Patents

Literature

80 results about "Air trapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air trapping, also called gas trapping, is an abnormal retention of air in the lungs where it is difficult to exhale completely. It is observed in obstructive lung diseases such as asthma, bronchiolitis obliterans syndrome and chronic obstructive pulmonary diseases such as emphysema and chronic bronchitis.

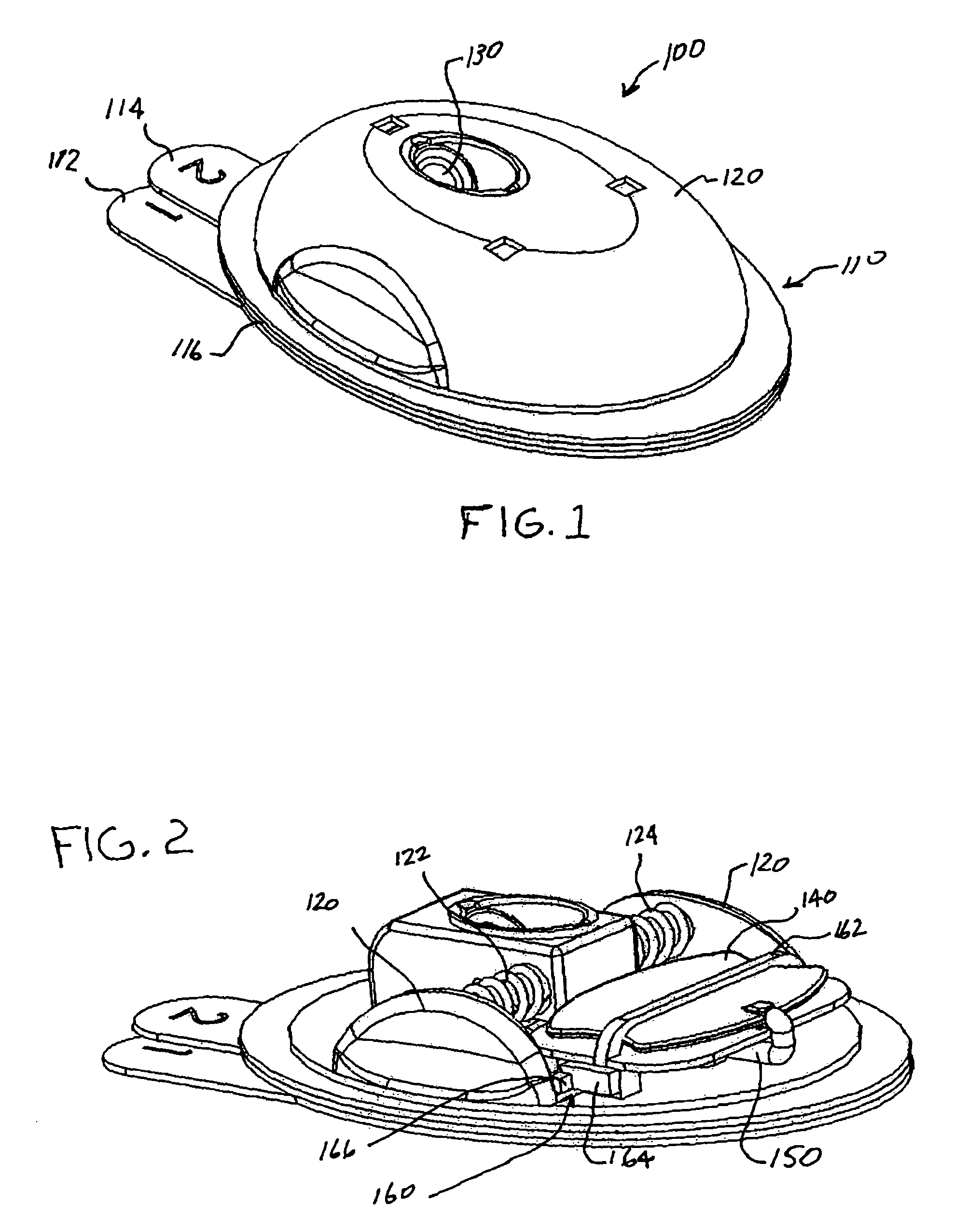

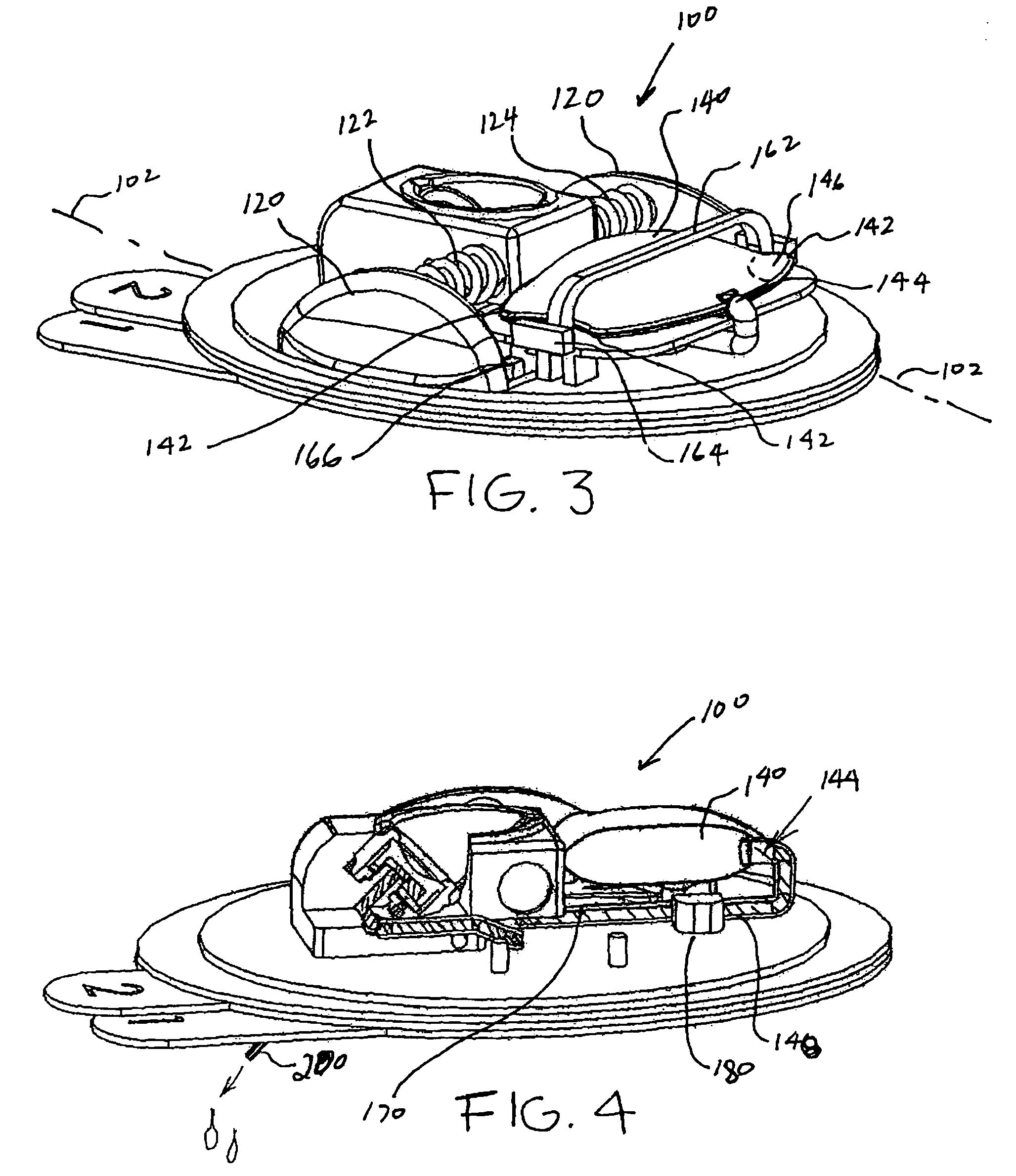

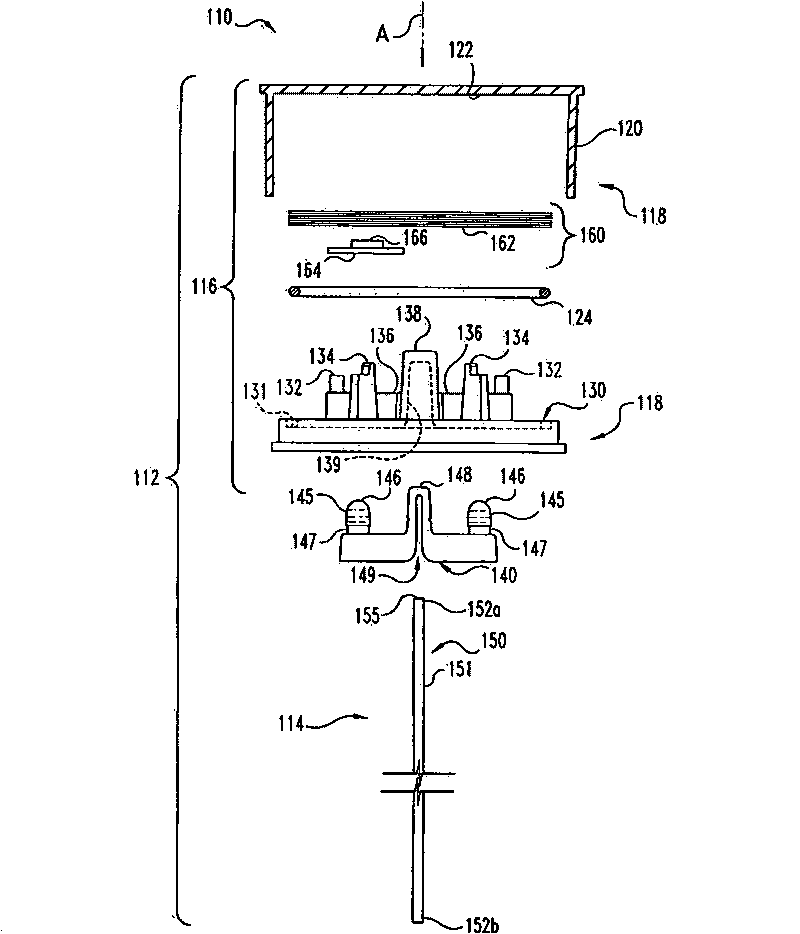

Disposable infusion device with air trapping collapsible reservoir

A wearable infusion device delivers a liquid medicant to a patient. The infusion device comprises a reservoir arranged to contain a liquid medicant to be delivered beneath a patient's skin. The reservoir has an outlet through which the medicant flows and a shape that forms at least one pocket that traps air isolated from the outlet. The infusion device further includes a conduit communicating with the outlet of the reservoir, and a pump that causes the medicant to flow from the reservoir into the conduit.

Owner:CALIBRA MEDICAL

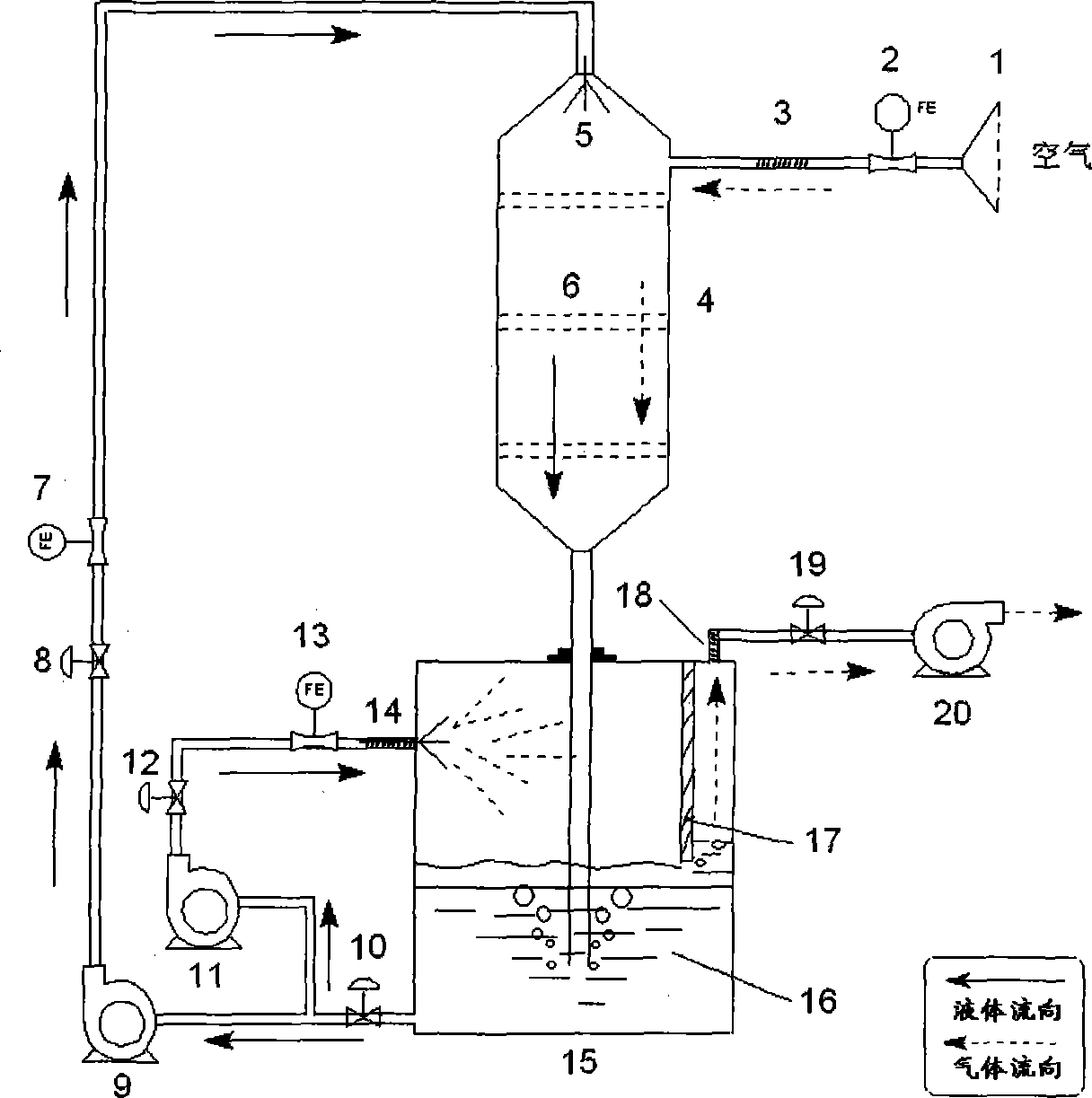

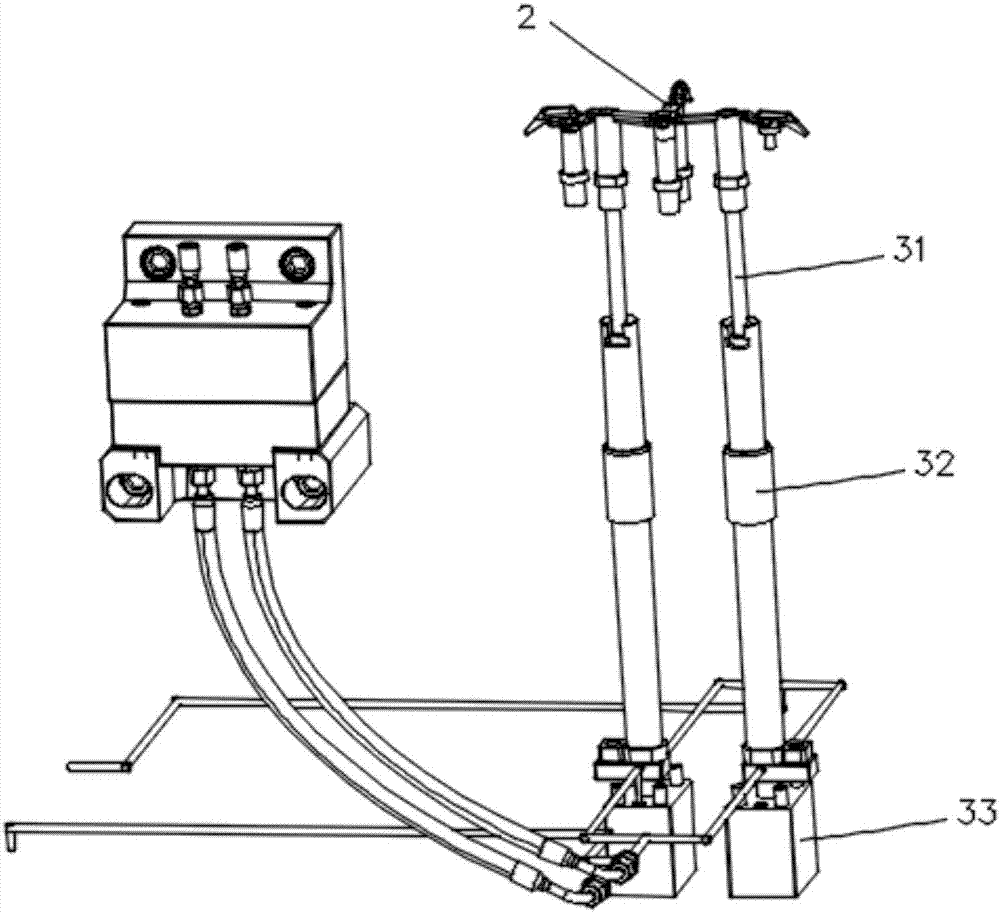

High-efficient trapping system for micro-nano powder dust in air

InactiveCN101502735AEfficient captureImprove wettabilityCombination devicesUsing liquid separation agentMicro nanoFiber

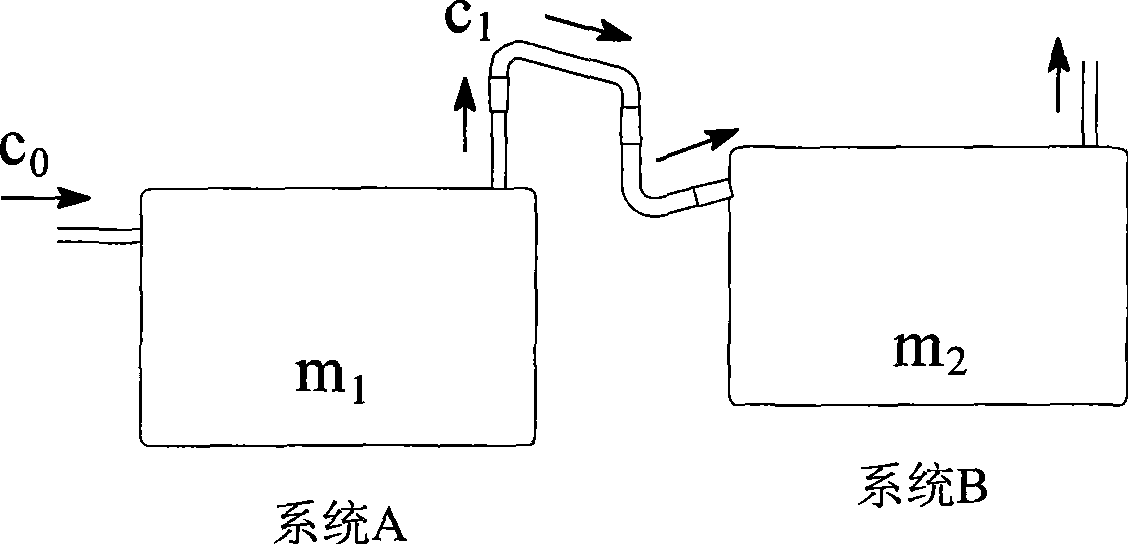

The invention discloses an efficient trapping system of micro-nanometer dust in the air. The invention comprises an air trapping opening, a filter core, a sprayer, a big and small flow micro pump, an atomizing nozzle, a liquid storage chamber, trapping liquid, a baffle and a vacuum pump, which construct an air flow route and a liquid circulation route, the system designs the air containing dust and the trapping liquid to experience four different absorption and trapping processes continuously, so as to realize efficient trapping of the micrometer and nanometer dust composed of various grains. By changing the variety of the trapping liquid or adjusting the hydrophile-lipophile balance (HLB) value of the trapping liquid, and improving the wettability of the trapping liquid and the nano dust in the air, micro nanometer fiber, thin sheet dust and other solid dust particles of various forms, containing micro-nano particles, can be efficiently trapped. The invention designs a plurality of air-liquid continuous contact processes, the air containing dust and the trapping liquid are only mixed and absorbed in the system, thus efficiently trapping nano dust in various dust density environment air including occupation workplaces.

Owner:NANJING UNIV OF SCI & TECH

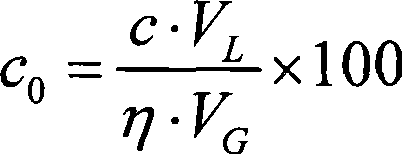

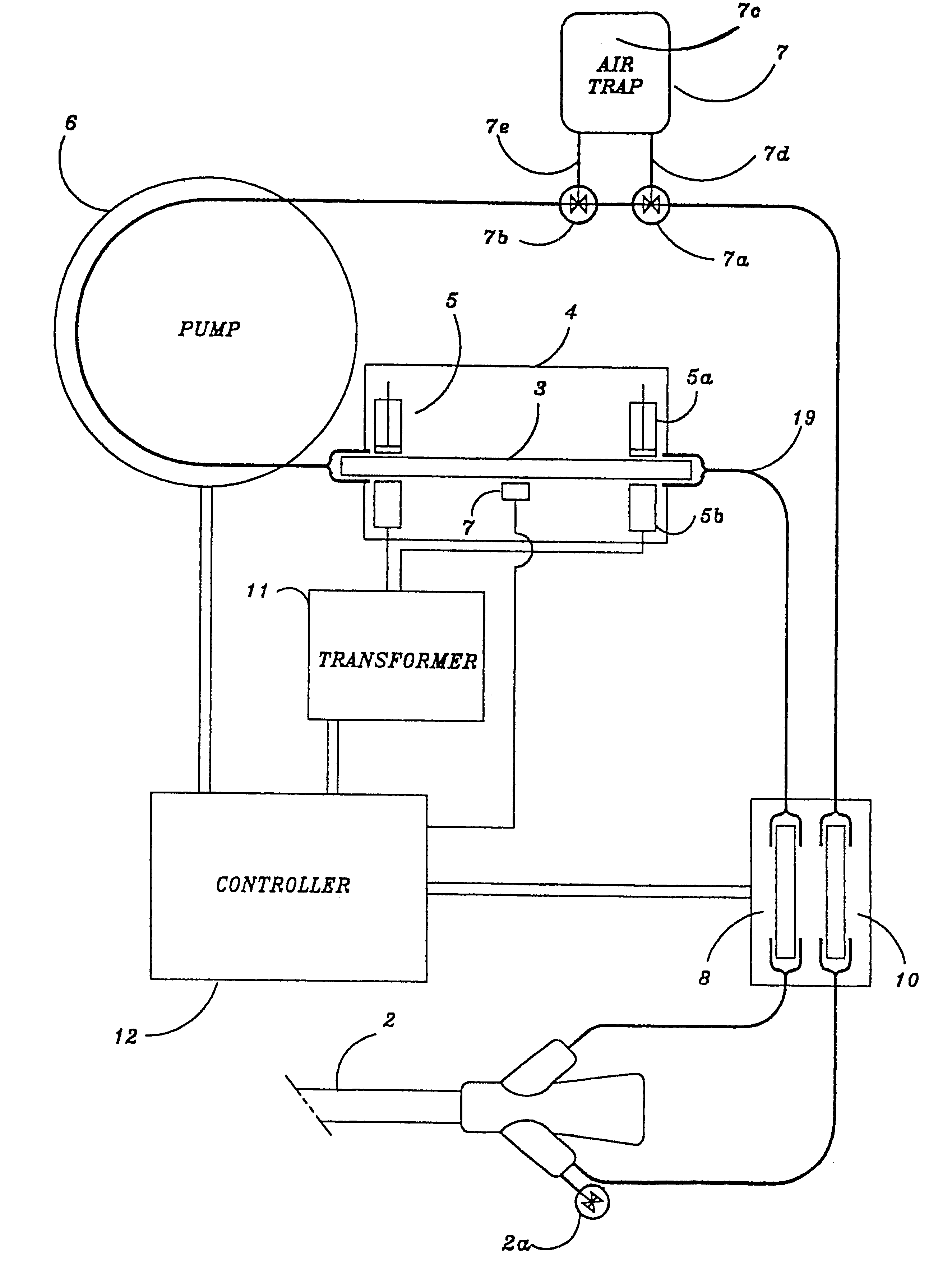

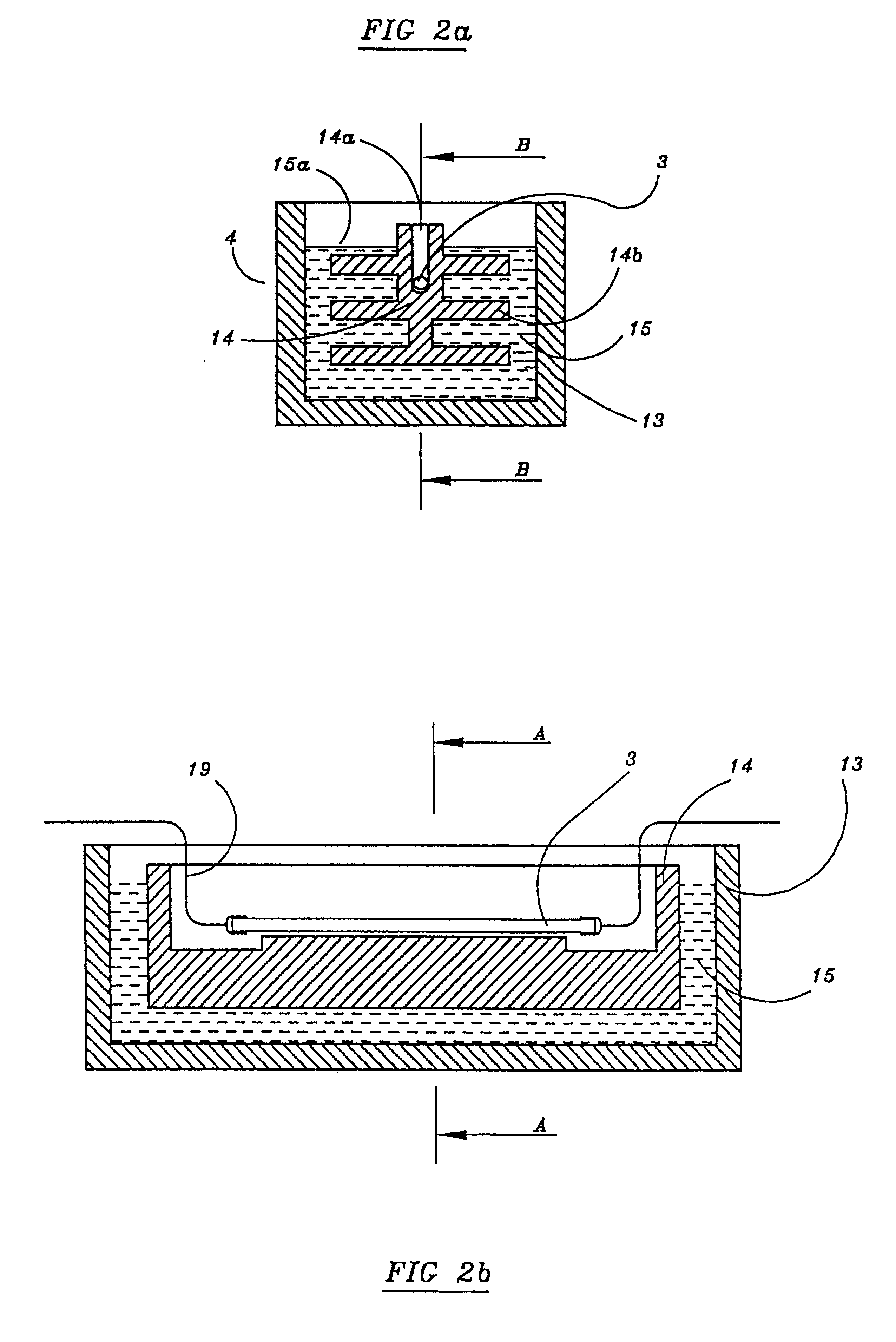

Thermal treatment apparatus

InactiveUS6849063B1Good thermal couplingIncrease contact areaFlexible member pumpsSurgical instrument detailsElectricityAir trapping

A temperature-setting device for providing a predetermined temperature to a quantity of fluid circulating therethrough, a thermal treatment apparatus including such device for selectively treating a targeted tissue adjacent a subject's body cavity, and techniques using such thermal treatment apparatus are provided. The temperature-setting device comprises: an electrically conducting tubular element, a housing element for receiving the tubular element; and a transformer electrically connectable to the housing element. The tubular element functions as a resistor and heats the fluid circulating therethrough. Alternatively, the housing element comprises a thermal conducting member disposed within a bath of a cooling substance, the thermal conducting member having a recess for receiving the tubular element. The tubular element may alternately be placed in a housing element functioning as a heater and a housing element functioning as a cooler, thereby alternately heating or cooling the fluid circulating therethrough. The thermal treatment apparatus comprises: a temperature-setting device according to the present invention; a catheter insertable into a subject's body cavity, the catheter including a thermal treating section for thermally treating a targeted tissue; a pump; thermal sensor assemblies; and an air trapping element.

Owner:JPMORGAN CHASE BANK AS ADMINISTATIVE AGENT

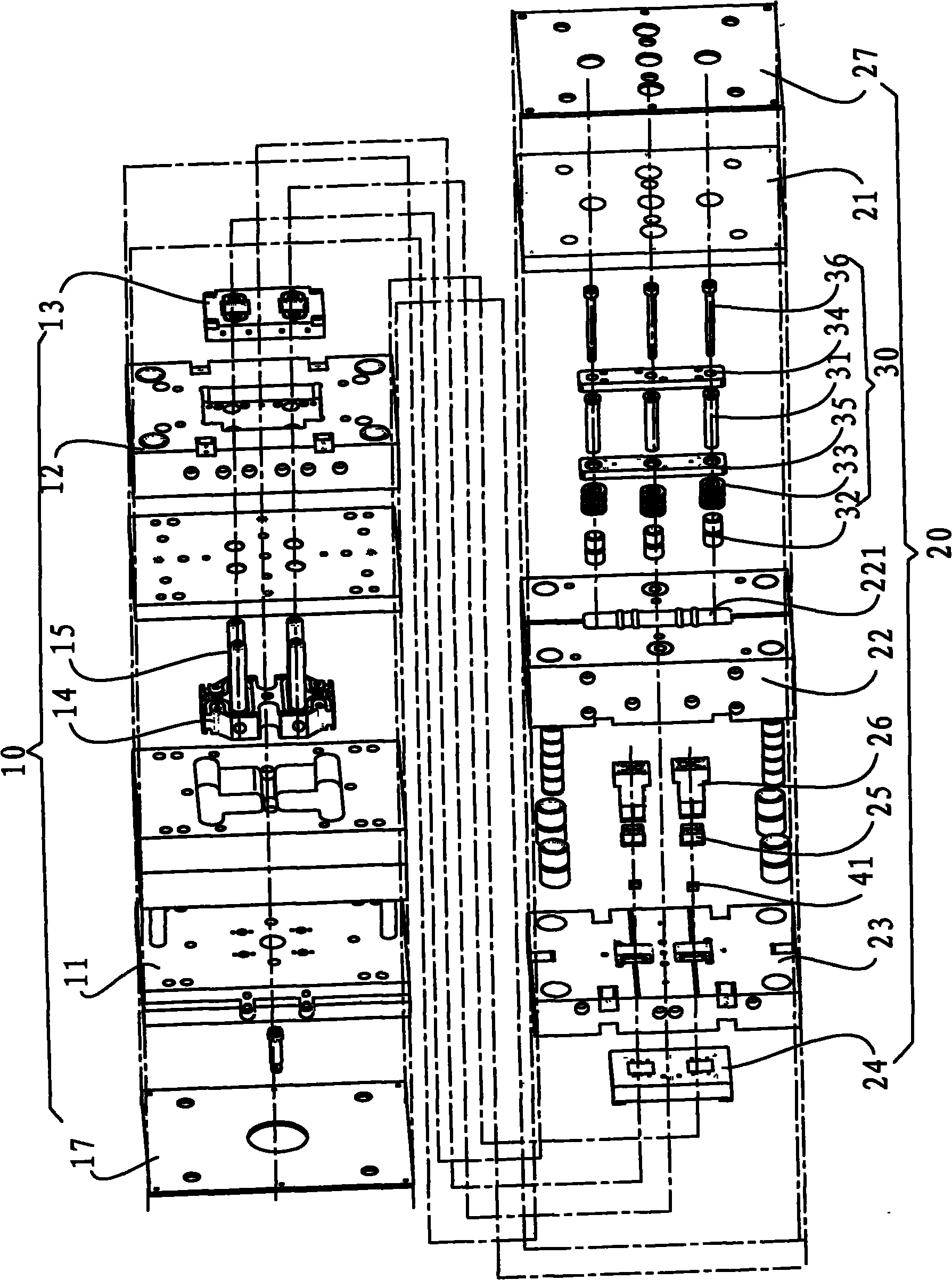

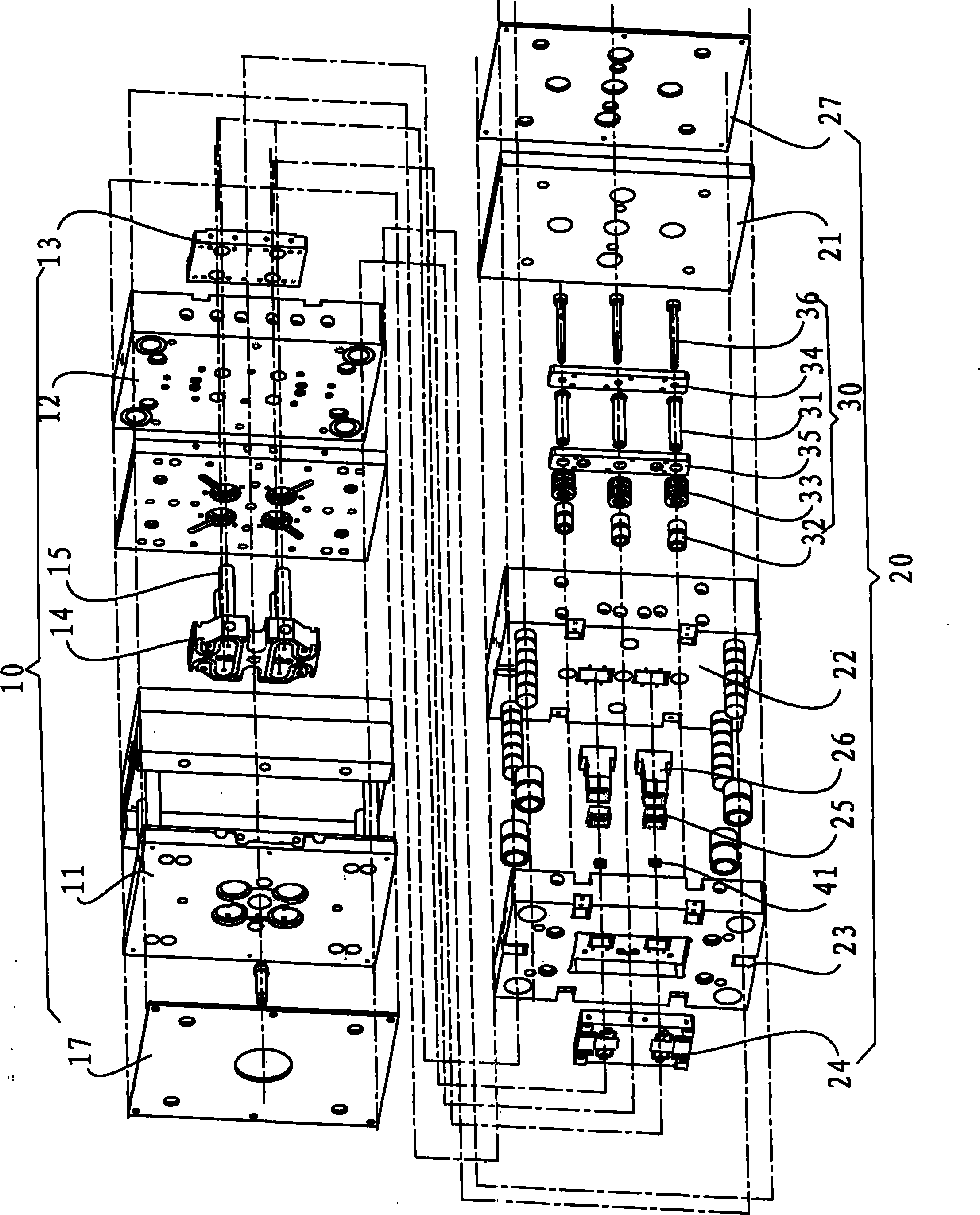

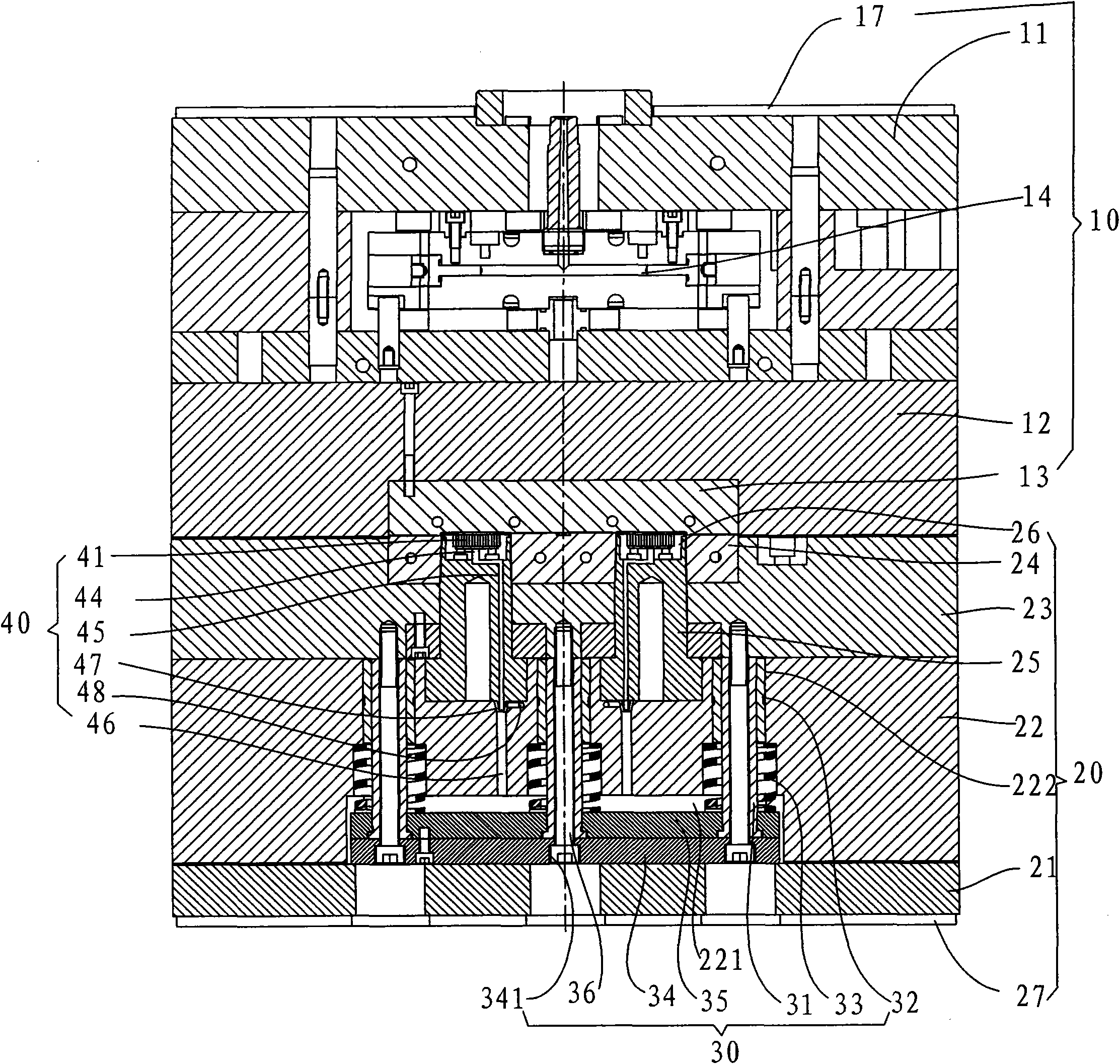

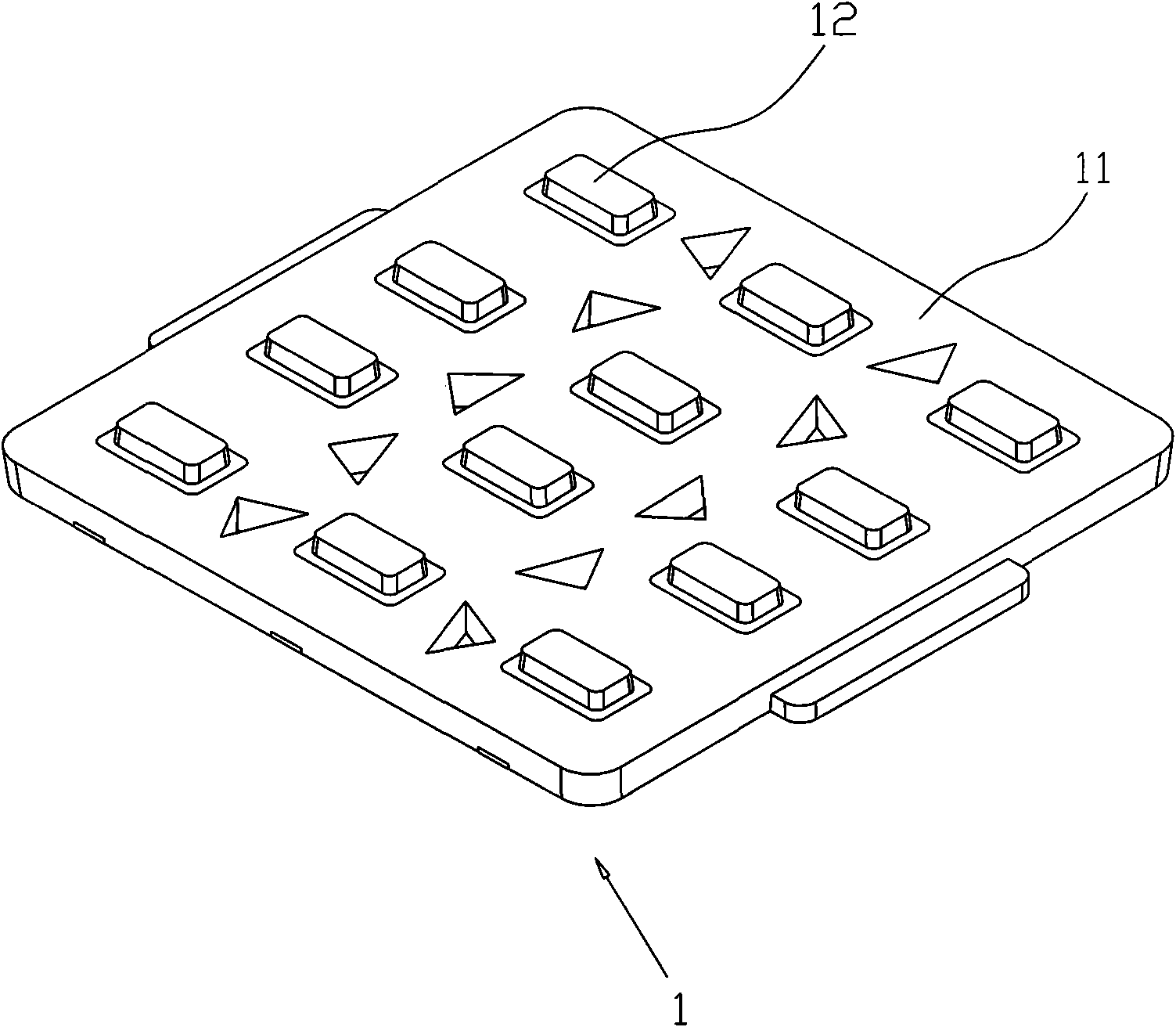

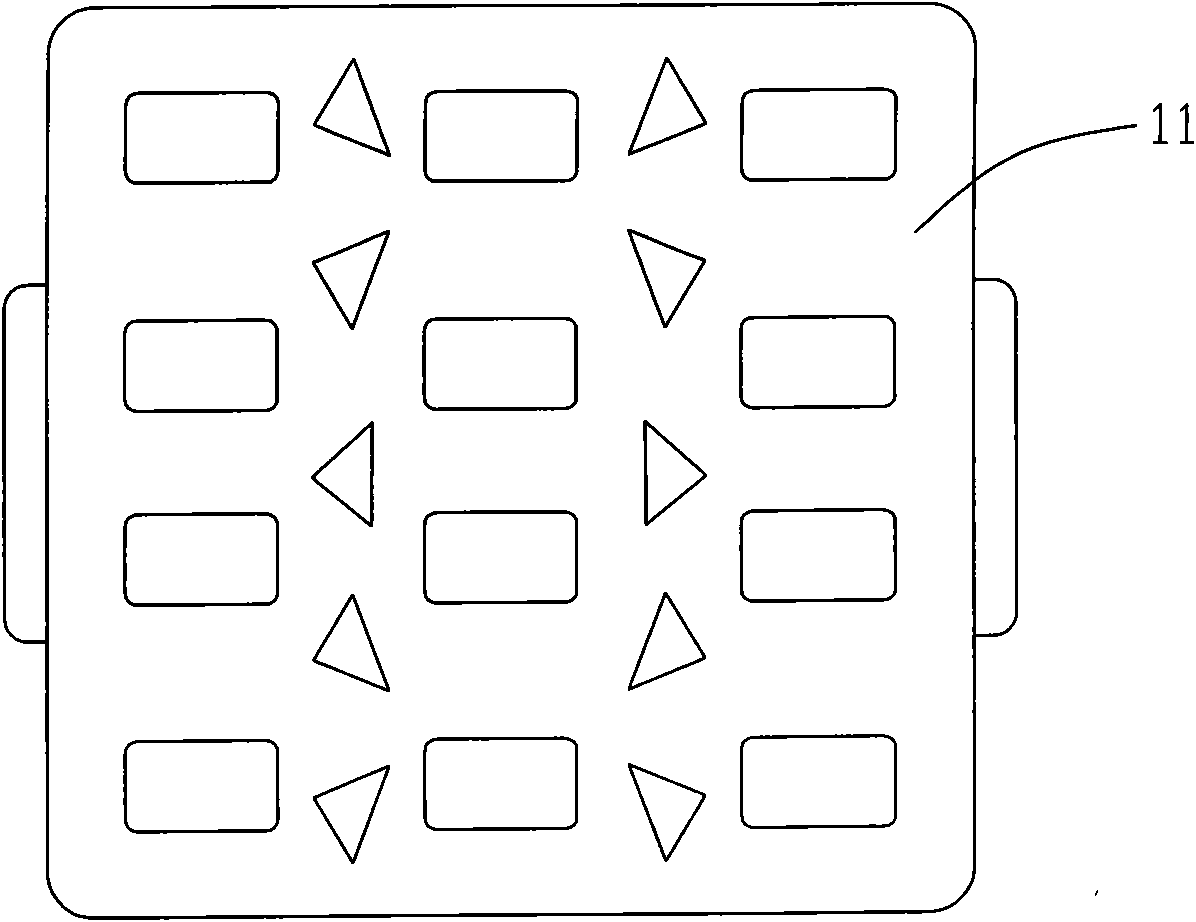

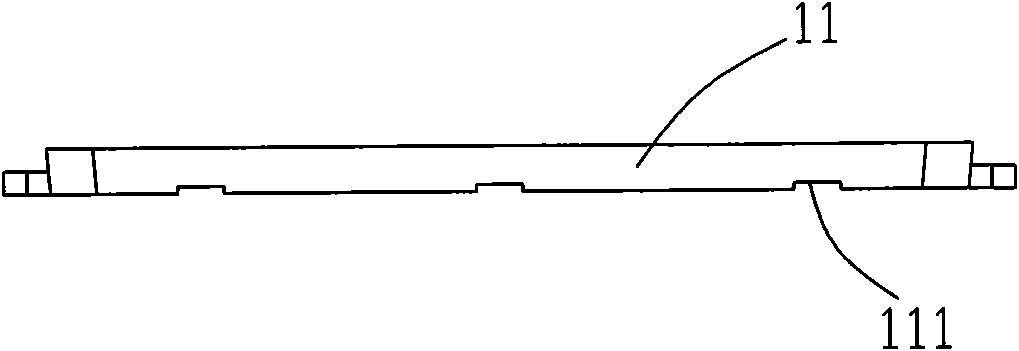

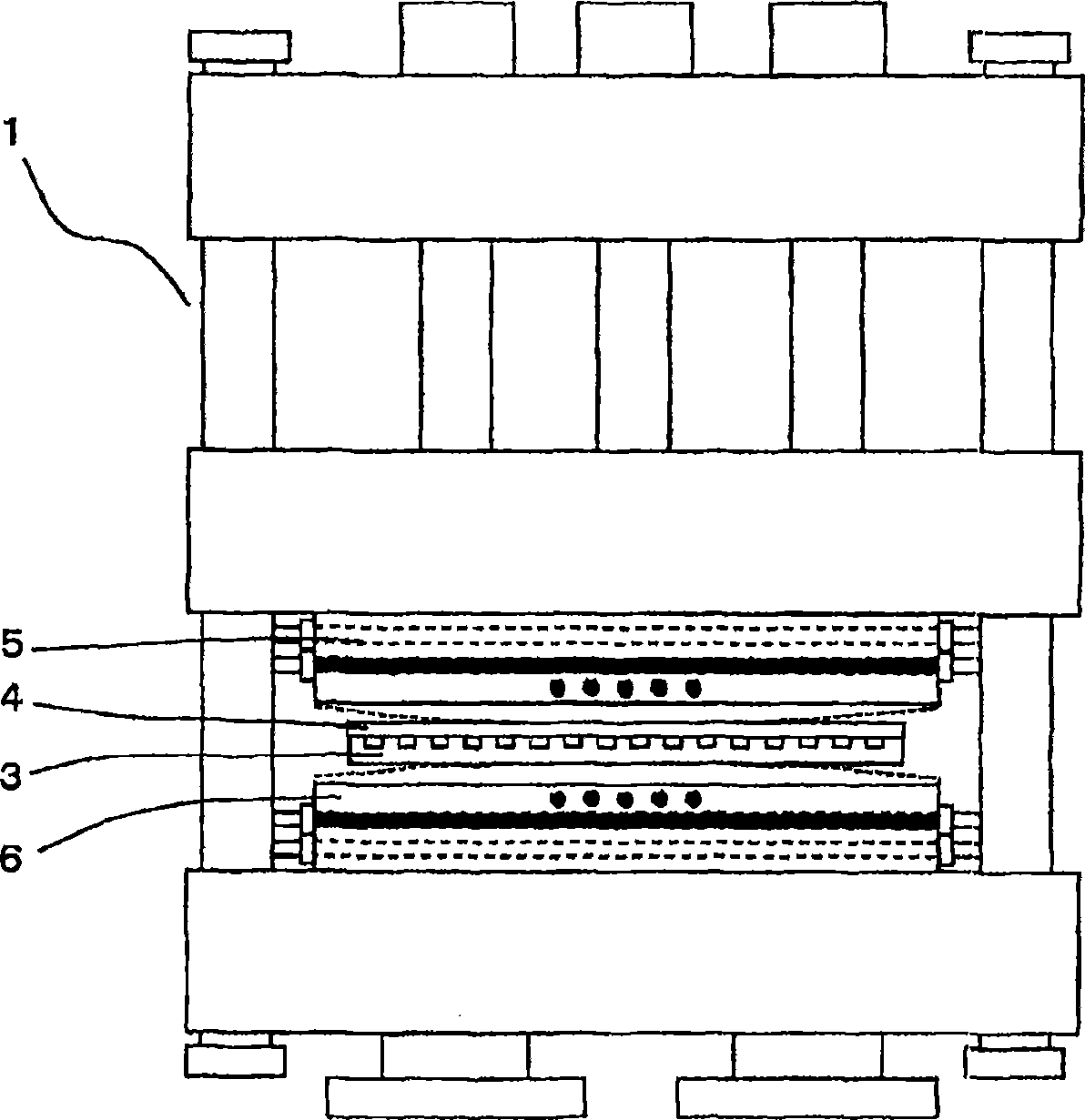

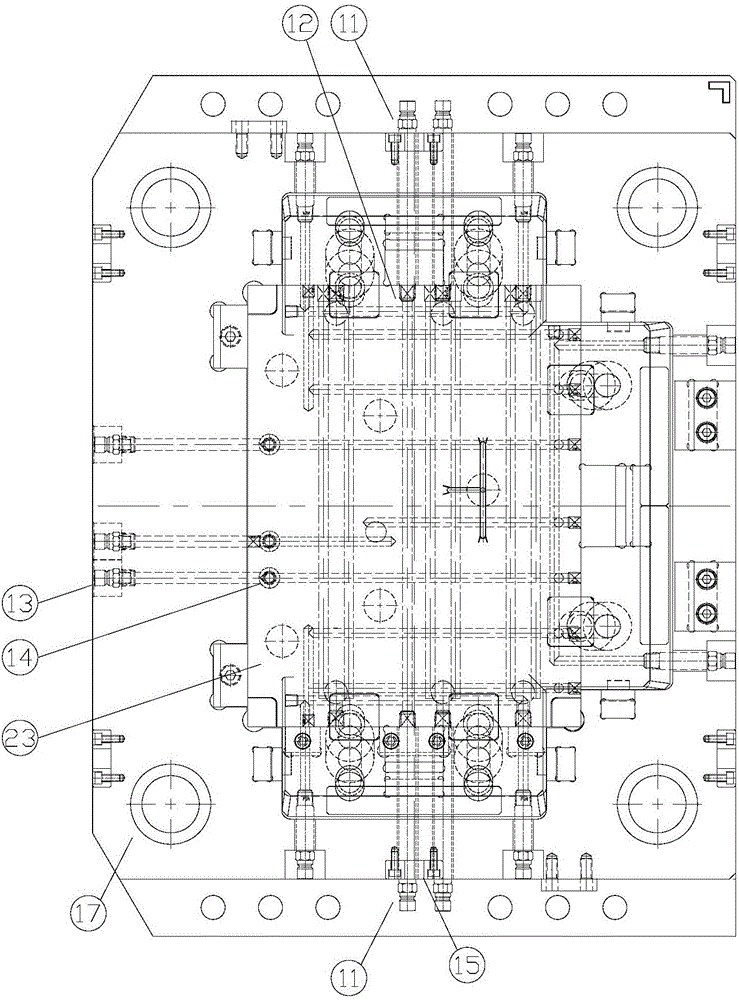

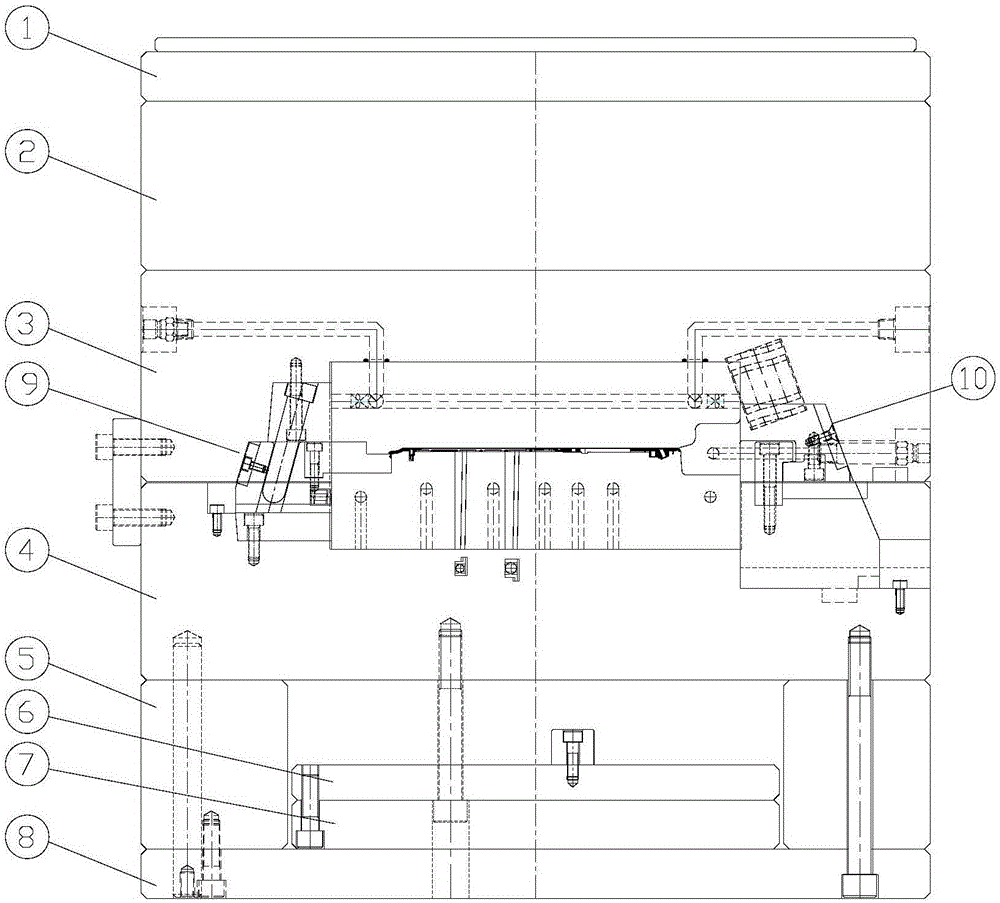

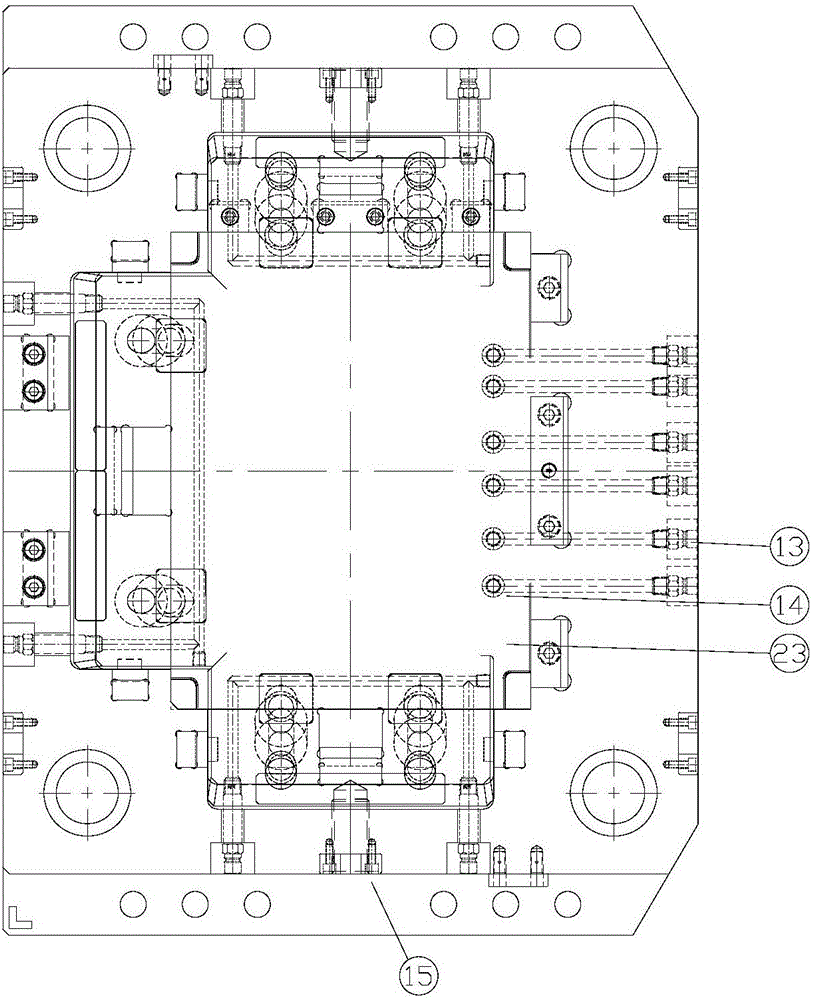

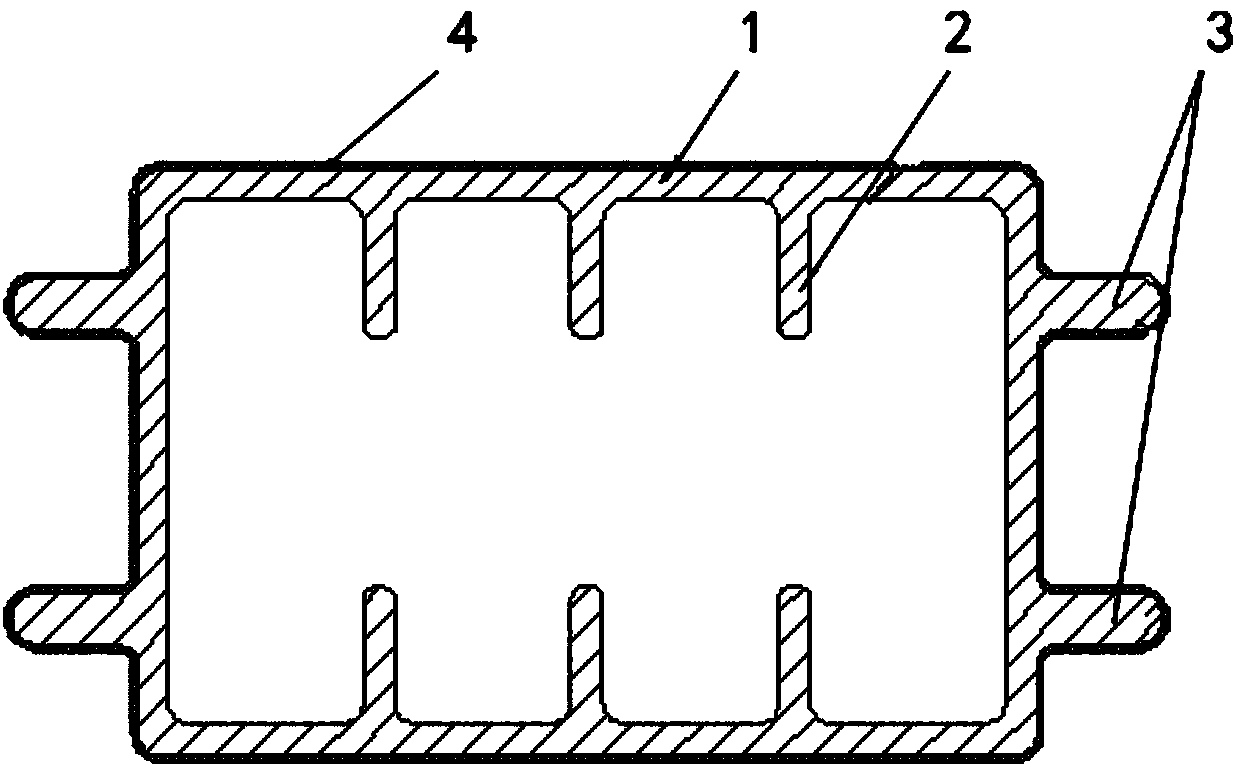

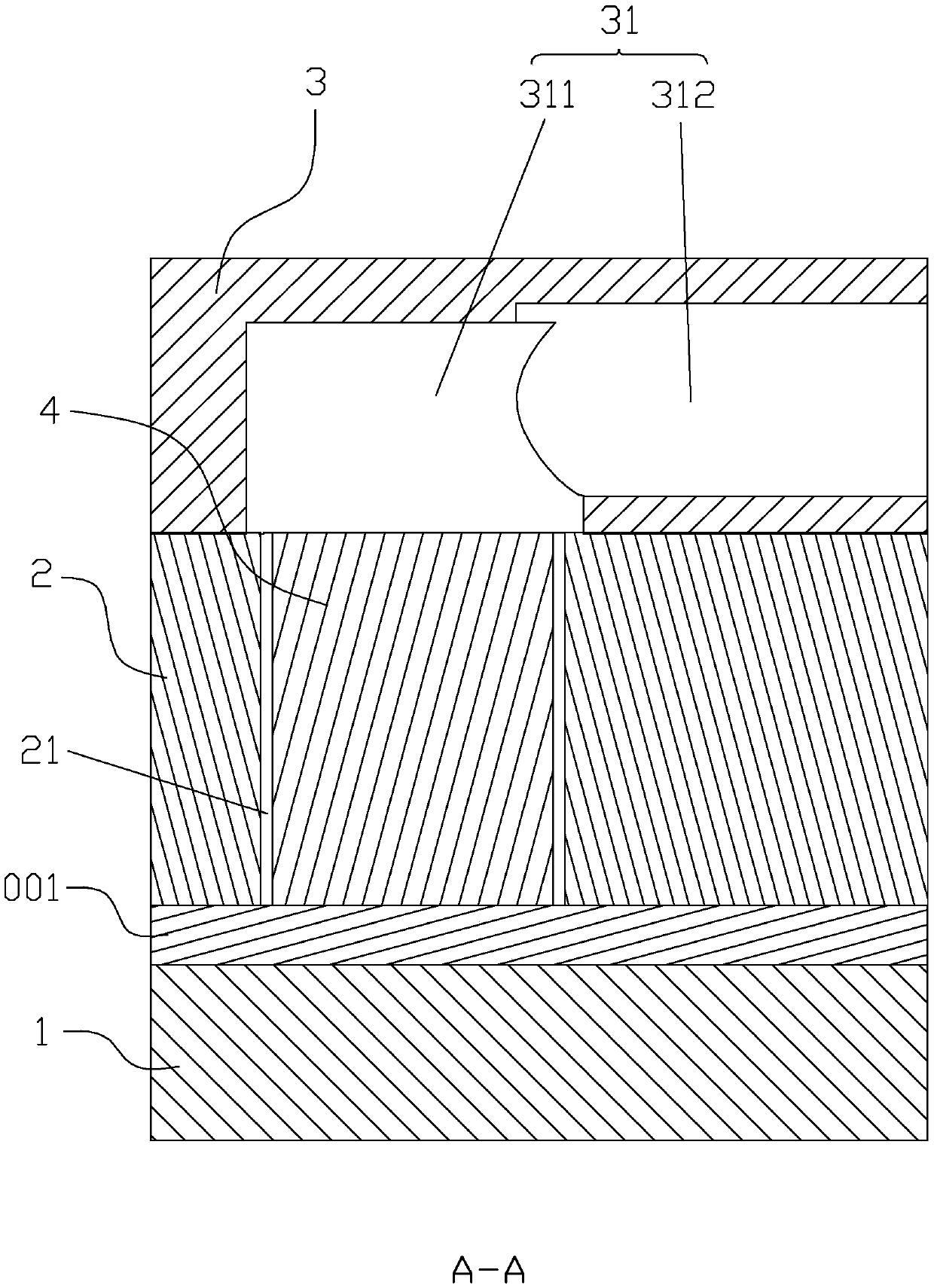

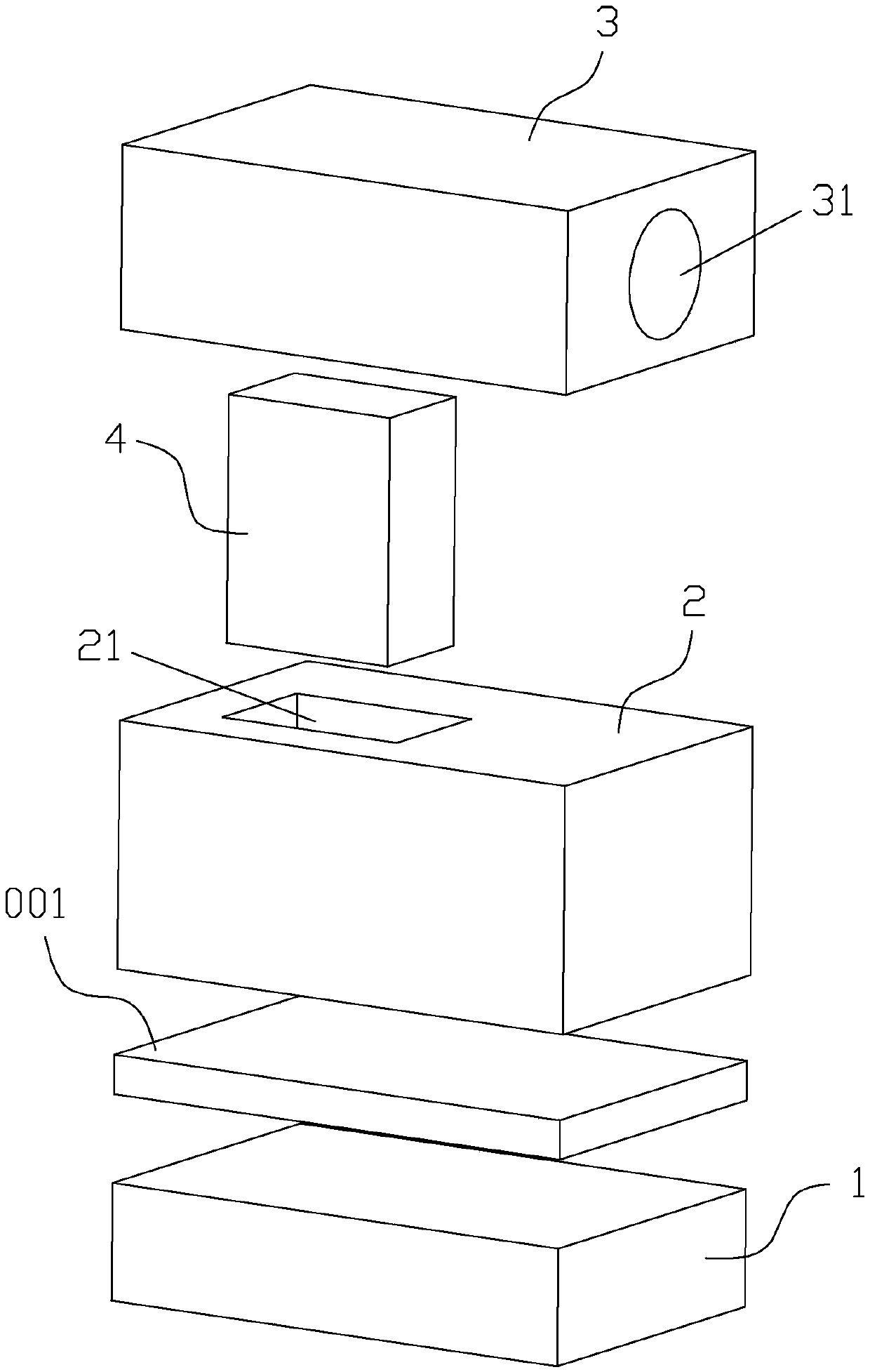

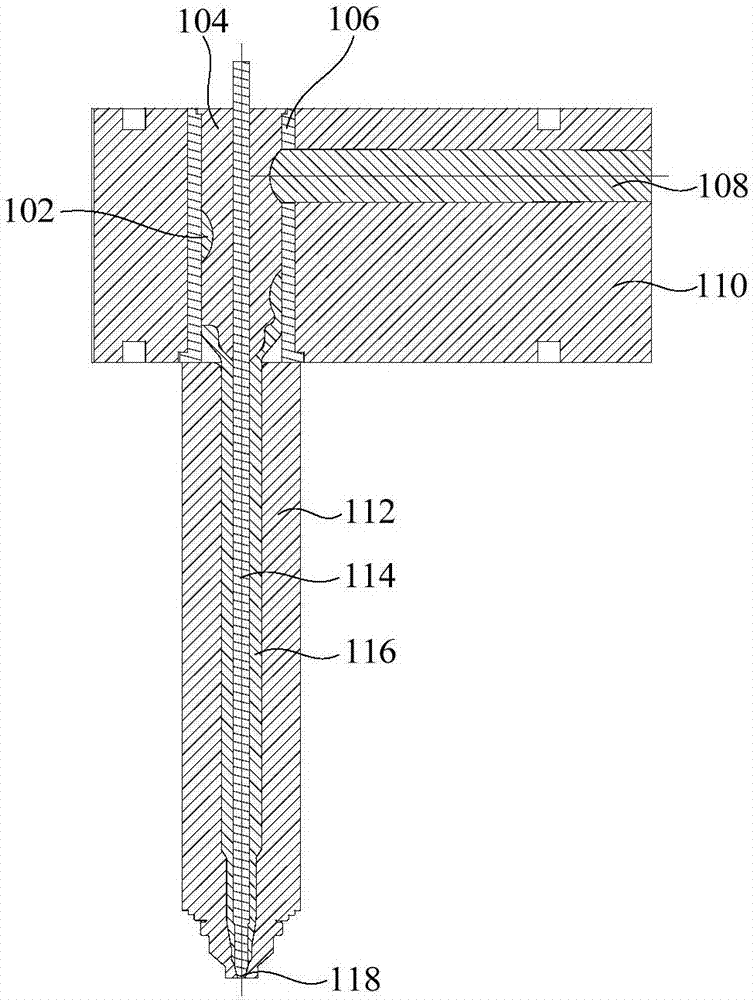

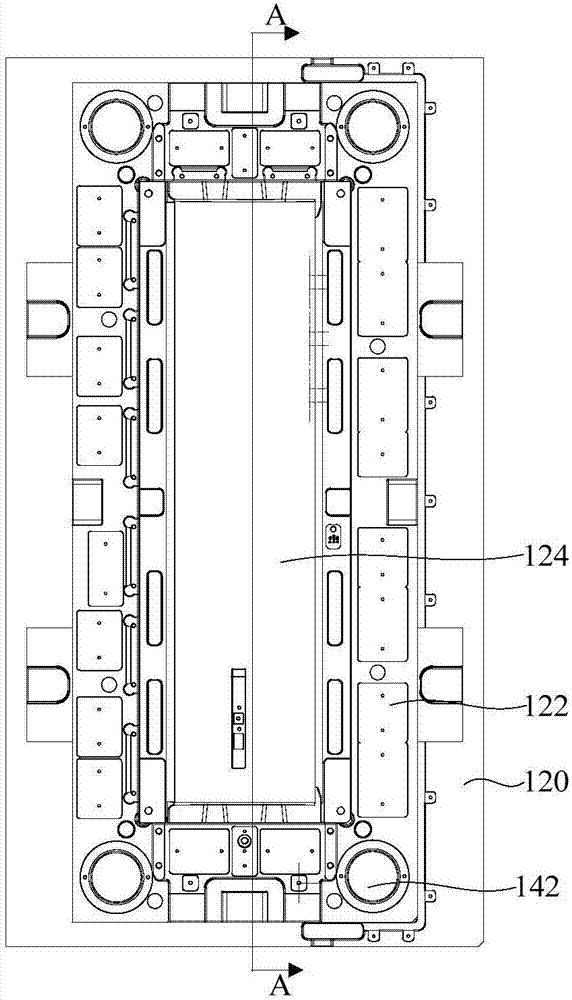

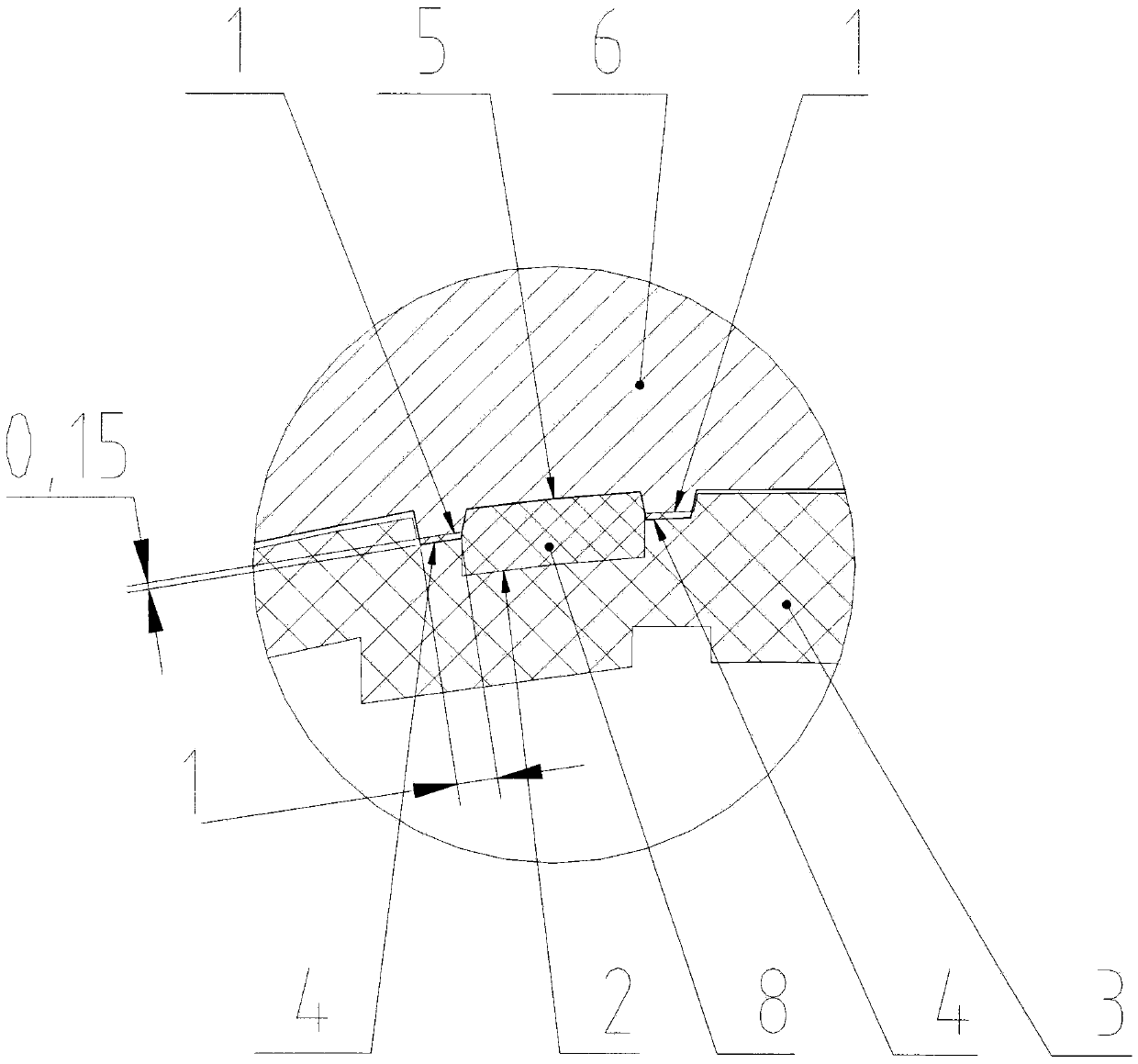

Large-area ultrathin plastic part injection mould

ActiveCN102120357AImprove pressure bearing capacityExtend your lifeAir trappingPlastic injection molding

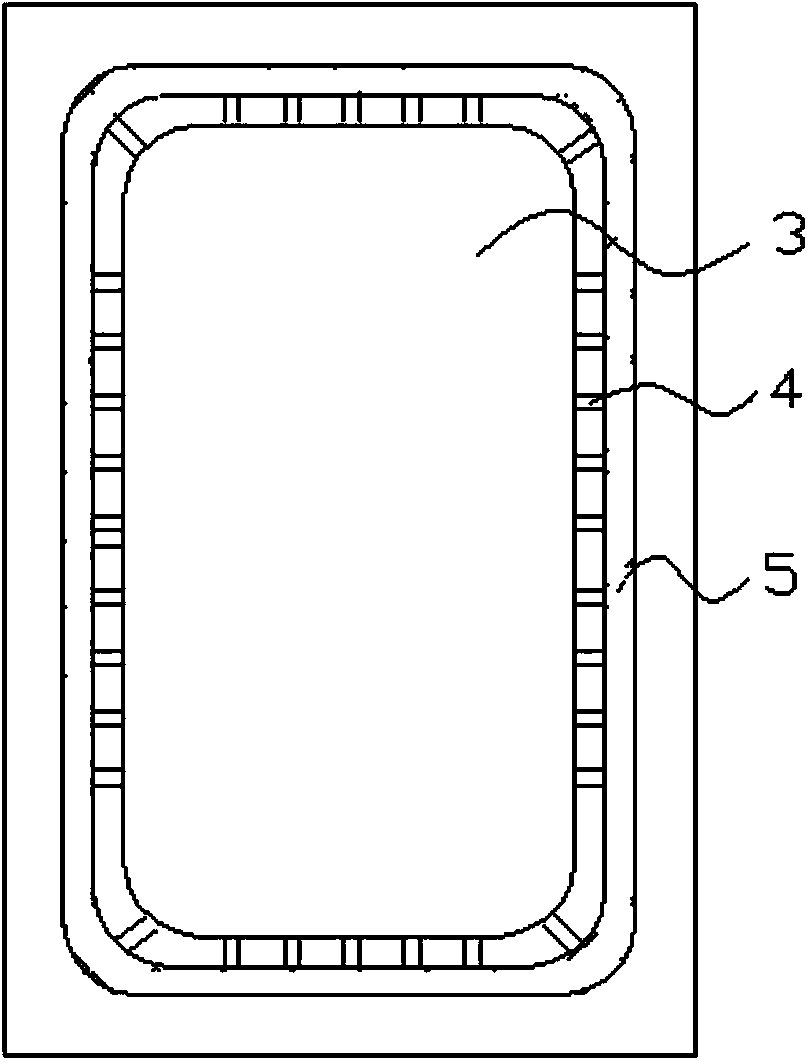

The invention relates to the field of plastic injection molding moulds, and particularly relates to a large-area ultrathin plastic part injection mould. The mould comprises a static mould and a movable mould, wherein the static mould is composed of a static mould fixing plate, and the static template and a static mould core, a movable mould composed of a movable mould fixing plate, a pad, a movable template and a movable template core; the static template is a thickened static template; the pad is a whole square thick steel block; an ejection device is a push board ejection device; an exhaustsystem comprises a group of exhaust plates at the bottom of a mould cavity, an exhaust groove at the periphery of the mould cavity and an exhaust channel connected with the exhaust plates and the exhaust groove; and a compressed air blow pipe leading the exhaust channel to generate negative pressure is arranged on the exhaust channel. The mould has high strength, the service life is up to 2 million times; the exhaust is smooth, and adverse phenomena, such as insufficient filling, burning, air trapping, heavy fused connecting wire and the like, are prevented, so that the purpose of large area of 1,429mm<2> and ultrathin of 0.18mm molding is achieved; and the extrusion or deformation of a product is effectively avoided by adopting the push board ejection device.

Owner:DONGMING XINGYE SCI TECH CO LTD

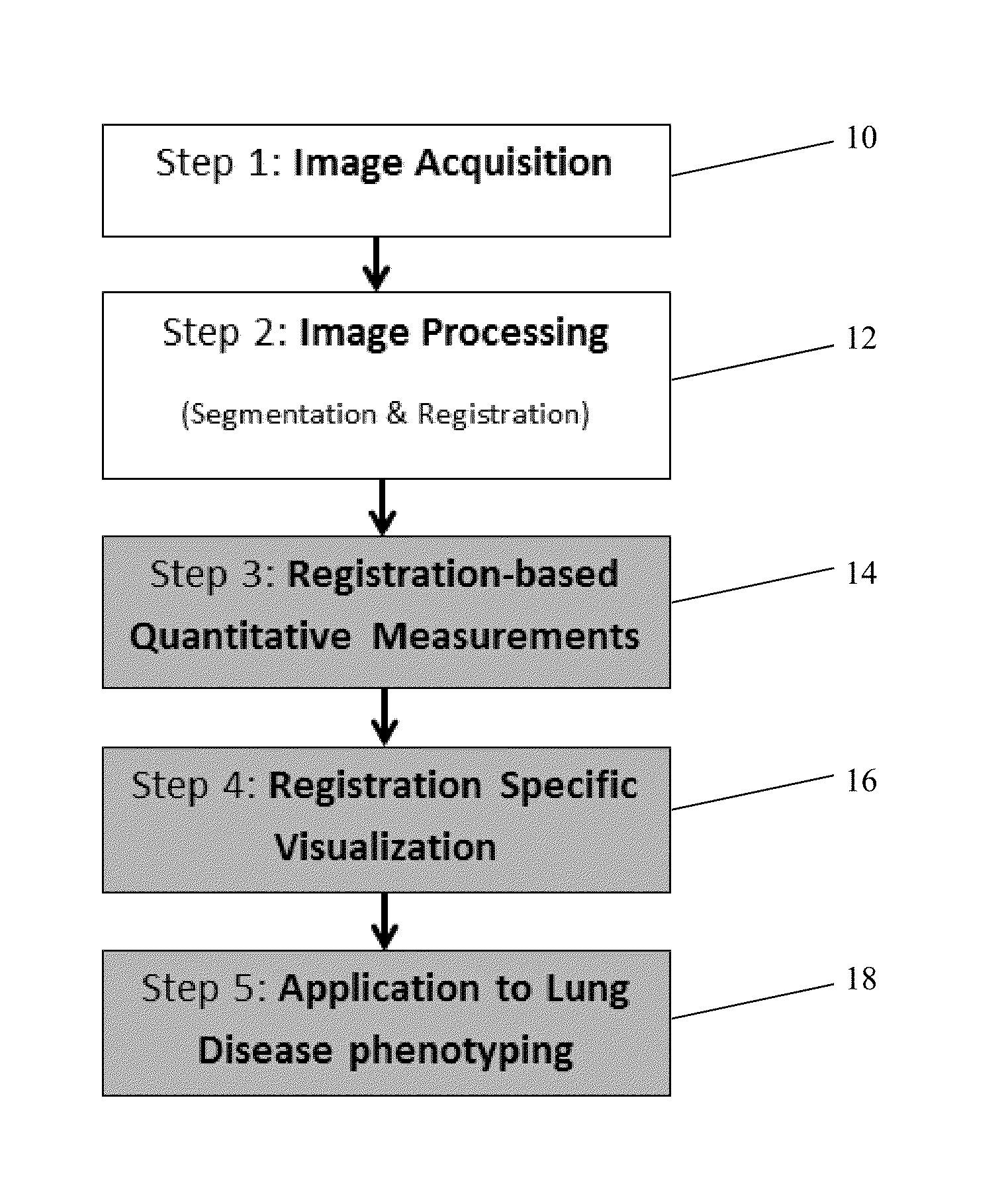

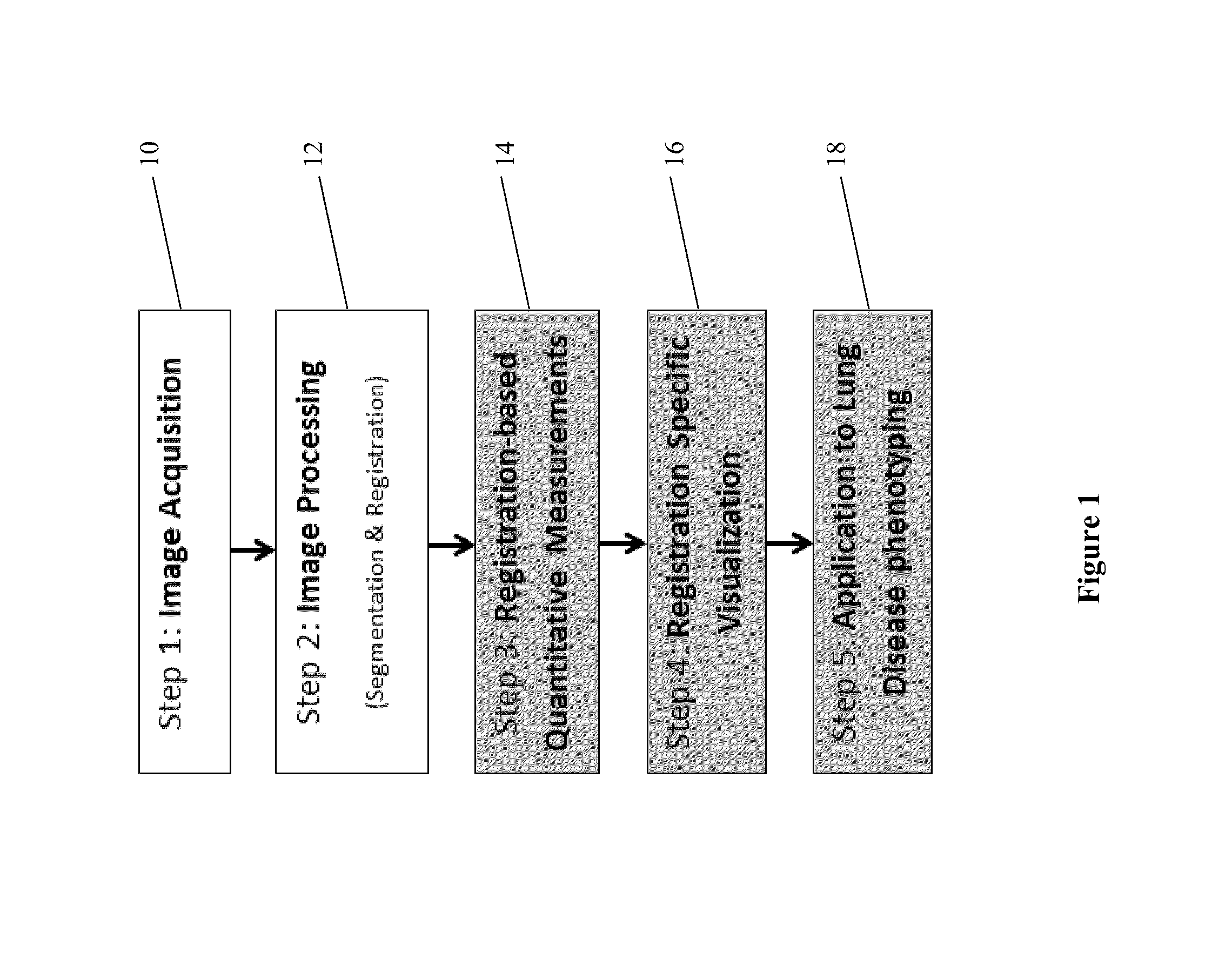

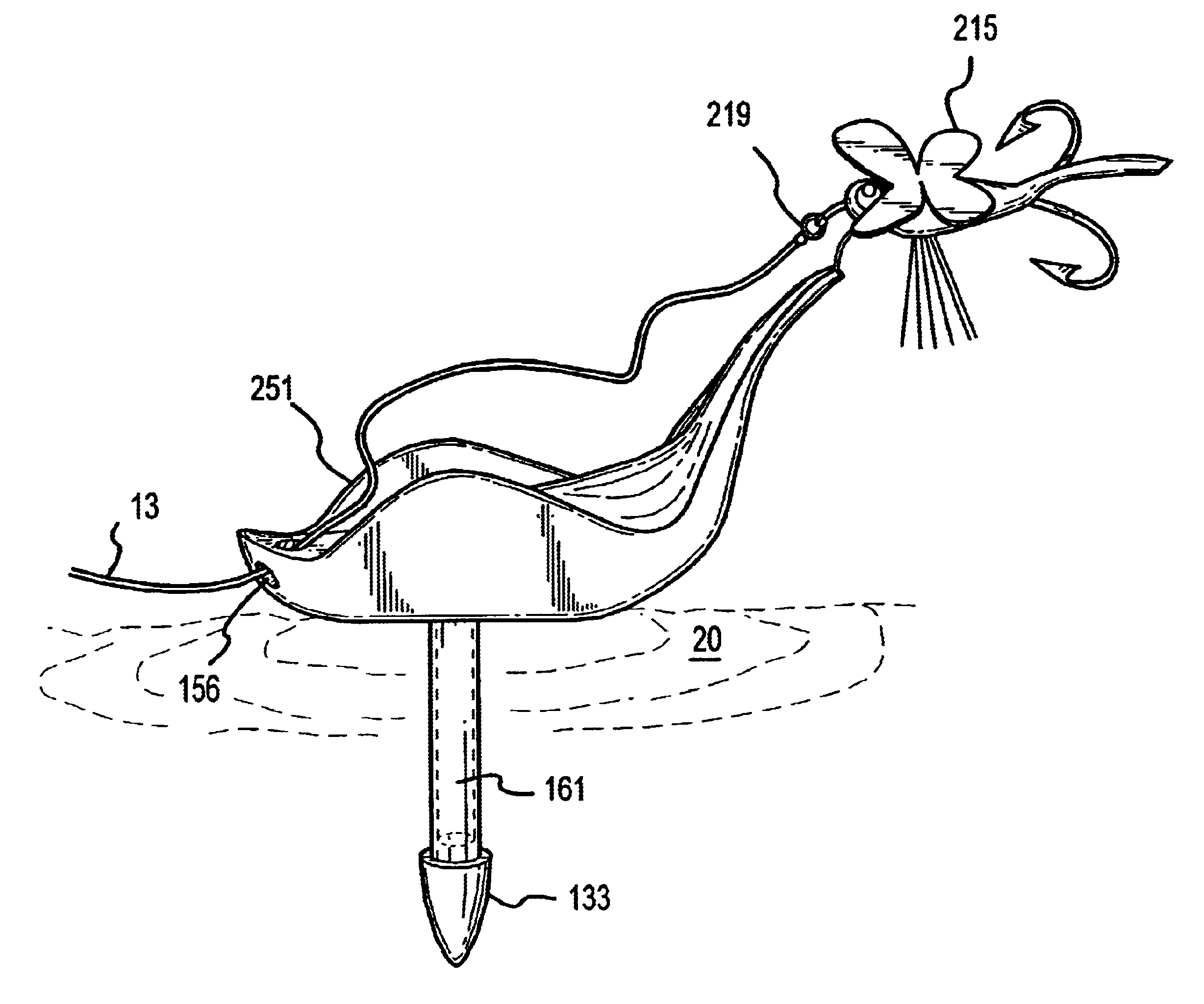

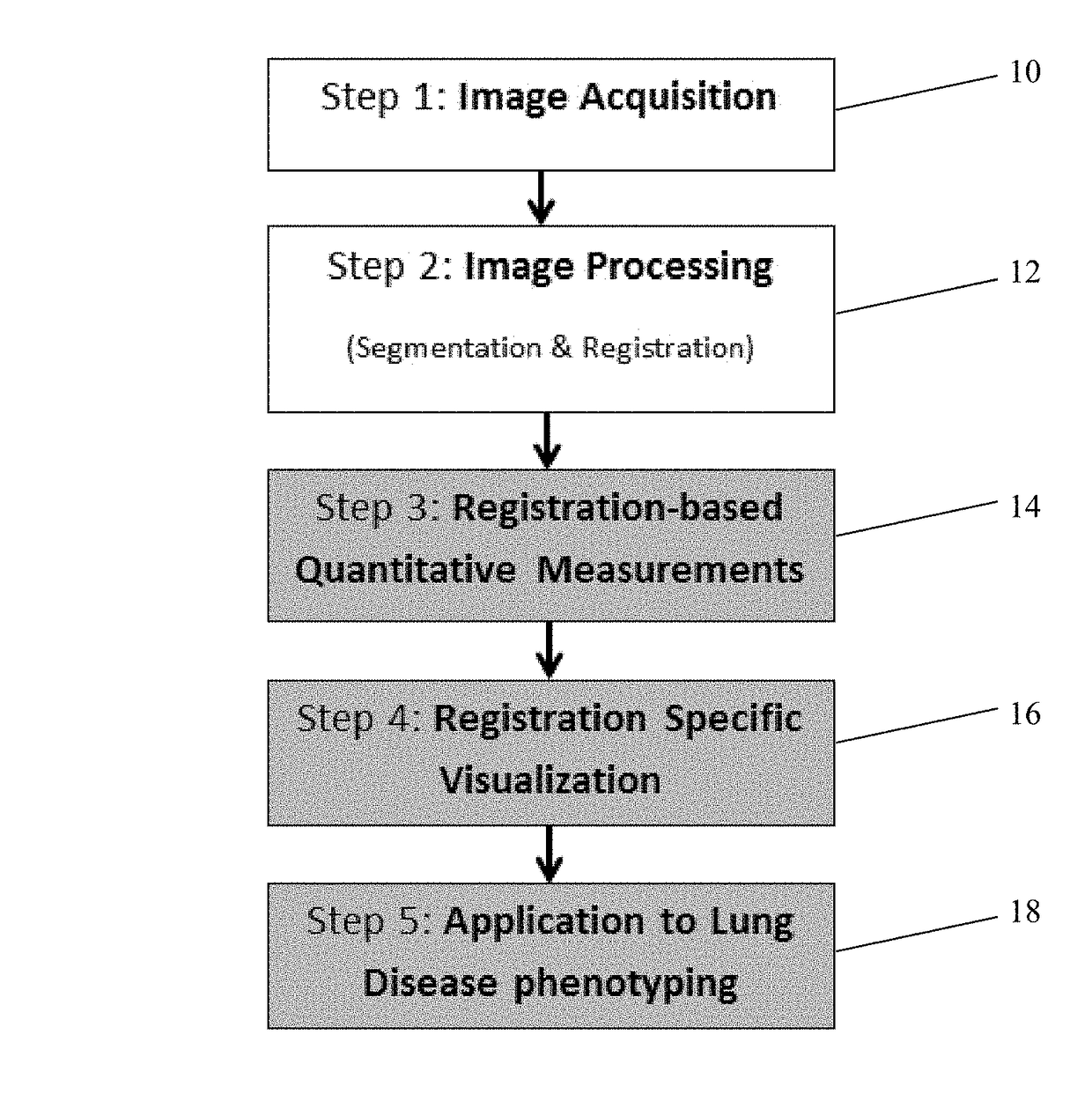

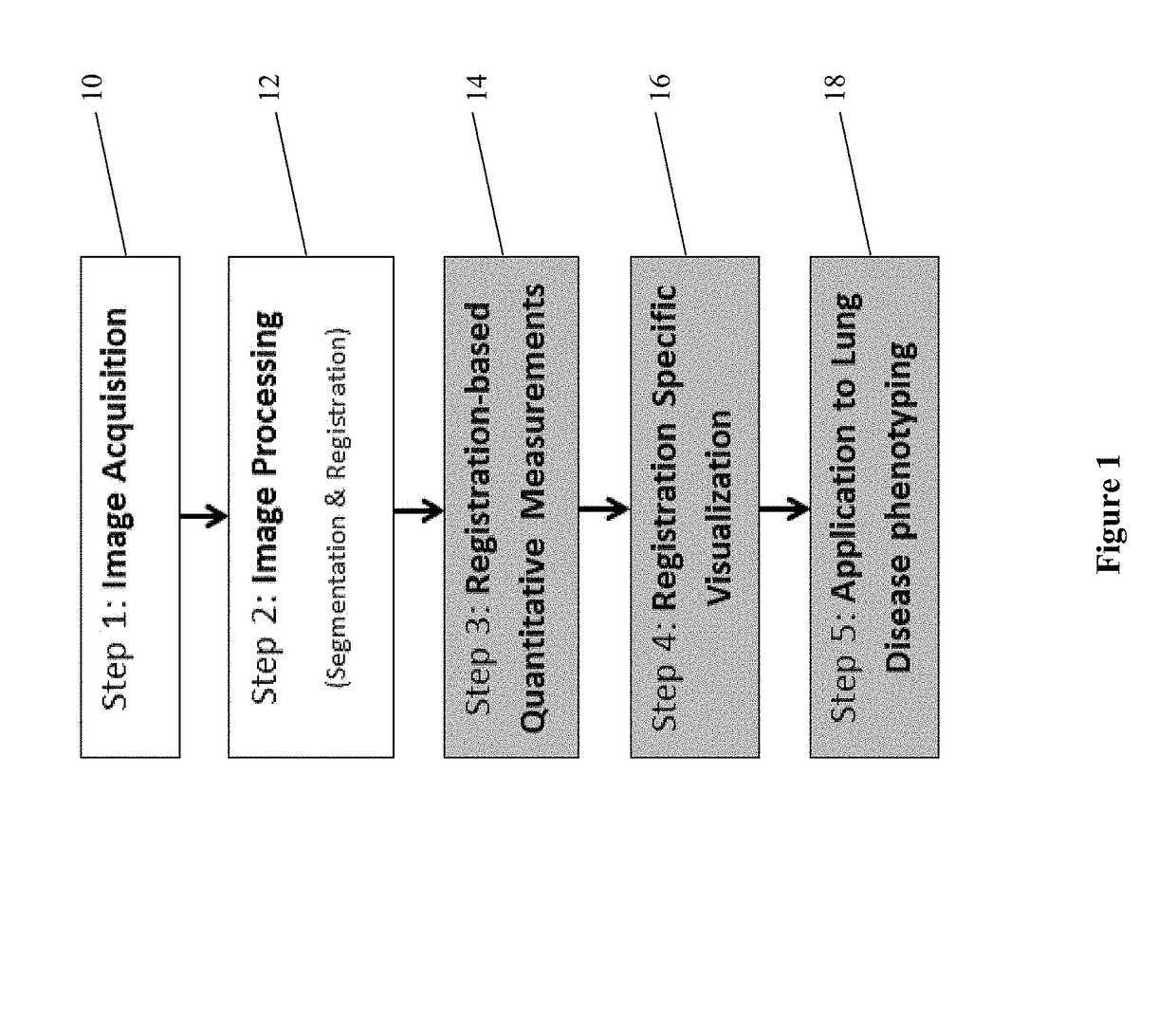

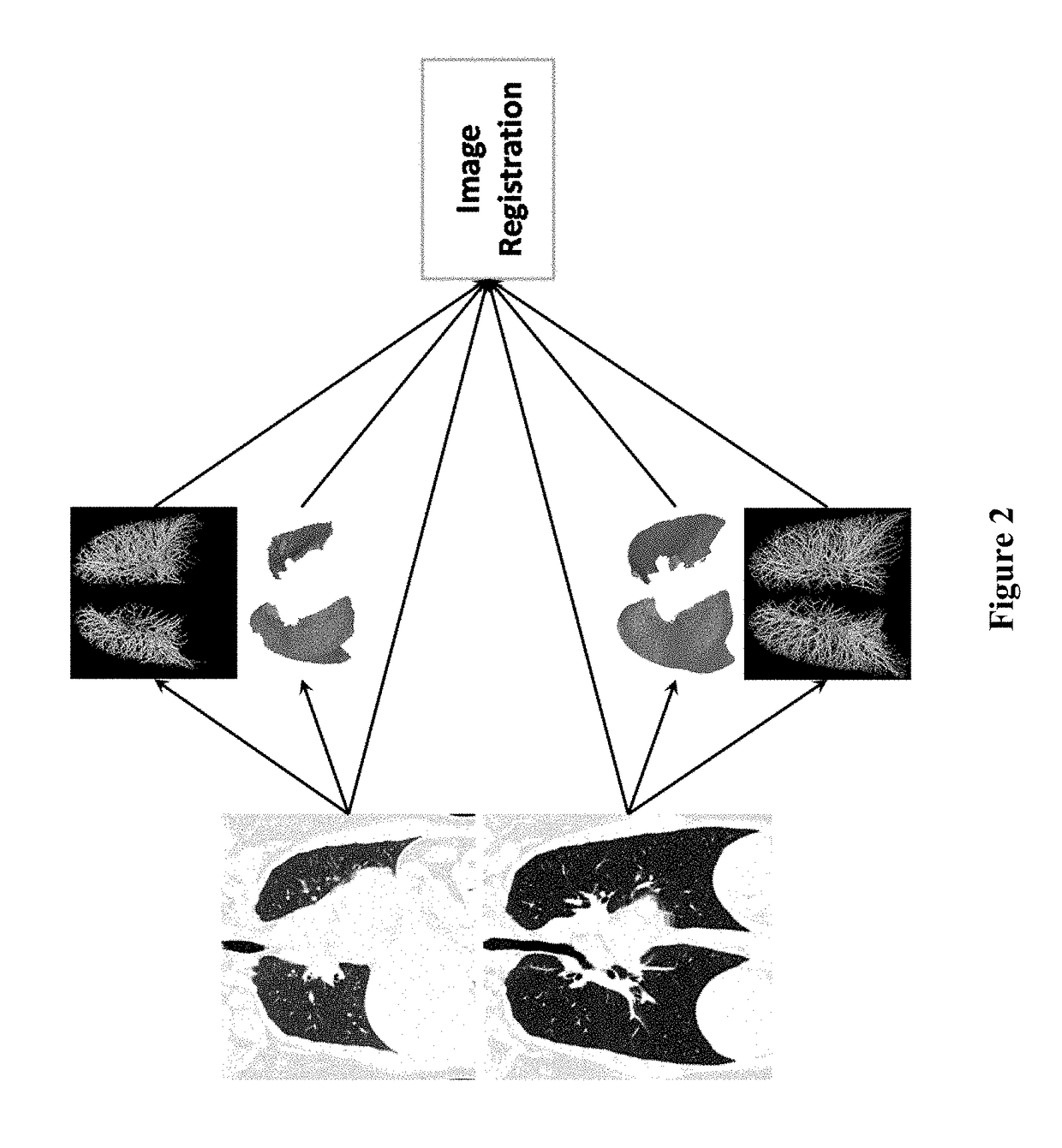

Visualization and quantification of lung disease utilizing image registration

Methods and systems for assessing lung function using volumetric images obtained at inspiration and expiration. The method may include processing the first and second set of images to identify known anatomical structures of the lungs, registering the first set of images to the second set of images to match voxels of the first set of images to voxels of the second set of images as matched pairs of inspiratory and expiratory voxels, calculating a continuous probability of a lung characteristic at a location of the matched pairs of voxels, and displaying the result on a display. The method may also include classifying lung tissue at each location as normal, having air trapping without emphysema, or being emphysematous.

Owner:VIDA DIAGNOSTICS

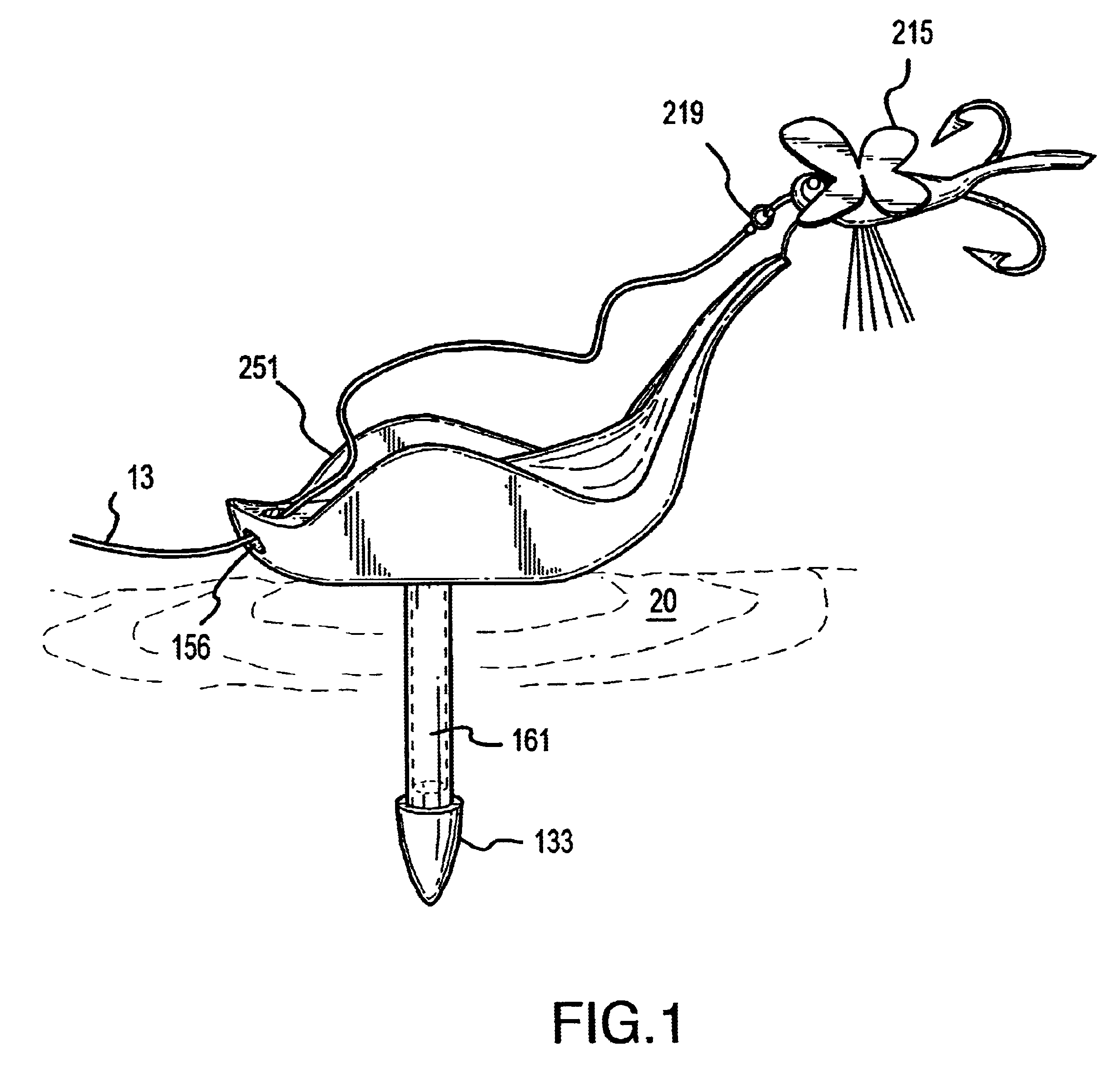

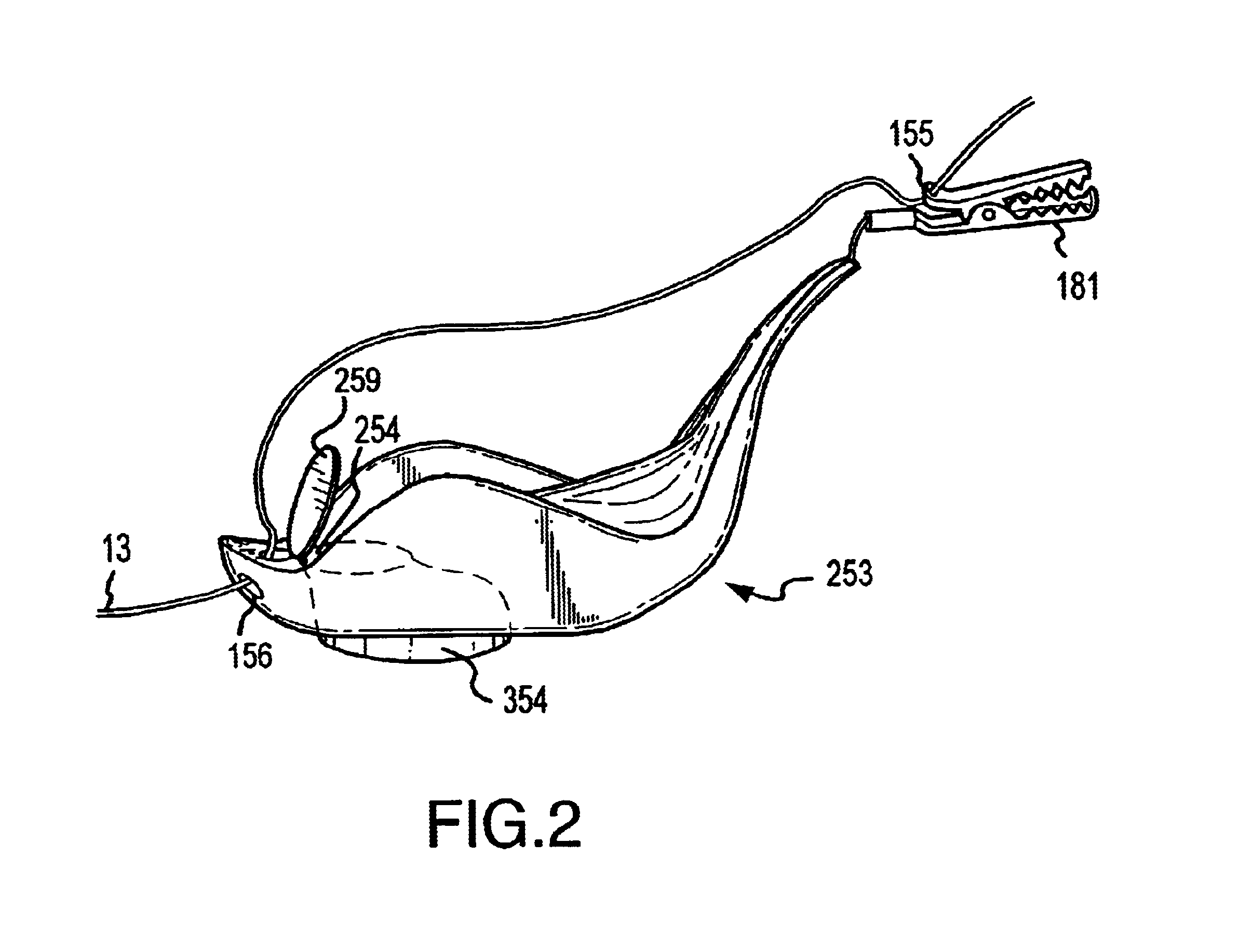

Scrobiculate and other fishing floats, demountably attachable fishing lures and kits for assembling them

InactiveUS6955005B2Minimize and eliminate disadvantageous snagRealisticLinesOther angling devicesAir trappingDecoy

A counterweighted weedless fishing float suitable for suspending at least part of an attractant, such as live bait or an insect replica, above the surface of water in which the float is borne, and kits for assembling a variety of attractants, are provided. The float is counterweighted, and may comprise a plurality of air-trapping channels arranged within it to trap an amount of air sufficient to support the float and a connected attractant. In other embodiments, the float may comprise one or more sealed chambers to provide buoyancy. The float may be disguised as a water plant, fallen tree leaf, twig or other floating detritus or water creature. The attractant may replicate an insect such as a dragonfly, an insect larva such as a hellgrammite, or any other natural or artificial fish bait or prey. The float includes an adjustable stem so that the relative position of the attractant or bait with respect to the float and the water surface may be changed depending on the particular fish sought or the conditions present. In one form, the specific gravity of the invention may be adjusted by adding weights to vary its floating characteristics.

Owner:STORELLI JOHN

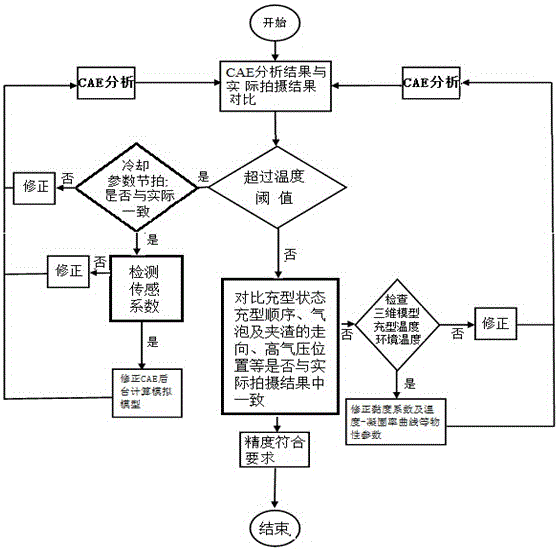

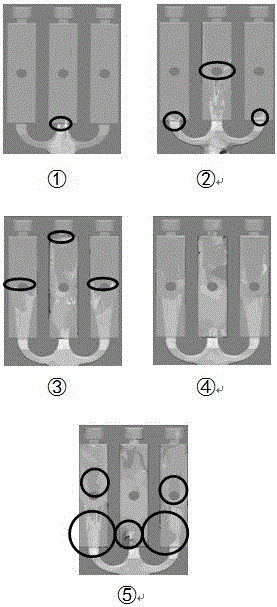

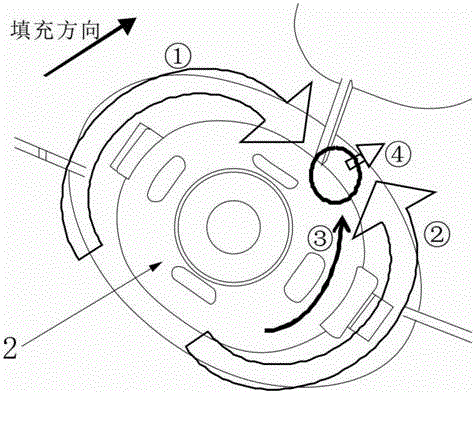

Method for improving CAE analysis precision in high-pressure casting mold-filling process

InactiveCN106845007AAvoid trapped air, air entrainment, and insufficient wateringAvoid filling defects such as oxidized slag inclusionsComputer aided designSpecial data processing applicationsSystems designAir trapping

The invention provides a method for improving the CAE analysis precision in the high-pressure casting mold-filling process and belongs to the technical field of numerical simulation of casting computers. The method comprises the specific steps that 1, the high-pressure mold-filling process of a casting is simulated by using CAE software, CAE analysis parameters are set according to a process in actual production, and CAE simulation is conducted on the high-pressure casting process; 2, a high-pressure casting visualization device is applied to shoot the high-pressure mold-filling process of the casting; 3, a CAE analysis result is compared with an actual shooting result, main factors affecting the mold-filling precision for CAE analysis are found, input parameters for CAE analysis are corrected, and the CAE analysis precision is improved. The part which does not conform to the actual situation in CAE simulation analysis can be accurately looked up, the cause of difference existing is analyzed in a targeted mode, a numerical simulation calculation model is modified by modifying the CAE simulation parameters, then the modified numerical simulation calculation model is applied to the casting complicated in structure, a mold casting system is optimized, and the mold-filling defects such as air trapping, air involving, misrun and oxidization and slag inclusion produced by improper design of the mold casting system are avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Multicomponent and multiple boundary layer composite heat insulation material and its producing method

InactiveCN1899814AGood warmth retentionHigh heat retentionHollow filament manufactureLayered productsPolyesterAir trapping

The present invention relates to a kind of multicomponent and multiple boundary layer composite heat insulating material and its production process. The composite heat insulating material is produced through arranging and adhering the following layers: superfine polypropylene non-woven fabric layer as the main air blocking layer, infrared radiation layer, down-like polyester / polypropylene layer as the main air trapping layer, infrared radiation and air blocking layer, and air holding hollow 3D crimping polyester layer. It has the thermal protection quality of 1.03-1.45clo, vapor transfer rate of 6200-8214g / sq m .24h, and air permeability of 2617-3267 ml / sq m .s. The composite heat insulating material has the advantages of being waterproof, poromeric, wind-proof, heat insulating and light.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

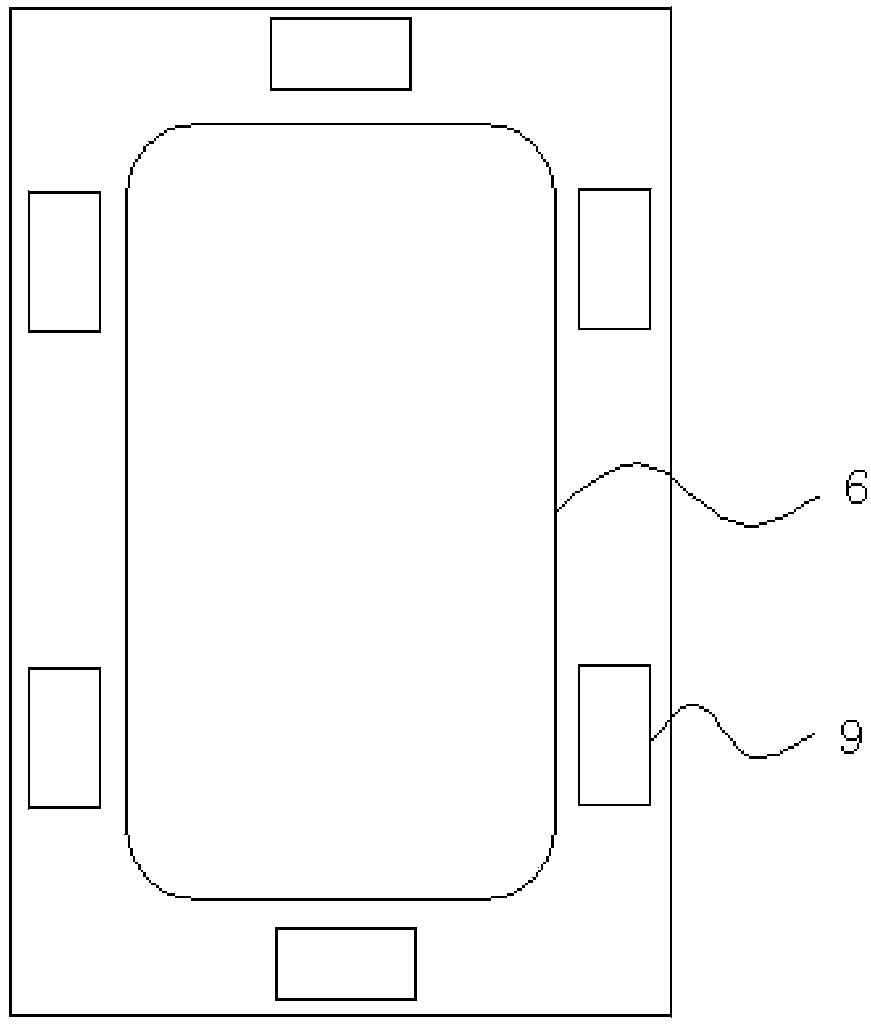

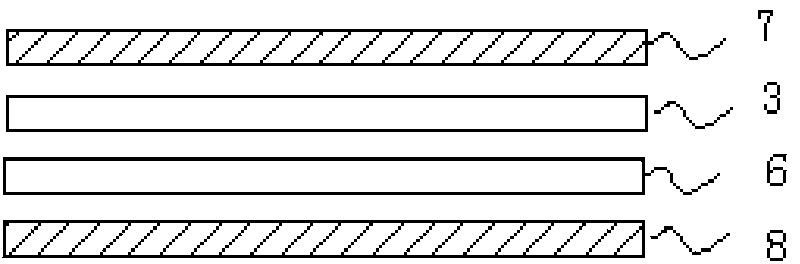

Mould for shaping mobile phone light guide panel and technology for preparing mobile phone light guide panel

InactiveCN101767406AAvoid the process of manual removal of overflow glueIncrease productivityOptical articlesDomestic articlesAir trappingAdhesive

The invention belongs to the injection mould field and provides a mould for shaping a mobile phone light guide panel. The mould comprises a first injection mould used for shaping a PC board and a second injection mould used for shaping silicone keypad bases on the PC board, wherein raised adhesive-pressing lines are arranged on the periphery of cavities which are used for shaping the silicone keypad bases and arranged on a front mould core of the second injection mould, and a back mould core of the second injection mould is provided with a material cutting groove. The invention also provides a technology for preparing the mobile phone light guide panel. Compared with the prior art, the invention adopts a special structure, namely the adhesive-pressing lines; when the silicone keypad basesare shaped on the PC board, the adhesive can not overflow on the periphery of the mobile phone light guide panel and near the silicone keypad bases and inner bores, thus avoiding the process of removing excessive adhesive manually, greatly increasing the production efficiency and lowering the production cost; and the invention adopts the structure of the material cutting groove, thus avoiding thephenomenon of air trapping in the cavity of the mould, ensuring the appearance quality of the product, reducing the reject ratio and increasing the product quality.

Owner:BYD CO LTD

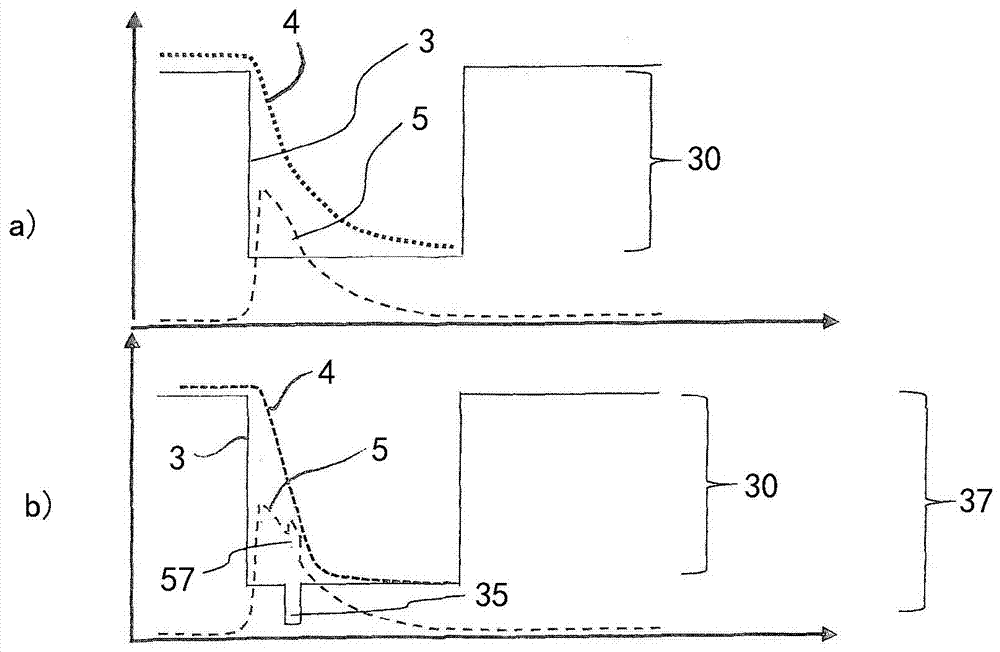

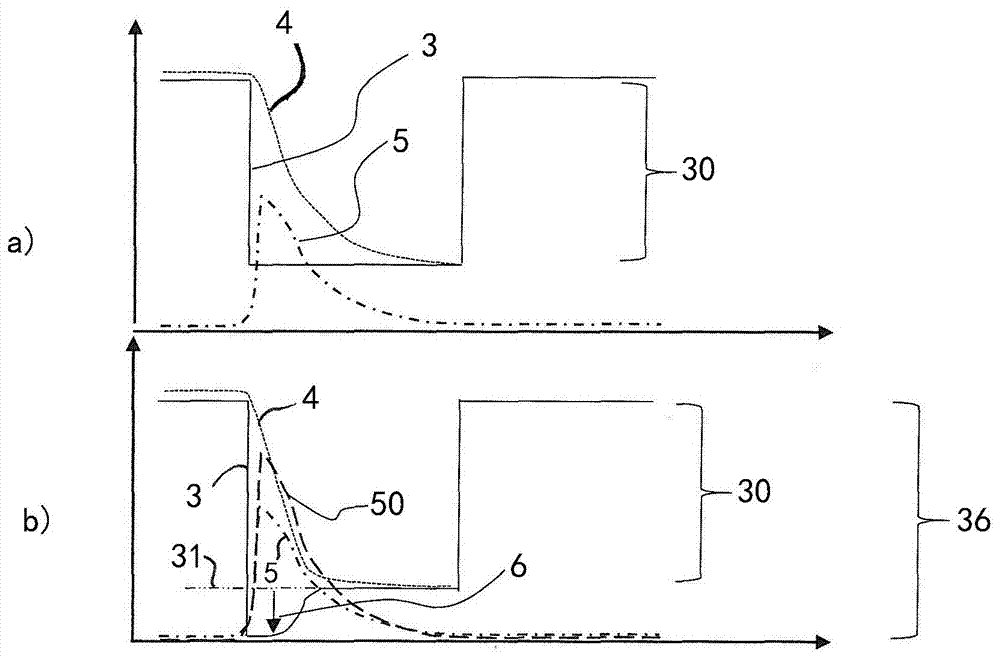

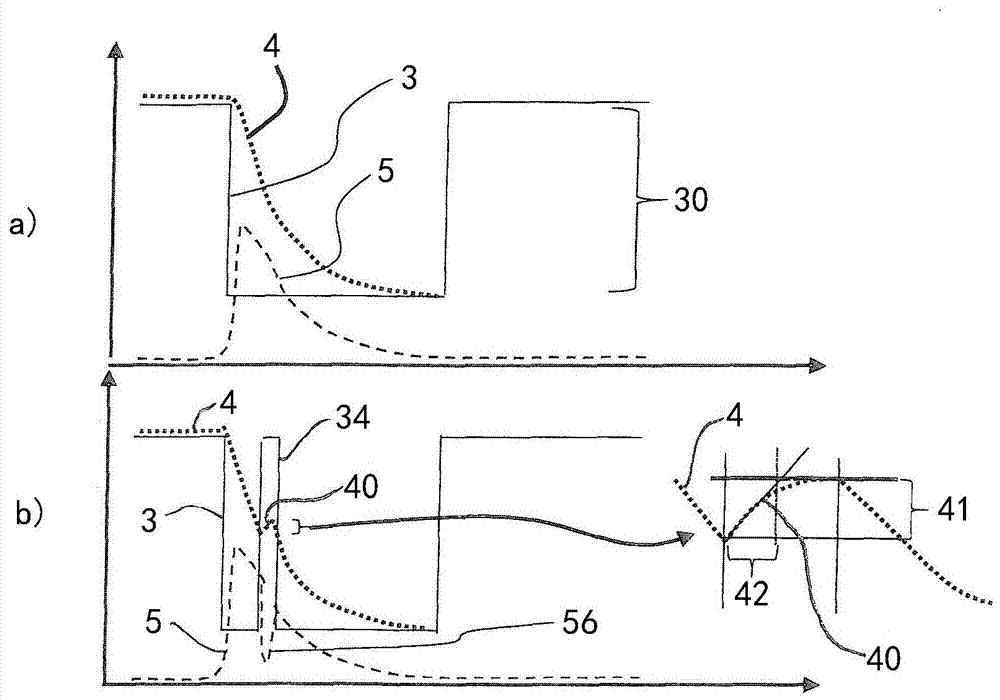

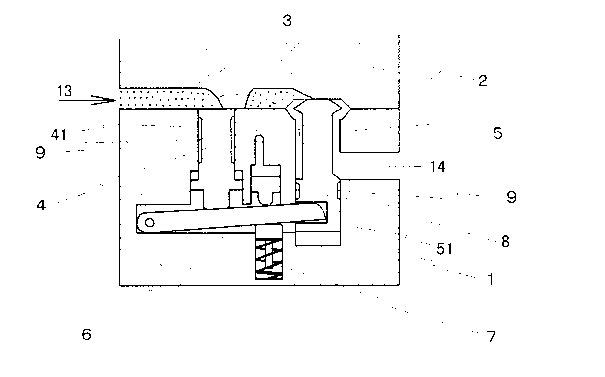

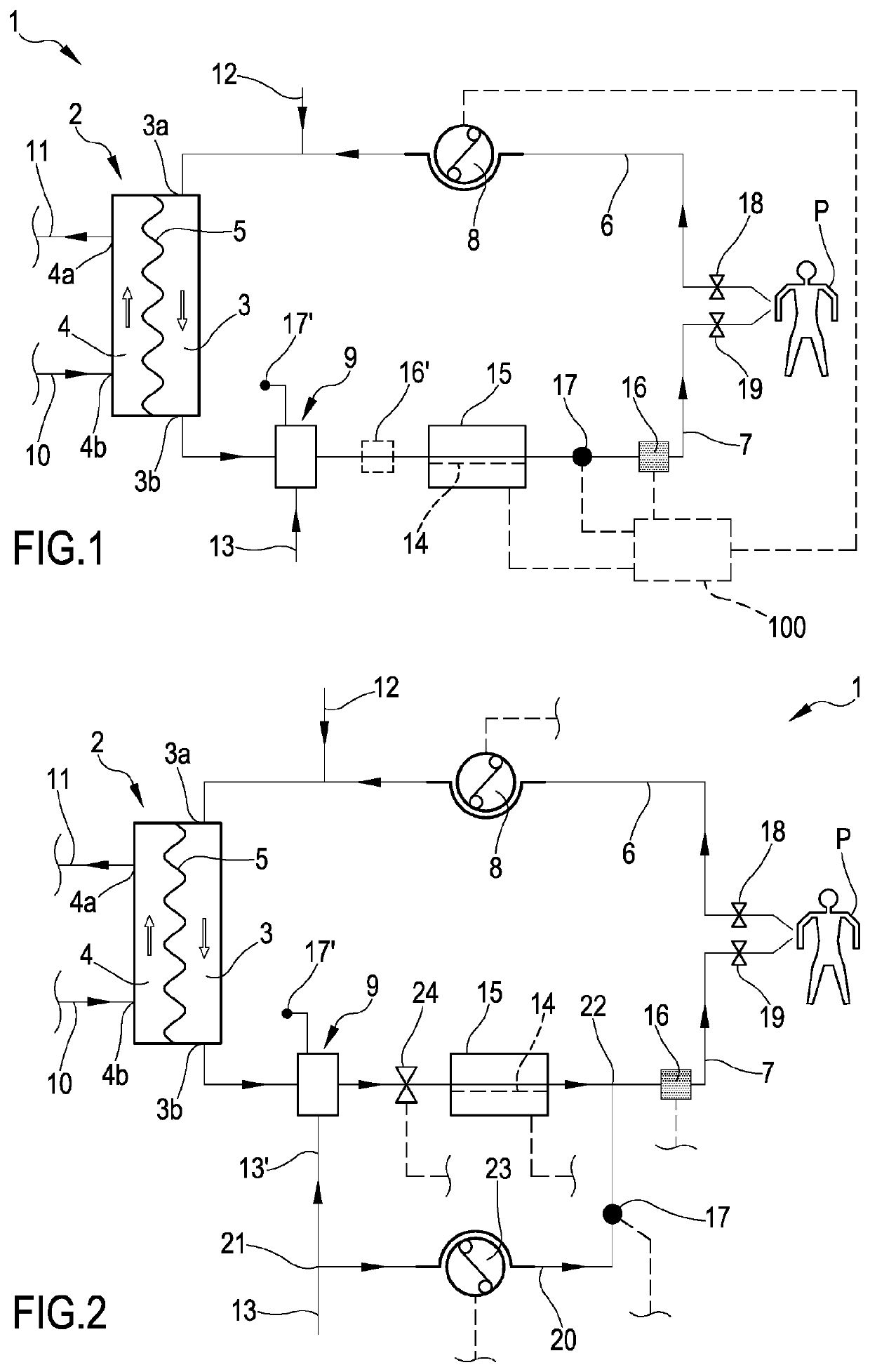

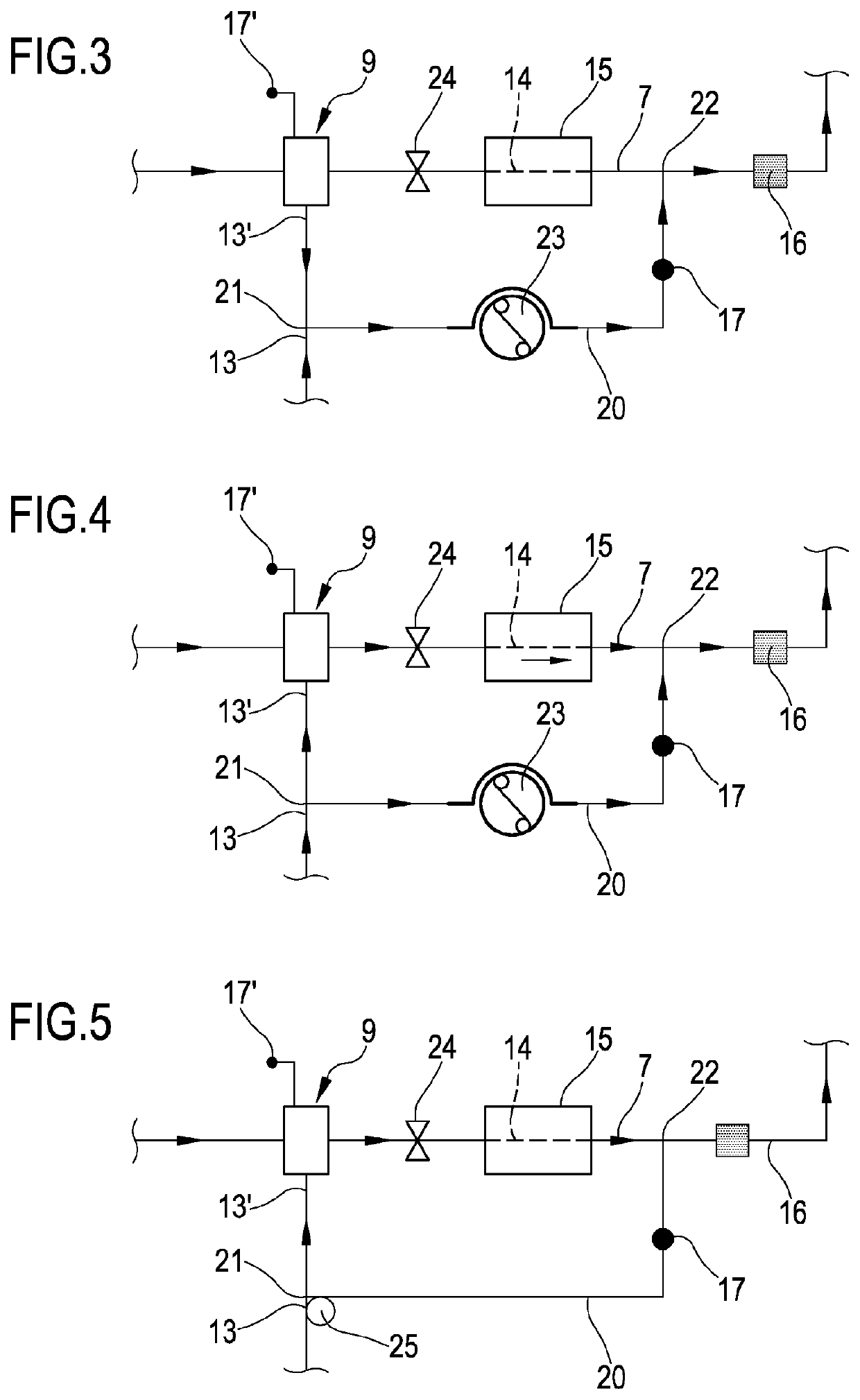

Method and device for the adaptive regulation of a positive end-expiratory pressure (PEEP)

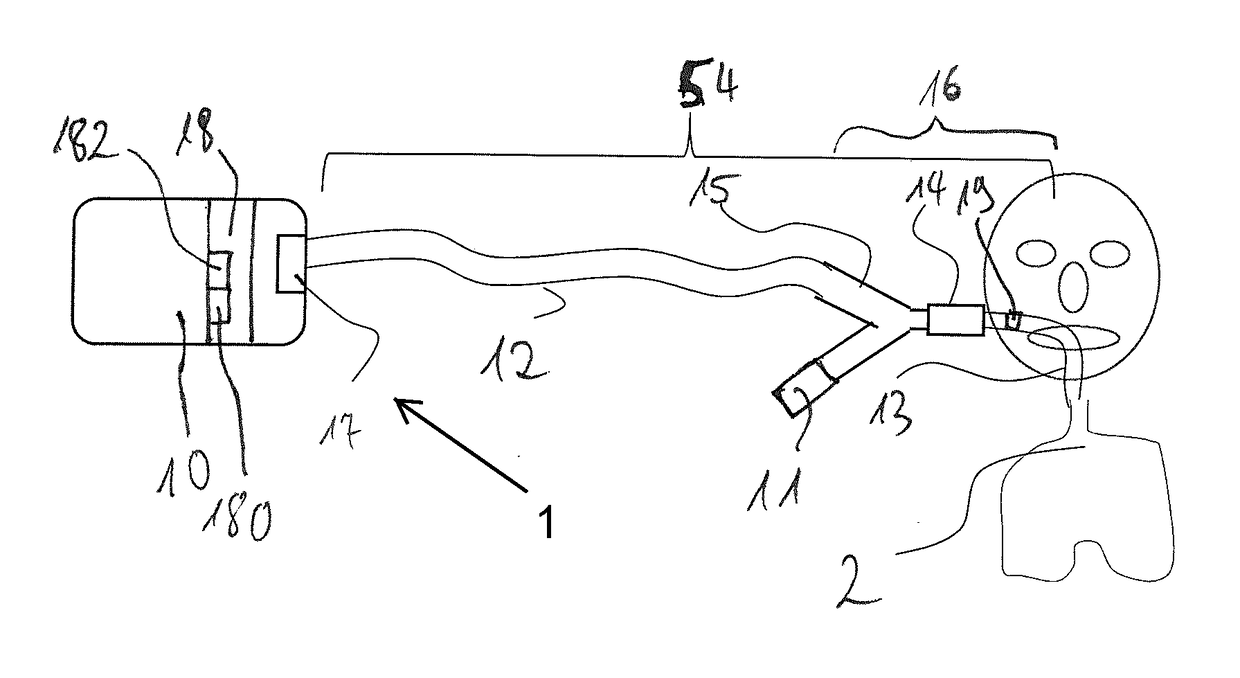

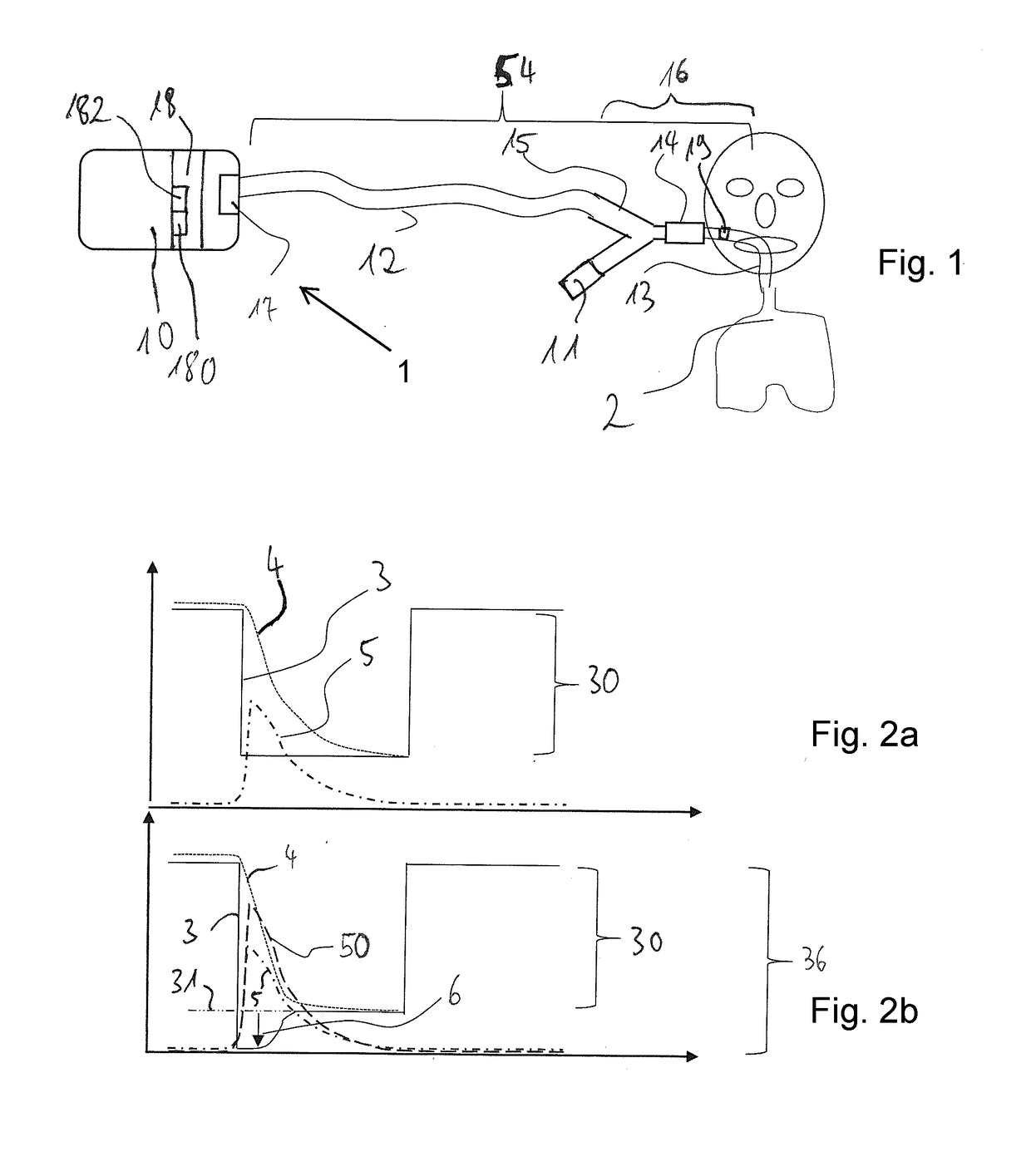

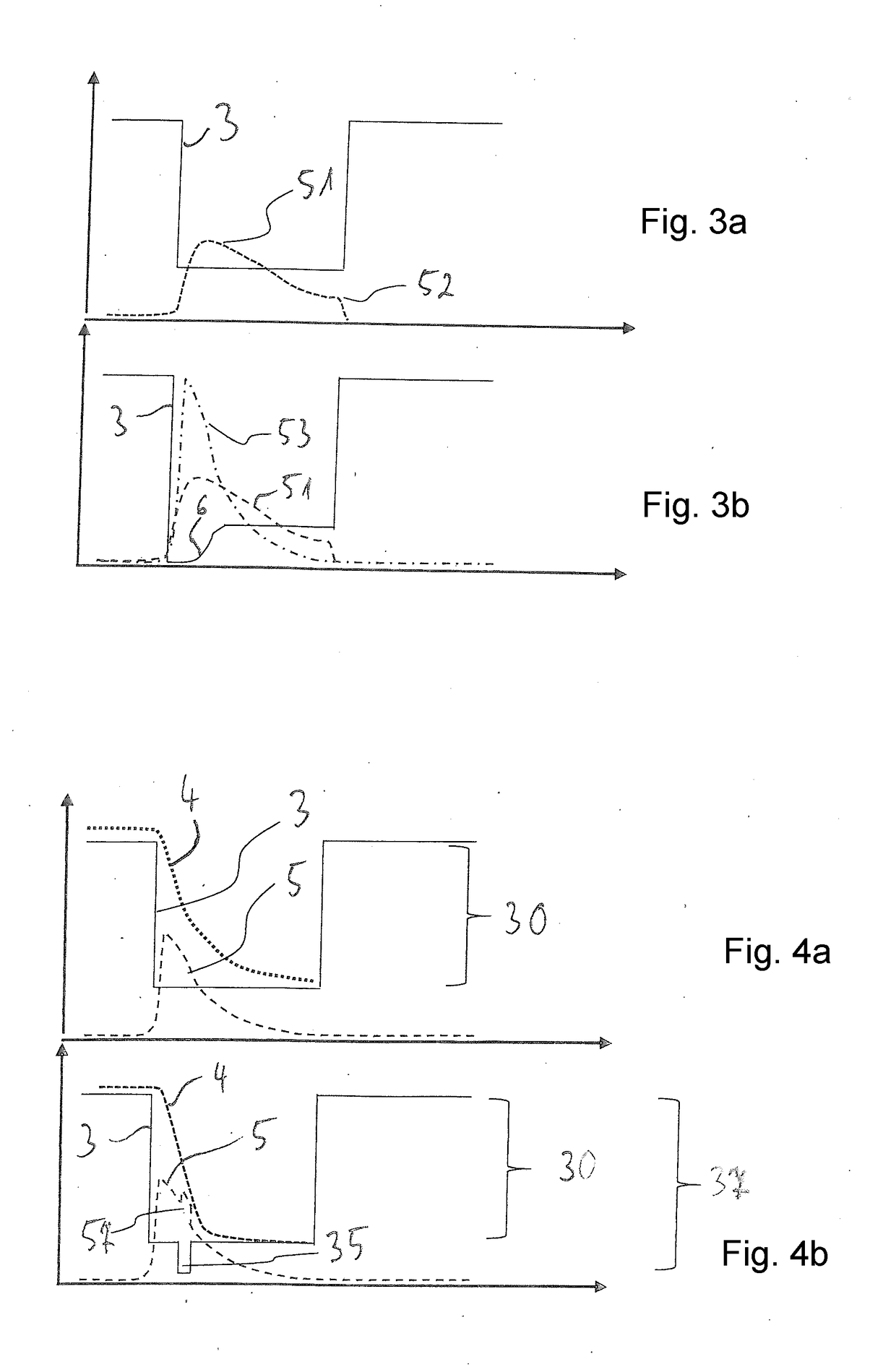

A method controls an expiratory gas flow at a user interface (16) of a ventilator (1) wherein the user interface (16) has an exhalation valve (11), which provides a positive end-expiratory pressure (PEEP). The method includes the following steps during a phase of exhalation: changing the positive end-expiratory pressure from a basic PEEP value (31) with the exhalation valve (11); returning the positive end-expiratory pressure to the basic PEEP value (31) with the exhalation valve (11); and determining an exhalation parameter. The method permits an adaptive change in the expiratory flow during the exhalation. Air trapping can be avoided, and it is possible to respond to changed exhalation parameters within one and the same phase of exhalation.

Owner:DRAGERWERK AG

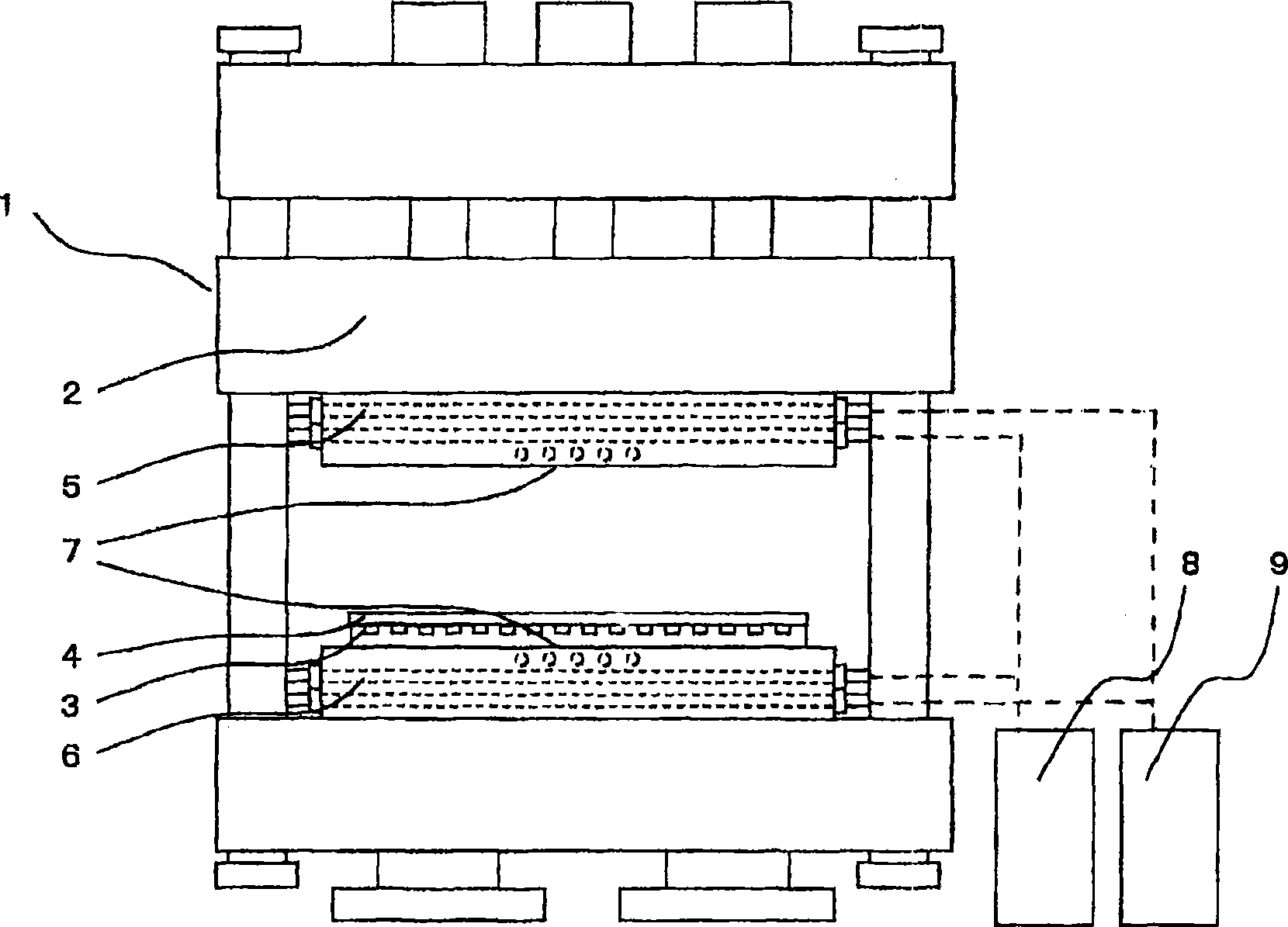

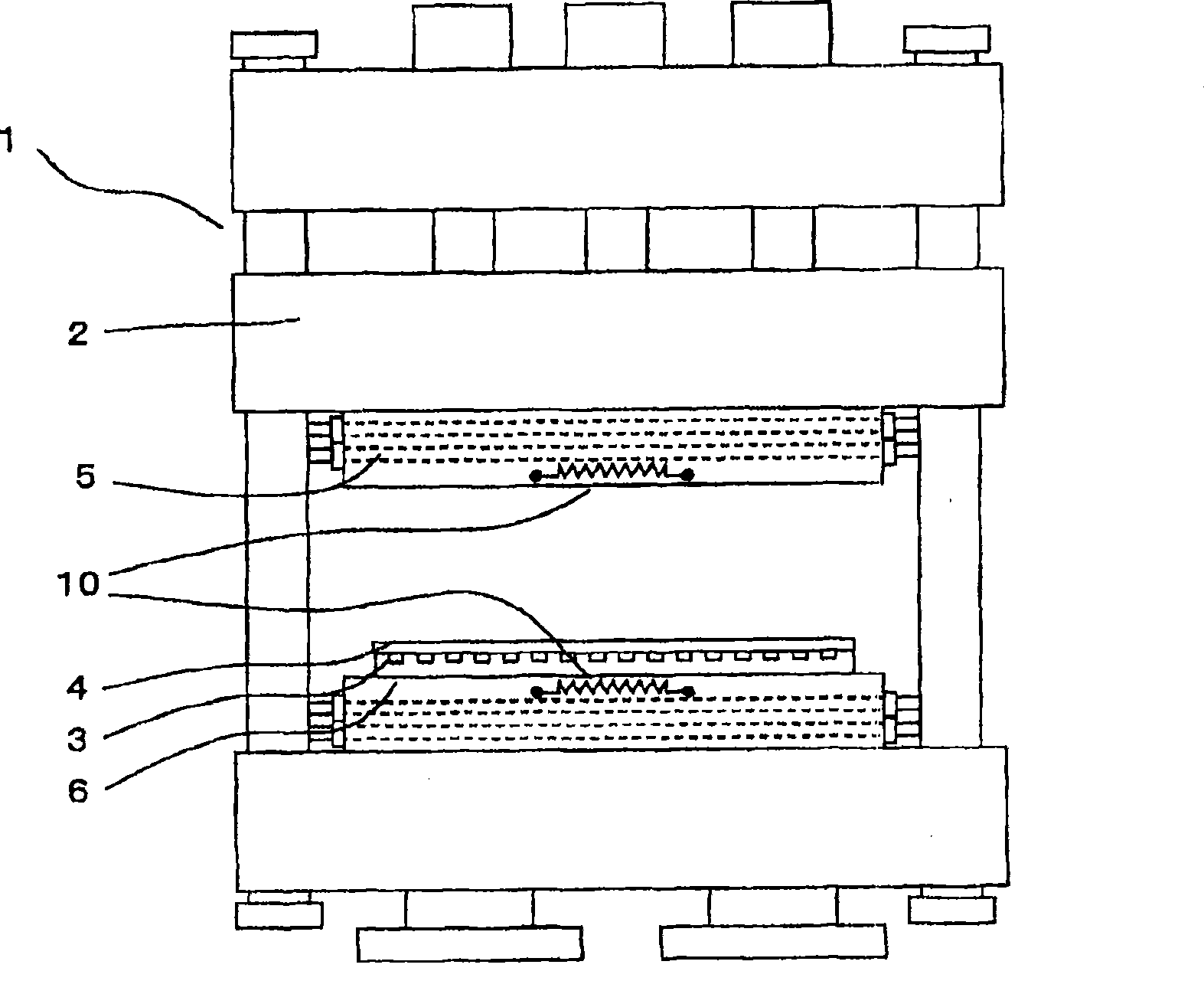

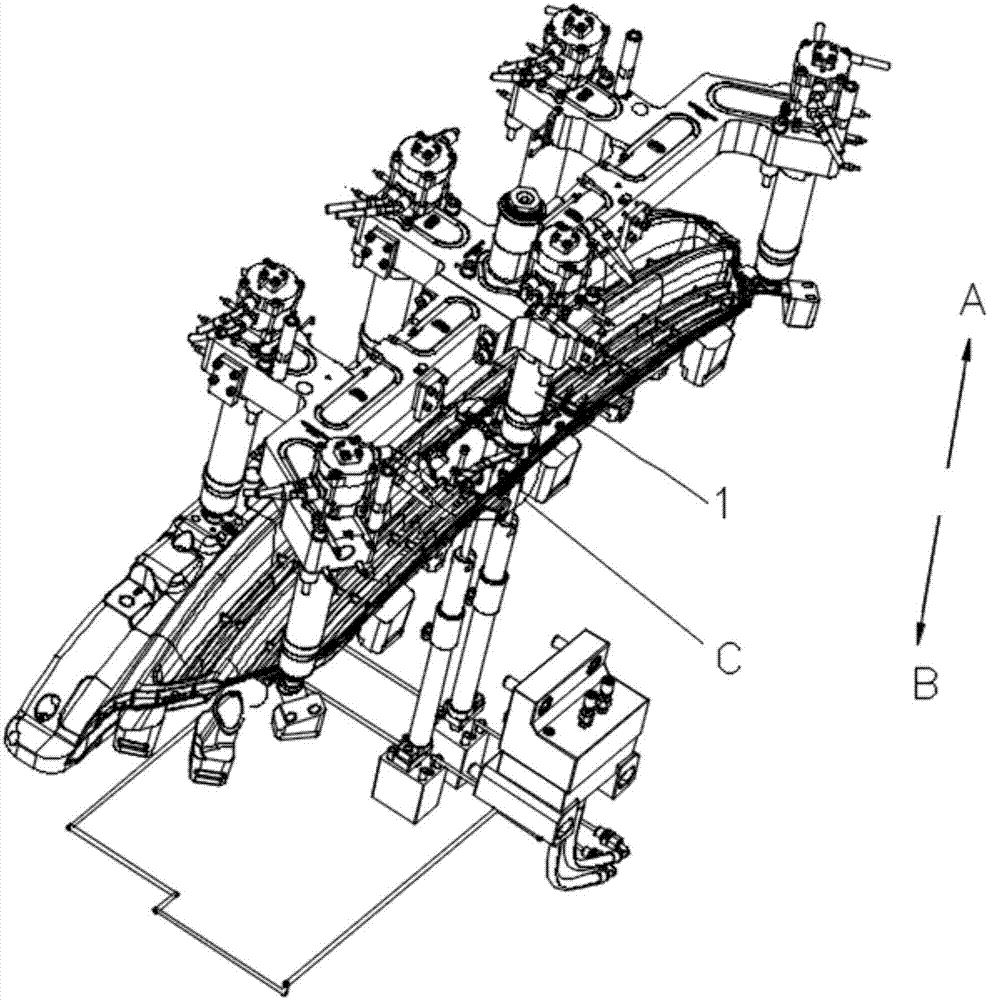

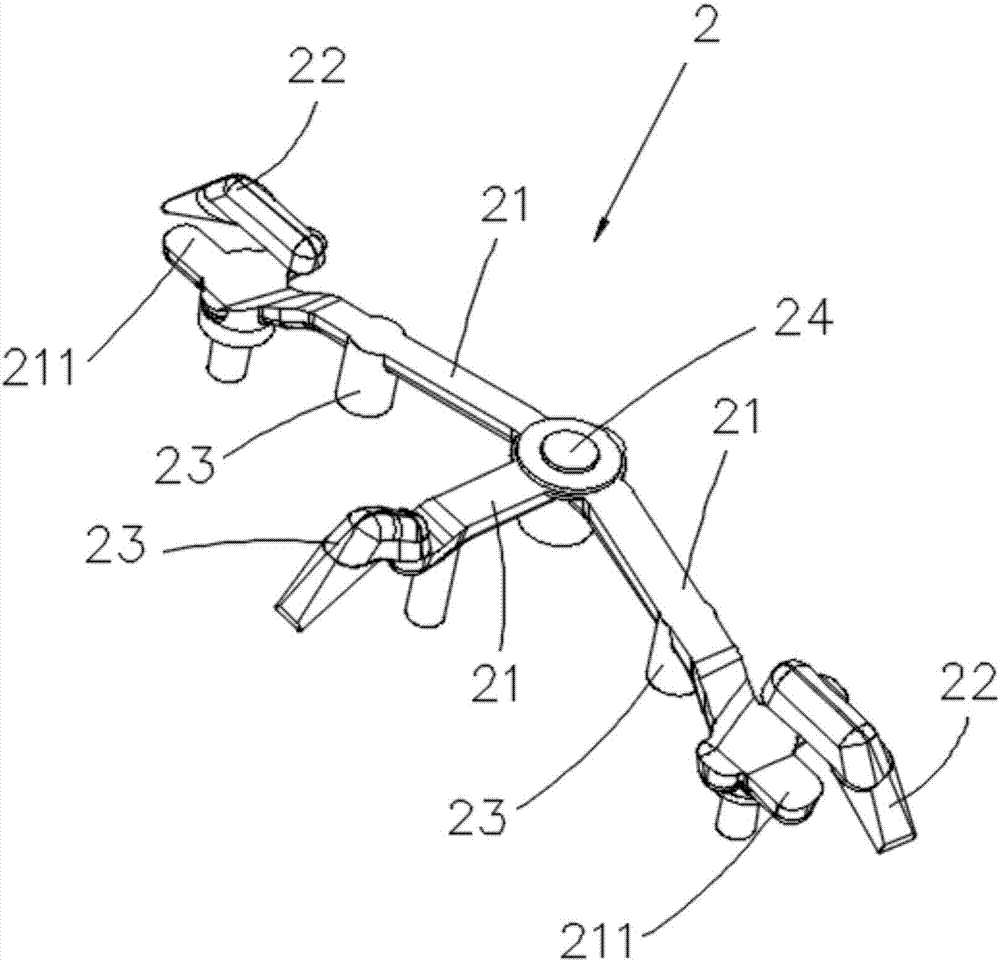

Mould pressing device and method of composite material

The invention provides a mould pressing device of a composite material. The mould pressing device of the composite material comprises an upper hot press plate, a concave mould, a convex mould and a lower hot press plate, wherein the concave mould comprises a middle sunken area and a platform area surrounding the sunken area; the convex mould comprises a middle protruded area and a platform area surrounding the protruded area; at least one exhaust slot is formed in an adjacent area of the platform area and the sunken area of the convex mould. A mould pressing method of the composite material, which is further provided by the invention, comprises a process of controlling the upper hot press plate and the lower hot press plate to tight fold the concave mould and the convex mould so as to heat and pressurize materials in a mould, wherein air in the mould is discharged through the exhaust slot in the heating and pressurizing process. According to the mould pressing device and the mould pressing method of the composite material, which are provided by the invention, the problem of air trapping in a mould pressing process can be effectively solved, and the surface effect of product shells is improved.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Process for producing microconfiguration transfer sheet and apparatus therefor

A process for producing a sheet and apparatus therefor that in the operation of heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutual contact and pressurizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, avoid transfer failure attributed to air trapping at the transfer face between the metal mold and the sheet substratum to thereby obtain a sheet having the desired fine uneven configuration formed on its surface. There are provided a process for producing a microconfiguration transfer sheet, and apparatus therefor, comprising, in the microconfiguration transfer sheet producing operation including heating a sheet substratum and a metal mold with fine uneven configuration, bringing them into mutual contact and pressurizing the same so as to form the fine uneven configuration on a surface of the sheet substratum, carrying out the configuration formation while changing the planarity of a configuration forming face consisting of at least one, or a combination, of a pair of pressurization plates or metal molds arranged so as to apply pressure to the sheet substratum and the metal mold.

Owner:TORAY IND INC

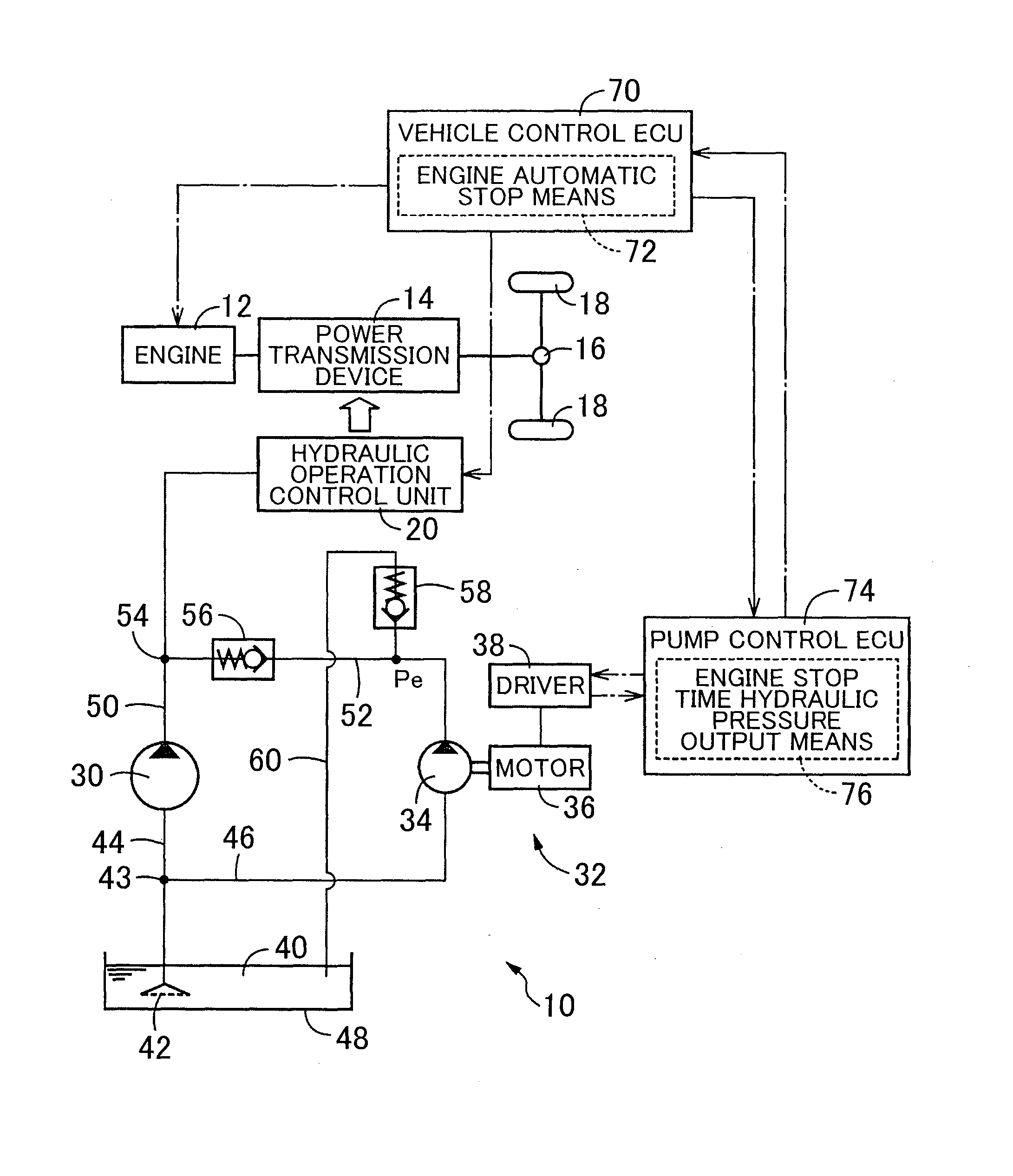

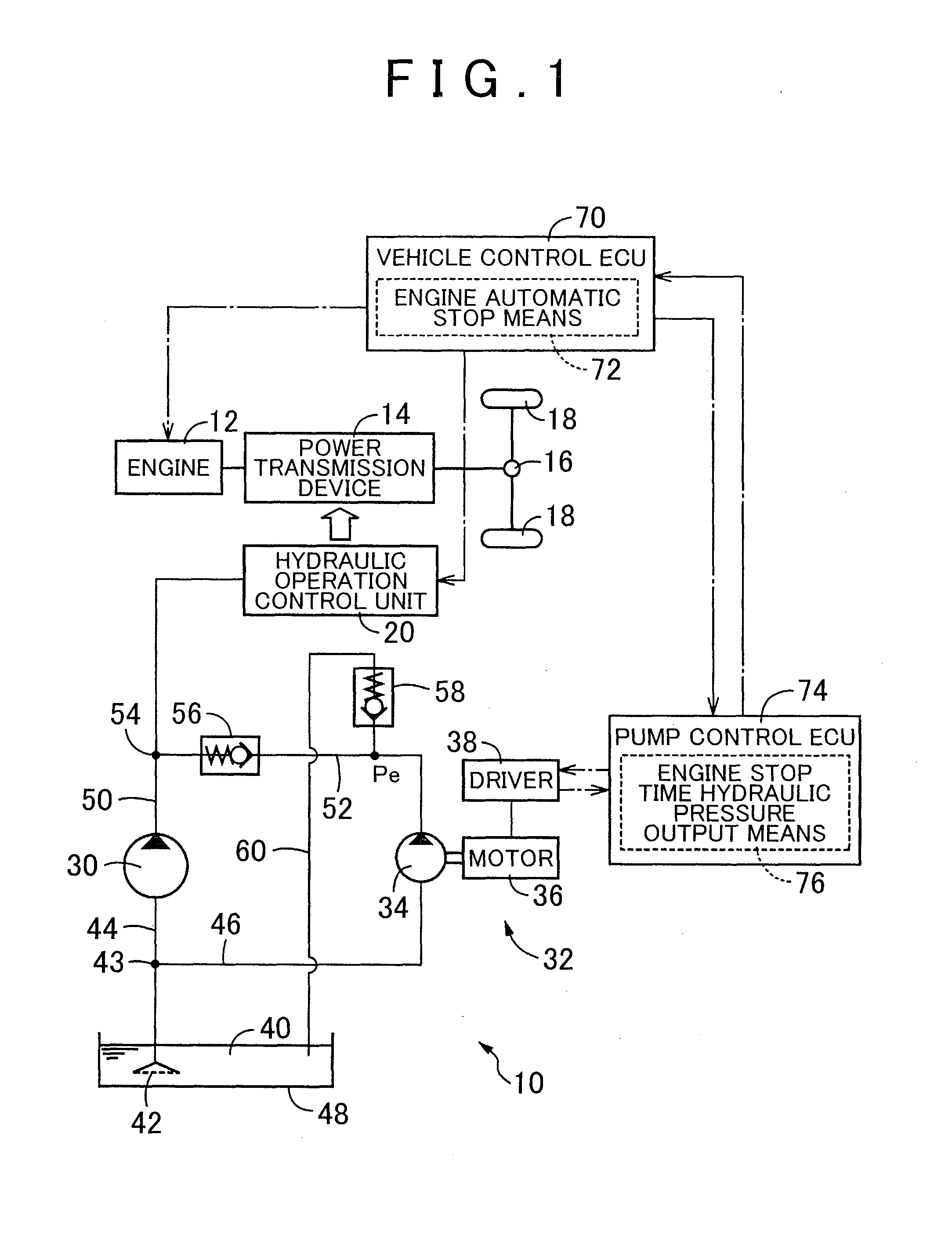

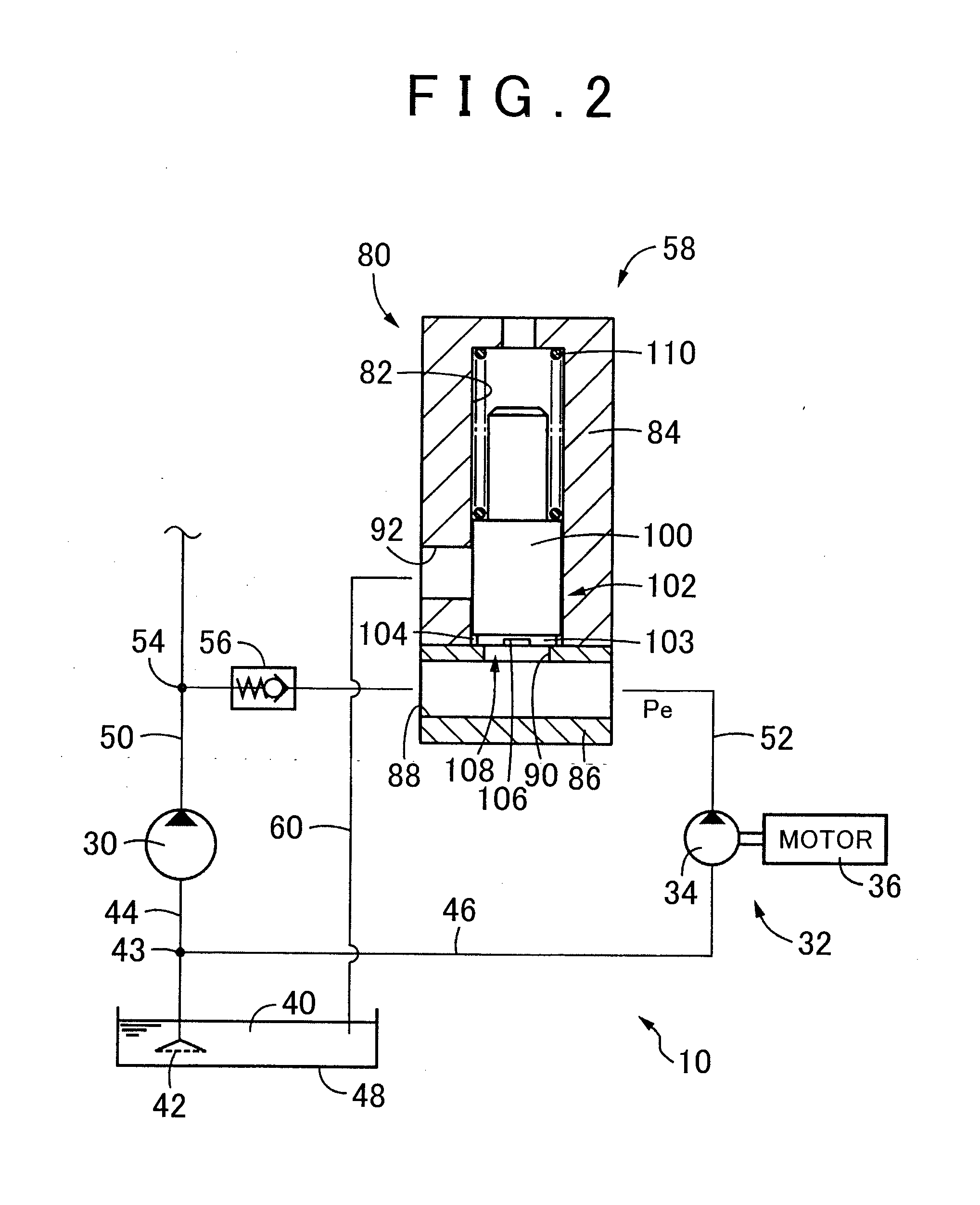

Hydraulic circuit for power transmission device of vehicle

ActiveUS20160245399A1Deteriorating efficiencyDeteriorating mountabilityGearing controlMultiple way valvesAir trappingHydraulic circuit

A fitting clearance of a relief valve functions as an air bleeding orifice. When a discharge pressure reaches a relief pressure so that the relief valve turns into a relief state, a spool is moved so as to limit flow-out of hydraulic oil through the fitting clearance. As a result, generation of air trapping is suppressed by air bleeding function of the relief valve in a closed state. Air in a discharge oil passage is discharged quickly in the initial period of the startup of an electric oil pump, thereby improving rise-up of discharge pressure. During normal pump operation in which the relief valve is held in a relief state, pressure loss due to flow out of the hydraulic oil from the fitting clearance is suppressed and consequently, an electric oil pump having substantially the same discharge performance as conventionally can be used.

Owner:TOYOTA JIDOSHA KK

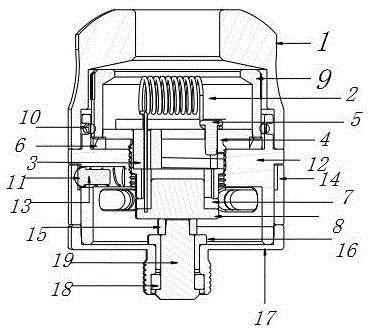

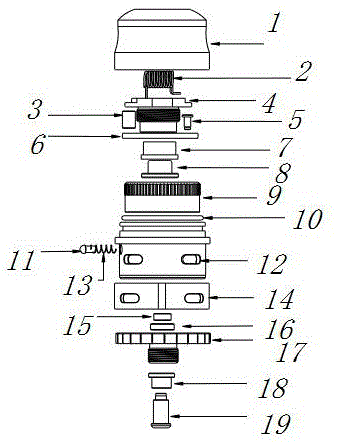

Structure for rapid core exchange and airflow automatic regulation of atomizer

The invention discloses a structure for rapid core exchange and airflow automatic regulation of an atomizer. The structure comprises a first atomizer housing, a heating wire, an upper atomizer base, a fixed pin, a silica gel ring, an upper insulating cover, an atomizer upper positive electrode, an atomizer housing, a floating head, an atomizer base main body, a spring, an atomizer regulating ring, a conducive copper ring and a lower atomizer base, wherein one end of the heating wire is fixedly arranged on the upper atomizer base by virtue of the fixed pin, and the other end of the heating wire runs through the atomizer base main body and is connected to the atomizer upper positive electrode; the atomizer base is arranged at the bottom end of the atomizer base main body; the atomizer regulating ring is arranged at the outer end of the atomizer base main body; and the first atomizer housing is arranged outside the atomizer base. Through structural design, the structure can be used for improving the problems that the heating wire is not removable as a whole and is difficult to install as well as the problems of unsmooth airflow, oil leak, air trapping and the like, so as to effectively achieve the purposes of conveniently removing and exchanging the heating wire and automatically regulating airflow.

Owner:GD SIGELEI ELECTRONICS TECH CO LTD

Visualization and quantification of lung disease utilizing image registration

Methods and systems for assessing lung function using volumetric images obtained at inspiration and expiration. The method may include processing the first and second set of images to identify known anatomical structures of the lungs, registering the first set of images to the second set of images to match voxels of the first set of images to voxels of the second set of images as matched pairs of inspiratory and expiratory voxels, calculating a continuous probability of a lung characteristic at a location of the matched pairs of voxels, and displaying the result on a display. The method may also include classifying lung tissue at each location as normal, having air trapping without emphysema, or being emphysematous.

Owner:VIDA DIAGNOSTICS

High-strength carbon fiber upper cover mold

The invention discloses a high-strength carbon fiber upper cover mold. The high-strength carbon fiber upper cover mold comprises an injection molding machine, a first female mold, a second female mold and a male mold; the first female mold and the second female mold are fixed on the injection molding machine; the male mold is driven to rotate by the injection molding machine, and is respectively closed with the first female mold and the second female mold; the male mold and the first female mold are closed to form a first injection mold for injecting hard plastic; the male mold and the second female mold are closed to form a second injection mold for injecting soft plastic; and carbon fiber products are arranged in the male mold. The high-strength carbon fiber upper cover mold can produce bicolor upper cover injection parts with PC plus carbon fibers and surrounded by TPE soft plastic on a large scale; and the produced plastic products are high in strength, beautiful and excellent in touch. The high-strength carbon fiber upper cover mold is excellent in exhaust, effectively solves the difficulty of easiness in air trapping in carbon fiber plastic injection, and improves the product yield. The injection products adopt bicolor injection molding, are excellent in bonding of soft and hard plastic, and are beautiful in surfaces. The mold is high in precision, is high in closing precision of two sets of molds in injection, and has no other defects such as burrs and bad exhaust.

Owner:SUZHOU VICTORY PRECISION MFG

Method and device for the adaptive regulation of a positive end-expiratory pressure (PEEP)

A method controls an expiratory gas flow at a user interface (16) of a ventilator (1) wherein the user interface (16) has an exhalation valve (11), which provides a positive end-expiratory pressure (PEEP). The method includes the following steps during a phase of exhalation: changing the positive end-expiratory pressure from a basic PEEP value (31) with the exhalation valve (11); returning the positive end-expiratory pressure to the basic PEEP value (31) with the exhalation valve (11); and determining an exhalation parameter. The method permits an adaptive change in the expiratory flow duringthe exhalation. Air trapping can be avoided, and it is possible to respond to changed exhalation parameters within one and the same phase of exhalation.

Owner:DRAGERWERK AG

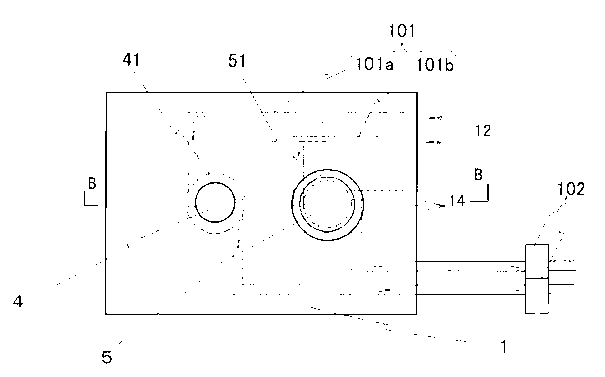

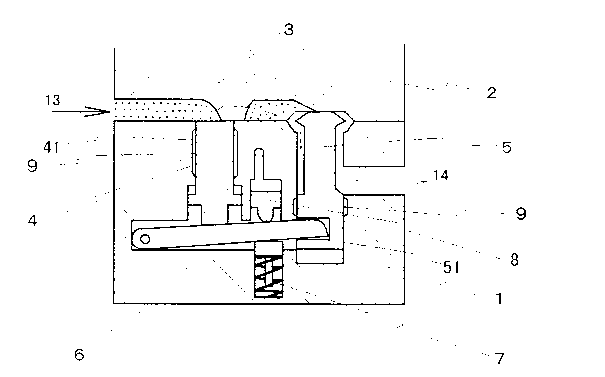

Exhaust device used for casting die

ActiveCN102794430AAvoid enteringExtended replacement cycleValve arrangementsMachines/enginesAir trappingEngineering

An exhaust device used for a casting die comprises an exhaust passage which is formed between a fixed die and a moving die and is communicated with a casting die cavity. The exhaust device used for the casting die at least comprises: a pressed plunger arranged at an inlet side of the exhaust passage, a holding valve arranged at an outlet side of the exhaust passage, an opening-closing fulcrum bar for transmitting motion of the pressed plunger to the holding valve, an opening device for enabling the holding valve to move towards an open position, and a closing device for pushing the holding valve towards a closing direction through the opening-closing fulcrum bar. An air trapping part is formed on a plunger sliding part of the pressed plunger and a valve sliding part of the holding valve, and a gas transmission device for supplying a pressure gas for the plunger sliding part and the valve sliding part is provided. The present invention solves the problems of low production efficiency and high maintenance cost in the prior art.

Owner:JAPAN MOLD TRADE

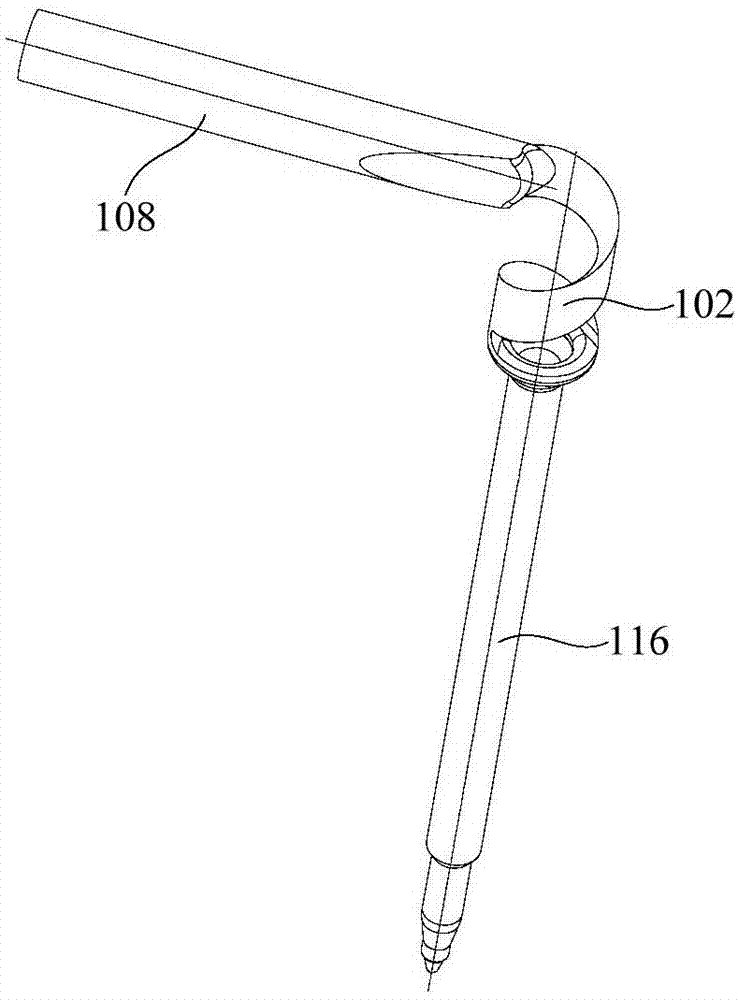

Needle vale control system for cold runner sprues

The invention relates to the technical field of injection molding and discloses a needle vale control system for cold runner sprues. The needle vale control system comprises a front mold, a rear mold, a needle valve hot sprue and a runner assembly, wherein the needle valve hot sprue is used for outputting molten-state plastic, and the runner assembly is mounted on the needle valve hot sprue. The runner assembly is internally provided with a runner which can allow the molten-state plastic to flow therein. The runner assembly is provided with one or more normally-opened sprues and one or more controllable sprues. A control structure is arranged at each controllable sprue, wherein each control structure is used for controlling the corresponding controllable sprue to be opened and closed. By means of the needle vale control system for the cold runner sprues, different numbers of normally-opened sprues and controllable sprues can be designed as needed; each controllable sprue is controlled to be opened and closed according to different injection molding process requirements, thus the injection molding sequence of the multiple sprues can be controlled, and injection molding is conducted at the same time at multiple points; due to the fact that the number of needle valves is reduced, the space occupied by the needle vale control system is small; and after injection molding is achieved, injection molding defects such as welding marks and air trapping cannot be generated easily.

Owner:SHENZHEN SILVER BASIS TECH

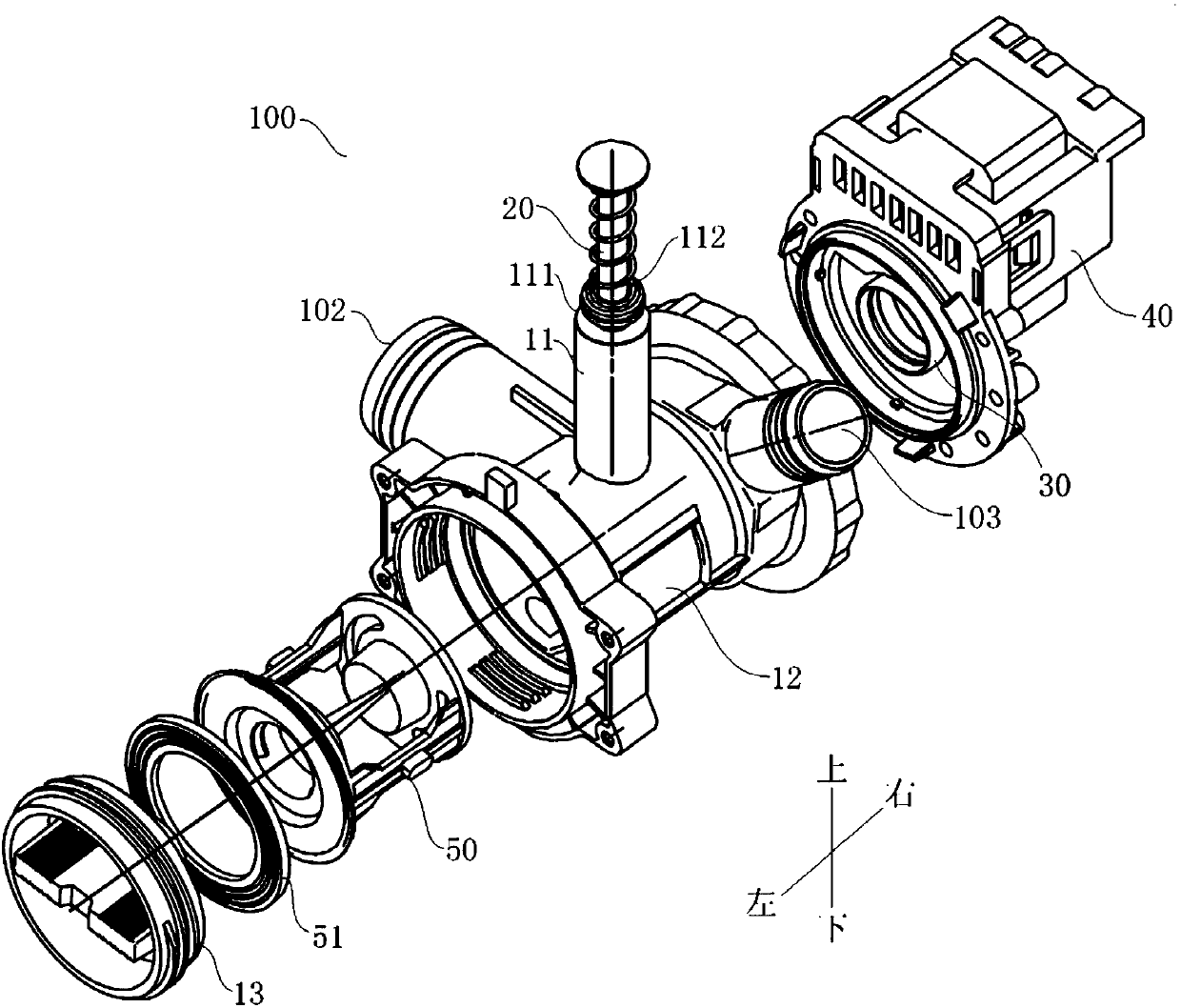

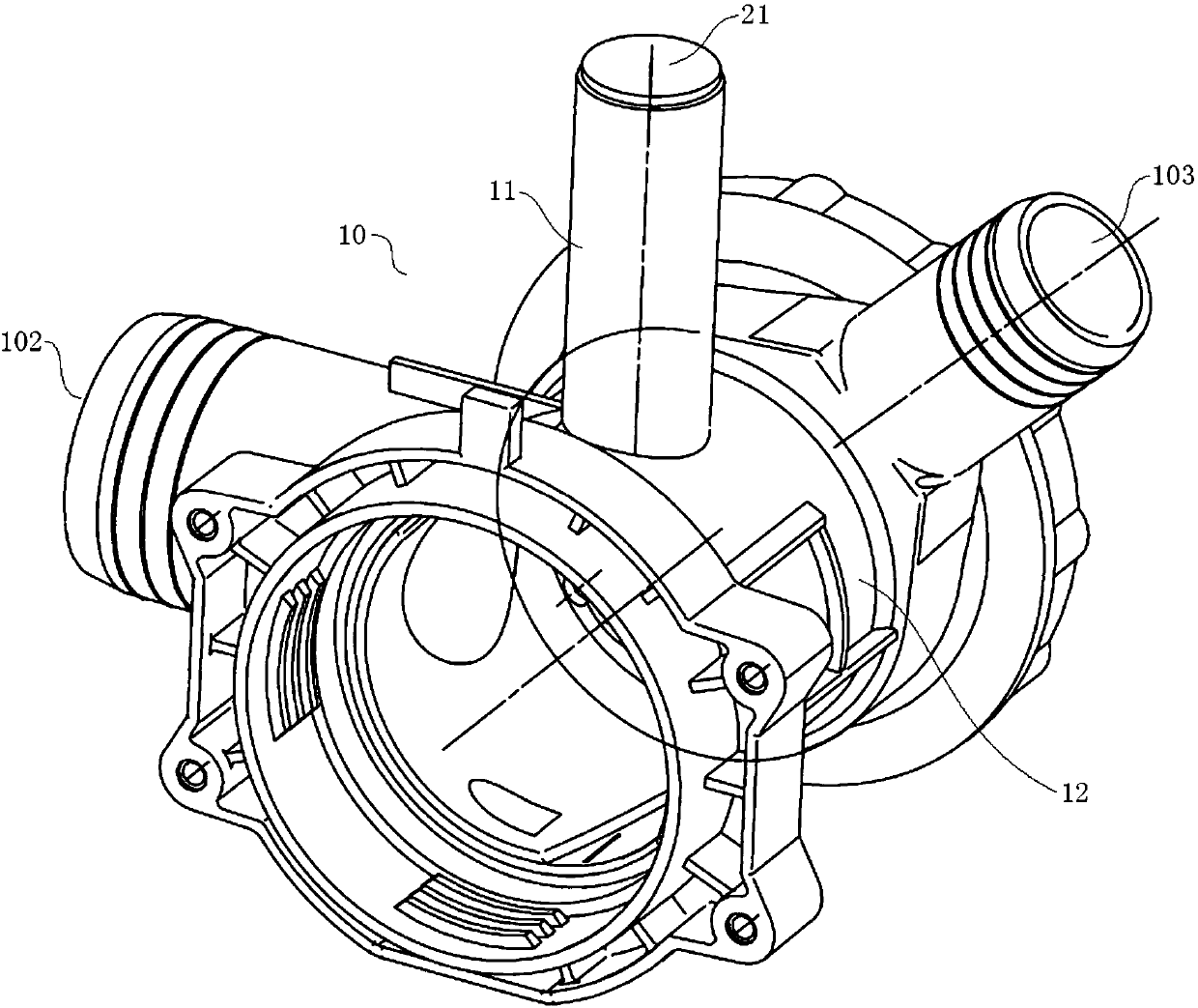

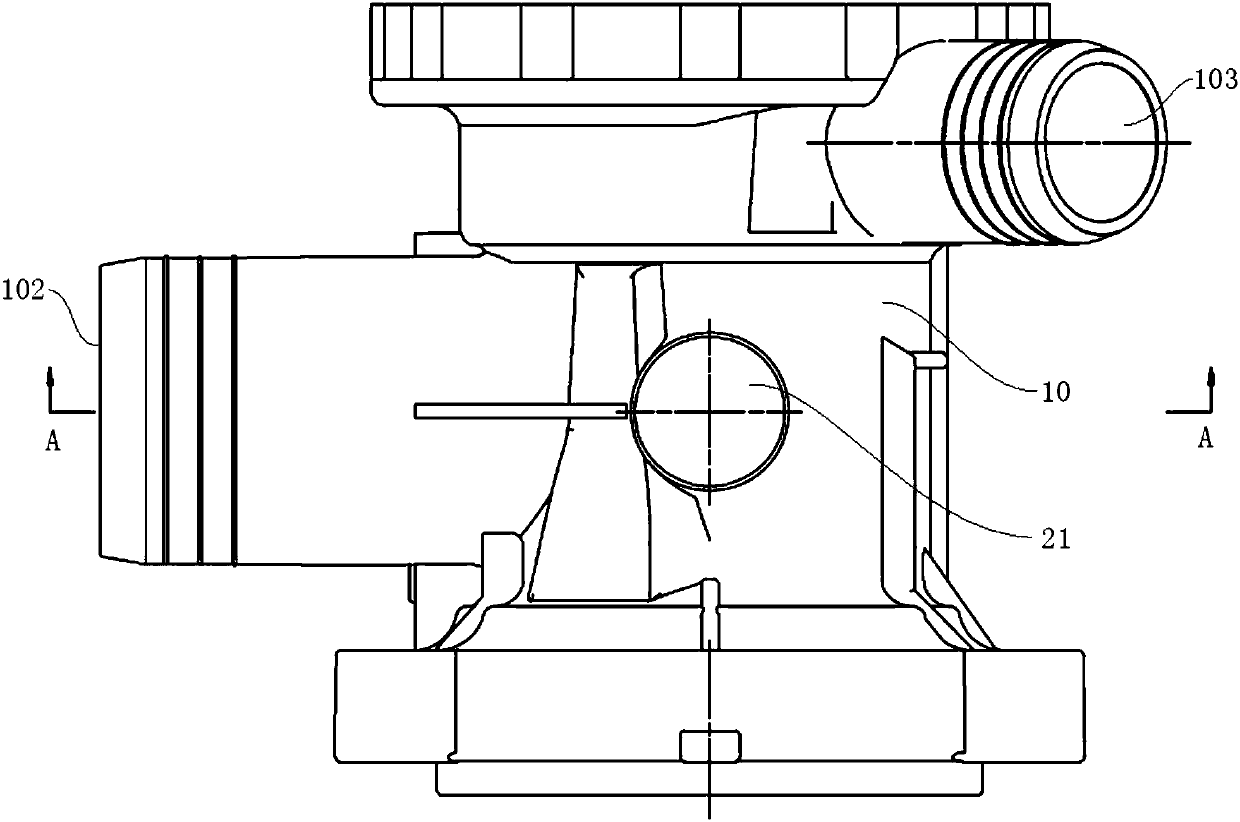

Drainage pump and washing machine with same

ActiveCN107904870AImprove work efficiencyIncrease or decrease in volumeOther washing machinesTextiles and paperImpellerAir trapping

The invention discloses a drainage pump and a washing machine with the same. The drainage pump includes a pump shell, a piston assembly, an impeller and a driving device, wherein the pump shell is internally provided with a drainage cavity, and a water inlet and a water outlet which are communicated with the drainage cavity are formed in the pump shell; the piston assembly is movably arranged on the pump shell, and an air storage cavity which is communicated with the drainage cavity and has a variable volume is defined on the pump shell by the piston assembly; the impeller is rotatablely arranged in the drainage cavity; the driving device is installed on the pump shell and in transmission connection with the impeller. According to the drainage pump, by arranging the piston assembly, and adopting the piston assembly and the pump shell to define the air storage cavity with the variable volume, the piston assembly can move according to the work conditions of the drainage pump, therefore,the capacity of the air storage cavity can be increased or decreased, it is ensured that water flow can be normally sucked and discharged, the problem of air trapping is effectively solved, and then the work efficiency of the drainage pump is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Mobile motherboard heat dissipation graphite sheet and mobile phone

InactiveCN107624016AImprove cooling effectImprove fit qualityTelephone set constructionsCooling/ventilation/heating modificationsAir trappingGraphite

The present invention discloses a mobile motherboard heat dissipation graphite sheet. The sheet comprises a square-shaped heat-dissipating tube; a plurality of inner fins are symmetrically and uniformly distributed on two corresponding sides of the inner portion of the tube wall of the heat-dissipating tube; the inner fins are embedded in a graphite basal body; the heat-dissipating tube wraps thegraphite basal body; a plurality of external fins are symmetrically arranged on the other two opposite sides of the outer portion of the tube wall of the heat-dissipating tube; and the outer side of the tube wall of the heat-dissipating tube is uniformly coated with a spray layer. According to the mobile motherboard heat dissipation graphite sheet of the invention, aluminum alloy with high thermalconductivity is adopted; the inner wall and outer wall of the heat-dissipating tube are provided with the fins; the inner wall is in full contact with the graphite sheet, the heat dissipation area ofthe outer wall is large, and therefore, a heat dissipation rate can be greatly improved; and heat dissipation holes are formed in the graphite sheet, when the graphite sheet is bonded, air can be discharged easily through the heat dissipation holes, and therefore, air trapping can be avoided, the bonding quality of the graphite sheet and an electronic product is improved, and thus, the heat dissipation effect of the graphite sheet is improved, at the same time, assembly efficiency is improved, and production costs are reduced.

Owner:SHANGHAI MANYU INFORMATION TECH CO LTD

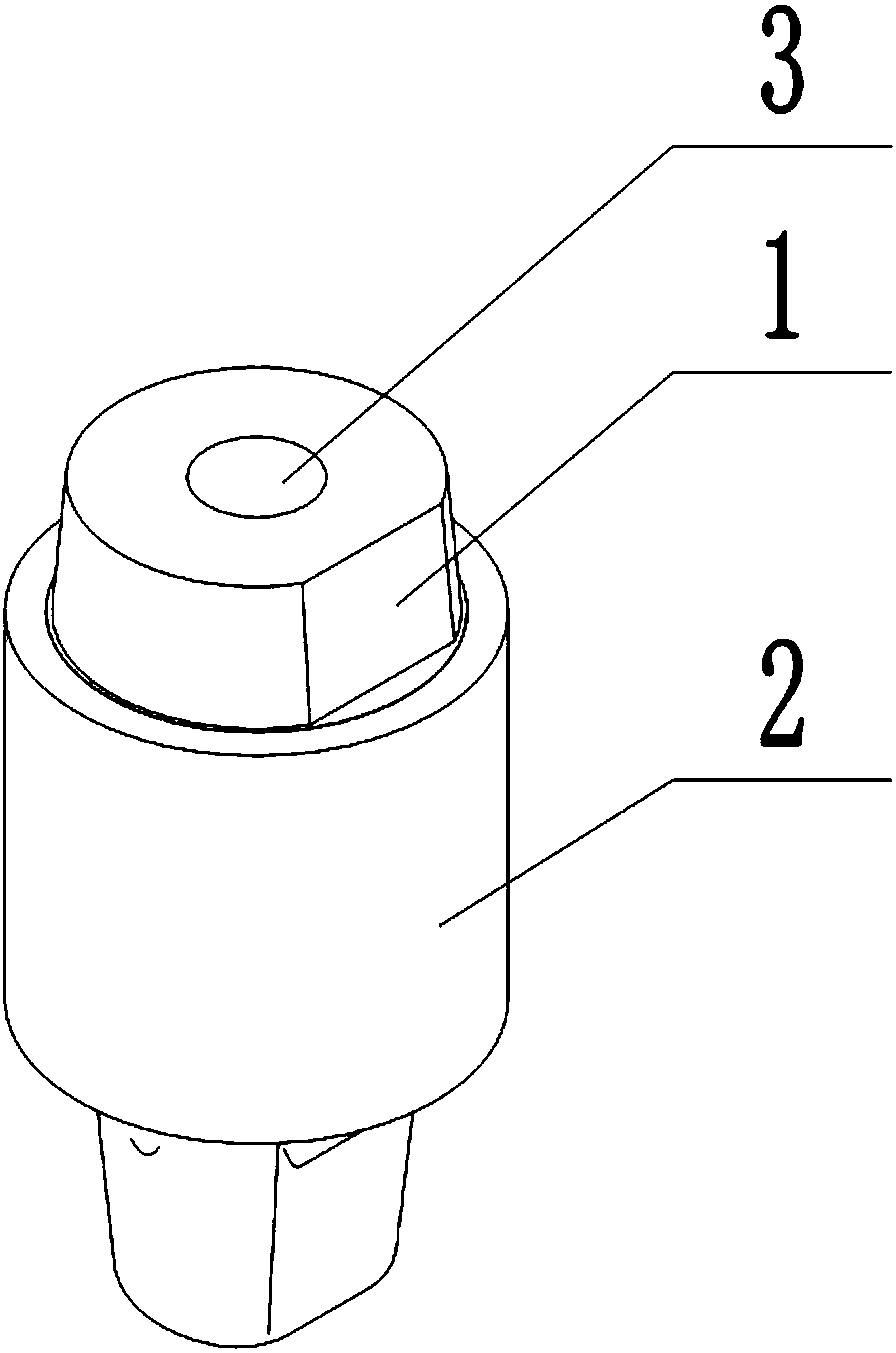

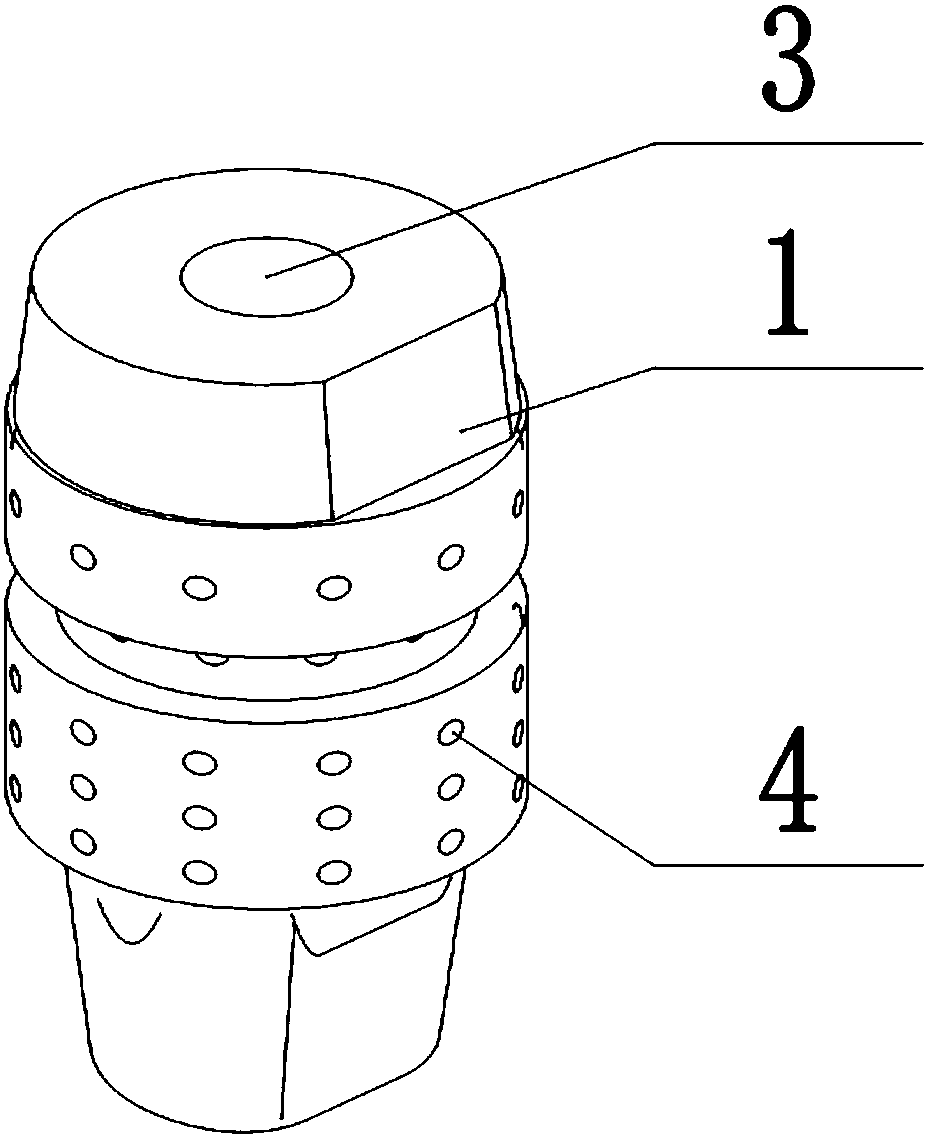

Novel chill coating sand core mold capable of exhausting air

InactiveCN108057867ASimple structureRemoval of nest gas phenomenonFoundry mouldsFoundry coresAir trappingEngineering

The invention discloses a novel chill coating sand core mold capable of exhausting air. The novel chill coating sand core mold comprises a central chill, and a sand core is arranged on the periphery of the central chill; a central exhaust hole is formed in the central chill in a penetrating manner from up to down; five rows of small exhaust holes are drilled in the side wall, in contact with the sand core, of the central chill; the small exhaust holes extend into the central chill and communicate with the central exhaust hole; the horizontal section of the central exhaust hole is circular; thediameter of the small exhaust holes is 3 mm; ten small exhaust holes are in each row; and the sand core is of a cylindrical structure of which the interior is hollow. According to the novel chill coating sand core mold, the structure is simple, stable and reliable, the air trapping phenomenon in a product can be quickly and effectively eliminated, and casting cost is reduced.

Owner:TIANJIN HANGYU METAL PROCESSING

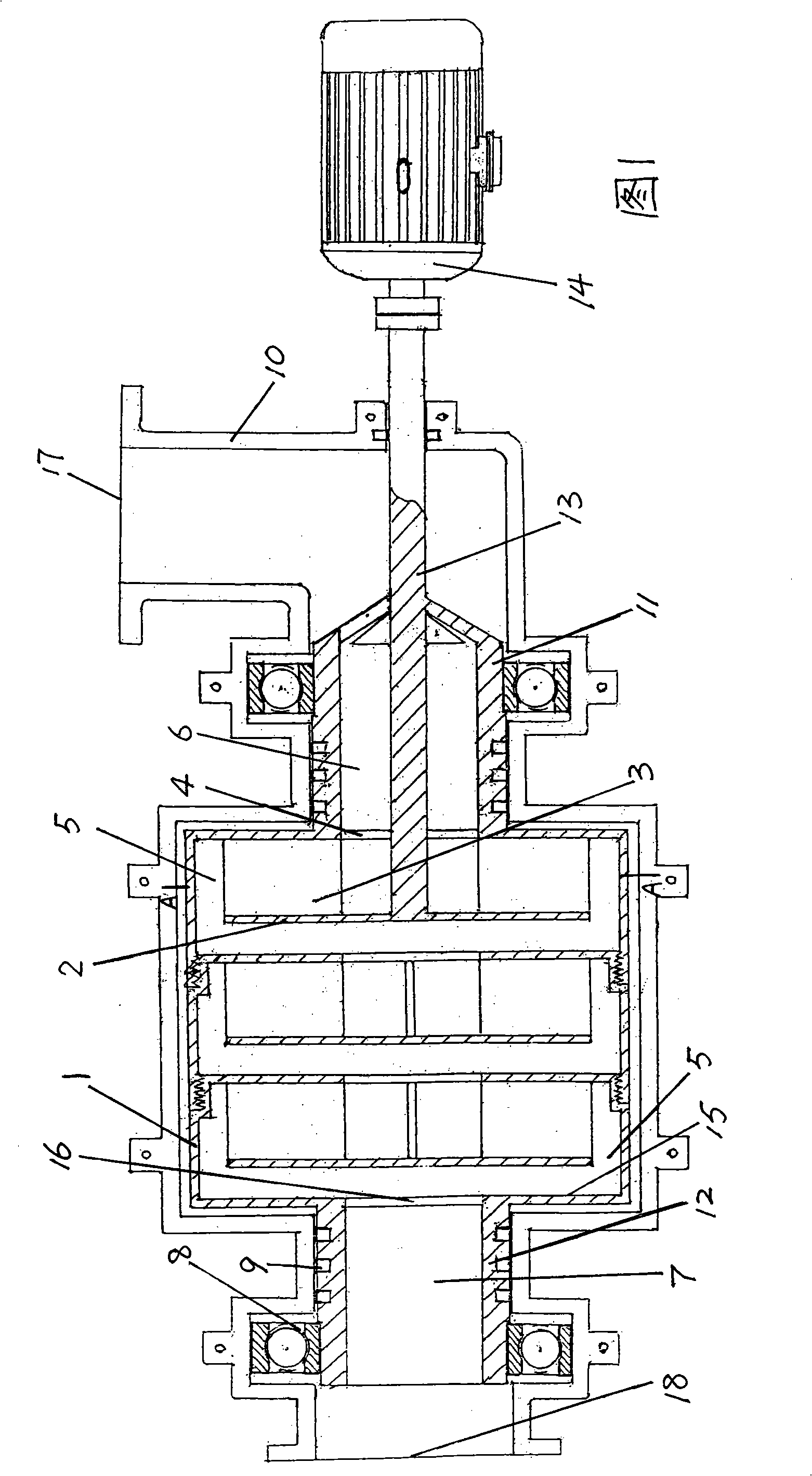

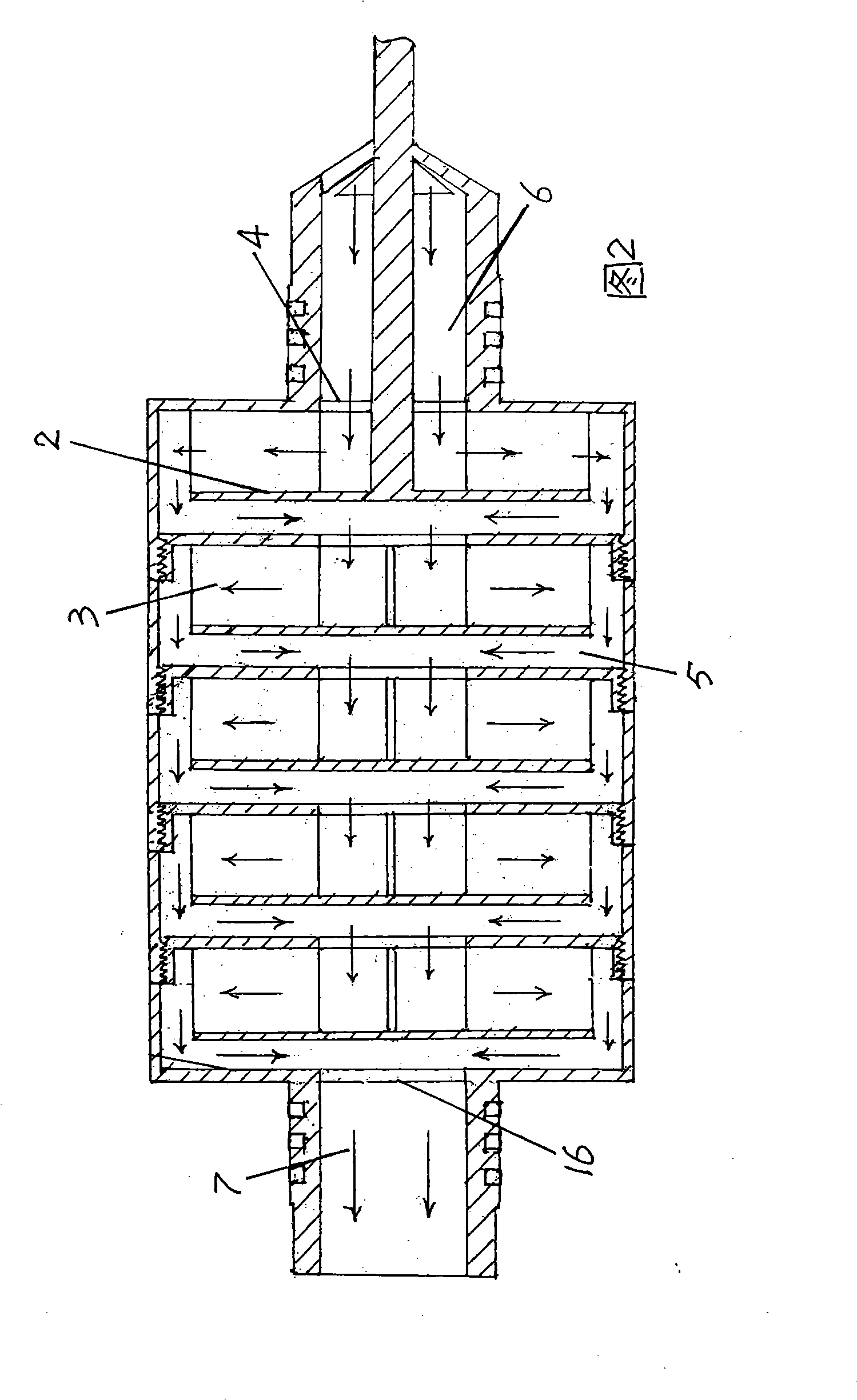

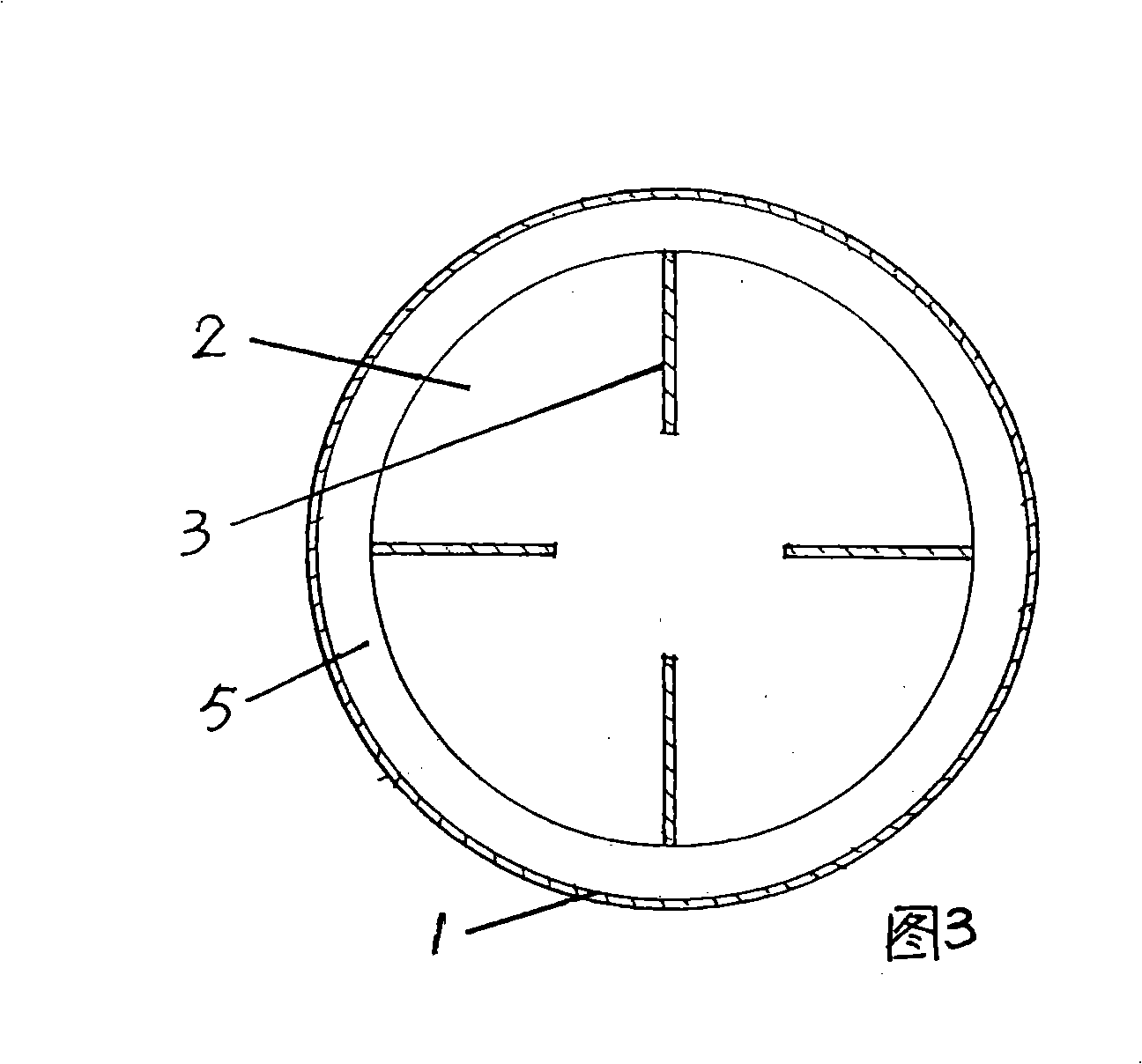

Fan type air pump

The invention pertains to the technical field of air pumping and compressing devices, and in particular relates to a fan-typed air pump which realizes the pumping of compressed air continuously in large flow. The fan-typed air pump comprises a shell provided with an air inlet and an air outlet, and the air inlet is communicated with an air supplying device while the air outlet is communicated with an air consumption device; an air shell which can rotate relatively to the shell is arranged inside the shell; the air shell is internally provided with an air trapping sheet and a plurality of fan blades are arranged between the air trapping sheet and the air shell, the fan blades are evenly distributed around the center of the air trapping sheet; air paths are reserved among the fan blades as well as the periphery of the air trapping sheet and the inner wall of the air shell; an air intake hole is cut at one side of the air shell, which is provided with the fan blades, while an air outtake hole is cut at the other side thereof, and the air intake hole is communicated with the air inlet of the shell while the air outtake hole is communicated with the air outlet of the shell; the center of the air trapping sheet is connected with a rotary shaft which passes through the air intake hole to be connected with a motor. The fan-typed air pump realizes the pumping of the compressed air continuously in large flow and can be applied to highly effective air supply on various occasions.

Owner:STATE GRID CORP OF CHINA +1

Injection mold

The invention provides an injection mold comprising a first mold core, a second mold core, a third mold core, a mold insert and an exhaust device. The second mold core is provided with an inlaying channel, and the third mold core is provided with an exhaust channel arranged correspondingly to the inlaying channel; the exhaust channel is connected with the exhaust device, and the mold insert is inlaid in the inlaying channel; spacing for air to pass is formed between the inner walls of the mold insert and the inlaying channel; when the first mold core, the second mold core and the third mold core are combined through injection molding, a cavity is formed between the first mold core and the second mold core, and the inlaying channel communicates with the cavity and the exhaust channel; molten plastic in the cavity is prevented from entering the exhaust channel by the mold insert, and the exhaust device is used for vacuum-pumping the exhaust channel so that air in the cavity is pumped out. According to the injection mold, the rate of air discharge of the injection mold can be improved, and the air trapping phenomenon of the injection mold can be eliminated effectively, so that the quality of products produced with the injection mold is improved.

Owner:AAC TAIRUIMEI MODULE SHENZHEN CO LTD

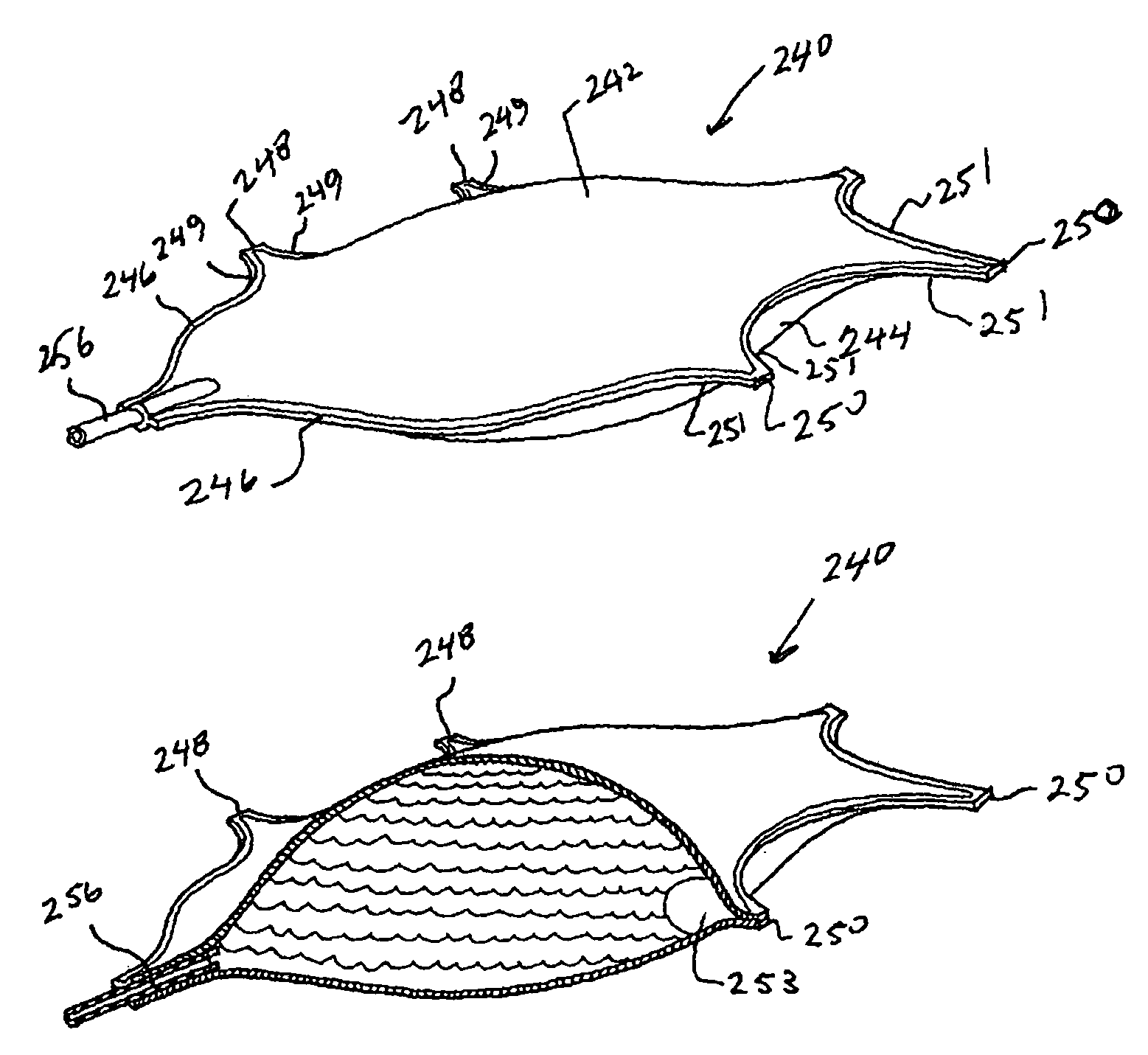

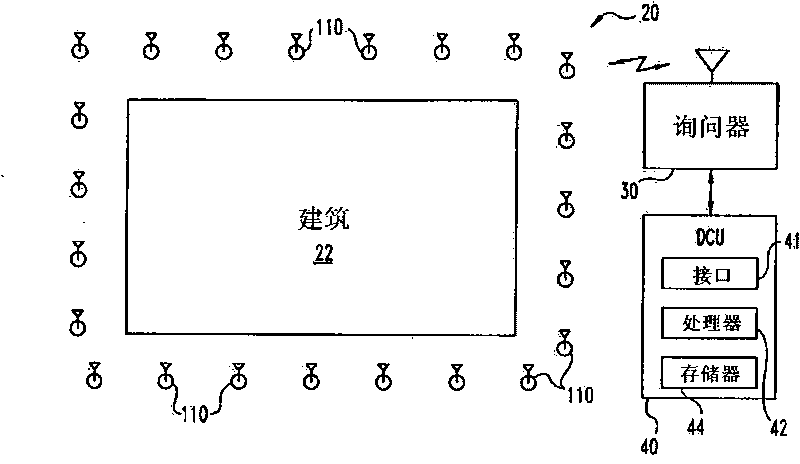

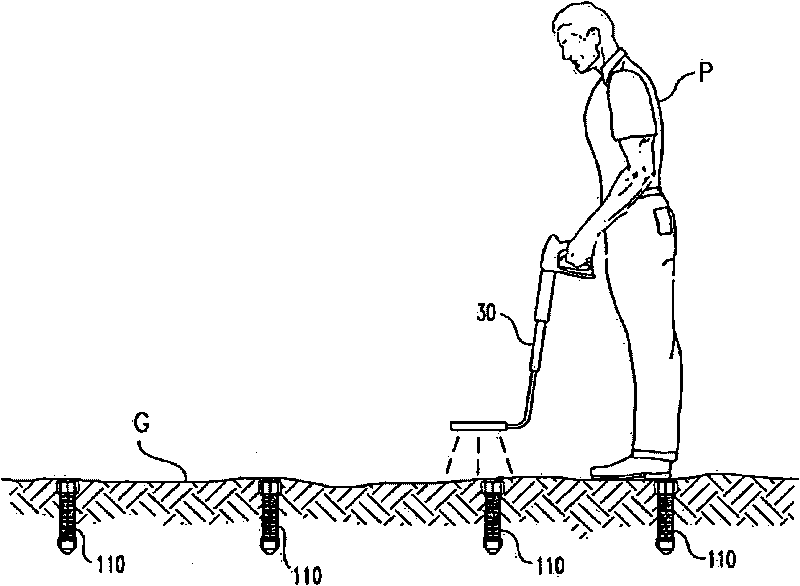

Techniques for maintaining palatability of a bait material in a pest control device

A termite control bait container (200) includes an upper end portion (204) opposite a lower end portion (206). The bait container includes a chamber (240) containing a termite bait (318). The lower end portion includes an air-trapping pocket (280) below at least a portion of the bait to reduce intrusion of water through the lower end portion (206) when installed in a selected orientation at least partially below ground.

Owner:DOW AGROSCIENCES LLC

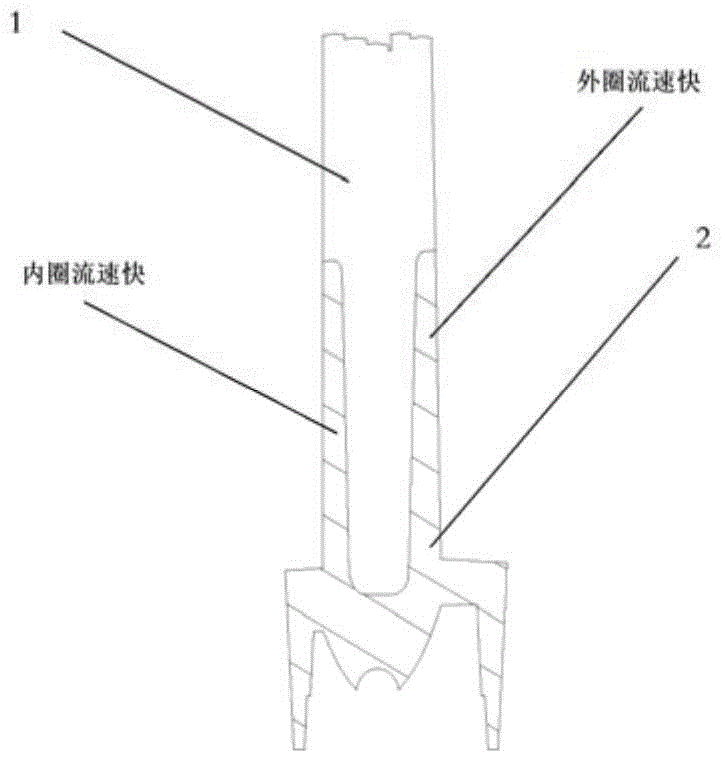

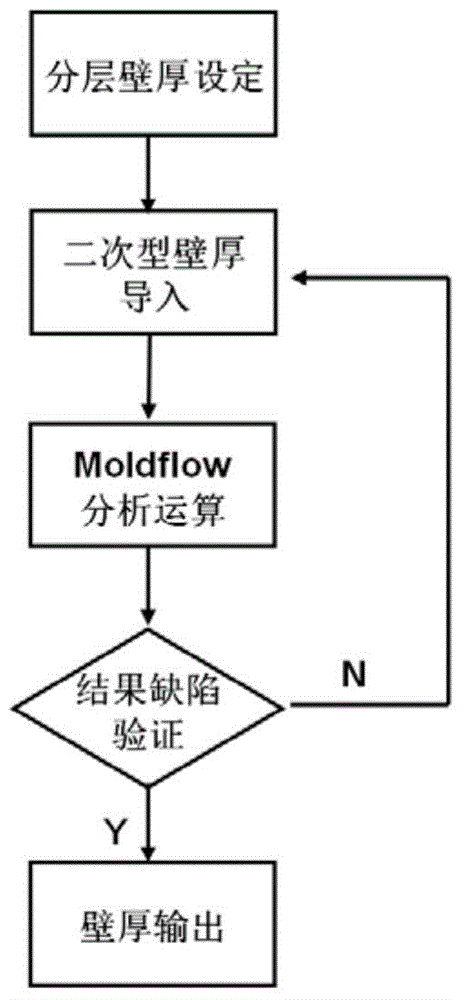

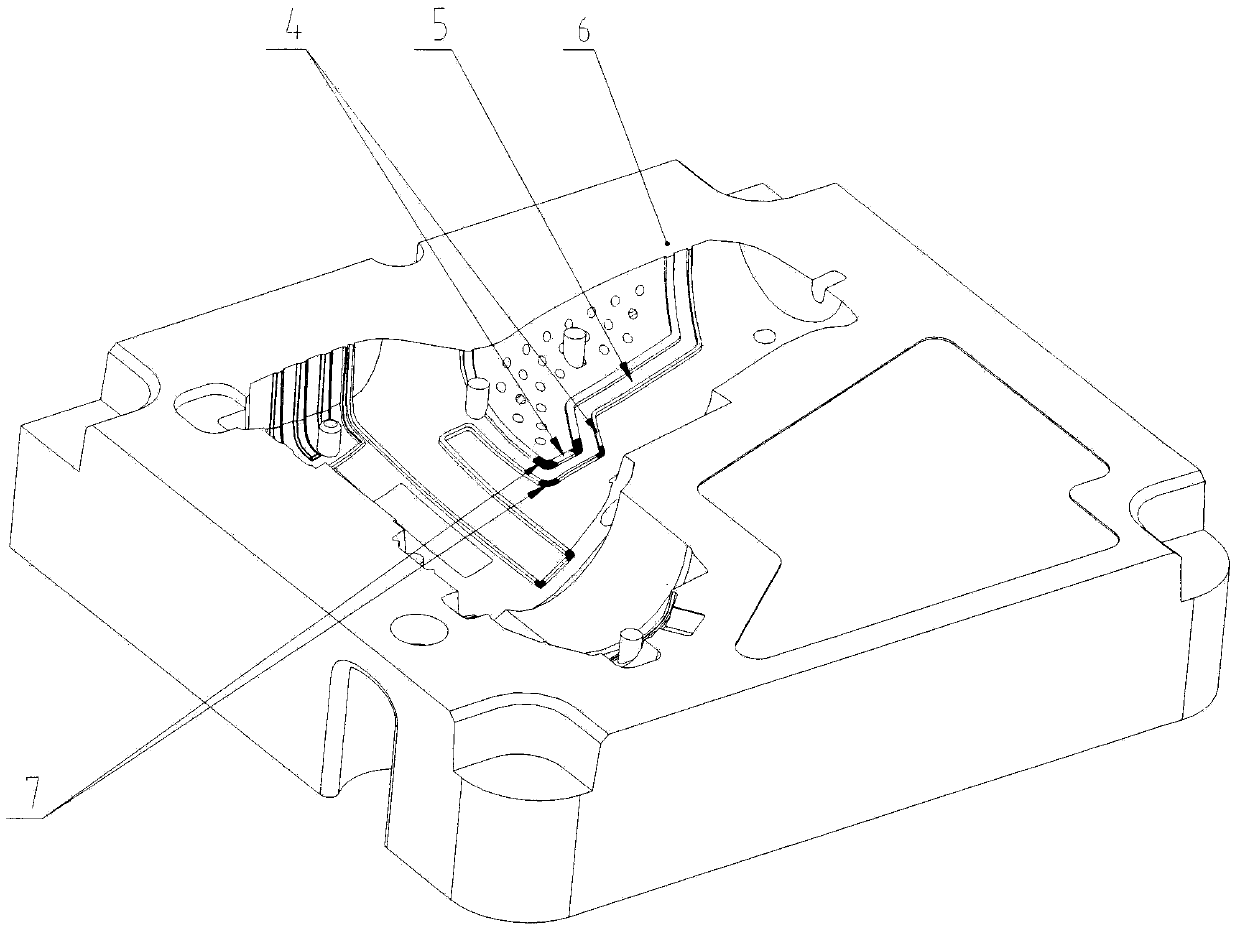

Corner streamhandling method for double-layer injection molding of LED light-guide components

ActiveCN104690917ARational stratification methodSolve the trapped gas defectAir trappingChinese characters

The invention discloses a corner streamhandling method for the double-layer injection molding of LED light-guide components. According to the method, a double-layer injection mold for carrying out injection molding on thick-walled light-guide components is adopted, and comprises a primary injection mold cavity part and a secondary injection mold cavity part which are respectively in the shape of a Chinese character 'tu' corresponding to the shape of the cross section of a product and in the shape of a Chinese character 'ao' corresponding to the shape of the cross section of the product. The method is characterized by comprising the following steps: setting a basic mold cavity wall thickness between the inner side and outer side of a portion, for forming the part in the shape of a Chinese character 'ao' at a corner of a light-guide component, of the secondary injection mold cavity; carrying out wall thickness compensation adjustment: the wall thickness difference is sequentially increased, i.e. the wall thickness of the outside cavity, for forming the part in the shape of a Chinese character 'ao' at the corner of the light-guide component, of the secondary injection mold cavity is increased by 0.1-0.3 mm, and the wall thickness of the inside cavity of the secondary injection mold cavity is correspondingly reduced by 0.1-0.3 mm; and respectively gradually increasing and reducing the curvatures of the inner side and outer side of a portion formed at the corner of the light-guide component, of the secondary injection mold cavity, so that the flow speed of an injection molding fluid flowing through the corner of the secondary injection mold cavity and reaching a vehicle headlight is consistent, and a defect of air trapping does not occur in the process of injection molding.

Owner:HASCO VISION TECHNOLOGY CO LTD

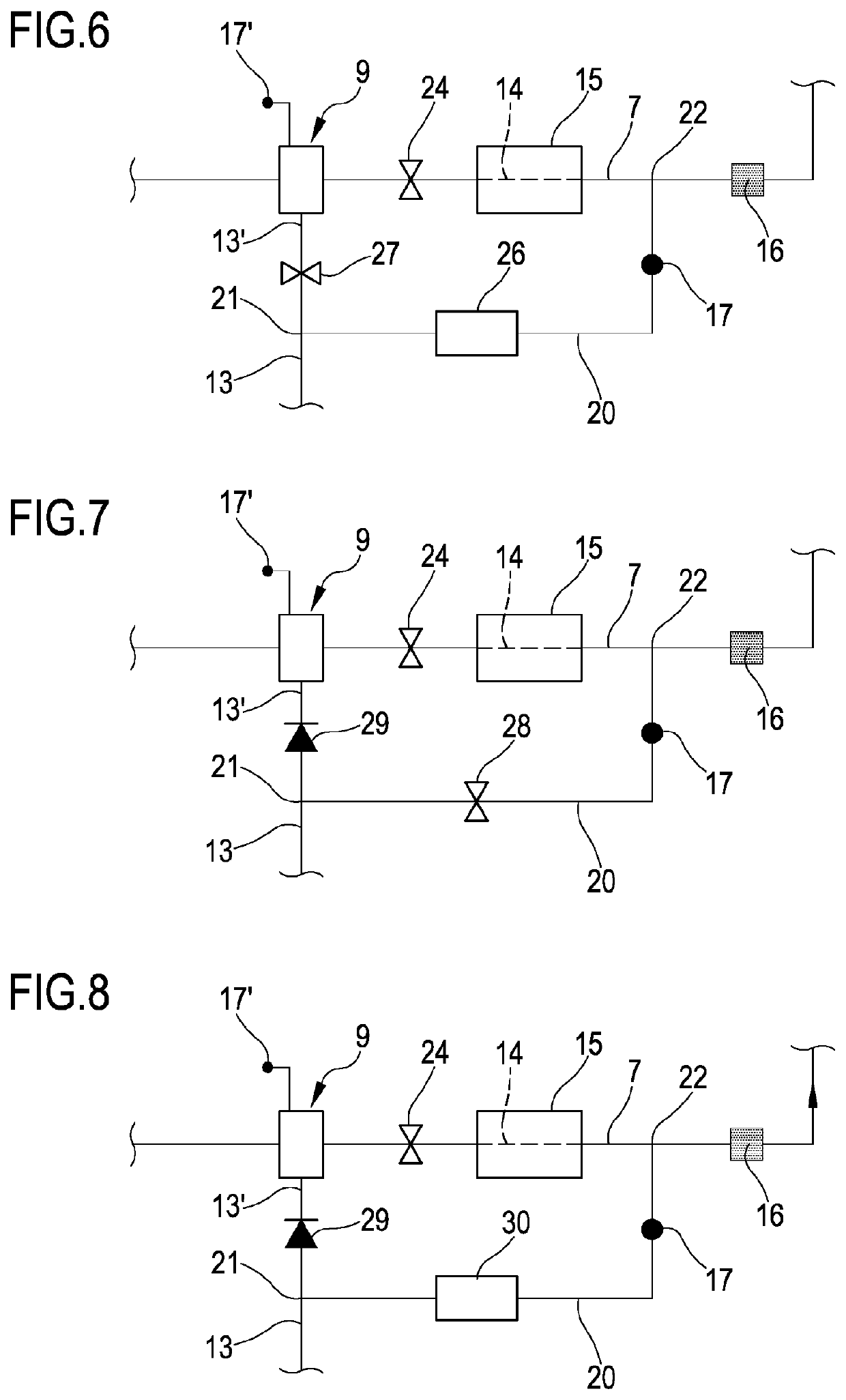

Apparatus for extracorporeal treatment of blood and method of priming an extracorporeal blood circuit

ActiveUS20200179588A1Improve securityReduce and prevent air trappingOther blood circulation devicesMedical devicesBlood treatmentsBlood warmers

An extracorporeal blood treatment apparatus comprises: a blood treatment device (2); an extracorporeal blood circuit comprising a blood withdrawal line (6) and a blood return line (7) coupled to the extracorporeal blood treatment device (2), wherein the blood return line (7) presents a heating zone (14) coupled or configured to be coupled to a blood warmer (15); a blood pump (6) configured to be coupled to a pump section of the blood withdrawal line (6); at least a post-infusion line (13, 13′) connected to the blood return line (7) upstream of the heating zone (14); an air trapping device (9) placed on the blood return line (7) upstream of the heating zone (14).

Owner:GAMBRO LUNDIA AB

Hot runner structure, injection mold, machining method and injection method

The invention provides a hot runner structure, an injection mold, a machining method and an injection method. The hot runner structure comprises a first hot runner insert, a second hot runner insert, a hot runner plate and a hot nozzle; the second hot runner insert is arranged on the outer side of the first hot runner insert in a sleeving manner, the outer wall of the first hot inner inset and / or the inner wall of the second hot runner insert are / is provided with a spiral groove which serves as a first hot runner, a second hot runner is arranged on the hot runner plate, and the second hot runner is connected with one end of the first hot runner; a third hot runner is arranged on the hot nozzle, one end of the third hot runner and the other end of the first hot runner are connected, and the other end of the third hot runner serves as a hot nozzle sprue. The first spiral hot runner is arranged, and therefore in the injection process, no dead corners exist in the hot runners, and encapsulation air trapping is avoided.

Owner:FOSHAN CITY SHUNDE DISTRICT BAINIAN TECH CO LTD

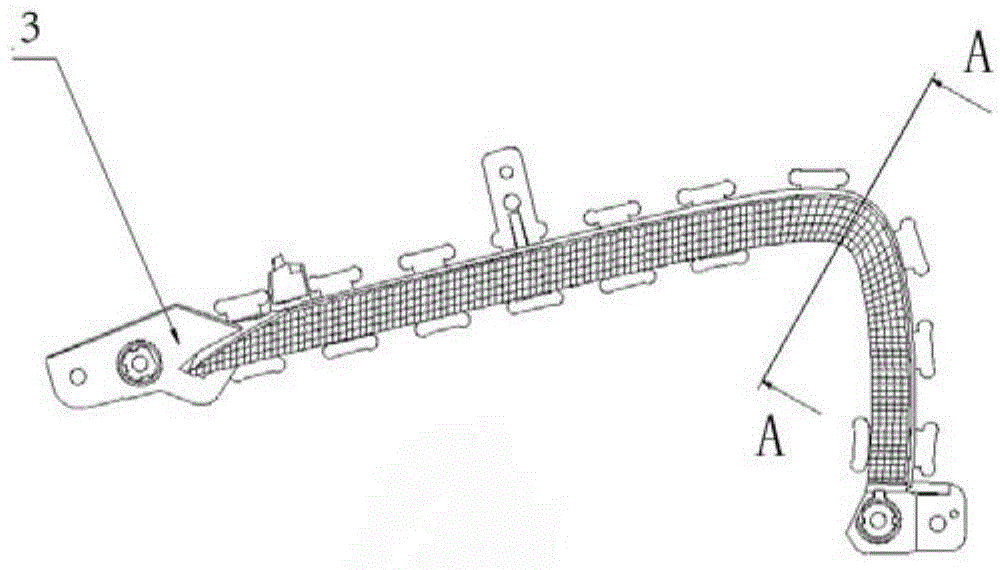

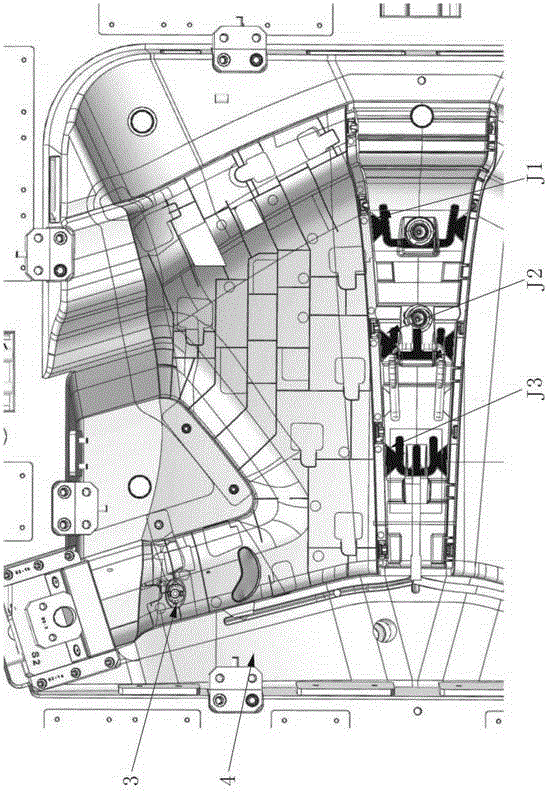

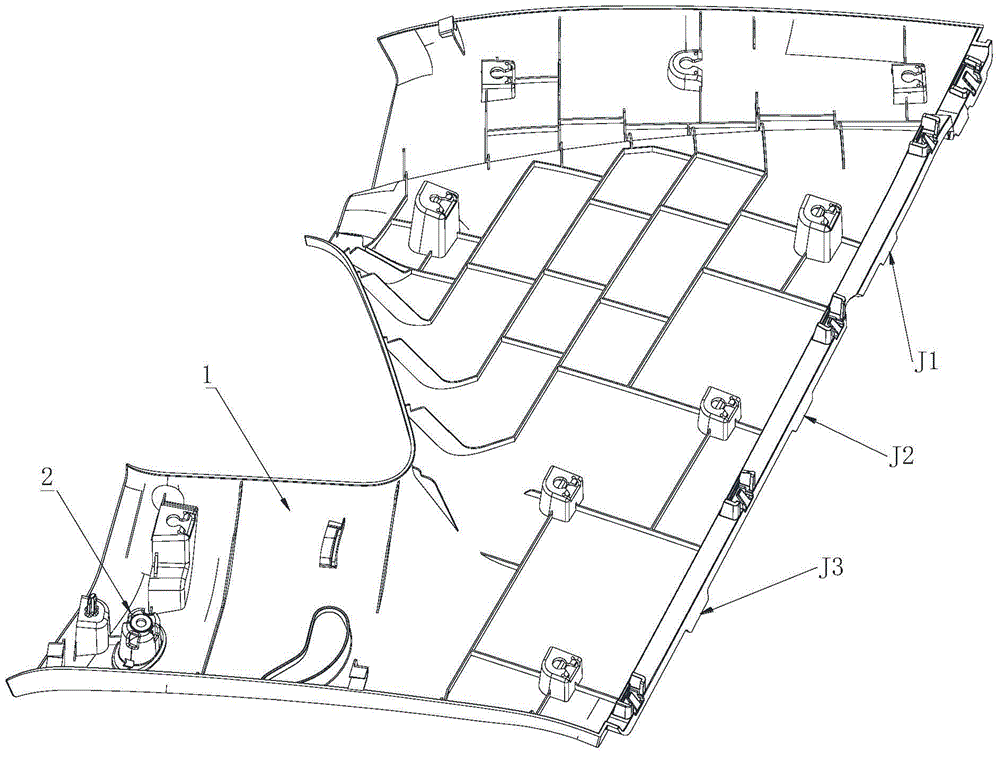

Back column upper decoration plate and mold and injection molding method thereof

ActiveCN104401267ASolve the air marksSolve the appearanceSuperstructure subunitsDomestic articlesAir trappingEngineering

The invention discloses a back column upper decoration plate and a mold and an injection molding method of the back column upper decoration plate. A deep-hole structure is arranged on the back column upper decoration plate and comprises hole side walls, wherein structures for preventing material flow from passing through the hole side walls are arranged on the hole side walls on two opposite sides. The mold of the back column upper decoration plate comprises a deep-hole structure cavity, wherein a flow choking hole forming block for forming a flow choking hole is respectively arranged on two side walls of the deep-hole structure cavity. The injection molding method of the back column upper decoration plate comprises the steps of adjusting the material flow direction to enable the two flow choking hole forming blocks to be respectively located on two sides of the material flow direction, enabling material flow 1 and material flow 2 to be converged in advance, enabling the material flow to flow downwards to be converged at the top of the deep-hole structure, and enabling air to be discharged through an exhaust mechanism at the bottom of the deep-hole structure cavity so as to avoid air trapping. The defects of air marks on the product surface nearby the deep-hole structure and other appearance problems are overcome, a product with good appearance is obtained, and batch production is successively achieved. In addition, the improved portion of the mold is simple in structure and easy to achieve, and only a little cost is increased.

Owner:CHENGDU AEROSPACE MOLD & PLASTIC CO LTD

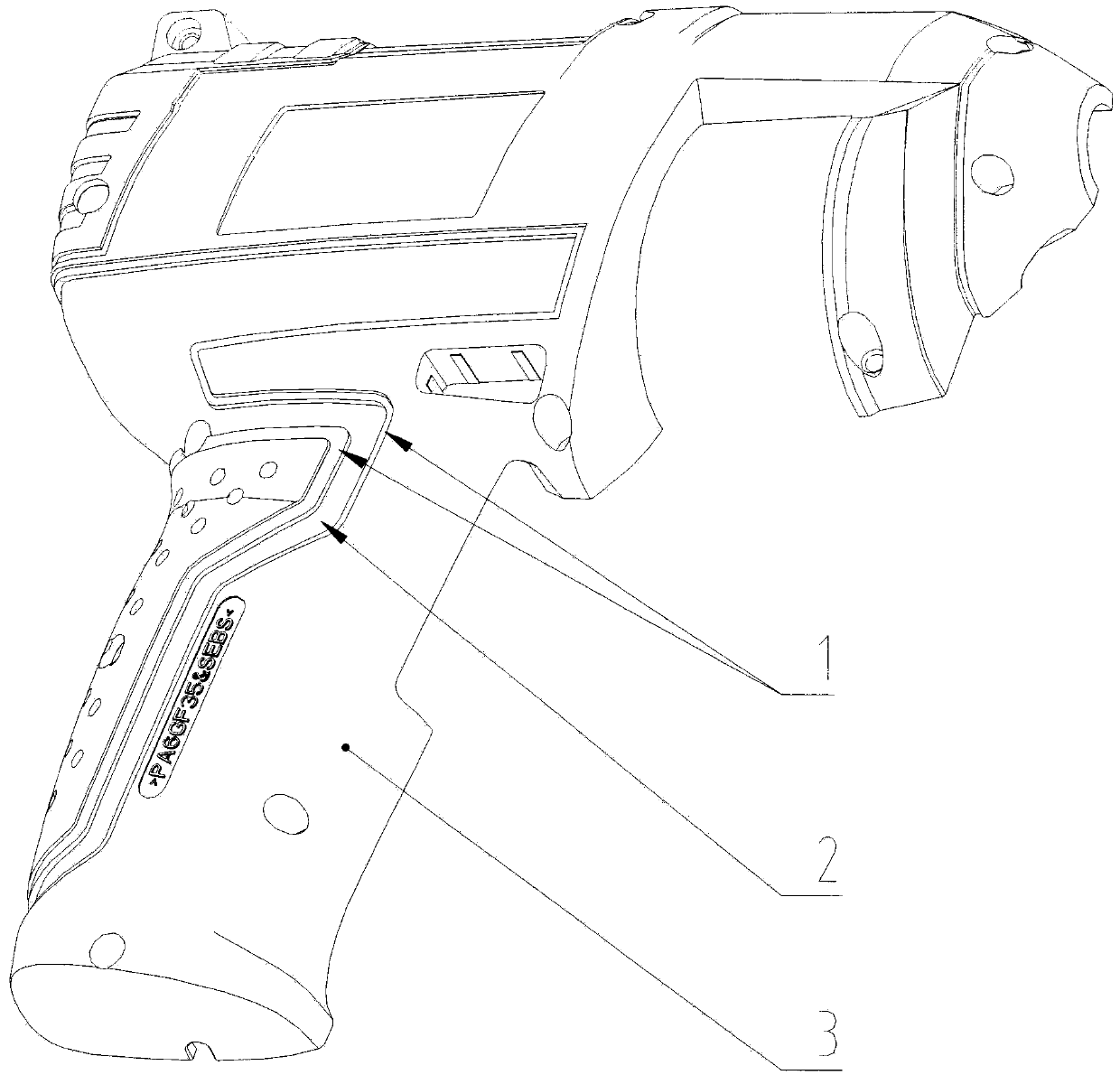

Over mold structure used for long and thin region on tool handle

ActiveCN104260277ATo achieve the exhaust effectDilute parting line marksDomestic articlesInterference fitAir trapping

Owner:ZHANGJIAGANG ZHONGTIAN PRECISION MOLDING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com