Patents

Literature

882 results about "Plastic injection molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

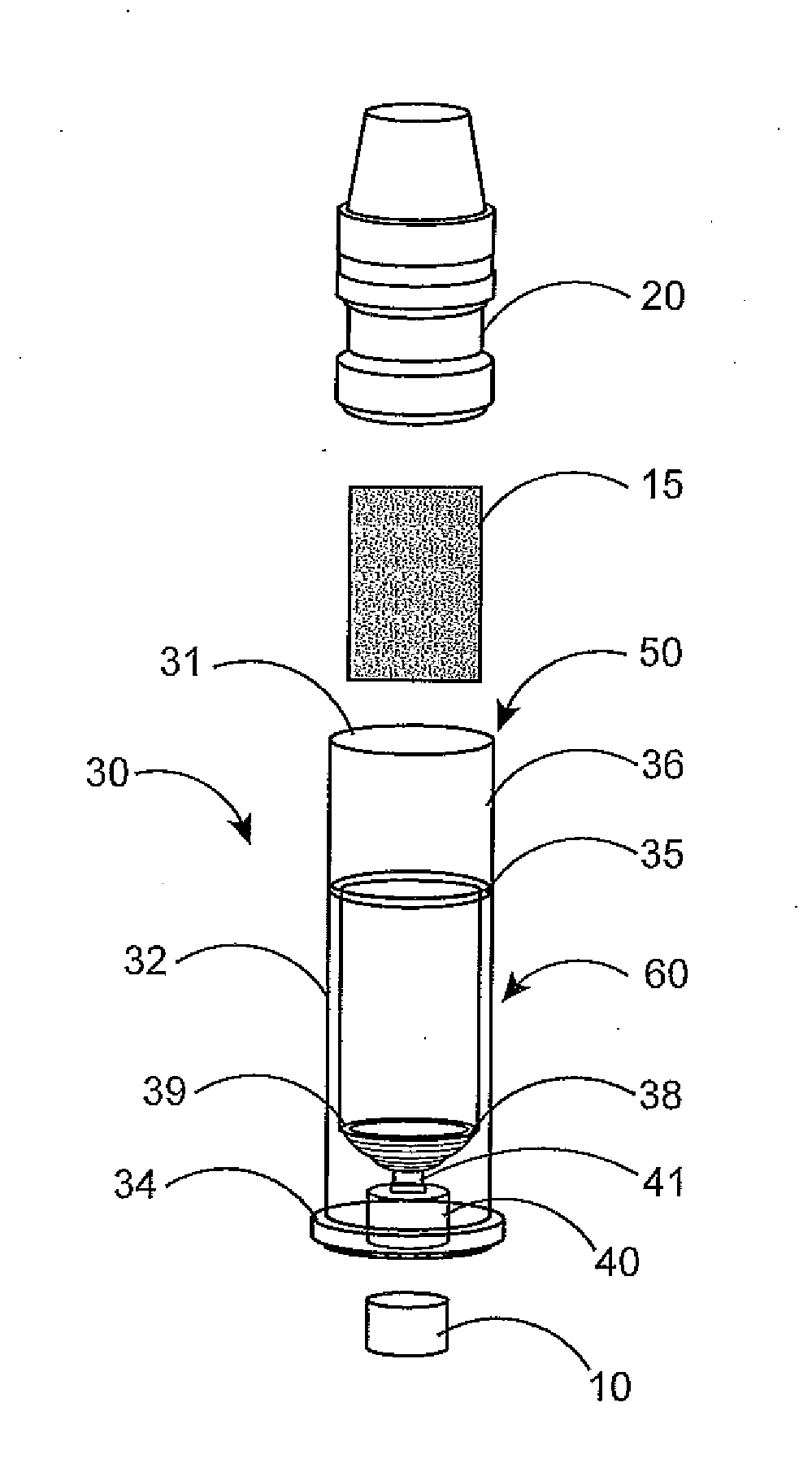

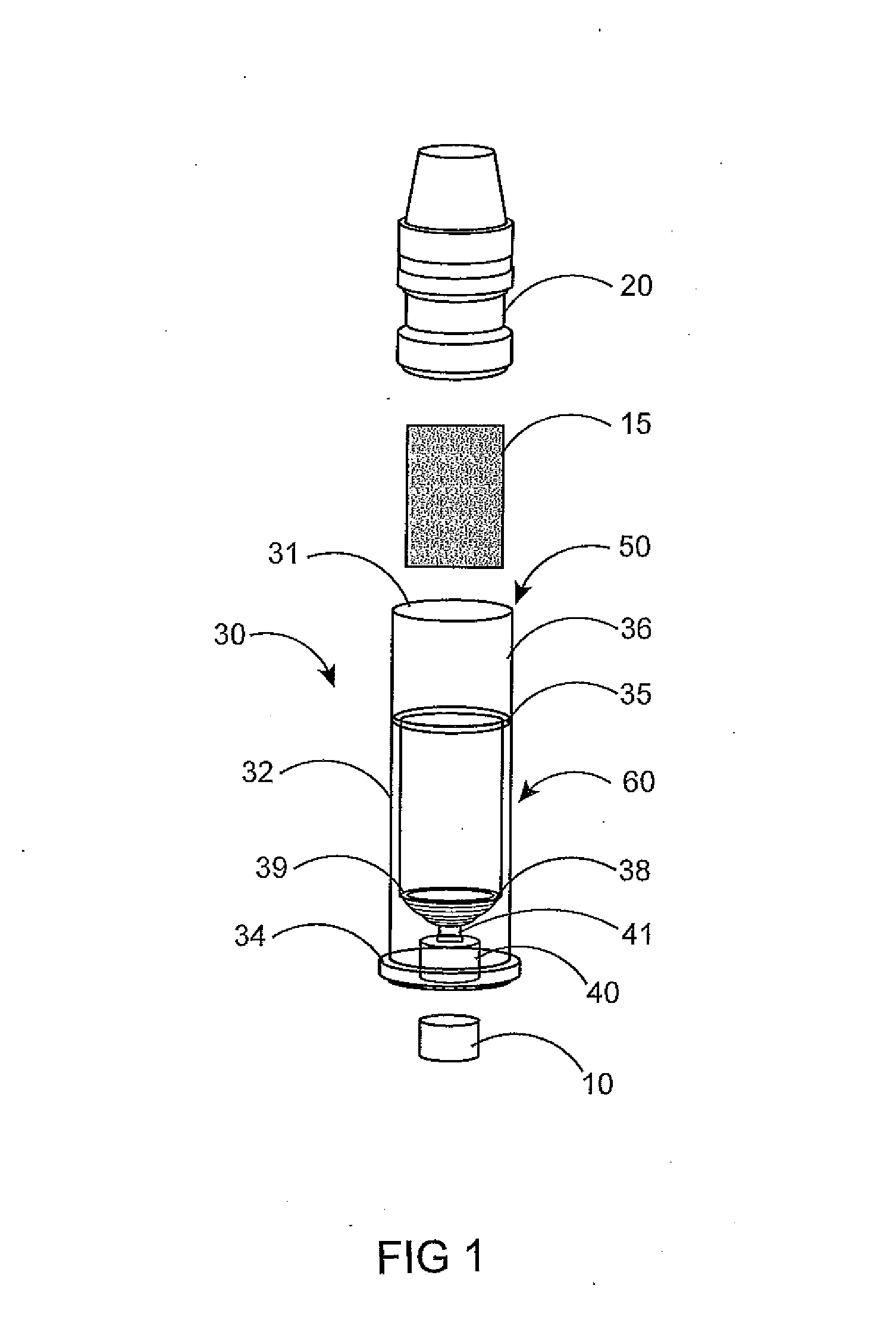

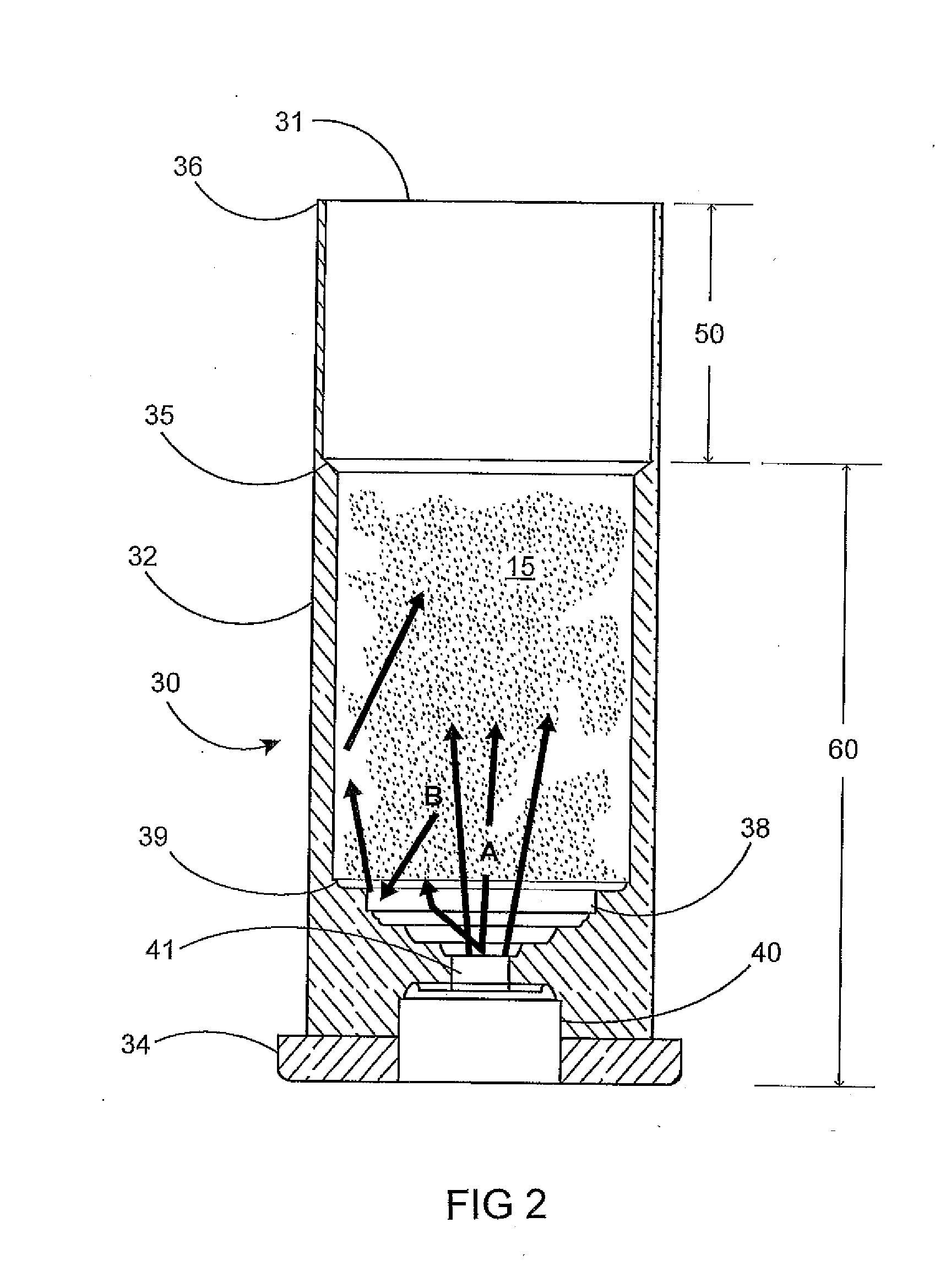

Reusable Plastic Ammunition Casing

InactiveUS20160265886A1Evenly dispersedCartridge ammunitionPlastic injection moldingStructural failure

A reloadable plastic ammunition casing is provided for firearm use. The plastic casing is preferably constructed from currently available polymeric materials using plastic injection molding techniques. In the preferred embodiment the casing includes a cylindrical body having a top portion and a bottom portion. The top portion having an open end for receiving a propellant and a top lip for retaining a projectile. The bottom portion has an internal casing floor that includes at least one concentric step down towards a centrally located primer pocket such that an installed primer is located in blast communication with the concentric steps on the casing floor. The concentric steps uniformly disburse, distribute, and deflect the heat and gas pressures within the casing when fired, thereby avoiding structural failure, allowing for multiple reloads of a casing constructed entirely out of plastic.

Owner:ALDRICH LONNIE +2

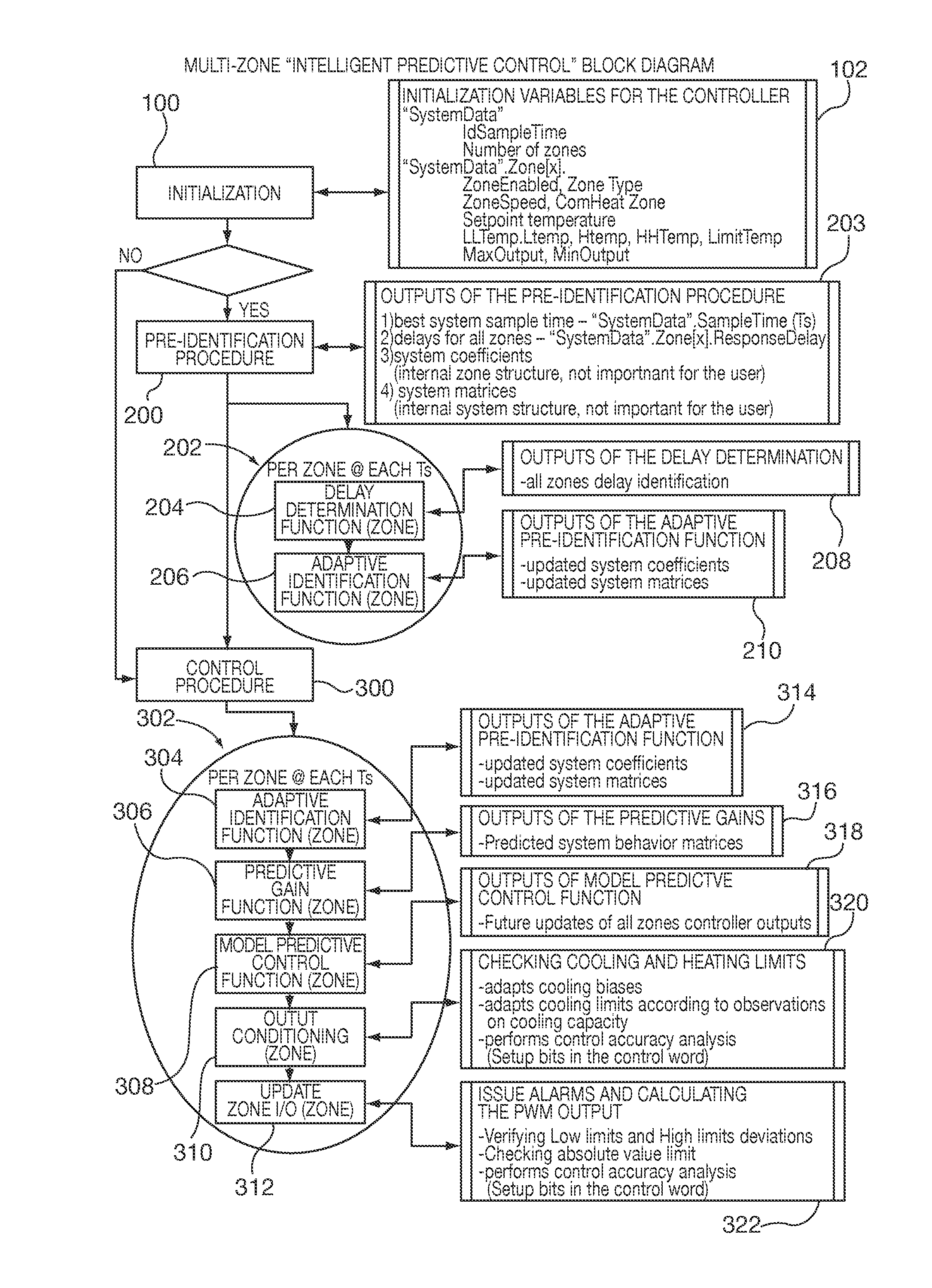

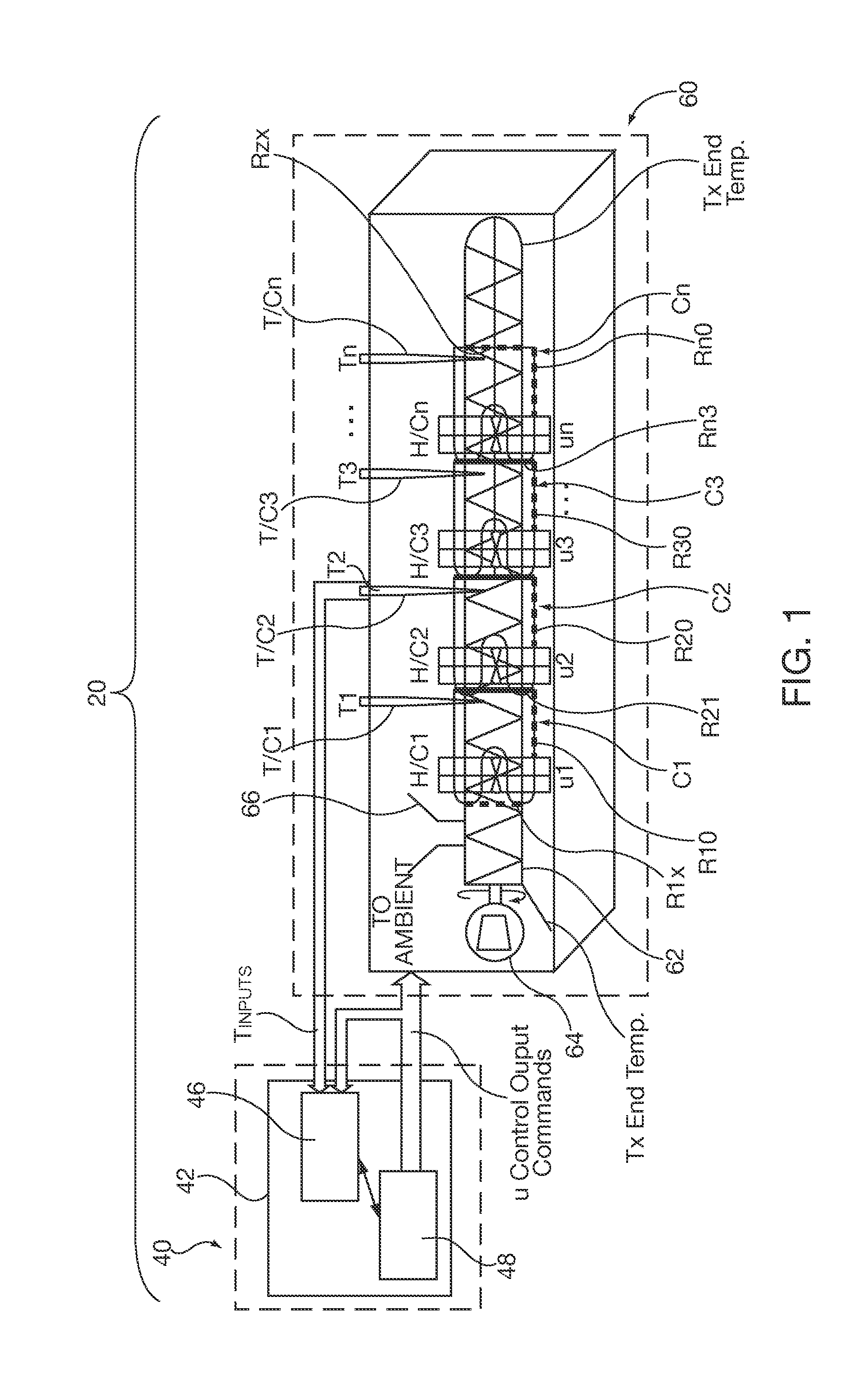

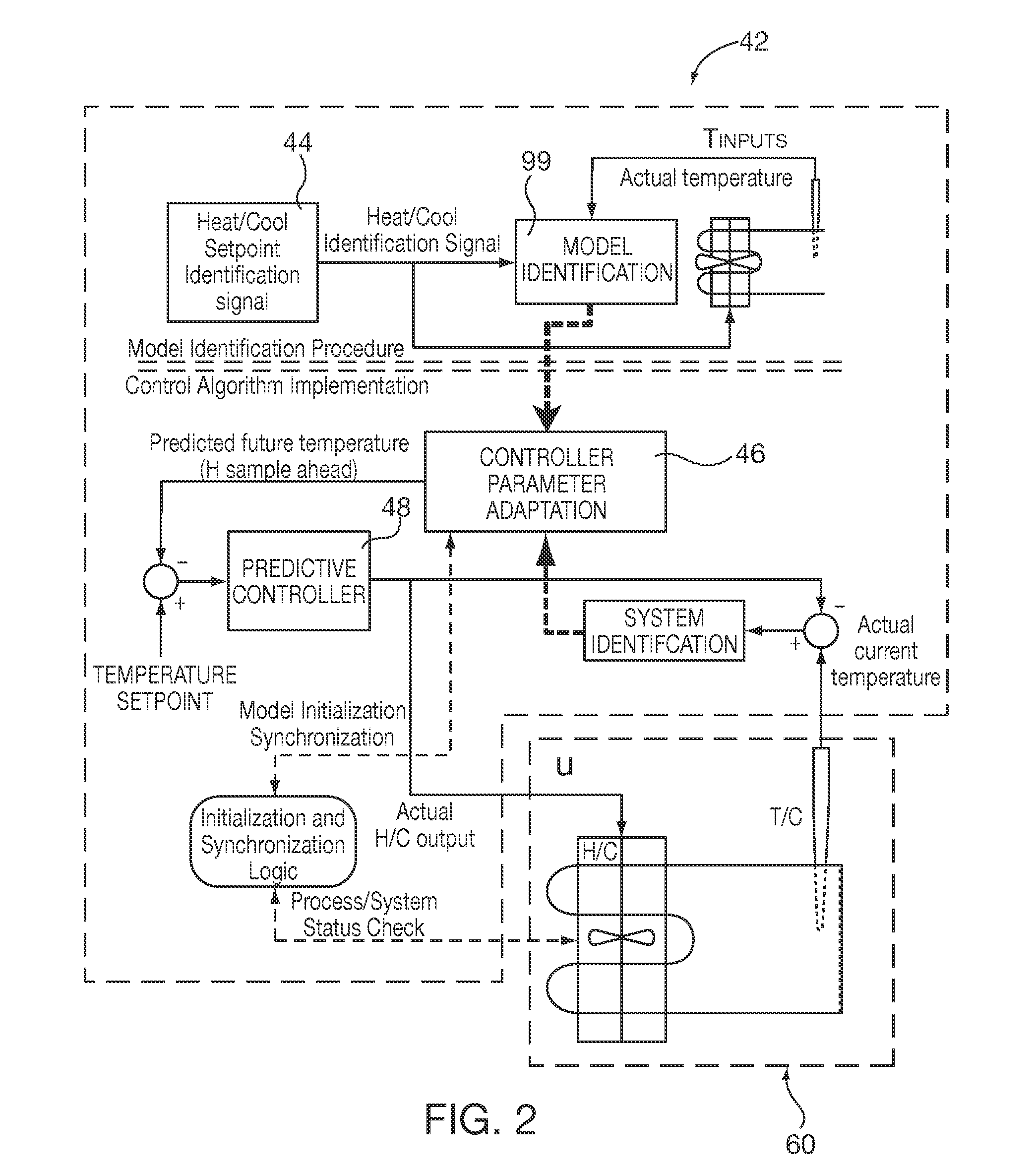

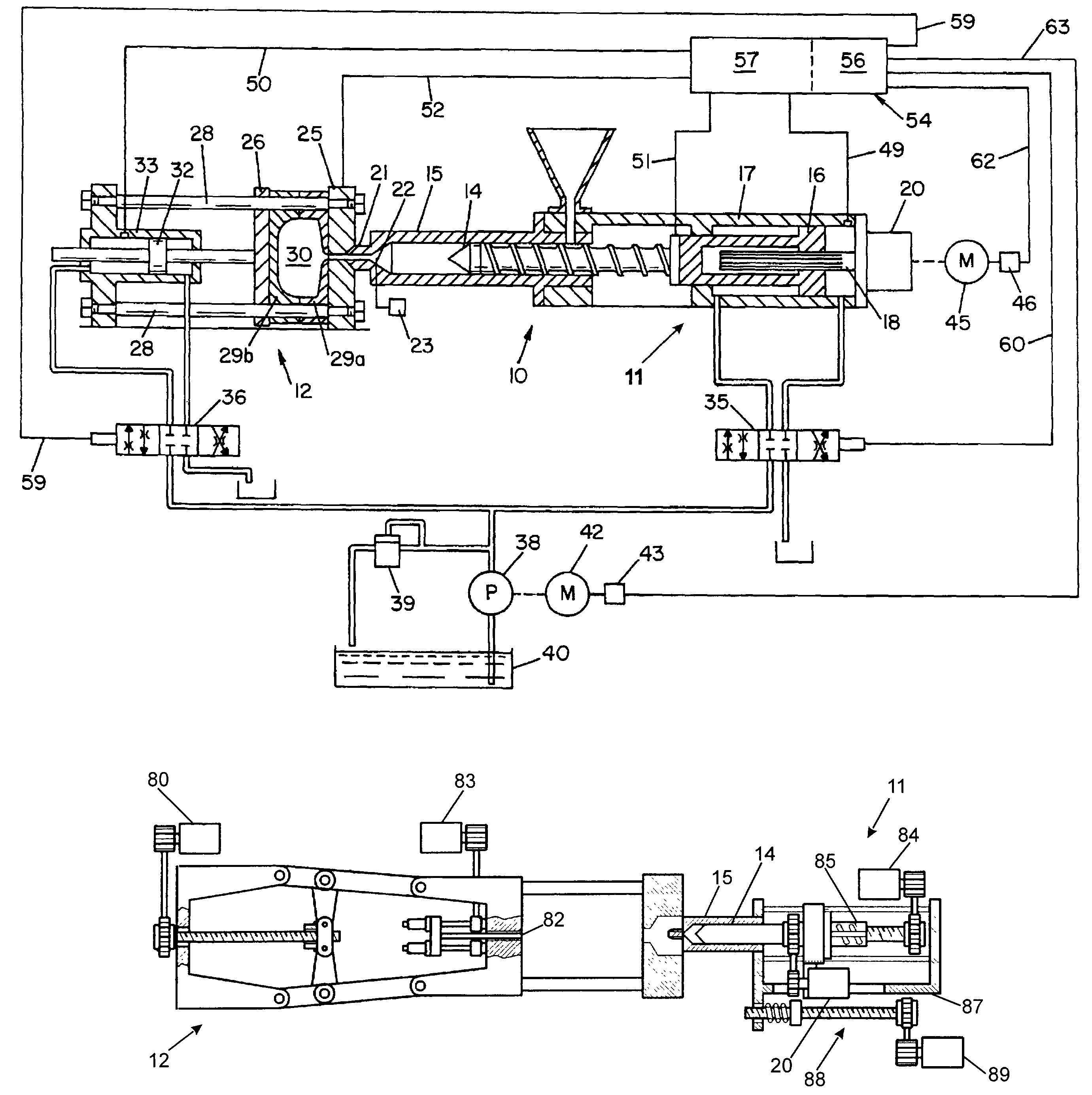

Method and apparatus of a self-configured, model-based adaptive, predictive controller for multi-zone regulation systems

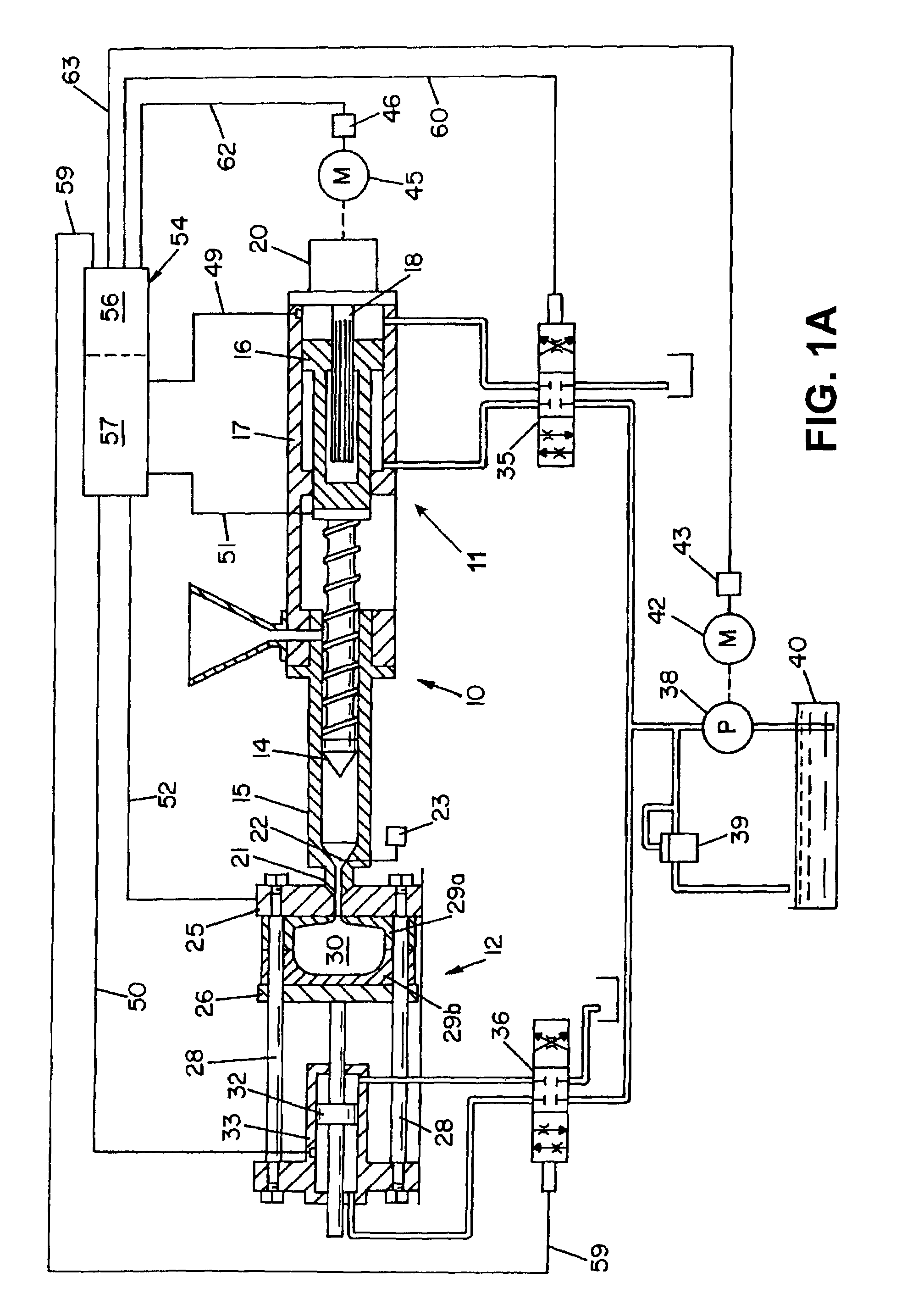

InactiveUS20110022193A1Easy to addPrecise processingSampled-variable control systemsTravelling carriersHorizonPlastic injection molding

A control system simultaneously controls a multi-zone process with a self-adaptive model predictive controller (MPC), such as temperature control within a plastic injection molding system. The controller is initialized with basic system information. A pre-identification procedure determines a suggested system sampling rate, delays or “dead times” for each zone and initial system model matrix coefficients necessary for operation of the control predictions. The recursive least squares based system model update, control variable predictions and calculations of the control horizon values are preferably executed in real time by using matrix calculation basic functions implemented and optimized for being used in a S7 environment by a Siemens PLC. The number of predictions and the horizon of the control steps required to achieve the setpoint are significantly high to achieve smooth and robust control. Several matrix calculations, including an inverse matrix procedure performed at each sample pulse and for each individual zone determine the MPC gain matrices needed to bring the system with minimum control effort and variations to the final setpoint. Corrective signals, based on the predictive model and the minimization criteria explained above, are issued to adjust system heating / cooling outputs at the next sample time occurrence, so as to bring the system to the desired set point. The process is repeated continuously at each sample pulse.

Owner:SIEMENS IND INC

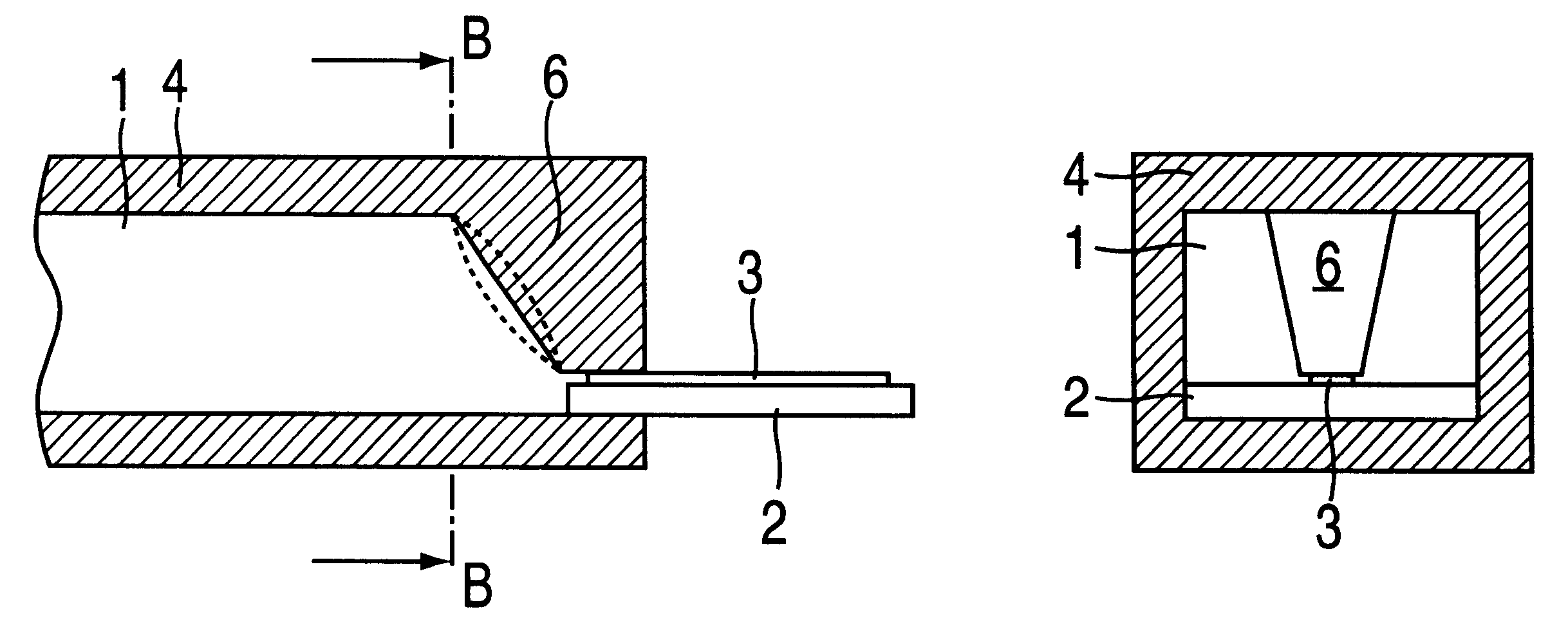

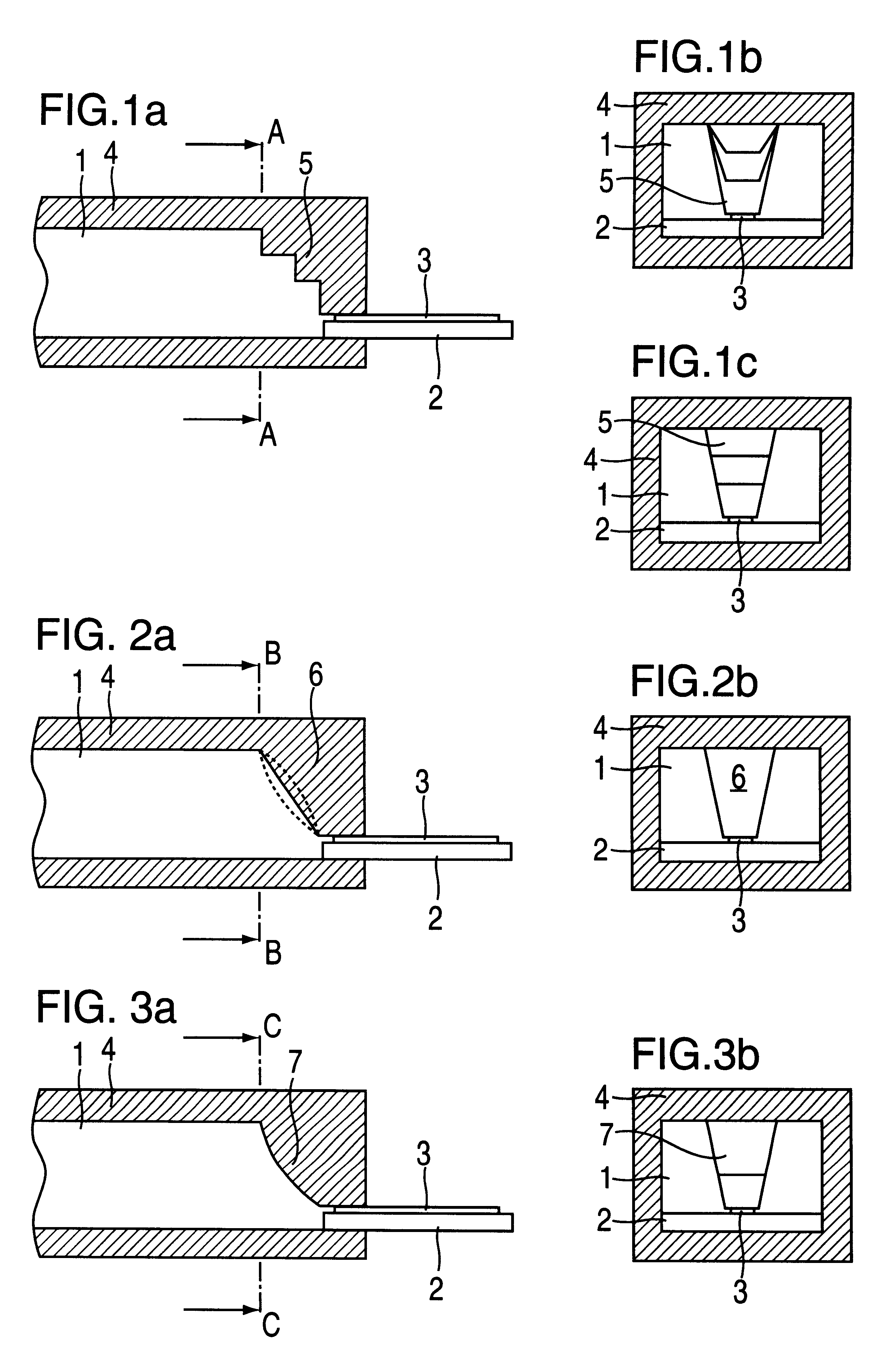

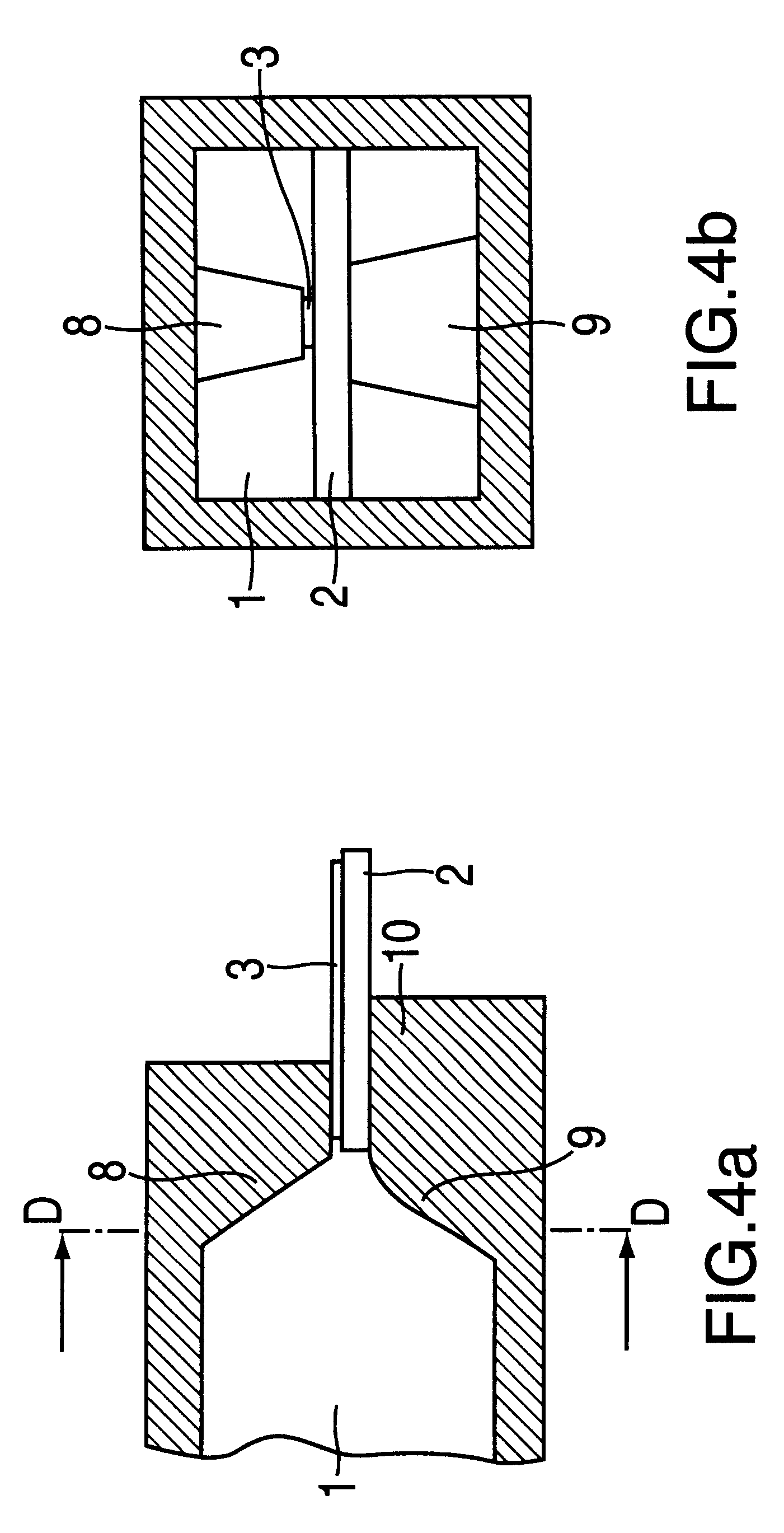

Transition from a waveguide to a strip transmission line

In order for it to be possible to manufacture a transition with a cost-effective stamping or diecasting or cold-molding process or with a plastic injection-molding process with subsequent metal plating, at least one ridge situated in the waveguide, which reduces the waveguide cross section in the direction of the stripline, has a cross section which tapers conically in the direction of the stripline.

Owner:ROBERT BOSCH GMBH +1

Nutrition slow-release type biofiller for water treatment and its preparation method

InactiveCN100999361AIncrease roughnessIncrease specific surface areaSustainable biological treatmentWater/sewage treatment by substance additionPlastic injection moldingInjection molding machine

This invention discloses a nourishing slow-released type organic bulking agent for processing water and its preparation. This bulking agent includes 60-100 parts of high polymer basis material, 1-15 parts of nutrient substance, 1-10 parts of slow-releasing control substance, and 1-10 parts of dispersing lubricant. When prepare, lubricate slow-releasing control substance with 0.5-3 parts of dispersing lubricant; lubricate high polymer basis material with remaining dispersing lubricant, add in stirring machine, mix with above mixture, mix uniformly, transfer mixture into stirring dipper of plastic injection molding machine, extrude and form by bulking agent tooting. Organic bulking agent prepared by this invention slow-releases nutrient substance that is required for microbes forming biofilm. It has characteristics of fast forming biofilm, more microbial biomass, and activity. It is especially suitable for oxygen degrading process of waste water that contains difficult degraded toxic pollutant.

Owner:SOUTH CHINA UNIV OF TECH

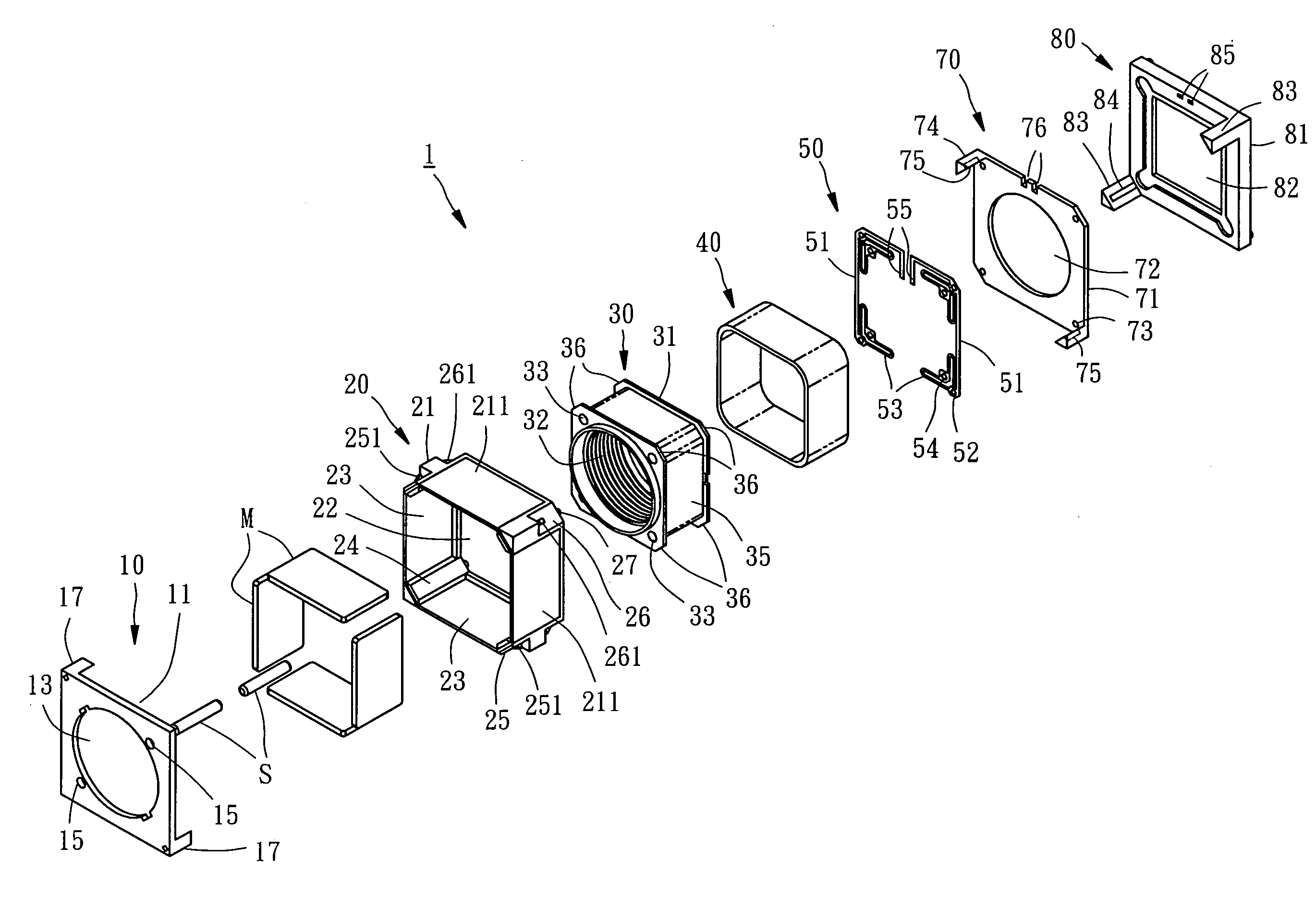

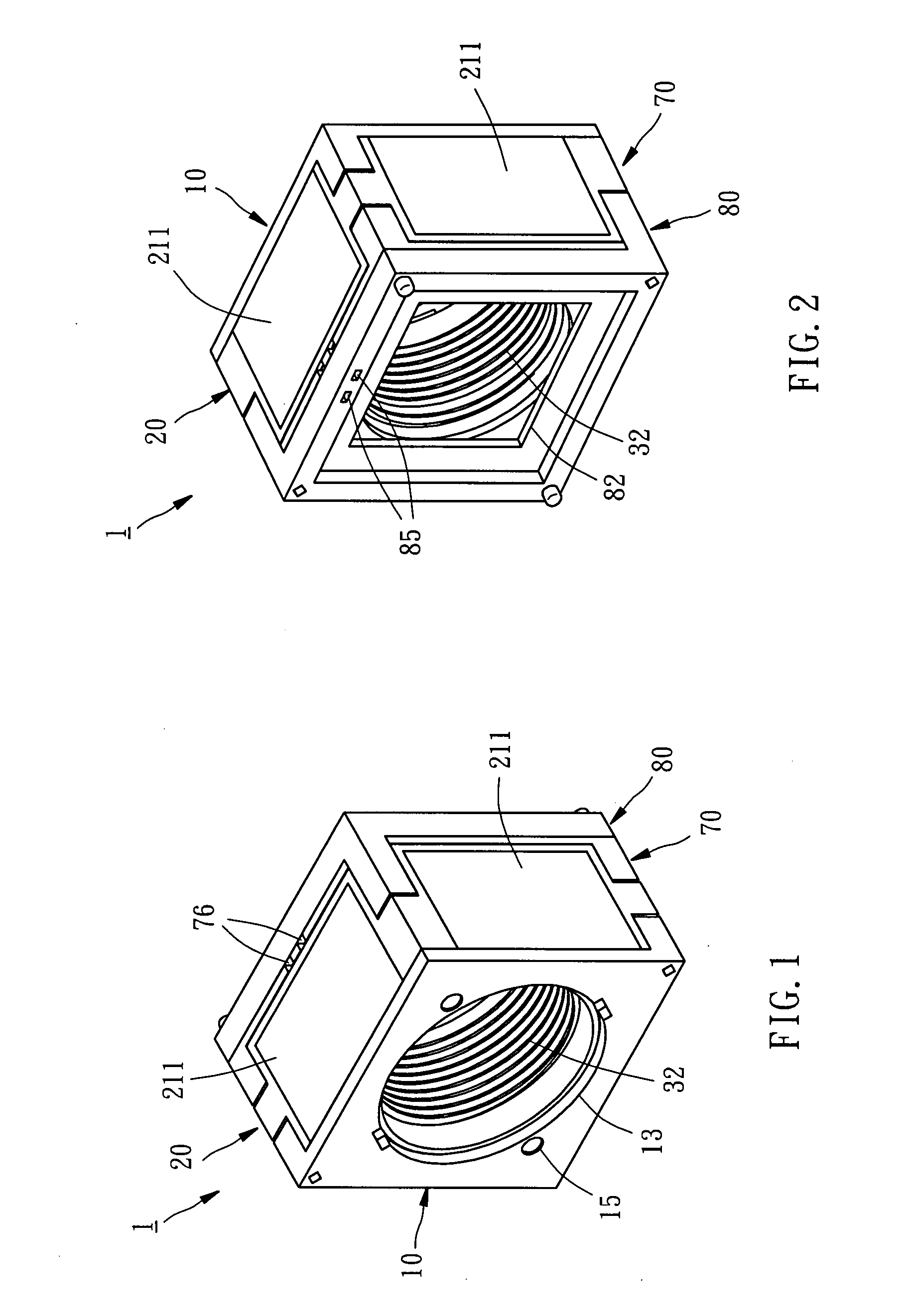

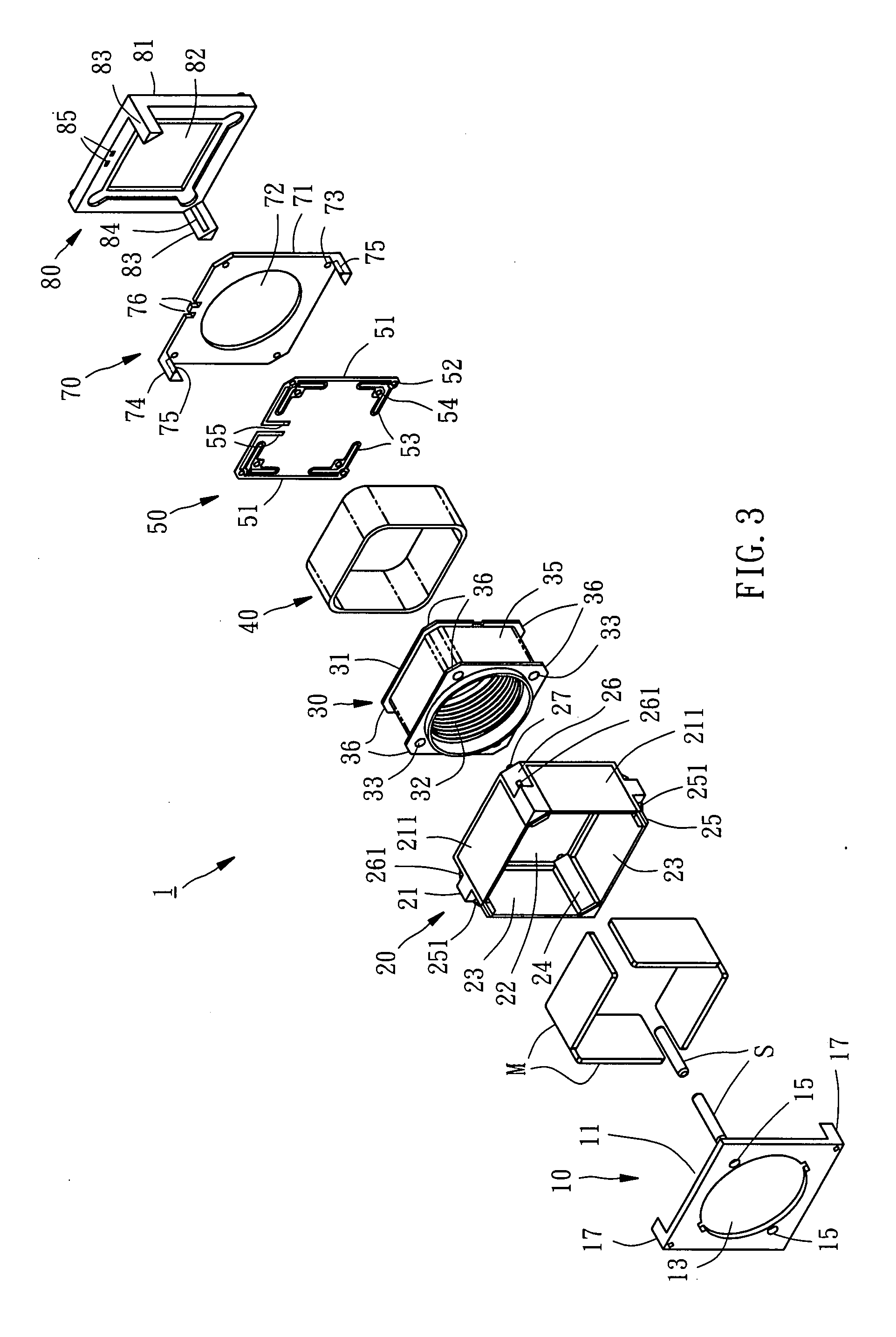

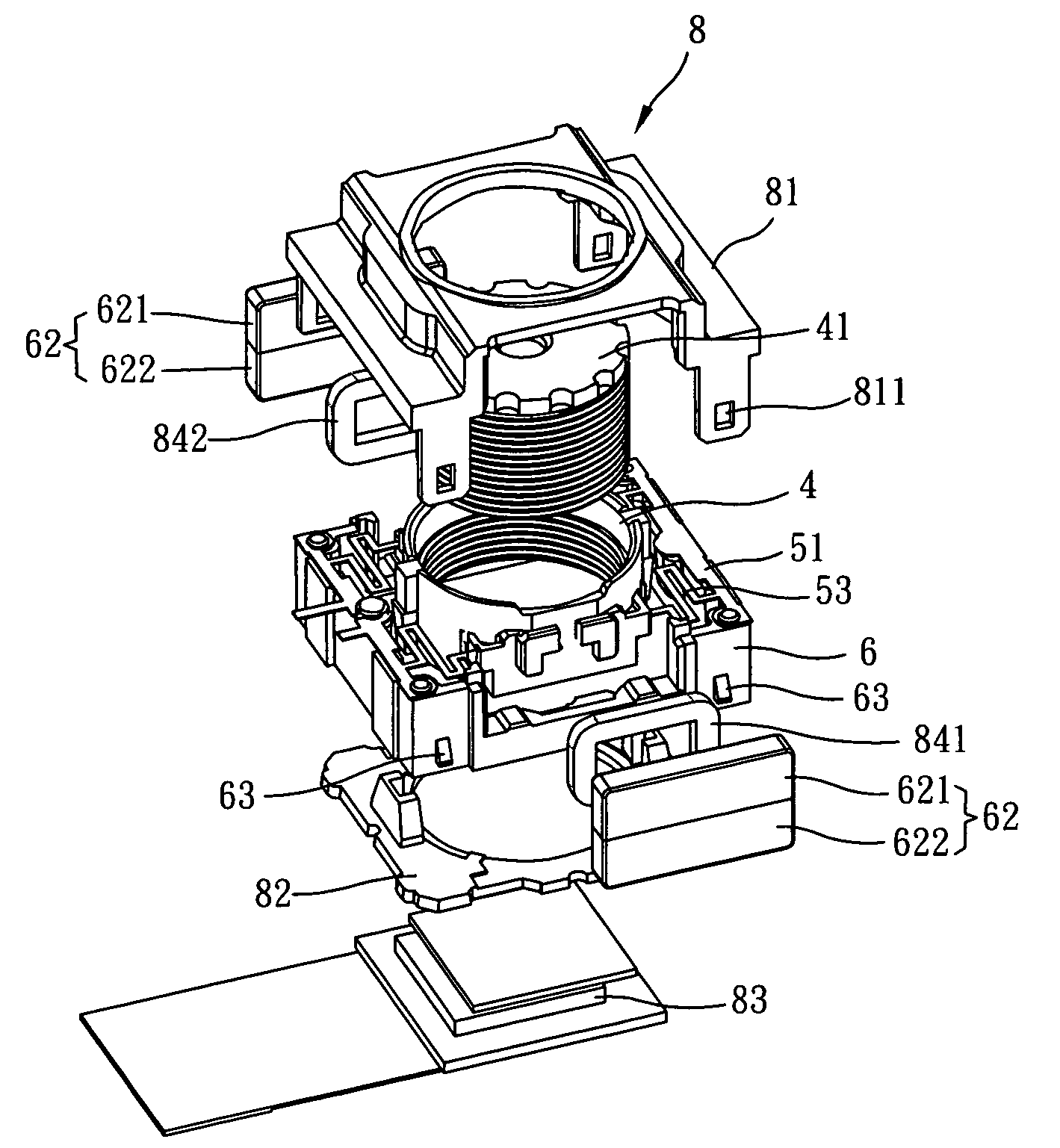

Voice coil motor type focusing actuator

InactiveUS20080007850A1High strengthReduce assembly processPiezoelectric/electrostriction/magnetostriction machinesMountingsPlastic injection moldingActuator

Owner:TRICORE CORP

Method for producing breaker pole parts for low-voltage, medium-voltage and high-voltage switchgear assemblies, and breaker pole part itself

ActiveUS20080142485A1Meet the requirementsMouldsHigh-tension/heavy-dress switchesPlastic injection moldingLow voltage

The disclosure relates to a method for producing circuit-breaker parts and plastic components for low, medium and high-voltage switching stations and to a corresponding circuit-breaker part. To obtain a simpler method of production with a higher variance of material characteristics, the outer insulation sleeve is produced in a plastic injection molding method, in which a vacuum interrupter chamber is sheathed in plastic.

Owner:ABB (SCHWEIZ) AG

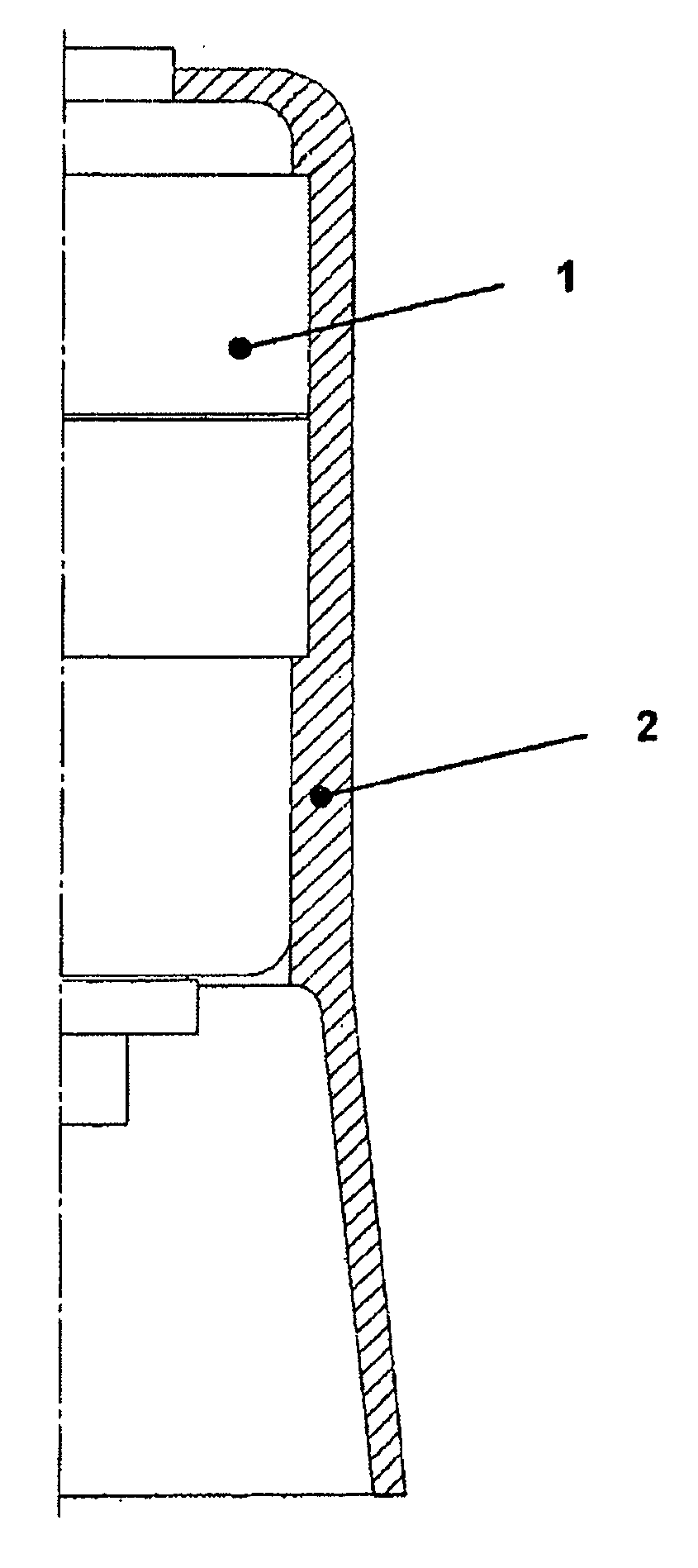

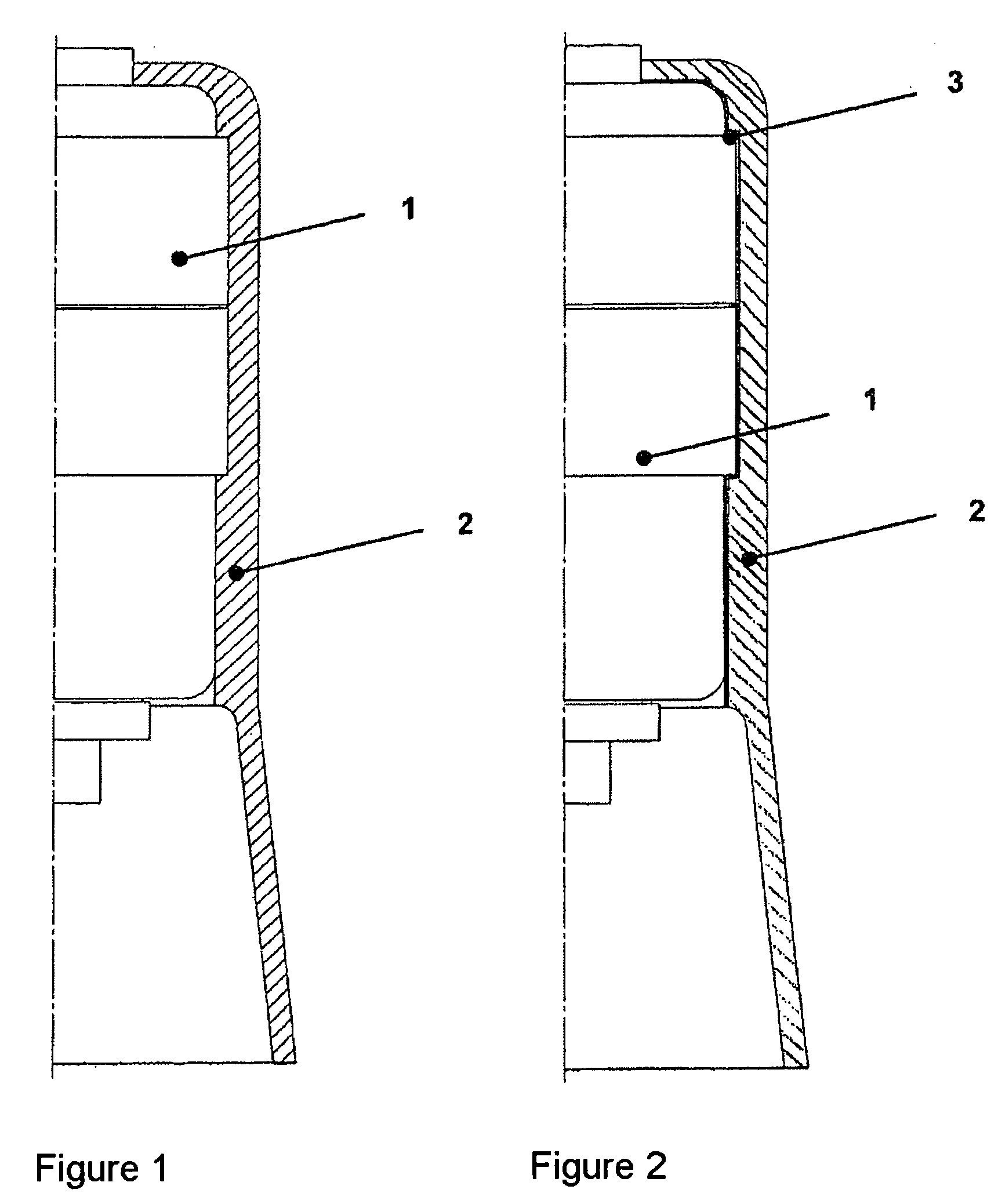

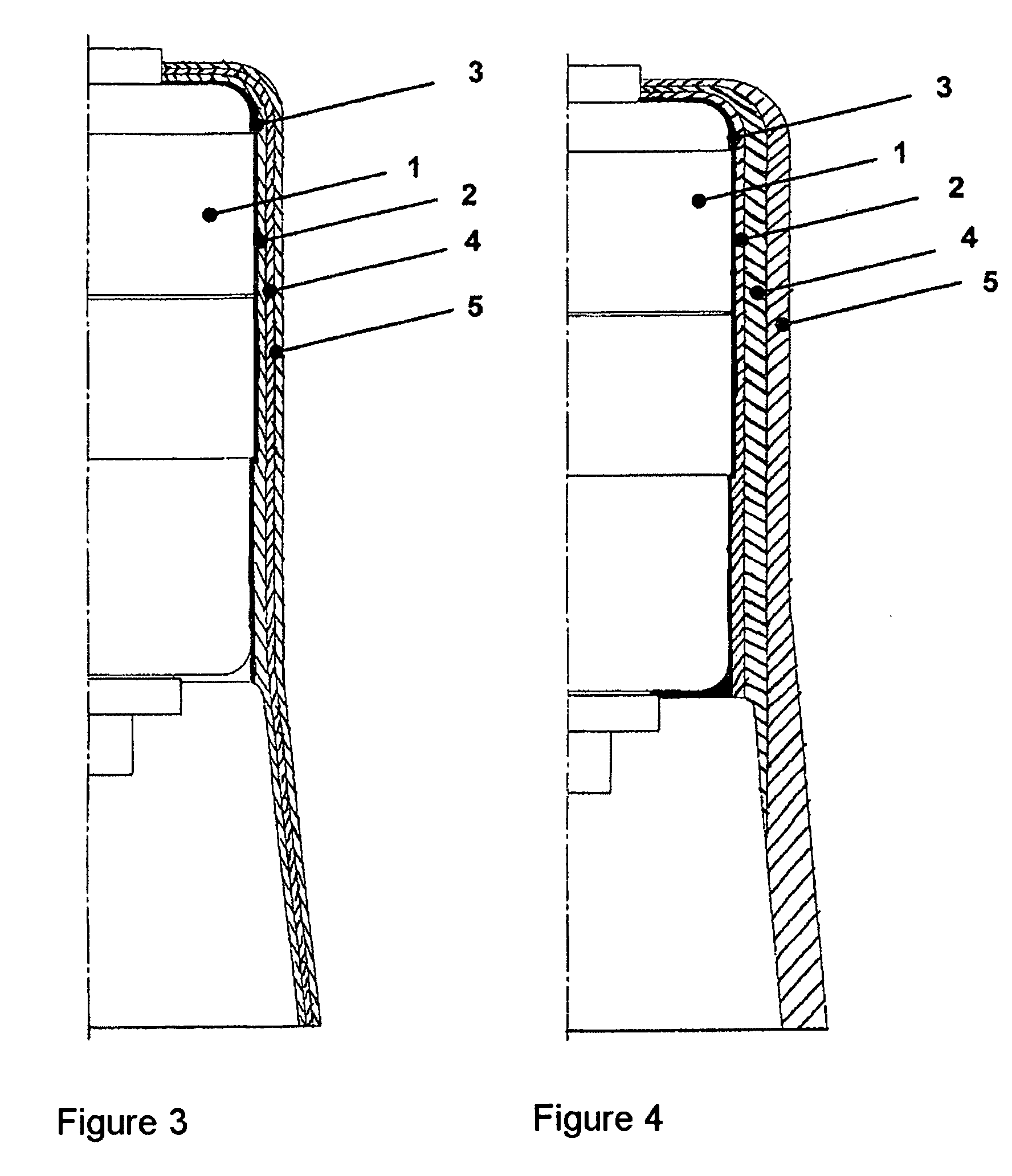

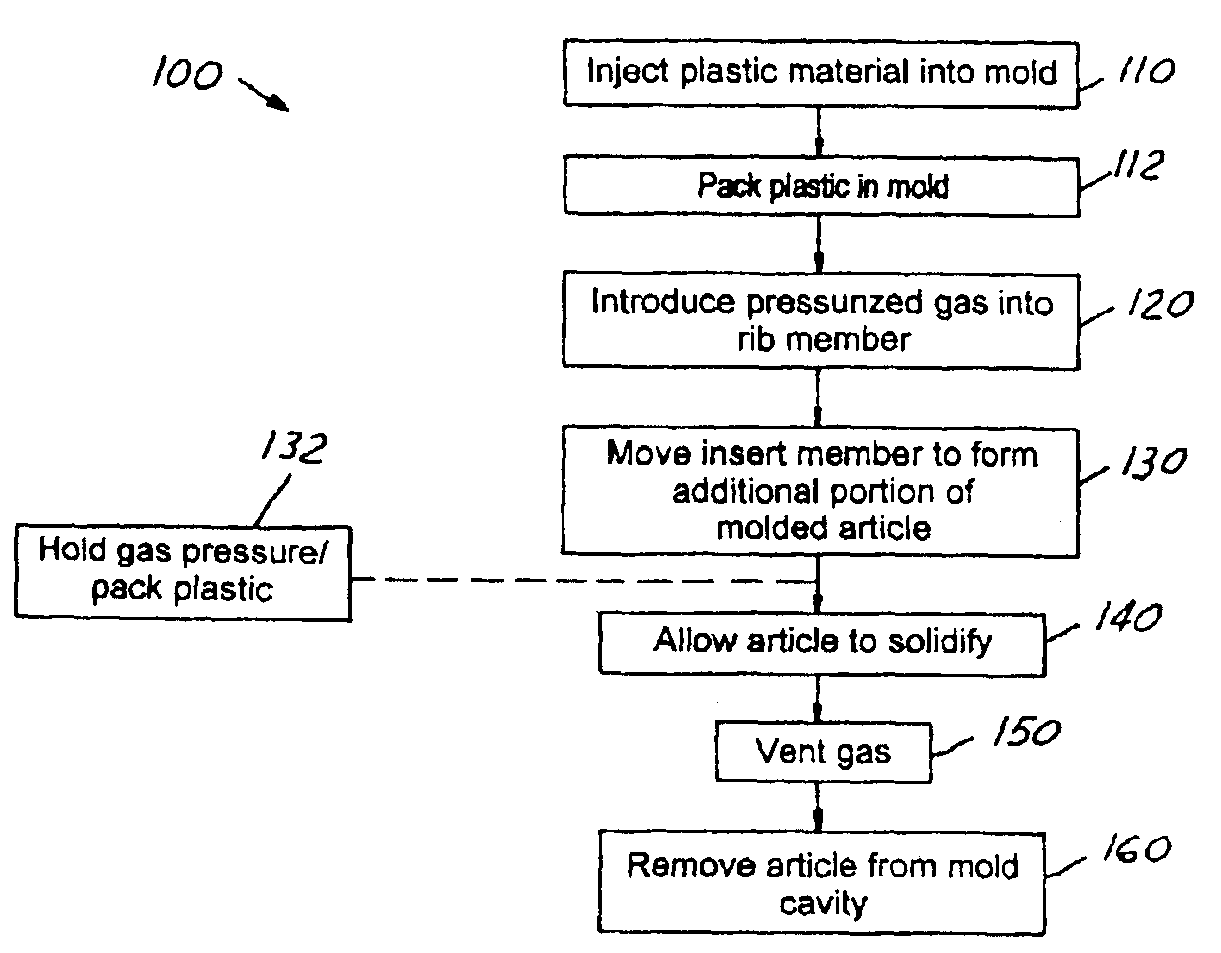

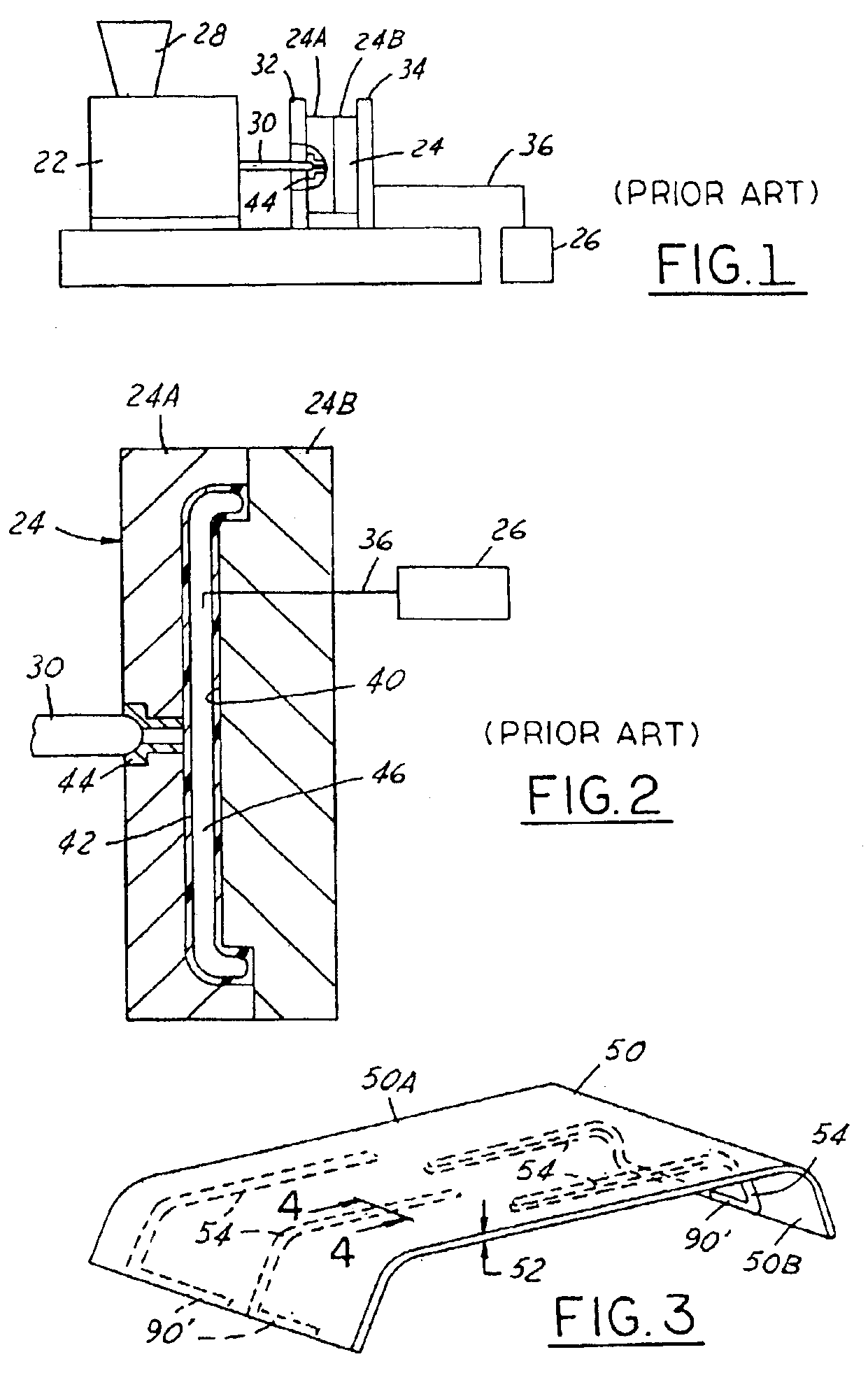

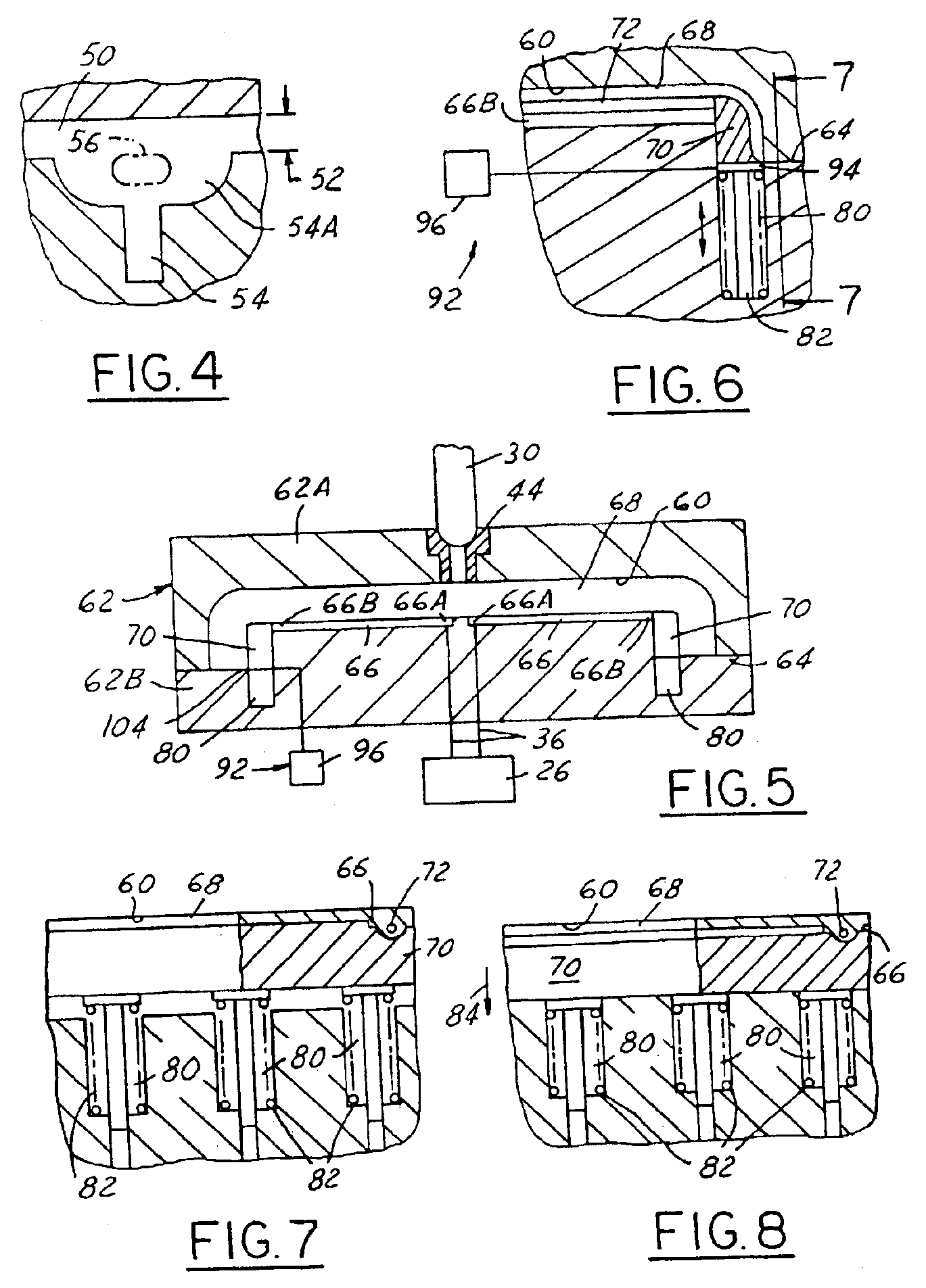

Plastic injection molding with moveable insert members

InactiveUS6939504B2Improve surface propertiesConfectionerySweetmeatsPlastic packagingPlastic injection molding

A method and system for producing hollow rib structures for trim components and panels using gas assisted injection molding. Movable insert members are provided in the mold cavity, particularly at the ends of the structural rib members. After the plastic material is injected into the mold cavity, the plastic is packed in the mold, and the insert members are locked in position. Selectively activatable locking mechanisms are used to lock up the insert members. Thereafter, gas or another fluid is introduced into the rib members in order to provide hollow channels therein. Movement of the insert members provides a recess or groove for placement of the displaced resin from the rib members. The displaced resin material completes the formation of the molded plastic article.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

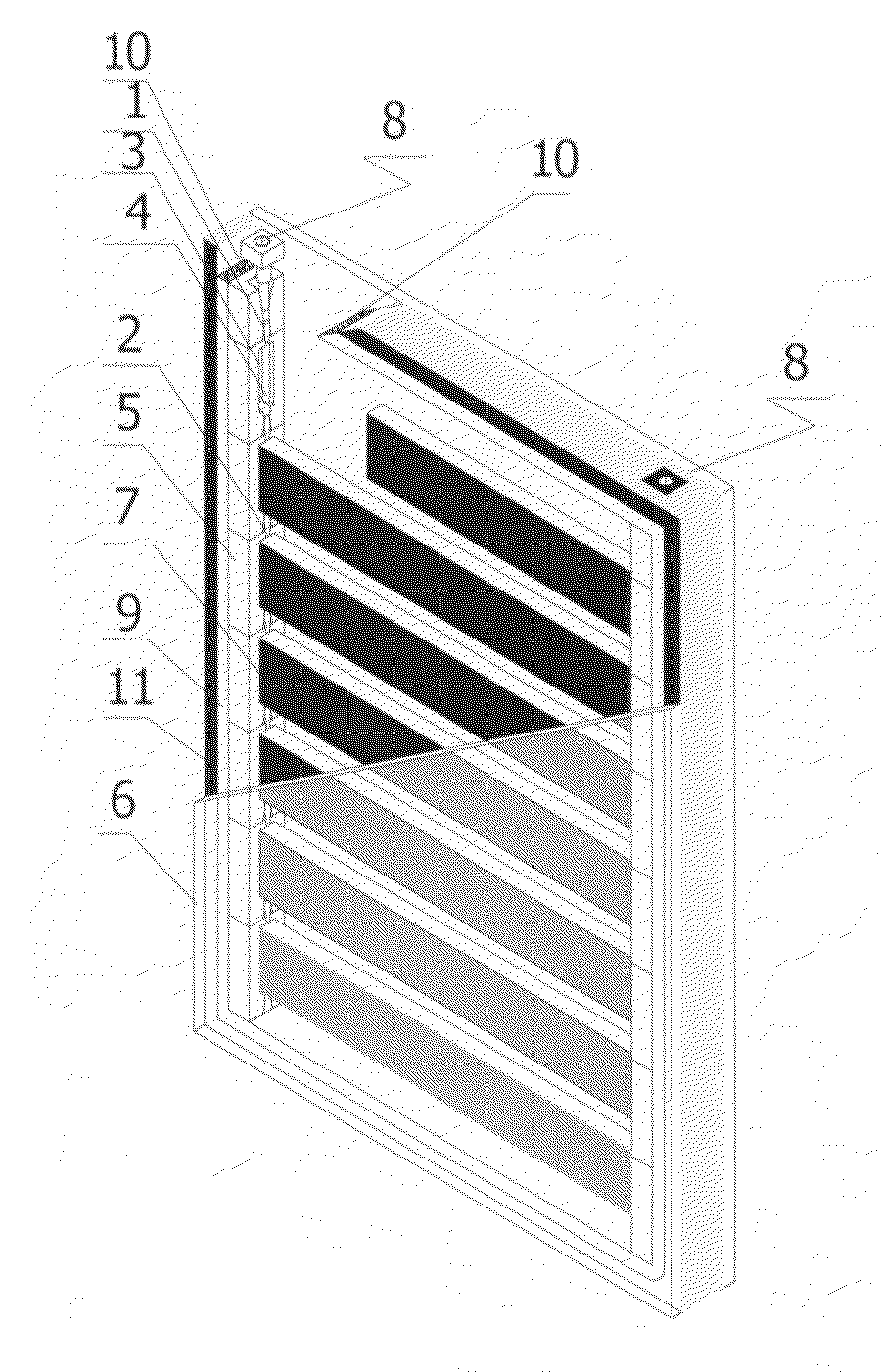

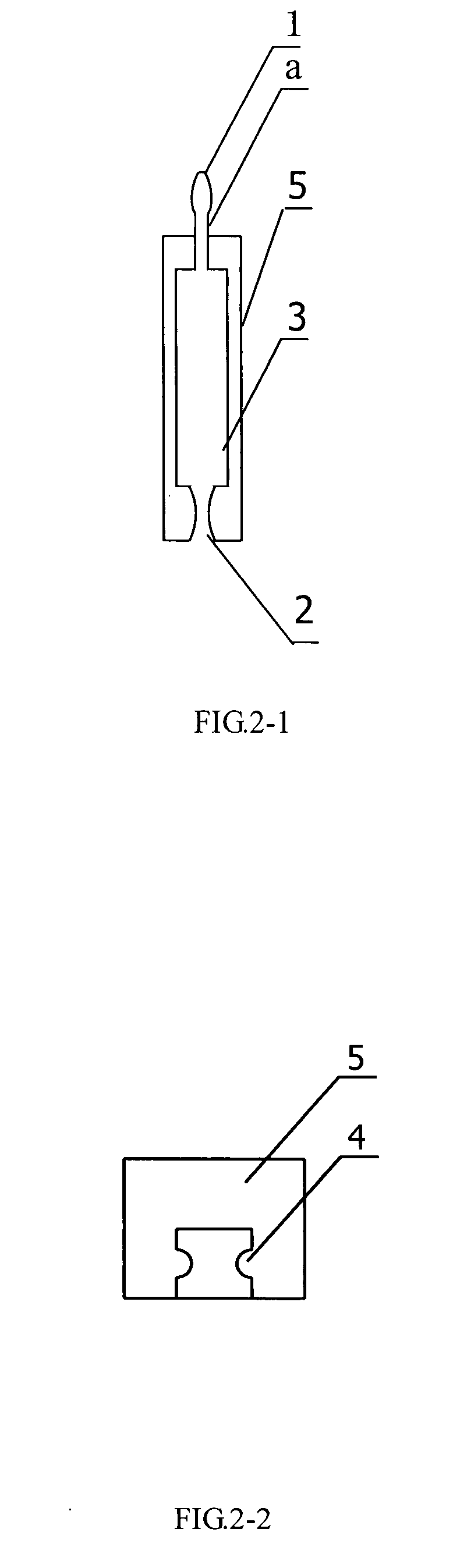

Integrated photovoltaic modular panel for a curtain wall glass

ActiveUS20080163918A1Easy to modifySuitable for mass productionWallsPV power plantsPlastic injection moldingAmorphous silicon solar cell

An integrated photovoltaic modular panel for a curtain wall glass is used for the field of building integrated photovoltaic. The invention provides the standardized photovoltaic units, so that the electrodes in a photovoltaic panel main body can be internally parallel connected. The connector may be a metal piece of stamping or casting, which has a plug 1 and a socket 2 on both ends, a waist b in the middle, an inward concave straight strip 4 on both sides of the waist, an electrode plug-in socket 3 in the waist for firmly clamping solar cell, a plastic injection molding crust 5 for fixing and securing the connector, forming a module. It can combine with different kinds of glass, forming different kinds of photovoltaic curtain wall glass. The solar cell here may be an amorphous silicon solar cell.

Owner:LI YI

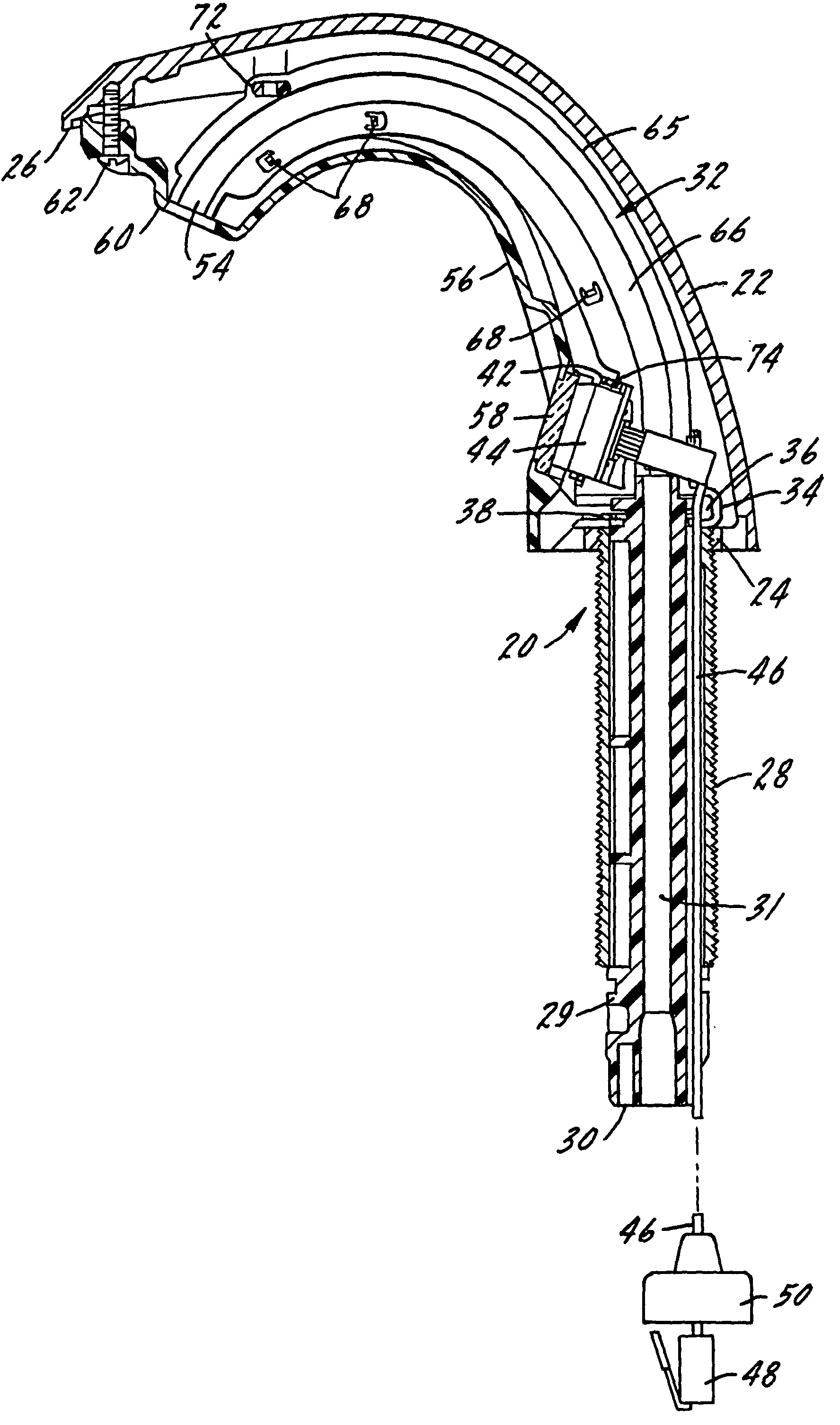

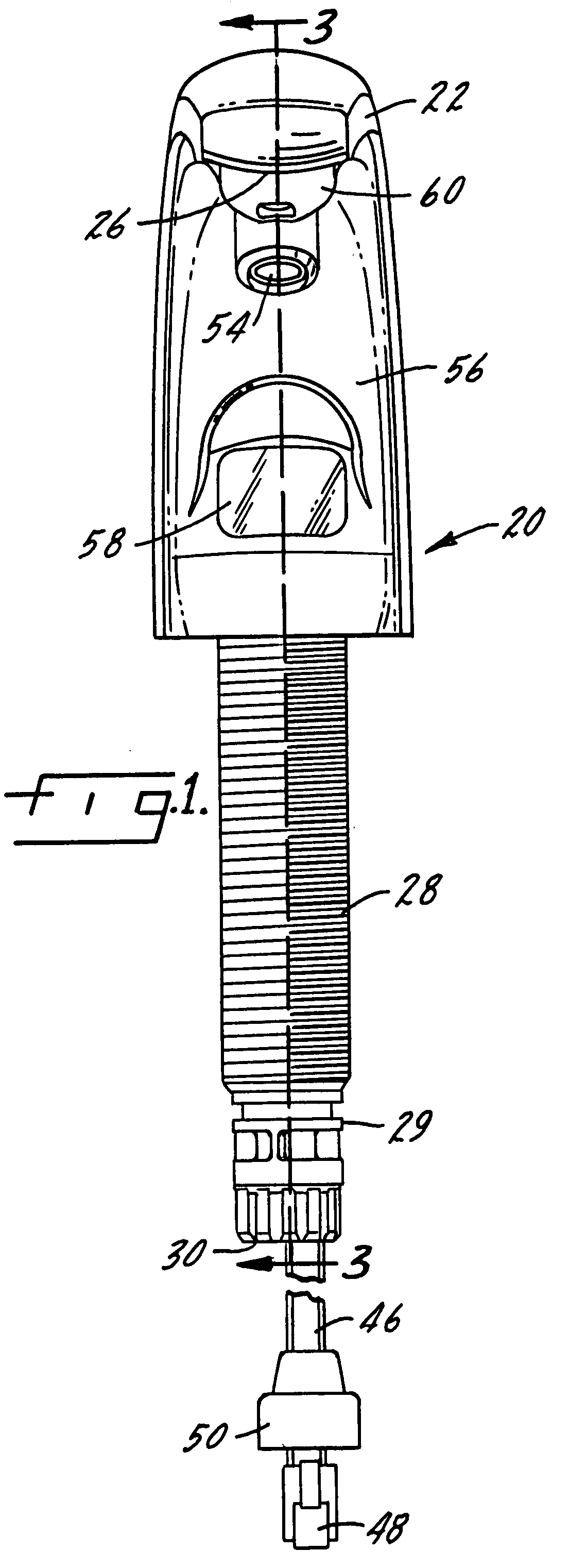

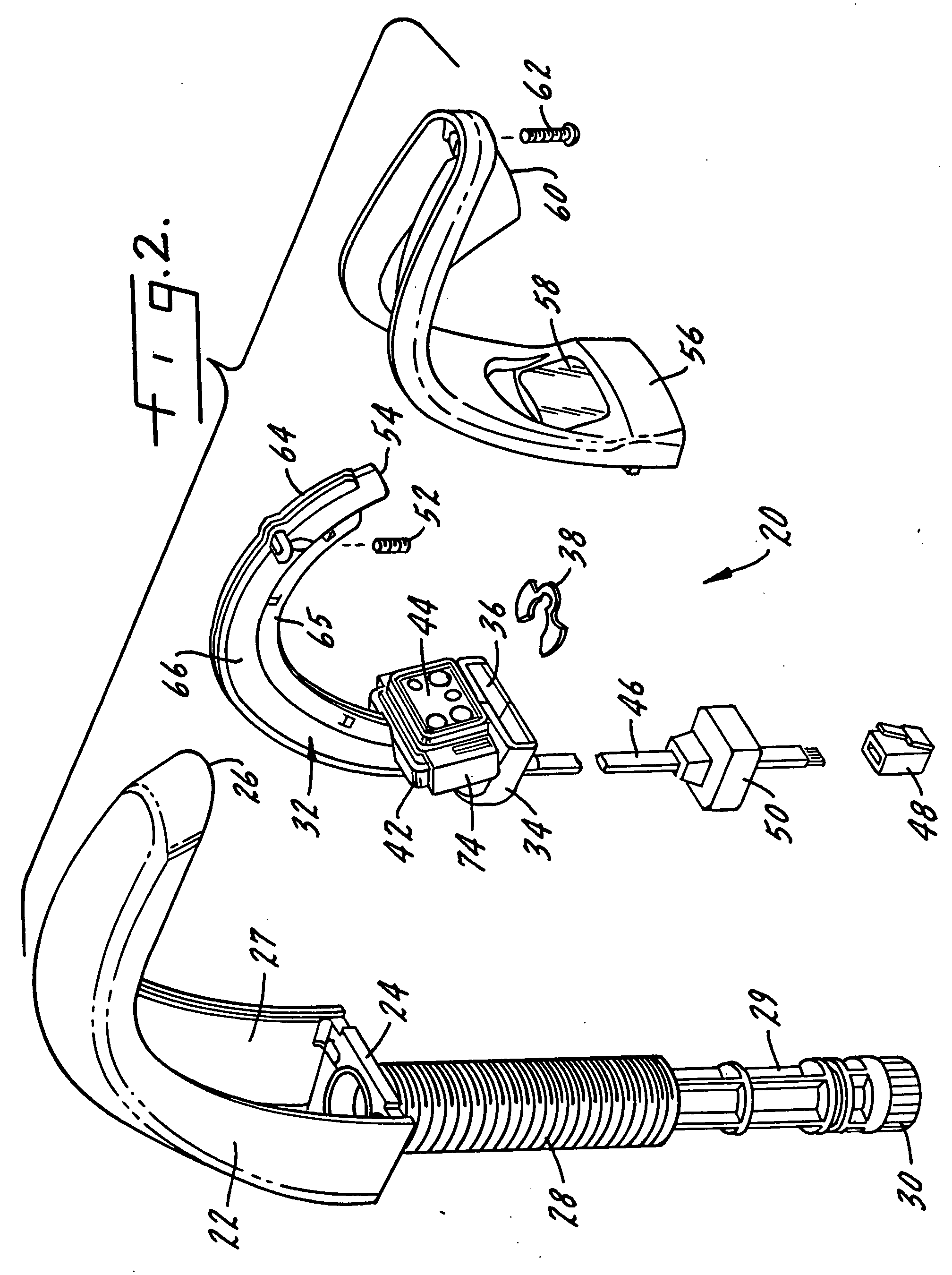

Electronic soap dispenser

ActiveUS7025227B2Increased durabilityImprove the immunityVolume measurement and fluid deliveryLarge containersPlastic injection moldingSoap dispenser

A liquid soap dispenser includes a housing, a shank that engages a base of the housing, a soap path retainer disposed in the interior of the housing, a shank adapter disposed in the shank, and an infrared sensor to sense the presence of a user. A generally continuous passageway is defined through the shank adapter and the soap path retainer such that an elongated soap delivery tube of a liquid soap reservoir may be inserted through the passageway from the bottom of the soap dispenser to the spout end. The reservoir may be attached to the bottom end of the shank adapter. The soap path retainer is preferably formed of complementary halves, such as by plastic injection molding, that mate together to provide a curved passageway from near the base of the housing to the soap dispensing end and to support the sensor assembly.

Owner:SLOAN VALVE COMPANY

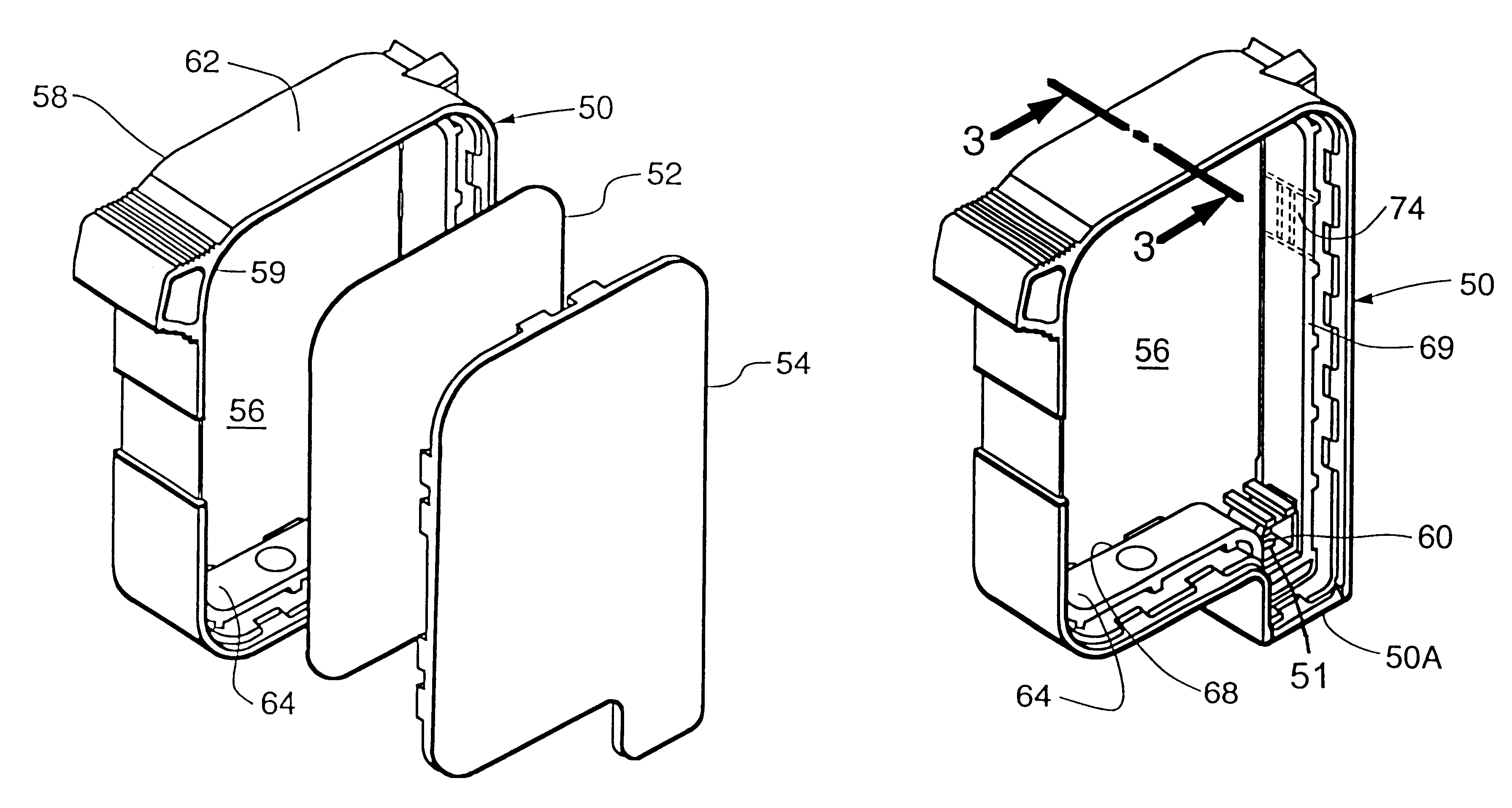

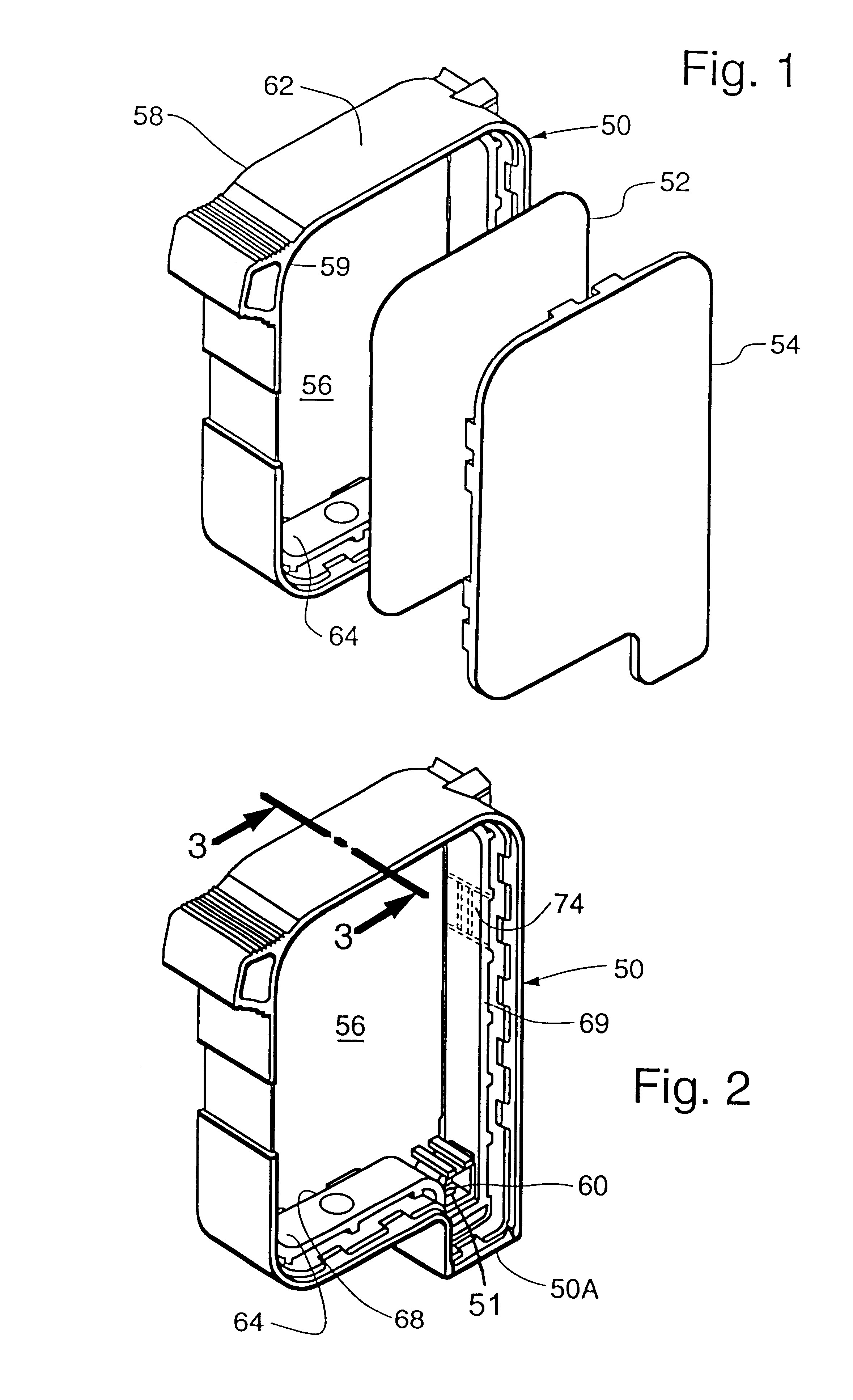

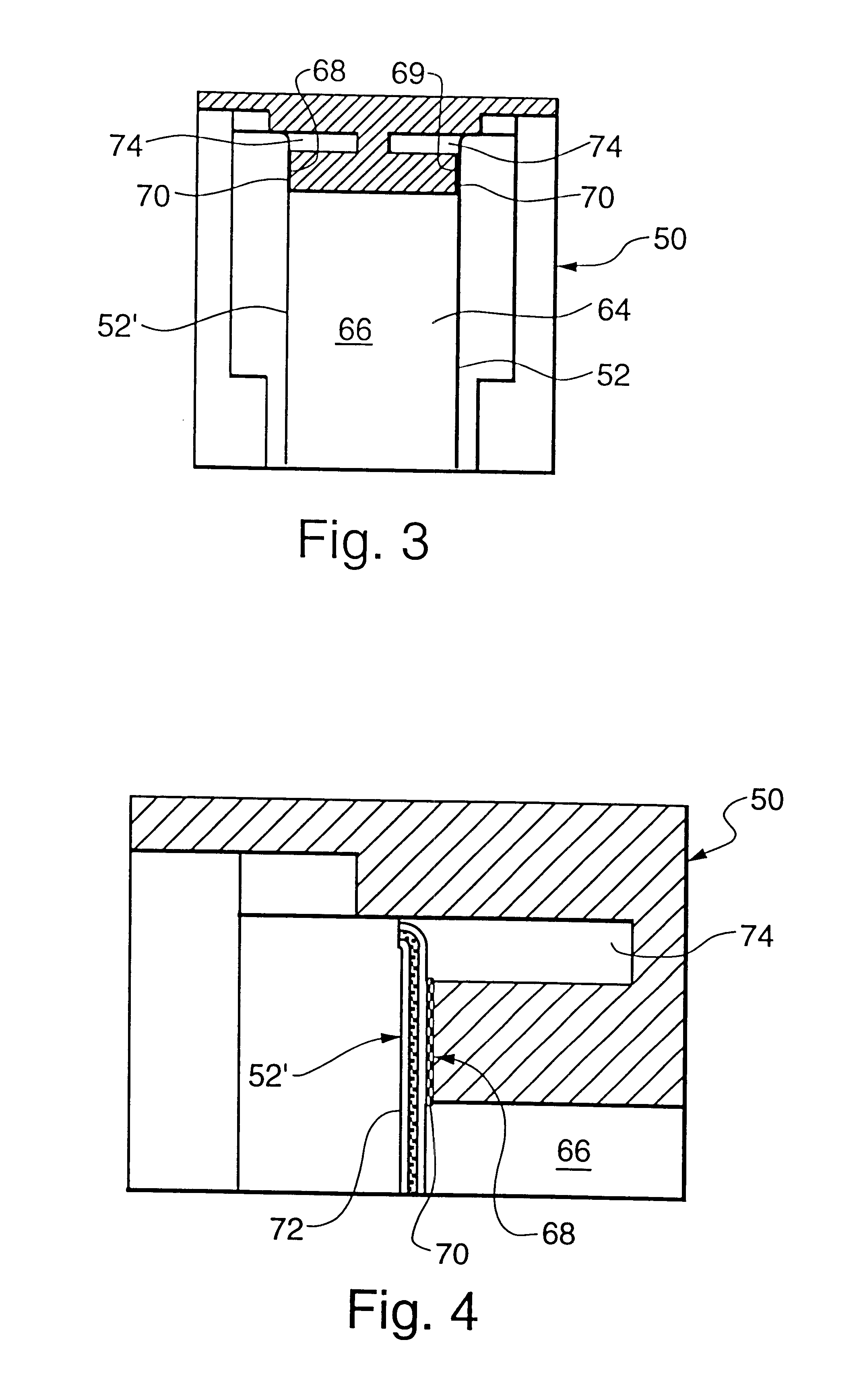

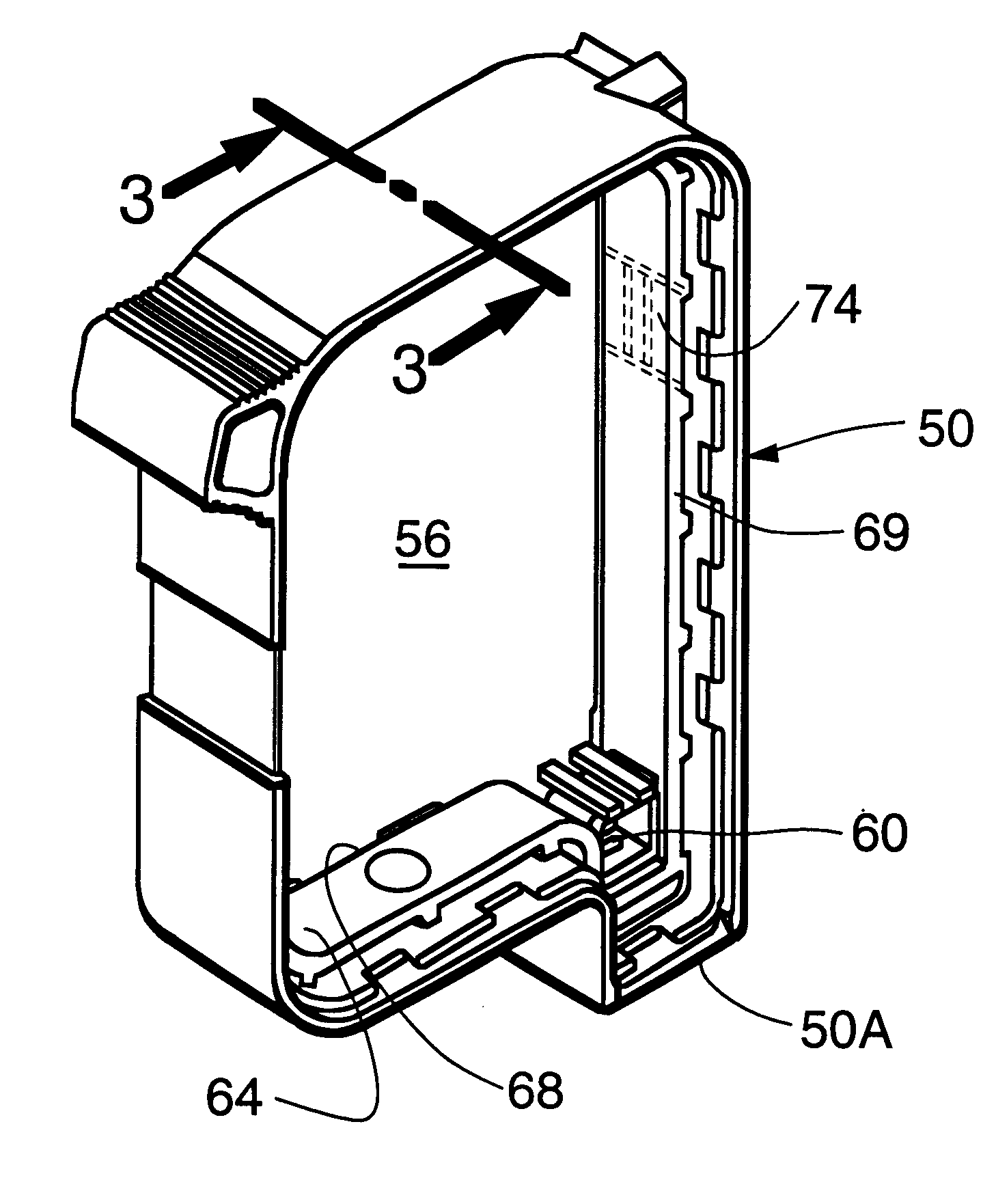

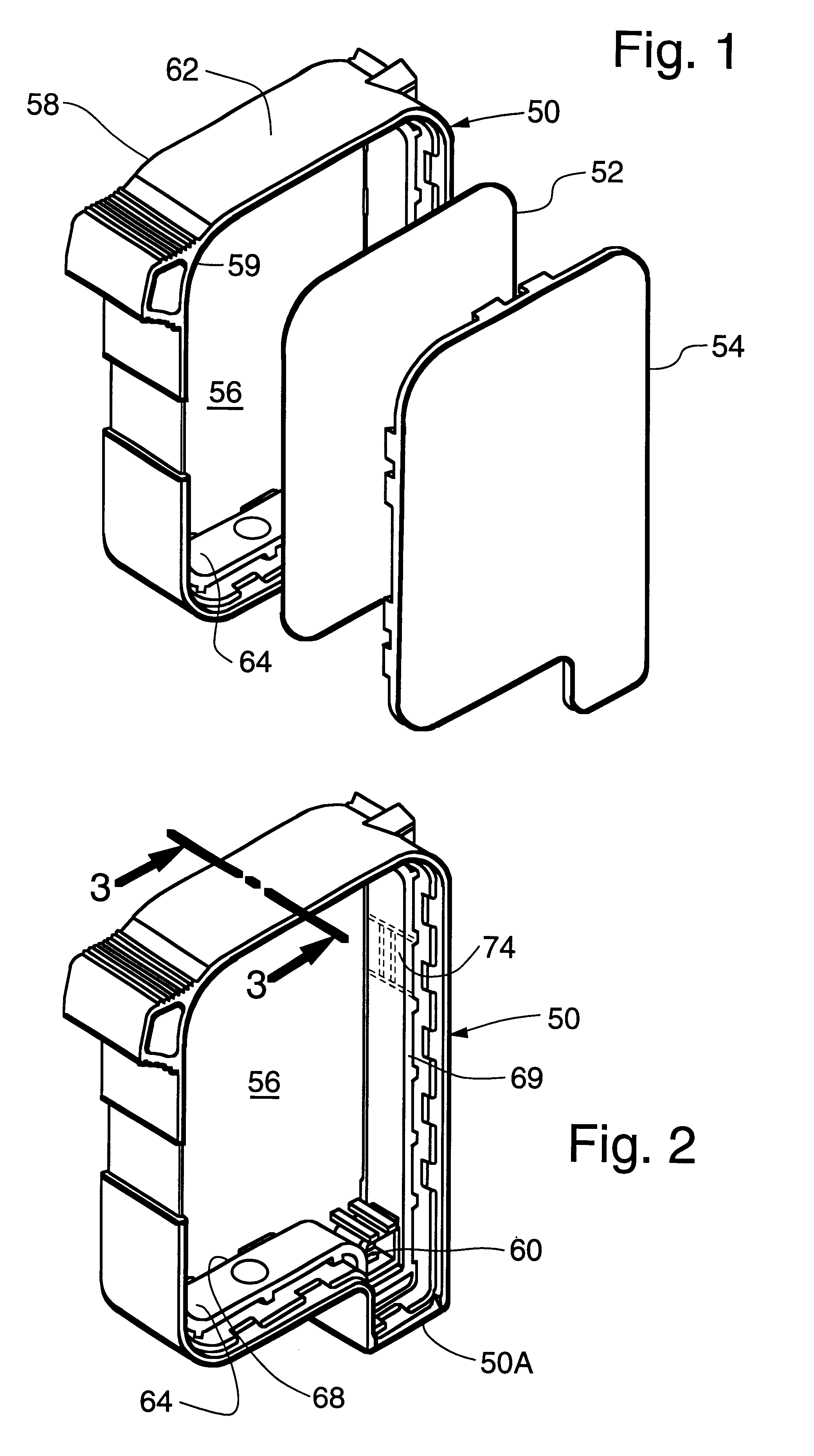

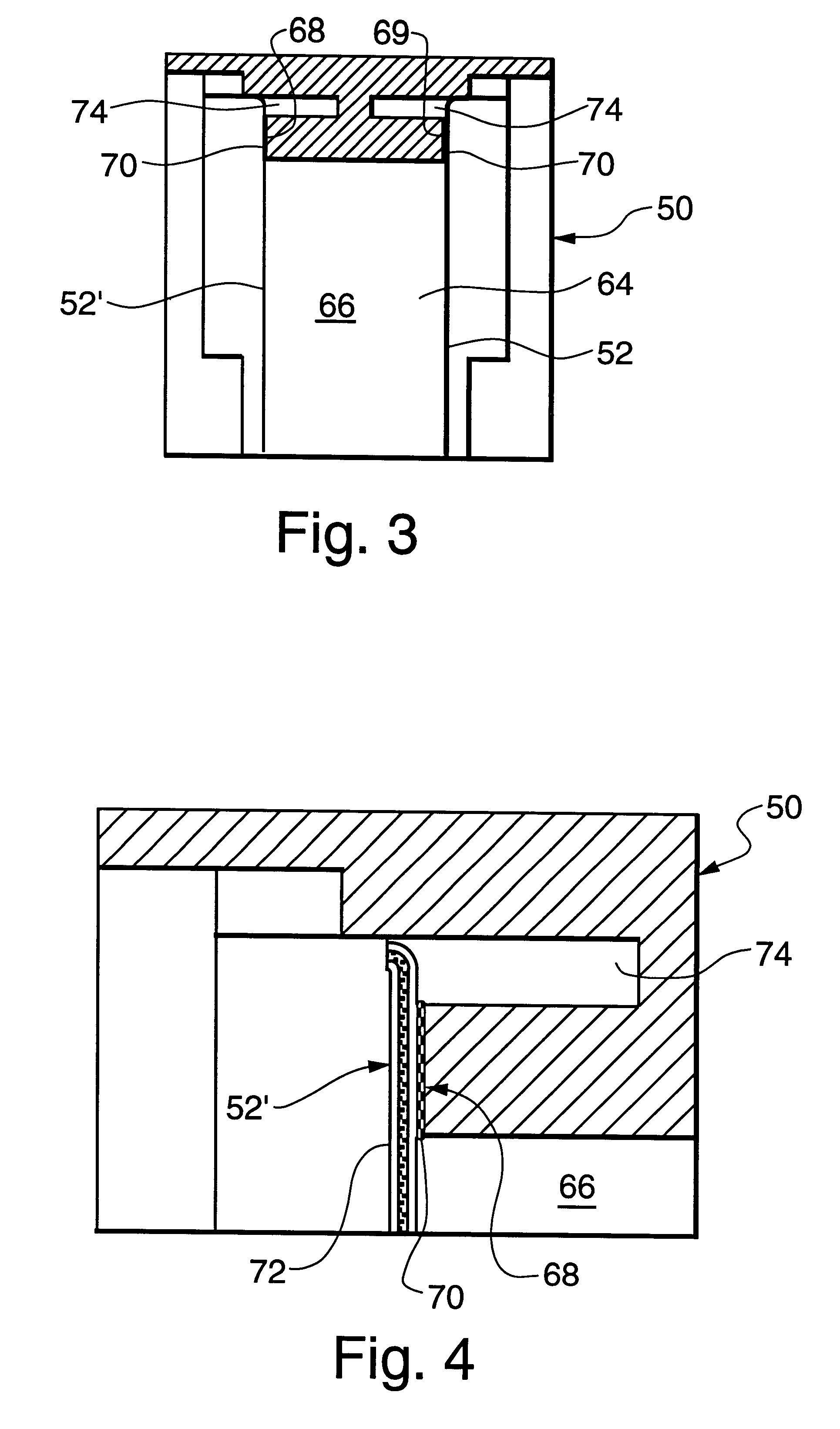

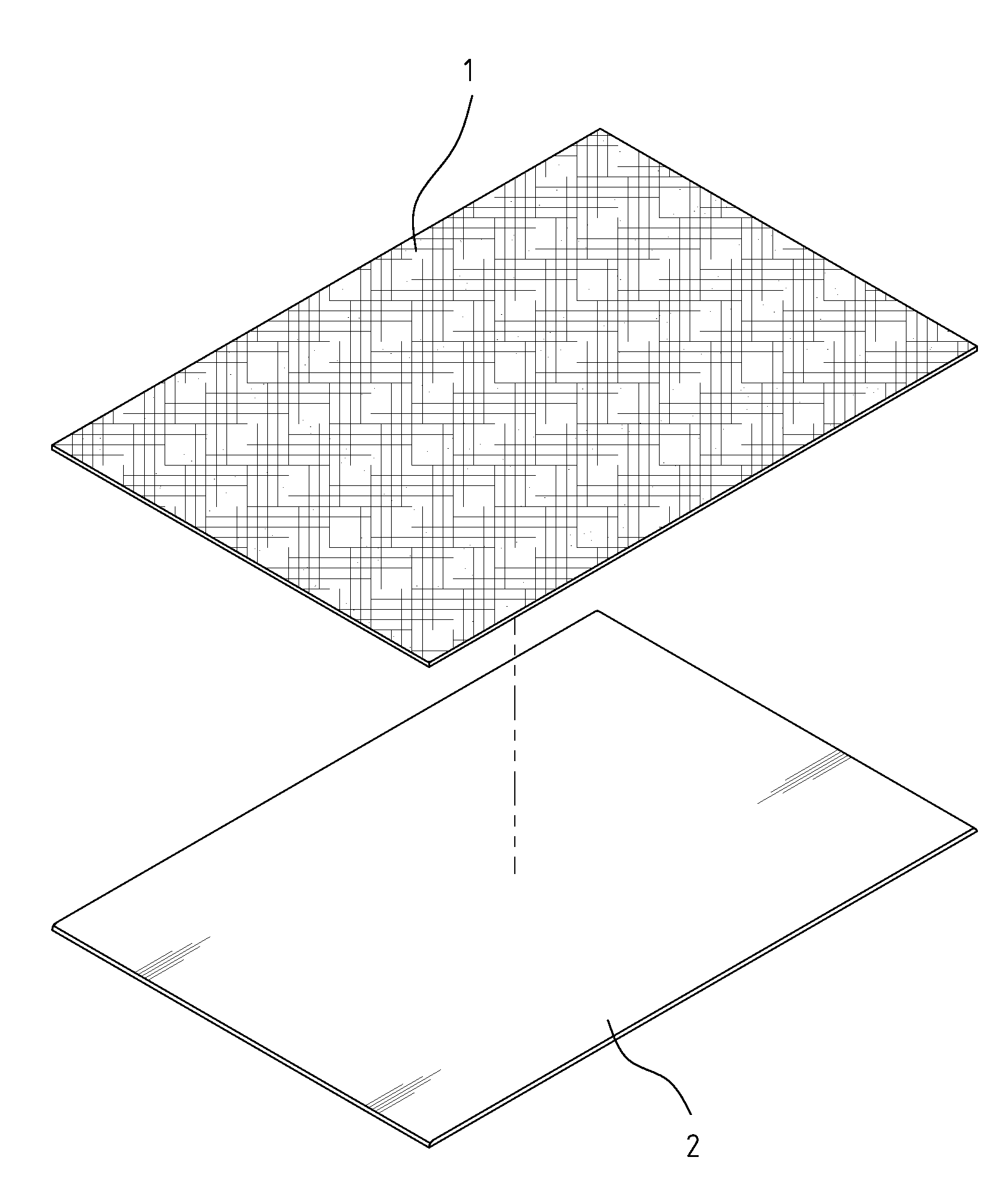

Print head cartridge made with jointless one-piece frame consisting of a single material throughout

A print head having an ink reservoir therein is made by forming, in a one-shot plastic injection molding step, a rigid monolithic frame including high melt temperature material having an opening therein extending from a first side to a second side, and first and second bonding surfaces surrounding the opening and facing the first and second sides, respectively. First and second thin flexible films are adhesively secured to the first and second bonding surfaces, respectively. The adhesive material may be a hot melt adhesive or dry adhesive films pre-formed to the shape of the bonding surfaces. By securing the flexible films to the bonding surfaces adhesively, rather than by heat staking, it is not necessary to form the frame of different materials during two separate molding steps.

Owner:FUNAI ELECTRIC CO LTD

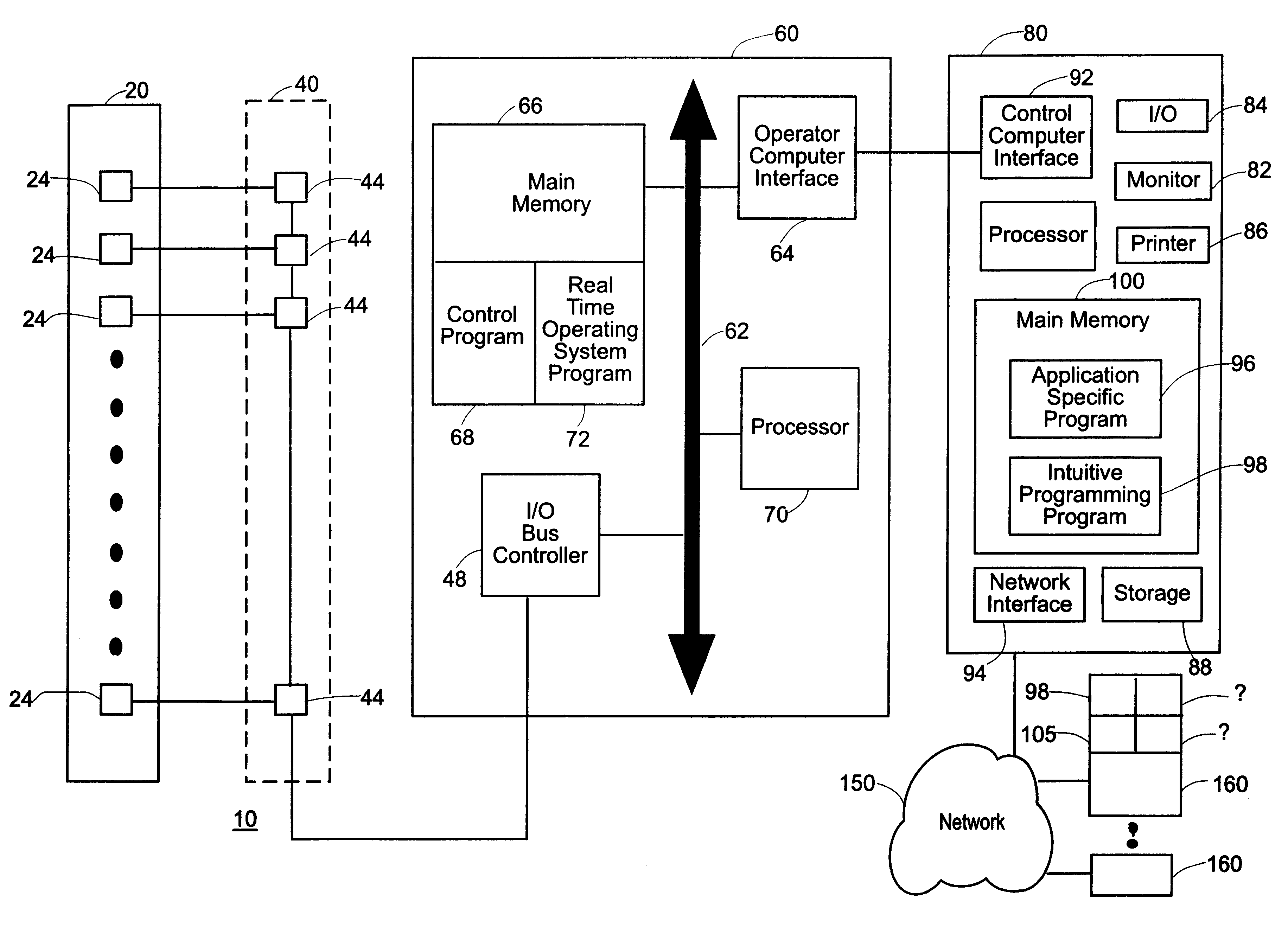

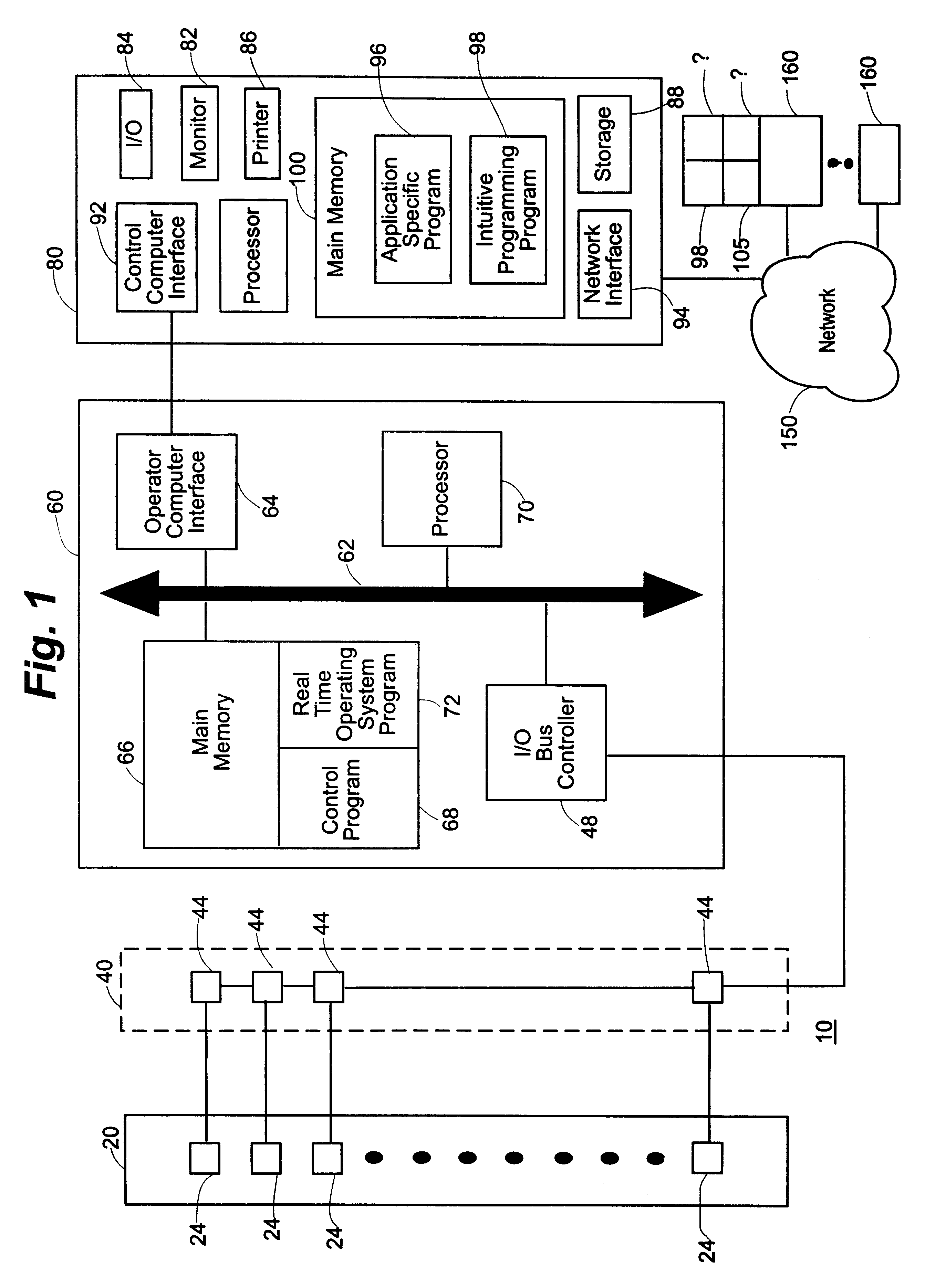

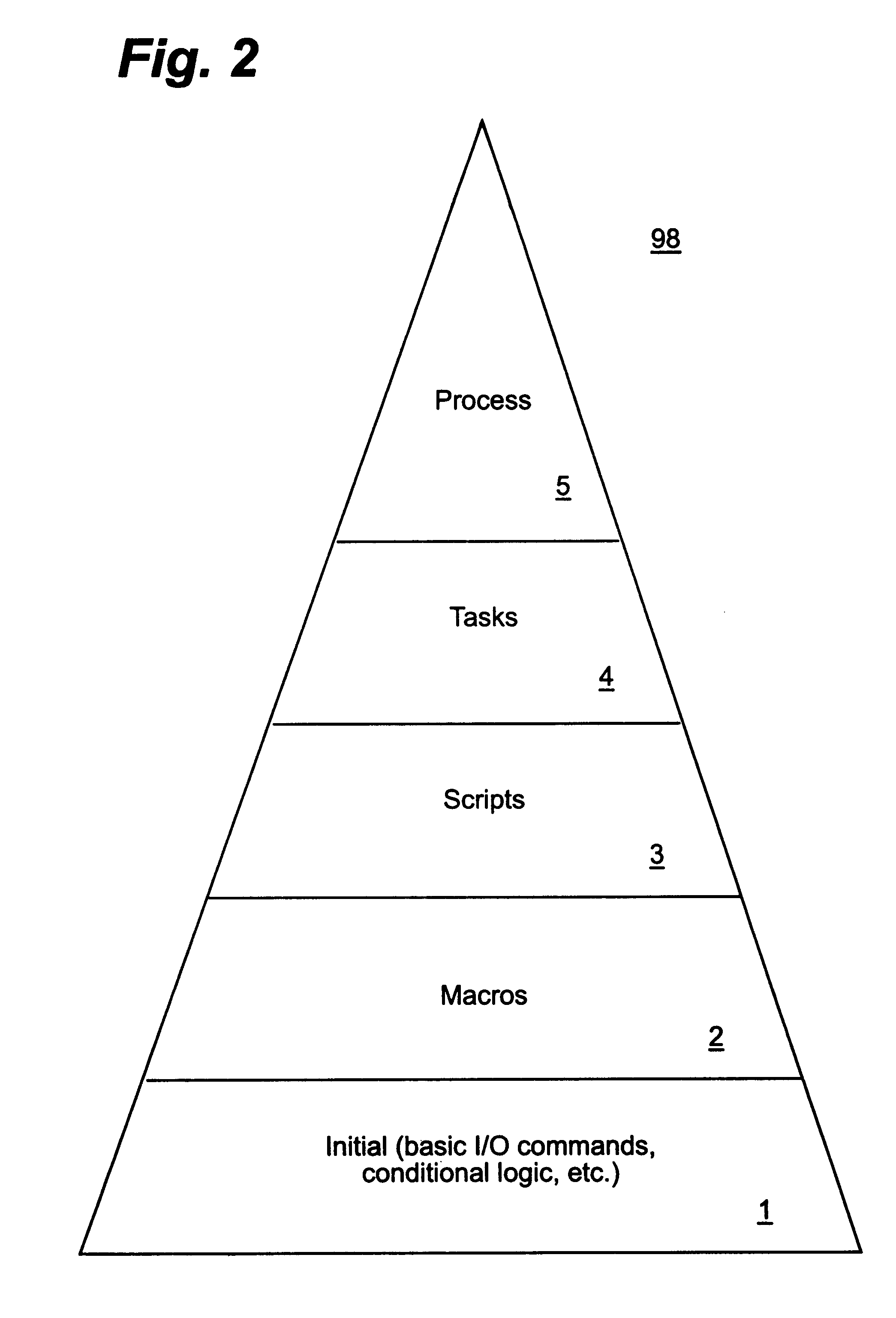

Processor-based process control system with intuitive programming capabilities

A system having a processor-based process control system for a plastic injection molding machine performing a plastic injection molding process having an I / O bus network containing a plurality of I / O modules operably connected to a corresponding I / O device associated with the plastic injection molding machine and a first computer having and I / O bus controller directly connected to the I / O bus network, a real-time operating system, and a first processor executing a plastic injection molding control program for controlling the plastic injection molding process.

Owner:HETTINGA SIEBOLT

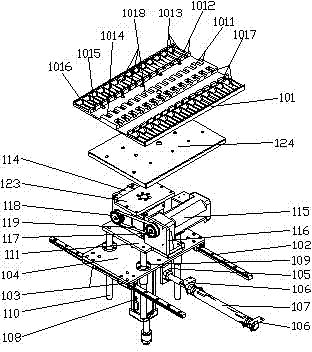

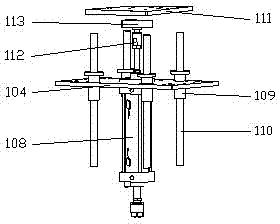

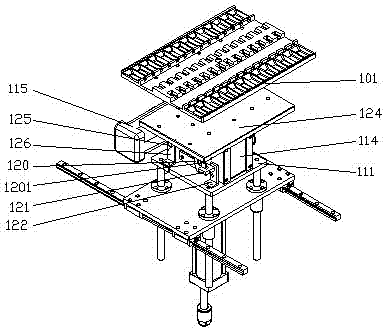

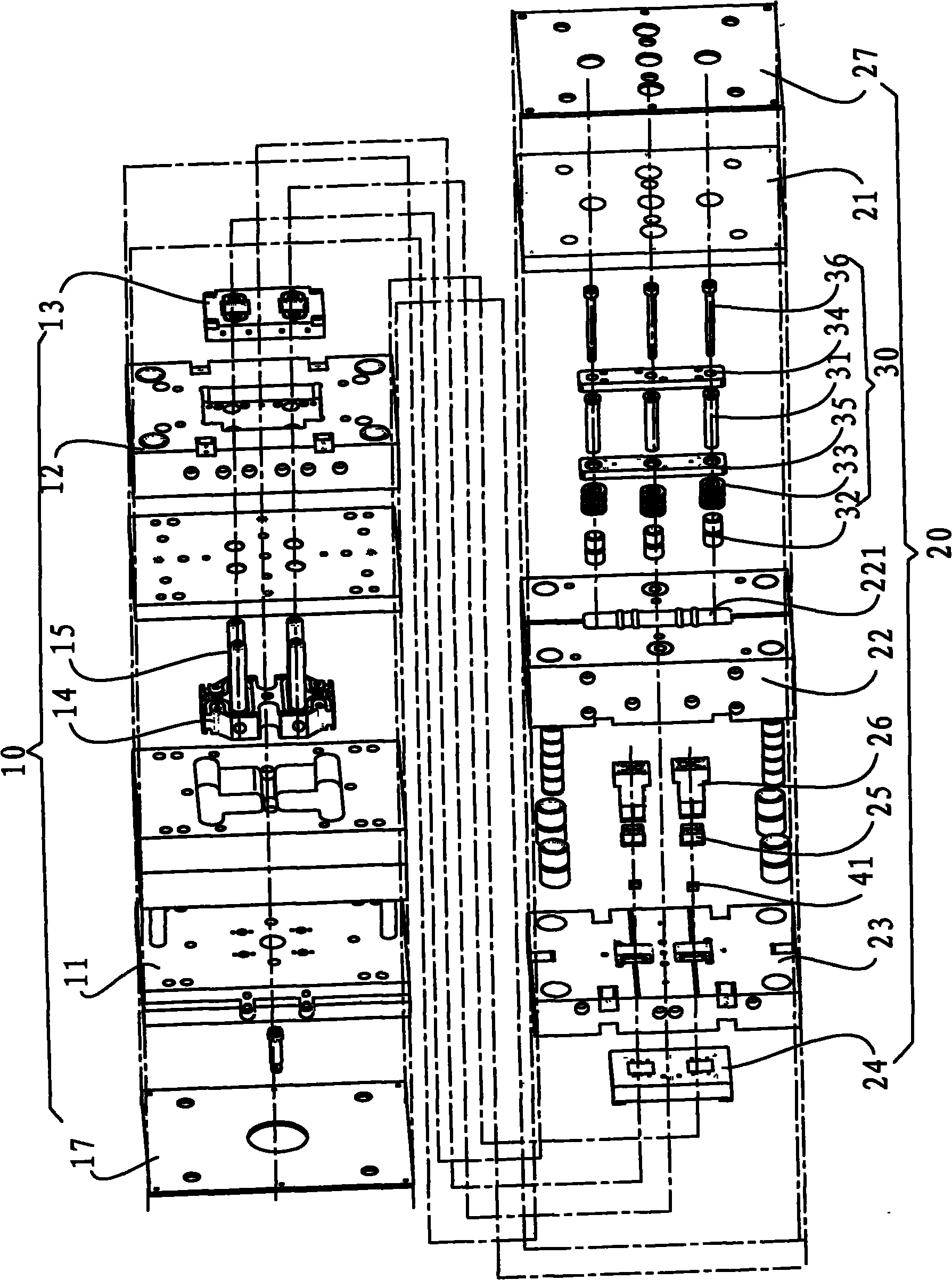

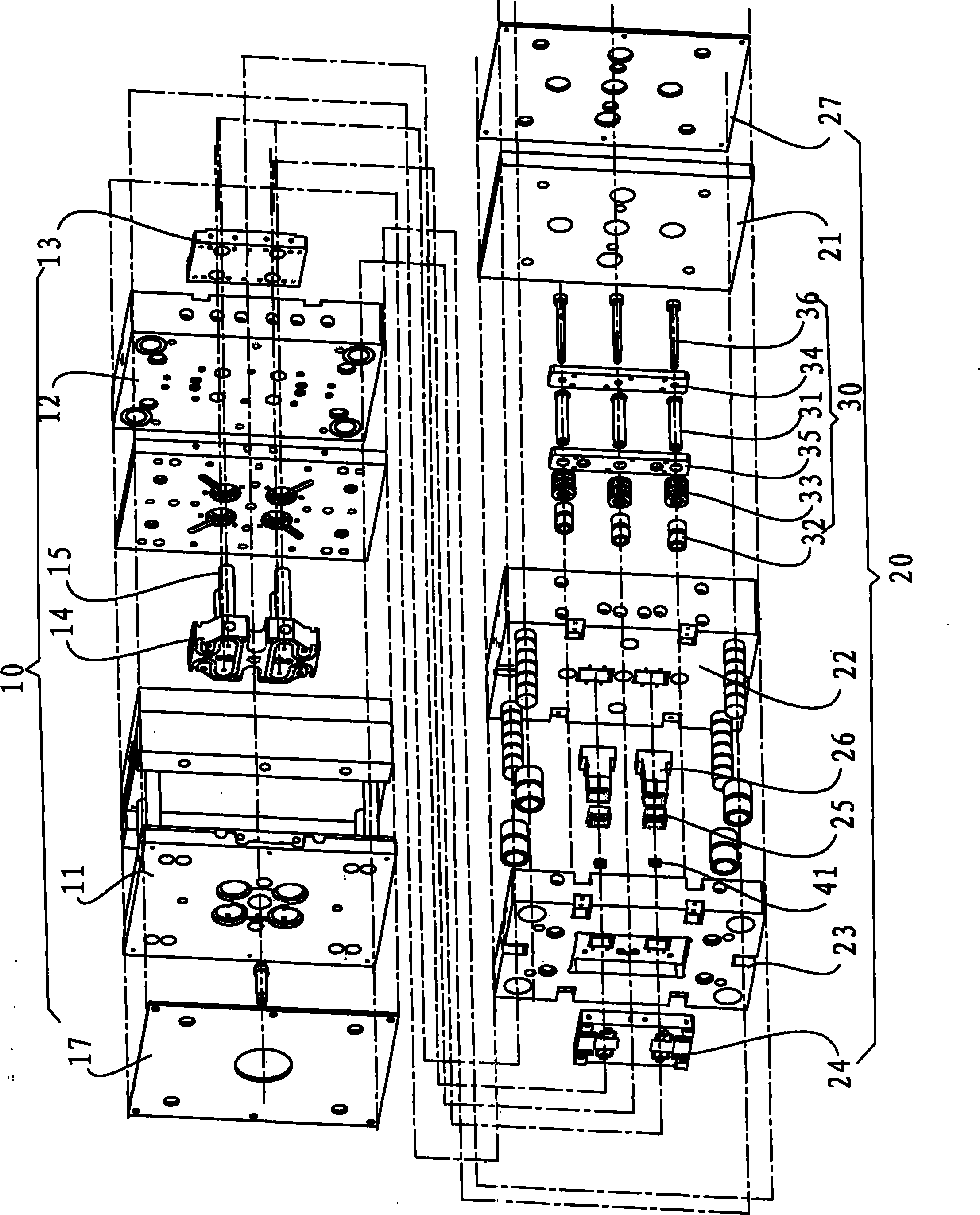

Packaging feeding machine of plastic injection molding products

InactiveCN103896061ARealize automatic controlImprove automationConveyorsControl devices for conveyorsMedical equipmentPlastic injection molding

The invention relates to a packaging feeding machine, in particular to a packaging feeding machine of plastic injection molding products. The packaging feeding machine comprises a machine frame, electrical equipment and a control program. The packaging feeding machine is characterized by further comprising a receiving mechanism, a first reclaiming mechanism, a distribution mechanism, a conveying mechanism and a second taking mechanism, wherein a feeding process is sequentially completed through the mechanisms arranged on the machine frame in a front and back connection mode, the packaging feeding machine can enable the agminate plastic injection molding products getting out of a mold of an injection molding machine in a monolithic mode to be separated from one another during packaging and conveyed to a packaging machine. By means of the packaging feeding machine, feeding work efficiency is greatly improved compared with manual operation, automatic operation is completely achieved in the whole production process, workers do not make contact with or pollute the products any longer, and the packaging feeding machine is applied to the fields of medical equipment, food utensils, tableware and the like and has great significance.

Owner:台州华曙机械有限公司

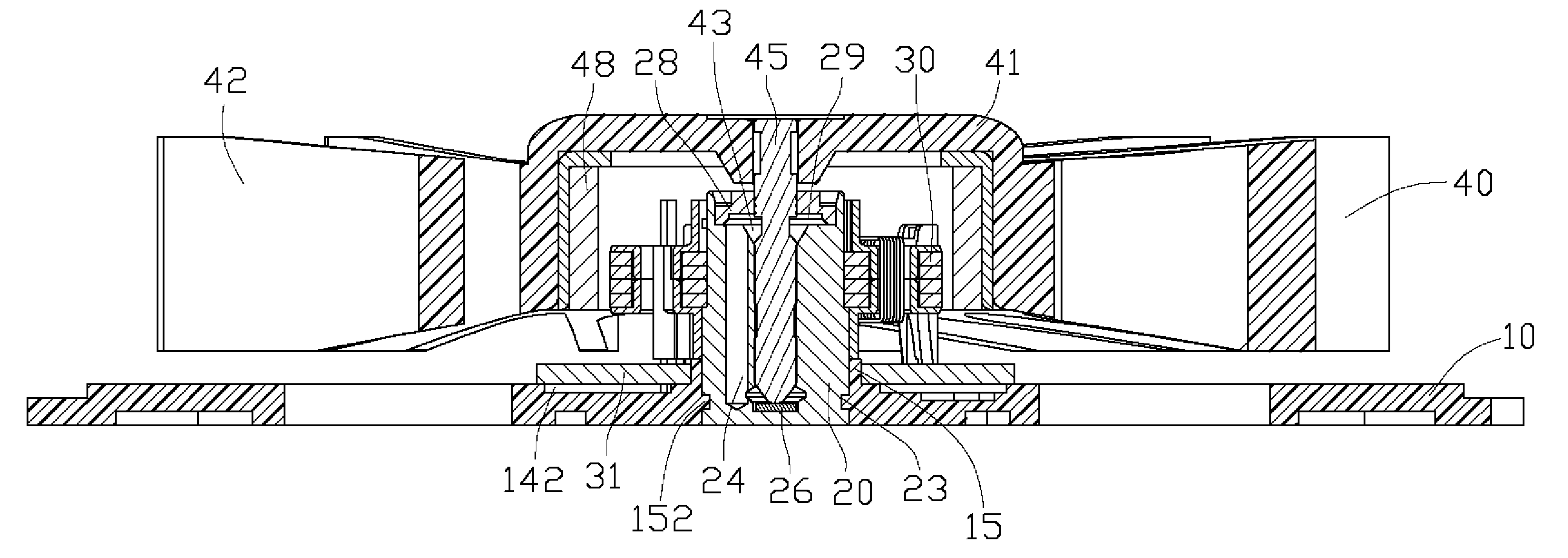

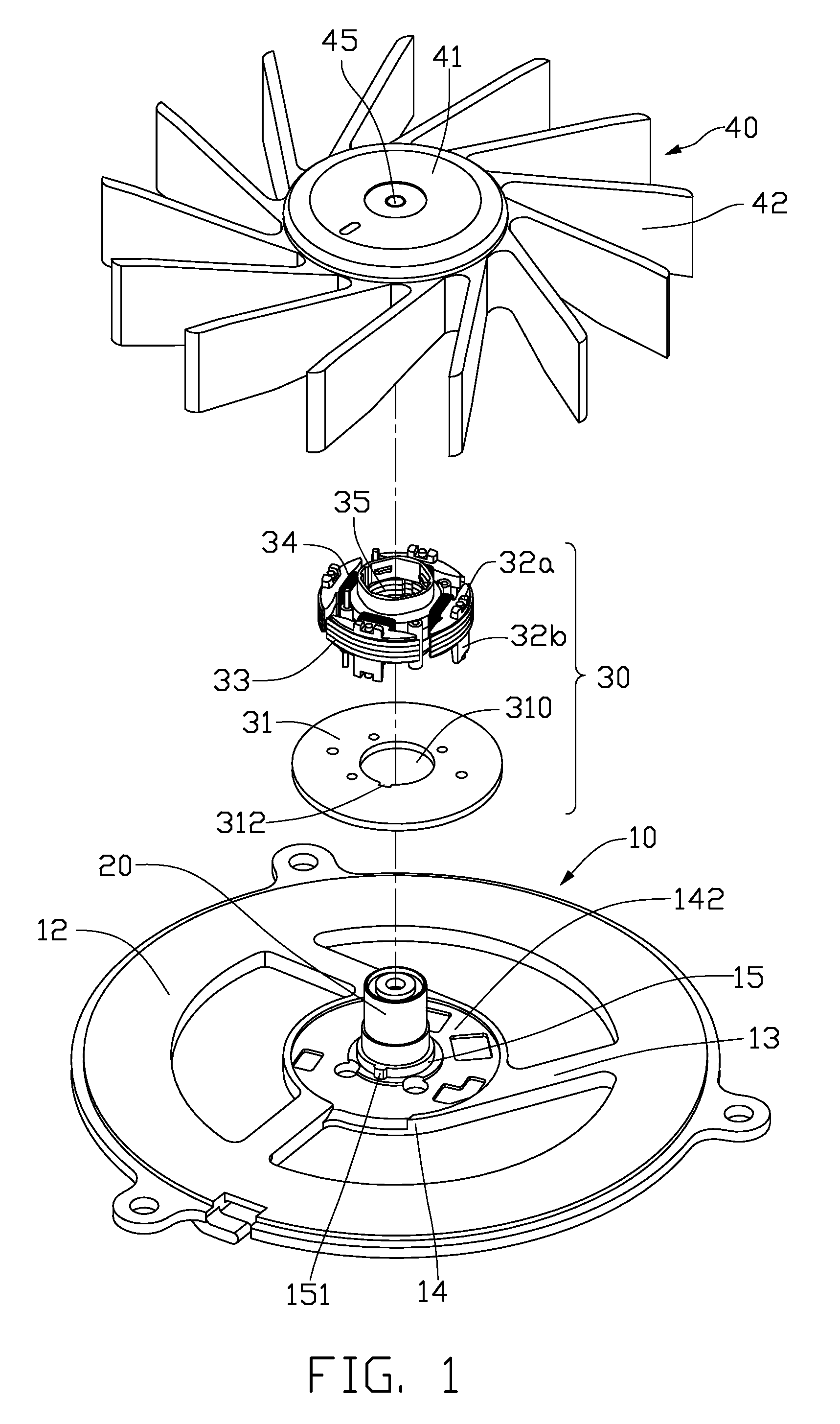

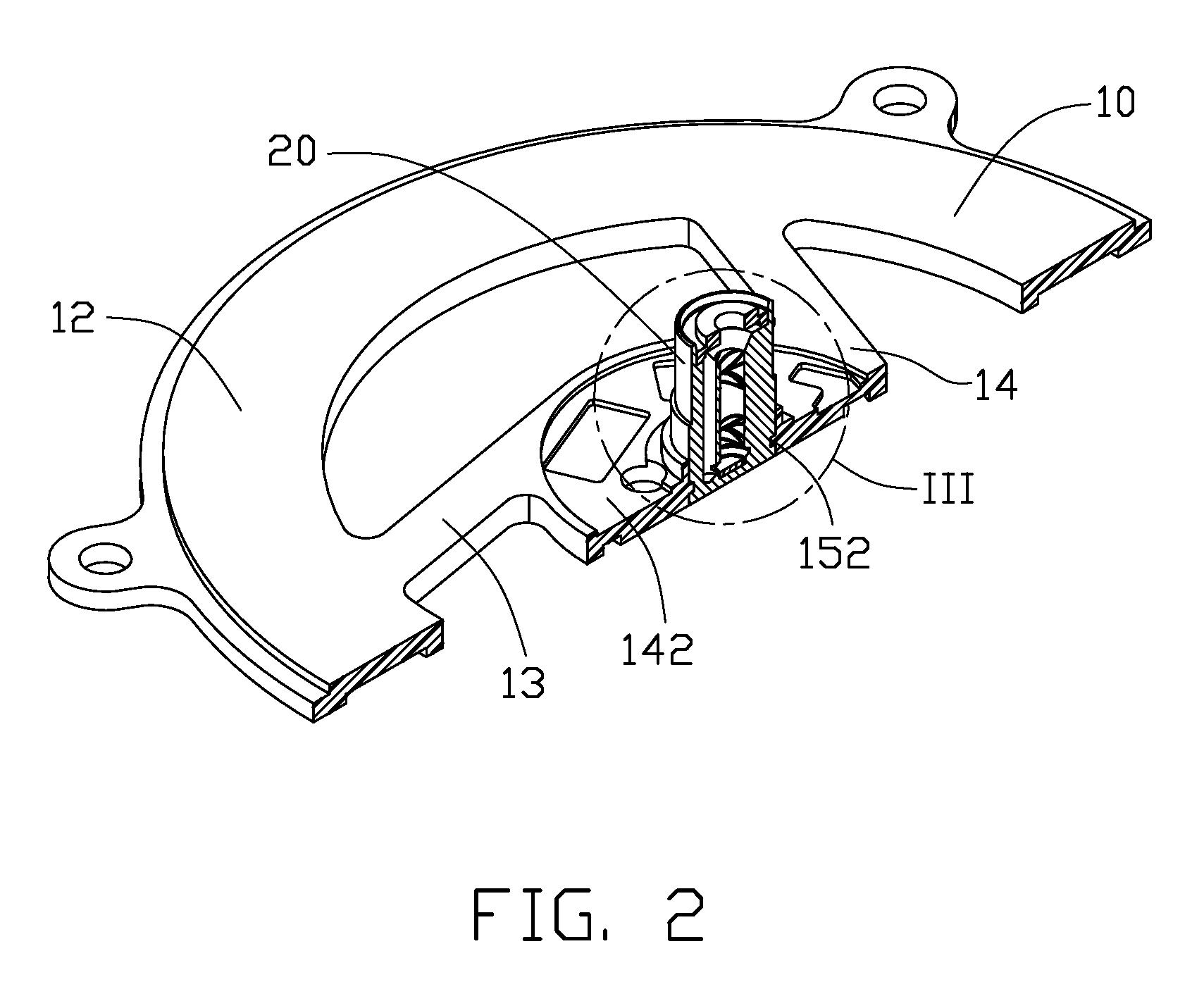

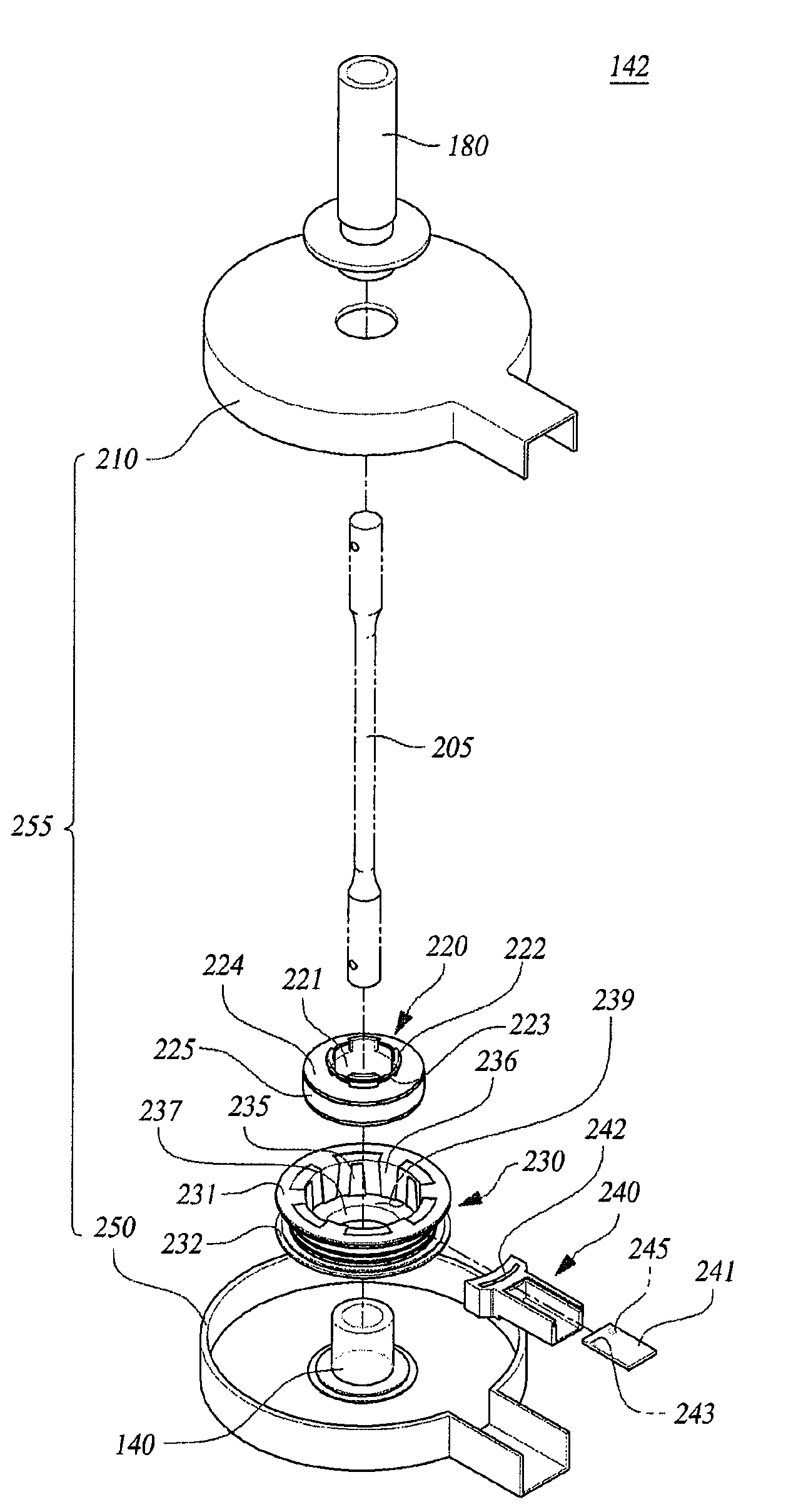

Cooling fan and method of fabrication

InactiveUS20080218018A1Pump componentsMagnetic circuitPlastic injection moldingMechanical engineering

A cooling fan includes a fan housing (10) having a central tube (15) extending upwardly therefrom, a bearing (20) defining a bearing hole (22) therein, a stator (30) mounted on the central tube, and a rotor (40) including a hub (12) having a shaft (18) extending from the hub into the bearing hole of the bearing. The bearing is received and fixedly connected to the central tube during the plastic injection molding of the fan housing; thus the bearing and the central tube are integrally connected together. The bearing can be precisely and firmly secured to the central tube of the fan housing.

Owner:HON HAI PRECISION IND CO LTD

Print head cartridge and method of making a print head cartridge by one-shot injection molding

A print head having an ink reservoir therein is made by forming, in a one-shot plastic injection molding step, a rigid monolithic frame comprising high melt temperature material having an opening therein extending from a first side to a second side, and first and second bonding surfaces surrounding the opening and facing the first and second sides, respectively. First and second thin flexible films are adhesively secured to the first and second bonding surfaces, respectively. The adhesive material may be a hot melt adhesive or dry adhesive films pre-formed to the shape of the bonding surfaces. By securing the flexible films to the bonding surfaces adhesively, rather than by heat staking, it is not necessary to form the frame of different materials during two separate molding steps.

Owner:FUNAI ELECTRIC CO LTD

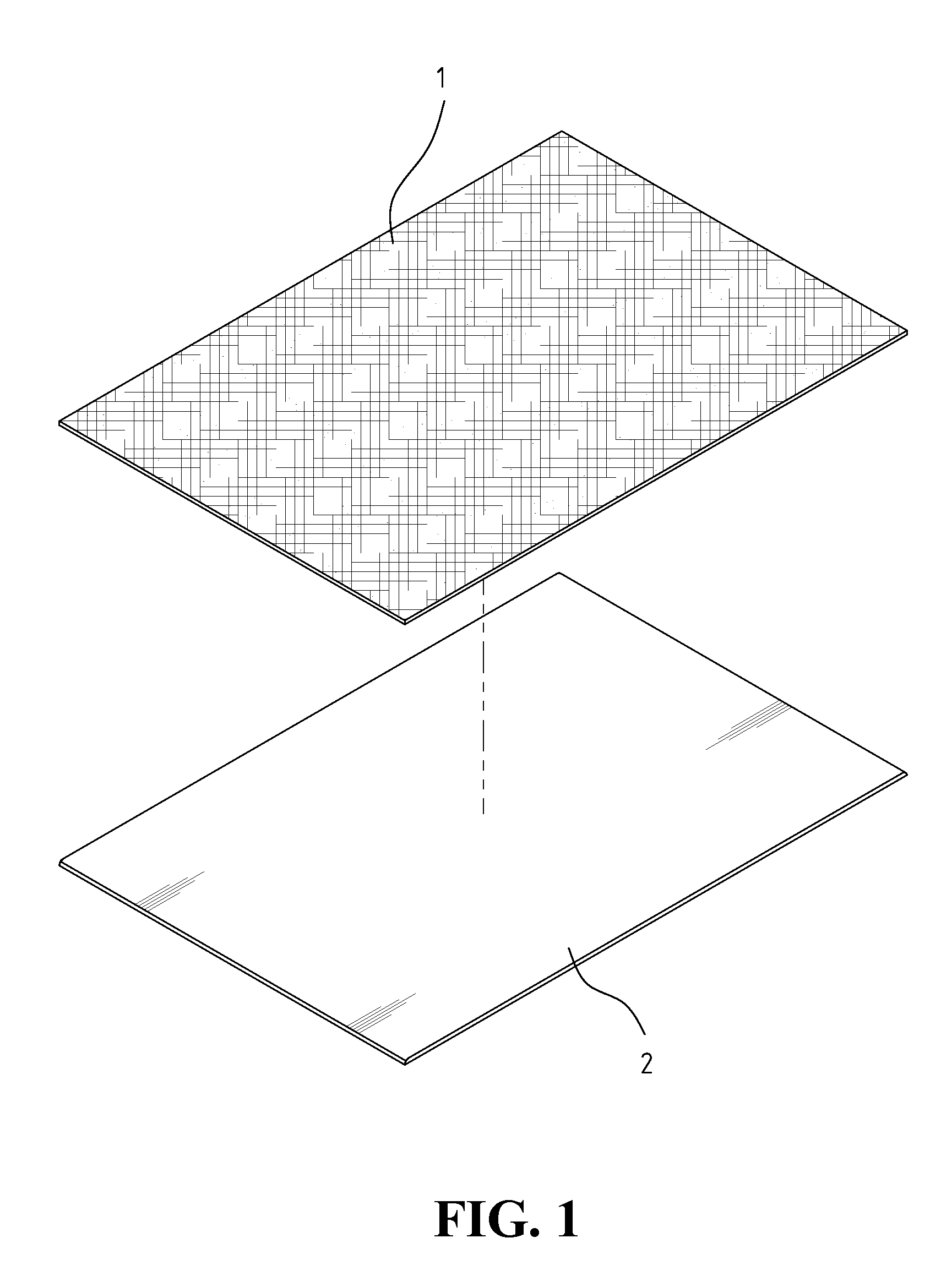

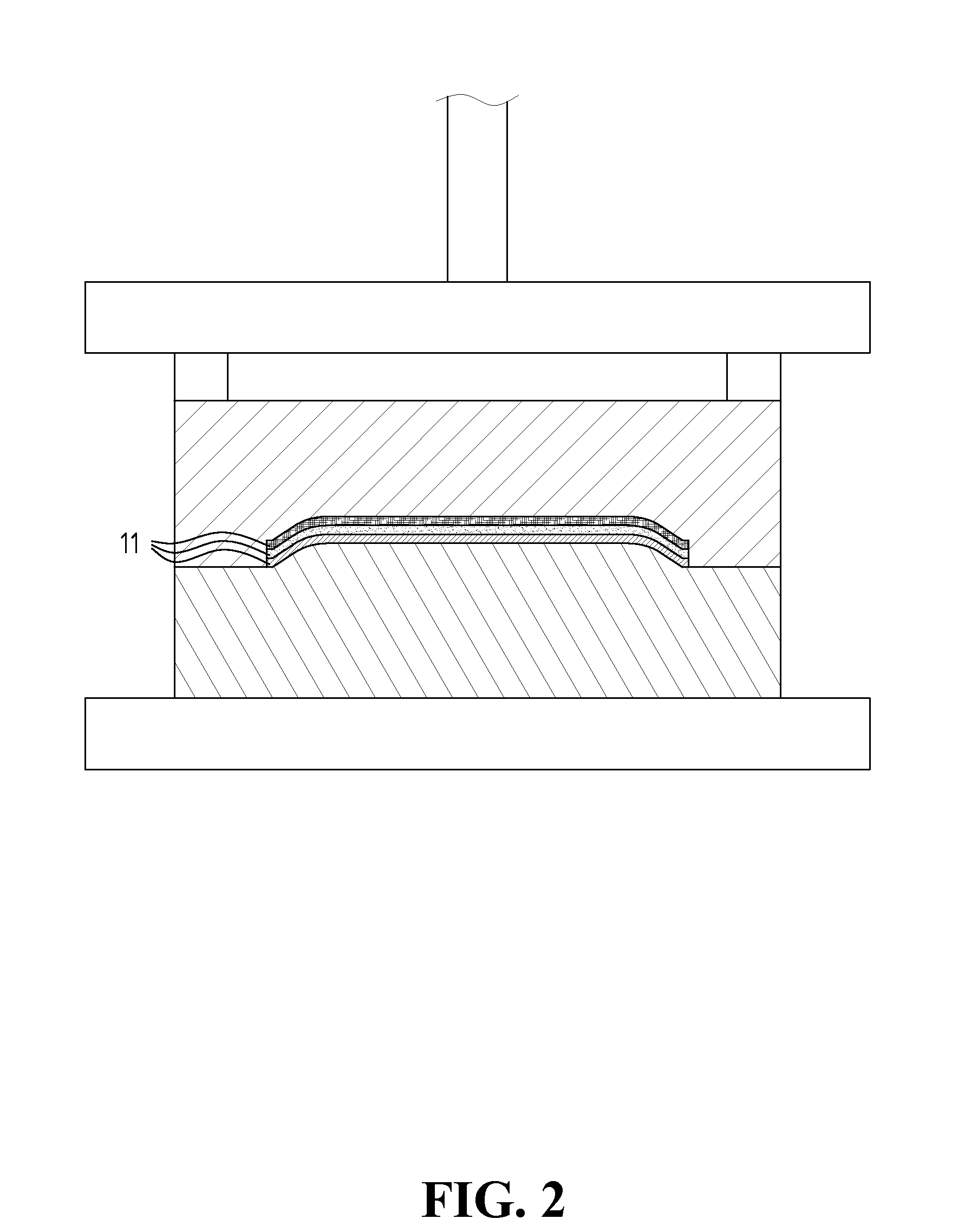

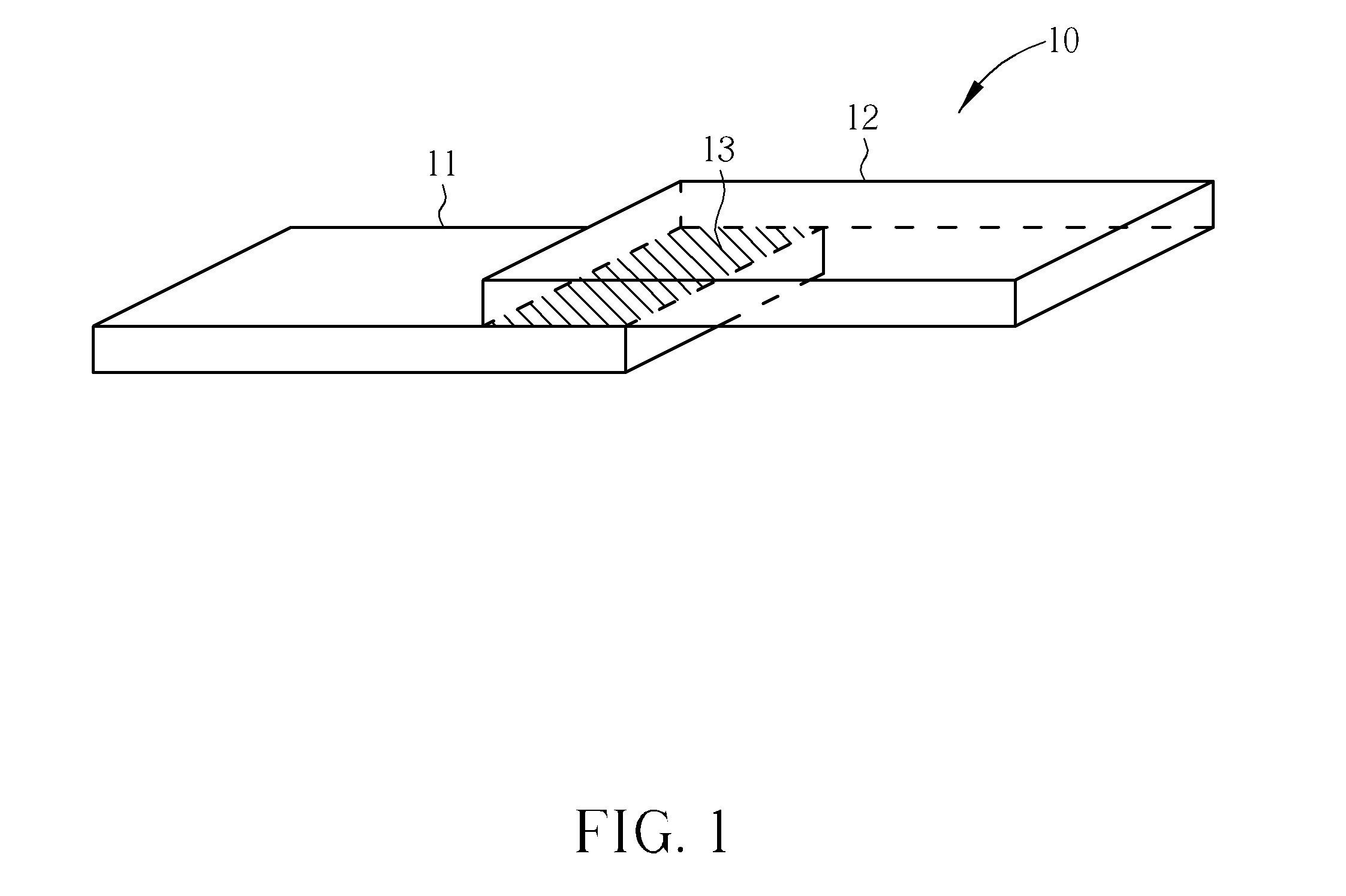

Composite Structure Of Composite Substrate And Plastic Material

InactiveUS20090136708A1Improve adhesionAvoid problemsSynthetic resin layered productsElectrical equipmentCompression moldingPlastic injection molding

A composite structure of a composite substrate and a plastic material is provided. The composite structure is fabricated by a method including the steps of: preparing a plurality of fiber layers weaved in different directions and laminating the fiber layers to configure a stack; soaking the stack in a resin, and drying the soaked stack to obtain a composite substrate; conducting a compression molding process to the composite substrate to achieve a predetermined shape; putting the compression molded composite substrate in a mold of a plastic injection molding machine; injecting a melting plastic material obtained from plastic particles melted by an extrusion machine into the mold, for combining with the composite substrate; and water cooling for hardening the combination, thus achieving a product of the composite structure.

Owner:HUANG CHUN YING +1

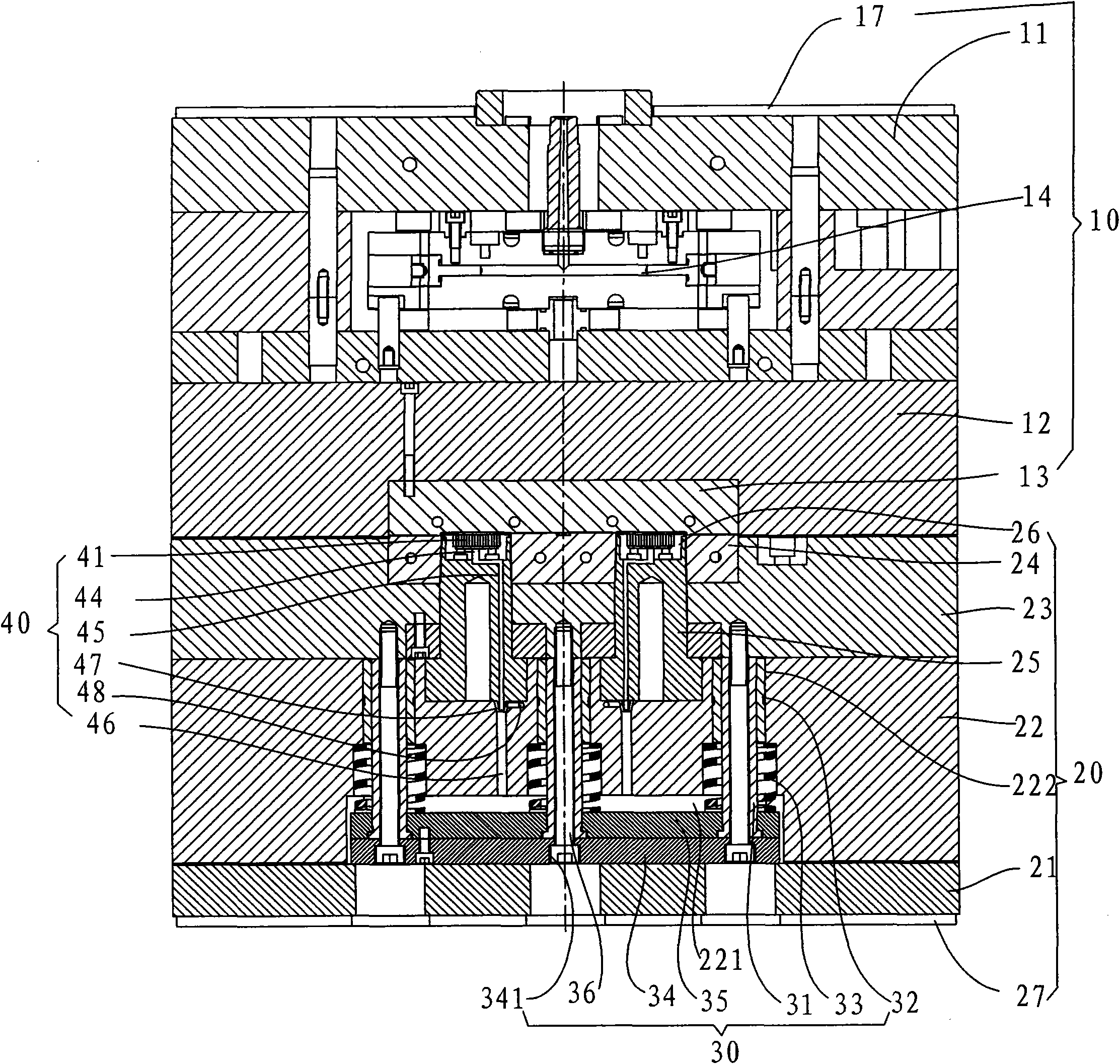

Large-area ultrathin plastic part injection mould

ActiveCN102120357AImprove pressure bearing capacityExtend your lifeAir trappingPlastic injection molding

The invention relates to the field of plastic injection molding moulds, and particularly relates to a large-area ultrathin plastic part injection mould. The mould comprises a static mould and a movable mould, wherein the static mould is composed of a static mould fixing plate, and the static template and a static mould core, a movable mould composed of a movable mould fixing plate, a pad, a movable template and a movable template core; the static template is a thickened static template; the pad is a whole square thick steel block; an ejection device is a push board ejection device; an exhaustsystem comprises a group of exhaust plates at the bottom of a mould cavity, an exhaust groove at the periphery of the mould cavity and an exhaust channel connected with the exhaust plates and the exhaust groove; and a compressed air blow pipe leading the exhaust channel to generate negative pressure is arranged on the exhaust channel. The mould has high strength, the service life is up to 2 million times; the exhaust is smooth, and adverse phenomena, such as insufficient filling, burning, air trapping, heavy fused connecting wire and the like, are prevented, so that the purpose of large area of 1,429mm<2> and ultrathin of 0.18mm molding is achieved; and the extrusion or deformation of a product is effectively avoided by adopting the push board ejection device.

Owner:DONGMING XINGYE SCI TECH CO LTD

Interface card securing device including grounding element

ActiveUS7335032B1Reduce distractionsImprove signal transmission qualityDigital data processing detailsClamping/extracting meansPlastic injection moldingEngineering

An interface card securing device including a grounding element is disclosed. The grounding element may reduce the interference during high speed signal transmission of the interface card. The grounding element is integrally formed with the securing device as single unit using a plastic injection molding process. Thus, the assembly of the securing device is simplified, and the fabrication cost of the interface card securing device is significantly reduced, and the signal transmission quality is significantly promoted.

Owner:T CONN PRECISION CORP

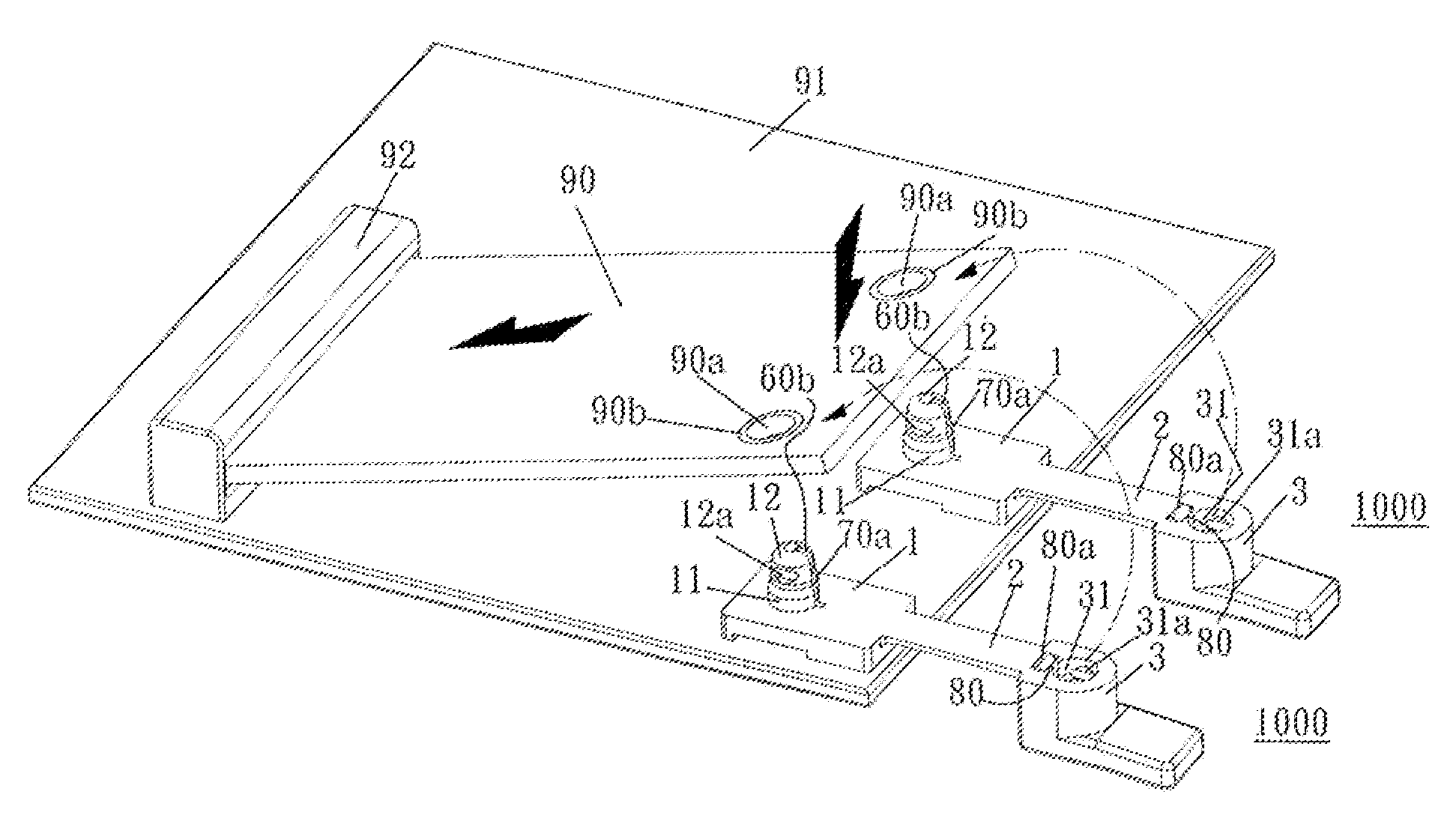

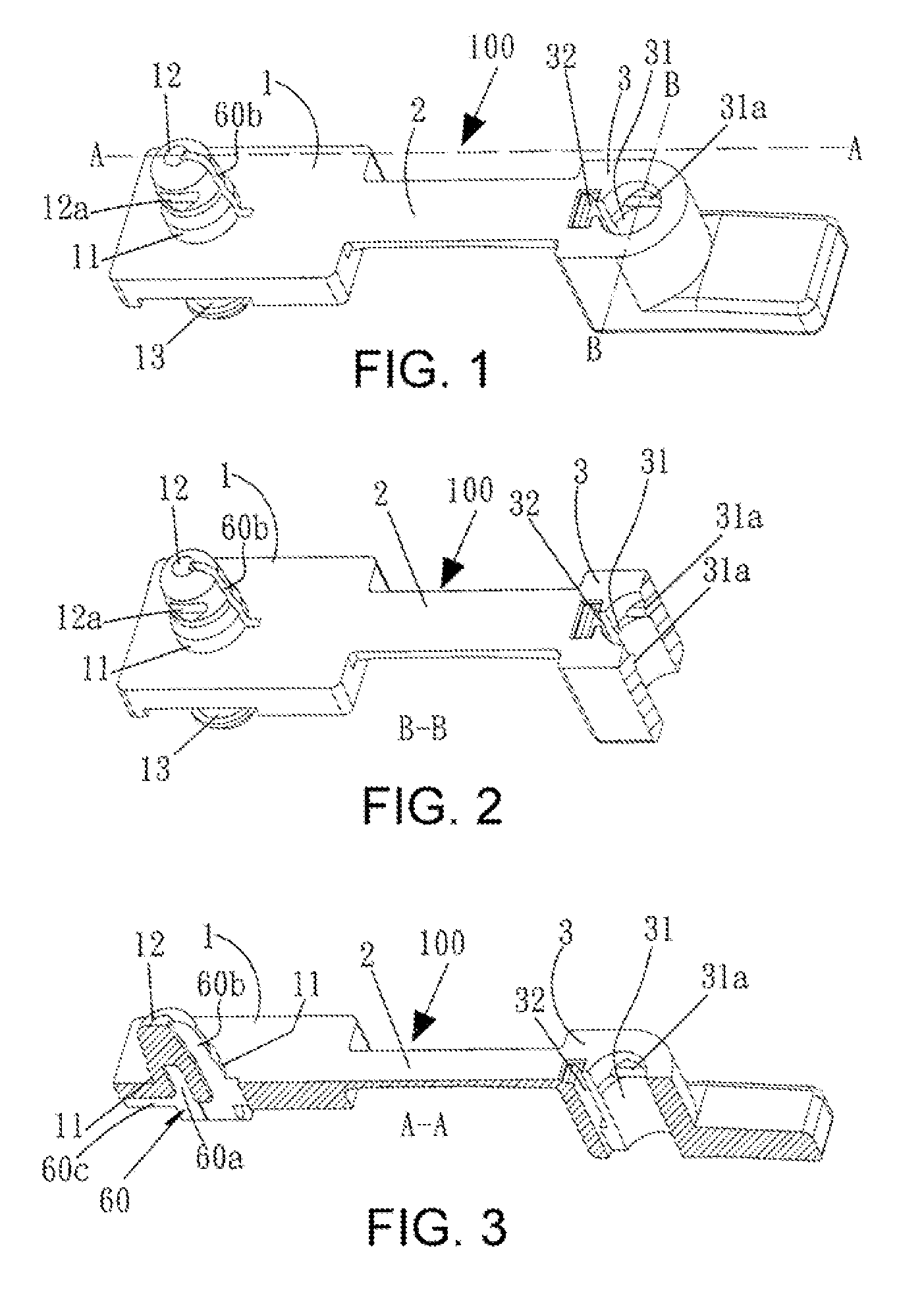

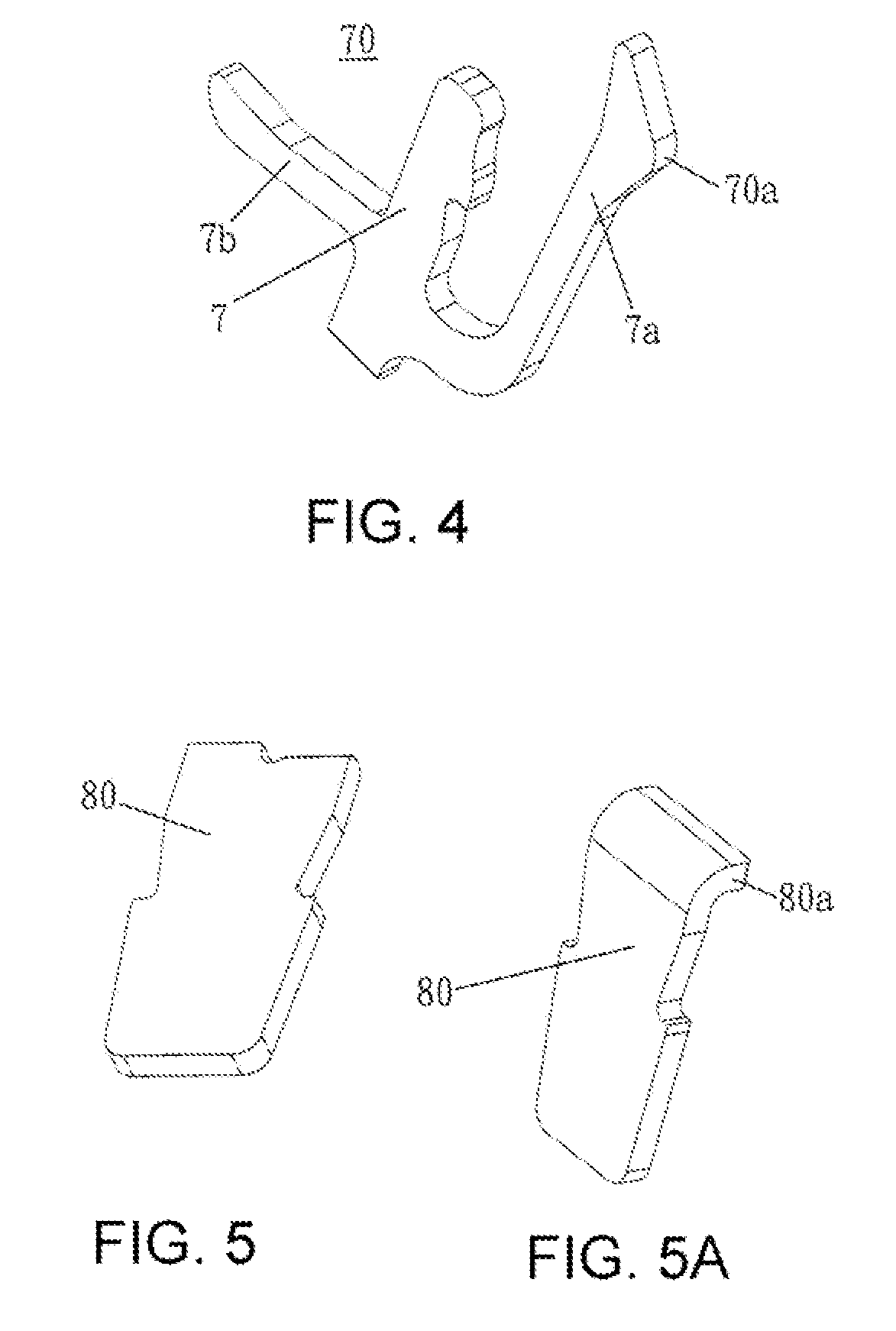

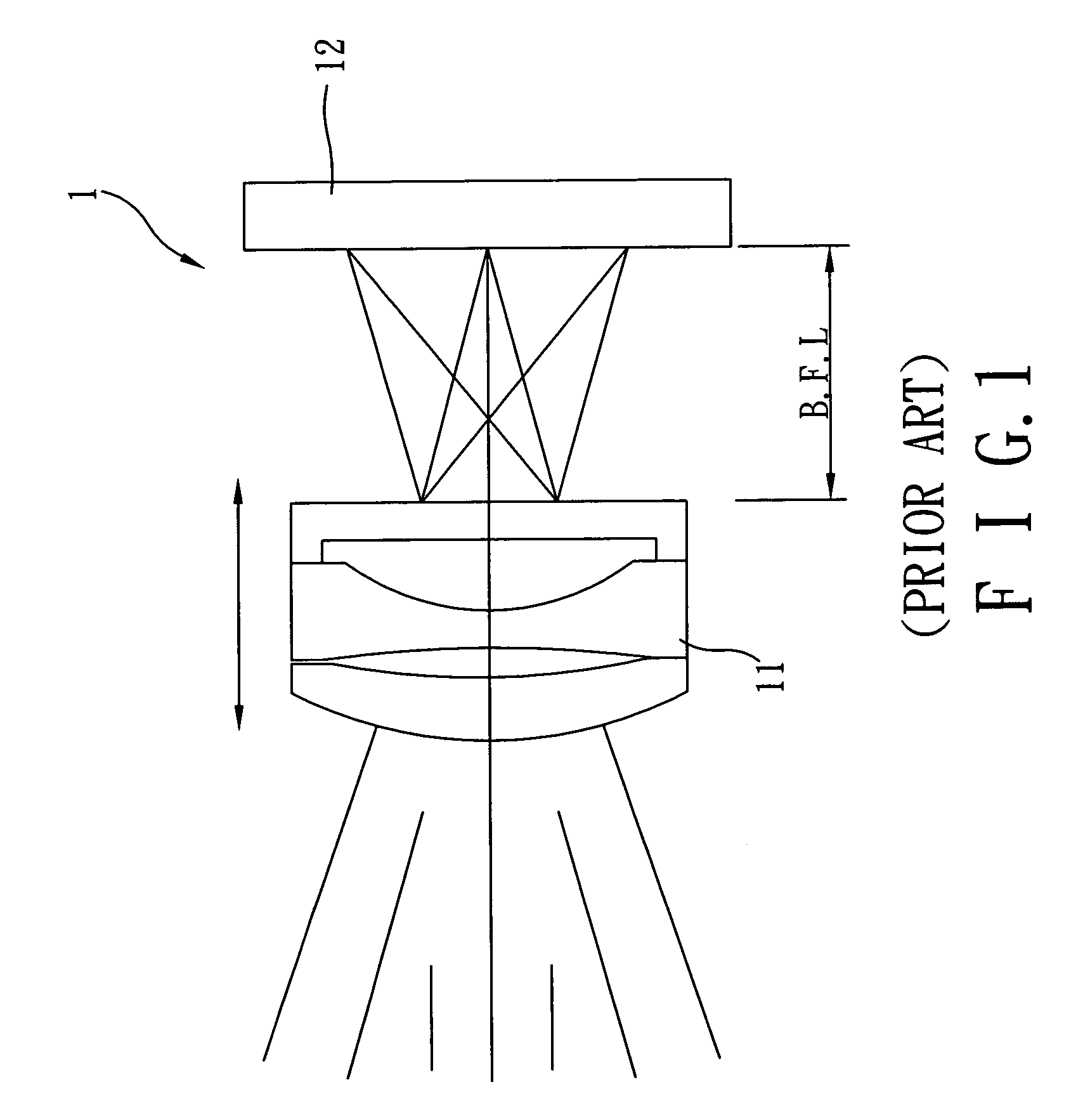

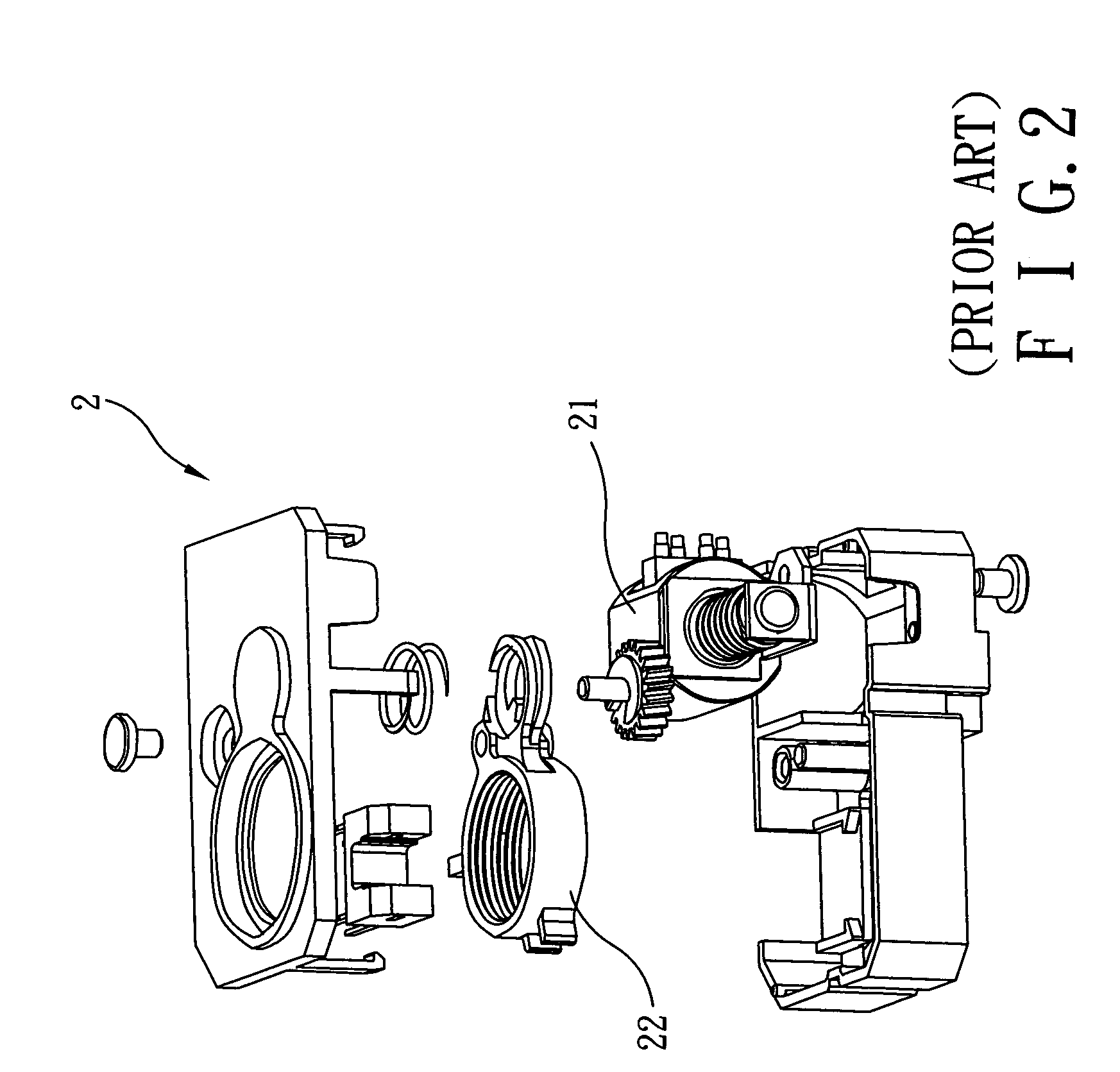

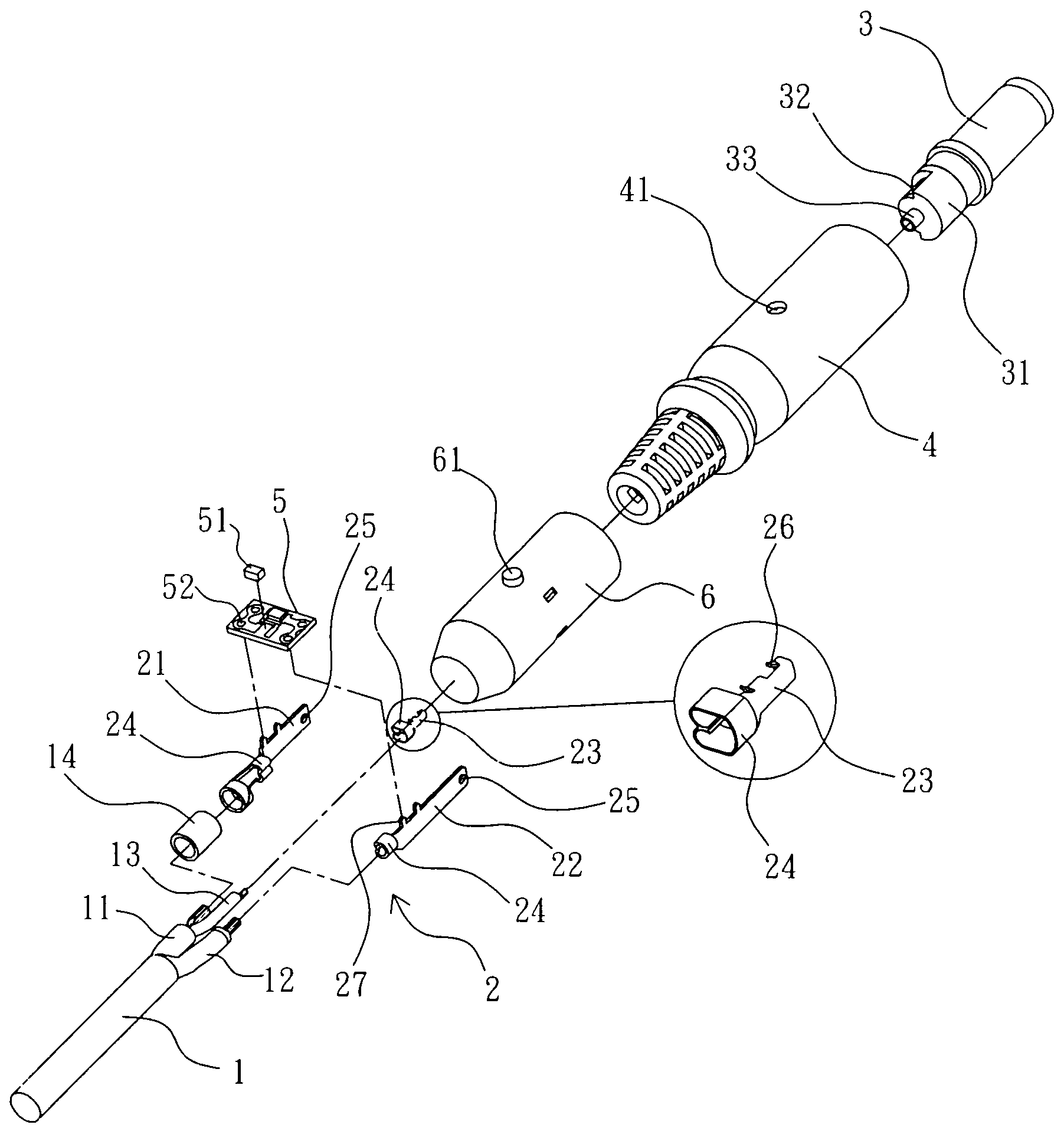

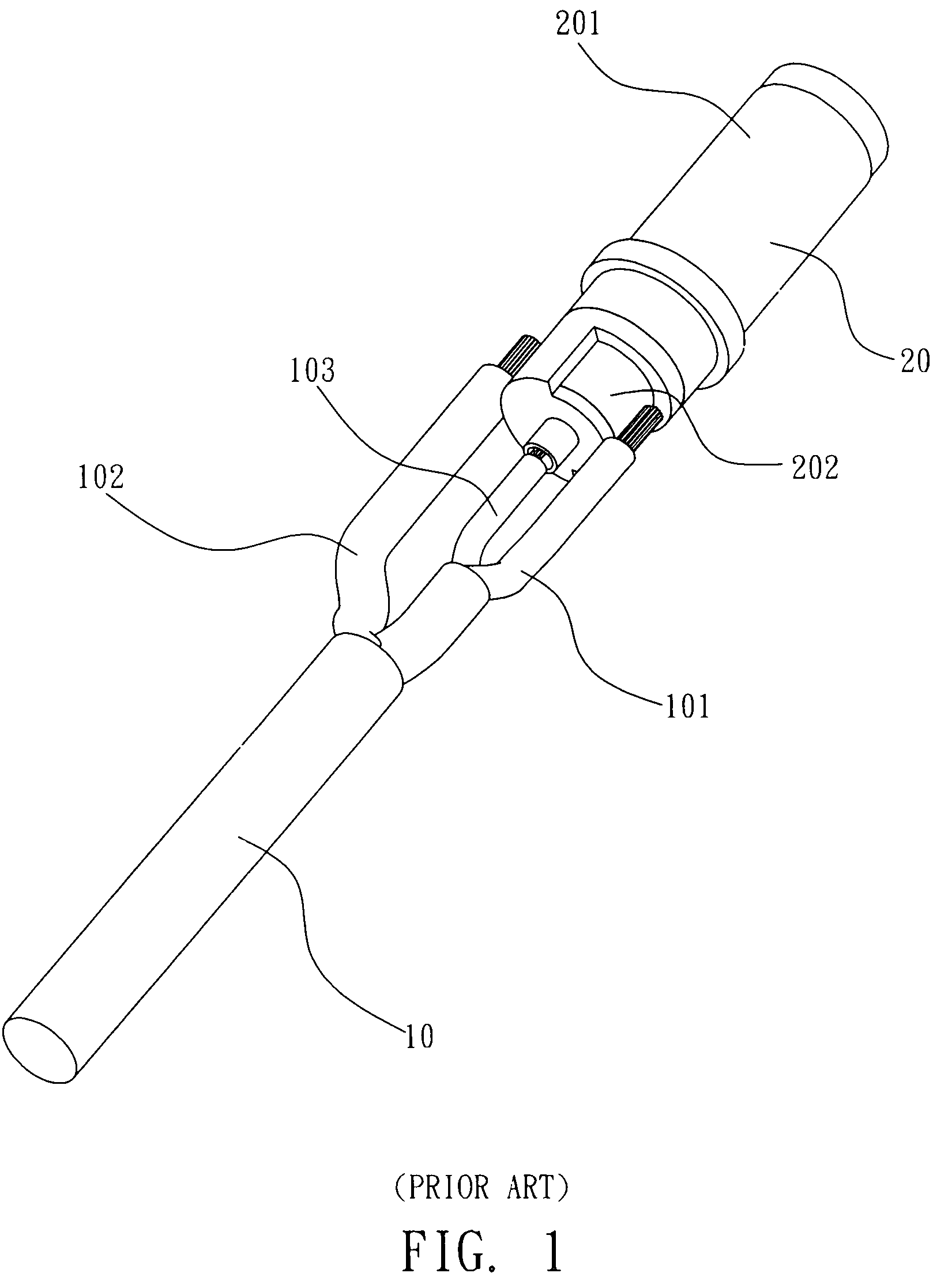

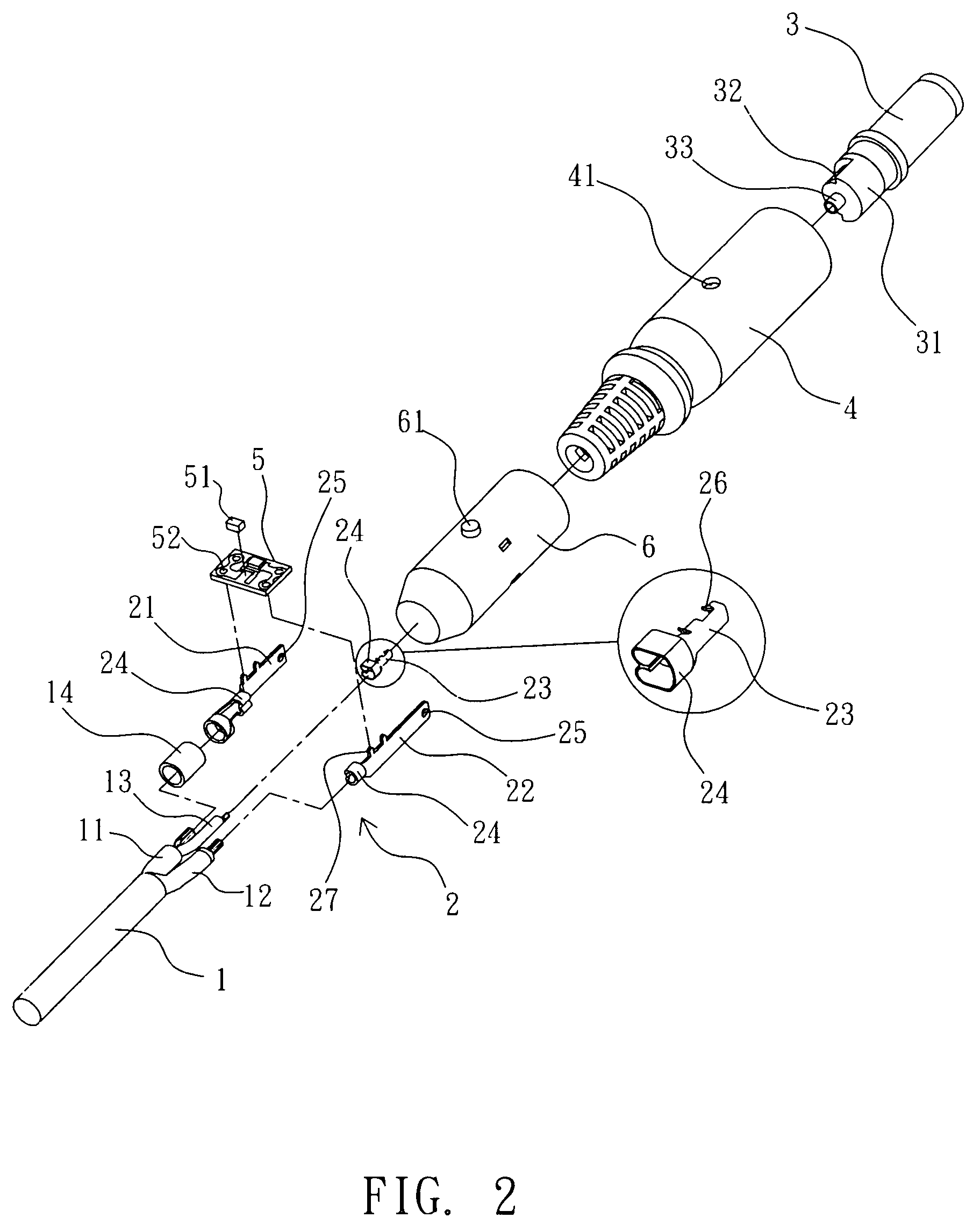

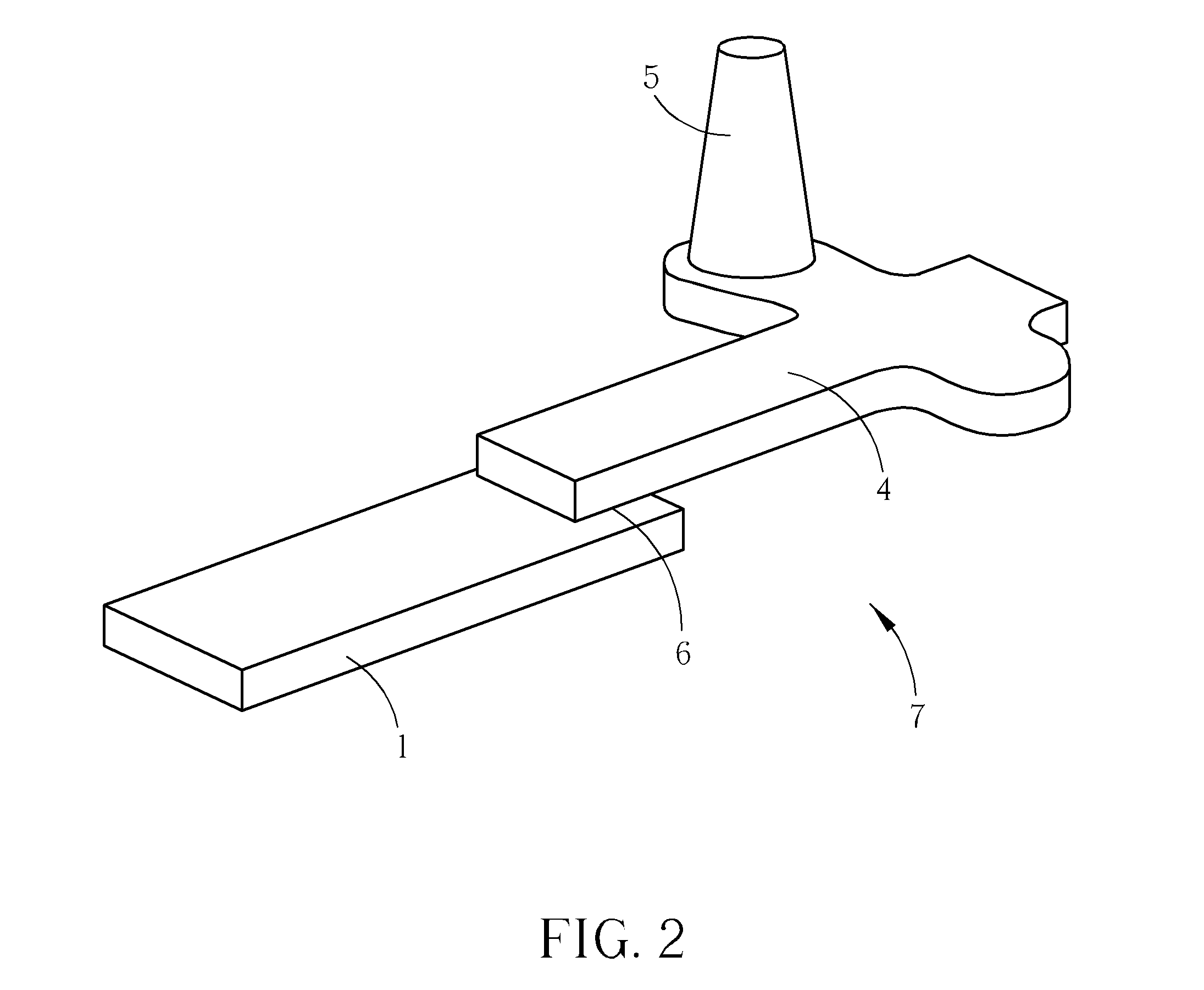

Suspension apparatus for auto-focus lens device and a method for fabricating the same

InactiveUS7158316B2Simplify the assembly processLow costProjector focusing arrangementCamera focusing arrangementCamera lensPlastic injection molding

A suspension apparatus comprises a lens holder, a suspension spring and a supporting base. The supporting base is formed with an opening for accommodating the lens holder. The lens holder is for positioning a lens unit. The suspension spring is manufactured by stamping process to form a long strip with a plurality of suspension springs. The strip is then guided into a mold, and plastic injection molding process is performed in that mold so as to produce the lens holder and supporting base affixed respectively to either end of the suspension spring in one piece. After that, excess material of the strip is cut off. The suspension apparatus as above described is suitable for mass production. In addition, because of the high precision of mold, the inaccuracy of assembly and fabrication is minimized. The volume of the whole apparatus and the cost of production are also vastly decreased.

Owner:POWERGATE OPTICAL INC

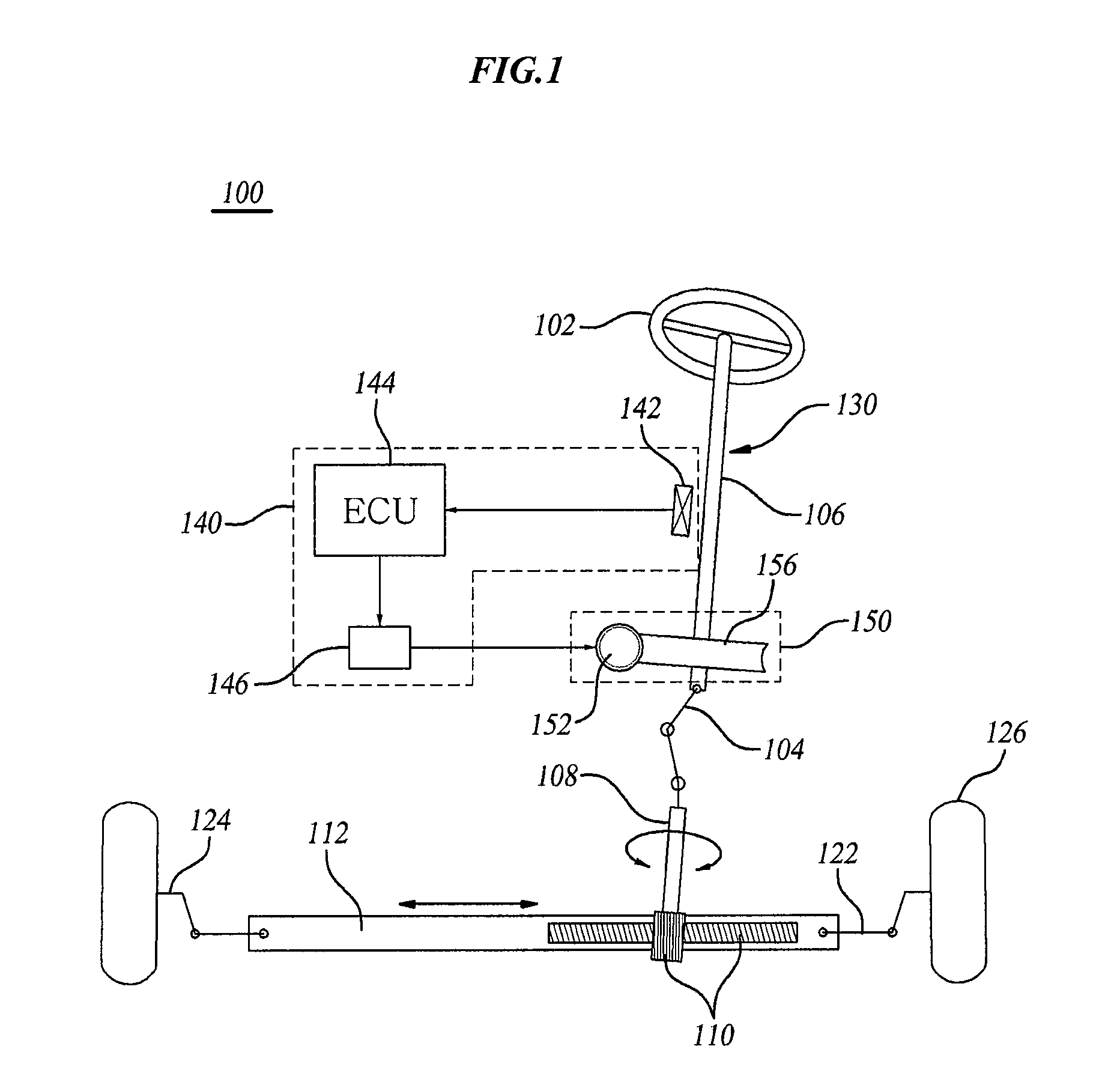

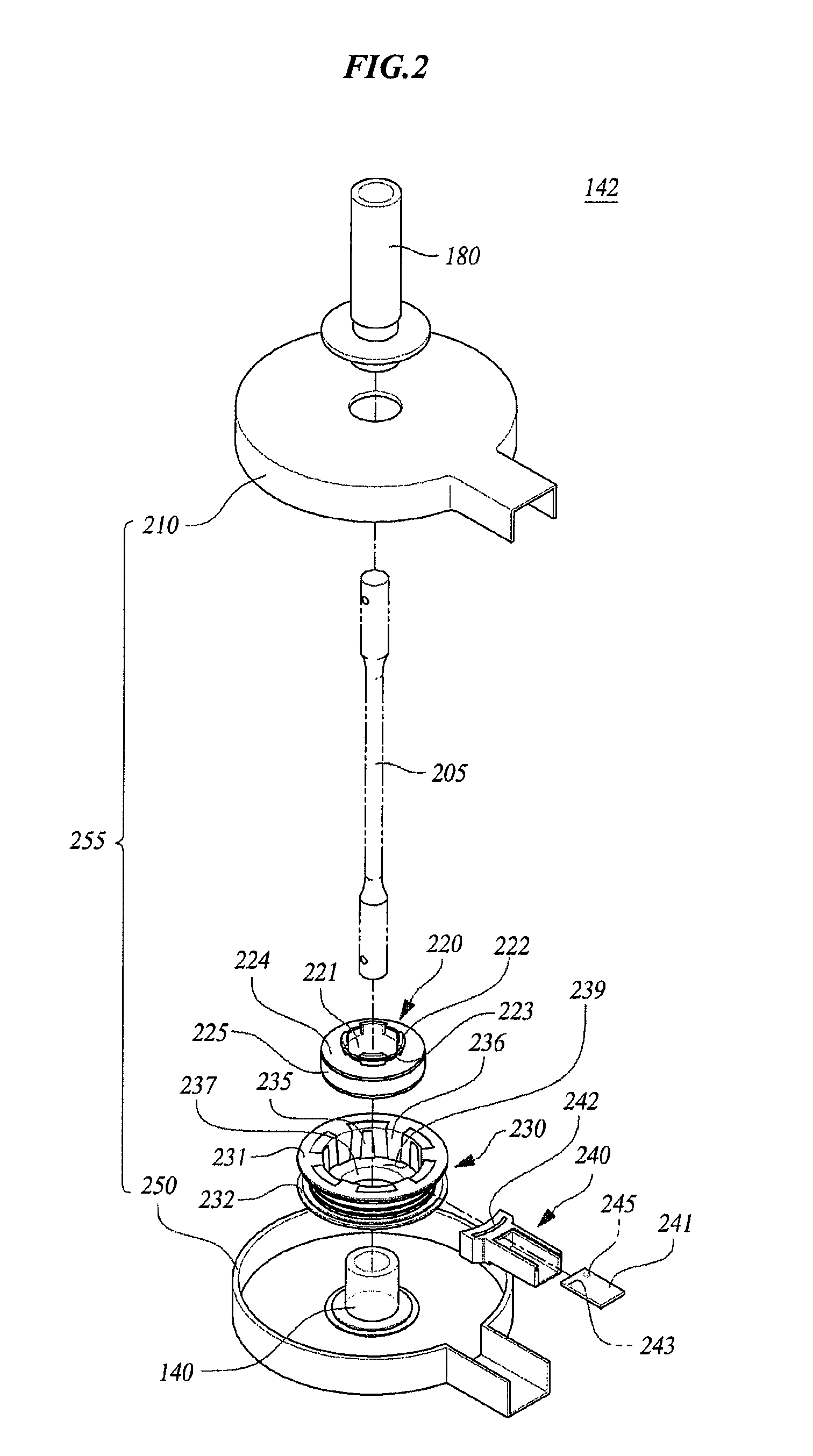

Torque rotor and method for manufacturing the same

ActiveUS20100244606A1Preventing degradation of roundnessPrevent inflowMagnetic circuit rotating partsAutomatic steering controlPlastic injection moldingEngineering

Disclosed is a torque rotor and method for manufacturing the torque rotor having an effect of preventing inflow of plastic between a yoke and a magnet during a conventional plastic injection molding process for forming an assembling structure after assembling between the yoke and the magnet, thereby preventing degradation of a roundness of the magnet or damage of the magnet due to the difference in the temperature expansion coefficients, and preventing idle rotation of the yoke and the magnet relative to each other.

Owner:HL MANDO CORP

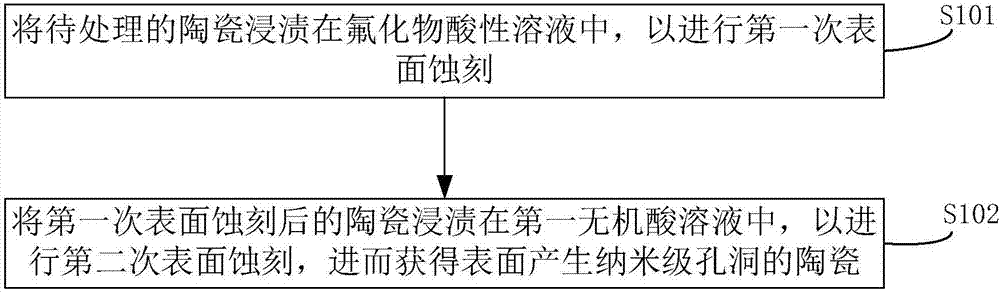

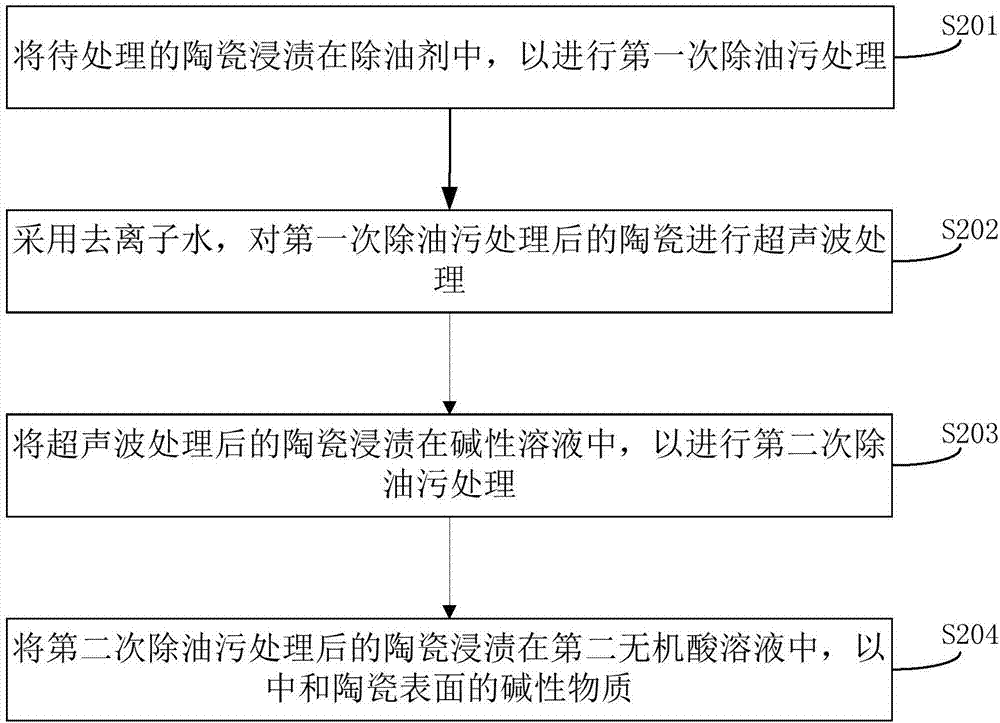

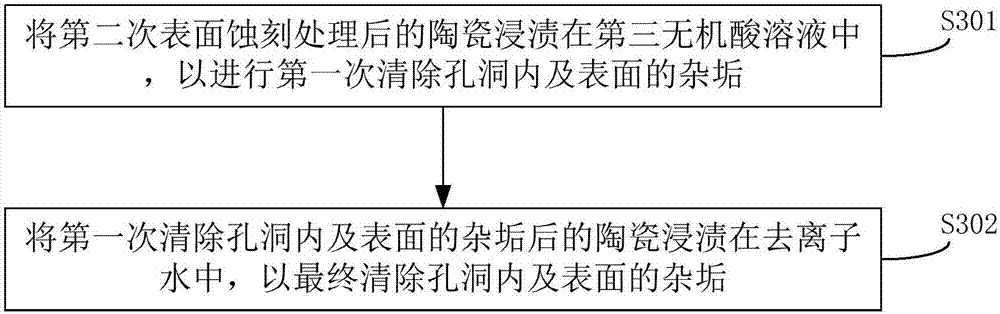

Ceramic surface treatment method, ceramic product and ceramic plastic composite body

ActiveCN107010998AImprove permeabilityPromote infiltrationCoatingsPlastic injection moldingInjection moulding

The invention discloses a ceramic surface treatment method, a ceramic product and a ceramic plastic composite body. The method comprises the following steps of soaking ceramic to be treated into a fluoride acid solution so as to perform primary surface etching; soaking the ceramic subjected to primary surface etching into a first inorganic acid solution so as to perform secondary surface etching; further obtaining the ceramic with nanometer level holes on the surface. By using the mode, the ceramic with the nanometer hole structures can be prepared; after the plastic injection molding forming, the bonding force of the product is high; the combination is very tight.

Owner:GUANGDONG EVERWIN PRECISION TECH

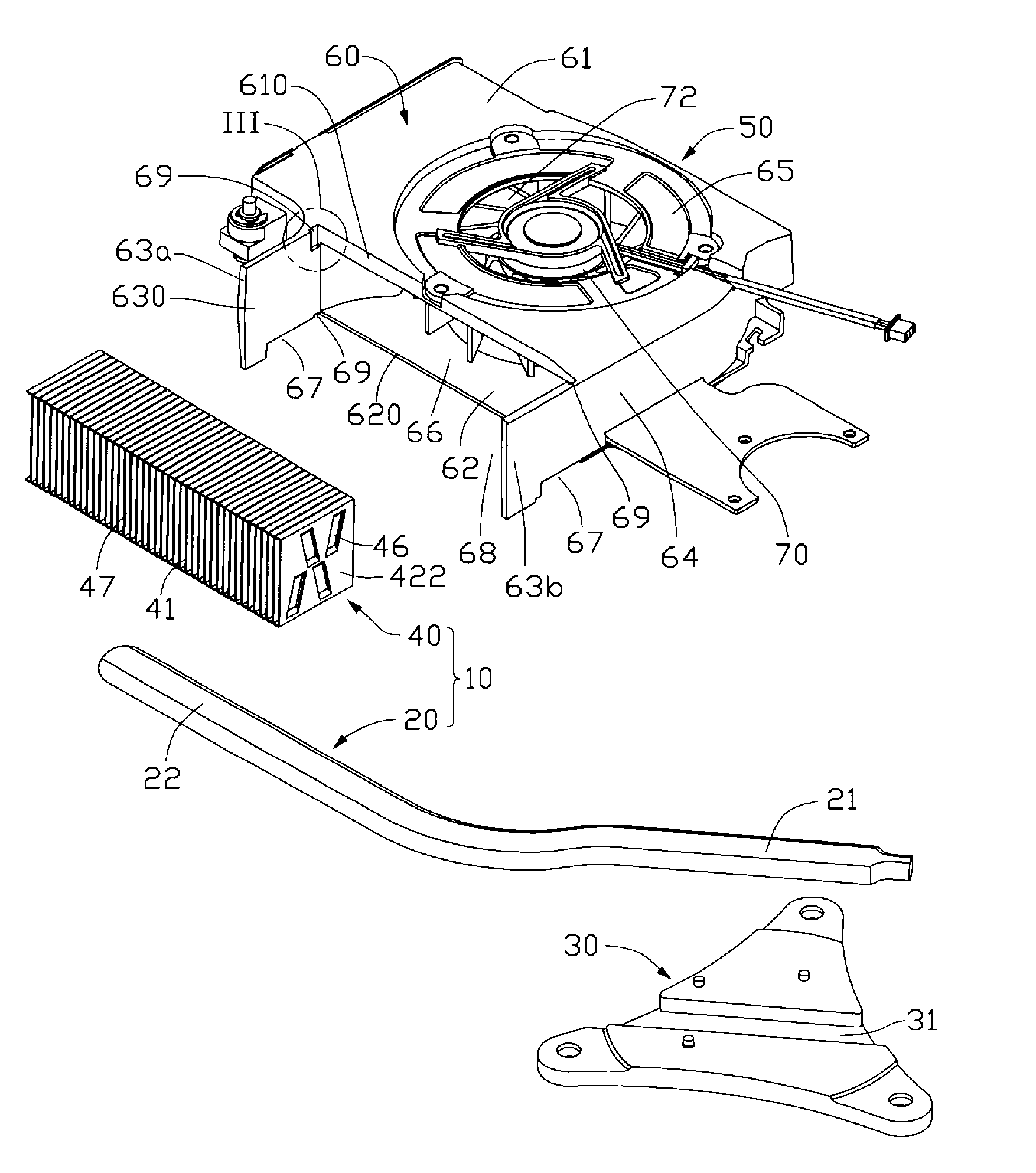

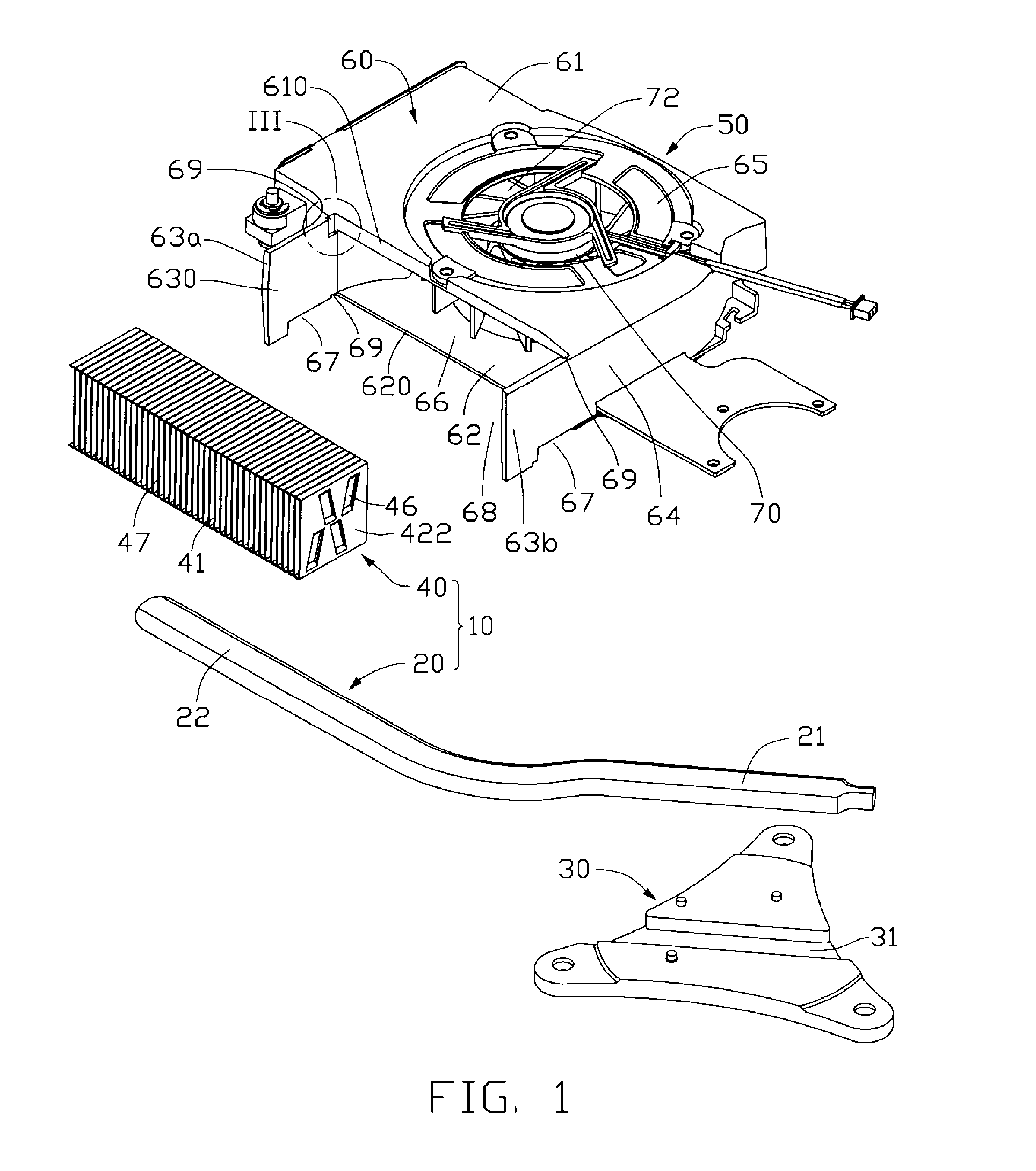

Heat dissipation device

InactiveUS20080023176A1Easy to assembleSolve the low heat dissipation efficiencyPump componentsDigital data processing detailsPlastic injection moldingDie casting

A heat dissipation device includes a heat sink (10) and a blower (50) for generating an airflow to the heat sink. The blower includes a housing (60) and at least one plate (63a, 63b) extending outwardly from the housing. The housing forms a contacting surface (610, 620) abutting a side of the heat sink. The plate includes an inner surface (630) abutting another side of the heat sink. A groove (69) is defined in a junction of the housing and the plate, and thus the contacting surface of the housing and the inner surface of the plate are planar-shaped to avoid interference between the housing of the blower and the heat sink. The groove has chamfer angles R therein. The housing is made by plastic injection molding or die casting.

Owner:HON HAI PRECISION IND CO LTD +1

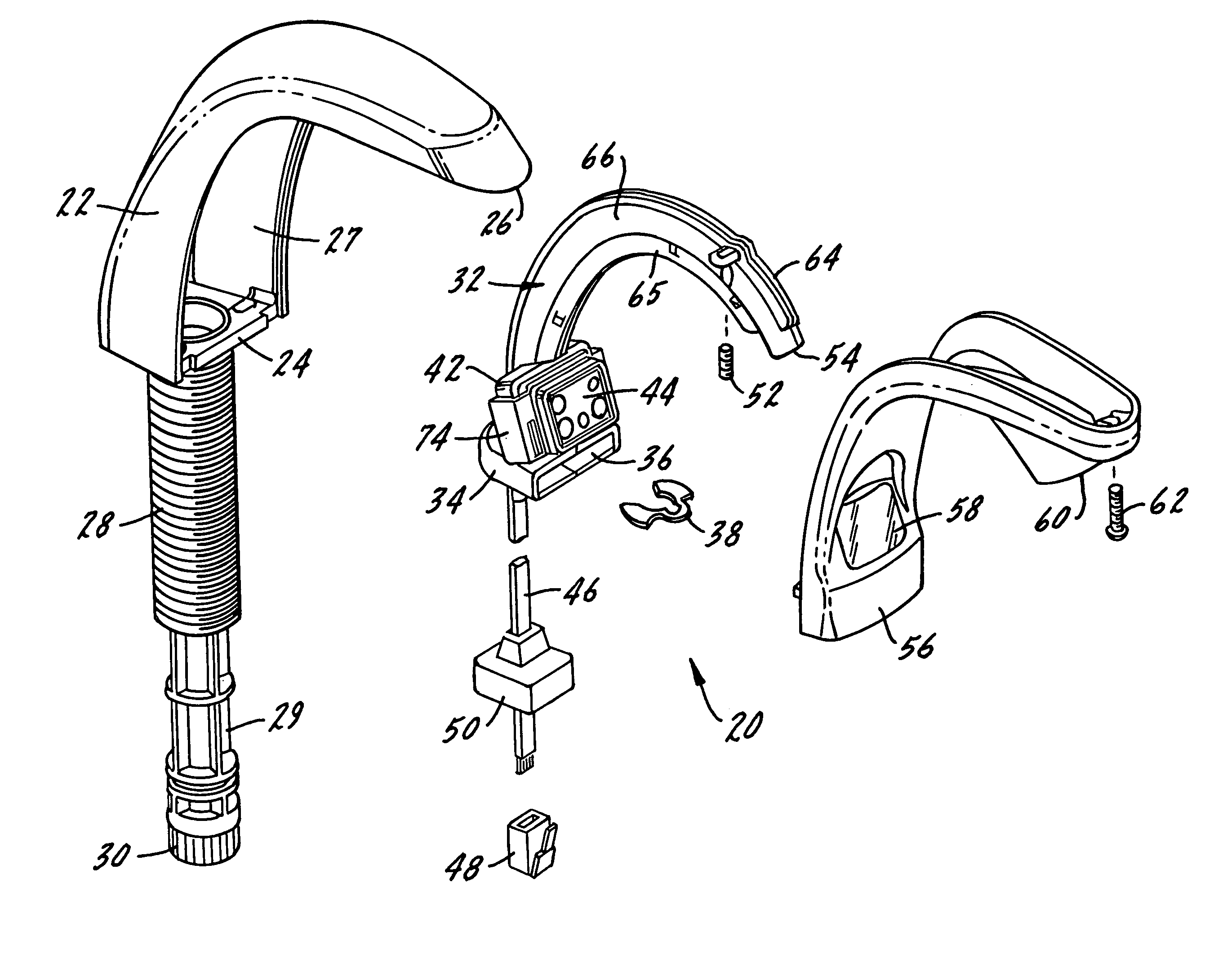

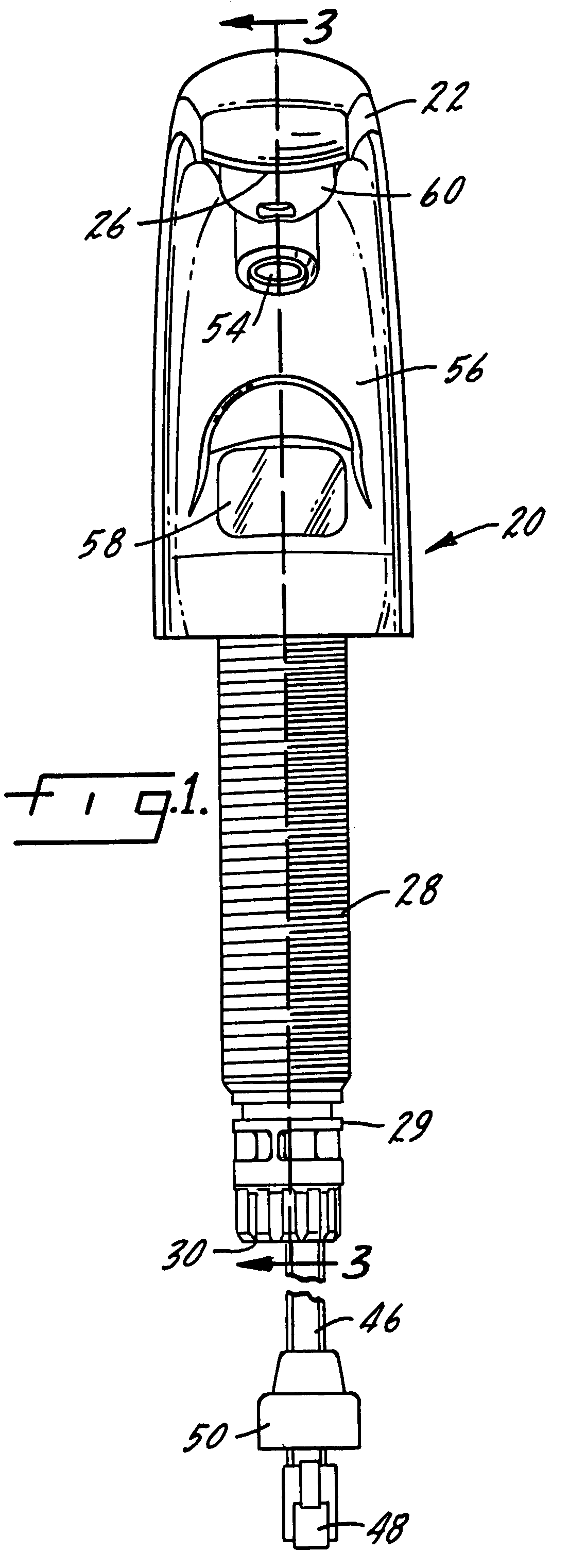

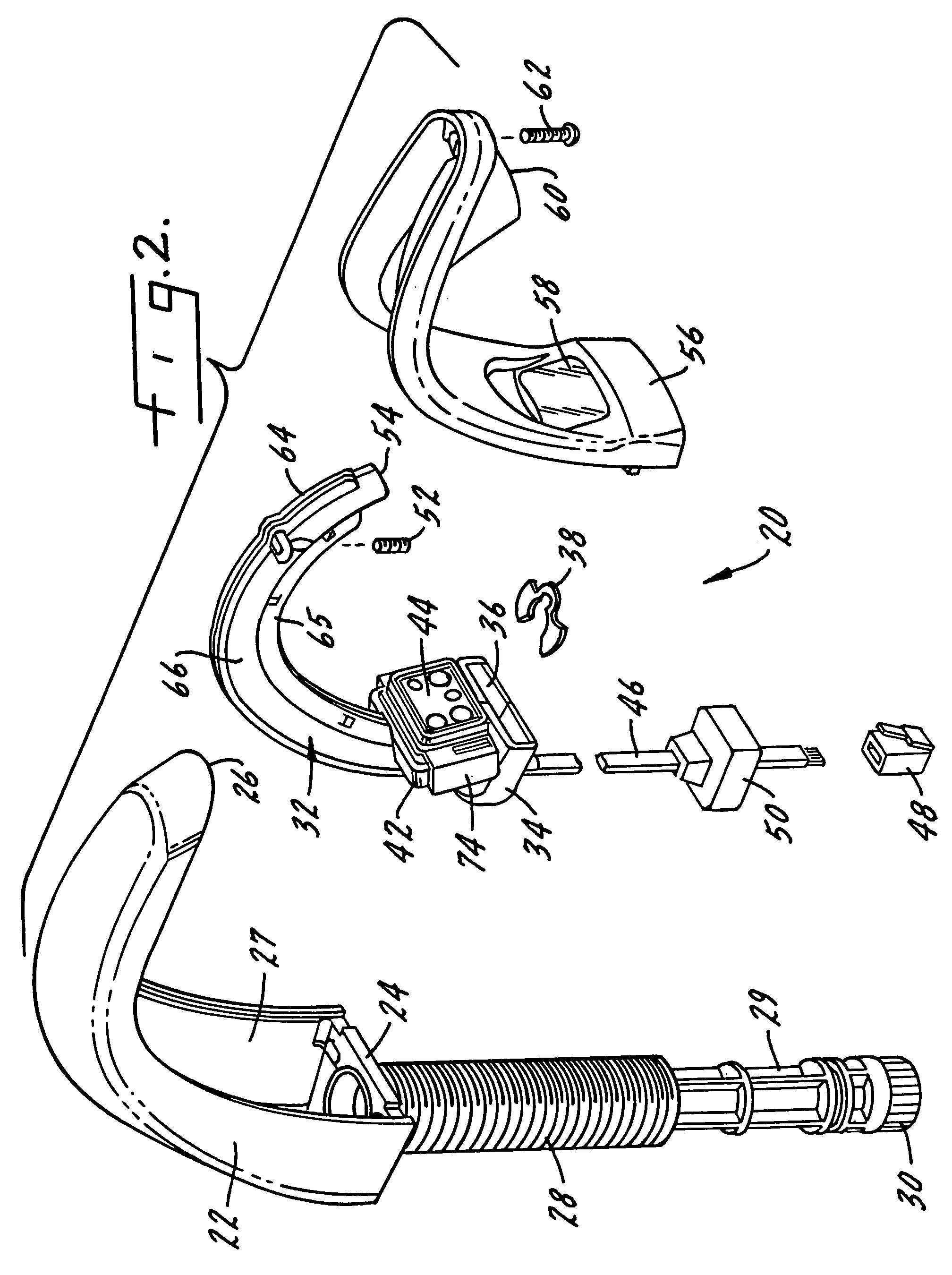

Electronic soap dispenser

ActiveUS20050087557A1Avoid insufficient lengthIncreased durabilityVolume measurement and fluid deliveryLarge containersPlastic injection moldingSoap dispenser

A liquid soap dispenser includes a housing, a shank that engages a base of the housing, a soap path retainer disposed in the interior of the housing, a shank adapter disposed in the shank, and an infrared sensor to sense the presence of a user. A generally continuous passageway is defined through the shank adapter and the soap path retainer such that an elongated soap delivery tube of a liquid soap reservoir may be inserted through the passageway from the bottom of the soap dispenser to the spout end. The reservoir may be attached to the bottom end of the shank adapter. The soap path retainer is preferably formed of complementary halves, such as by plastic injection molding, that mate together to provide a curved passageway from near the base of the housing to the soap dispensing end and to support the sensor assembly.

Owner:SLOAN VALVE COMPANY

OO control for injection molding machine

InactiveUS7031800B2Error minimizationSimple modelAuxillary shaping apparatusProgramme control in sequence/logic controllersPlastic injection moldingActuator

A plastic injection molding machine has an object oriented programmed routine to control the molding cycle of the machine. The programmed routine implements the inter-related molding cycle of clamp, inject, hold, eject and recover by development of classes corresponding to machine structure performing basic molding cycle steps. The basic classes use object oriented concepts of data encapsulation, inheritance, polymorphism, abstraction and the like that are linked together to produce objects during run time. The classes in turn include controller, observer and actuators classes. The controller class functions as a state machine. The observer class functions to determine the current state and the actuator class produces command signals controlling class related machine hardware. A modeling system is also disclosed for constructing the OO programmed routine for any injection molding machine using existing classes, principally by difference.

Owner:VAN DORN DEMAG CORP

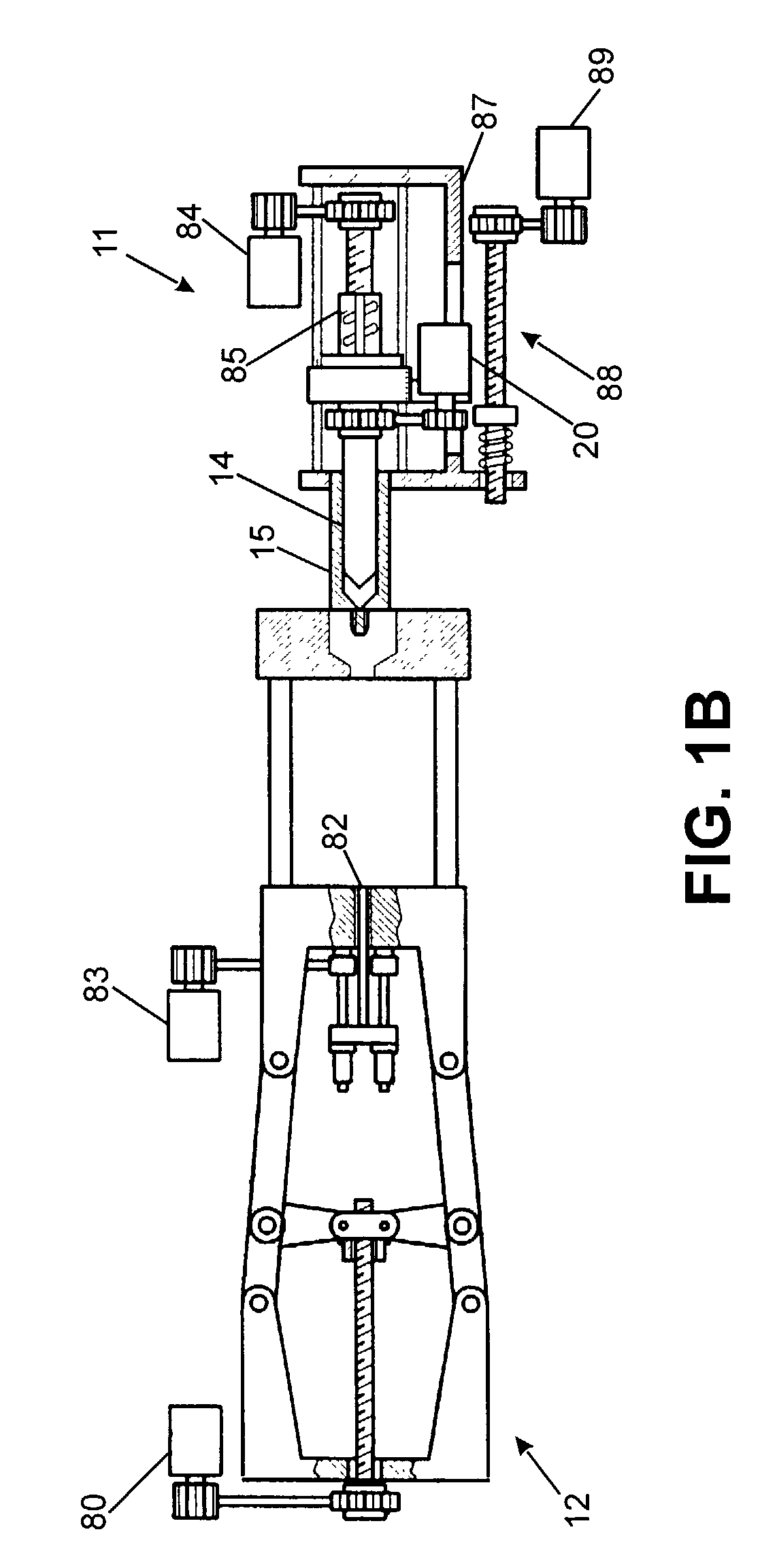

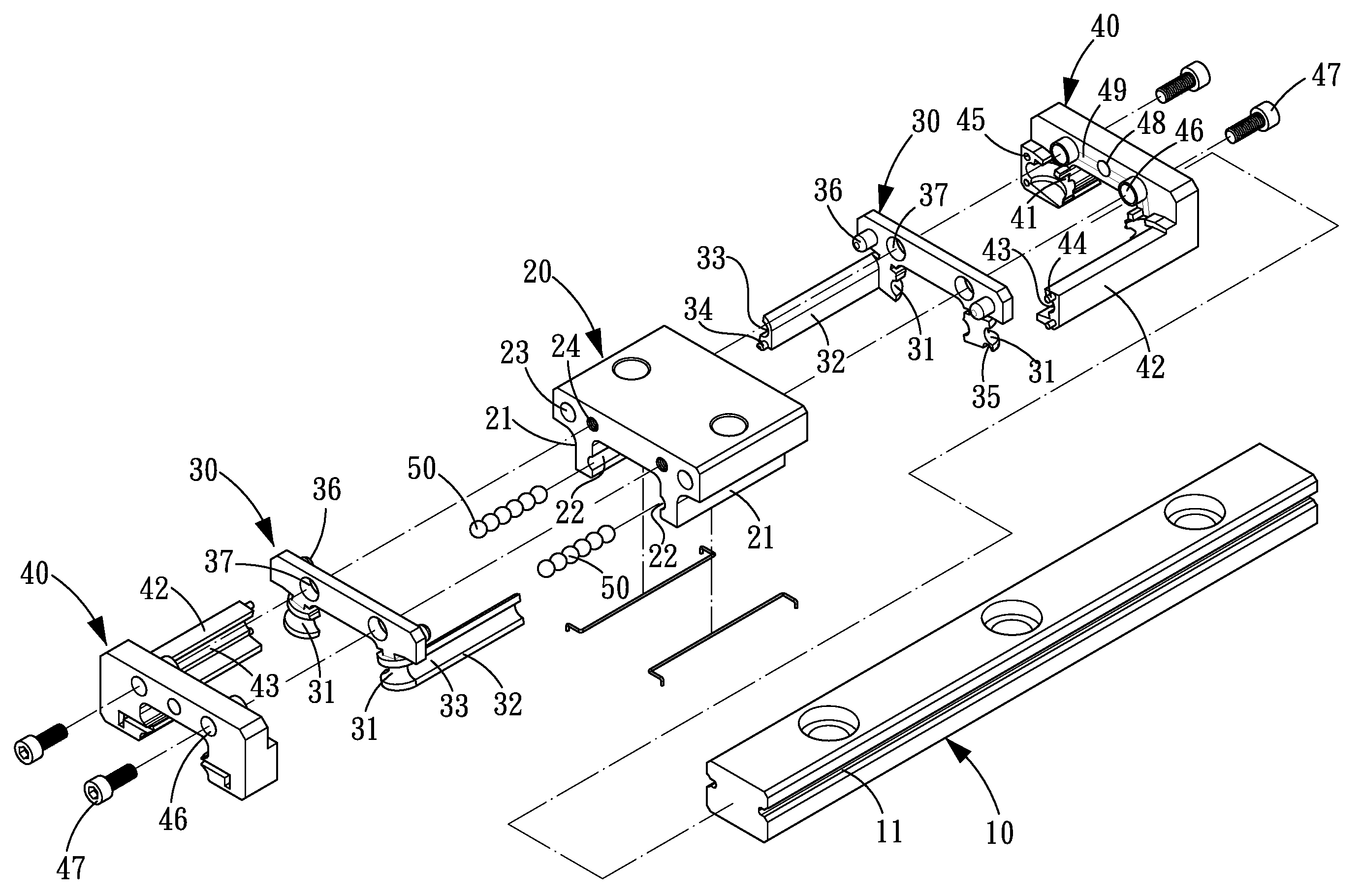

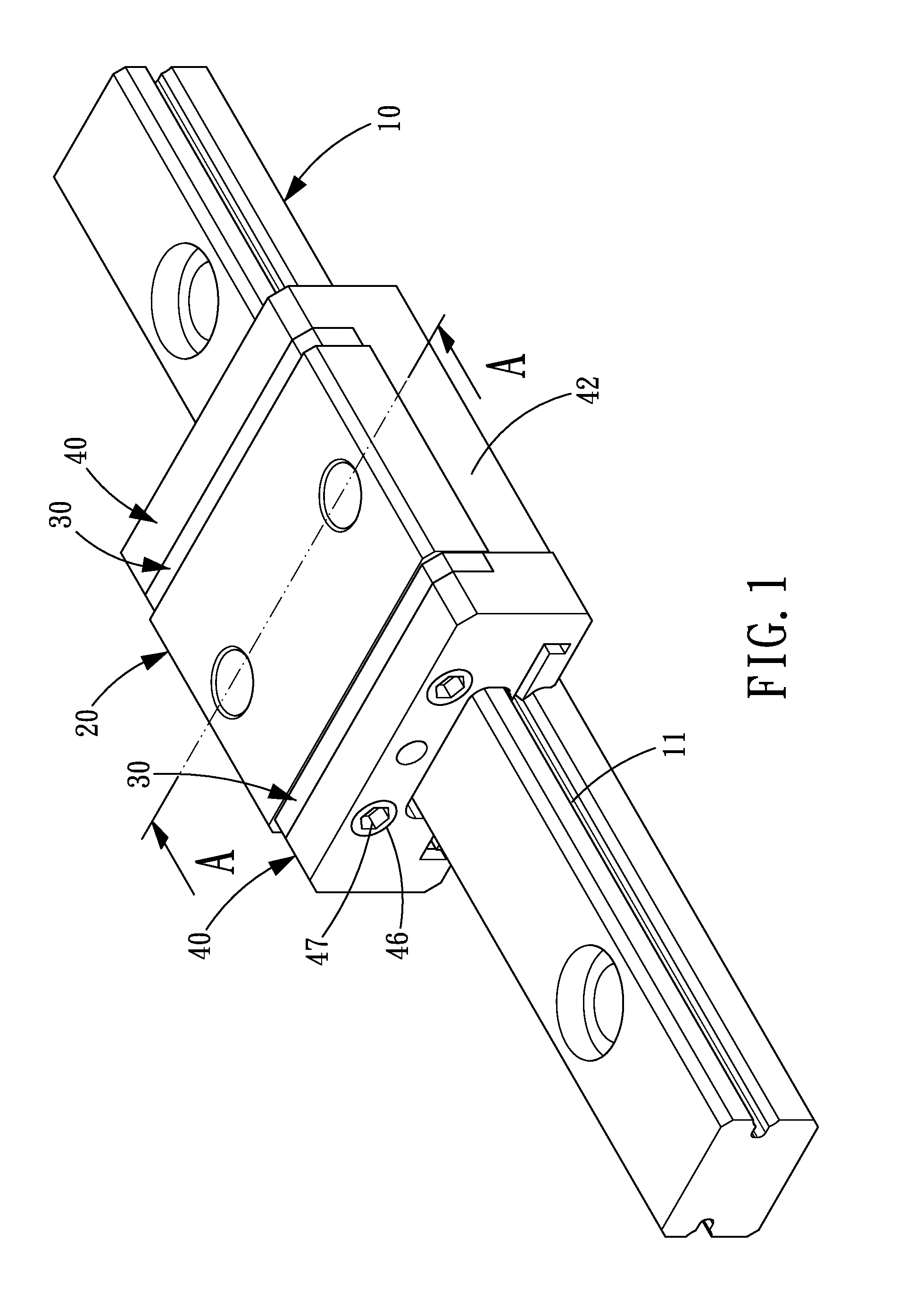

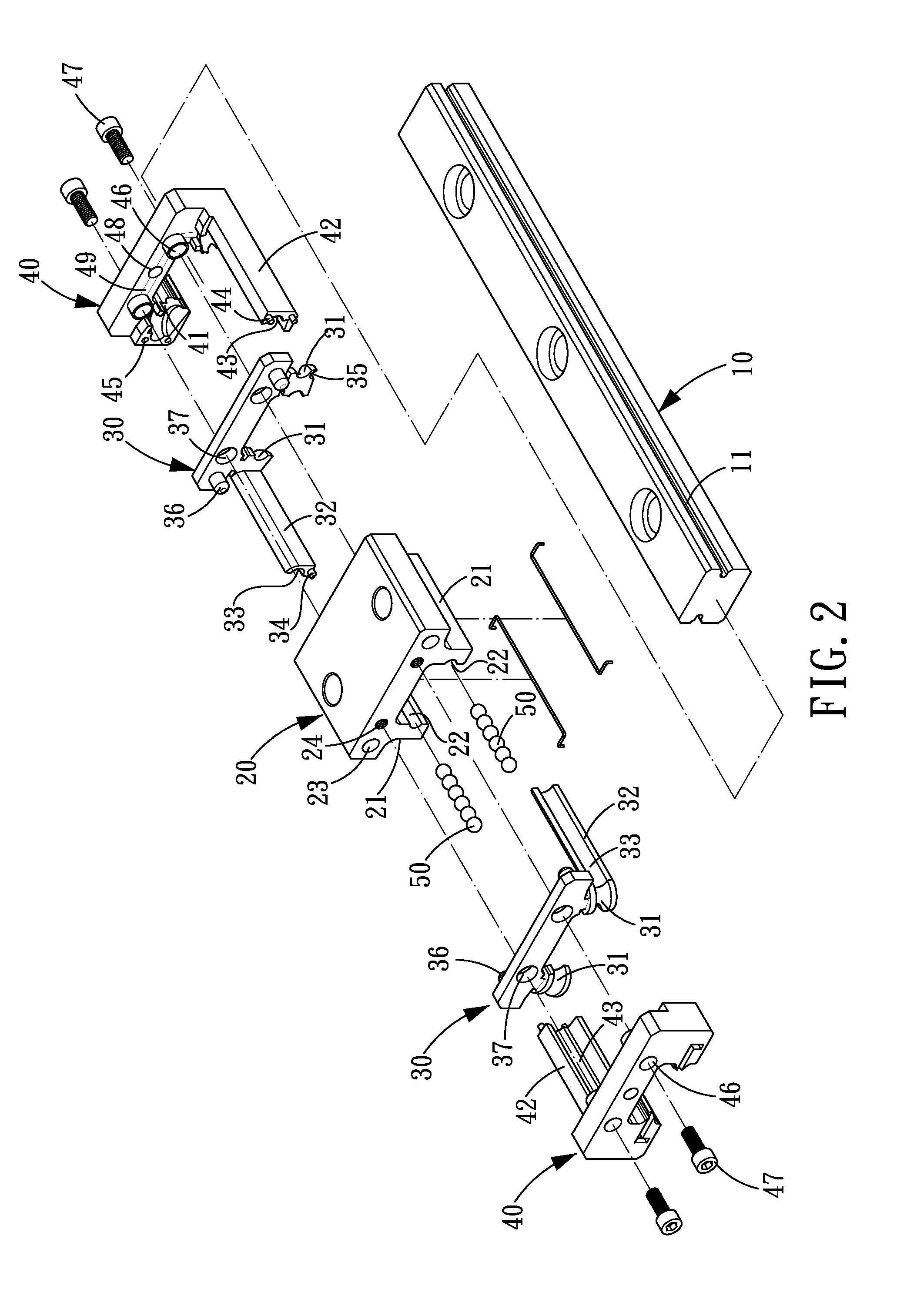

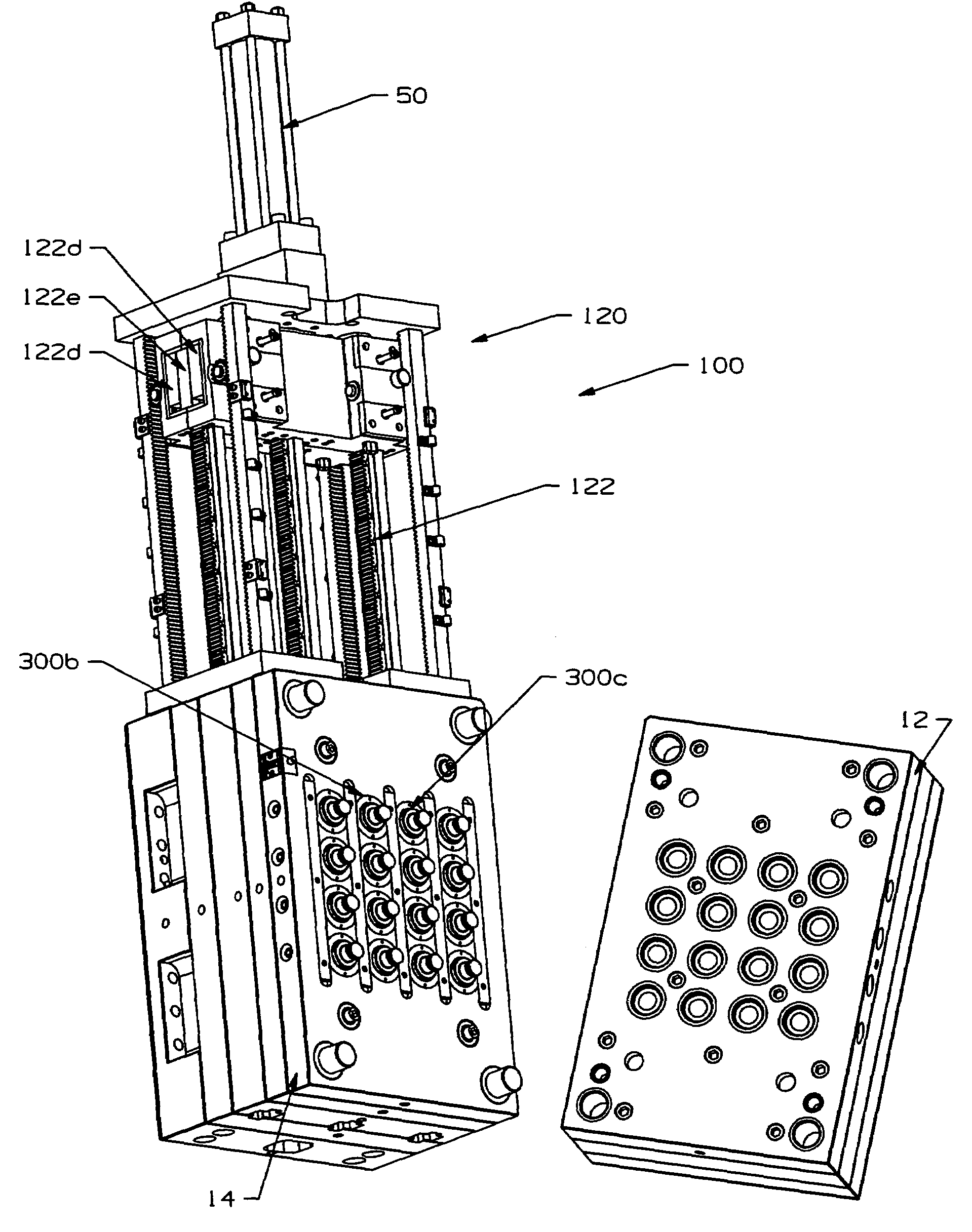

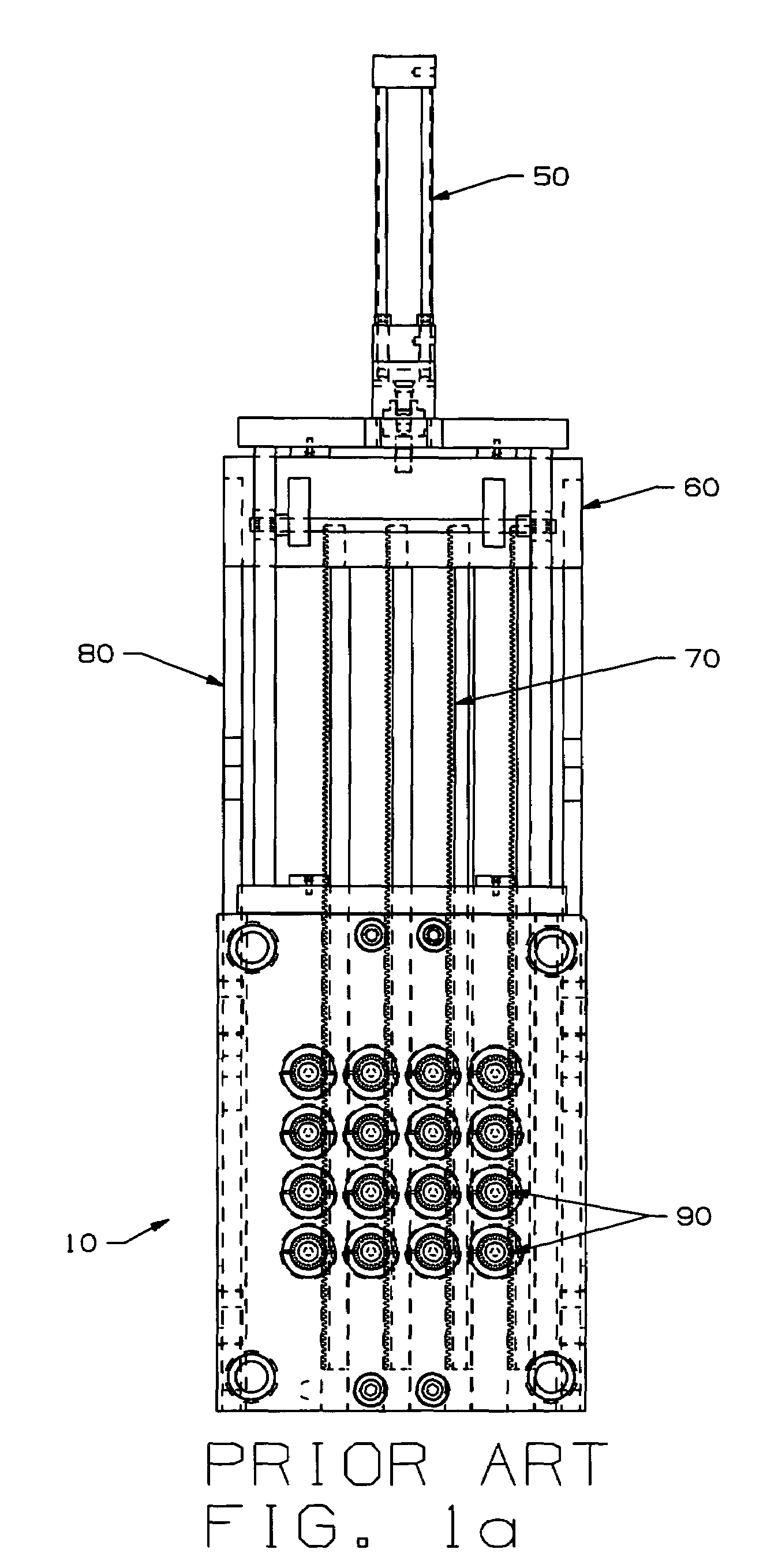

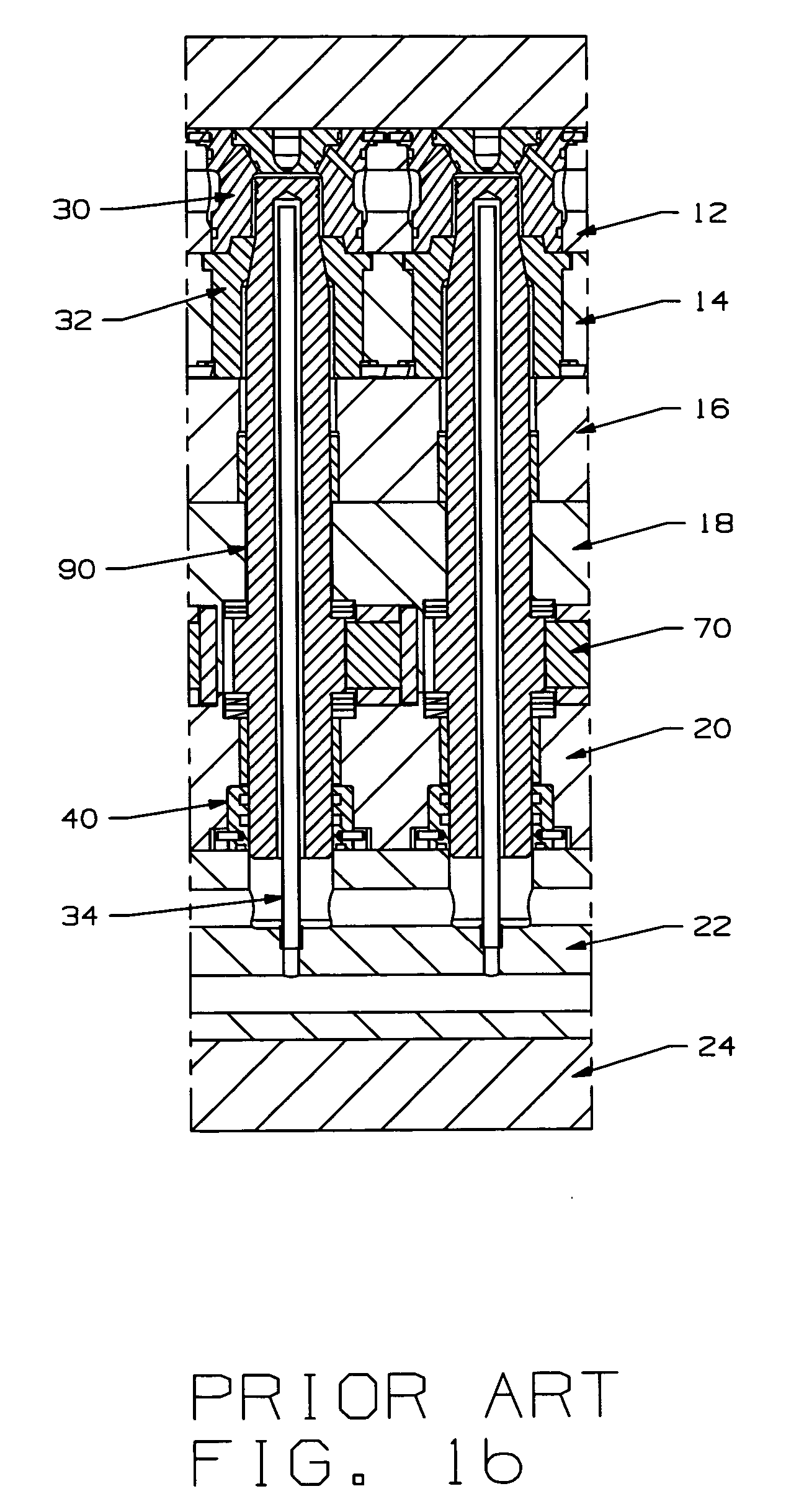

Circulating System for a Linear Guideway

ActiveUS20110033141A1Reduce the cost of the whole machineFacilitate quick mass productionLinear bearingsPlastic injection moldingPlastic materials

A circulating system for a linear guideway comprises a slide block, a slide rail, two cover plates, two end caps and plural rolling elements. The slide block is disposed on the slide rail. The two cover plates and the two end caps are disposed at two opposite ends of the slide block, respectively. Between the two cover plates and the two end caps are disposed inner return and outer return blocks, respectively, and the inner return and the outer return blocks each are defined with half rolling paths to form complete rolling paths. Both ends of a complete rolling path and both ends of a complete loaded path are connected to both ends of two complete return paths to complete circulation paths. The inner and outer return blocks are made by common plastic injection molding, and the formed rolling paths are made of plastic material.

Owner:HIWIN TECH

Apparatus for making threaded articles in a plastic injection molding process

A Bi-directional rack assembly that rotates one column of threaded cores and unscrews threaded closures while moving in the forward direction. The Bi-directional rack then mechanically changes position to engage an adjacent column of rotating threaded cores and at the end of a second molding cycle rotates the threaded cores and unscrew threaded closures while moving in the reverse (reset) direction. A set of timed-advance devices are engaged by a smaller pinion gear and idler gear assemblies to the Bi-directional rack and as the Timed-Advance devices are activated, they allow pneumatic pistons to advance the stripper plate in time with the threaded closures as they are being unscrewed from the threaded cores. A second “rapid advance” pneumatic piston eliminates the need for an external rapid rise camming feature. A rotating core comprising a stock, rotating core, a stock water-seal insert and a custom core top.

Owner:CREATIVE MOLD SOLUTIONS

Power plug assembly

InactiveUS7677916B2High strengthImprove connection strengthElectrically conductive connectionsContact member assembly/disassemblyPlastic injection moldingEngineering

The present invention relates to a power plug assembly, comprises a cable having two power wires, end sections of each wire has plural conductive metal wires; a terminal set composed by a positive terminal and a negative terminal, a connecting section is respectively provided to the rear ends of the positive and the negative terminals and the connecting sections are respectively connected to plural conductive metal wires of end sections of the power wires, the surfaces of the positive and the negative terminals are provided with welding holes; a conductive sleeve tube having an inner tube and an outer tube, an insulating material is provided between the inner tube and the outer tube for insulation; after the two terminals are respectively provided on the outer tube and the inner tube of the conductive sleeve tube, a welding operation is processed and the welding material passes through the welding holes so the two terminals are connected and retained on the conductive sleeve tube; an outer covering member formed by a plastic injection molding and the rear portion of the conductive sleeve tube, the terminal set and the front portion of the cable are covered by the outer covering member via the plastic injection molding. With the improved connecting method of the cable, the terminal set and the conductive sleeve tube provided by the present invention, the connecting strength and the welding speed are increased, and the defective rate is lower and the quality can be ensured.

Owner:TAIWAN LINE TEK ELECTRONICS

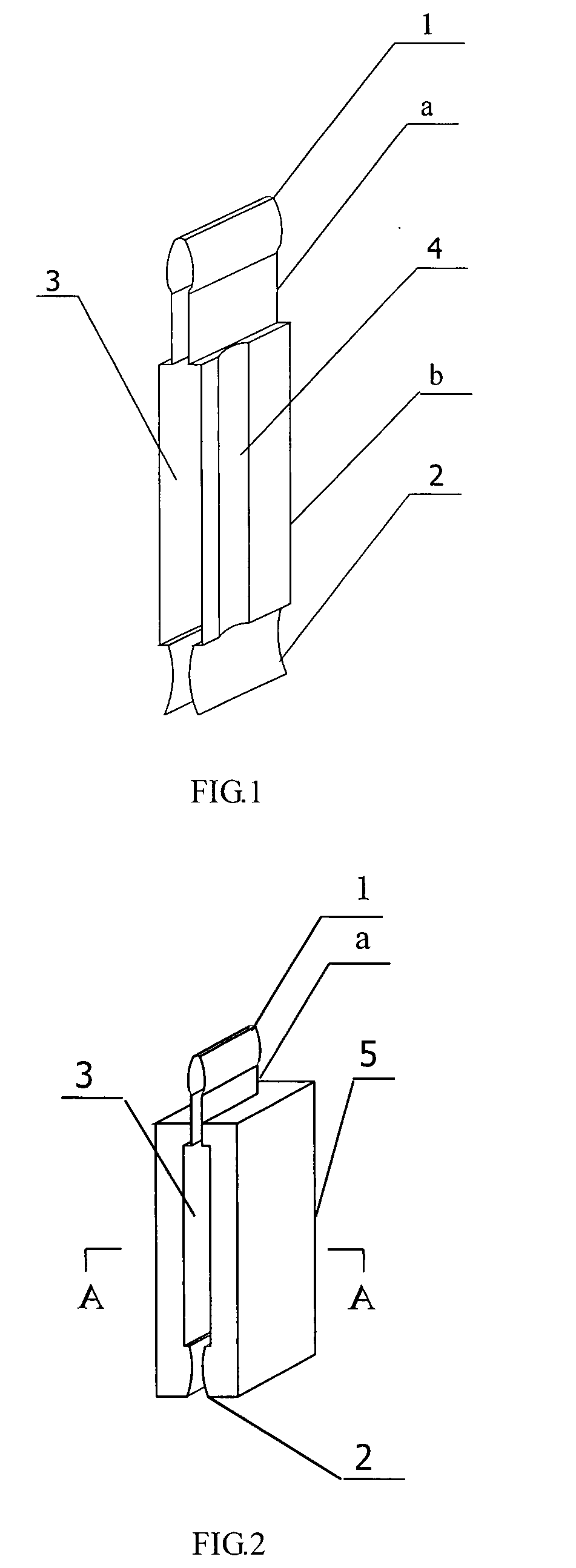

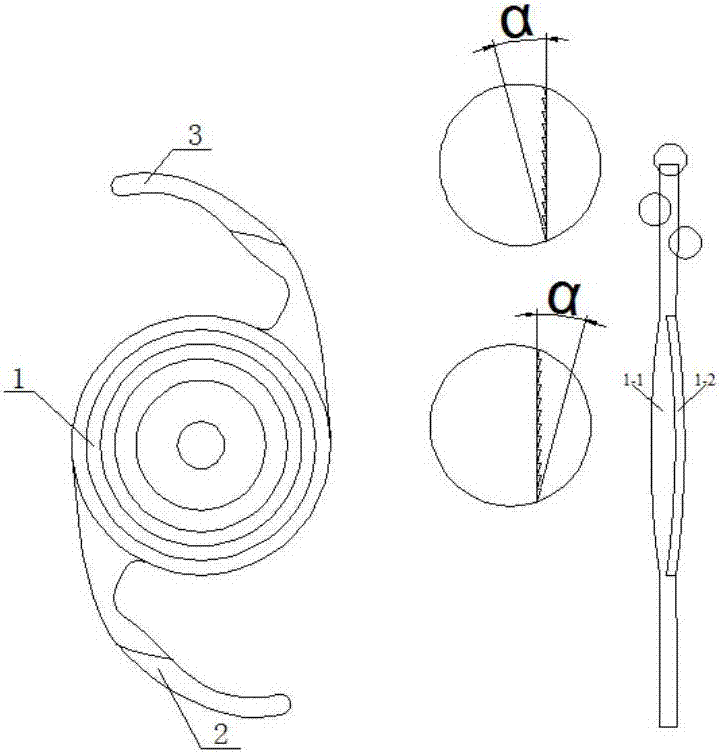

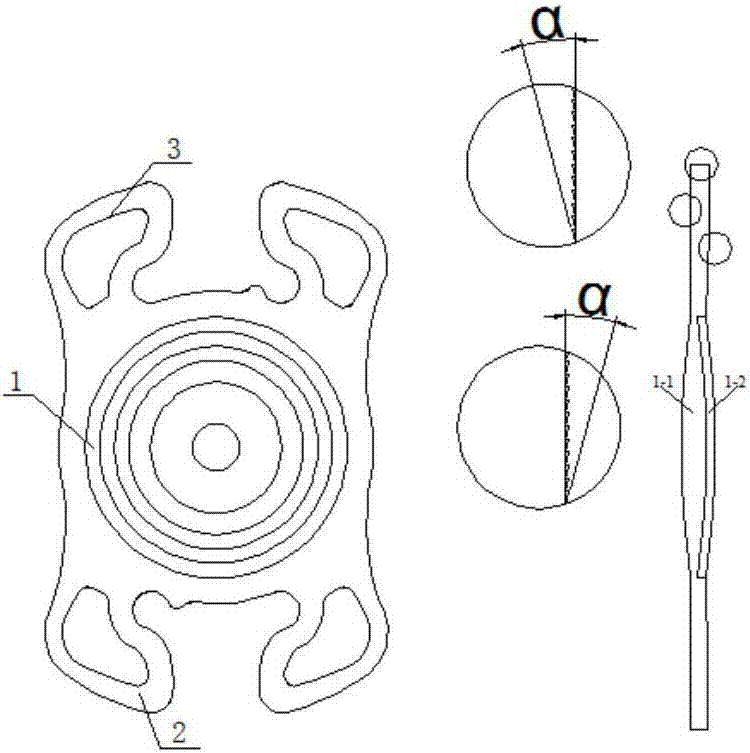

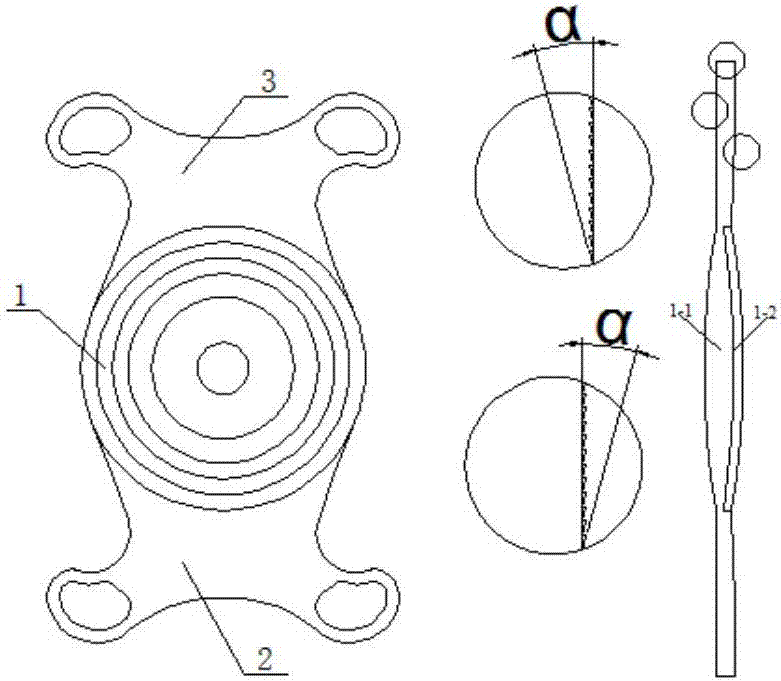

Multi-focus intraocular lens

ActiveCN107212949AEliminate chromatic aberrationLarge depth of focusIntraocular lensIntraocular lensPlastic injection molding

The invention discloses a multi-focus intraocular lens. The intraocular lens comprises an optical body (1), a first supporting loop (2) and a second supporting loop (3). The optical body (1) consists of a substrate layer (1-1) and a coating layer (1-2); the substrate layer (1-1), the first supporting loop (2) and the second supporting loop (3) are in an integral structure and integrally made of a same material; the coating layer (1-2) is adhered to the substrate layer (1-1) by means of plastic injection molding; the substrate layer (1-1) and the coating layer (1-2) are made of different materials. The optical body is a multi-focus optical area with double gluing structures, and by multiple binary faces (in a quantity of 2-4) and non-spherical faces in the optical area, secondary spectral chromatic aberration can be effectively corrected, image quality is improved, an additional focal power range is expanded, and full vision is realized.

Owner:WUXI VISION PRO

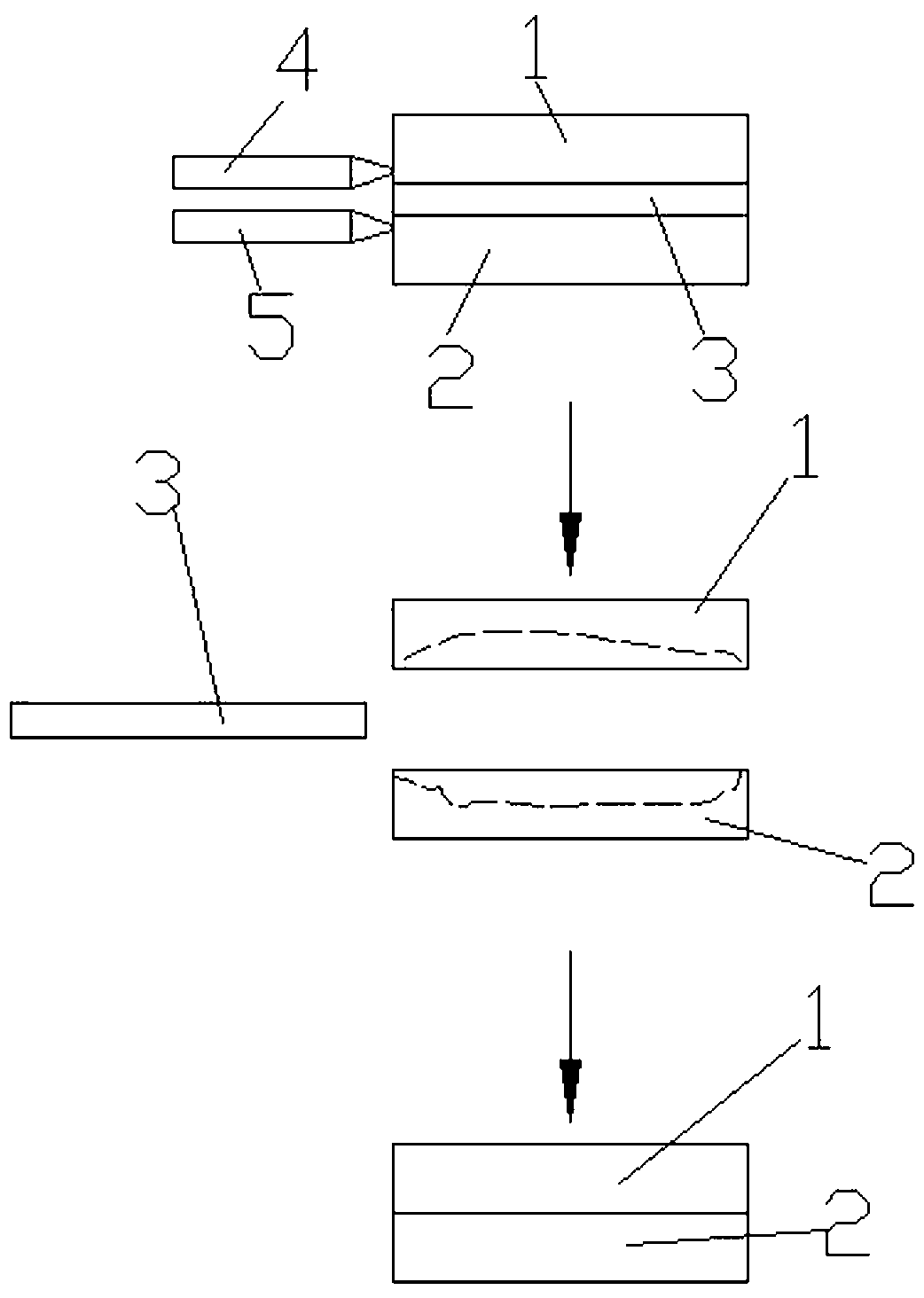

Forming technology and preparation method for double-color and double-hardness sole

ActiveCN103128978AEliminates manual hand gluing stepsSimple processDomestic articlesPlastic injection moldingHardness

The invention discloses a forming technology and a preparation method for a double-color and double-hardness sole. The forming technology and the preparation method for the double-color and double-hardness sole mainly includes the following steps: step 1, a mold is prepared, wherein a set of plastic injection mold is prepared; step 2, a plastic injection molding process is prepared, wherein a plastic injection molding machine is provided with two injection gun barrels which can be used for injecting plastics into the plastic injection mold simultaneously; step 3, the plastic injection molding process is carried out, wherein the plastic injection mold is placed on a mold frame of the plastic injection molding machine, the plastic injection molding machine is started, the two injection gun barrels are used for injecting the plastics into an upper mold body and a lower mold body of the plastic injection mold simultaneously, then the plastic injection mold is pre-pressed through a partition plate and then opened, the upper mold body and the lower mold body are separated, and then the partition plate is drawn out; and step 4, a bonding and cross-linked foaming forming process is carried out, wherein the upper mold body and the lower mold body are closed again, an upper-layer composite material and a lower-layer composite material are subjected to bonding and cross-linked foaming forming in a closed mold cavity, then the plastic injection mold is opened, and the double-color and double-hardness sole is obtained. According to the double-color and double-hardness sole produced through the preparation method, a shoe outsole portion and a shoe middle sole portion are not degummed when meeting water, do not separate from each other and are long in service live, the foaming forming process is fast, and a color bleeding phenomenon cannot happen.

Owner:JINJIANG CHENGCHANG SHOES

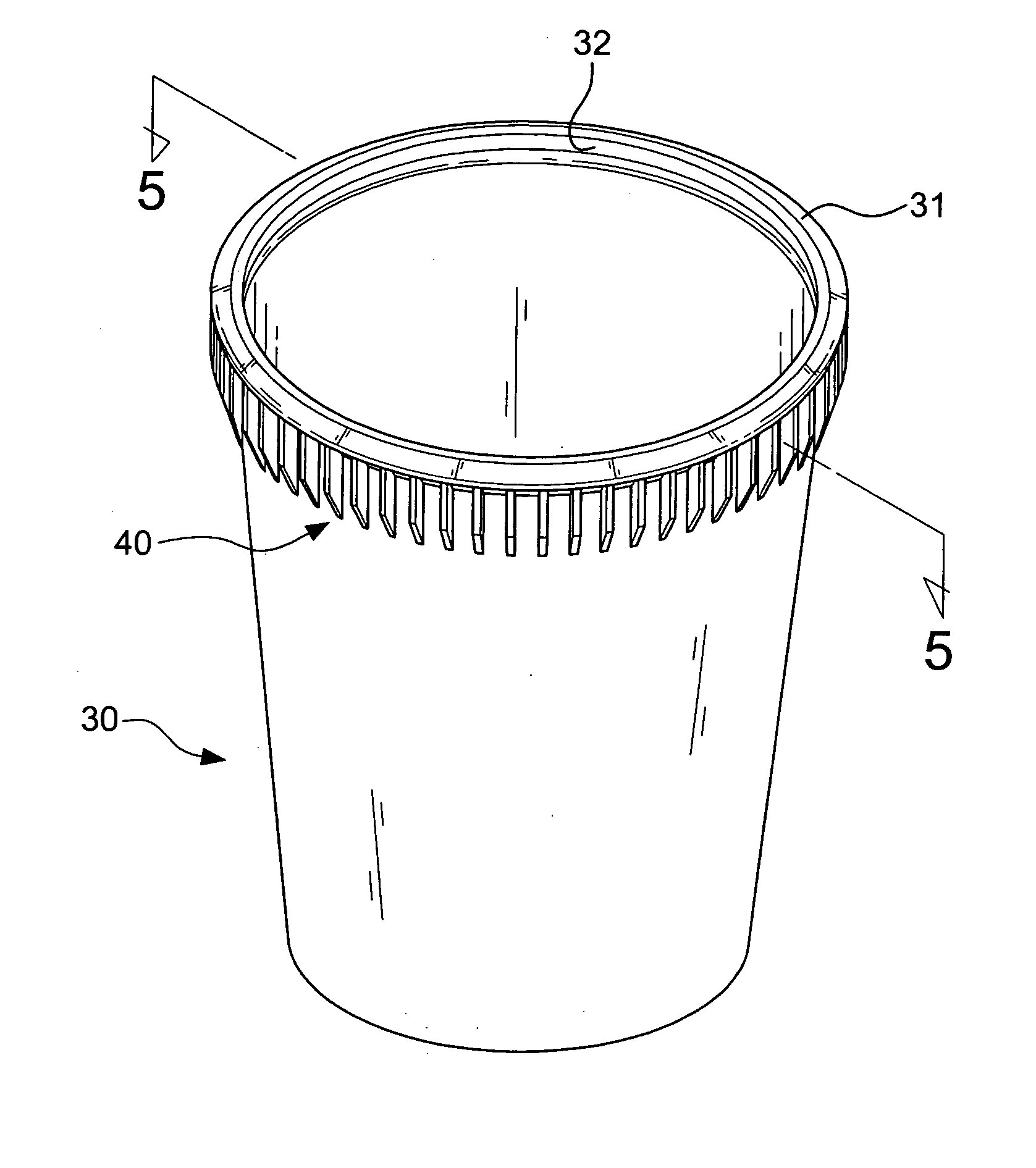

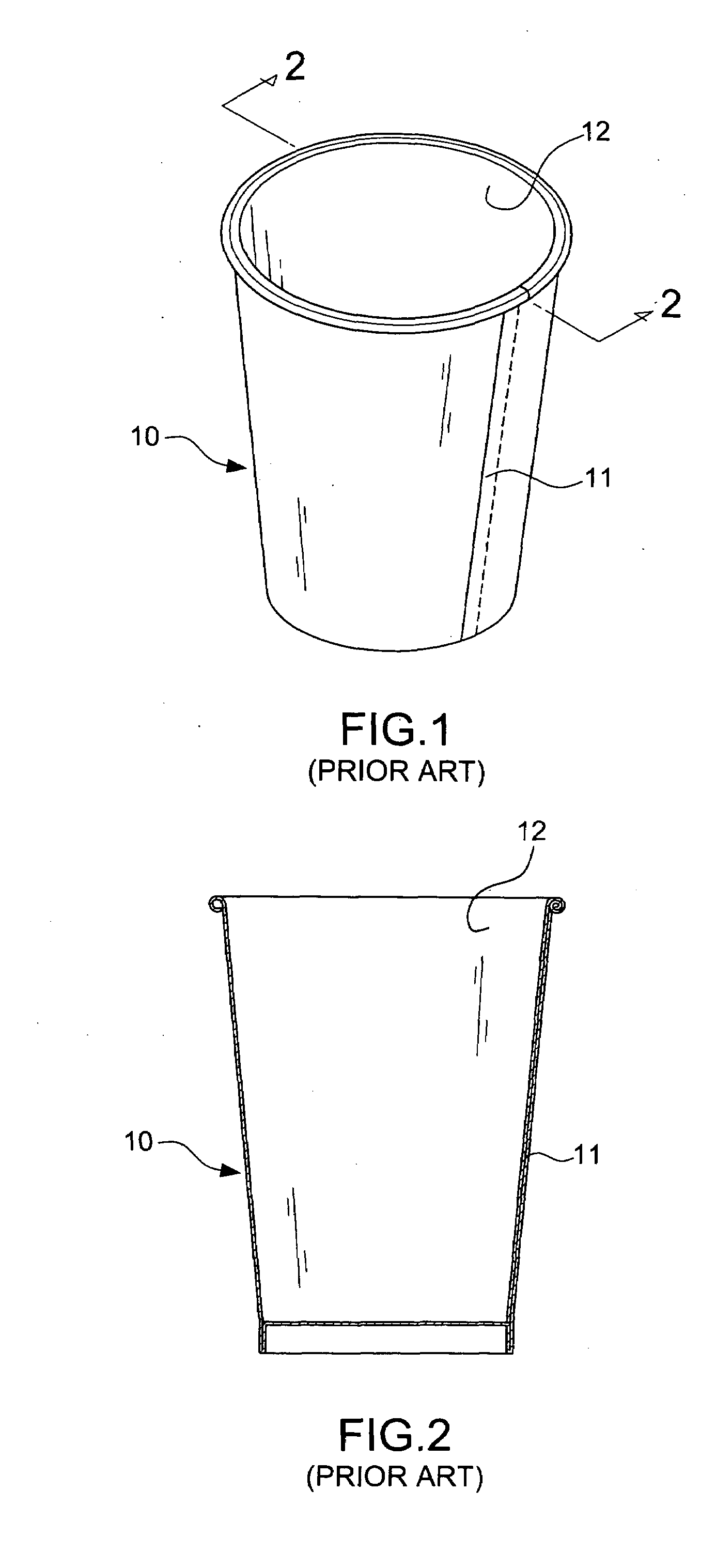

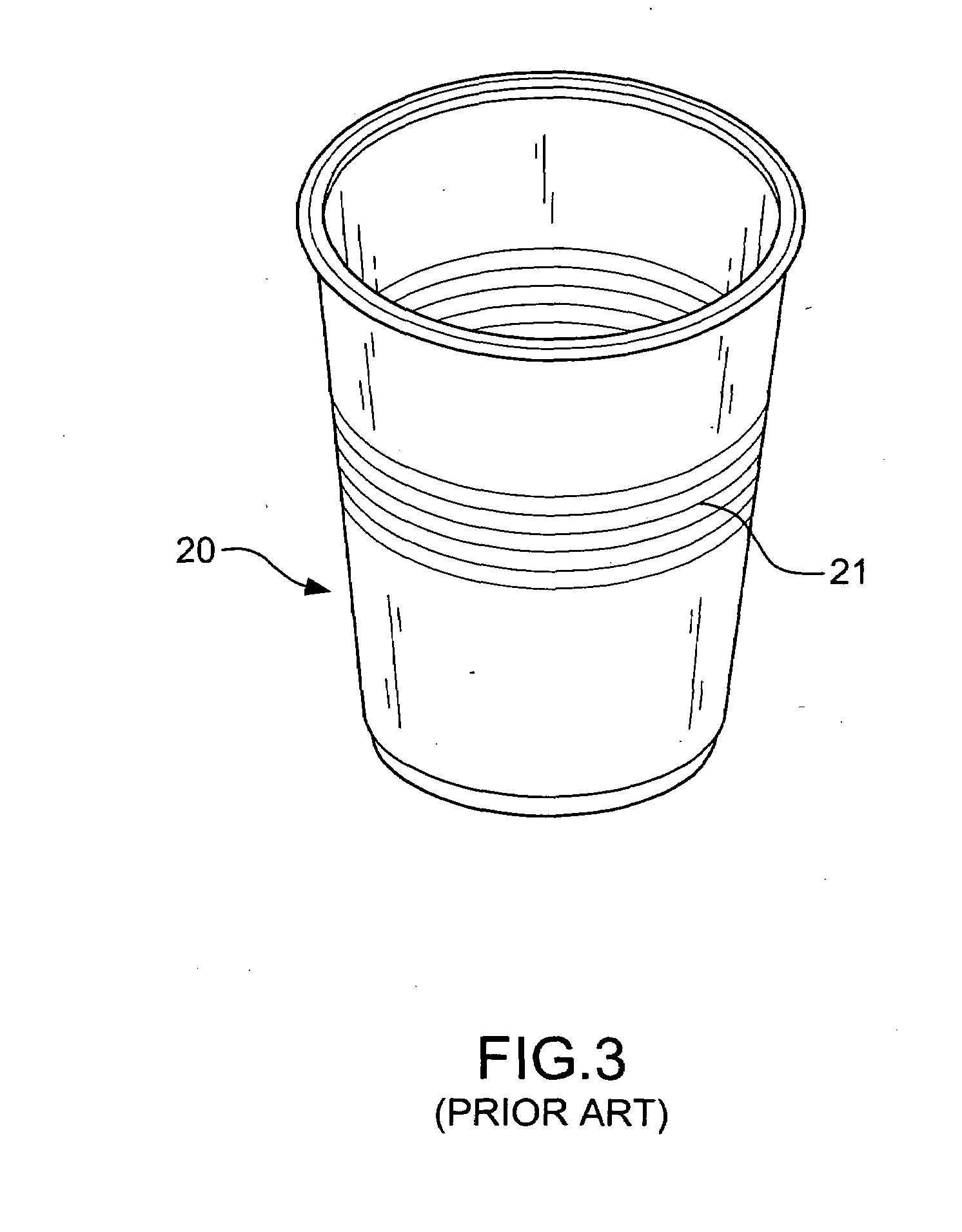

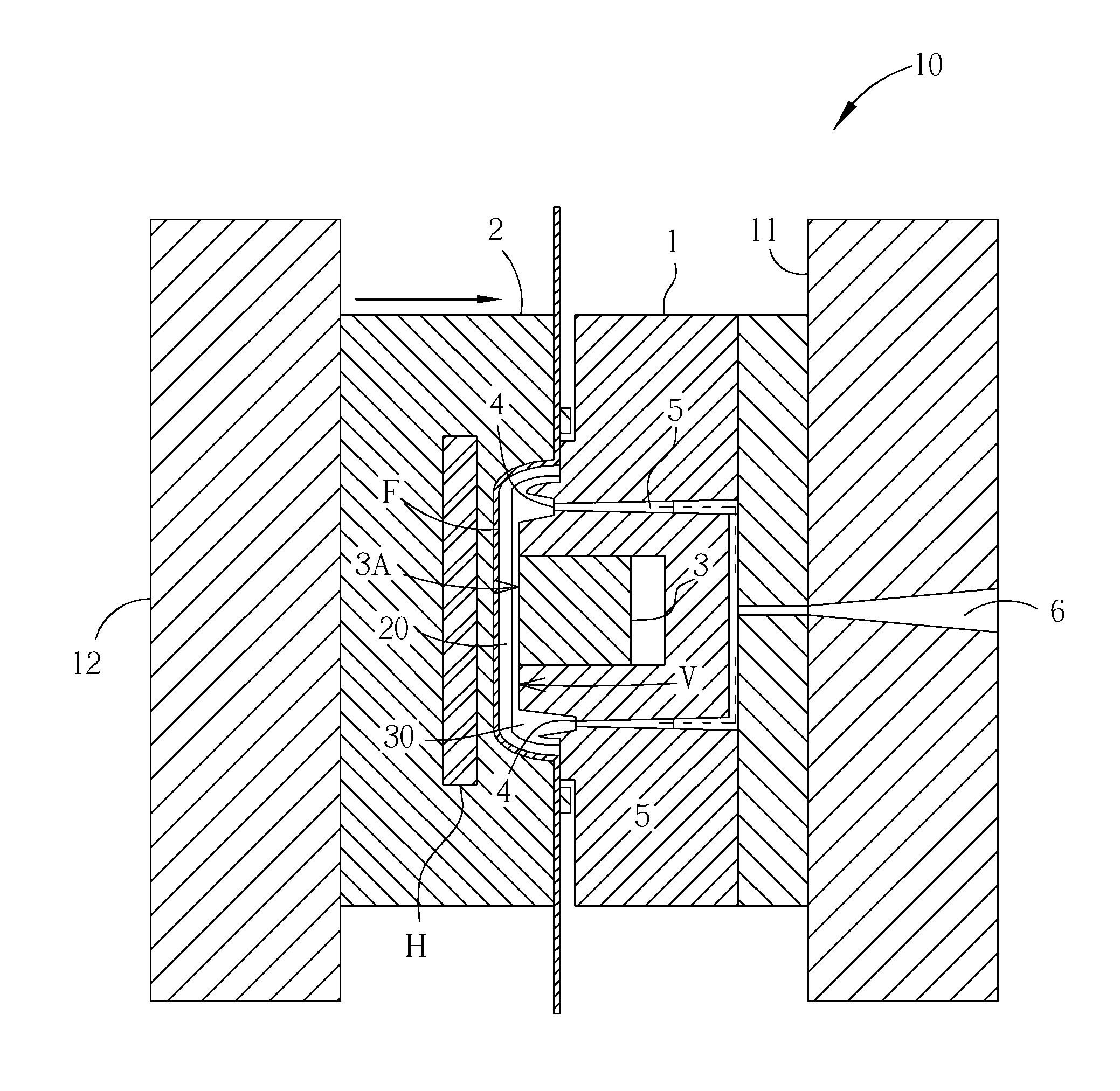

Integral heat-resisting structure of a disposable drinking cup

InactiveUS20080173652A1Joint and riskGood effectDomestic cooling apparatusLighting and heating apparatusPlastic injection moldingEngineering

The present invention discloses a heat-resisting disposable drinking cup comprising: a cup body made by a plastic injection molding and having a cup opening disposed at the top of the cup body and folded outward to form a cup lip; several tens of radial ribs integrally formed at the bottom of the cup lip of the cup opening, and the radial rib is extended more than 1.5 mm from the surface of the cup body but remained within the external periphery of the cup lip of the cup opening, and the interval between two adjacent radial ribs falls within a range of 3˜5 mm, and the height of each radial rib is less than 10 mm measured downward from the cup lip of the cup opening; such that radiating fins can be formed around the external periphery of the cup opening.

Owner:CHOU BOB

Method for bonding plastic mold member onto metal housing

InactiveUS20130075941A1Overcome disadvantagesAdhesive processes with surface pretreatmentOptical articlesPlastic injection moldingEngineering

A method for bonding a plastic member onto a metal housing is provided. A metal housing having an inner surface and an outer surface is prepared. A hollow-carved area is provided on the metal housing. The inner surface of the metal housing is subjected to physical process, thereby forming a bonding area. An adhesive layer is formed on the bonding area. A plastic mold member is formed on the adhesive layer by performing a first plastic injection molding. An optical plastic member is molded on the hollow-carved area by performing a second plastic injection molding.

Owner:ICHIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com