Patents

Literature

89results about "Vacuum condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

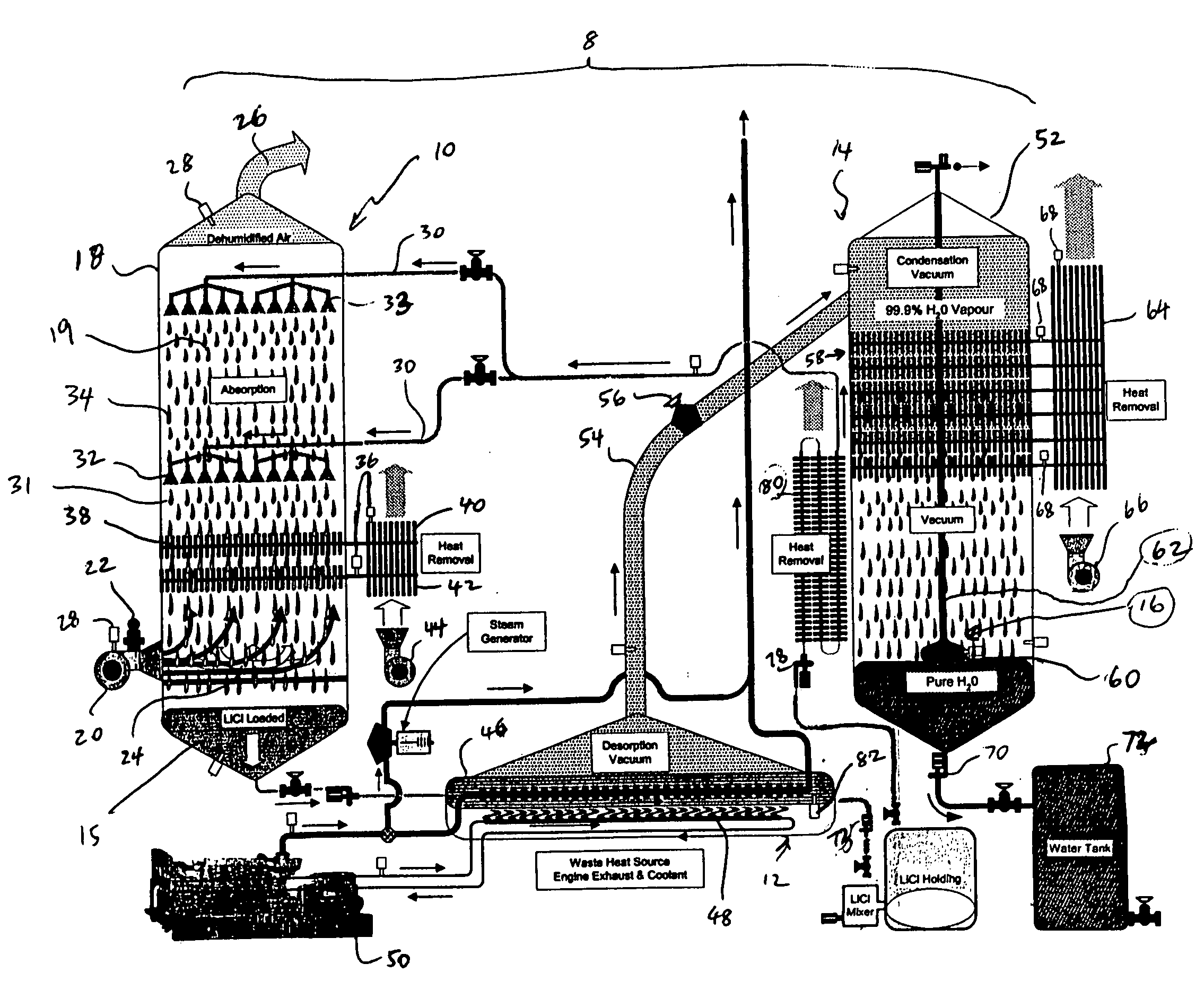

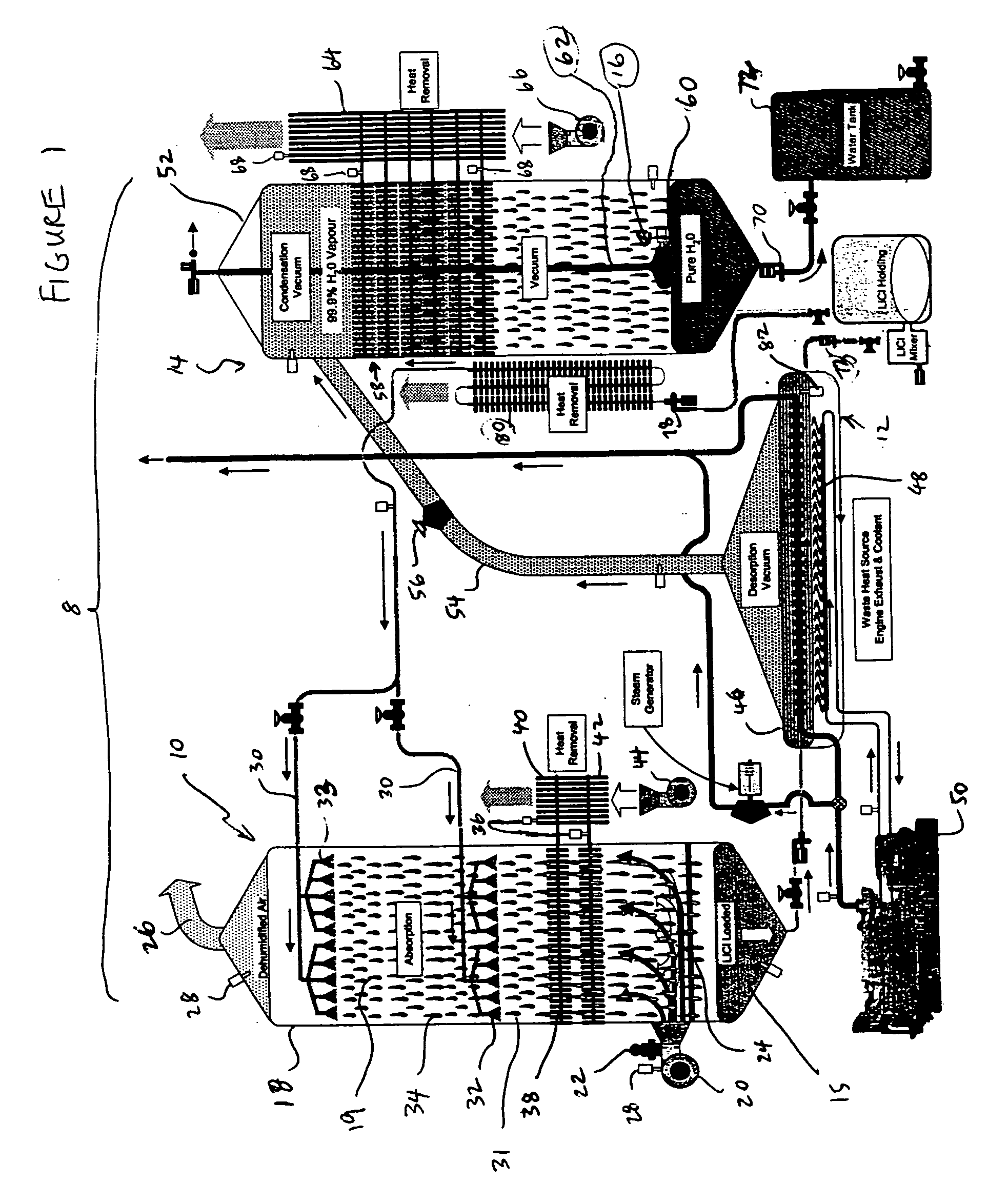

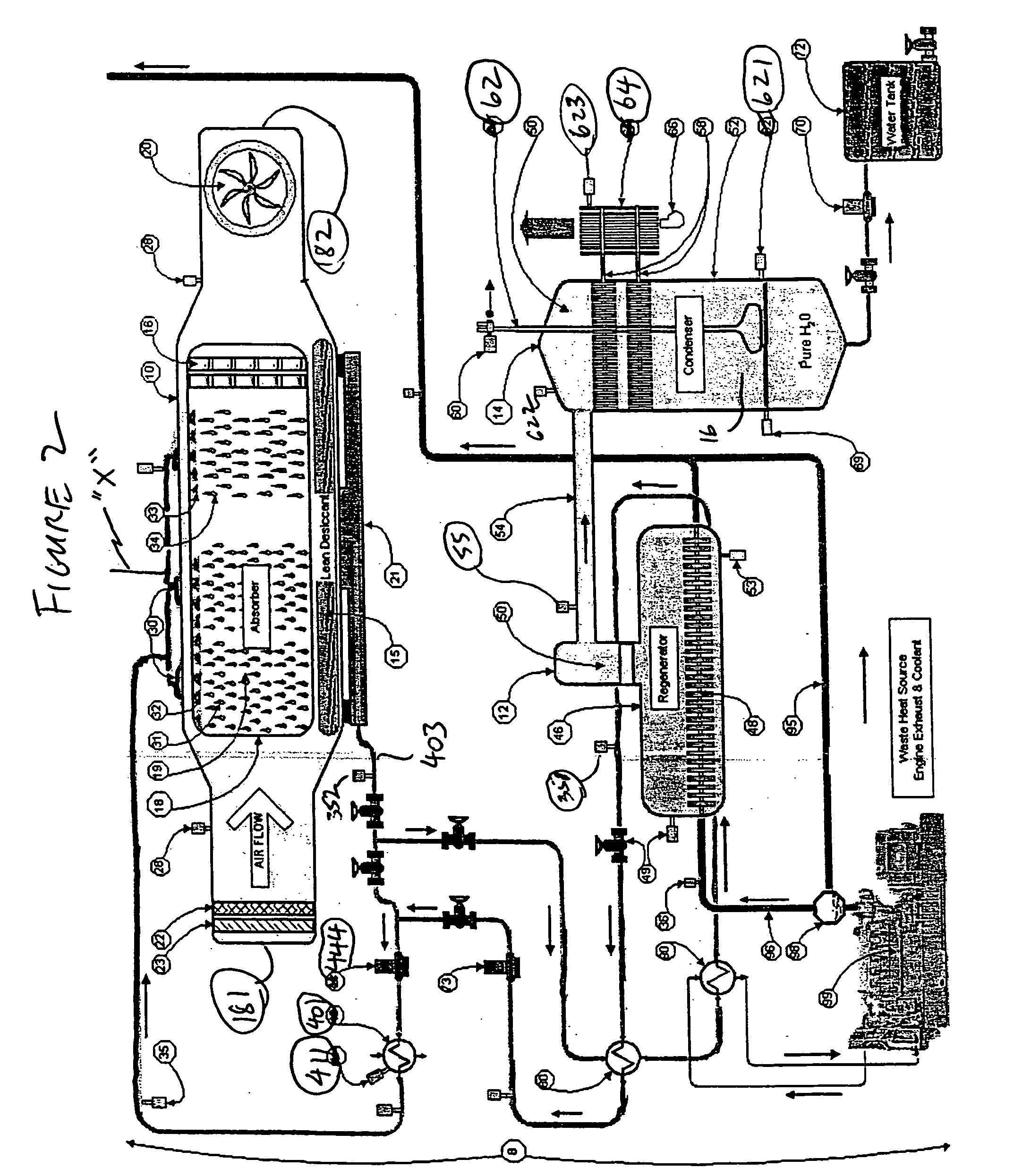

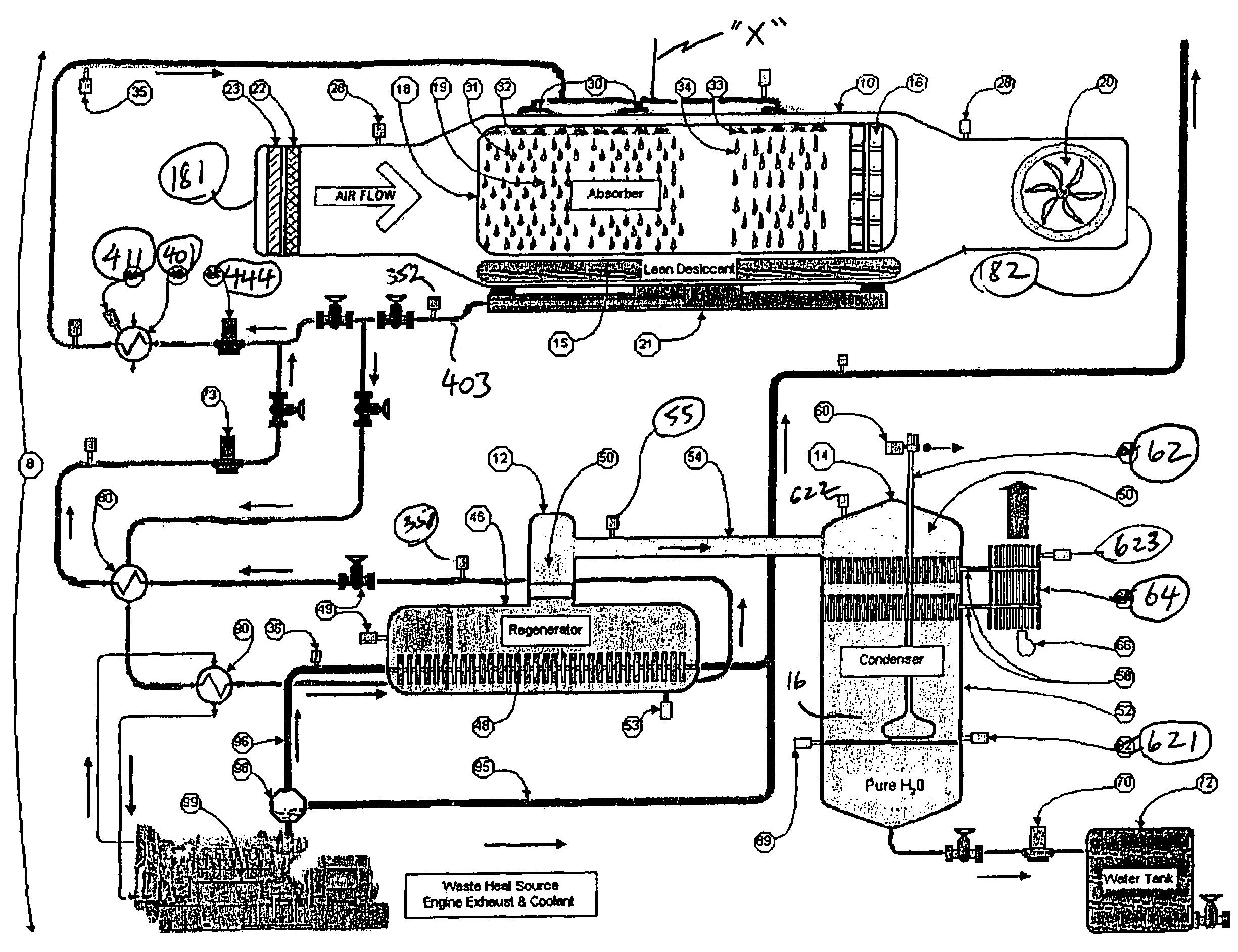

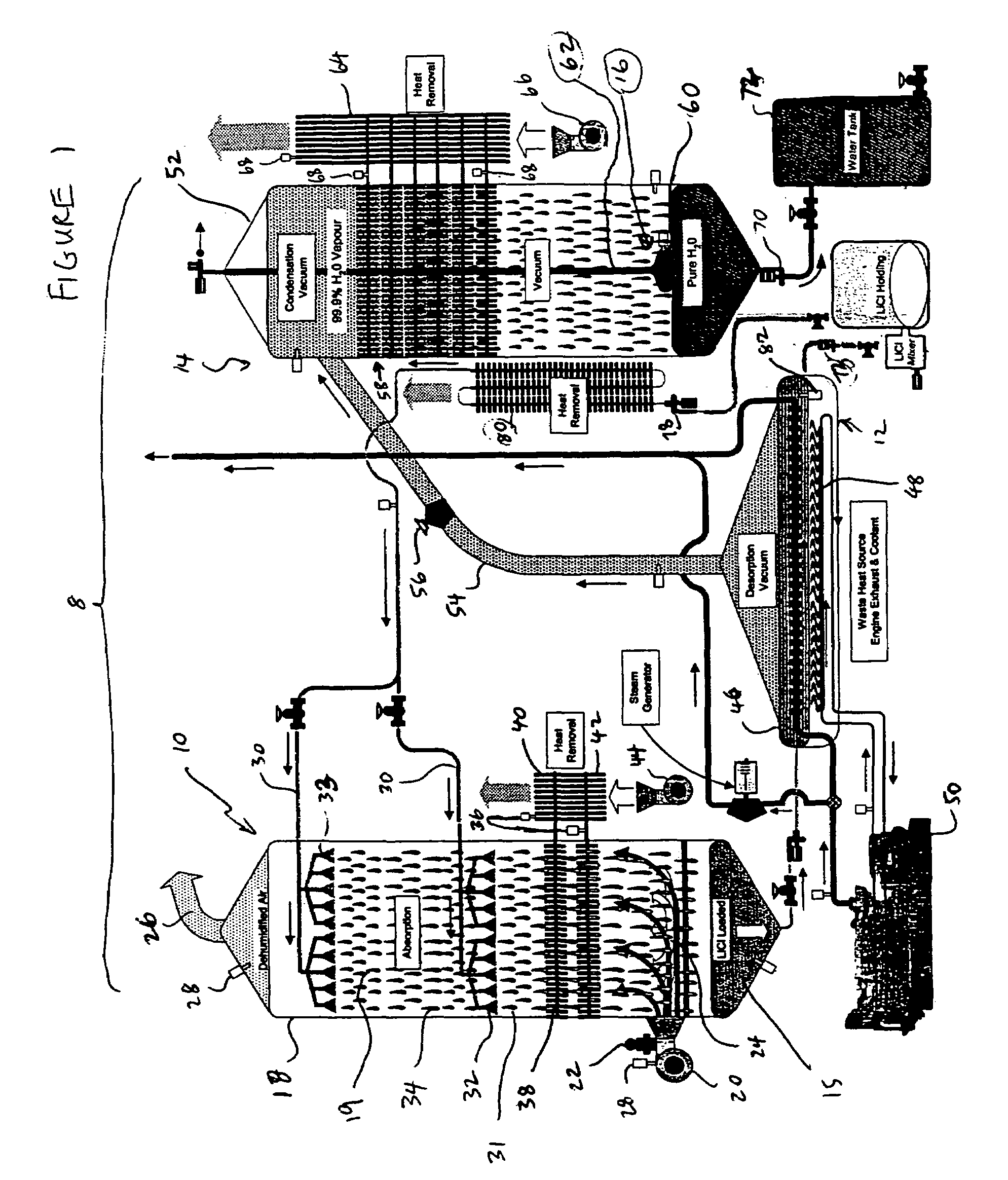

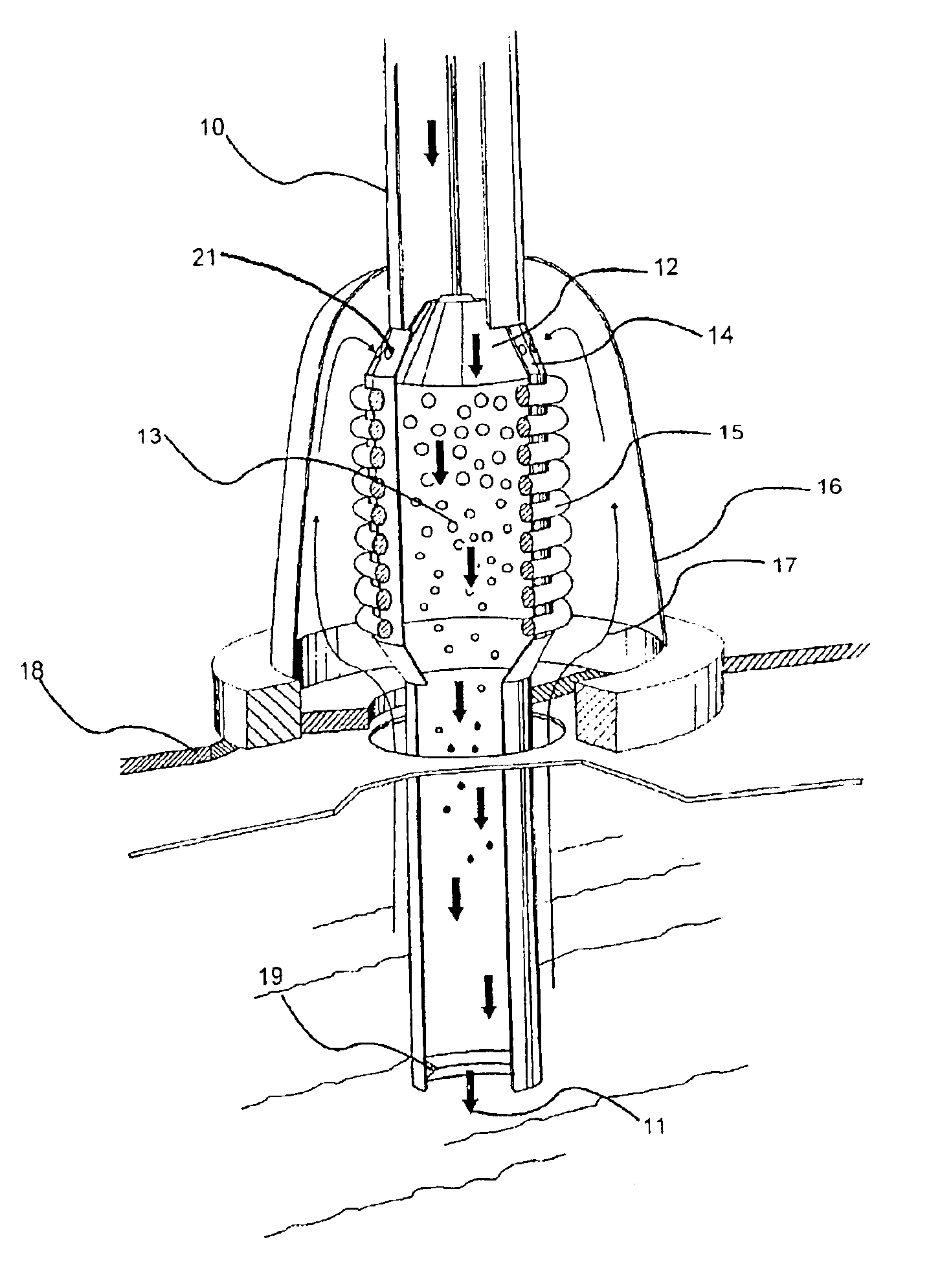

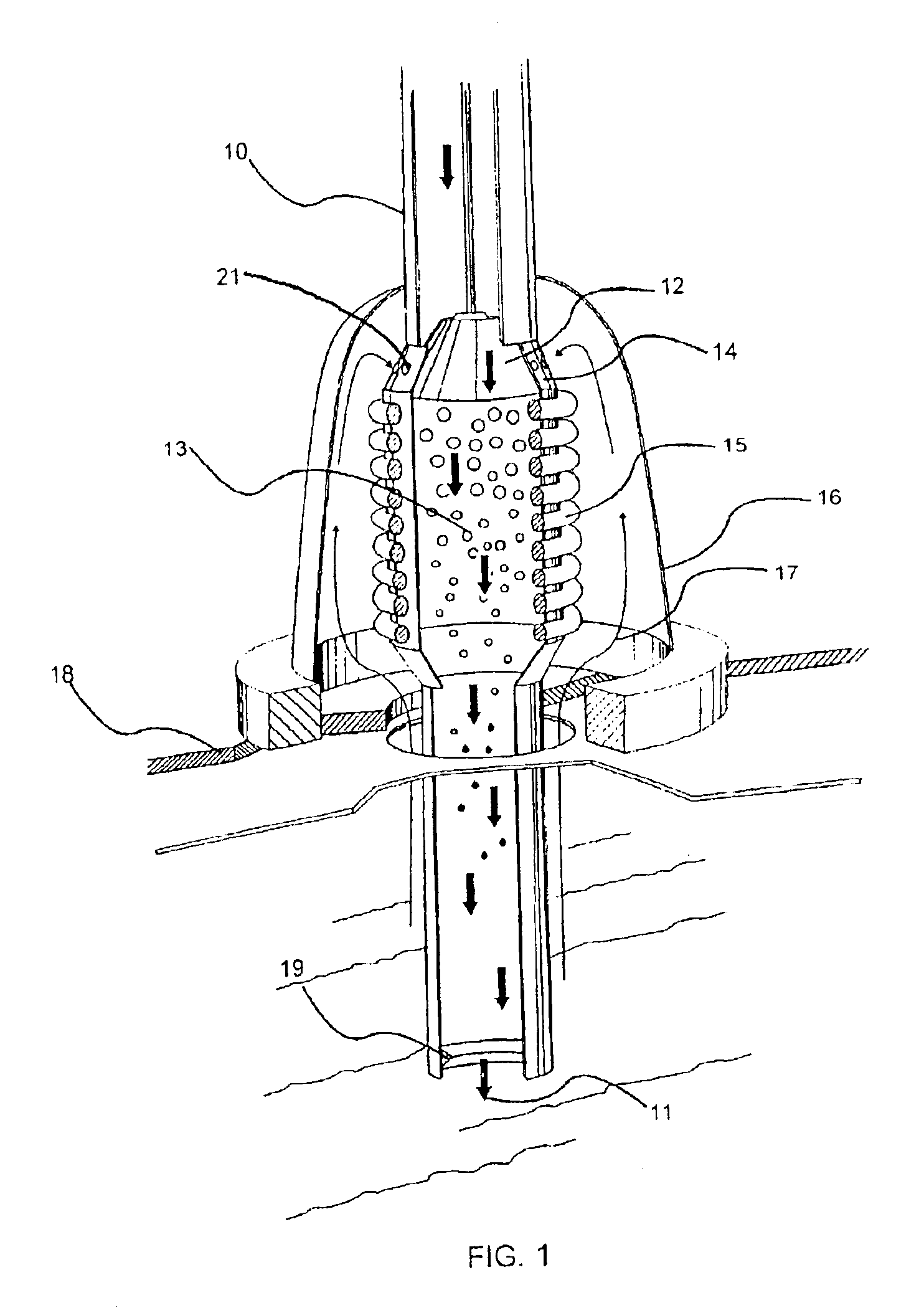

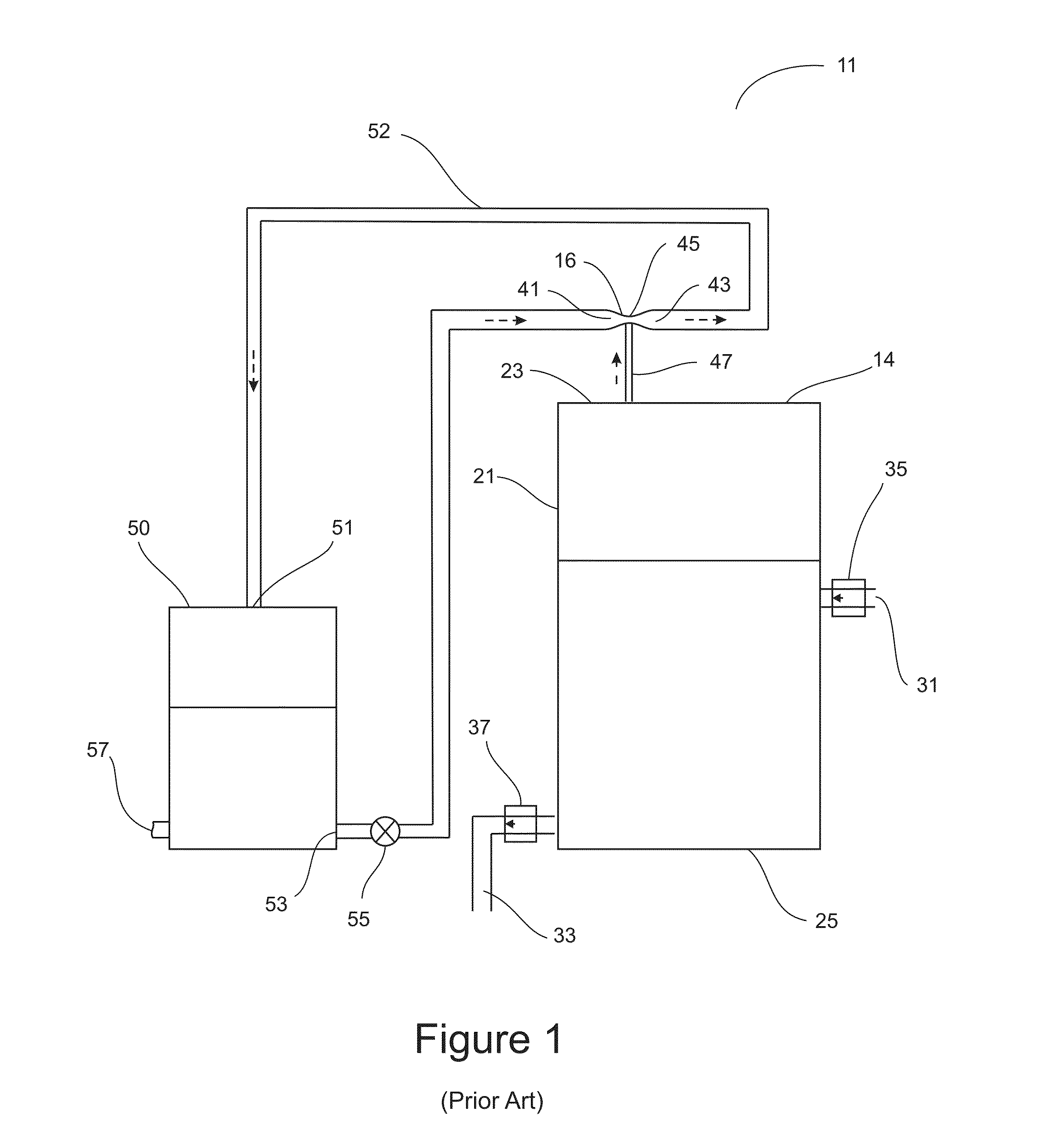

Method and apparatus for recovering water from atmospheric air

A method of separating water from air is provided comprising the steps of (a) contacting air having water vapour with an hygroscopic liquid mixture to produce a water rich hygroscopic liquid mixture, (b) heating at least a portion of the water rich hygroscopic liquid mixture to produce a gaseous mixture including water vapour and at least one other gaseous component, (c) condensing at least a portion of the water vapour in the gaseous mixture to produce liquid water and a depleted gaseous mixture at a first pressure, and (d) removing at least a portion of the at least one other gaseous component to maintain the first pressure below a predetermined pressure, wherein the depleted gaseous mixture is in fluid communication with the water rich hygroscopic liquid mixture. An absorber vessel is also provided for effecting the method of separating water from air.

Owner:KING RONALD +1

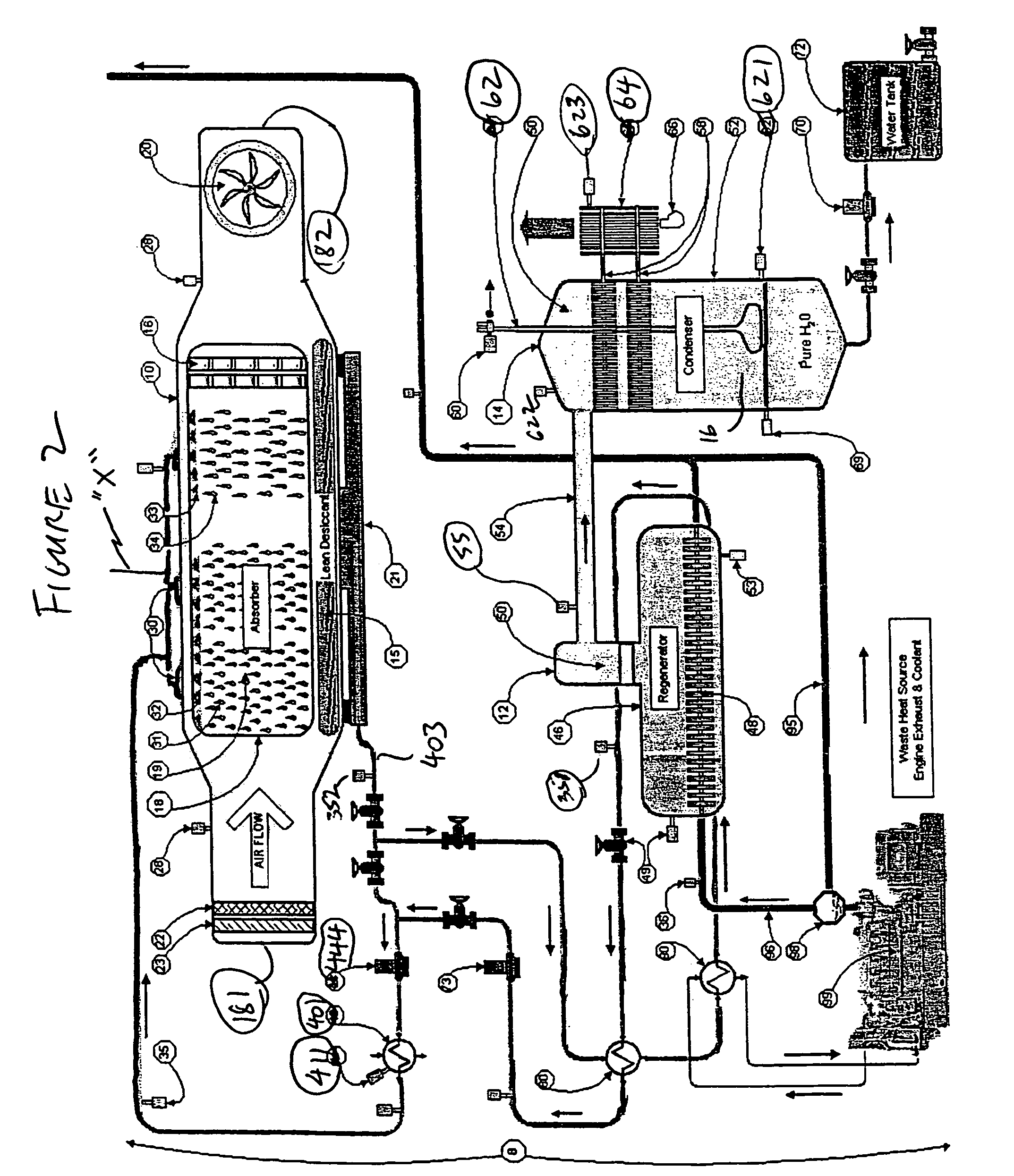

Method and apparatus for recovering water from atmospheric air

A method of separating water from air is provided comprising the steps of (a) contacting air having water vapor with an hygroscopic liquid mixture to produce a water rich hygroscopic liquid mixture, (b) heating at least a portion of the water rich hygroscopic liquid mixture to produce a gaseous mixture including water vapor and at least one other gaseous component, (c) condensing at least a portion of the water vapor in the gaseous mixture to produce liquid water and a depleted gaseous mixture at a first pressure, and (d) removing at least a portion of the at least one other gaseous component to maintain the first pressure below a predetermined pressure, wherein the depleted gaseous mixture is in fluid communication with the water rich hygroscopic liquid mixture. An absorber vessel is also provided for effecting the method of separating water from air.

Owner:KING RONALD +1

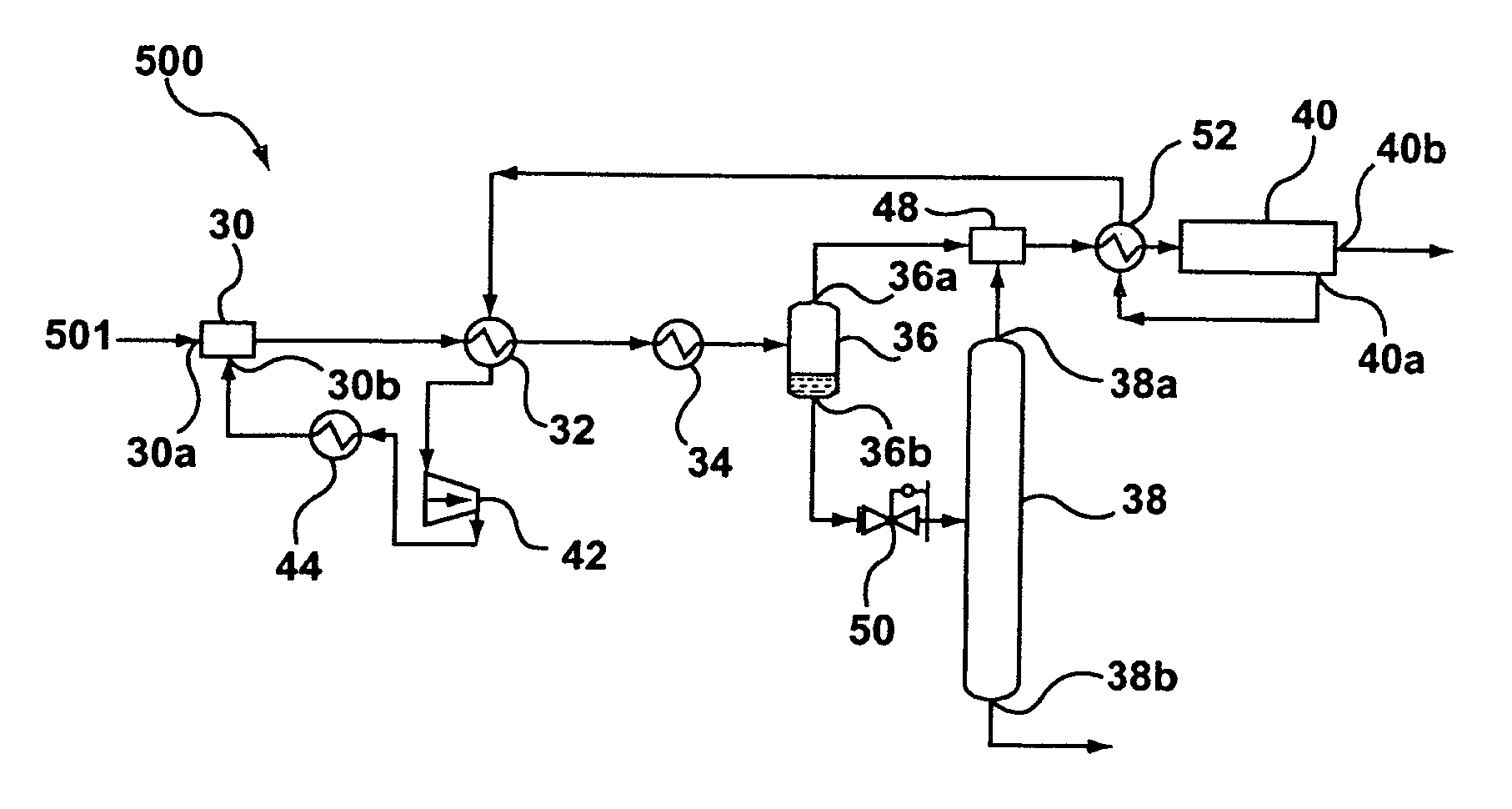

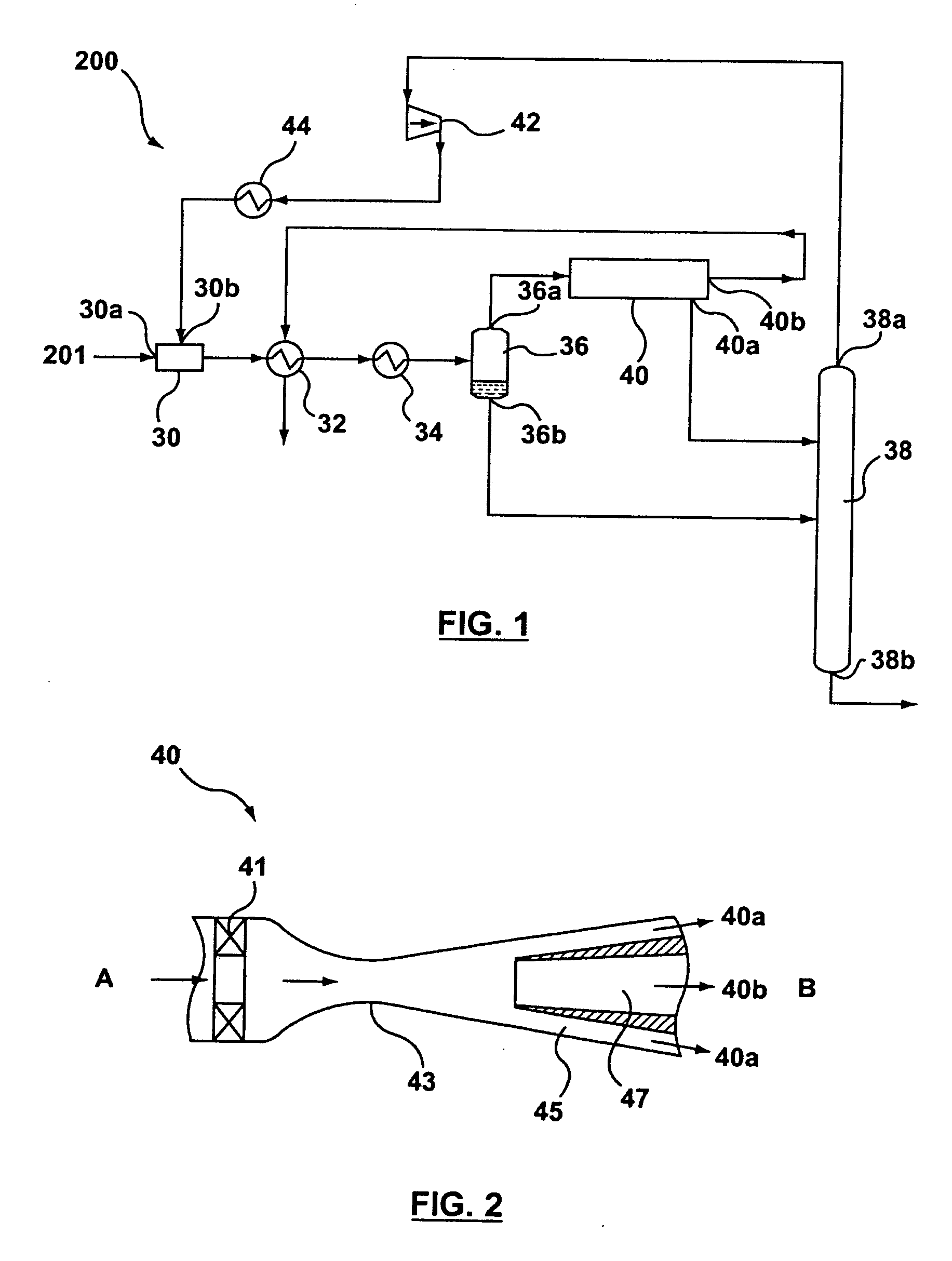

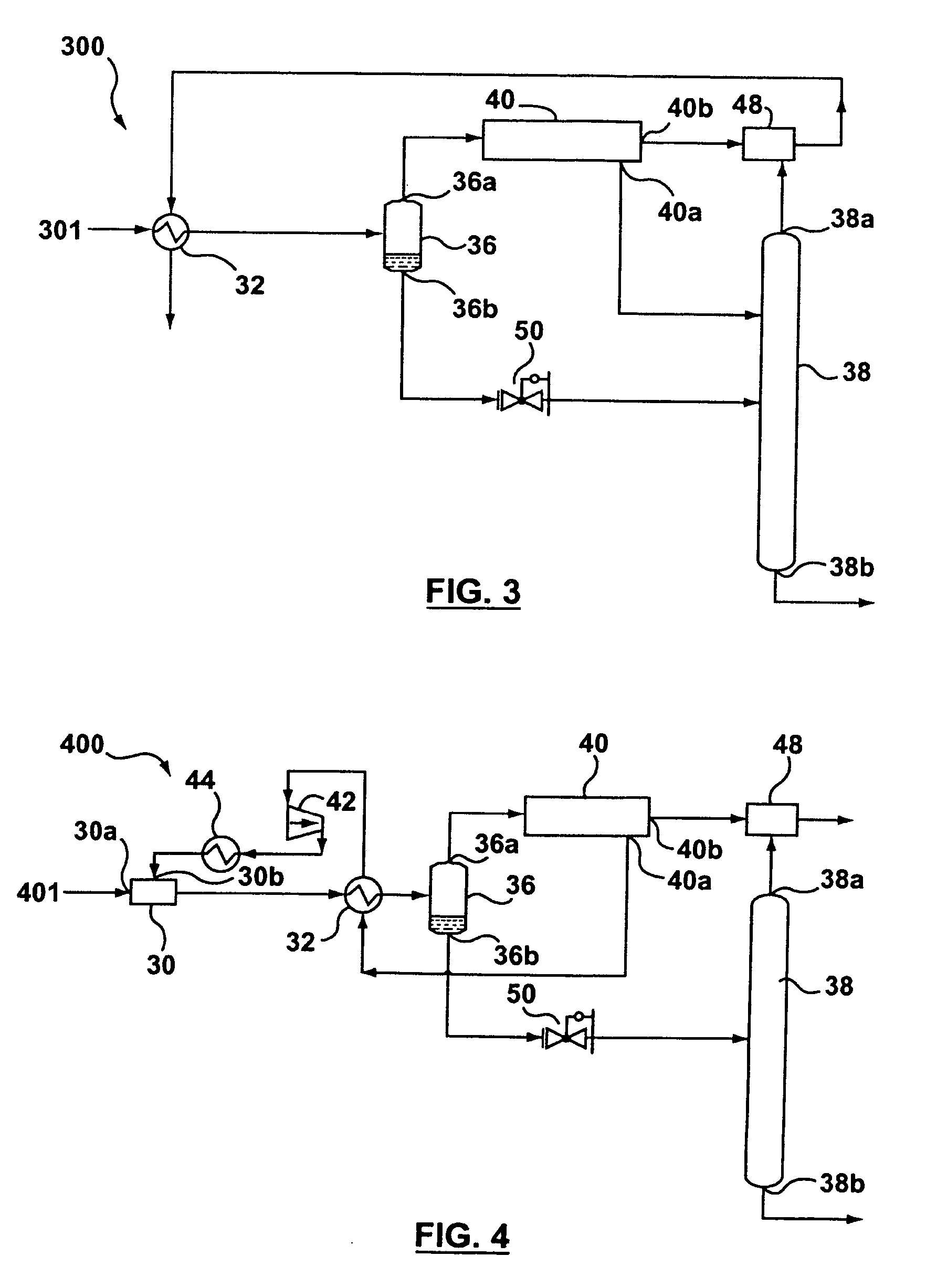

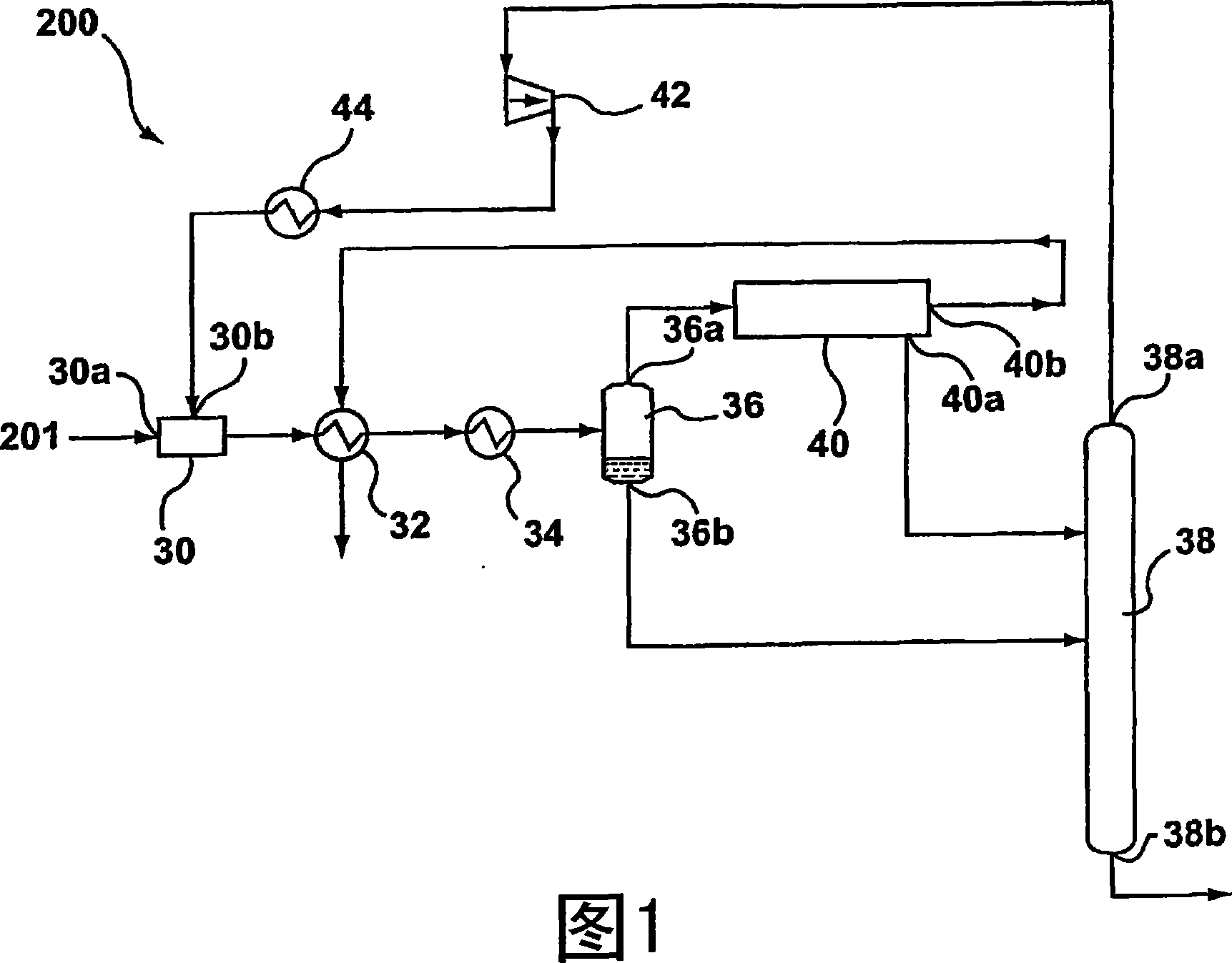

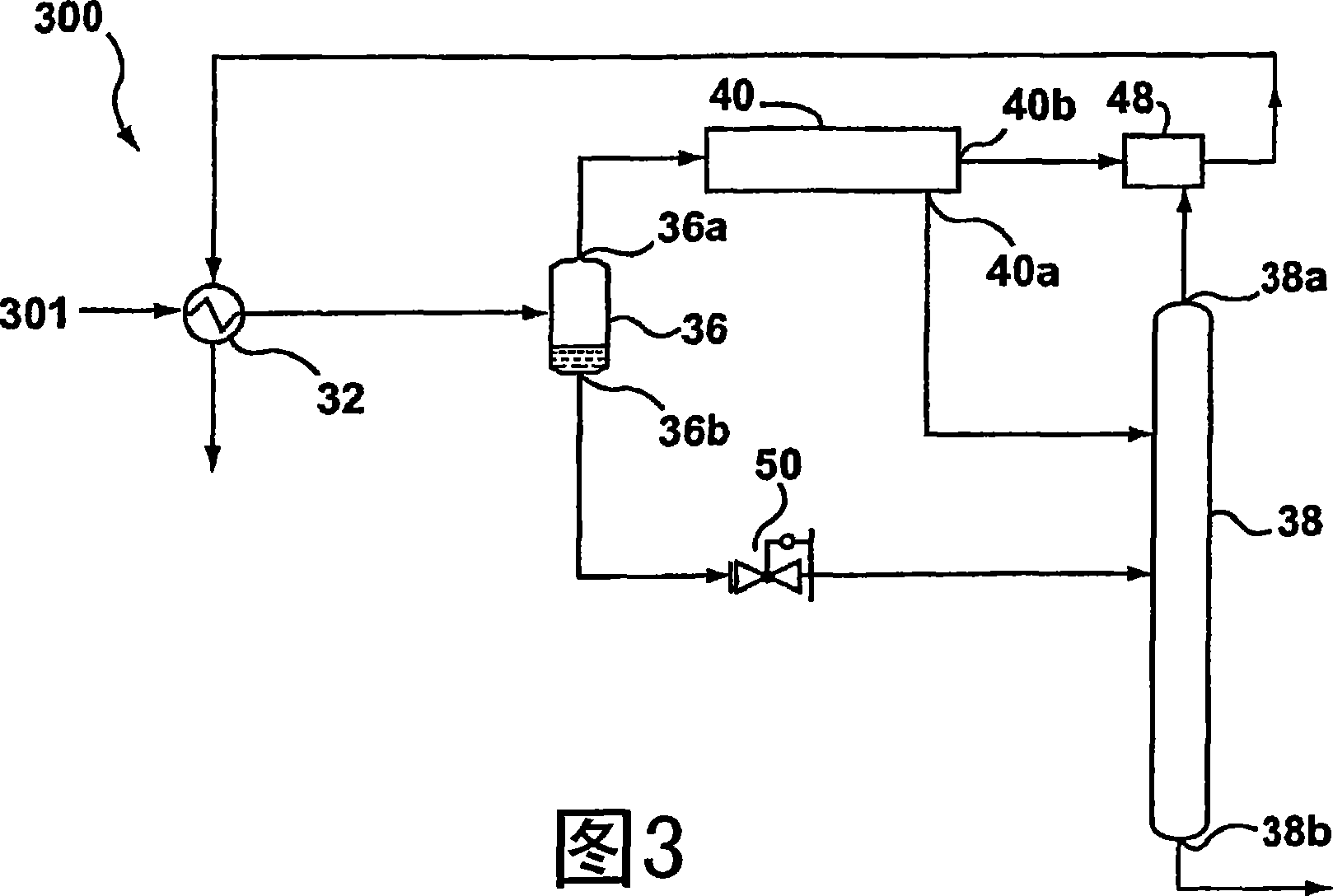

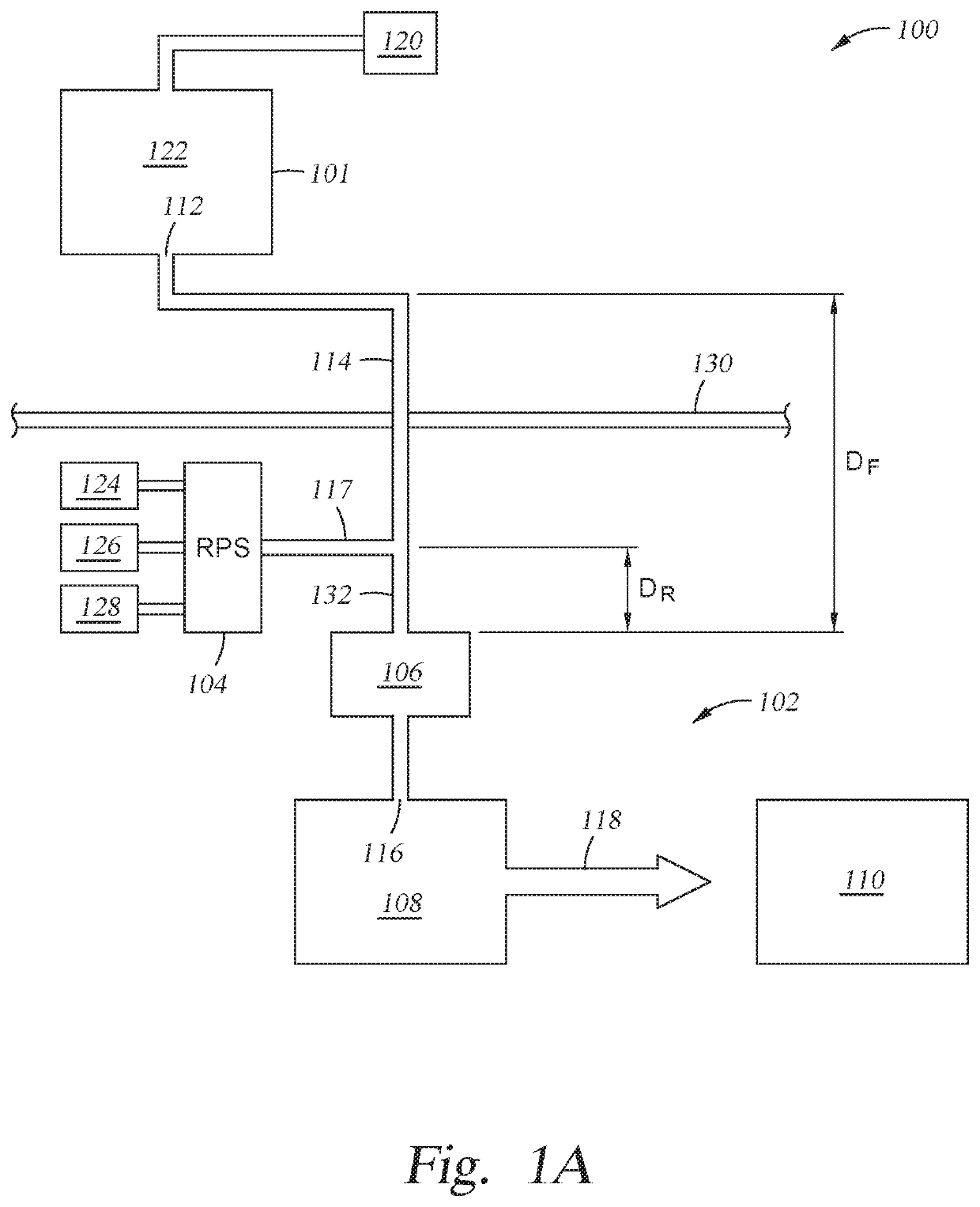

Systems and methods for low-temperature gas separation

One of the drawbacks common to many currently available low-temperature gas mixture separation techniques is that known systems and methods that embody the techniques are inefficient. In contrast to known systems and methods for low-temperature gas mixture separation, some embodiments of the present invention provide a system for low-temperature gas mixture separation that recycles energy and reduces power consumption by re-circulating heated and / or cooled flows (e.g. gas, liquid and mixed-phase flows) within the system. Accordingly, in some embodiments efficiency is somewhat improved, as compared to comparable systems that do not include the re-circulation of heat energy. In some embodiments the heat energy that is re-circulated is a combination of heat added to the system (i.e. inputs to the system) and heat released within the system (i.e. byproducts from within the system) that are subsequently recovered. In particular, some systems and methods provided in accordance with embodiments of the invention are suited for separating the constituent components of natural gas and other hydrocarbon gas mixtures.

Owner:3S GAS TECH LTD

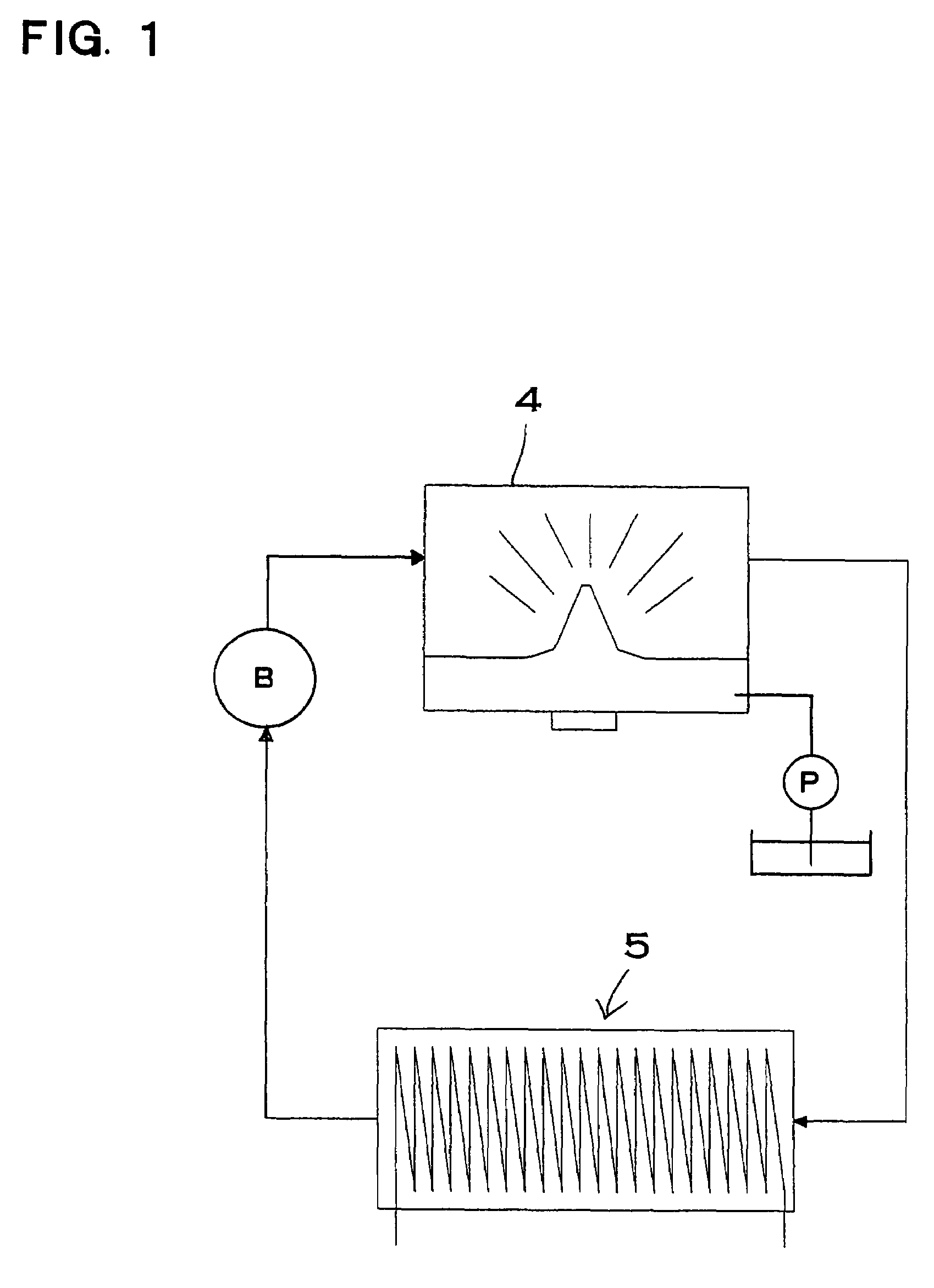

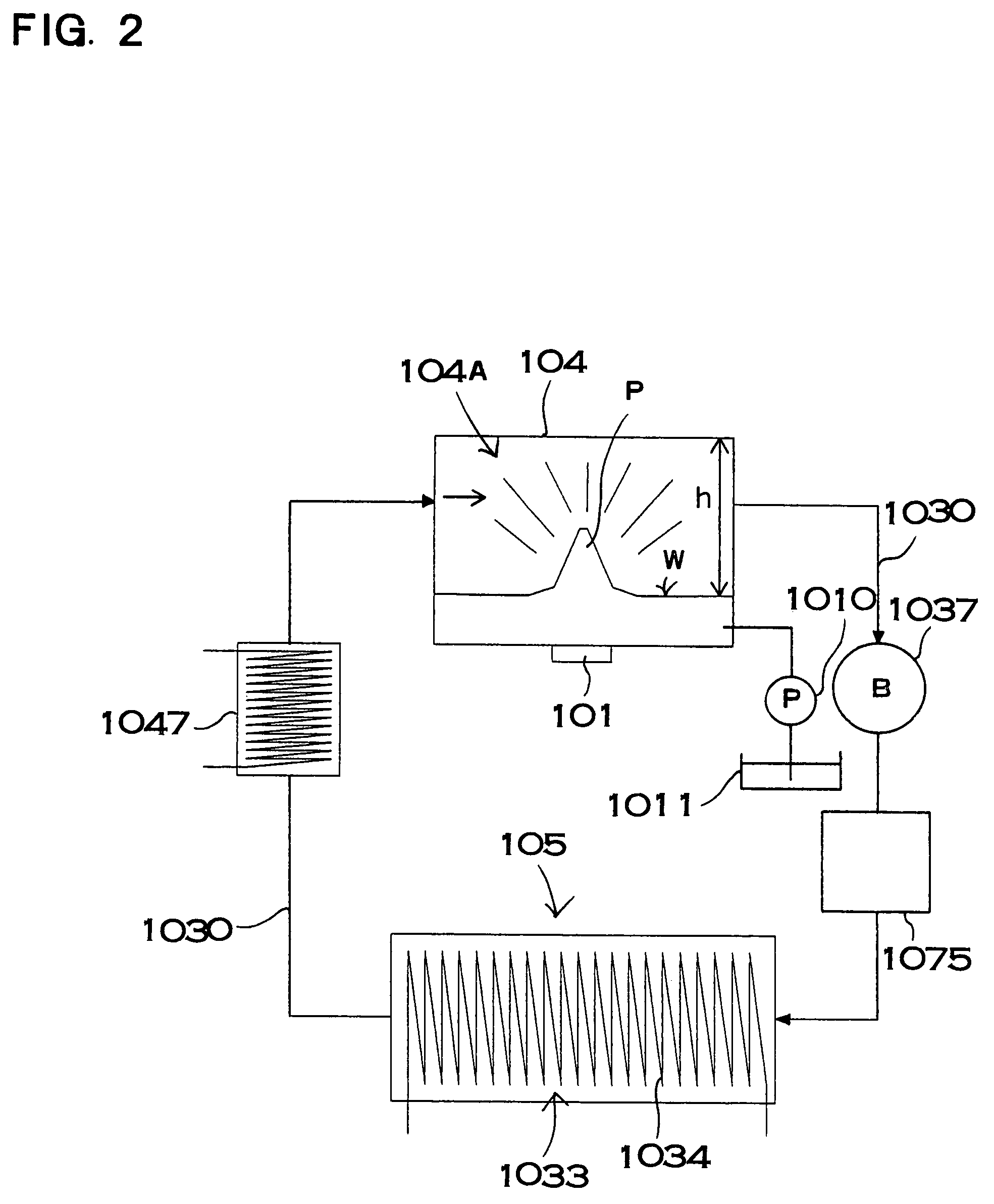

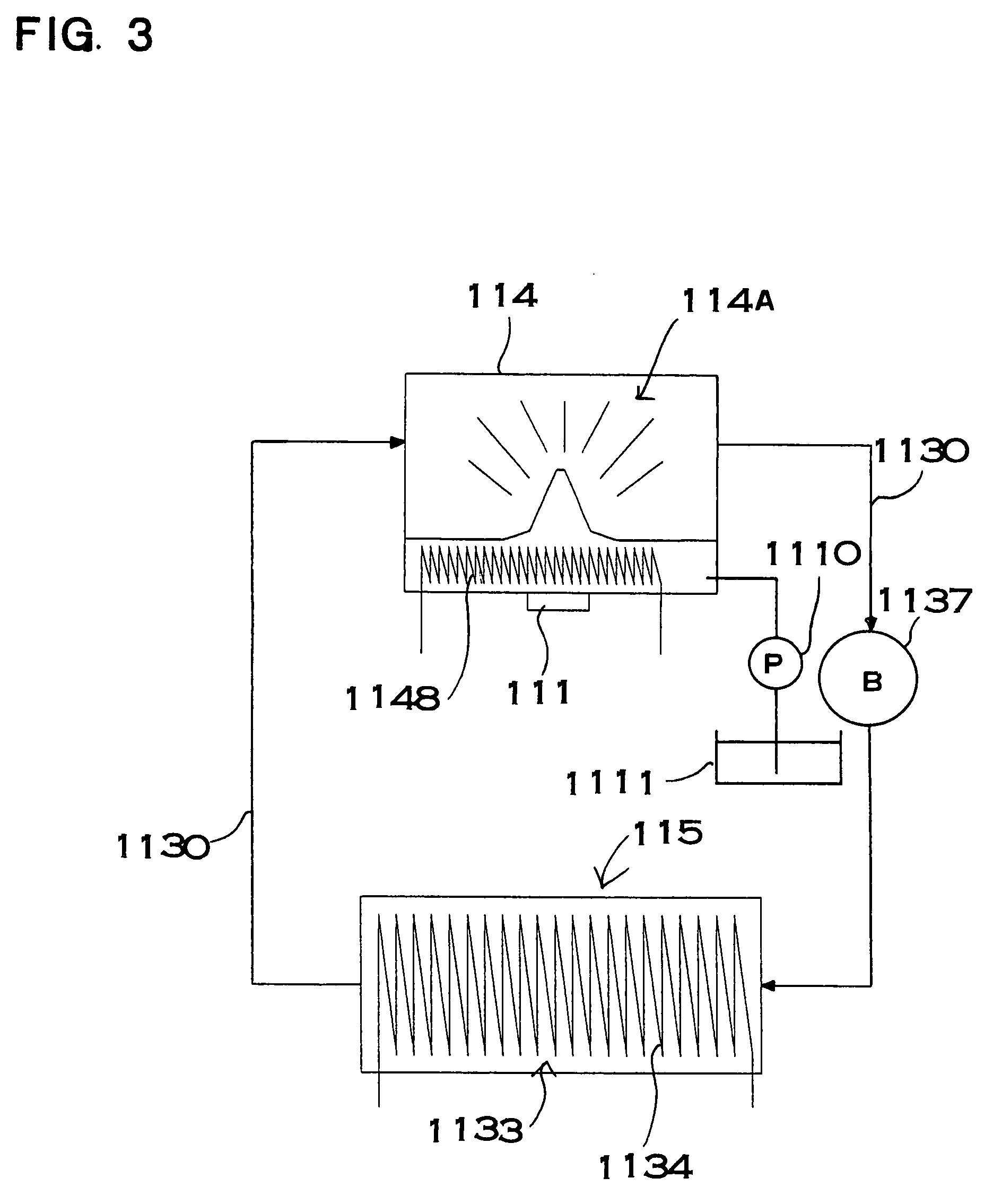

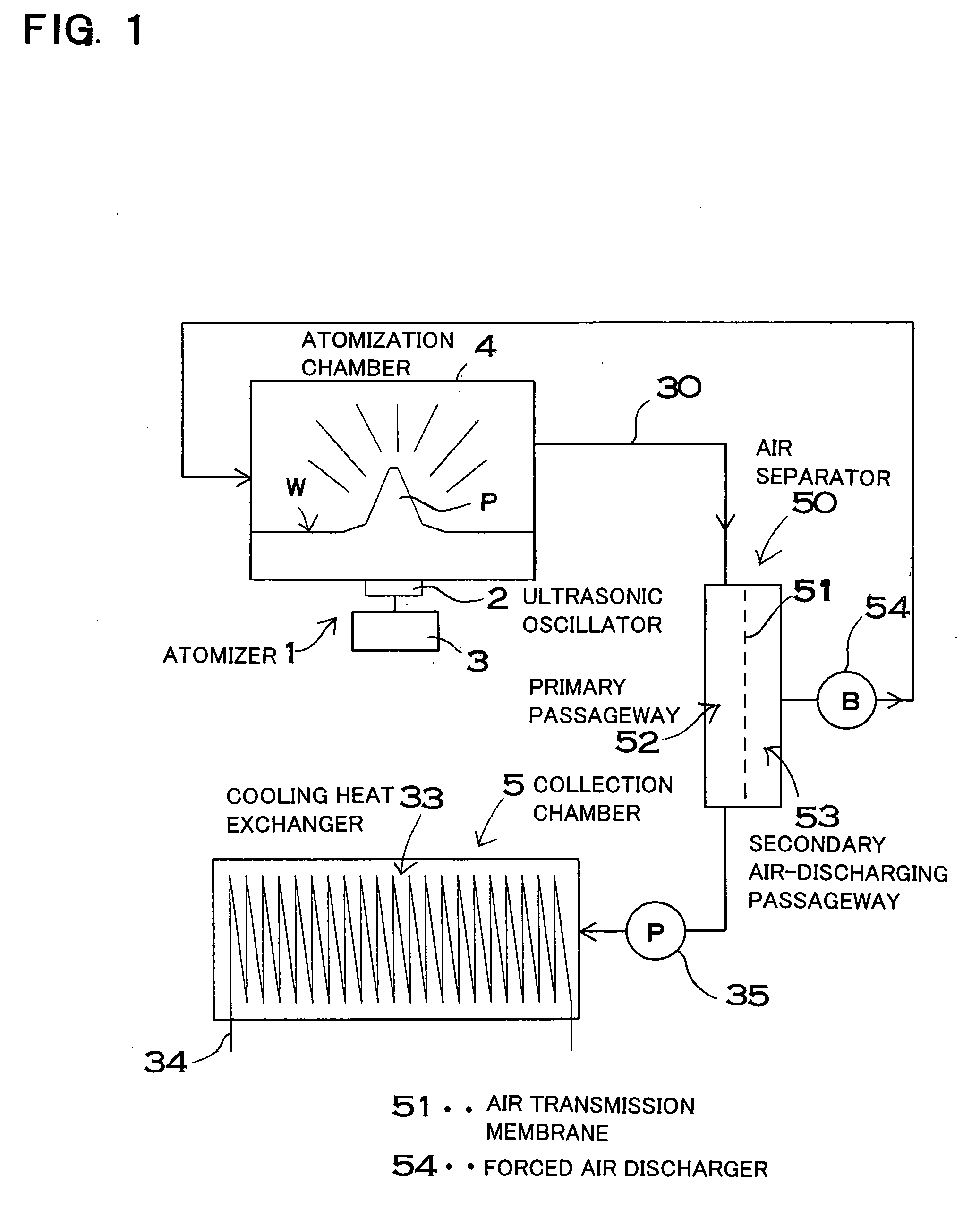

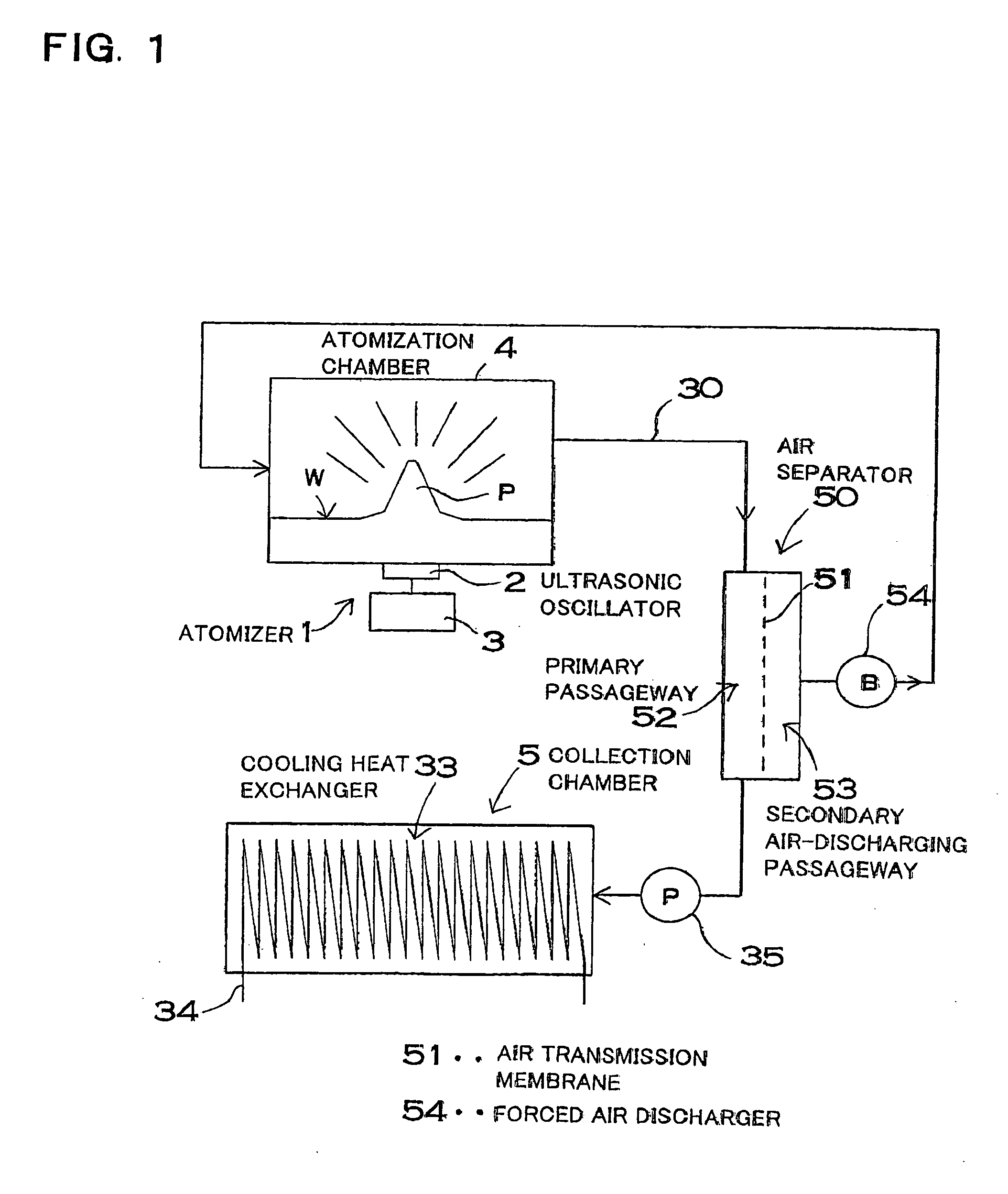

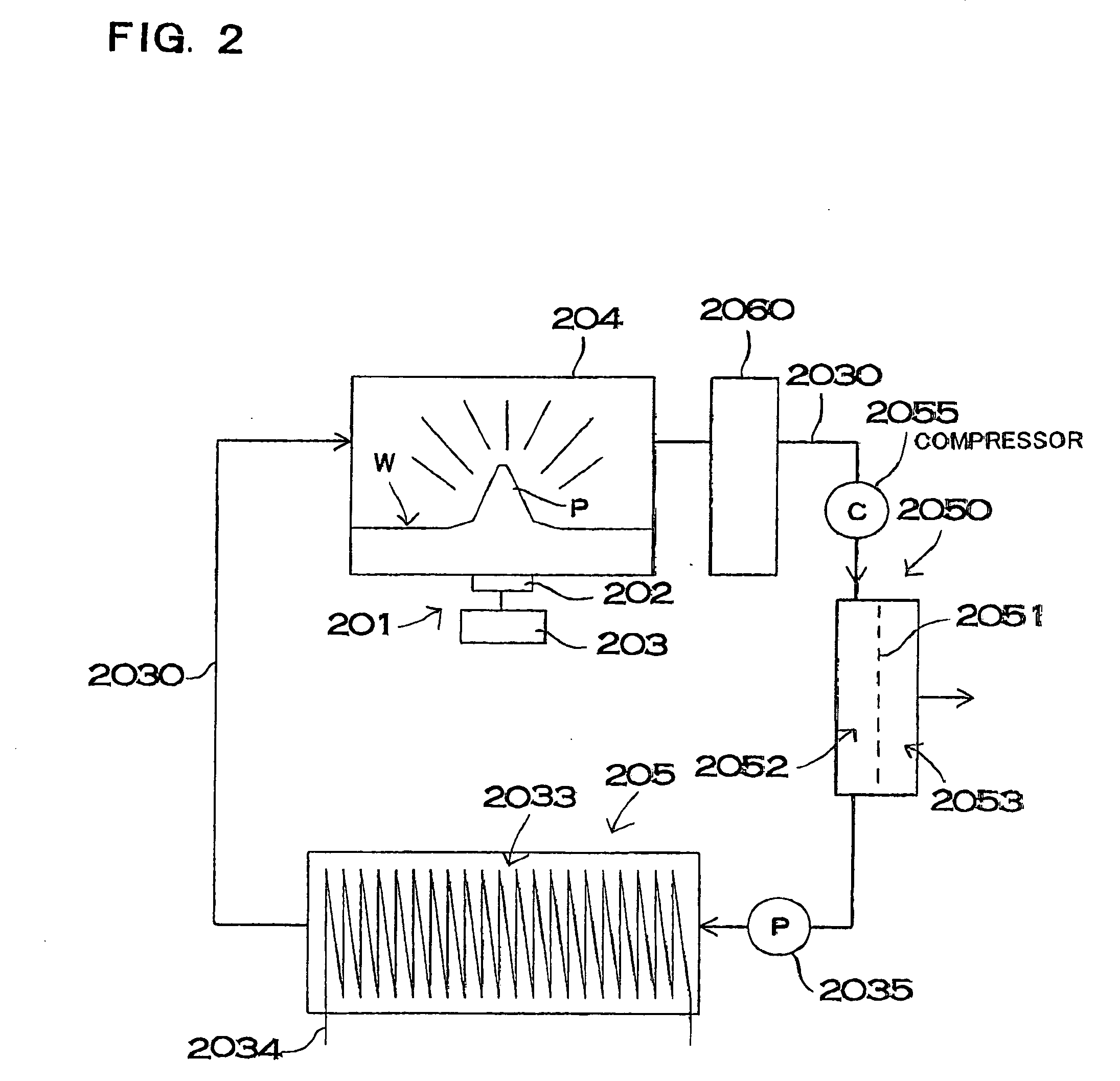

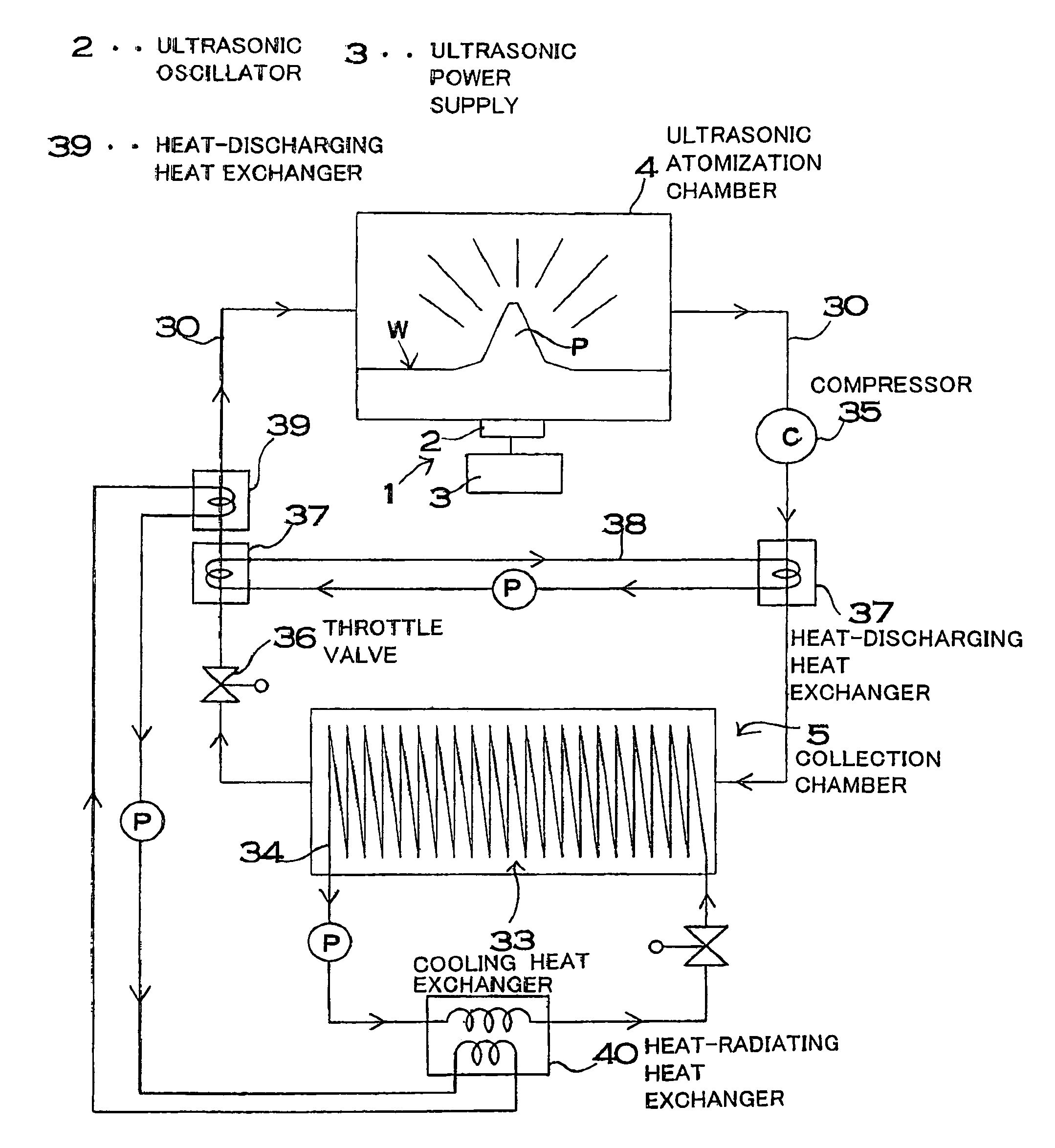

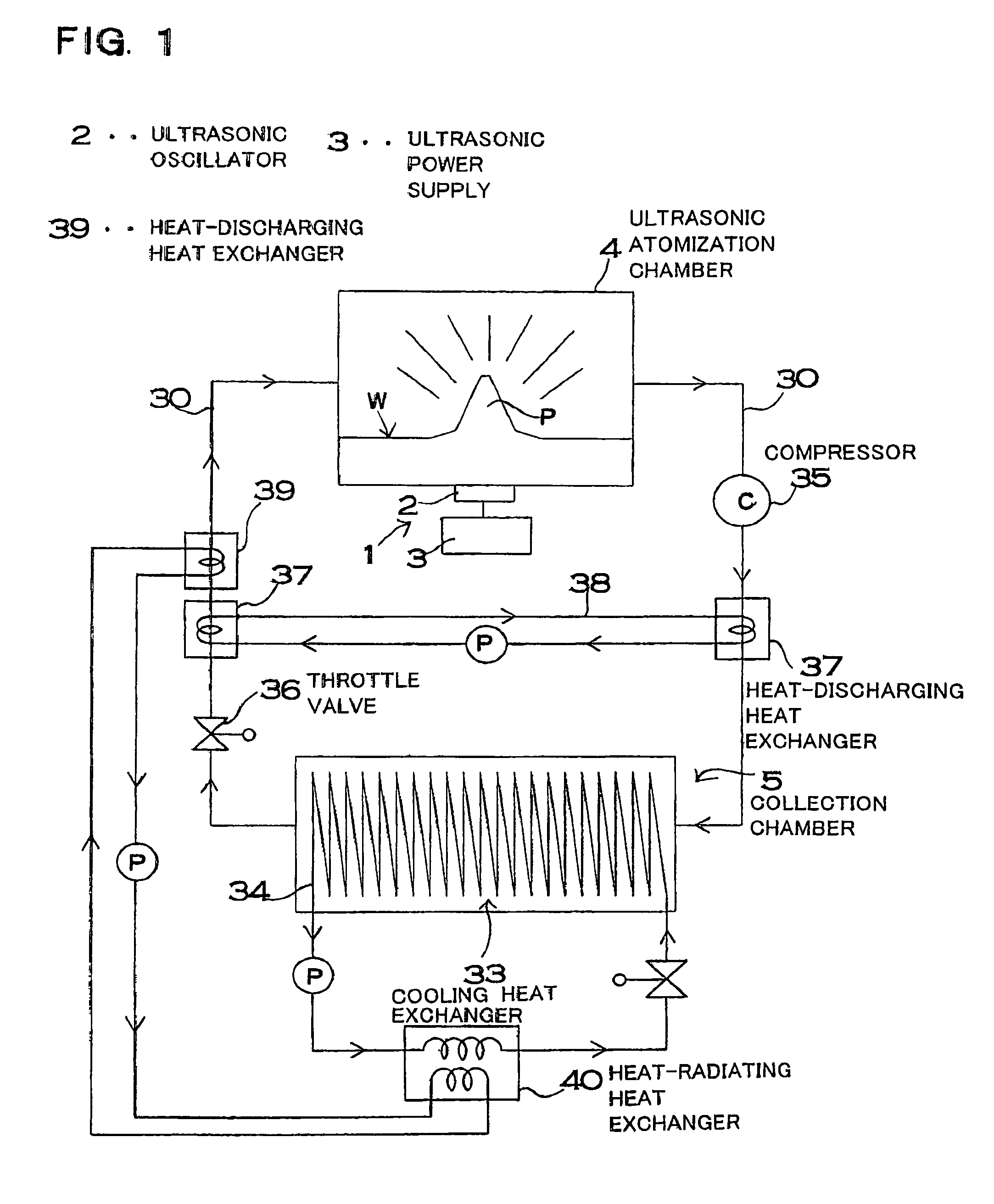

Ultrasonic solution separator

ActiveUS7347889B2Efficient productionEfficient separationThermo-electric condensationCombination devicesHigh frequency powerUltrasonic atomization

An ultrasonic solution separator including an ultrasonic atomization chamber supplied with a solution containing a target material; an ultrasonic oscillator producing mist from the solution in the ultrasonic atomization chamber with ultrasonic oscillation; a power supply for ultrasonics connected to the ultrasonic oscillator, and a collection portion transporting the mist produced by the ultrasonic oscillator with a carrier gas and aggregating and collecting the mist included in the carrier gas. The power supply supplying high-frequency power to the ultrasonic oscillator so that the ultrasonic oscillator oscillates at an ultrasonic frequency. The ultrasonic separator aggregates and collects the mist produced in the ultrasonic atomization chamber by means of the collection portion. With this ultrasonic solution separator, the temperature of carrier gas in the ultrasonic atomization chamber is at least 5° C. higher than the carrier gas in the collection portion.

Owner:ULTRASOUND BREWERY

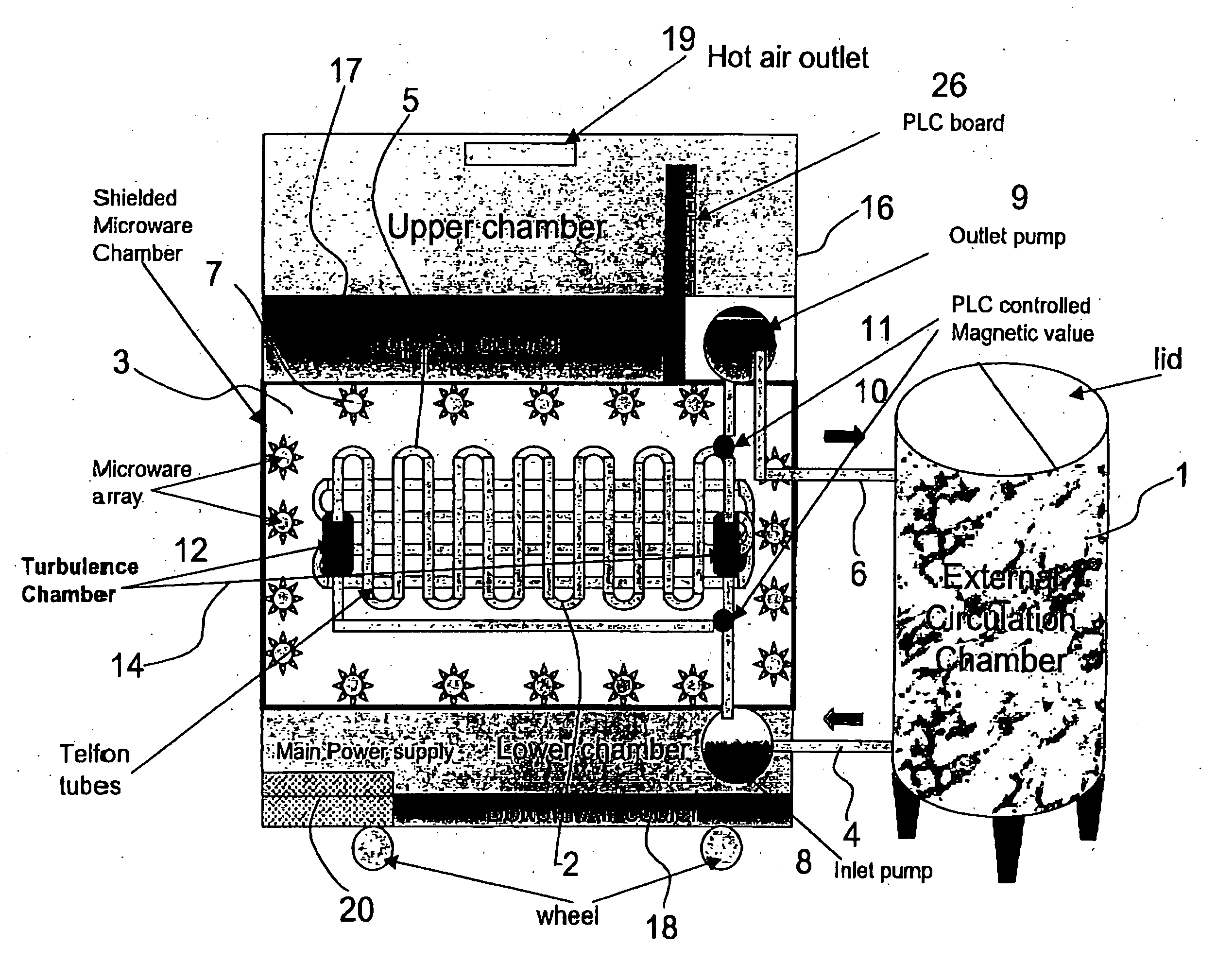

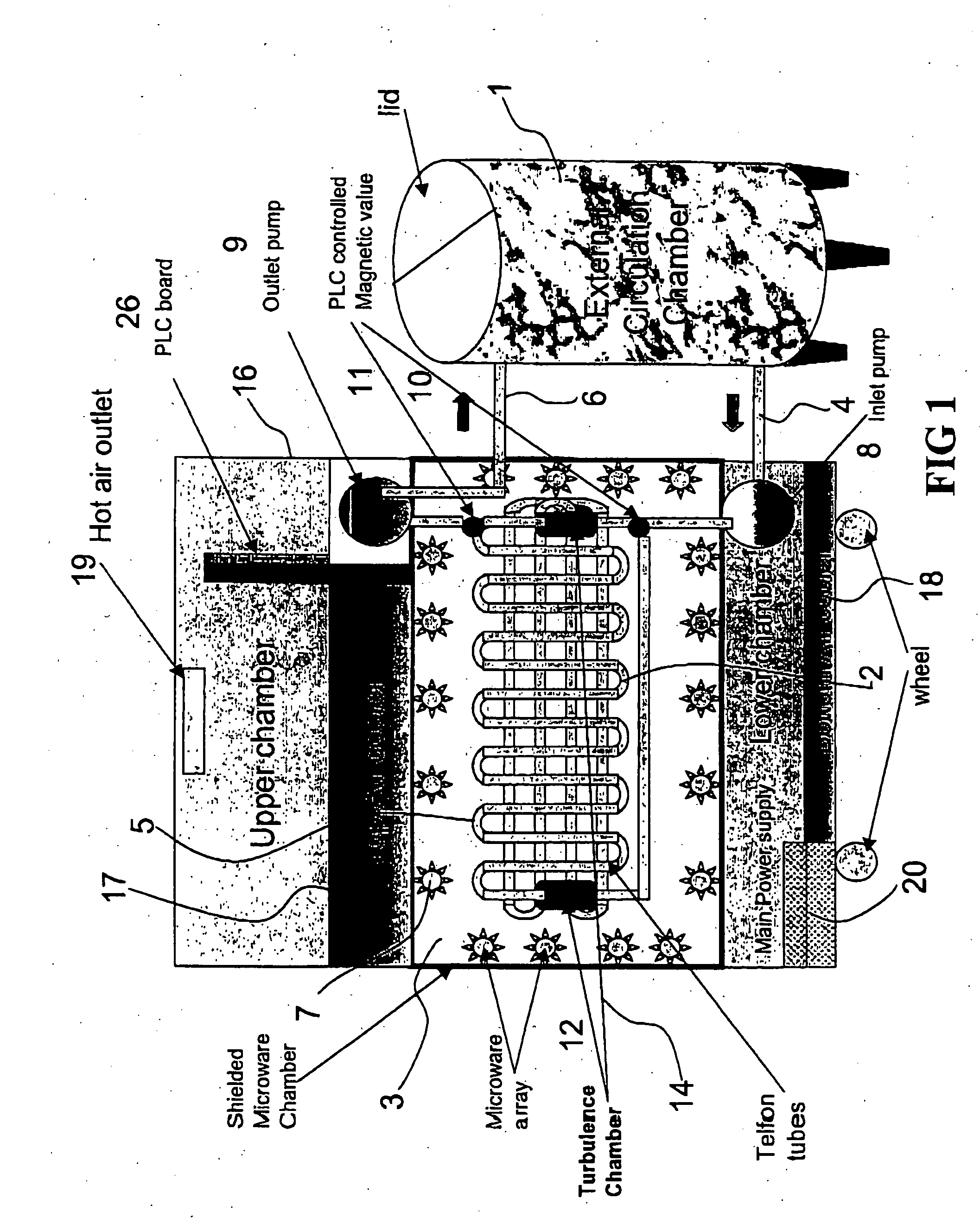

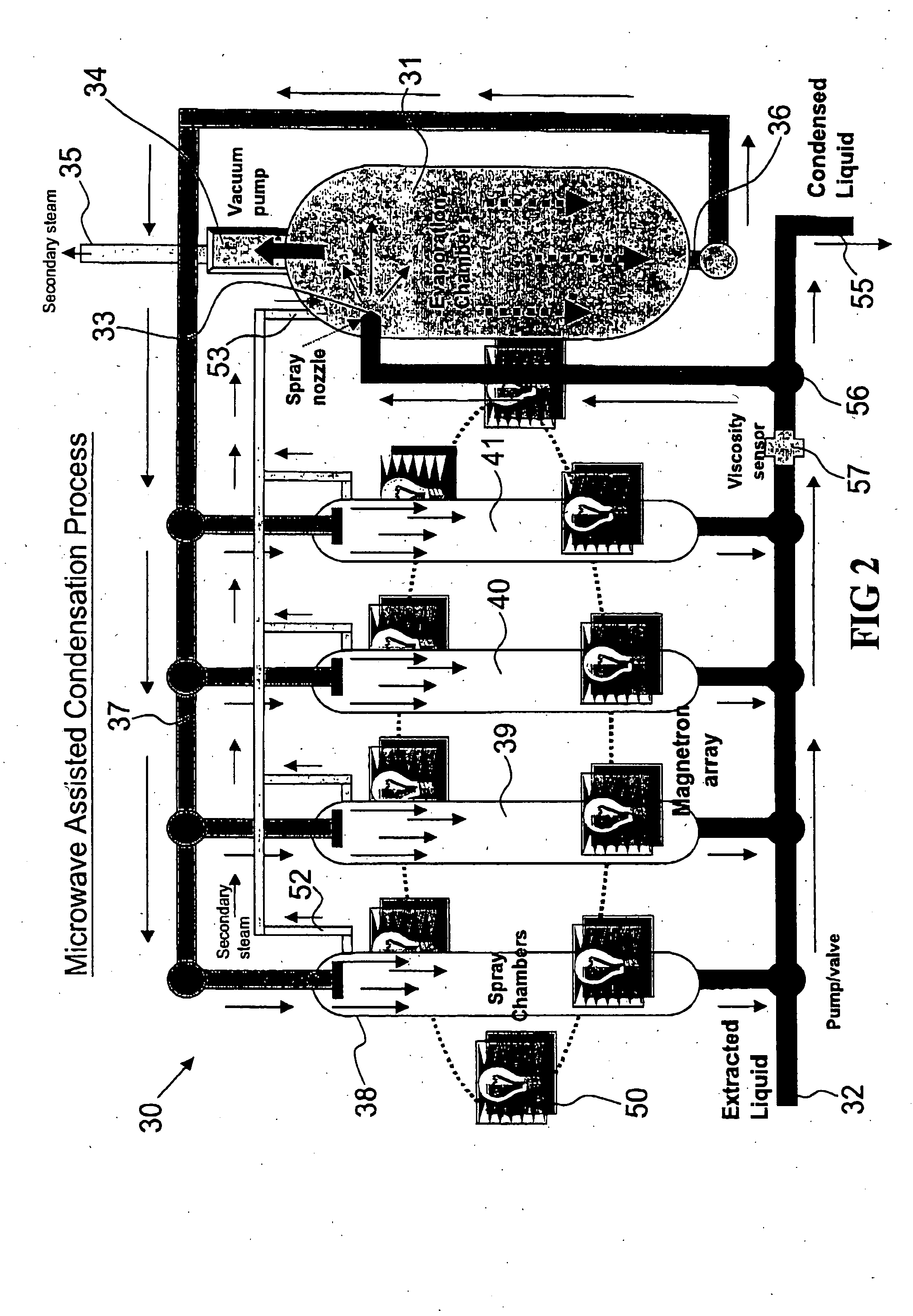

Method and apparatus for the extraction of plant constituents

InactiveUS20060153758A1Inexpensive productionReasonable yieldThermo-electric condensationVacuum condensationCondensation processEngineering

This invention provides a method and apparatus for the extraction of plant constituents such as may be used in the production of traditional Chinese medicines. The apparatus uses a fluid chamber to hold a mixture of plant and carrier fluid which is then passed through a conduit through a second chamber. The second chamber includes microwave sources to heat the mixture and preferably, some mechanical mechanism such as means to create turbulence to assist in breaking cell walls within the plant material. The heated mixture is returned to the fluid chamber and the process continued on further fluid and plant mixture until the batch itself is at elevated temperature and retained for a predetermined period of time. The resultant mixture may then be processed through a microwave assisted condensation process to provide a condensed extract for eventual use.

Owner:CHEUNG KAM WAI AINSTEIN

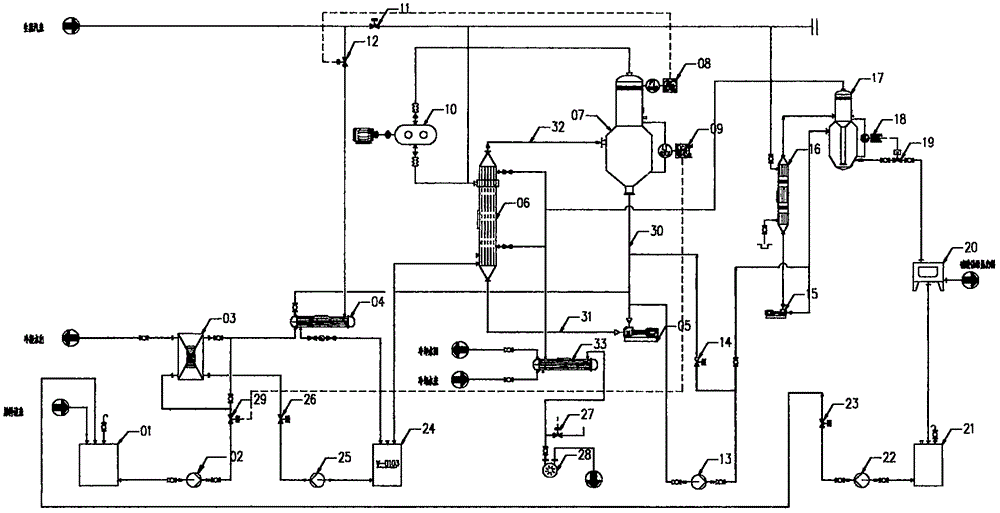

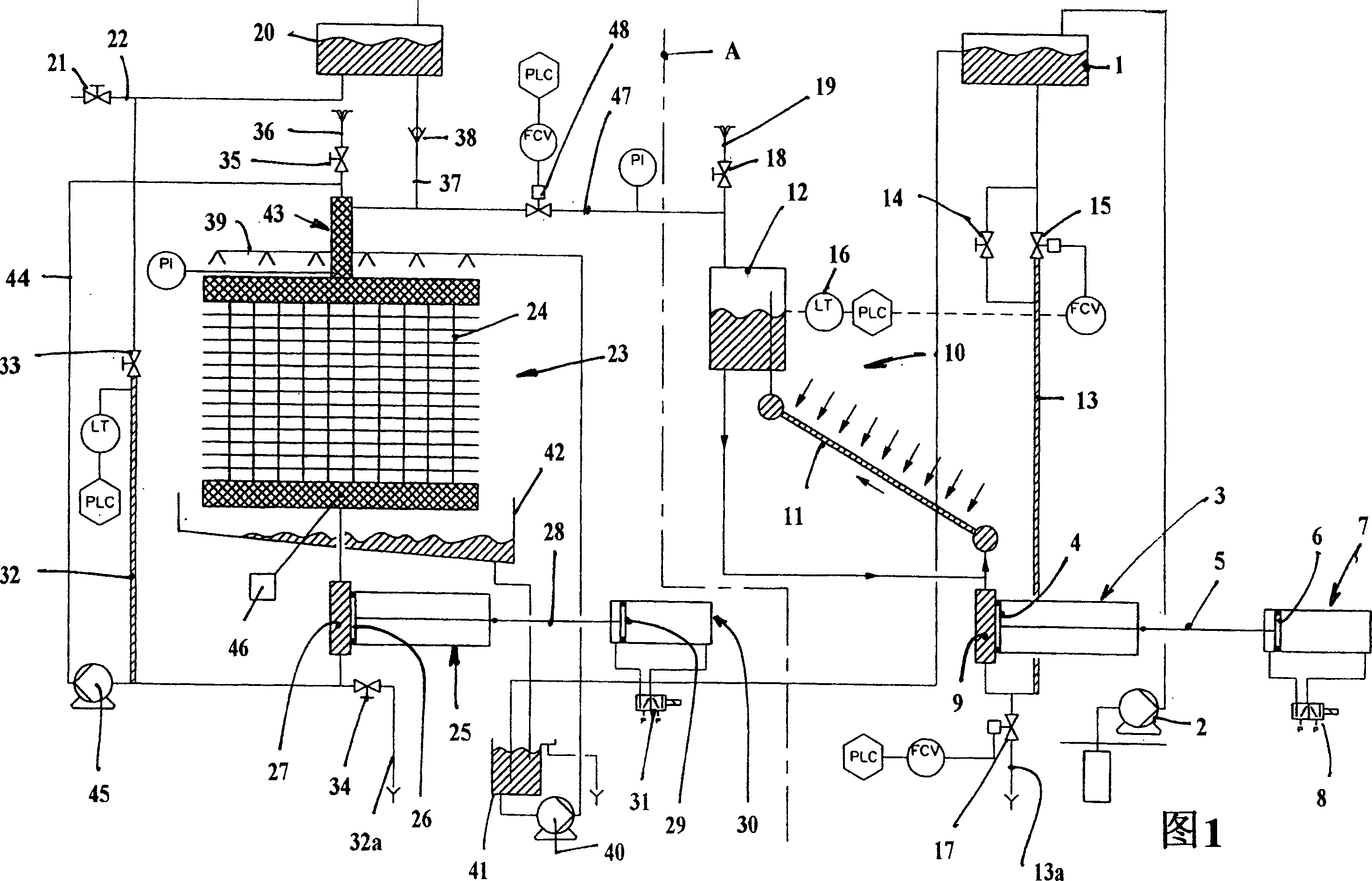

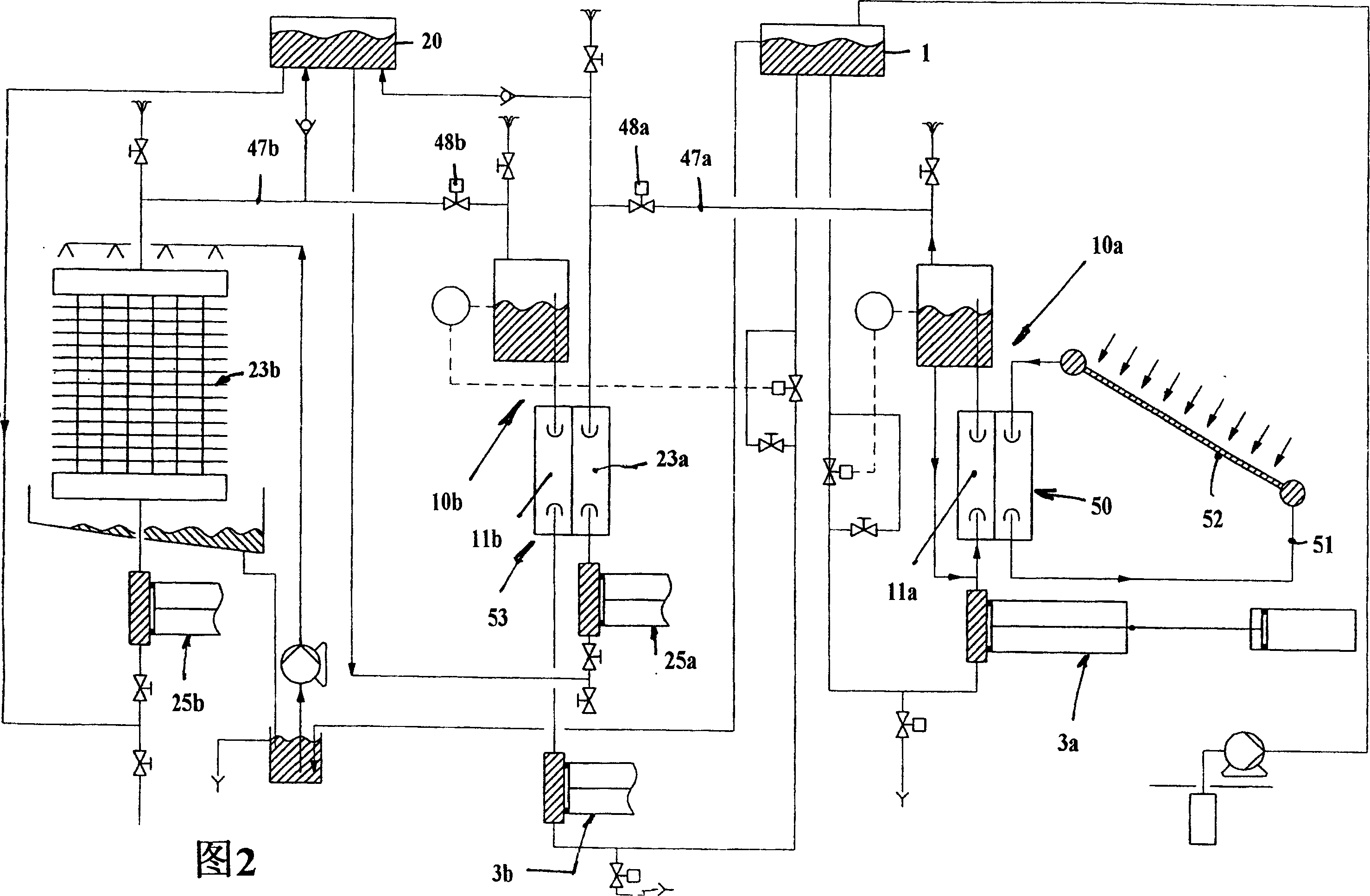

Device system for efficient cobalt sulfate concentration and continuous crystallization

ActiveCN106115804AGuaranteed cooling temperatureReduce dosageVacuum condensationEvaporation with vapour compressionEvaporationStock solution

The invention relates to a device system for efficient cobalt sulfate concentration and continuous crystallization. The device system provided by the invention comprises an evaporation heater (06), an evaporation separator (07), an OSLO vacuum crystallizer (17), a fine grain eliminating heater (16), a steam compressor (10), a condensate water preheater (03), a steam preheater (04), a centrifugal machine (20) and a pump. A stock solution enters the evaporation heater through the preheater, and the heater is connected with the separator and the circulating pump; the separator is connected with the OSLO vacuum crystallizer; a material liquid drop device is arranged in the middle of the OSLO vacuum crystallizer, a flash chamber is arranged at the top of a pipe, a circulating liquid outlet is formed in the side part, a secondary steam outlet is formed in the top of the flash chamber and is connected with a condenser and a fine grain eliminator, the crystallizer is connected with the centrifugal machine, and the centrifugal machine is connected with a mother liquid tank and a stock solution buffer tank to realize overall material liquid circulation. The system has the characteristics of energy conservation, continuity, automation and high efficiency, and obtained products are large in grain size and high in quality.

Owner:湖州惠鹏达节能环保科技有限公司

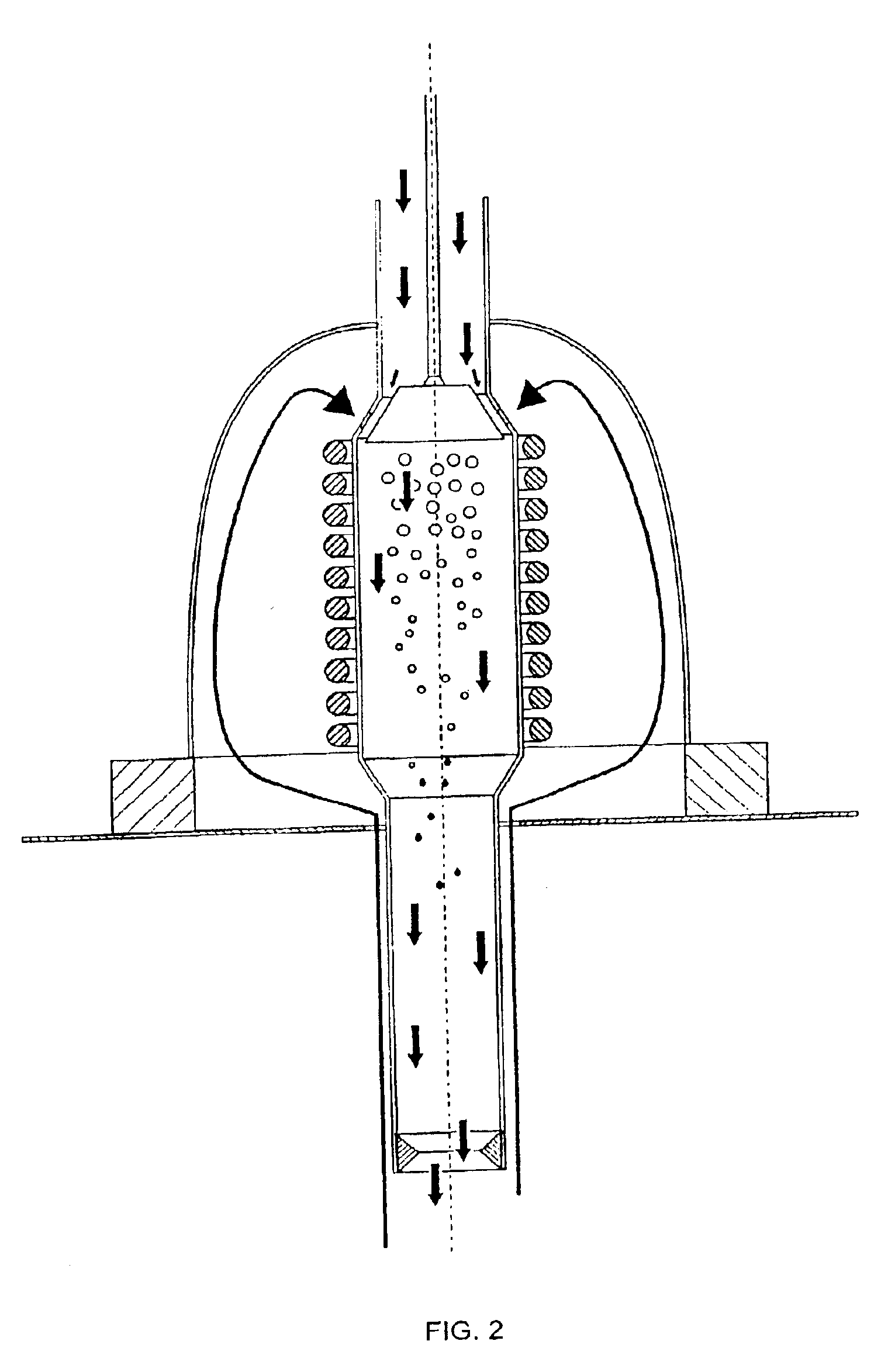

Systems and methods for low-temperature gas separation

Disclosed is a method of gasifying a biomass, comprising heating a fluidized bed reactor loaded with a catalyst represented by Rh / CeO2 / M, where M represents SiO2, Al2O3 or ZrO2, to temperatures lower than 800 DEG C. introducing biomass particles into the fluidized bed reactor from an upper portion thereof, introducing air and steam into the fluidized bed reactor from a lower portion thereof, and allowing the biomass particles to react at the surface of the Rh / CeO2 / M catalyst so as to manufacture hydrogen and a syngas.

Owner:3S GAS TECH LTD

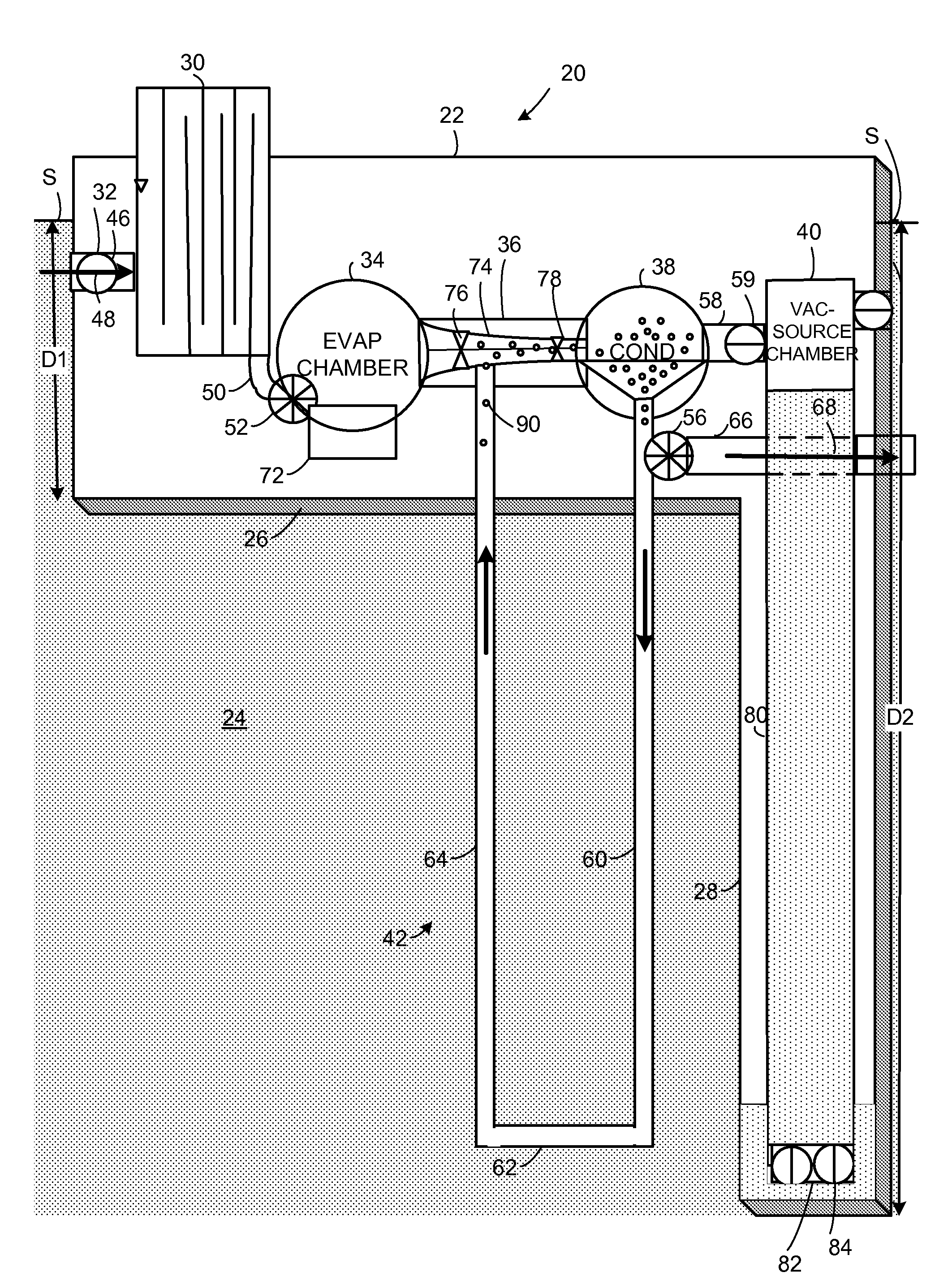

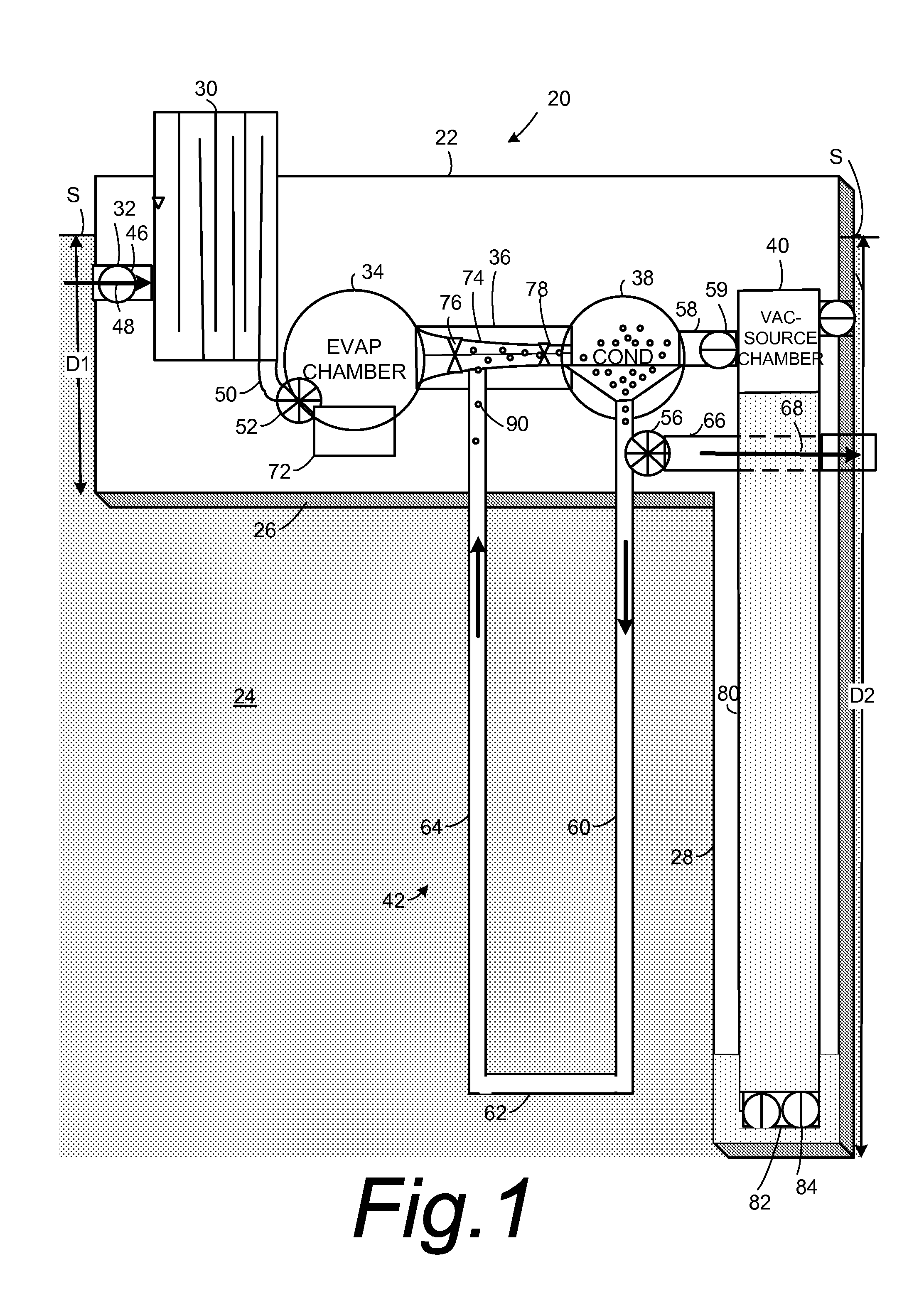

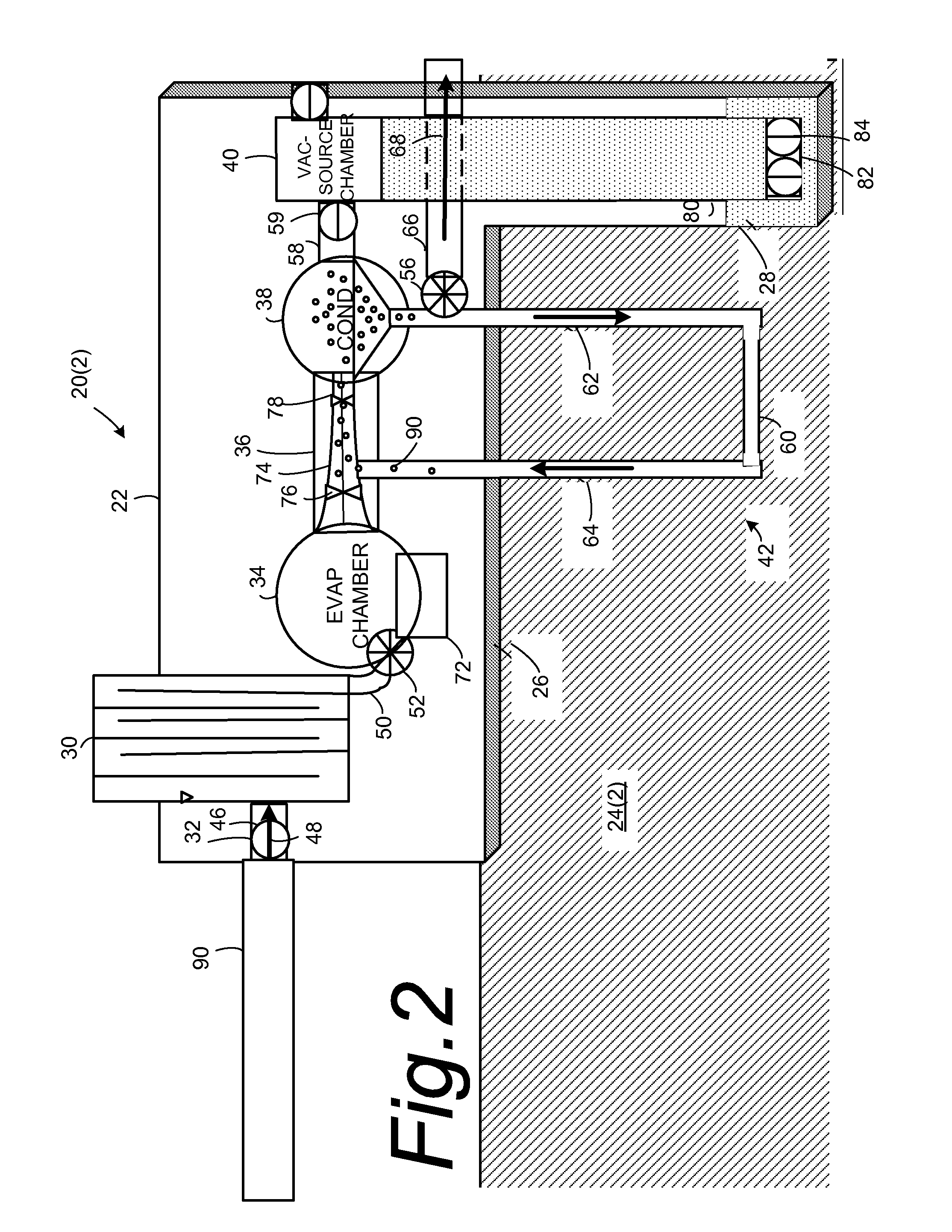

Method and apparatus for treatment of impotable water

Apparatus and method are provided for treatment of impotable water and for optionally simultaneously creating surplus electricity. Briefly, water is marshaled through a series of chambers by variances in pressure which are created as the water changes state from liquid to gas and from gas to liquid. The source or input water moves through the system, first heated, then vaporized where the impurities fall out, then pushed and pulled through a nozzle where it turns the blades of a turbine-type generator, and finally condensed where the newly-distilled water is removed from the system.

Owner:SWENHOLT HELMER C

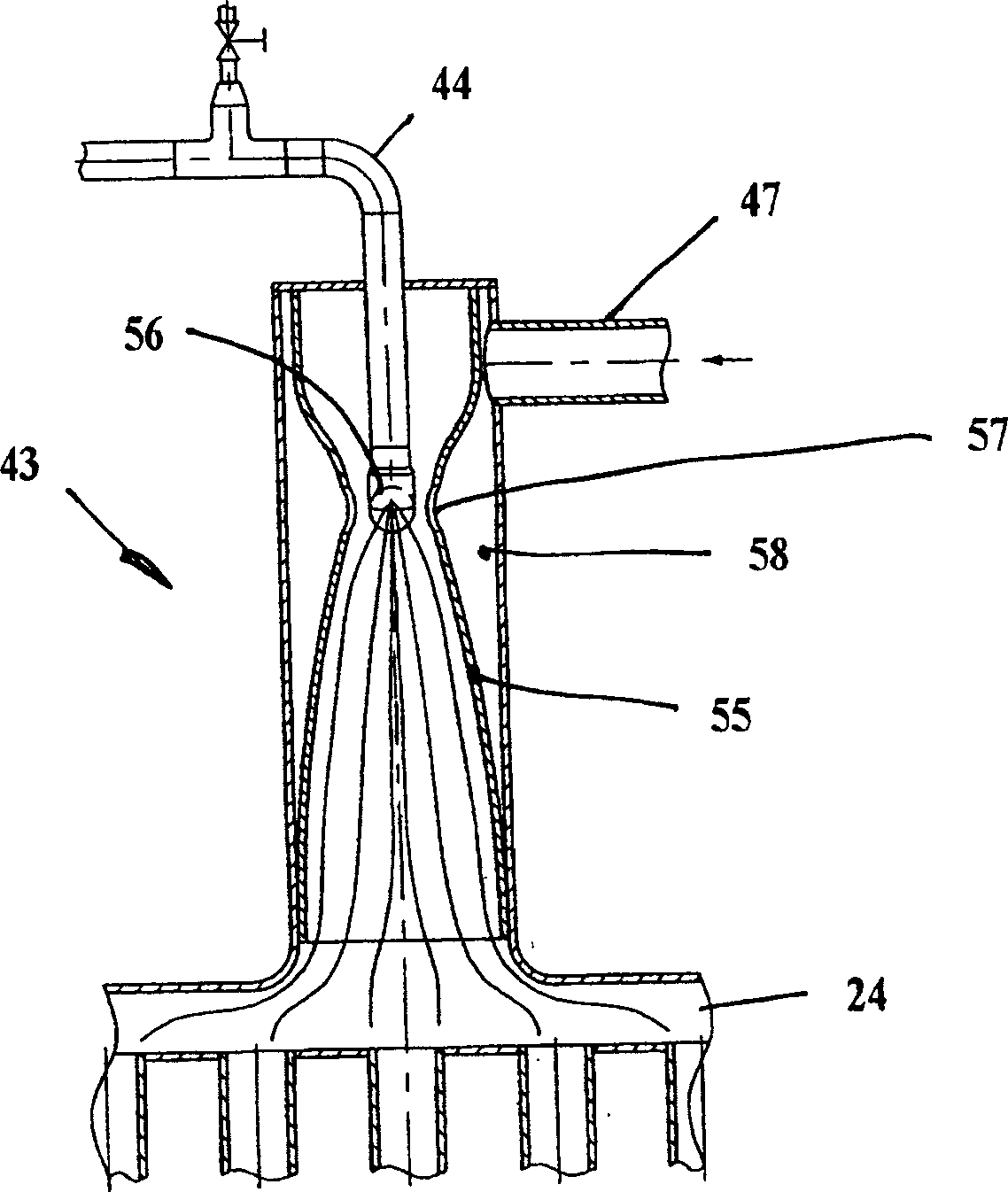

Method, apparatus and system for the condensation of vapors and gases

A method for condensing fumes or gases from a tank containing a liquid. The method includes leading the liquid into a venturi to create a low pressure at the venturi. Ports are provided in the venturi at the area where the low pressure is created, and gas / vapor is lead to the ports in the venturi in the low pressure area in such a way that the liquid entrains the gas / vapor and forms a fluid, such that the velocity is reduced and the pressure increased to condense the gas / vapor. The fluid is then led from the chamber to a lower part of the tank for further condensation due to the hydrostatic pressure. An apparatus, a system and uses thereof are also described.

Owner:VENTURIE

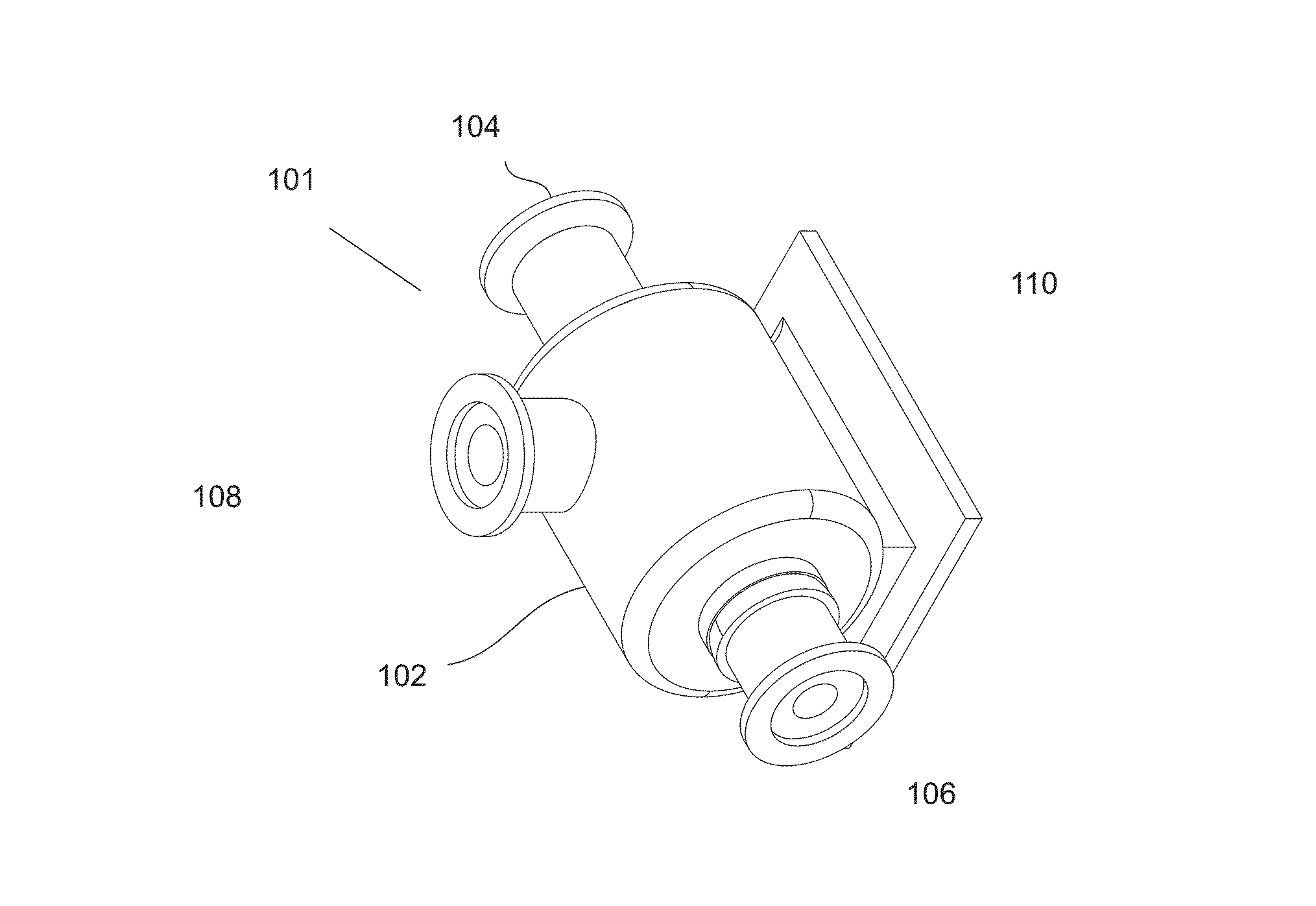

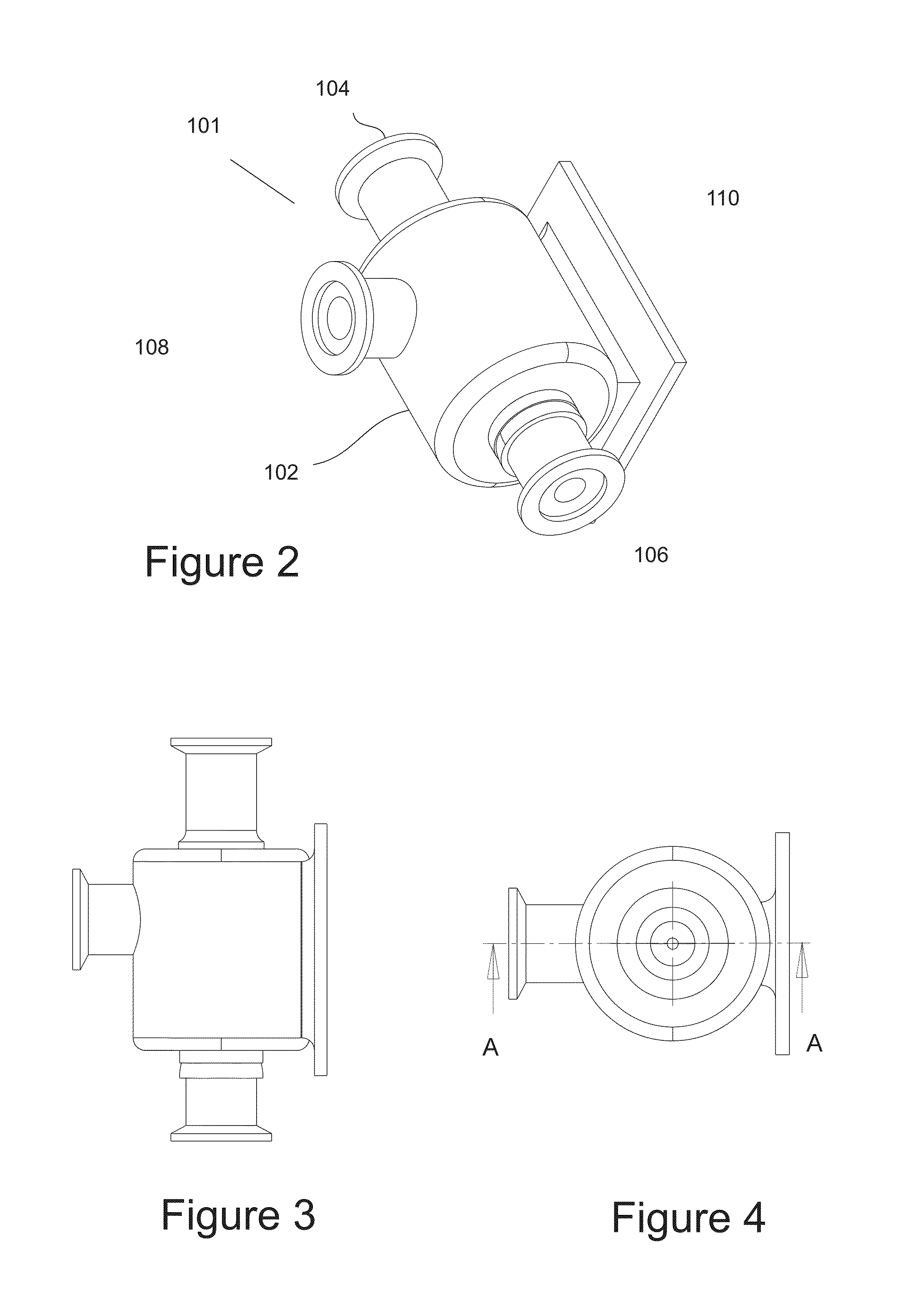

Vacuum Condenser

InactiveUS20160271519A1Reduce pressureIncrease productionVacuum condensationMultiple-effect/fractional condensationEngineeringOperating temperature

A vacuum condenser adapted to reduce pressure in an enclosure containing a secondary liquid and thereby cause the accelerated production of vapor from the secondary liquid by the passage of a primary liquid through the vacuum condenser and whereby the vapor produced is absorbed by the primary liquid within the vacuum condenser by being entrained and condensed within the primary liquid wherein the vacuum condenser is configured to cause the operating temperature of the secondary liquid within the enclosure to maintain a stable minimum temperature for a predetermined substantial rate of production of vapor.

Owner:HARMAN JAYDEN DAVID +4

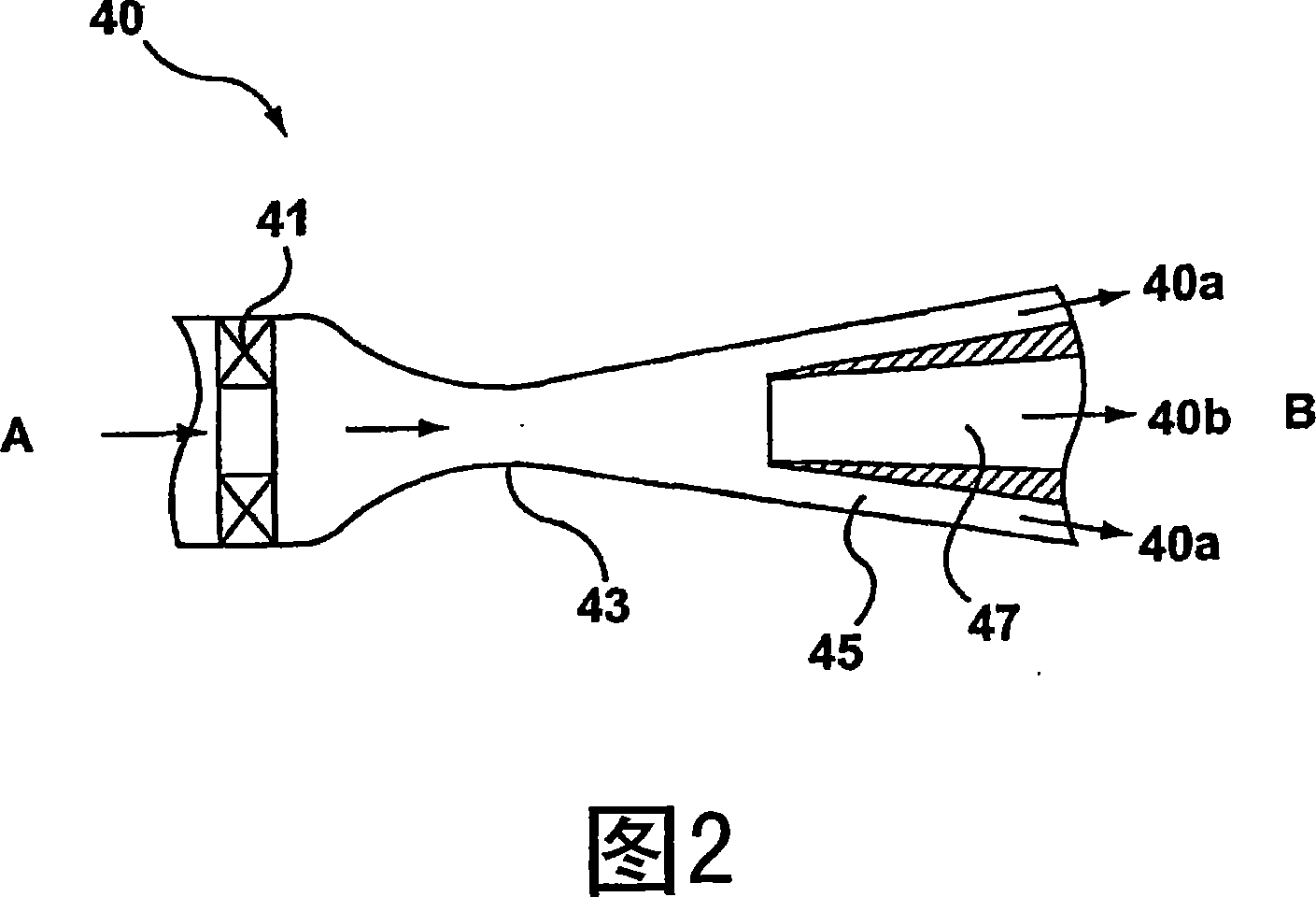

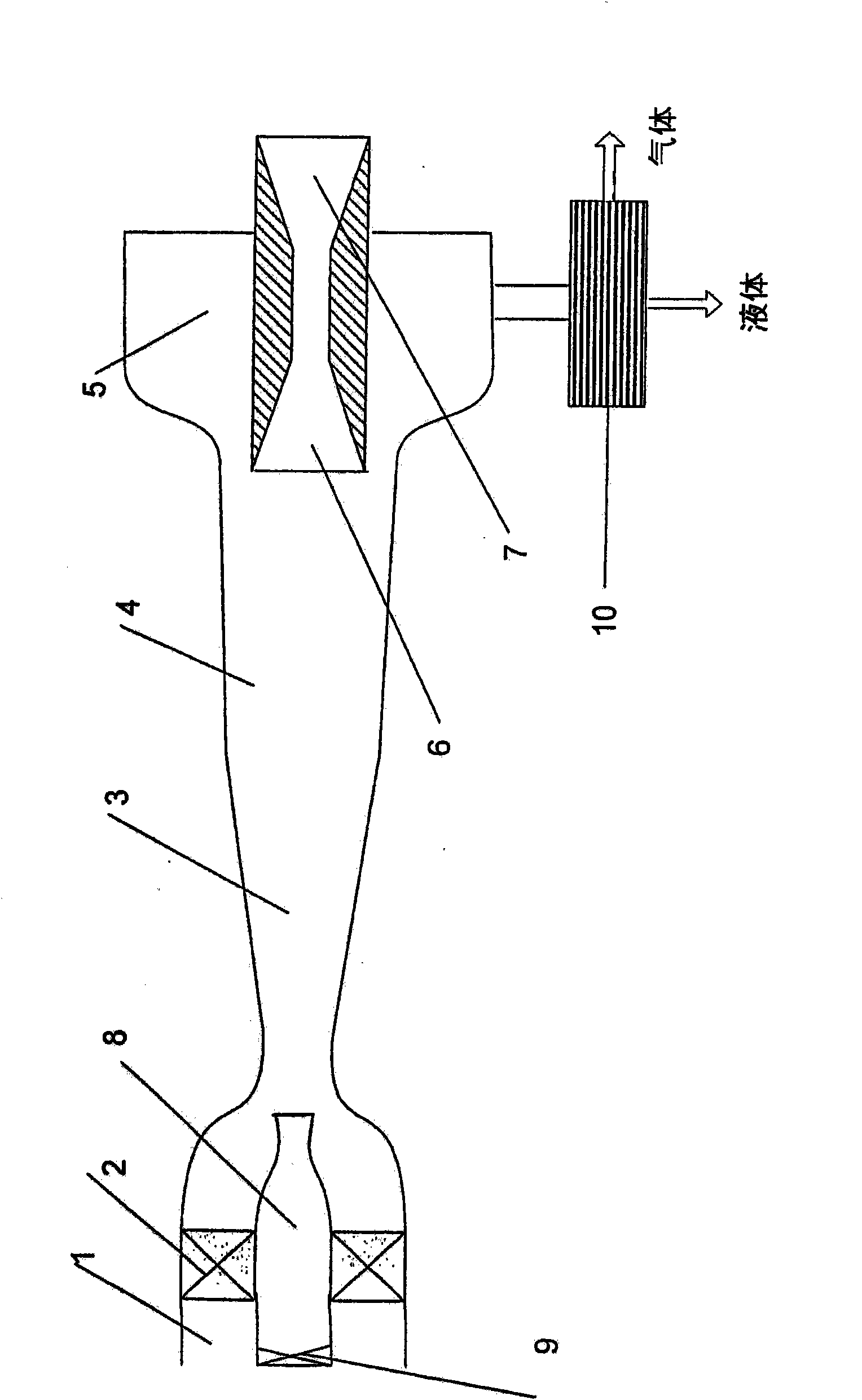

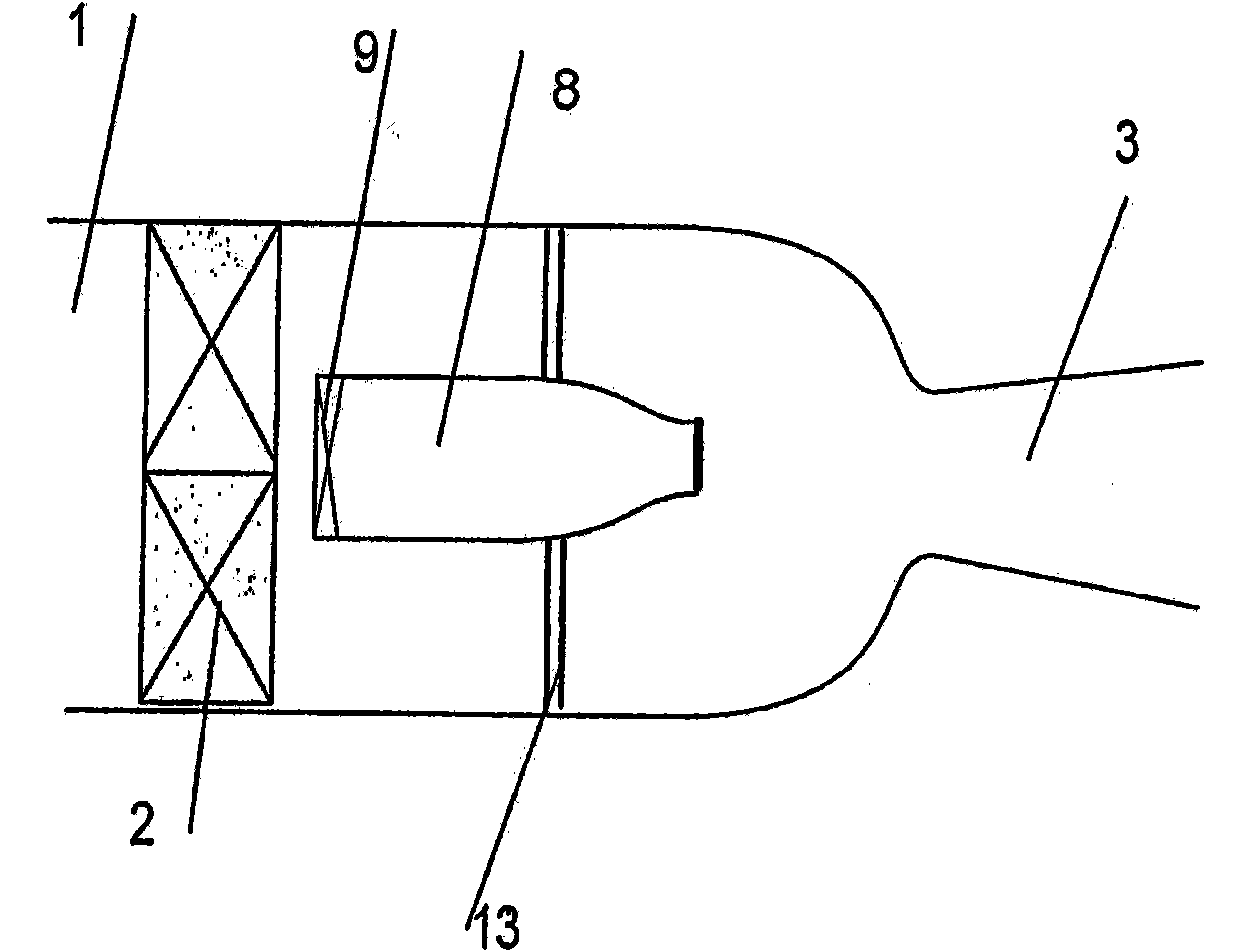

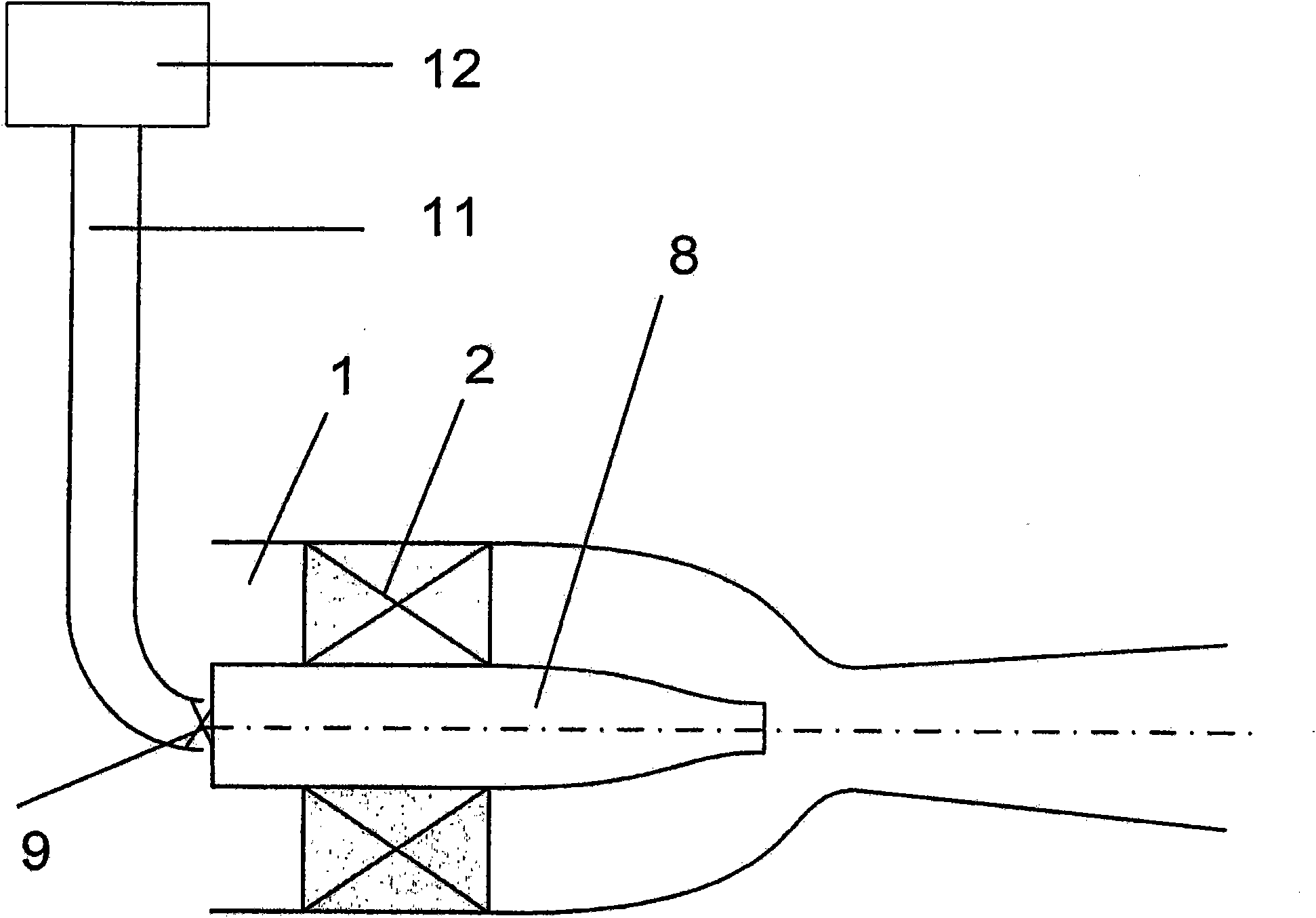

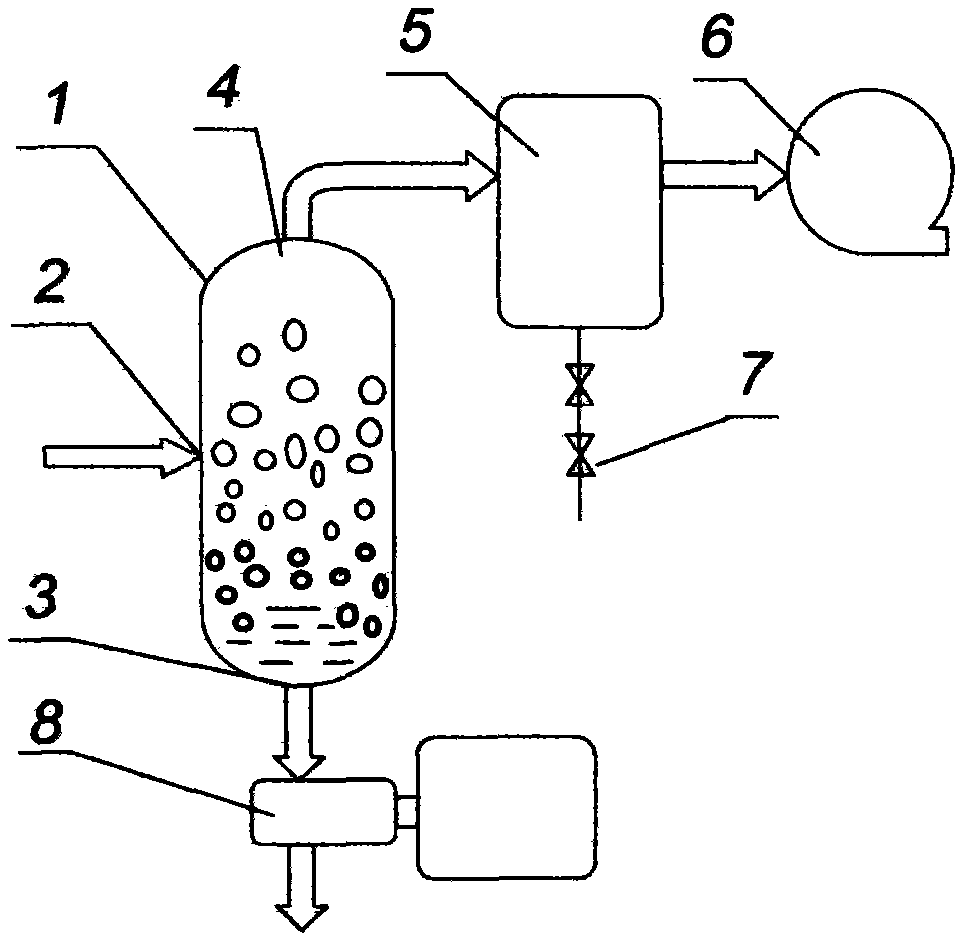

Gas liquefaction and separation device

ActiveCN101828088AReduce pressure differenceImprove equipment efficiencySolidificationVacuum condensationProduct gasEngineering

The invention relates to cryogenic engineering. The inventive device for liquefying and separating gas and for releasing one or more gases from a mixture thereof, comprises, in series axially positioned, a prechamber (1) with gas flow whirling means (2) arranged therein, a subsonic or supersonic nozzle (3) with a working segment (4), which is abutted thereto and to which liquid phase extracting means (5) is connected, and a subsonic diffuser (7) or the combination of a supersonic (6) and the subsonic diffuser (7). The nozzle (3) is designed in such a way that it makes it possible to achieve the ratios, between the inlet and outlet cross-sectional areas and the minimum cross-section thereof, which provides, at the output of the nozzle, a statical pressure and a statical temperature corresponding to the conditions of condensation of gas or target gas mixture components. The length of the working segment (4) is selected according to a condition of forming condensate drops with a size greater than 0.5 mkm and of drifting them, by centrifugal forces, from the axial area of the working segment to the walls of the drop extracting means, and the aperture angle of the working segment (4) is selected such as to maintain the conditions of condensation of the gas or the target components thereof. The device is provided with an additional nozzle (8) arranged in the prechamber. The invention makes it possible to increase the separation efficiency.

Owner:3S GAS TECH LTD

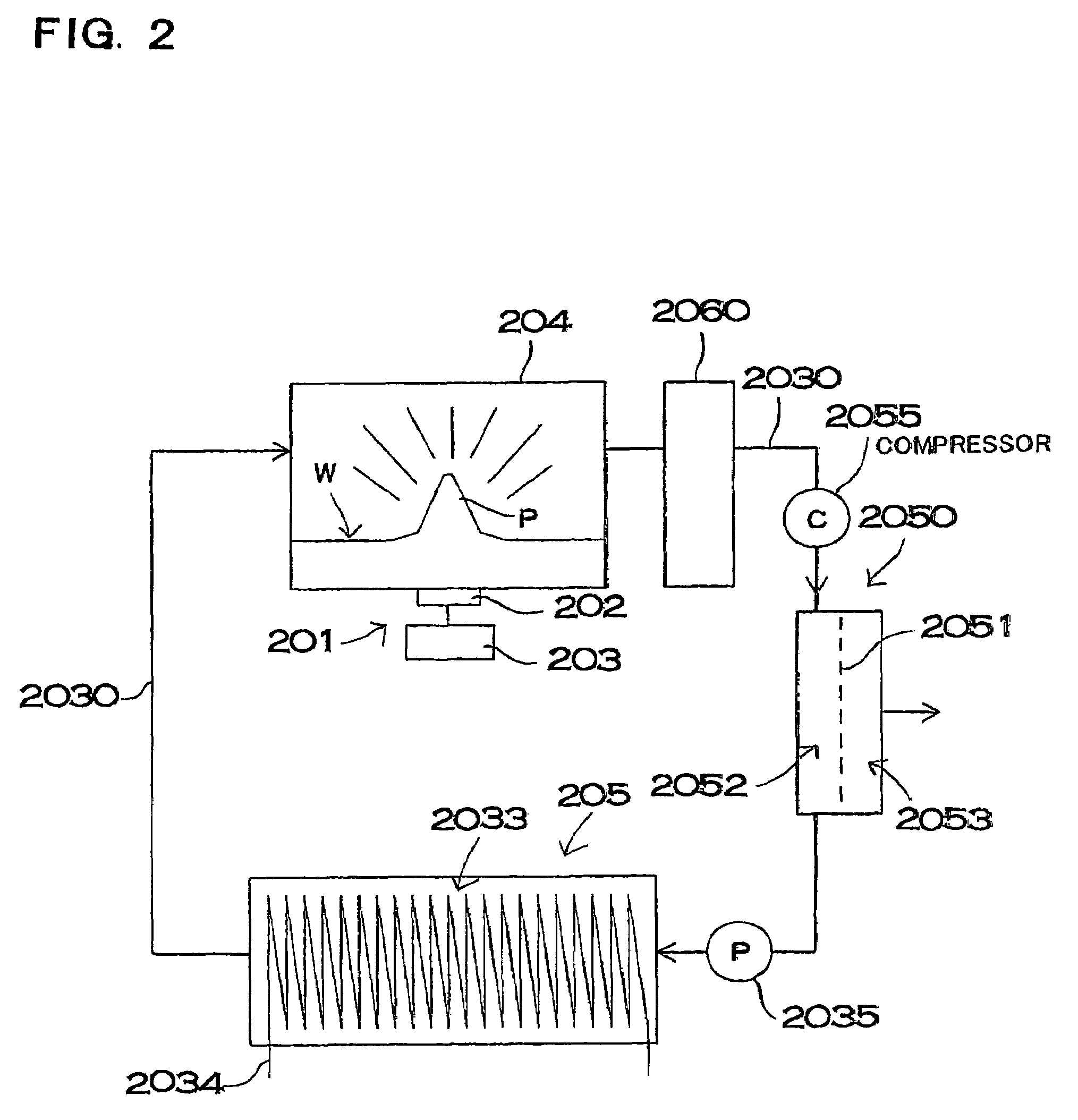

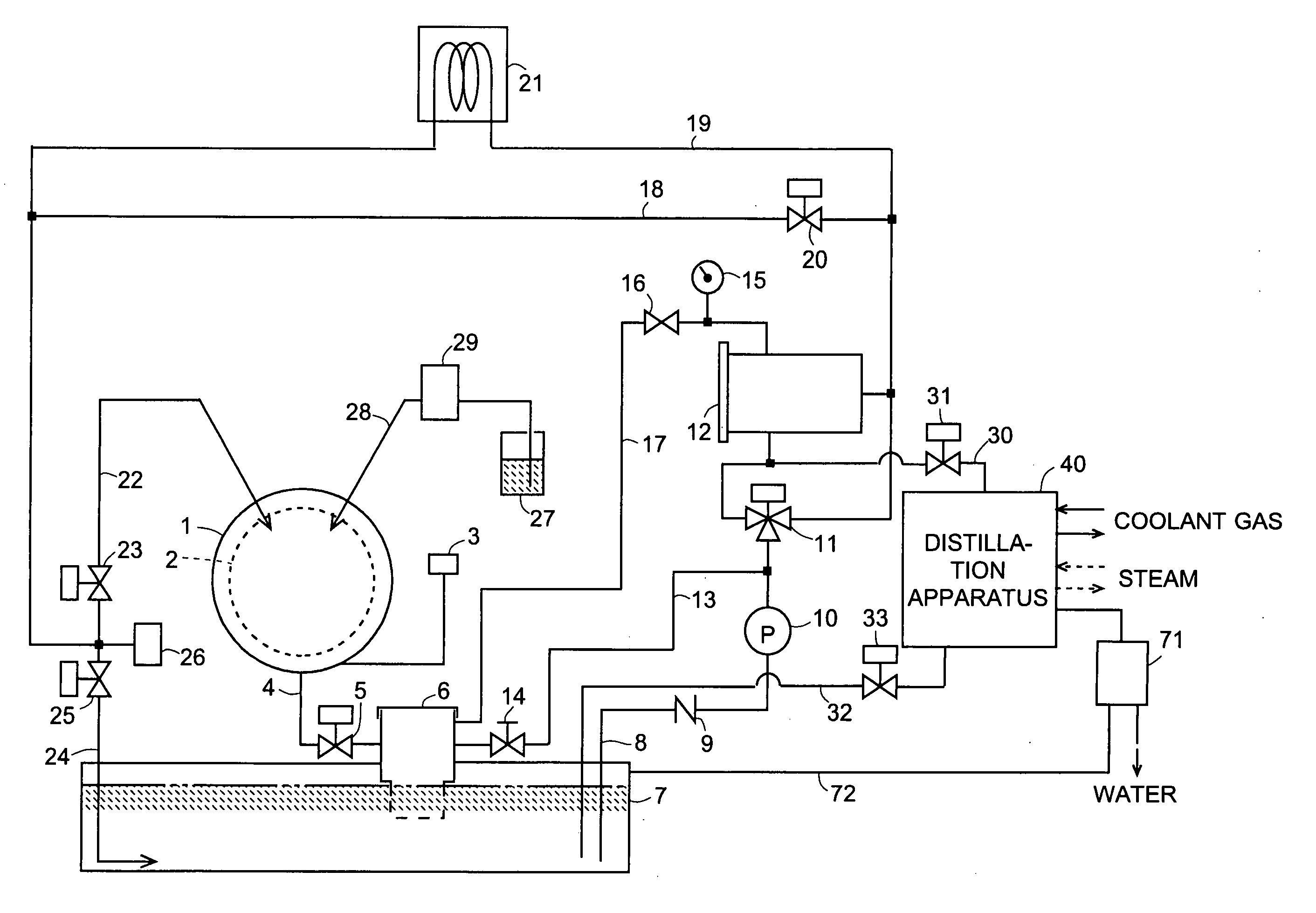

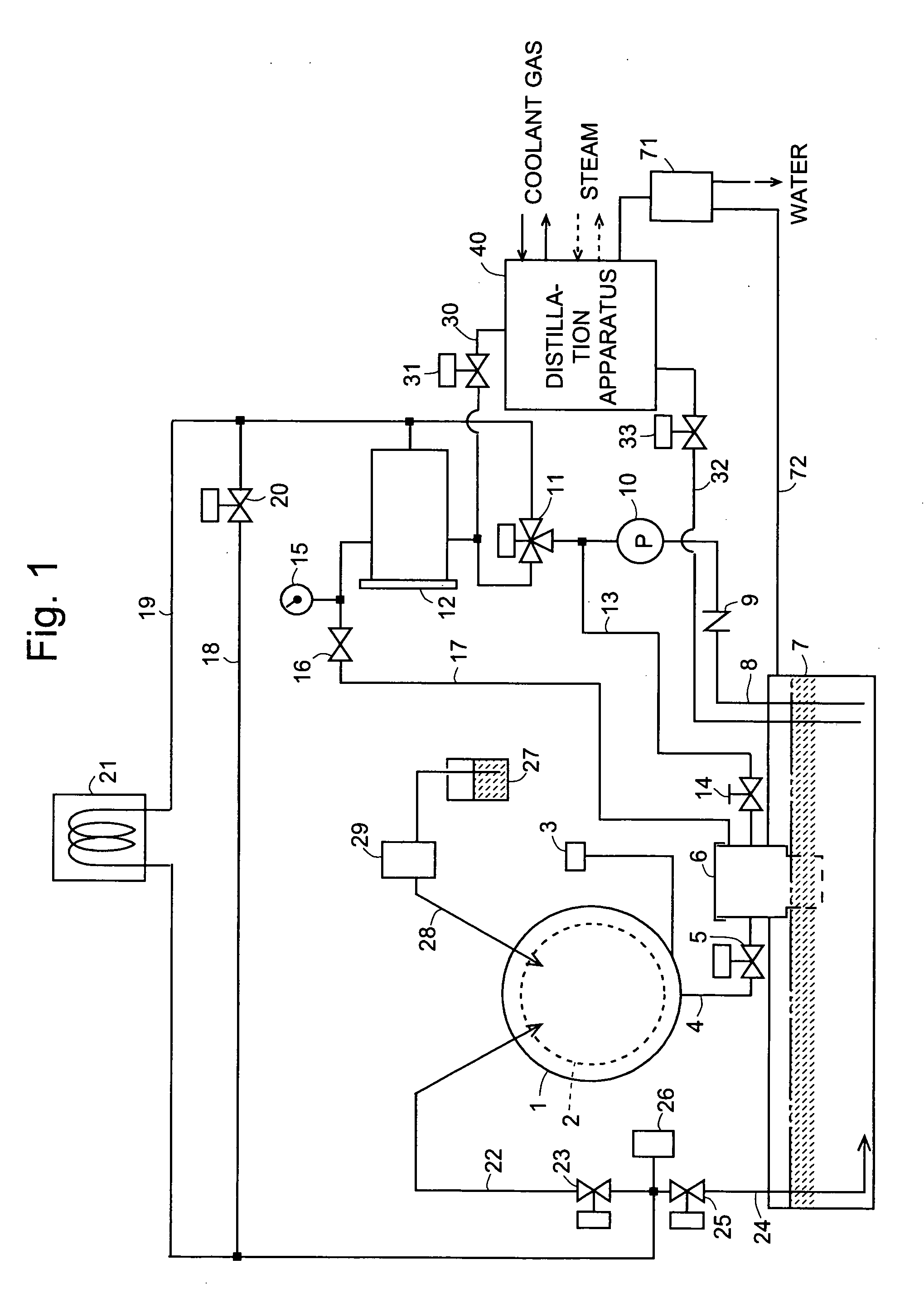

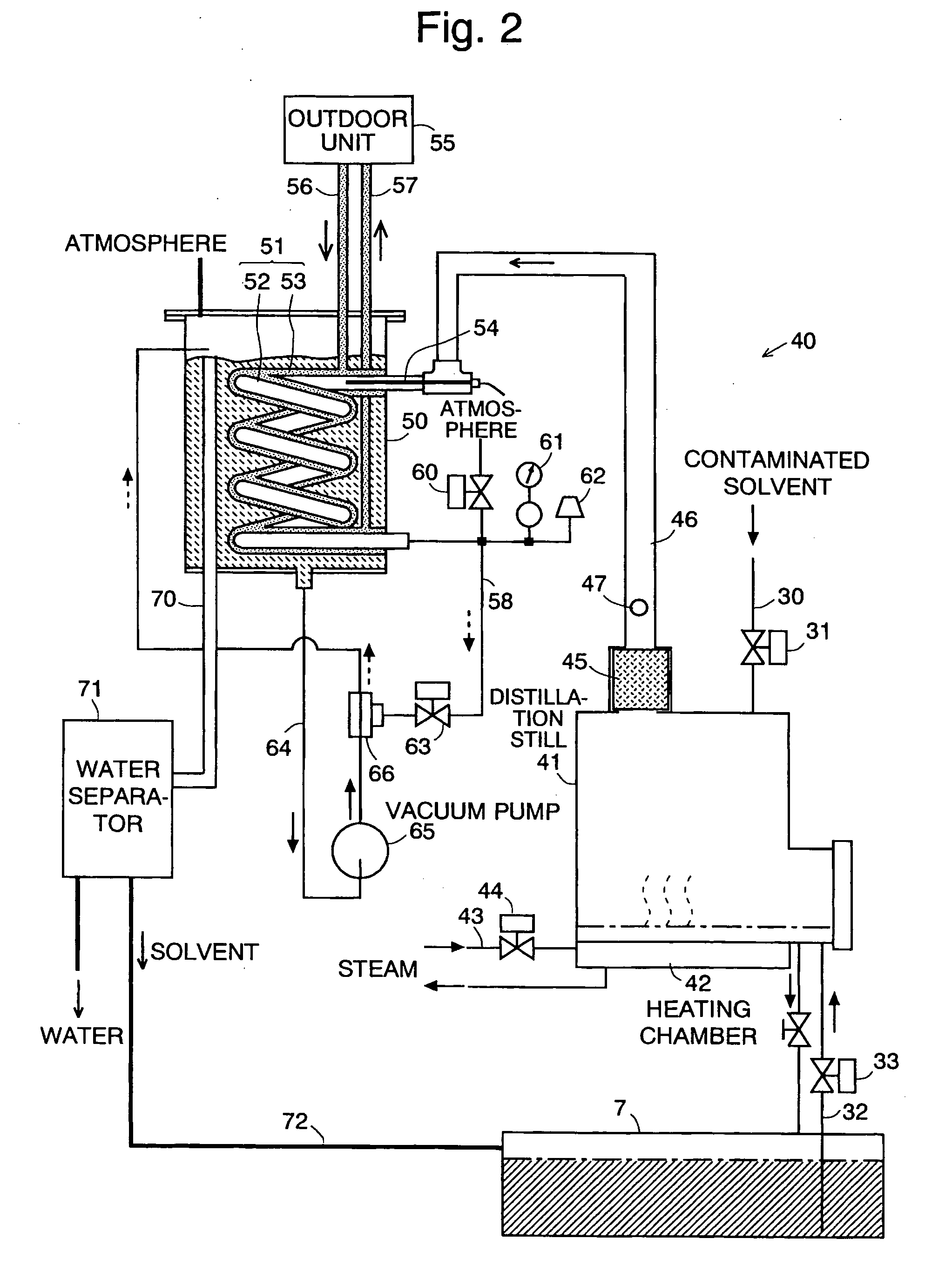

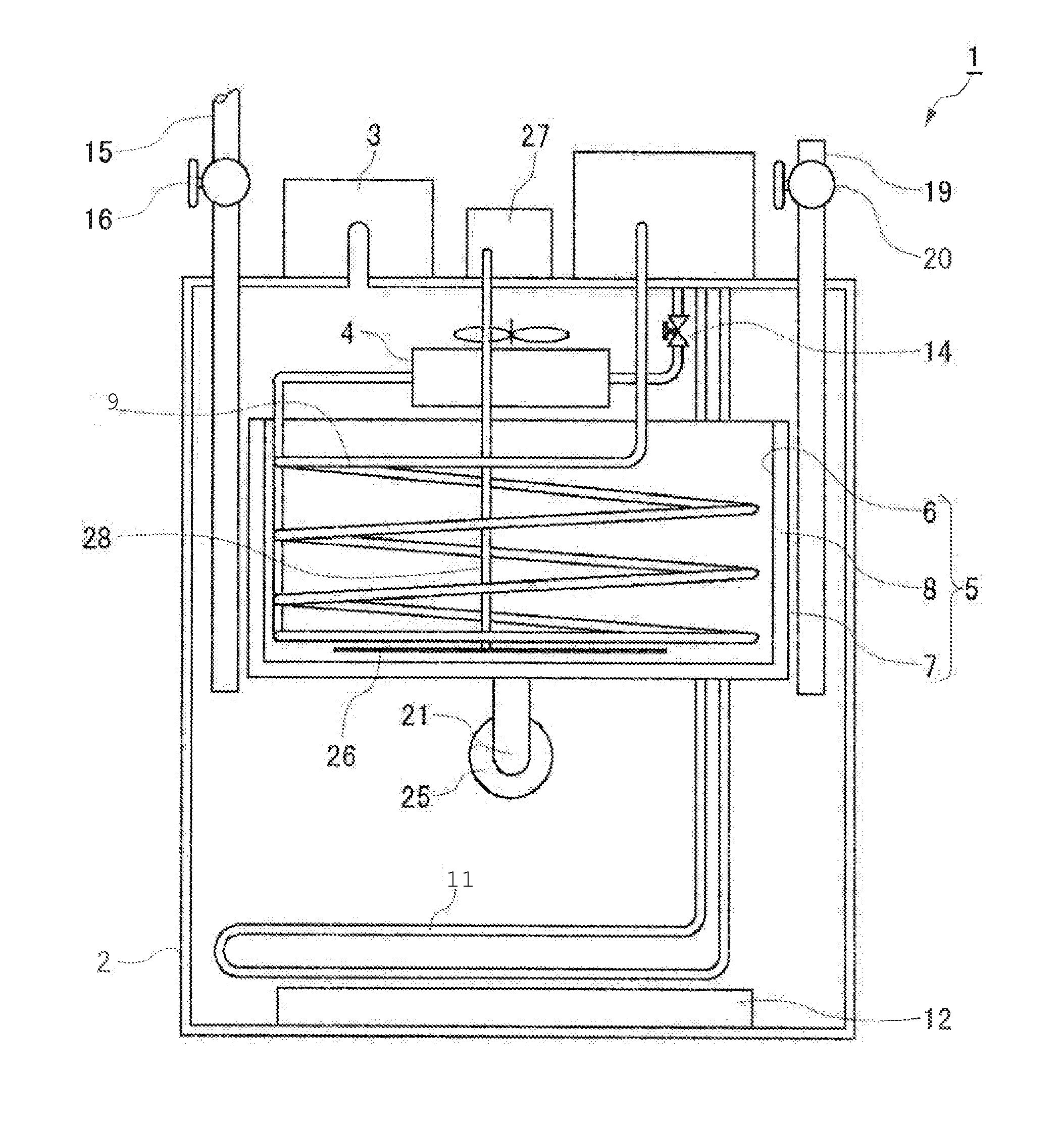

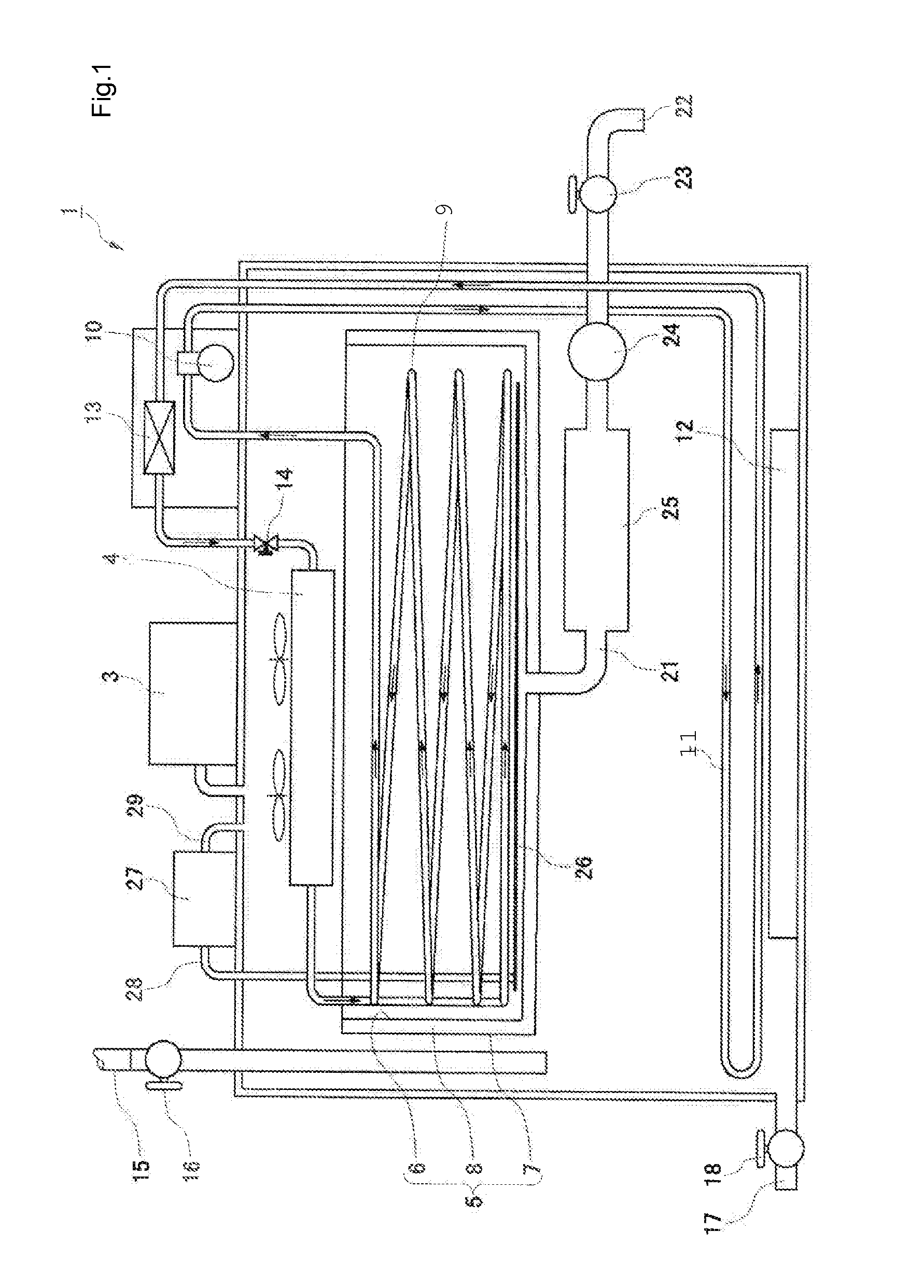

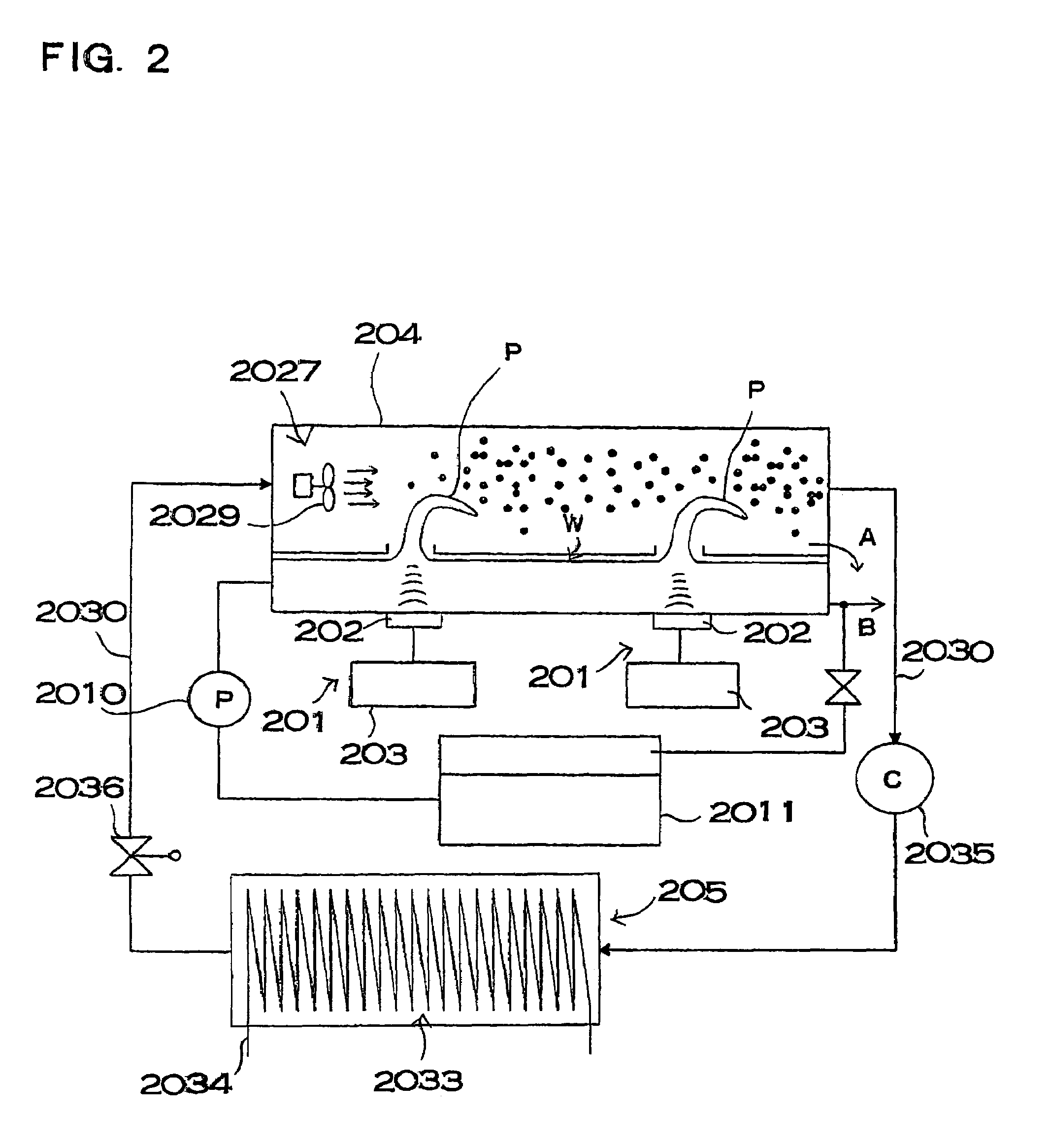

Distillation apparatus

InactiveCN101156994ASpeed up distillationImprove cooling effectVacuum condensationDry-cleaning apparatusSolvent vaporBuffer tank

Owner:SANYO ELECTRIC CO LTD +1

Low-volatile liquid vacuum dehydrating method and device

InactiveCN104069652ASolve the problem of difficult to discharge the vacuum tankReduce volumeVacuum condensationLiquid degasificationWater dischargeProduct gas

Owner:王文兵

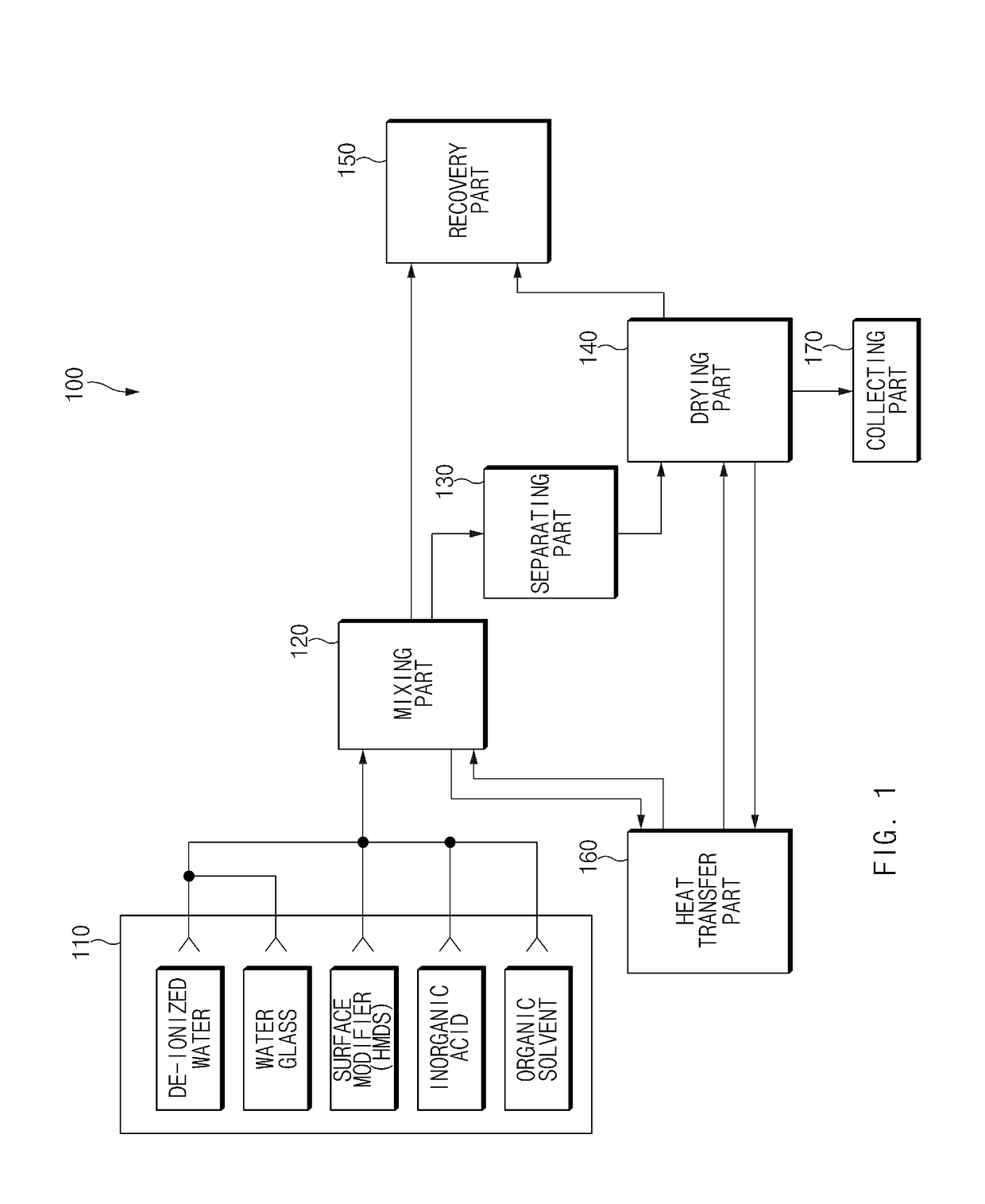

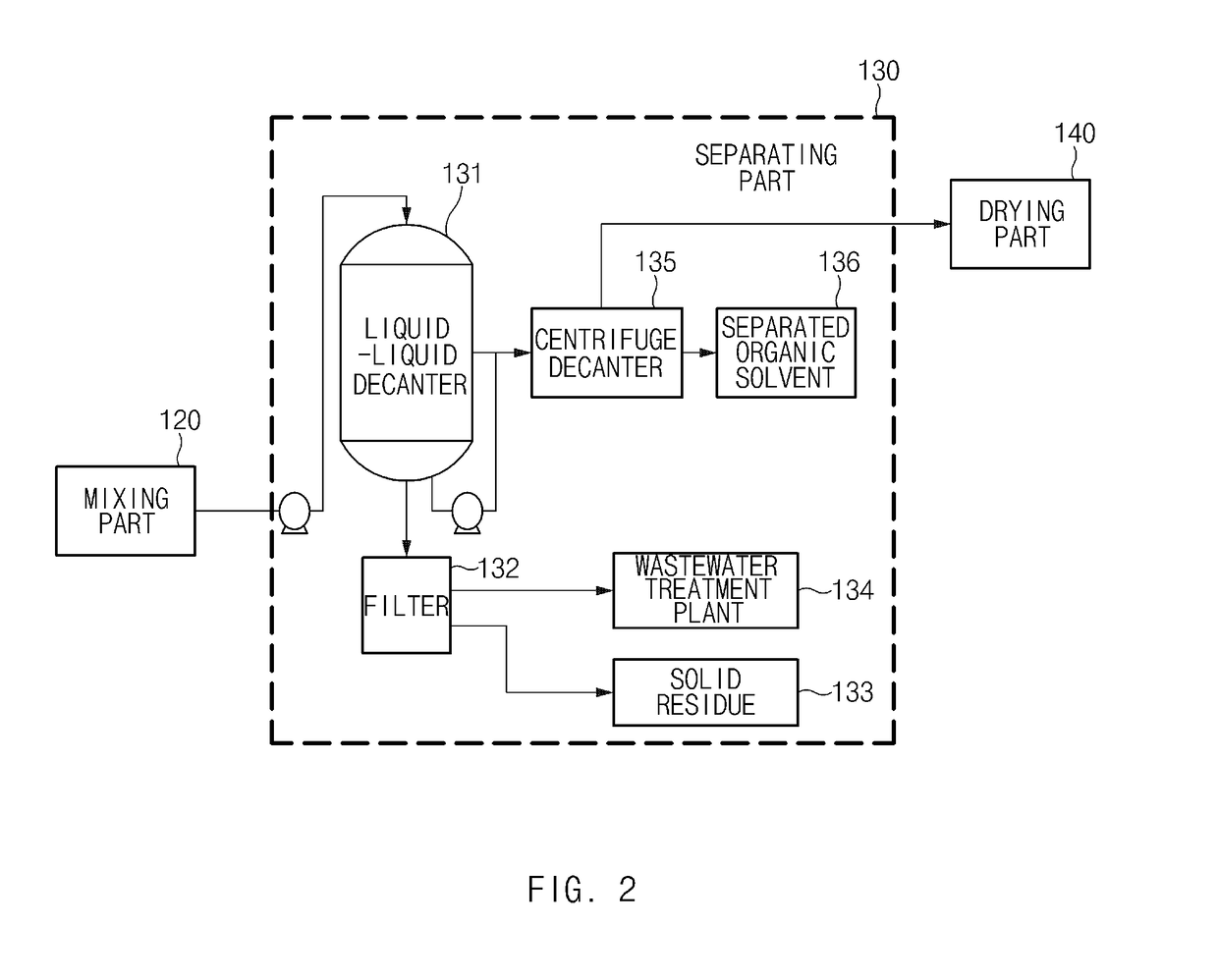

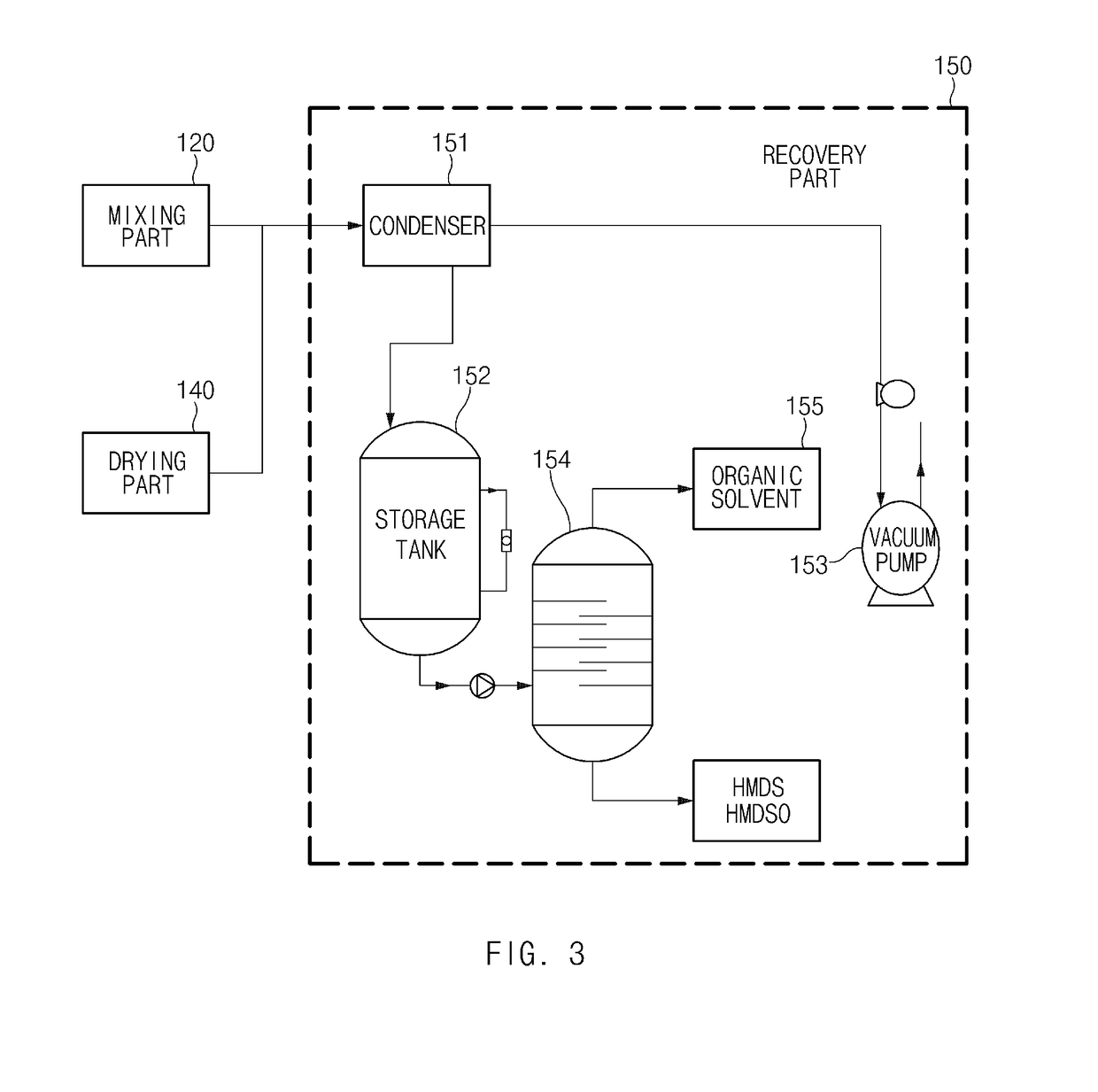

System for preparing silica aerogel

ActiveUS20180370809A1High recovery rateReduce energy costsVacuum condensationWater/sewage treatment by flocculation/precipitationOrganic solventSilica gel

The system for preparing silica aerogel comprises a raw material supply part transferring at least one raw material of de-ionized water, water glass, a surface modifier, an inorganic acid, and an organic solvent to a mixing part, the mixing part mixing the raw materials transferred from the raw material supply part to produce silica wet gel, a separating part separating at least one raw material of the raw materials from the mixture containing the silica wet gel transferred from the mixing part, a drying part drying the silica wet gel transferred from the separating part to produce the silica aerogel, a recovery part recovering a portion of the vaporized raw material of the raw materials used in at least one of the mixing part and the drying part, and a heat transfer part transferring heat to at least one of the mixing part and the drying part.

Owner:LG CHEM LTD

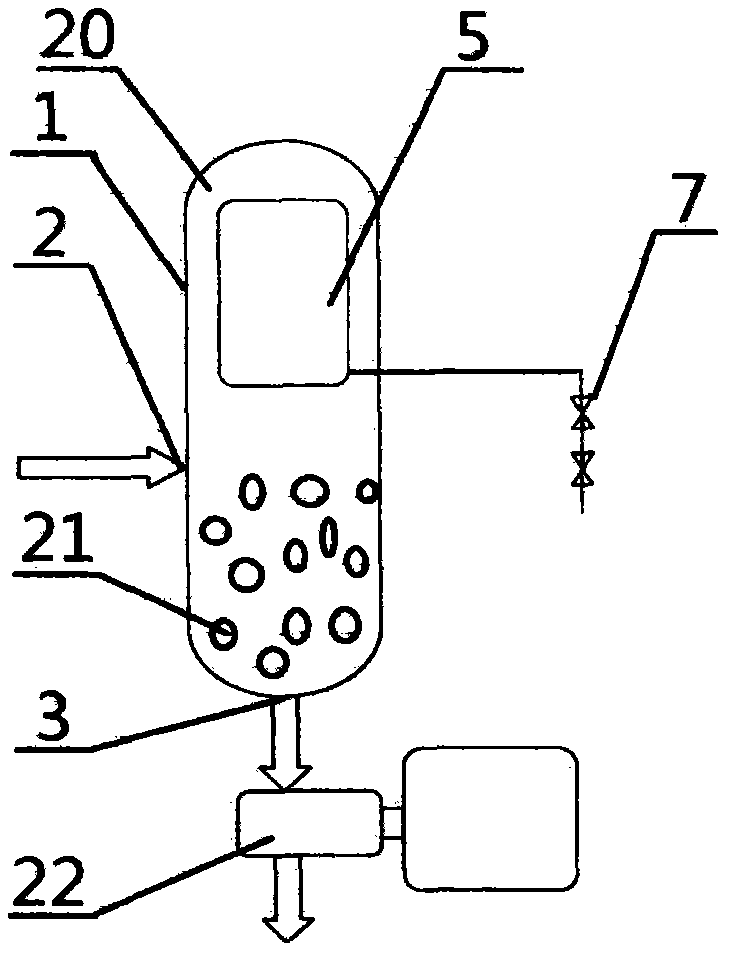

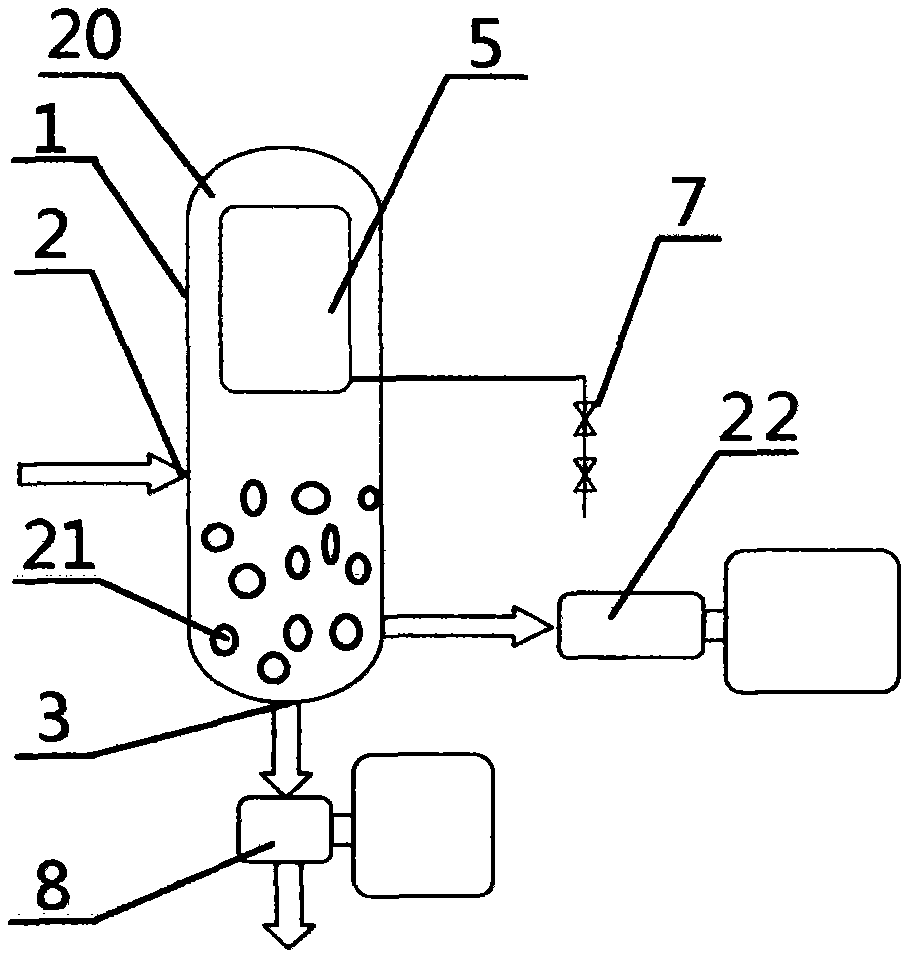

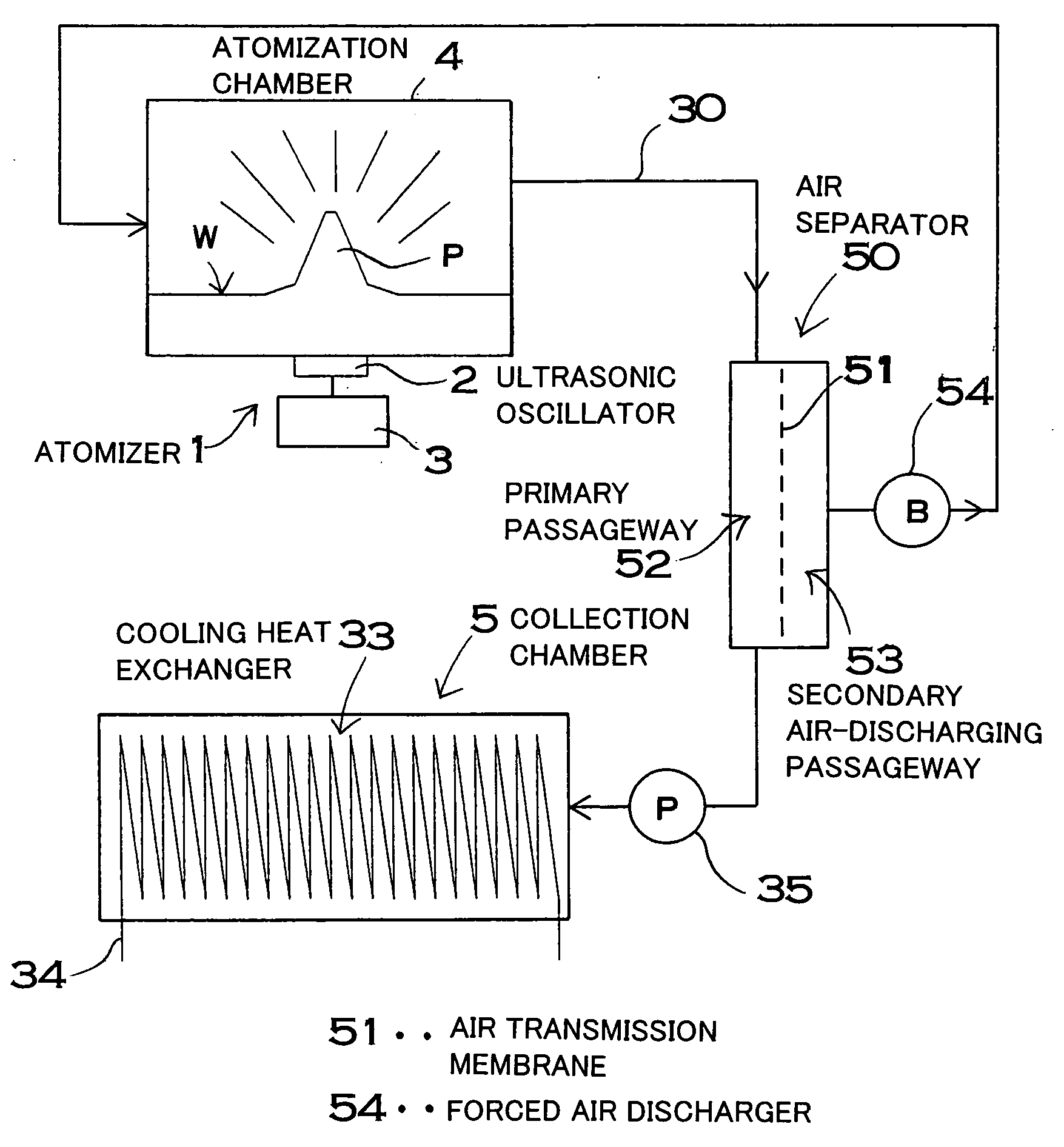

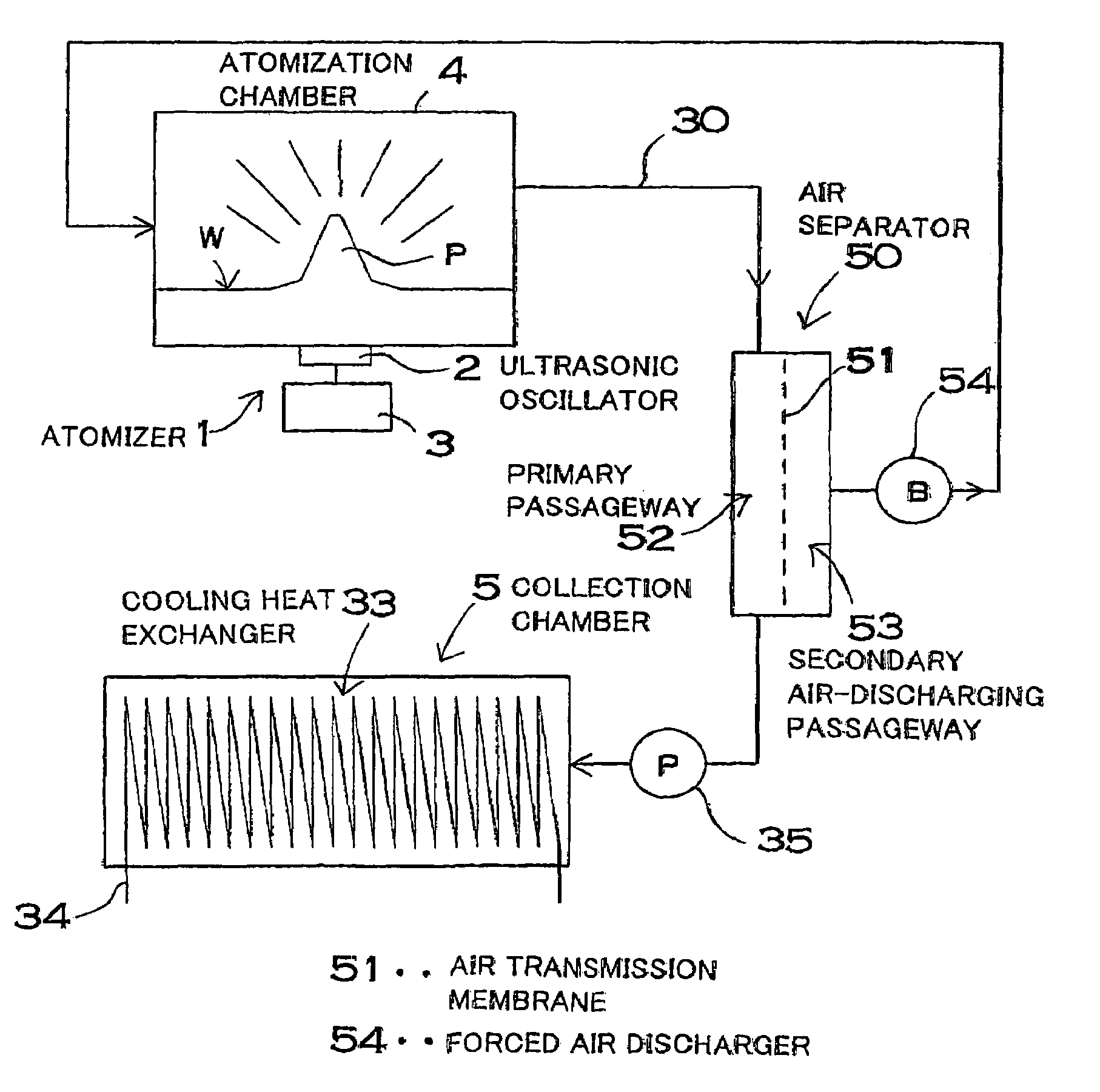

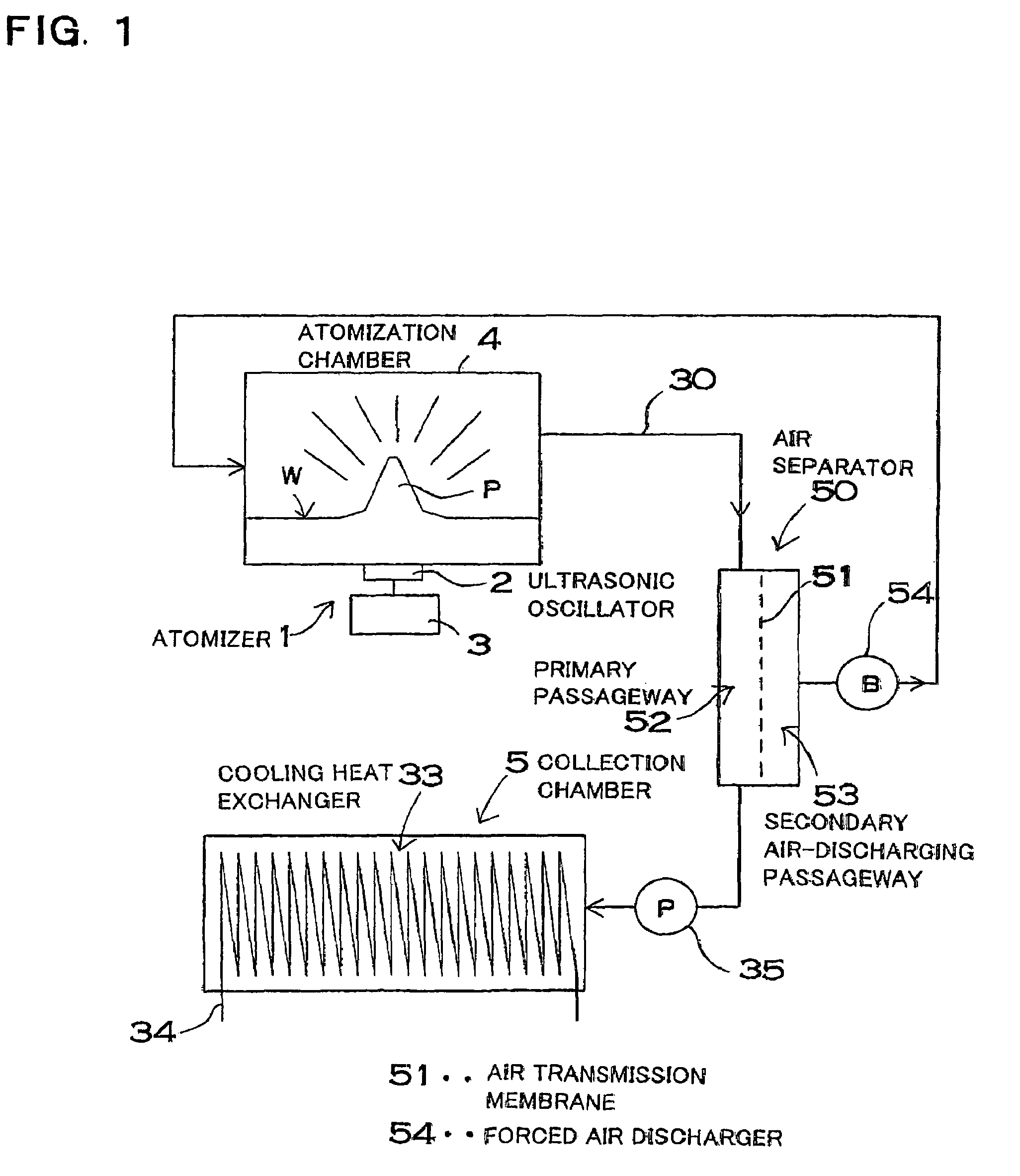

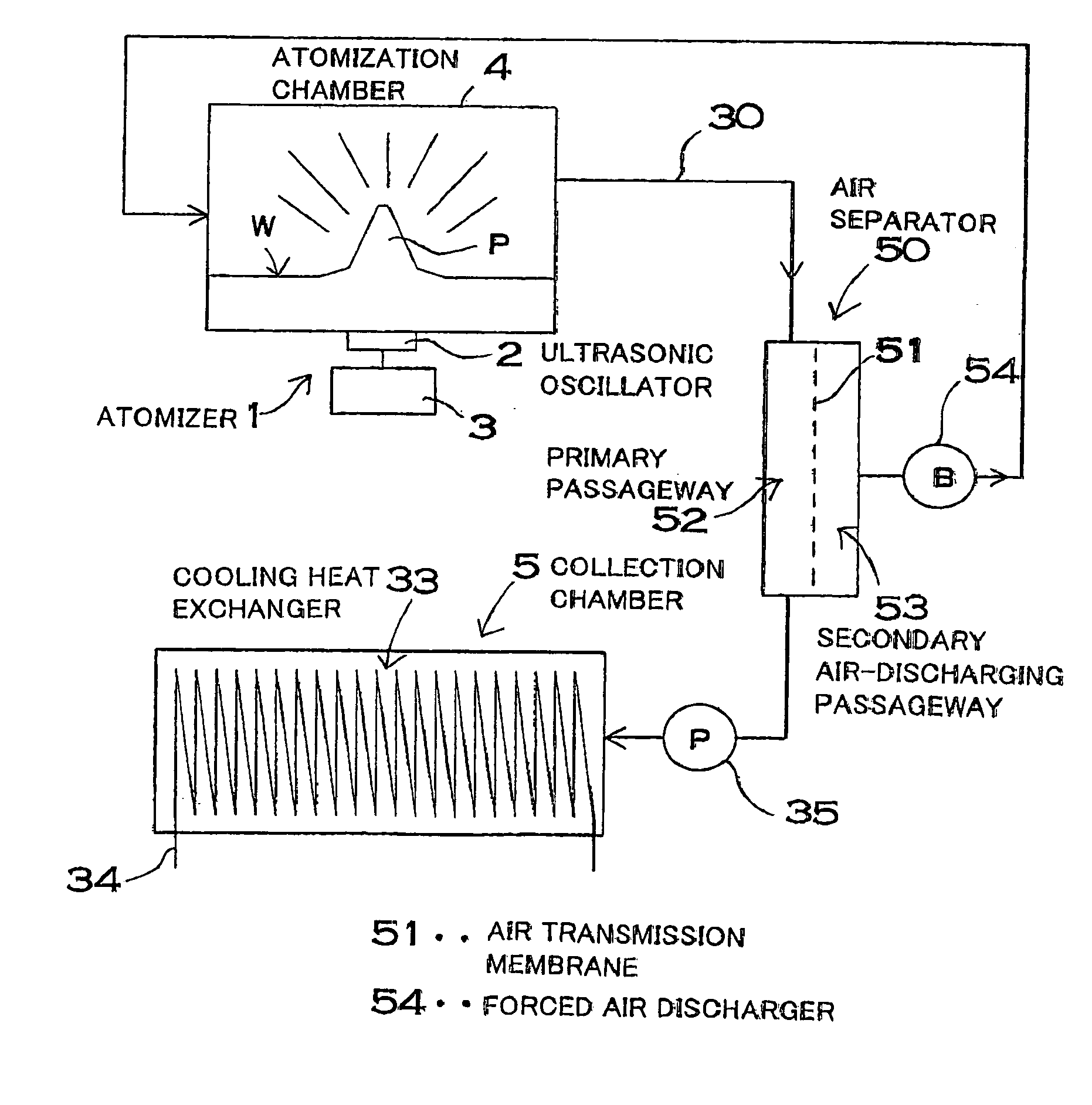

Method and apparatus for separating a solution

InactiveUS20080202333A1Improve efficiencyEfficiently atomizedThermo-electric condensationVacuum condensationProduct gasEngineering

In the present invention, a solution containing a target substance is atomized into a mist in an atomizer 1 to produce a mixed fluid of mist and gas. In the collection of the mist from this mixed fluid, a gas transmission membrane 51 of a pore size is used that transmits gas but does not transmit the target substance contained in the mist. In the present invention, the mixed fluid is brought into contact with the primary surface of the gas transmission membrane 51, and the pressure on the primary surface is made higher than the pressure on the secondary surface of the opposite side, whereby the gas in the mixed fluid is let to pass through the gas transmission membrane 51 to separate part or all of the gas contained in the mixed fluid.

Owner:ULTRASOUND BREWERY

Method and apparatus for separating a solution

InactiveUS7357334B2Improve efficiencyEfficiently atomizedThermo-electric condensationVacuum condensationEngineering

Owner:ULTRASOUND BREWERY

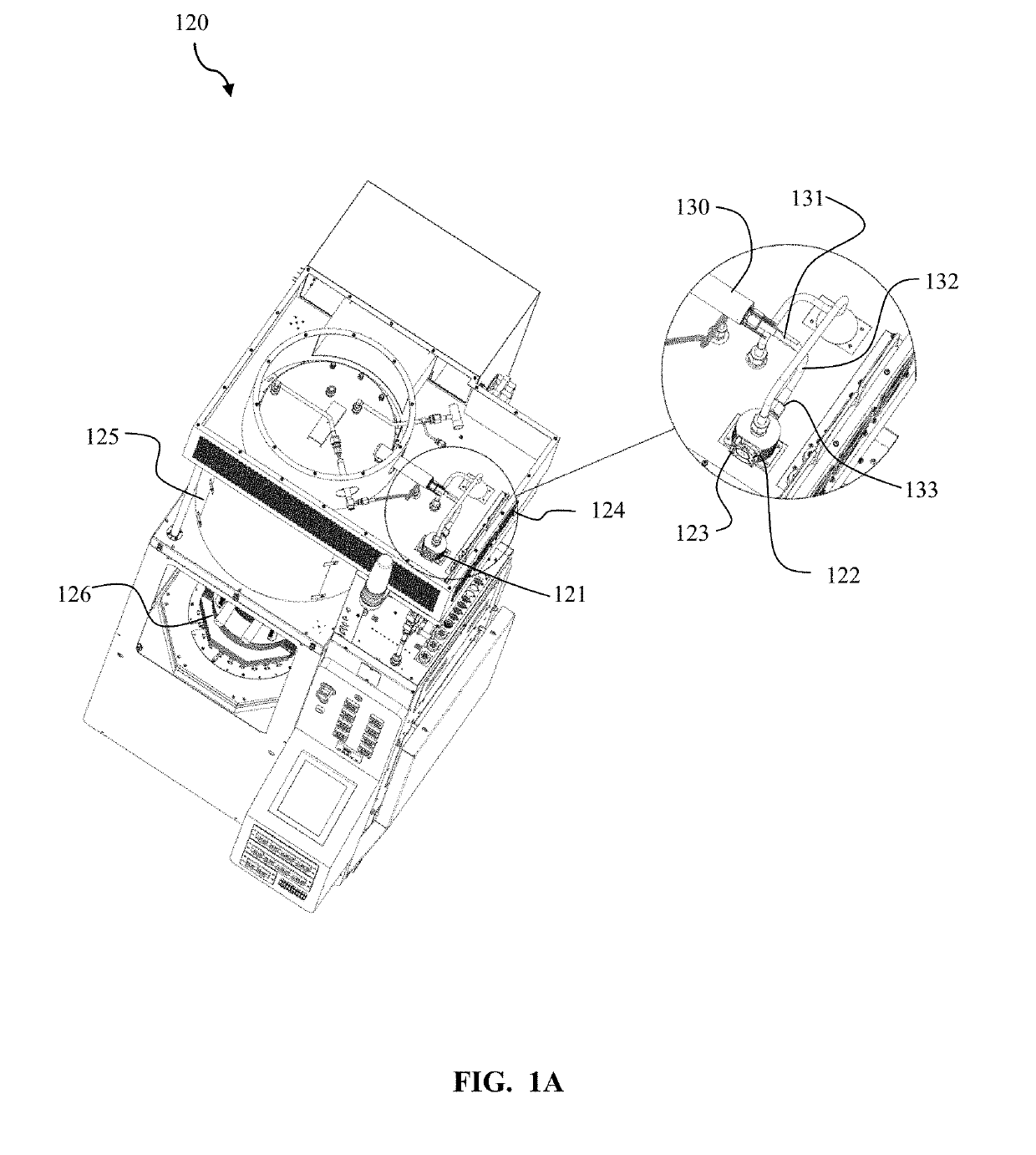

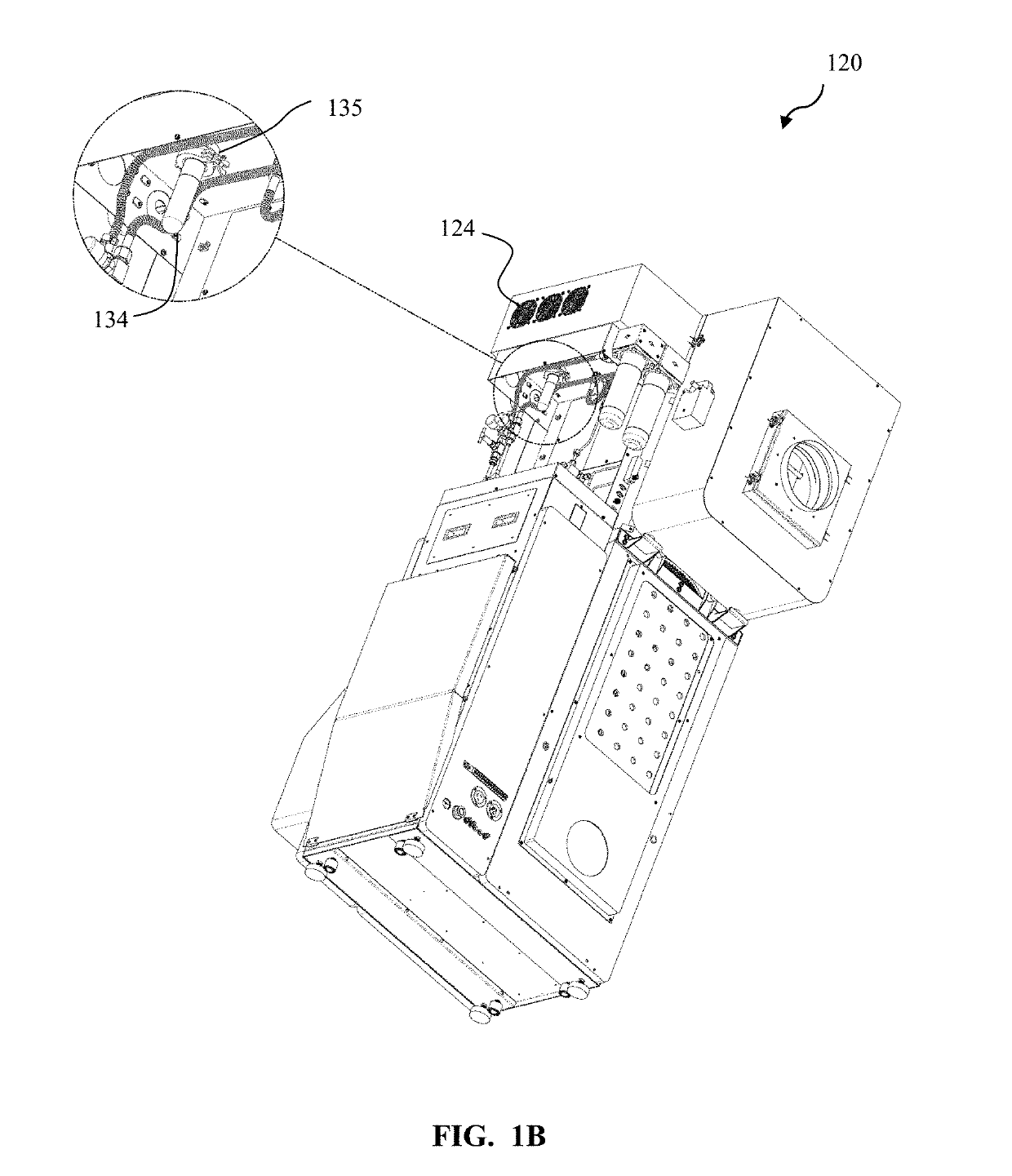

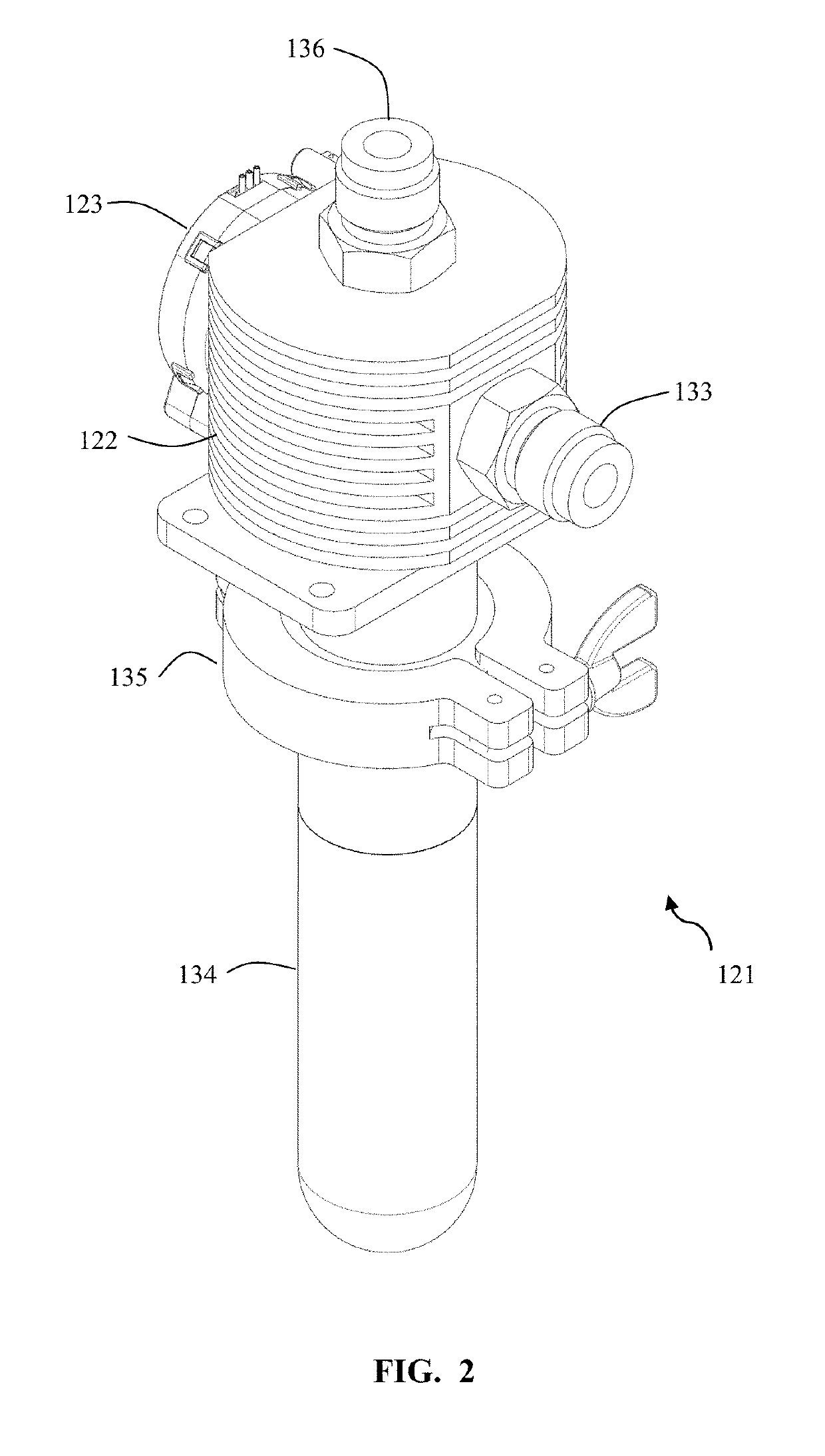

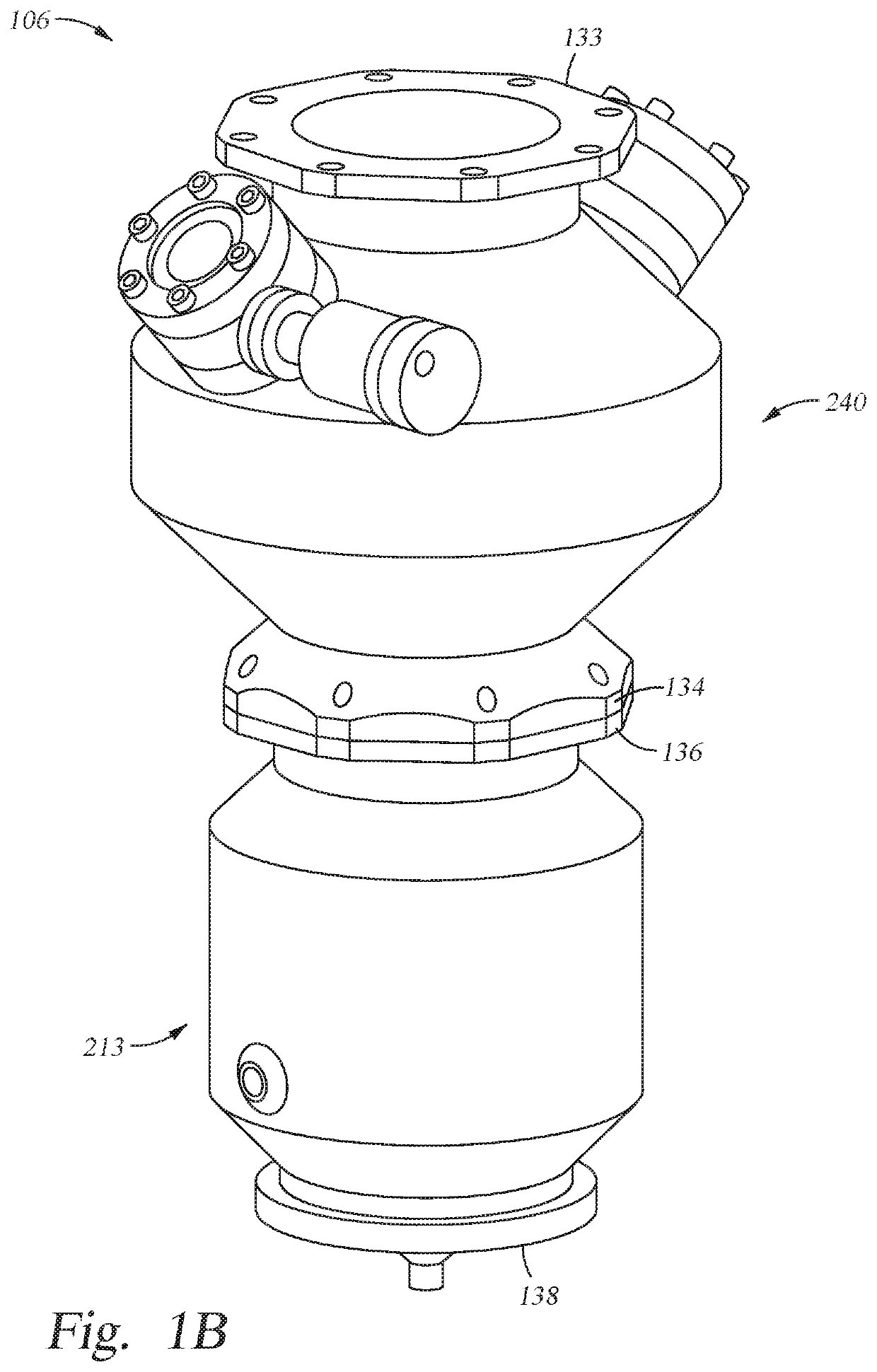

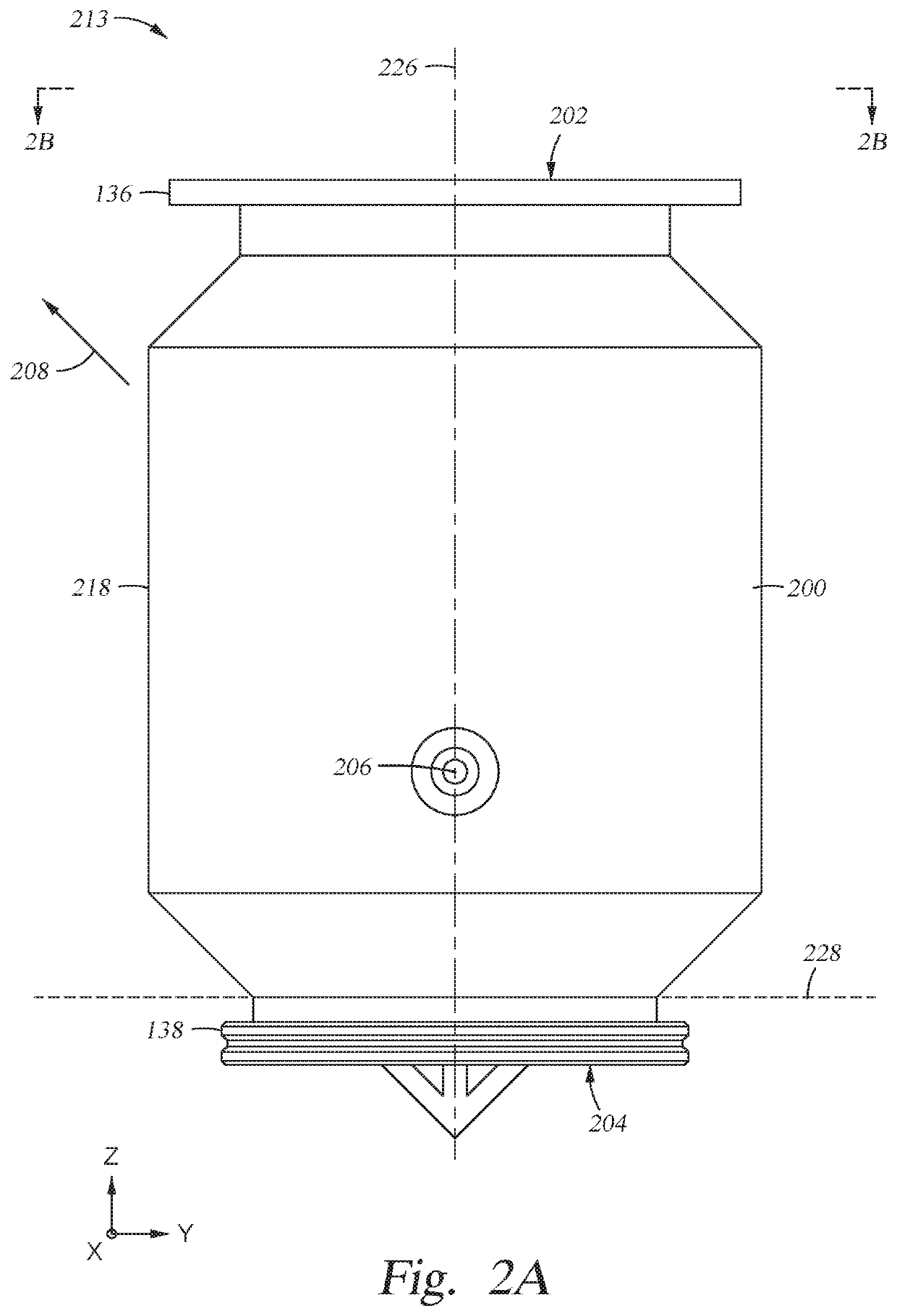

Trap assembly and system for trapping polymer vapors in process oven vacuum systems

A trap system adapted to trap polyimide or other vapors exiting from a process chamber. The vapors are routed from the process chamber through a heated exit line at low pressure and then cooled, resulting in condensation at a selected location. The condensed vapors accumulate in a liquid trap. A method of condensing polymer vapors in vacuum exit lines of process chambers, where the flow which may have vaporized polymer vapor is cooled to enhance condensation at a chosen location. The liquid trap can be emptied and replaced, resulting in the removal of the condensed liquid. The chamber exit lines are protected from condensation build up.

Owner:YIELD ENG SYST INC

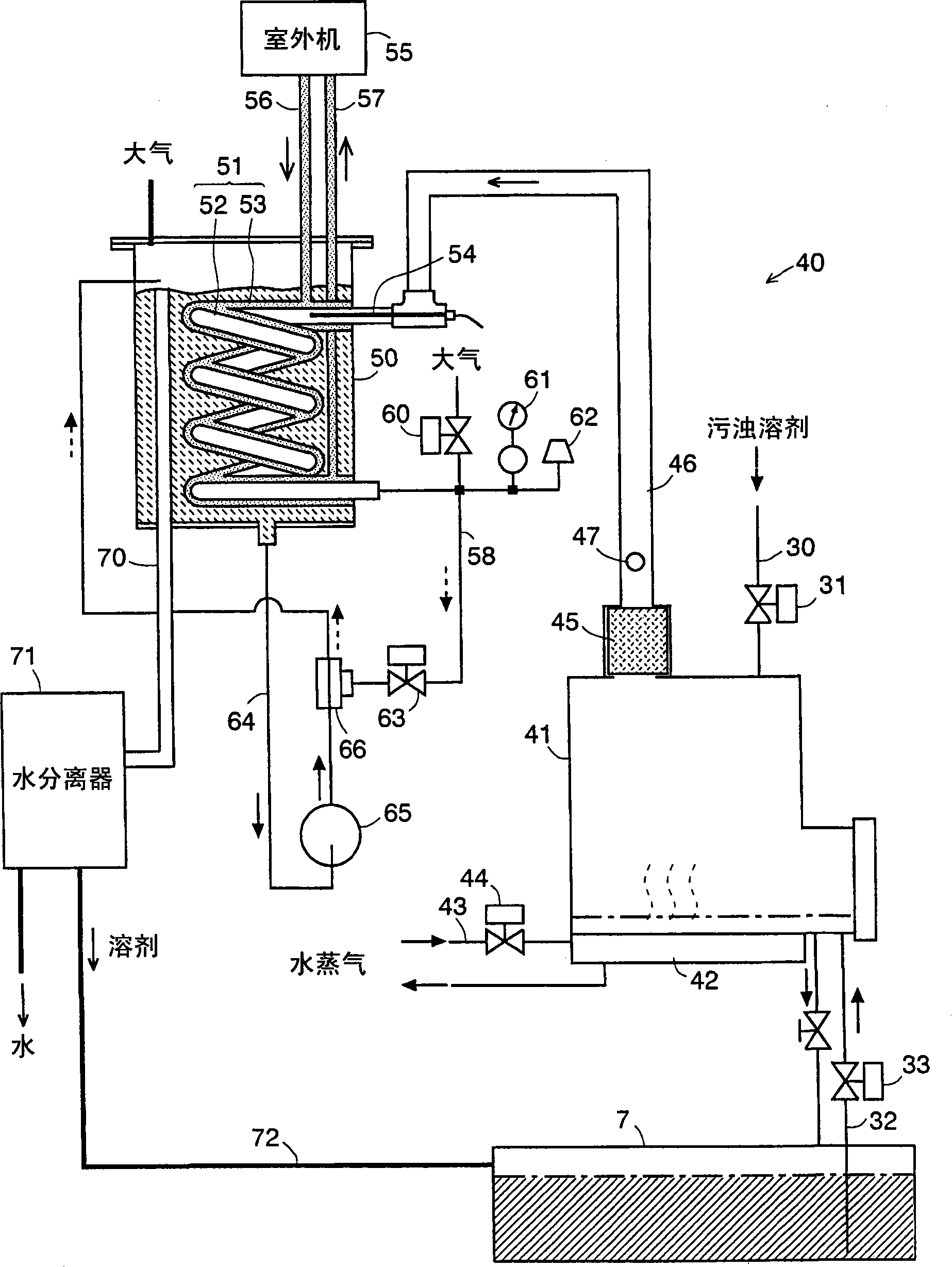

Distillation apparatus

ActiveUS20090283398A1Improve cooling effectPrevent rustVacuum condensationDry-cleaning apparatusDouble tubeSolvent vapor

A spiral double-tube structure including an inner tube for introducing a solvent vapor resulting from vaporization within a distillation still and an outer tube which a coolant gas cooled by an outdoor machine is passed through is disposed in a buffer tank; the solvent vapor is directly cooled from the surrounding area by the coolant gas with a large temperature difference and thus condensed into a liquid state; by means of an ejector, the liquid is mixed with the solvent suctioned from the buffer tank and returned into the buffer tank; since the solvent in the buffer tank is also directly cooled by the coolant gas, the cooling efficiency is high; accordingly, both the solvent vapor generated from the distillation still and the solvent in the buffer tank for reducing the pressure inside the distillation still can be efficiently cooled without using cooling water, and downsizing of the apparatus can also be attained.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Method and apparatus for separating a solution

InactiveUS20050218241A1Efficient collectionReduce energy consumptionThermo-electric condensationVacuum condensationPore diameterMembrane configuration

Owner:ULTRASOUND BREWERY

Method and device for producing a pure liquid from a crude liquid

InactiveCN1729037AHigh outputDesign freedomVacuum condensationGeneral water supply conservationSaline waterPhysical chemistry

When fresh water is produced from salt water or similar by evaporation of untreated or crude liquid in an evaporation device under partial vacuum and by vapour condensation in a condensation device connected with the vapour outlet of the evaporation device a high degree of evaporation and cost effectiveness can be obtained in that the evaporation device and the condensation device in a disconnected condition, are filled with crude or clean liquid, respectively, and are subsequently exposed to a partial vacuum created by volume enlargement under hermetically sealed conditions and that the evaporation device and the condensation device are not flow-connected with each other until they are under partial vacuum.

Owner:KBH ENGINEERING GMBH

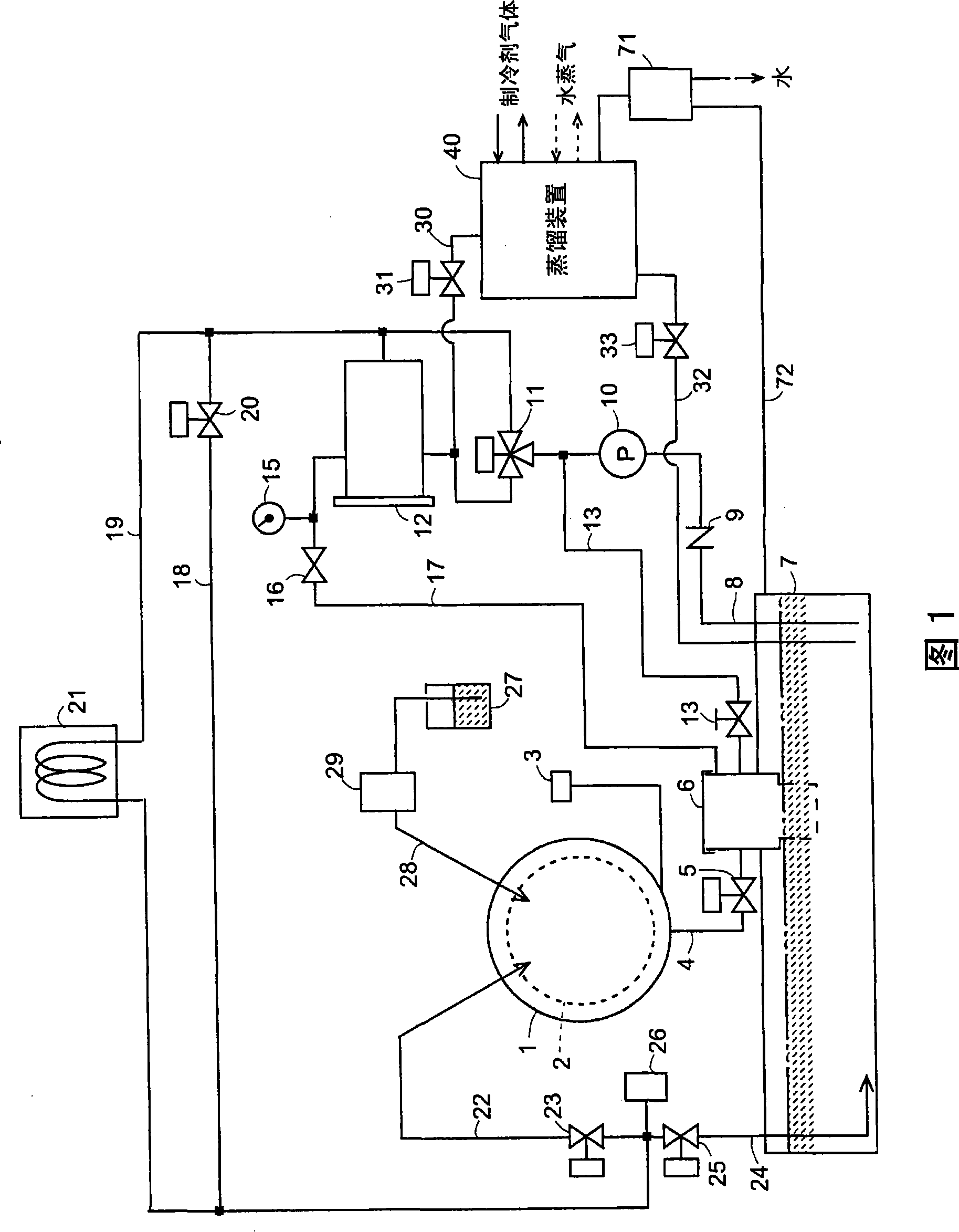

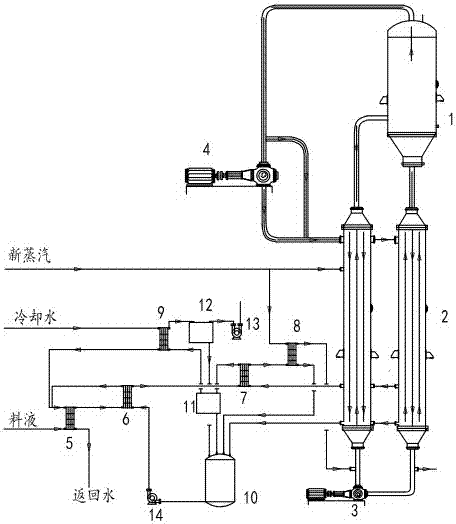

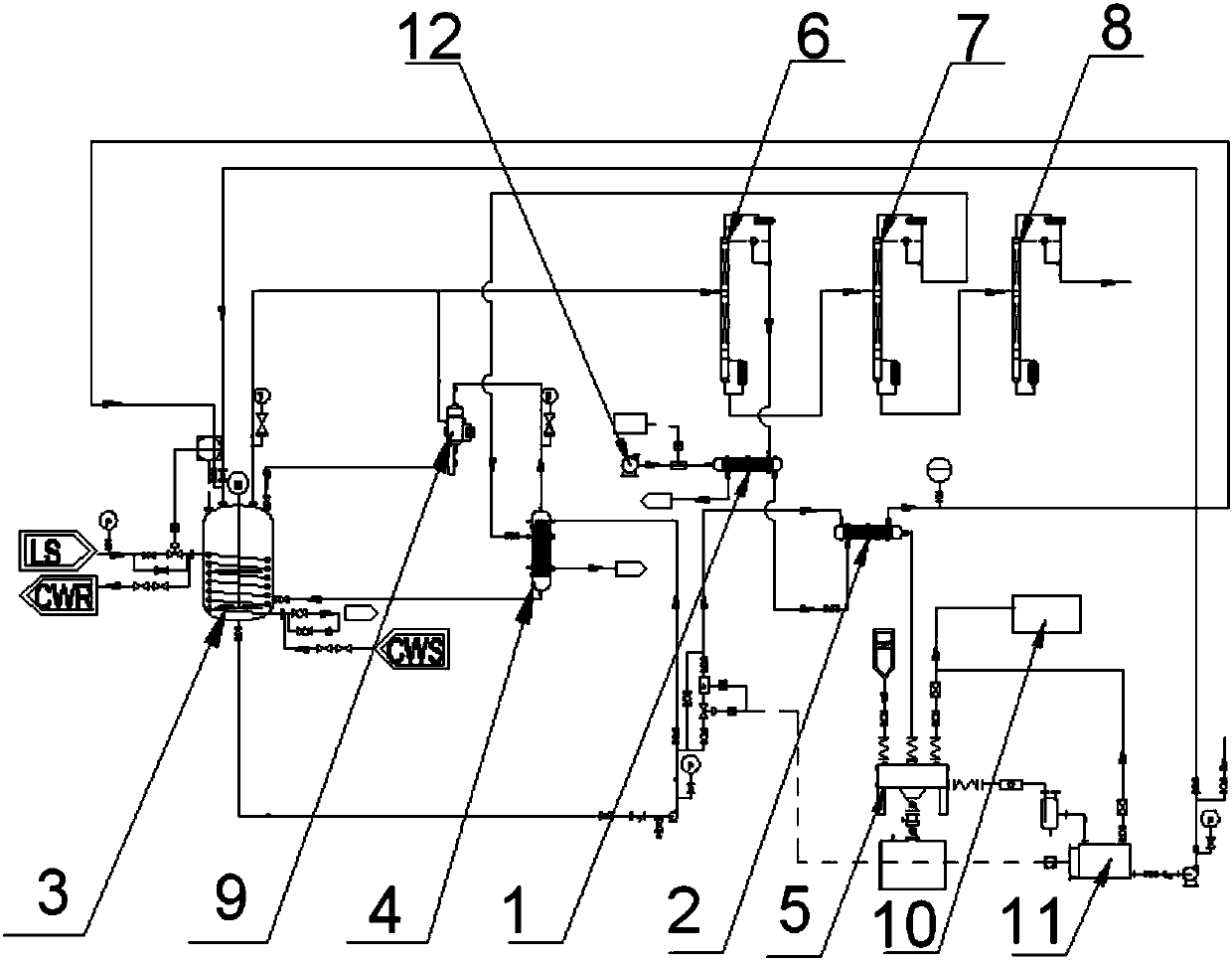

Cobaltous sulfate solution evaporation system and process thereof

ActiveCN107982943AShorten the lengthLow investment costVacuum condensationEvaporation with vapour compressionVapor–liquid separatorEvaporation

The invention discloses a cobaltous sulfate solution evaporation system and a process thereof. The evaporation system comprises an evaporation unit, a vacuum unit, a preheating unit and a connecting pipeline, wherein the evaporation unit comprises a separator, a steam compression machine, evaporators and a forced circulation pump; a secondary steam outlet of the separator is directly communicatedwith the evaporators through pipelines and is indirectly communicated with the evaporators through the steam compression machine; the two groups of evaporators are in parallel and are communicated through the circulation pump; the vacuum unit comprises a two-stage condenser, a two-stage gas-liquid separator, a vacuum pump and a condensate tank; the preheating unit comprises four preheaters; a medium heat inlet and a second-level condensation liquid cooling medium outlet of a first-level preheater are connected with a heat medium outlet of a second-level preheater; a medium inlet of the second-level preheater is connected with a condensation liquid tank through a condensation liquid pump; a heat medium inlet of a third-level preheater is connected with non-condensable gas outlets of the evaporators. Compared with an existing evaporation process, the process utilizing the system for evaporating a cobaltous sulfate solution has the advantages of high heat recovery rate, high continuity and low investment cost.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

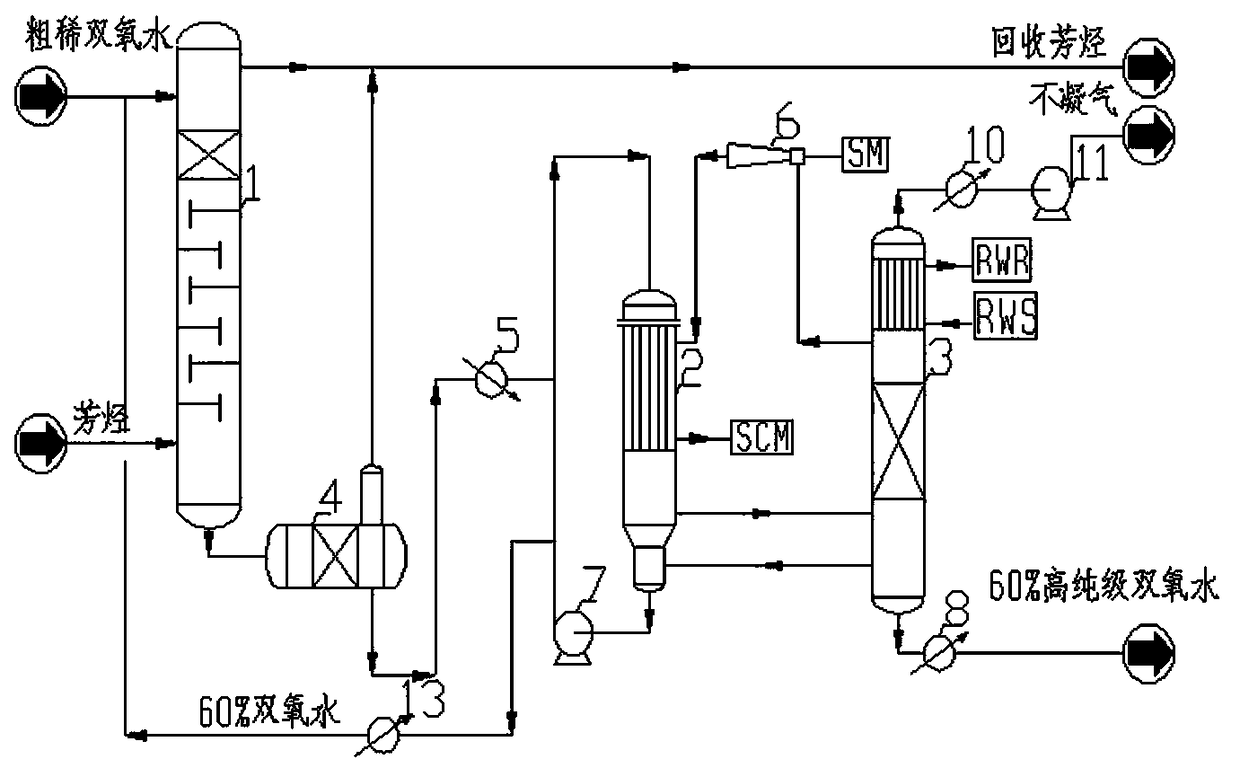

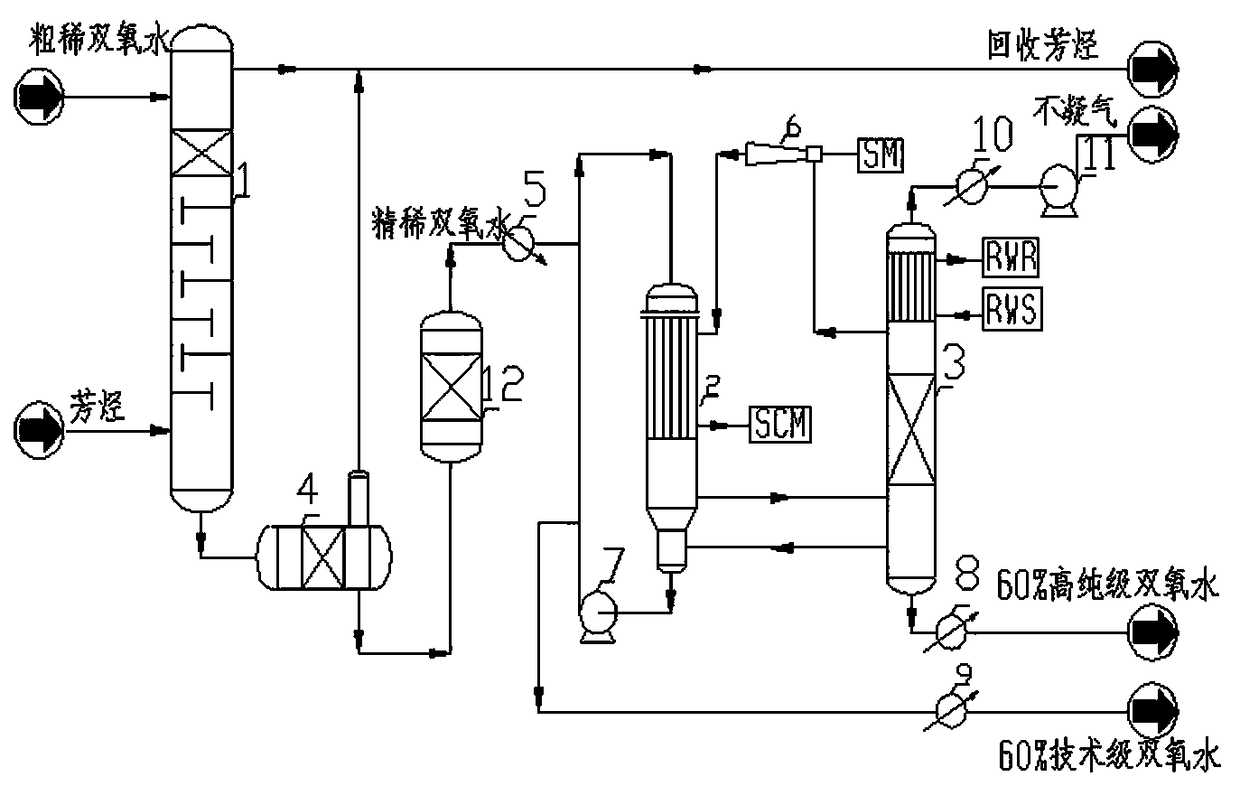

Hydrogen peroxide concentration and purification device and application thereof to hydrogen peroxide concentration and purification

ActiveCN109019521ALess investmentHigh purityVacuum condensationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAromatic hydrocarbonVacuum pump

The invention discloses a hydrogen peroxide concentration and purification device and application thereof to hydrogen peroxide concentration and purification. The hydrogen peroxide concentration and purification device is mainly composed of a purification tower (1), a falling film evaporator (2) and a rectifying tower (3); a thick diluted hydrogen peroxide pipeline is connected with the upper partof the purification tower and an aromatic hydrocarbon pipeline is connected with the lower part of the purification tower; a bottom hydrogen peroxide outlet of the purification tower is connected with a hydrogen peroxide inlet of the falling film evaporator; a lower hydrogen peroxide outlet of the falling film evaporator is connected with the lower part of the rectifying tower; a bottom hydrogenperoxide outlet of the falling film evaporator is connected with the upper part of the purification tower; a top gas phase outlet of the rectifying tower is connected with a rectifying tower condenser(10); a top gas phase outlet of the rectifying tower condenser is connected with a vacuum pump (11); a hydrogen peroxide outlet of the rectifying tower is connected with a high-purity-grade hydrogenperoxide cooler (8). According to the hydrogen peroxide concentration and purification device, an adsorption tower is not used, and part of concentrated hydrogen peroxide is returned back into the purification tower. Therefore, waste liquid and waste adsorbents, generated in an adsorption process, are reduced; meanwhile, effective components of a working solution are also recycled, the consumptionis reduced and the safety performance of the device is improved.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

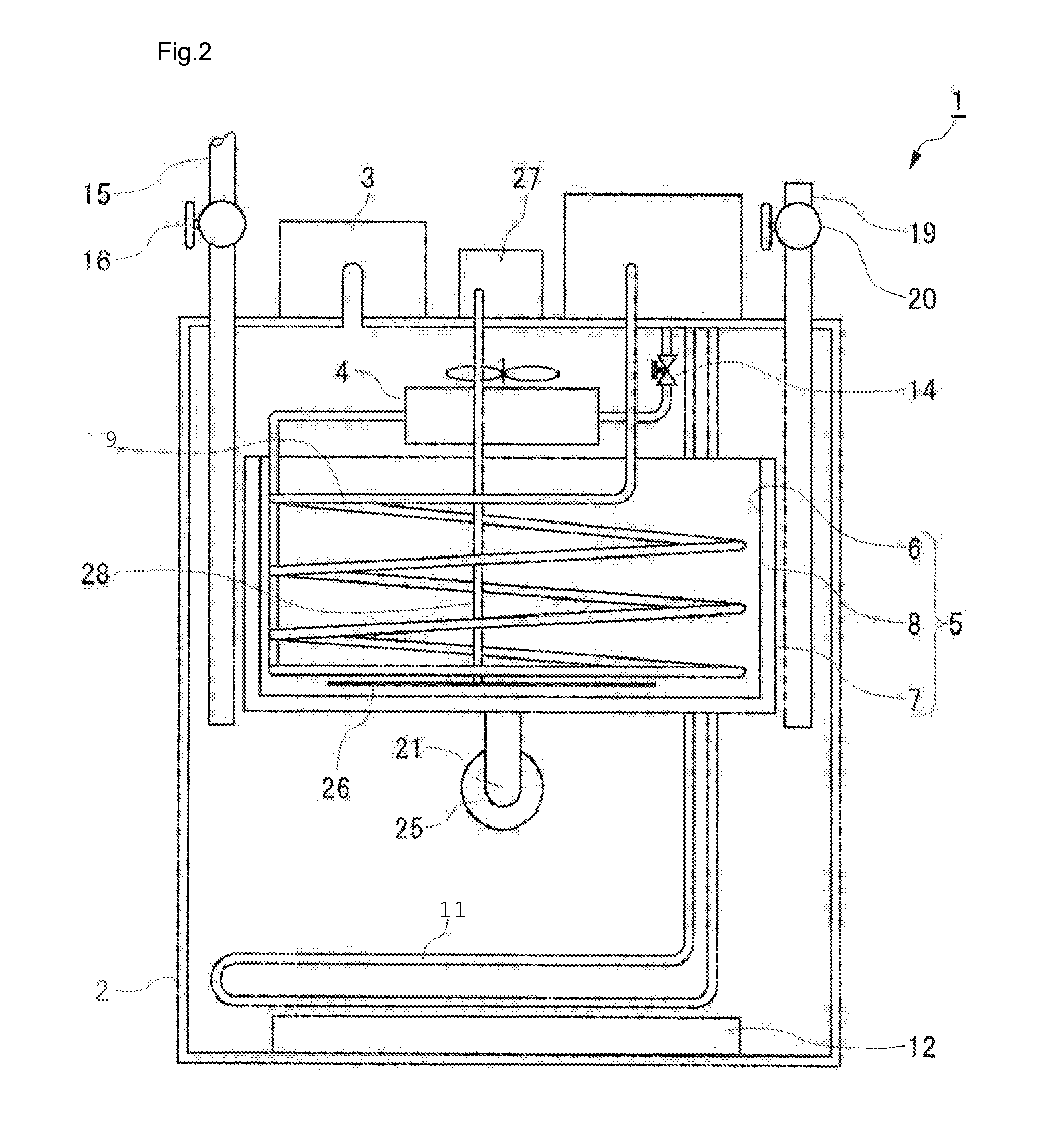

Distilled water production system

InactiveUS20120261250A1Construction be to be lowReduce equipment costsVacuum condensationGeneral water supply conservationWater vaporWater production

A distilled water production system (1) includes a main tank (2), a pressure reducer (3), a cooler (4) and a pool (5). Sea water or dirty water is contained in the main tank (2) as raw water for producing distilled water. The pressure reducer (3) brings an inside of the main tank (2) into a reduced pressure state. The cooler (4) is disposed in an upper part within the main tank (2) and cools water vapor produced by evaporation of the raw water occurring in the reduced pressure state. The pool (5) is disposed at a position below the cooler (4) within the main tank (2) and contains the distilled water obtained by cooling and condensation of the water vapor by the cooler (4). According to the distilled water production system (1), the running cost and construction and equipment costs can be suppressed to be low.

Owner:NAKAYAMA YOSHINAKA

Heat exchanger with multistaged cooling

Embodiments described herein relate to a heat exchanger for abating compounds produced in semiconductor processes. When hot effluent flows into the heat exchanger, a coolant can be flowed to walls of a fluid heat exchanging surface within the heat exchanger. The heat exchanging surface can include a plurality of channel regions which creates a multi stage cross flow path for the hot effluent to flow down the heat exchanger. This flow path forces the hot effluent to hit the cold walls of the fluid heat exchanging surface, significantly cooling the effluent and preventing it from flowing directly into the vacuum pumps and causing heat damage. Embodiments described herein also relate to methods of forming a heat exchanger. The heat exchanger can be created by sequentially depositing layers of thermally conductive material on surfaces using 3-D printing, creating a much smaller footprint and reducing costs.

Owner:APPLIED MATERIALS INC

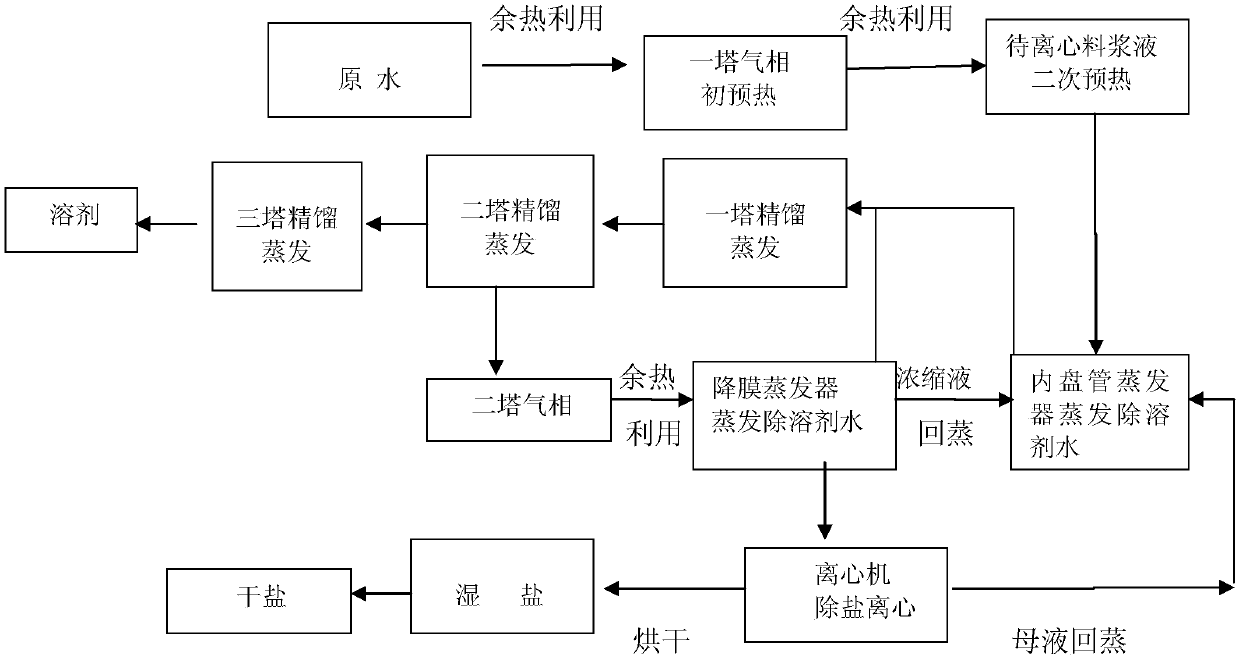

High-salt and -solvent wastewater treatment system and process

PendingCN108101295AHigh purityRealize continuous desalination and rectificationVacuum condensationSpecific water treatment objectivesSolventEngineering

The invention discloses high-salt and -solvent wastewater treatment system and process. The outlet of a raw water pump is successively connected to a first heat exchanger and a second heat exchanger;the gas outlet of an inner coil evaporator is connected to a first rectifying column through a gas phase pipeline; the first rectifying column is successively connected to a second rectifying column and a third rectifying column through pipelines; a steam outlet of the first rectifying column is connected to a heat medium inlet of the first heat exchanger; the steam outlet of the second rectifyingcolumn is connected to a steam inlet of a falling-film evaporator; the liquid outlet of the inner coil evaporator is connected to two branch pipes: one is connected to the feeding inlet of the falling-film evaporator, wherein a gas-liquid separator is connected to a gas outlet of the falling-film evaporator and the gas outlet pipe of the gas-liquid separator is merged into the gas phase pipeline;the other one is connected to a centrifuge through the second heat exchanger, and the centrifuge is connected to the liquid inlet on the upper part of the inner coil evaporator through a delivery pump. The system achieves continuous desalting rectification, is high in purity of the recycled solvent, and can fully recycle and utilize residual heat.

Owner:HUAIAN GUORUI CHEM CO LTD

Process for producing (meth)acrylic acid

ActiveUS10239816B2Resistive lossRemove waterVacuum condensationOrganic compound preparationSolventOrganic chemistry

Owner:ARKEMA FRANCE SA

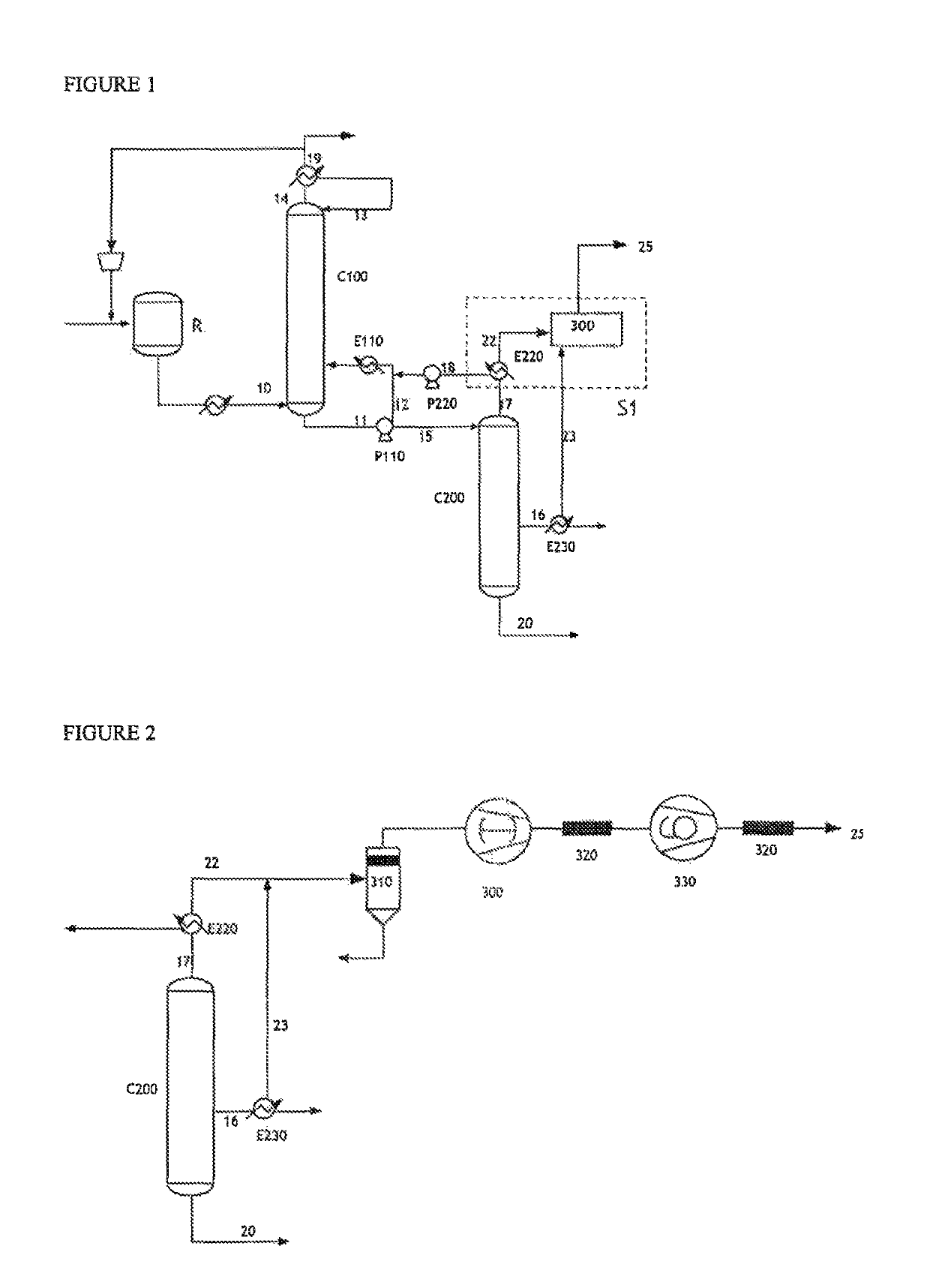

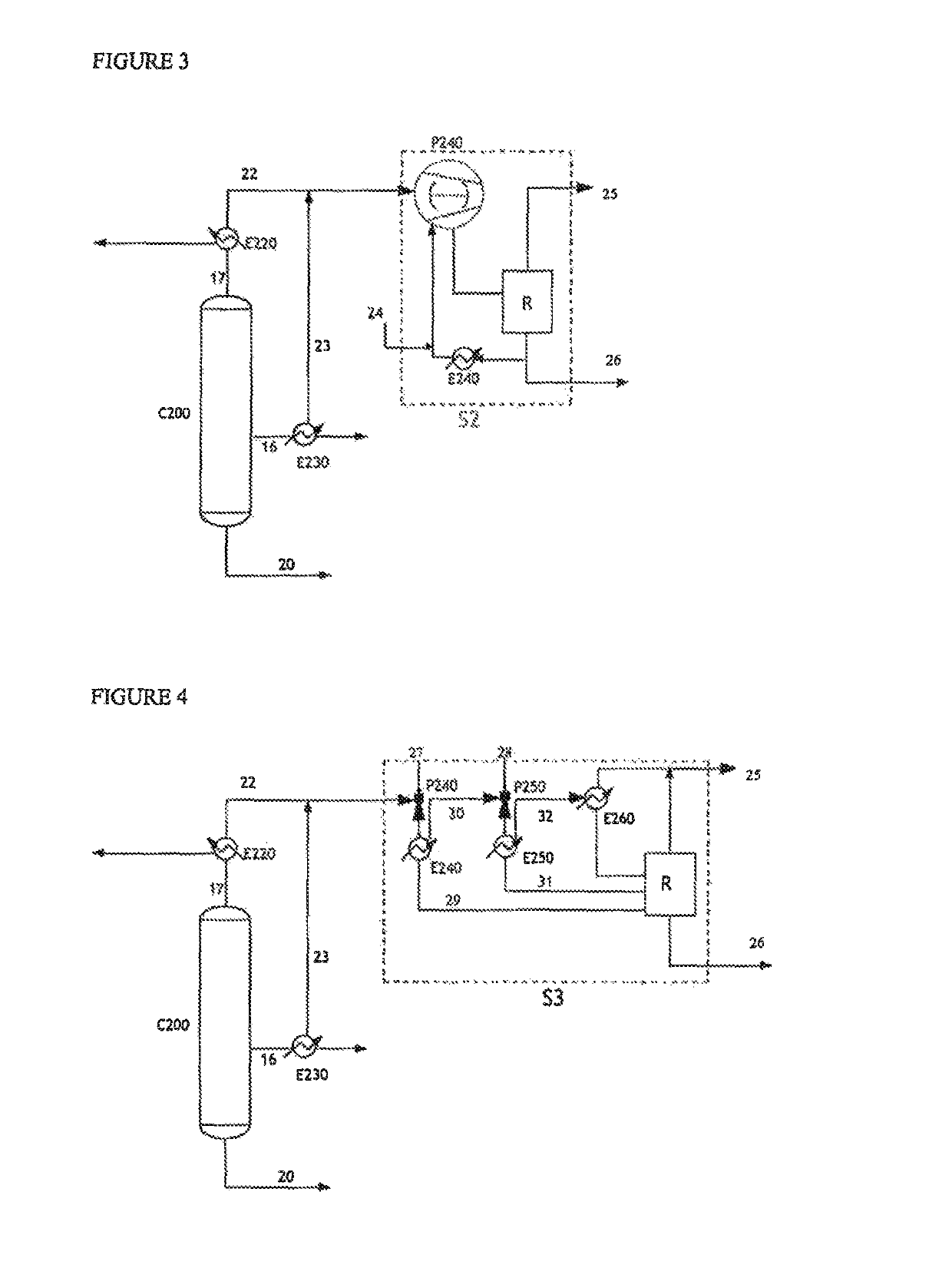

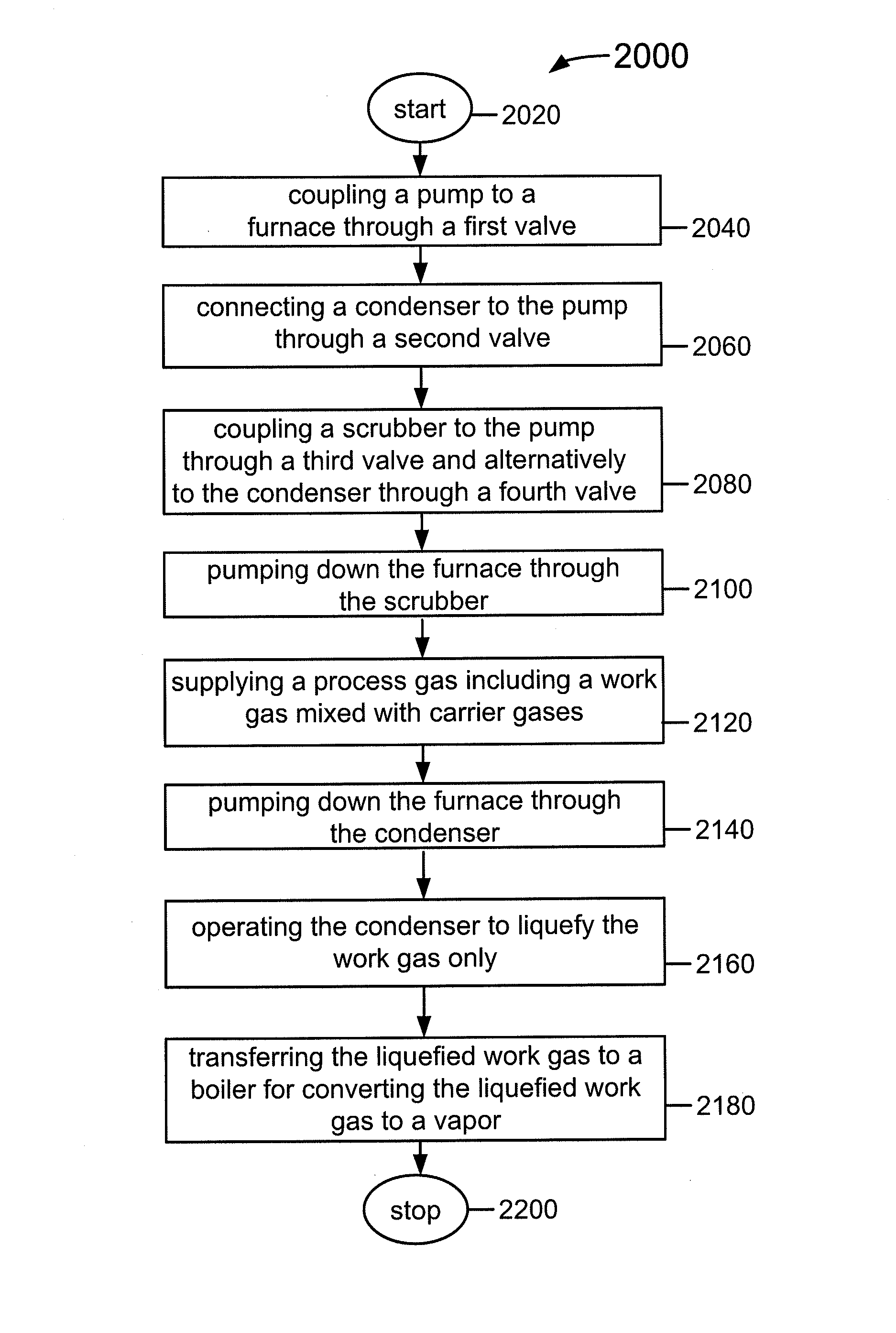

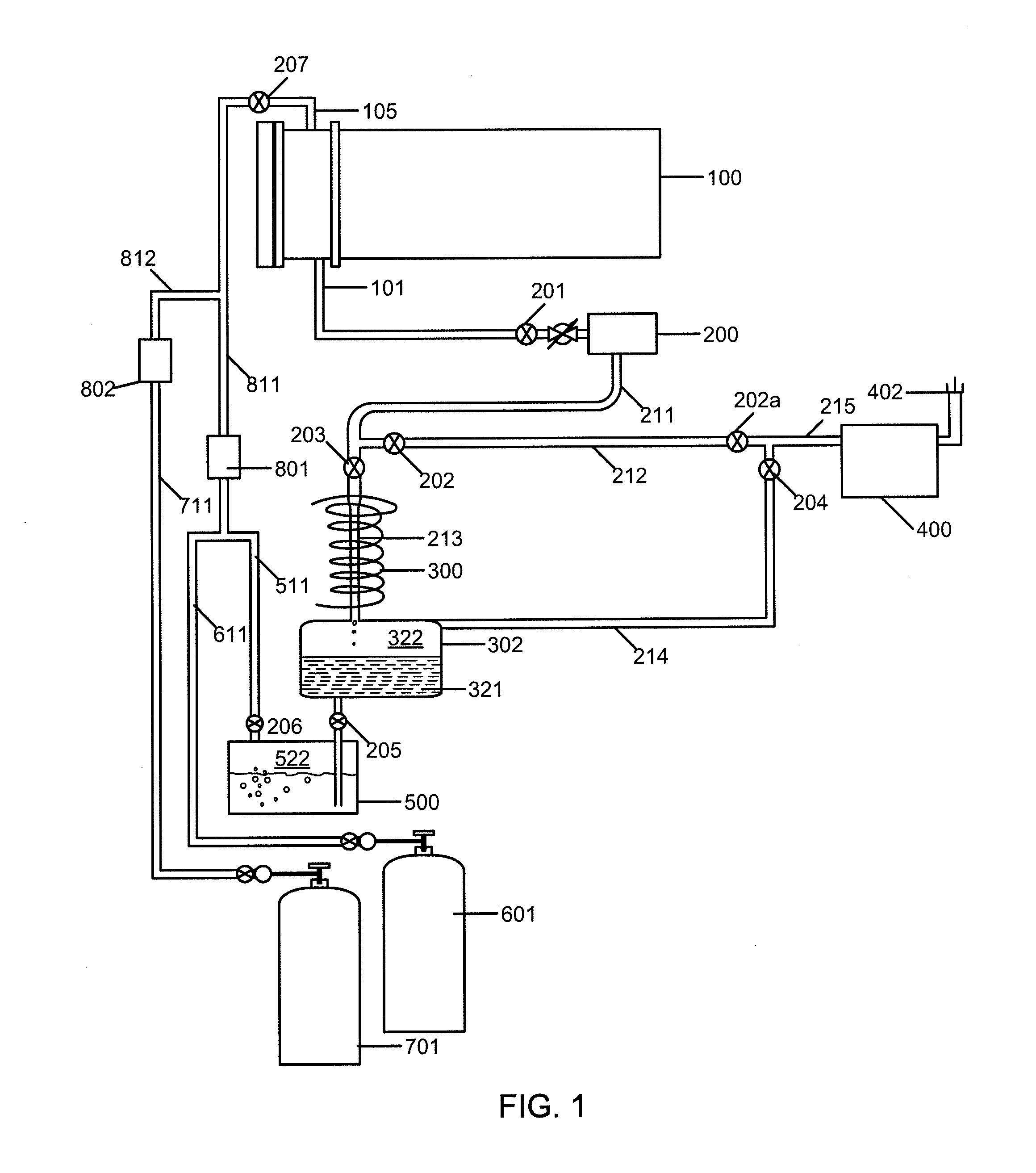

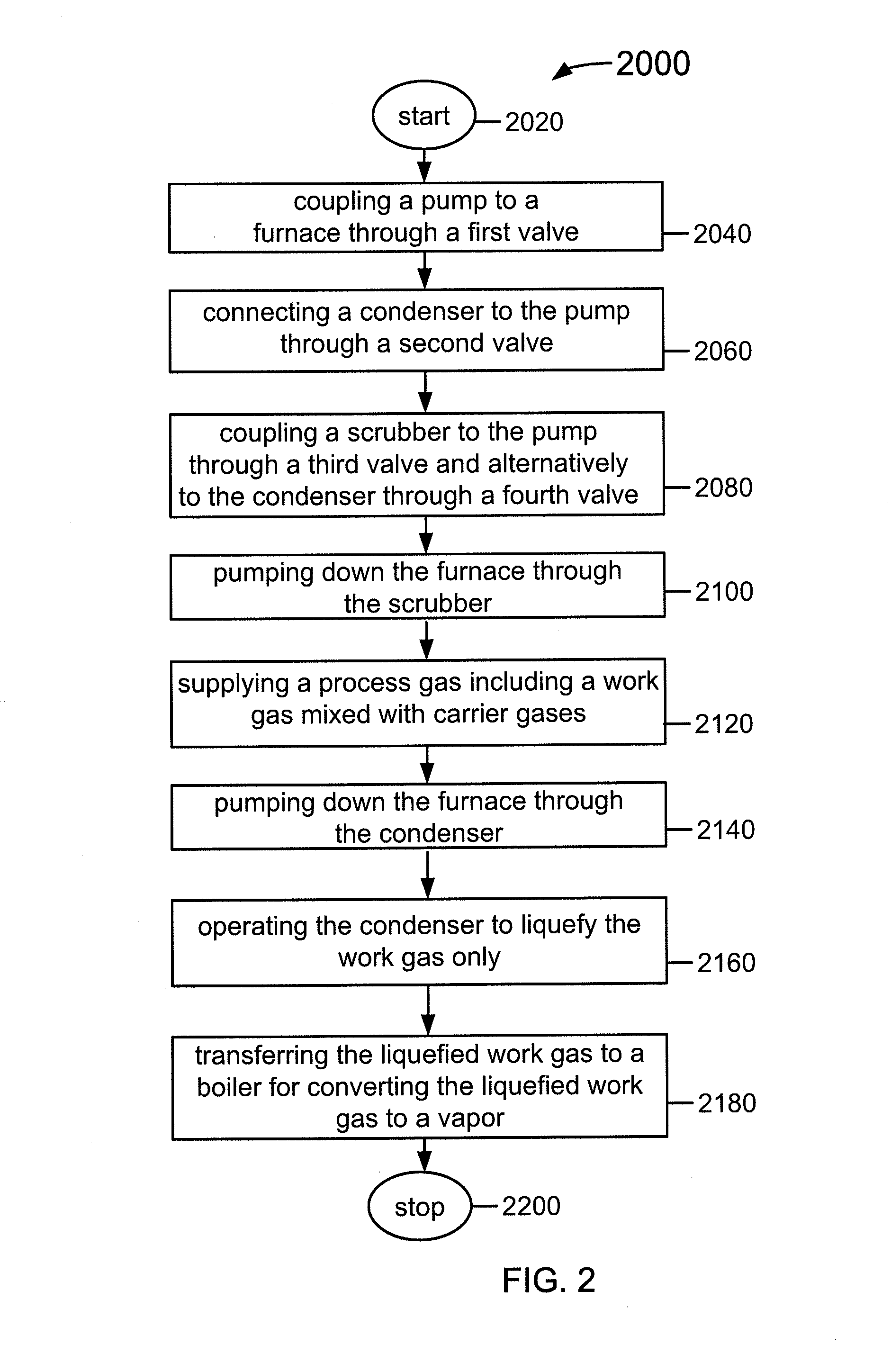

Method and system for recycling processing gas for selenization of thin film photovoltaic materials

InactiveUS9084969B1Reduce wasteCost effectiveVacuum condensationGas treatmentBoiling pointProcess engineering

A system for recycling a work gas used in a thermal reactor for treating sample materials includes a thermal reactor using a work gas from a first source mixed with carrier gases. The work gas has a boiling point higher than the carrier gases. The system includes a pump, a condenser which converts the work gas into a liquid, and a scrubber.

Owner:STION

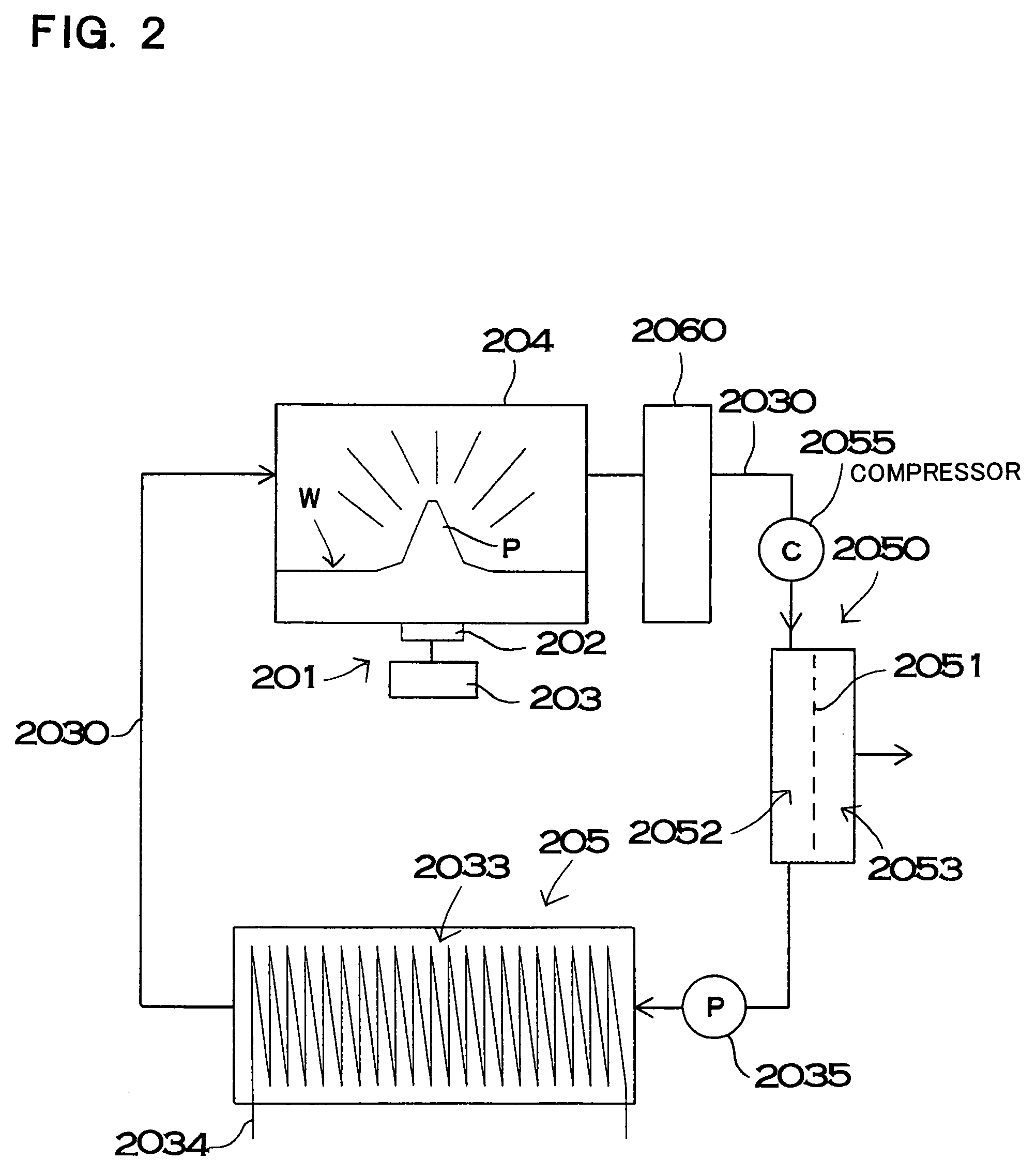

Method and apparatus for concentrating a solution

InactiveUS7399338B2Increase pressureIncrease resistanceThermo-electric condensationCombination devicesGas phaseAtmospheric pressure

In the present invention, a solution containing a target substance is atomized into a mist by ultrasonic oscillation in an ultrasonic atomization chamber, and the target substance is collected by aggregating the atomized mist in a collection chamber, whereby the target substance is separated from the solution. Further, in the present invention, the gas phase pressure in the collection chamber is maintained to be higher than an atmospheric pressure, whereby the saturation vapor pressure of the target substance in the gas phase is made lower than the saturation vapor pressure under atmospheric pressure.

Owner:ULTRASOUND BREWERY

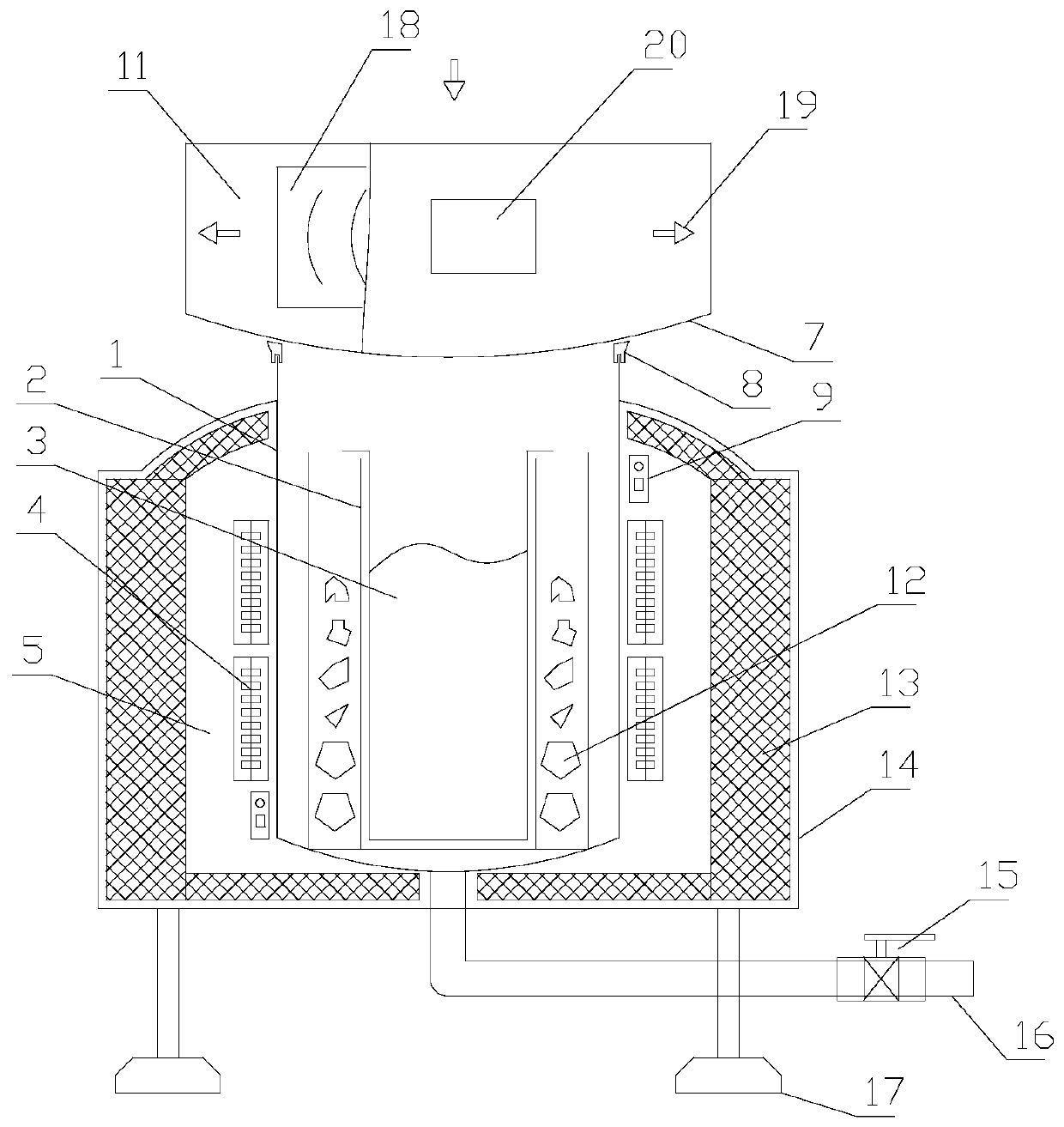

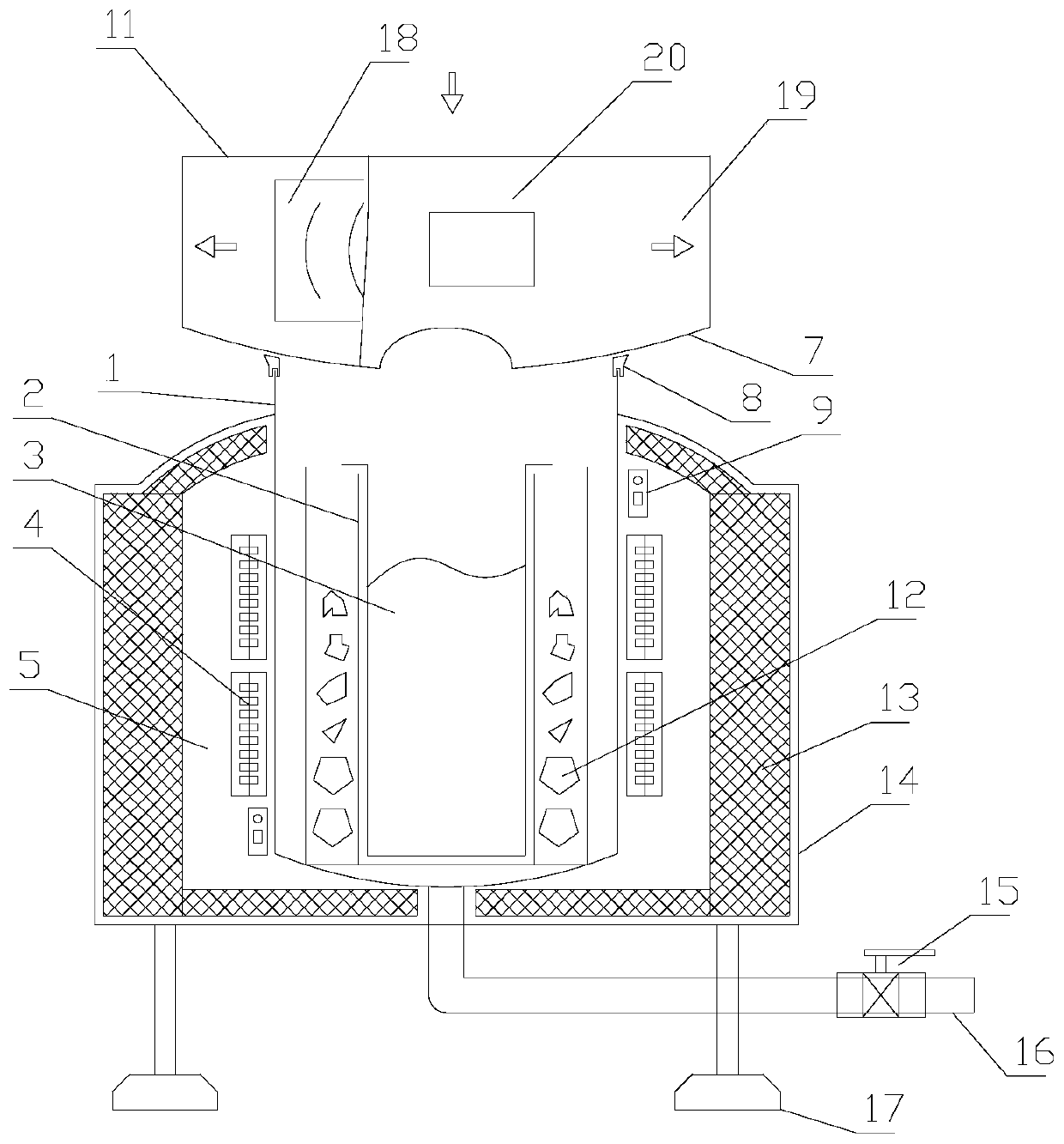

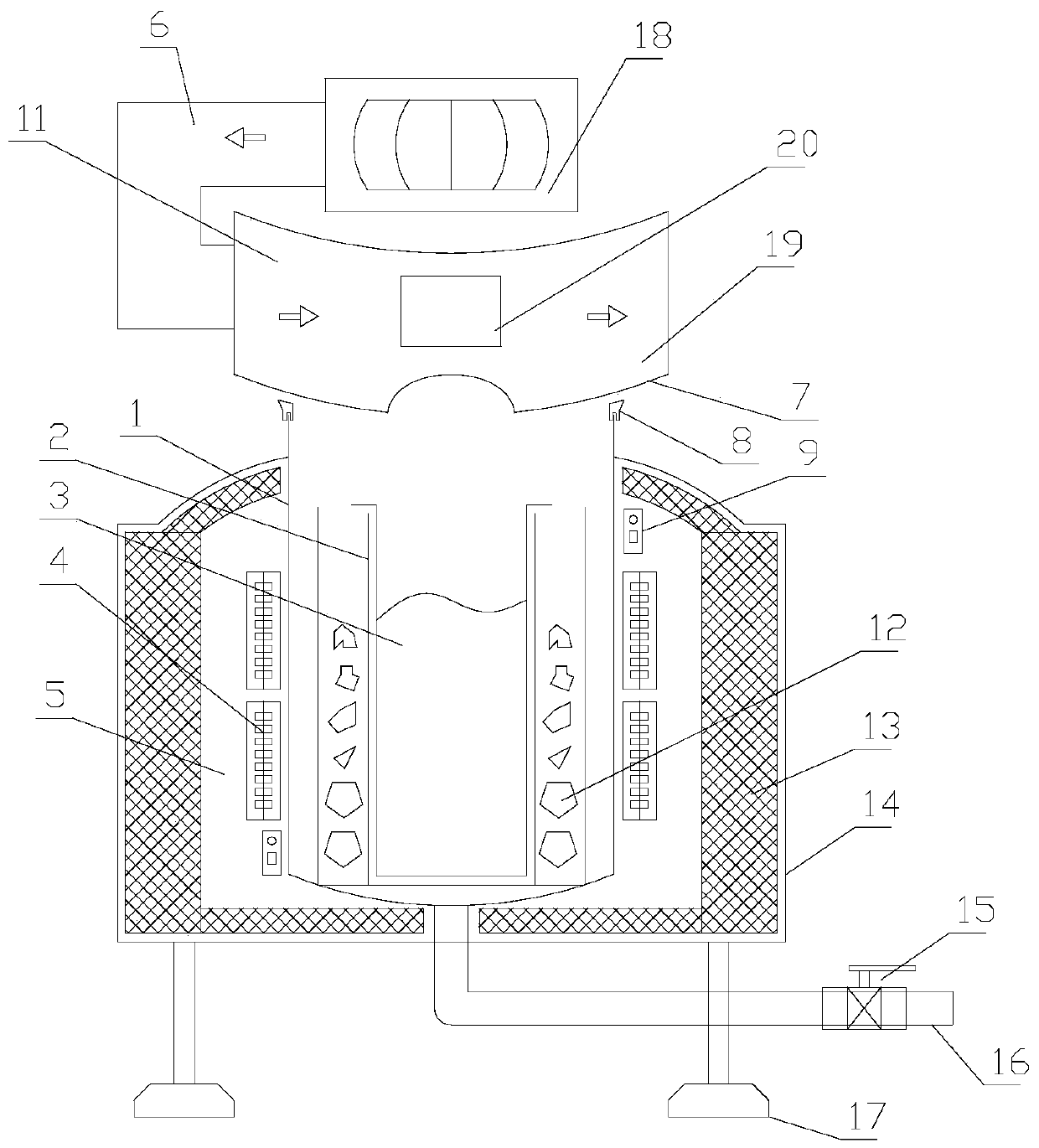

Leaf plant cell sap extraction device and process

InactiveCN111282298AIngenious structureHigh extraction rateVacuum condensationEvaporator accessoriesBiotechnologyPlant cell

The invention discloses a leaf plant cell sap extraction process and device. The process comprises the following steps: (S1) heating leaves or petals at high temperature of 198-213 DEG C and high absolute pressure of 130-320 KPa in a closed container; (S2) locally cooling the top of the container in an air-cooling or water-cooling manner, keeping the absolute pressure in the container at 70-100KPa, controlling the temperature in the container at 198-213 DEG C, continuously evaporating cell sap in the container, and forming liquid drops at the top and enabling the liquid drops to fall into a containing cup in the container; and (S3) keeping the internal absolute pressure at 70-100KPa and the temperature at 176-196 DEG C to purify and stabilize the cell sap, so as to obtain stabilized micro-clustered cell sap. The cell sap extraction device is ingenious in structure, nutritional ingredients of raw materials can be completely extracted into the cell sap container at high temperature to form cell sap, harmful impurities such as drug residues and heavy metal possibly carried in plant cells are completely removed, the extraction rate is high, and the quality is good.

Owner:梁小毛

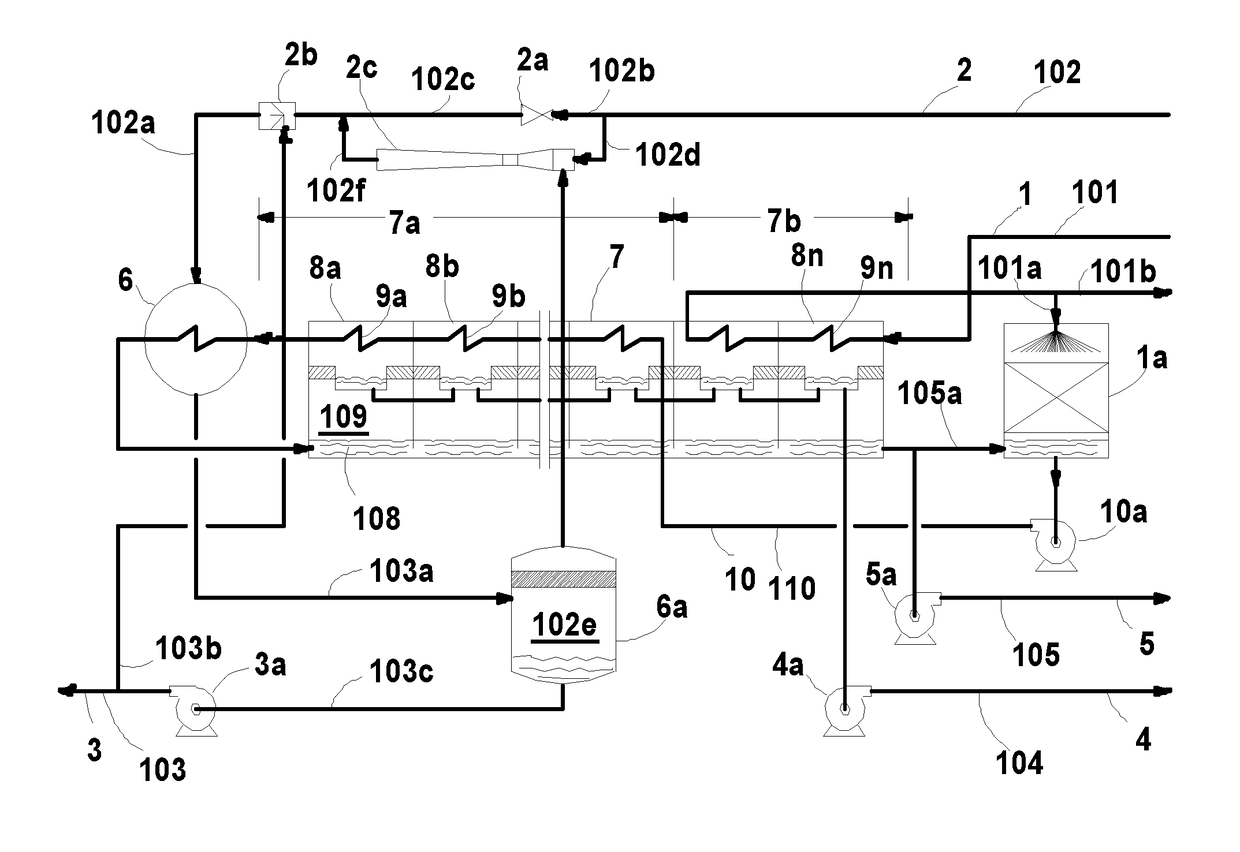

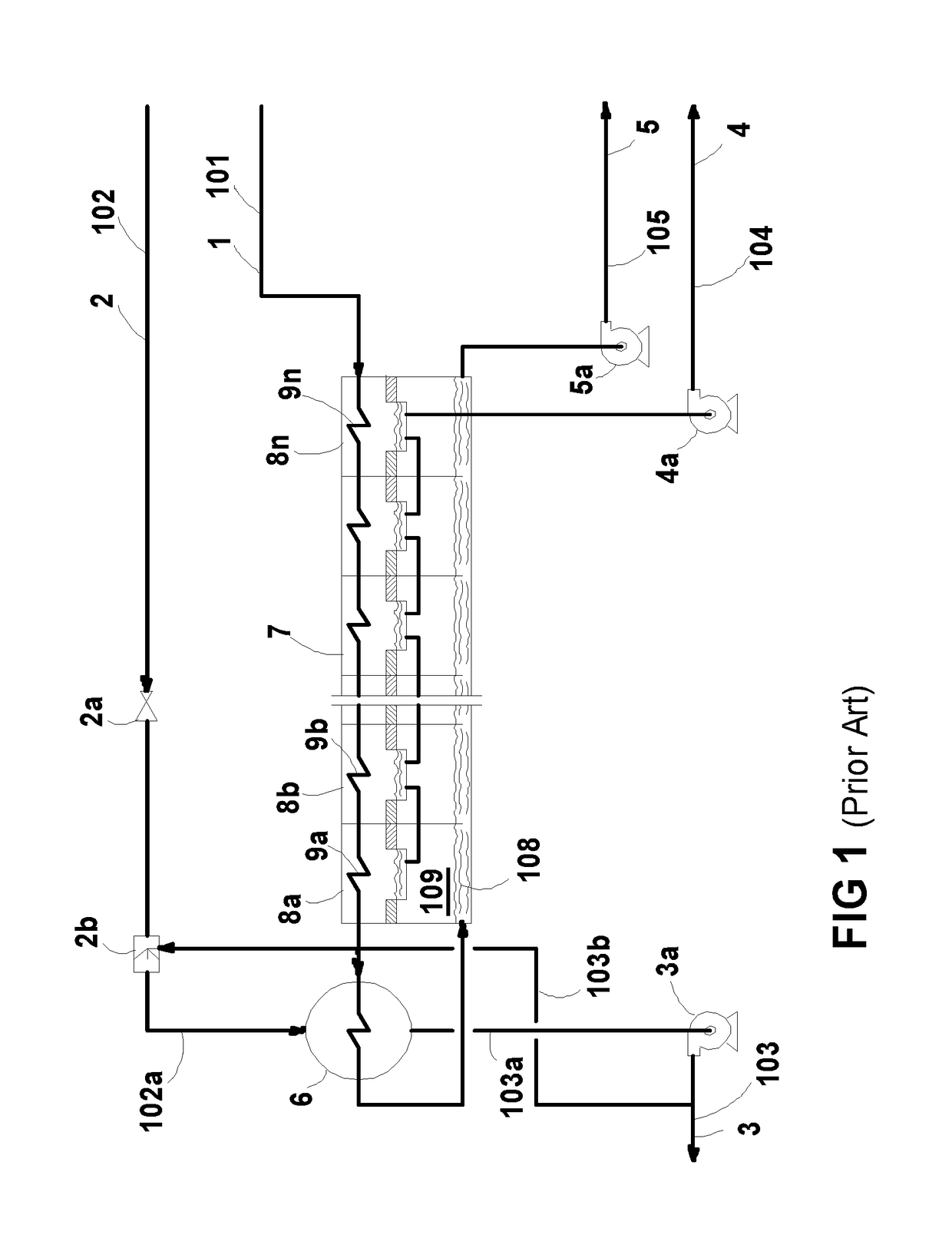

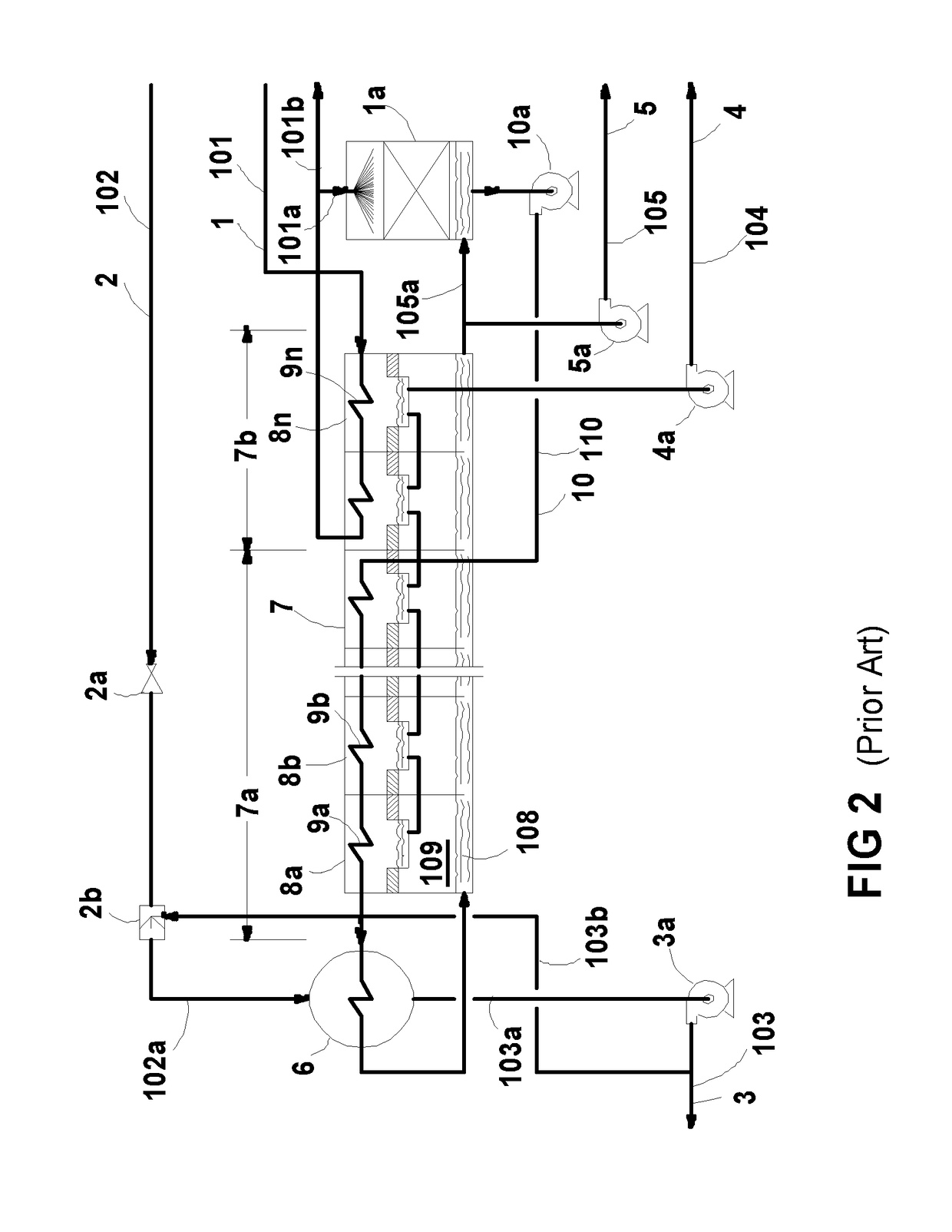

Multi-stage flash desalination system with thermal vapor compressor

InactiveUS20180154277A1Reduce in quantityImprove thermal efficiencyVacuum condensationGeneral water supply conservationPower stationMulti-stage flash distillation

The present invention provides a configuration of a multi-stage flash desalination system including a thermal vapor compressor and a condensate flash tank, which allows to extract a vapor from the condensate before it is returned to the power plant and to compress this vapor and use it as part of the heating steam in the brine heater, which reduces the required amount of steam supply from the power plant, while the condensate returned to the power plant at a reduced temperature allows to utilize low grade heat of exhaust gases of a steam generator to re-heat the condensate, which results in a reduced energy consumption allocated to the multi-stage flash desalination plant and an improvement of the energy efficiency of the power plant.

Owner:ALT FRIEDRICH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com