Patents

Literature

1020results about How to "Easy to use for a long time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

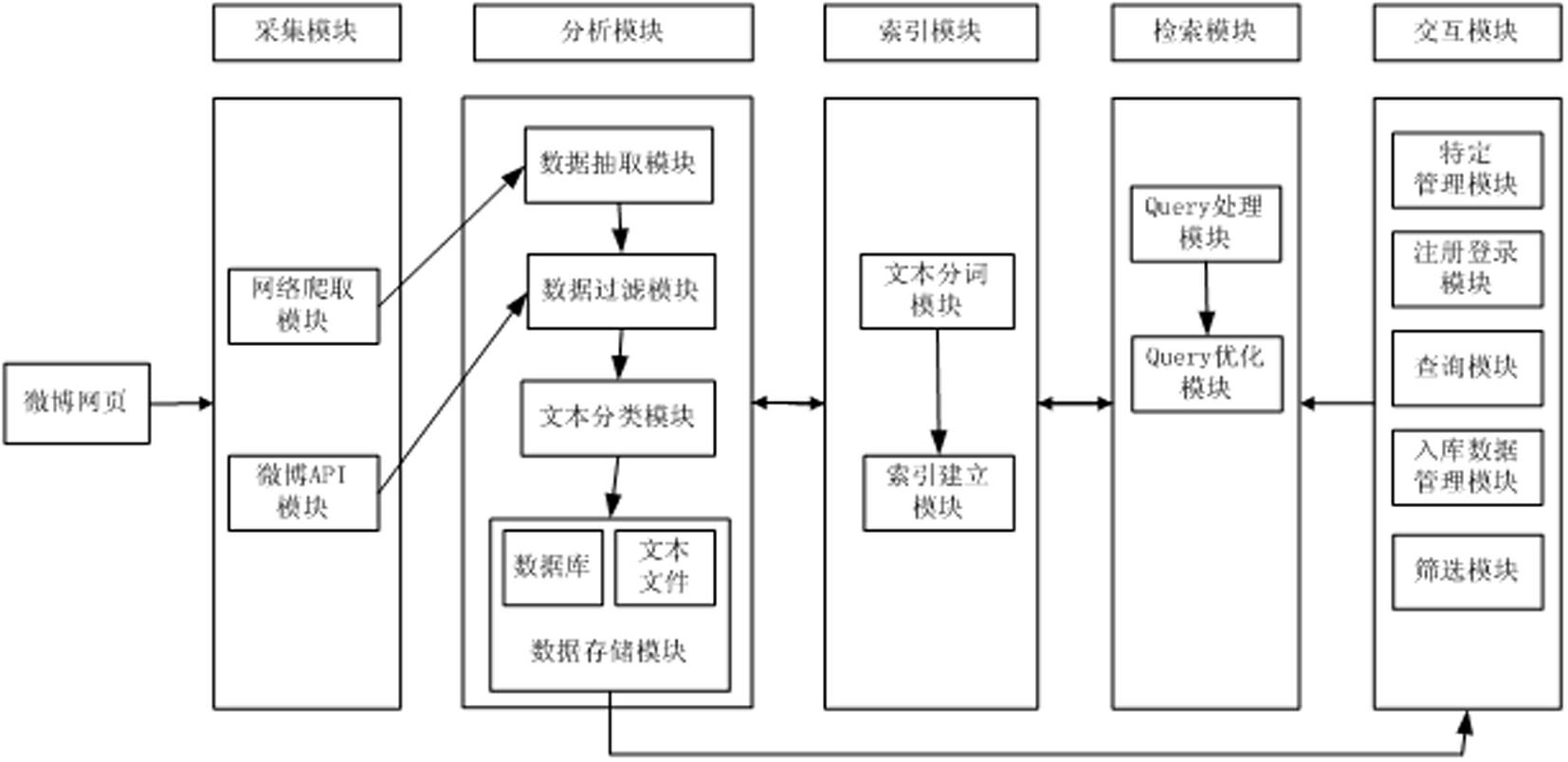

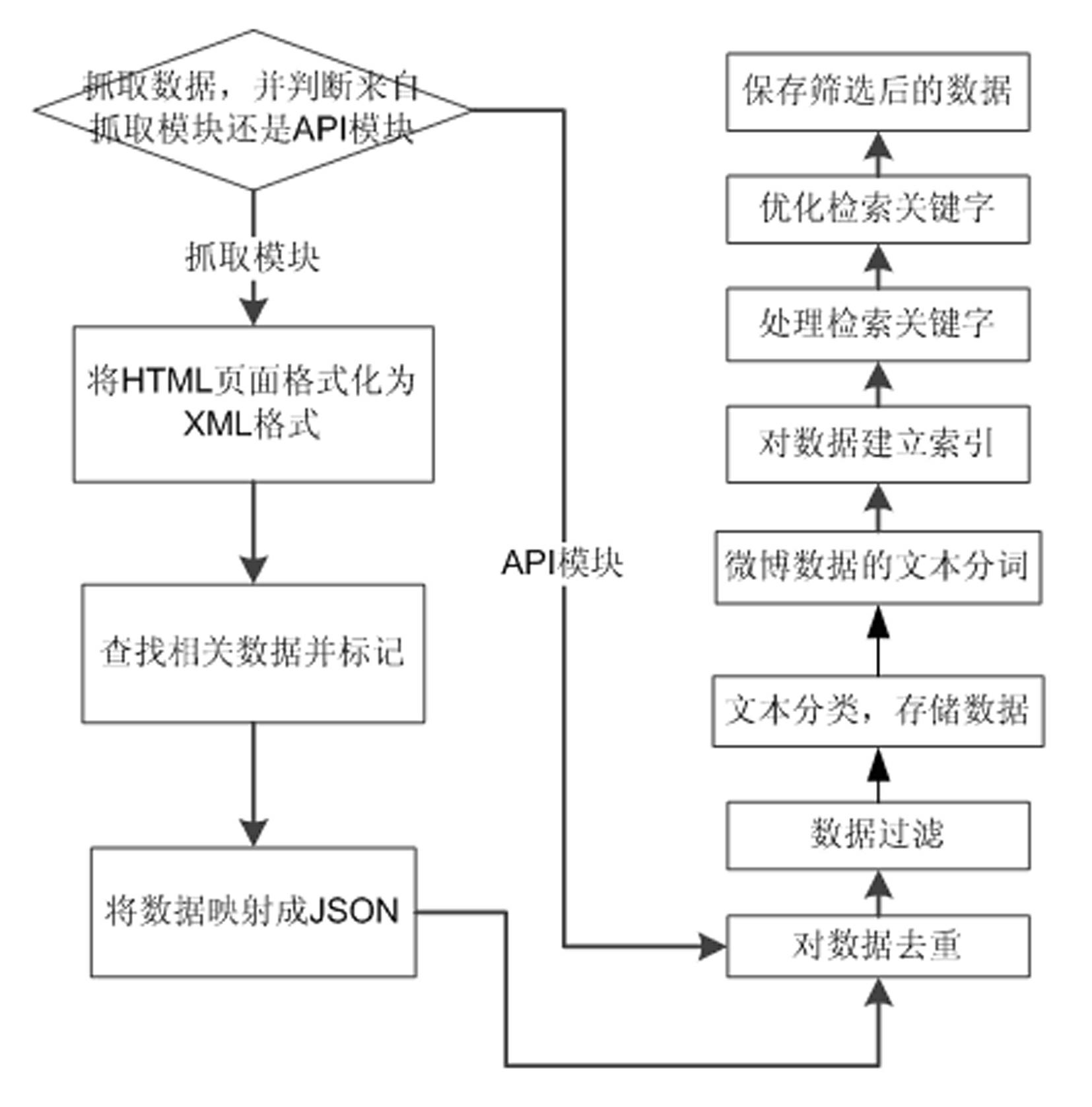

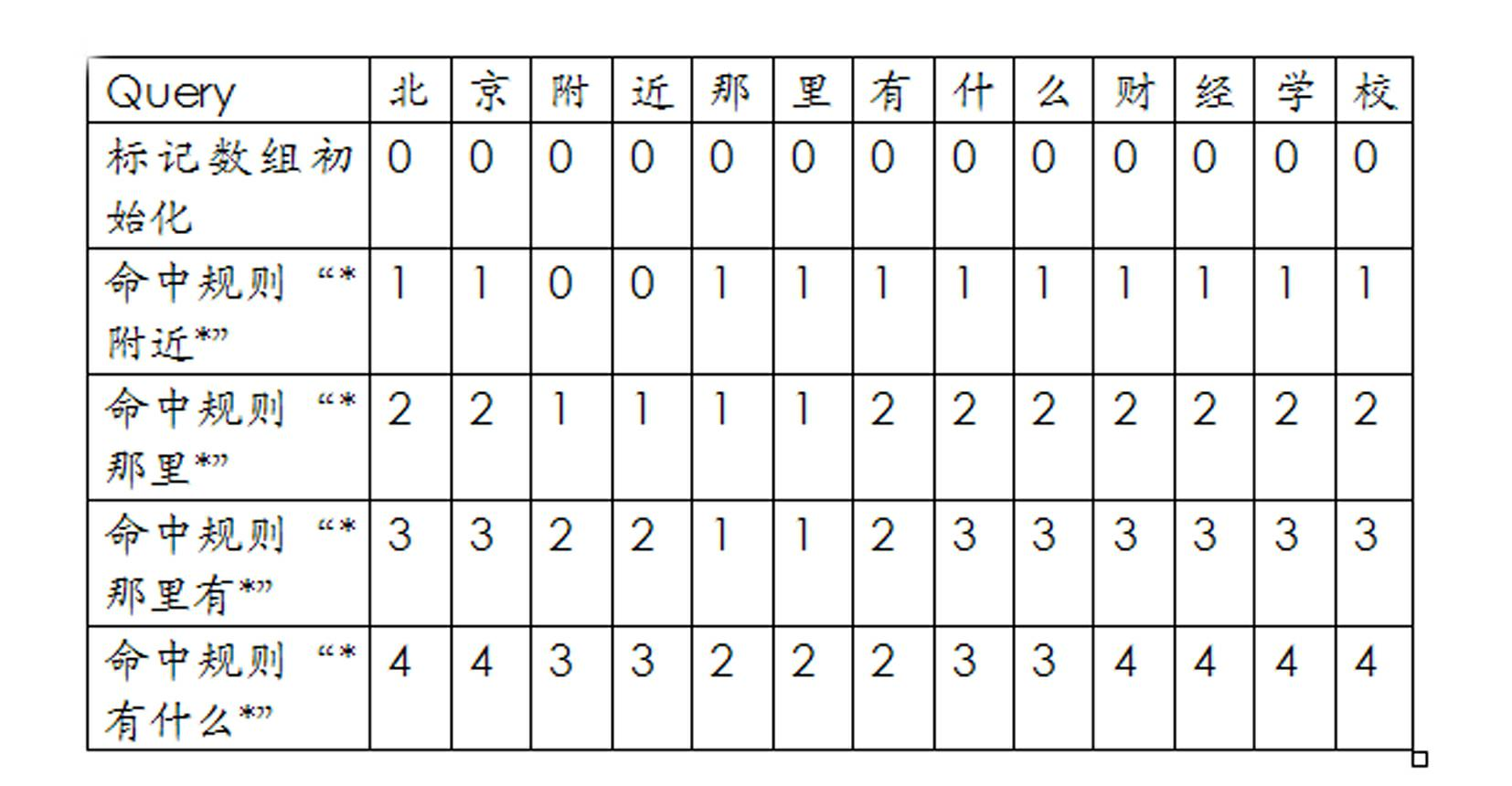

Customized screening system and method for microblog

InactiveCN102622443AEasy to use for a long timeReduce couplingSpecial data processing applicationsFunctional expansionAnalysis data

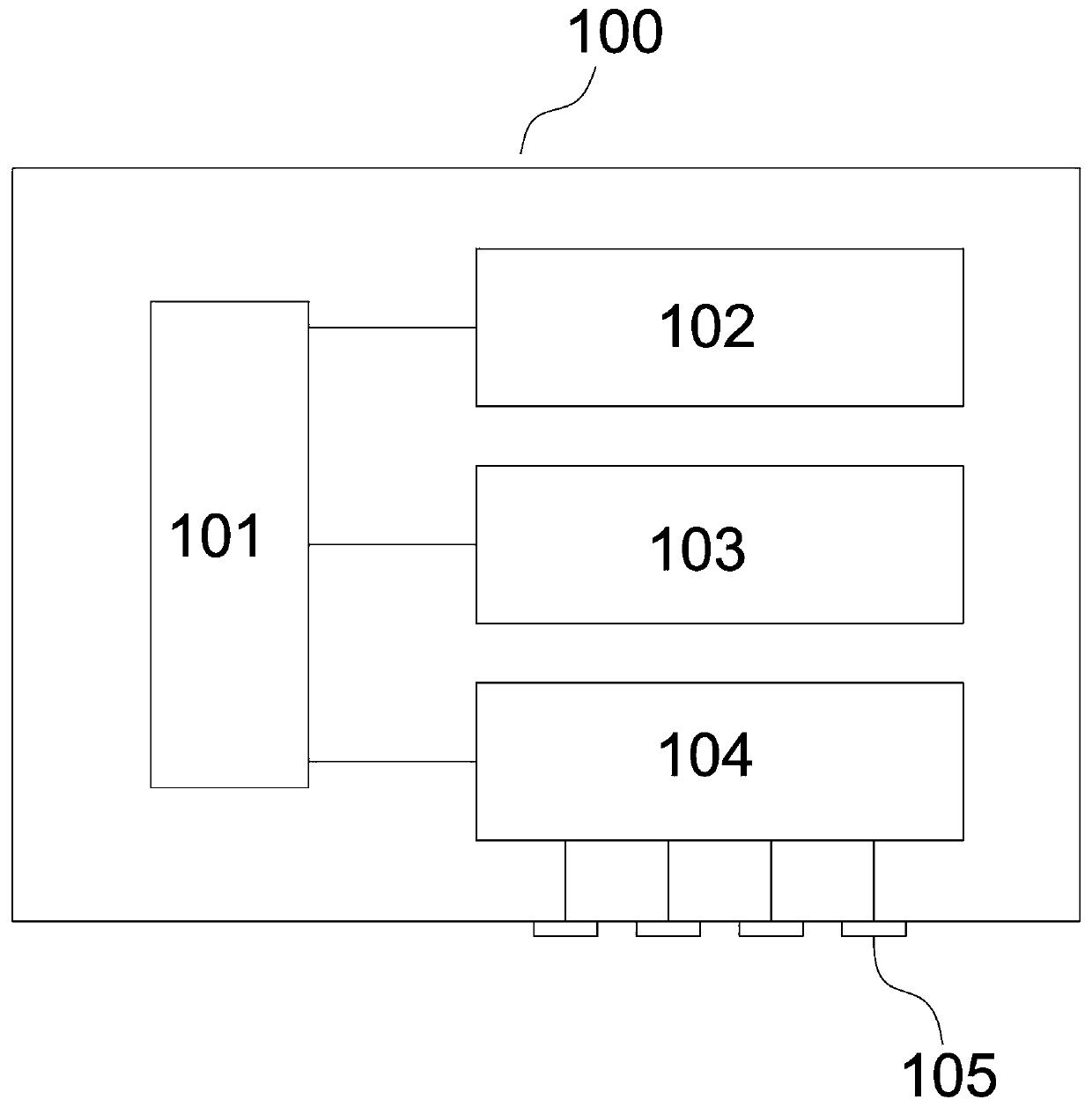

The invention relates to a customized screening system and a customized screening method for microblog. The customized screening system for the microblog comprises a background module and an interactive module, wherein the background module is used for acquiring data, analyzing the data, performing local storage, establishing an index and providing a search function; and the interactive module performs information interaction with the background module and provides a WEB interface interacted with the background module. The system is a solution for solving the problem of information overloading, namely, a type of information which a user concerns is targetedly screened out of huge microblog data, a great deal of non-concerned information is filtered for the user, and the data can be locally stored so that the user can use the data for a long time conveniently; the safety of the system is enhanced by a verification mechanism; the working logic of the whole system is clear and smooth; the coupling degree among modules of the system is reduced; and each module consists of a plurality of modules so as to facilitate the functional expansion of each module.

Owner:BEIJING UNIV OF POSTS & TELECOMM

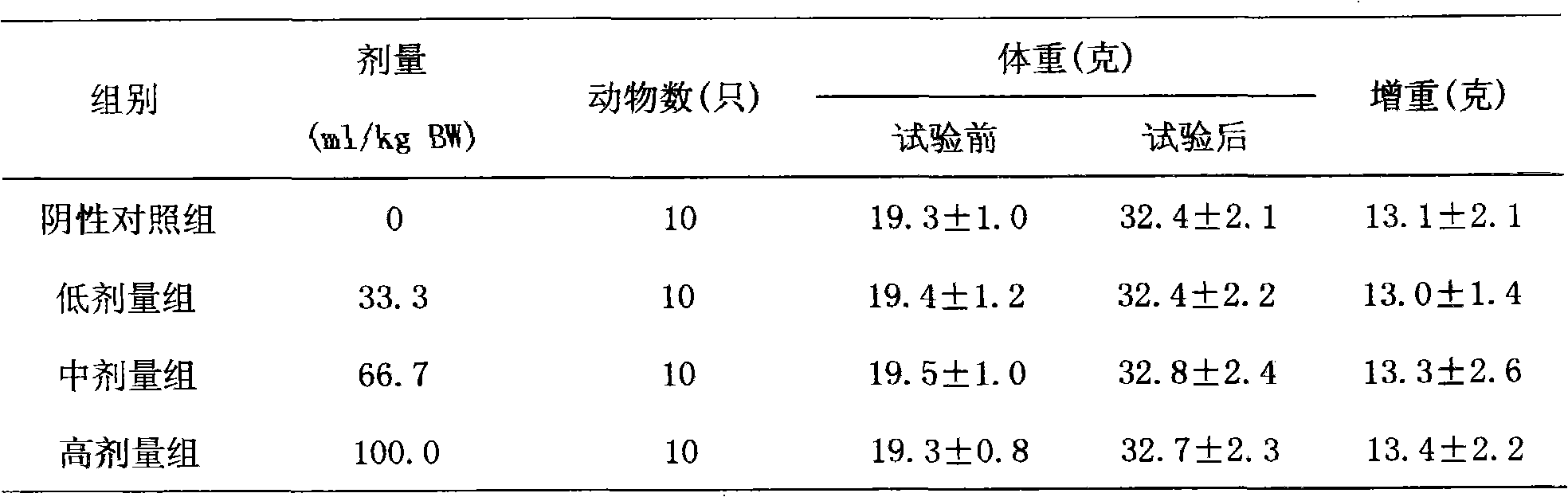

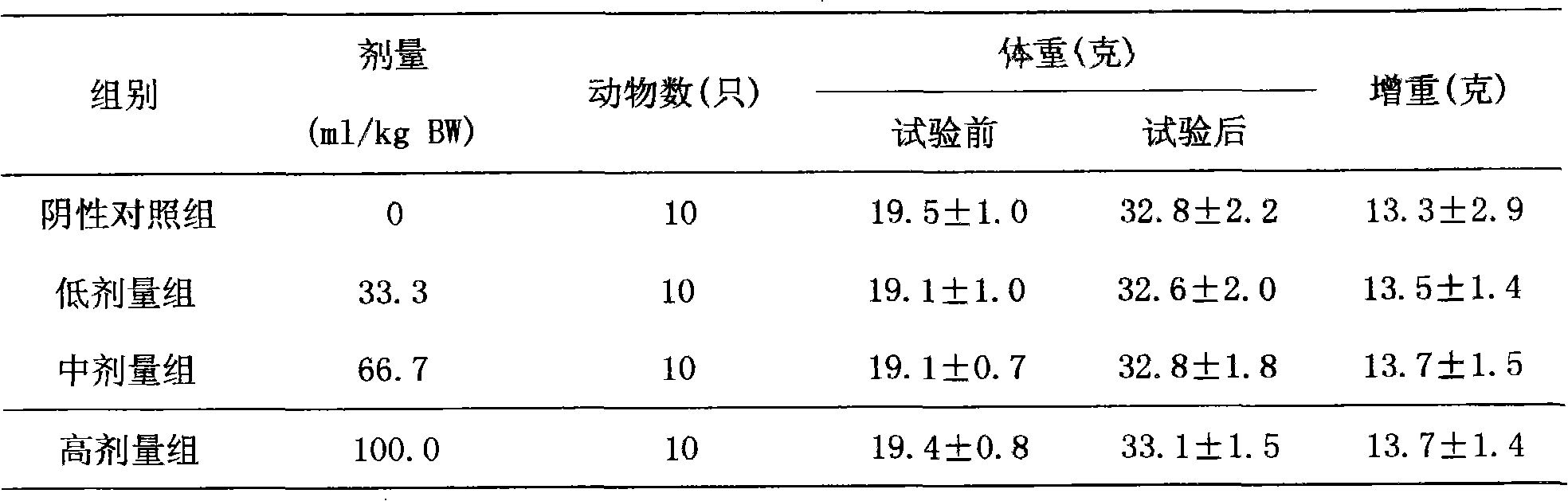

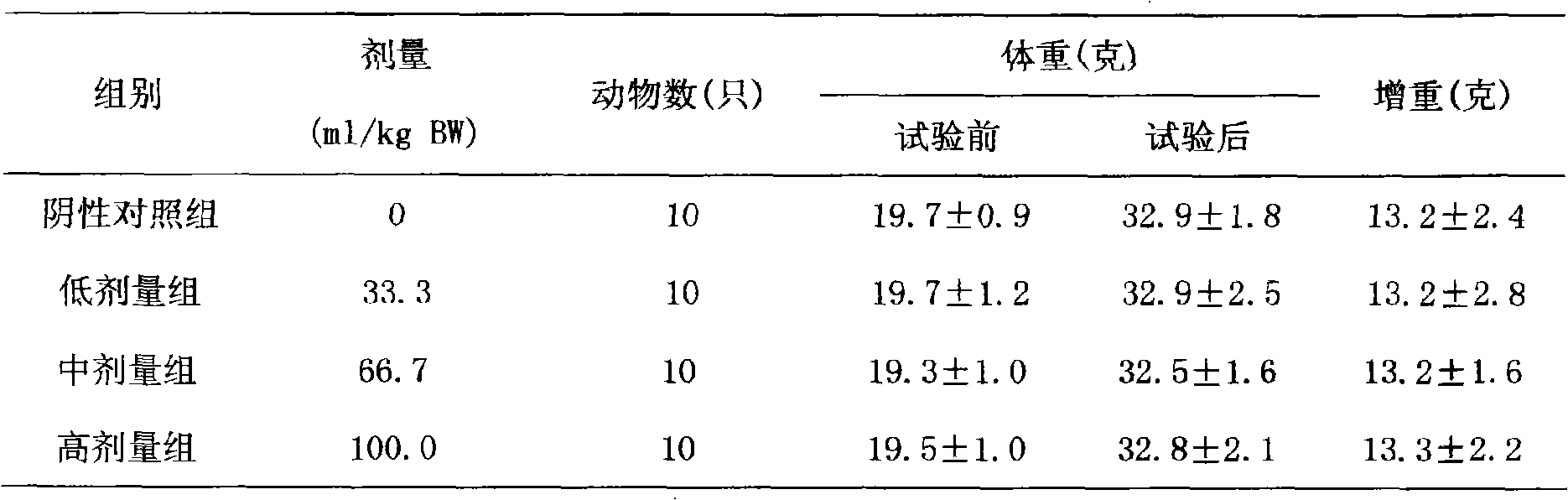

Health food for reinforcing immune function of human body and preparation technique thereof

ActiveCN101292742ACheap sourceStable sourceImmunological disordersFood preparationPharmacyCordycepin

The invention aims at providing a health-care food enhancing immune function of human body and provides a preparation technique thereof. The health-care food, according to weight proportion, is produced by raw materials comprising 10-50 portions of gen-seng, 10-50 portions of glossy ganoderma and 10-50 portions of zymotic cordycepin powder; the raw materials comprising the gen-seng, the glossy ganoderma and the zymotic cordycepin powder are positioned in a hop-pocket; the processed raw materials are carried out heating and decoction for 1-3 times (each time is for 1-2 hours) after being added with water for soaking for one hour; extraction solution is mixed, filtered and concentrated to defined amount; after being cooled, concentrated solution is carried out high-speed centrifugal impurity removal; the obtained concentrated solution is produced into required preparation independently or by adding with accessories acceptable in medical science with the conventional processes of pharmacy.

Owner:JIANGZHONG PHARMA

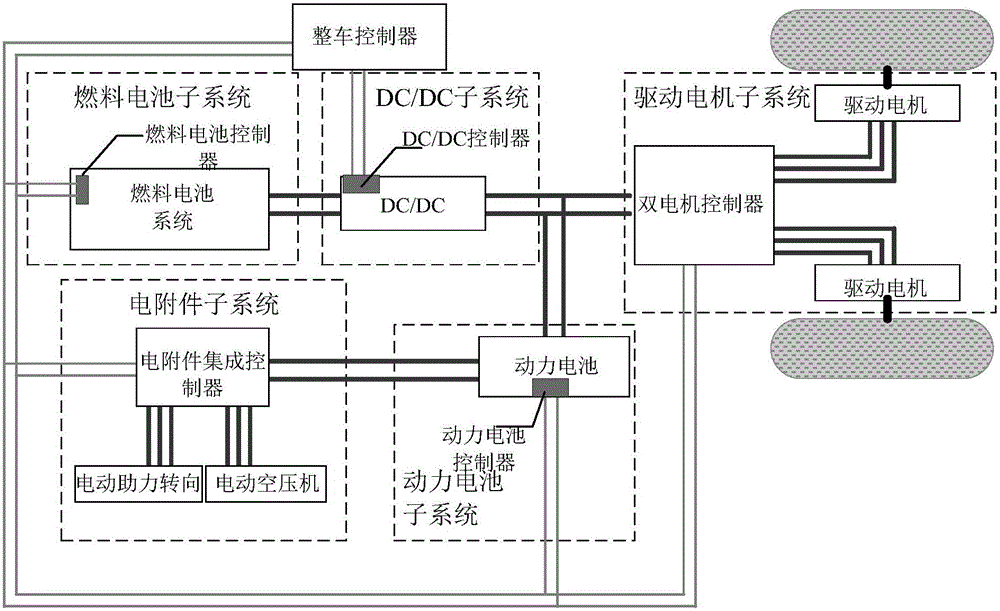

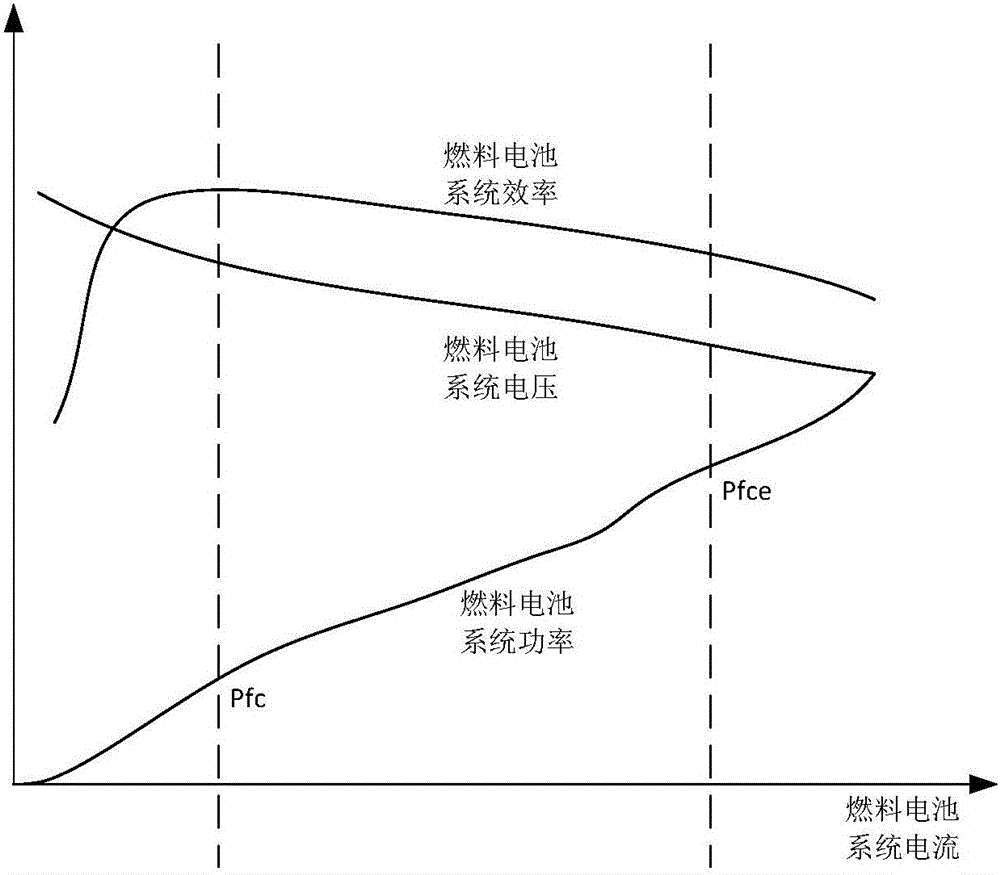

Power control method for fuel cell bus and power system of fuel cell bus

InactiveCN105835712AIncreased durabilityEasy to use for a long timeVehicular energy storageBattery/fuel cell control arrangementElectrical batteryEngineering

The invention relates to a power control method for a fuel cell bus and a power system of the fuel cell bus. The power control method comprises the steps that required power P of the bus is acquired in real time; when the required power P of the bus meets the condition that P is smaller than Pfc, a fuel cell operates at Pfc, and a (Pfc-P) part charges a power cell; when the required power P of the bus meets the condition that P is larger than or equal to Pfc and is smaller than Pfce, the fuel cell operates at Pfce, and a (Pfce-P) part charges the power cell; when the required power P of the bus meets the condition that P is larger than or equal to Pfce, the fuel cell operates at Pfce, and a (P-Pfce) part is provided by the power cell, wherein Pfc and Pfce are two set threshold values of certain output power of the fuel cell. With adoption of the control mode, the output power of the fuel cell is prevented from frequent fluctuation and continuous loading and unloading, the durability of the fuel cell can be improved, investment cost is saved, and reliable operation of the power system is guaranteed.

Owner:ZHENGZHOU YUTONG BUS CO LTD

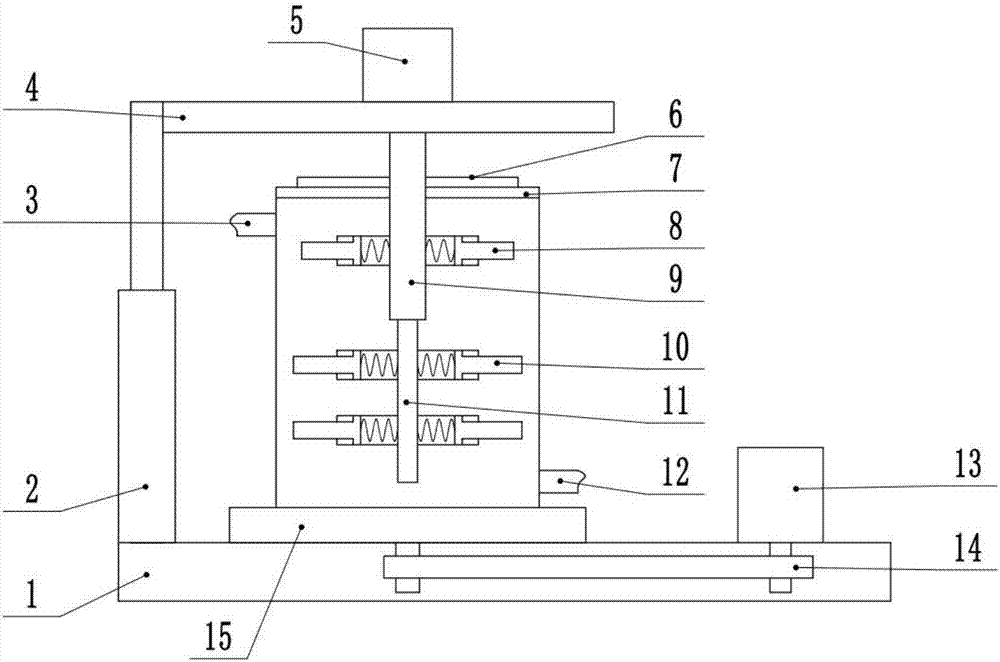

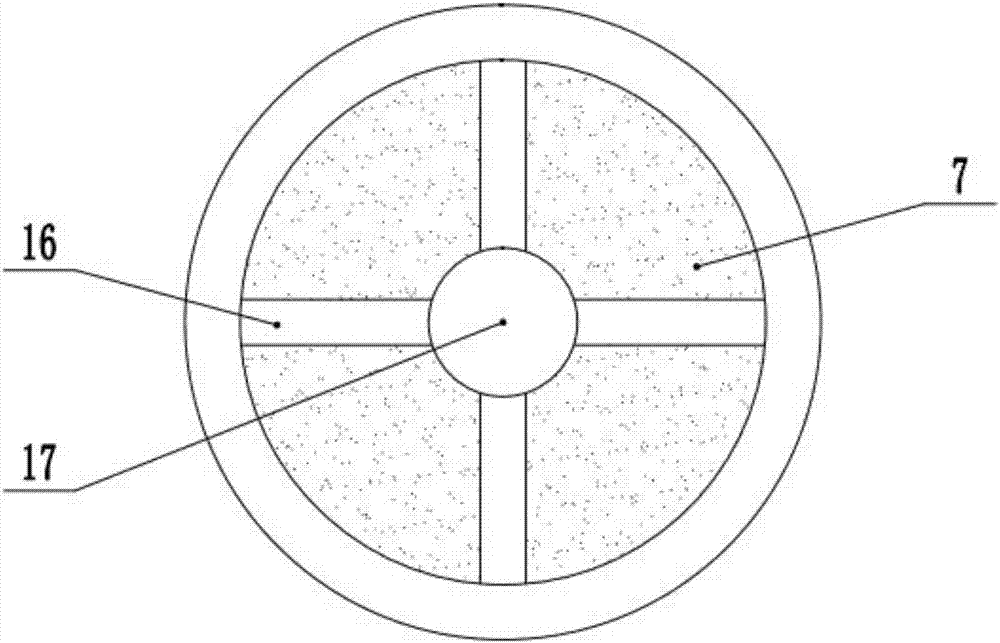

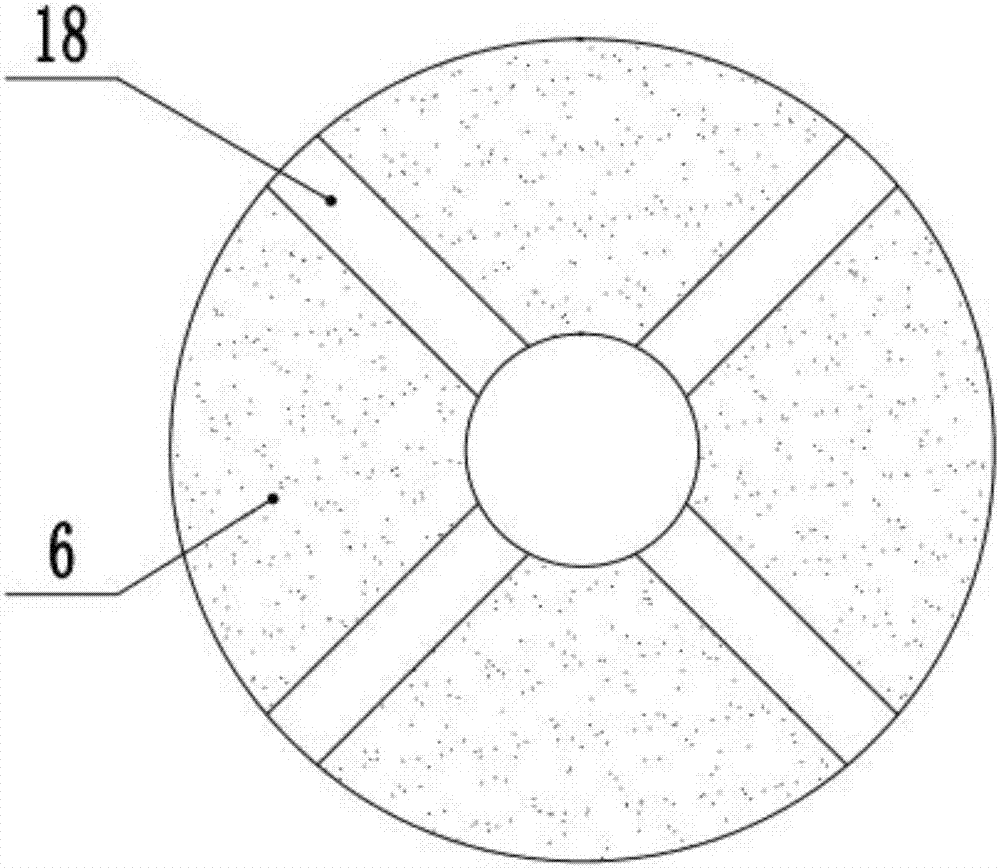

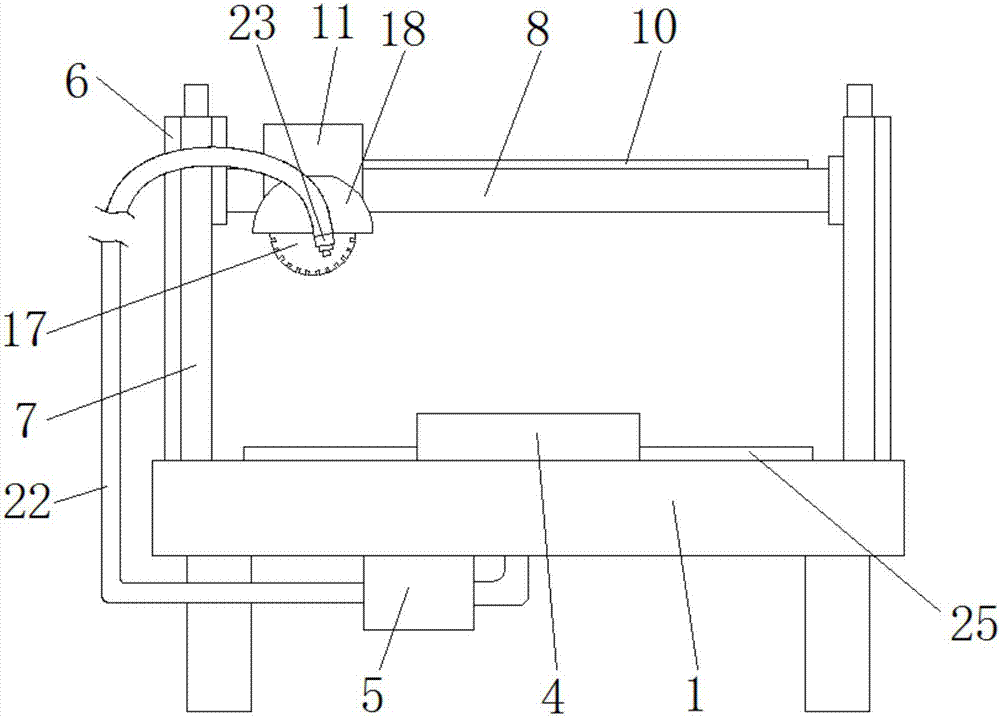

Building-paint stirring device convenient for cleaning of stirring shaft

InactiveCN107126889AEasy to cleanEasy to use for a long timeRotating receptacle mixersTransportation and packagingCouplingEngineering

The invention discloses a building-paint stirring device convenient for cleaning of a stirring shaft. The building-paint stirring device comprises a base, a stirring motor, a fixing cover and rotary seat; the rotary seat is rotatably installed on the base, and a stirring barrel is fixedly installed on the rotary seat; a telescopic support is fixedly installed on the left side of the base, a top plate is fixedly installed at the telescopic end of the telescopic support, the stirring motor is fixedly installed on the upper side of the top plate, and the output end of the stirring motor is fixedly connected with the stirring shaft through a coupler; the stirring shaft is of a telescopic structure and is composed of a main telescopic rod and an auxiliary telescopic rod; a first stirring blade and a second stirring blade are respectively and symmetrically arranged on a main stirring rod and an auxiliary stirring rod. The building-paint stirring device is simple in structure; after stirring is competed, the stirring shaft can be taken out from the stirring barrel and cleaned conveniently, and long-term use of the stirring device is facilitated; paint stirring efficiency is improved through arrangement of the telescopic stirring blades and the rotatable stirring barrel.

Owner:宋衡星

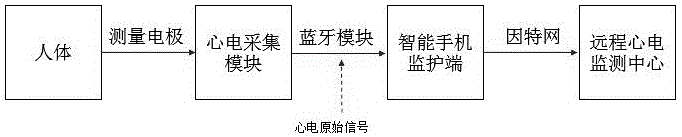

Realizing method for long-distance electrocardiogram monitoring system with automatic analyzing and real-time information sharing functions

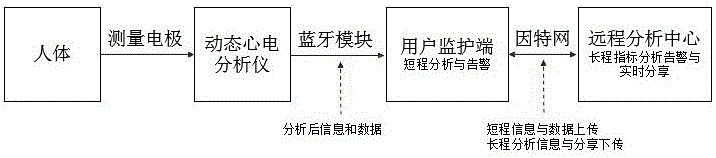

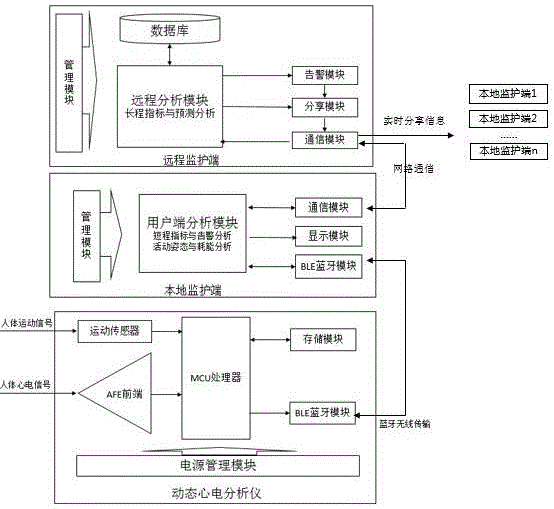

ActiveCN105147278AReflect daily healthEnable real-time analysisDiagnostic recording/measuringSensorsTime informationEcg signal

The invention discloses a realizing method for a long-distance electrocardiogram monitoring system with automatic analyzing and real-time information sharing functions. The method comprises the steps that 1, automatic dynamic electrocardiogram analyzing equipment collects electrocardiogram signals and motion sensor signals and analyzes the signals in real time; 2, the automatic dynamic electrocardiogram analyzing equipment transmits analysis results in a wireless mode through a low-power-consumption Bluetooth communication module; 3, a user monitoring terminal receives data, processes the data locally in real time and the transmits the data to a long-distance monitoring terminal; 4, information received by the long-distance monitoring terminal is transmitted to a long-distance index real-time analysis processing and early warning module, and processed results are submitted to an information sharing module; 5, the information sharing module enables received information to be shared in real time according to the preset share range and the sharing mechanism. The method has the advantages that data wirelessly transmitted are reduced to the maximum degree, human intervention is reduced, high automation degree analysis is achieved, and the real-time prediction and early warning ability of severe events is improved.

Owner:成都信汇聚源科技有限公司

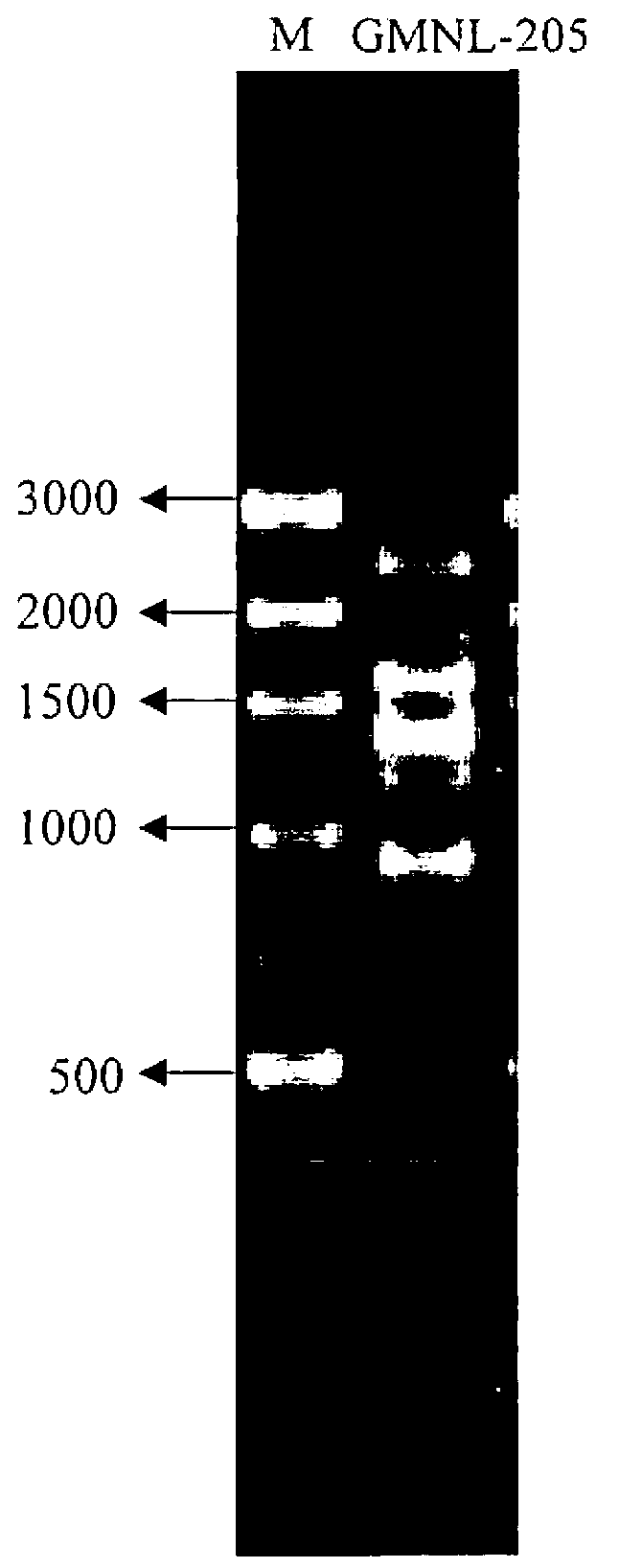

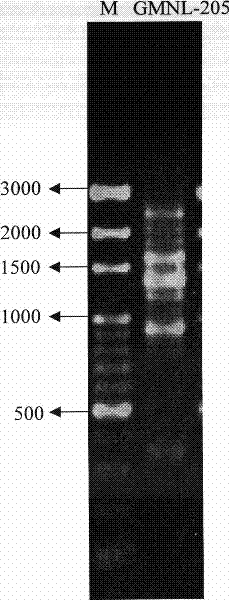

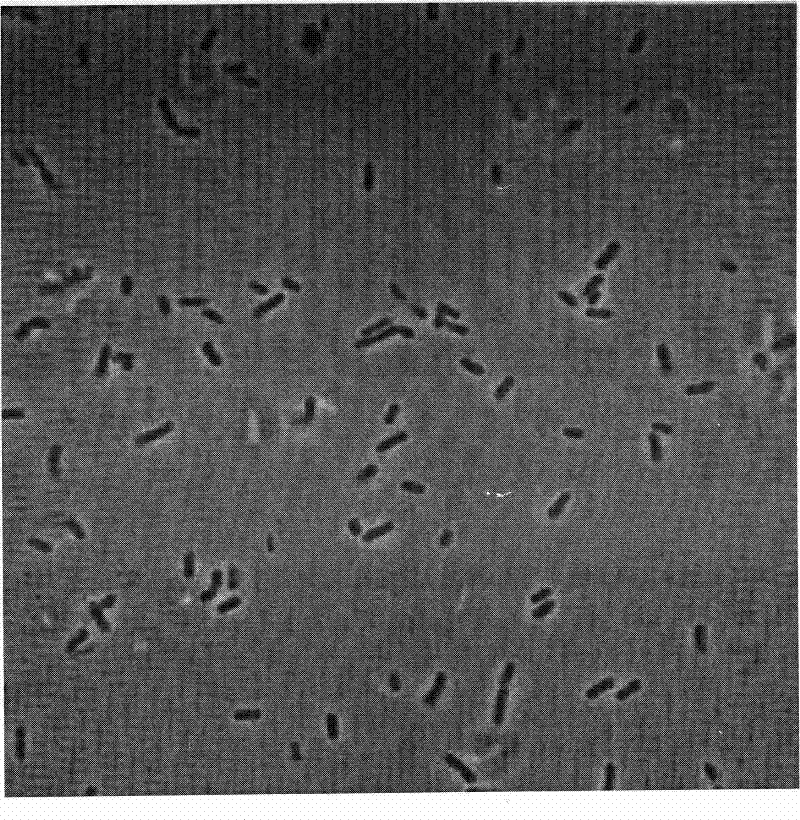

Novel lactobacilli and composition thereof, and application thereof in preparing medicines used for ameliorating diabetes and complications thereof

The invention discloses novel lactobacilli and a composition thereof, and an application thereof in preparing medicines used for ameliorating diabetes and complications thereof. The composition comprises an effective amount of at least one lactobacillus selected from: lactobacillus reuteri GMNL-89, lactobacillus gasseri GMNL-205, and lactobacillus reuteri GMNL-263; and a pharmaceutically acceptable carrier. The lactobacillus gasseri GMNL-205 and the lactobacillus reuteri GMNL-263 are novel lactobacilli. The composition and novel lactobacilli provided by the invention have novel applications for ameliorating diabetes and complications thereof.

Owner:GENMONT BIOTECH

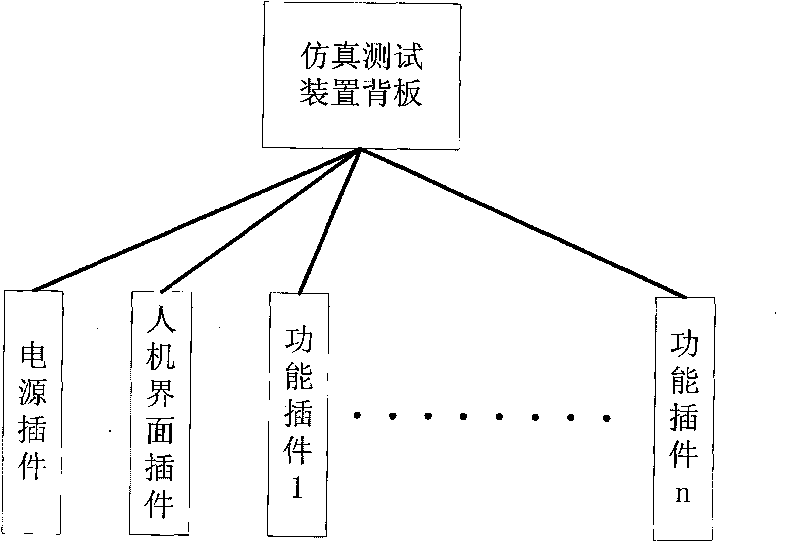

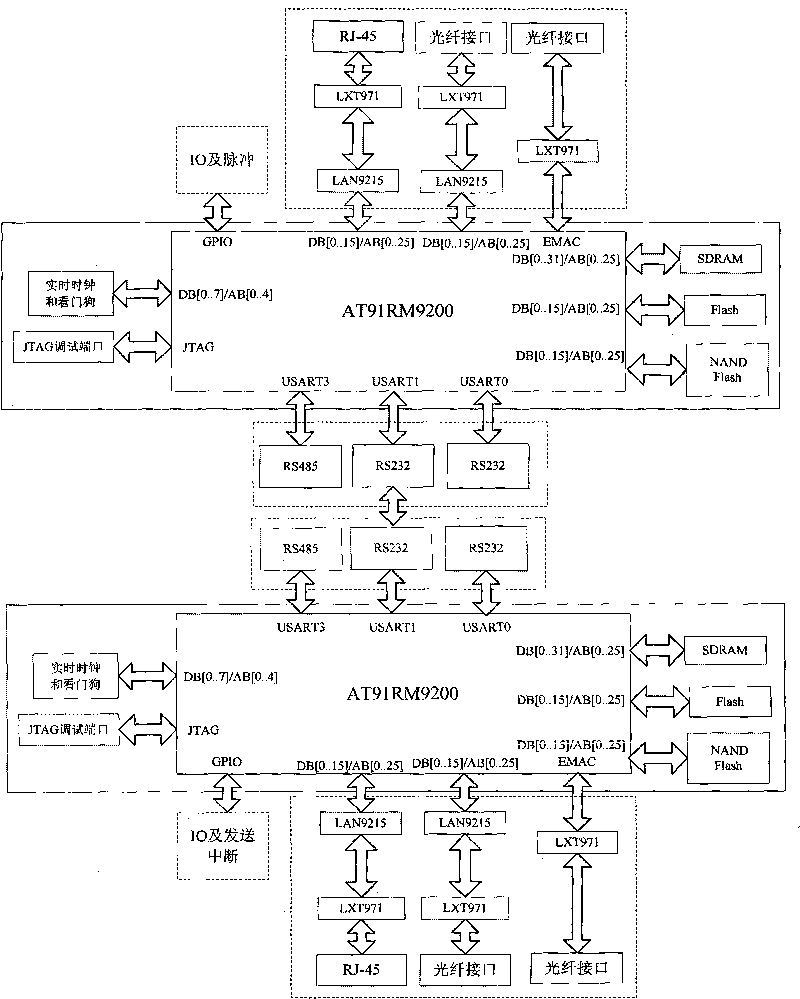

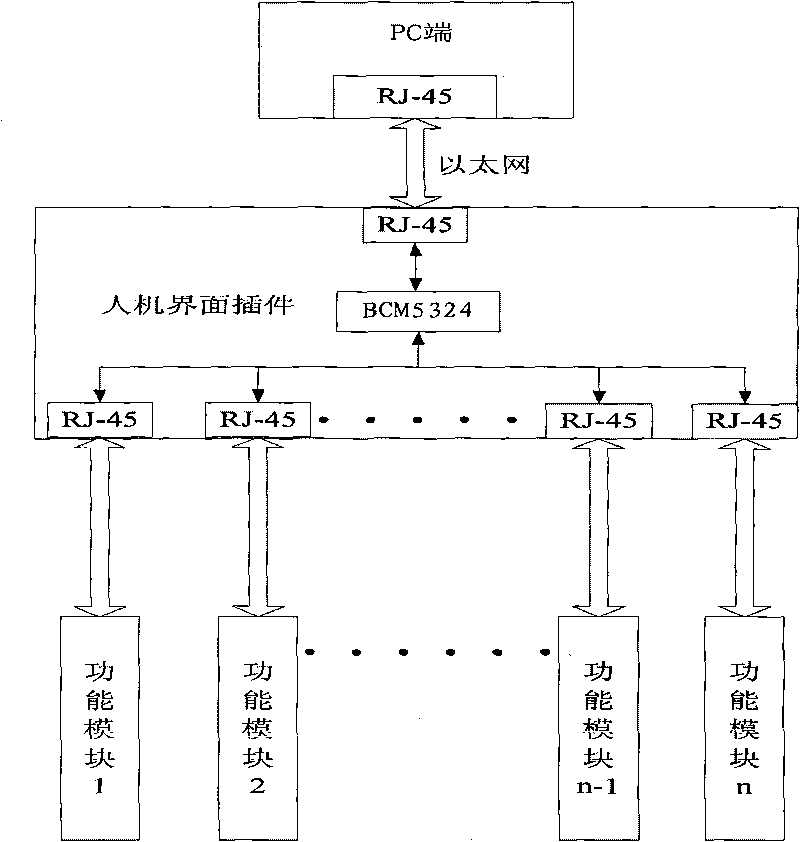

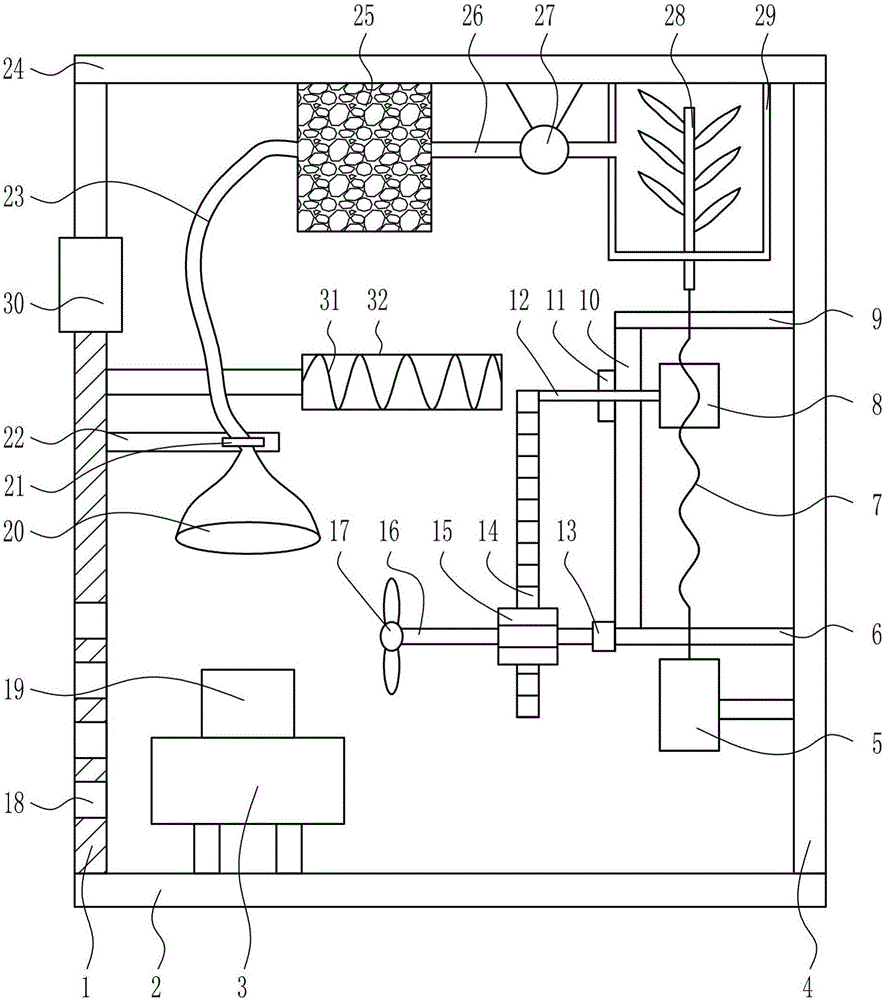

Simulation test platform of process layer of digitalization transformer substation

ActiveCN101727106AImprove performanceIncrease opennessElectric testing/monitoringTransformerSystem testing

The invention discloses a simulation test platform of a process layer of a digitalization transformer substation, which is characterized by comprising a PC carrying out communication through the Ethernet and a simulation test embedded device, wherein the simulation test embedded device is connected with a tested protecting and monitoring device; the PC is internally provided with a simulation module used for simulating a dynamic process of process layer equipment to generate required data and downloading the data into an FLASH of a corresponding functional module of a simulation test device; and the simulation test embedded device is used for receiving simulation data of the PC, simulating the process layer equipment as required so as to send and receive the data according to a standard message, carrying out information exchange with test and control protection equipment of a spacer layer in a station, analyzing a received message and then returning an analysis result to the PC. The platform simulates a process layer equipment group of a certain voltage level through high-efficiency, economical and convenient configuration and realizes the test operation of a transformer substation equipment system.

Owner:JIANGSU FRONTIER ELECTRIC TECH +1

Novel lactobacillus and its composition and its application in the preparation of drugs for improving diabetes and its complications

ActiveCN102274245AImprove diabetes symptomsImprove its complicationsBacteriaMetabolism disorderPharmaceutical drugDiabetic complication

The invention discloses novel lactacidophilus, a composition thereof and use thereof in preparation of medicines for relieving diabetes mellitus and diabetic complications. The composition comprises at least one lactacidophilus which may be lactobacillus reuteri CMNL-89, lactobacillus gasseri GMNL-205 and lactobacillusreuteri CMNL-263. The lactobacillus gasseri GMNL-205 and the lactobacillusreuteri CMNL-263 are novel lactacidophilus. The composition or novel lactacidophilus can be used for relieving symptoms of diabetes mellitus and diabetic complications.

Owner:GENMONT BIOTECH

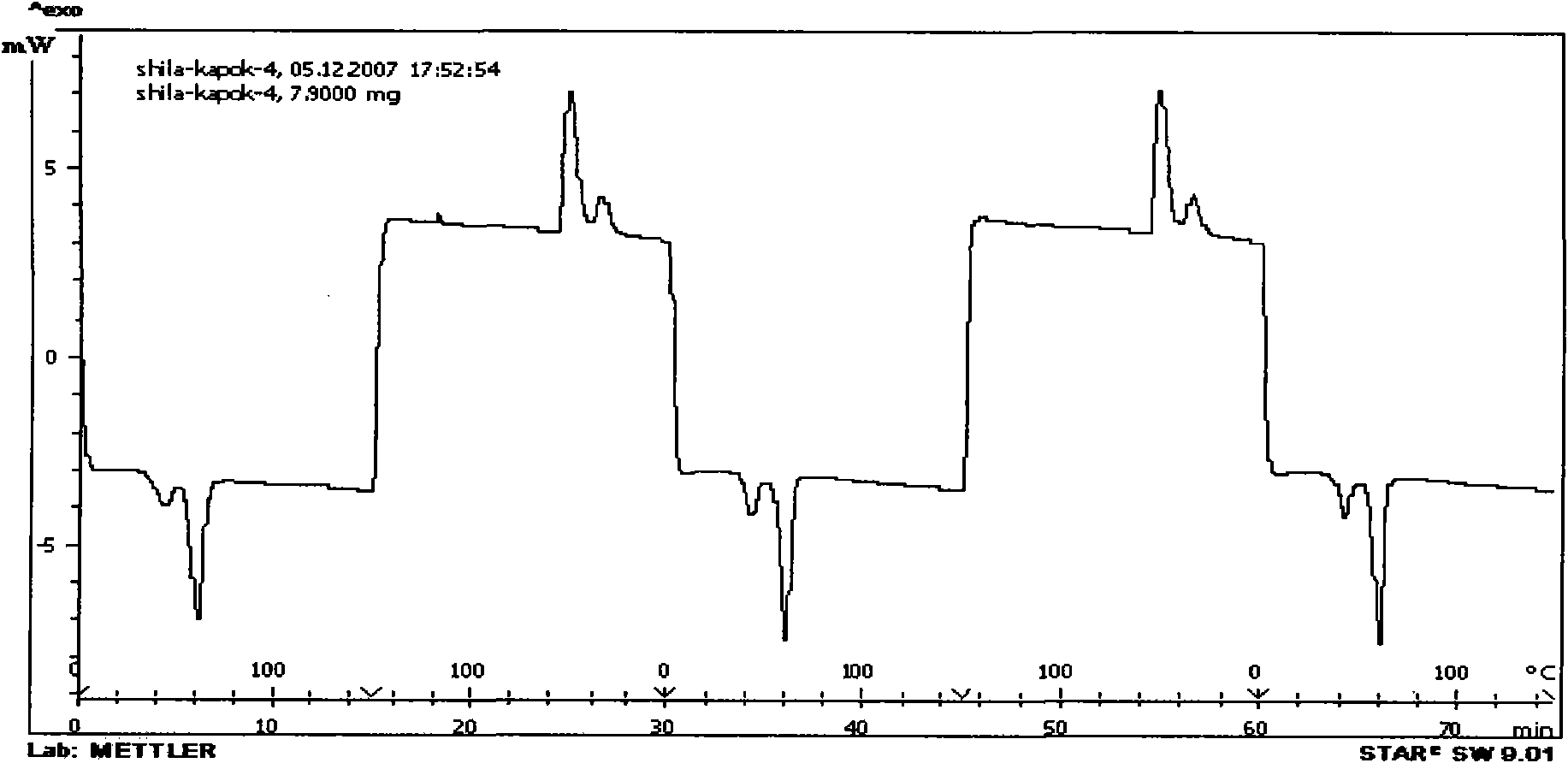

Phase change material microcapsules encapsulated by natural microtubules and preparation method thereof

ActiveCN101684403AImprove thermal stabilityNo thermal degradationHeat storage plantsHeat-exchange elementsHigh availabilityVolumetric Mass Density

Owner:INST OF CHEM CHINESE ACAD OF SCI

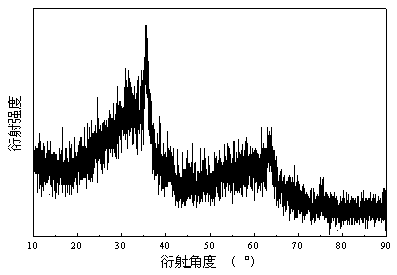

Polymer based temperature-sensitive resistance material with negative temperature coefficient (NTC) effect and preparation method thereof

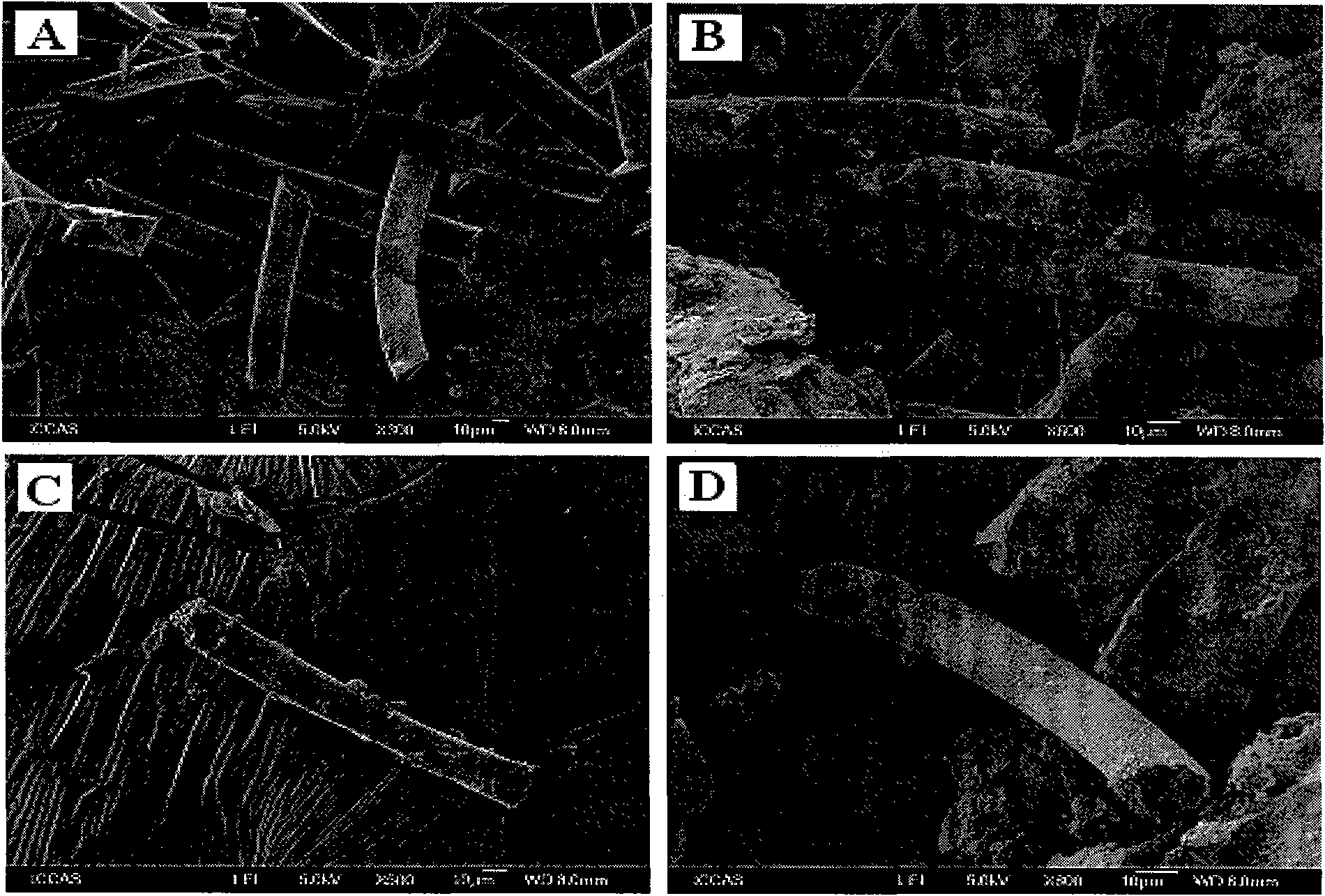

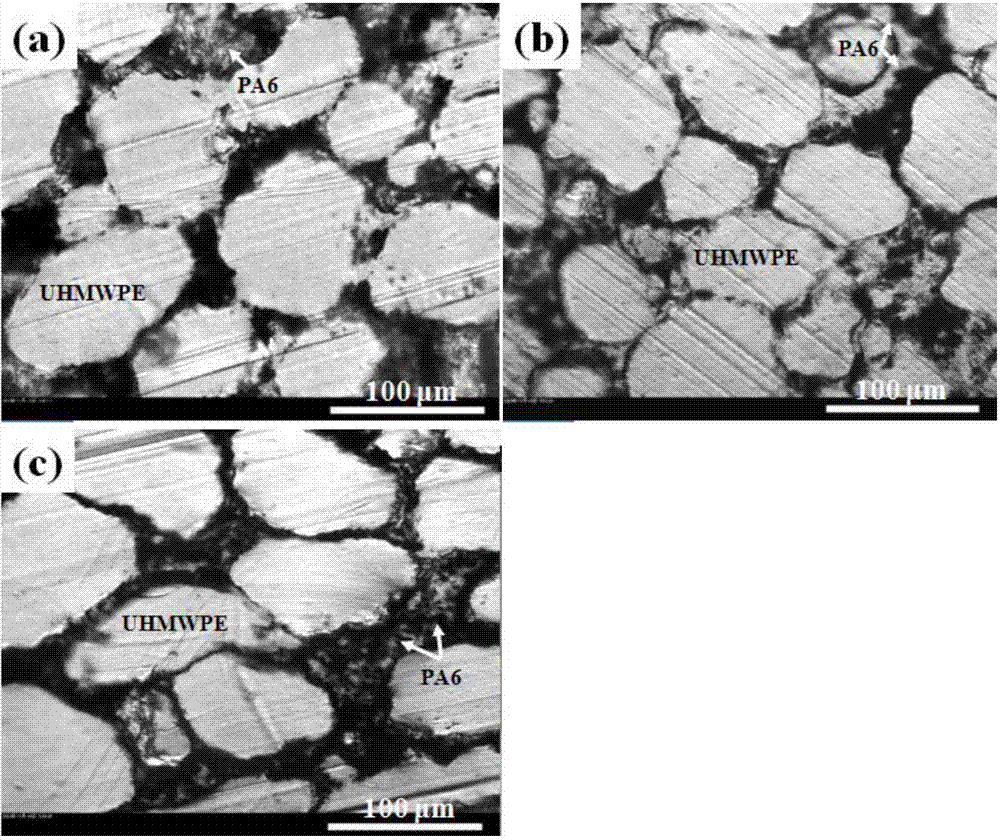

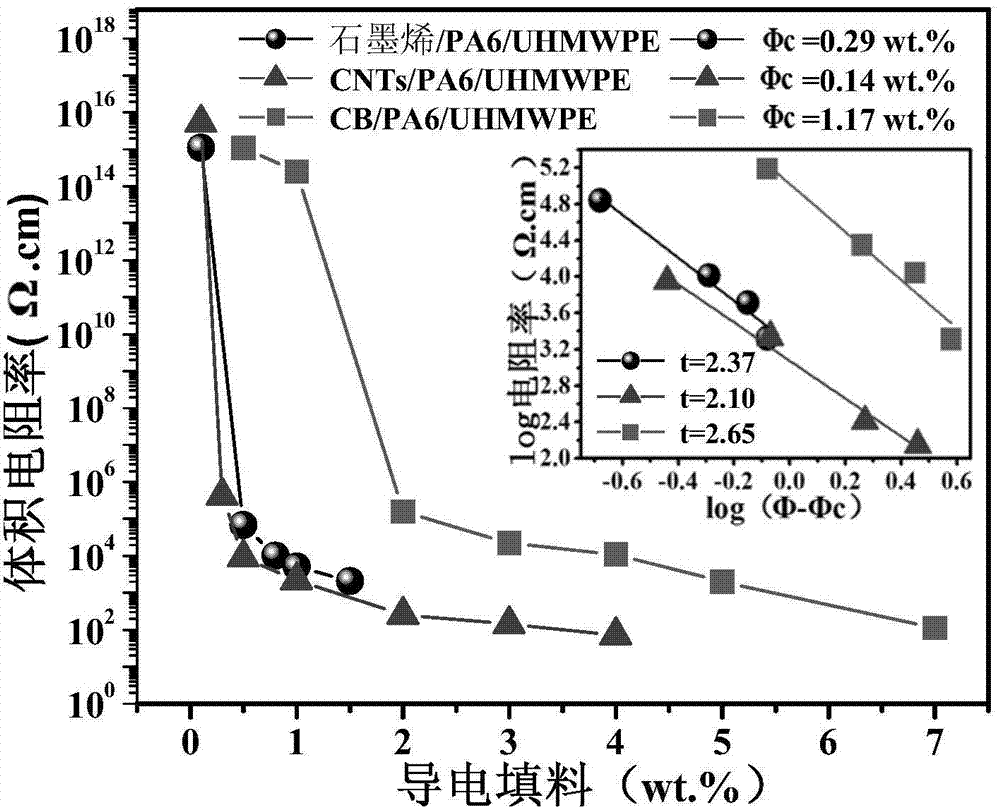

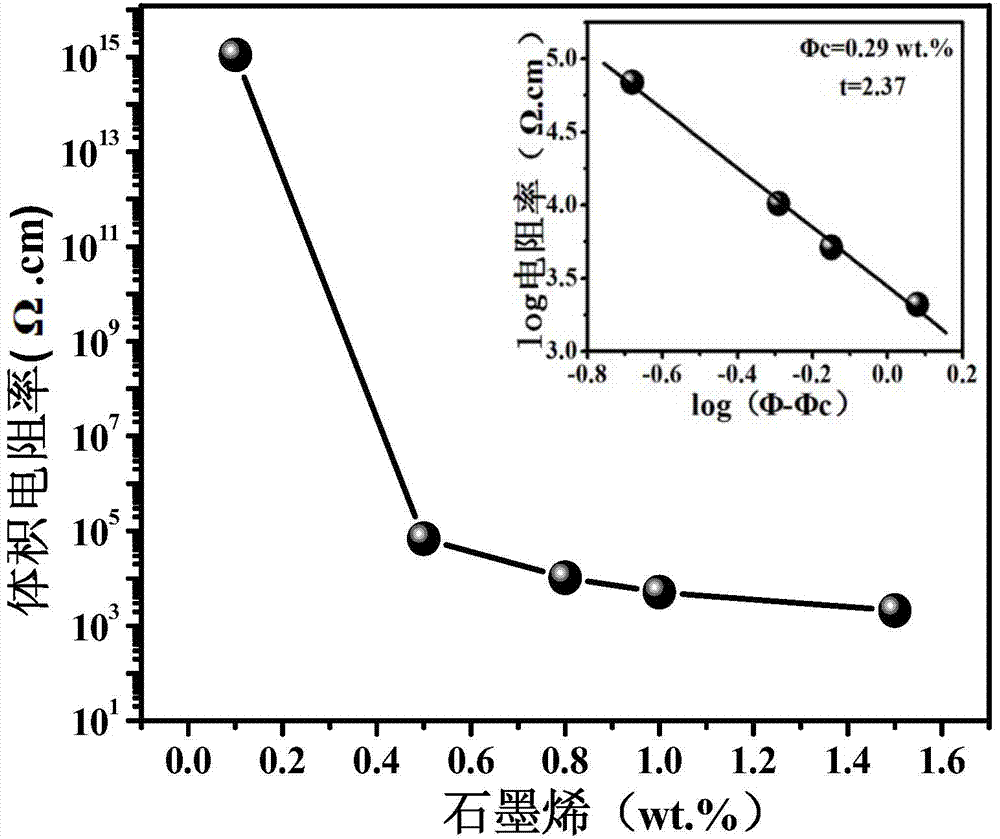

ActiveCN104497394AImprove electrical performanceLow percolation valueElectrical resistance and conductanceManufacturing technology

The invention belongs to the technical field of manufacturing of conductive polymer composites, and in particular relates to a preparation method of a conductive polymer composite with negative temperature coefficient (NTC) characteristics. The invention discloses a polymer based temperature-sensitive resistance material with a NTC effect, and the polymer based temperature-sensitive resistance material comprises the following raw materials in parts by weight: 88.5-96.9 parts of a polymer 1 and a polymer 2, 0.1-1.5 parts of a conductive filler and 3-10 parts of a compatilizer; moreover, the conductive filler is selectively distributed in the polymer 2; the MFI of the polymer 1 is less than or equal to 7g / 10 minutes, and the MFI of the polymer 2 is more than or equal to 12g / 10 minutes; the thermal expansion coefficient of the polymer 2 is greater than that of the polymer 1, and the conductive filler is a two-dimensional conductive filler; and the mass ratio of the polymer 1 to the polymer 2 is (3:7)-(7:3). The resistance material prepared by the method disclosed by the invention is low in percolation threshold, the NTC characteristic repeatability of the obtained resistance material is good, and the resistance material is convenient to use for a long time.

Owner:ZHENGZHOU UNIV

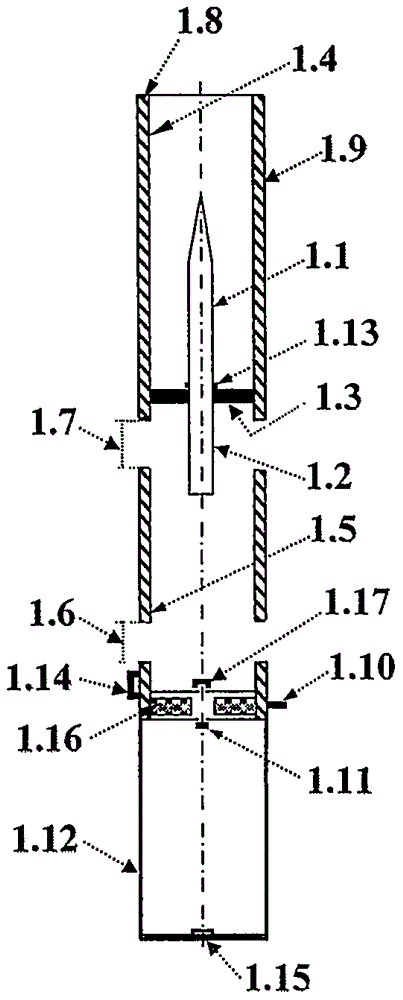

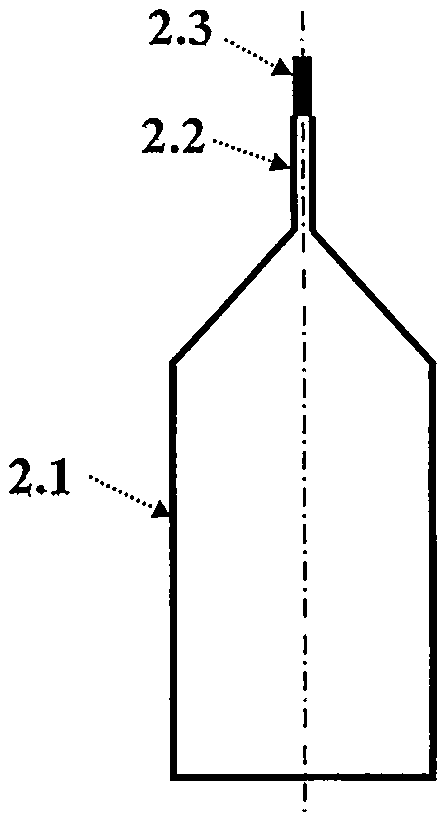

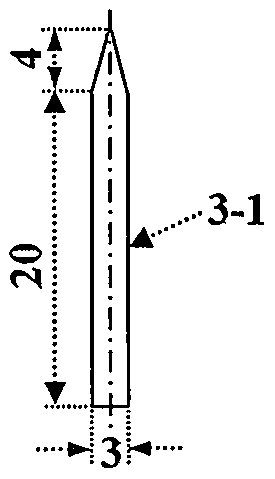

Heating type cigarette-noncombustible heater

Smoking is harmful to health, and the main harmful components come from the combustion of tobaccos; if a cigarette is just heated rather than combustion, advantages can be drawn while disadvantages can be avoided. The invention relates to a heating type cigarette-noncombustible heater and a manufacturing method thereof, wherein the heating type cigarette-noncombustible heater is composed of a thin metal heat-conduction pipe, a cigarette heating chamber, a combustion chamber, an ignition device, a liquid fuel supply valve, a sensor, a liquid storage bin and the like, and is characterized in that the heater provides heat to the heat-conduction pipe through the combustion of liquefied gas; the heat-conduction pipe is inserted in tobacco shreds for heating; the heater has a temperature control function and a thermal insulation layer, so that the temperature of the heat-conducting pipe is limited in a given range, and a consumer does not feel hot when holding a housing of the heater. The heating type cigarette-noncombustible heater provided by the invention has the advantages that after a cigarette is inserted in the heating chamber, the heater can be started up in an instant, has a higher power and a broader application range, not only can heat general cigarettes, but also is suitable for heating large cigars, is particularly convenient for use in the wild for a long time, can heat dozens of cigarettes after complementing fuel fluid at a time, and is more convenient to carry and lower in cost.

Owner:黄争鸣

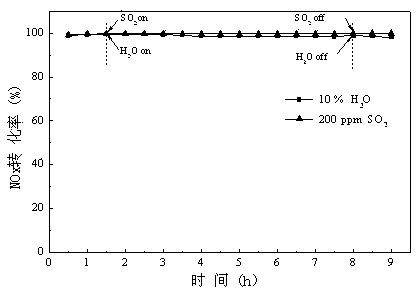

Ferro-tungsten composite oxide denitrification catalyst with flower petal structure and preparation method and application of ferro-tungsten composite oxide denitrification catalyst with flower petal structure

ActiveCN103877986AEasy to prepareLow costInternal combustion piston enginesDispersed particle separationComposite oxideFlue gas

The invention discloses a ferro-tungsten composite oxide. The ferro-tungsten composite oxide comprises three elements including ferrum (Fe), tungsten (W) and oxygen, wherein Fe and W are highly dispersed in the composite oxide with molar ratio of (5.8-12.9):1, preferentially, with molar ratio of 6.8:1. The ferro-tungsten composite oxide has a total or partial three-dimensional flower petal structure, and the flower petal structure is composed of multiple petals. The invention also discloses preparation and application of the ferro-tungsten composite oxide. The preparation method is simple and practicable, the adopted precursor is commonly used metal salt such as sulfate, tungstate, is low in cost, is easy to obtain, and can reach industrial production conveniently. The obtained ferro-tungsten composite oxide with the flower petal structure as the denitrification catalyst has high catalytic activity and N2 selectivity, is wide in temperature range, and high in sulfur dioxide and water poisoning resistance, and is used for purifying or eliminating nitric oxide in flue gas from a regular source, diesel exhaust and tail gas from a lean-burning gasoline engine.

Owner:UNIV OF JINAN

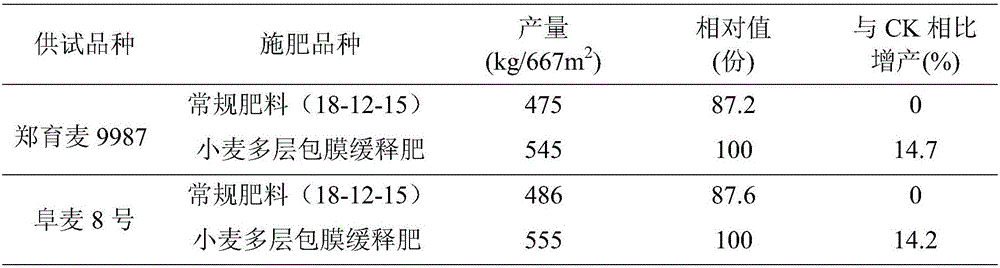

Preparation method of multilayer-coated slow release fertilizer for wheat

InactiveCN106380337AEnhance coordinationImprove utilization efficiencyCalcareous fertilisersMagnesium fertilisersNutrientPhosphoric acid

The invention discloses a preparation method of a multilayer-coated slow release fertilizer for wheat. The preparation method comprises the following steps: uniformly mixing a nitrogen fertilizer, a nitrogenous fertilizer synergist, a phosphate fertilizer, a potash fertilizer, medium trace element fertilizer and auxiliary materials, adding modified cassava powder as a binder, crushing, and granulating to obtain core particles; carrying out aging reaction on concentrated sulfuric acid, phosphoric acid and liquefied ammonia to obtain slurry, coating the core particles with the slurry as an internal coating material so as to form particles with the internal coating layer; humidifying the particles with the internal coating layer, adding an external coating material to uniformly coat the particles with the internal coating layer so as to obtain particles with an external coating layer, drying, polishing, and sieving to obtain the multilayer-coated slow release fertilizer for wheat. The multilayer-coated slow release fertilizer for wheat can fully supply wheat with nutrients. The supply of nutrients is lasting and harmonious, and release of nutrient elements can be controlled. Topdressing is not required by one-time fertilization. By the use of the fertilizer, quality and yield of wheat are remarkably enhanced.

Owner:ANHUI SIERTE FERTILIZER IND

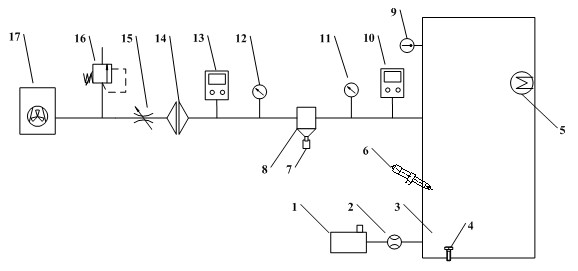

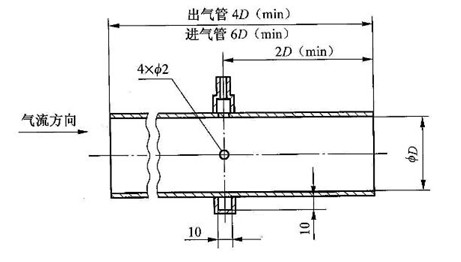

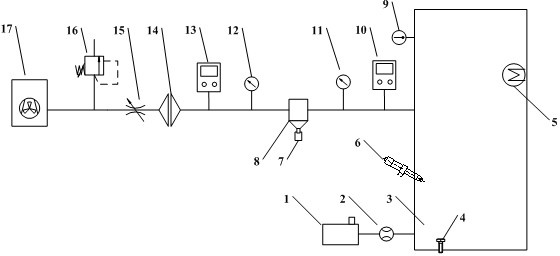

Vehicle diesel engine oil and gas separator test apparatus and method thereof

InactiveCN102426104AGuaranteed credibilityControl concentrationVehicle testingDiesel engineVacuum pump

The invention discloses a vehicle diesel engine oil and gas separator test apparatus and a method thereof. In the invention, an outlet port of an air cleaner is connected with one end of a flowmeter. The other end of the flowmeter is connected with an input port of an oil gas mixing box. A sidewall of the oil gas mixing box is provided with a fuel injector and a heater. A temperature controller is provided outside the oil gas mixing box. A pipeline from an outlet port of the oil gas mixing box to an air intake of an oil and gas separator is provided with a first particle counter and a first pressure gauge in order. A pipeline from an air outlet of the oil and gas separator to an input port of an absolute cleaner is provided with a second compression gauge and a second particle counter in order. An outlet port of the absolute cleaner is connected with one end of a throttle valve. The other end of the throttle valve is connected with a vacuum pump. A pipeline between the throttle valve and the vacuum pump is provided with an overflow valve. In the invention, oil gas mixing is carried out with only a simple oil injection apparatus, through adjusting fuel injection quantity, gas mixture concentration is controlled well, an experiment requirement is reached, and credibility of an experiment is ensured.

Owner:HANGZHOU DIANZI UNIV

Odor protection garbage can

ActiveCN109625709AAvoid distributingAvoid discomfortRefuse receptaclesNon-removalbe lids/coversEngineering

The invention relates to the field of daily necessities, and discloses an odor protection garbage can. The garbage can comprises a can body and a can cover which are connected; the opening part of thecan body is movably provided with a baffle capable of turning over in the can body, the baffle is located between the can cover and the can body, the baffle is connected with a control mechanism, thecontrol mechanism is used for controlling and adjusting the baffle to close to open the opening, and the can cover is hinged to the outer can body. The problems that an existing garbage can is largein odor, and discomfort is easily caused are solved.

Owner:CHONGQING VOCATIONAL INST OF ENG

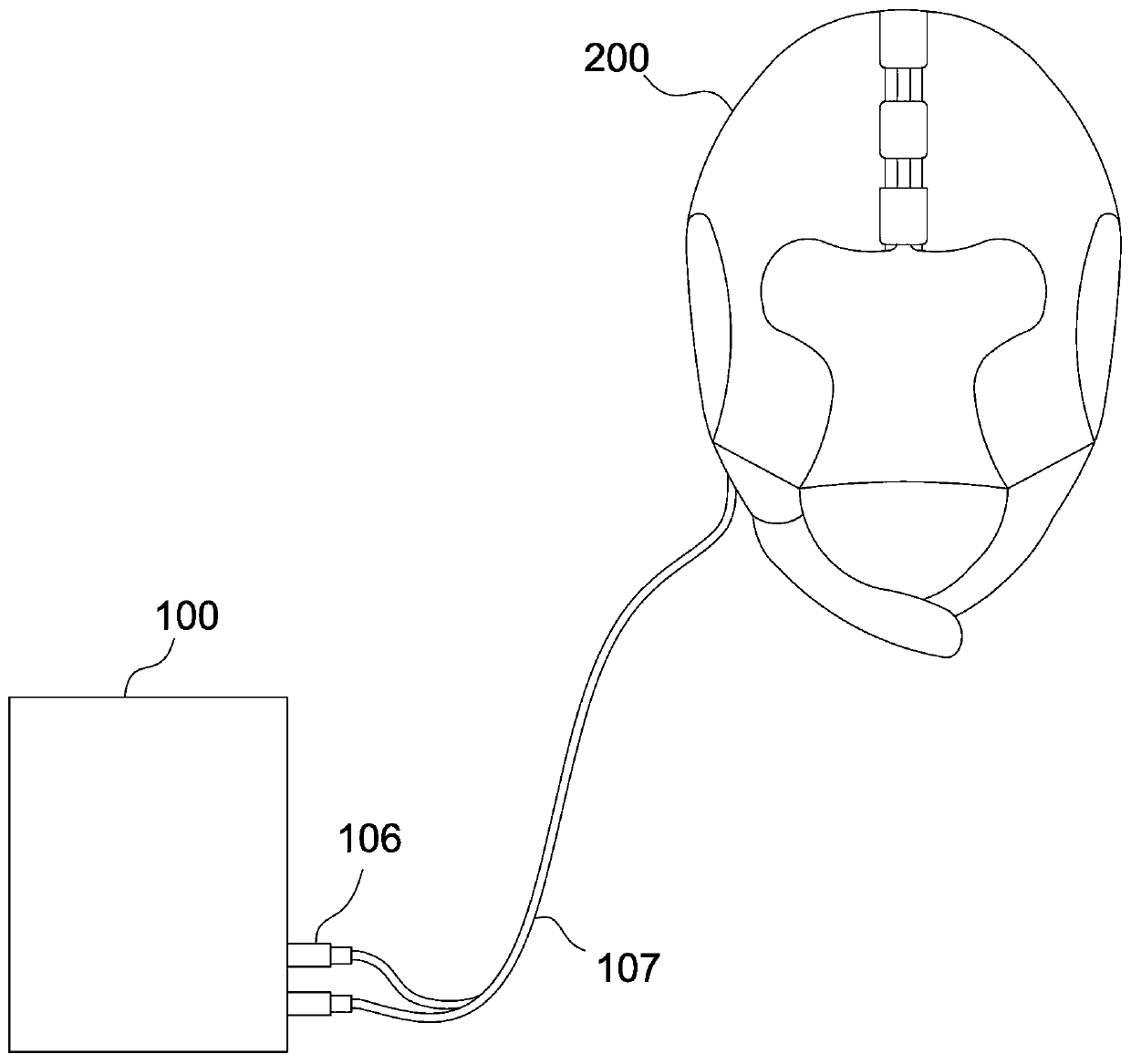

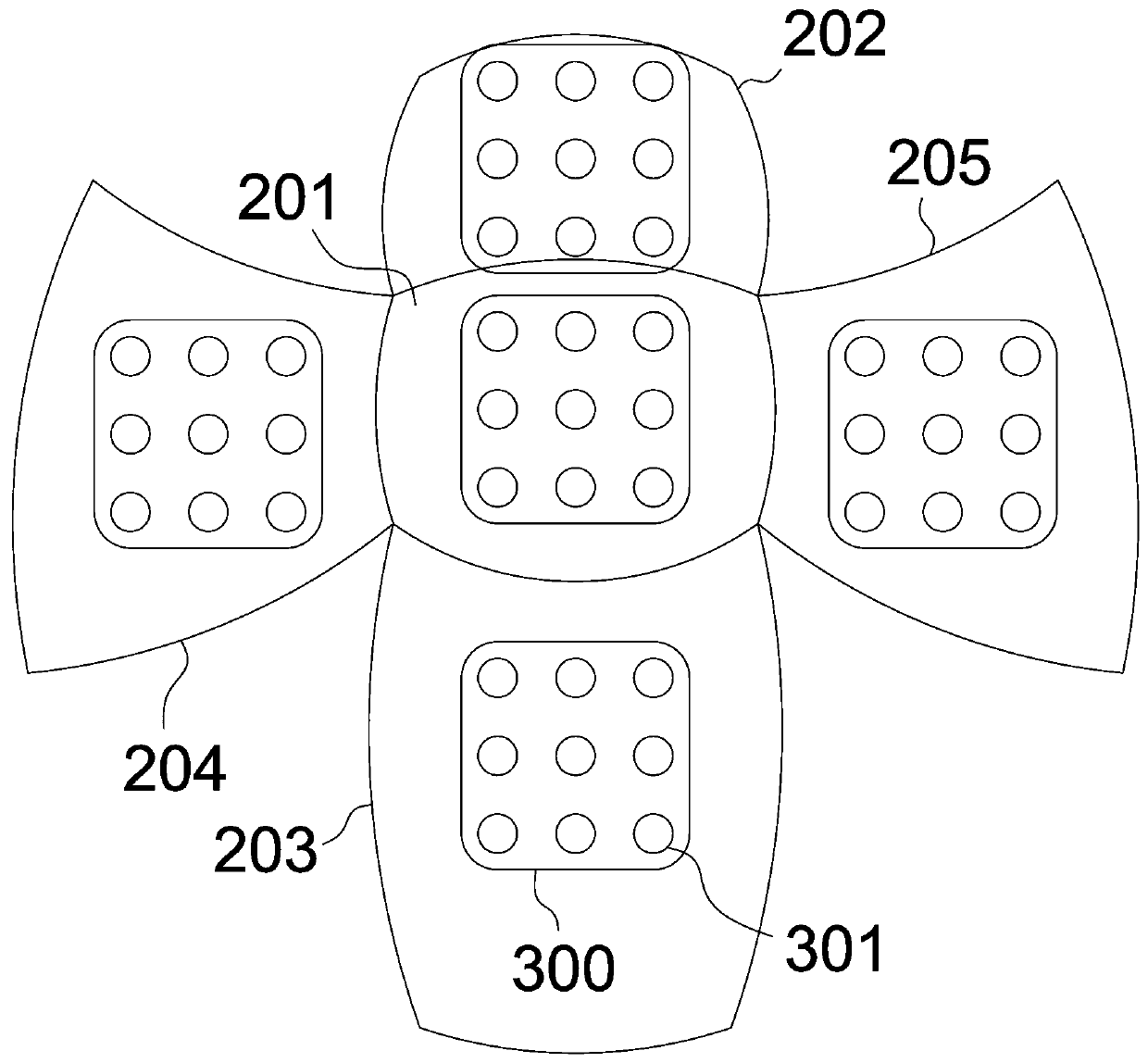

Device for treating multi-organ tumors based on electric field

The invention relates to a device for treating multi-organ tumors based on an electric field. The device comprises: an electric field generation device which is used for outputting an AC signal with adjustable voltage waveform, amplitude and frequency; a wire with one end connected with the electric field generating device and the other end connected with a field energy electrode patch; a field energy electrode patch including a flexible substrate and a plurality of electrode plate bodies which are arranged on the substrate in an array mode and made of an insulating capacitor material, whereinthe electrode plate bodies can effectively excite an electric field and avoid generation of conduction current, and the electrode plate bodies are connected with the wire; and a wearable device, wherein a plurality of the field energy electrode patches are arranged at the inner side of the wearable device, and the wearable device comprises one or any combination of a hat, a waistcoat, a bra and shorts.

Owner:HEBEI PUNI MEDICAL TECH CO LTD

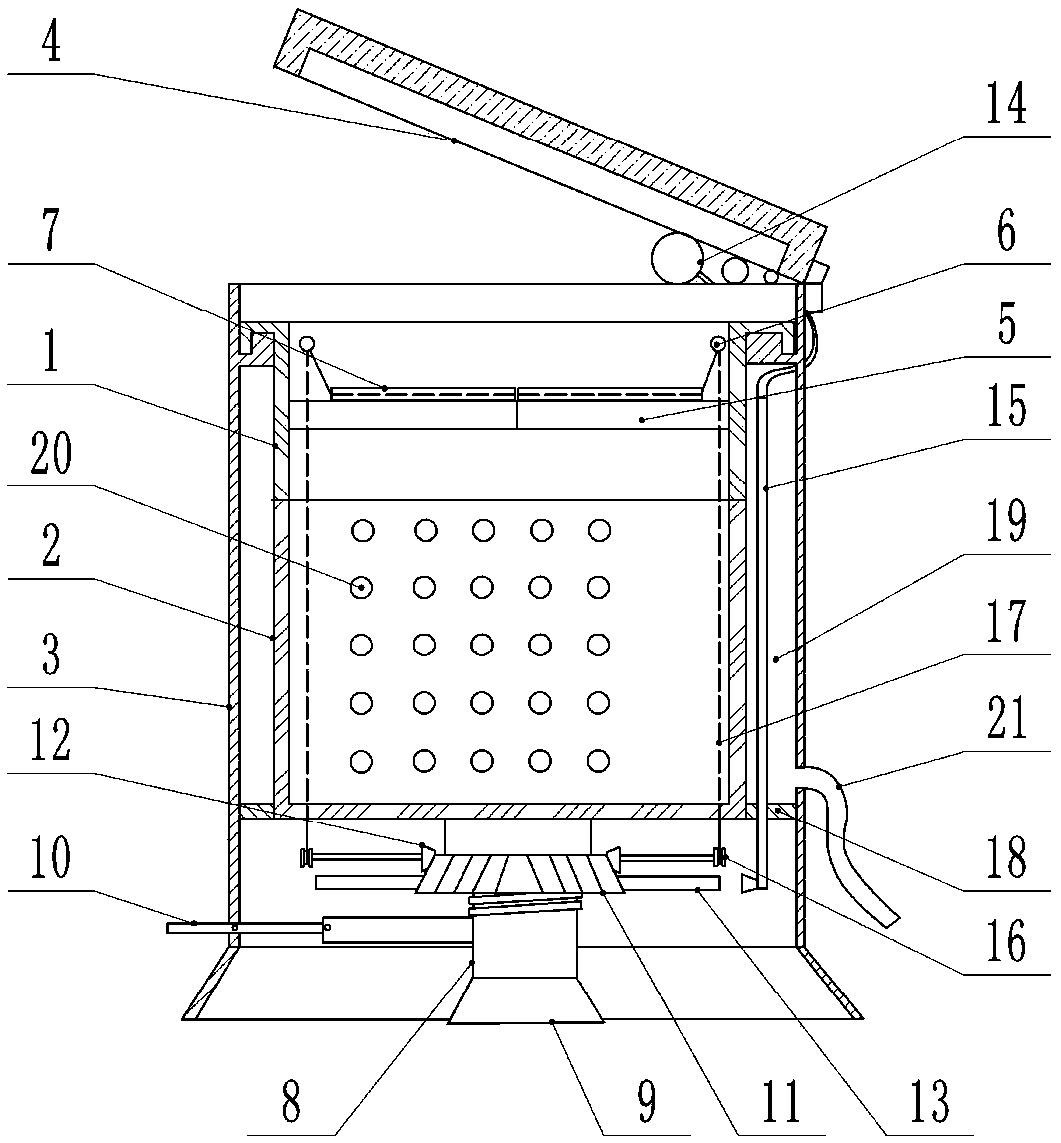

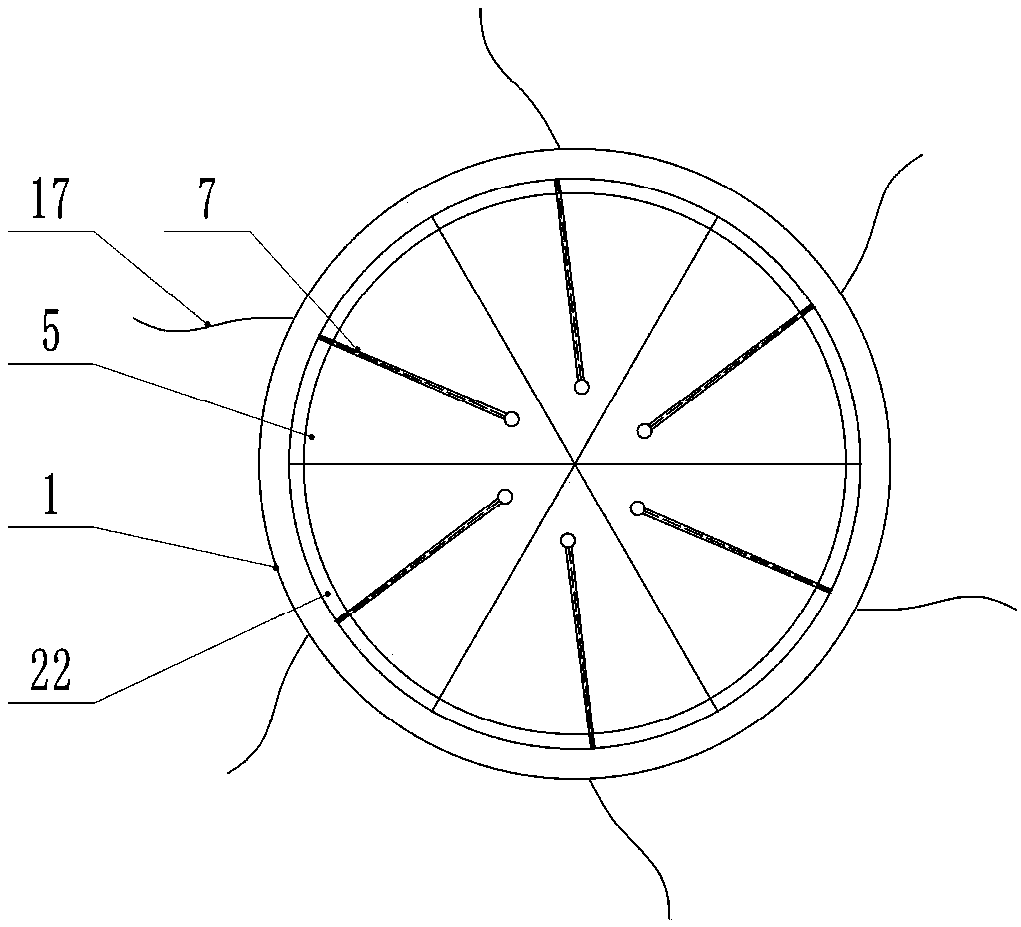

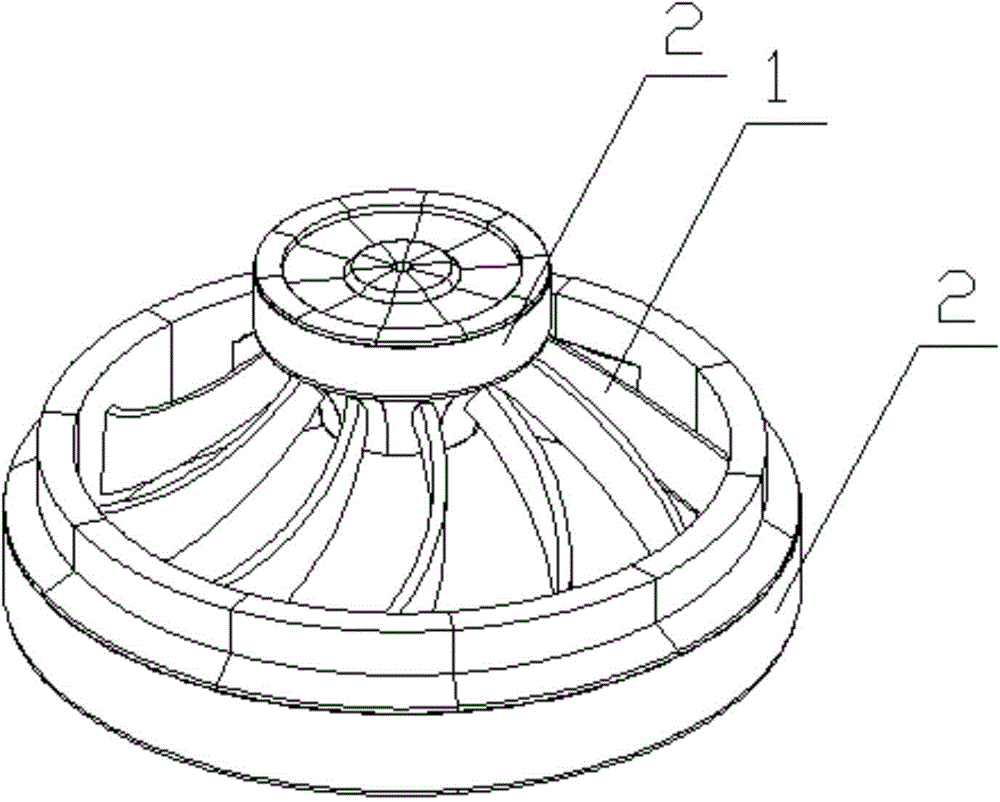

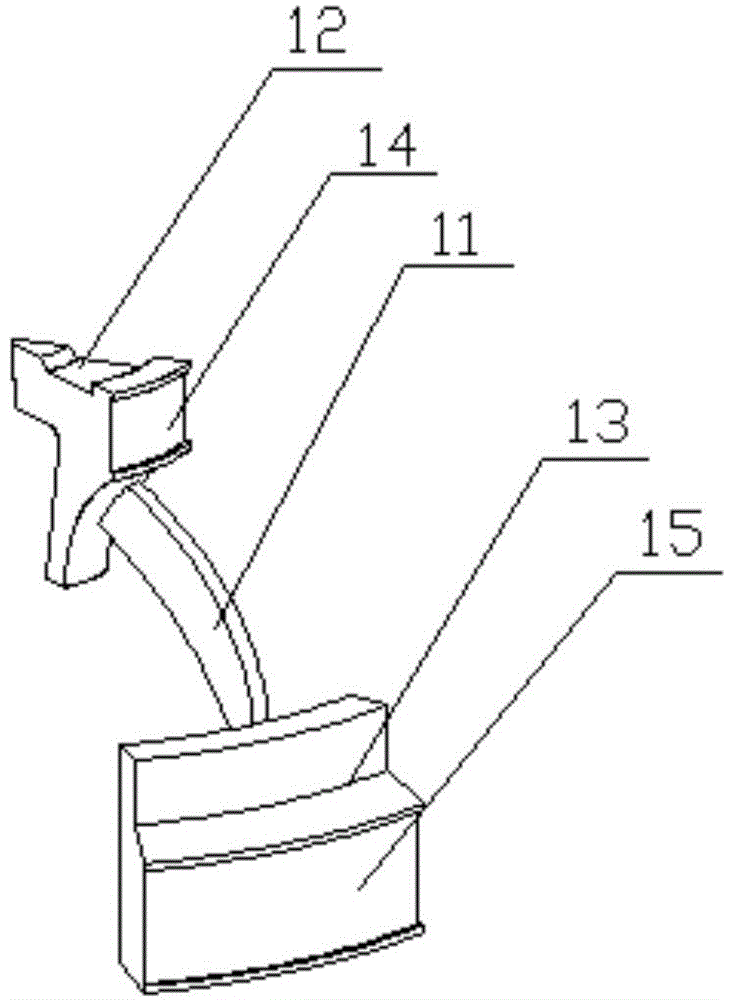

Water turbine rotating wheel and manufacturing method thereof

ActiveCN105332846ASolve engineering problems that are too heavy to be transportedExtended service lifeFinal product manufactureHydro energy generationWater turbineHeat treated

The invention discloses a water turbine rotating wheel and a manufacturing method of the water turbine rotating wheel. The water turbine rotating wheel is formed by splicing a plurality of blades, and the upper crown outer side and the lower ring portion outer side of the water turbine rotating wheel are wrapped with a first steel wire winding layer and a second steel wire winding layer respectively; each blade comprises a water turbine blade body, an upper crown portion and a lower ring portion, wherein the upper crown portion and the lower ring portion are arranged at the two ends of the blade body; and the manufacturing method of the water turbine rotating wheel sequentially comprises the steps of blade designing, blade primary blank casting, heat treatment, surface cutting machining to obtain a refined blank, and sequentially conducting of surface anticorrosion treatment on the refined blank, heat treatment and grinding on the refined blank to complete industrialized manufacturing of the blades. The blades are transported to a dam, and after the blades are assembled, steel wire winding is carried out on the upper crowns and the lower rings of the blades; and sealing protection treatment is carried out on combined gaps and steel wire layers on the water turbine rotating wheel, and finally, finishing operation and debugging are carried out. According to the water turbine rotating wheel and the manufacturing method of the water turbine rotating wheel, the engineering problems that the water turbine rotating wheel is huge, and cannot be transported are solved, damaged portions can be conveniently and locally split or repaired or replaced, and the service life of the rotating wheel is greatly prolonged.

Owner:KUNSHAN YONGNIAN ADVANCED MFG TECH

Kidney-replenishing yang-invigorating medicine and its preparing method

InactiveCN1768811ABreak through the limitation of slow effectMask unpleasant smellsUnknown materialsSexual disorderCornus officinalisLicorice roots

The invention discloses a medicament for kidney tonifying, which is prepared from gen-seng, broomrape, hairy deerhorn, cornus officinalis, eucommia bark, cynomorium songaricum, epimeddium, morinda root, wolferry fruit, fleece-flower root, poria cocos and licorice root. The medicament can be prepared into any of the conventional oral dosage forms.

Owner:胡正岳

Method of separating olefins/alkanes via eutectic solvent based on protonated ionic liquid

ActiveCN107261765ASimple preparation processLow costGas treatmentDispersed particle separationIonChemistry

The invention provides a method of separating olefins / alkanes via a eutectic solvent based on protonated ionic liquid; the method comprises the steps of preparing the protonated ionic liquid with an imidazole, amine or amide organic matter and an inorganic acid in the molar ratio of 1:1; (2) mixing the protonated ionic liquid prepared in step (1) and a hydrogen bond donor in the molar ratio of 1:1 to 1:3 to obtain a eutectic solvent; (3) mixing the eutectic solvent prepared in step (2) and a metal salt capable of coordinating with an olefin to obtain an active eutectic solvent containing the metal salt; (4) using the active eutectic solvent prepared in step (3) as an absorbent to separate olefins / alkanes. The method has the advantages of good olefin / alkane separating performance, ease of preparation, low cost, and high solubility for silver salts and copper salts.

Owner:TIANJIN UNIV

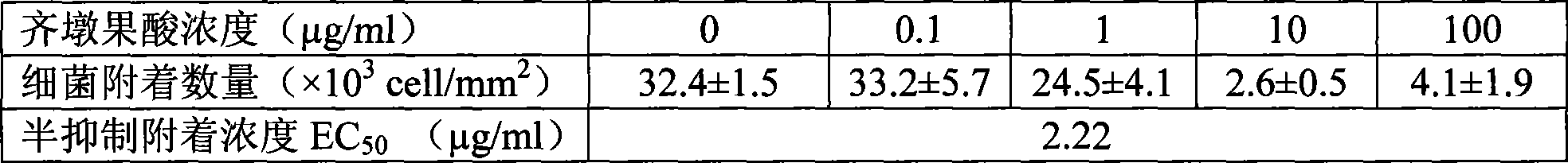

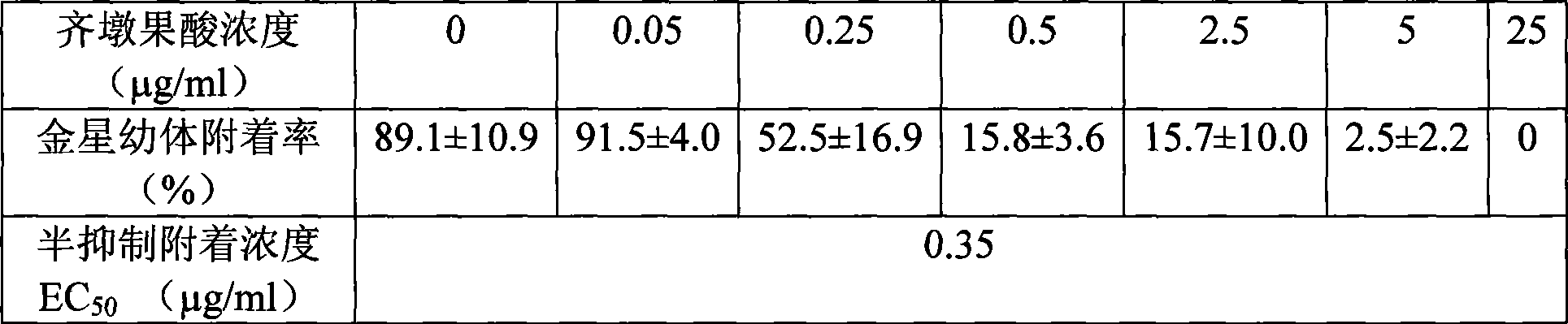

Application of oleanolic acid in preparing sea environment-friendly antifouling agent

InactiveCN101485321AThere are no disadvantages that are difficult to practically promote and applyImprove antifouling performanceBiocideAntifouling/underwater paintsSeawaterSubmarine

The invention discloses application of oleanolic acid in preparing a marine environment-friendly antifouling agent, and relates to an antifouling agent, in particular to application of a natural active material oleanolic acid as the marine environment-friendly antifouling agent. The oleanolic acid applied to a marine antifouling coating can prevent marine plants from adhering and growing on the surfaces of submarine artificial facilities such as the bottom of a ship, an offshore oil-gas platform, a buoyage, a wharf, a bridge pier, a seawater pipeline, an aquaculture net cage, and the like. The invention provides application of the oleanolic acid in preparing the marine environment-friendly antifouling agent and the marine antifouling coating.

Owner:XIAMEN UNIV

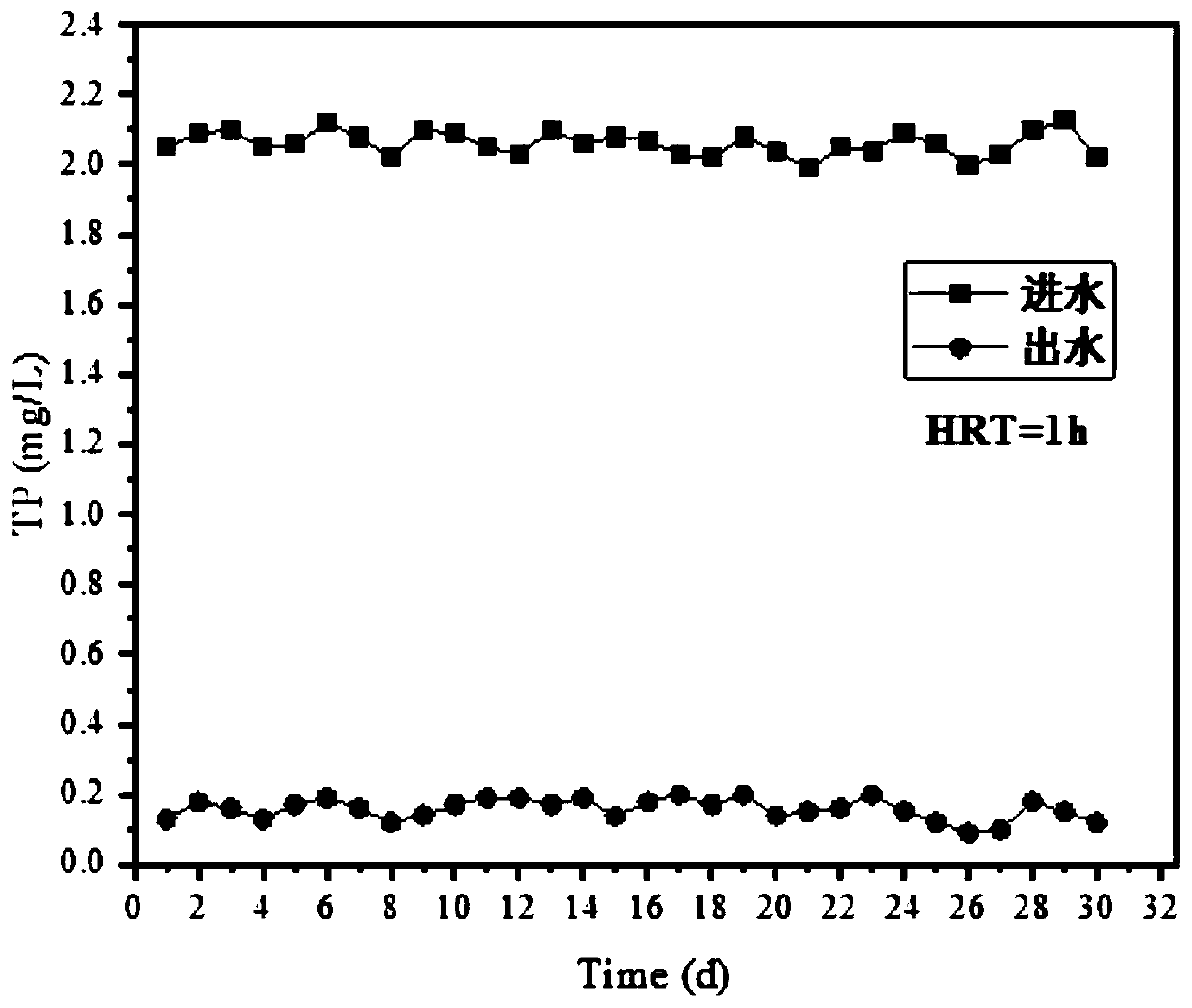

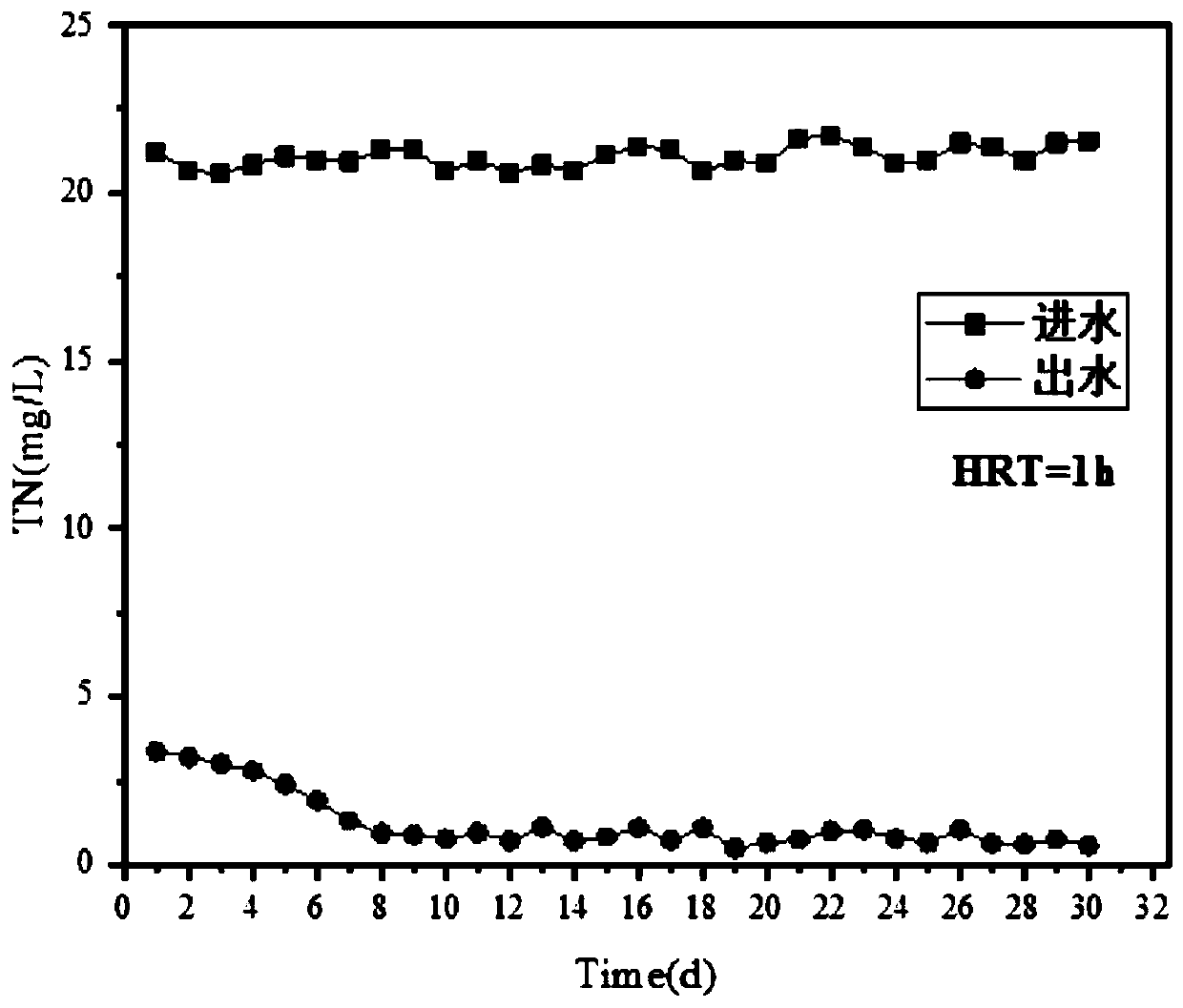

Synchronous denitrification and phosphorus removal composite filler and preparation method and application thereof

InactiveCN110683631AAchieve removalImprove stabilityTreatment with microorganism supports/carriersCarbonate mineralsSilicate Cement

The invention relates to the technical field of sewage treatment, and discloses a synchronous denitrification and phosphorus removal composite filler and a preparation method and application thereof.The composite filler comprises the following components in parts by weight: 15-20 parts of pyrite; 2-8 parts of sulfur; 0.5-1 part of carbonate minerals of calcium; 4.5-10 parts of Portland cement; 7.5-19.5 parts of water; and 0.5-3.0 parts of a foaming agent aqueous solution. Compared with a traditional sulfur autotrophic denitrification pyrite filler, the composite filler has a large specific surface area, high reactivity, light weight, and high hardness and strength, has efficient adsorption and precipitation effects on phosphorus, and has the characteristic that a large number of microorganisms can be loaded for biological denitrification, so that the composite filler is a multifunctional composite filler, and has good application prospects.

Owner:南京华创环境技术研究院有限公司

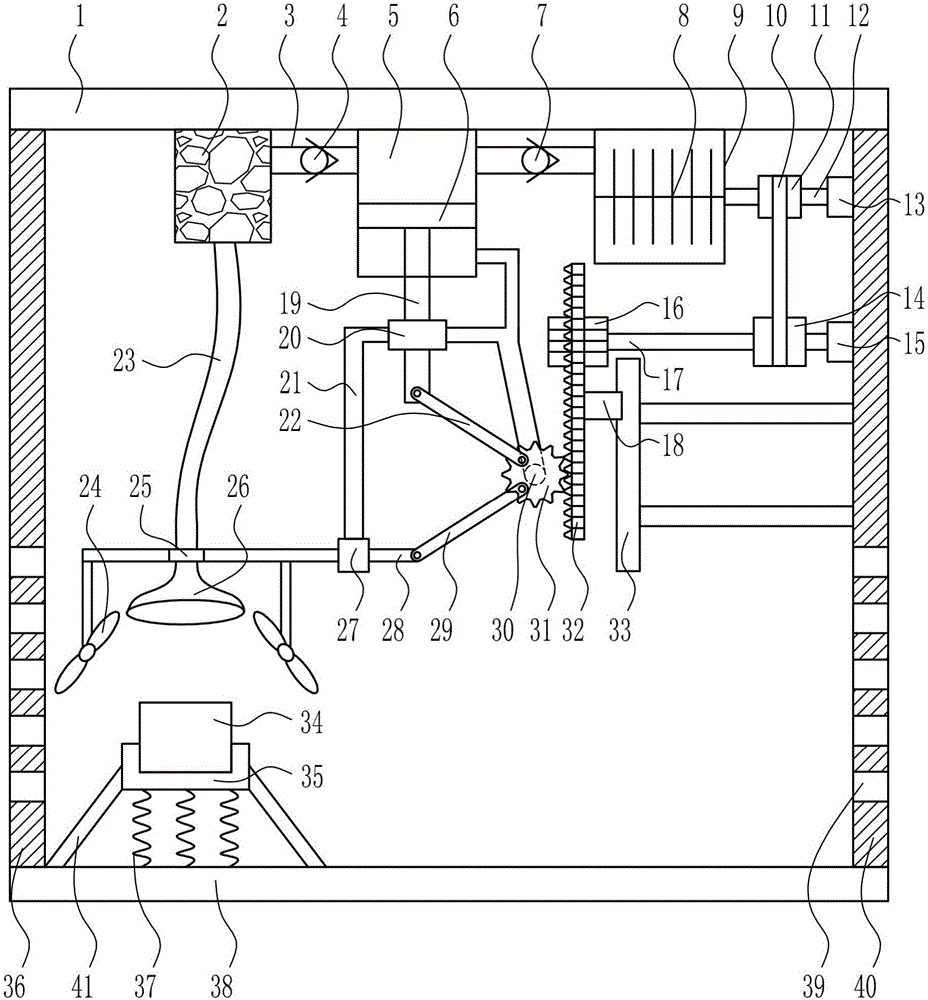

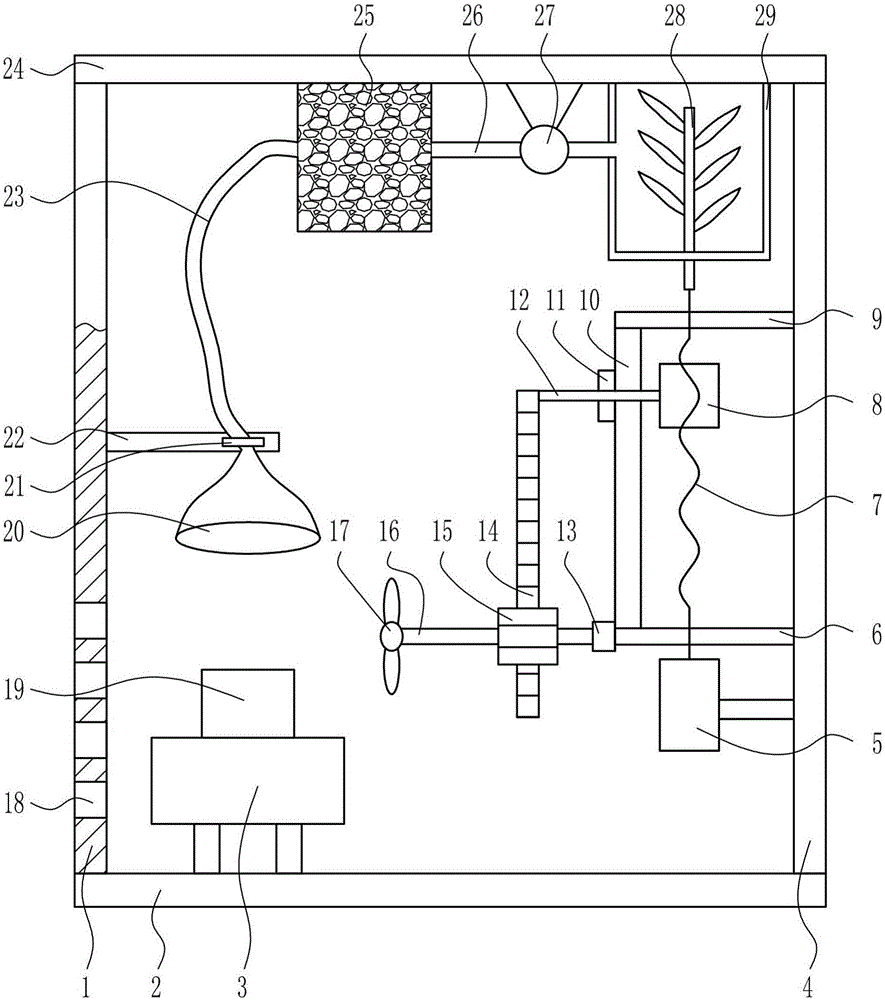

Heat dissipation shockproof device of filter for high-voltage harmonic treatment

ActiveCN106195107AGood load-bearing capacityGood fixed effectNon-rotating vibration suppressionModifications using liquid coolingPistonIce storage

The invention relates to a shockproof device, in particular to a heat dissipation shockproof device of a filter for high-voltage harmonic treatment. The heat dissipation shockproof device of the filter for high-voltage harmonic treatment has the technical effects that the heat dissipation effect is great, the shockproof effect is good, and the operation difficulty is low. To achieve the technical effects, the heat dissipation shockproof device of the filter for high-voltage harmonic treatment comprises a top plate, a drying box, a first cold air pipe, a first one-way valve, a cylinder body, a piston, a second one-way valve, a stirring rod, an ice storage box, a flat belt, a small belt pulley and the like. The top of a bottom plate is sequentially provided with a left support, springs and a right support from left to right. The left support and the right support are provided with vent holes. A containing tank is arranged at the top ends of the springs. Through the heat dissipation shockproof device, the effects that the cooling speed is high, the heat dissipation effect is great, and the operation difficulty is low are achieved, application of the filter is facilitated by keeping the application environment of the filter dry, and long-term application of the filter is also facilitated.

Owner:张晶星

Novel method for preparing composite organic calcium with high water solubility by using acid fruit juice and eggshell

A new preparing high dissolved complex organic calcium method using acid fruit juice and eggshell as raw materials which is that cleaning, triturating and drying the eggshell, then calcining to eggshell powder, preparing and getting fruit juice by fruits flayed, enucleated, extracted and filtrated; dissolving eggshell powder into fruit juice with mixing at some temperate to make fruit juice of neutrality from acid, where the most suitable quality is 1~5g per fruit juice 100g; putting reacted resultant into petri dish, heating and drying to get calcium preparation at 80 deg.C, or packaging to liquid product directly without drying. The method uses natural fruit juice in place of lactic acid, acetic acid, gluconic acid, citric acid and malic acid artificial composed or fermentation, from which the product can solved in water very easy, contains mass calcium and many kinds natural benefit ingredient, and is propitious to absorb and take for long time.

Owner:李理

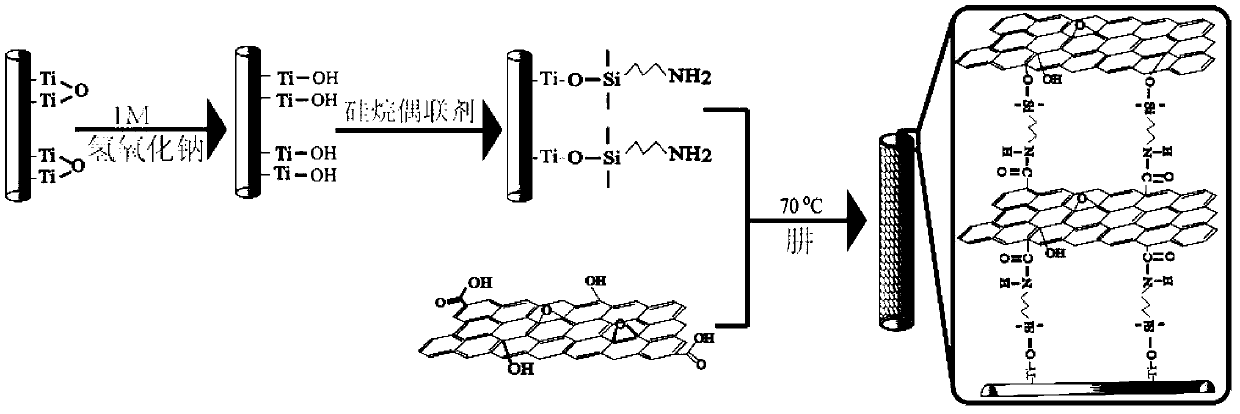

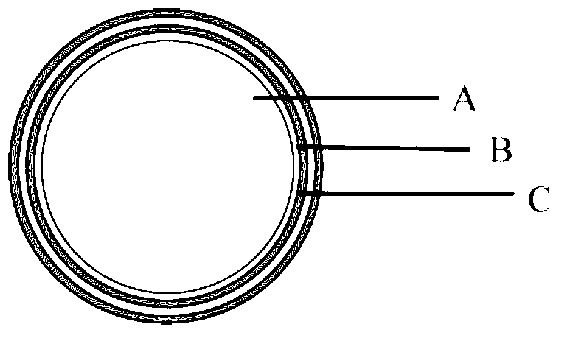

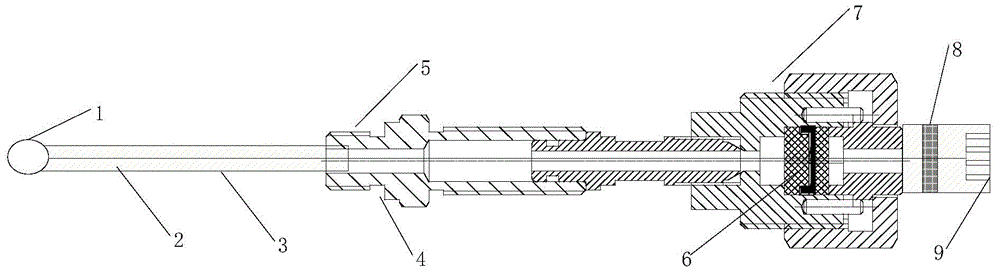

Method for preparing titanium-based graphene coating for solid phase microextraction

InactiveCN103127919AStrong toughnessEasy to use for a long timeOther chemical processesSolid sorbent liquid separationSolid-phase microextractionSolid phase extraction

The invention discloses a method for preparing a titanium-based graphene coating for solid phase microextraction. The method comprises five steps. According to the method, a silanization agent serves as an intermediate carrier, graphene is modified on the surface of a metal titanium wire, a coating which has a multi-layer sheet graphene structure is formed on the titanium-based surface, and the material can be applied to the extraction head in the solid phase microextraction technology. The method is advanced in thought, clear in concept, simple and convenient in coating preparation, the thickness is controllable, and the obtained coating is uniform, stable and high-temperature resistant. According to the solid phase microextraction head, trace phthalate in different water samples such as running water, underground water and lake water can be extracted at high efficiency, the corresponding detection limit can be 0.030mu g / L, the reproducibility is 2.2-12.6 percent, the marked recovery rate is 73.8-104.5 percent, and the repeated extraction frequency exceeds 200 times. The method has wide application prospects in the technical field of analytical chemistry and environmental analysis.

Owner:BEIJING NORMAL UNIVERSITY

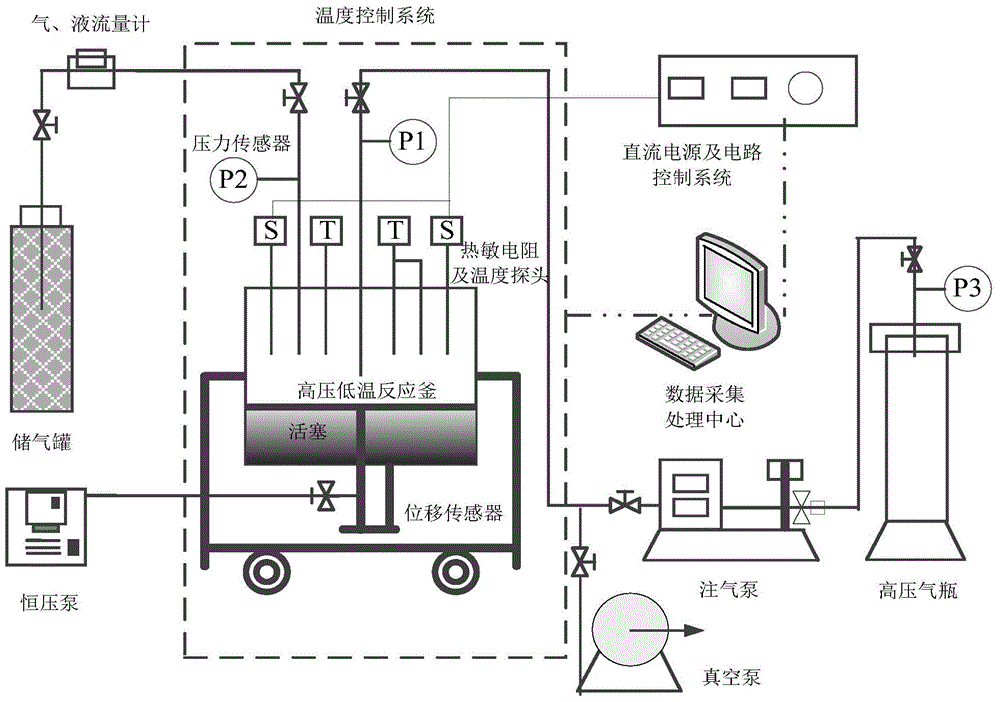

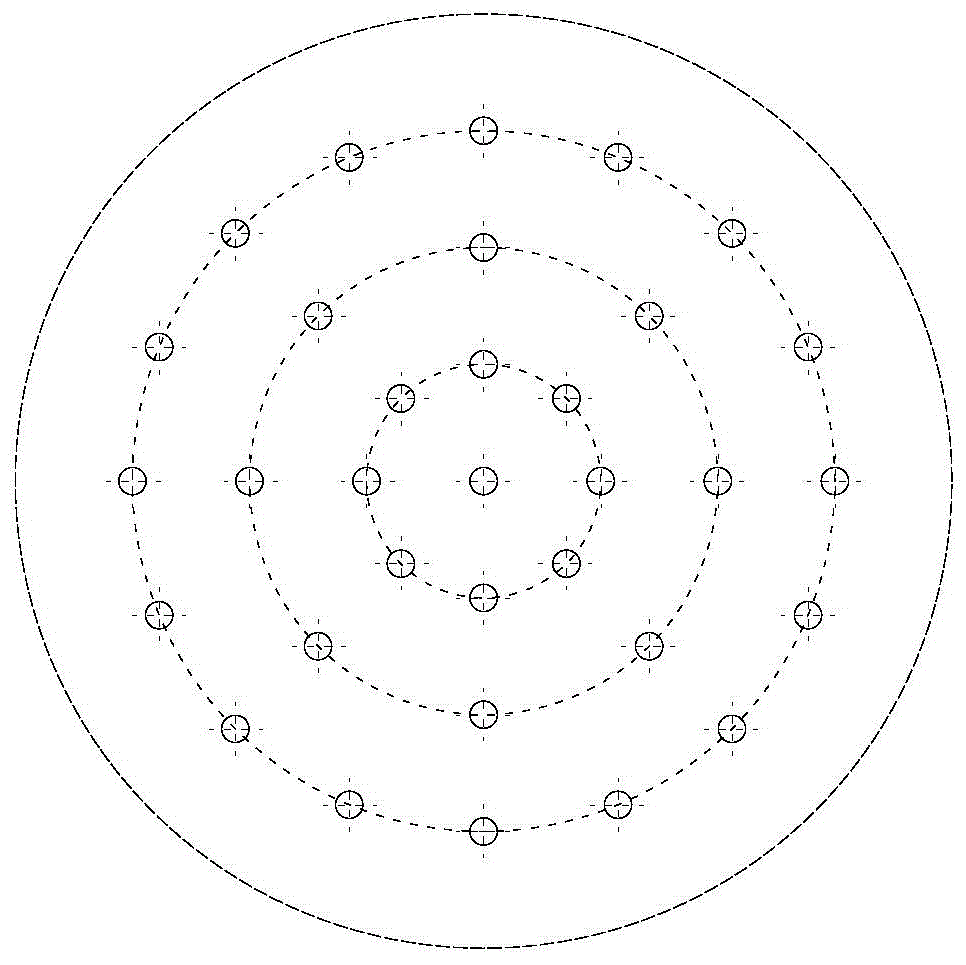

In-situ test method for high-pressure low-temperature heat conductivity coefficients and heat transfer coefficients

ActiveCN104458798AAvoid phase change effectsHigh reference valueMaterial thermal conductivityMaterial heat developmentData acquisitionInput control

The invention discloses an in-situ test method for high-pressure low-temperature heat conductivity coefficients and heat transfer coefficients. The heat conductivity coefficients and the heat transfer coefficients of media are measured based on a point heat source thermistor method. The power of a thermistor is determined, and the heat conductivity coefficient and the heat transfer coefficient of a measured medium are obtained according to the resistance feedback and temperature attenuation data of the thermistor by utilizing a calculation model. The method comprises the following steps: correcting parameters of a thermistor measurement model; slowly extruding a to-be-measured medium by utilizing a piston on the lower part of a reaction kettle, and unifying the standard of to-be-detected samples; introducing reactive gas and controlling the pressure and temperature in a target range; and inputting the determined power value into the thermistor by virtue of a power input control system, acquiring the resistance value and temperature value of the thermistor by utilizing a data acquisition device, and finally, obtaining the heat conductivity coefficient and the heat transfer coefficient by utilizing the calculation model. According to the design of the invention, in-situ synthesis of different media under high pressure and at low temperature can be met, and in-situ measurement of the heat conductivity coefficients and heat transfer coefficients of multi-phase condition substances in different spaces and different time is realized.

Owner:DALIAN UNIV OF TECH

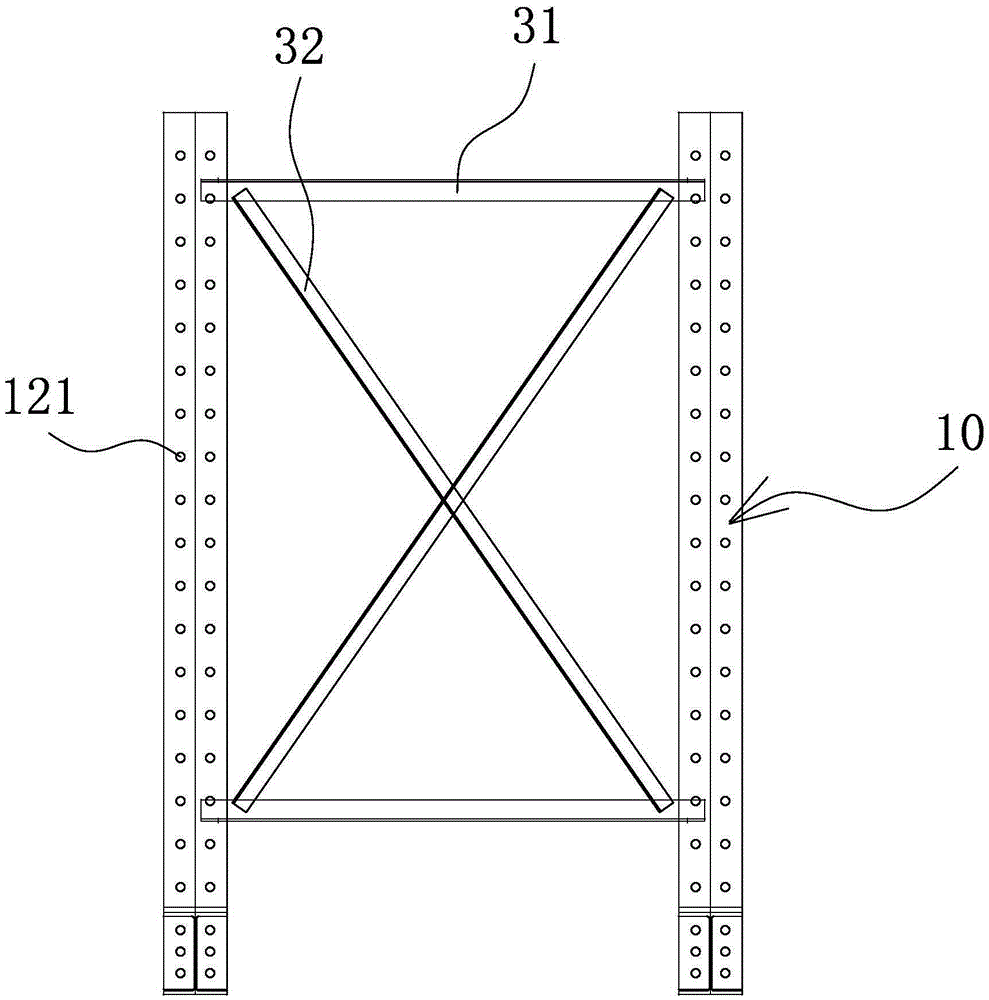

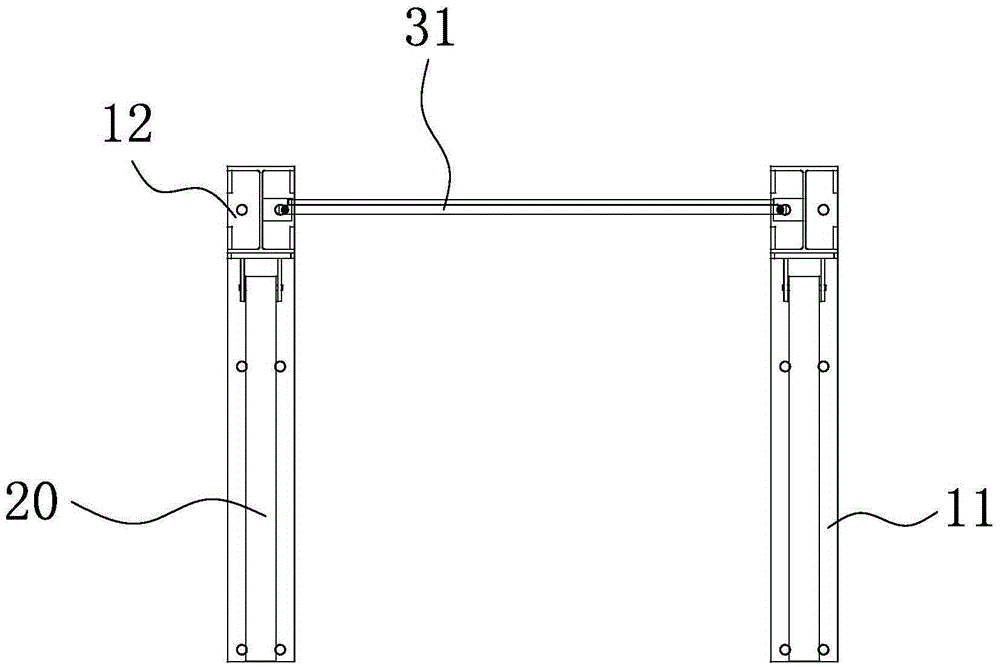

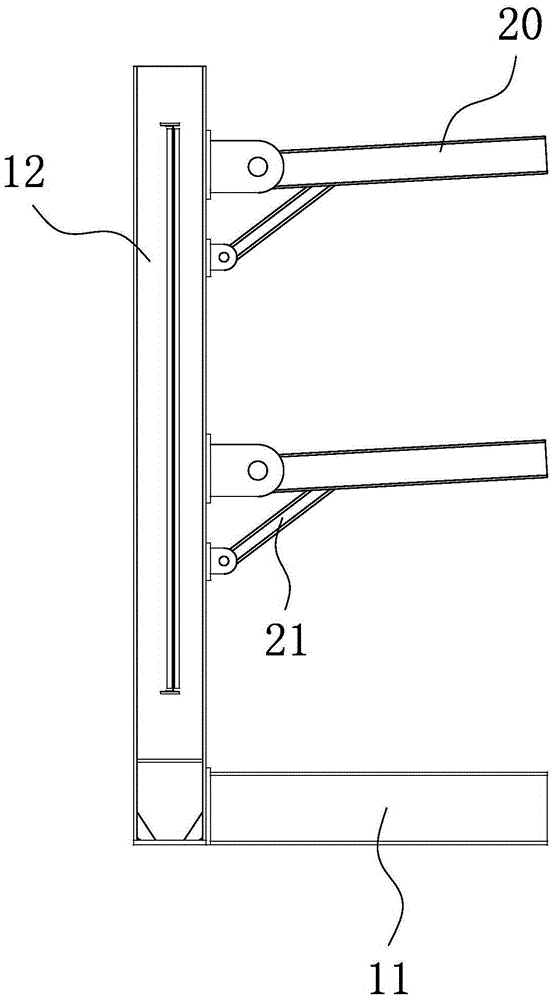

Single-face combined cantilever rack

The invention provides a single-face combined cantilever rack, and belongs to the technical field of machines. The problem that an existing cantilever rack cannot be folded is solved. The single-face combined cantilever rack comprises two supports and a plurality of cantilevers. Each support is arranged in an L shape, and the two supports are connected through a supporting assembly. The cantilevers are rotationally arranged on the supports from top to bottom, and a plurality of supporting arms corresponding to the cantilevers are rotationally connected to the supports. One ends of the supporting arms are connected with the supports, and the other ends of the supporting arms can be connected to the corresponding cantilevers in an inserted manner. The supporting arms are located below the corresponding cantilevers, and the supporting arms and the corresponding cantilevers are located in the same vertical plane. The single-face combined cantilever rack has the advantages of being capable of being folded and good in stability.

Owner:NINGBO CITY XINGUANG SHELF

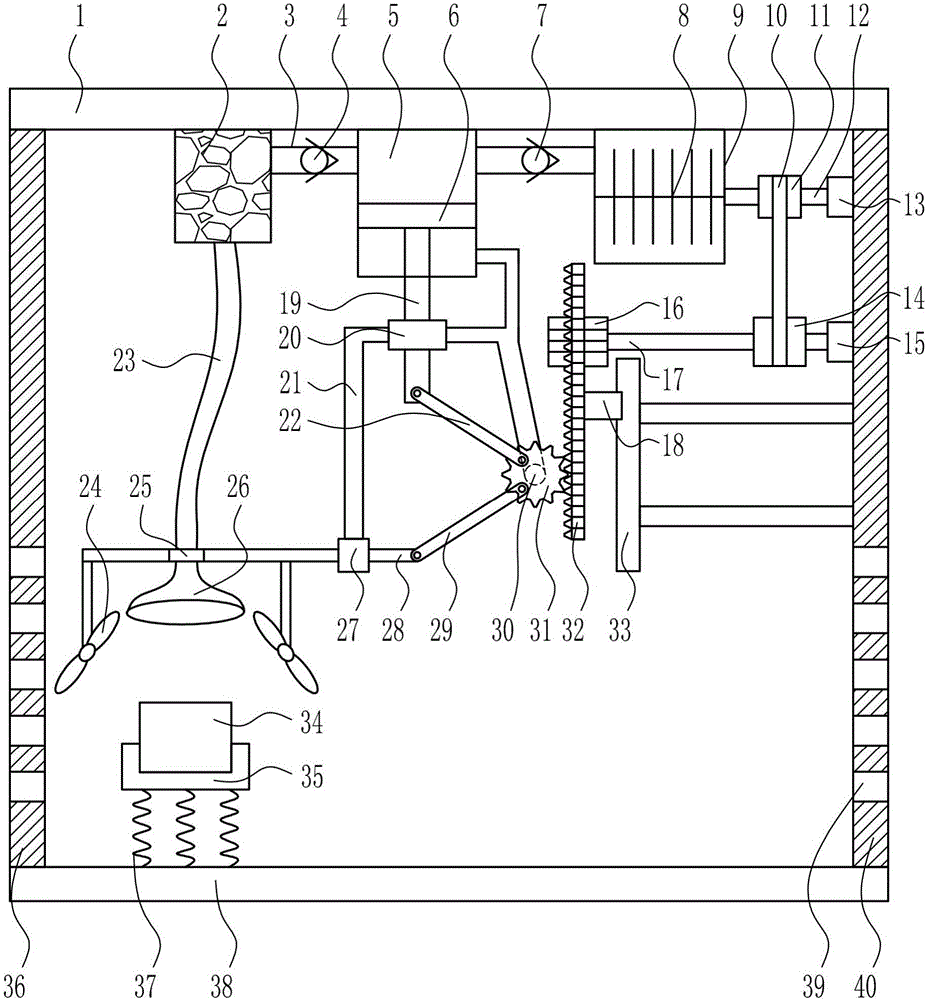

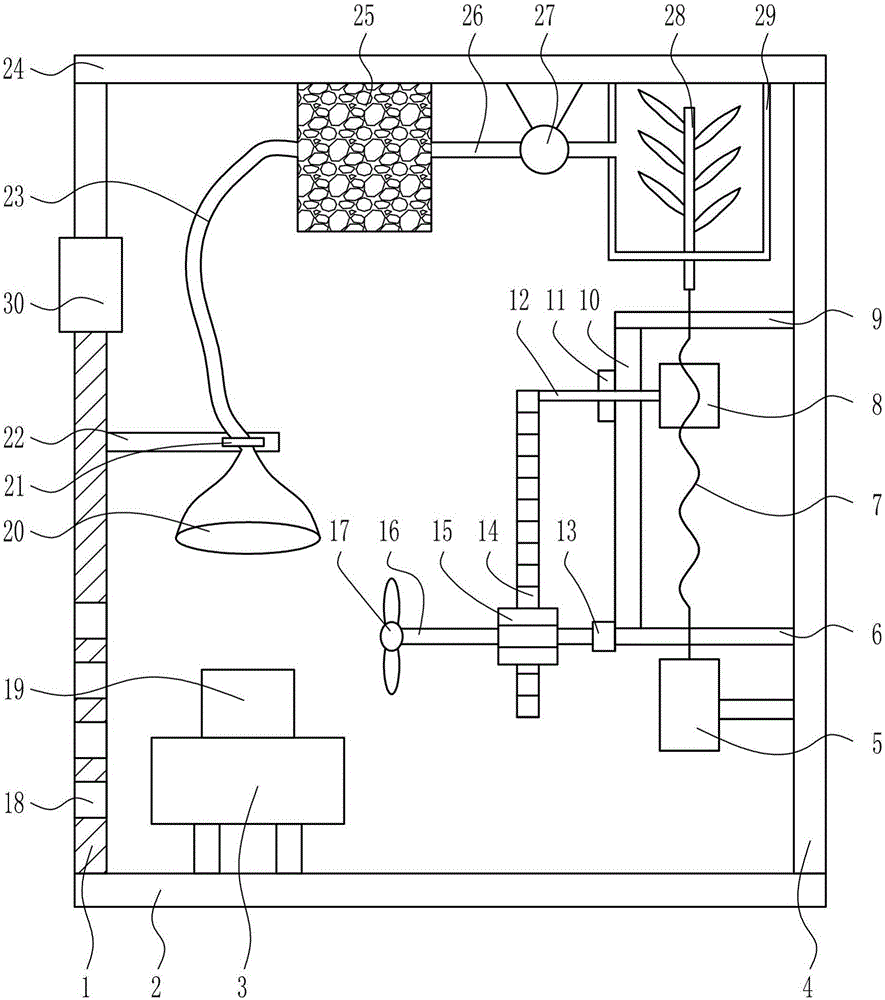

Filter temperature reduction and heat radiation device for high voltage harmonic processing

InactiveCN106304792AImprove cooling effectEffective coolingModifications for power electronicsHarmonicEngineering

The invention relates to a heat radiation device, in particular to a filter temperature reduction and heat radiation device for high voltage harmonic processing, and aims at solving the technical problems to provide the filter temperature reduction and heat radiation device for high voltage harmonic processing with the advantages that the temperature reduction speed is high; the heat radiation effect is good; the operation difficulty is small. In order to solve the technical problems, the invention provides the filter temperature reduction and heat radiation device for high voltage harmonic processing. The filter temperature reduction and heat radiation device for high voltage harmonic processing comprises a left support frame, a bottom plate, a heat radiator, a right support frame, a motor, a first support rod, a lead screw, a screw nut, a second support rod, a guide rail, a guide block, a connecting rod, a bearing seat and the like, wherein the top of the bottom plate is sequentially provided with the left support frame, the heat radiator and the right support frame from the left side to the right side; ventilation holes are formed in the left support frame; a third support rod is arranged at the right side of the left support frame. The filter temperature reduction and heat radiation device achieves the effects that the temperature reduction speed is high; the heat radiation effect is good; the operation difficulty is small; the use environment of a filter maintains the dryness; the use of the filter is facilitated; the long-time use of the filter is also facilitated.

Owner:重庆恒泰聚能科技有限公司

Soaking cleaning agent for optical glass and preparation method thereof

InactiveCN103834500AAvoid corrosionGood cleaning effectOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsTriethanolamineSilicone oil

The invention relates to the technical field of a cleaning agent, and particularly relates to a soaking cleaning agent for optical glass and a preparation method thereof. The soaking cleaning agent comprises the following raw materials in percentage by weight: 3-8% of sodium hydroxide, 8-15% of anhydrous sodium sulphate, 2-6% of complexing agent, 1- 3% of wetting agent, 1-5% of triethanolamine and the balance of pure water, wherein the complexing agent is one of tetrasodium EDTA (ethylene diamine tetraacetic acid), organic phosphonate, hydroxy carboxylic acid salt or a compound complex, and the wetting agent is one of ethyl-glucoside, polyether modified silicone oil, polyether modified polysiloxane or a polyether modified polydimethylsiloxane polymer. The soaking cleaning agent for the optical glass, provided by the invention, can be used for completely removing white dots from the optical glass, effectively avoids corroding the optical glass, has a good cleaning effect and is simple in a preparation technology, convenient to use and beneficial to popularization and application.

Owner:广东剑鑫科技股份有限公司

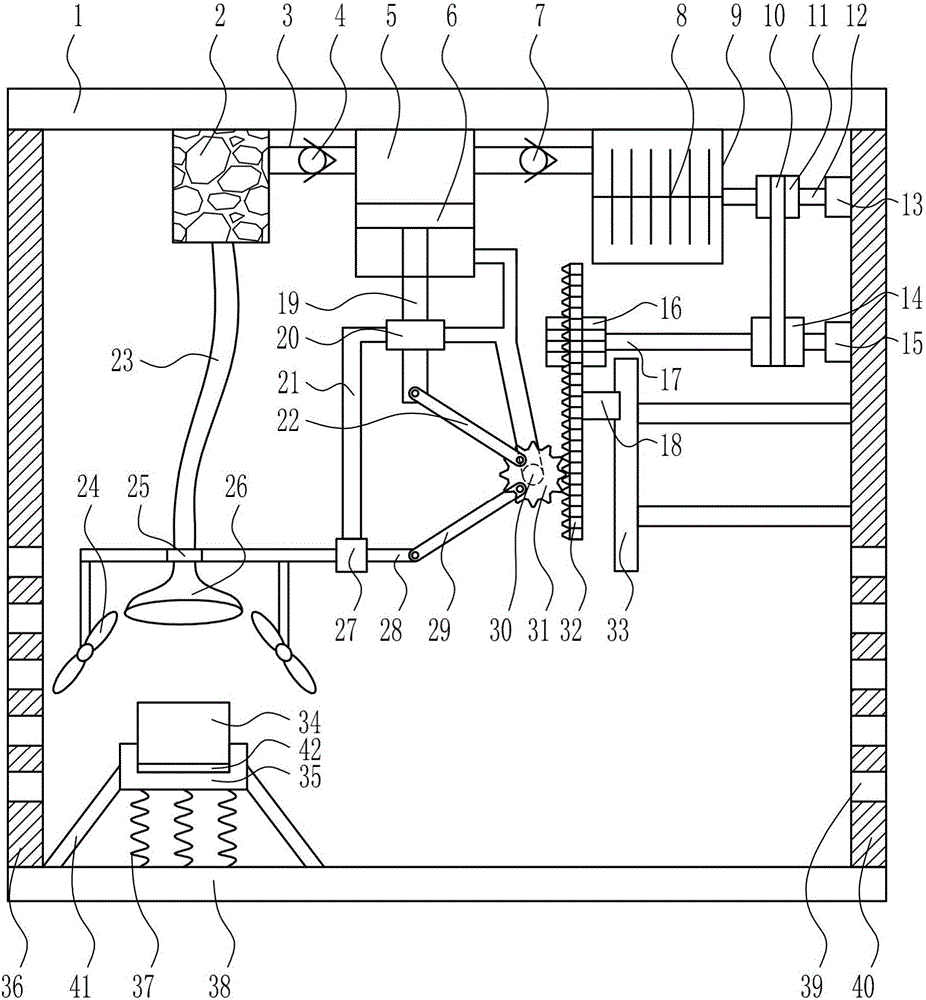

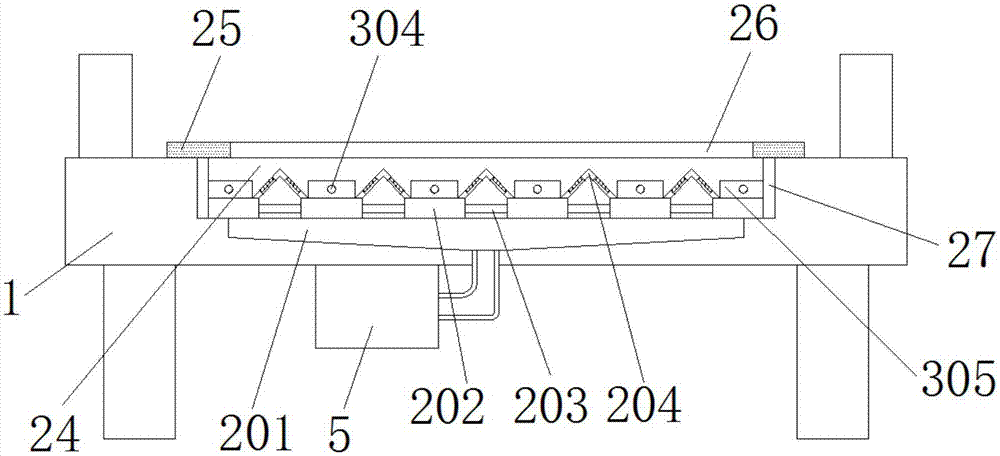

Stone cutting machine

InactiveCN107984639ASave waterEasy to recycleWorking accessoriesStone-like material working toolsElectric driveScrap

The invention discloses a stone cutting machine, and relates to the technical field of stone processing. The stone cutting machine comprises a workbench. A drainage channel is formed in the middle ofthe upper surface of the workbench. The position, located on the edge of the drainage channel, of the upper surface of the workbench is fixedly connected with the edge of the lower surface of a placing plate, and the plating plate is provided with a bar-shaped hole which extends from left to right. The stone cutting machine is provided with clamping devices, a first clamping plate can be pushed through electric drive pushers in the two clamping devices so that a protection pad on the first clamping plate can make contact with stone, and then two second electric drive pushers in the clamping devices are used for pushing a connecting block so that second clamping plates can move towards the stone to clamp the stone. The two clamping devices are matched so that the position of the stone on the placing plate can be fixed, displacement by vibration of the stone in the stone cutting process can be avoided, the phenomenon that cutting blades are broken due to movement of the stone or scraps appear by cutting mistakes of the stone can be avoided, and the problems put forward in the background technology are solved.

Owner:SHAOXING DAWEI KNITTING MACHINERY

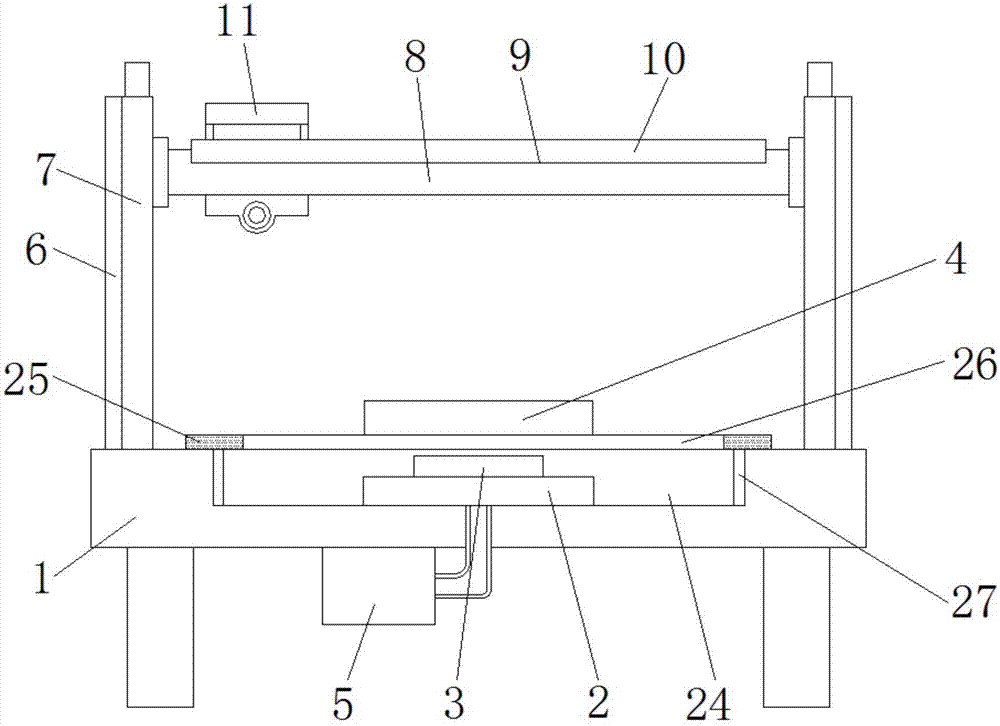

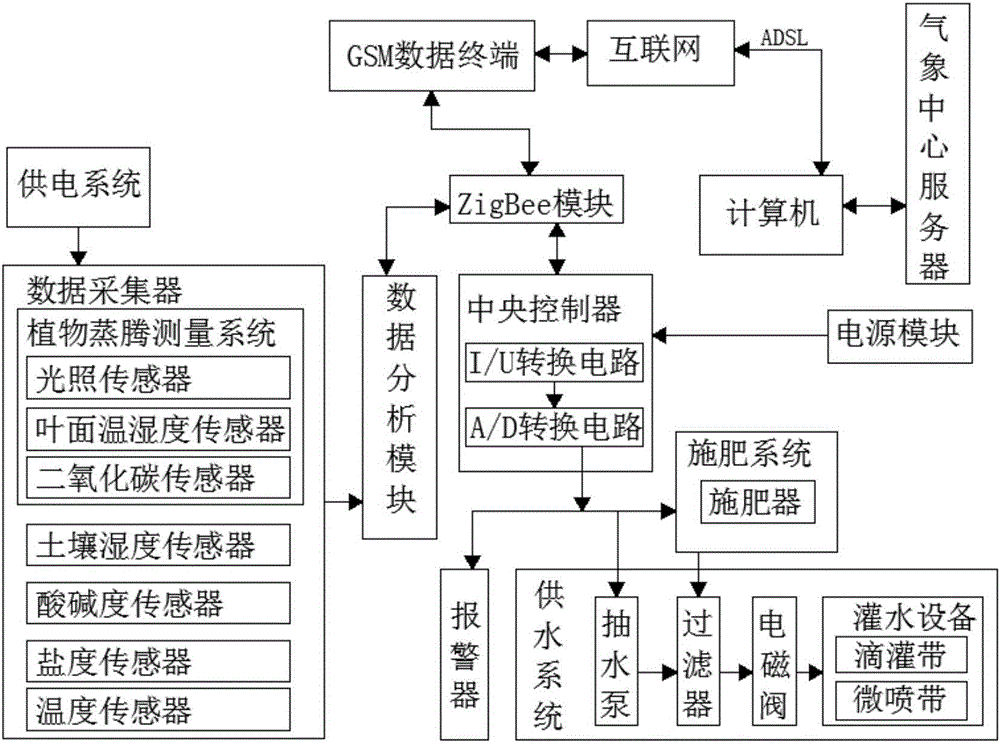

Alternative irrigation intelligent control system

InactiveCN106376437AImprove water saving potentialReduce difficultyClimate change adaptationWatering devicesFertilizerAutomatic control

The invention discloses an alternative irrigation intelligent control system comprising a weather center server, a power supplying system, a central controller, a water supplying system and a fertilizer applying system. An output end of the power supplying system is electrically connected with a data collector; an output end of the data collector is electrically connected with a data analyzing module; and an output end of the data analyzing module is bidirectionally connected with a ZigBee module in a remote way. Three control ways of automatic control, remote control and intelligent control are integrated; with cooperation of the water supplying system and the fertilizer applying fertilizer, part roots of crops can be irrigated at different time periods, so unevenness of root water supplying can be achieved and crop anti-drought physiological ecological features can be developed, and crop water-saving potential can be improved; crop irrigation difficulty and labor intensity can be reduced, irrigating efficiency can be improved, and timely, quick and precise alternative irrigation can be achieved for crops.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com