New additive for producing sugar from sugarcane, preparation method thereof and application method thereof in sugar production

An application method and technology of new additives, which can be applied in the production of sucrose, production and application of sugar, etc., can solve the problems such as the residue of white granulated sugar sulfur dioxide and its derivatives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The first new additive for sugar cane sugar production comprises the following raw materials in parts by weight: 100 parts of concentrated phosphoric acid and 0.5-50 parts of chitosan.

[0032] The new auxiliary agent for sugar cane sugar production is a basic auxiliary agent. The reaction product obtained from the above-mentioned raw materials is a high-fiber polyphosphate macromolecular compound with strong positive charge, which can perform the function of clarifying and decolorizing the sugarcane juice.

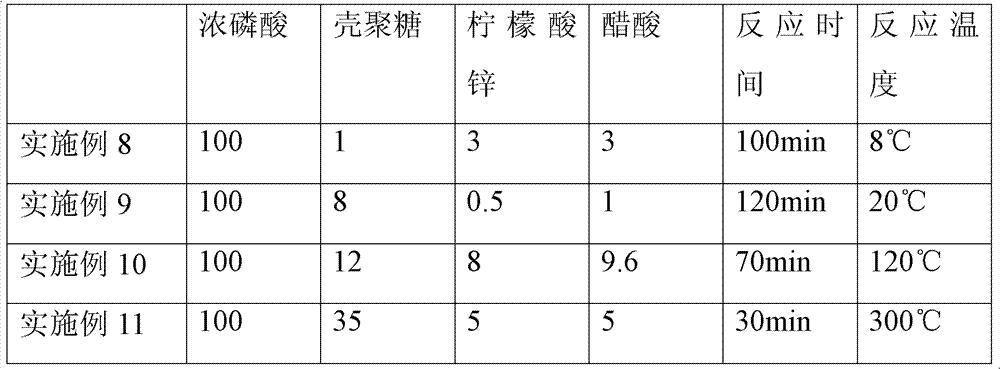

[0033] Table 1

[0034]

concentrated phosphoric acid

Reaction time

temperature reflex

Example 1

100

0.5

120min

8℃

Example 2

100

30

30min

300℃

Example 3

100

50

60min

120℃

[0035] The preparation method of the first new auxiliary agent for sugar cane sugar production is as follows: Weigh 100 parts by weight of concentrated phosphoric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com