Patents

Literature

1030 results about "Mixed phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

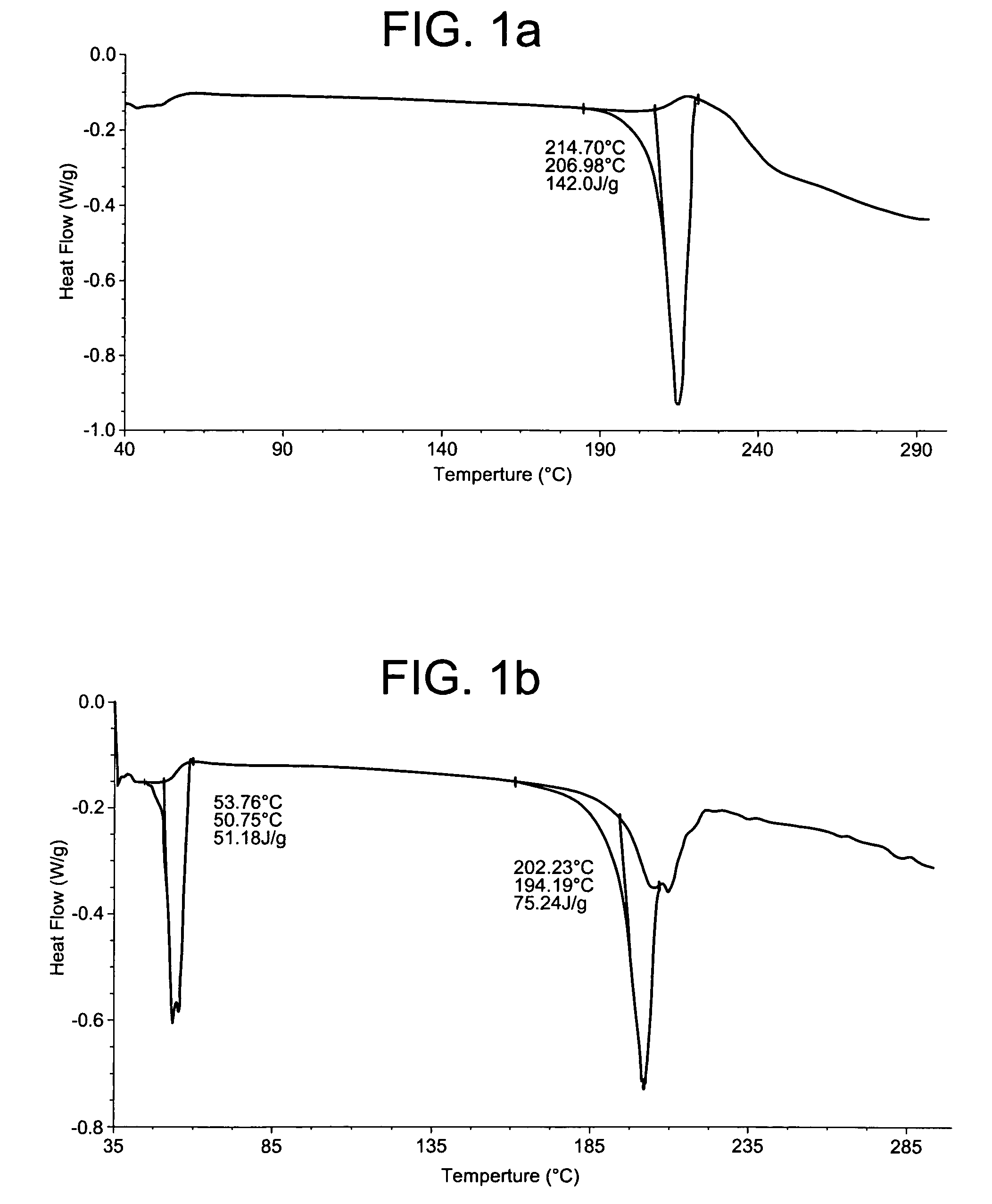

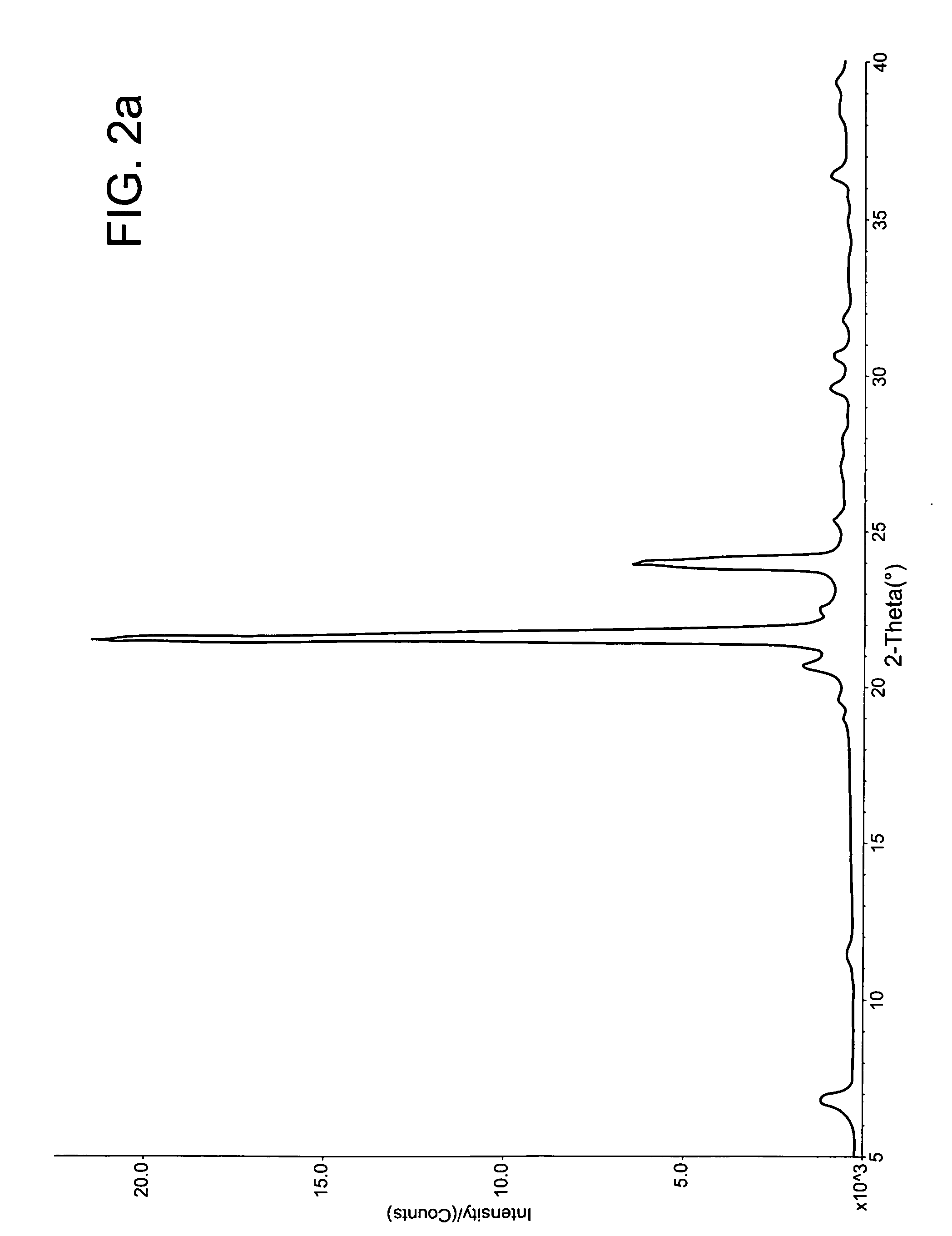

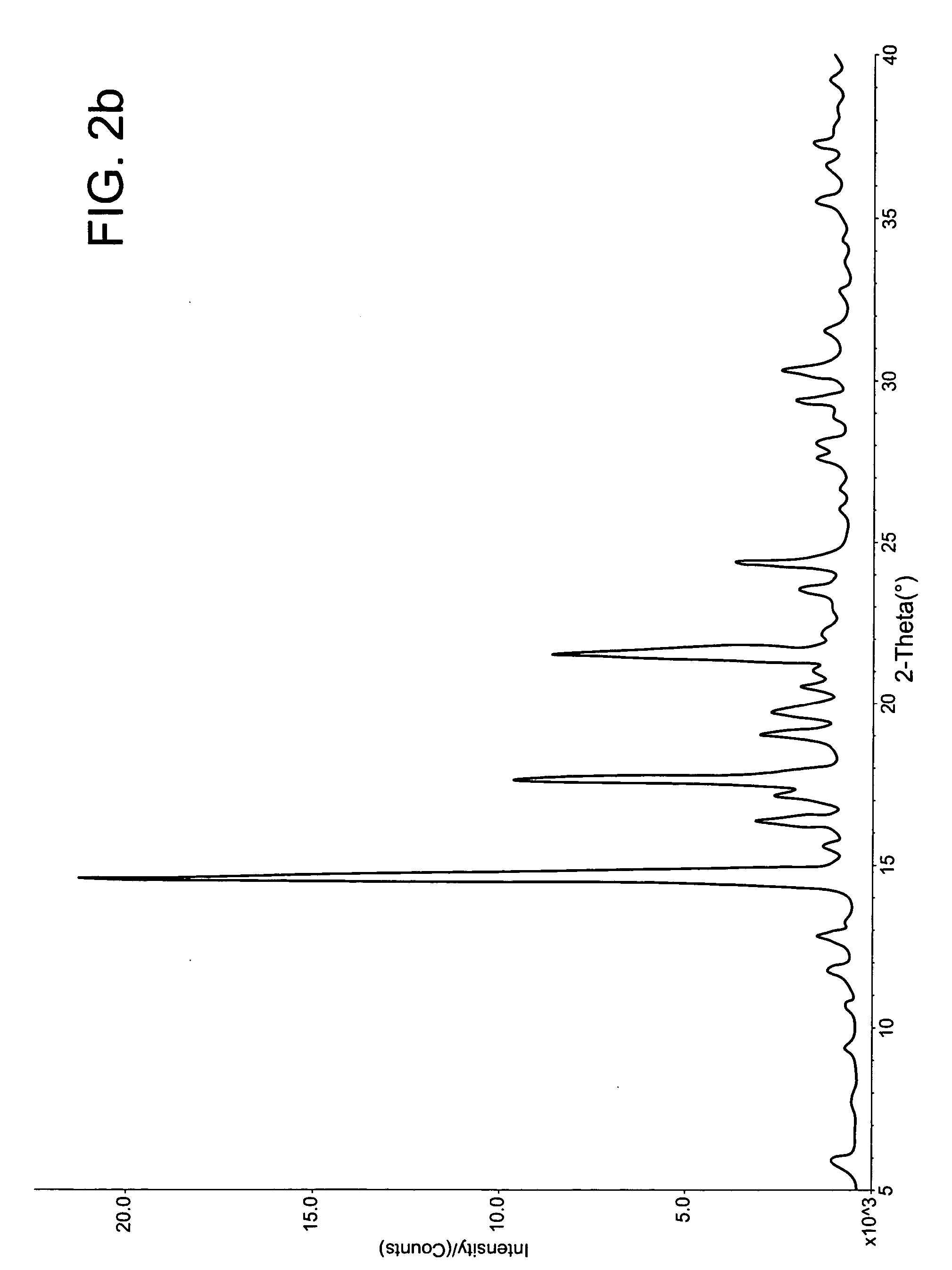

Method of preparation of mixed phase co-crystals with active agents

This invention pertains to a method of preparing mixed phase co-crystals of active agents with one or more materials that allows the modification of the active agent to a new physical / crystal form with unique properties useful for the delivery of the active agent, as well as compositions comprising the mixed phase co-crystals.

Owner:MEDCRYSTALFORMS

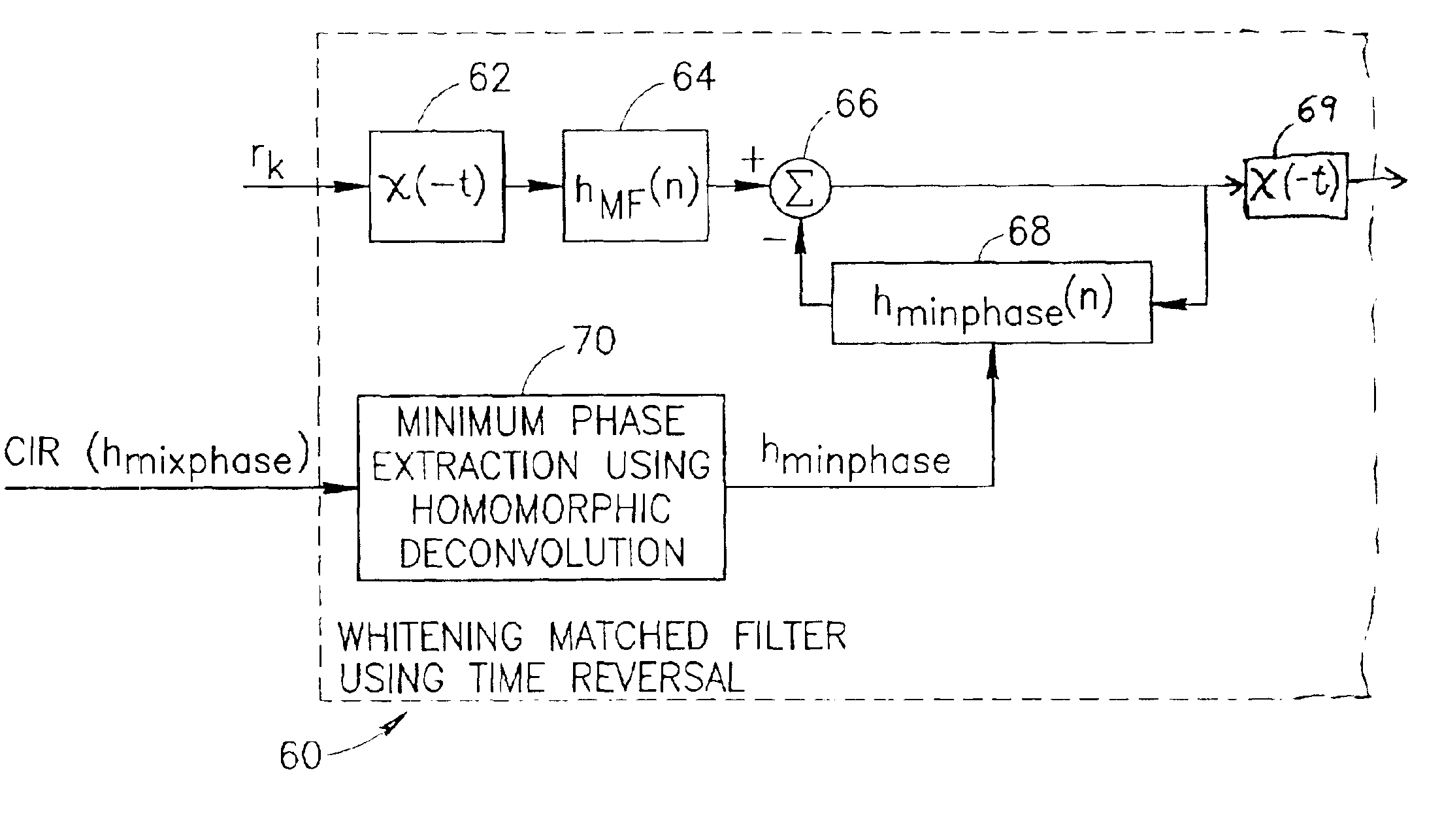

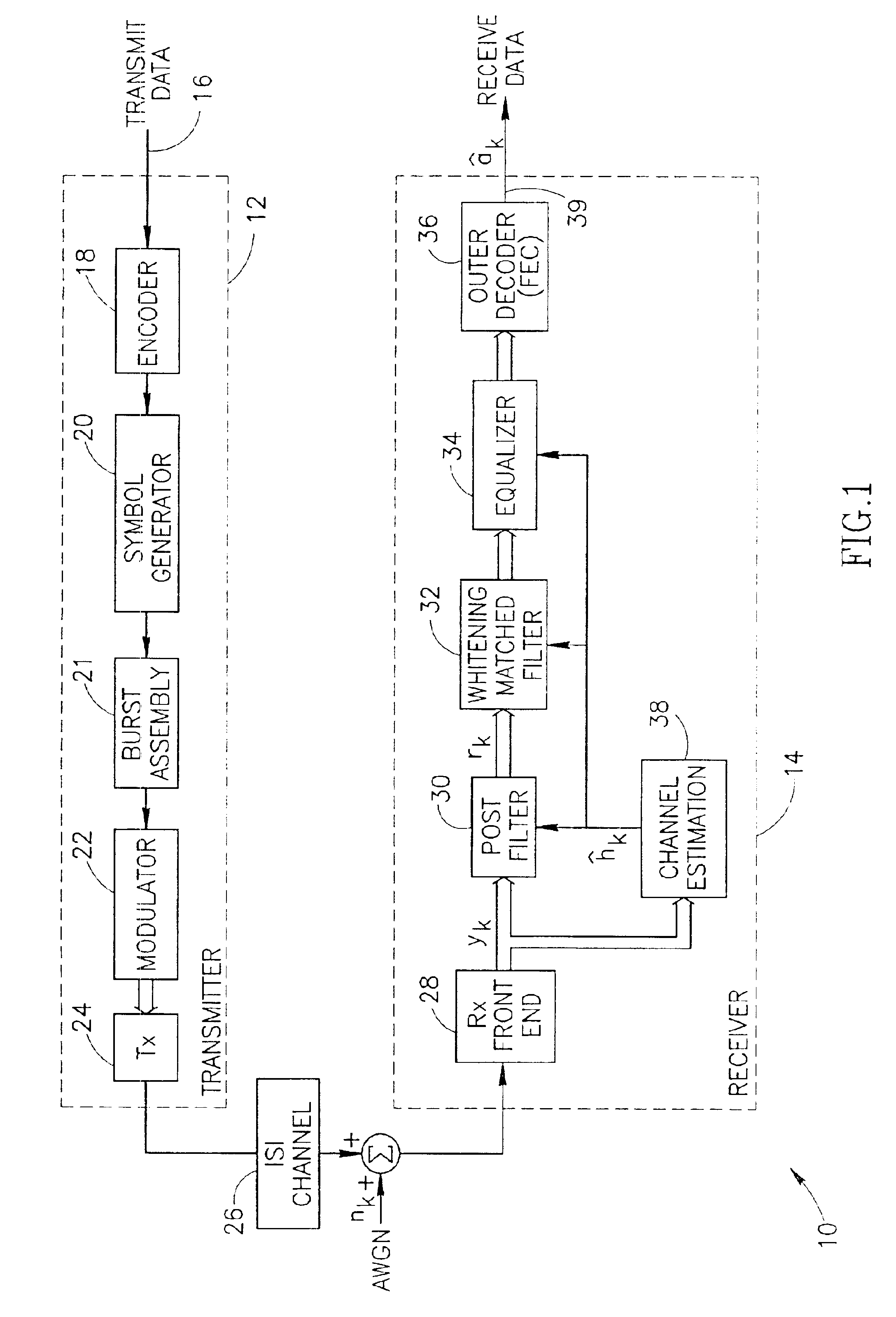

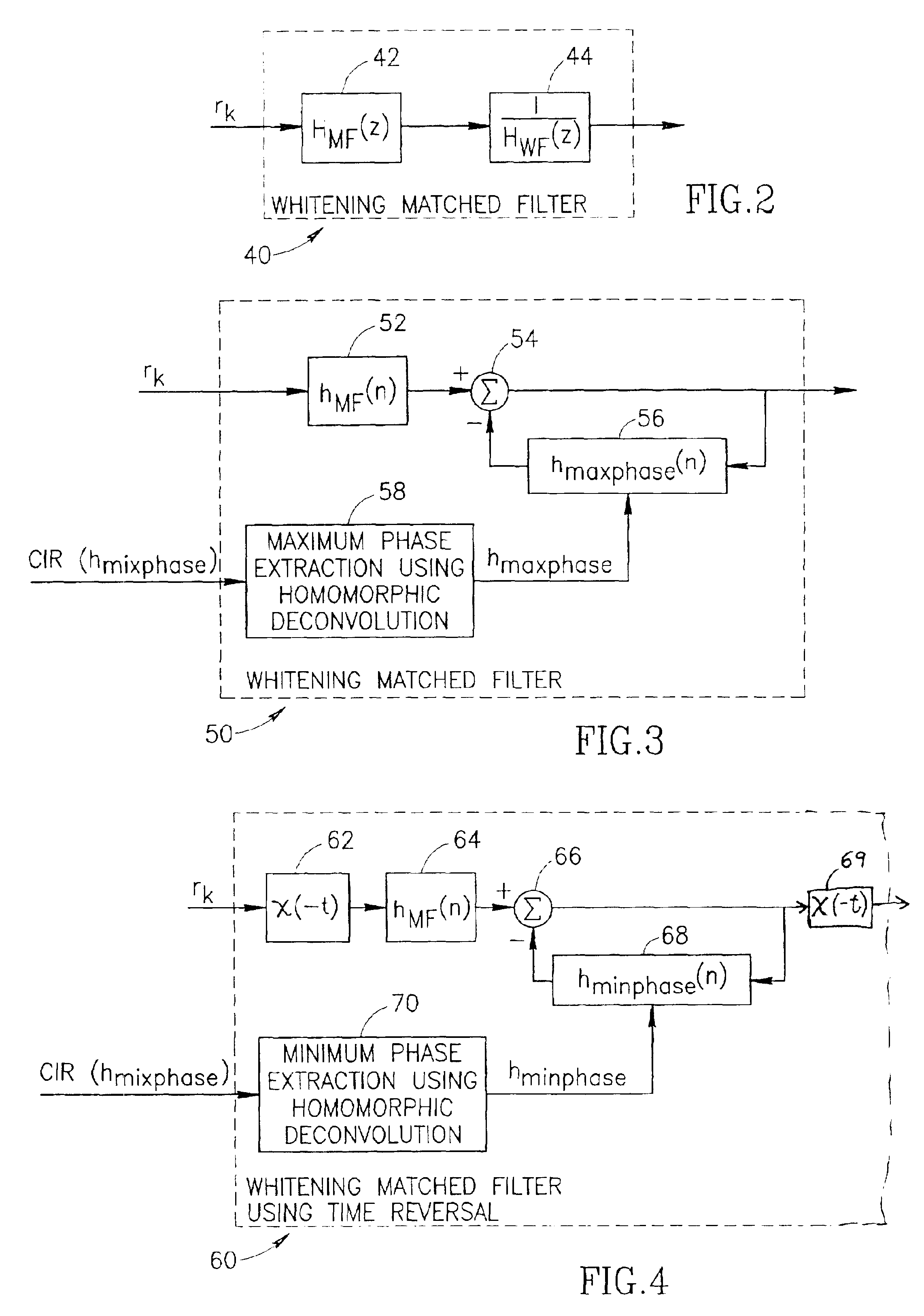

Whitening matched filter for use in a communications receiver

InactiveUS6862326B1Improve performanceMultiple-port networksDigital technique networkIir filteringChannel impulse response

A novel and useful whitening matched filter (WMF) for use in a communications receiver. The WMF is constructed by cascading a matched filter and a noise-whitening filter. The response of the matched filter is derived from the time reversed complex conjugate of the channel impulse response. The whitening filter is derived by extracting the minimum phase portion of the mixed phase channel impulse response using homomorphic deconvolution. The whitening filter is implemented using either an FIR or IIR filter adapted to process the data received before and after the training sequence using a minimum phase system in a direction in time opposite to that of the direction of corresponding data sample processing performed by the equalizer.

Owner:COMSYS COMM & SIGNAL PROC

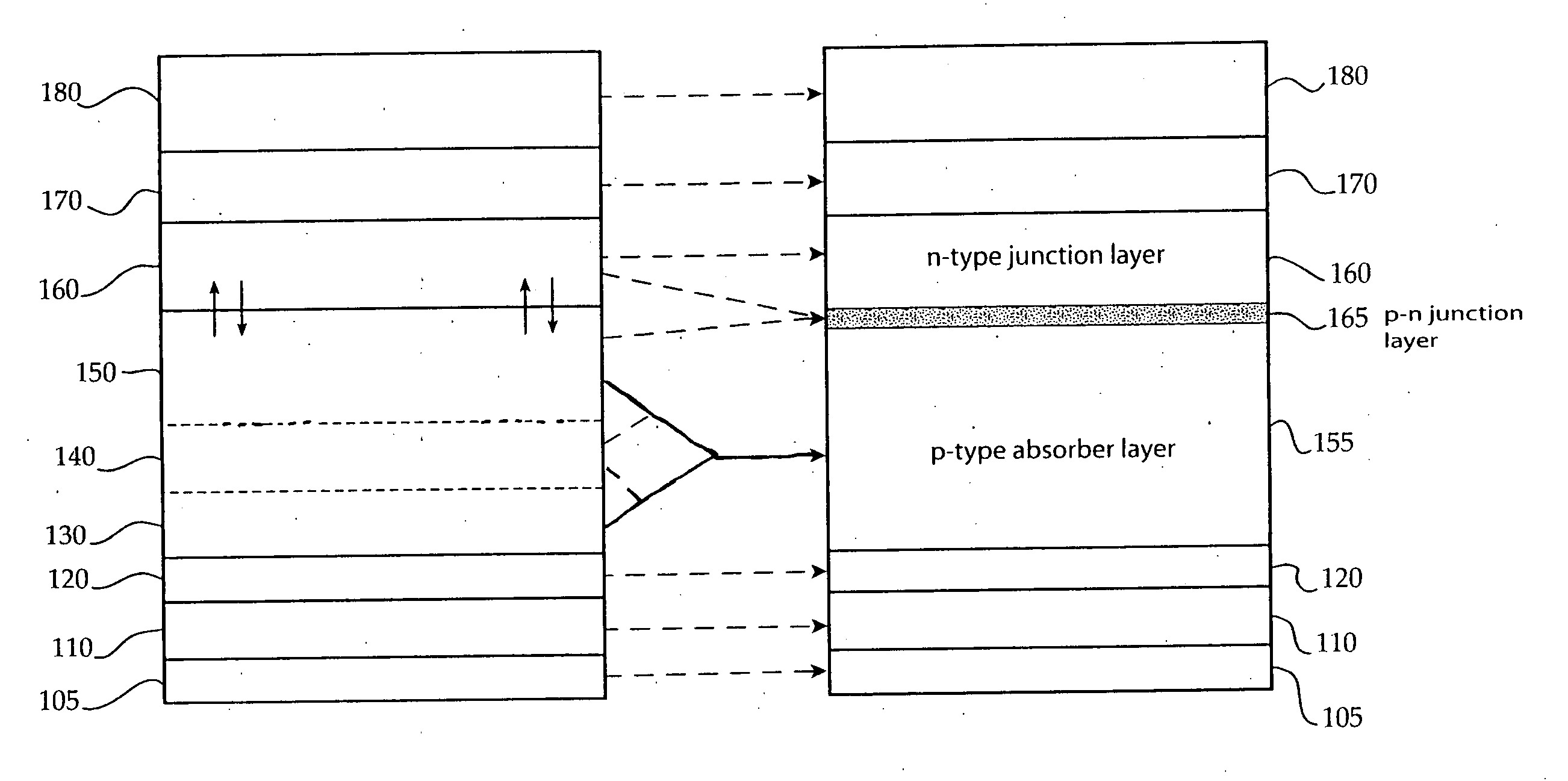

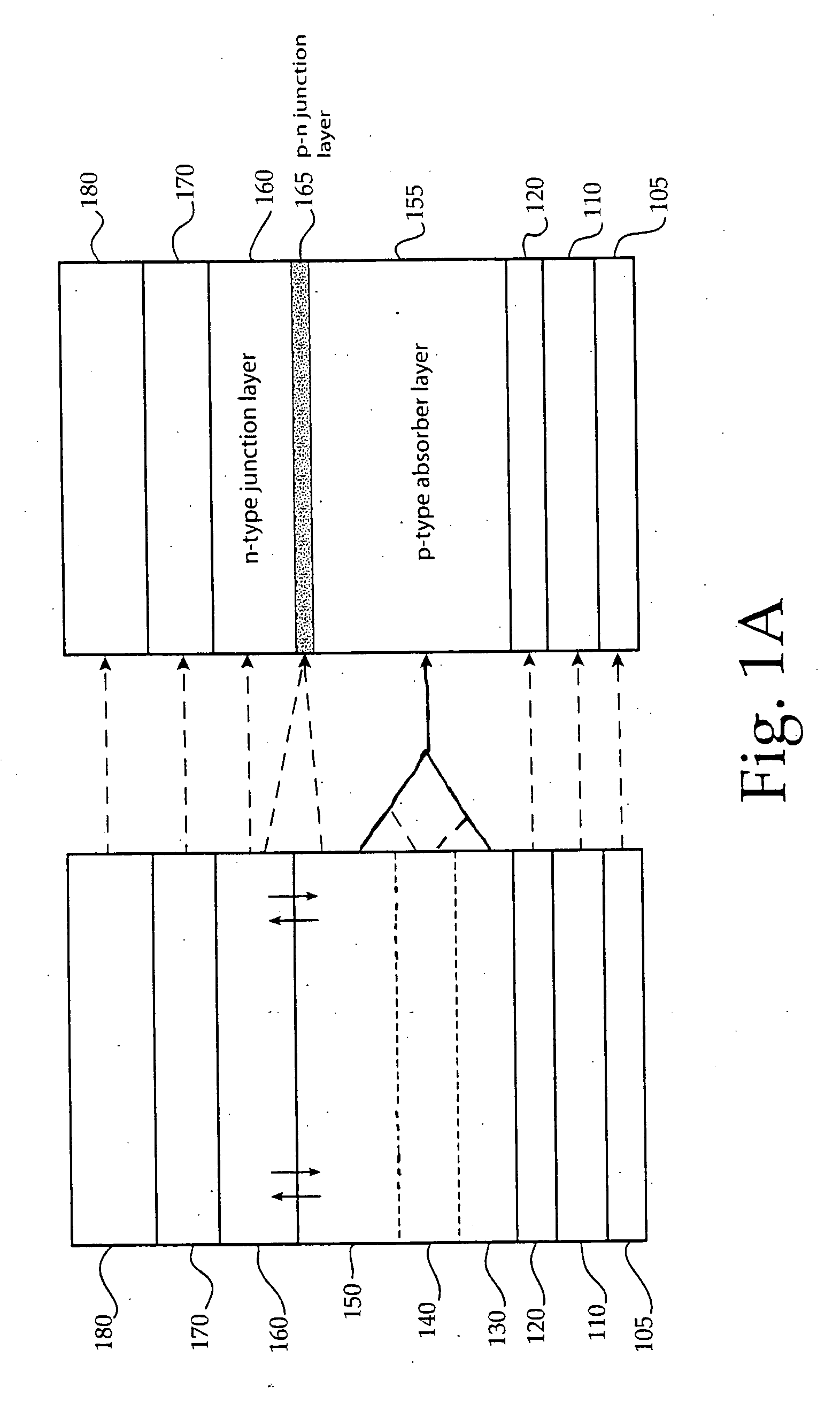

Process and photovoltaic device using an akali-containing layer

This invention describes the product and method of developing a photovoltaic device using an alkali-containing mixed phase semiconductor source layer to enhance cell efficiency and minimize molecular structure defects.

Owner:DAYSTAR TECHNOLOGIES

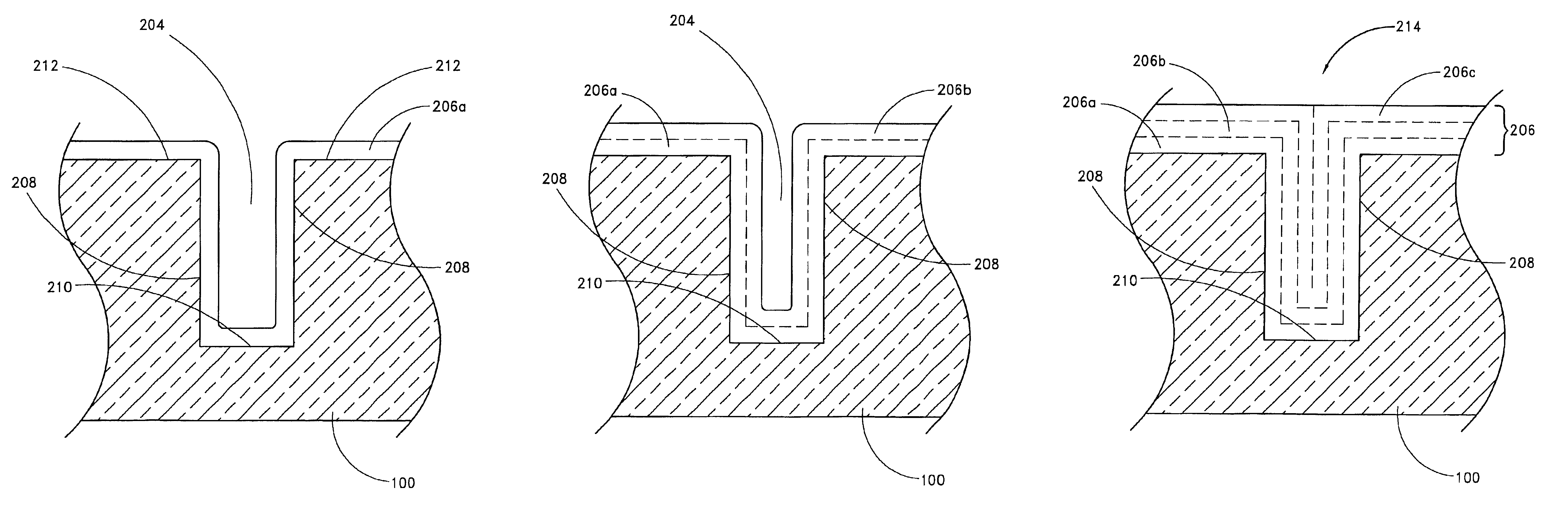

Method of fabricating trench isolation structures for integrated circuits using atomic layer deposition

InactiveUS6861334B2Semiconductor/solid-state device manufacturingSemiconductor devicesMulliteSilicon oxide

A dielectric film is formed by atomic layer deposition to conformally fill a narrow, deep trench for device isolation. The method of the illustrated embodiments includes alternately pulsing vapor-phase reactants in a string of cycles, where each cycle deposits no more than about a monolayer of material, capable of completely filling high aspect ratio trenches. Additionally, the trench-fill material composition can be tailored by processes described herein, particularly to match the coefficient of thermal expansion (CTE) to that of the surrounding substrate within which the trench is formed. Mixed phases of mullite and silica have been found to meet the goals of device isolation and matched CTE. The described process includes mixing atomic layer deposition cycles of aluminum oxide and silicon oxide in ratios selected to achieve the desired composition of the isolation material, namely on the order of 30% alumina and 70% silicon oxide by weight.

Owner:ASM INTERNATIONAL

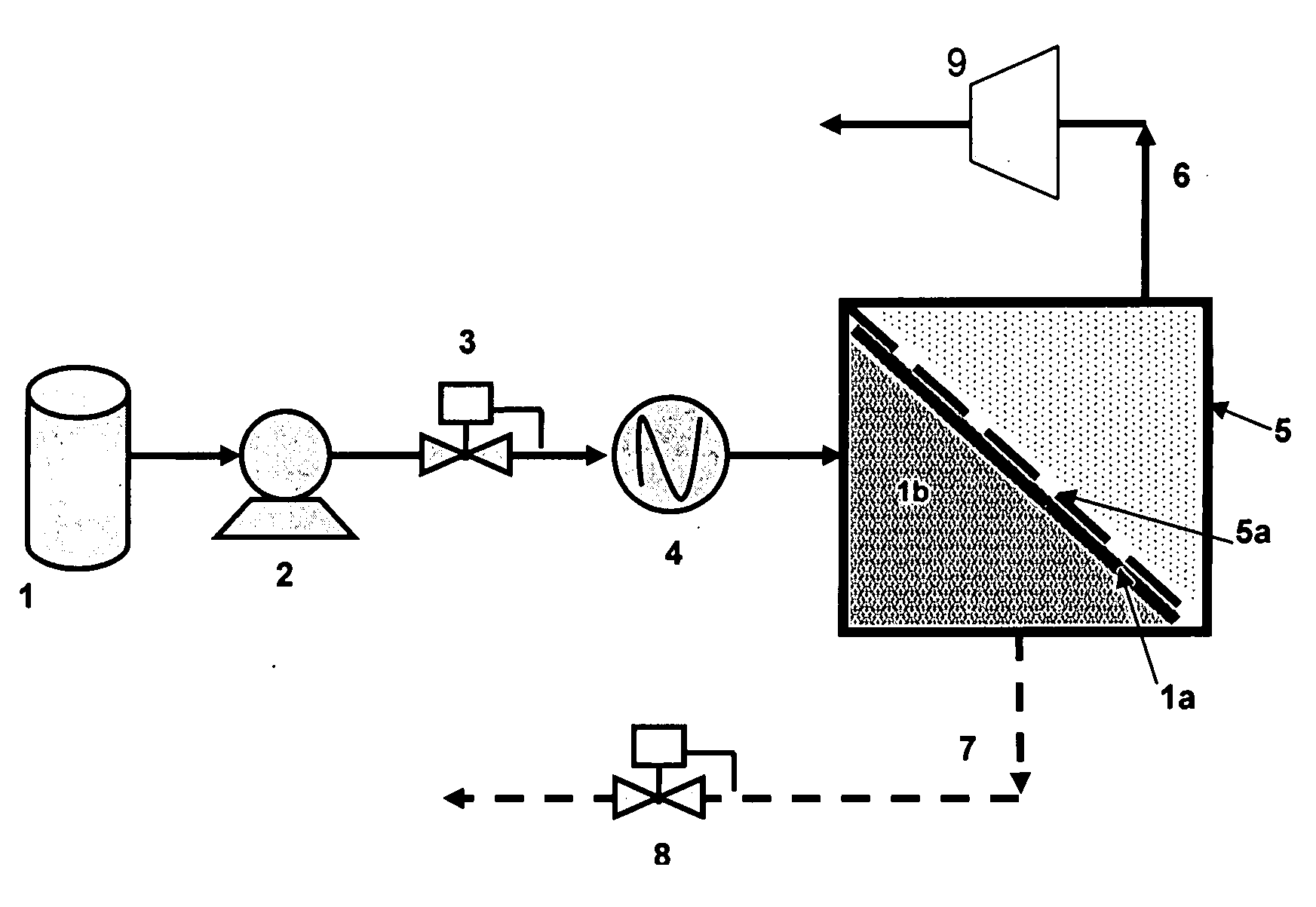

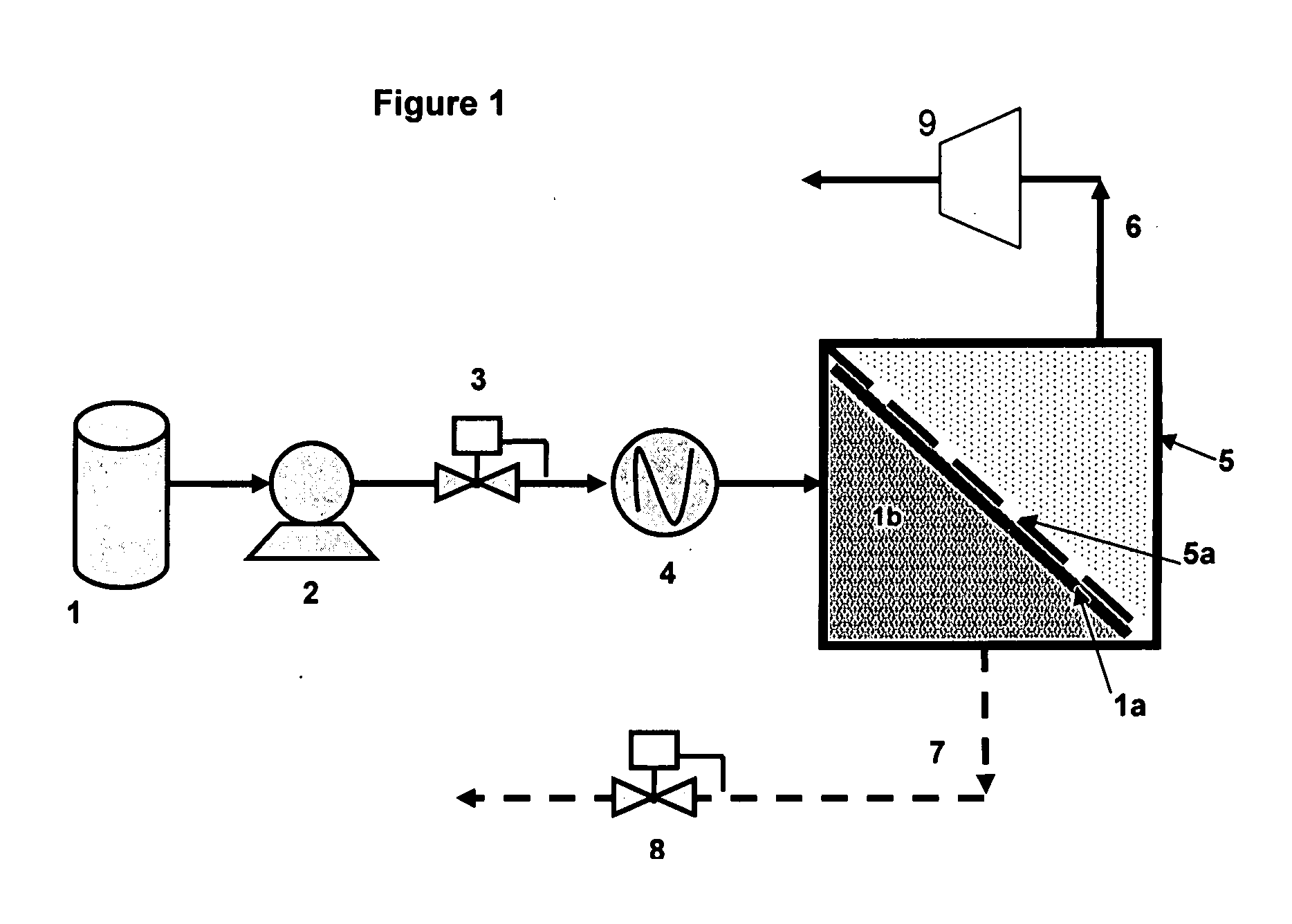

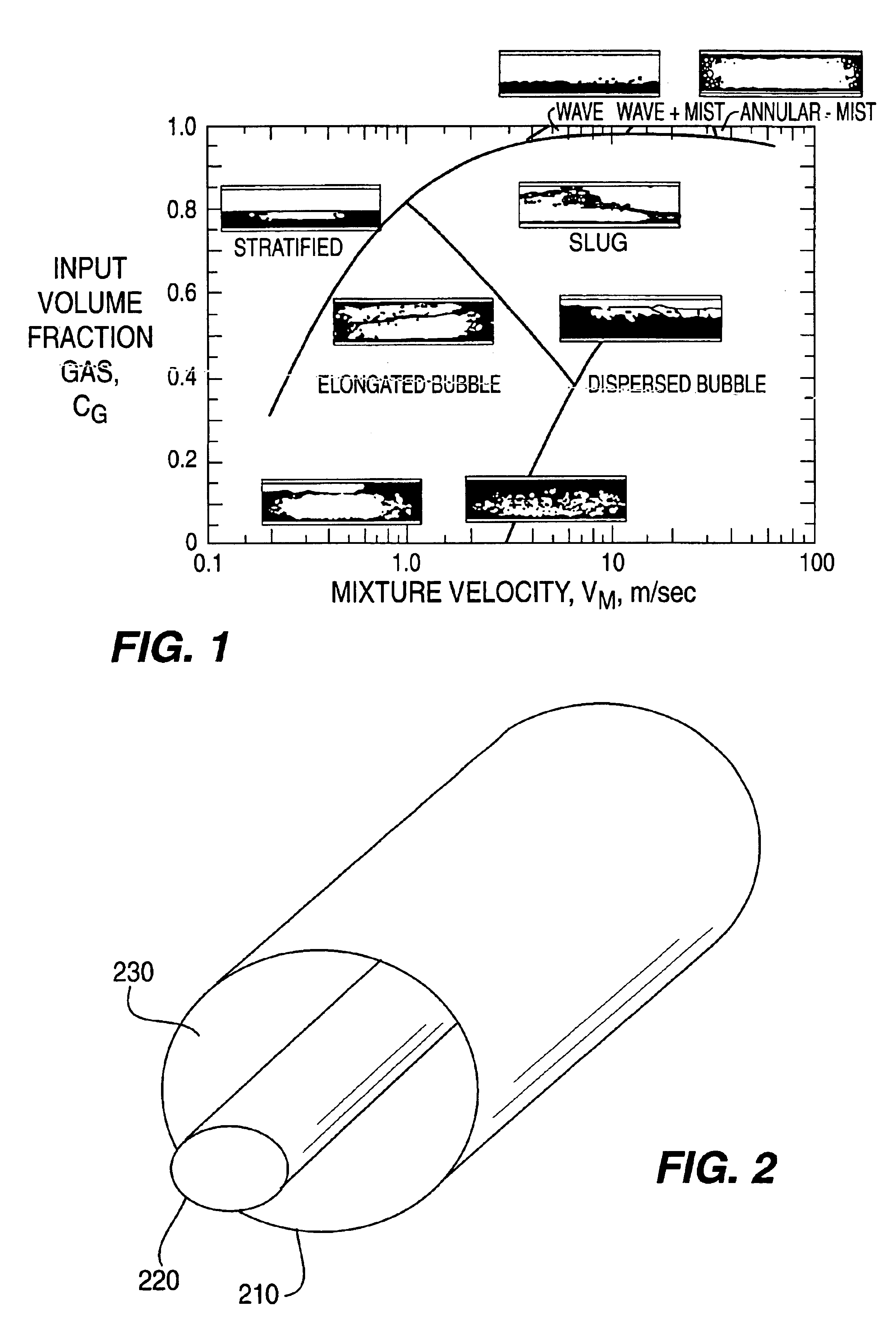

Membrane separation process using mixed vapor-liquid feed

ActiveUS20080011680A1Reduce the impactEfficient executionMembranesSemi-permeable membranesVapor liquidChemical physics

The present invention pertains to a process for the separation of aromatics from a feed stream, including aromatics and non-aromatics by selectively permeating the aromatics through a membrane comprising feeding a mixed phase vapor-liquid feed to a membrane wherein said liquid phase preferentially wets the surface of the membrane.

Owner:EXXON RES & ENG CO

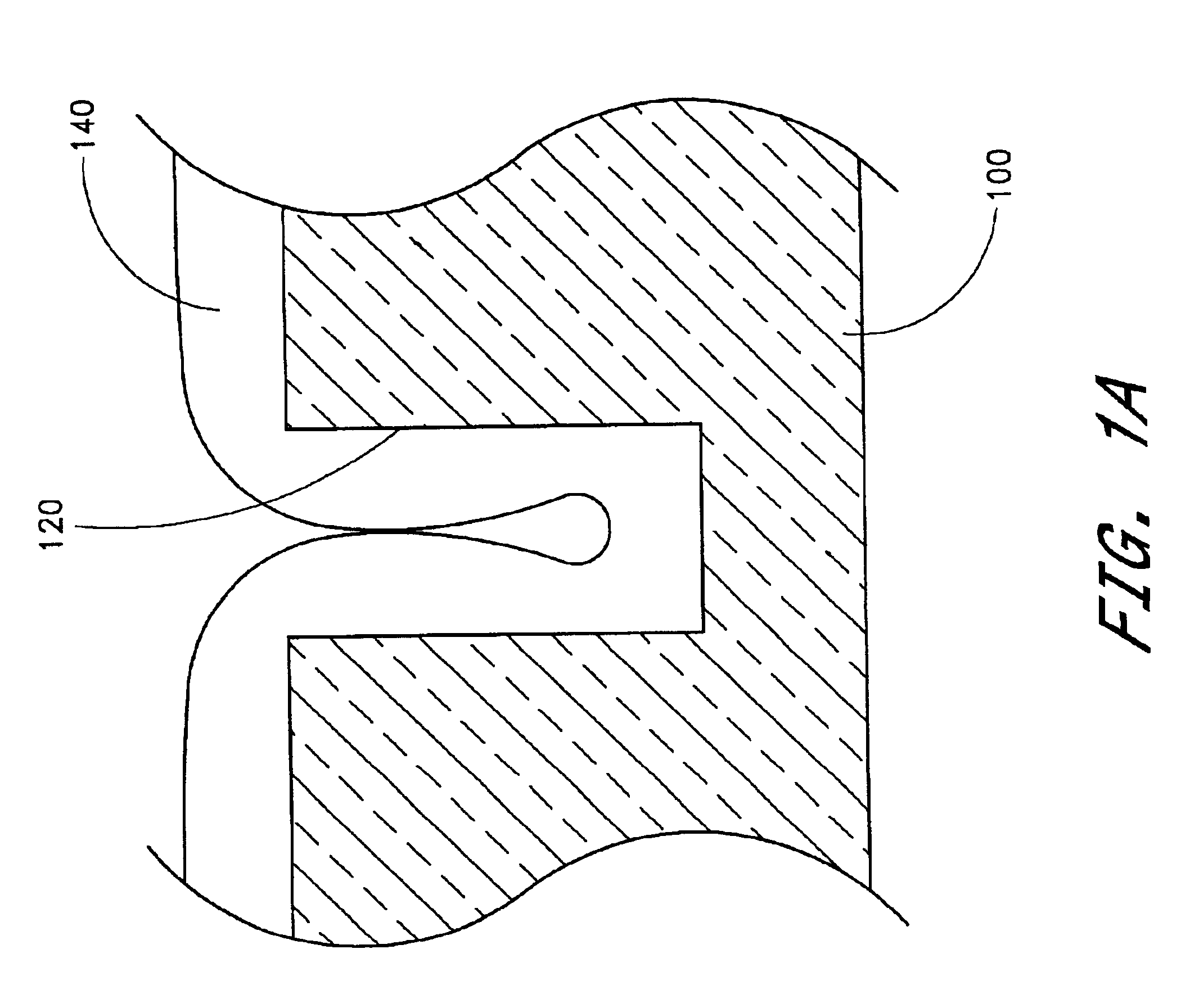

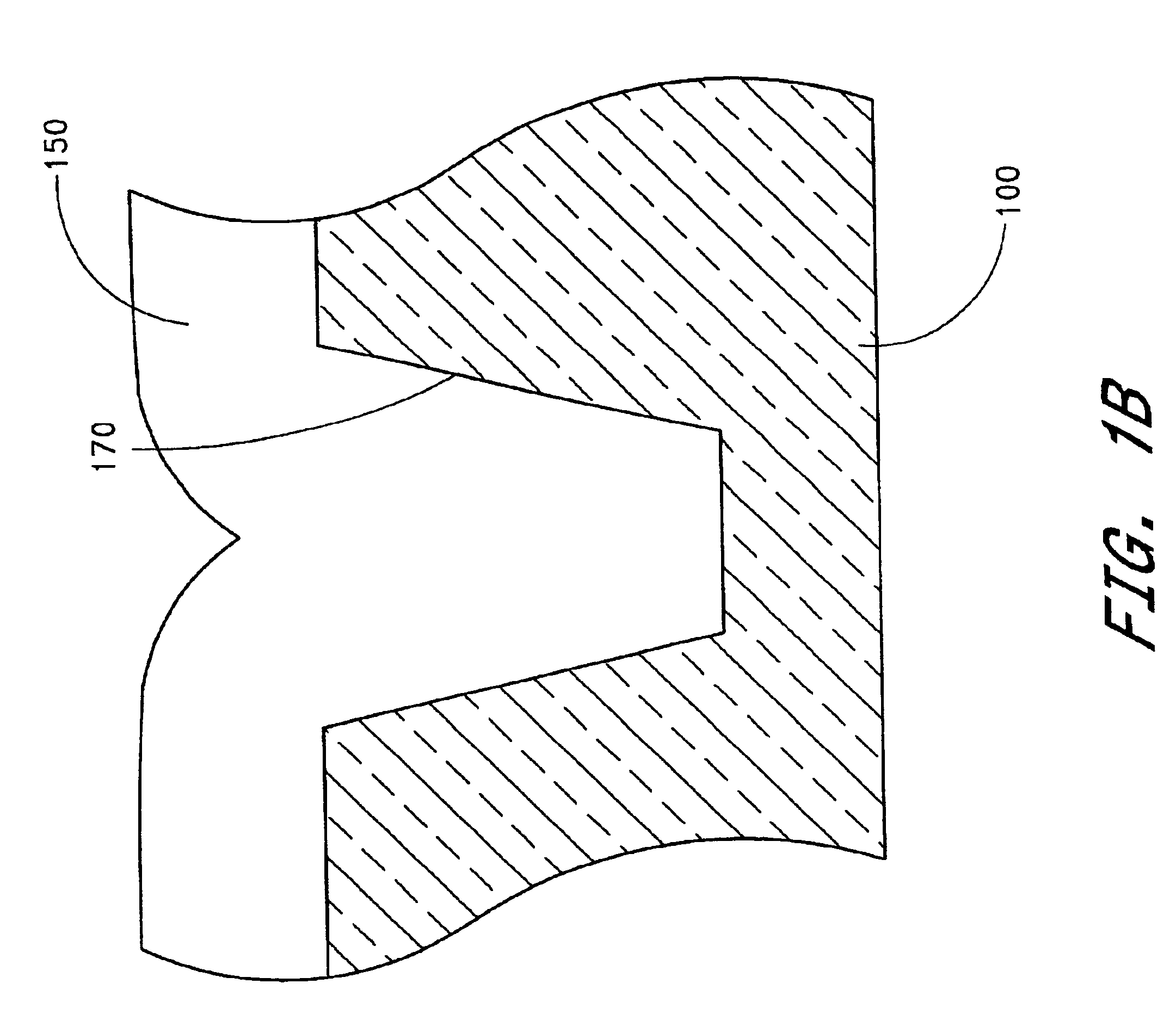

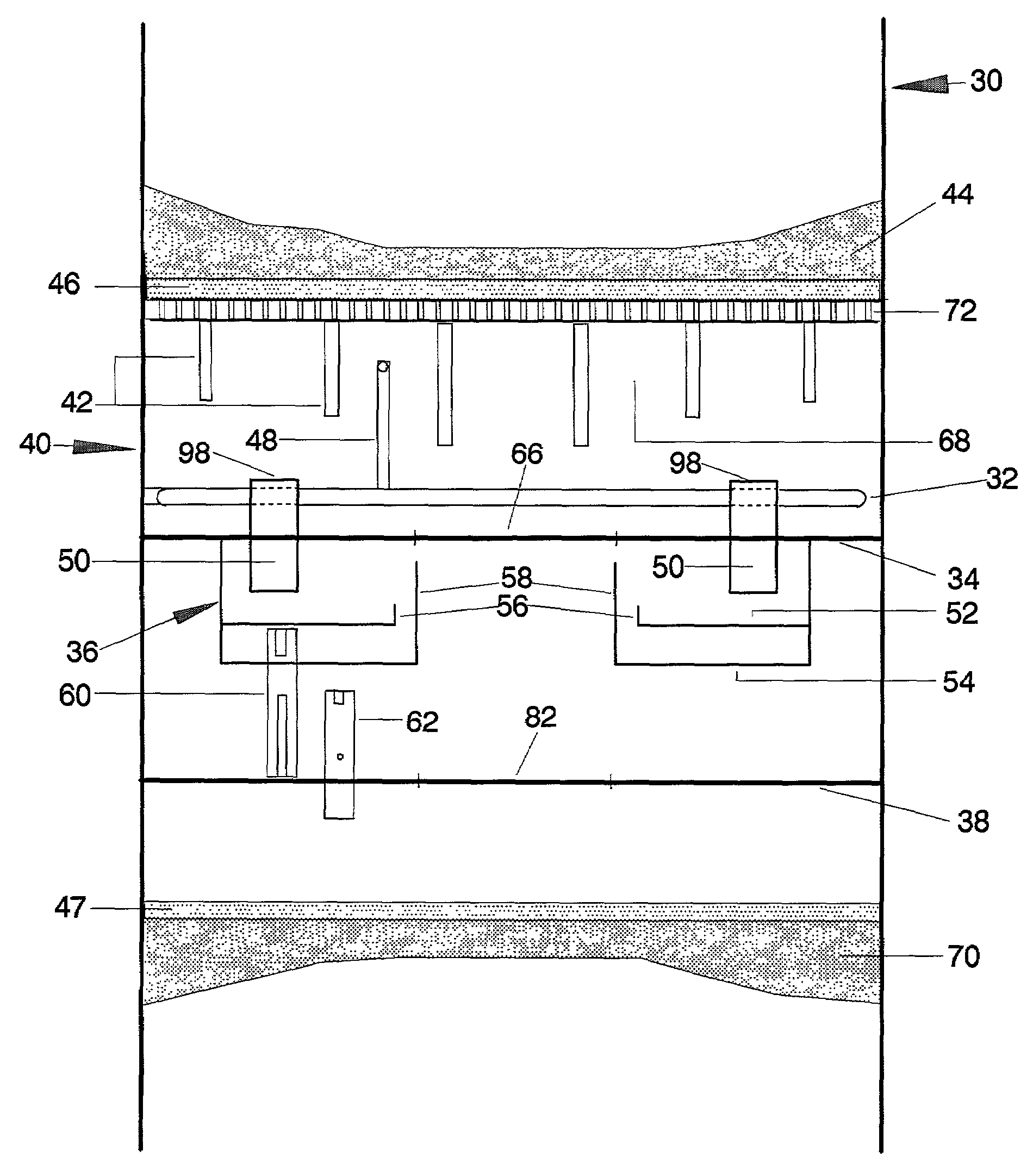

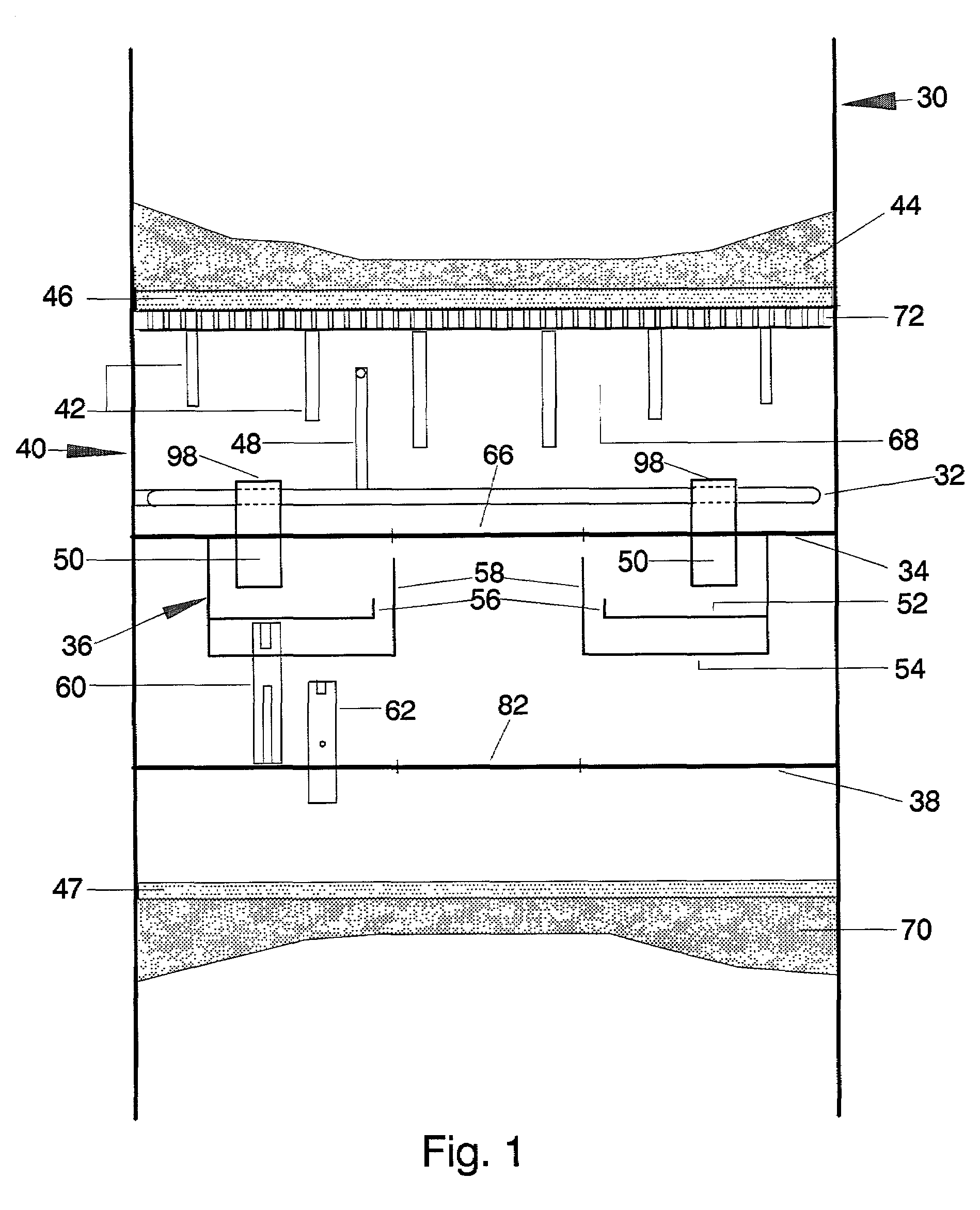

Gating apparatus and method of manufacture

InactiveUS7025324B1Improve sealingPractical problemOperating means/releasing devices for valvesNanoparticle analysisMulti materialManufacturing technology

A gating apparatus for controlling the gap between two surfaces that includes an upper structure having a polished central region portion, an elastically deformable fulcrum structure, and an elastically deformable lever region. The upper structure can be fabricated from silicon using microelectromechanical system (MEMS) fabrication techniques. The gating apparatus also includes a lower structure coupled to the upper structure at the elastically deformable fulcrum structure. The upper structure, in response to a force, can bend about the fulcrum structure, thereby forming a variable gap between the polished central region portion and the lower structure. The variable gap can be used as a filter to filter fluids and mixed phase fluids. The structures can be made from a wide variety of materials including silicon, glass, ceramic, metal, and plastic.

Owner:MASSACHUSETTS INST OF TECH

Composition and method employing membrane structured solid nanoparticles for enhanced delivery of oral care actives

An oral care composition containing membrane-structured solid nanoparticles formed from a lyotropic liquid-crystalline mixed phase having an average particle diameter in the range of 10 to 1,000 nm. The nanoparticles are generally solid at 25° C. and are a combination of agent-carrier particles and emulsifiers. The membranes penetrate the nanoparticles so that the emulsifiers are present in the interior and on the surface of the nanoparticles.

Owner:RECKITT BENCKISER (UK) LTD

Active material for battery, manufacturing method of the same, non-aqueous electrolytic battery and battery pack

InactiveUS20090042095A1Easy to manufactureImprove performanceAlkali titanatesElectrode manufacturing processesDesorptionTitanium

An active material for a battery includes a mixed phase includes a lithium titanium composite oxide phase and a nonstoichiometric titanium oxide phase. This active material is excellent in lithium absorption / desorption performance, exhibiting high electric potentials in lithium absorption / desorption and high conductivity.

Owner:KK TOSHIBA

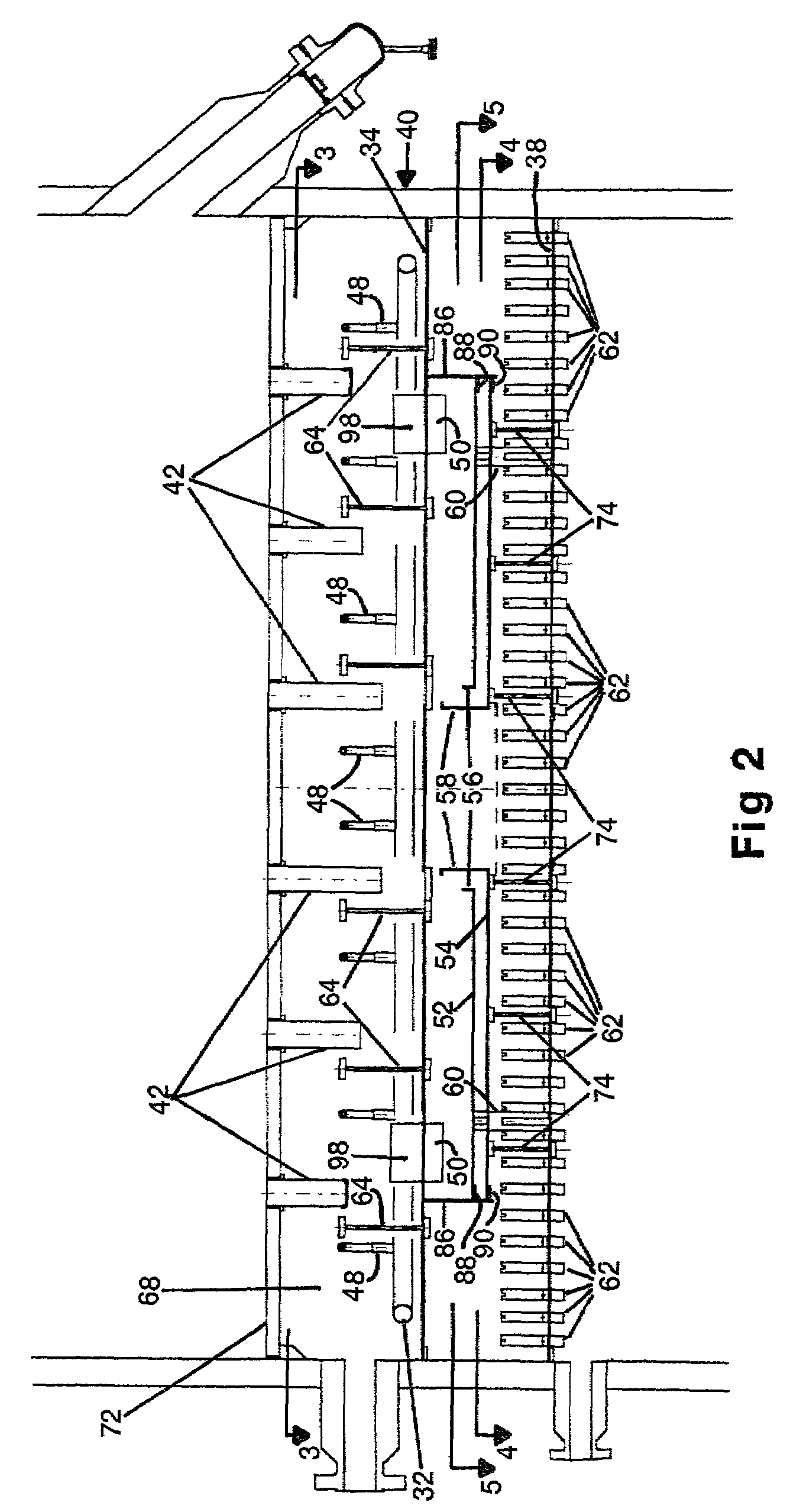

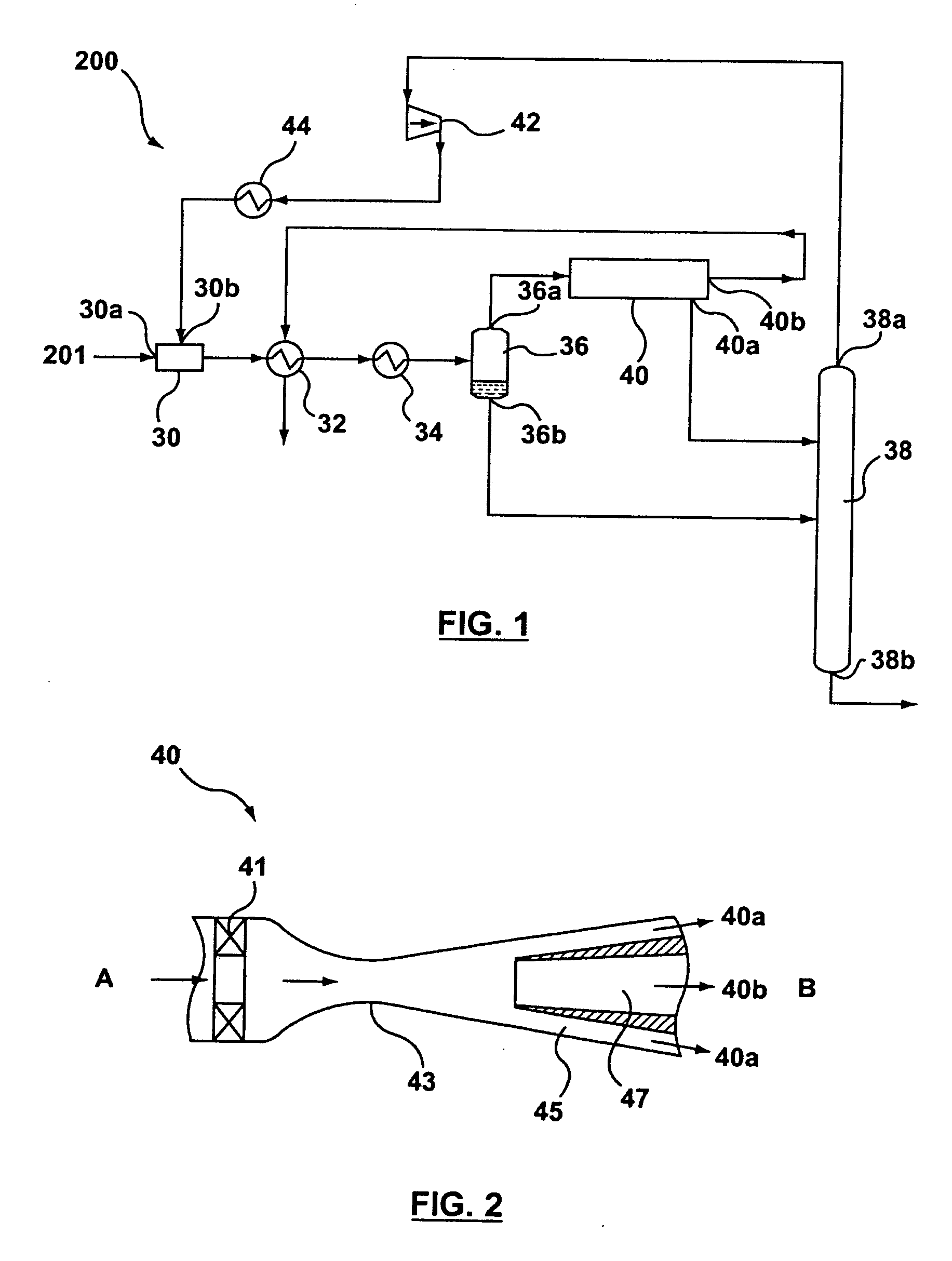

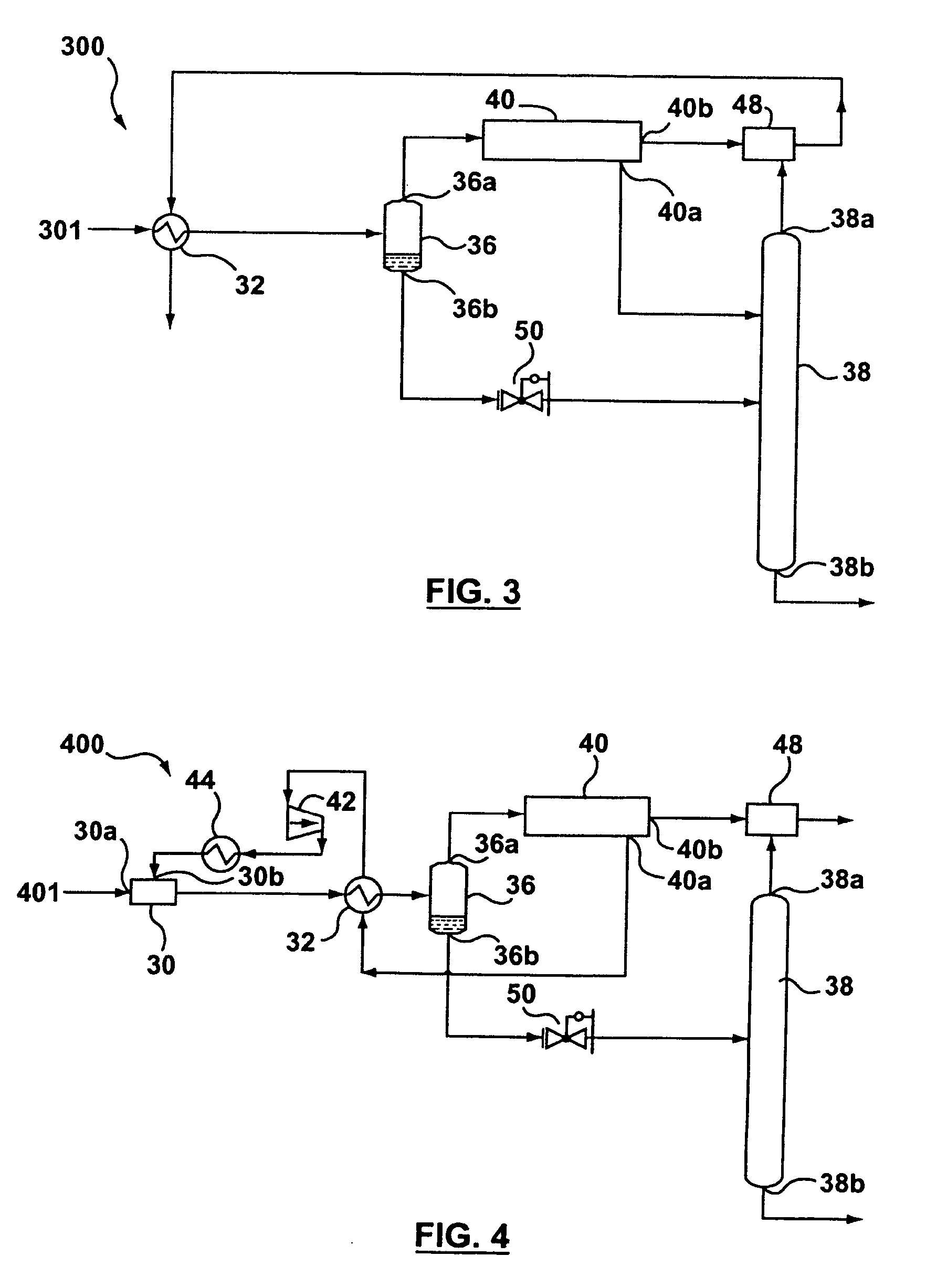

Quench box for a multi-bed, mixed-phase cocurrent downflow fixed-bed reactor

InactiveUS7112312B2Reduce in quantitySimple designPhysical/chemical process catalystsFlow mixersFixed bedEngineering

Owner:H2ADVANCE

Multilayer ceramic electronic component and method for making the same

ActiveUS20090323253A1Improve bindingFixed capacitor electrodesStacked capacitorsCopper platingElectrical conductor

A multilayer ceramic electronic component includes external terminal electrodes that are formed by depositing metal plating films on exposed portions of internal conductors embedded in a ceramic body, depositing a copper plating films that cover the metal plating films and make contact with the ceramic body around the metal plating films, and heat-treating the ceramic body to generate a copper liquid phase, an oxygen liquid phase, and a copper solid phase between the copper plating films and the ceramic body. The mixed phase including these phases forms a region at which a copper oxide is present in a discontinuous manner inside the copper plating film at least at the interfaces between the ceramic body and the copper plating films. The copper oxide securely attaches the copper plating films to the ceramic body and enhances the bonding force of the external terminal electrodes.

Owner:MURATA MFG CO LTD

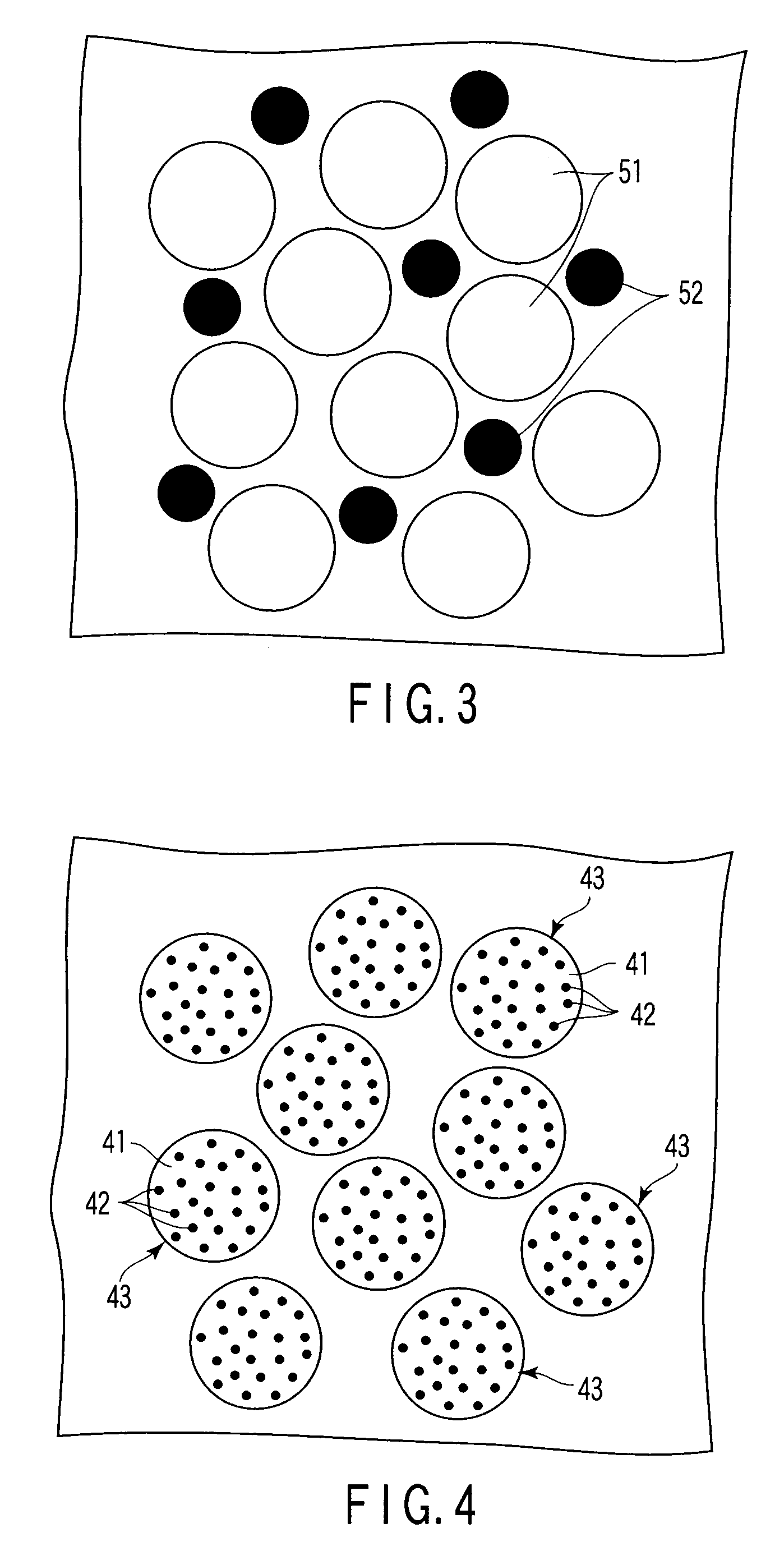

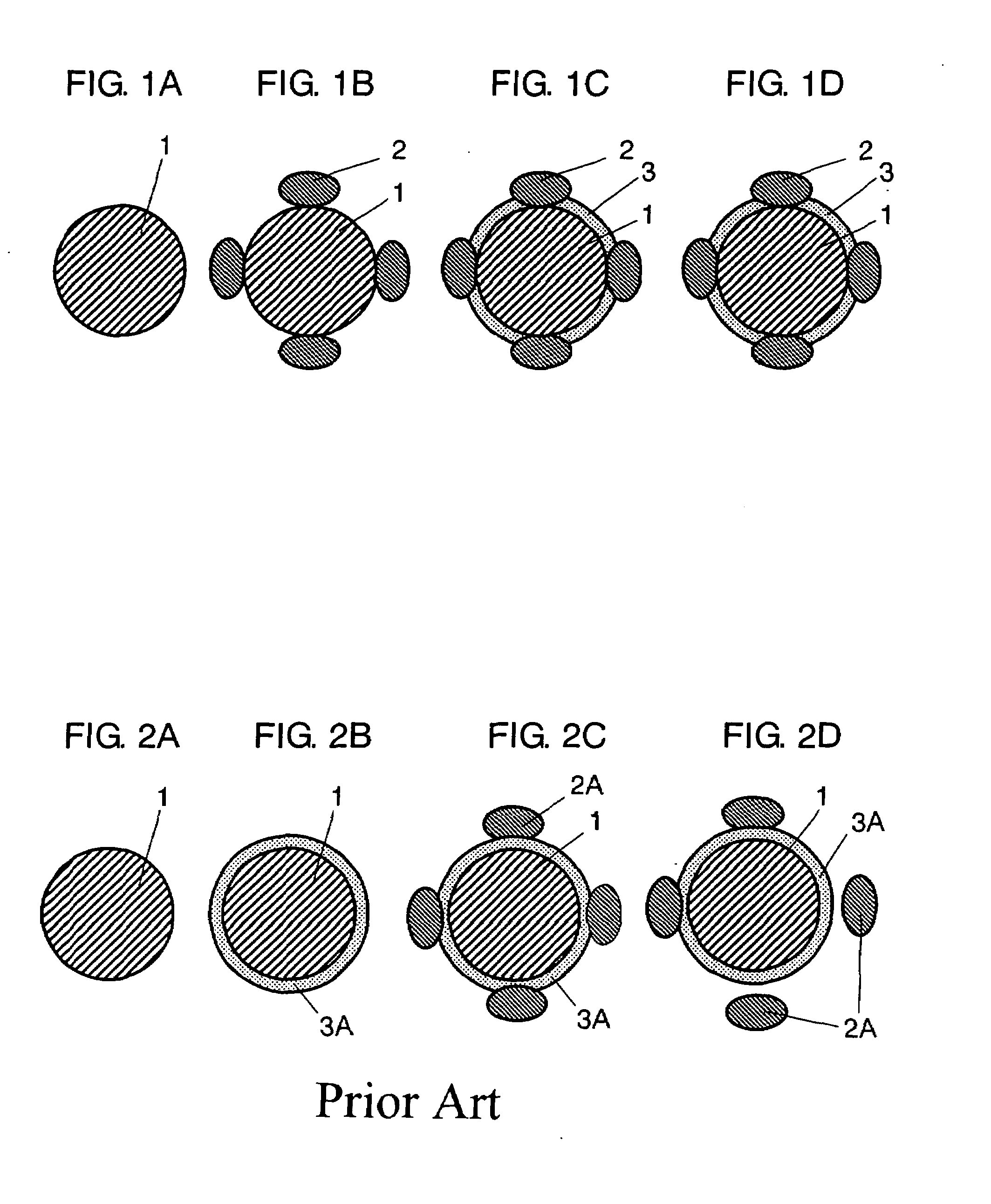

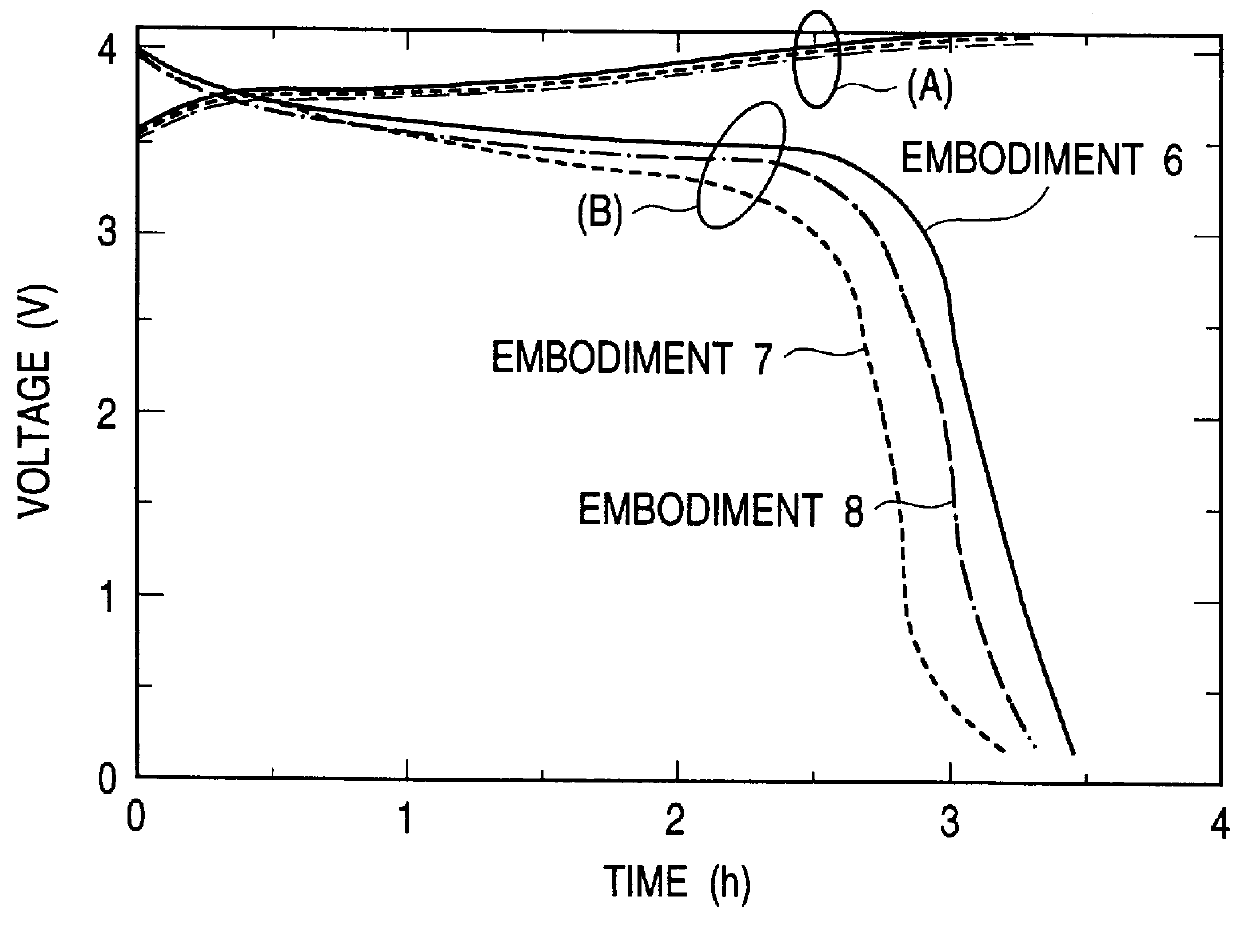

Negative Electrode Material For Lithium Secondary Battery, Negative Electrode Using The Material, Lithium Secondary Battery Using The Negative Electrode, And Manufacturing Method Of Negative Electrode Material

InactiveUS20080113269A1Excellent discharge cycle characteristicSmall in irreversible capacityPrimary cellsElectrode carriers/collectorsLithiumSilicon oxide

In a negative electrode material for lithium secondary batteries, basic material particles include one of phase A having silicon as a main component, and a mixed phase of phase B including an intermetallic compound of a transition metal element and silicon and the phase A. The phase A or the mixed phase is microcrystalline or amorphous. A carbon material is adhered to surfaces of the basic material particles, and a film containing a silicon oxide is formed on remained surface portions.

Owner:PANASONIC CORP

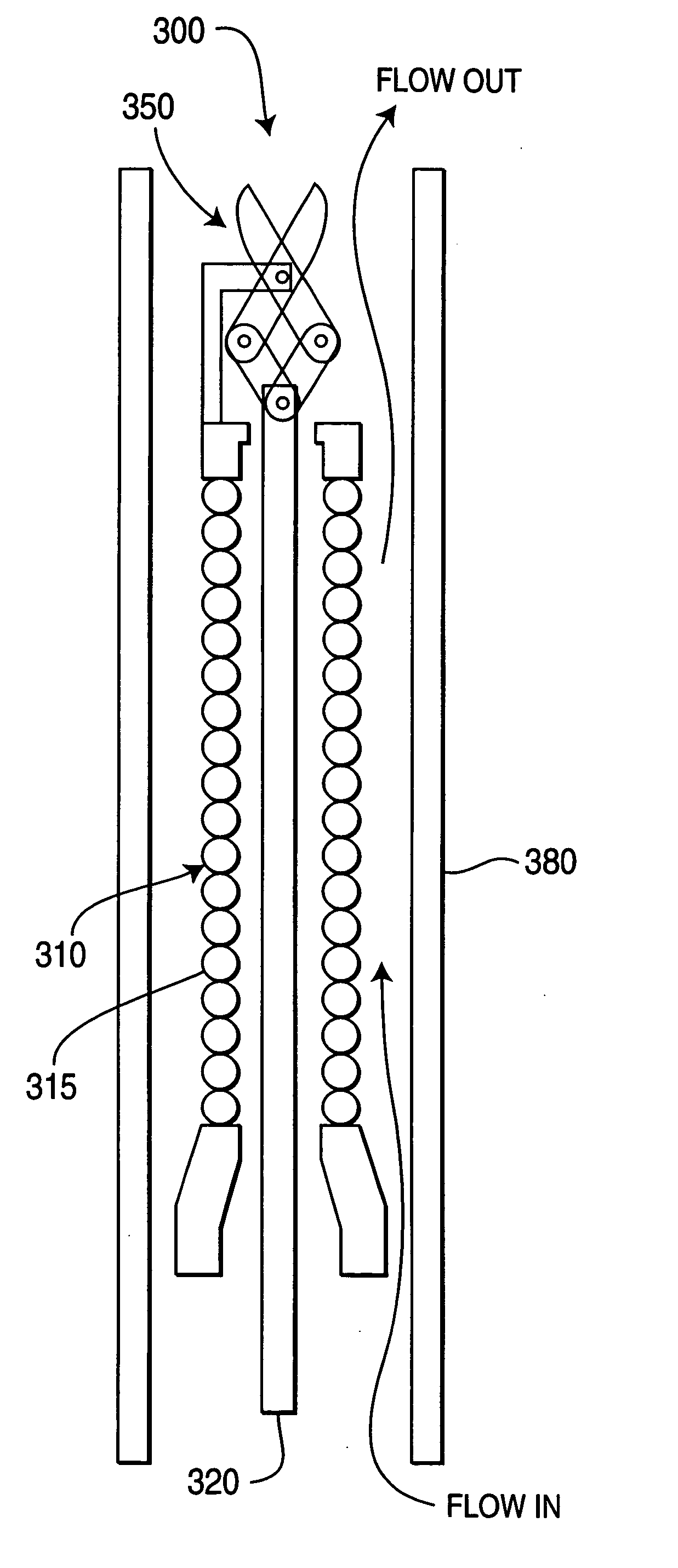

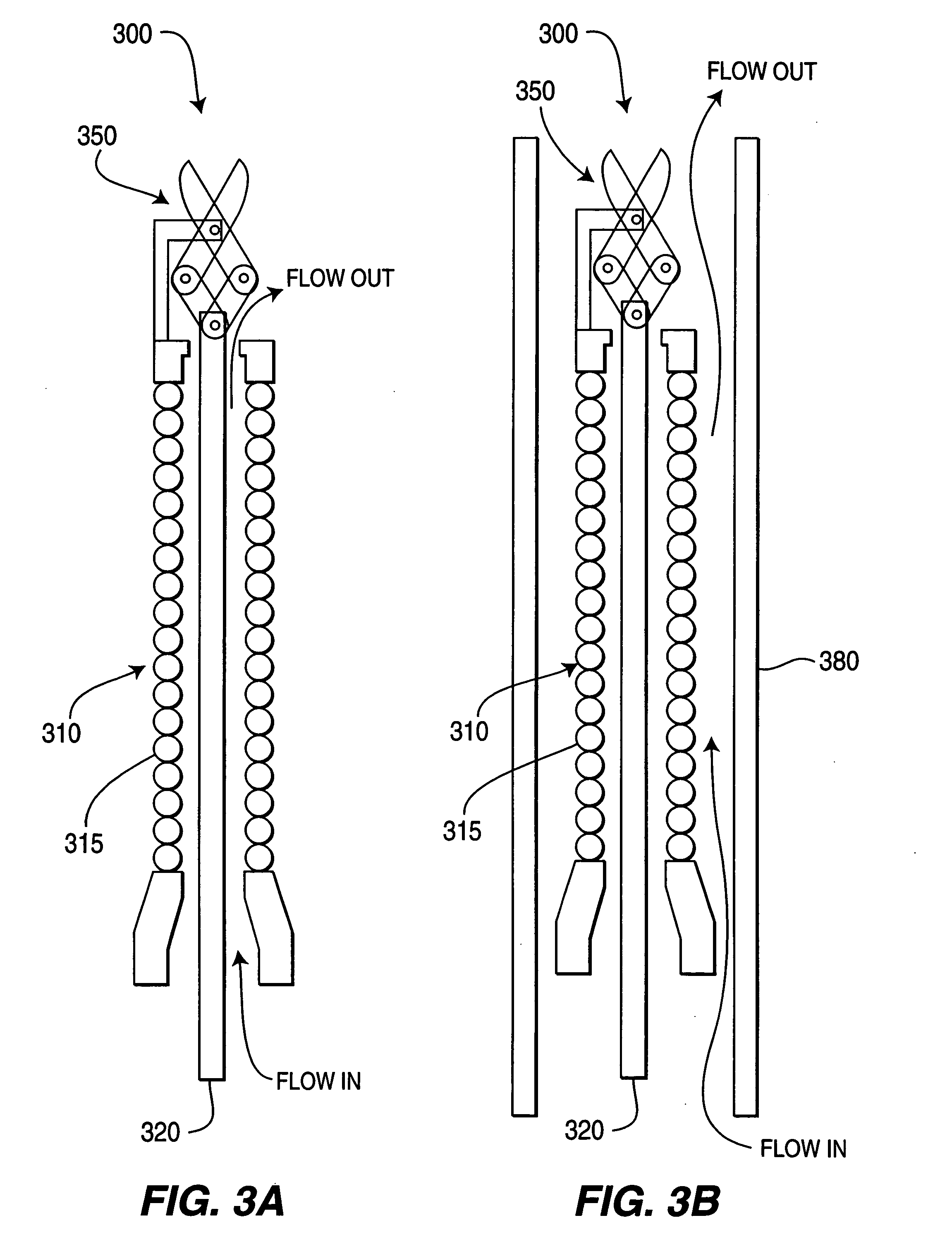

Method of cleaning passageways using a mixed phase flow of a gas and a liquid

InactiveUS6857436B2Easy to cleanEnlarge regionInorganic/elemental detergent compounding agentsSemi-permeable membranesSufficient timePorous membrane

A method of cleaning surfaces using a mixed phase cleaning mixture of an aqueous solution and a flow of gas sufficient to produce droplets of the liquid which are entrained by the gas for a time sufficient to clean tubing of various lengths and geometries and porous membranes to remove biofilm, debris and contaminants.

Owner:OLYMPUS CORP

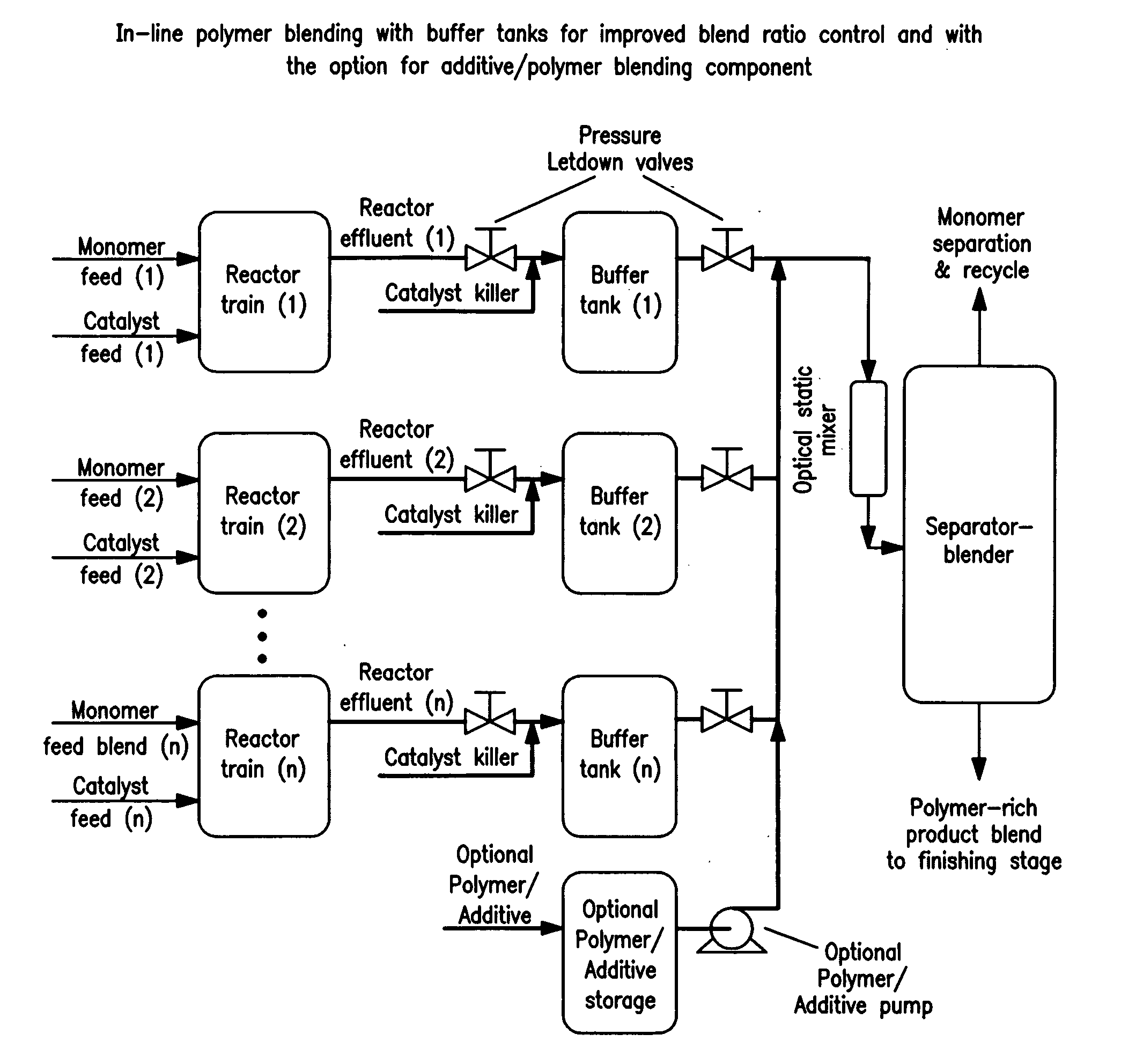

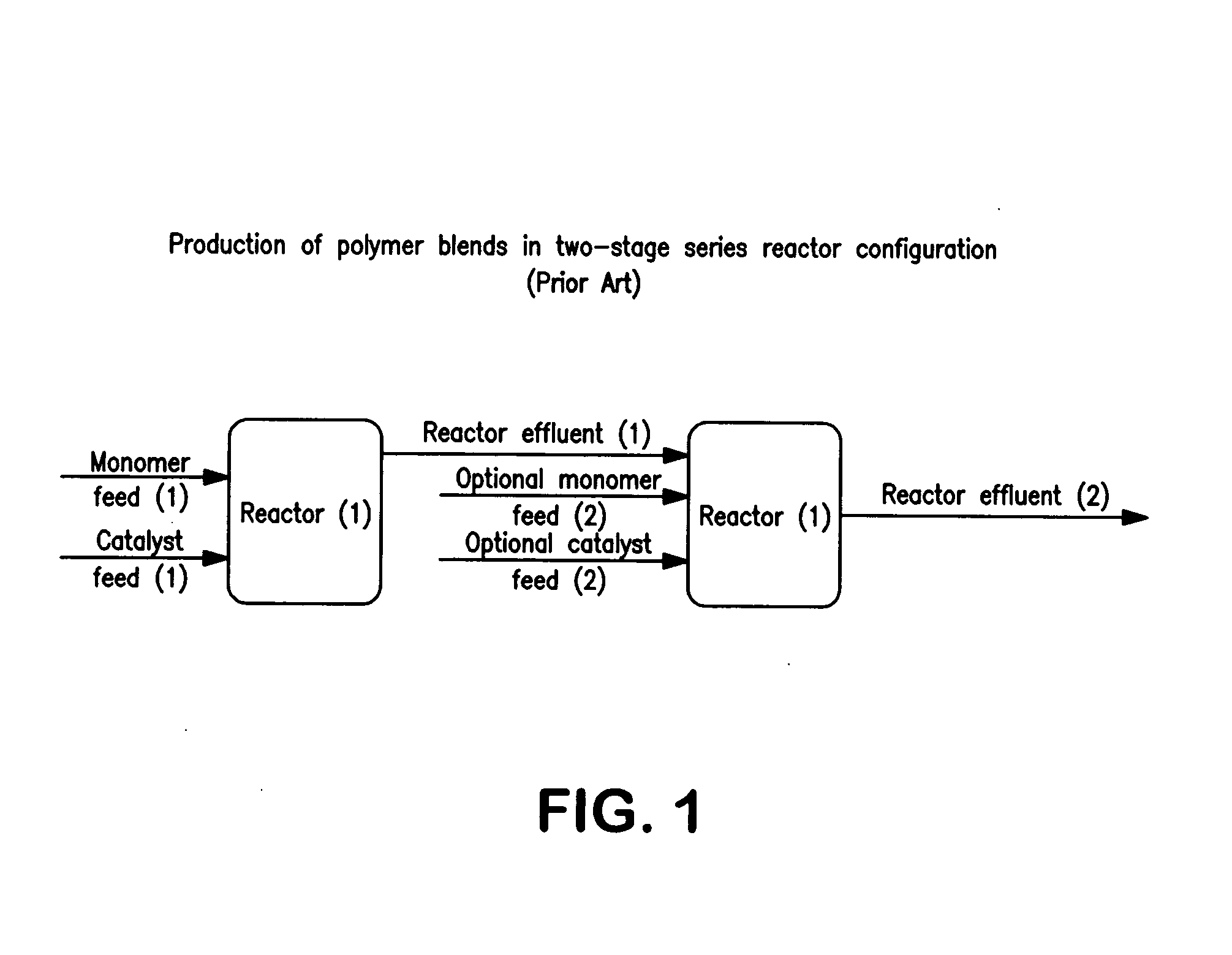

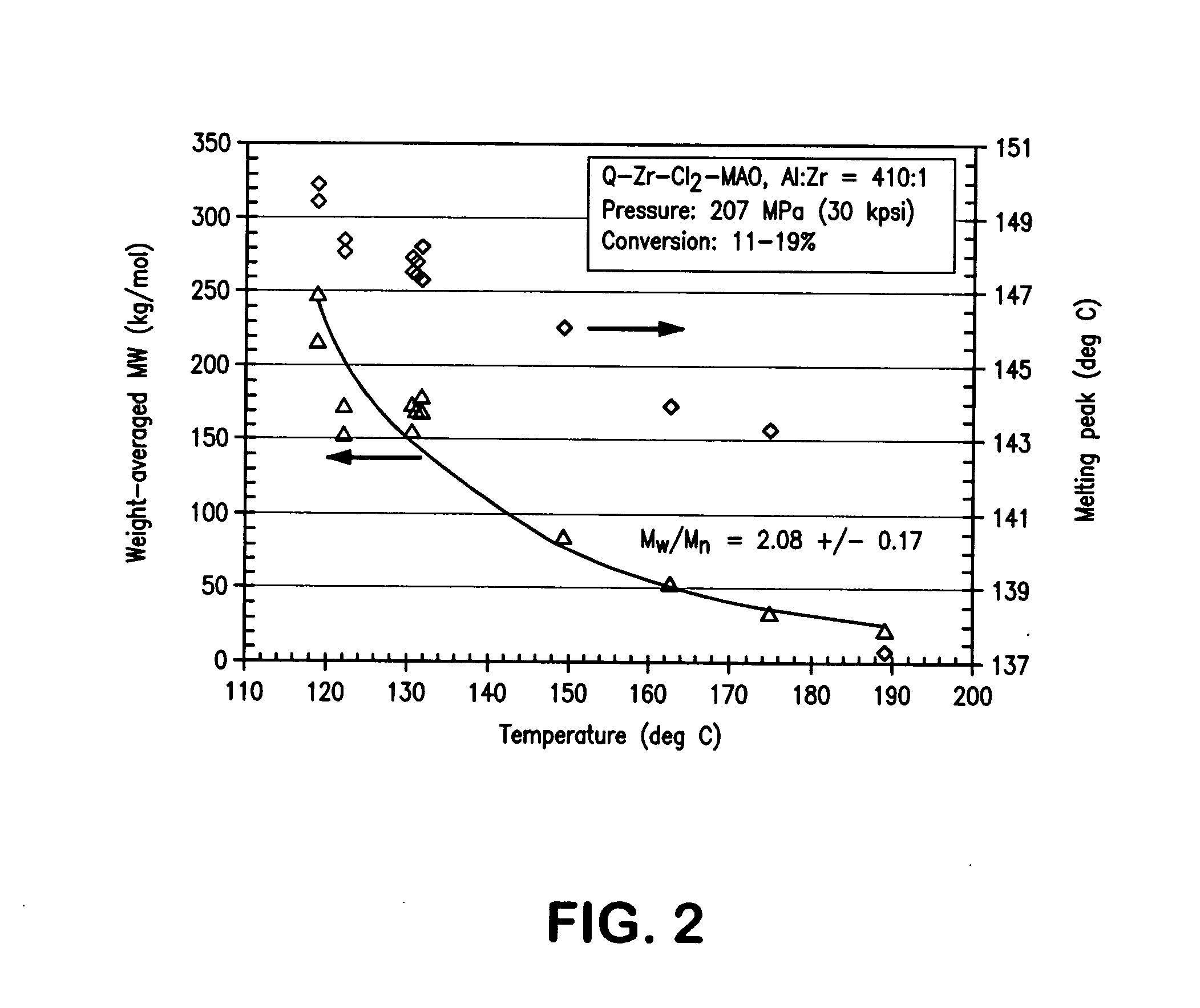

Process for fluid phase in-line blending of polymers

ActiveUS20080234443A1Maintain temperatureSpecial tyresChemical/physical/physico-chemical stationary reactorsScavengerSolvent

A process for fluid phase in-line blending of polymers. The process includes providing two or more reactor trains configured in parallel and a separator for product blending and product-feed separation; contacting in at least one of the parallel reactor trains olefin monomers having three or more carbon atoms, catalyst systems, optional comonomers, optional scavengers, and optional inert diluents or inert solvents, at a temperature above the solid-fluid phase transition temperature of the polymerization system and a pressure no lower than 10 MPa below the cloud point pressure of the polymerization system and less than 1500 MPa; forming a reactor effluent including a homogeneous fluid phase polymer-monomer mixture in each parallel reactor train; combining the reactor effluent from each parallel reactor; passing the combined reactor effluent through the separator; maintaining the temperature and pressure within the separator above the solid-fluid phase transition point but below the cloud point pressure and temperature to form a fluid-fluid two-phase system including a polymer-rich blend phase and a monomer-rich phase; and separating the monomer-rich phase from the polymer-rich blend phase. The separated monomer-rich phase is recycled to the polymerization reactor bank. The polymer-rich blend phase is conveyed to a downstream finishing stage for further monomer stripping, drying and / or pelletizing to form a polymer product blend.

Owner:EXXONMOBIL CHEM PAT INC

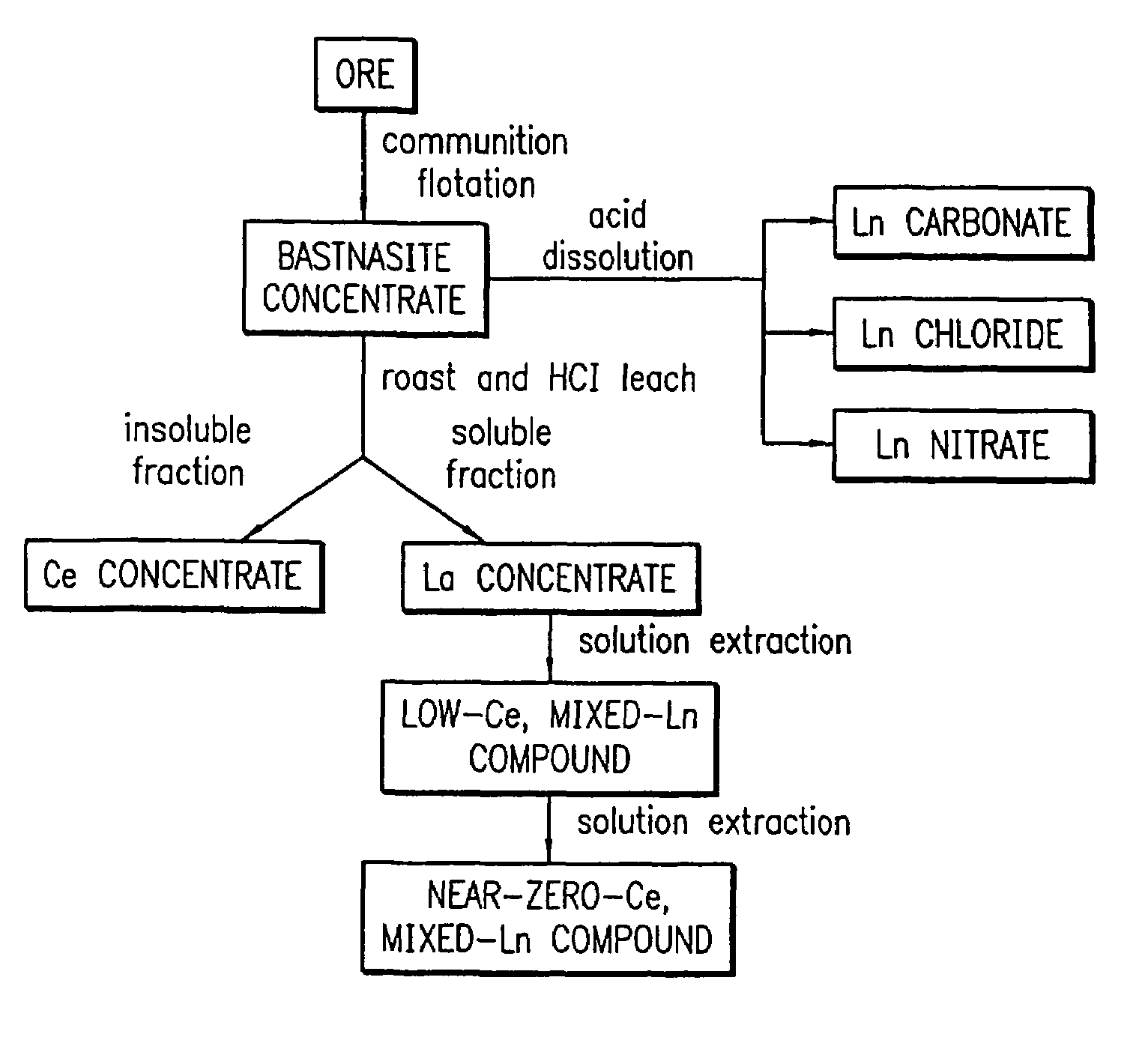

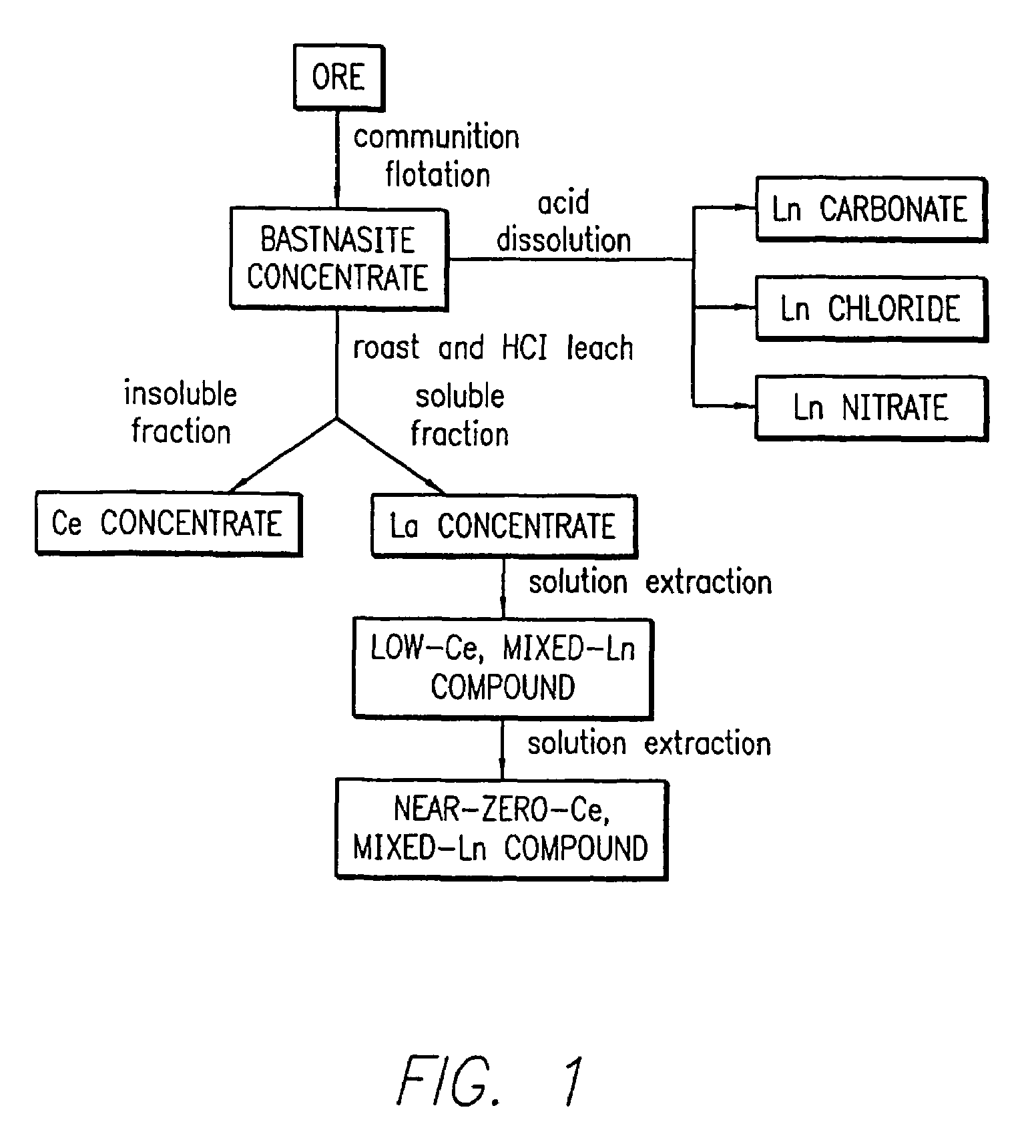

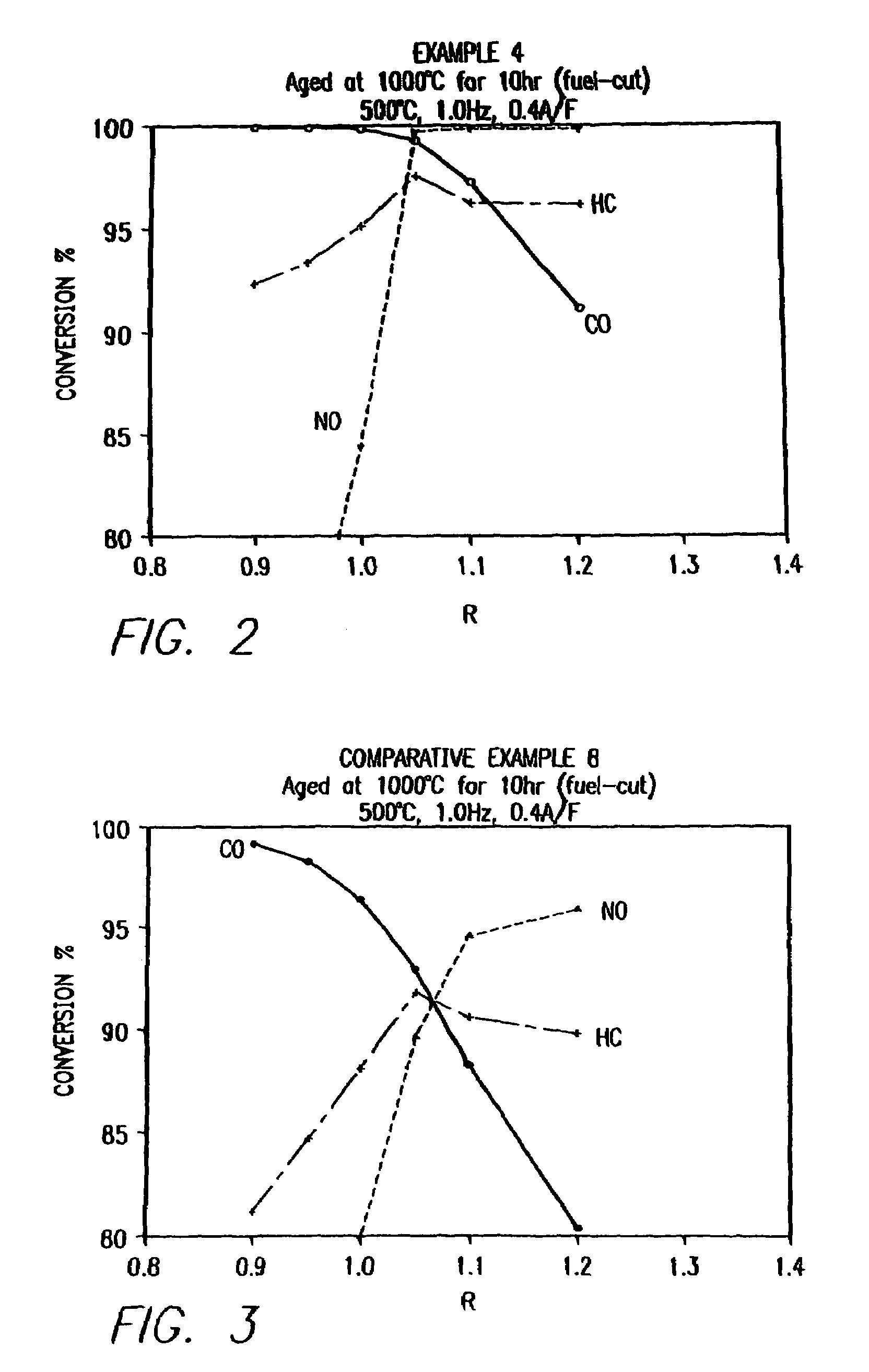

Mixed-phase ceramic oxide three-way catalyst formulations and methods for preparing the catalysts

InactiveUS7641875B1Improve efficiencyLess timeOrganic chemistryNitrogen compoundsLanthanidePt element

A multi-phase catalyst for the simultaneous conversion of oxides of nitrogen, carbon monoxide, and hydrocarbons is provided. A catalyst composition comprising the multi-phase catalyst and methods of making the catalyst composition are also provided. The multi-phase catalyst may be represented by the general formula of CeyLn1-xAx+sMOZ, wherein Ln is a mixture of elements originally in the form of single-phase mixed lanthanides collected from natural ores, a single lanthanide, or a mixture of lanthanides; A is an element selected from a group consisting of Mg, Ca, Sr, Ba, Li, Na, K, Cs, Rb, or any combination thereof; and M is an element selected from the group consisting of Fe, Mn, Cr, Ni, Co, Cu, V, Zr, Pt, Pd, Rh, Ru, Ag, Au, Al, Ga, Mo, W, Ti, or any combination thereof; x is a number defined by 0≦x<1.0; y is a number defined by 0≦y<10; s is a number defined by 0≦s<10; where s=0 only when y>0 and y=0 only when s>0. The multi-phase catalyst can have an overlayer of an oxide having the fluorite structure with a combination of platinum and / or rhodium.

Owner:CATALYTIC SOLUTIONS INC

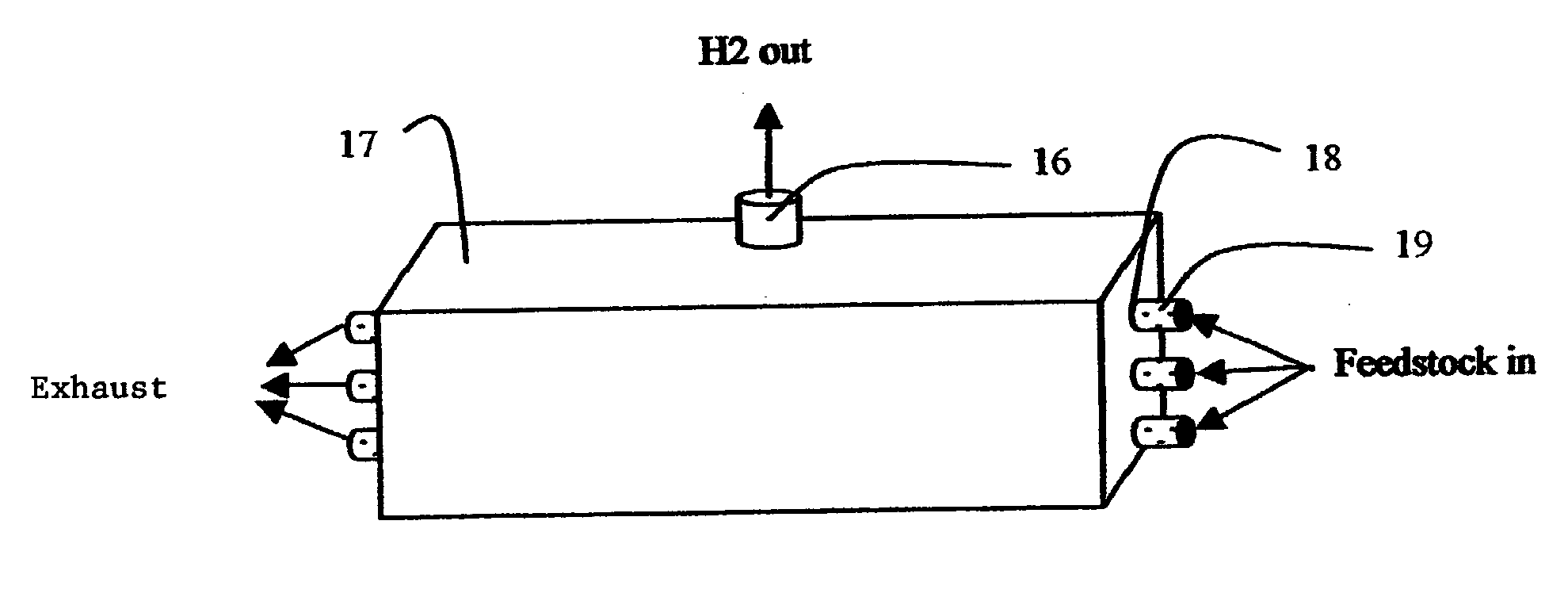

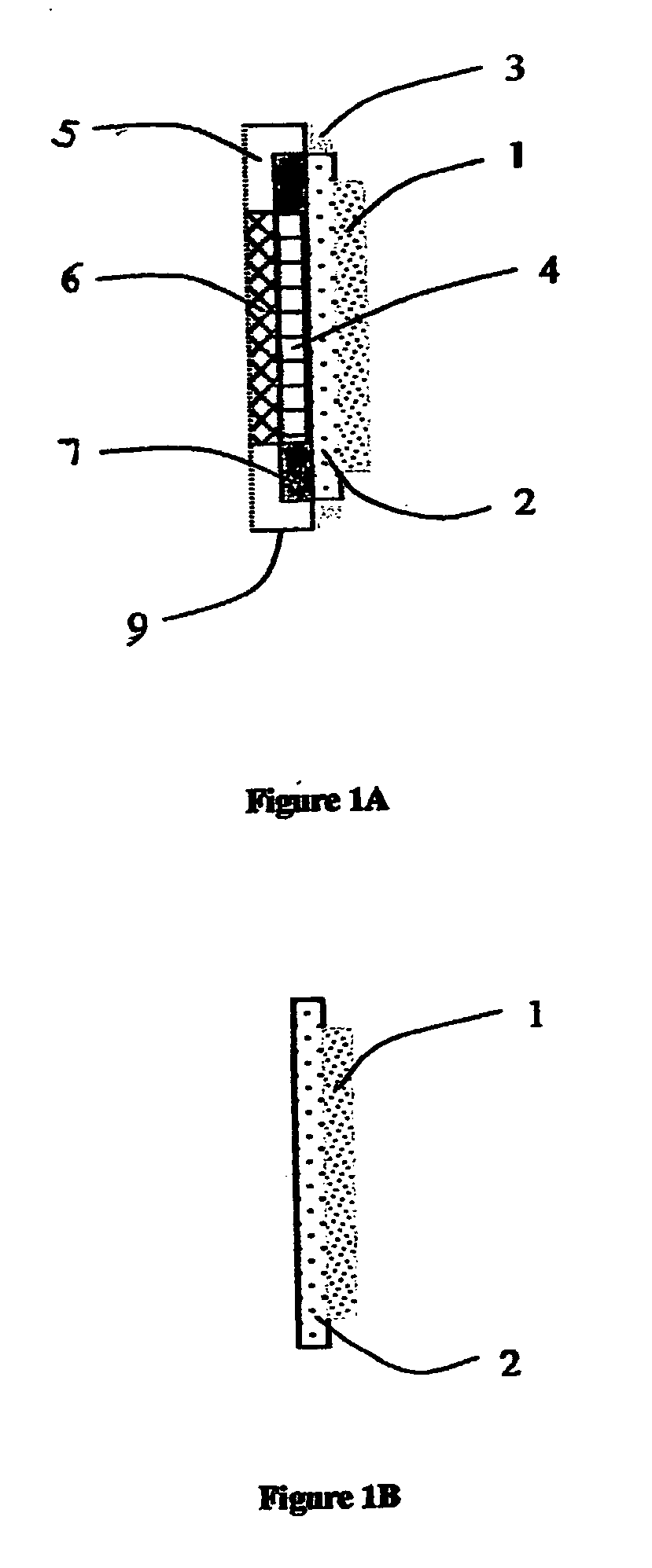

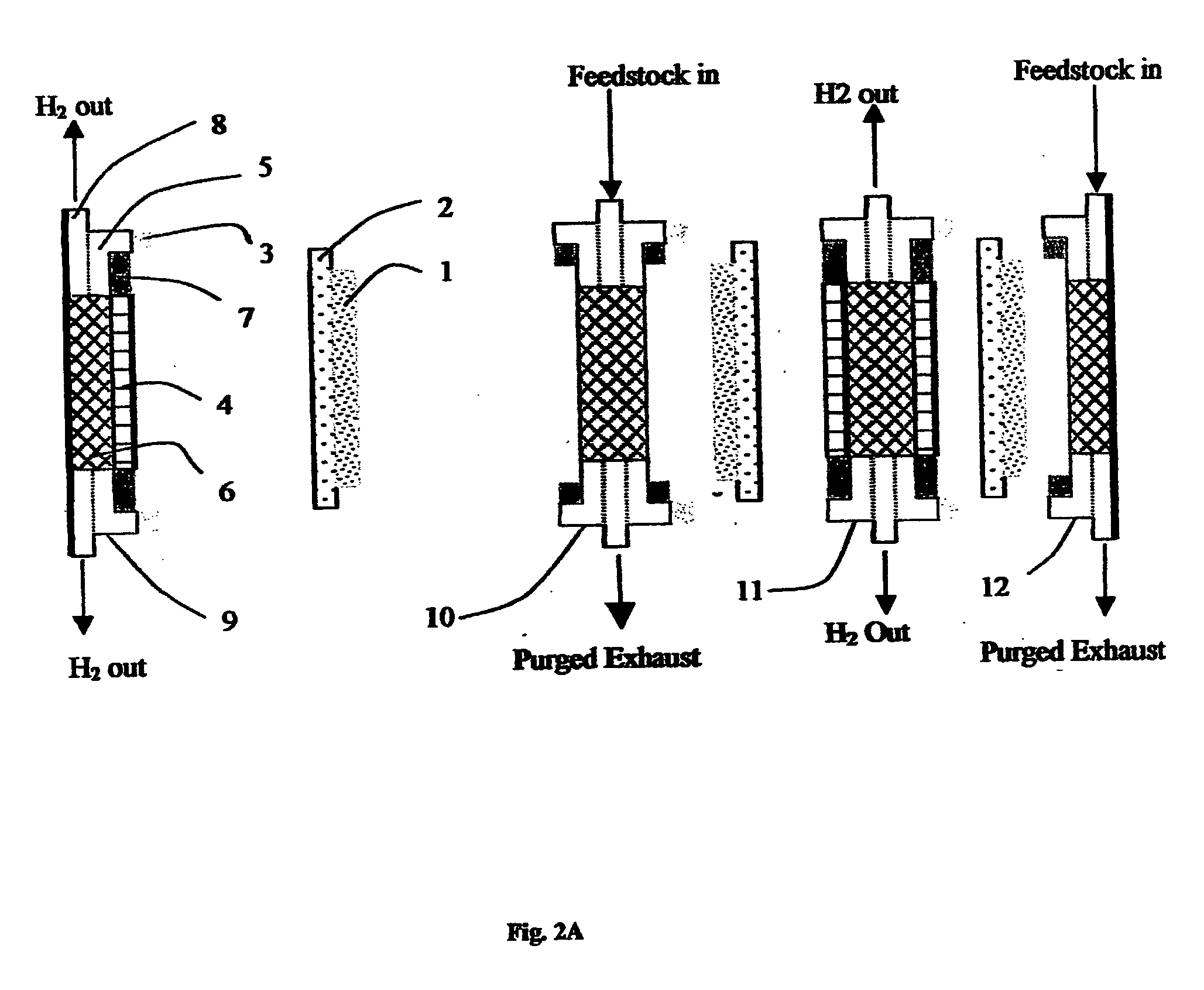

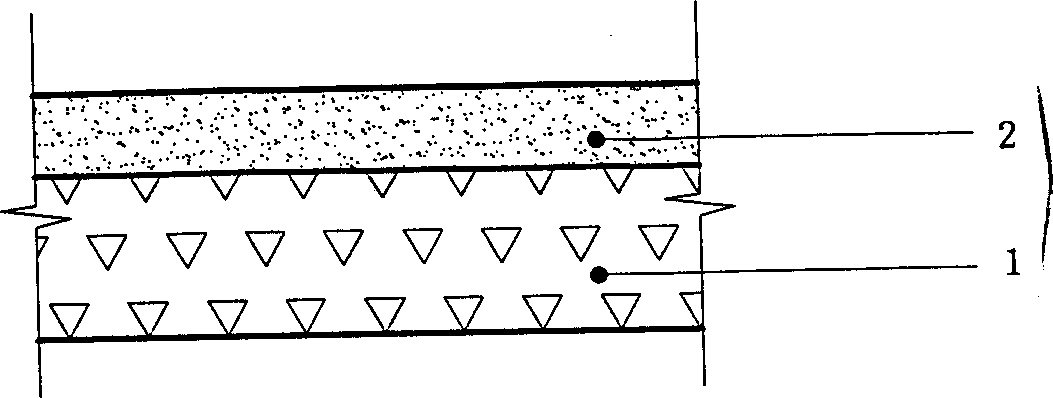

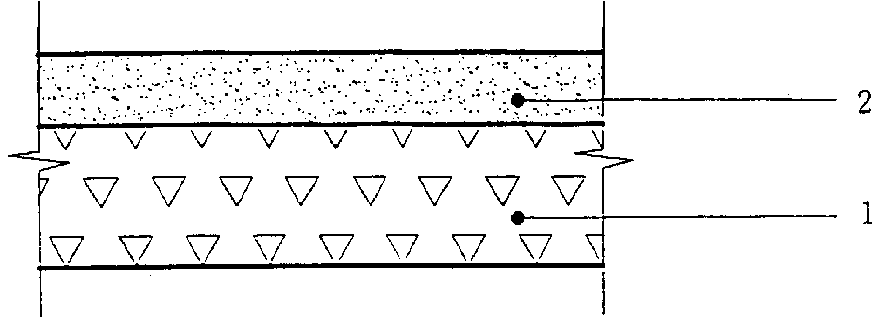

Single stage membrane reactor for high purity hydrogen production

InactiveUS20070157517A1Improve responseEasy to operateCatalytic gas-gas reactionMembranesSteam reformingMembrane reactor

Hydrogen generating method and apparatus. The apparatus comprises a mixed phase protonic-electron conducting cermet membrane (2), wherein said membrane is coated with porous metal or composite catalyst (1) effective to decompose hydro-carbon and water reactants into a hydrogen-rich syngas at elevated temperature and pressure. The hydrogen ions are continuously withdrawn in situ by diffusing them through the mixed phase conducting cermet membrane (2) to the second membrane side where the hydrogen ions can be reconstituted into molecular hydrogen with a supply of electrons. The method favorably shifts the equilibrium of steam reforming and water gas shift reaction by use a single stage, high efficiency and high purity membrane reactor.

Owner:TSAY DAVID +2

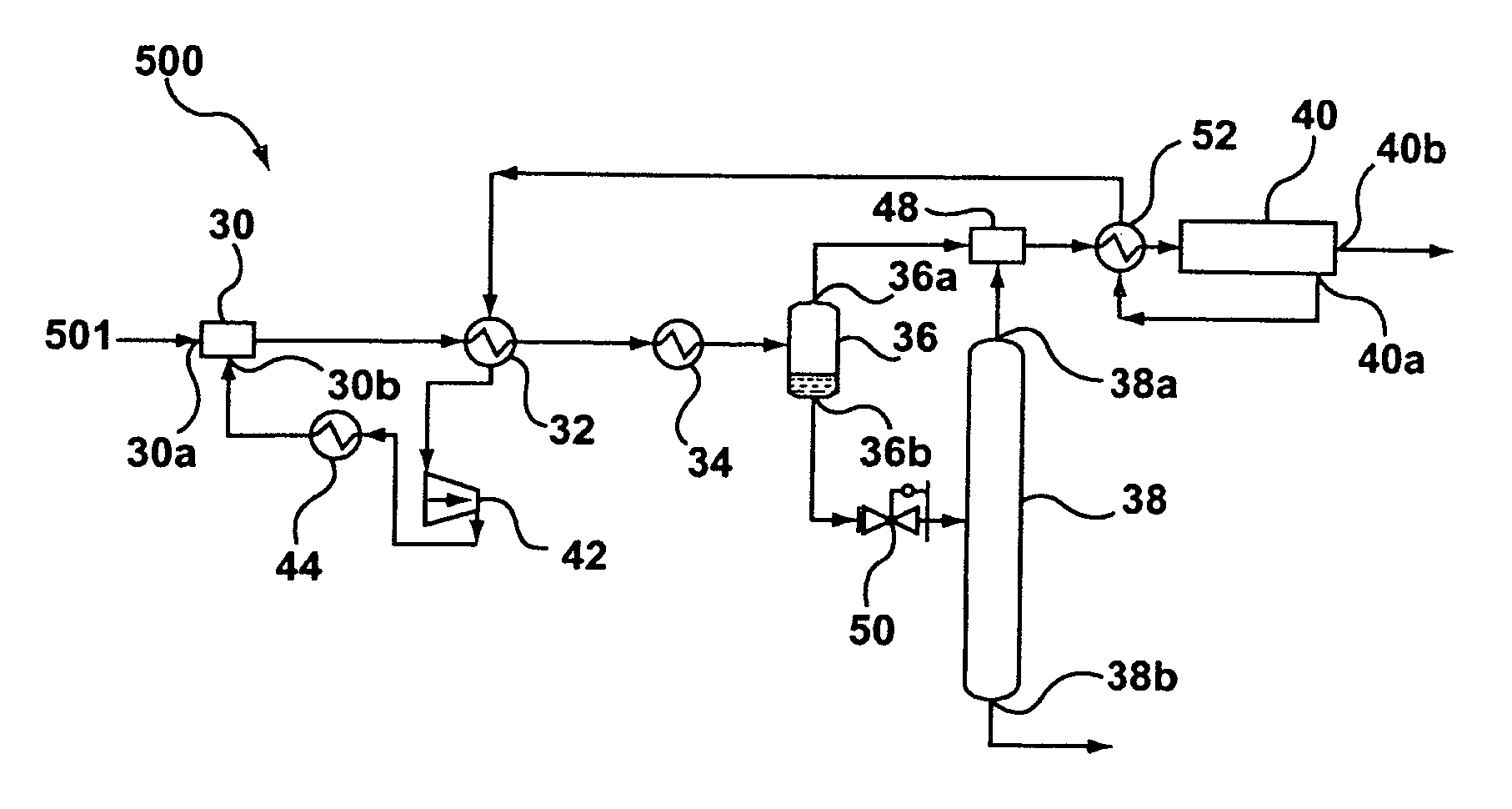

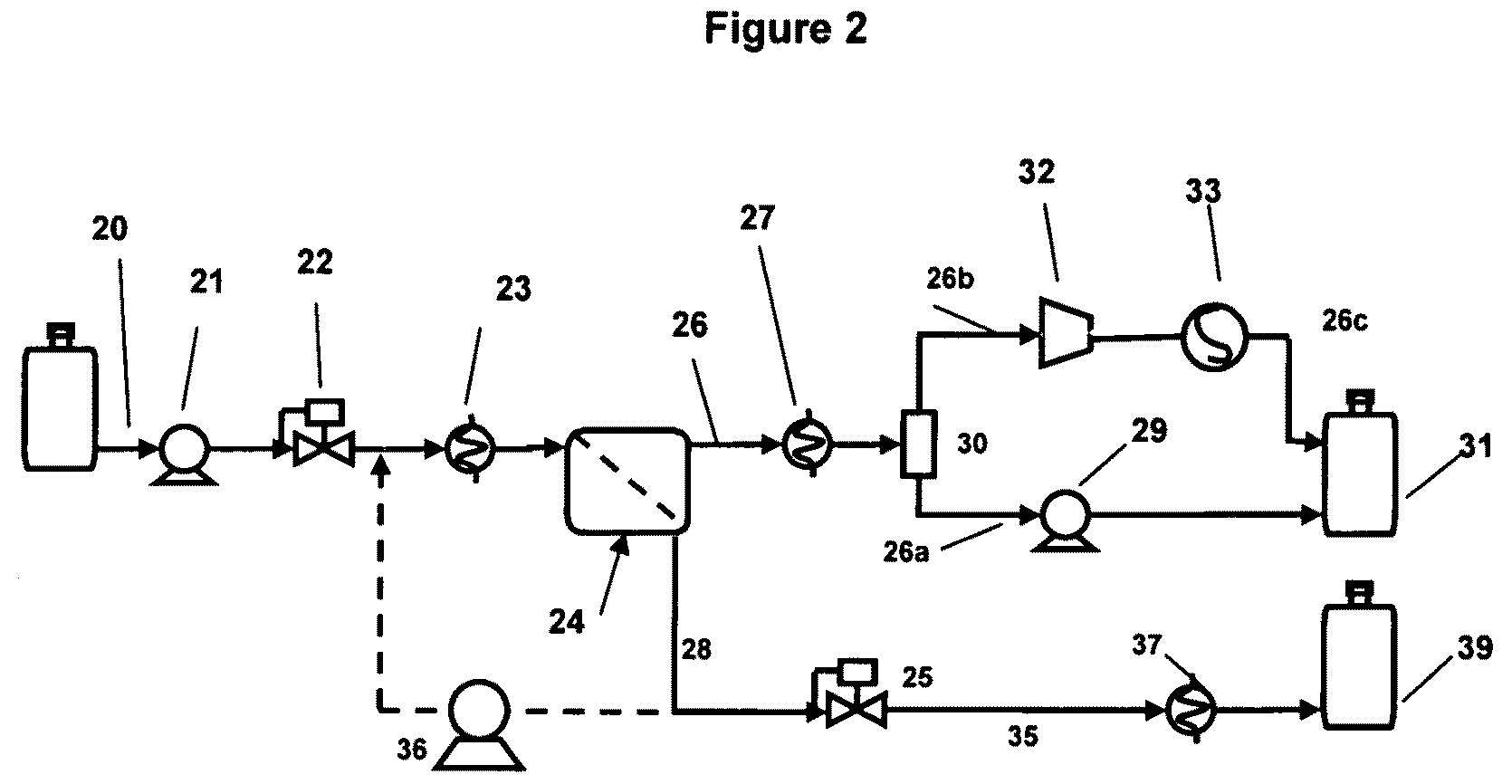

Systems and methods for low-temperature gas separation

One of the drawbacks common to many currently available low-temperature gas mixture separation techniques is that known systems and methods that embody the techniques are inefficient. In contrast to known systems and methods for low-temperature gas mixture separation, some embodiments of the present invention provide a system for low-temperature gas mixture separation that recycles energy and reduces power consumption by re-circulating heated and / or cooled flows (e.g. gas, liquid and mixed-phase flows) within the system. Accordingly, in some embodiments efficiency is somewhat improved, as compared to comparable systems that do not include the re-circulation of heat energy. In some embodiments the heat energy that is re-circulated is a combination of heat added to the system (i.e. inputs to the system) and heat released within the system (i.e. byproducts from within the system) that are subsequently recovered. In particular, some systems and methods provided in accordance with embodiments of the invention are suited for separating the constituent components of natural gas and other hydrocarbon gas mixtures.

Owner:3S GAS TECH LTD

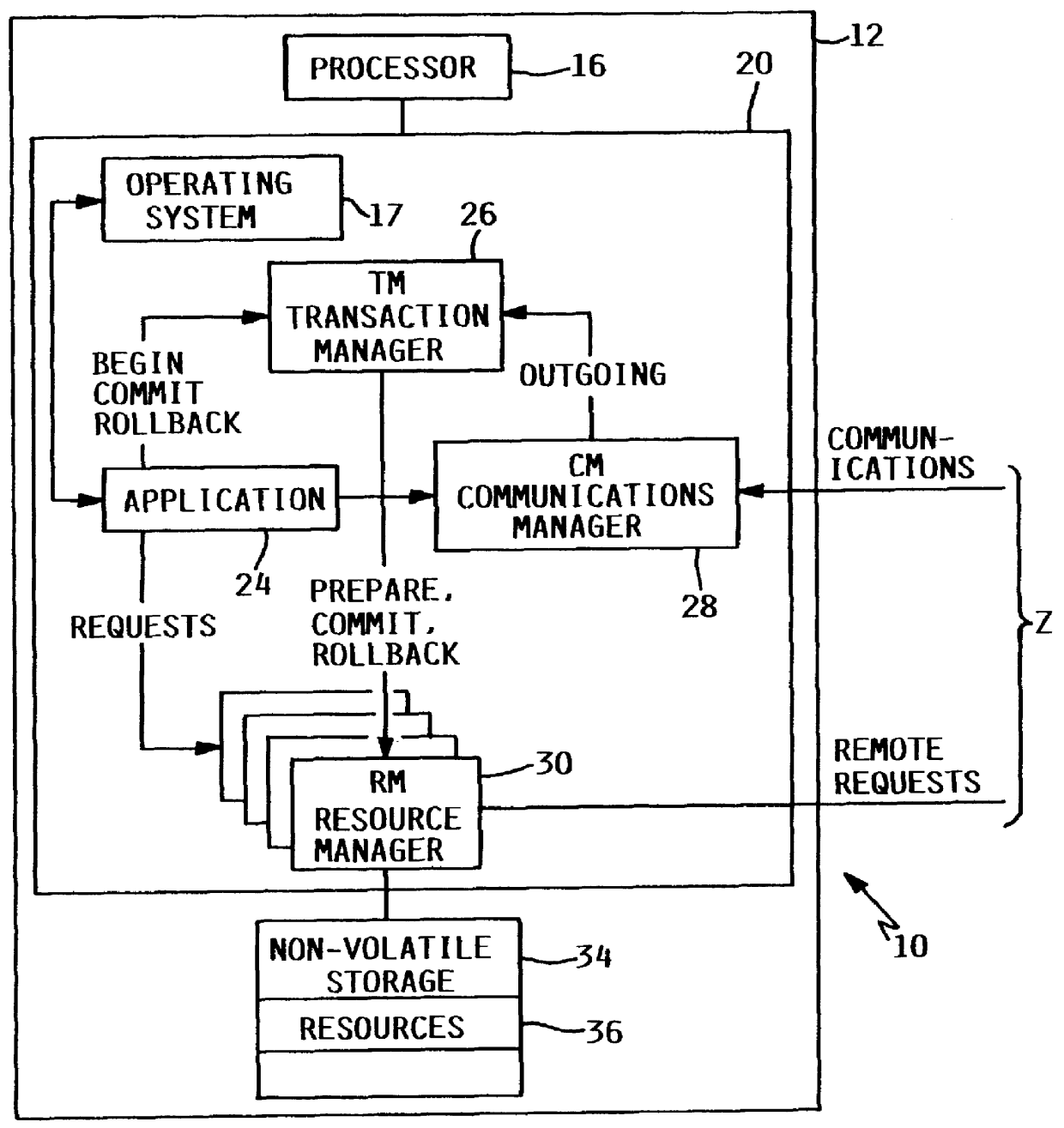

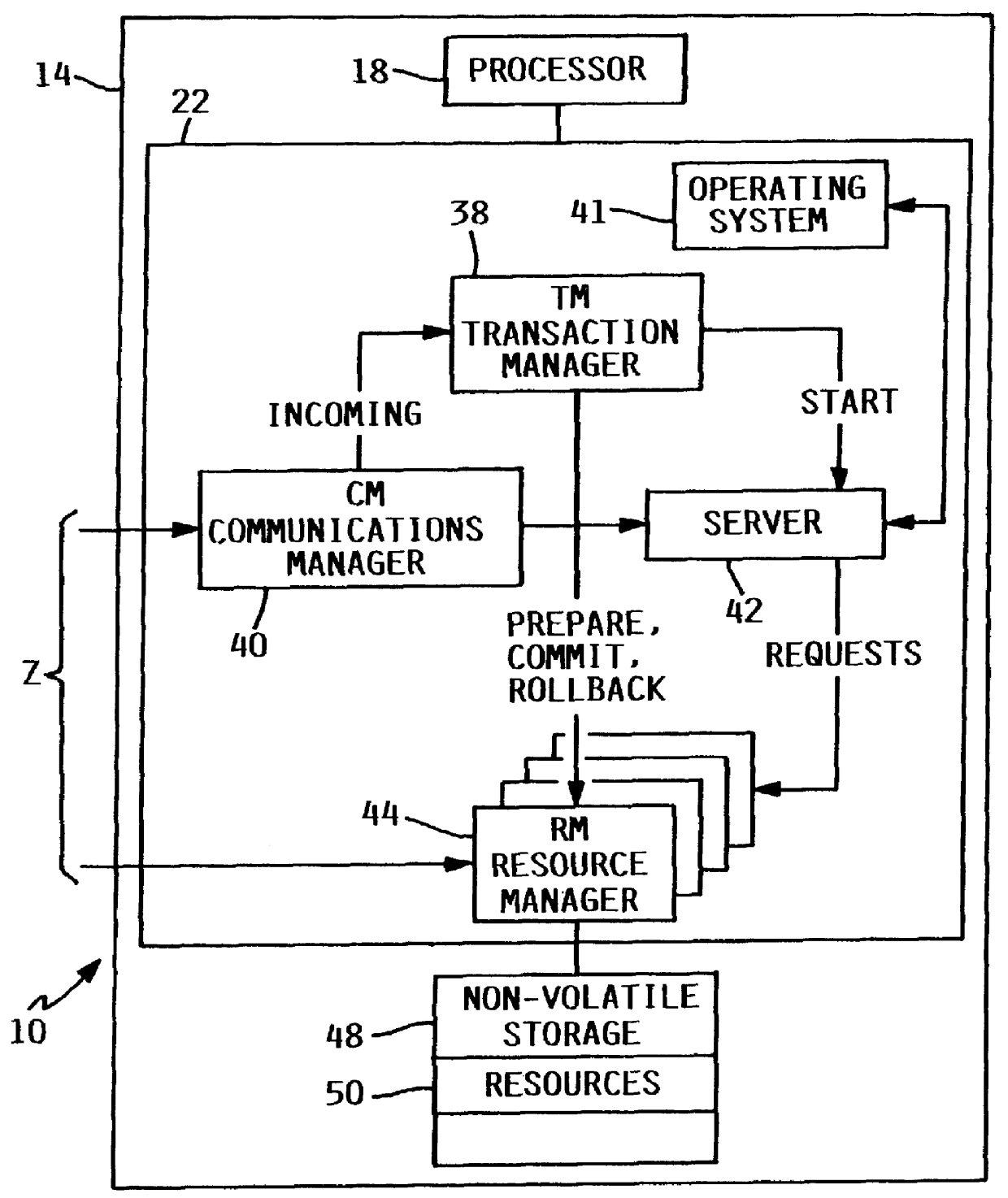

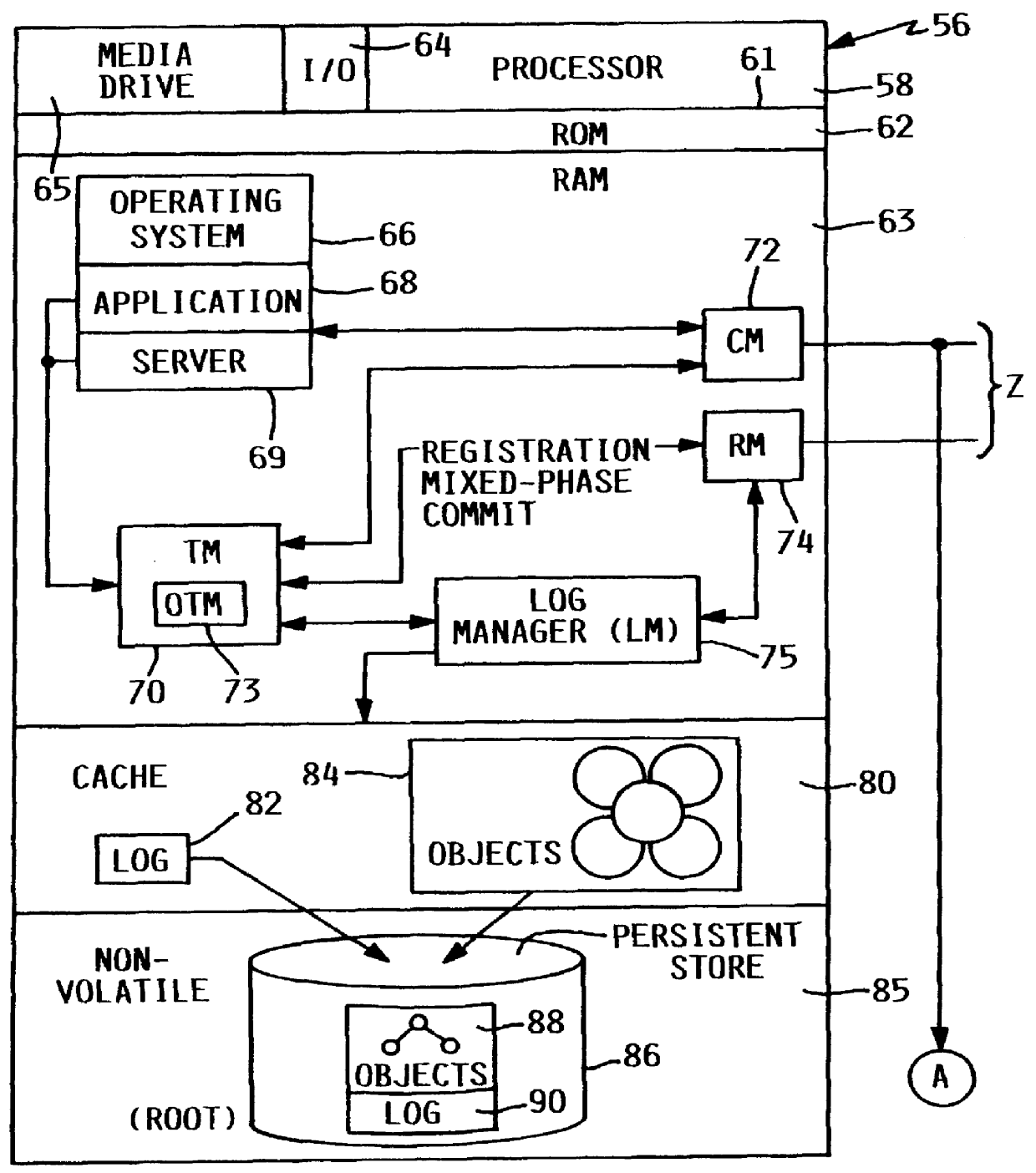

System and method for supporting mixed-phase transactions in an object-oriented environment

A system, method, and apparatus for ensuring data integrity in a distributed object-oriented transaction processing environment, including support of single- and two-phased commit protocol transactions with a new protocol defined as a mixed-phase commit protocol. A root transaction manager on a server registers distributed object resources requested by a client application for a global transaction as being committable by either the single-phase, two-phase, or mixed-phase protocol. The root transaction manager commits the registered resources in accordance with the results of the registration step.

Owner:IBM CORP

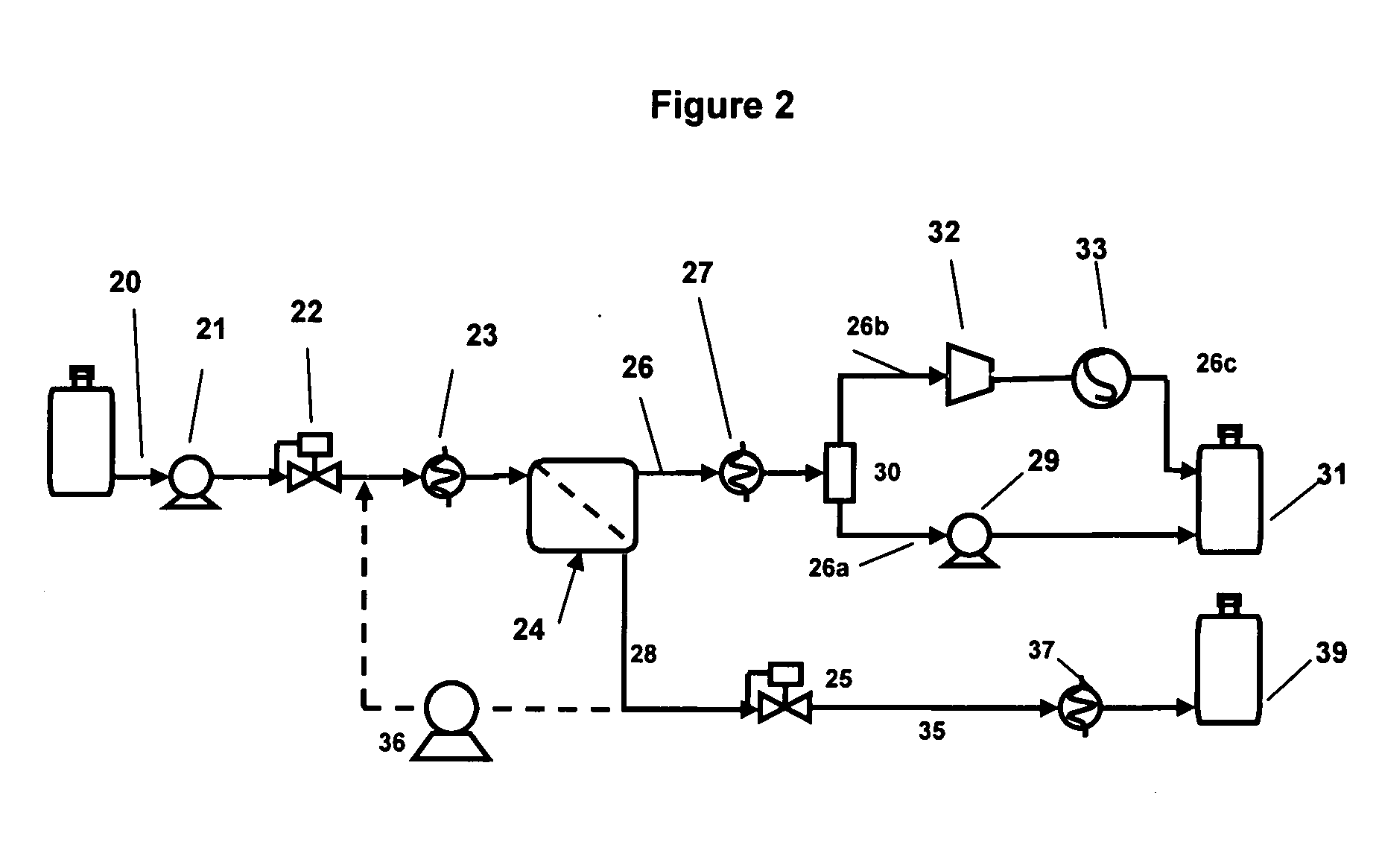

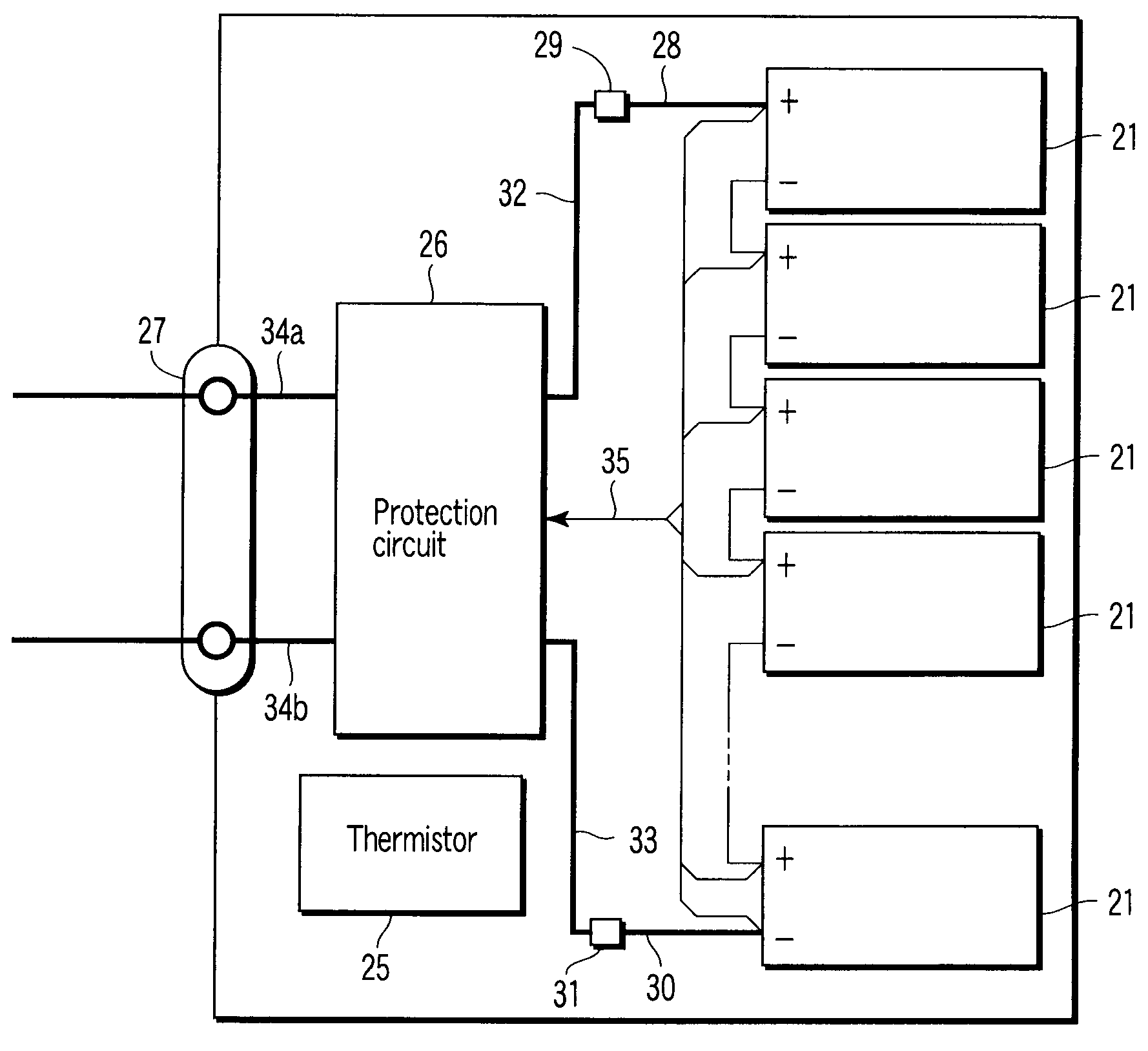

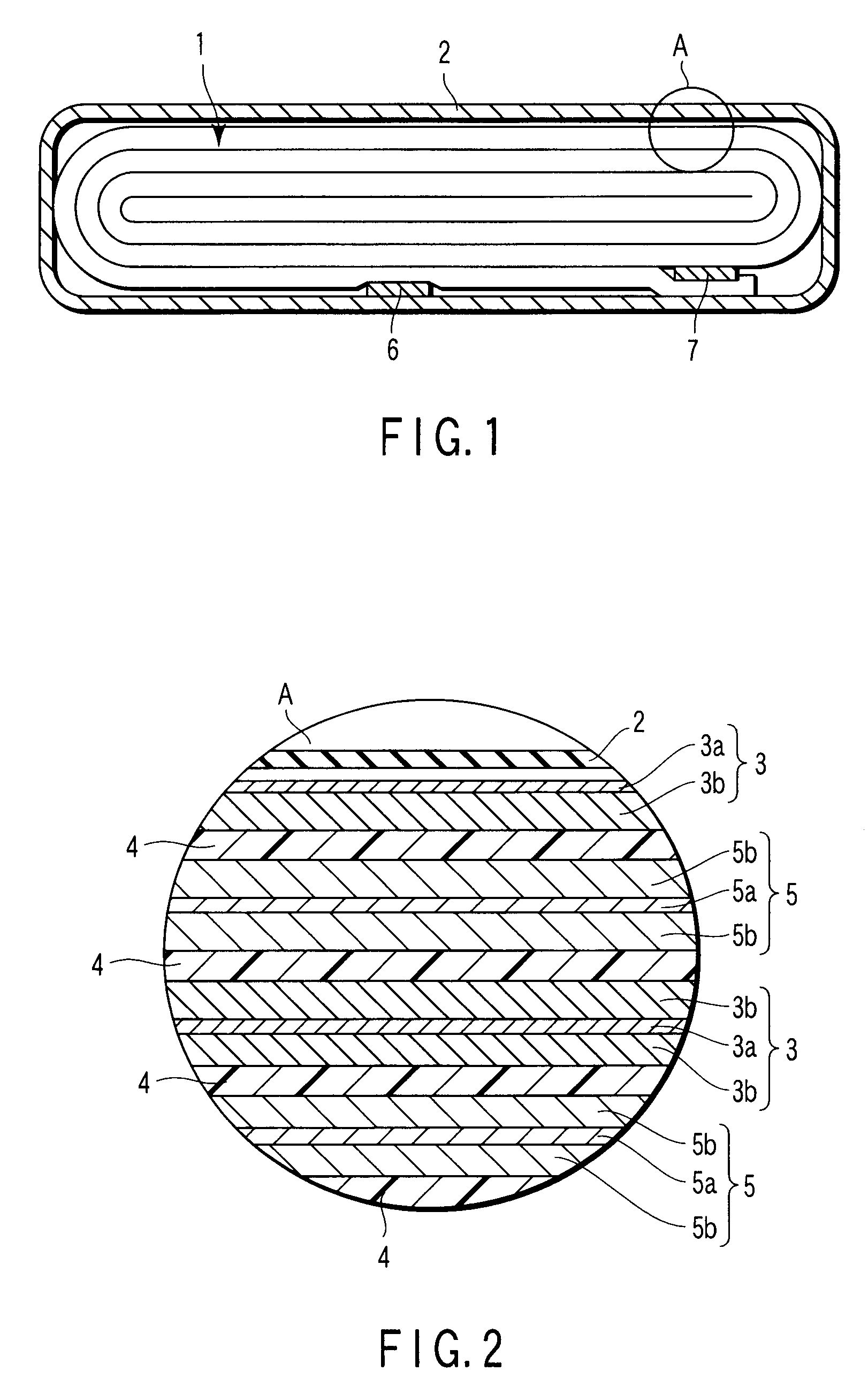

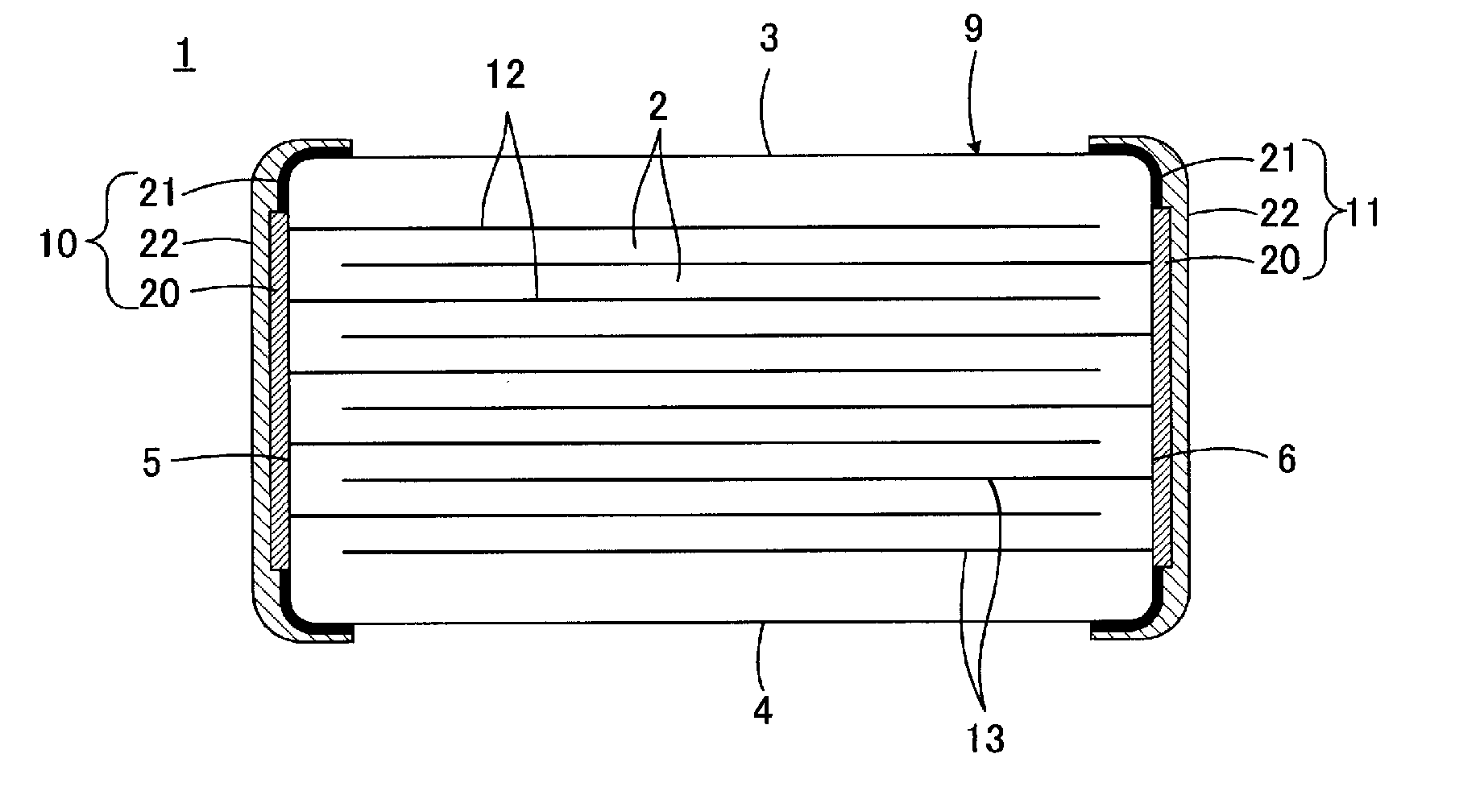

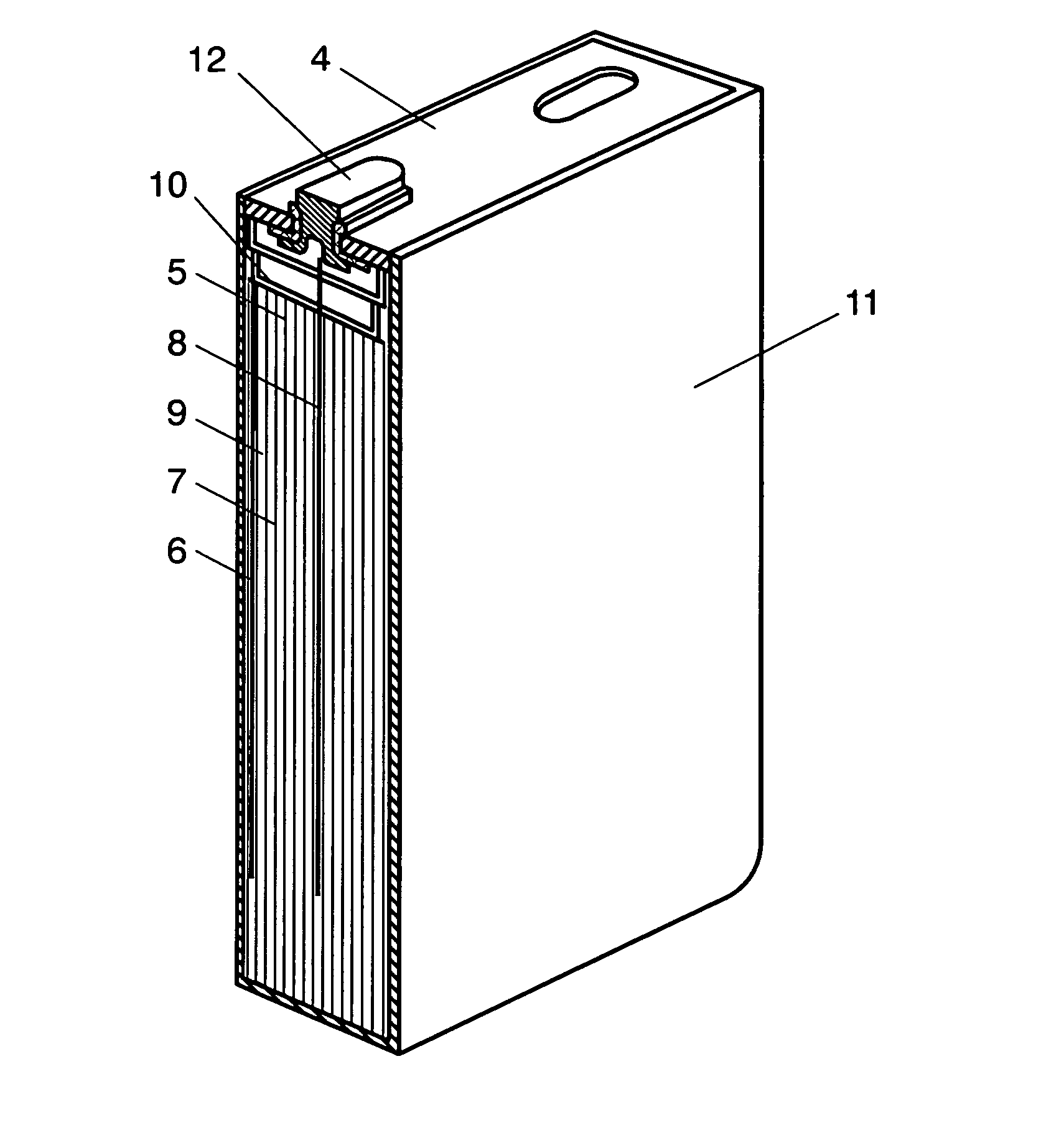

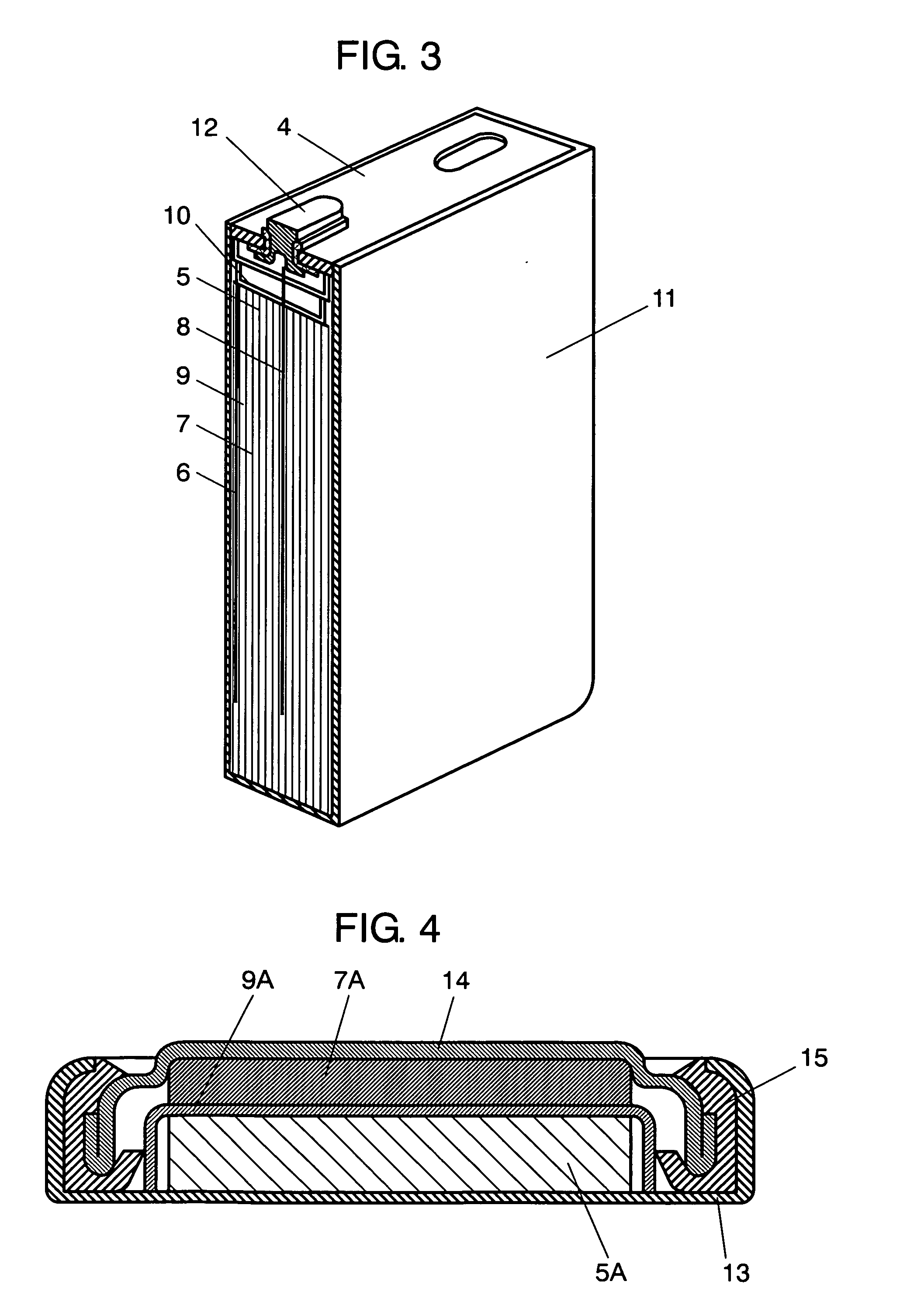

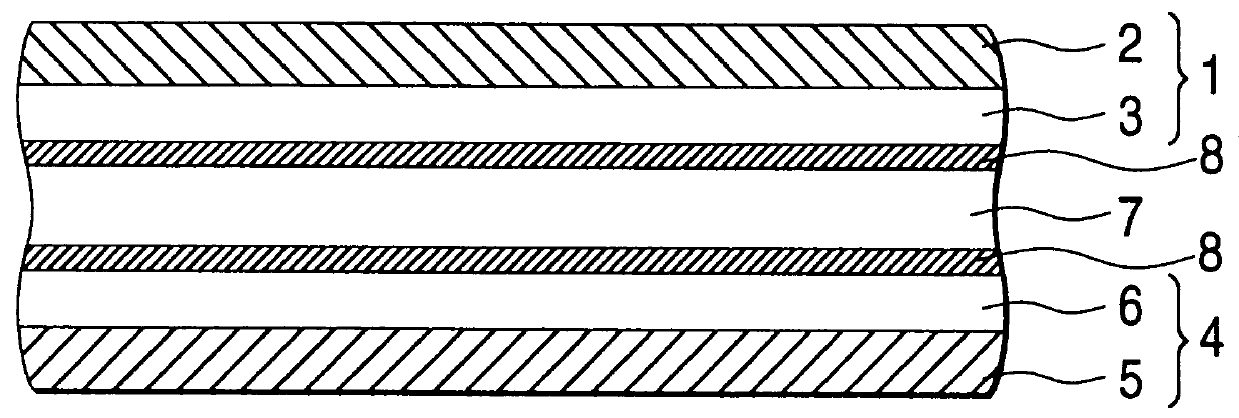

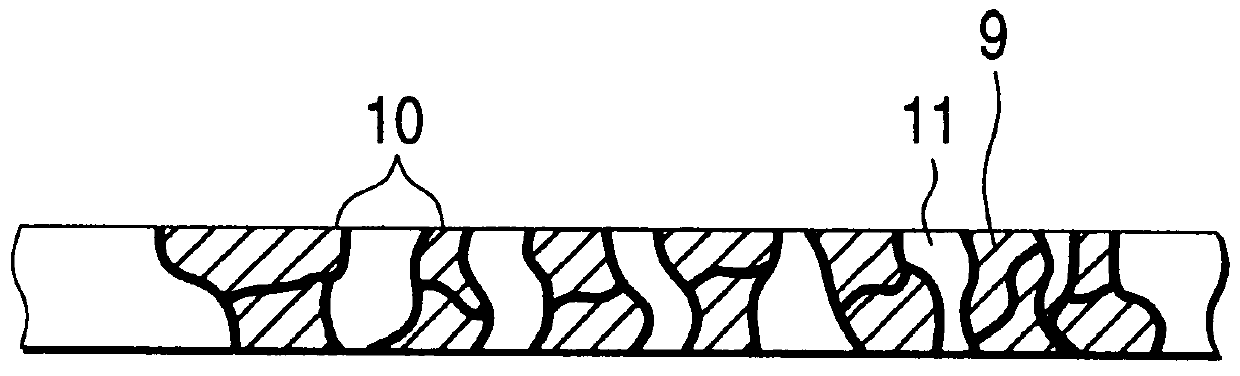

Lithium ion secondary battery and method of fabricating thereof

InactiveUS6051342AFinal product manufactureElectrode carriers/collectorsElectrolytic agentAdhesion strength

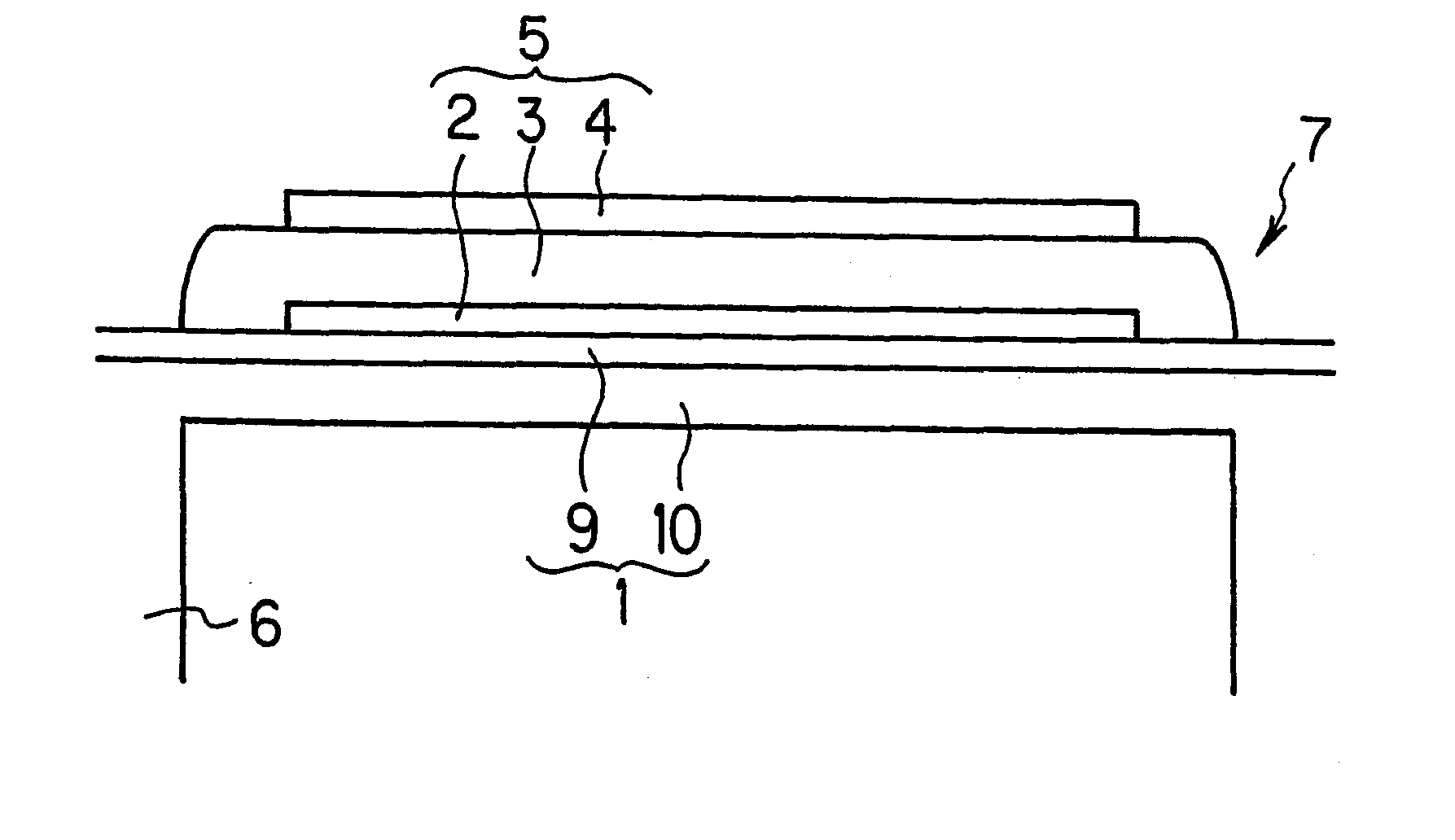

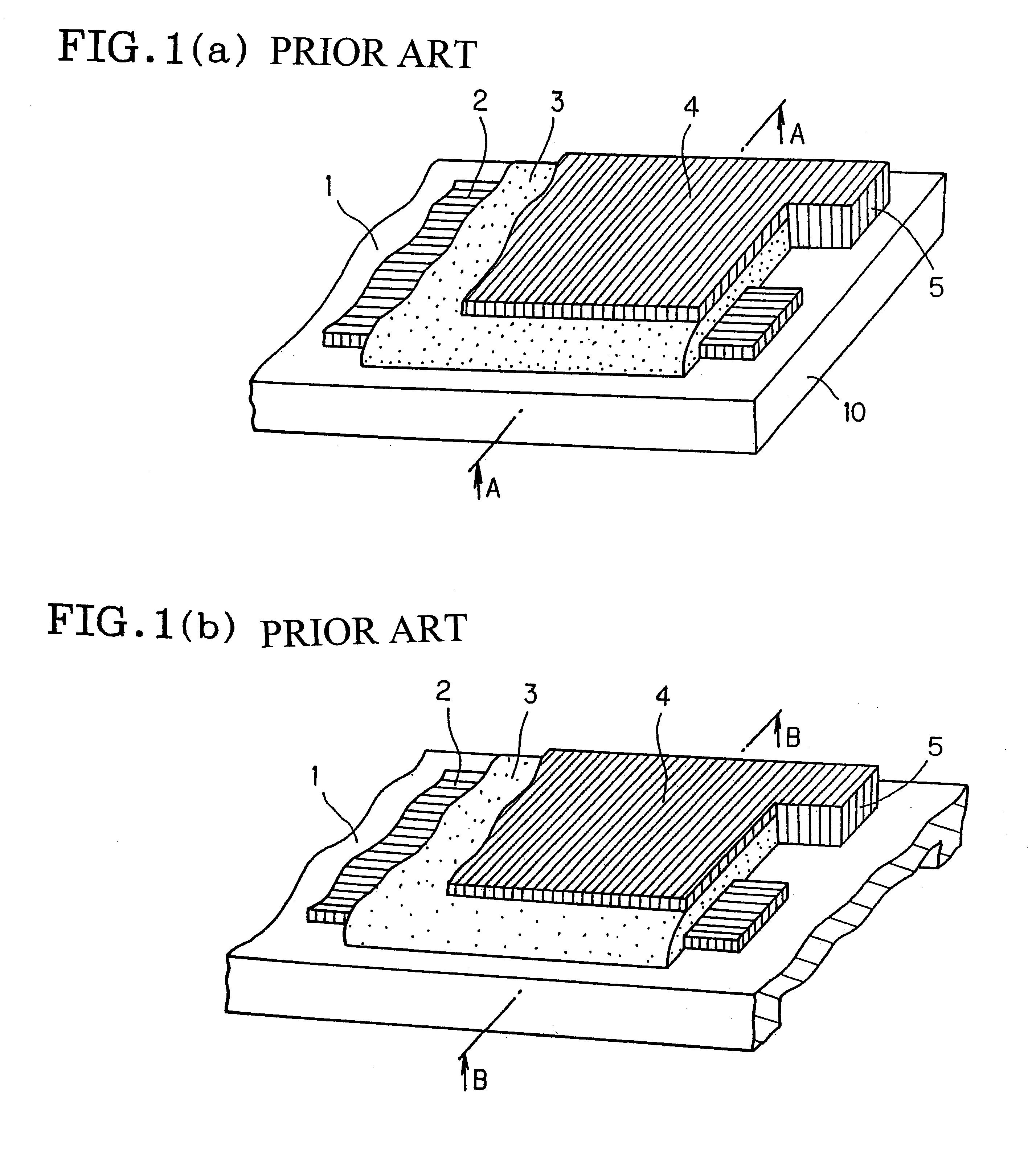

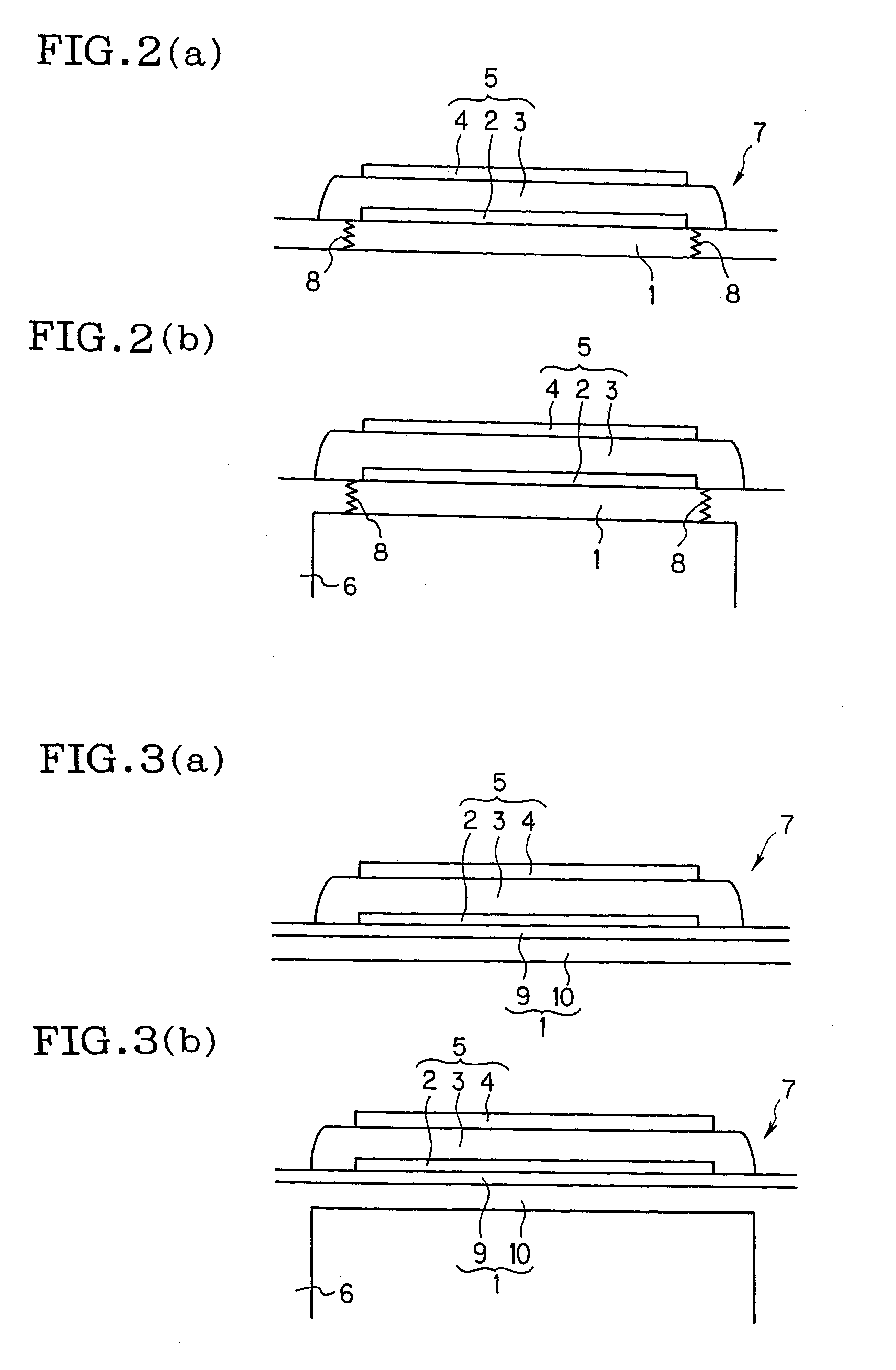

In a lithium ion secondary battery which is composed of a positive electrode 1, a negative electrode 4 and a separator 7 which contains a Li ion-containing non-aqueous electrolytic solution, both of the ionic conductivity and adhesion strength were ensured by making an adhesive resin layer 8 which bonds the positive electrode 1 to the separator 7 and the negative electrode 4 to the separator 7 into a mixture phase consisting of an electrolytic solution phase 9, an electrolytic solution-containing a polymer gel phase 10 and a polymer solid phase 11.

Owner:MITSUBISHI ELECTRIC CORP

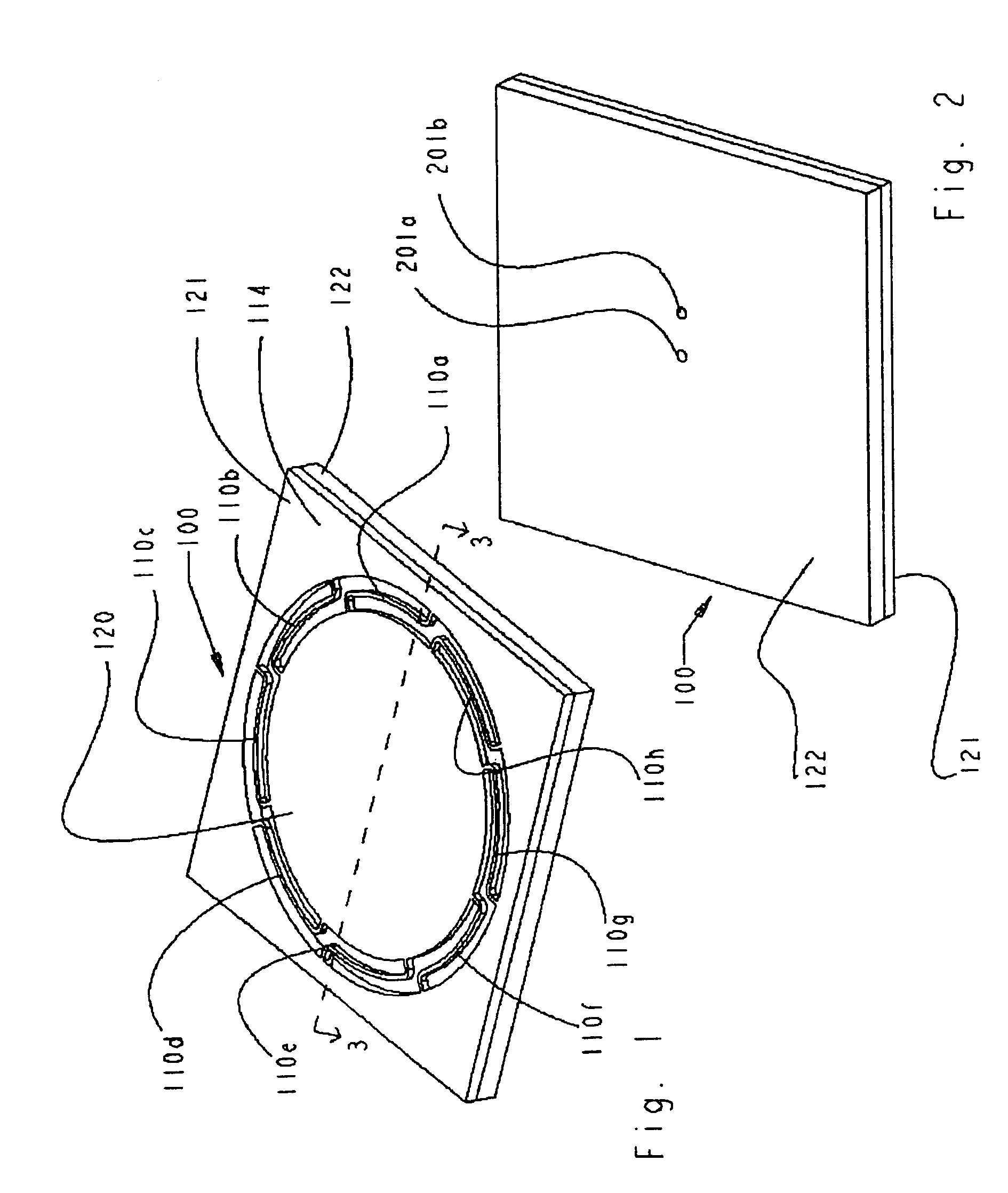

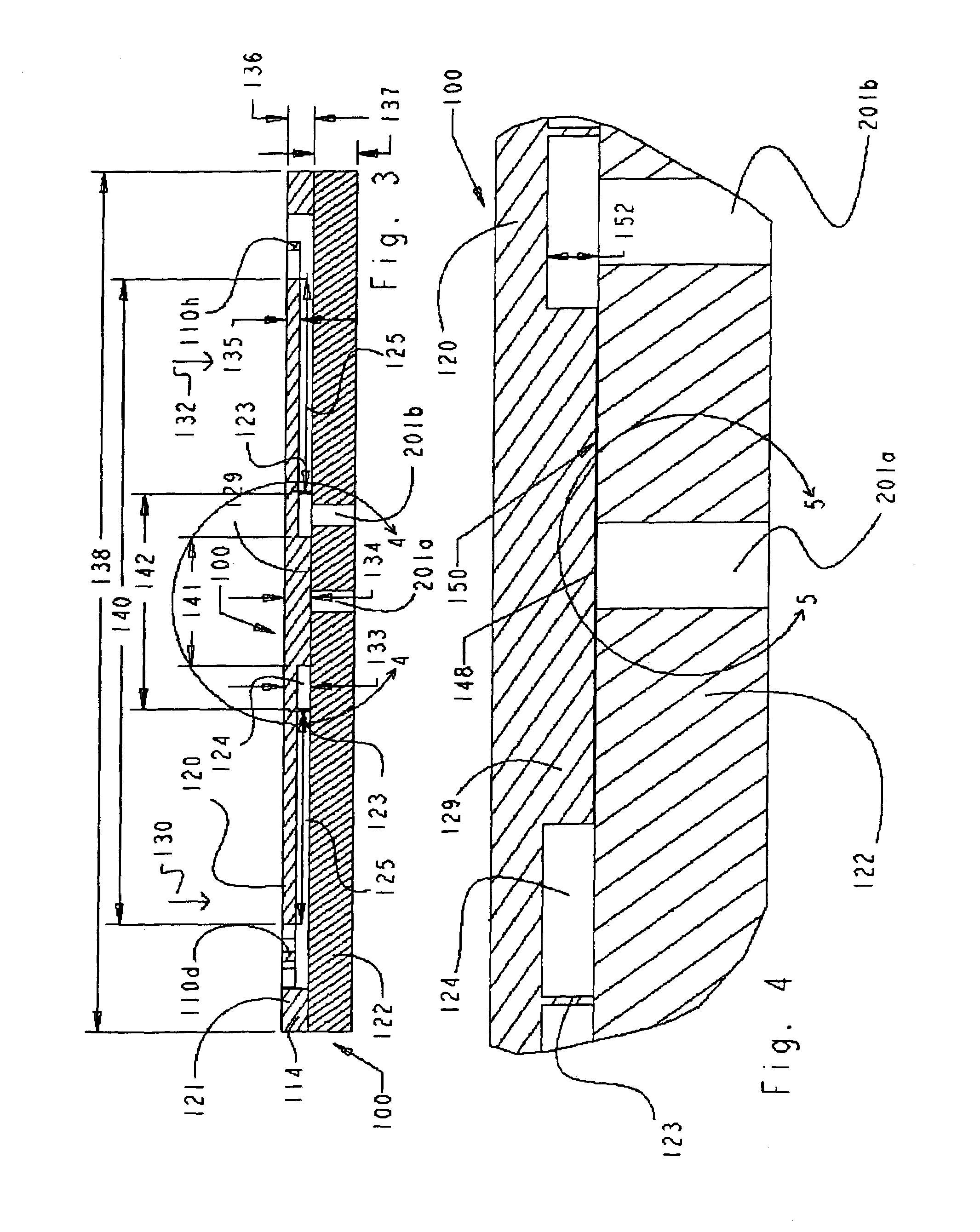

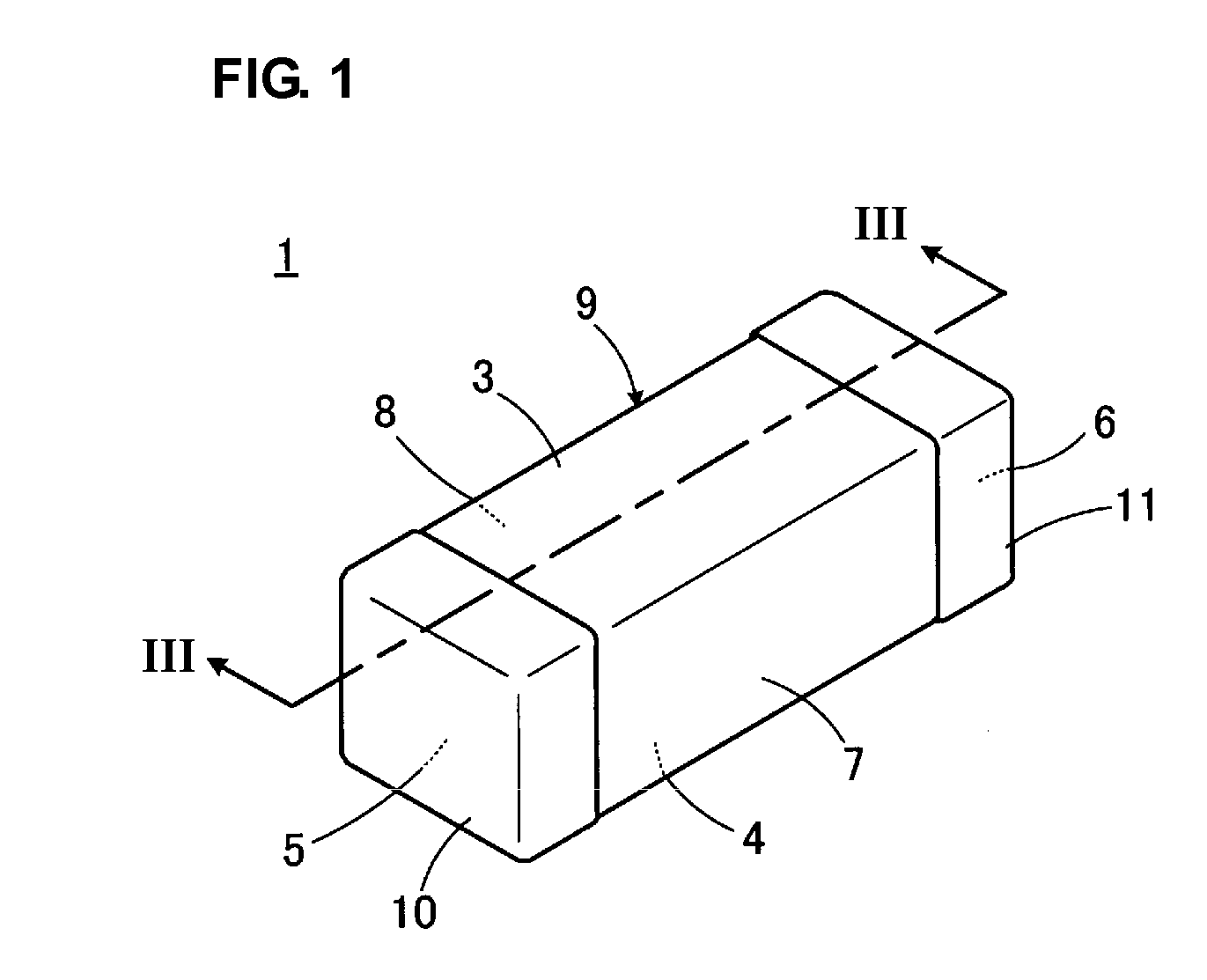

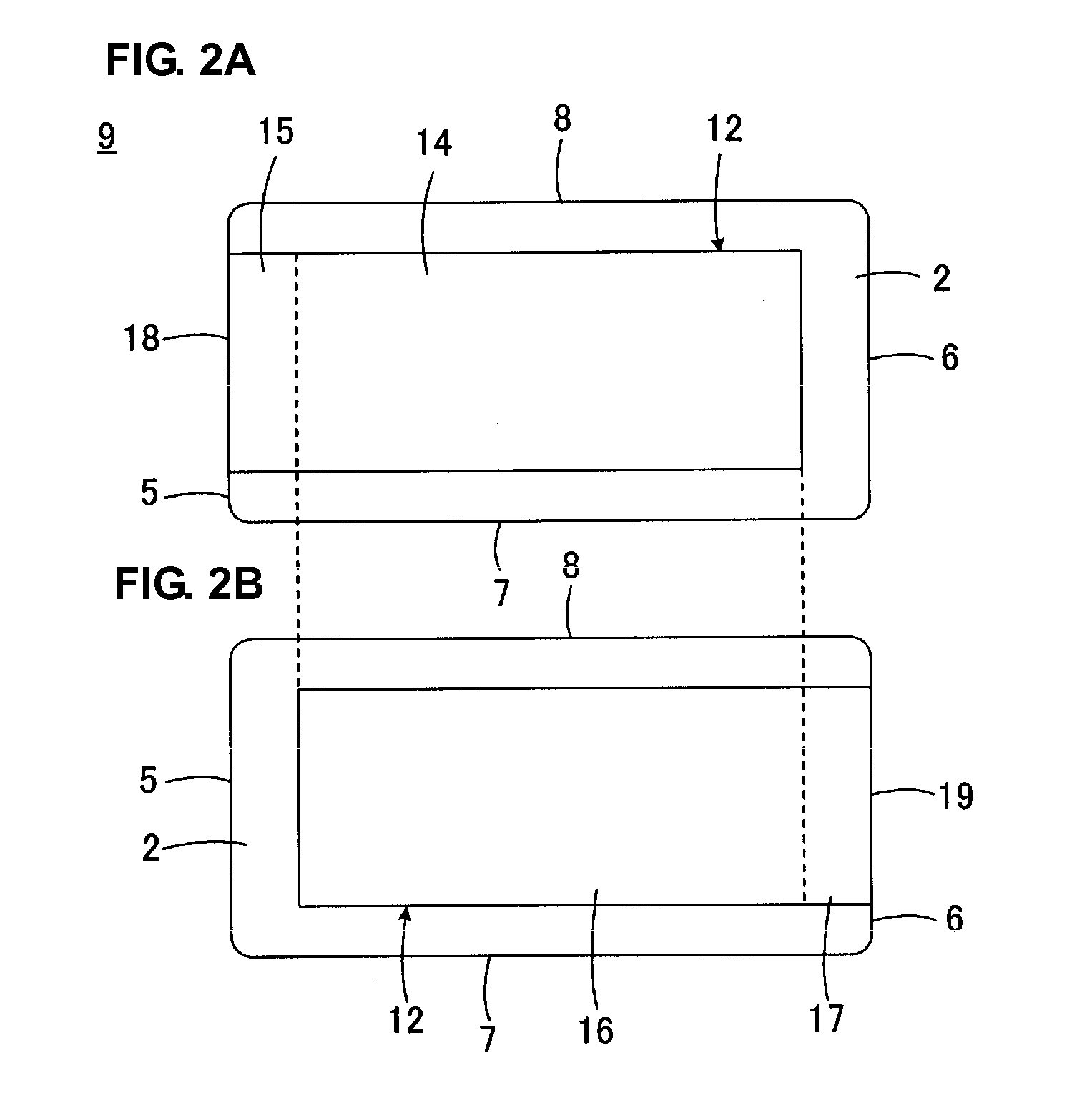

Piezoelectric/electrostrictive element

InactiveUS6246156B1Piezoelectric/electrostriction/magnetostriction machinesFlow propertiesSurface layerInternal factor

A piezoelectric / electrostrictive element has at least one film-type piezoelectric / electrostrictive operating portion constituted with a first electrode film, a piezoelectric / electrostrictive film, and a second electrode film on a ceramic substrate having a material whose main component is zirconium oxide. The ceramic substrate comprises a base layer and a surface layer, the crystal phase of the zirconium oxide of the base layer is a tetragonal phase or a mixed phase of tetragonal and cubic phase, tetragonal and monoclinic phase, or tetragonal, cubic, and monoclinic phase. The crystal phase of the zirconium oxide of the surface layer is mainly a cubic phase, and the piezoelectric / electrostrictive operating portion is formed on the surface layer. So it is possible to provide a high performance piezoelectric / electrostrictive element making sure of the strength of a ceramic substrate (diaphragm) and moreover, preventing a crack from occurring due to an internal factor in the firing process of a piezoelectric / electrostrictive film.

Owner:NGK INSULATORS LTD

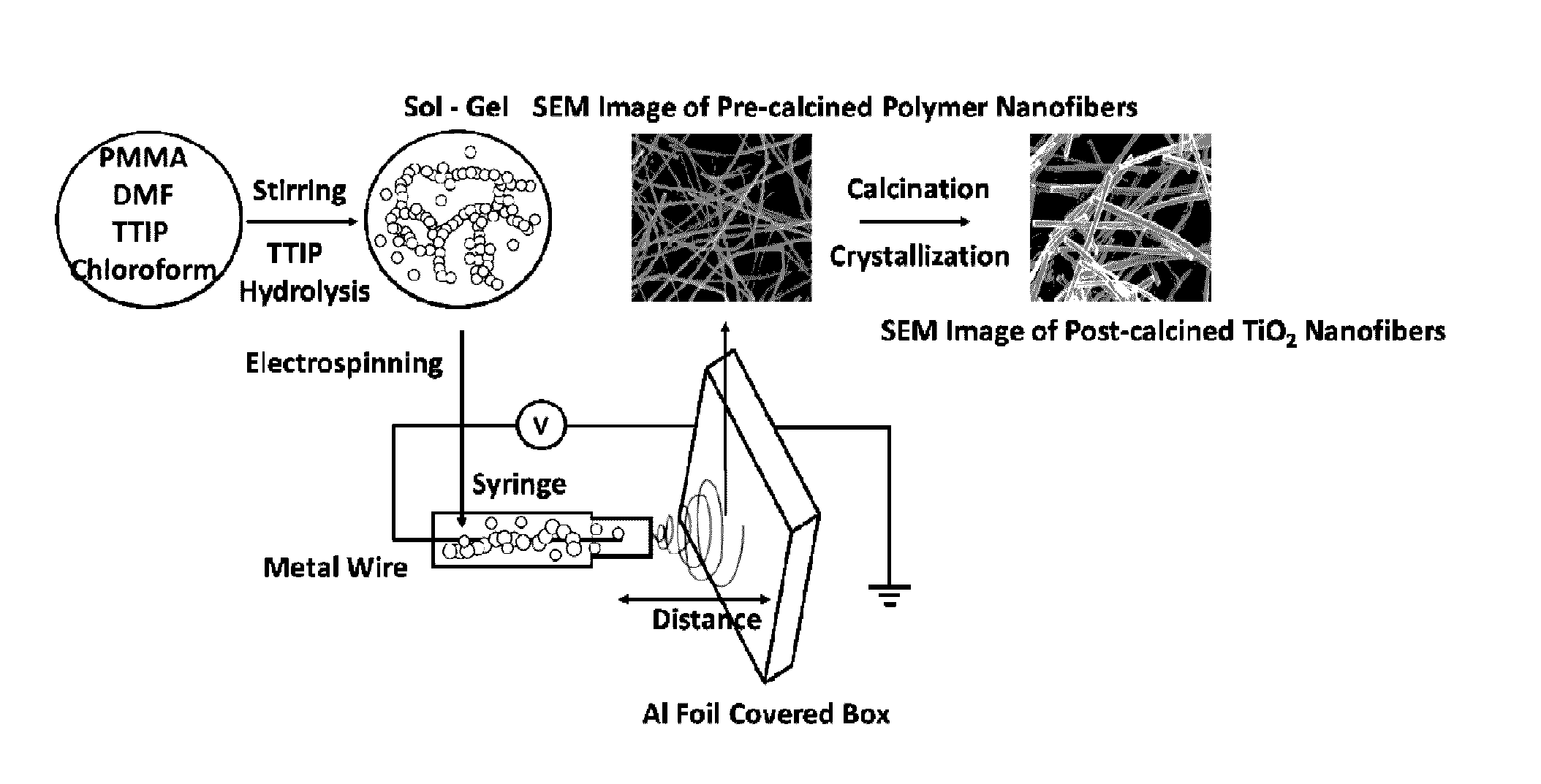

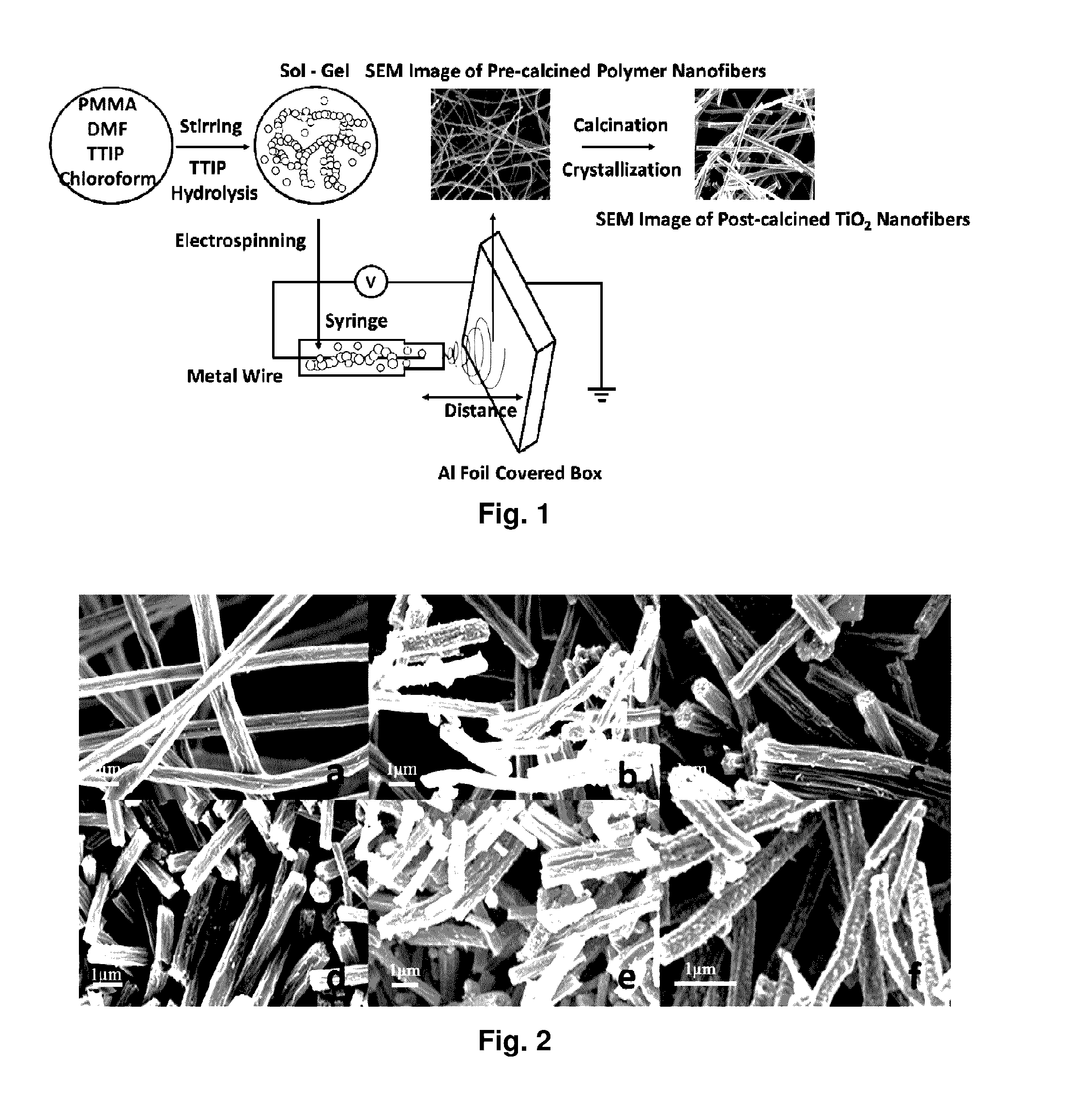

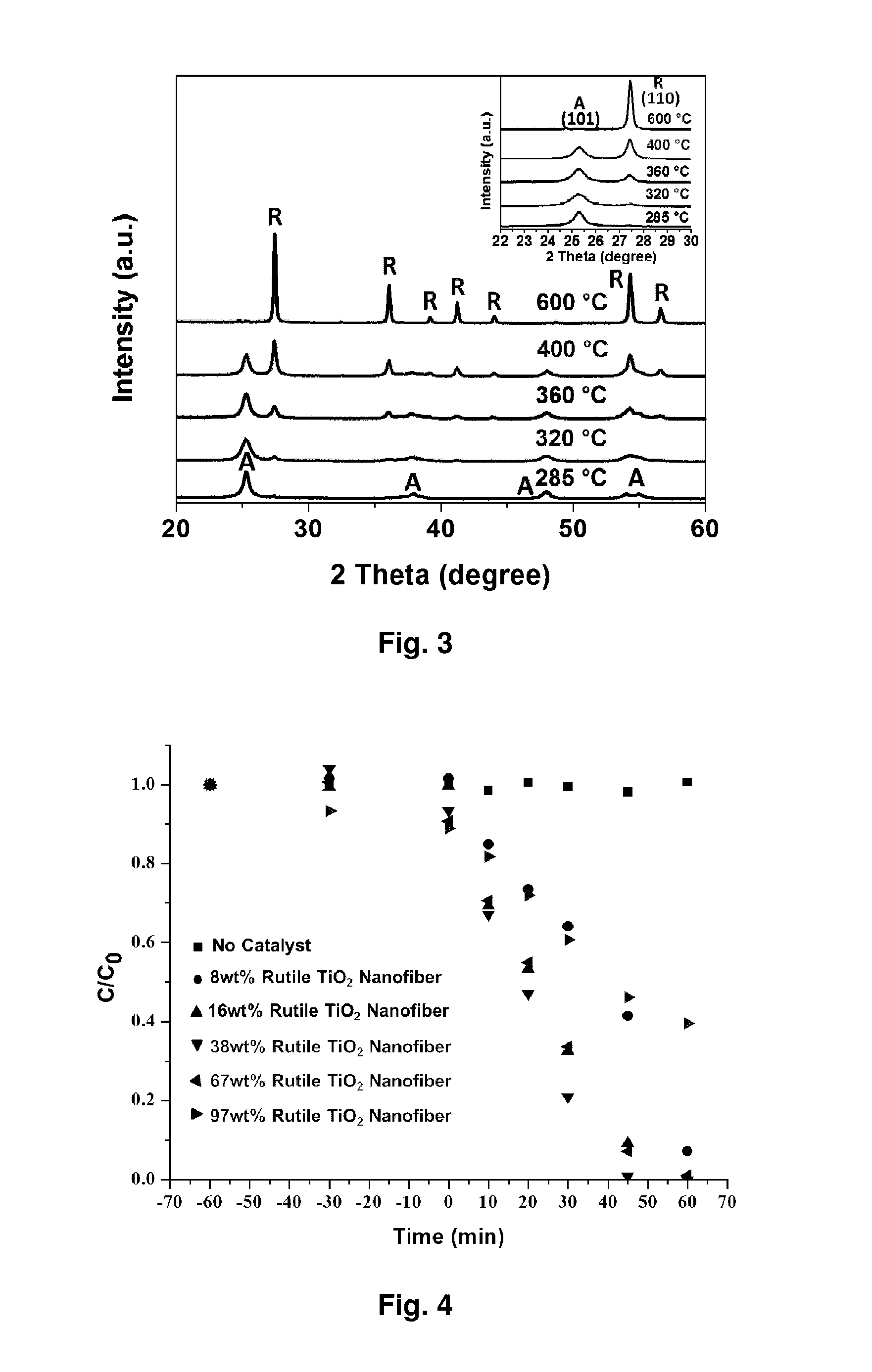

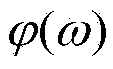

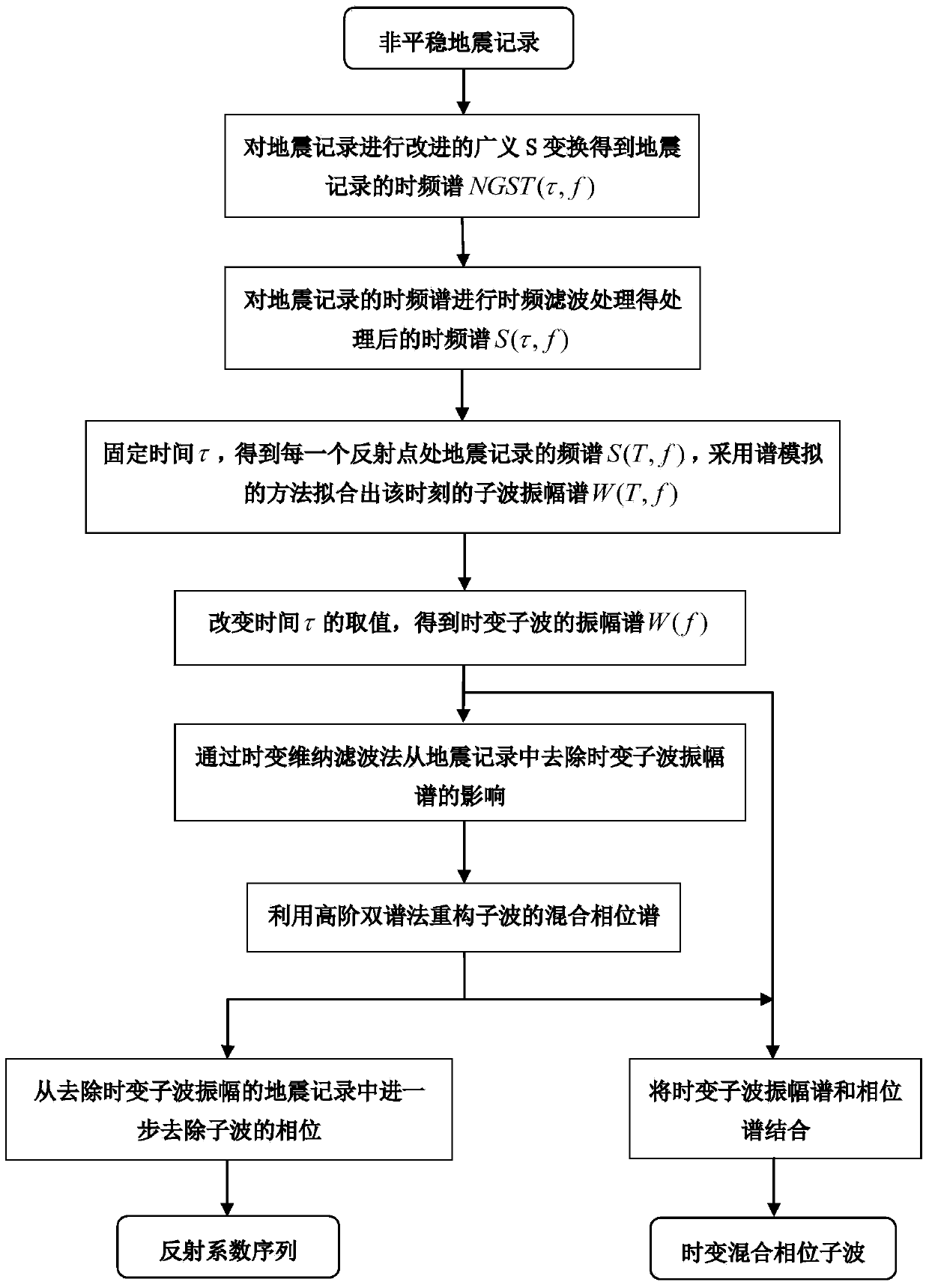

Metal oxide nanofibrous materials for photodegradation of environmental toxins

ActiveUS20170056873A1Rapid and inexpensiveAccelerated photodegradationWater/sewage treatment by irradiationWater treatment compoundsFiberRutile

Mixed-phase TiO2 nanofibers prepared via a sol-gel technique followed by electrospinning and calcination are provided as photocatalysts. The calcination temperature is adjusted to control the rutile phase fraction in TiO2 nanofibers relative to the anatase phase. Post-calcined TiO2 nanofibers composed of 38 wt % rutile and 62 wt % anatase exhibited the highest initial rate constant of UV photocatalysis. This can be attributed to the combined influences of the fibers' specific surface areas and their phase compositions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

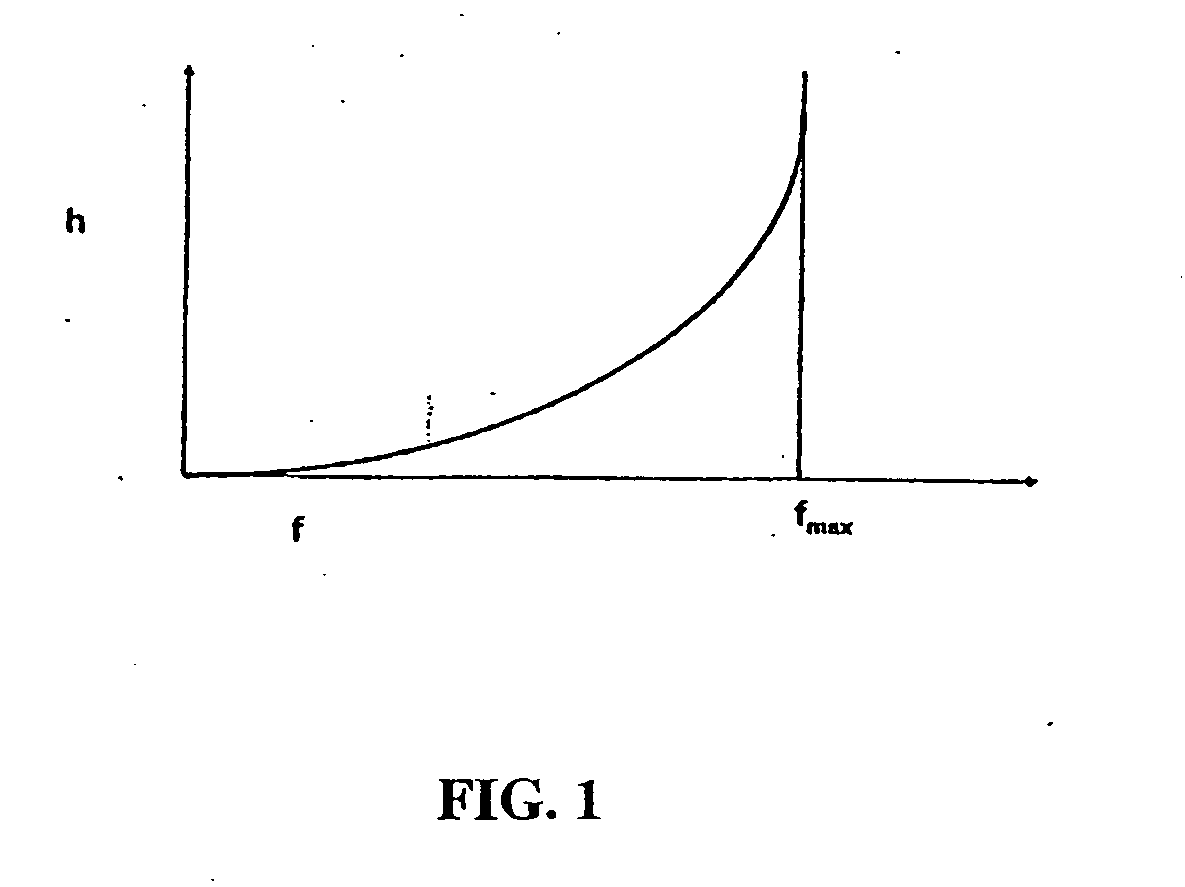

Time-varying mixed-phase seismic wavelet extraction method based on time-frequency spectrum simulation

InactiveCN103995289AImprove estimation accuracyAccurate analysis and processingSeismic signal processingFrequency spectrumImage resolution

The invention discloses a time-varying mixed-phase seismic wavelet extraction method based on time-frequency spectrum simulation. The method is characterized in that on the basis that improved generalized S transformation is carried out on a non-stationary seismic record, a time-frequency filter is introduced for the first time to filter a time-frequency spectrum of the seismic record, then a wavelet amplitude spectrum at each moment is estimated according to the spectrum simulation method, a mixed-phase spectrum of the wavelets is reconstructed in the seismic record with the time-varying wavelet amplitude spectrums removed according to the bispectrum method of high-order cumulants under the assumed condition that the phases of the wavelets are time-invariant, and the amplitude spectrums and the phase spectrum are combined to achieve extraction of the time-varying mixed-phase wavelets. Compared with a conventional stage extraction method, the time-varying wavelet extraction method has the advantages that the assumption that stages of the wavelets are stable is not needed, the time-varying wavelets can be accurately estimated even though the attributes of the wavelets at adjacent stages vary greatly, the mixed phase of the extracted wavelets is more consistent with the reality and seismic data can be analyzed and processed more finely and more accurately. The method has great application value in improving the resolution of the seismic data.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

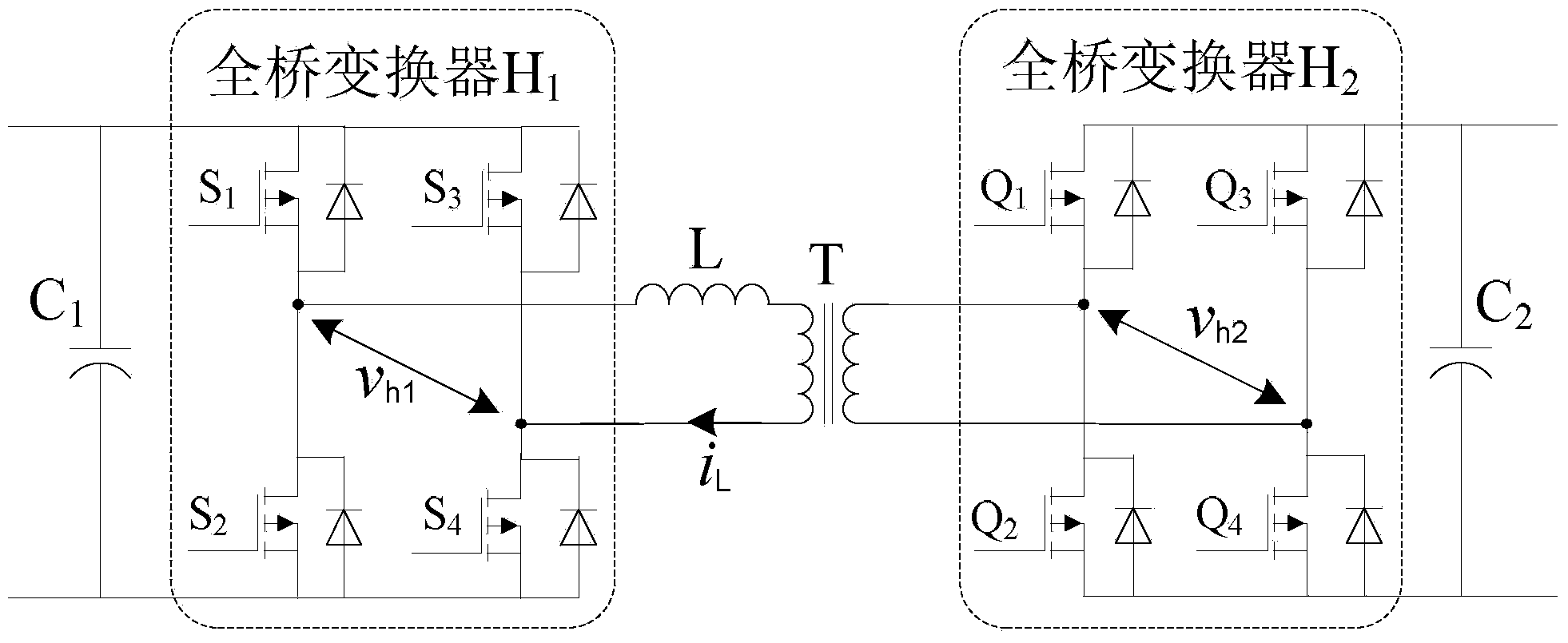

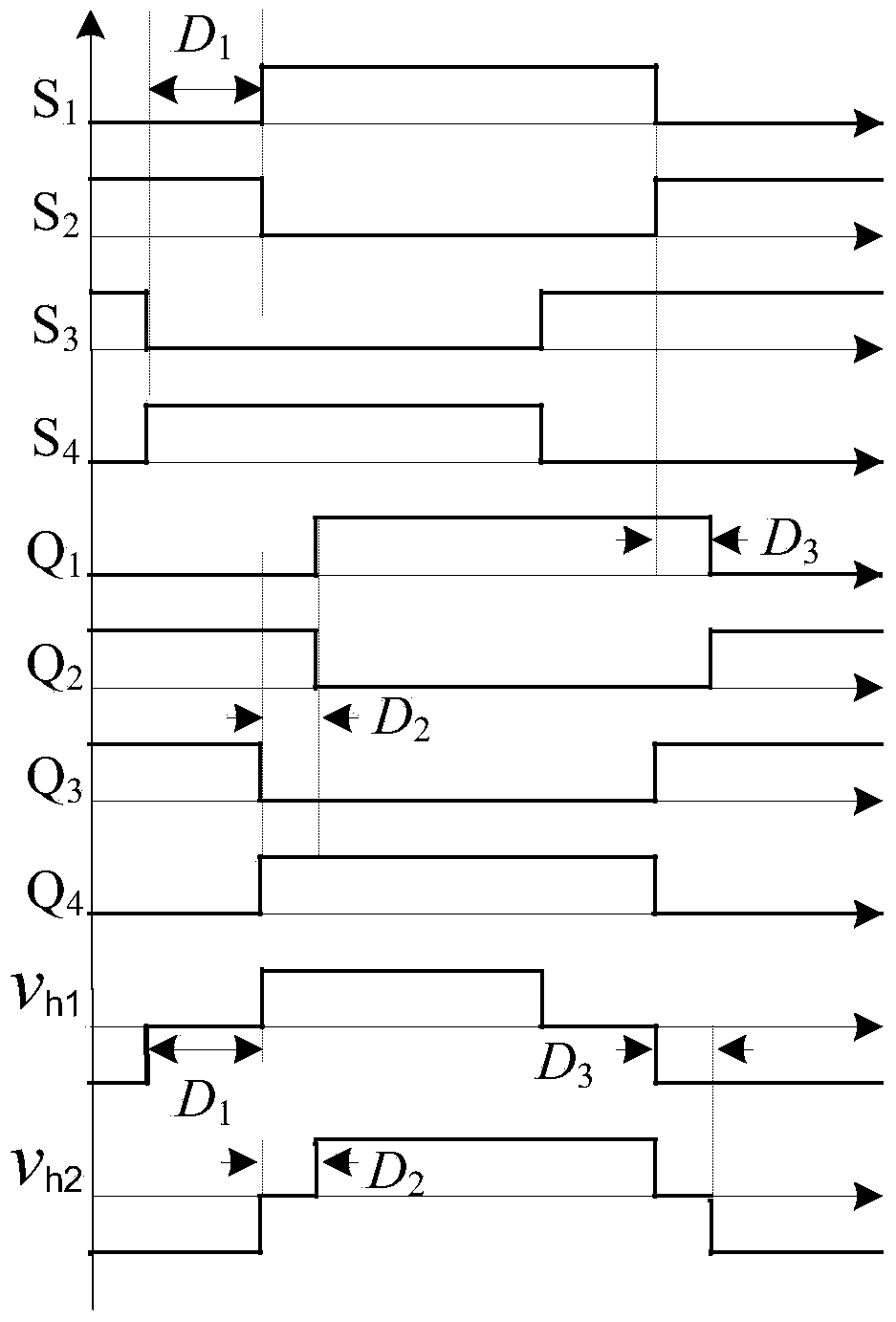

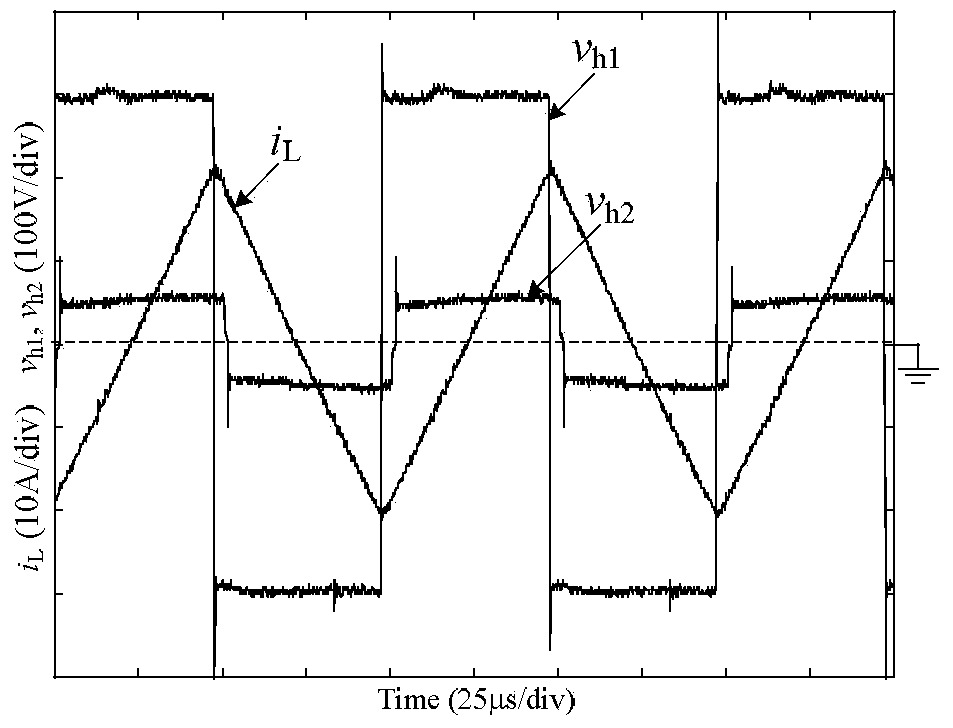

Mixed phase-shifting control method used for dually-active full-bridge direct current converter

InactiveCN103516224ASmall current stressLow on-state lossDc-dc conversionElectric variable regulationFull bridgeThree-phase

The invention discloses a mixed phase-shifting control method used for a dually-active full-bridge direct current converter, and belongs to the technical field of power electronics. The mixed phase-shifting control method comprises the following steps: drive pulses of eight switching tubes in the converter are all set to be square waves; the drive pulse of the first switching tube and the drive pulse of the third switching tube in a first full bridge are set to be complementary with the drive pulse of the second switching tube and the drive pulse of the fourth switching tube in the first full bridge respectively, and the drive pulse of the first switching tube and the drive pulse of the third switching tube in a second full bridge are set to be complementary with the drive pulse of the second switching tube and the drive pulse of the fourth switching tube in the second full bridge respectively; a phase-shifting angle D1 is formed between the drive pulse of the first switching tube and the drive pulse of the fourth switching tube in the first full bridge, another phase-shifting angle D1 is formed between the drive pulse of the second switching tube and the drive pulse of the third switching tube in the first full bridge, and similarly a phase-shifting angle D2 is formed between the drive pulses of the switching tubes in the second full bridge; a phase-shifting angle D3 is formed between the drive pulse of the first switching tube in the first full bridge and the drive pulse of the corresponding switching tube in the second full bridge, and another phase-shifting angle D3 is formed between the drive pulse of the second switching tube in the first full bridge and the drive pulse of the corresponding switching tube in the second full bridge; the magnitude and flow direction of output voltage and the magnitude and flow direction of transmission power of the converter are controlled by adjusting the three phase-shifting angles. By means of the mixed phase-shifting control method, the voltage and current stress of the converter can be reduced, loop currents are reduced, and efficiency is improved.

Owner:TSINGHUA UNIV +1

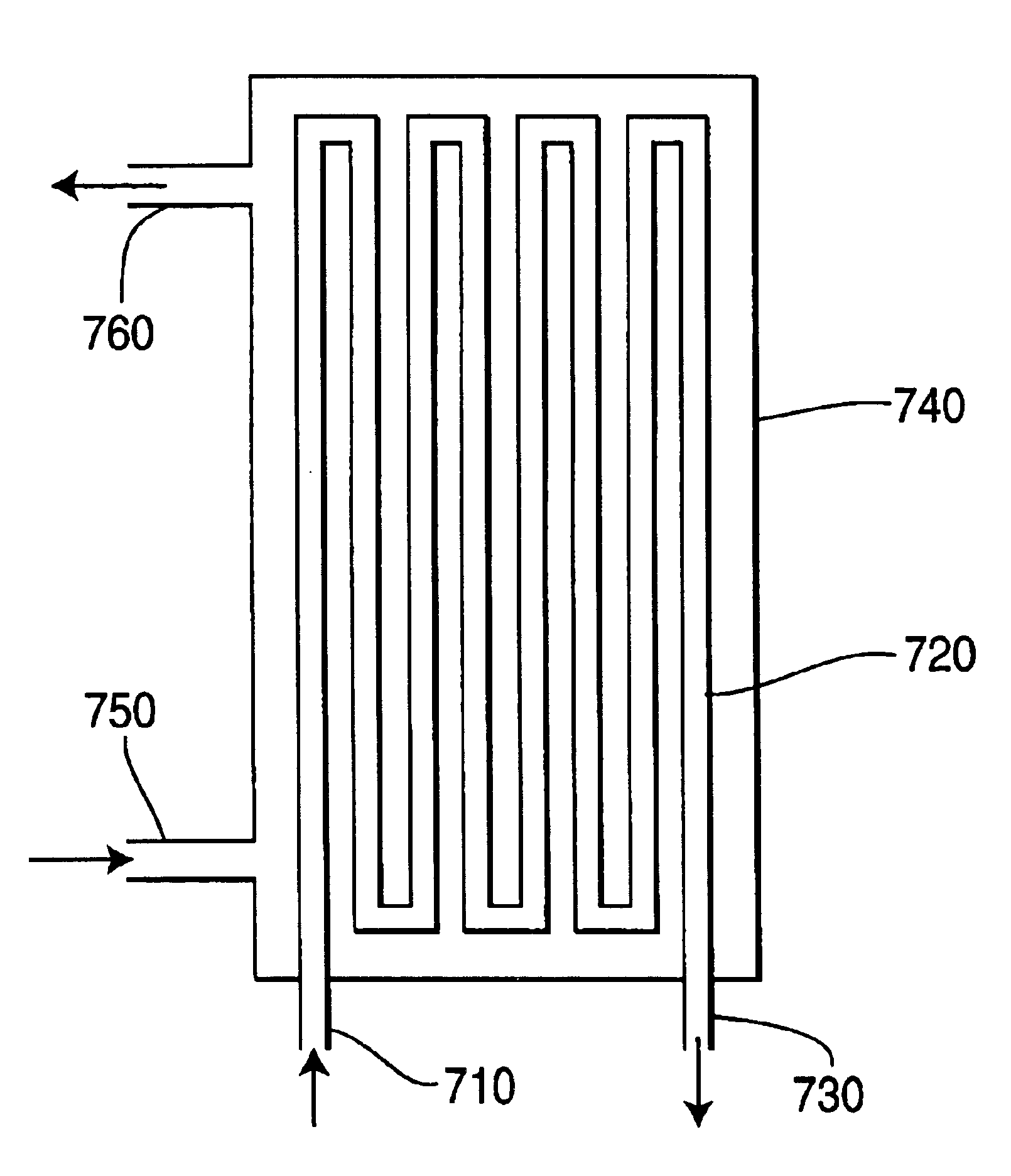

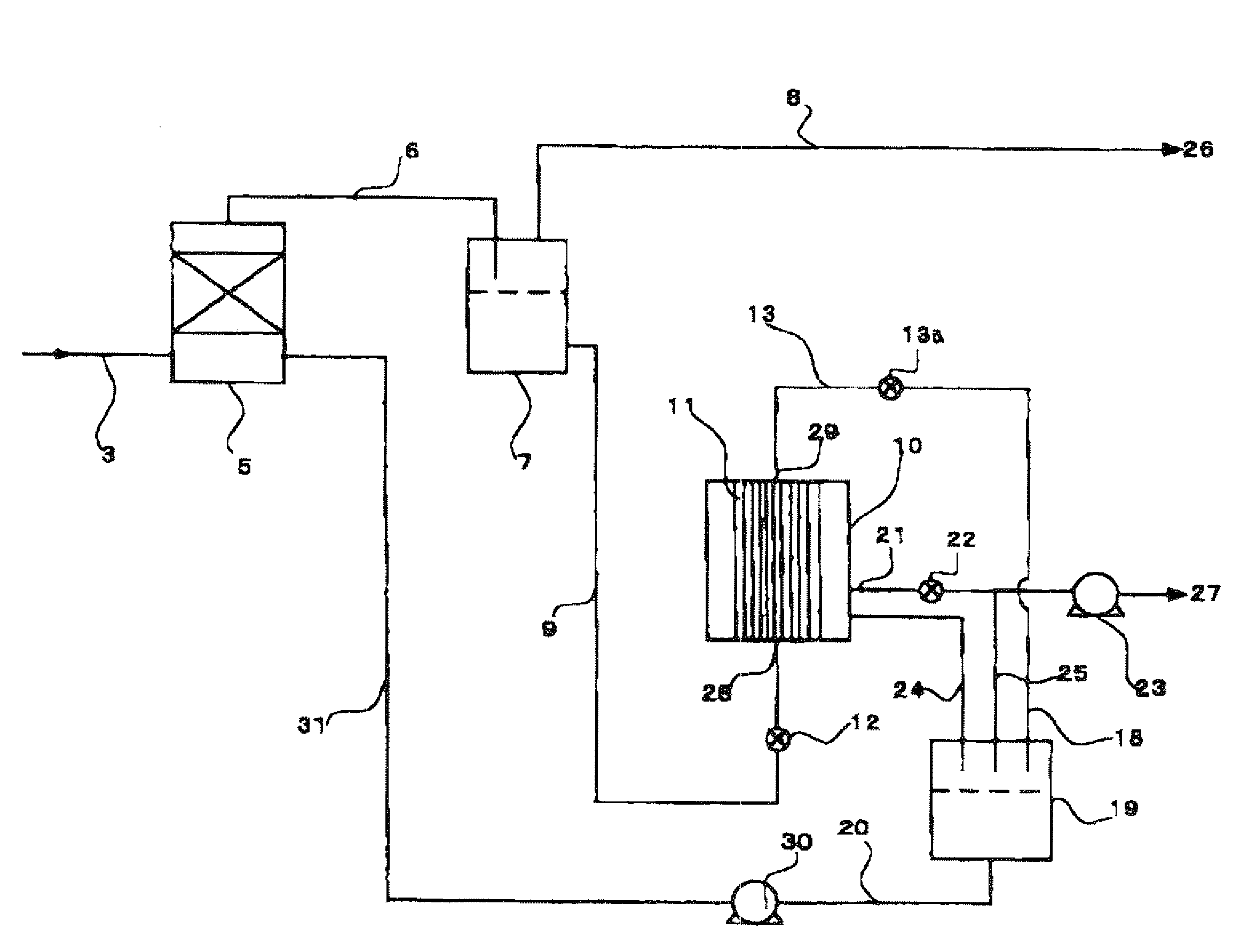

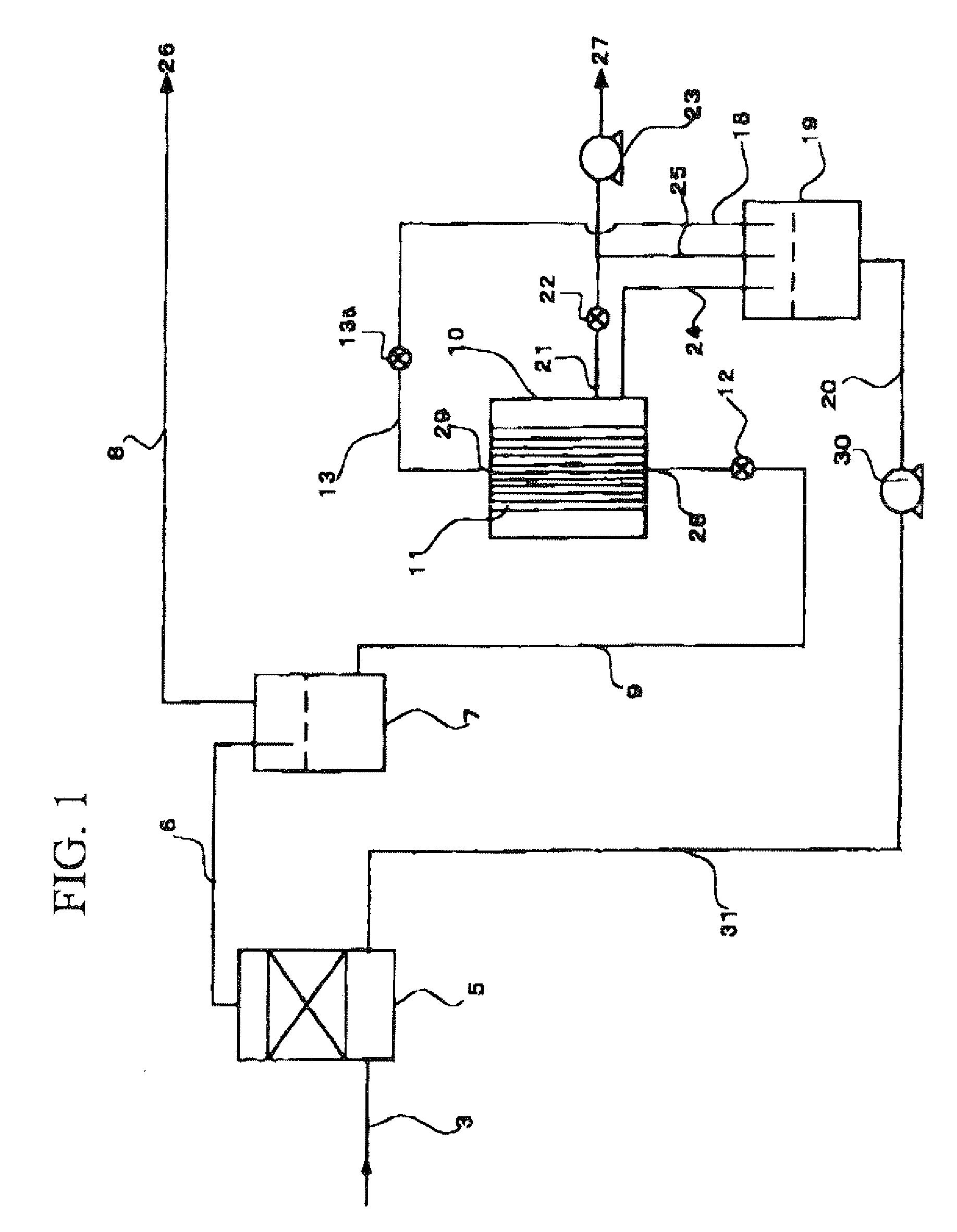

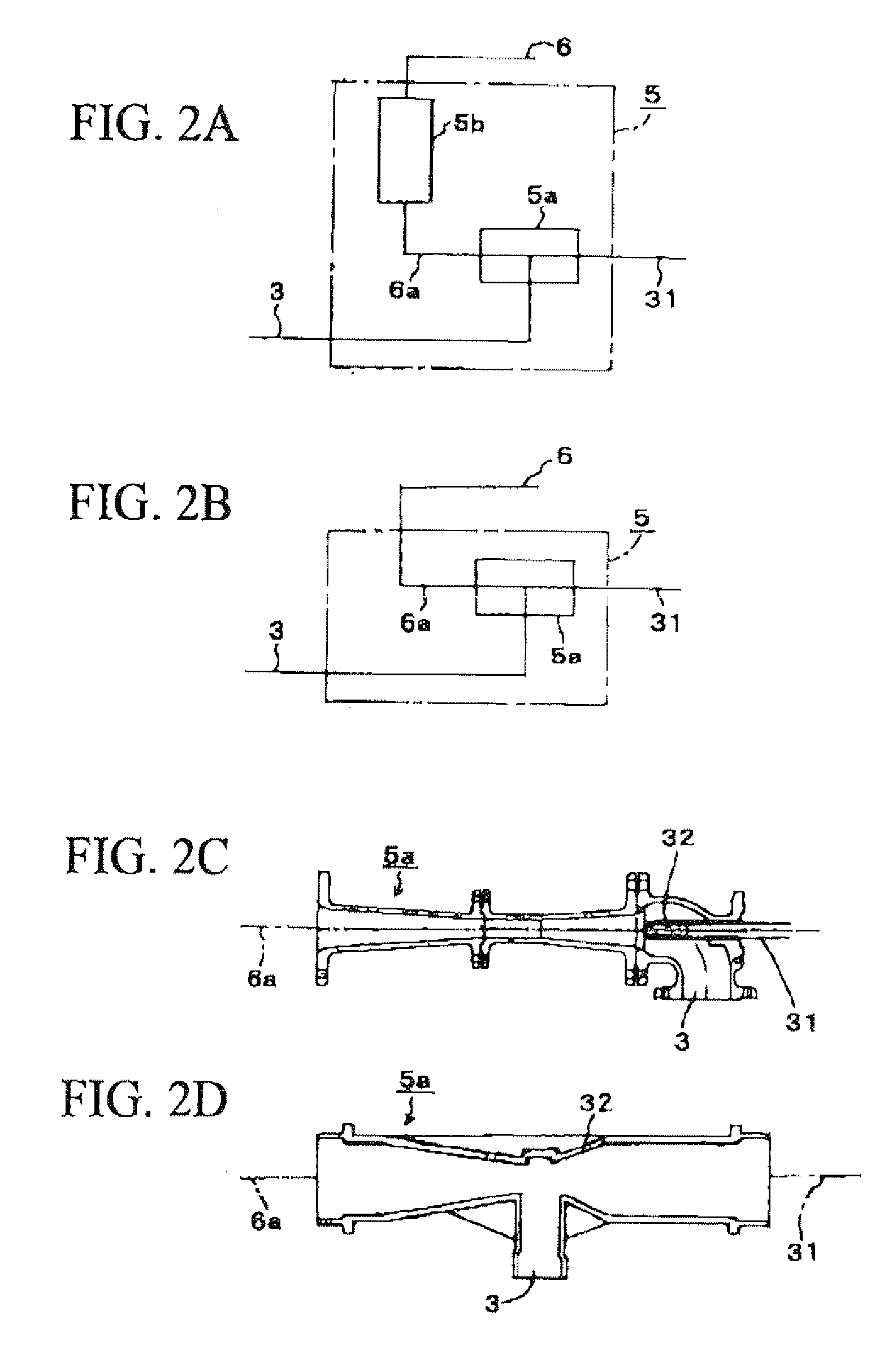

Methane separation method, methane separation apparatus, and methane utilization system

InactiveUS20090156875A1Improve efficiencyReduce module costSemi-permeable membranesGas treatmentFiberLiquid phase

A methane separation method of the present invention at least includes: mixing the biogas and an absorbing liquid that absorbs carbon dioxide in a mixer so as to form a mixed fluid of a gas-liquid mixed phase; introducing the mixed fluid into a first gas / liquid separator so as to separate the mixed fluid through gas / liquid separation into methane and a CO2-absorbed liquid formed due to an absorption of the carbon dioxide by the absorbing liquid; recovering methane separated in the first gas / liquid separator; and supplying the CO2-absorbed liquid through a supply port of a membrane module comprised of a container and a plurality of hollow fiber permeable membranes built therein to inside of the membranes so as to make the CO2-absorbed liquid permeate the permeable membranes, and lowering a pressure outside the permeable membranes to a level lower than that inside the permeable membranes.

Owner:TAIYO NIPPON SANSO CORP +1

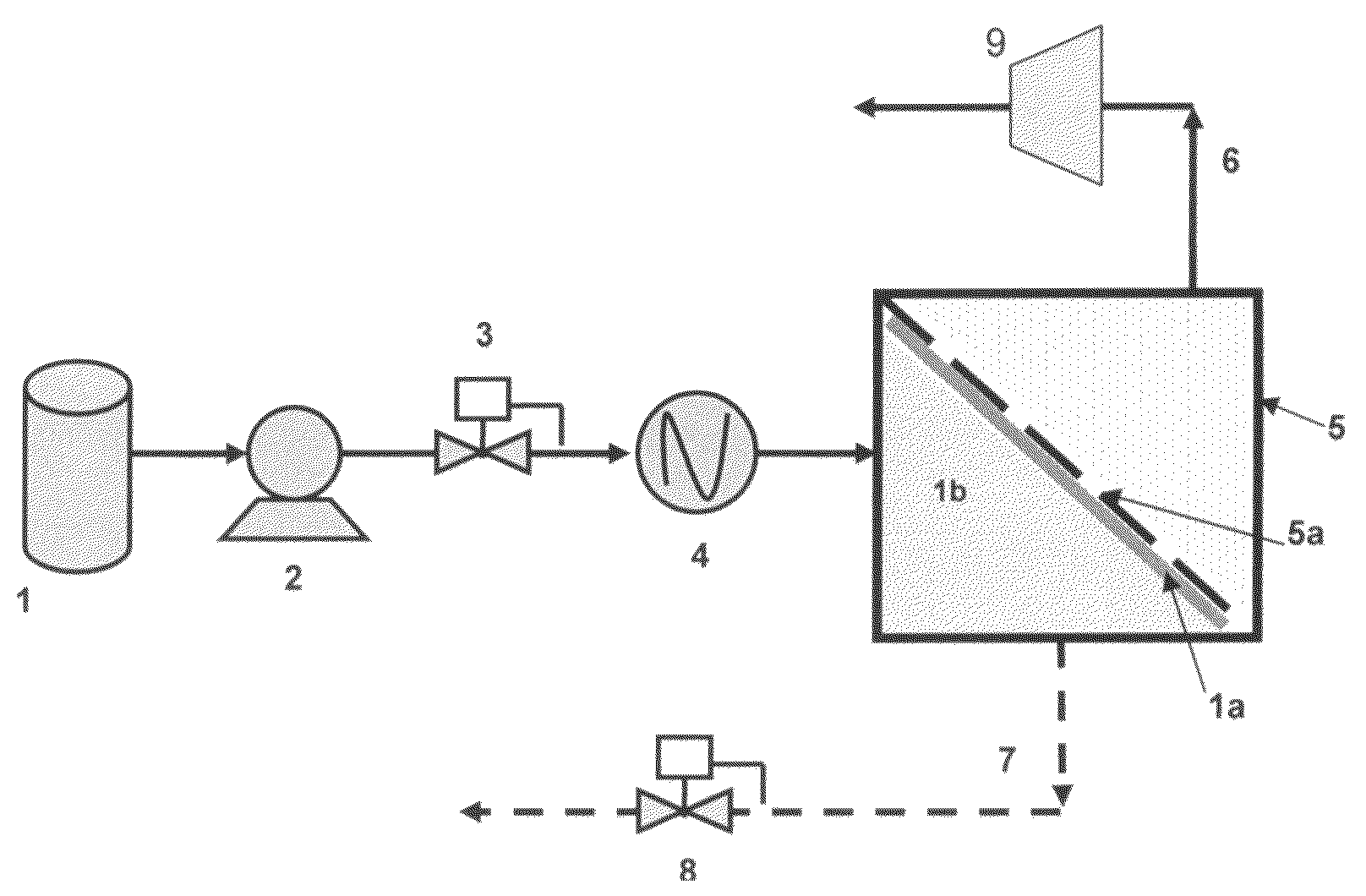

Membrane separation process using mixed vapor-liquid feed

ActiveUS7803275B2Reduce penetrationEfficient executionSemi-permeable membranesMembranesVapor liquidChemical physics

The present invention pertains to a process for the separation of aromatics from a feed stream, including aromatics and non-aromatics by selectively permeating the aromatics through a membrane comprising feeding a mixed phase vapor-liquid feed to a membrane wherein said liquid phase preferentially wets the surface of the membrane.

Owner:EXXON RES & ENG CO

Method of cleaning passageways using a mixed phase flow of a gas and a liquid

InactiveUS20050126599A1Long processEasy to cleanInorganic/elemental detergent compounding agentsSemi-permeable membranesPorous membraneAqueous solution

A method of cleaning surfaces using a mixed phase cleaning mixture of an aqueous solution and a flow of gas sufficient to produce droplets of the liquid which are entrained by the gas for a time sufficient to clean tubing of various lengths and geometries and porous membranes to remove biofilm, debris and contaminants.

Owner:NOVAFLUX INC

Titanium dioxide photocatalysis air-cleaning film and its preparation method

The present invention relates to a titanium dioxide photocatalysis air-cleaning film and its preparation method. It is characterized by that it utilizes the megnetron sputtering to form titanium dioxide photocatalysis air-cleaning film on the carriers of glass, metal and ceramics. It uses the direct synthesis of pure metal titanium target material and oxygen gas and utilzies are controlling power supply to prevent pure metal target material from poisoning, in which the crystal grains formed by titanium dioxide film can be grown along the vertical direction or horizontal direction of carrier. The grain size is 10-100 nano, and the thickness of the film is 20-100 nano. Said titanium dioxide film is formed from single anatase phase or single rutile phase or their mixed phase, in which the anatase content is 50%-98% and rutile phase content is 2%-50%. Said film can effectively degrade harmful gases of formaldehyde and phenol, etc.

Owner:TSINGHUA UNIV +1

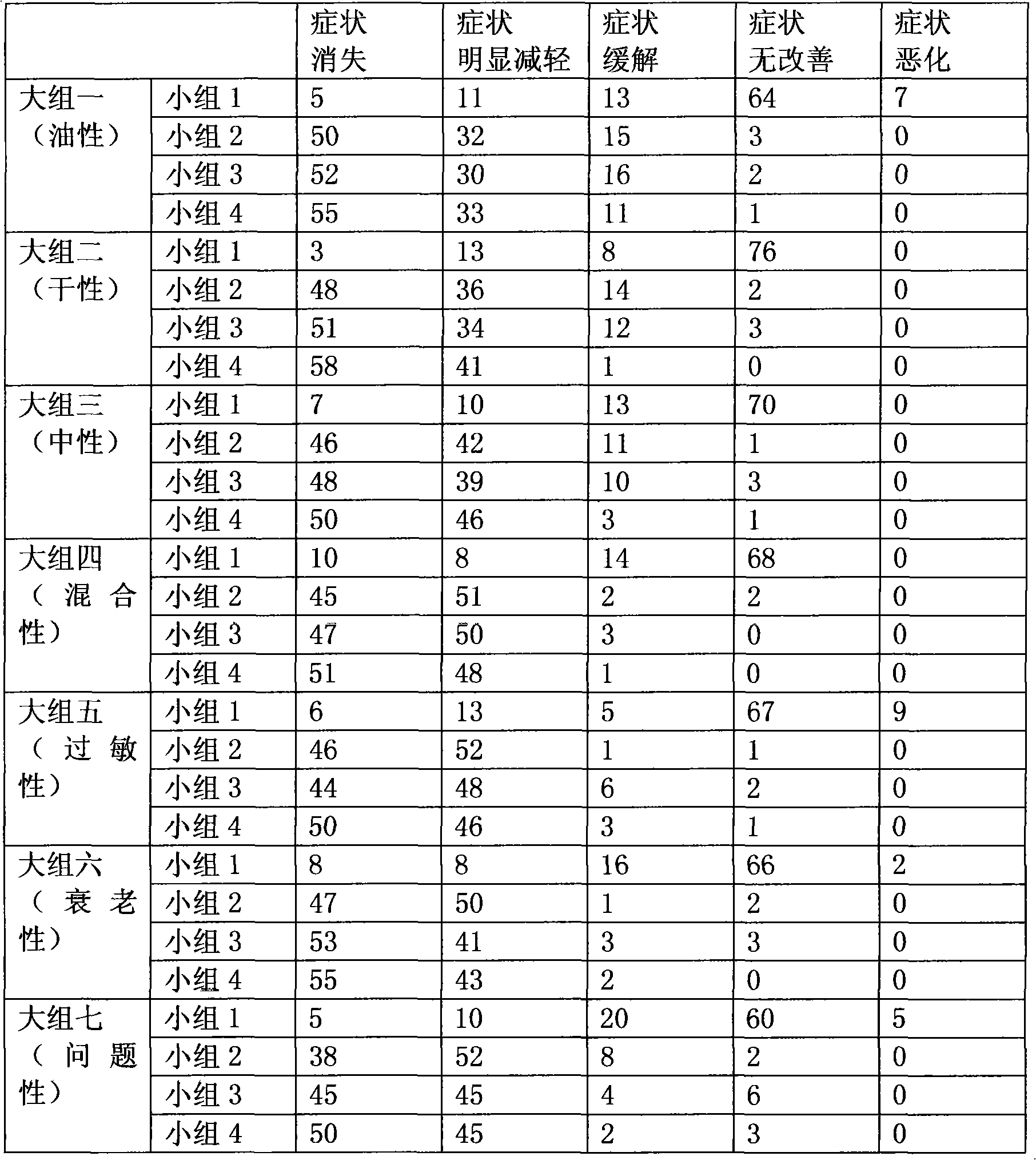

Whitening spot-relieving cream cosmetic and preparation method thereof

ActiveCN101590003AInhibitory activityInhibition interconversionCosmetic preparationsToilet preparationsOil phaseMixed phase

The invention discloses a whitening spot-relieving cream cosmetic, which comprises the following components by weight: A, a main body whitening spot-relieving component; B, an auxiliary whitening spot-relieving component; C, an oil phase component; D, a water phase component; E, thickening stabilization component; and F, an auxiliary agent component. The method for preparing the cosmetic comprises the following steps: a, raising the temperature of the C phase to between 65 and 95 DEG C, keeping the temperature between 75 and 85 DEG C, adding the B phase, and stirring and dissolving the mixture completely; b, raising the temperature of the D phase to between 65 and 95 DEG C, keeping the temperature between 75 and 85 DEG C, and stirring and dissolving the D phase completely; c, sucking the C mixed phase into an emulsification pot first, then sucking the D phase into the emulsification pot slowly, adding the A phase, homogenizing the mixture for 5 to 15 minutes, keeping the temperature and stirring the mixture for 5 to 15 minutes, and vacuumizing the mixture to reduce the temperature; d, adding the E phase when the temperature is between 50 and 70 DEG C, homogenizing the mixture for 2 to 3 minutes, and stirring the mixture evenly; and e, adding the F phase when the temperature is between 30 and 50 DEG C, and stirring the mixture evenly to obtain the product of the whitening spot-relieving cream cosmetic. The invention aims to overcome the defects of the prior art and provide a quick, high-efficiency, green and safe whitening spot-relieving cream cosmetic product.

Owner:ATHENA GUANGZHOU COSMETICS MFR

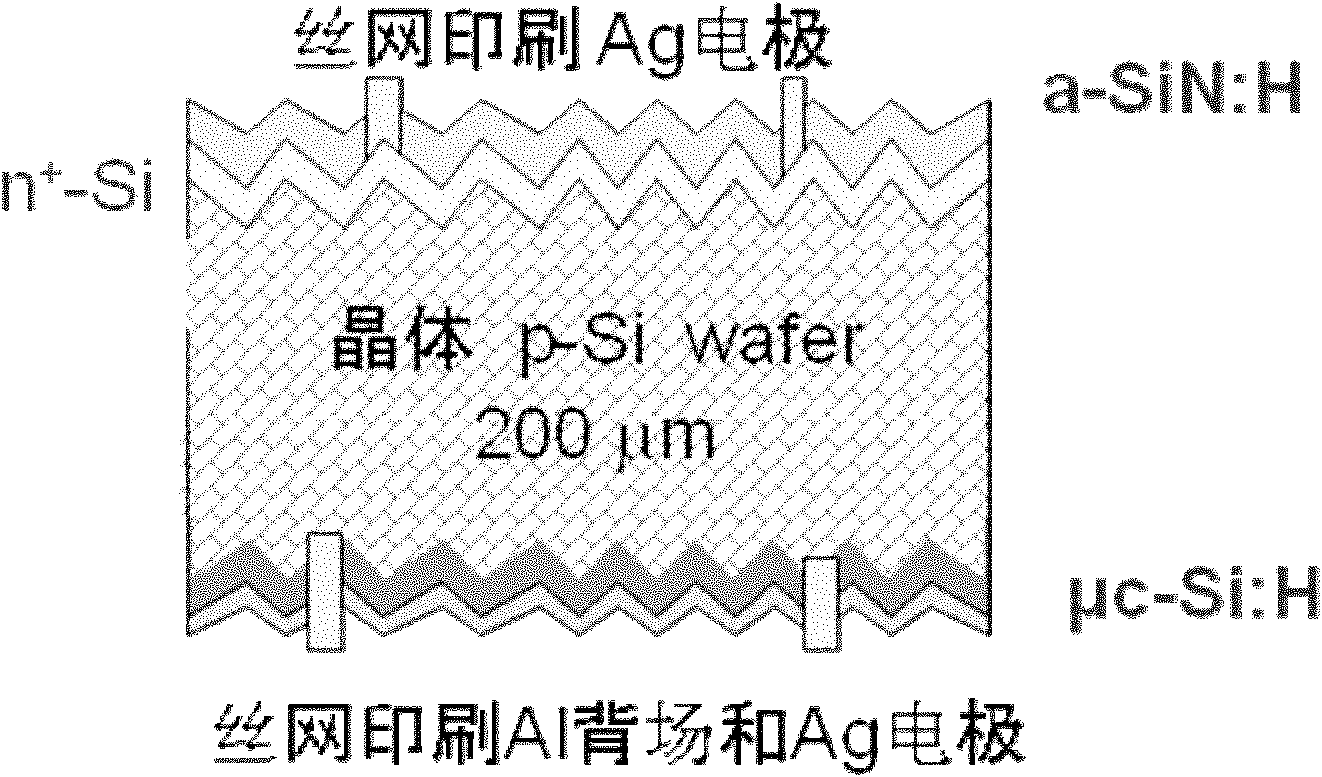

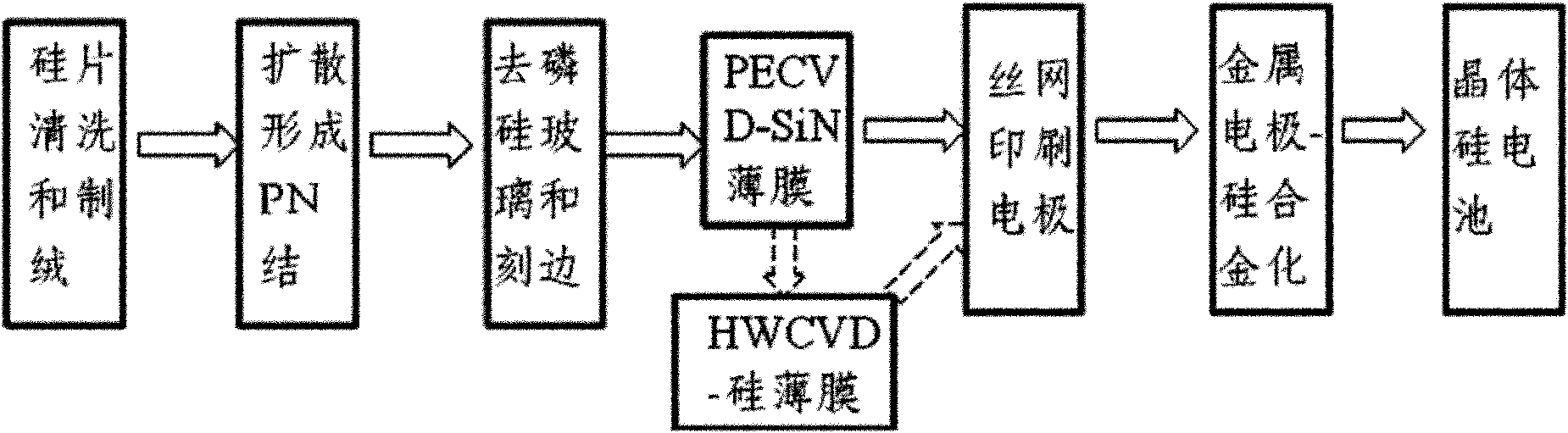

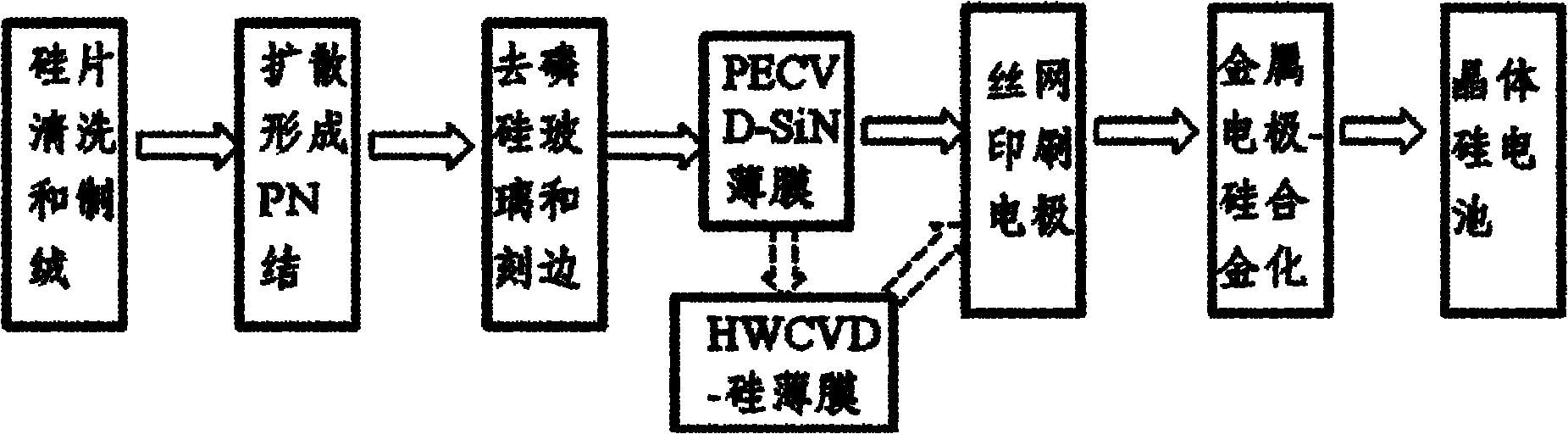

Preparation method of double-sided passivated crystalline silicon solar cell

InactiveCN101937944APrevent escapeAdjustable bandgapSemiconductor devicesP type siliconMicrocrystalline silicon

The invention discloses a preparation method of a double-sided passivated crystalline silicon solar cell, belonging to the technical field of photovoltaic power generation. The preparation method comprises the following steps of: firstly, respectively carrying out surface precleaning and surface texturing on P-shaped single crystal silicon and a polycrystalline silicon wafer by adopting an alkaline solution and an acid solution; secondly, diffusing by using phosphorus oxychloride as a diffusion source to form a PN junction; thirdly, removing a phosphosilicate glass on the surface of the silicon wafer by adopting a chemical wet method, and etching the edge of the silicon wafer by adopting a plasma; fourthly, preparing a silicon nitride film on the surface of an emitting region of a P-type silicon wafer by adopting a plasma enhanced chemical vapor deposition method; fifthly, preparing a mixed phase film material of hydrogenated microcrystalline silicon and amorphous silicon by adopting a hot filament chemical vapor deposition method, depositing a film at one side of the P-type silicon wafer, and passivating the defects and a dangling bond on the surface of the P-type silicon wafer; and sixthly, sintering a screen printing back electrode and a screen printing positive electrode to form the solar cell. The invention lowers the probability of compounding photo-generated minority carriers on the back surface, enhances the long-wave light quantum efficiency and creates the conditions of transportation and collection of the photo-generated carriers.

Owner:SHANGHAI JIAO TONG UNIV

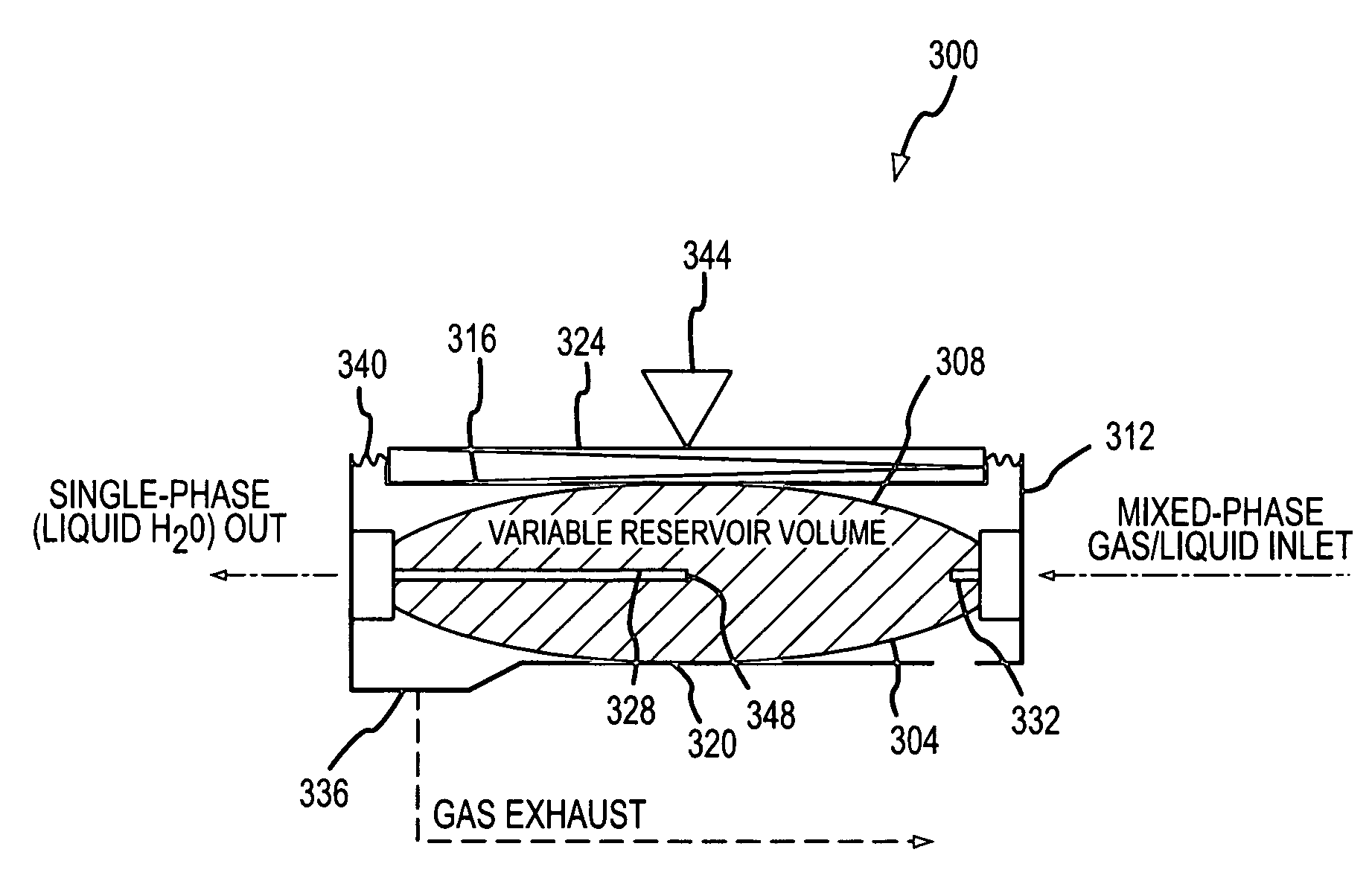

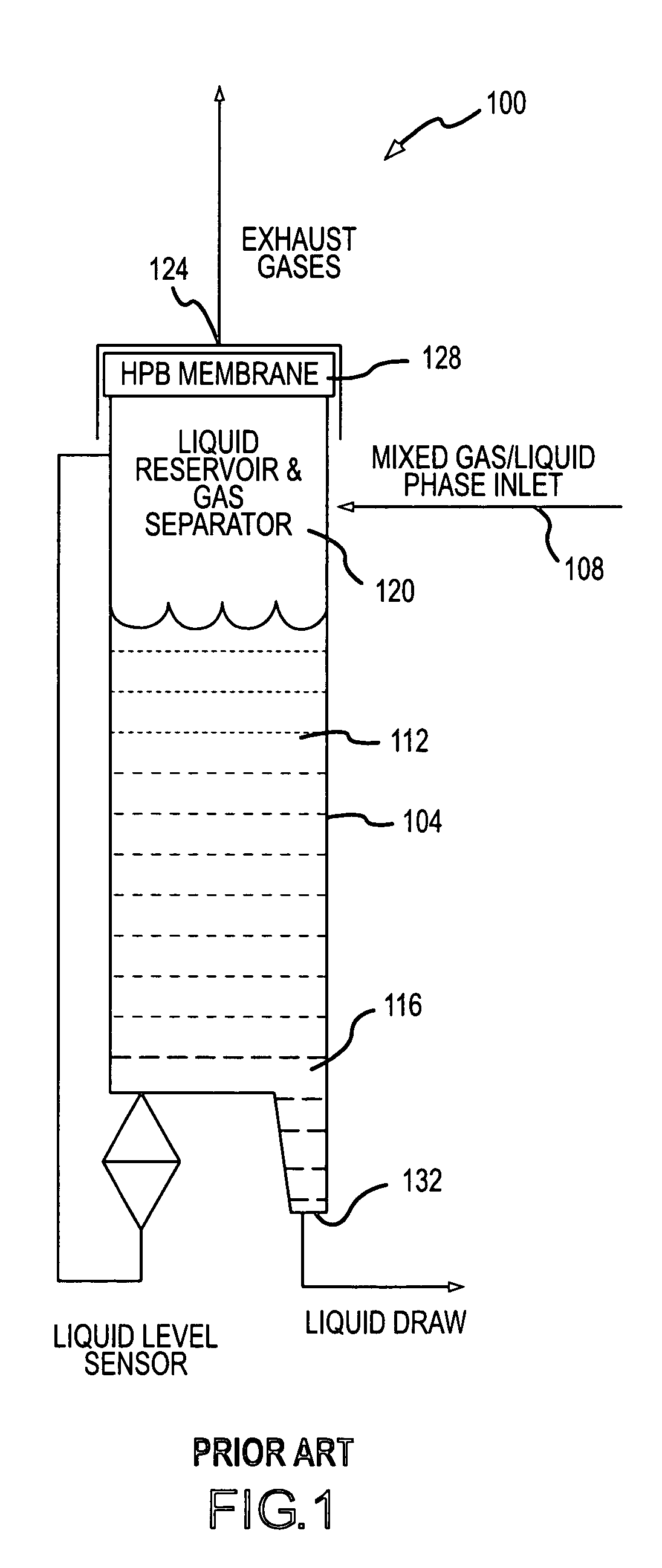

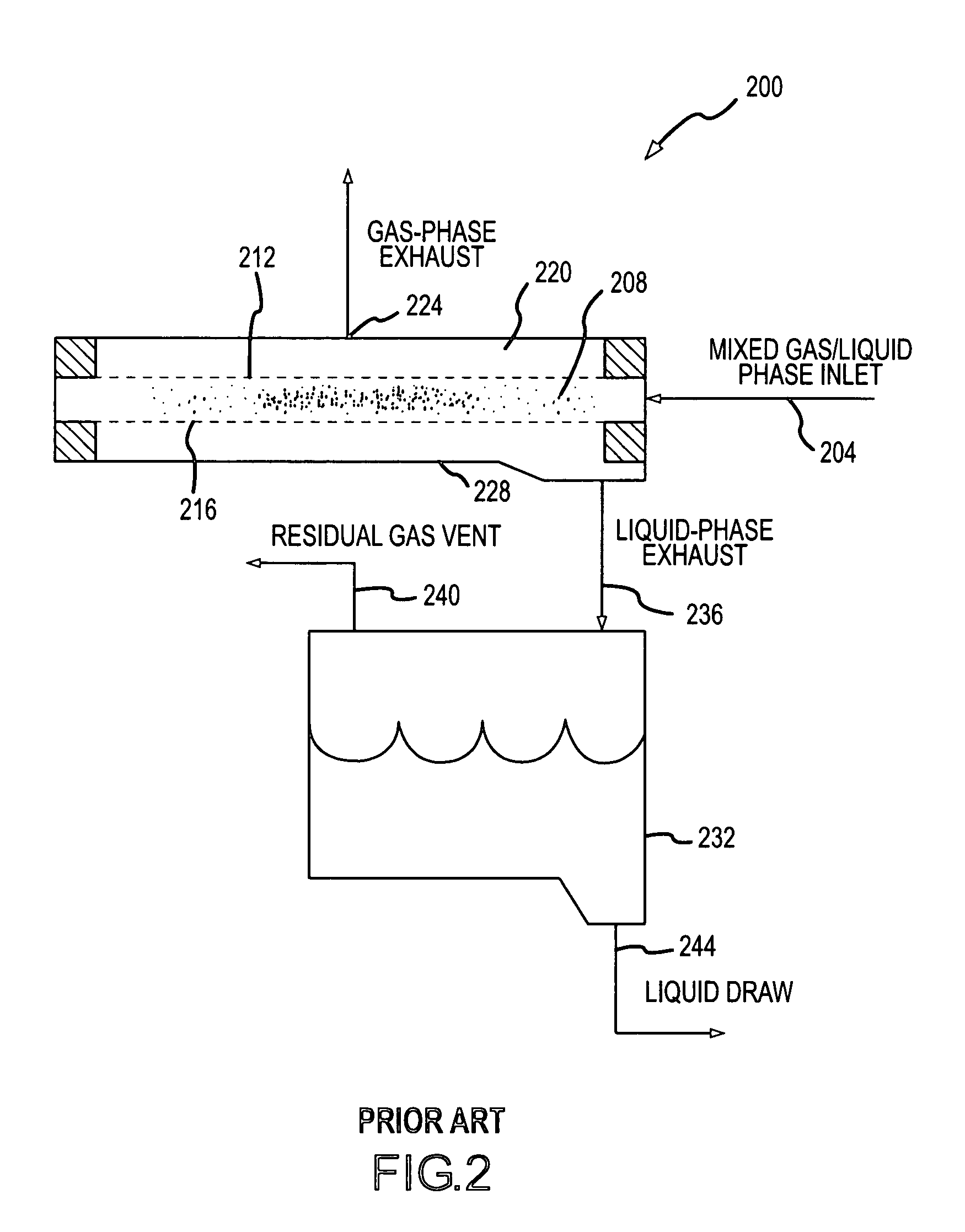

Orientation insensitive combined liquid reservoir and gas/liquid separator

InactiveUS6942718B1Reliable separation of liquidReliable separationIsotope separationLiquid degasification by filtrationGas phaseReservoir volume

In accordance with the present invention, a system for separating gas and liquid phases from a mixed phase system is provided. Furthermore, the present invention provides for the reliable separation of liquid and gas phases, regardless of the orientation of the system with respect to a gravitational field, and in low or zero gravity environments. The system of the present invention generally provides a reservoir having a variable volume that is formed from a gas permeable, hydrophobic, microporous, polymer material. Material confined within the reservoir is maintained under pressure, to expel any gases introduced to the interior of the reservoir as part of a mixed phase inlet stream. The liquid phase component of the mixed phase inlet stream may be removed from the reservoir through an outlet located within the reservoir volume.

Owner:BALL AEROSPACE & TECHNOLOGIES

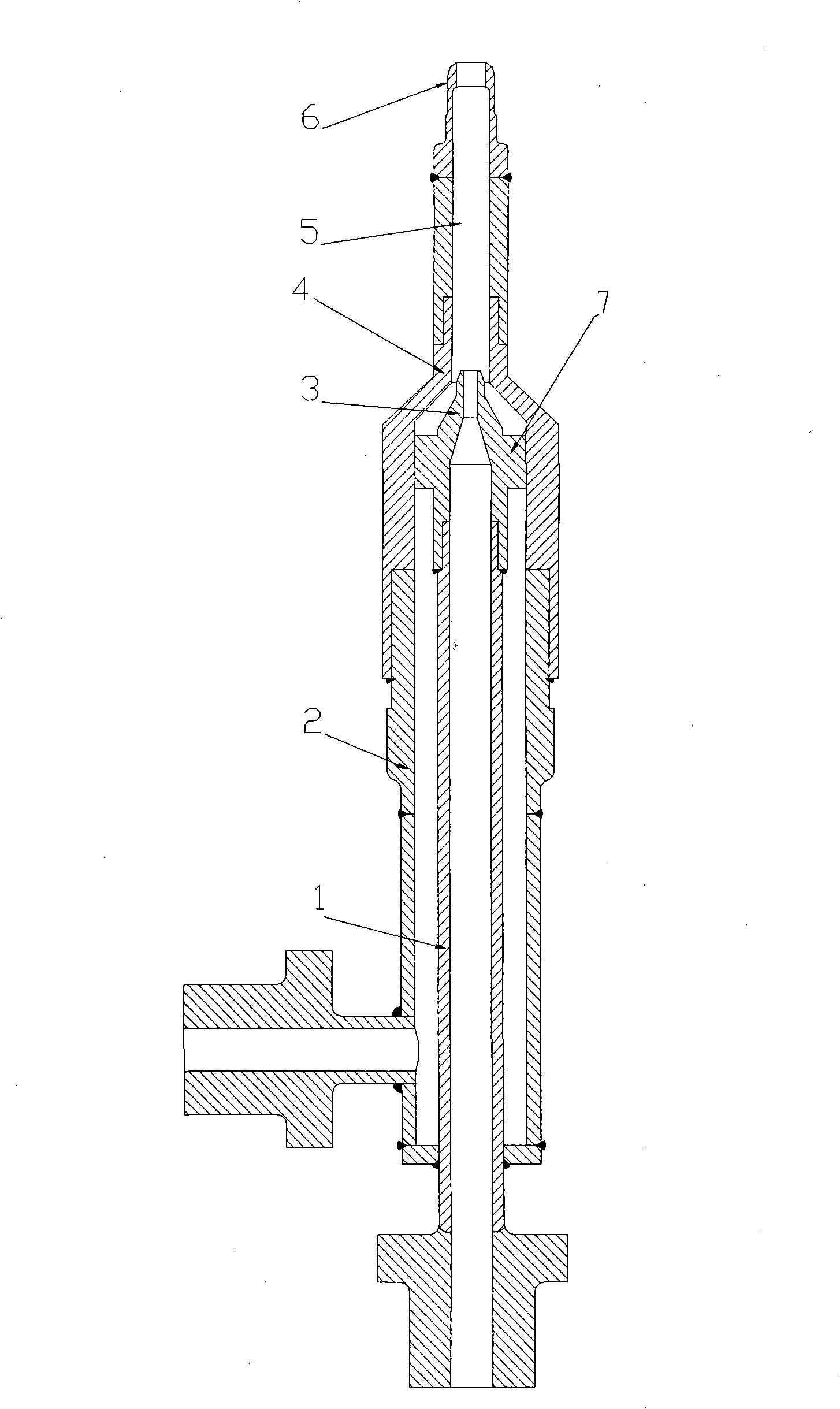

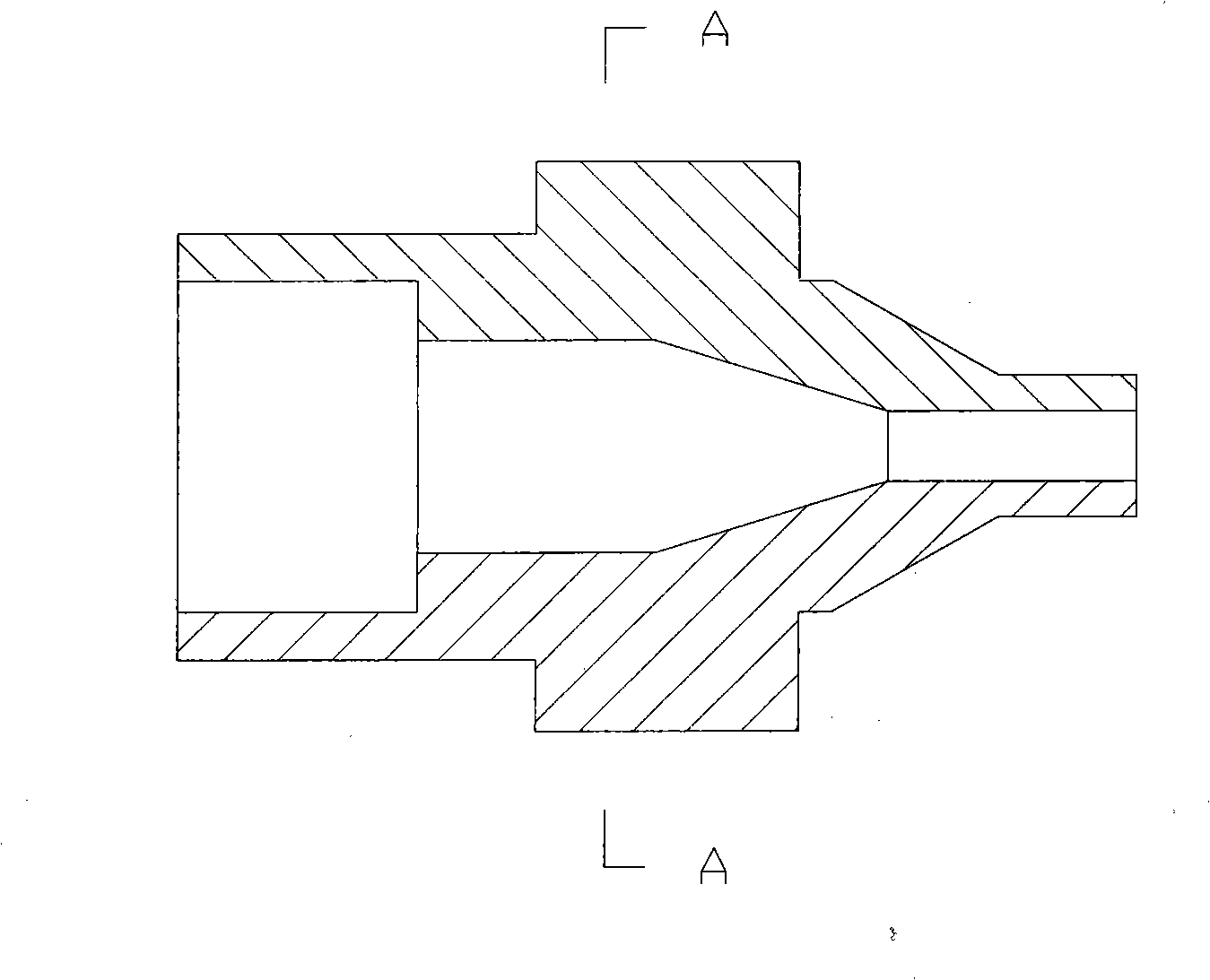

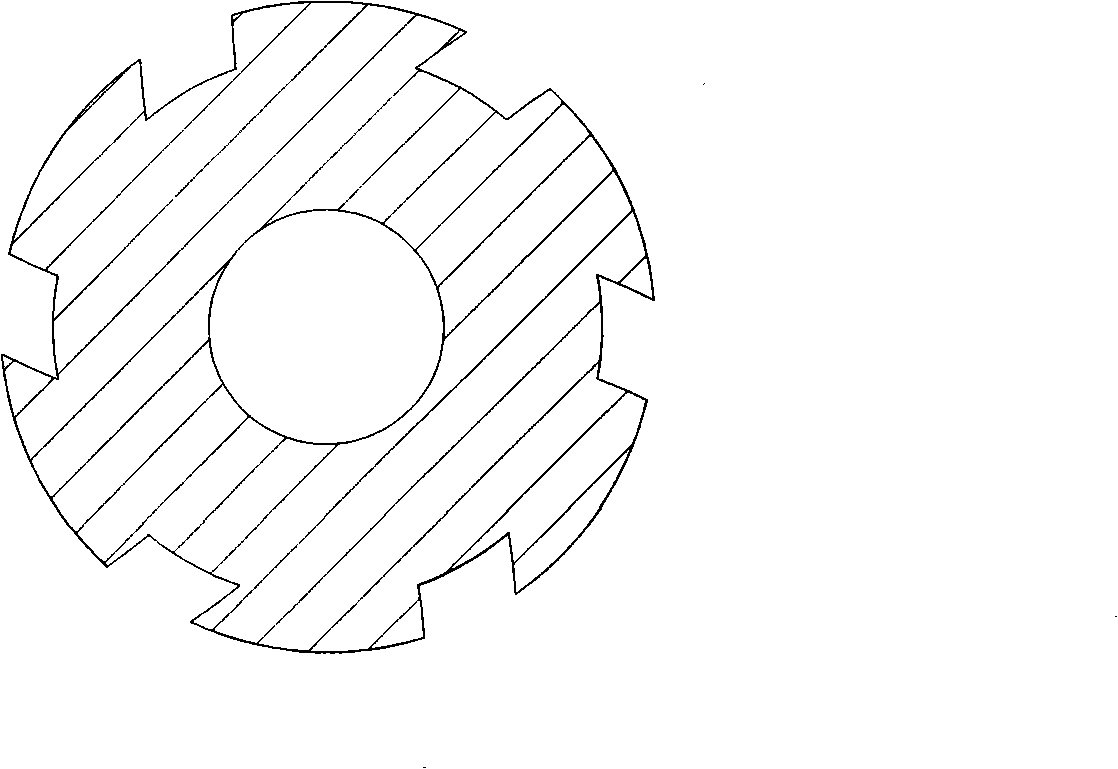

High-speed jet gas-liquid mixing-phase ejector

InactiveCN101491794AGuaranteed high-speed jetStrong penetrating powerLiquid spraying apparatusJet flowGas phase

The invention relates to a fluid ejector, and aims to provide a gas-liquid mixed phase ejector for ejecting at a high speed. The ejector comprises a liquid phase inlet pipe and a gas phase inlet pipe which are provided with a quick coupler respectively; the tail end of the liquid phase inlet pipe is connected with a liquid phase nozzle; the tail end of the gas phase inlet pipe is connected with a gas phase nozzle; the liquid phase nozzle is a single-hole nozzle; a flow passage from the liquid phase inlet pipe to the liquid phase nozzle has smooth transition; the gas phase inlet pipe encloses the outside of the liquid phase inlet pipe to form an annular gas phase flow passage; the gas phase nozzle encloses the outside of the liquid phase nozzle and is connected with a mixed phase flow passage; the tail end of the mixed phase flow passage is connected with an outlet nozzle; and an outlet circulation sectional area of the outlet nozzle is smaller than that of a circulation sectional area of the mixed phase flow passage. The liquid phase nozzle has high-speed outlet liquid flow, and the high-speed outlet liquid flow is interacted with high-speed gas phase flow in the mixed phase flow passage to realize atomization and once more acceleration, thereby the ejector greatly weakens boundary layer effect on the outlet, avoids that liquid drops separating from main jet flow are convergent to drop on the outlet, and can flexibly adjust and control atomization fineness and distribution.

Owner:ZHEJIANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com