Reinforced type all-dielectric and rodent-resistant cable and manufacturing process thereof

A reinforced, all-dielectric technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of poor anti-rodent effect of anti-rodent optical cable, puncture the mouth of rodents, and failure to achieve anti-rat effect, so as to achieve multiple laying methods and satisfy EVERYDAY USE, LIGHTWEIGHT RESULTS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

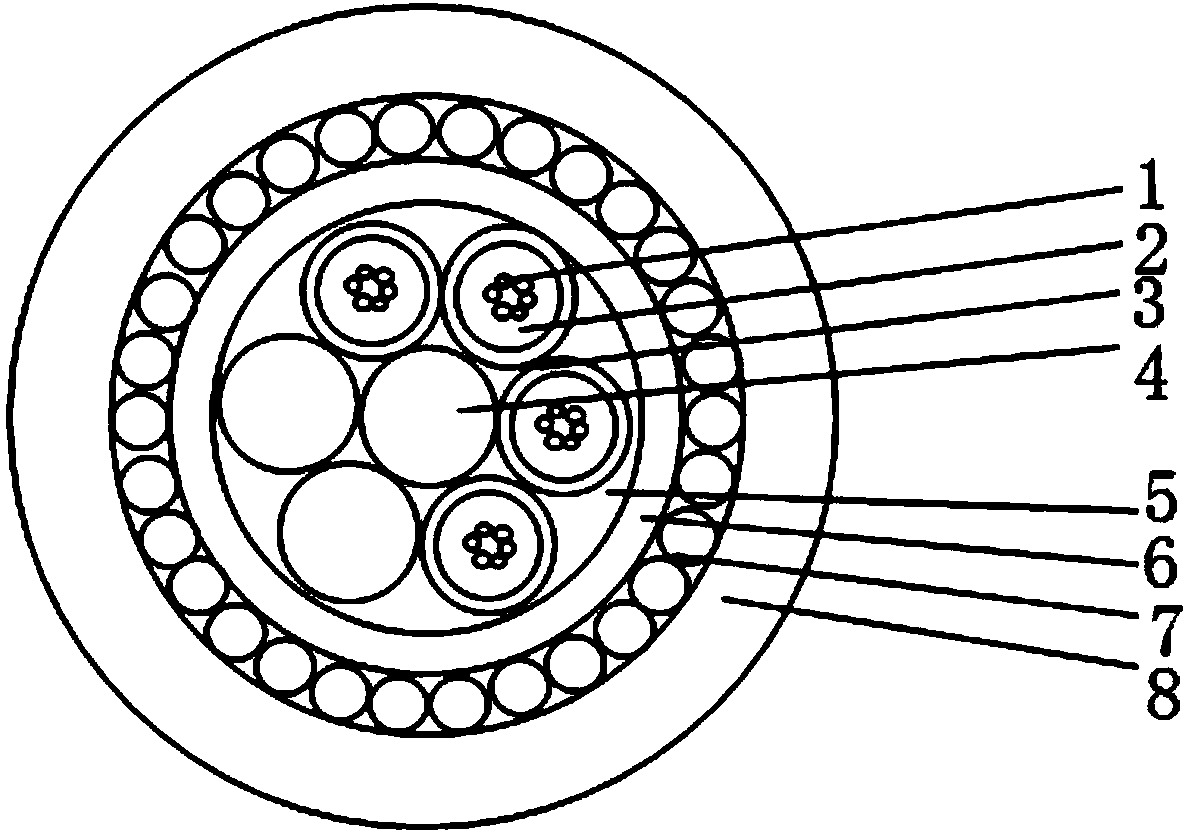

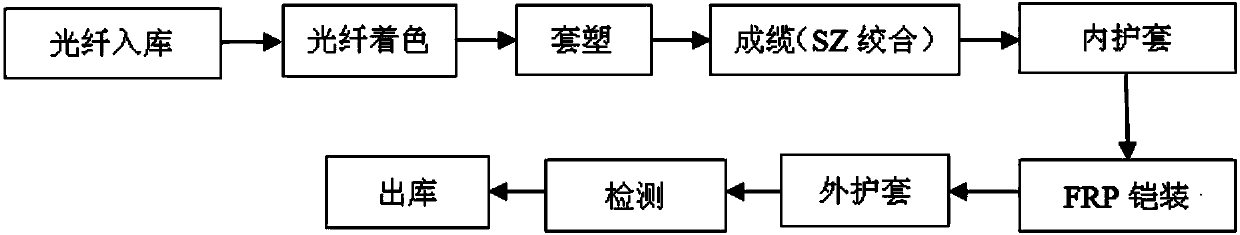

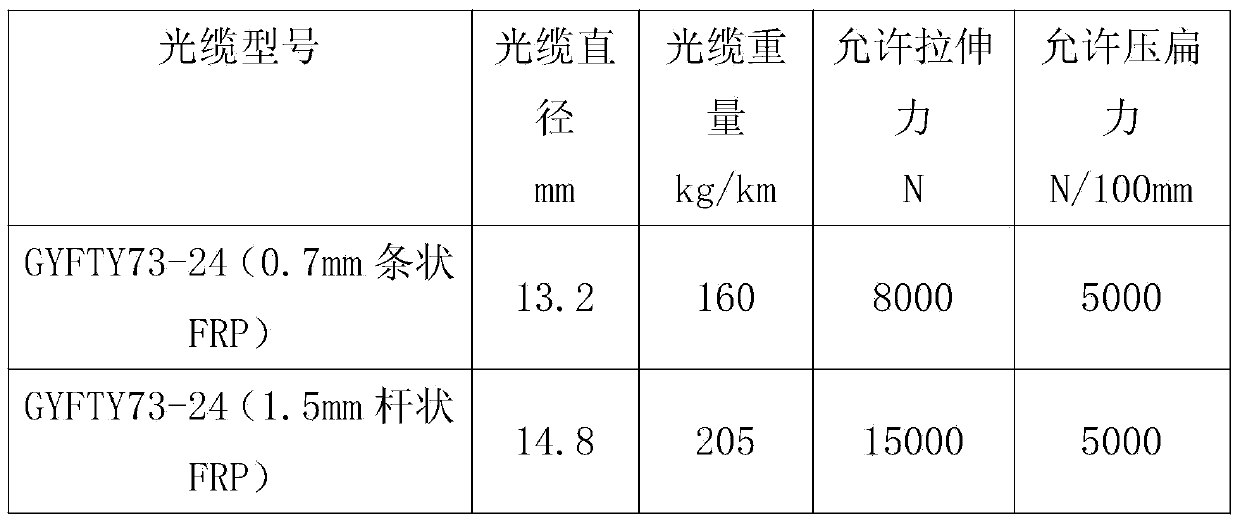

[0024] refer to Figure 1-Figure 2 , the specific embodiment adopts the following technical solutions: reinforced all-dielectric rodent-proof optical cable, including optical fiber 1, fiber paste 2, loose tube 3, central reinforcement 4, cable core water-blocking compound 5, inner sheath 6, rod-shaped FRP7 and the outer sheath 8, a plurality of rod-shaped FRP7 is arranged between the outer sheath 8 and the inner sheath 6, a plurality of optical fibers 1 are arranged in the inner sheath 6, a loose tube 3 is arranged outside the optical fiber 1, and the optical fiber 1 and the Fiber paste 2 is filled between the loose tubes 3 , cable core water-blocking compound 5 is filled between the loose tube 3 and the inner sheath 6 , and a central strengthenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com