 6.6 prior to any process involving the clarification of juice, cane syrup or molten liquor.

Owner:BOLANOS MARIO ALAVES

Process for the production of invert liquid sugar

InactiveUS20040255934A1Purification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

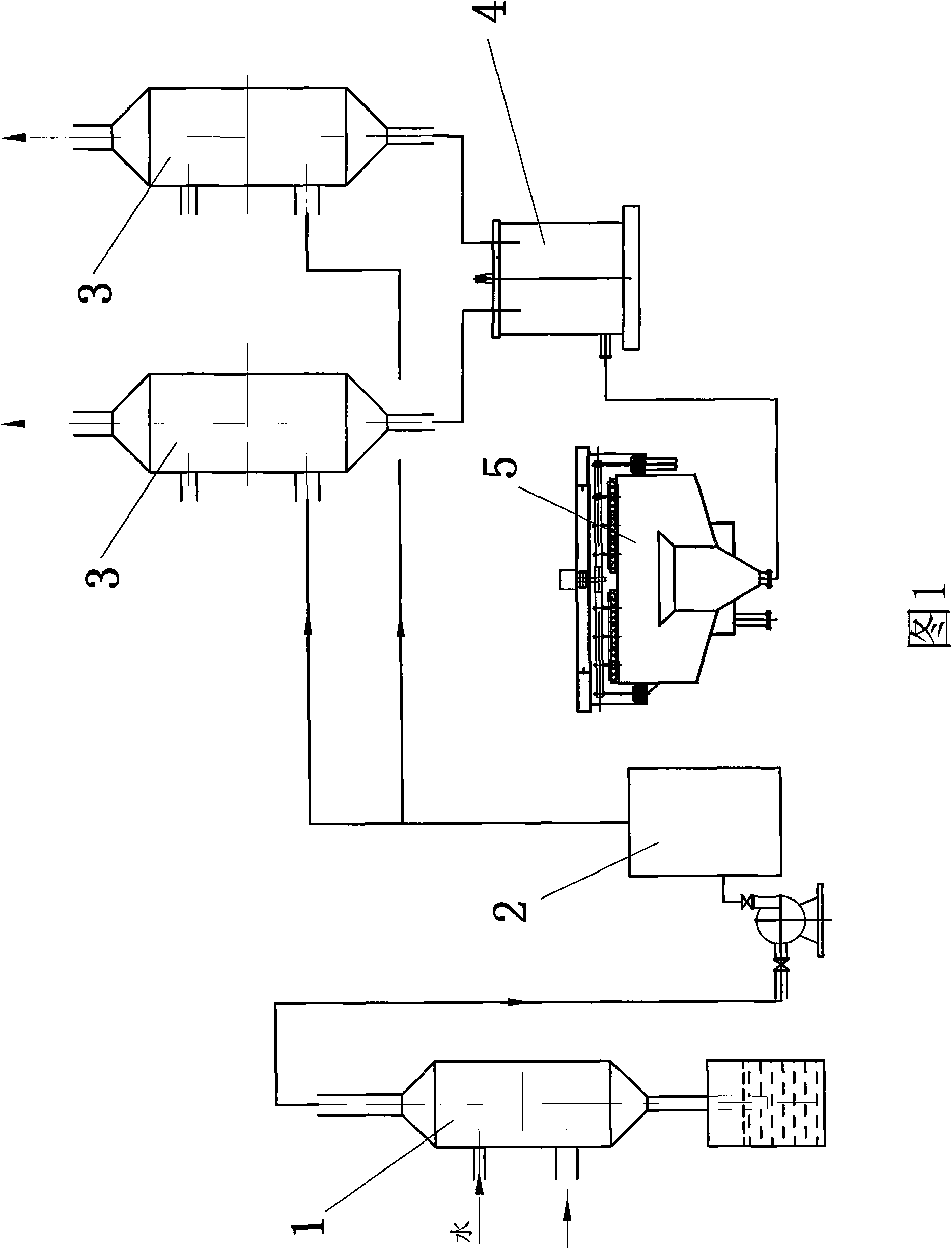

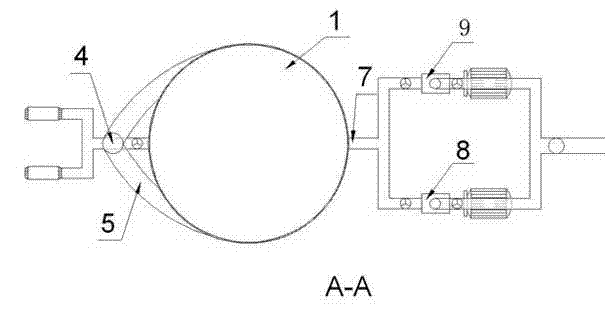

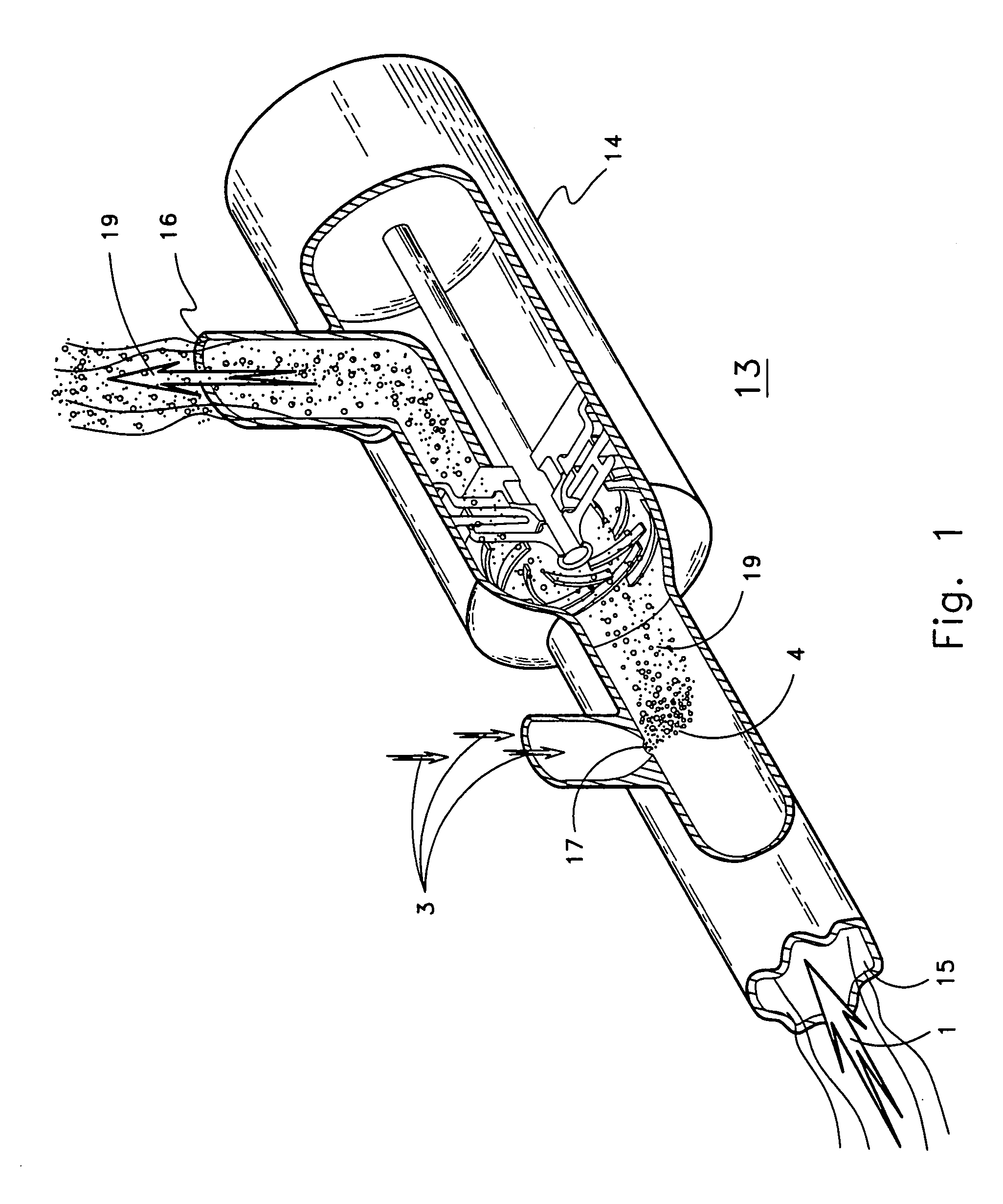

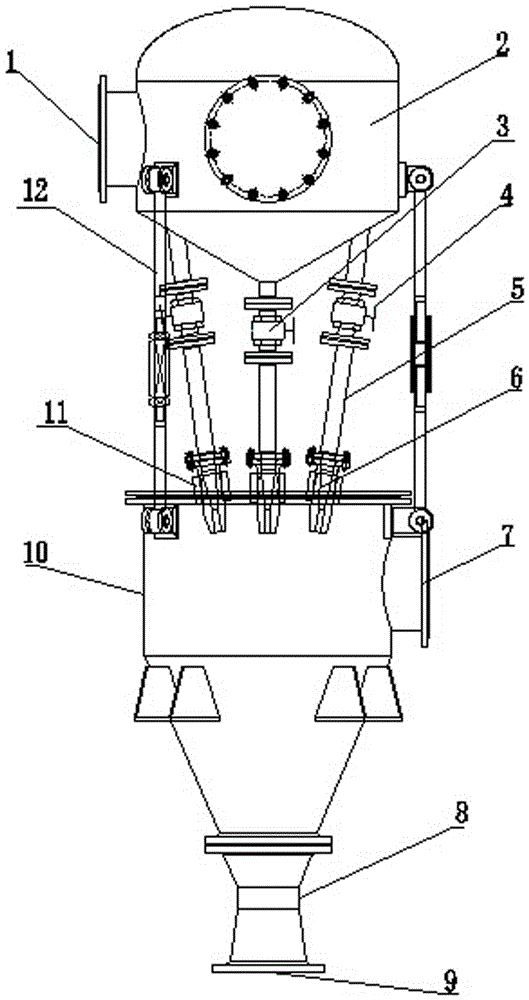

Stoving neutralizing auxiliary reaction tower

InactiveCN103173579AControl dwell timeControl unit controls dwell timePurification by oxidation/reductionPurification using alkaline earth metal compoundsChemical reactionSulfur

The invention aims to provide a stoving neutralizing auxiliary reaction tower. The stoving neutralizing auxiliary reaction tower comprises a cylindrical tank body, a stoving neutralizing reactor, a tube diffuser, a juice outlet pipe, a variable frequency juice outlet pump and a liquid level control device. By using the stoving neutralizing auxiliary reaction tower, the defects of the conventional neutralizing reaction device in a sugar refinery are overcome, and the problem of incomplete chemical reaction of the cane juice subjected to stoving liming is solved. The invention also provides a method for carrying out stoving neutralizing reaction by using the stoving neutralizing auxiliary reaction tower. According to the method, the stoving neutralizing auxiliary reaction tower is reasonably utilized, so that the standing time of the cane juice subjected to stoving liming is greatly increased, the uniformity of the cane juice is improved, the reaction of neutralized juice is more complete, and remarkable effects of improving the syrup purity, reducing the color value of white sugar and turbidity and lowering the sulfur dioxide residues are achieved.

Owner:南宁苏格尔科技有限公司

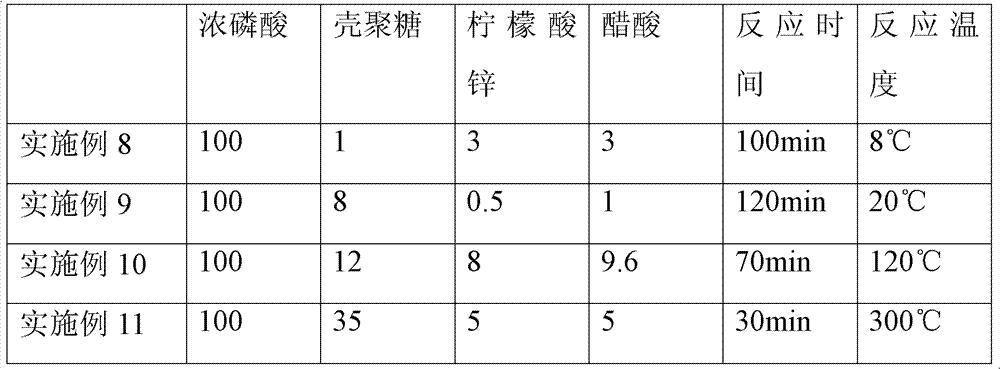

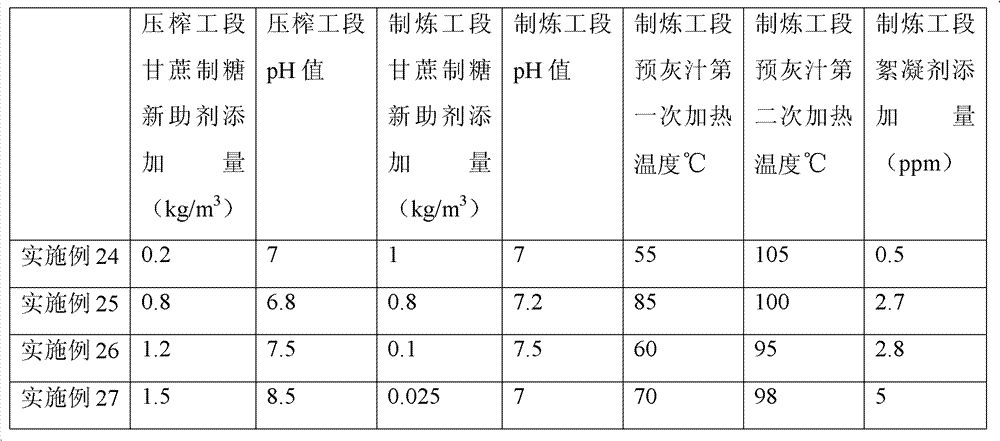

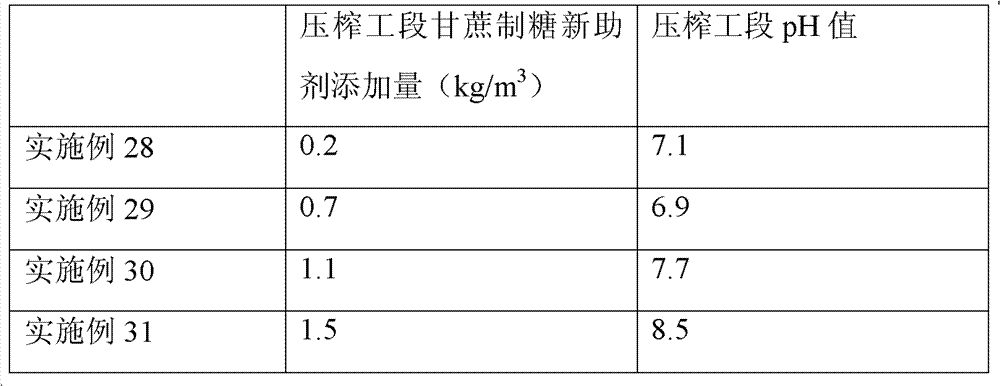

New additive for producing sugar from sugarcane, preparation method thereof and application method thereof in sugar production

ActiveCN102952904ARich choiceImprove qualityPurification by oxidation/reductionPurification using adsorption agentsFiberEnvironmental resistance

The invention discloses a new additive for producing sugar from sugarcane, a preparation method thereof and an application method thereof in a sugar production. The new additive comprises the following raw materials by weight parts: 100 parts of concentrated phosphoric acid, 0.5 to 50 parts of chitosan and 15 to 90 parts of diatomite used as a carrier raw material. The preparation method comprises adding 0.5 to 50 parts of the chitosan into 100 parts of the concentrated phosphoric acid, reacting for 30 to 120 minutes under a temperature of 8 to 300 DEG C, generating a new sugar-production additive of polyphosphate polymer compound with a strong positive charge and a high fiber after complete reaction, and absorbing the above reaction product with 15 to 90 parts of the diatomite to prepare the new additive with relatively high performance. The new additive, completely instead of sulfur dioxide, is used in cane sugar manufacture industries to decolorize and clarify sugarcane juice, mixed juices thereof and pre-heated and pre-limed juice, and as well can be used to re-treat clear juice or syrup. According to the invention, safe, green, environmental-protection and high-quality sugar products is ensured to produce.

Owner:SHENZHEN HIGHWIND BIOLOGICAL TECH

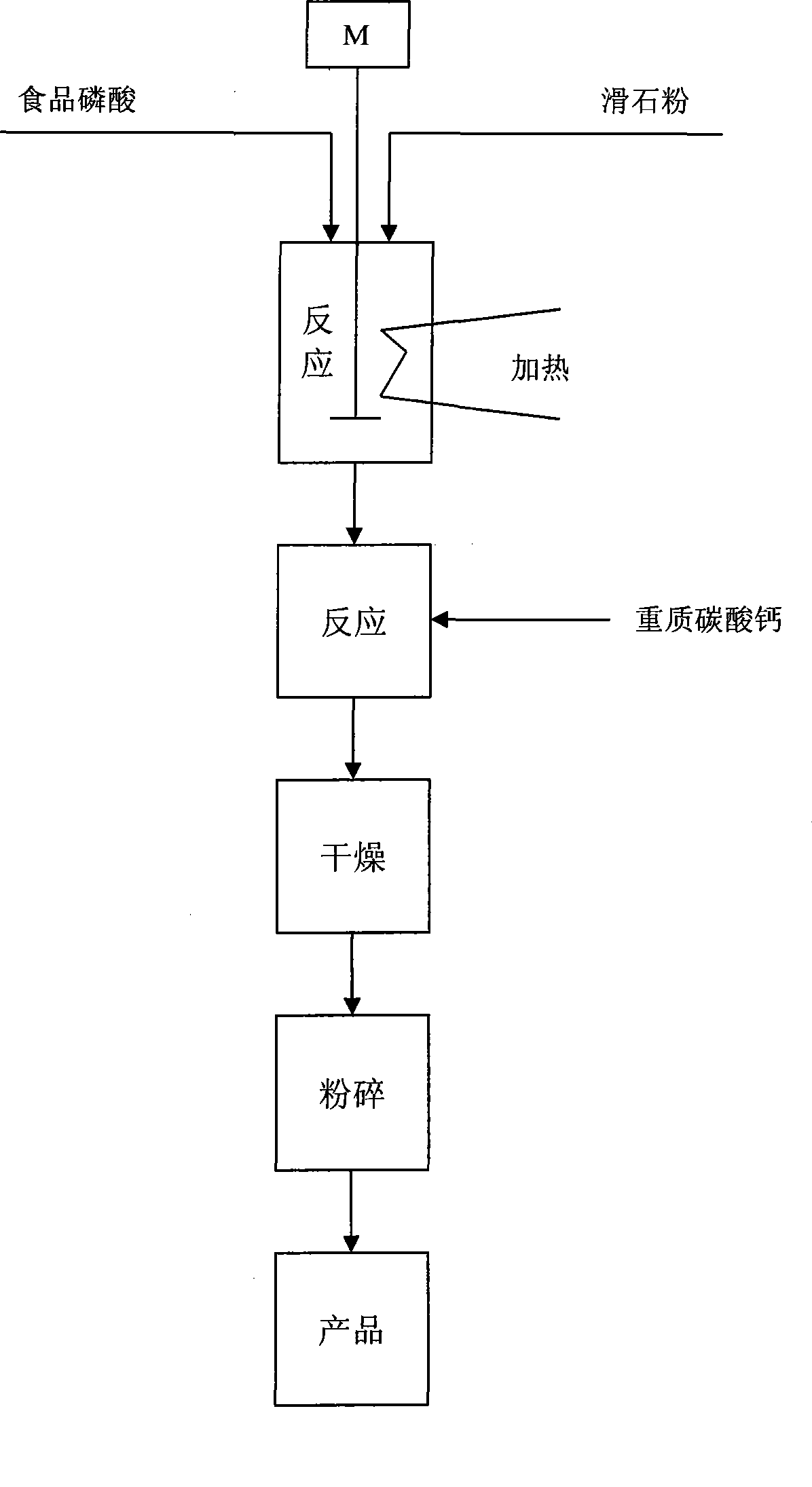

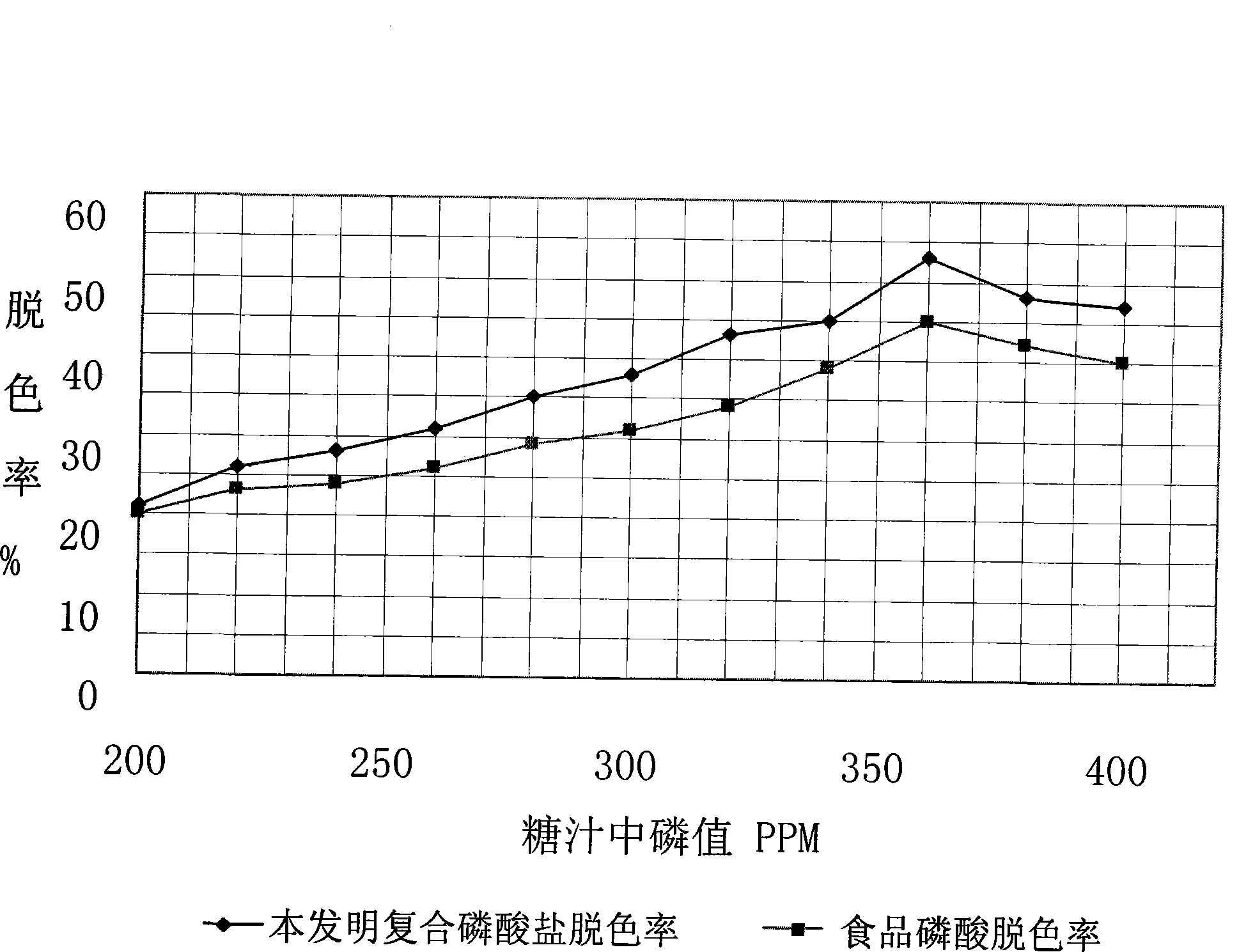

Composite phosphates sugar juice decoloring agent and preparation thereof

ActiveCN101440412AEasy to storeEasy to transportPurification by oxidation/reductionMonomagnesium phosphatePhosphate

The invention provides a composite phosphate sugar juice decoloring agent and a preparation method thereof, which belongs to the technical field of chemical engineering. The decoloring agent consists of the following four components: (1) calcium biphosphate, (2) magnesium dihydrogen phosphate, (3) precipitated silica and (4) free phosphoric acid. The preparation method for the decoloring agent comprises the following steps: (1) talc is added to food-grade phosphoric acid hydrolysate and dissolved, so as to obtain a phosphoric acid aqueous solution which dissolves magnesium dihydrogen phosphate and disperses precipitated silica; and (2) heavy calcium carbonate powder is put into a mixer and added with the phosphoric acid aqueous solution in a step (1), and reaction evaporates the moisture of materials and progressively cures the materials, so as to obtain the composite phosphate sugar juice decoloring agent containing moisture. Compared with the food-grade phosphoric acid used by the prior sugar factories, the decoloring agent has the advantages of good decoloring effect, economical efficiency, convenience, no relation to dangerous chemicals, and the like.

Owner:YUNNAN JIANGLIN GROUP

Low temperature processing technique for sugar mill mixing liquor by sulfurous acid method

InactiveCN101144109AQuality improvementReduce turbidityPurification by oxidation/reductionFlocculationProduct gas

The present invention relates to a mixing low-temperature treatment process used in a sulfitation sugar mill where sugar cane juice is treated. The present invention is characterized in that 2 to 10 baume degrees of lime cream watery solution is added into the pressed combination juice manufactured according to the traditional process, 5 to 1000 ppm of clarificant used by a G409 aluminum raw massecuite, 50 to 1000 ppm of chitosan exclusively used for the flocculation and the purification, one or more of CO 2 can be added to be matched and used, to lead the solution to be prepared into the solution of pH value (6-12) after the solution is mixed; the clarificant with 0.01-0.2 percent of concentration and 1 to 4 ppm of mass is mixed; the mixed solution is sent into a float-up device. The present invention has the advantage that the stoving intensity can be decreased by 35 percent to 45 percent. Thus the loss of the sugar share is decreased, and the quantity of the raw material is saved. The reduction of the depositional area is greatly helpful to improve the juicing amount and the withdrawal, thereby decreasing the investment; the product quality and the withdrawal are improved; the production cost is low, the material which is harmful to the food is not required to be added, and only the usual drug in the sugar manufacturing process of the sugar mill is required to be added.

Owner:黄桂忠

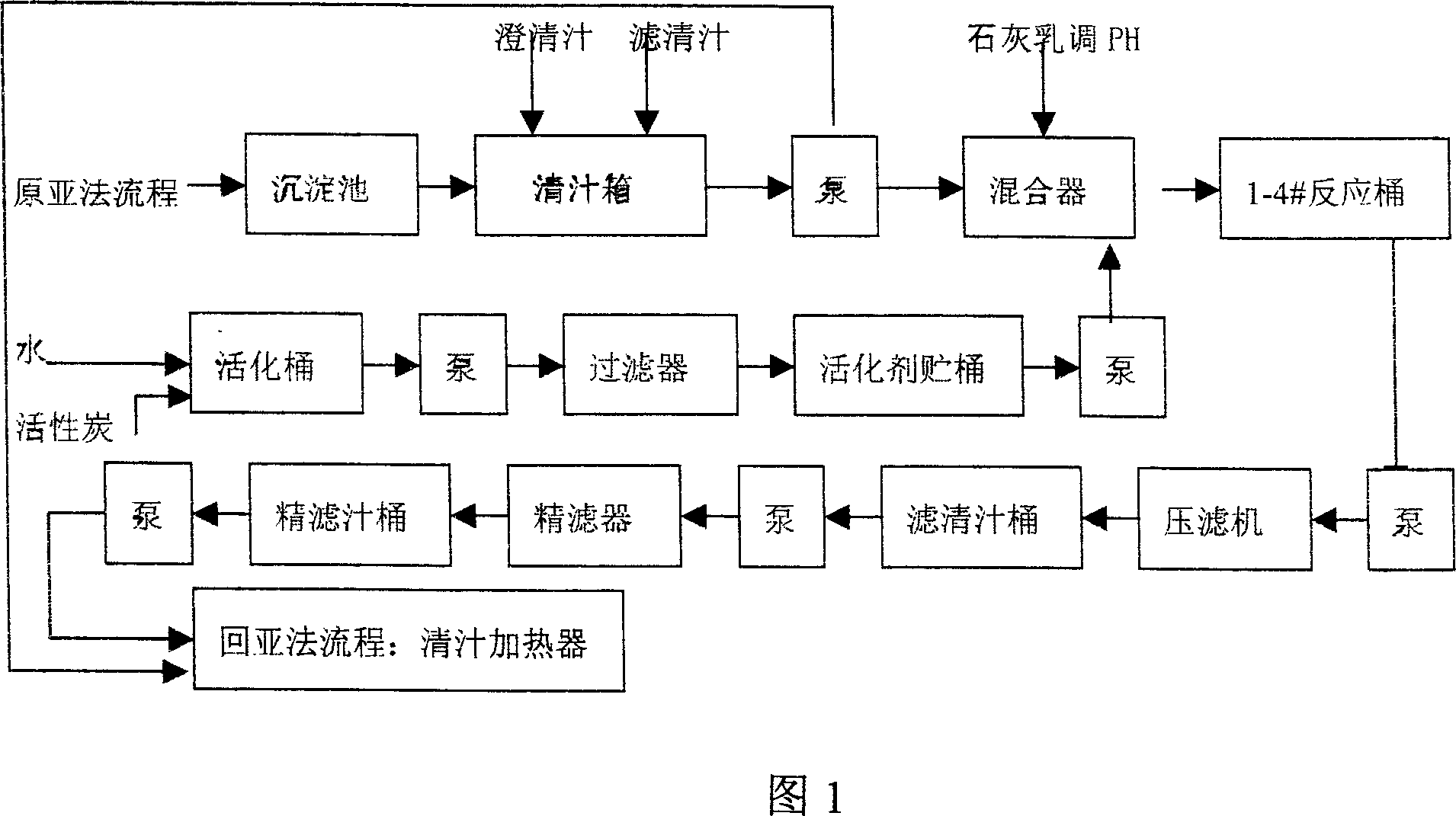

Method for producing desulfurized sugar by high efficiency active carbon improved sufurous acid method sugar producing process

InactiveCN1944684AReduce investmentExemption from the secondary sulfur fumigation processPurification by oxidation/reductionPurification using adsorption agentsActivated carbonTurbidity

The present invention is improved desulfurized sugar producing sulfurous acid process with high efficiency carbon. The process includes the first mixed sugar cane juice clarifying treatment with sulfurous acid, the subsequent adding high efficiency active carbon in the amount of 0.09-0.2 wt% of juice into the clear juice and adding lime milk to regulate pH value to 6.8-7.6 through full mixing for adsorption in 20-30 min, pressure filtering and straining to obtain high quality juice, evaporating, boiling sugar and purging to obtain high quality desulfurized sugar. The present invention has high sugar quality.

Owner:云南永德糖业集团有限公司

Preparation of phosphoric acid composite decolorizer and application method thereof

InactiveCN101812546AStrong targetingEasy to synthesizePurification by oxidation/reductionSulfurPhosphoric acid

The invention discloses a preparation of a phosphoric acid composite decolorizer and an application method thereof. The decolorizer takes phosphoric acid as the raw material; after being diluted to 0.85%, the phosphoric acid is mixed with urea or quaternary ammonium salt; and the mixture reacts at the temperature of 50 DEG C-80 DEG C for 30-60 minutes to obtain the phosphoric acid composite decolorizer solution. In the common sugarcane sulfurous method sugar preparation process, the phosphoric acid composite decolorizer solution replaces industrial phosphoric acid to be added into mixed juice, rough syrup or remelt syrup of brown granulated sugar, and the addition is equivalent to 200-400 mg / kg of P2O5. Compared with the prior art, the invention has the advantages: 1, the invention is suitable for sugarcane sulfurous method process and has strong pertinence; 2, the phosphoric acid composite decolorizer is simple and quick to synthesize; 3, the application of the phosphoric acid composite decolorizer improves the decoloration effect of sugarcane juice and reduces the dosage of other auxiliary clarifying agents (sulphur, phosphoric acid, lime and polyacrylamide).

Owner:GUANGXI UNIV

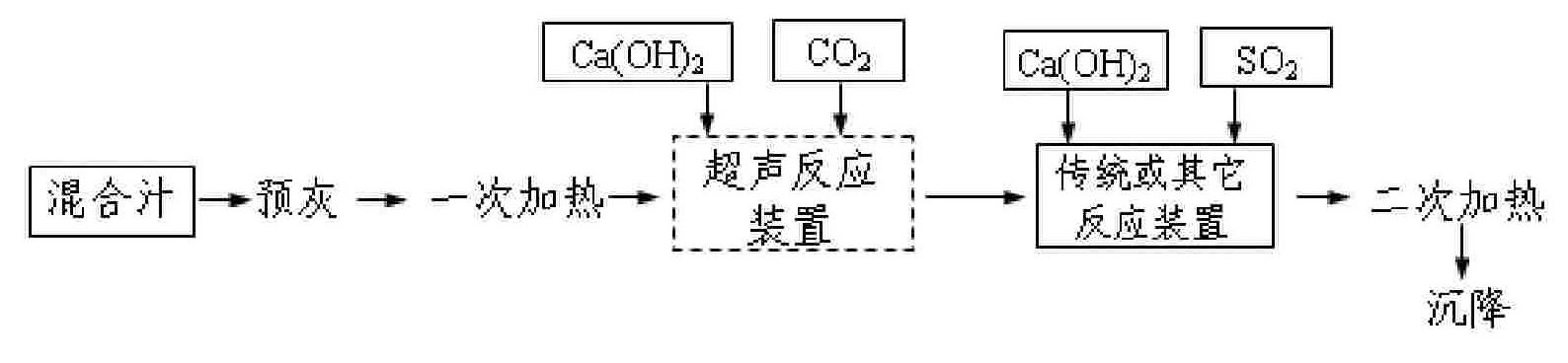

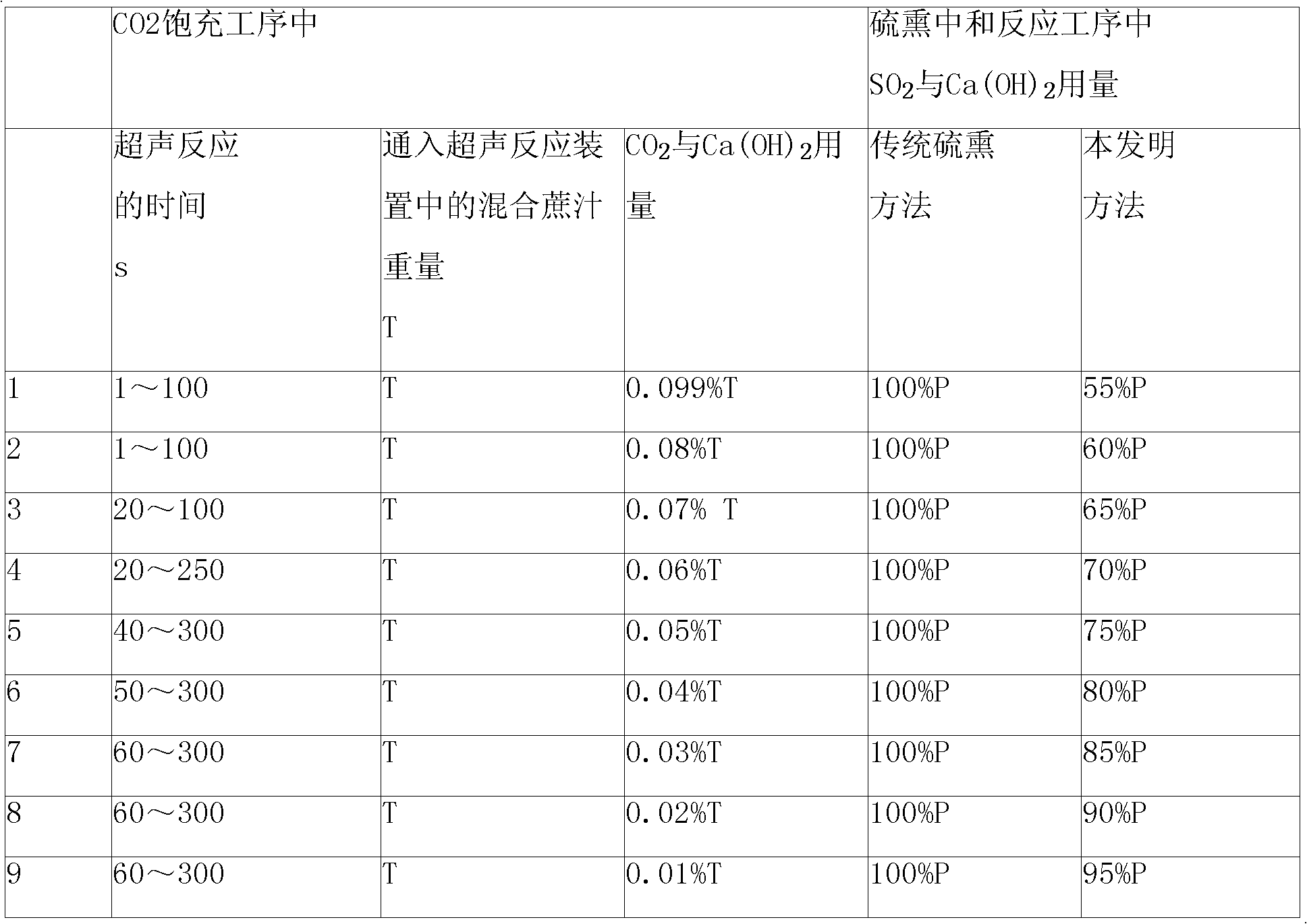

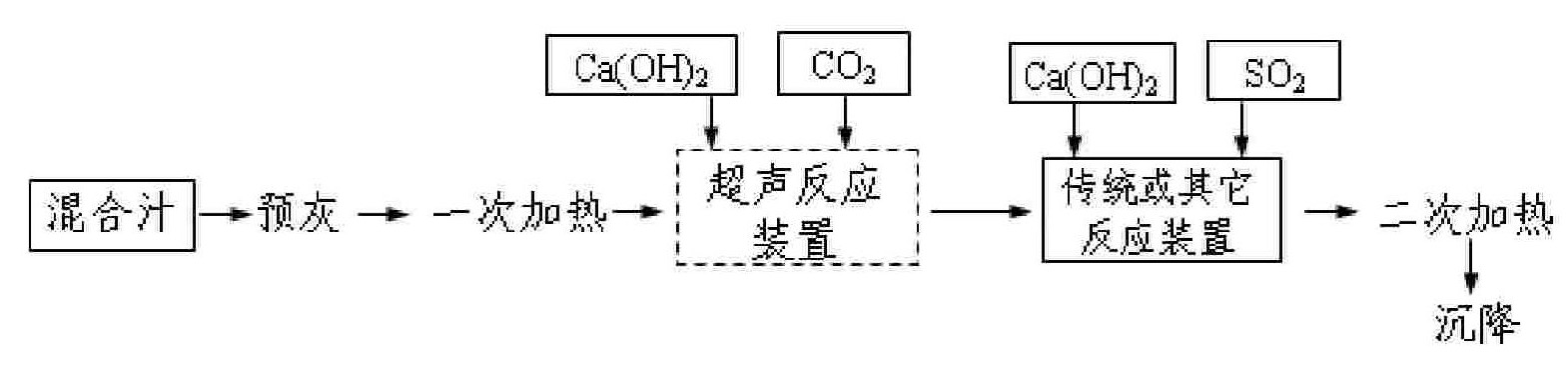

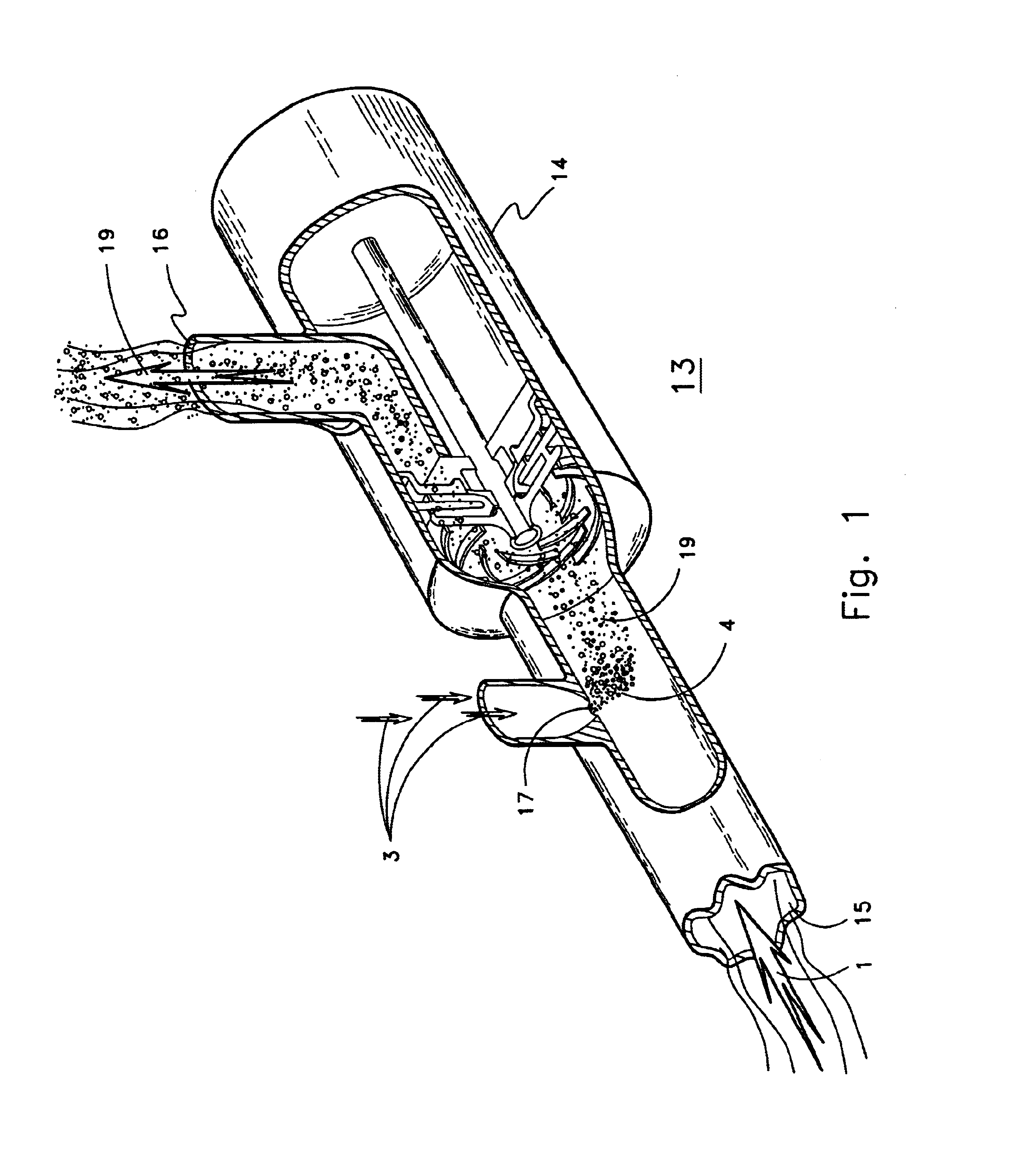

Method for clarifying ultrasonically-enhanced sugarcane juice

InactiveCN101805805ALow residual sulfurQuality improvementPurification by oxidation/reductionPurification using alkaline earth metal compoundsComing outSulfur

The invention discloses a method for clarifying ultrasonically-enhanced sugarcane juice, comprising the following steps: preliming the mixed sugarcane juice; heating the mixed sugarcane juice for the first time; leading CO2 and Ca(OH)2 to the mixed sugarcane juice to carbonize the mixed sugarcane juice in a ultrasonic reaction device, wherein the weight of the Ca(OH)2 is 0.01-0.3 percent of the weight of the mixed sugarcane juice, and the molar mass ratio of the CO2 to the Ca(OH)2 is 1:1; adding SO2 and Ca(OH)2 to enable the mixed sugarcane juice which comes out of the ultrasonic reaction device to be subjected to the sulphitation and the neutralization, or adding part of the mixed sugarcane juice which is not carbonized by the CO2 to the mixed sugarcane juice which comes out of the ultrasonic reaction device to enable the same two to be subjected to the sulphitation and the neutralization, where the addition amount of the SO2 and the Ca(OH)2 is 55-59 percent of the addition amount of the SO2 and the Ca(OH)2 which are added to enable the mixed sugarcane juice to be subjected to the sulphitation and the neutralization; heating the mixed sugarcane juice; and precipitating the mixed sugarcane juice. The method for clarifying the ultrasonically-enhanced sugarcane juice can improve the neutralization speed and the neutralization degree of the sugarcane juice and reduce the content of the residual sulfur.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Process for the production of invert liquid sugar

InactiveUS6916381B2Reduce amountFew stepsPurification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

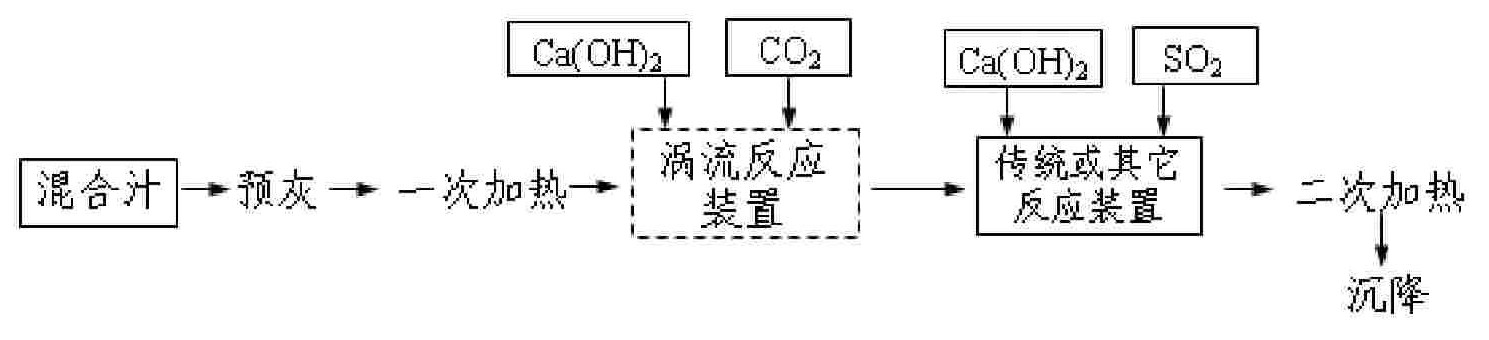

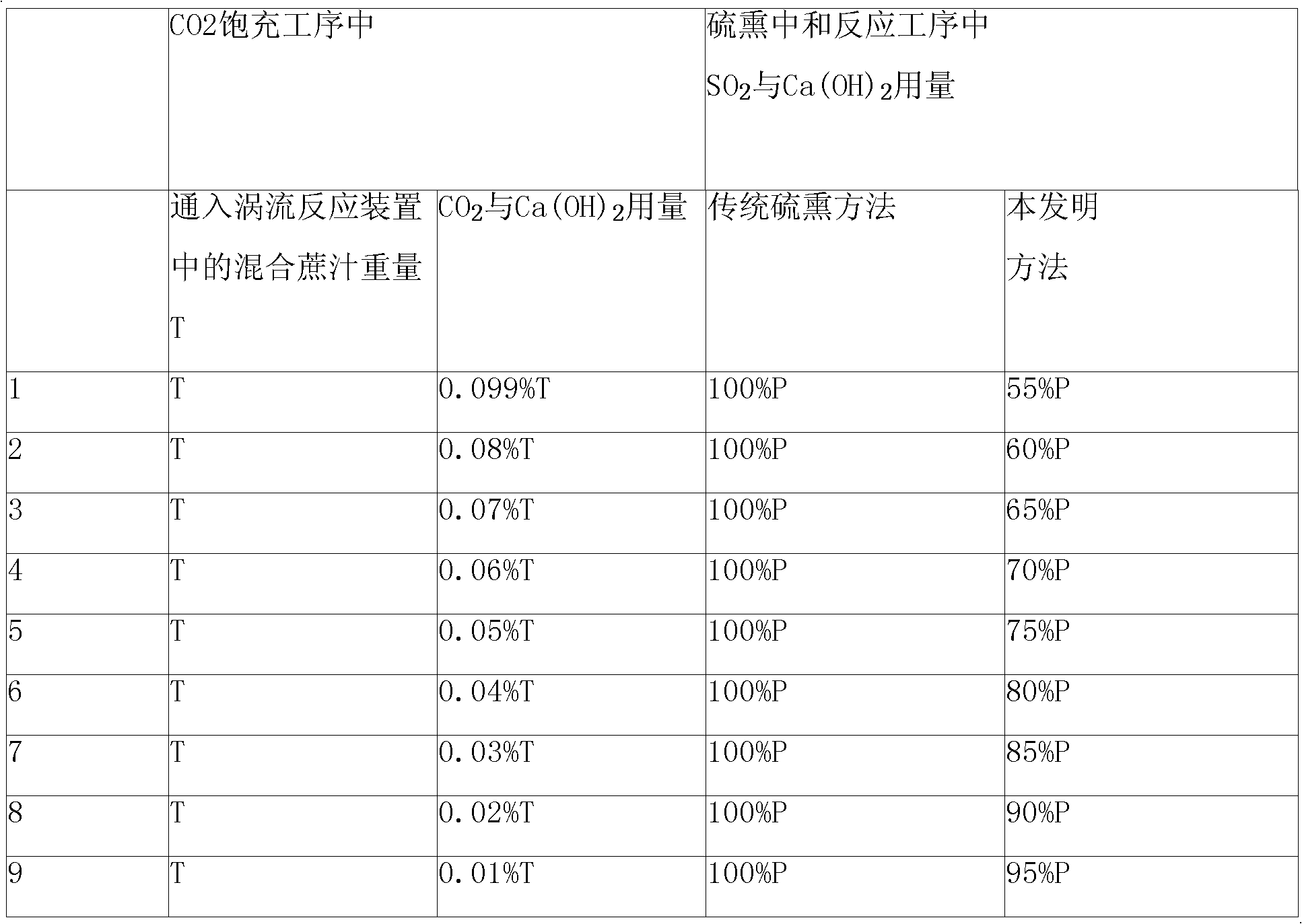

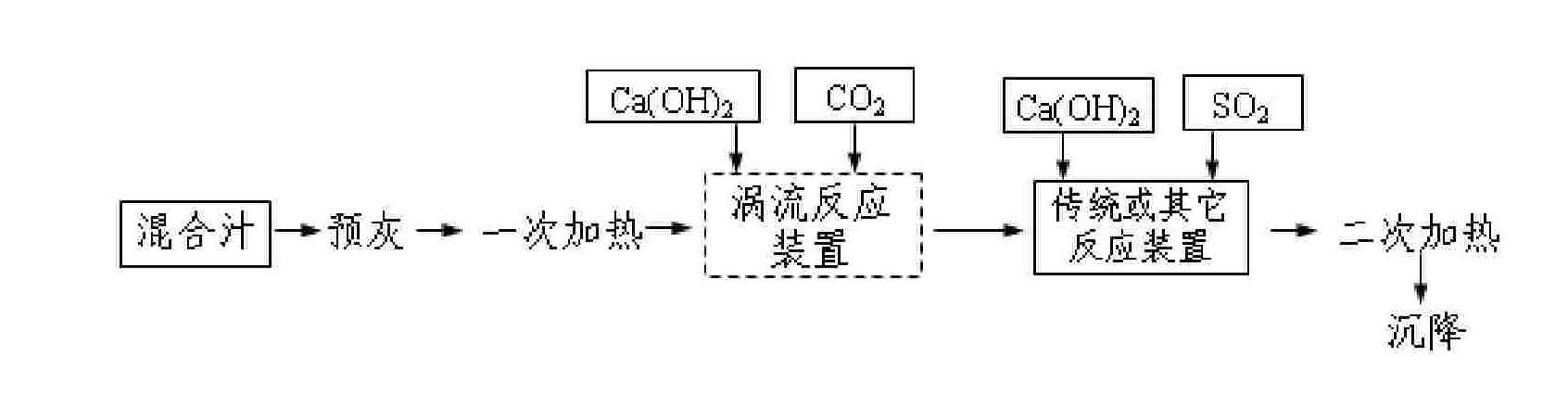

Intensified cane juice clarification method

InactiveCN101805806ALow residual sulfurQuality improvementPurification by oxidation/reductionPurification using alkaline earth metal compoundsJuice clarificationSulfur

The invention relates to an intensified cane juice clarification method which comprises pre-liming, primary heating, CO2 full filling, sulphitation and neutralization, secondary heating and settlement; the CO2 full filling procedure is as follows: pre-limed and primarily heated mixed juice is fed with CO2 and Ca(OH)2, the mixed juice is fed into an eddy reactor to have CO2 full filling reaction, and then the cane juice from the eddy reactor has sulphitation and neutralization reactions or is added with some the mixed juice which does not have CO2 full filling reaction to carry out the sulphitation and neutralization reactions; the amount of the Ca(OH2) which is fed into the mixed juice in the CO2 full filling procedure is about 0.05 percent of the weight of the cane juice, and the molar ratio of the amount of CO2 to the amount of Ca(OH)2 is 1:1, and the amount of SO2 and the Ca(OH)2 added in the sulphitation and neutralization reactions is 55 to 95 percent of the amount required in the traditional sulphitation and neutralization reactions. The method can improve the cane juice neutralization reaction speed and the reaction degree as well as the decolorization effect, and reduce the residual sulfur.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Sugar juice decoloring method

InactiveCN101481746AReduce color valueQuality improvementPurification by oxidation/reductionComing outSulfur

The invention discloses a sugar juice decoloring method. The method comprises the following steps: during a sugar making process, ClO2 is used for decoloring a sugar juice; the sugar juice refers to any one, two, three or four of a clear juice coming out of a clarification section, crude syrup or re-dissolution syrup coming out of an evaporation section, or massecuite coming out of a crystallization section; CIO2 is respectively added to any one, two, three, or four of the clear juice, the syrup or the messecuite; any one, two, three or four of the four sugar juices are respectively or simultaneously oxidized and declored; the amount of CIO2 added into the sugar juice is 0.0005 percent to 0.3 percent of the weight of the sugar juice; and the adding method is that CIO2 is directly added to a corresponding sugar juice, and the sugar juice is fully mixed and reacted with CIO2 during a flow and pumping process, so as to achieve the aim of oxidation and decoloration. The sugar juice decoloring method of the invention can effectively reduce the color value of the sugar juice, reduce the color value of a product sugar and the residue of sulfur, and simultaneously improve the purity and the quality of the sugar.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

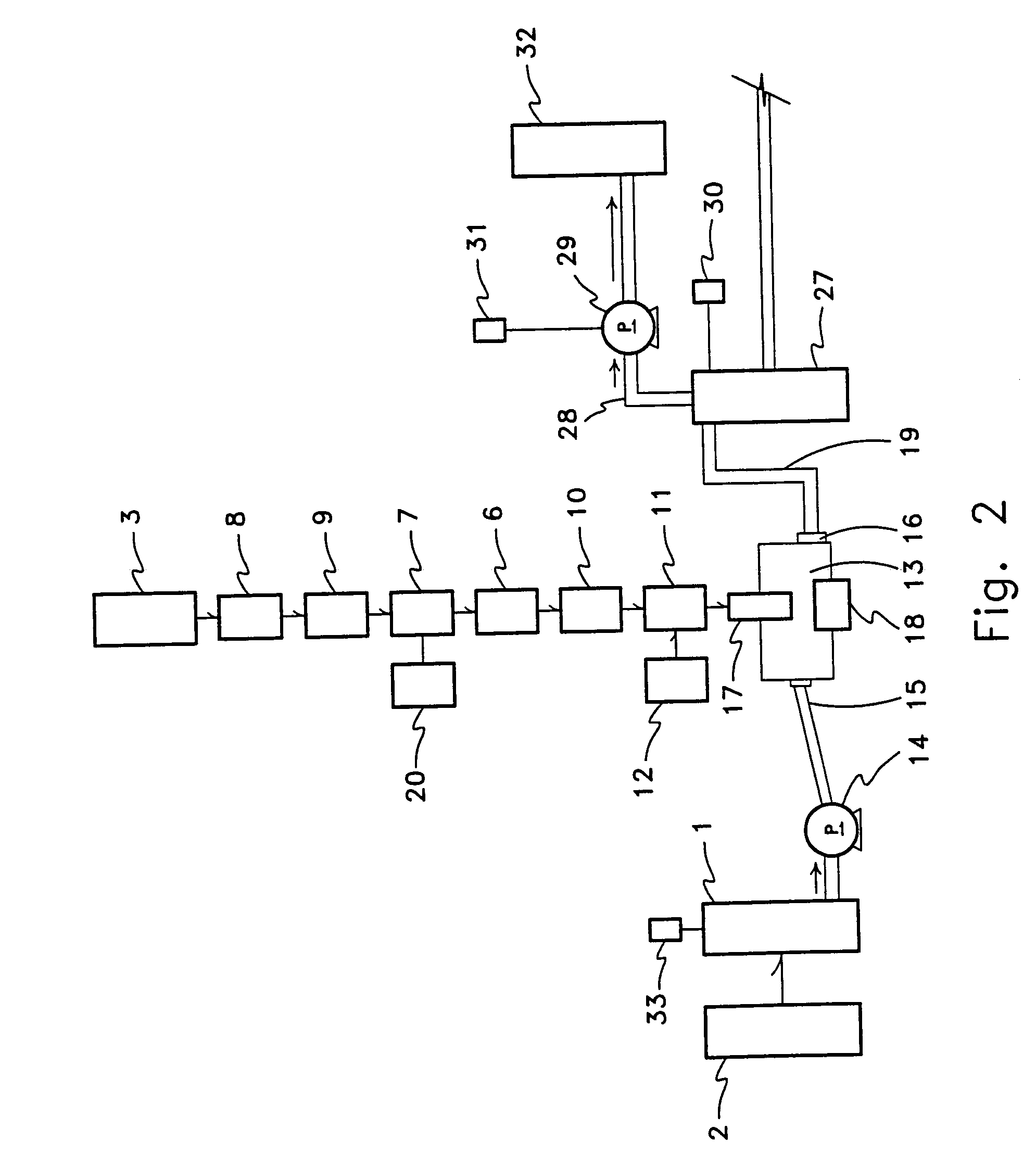

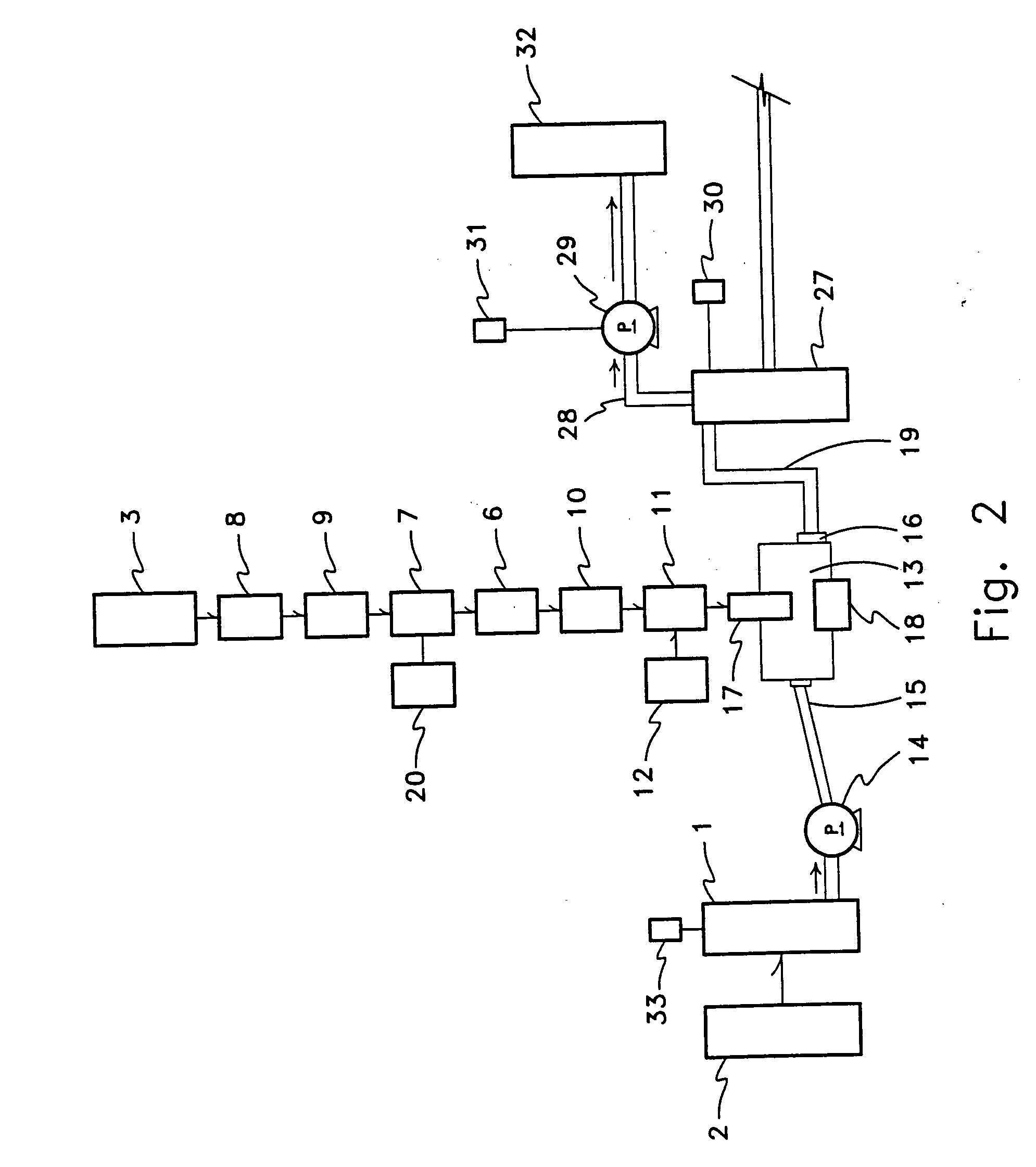

System to produce sugar from plant materials

InactiveUS6656287B2Reduce the amount requiredReduce concentrationPurification by oxidation/reductionPurification using adsorption agentsProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

Method utilizing enzyme to catalyze H2O2 to discolor sugar juice

InactiveCN101768644AGood decolorization effectImprove product qualityPurification by oxidation/reductionSoftened waterSulfur content

The invention discloses a method utilizing enzyme to catalyze H2O2 to discolor sugar juice. The method includes the following steps: in the clearing technique of the sugarcane or beet sugar manufacturing process, peroxidase and the H2O2 are adopted to discolor the sugar juice; the peroxidase and the H2O2 are diluted by softened water, the diluted concentration of the peroxidase is within 0.01 to 0.1%, and the diluted concentration of the H2O2 is within 0.01 to 0.05%; the peroxidase and the H2O2 are mixed together according to the proportion of 1:8 to 8:1 so as to obtain peroxidase mixed solution; finally, the peroxidase mixed solution is added to the sugar juice to discolor the sugar juice. The method in the invention can effectively remove polyphenols in the sugar juice, lower the color value, improve the product quality of white granulated sugar, reduce the residual sulfur content, and advance the product grade.

Owner:GUANGXI UNIV

Method for cleaning refractory cane juice for sugar factories by using sulfurous method

InactiveCN102978296AStabilizationEfficient removalPurification by oxidation/reductionWater insolublePhosphoric acid

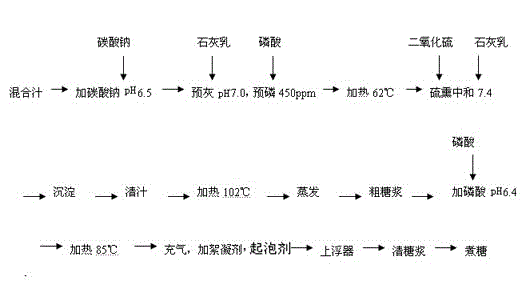

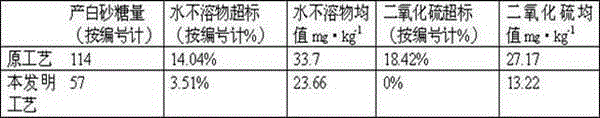

The invention discloses a novel method for cleaning refractory cane juice for sugar factories by using a sulfurous method, belonging to the field of cane juice cleaning. The method is characterized by comprising the steps of: before preliming mixed juice, adding sodium carbonate aqueous solution with the weight content of 5-30%, regulating the pH of the solution to 6.5-6.7, producing to obtain crude syrup through a conventional processes, regulating the pH to 6.3-6.5 by using phosphoric acid, adding micro bubbles after heating, adding 2-5PPM flocculant and mixing with a foaming agent, entering to a floating device, condensing non-sugar impurities such as colloid and pigment in the sugar juice together, lifting by utilizing the bubbles, forming scum and removing. According to the invention, only a sodium carbonate dissolving bucket and a syrup floating system are needed to be added on the basis of the conventional equipment; lime and saccharifying calcium are not needed to be added and serve as auxiliaries during the floating treatment; therefore, the method has the advantages that the operation is simple, the investment cost is low, the cleaning effect is remarkably increased and the colloid, residual sulfur dioxide and water insoluble matters are obviously removed; and the method is suitable for producing qualified white granulated sugar by using poor-quality refractory cane juice.

Owner:GUANGXI CHONGZUO XIANGGUI SUGAR

Complex enzyme detergent for high-temperature-resisting cane sugar manufacturing industry as well as preparation and application thereof

InactiveCN109321553AAchieve the effect of removing impurities and clarifyingImprove qualityPurification by oxidation/reductionPurification using chemicalsPectinaseFiltration

The invention discloses a complex enzyme detergent for a high-temperature-resisting cane sugar manufacturing industry as well as preparation and application thereof and belongs to the technical fieldof clarifying technologies of the sugar manufacturing industry. The complex enzyme detergent is prepared from the following components in percentage by weight: 20 to 50 percent of heat-resisting dextranase, 5 to 35 percent of high-temperature-resisting alpha-amylase, 5 to 25 percent of heat-resisting pectinase, 4 to 20 percent of high-temperature-resisting laccase, 3 to 20 percent of heat-resisting horseradish peroxidase, 3 to 20 percent of high-temperature-resisting cellulase and 0 to 10 percent of water. After raw material enzymes are mixed according to a ratio, a mixture is subjected to membrane filtration and is quantitatively filled to obtain a product. In a process from primary heating to secondary heating, the complex enzyme detergent is added into crude sugar juice to carry out clarification treatment. A complex enzyme preparation formed by a proper ratio prevents a condition that only one enzyme usually cannot reach a predicated impurity removal and clarification effect; a buffering stage does not need to be set, adding sites are wide and the limitation caused by temperature is relatively small.

Owner:广西糖业集团金光制糖有限公司

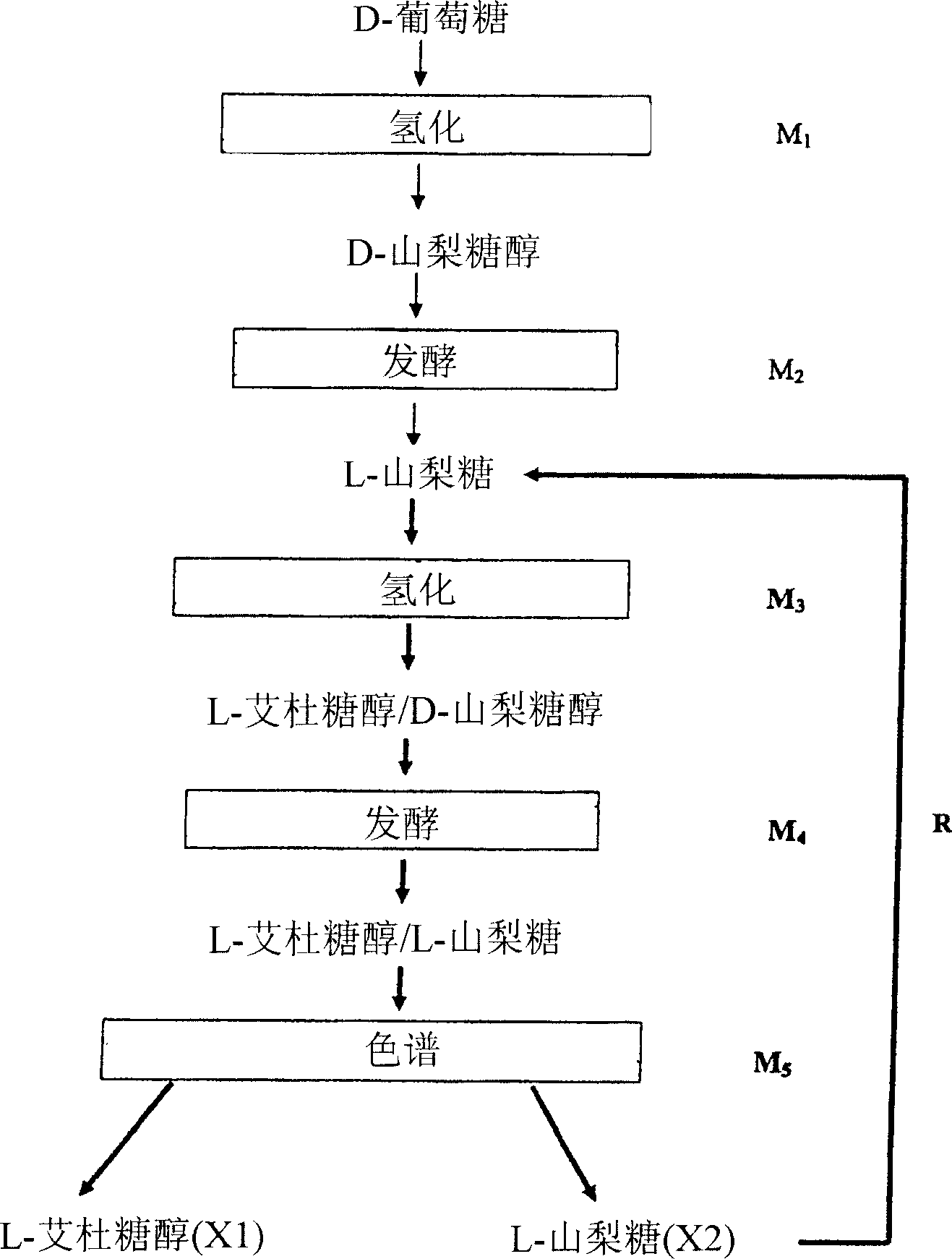

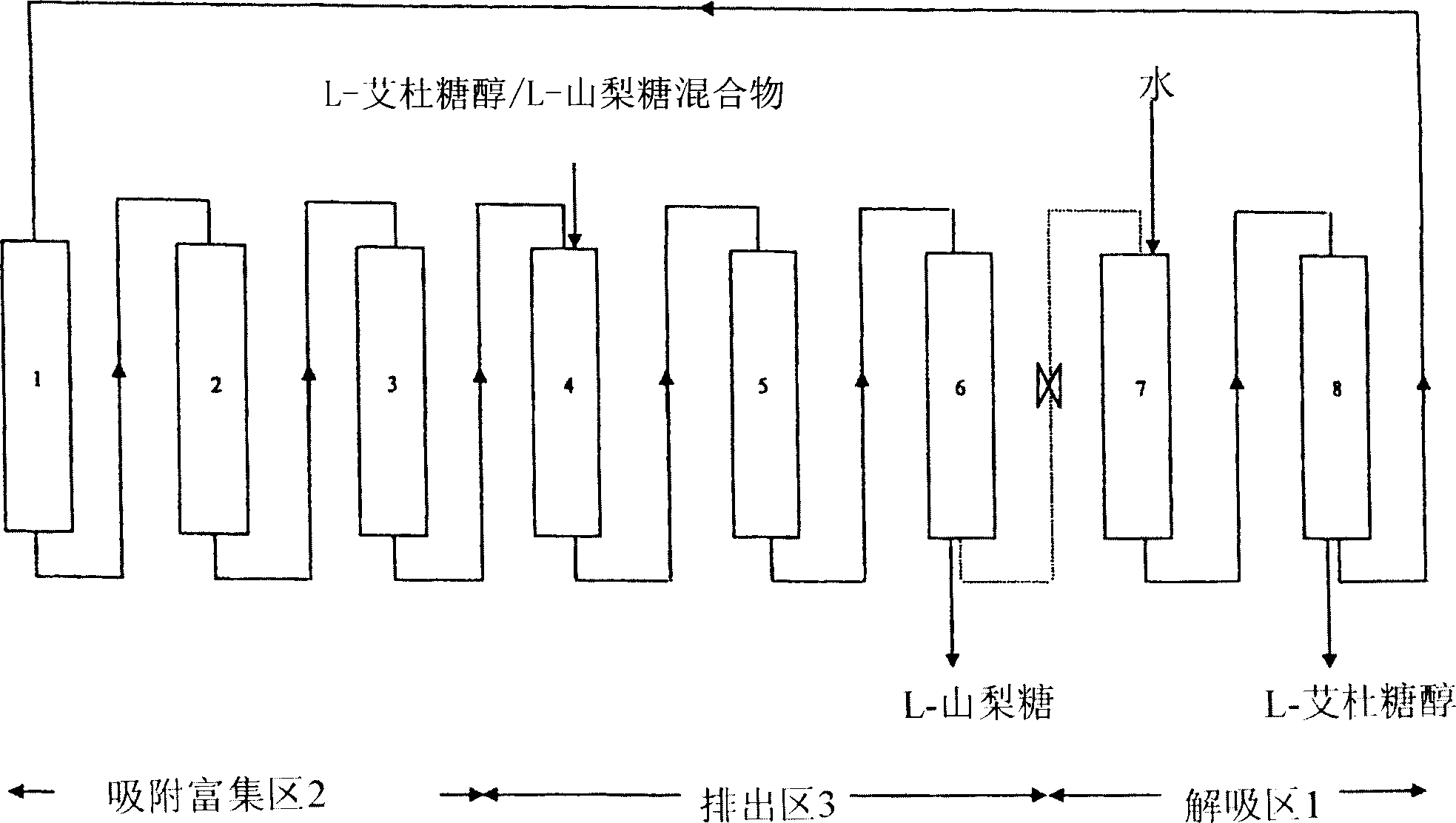

Method for preparing L-iditol

InactiveCN1762939APromote enrichmentEnrichment overPurification by oxidation/reductionOrganic compound preparationIditolAlcohol

A method for preparing high-purity L-iditol, which includes subjecting a mixture of L-iditol and L-sorbose to chromatography, thereby obtaining at least two fractions, one of which is highly enriched L-iditol. Iditol, and another of them is a fraction highly enriched in L-sorbose.

Owner:ROQUETTE FRERES SA

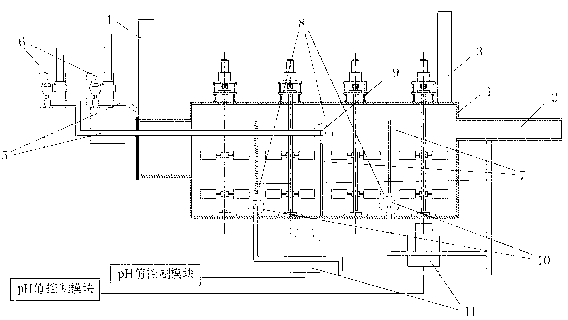

Progressive stoving neutralization reaction device and method

InactiveCN103266184AIncrease flow itineraryImprove uniformityPurification by oxidation/reductionPurification using alkaline earth metal compoundsReaction layerPh control

The invention aims to provide a progressive stoving neutralization reaction device, comprising a box body, an exhaust port, a tube diffuser, a stove tail tube, a lime milk adding tube, an ash adding actuator, more than one separator and a pH control device, wherein the box body is internally divided into more than two reaction layers by the separator in the horizontal direction; and the pH control device is used for detecting the pH of mixed sugarcane juice in the box body and controlling the dosage of the lime milk according to pH information, thus keeping the pH value of the mixed sugarcane juice stable. The invention also provides a stoving neutralization reaction method, wherein pH detection and control are performed on the sugarcane juice in reaction through the pH control device, so that the pH of the sugarcane juice after reaction is kept in a predetermined range. The progressive stoving neutralization reaction device and method provided by the invention have the characteristics that the pH of the sugarcane juice is regulated and controlled in sections and the reaction efficiency of the neutralization reaction is enhanced through a stirring device, so that the pH of the sugar juice is stabilized, the cleaning efficiency is improved and the reaction time is prolonged; and therefore, the device and the method play an important role in improving the product quality and the sugar yield of a sugar refinery.

Owner:南宁苏格尔科技有限公司

Stoving neutral reaction system

InactiveCN104450979AReduce dosageReduce pollutionPurification by oxidation/reductionPurification using alkaline earth metal compoundsSulfurEngineering

The invention discloses a stoving neutral reaction system which comprises a stoving neutralizer, a reaction barrel and a degassing barrel, wherein the reaction barrel is connected with the stoving neutralizer by virtue of a lime milk pipe, the degassing barrel is connected with the reaction barrel by virtue of a pipeline, the stoving neutralizer is provided with a first cane juice injection pipe and a SO2 injection pipe, and a first juice discharge pipe is arranged on the lower part of the degassing barrel. The system further comprises an absorption tower which is connected with the degassing barrel by virtue of a tail gas pipe, the absorption tower is further provided with a second cane juice injection pipe, a second juice discharge pipe is arranged on the lower part of the absorption tower, residual SO2 in the degassing barrel enters into the absorption tower by virtue of a tail gas pipe, and juice injected into the absorption tower is stoved, so that the tail gas is recycled. Equivalently, the system disclosed by the invention utilizes unspent SO2, so that the use level of sulfur is reduced and the cost and expenditure are saved, and moreover, the surrounding environmental pollution of SO2 gas can be reduced.

Owner:山西潞宝兴海新材料有限公司

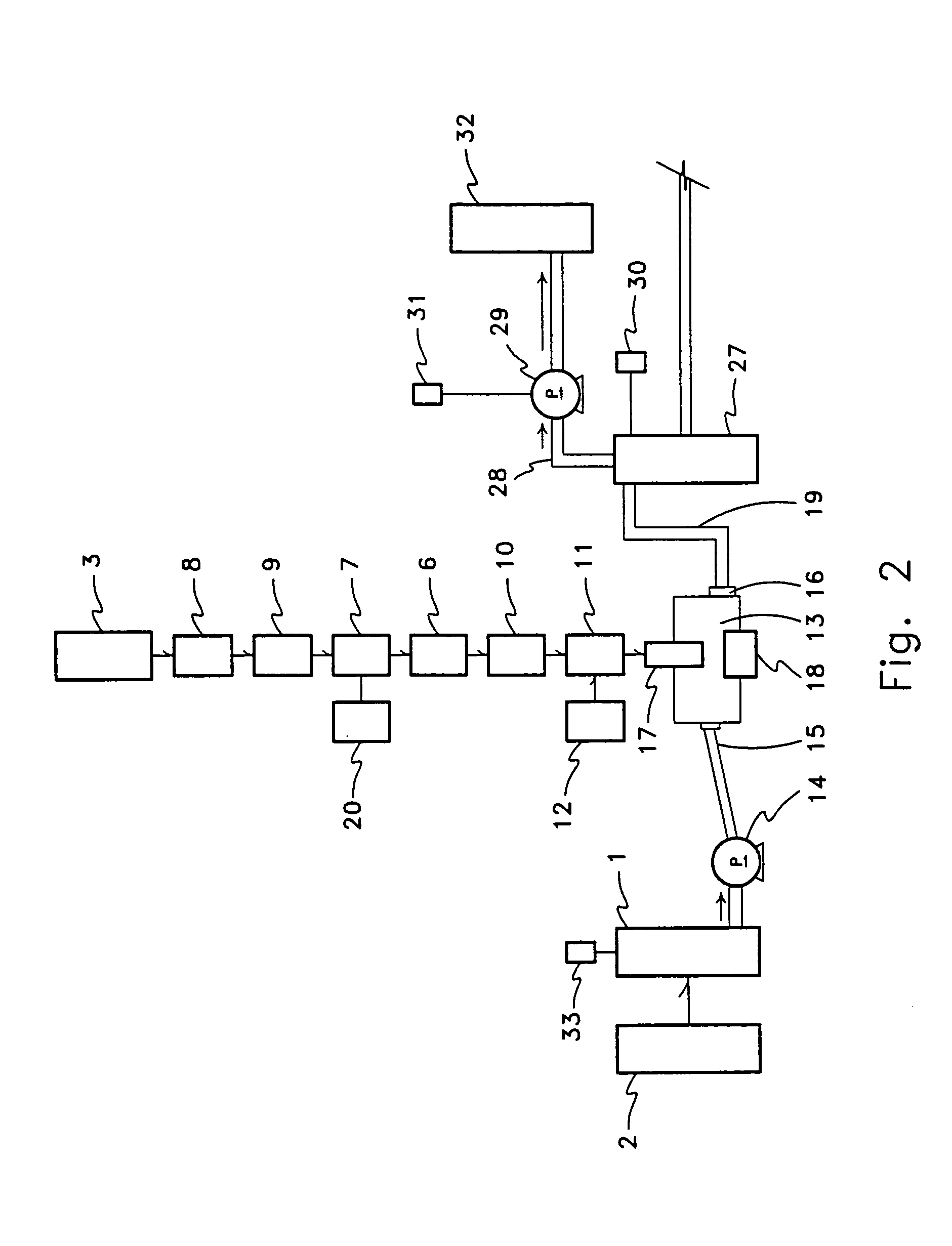

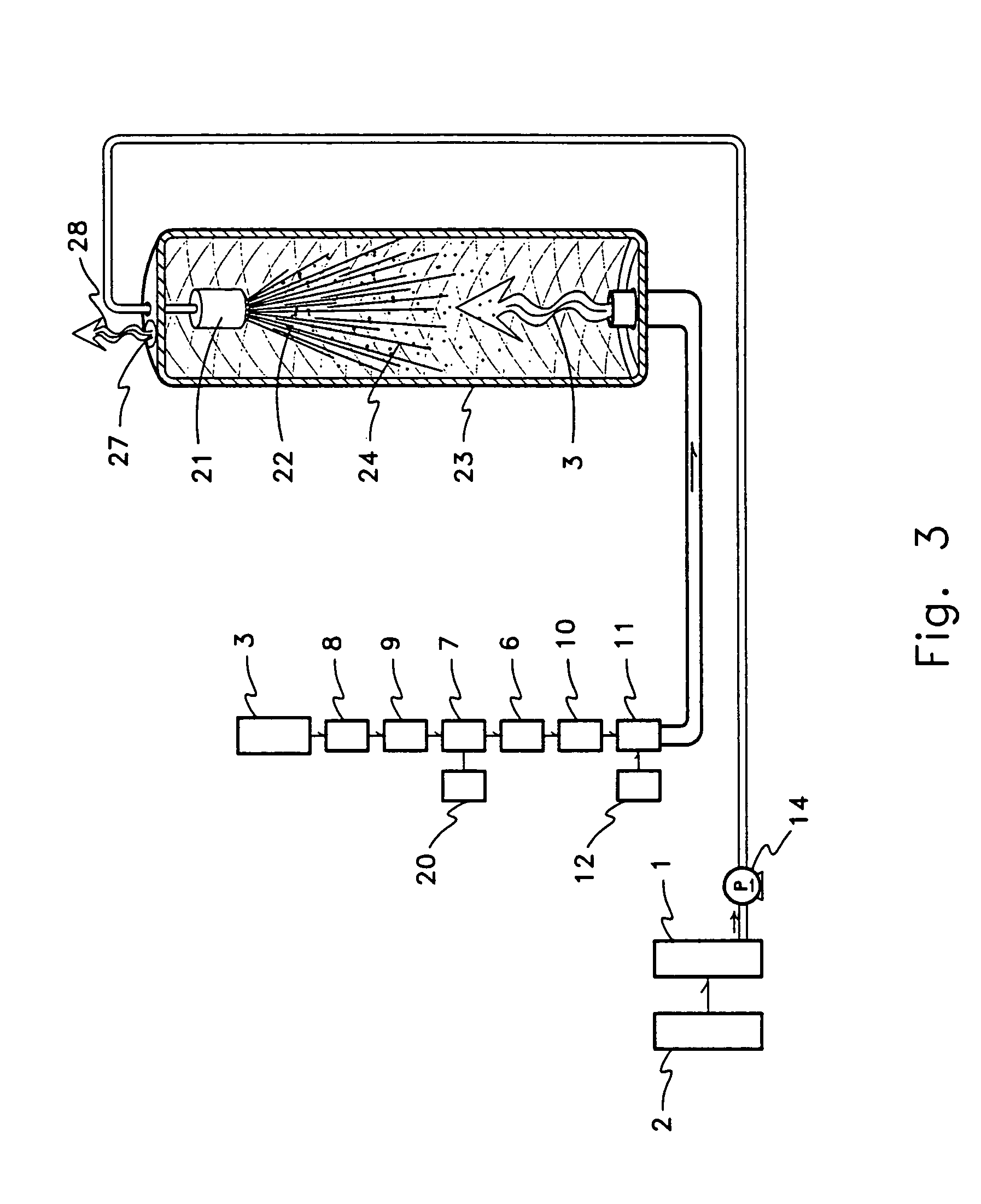

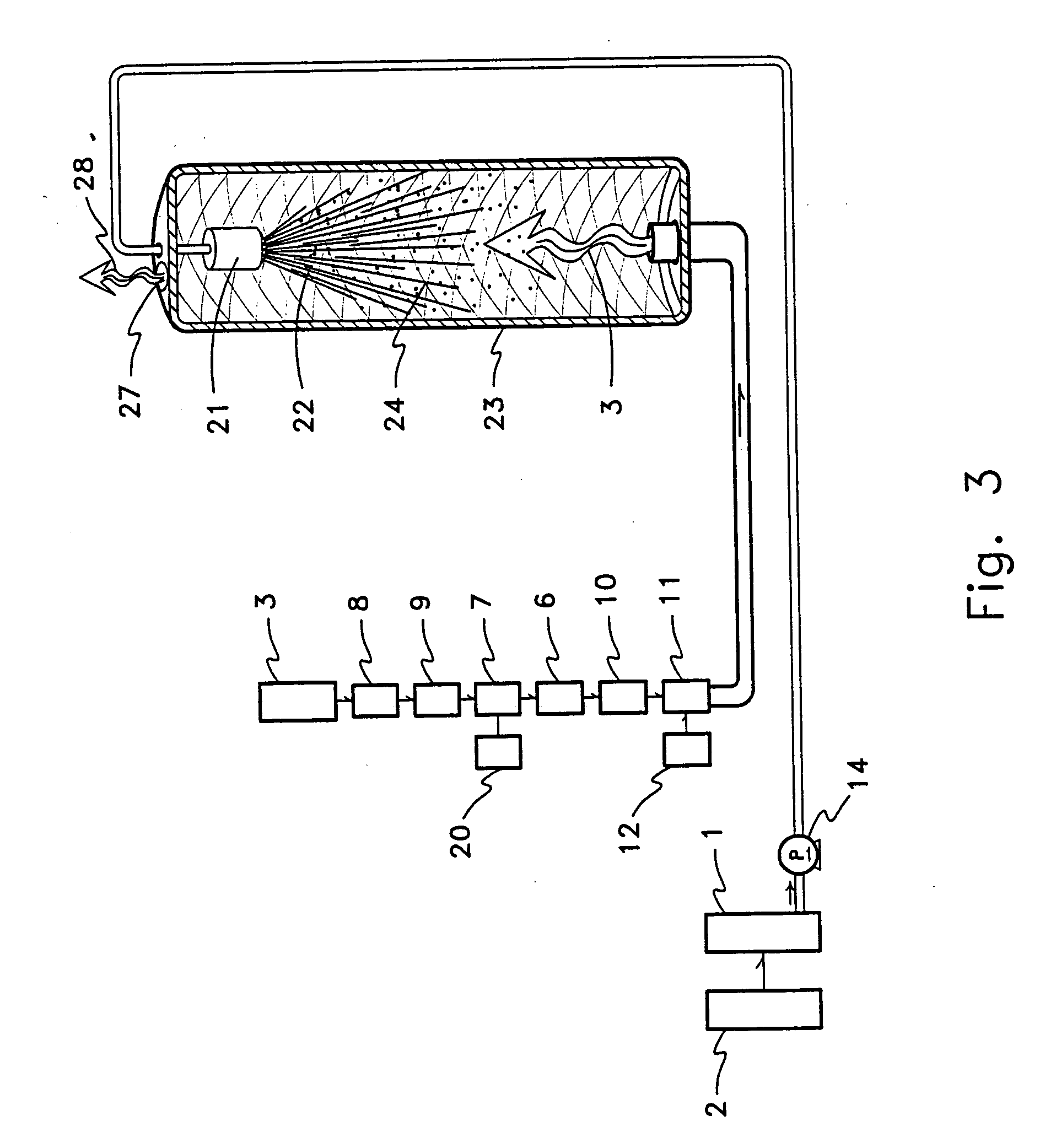

System to produce sugar from plant materials

InactiveUS7182818B2Low costReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsBiotechnologyFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice or other process liquid (1) obtained from plant material (2) such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice or other process liquid (1) to increase pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification in subsequent steps, such as preliming (33).

Owner:ECOLAB USA INC

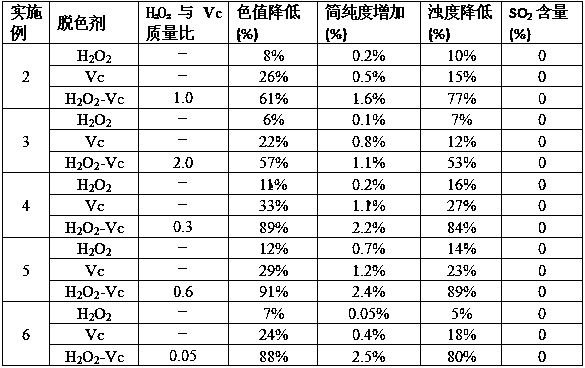

Sugar juice compound decolorizing agent and sugar juice decolorization method

ActiveCN108251564AReduce color valueQuality improvementPurification by oxidation/reductionVitamin CSulfur

The invention relates to a sugar juice compound decolorizing agent and a sugar juice decolorization method. The sugar juice compound decolorizing agent is an H2O2-Vc compound reagent composed of H2O2and vitamin C in a mass ratio of 0.01-10. The sugar juice decolorization method includes: using the H2O2-Vc compound reagent for decolorization treatment on sugar juice, which is mixed juice, clear juice, syrup or / and massecuite, wherein the adding amount of the H2O2-Vc compound reagent and the corresponding sugar juice are in a mass ratio of 10*10<-6>-2*10<-3> in the decolorization process. The method provided by the invention can greatly reduce the color value of sugar juice and sulfur dioxide residual, can effectively lower the content of colored matters and sulfur residue in the final white granulated sugar finished product, at the same time can enhance the purity of white granulated sugar, thus improving the quality of the white granulated sugar finished product; and on the other hand, the process is simple, has no need for change of the original technological process, also in low in investment and utilization cost, and can significantly improve the economic benefits of sugar factories.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

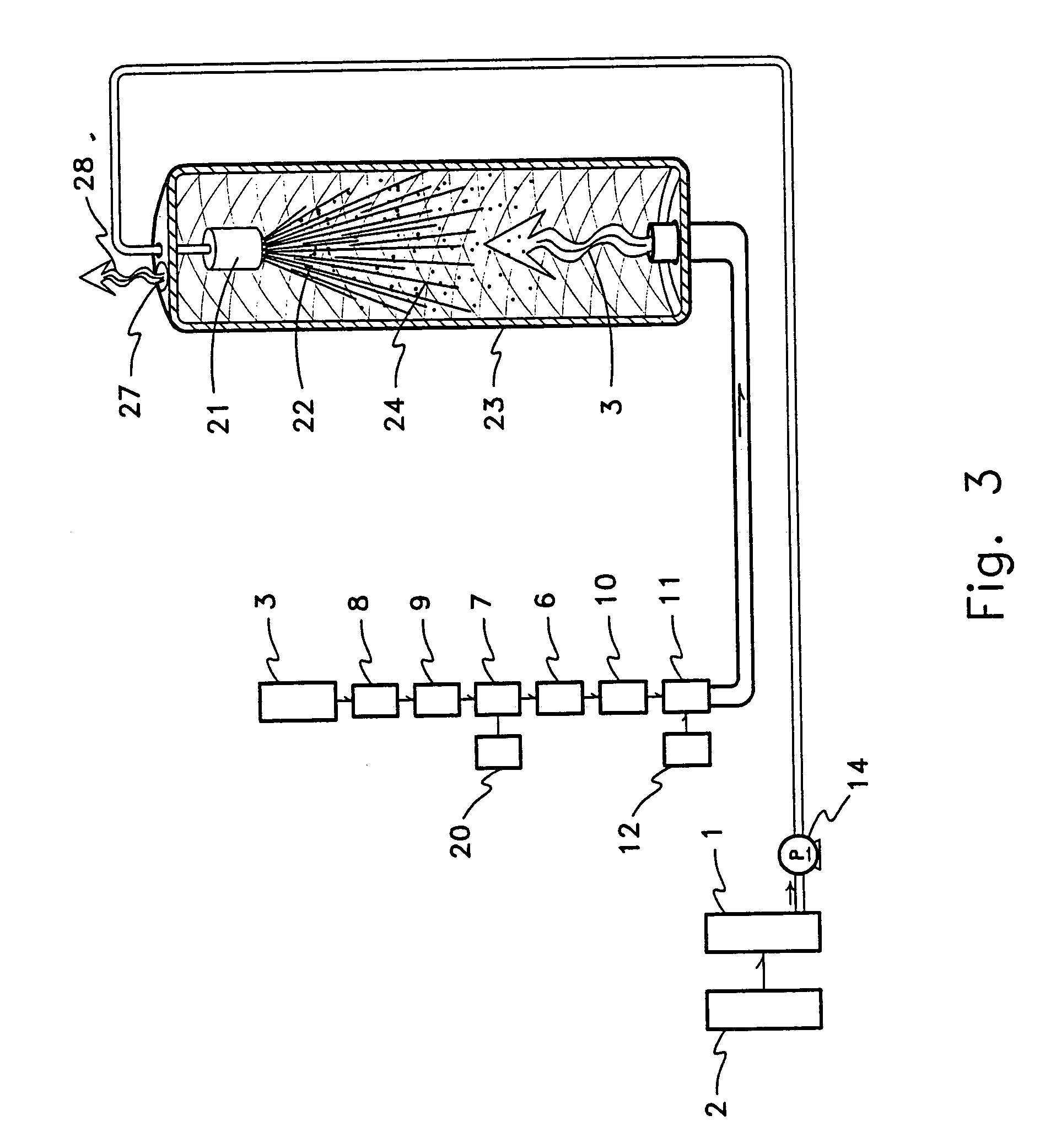

Sugar production system

ActiveCN1791684AReduce concentrationDecrease in amount or concentrationPurification by oxidation/reductionPurification using chemicalsVacuum chamberChemistry

The present invention provides a sugar processing system for conditioning a sugar processing liquid obtained from plant material, the sugar processing system comprising an aeration chamber (37) and / or a vacuum chamber (42).

Owner:NALCO CO

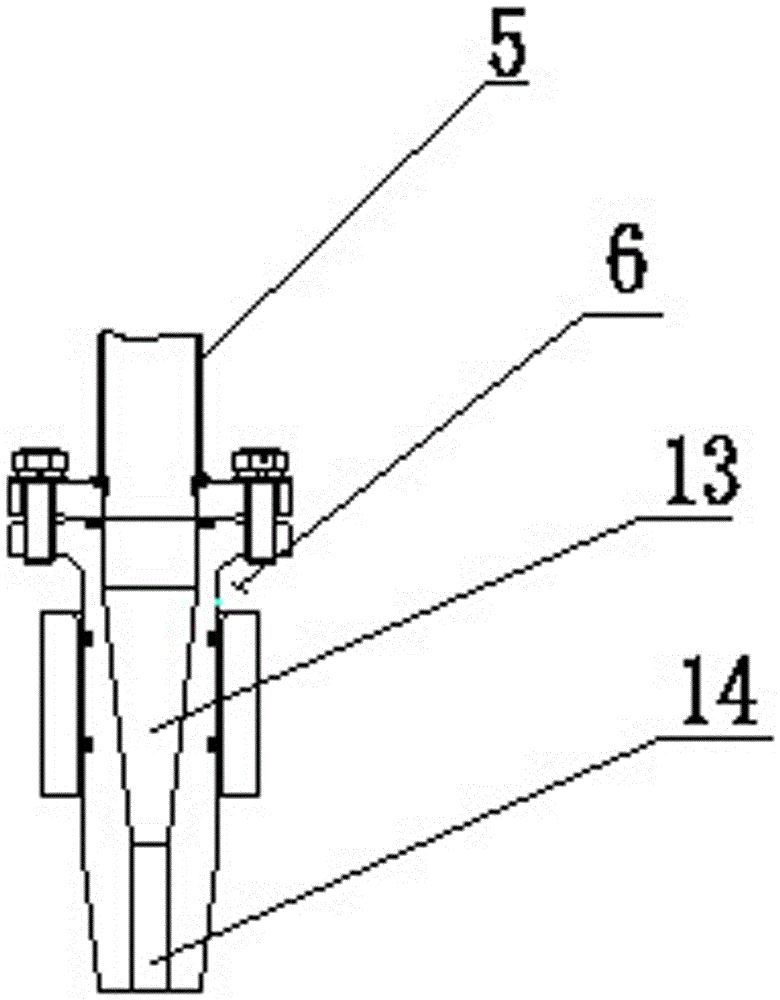

Sulphitation and neutralization reaction tower

InactiveCN103866051AImprove cleaning efficiencyImprove adsorption efficiencyPurification by oxidation/reductionPurification using alkaline earth metal compoundsHigh concentrationReaction layer

The invention aims to provide a sulphitation and neutralization reaction tower. The sulphitation and neutralization reaction tower comprises a sulphitation tail pipe, a tank body, air dispersing pipes and a lime milk adding pipe, wherein more than one transverse partition plate is arranged in the vertical tank body, and the tank body is divided into more than two reaction layers by the partition plates. A vertical multilayer design structure is adopted, so that a sulphitation and neutralization reaction can be more balanced and controllable, and adverse effects brought by excessively high concentration of local lime milk are avoided at the greatest extent; and meanwhile, with cooperation of pH sampling and full mixing of each layer, the controllability of the pH value of each reaction layer is further strengthened. The tower is scientific and reasonable in structure collocation, and has extremely high practical value; and compared with the prior art, the tower is brand-new in design idea, and has distinguishing substantive characteristics and significant progresses.

Owner:南宁苏格尔科技有限公司

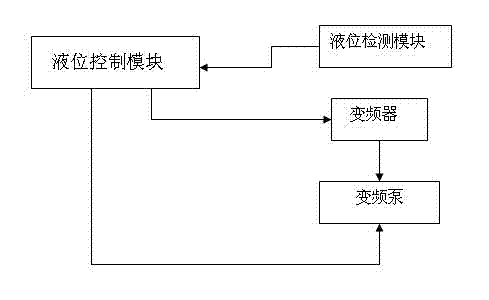

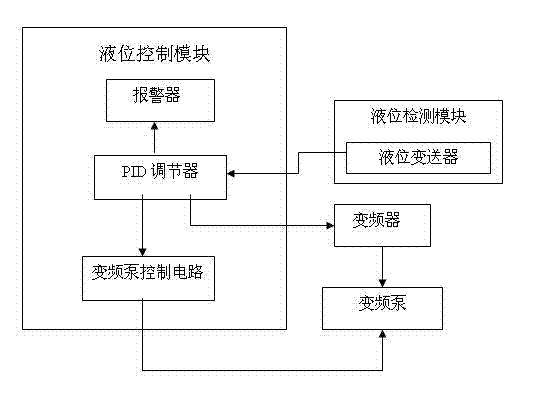

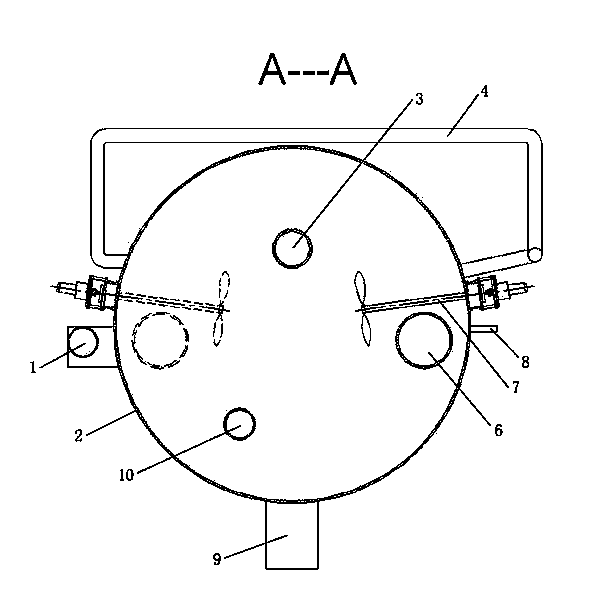

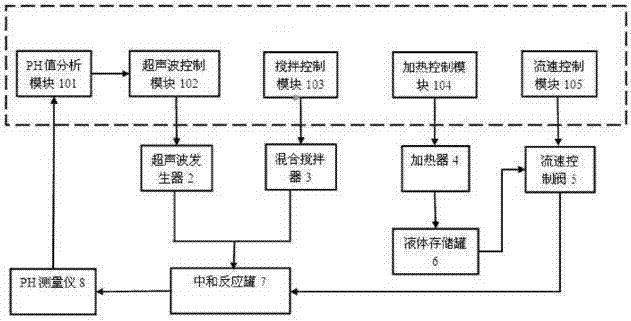

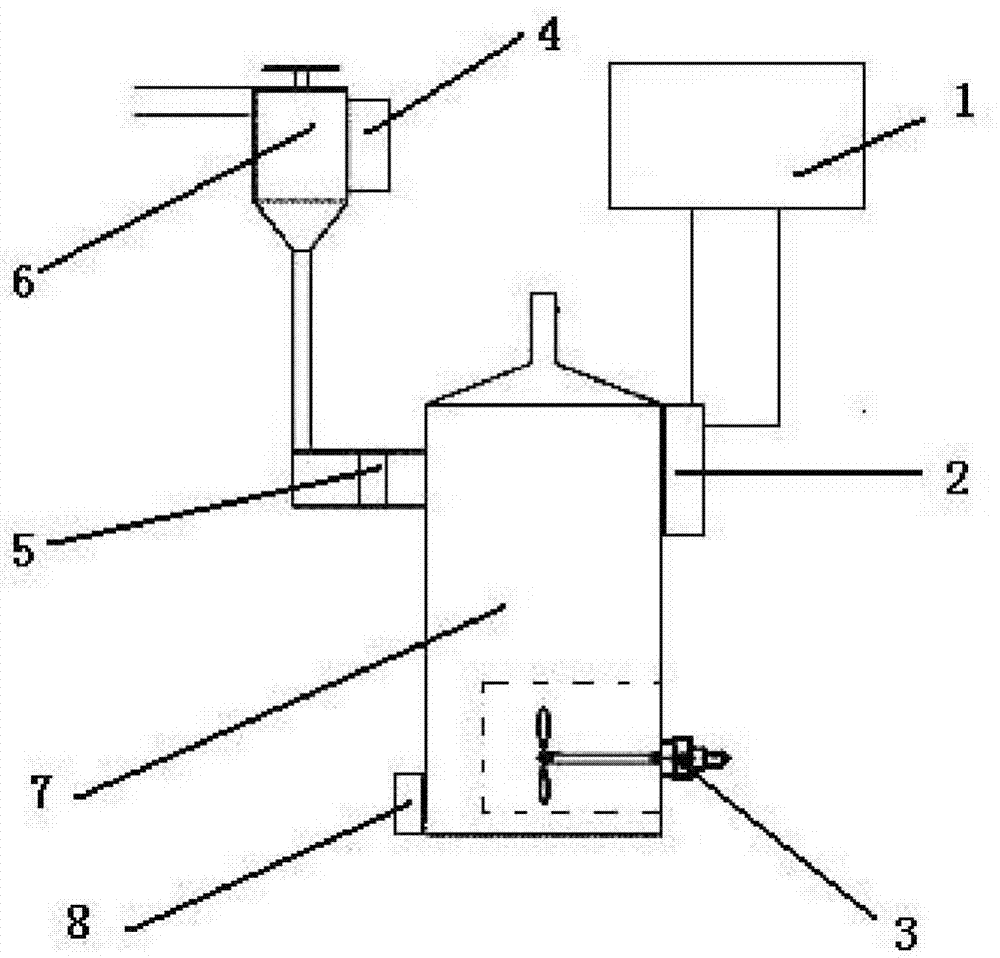

Cane juice stoving neutralization reaction control system

InactiveCN103699148APH controlAccurate pH ControlPurification by oxidation/reductionControlling ratio of multiple fluid flowsControl systemSulfur

The invention discloses a cane juice stoving neutralization reaction control system which comprises a control main board (1) for controlling the neutralization reaction, wherein the control main board comprises a pH value analyzing module (101), an ultrasonic control module (102), a stirring control module (103), a heating control module (104) and a velocity control module (105). According to the cane juice stoving neutralization reaction control system disclosed by the invention, the mode of feedback regulation is sufficiently utilized to regulate the neutralization reaction process in real time, and the cane sugar velocity, the cane sugar solution pH value and the temperature of primary heating and secondary heating of a stoving neutralization reaction device are accurately and controlled, and the mixing degree of lime milk and SO2 is greatly improved.

Owner:GUANGXI LIUZHOU JUNYE TECH

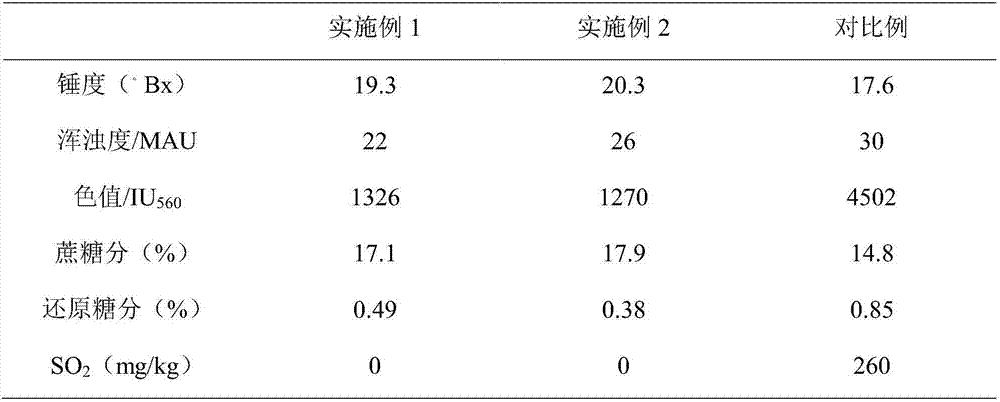

Process for preparing sugar from sugarcane

InactiveCN107267673APromote hydrolysis reactionFacilitate segmental softeningPurification by oxidation/reductionPurification using alkaline earth metal compoundsUltrafiltrationHydrolysate

The invention discloses a process for preparing sugar from sugarcane. The process comprises the following steps: step 1, subjecting sugarcane to cleaning, chopping, squeezing and filtering successively so as to obtain bagasse and sugarcane juice; step 2, carrying out steam explosion on the bagasse and collecting bagasse having undergone steam explosion; step 3, sprinkling a compound enzyme solution onto the surface of the bagasse having undergone steam explosion so as to obtain enzymatic hydrolysate; step 4, heating the enzymatic hydrolysate, carrying out preliming, introducing nitrogen and carrying out settling separation so as to obtain first clear liquid; step 5, heating the first clear liquid, carrying out preliming, introducing ozone and carrying out settling separation so as to obtain second clear liquid; and step 6, heating the second clear liquid to a boiling state, removing impurities through filtering, carrying out cooling to room temperature and then successively carrying out ultrafiltration, evaporative concentration, crystallization and purging. Sugar prepared in the invention does not contain SO2, so the chromatic value and turbidity value of the prepared sugar are effectively reduced, and the purity and concentration of the prepared sugar are improved.

Owner:陆丽英

Method utilizing enzyme to catalyze H2O2 to discolor sugar juice

InactiveCN101768644BGood decolorization effectImprove product qualityPurification by oxidation/reductionPeroxidaseSugar cane

The invention discloses a method utilizing enzyme to catalyze H2O2 to discolor sugar juice. The method includes the following steps: in the clearing technique of the sugarcane or beet sugar manufacturing process, peroxidase and the H2O2 are adopted to discolor the sugar juice; the peroxidase and the H2O2 are diluted by softened water, the diluted concentration of the peroxidase is within 0.01 to 0.1%, and the diluted concentration of the H2O2 is within 0.01 to 0.05%; the peroxidase and the H2O2 are mixed together according to the proportion of 1:8 to 8:1 so as to obtain peroxidase mixed solution; finally, the peroxidase mixed solution is added to the sugar juice to discolor the sugar juice. The method in the invention can effectively remove polyphenols in the sugar juice, lower the color value, improve the product quality of white granulated sugar, reduce the residual sulfur content, and advance the product grade.

Owner:GUANGXI UNIV

Method of reducing materials contained in juice

InactiveUS7150793B2Low costReduce the amount requiredSolid sorbent liquid separationSucrose extraction by chemical meansProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

Method of reducing materials contained in juice

InactiveUS20040105924A1Low costReduce the amount requiredSolid sorbent liquid separationCocoaProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

Sulfur fumigation neutralizer and method for sulfur fumigation neutralization reaction by the same

InactiveCN106011318AFocusImprove suction efficiencyPurification by oxidation/reductionPurification using alkaline earth metal compoundsHoneycombSugar factory

The invention discloses a sulfur fumigation neutralizer, which includes a juice chamber and a suction chamber. Several cane juice honeycomb ducts are arranged at an interval between the juice chamber and the suction chamber, the upper ends of the cane juice honeycomb ducts are connected to the juice chamber, the lower ends of the cane juice honeycomb ducts are connected to the suction chamber through nozzles, and the cane juice honeycomb ducts are also equipped with valves. The process using the sulfur fumigation neutralizer to carry out sulfur fumigation reaction consists of: (1) letting cane juice enter the juice chamber, and then distributing the cane juice into each cane juice honeycomb duct; and (2) jetting the cane juice to the suction chamber through the nozzles to form a stable negative pressure, then sucking sulfur dioxide gas, and mixing the cane juice and sulfur dioxide gas in the suction chamber to form a gas-liquid mixed flow. The sulfur fumigation neutralizer and the process provided by the invention can effectively improve the sulfur sucking efficiency, stabilize sulfur fumigation intensity, improve the cleaning efficiency of cane juice, reduce sulfur consumption, lower sulfur dioxide residue of sugar factory cane juice, reduce soluble calcium salt in the cane juice, lower the production cost and ensure the sulfur content of white granulated sugar, thus guaranteeing the quality of finished sugar product.

Owner:GUANGXI JIRAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com