Systems and methods for low-temperature gas separation

a low-temperature gas and gas separation technology, applied in the direction of separation processes, liquefaction, lighting and heating apparatus, etc., can solve the problems of high energy consumption and significant mixture pressure loss in the low-temperature separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

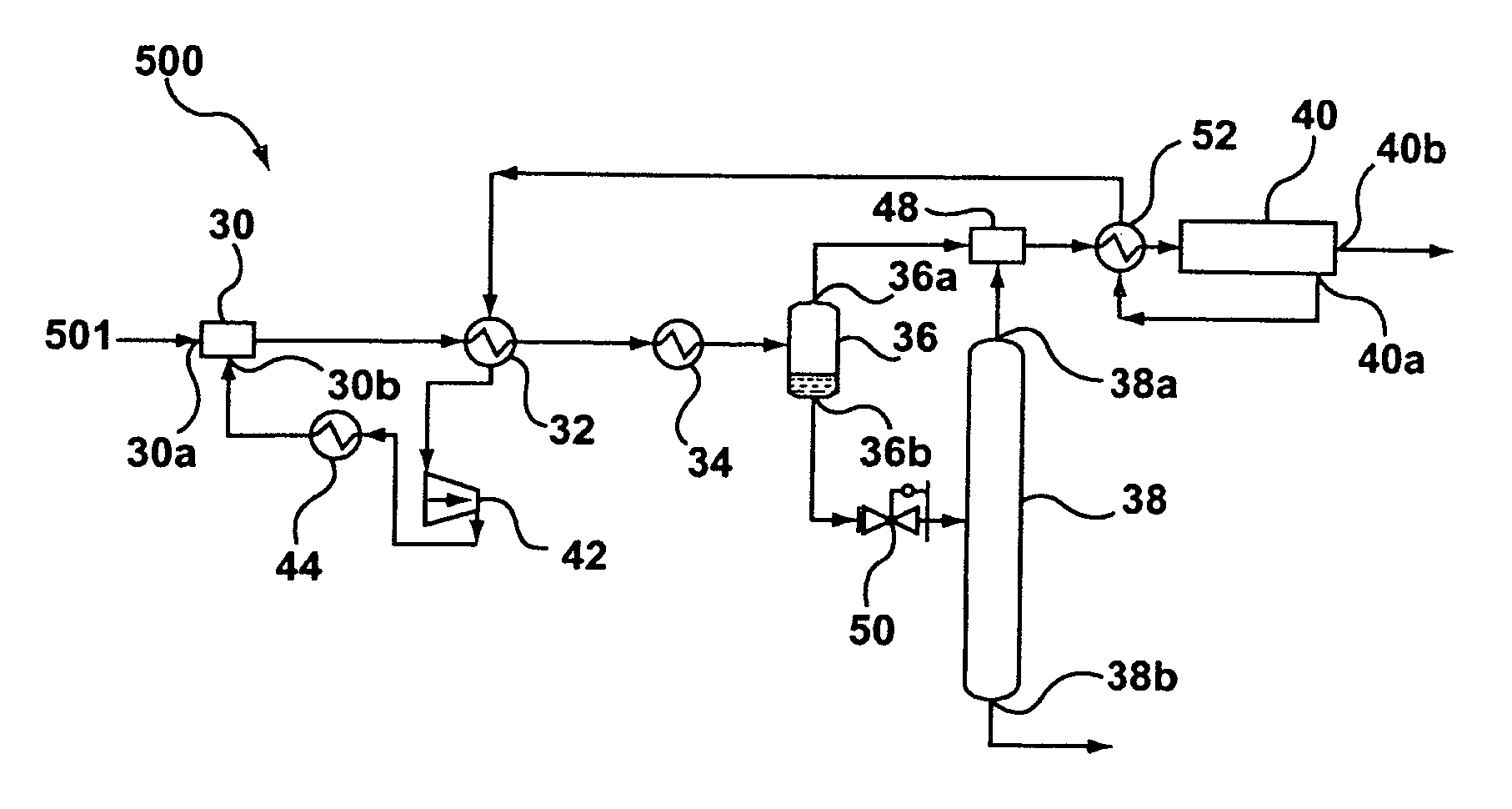

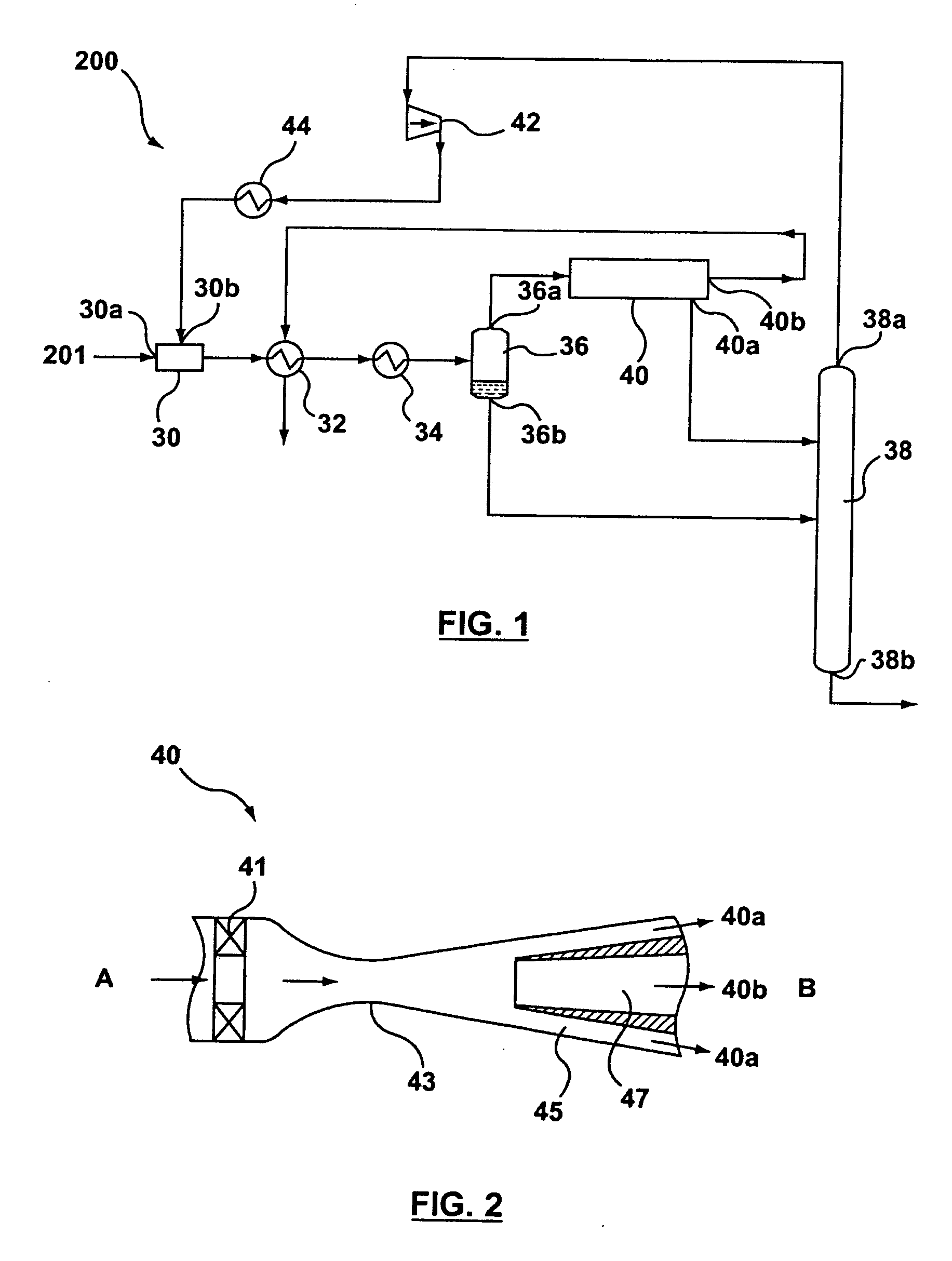

[0074] Referring to FIG. 1, shown is a schematic drawing of a low-temperature gas mixture separation system 200 according to the invention, referred to as the system 200 hereinafter for brevity. Those skilled in the art will appreciate that the system 200 includes a suitable combination of associated structural elements, mechanical systems, hardware, firmware and software that is employed to support the function and operation of the system 200; however, the system 200 is illustrated showing only those elements necessary to describe aspects of this embodiment.

[0075] The system 200 includes a first mixer 30, a first heat-exchanger 32, a first chiller 34 and a gas / liquid separator 36 connected respectively in series. The first mixer 30 includes respective first and second inputs 30a and 30b. The first input 30a serves as an input to the system 200 as a whole as well as an input of the first mixer 30. The second input 30b serves a feedback input, the purpose of which is described in mor...

second embodiment

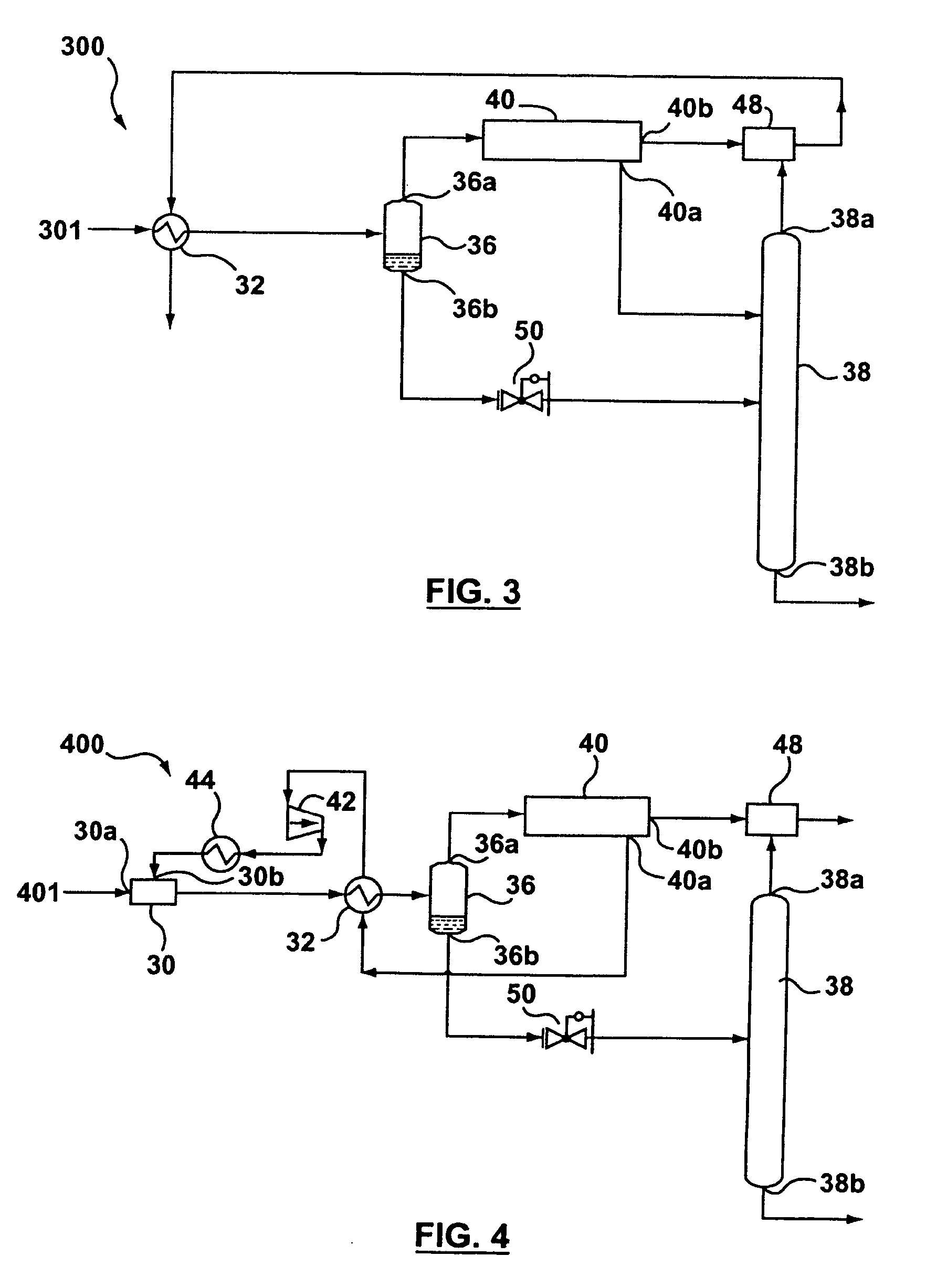

[0087] Referring to FIG. 3, shown is a schematic drawing of a low-temperature gas mixture separation system 300 according to the invention, referred to as the system 300 hereinafter for brevity. The system 300 illustrated in FIG. 3 is similar to the system 200 illustrated in FIG. 1, and accordingly, elements common to both share common reference numerals. Moreover, for the sake of brevity, portions of the description of FIG. 1 will not be repeated with respect to FIG. 3. Again those skilled in the art will appreciate that the system 300 includes a suitable combination of associated structural elements, mechanical systems, hardware, firmware and software that is employed to support the function and operation of the system 300; however, the system 300 is illustrated showing only those elements necessary to describe aspects of this embodiment of the invention.

[0088] The differences between the systems 200 and 300 are as follows. The system 300 does not include the first mixer 30, the f...

third embodiment

[0091] Referring to FIG. 4, shown is a schematic drawing of a low-temperature gas mixture separation system 400 according to the invention, referred to as the system 400 hereinafter for brevity. The system 400 illustrated in FIG. 4 is similar to the respective systems illustrated in FIGS. 1 and 3, and accordingly, elements common to each share common reference numerals. Moreover, for the sake of brevity, portions of the descriptions for FIGS. 1 and 3 will not be repeated with respect to FIG. 4. Those skilled in the art will appreciate that the system 400 includes a suitable combination of associated structural elements, mechanical systems, hardware, firmware and software that is employed to support the function and operation of the system 400; however, the system 400 is illustrated showing only those elements necessary to describe aspects of this embodiment of the invention.

[0092] The arrangements specifically shown with respect to the system 400 are as follows. The system 400 inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| heat energy | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com