Ferro-tungsten composite oxide denitrification catalyst with flower petal structure and preparation method and application of ferro-tungsten composite oxide denitrification catalyst with flower petal structure

A composite oxide and flower-shaped technology, applied in the field of catalytic denitrification, can solve the problems of poor water resistance, sulfur resistance and thermal stability, limit large-scale industrial application, high denitrification activity temperature, etc., achieve low cost, good resistance to SO2 and H2O poisoning ability, the effect of high N2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

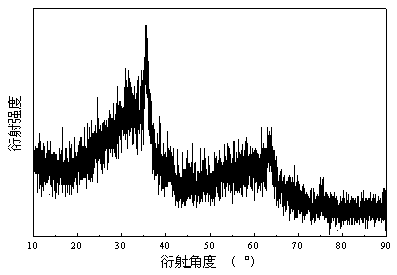

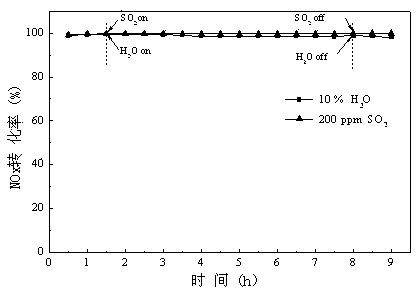

[0045] Weigh 1.9791 g Na 2 WO 4 2H 2 O, completely dissolved in 200 mL deionized water, weighed 6.6732 g FeSO 4 ·7H 2 O and 100 mg C 6 h 8 o 6 , completely dissolved in 100 mL deionized water. Put the tungsten-containing aqueous solution into a constant temperature water bath and keep the temperature at 35 o C. Add the iron-containing aqueous solution drop by drop into the vigorously stirred solution, and keep the pH of the mixed solution in the range of 6-10 during the titration process. If the pH is lower than this range, add ammonia water to adjust. After the titration is completed, add ammonia water to adjust the mixture The pH of the solution was 8, and the stirring was continued for 3 hours. After the reaction, wash the precipitate with deionized water and ethanol several times until the filtrate is neutral, and put the filter cake in a drying box for 70 o C dried for 12 hours, and the dried sample was placed in a muffle furnace at 500 o C roasting for 5 ho...

Embodiment 2

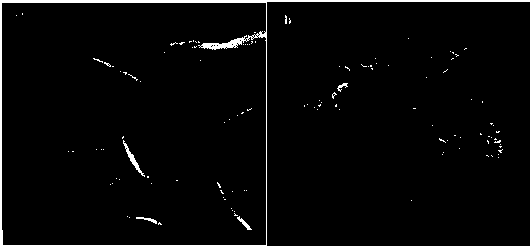

[0052] Identical with embodiment 1 method, difference is: the sample after drying is put into muffle furnace 800 o C roasting for 5 hours to obtain iron-tungsten composite oxide. XRD results (see attached Figure 4 ) shows that the product presents a strong diffraction peak, which is Fe 2 o 3 and Fe 2 WO 6 The mixed phase of the two phases shows that after the catalyst is calcined at high temperature, the original highly dispersed iron and tungsten species aggregate to form a stable phase with high crystallinity. photo by SEM (see attached Figure 5 ) It can be seen that the unique flake-like structure of the product disappears, and it is completely composed of particles, and the particle size is less than 100 nm. ICP-AES confirms that its component content is identical with embodiment 1 product.

[0053] Weigh 400 mg of the above-prepared iron-tungsten composite oxide, press it into tablets, and sieve out 40-60 mesh particles as a catalyst for denitration performance t...

Embodiment 3

[0057] Identical with embodiment 1 method, difference is: the soluble iron salt of selection is ferric sulfate, takes by weighing Fe 2 (SO 4 ) 3 9.5971g as iron source. XRD results (see attached Figure 6 ) shows that the product has no obvious diffraction peaks, indicating that the catalyst is amorphous. photo by SEM (see attached Figure 7 ) It can be seen that the product is only composed of particles.

[0058] Weigh 400 mg of the above-prepared iron-tungsten composite oxide, press it into tablets, and sieve out 40-60 mesh particles as a catalyst for denitration performance test. The denitration rate test results are shown in Table 3.

[0059]

[0060] As can be seen from the above table: the catalyst is at 225-450 o In the C temperature range, the denitrification efficiency is significantly lower than that of the sample of Example 1, only at 250-400 o In the C range, the denitrification efficiency is greater than 90%, while the N 2 The selectivity decreased sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com