Environment-friendly type full automatic cake making machine

A fully automatic and environmentally friendly technology, applied in food processing, baking, baked food, etc., can solve the problems of high labor intensity, difficult movement, large floor space, etc., to achieve clean and hygienic food, wide application range, and land occupation. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Describe the specific embodiment of the present invention in detail below in conjunction with accompanying drawing

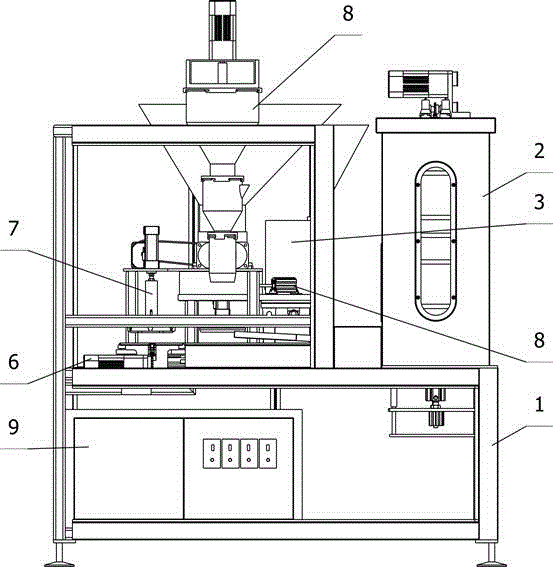

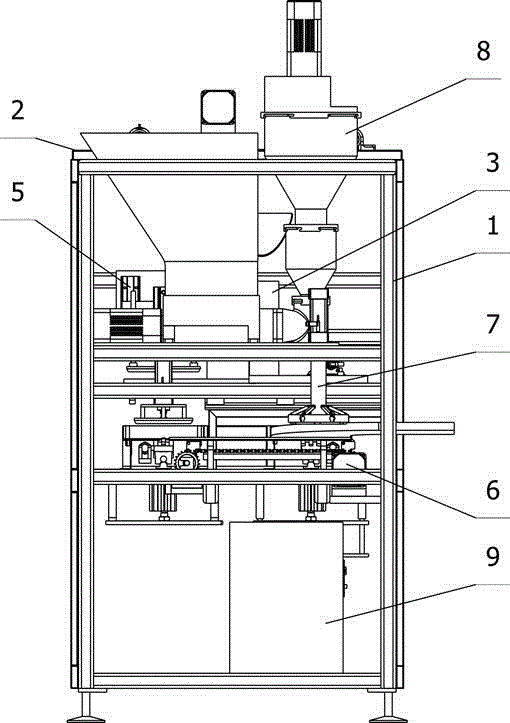

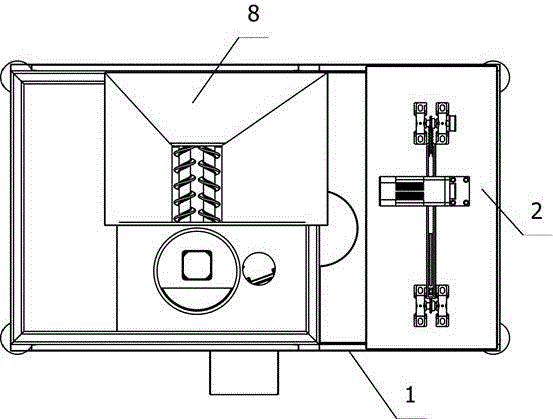

[0045] Figure 1 to Figure 3 Among them, the machine housing 1 is provided with a dough mixing mechanism 8, a product translation mechanism 6, an expansion and compression mold mechanism 7, a forming mechanism 5, a sesame supply mechanism 3, an oven 2 and an electric controller arranged in the electrical appliance placement box 9. The electric controller controls the dough mixing mechanism 8, the product translation mechanism 6, the expansion and compression mold mechanism 7, the forming mechanism 5, the sesame supply mechanism 3 and the oven 2 to work, which can realize man-machine interface operation, infrared heating, automatic temperature control, and trouble-free operation. , Insufficient material automatic alarm, production data display. It achieves full automatic control from feeding, filling, chewing, forming, sticking sesame seeds to finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com