Method and device for producing a pure liquid from a crude liquid

An untreated, liquid technology, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as breaking vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention is mainly used for seawater desalination, that is to say for producing fresh water from brine. The device according to the invention is therefore advantageously installed on the coast in order to be able to obtain from the sea the almost unlimited amount of required brine.

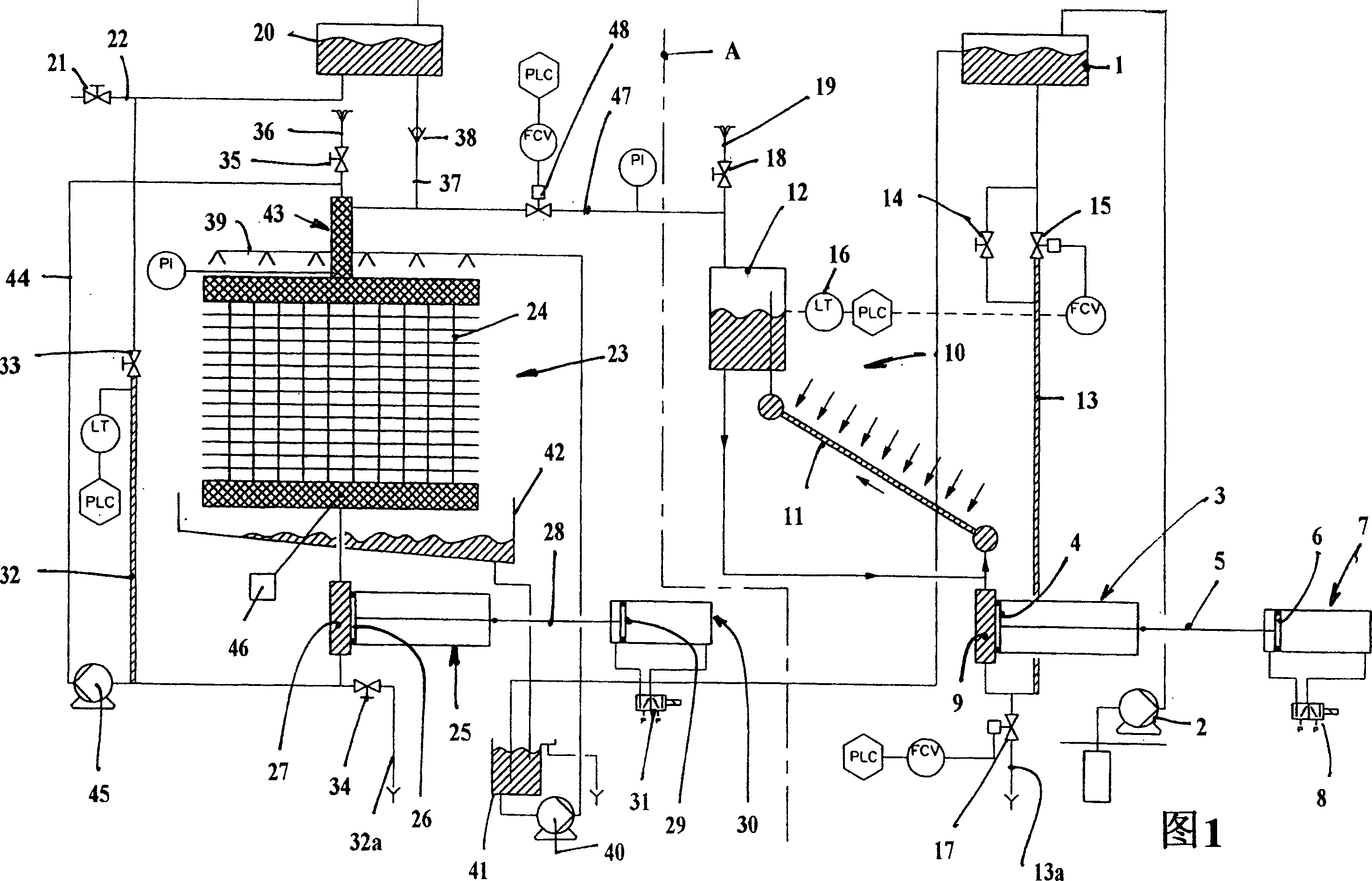

[0017] The apparatus according to the invention comprises an evaporator side and a condenser side. Figure 1 contains a dotted line A, on the right hand side of which is the evaporator side and on its left hand side the condenser side. The evaporator side includes a raw water tank 1 designed as an upwardly open tank and fed with seawater by a pump 2 . Under the raw water tank 1, the lower water level cylinder piston unit 3 is arranged, which includes a piston 4 arranged in the cylinder, which is connected to the piston 6 of the same stroke cylinder piston unit 7 through the piston rod 5, and the cylinder piston unit 7 is controlled by hydraulic pressure or It is preferably pneumatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com